Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142 results about "Corrosive chemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

Metal nitride deposition by ALD with reduction pulse

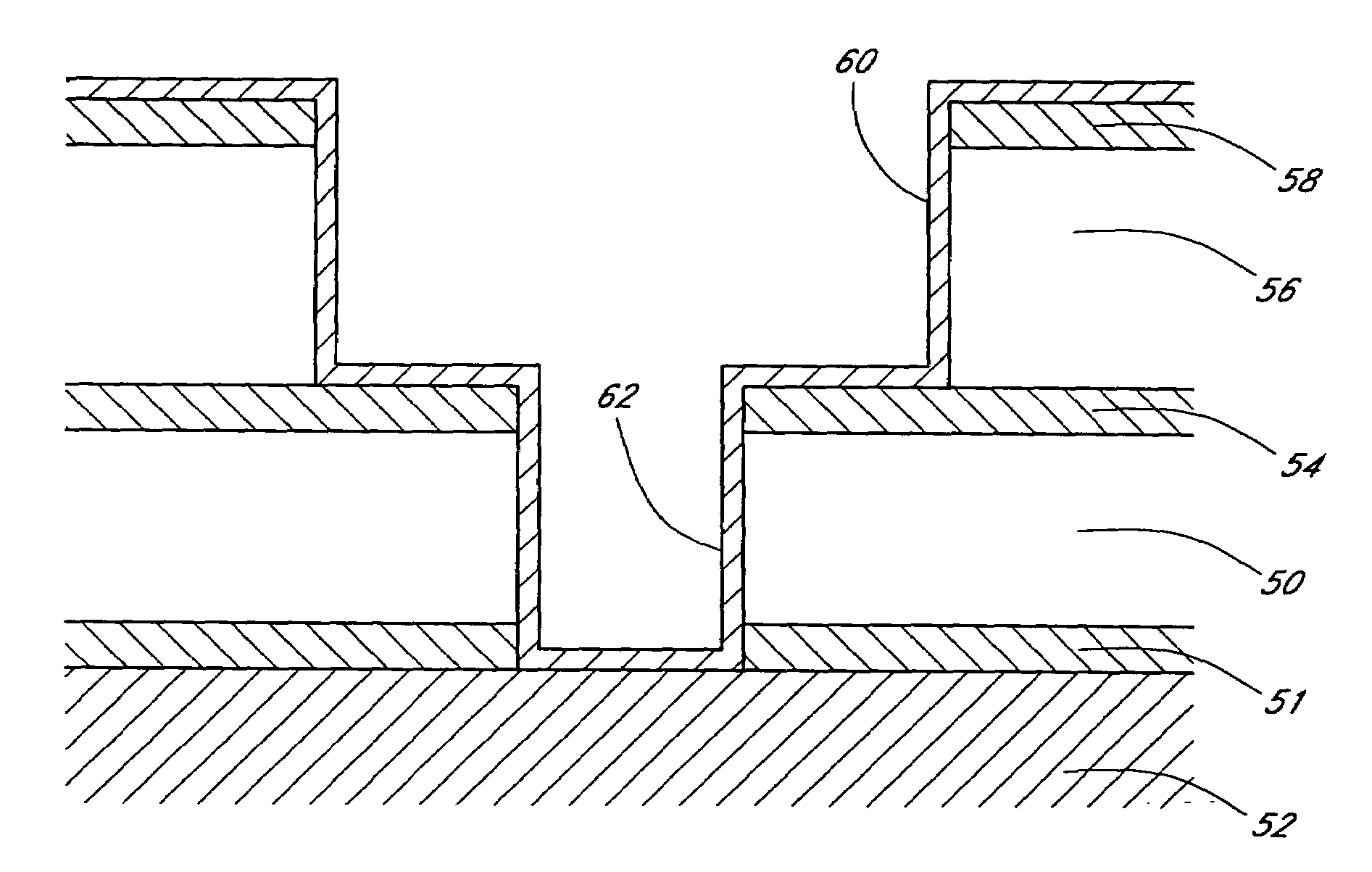

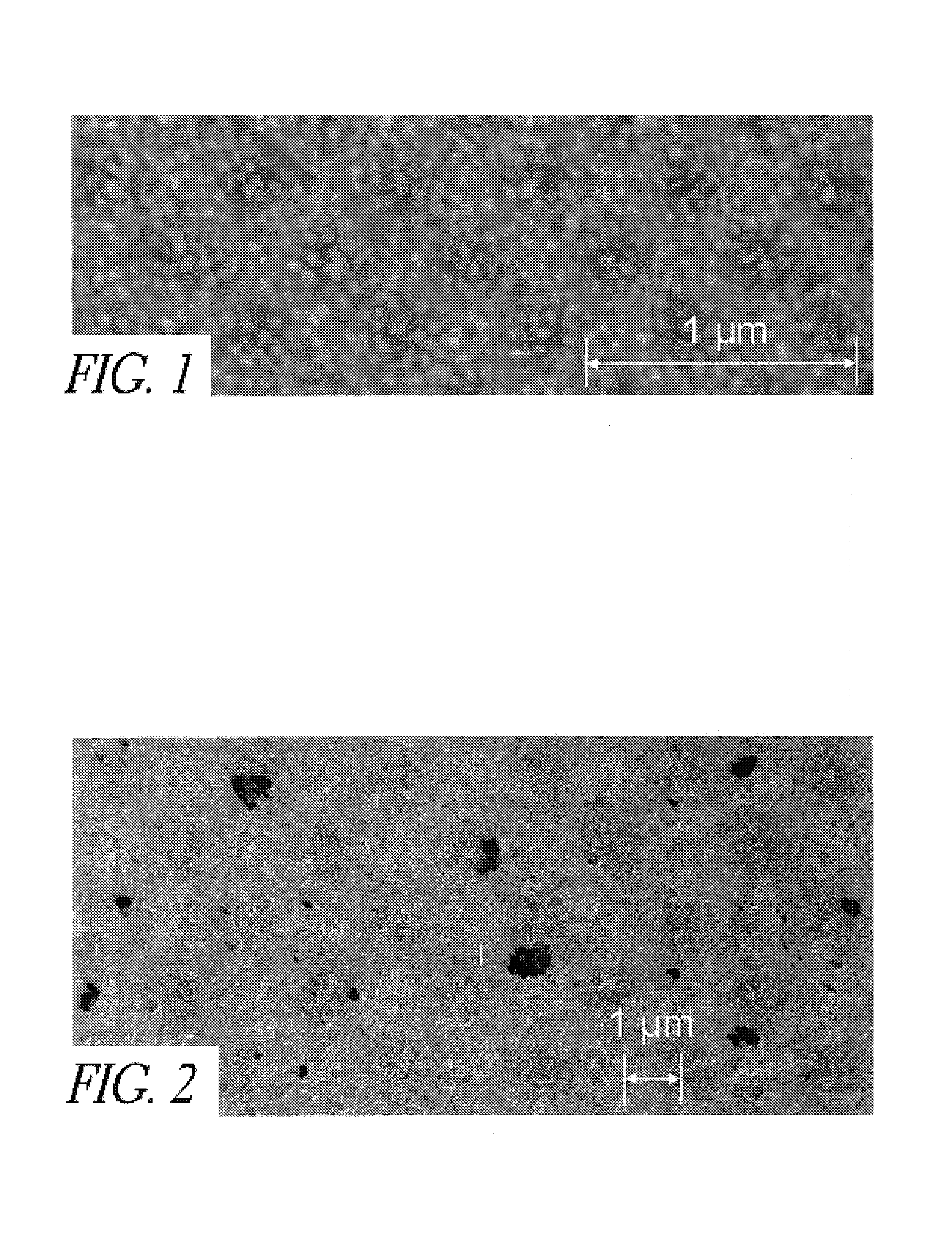

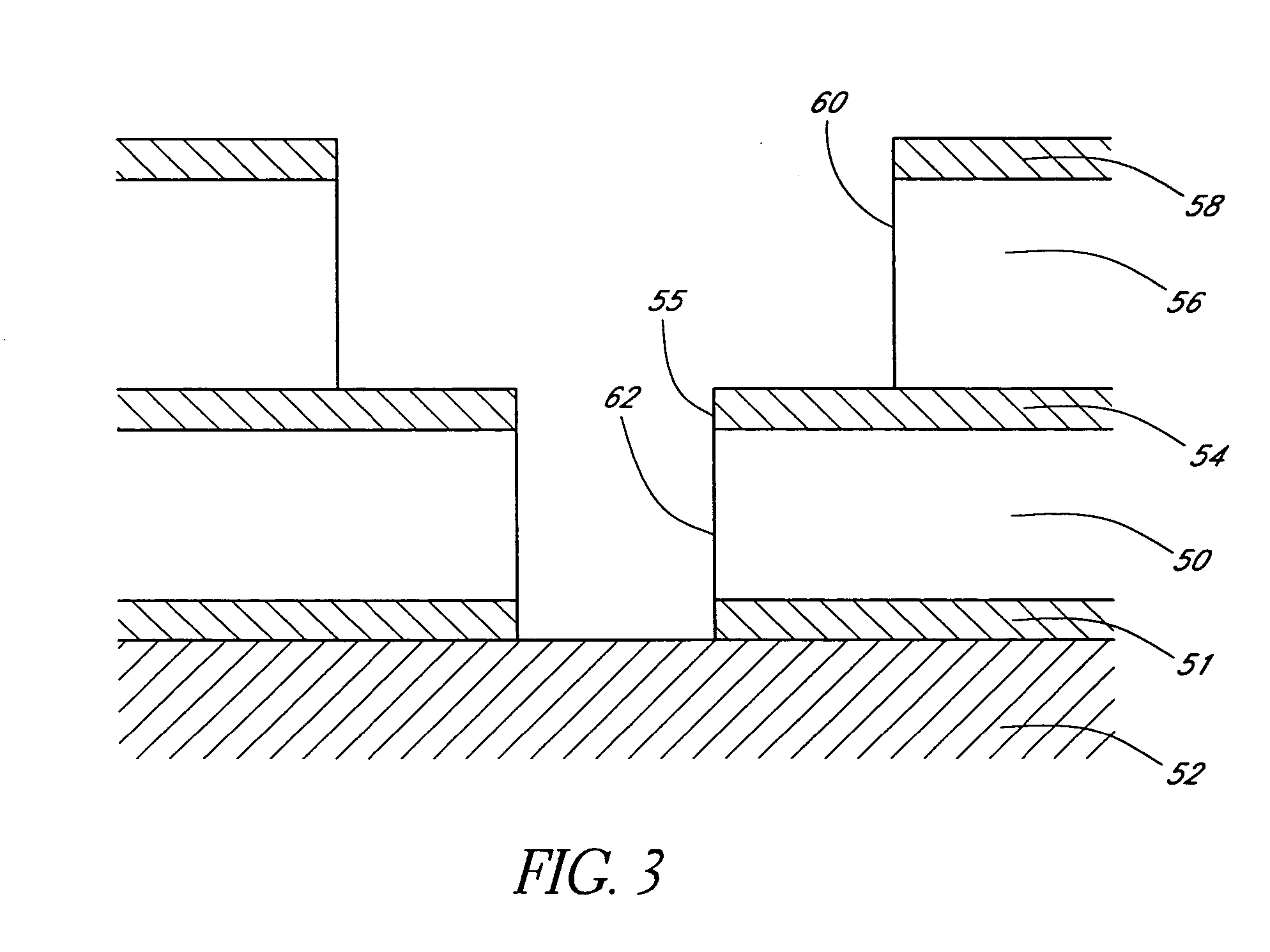

