Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8272 results about "Thermoplastic elastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection molding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties.

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

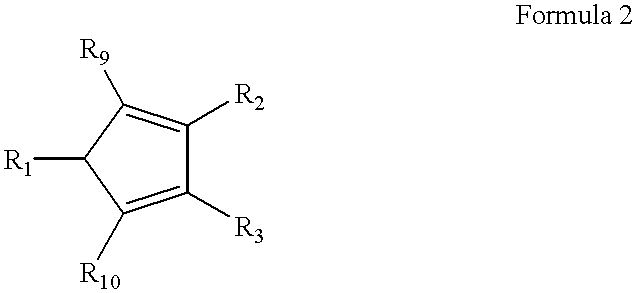

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

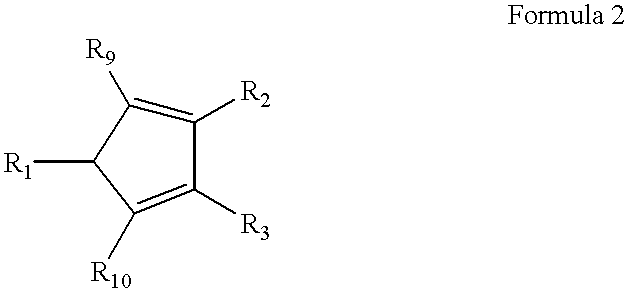

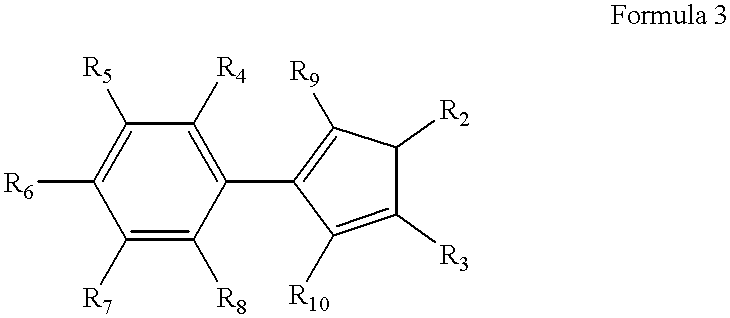

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

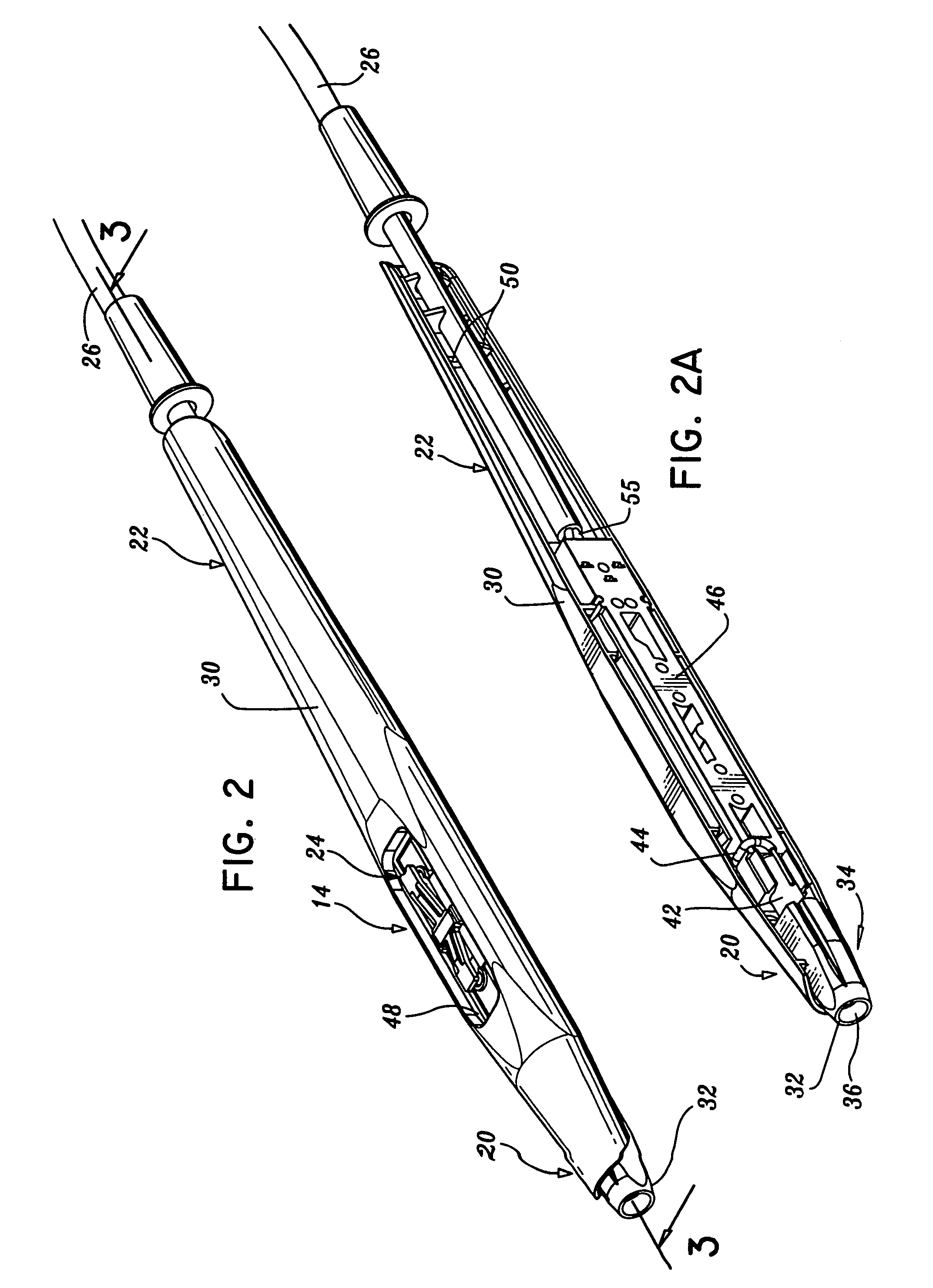

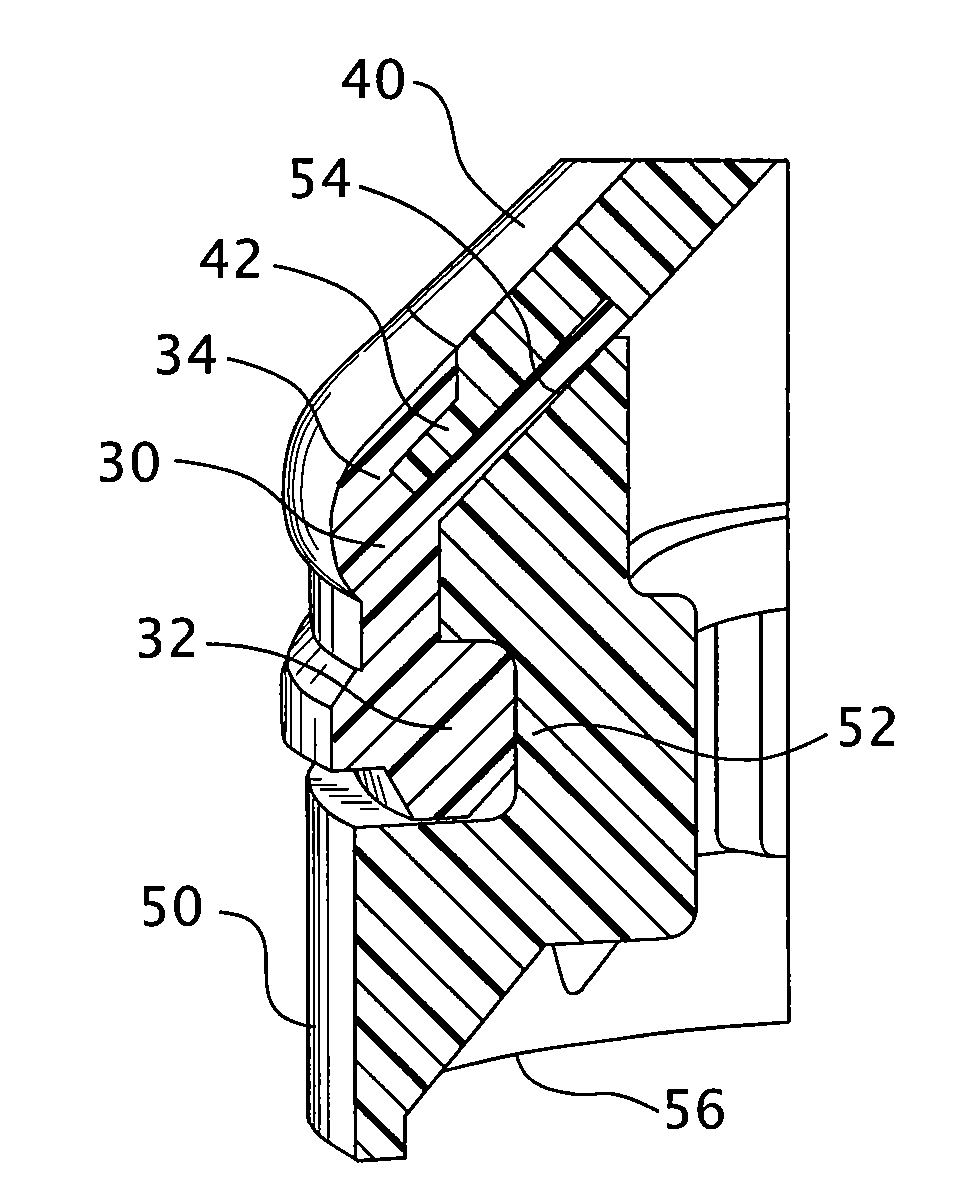

Electrosurgical device having a dielectric seal

A method of manufacturing a seal in an electrosurgical device includes placing components of the electrosurgical device within an elongated housing section, the housing section including an actuator opening, introducing the housing section within a mold filled with a liquid thermoplastic elastomer and allowing the elastomer to flow within the housing, forming an elastomeric inwardly-extending lip portion circumferentially surrounding an opening at a distal end of the electrosurgical device for introducing an electrode therein, and allowing the molded elastomer to cure and become integral with the housing to seal the components within the molded elastomer contained within the housing section. The method may also include the step of forming an elastomeric actuator seal around the actuator opening.

Owner:COVIDIEN AG

Thermoplastic Elastomer Composition, Method for Producing Same and Formed Article

The invention provides a thermoplastic elastomer composition having mechanical properties equivalent or superior to those of conventional thermoplastic elastomer compositions and having excellent heat resistance and oil resistance and a preparation process thereof, and molded or formed products making use of this thermoplastic elastomer composition. The thermoplastic elastomer composition according to the present invention contains a thermoplastic resin having a polar group and an ethylene•α-olefin elastomer having a functional group. The ethylene•α-olefin elastomer having the functional group is preferably a random copolymer obtained by copolymerizing ethylene, an α-olefin having 3 to 10 carbon atoms, an unsaturated monomer having the functional group and an optional non-conjugated diene.

Owner:JSR CORPORATIOON

Interface for use between medical instrumentation and a patient

InactiveUS20050215901A1Obstruct passagePermit transmissionUltrasonic/sonic/infrasonic diagnosticsSurgeryULTRASOUND PROCEDURESThermoplastic elastomer

Disclosed herein are methods, devices, compositions, and systems for providing an interface between medical instrumentation and a patient. In various embodiments, the interface provides a sterile barrier, acoustic coupler, and thermal insulator between the patient and a medical instrument. In some embodiments, an acoustic coupler interface is used between an ultrasound instrument and a patient. In some embodiments, the acoustic coupler comprises a thermoplastic elastomer (“TPE”) and in particular oil-enhanced or gelatinous TPEs that can be used in diagnostic and therapeutic (HIFU) ultrasound procedures.

Owner:CERUS CORP +1

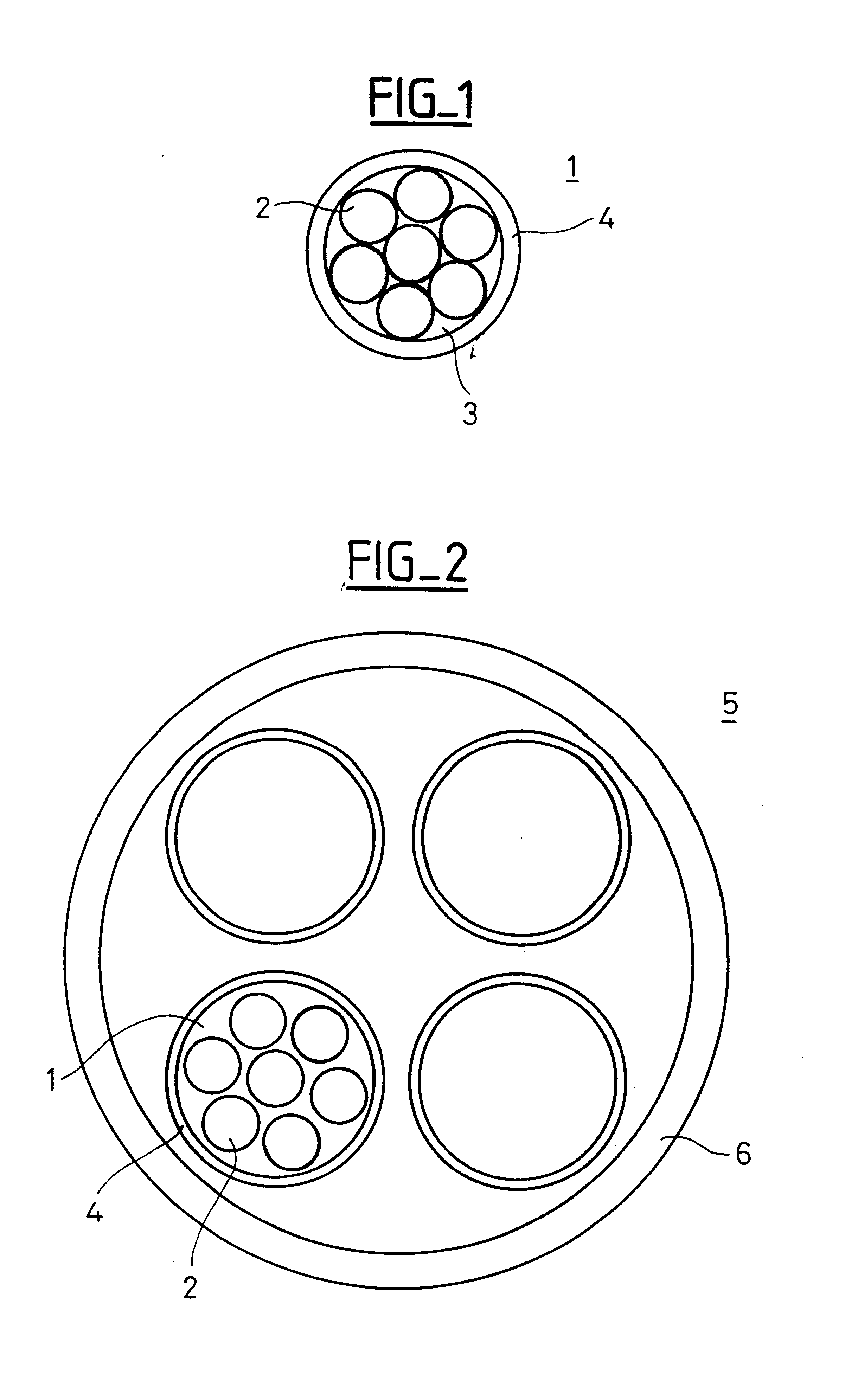

Protective skin for optical fibers

Owner:ALCATEL LUCENT SAS

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

Thermoplastic elastomers having improved processing and physical property balance

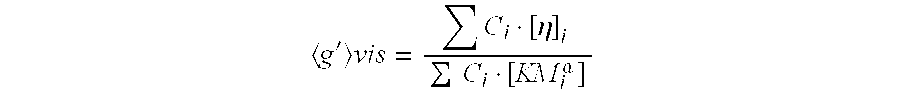

InactiveUS6451915B1Without deleteriously sacrificing mechanical propertyEasy to processThermoplasticPolymer science

A thermoplastic elastomer formed by a process comprising the steps of dynamically vulcanizing a rubber within a mixture that includes the rubber, from about 10 to about 80 percent by weight of a thermoplastic resin based upon the total weight of the rubber and the thermoplastic combined, and from about 1 to about 25 percent by weight of a polymeric processing additive based upon the total weight of the rubber and the thermoplastic combined, where the polymeric processing additive is a linear polyolefin resin that has an melt flow rate that is greater than about 1,000 dg / min, a diene-modified polyolefin polymer that has an melt flow rate that is greater than about 1,000 dg / min, from about 0.005 to about 2.00 mole percent polymeric units deriving from dienes, and a viscosity average branching index that is from about 0.4 to about 0.95, or a mixture of the linear polyolefin resin and the diene-modified polyolefin polymer, where the step of dynamically vulcanizing the rubber results in vulcanized rubber having a crosslink density of about 40 to about 180 mole per milliliter of rubber.

Owner:CELANESE INT CORP

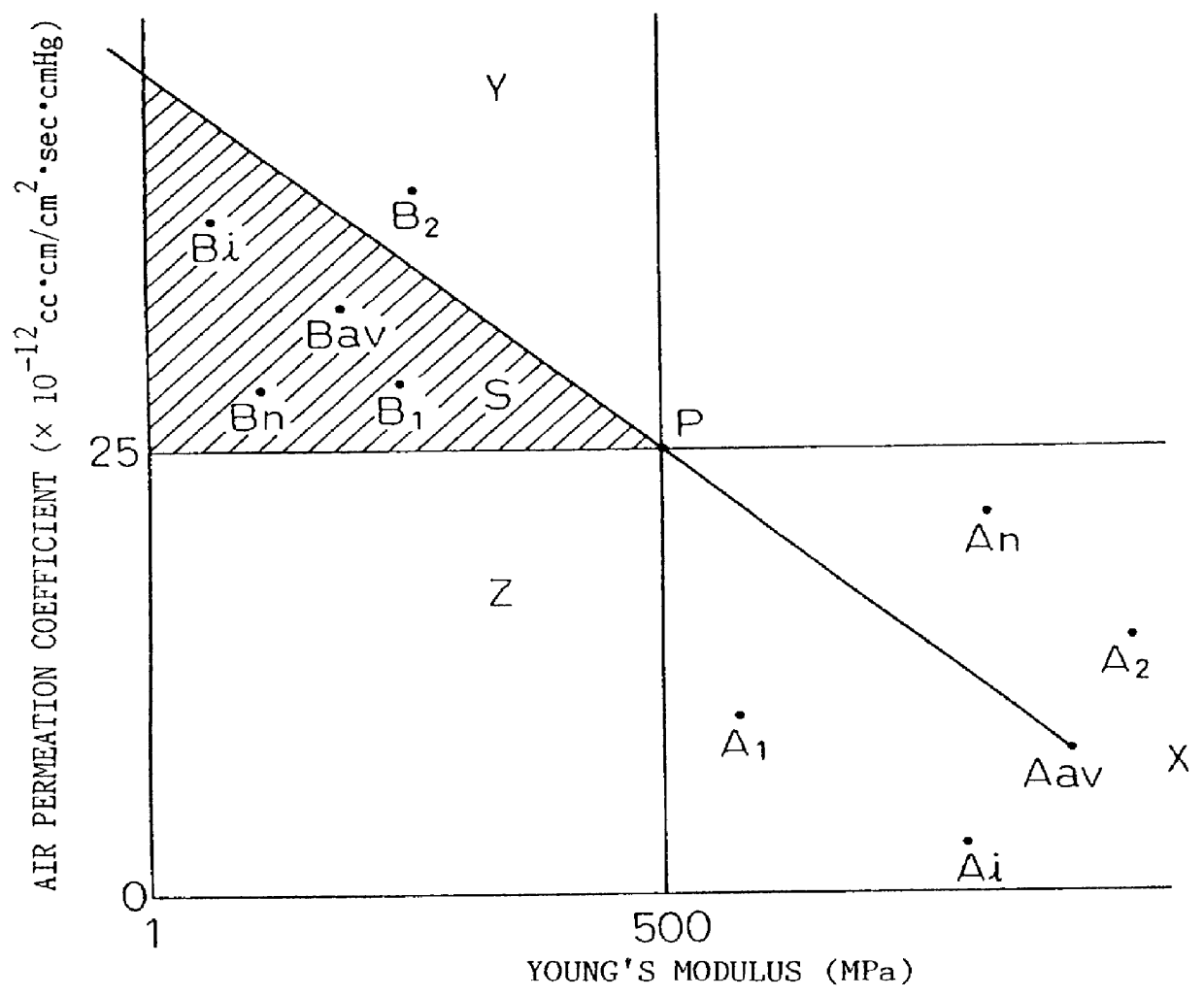

Pneumatic tire made by using lowly permeable thermoplastic elastomer composition in gas-barrier layer and thermoplastic elastomer composition for use therein

InactiveUS6062283AHigh elastomer ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

