Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

297results about How to "Improve high rate discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode active material powder for lithium secondary battery

ActiveUS20070099087A1Large volume capacity densityHigh safetyPositive electrodesCobalt compoundsComposite oxideCharge and discharge

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

Anode material of lithium ion cell and preparation method

InactiveCN1627550AGood cycle performanceGood high temperature performanceElectrode thermal treatmentActive material electrodesAnodeMetallurgy

The anode material is prepared from oxidation material layer of covering surface of at least one anode active material among LiCoO2, LiNi1-xCOxO2, LiNi1 / 3Mn1 / 3O2 and LiMn2O4. Weight of non-oxygen element in oxidation material layer can be 0.01-10 weight% of anode active material. Advantages of the anode material are: good cycle performance, favorable high temp property and high power discharge property, and anti over change property as well as simple technique and easy of production.

Owner:BYD CO LTD

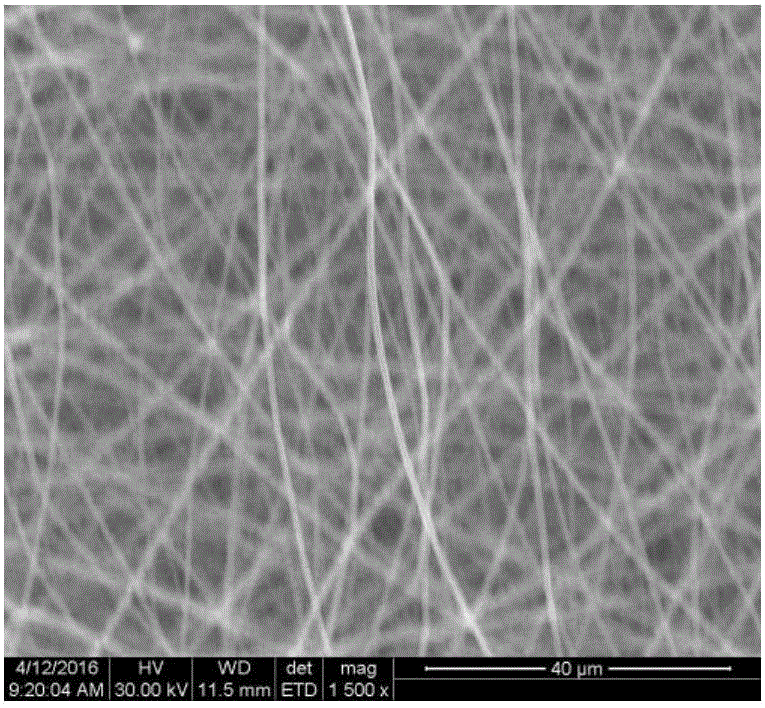

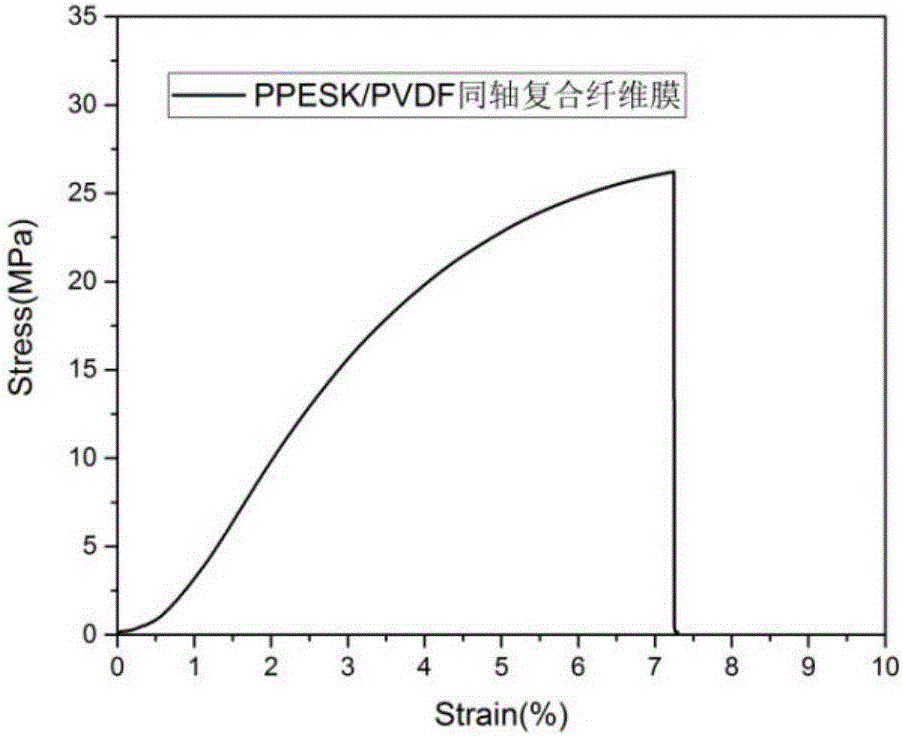

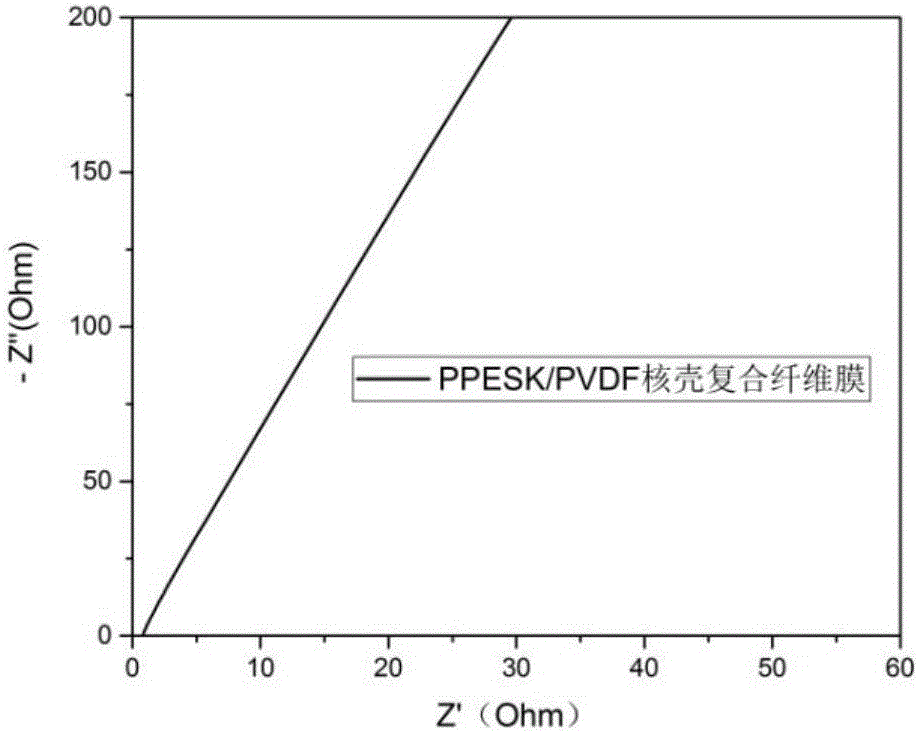

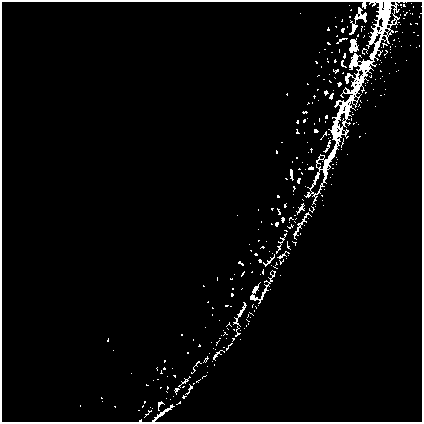

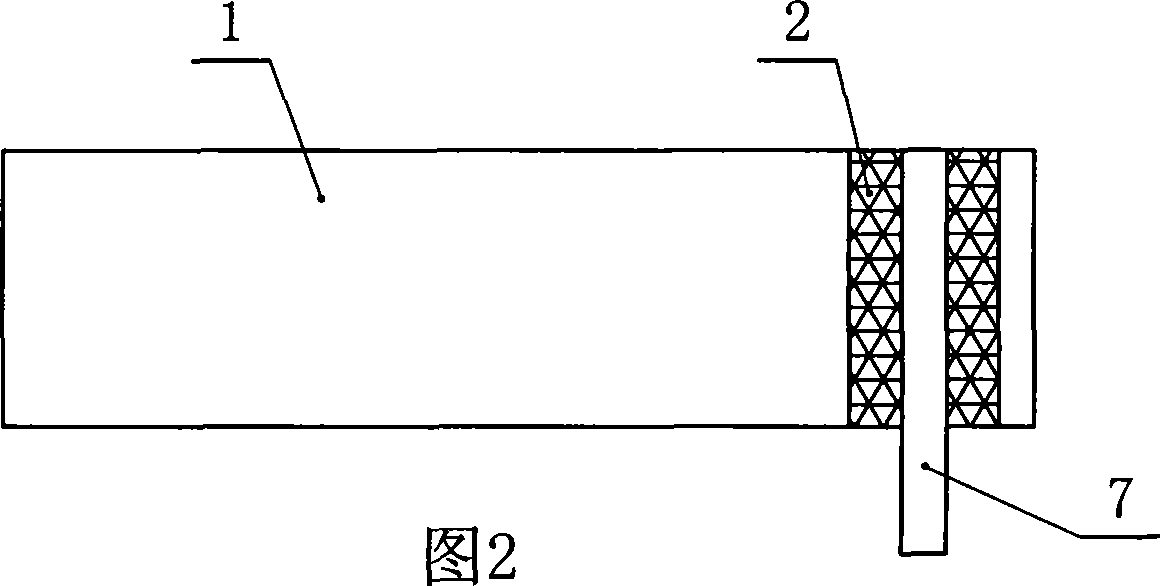

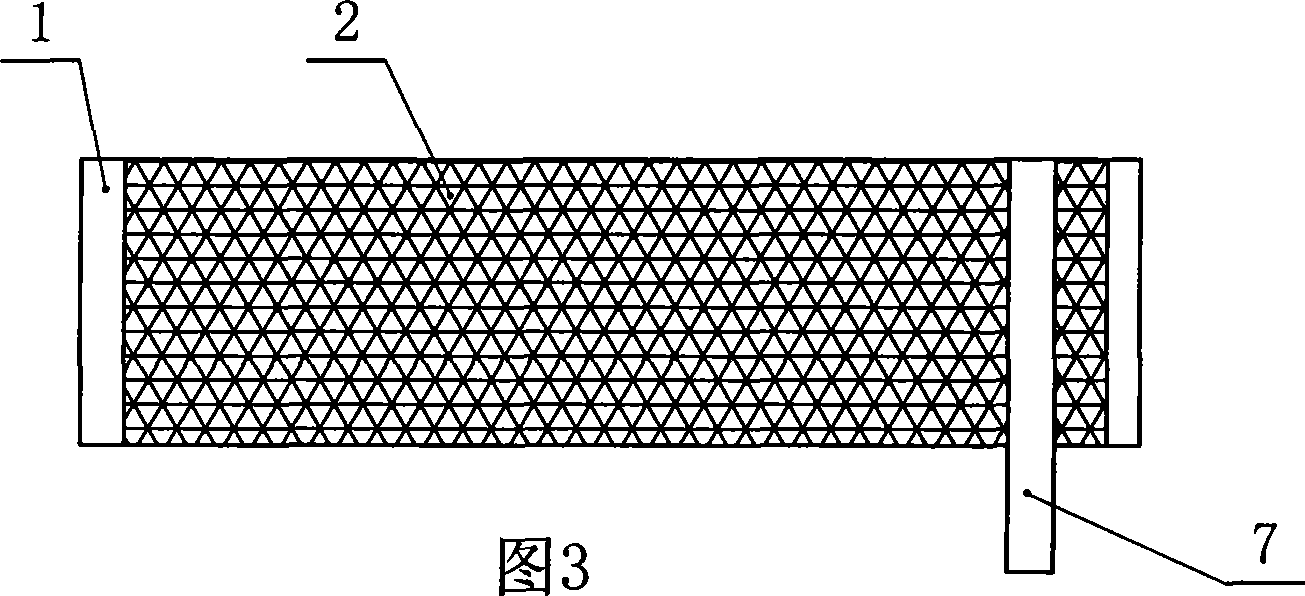

Method for preparing novel lithium battery diaphragm by coaxial electrostatic spinning

ActiveCN106450101AGood high temperature resistanceImproved high temperature thermal stabilityElectro-spinningCell component detailsPolyvinylidene fluorideElectrospinning

The invention provides a method for preparing a novel lithium battery diaphragm by coaxial electrostatic spinning, and belongs to the technical field of the lithium battery diaphragm. The novel lithium battery diaphragm is a composite fiber membrane prepared by a coaxial electrostatic spinning technology and having a core / shell structure; the core and shell layers of the composite fiber membrane are concentric-coaxial-shaped; the core layer consists of high-melting-point polyarylether sulfone ketone nanofibers; the shell layer consists of low-melting-point polyvinylidene fluoride nanofibers; particularly, the coaxial composite diaphragm is subjected to hot-press treatment at certain temperature and pressure; and the shell layer fibers generate micro melting or melting to enhance the binding power between fibers, so that the tensile strength of the composite diaphragm in each direction is greatly improved. The porosity of the novel lithium battery diaphragm reaches greater than 75%; and the electrolyte absorption rate reaches greater than 550%; the diaphragm can withstand a temperature of 180 DEG C, so that the diaphragm prepared by the method has good electrochemical property, thermal performance and mechanical performance, which has high application value in the fields of aviation, spaceflight, electric vehicle and the like.

