Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2066results about "Direct heating destructive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

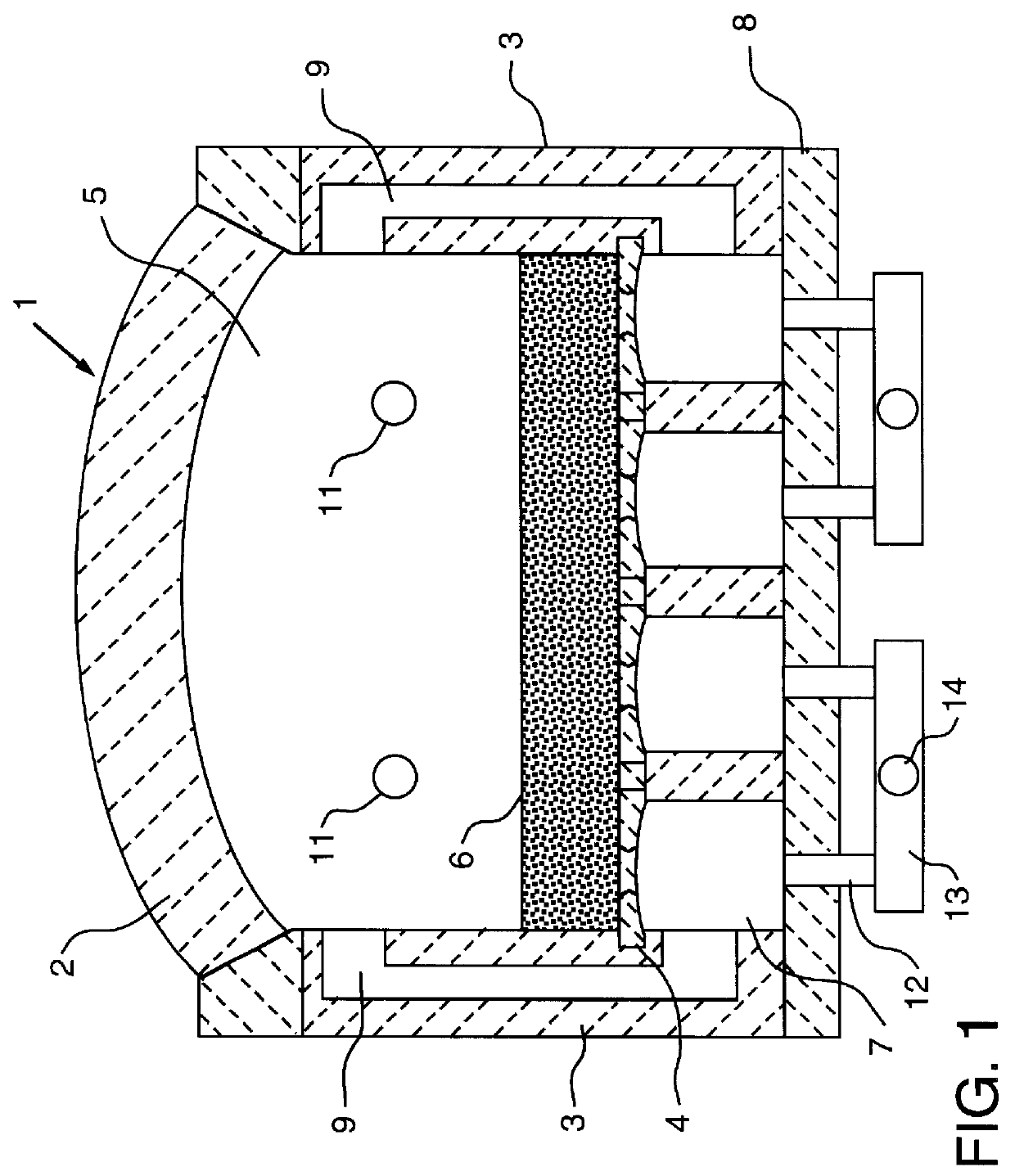

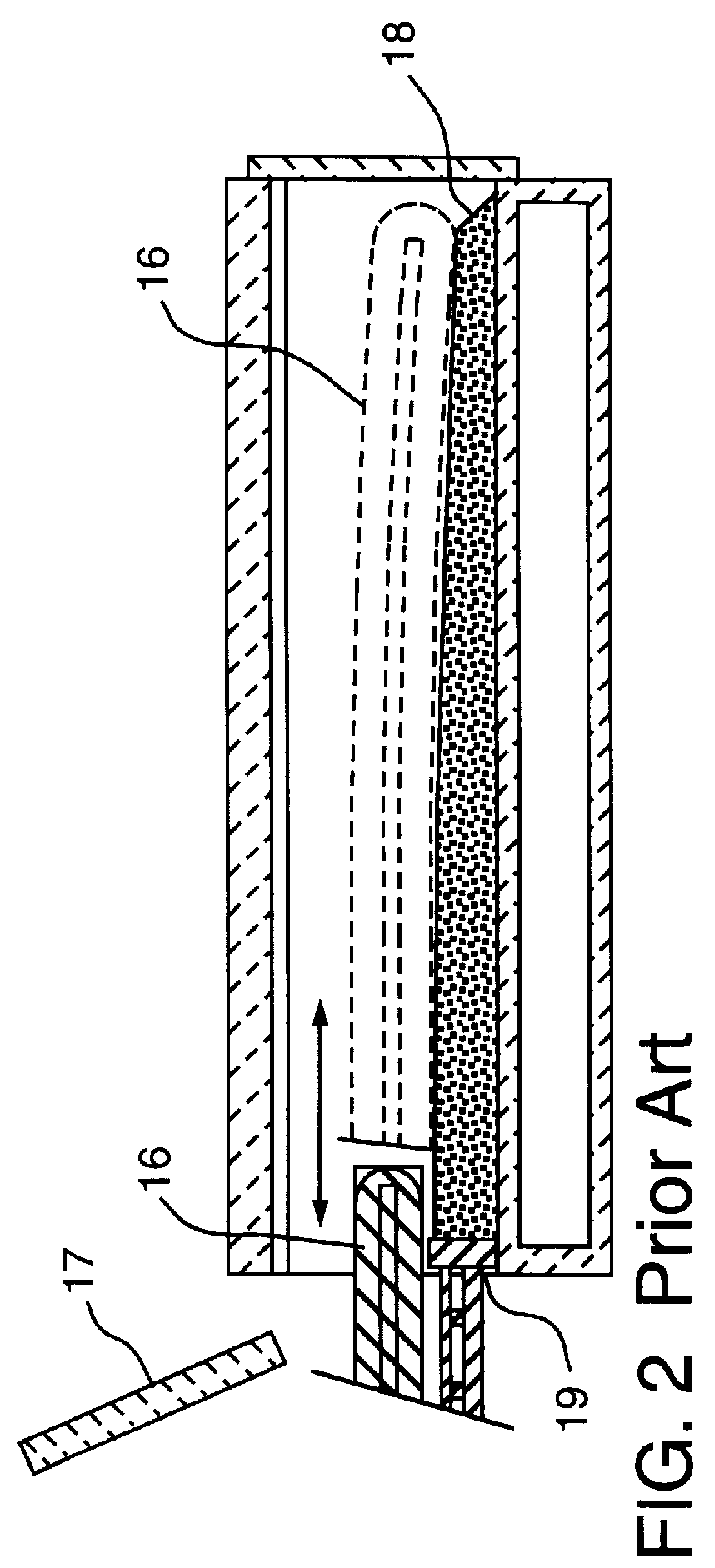

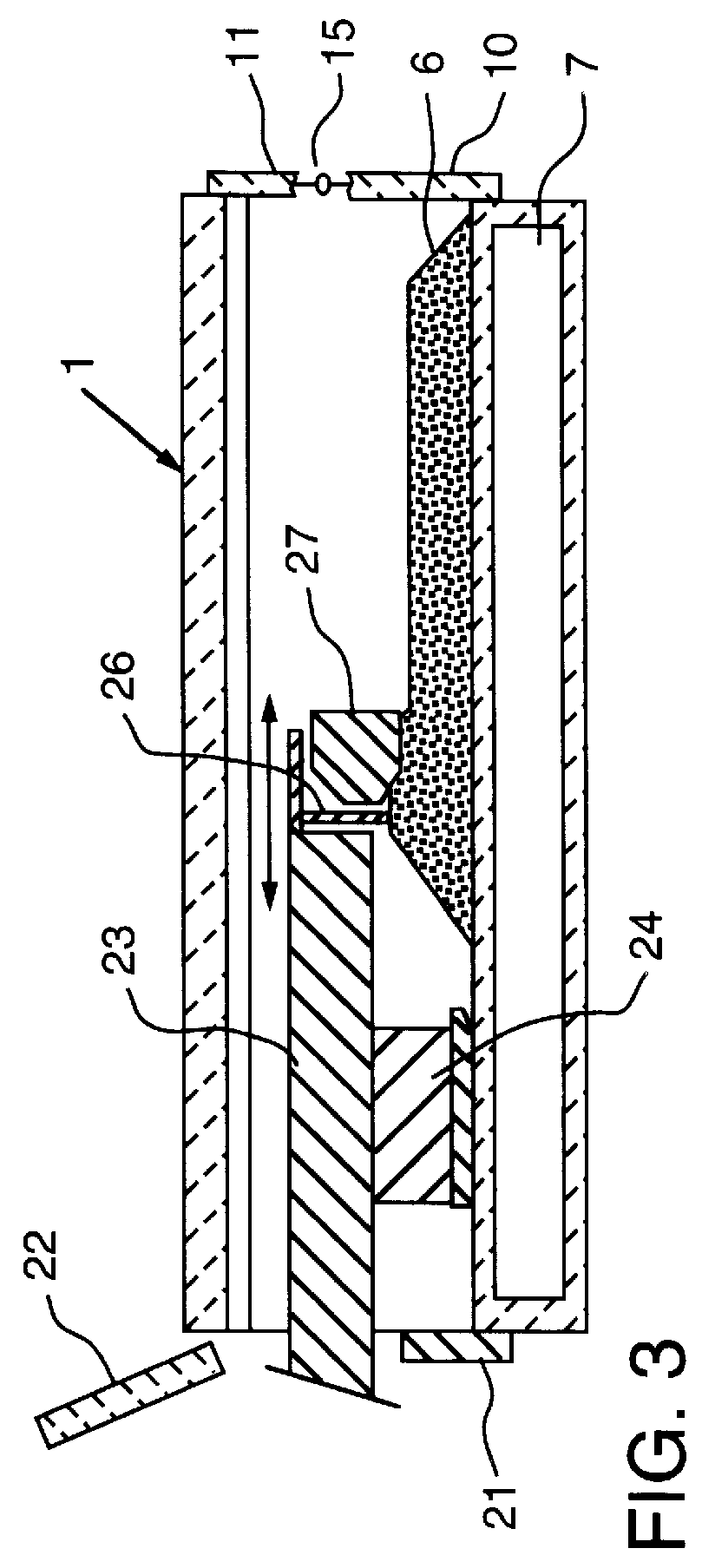

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

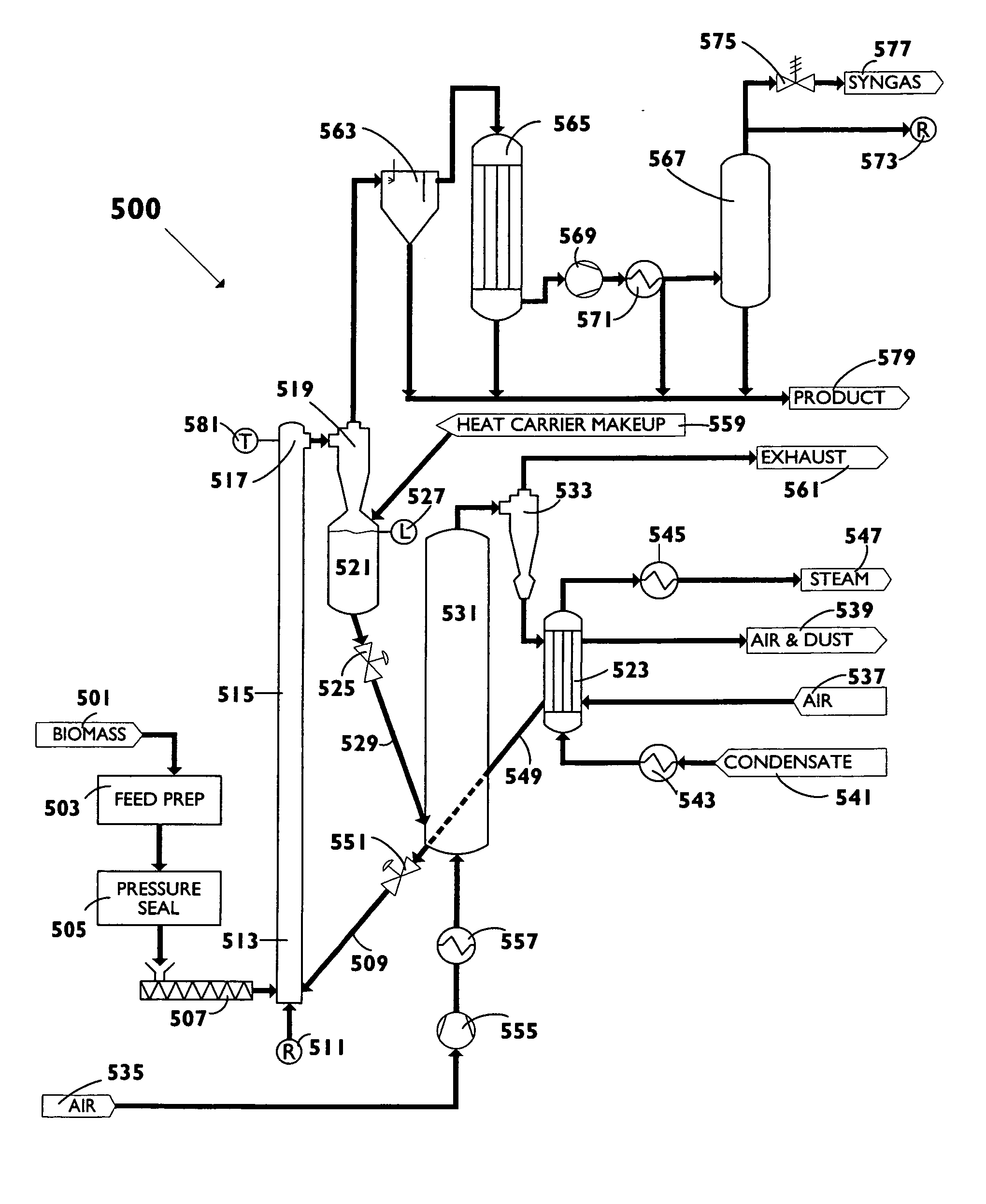

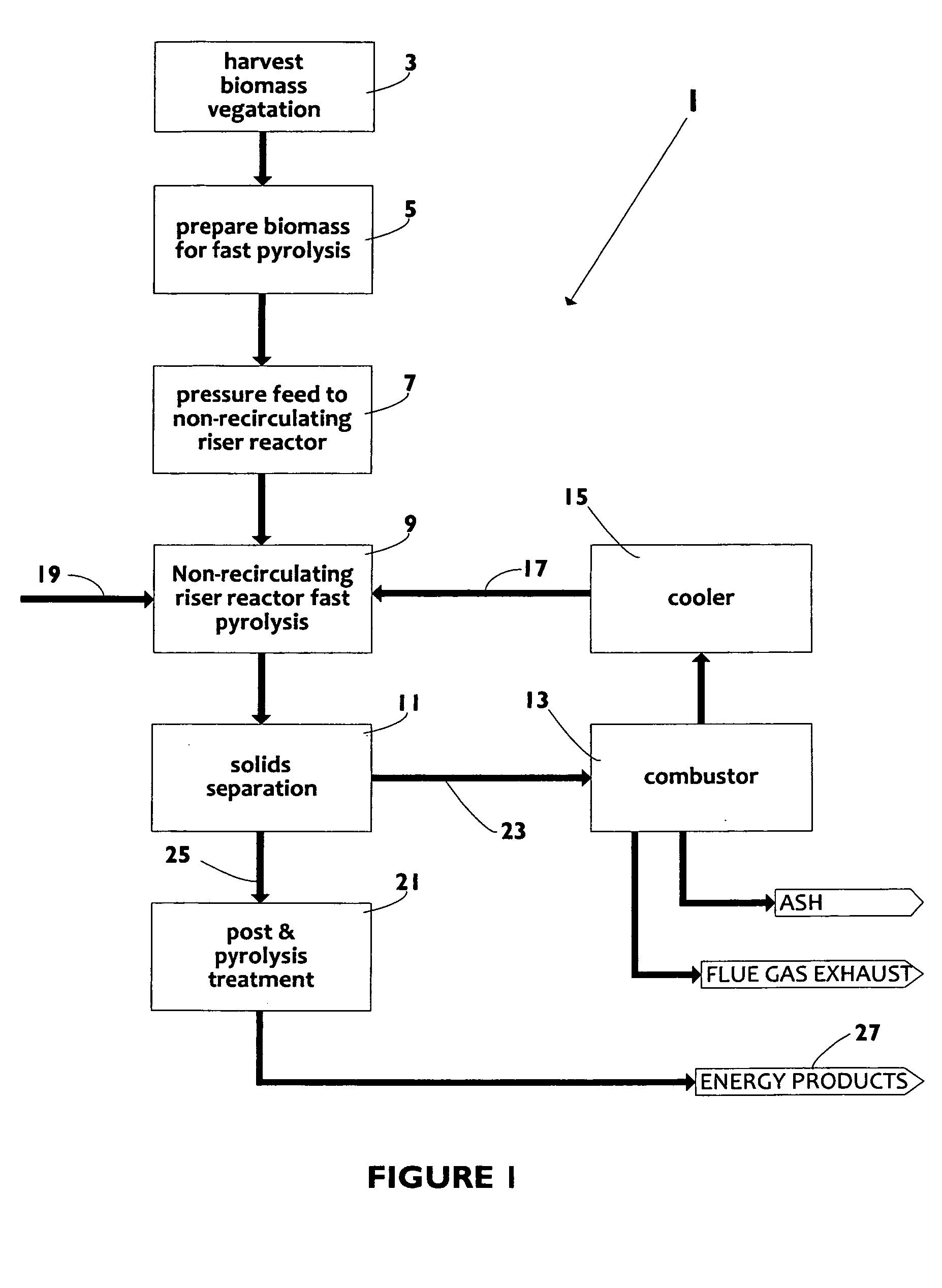

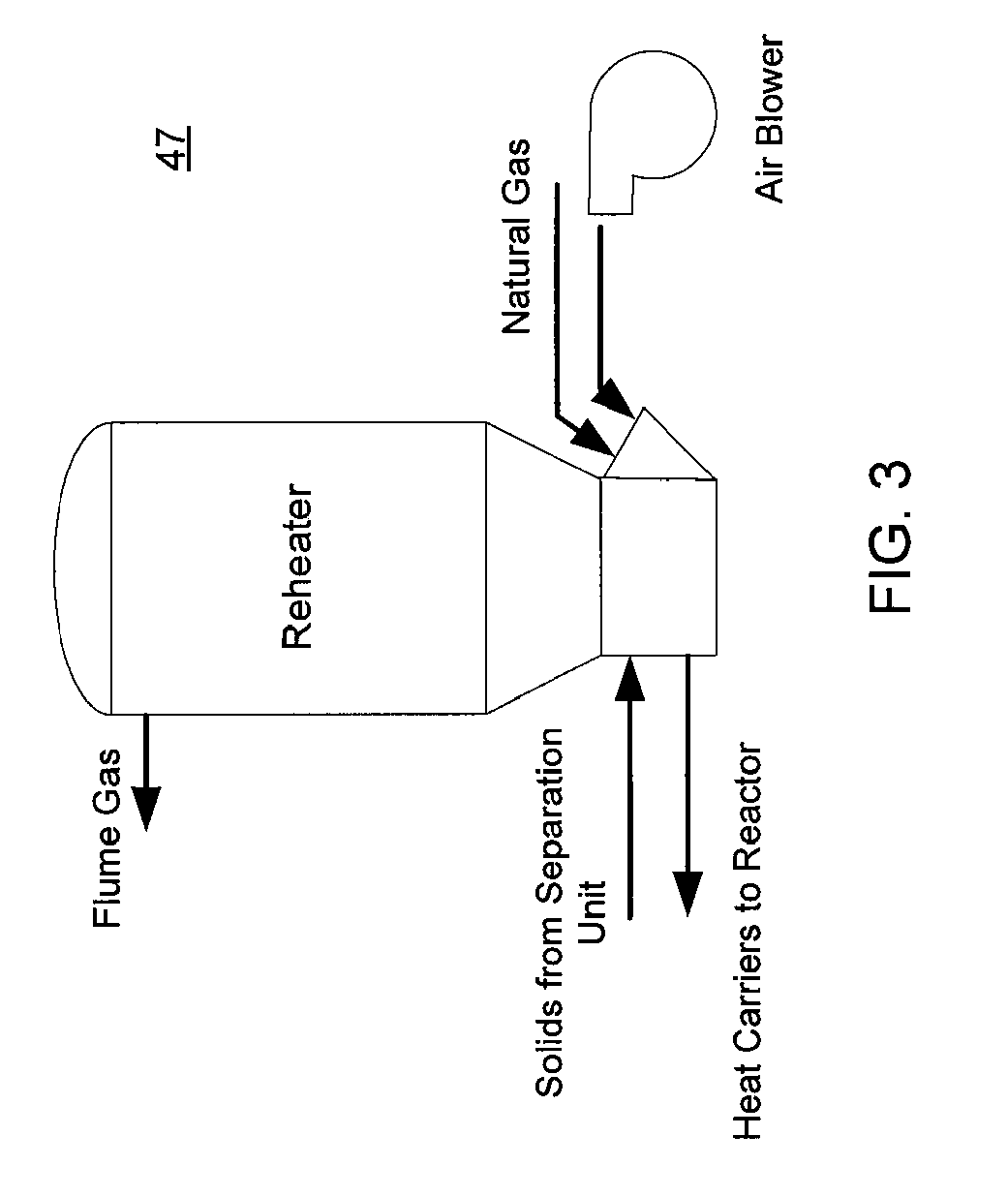

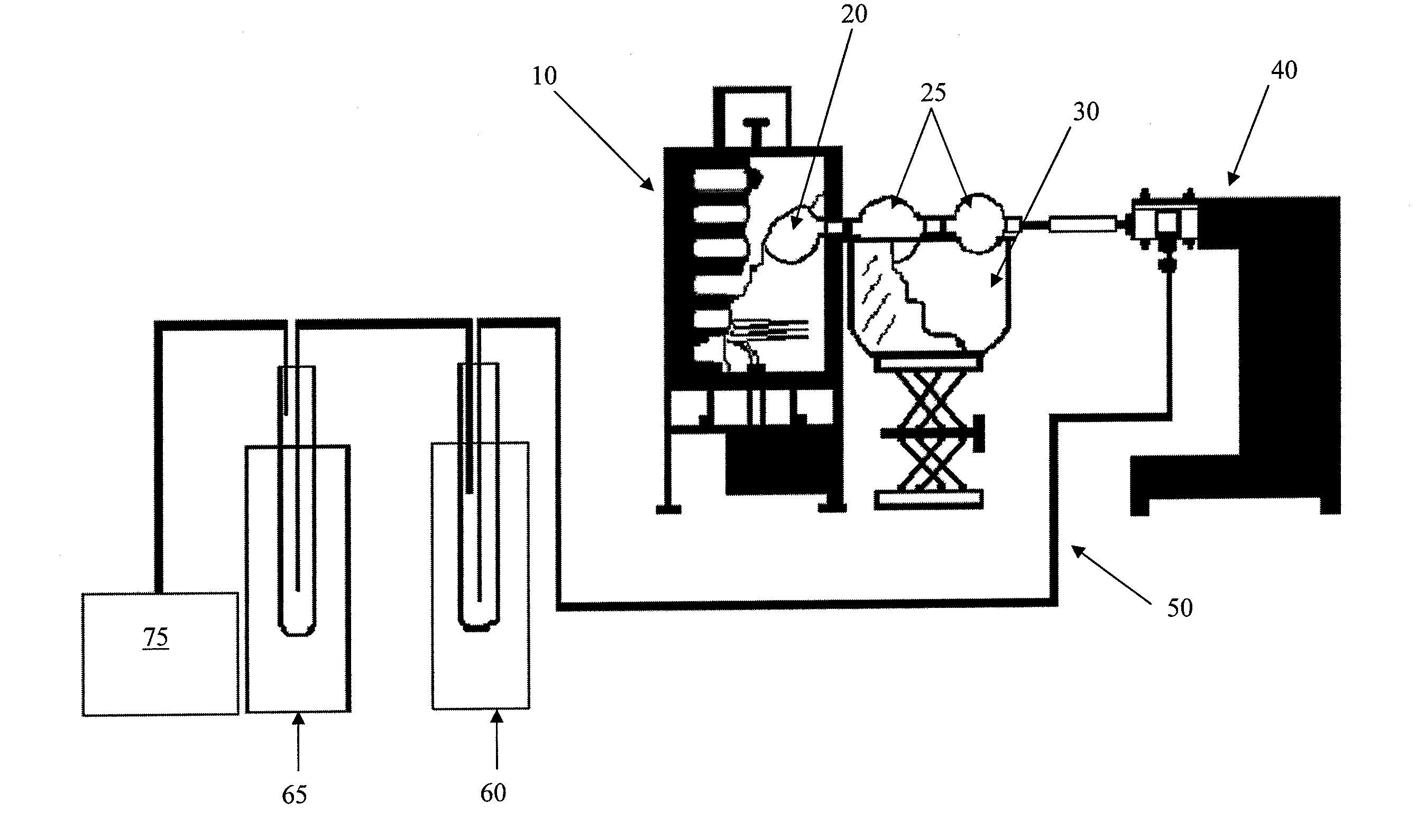

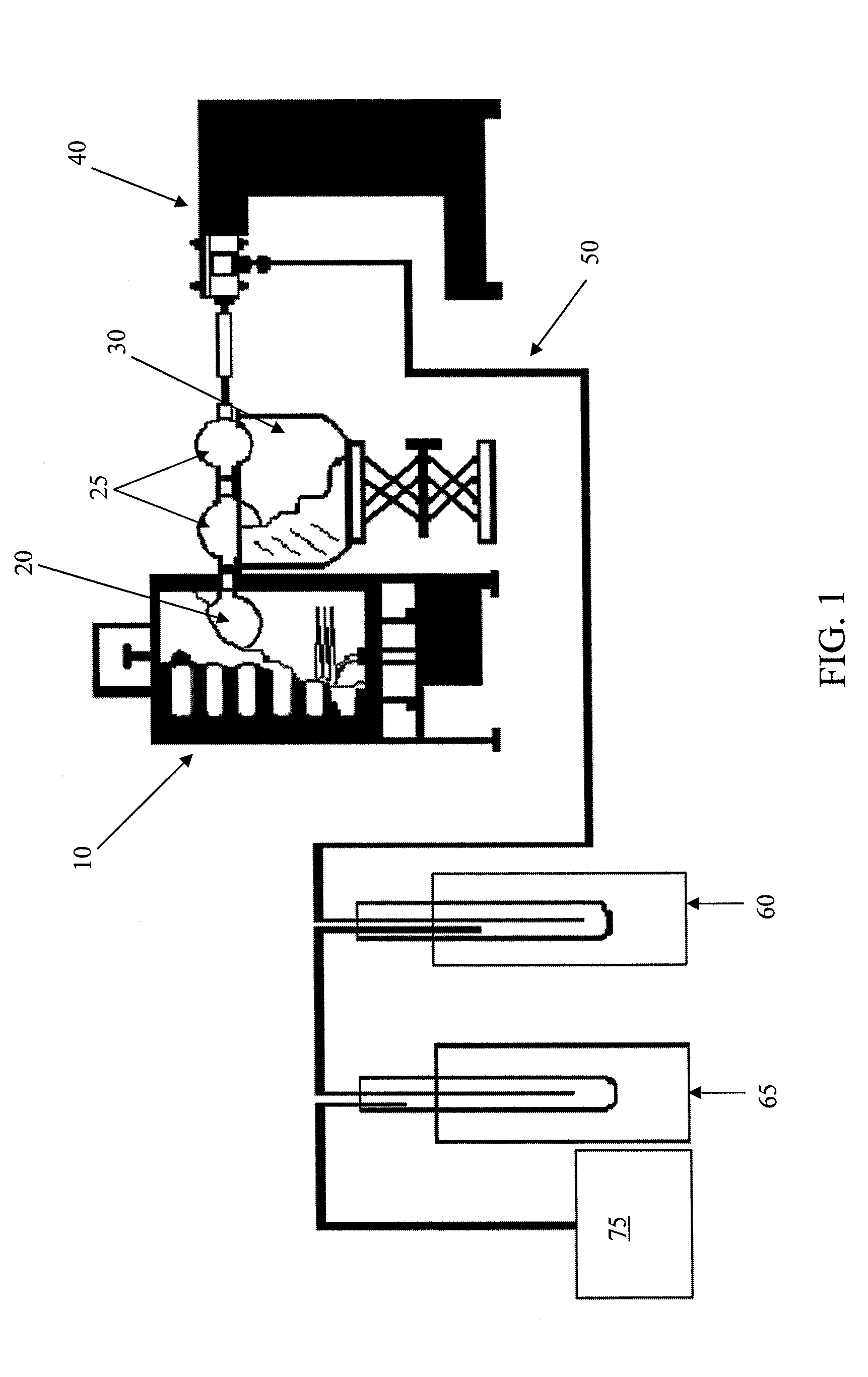

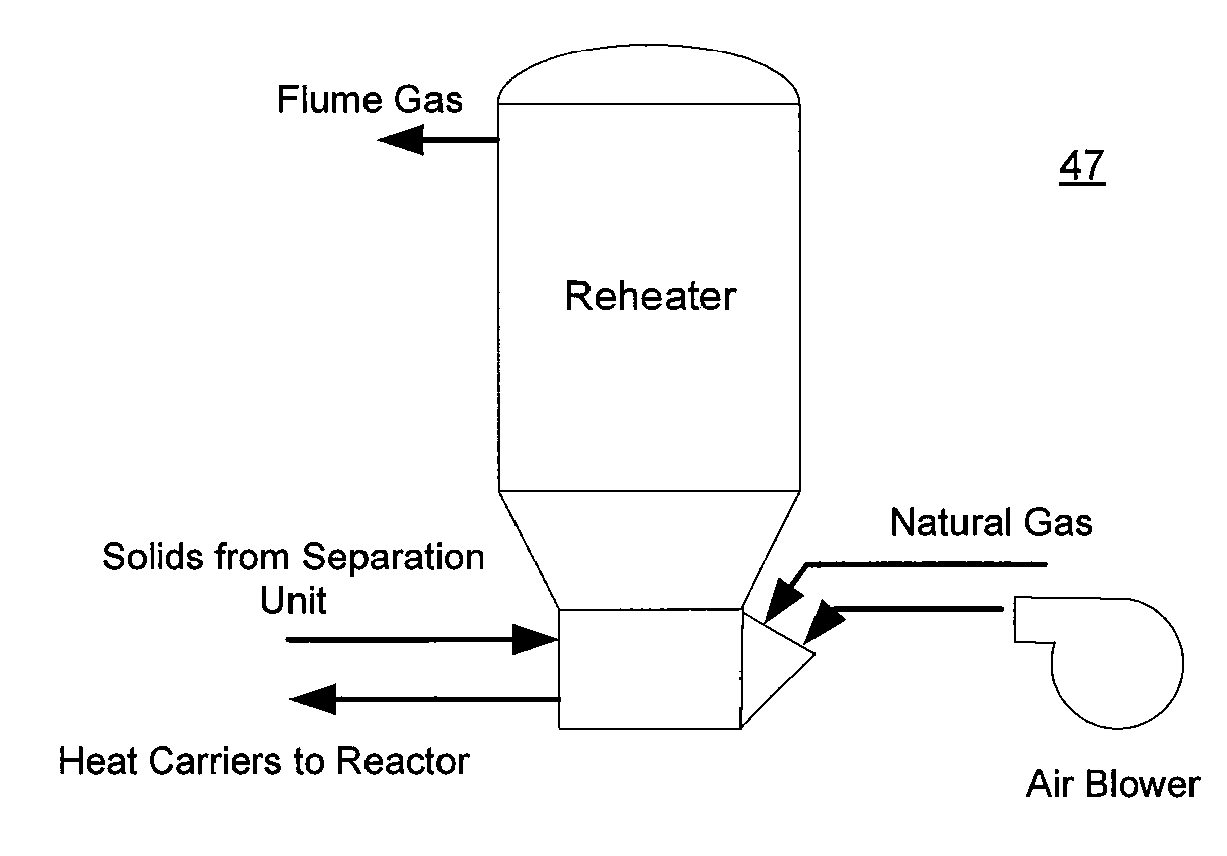

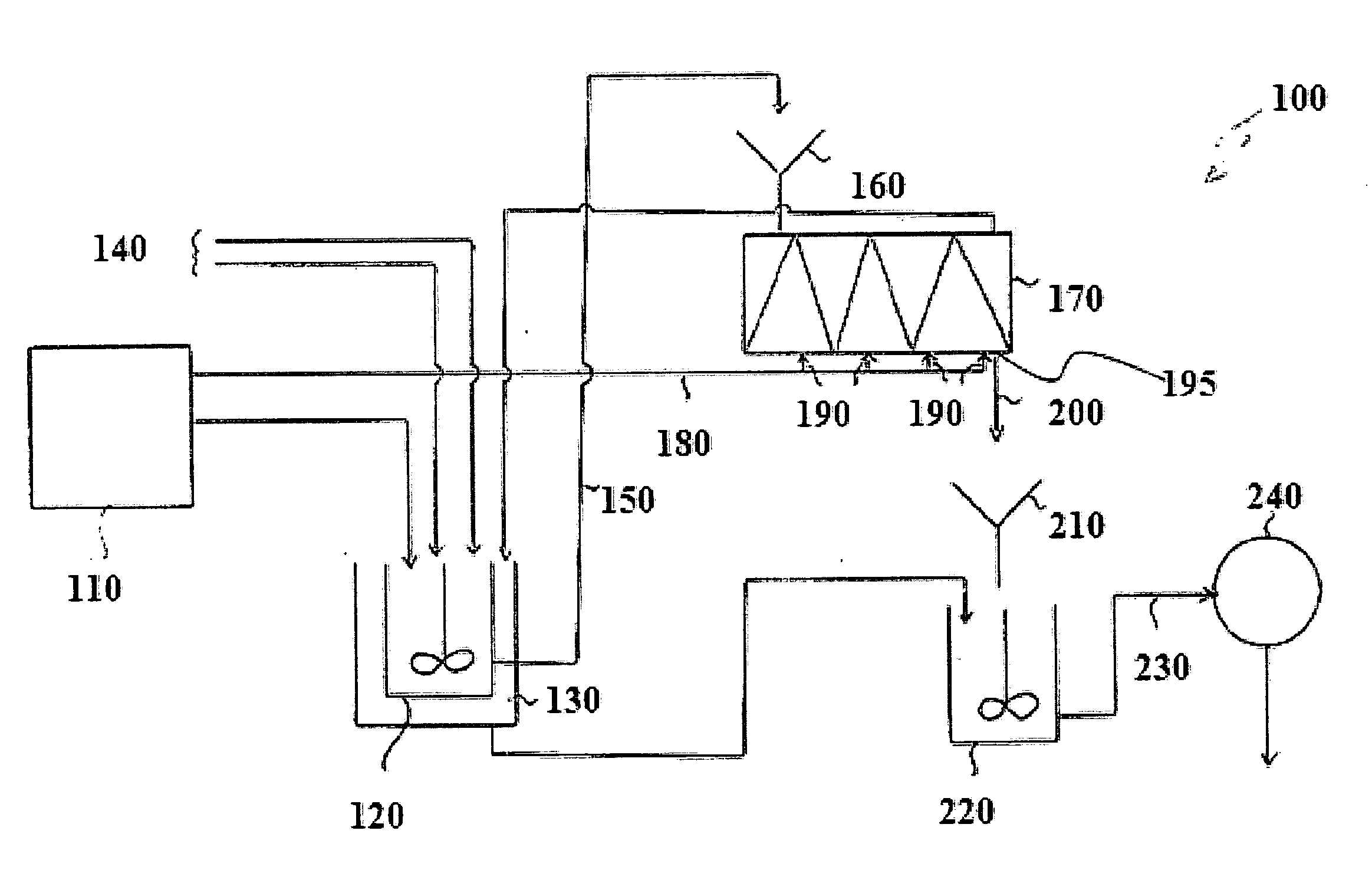

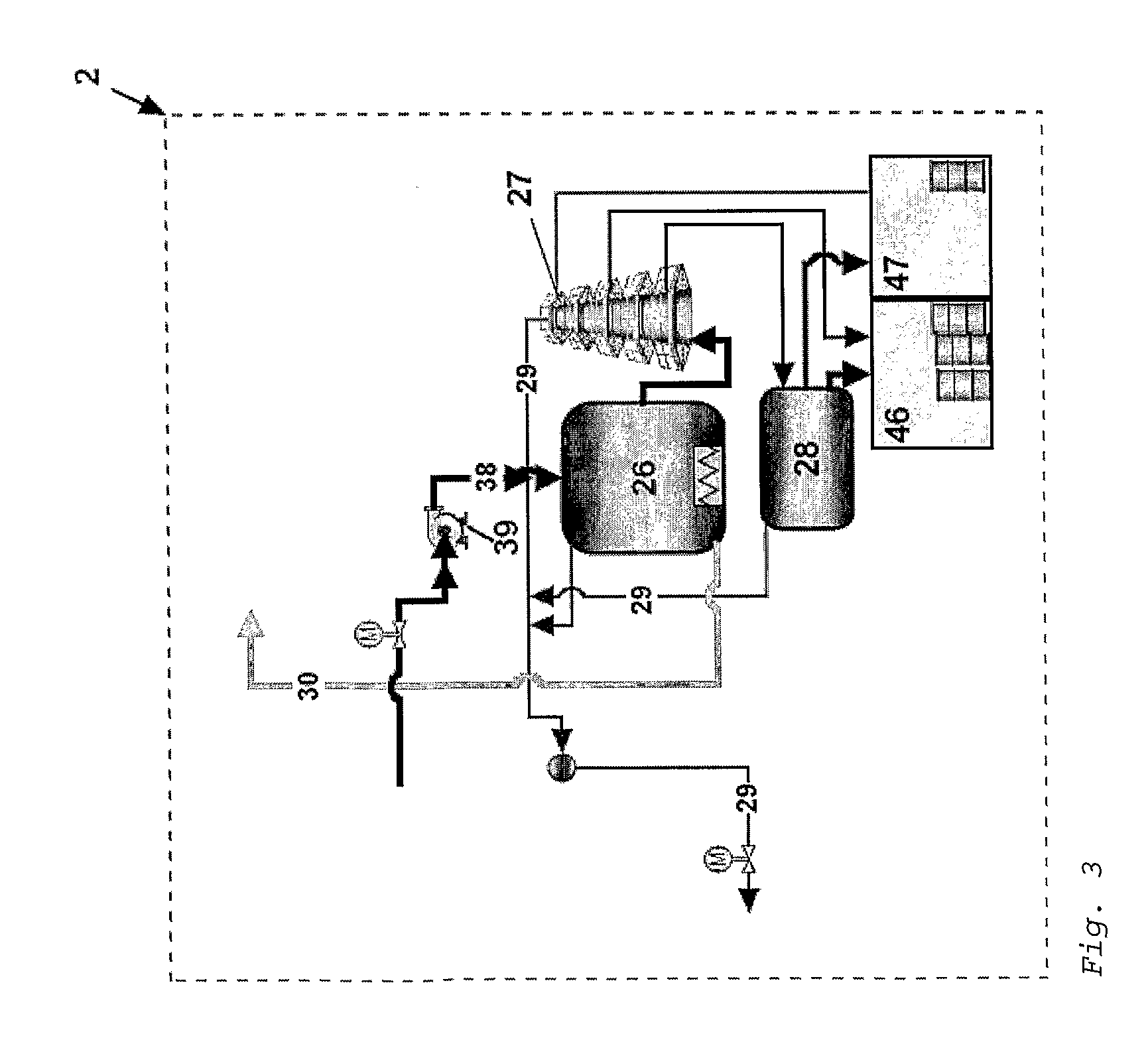

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

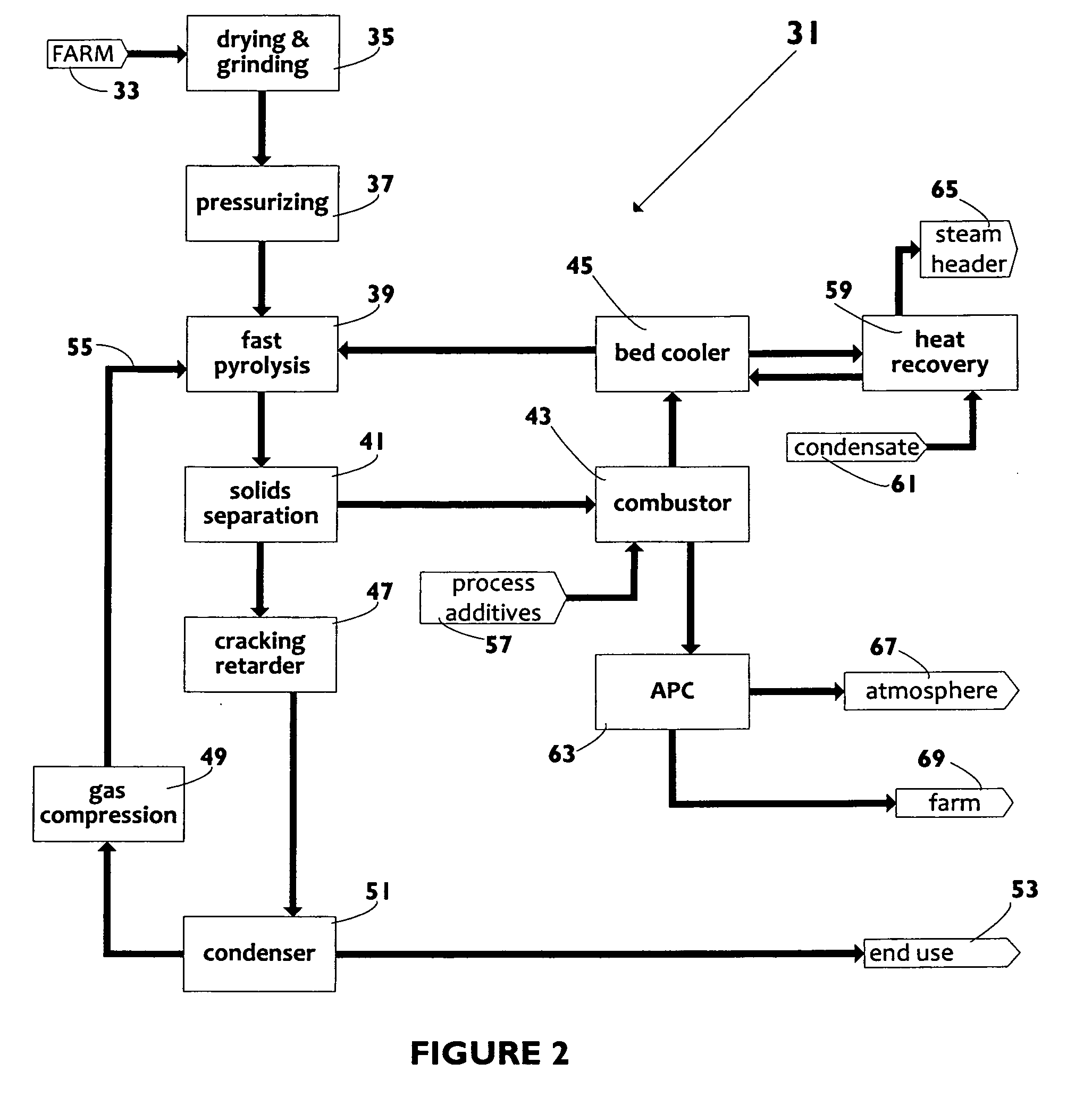

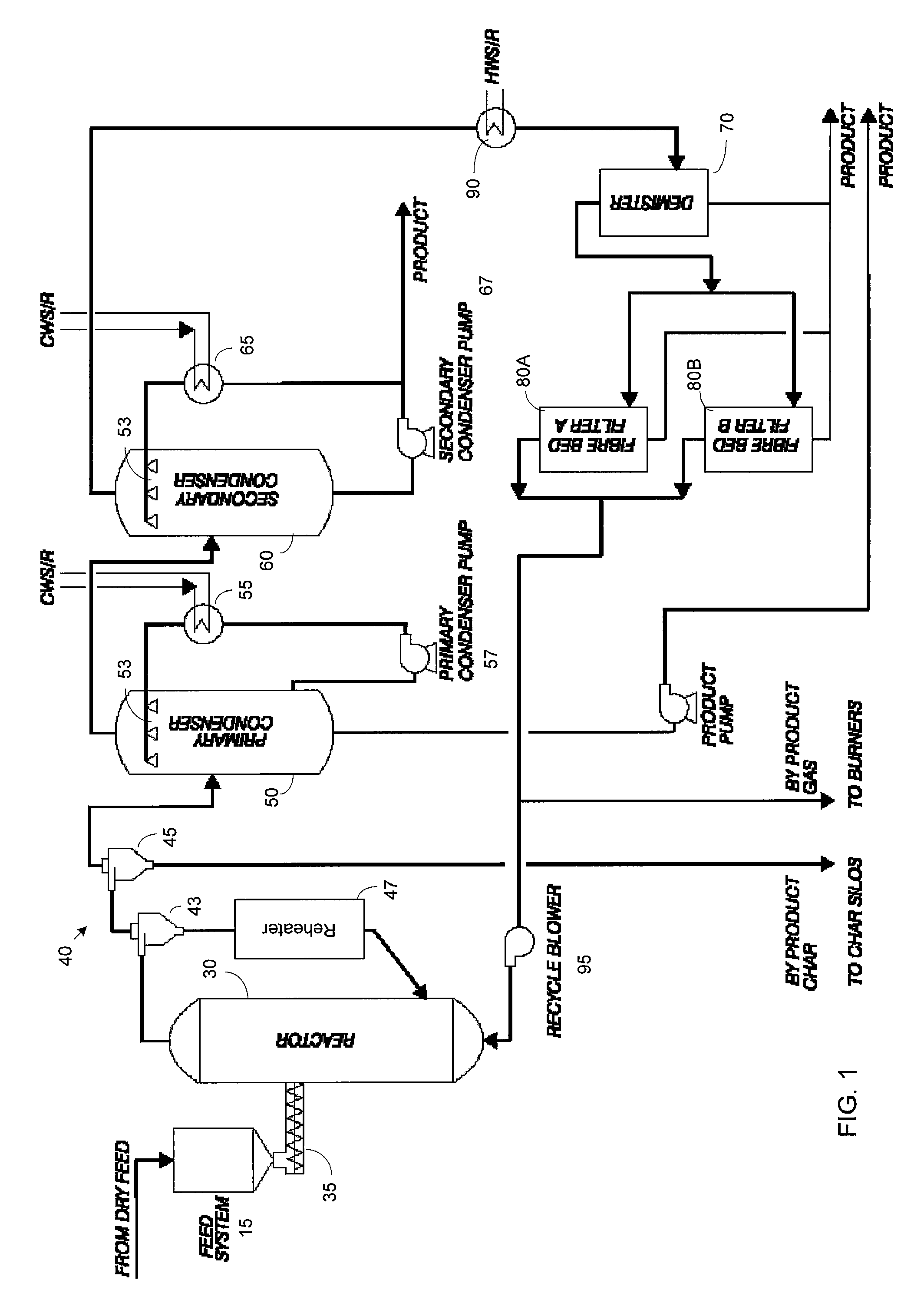

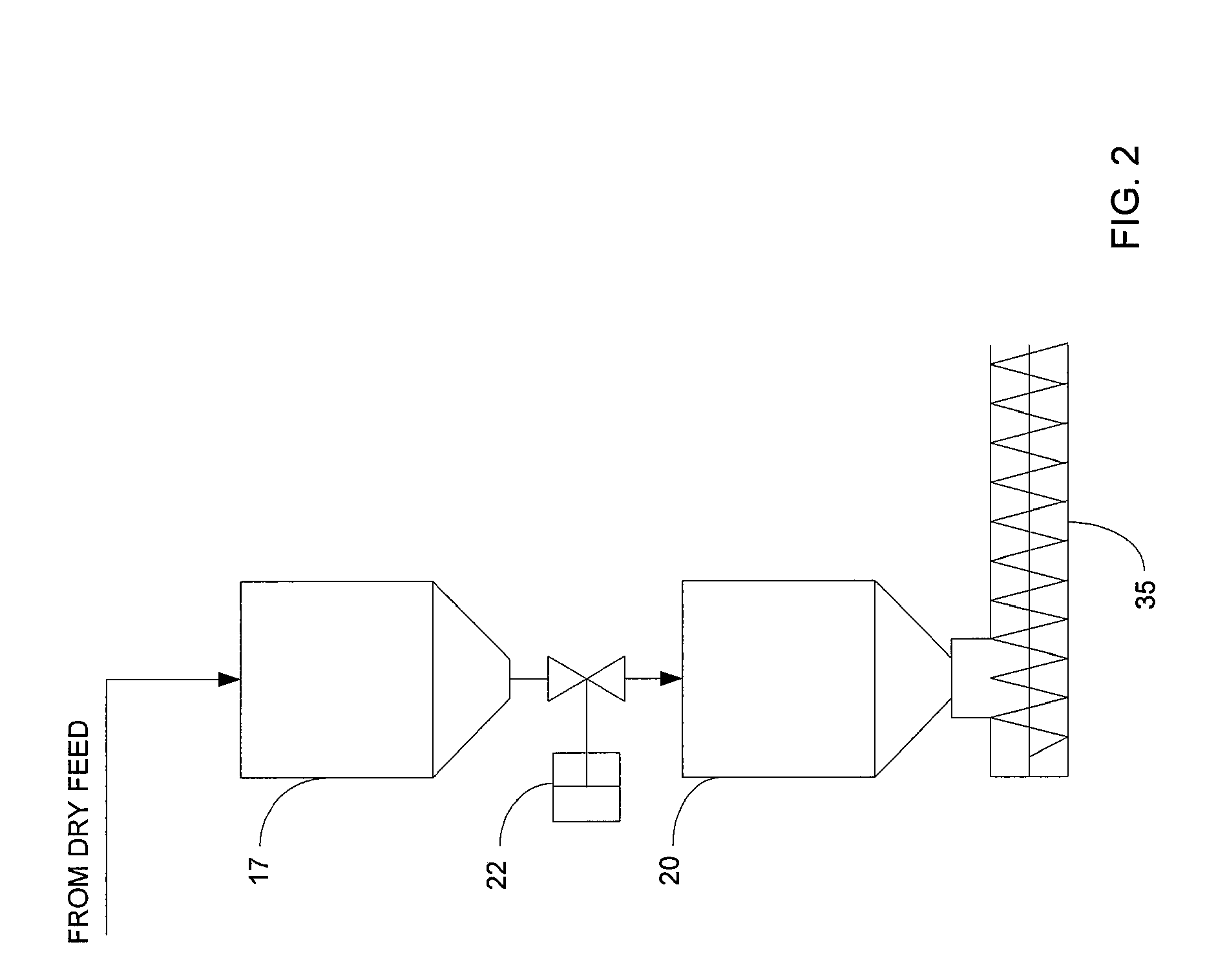