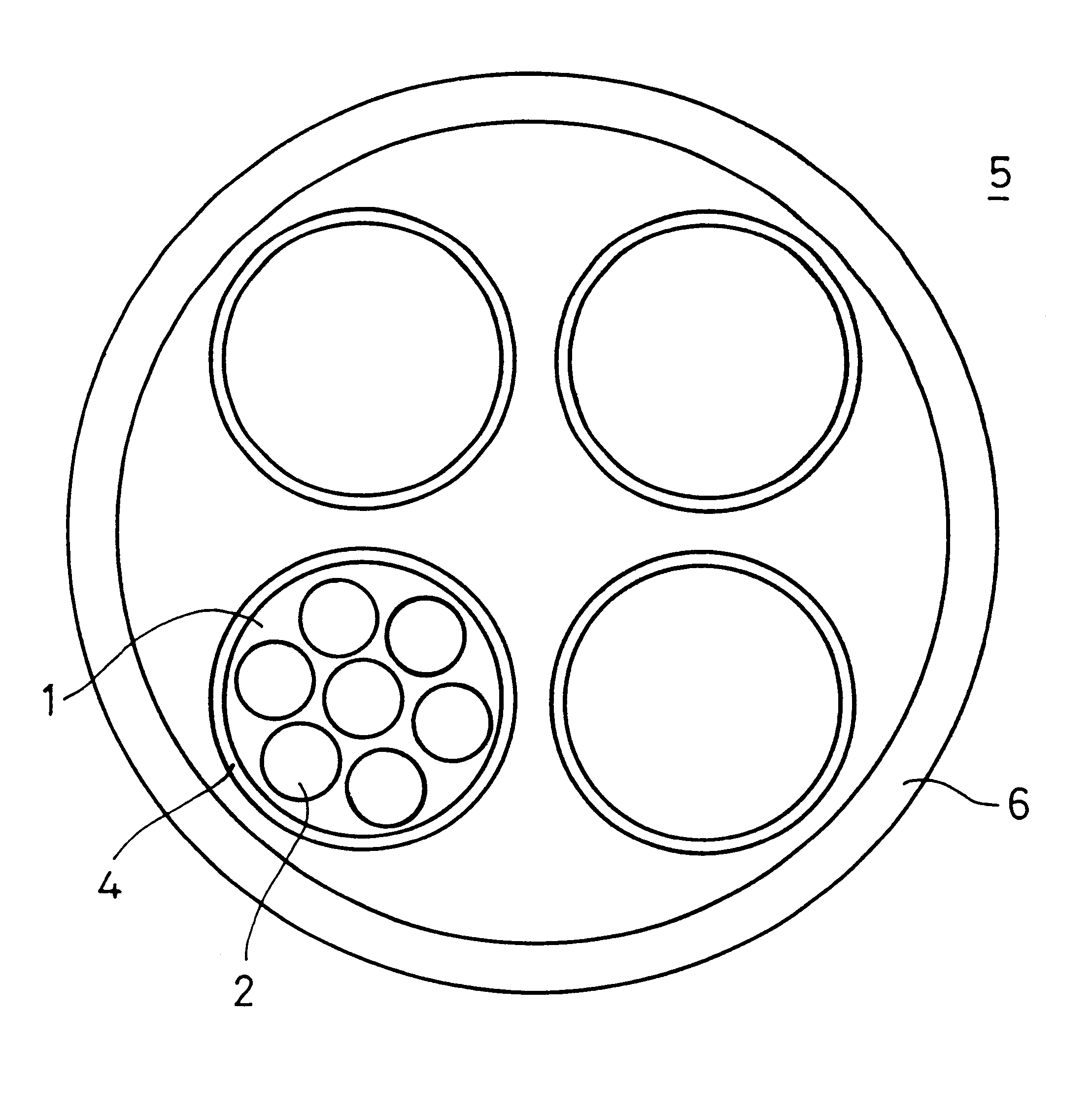

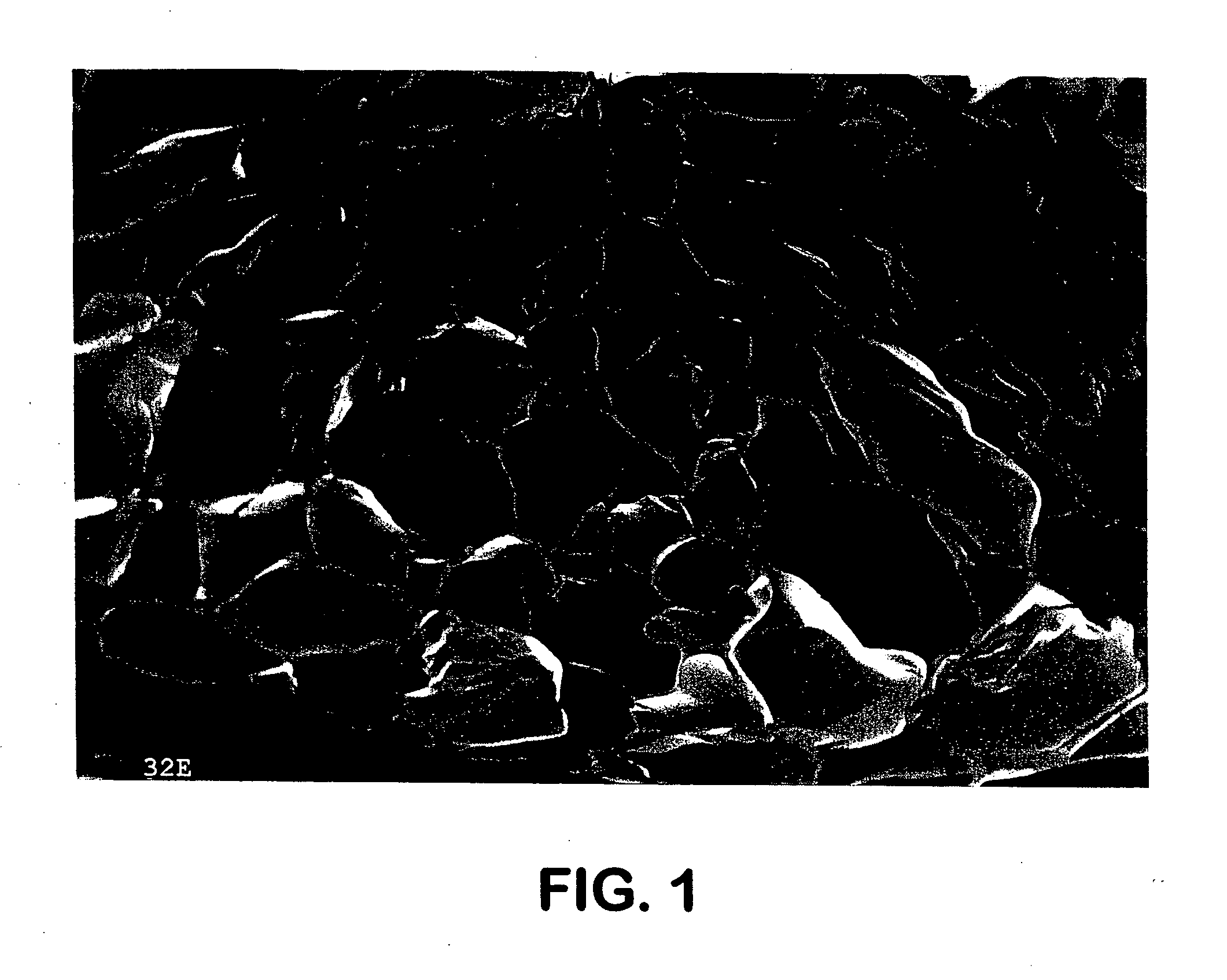

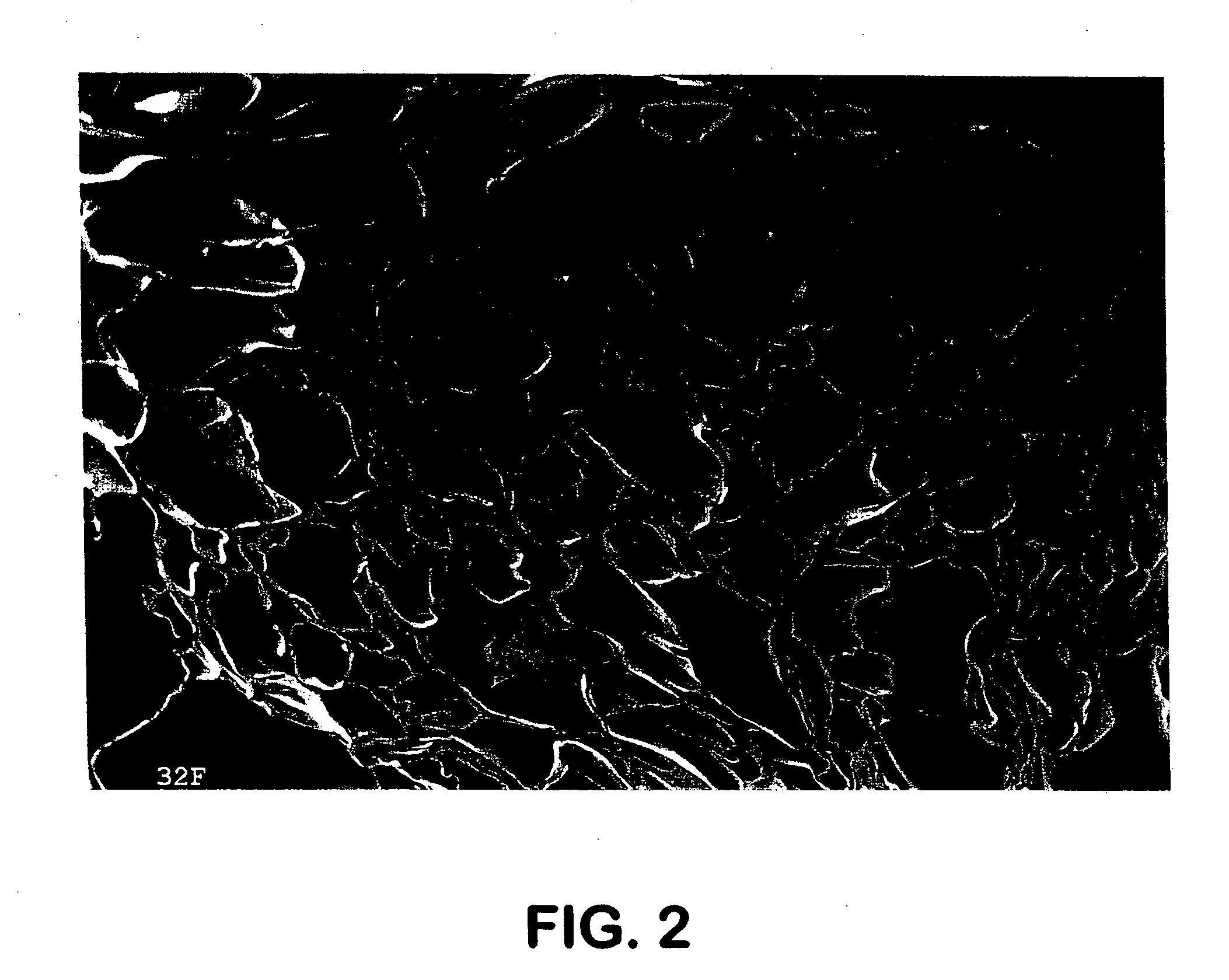

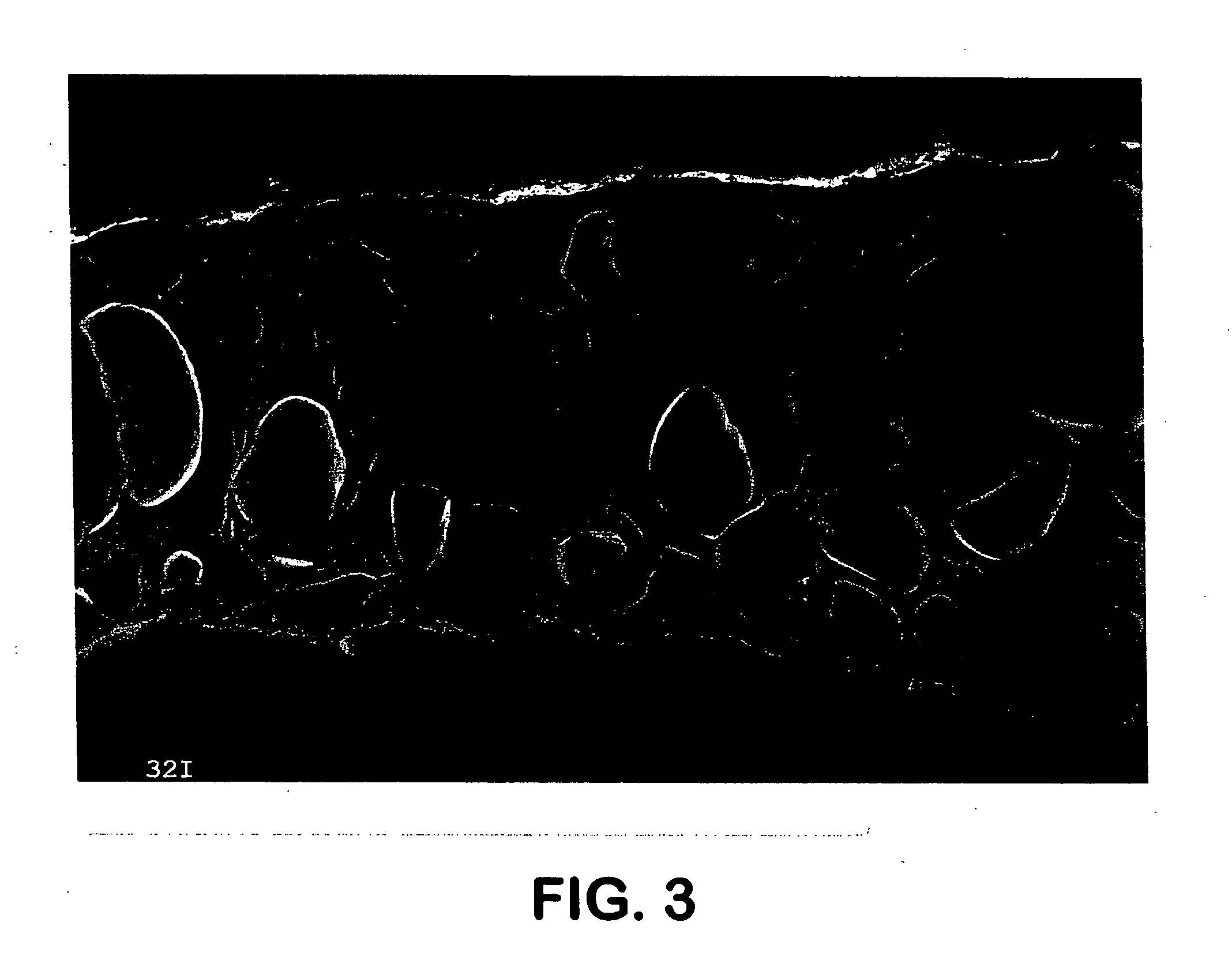

PCT No. PCT / JP97 / 01514 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 45489 PCT Pub. Date Dec. 4, 1997A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:YOKOHAMA RUBBER CO LTD

Thermoplastic vulcanizates and process for making the same

InactiveUS6437030B1Low hygroscopicityReduced halideSynthetic resin layered productsSolid ballsThermoplastic elastomerMetal halides

A process for forming a thermoplastic vulcanizate compromising the steps of dynamically vulcanizing a rubber within a blend that comprises the rubber and a thermoplastic polymer, where said step of vulcanizing is carried out by using a phenolic resin in the presence of a catalyst system formed by combining a metal halide and a metal carboxylate. Also, a thermoplastic vulcanizate having low moisture pick-up with a technologically useful cure.

Owner:ADVANCED ELASTOMER SYST LP

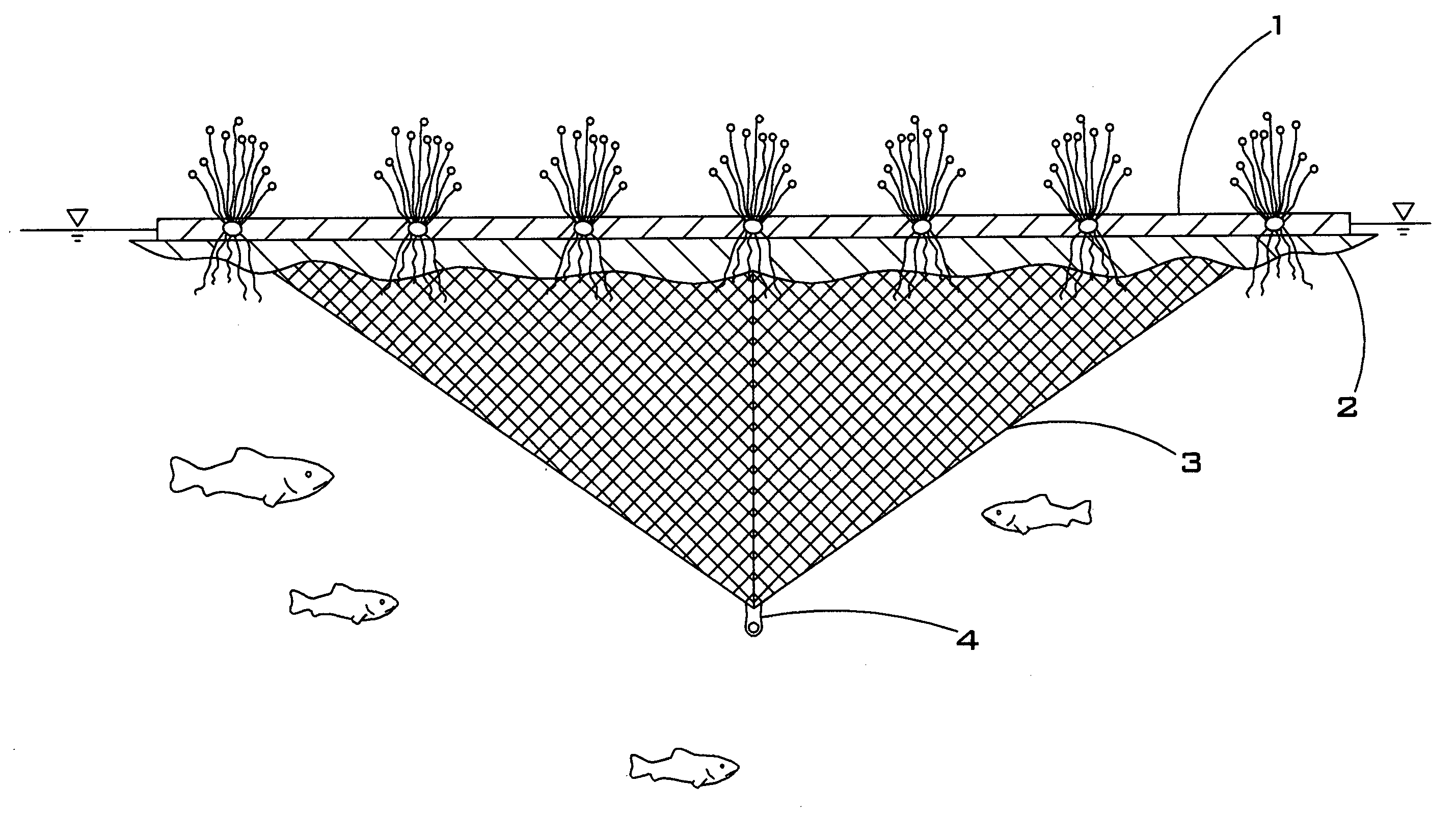

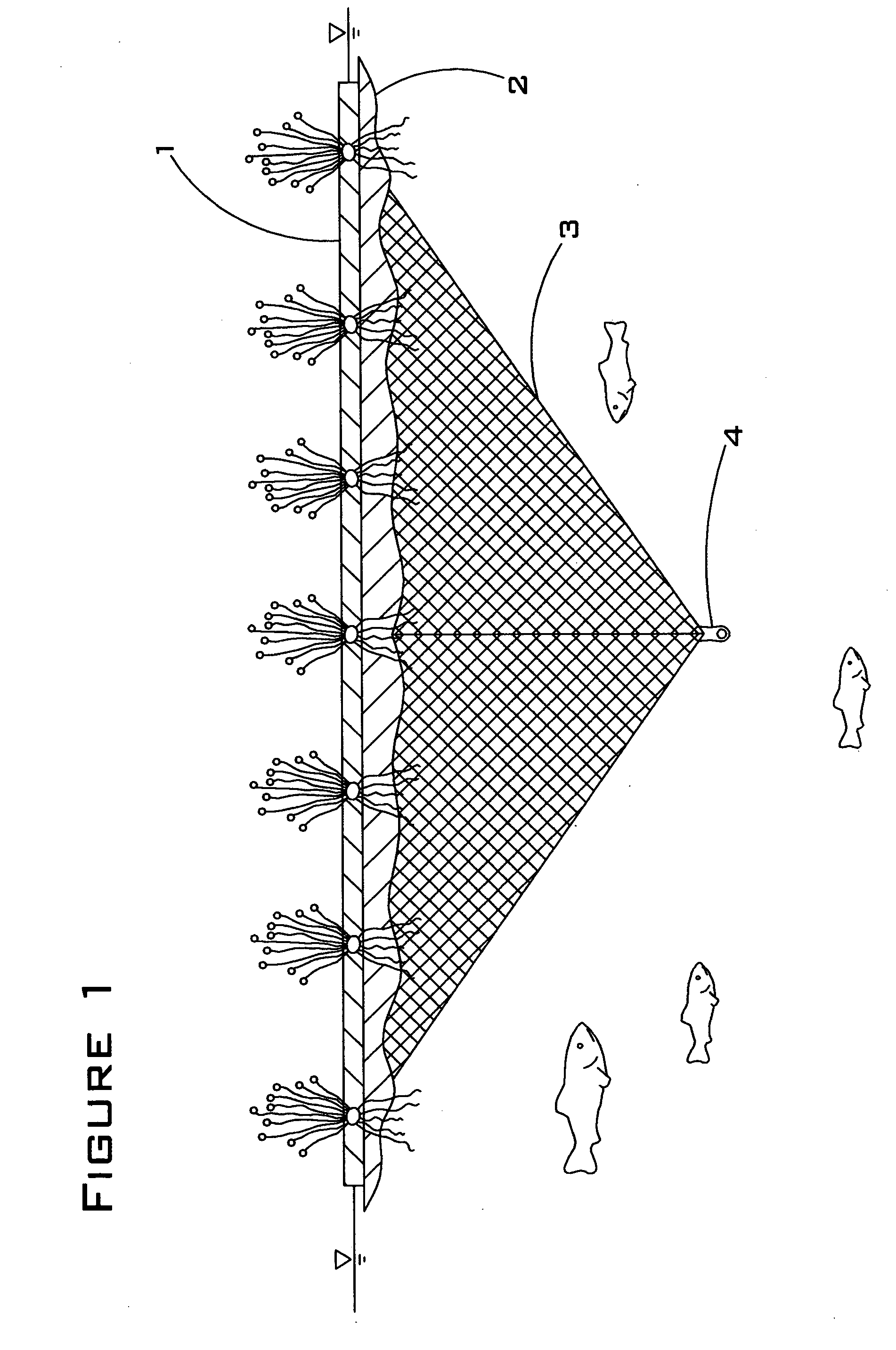

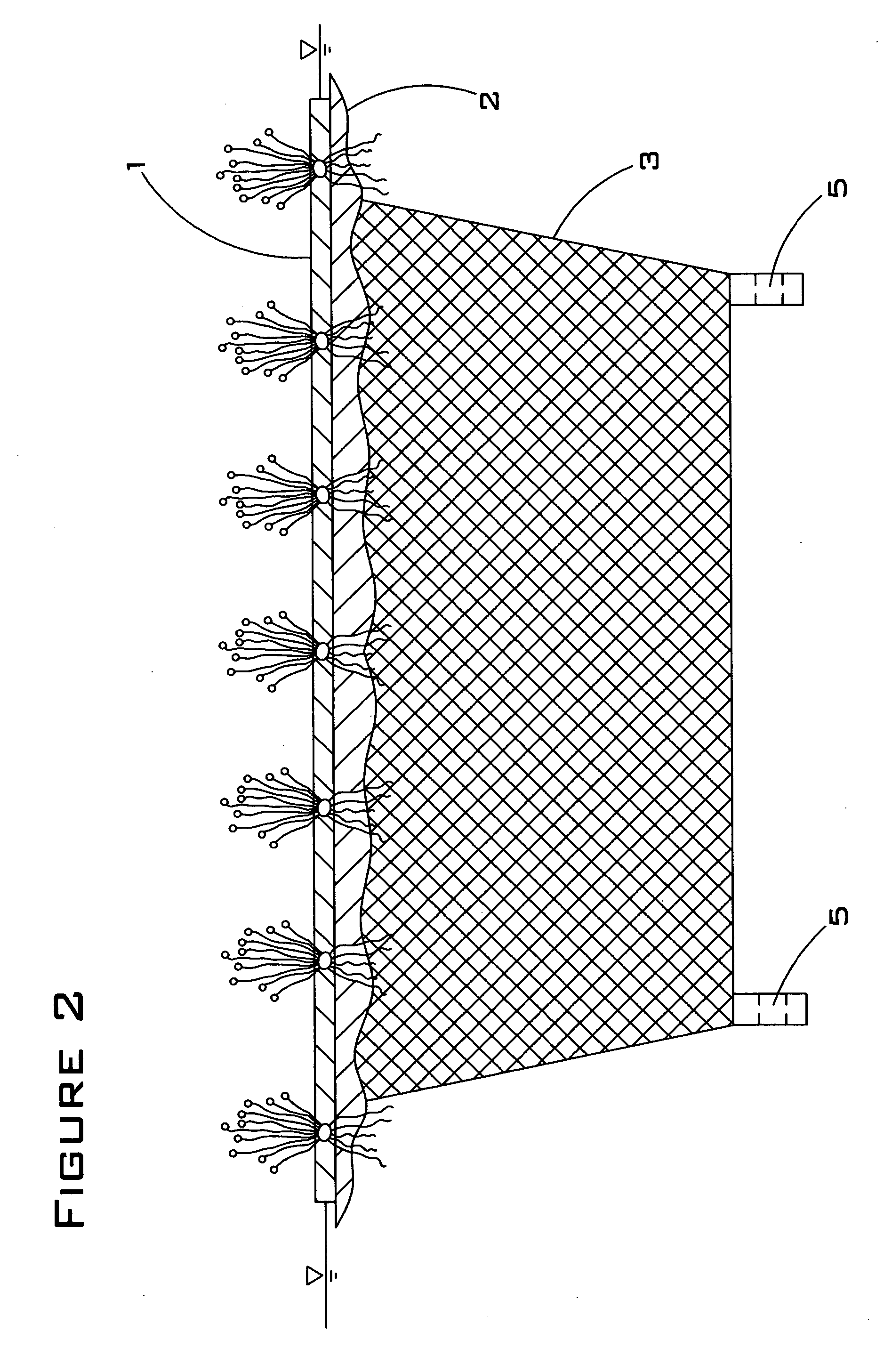

Super-enhanced aquatic floating island plant habitat

InactiveUS20050183331A1Increase plantingEnhance animal lifeWater cleaningClimate change adaptationThermoplastic elastomerCompound (substance)

A super-enhanced aquatic floating island plant habitat that is adjustably buoyant and optionally biodegradable. The first embodiment is comprised of a thermoplastic elastomer, a mat, soil / flotation chambers, apertures, nutrient channels, buoyant waterscape options, and a tethering system. The floating island can include monitors that measure water and atmospheric conditions, dispensers for fish food or chemicals, and a water agitation / oxygenation device. Another embodiment comprises a positively buoyant soil matrix contained within a water-permeable bag. Another embodiment comprises a flotation collar, an outrigger, and one or more water-permeable bladders containing negatively or neutrally buoyant bedding soil. The present invention also covers an aquarium-scale floating island and submersible planter, a plant containment bag made out of thermoplastic elastomer, and several methods of adjusting the buoyancy of a floating island. A method of manufacturing a floating island comprising molded thermoplastic elastomer.

