Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1868results about "Disc wheels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

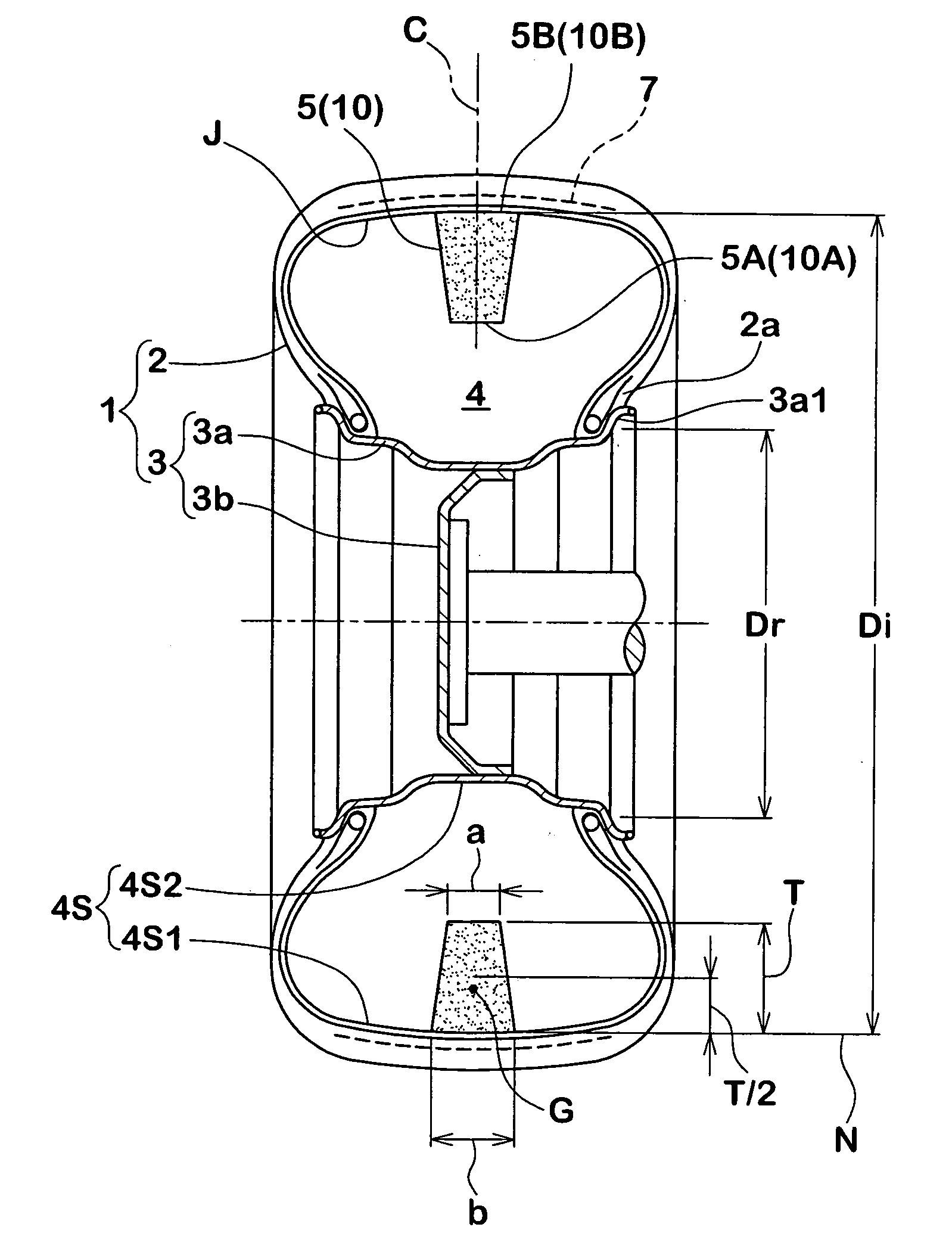

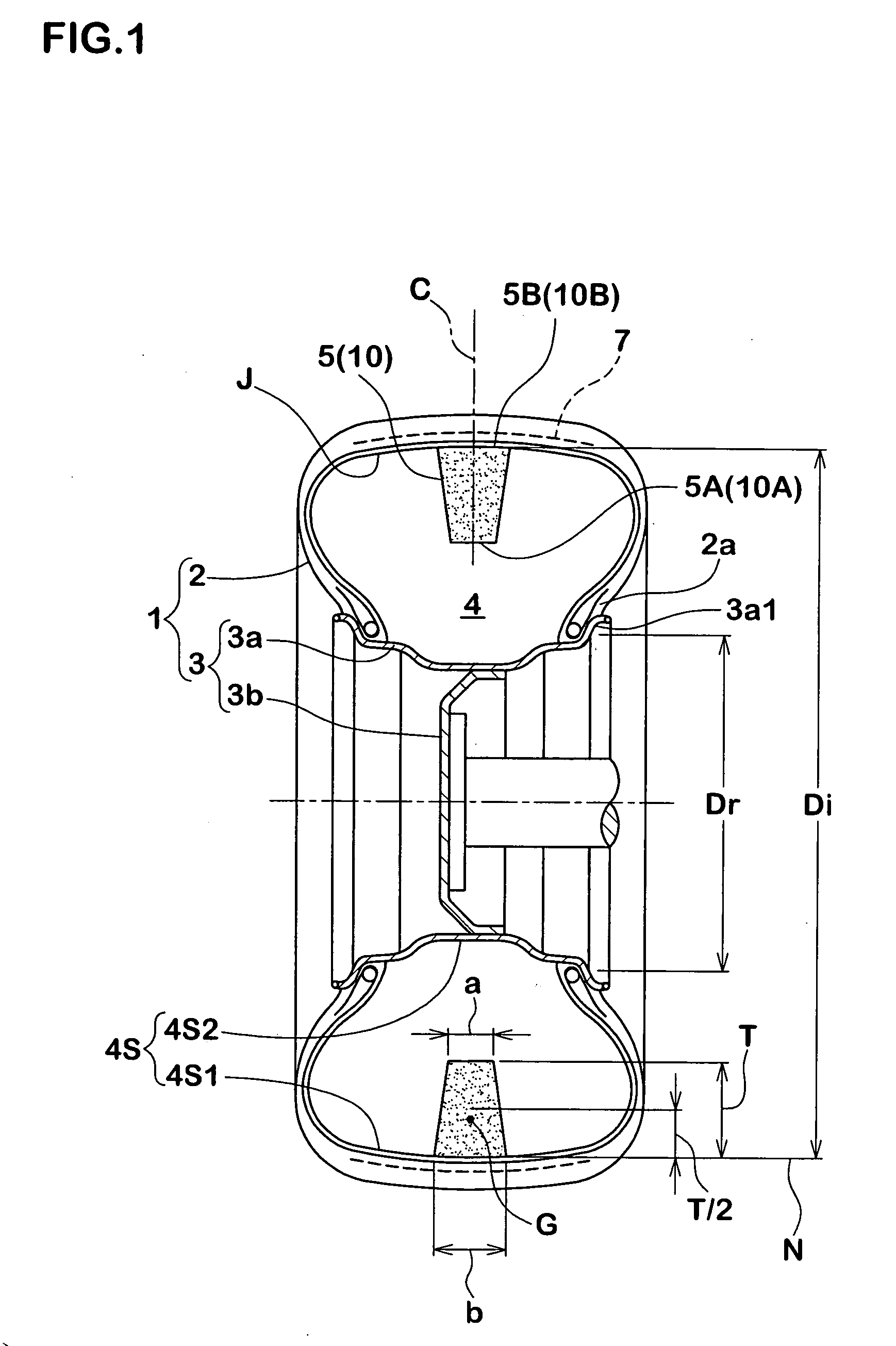

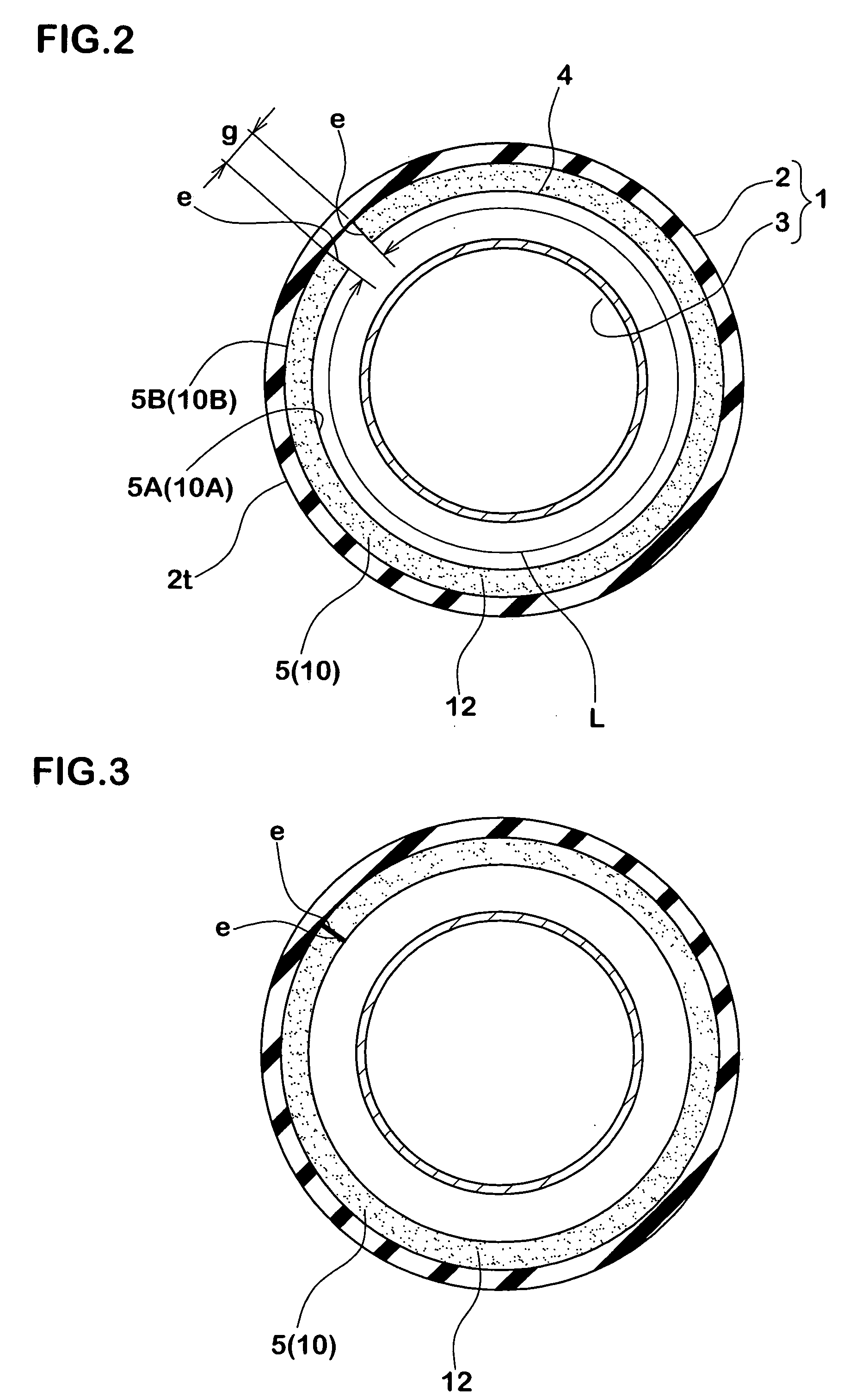

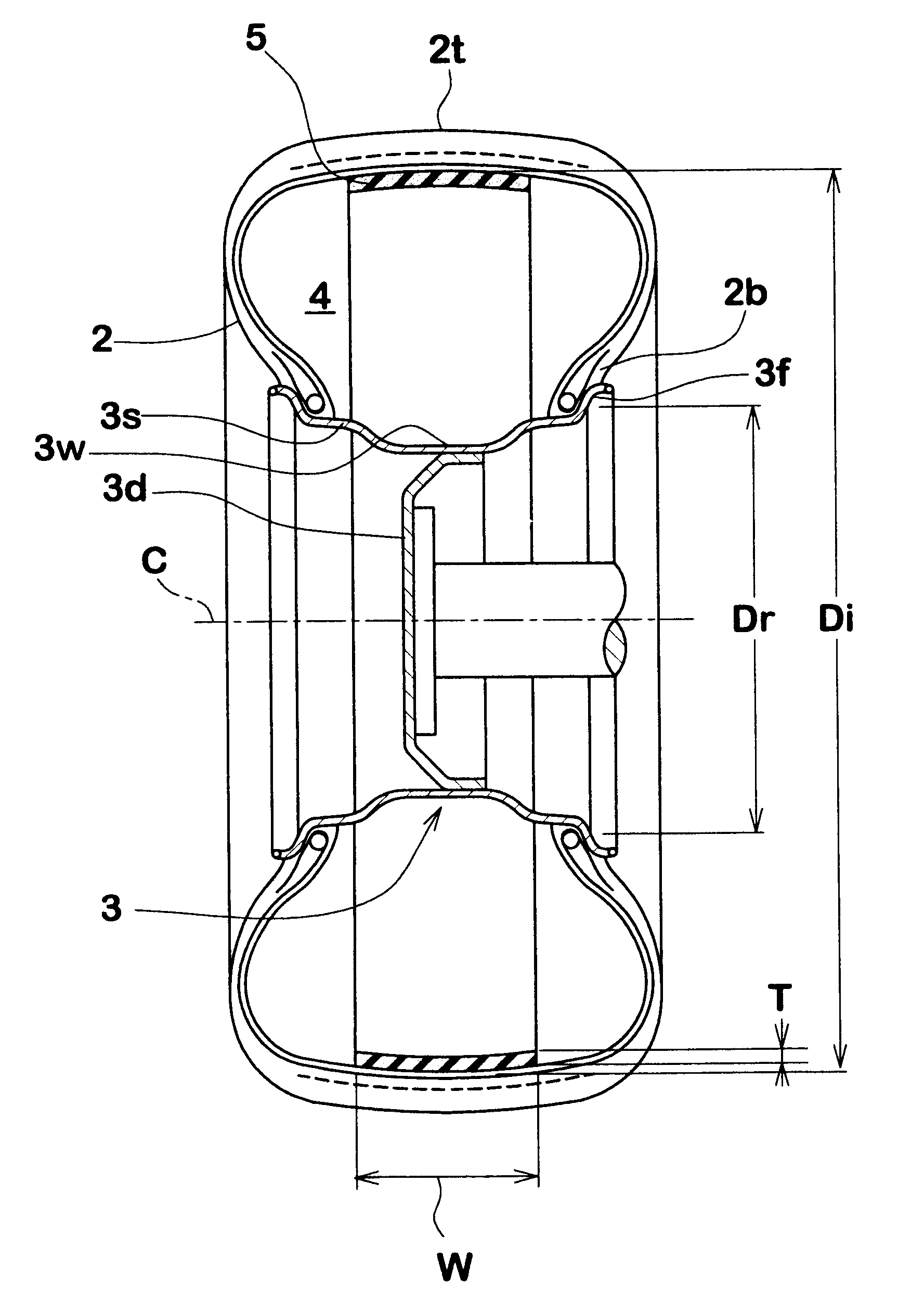

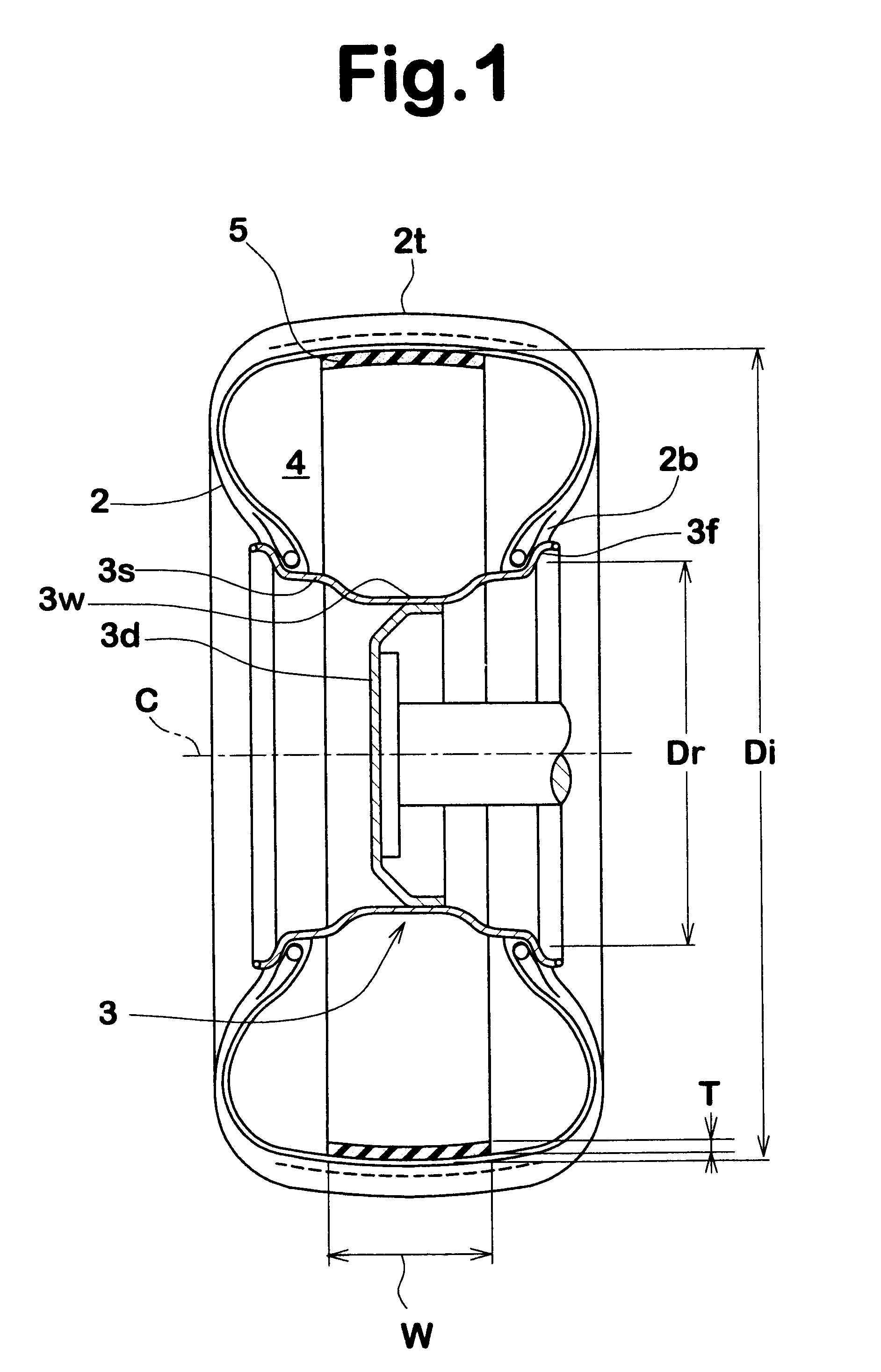

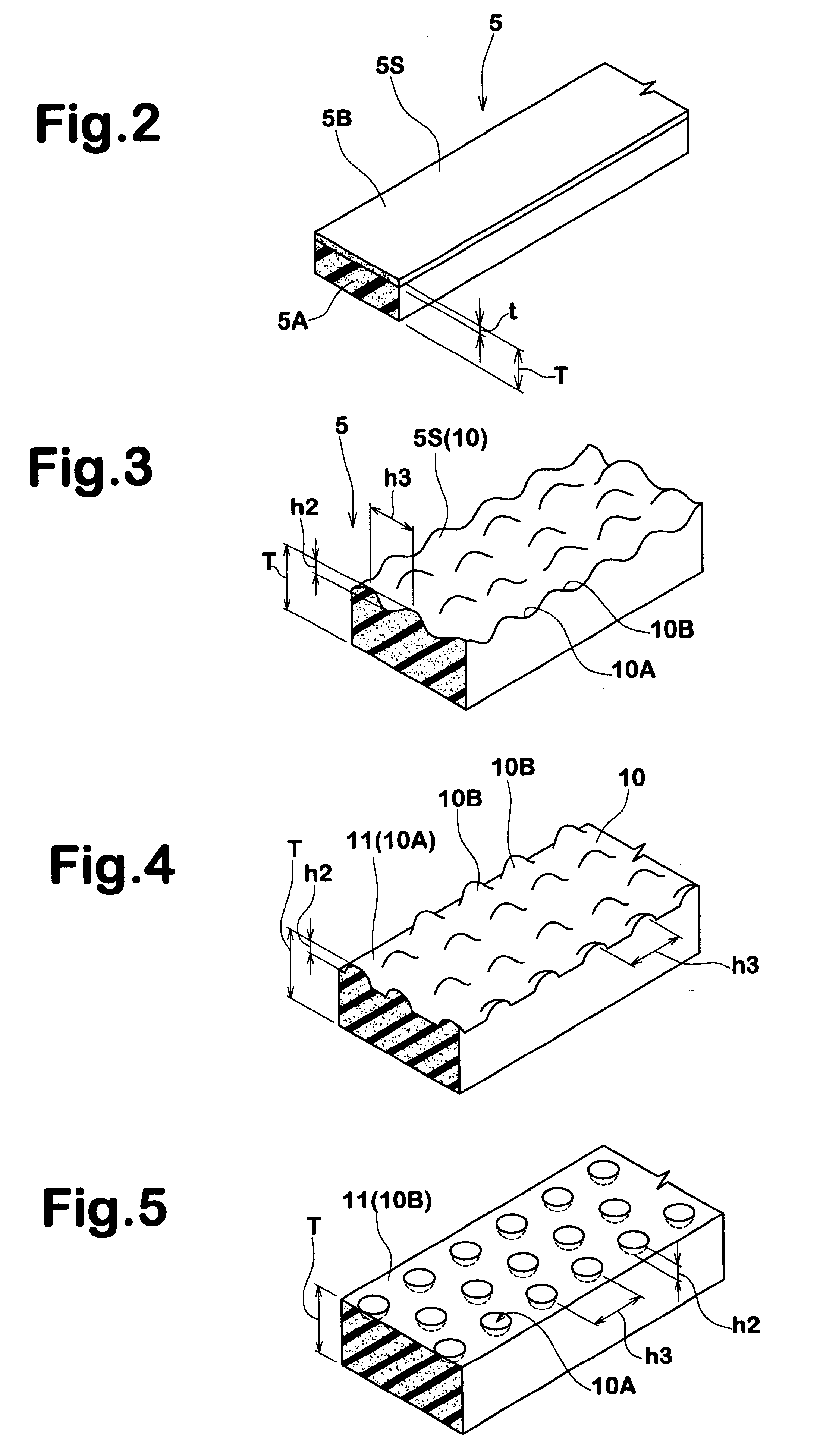

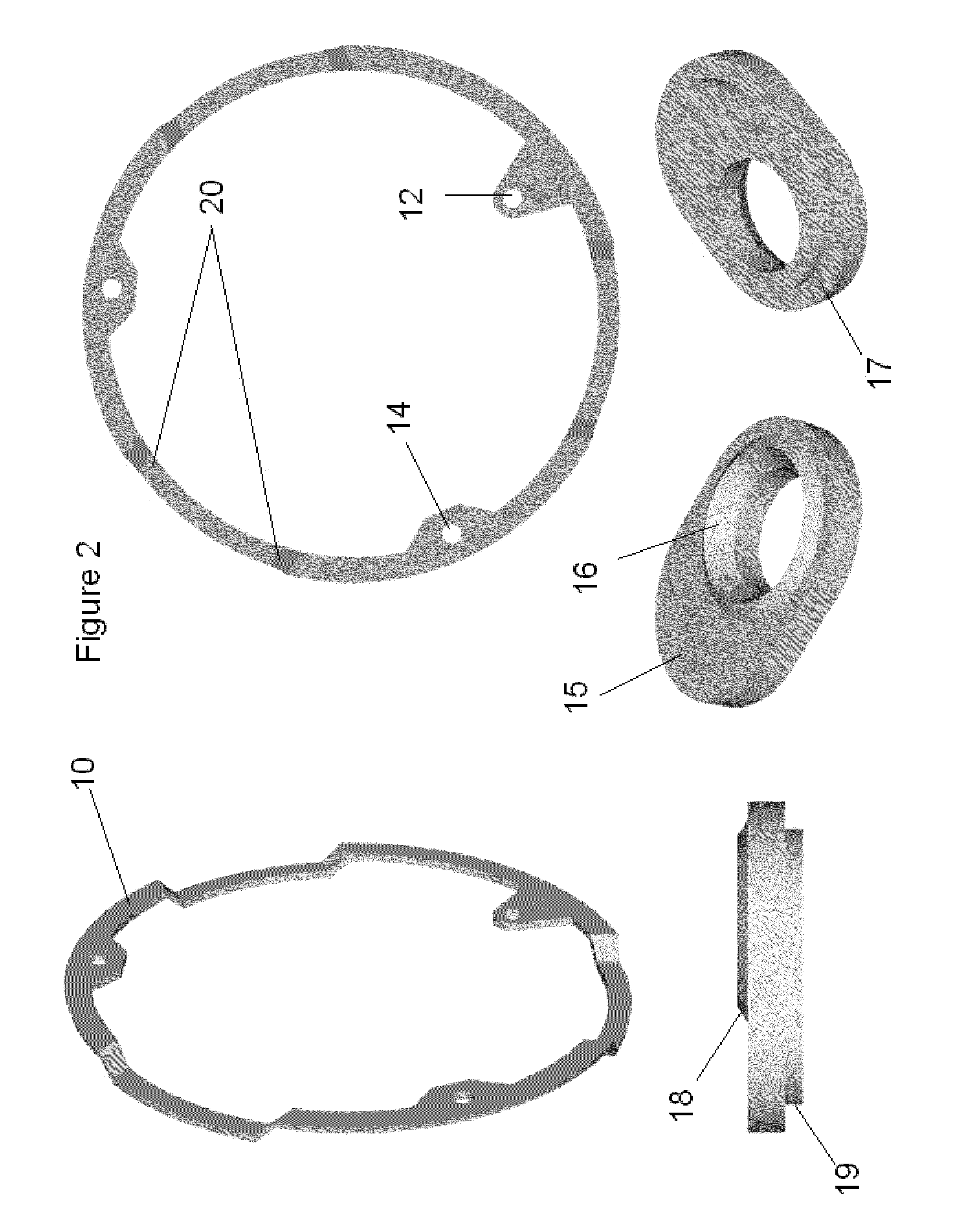

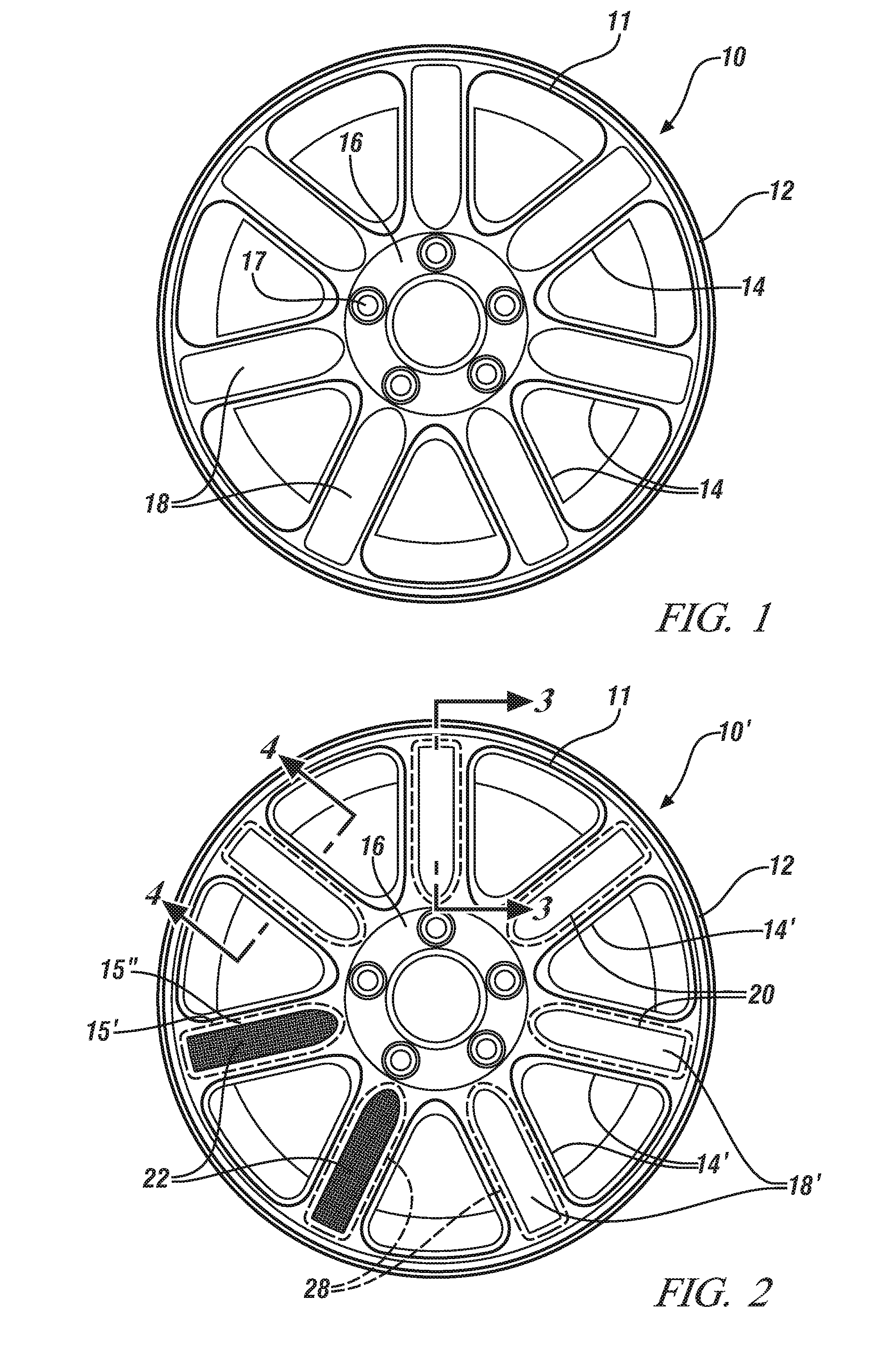

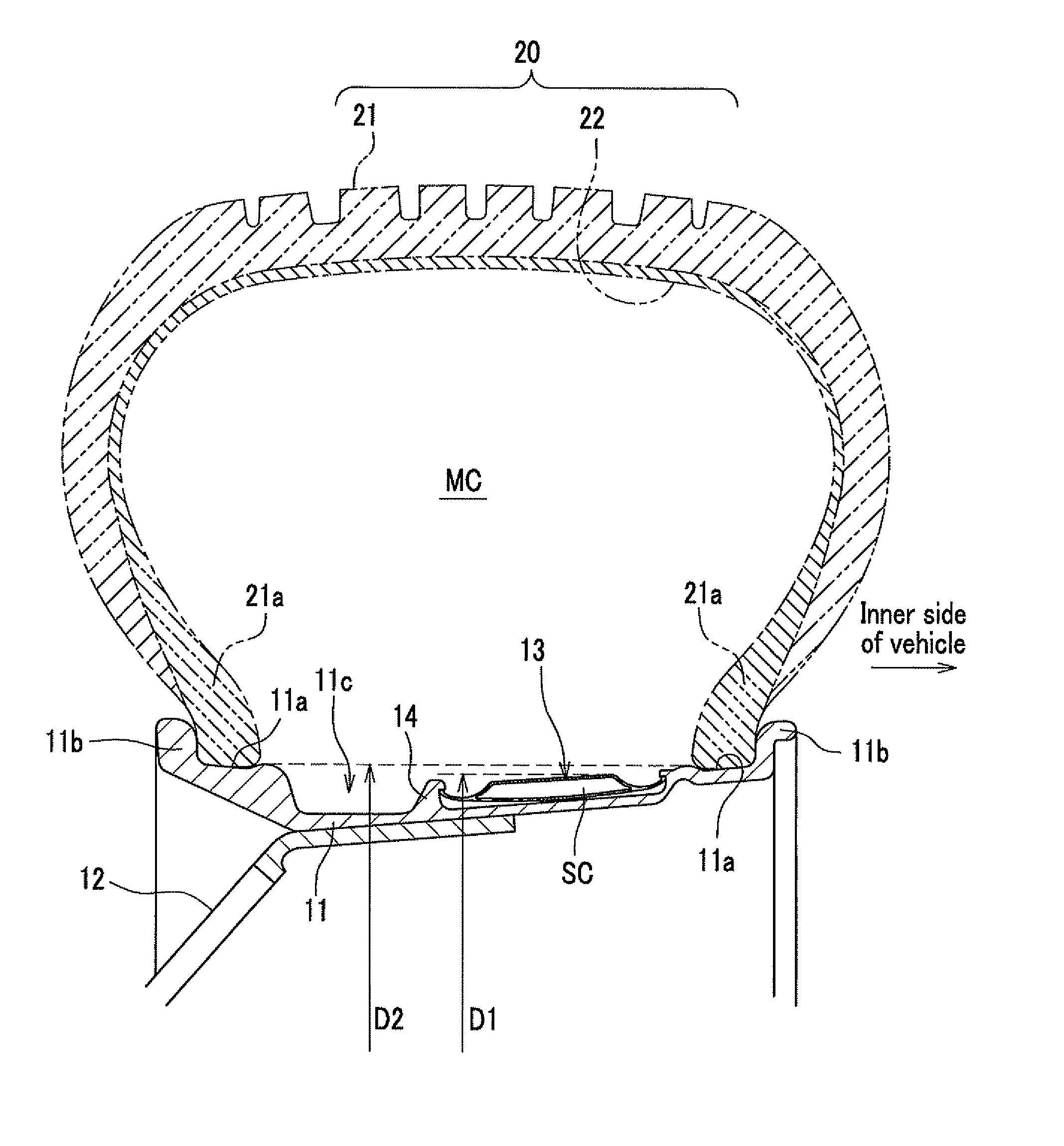

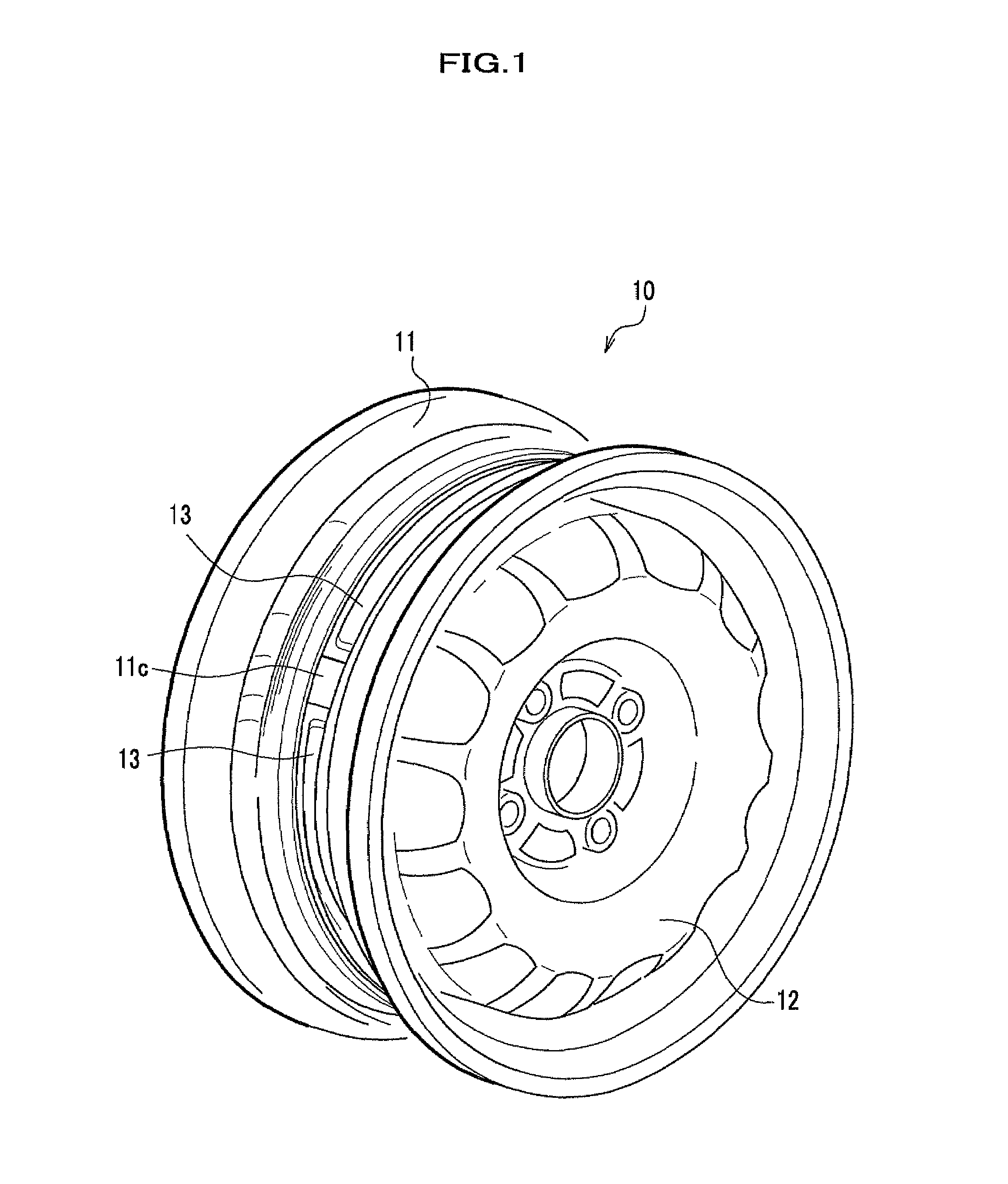

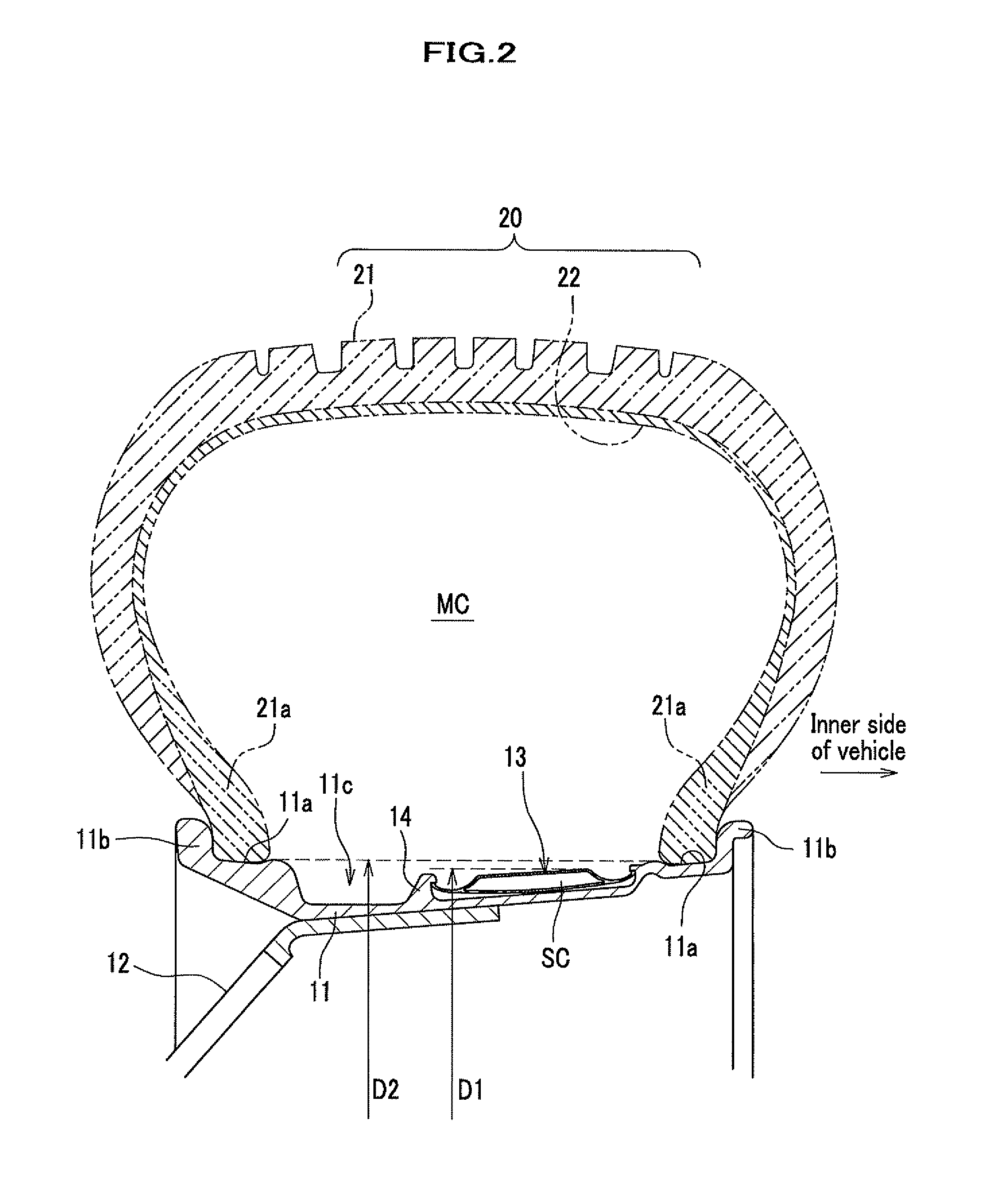

Assembly of pneumatic tire and rim, sound suppressing body used for the assembly and pneumatic tire storage method

