Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

536 results about "Aluminium-ion battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

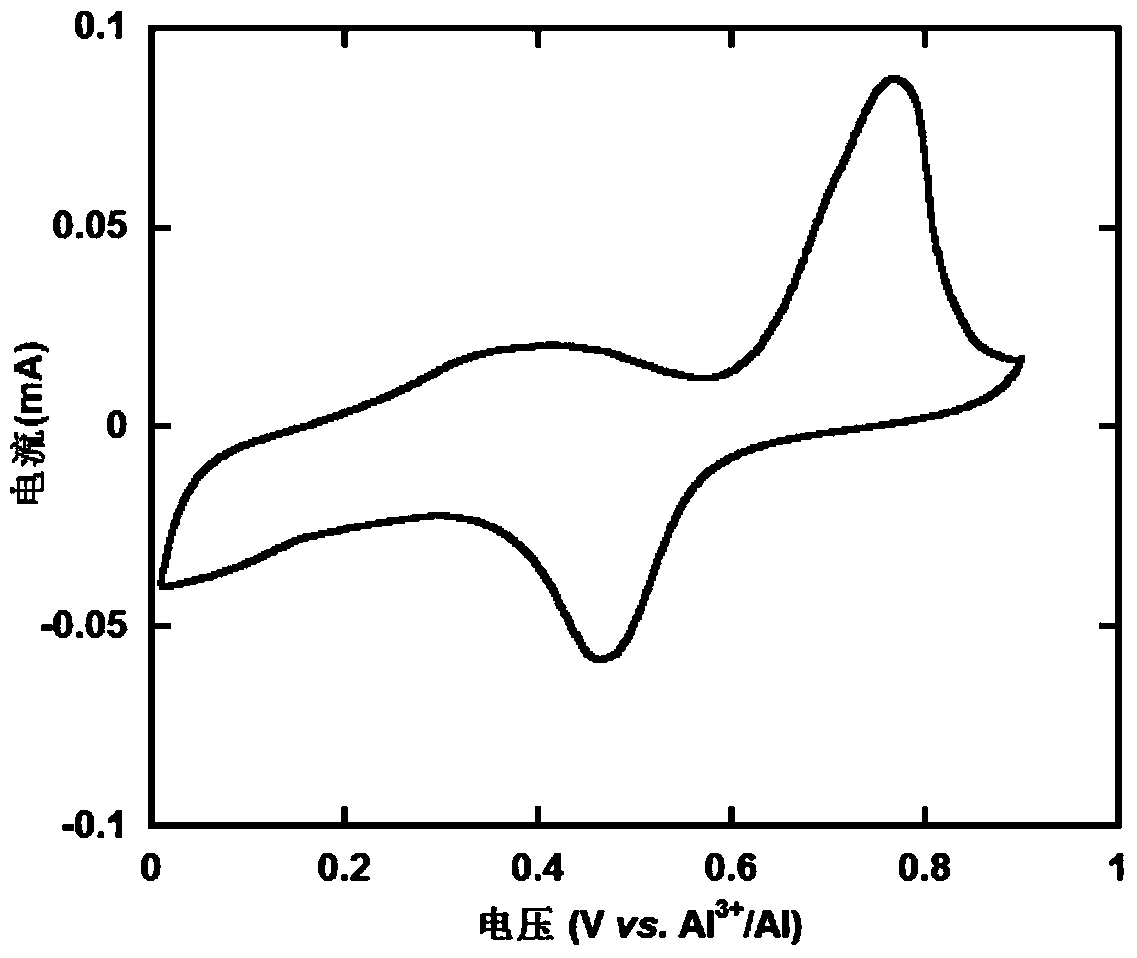

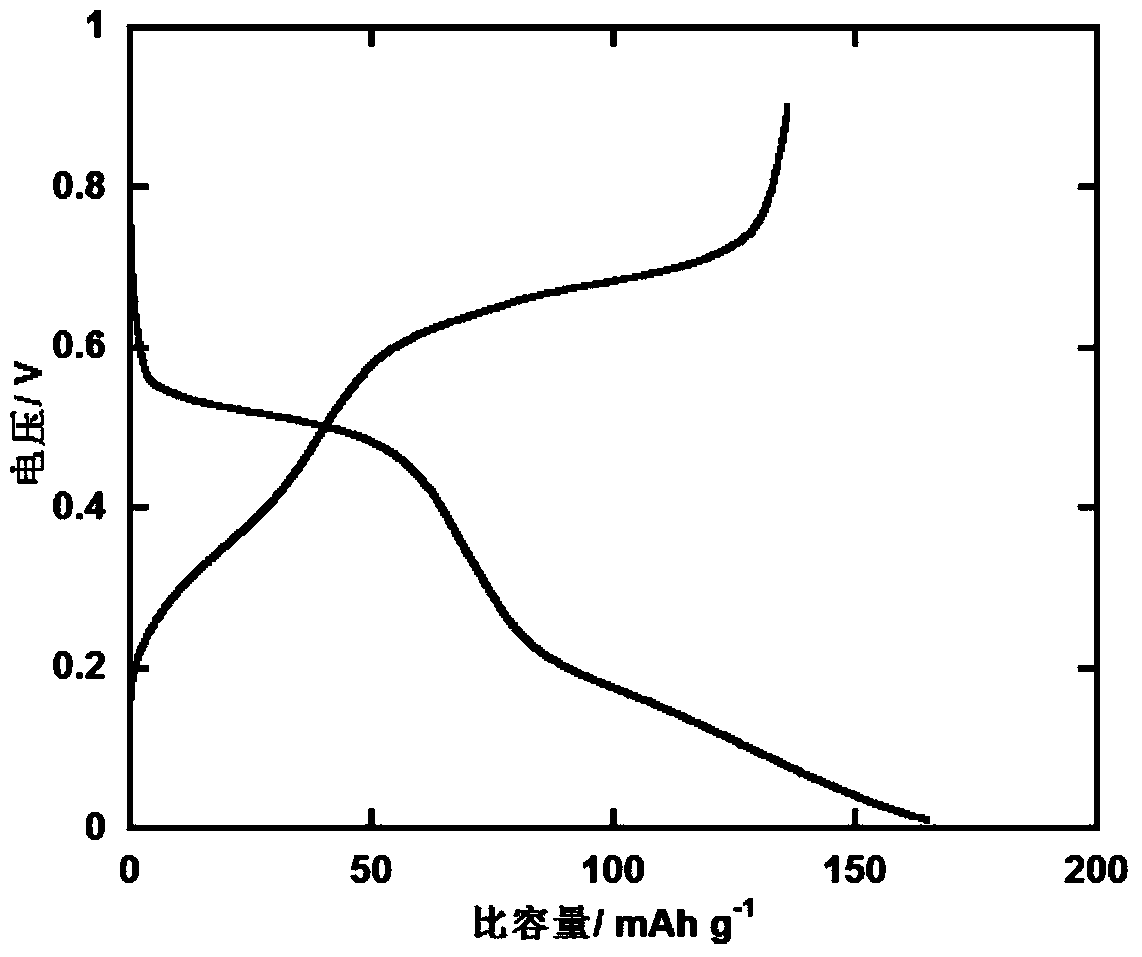

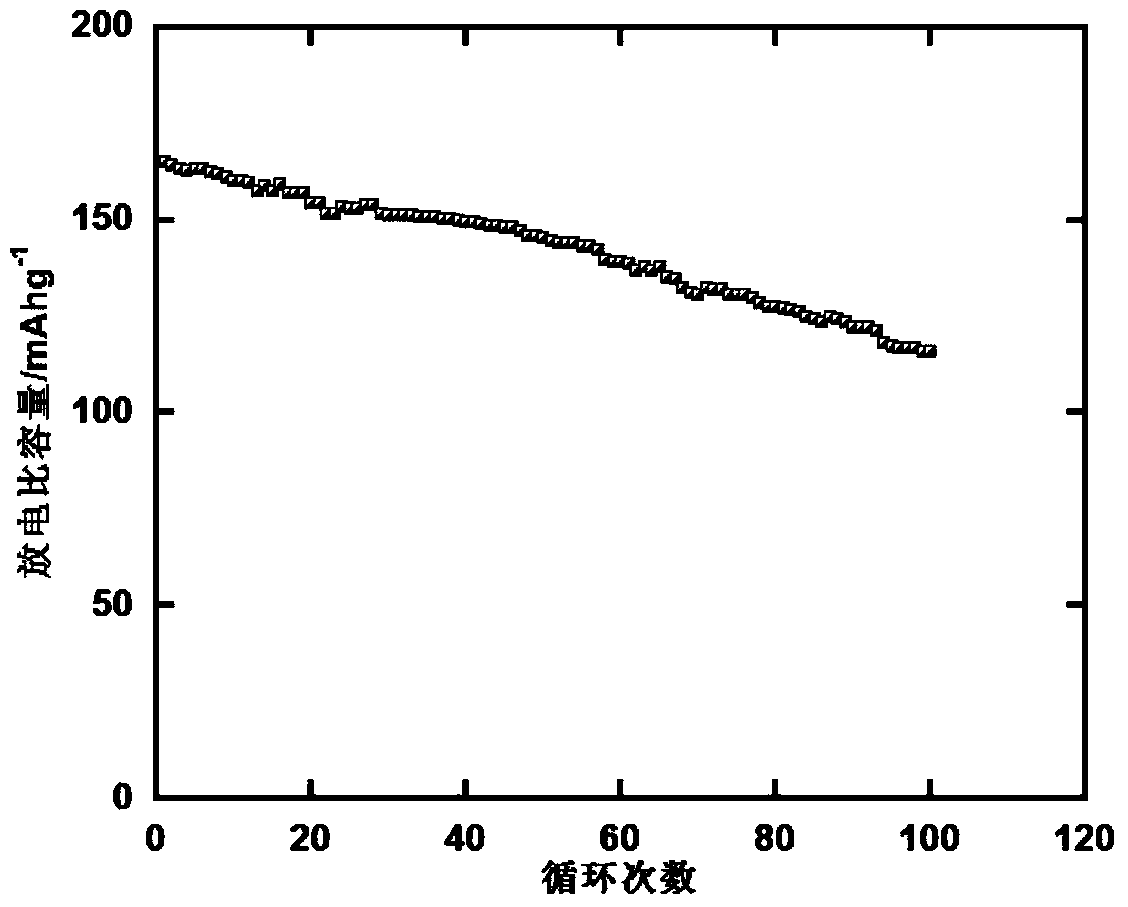

Aluminium-ion batteries are a class of rechargeable battery in which aluminium ions provide energy by flowing from the negative electrode of the battery, the anode, to the positive electrode, the cathode. When recharging, aluminium ions return to the negative electrode, and can exchange three electrons per ion. This means that insertion of one Al³⁺ is equivalent to three Li⁺ ions in conventional intercalation cathodes. Thus, since the ionic radii of Al³⁺ (0.54 A) and Li⁺ (0.76 A) are similar, significantly higher models of electrons and Al³⁺ ions can be accepted by the cathodes without much pulverization. The trivalent charge carrier, Al³⁺ is both the advantage and disadvantage of this battery. While transferring 3 units of charge by one ion significantly increase the energy storage capacity but the electrostatic intercalation of the host materials with a trivalent cation is too strong for well-defined electrochemical behaviour.

Man-made graphite cathode material for lithium ion battery and its making method

ActiveCN101087021AImprove discharge capacityPromote circulationCell electrodesAluminium-ion batteryElectrical battery