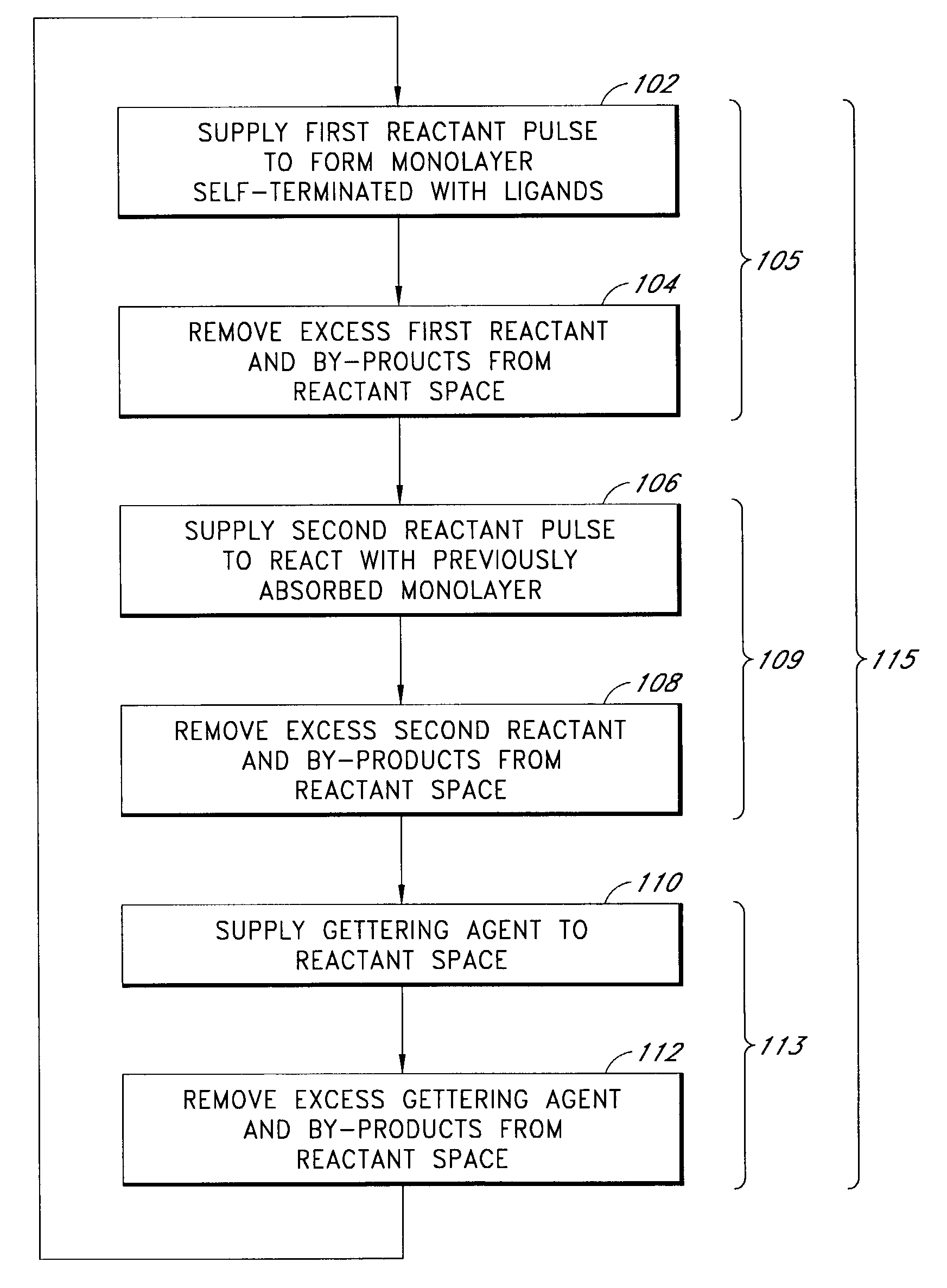

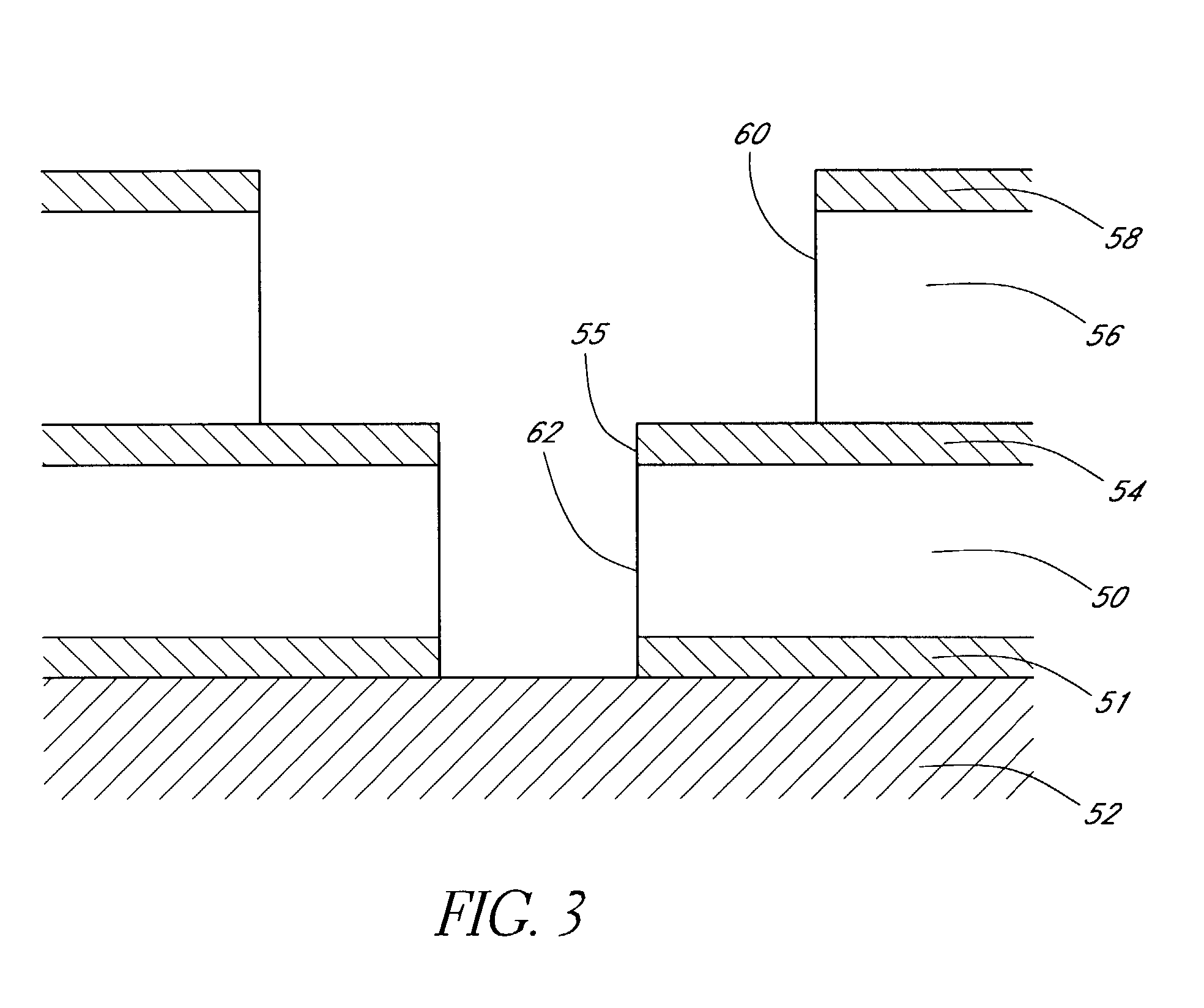

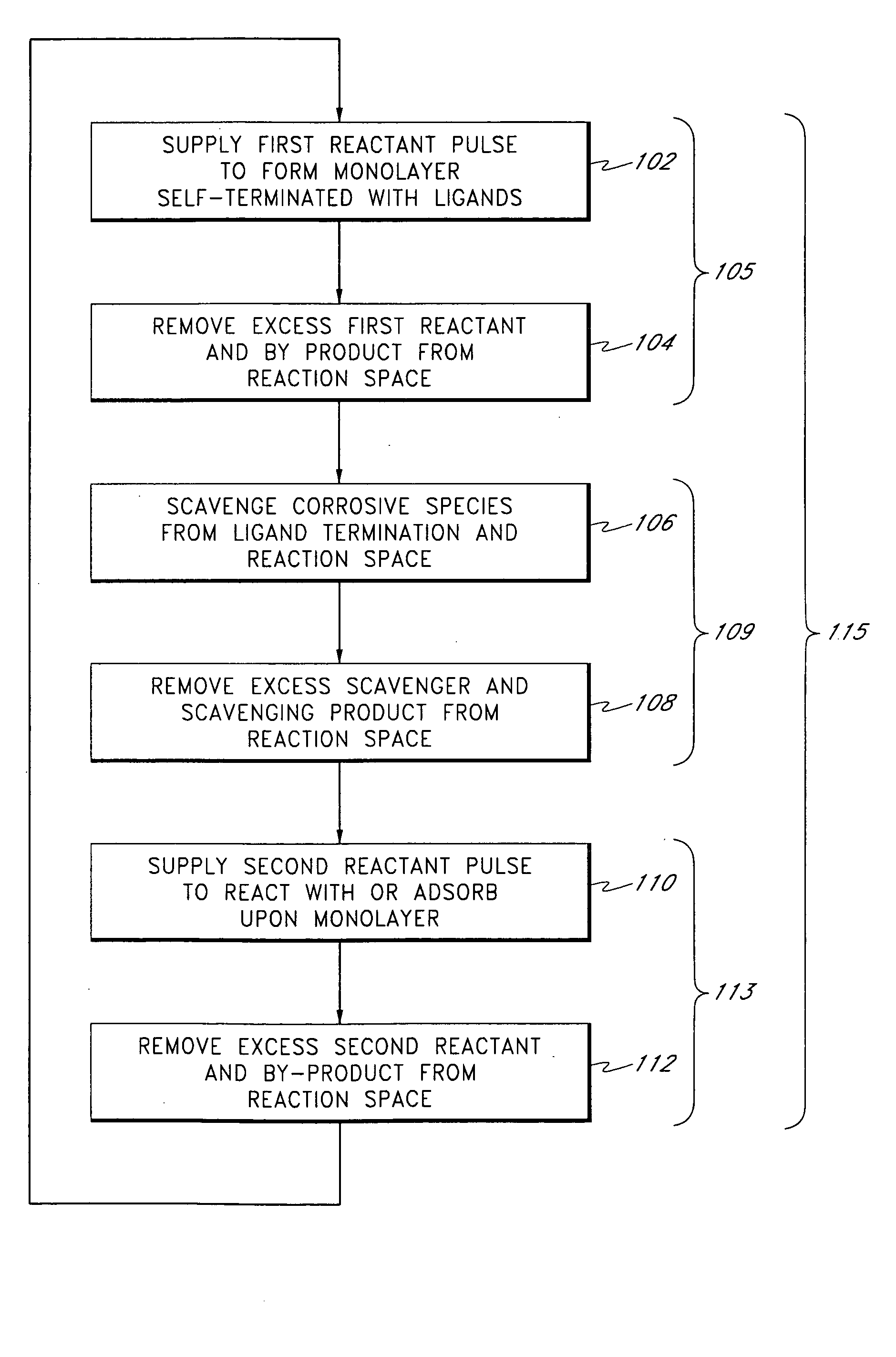

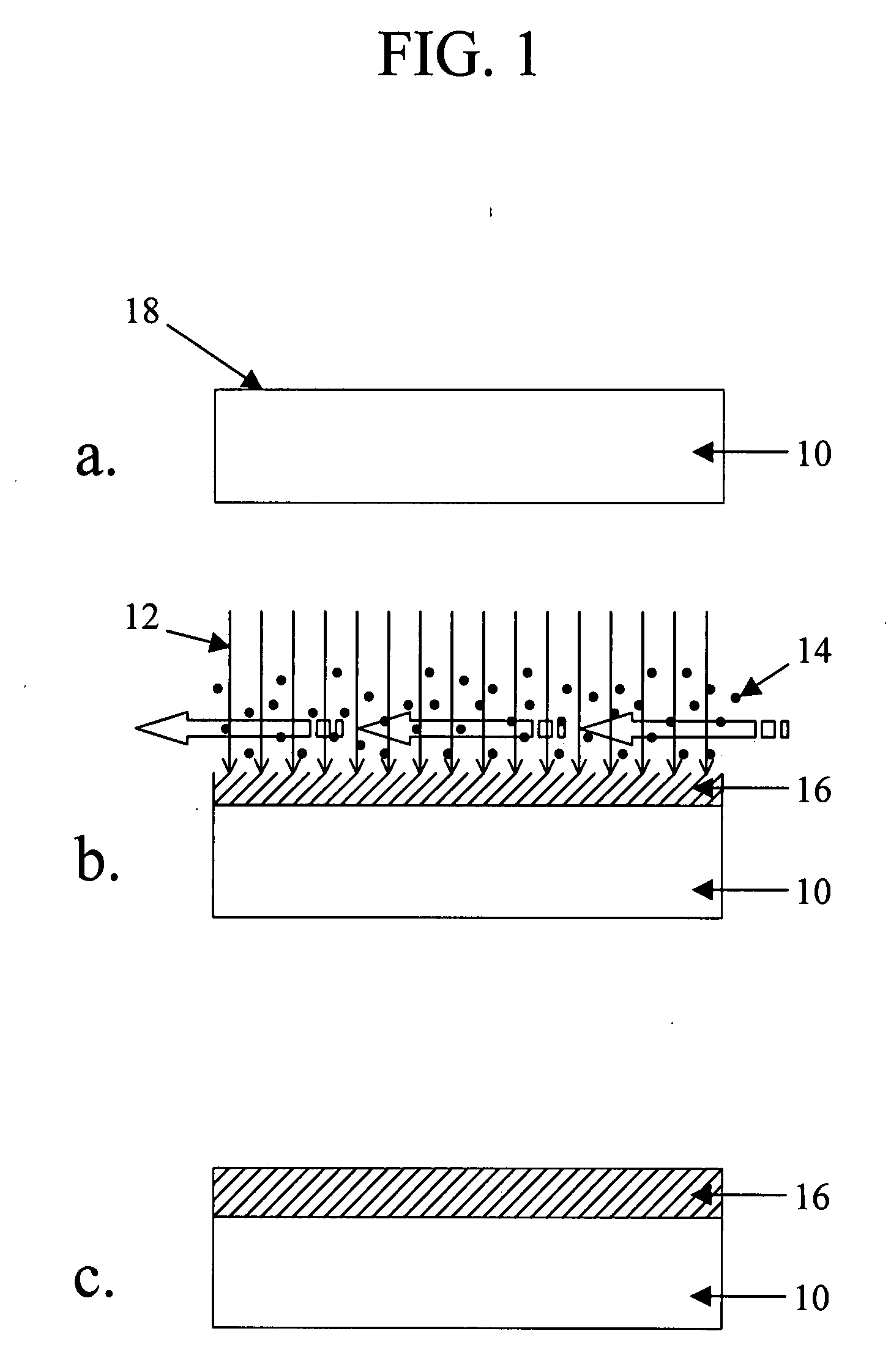

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20050106877A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