Owner:FOUNTAINHEAD

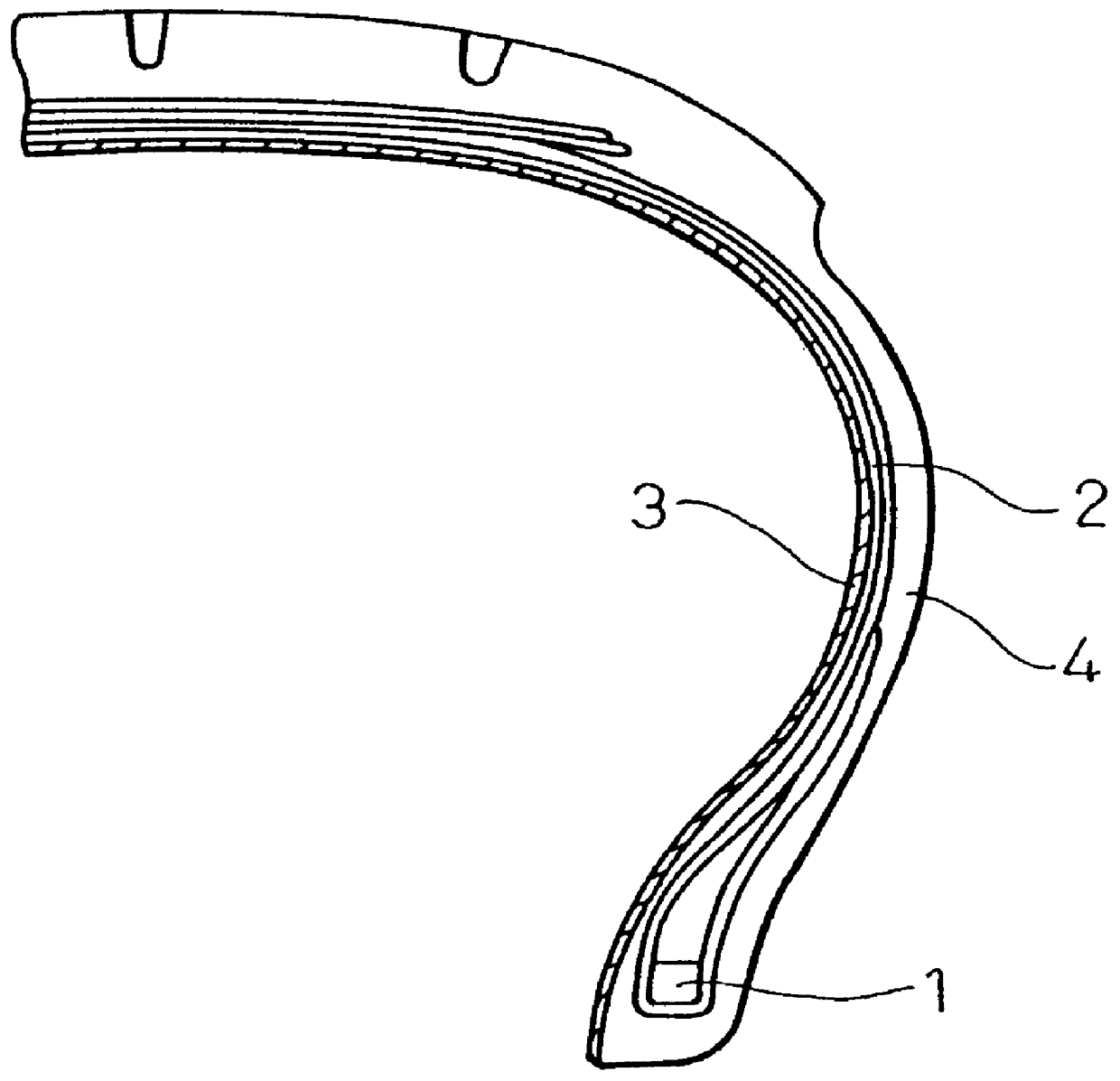

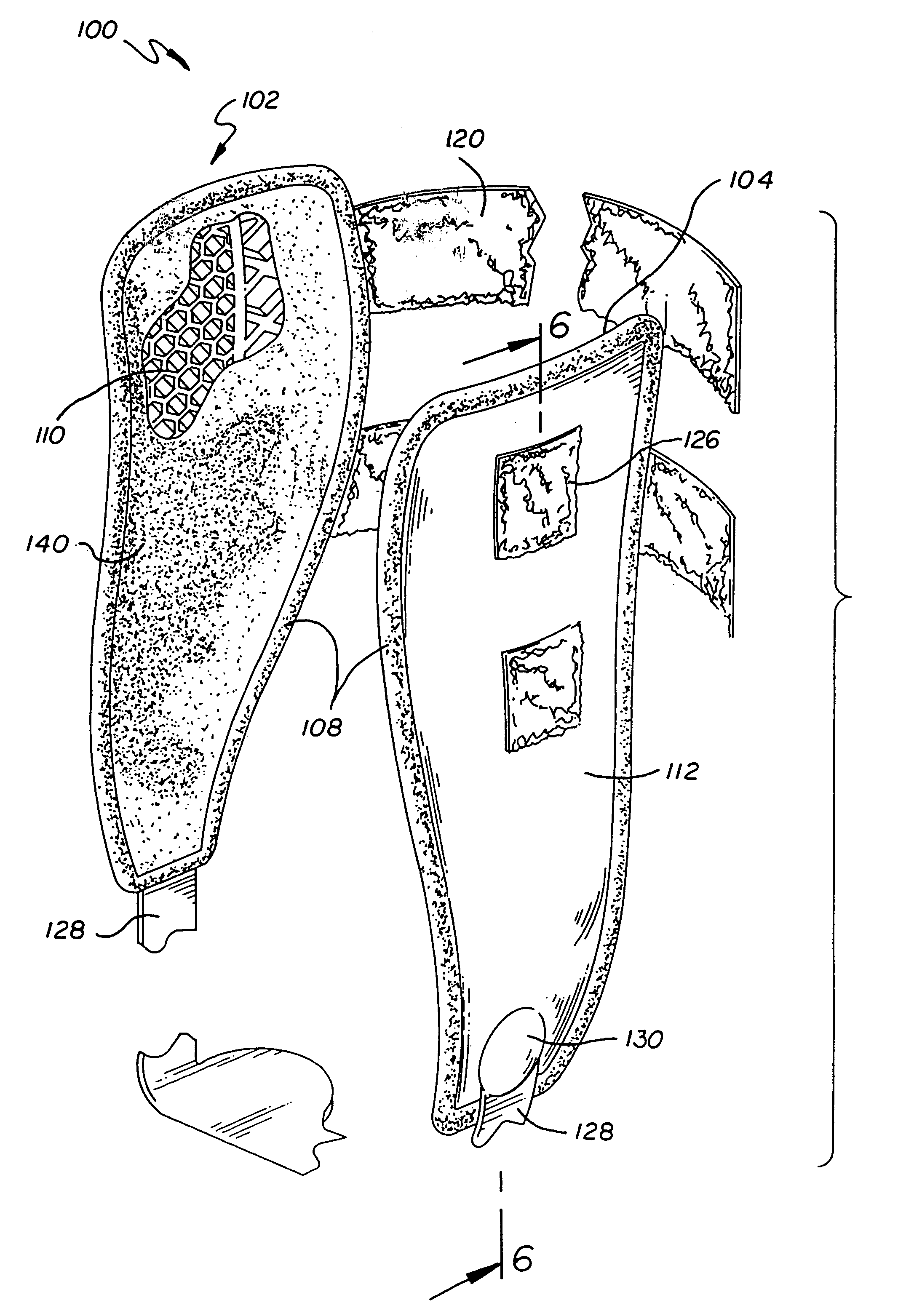

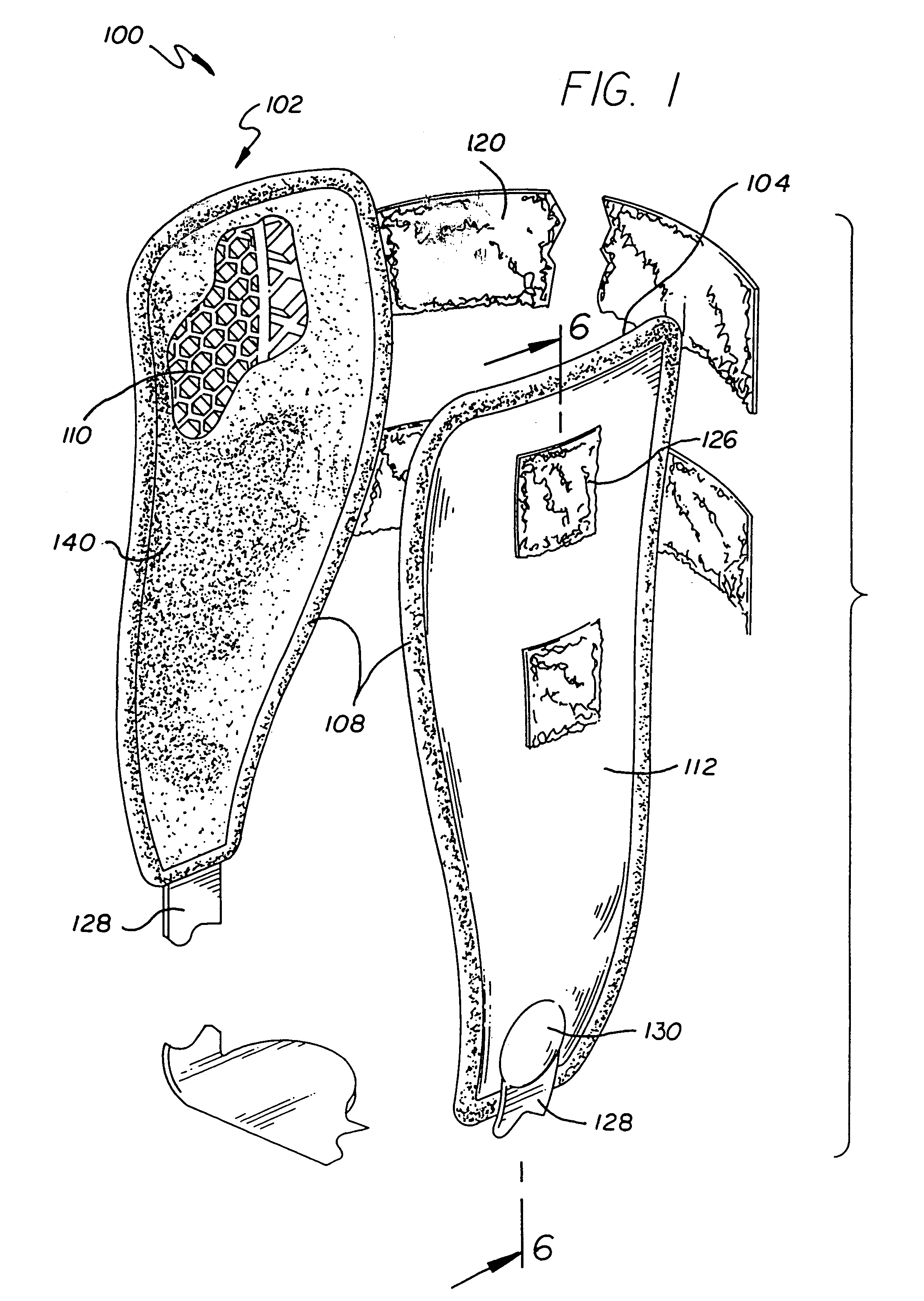

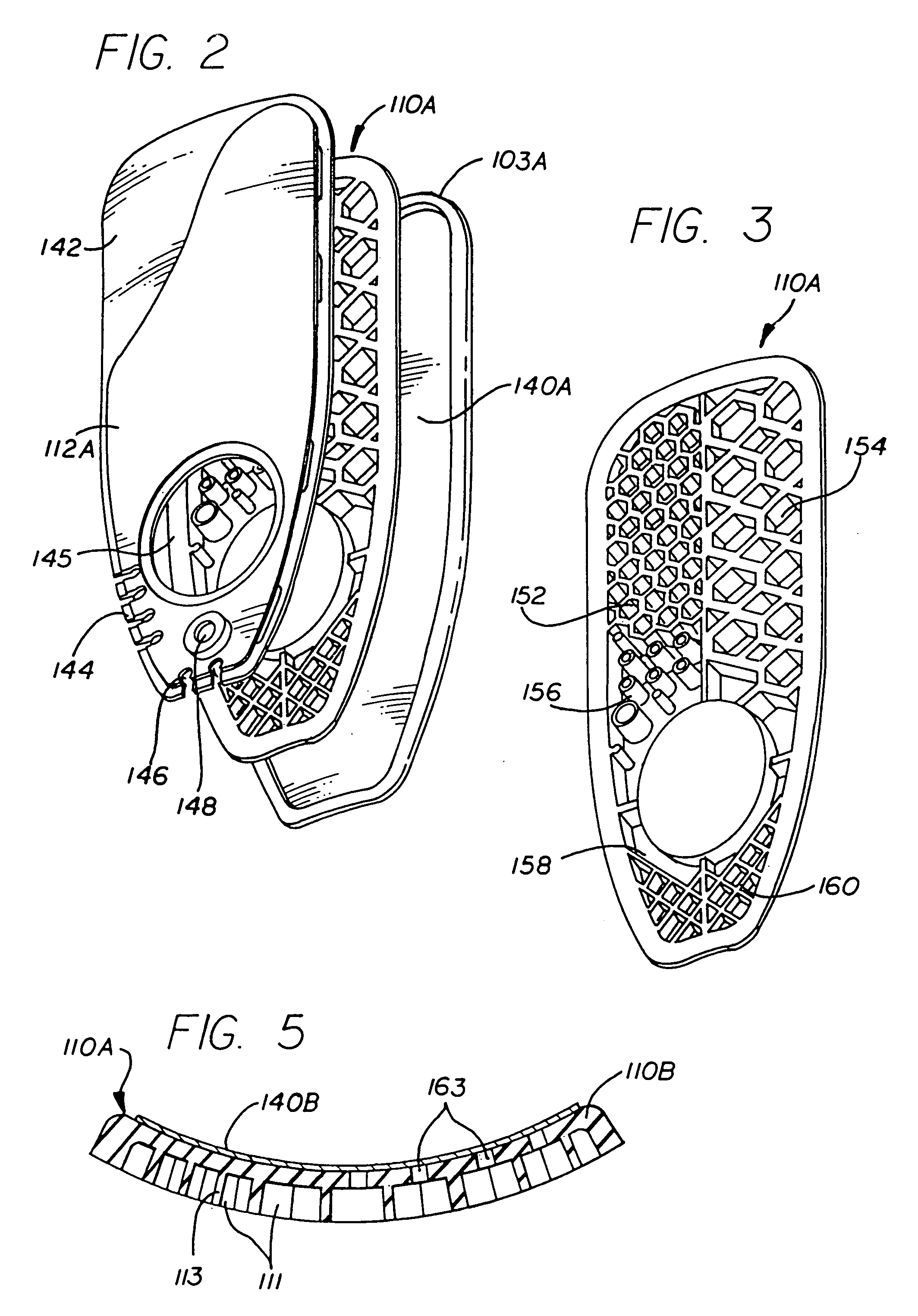

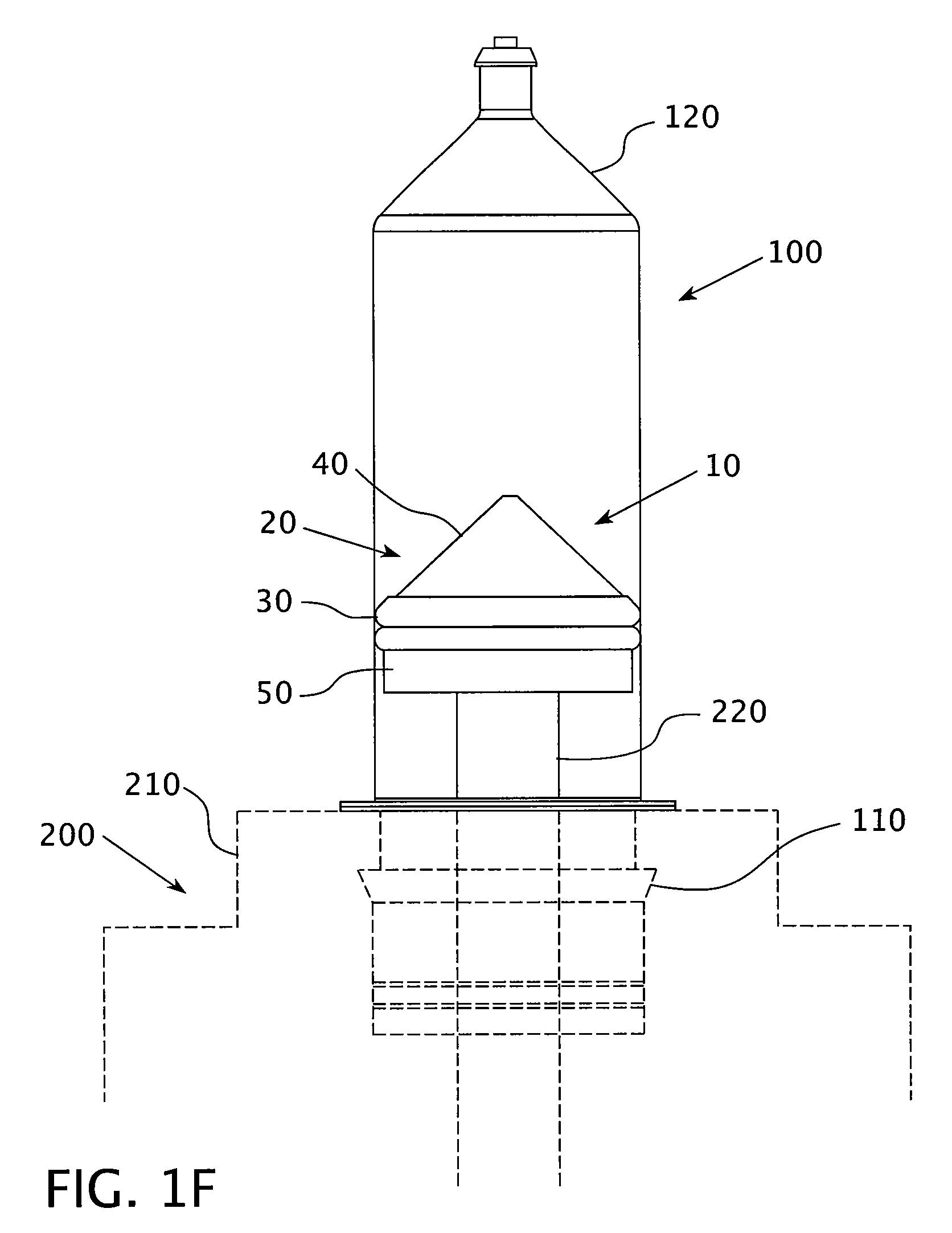

Comfortable orthopaedic support and the method of making the same

InactiveUS7018351B1Varying degreeHighly detailed designRestraining devicesNon-surgical orthopedic devicesThermoplastic elastomerCompression set

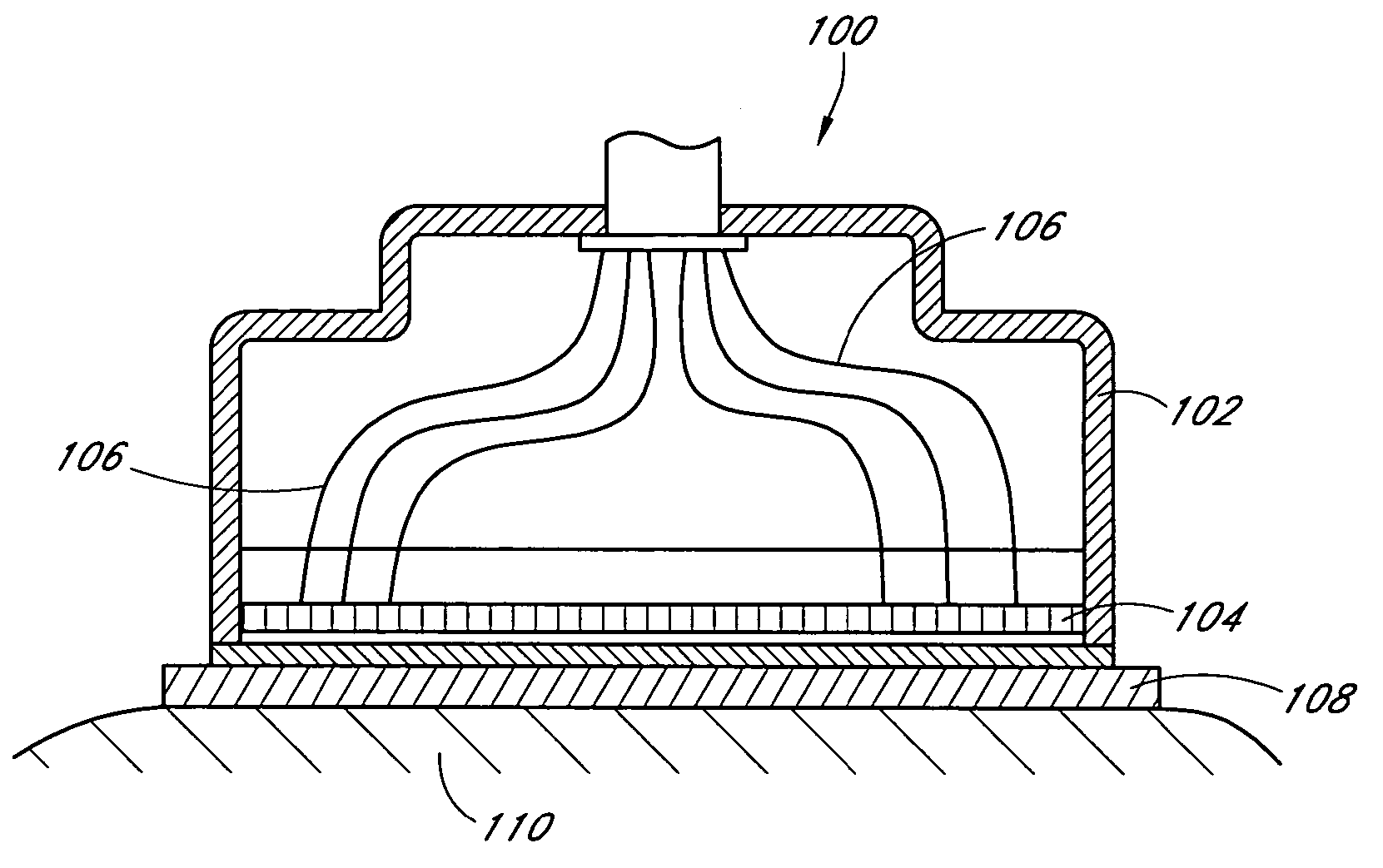

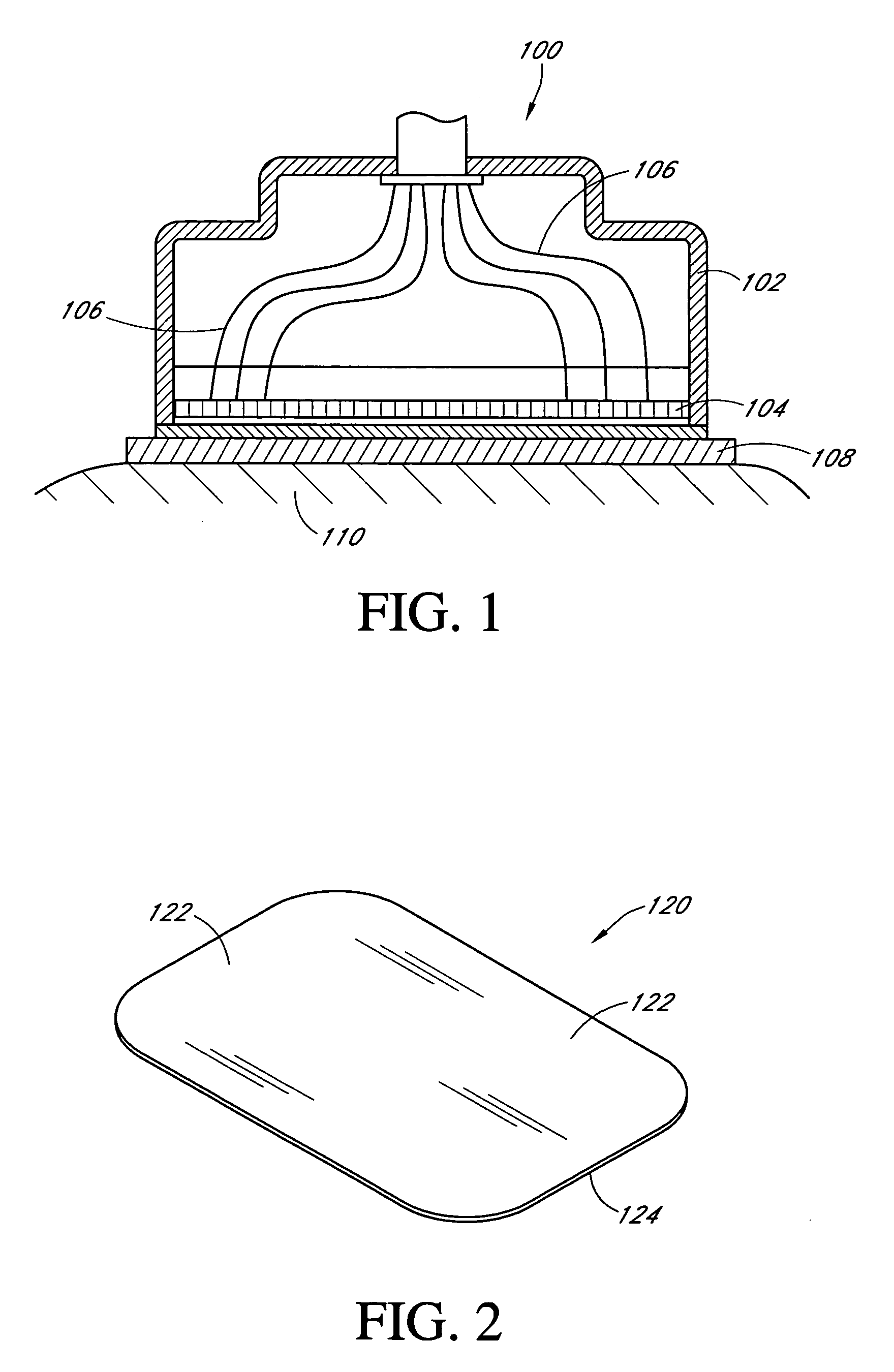

An ankle support (100) is constructed using a molded pad (110) and a rigid shell (112). The pad (110) and the shell (112) may be sealed together to form a bladder-pad cushion for comfort. The internal structure of the pad (110) is molded to include geometrically shaped cells of various size, shape and thickness to provide differing levels of localized comfort to the user of the ankle support (100). The pad may be made from a thermoplastic elastomer (TPE) which is spring-like and resists compression sets. The pad may include integrally-molded fingers extending to the shell. The fingers may have different lengths in one or more regions, in order to increase the cushioning effect in a particular region. The pad / shell combination may form a sealed bladder, and a pneumatic pump may be provided in conjunction with the shell so that the user can inflate the bladder.

Owner:OSSUR HF

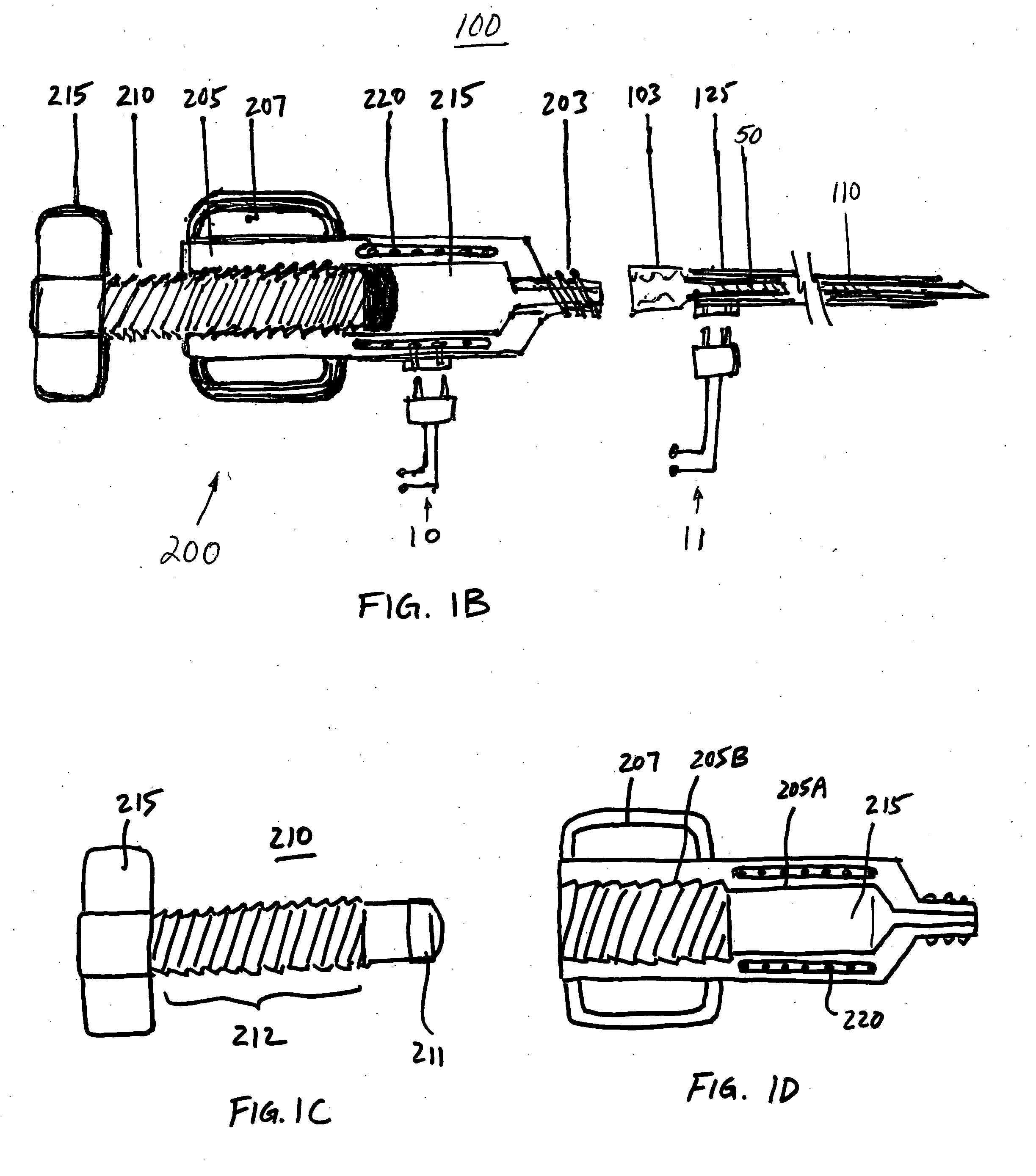

Method and apparatus for minimally invasive repair of intervertebral discs and articular joints

InactiveUS20050245938A1Easy to handleLow costInternal osteosythesisDilatorsArticular spaceArticular cartilage

A device for repair of intervertebral discs and cartilages in articular joints includes a catheter for inserting through a cannula, the catheter having a distal end and a proximal end and a lumen extending longitudinally therethrough. An expandable balloon may optionally be detachably attached to the catheter near the distal end. The proximal end of the catheter is coupled to an injector that holds a supply of a thermoplastic elastomer material at a predetermined elevated temperature sufficiently high to maintain the thermoplastic elastomer at a liquid state. The device allows a thermoplastic elastomer material to be injected into the intervertegral disc space or the articular joint space as a replacement prosthetic for the disc's nucleus pulposus or the joint's cartilage. This procedure is carried out percutaneously through the cannula.