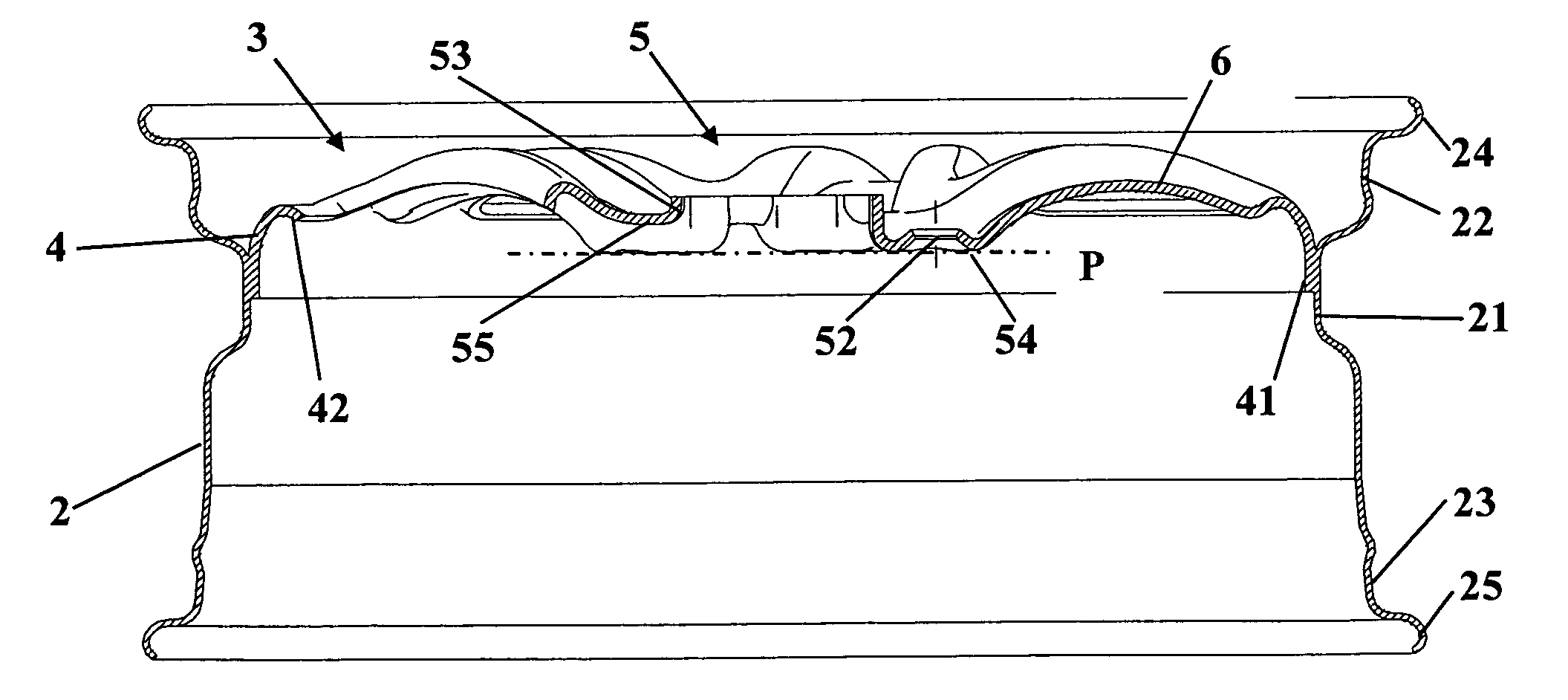

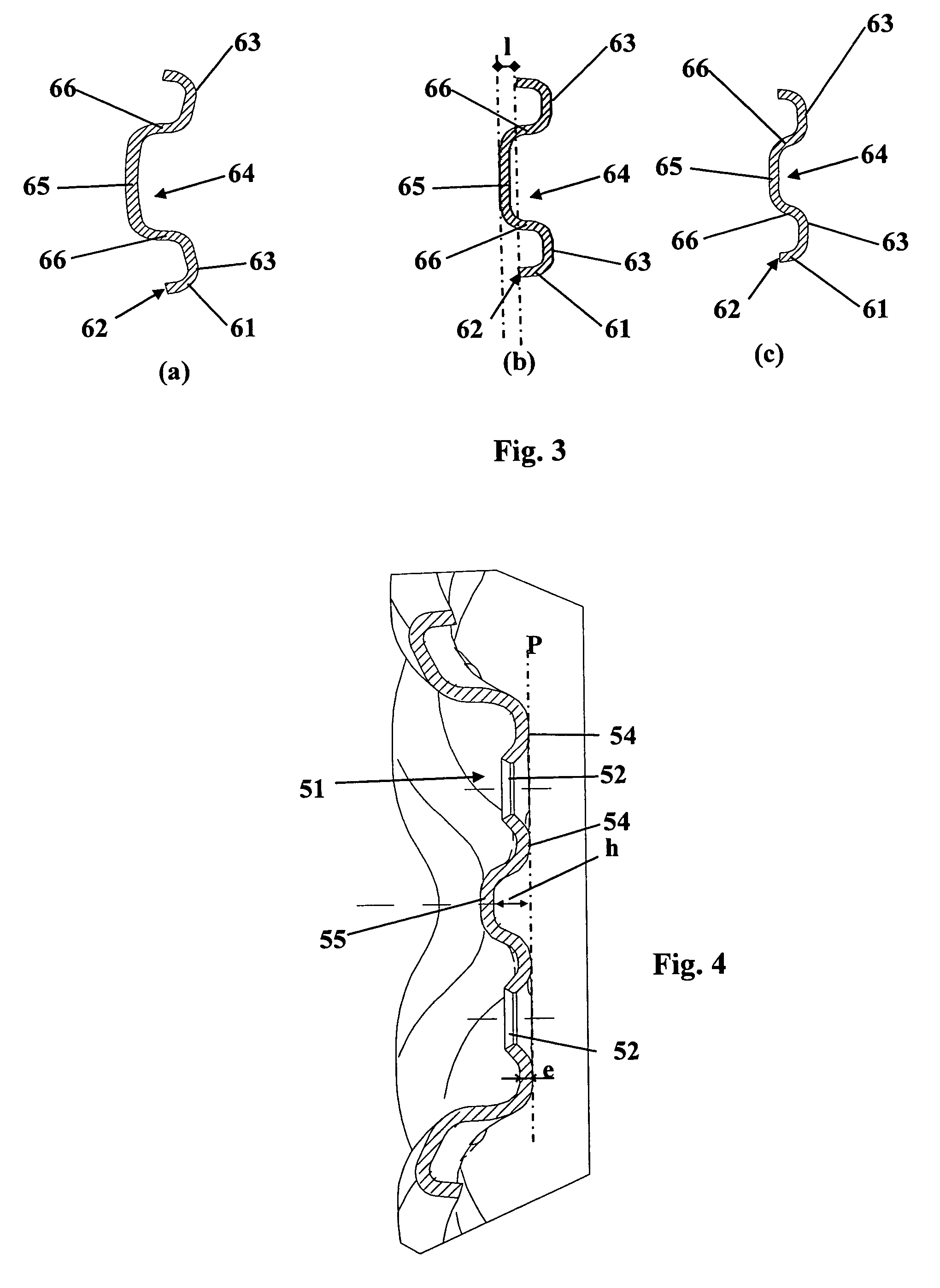

An Assembly of a pneumatic tire and a rim and a sound suppressing body used for the assembly, the assembly wherein the sound suppressing body having a volume (V2) of 0.4 to 20% of the total volume (V1) of a tire inside hollow and formed of a sponge material extending in circumferential direction is installed in the tire inside hollow formed by the tire and the rim; the sound suppressing body comprising a tire side sound suppressing body having a bottom face fixed to the tire or a rim side sound suppressing body having a bottom face fixed to the rim, wherein the area gravity of the tire side sound suppressing body main part exceeding the bead base line of the rim side sound suppressing body is positioned in an area ranging form the middle point of a height form a reference plane to the trip of the sound suppressing body to the reference plane.

Owner:SUMITOMO RUBBER IND LTD

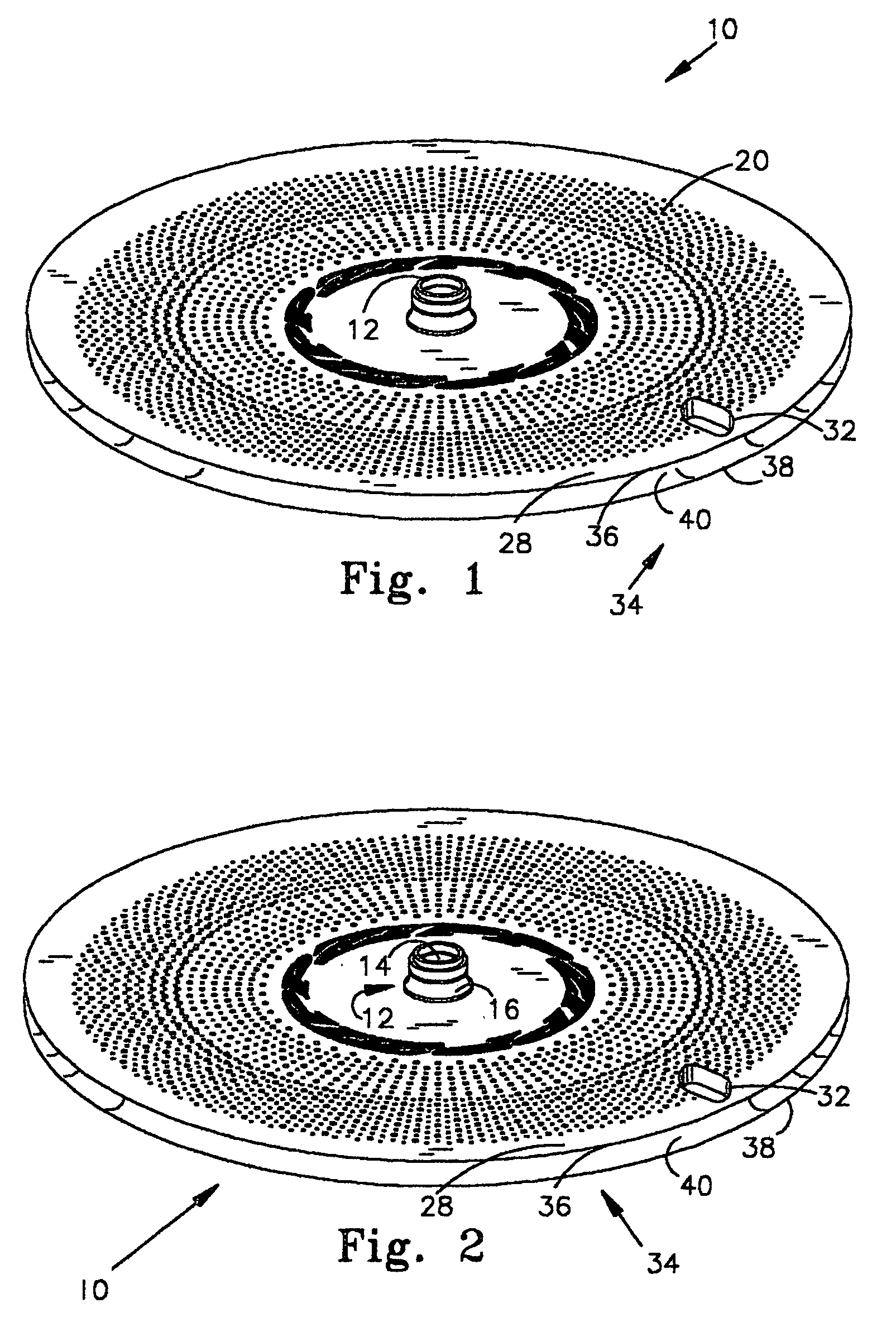

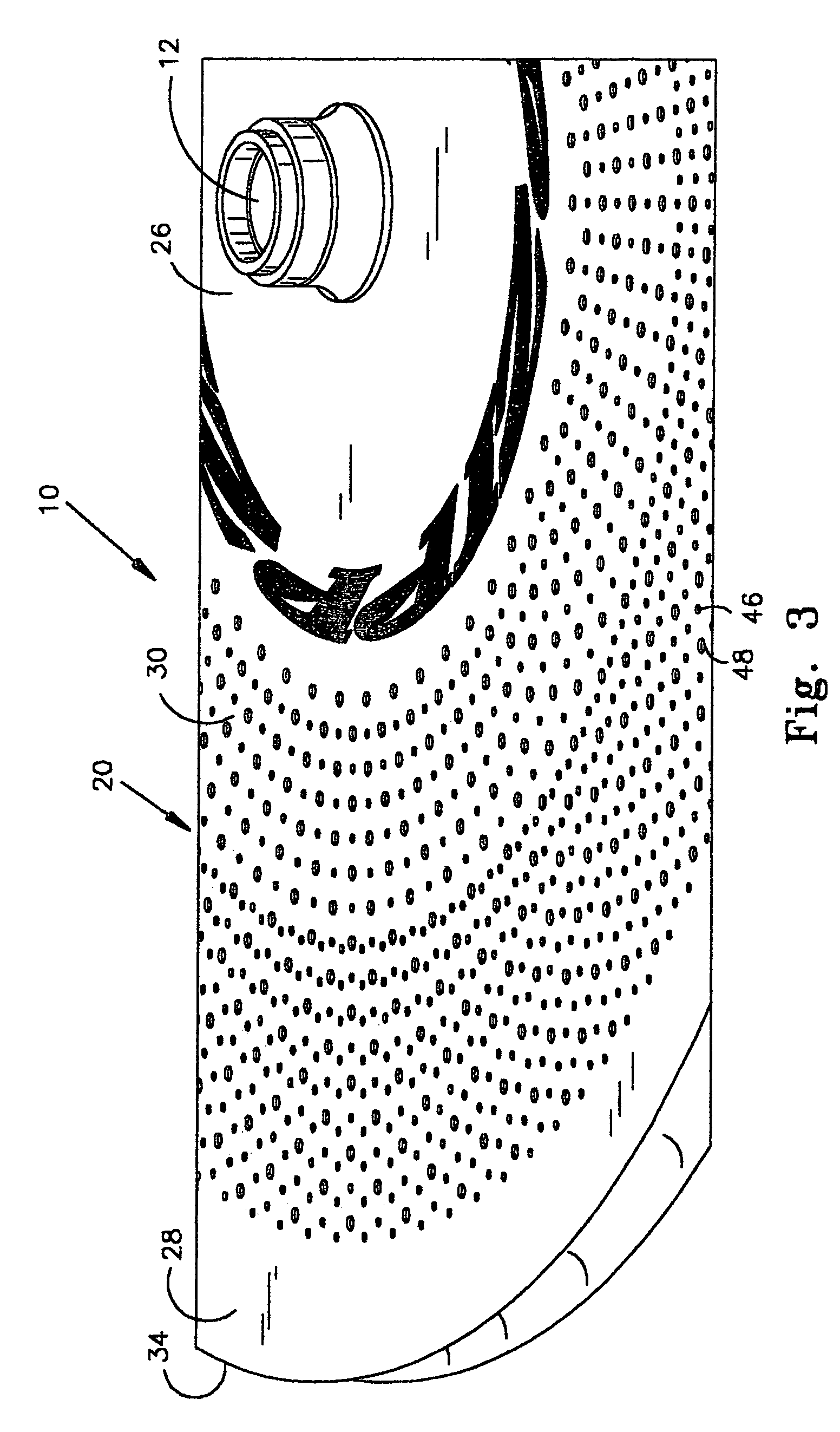

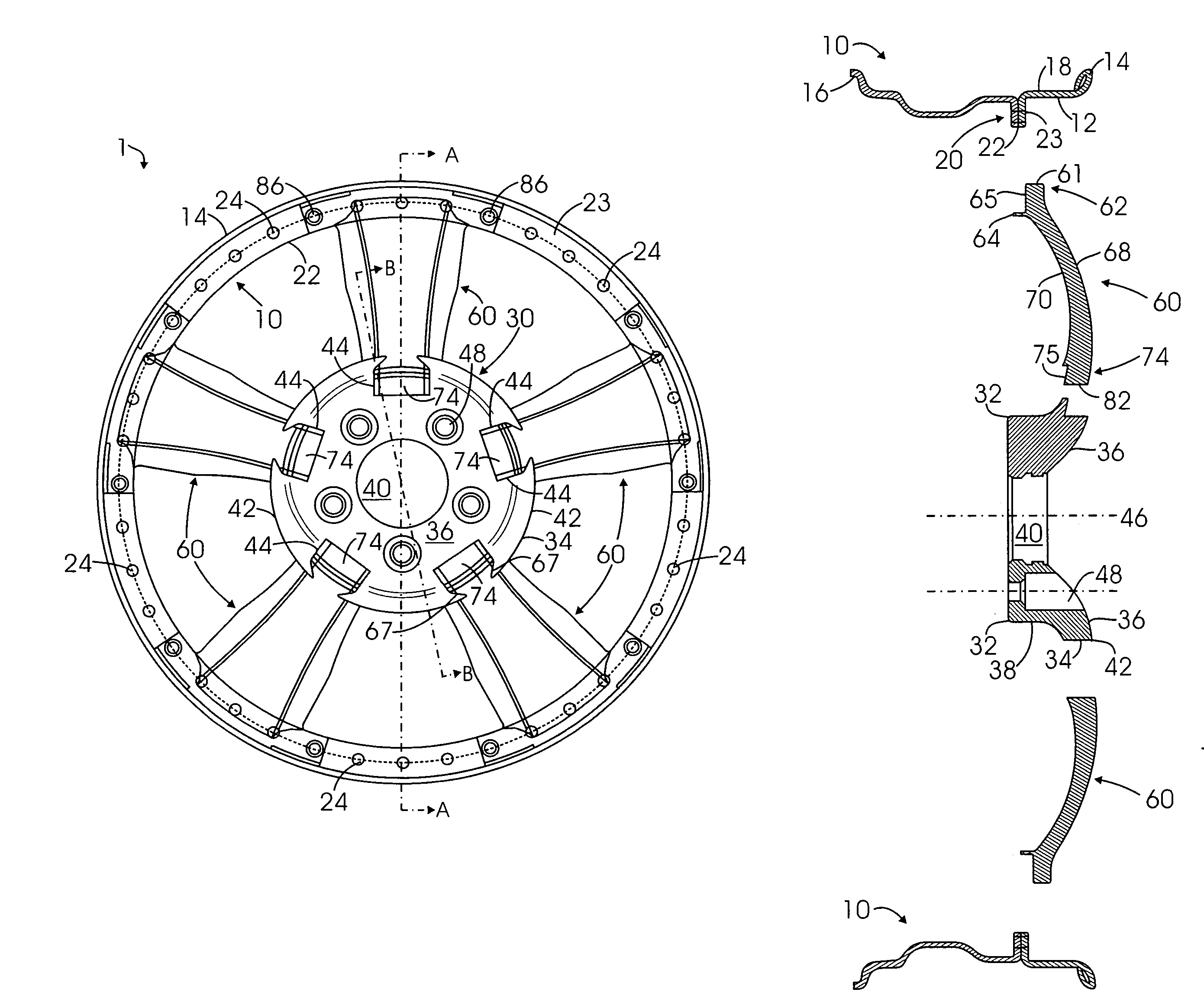

Aerodynamic surfaced bicycle wheel

InactiveUS7114785B2Reduce air resistanceHigh speedNon-metallic wheel bodyWheel protectionAerodynamic dragEngineering

A bicycle wheel includes a tire engaging portion located at the outward perimeter of the wheel, an inner portion located radially inward from the tire engaging portion A pair of air engaging side surfaces extend radially between the inner portion and the tire engaging portion forming the sides of the wheel. The air engaging side surfaces contain a plurality of surface features designed to create a turbulent boundary layer when the wheel travels through air to reduce aerodynamic drag on the wheel.

Owner:COMPOSITECH

Plastic wheel assembly and mounting sleeve with stabilizing recess

Owner:GEO PLASTICS

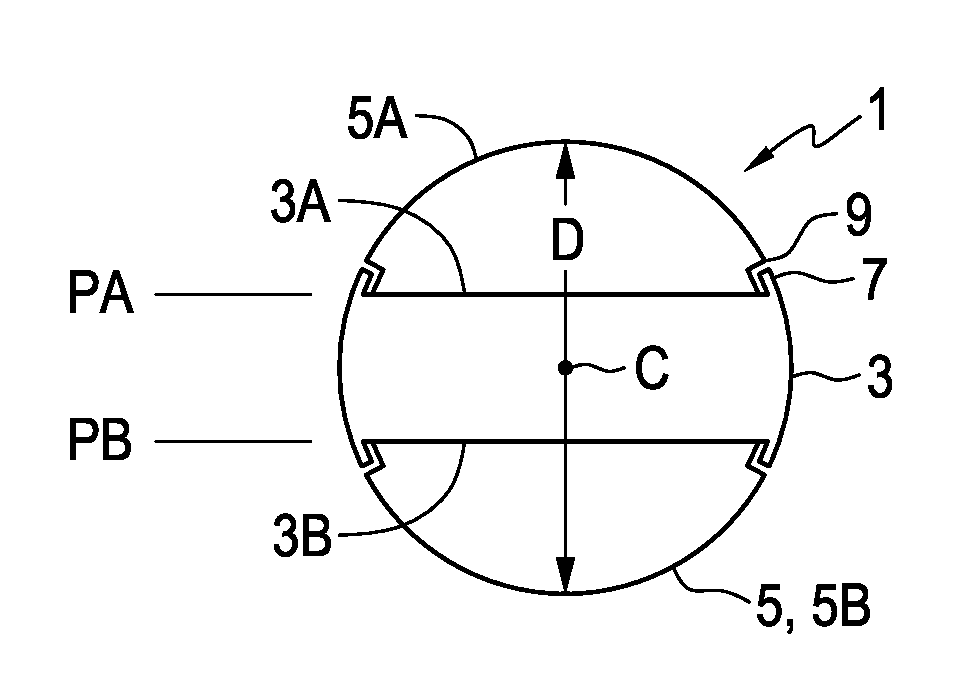

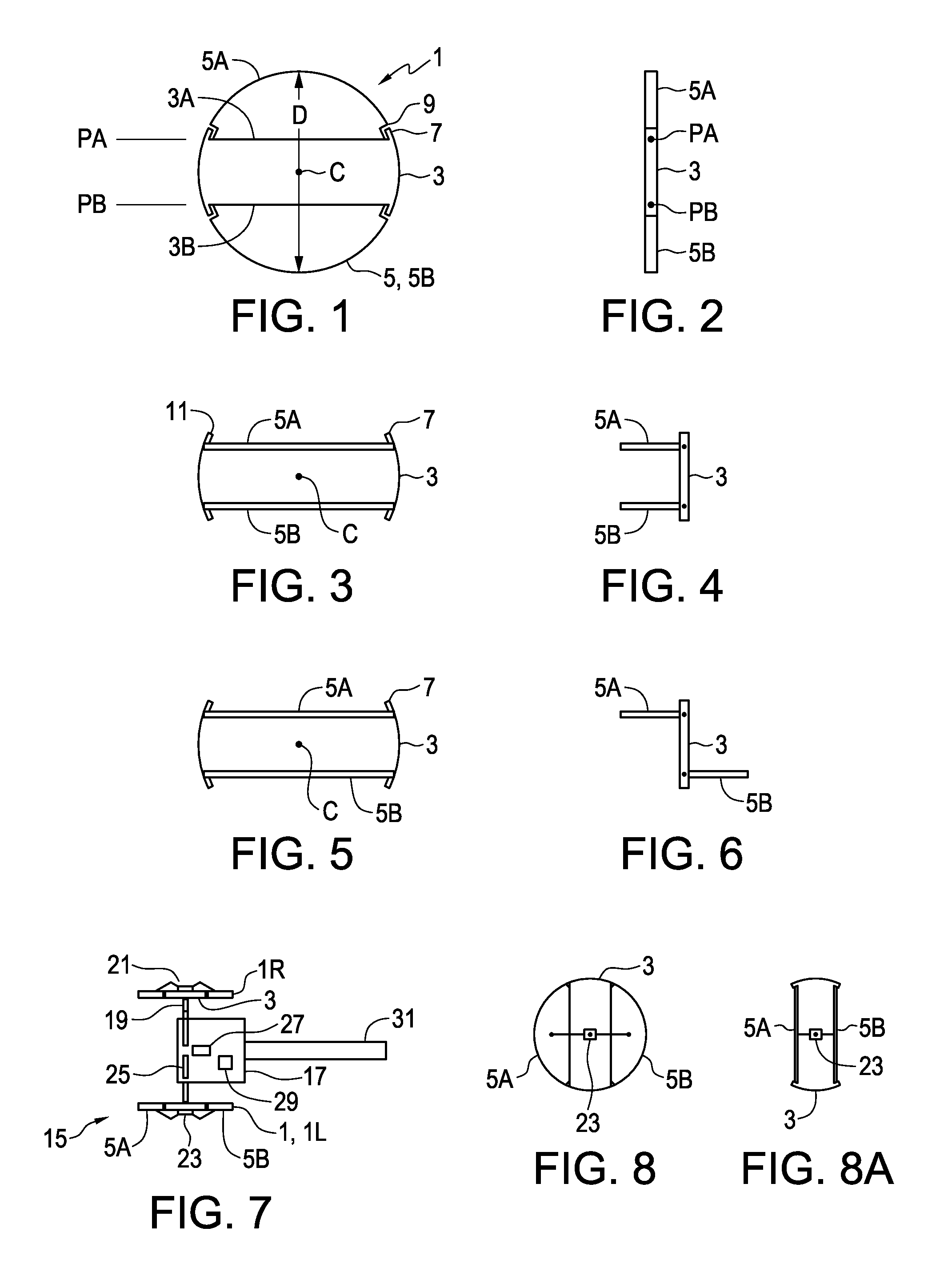

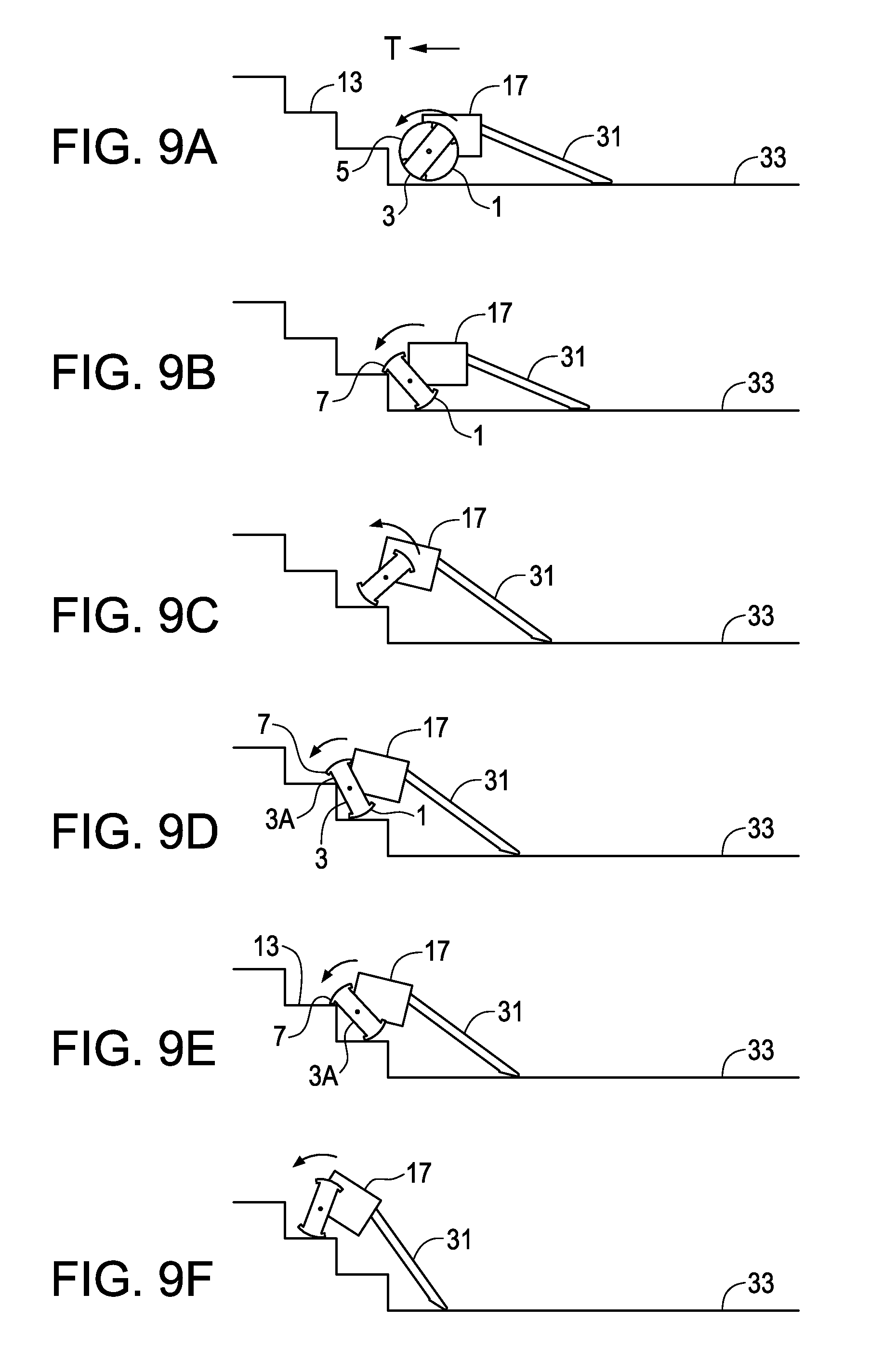

Wheel with folding segments

ActiveUS8753155B2Efficient advancementEconomical and simpleAmphibious vehiclesCarriage/perambulator accessoriesEngineeringMechanical engineering

