Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

819 results about "Olivine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mineral olivine ( /ˈɒlɪˌviːn/) is a magnesium iron silicate with the formula (Mg²⁺, Fe²⁺)₂SiO₄. Thus it is a type of nesosilicate or orthosilicate. The primary component of the earth's upper mantle, it is a common mineral in Earth's subsurface but weathers quickly on the surface.

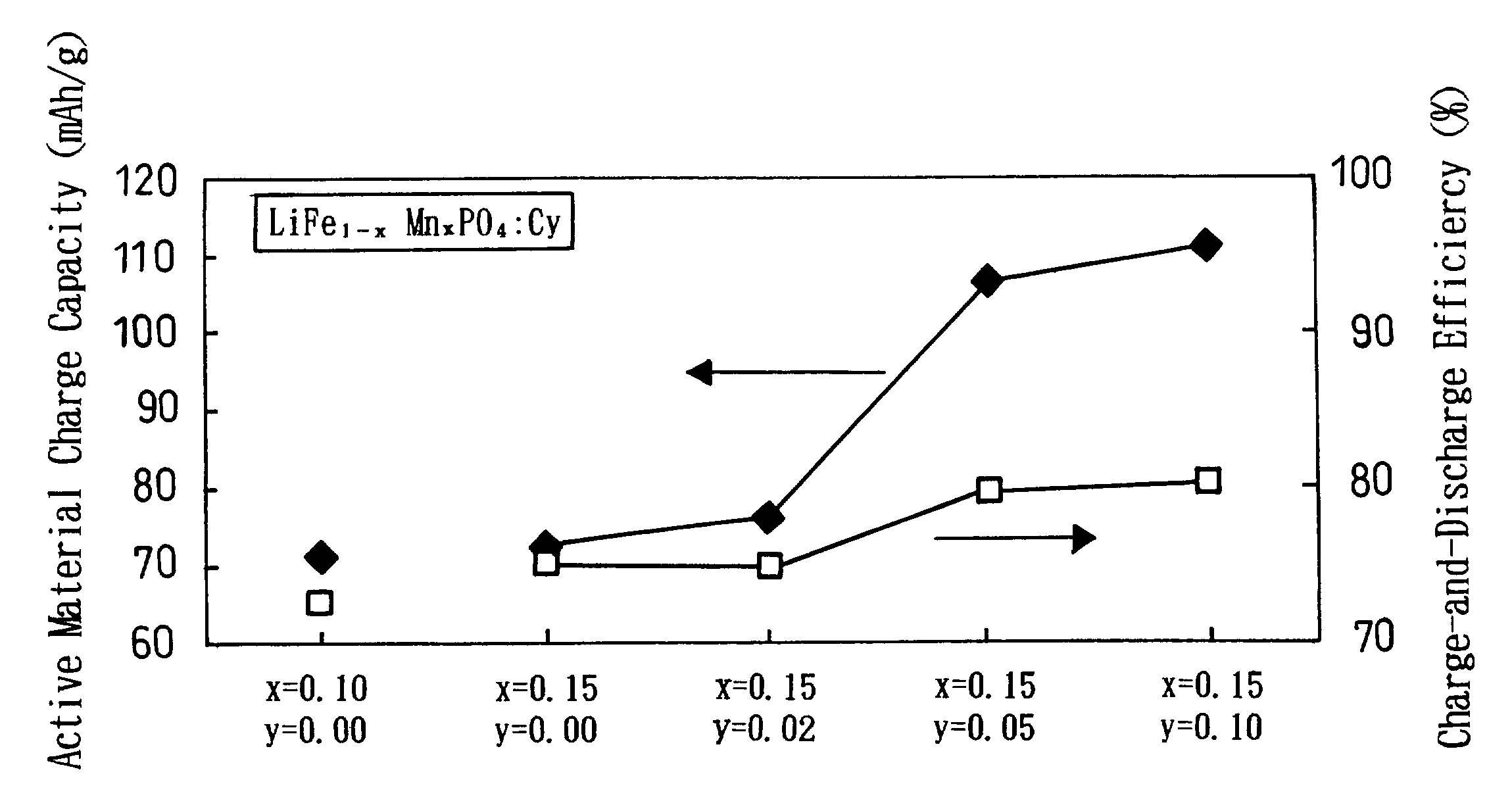

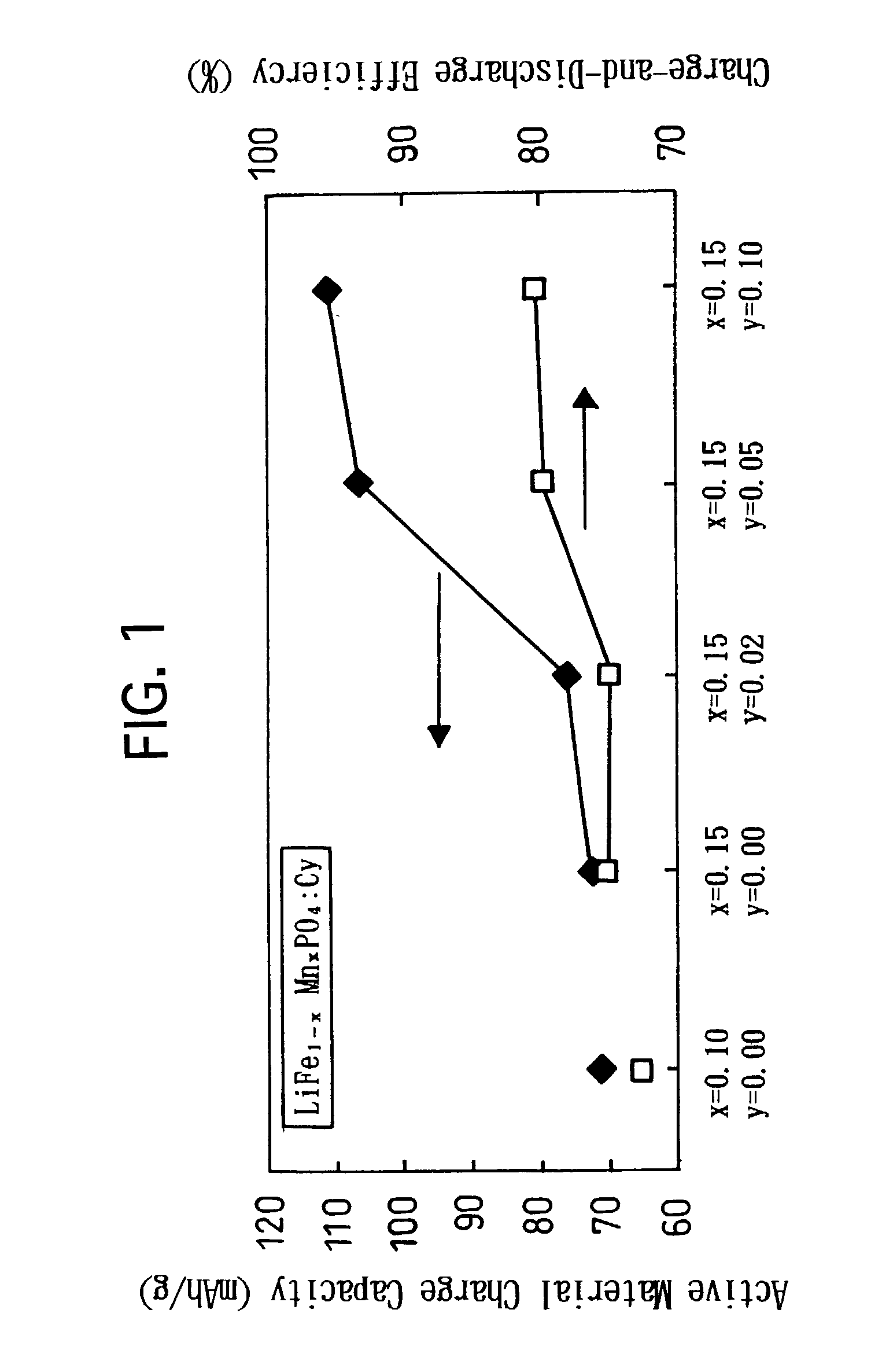

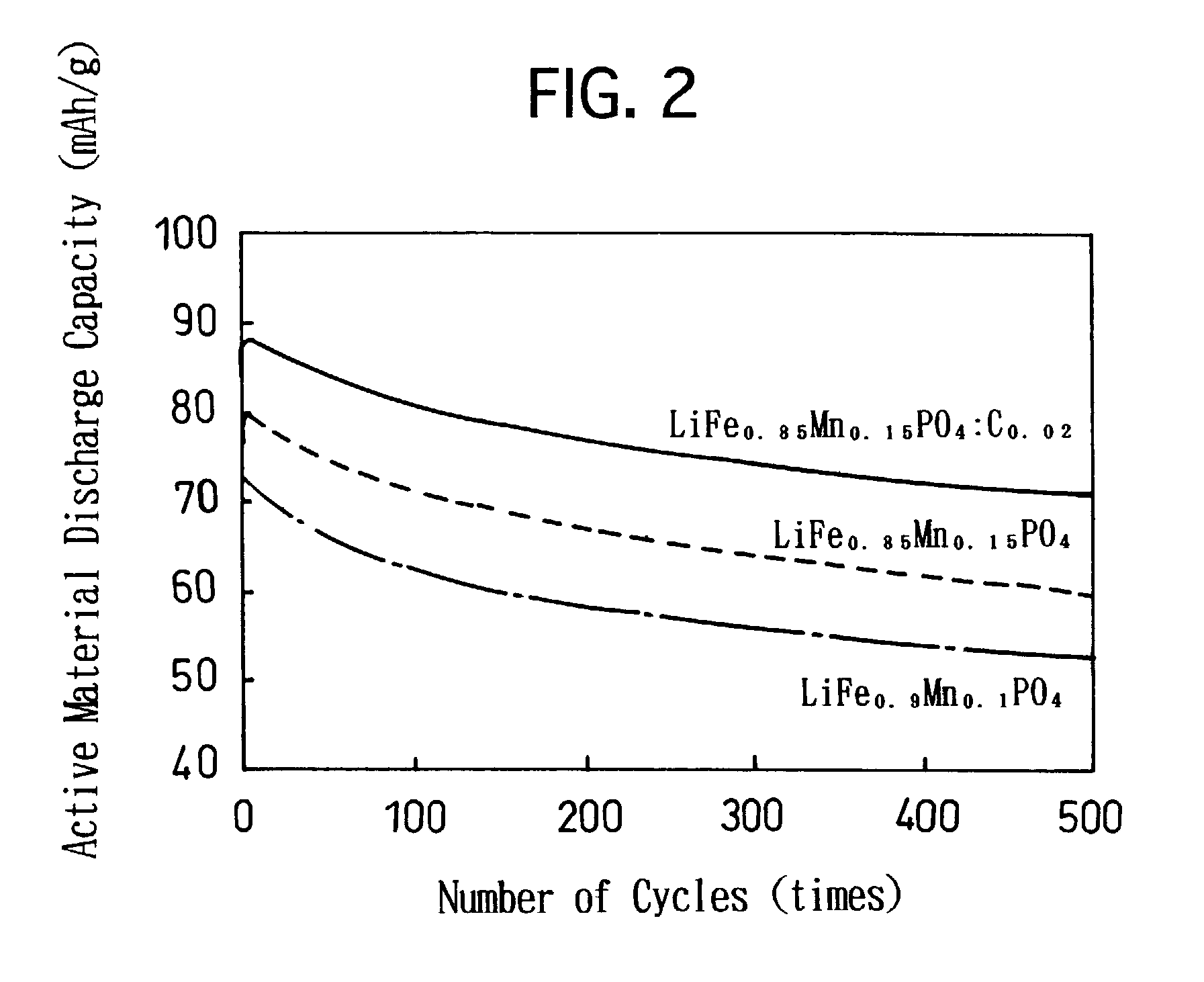

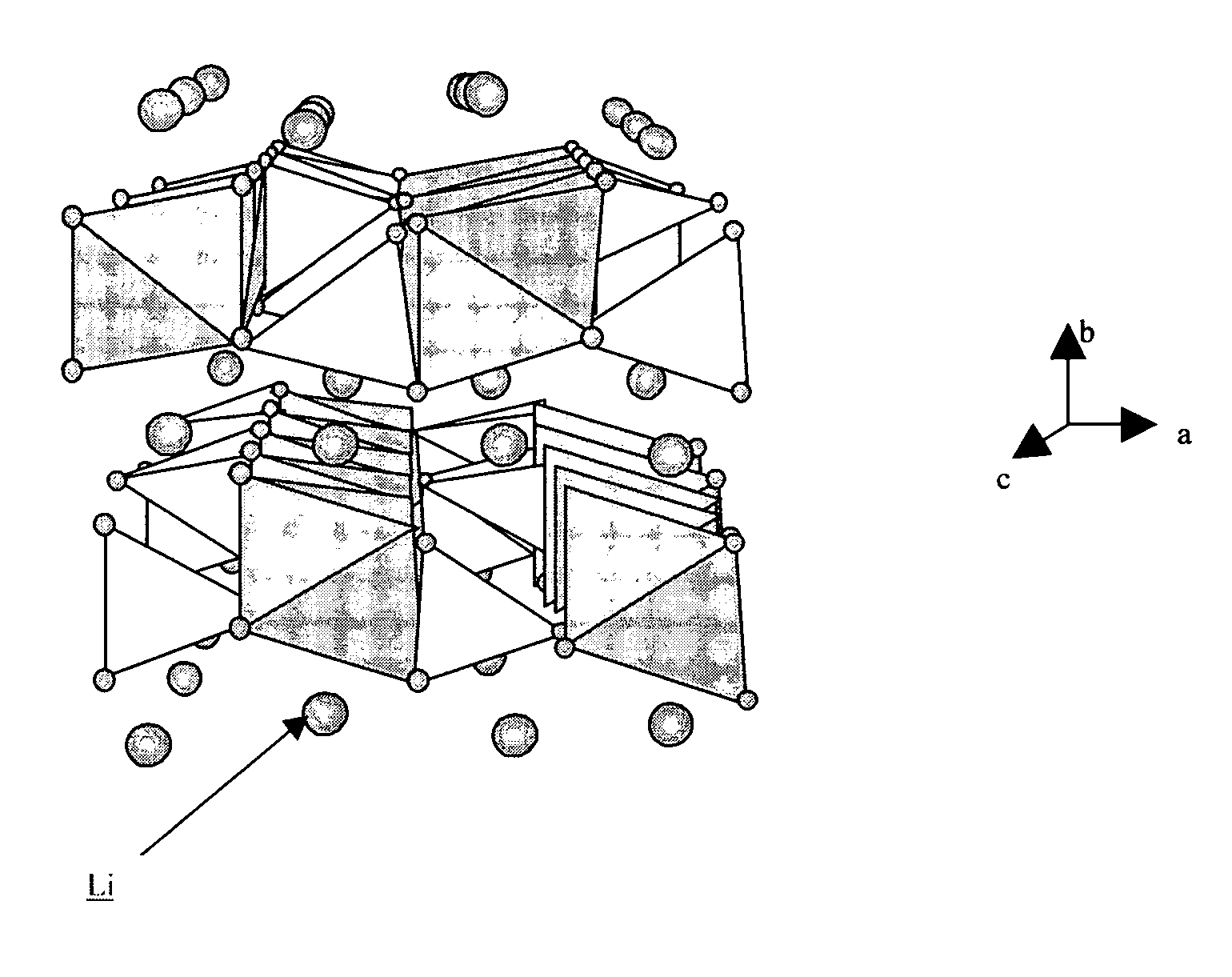

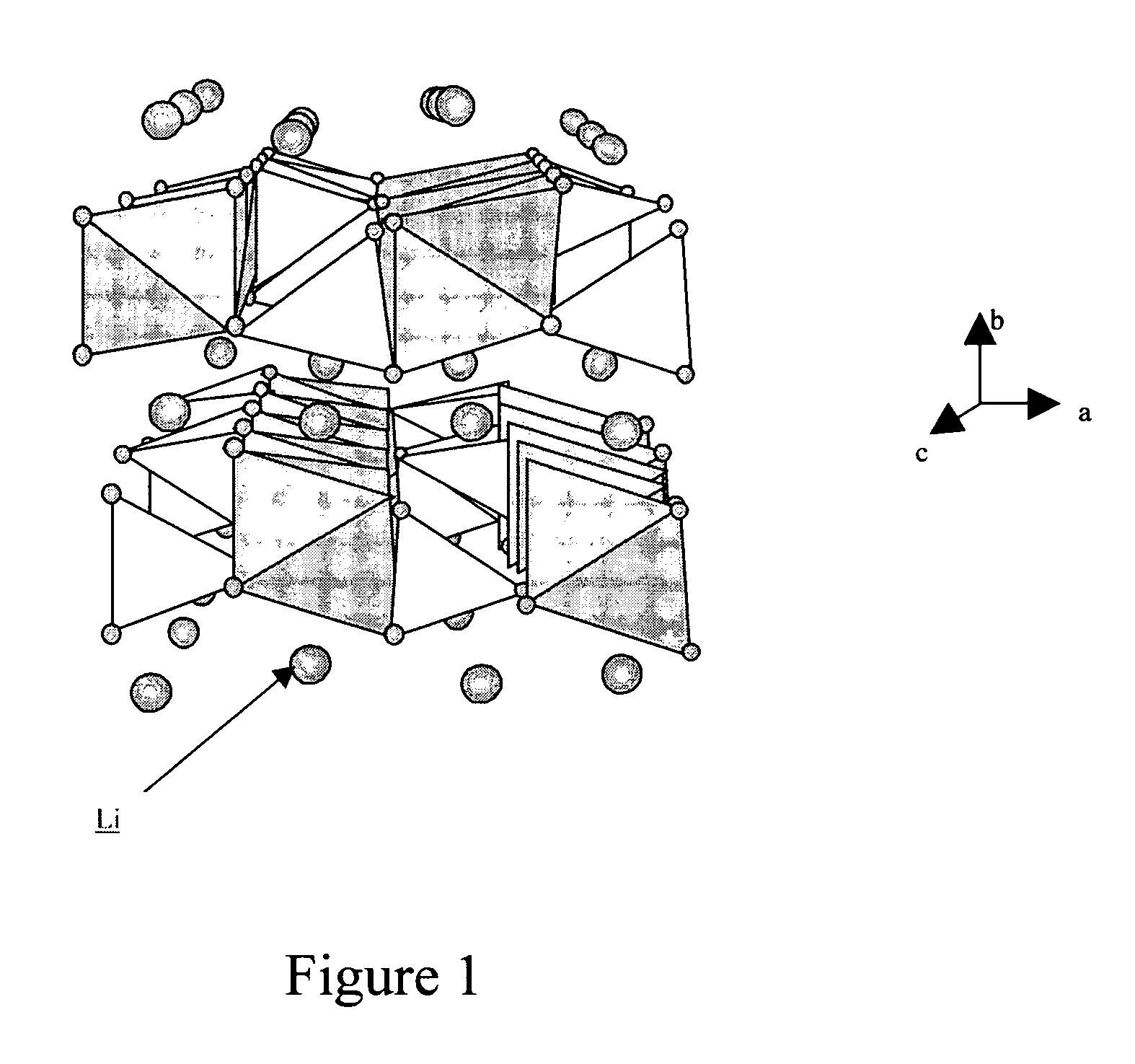

Method for making a lithium mixed metal compound having an olivine structure

ActiveUS20070207080A1Mitigate such drawbackNon-metal conductorsLiquid surface applicatorsLithiumCarbon layer

Owner:AQUIRE ENERGY CO LTD

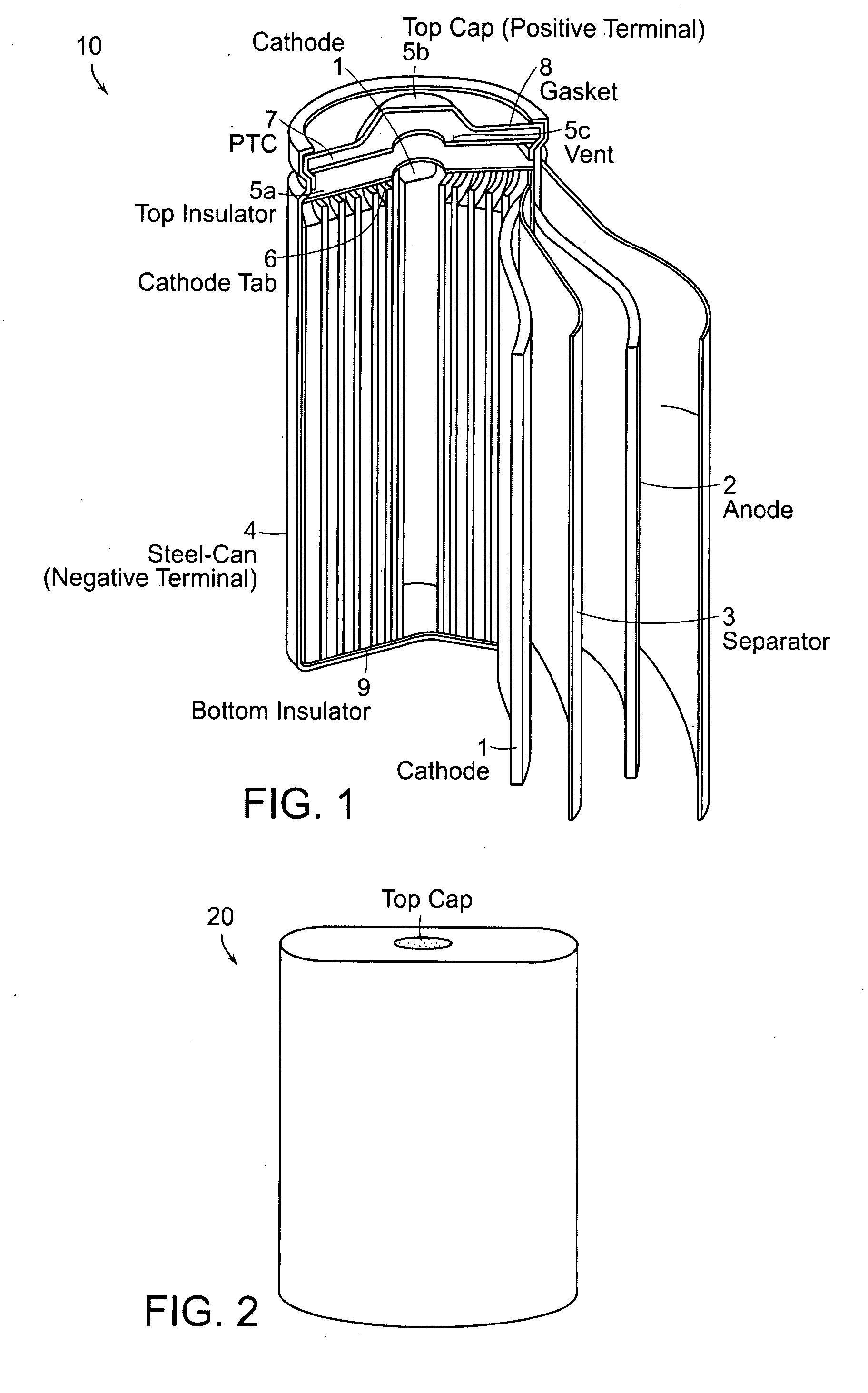

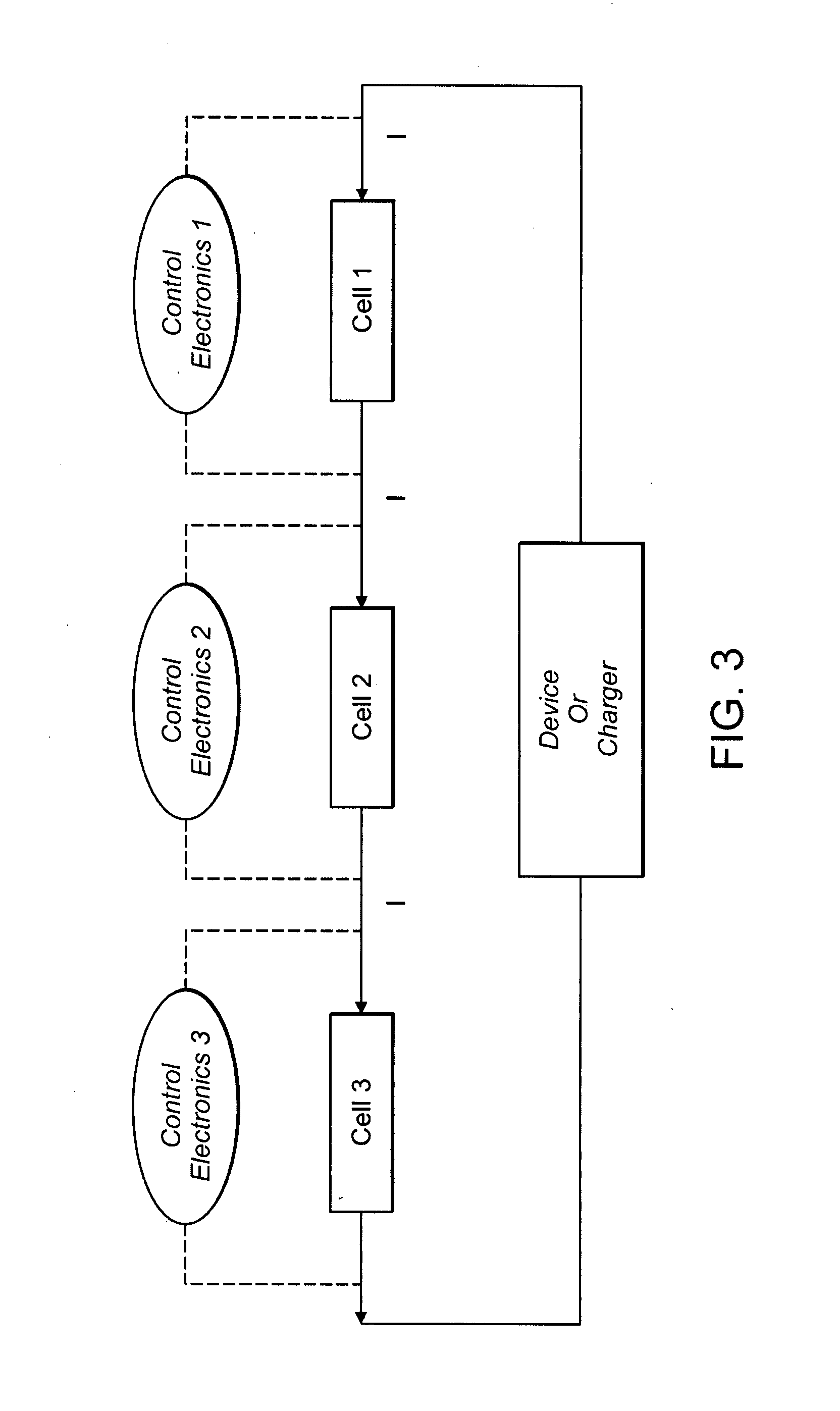

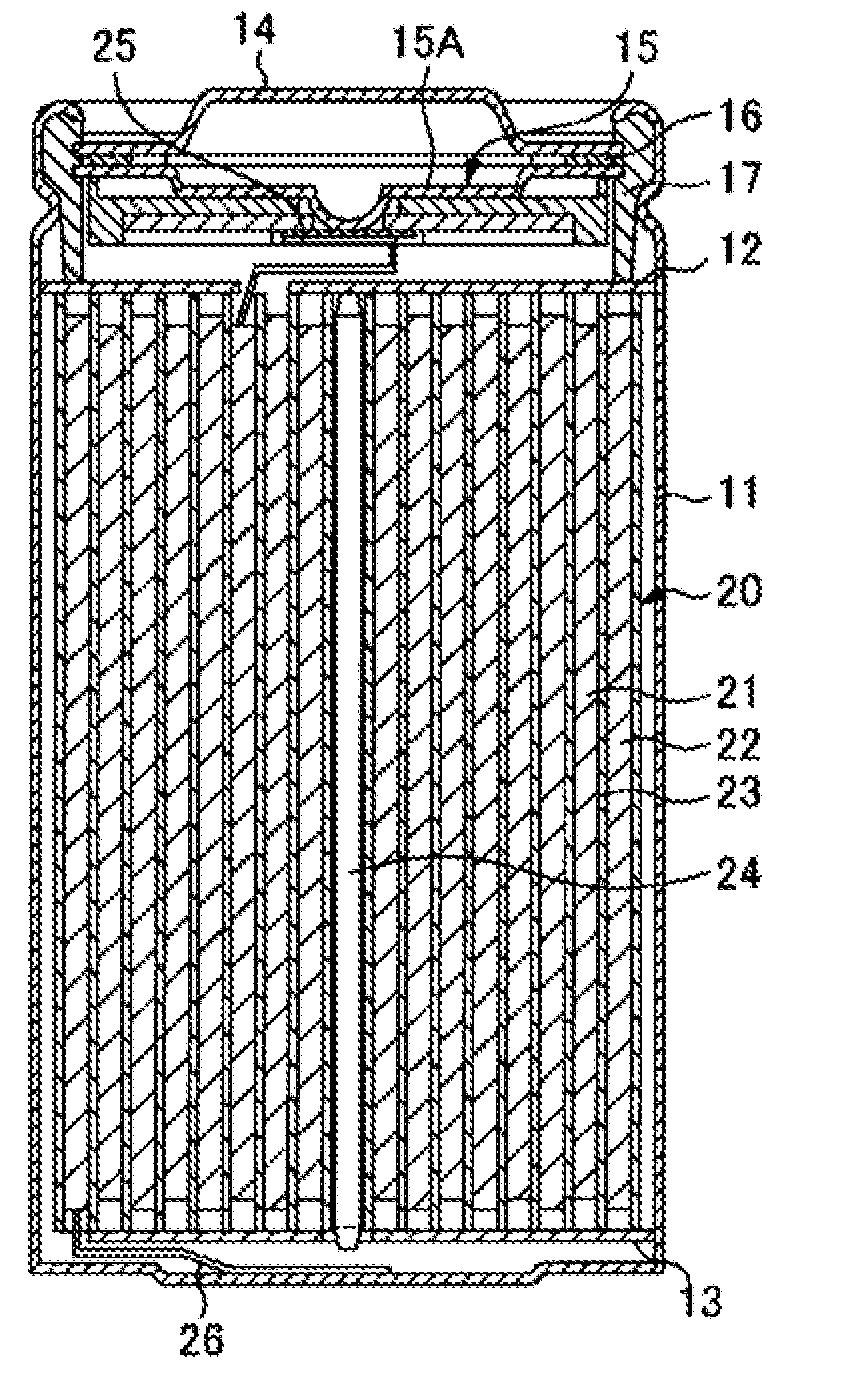

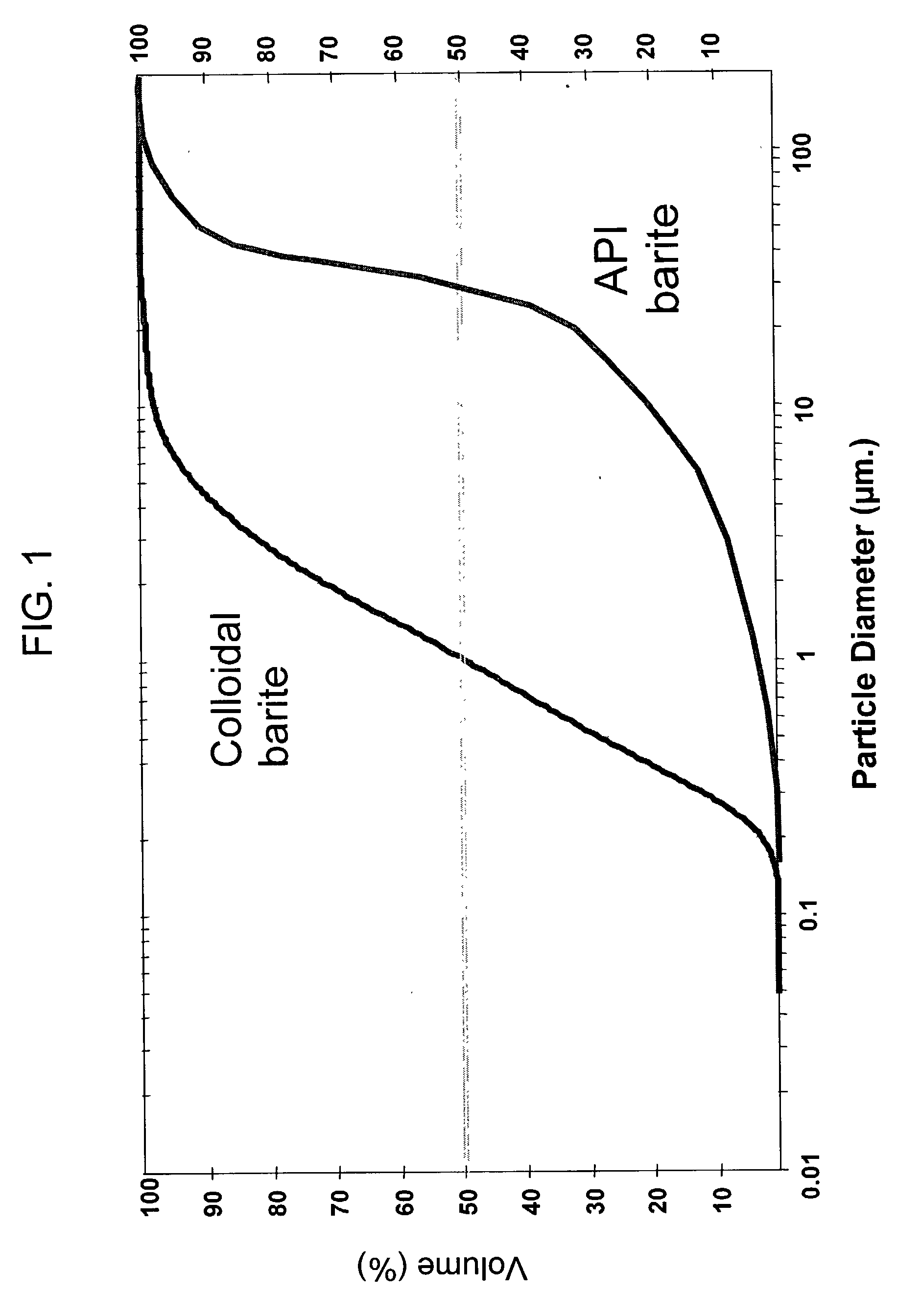

Lithium-ion secondary battery

InactiveUS20080008933A1Safer chemistry characteristicLow cathode costPrimary cell to battery groupingElectrode carriers/collectorsManganateManganese

In one embodiment, an active cathode material comprises a mixture that includes: at least one of a lithium cobaltate and a lithium nickelate; and at least one of a manganate spinel represented by an empirical formula of Li(1+x1)(Mn1−y1A′y1)2−x1Oz1 and an olivine compound represented by an empirical formula of Li(1−x2)A″x2MPO4. In another embodiment, an active cathode material comprises a mixture that includes: a lithium nickelate selected from the group consisting of LiCoO2-coated LiNi0.8Co0.15Al0.05O2, and Li(Ni1 / 3Co1 / 3Mn1 / 3)O2; and a manganate spinel represented by an empirical formula of Li(1+x7)Mn2−y7Oz7. A lithium-ion battery and a battery pack each independently employ a cathode that includes an active cathode material as described above. A method of forming a lithium-ion battery includes the steps of forming an active cathode material as described above; forming a cathode electrode with the active cathode material; and forming an anode electrode in electrical contact with the cathode via an electrolyte. A system comprises a portable electronic device and a battery pack or lithium-ion battery as described above.