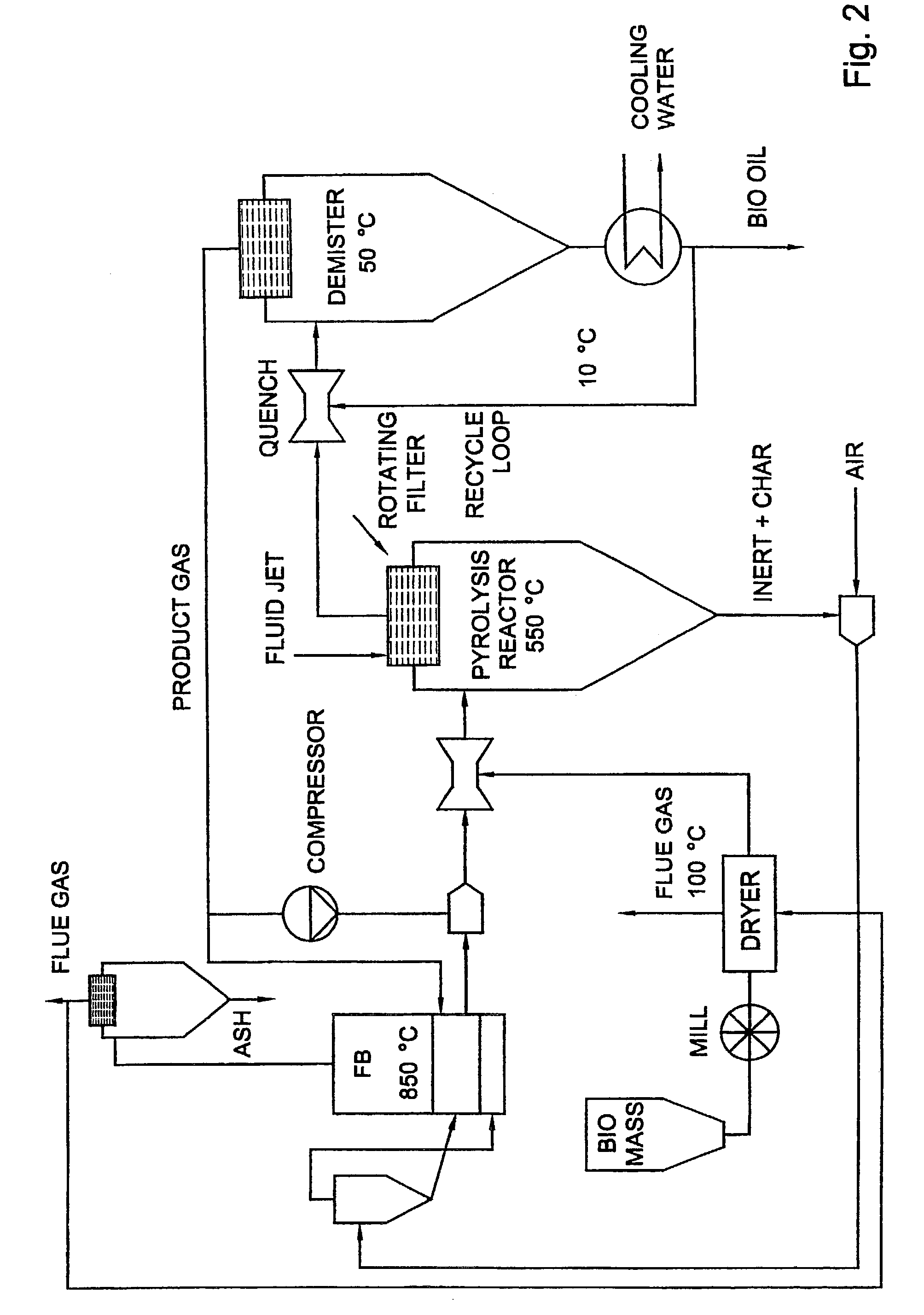

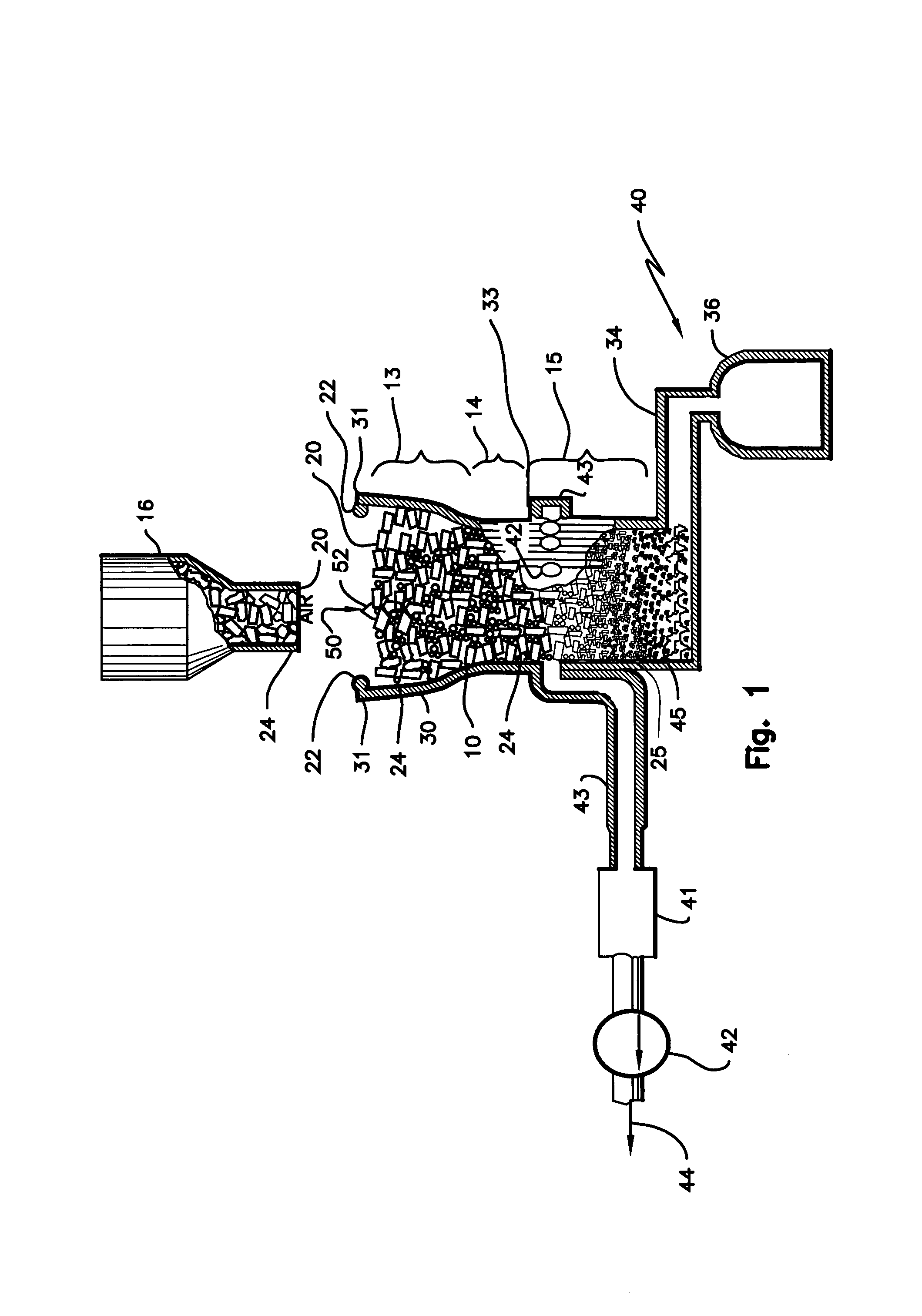

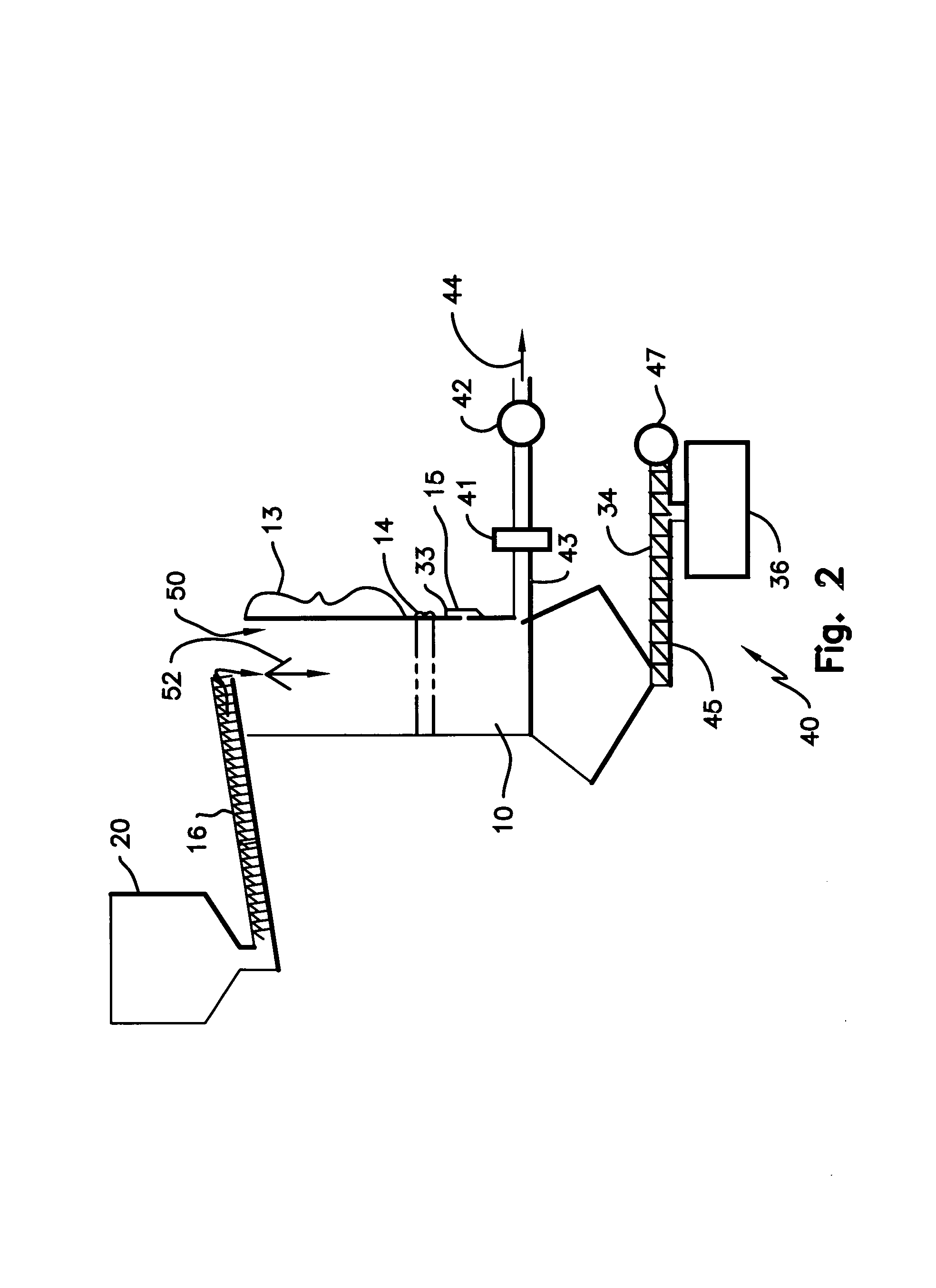

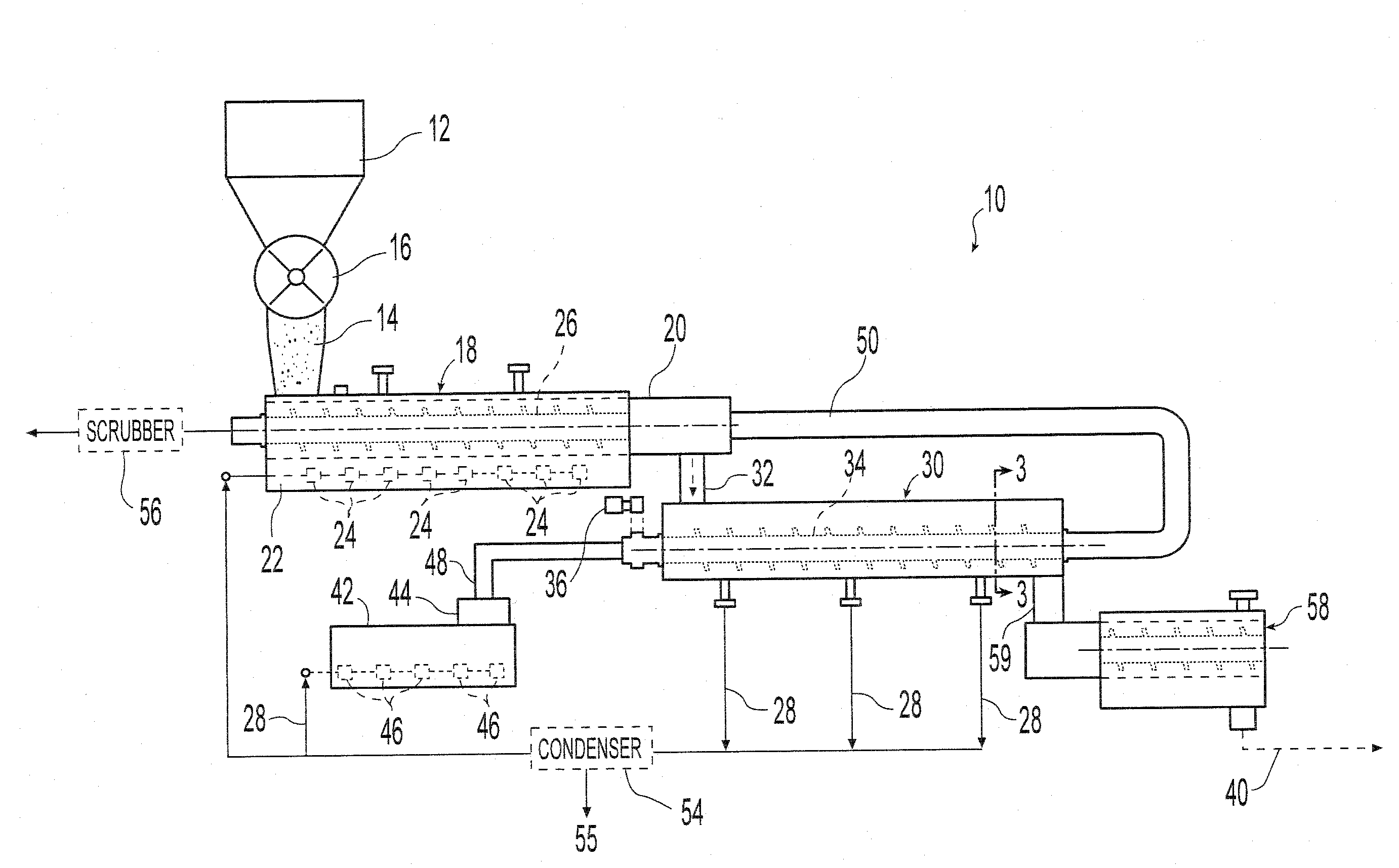

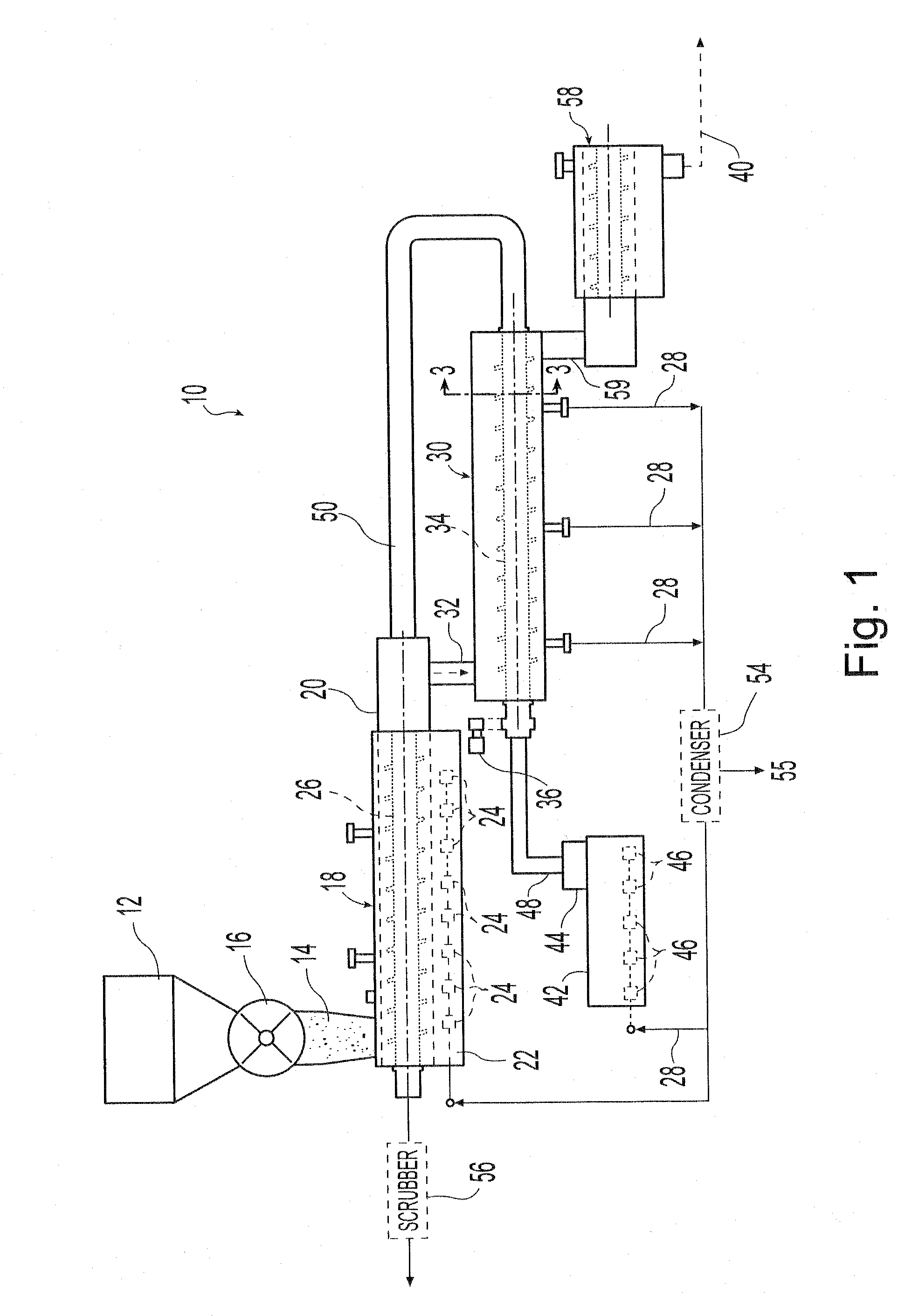

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

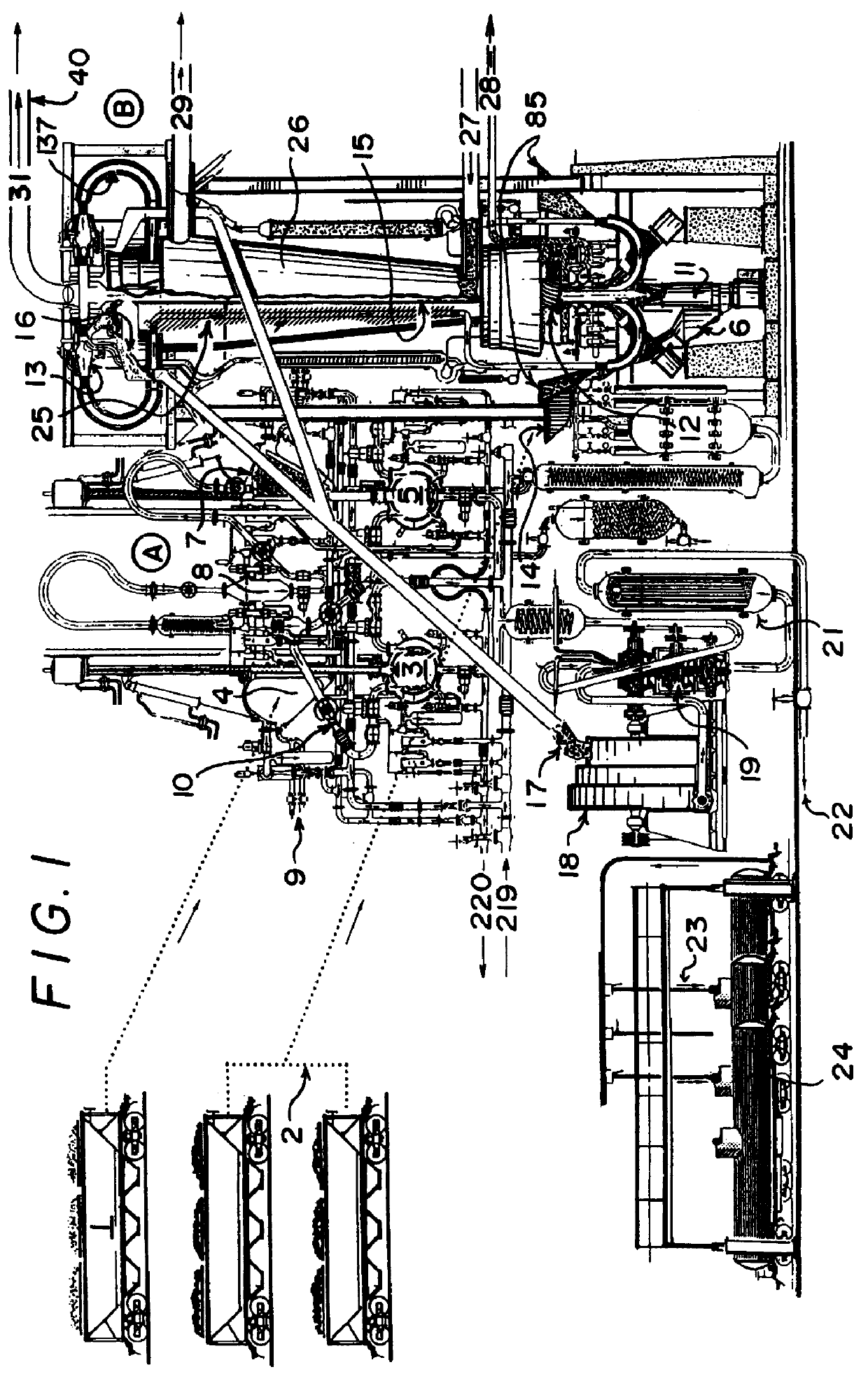

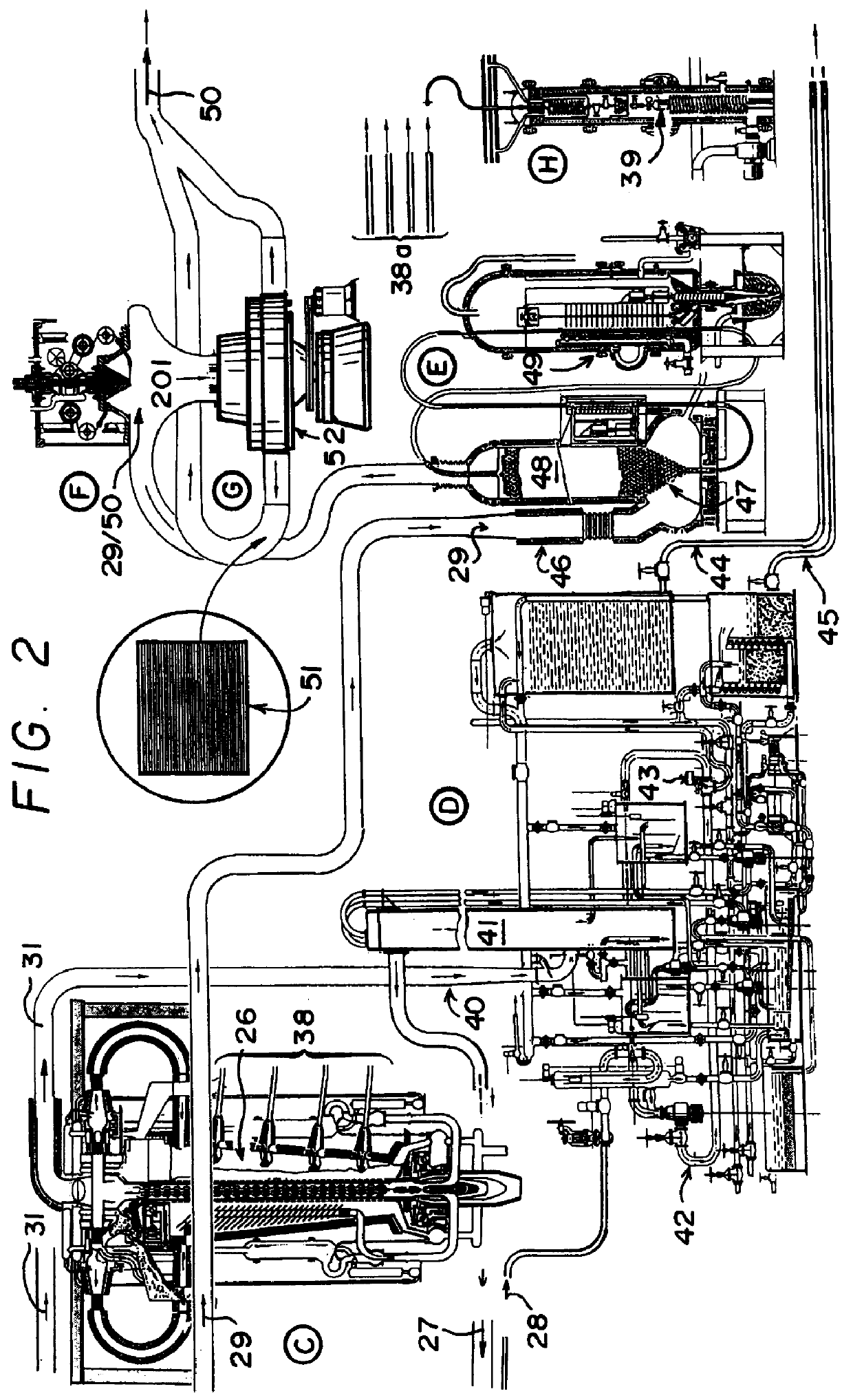

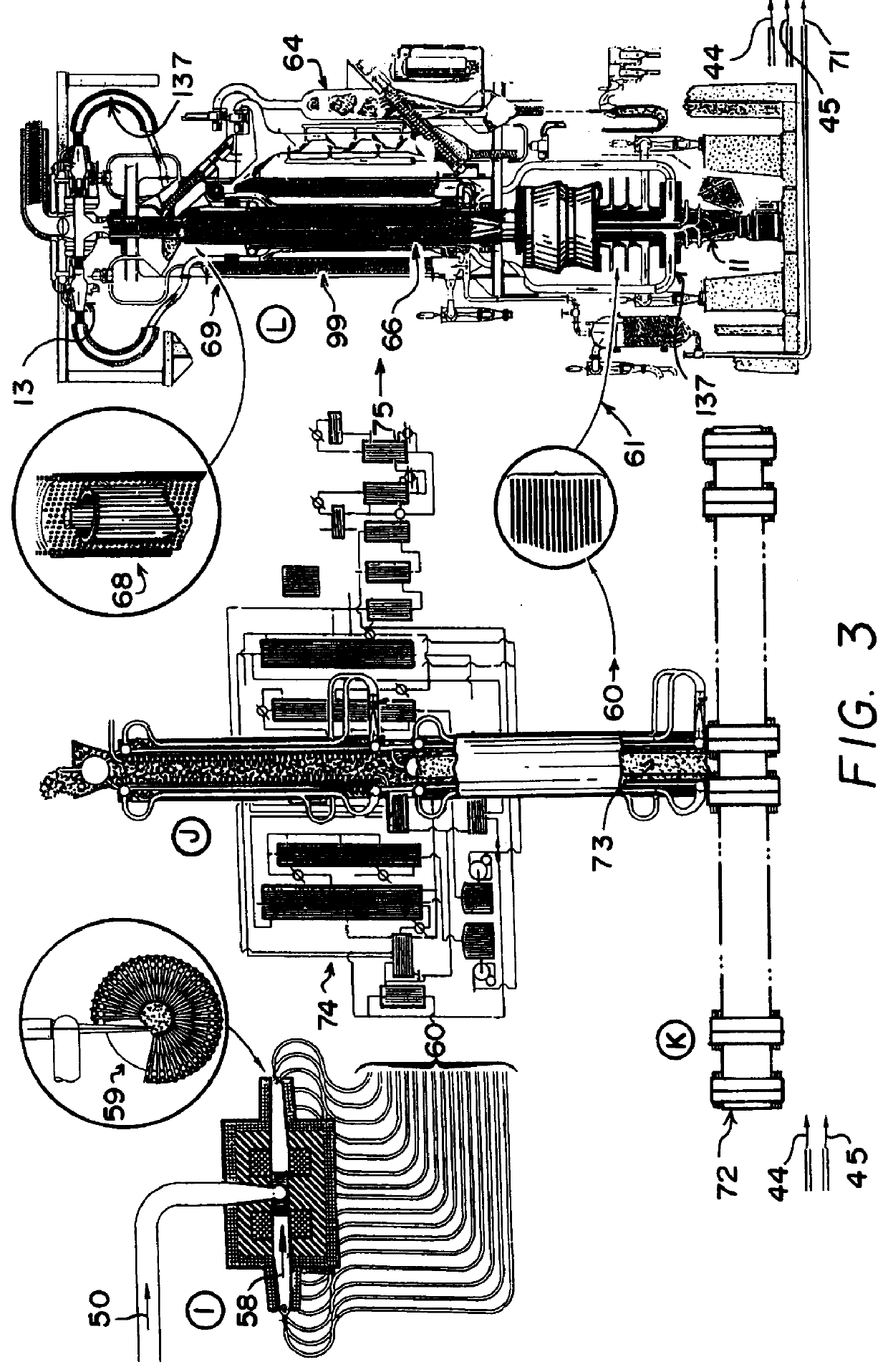

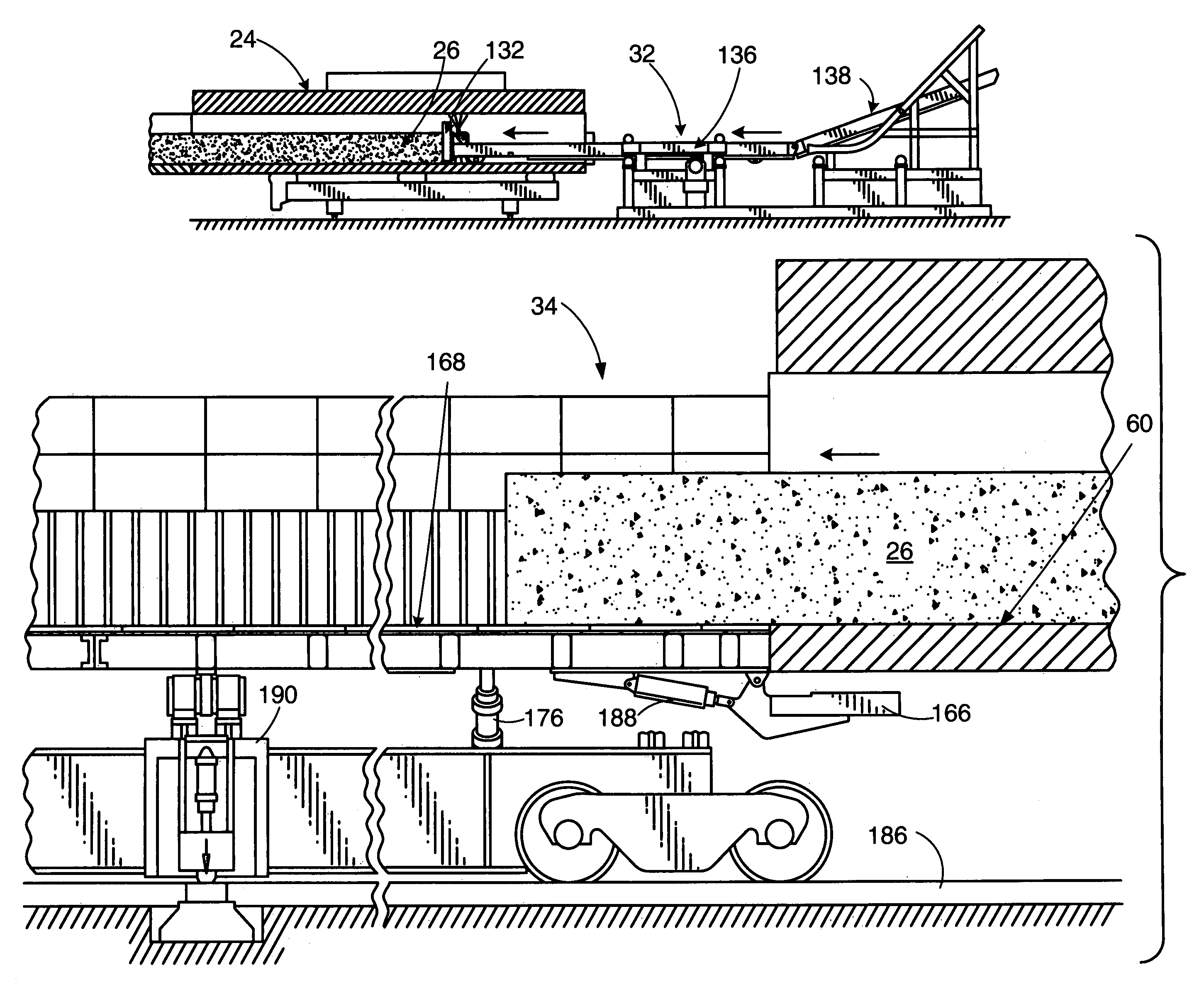

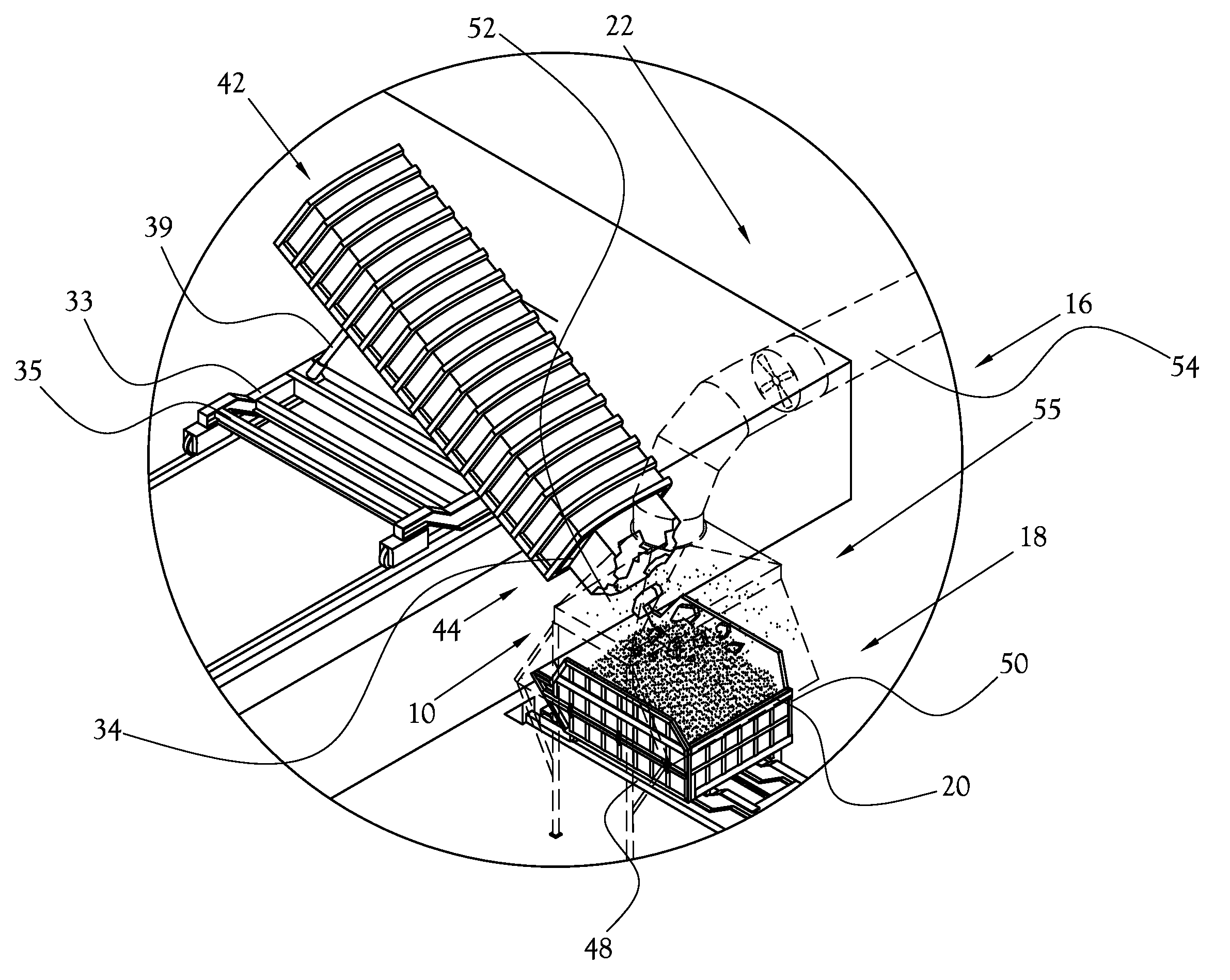

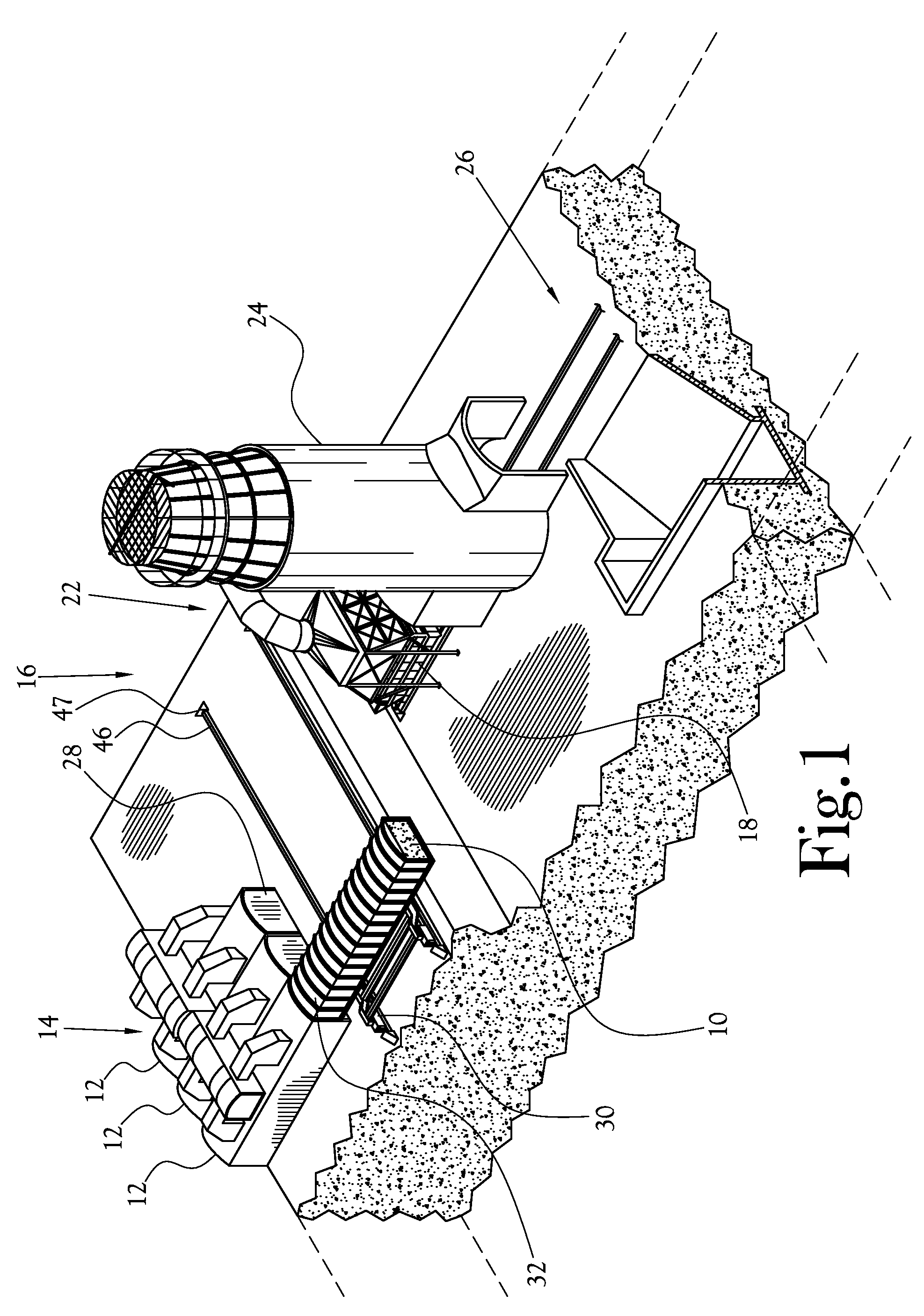

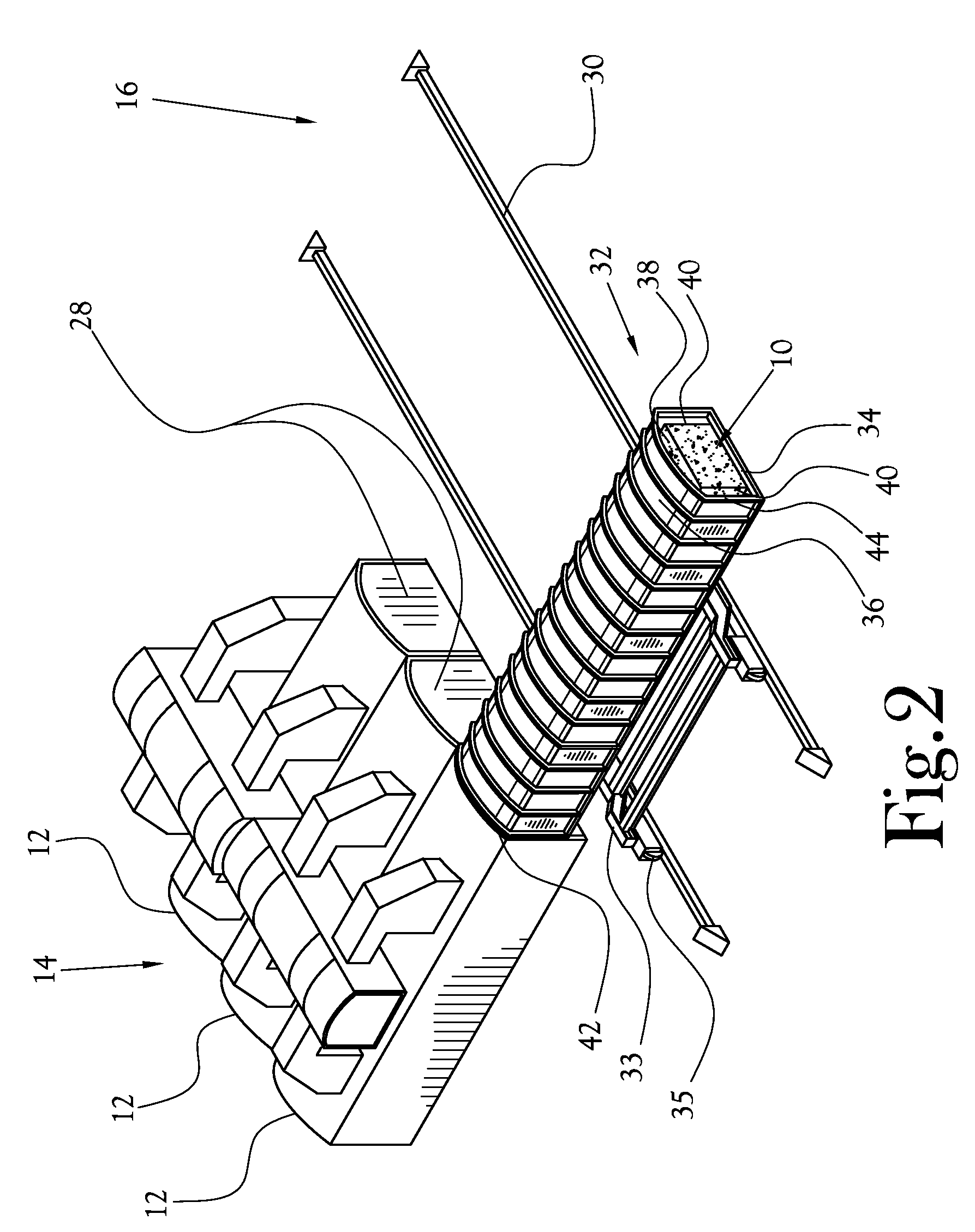

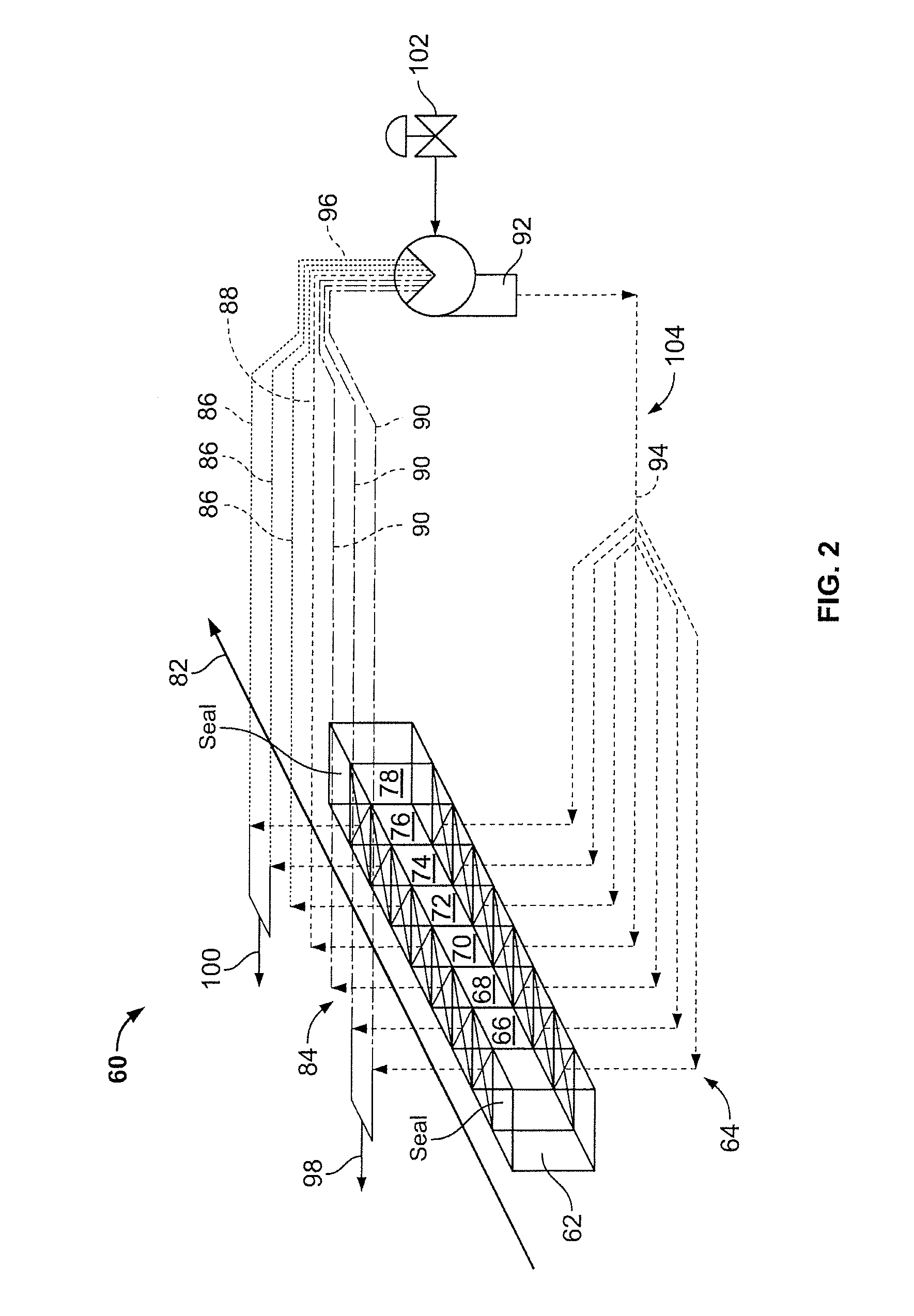

Coal bed vibration compactor for non-recovery coke oven

InactiveUS6059932AMechanical conveying coke ovensCharging-discharging device combinationsEngineeringCoke oven

A coal compaction system and method for a non-recovery coke oven having refractory roof, floor, side walls and end doors for coal charging and coke discharge provides an improved coal charging machine carrying a coal conveyor supported intermediate the ends of the conveyor to avoid conveyor sagging and non-uniform depth of a deposited coal bed, a number of pressurized fluid-driven vibratory compactors mounted on an end of the charging machine and spaced-apart across the width of the coal bed and serving to compact the coal bed on a retraction stroke of the charging machine, a pivoted lifting frame mounted on the charging machine above the compactors and from which the compactors individually are suspended and are provided with individual supply of pressurized fluid, and a coke pusher head mounted on the charging machine behind the compactors and serving, when the lifting frame and associated compactors are raised, to push finished coke from the coke oven.