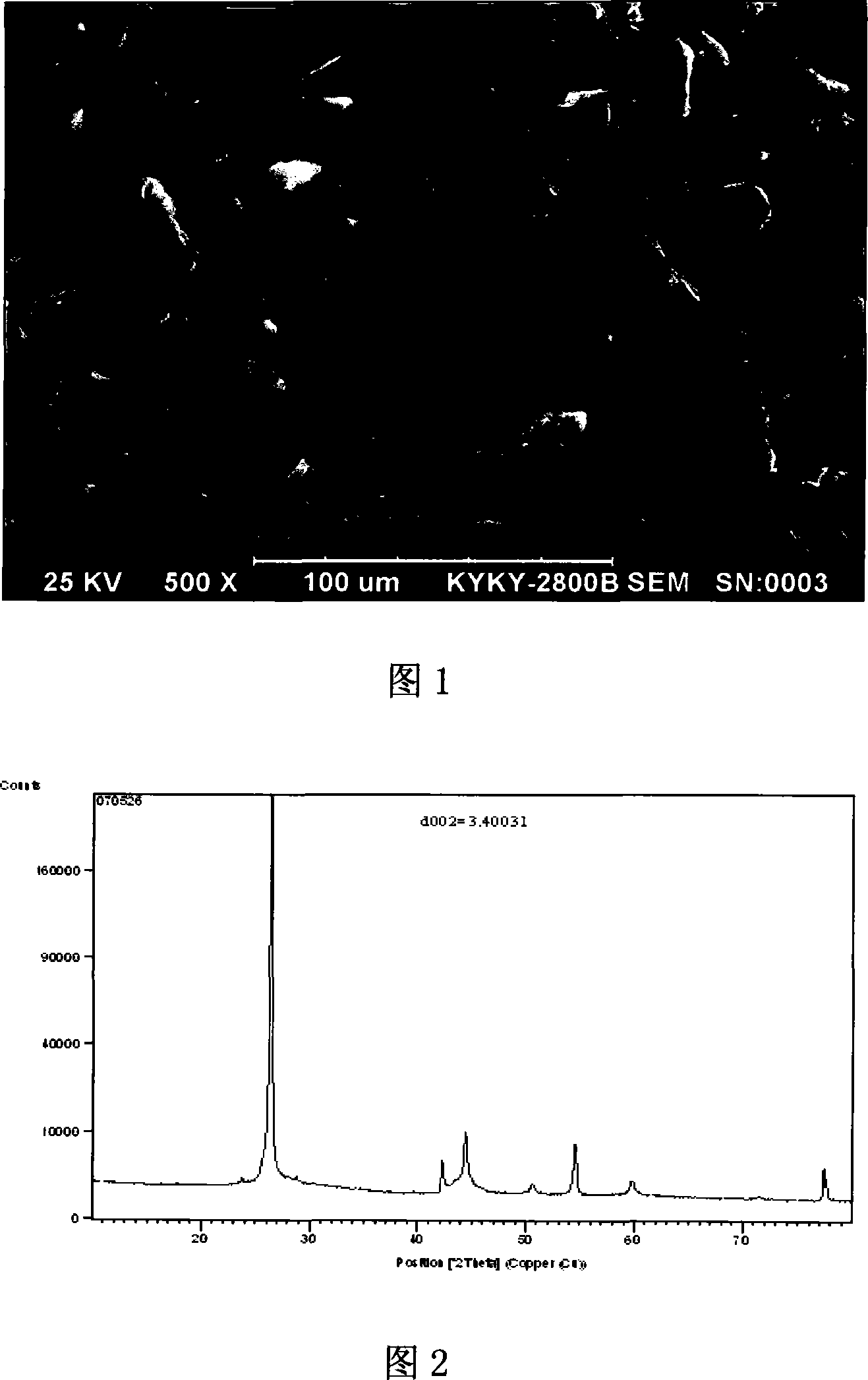

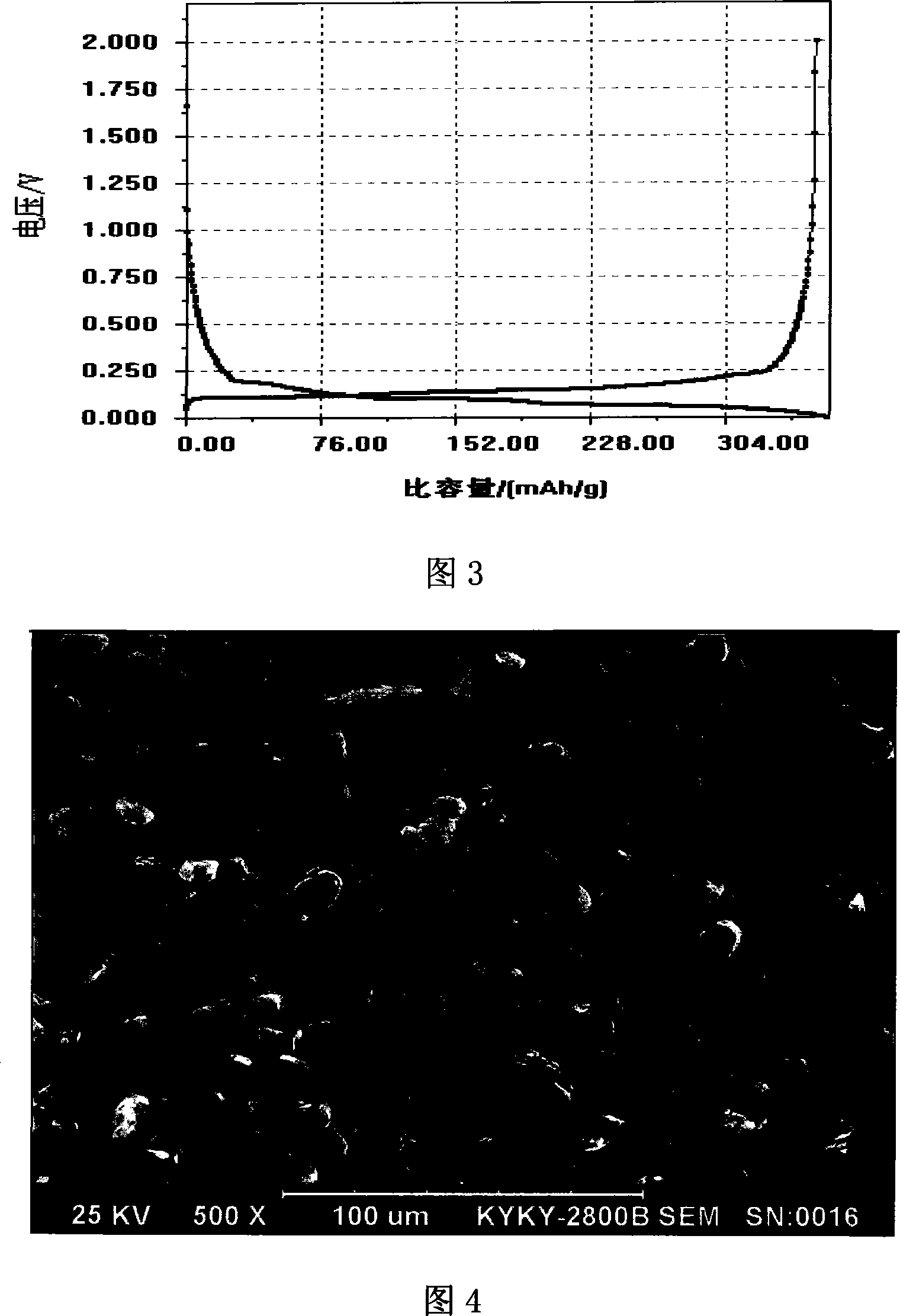

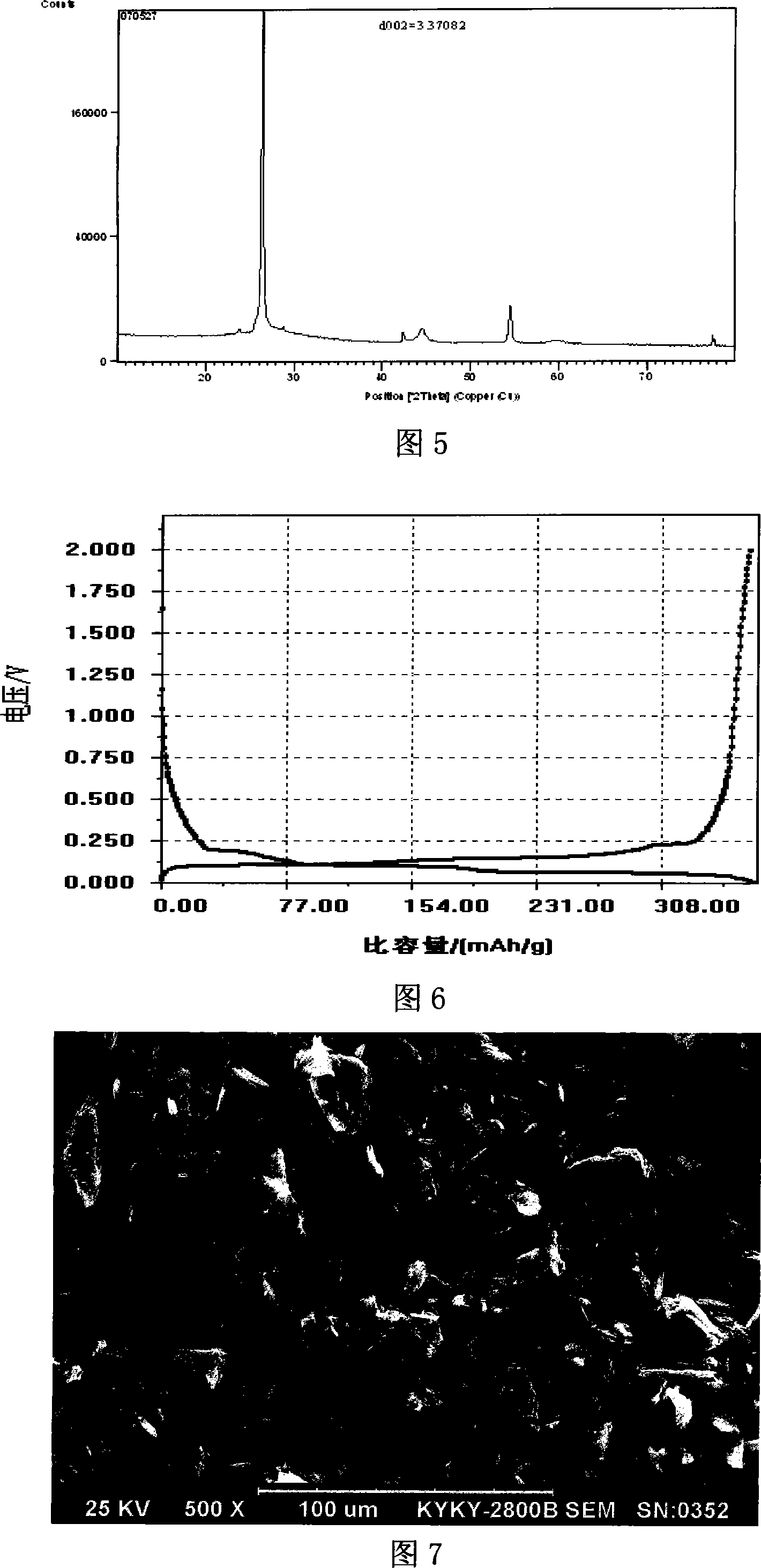

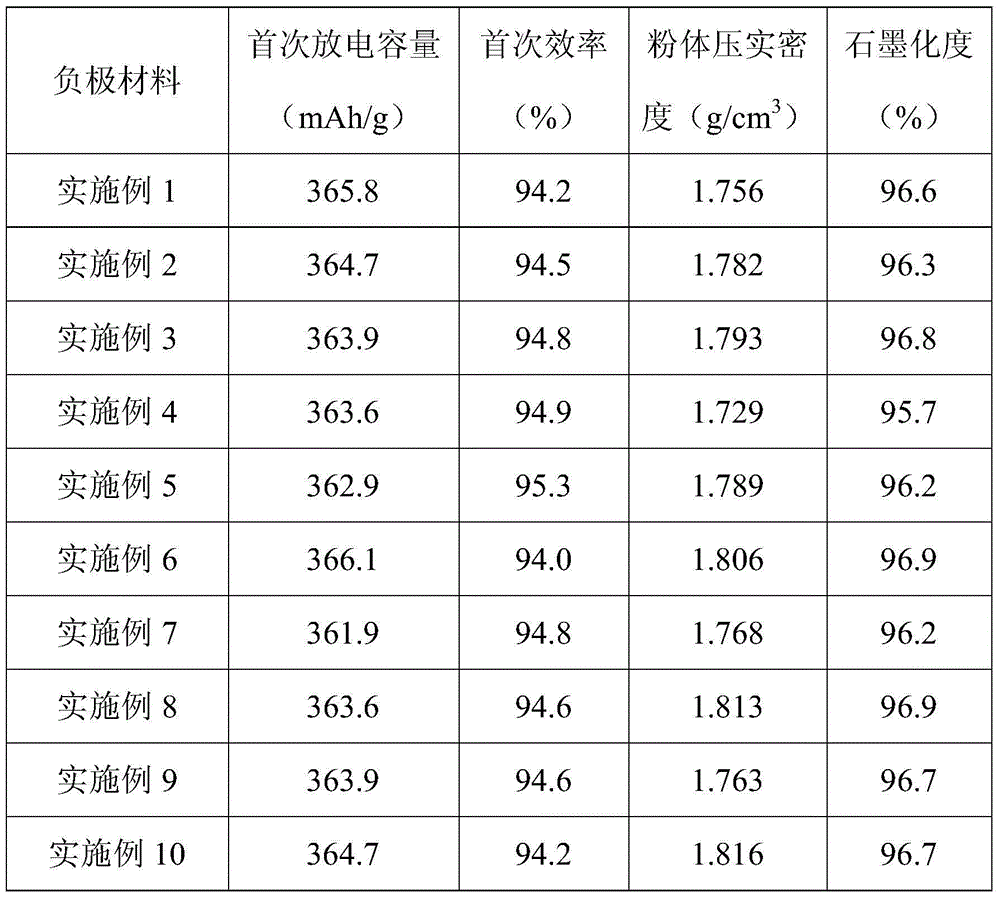

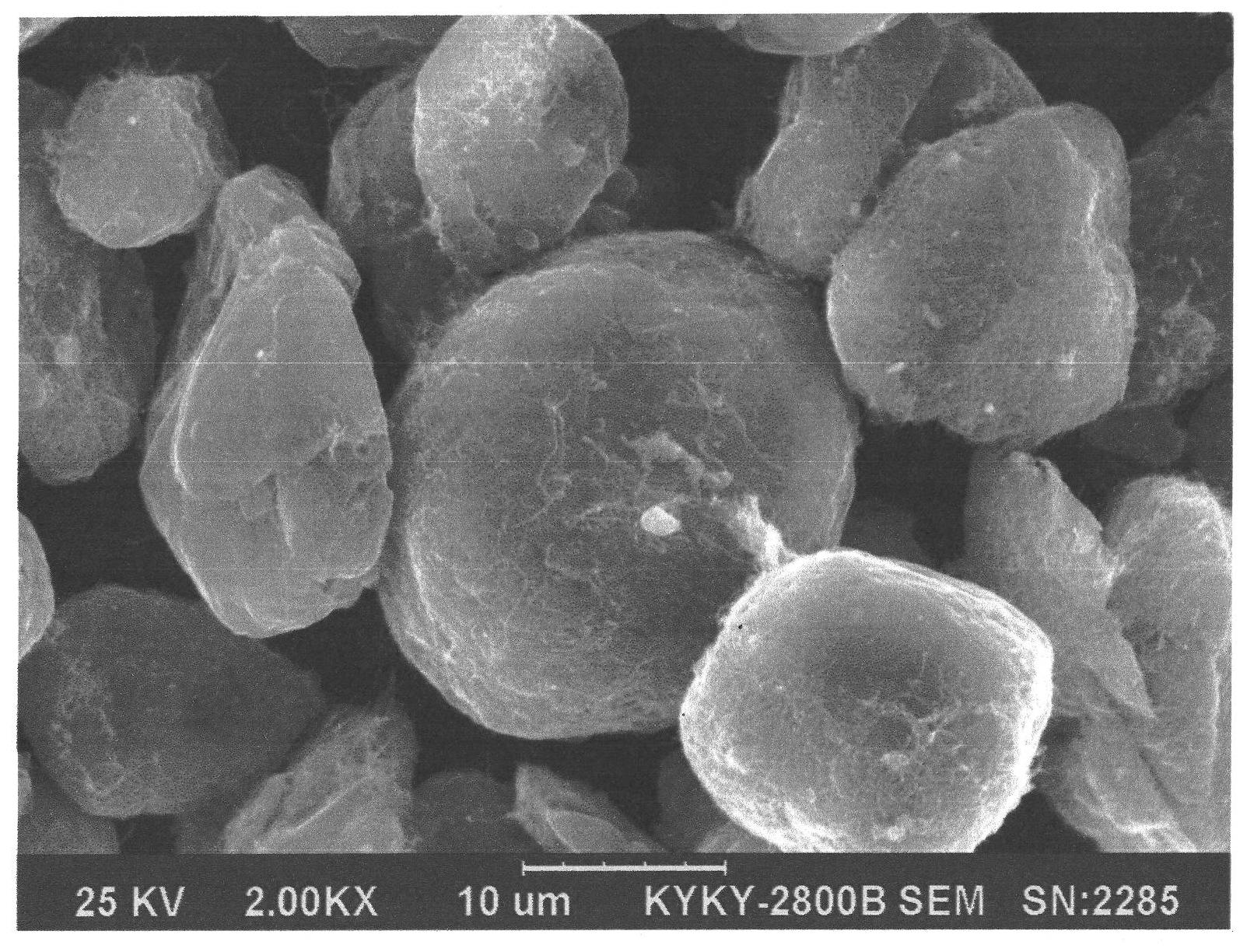

The invention discloses a preparing method of an artificial graphite cathode material used in lithium ion battery; it aims at resolving problems that cathode material possesses higher discharging capacity, coulomb efficiency and long circle life. The preparing method includes following steps: coal or petroleum needle-type coke is comminuted, and hot processed for 1-48 hours at 800deg.C-3000deg.C, comparing with current technique, the cathode material adopts needle-type coke to be comminuted, and hot process, defect that high crystallinity graphite material can not be circled in electrolyte system of PC solvent stably, and it can discharge in big times, it can be used in lithium ion drive battery, and craft is easy, and it fits for industrialization production.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium ion battery conductive additive and preparation method thereof

InactiveCN101997120AImprove performanceImprove conductivityCell electrodesAluminium-ion batteryLithium-ion battery