Owner:BOSTON POWER INC

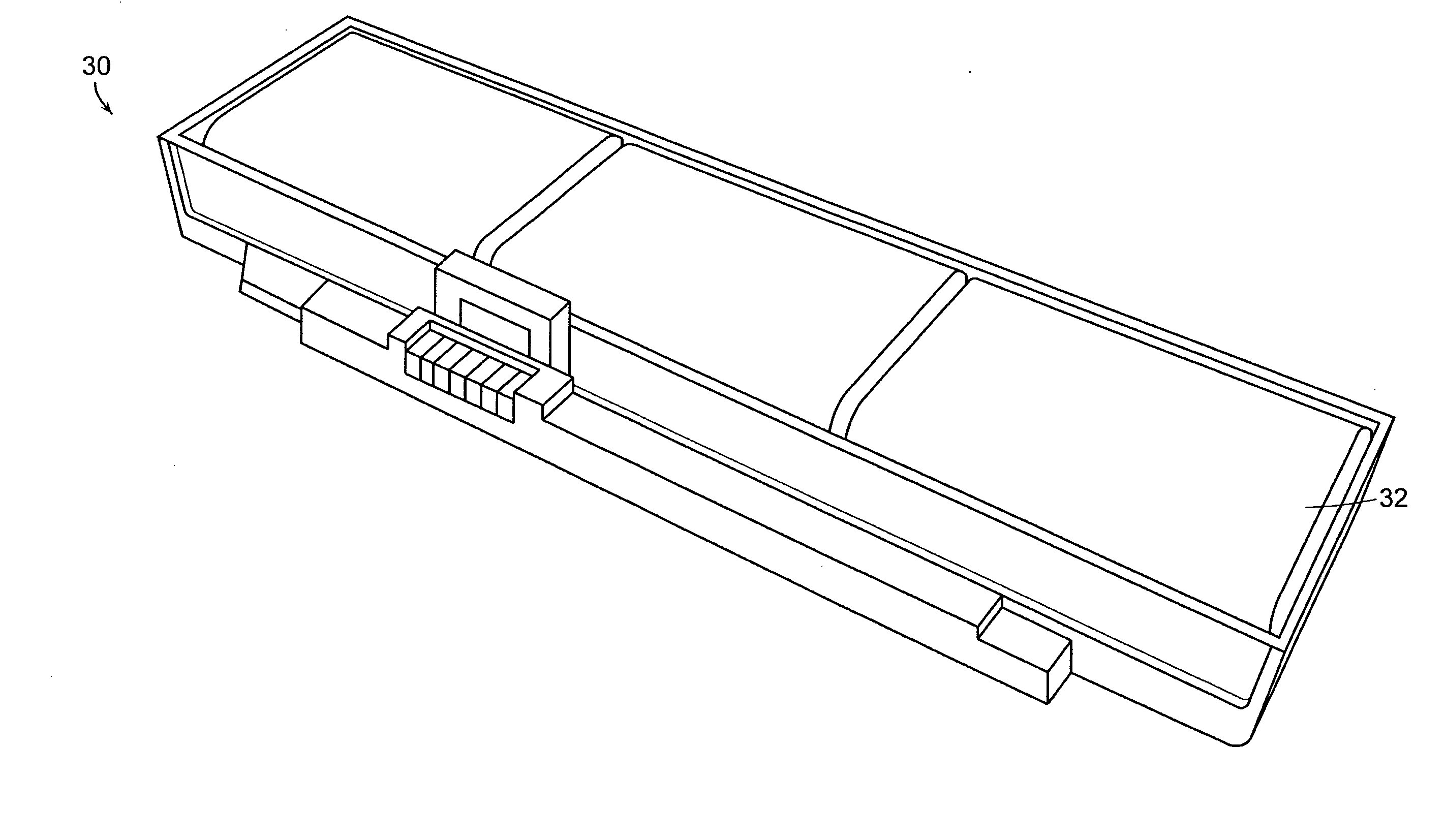

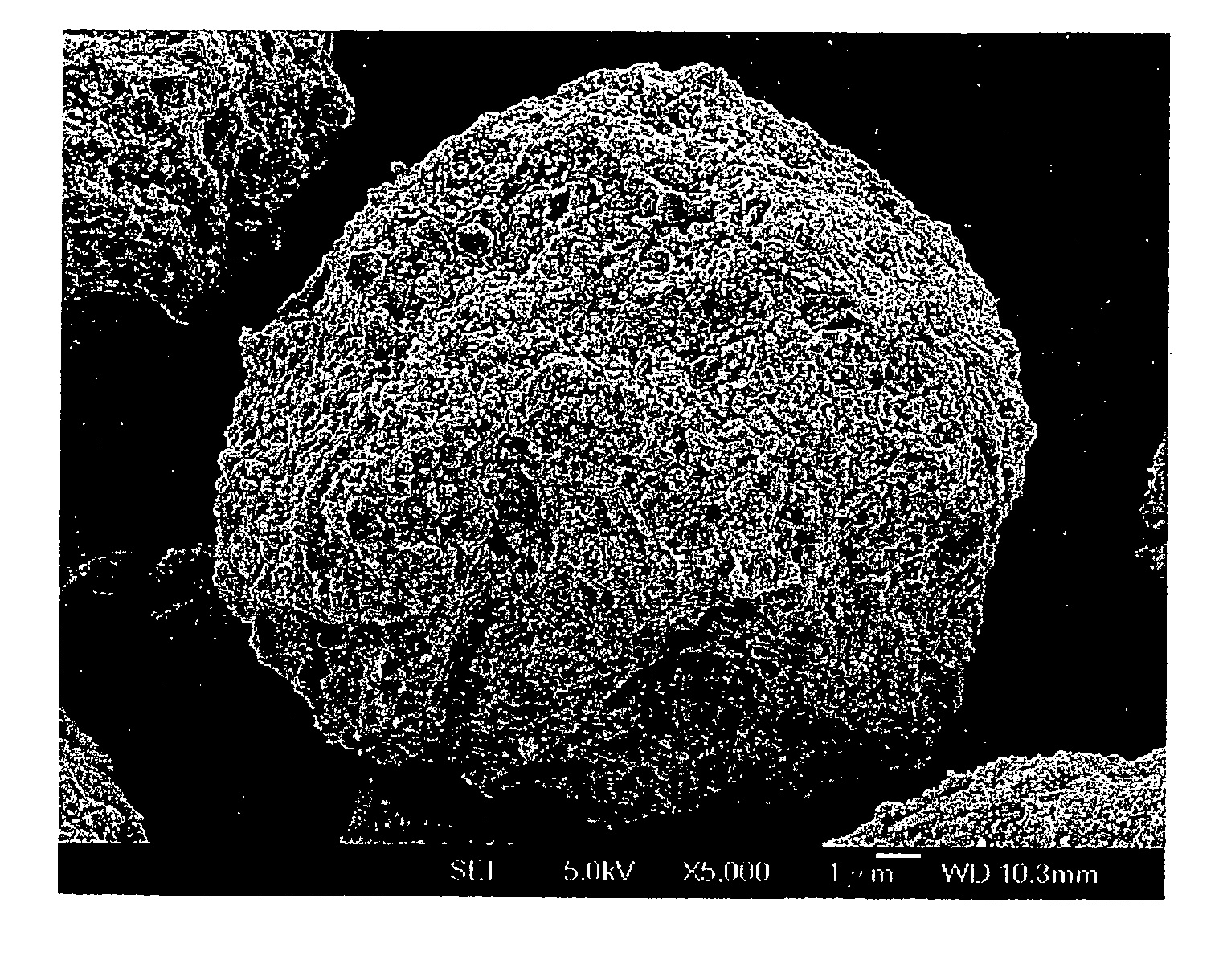

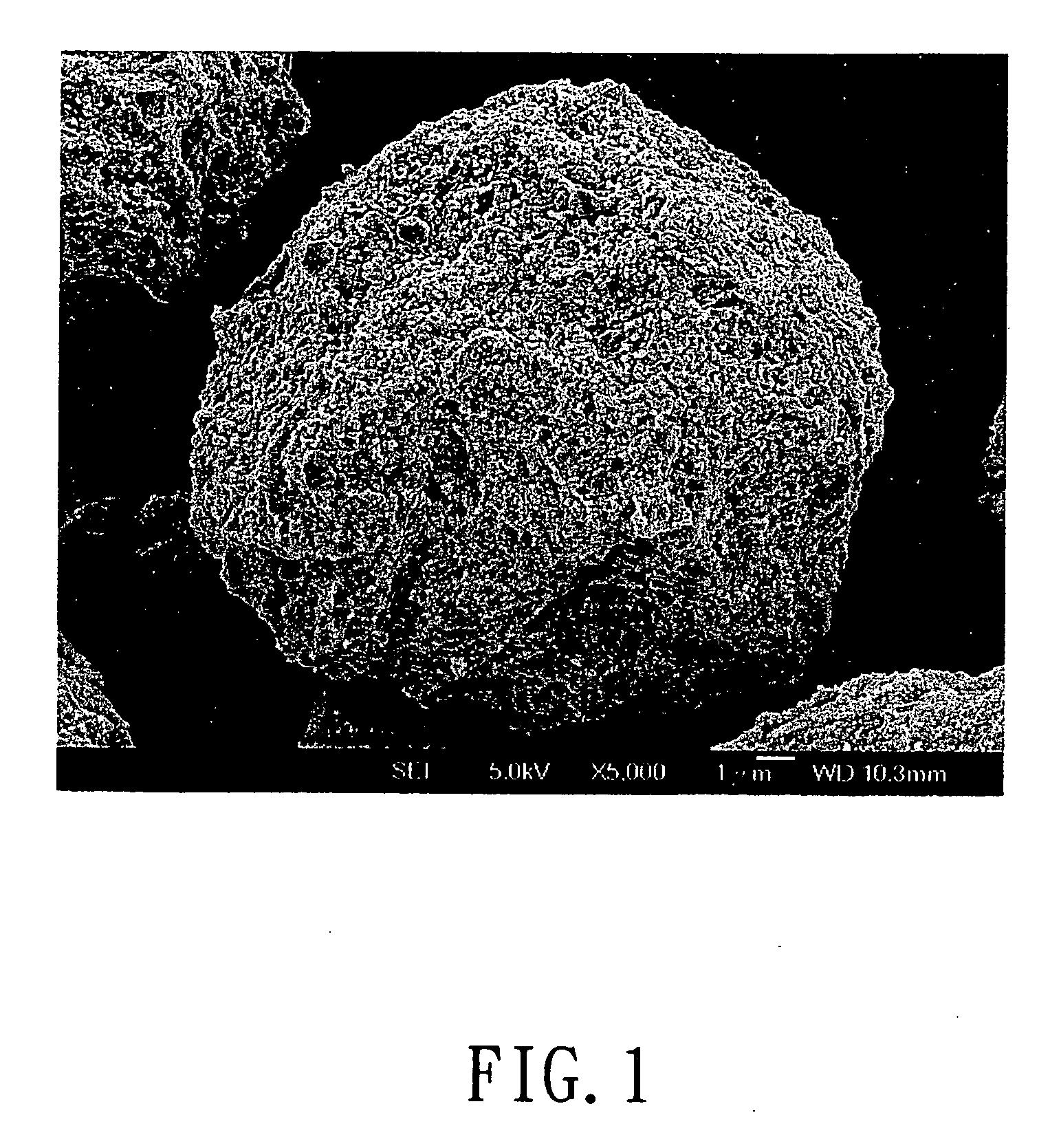

Cathode material for manufacturing a rechargeable battery

A cathode material has one of olivine and NASICON structures and includes micrometer-sized secondary particles having a particle size ranging from 1 to 50 μm. Each of the micrometer-sized secondary particles is composed of crystalline nanometer-sized primary particles of a metal compound having a particle size ranging from 10 to 500 nm.

Owner:ADVANCED LITHIUM ELECTROCHEMISTRY CO LTD

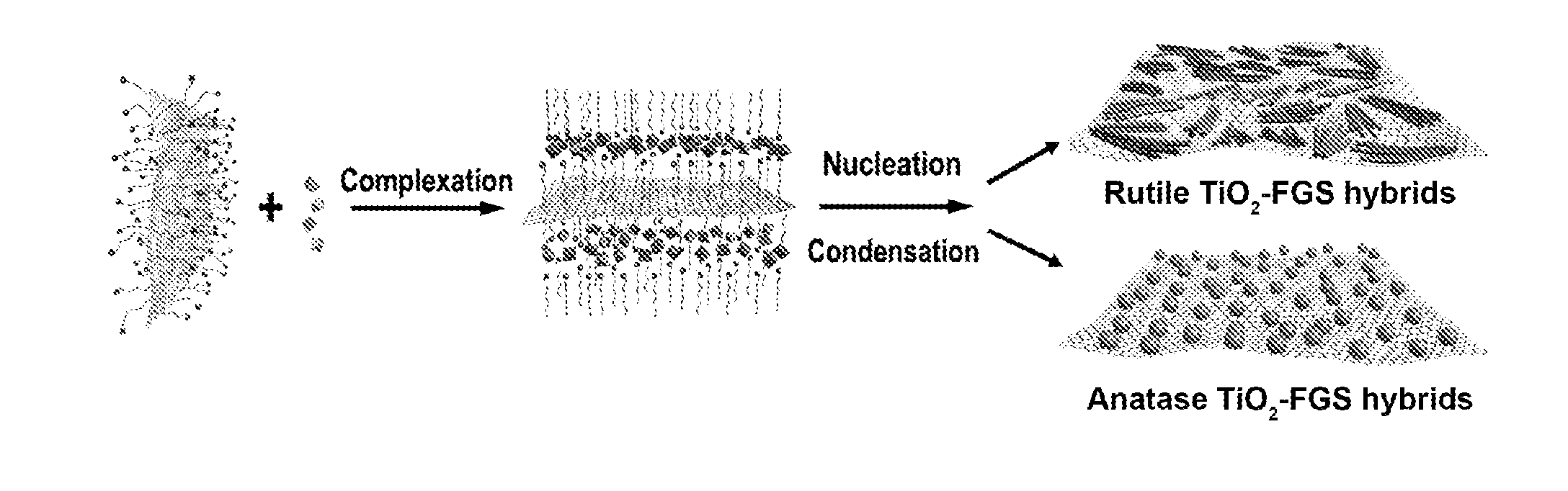

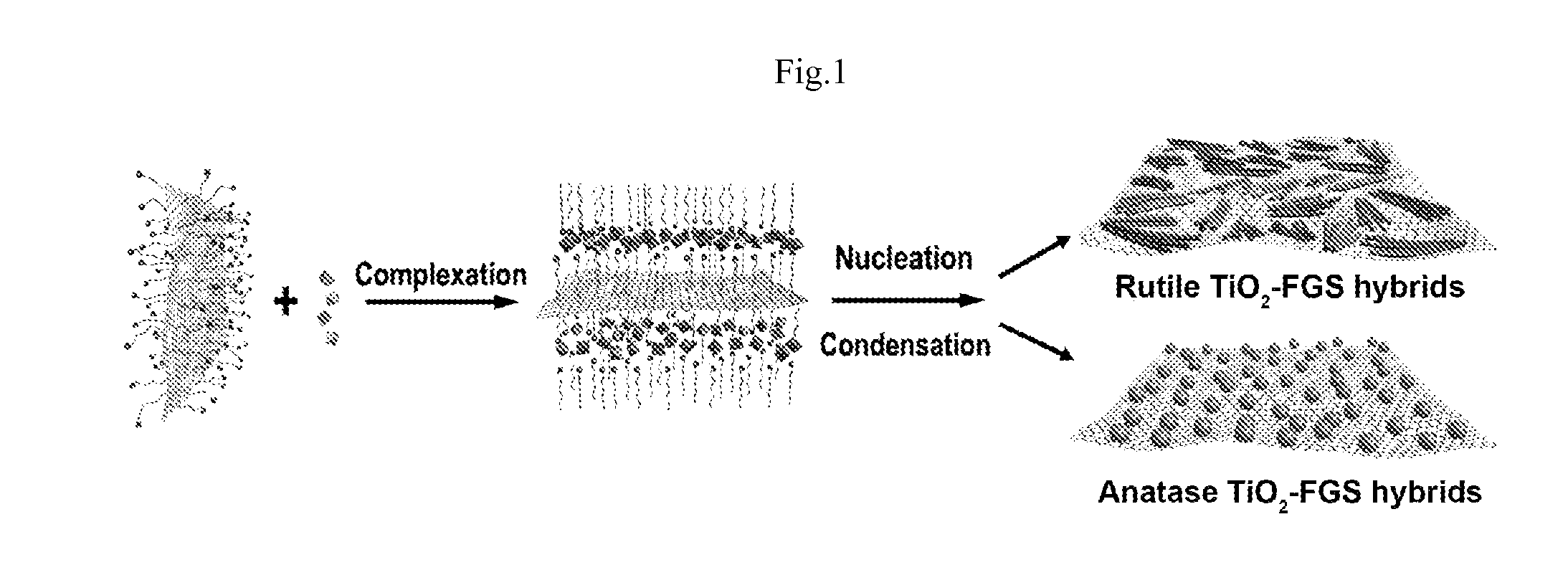

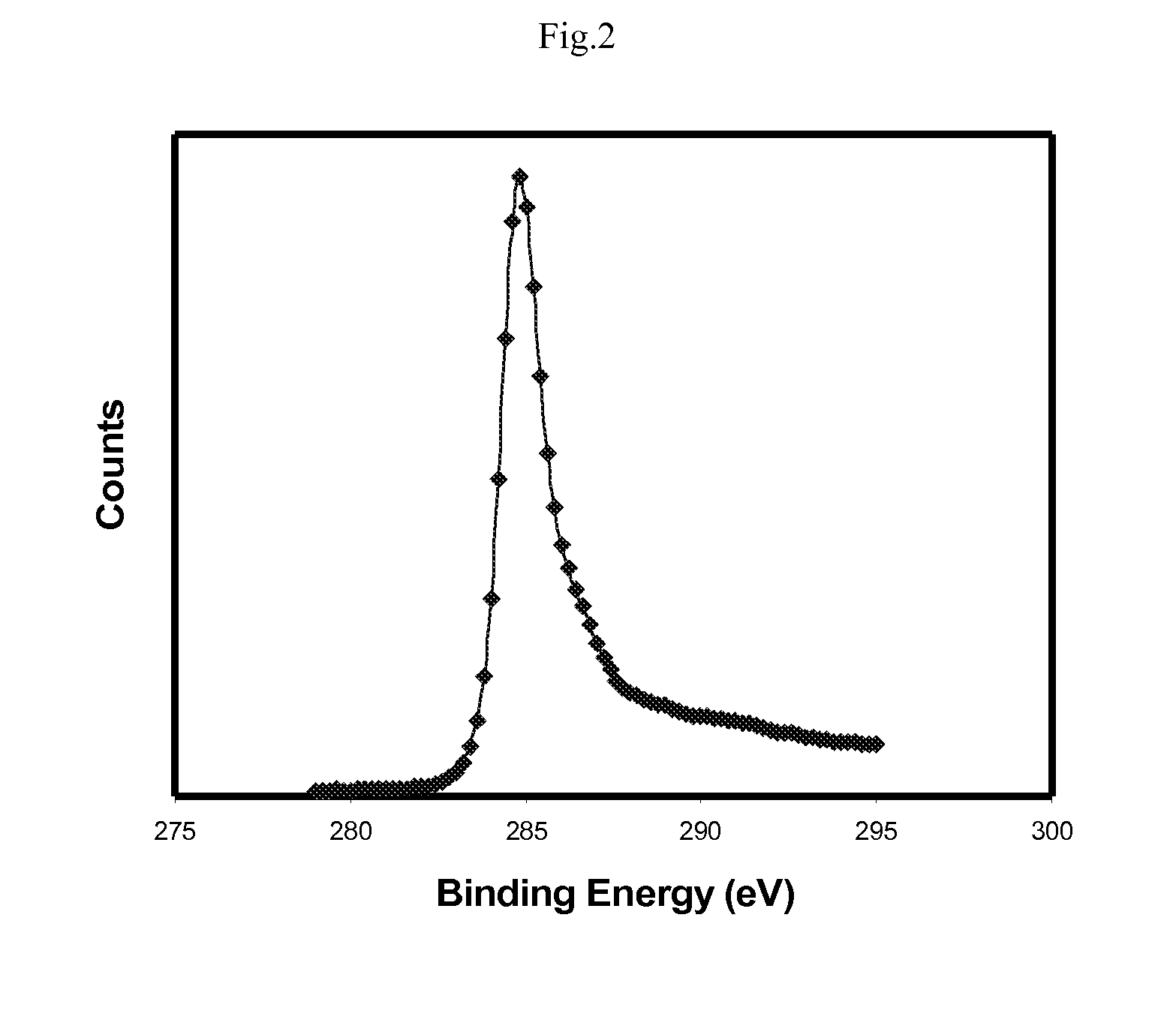

Lithium ion batteries with titania/graphene anodes

InactiveUS20110111299A1Easy to distinguishMaterial nanotechnologyWave amplification devicesDischarge rateOlivine

Lithium ion batteries having an anode comprising at least one graphene layer in electrical communication with titania to form a nanocomposite material, a cathode comprising a lithium olivine structure, and an electrolyte. The graphene layer has a carbon to oxygen ratio of between 15 to 1 and 500 to 1 and a surface area of between 400 and 2630 m2 / g. The nanocomposite material has a specific capacity at least twice that of a titania material without graphene material at a charge / discharge rate greater than about 10 C. The olivine structure of the cathode of the lithium ion battery of the present invention is LiMPO4 where M is selected from the group consisting of Fe, Mn, Co, Ni and combinations thereof.

Owner:BATTELLE MEMORIAL INST

Cathode active material, cathode, and nonaqueous electrolyte secondary battery

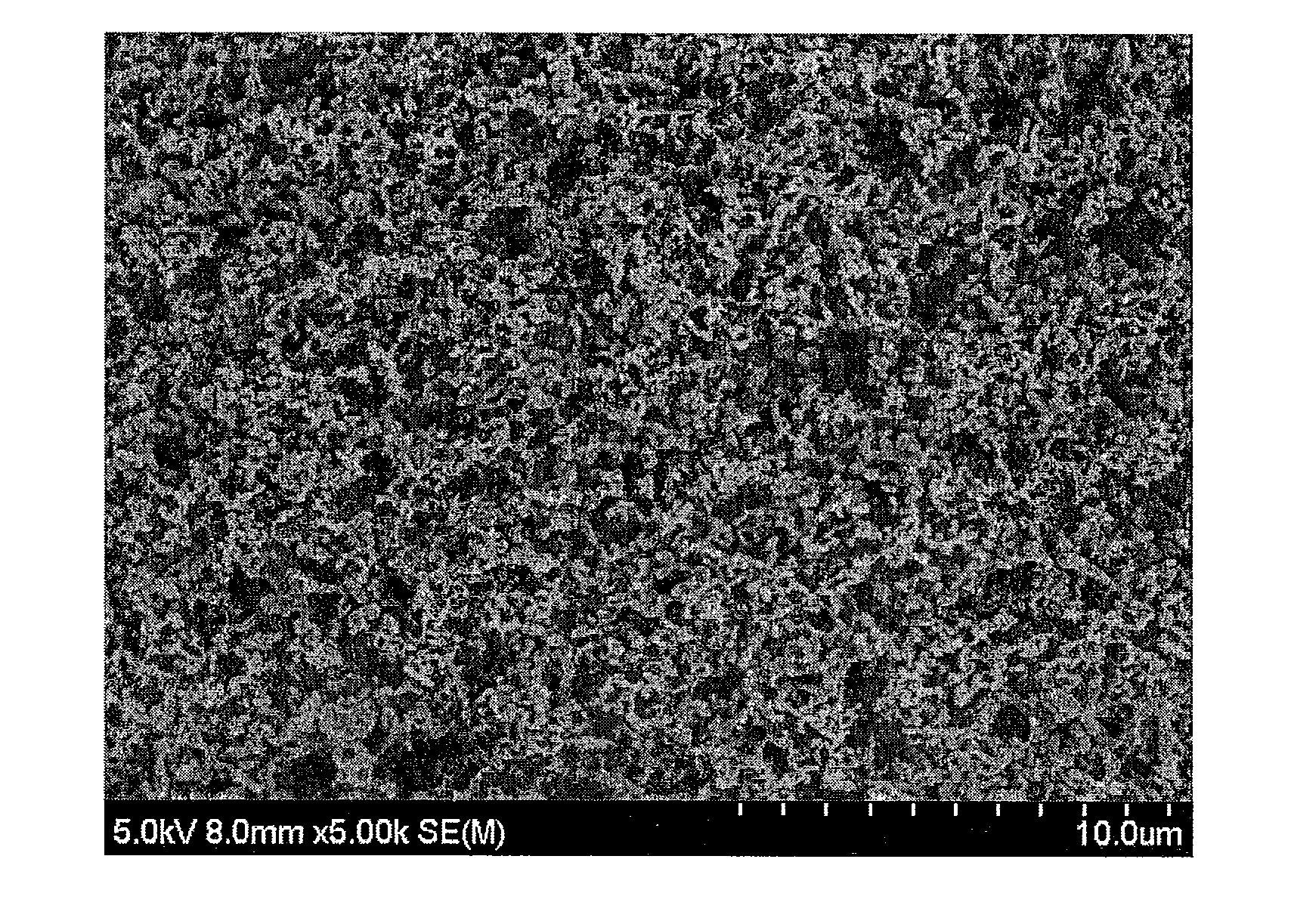

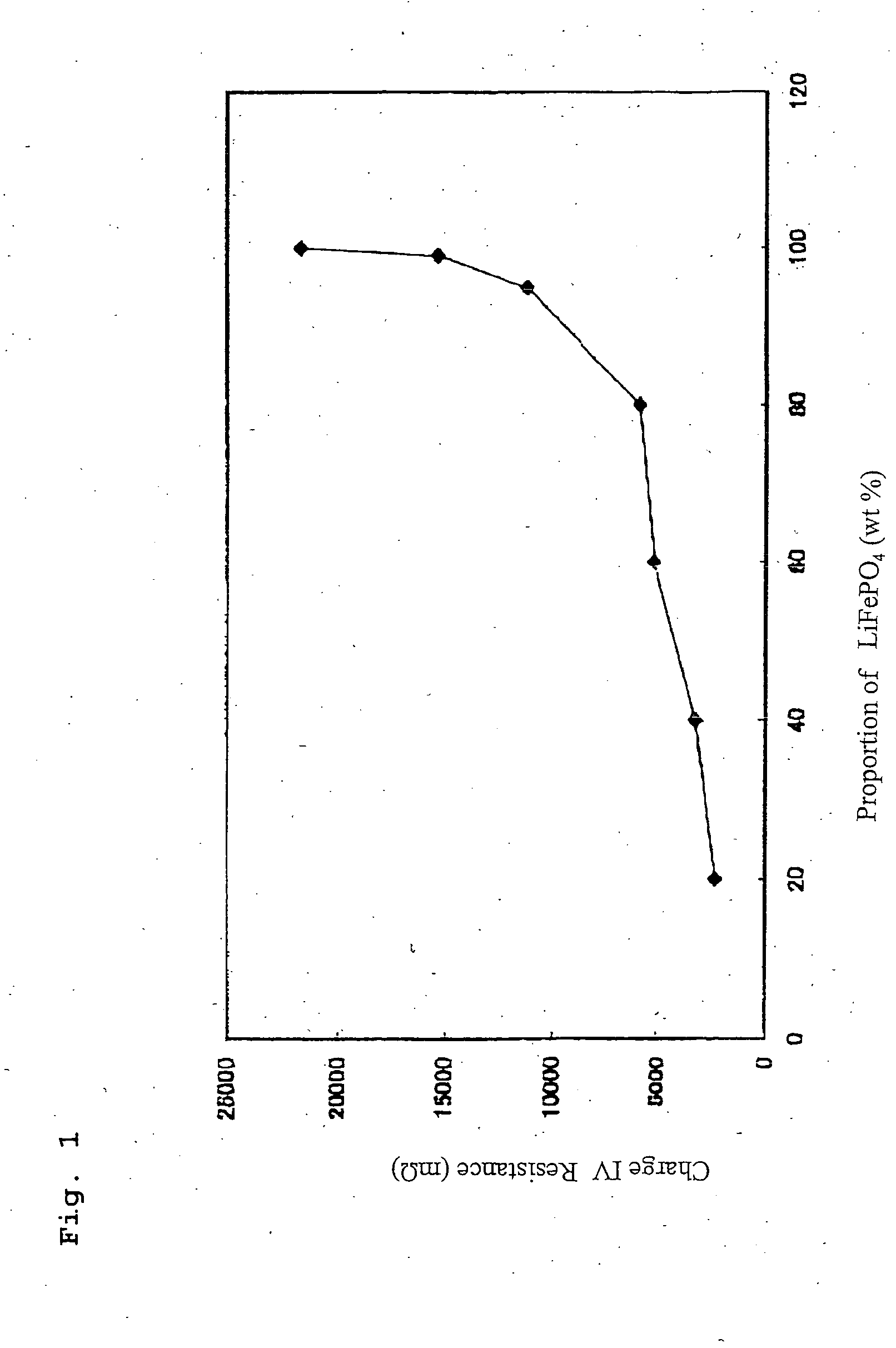

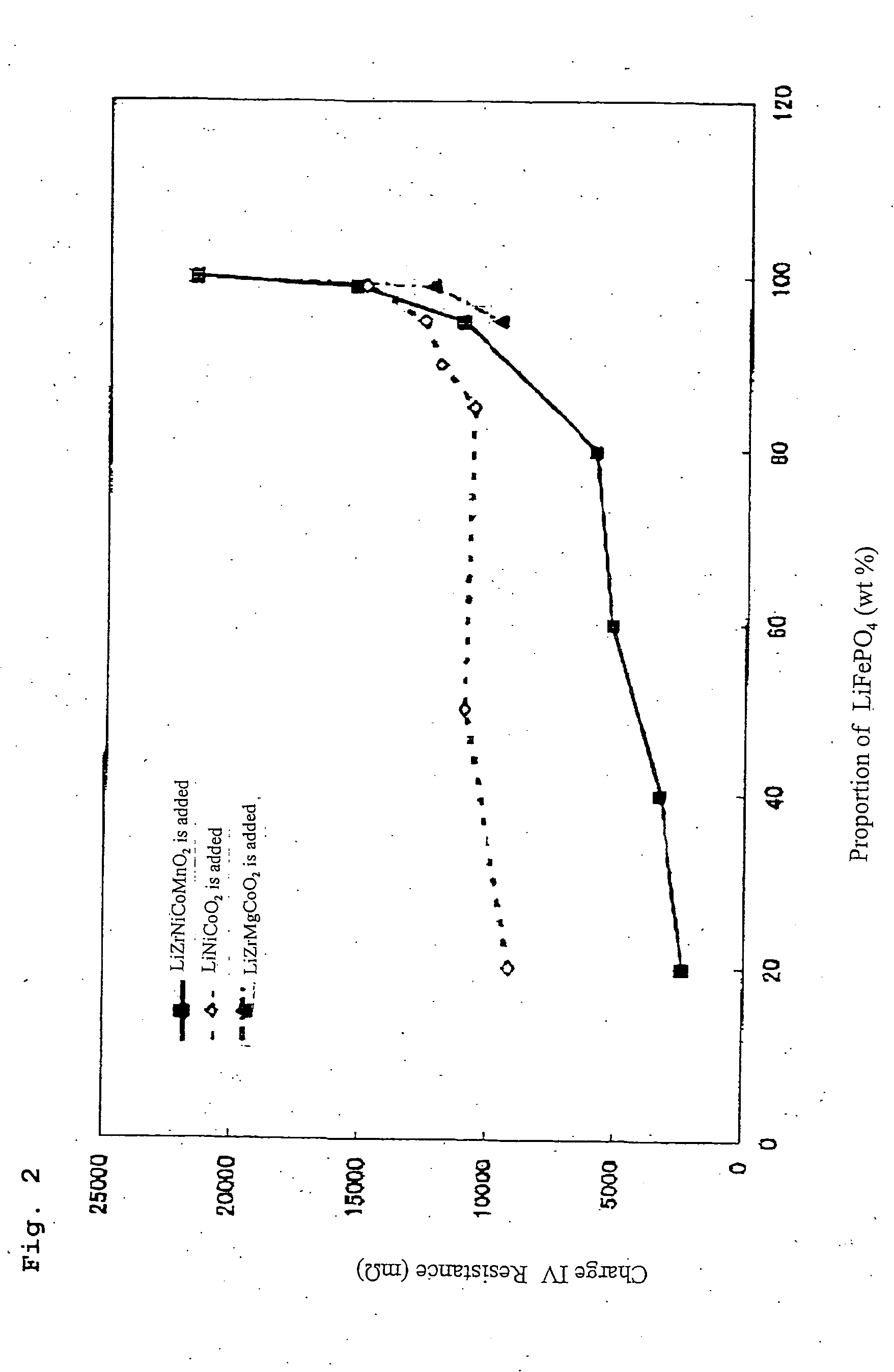

ActiveUS20090142668A1ResistanceReduce electrical conductivityFinal product manufacturePositive electrodesLITHIUM PHOSPHATEPore diameter

The present application provides a nonaqueous electrolyte secondary battery which includes a cathode having a cathode active material layer, an anode, and a nonaqueous electrolyte, wherein the cathode active material layer includes secondary particles of a lithium phosphate compound having olivine structure, an average particle diameter A of primary particles constituting the secondary particles is 50 nm or more and 500 nm or less, and a ratio B / A of a pore diameter B of the secondary particles to the average particle diameter A of the primary particles is 0.10 or more and 0.90 or less.

