Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1046 results about "Polymer melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

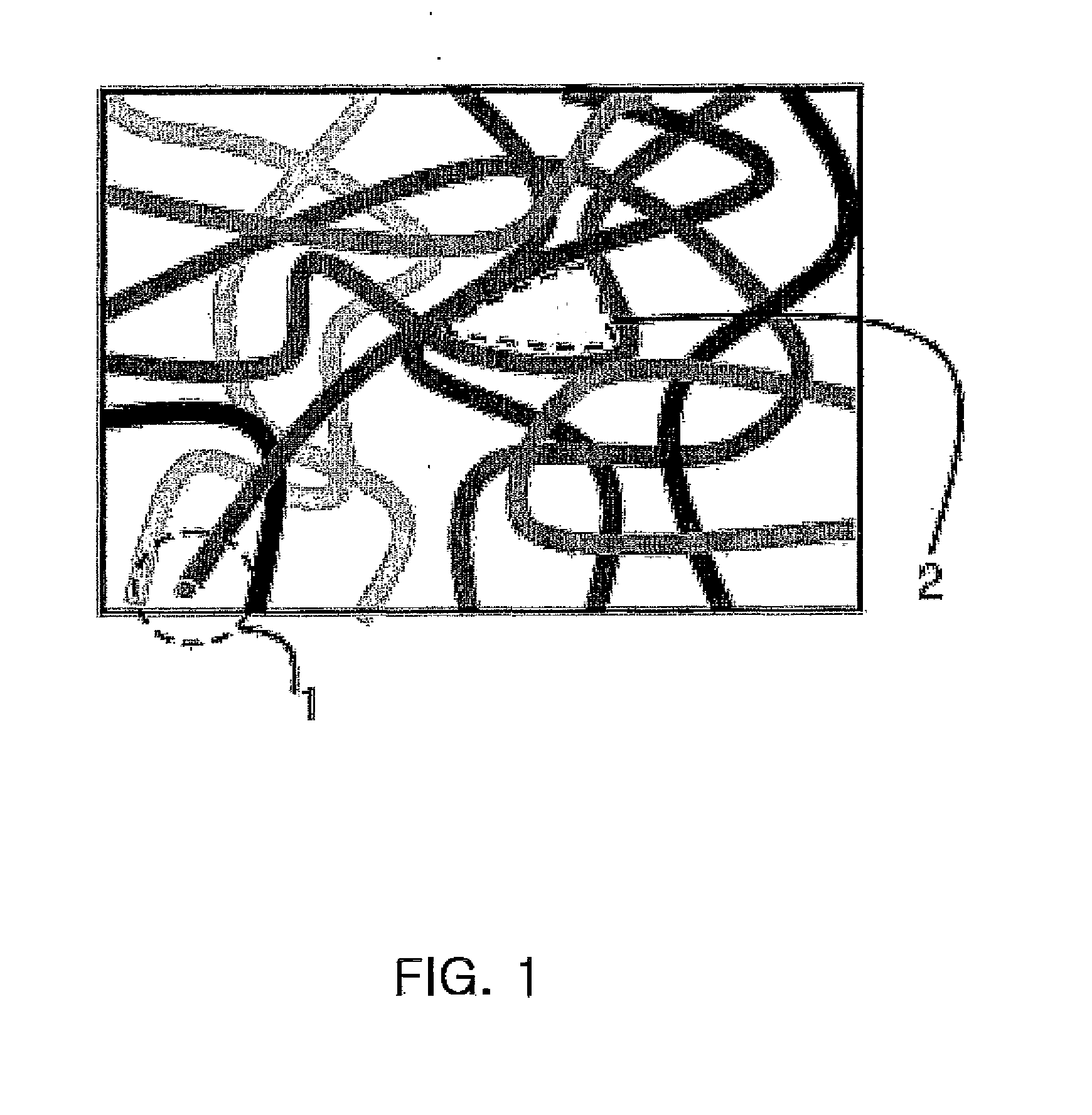

Dissolvable Nano Web Porous Film and Method of Preparing the Same

InactiveUS20110250256A1Excellent in dissolvabilityImprove solubilityBiocideElectric discharge heatingSolubilityFiber

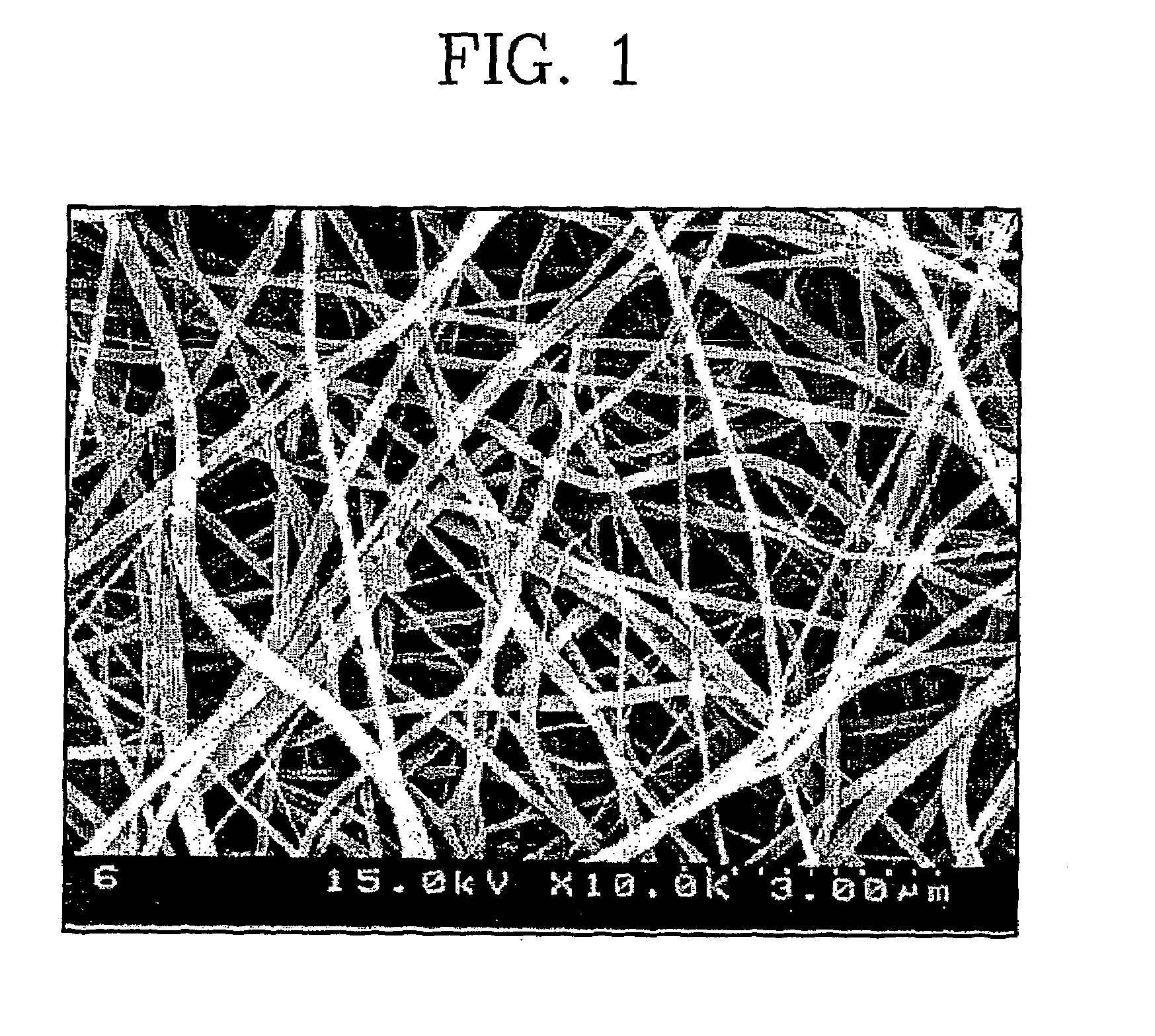

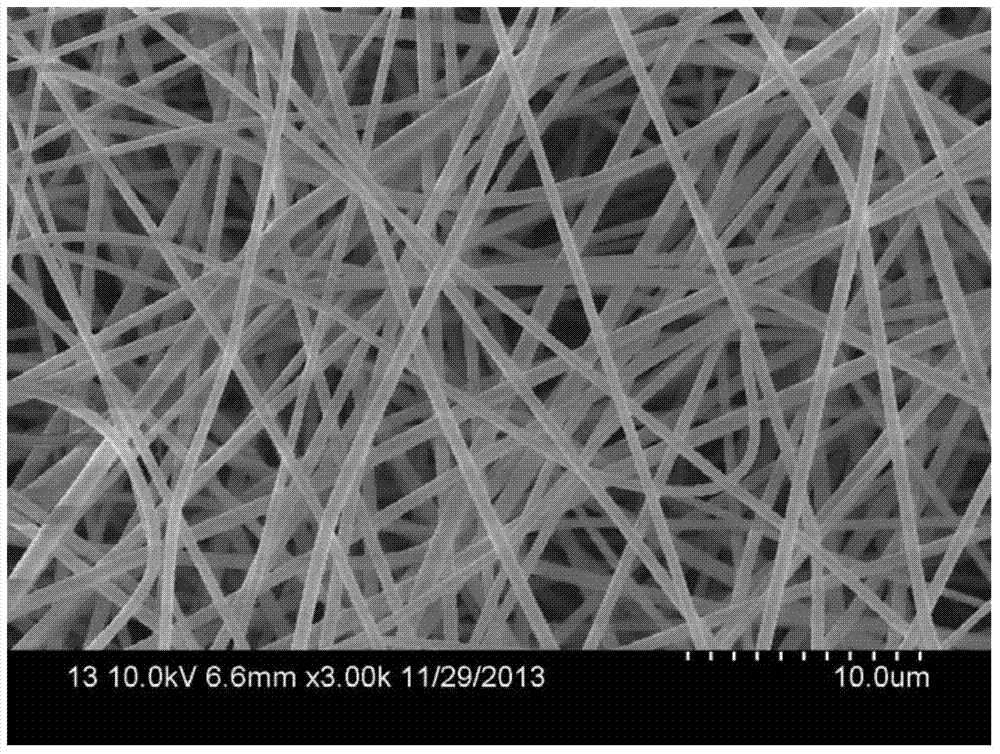

A dissolvable nano web porous film has a network structure and a large specific surface area. The network structure is formed by stacking nano fibers that have a thickness of 10˜50,000 nm. The nano fibers are formed of a composition comprising nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and an optional additive. A method of preparing a dissolvable nano web film comprises producing a polymer melt or solution formed of a composition that comprises a nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and additives, spinning the melt or solution to form a nano web porous film having nano webs stacked in a network structure, drying the nano web porous film, and stabilizing the nano web porous film. The porous film has a 5˜5000 times higher specific surface area and a 2˜20 times faster dissolving time than a conventional film. The dissolvable nano web porous film has excellent dissolvability and solubility.

Owner:GENIC

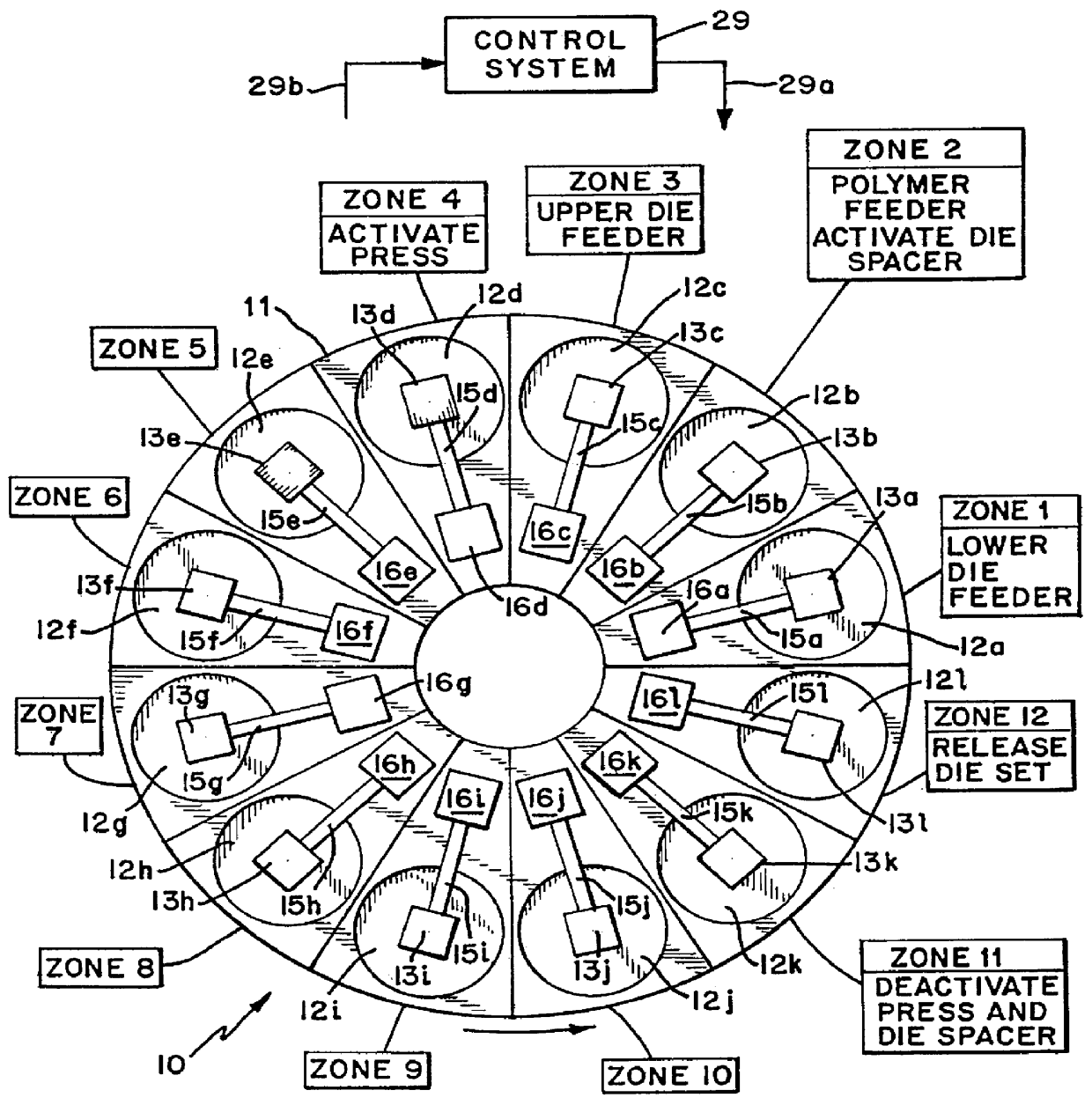

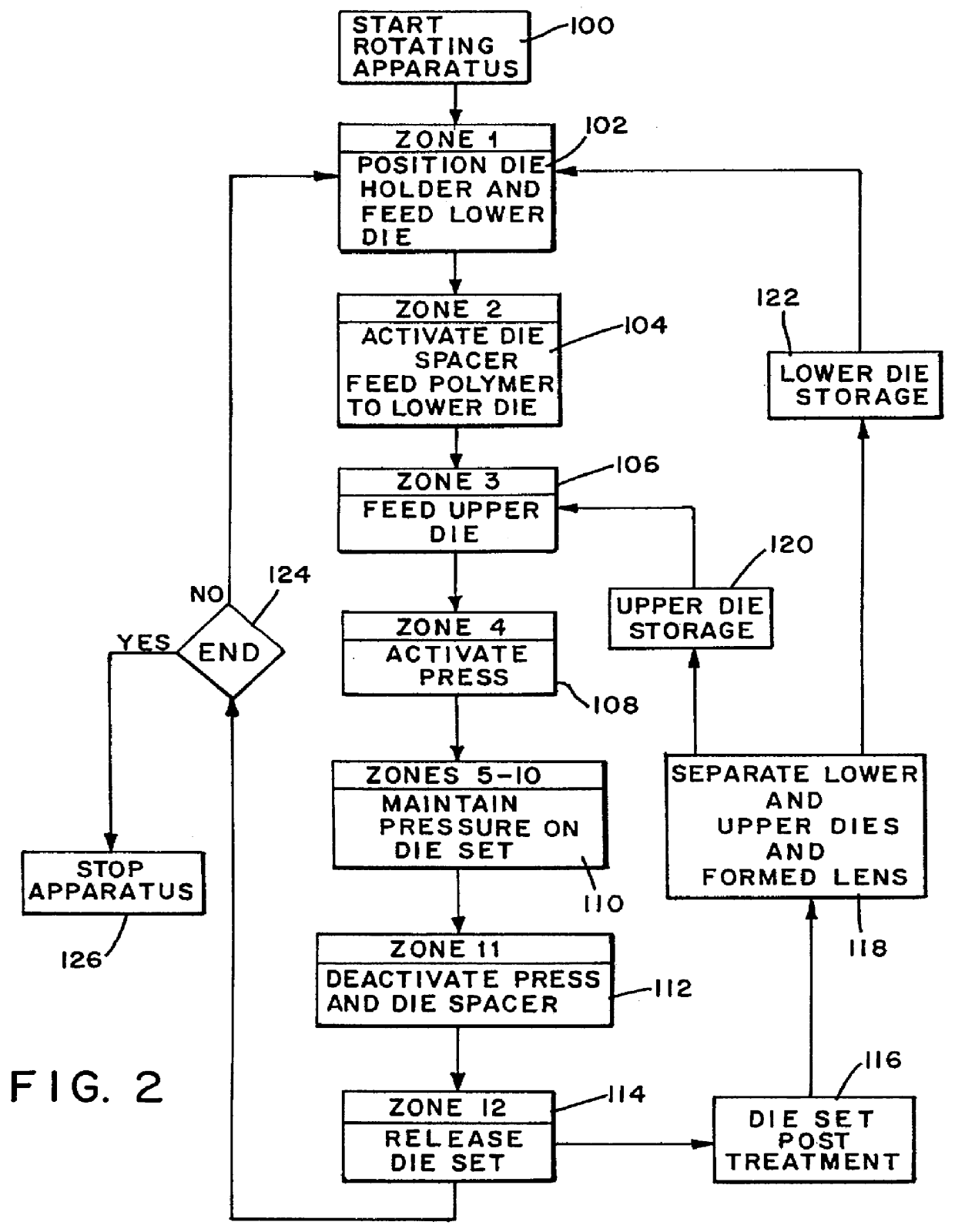

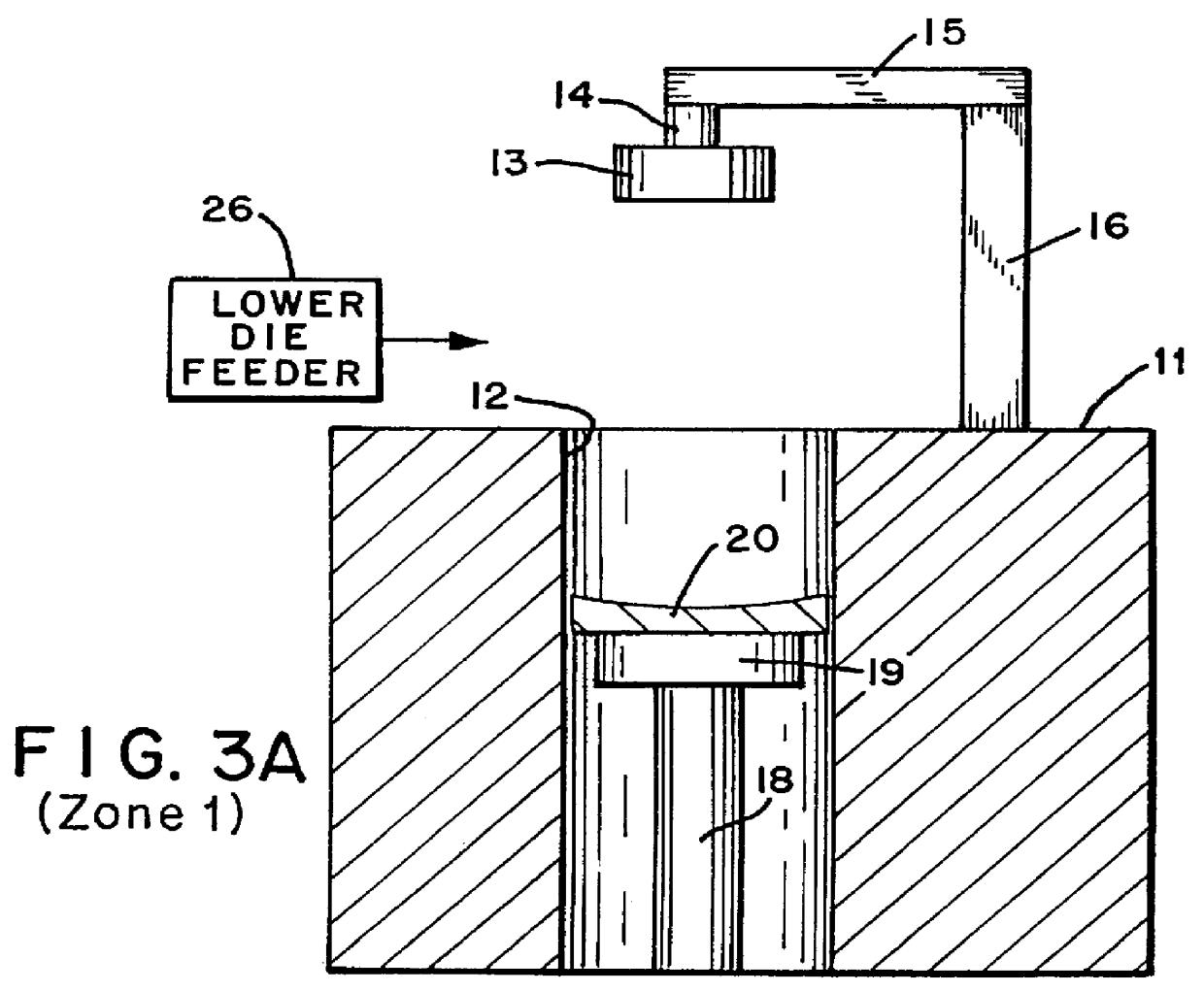

Continuous extrusion-compression molding process for making optical articles

InactiveUS6042754AEasy to processLong lastingRecord carriersConfectioneryCompression moldingShell molding

The present invention relates to making optical articles such as opthalmic lenses by molding and, in particular, to using a continuous extrusion-compression molding method to make plastic lenses whereby a polymer melt is fed from an extruder or melting apparatus to a first die of a plurality of rotating or conveyed sequentially processed compression die sets comprising a first die and a second die. The die sets are positioned on die supports on a rotating turntable or conveying system, the lenses formed by compressing the die sets with pressing means associated with each die support, the lenses separated from the dies and the dies recycled to die loading and the melt feed step of the process and the process repeated until the desired number of lenses or other optical articles such as compact disk substrates are produced.