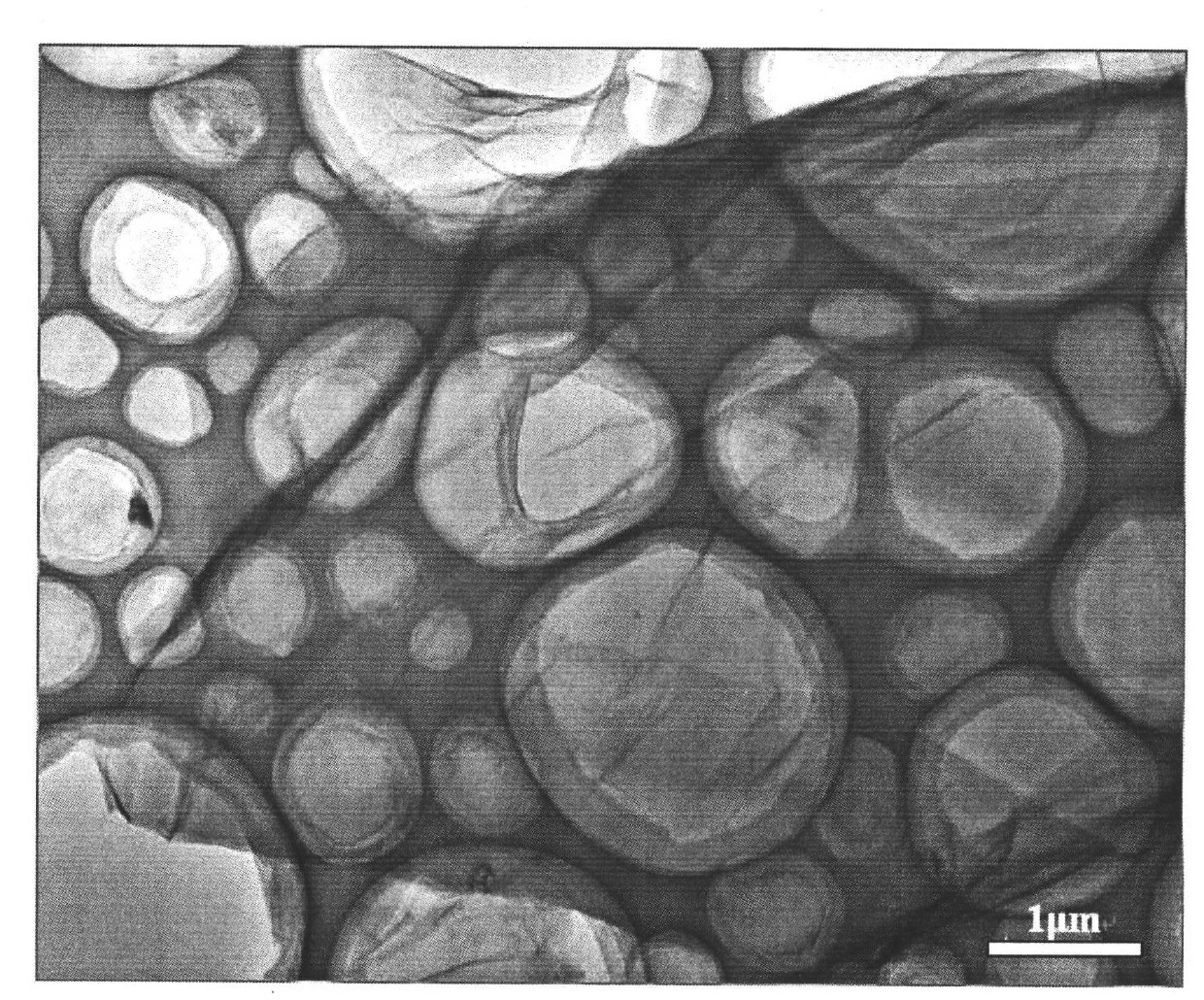

The invention discloses a lithium ion battery conductive additive and a preparation method thereof, and solves the technical problems of improving the conductive performance and cycle life of anode and cathode materials of a lithium ion battery. The lithium ion battery conductive additive is graphene, is black powder with grain size distribution of between 10 nanometers and 100 microns, and is a carbonaceous material consisting of single or 1,000 parallel or approximately parallel graphene lamellae. The preparation method comprises oxidization and stripping reduction. Compared with the prior art, the additive has higher electric conductivity; when the additive is applied to the electrode material, the performance of the conventional battery can be greatly improved only by a little amount; the material serving as the conductive additive has good conductive performance, is easy for dispersion, and can effectively enhance the conductive performance and the magnification charging and discharging performance of the electrode material of the lithium ion battery and prolong the cycle life; and the preparation method has low requirements for raw materials and equipment, is easy to control the process, and is suitable for industrialized production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH +1

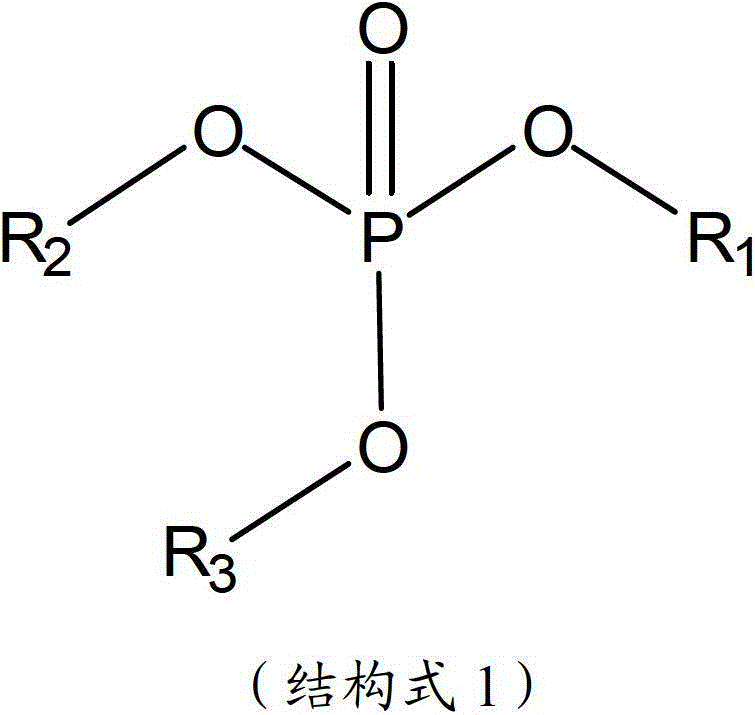

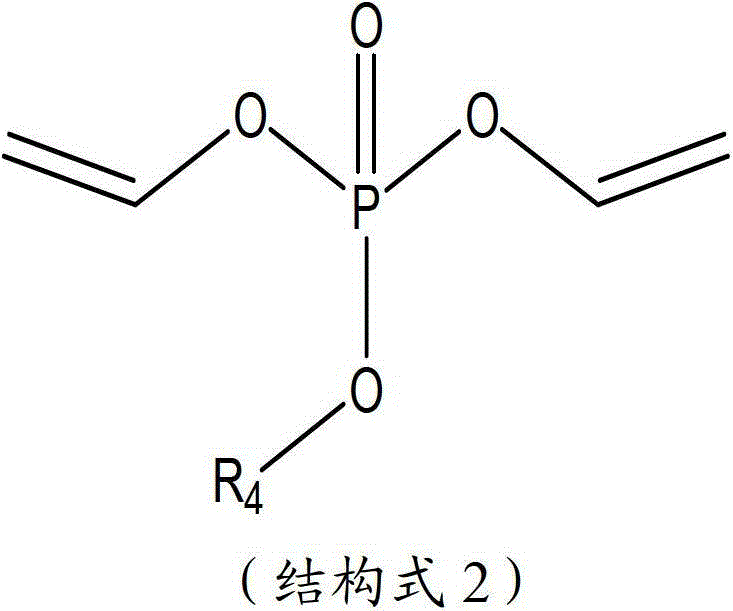

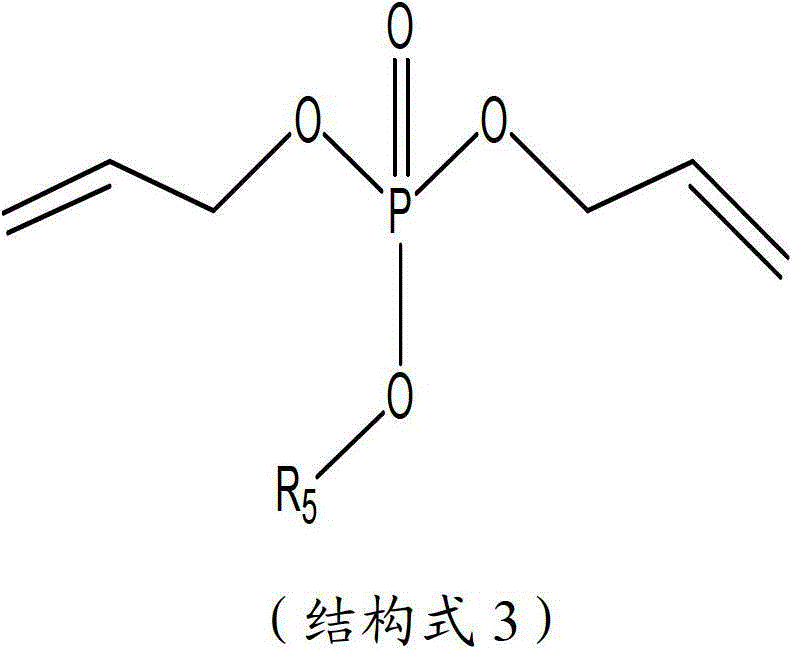

Non-aqueous electrolyte solution for lithium ion battery and corresponding lithium ion battery

The invention aims to provide a high performance non-aqueous electrolyte solution used for a lithium ion battery. The non-aqueous electrolyte solution includes: a lithium salt; an organic solvent; and an unsaturated phosphate compound. The unsaturated phosphate compound is in favor of forming a stable and compact passivation film (SEI (solid electrolyte interface)) on an electrode surface so as to prevent further decomposition of solvent molecules. The electrolyte solution obtained according to the scheme involved in the invention can improve the high-temperature storage performance and cycle performance of the battery.