Owner:MURATA MFG CO LTD

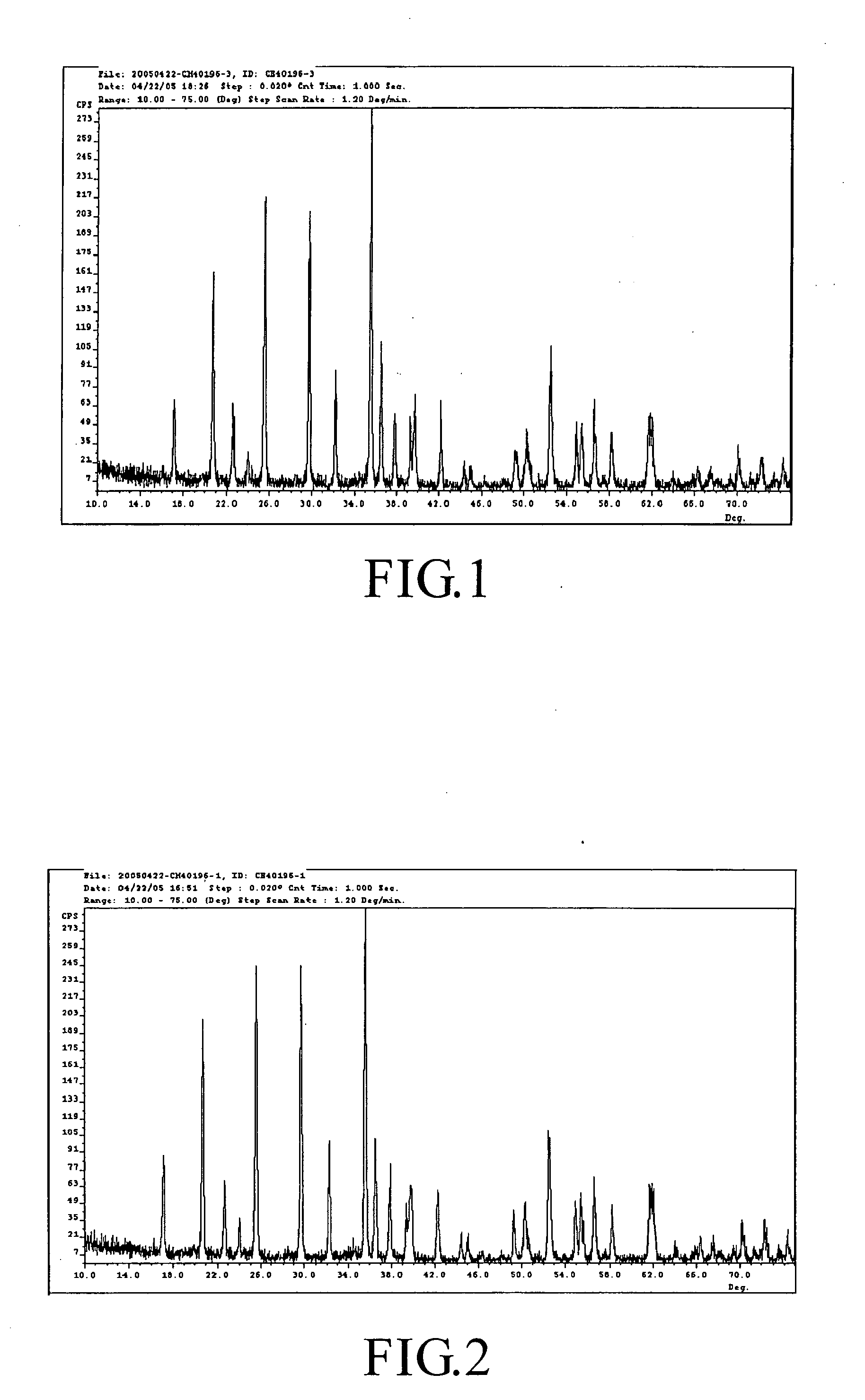

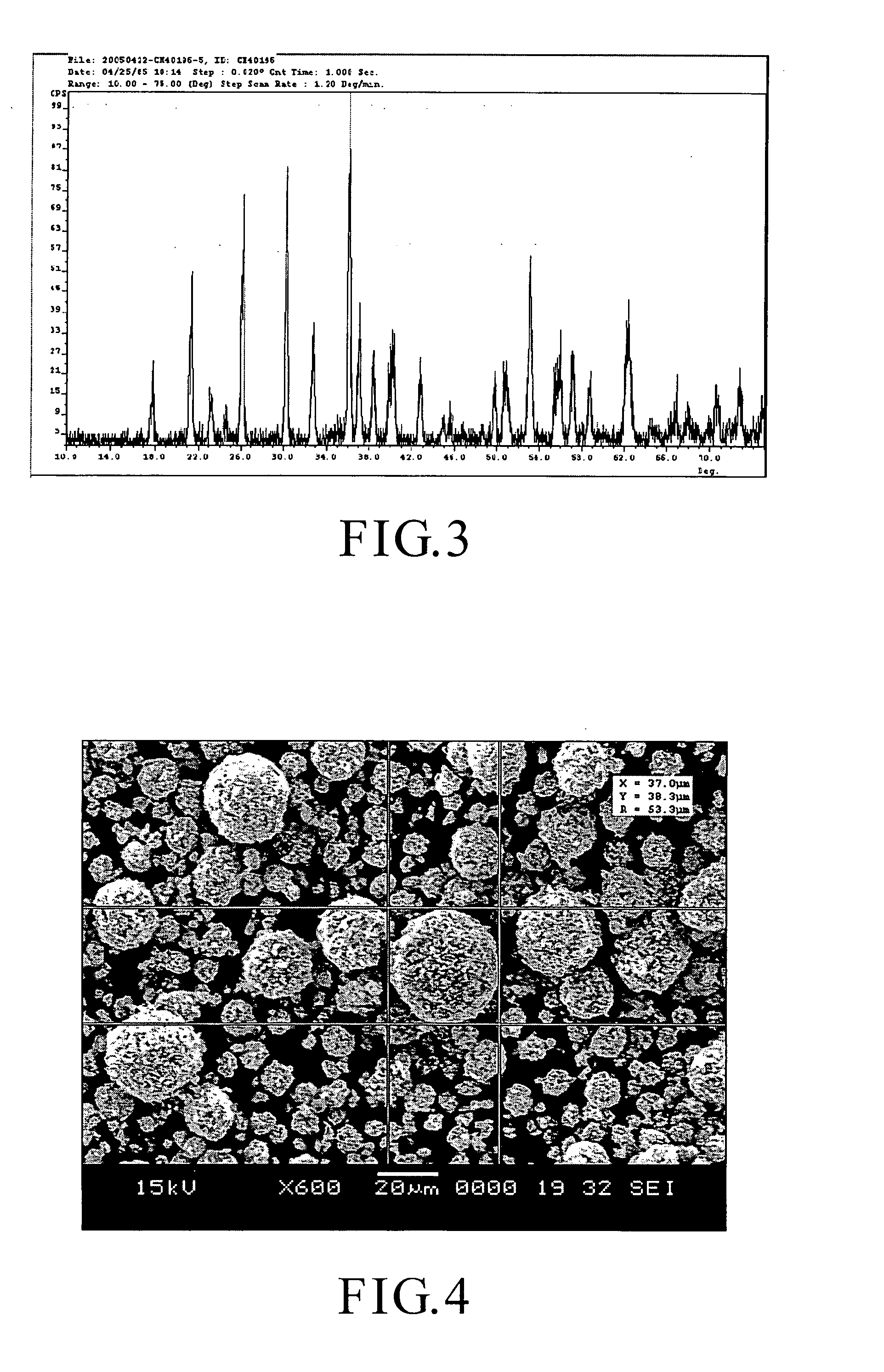

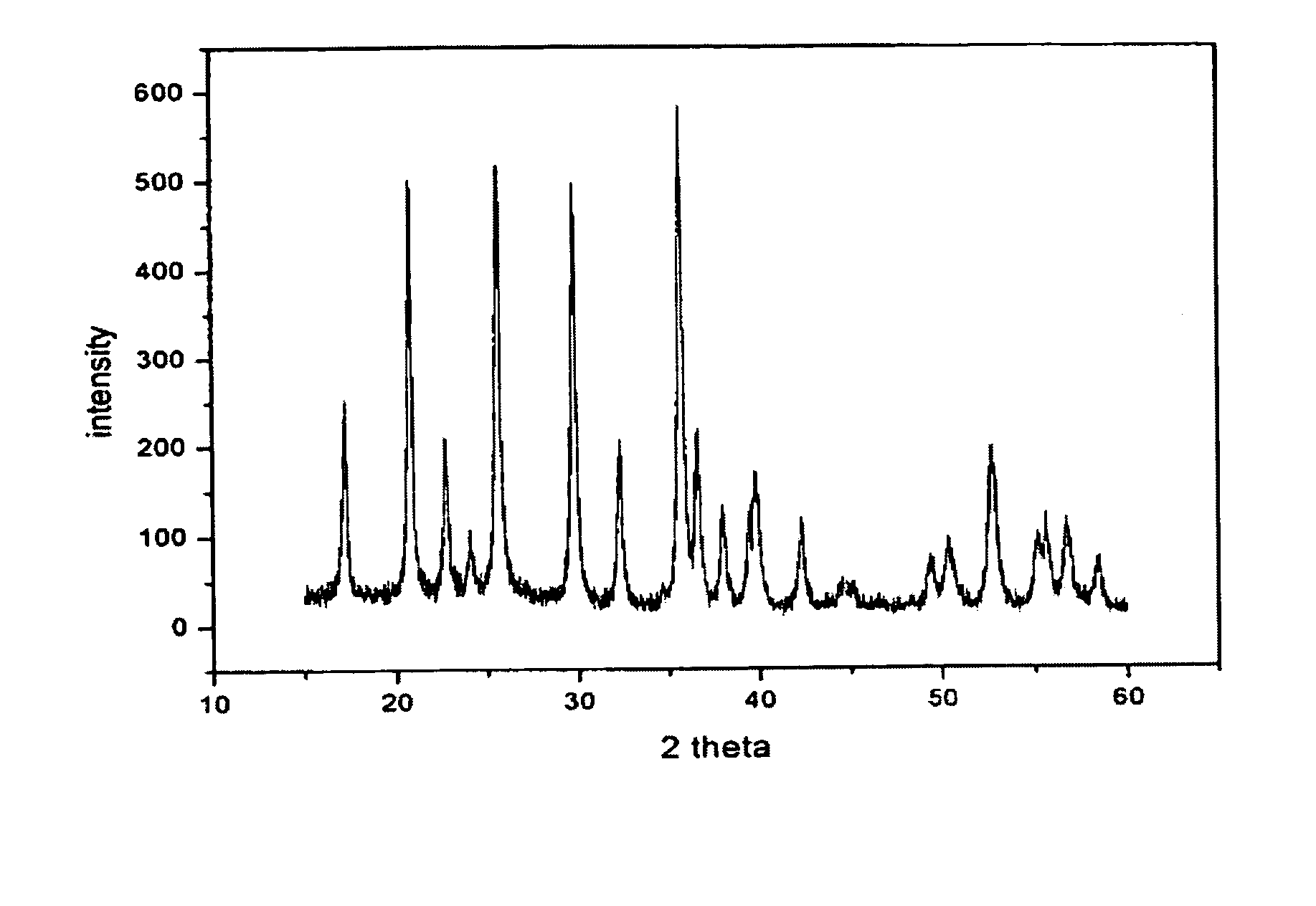

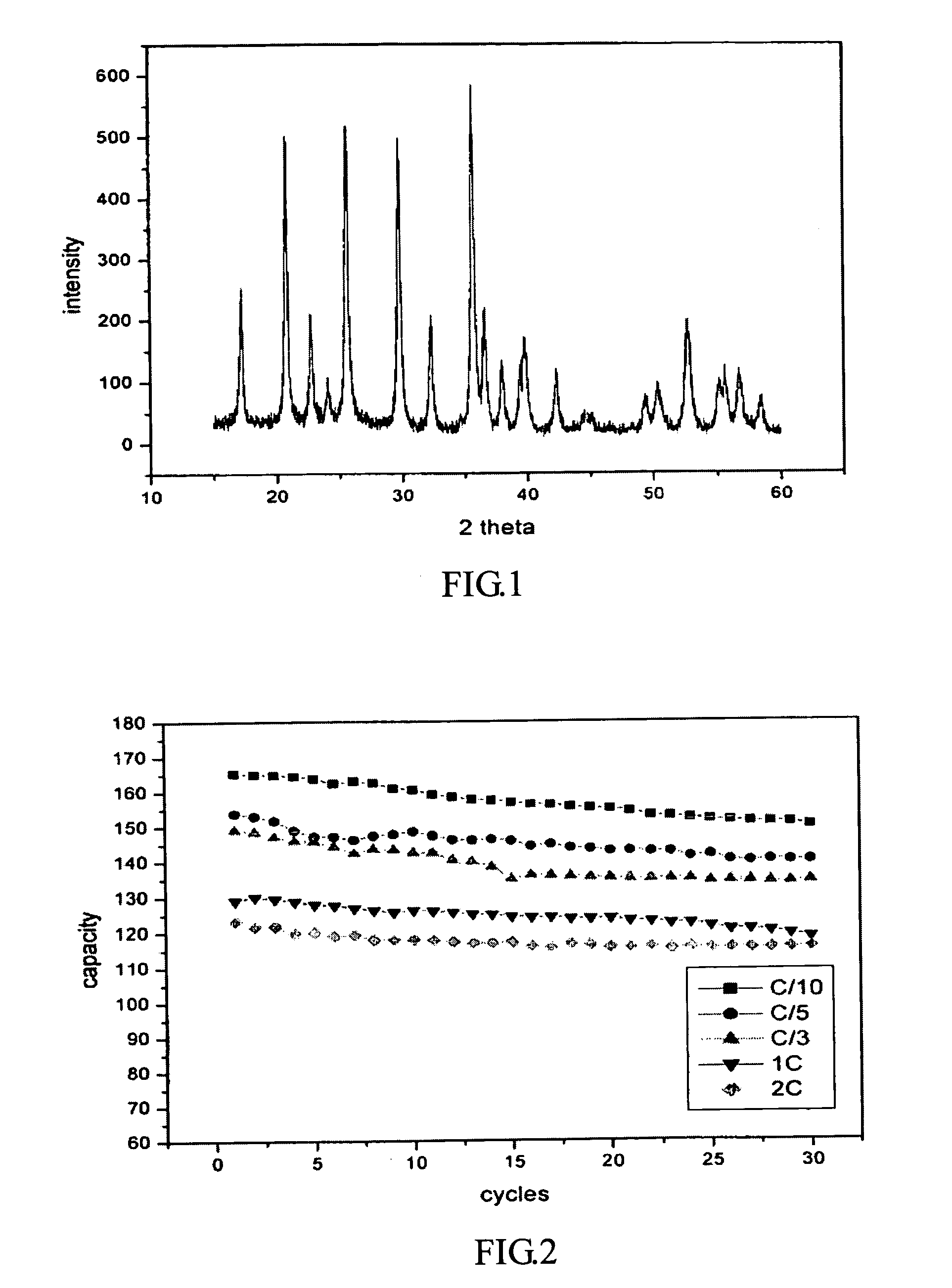

Preparation of olivine Li Fe PO4 cathode materials for lithium batteries via a solution method

InactiveUS20060263286A1Low costImprove conductivityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesIron powderPhosphate

A preparation method of olivine Li1+xFe1+yPO4 is disclosed, wherein −0.2≦x≦0.2 and −0.2≦y≦0.2, which includes the following steps: (A) adding iron powder, lithium salt, and phosphate into an acid solution to form a mixture, wherein the molar ratio of Li+:Fe2+:PO43− is 1+x:1+y:y; (B) stirring the mixture; (C) drying the mixture to obtain solid precursor powder; and (D) heating the precursor solid powder at a temperature over 500° C. to form olivine structured powders.

Owner:TATUNG COMPANY

Nonaqueous electrolyte battery

A nonaqueous electrolyte battery includes a positive electrode, a negative electrode and a nonaqueous electrolyte. The positive electrode includes a lithium / manganese-containing oxide represented by LiaMnbMcOZ (M is at least one selected from the group consisting of Ni, Co, Al and F, and a, b, c and Z satisfy the following equations: 0≦a≦2.5, 0<b≦1, 0≦c≦1 and 2≦Z≦3) and a Fe-containing phosphorous compound having an olivine structure. The negative electrode includes a titanium-containing metal oxide into which lithium ions are inserted and from which lithium ions are extracted.

Owner:KK TOSHIBA

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20060188651A1Liquid surface applicatorsOther chemical processesVolumetric Mass DensitySolid particle

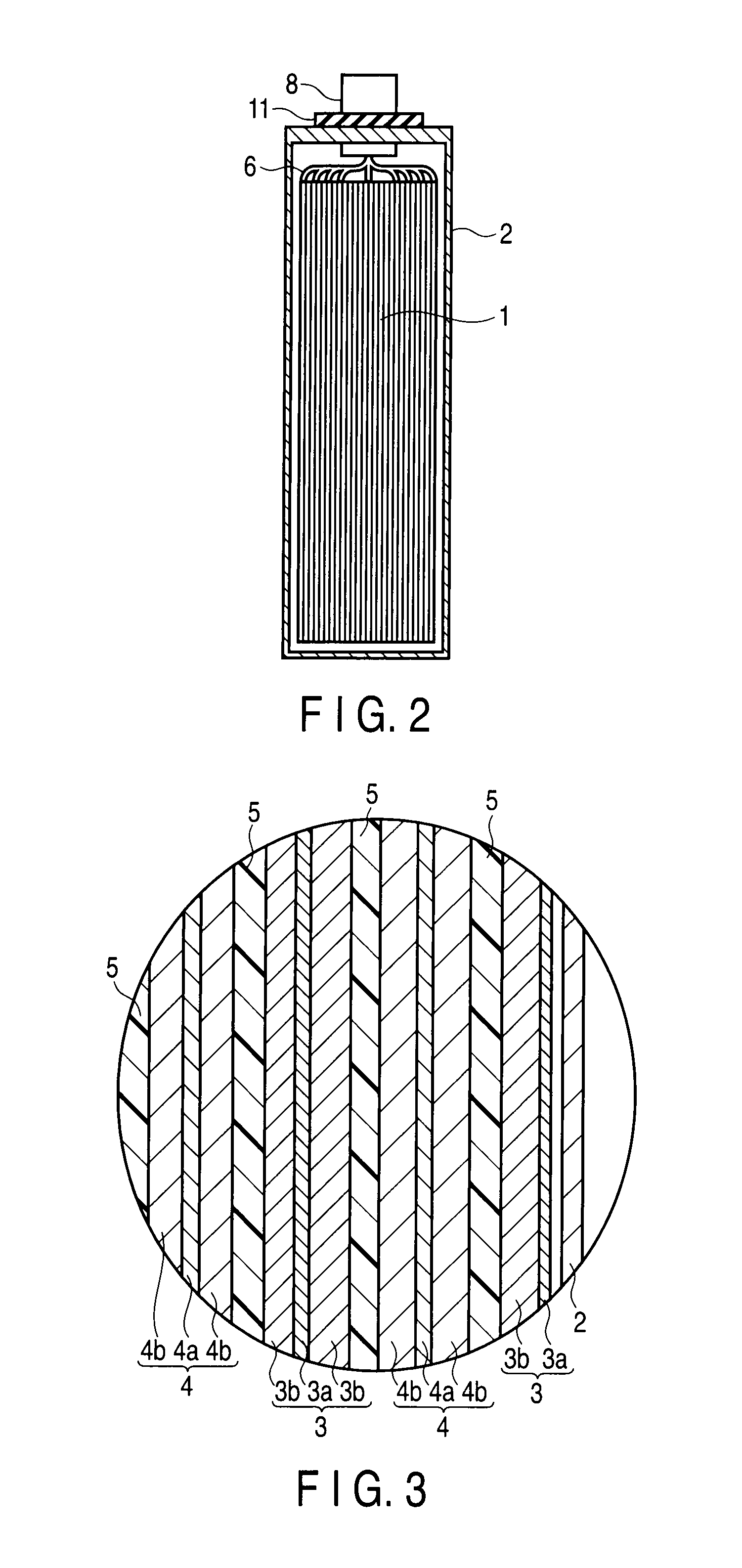

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Lithium iron phosphate having olivine structure and method for preparing the same

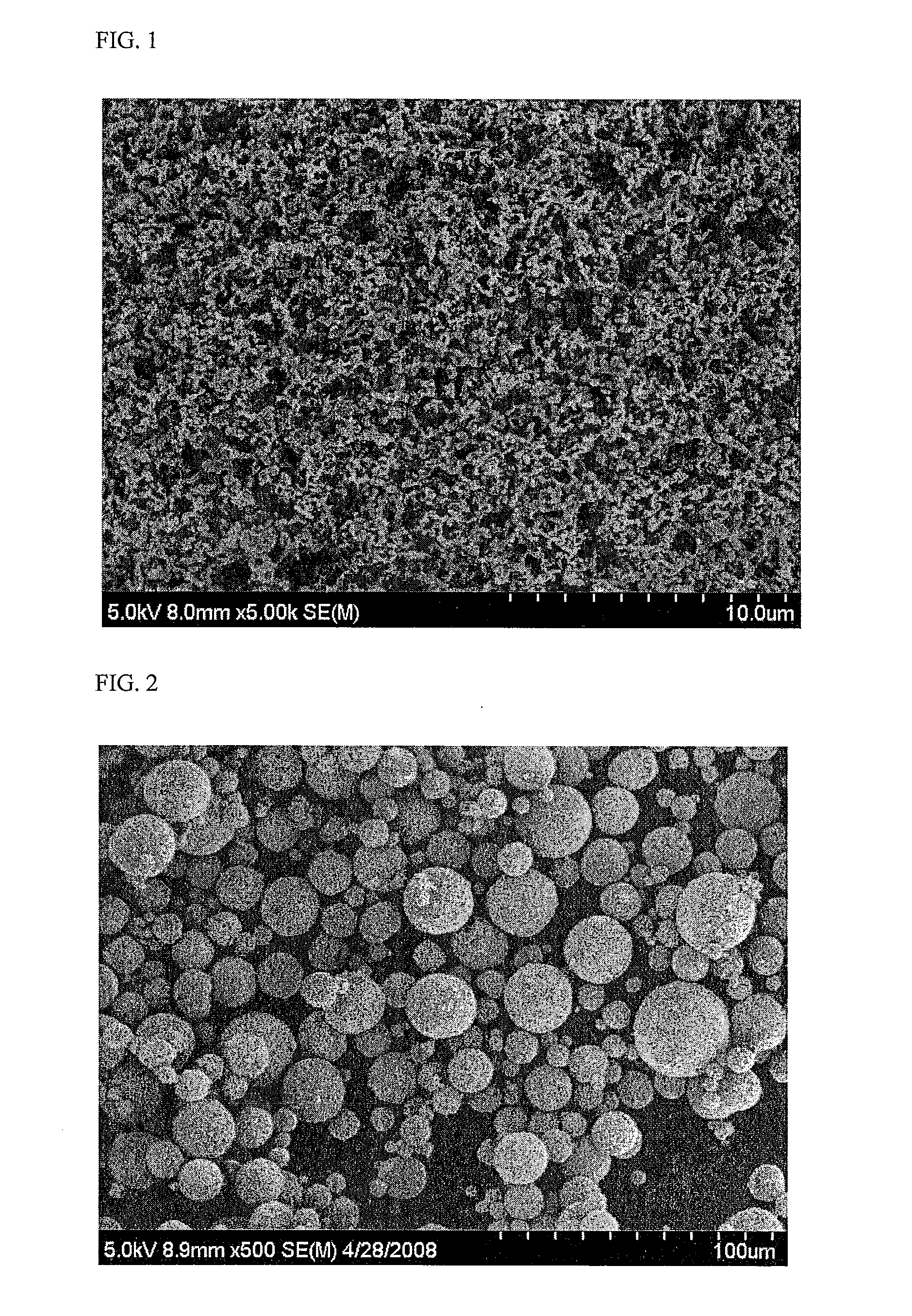

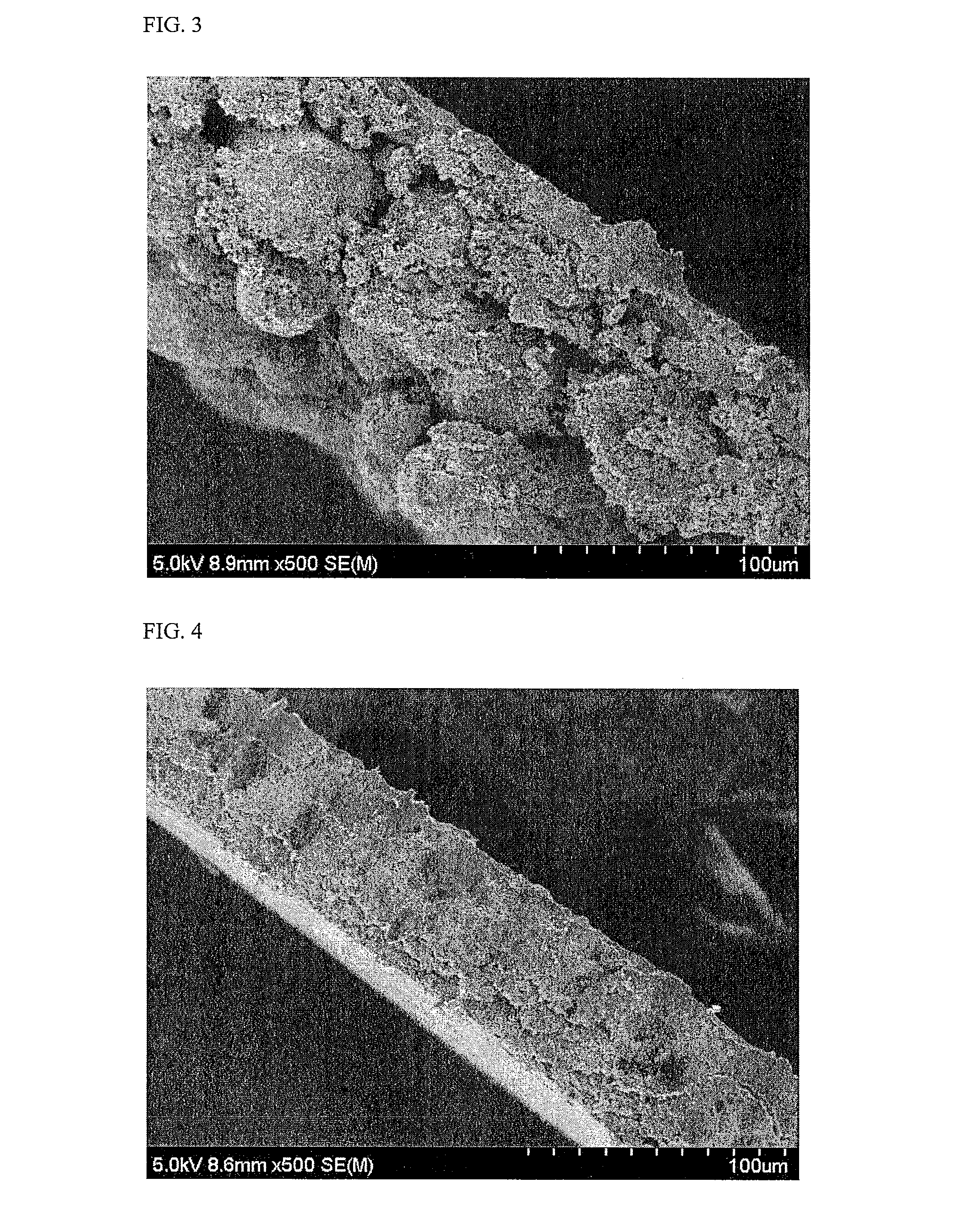

ActiveUS20100233540A1Improve conductivityStable crystal structureNon-aqueous electrolyte accumulator electrodesPhosphorus compoundsPorosityLithium iron phosphate

Provided is an olivine-type lithium iron phosphate composed of secondary particles having a mean particle diameter (D50) of 5 to 100 μm, formed by aggregation of primary particles having a mean particle diameter (D50) of 50 to 550 nm, wherein the primary and secondary particles have a composition represented by Formula I below and the secondary particles have a porosity of 15 to 40%: Li1+aFe1-xMx(PO4-b)Xb (I) wherein M, X, a, x and b are as defined above.The olivine-type lithium iron phosphate is in the form of secondary particles, thus imparting a high bulk density to lithium secondary batteries and exhibiting superior process efficiency due to shortened mixing time, when used to fabricate the lithium secondary batteries. Furthermore, the olivine-type lithium iron phosphate has the high porosity, thus allowing at least a portion of the secondary particles to be deformed and converted into primary particles in the process of pressing to fabricate electrodes and preventing deterioration in ionic conductivity due to the large particle diameter.