Owner:ZENON DRAGAN

Tire noise reducing system

Owner:SUMITOMO RUBBER IND LTD

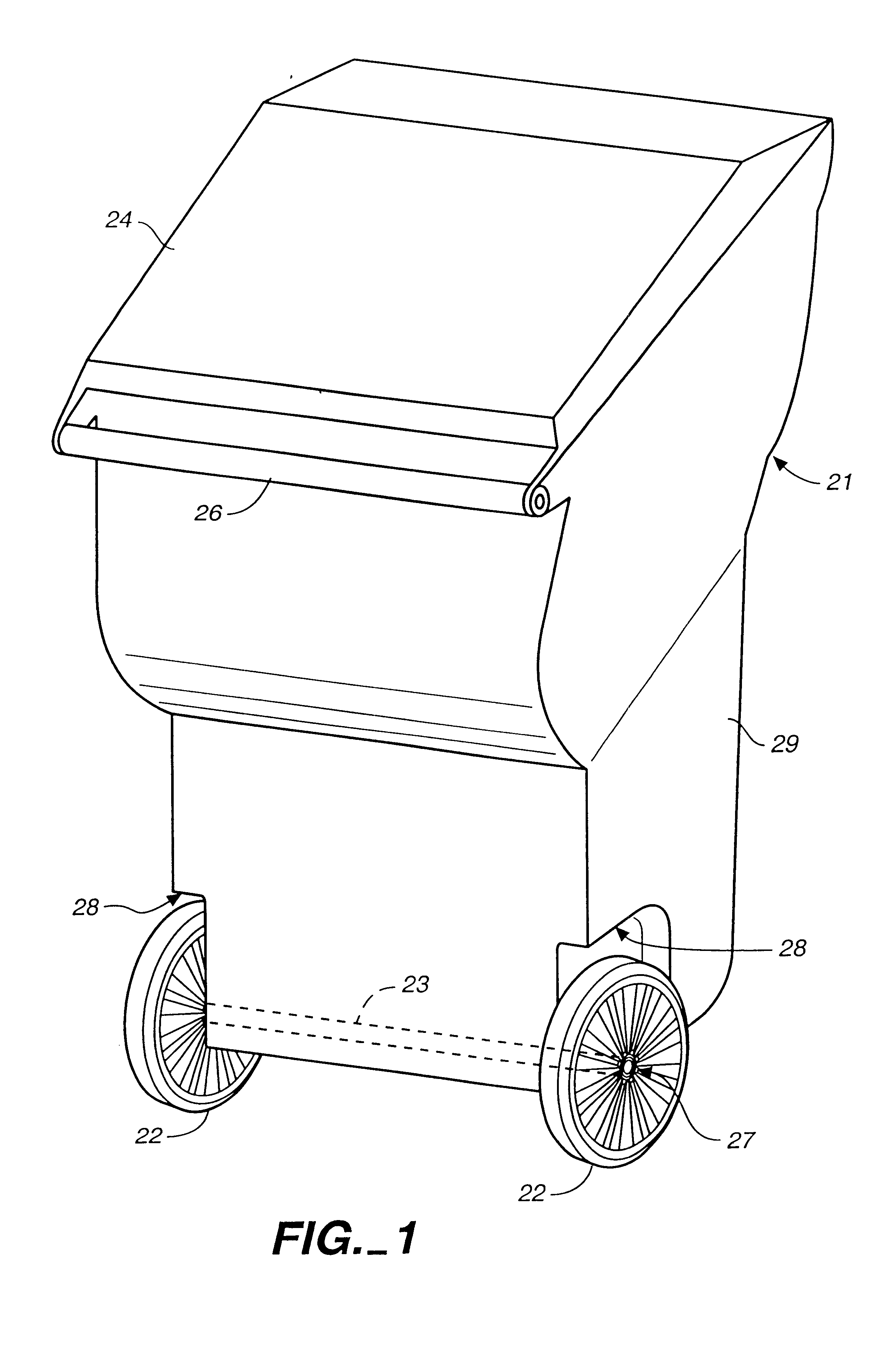

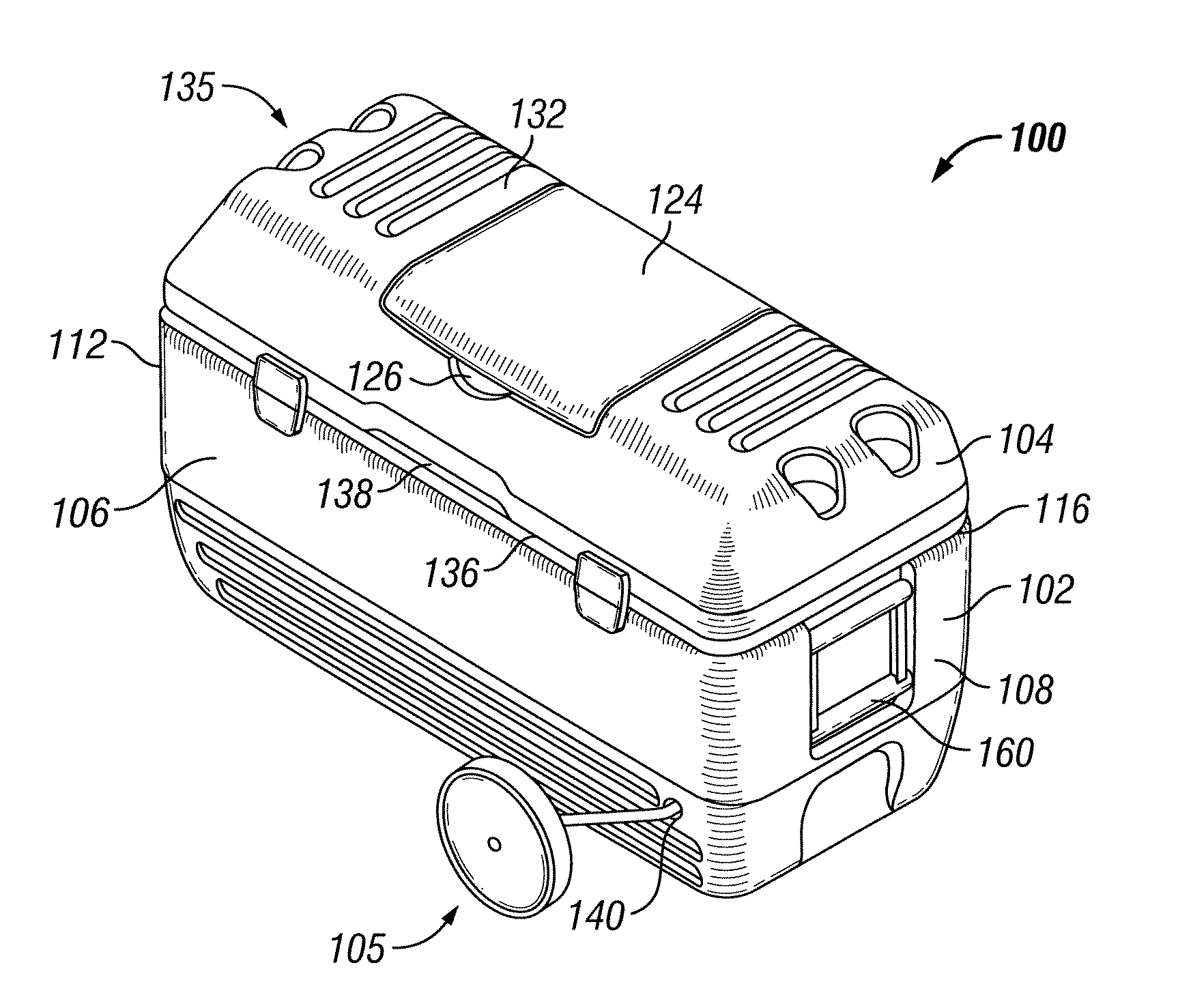

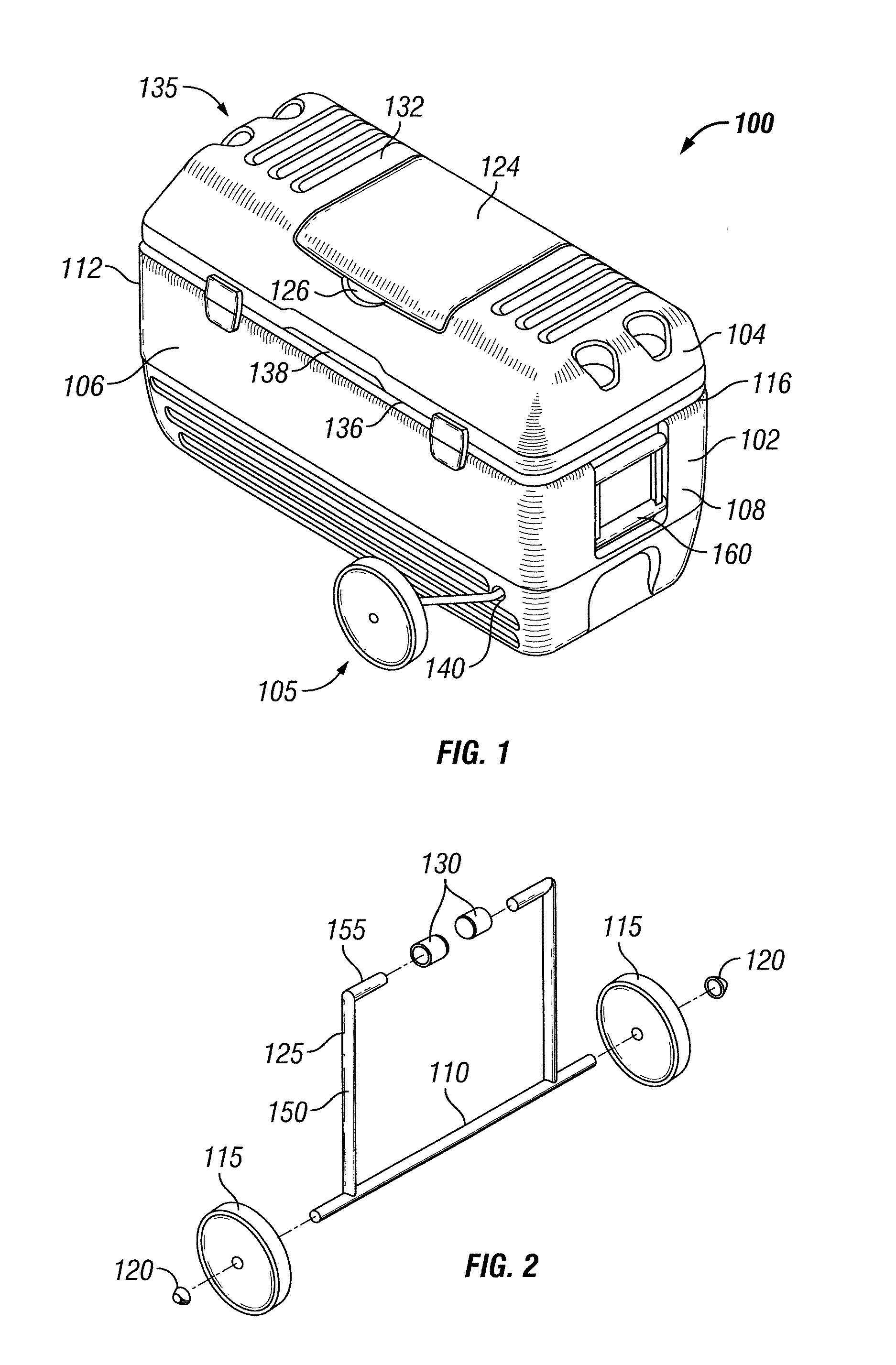

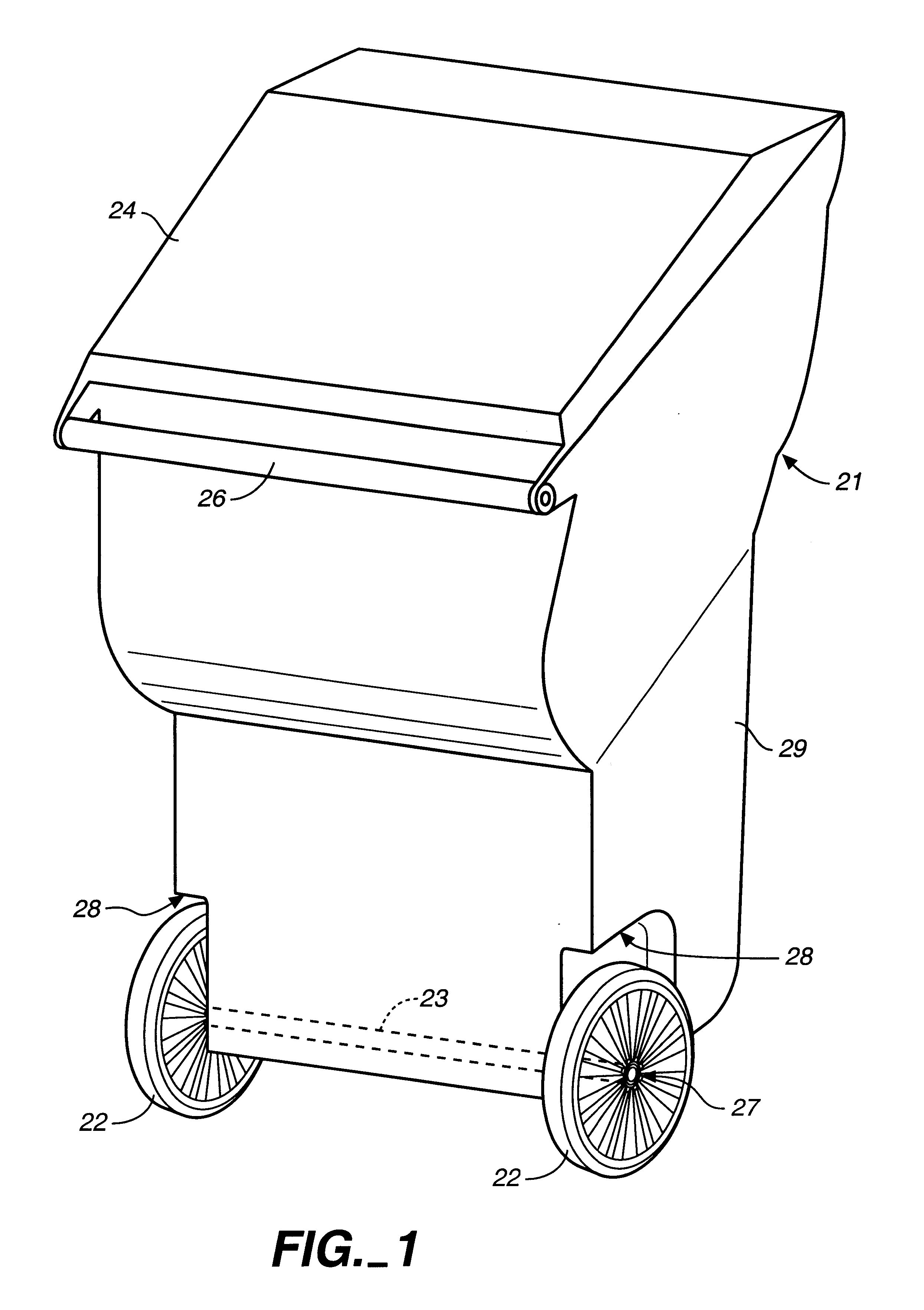

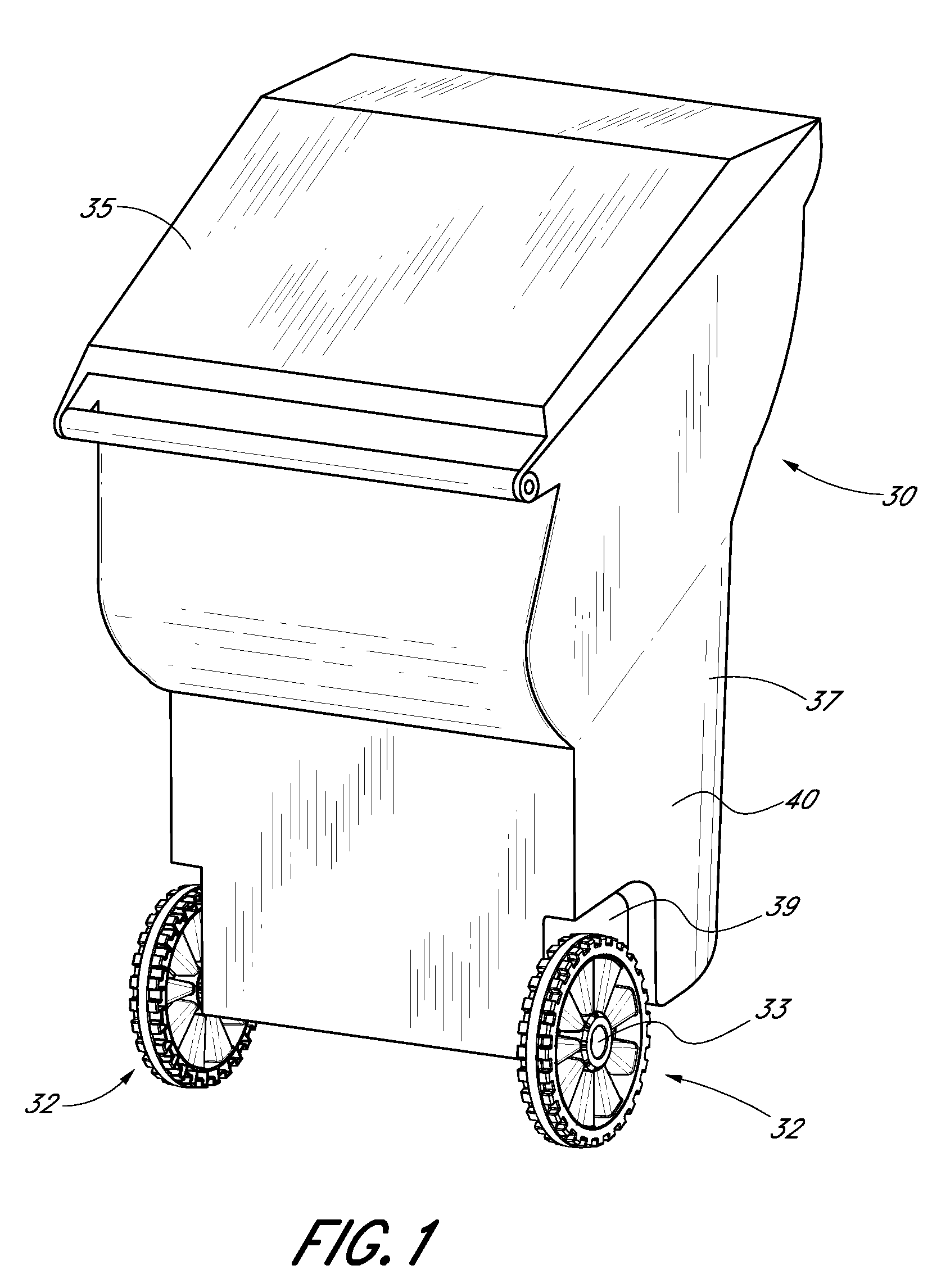

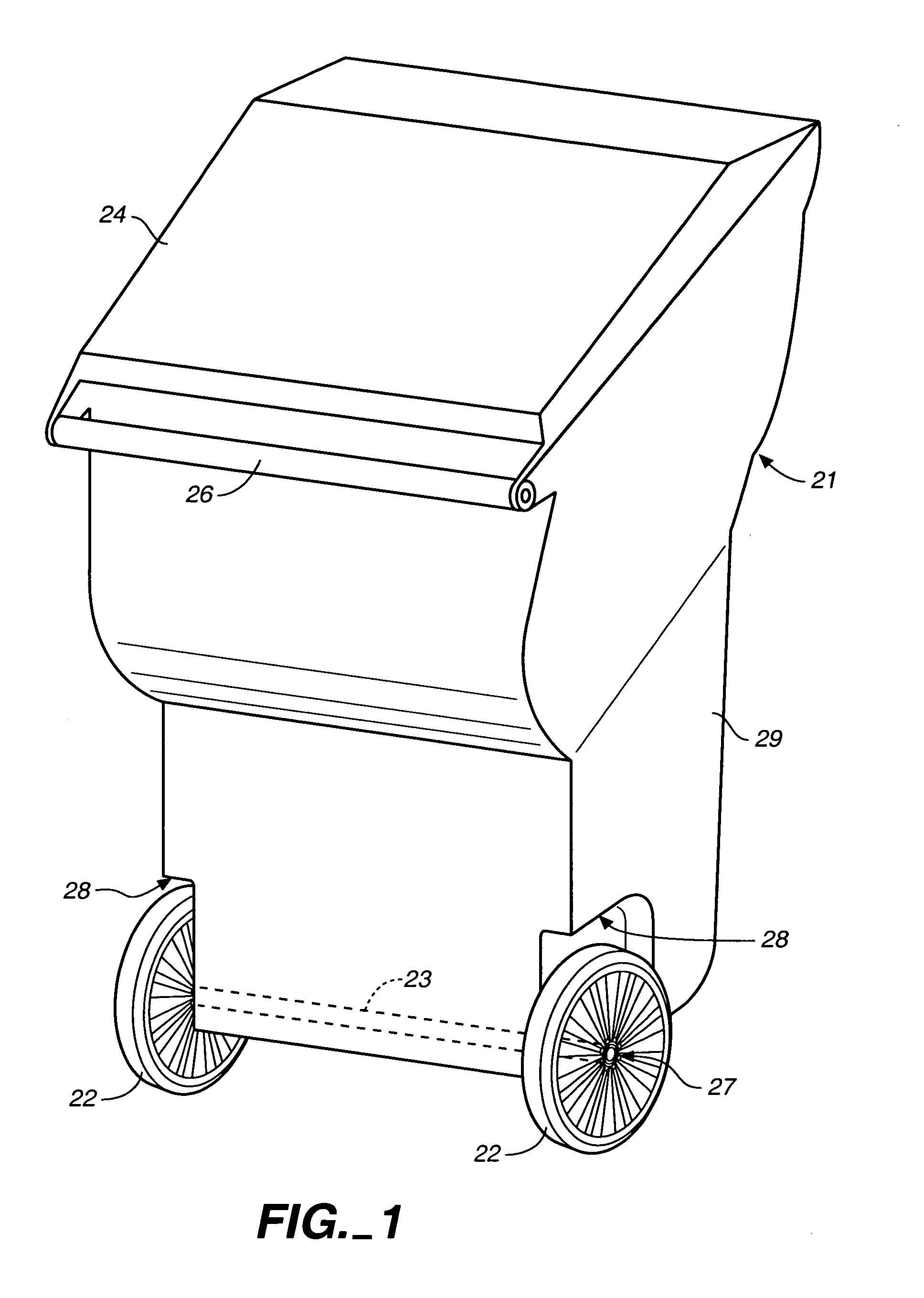

Rotatable wheel assembly for coolers

InactiveUS20080001373A1Increase distanceReducing unstable natureCarriage/perambulator with single axisLighting and heating apparatusRest positionEngineering

The rotatable wheel assembly includes an axle and wheels. Mounting arms with mounting pins or L-shaped rods are coupled to the axle and may include end caps covering portions of the mounting pin or rod. The mounting pin or end cap is inserted into a receptacle on opposing sides of a cooler. Alternatively, the mounting arms may have an eyelet that may be rotatably coupled to a mounting stud on each side of the cooler. The assembly may be placed in a resting or rolling position along the cooler body. In the resting position, the assembly rests or snaps into a groove along the side of the cooler and out of contact with the surface. The assembly can be rotated from the resting position to a rolling position with the axle positioned under the cooler and the wheels in contact with the surface to assist in transporting the cooler.

Owner:IGLOO PROD CORP

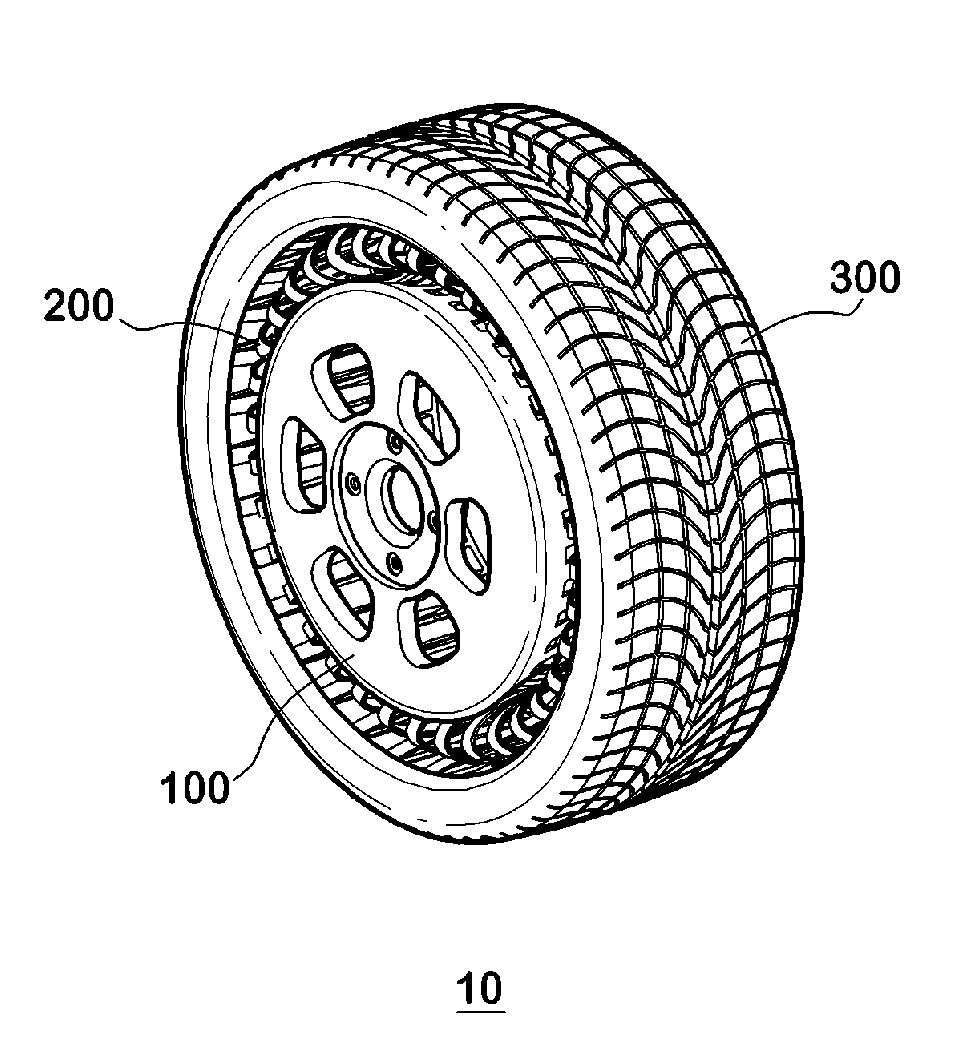

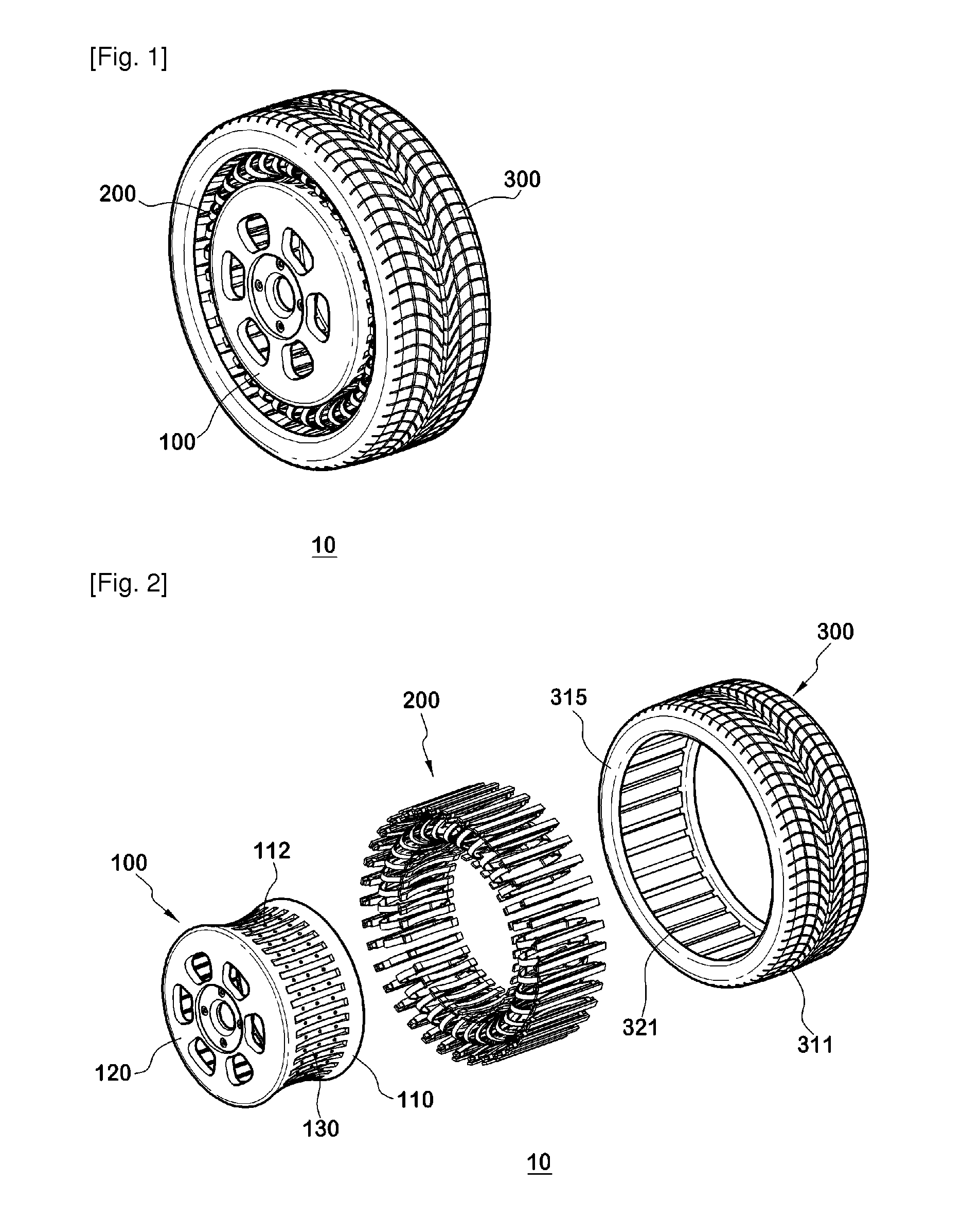

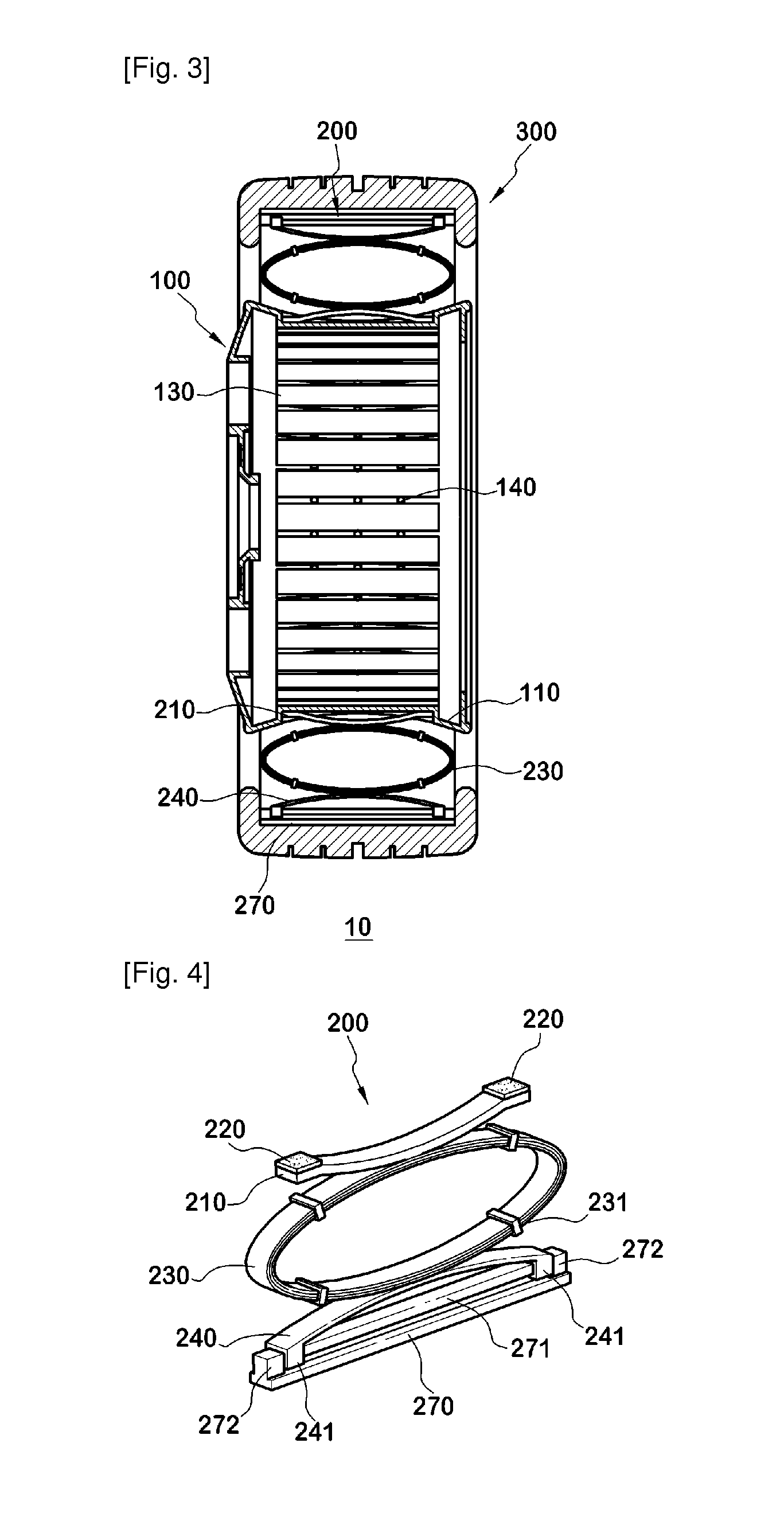

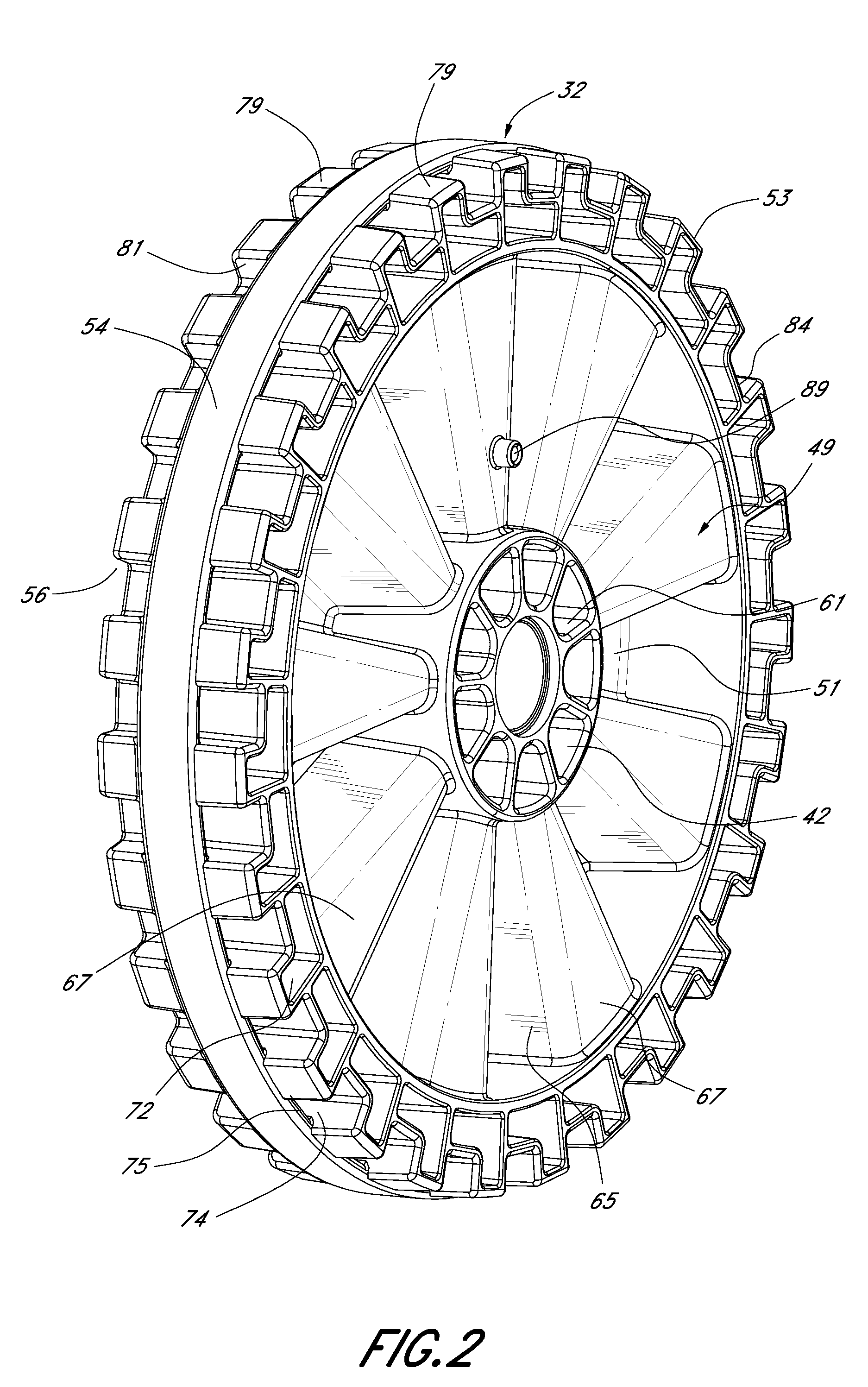

Non-pneumatic wheel and wheel, suspension and tire used therein

InactiveUS20110248554A1Prevent tire blowoutReduce vehicle accidentRimsLeaf springsCornering forceBrake fade

Provided is a non-pneumatic wheel (100) for a vehicle, and a wheel (100), suspension (200; 200-1), and tire (300) used therein that are capable of ensuring driving stability because there is no air chamber between a wheel (100) and a tire (300) to blowout. They are also capable of ensuring good road holding, preventing standing waves, reducing brake fade and cornering force, providing good handling and ride comfort, staying quiet when rolling, and are economical and environmentally friendly. The non-pneumatic wheel (100) includes a wheel (100), a shock absorbing member (220; 220-1) coupled to an outer periphery of the wheel (100) and absorbing or attenuating noise and vibration due to external shock, a plurality of resilient members (230; 230-1; 230-2) arranged around and coupled to an outer periphery of the shock absorbing member (220; 220-1) in a radial direction and having a plurality of resilient rings (230-1a) that are resiliently deformed in response to an external force, resilient links (240) respectively coupled to the resilient rings (230-1a) to evenly transmit external shock to the resilient rings (230-1a), rail plates (270) to which sliders (261) formed at both ends of the resilient links (240) are slidably coupled, and a tire (300) having a plurality of coupling grooves (321) formed along an inner periphery such that the rail plates (270) are inserted into the coupling grooves (321).

Owner:CHON YOUNG ILL +4

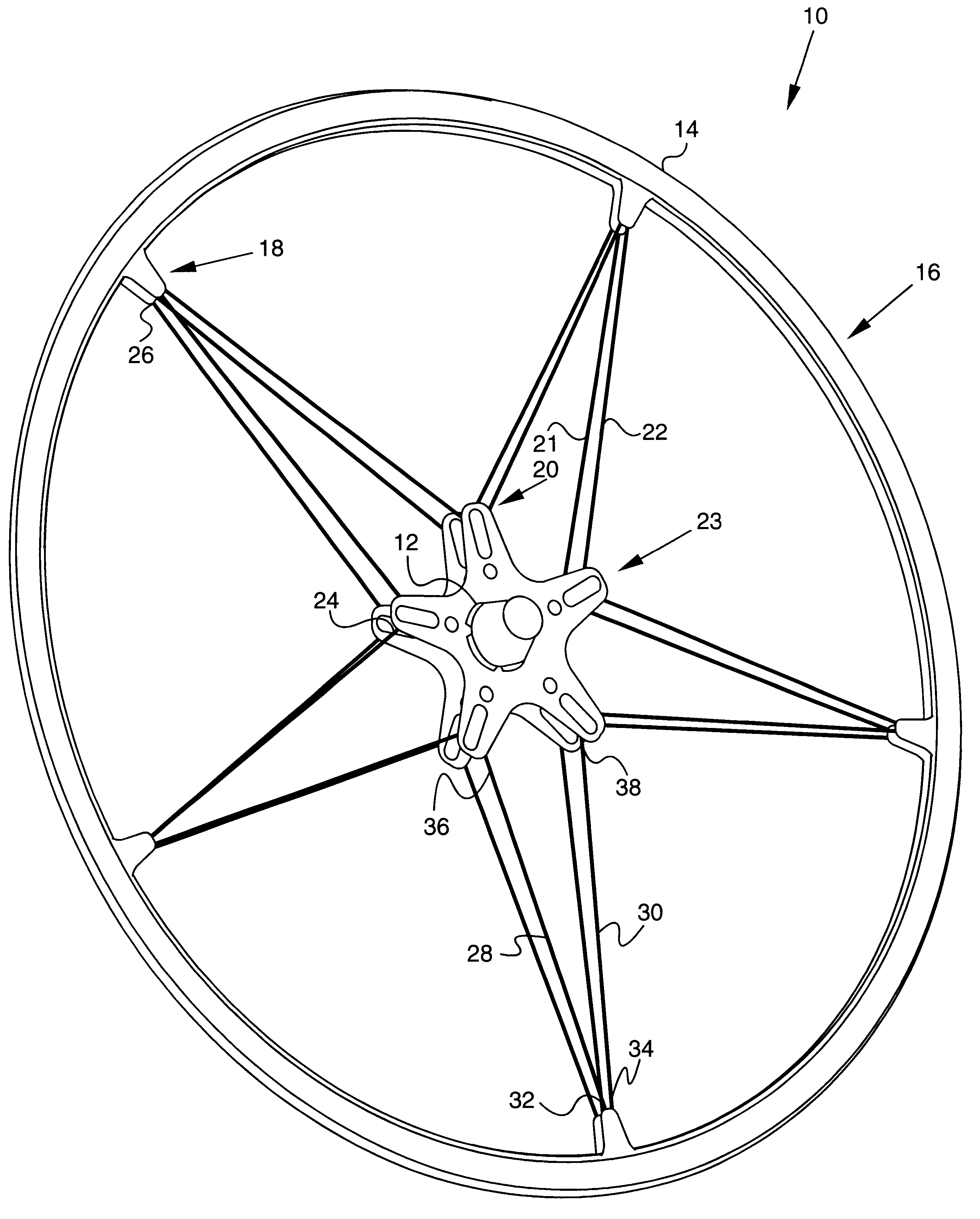

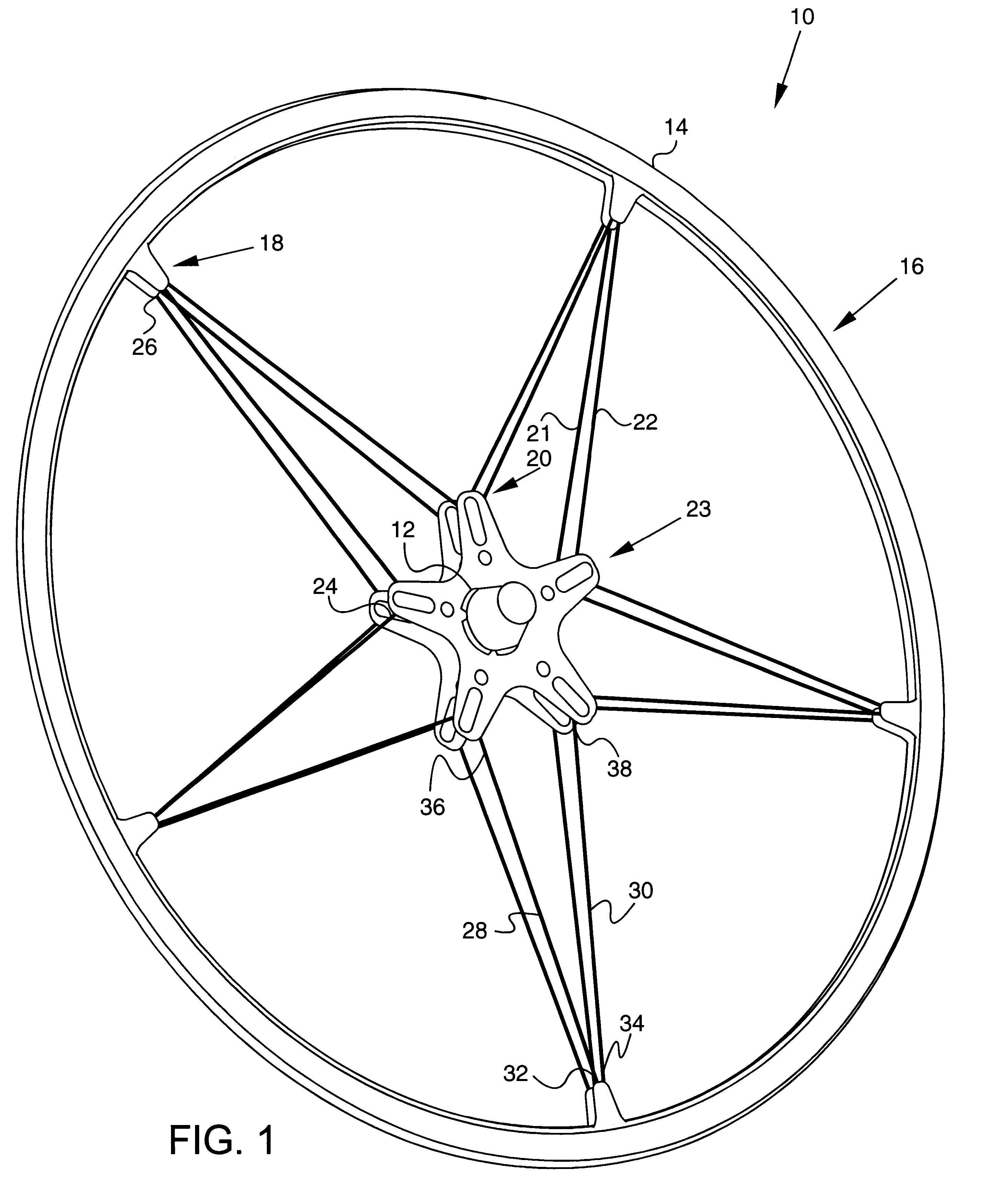

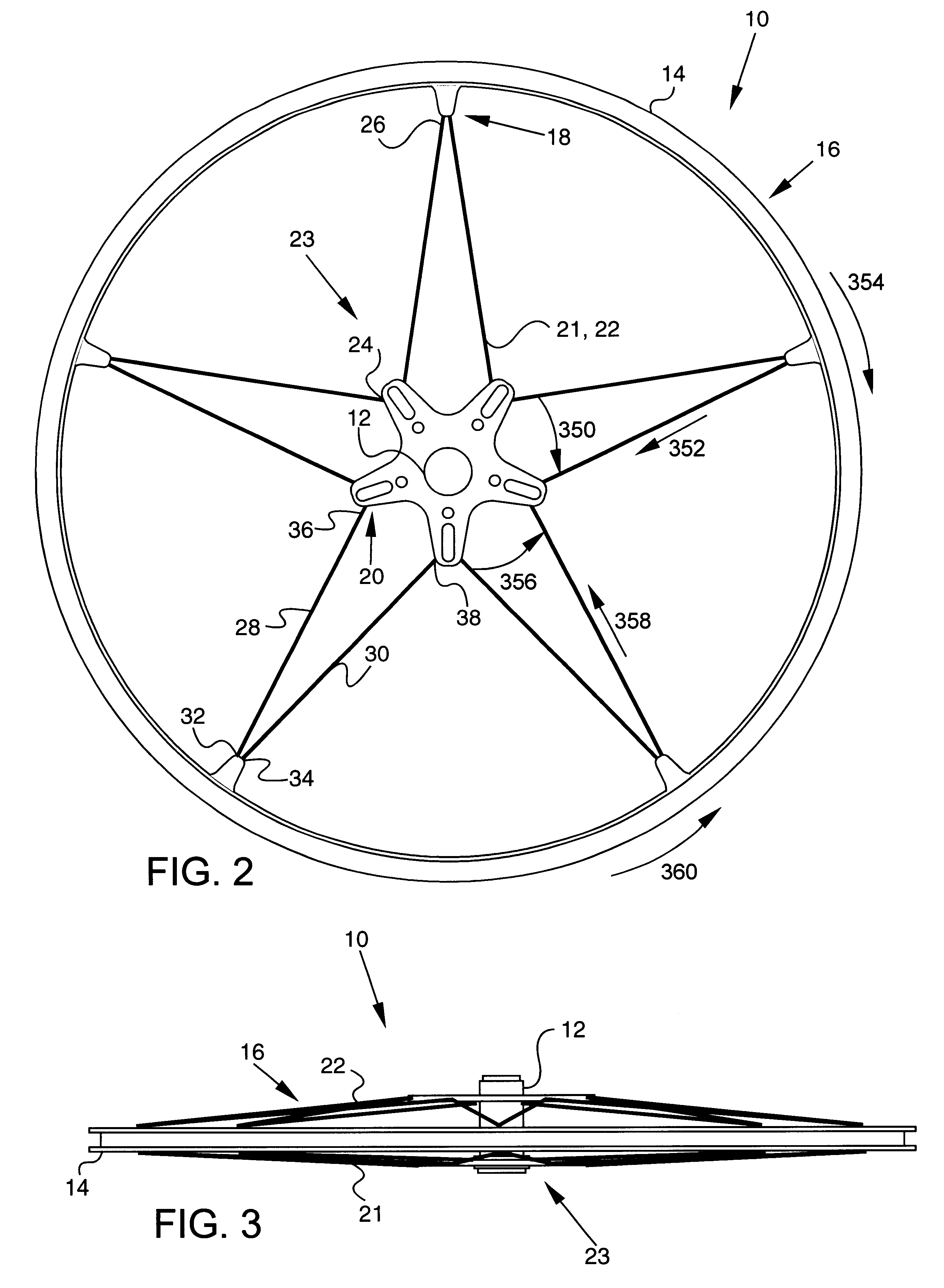

Wheel and tension spoke system

InactiveUS6238008B1Solve the lack of durabilityIncreased durabilityRimsSpoked wheelsEngineeringMechanical engineering

A spoke system includes at least three rim pivots, at least three hub pivots, and plural shafts each extending along a substantially linear path between a rim pivot and a hub pivot, each path being substantially aligned with the center of a rim pivot and the center of a hub pivot. Each shaft includes an integral rim end forming a loop around a rim pivot and an integral hub end forming a loop around a hub pivot. The present invention also includes a tensioning system for biasing the inner vertices away from the outer vertices, thereby tensioning the continuous spoke. The path of each shaft may be substantially aligned with the center of a rim pivot and the center of a hub pivot so that a tension along the length of the shaft will not produce a moment about the rim pivot or the hub pivot. The tensioning system may include plural tensioning mechanisms, with each tensioning mechanism including a clevis with a base attached to the hub and two arms extending from the base, a reaction pin extending between the two arms, a hub attachment pin extending through a central portion of a vertex, a pusher pad engaging the hub attachment pin, and a tension adjusting screw engaging the reaction pin and biasing the pusher pad so as to bias the hub attachment pin and the vertex, thereby tensioning the shafts.