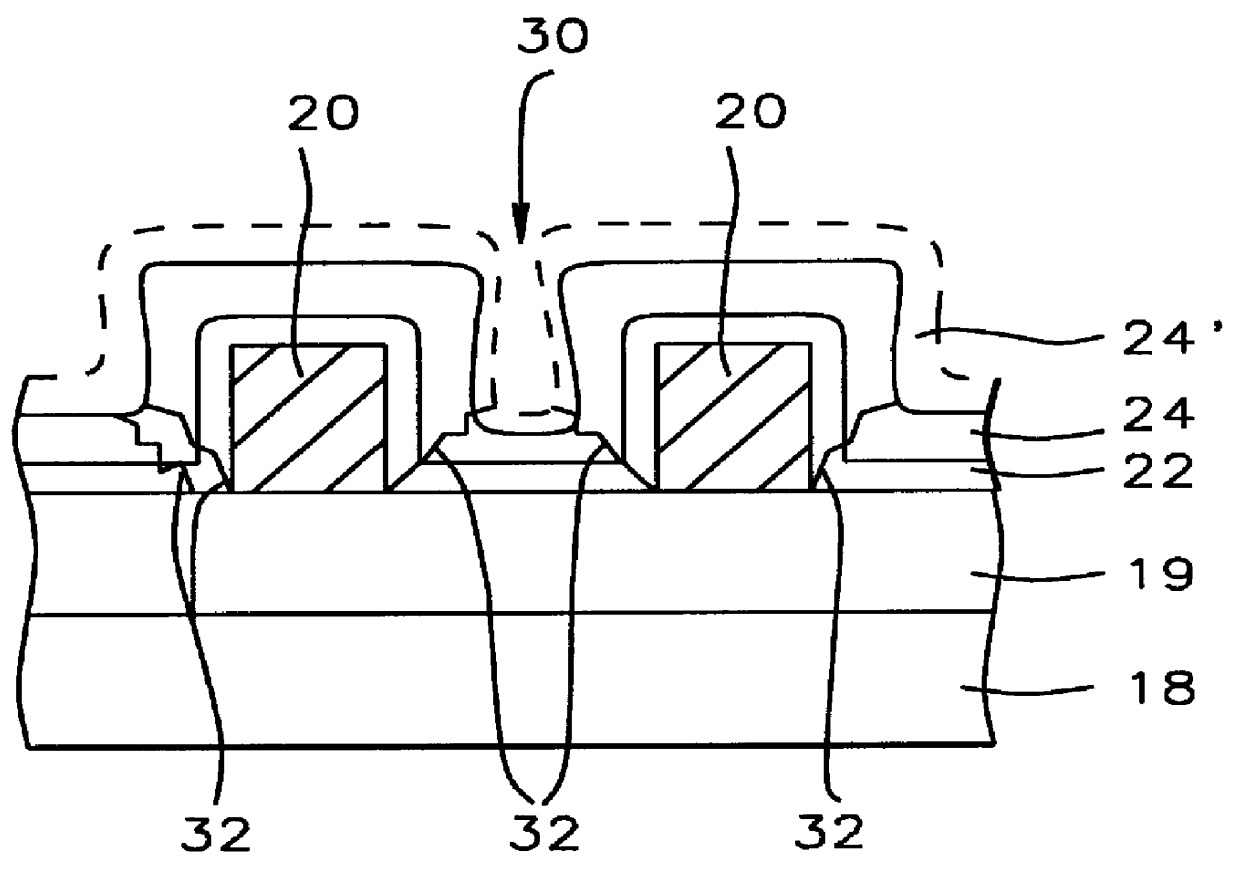

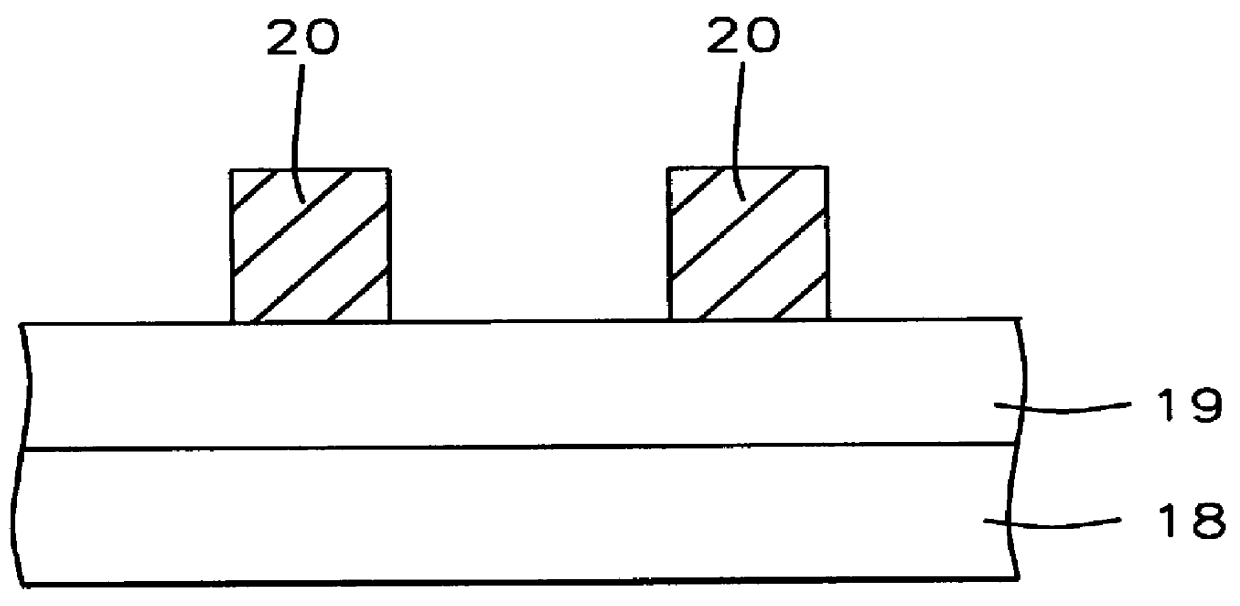

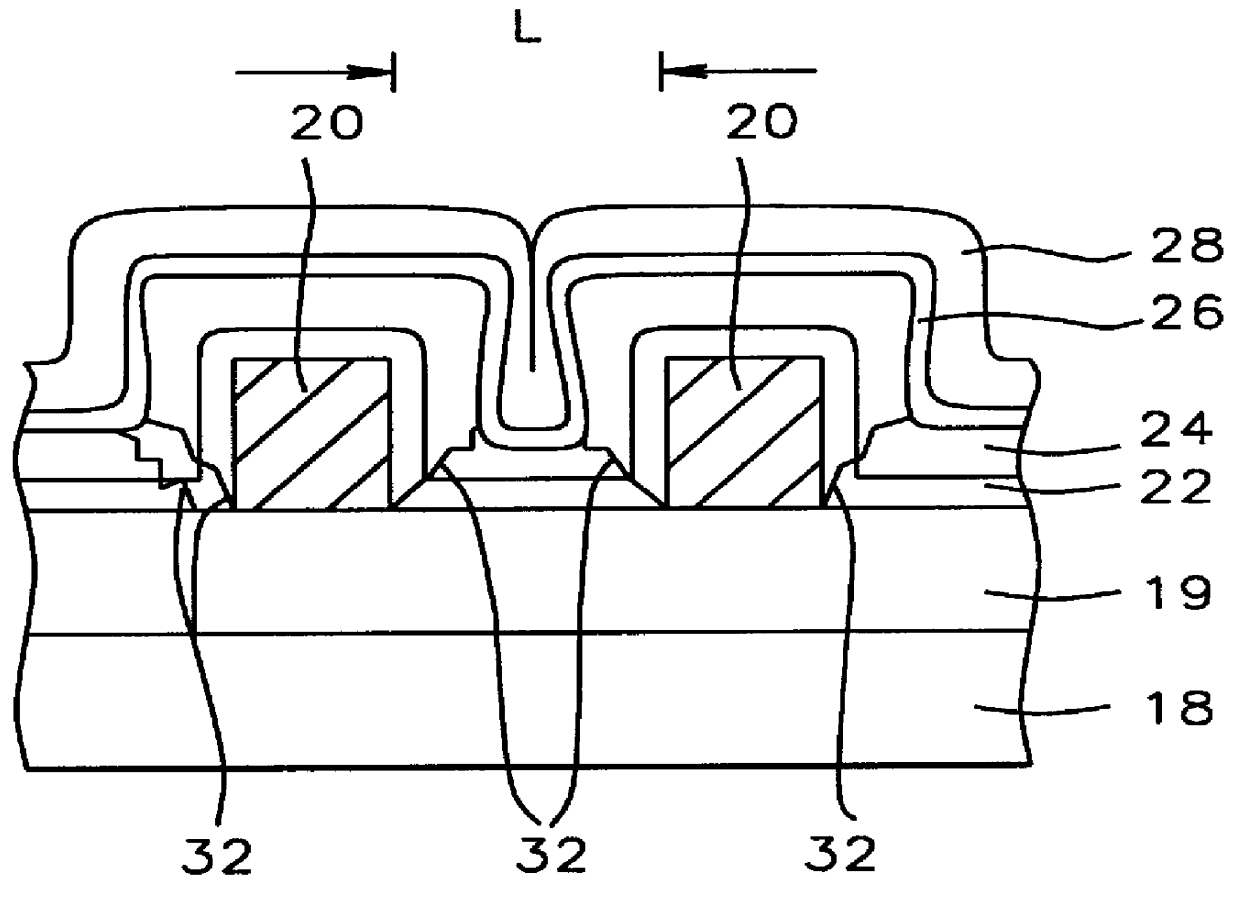

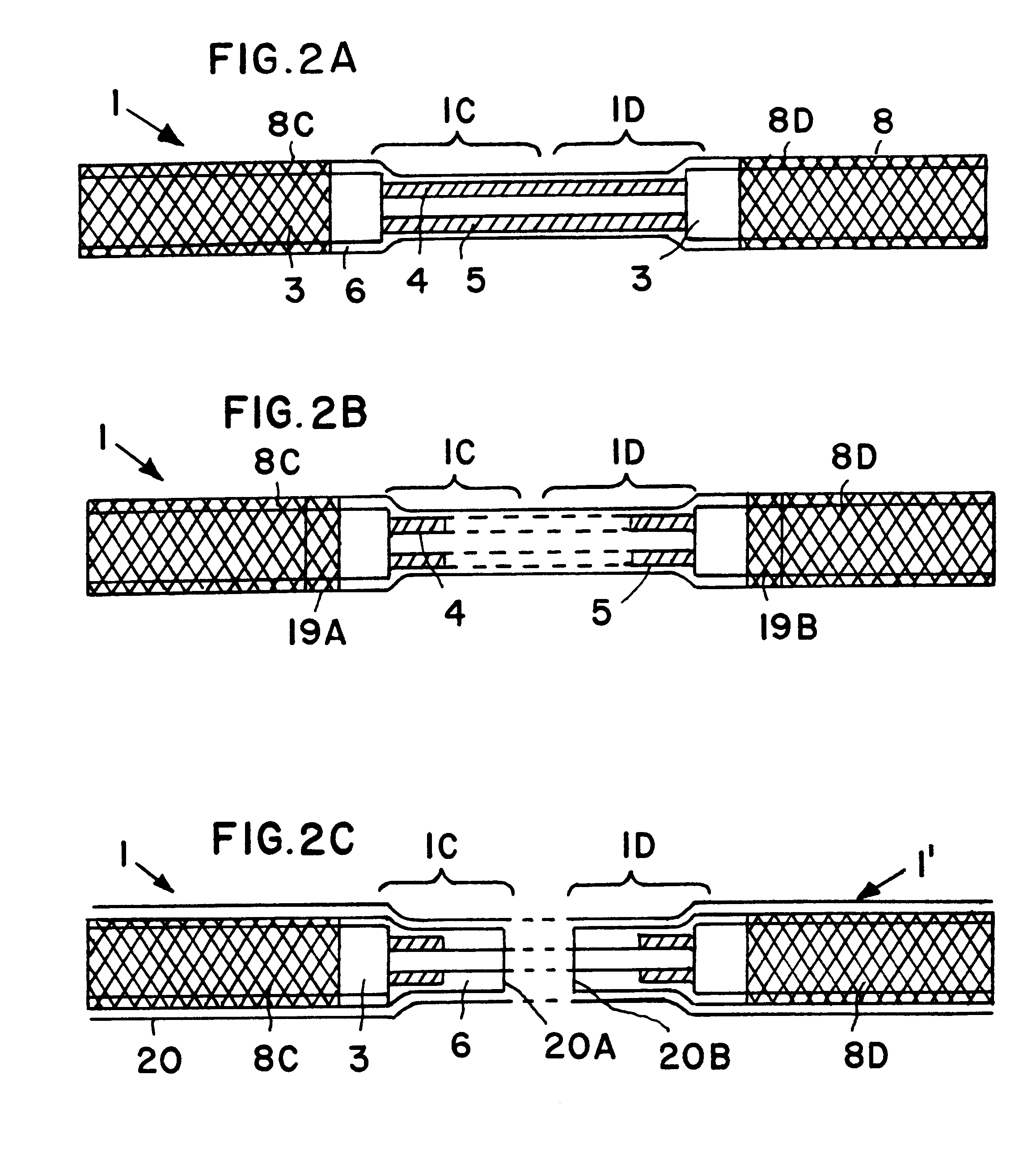

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

Metal nitride carbide deposition by ALD

InactiveUS20060078679A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

Plasma-enhanced chemical vapor deposited SIO2/SI3N4 multilayer passivation layer for semiconductor applications

InactiveUS6017614ASemiconductor/solid-state device detailsSolid-state devicesResistCorrosive chemical

A method was achieved for forming a multilayer passivation layer comprised of a silicon oxide / silicon nitride / silicon oxide / silicon nitride by depositing the layers consecutively in a single PECVD system. The method consists of depositing a first SiO2 layer that serves as a stress-release layer, a thin Si3N4 layer that serves as a buffer layer that minimizes cracking and as a passivation layer that prevents mobile alkaline ion penetration, a thin second SiO2 layer to fill and seal any remaining cracks and pinholes in the first Si3N4 layer, and a main Si3N4 passivation layer that prevents water and / or other corrosive chemicals from attacking the metal. Since this multilayer passivation layer can be deposited essentially pinhole-free to a thickness that is less than the prior art's passivation layer of 8000 Angstroms needed to prevent pinholes, it can be used on 0.38 to 0.25 um DRAM technology, which eliminates voids that could otherwise trap photoresist which can later cause corrosion of the metal lines.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20060079090A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