Owner:KOCHAN JEFFREY P

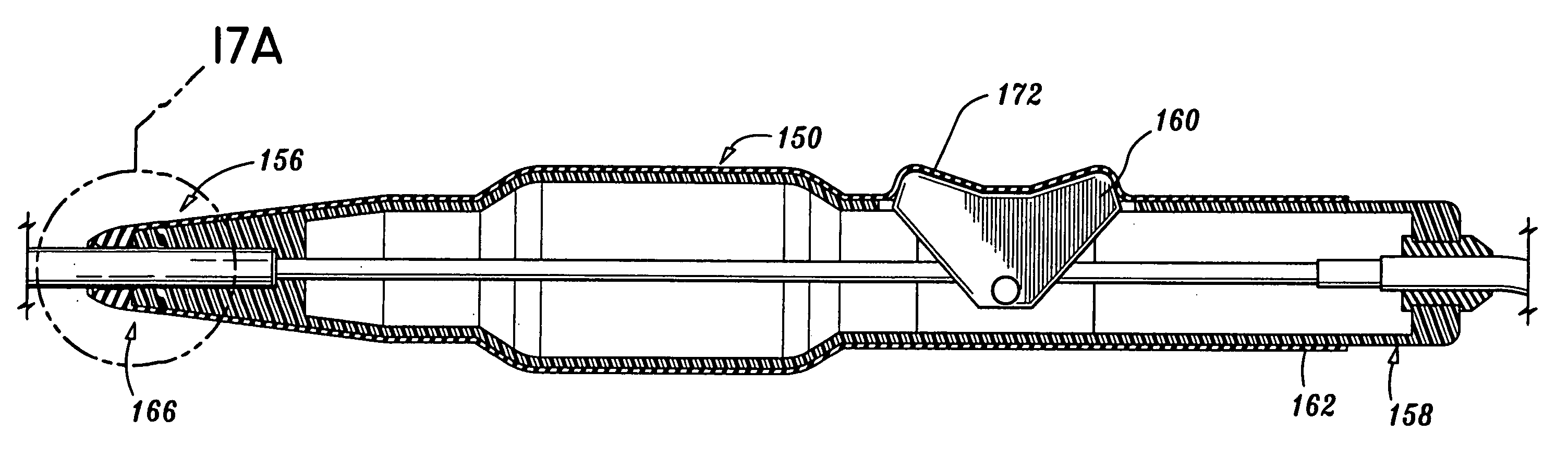

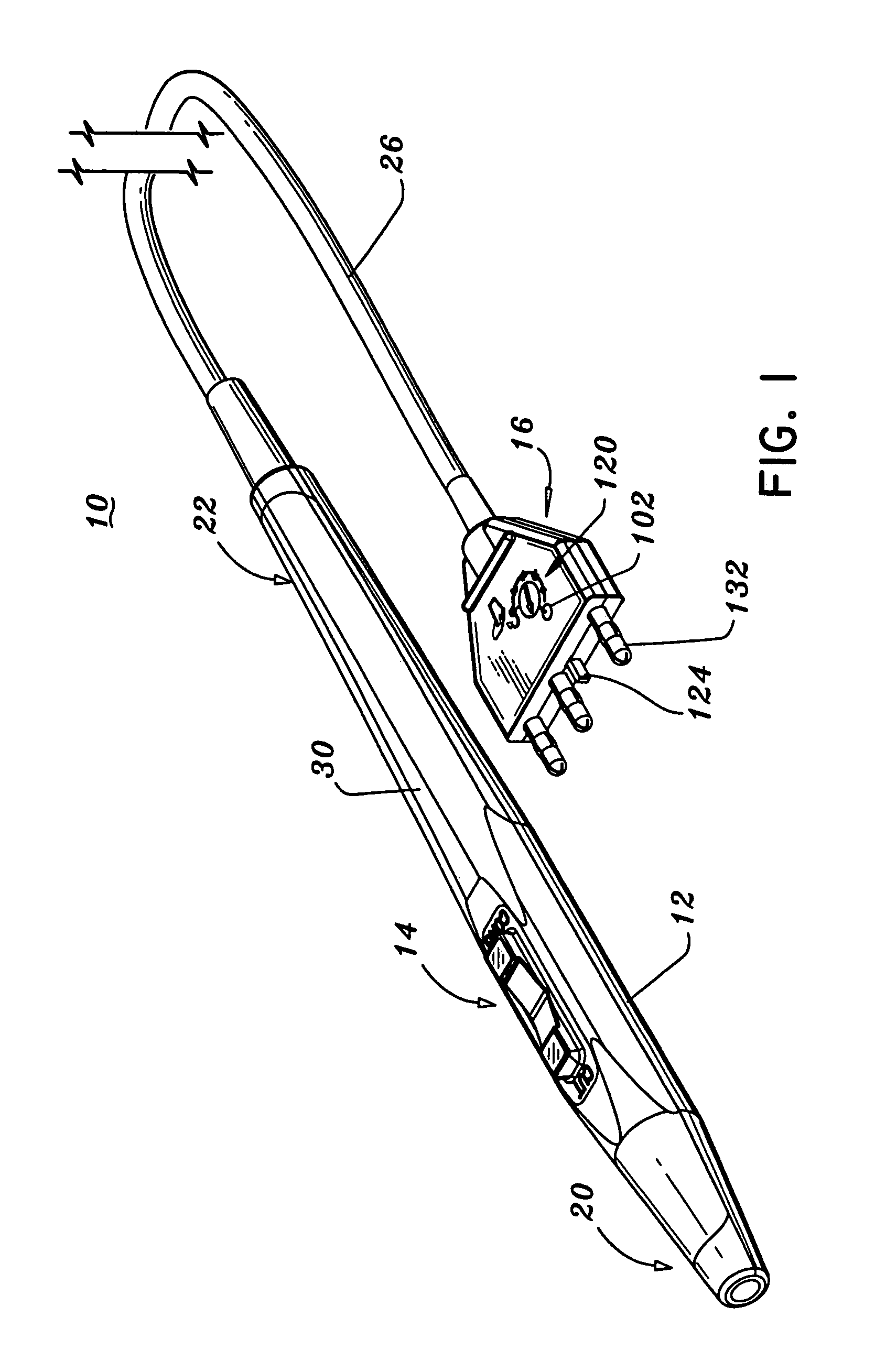

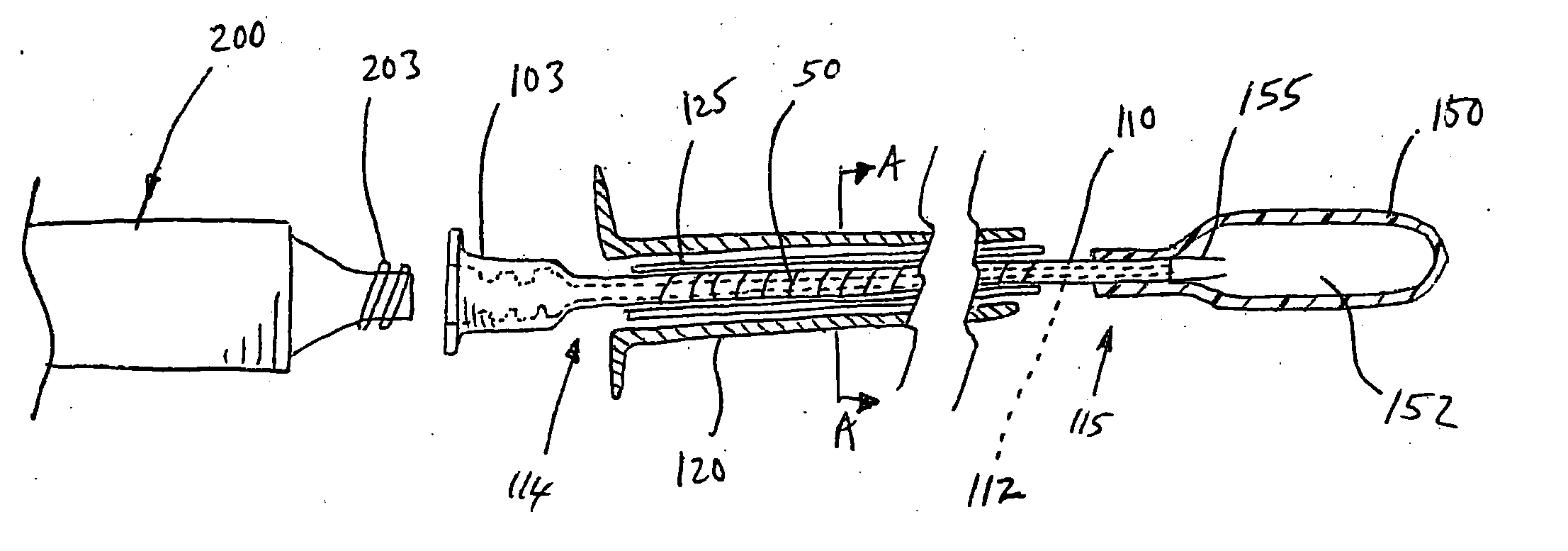

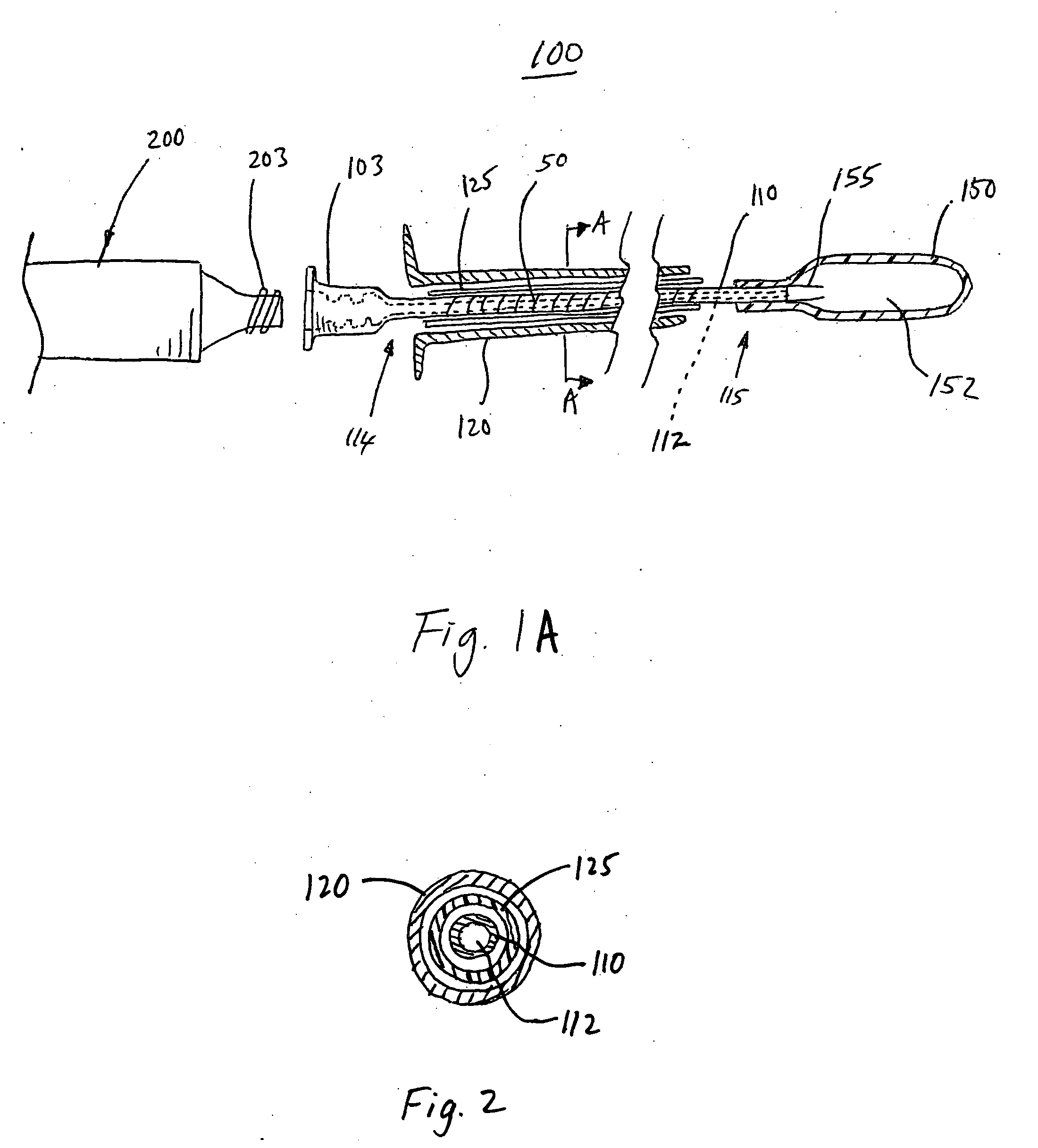

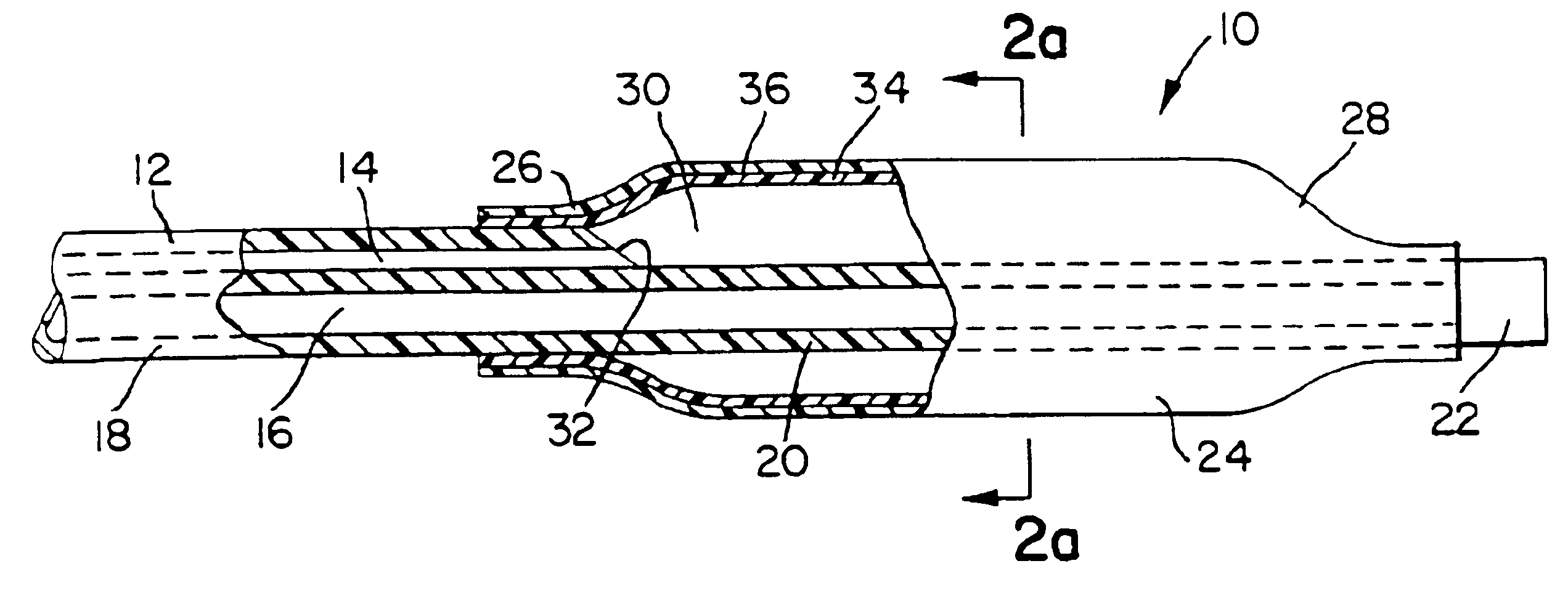

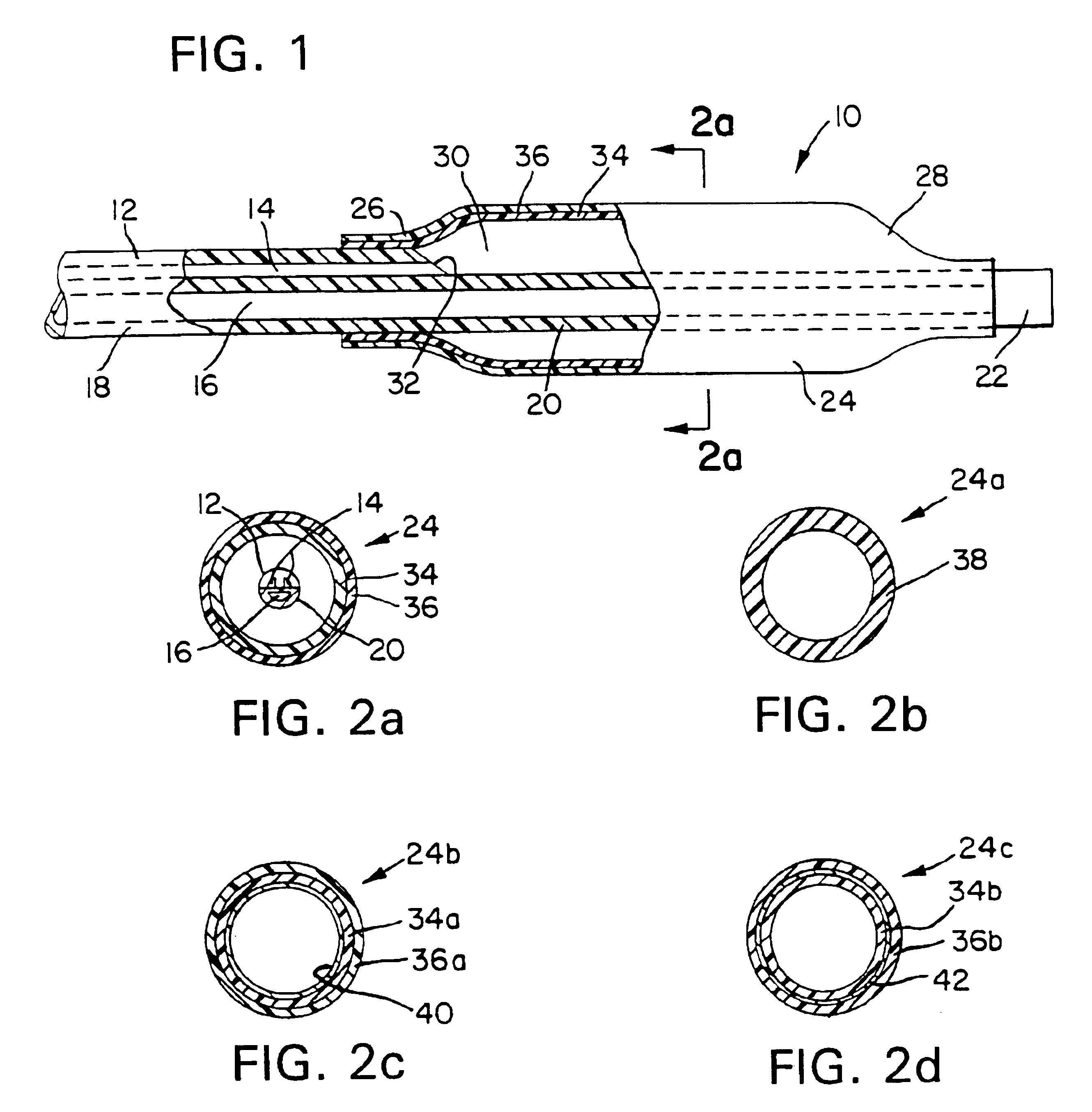

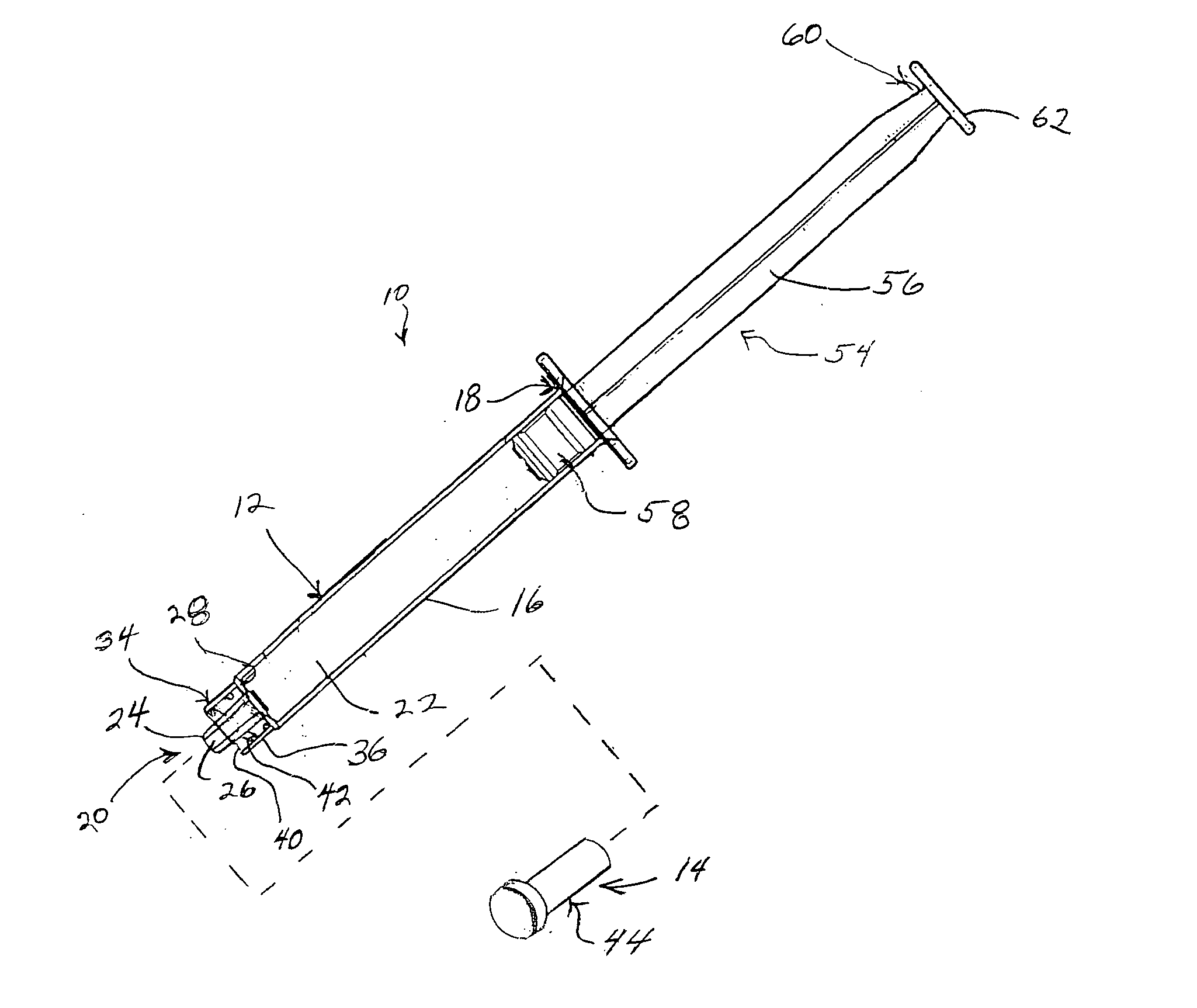

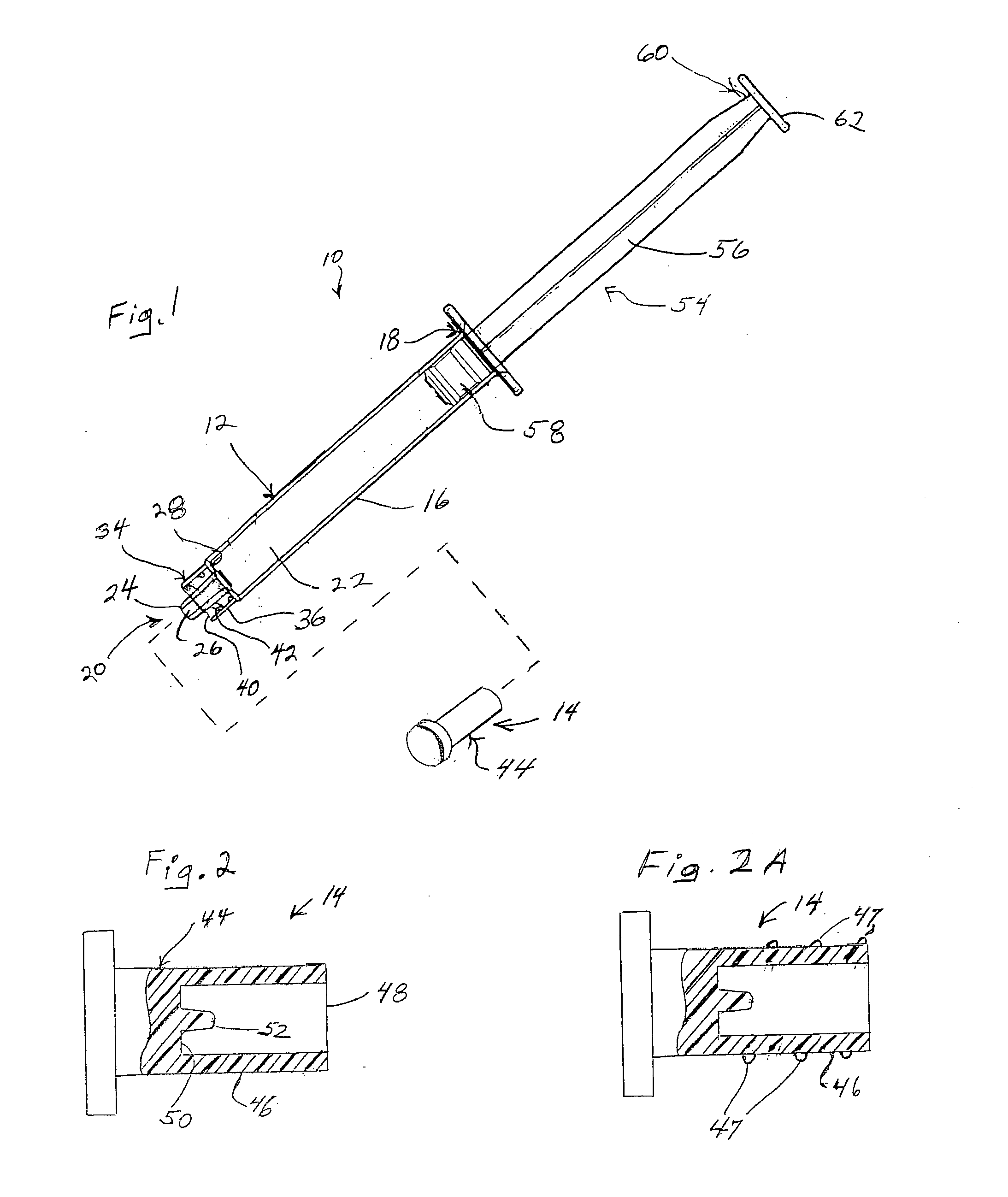

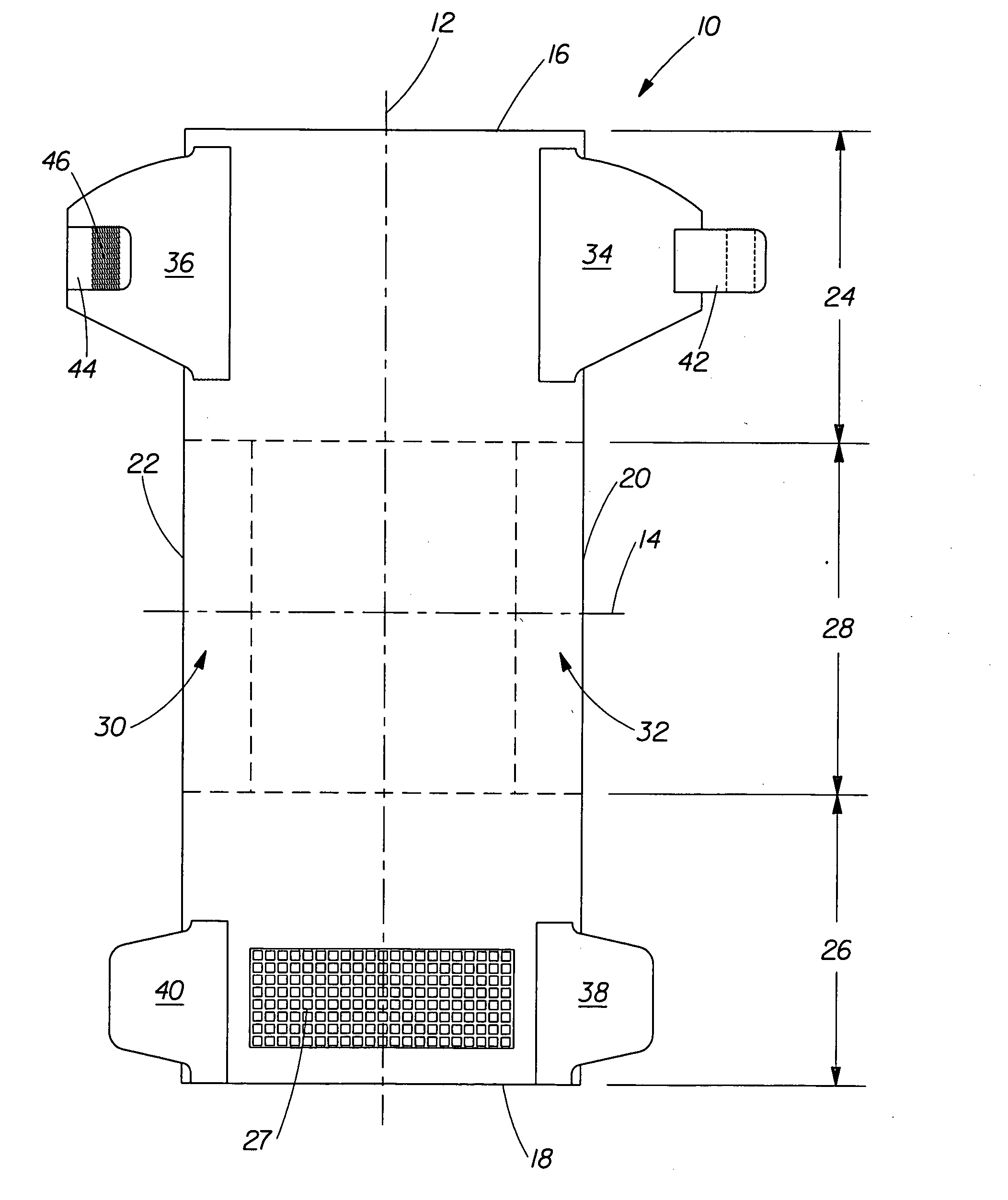

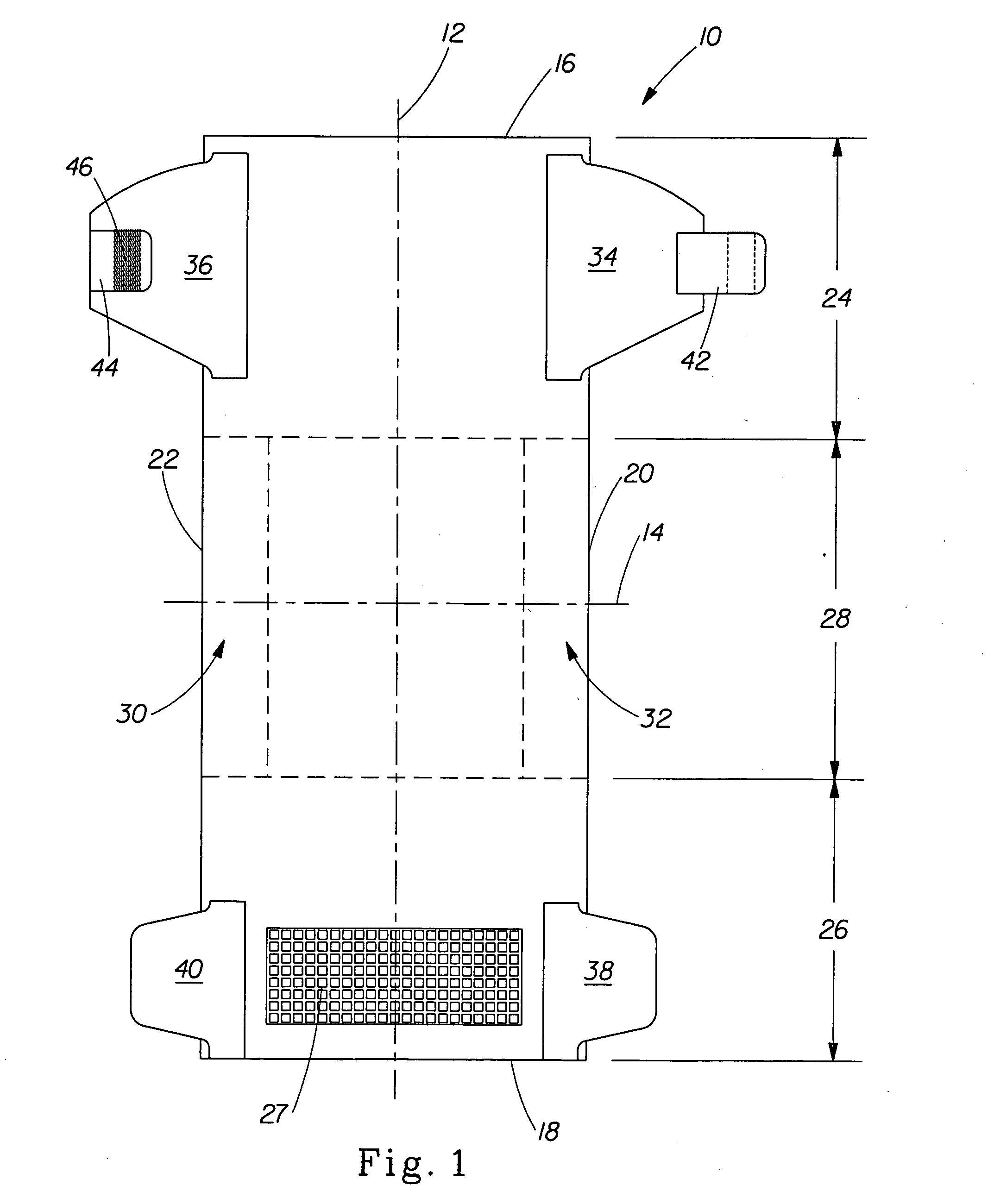

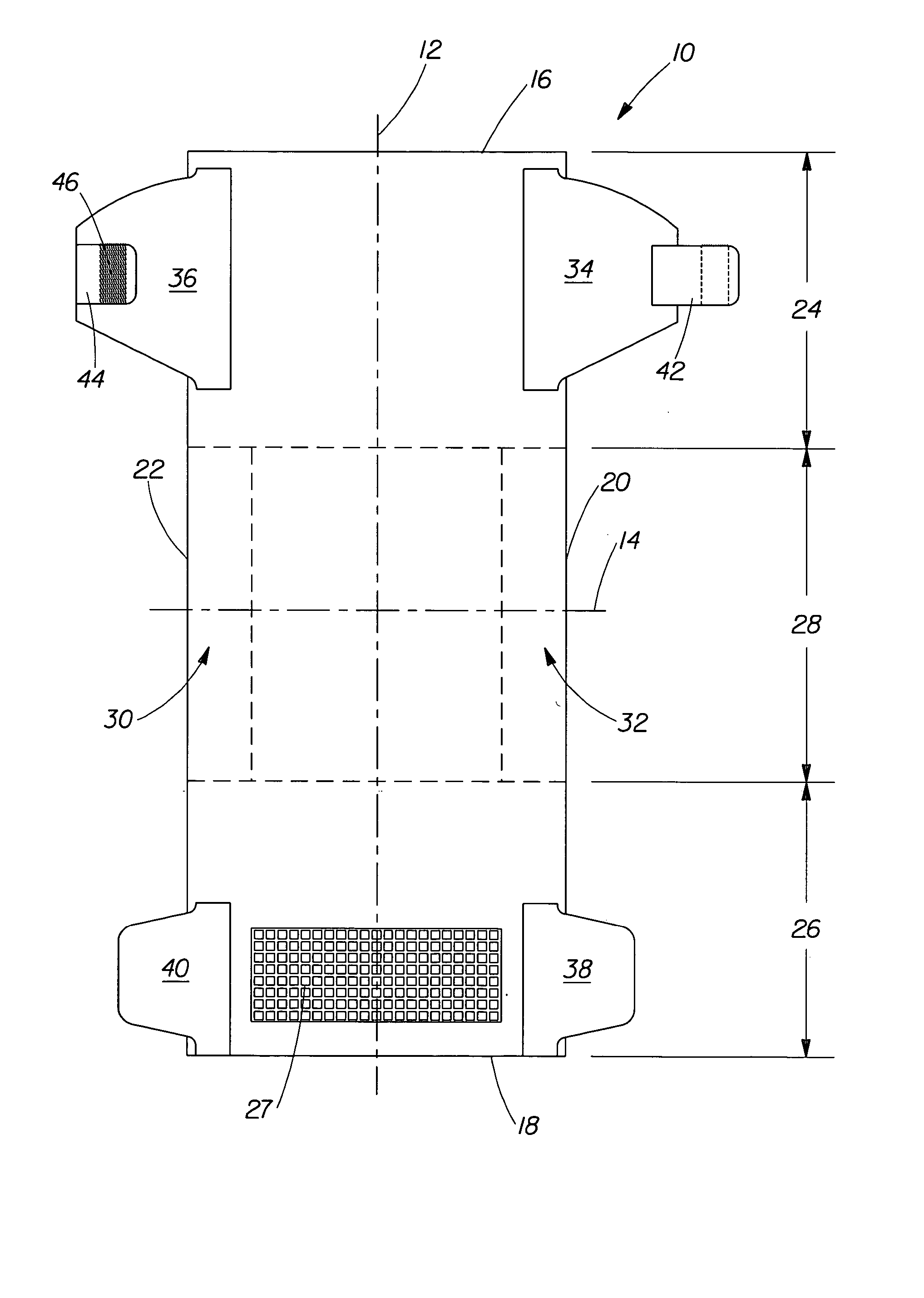

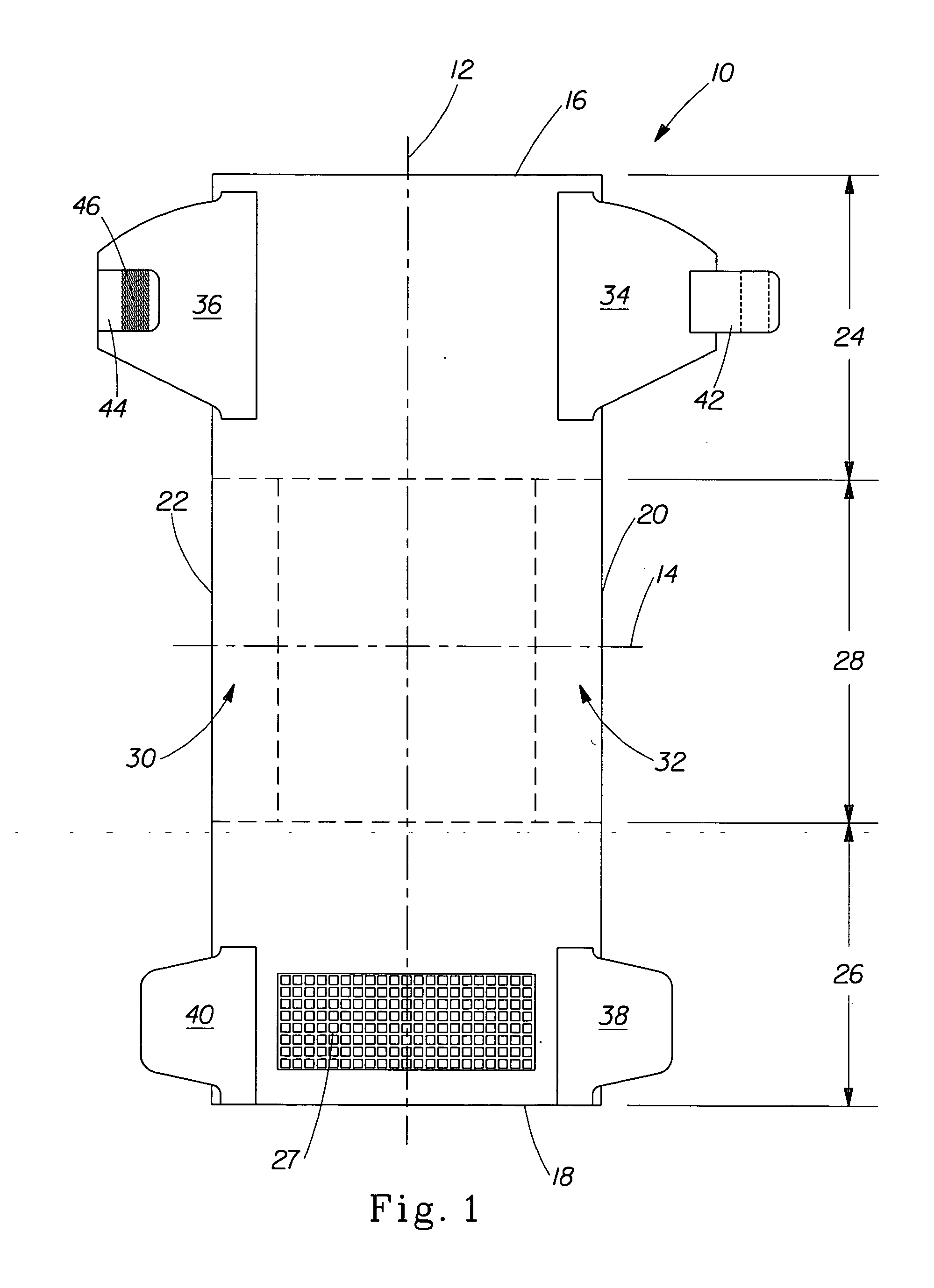

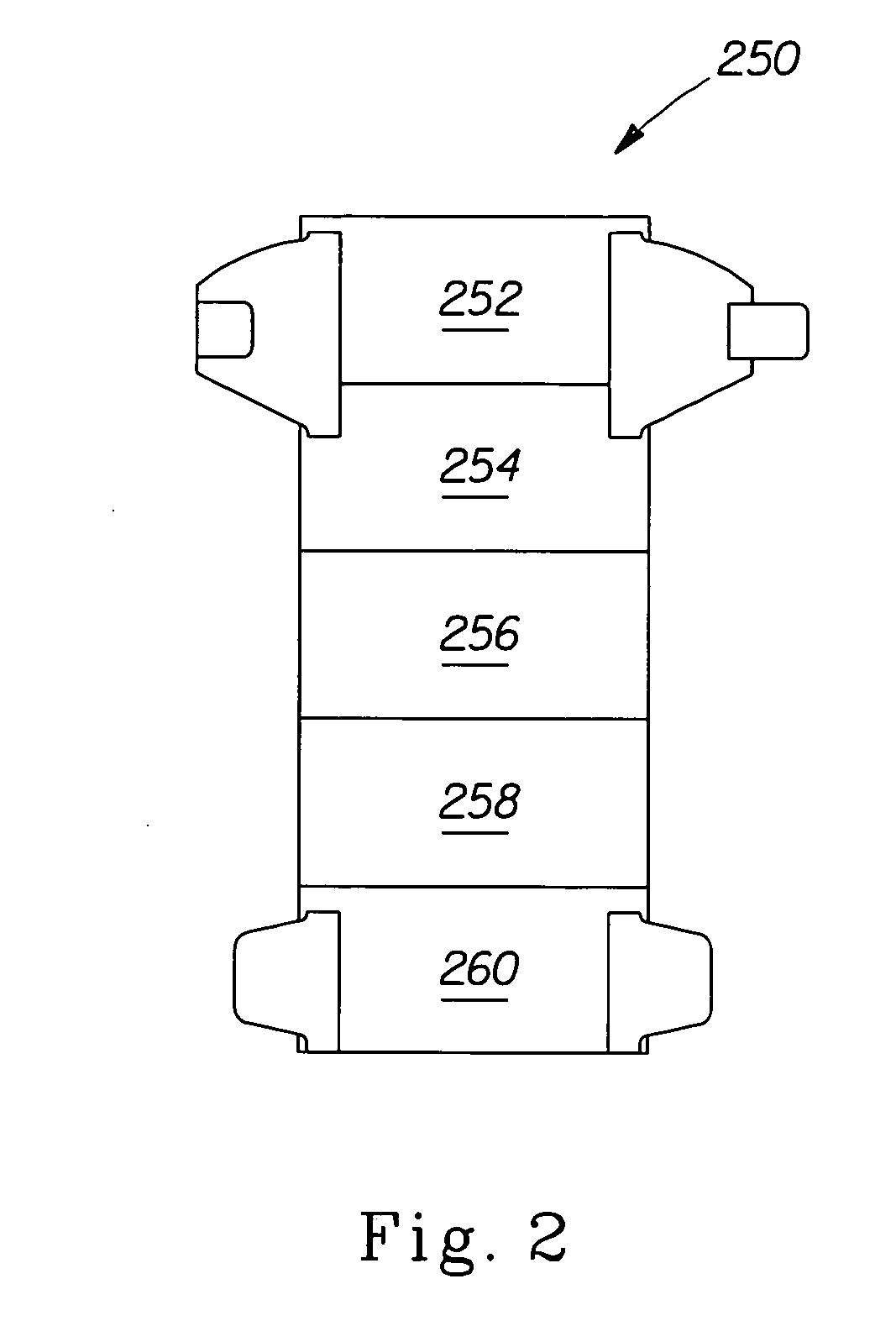

Medical device balloons containing thermoplastic elastomers

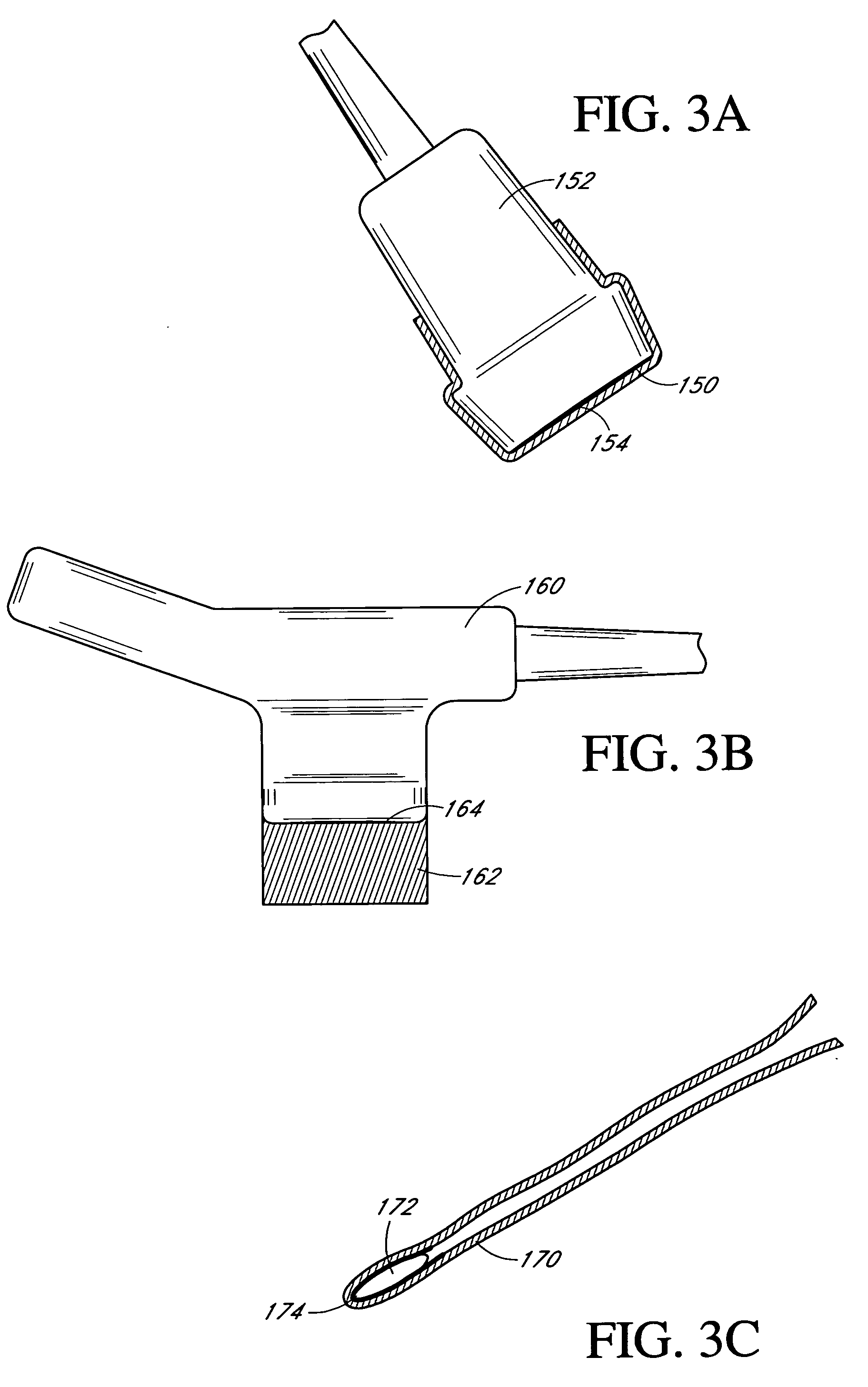

A dilatation balloon and catheter for insertion into a bodily conduit. The catheter (10) includes shaft (12) and a dilatation balloon (24) at the distal end of the shaft. The balloon is inflated via a central lumen (14) in the shaft for delivery of a fluid inflation media. The balloon is fabricated from a combination of a thermoplastic elastomer (TPE), preferably an engineering thermoplastic elastomer (ETE), with a non-compliant structural polymeric material. The combination may be a blend of the non-compliant structural polymer and the TPE. Alternatively, the combination may be a layered balloon having, for example, a non-compliant structural polymer inner layer and a soft, abrasion resistant, elastomeric outer layer. Methods for fabricating the balloon from the combination of a TPE and a non-compliant structural polymer are also disclosed.

