Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

A solid fuel, catalytic gasification technology, applied in the manufacture of combustible gas, hydrogen production, petroleum industry, etc., can solve the problems of difficult control of deactivated catalyst reduction and regeneration, complex reactor structure, limited application conditions, etc., to achieve energy balance Effects that are easy to achieve, highly adaptable to raw materials, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

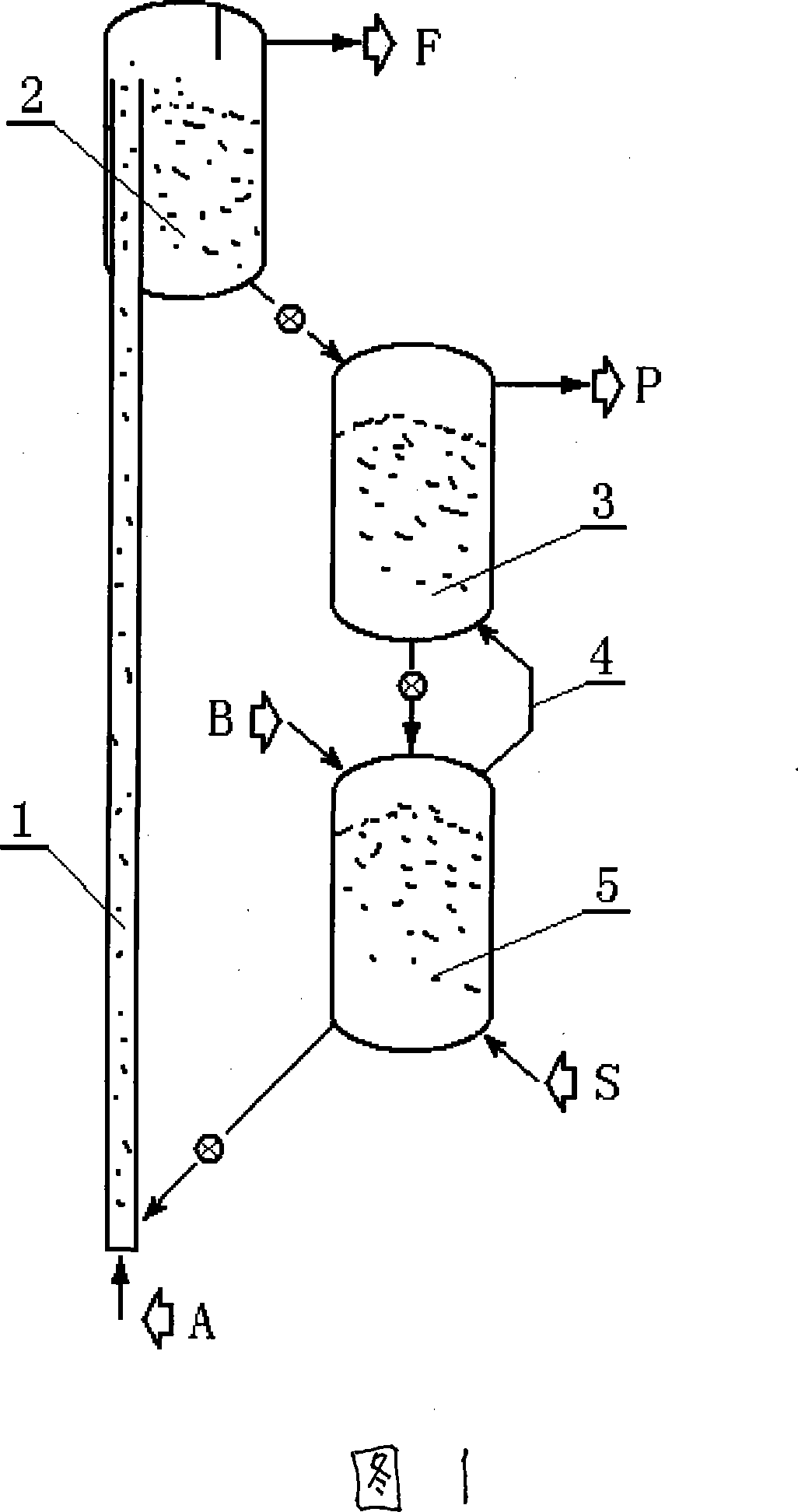

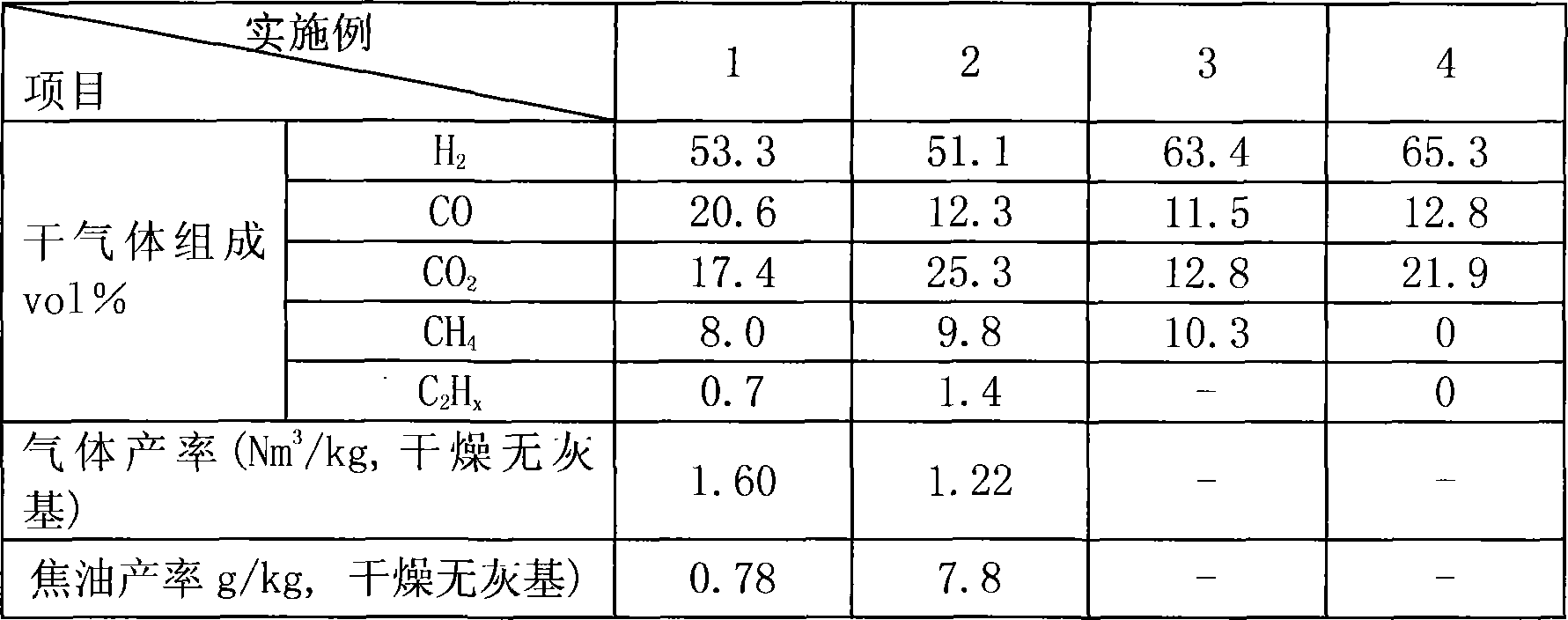

[0021] In the atmospheric pressure experimental device with a biomass treatment capacity of 1kg / h shown in Figure 1, the biomass raw material used is white pine sawdust, with a particle size of 1-3mm, and its element mass composition on a dry, ash-free basis is: C 50.3%, H 6.7% , O 42.7%, N 0.1%, S 0.2%. The solid thermal carrier catalyst used is natural olivine calcined at 900° C. for 4 hours, and the particle size is 1-2 mm. The temperature of the pyrolysis reactor is controlled to be 600-650°C, the temperature of the riser combustion reactor 1 is 900-950°C, and the temperature of the catalytic reforming reactor 3 is 750-800°C. The biomass feed rate is 0.24-0.30kg / h, the solid heat carrier catalyst circulation rate is 6-8kg / h, the water vapor / biomass mass ratio is 0.3-0.6, and the air volume is 8.0-9.0Nm 3 / h. The data of gas composition and yield are shown in Table 1.

Embodiment 2

[0023] The raw material used is lignite, and its element mass composition on a dry ash-free basis is: C 72.2%, H 5.6%, O 21.1%, N 1.0%, S 0.1%. , all the other are with embodiment 1.

Embodiment 3

[0025] Used solid heat carrier catalyst is limestone, and all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com