Owner:LG ENERGY SOLUTION LTD

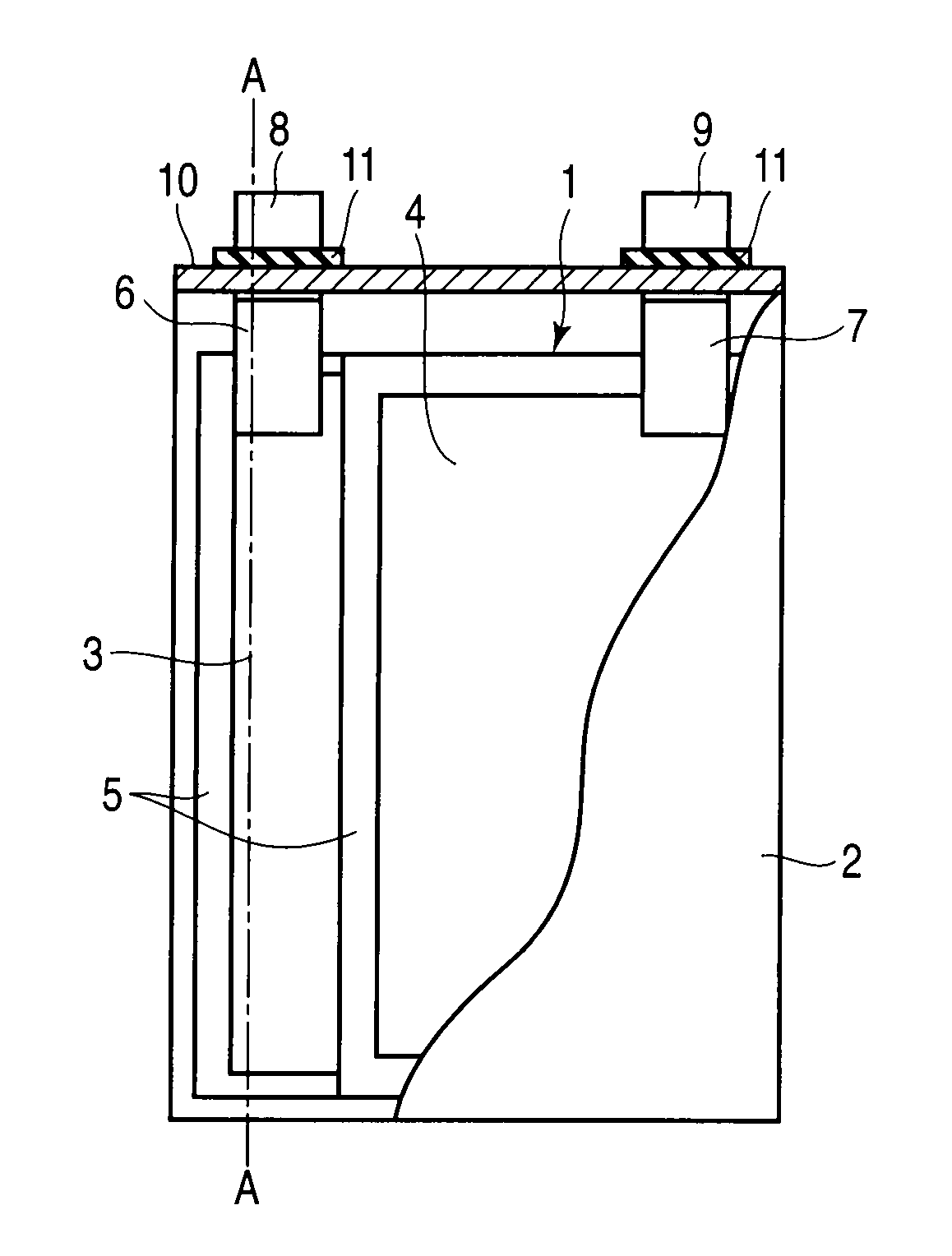

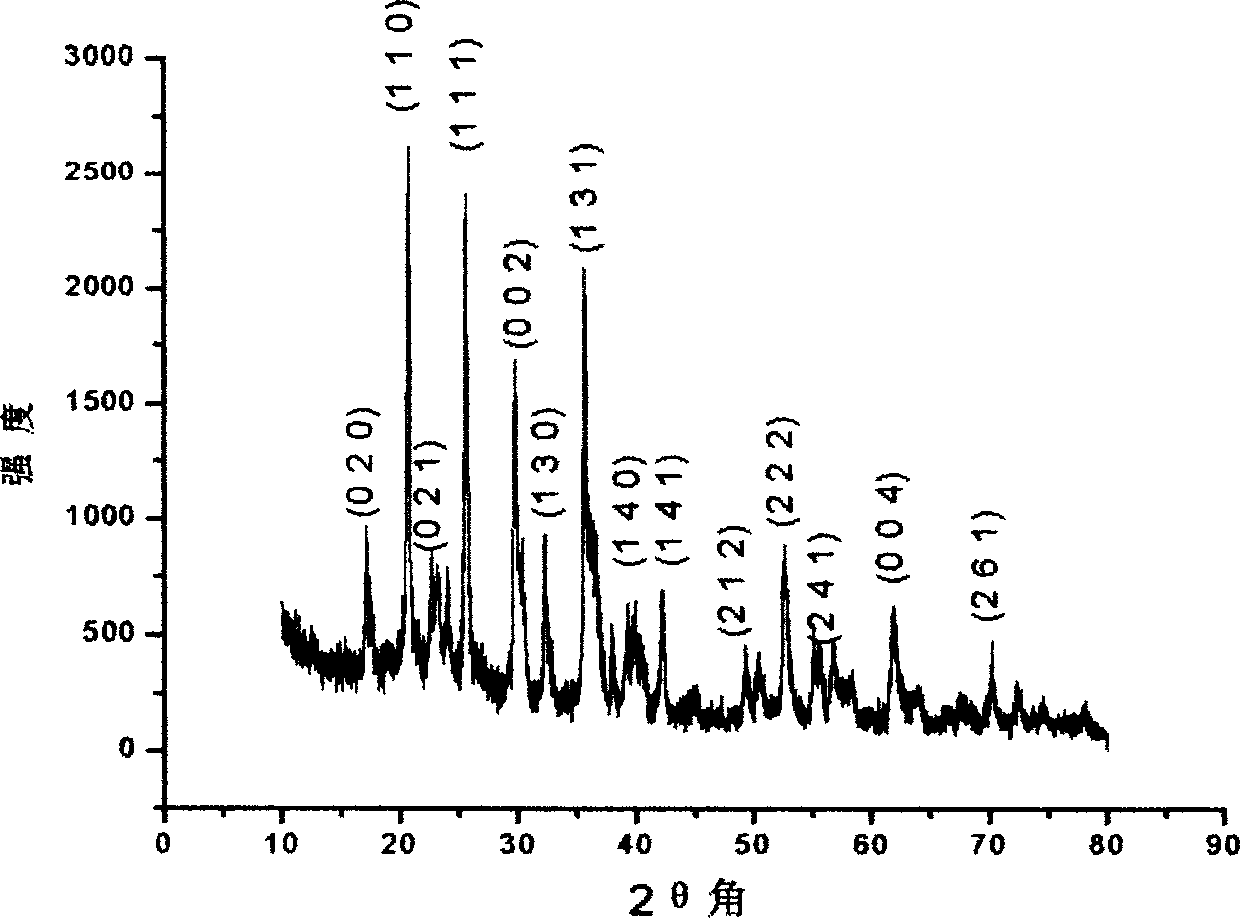

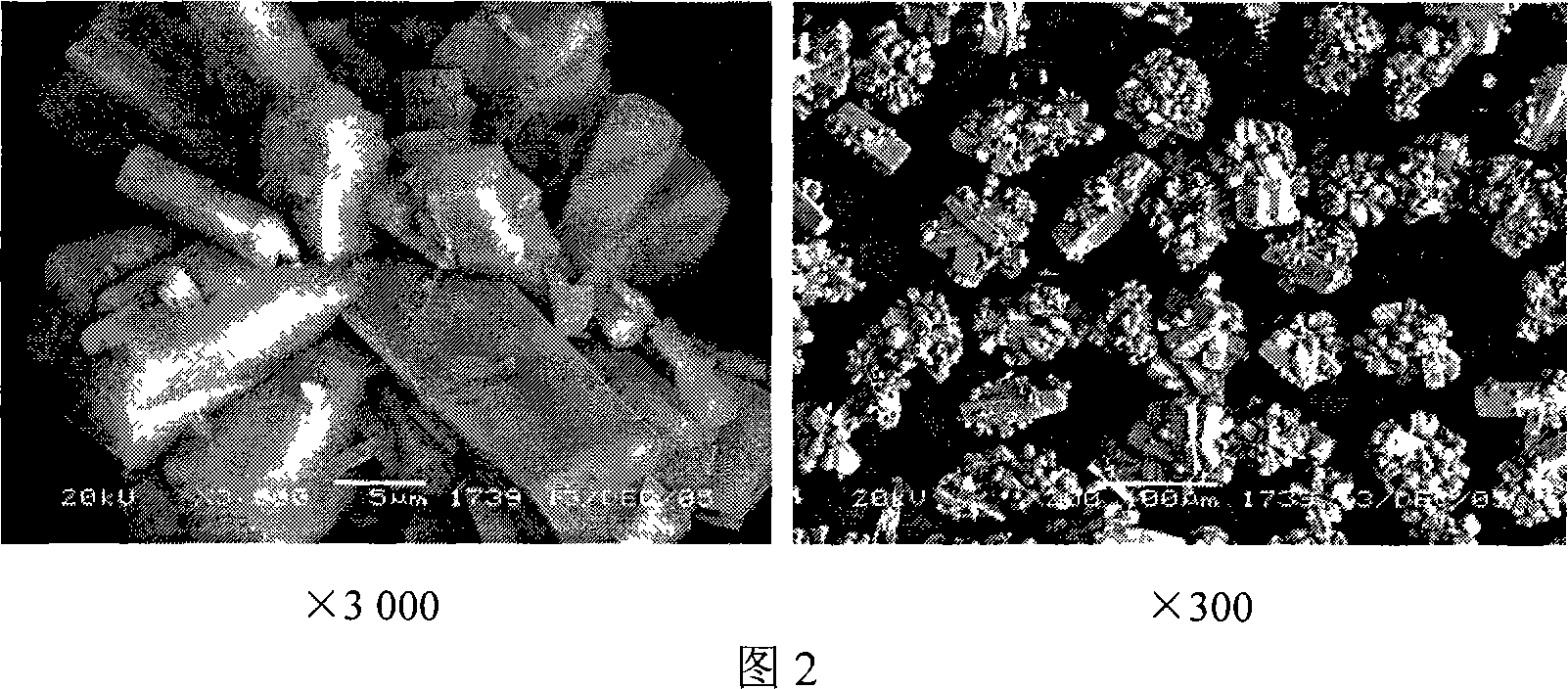

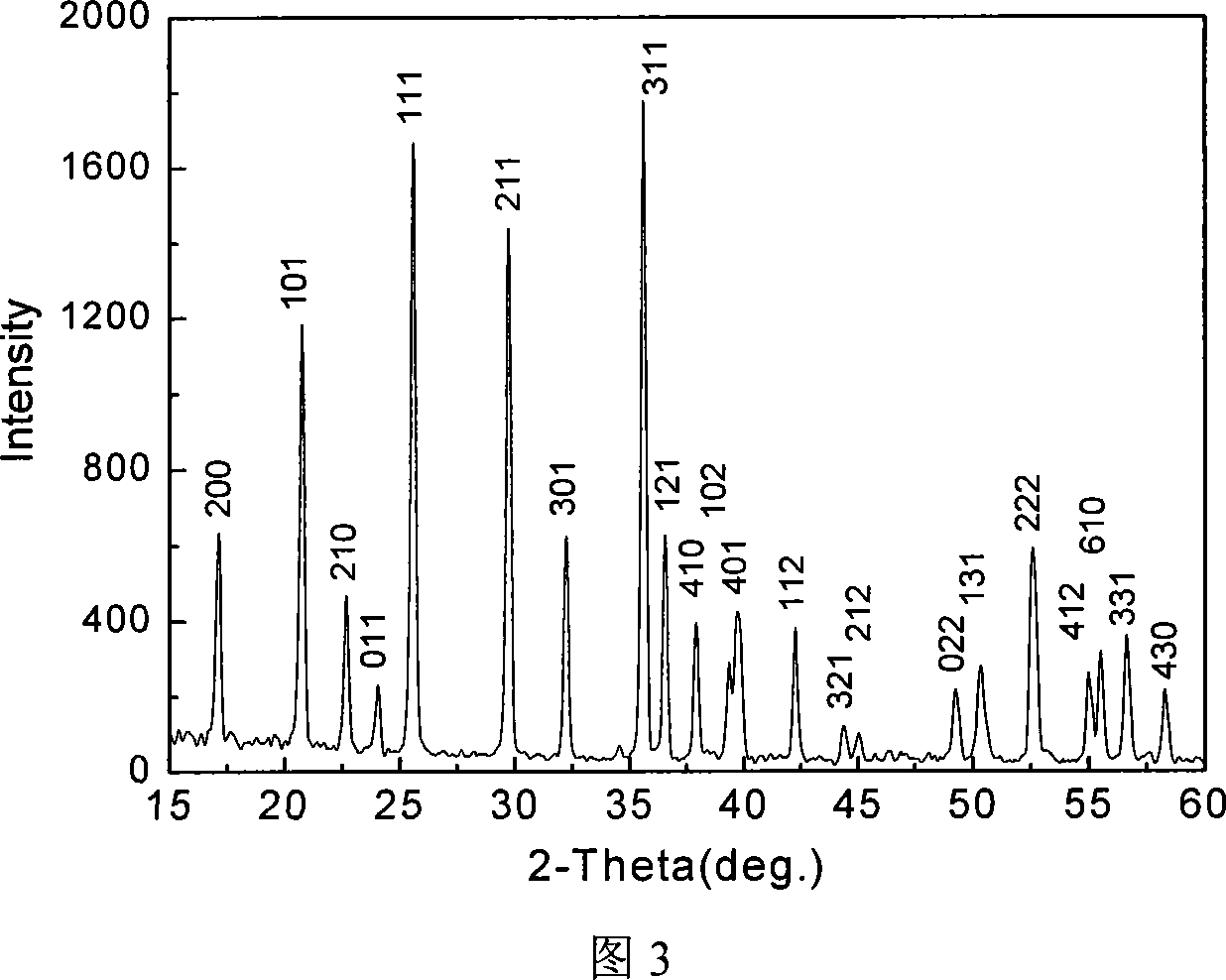

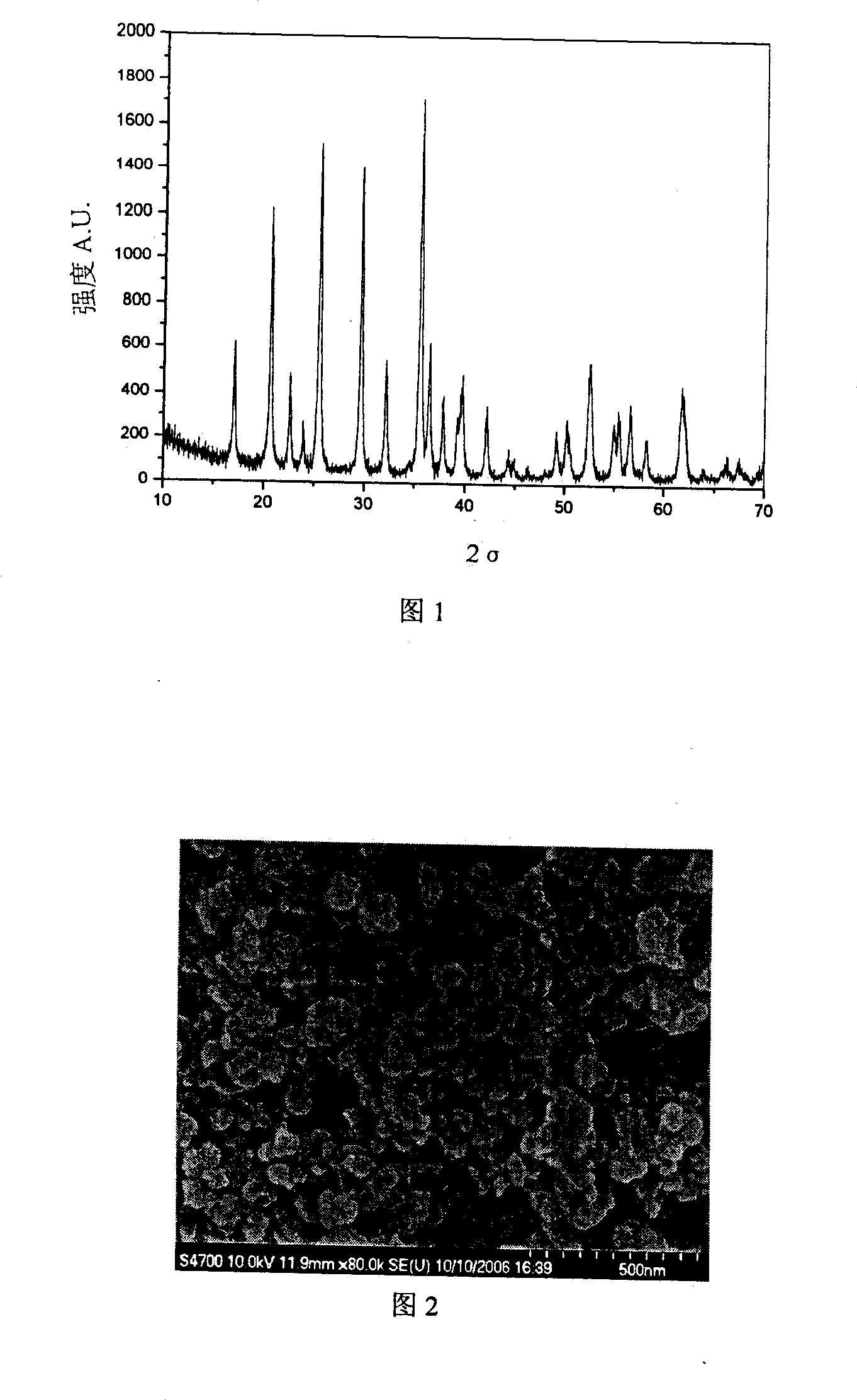

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

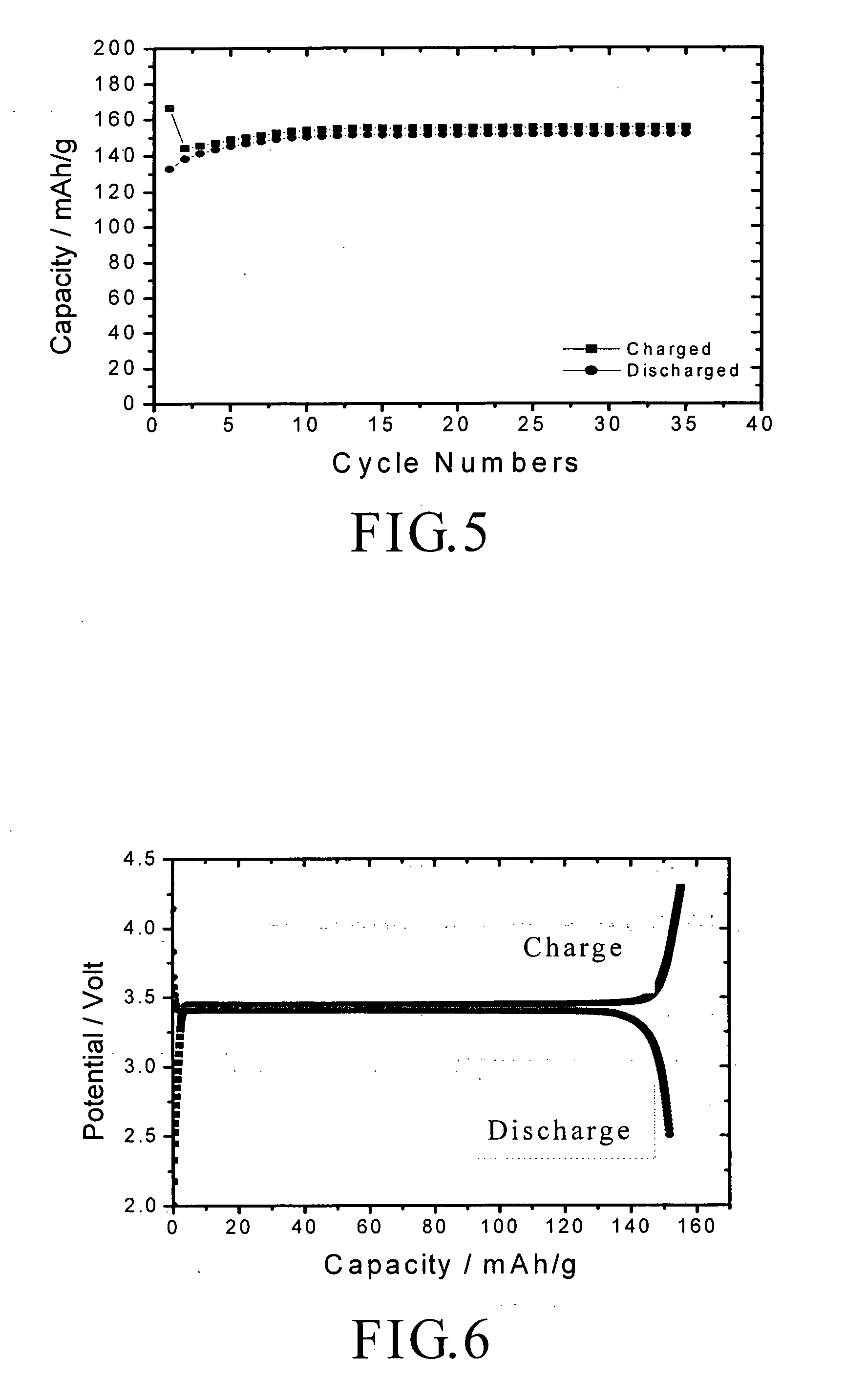

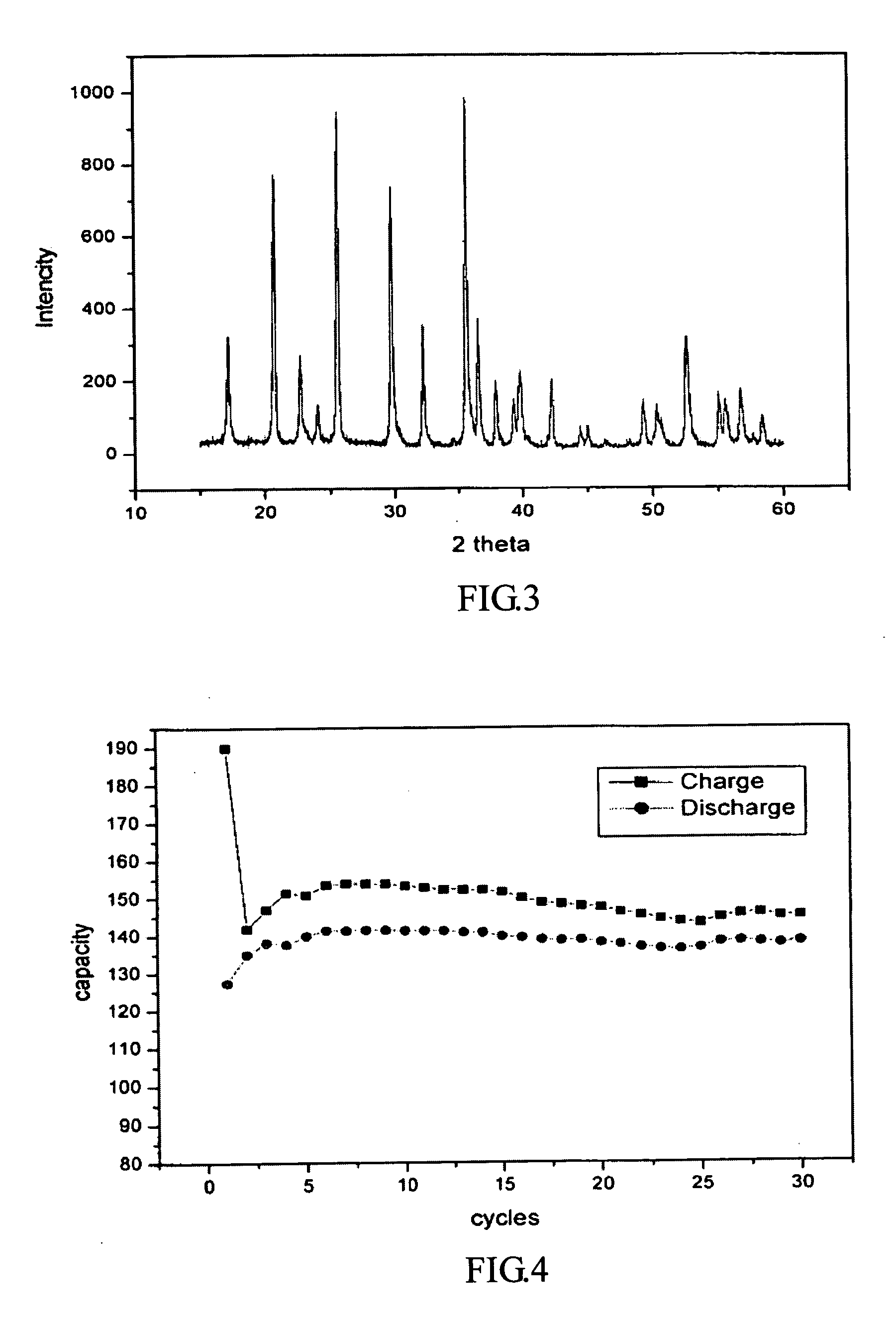

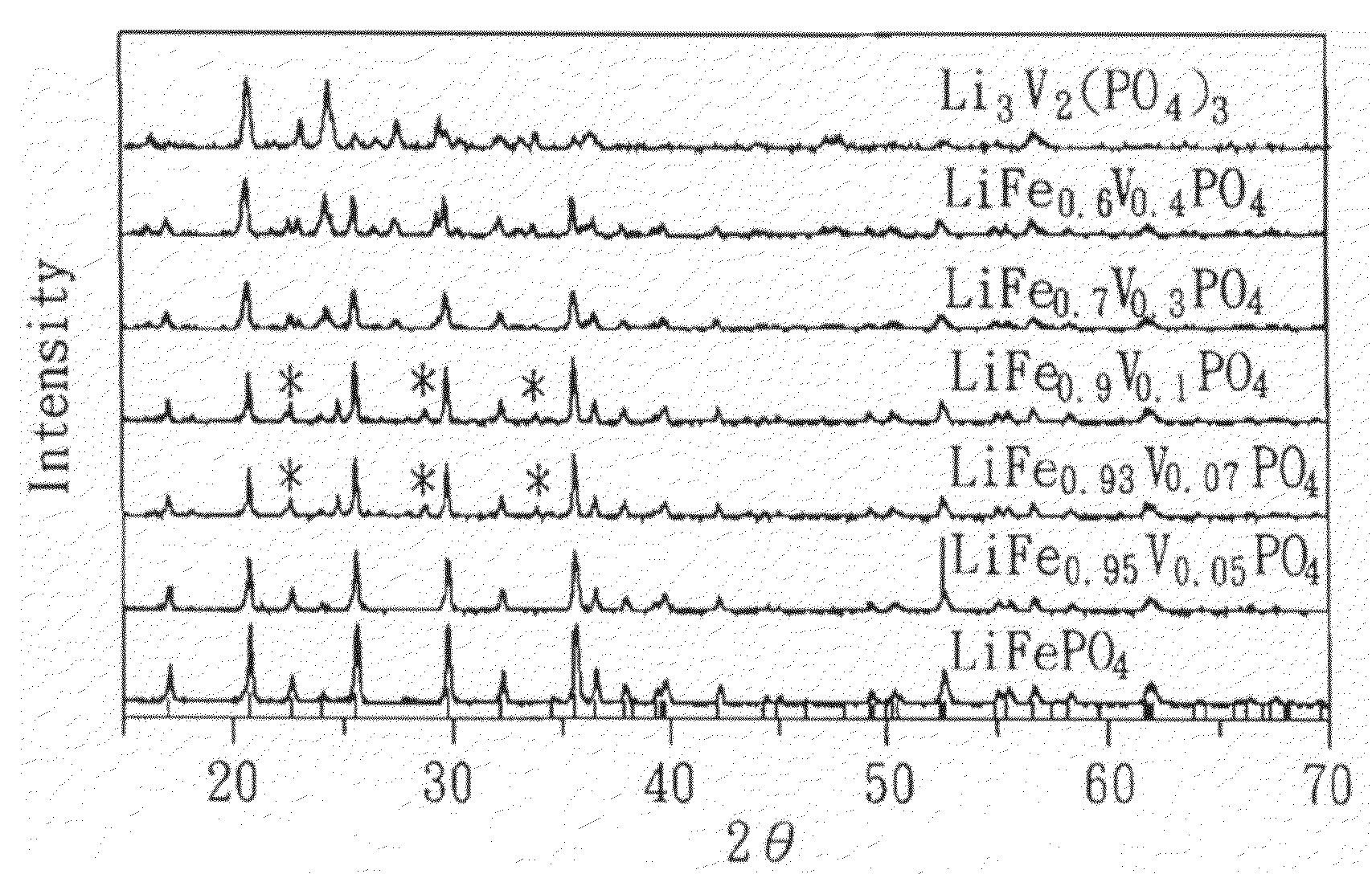

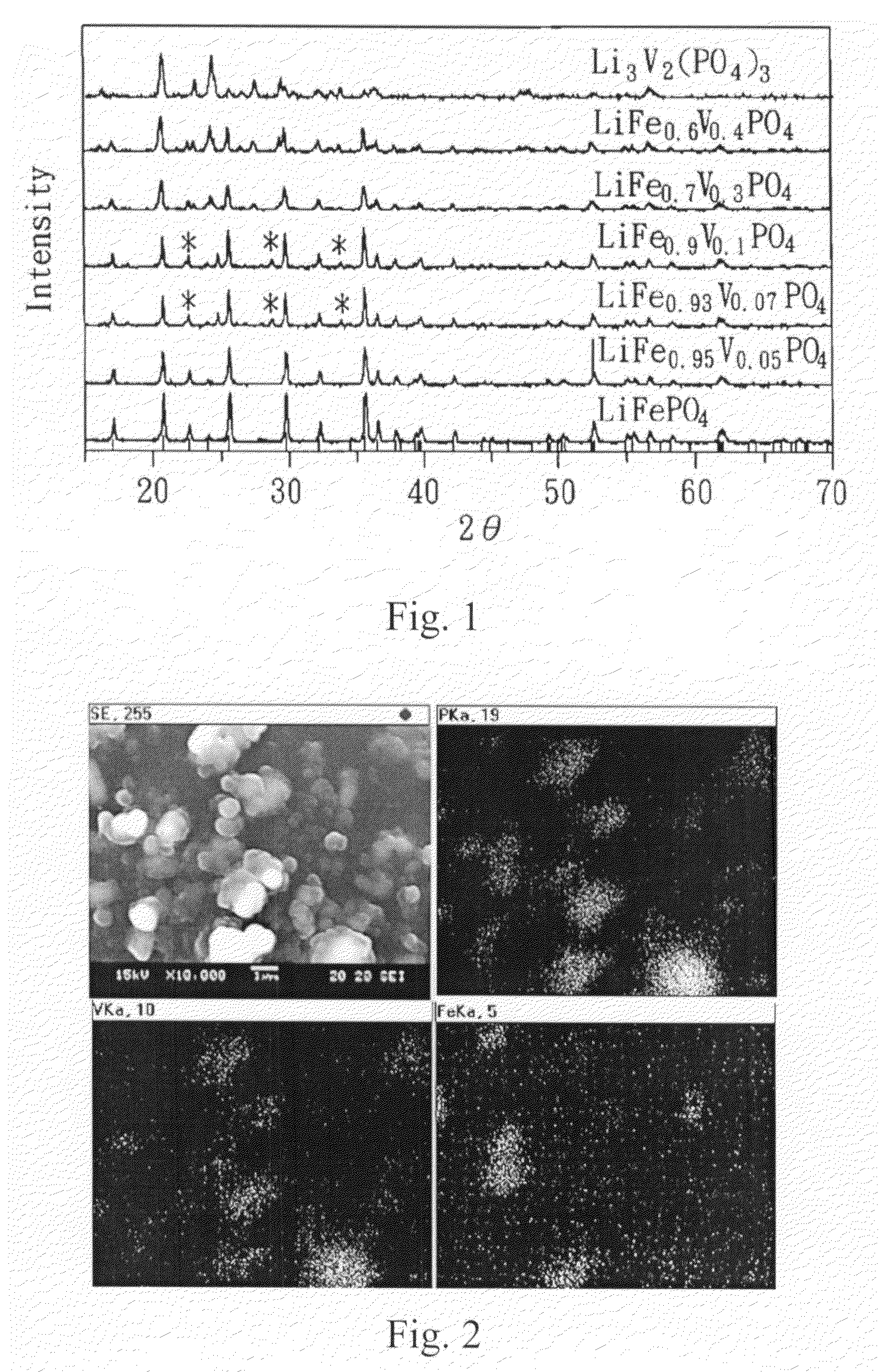

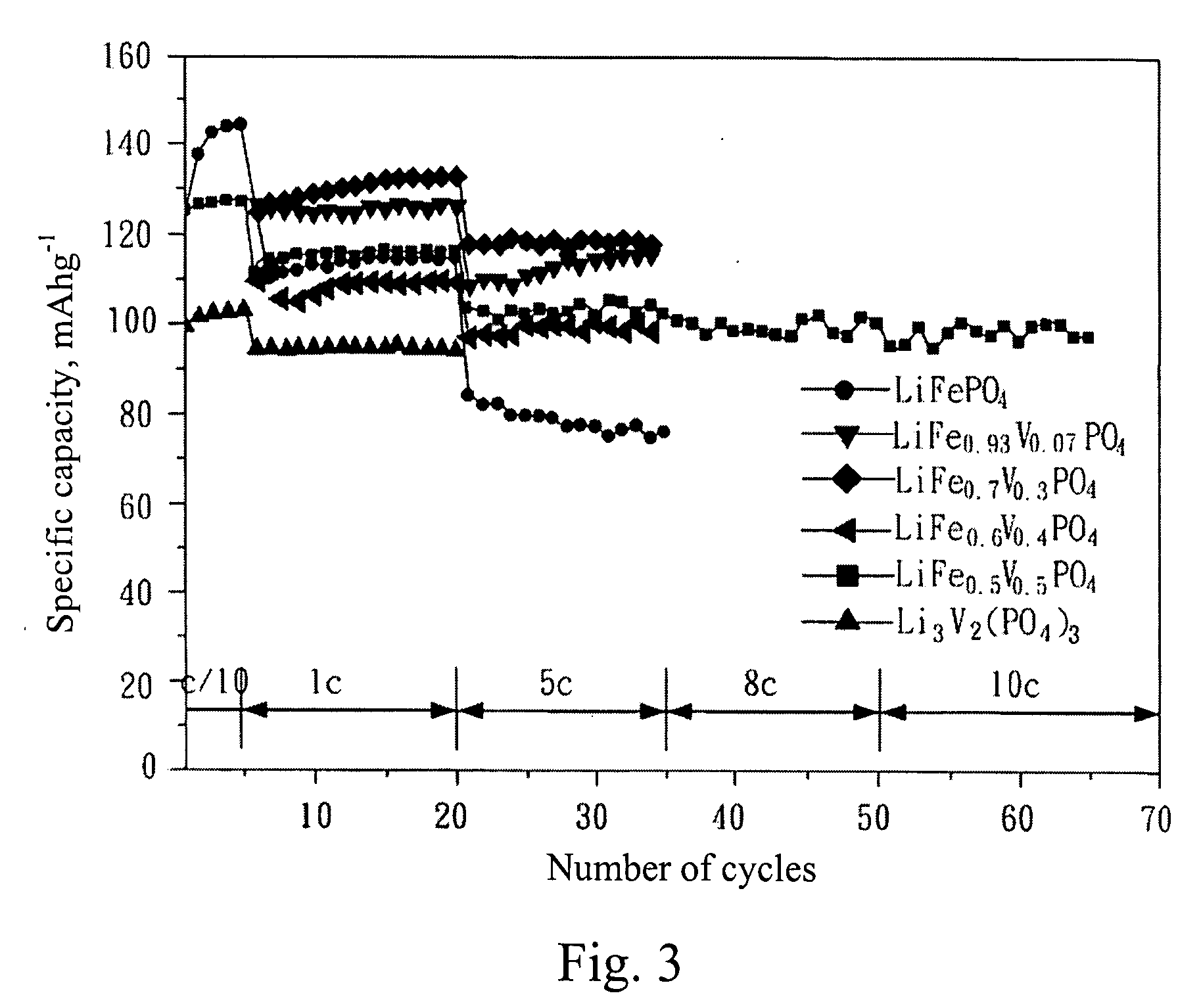

Preparation and application of LiFePO4/Li3V2 (PO4)3 composite cathode materials for lithium ion batteries

InactiveUS20080008938A1Improve conductivityCathode material of highElectrode manufacturing processesDuplicating/marking methodsComposite cathodeIron powder

A method of preparing LiFePO4 / Li3V2(PO4)3 composite cathode materials and their applications as cathode materials for lithium ion batteries are disclosed. The preparation method includes the following steps: (A) providing a mixture of iron powder, lithium salt, vanadium salt, and a phosphate salt whereafter these compounds are dissolved into a mixed acid solution; (B) drying the solution in order to obtain precursor powders; and (C) heating the precursor powders at a temperature ranging between 400 and 1000° C. to form LiFe1-y′Vy′PO4 / Li3V2-y″Fey″(PO4)3 composite powders. Alternatively, prepare the composite cathode by preparing olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y′Fey″(PO4)3 powders as in previous procedures followed by mixing adequately. The low cost of iron powder thus facilitates to prepared composite cathode materials exhibiting higher electrical conductivity and superior cycling performance at high C rates than those of olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y″Fey″(PO4)3. The invention will help the development of the lithium ion batteries and related industries.