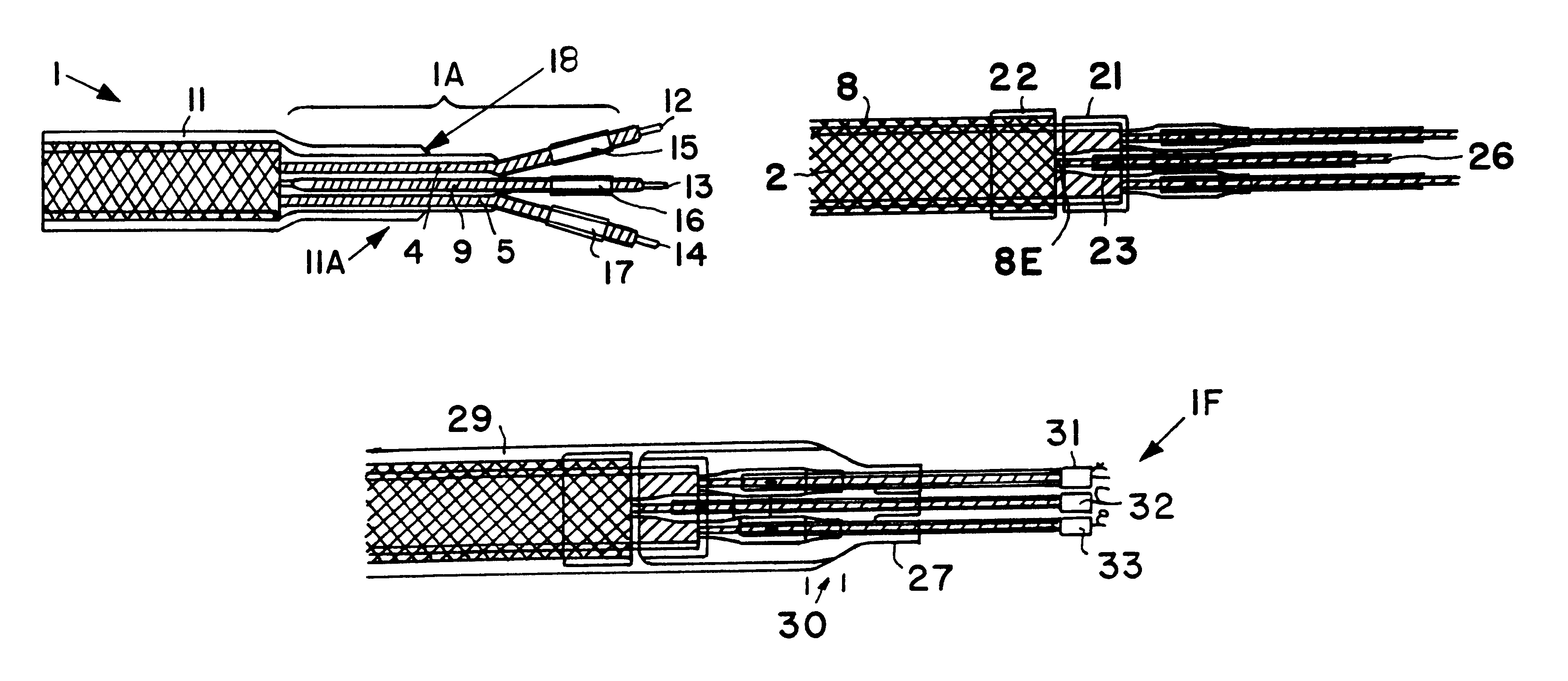

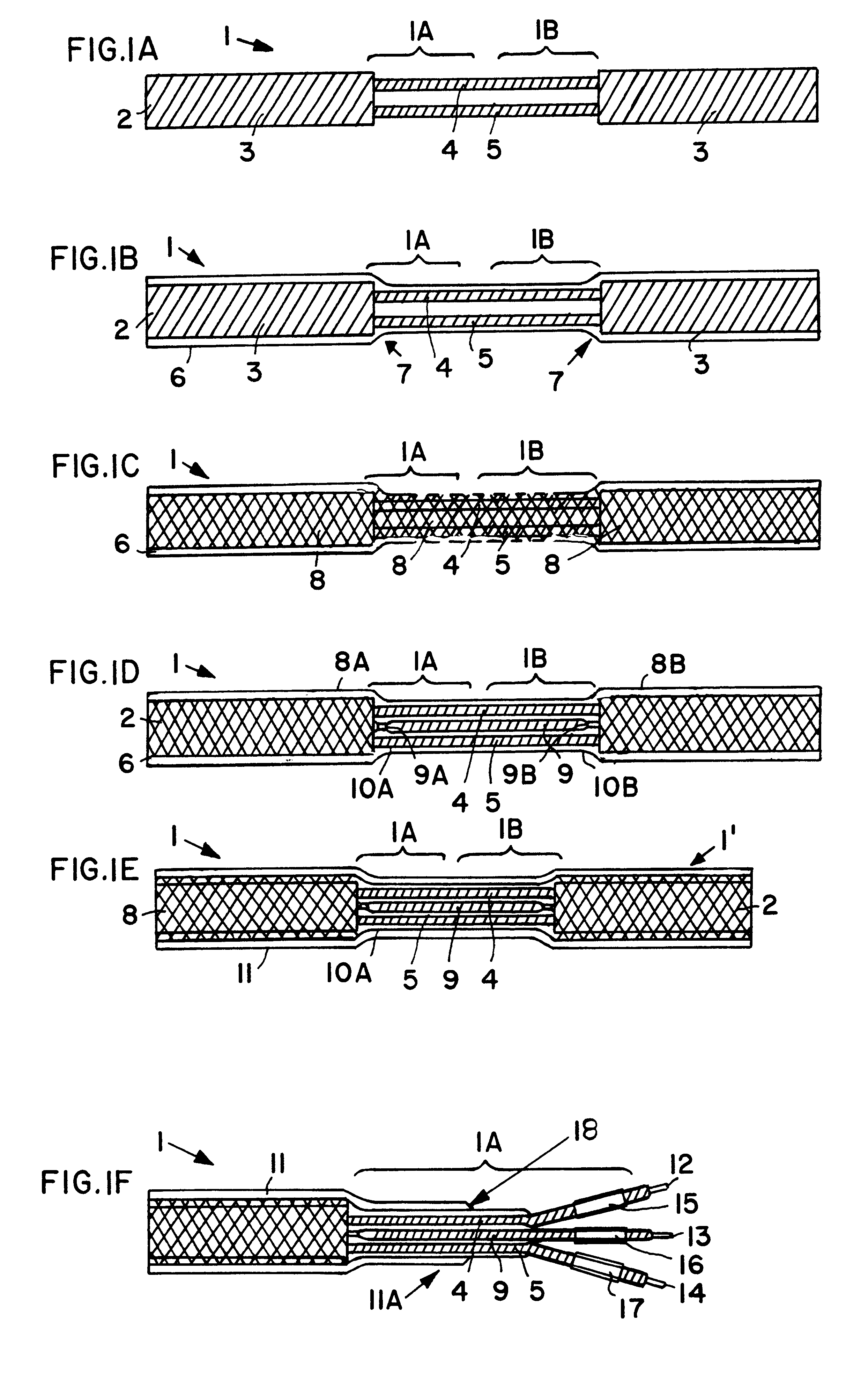

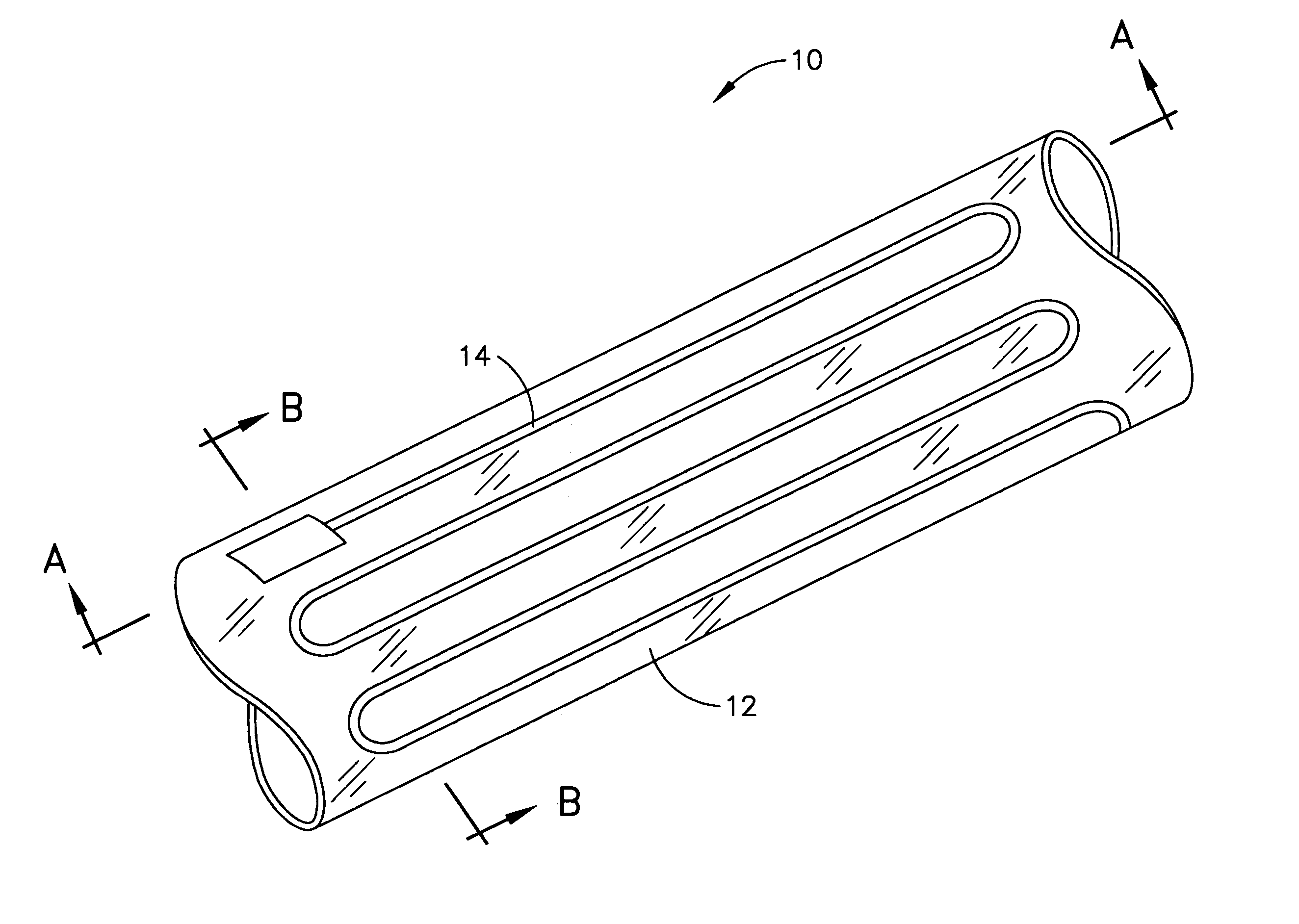

Heater arrangement with connector or terminating element and fluoropolymer seal, and method of making the same

InactiveUS6423952B1Improve protectionGood flexibilityHeater elementsCouplings bases/casesCorrosive chemicalElectrical conductor

A heater arrangement such as a heating band is especially suitable for providing freeze protection for water pipes in an aircraft, because it is resistant to vibrations, greatly varying temperatures, low pressure conditions, and aggressive chemicals, while achieving a reliable seal against the penetration of moisture or liquid into the areas of the electrical connections. The heater arrangement includes a heating element with a heater band matrix and heating conductors extending therein, as well as a fluoropolymer protective layer thereover. A connecting element or a terminating element is connected to exposed ends of the heating conductors. To seal the area at which the connecting element or terminating element is connected to the heater arrangement, a fluoropolymer is extruded over this area, and / or a fluoropolymer molded part is used as a connection block or end cap. The fluoropolymer materials are thermally fused together to form a continuous integral seal.