Owner:BOSTON SCI SCIMED INC

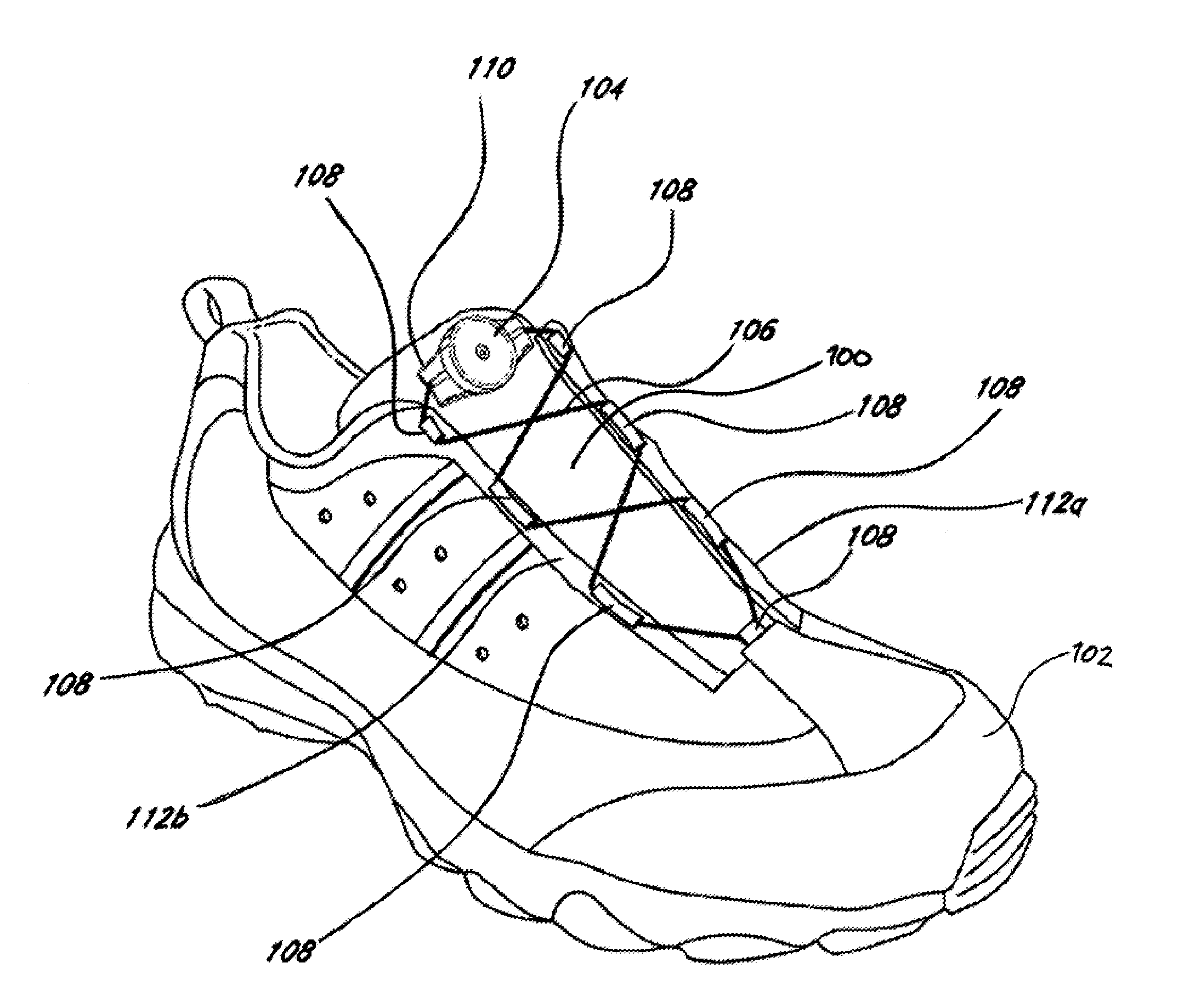

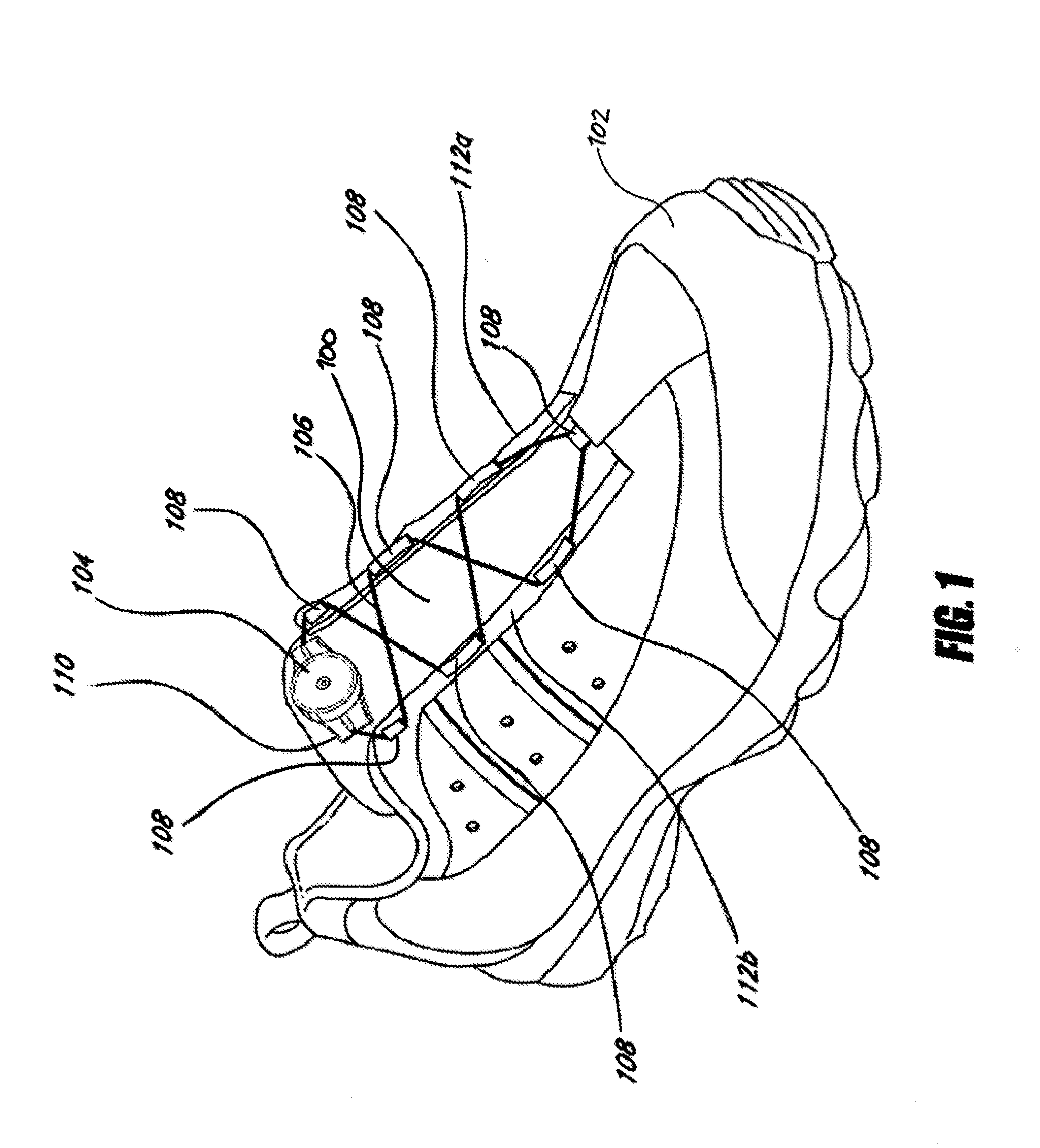

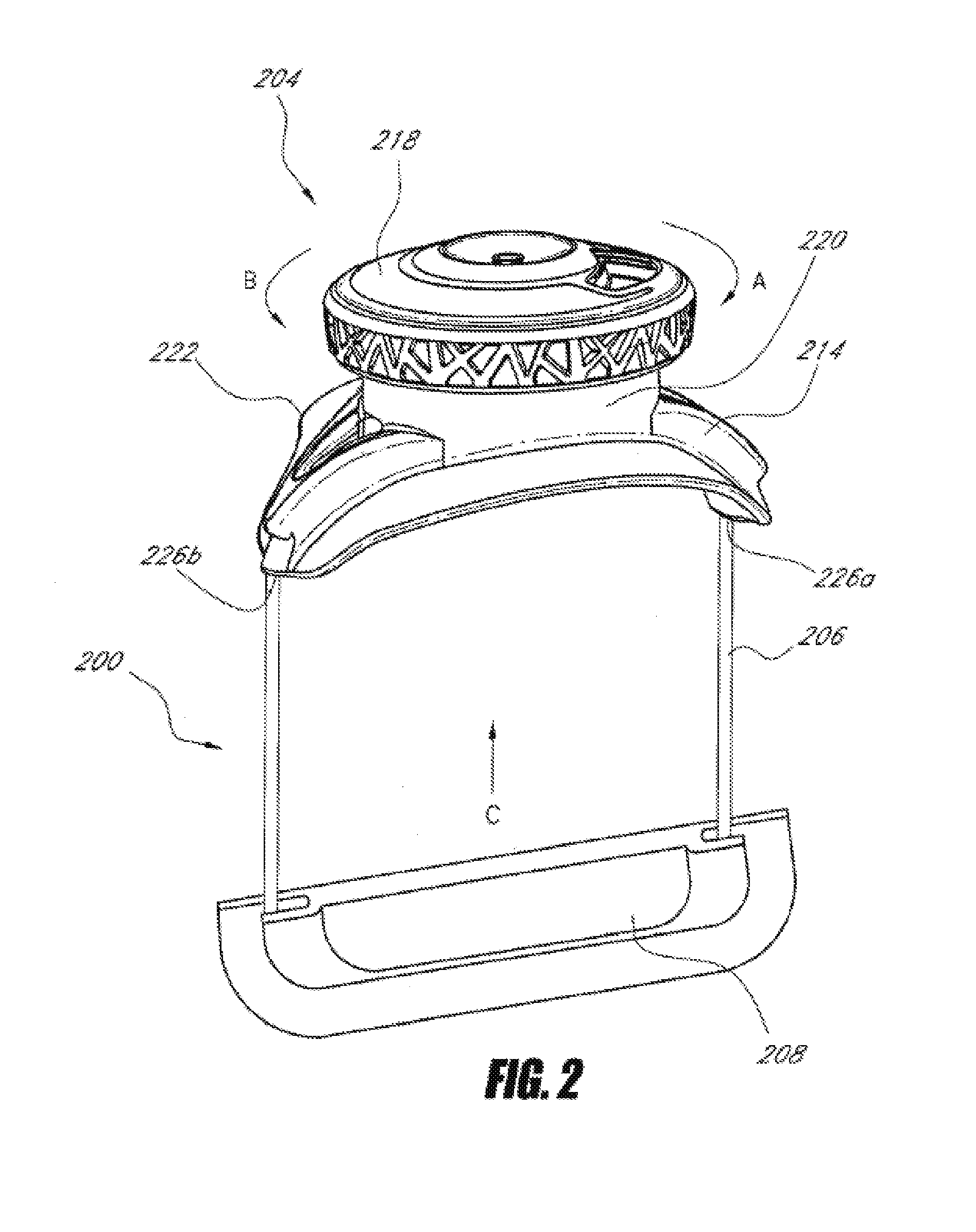

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6518378B2Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerPolyolefin

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:BP AMOCO CORP +1

Thermoplastic elastomer composition, process for the preparation there of, hose made by using the composition, and process for the production thereof

InactiveUS6179008B1Improvement of hose flexibilityLow production costSynthetic resin layered productsFlexible pipesElastomerVulcanization

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:YOKOHAMA RUBBER CO LTD

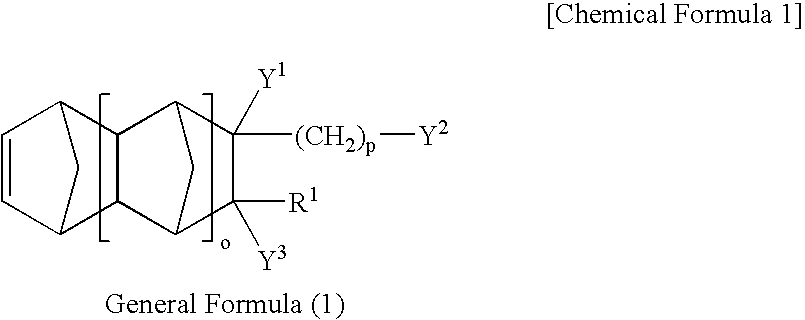

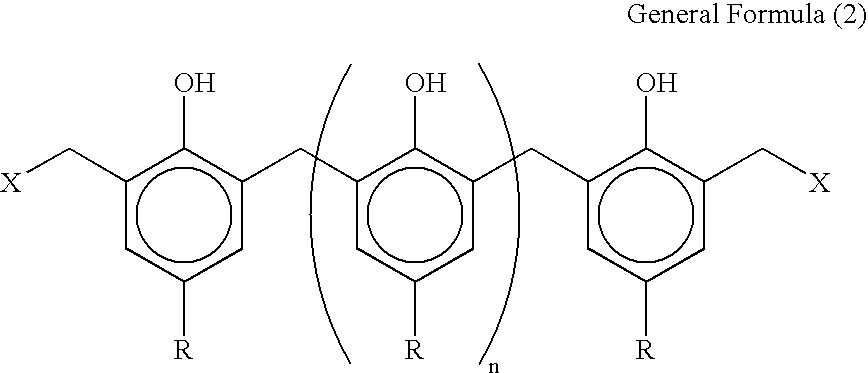

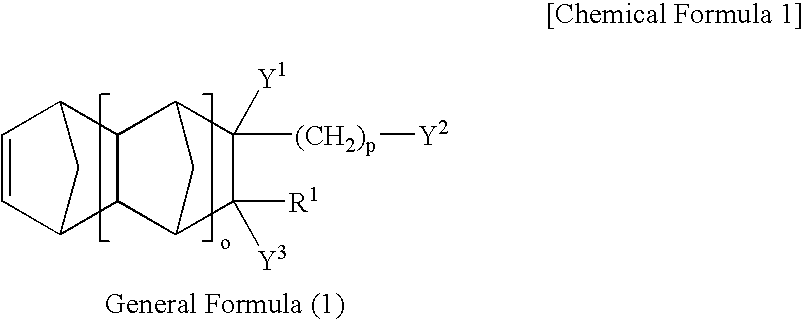

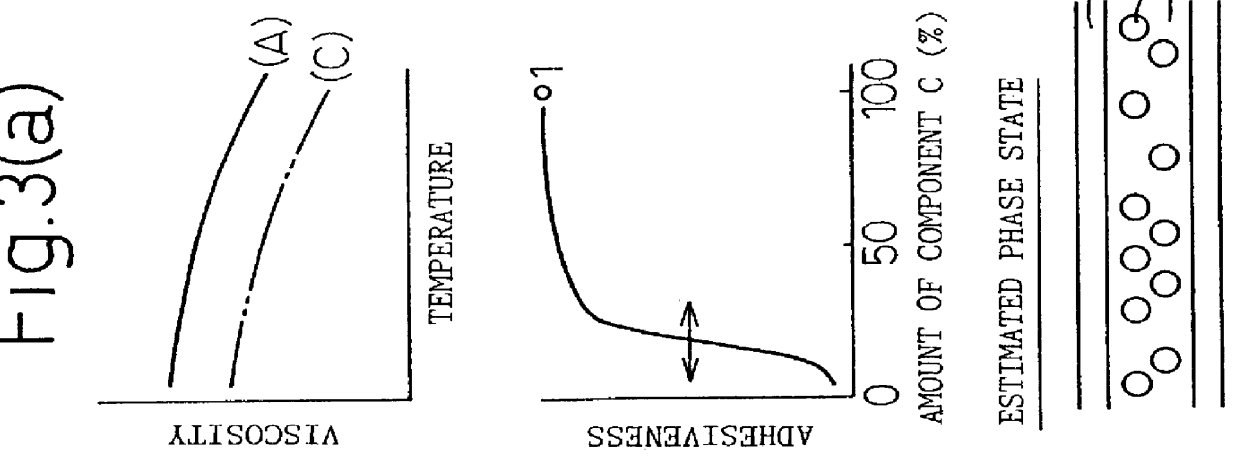

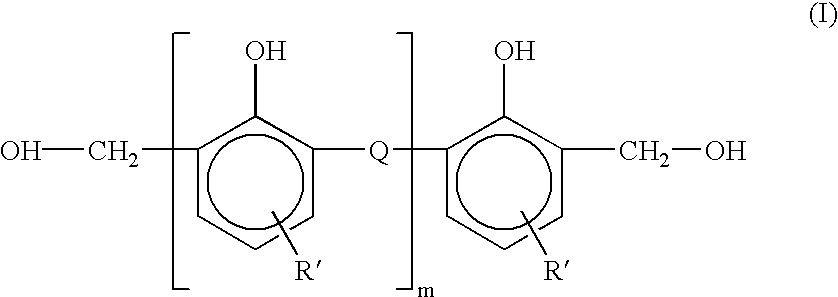

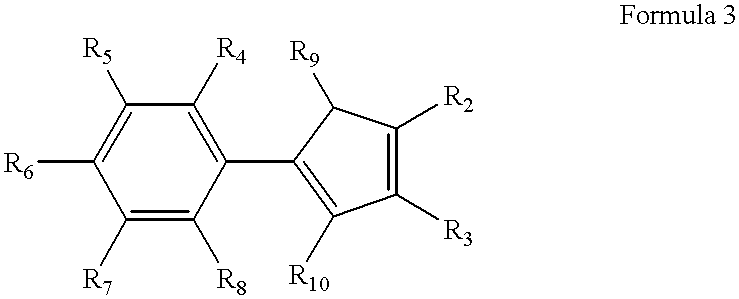

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

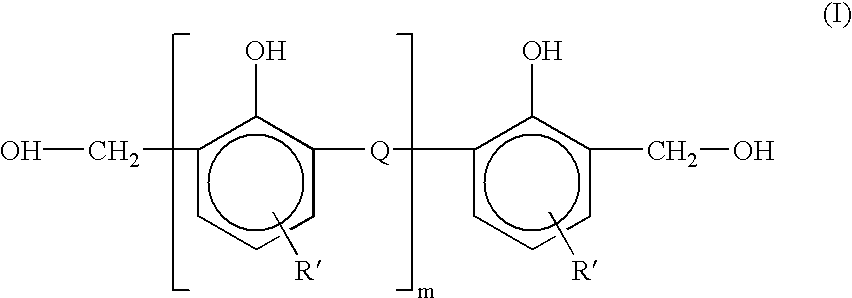

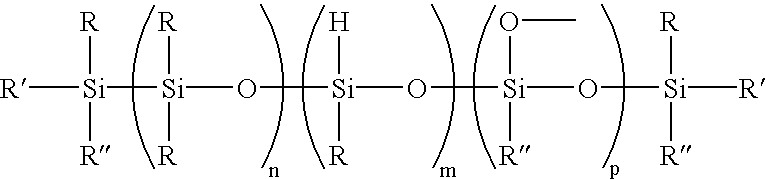

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

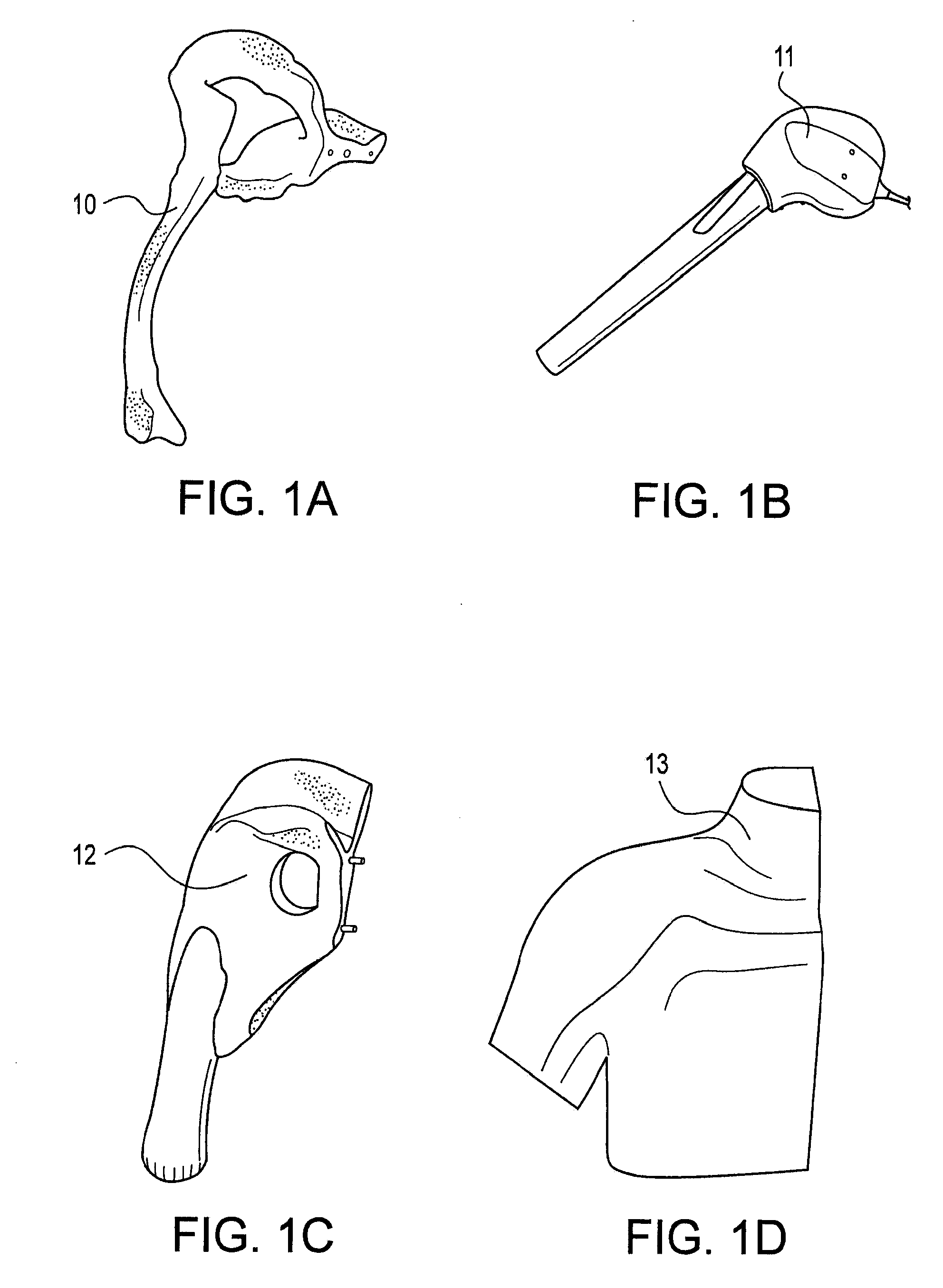

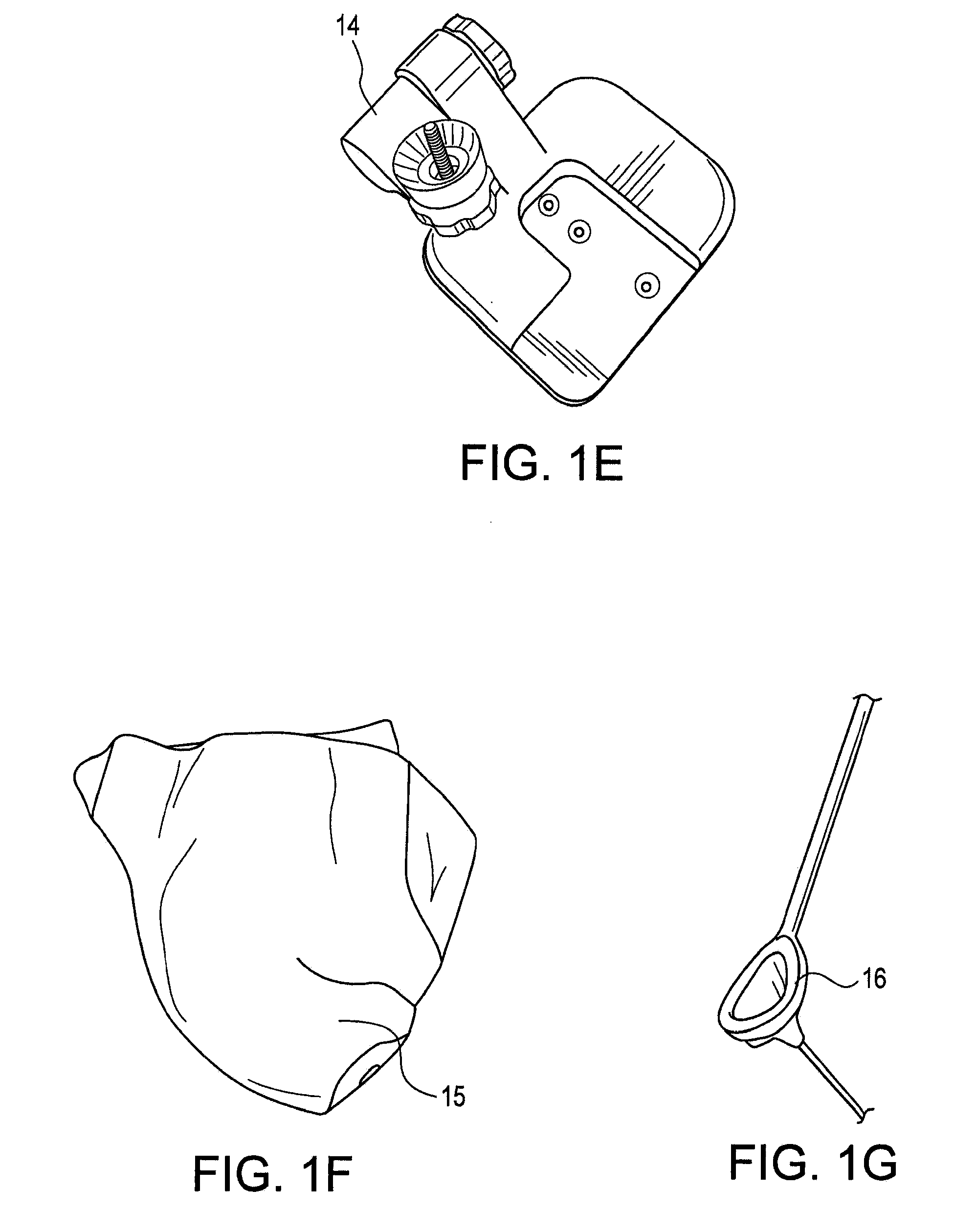

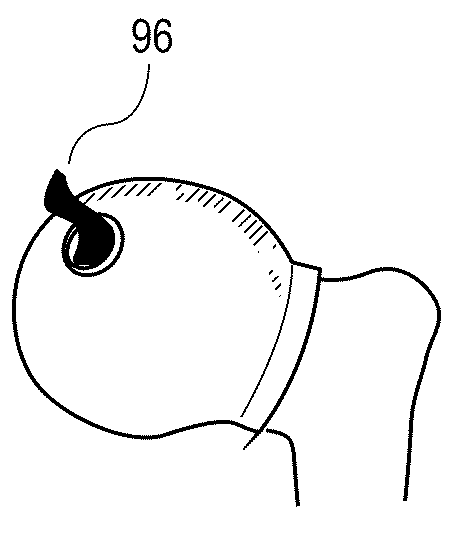

Shoulder model for shoulder arthroscopy

A shoulder model and methods of shoulder arthroscopy using the shoulder model. The shoulder model includes an acromioclavicular (AC) joint assembly, a joint capsule assembly, a scapula mount, a shoulder musculature, a skin, and a base. The AC joint assembly is mounted on the scapula mount and the joint assembly is attached to the AC joint assembly and fastened using a screw / nut to form the shoulder assembly. The shoulder assembly is placed in the shoulder musculature and the skin is rolled over the shoulder musculature and zipped in place. The bones of the shoulder assembly are made of foam-cortical shell, the shoulder musculature is made of foam, the soft tissue components are made of thermoplastic elastomers, and the skin is made of vinyl. A method of practicing shoulder arthroscopy using the shoulder model includes mounting the shoulder model in a beach chair position, making anatomical references, establishing a posterior viewing portal, inserting cannulas into the glenohumeral joint or the subacromial space, creating a labral disruption or a rotator cuff tear, and repairing the rotator cuff tear or labral disruption.