Owner:TATUNG COMPANY

Carbon-containing lithium-iron composite phosphorus oxide for lithium secondary battery positive electrode active material and process for producing the same

InactiveUS7025907B2Shorten the diffusion distanceIncrease capacityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMicroparticleOlivine

A carbon-containing lithium-iron composite phosphorus oxide for a lithium secondary battery positive electrode active material, includes particles being composed of a lithium-iron composite phosphorus oxide having an olivine structure whose basic composition is LiFePO4, and being composited with carbonaceous fine particles. A process for producing the same includes the steps of mixing a lithium compound making a lithium source, an iron compound making an iron source, a phosphorus-containing ammonium salt making a phosphorus source and carbonaceous fine particles, thereby preparing a mixture, and calcicing the mixture at a temperature of from 600° C. or more to 750° C. or less.

Owner:TOYOTA CENT RES & DEV LAB INC

Anode material of Li-ion secondary battery and battery containing the same

InactiveCN101212048AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsHigh temperature storagePhosphoric acid

The invention relates to an anode material for a lithium ion secondary battery. The anode material comprises anode active substance, a conductive agent and a caking agent, wherein the anode active substance comprises material A and material B. The material B is the oxide C of plated metal lithium and / or the oxide D of plated metal lithium which are coated and processed by the material A. The material A is the lithium phosphate slat with a olivine structure. The anode material can obviously improve the safety performance of the lithium ion secondary battery; the battery has a big capacity; the anode material has a good performance of charge and discharge for a big current, circulation and high temperature storage.

Owner:BYD CO LTD

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20050101493A1Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

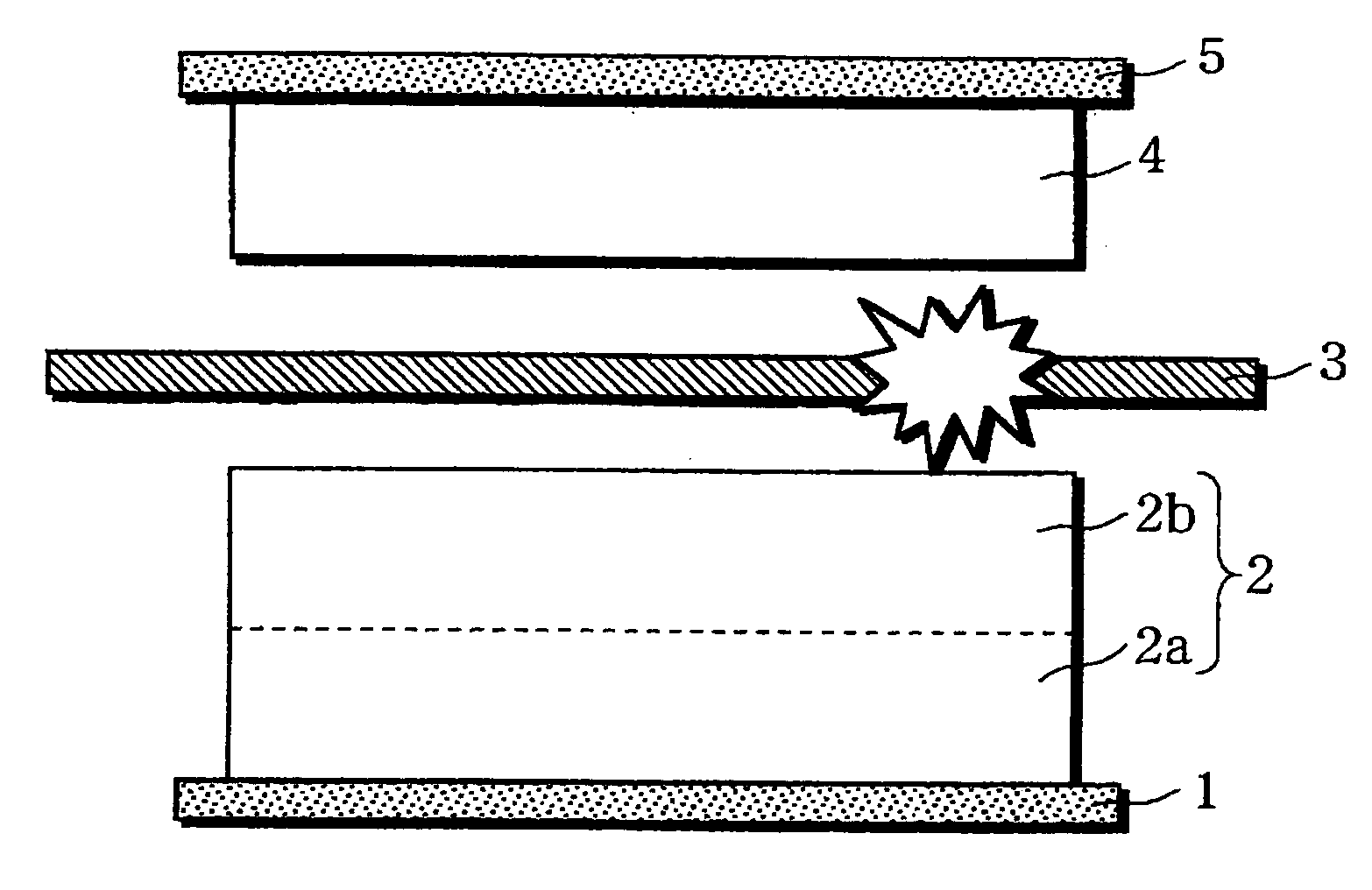

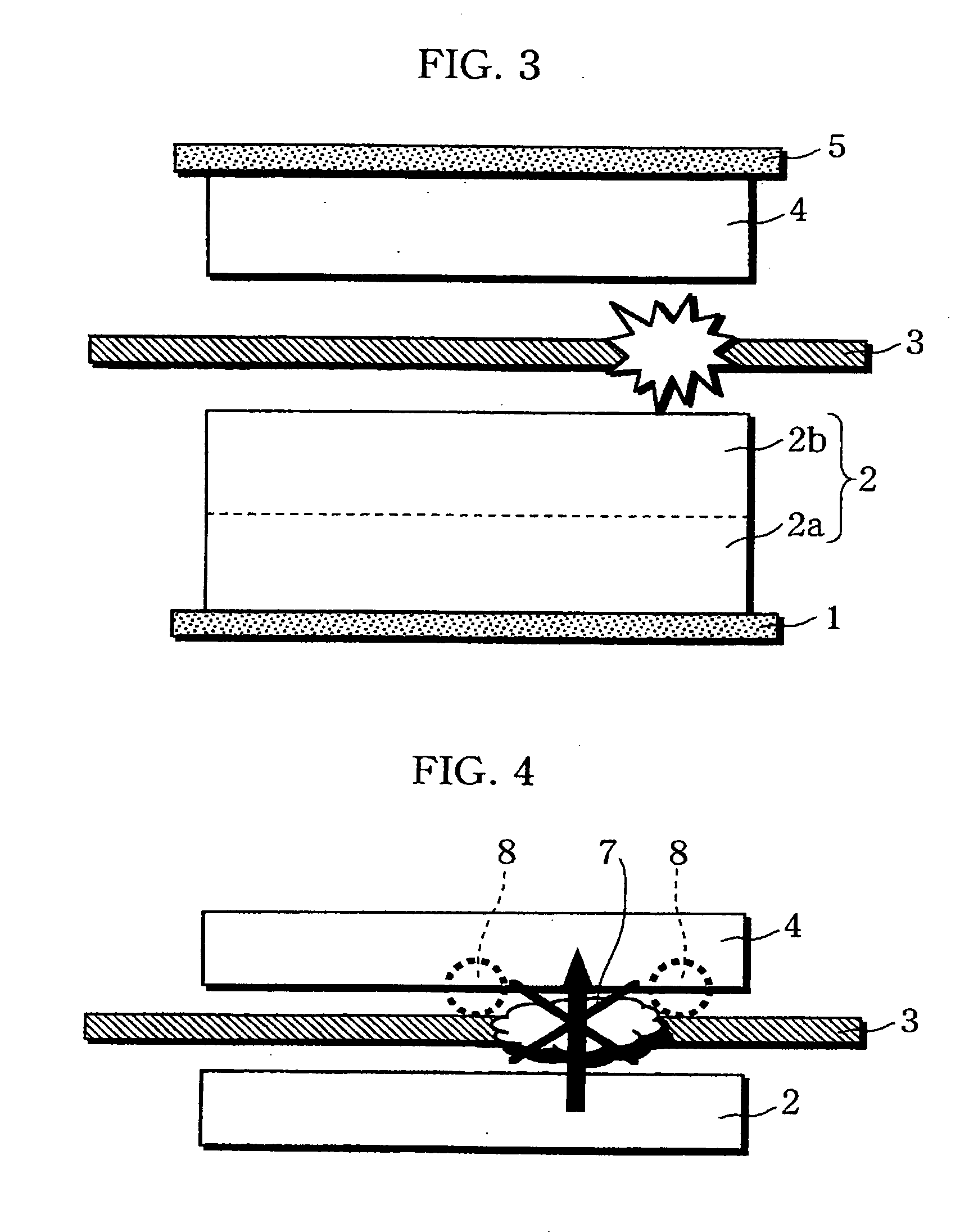

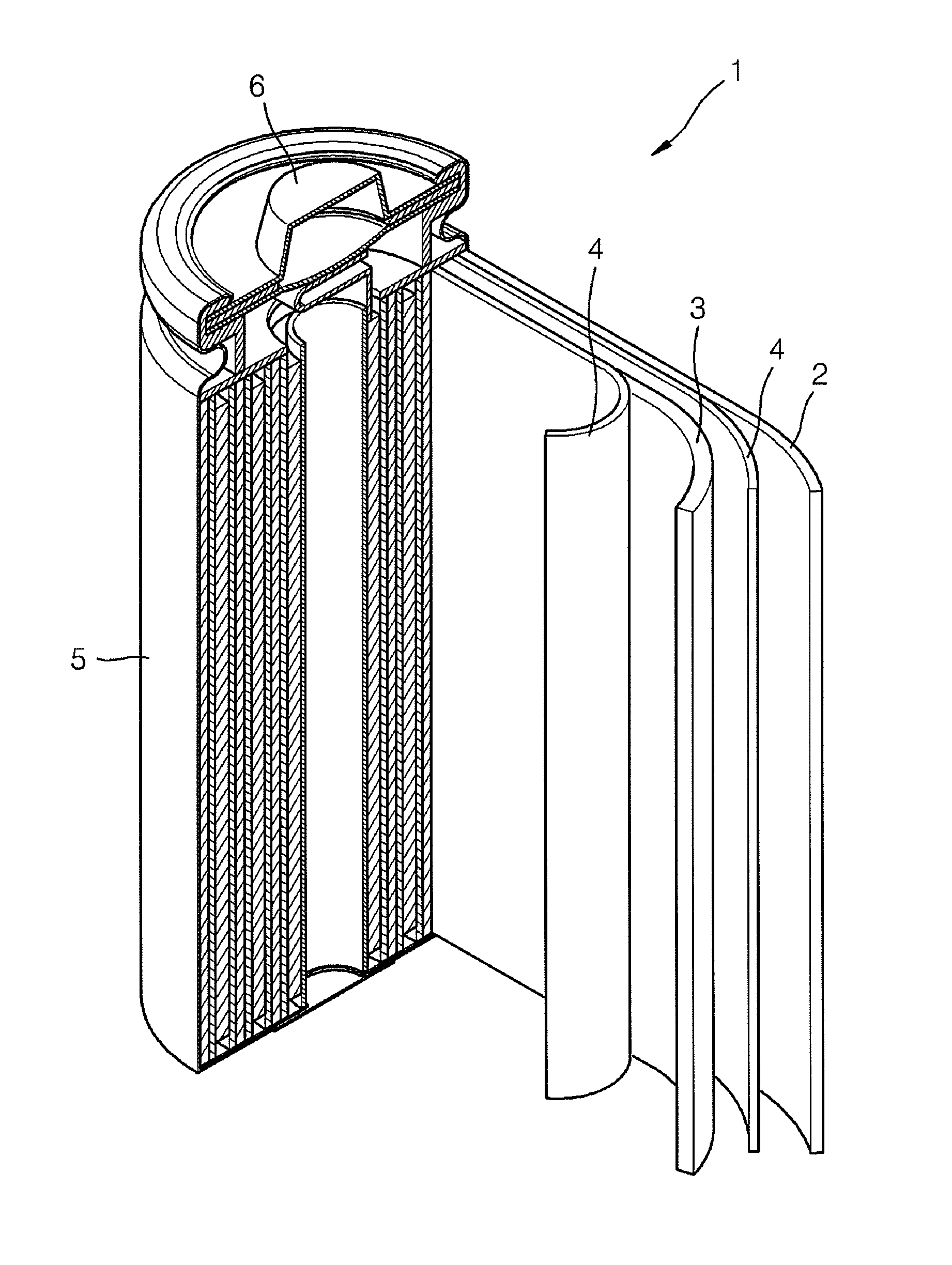

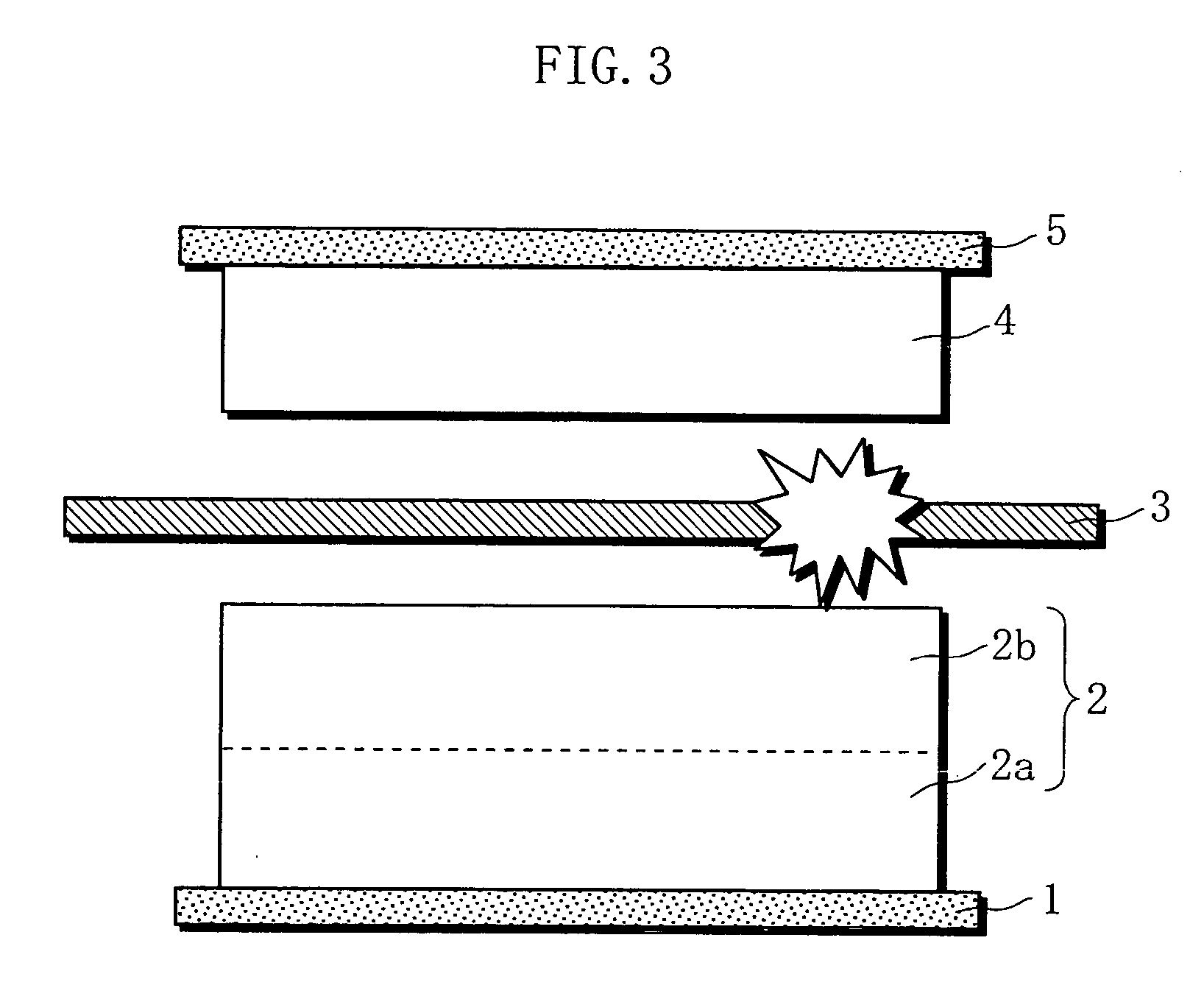

Non-aqueous electrolyte battery

InactiveUS20060019151A1Avoid depositionIncrease probabilityFinal product manufactureCell temperature controlSpinelEngineering

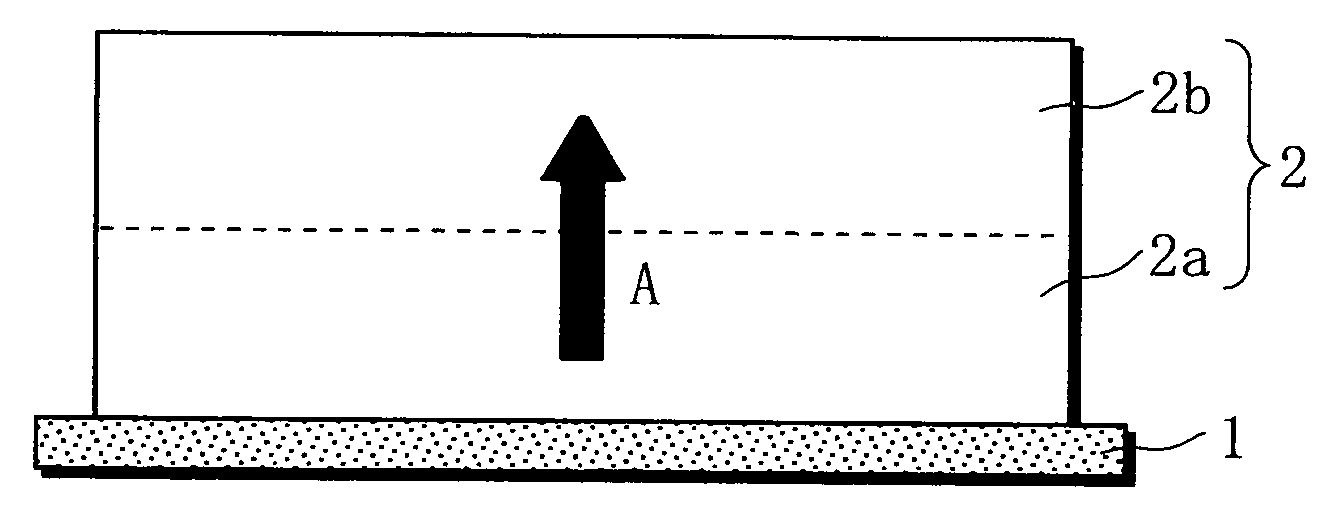

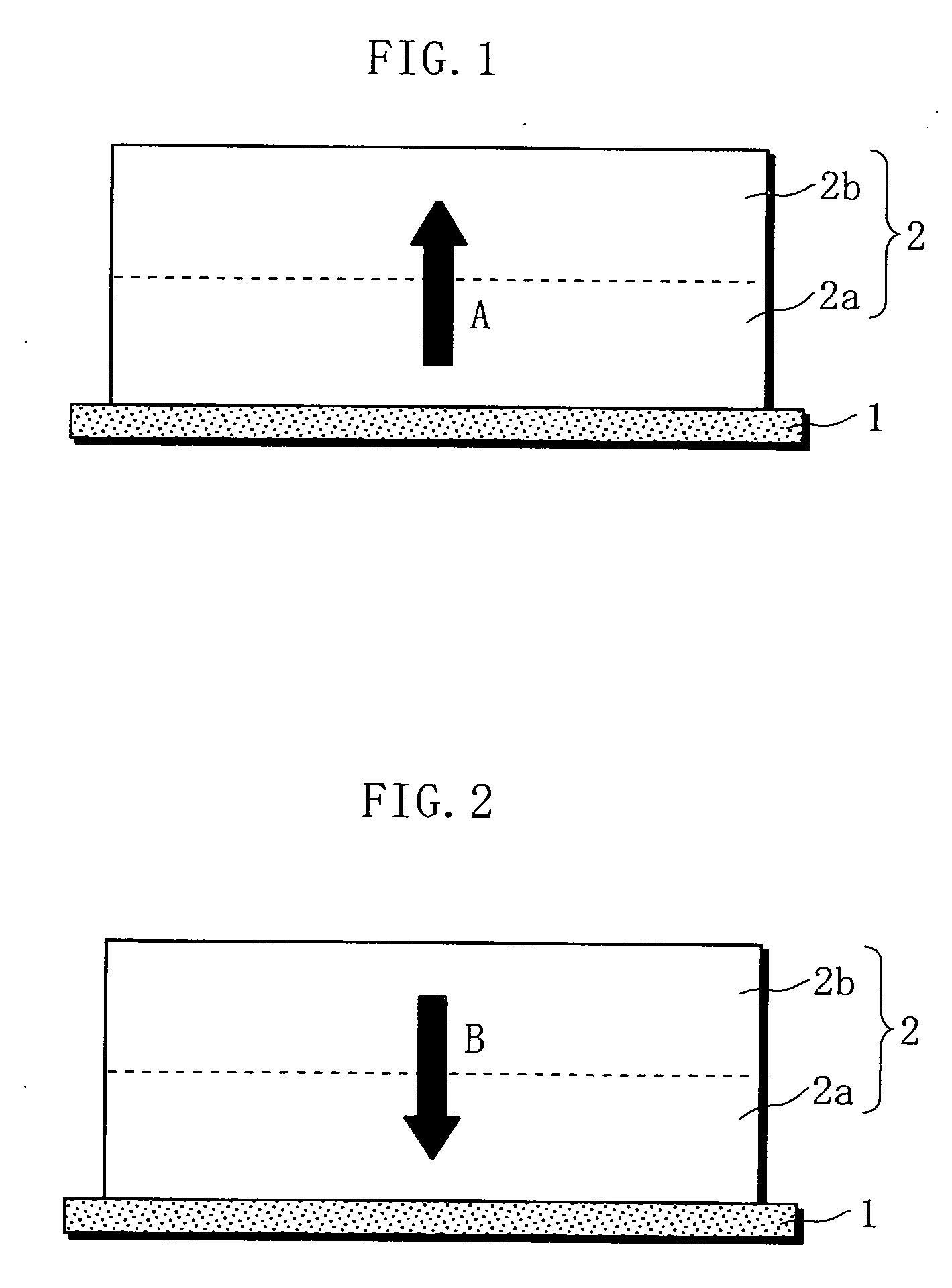

A non-aqueous electrolyte battery is provided that is capable of improving safety, particularly the tolerance of the battery to overcharging, without compromising conventional battery constructions considerably. A non-aqueous electrolyte battery is furnished with a positive electrode including a positive electrode active material-layer (2) containing a plurality of positive electrode active materials and being formed on a surface of a positive electrode current collector (1), a negative electrode including a negative electrode active material layer (4), and a separator (3) interposed between the electrodes. The positive electrode active material-layer (2) is composed of two layers (2a) and (2b) having different positive electrode active materials, and of the two layers (2a) and (2b), the layer (2b) that is nearer the positive electrode current collector contains, as its main active material, a spinel-type lithium manganese oxide or an olivine-type lithium phosphate compound.

Owner:SANYO ELECTRIC CO LTD

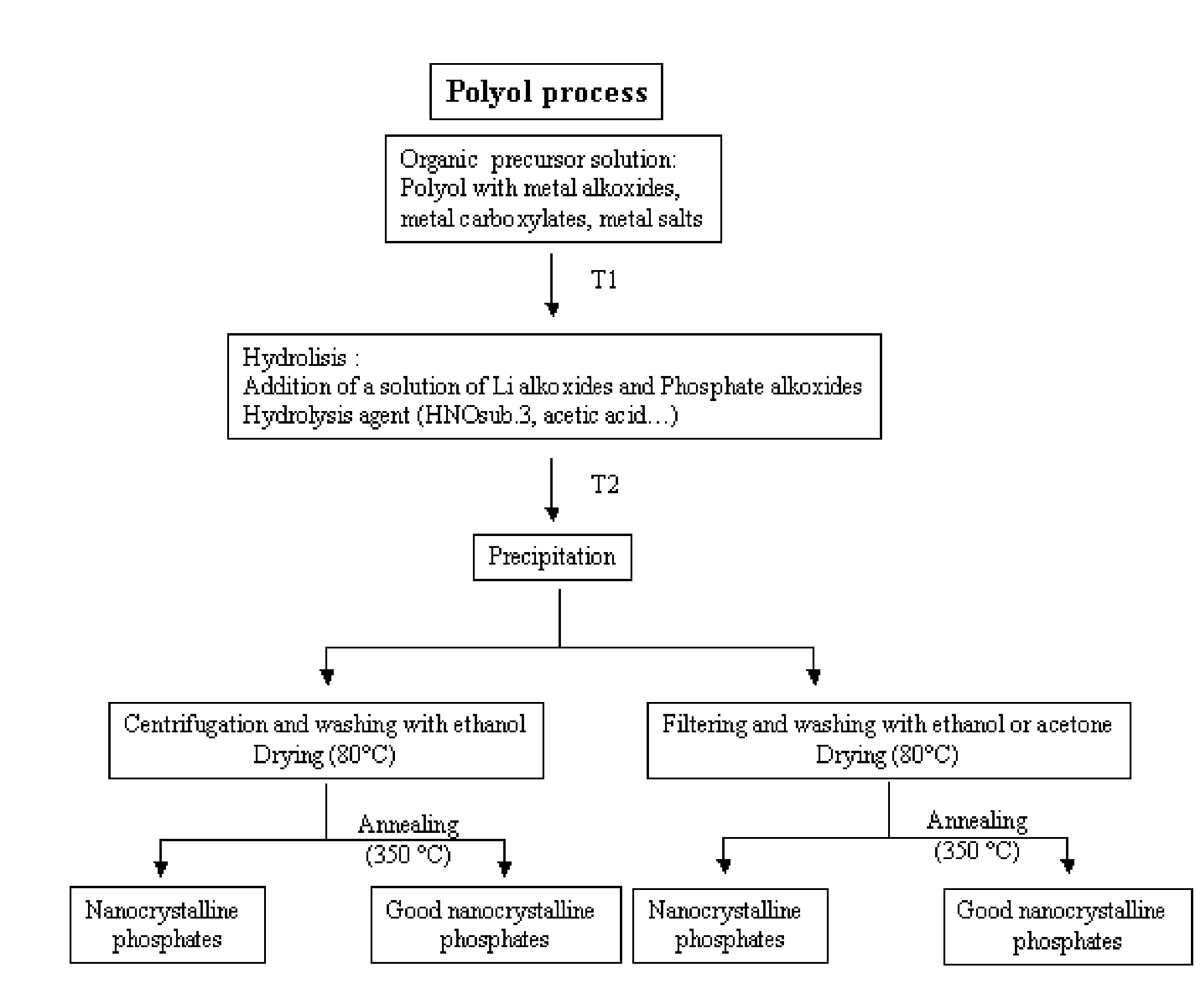

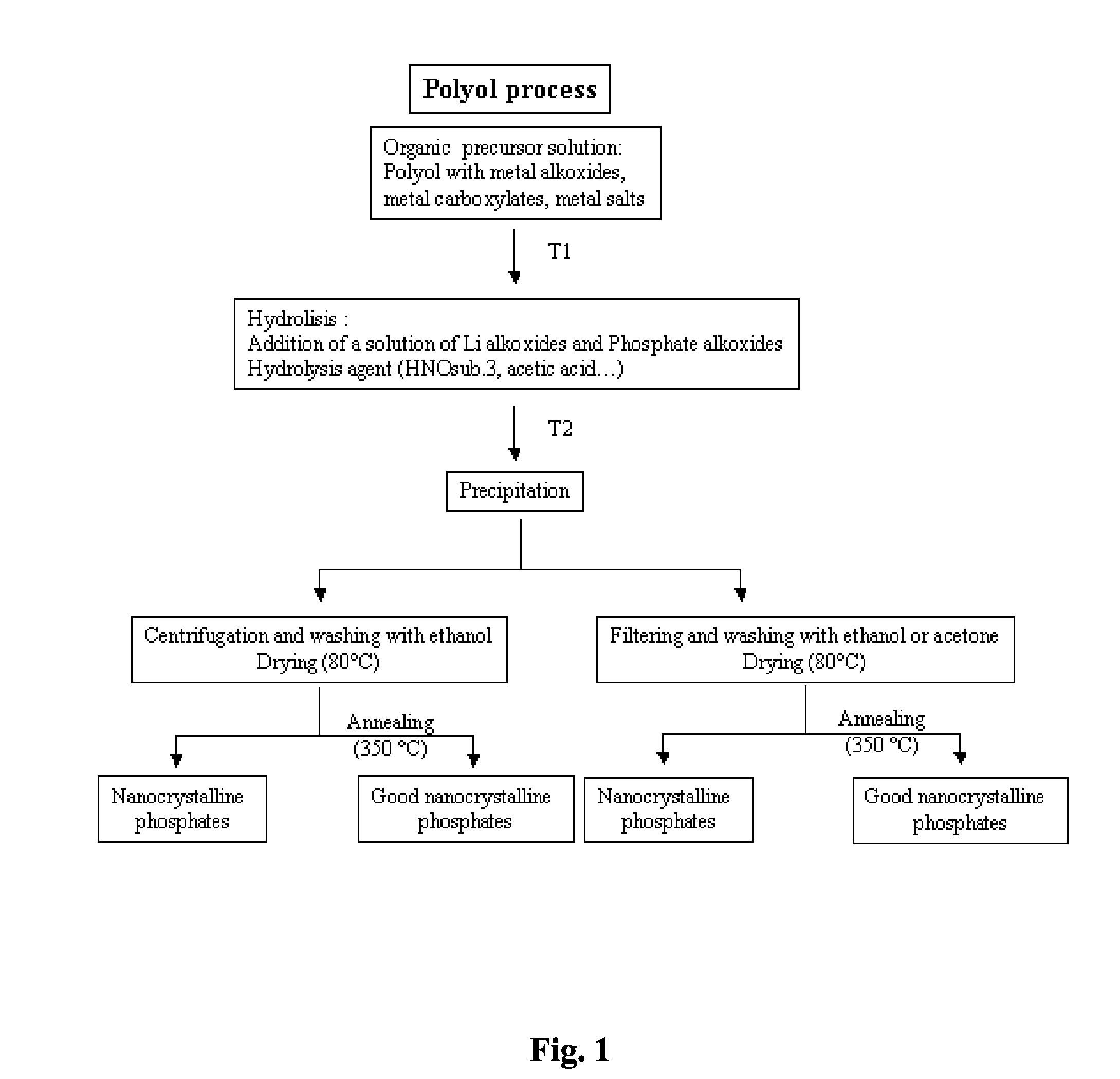

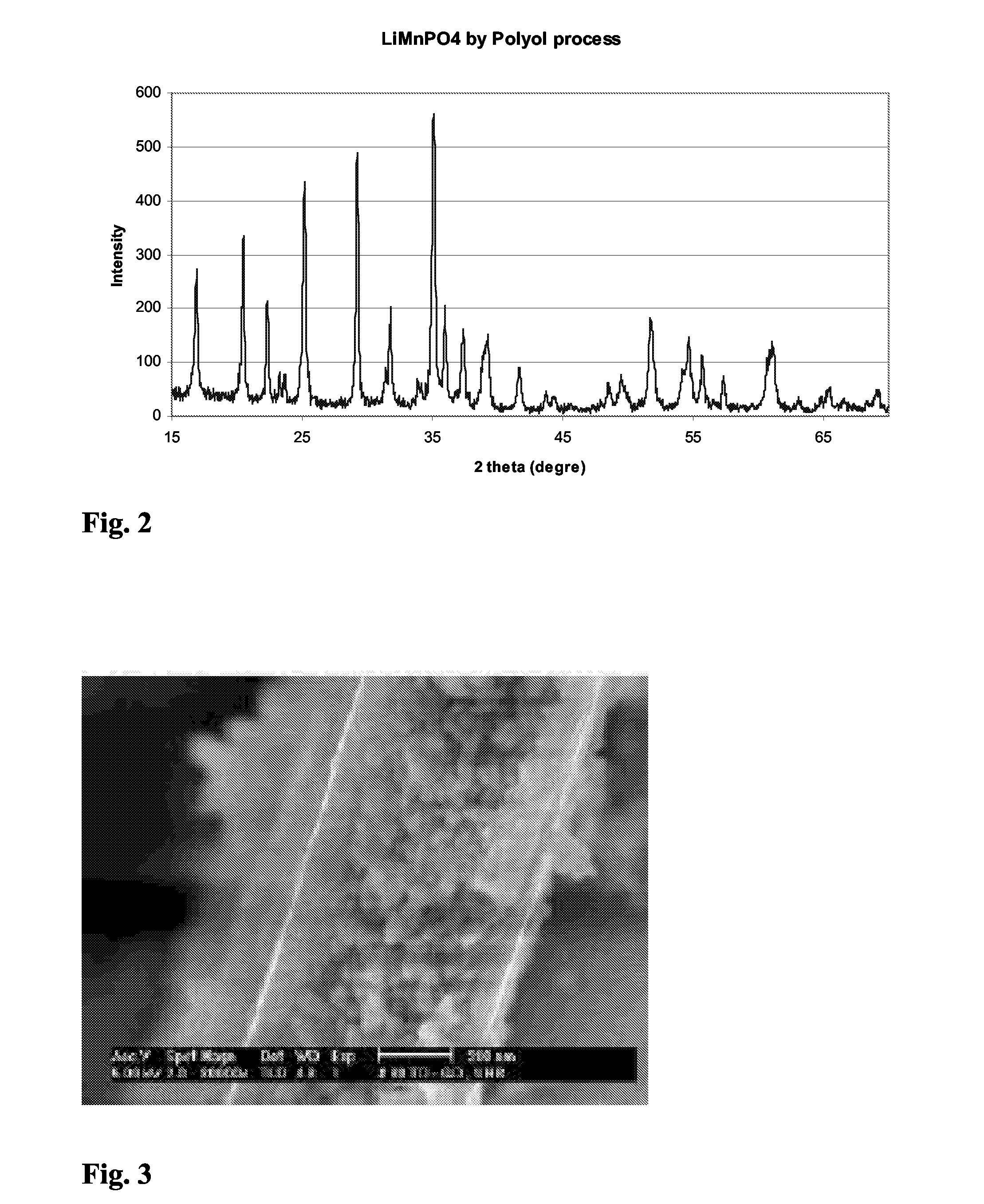

Synthesis of nanoparticles of lithium metal phosphate positive material for lithium secondary battery

InactiveUS20090186275A1Improve material performanceImprove electrochemical performanceNon-metal conductorsPhosphatesPhosphateLithium metal

Novel process for the preparation of finely divided, nano-structured, olivine lithium metal phosphates (LiMPO.sub.4) (where metal M is iron, cobalt, manganese, nickel, vanadium, copper, titanium and mix of them) materials have been developed. This so called Polyol” method consists of heating of suited precursor materials in a multivalent, high-boiling point multivalent alcohol like glycols with the general formula HO—(—C2H4O—).sub.n-H where n=1-10 or HO—(—C3H6O—).sub.n.-H where n=1-10, or other polyols with the general formula HOCH2—(—C3H5OH—).sub.n-H where n=1-10, like for example the tridecane-1,4,7,10,13-pentaol. A novel method for implementing the resulting materials as cathode materials for Li.-ion batteries is also developed.