Owner:AIRBUS OPERATIONS GMBH

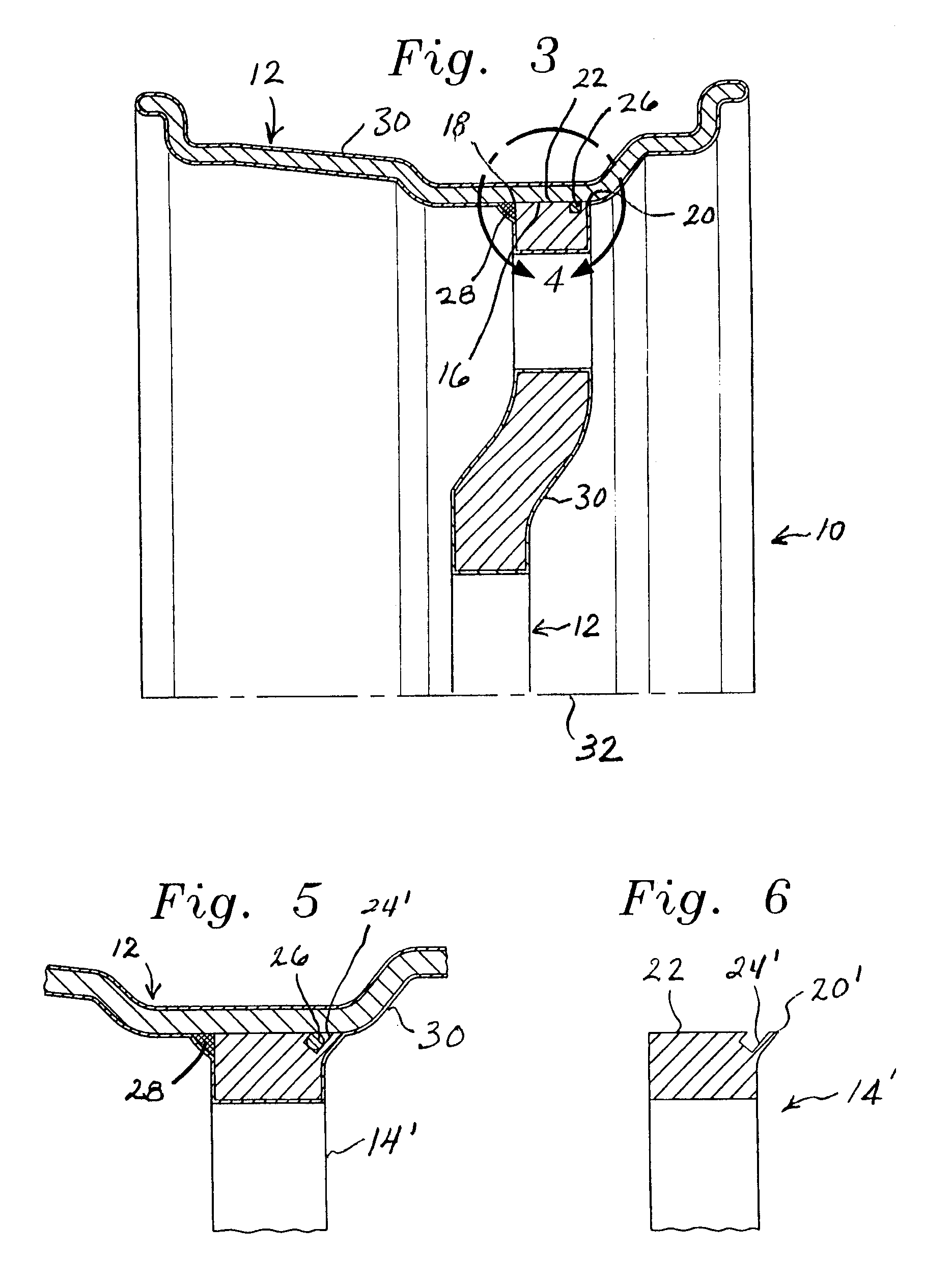

Fluoroplastic composite elastomer

InactiveUS20060018777A1Improve bending resistanceLow costEnvelopes/bags making machineryFlexible member pumpsElastomerFiber

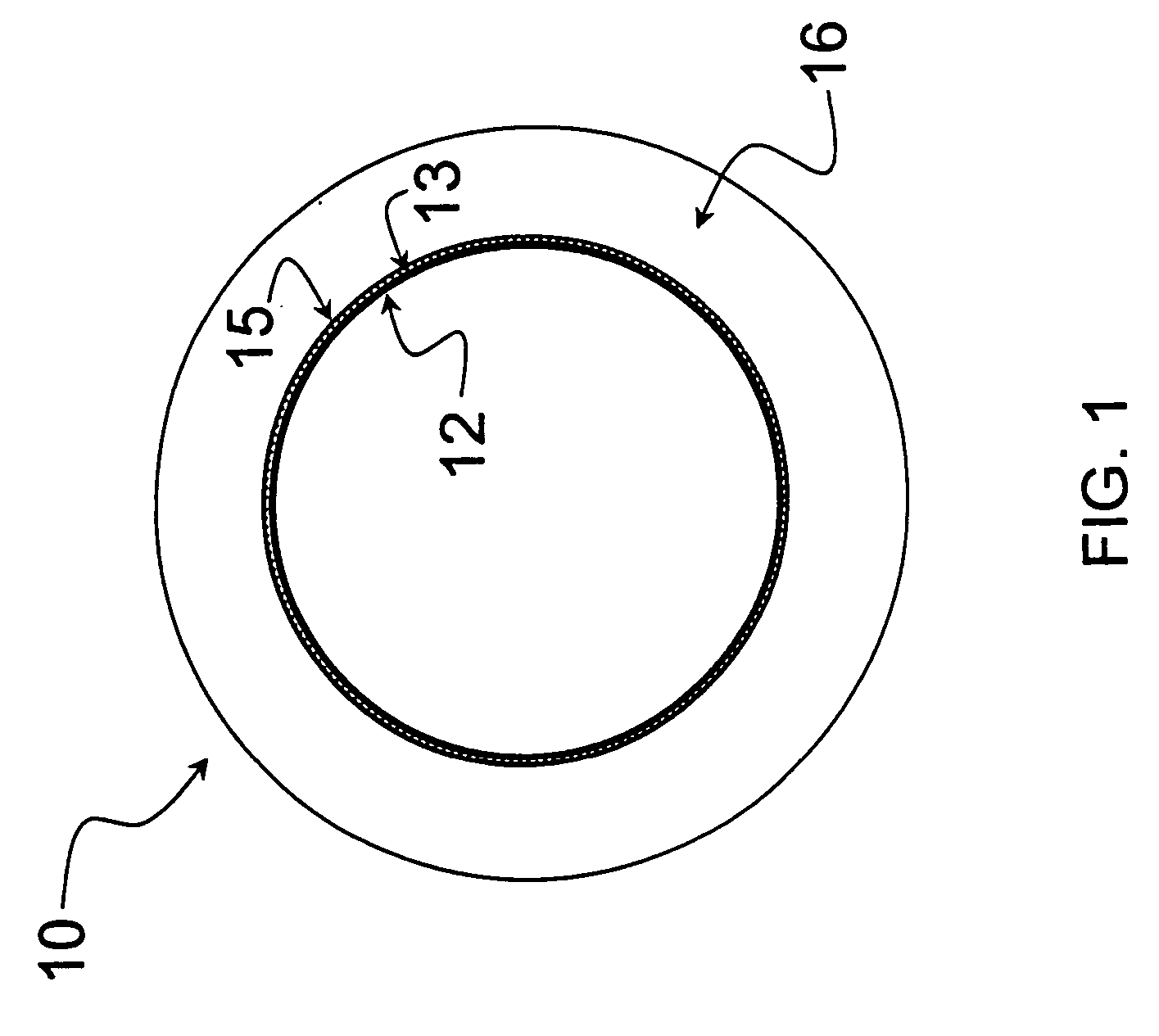

An improved fluoroplastic lined elastomeric tube that can maintain a stable flow rate while pumping aggressive chemicals in a peristaltic pump for an extended period of time and is fabricated in sizes ranging from 0.5 mm to 100 mm in inside diameter. The inner fluoroplastic liner comprises a composite of expanded polytetrafluoroethylene and a fluoroplastic polymer resulting in improved flex life over single component fluoroplastics. The inventive liner is bonded to either an unreinforced elastomer or a fiber reinforced elastomer for use in both low and high pressure peristaltic pump applications.

Owner:MAZTECH

Abrasive diamond composite and method of making thereof

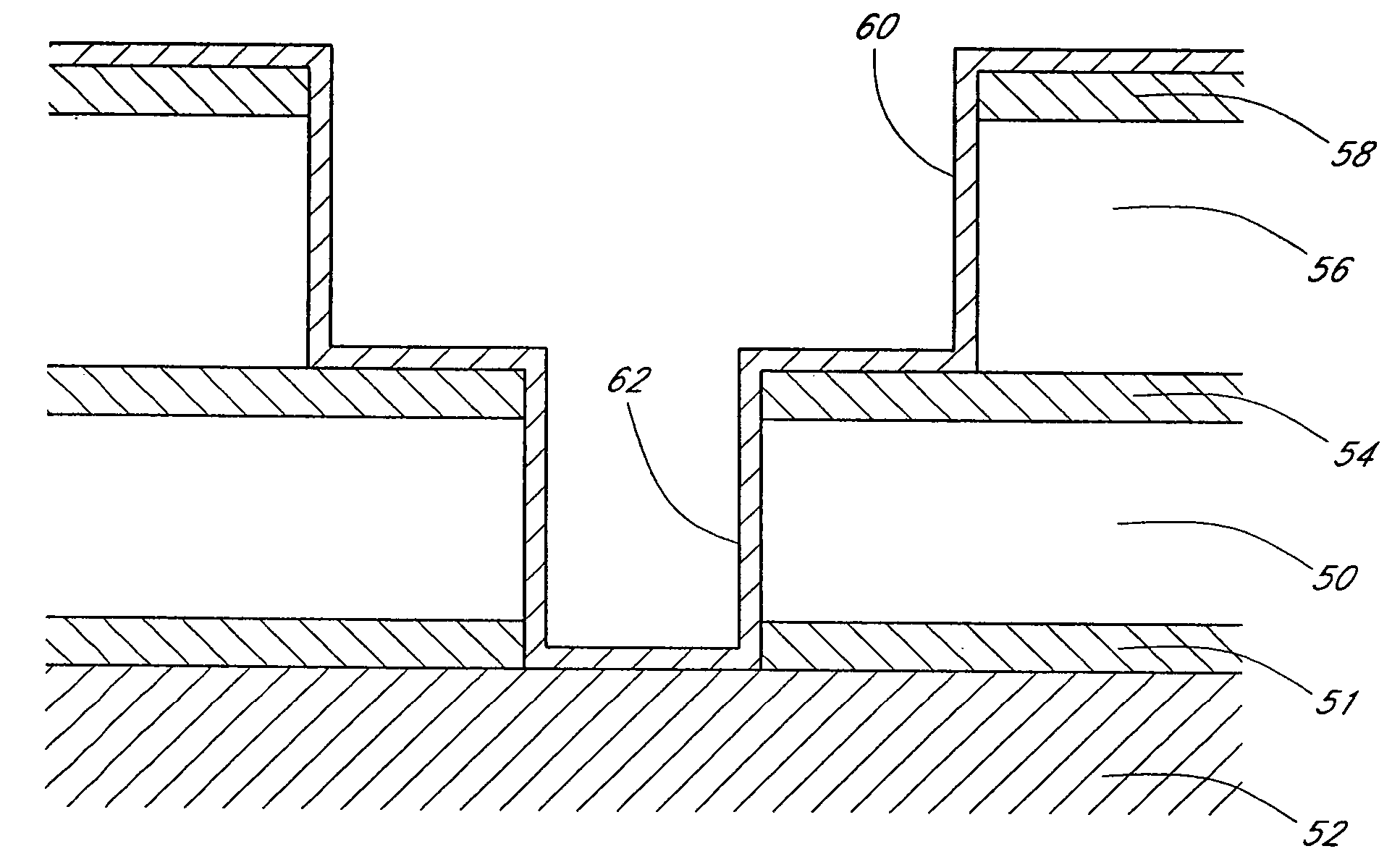

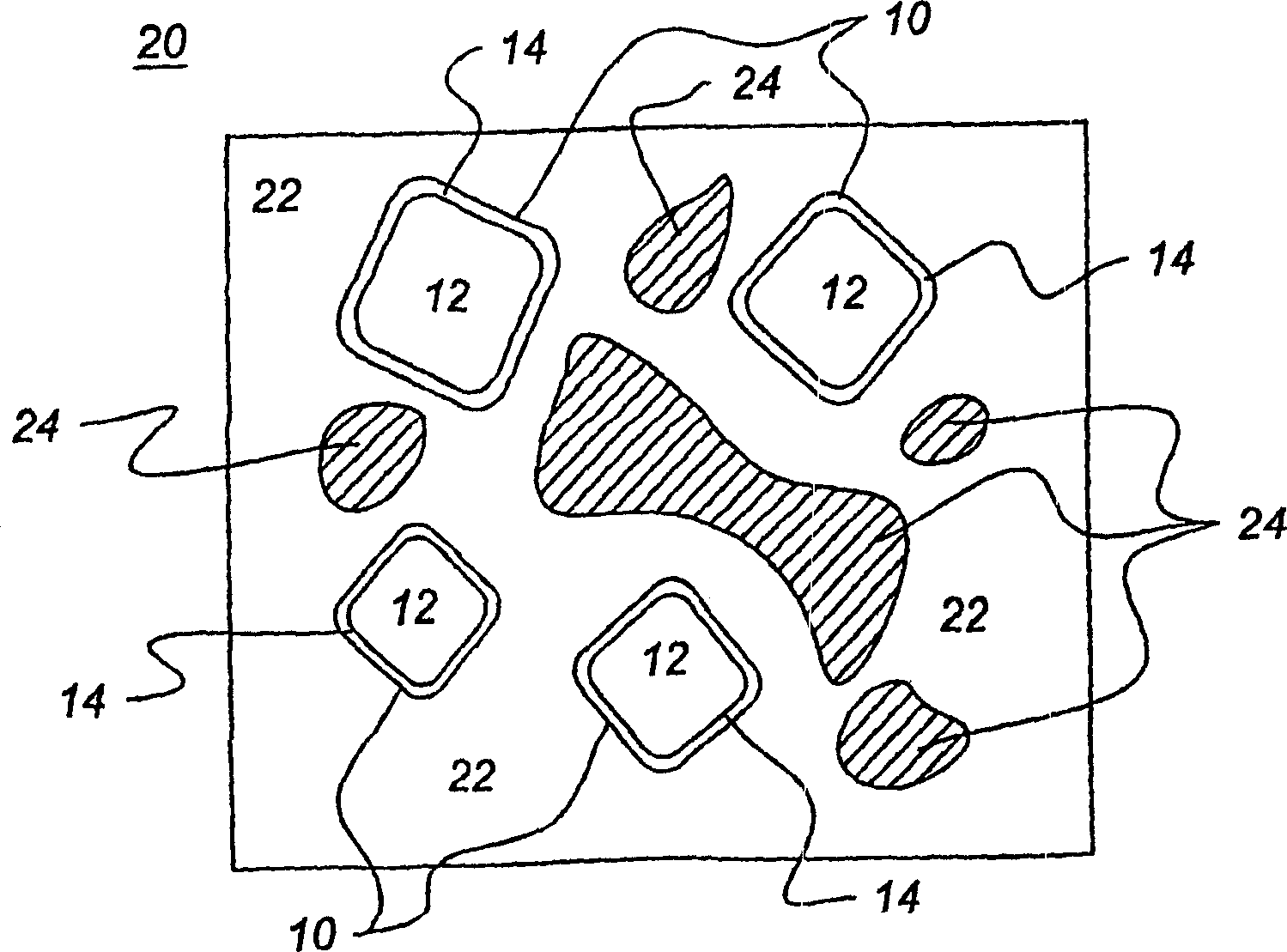

An abrasive diamond composite (60) formed form coated diamond particles (10) and a matrix material (22). The diamonds (12) have a protective coating (14) formed from a refractory material having a composition MCxNy, that prevents corrosive chemical attack of the diamonds by the matrix material (22). The abrasive diamond composite (60) may further include an infiltrant, such as a braze material (40). Alternatively, the abrasive diamond composite (60) may include a plurality of coated diamond particles (10) and a braze material (40) filling interstitial spaces between the coated diamond particles (10). Methods of making such abrasive diamond composites (60) are also disclosed.