Owner:COMPOSITES DESIGN SERVICES

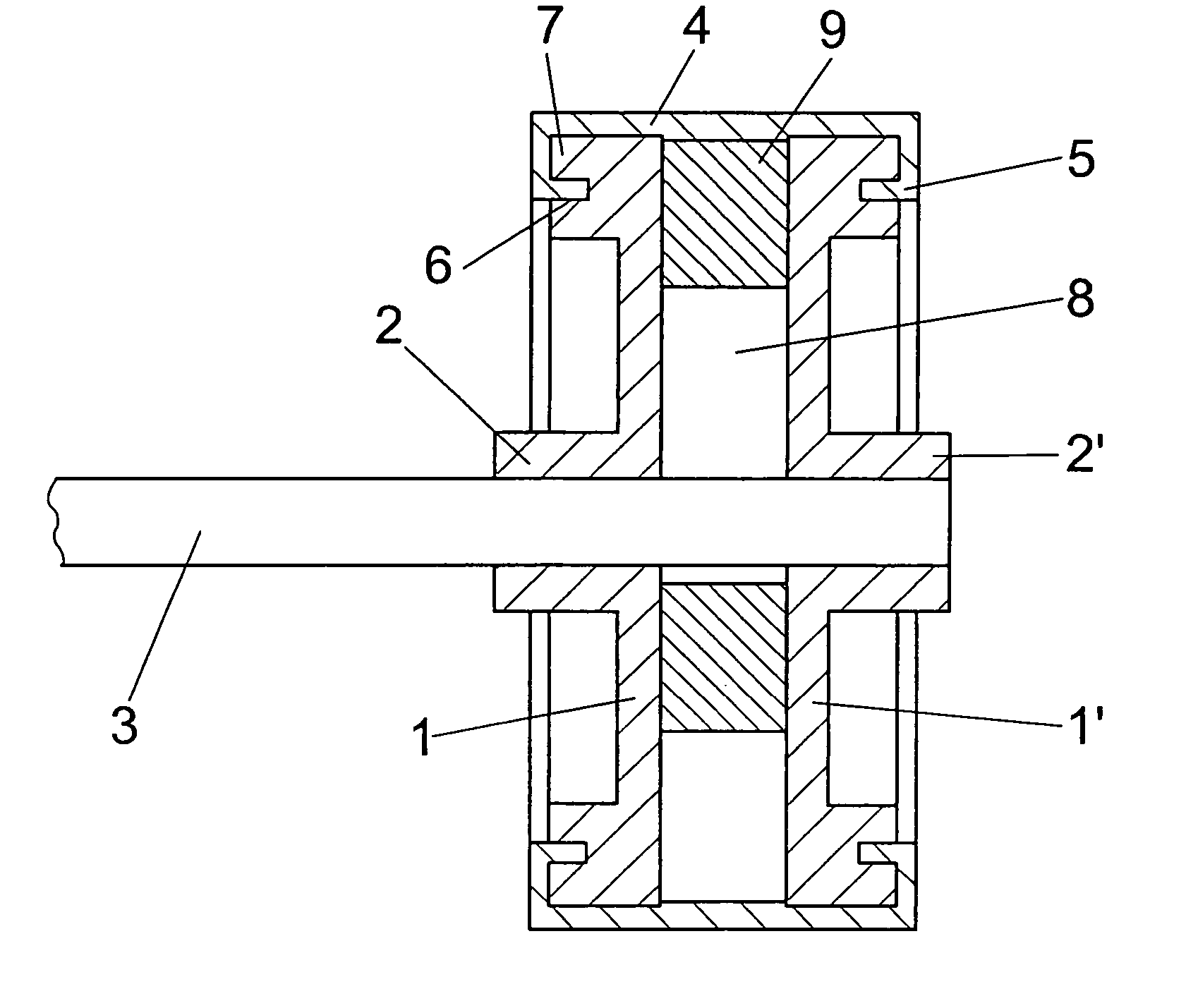

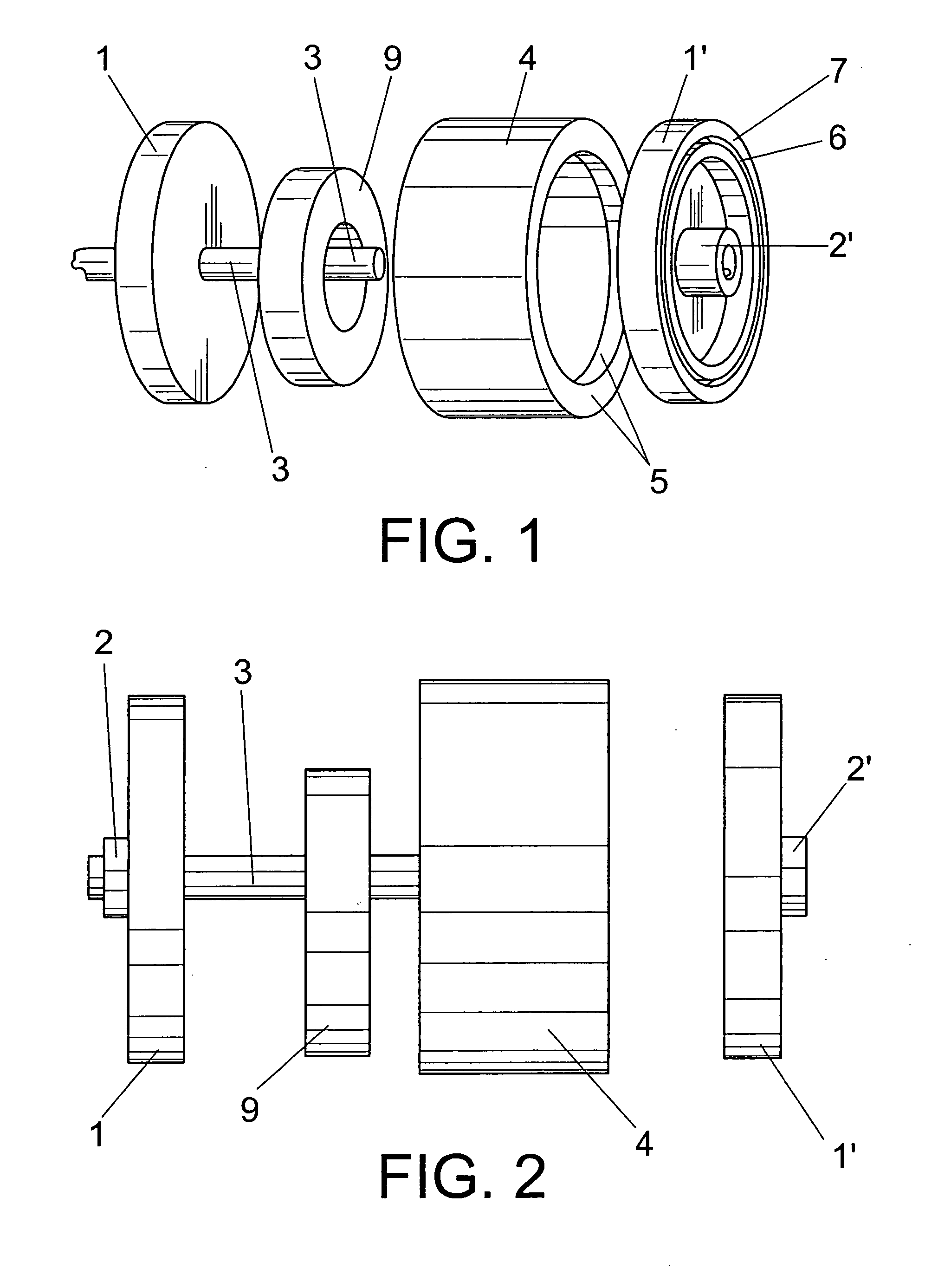

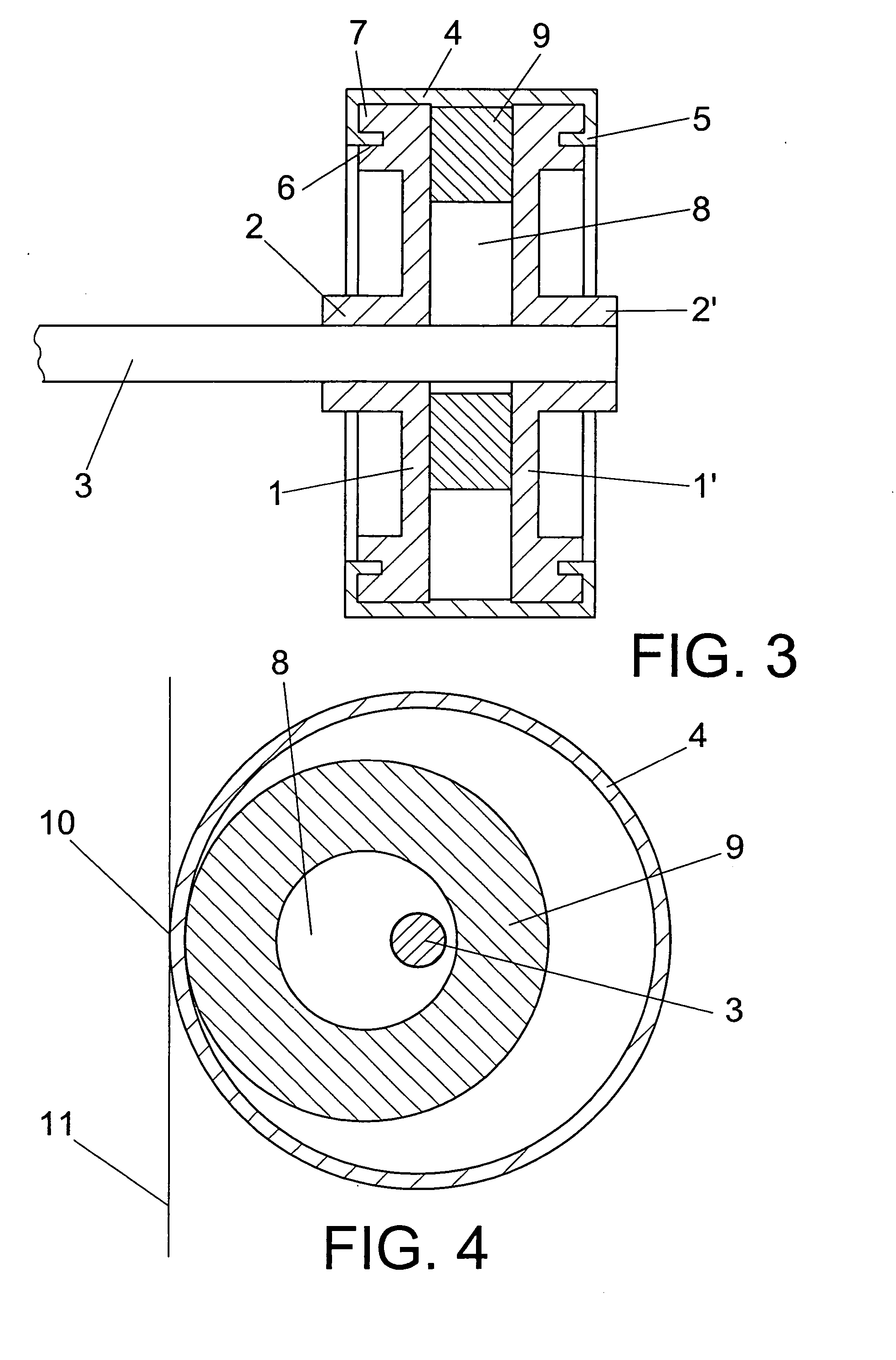

Magnetic wheel for vehicles

Specially conceived for vehicles which have to be displaced over ferromagnetic surfaces, like the iron or steel walls of large tanks for example, it is incorporated by the combination of a hollow rim (1-1′) and a tyre (4) of an elastomer or similar material, which define a cylindrical chamber (8) inside which a magnetic annulus (9) runs, materialized in a permanent magnet of adequate strength, with the particularity that said magnetic annulus (9) has a substantially smaller diameter than that of the cited chamber (8), so that it is capable of carrying out a planetary motion inside the same, maintaining a permanently tangential condition with the tyre (4) at the point in which the latter is in contact at all times with the ferromagnetic surface over which the vehicle is displaced, achieving maximum adherence at said point. In this way it is managed to improve the grip of the wheel on said surface, overcome possible obstacles of the same, lighten the wheel and increase safety through not requiring an electricity supply.

Owner:APPLUS NORCONTROL SL SOC UNIPERSONAL

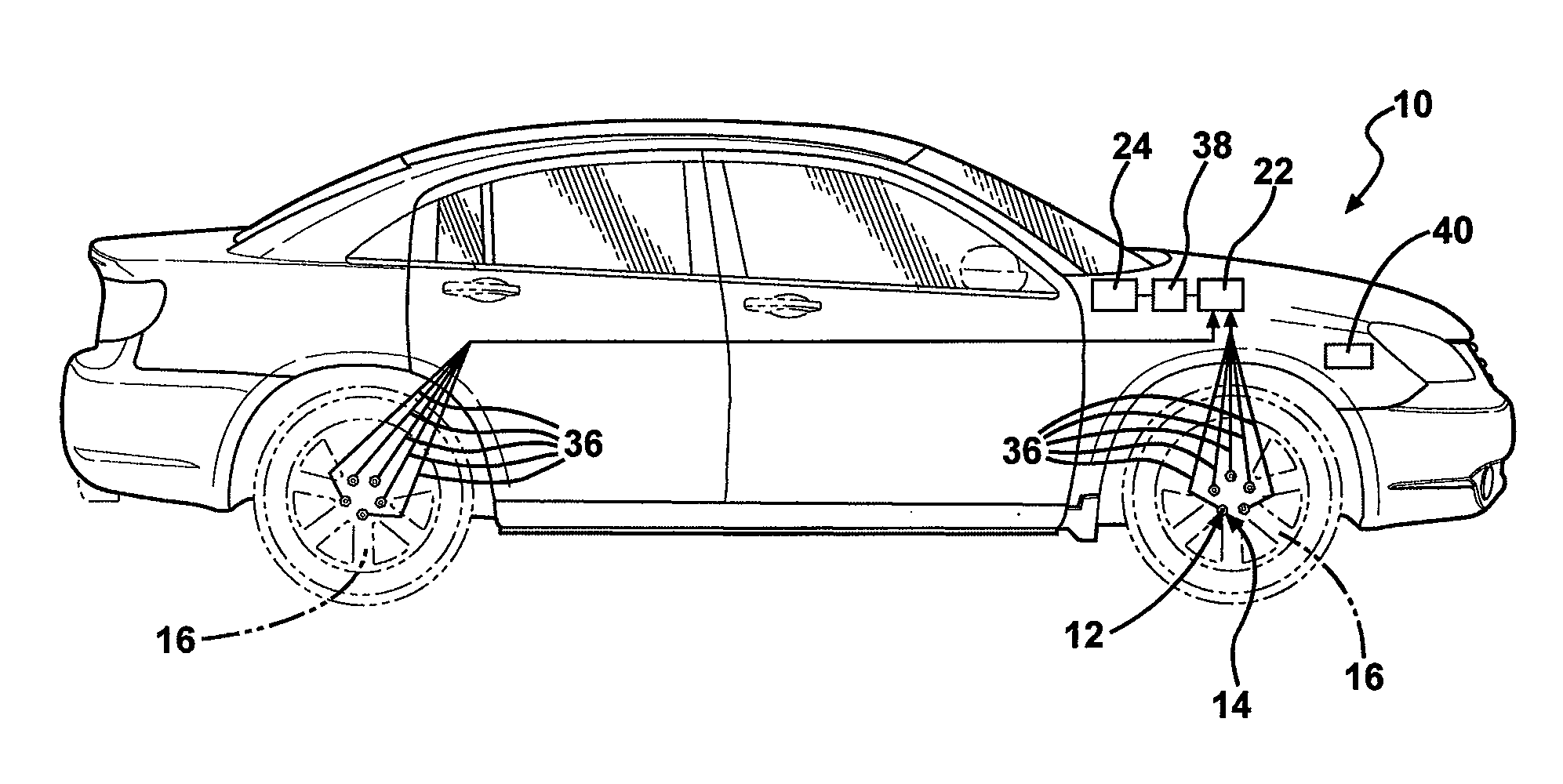

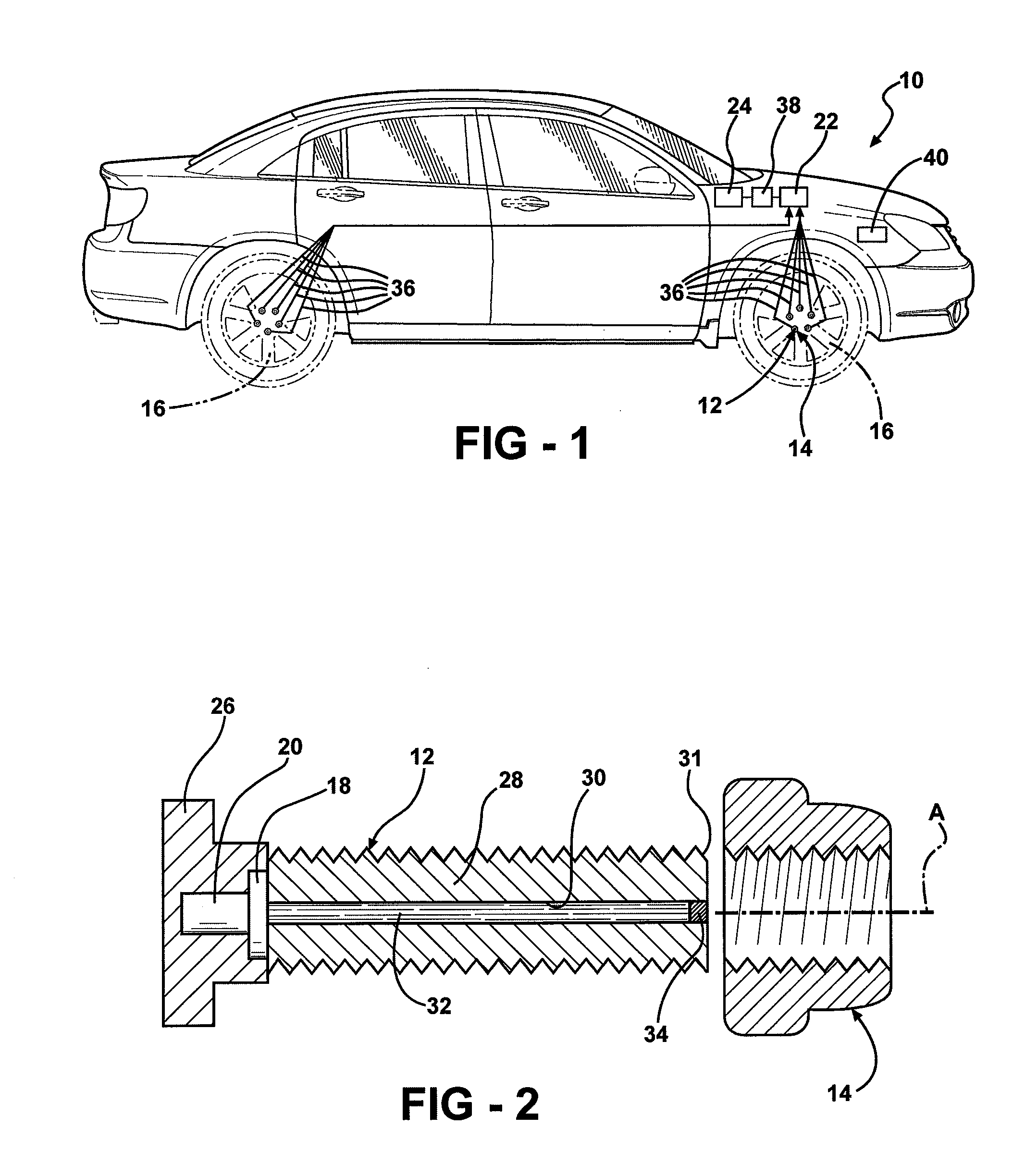

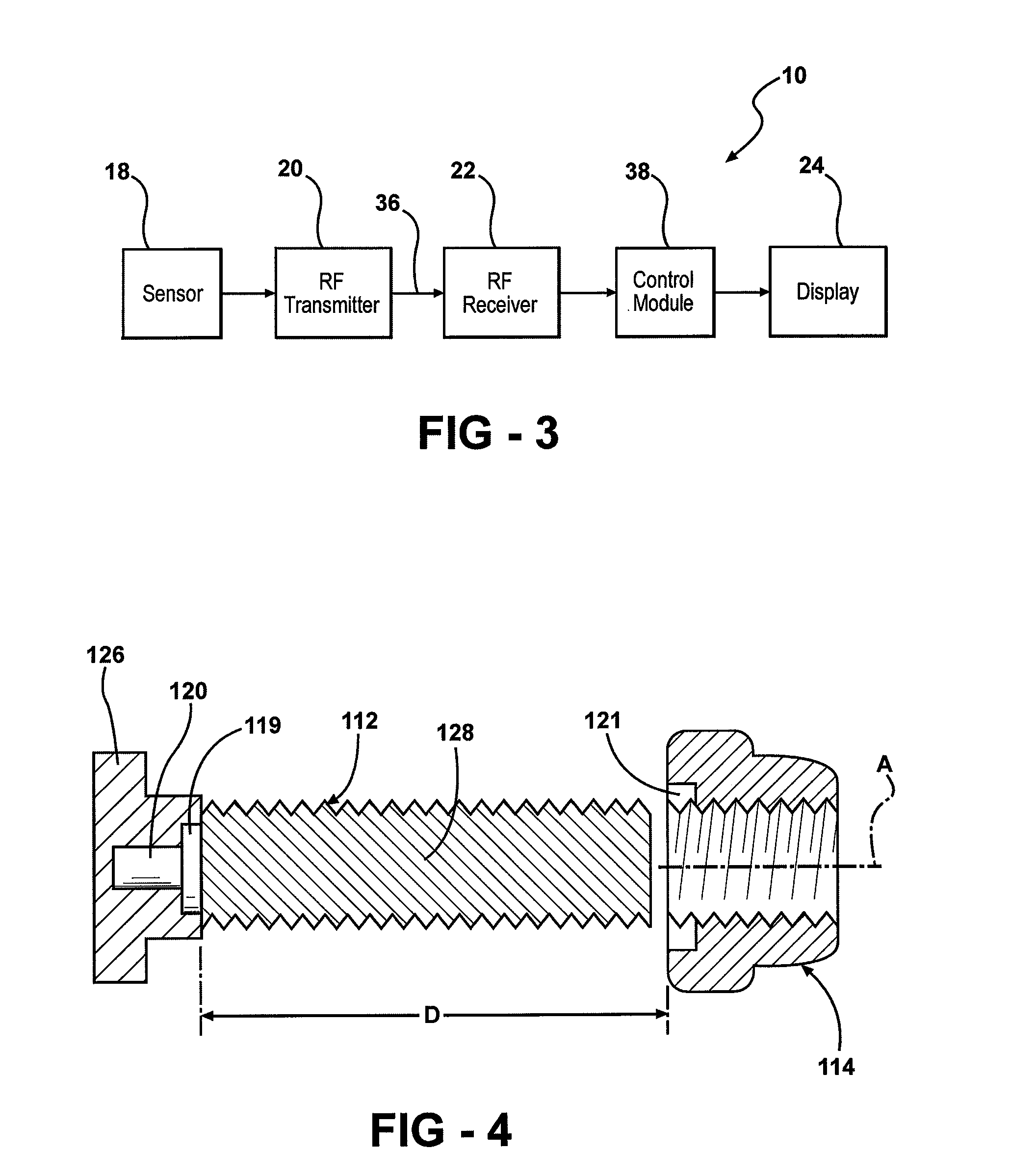

Lug Stud and Lug Nut Monitoring System, Method, and Components Therefor

A lug stud and lug nut monitoring system, method, and components for a vehicle may have a lug stud, a lug nut, at least one sensor, and an indicator. The lug stud has a shank. The lug nut is constructed to fasten on the shank. The sensor can be carried by the lug stud, by the lug nut, or by both the lug stud and the lug nut. The sensor takes at least one measurement. The indicator communicates with the sensor in order to determine a value based on the measurement, and to alert an operator of the vehicle if and when the value reaches a predetermined relationship to a reference value.

Owner:TAG BLUE

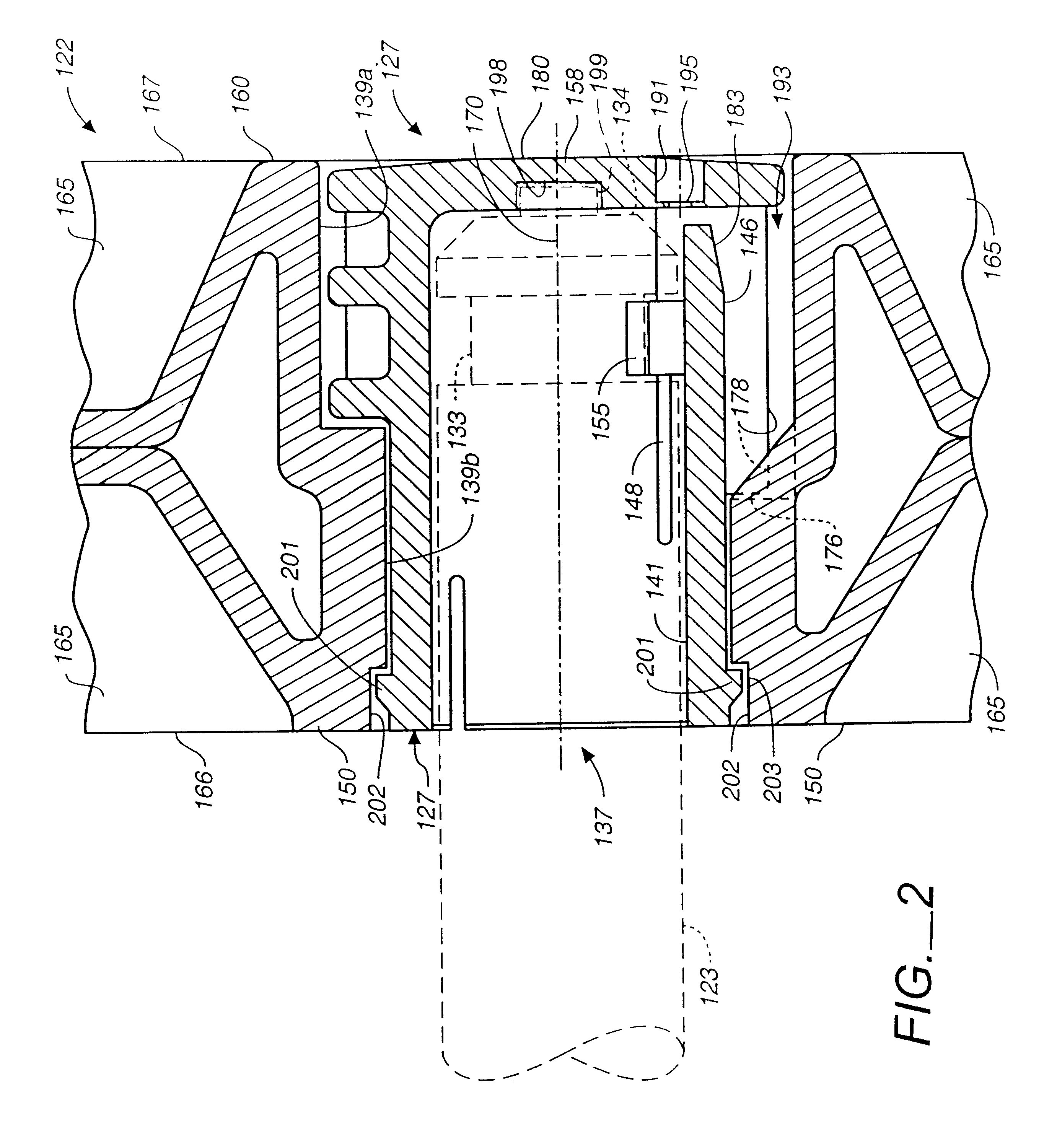

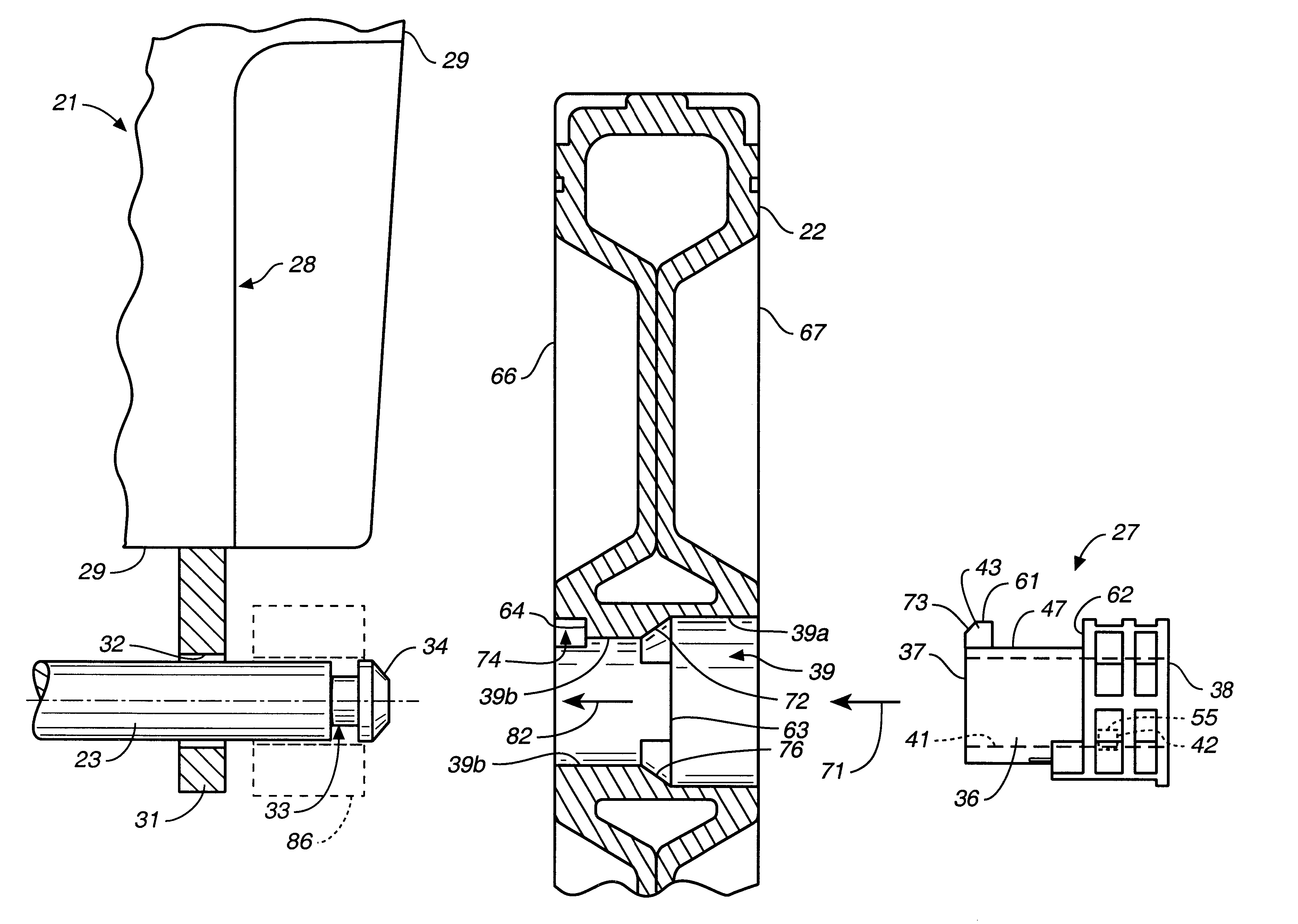

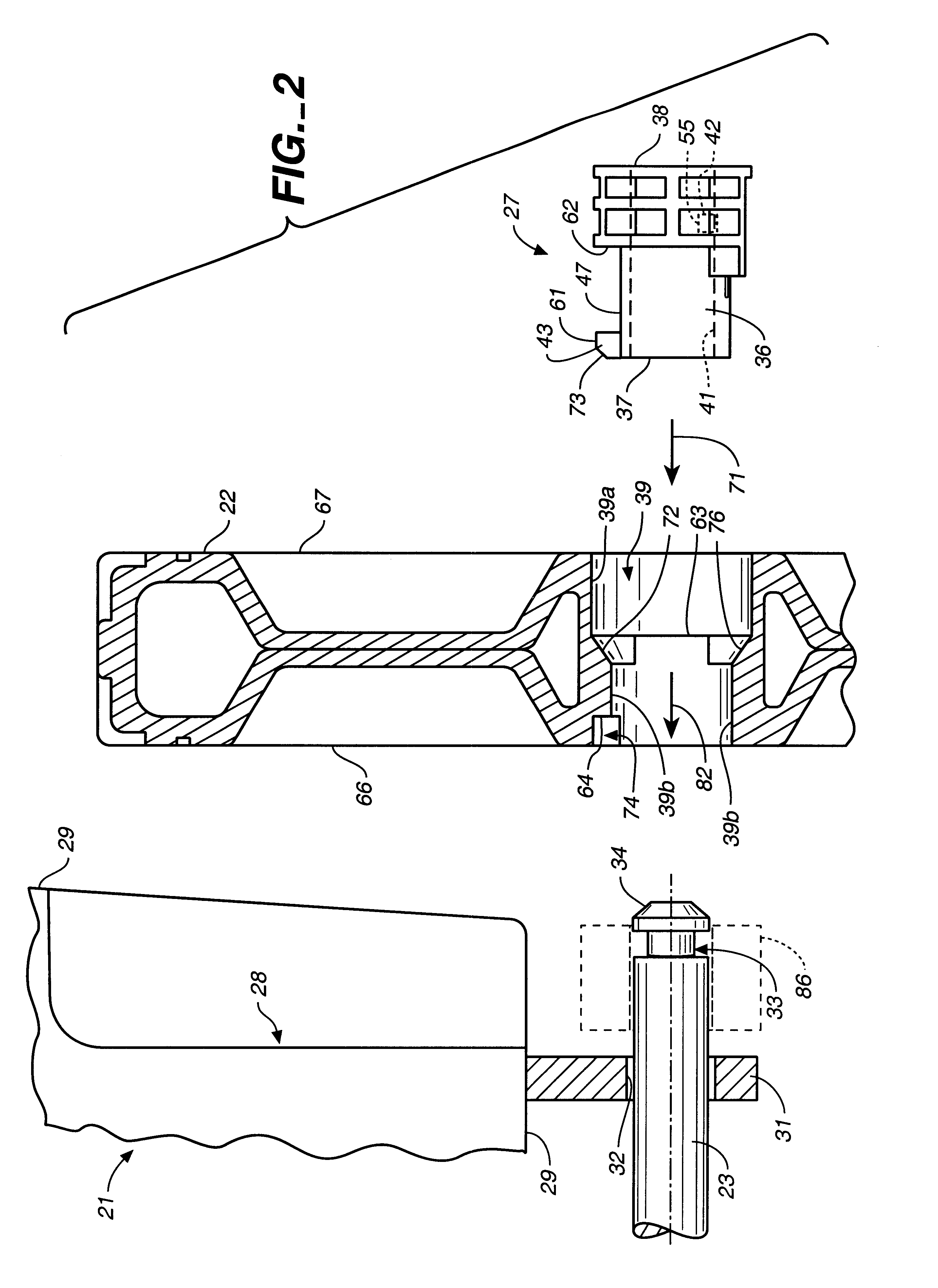

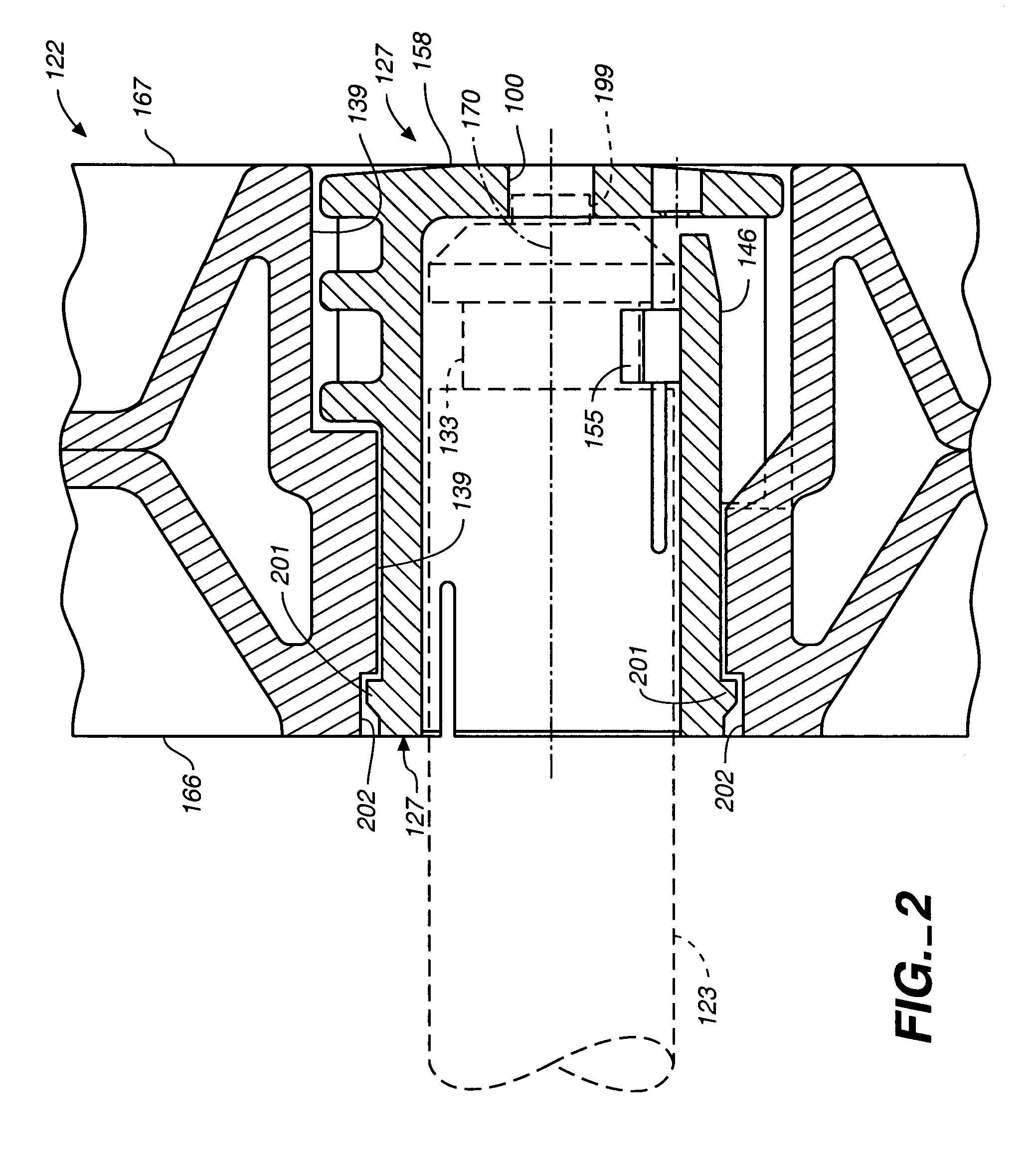

Plastic wheel assembly and mounting sleeve therefor

A plastic wheel (22) and wheel mounting sleeve (27, 27a, 27b, 27c) used to releasably secure the wheel (22) onto an axle (23). The wheel mounting sleeve (27) preferably includes two resilient, radially displaceable, axially extending, cantilevered fingers (46, 47) which are cantilevered from and extend axially in opposite directions on the sleeve (27). An axle-engaging shoulder (42) is provided on a radially inwardly extending lug (55) on one finger (46), while a wheel-engaging shoulder (43) is provided on a radially outwardly extending lug (61) on the other resilient finger (47). The respective shoulders (42, 43) cooperate with oppositely facing shoulders (58, 62) so as to releasably latch the sleeve (27) to the axle (23) and the wheel (22) to the sleeve (27). Assembly can be accomplished without any tools and a screwdriver can be used to disassemble the components. Alternative sleeves (27a, 27b, 27c) include an annular rib (101) which mates with an annular bore recess (102) to further limit relative movement between the sleeve (27a, 27b, 27c) and the wheel (22).