Owner:PENNSYLVANIA COKE TECH

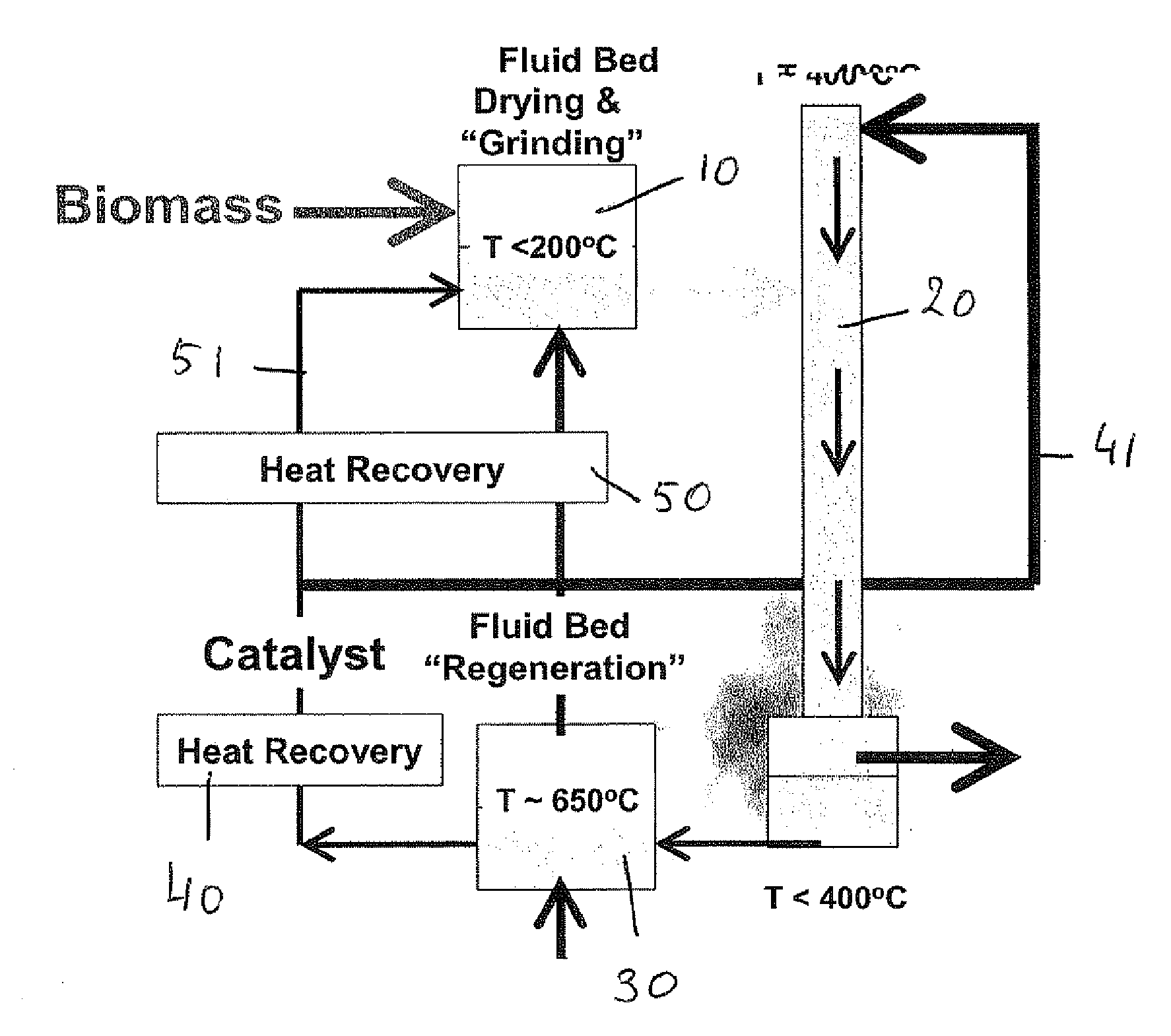

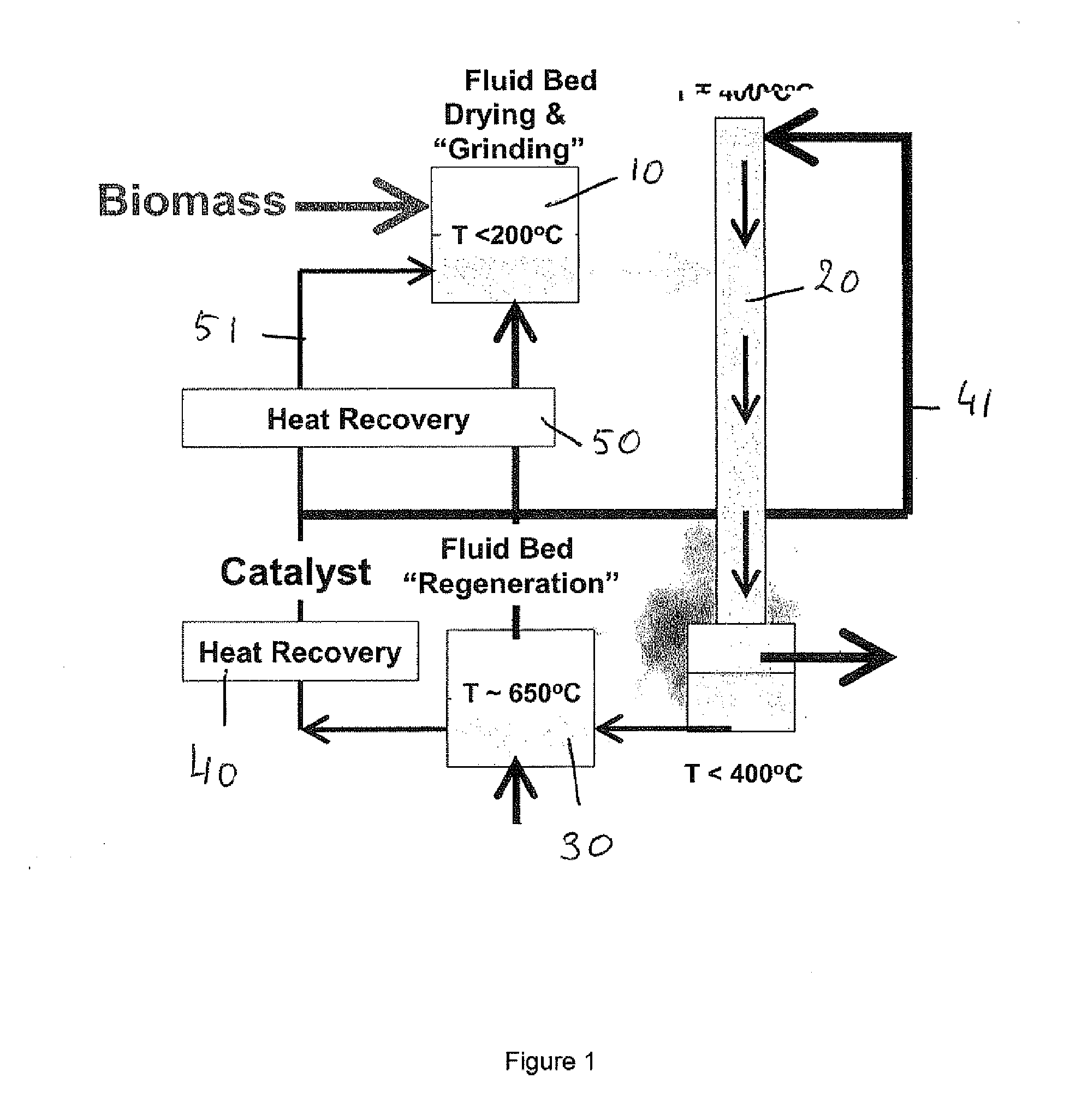

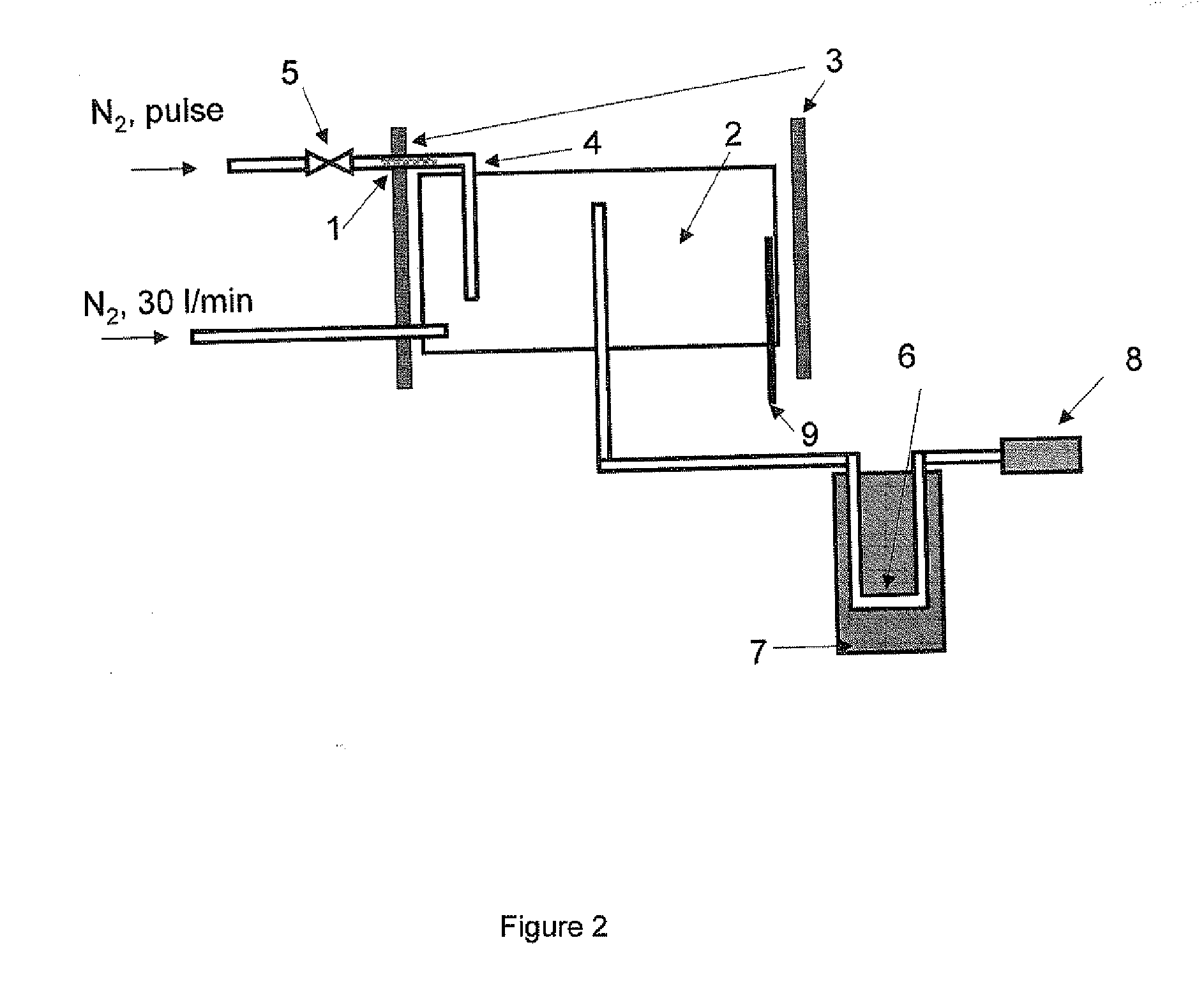

Process for converting carbon-based energy carrier material

InactiveUS20090308787A1Thermal non-catalytic crackingCatalytic crackingPtru catalystPhysical chemistry

A process is disclosed process for converting a solid or highly viscous carbon-based energy carrier material to liquid and gaseous reaction products, said process comprising the steps of: a) contacting the carbon-based energy carrier material with a particulate catalyst material b) converting the carbon-based energy carrier material at a reaction temperature between 200° C. and 450° C., preferably between 250° C. and 350° C., thereby forming reaction products in the vapor phase. In a preferred embodiment the process comprises the additional step of: c) separating the vapor phase reaction products from the particulate catalyst material within 10 seconds after said reaction products are formed; In a further preferred embodiment step c) is followed by: d) quenching the reaction products to a temperature below 200° C.