Owner:DALIAN UNIV OF TECH

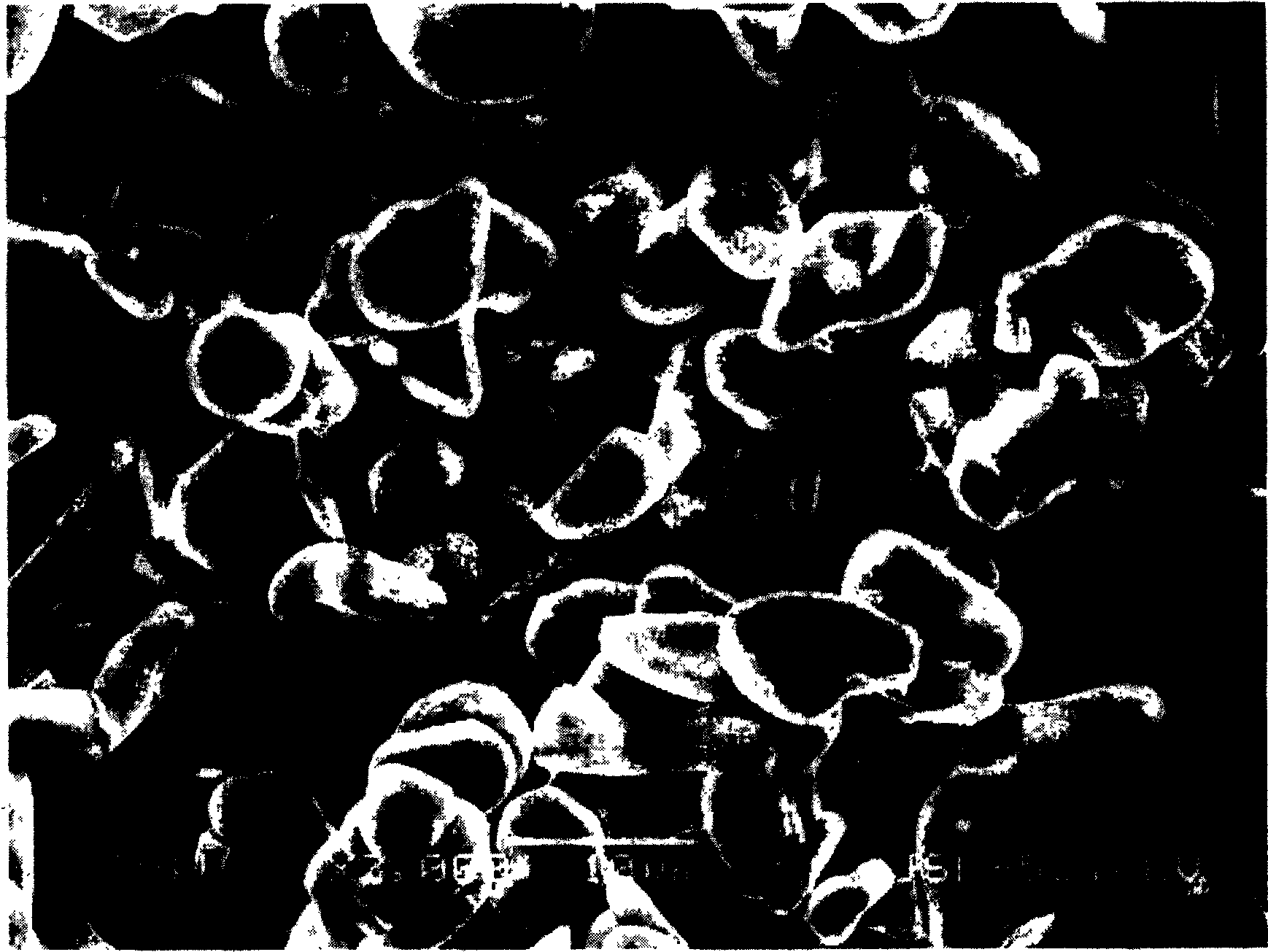

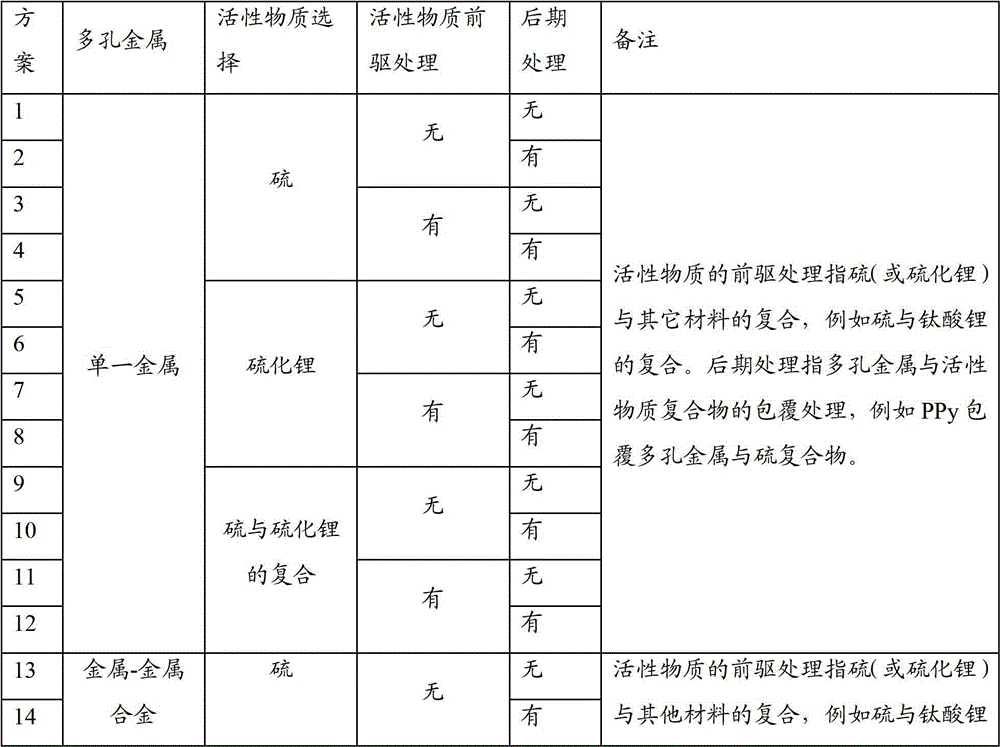

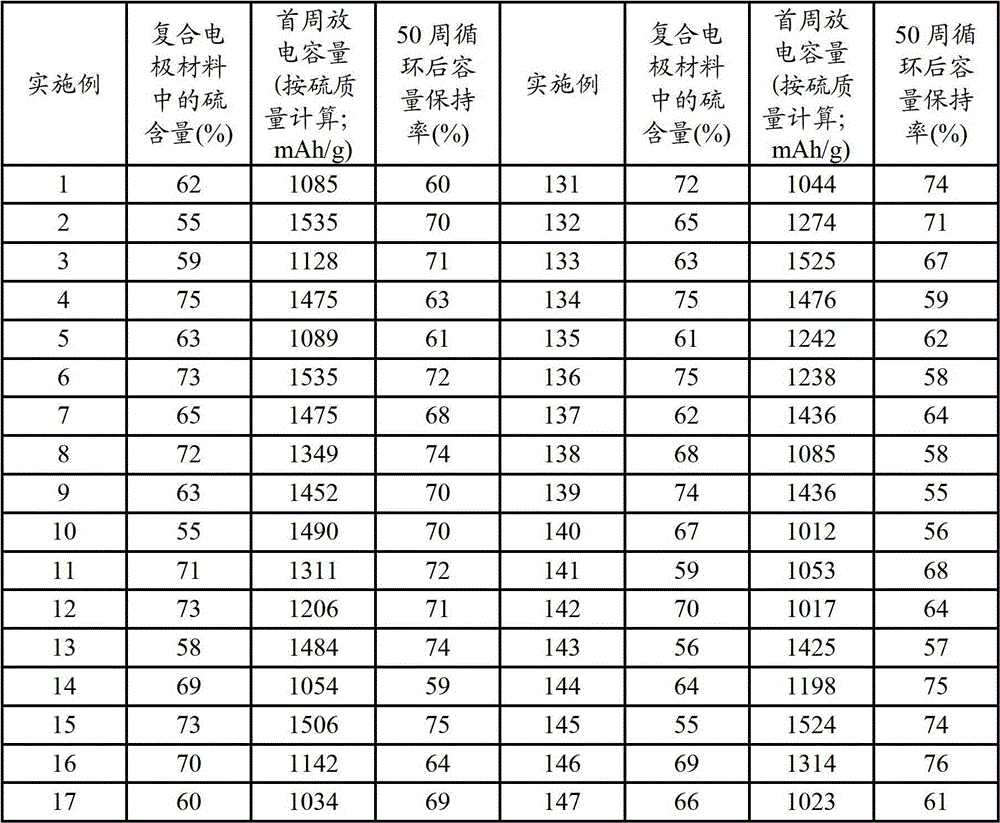

Lithium-sulfur battery anode material comprising porous metal and preparation method thereof

ActiveCN102723470ALarger than surfaceHigh porosityCell electrodesLithium sulfideLithium–sulfur battery

The invention discloses lithium-sulfur battery anode material comprising porous metal. The porous metal is compounded with lithium sulfide so as to be used as the anode material of the lithium-sulfur battery. The invention also discloses a preparation method of the lithium-sulfur battery anode material comprising the porous metal. According to the invention, by utilizing the characteristics of high electric conductivity, high porosity, high specific surface area and the like of the porous metal, elemental sulfur or the lithium sulfide is filled into pores of the porous metal, metal / sulfur composite material can be manufactured, and the utilization rate of the elemental sulfur and the lithium sulfide and the multiplying performance of the composite electrode can be increased; and simultaneously, by utilizing the strong interaction between the porous metal and the elemental sulfur or the lithium sulfide, the elemental sulfur, the lithium sulfide or polysulfide generated in a charge-discharge process can be more firmly attached on the surface of the porous metal, the dissolution of the polysulfide in an electrolyte, the shuttle effect caused by the dissolution of the polysulfide in the electrolyte and the deactivation on an anode and a cathode by redox product of the polysulfide can be restrained, and the circulation stability of a metal / sulfur composite electrode and the lithium-sulfur battery can be increased.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

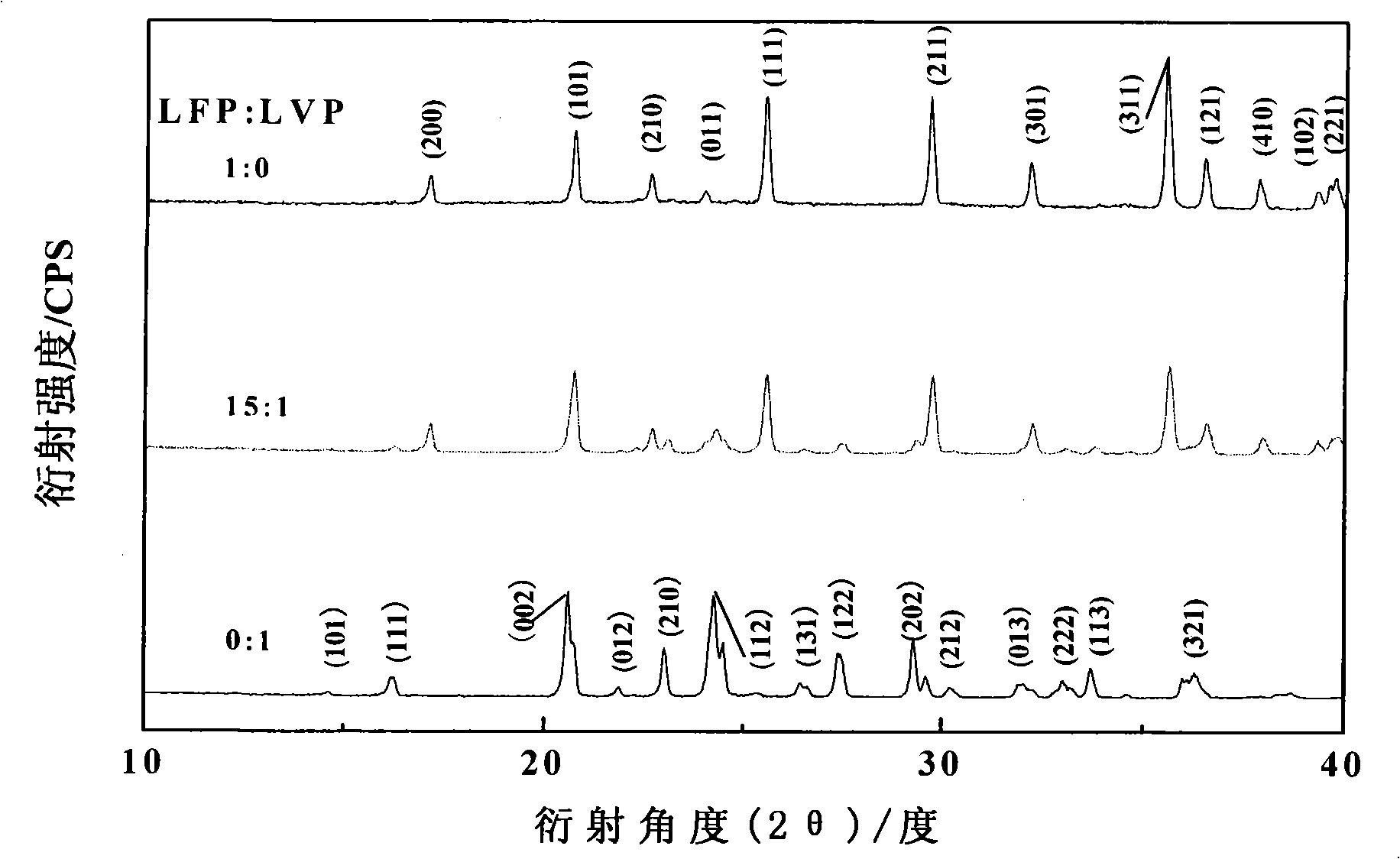

An anode material for compound lithium ion battery

InactiveCN101262058AOvercoming the problem of low conductivityImprove high rate discharge performanceCell electrodesPhysical chemistrySolid solution