Owner:DOW GLOBAL TECH LLC

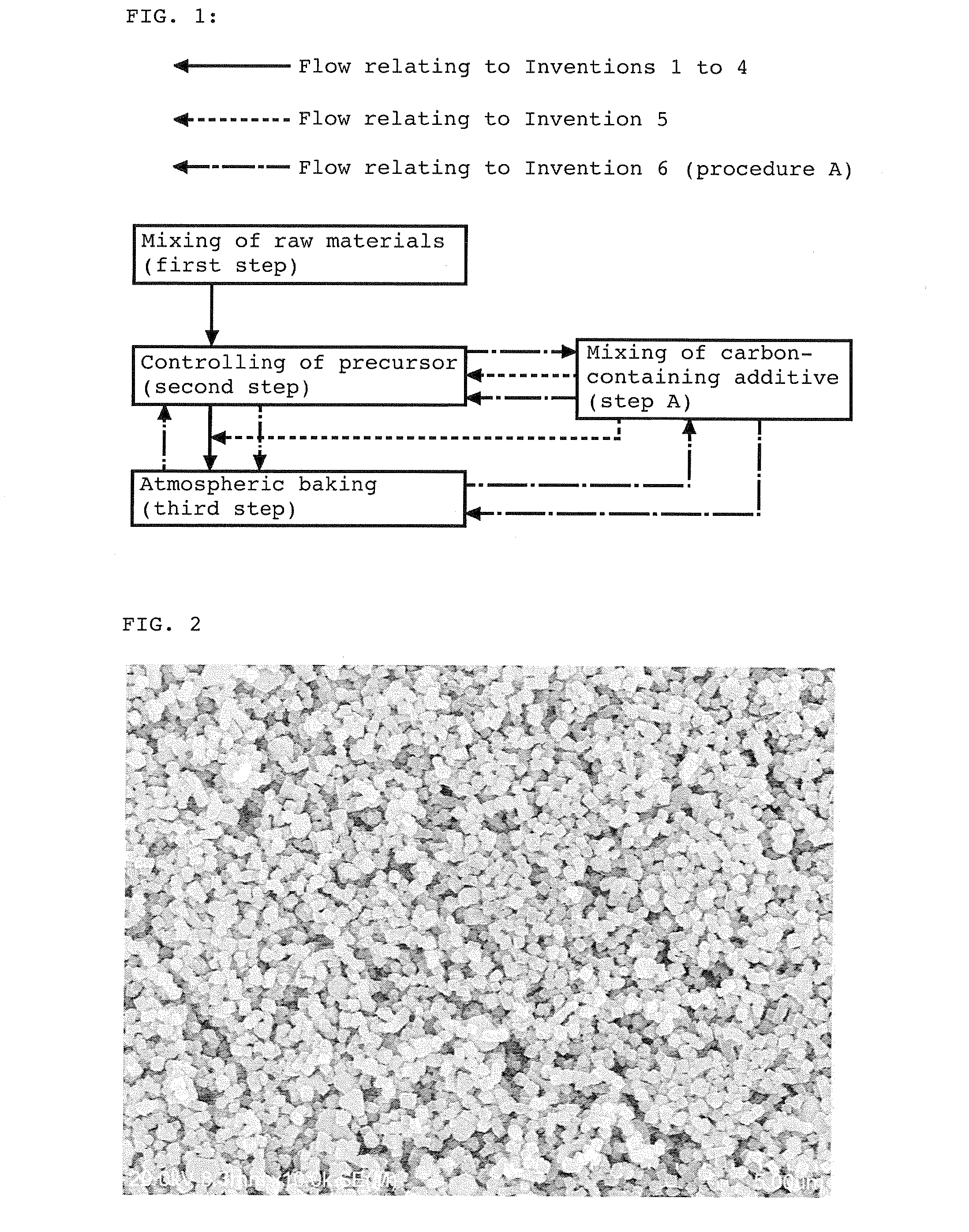

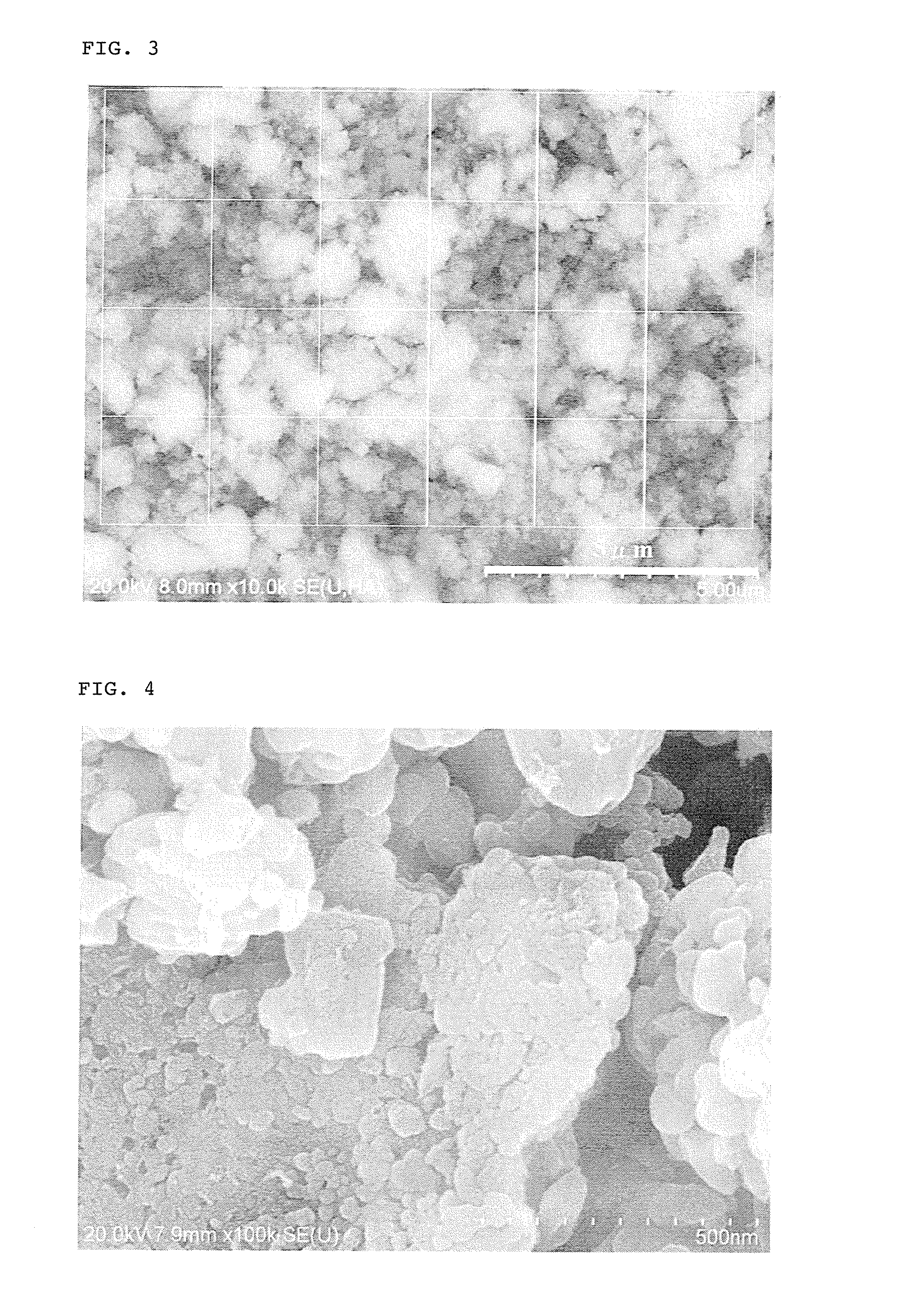

Process for producing lithium iron phosphate particles, lithium iron phosphate particles having olivine type structure, and positive electrode sheet and non-aqueous solvent-based secondary battery using the lithium iron phosphate particles

InactiveUS20110091772A1Low costReduce environmental burdenElectrode manufacturing processesPhosphatesOxygenOlivine

The present invention relates to a process for producing lithium iron phosphate particles having an olivine type structure, comprising a first step of mixing an iron oxide or an iron oxide hydroxide as an iron raw material which comprises at least one element selected from the group consisting of Na, Mg, Al, Si, Cr, Mn and Ni in an amount of 0.1 to 2 mol % for each element based on Fe, and a carbon element C in an amount of 5 to 10 mol % based on Fe, and has a content of Fe2+ of not more than 40 mol % based on an amount of Fe and an average primary particle diameter of 5 to 300 nm, with a lithium raw material and a phosphorus raw material; a second step of controlling agglomerates diameter in the resulting mixture is 0.3 to 5.0 μm; and a third step of sintering the mixture obtained in the second step in an inert gas or reducing gas atmosphere having an oxygen concentration of not more than 0.1% at a temperature of 250 to 750° C.

Owner:TODA IND

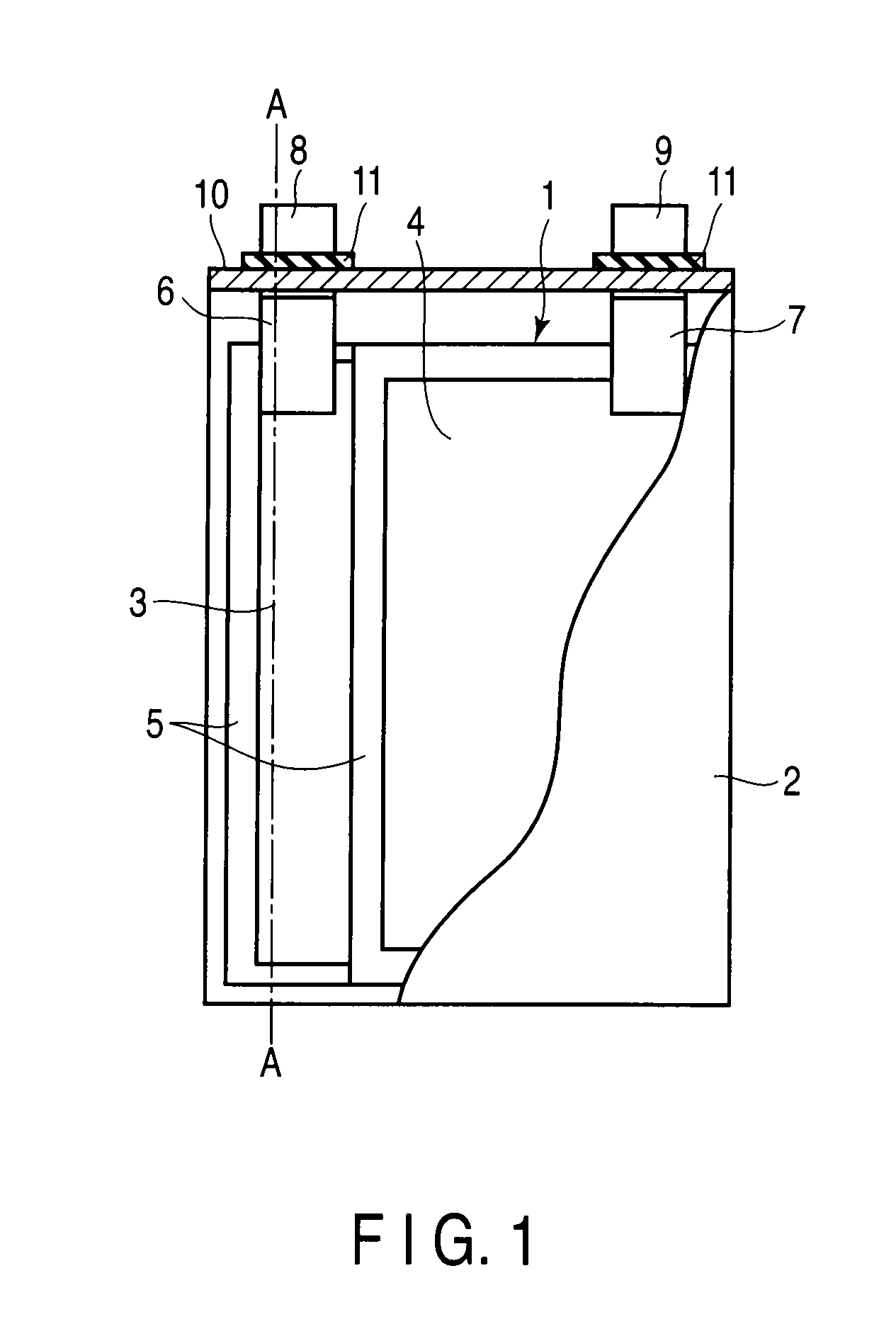

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

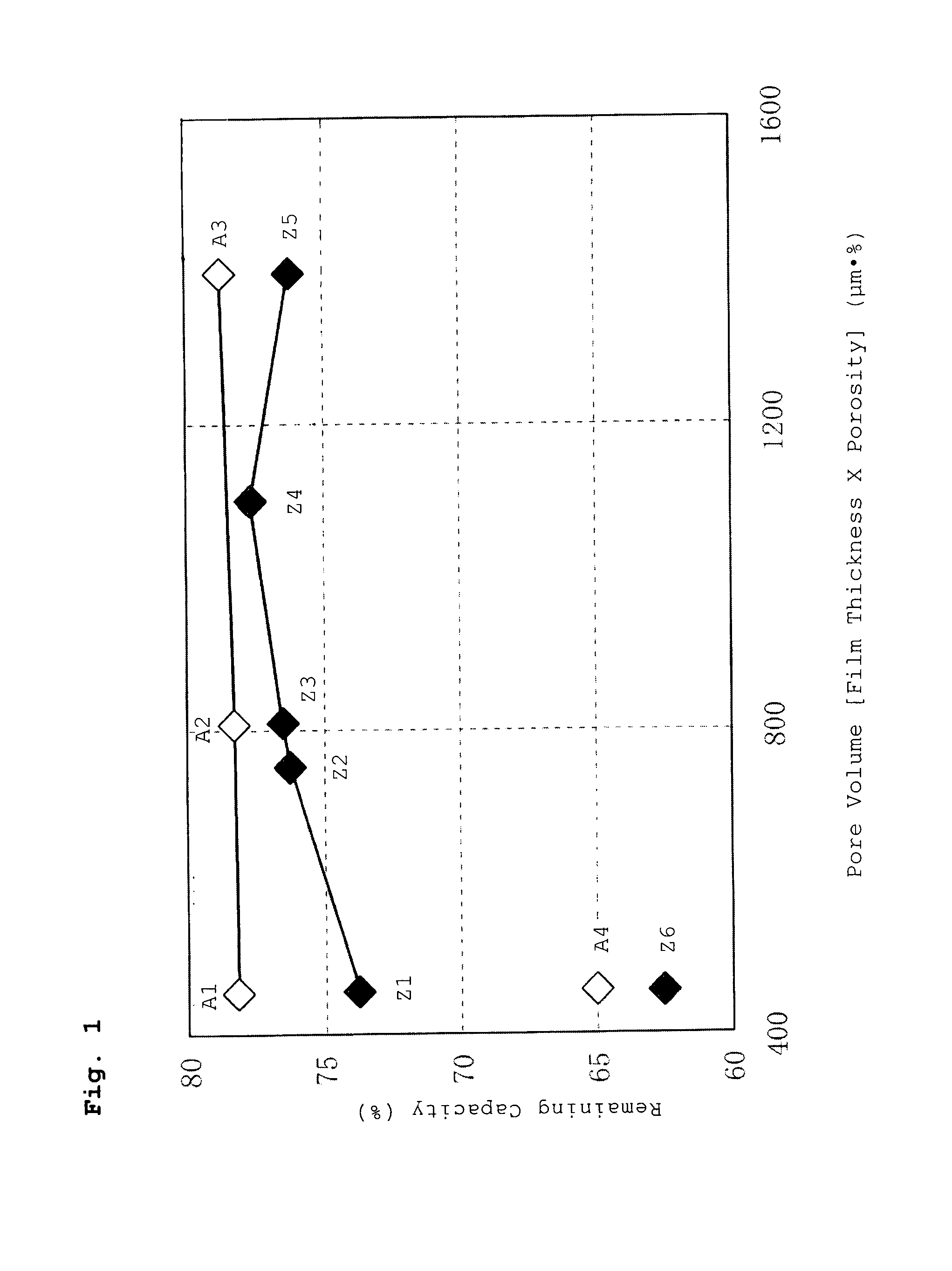

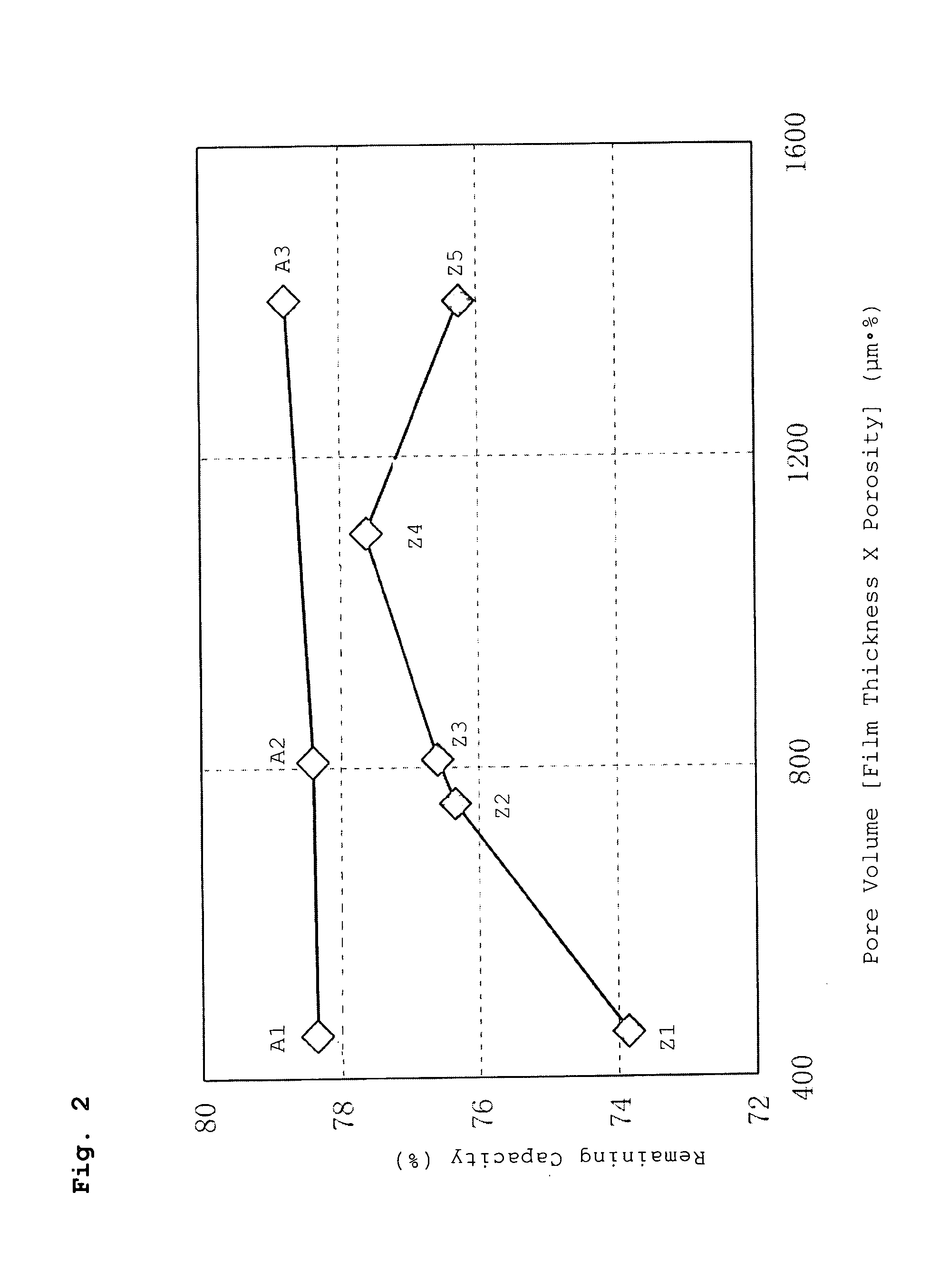

Non-aqueous electrolyte battery

InactiveUS20070254209A1Good benefitImprove stabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureElemental compositionInorganic particle

A battery has a positive electrode active material containing an olivine lithium phosphate-based compound having an elemental composition represented as LiMPO4, where M is a transition metal including at least Fe. The product of a separator thickness x (μm) and a separator porosity y (%) is controlled to be equal to or less than 1500 (μm·%). A porous layer containing inorganic particles and a binder is disposed between the separator and the positive electrode and / or between the separator and the negative electrode.