Owner:MARD INC

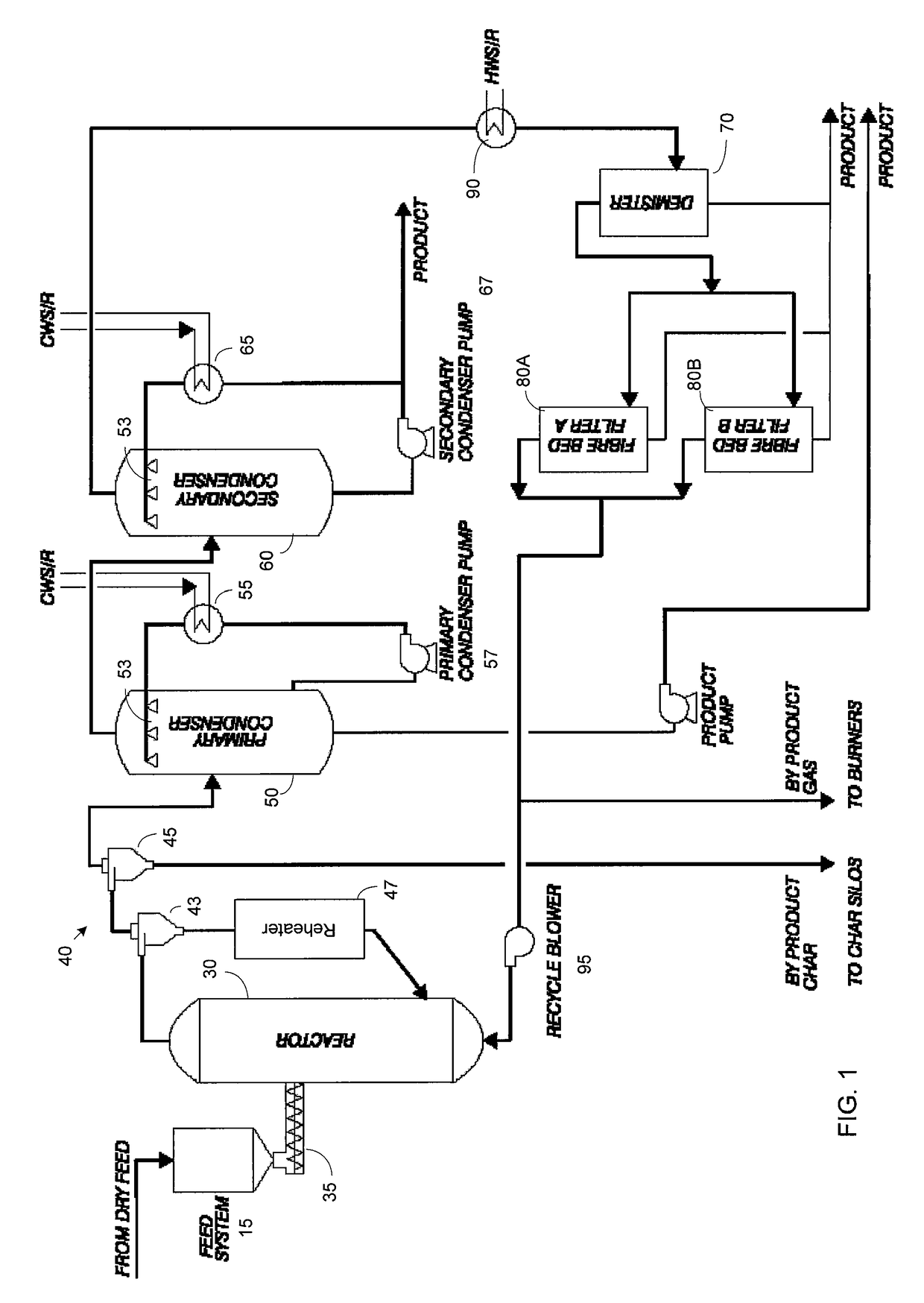

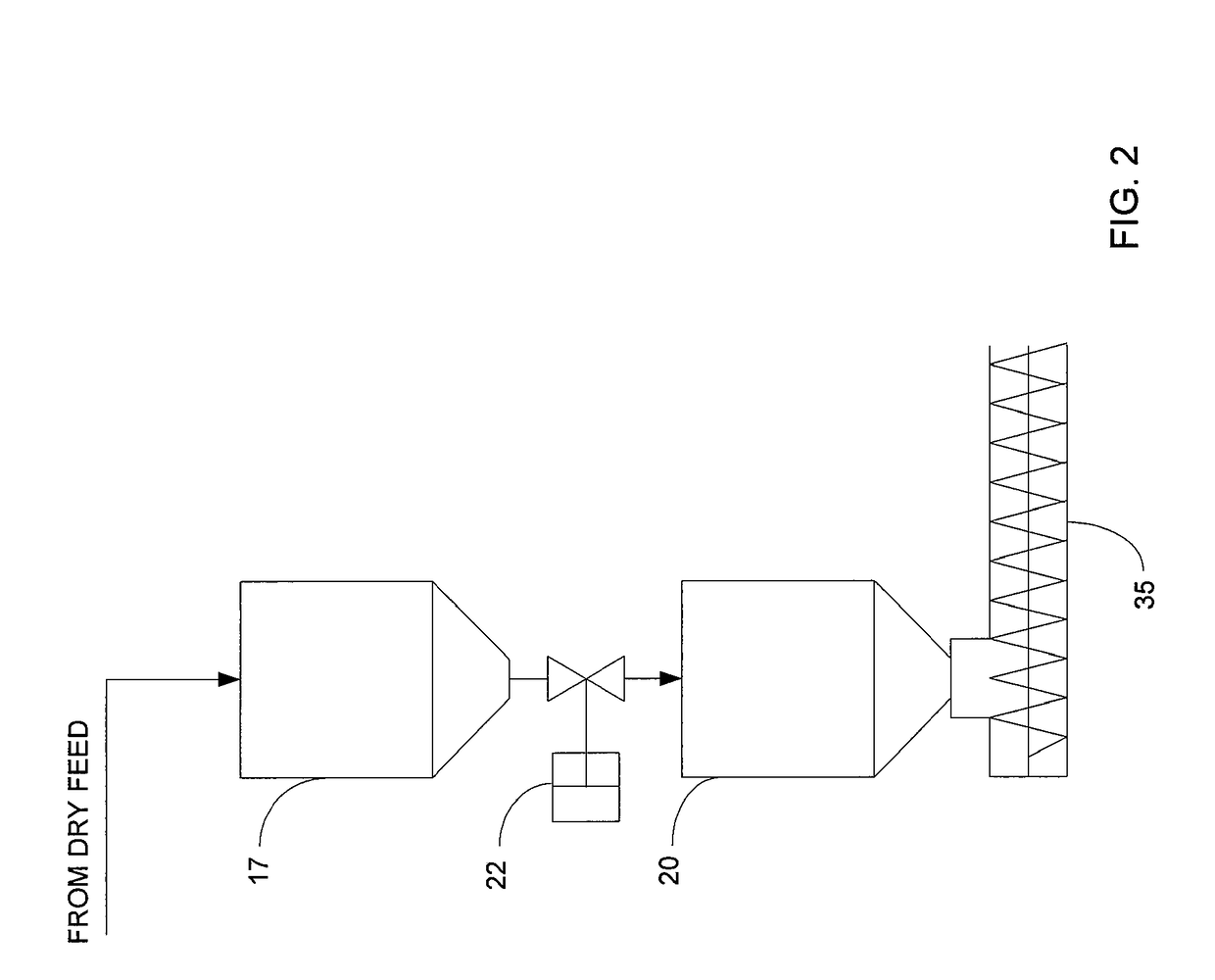

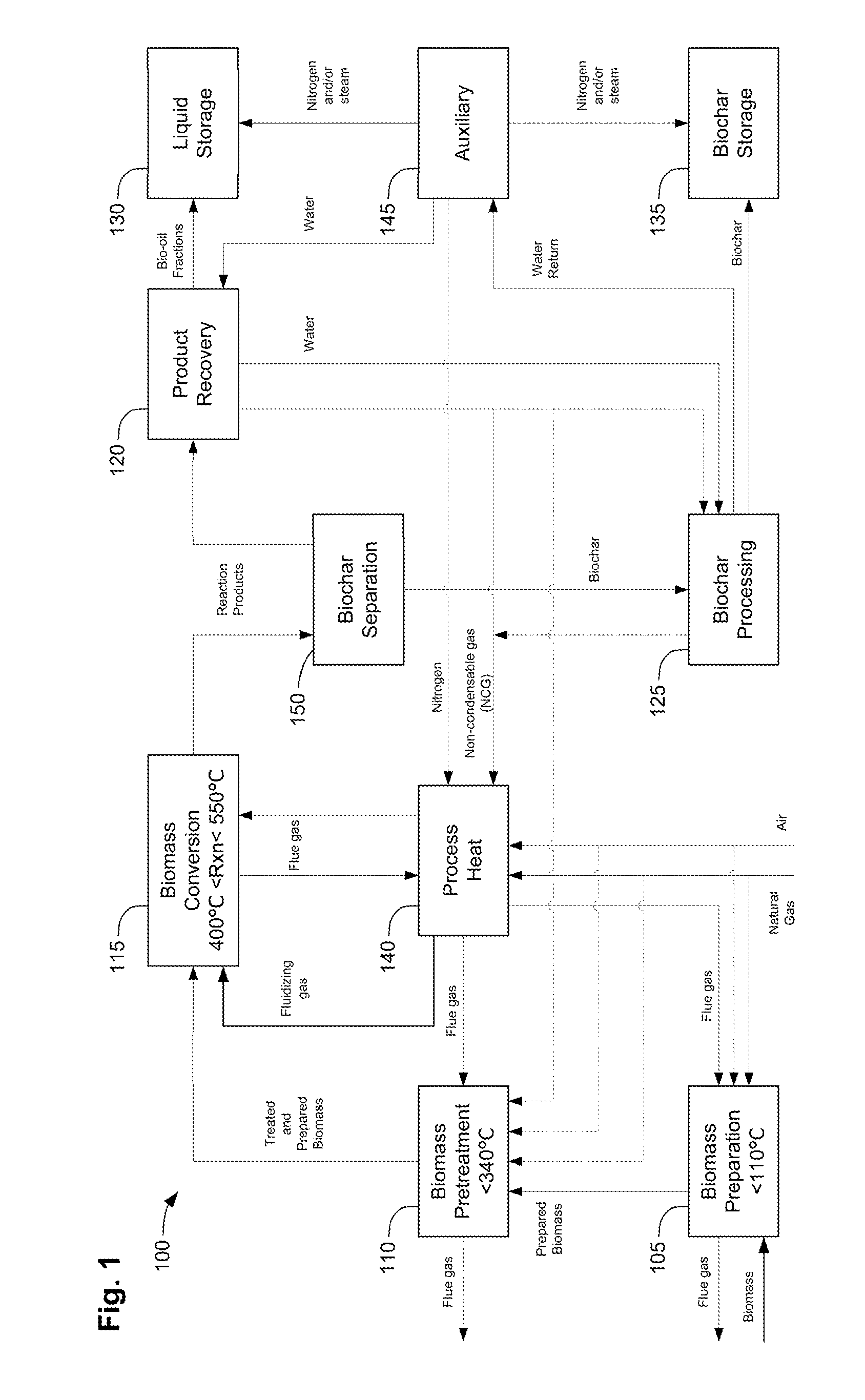

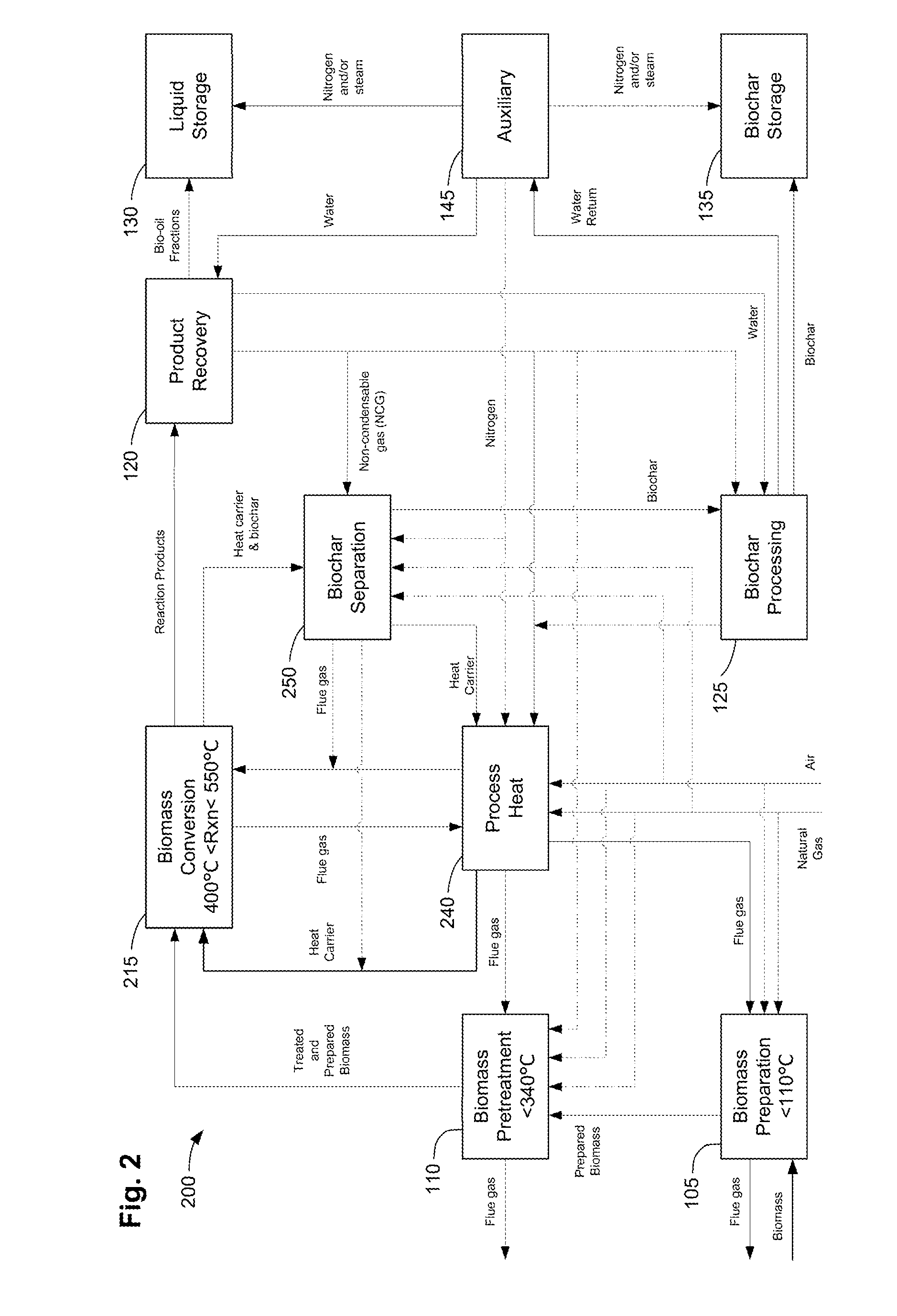

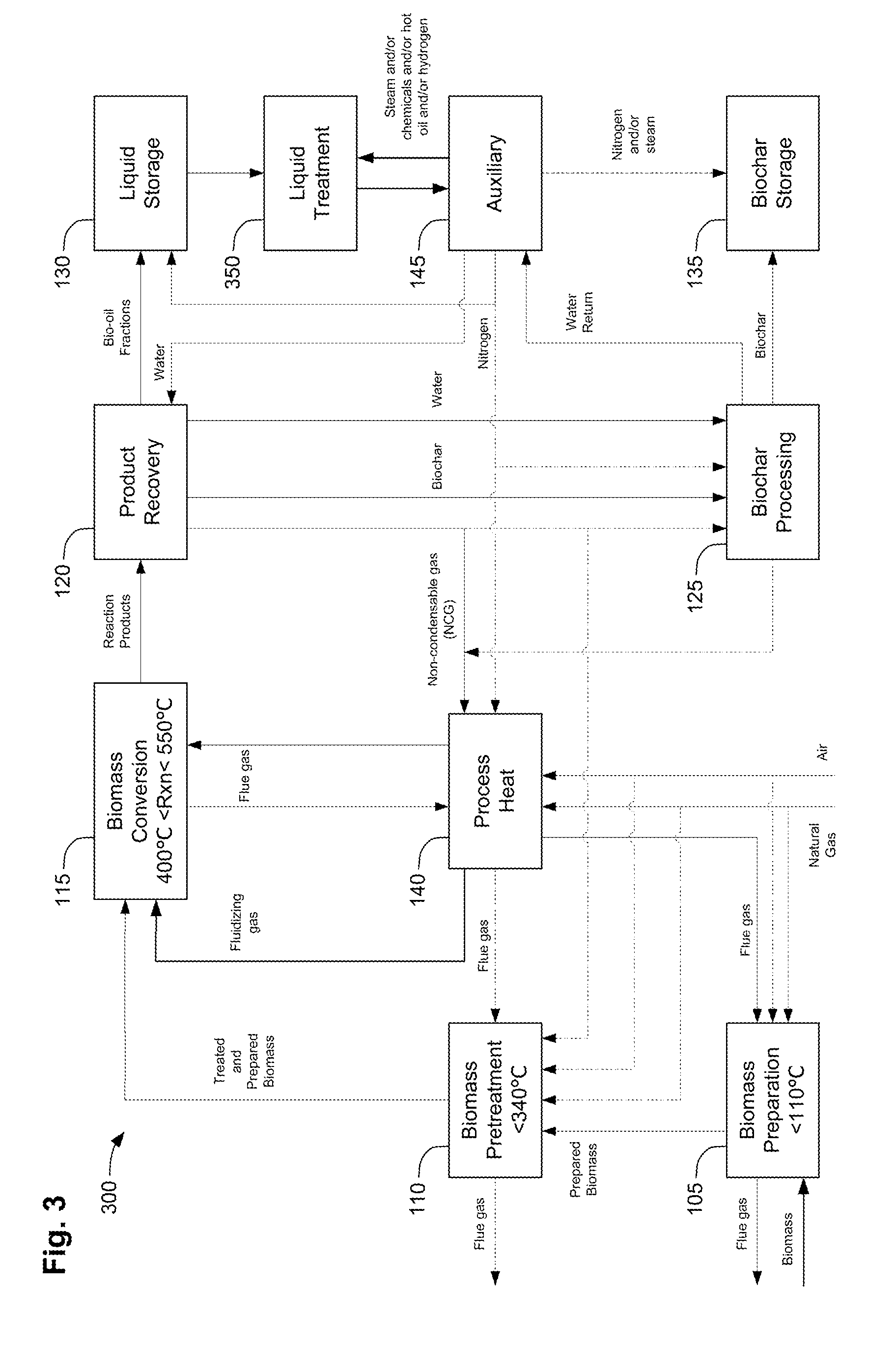

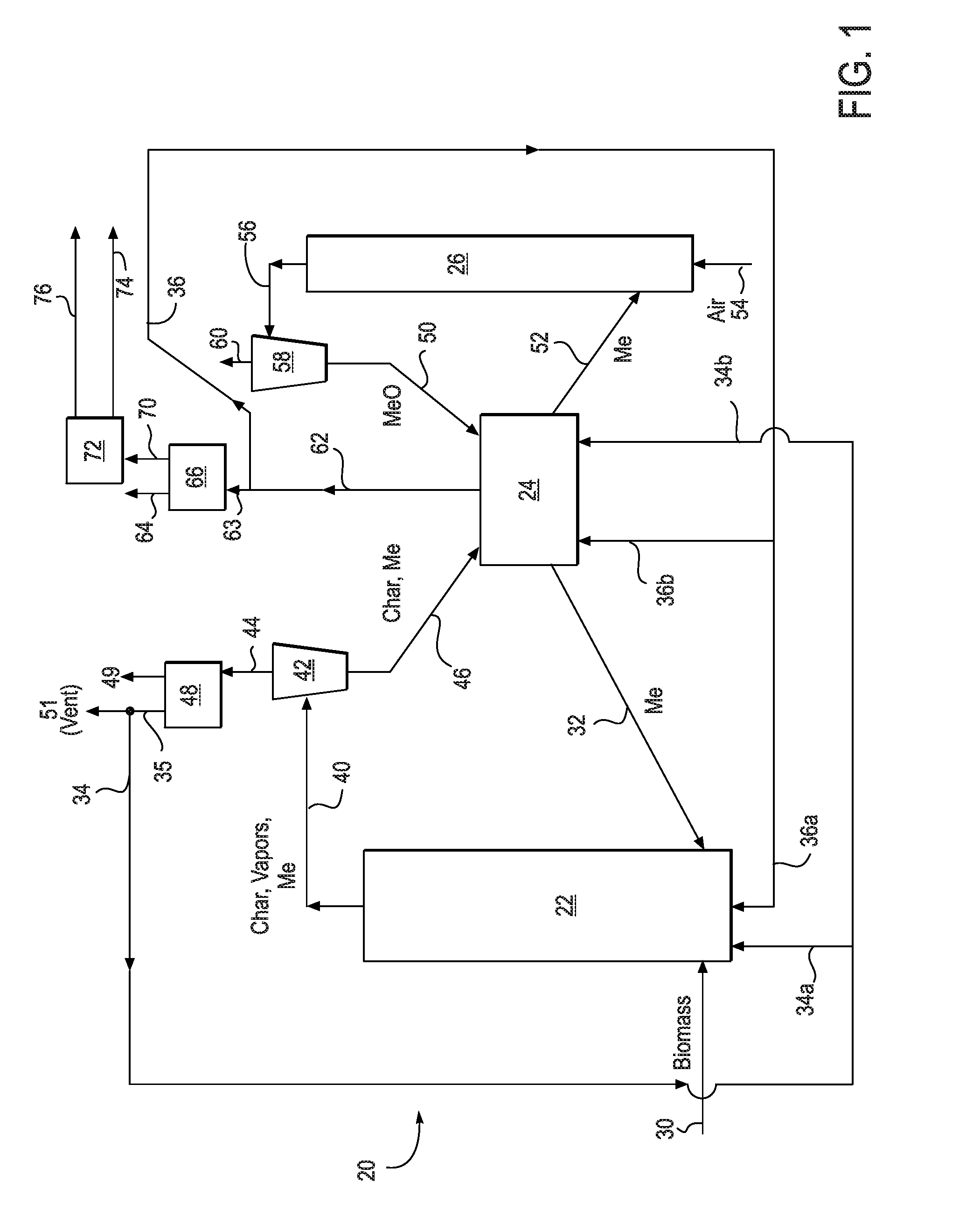

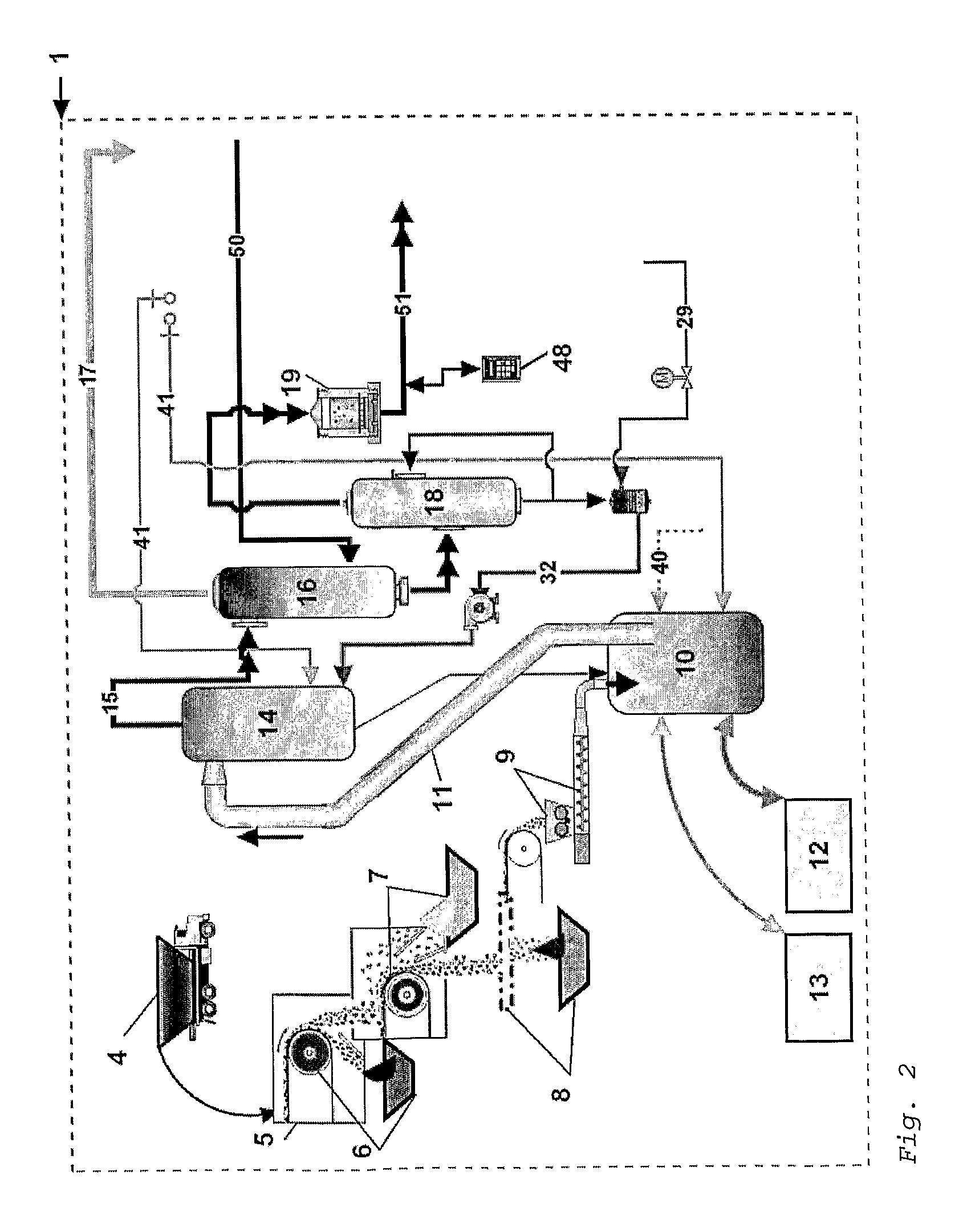

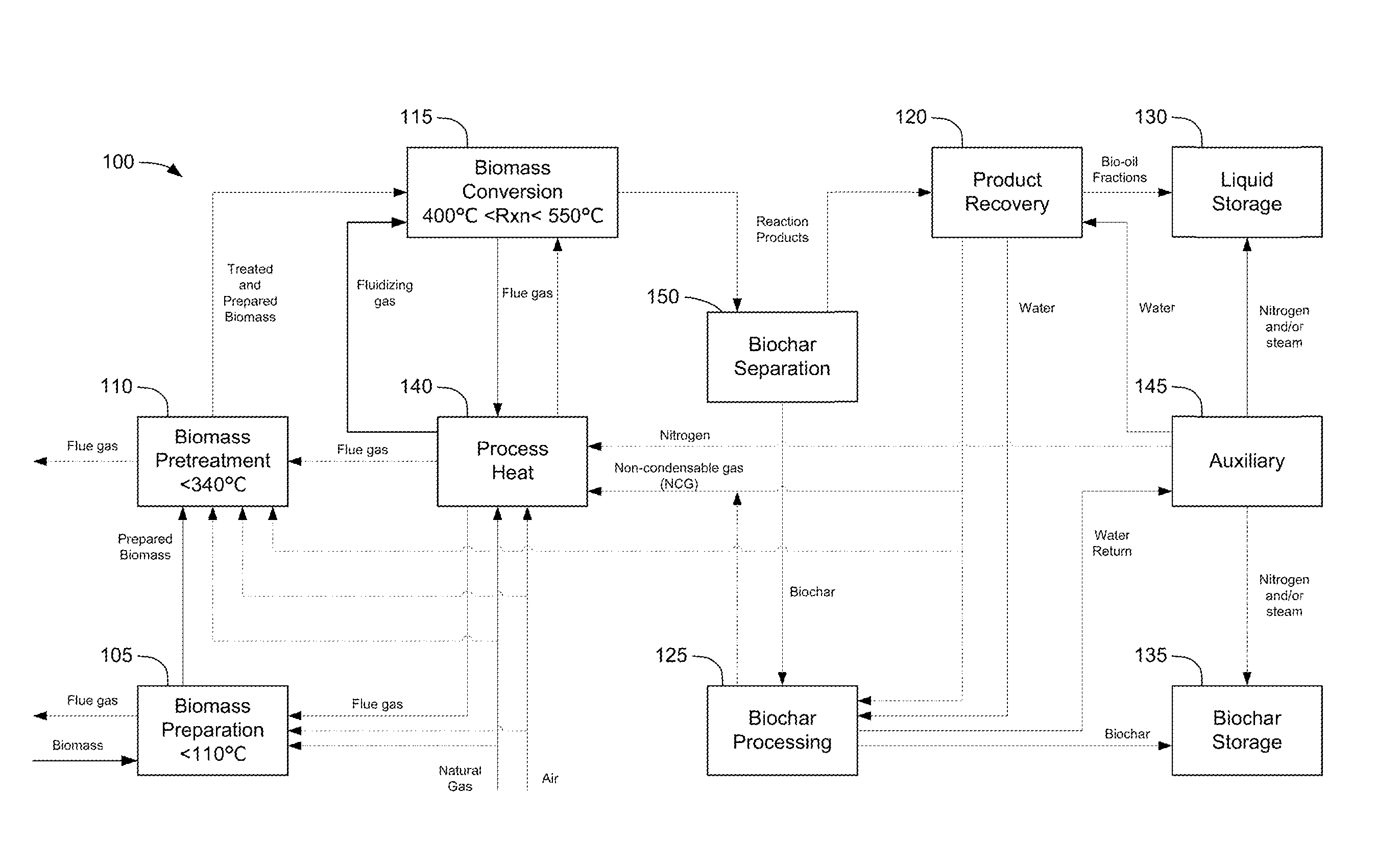

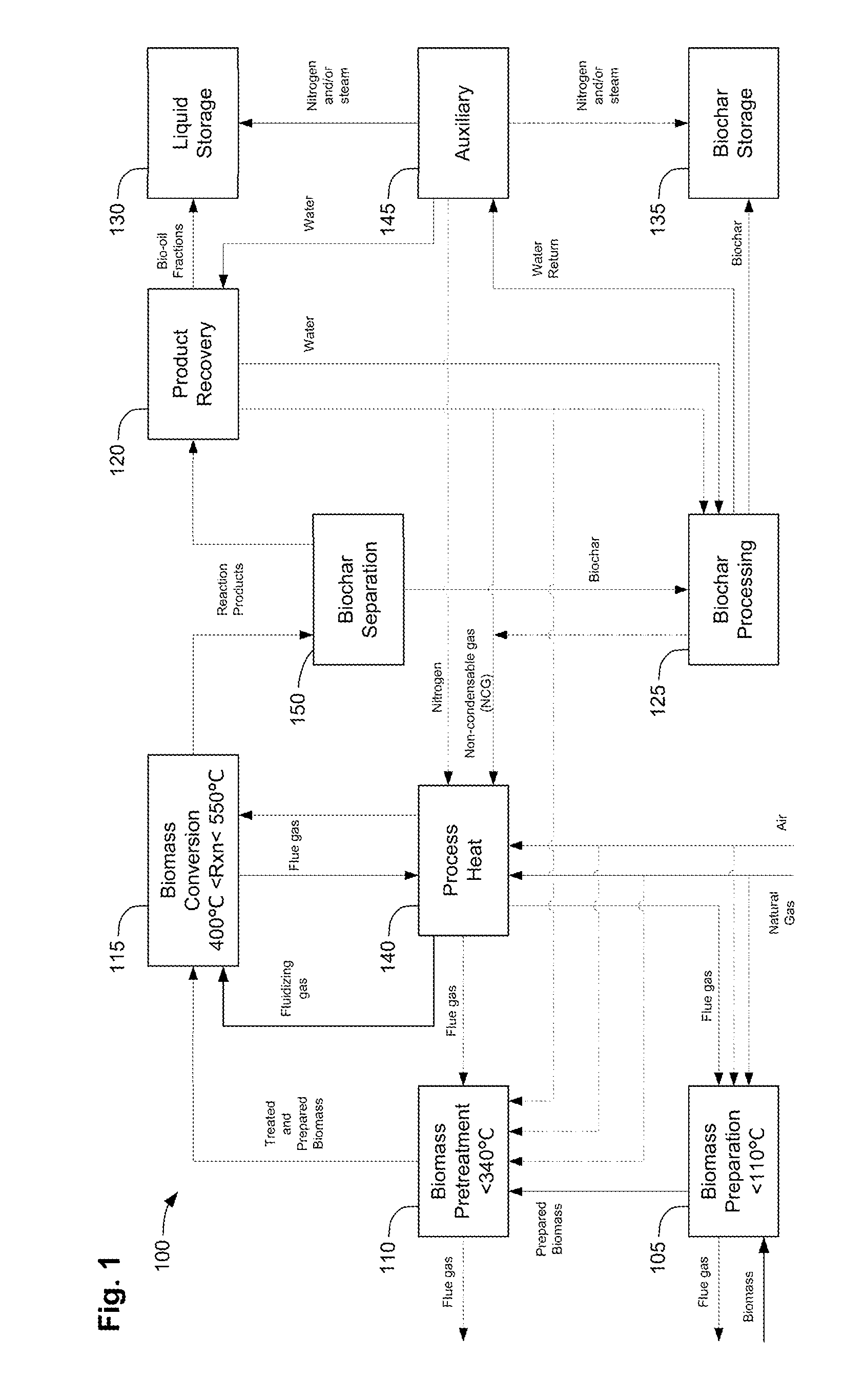

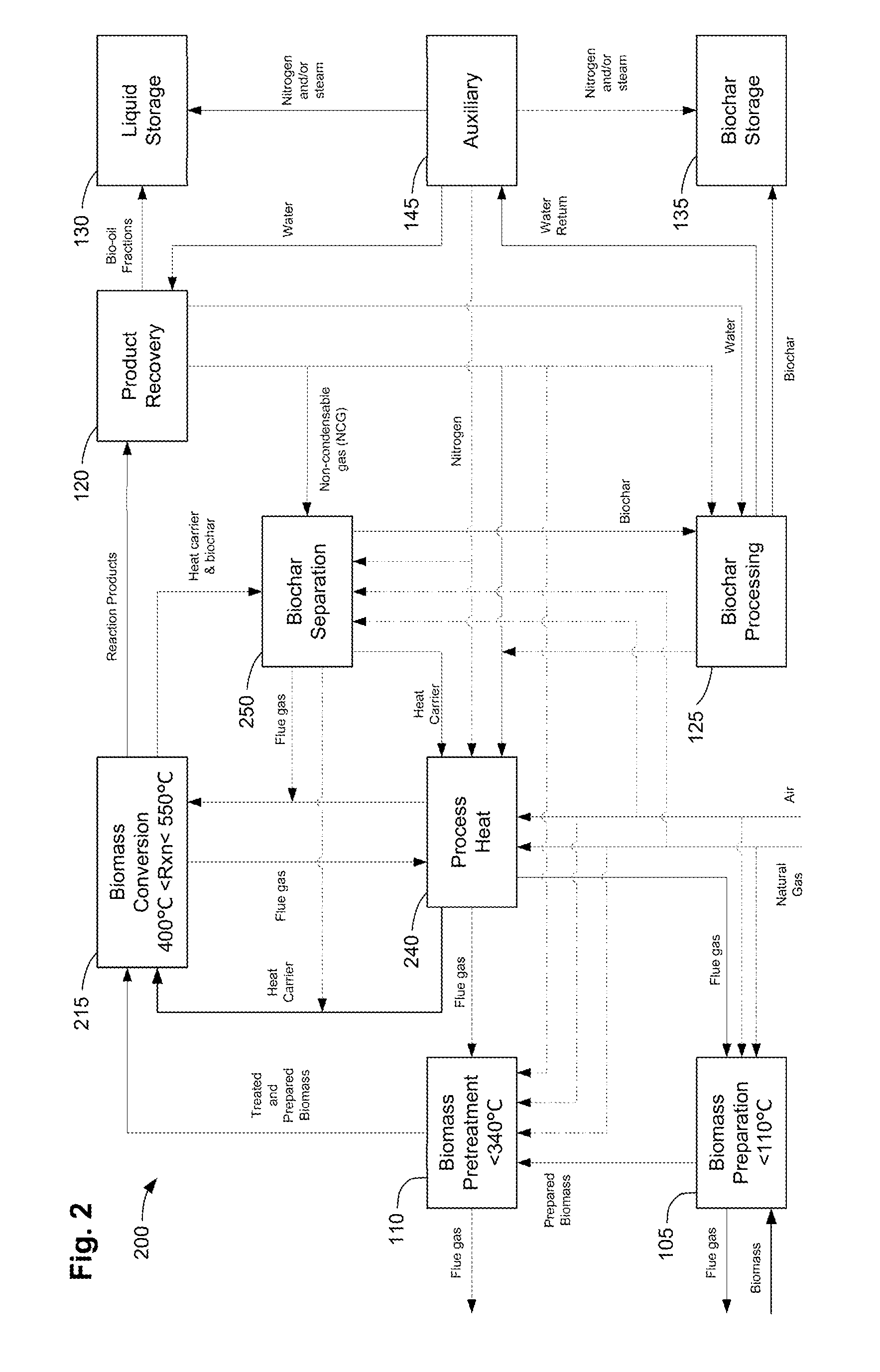

Methods for integrated fast pyrolysis processing of biomass

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

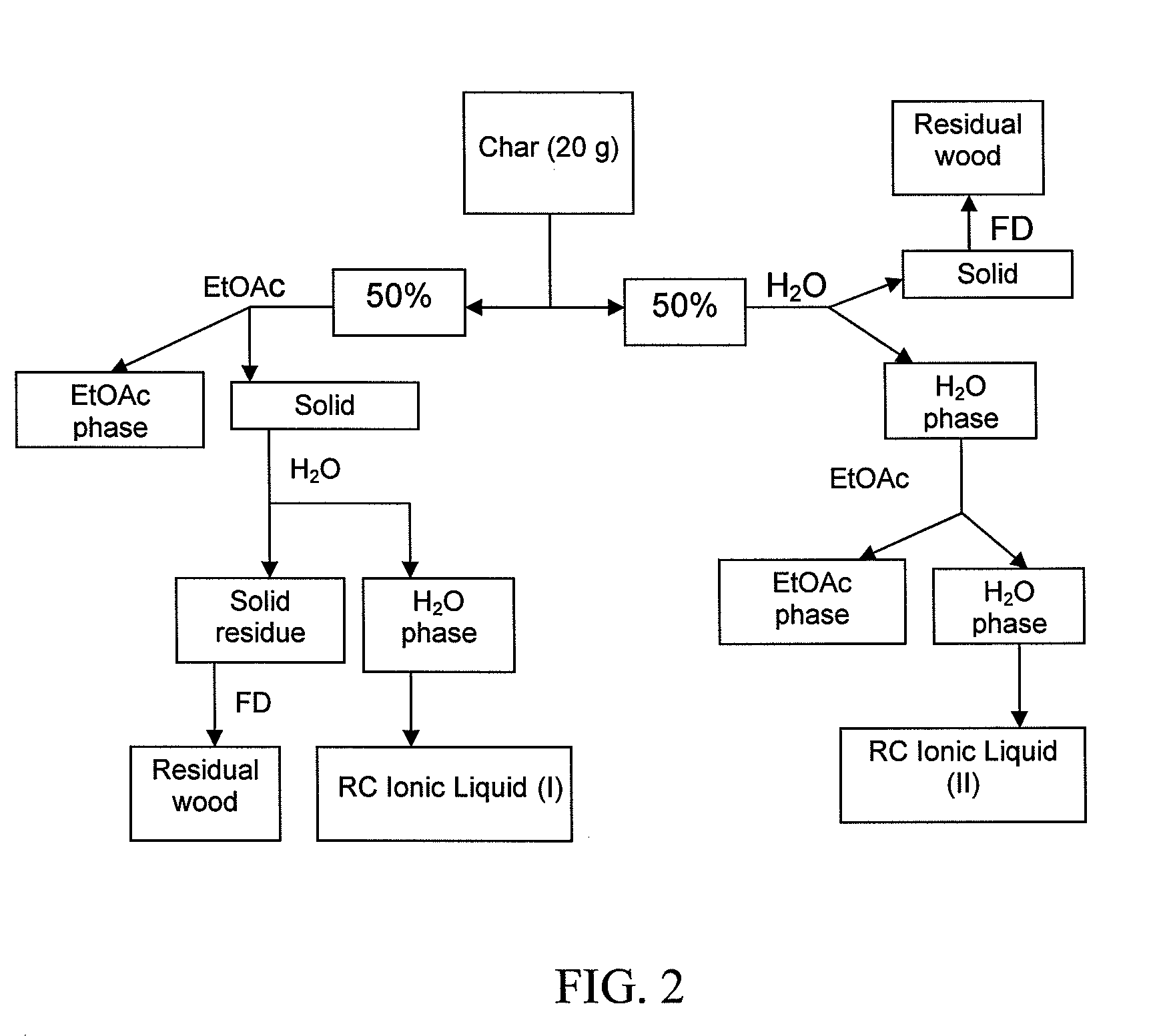

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

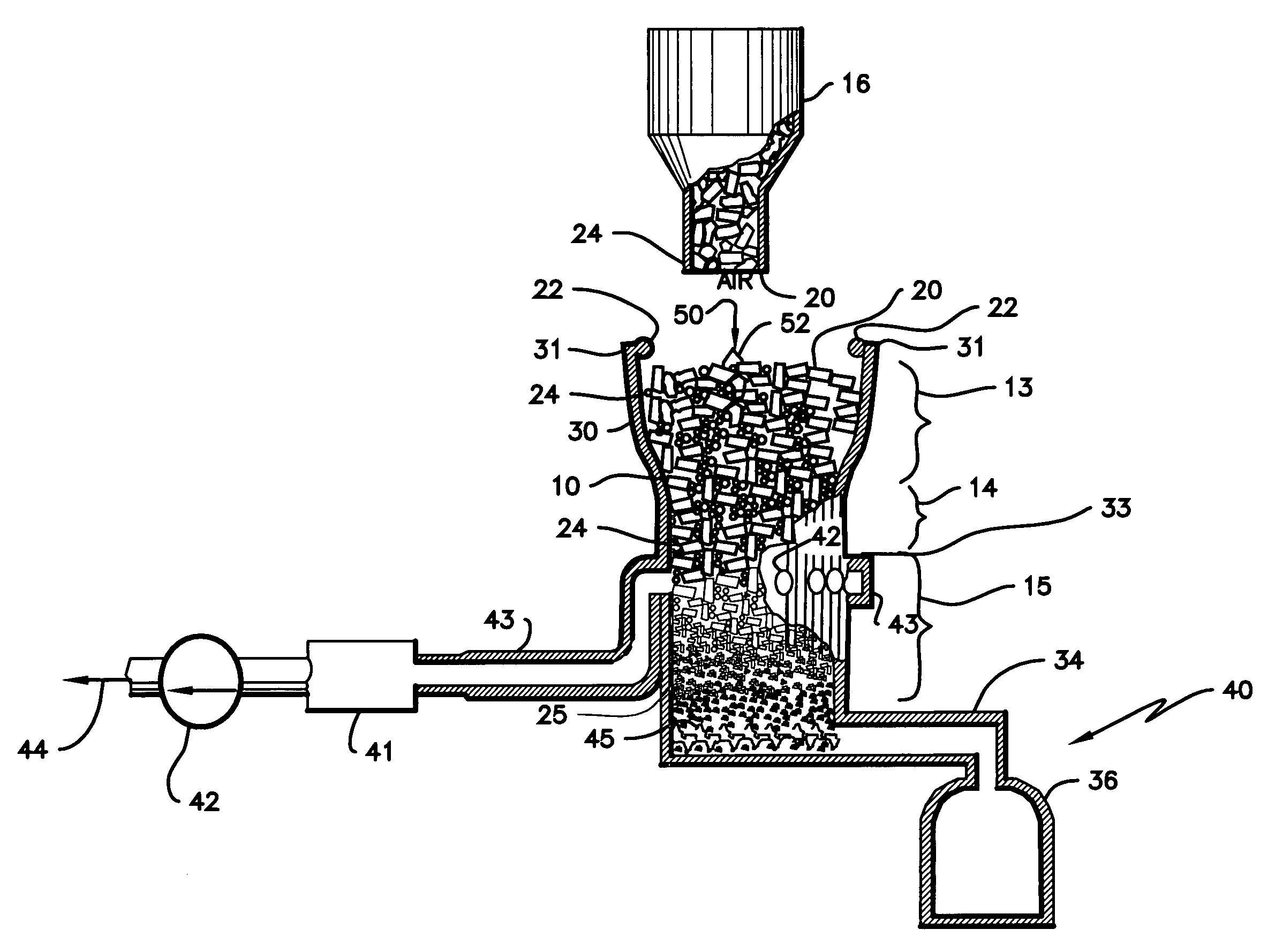

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

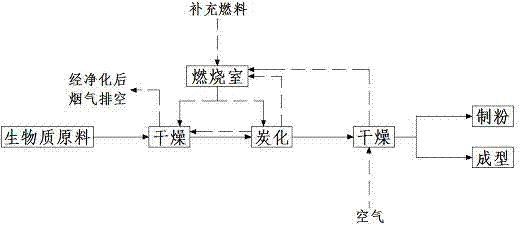

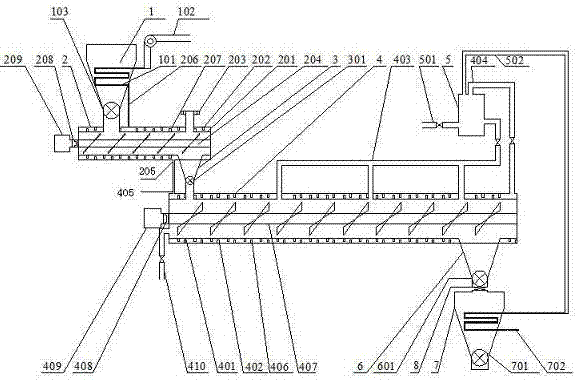

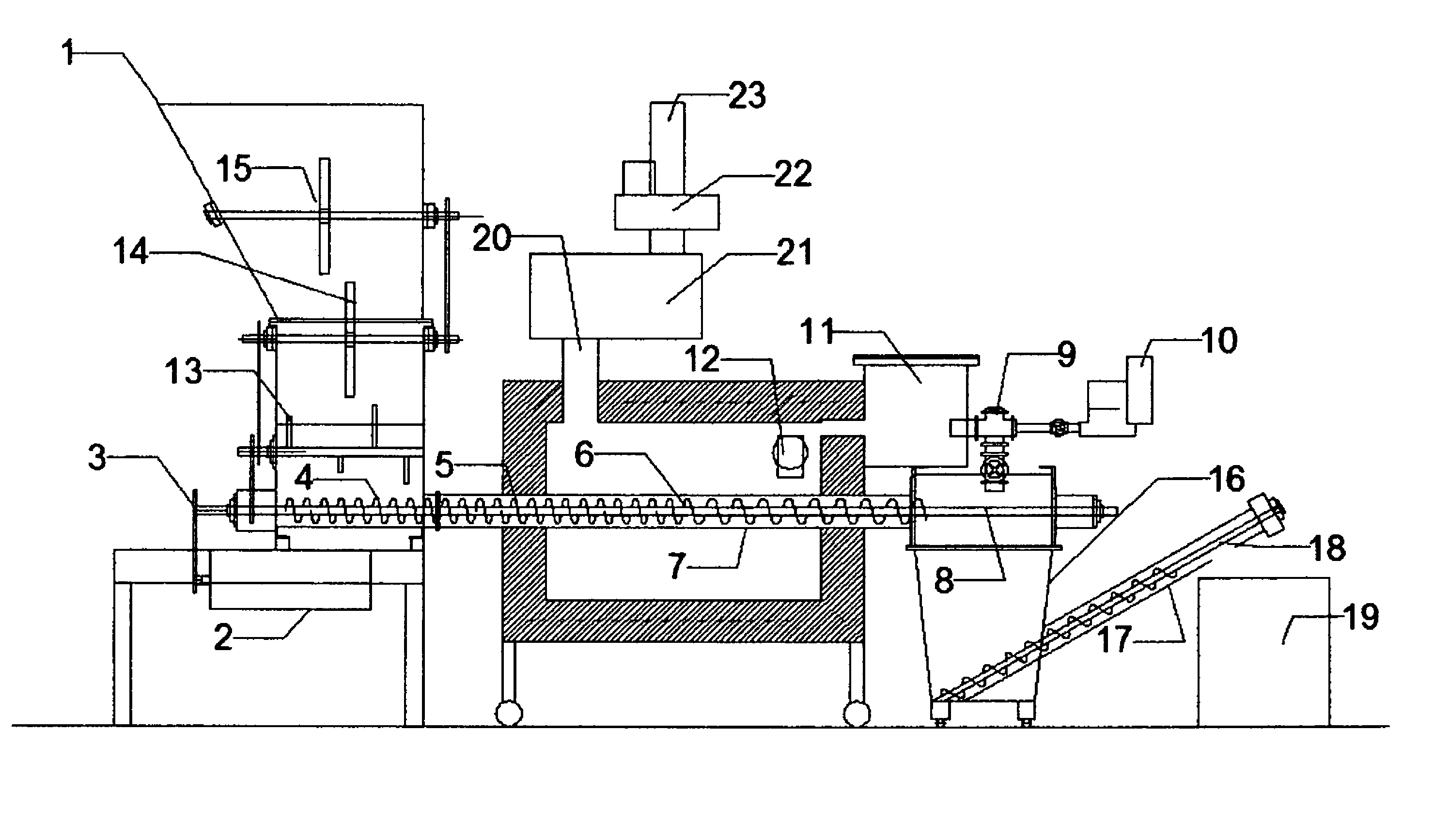

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

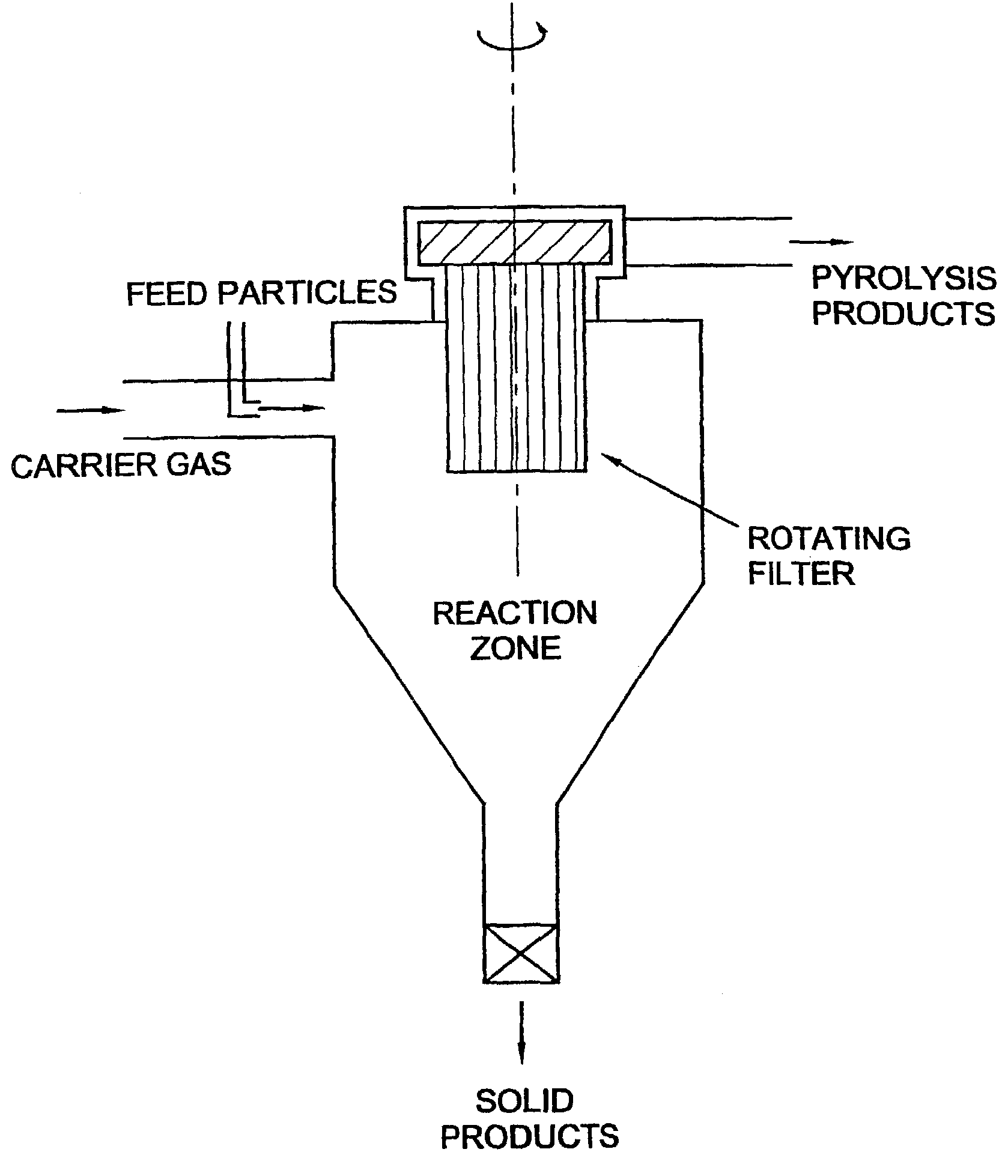

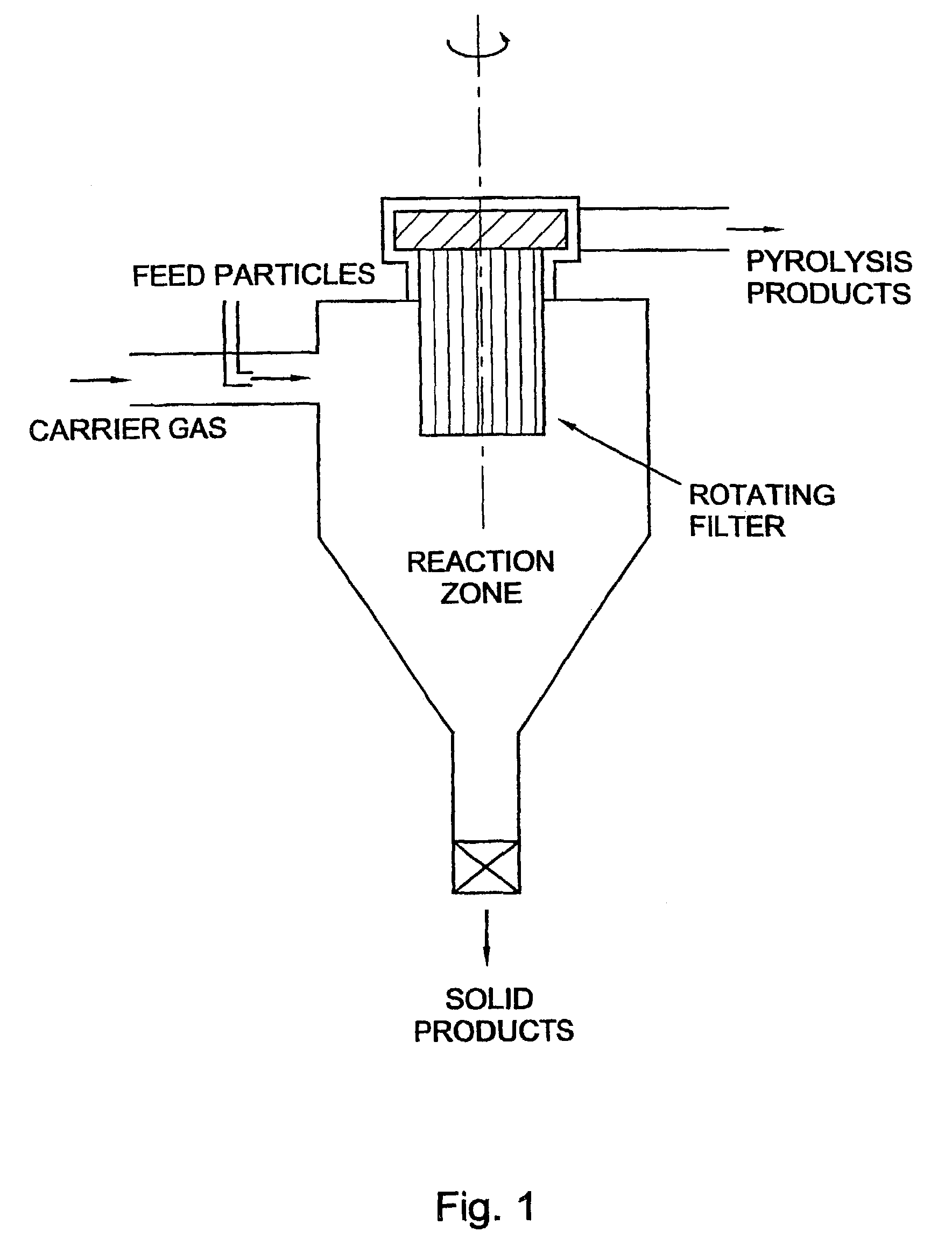

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

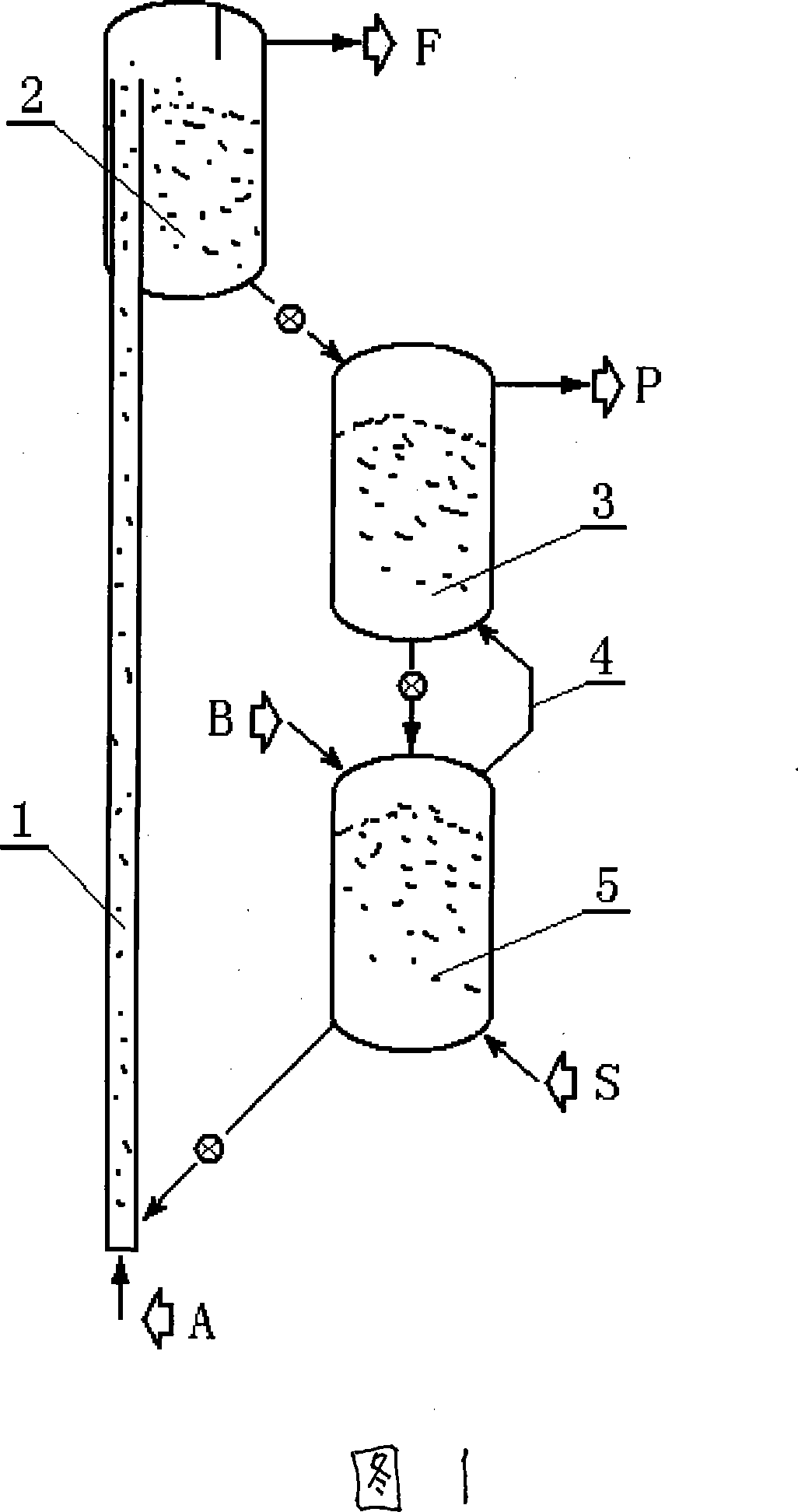

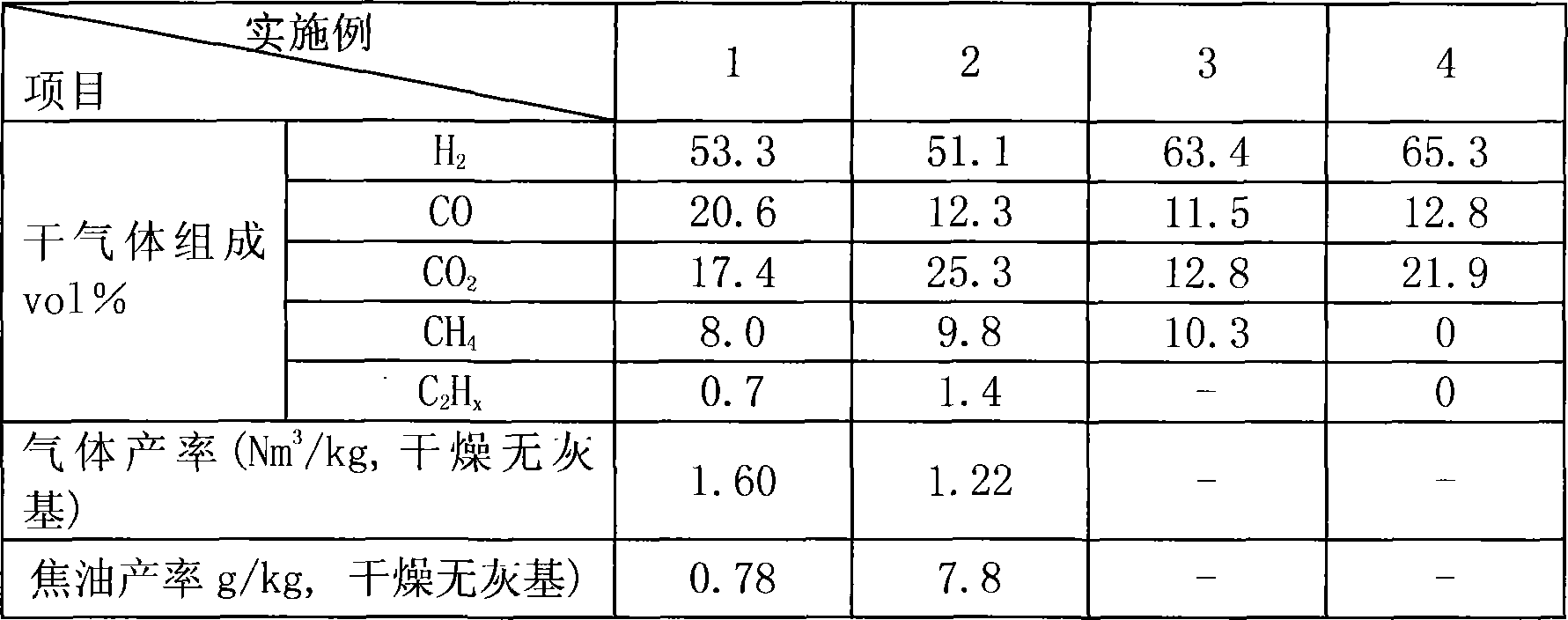

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

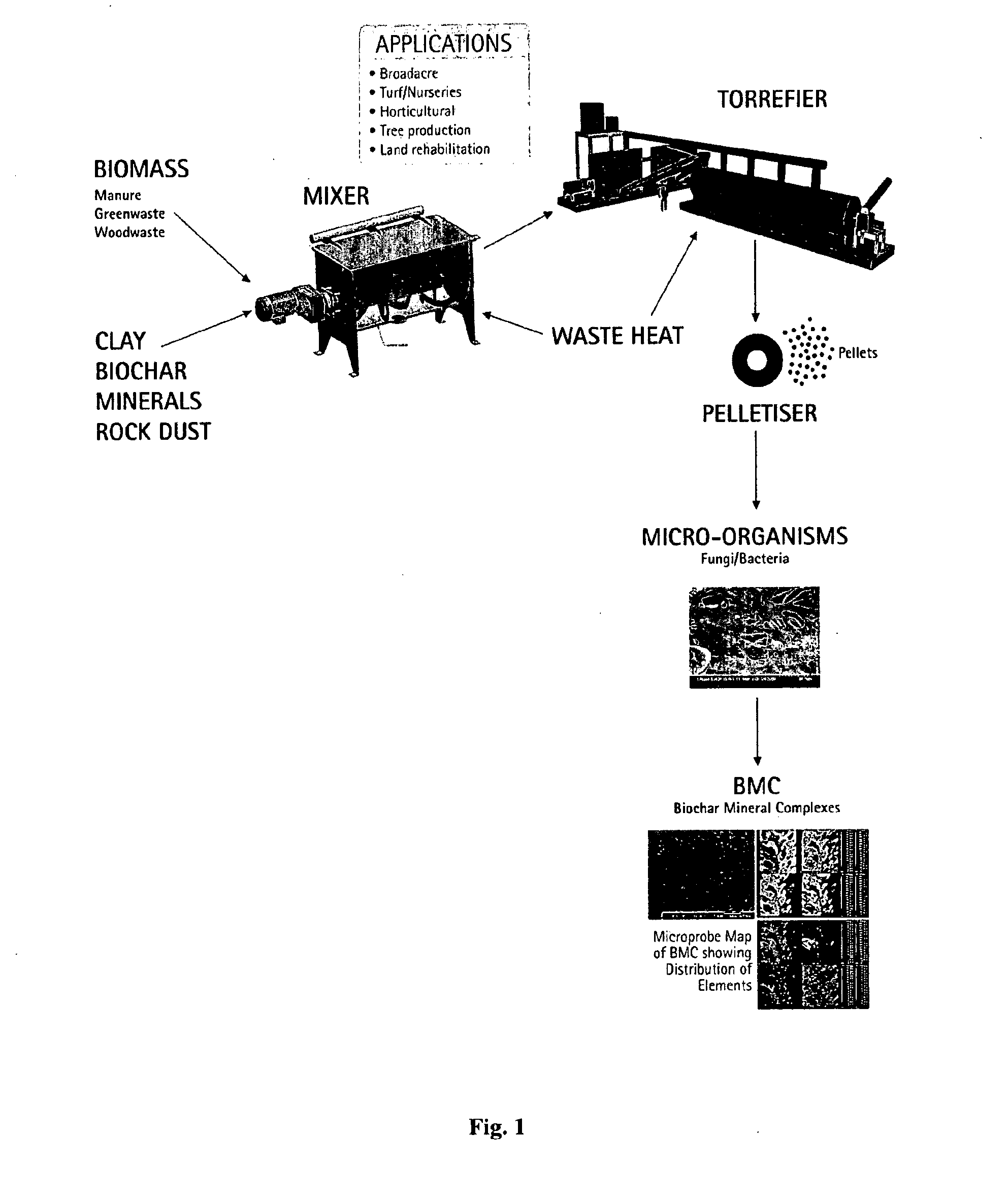

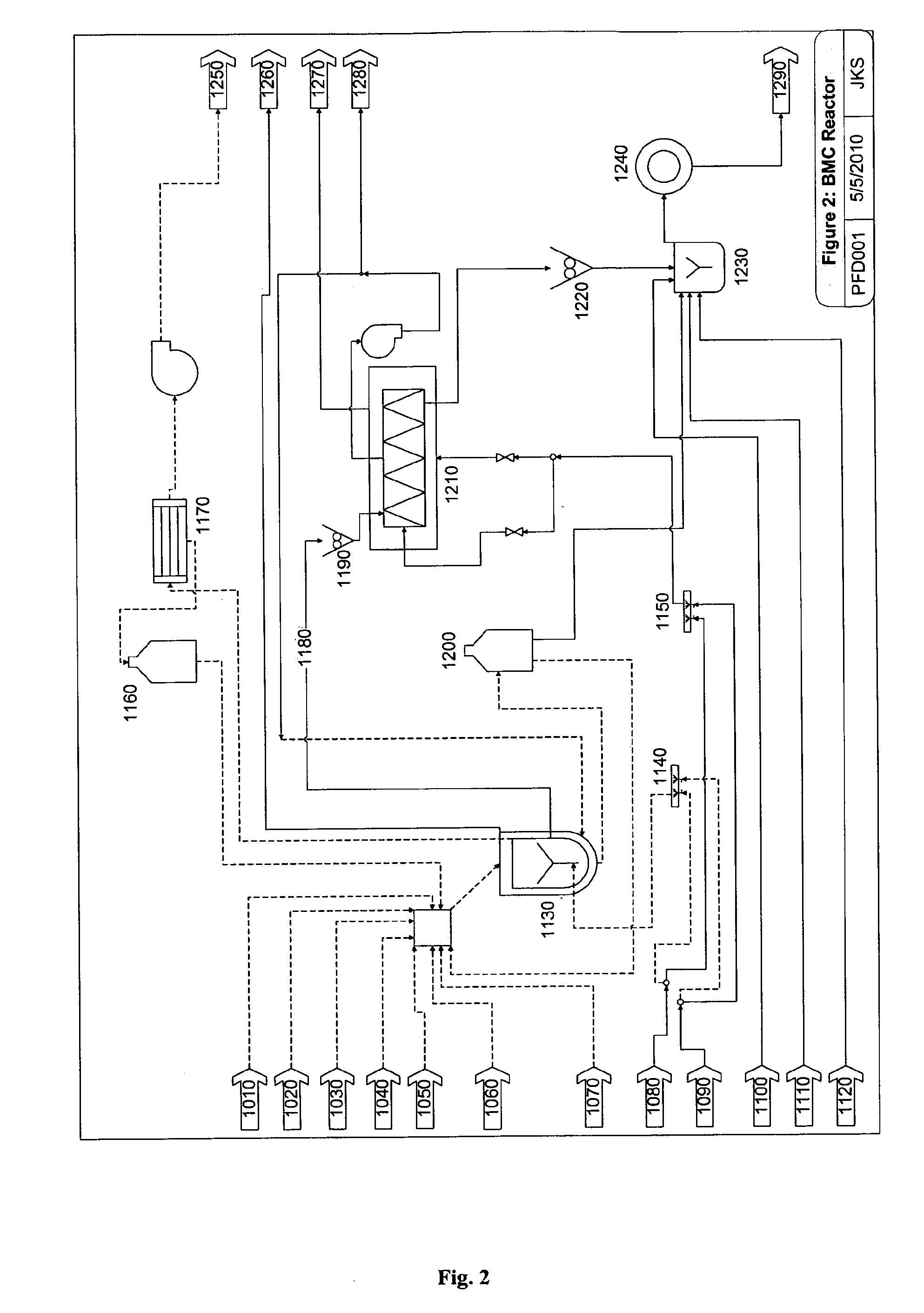

Biochar complex

InactiveUS20120125064A1Increase productionLow application rateDirect heating destructive distillationBiofuelsGrowth plantClay minerals

The invention relates to a biochar-containing composition comprising biochar having organic matter therein and / or thereon, clay associated, optionally intercalated, with the organic matter, a non-clay mineral and optionally also a plant growth promoter.