Owner:FOREVER VISION

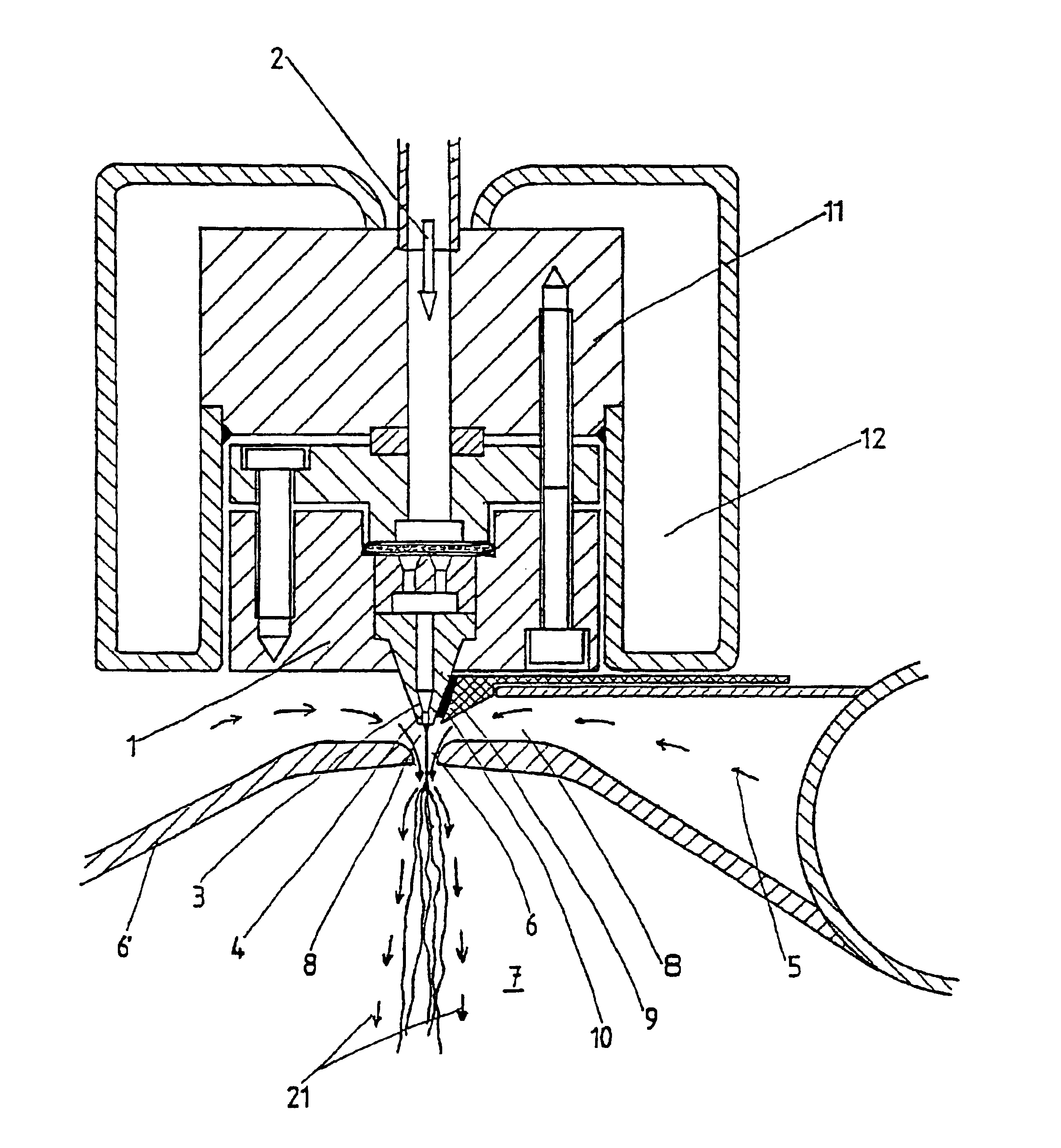

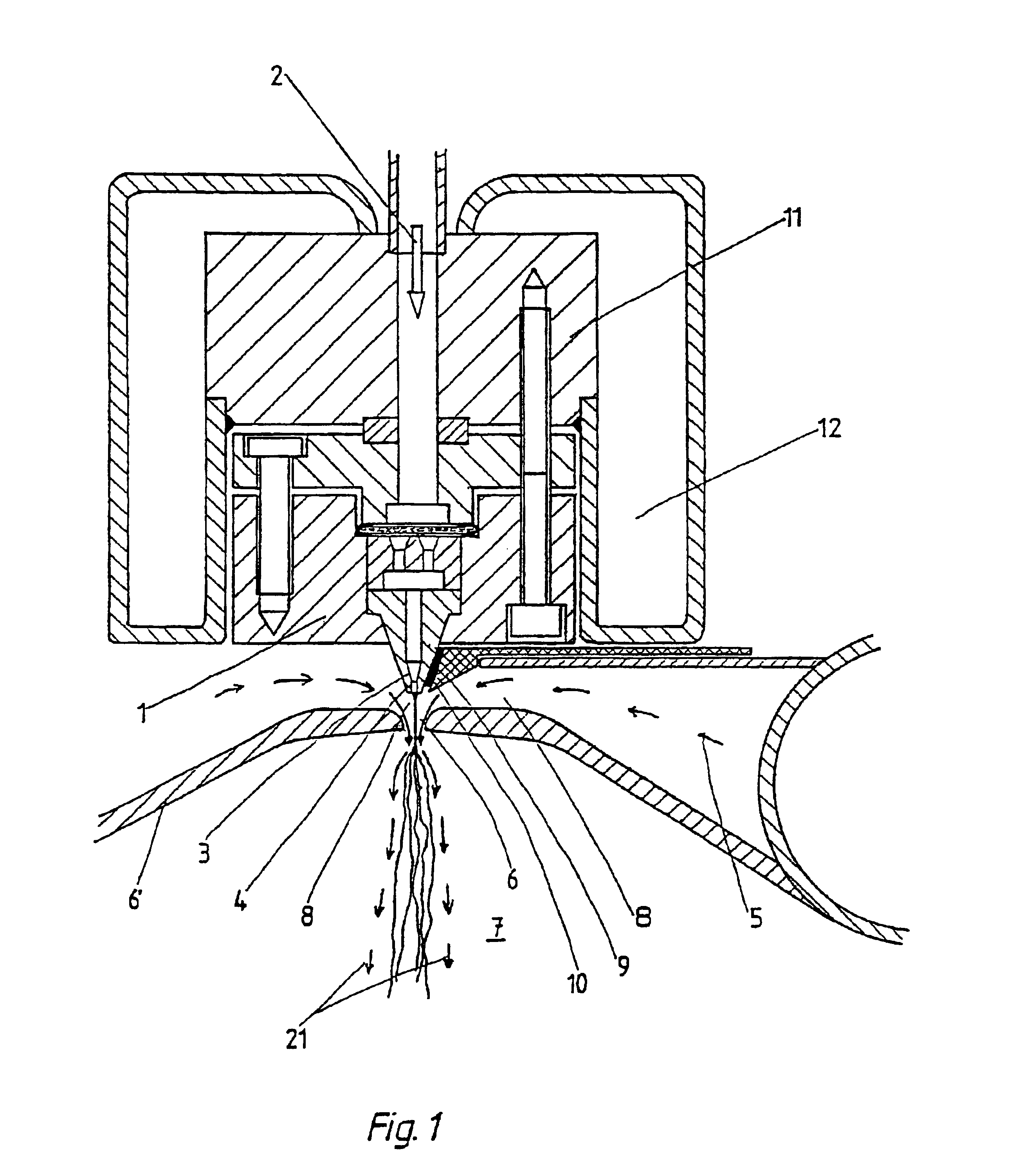

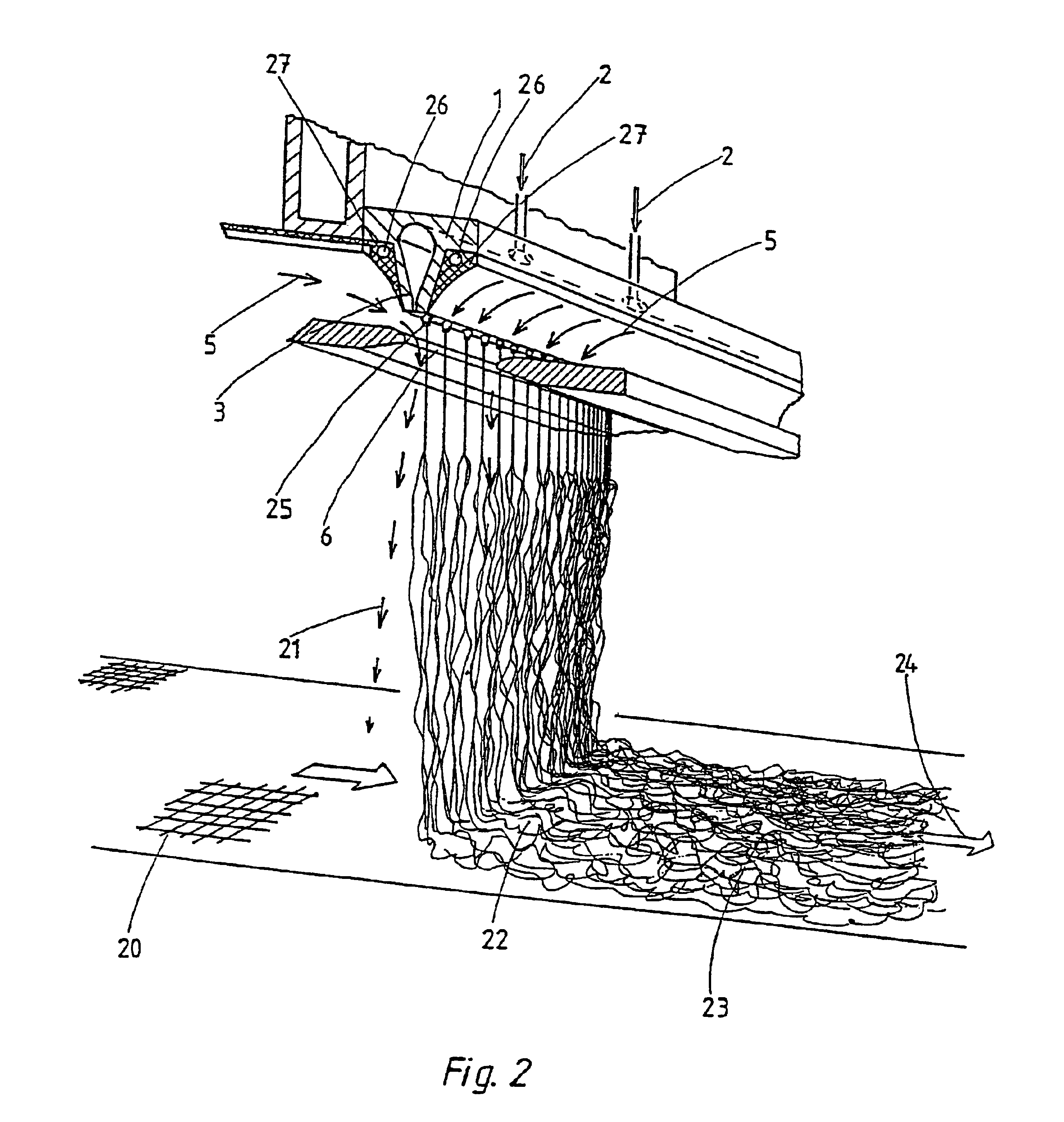

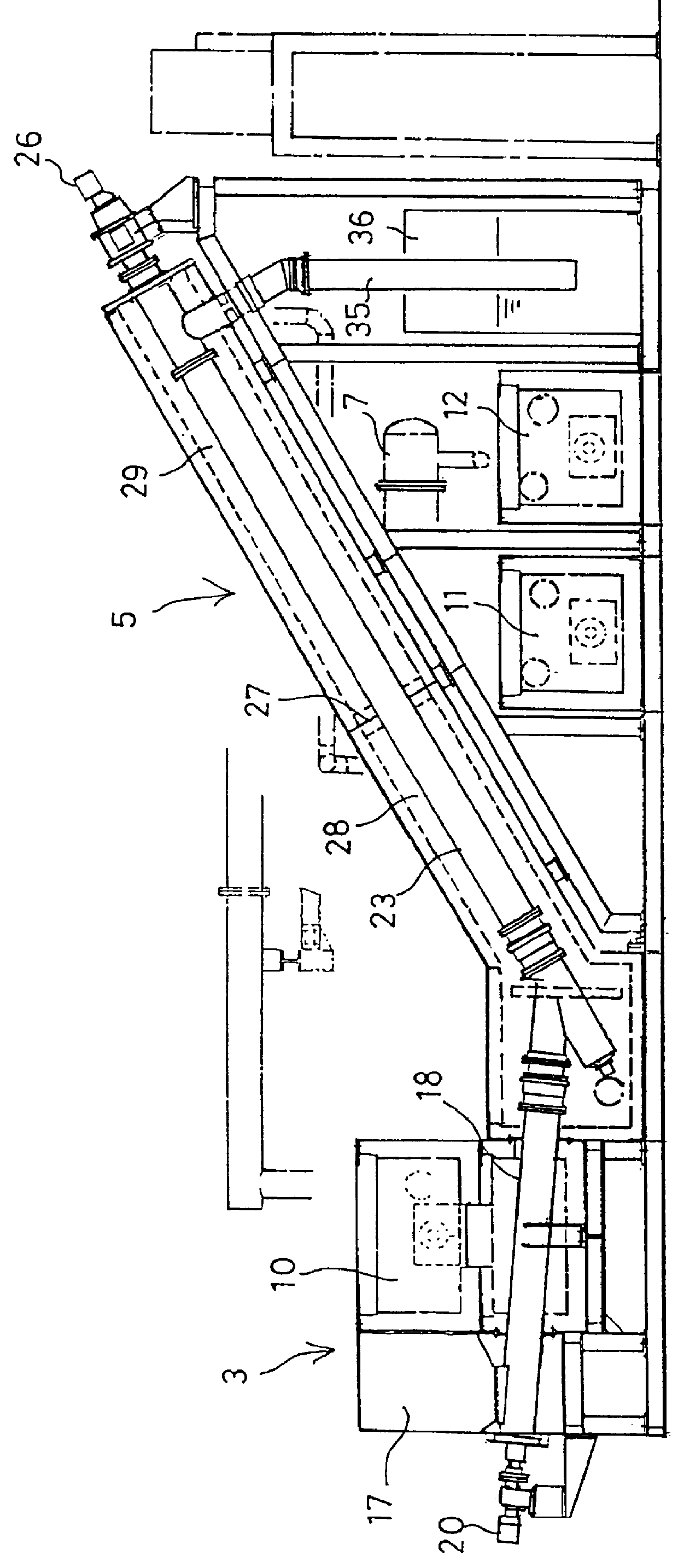

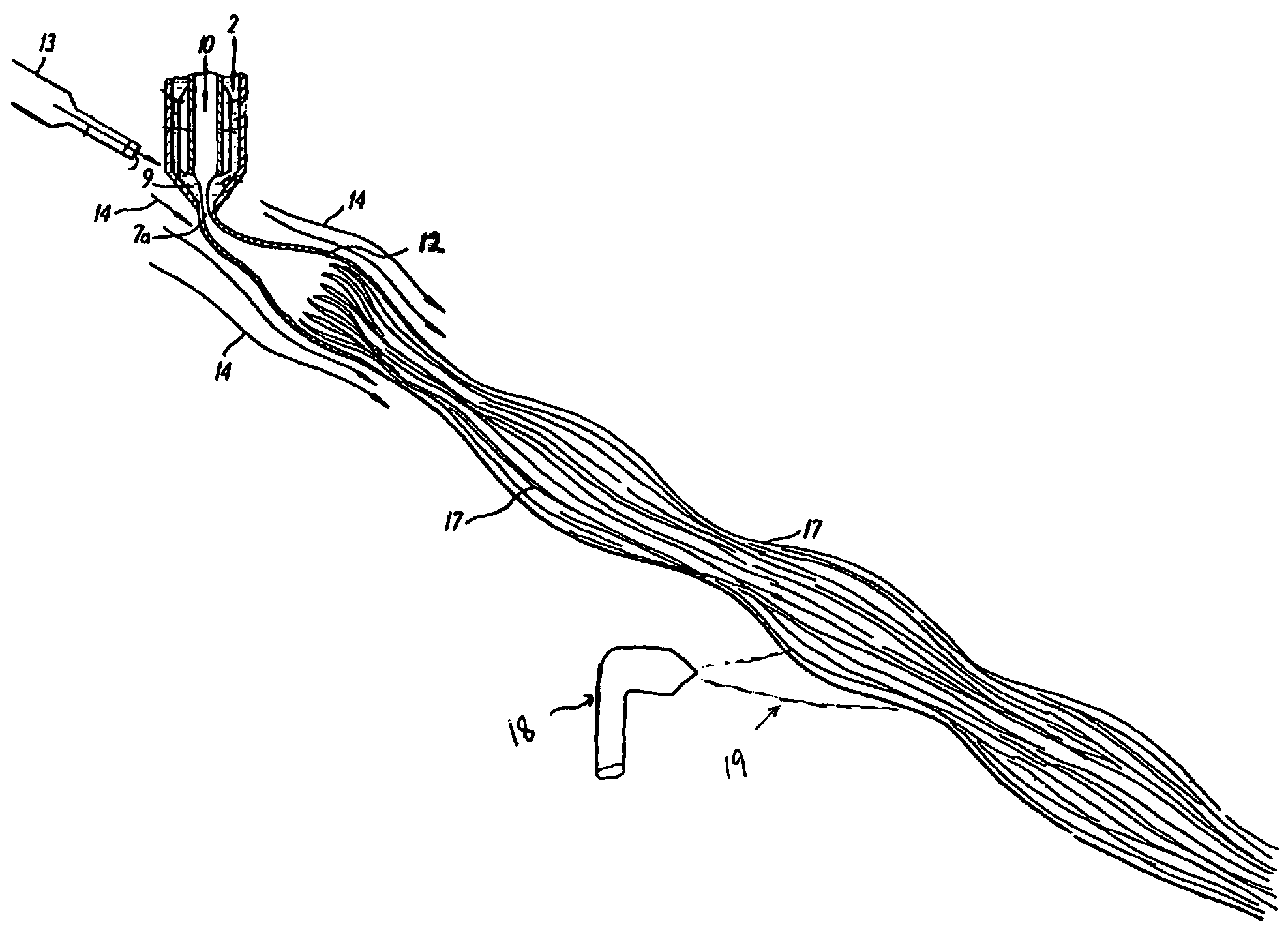

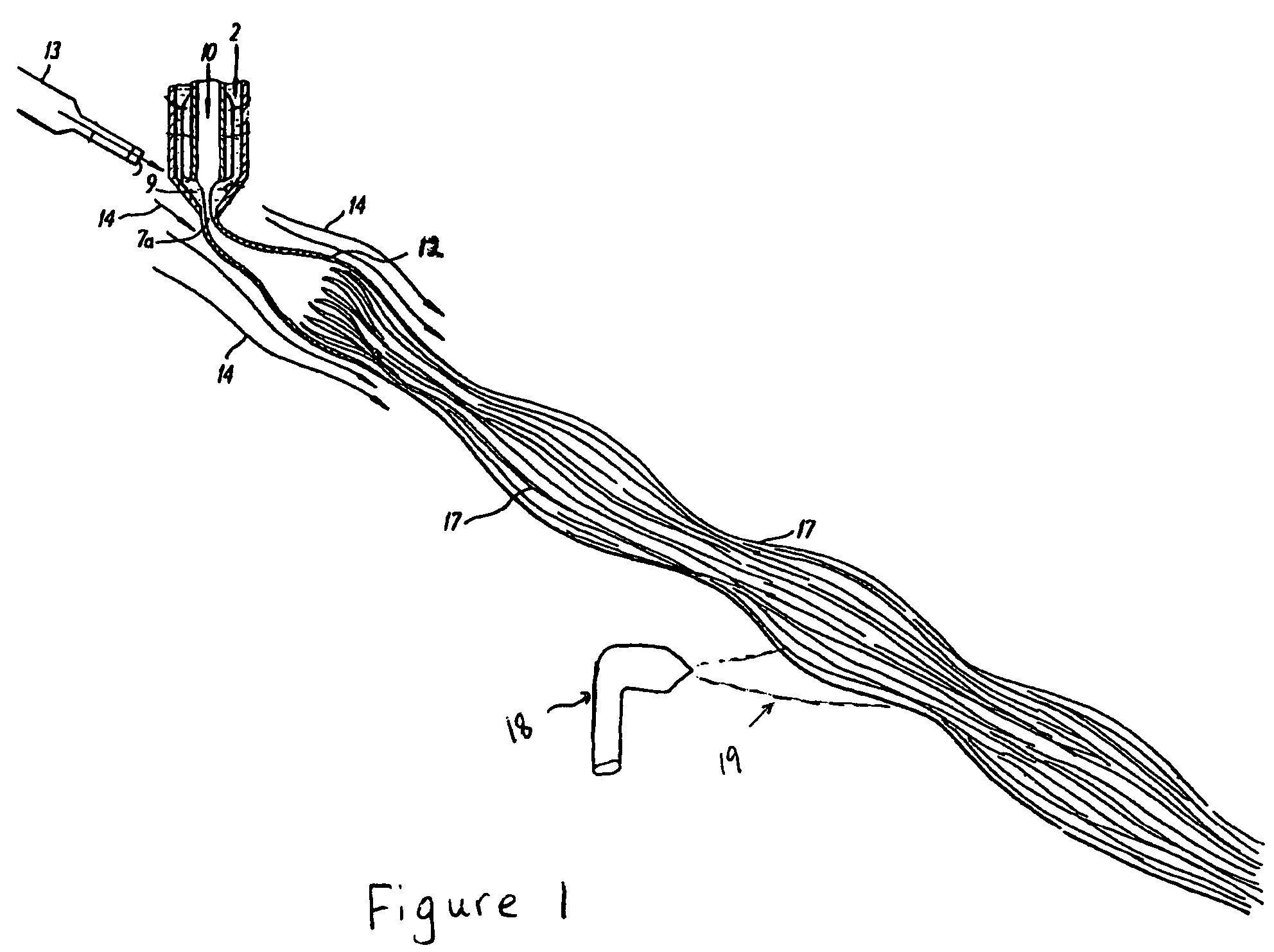

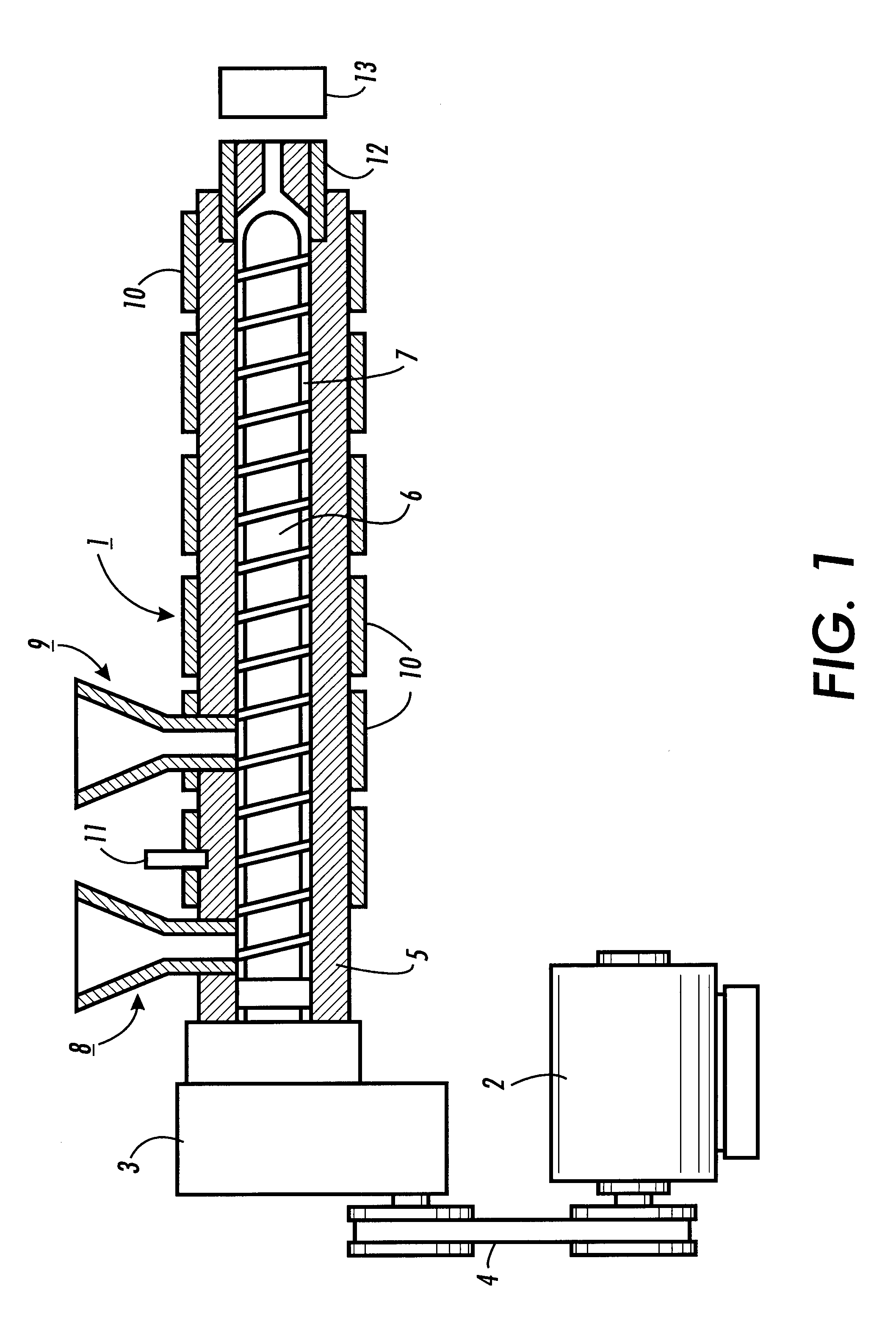

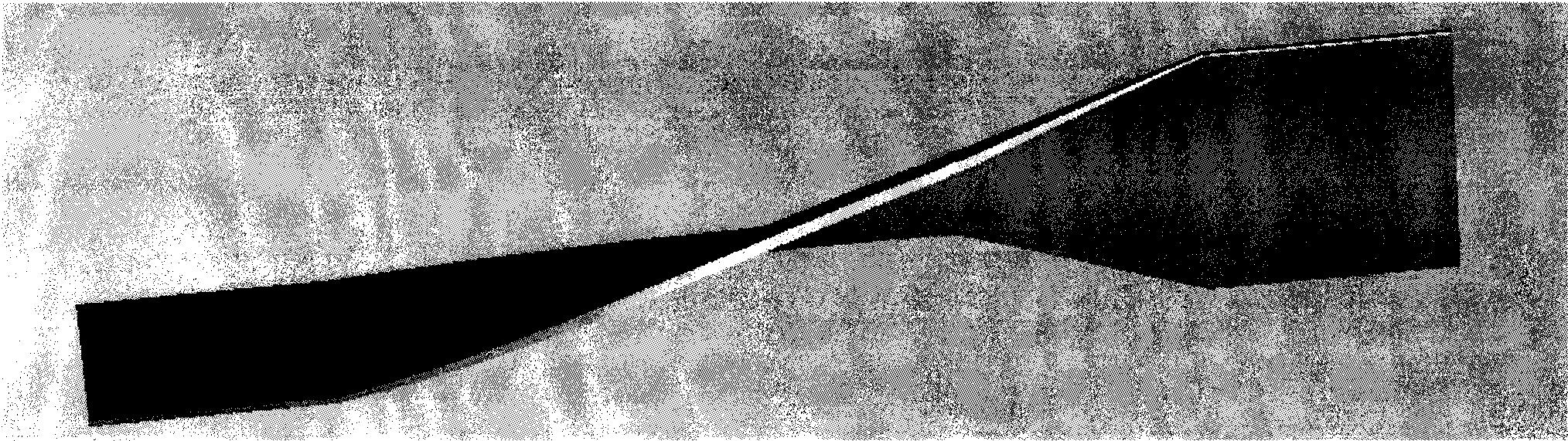

Method and device for the production of an essentially continous fine thread

InactiveUS6800226B1Simple and economical mannerReduced strengthSpinnerette packsMelt spinning methodsFine lineYarn

The invention relates to a method and a device for the production of essentially continuous fine threads made of meltable polymers. The polymer melt is spun from at least one spin hole (5) and the spun thread is attenuated using gas flows which are accelerated to achieve high speeds by means of a Laval nozzle (6). As a result of the specific geometry of the melt hole (4) and the position thereof in respect to the Laval nozzle (6), the temperature of the polymer melt, the throughout per spin hole and the pressures determining the velocity of the gas flow upstream and downstream from the Laval nozzle (6) are controlled in such a way that the thread reaches an internal hydrostatic pressure before solidifying, whereby said thread bursts into a plurality of fine threads.

Owner:GERKING LUDER

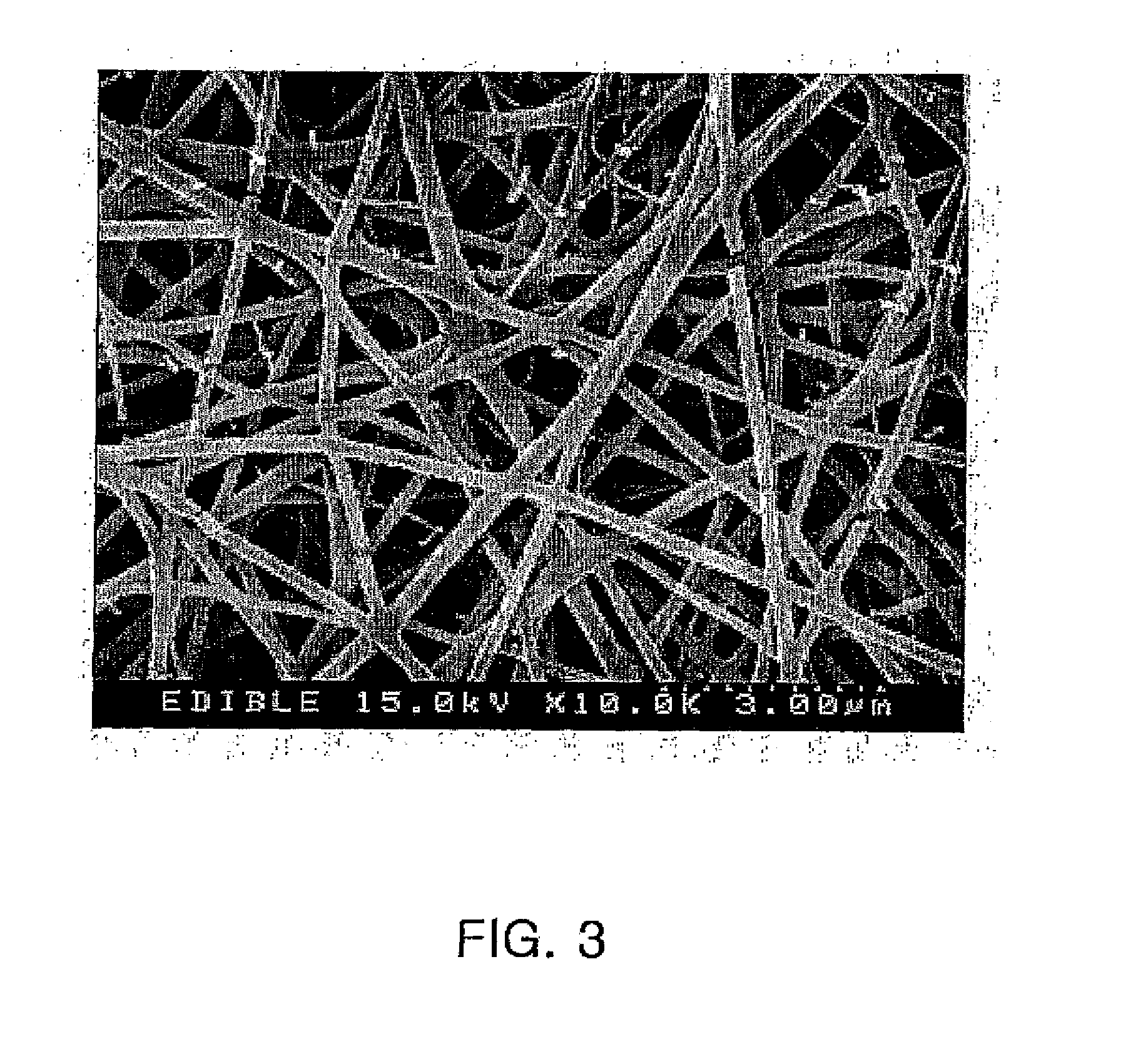

Coated nanofiber webs

ActiveUS20050008776A1Liquid surface applicatorsSynthetic resin layered productsPlasticizerNanoparticle

The present invention is directed to a method of forming nonwoven webs comprising coated fibers. The method of forming the nonwoven web generally comprises the steps of forming fibers from a melt fibrillation process, forming at least one fluid stream containing a coating substance, applying the coating substance onto the surface of the fiber, and depositing the coated fibers on a surface to form a web. Typically, the fibers are coated in flight. Preferably, the melt fibrillation process to form the fibers is a melt film fibrillation process. A melt film fibrillation process generally includes the steps of providing a polymeric melt, utilizing a central fluid stream to form an elongated hollow polymeric film tube, and using air to form multiple nanofibers from the hollow tube. The nonwoven web may comprise a layer having a significant number of nanofibers with diameters less than one micron. The layer may comprise two or more pluralities of fiber diameter distributions wherein at least one plurality has an average fiber diameter of less than about one micron. The coating substance can be selected from the group consisting of lotions, powders, surfactants, softeners, nanoparticles, creams, gels, conducting fluids, hydrophilic agents, hydrophobic agents, hygroscopic agents, emollients, plasticizers, absorbent gelling material, antimicrobial agents, and combinations thereof. A preferred coating substance is a surfactant. Another preferred coating substance is a hydrophilic or hydrophobic substance. The present invention is also directed to a nonwoven web comprising a layer having a significant number of nanofibers with diameters less than one micron and a coating substance is applied to a surface of said nanofibers