Owner:SANYO ELECTRIC CO LTD

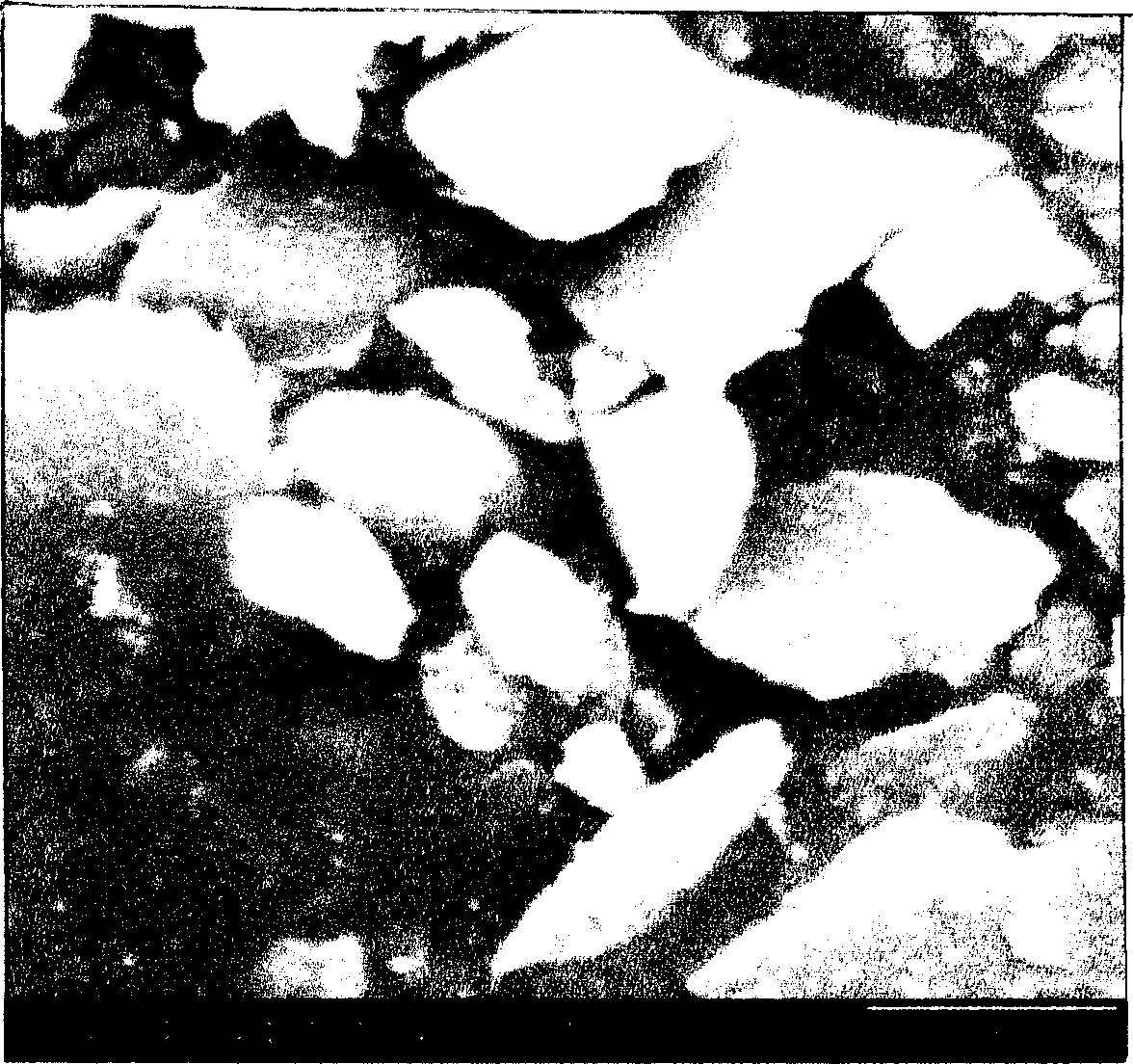

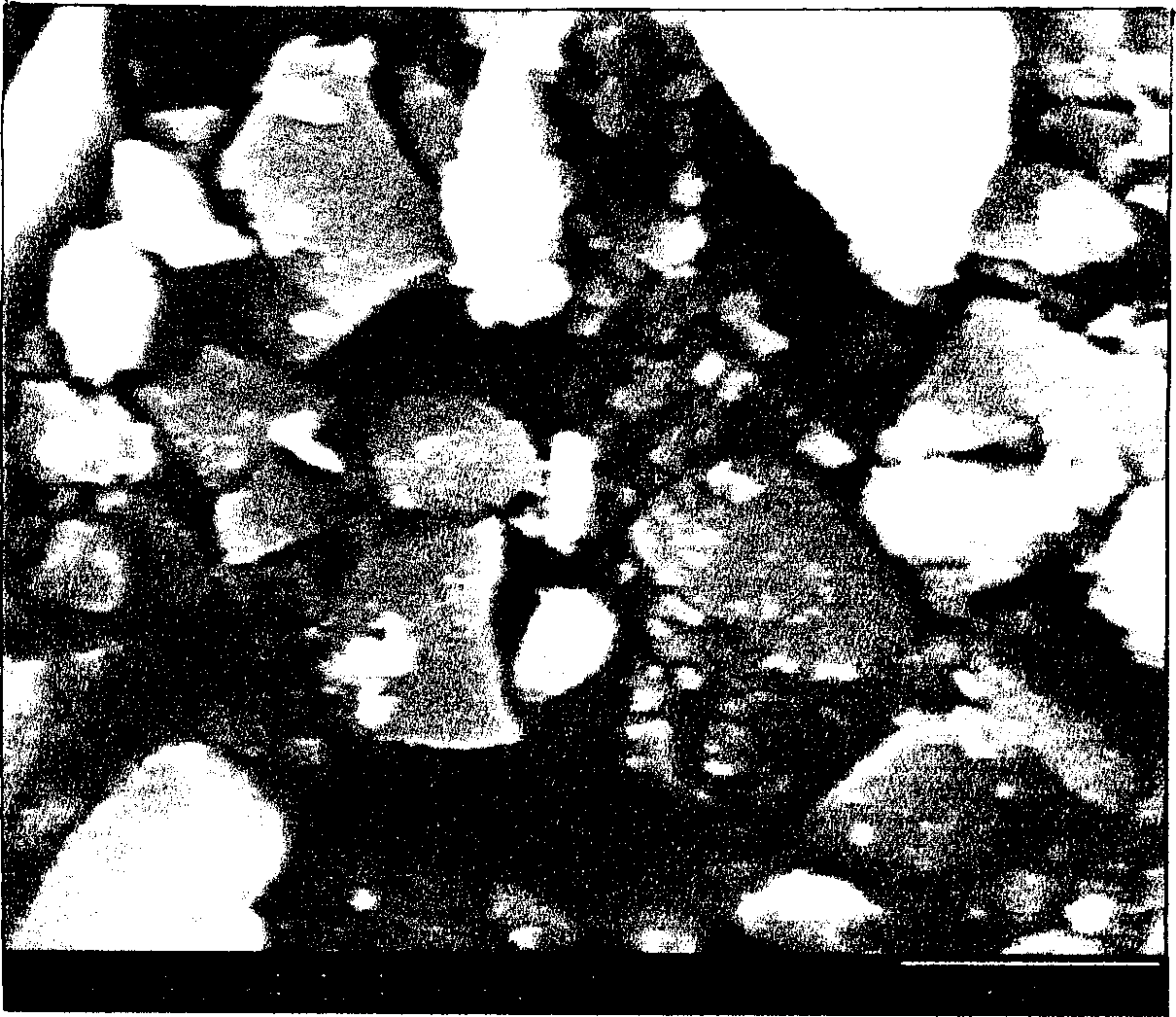

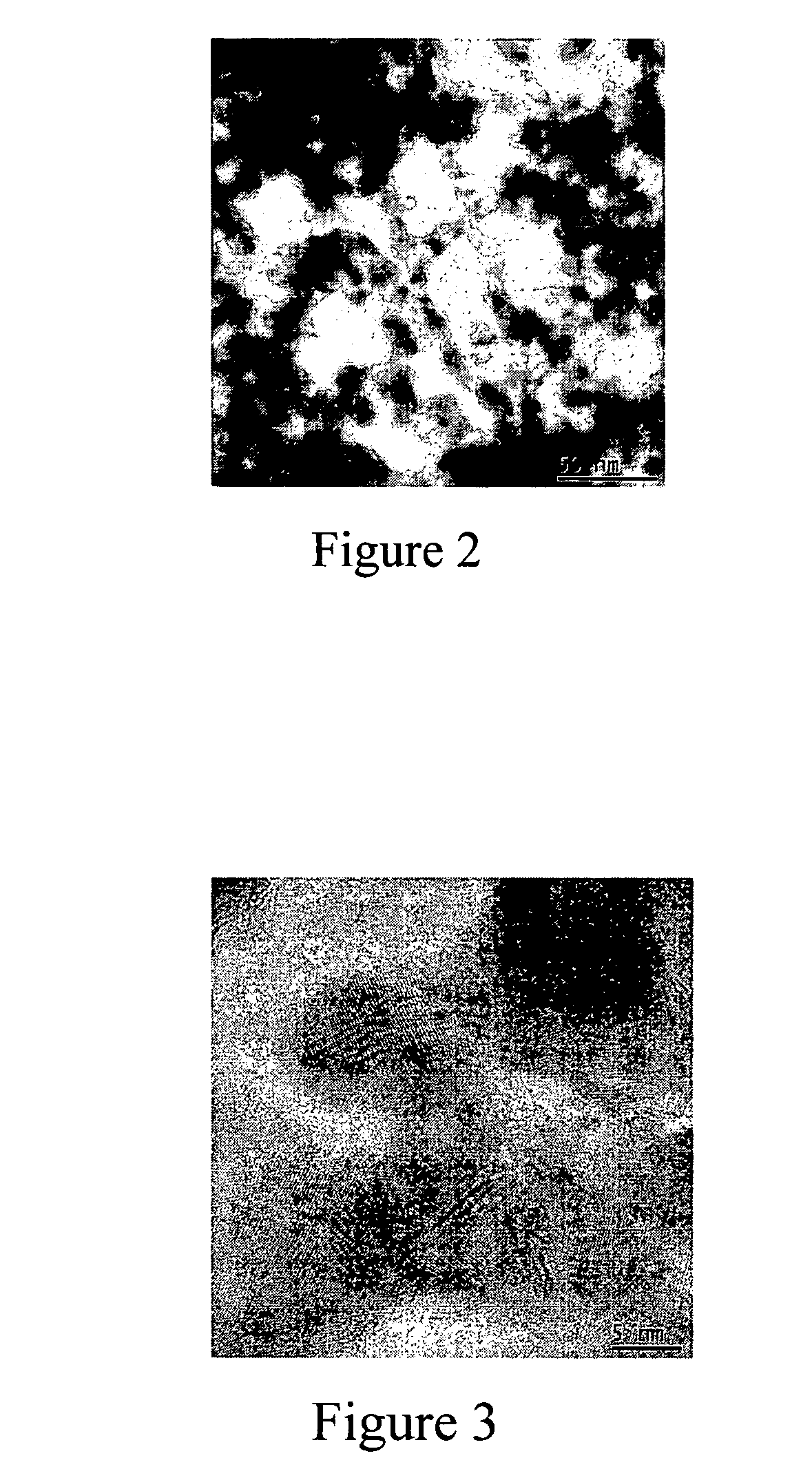

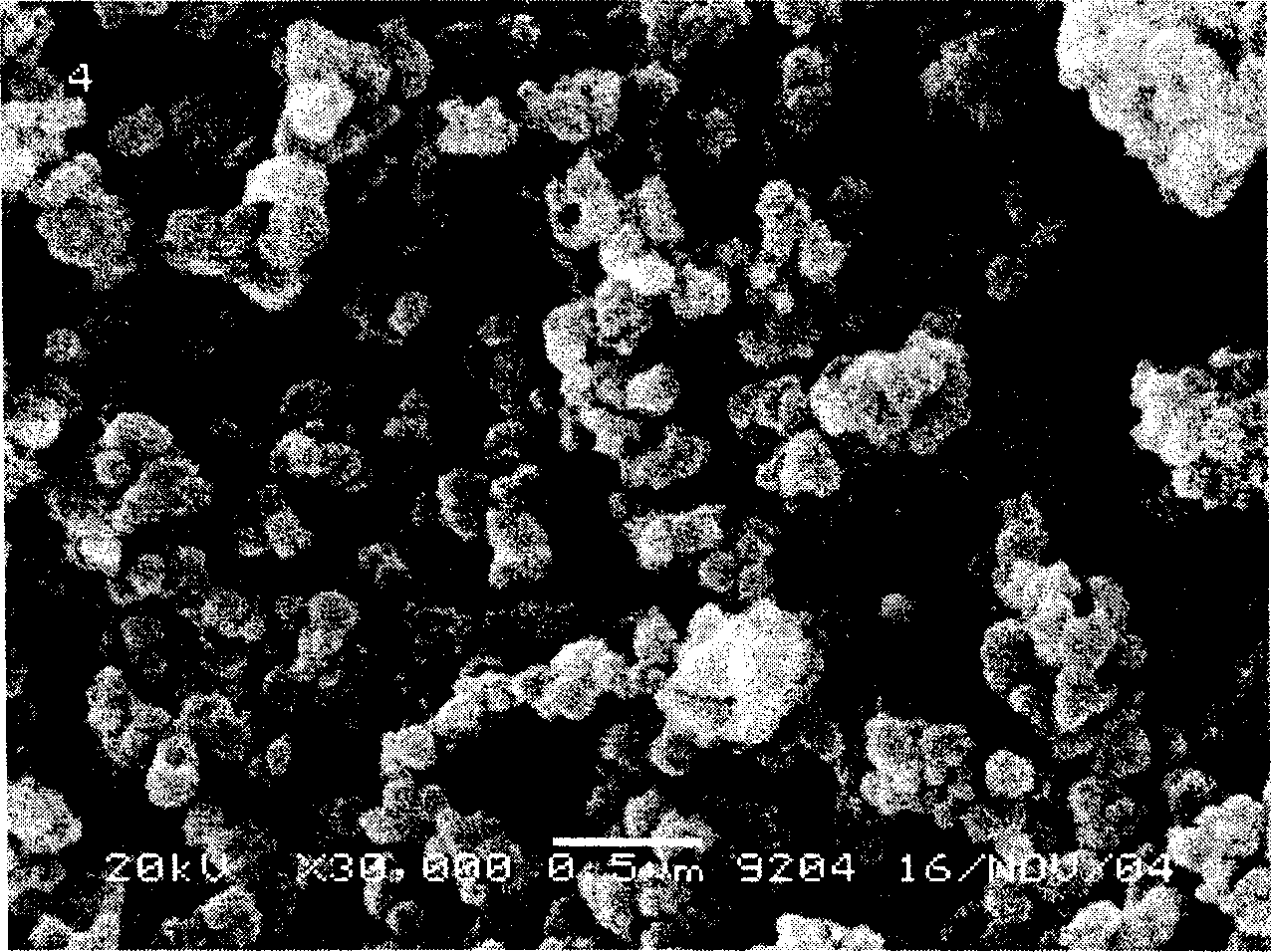

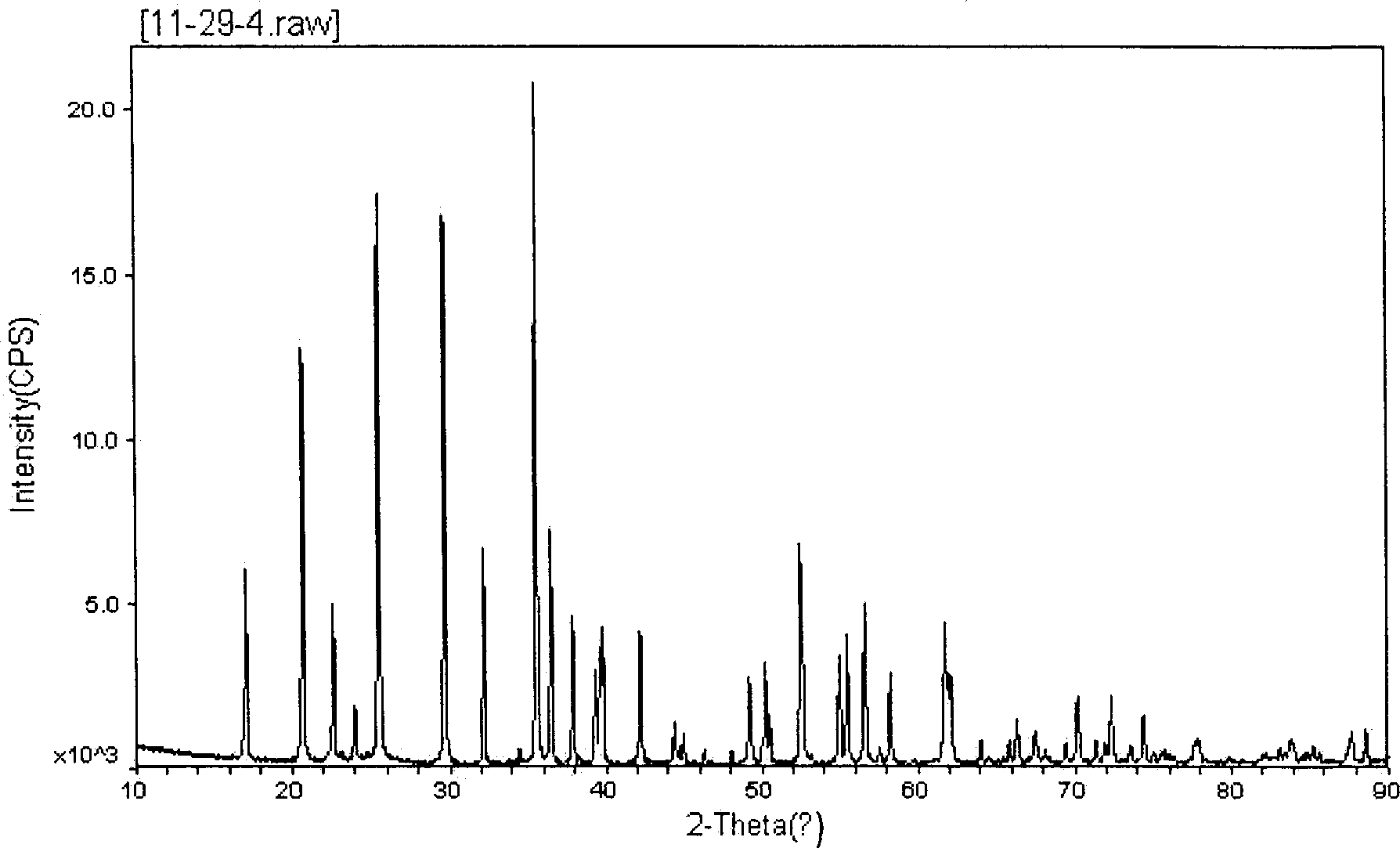

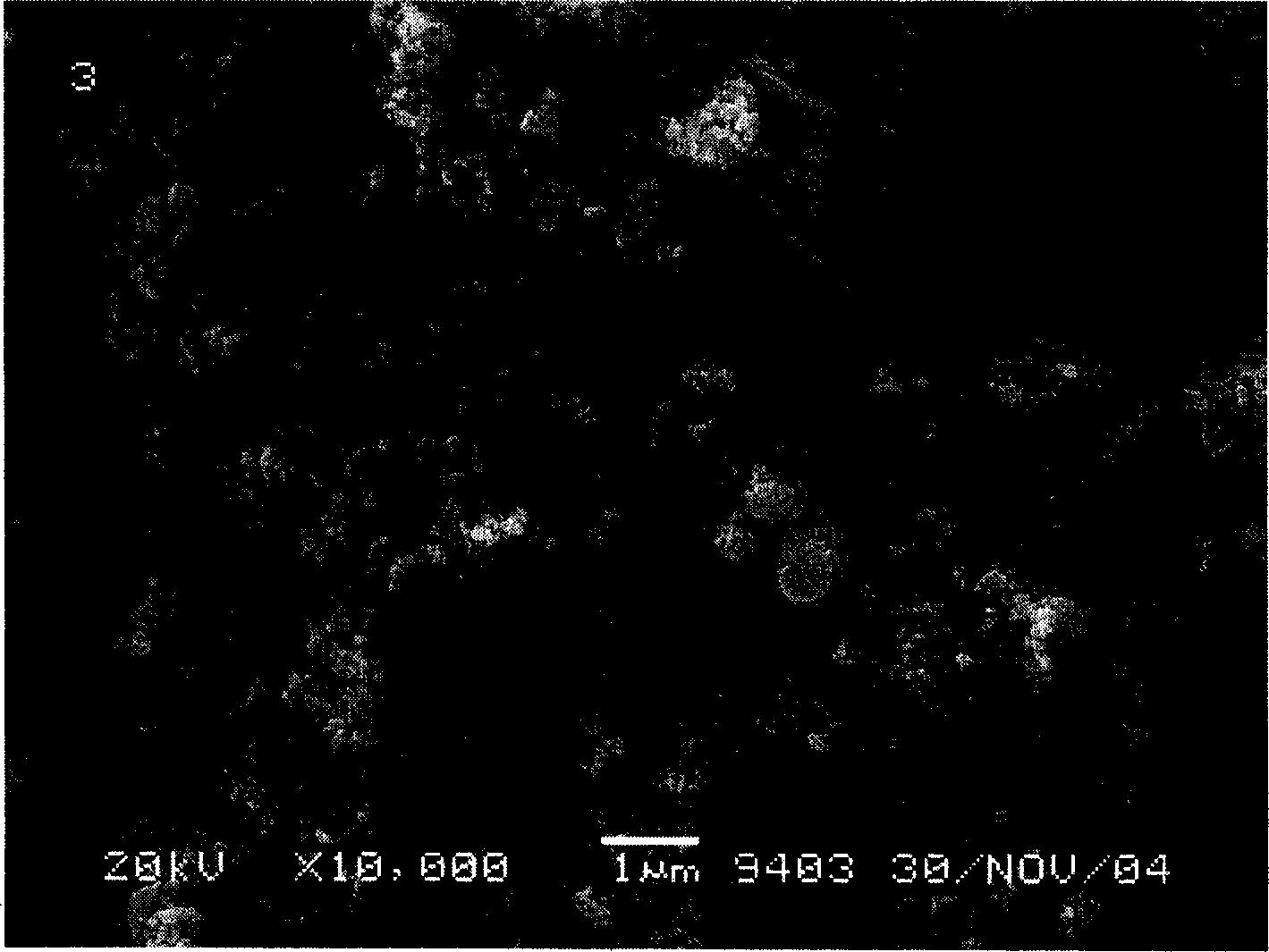

Method of making nanostructured lithium iron phosphate-based powders with an olivine type structure

InactiveUS7390472B1Low costImprove scalabilityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesLithium iron phosphateOlivine

A low cost and scalable processes for producing nanostructured LiFexM1-xPO4 and nanostructured LiFexM1-xPO4 / C composite powders, where 1≦x≦0.1 and M is a metal cation, such as Mn, Co, Ni, and V. Electronics made of either nanostructured LiFexM1-xPO4 powders or nanostructured LiFexM1-xPO4 / C composite powders exhibit good electrochemical properties. The electronic conductivity of nanostructured LiFexM1-xPO4 powders is enhanced by intimately mixing them with ultrafine carbon particles. Thus, the use of nanostructured LiFexM1-xPO4 / C composite powders will lead to high power density, low cost and environmentally friendly rechargeable Li-ion batteries.

Owner:NORTHERN ENG IND PLC

Making method for nano LiFePO4-carbon composite cathode material

InactiveCN101106189AStable structureImprove cycle stabilityElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesElectricity

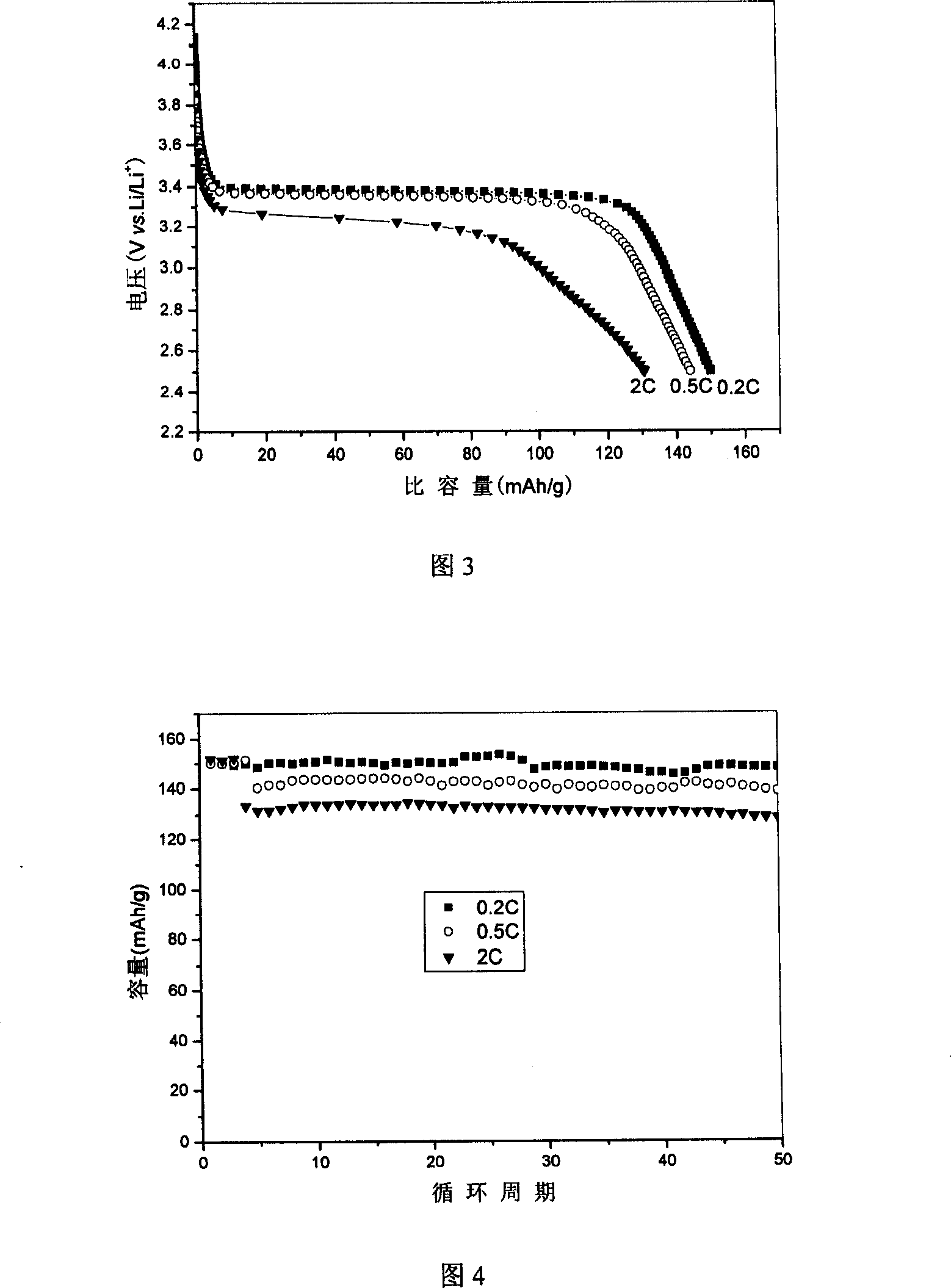

The invention relates to a method for preparing a nano-ferrous lithium phosphate-carbon compound positive material, which is characterized in that based on the ethers organic solvent system and by a sol-process of precursor materials, the mixture at the molecular level of Fe3+, Li+1 and PO42- is realized, and then the technology of low-temperature sintering is used to prepare. Ferrous lithium phosphate in the prepared compound material is in an olivine type with carbon wrapping outside in an amorphous form and the particle size of 45-60nm, and a stable charging and discharging voltage platform at 3.4V is provided, and the charging-discharging capacity under the current of 2C can reach to 133mAh / g. The invention is characterized by simple technique, environment-friendly performance and so on.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Cathode materials for secondary (rechargeable) lithium batteries

InactiveUS20050003274A1Cell electrodesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlkali ionsRechargeable cell

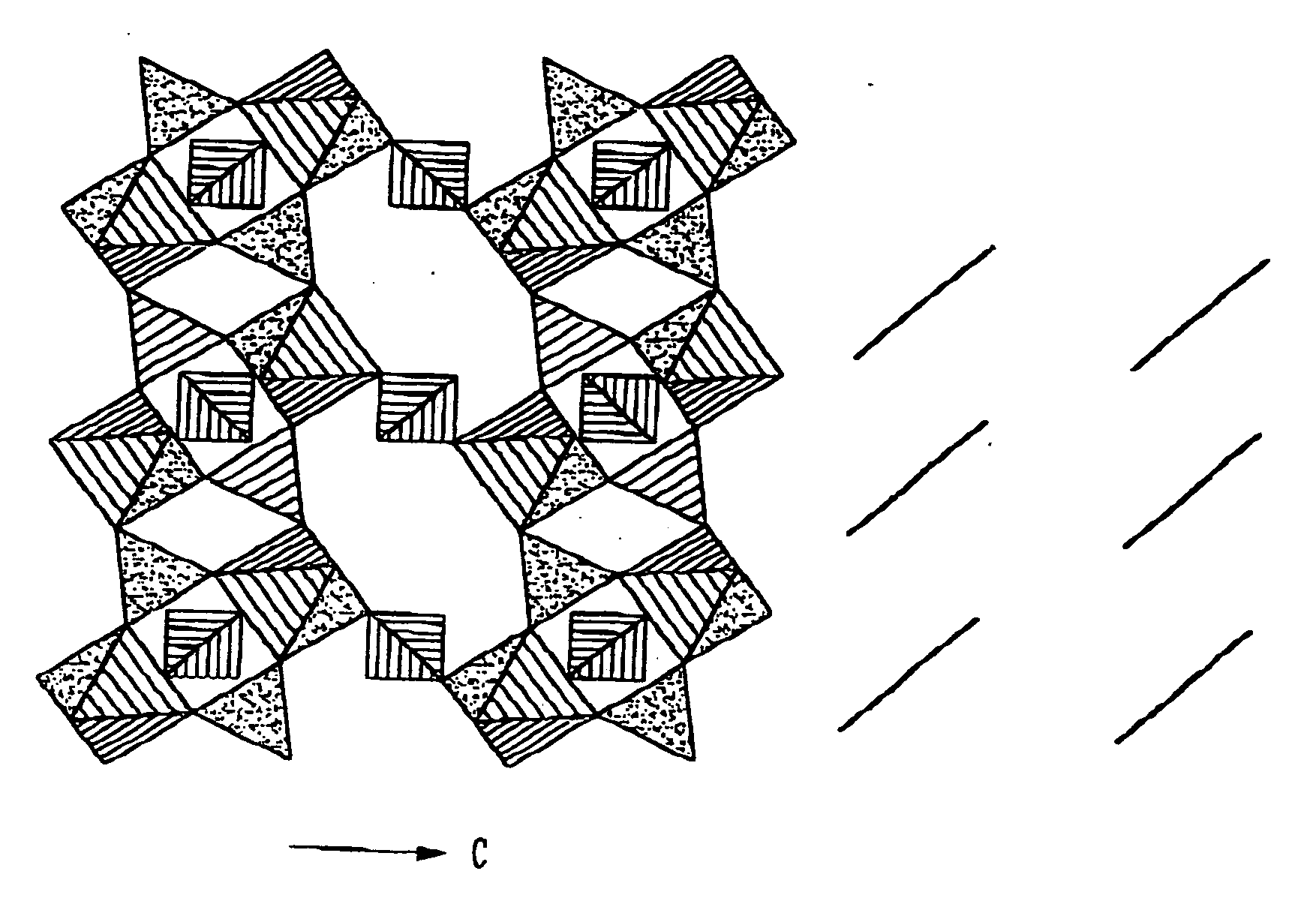

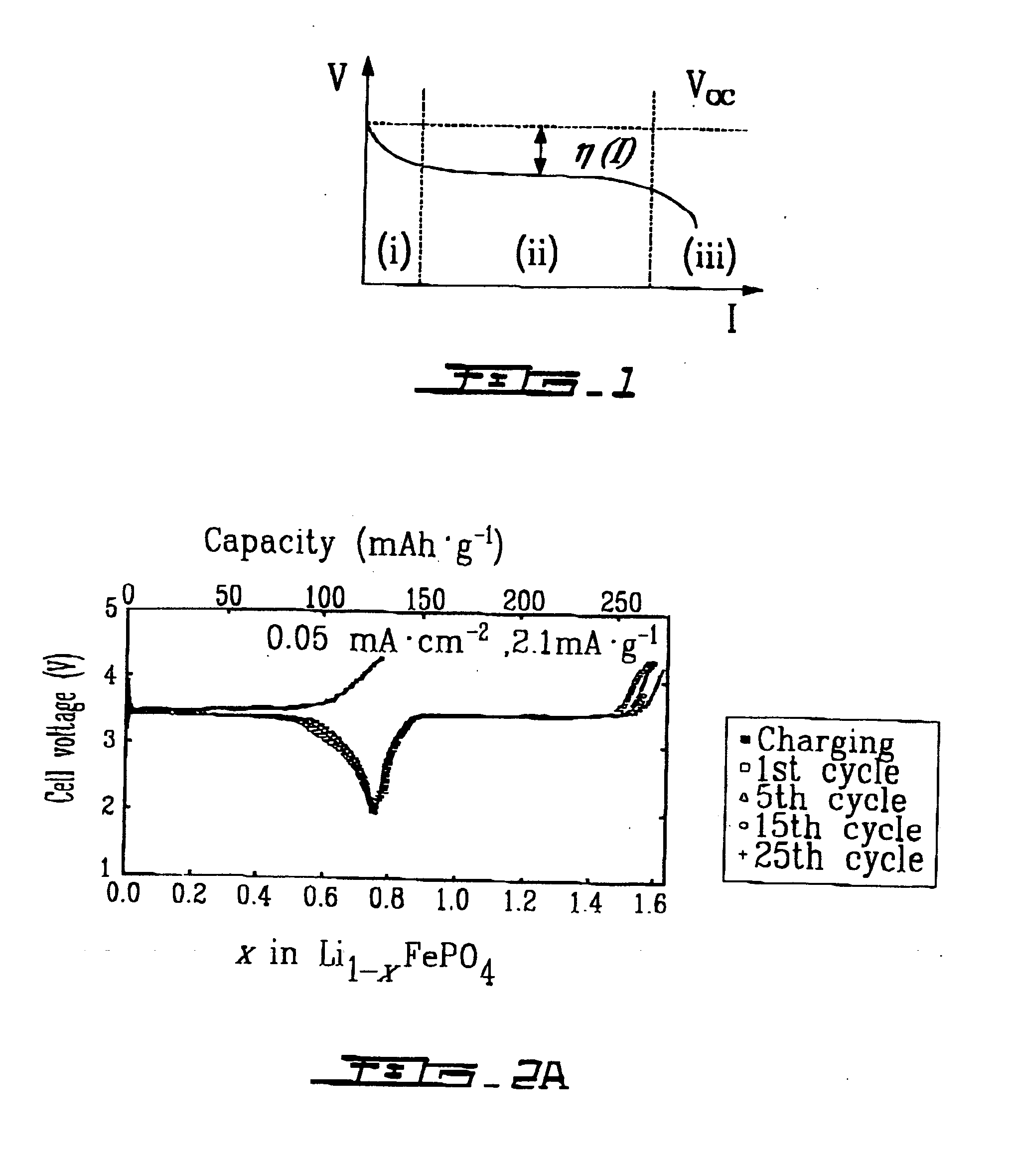

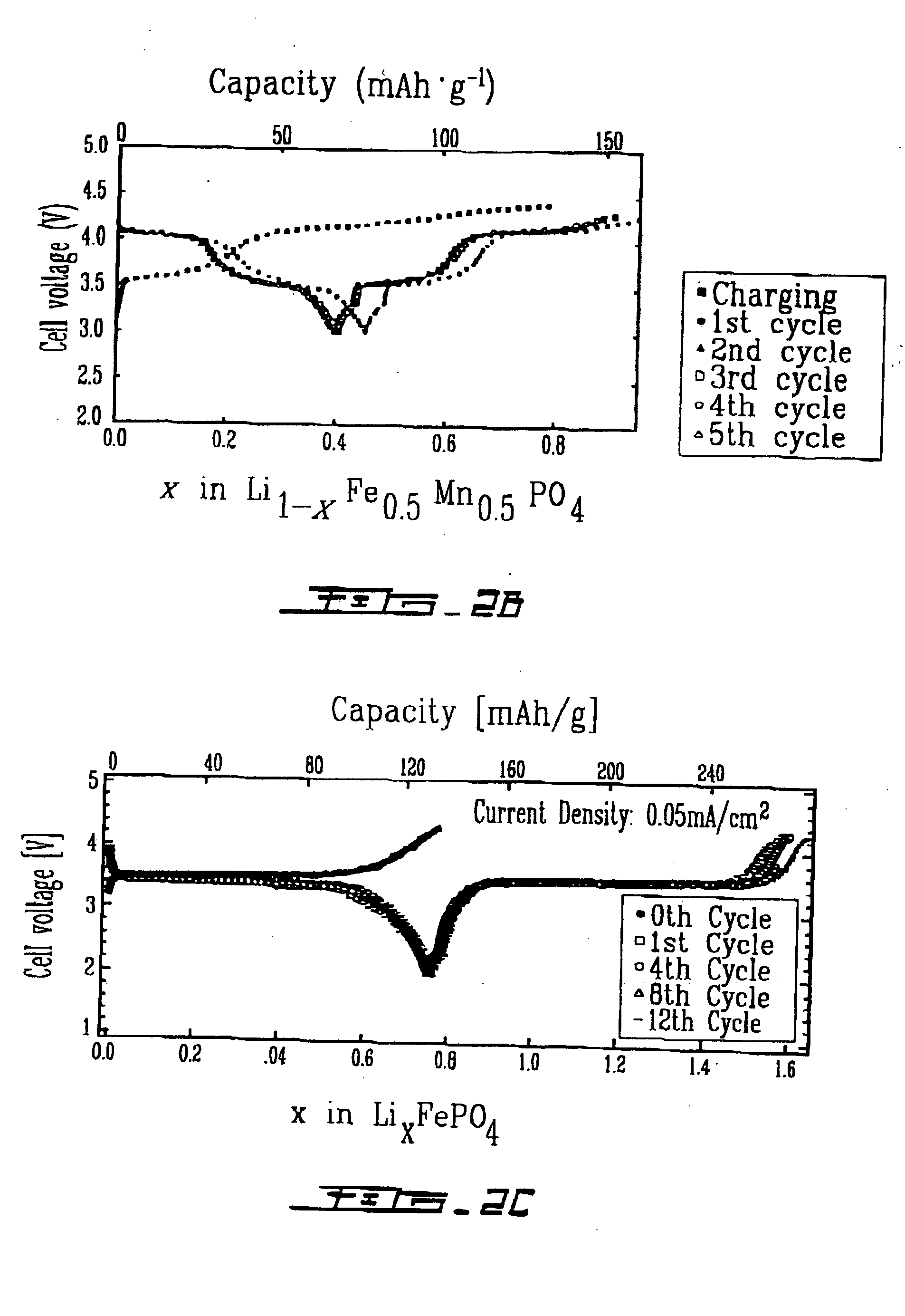

The invention relates to materials for use as electrodes in an alkali-ion secondary (rechargeable) battery, particularly a lithium-ion battery. The invention provides transition-metal compounds having the ordered-olivine, a modified olivine, or the rhombohedral NASICON structure and the polyanion (PO4)3− as at least one constituent for use as electrode material for alkali-ion rechargeable batteries.