Owner:ARTHREX

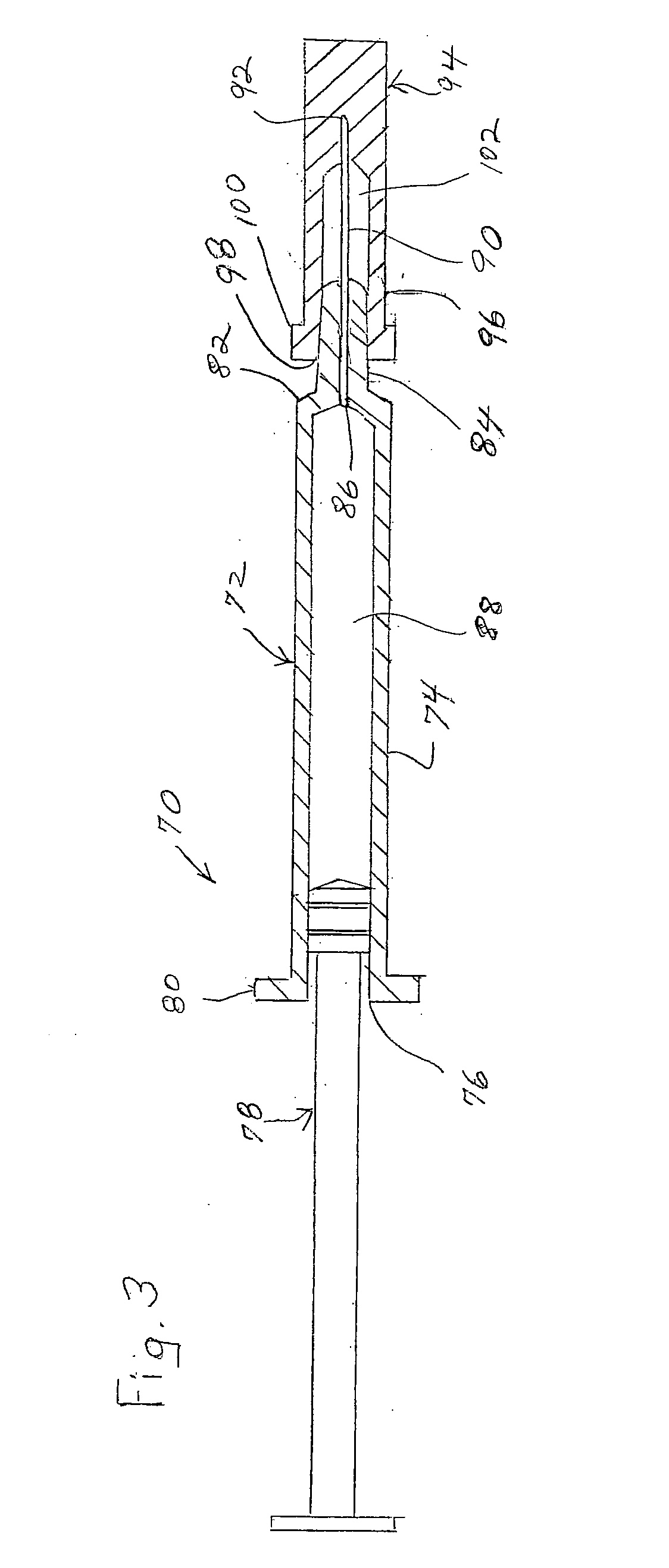

Low extractable, thermoplastic syringe and tip cap

InactiveUS20050075611A1Low extractable levelWithout loss of flexible and resilient propertyAmpoule syringesLavatory sanitoryThermoplastic elastomerPrefilled Syringe

A prefilled syringe and syringe assembly having a syringe and a tip cap are produced from materials that do not interfere with the substance contained in the syringe and enable long term storage. The tip cap is made from a blend of a cyclic olefin polymer or copolymer and a thermoplastic elastomer. The thermoplastic elastomer is blended with the cyclic olefin copolymer in an amount so that the normally stiff and hard cyclic olefin copolymer is flexible and resilient to effectively seal and couple to the tip of a prefilled syringe.

Owner:BECTON DICKINSON & CO

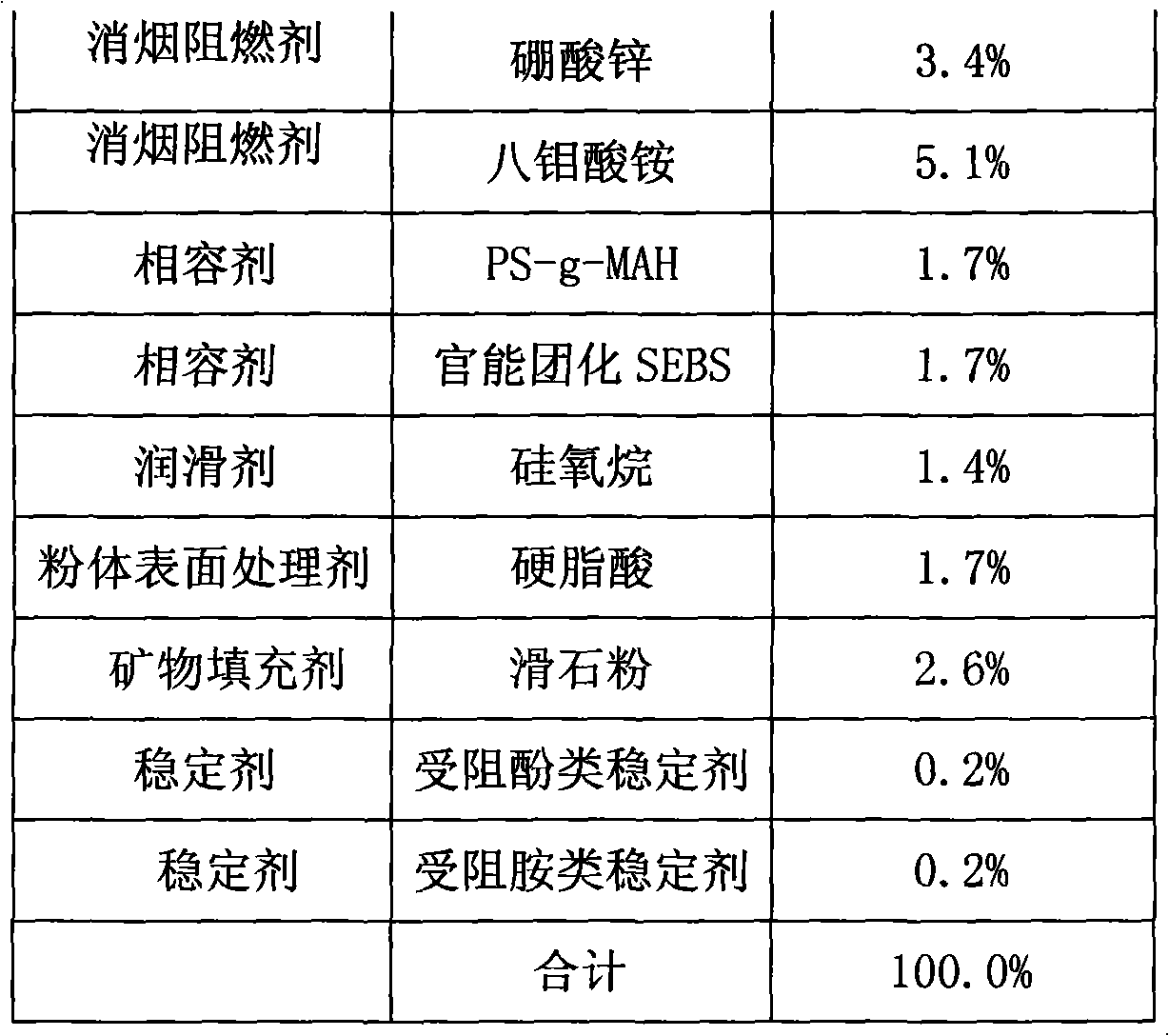

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

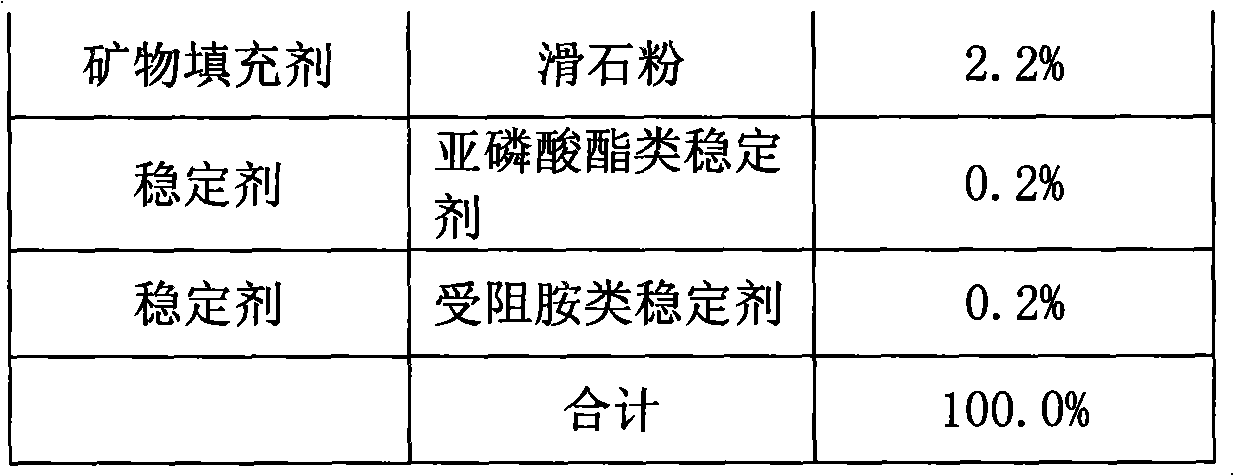

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

Low-density, open-cell, soft, flexible, thermoplastic, absorbent foam and method of making foam

A soft, flexible, low-density, open-cell, thermoplastic, absorbent foam formed from a foam polymer formula including a balanced amount of a plasticizing agent and a surfactant in combination with a base resin. Thermoplastic elastomers can be added to the foam polymer formula to improve softness, flexibility, elasticity, and resiliency of the resulting foam. The surfactant may be either a single surfactant or a multi-surfactant system. The foam possesses a number of qualities, such as softness and strength, which render the foam particularly suitable for use in a variety of personal care products, medical products, and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

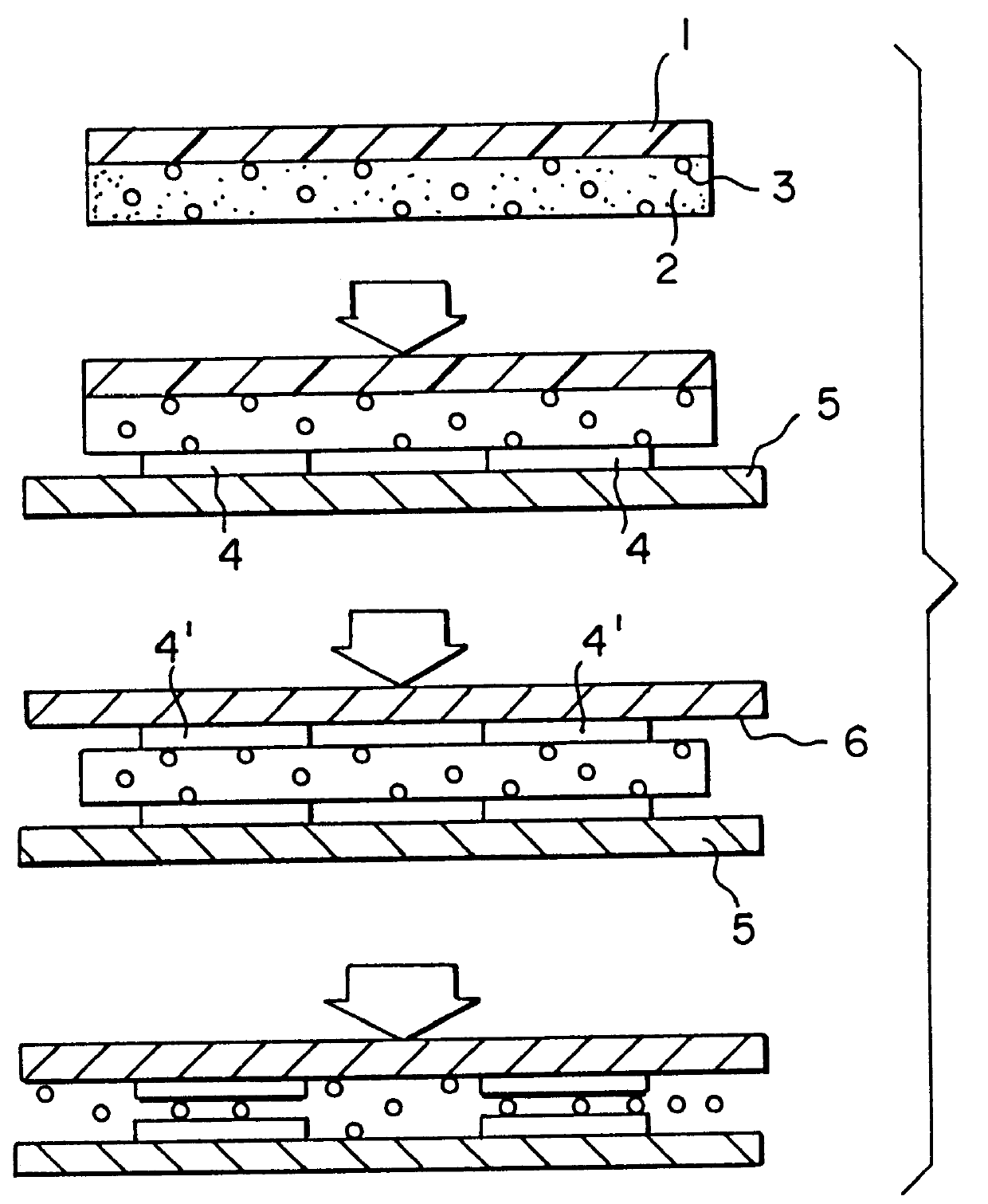

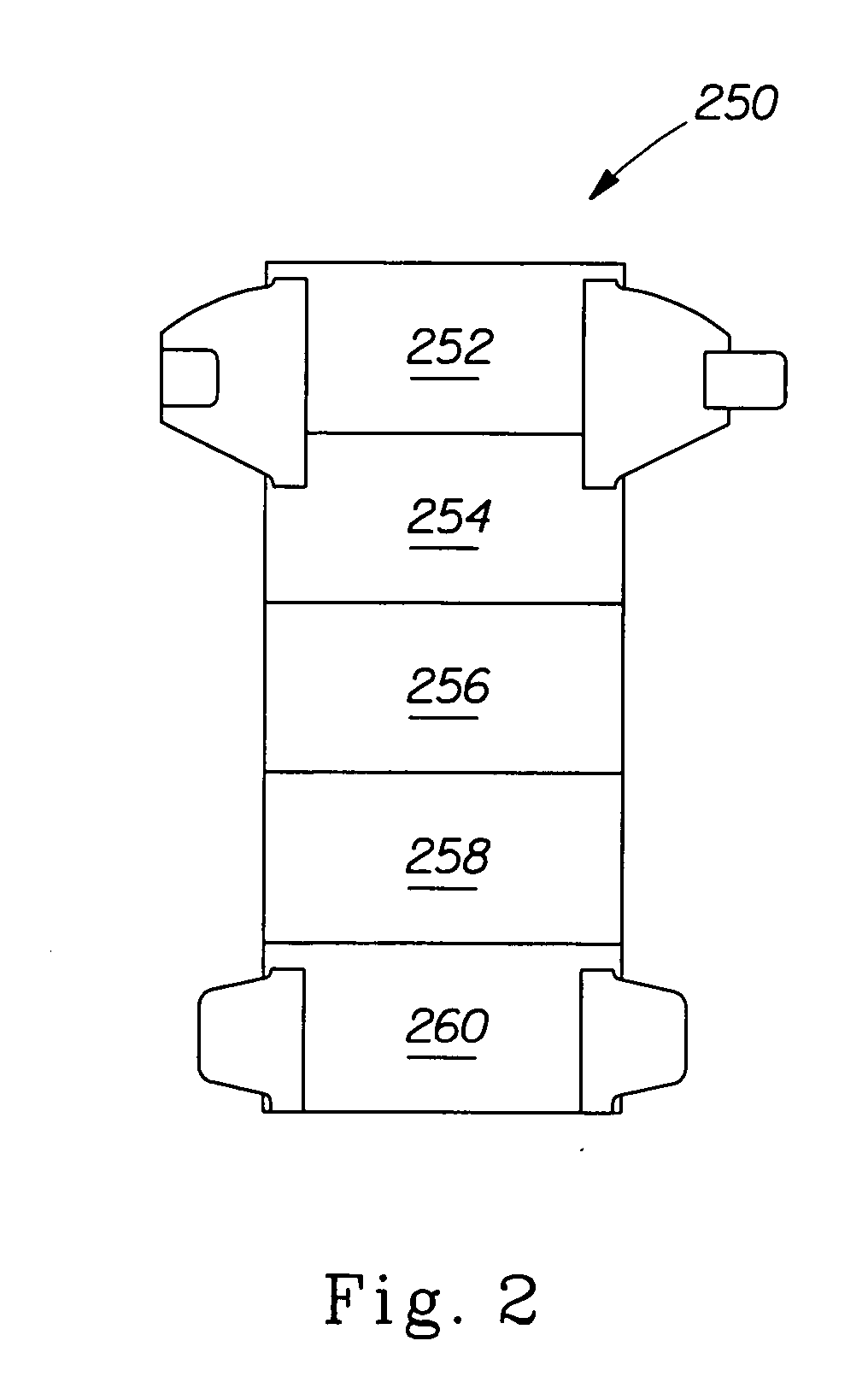

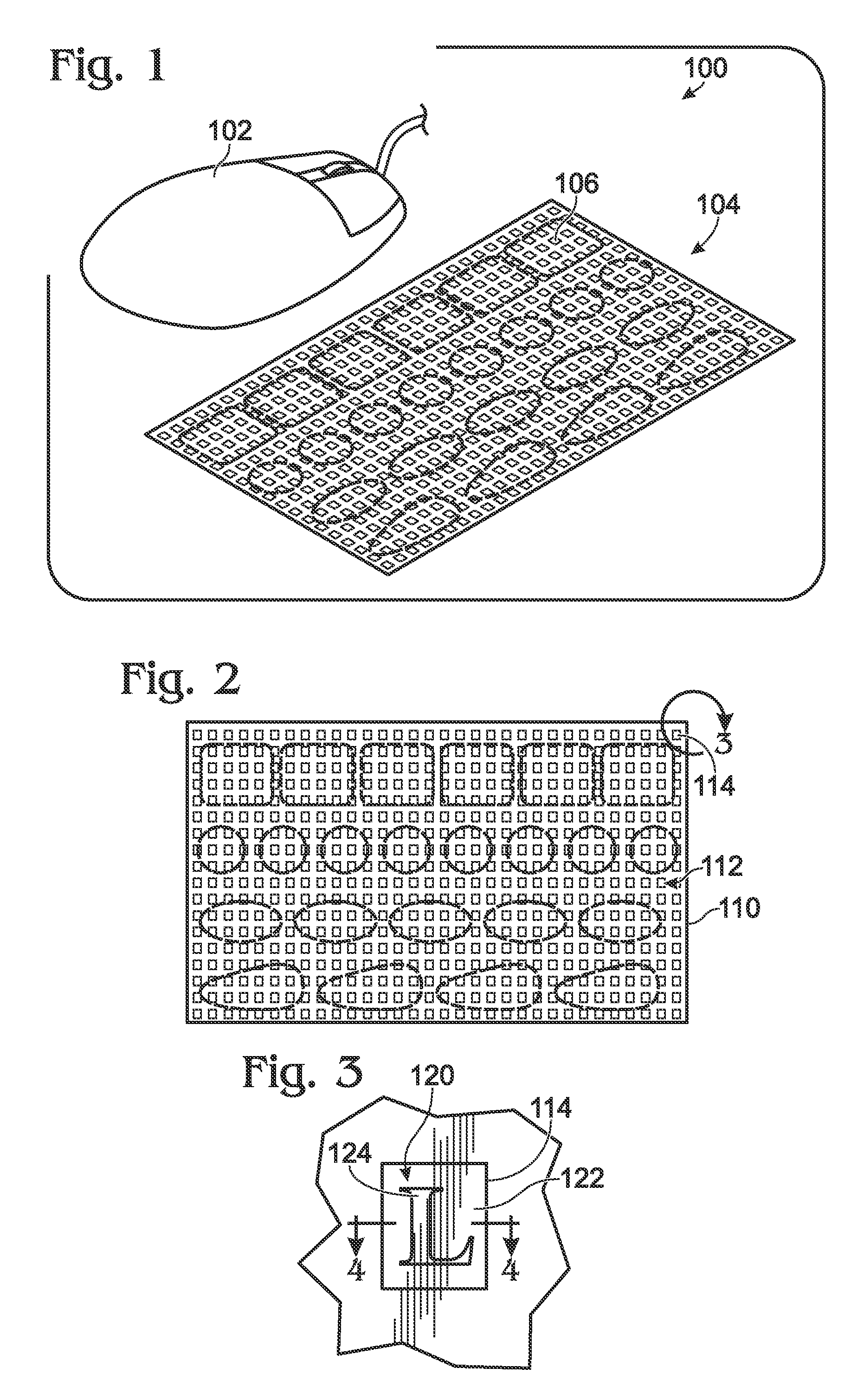

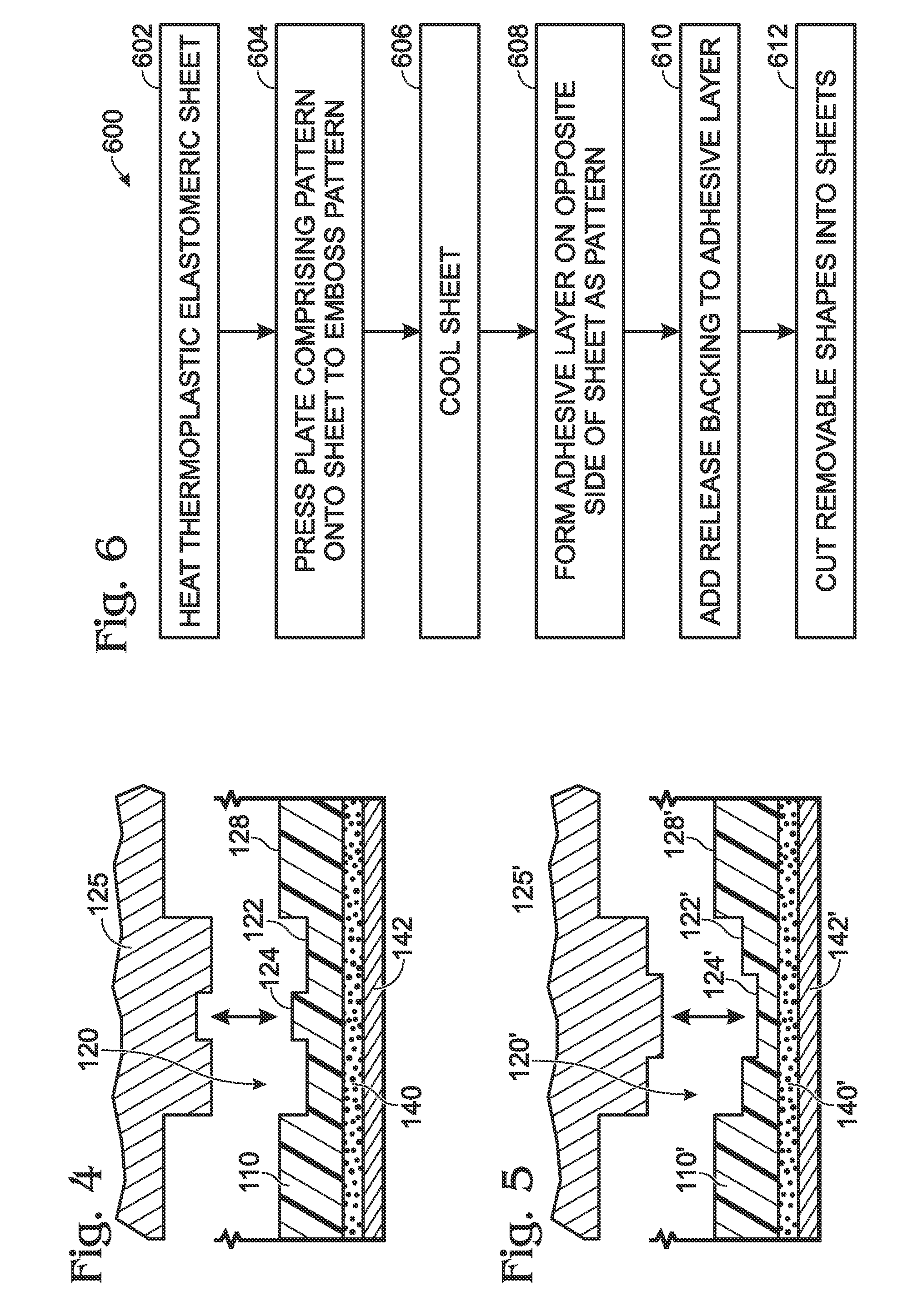

Tactile Enhancement For Input Devices

InactiveUS20100038821A1Well formedLayered productsCeramic shaping apparatusThermoplastic elastomerEngineering

Embodiments related to the tactile enhancement of a computer input device are disclosed herein. In one disclosed embodiment, a method of making removable tactile-enhancing grips for a computer input device is disclosed. The method comprises heating a thermoplastic elastomeric sheet to a temperature at which the thermoplastic elastomeric sheet is capable of receiving and retaining an imprinted feature, pressing onto the thermoplastic elastomeric sheet a plate comprising a pattern, thereby embossing the pattern onto the thermoplastic elastomeric sheet, and cooling the thermoplastic elastomeric sheet to a temperature at which the pattern is retained in the thermoplastic elastomeric sheet. An adhesive layer is then formed on an opposite side of the thermoplastic elastomeric sheet as the pattern.