Owner:GEO PLASTICS

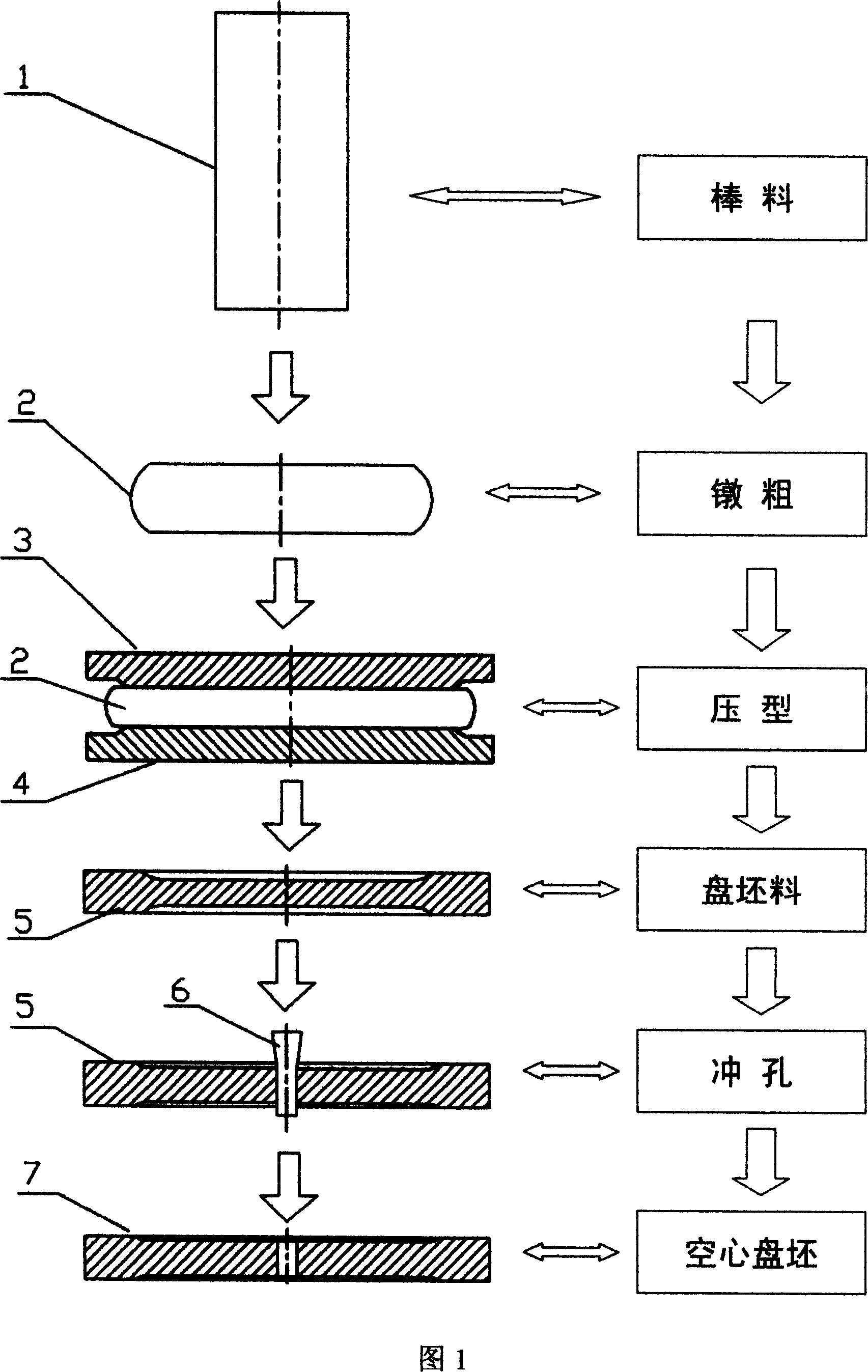

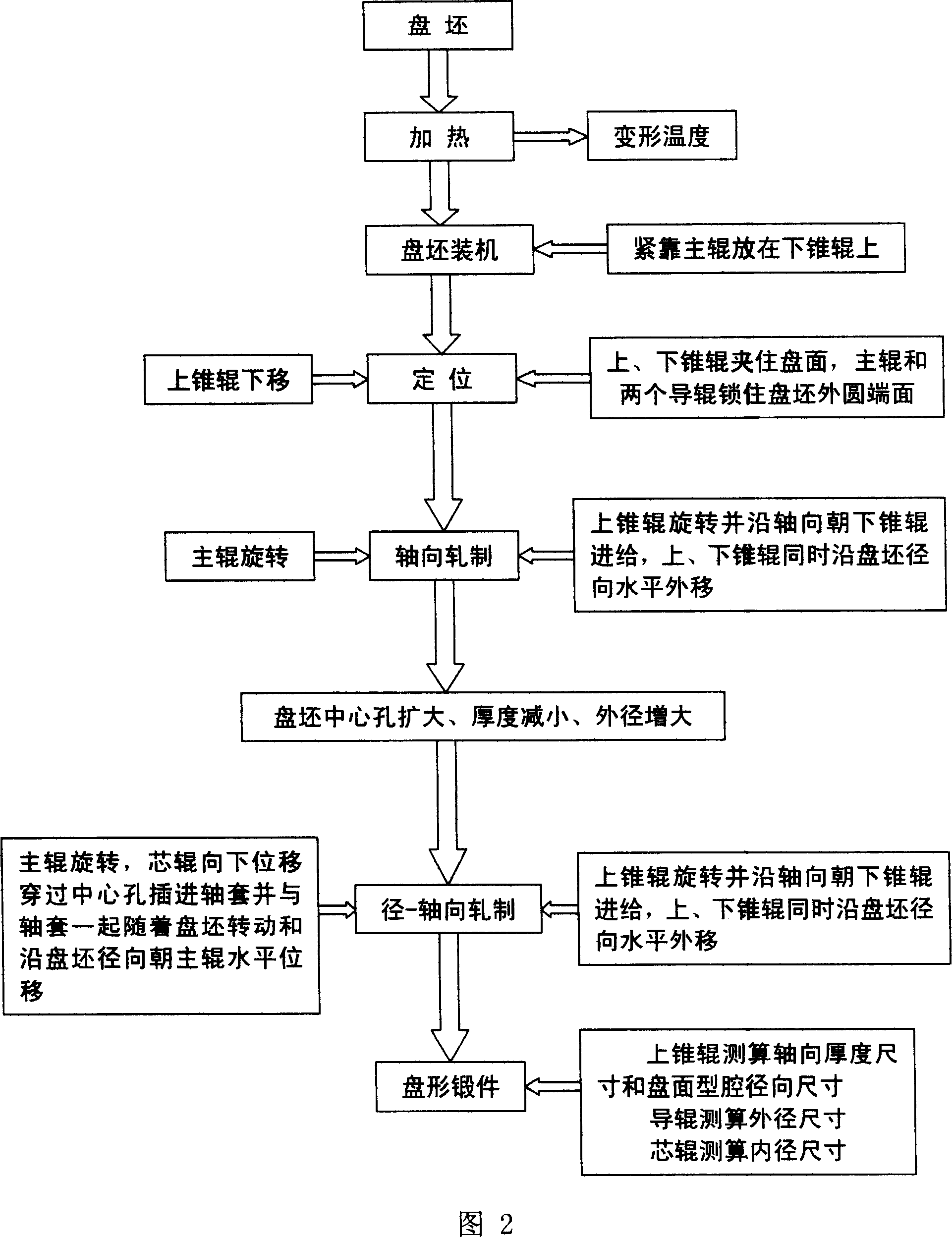

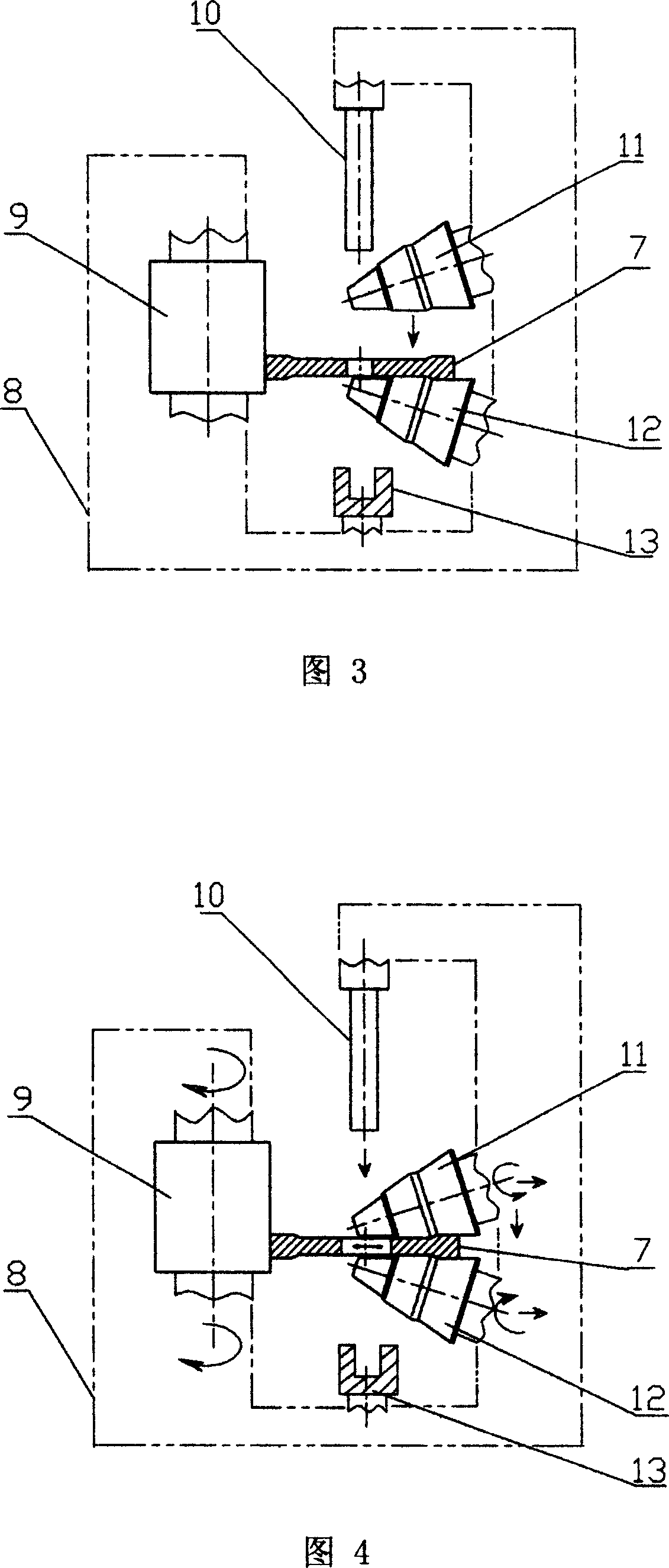

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

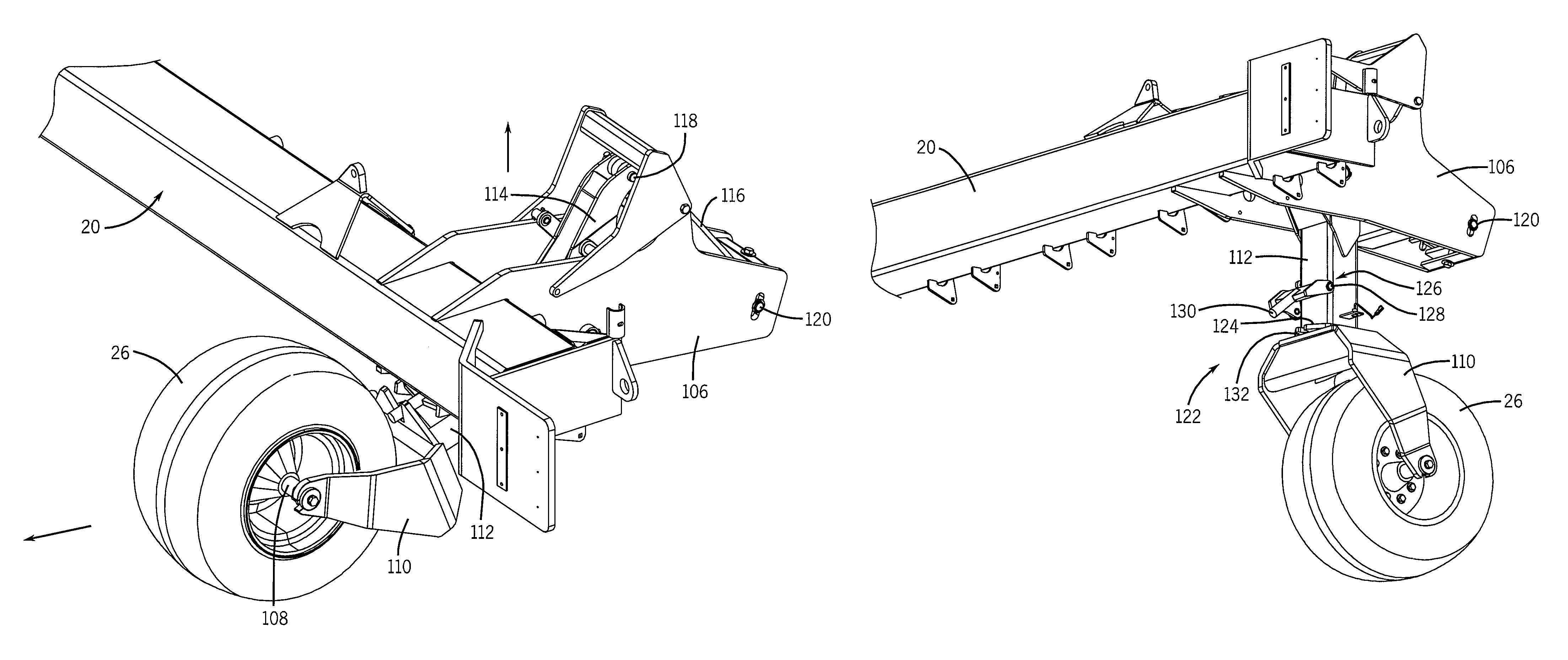

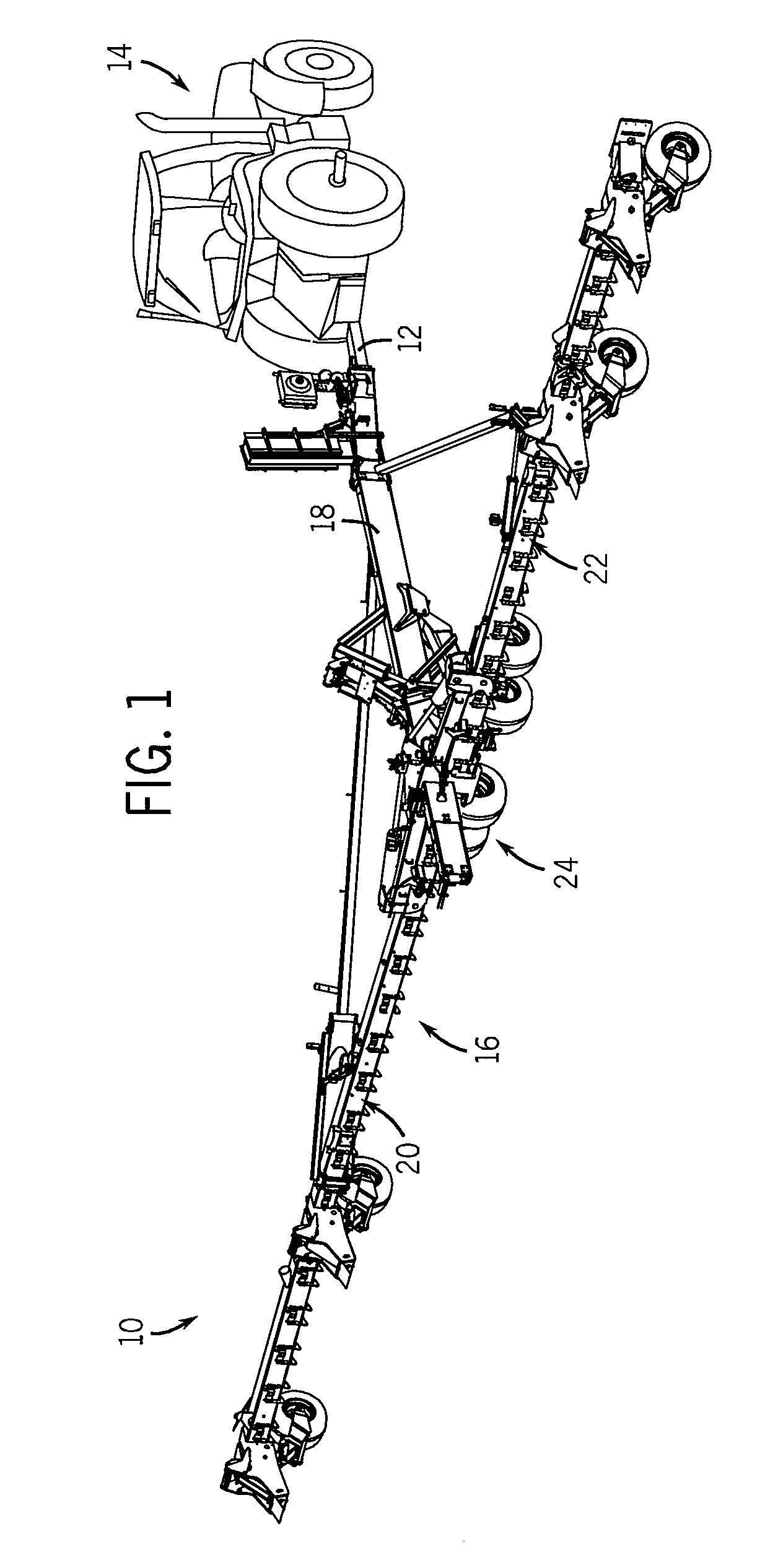

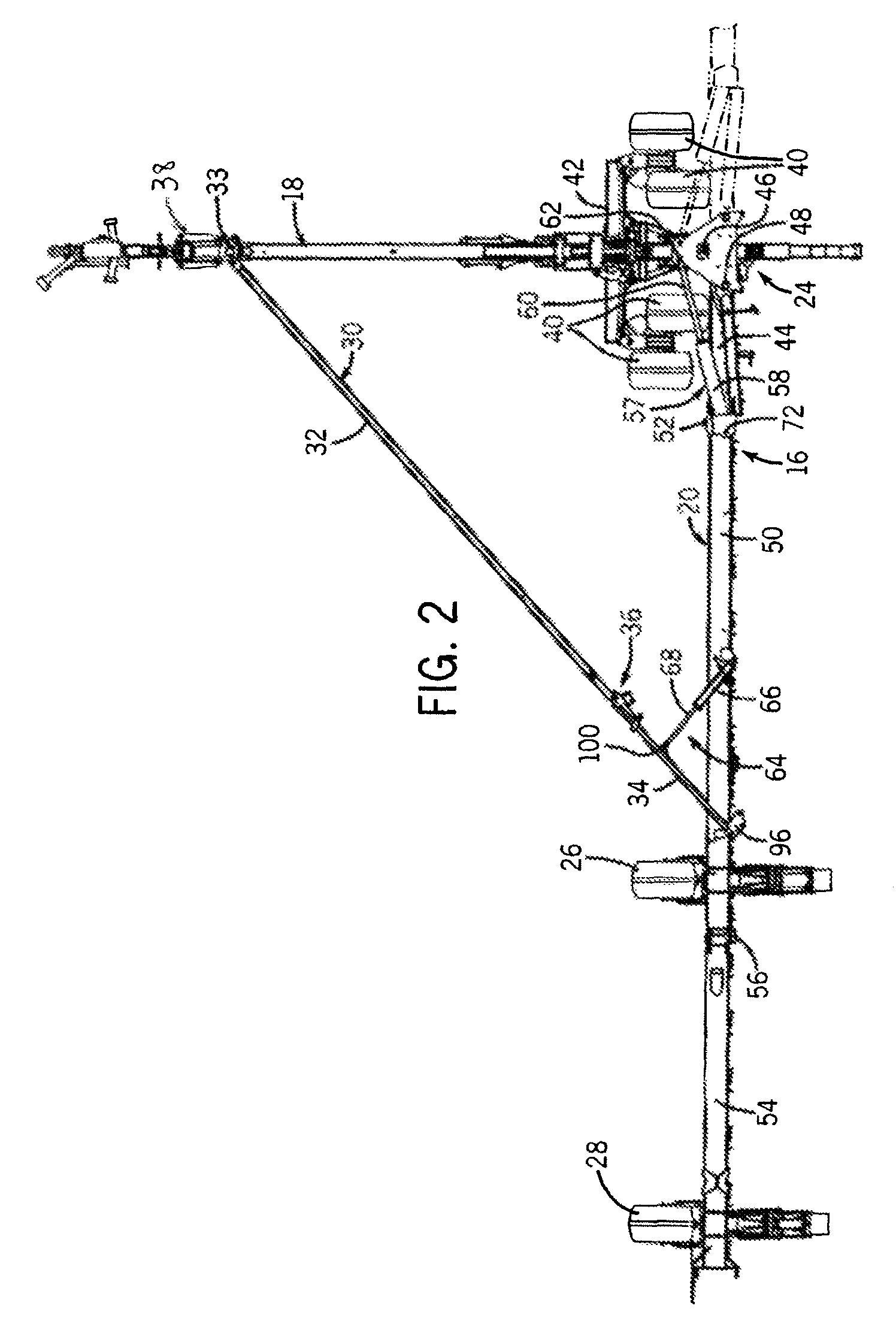

Agricultural implement having wheels that caster

Owner:CNH IND CANADA

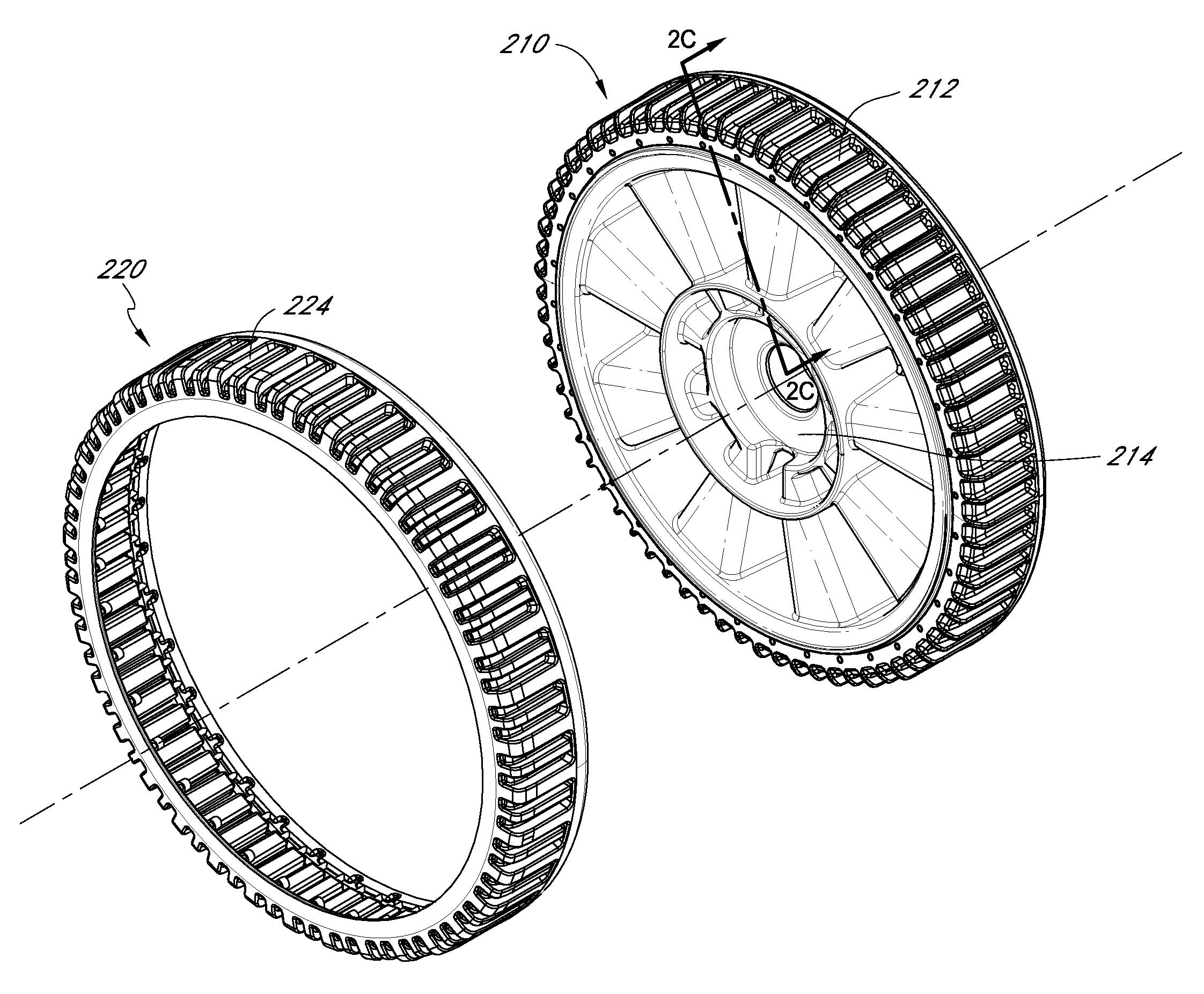

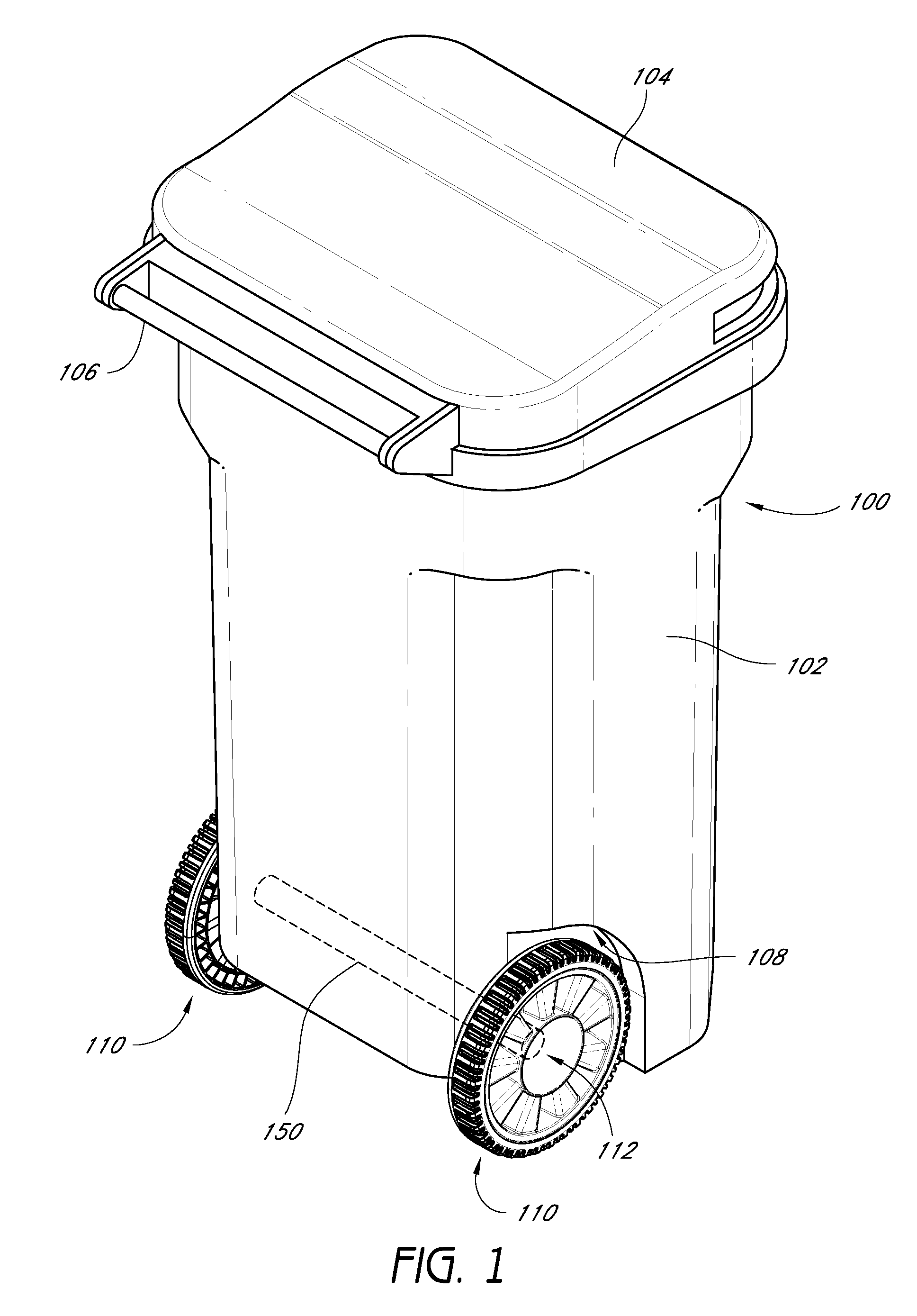

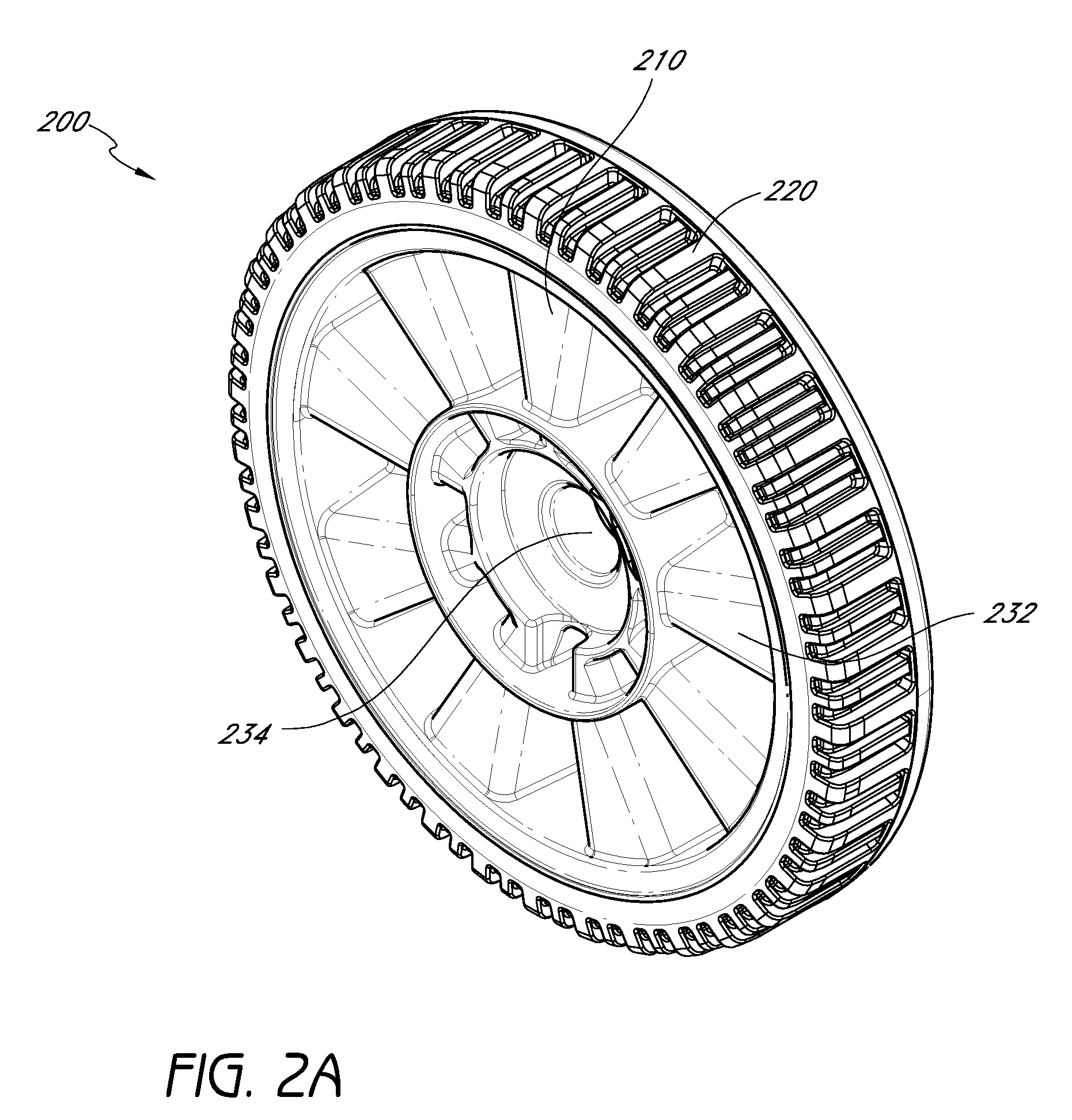

Wheel including tread

Wheels and methods of making wheels are disclosed including an inner portion and a tread mechanically coupled to the inner portion. The tread may be mechanically coupled to the inner portion on an inside and an outside of the wheel. The inner portion may include a rim including a plurality of apertures. The inner portion may be high density polyethylene and the tread may be thermoplastic elastomer.

Owner:GEO PLASTICS

Custom engineered steel wheel with ABS plastic wheel cover

InactiveUS20100194181A1Improves replicated lookPrevent fallingWheel protectionSpoked wheelsTruckMagnet

An aftermarket custom engineered deep lip wheel cover in any design, that mates with a custom engineered aftermarket metal wheel that fits most passenger cars, light trucks, and SUV, or golf cart type vehicles. A painted metal wheel custom engineered to jointly except a custom engineered deep lip ABS plastic wheel cover. The wheel cover is designed and contoured to fit exclusively on to the custom engineered metal wheel using a plastic cap, screws, molded attachment clips, magnets, and a special bead system on the lip portion of the wheel cover.