Owner:SHENZHEN CAPCHEM TECH CO LTD

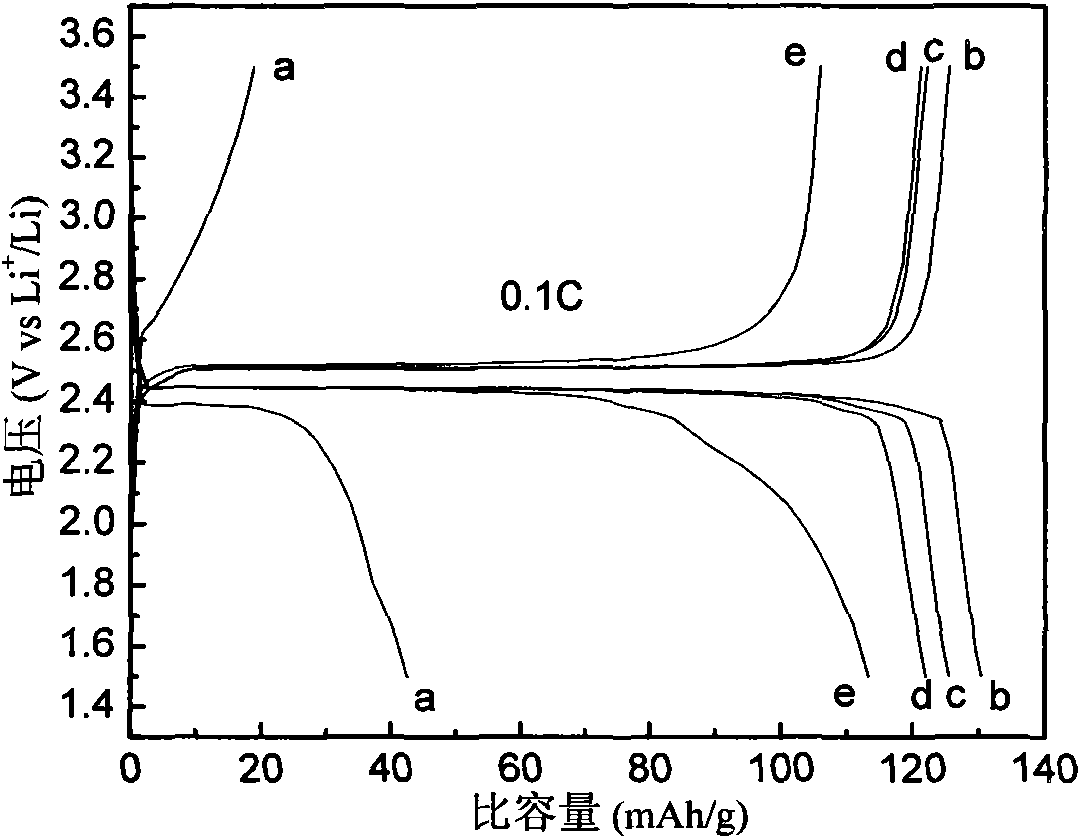

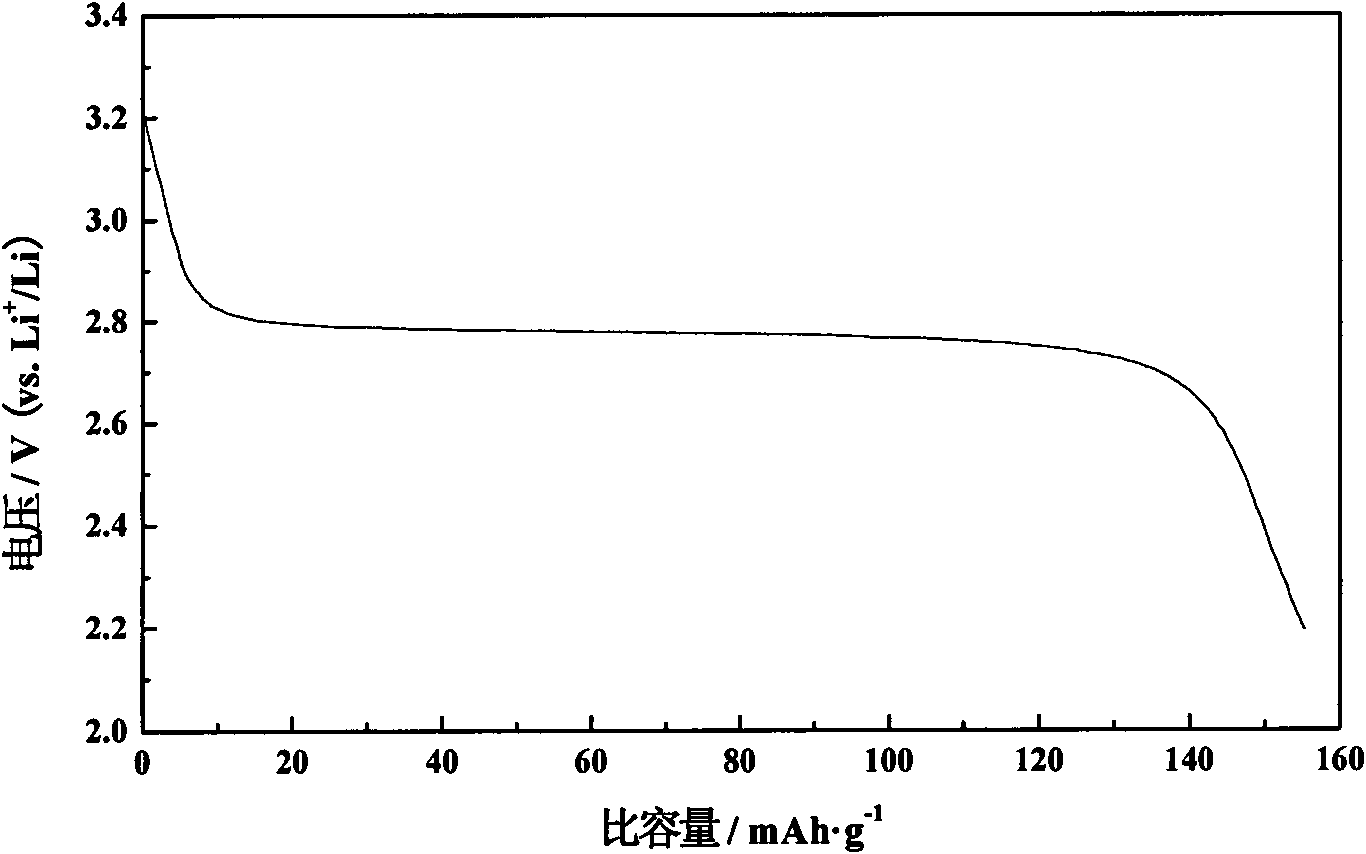

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

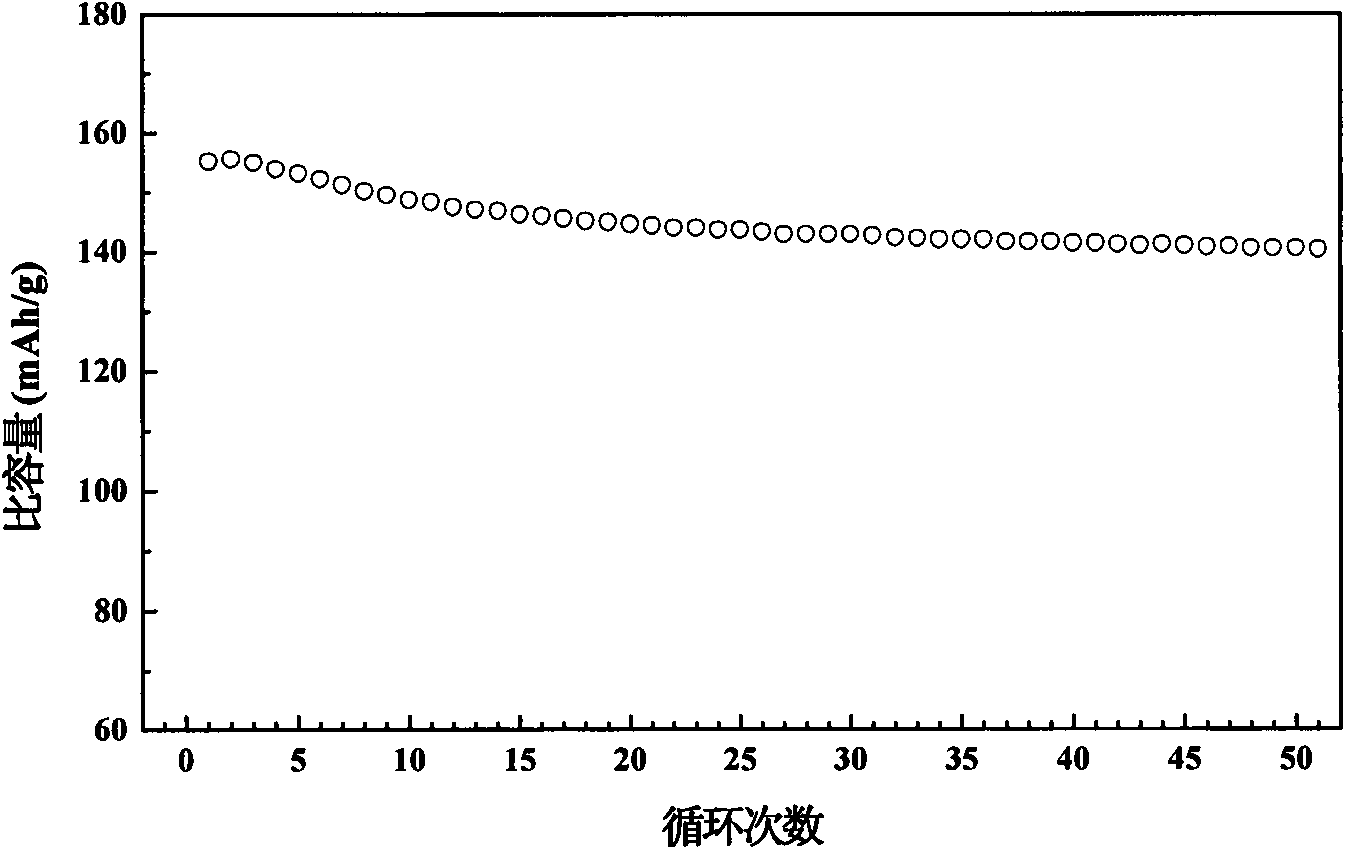

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

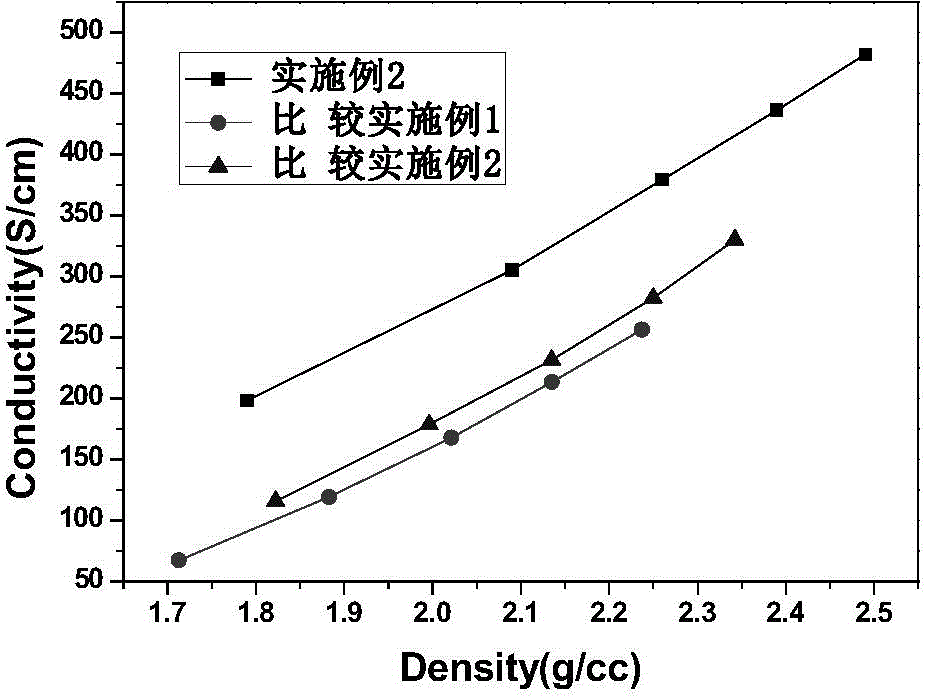

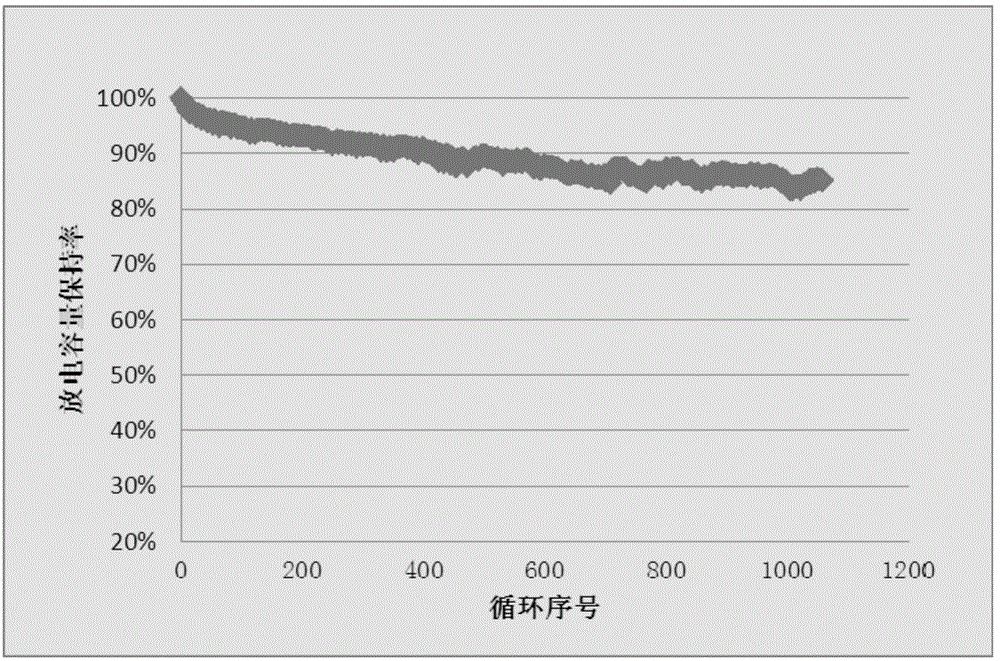

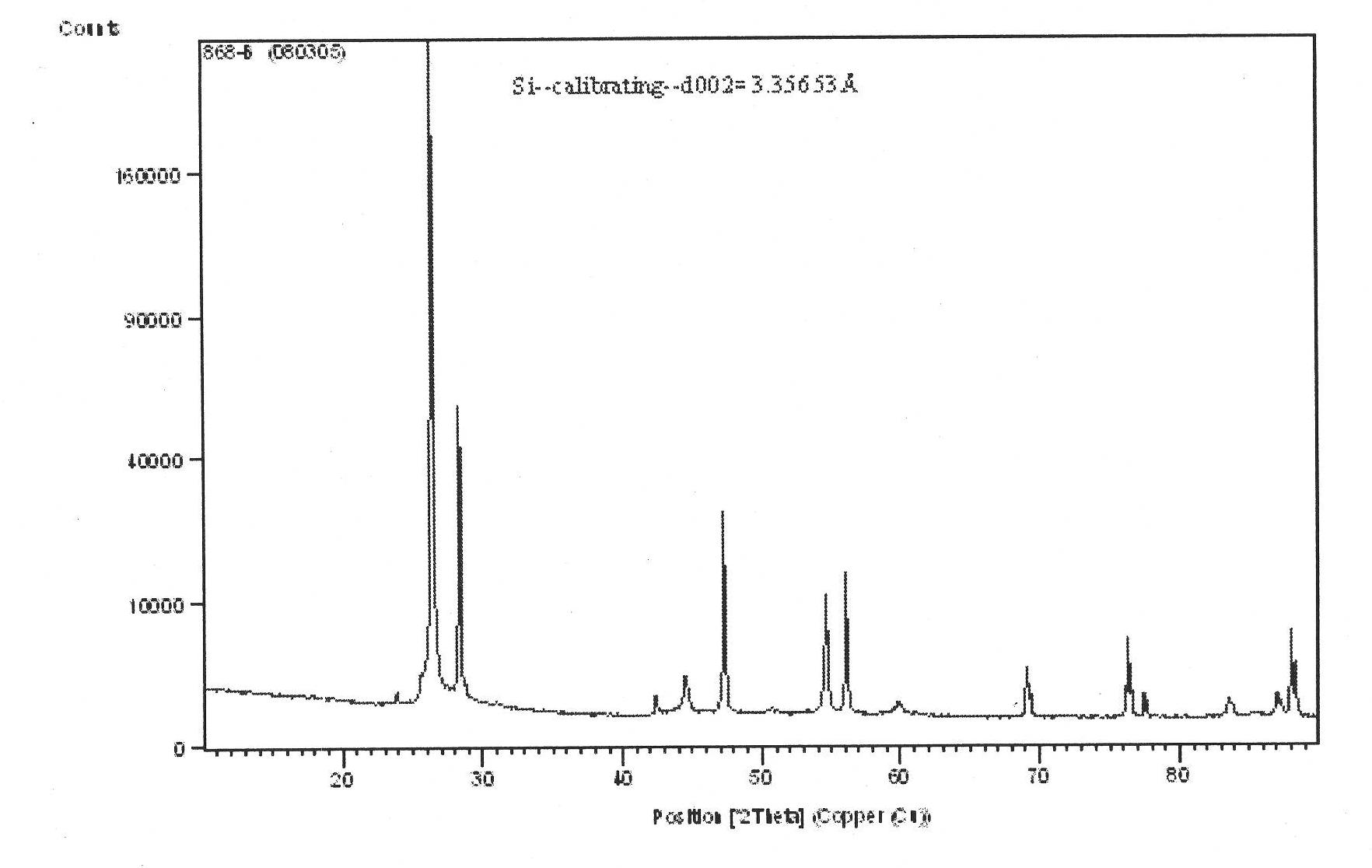

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

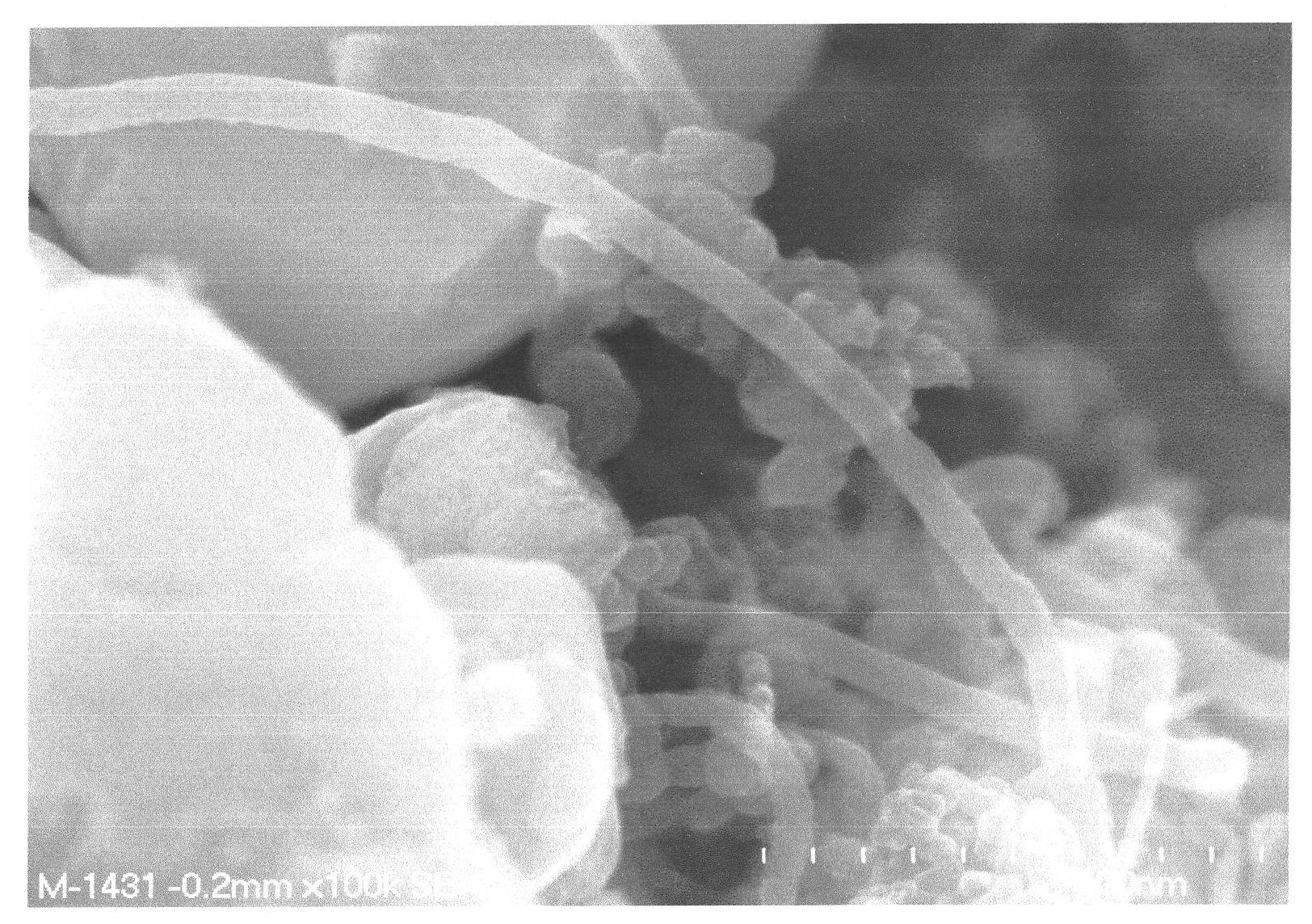

Anode material and cathode material for lithium ion battery and modifying method thereof

ActiveCN101969112AImprove electrochemical performanceImprove performanceCell electrodesCarbon fibersAluminium-ion battery

The invention discloses an anode material and a cathode material for a lithium ion battery and a modifying method thereof, solving the technical problem, i.e. how to improve the electrochemical performance of an electrode material. The surface of either anode material or the cathode material for the lithium ion battery is coated with a layer of carbon nanotubes or carbon nanofibers in a net structure, the coating layer of the cathode material has the thickness of 1-400 nm, and the coating amount of the anode material is 0.5-5 percent of the electrode material. The modifying method of the anode material and the cathode material for the lithium ion battery comprises the following steps of: forming a mixture of the electrode material, a catalyst and the carbon nanotubes or carbon nanofibers;adding water to stir the mixture into mash; and heating and reacting. Compared with the prior art, by coating a layer of carbon nanotubes or carbon nanofibers on the surface, the invention improves the material performance in all aspects and the electrochemical performance of the electrode material, achieves the aim of avoiding adding an additional conductive agent when applying the material and simplifies the manufacture process of the pole pieces of the lithium ion battery.