The invention discloses a positive electrode material for a compound lithium ion battery. LiFePO4 is adopted as matrix, and Li3V2 (PO4)3 or LiVPO4F is adopted to wrap the surface of LiFePO4 particles or to exist among LiFePO4 particles or to directly form a solid solution with LiFePO4, and the molar ratio of LiFePO4 and Li3V2 (PO4)3 or LiVPO4F is (1-100):(100-1). The compound lithium ion battery of the invention has excellent performances of charge / discharge and magnification, and the positive electrode material of the compound lithium ion battery is suitable for producing power cells.

Owner:CENT SOUTH UNIV

First-time charging forming method for lithium-ion secondary battery

InactiveCN103151565AImprove cycle performanceImprove high rate discharge performanceFinal product manufactureSecondary cells charging/dischargingHigh rateElectrical battery

The invention belongs to the technical field of lithium-ion secondary batteries, and in particular relates to a first-time charging forming method for a lithium-ion secondary battery. The method comprises the following steps that: carrying out aging treatment on the lithium-ion secondary battery poured with electrolyte, then gradually increasing the charging current to carry out a sectional charge formation on the battery in the state of negative pressure, and sealing the battery when the voltage reaches 3.6 volts; and carrying out aging treatment on the battery, carrying out constant-current charging to 3.8-4.0 volts at a rate of 0.5 C-1 C, then carrying out constant-current charging to 4.2 volts at a rate of 0.2 C-0.5 C, and carrying out constant-voltage charging in the state of 4.2 volts at last. Compared with the prior art, the invention adopts the method of sectional charge formation to charge the battery to 3.6 volts firstly, so as to exhaust the harmful gas produced in the process of forming SEI (solid electrolyte interface), ensure the migration of Li<+> better, enable the formed SEI to be more uniform, stable and compact, and thus improving the cycling performance and high rate discharging performance.

Owner:湖北力莱科技有限公司

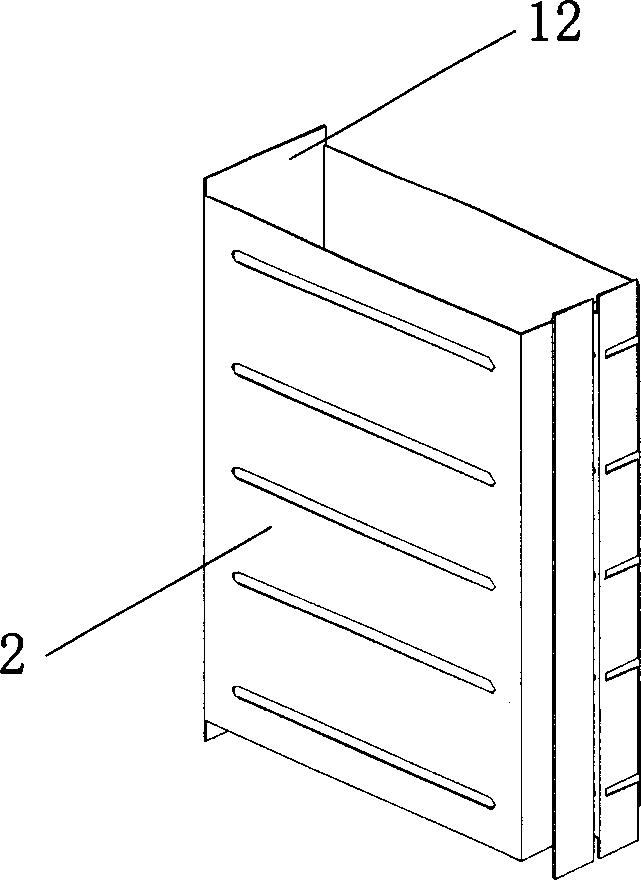

Polyalcohol microporous barrier for high ratio polyalcohol lithium ion power cell

ActiveCN101153084AStrong liquid absorption capacityHigh rate discharge performance is goodSecondary cellsChemistryPlasticizer

The present invention relates to a polymer microporous membrane for high-rate polymer lithium-ion power battery. The polymer microporous membrane is mainly used in gel polymer lithium-ion power battery. The power battery can provide powered power supply for equipment of high energy consumption and large current discharge, such as an electric vehicle, an electric motorcycle, uninterruptible power supply and so on. The microporous membrane is made of polymer material, inorganic filler, plasticizer and organic solvent. The porosity rate is between 20 percent and 70 percent. After treatment, the microporous membrane can be transformed into electrolyte membrane; the high-rate gel polymer lithium-ion power battery can be made with a square-layered battery structure. The power battery has excellent high-rate charge and discharge performances and security performances.

Owner:WANXIANG 123 CO LTD

Cathode active material powder for lithium secondary battery

ActiveUS7429434B2Increase volume capacity densityImprove securityPositive electrodesCobalt compoundsAlkaline earth metalComposite oxide

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

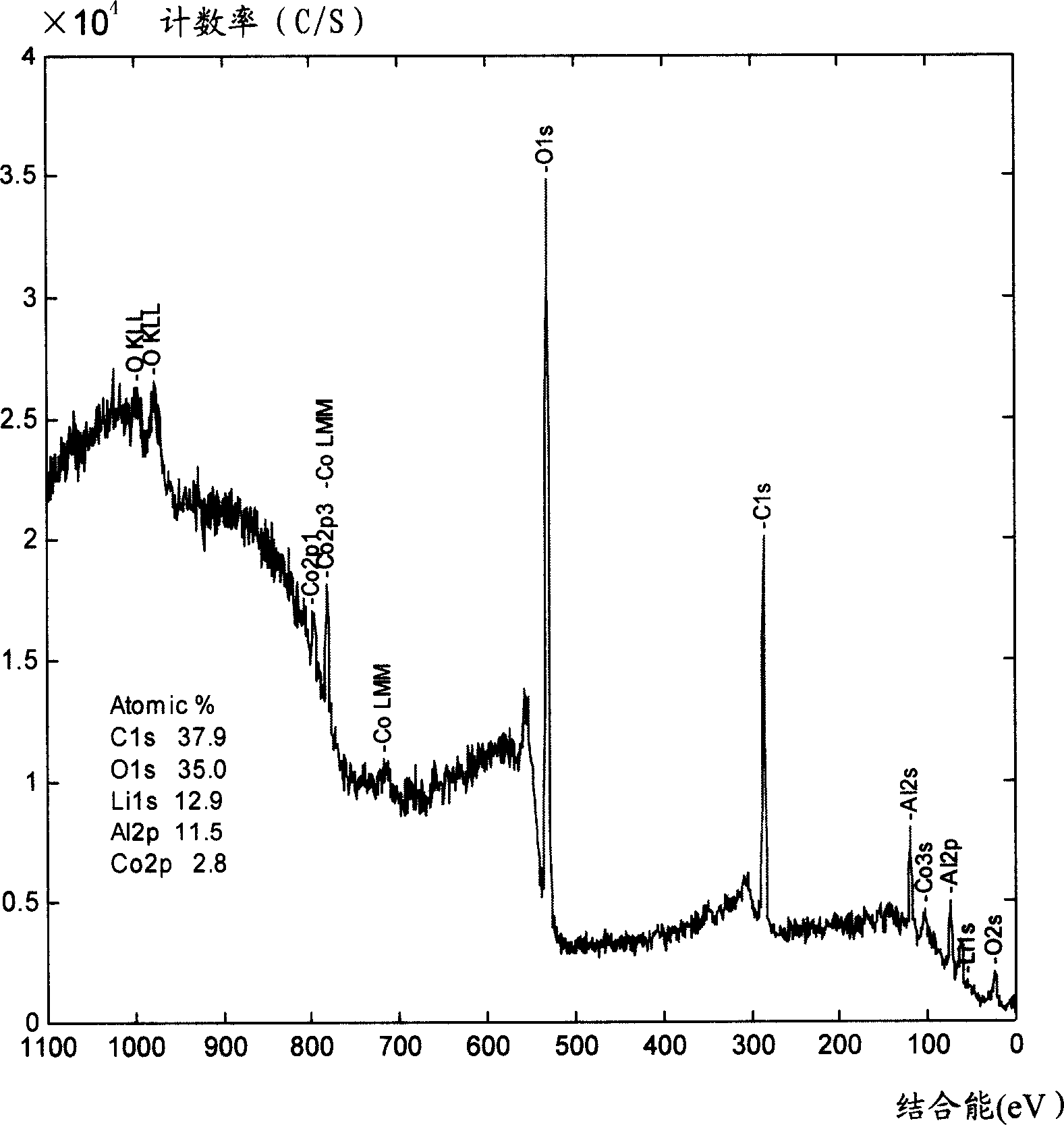

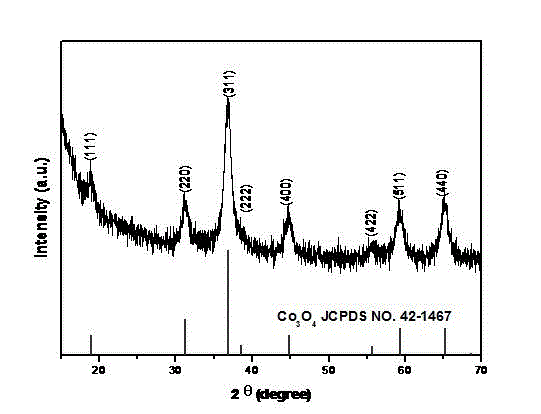

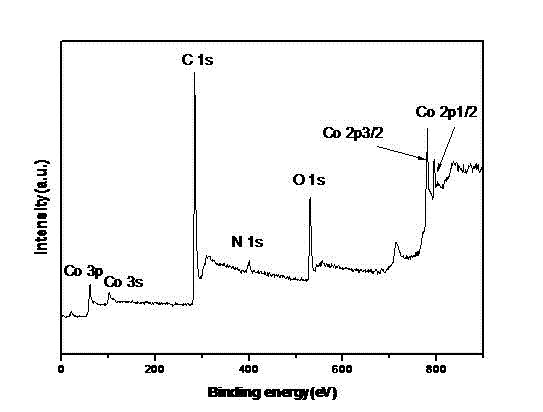

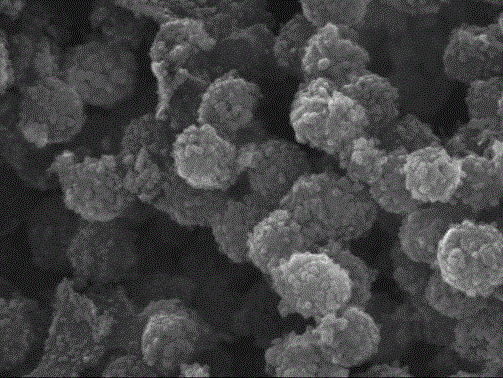

Nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and preparation method thereof

InactiveCN104966824AShorten the diffusion distanceImprove mobilityCell electrodesSecondary cellsPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and a preparation method thereof and belongs to the fields of electrochemistry and new energy resource materials. According to the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on the chitosan and the derivatives thereof and the preparation method thereof, firstly the chitosan and the derivatives thereof are taken as carbon source and nitrogen source precursors, a hard template carbonization method is adopted to prepare nitrogen-doped porous carbon spheres; then a mild hydrothermal method is adopted to load cobaltous oxide nano particles to the nitrogen-doped porous carbon spheres, and then the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material is obtained. The material synthesizes the structural features of the nitrogen-doped porous carbon spheres and the small-size effect advantages of the cobaltous oxide nano particles, and due to the expression of the synergistic effect of the nitrogen-doped porous carbon spheres and the cobaltous oxide nano particles, the prepared material shows higher reversible specific capacity, better cycling stability and more excellent large rate discharge performance than a commercial graphite material when used as a lithium ion battery anode material. The method is strong in operability, preparation conditions are mild, the requirement for equipment is not rigorous, and the preparation method is suitable for industrial production; the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material prepared by the method has potential application value in electrochemistry fields including lithium ion batteries, supercapacitors and the like.