Owner:THE PROCTER & GAMBLE COMPANY

Hygiene articles containing nanofibers

The present invention is directed to hygiene articles comprising nanofibers. The hygiene articles include diapers, training pants, adult incontinence pads, catamenials products such as feminine care pads and pantiliners, tampons, personal cleansing articles, personal care articles, and personal care wipes including baby wipes, facial wipes, body wipes, and feminine wipes. The nanofiber webs can be used as a barrier, wipe, absorbent material, and other uses. Particularly, the nanofiber web is used in a diaper as a barrier-on-core, outercover, and / or leg cuff. It may also be used as a wipe for reducing the gradient of liquid, controlled delivery of materials, and other uses. The nanofibers, having a diameter of less than 1 micron, must comprise a significant number of the fibers in one layer of the web contained by the hygiene article. The nanofibers are produced from a melt film fibrillation process. The process generally includes the steps of providing a polymeric melt, utilizing a central fluid stream to form an elongated hollow polymeric film tube, and using this and / or other fluid streams to form multiple nanofibers from the hollow tube.

Owner:THE PROCTER & GAMBLE COMPANY

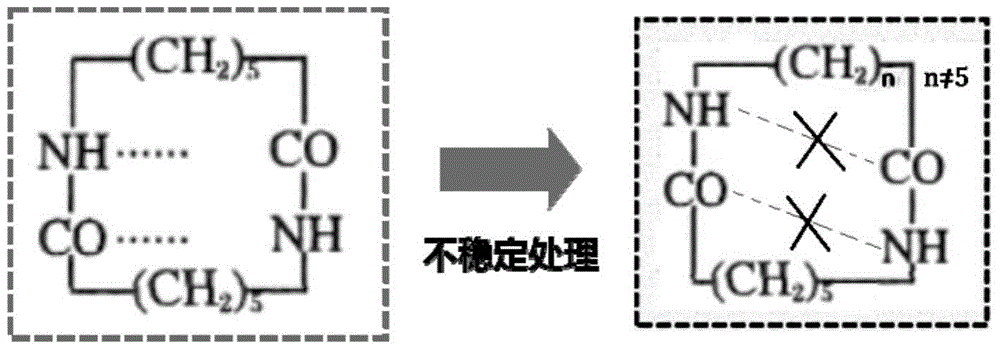

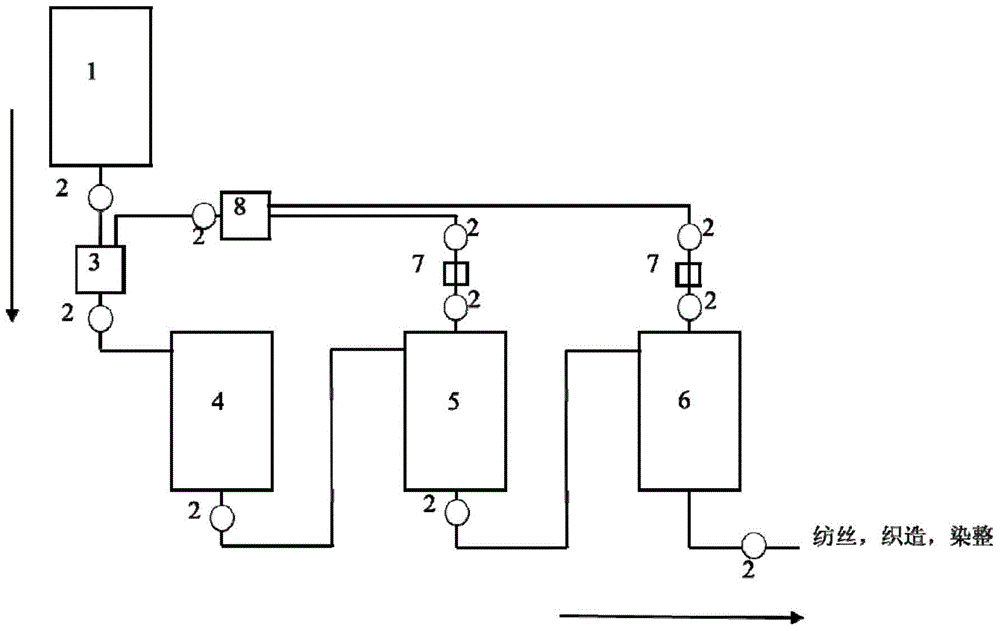

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

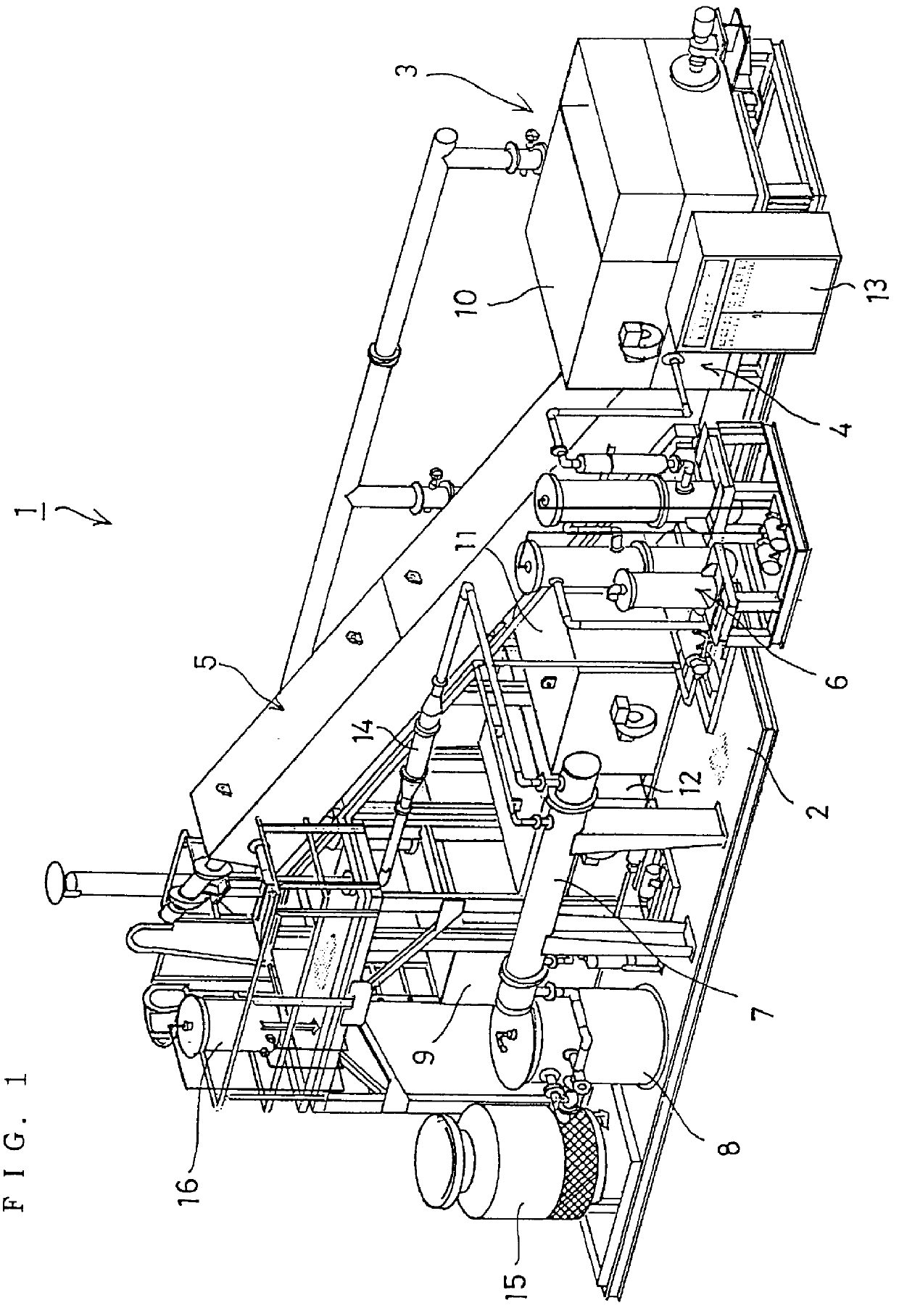

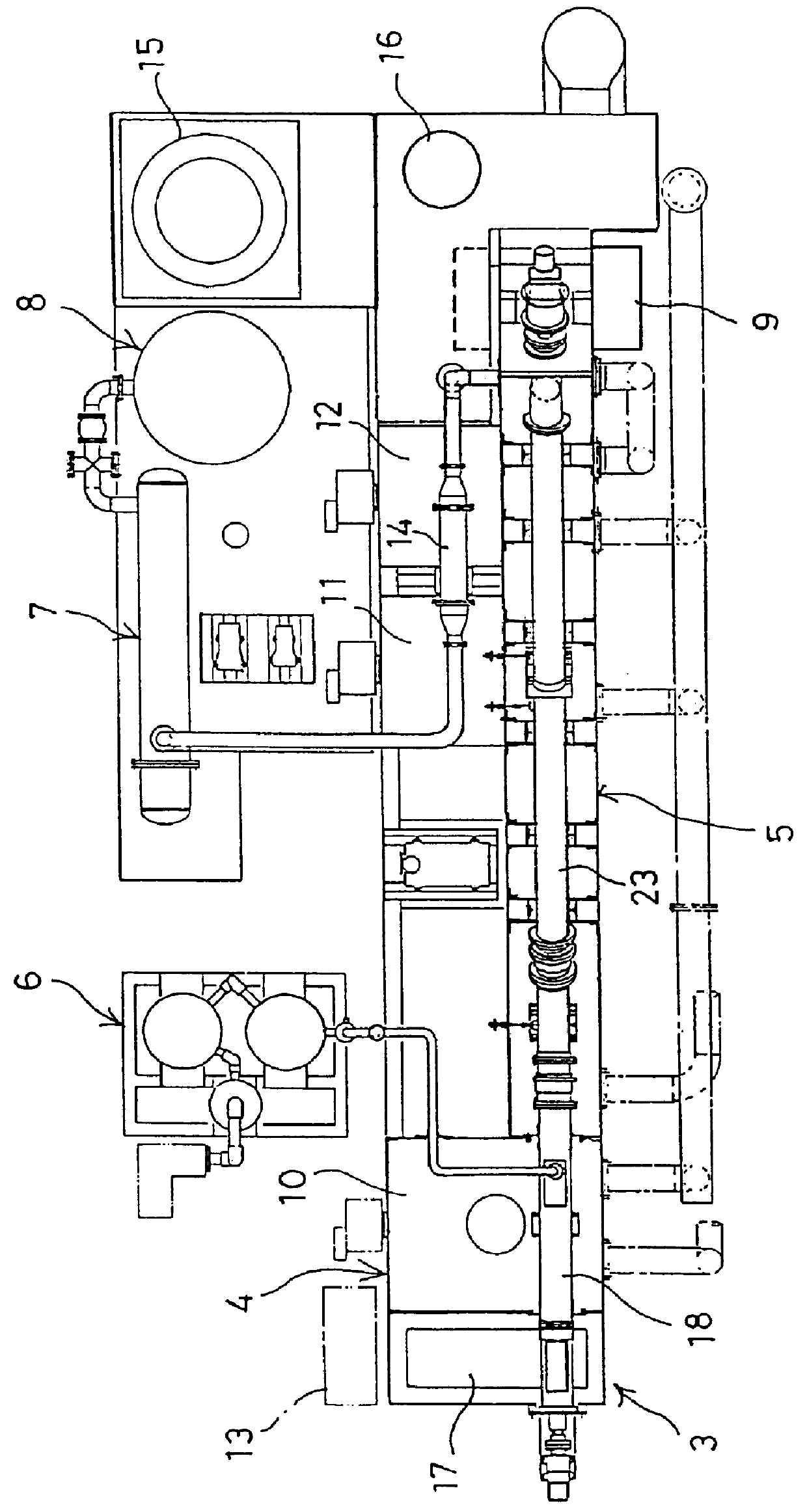

Thermal decomposition apparatus of reversed temperature gradient type for polymer waste

InactiveUS6126907ASimple structureSmall sizeSolid waste disposalDirect heating destructive distillationDecompositionSludge

A thermal decomposition apparatus for decomposing polymer waste is provided which is simple in structure, small in size and inexpensive, and also the operating cost thereof is low. A feed pipe 18 and an inclined pipe 23 are connected in the form of the letter V at a large angle therebetween, and a feed screw 19 and an feed-up screw 25 are arranged inside the respective pipes. Polymer waste introduced into a hopper 17 is melted in the interior of the feed pipe 18 by heat from a first hot air furnace 10 and accumulated in the V-shaped portion. The polymer melt is then conveyed upward by the feed-up screw 25. In the process of conveyance, the polymer melt undergoes primary decomposition by means of heat from a second hot air furnace 11 and the cracked gas thus generated undergoes secondary decomposition by the heat from a third hot air furnace 12, the resultant gas being guided to a condenser 7. Sludge drops down through a chute pipe 35 into a water tank 36.