Owner:GUANGDONG DONGDAO NEW ENERGY

Lithium-ion battery diaphragm, lithium ion battery and preparation method thereof

ActiveCN107785522AImprove stabilitySmall thermal shrinkage at high temperatureFinal product manufactureCell component detailsAluminium-ion batteryHeat resistance

The invention relates to the field of lithium ion batteries, and discloses a lithium-ion battery diaphragm, a lithium ion battery and a preparation method thereof. The lithium-ion battery diaphragm comprises a porous base membrane and a heat-resistant layer which covers at least one side surface of the porous base membrane; the heat-resistant layer contains a high-temperature polymer and a nano-material, wherein the high-temperature polymer and the nano-material are in the weight ratio of (99 to 1) to (3 to 7); the heat-resistant layer is of a porous structure, the average pore diameter is 10to 1,000 nm, and the porosity is 30 to 60 percent. The lithium-ion battery diaphragm provided by the invention has high ionic conductivity, and also has high heat resistance and high mechanical strength at a high temperature.

Owner:BYD CO LTD

Aluminium ion battery and preparation method thereof

InactiveCN103825045AImprove securityImprove insulation performanceCell electrodesFinal product manufactureAluminum IonAluminium-ion battery

The invention relates to an aluminium ion battery and a preparation method thereof and belongs to the field of aluminium ion batteries and preparation thereof. The aluminium ion battery comprises a positive electrode, a negative electrode and an aluminium ion electrolyte, wherein the positive electrode is made of transition metal oxide; the negative electrode is made of high purity aluminium; the battery comprises a diaphragm material when the aluminium ion electrolyte is in a liquid state. Since abundant aluminium elements are stored, the cost for the ion battery is greatly reduced; the safety performance is improved; the transition metal oxide is applicable to hypervalent ion batteries due to relative stability under the variable valence states and different valence states. The ion liquid serves as the electrolyte for the hypervalent ion battery, so that aluminium ion is high in conductivity, good in heat stability, broad in electrochemical window and high in chemical stability and almost incapable of reacting with the positive electrode materials, the negative electrode materials, a current collector, a binder and a diaphragm in a battery system and capable of maintaining the liquid state in a board temperature range. The aluminium ion battery can be applied to various fields, such as electronic industries, communication industries and electric vehicles and the like.

Owner:UNIV OF SCI & TECH BEIJING

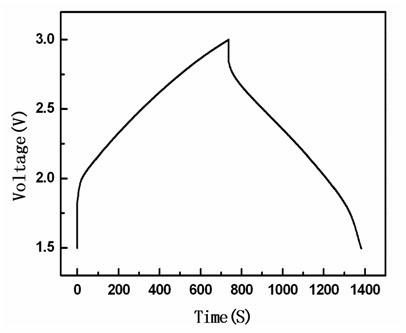

Energy storage device combining with characteristics of lithium ion battery and super-capacitor

ActiveCN102651484AWide variety of sourcesLow costFinal product manufactureCell electrodesCapacitanceAluminium-ion battery

The invention relates to an energy storage device combining with characteristics of a lithium ion battery and a super-capacitor, which comprises a positive pole, a negative electrode, a diaphragm, electrolyte and a shell, wherein the positive pole and the negative electrode are respectively formed in a way that an active substance, a conductive additive and a binder are respectively coated on a current collector, wherein the positive pole active substance is a biomass activated carbon material which can perform ion reversible adsorption, and the negative electrode active substance is a lithium-titanium-oxygen compound which can perform lithium-ion reversible de-intercalation. The energy storage device combining with the characteristics of the lithium ion battery and the super-capacitor is formed as follows: the activated carbon material with the double-electrode-layer energy storage characteristic of the super-capacitor is combined with the lithium-titanium-oxygen compound with a de-intercalation lithium energy storage characteristic of the lithium ion battery, wherein the materials used in the forming process of the energy storage device are mature materials which are widely applied to energy storage devices, and the materials are environment-friendly, rich in resource, and relatively low in cost.