Owner:HUBEI ENG UNIV

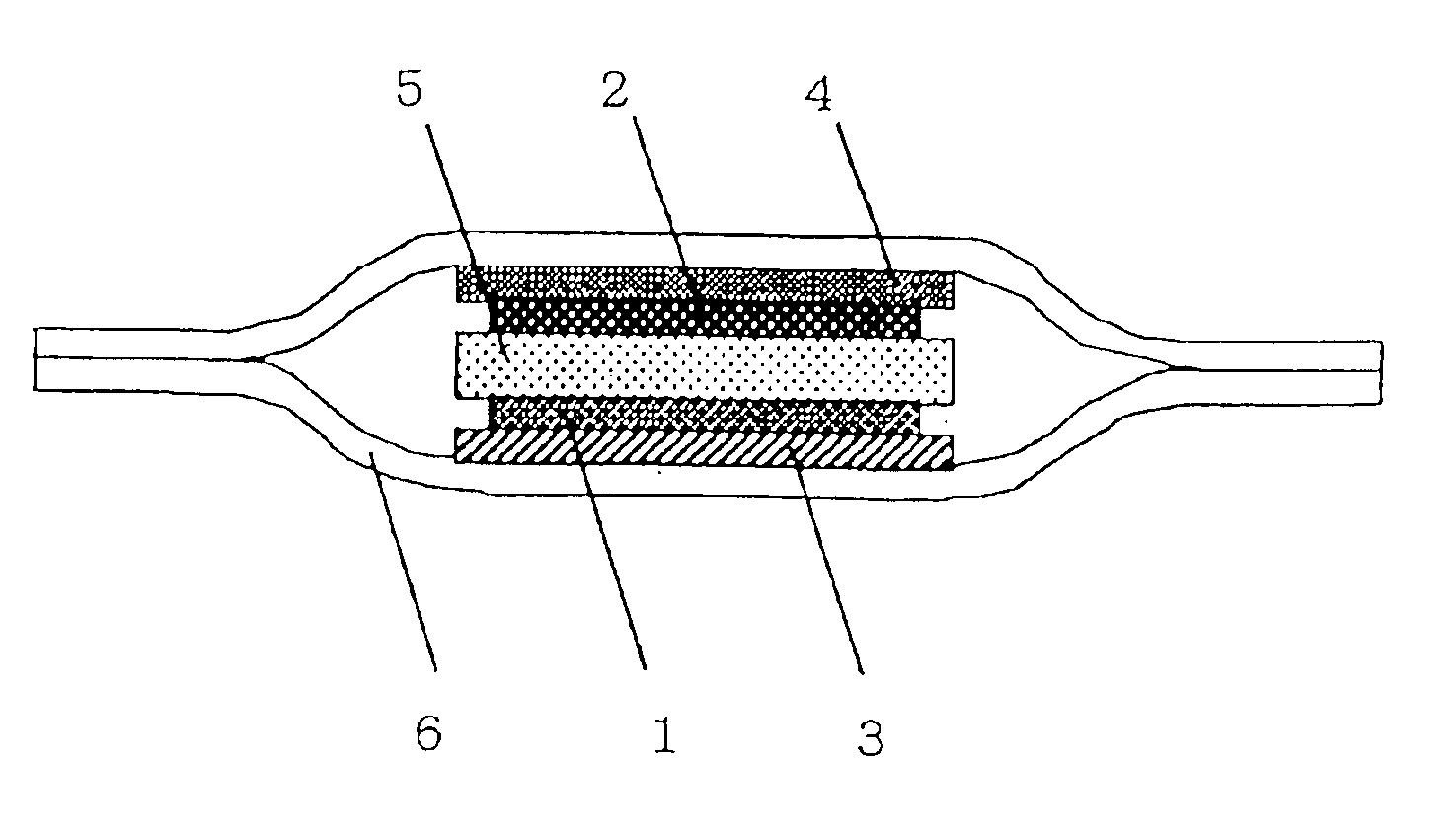

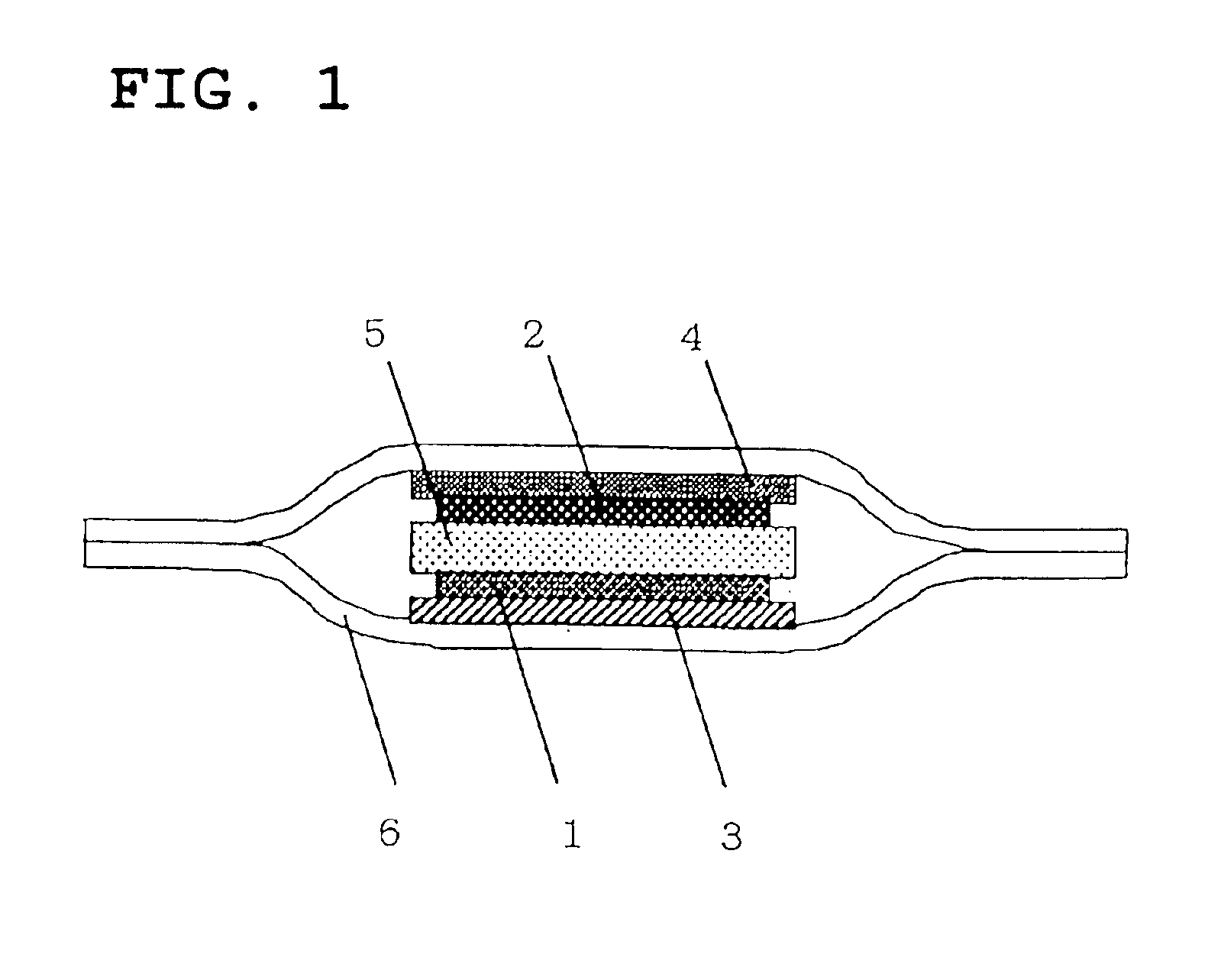

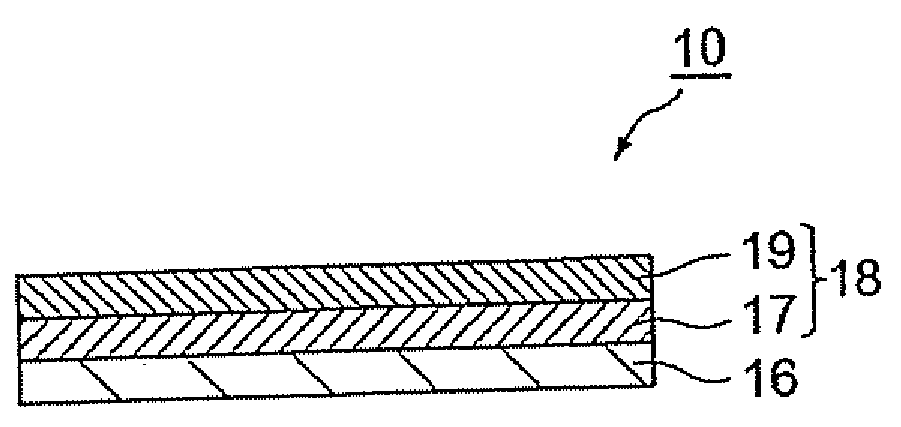

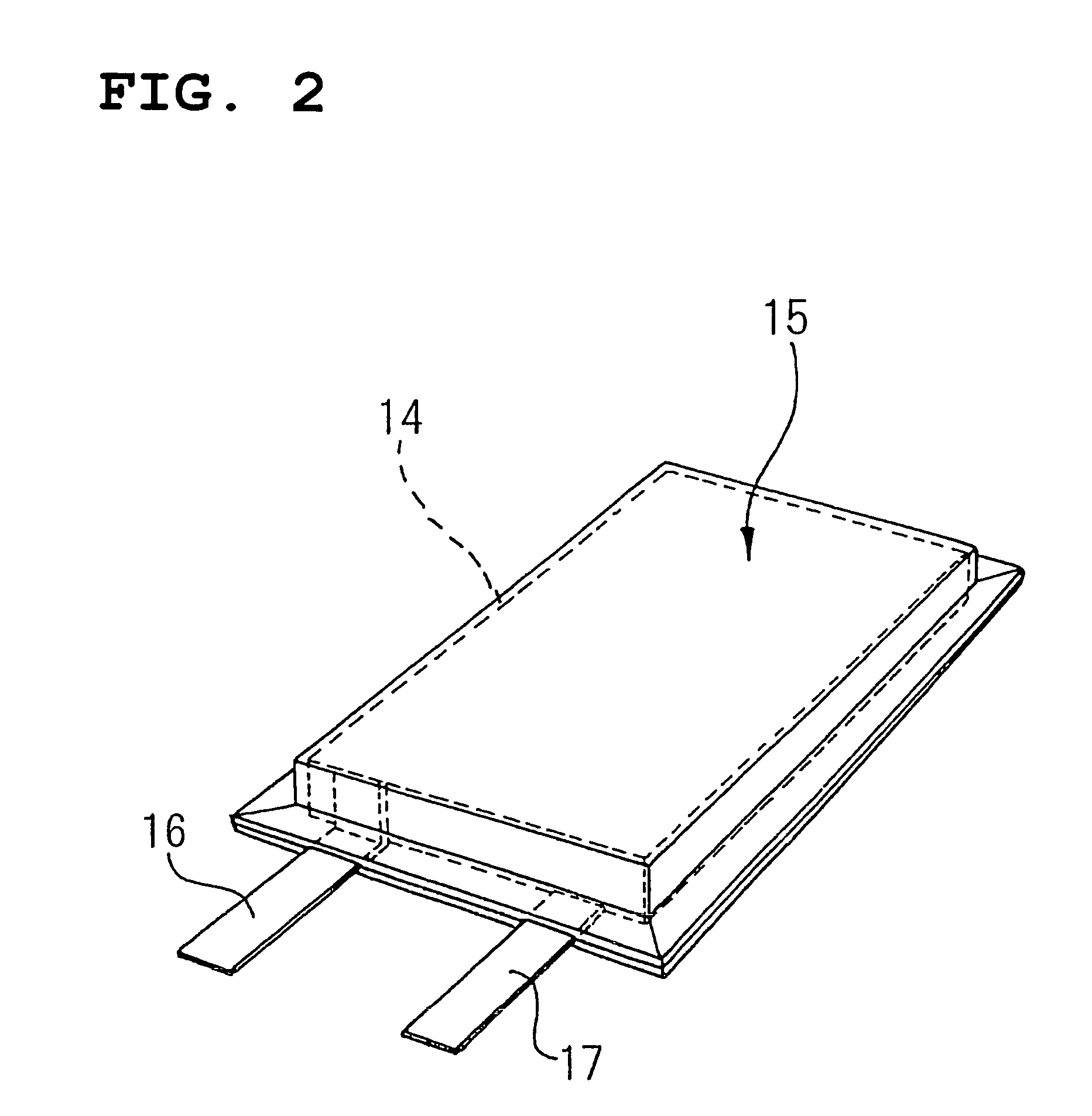

Lithium battery including a gel electrolyte

InactiveUS6902848B1Improve high rate discharge performanceImprove thermal stabilityOrganic electrolyte cellsSolid electrolyte cellsHigh rateLithium-ion battery

A lithium battery excellent in initial capacity, high rate discharge performance, low temperature performance and cycle life performance can be provided without the necessity of any special production step.In other words, the present invention lies in a lithium battery having a power-generating element comprising at least a positive electrode, a negative electrode and a separator wherein a gel electrolyte comprising at least a polymer and a liquid electrolyte is used in at least a part of the power-generating element, characterized in that the concentration of lithium salt in the liquid electrolyte is from 1.5 to 5 mols per l of the liquid electrolyte.