Owner:DIAMOND INNOVATIONS INC

Method and apparatus for laser oxidation and reduction

InactiveUS20080299780A1Significant handlingSignificant process timeSemiconductor/solid-state device manufacturingCorrosive chemicalProduct gas

A method and apparatus using electromagnetic radiation and gas to create oxidation and reduction reactions on a device, such as a semiconductor wafer surface. In one embodiment, a scanned laser and gas may be employed in a number of oxidation and / or reduction reactions in a single system without using multiple pieces of equipment, corrosive chemicals and gases, high temperature and pressure chamber environments, waste treatment processes, and / or extra process steps typically required in existing processes.

Owner:UVTECH SYST

Dielectric constant measuring device

ActiveCN103308778ASensitive to media changesHigh measurement accuracyResistance/reactance/impedenceMaterial analysis using microwave meansMicrowave applicationsCorrosive chemical

The invention relates to the technical field of microwave application and discloses a dielectric constant measuring device which is not only used for measuring dielectric constant of a solid dielectric material but also used for measuring corrosive chemical solution dielectric constant. The dielectric constant measuring device comprises a groove structure. Signal interfaces are arranged at two ends of the groove structure and used for connecting a testing instrument and transmitting a testing signal. A hole is formed in the groove structure and located in a groove and used for placing a container for containing tested materials. The hole is large enough in size so that the tested materials contained in the container matched with the hole can fully affect the transmission property of the groove structure. The dielectric constant measuring device is simple in structure and high in sensitivity. A double-interface measuring method can avoid multiple solutions and is favorable for improving measuring precision and speed. The dielectric constant measuring device can be used for measuring the corrosive chemical solution dielectric constant, can achieve broadband measuring and online measuring and has wide applicability.

Owner:SICHUAN UNIV

High efficiency electro-static chucks for semiconductor wafer processing

ActiveUS20090199765A1Liquid surface applicatorsVacuum evaporation coatingCorrosive chemicalTemperature resistance

The present invention generally provides a high efficiency electrostatic chuck for holding a substrate in a processing volume. The high efficiency electrostatic chuck includes an electrode embedded within a high-purity, thermoplastic member. In particular, the high-purity, thermoplastic member may include a high-purity, polyaryletherketone having an extremely low level of metallic ions present therein. The high-purity, polyaryletherketone has excellent wear resistance, high temperature resistance, plasma resistance, corrosive chemical resistance, electrical stability, and strength as compared to polyimide films used in electrostatic chucks. The present invention also provides a simplified method of manufacturing the high efficiency electrostatic chuck.

Owner:APPLIED MATERIALS INC

Method Of Protecting Teeth Against Erosion

InactiveUS20170007514A1Provide protectionCosmetic preparationsImpression capsCorrosive chemicalPresent method

Disclosed are methods of treating and protecting teeth against erosion by use of oral compositions comprising polymeric mineral surface active agents, metal ions such as stannous and zinc and combinations thereof. The present methods provide improved resistance of teeth to erosive demineralization or dissolution and prevention of tooth damage by subsequent exposure of teeth to erosive chemicals such as acidic foods and beverages.

Owner:THE PROCTER & GAMBLE COMPANY

Crystalline silicon solar battery edge etching process

InactiveCN101777605AReduce photocurrent lossPhotocurrent loss increasesFinal product manufactureSemiconductor devicesCorrosive chemicalEtching

The invention belongs to the field of a solar battery manufacture process, in particular to a crystalline silicon solar battery edge etching process, which comprises the steps of edge etching and residue removal. The invention adopts a corrosive chemical pulp spray coating method for etching the edge of a silicon chip, the etching amount of the periphery of the silicon chip surface can be controlled within 0.2 mm, the PN junction loss of the silicon chip surface can be greatly lowered, the light absorption of the light absorption surface of the silicon chip can be improved, the photoelectric efficiency of batteries can be improved, the process is stable, and the control is easy.

Owner:山东力诺太阳能电力股份有限公司

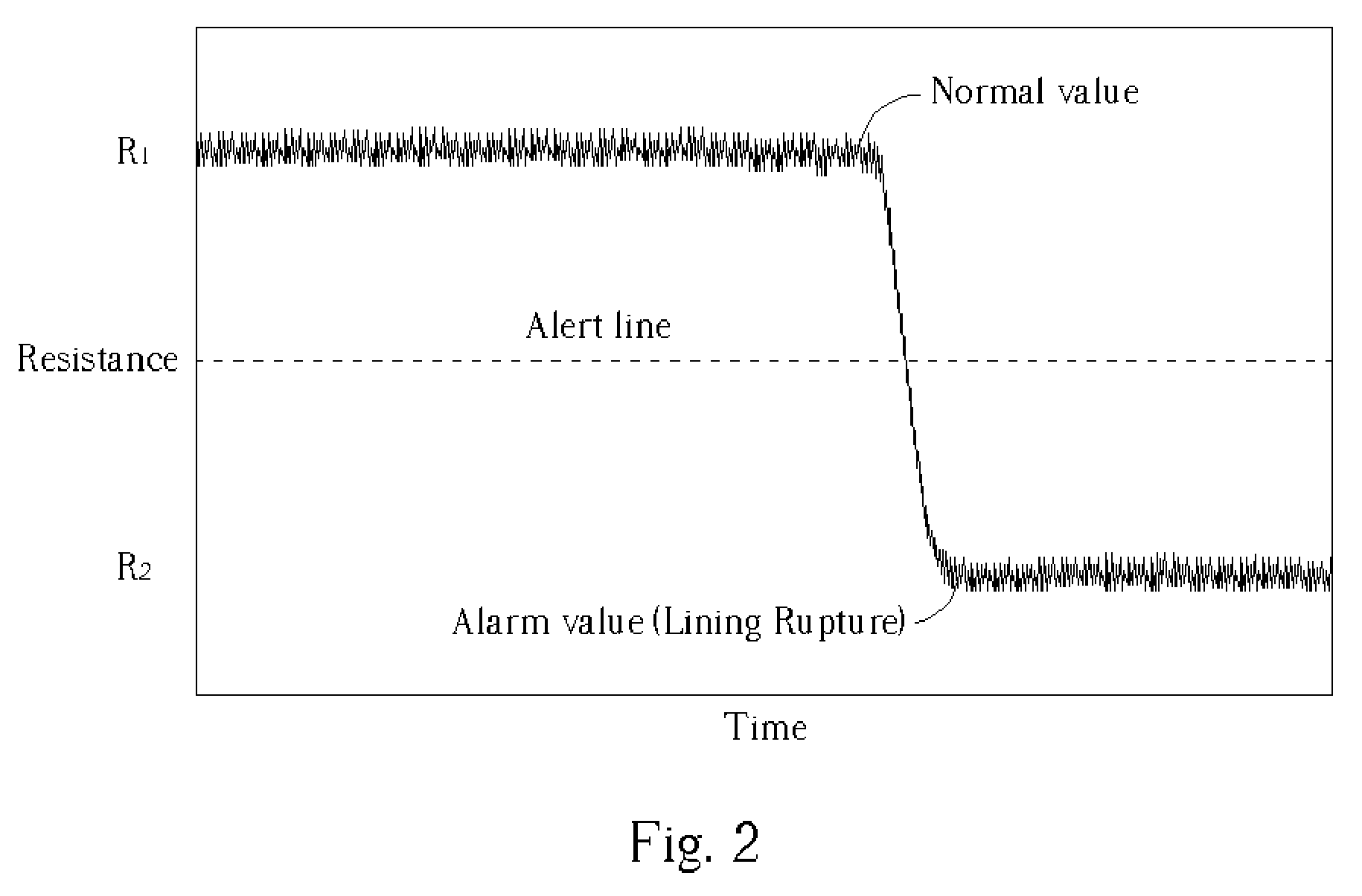

In-situ monitoring and controlling system for chemical vessels or tanks

InactiveUS20060011475A1Promote yield and qualityWeather/light/corrosion resistanceMaterial electrochemical variablesCorrosive chemicalElectricity

An in-situ and real-time monitoring and controlling system for chemical vessels, tanks, reactors or the like is disclosed. The chemical vessels, tanks, or reactors are employed to contain high-purity corrosive chemicals such as acids, alkaline liquids or the like. The monitoring and controlling system encompasses a vessel including a conductive shell and insulating interior lining coated therein. A robust detection electrode is dipped into the chemical liquid contained by the vessel. The detection electrode is electrically connected to a measurement means such as an ohmmeter that is mounted outside the vessel. The measurement means is further electrically connected to the conductive shell. When the interior lining is pitted due to the chemical attack by the chemical liquid and the chemical liquid contacts the conductive shell, the measurement means promptly receives a corresponding signal. According to one preferred embodiment, the measurement means is further connected to a controller unit that can control a semi-conductor-processing unit.

Owner:UNITED MICROELECTRONICS CORP

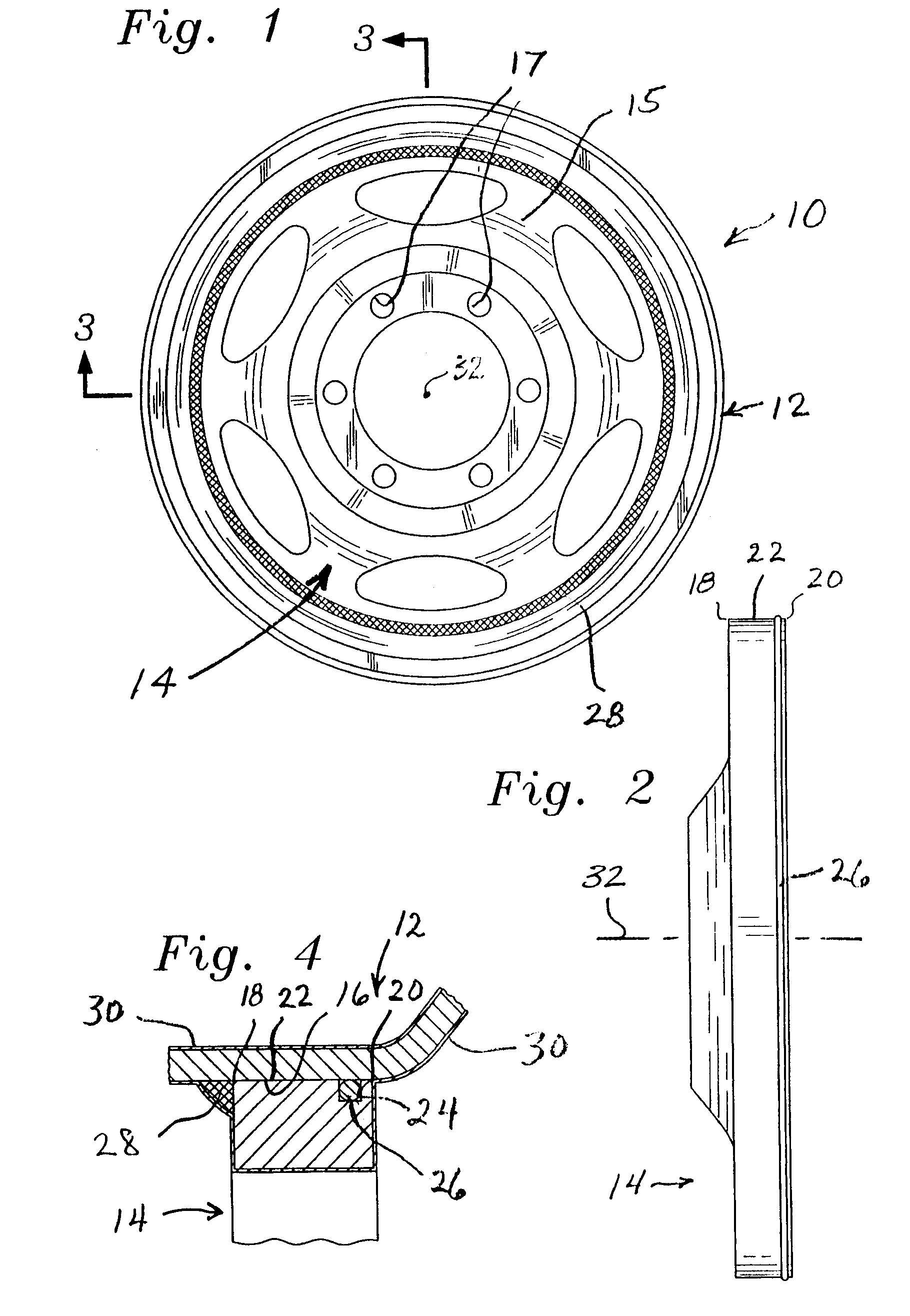

Nonblistering chrome-plated wheel and method of fabrication

An improved automotive vehicle wheel plated with an overcoating, such as chrome, is constructed in such a manner as to be free of the blistering effects of residual acidic and caustic chemicals employed in the chrome-plating process. Like conventional automotive vehicle wheels of this type, the wheel of the invention is comprised of an outer rim into which a wheel center is set. However, unlike conventional wheels, the center of the wheel of the invention is provided with a radially inwardly directed groove into its rim-contacting surface near the outboard extremities of the contacting surfaces of the wheel rim and wheel center. A resilient O-ring is seated in the groove prior to setting the wheel center within the wheel rim. The outer rim is then heated so as to thermally expand it to receive the wheel center. When the rim cools it shrinks into tight, intimate contact with the radially outwardly facing surface of the wheel center. The wheel rim and center are then secured by an annular weld at the inboard extremities of their contracting surfaces. The resilient O-ring prevents caustic or acidic chemicals that are employed in the chrome-plating process from seeping into the interface between the structures of the wheel rim and wheel center. As a consequence, these caustic and acidic substances are not entrapped beneath the overcoating chrome layer, thereby preventing blistering of the chrome coating on the wheel.