Owner:NORIEGA FR

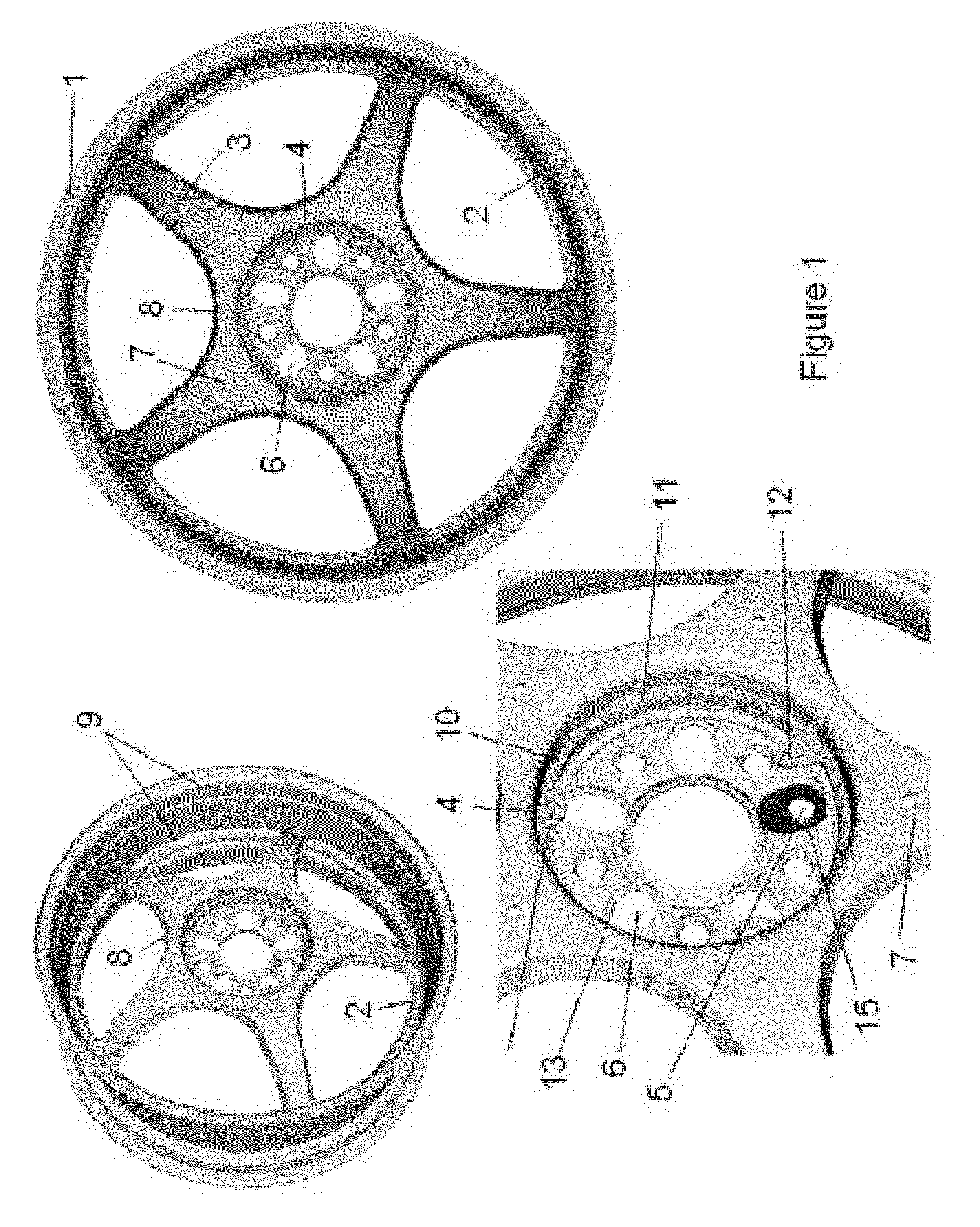

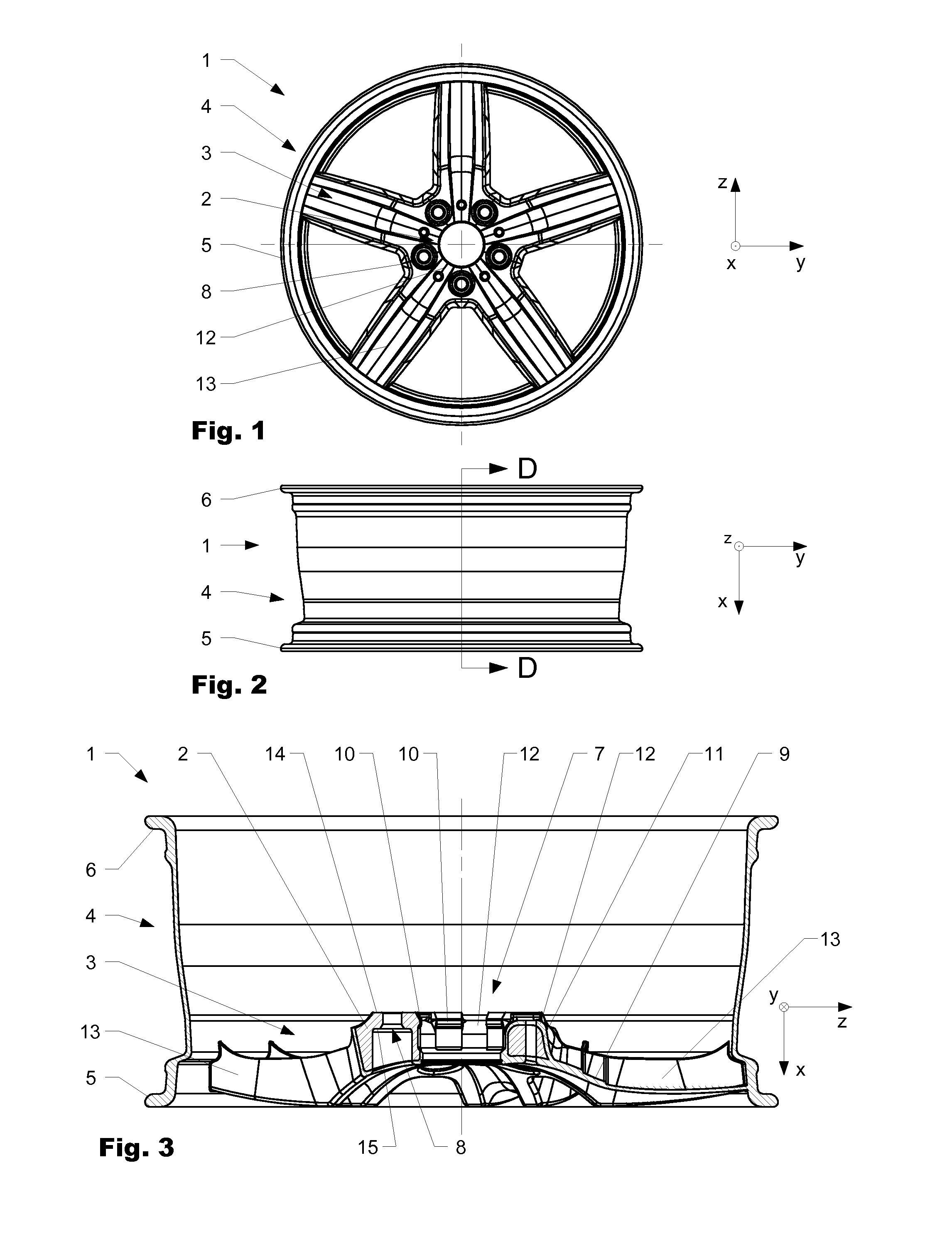

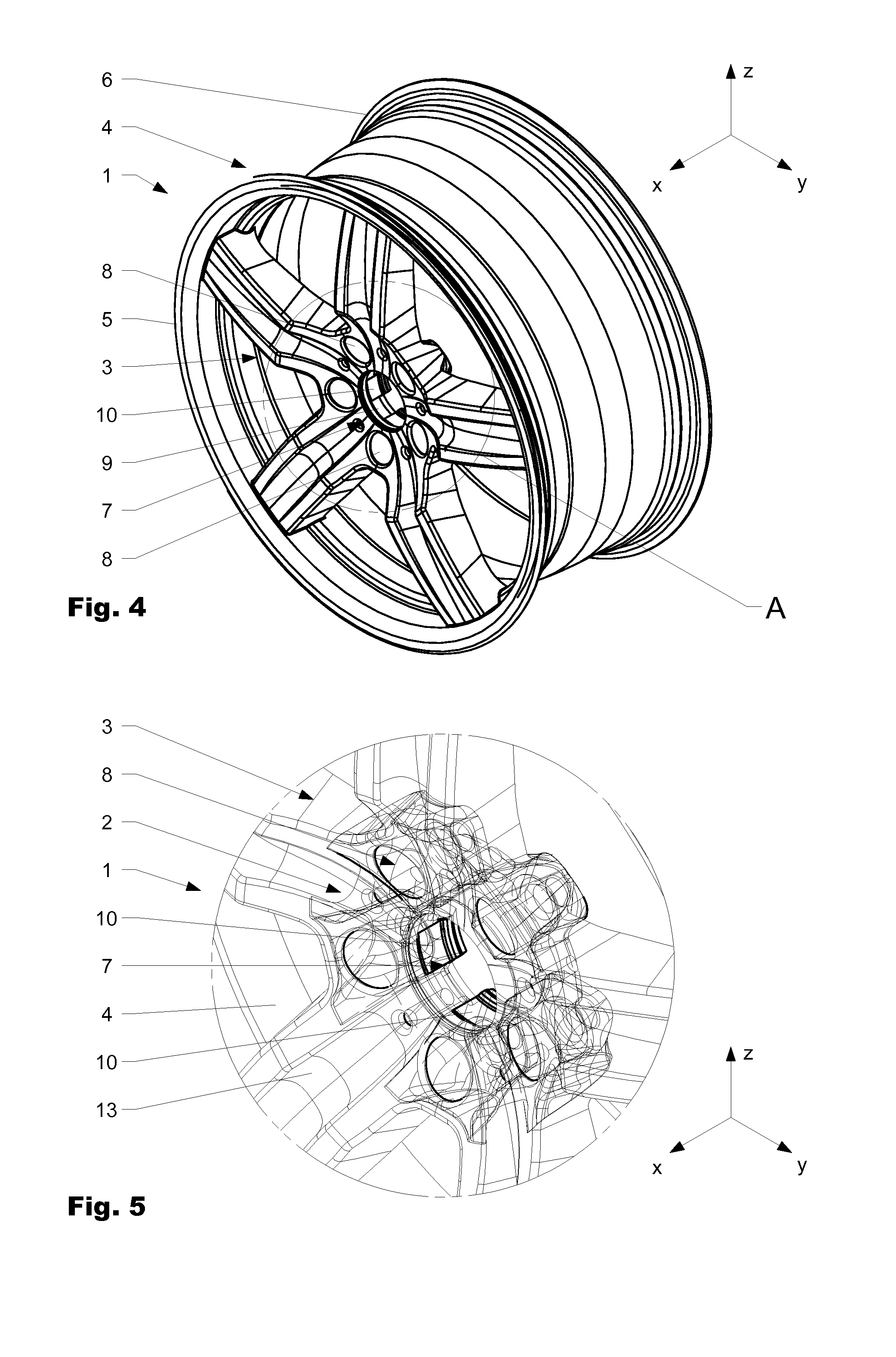

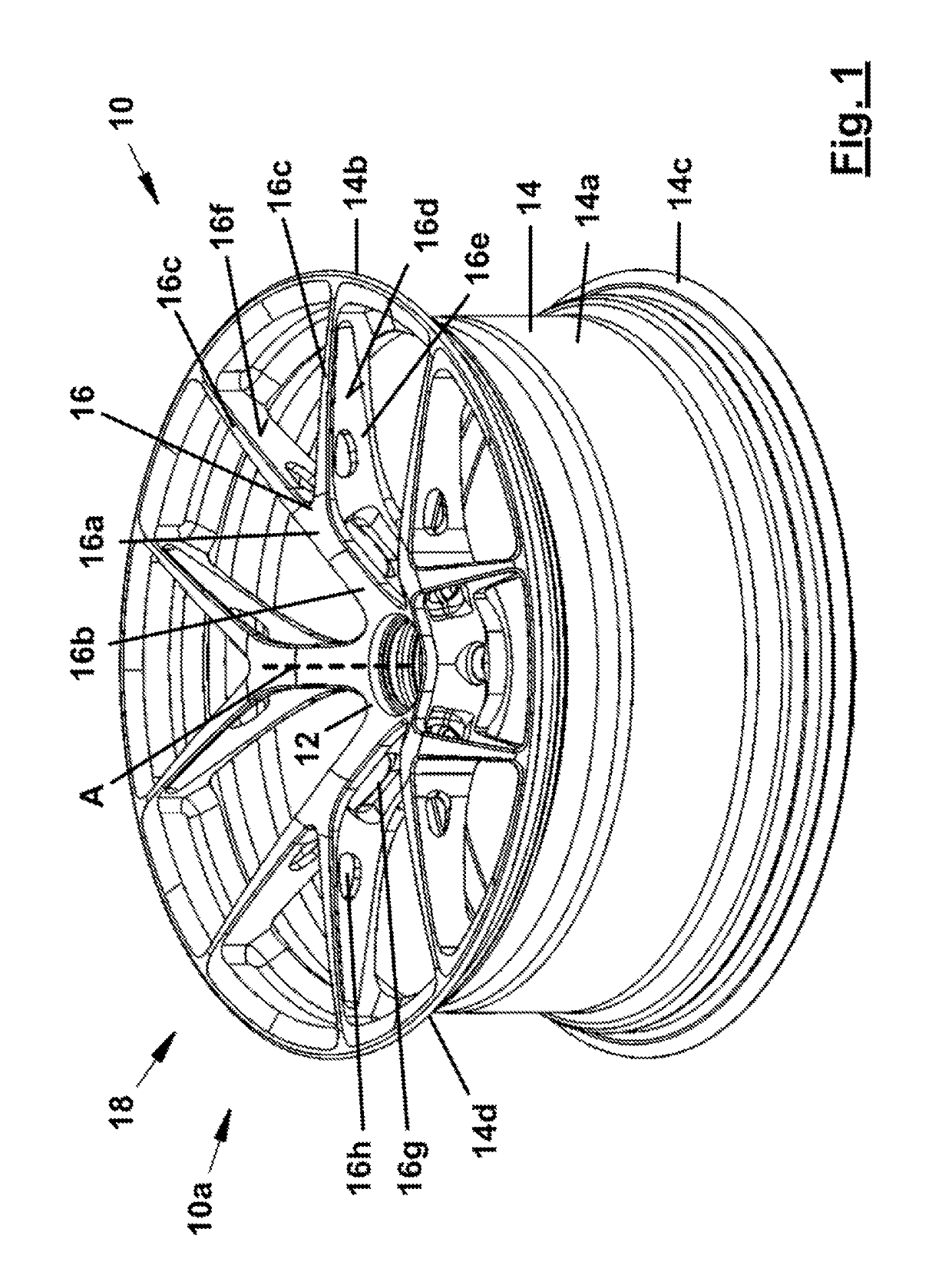

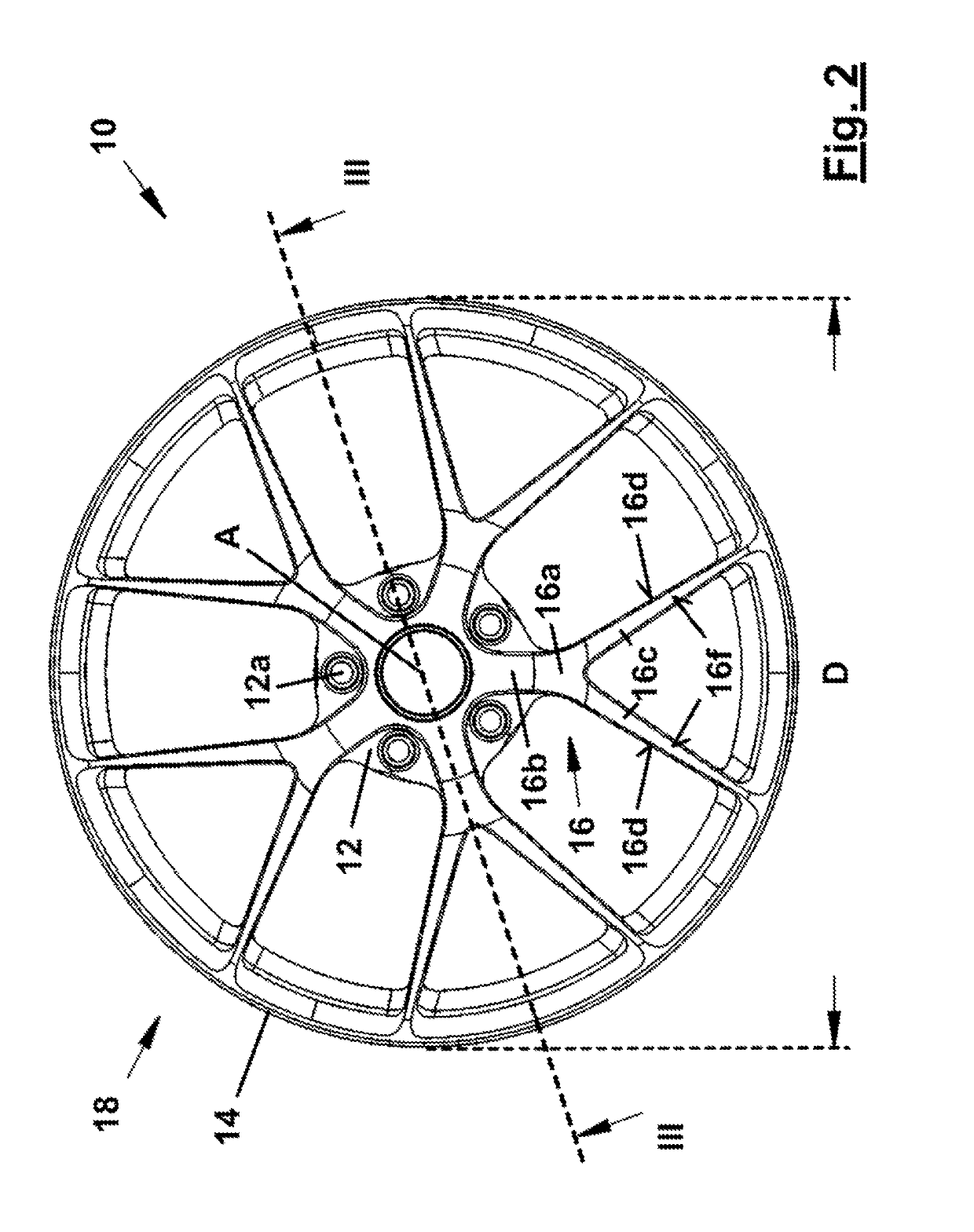

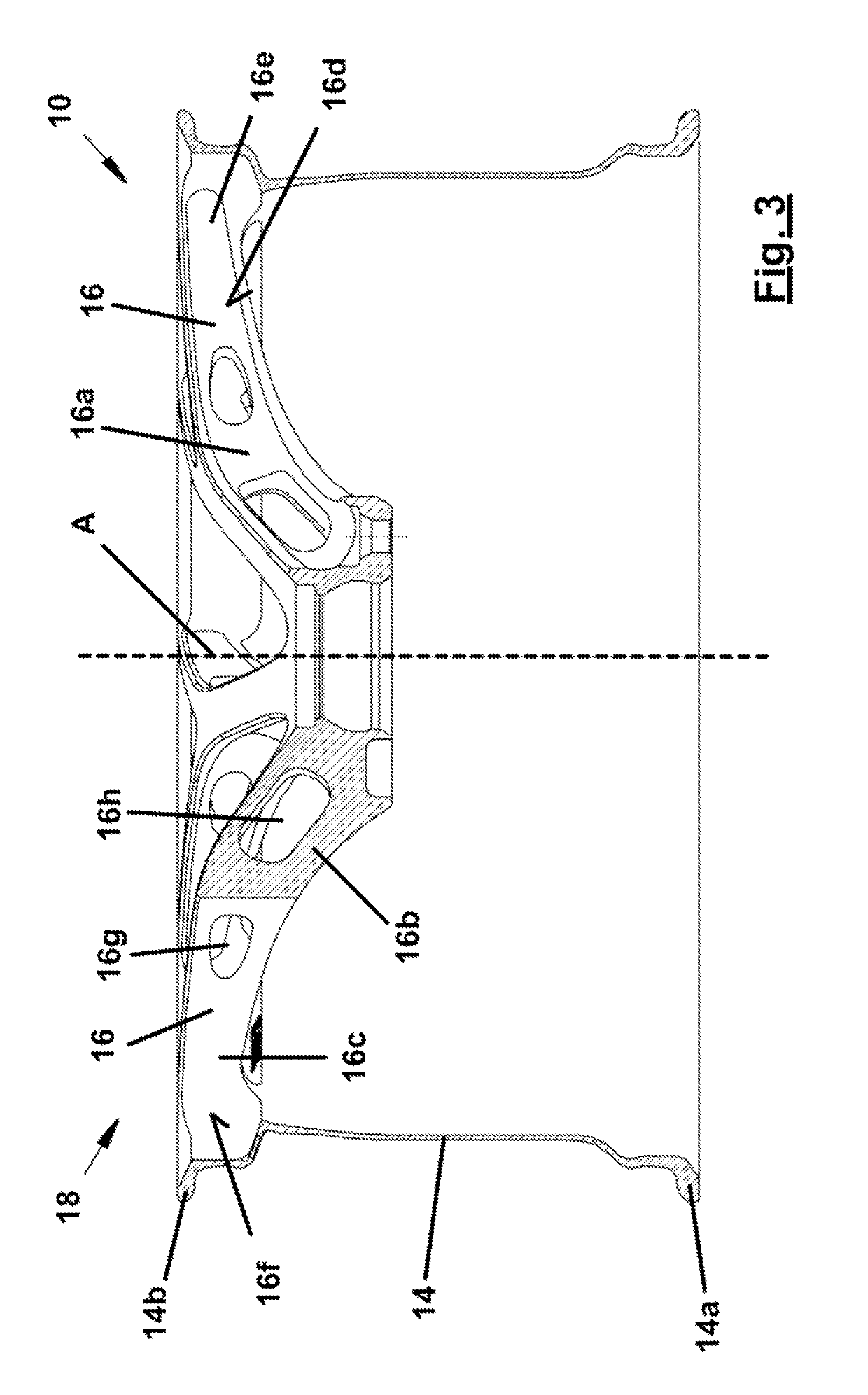

Wheel made out of fiber reinforced material and procedure to make an according wheel

ActiveUS20140346845A1Avoid contactEasy to changeNon-metallic wheel bodyWheel manufacturePlastic materialsMechanical engineering

The invention is directed to a wheel (1) which comprises a rim (4) and a thereto connected spoke structure (3) made out of fiber reinforced plastic material. An insert (2) is embedded in the fiber reinforced material at the center of the spoke structure (3). The insert (2) protrudes in at least one region above the surface of the fiber reinforced plastic material (16) forming at least one contact area (10, 14, 5).

Owner:MUBEA CARBO TECH GMBH

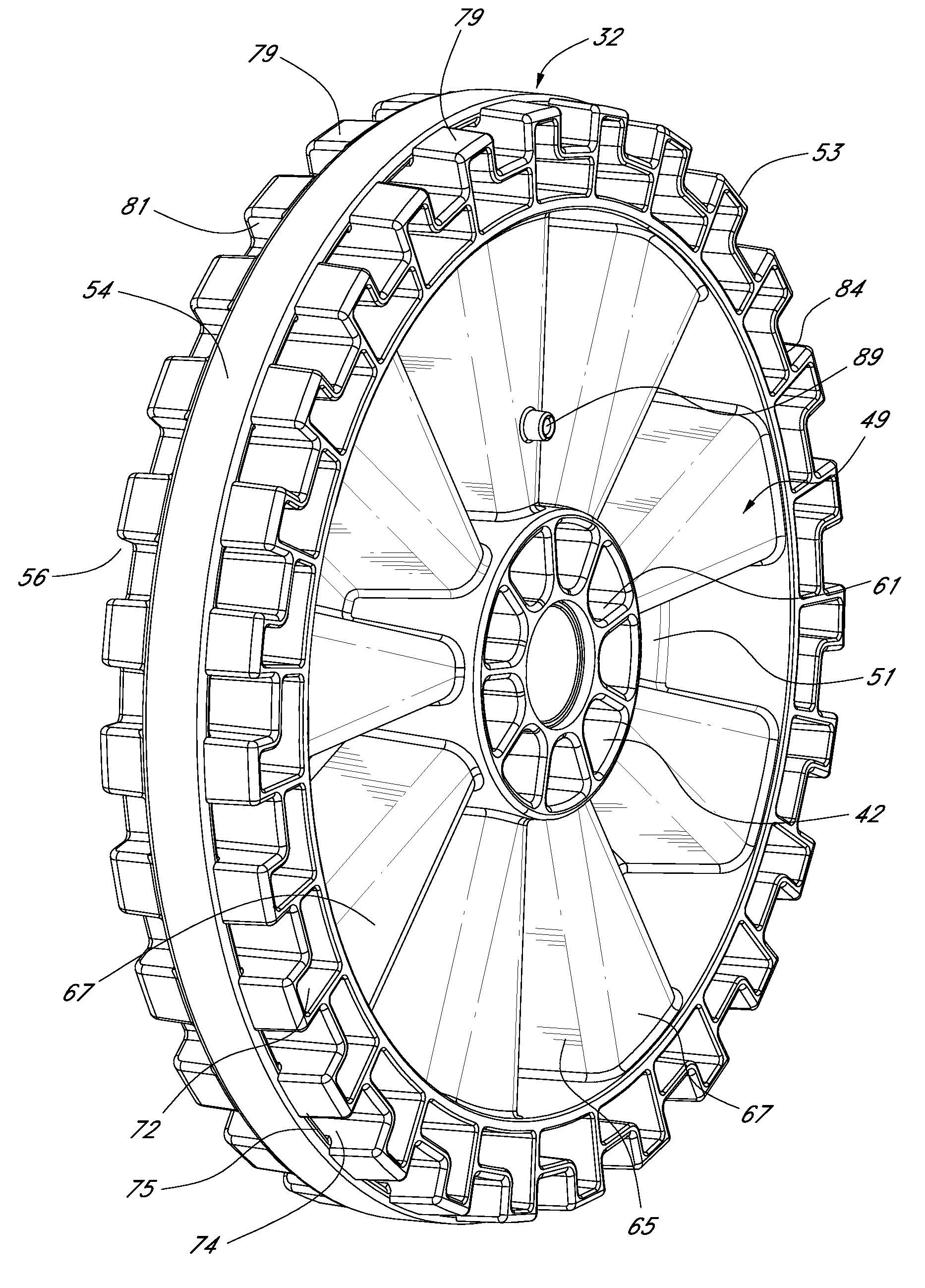

Injection-molded wheel having a plurality of recesses in a rim portion

A wheel when viewed from the outside having the general appearance of a wheel with a tread pattern. The wheel comprising a hub having a central bore dimensioned and configured to receive an axle, a web extending radially from the hub, and an annular rim encircling the web, the rim including a plurality of deep recesses extending in a transverse direction from an inner surface to an outer surface of the rim, each deep recess having a depth substantially equal to a width of the rim. The wheel further includes a plurality of shallow recesses each having a depth less than the deep recesses.

Owner:GEO PLASTICS

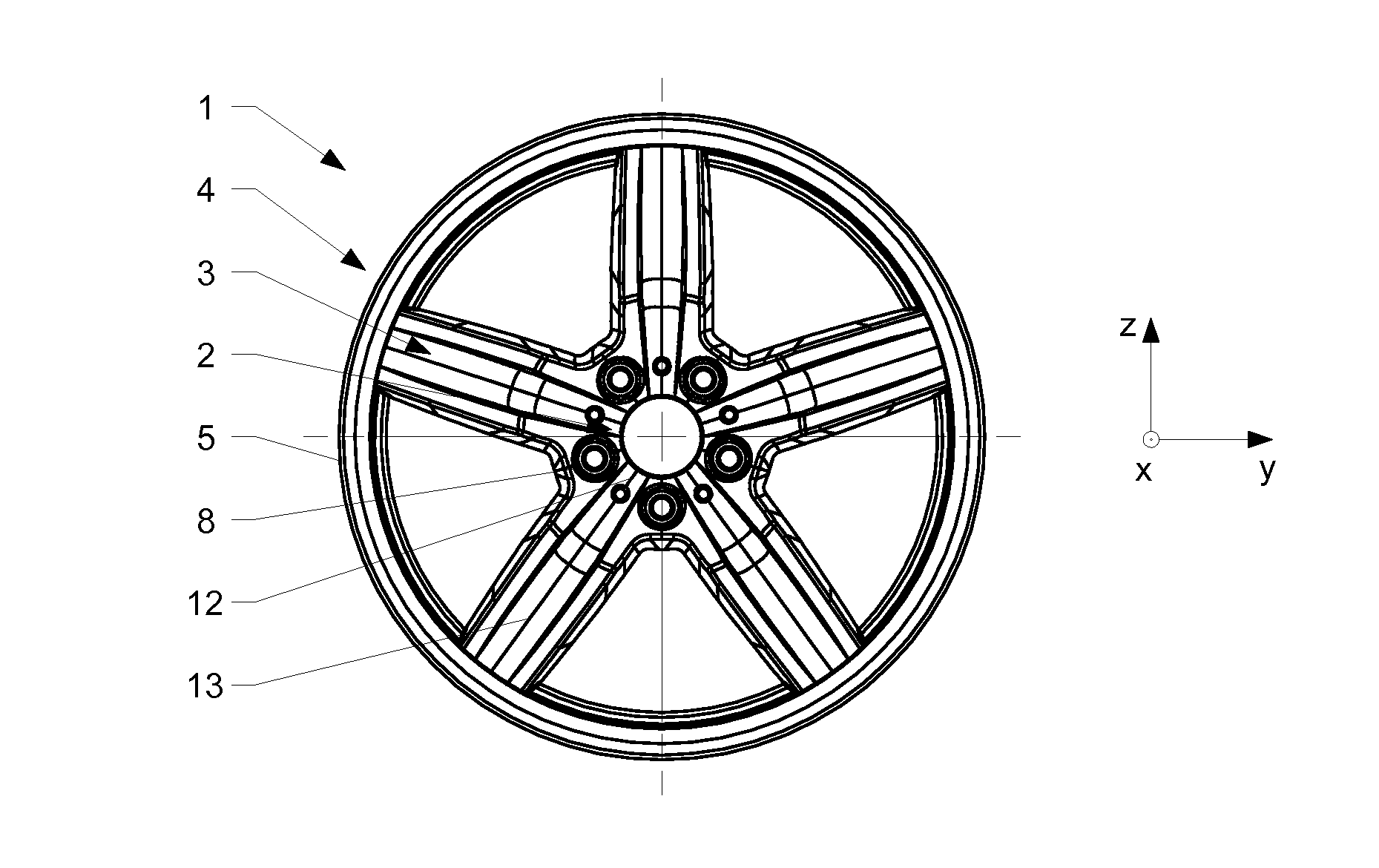

Wheel for a motor vehicle

ActiveUS10357993B2High strengthWithout capacityNon-metallic wheel bodySpoked wheelsMotorized vehicleMechanical engineering

A wheel for a motor vehicle comprises a rim having an outer radius and a wheel spider including a radially inner hub and a plurality of spokes extending from said hub towards said rim. At least one through-hole extends, with respect to the wheel axis, in a circumferential direction through at least one of said spokes. A radially outer edge of said through-hole or of an outermost of said through-holes is located at maximum at 75%, preferably at maximum at ⅔, of said outer radius of the rim measured at a wheel spider side of the rim.

Owner:BBS MOTORSPORT

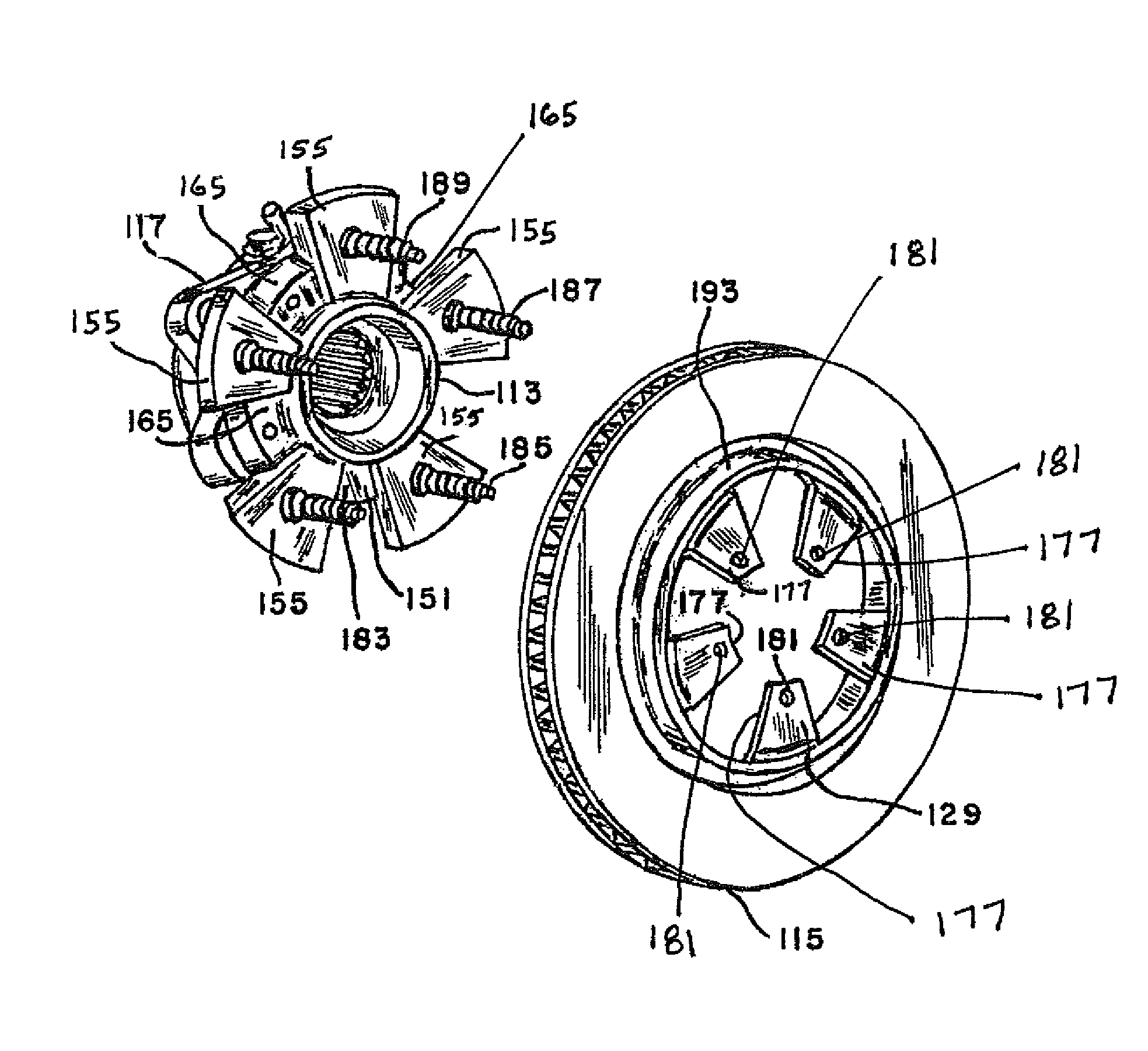

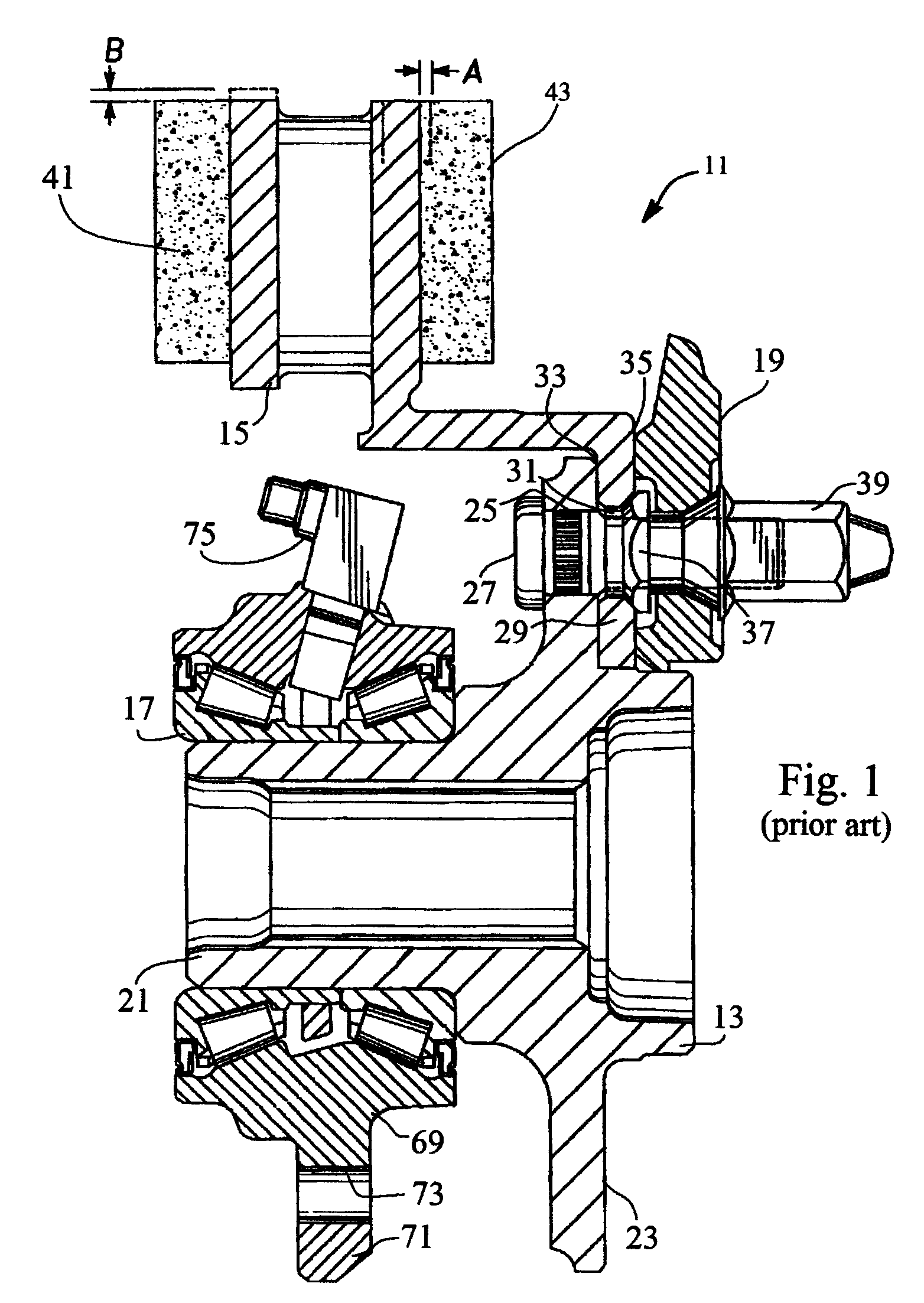

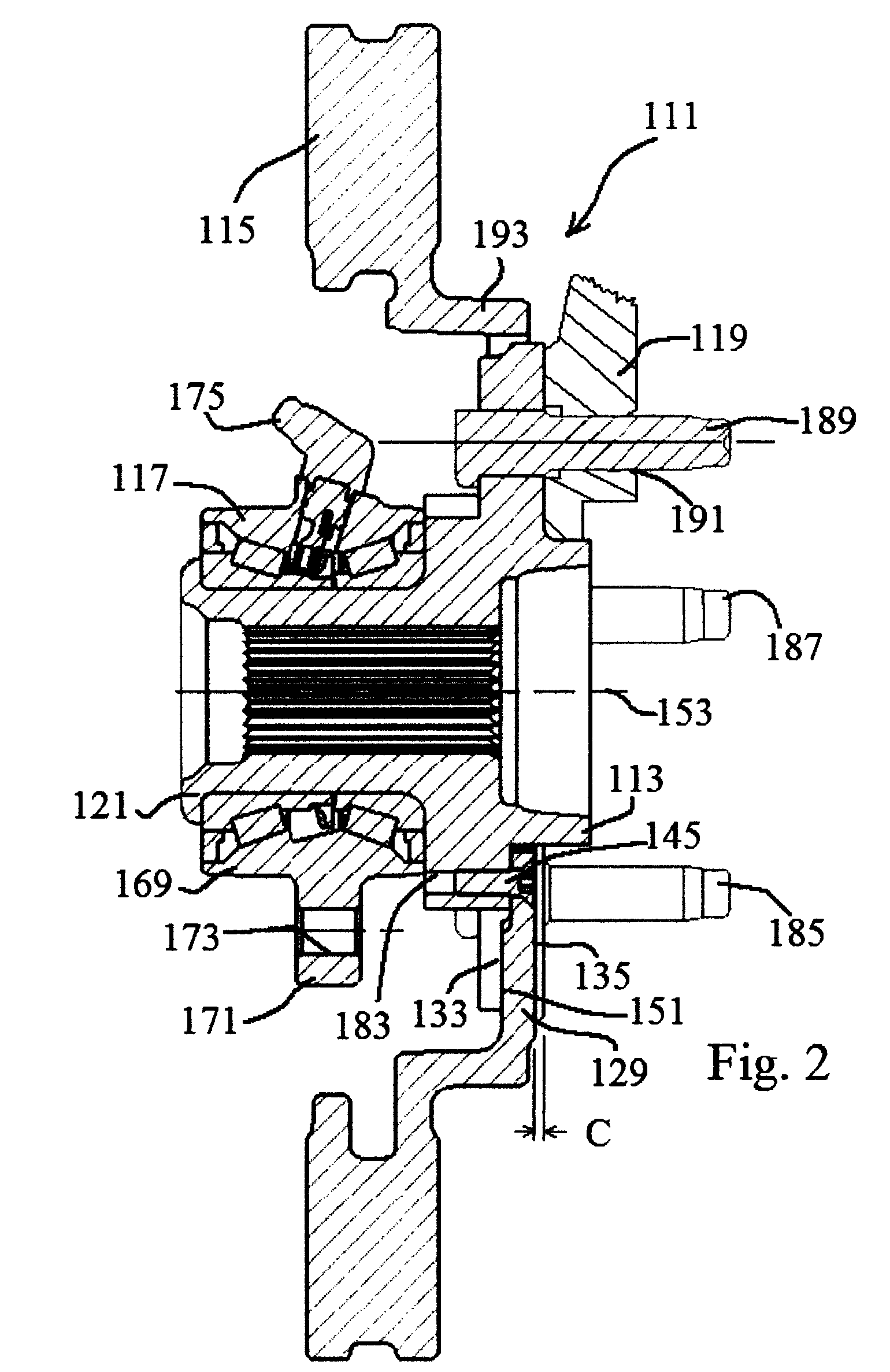

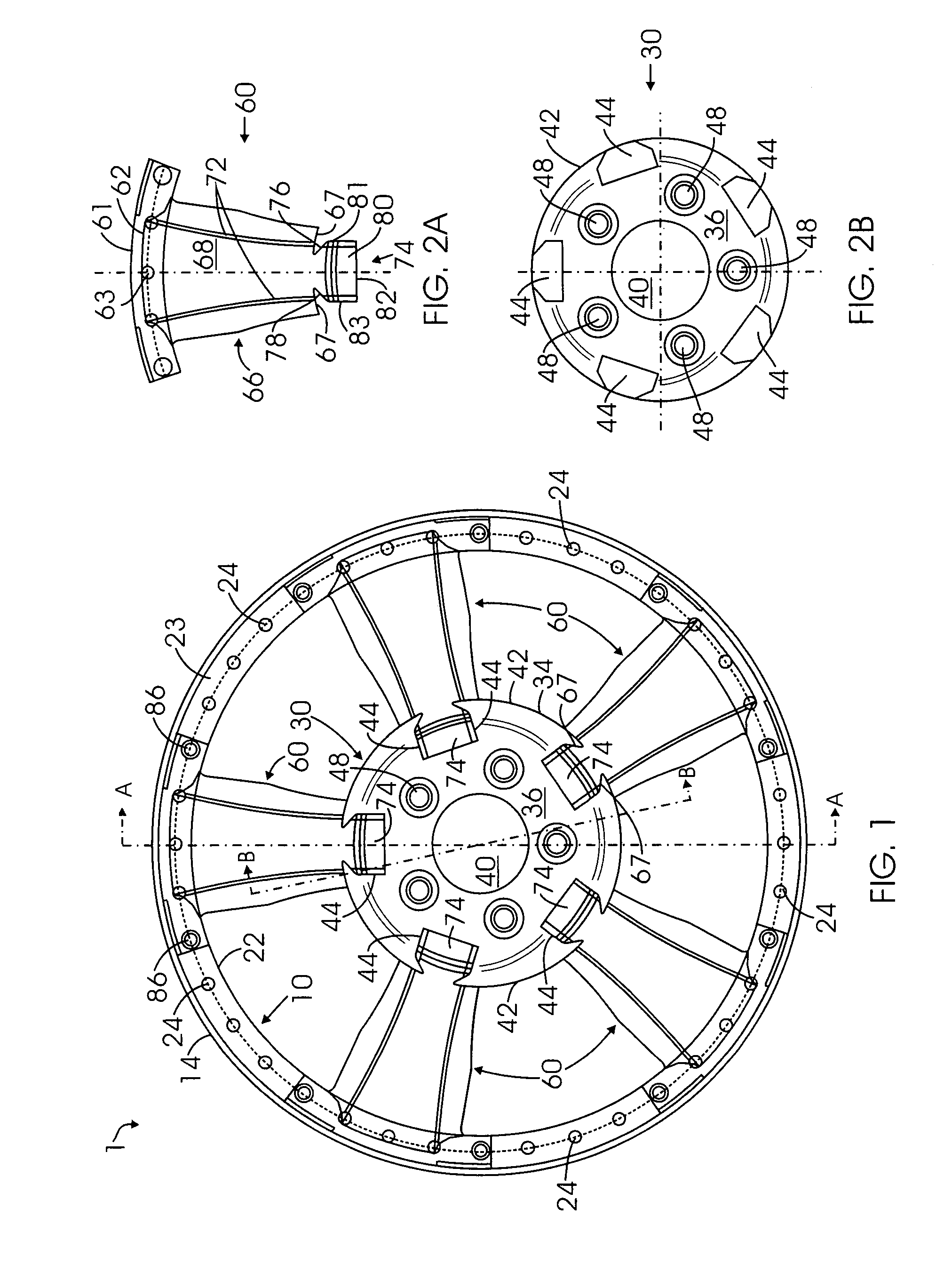

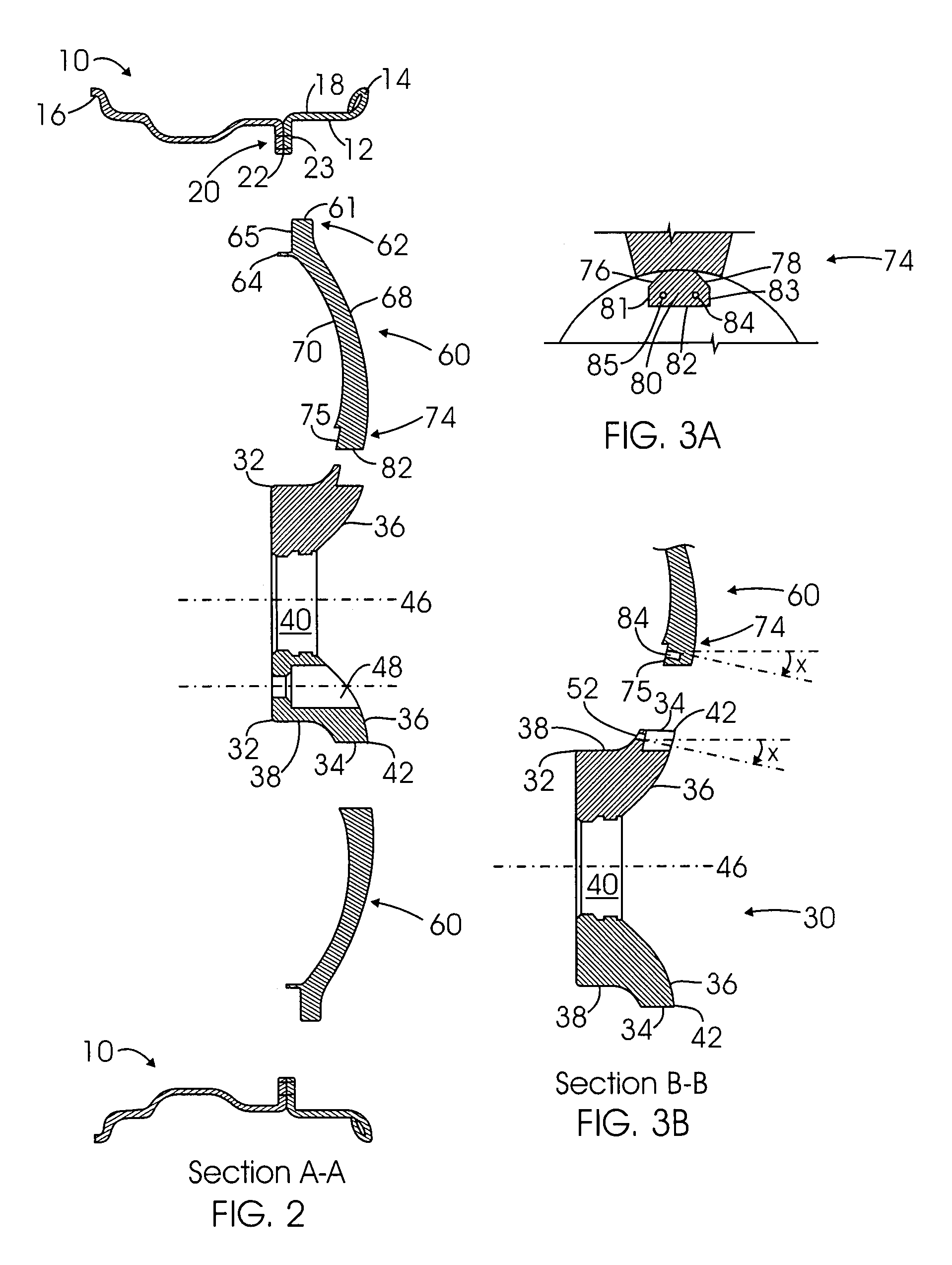

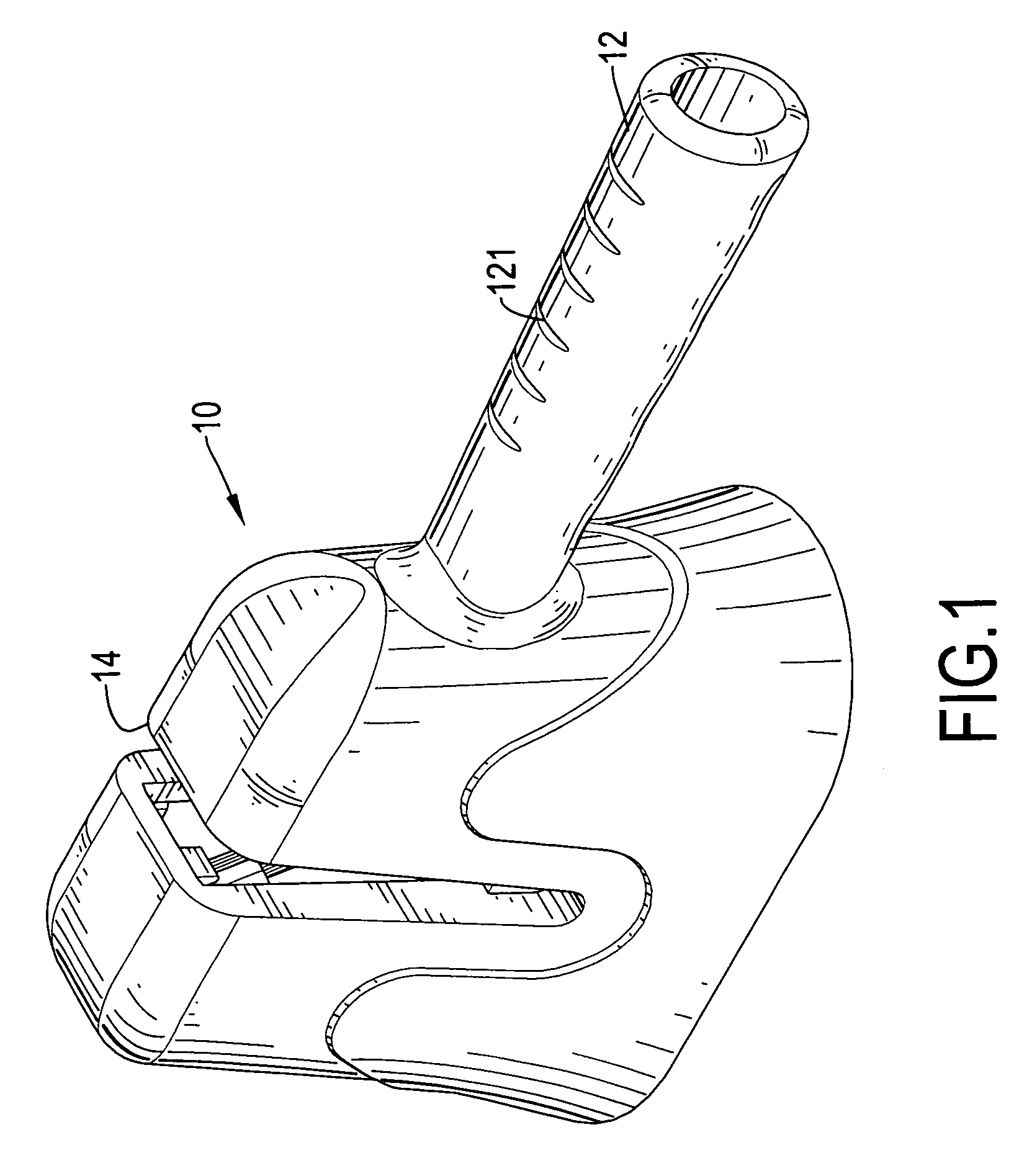

Outboard hub barrel mounted rotor

A vehicle wheel assembly includes a vehicle wheel, a disc brake rotor, and a rotatable hub in which the rotor is securely clamped to the hub independently of the clamping of the wheel to the hub providing a desirable rigid coupling of the rotor and wheel without any physical contact between the wheel and rotor. The hub functions as an intermediate member for supporting both the rotor and the wheel while precluding direct contact therebetween to reduce any rotor deformation which might be induced by the more conventional technique of clamping of the rotor between the wheel and the hub.