Owner:GS YUASA CORP

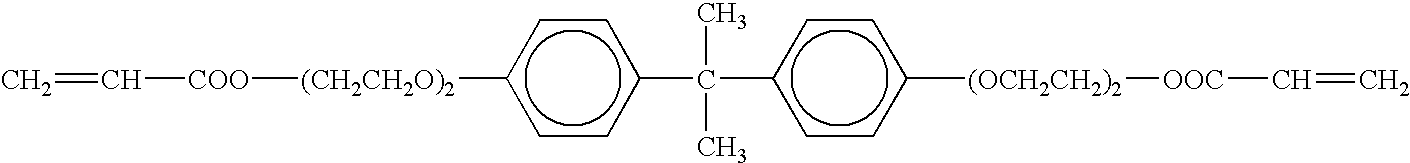

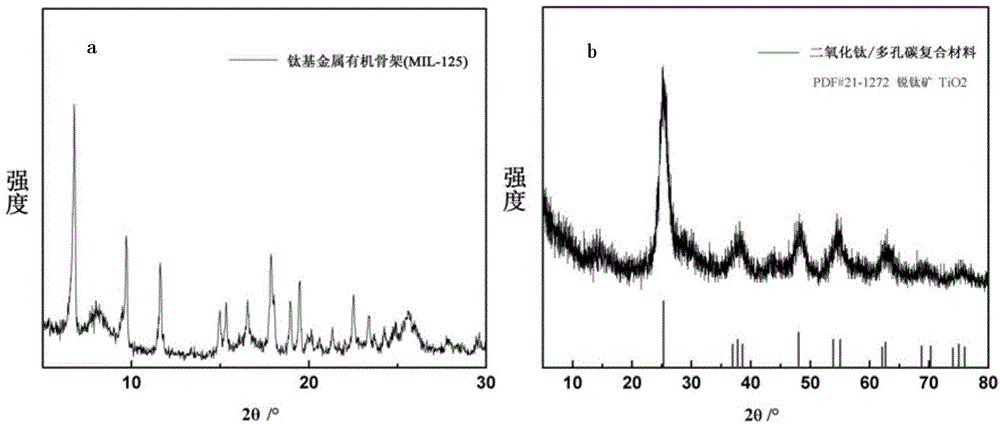

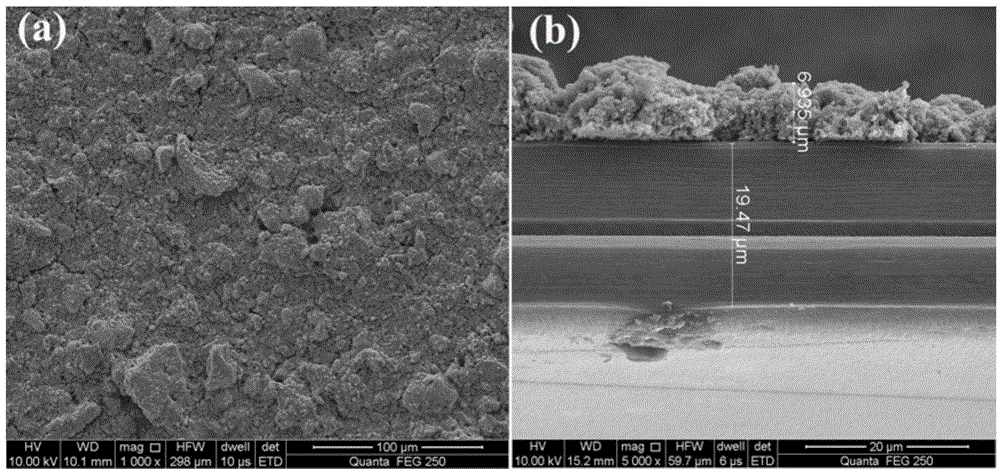

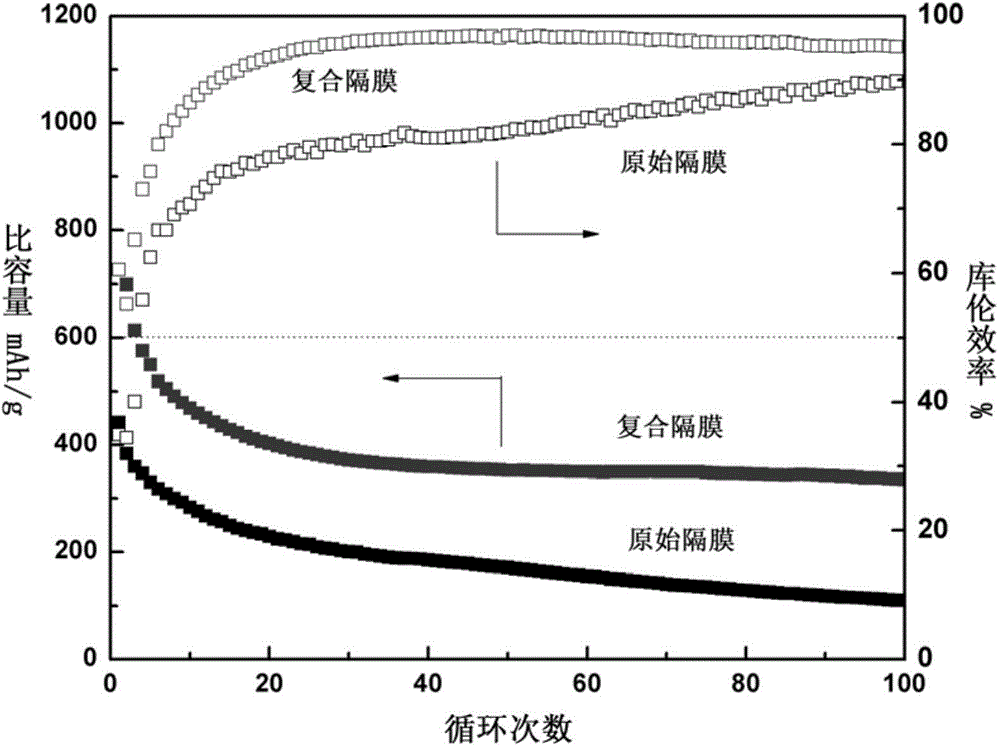

Composite diaphragm for lithium-selenium battery and preparation method of composite diaphragm

ActiveCN104638219AImprove wettabilityImprove carrying capacityCell component detailsLithiumHigh volume manufacturing

The invention discloses a composite diaphragm for a lithium-selenium battery and a preparation method of the composite diaphragm. The composite diaphragm is formed by smearing a coating material on an original diaphragm basal body, wherein the coating material consists of a titanium dioxide / porous carbon composite material, a conducting agent and a binder, and the titanium dioxide / porous carbon composite material is prepared by adopting a titanium-based metal organic framework as a precursor in a high-temperature carbonization manner. By adopting the composite diaphragm disclosed by the invention, a shuttle effect of poly-selenium ions generated in the charging and discharging process of the lithium-selenium battery between a selenium positive electrode and a lithium negative electrode can be effectively inhibited, and the cycling performance and the rate capability of the lithium-selenium battery can be remarkably improved. The preparation method is simple to operate, the composite diaphragm is low in cost and high in application potential and commercial value, and industrial implementation and mass production can be realized easily.