Owner:WADA YOUICHI

Coated nanofiber webs

The present invention is directed to a method of forming nonwoven webs comprising coated fibers. The method of forming the nonwoven web generally comprises the steps of forming fibers from a melt fibrillation process, forming at least one fluid stream containing a coating substance, applying the coating substance onto the surface of the fiber, and depositing the coated fibers on a surface to form a web. Typically, the fibers are coated in flight. Preferably, the melt fibrillation process to form the fibers is a melt film fibrillation process. A melt film fibrillation process generally includes the steps of providing a polymeric melt, utilizing a central fluid stream to form an elongated hollow polymeric film tube, and using air to form multiple nanofibers from the hollow tube. The nonwoven web may comprise a layer having a significant number of nanofibers with diameters less than one micron. The layer may comprise two or more pluralities of fiber diameter distributions wherein at least one plurality has an average fiber diameter of less than about one micron.

Owner:PROCTER & GAMBLE CO

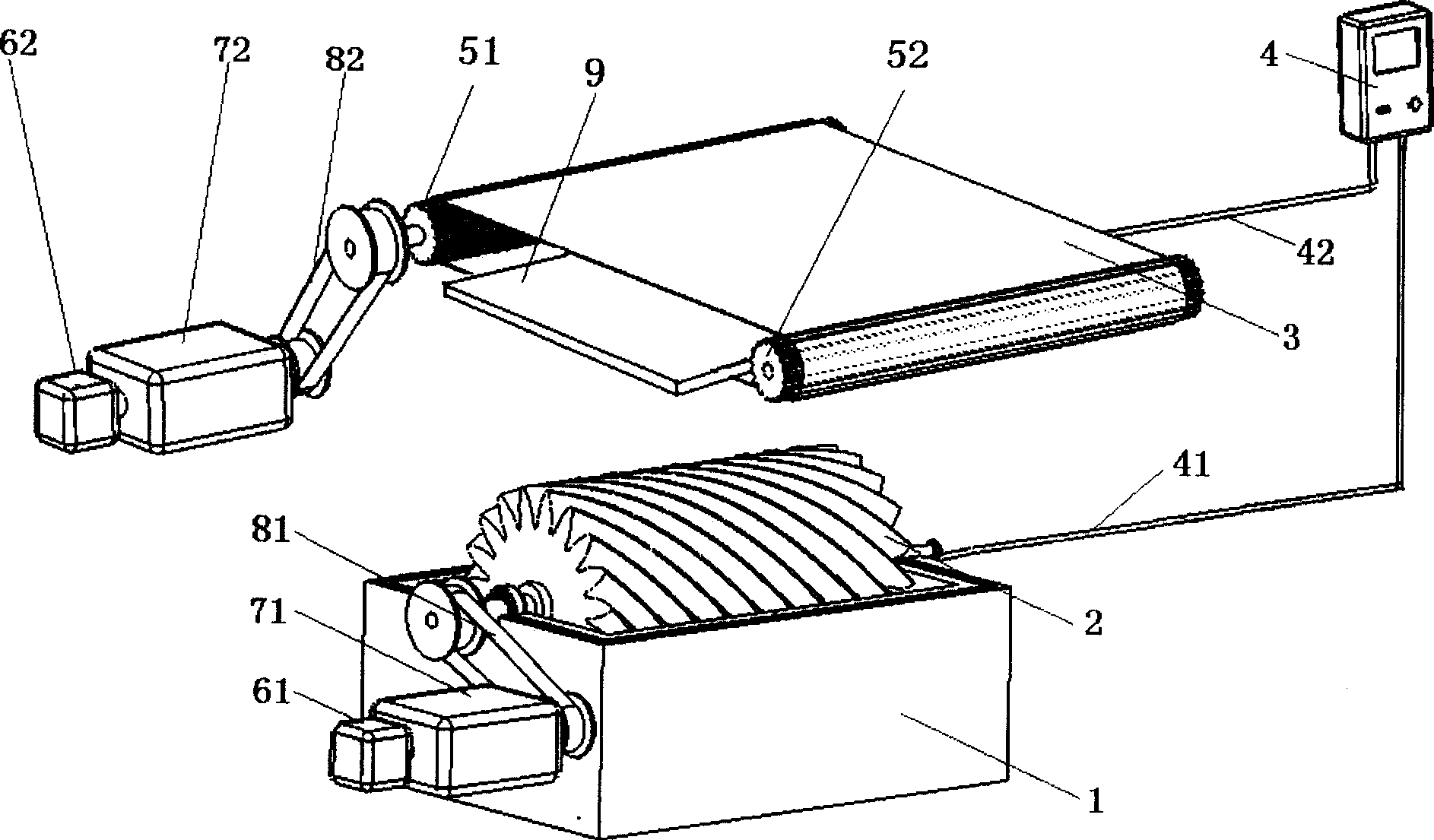

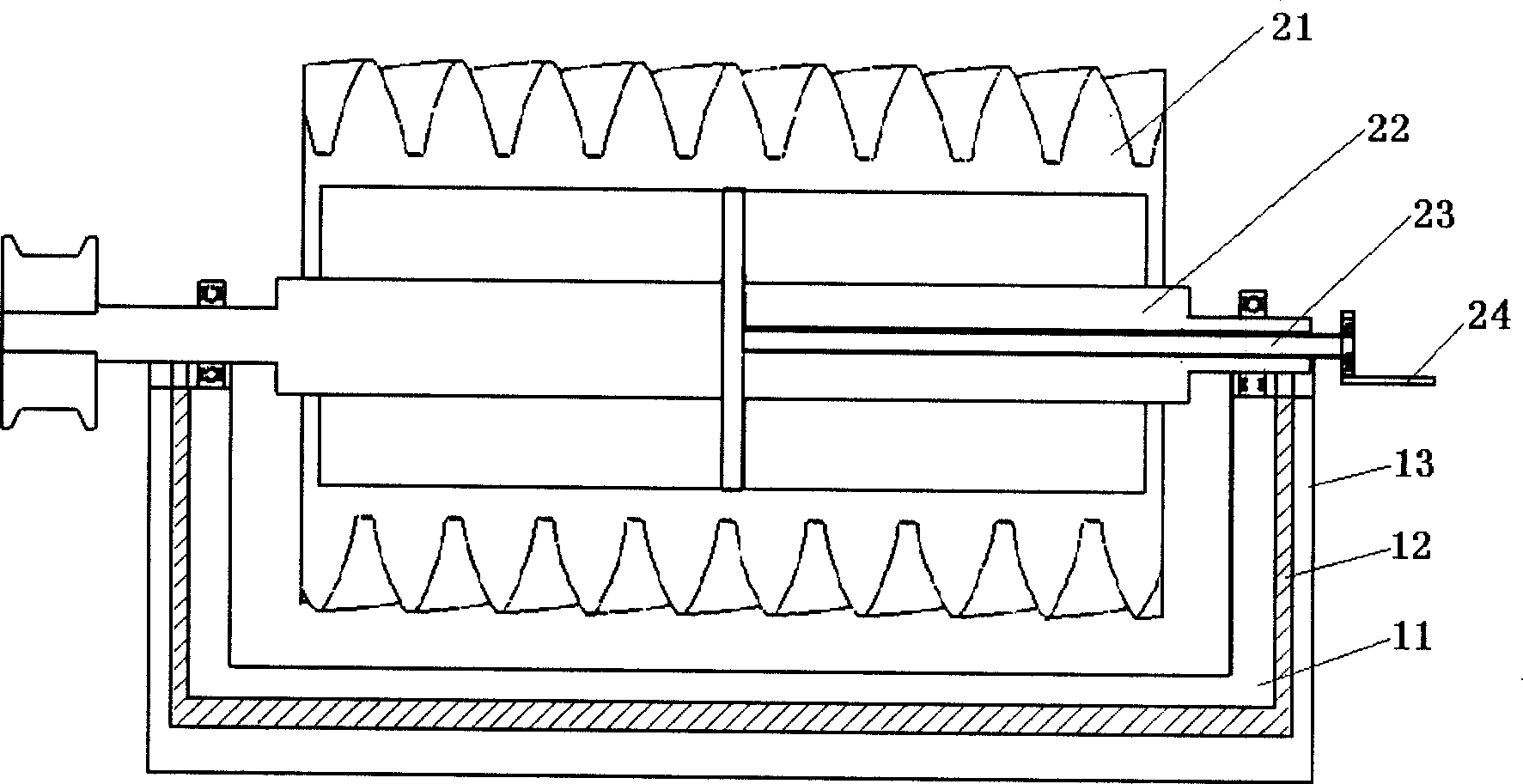

Electro-spinning nano fibre nonwoven production apparatus

ActiveCN101476167AImprove melting effectSolve insulation problemsFilament/thread formingNon-woven fabricsSynchronous motorNanofiber

The invention provides a production unit for mass producing electro-spinning nano fibre non-weaving cloth which includes: a meltdown pool 1, a metal roller 2, a receiving lace curtaining 3, a high voltage static generator 4, an initiative guide roll 51 and a passivity guide roll 52, a roller synchronous motor 62, a roller reductor 71, a roller belt pulley 72, a lace curtaining reductor 81, a lace curtaining belt pulley 82, an earth metal plate 9. Four sides and bottom of the meltdown pool 1 is composed of a ceramic outside wall 13, a middle heating layer 12 and a ceramic inner wall 11, the sandwich design structure has better insulation effect and solves heating problem of polymer melt. Compared with prior electro-spinning mass production, the unit can satisfy melt electro-spinning need, and also can be used for solution electro-spinning for realizing multi-use of one machine.

Owner:TIANJIN WEICHER TECH

Process for introducing an additive into a polymer melt

InactiveUS20070246867A1Ready-for-oven doughsSynthetic resin layered productsPolymer scienceVaporization

A process includes introducing a base polymer into an extruder, heating to a temperature sufficient to form a polymer melt, introducing a liquid such as water including an additive with mixing and subsequent vaporization and venting of the liquid to produce an extrudate having a uniform distribution of preferably uniformly small additive particles.

Owner:BEMIS COMPANY INC

Polymer-nanotube composites, fibers, and processes

Disclosed are processes for preparing nanotube composite materials and fibers that provide exceptional nanotube alignment and dispersion. The disclosed processes include contacting nanotube dispersions with polymer melts. Also disclosed are nanotube composite fibers having high nanotube concentrations, exceptional nanotube alignment, and high thermal conductivity.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

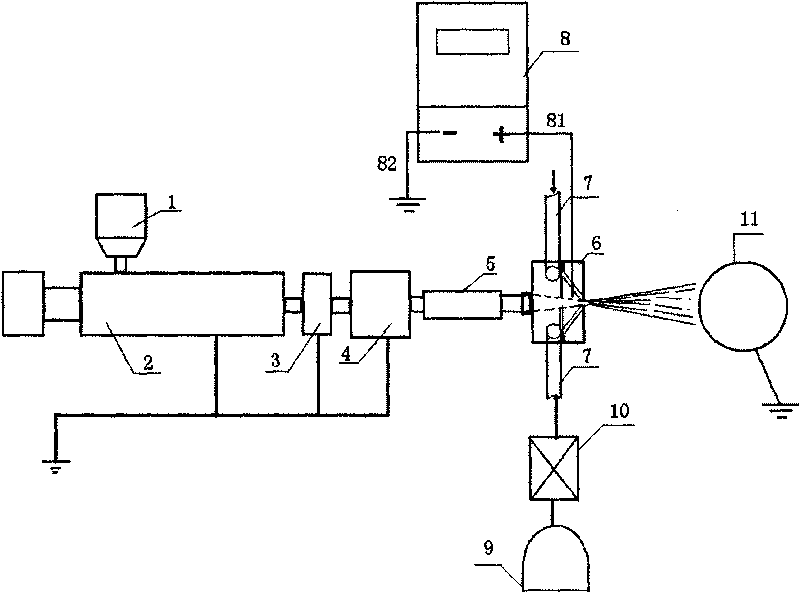

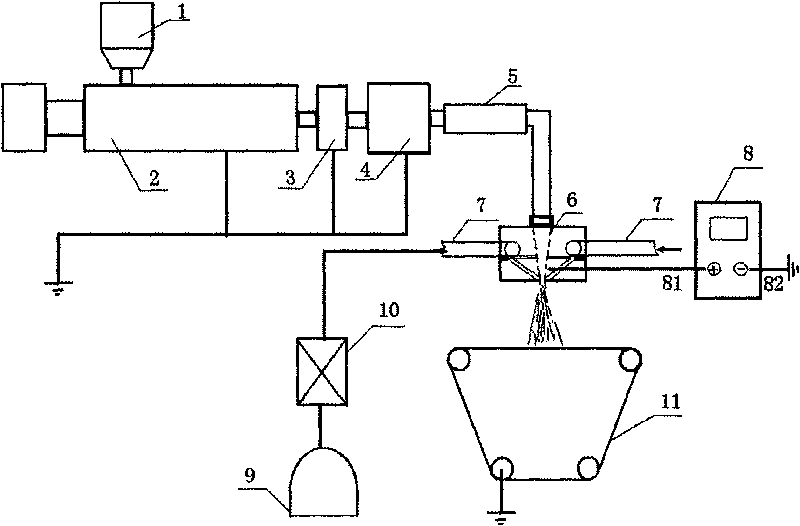

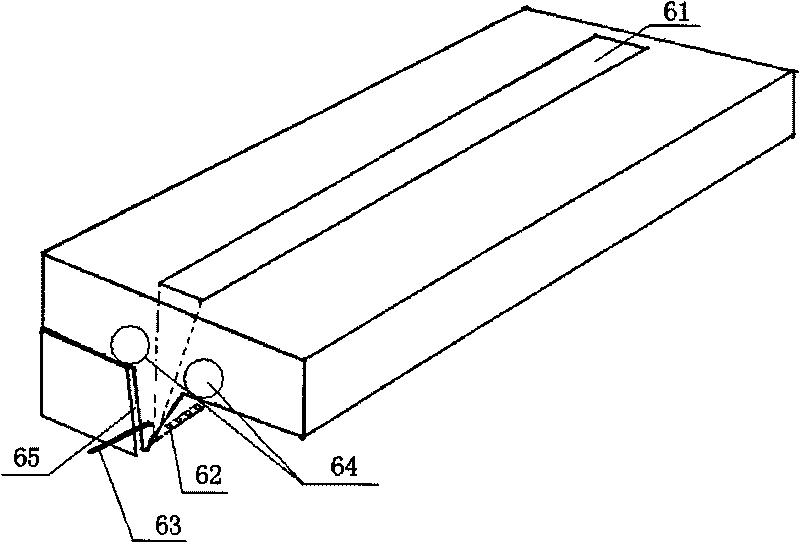

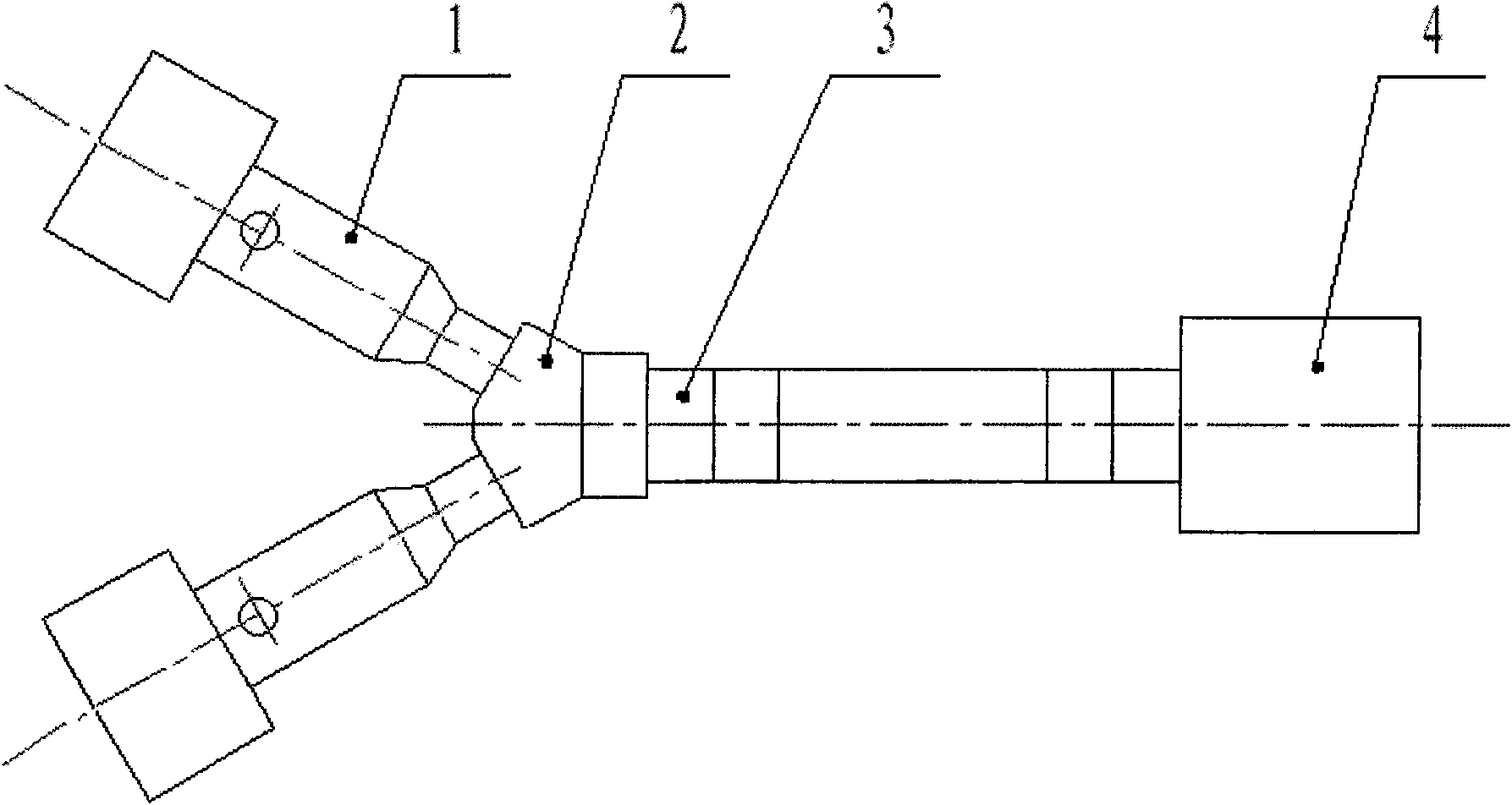

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

Hygiene articles containing nanofibers

The present invention is directed to hygiene articles comprising nanofibers. The hygiene articles include diapers, training pants, adult incontinence pads, catamenials products such as feminine care pads and pantiliners, tampons, personal cleansing articles, personal care articles, and personal care wipes including baby wipes, facial wipes, body wipes, and feminine wipes. The nanofiber webs can be used as a barrier, wipe, absorbent material, and other uses. Particularly, the nanofiber web is used in a diaper as a barrier-on-core, outercover, and / or leg cuff. It may also be used as a wipe for reducing the gradient of liquid, controlled delivery of materials, and other uses. The nanofibers, having a diameter of less than 1 micron, must comprise a significant number of the fibers in one layer of the web contained by the hygiene article. The nanofibers are produced from a melt film fibrillation process. The process generally includes the steps of providing a polymeric melt, utilizing a central fluid stream to form an elongated hollow polymeric film tube, and using this and / or other fluid streams to form multiple nanofibers from the hollow tube.