Owner:GOODMAN LARRY K

Composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and preparation method thereof

ActiveCN105042219AImprove adhesionAvoid safety hazardsFlexible pipesLow-density polyethyleneCorrosive chemical

The invention discloses a composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and a preparation method thereof. Low density polyethylene, ultra-high molecular weight polyethylene and macromolecule cross-linked polyethylene serve as raw materials; after scientific compound and vulcanization of a rubber hose, a chemical substance with a good adhesive property is obtained for preparing a liner film; meanwhile, corona treatment is carried out on the bonding face of the liner film and the bonding face of the rubber hose, and fiberglass reinforcing fiber with radiation protection performance is compounded on the surface layer; therefore, the surface layer of the rubber hose has good radiation protection performance, hidden danger of conveying pipelines caused by ionizing radiation is avoided, and finally the composite rubber hose which has the firmly bonded liner film, and is high in radiation protection and capable of conveying LPG, LNG and strongly corrosive chemical solvents is prepared, the hose can absorb as much as 97.5% to 99.5% of X-rays, gamma-rays and various neutrons in nuclear radiation, and the adhesive force (N / 25mm) between the liner film and a rubber layer reaches 160-180.

Owner:河北泽邦塑胶科技有限公司

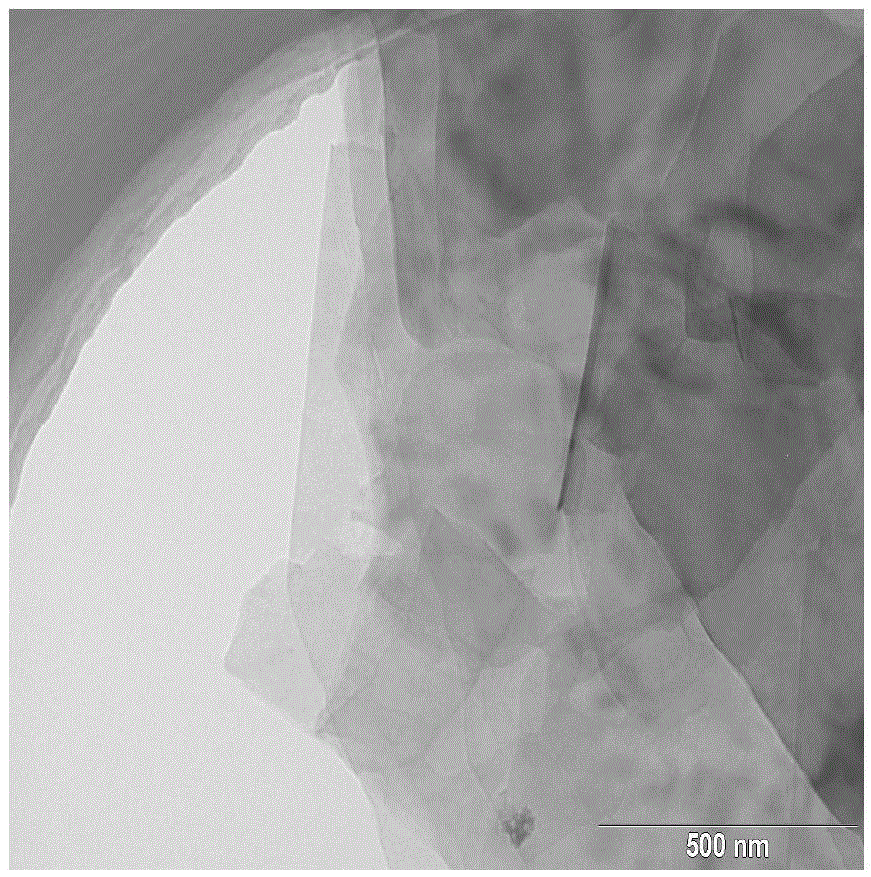

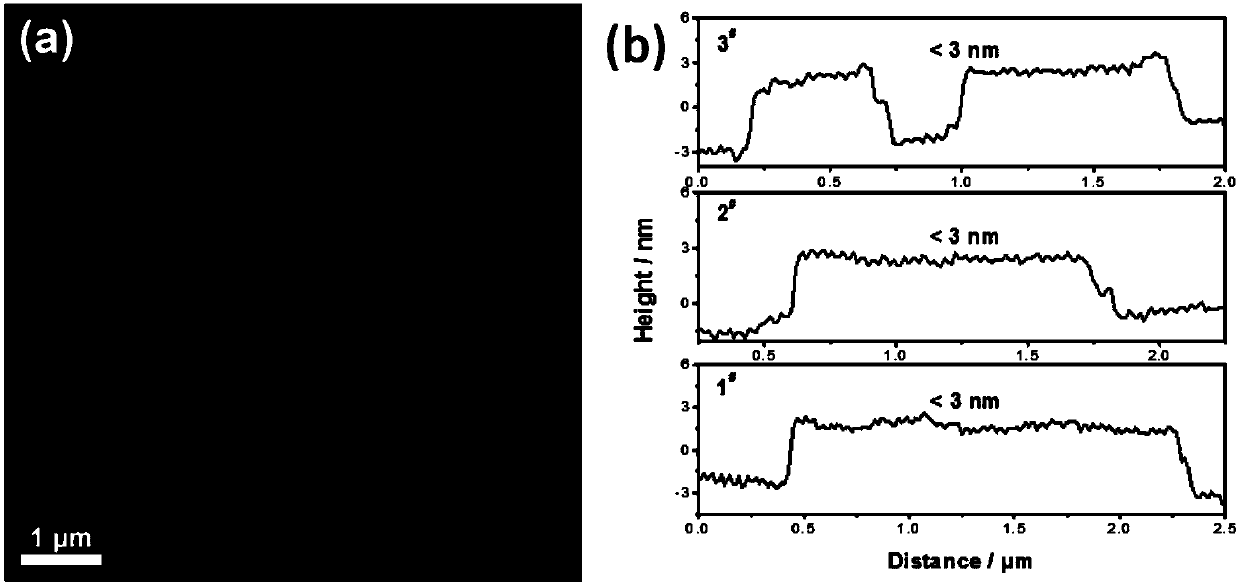

Method for preparing boron nitride nanosheet by using eutectic salt to strip boron nitride powder at high temperature

ActiveCN105523528AHigh aspect ratioComplete structural featuresMaterial nanotechnologyNitrogen compoundsCorrosive chemicalHigh volume manufacturing

The invention provides a method for preparing a boron nitride nanosheet by using a eutectic salt to strip boron nitride powder at high temperature. The method comprises following steps: grinding and mixing sodium chloride / potassium chloride eutectic salt with boron nitride powder, thermally treating at high temperature, and preparing in steps such as ultrasonic treatment, filtering, cleaning and drying to obtain the boron nitride nanosheet. The stripping method provided by the invention enables the preparation of a boron nitride nanosheet which is high in aspect ratio (that is large in lateral dimension and small in thickness), low in defect quantity and complete in structural features, and this method is suitable for batch production, does not relate to the use of toxic corrosive chemical reagents and is easy to perform.

Owner:香港城市大学深圳研究院

Clean water and method for preparing same

InactiveCN106007159ANo stimulationStimulation withoutTreatment involving filtrationMultistage water/sewage treatmentCorrosive chemicalOil and grease

The invention provides clean water and a method for preparing the same. The method for preparing the clean water includes steps of S10, sequentially carrying out aeration treatment by the aid of aeration layers on water, filtering the water by the aid of iron and manganese sand layers, filtering the water by the aid of quartz sand layers, filtering the water by the aid of activated carbon layers, then carrying out refined filtration, ultra-filtration and nano-filtration on the water and reserving the water for standby application; S20, arranging the water in alternating electromagnetic fields with the frequencies of 20,000-30,000 hertz to obtain magnetized water; S30, electrolyzing the magnetized water. The clean water and the method have the advantages that surfactants and irritant or corrosive chemical reagents are omitted in clean water production procedures, and accordingly the clean water is colorless and tasteless and is free of additives, irritation, corrosion, foam, residues and hand injury; fruits, vegetables, uncooked and cooked foods and tableware can be effectively cleaned, excellent effects of dispersing, suspending and washing grease and fine sundry particles can be realized, and heavy metal and certain pesticide toxin can be removed by means of electrostatic attraction; the clean water is free of skin allergy and irritation, and certain whitening and moisturizing effects can be realized by the clean water.

Owner:潘景慧

Stripping solution for preparing two-dimensional nanomaterial and application thereof

ActiveCN107555423AAvoid the disadvantages of flammability and explosionEasy to cleanGrapheneNanotechnologyCorrosive chemicalOrganic solvent

The invention provides a stripping solution for preparing a two-dimensional nanomaterial and application thereof. The stripping solution comprises the following components: an alcohol substance with the volume content of 0.05-59%, a methyl-containing organic solvent with the volume content of 0.03-8%, a fused ring compound with the concentration of 0.01mg / L-1g / L and the balance of water. The invention further provides application of the stripping solution. The stripping solution provided by the invention uses liquid water as a main body, so that the defects that the organic solvent is flammable and explosive are avoided, the cost is reduced, and use of strong acids and strong corrosive chemical reagents is avoided; layered solid particles are dispersed in the stripping solution, and underthe actions of mechanical shearing and ultrasonic, stripping of the layered solid particles into two-dimensional nanoflakes can be effectively accelerated, so that secondary aggregation of the two-dimensional nanoflakes is avoided.

Owner:北京华科讯能石墨烯新技术研究院有限公司

Process and system for rinsing of semiconductor substrates

InactiveUS6878213B1Inorganic/elemental detergent compounding agentsNon-surface-active detergent compositionsCorrosive chemicalSemiconductor materials

Semiconductor substrates, particularly metallized substrates such as partially processed wafers, are rinsed with an aqueous medium, preferably deionized water, which further contains an anti-corrosive chemical agent or agents selected so as to minimize corrosion of metals resulting from contact with the water. The amount of anti-corrosive chemical agent is maintained in a controlled manner at a predetermined level or within a predetermined range preferably the rinsing with aqueous medium containing anticorrosive chemical agent is also carried out for a specified time, followed by further rinsing with deionized water alone. The rinsing may be combined, either in the same vessel or in a different vessel, with a subsequent drying step, such as a drying process utilizing a drying vapor introduced into the rinse tank or into a downstream vessel. The drying vapor condenses on the surface of the semiconductor material and reduces the surface tension of residual process fluid, causing the residual process fluid to flow off the surface.

Owner:SCP SERVICES

Manufacture method of chemicals independent cargo hold in hull

A manufacture method of a chemicals independent cargo hold in a hull is characterized by including the steps of designing drawing stock, and directly manufacturing stainless steel parts to be machined, in a manufacturer; scribing steel material, cutting and blanking; cold-machining the stainless steel parts; assembling and welding the stainless steel parts cold-machined; assembling and welding section by section; assembling an independent cargo hold; launching after pickling-passivation tightness test. The stainless steel parts are directly manufactured by the stainless steel manufacturer, so that expenditure on purchasing machining equipment is greatly saved, management cost is reduced, and construction period is short; in addition, the parts, in contact with liquid cargoes, of both side of the cargo hold are made of double-phase stainless steel, the part, in contact with the liquid cargoes, of one side of the cargo hold is made of stainless steel composite plates, and accordingly the cargo hold has high strength and corrosion resistance and the cost is saved; the process is reasonable, manufacture period is short, the cost is low, the manufactured independent cargo hold is high in strength, high in tightness and resistant to corrosion, and the needs for carrying high-corrosive chemicals are met.

Owner:ZHOUSHAN PENGLAI SHIP REPAIR & BUILDING CO LTD

Corrosive chemical liquid used for corrosion of silicon magma on surface of silicon chip and corrosion method thereof

The invention discloses corrosive chemical liquid used for corrosion of silicon magma on the surface of silicon chips. The corrosive chemical liquid comprises the following components, by volume percentage, 40 to 43% of an aqueous solution of NH4F, 8 to 10% of an aqueous solution of HF and 48 to 52% of H2O2. The corrosive chemical liquid has a strong corrosion effect and a stable corrosion rate, and enables the goal of corroding silicon magma on the surface of silicon chips to be realized; preparation of the corrosive chemical liquid is convenient and has the advantage of strong repeatability; the invention also discloses a method of corroding silicon magma with the corrosive chemical liquid, and the method has the advantages of a simple process, easily controllable reaction process and low cost.