Owner:CENT SOUTH UNIV

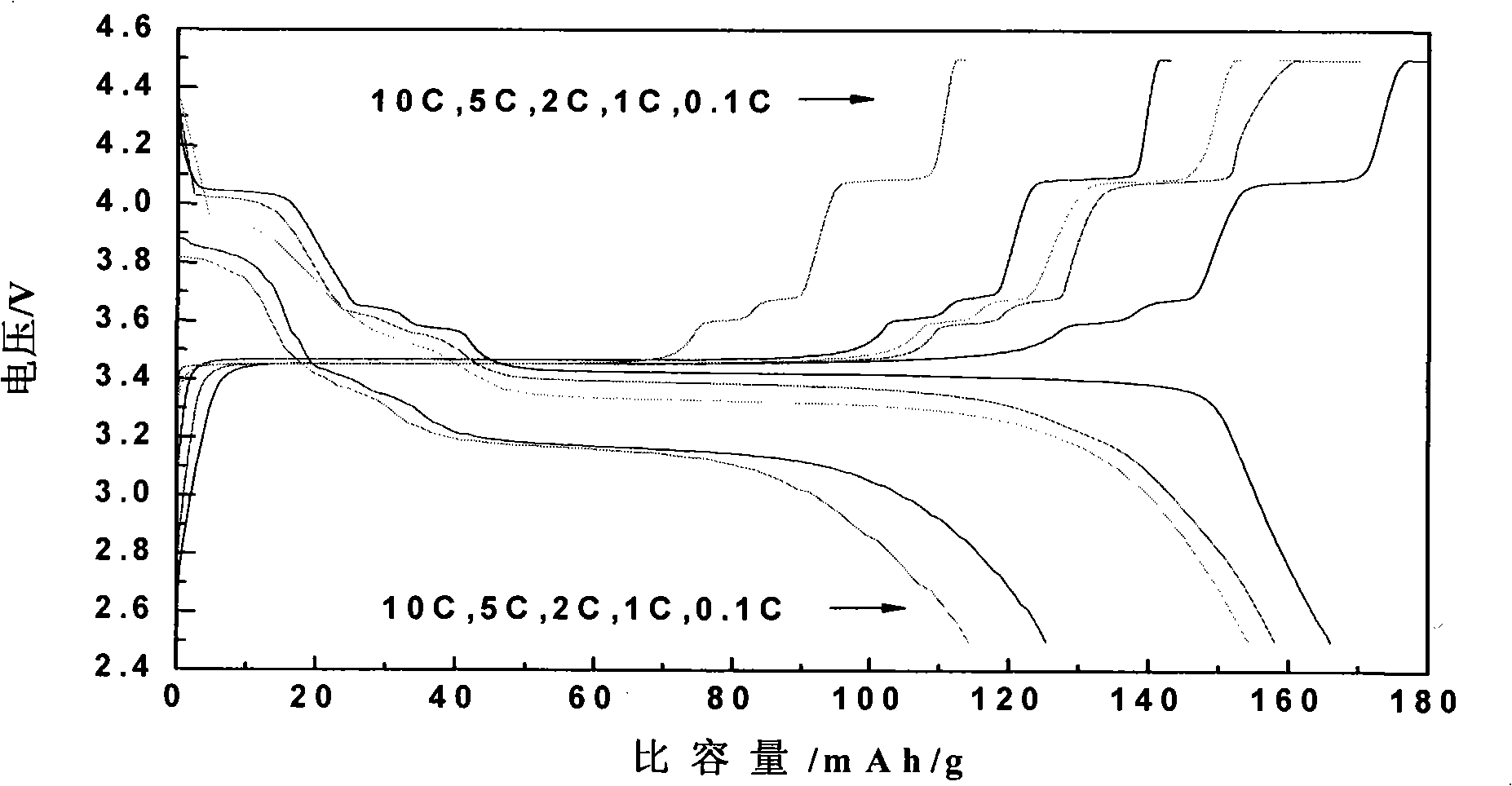

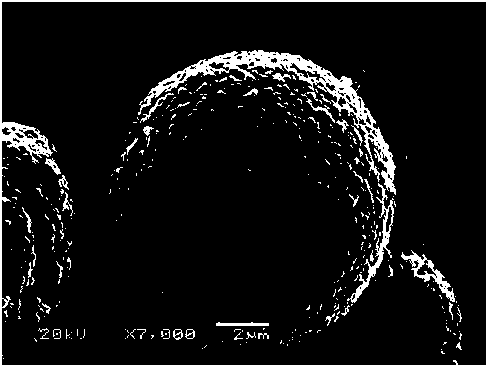

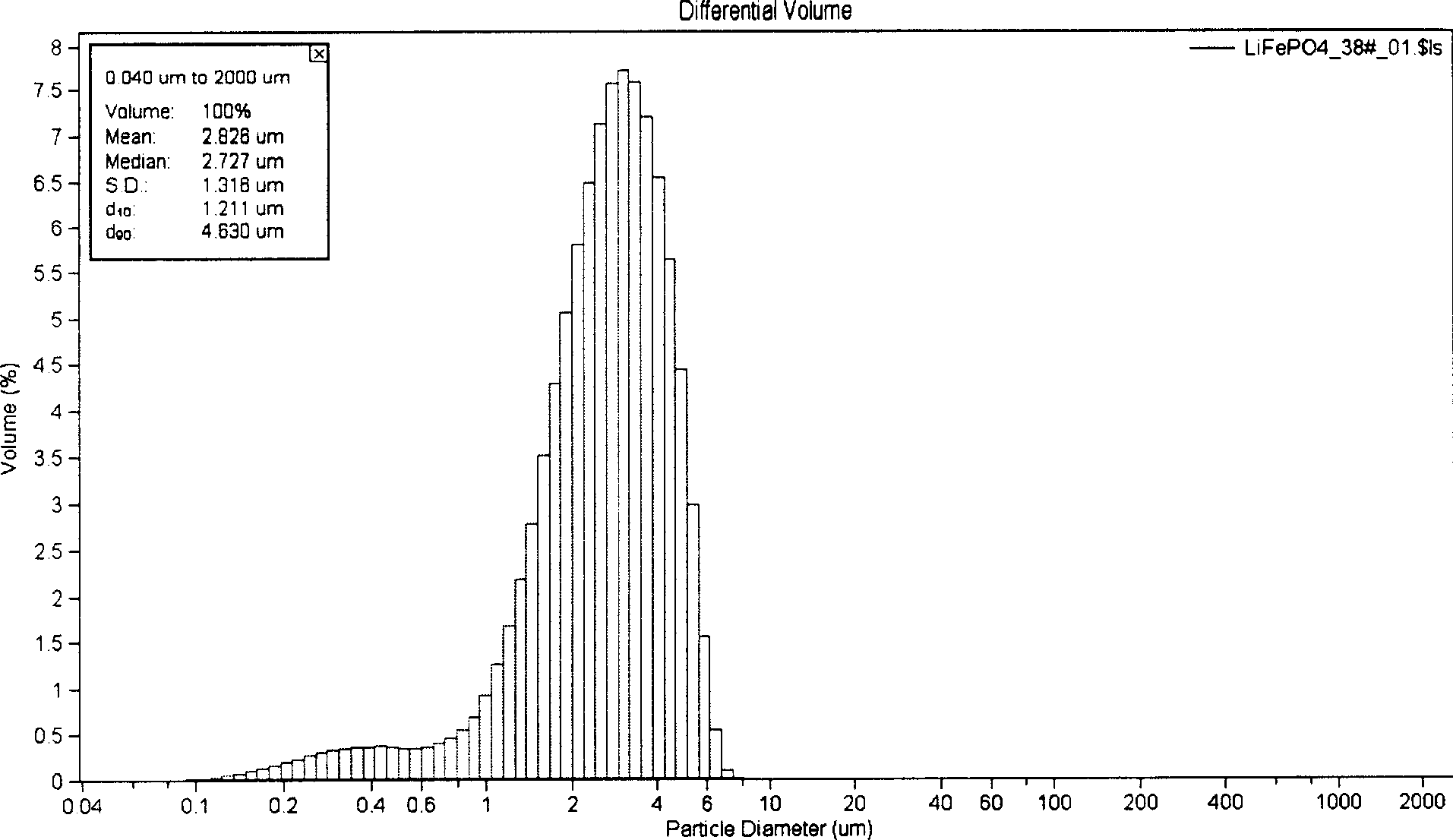

Lithium iron phosphate anode material for lithium ion battery and modification method

InactiveCN101315981AUniform structureEasy to processElectrode manufacturing processesChemical/physical/physico-chemical processesSolid state reaction methodLithium-ion battery

The invention provides a lithium iron phosphate anode material used for lithium ion batteries; the lithium iron phosphate which is prepared by a water heating method is taken as a precursor which is then uniformly mixed with a conductive matter precursor and metal ion salt, and finally baked in inert gas to obtain the lithium iron phosphate anode material which is coated by the conductive matter and doped by the metal ions. Compared with a pure solid phase reaction method, the method of the invention has small energy dissipation, the chemical uniformity of the synchronized outcome is good, the dimension and the appearance of the outcome are uniform, and the electromechanical performance and the processing performance have good stability and repeatability. Compared with the a pure water heating method, as the coating of the conductive matter, the doping and modifying performance of the metal ions are added during the anaphase, the electric conductivity of the material is greatly improved, and the high magnification electromechanical performance of the material is excellent; wherein, under the 10C discharging magnification, the discharging content of the lithium iron phosphate anode material with the copper ion doped is kept at 107mAh / g. After circulation for 50 times, the discharging content of the material is kept unchangeable basically, which can certify that the material has good circulation performance.