Owner:PROCTER & GAMBLE CO

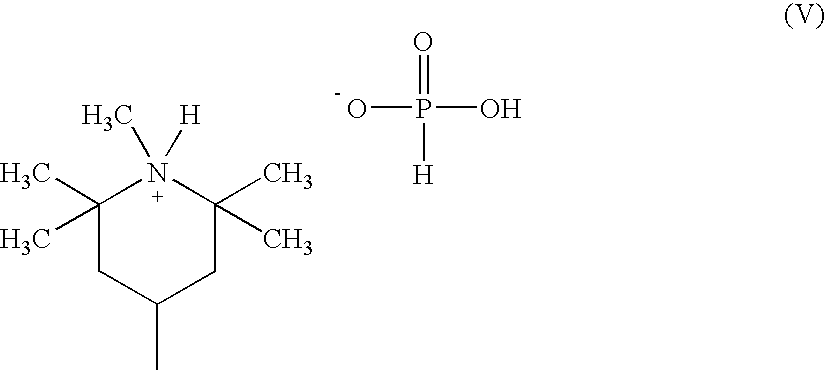

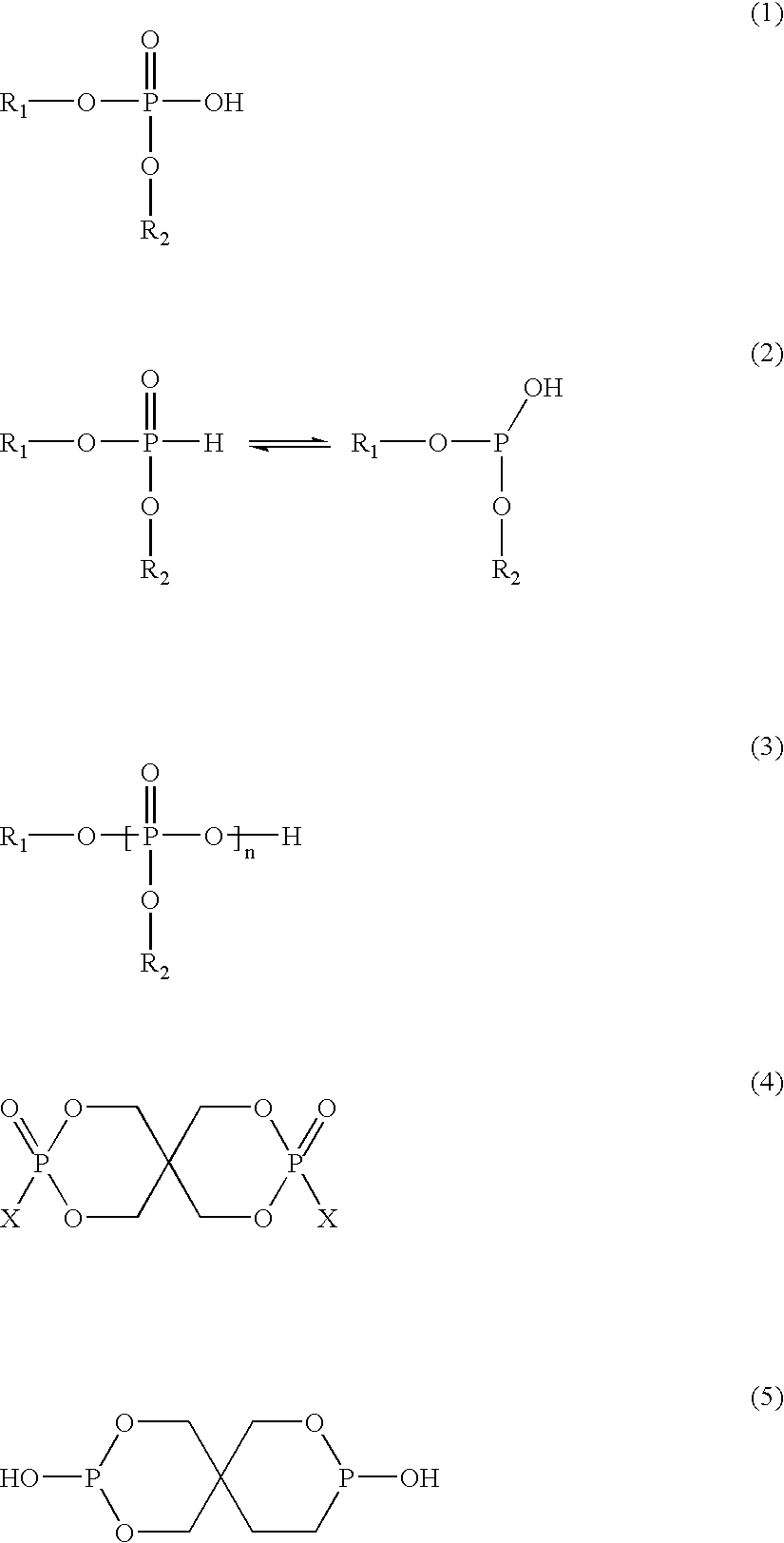

Melt-processible polymer composition comprising fluoropolymer having long chain branches

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 107 Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycaprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

High melt flow fluoropolymer

ActiveUS7122609B2Quality improvementLong extrusion runPlastic/resin/waxes insulatorsInsulated cablesVinyl etherPolymer science

The present invention relates to a partially-crystalline copolymer comprising tetrafluoroethylene, hexafluoropropylene in an amount corresponding to a hexafluoropropylene index (HFPI) of from about 2.8 to 5.3, and preferably from about 0.2% to 3% by weight of perfluoro(alkyl vinyl ether), said copolymer being polymerized and isolated in the absence of added alkali metal salts, having a melt flow rate of within the range of about 30±3 g / 10 min, and having no more than about 50 unstable endgroups / 106 carbon atoms can be extruded at high speed onto conductor over a broad polymer melt temperature range to give insulated wire of high quality.

Owner:THE CHEMOURS CO FC LLC

Aluminum/alkaline or alkali/titanium containing polyesters having improved reheat, color and clarity

ActiveUS20070066735A1Improving reheat rateIncrease ratingsHydrogenOther chemical processesPolyesterPolymer science

A polyester composition containing: a) aluminum atoms; and b) alkaline earth atoms or alkali metal atoms or alkali compound residues such as lithium atoms; and c) particles comprising titanium, zirconium, vanadium, niobium, hafnium, tantalum, chromium, tungsten, molybdenum, iron, or nickel atoms or combinations thereof, where the particles improve the reheat rate of the polyester composition. The polyester polymer compositions may also contain phosphorus catalyst deactivators / stabilizers. The polyester compositions and the articles made from the compositions such as bottle preforms and stretch blow molded bottles have improved reheat rate while maintaining low haze, high L*, a b* below 3, and have low levels of acetaldehyde. In the process for making the polyester polymer, the polymer melt is polycondensed in the presence of a) and b), with the particles c) added in a melt phase process or added to the polymer in an injection molding machine or extruder. The polyester polymer composition can be made to high IV from the melt phase while avoiding solid state polymerization.