Owner:CHINA FIRST AUTOMOBILE

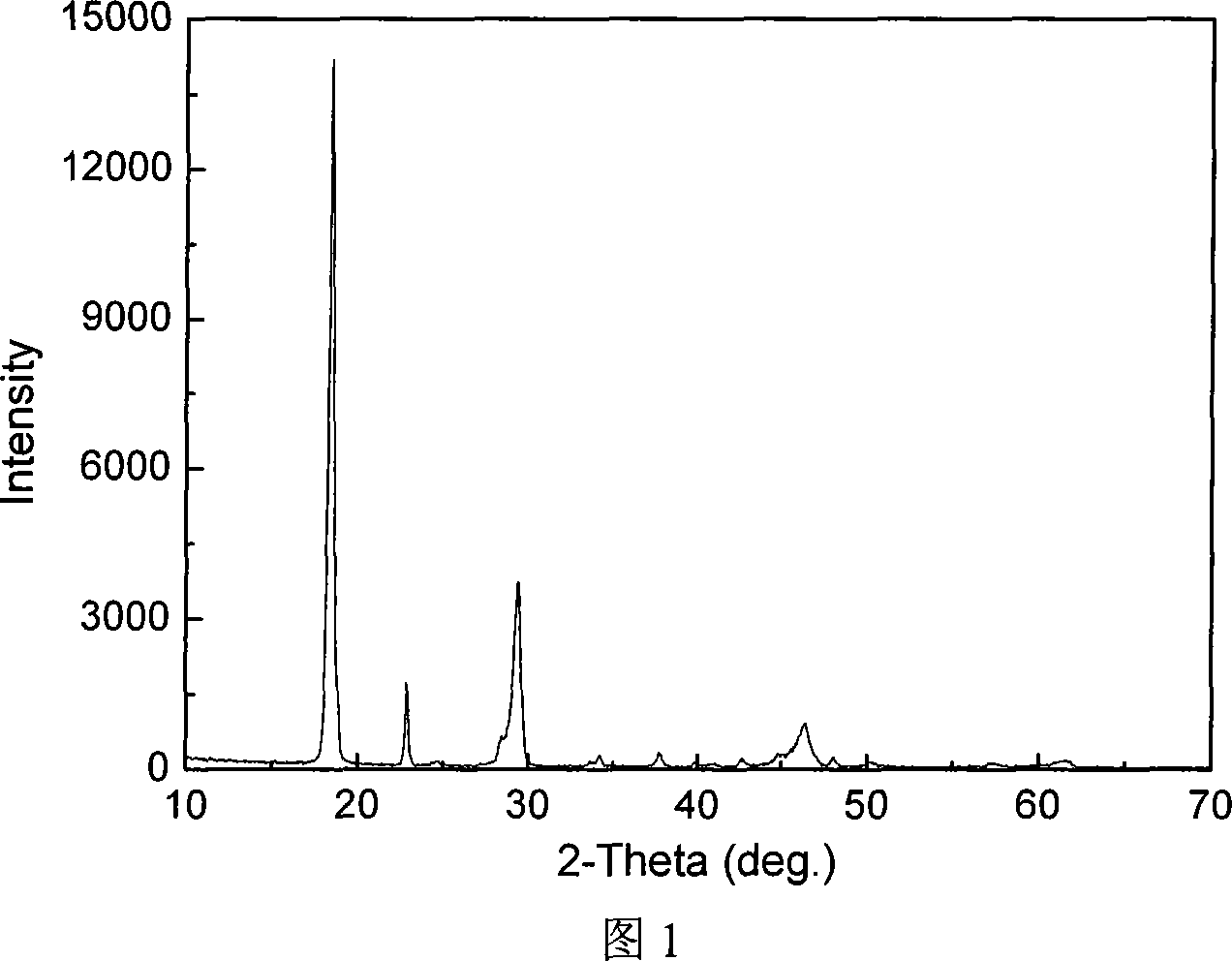

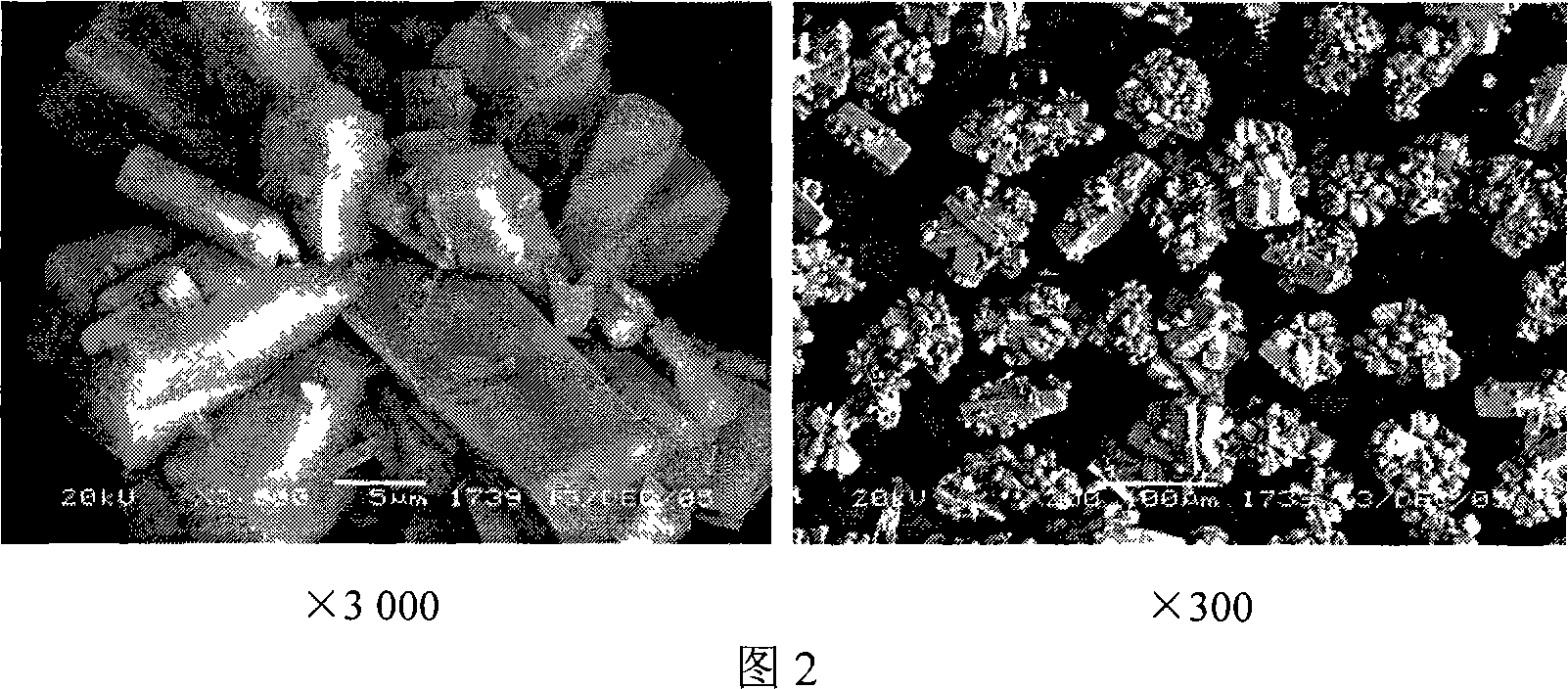

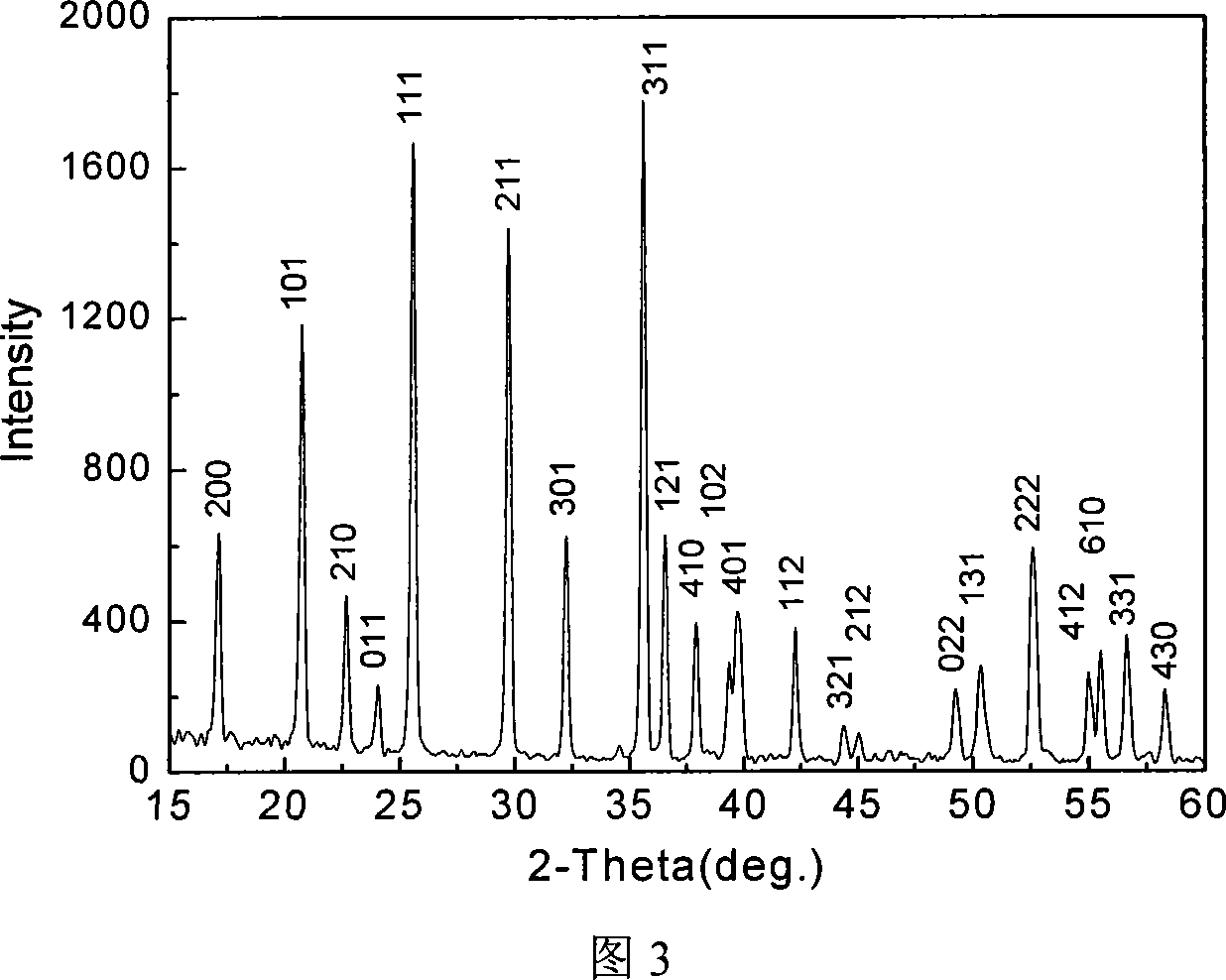

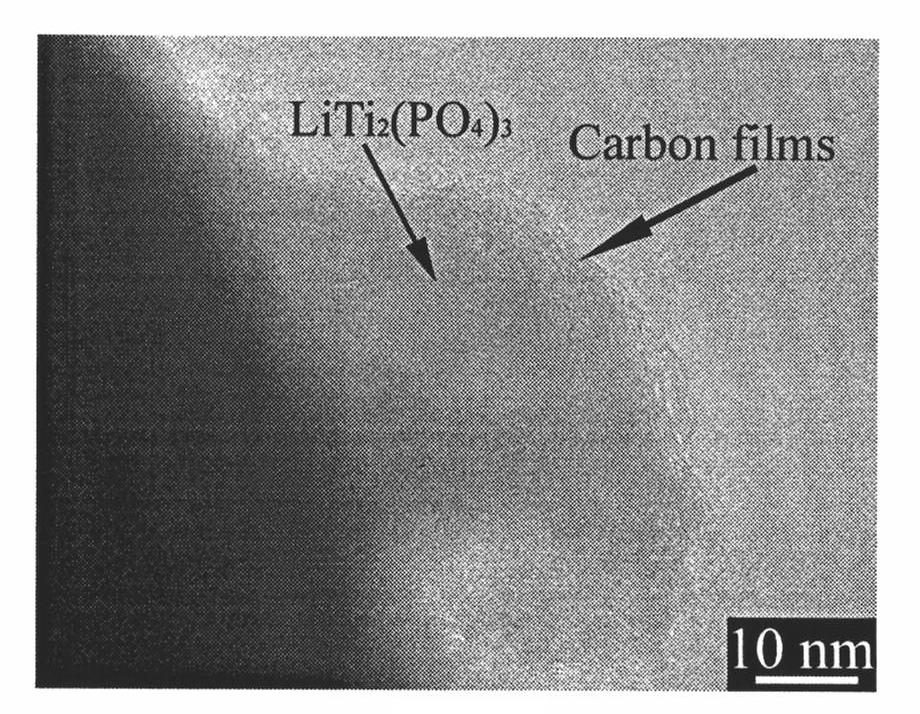

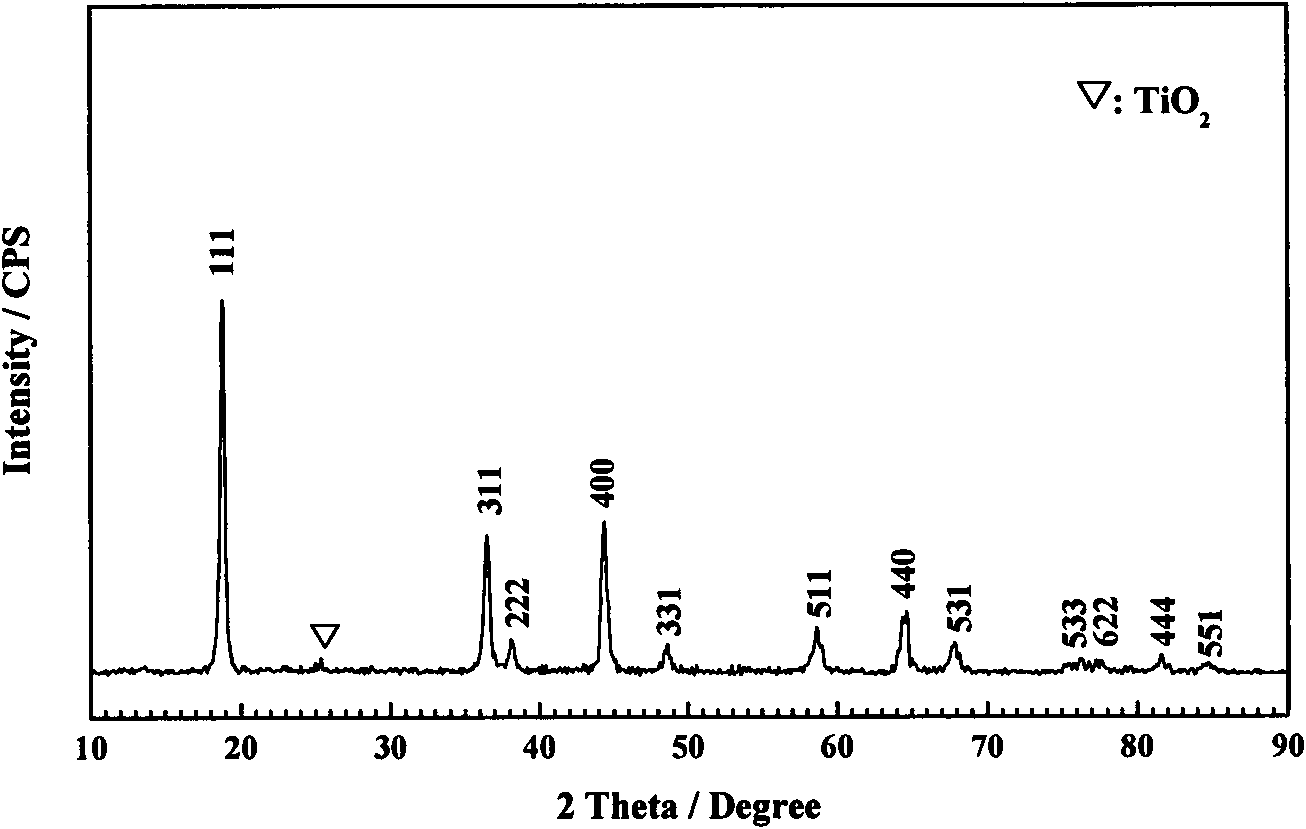

Titanium phosphate lithium material used for cathode of lithium ion battery and preparation method thereof

InactiveCN101807696AStable structureImprove securityCell electrodesPhosphorus compoundsAir atmosphereAluminium-ion battery

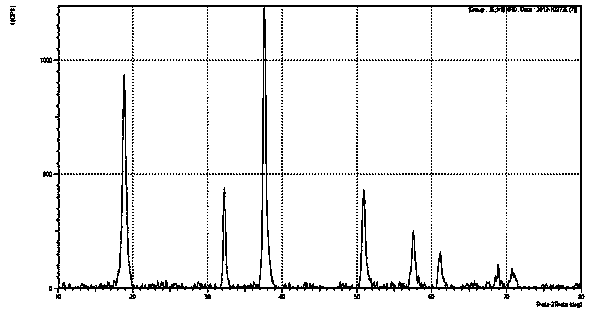

The invention relates to a titanium phosphate lithium material used for the cathode of a lithium ion battery and a preparation method thereof. The crystal structure of the titanium phosphate lithium material is an NASICON structure, and the composition is LixTi2(PO4)3, wherein x is 1 to 1.05. The preparation method of the material comprises the following steps: firstly, evenly mixing lithium-contained, titanium-contained and phosphorus-contained inorganic matter raw materials, and carrying out one-step roasting in an air atmosphere with the temperature of 800 to 1000 DEG C to prepare high-purity titanium phosphate lithium; then mixing the prepared titanium phosphate lithium with organic matter of glucose and the like in a certain proportion; milling and evenly mixing by a planet ball mill; then roasting in an inert atmosphere to obtain the carbon-cladding titanium phosphate lithium material. The preparation method is simple and has low cost, and the obtained titanium phosphate lithium cathode material has high purity, complete structure, high electrical conductivity and good electrochemical properties.

Owner:ZHEJIANG UNIV

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

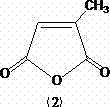

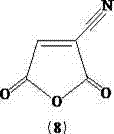

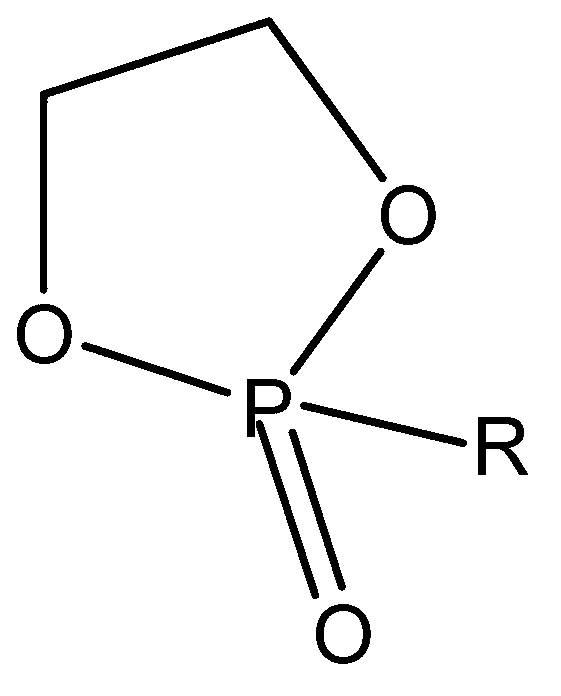

Electrolyte additive, high-voltage electrolyte and lithium ion battery containing electrolyte additive

InactiveCN103094616AInhibit surface activityAvoid contactSecondary cellsAluminium-ion batteryOrganic solvent

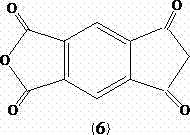

The invention discloses an electrolyte additive, a high-voltage electrolyte and a lithium ion battery containing the electrolyte additive. The high-voltage electrolyte is prepared by adding the electrolyte additive into the conventional electrolyte; the conventional electrolyte comprises a non-aqueous organic solvent and lithium salt, wherein the content of the non-aqueous organic solvent is 80-85 percent of the total mass; the mass of the electrolyte additive is 0.01-10 percent of the total mass; and the electrolyte additive is maleic anhydride C4H2O3 or one of derivatives thereof and has the structure formula as shown in the abstract. According to the high-voltage electrolyte, a stable interfacial film can be formed on the surfaces of a positive electrode and a negative electrode, the reaction activity on the electrode surface is inhibited, oxidative decomposition of the electrolyte is reduced, and gas swelling is effectively inhibited, so that the safety performance and the cycle performance of the lithium ion battery under normal pressure and high voltage are improved and the service life of the lithium ion battery under normal pressure and high voltage is prolonged. The electrolyte is simple in preparation process and is suitable for industrial production.

Owner:JIANGXI YOULI NEW MATERIALS

Preparation method of lithium vanadium phosphate (Li3V2(PO4)3)/graphene composite material for positive electrode of lithium ion battery

InactiveCN102623708AHigh purityHigh crystallinityCell electrodesAluminium-ion batterySodium-ion battery

The invention relates to a preparation method of a lithium vanadium phosphate (Li3V2(PO4)3) / graphene composite material for a positive electrode of a lithium ion battery. The method comprises the steps that firstly, a mixed precursor solution is prepared; pretreatment of spray drying is conducted and a precursor is obtained; and then the lithium vanadium phosphate positive electrode material of the lithium ion battery is prepared through a calcination reaction under an inert atmosphere condition. Compared with the prior art, the preparation method has the advantages that the combination mode of the Li3V2(PO4)3 and the graphene, the contents of carbon and the graphene, and the particle size of the material are effectively controlled, thereby improving the stability and the electrical conductive performance of the material.