Owner:HYDRO QUEBEC CORP

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

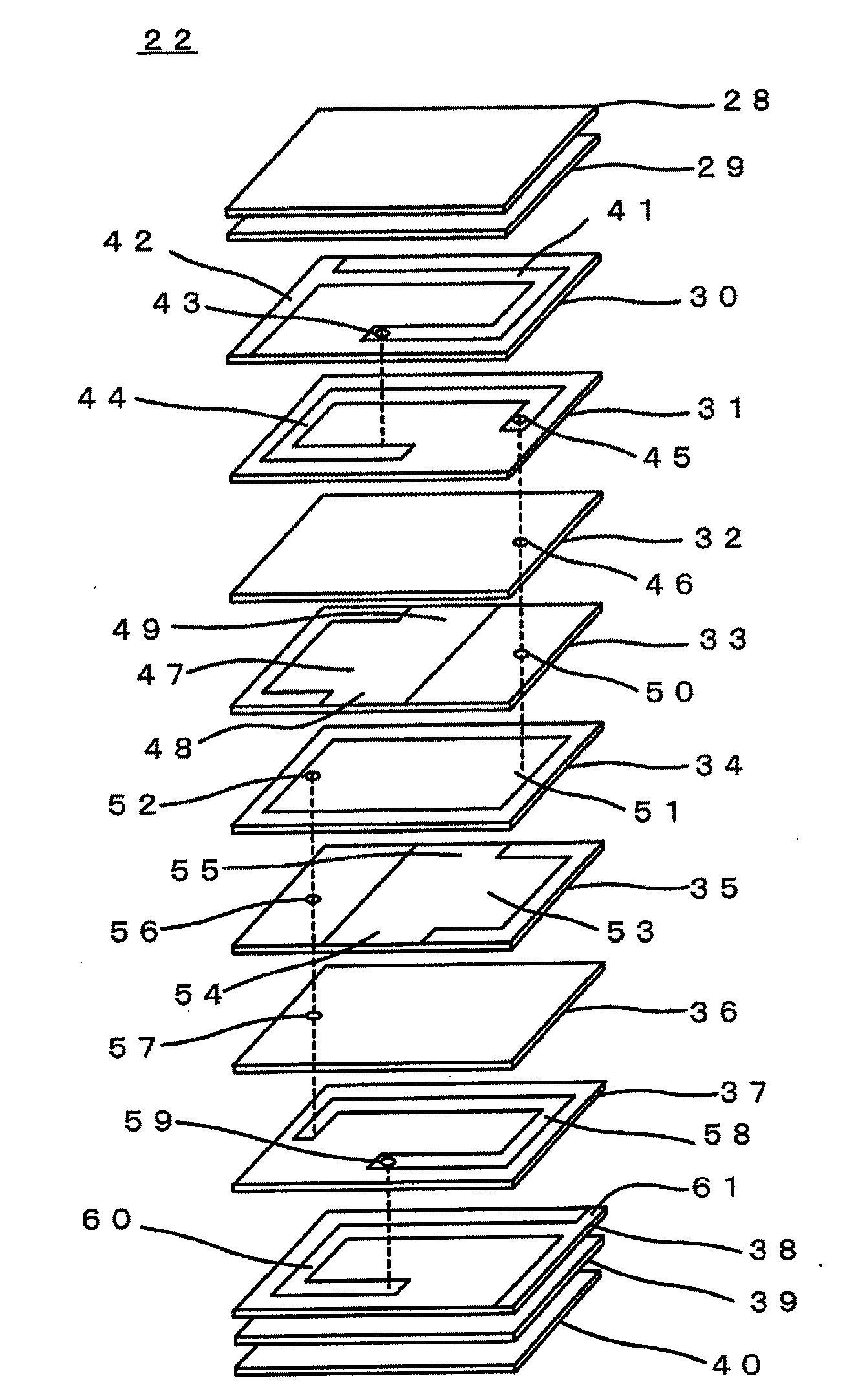

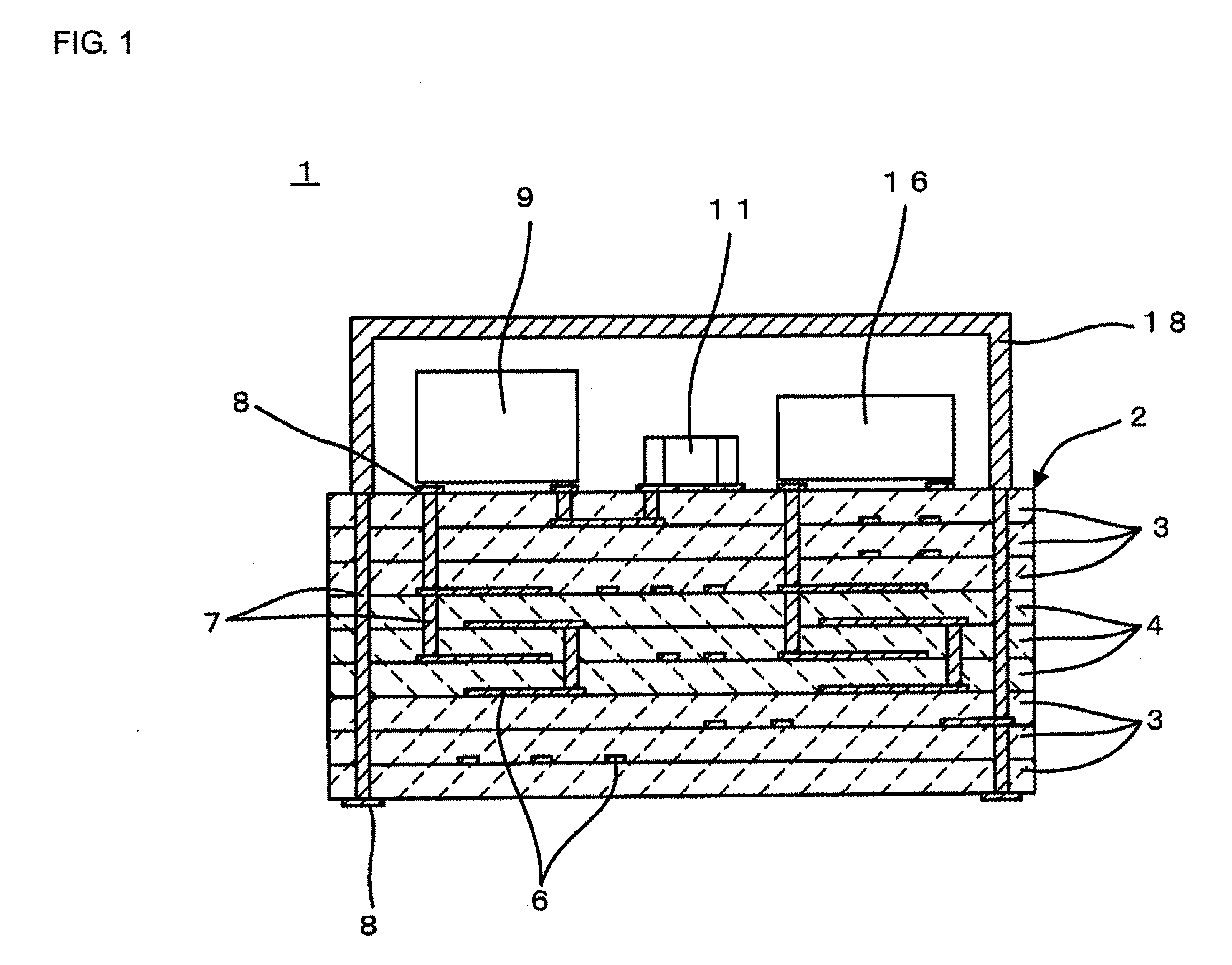

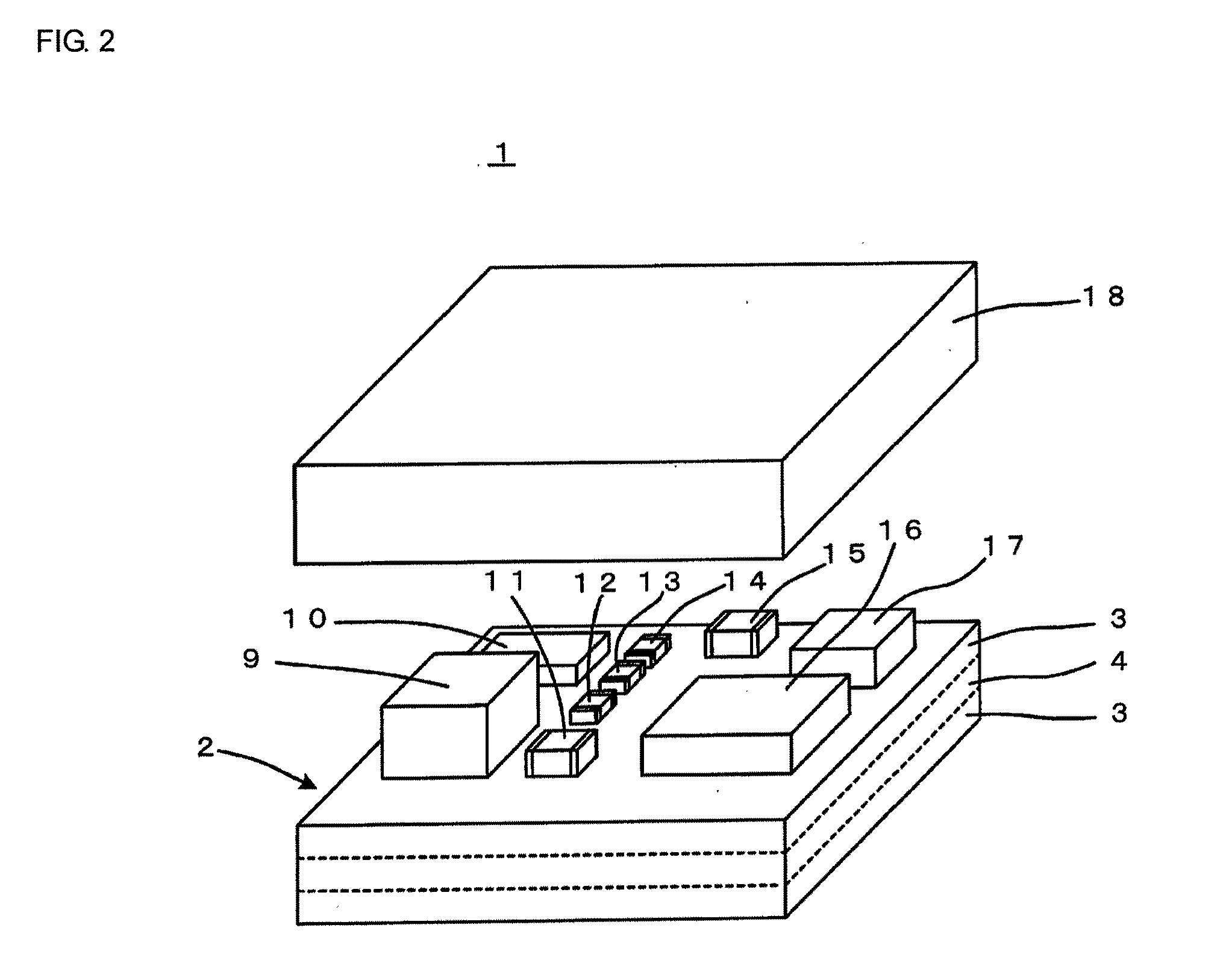

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

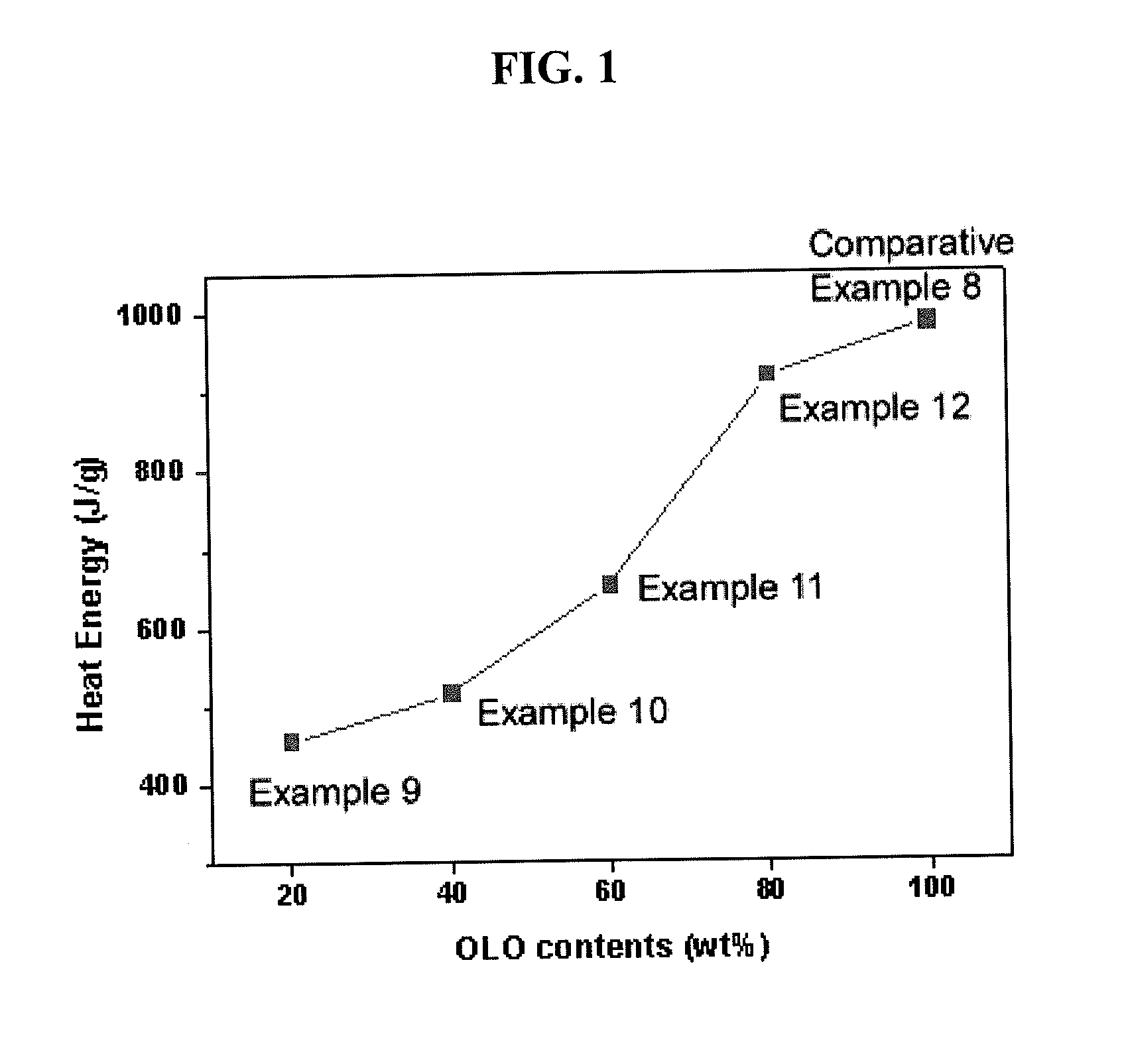

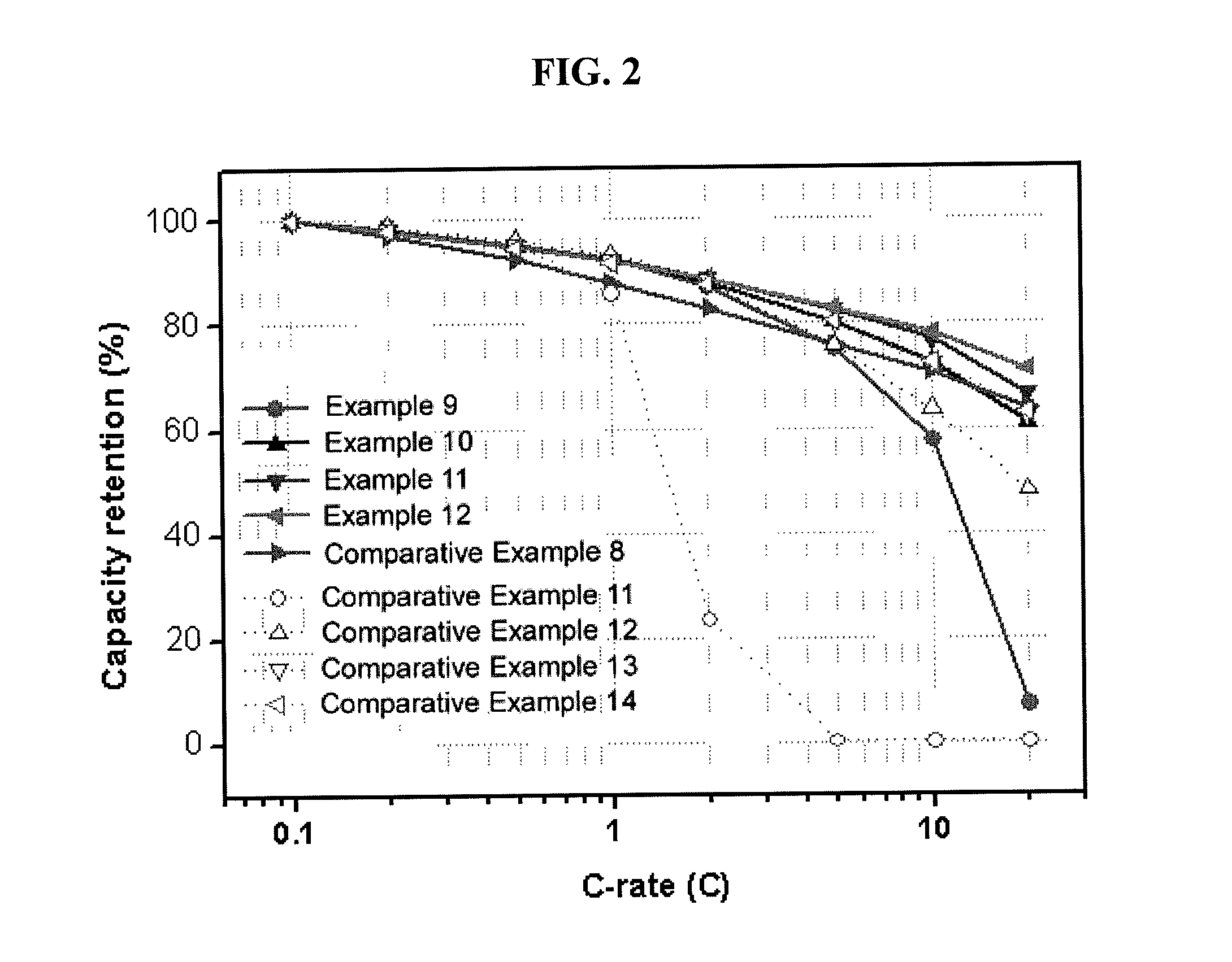

Composite cathode active material, and cathode and lithium battery including the material

A composite cathode active material including an overlithiated metal oxide having a layered structure, a material having an olivine structure, and one or more of: an inorganic material, and nitrogen atoms doped in the material having an olivine structure. The inorganic material includes a nitride or carbide of a non-transition metal. The composite cathode active material may be included in a cathode, and the cathode may be included in a lithium battery.

Owner:SAMSUNG SDI CO LTD

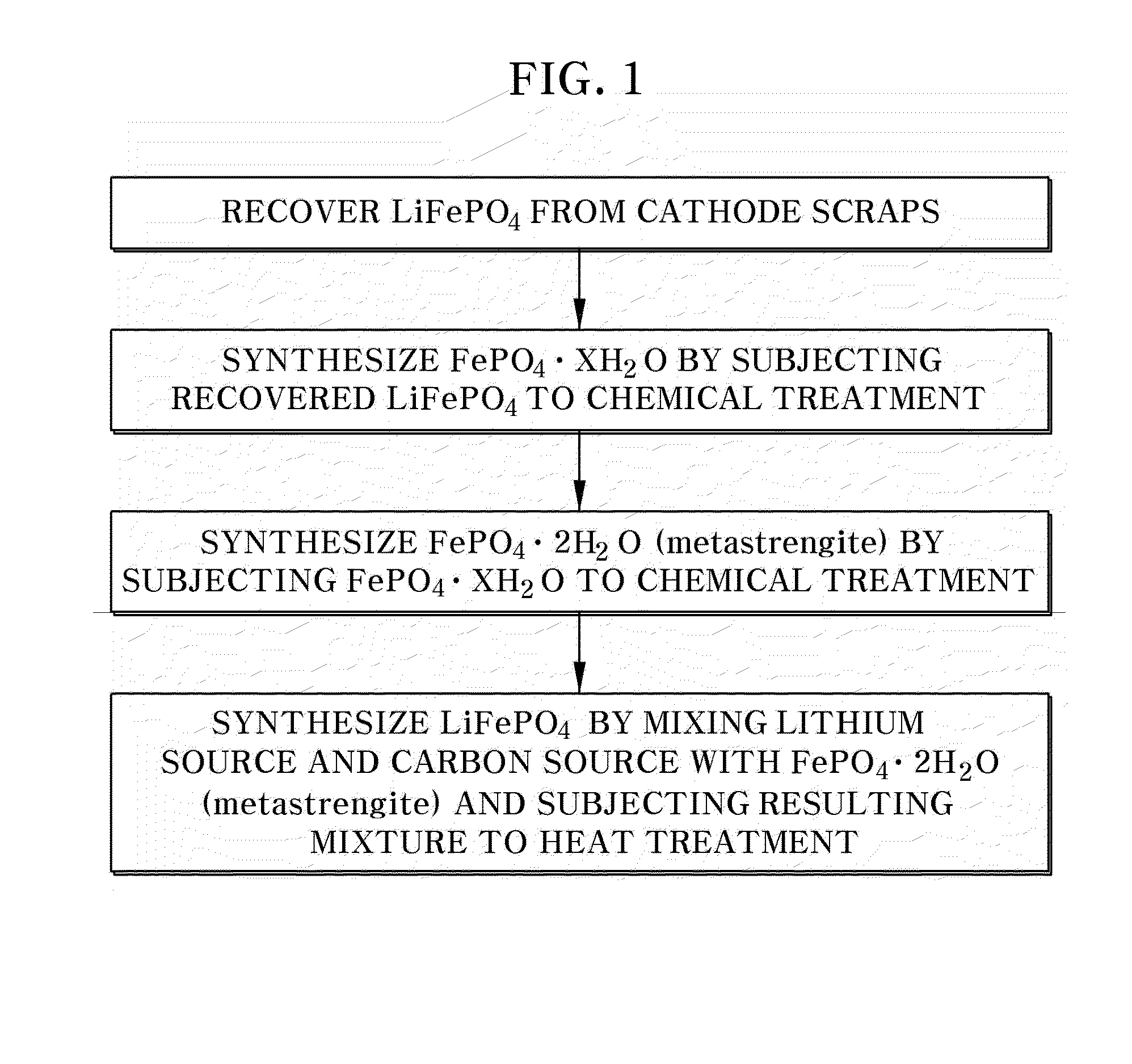

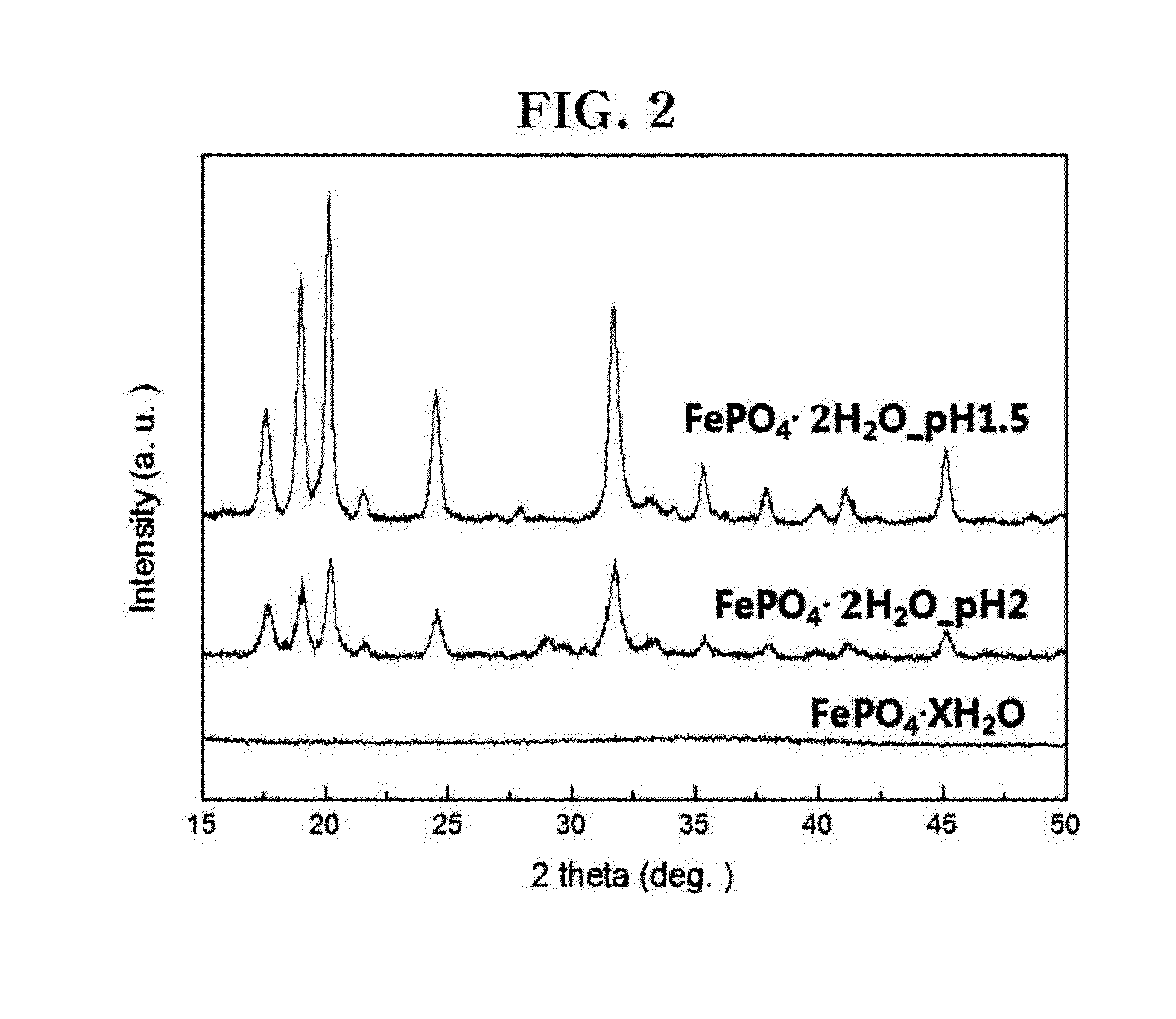

Recycling method of olivine-based cathode material for lithium secondary battery, cathode material fabricated therefrom, and cathode and lithium secondary battery including the same

ActiveUS20140264185A1Deterioration in performanceReduce manufacturing costNon-metal conductorsPhosphatesCycle efficiencyOlivine

Owner:KOREA INST OF SCI & TECH

Porous refractory material and preparation method thereof

InactiveCN105481464ALow costSimple process equipmentSolid waste disposalCeramicwarePorosityThermal insulation

The invention relates to a porous refractory material and a preparation method, and relates to the technical field of refractor materials. The preparation method is characterized in that fly ash and a natural mineral material magnesite are adopted as main raw materials; and the porous refractory material is prepared through the processes such as blending and mixing, molding, drying, sintering and the like. Among the raw materials, the addition amount of fly ash is 10.0-90.0wt%, the addition amount of magnesite is 5.0-85.0wt%, the addition amount of a pore-forming agent is 5-15.0wt%, and the addition amount of a binding agent is 1-8wt%. A main phase of the porous refractory material prepared through high-temperature sintering is forsterite. The material has the characteristics of high porosity, low volume density, high strength, good thermal insulation effect, low cost and the like. According to the invention, a novel technical approach is provided for high-efficiency value-added exploitation of solid wastes such as fly ash and magnesite.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing olivine structure lithium iron phosphate

InactiveCN1800003ASolve easy oxidationSolve the problem of difficult to mix evenlyPhosphorus compoundsLithium iron phosphateMaterial synthesis

The invention discloses a making method of chrysolite-structured ferric lithium phosphate, which is characterized by the following: mixing the bivalent Fe source compound, P source compound and oxidant at LiFePO4 chemical gauge; controlling the pH value equal to 1-8; filtering; cleaning; drying; generating about 100 nm FePO4 pioneer body; putting the mixture of FePO4 pioneer body and Li source compound and reducer in the furnace; calcining the mixture in the non-oxidized atmosphere to make LiFePO4. The invention prevents the ferrous ion from oxygenizing and difficult blending of raw material, which improves the material synthesis and property to cover the residual carbon on the LiFePO4 particle.

Owner:CENT SOUTH UNIV

Non-aqueous electrolyte secondary battery

InactiveUS20060216605A1Improve poor battery power regeneration performanceGood power regeneration performancePillowsPositive electrodesElectric forceEngineering

In a non-aqueous electrolyte secondary battery employing an olivine-type lithium phosphate as a positive electrode active material, power regeneration performance is improved. The non-aqueous electrolyte secondary battery for use as a power source for regenerative charging includes: a positive electrode including a mixture layer containing a positive electrode active material, a binder agent, and a carbon material as a conductive agent; a negative electrode; and a non-aqueous electrolyte. The mixture layer contains, as the positive electrode active material, an olivine-type lithium phosphate represented by the formula LiMPO4, where M is at least one element selected from the group consisting of Co, Ni, Mn, and Fe, and the mixture layer further contains a metal oxide such as a lithium-containing transition metal oxide containing at least Ni or Mn.

Owner:SANYO ELECTRIC CO LTD

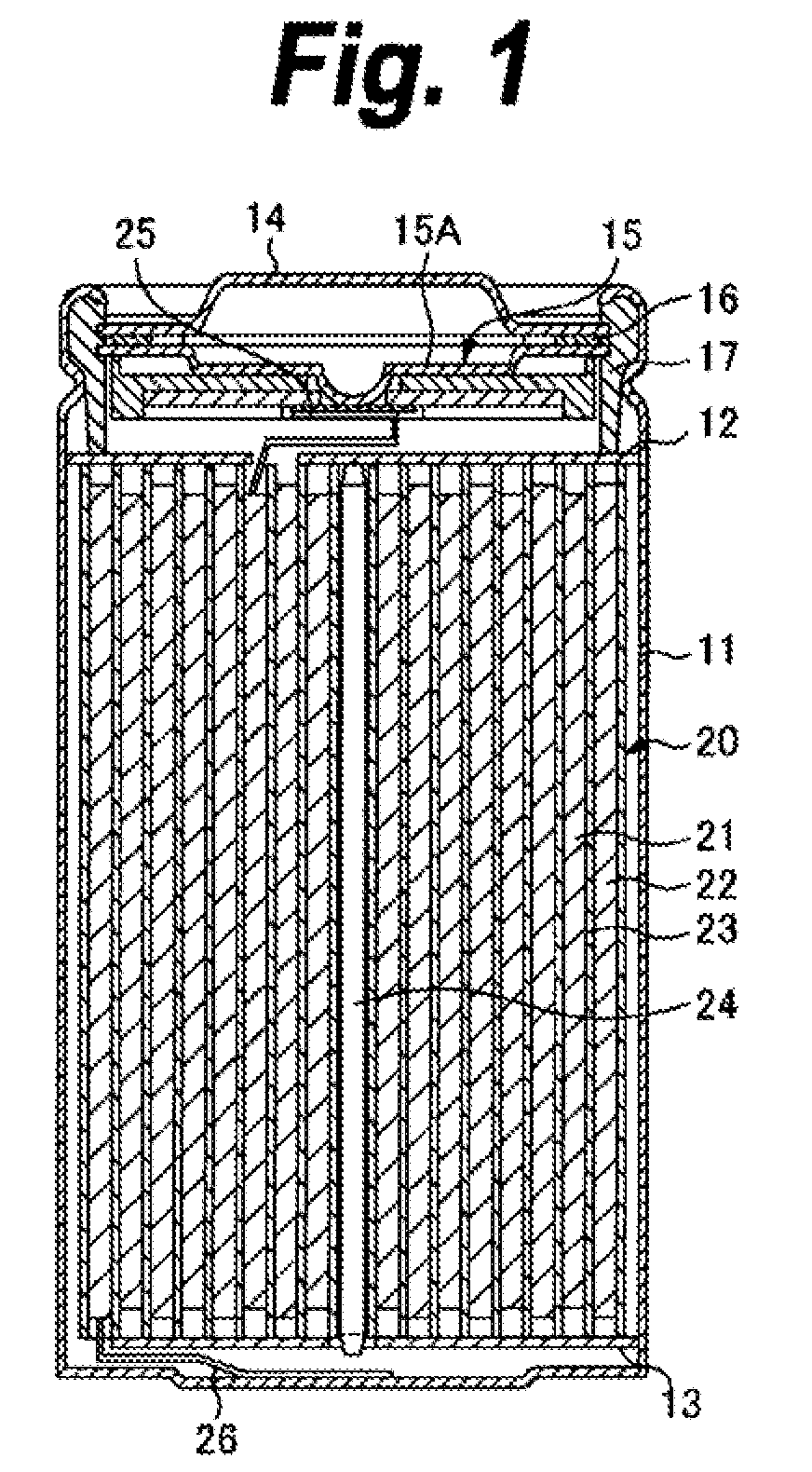

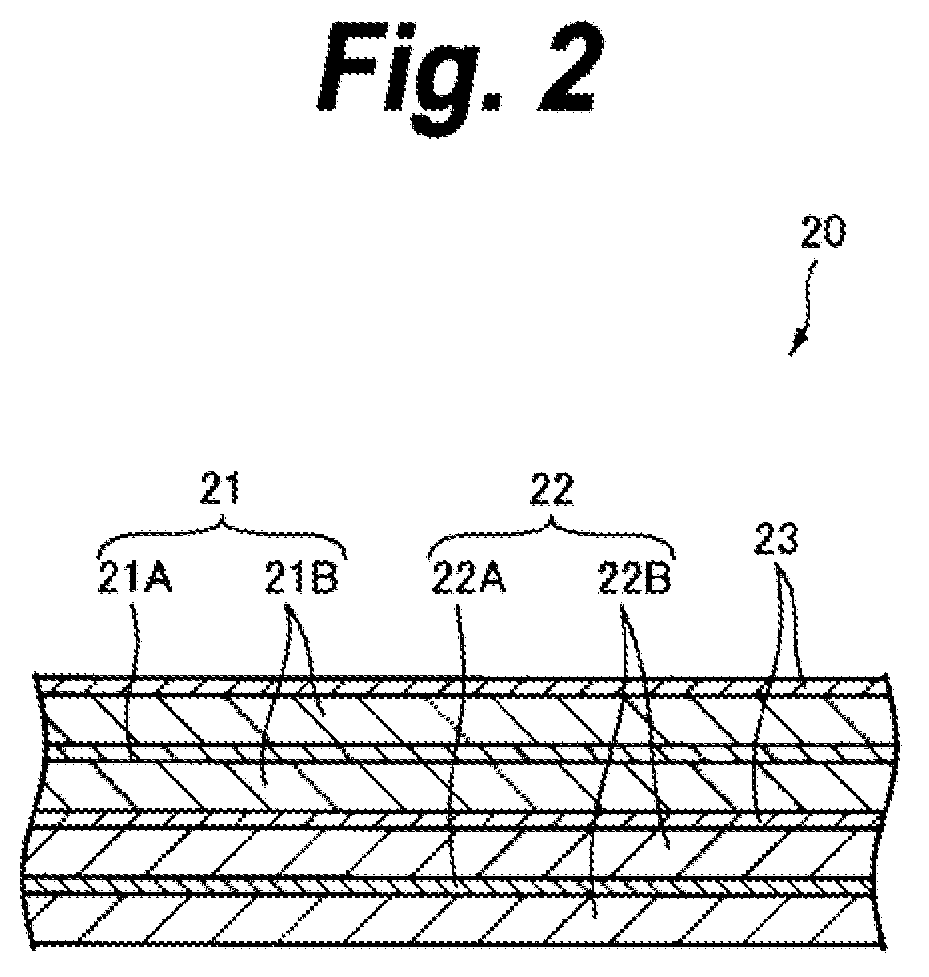

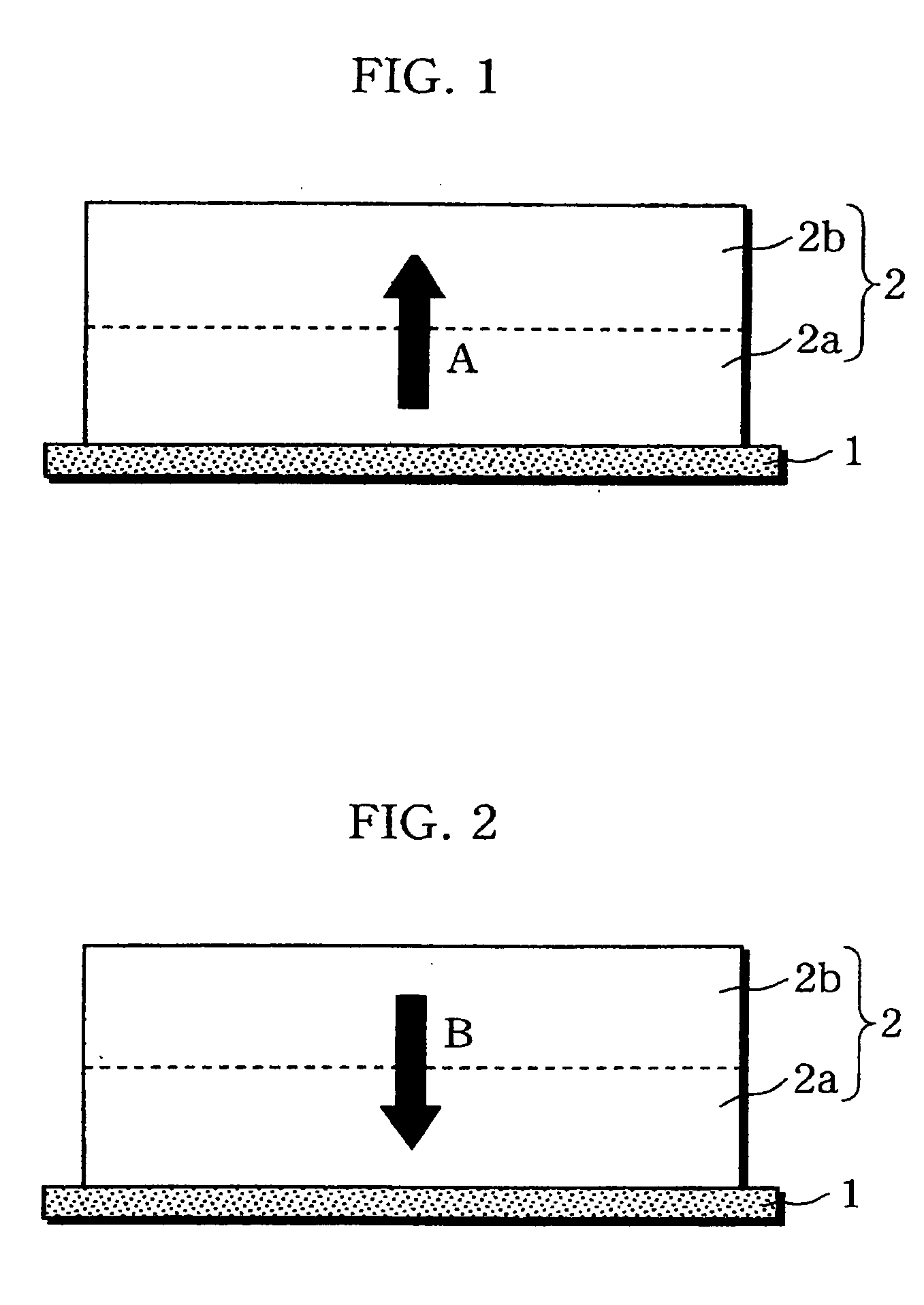

Non-aqueous electrolyte battery

InactiveUS20070026316A1Improve thermal conductivityImprove thermal stabilityNon-aqueous electrolyte accumulatorsActive material electrodesEngineeringLITHIUM PHOSPHATE

A non-aqueous electrolyte battery is provided that achieves an improvement in safety, particularly an improvement in tolerance of the battery to overcharging, and also prevents discharge capacity from degrading, without compromising conventional battery designs considerably. The non-aqueous electrolyte battery has a positive electrode including a positive electrode active material-layer stack and a positive electrode current collector, a negative electrode including a negative electrode active material layer, and a separator interposed between the electrodes. The positive electrode active material-layer stack has two layers respectively having different positive electrode active materials. Of the two layers, a first positive electrode active material layer (11) that is nearer the positive electrode current collector (16) contains an olivine-type lithium phosphate compound as its positive electrode active material and uses VGCF (18) as a conductivity enhancing agent.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com