Owner:ROBERT BOSCH CORP +1

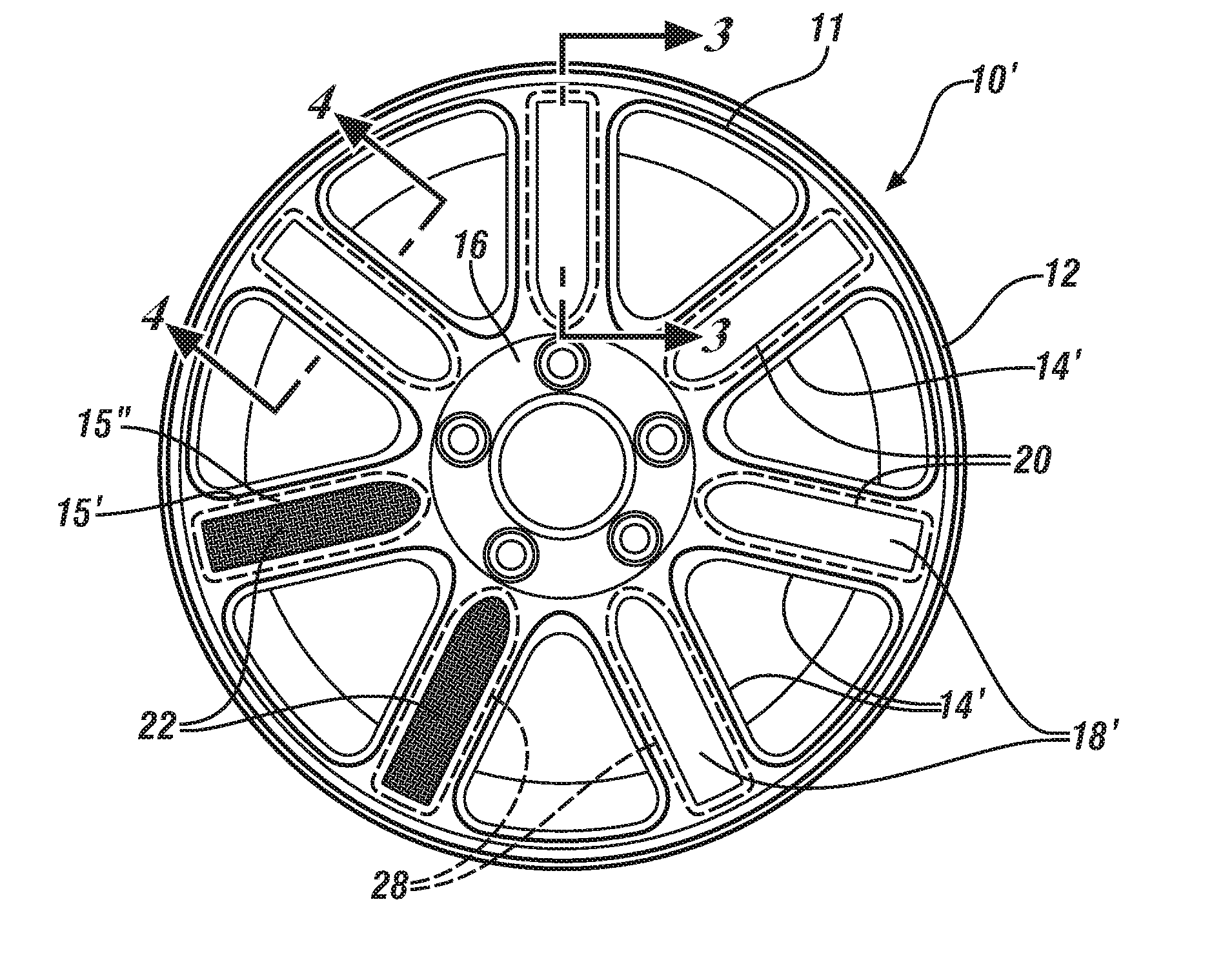

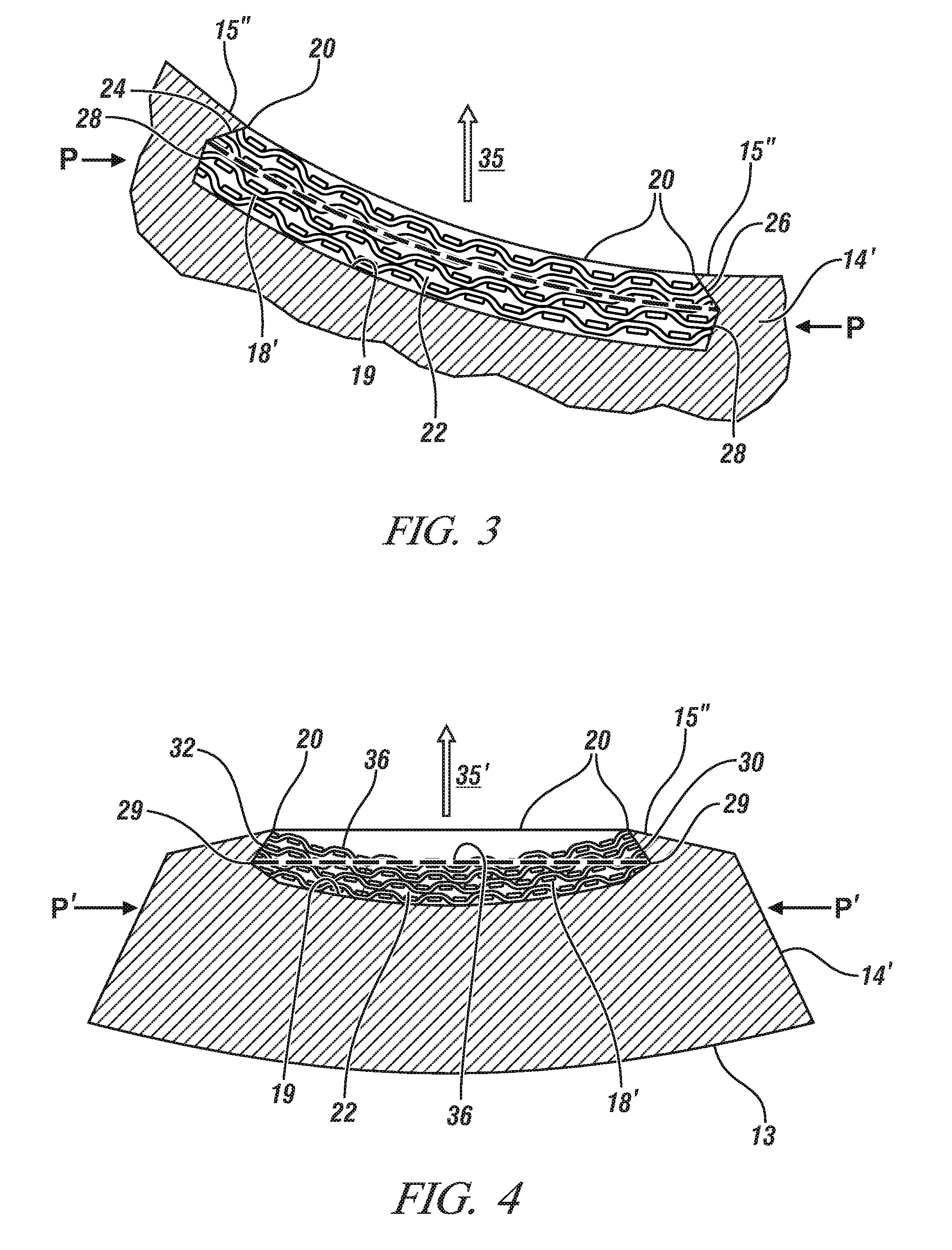

Light-weight vehicle wheels with carbon fiber inserts

ActiveUS20130026816A1Portion is increasedHigh modulusRimsNon-metallic wheel bodyFiberThermal dilatation

Application of carbon fiber reinforced polymer structures to metal vehicle wheels is effective in reducing the mass of the wheel while retaining suitable stiffness in the wheel structure. For maximum effect the reinforced polymer structure and the metal wheel must operate cooperatively. Because of the wide range of operating temperatures experienced by wheels and the large difference in coefficient of thermal expansion between metals and carbon fiber reinforced composites attachment of the polymer structure to the wheel by adhesive alone is problematical. However a wheel with an effective and durable reinforcement may be fabricated by confining, through mechanical interference, the reinforced polymer in a cavity in or on the spoke and by preheating the wheel before curing the polymer.

Owner:GM GLOBAL TECH OPERATIONS LLC

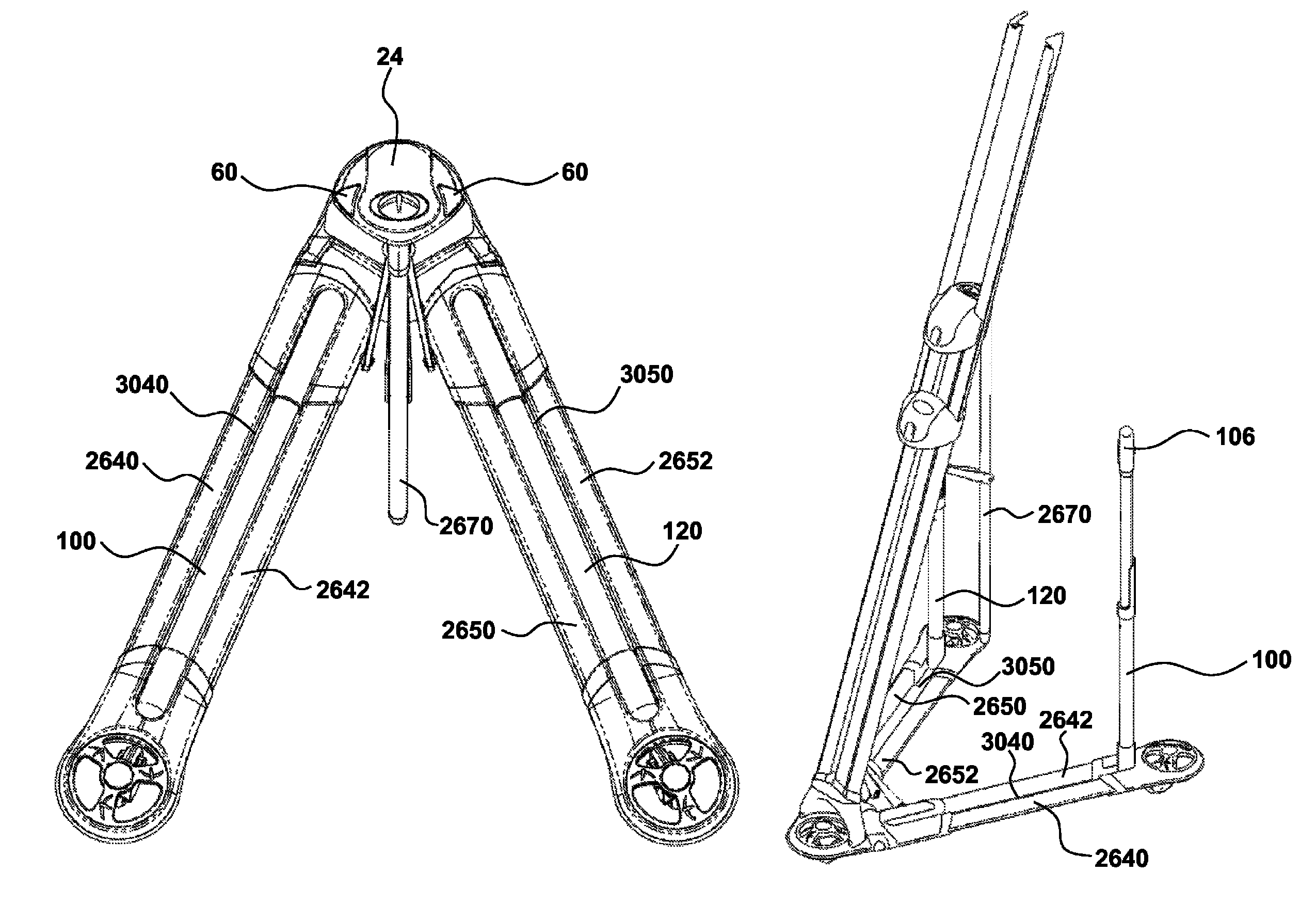

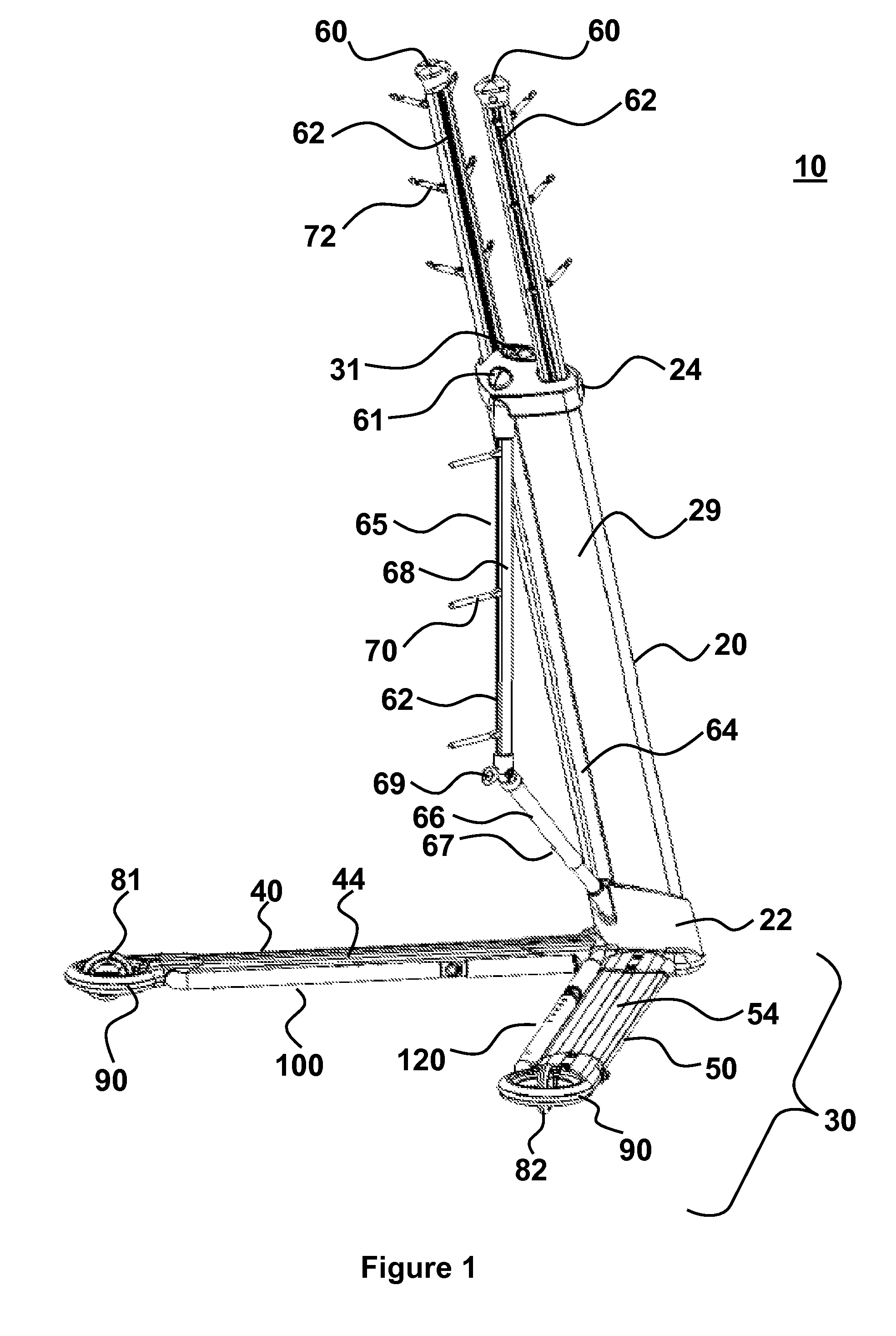

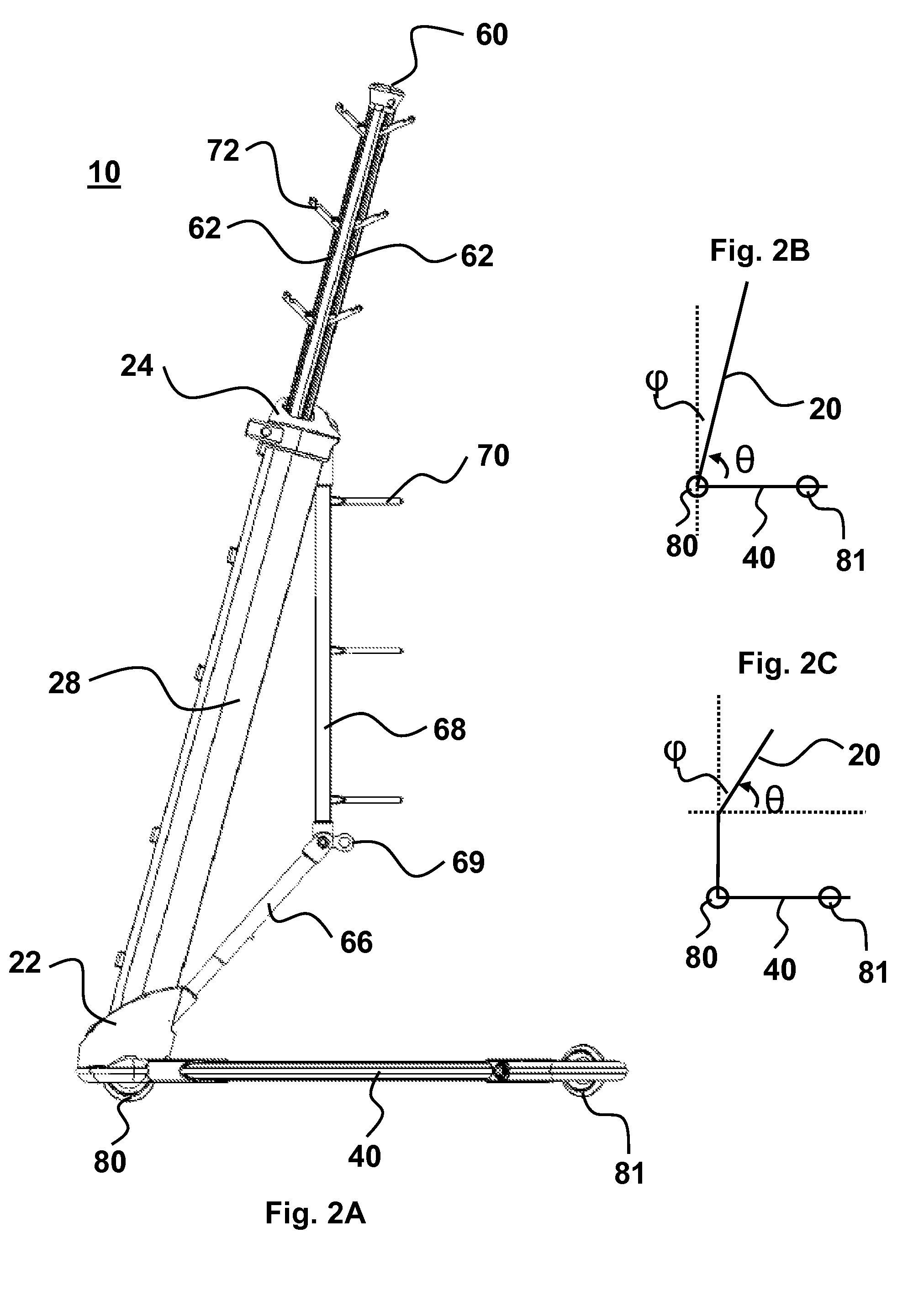

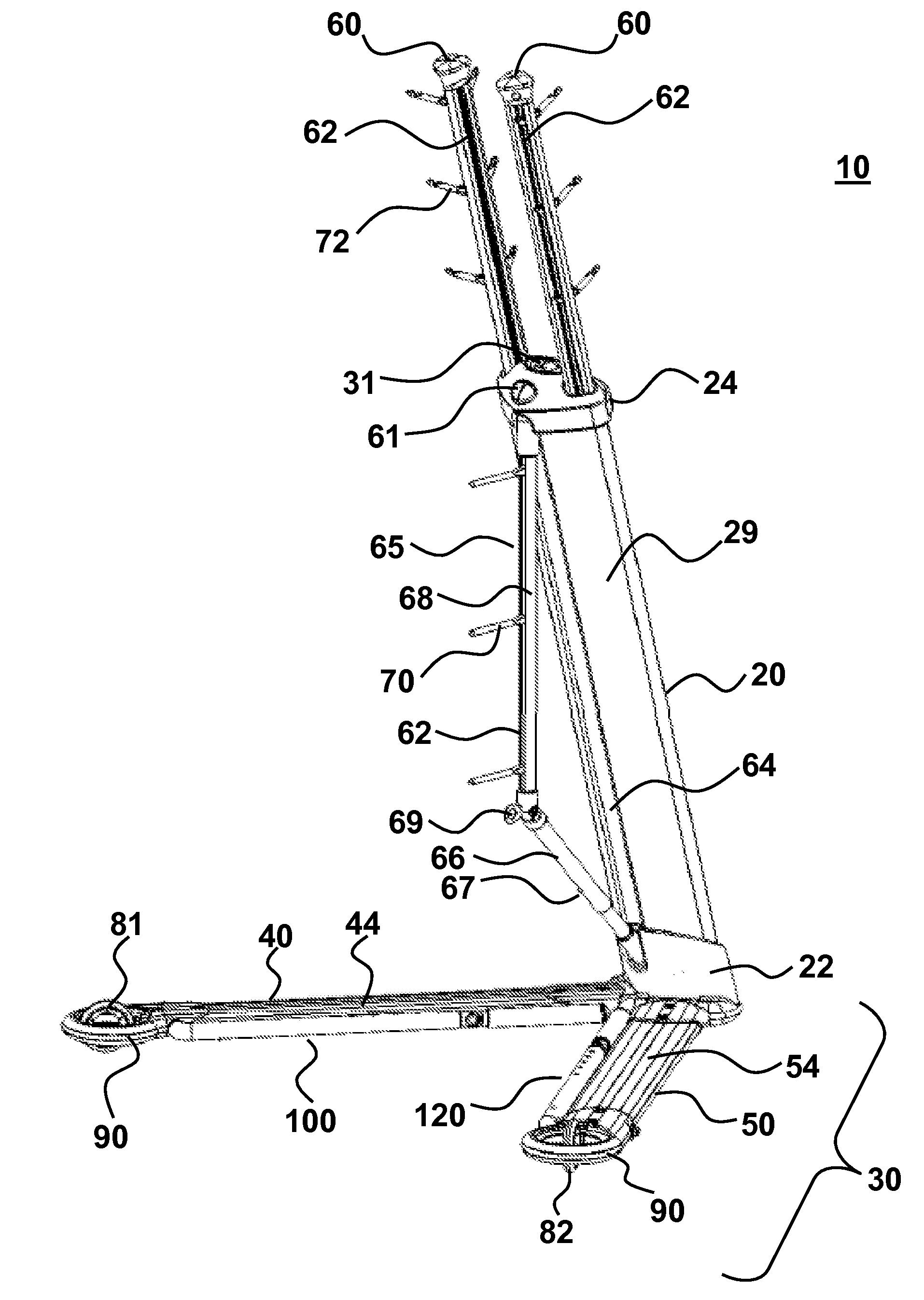

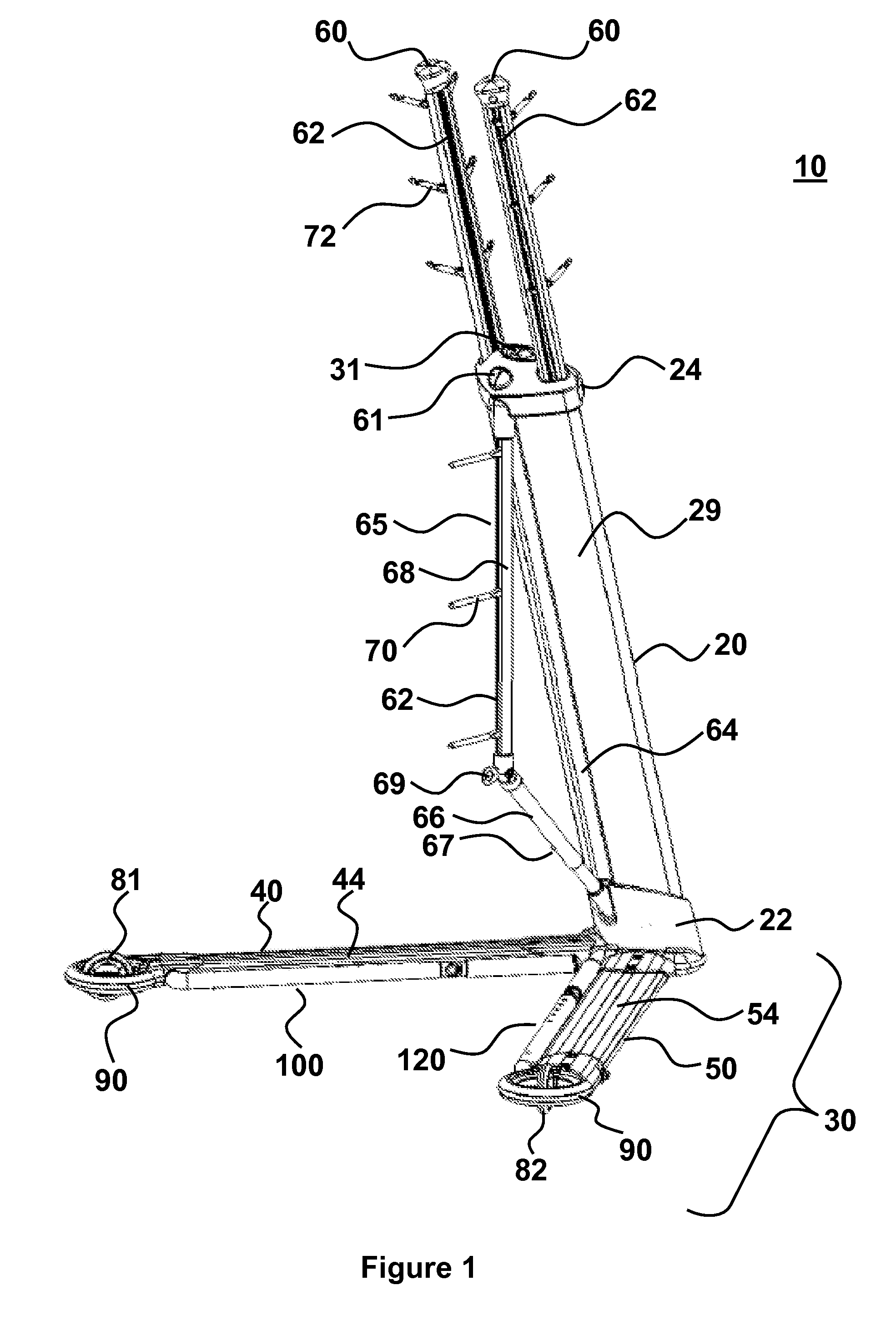

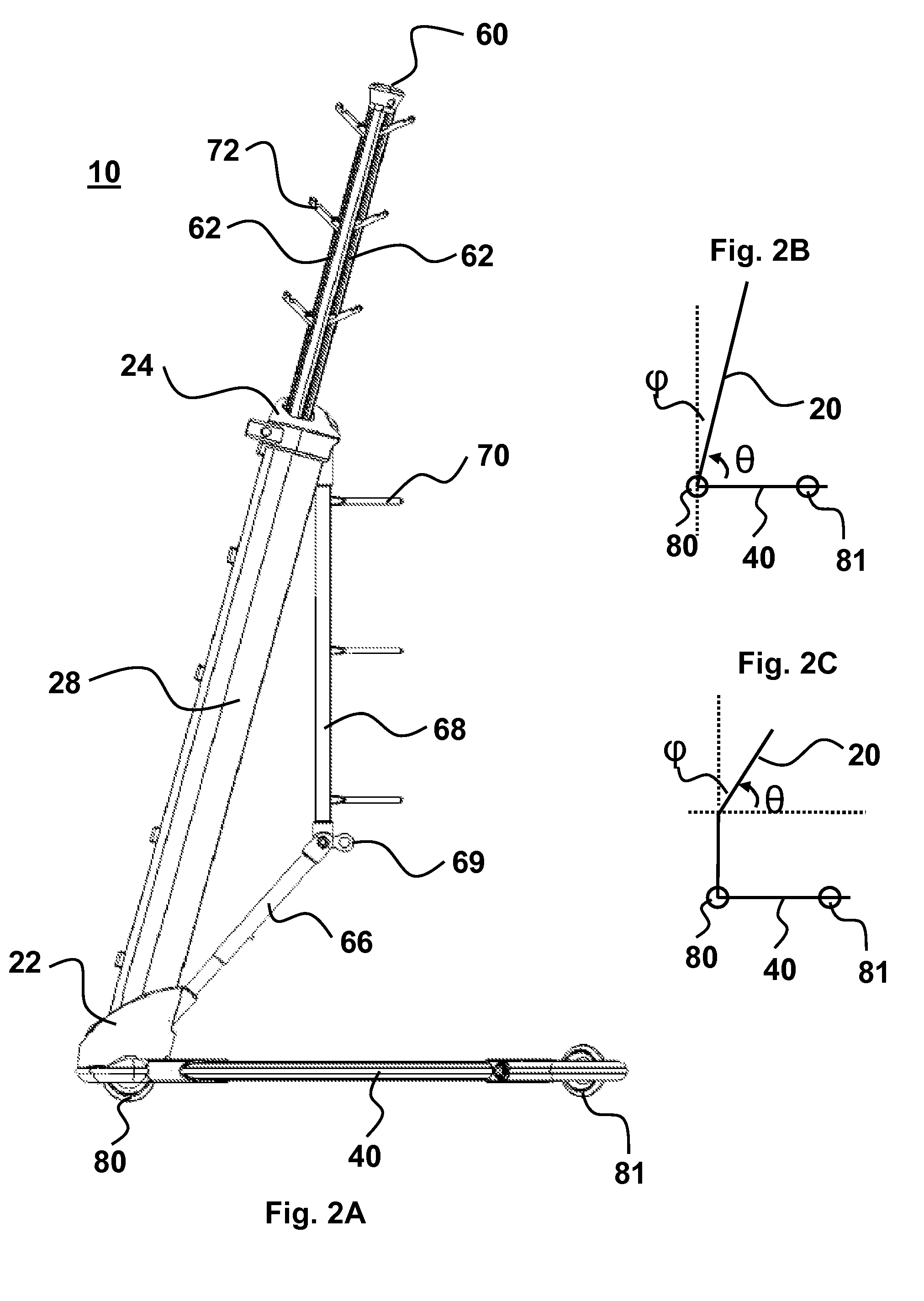

Integrated infusion management system

An integrated infusion management system provides for stable support of components attached to the system, even when the system is mobile. The system is optionally a mobility assist or walker for a patient who is attached to any number of medical components. A central trunk connects to a two-sided base that does not interfere with patient motion. The trunk may be angled with respect to vertical and oriented to support medical components in a configuration that is tip-resistant. The system is optionally deployable to facilitate conversion between a compact storage configuration and a stable deployed configuration. In an embodiment, additional deployable features include holding arms for holding various medical components, wheels, mobility arms and handles. Also provided is a novel wheel system with deployable wheels and methods associated with providing compact storage of any one or more of the systems presented herein.

Owner:FIREFLY MEDICAL

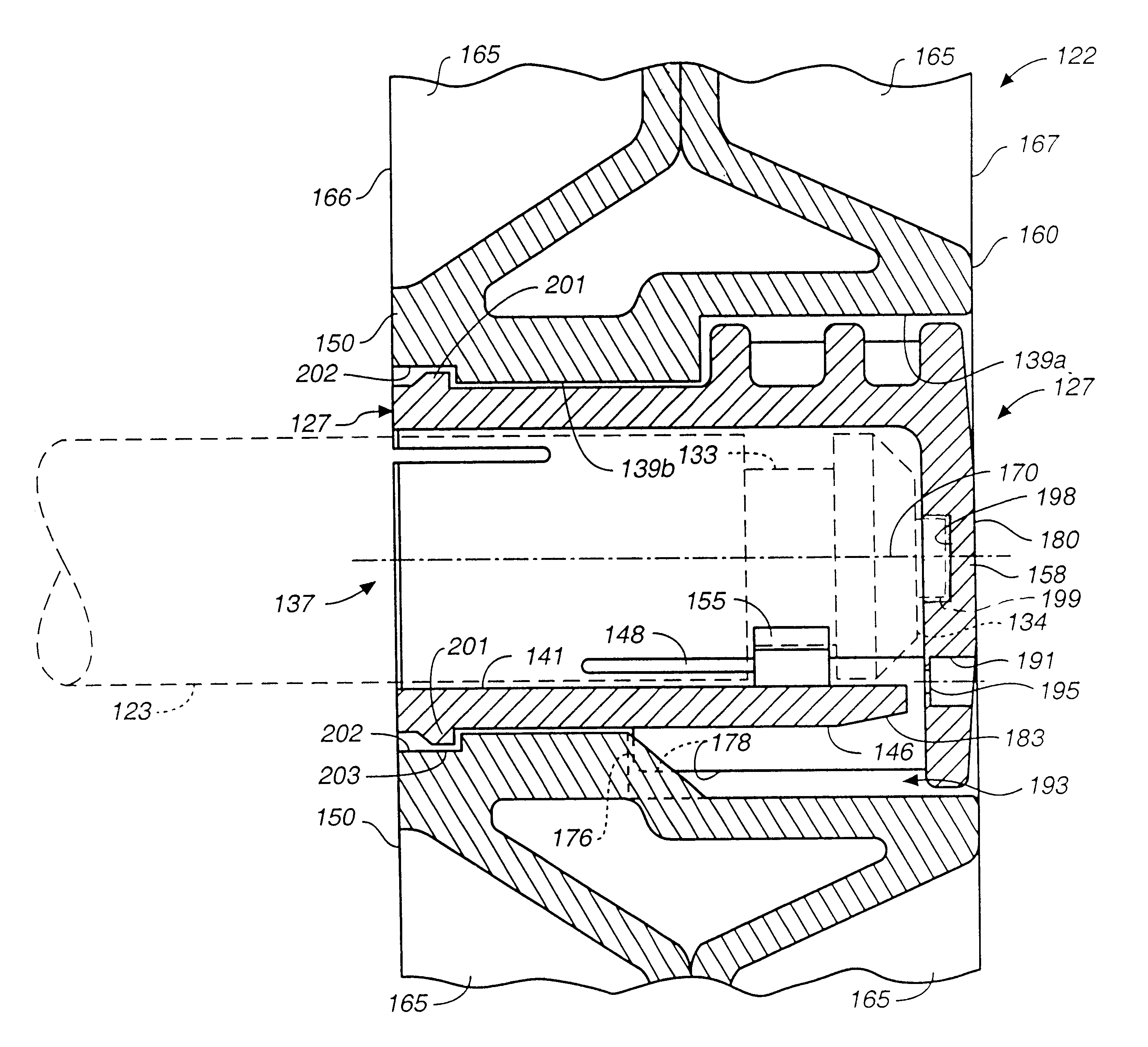

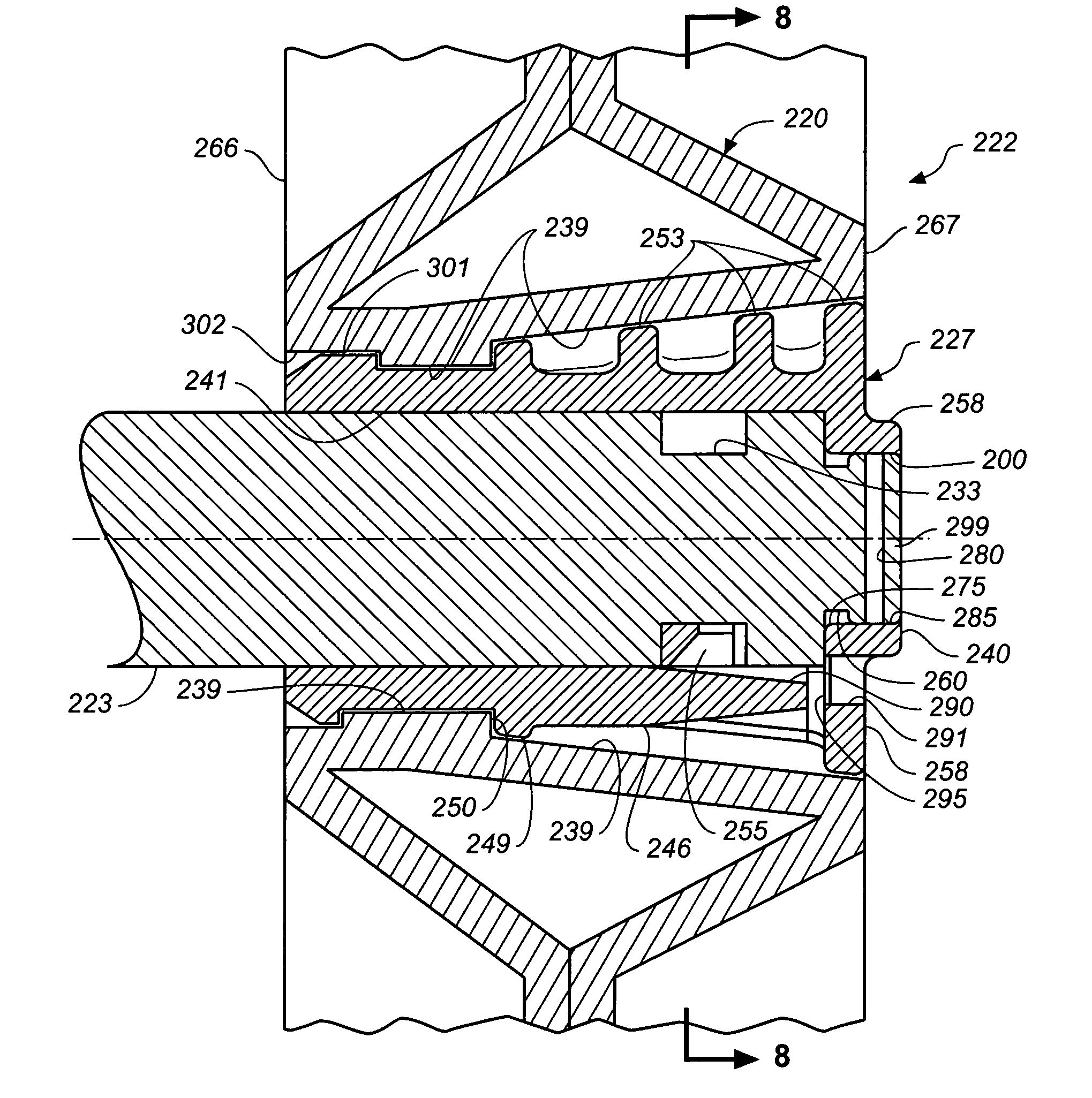

Plastic wheel assembly, mounting sleeve and universal axle

A plastic wheel assembly (122, 222) and wheel mounting sleeve (127, 227) used to releasably secure the wheel (122, 222) onto an axle (123, 223). The wheel mounting sleeve (127, 227) includes an axle stabilizing opening (100, 200) positioned in an end wall (158, 258) of the sleeve which receives an axle outer end or axle stub (199, 299) that supports the axle (123, 223) against lateral loading and stabilizes it to reduce wobble, chatter and vibration. The opening (100, 200) permits visual confirmation of proper section of the axle outer end (199, 299) in the opening (100, 200). A universal axle (223, 223a) is also provided which can be used to couple wheels (122, 222) having shaped axle bores (139, 239) to the axle using wheel mounting sleeves (127, 227), as well as being used to couple wheels (420), having straight or substantially cylindrical bores (439), to the axle using conventional fasteners (450, 461, 470).