Owner:ALPEK POLYESTER SA DE CV

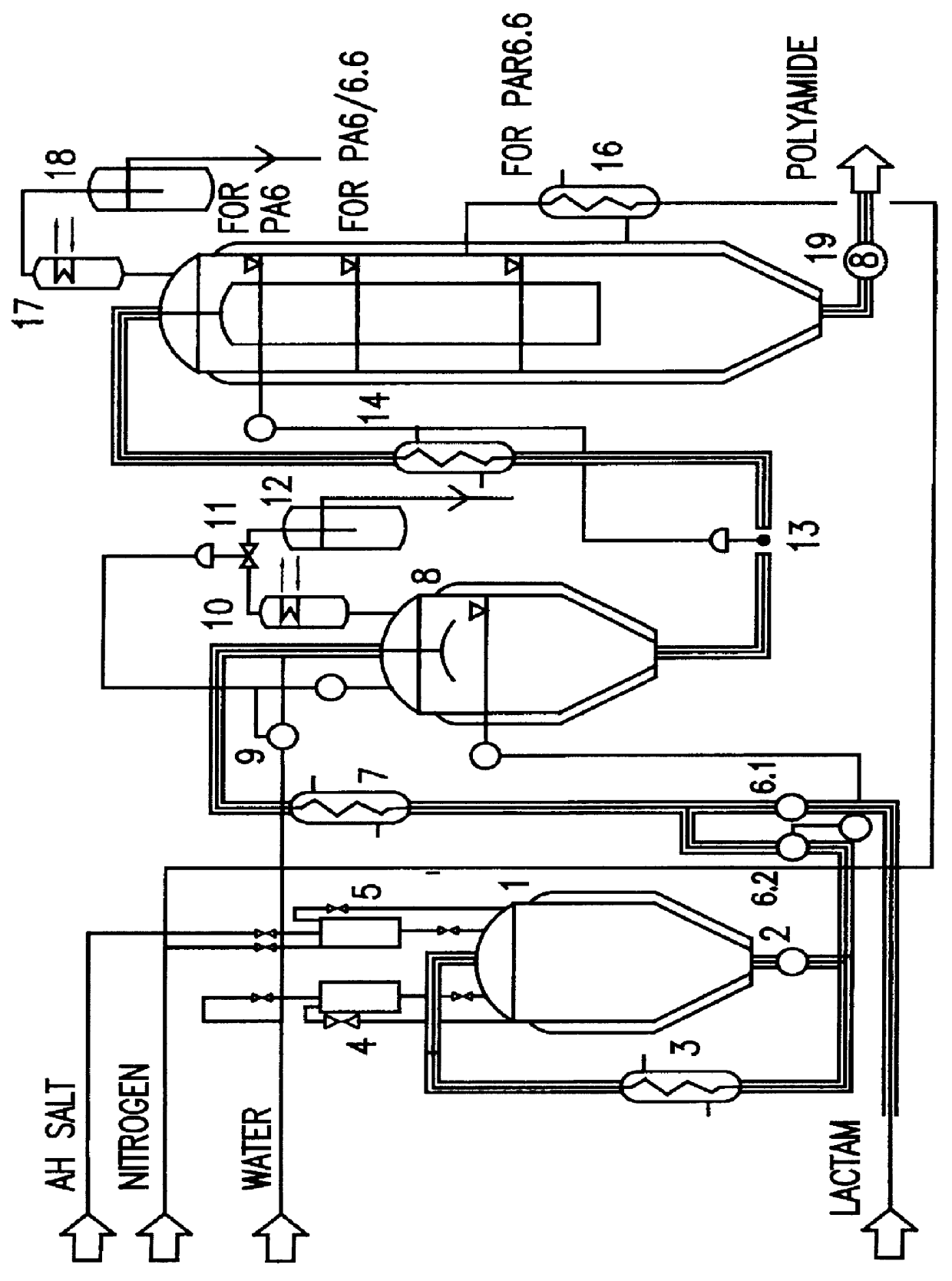

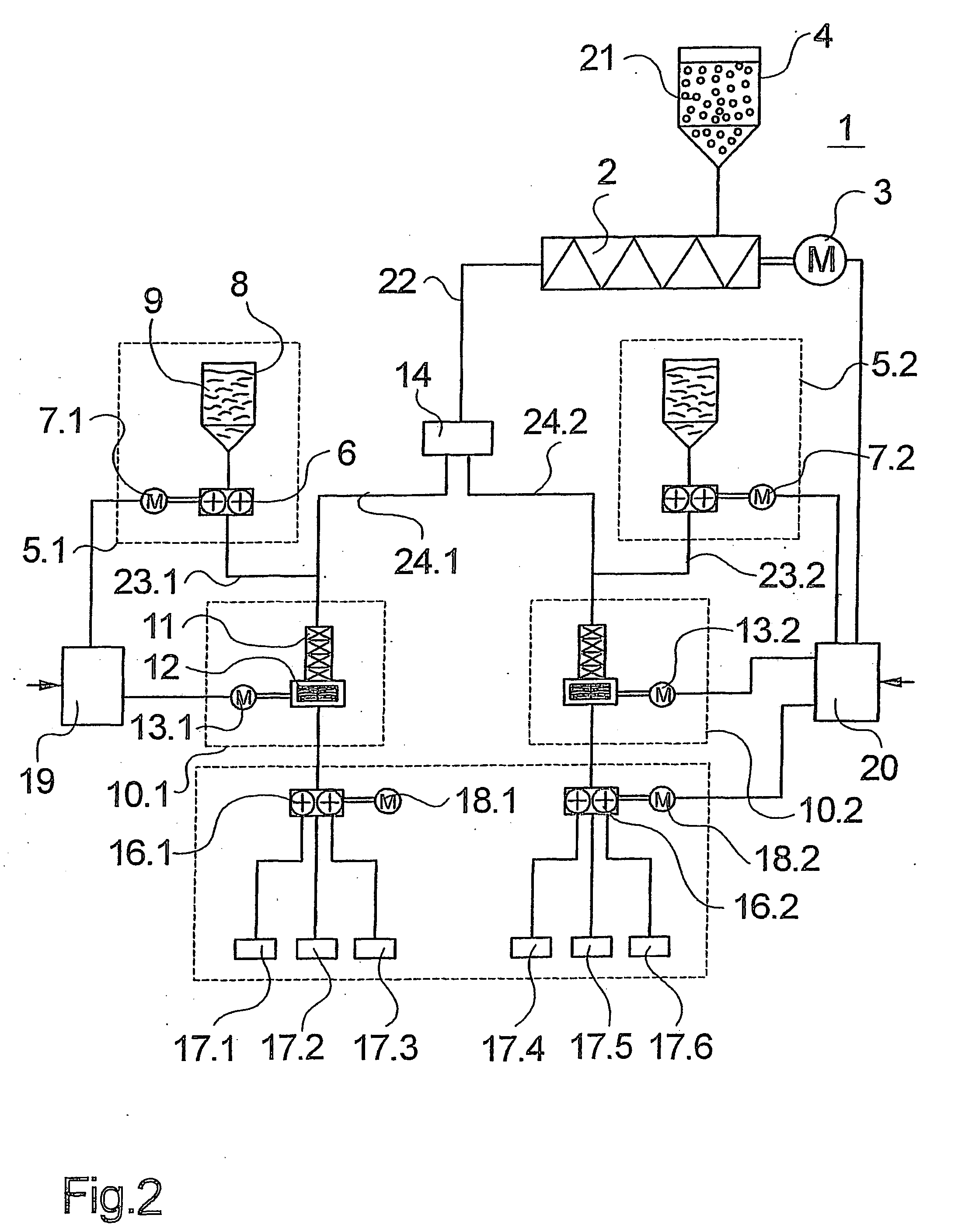

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

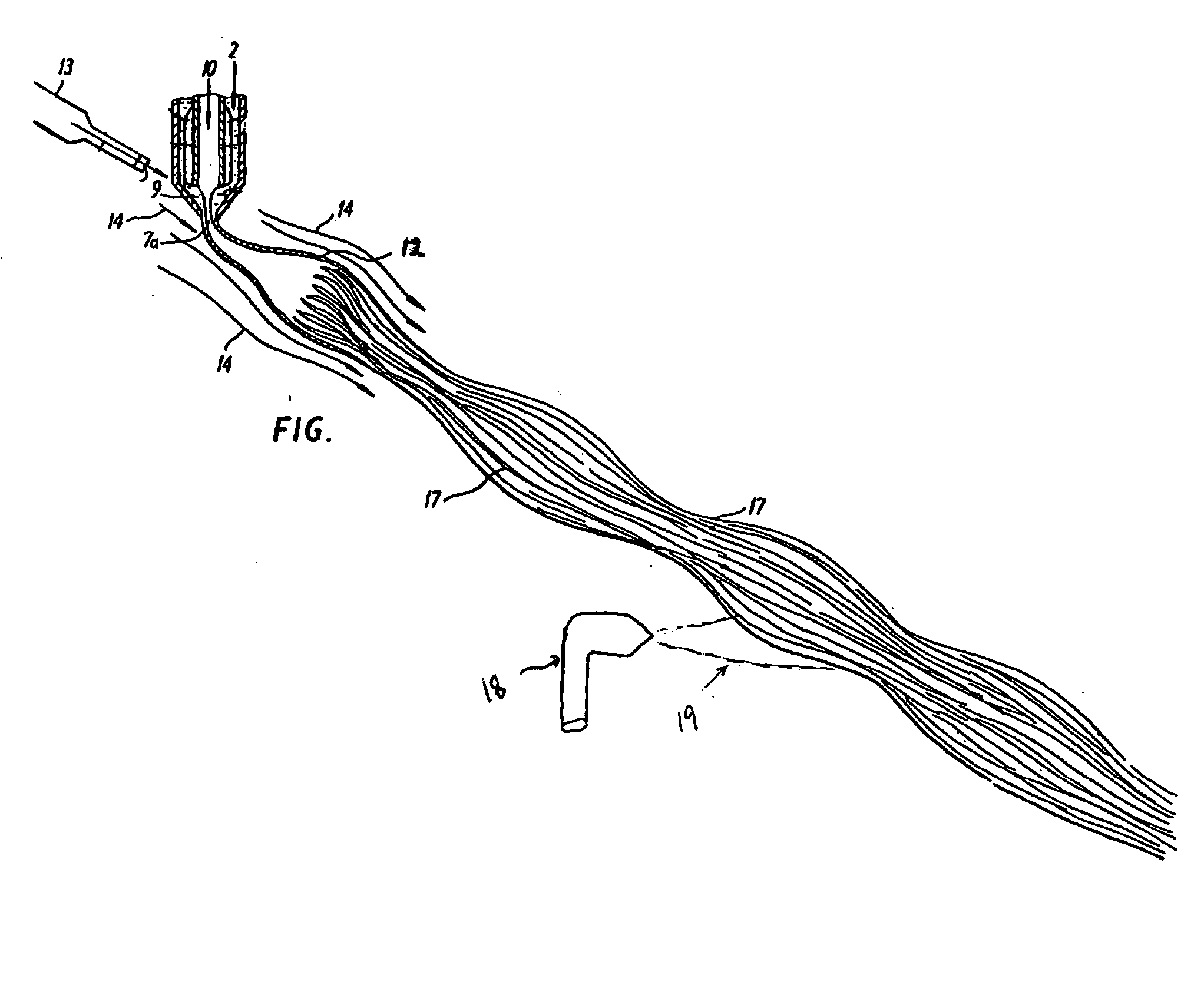

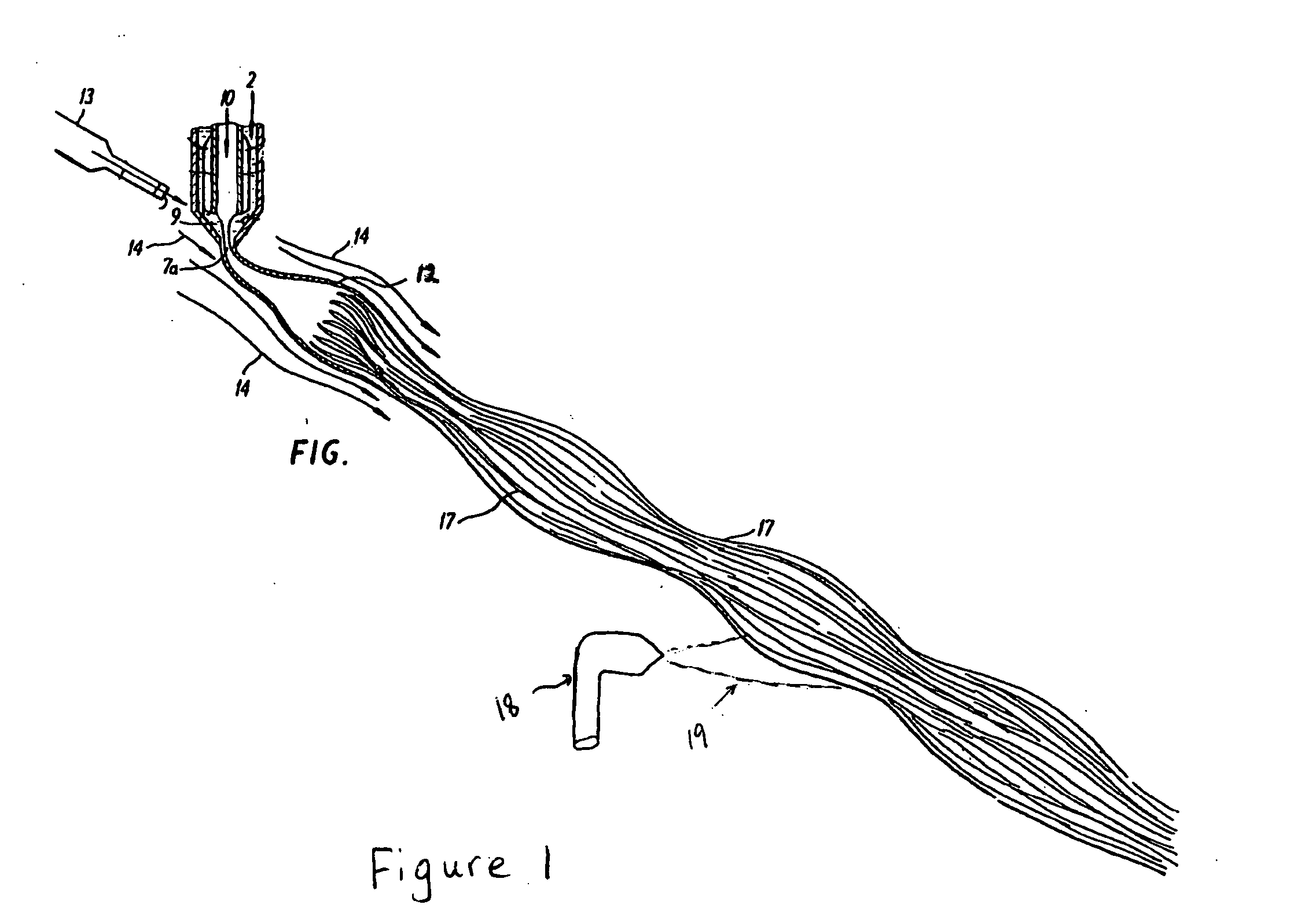

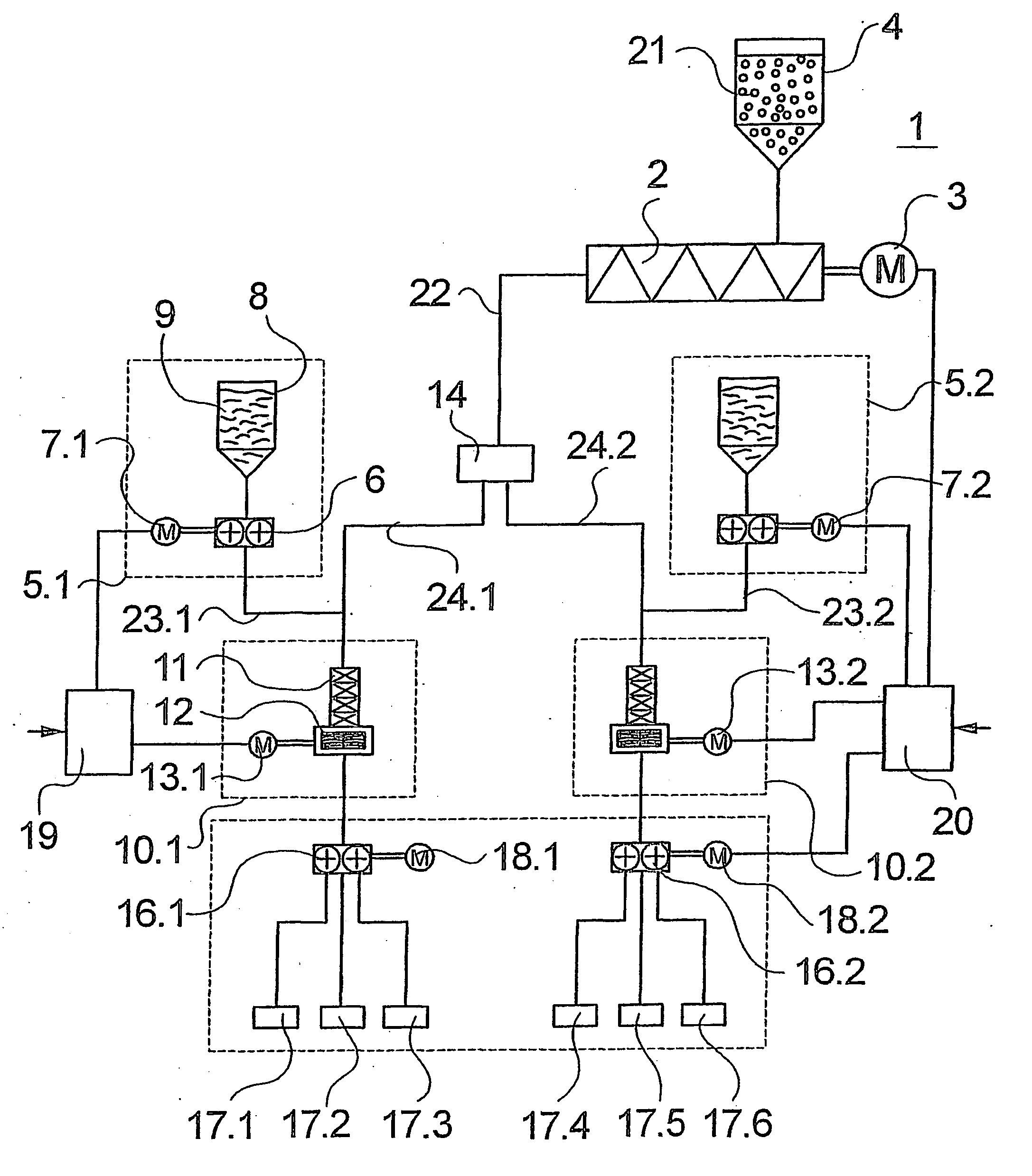

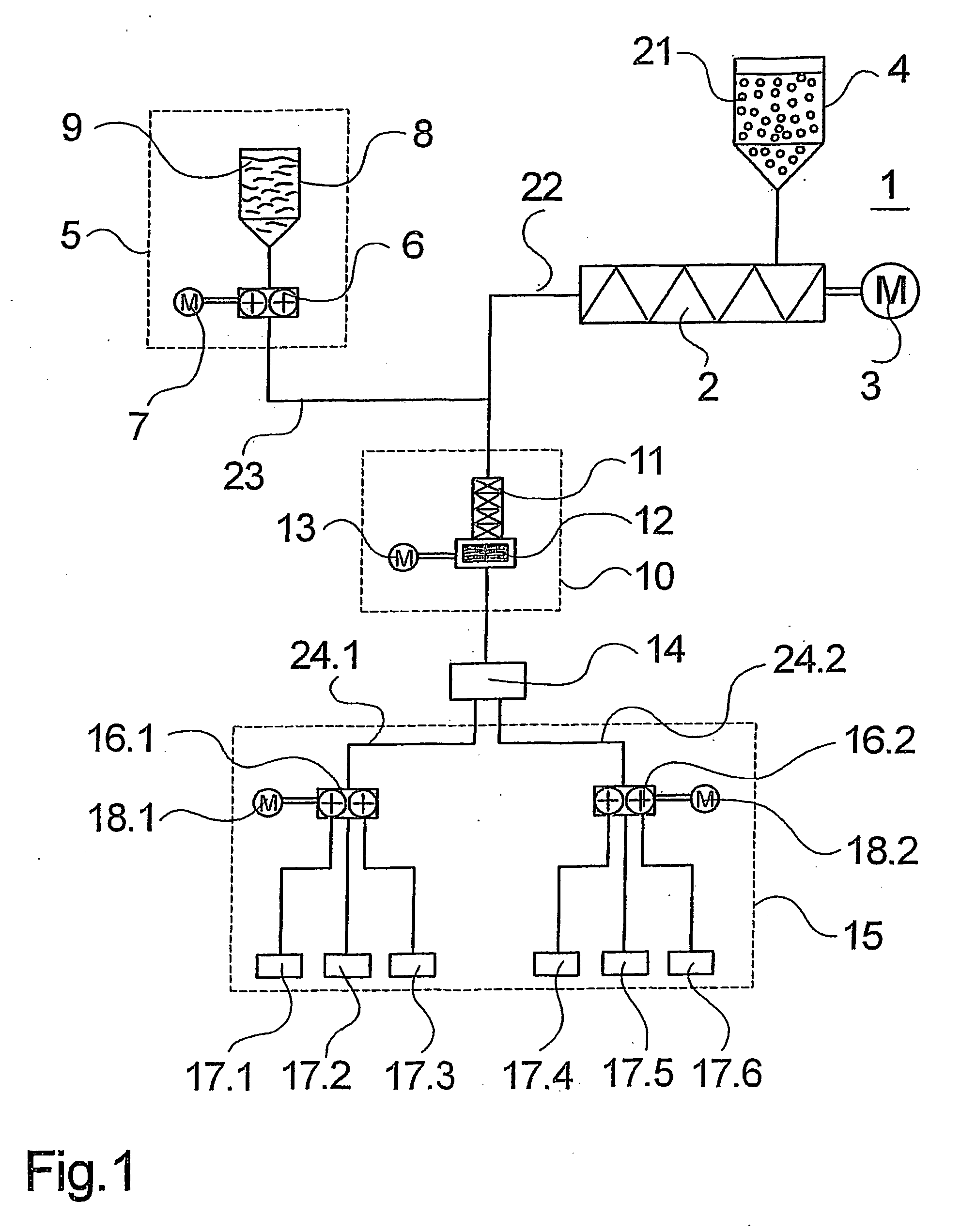

Apparatus and method for melt spinning dyed yarn filaments

InactiveUS20050263941A1Good flexibilityPolymer meltDough homogenizationSpinning head liquid feederYarnStatic mixer

An apparatus and a method for spinning dyed filaments from a dyed polymer melt, wherein an undyed polymer melt is produced by a melt producer. A liquid dye is added to the polymer melt by means of a dye metering device. To mix the liquid dye and dye the polymer melt, a mixing unit is provided. The dyed polymer is then spun to filaments by means of a spin unit. To obtain before the spinning step a uniform coloration of the polymer melt despite the short dwelling time of the liquid dye in the polymer melt, the liquid dye and the polymer melt are mixed in a plurality of successive mixing units which are formed by a mixer combination comprising at least one static mixer and at least one dynamic mixer.

Owner:SAURER GMBH & CO KG

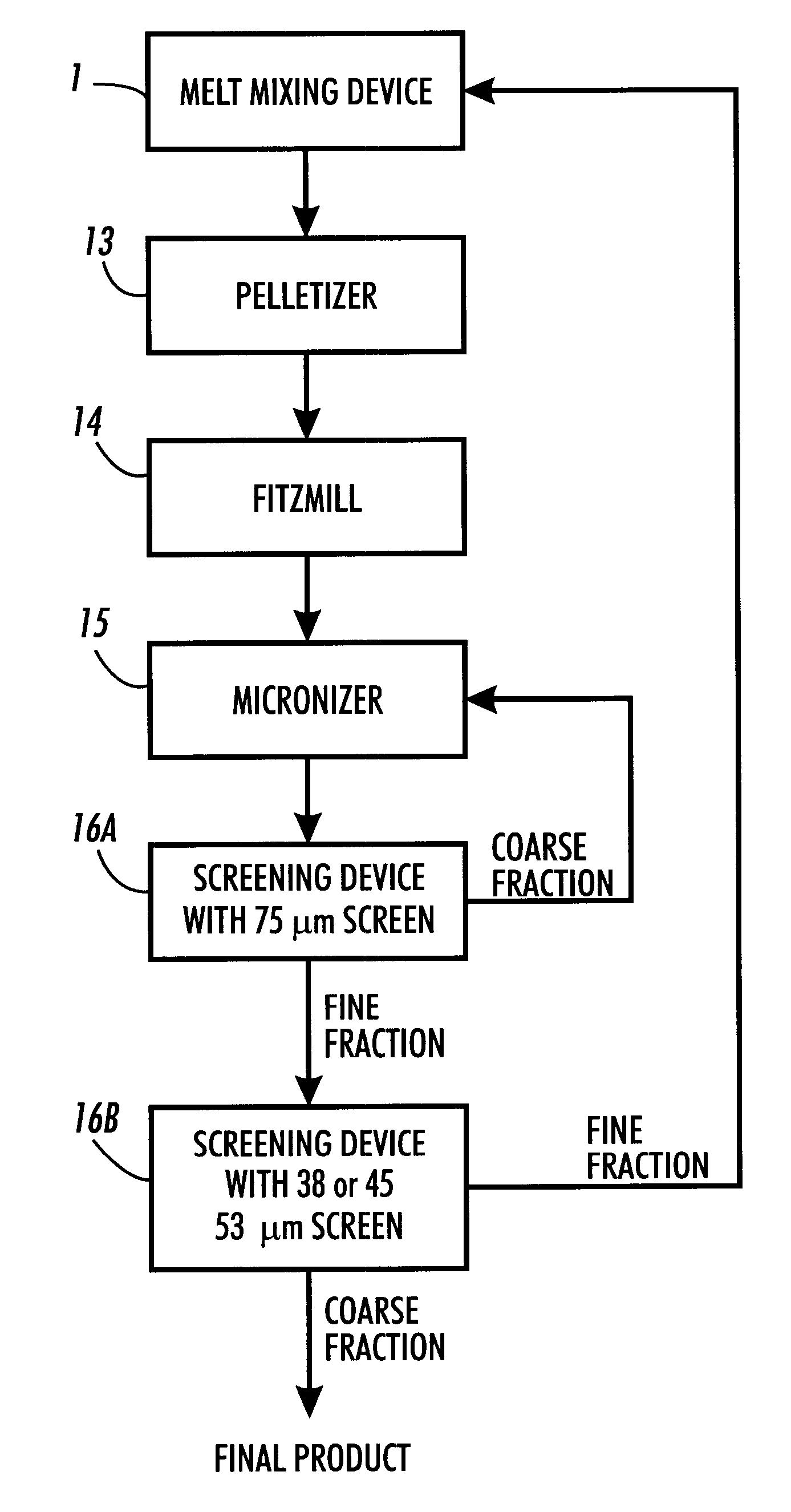

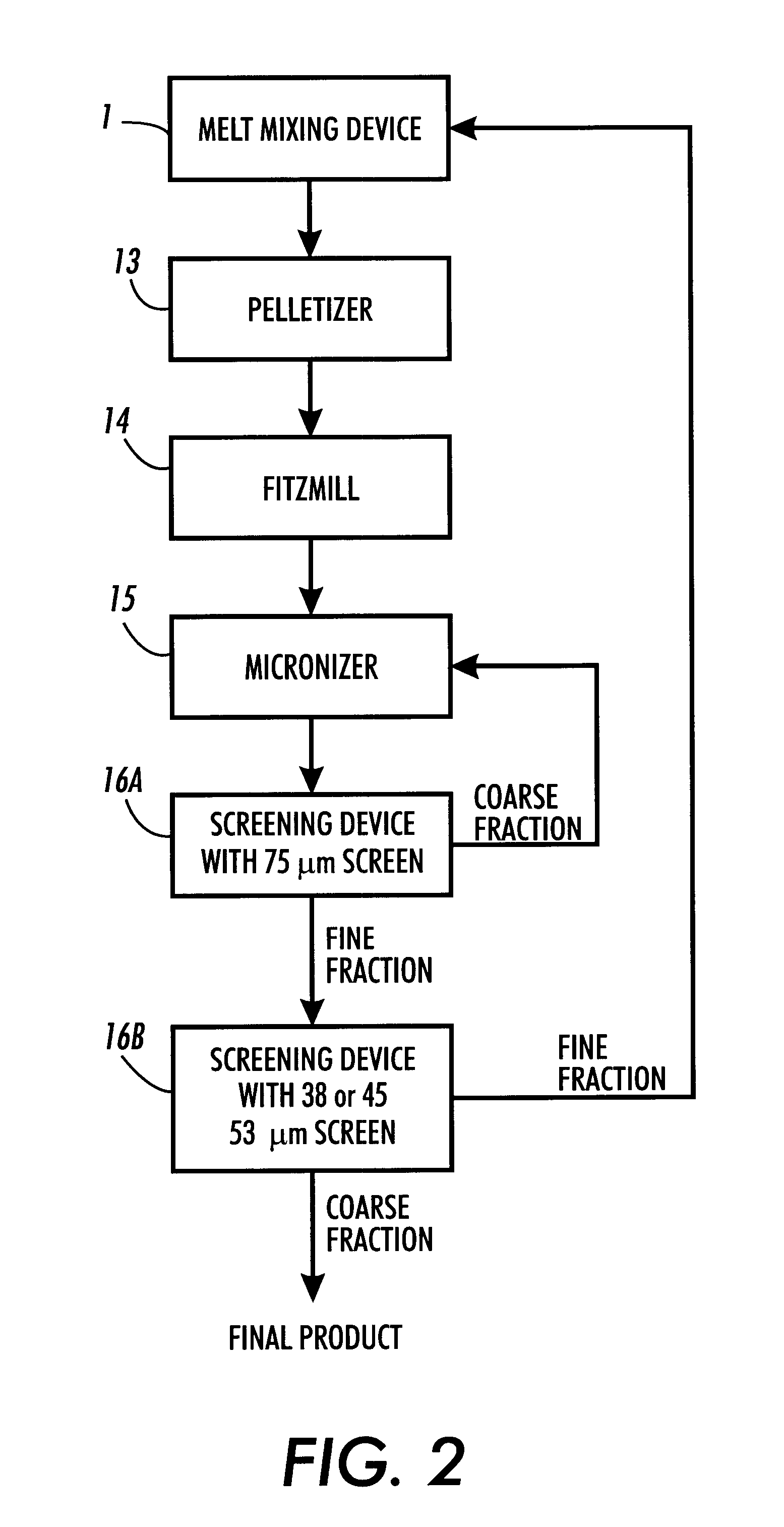

Carrier pelletizing processes

A process for the preparation of microsynthetic carrier comprising the melting of a mixture of binder resin, magnetic component, colorant and optionally charge control additive, thereby forming a polymer melt, and mixing said mixture in a melt mixing device, cooling and pelletizing said mixture, and thereafter grinding and classifying said pellets.

Owner:XEROX CORP

Polymer/foamed aluminium composite material and production method thereof

ActiveCN102501357AGood mechanical propertiesImprove thermal conductivityCoatingsPolyoxymethyleneCooking & baking

A polymer / foamed aluminium composite material and a production method thereof; polymer melt is injected into voids of foamed aluminium to form a composite material composed of foamed aluminium and polymer; the polymer is a mixture of one or more than one of polypropylene, polyethylene, polystyrene, and polyoxymethylene. The production method of the polymer / foamed aluminium composite material comprises the following steps: embedding foamed aluminium in a mold; preparing the polymer / foamed aluminium composite material by a injection molding method of the polymer or the mixture; performing heat preservation of the obtained polymer / foamed aluminium composite material in a baking oven at a temperature of 50-80 DEG C for 1-3 hours.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

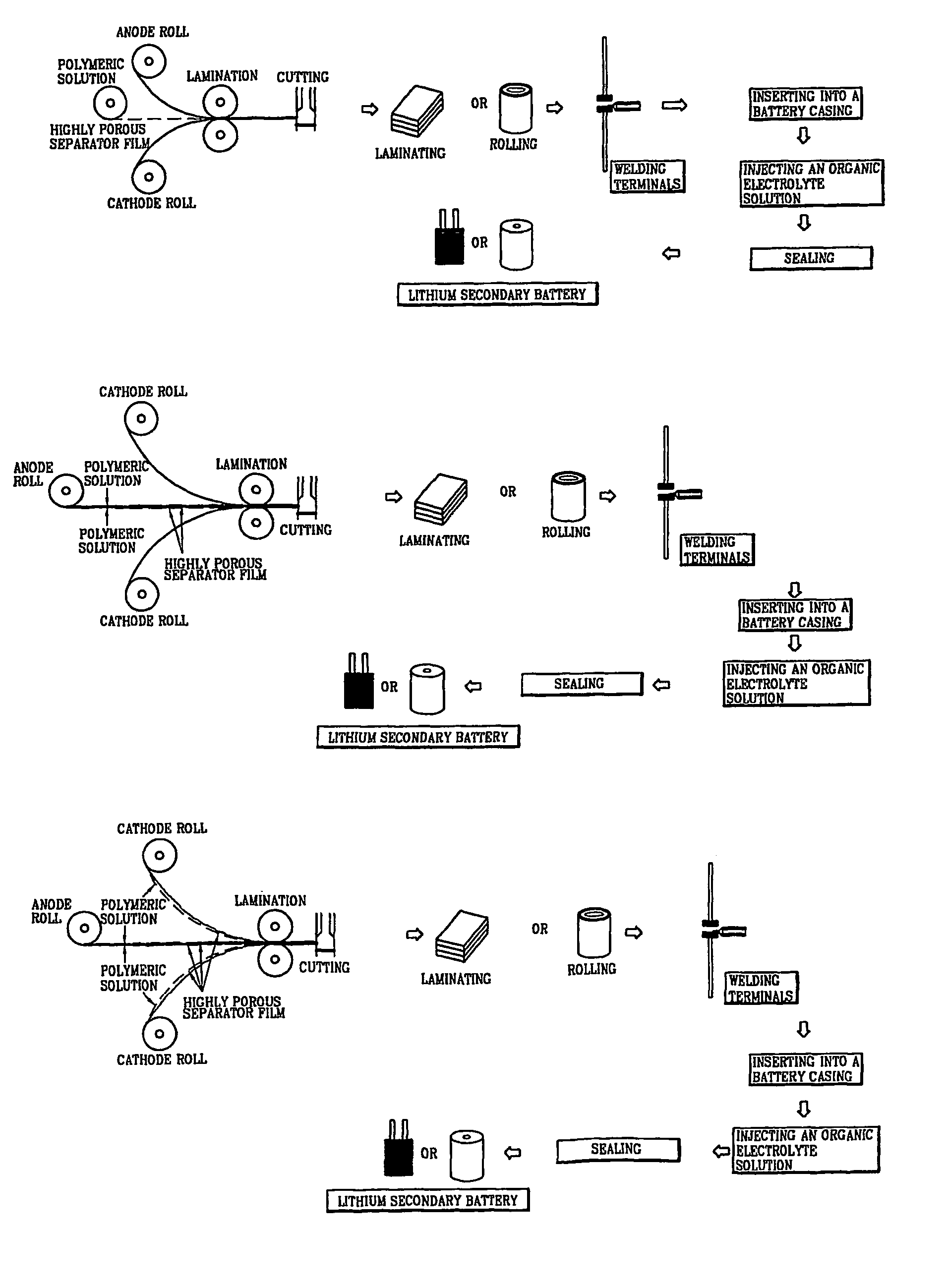

Lithium secondary battery comprising a super fine fibrous polymer separator film and its fabrication method

InactiveUS7279251B1Mechanical strengthReduce adhesionElectrode rolling/calenderingFinal product manufactureLithiumPolymer science

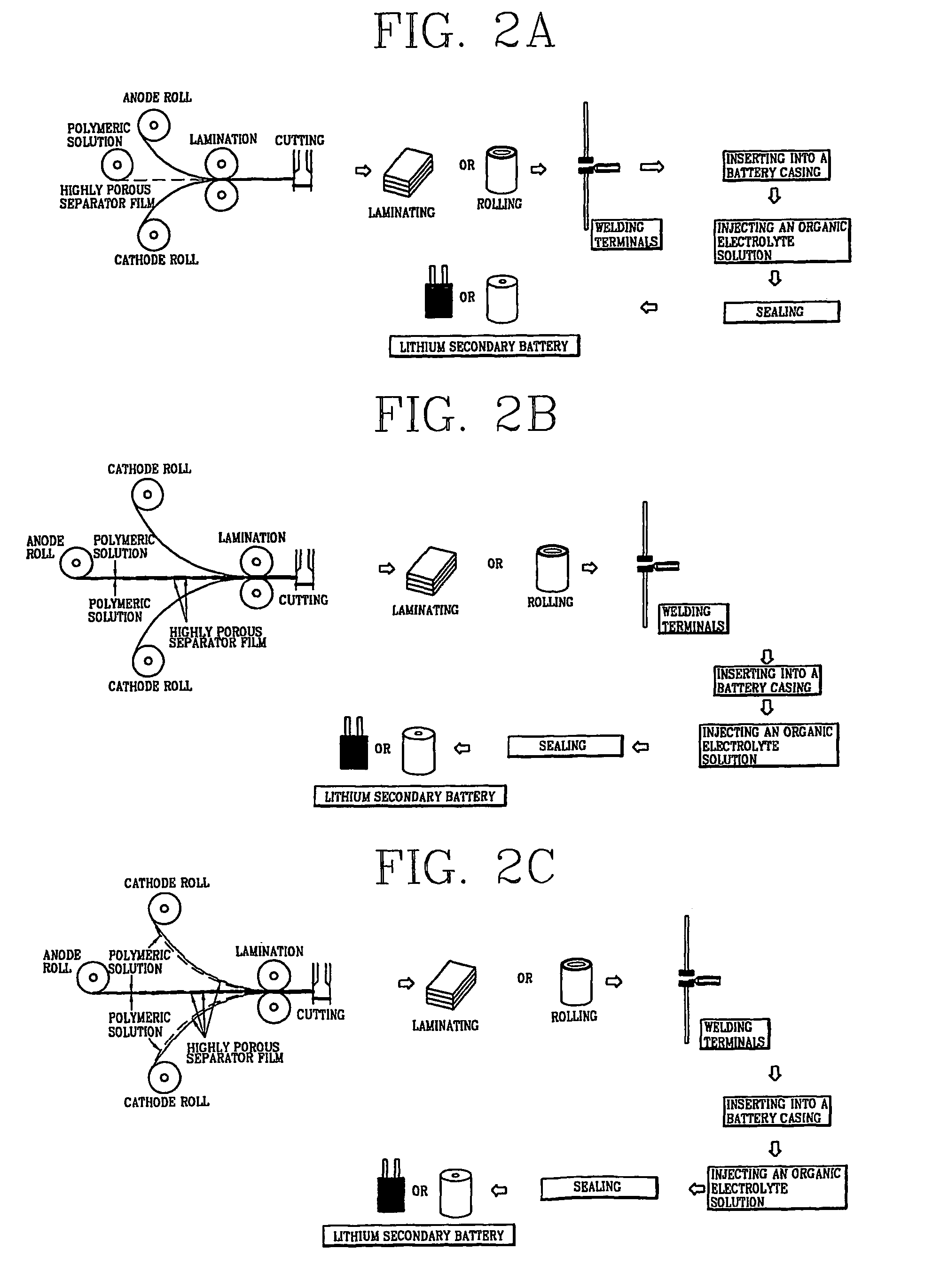

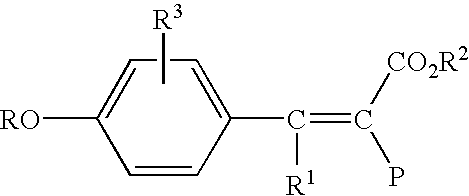

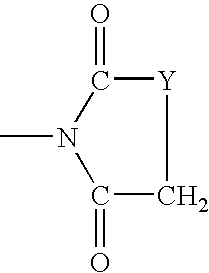

The present invention provides a lithium secondary battery and its fabrication method. More particularly, the present invention provides a lithium secondary battery comprising a super fine fibrous porous polymer separator film and its fabrication method, wherein the porous polymer separator film is fabricated by the following process: a) melting at least one polymer or dissolving at least one polymer with organic solvents to obtain at least one polymeric melt or at least one polymeric solution; b) adding the obtained polymeric melt or polymeric solution to barrels of an electrospinning machine; and c) discharging the polymeric melt or polymeric solution onto a substrate using a nozzle to form a porous separator film. The lithium secondary battery of the present invention has the advantages of better adhesion with electrodes, good mechanical strength, better performance at low and high temperatures, better compatibility with organic electrolyte solution of a lithium secondary battery.