Owner:VENEARTH GRP

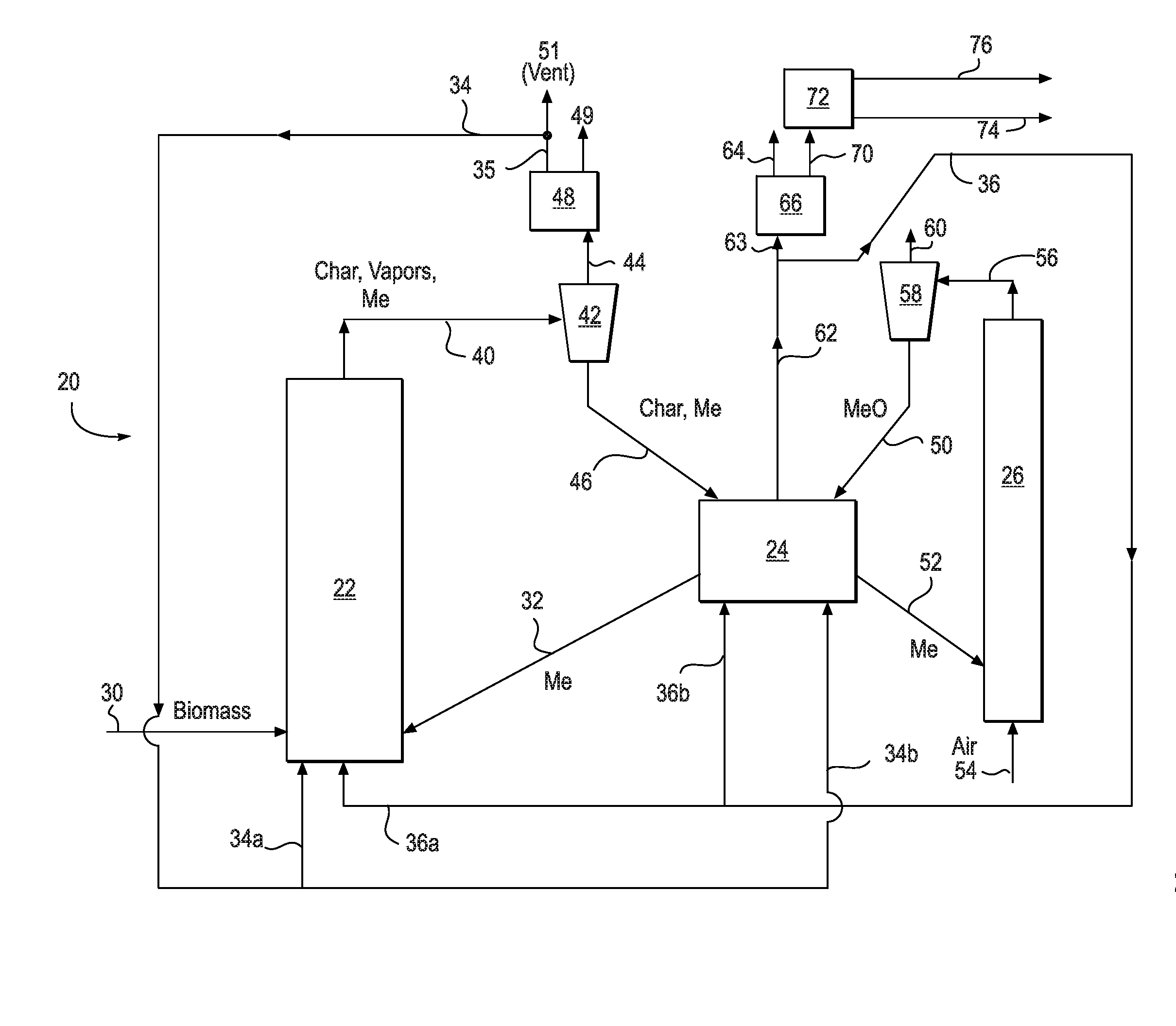

Method and system for capturing carbon dioxide from biomass pyrolysis process

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

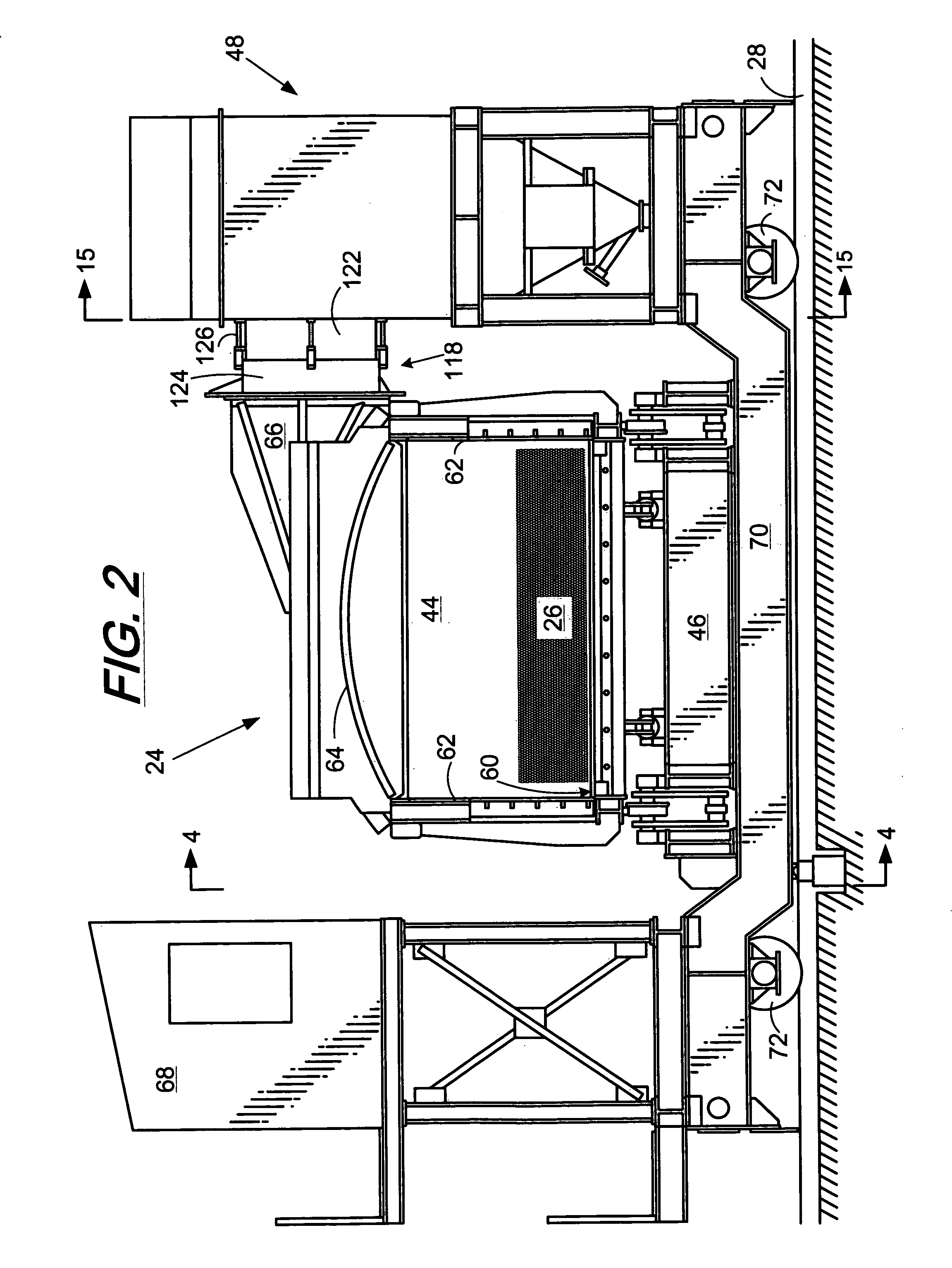

Method and apparatus for producing coke

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

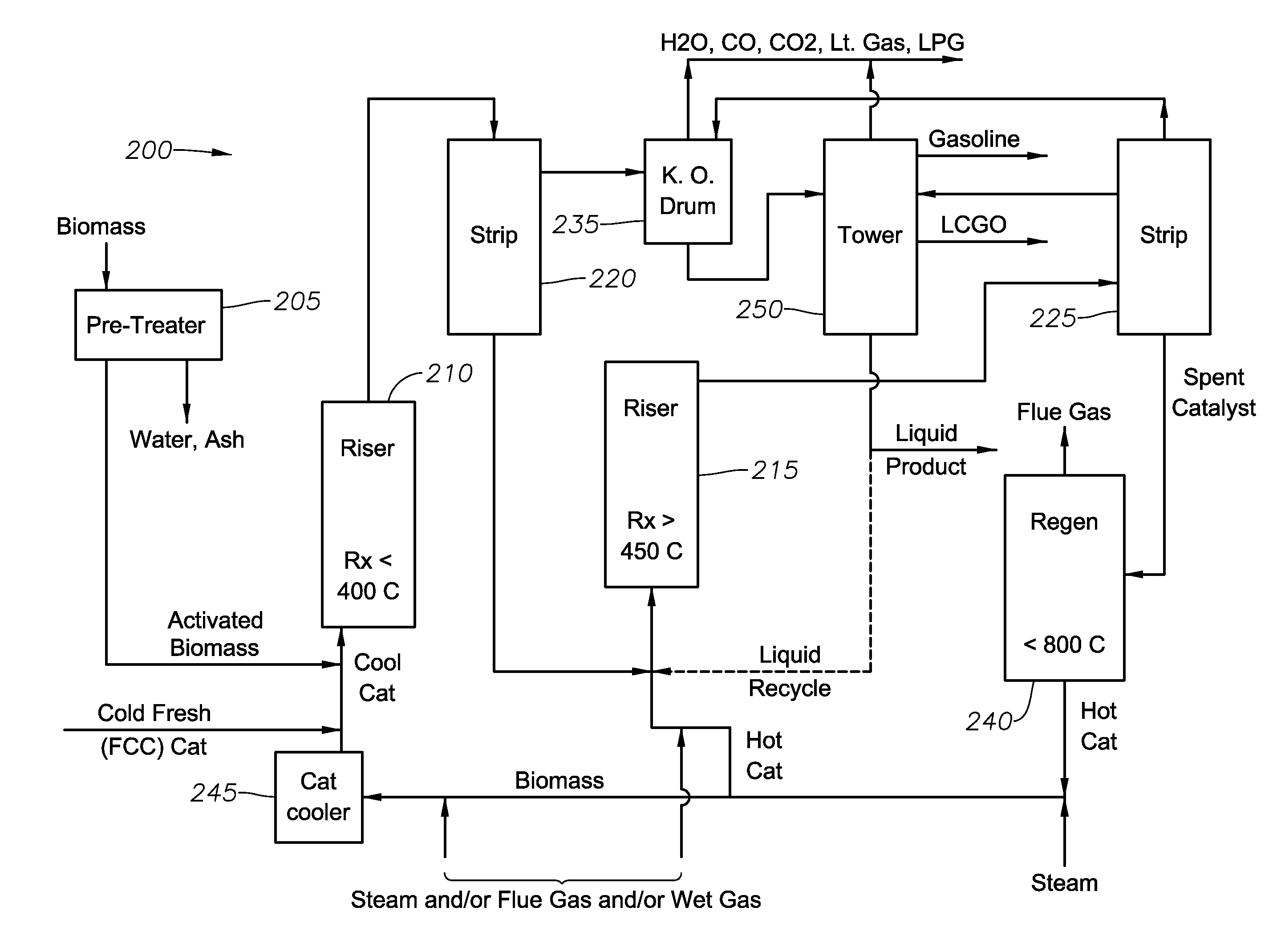

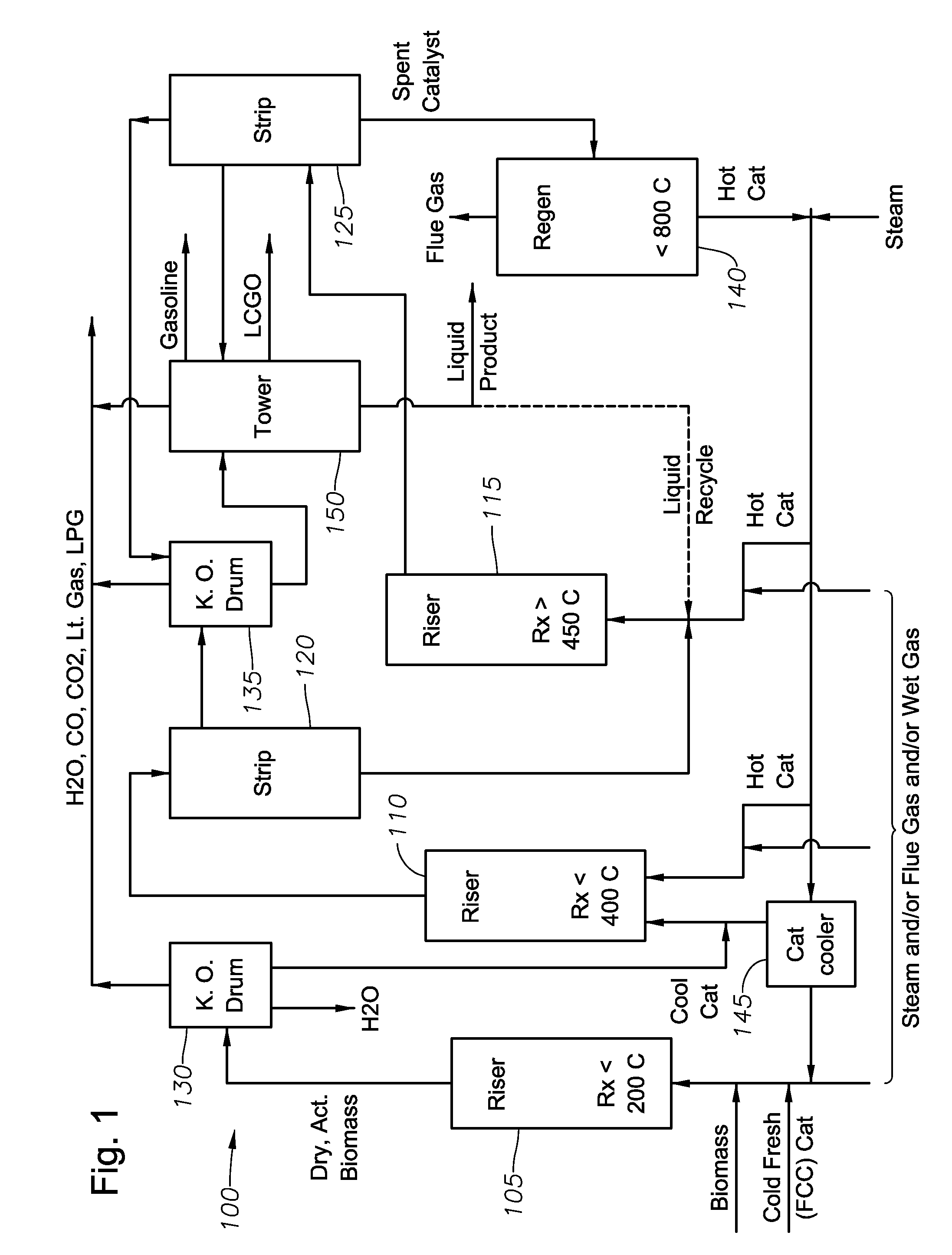

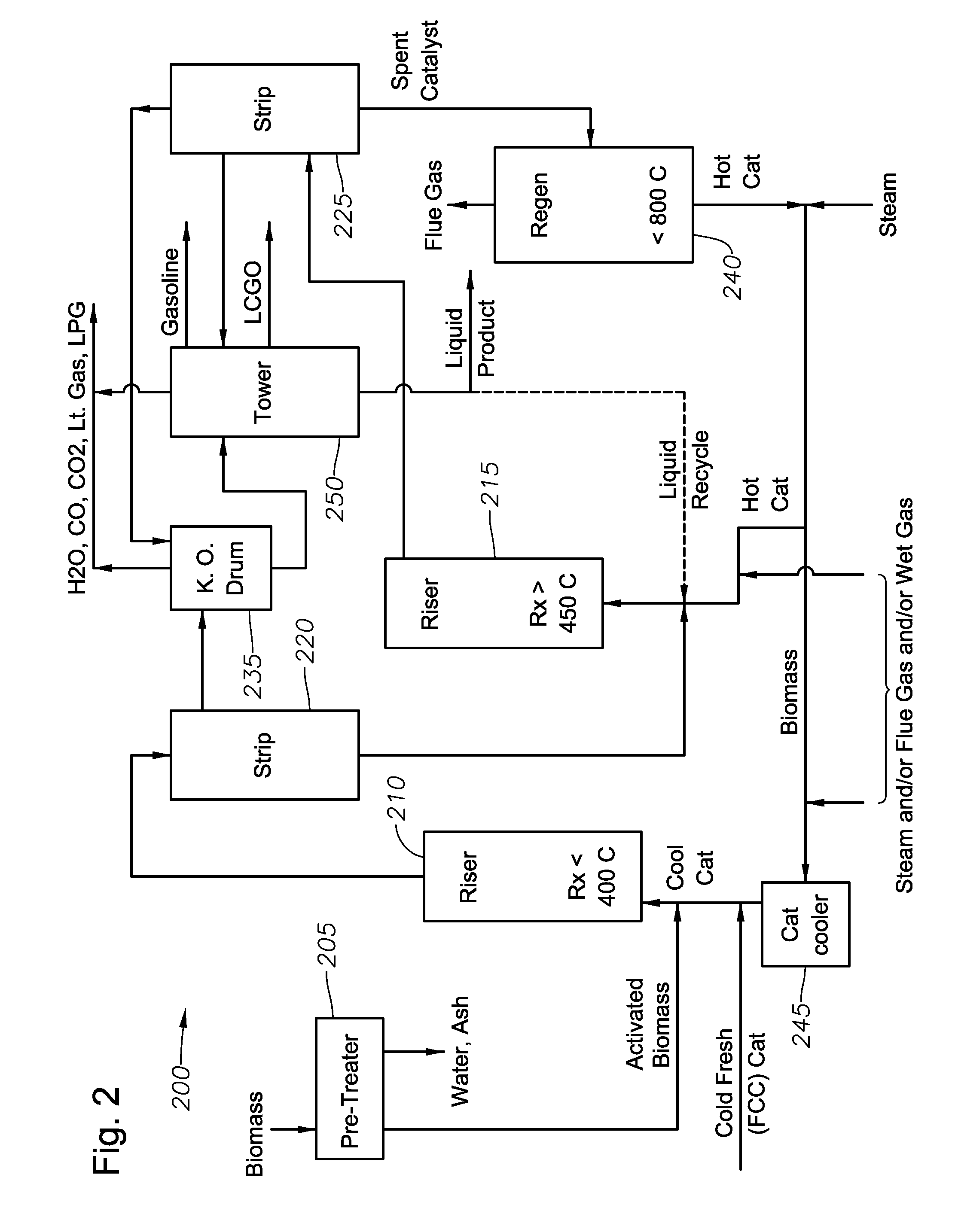

Biomass conversion process

InactiveUS20100105970A1Mitigate equipment cost and energy cost and degradationSpeed up the conversion processProductsReagentsBiomassHydrocarbon

A method for converting solid biomass into hydrocarbons includes contacting the solid biomass with a catalyst in a first riser operated at a temperature in the range of from about 50° C. to about 200° C. to thereby produce a first biomass-catalyst mixture and a first product comprising hydrocarbons; a) separating the first product from the first biomass-catalyst mixture; c) charging the first biomass-catalyst mixture to a second riser operated at a temperature in the range of from about 200° C. to about 400° C. to thereby produce a second biomass-catalyst mixture and a second product comprising hydrocarbons; d) separating the second product from the second biomass-catalyst mixture; e) charging the second biomass-catalyst mixture to a third riser operated at a temperature greater than about 450° C. to thereby produce a spent catalyst and a third product comprising hydrocarbons; and f) separating the third effluent from the spent catalyst.