Owner:GEO PLASTICS

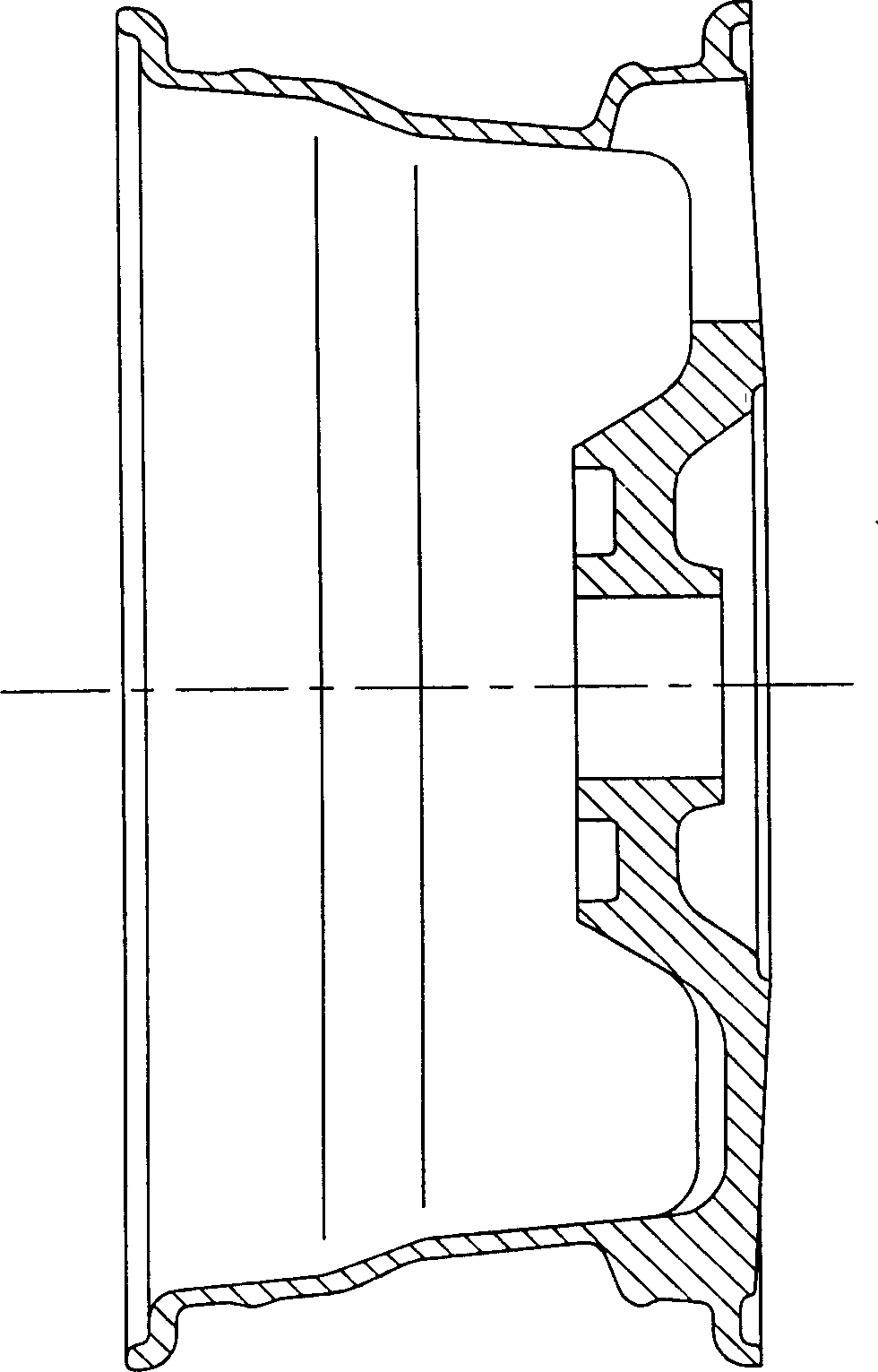

Vehicle wheel

A vehicle wheel in which an additional air chamber member in a tire air chamber is fixed on an outer circumferential surface of a well portion, includes: a first vertical wall surface rising outward in a radial direction from the outer circumferential surface of the well portion and extending in a circumferential direction of the outer circumferential surface; and a second vertical wall surface formed in the well portion facing the first vertical wall surface. The additional air chamber member has an additional air chamber and a communication hole formed therein. The communication hole provides communication between the additional air chamber and the tire air chamber. The additional air chamber member is fitted between the first and second vertical wall surfaces. Side end portions of the additional air chamber member in a width direction of the vehicle wheel are secured between the first and second vertical wall surfaces.

Owner:HONDA MOTOR CO LTD

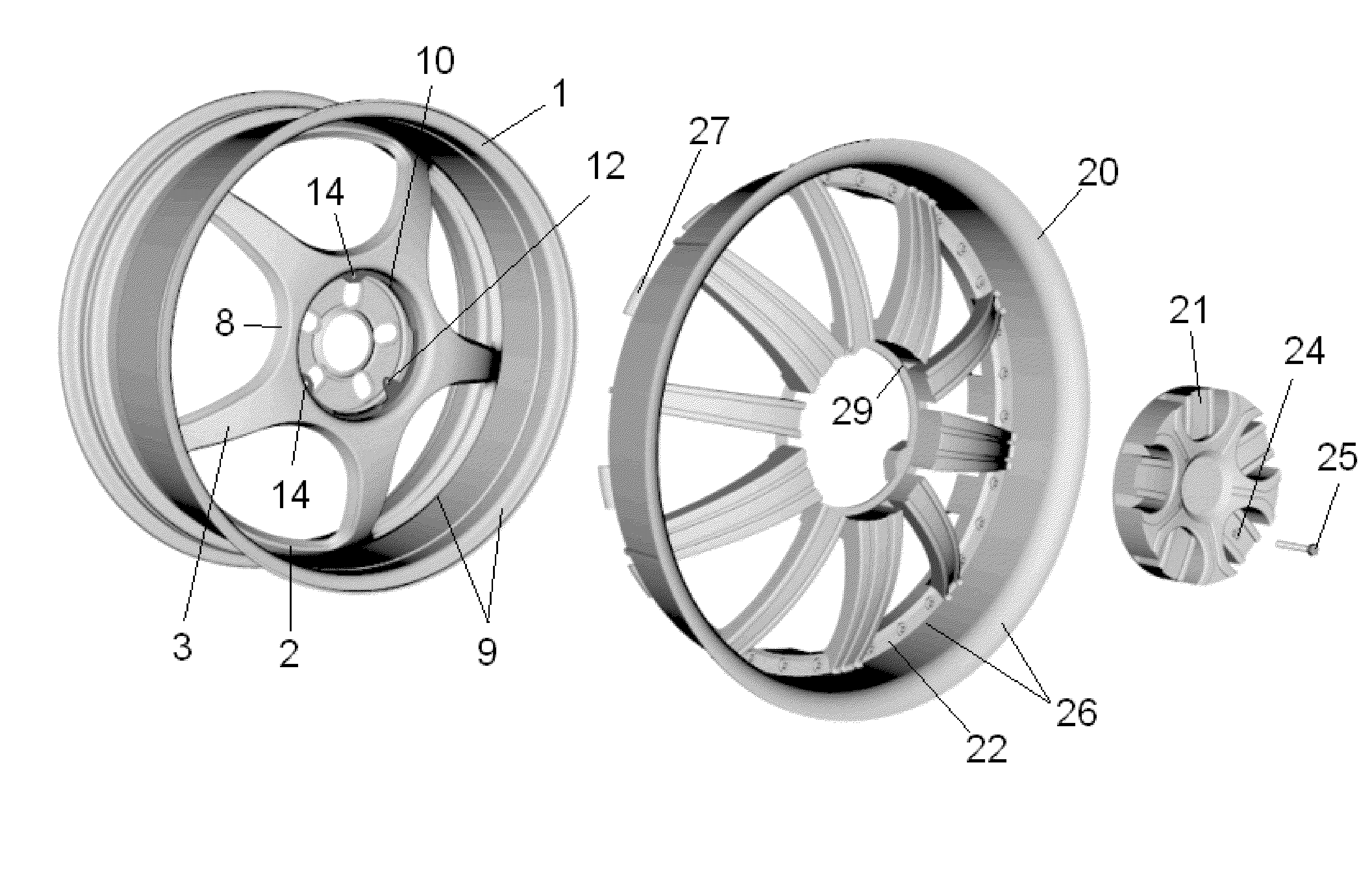

Multi-piece wheel

InactiveUS7681958B1Easy to changeReduce manufacturing costRimsMechanical vibrations separationEngineeringMechanical engineering

A multi-piece wheel, which is assembled with multiple pieces of pre-made structural members, including an outer wheel ring, a central hub and multiple spokes. The outer wheel ring is comprised of a circular wall for affixing a tire on its inner surface and connecting spokes on its outer surface. The spokes are the wheel intermediate members which at their respective first and second end are connected to the respective outer wheel ring and the central hub. The central hub is a circular structure including a central bore and front circular arcuate surface, wherein multiple pockets are placed on the front surface for connecting the spoke second ends to the central hub. Various structural variations of the central hub and spokes regarding their connection are also disclosed, which results in various embodiments of the present invention.

Owner:BAGDASARIAN KEN L

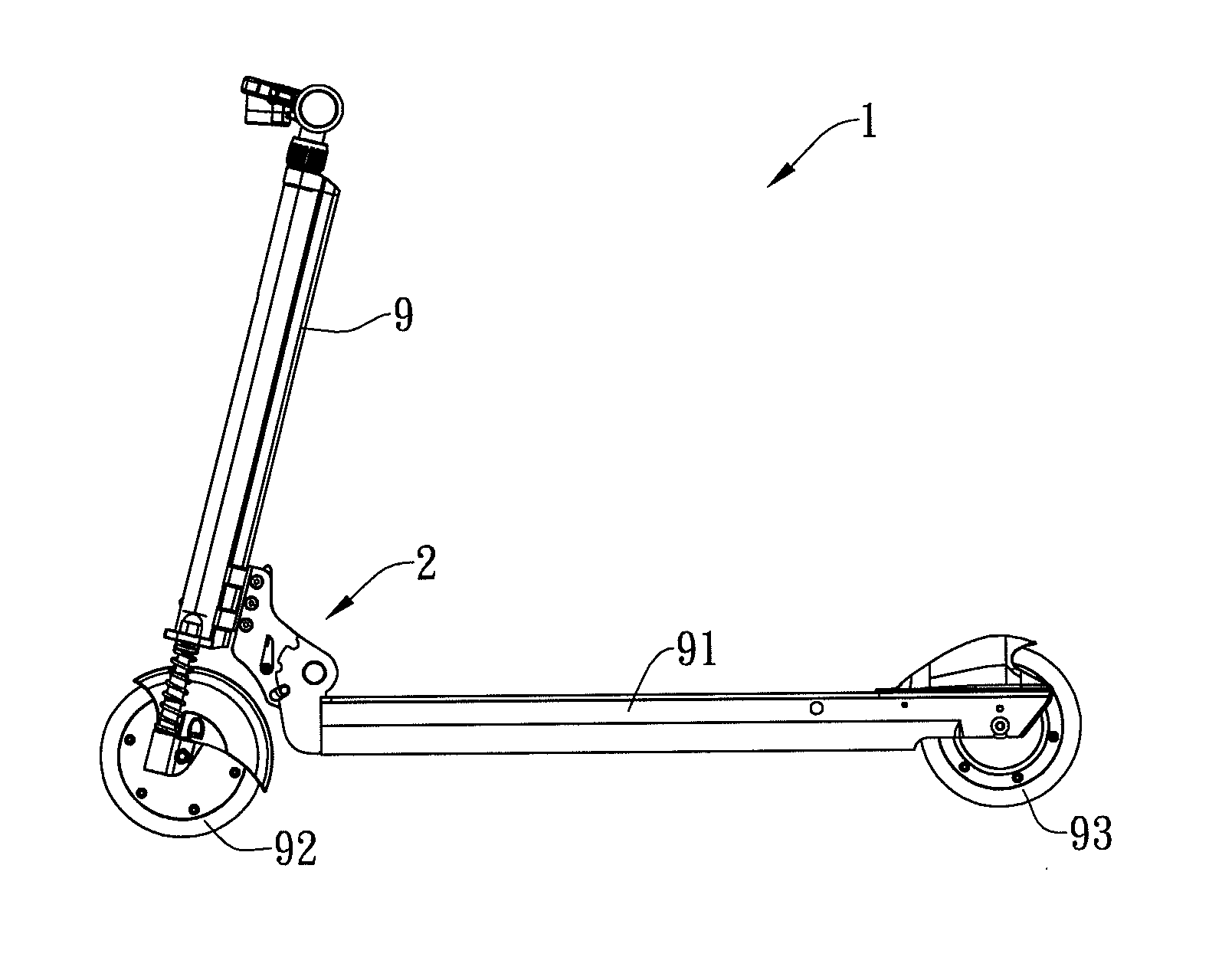

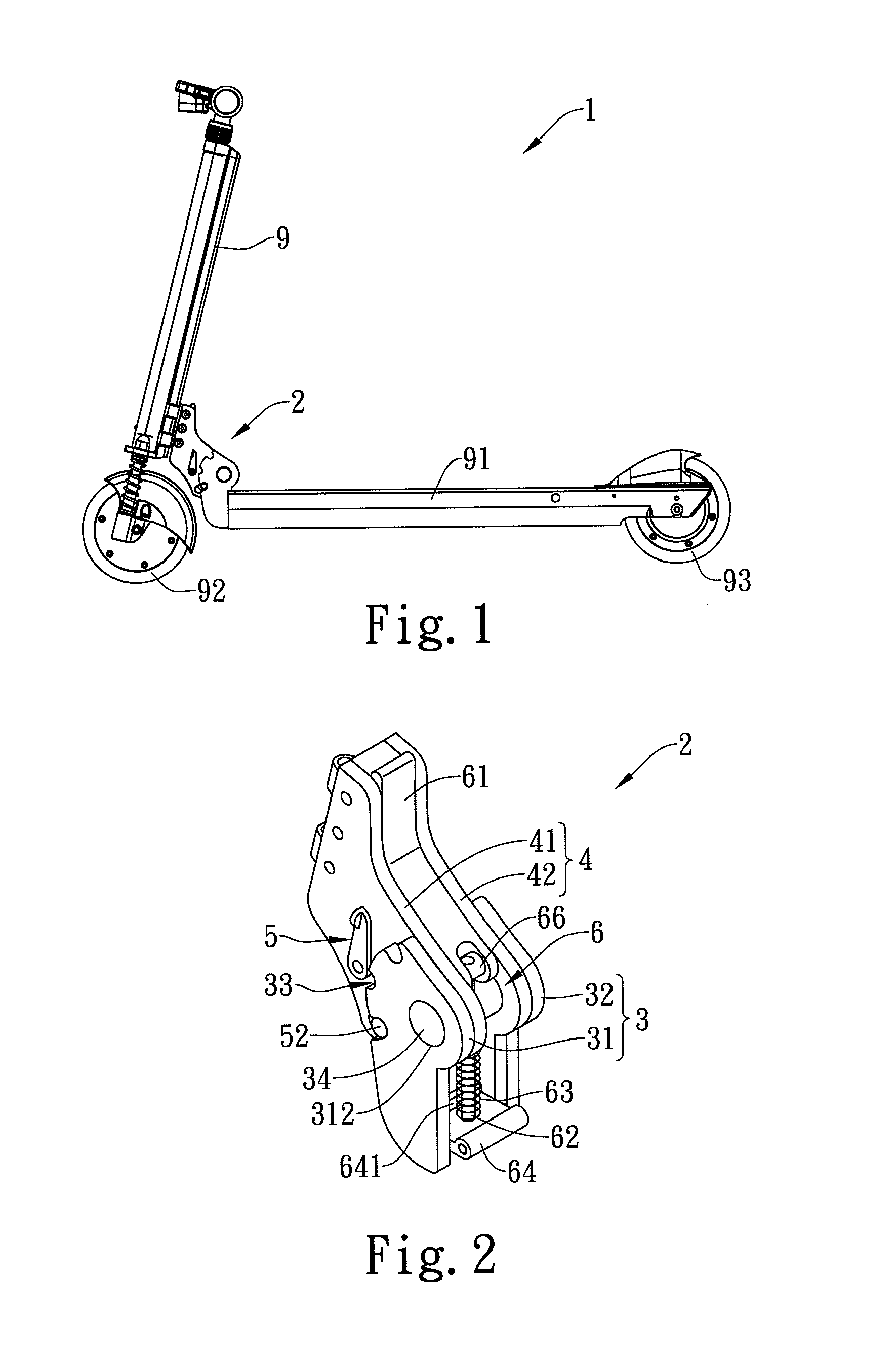

Integrated wheel and electric scooter using the wheel

ActiveUS20120048636A1Extended service lifeEnsure safetyRimsNon-inflatable tyresEngineeringMechanical engineering

An integrated wheel and an electric scooter using the wheel are disclosed. The electric scooter comprises an operation level and a footrest. The operation lever is provided with a front wheel at a lower end thereof. The footrest is provided with a rear wheel at a rear end thereof. At least one of the front and rear wheels is an integrated wheel. The integrated wheel comprises a wheel rim and a rubber tire. The external periphery of the wheel rim is provided with a plurality of positioning grooves. The rubber tire is integratedly formed on the external periphery of the wheel rim and has an internal periphery provided with a plurality of blocks each of which is correspondingly engaged into one of the positioning grooves. Thereby, the wheel rim can be firmly fixed with the rubber tire so as to prolong the lifetime of the wheel and ensure the driving safety.

Owner:DIJIYA ENERGY SAVING TECH

Integrated infusion management system

ActiveUS20080156946A1Improve stabilityIncrease resistanceWash-standsWalking aidsEngineeringManagement system

Owner:FIREFLY MEDICAL

Motor vehicle wheel disc, in particular for passenger car

Owner:MICHELIN RECH & TECH SA

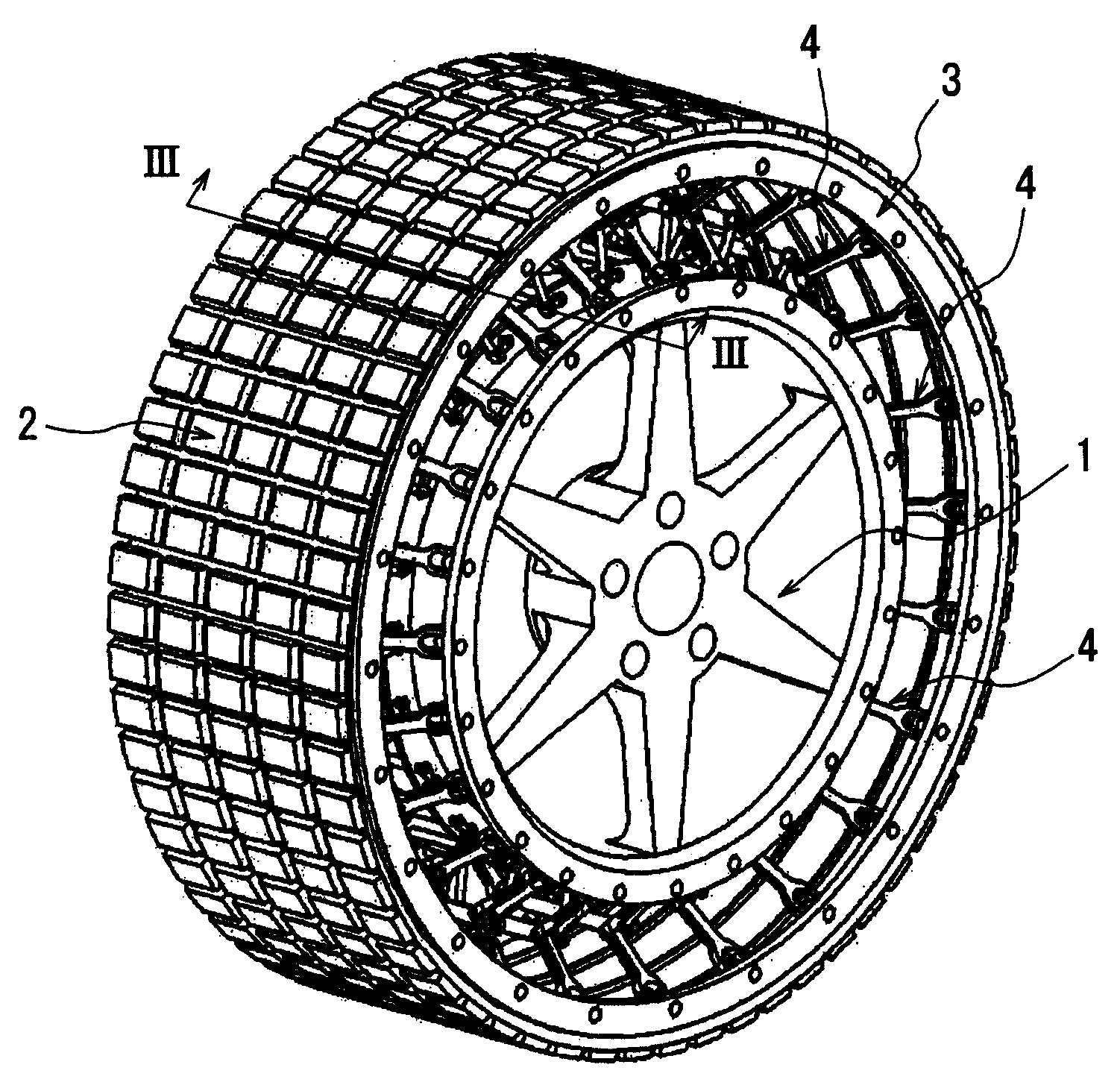

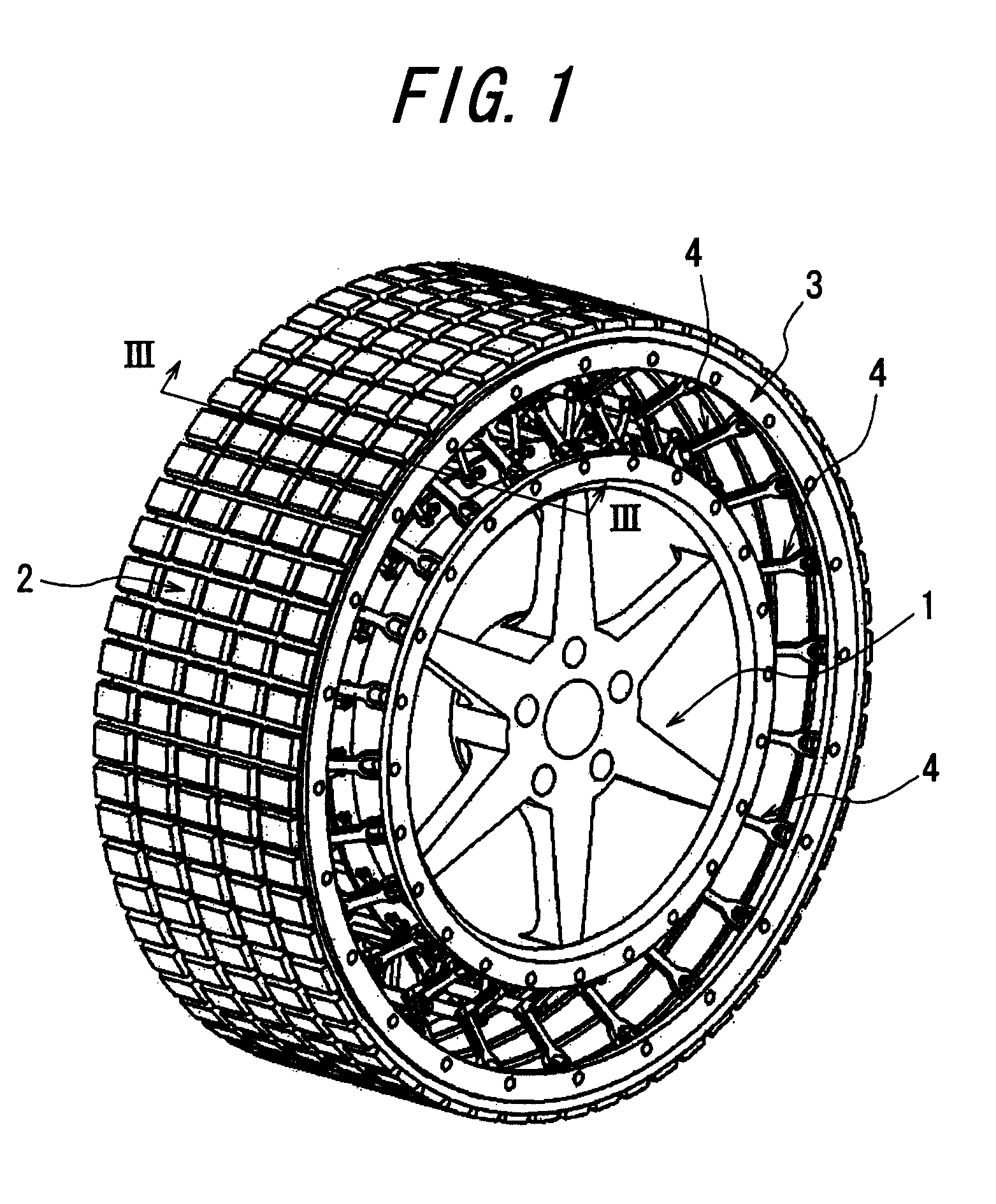

Non-pneumatic tire

InactiveUS20080073014A1Easy to provideReduce necessityRimsMetal-working apparatusRelative displacementInternal pressure

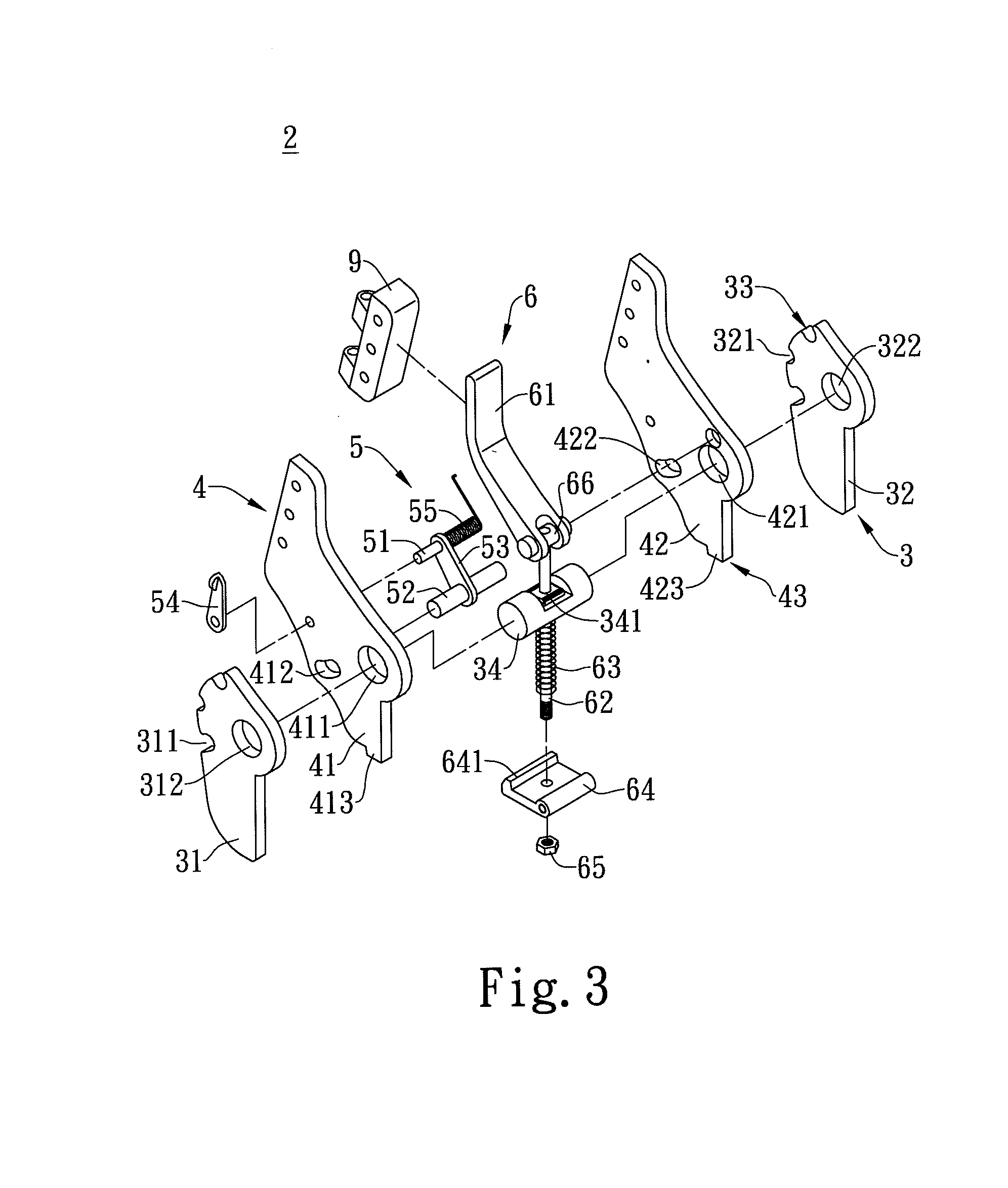

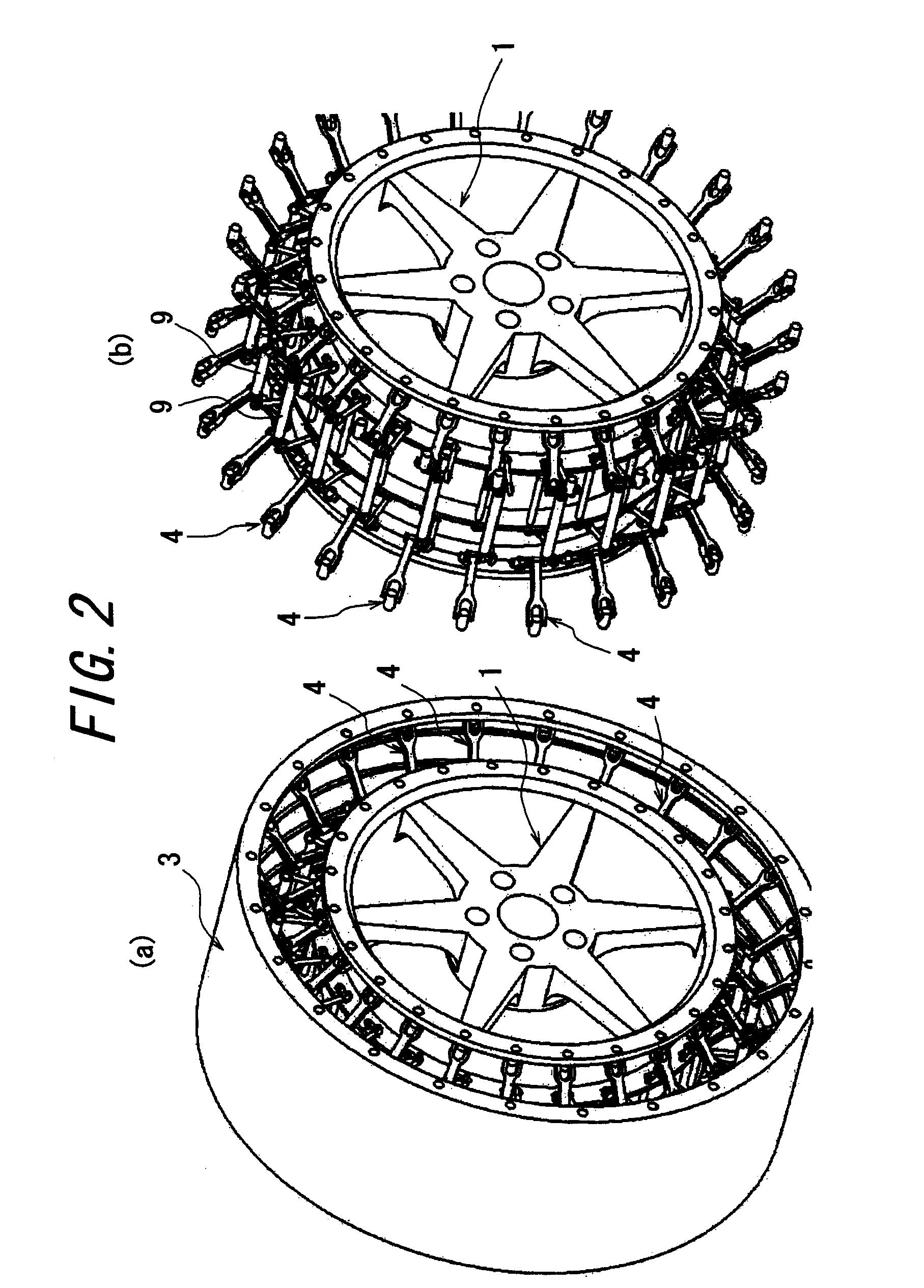

There is provided a non-pneumatic tire which can eliminate a necessity of filling a pressurized air or other gases to obviate a possibility of decrease or loss of the internal pressure of the tire and which can easily provide desired vertical, longitudinal and lateral stiffnesses in a mutually independent state.The non-pneumatic tire has a rim member 1, a ring member 3 disposed at an outer circumferential side of the rim member 1 and provided with a tread 2 on a circumferential face, and a plurality of link mechanisms 4 coupling the rim member with the ring member. Each of the link mechanisms 4 consists of a pair of link members 7a, 7b consisting of a link 5a, 5b which is connected at a first end with a side portion of the rim member 1 and which is swingable in the circumferential and meridian directions and another link 6a, 6b which is connected at a first end with a side portion of the ring member and 3 which is swingable in the circumferential and meridian directions with second ends of the links being hingedly connected one another to make the links swingable in the meridian direction. A spring member 9 imparting a stiffness against relative displacements in the radian, circumferential and width directions with respect to the rim and ring members 1, 3 is provided on the link mechanisms 4.

Owner:BRIDGESTONE CORP

Casting extruding compound shaping method of magnesium alloy automobile hub

InactiveCN1429717AFine internal organizationDense internal organizationDisc wheelsGraphiteSuperficial mass

A technology for forming the Mg-alloy hub of car features three procedures of preshaping, upsetting-squeezing formation and fine trimming and includes such steps as casting a blank; after preshaping,making allowance for apsetting-squeezing formation; upsetting-squeezing formation and deformation degree during isothermal squeezing by using the critical-controlled deformation method; coating graphite lubricant inside the die; and fine trimming. Its advantages are fine crystal grains, and high mechanical performance and surface quality.

Owner:ZHONGBEI UNIV

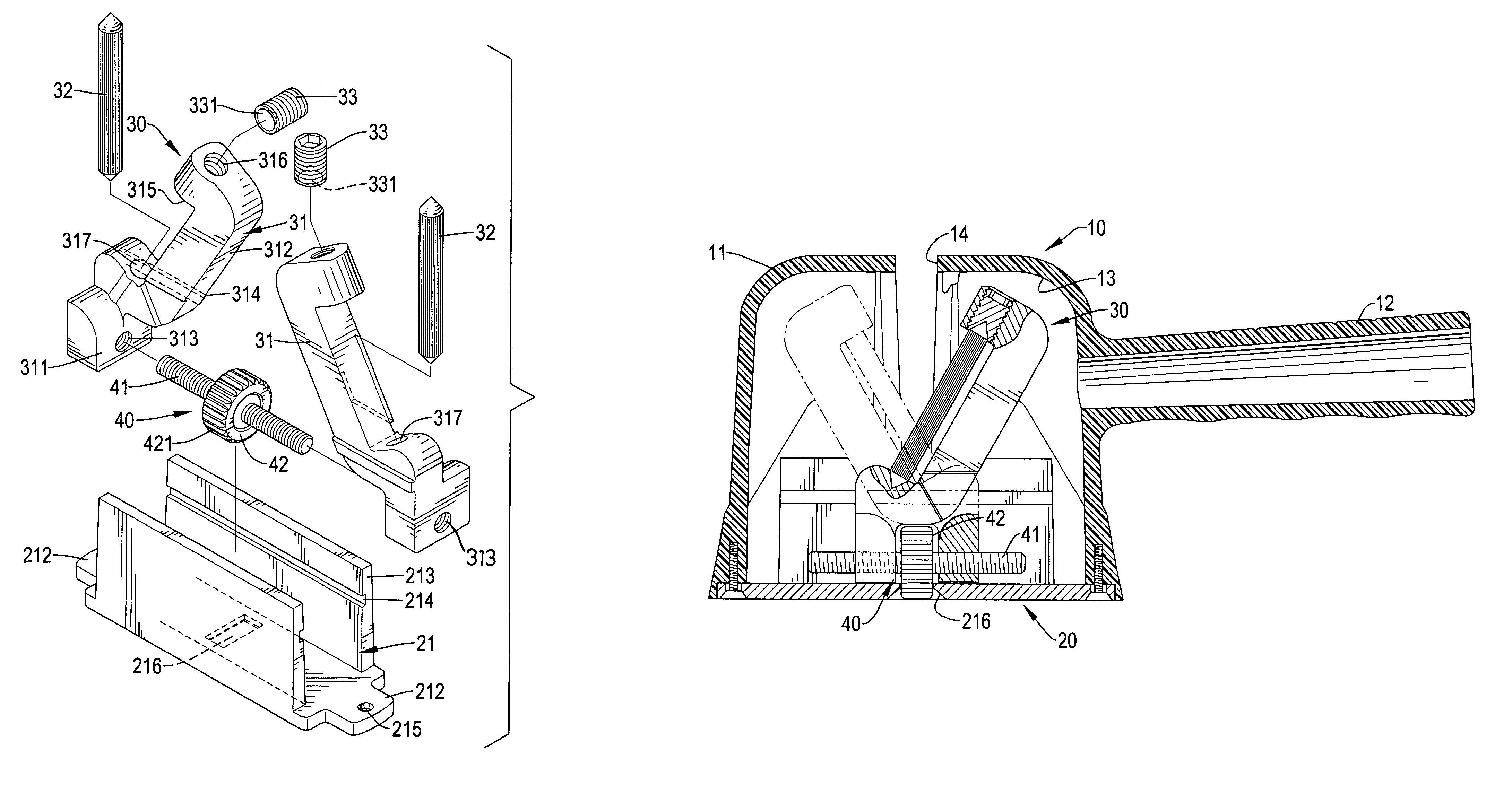

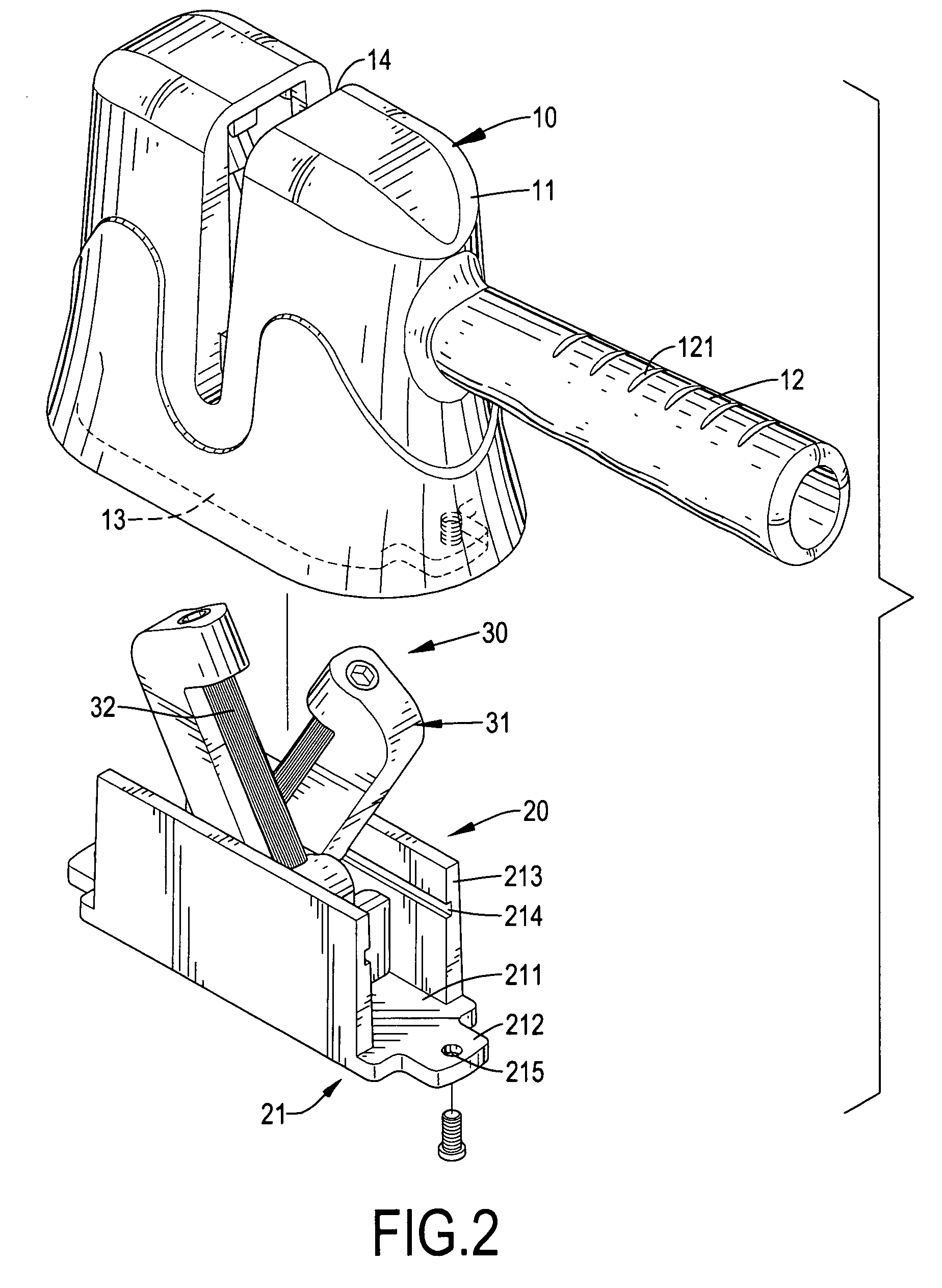

Knife sharpener

InactiveUS7172500B1Easy to useExtend your lifeAgriculture tools and machinesCutting toolsKnife sharpenerEngineering

A knife sharpener has a housing, a base, a sharpening device and an adjustable device. The housing has a case, a cavity and a slot. The cavity is defined in the case and the slot is defined in the case and communicates with the cavity. The base is mounted on the housing and has a base board and two side walls formed on the base board. The sharpening device is movable mounted on the base and is received inside the housing. The sharpening device has two sharpening arms with sharpening rods. The adjustable device is mounted on the sharpening device mounted between the two sharpening arms. When the knife sharpener is used, the adjustable device is rotated to change the cross-position of the sharpening device. Therefore, a knife may be sharpened at a different site on the sharpening rods for prolonging the life span of the knife sharpener.

Owner:WU WEN CHIU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com