Owner:MICROSOFT TECH LICENSING LLC

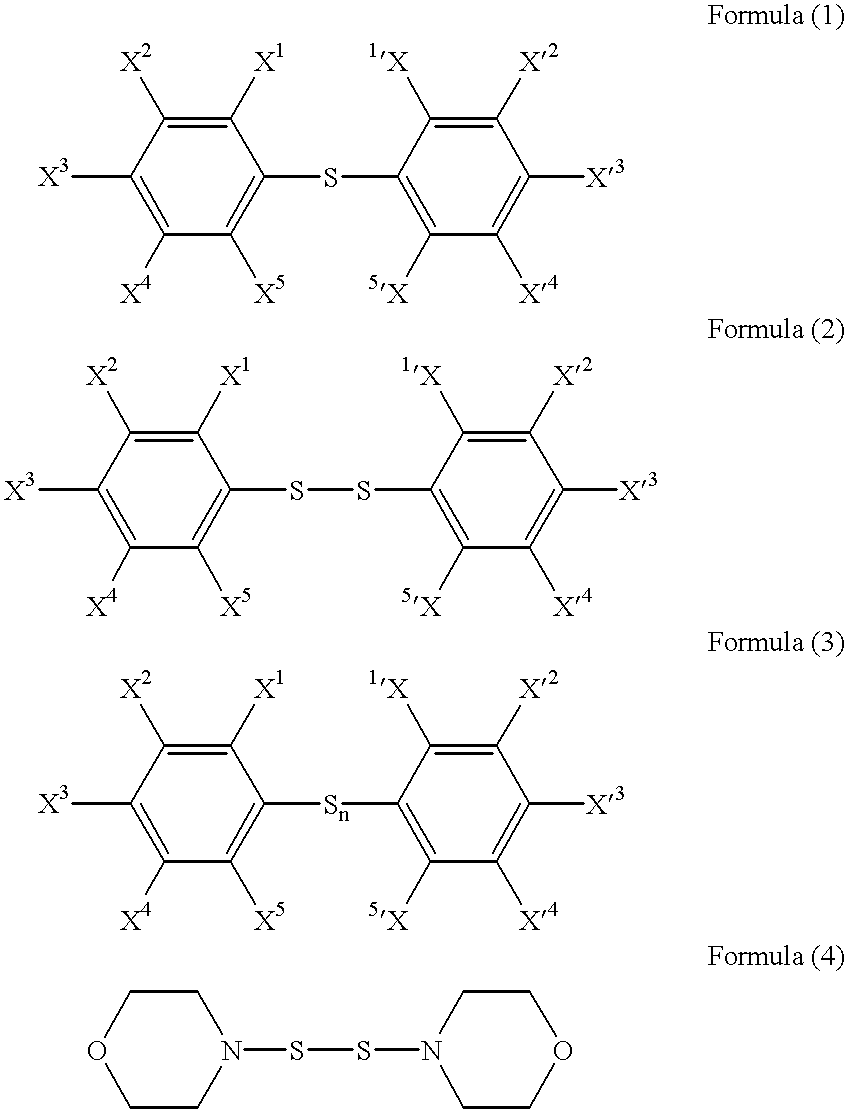

Solid golf ball

A golf ball has a cover member and a core member. The cover member contains: 3 to 30 parts by weight of a thermoplastic elastomer containing polyamide; 5 to 50 parts by weight of a terpolymer ionomer containing ethylene, (meth)acrylic acid, and (meth)acrylic ester; 30 to 80 parts by weight of a copolymer ionomer containing ethylene and (meth)acrylic acid; and 1 to 20 parts by weight of an epoxidized-diene-based block copolymer. The core member is formed by vulcanizing a rubber composition containing: 100 parts by weight of a base rubber, A parts by weight of an alpha, beta-unsaturated carboxylic acid or a metal salt thereof, B parts by weight of an organic peroxide, and C parts by weight of a sulfide where A, B, and C satisfies the relationship:andA lies in the range from 25 to 45.

Owner:DUNLOP SPORTS CO LTD

Ionomer/rubber/polyolefin blend and uses thereof

A thermoplastic ionomer blend or alloy exhibiting advantageous properties upon molding or extrusion and / or thermoforming, consisting essentially of the following components:A. about 15 to 85 parts by weight of a thermoplastic copolymer containing about 91 to 80 weight percent of alpha-olefin units and about 9 to 20 weight percent of alpha, beta-ethylenically unsaturated carboxylic acid units said carboxylic acid units being about 20 to 90 percent neutralized with metal ions, preferably zinc,B. about 10 to 80 parts by weight of a rubber, preferably a thermoplastic elastomer selected from the group consisting of (a) crosslinked ethylene-propylene-diene copolymers and equivalent polyolefin copolymers such as ethylene-butene, hexene, or octene, (b) acrylonitrile-butadiene copolymers, (c) styrene-butadiene copolymers, and (d) styrene acrylonitrile graft-crosslinked butadiene rubbers, andC. about 5 to 40 parts by weight of a thermoplastic polymer selected from the group consisting of polyethylene and polypropylene copolymers and homopolymers, the total number of parts being 100,and molded or extruded and / or thermoformed products produced from the same.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

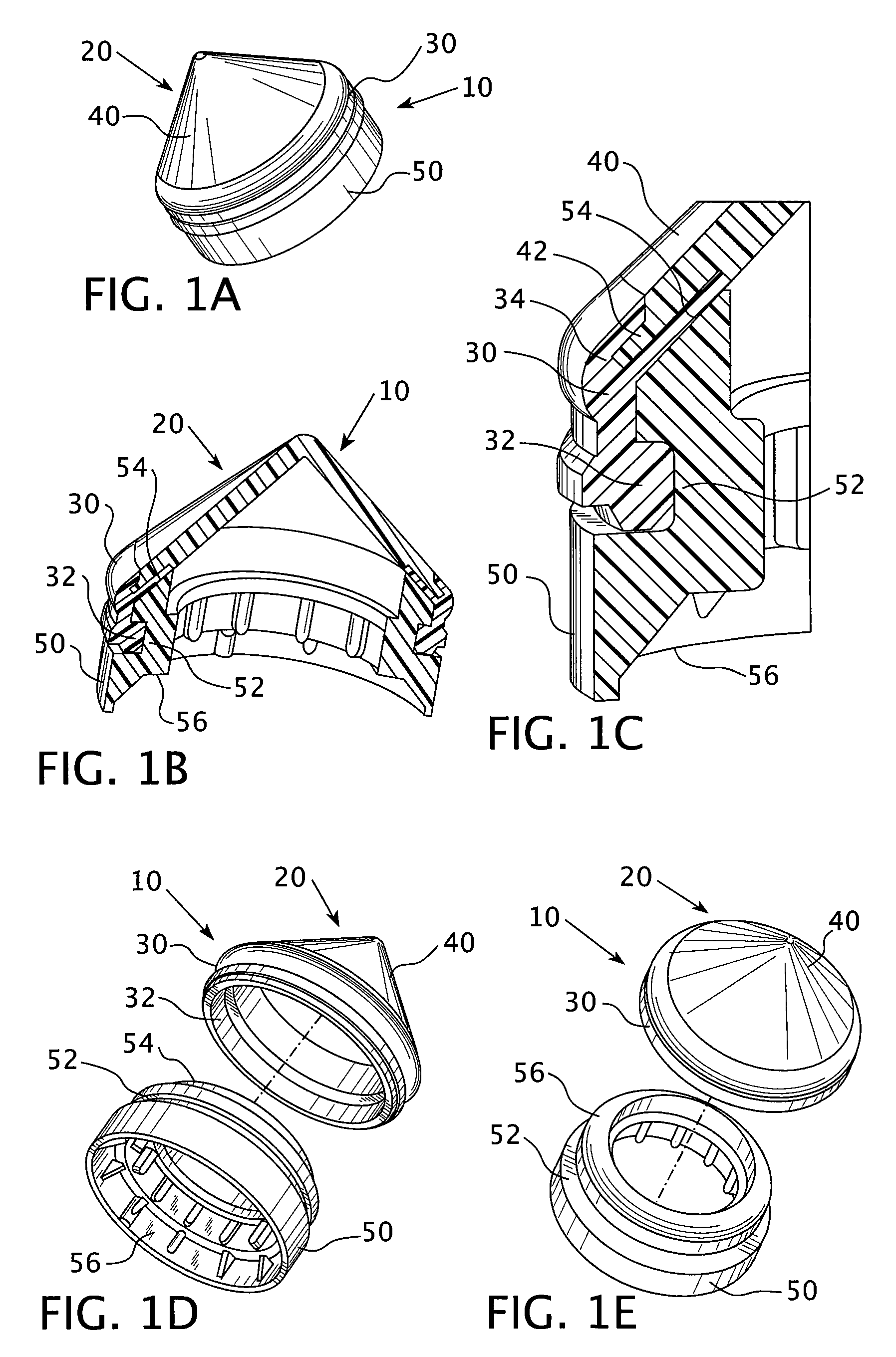

Plunger Covers and Plungers for Use in Syringes and Methods of Fabricating Plunger Covers and Plungers for Use in Syringes

A plunger cover for use with a syringe includes a sealing portion adapted to form a seal with the syringe and a central portion adapted to contact fluid within the syringe. The central portion can, for example, be more rigid than the sealing portion. The sealing portion and the central portion are connected in an overmolding process. The sealing portion can, for example, be formed from a thermoplastic elastomer or a thermoplastic polyurethane. The central portion can, for example, be formed from polypropylene, acrylonitrile butadiene styrene, polycarbonate or copolymers thereof.

Owner:BAYER HEALTHCARE LLC

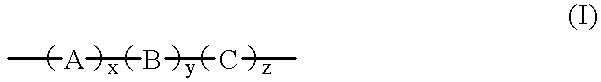

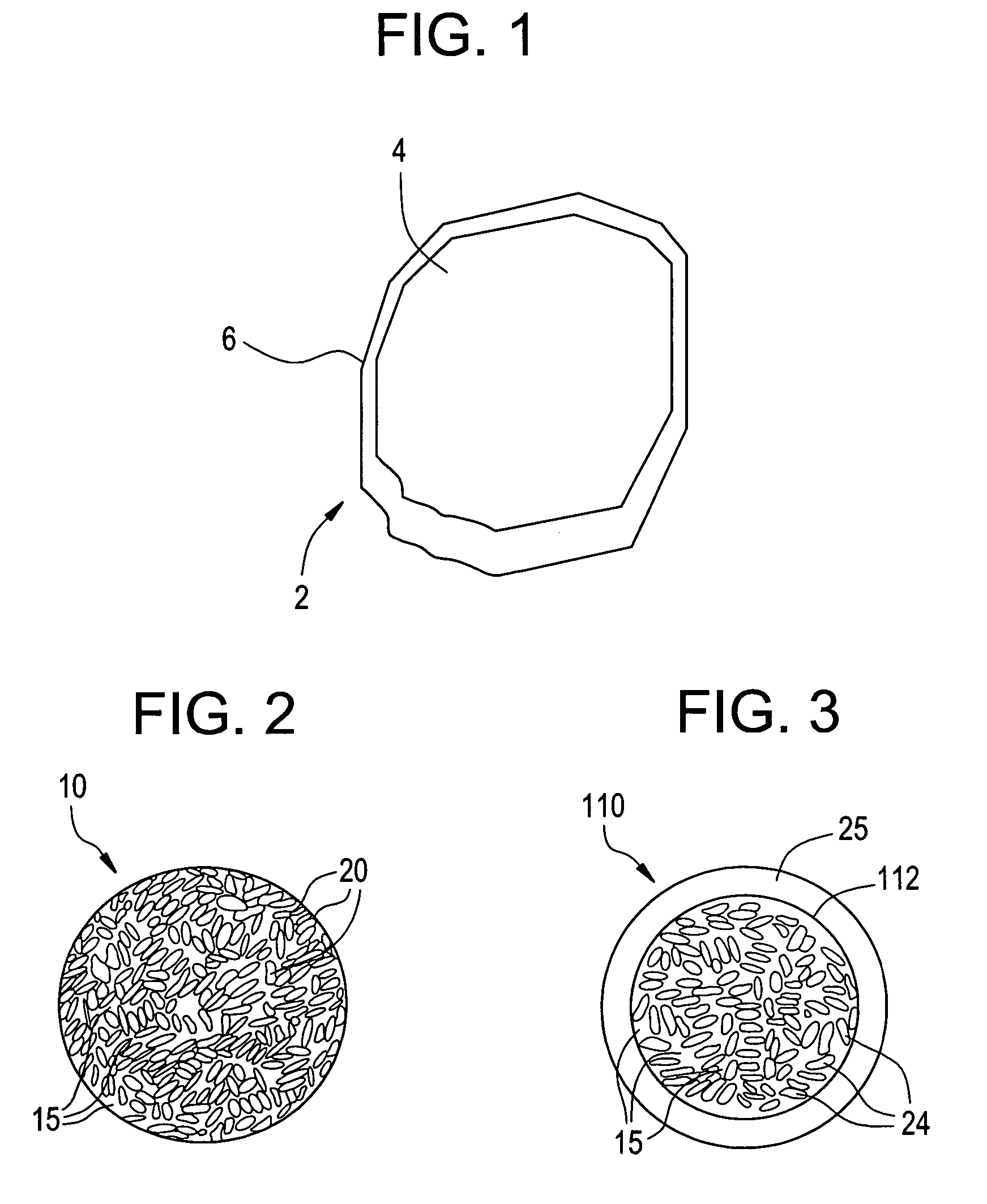

Particulate material containing thermoplastics and methods for making and using the same

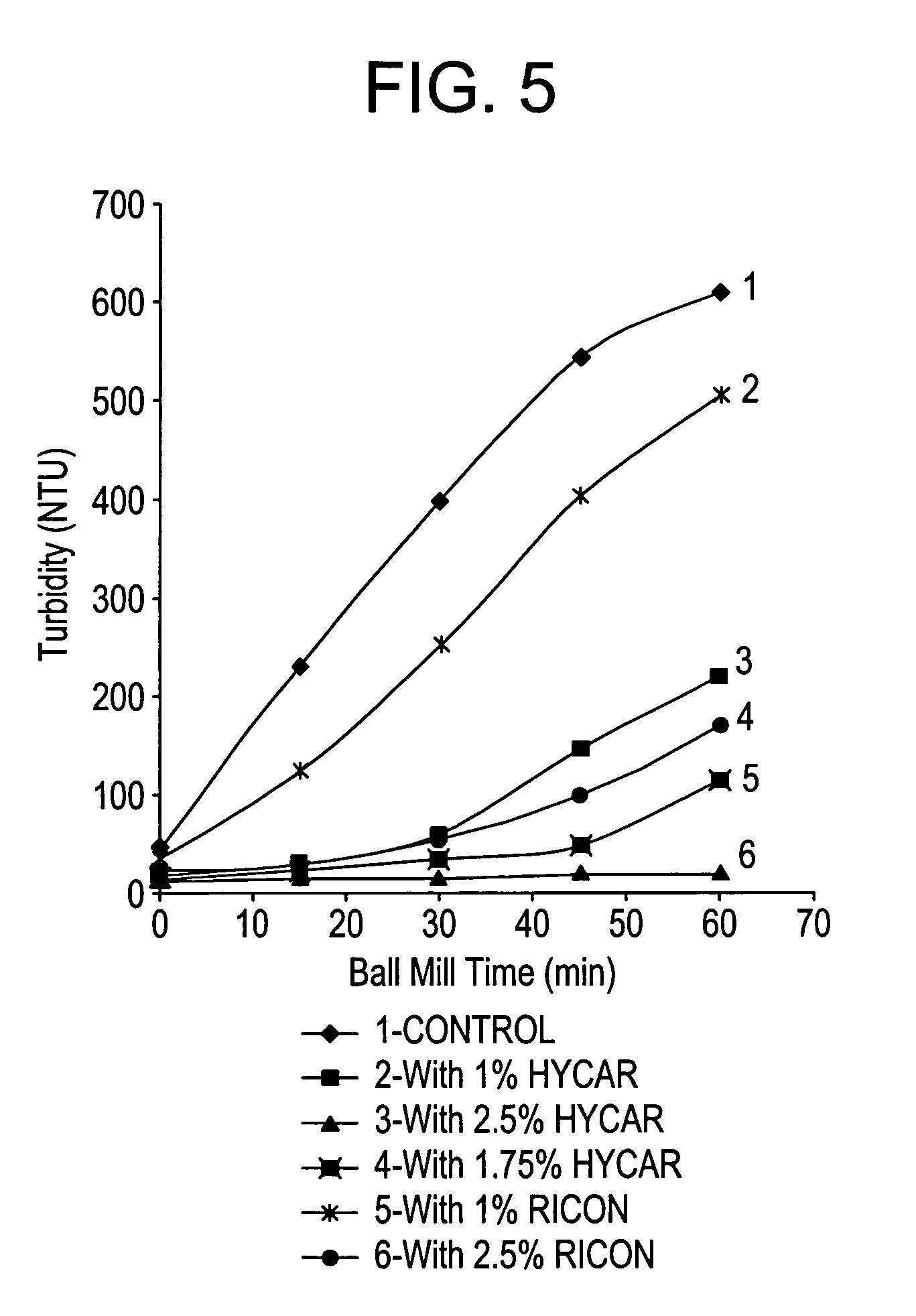

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

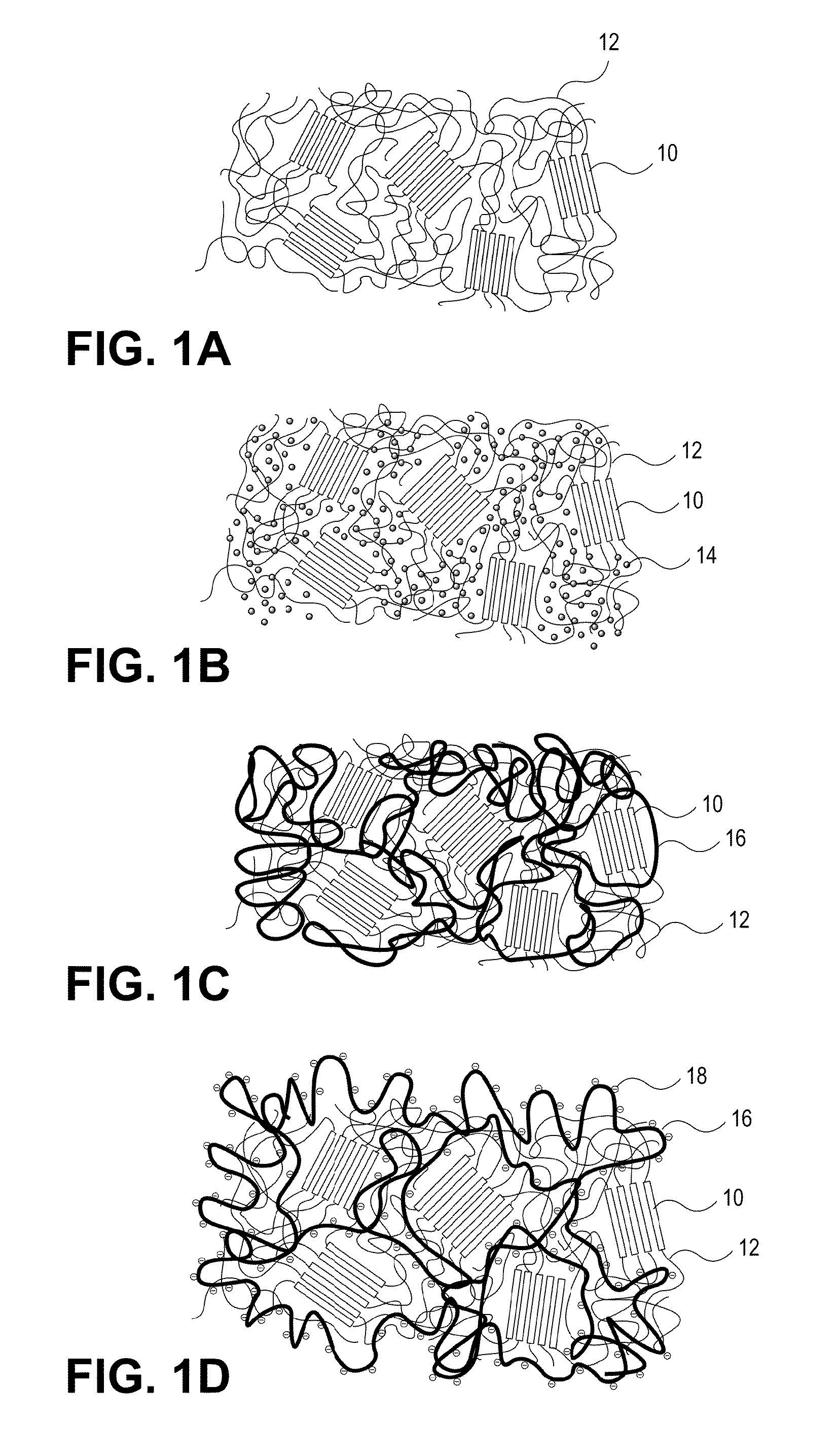

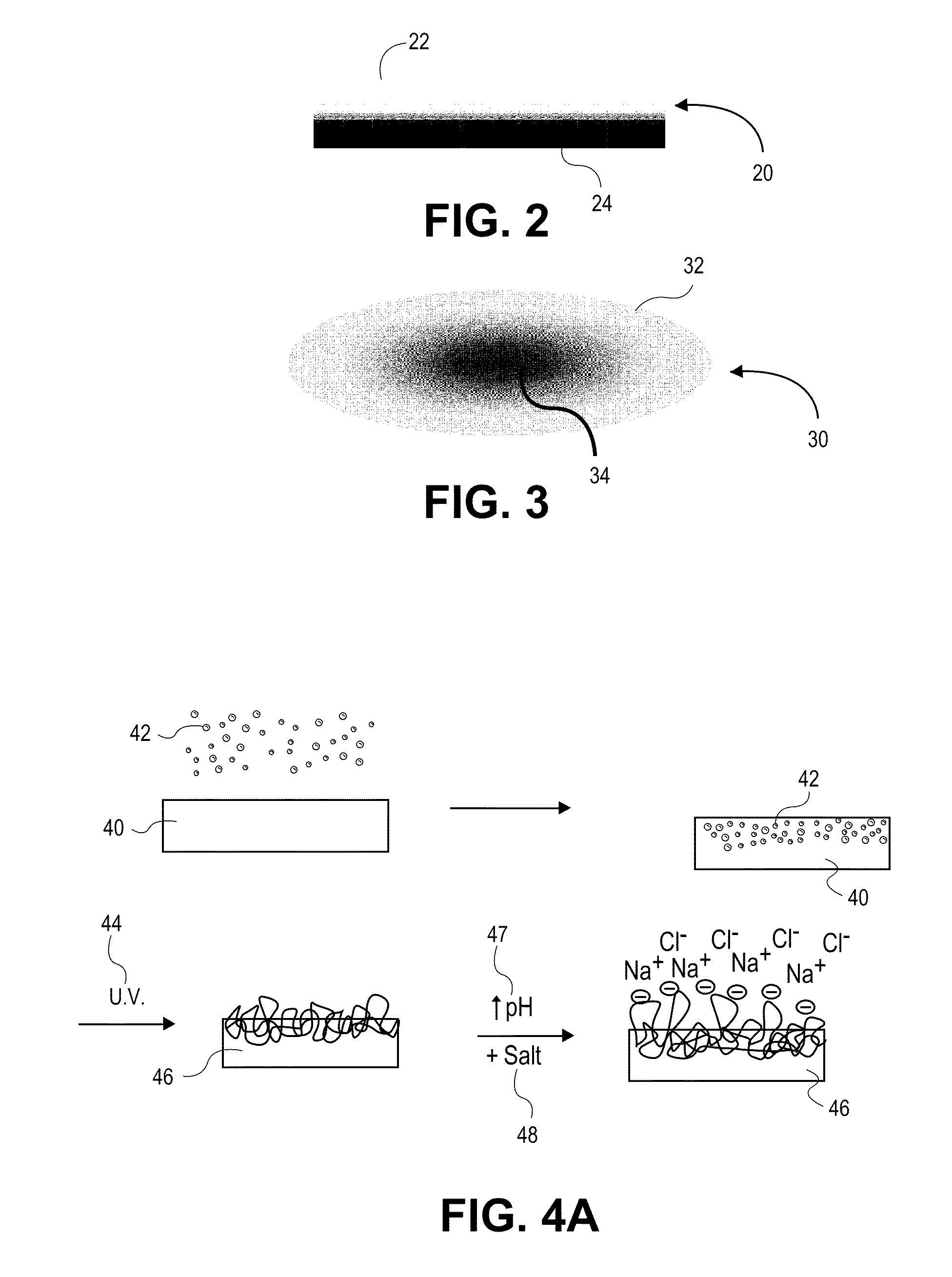

Hydrophilic Interpenetrating Polymer Networks Derived From Hydrophobic Polymers

InactiveUS20100010114A1High mechanical strengthReduce coefficient of frictionCosmetic preparationsImpression capsHydrophobic polymerThermoplastic elastomer

A composition of matter comprising a water-swellable IPN or semi-IPN including a hydrophobic thermoset or thermoplastic polymer and an ionic polymer, articles made from such composition and methods of using such articles. The invention also includes a process for producing a water-swellable IPN or semi-IPN from a hydrophobic thermoset or thermoplastic polymer including the steps of placing an ionizable monomer solution in contact with a solid form of the hydrophobic thermoset or thermoplastic polymer; diffusing the ionizable monomer solution into the hydrophobic thermoset or thermoplastic polymer; and polymerizing the ionizable monomers to form a ionic polymer inside the hydrophobic thermoset or thermoplastic polymer, thereby forming the IPN or semi-IPN.

Owner:BIOMIMEDICA

Disposable absorbent articles with zones comprising elastomeric components

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a thermoplastic elastomer joined to or disposed in a stretch zone on at least one component or region of the absorbent article to impart an elastic resistance that provides sizing or shaping capabilities to the article. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com