Owner:MARD INC

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

Coker feed method and apparatus

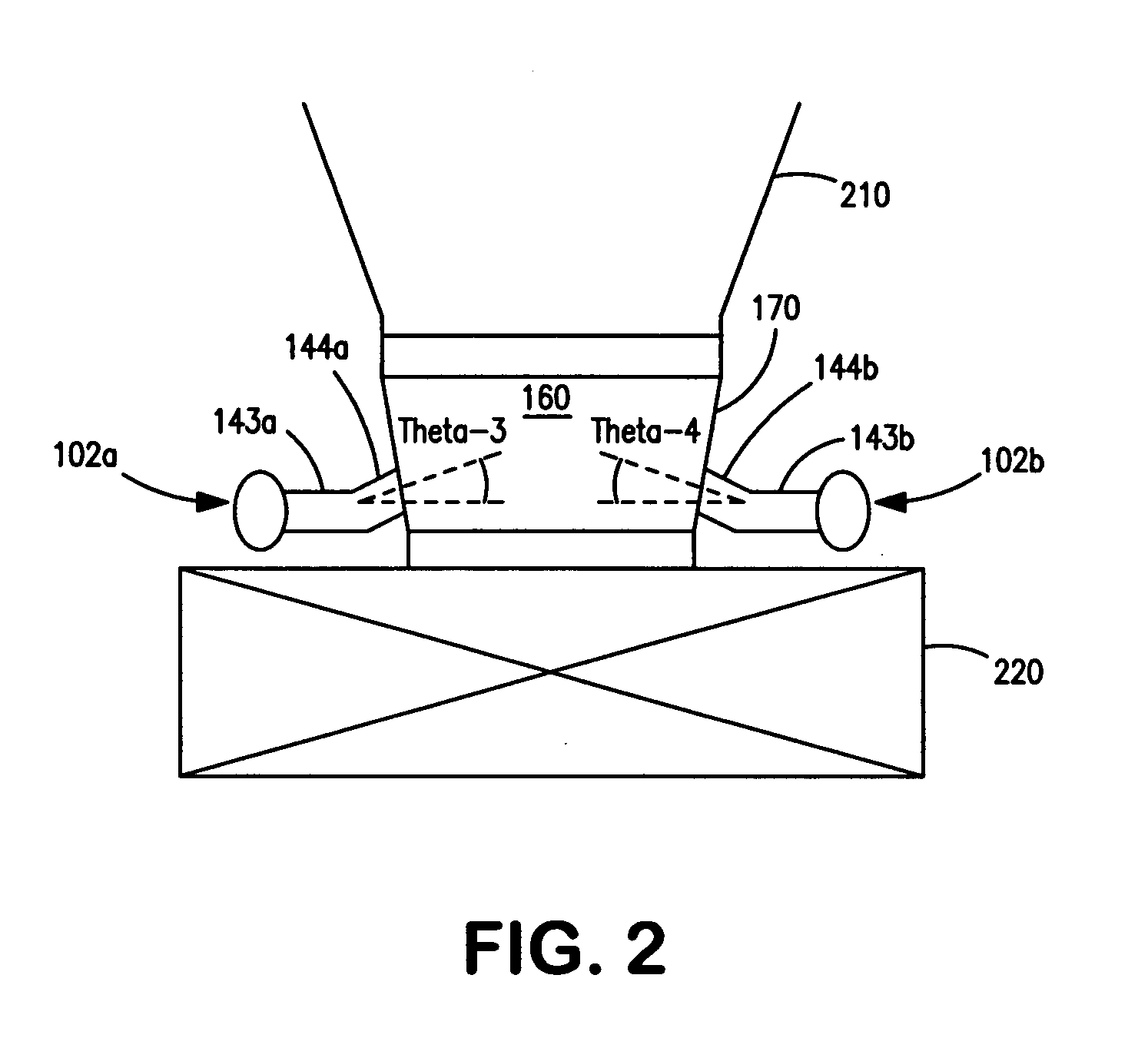

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

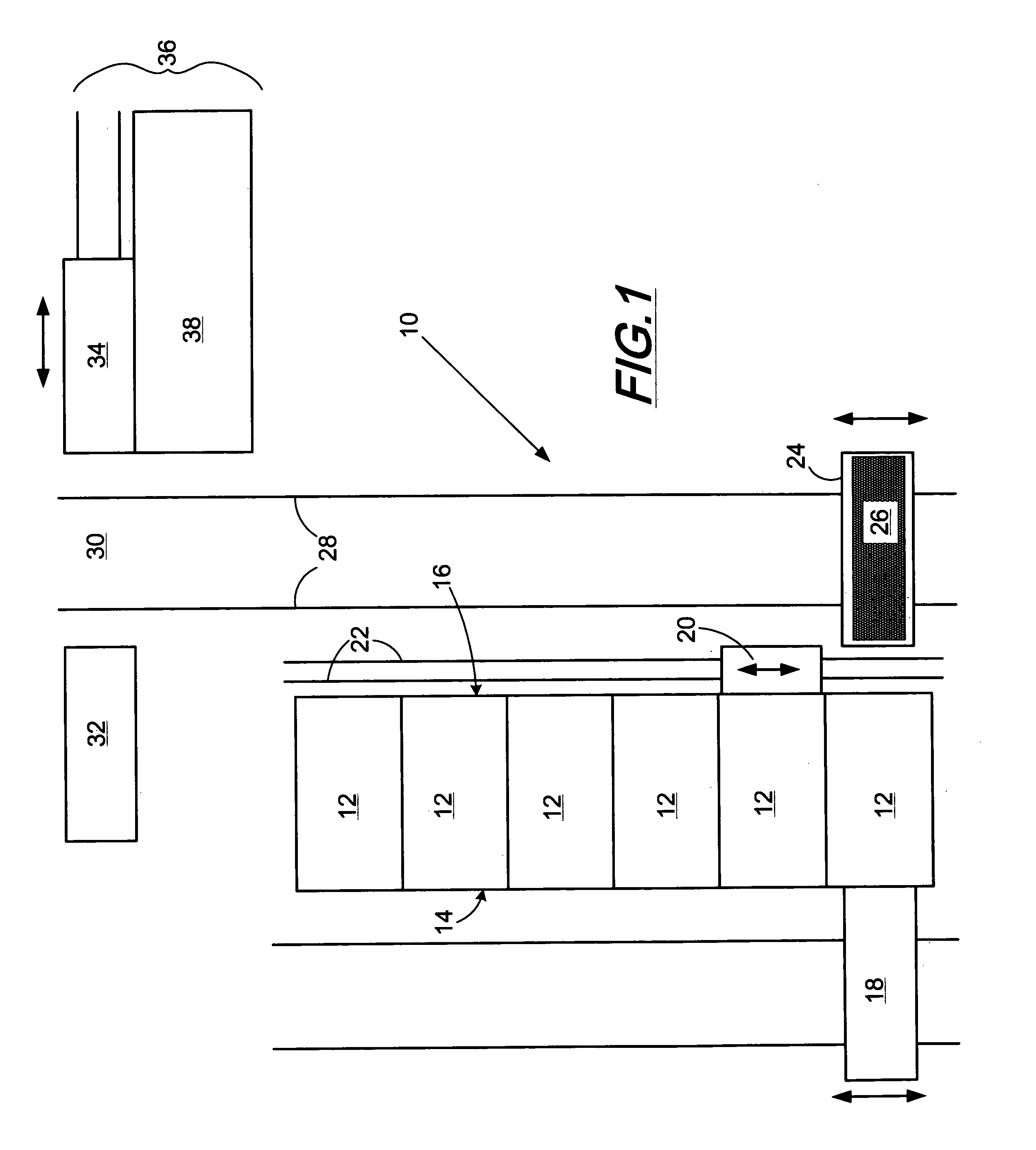

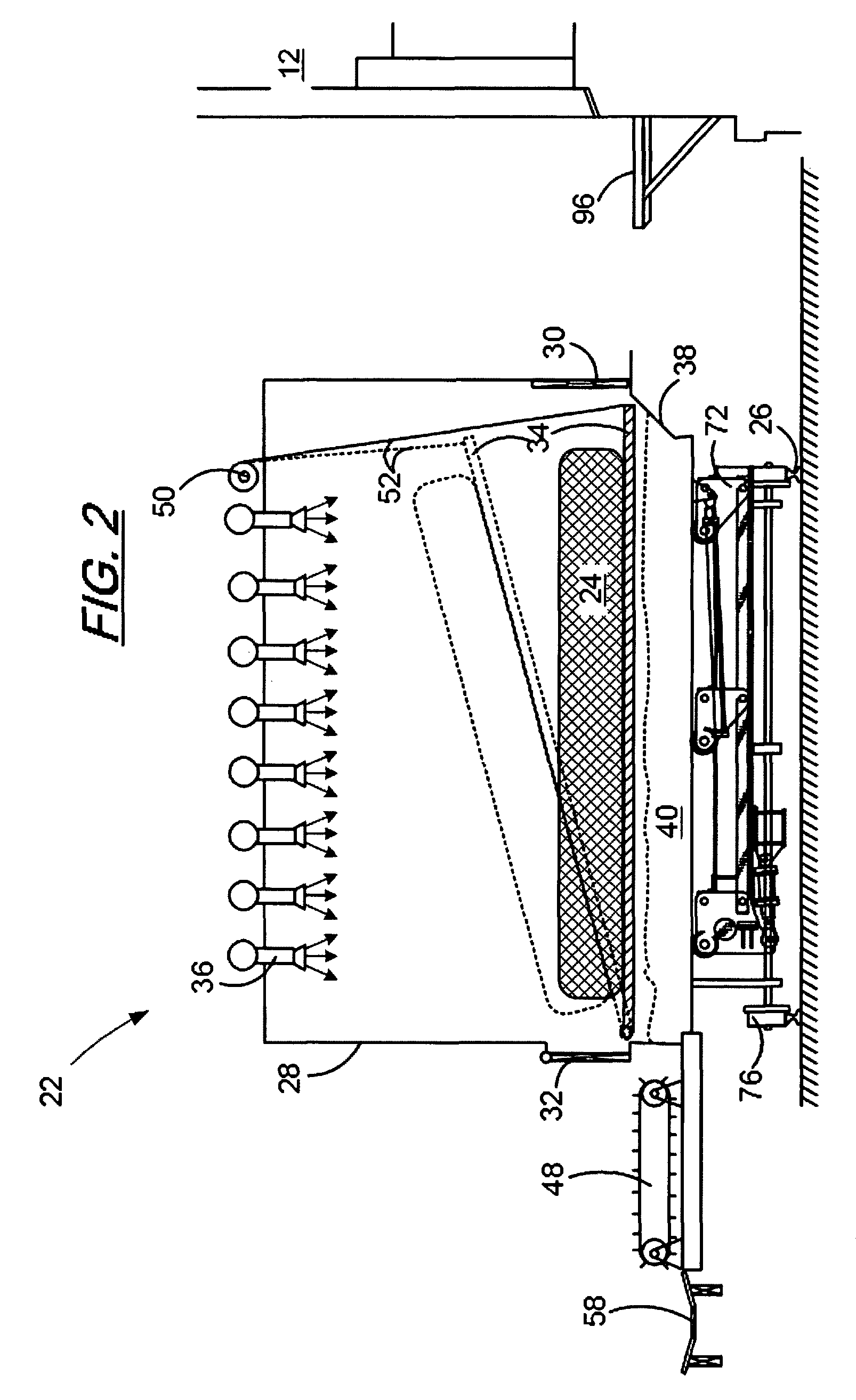

Flat push coke wet quenching apparatus and process

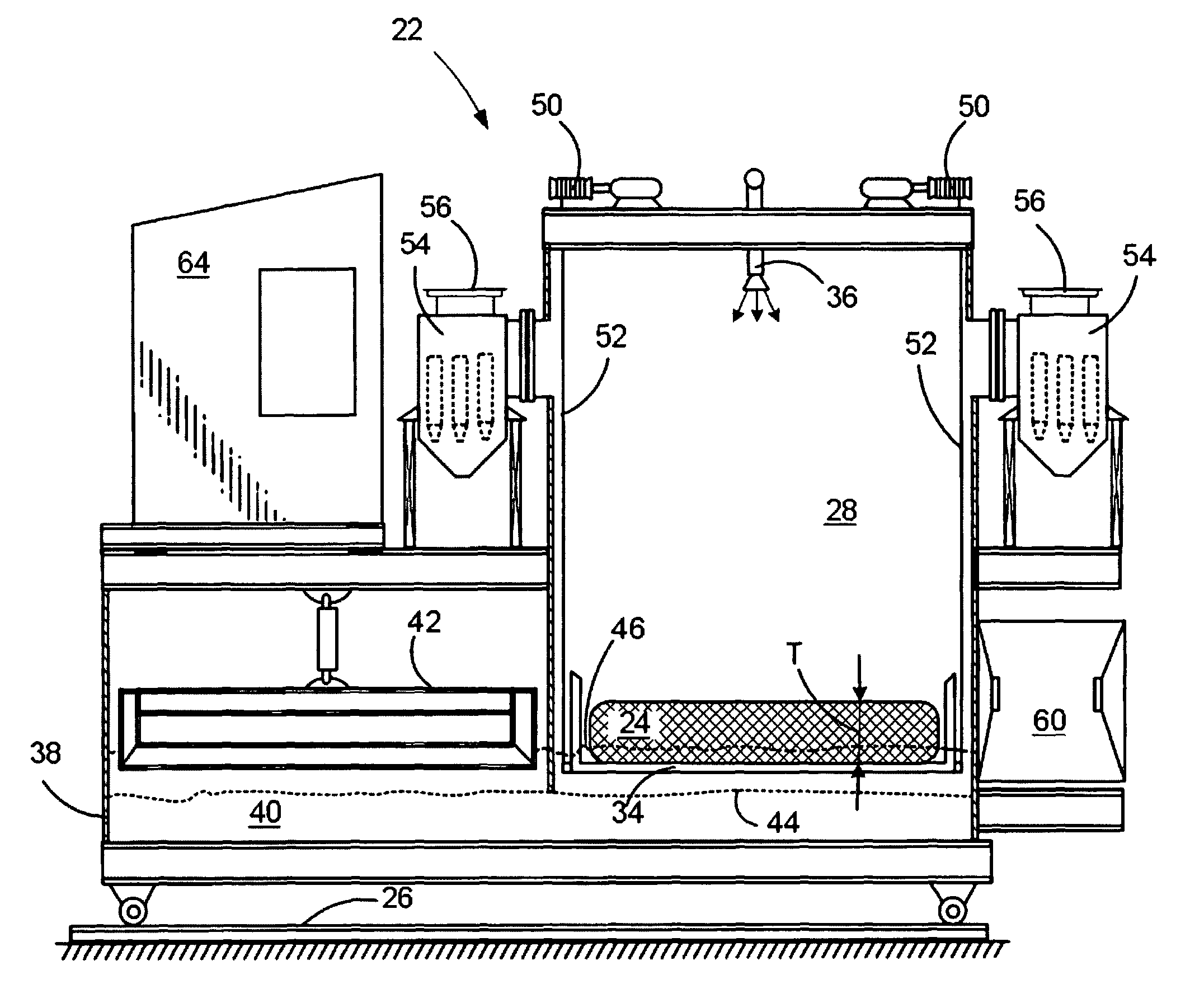

InactiveUS7998316B2Reduce the amount requiredImprove efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

Process for transporting and quenching coke

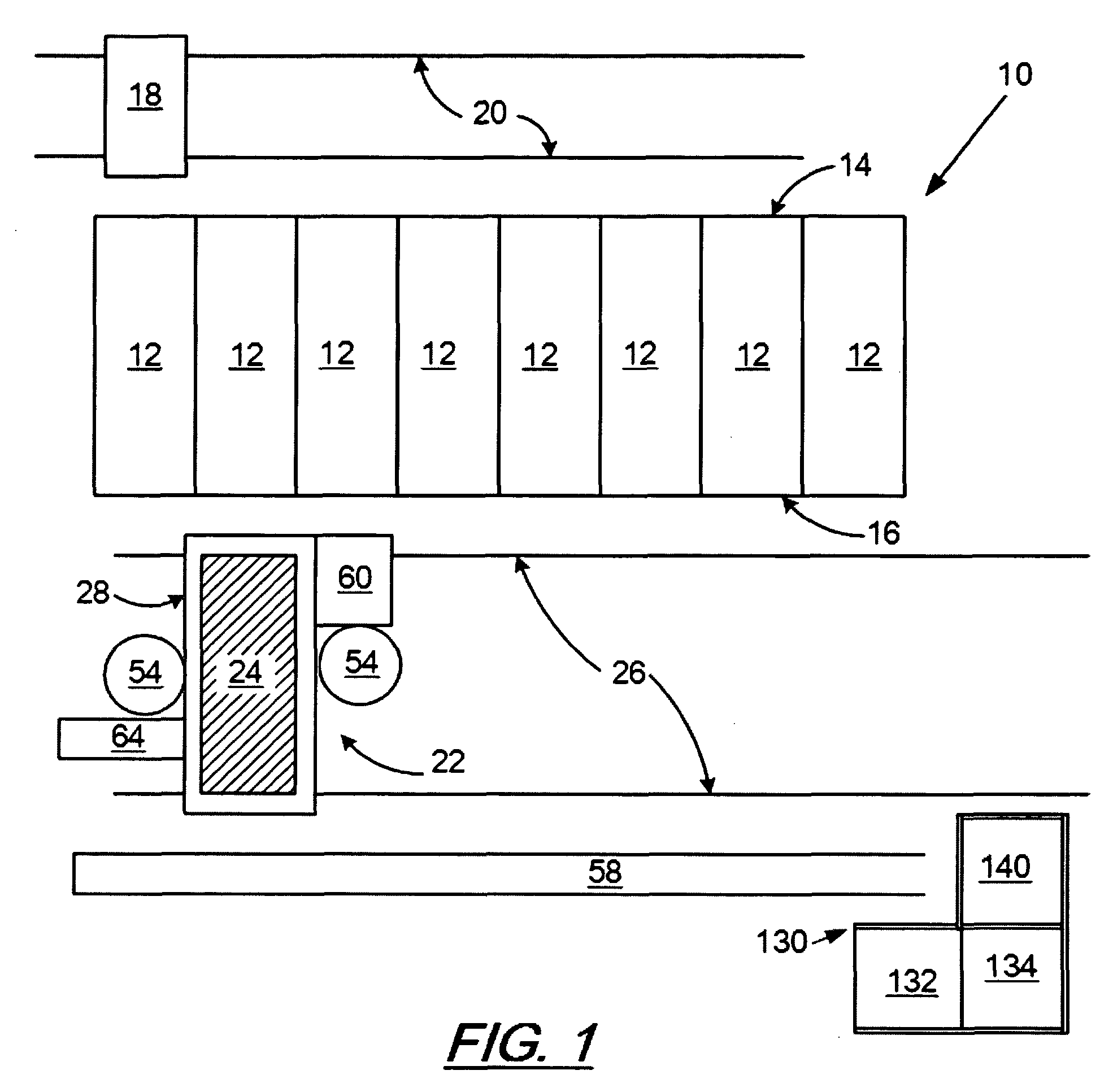

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

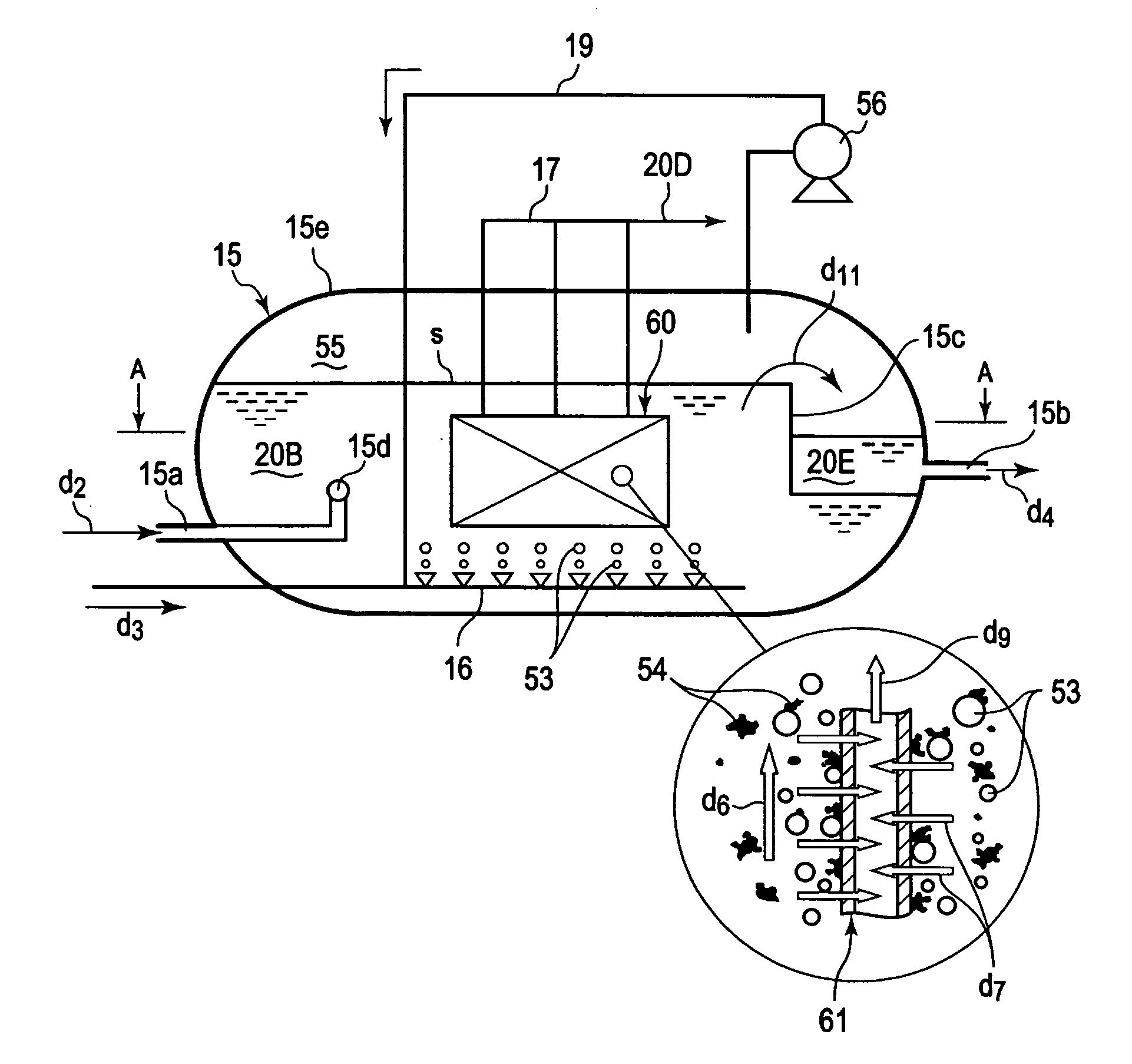

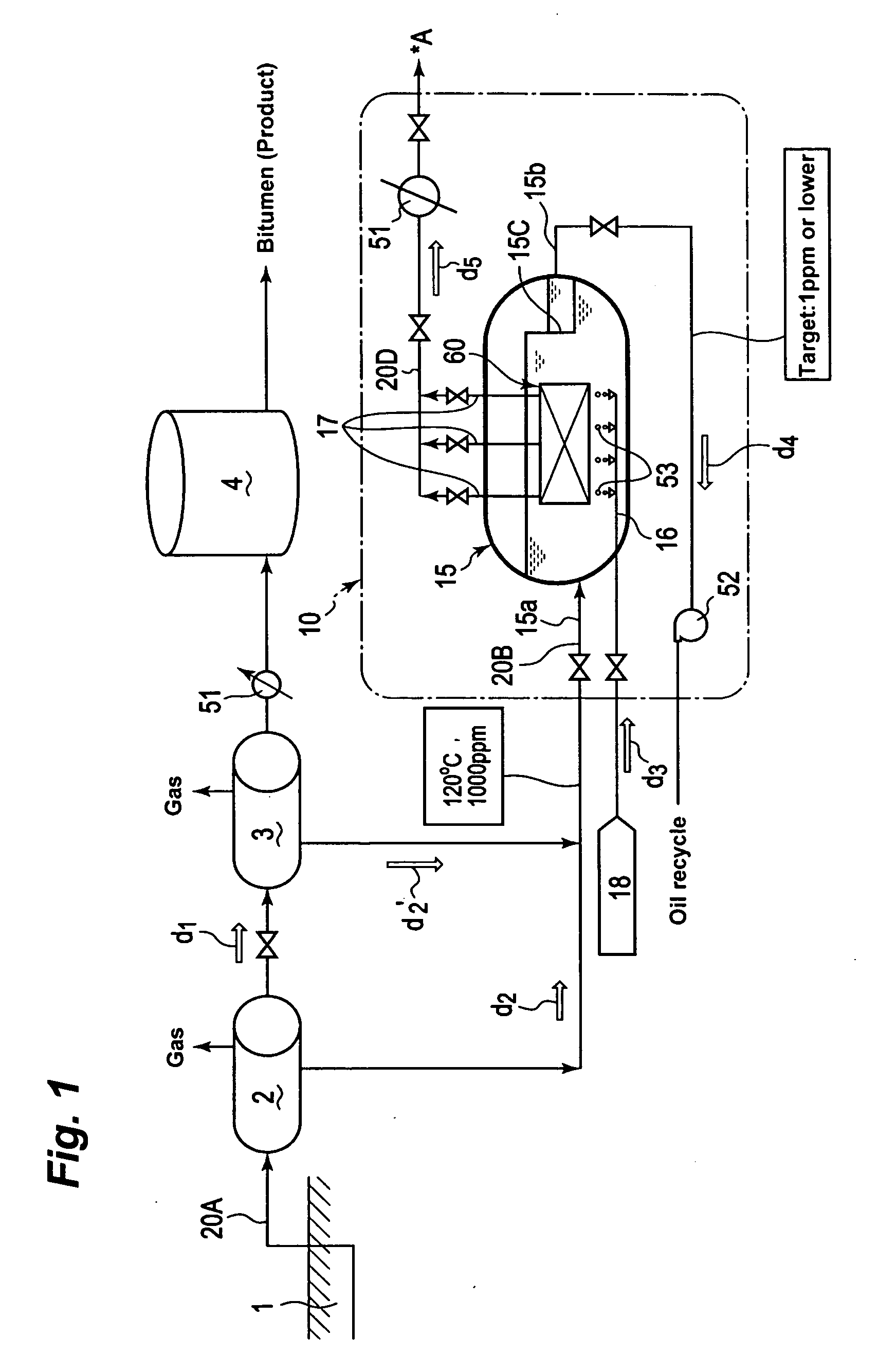

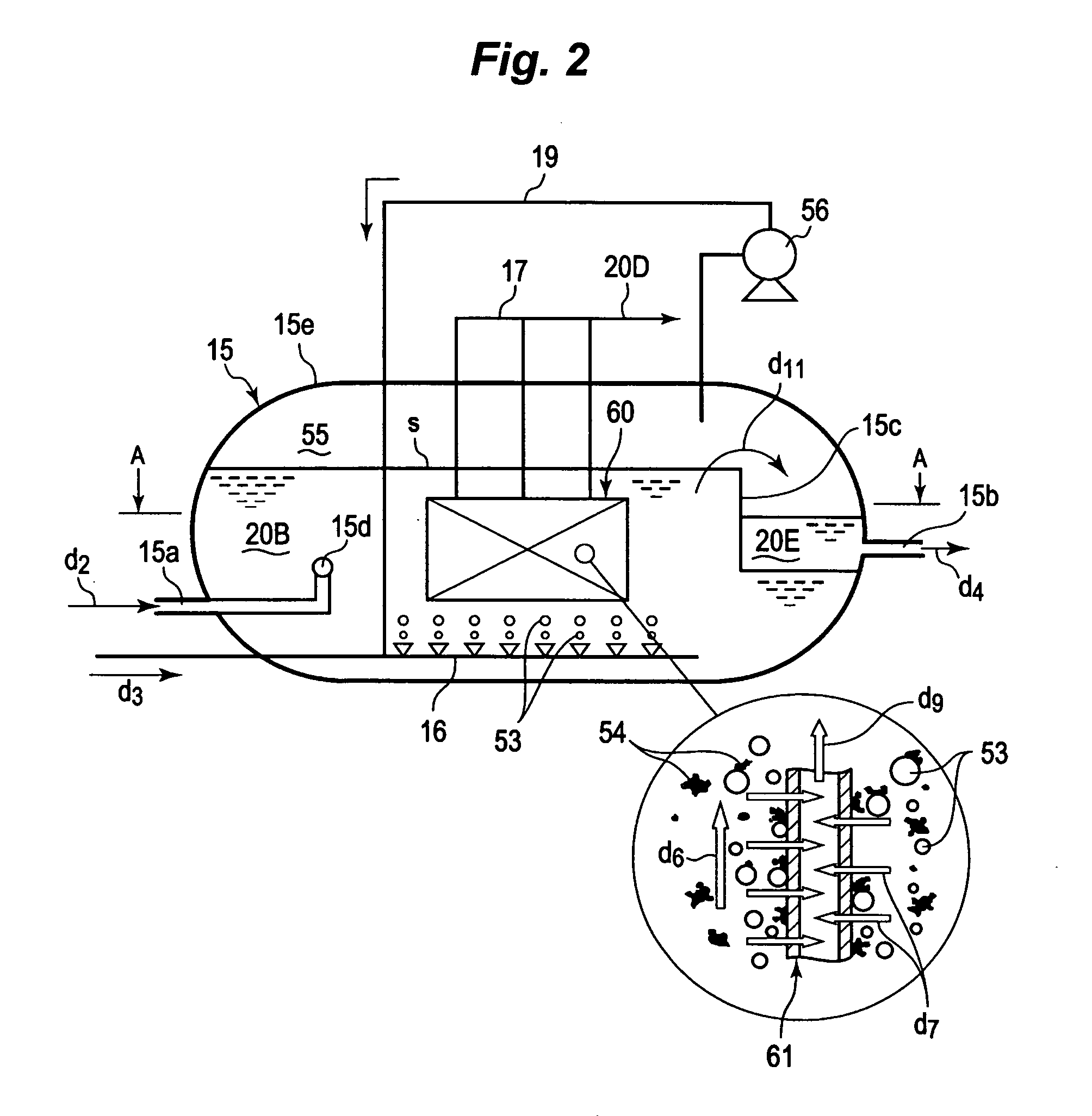

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

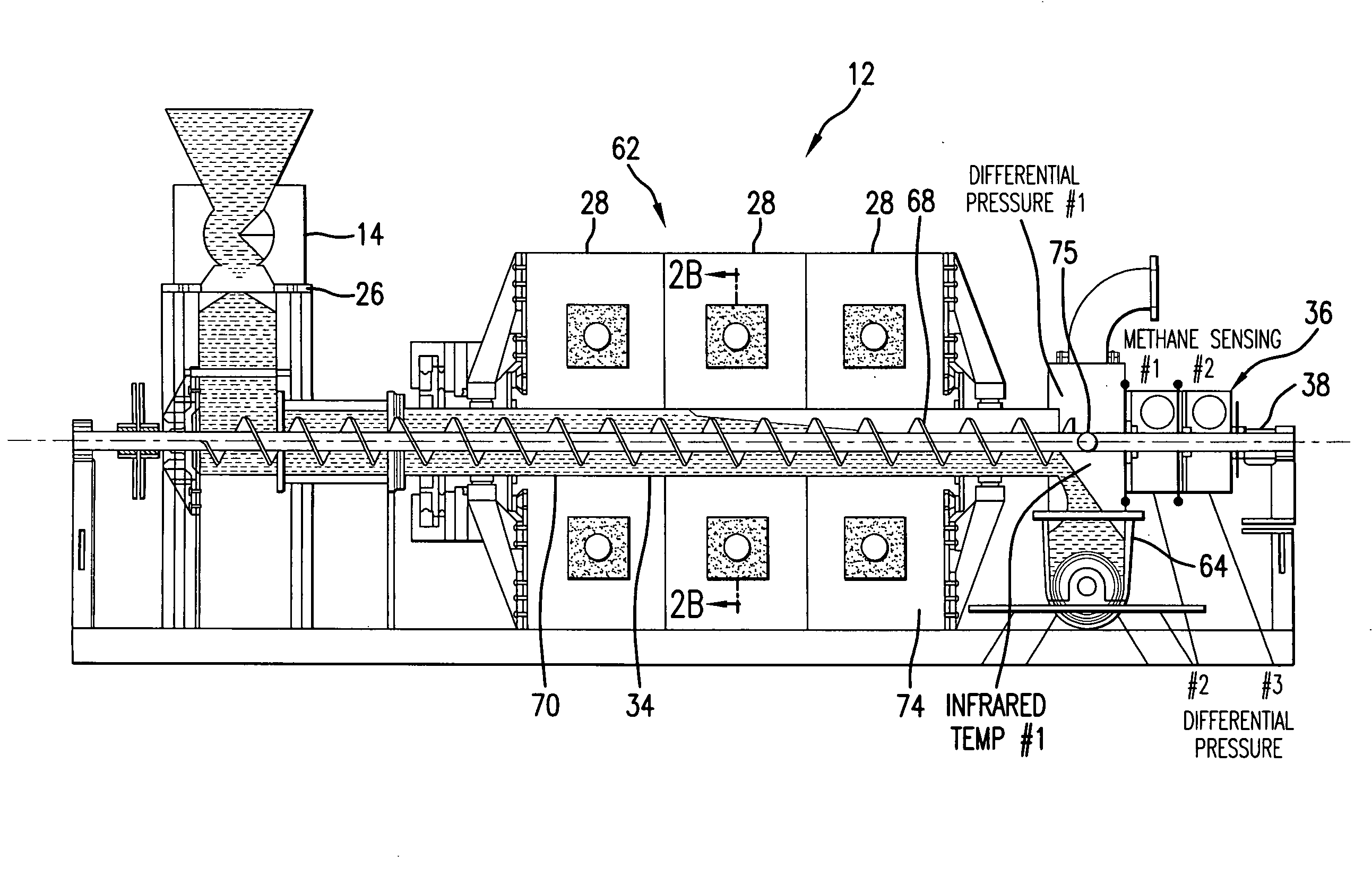

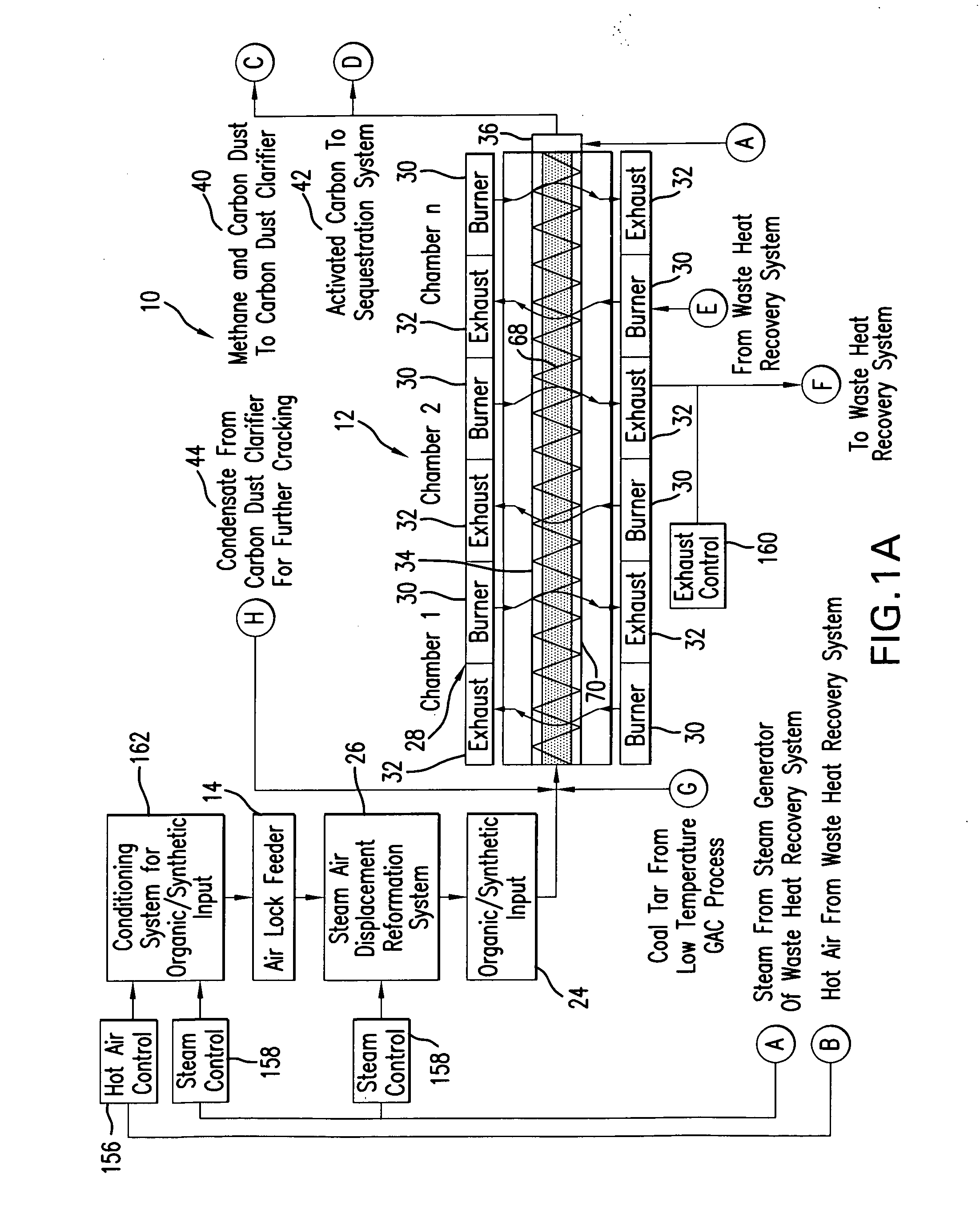

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

Flash pyrolosis method for carbonaceous materials

InactiveUS20070272538A1Efficient transferFast heatingThermal non-catalytic crackingDirect heating destructive distillationSufficient timeBoiling point

Methods are disclosed for pyrolizing carbonaceous materials to carbonaceous materials having lower boiling points by heating the carbonaceous material to a desired reaction temperature and holding the carbonaceous material in contact with the heat for a sufficient time to achieve the desired reaction to a lower boiling point carbonaceous materials, then rapidly cooling the desired reaction products. The heating source is a jet which will provide hot and high velocity gas streams to the carbonaceous material to be heated.