Owner:JA SOLAR +1

Method Of Protecting Teeth Against Erosion

Disclosed are methods of treating and protecting teeth against erosion by use of oral compositions comprising polymeric mineral surface active agents, metal ions such as stannous and zinc and combinations thereof. The present methods provide improved resistance of teeth to erosive demineralization or dissolution and prevention of tooth damage by subsequent exposure of teeth to erosive chemicals such as acidic foods and beverages.

Owner:PROCTER & GAMBLE CO

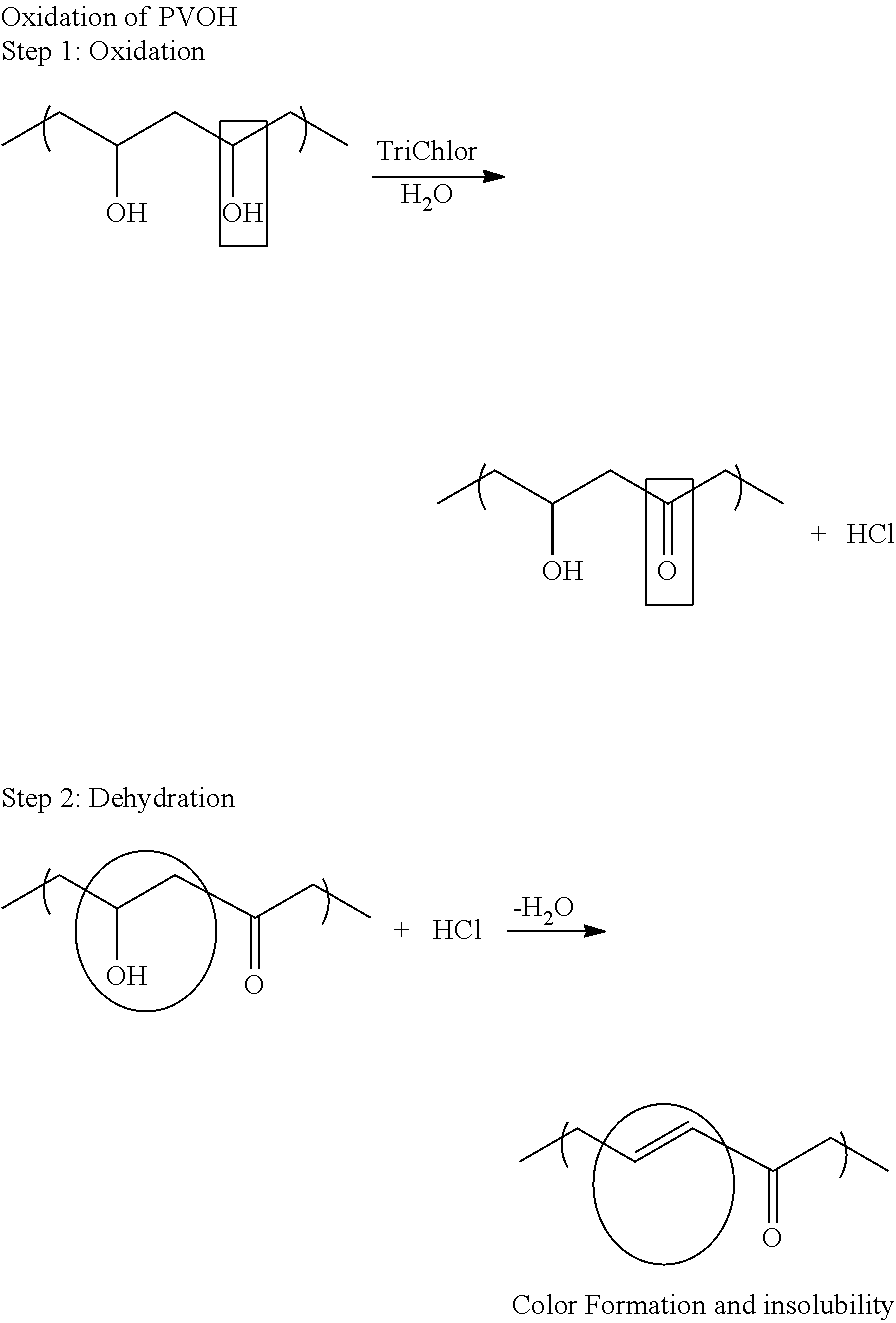

Stabilizer for aggressive chemicals packaging

ActiveUS20170058142A1Good colorIncrease flexibilityFlexible coversWrappersCorrosive chemicalSolubility

Water soluble films and coatings herein address the problem of water insolubility, color formation, and brittleness upon exposure to oxidizing chemicals, including strong or aggressive oxidizing chemicals. The water soluble films or coatings may include a water soluble polymer and a reactive precursor, such as an alkanolamine or an alkyl alkanolamine. The reactive precursor is water soluble and reactive with oxidizing compounds. Water soluble films or coatings herein may also include a water soluble polymer and an additive mixture including an alkanolamine or an alkyl alkanolamine. The films or coatings, upon exposure to an oxidizing chemical for 8 weeks at 40° C. and ambient humidity, may dissolve fully or achieve 90% dissolution at times of less than 10 minutes. The water soluble films and coatings may advantageously be used with oxidizing chemicals while maintaining water solubility, acceptable color, and flexibility, such as in unit dose packaging, even over extended exposure periods.

Owner:SEKISUI SPECIALTY CHEM AMERICA

Solvent-resistant, corrosion-resistant and high-flux composite nanofiltration membrane and preparation method thereof

ActiveCN106000121AHigh solvent throughputLoose structureSemi-permeable membranesMembranesCorrosive chemicalUltrafiltration

The invention discloses a solvent-resistant, corrosion-resistant and high-flux composite nanofiltration membrane and a preparation method thereof. The method comprises steps as follows: a mixed liquid of a reduced graphene oxide aqueous solution and ammonia water A flows through a porous supporting membrane, reduced graphene oxide is deposited on the porous supporting membrane, and the composite nanofiltration membrane is obtained; the mixed liquid flows through the porous supporting membrane under the action of pressure. According to the method, the preparation process is simple and easy to implement, the cost is relatively low, the porous supporting membrane used in the method is a microfiltration membrane at the relatively low price, and, however, ultrafiltration membranes in the relatively high price are frequently used in the prior art. A graphene composite nanofiltration membrane organic solvent prepared with the method is high in flux and has the organic dye rejection rate close to 100%. A separation layer of the graphene composite nanofiltration membrane prepared with the method comprises solvated graphene and has very good resistance to various organic solvents and corrosive chemical environments.

Owner:TSINGHUA UNIV

In-line heater for use in semiconductor wet chemical processing and method of manufacturing the same

ActiveUS20050274714A1Reduce thermal stressMolten spray coatingVacuum evaporation coatingThermal dilatationChemical treatment

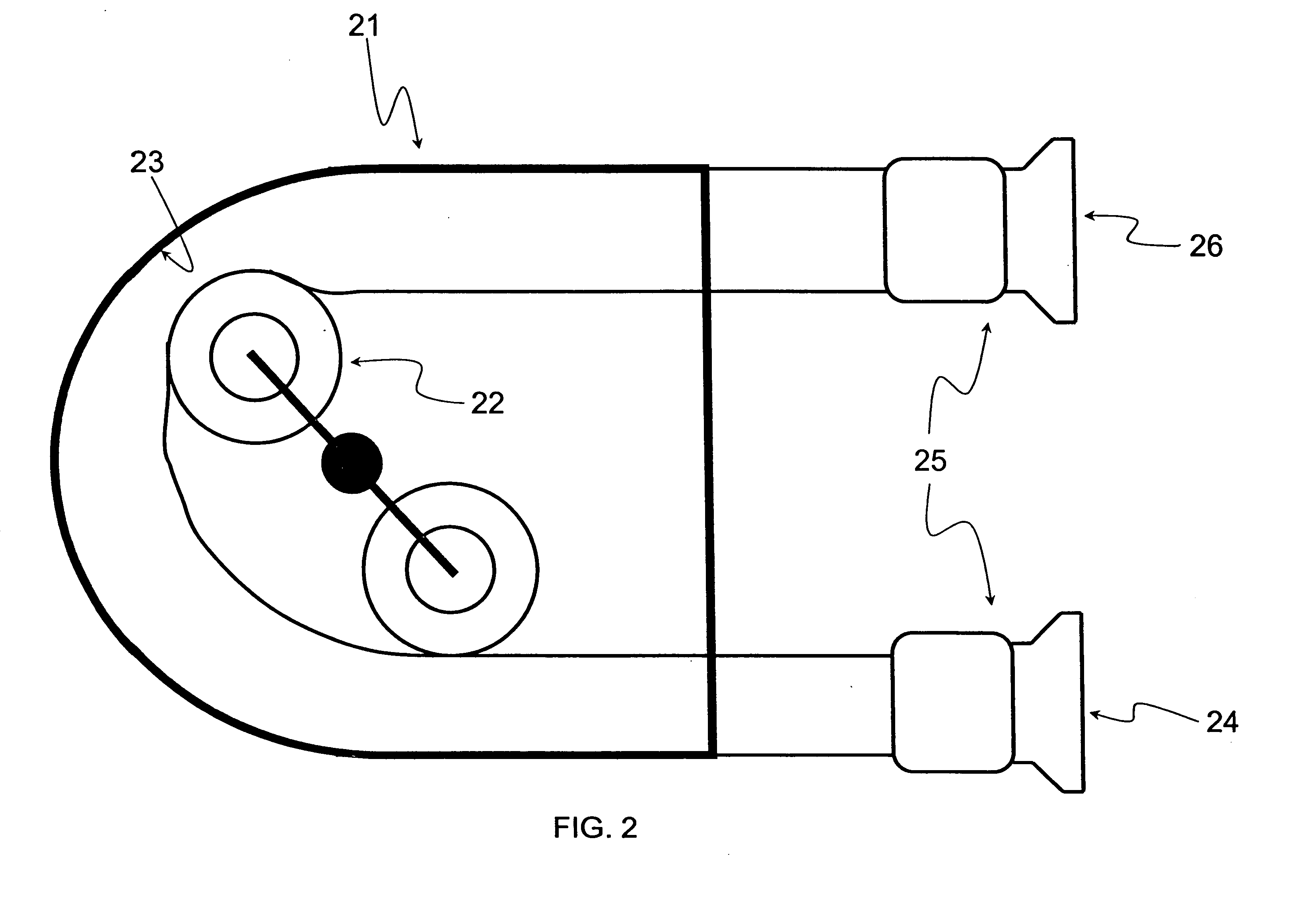

An in-line heater for use in semiconductor wet chemical processing comprises a single crystal alumina substrate, a resistive heating element disposed on the single crystal alumina substrate, and a protective layer disposed over the resistive heating element. The single crystal alumina substrate has a moderate coefficient of thermal expansion (CTE) that is substantially equivalent to the CTEs of the resistive heating element and the protective layer. Therefore, cracking between the substrate and the protective layer can be minimized. The in-line heater in accordance with this invention exhibits an excellent corrosion-resistance capability even at high temperature and can carry a wide variety of corrosive chemicals including hydrofluoride solution.

Owner:WATLOW ELECTRIC MFG

Fluoroplastic composite elastomer

InactiveUS8012555B2Improve bending resistanceLow costEnvelopes/bags making machineryFlexible member pumpsPeristaltic pumpElastomer

An improved fluoroplastic lined elastomeric tube that can maintain a stable flow rate while pumping aggressive chemicals in a peristaltic pump for an extended period of time and is fabricated in sizes ranging from 0.5 mm to 100 mm in inside diameter. The inner fluoroplastic liner comprises a composite of expanded polytetrafluoroethylene and a fluoroplastic polymer resulting in improved flex life over single component fluoroplastics. The inventive liner is bonded to either an unreinforced elastomer or a fiber reinforced elastomer for use in both low and high pressure peristaltic pump applications.

Owner:MAZTECH

Flange sealing gasket for chemical sewage pipe connection

InactiveCN104927125AImprove high temperature resistanceImprove corrosion resistanceCorrosive chemicalSodium stearate

The invention discloses a flange sealing gasket for chemical sewage pipe connection and relates to the technical field of sealing material production. The flange sealing gasket is prepared from raw materials in parts by mass as follows: 80-90 parts of NBR (nitrile butadiene rubber), 12-15 parts of nano glass fibers, 20-25 parts of polyphenylene sulfide, 15-20 parts of polyvinyl alcohol, 10-12 parts of kaolin, 8-11 parts of carboxymethyl chitosan, 5-8 parts of white carbon black, 4-7 parts of guar gum, 3-5 parts of sodium stearate, 1-3 parts of an anti-aging agent, 20-25 parts of polyethylene glycol and 25-30 parts of water. The NBR is modified with the nano glass fibers, multiple aids are used, the comprehensive performance of the sealing gasket is improved, and the prepared sealing gasket is applicable to corrosive chemical sewage at the temperature lower than 198 DEG C and is long in service life.

Owner:DONGZHI QUNSHENG CHEM EQUIP CO LTD

Cleaning compositions and methods for removing baked on grease from fryers and other hot surfaces

ActiveUS20190169550A1Less cleaningReduce exposureInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCorrosive chemicalOil and grease

Cleaning compositions and methods of use thereof for cleaning fryers and other hard surfaces soiled by grease, shortening, oils and other soils commonly encountered in the food service industry are disclosed. Cleaning compositions and methods of use which beneficially remove soils from vertical and / or inverted surfaces, reduce the cleaning time required for removing such difficult to remove and baked on soils, reduce exposure to hot surfaces by allowing cleaning at or near room temperature, reduce exposure to caustic chemicals, and / or eliminate the need for personal protective equipment (PPE) for use of the cleaning compositions are disclosed.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com