Owner:KOREA INST OF SCI & TECH

High IV melt phase polyester polymer catalyzed with antimony containing compounds

ActiveUS20050203267A1Wide latitudeEnergy recovery in ventilation and heatingMechanical apparatusPolyesterCompound a

A melt phase process for making a polyester polymer melt phase product by adding an antimony containing catalyst to the melt phase, polycondensing the melt containing said catalyst in the melt phase until the It.V. of the melt reaches at least 0.75 dL / g. Polyester polymer melt phase pellets containing antimony residues and having an It.V. of at least 0.75 dL / g are obtained without solid state polymerization. The polyester polymer pellets containing antimony residues and having an It.V. of at least 0.70 dL / g obtained without increasing the molecular weight of the melt phase product by solid state polymerization are fed to an extruder, melted to produce a molten polyester polymer, and extruded through a die to form shaped articles. The melt phase products and articles made thereby have low b* color and / or high L* brightness, and the reaction time to make the melt phase products is short.

Owner:ALPEK POLYESTER SA DE CV

Melt-processible polymer composition comprising fluoropolymer having long chain branches

ActiveUS20040260022A1Clearly detectable melting pointImprove efficiencyFibre treatmentFlotationProcedure AgentsPolymer science

A polymer melt additive that is suitable for use as a processing aid in the extrusion of a non-fluorinated polymer. The polymer melt additive composition includes a fluoropolymer that has a long chain branching index (LCBI) of at least 0.2 and a zero shear rate viscosity at 265° C. of not more than 10<7 >Pa's. The polymer melt additive may additionally include other compounds such as, polyoxyalkylene polymer or polycarprolactone.

Owner:3M INNOVATIVE PROPERTIES CO

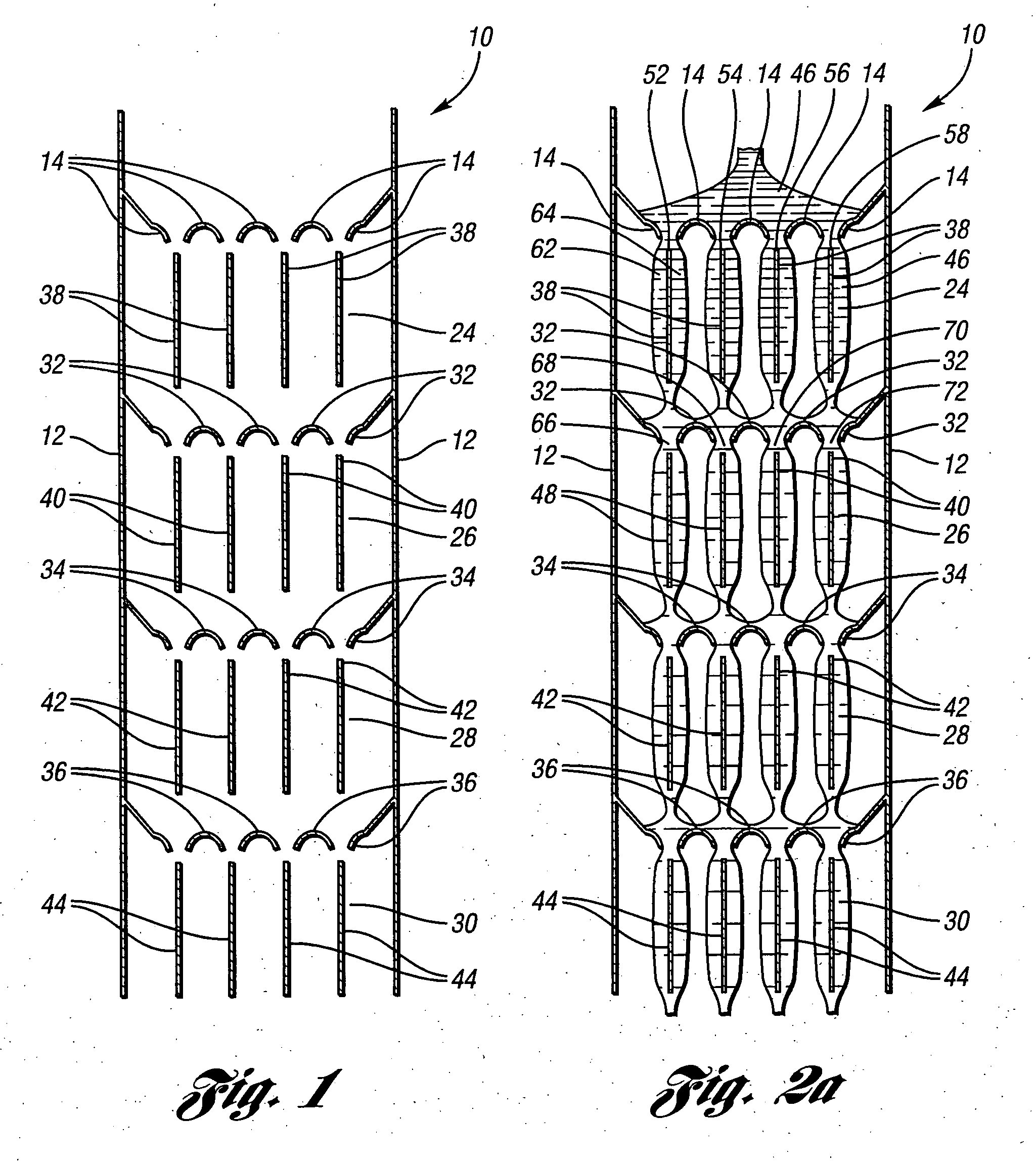

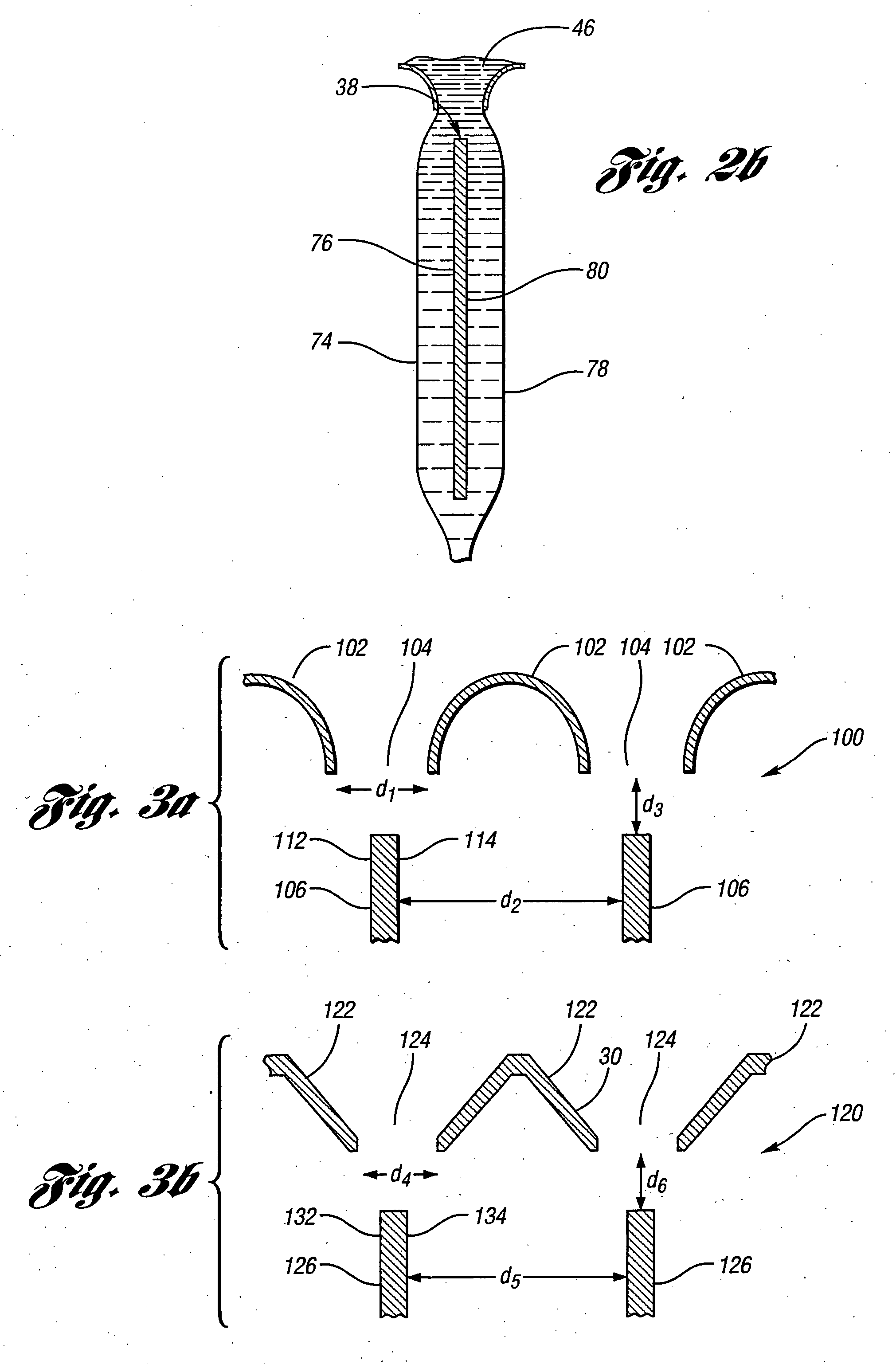

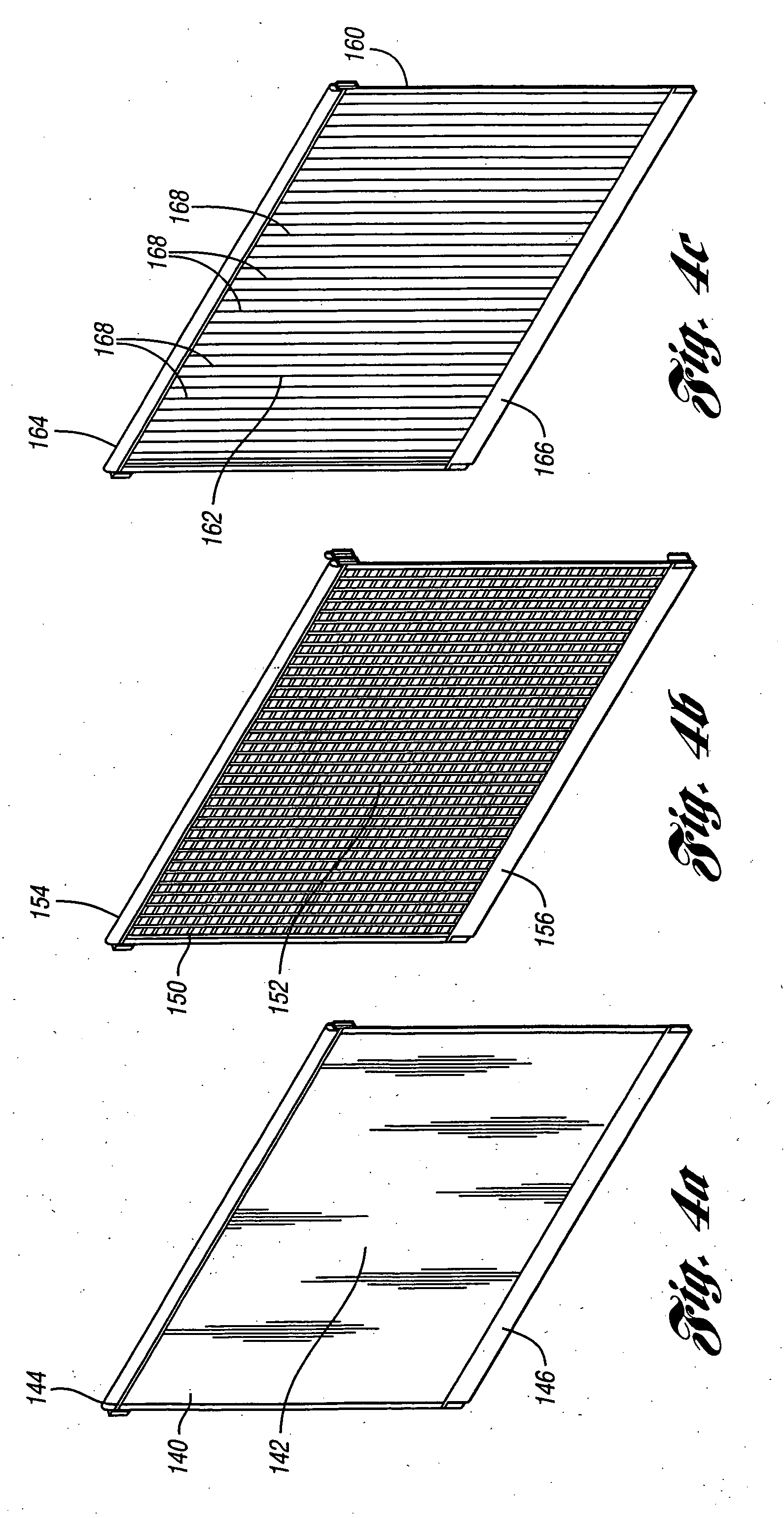

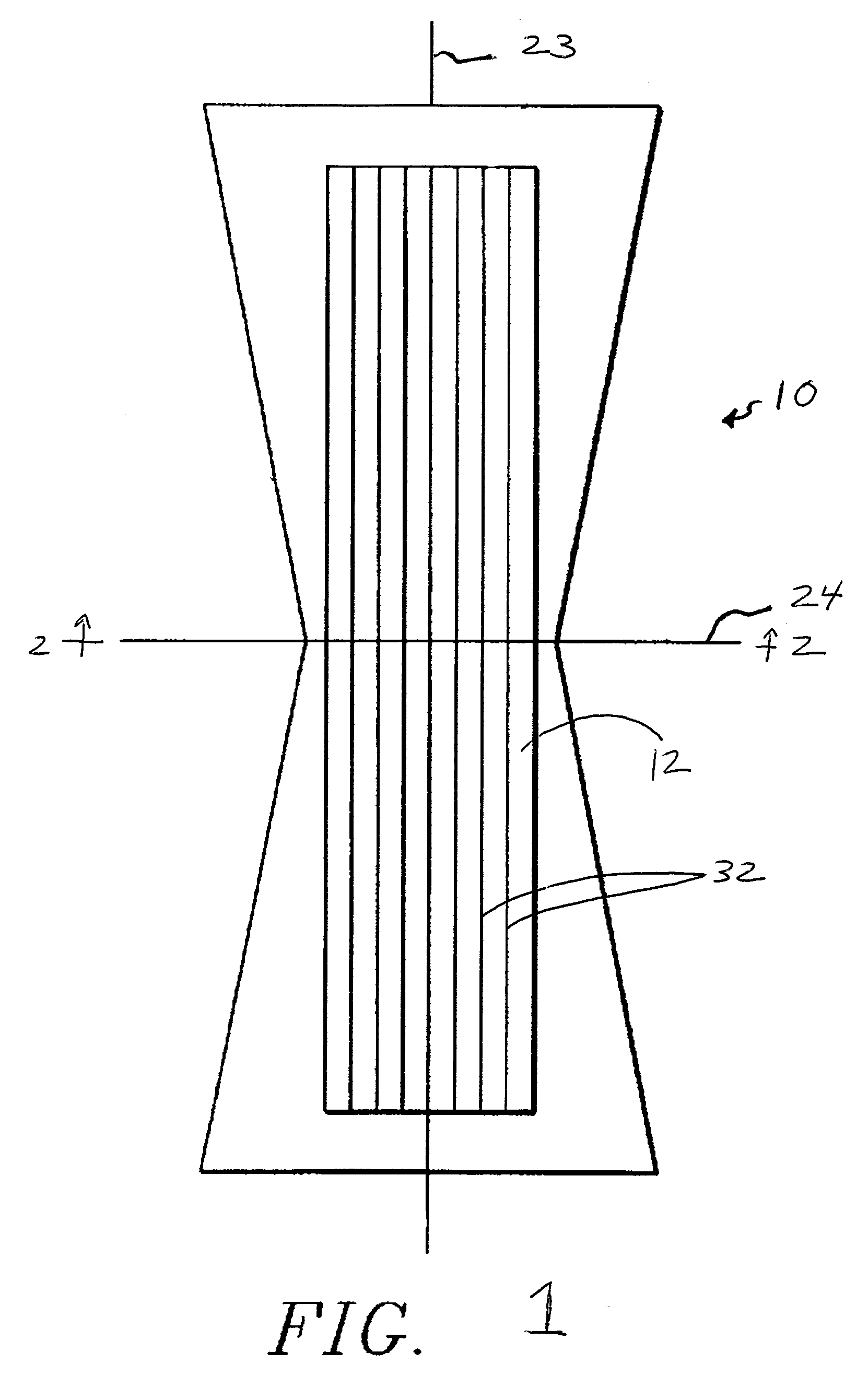

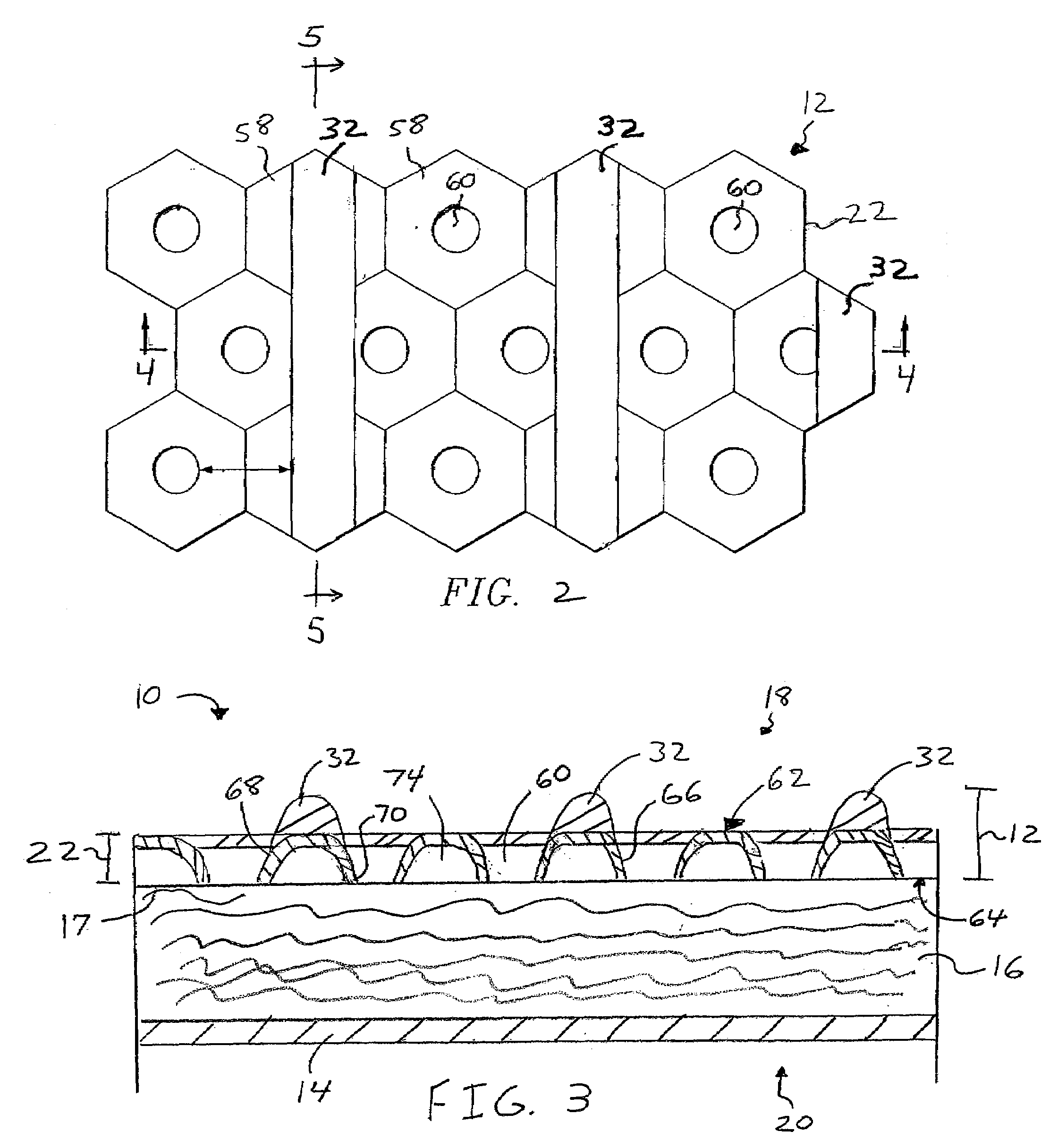

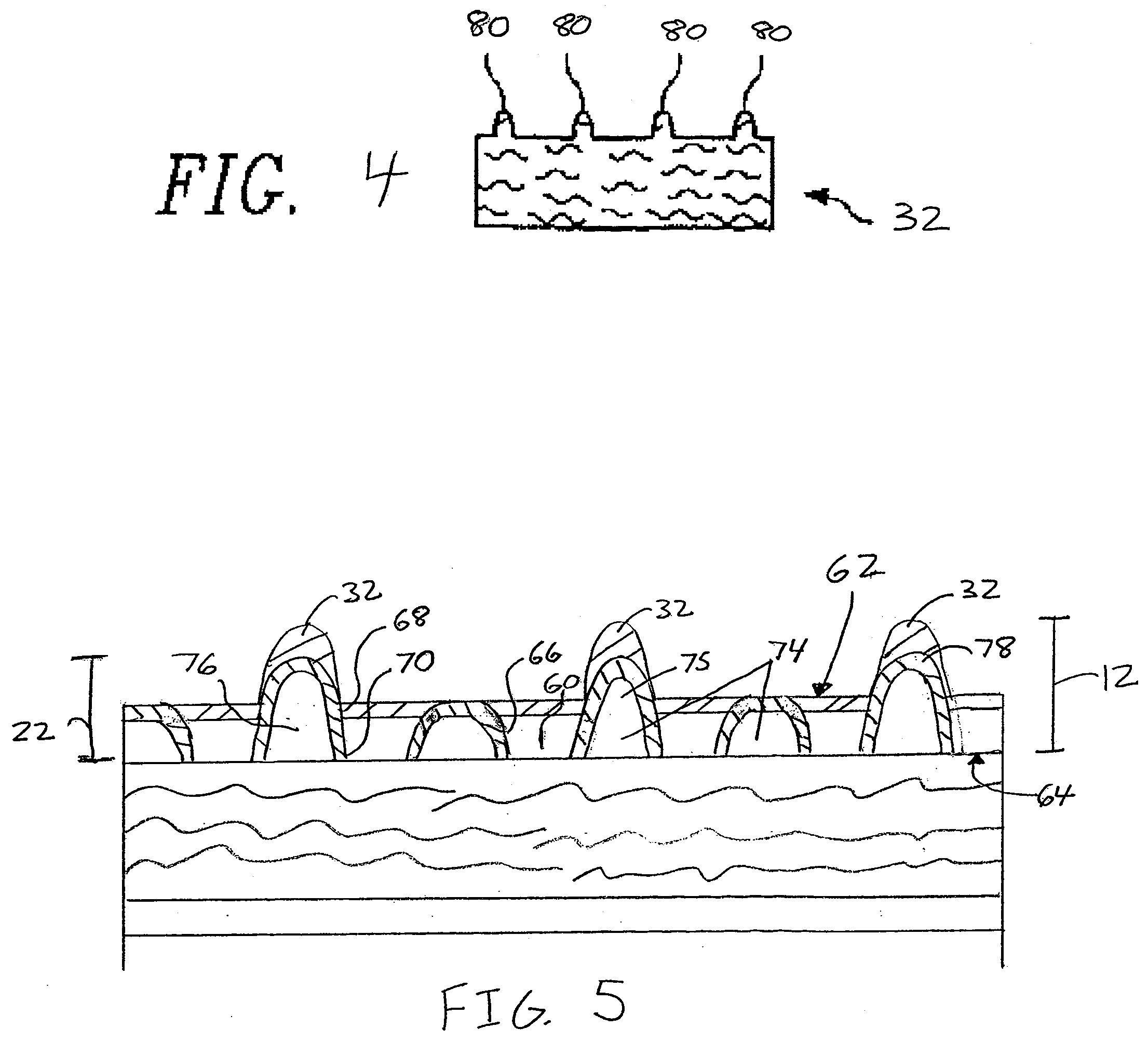

Family of stationary film generators and film support structures for vertical staged polymerization reactors