Owner:SHANGHAI ZHIRONG TECH

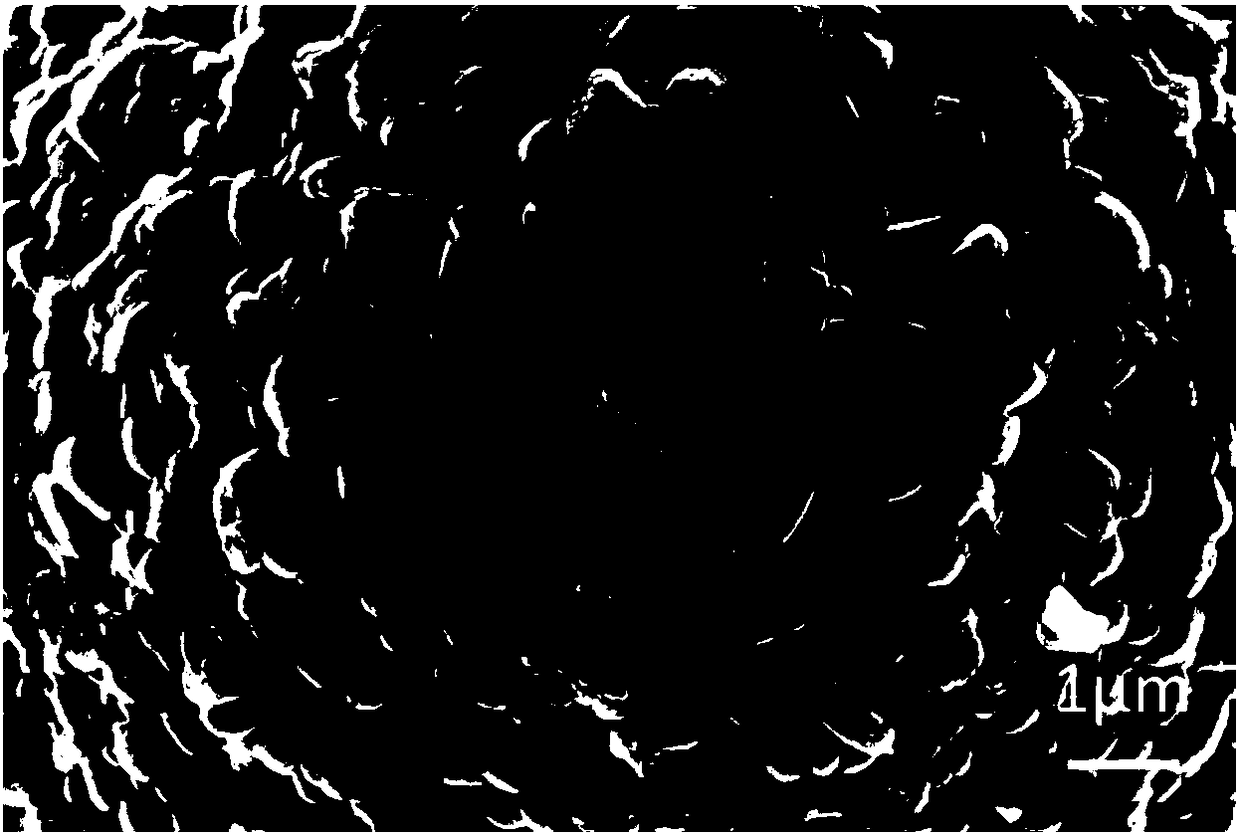

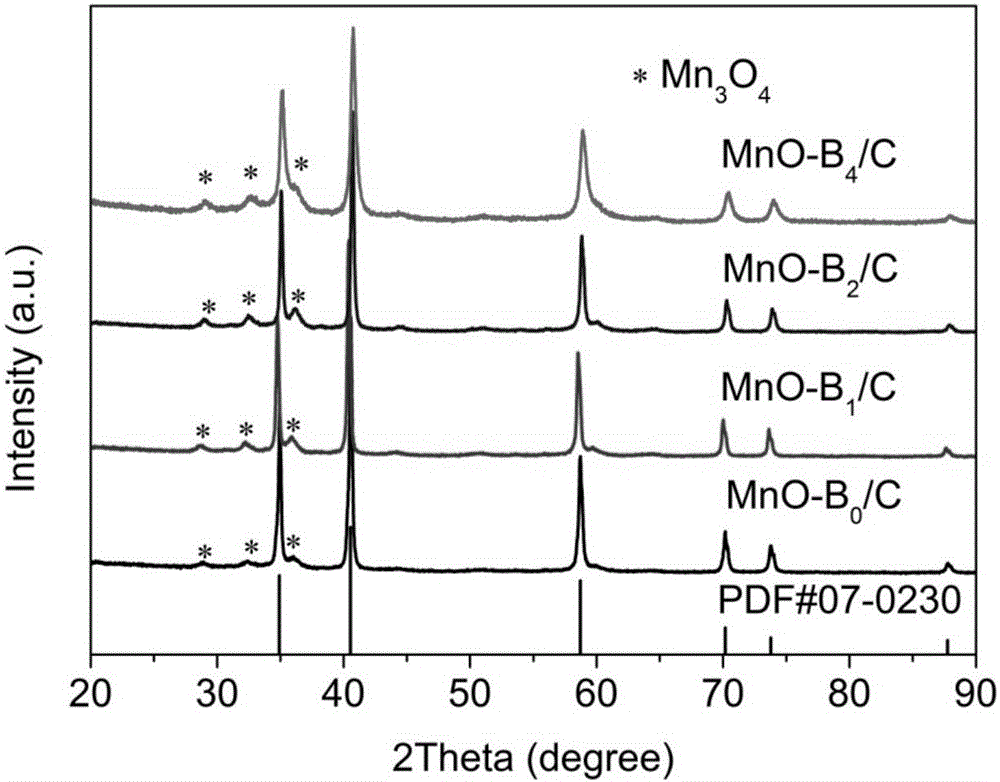

Morphological control method of metal oxide/carbon negative electrode material for lithium ion battery

ActiveCN106784658ALarge specific surface areaSimple processSecondary cellsNegative electrodesAluminium-ion batteryMetal-organic framework

The invention discloses a morphological control method of a metal oxide / carbon (MOx / C) composite material for the negative electrode of a lithium ion battery. The method comprises the following steps: adding metal ions and monodentate ligands with different proportions into a solvent, stirring for a period of time, then adding a multidentate ligand, and heating in a reaction kettle for a period of time to obtain the metal organic framework (MOF) precursor materials with different morphologies; and calcining the precursors in an inert gas atmosphere for a period of time to obtain the MOx / C composite materials with different morphologies. The composite materials disclosed by the invention have relatively high specific surface areas and rich pore structures, and have excellent rate performance and cycling stability as the negative electrode materials of the lithium ion battery. The morphological control method disclosed by the invention is simple to operate, easy to realize large-scale application, and can also be extended to other fields that focus on material morphology control.

Owner:CENT SOUTH UNIV

Soft carbon negative material of lithium ion battery, preparation method of soft carbon negative material and lithium ion battery

ActiveCN103708437AImprove electrochemical performanceReduce manufacturing costCell electrodesSecondary cellsCarbon layerAluminium-ion battery

The invention relates to the field of negative materials of lithium ion batteries and particularly relates to a novel high-volume soft carbon negative material, a preparation method thereof and a lithium ion battery utilizing the soft carbon negative material. The soft carbon negative material comprises a soft carbon powder particle kernel, a nanometer material coating and a conductive carbon layer, wherein the nanometer material coating is loaded on a surface layer of the soft carbon powder particle kernel in a monodisperse manner, and the outer surface of the nanometer material coating is coated by the conductive carbon layer. The soft carbon negative material has high volume and initial charge-discharge efficiencies and excellent rate capability and cycle performance. The soft carbon anode material is prepared by the steps of with soft carbon powder as a ram material, sequentially carrying preburning, nanometer material spraying and conductive carbon layer coating. The preparation method is simple and is easy to control, the manufacturing cost is low, and the scale production is easy to realize.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Preparation method for aqueous binder used for lithium ion battery

InactiveCN102746813AImprove cycle performanceImproved magnification performanceCell electrodesAcid polymer adhesivesHydrophilic monomerAluminium-ion battery

The invention provides a preparation method for an aqueous binder used for a lithium ion battery. The method comprises the following steps: weighing unsaturated hydrophilic monomers, unsaturated lipophilic monomers and auxiliary agents; dissolving the weighed unsaturated hydrophilic monomers in distilled water and uniform mixing the dissolved unsaturated hydrophilic monomers with the weighed unsaturated lipophilic monomers and auxiliary agents under stirring; adjusting the pH value of an obtained mixture to be 5 to 13, blowing in high purity nitrogen to remove oxygen and adjusting temperature to a constant temperature; adding an initiator for initiation of polymerization; and extracting residual monomers under vacuum so as to obtain the aqueous binder for a lithium ion battery. The aqueous binder for a lithium ion battery provided in the invention has the advantages of environment friendliness, low production cost and good bonding performance; an electrode slice prepared from the aqueous binder for a lithium ion battery has good flexibility and high compacted density and enables performance of positive and negative electrode materials of a lithium ion battery to be fully played; and a prepared lithium ion battery has good cycle performance and rate capability.

Owner:张倩

Surface modified anode material for lithium ion battery and method

InactiveCN103633312AEasy to getEasy to controlCell electrodesSecondary cellsAluminium-ion batteryPhosphate

The invention provides a surface modified anode material for a lithium ion battery and a method. The anode material and the method are characterized in that: LiNi[x]Co[y]MzO2 (M = Mn, Al or Mg), LiMn2O4 or a composite anode material thereof, a metal salt and a carbon source material are added into a solvent to form a flowable slurry; and the pH value is adjusted under stirring so that metal compounds and the carbon source material form sol and are adsorbed on the surface of the anode material. After being dried, the mixture is subjected to high-temperature thermal treatment to obtain the anode material compositely coated with the metal compounds and the carbon, wherein the metal compounds are metal oxides, metal fluorides or metal phosphates, and the like. That large-current charge and discharge performances of anode materials are influenced by the low electronic conductivity of metal compound coatings at present can be overcome by the coating method provided by the invention, thus enhancing application performances in electric tools, electric automobiles, and other occasions.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

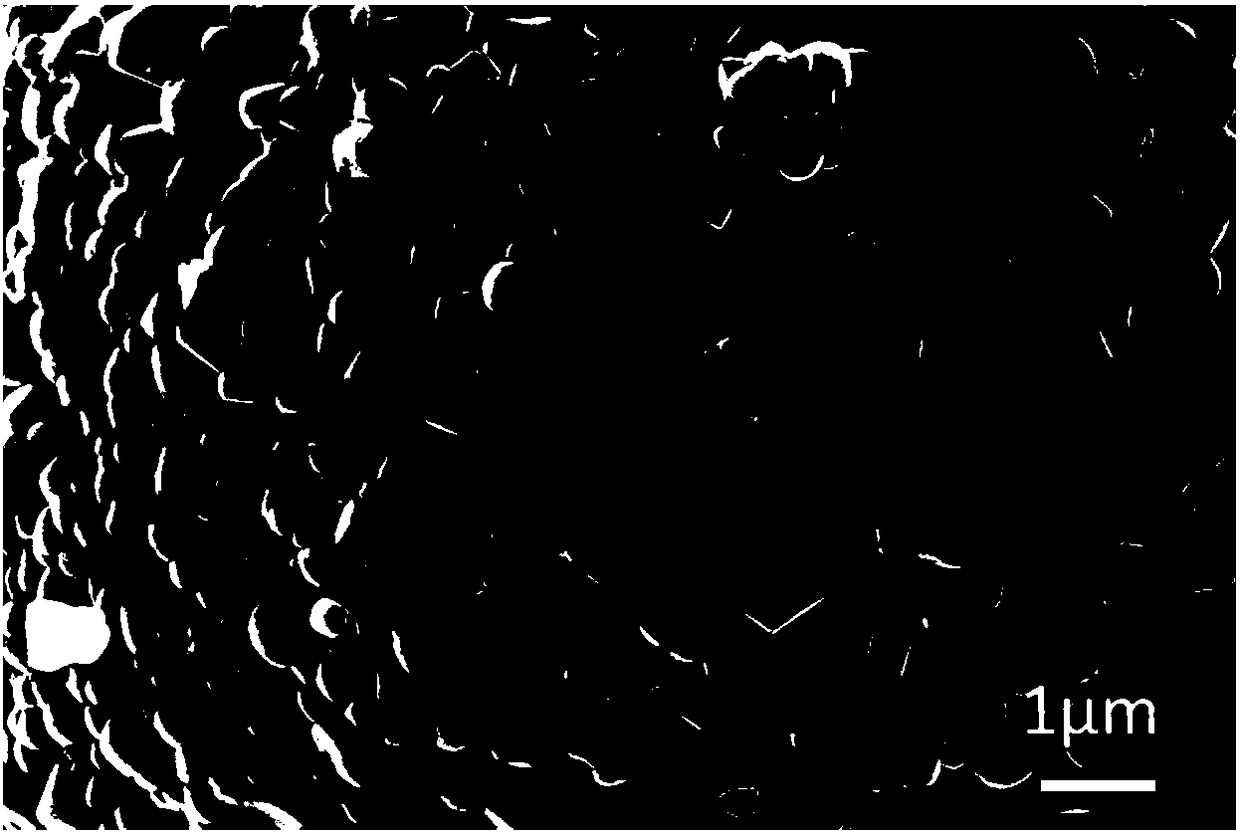

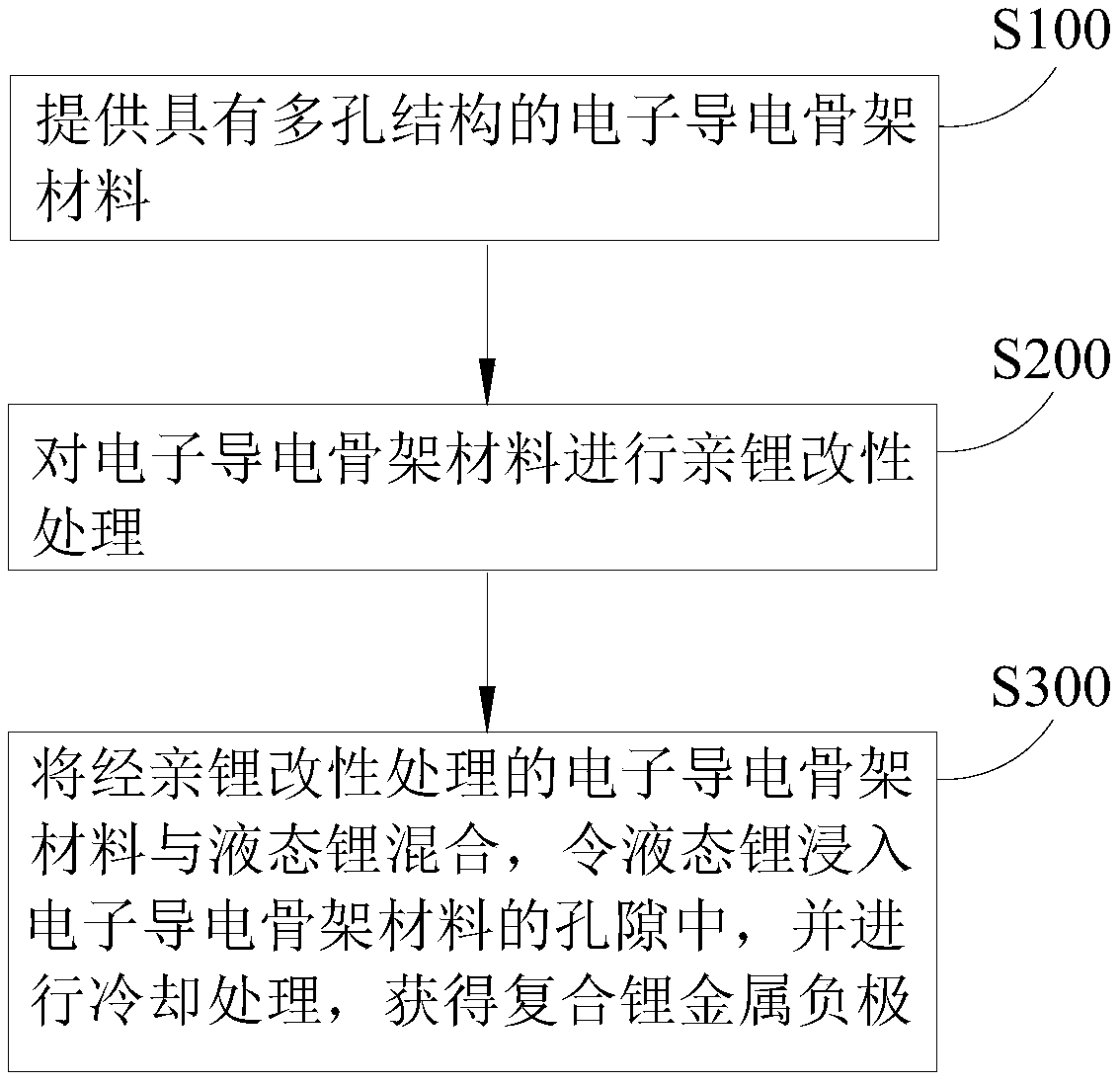

Composite lithium metal negative electrode, preparation method and lithium ion battery

ActiveCN109713224APrecise control of porositySufficient porosityActive material electrodesSecondary cellsPorosityAluminium-ion battery

The invention provides a composite lithium metal negative electrode, a preparation method and a lithium ion battery. The method for preparing the composite lithium metal negative electrode comprises the following steps: providing an electronic conductive framework material with a porous structure; carrying out lithium-philic modification treatment of the electronic conductive framework material; mixing the electronic conductive framework material subjected to the lithium affinity modification treatment with liquid lithium; immersing the liquid lithium into pores of the electronic conductive framework material, and performing cooling to obtain the composite lithium metal negative electrode; controlling the ratio of the volume of the liquid lithium to the total volume of the pores in the electronic conductive framework material to ensure that the porosity of the composite lithium metal negative electrode is 20-98% and lithium content of 0.01-0.01% 10mg / cm2. According to the invention, the porosity and the lithium content of the composite lithium metal negative electrode can be accurately controlled through the method, dendritic crystals are effectively prevented from being formed, and the problems of volume expansion, poor cycle performance, high safety risk and the like of the lithium metal negative electrode are solved, so that a battery applying the composite lithium metal negative electrode has high energy density and long-cycle stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