Owner:BOC GRP INC

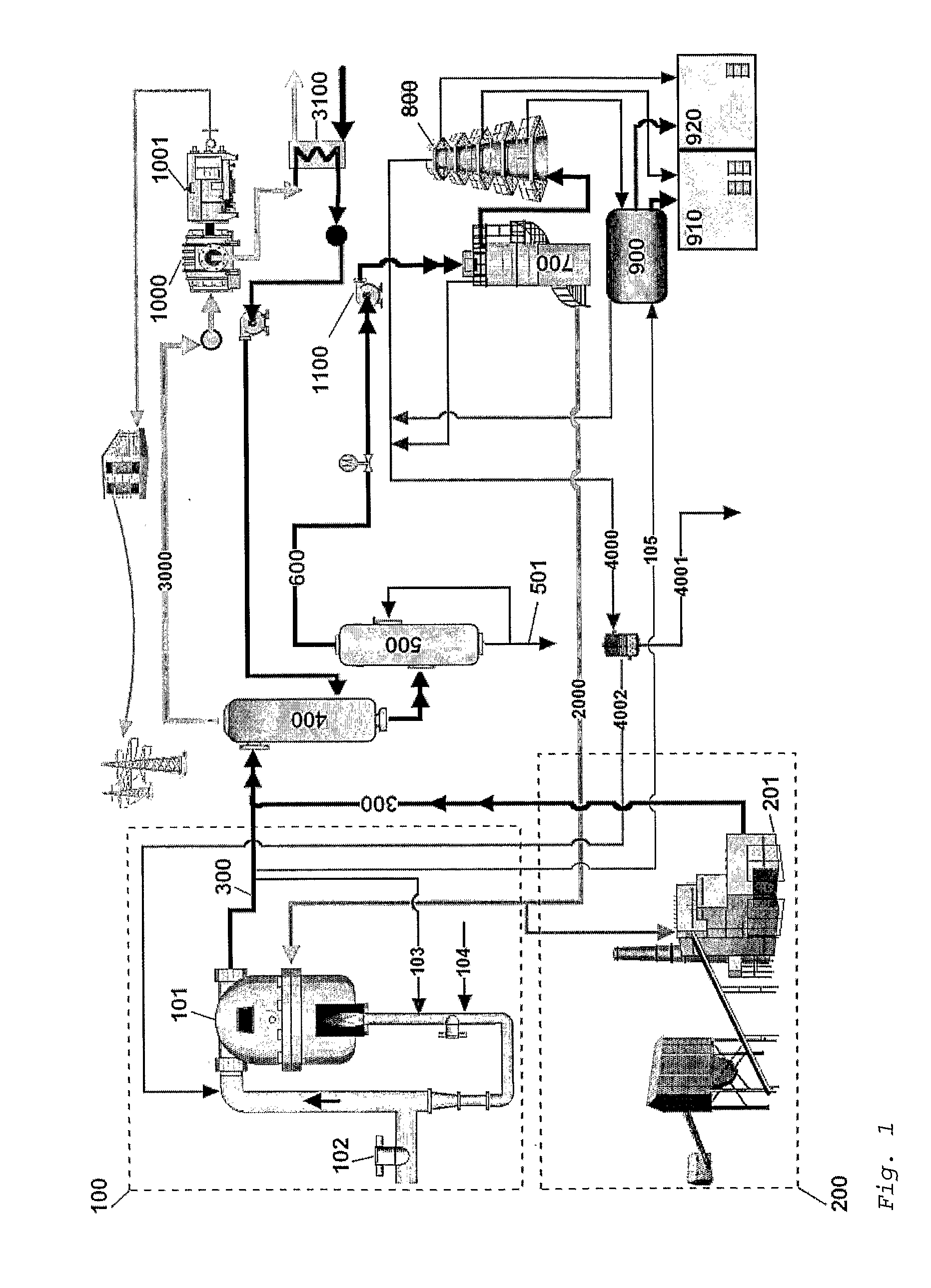

Waste to liquid hydrocarbon refinery system

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

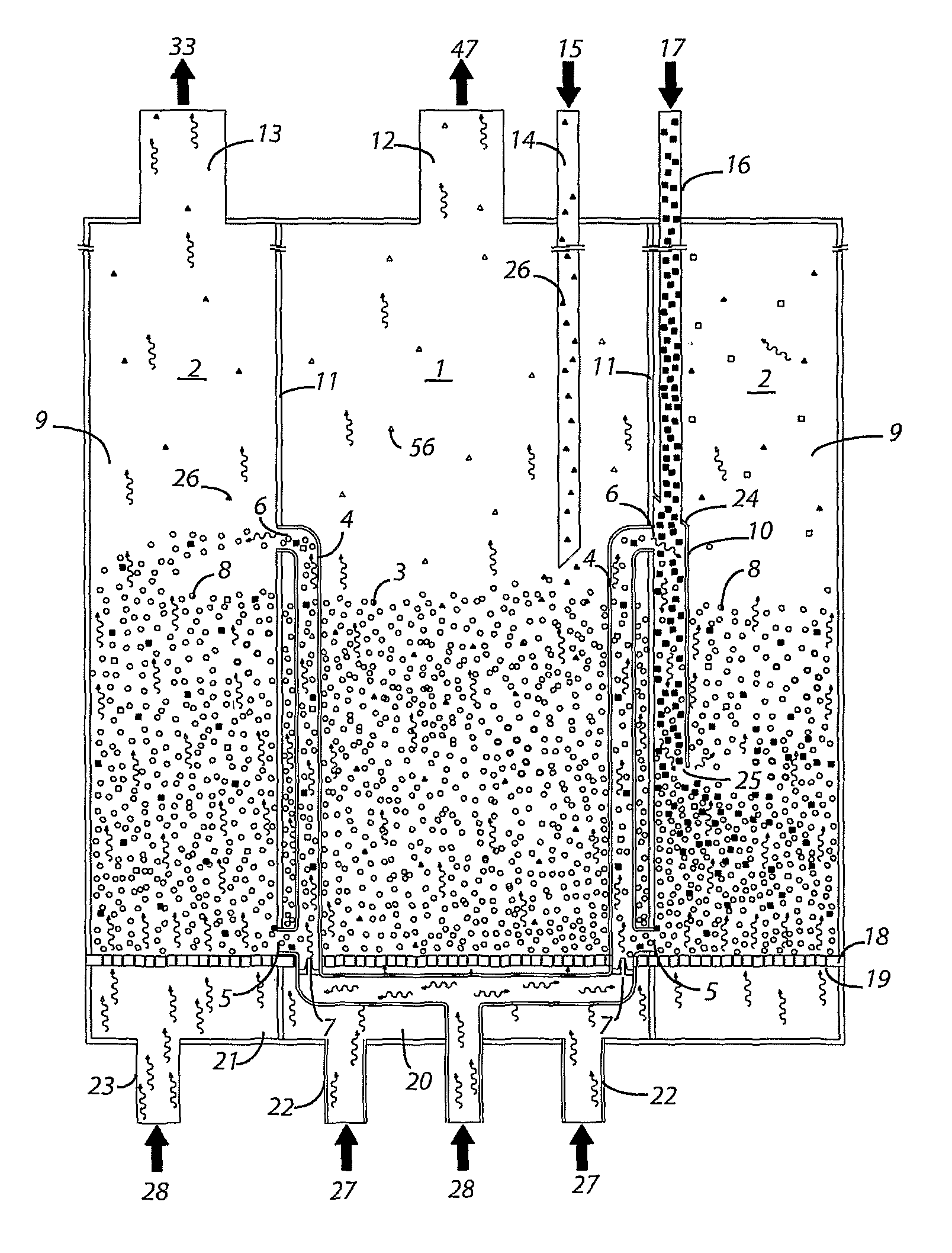

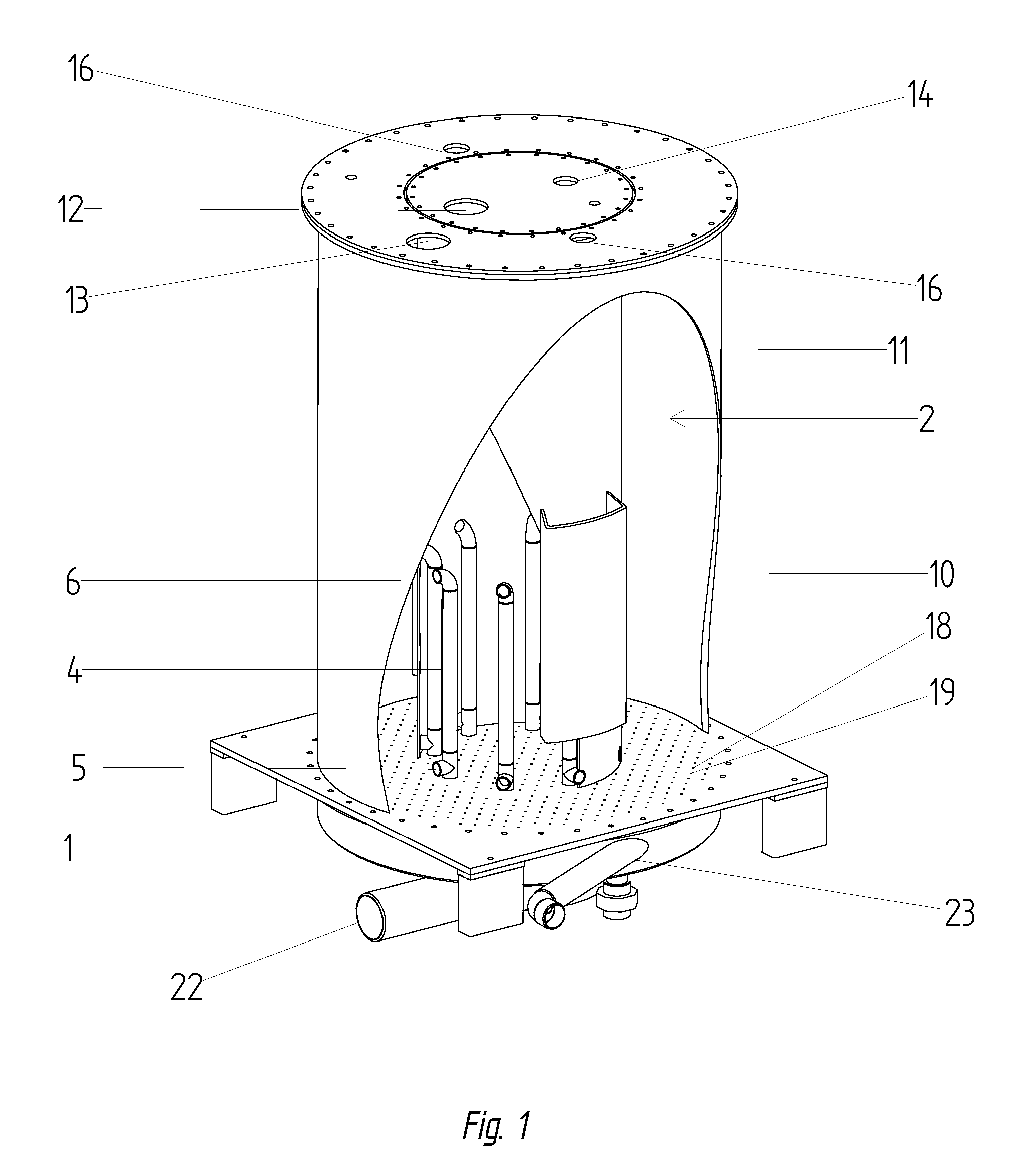

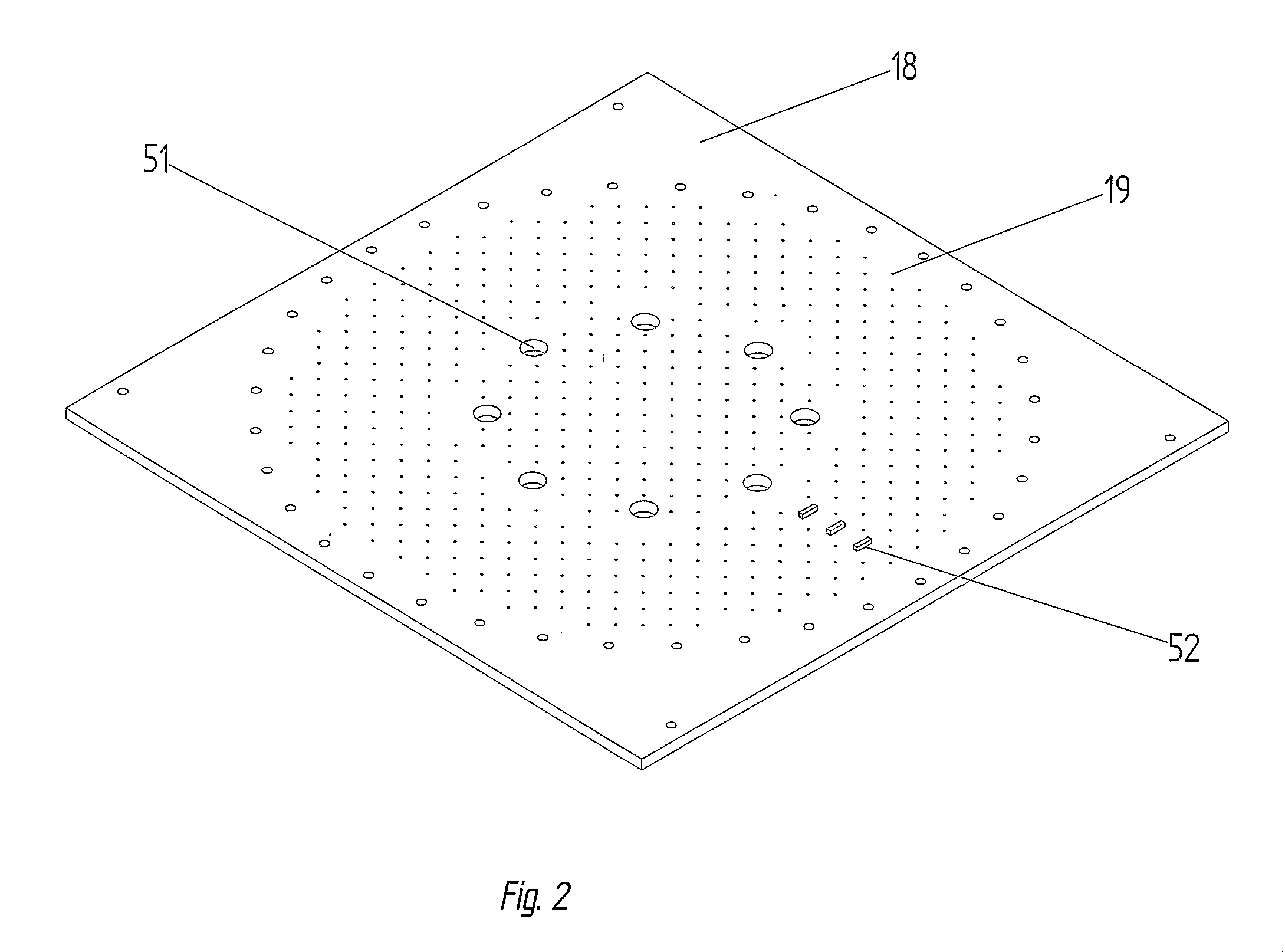

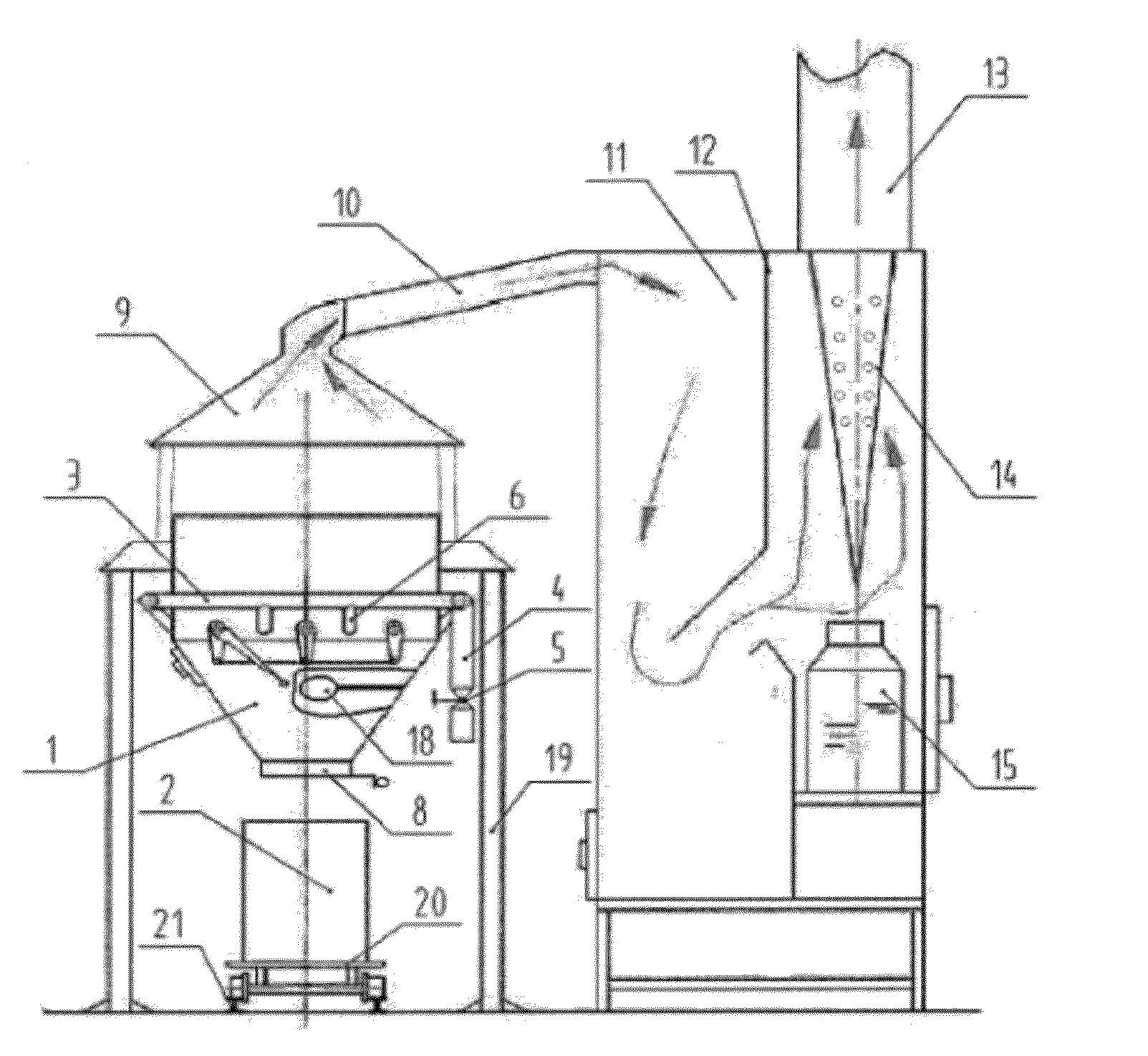

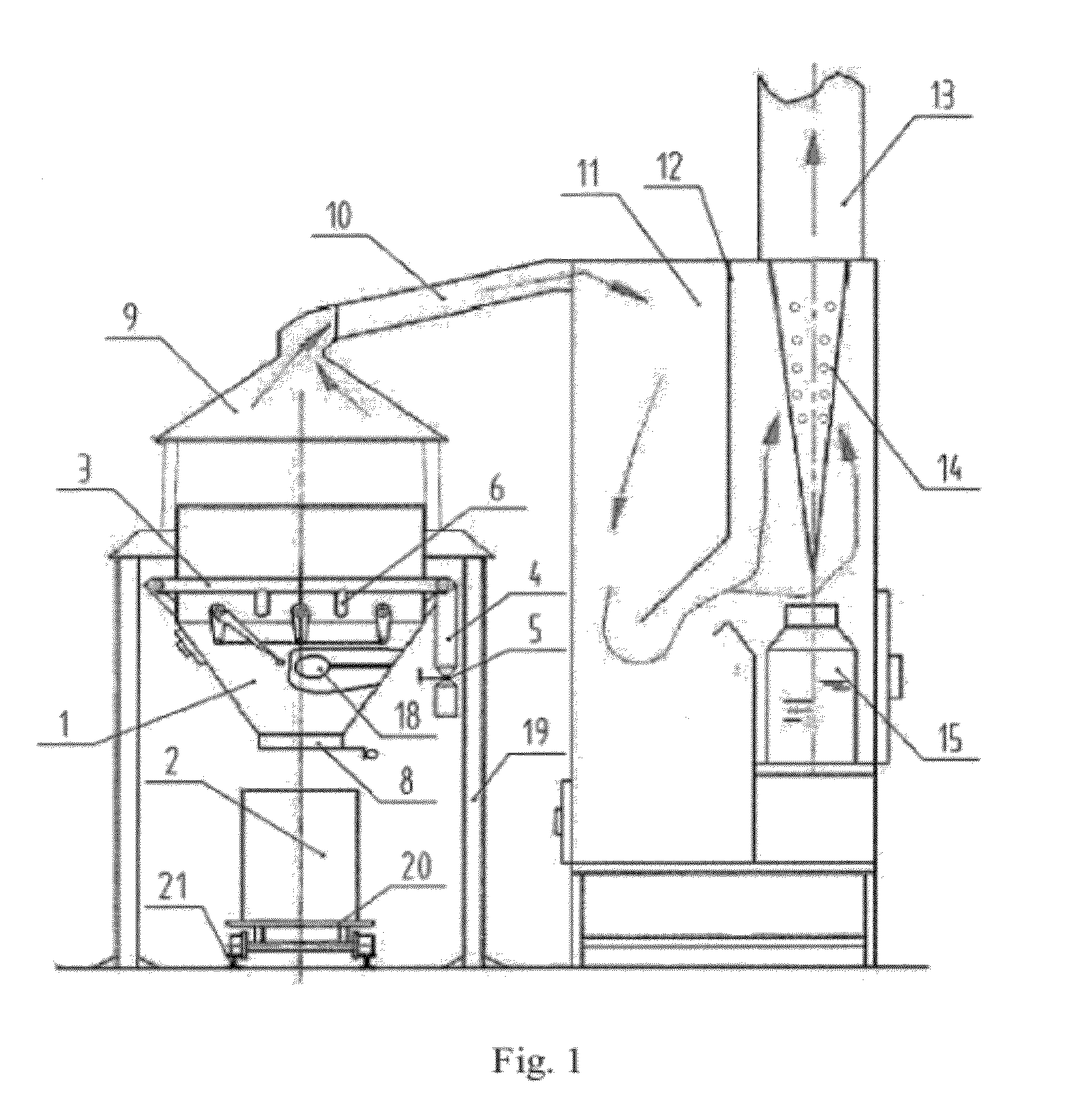

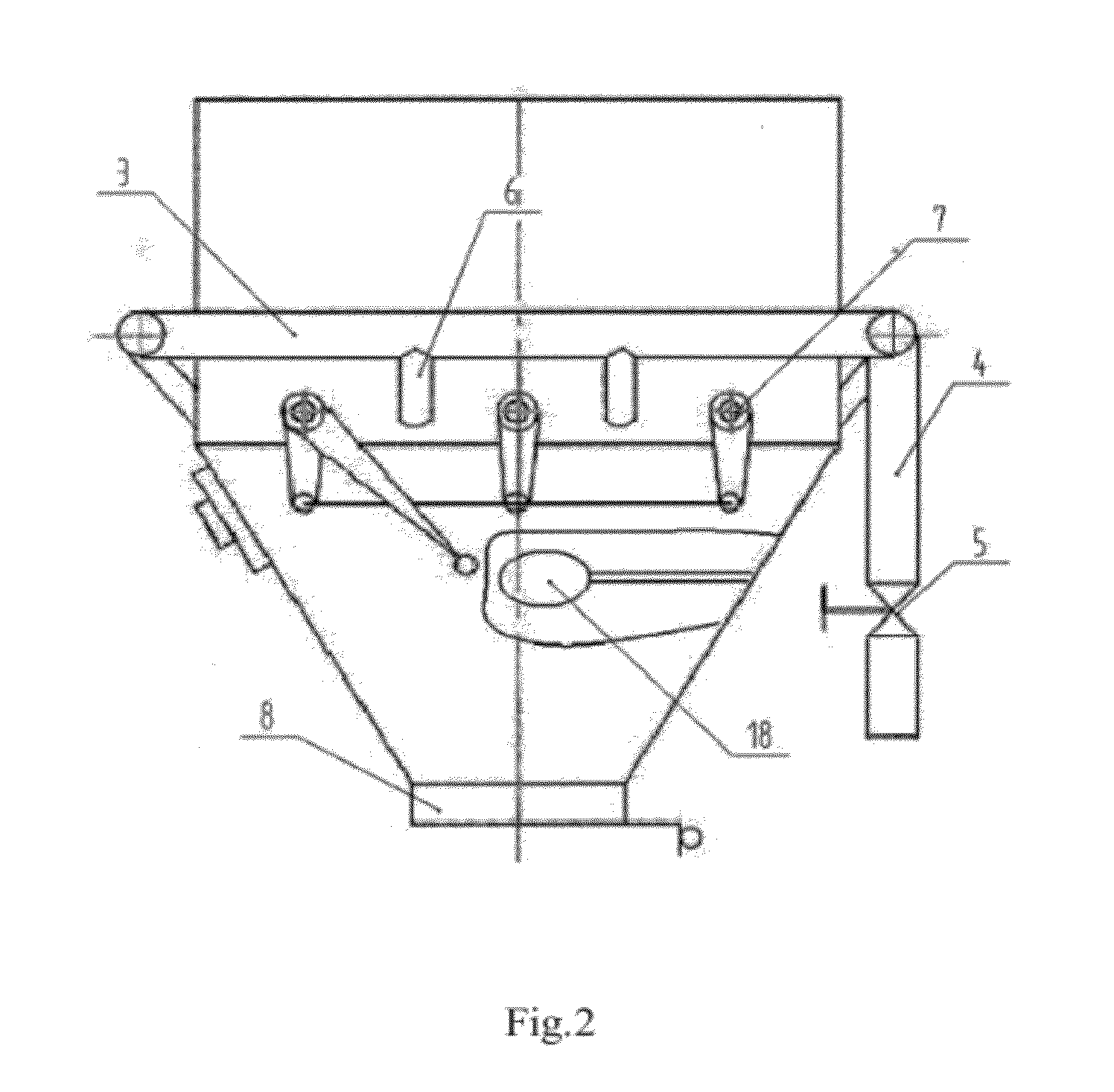

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

Method and device for carbonification of crop straws

ActiveUS20120305380A1SpeedReduce the temperatureCombustible gas coke oven heatingDirect heating destructive distillationEngineeringOxygen

The present invention is to provide a method for carbonification of crop straws and a device thereof. Pyrolysis process is controlled by regulating the feeding of oxygen during said pyrolysis process, and pyrolysis and carbonification are respectively conducted in separate pyrolysis and carbonification pools, wherein the straws are pyrolyzed in said pyrolysis pool and entered into said carbonification pool to be carbonified. The present invention can quickly raise the temperature of the pyrolysis process, shorten the time of the pyrolysis process, and improve the pyrolysis carbonification efficiency.

Owner:SHANXI SUPPLY & MARKETING COOP

Method of producing charcoal, conditioned fuel gas and potassium from biomass

InactiveUS7226566B2Reduce productionSuitable for useLiquid degasificationSolid waste disposalPotassiumProcess engineering

Owner:CSA ENERGY

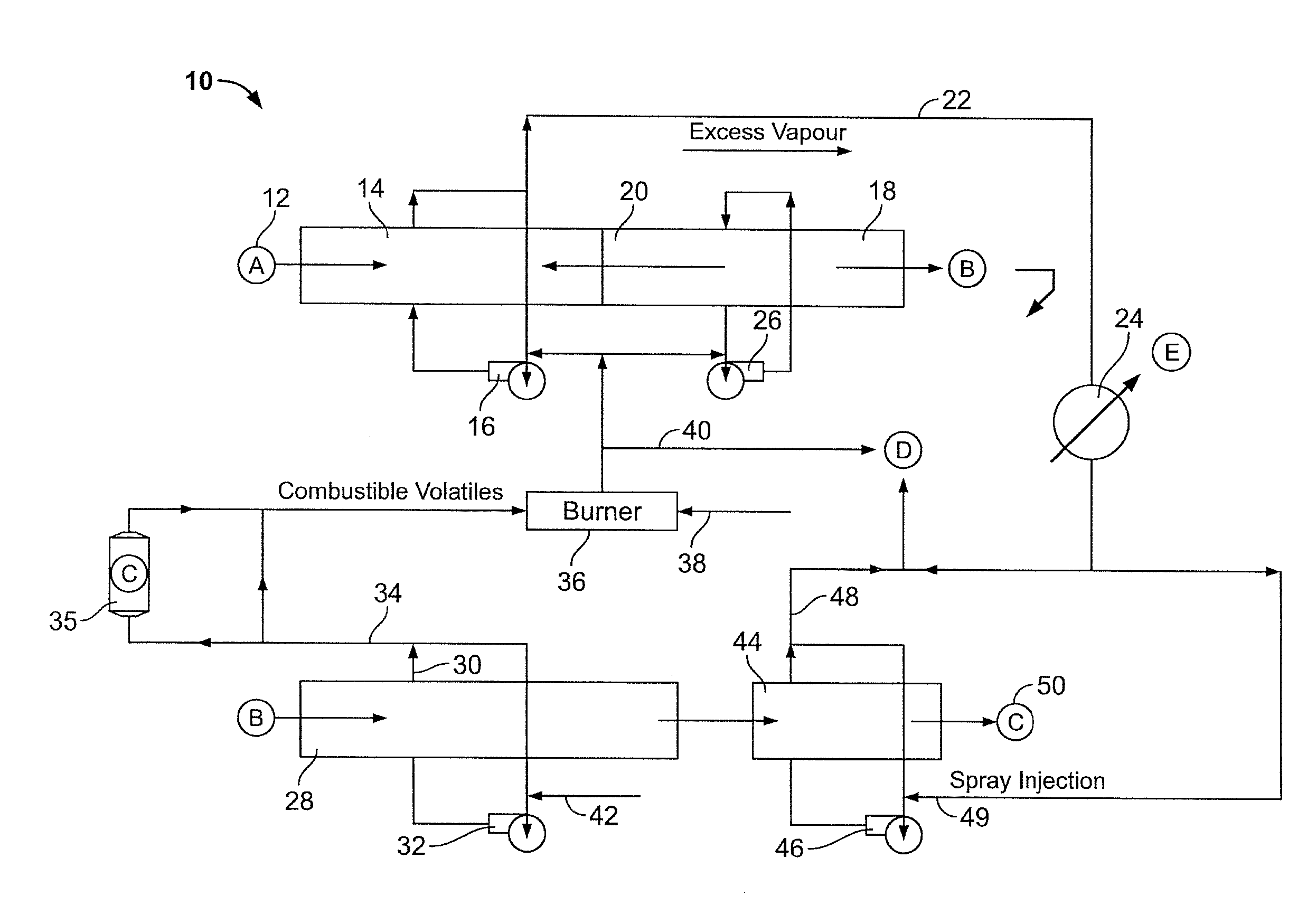

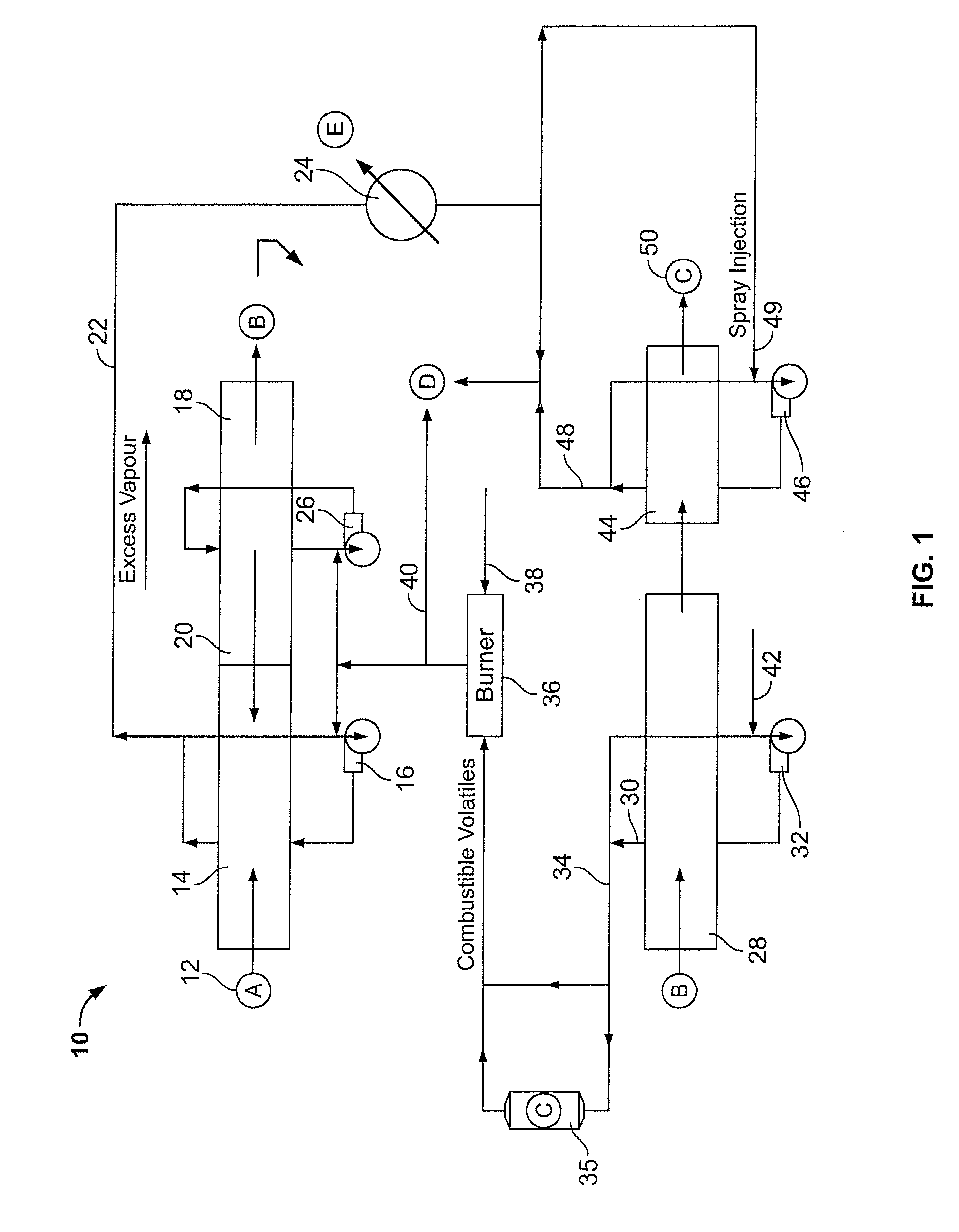

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

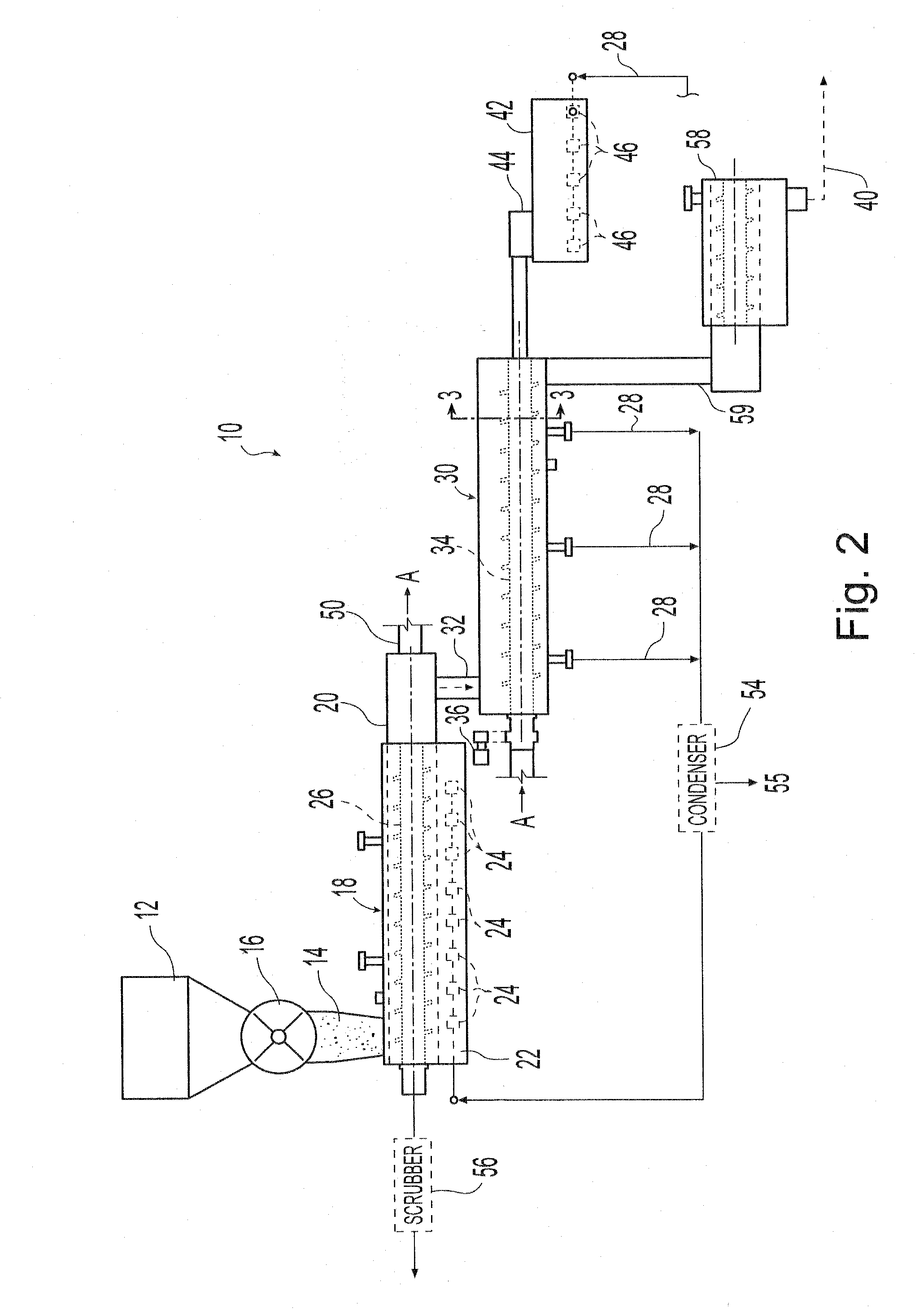

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20080149471A1Weaken energyLower Level RequirementsMechanical conveying coke ovensDirect heating destructive distillationCombustion chamberDrive shaft

A pyrolyzer and method is provided for devolatizing coal and other volatile materials. The pyrolyzer has a pyrolyzer furnace housing having at least two screws laterally positioned adjacent and overlapping rotatably mounted within the furnace for moving volatile material through the pyrolyzer furnace housing. The screws have hollow drive shafts with a diverter inside for converging heated fluid to heat the volatile material moving through the pyrolyzer furnace housing. A combustion chamber combusts fuel to create heated exhaust gas for directing through the hollow drive shafts to heat the volatile material. The pyrolyzer furnace housing may have a double wall with a cavity between, capable of receiving heated fluid for further heating of volatile material moving through the pyrolyzer furnace housing.

Owner:NUCOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com