InactiveUS20060251547A1Liquid-gas reaction of thin-film typeChemical/physical/physico-chemical reactor detailsHigh fluxEngineering

Owner:EASTMAN CHEM CO

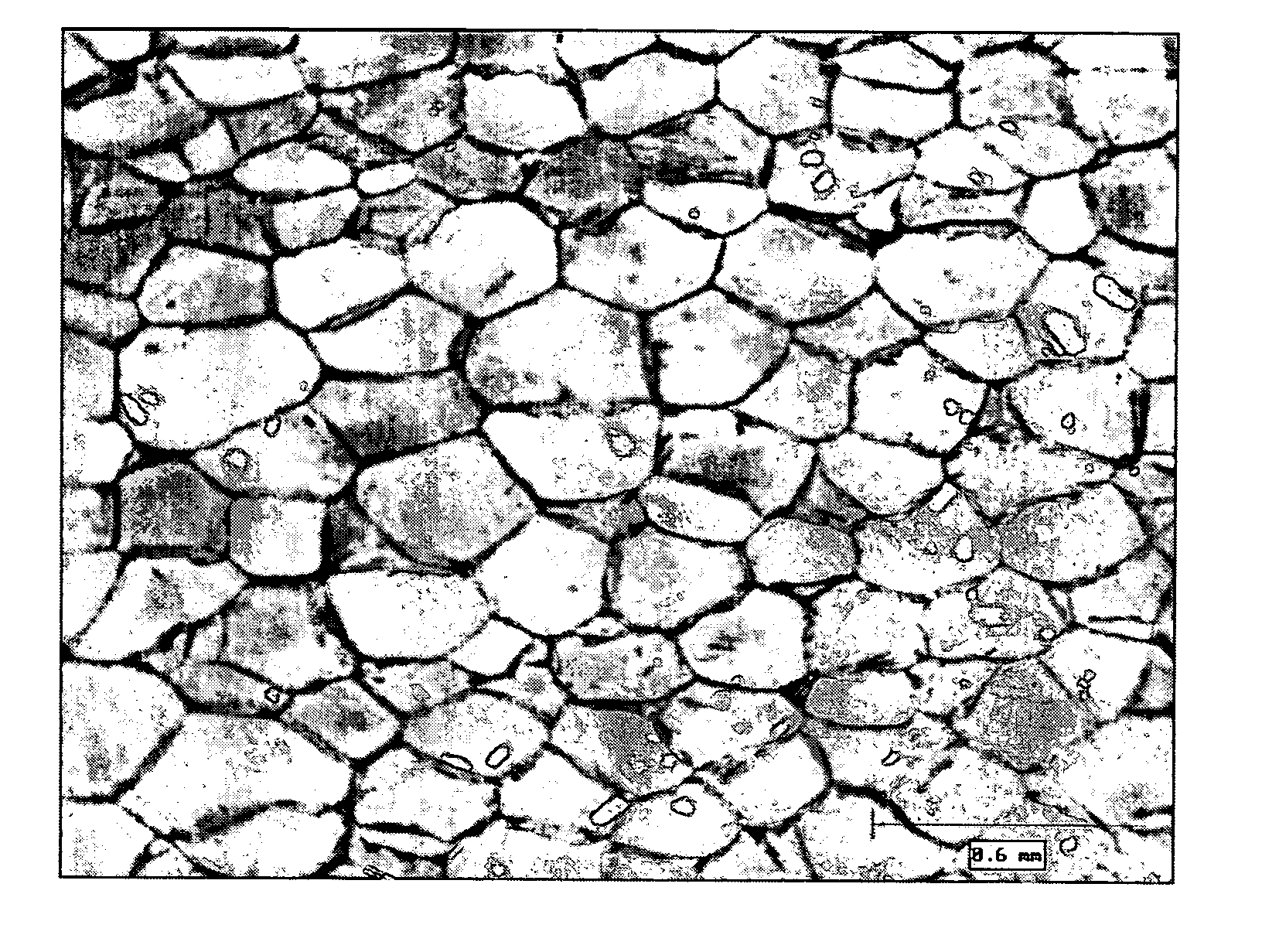

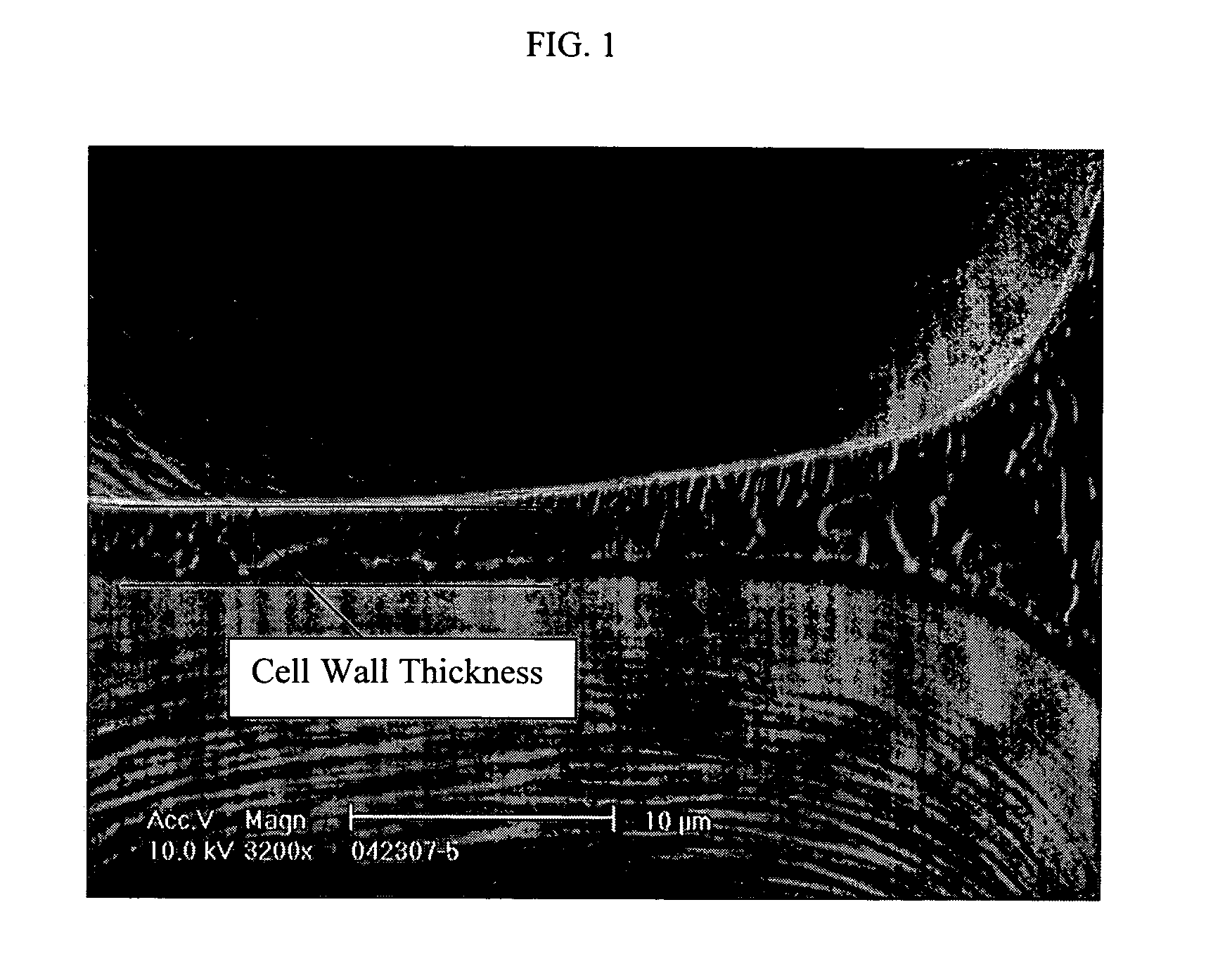

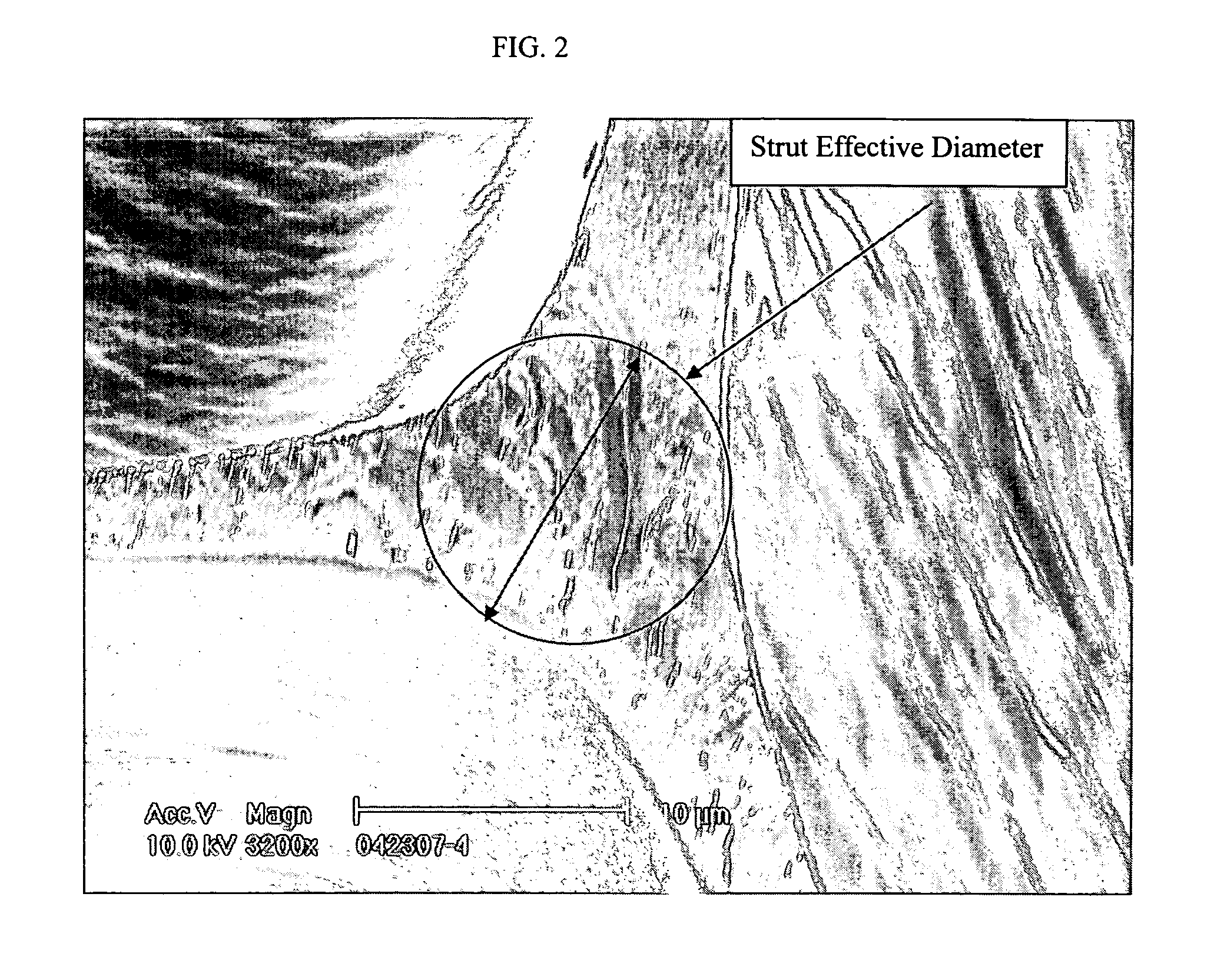

Method of forming thermoplastic foams using nano-particles to control cell morphology

ActiveUS20050112356A1Low thermal conductivitySmall cell sizeMaterial nanotechnologyLayered productsPolymer scienceHigh pressure

A process for making closed-cell, alkenyl aromatic polymer foams using nano-particle nucleation agents to control the cell morphology of the resulting foam includes forming a polymer melt at a temperature above the polymer glass transition temperature (for crystal polymers) or the polymer melt point (for amorphous polymers); incorporating selected nano-particles into the polymer melt; incorporating blowing agents into the polymer melt at an elevated pressure; optionally incorporating other additives, such as flame retardants, into the polymer melt; and extruding the polymer melt under conditions sufficient to produce a foam product having a desired cell morphology, characterized by parameters such as reduced average cell size range and / or increased asymmetry of the cells.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High melt flow fluoropolymer

ActiveUS7126056B2Long extrusion runInsulated cablesInsulated conductorsVinyl etherElectrical conductor

The present invention relates to a partially-crystalline copolymer comprising tetrafluoroethylene, hexafluoropropylene in an amount corresponding to HFPI of from about 2.8 to 5.3, and preferably from about 0.2% to 3% by weight of perfluoro(alkyl vinyl ether), said copolymer being polymerized and isolated in the absence of added alkali metal salts, having a melt flow rate of within the range of about 30±3 g / 10 min, and having no more than about 50 unstable endgroups / 106 carbon atoms can be extruded at high speed onto conductor over a broad polymer melt temperature range to give insulated wire of high quality.

Owner:THE CHEMOURS CO FC LLC

Nanofiber composite membrane and preparation method thereof

InactiveCN104727016AWide range of usesHigh hydrostatic pressure resistanceNon-woven fabricsAdhesivesPolymer scienceNanofiber

The invention provides a preparation method of a nanofiber composite membrane. The method includes the steps that a spinning solution and melt of a high-melting-point polymer are provided, a spinning solution and melt of a low-melting-point polymer are provided, and the melting point difference of the high-melting-point polymer and the low-melting-point polymer is not smaller than 10 DEG C; the spinning solution of the high-melting-point polymer and the spinning solution of the low-melting-point polymer are subjected to electrostatic spinning, and accordingly an electrostatic spinning high-melting-point polymer fiber membrane and an electrostatic spinning low-melting-point polymer fiber membrane are obtained; the low-melting-point polymer melt and the high-melting-point polymer melt are subjected to melt-blowing spinning, so that a melt-blowing spinning low-melting-point polymer fiber membrane and a melt-blowing spinning high-melting-point polymer fiber membrane are obtained; the melt-blowing spinning high-melting-point polymer fiber membrane and the electrostatic spinning low-melting-point polymer fiber membrane undergo composite hot pressing, or the melt-blowing spinning low-melting-point polymer fiber membrane and the electrostatic spinning high-melting-point polymer fiber membrane undergo composite hot pressing, and thus the nanofiber composite membrane is obtained. The nanofiber composite membrane has high tensile strength which reaches up to 22 MPa-32 MPa.

Owner:ZHEJIANG WEIXING IND DEV

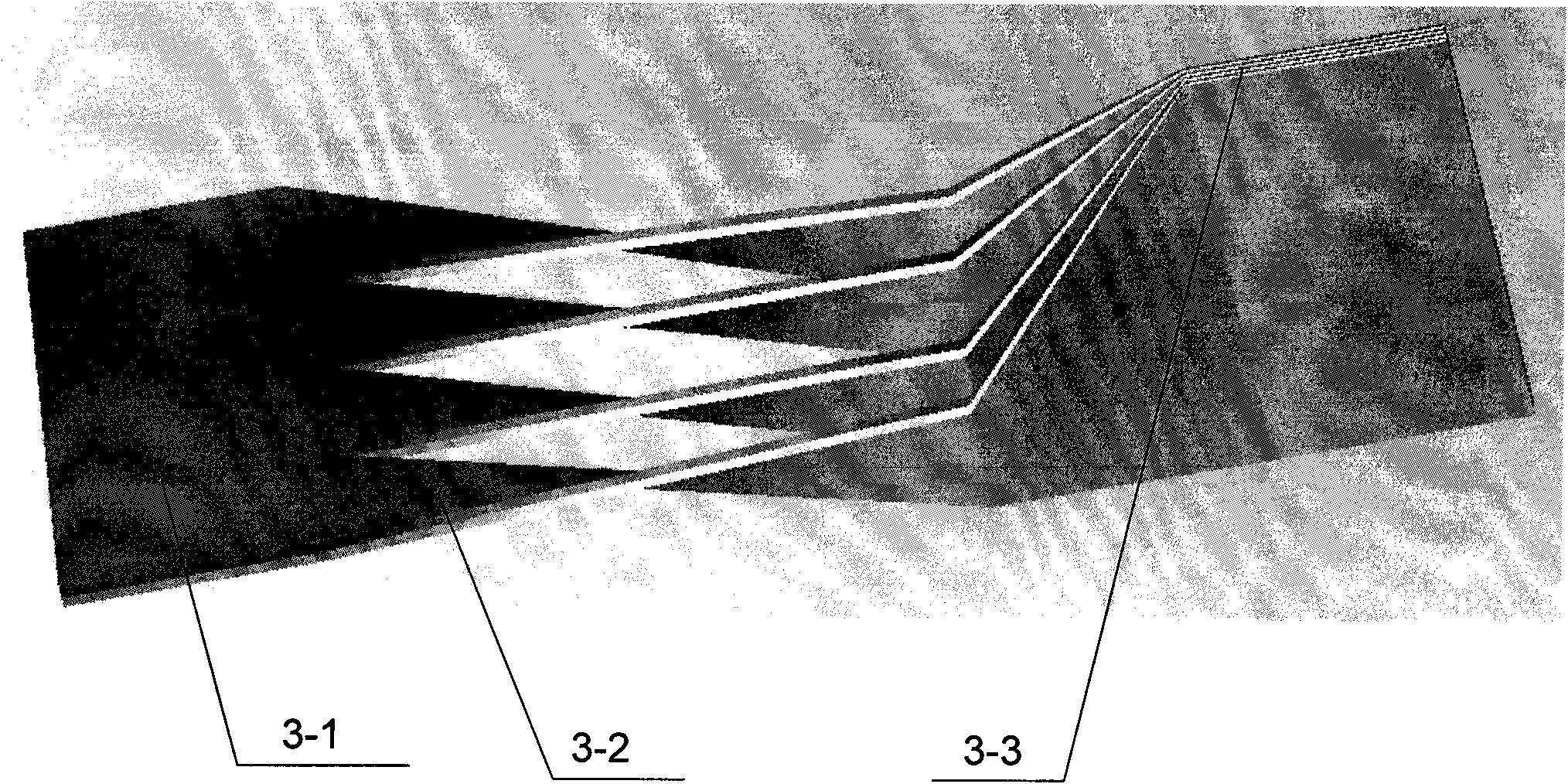

Device for manufacturing nano laminated composite material

The invention relates to a device for manufacturing a nano laminated composite material, which comprises a plastifying device, a converging device, a laminated composite generator and a molding device which are sequentially connected in series front and back, wherein the laminated composite generator is used for averagely dividing n layers of polymer melts extruded by the converging device into m equal parts along the width direction; when each equal part of melt continues to forwards flow in the laminated composite generator, the melt is rotated for 90 degrees and broadened by m times so as to mutually converge with an adjacent melt layer into a laminated structure at an outlet end; then an identical laminated composite generator is connected in series to obtain an n*m*m structure; and if k identical laminated composite generators are connected in series, a multi-layer structure composite material with n*mk layers can be obtained. In the invention, the laminated composite generators rotating for 90 degrees after melt segmentation are adopted, thus the segmentation quantity is large, the quantity of serial units can be reduced, and the melt is easy to maintain a symmetrical structure in a flow broadening and thinning process, so that the layer thickness precision is easy to guarantee, and a nano laminated composite multi-layer product can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

Dry top formed film

InactiveUS20080090050A1Good fluid acquisitionFeel goodLayered productsAbsorbent padsHydrophobic polymerEngineering

An apertured film is provided for use as a topsheet in an absorbent article. The apertured film includes an apertured continuous layer having a female side that is hydrophilic, and hydrophobic raised lanes extending upward from the female side of the apertured continuous layer. A method of making the film is provided also. The method includes: extruding a flat continuous layer of a polymer melt onto a screen assembly, the upper surface of the continuous layer being hydrophilic; coextruding lanes of a hydrophobic polymer melt onto the upper surface of the continuous layer; and applying a pressure differential across the screen assembly to form apertures in the continuous layer. An absorbent article including the film is provided also.

Owner:TREDEGAR FILM PROD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com