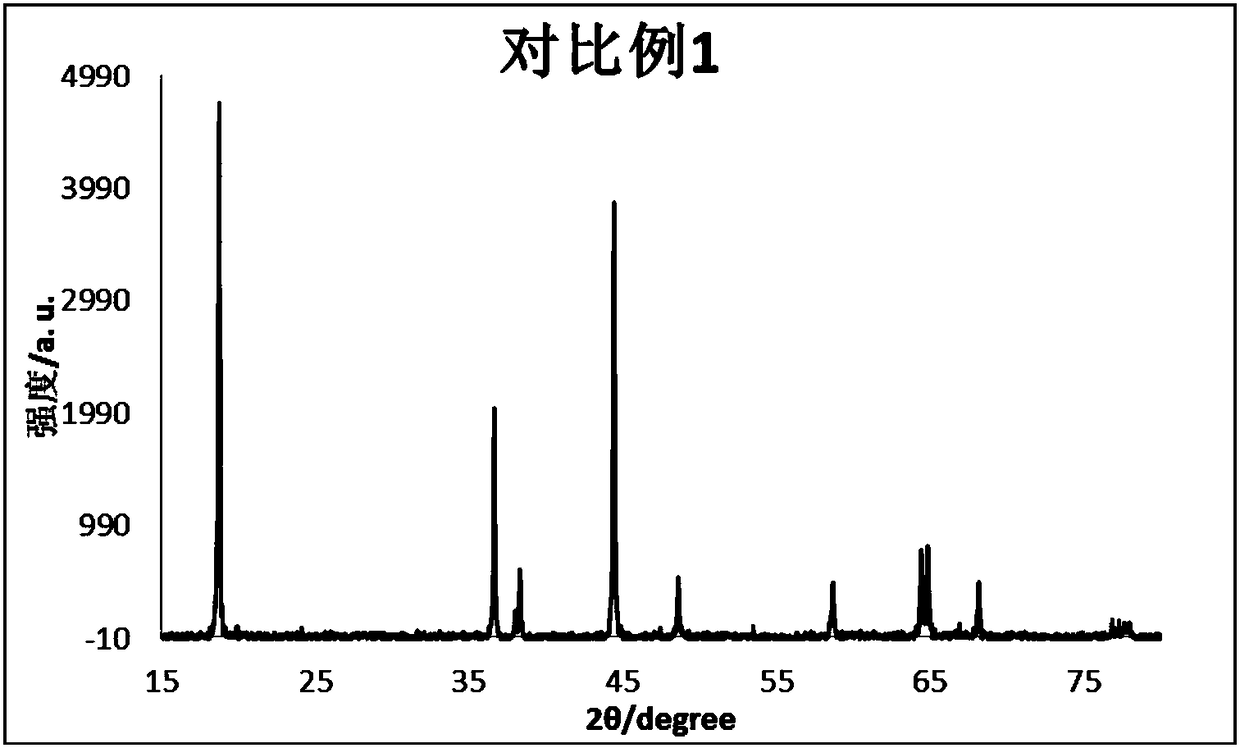

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

Electrolyte, lithium ion battery comprising same and preparation method of lithium ion battery

ActiveCN105047995APower optimizationImprove cycle performanceSilicon organic compoundsFinal product manufactureHigh temperature storageElectrolytic agent

The invention relates to an electrolyte, a lithium ion battery comprising the same and a preparation method of the lithium ion battery. The electrolyte comprises a lithium salt, an organic solvent, an addition agent A and an addition agent B. The addition agent A is one or more of phosphate ester compounds and boric acid ester compounds. The addition agent B is one or more of sulfurous ester compounds and sultone compounds. The electrolyte is applied in the lithium ion battery, and then the cycling performance, the high-temperature storage performance and the power performance of the lithium ion battery can be improved. When the lithium ion battery is prepared, some electrolyte E1 is added before being formed, and the rest of the electrolyte E2 is added before the capacity is tested. By selecting the preparation method, the lithium ion battery can have the excellent cycling performance, high-temperature storage performance and power performance.

Owner:NINGDE AMPEREX TECH

Method for the preparation of graphene/silicon multilayer structured anodes for lithium ion batteries

InactiveUS20140170483A1Effectively improves adhesionPrevent crushingActive material electrodesNon-aqueous electrolyte accumulator electrodesAluminium-ion batteryComposite film

Multilayer structures with alternating graphene and Si thin films were constructed by a repeated process of filtering liquid-phase exfoliated grapheme film and subsequent coating of amorphous Si film using plasma-enhanced chemical vapor deposition (PECVD) method. The multilayer-structure composite films, fabricated on copper current collectors, can be directly used as anodes for rechargeable lithium-ion batteries (LIBs) without the addition of polymer binders or conductive additives. Fabricated coin-type half cells based on the new anode materials easily achieved a capacity almost four times higher than the theoretical value of graphite even after 30 cycles. These cells also demonstrated improved capacity retention and enhanced rate capability during charge / discharge processes compared to those of pure Si film-based anodes.

Owner:RGT UNIV OF CALIFORNIA

High-security phosphate-based electrolyte and lithium ion battery

InactiveCN103296311AImprove securityOvercome the disadvantages of incompatibilitySecondary cellsAluminium-ion batteryInternal resistance

The invention relates to a phosphate-based electrolyte and a lithium ion battery. The electrolyte is mainly characterized by taking at least one cyclic phosphate and at least one chain phosphate as solvent components. The advantages of the phosphate-based electrolyte are that: the two kinds of phosphates both have a flame retardation characteristic, and the cyclic phosphate can be subjected to ring-opening polymerisation under abuse conditions of high temperature, over charge or the like, and the electrolyte is gelated, the internal resistance of a battery increases, and therefore the battery security is improved. The cyclic phosphate can form into membranes on an anode surface and a cathode surface of the lithium ion battery, and improves the compatibility between the electrolyte, and the anode and the cathode; the usage of the chain phosphate helps to reduce the electrolyte viscosity and improve the electrolyte conductivity, and good multiplying power performance and low temperature performance are provided in the corresponding battery system. The security of the lithium ion battery can be improved substantially by using the electrolyte.

Owner:HEFEI UNIV OF TECH +1

Composite electrode plate of lithium ion battery, preparation method of composite electrode plate and lithium ion battery

ActiveCN104124414AImprove thermal stabilityImprove securitySecondary cellsNon-aqueous electrolyte accumulator electrodesFiberAluminium-ion battery

The invention provides a composite electrode plate of a lithium ion battery. The composite electrode plate of the lithium ion battery is composed of an electrode plate body and a diaphragm layer arranged on the surface of the electrode plate body, wherein the electrode plate body is composed of a current collector and an active electrode material, the surface of the current collector is coated with the active electrode material, the diaphragm layer is prepared from inorganic ceramic particles, a binder and organic fibers, the melting point of the organic fibers is larger than 200 DEG C, the diameter of the organic fibers is 0.1 micron to 10 microns, the length of the organic fibers is 1-10mm, and the mass of the organic fibers is 0.1-2% of that of the inorganic ceramic particles. According to the composite electrode plate of the lithium ion battery, the diaphragm layer is stably attached to the electrode plate body and has high heat stability, the problem in the prior art that the diaphragm layer easily cracks and falls during winding can be solved, the safety performance of the lithium ion battery can be improved, and the circulation service life of the lithium ion battery can be prolonged. The embodiment of the invention also provides a preparation method of the composite electrode plate of the lithium ion battery and the lithium ion battery comprising the composite electrode plate.

Owner:HONOR DEVICE CO LTD

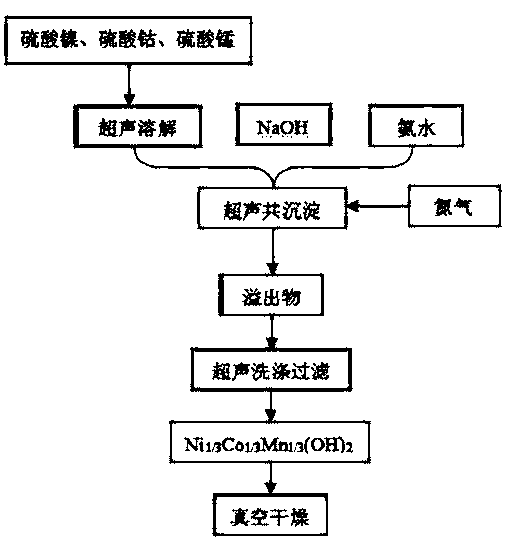

Ultrasonic assisted method for preparing precursor of ternary positive material of lithium ion battery

ActiveCN103482711AEasy to shapeNarrow particle size distributionCell electrodesManganese oxides/hydroxidesAluminium-ion batteryManganese

The invention discloses an ultrasonic assisted method for preparing the precursor of a ternary positive material of a lithium ion battery. The method disclosed by the invention comprises the following steps that under the protection of inert gas nitrogen, nickel, cobalt, and manganese in a metal mixed solution are continuously co-precipitated by using a sodium hydroxide and ammonium hydroxide mixed solution by means of mechanical stirring dispersion and ultrasonic wave assistance; the precipitated product grows and then overflows; the overflowed product is washed, and filtered to obtain fresh composite hydroxide precipitate of nickel, cobalt, and manganese; and the product is ultrasonically-assisted washed by using pure water, and dried in vacuum to obtain the precursor of the hydroxide of nickel, cobalt and manganese, which is good in degree of sphericity and high in purity. According to the method disclosed by the invention, the fresh hydroxide precipitate is treated by using the ultrasonic assisted method, the product is the composite hydroxide precursor, the content of the impurity ion is less, and the composite hydroxide precursor has the advantages of spherical shapes, narrow particle size distribution, high tap density and the like.

Owner:DALIAN RUIYUANPOWER CO LTD

Method for obtaining electrochemical model parameters of lithium ion battery

InactiveCN108761341AAccurate acquisitionEfficient acquisitionElectrical testingAluminium-ion batteryPower flow

A method for obtaining electrochemical model parameters of a lithium ion battery relates to the field of new energy research. The present invention is to solve the problems that the existing mechanismmodel parameters need to be acquired by means of an electrochemical measurement method or an intelligent algorithm, and the ability to acquire parameters quickly and without loss is not provided. Themethod comprises steps of 1, establishing an electrochemical simplification mechanism model for the lithium ion battery; 2, applying a parameter identification condition to the lithium ion battery tocharge and discharge the lithium ion battery, and obtaining voltage data and current data of the lithium ion battery under charge and discharge conditions; and 3, according to the electrochemical simplification mechanism model of the lithium ion battery and the voltage data and current data of the lithium ion battery under charge and discharge conditions, obtaining electrochemical model parameters of the lithium ion battery. The method is used to obtain electrochemical model parameters of lithium ion batteries.

Owner:HARBIN INST OF TECH

High charge-discharge magnification lithium iron phosphate material used for anode of lithium ion battery and its preparation method

InactiveCN1971981AHigh specific capacityImprove cycle stabilityElectrode manufacturing processesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to one lithium ion battery anode charging ferric phosphate lithium materials and its process method, which processes the front drive by gel-sol method under 30 to 90 degrees by materials of lithium compound, ferric compound and phosphate compound and conductive materials; then heating the front driver in inertia or weak educing atmosphere for analyzing under 100 to 450 degrees; in same atmosphere, heating by 1-30DEG C / min-1 and forging under 450 to 800 degrees for 2 to 24 hours and then culling naturally to get aim product.

Owner:NANKAI UNIV

Lithium ion battery waterborne positive electrode composite collector, positive plate, manufacturing methods for lithium ion battery waterborne positive electrode composite collector and positive plate, and lithium ion battery

ActiveCN105261760ALower internal resistanceImprove high rate discharge performanceFinal product manufactureElectrode carriers/collectorsHigh rateAluminium-ion battery

The invention relates to a lithium ion battery waterborne positive electrode composite collector, a positive plate, manufacturing methods for the lithium ion battery waterborne positive electrode composite collector and the positive plate, and the lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery waterborne positive electrode composite collector is prepared by the following steps of adding a binder into a solvent to uniformly mix to obtain a binder solution, wherein the mass ratio of the binder to the solvent is 1:10-30; adding a conductive agent to the binder solution, uniformly mixing, grinding and emulsifying to obtain a conducive slurry, wherein the mass ratio of the conductive agent to the binder is 1-99:1; and coating the surface of the positive electrode collector with the prepared conductive slurry, and drying to obtain the lithium ion battery waterborne positive electrode composite collector. The problem of low flexibility of the waterborne positive plate is greatly solved by the lithium ion battery waterborne positive electrode composite collector; and meanwhile, the adhesive force of the coating layer is improved, the internal resistance of the battery is reduced, and the high-rate discharge performance and the cycle performance of the battery are improved.

Owner:CALB CO LTD

Method for producing hard carbon lithium metal composite negative pole material for lithium ion battery

InactiveCN1889288AImprove electrochemical activityHigh reversible capacityElectrode manufacturing processesMixing methodsAluminium-ion batteryMass ratio

The present invention relates to lithium ionization cell used hard carbon - lithium metal compounding cathode material preparation method, belonging to chemical engineering and new material technology field, in particular relating to lithium secondary cell cathode material preparative technique field. One method is to make hard carbon material with lithium powder mixing upon inert gas atmosphere, to obtain hard carbon - lithium metal compounding cathode material. Another method is to prepare hard carbon material powder into electrode piece, then under inert gas atmosphere pressing lithium foil on hard carbon electrode piece surface to obtain hard carbon - lithium metal compounding cathode material. The mass ratio relation of lithium with hard carbon material in above-mentioned two methods satisfies that the lithic first excess loading capacity can compensate hard carbon first non-reversible capacity. Said invention provided method can prepare cathode material with more than first Coulomb 100 per cent, high electrochemical activity, large reversible capacity, fine cycle performance, low material cost, and simple technological process etc advantages.

Owner:TSINGHUA UNIV

Lithium ion battery formation sectional charging method

InactiveCN103390770AIncrease capacityImprove formation efficiencyFinal product manufactureElectrolyte accumulators manufactureAluminium-ion batteryElectrical battery

The invention discloses a lithium ion battery formation sectional charging method. The lithium ion battery formation sectional charging method is carried out at room temperature and comprises four stages, namely a constant current charging stage I, a constant current charging stage II, a constant current charging stage III and a constant voltage charging stage. According to the lithium ion battery formation sectional charging method, a small current charging stage is adopted for activating an electrode material, reducing impedance of positive and negative electrodes and improving battery capacity, and a large current charging stage is used for improving formation charging efficiency. The lithium ion battery formation sectional charging method has the beneficial effects that the formation efficiency of a lithium ion battery can be improved, that the good formation of an SEI (solid electrolyte interface) membrane can be guaranteed, and that the good cycle performance of the lithium ion battery can be maintained; meanwhile, formation charging time can be effectively shortened while the good performance of the lithium ion battery is maintained to be constant, and thus the production efficiency is improved.

Owner:TIANJIN LISHEN BATTERY

Electrolytic solution and lithium ion battery

InactiveCN109119685AImprove stabilityImprove conductivityCell electrodesSecondary cellsAluminium-ion batteryDecomposition

The invention relates to an electrolytic solution and a lithium ion battery, wherein the electrolytic solution comprises a lithium salt, a non-aqueous organic solvent and an additive, the additive comprises one or two selected from methylene methane disulfonate and ethylene sulfate, the lithium salt comprises lithium bis(fluorosulfonyl)imide, and the lithium bis(fluorosulfonyl)imide content is 5-15% of the total weight of the electrolytic solution. According to the present invention, the methylene methane disulfonate and / or the ethylene sulfate can significantly reduce the film forming impedance, the lithium bis(fluorosulfonyl)imide can improve the stability and the electrical conductivity of the electrolytic solution, reduce the production of hydrofluoric acid, inhibit the oxidative decomposition of non-aqueous organic solvents, and inhibit the dissolution of positive metal ions, such that the combination of the two materials can make the lithium ion battery have advantages of good low-temperature performance, fast charge performance and long cycle life.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com