Owner:HEFEI UNIV OF TECH

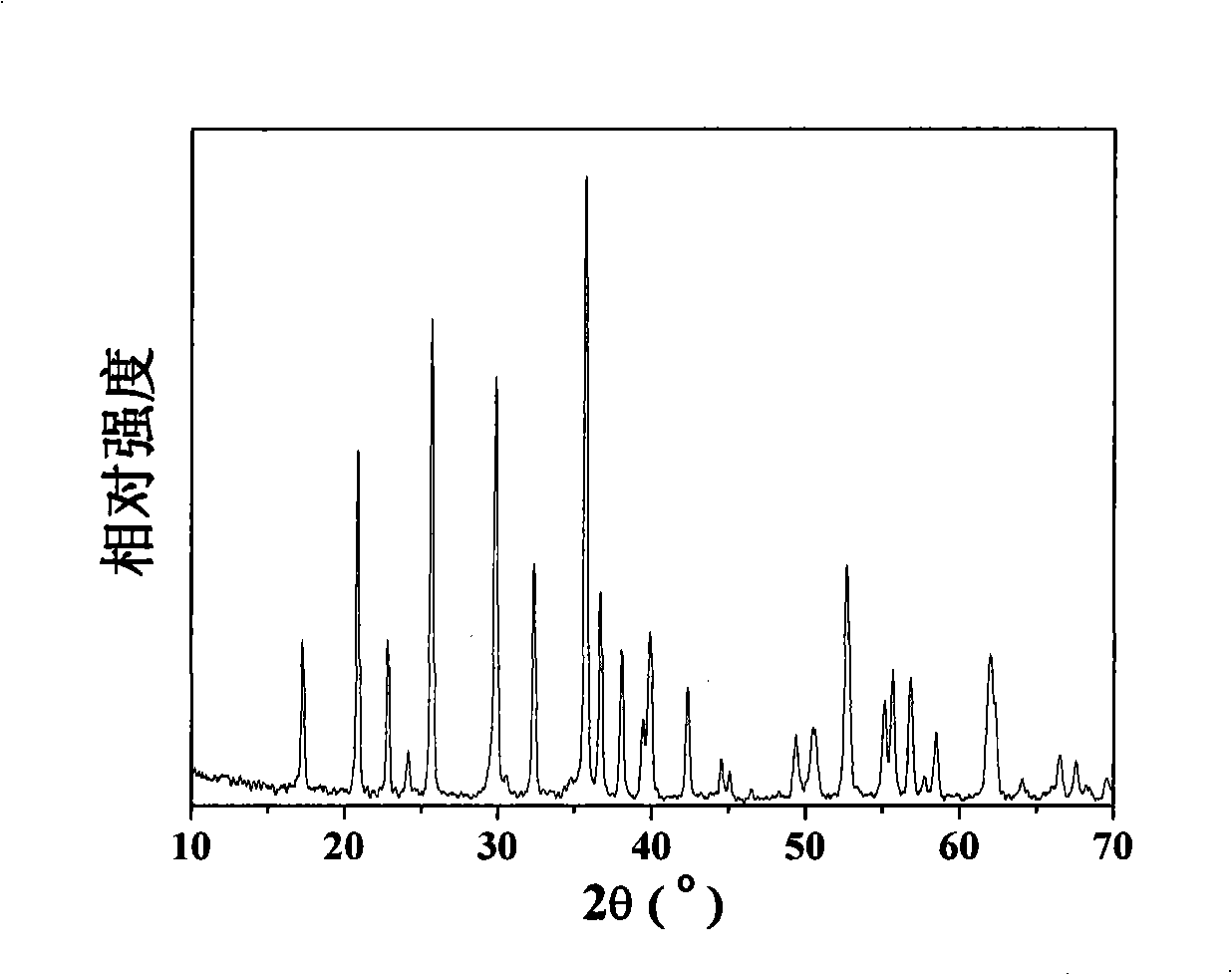

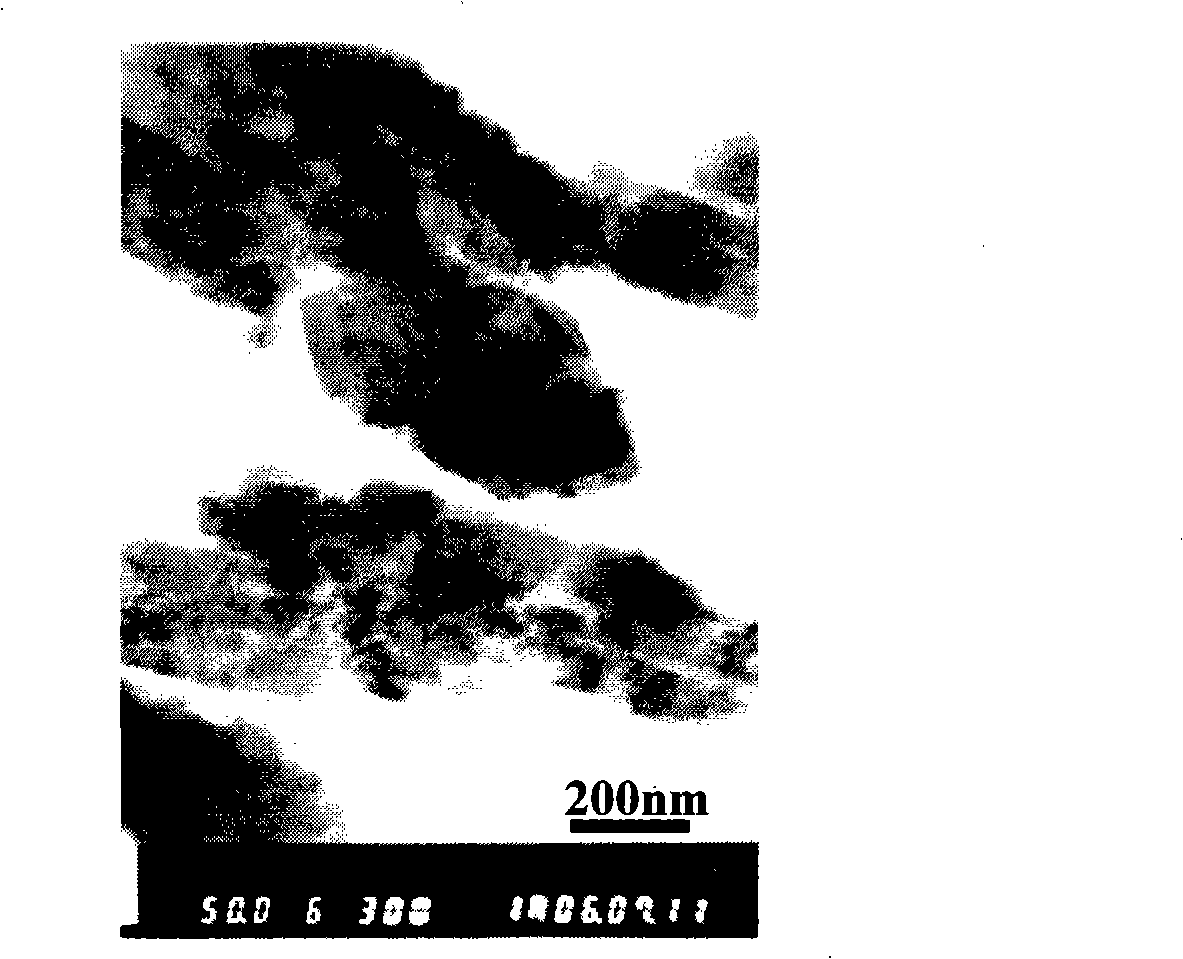

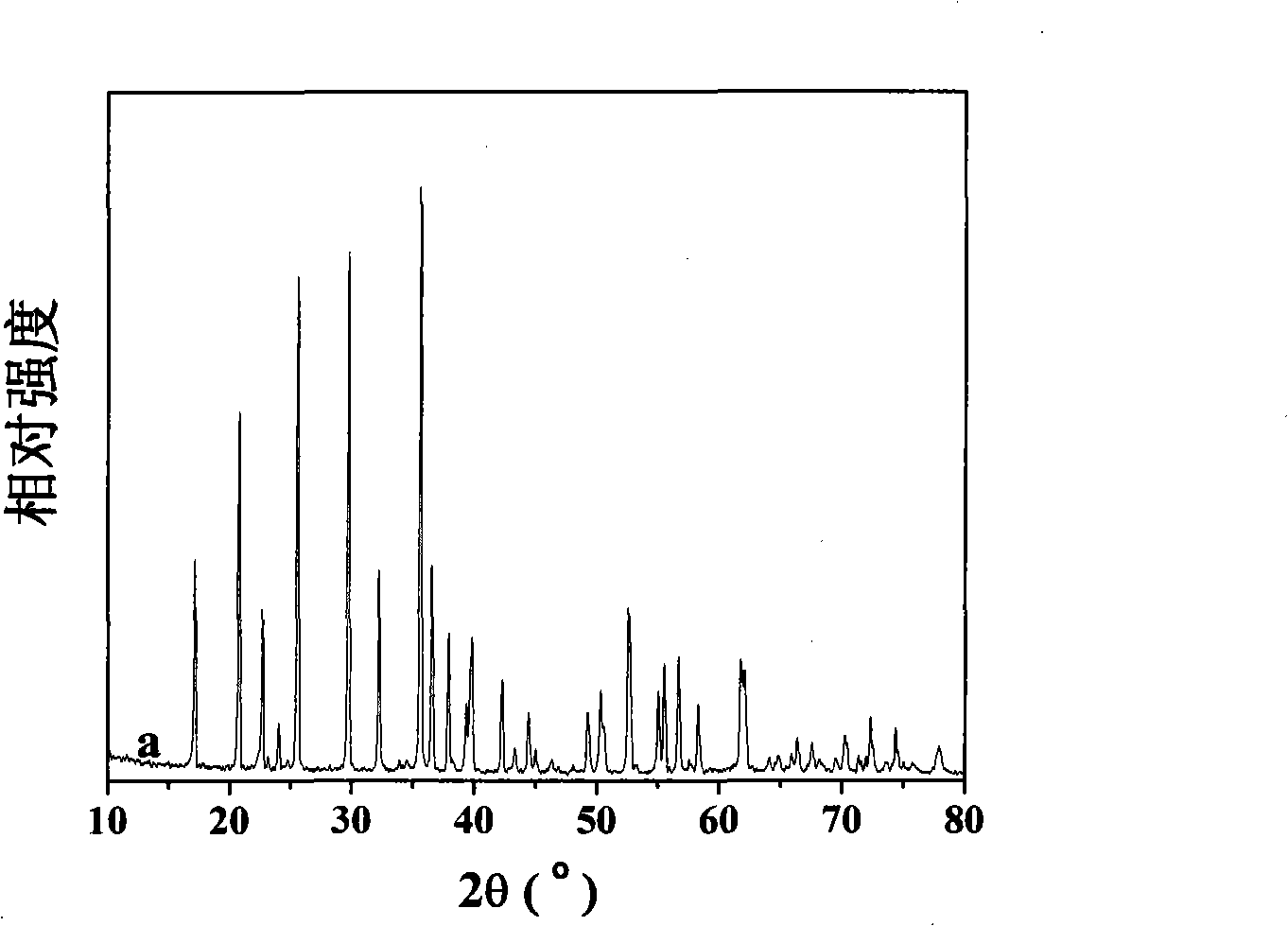

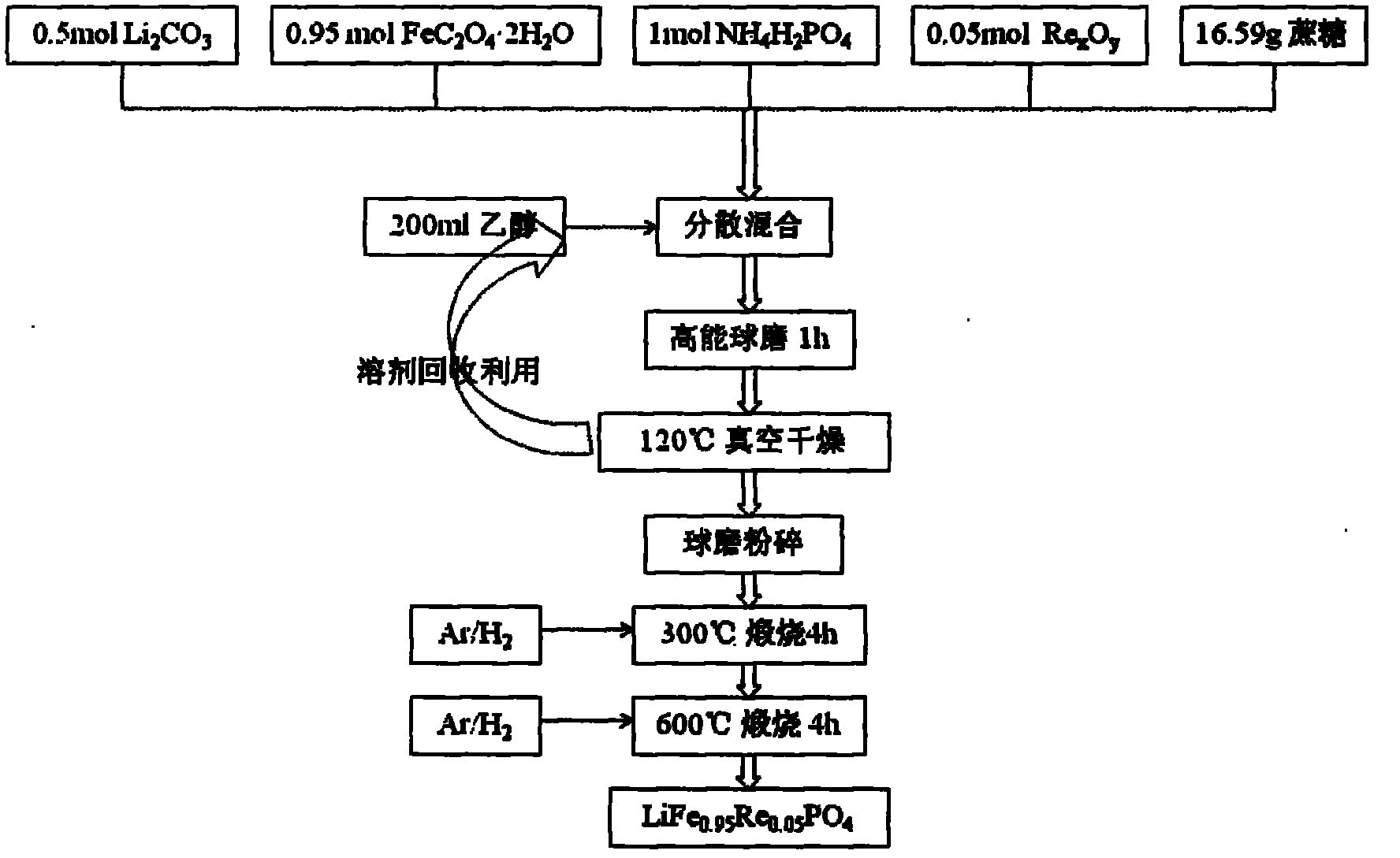

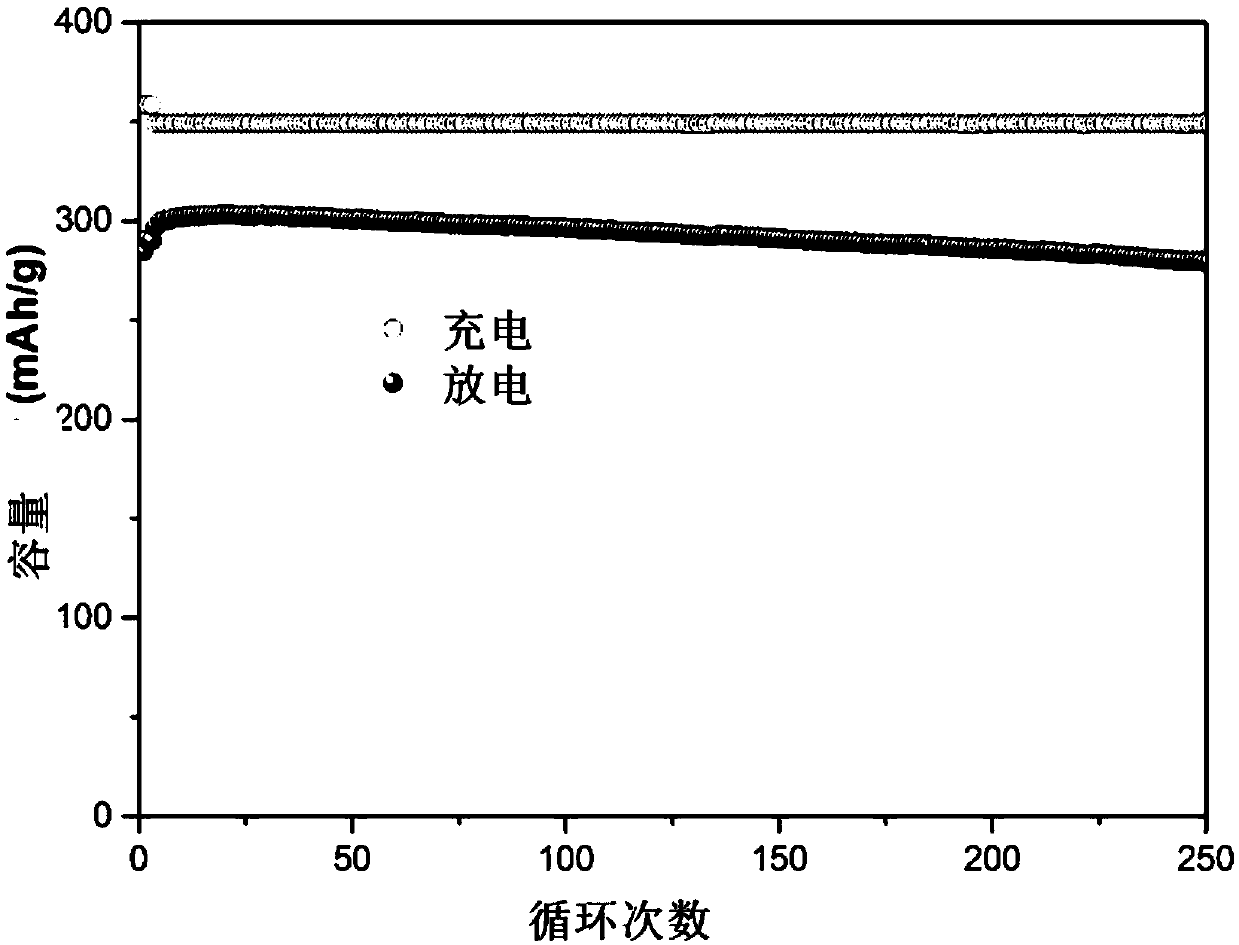

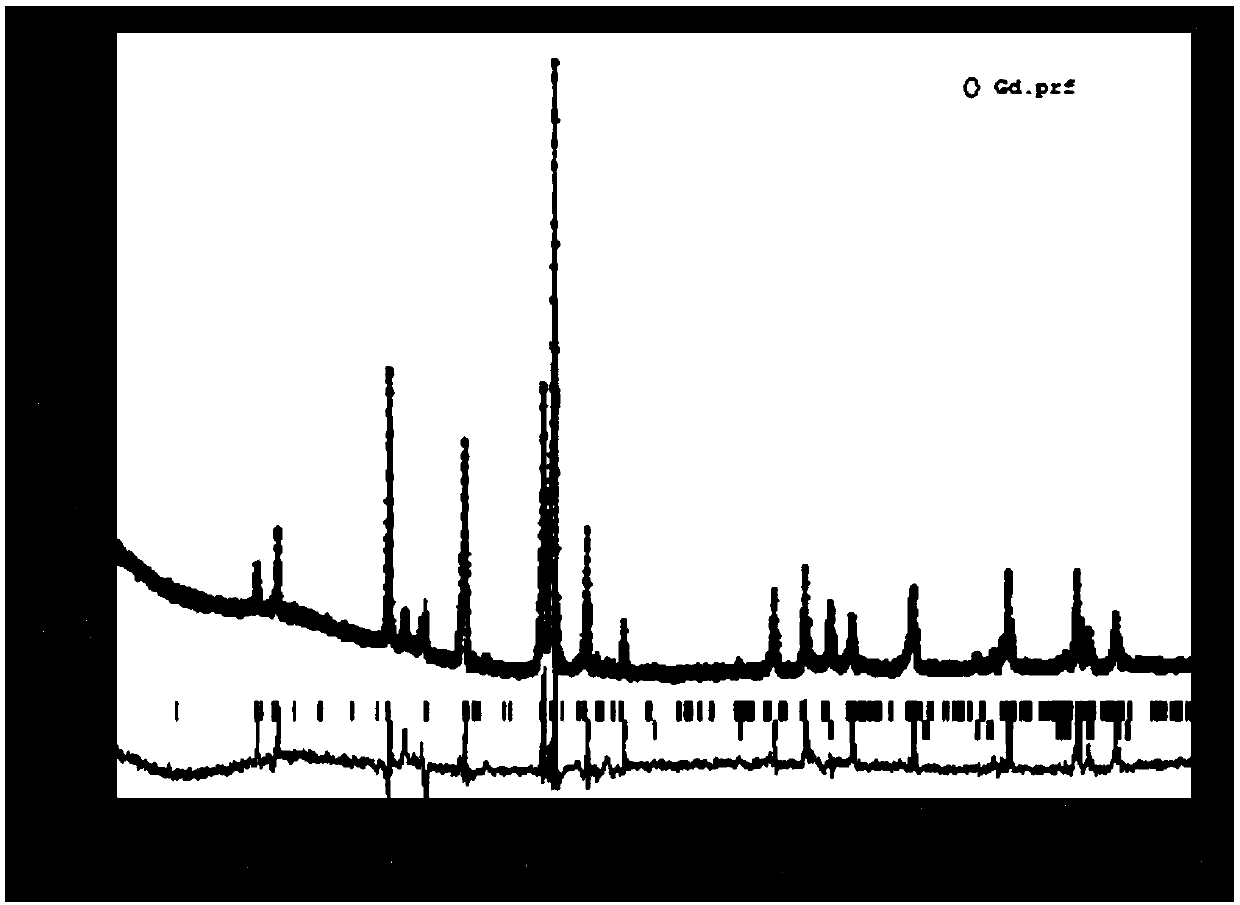

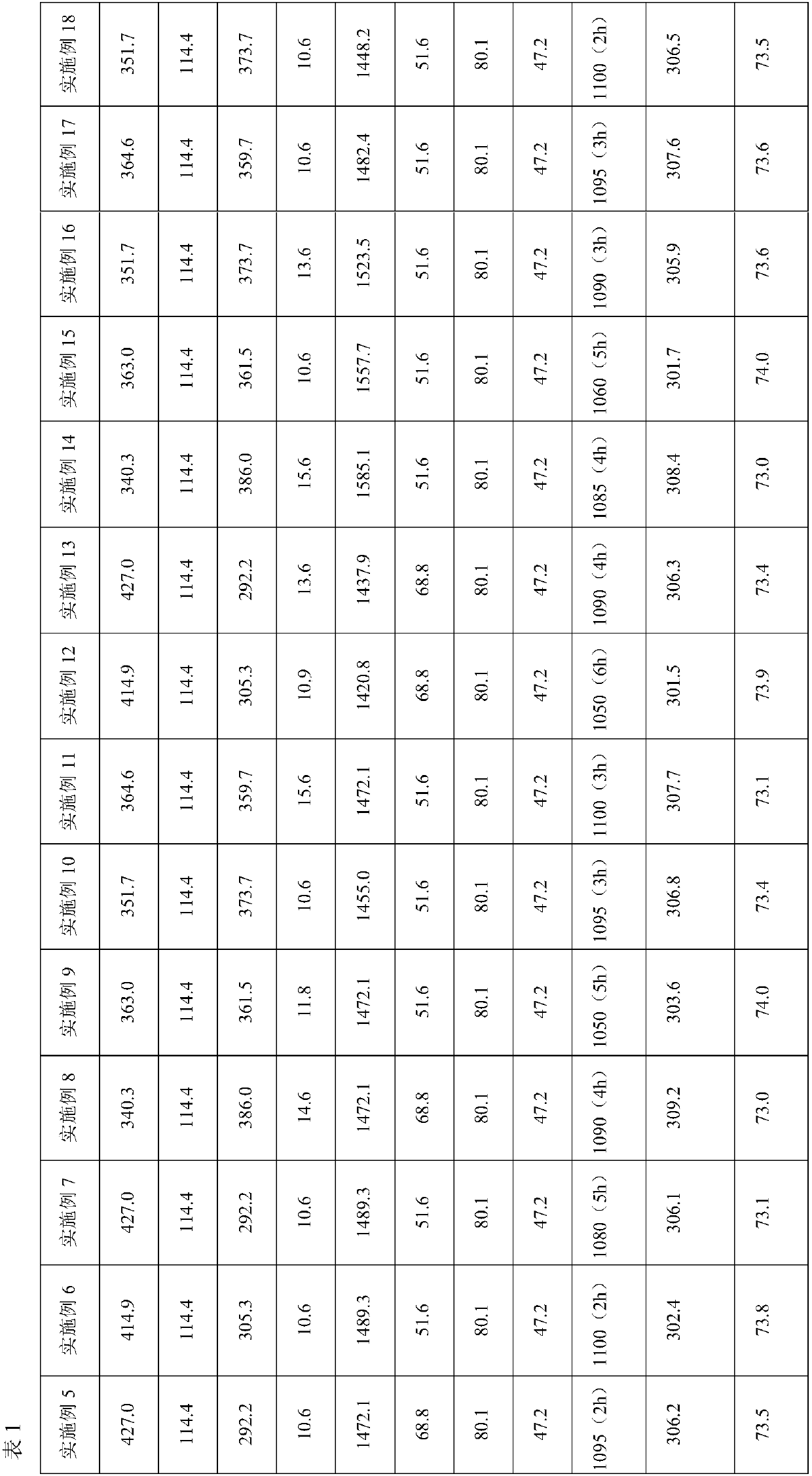

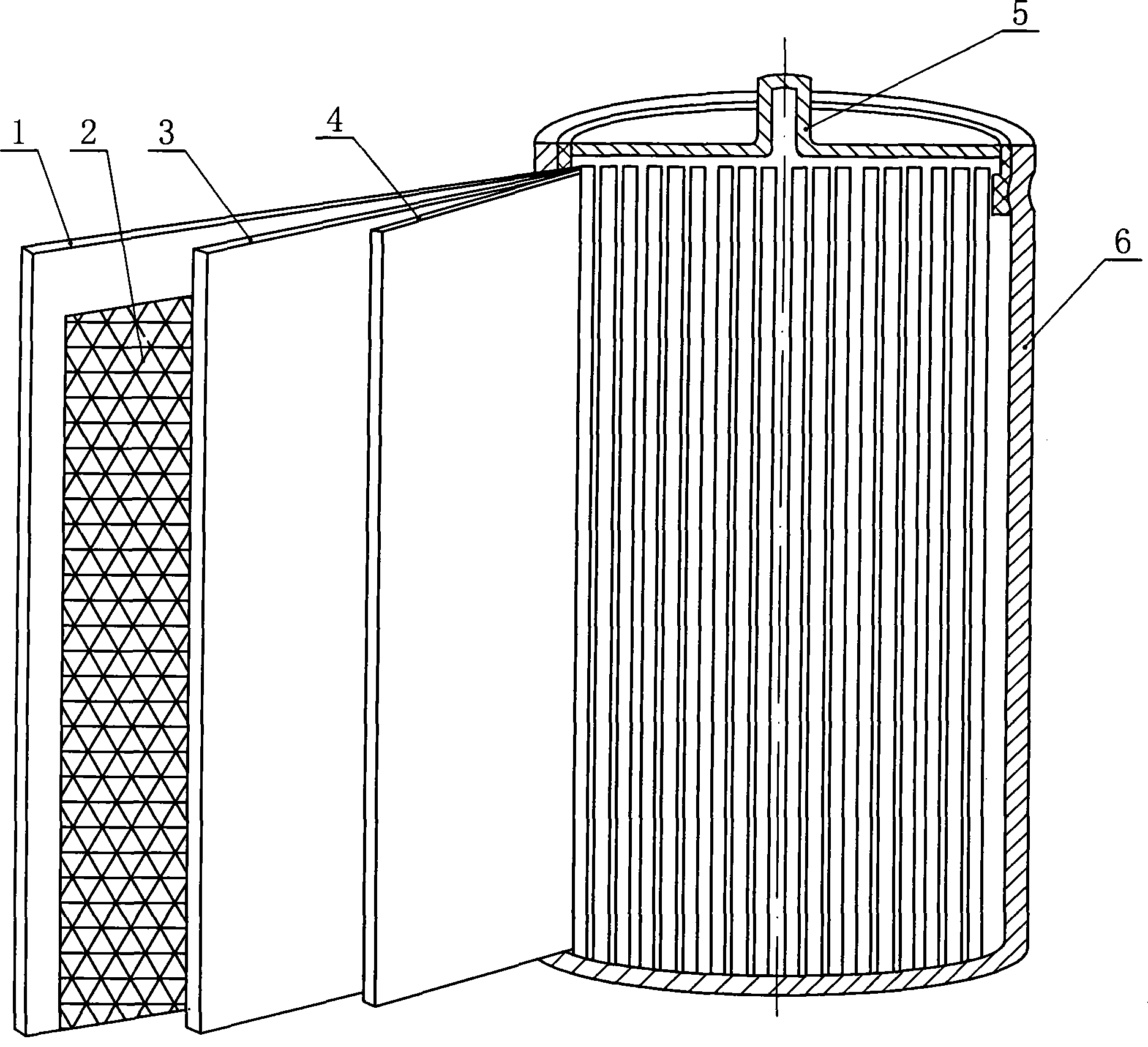

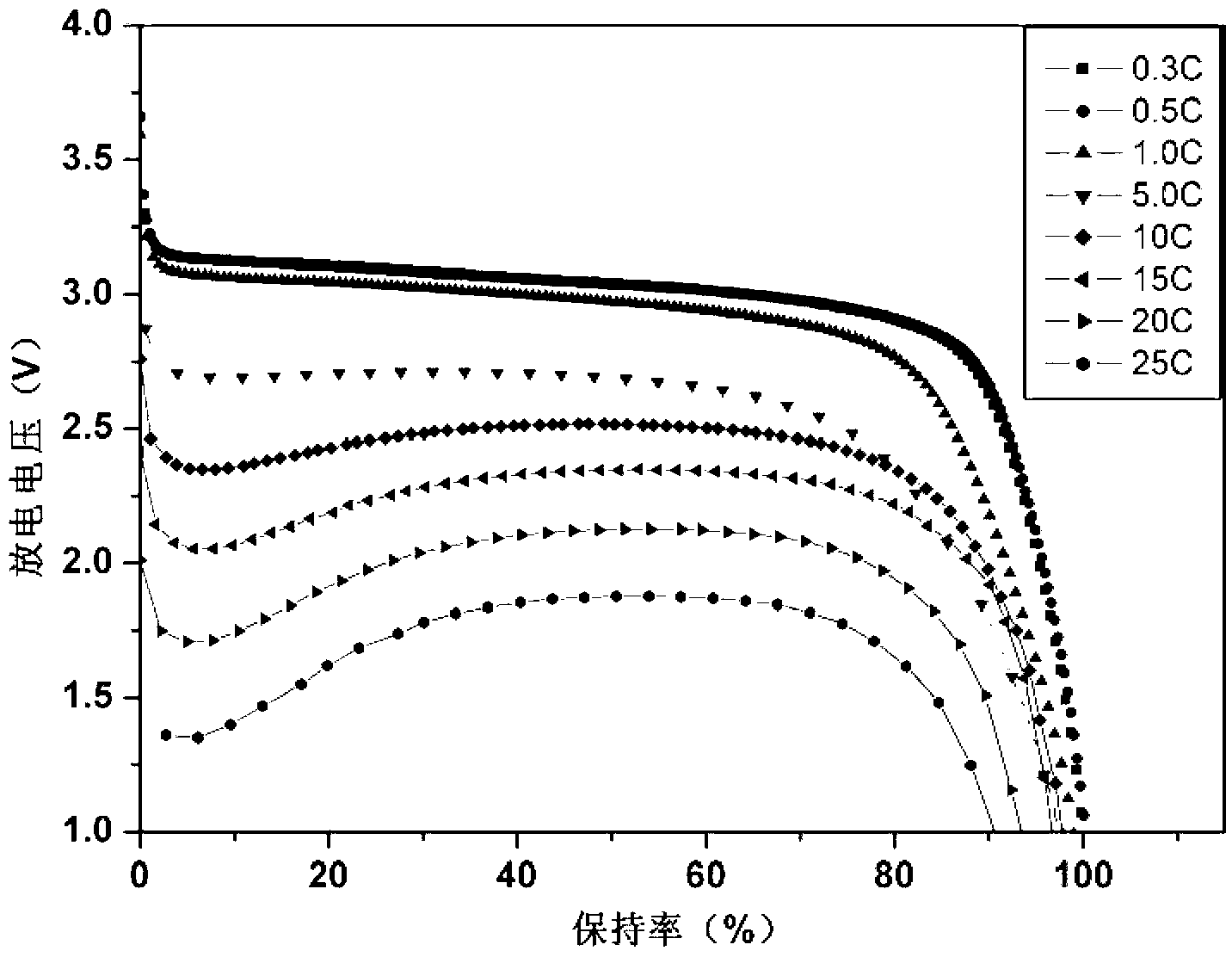

Mixed rare earth compound-doped and modified lithium iron phosphate cathode material and preparation method thereof

The invention discloses a mixed rare earth compound-doped and modified lithium iron phosphate cathode material and a preparation method thereof, and belongs to the technical field of preparation of electrochemical power materials. In the cathode material, Fe-site doping is performed on a LiFePO4 cathode material by at least one rare earth element in a mixed rare earth compound; and the LiFePO4 cathode material is doped and modified by utilizing the mixed rare earth compound with low price by a solid-phase synthesis method. The process comprises the following steps of: adding a lithium source, a carbon source, a phosphorus source and a doped mixed rare earth compound into a dispersant agent for mixing and dispersing; preparing a precursor of a lithium iron phosphate material after wet-grinding, drying and crushing; performing secondary calcining on the precursor in an inert atmosphere; cooling to the room temperature; and crushing by ball-milling to obtain the LiFePO4 cathode material. The material and the preparation method have the advantages that: the prepared LiFePO4 cathode material does not need to separate rare earth elements; and the prepared material has the performance of high capacity, high electric conductivity, stable cycle life, and capacity of performing high-rate discharge.

Owner:HOLD FORTUNE BEIJING SCI & TECH

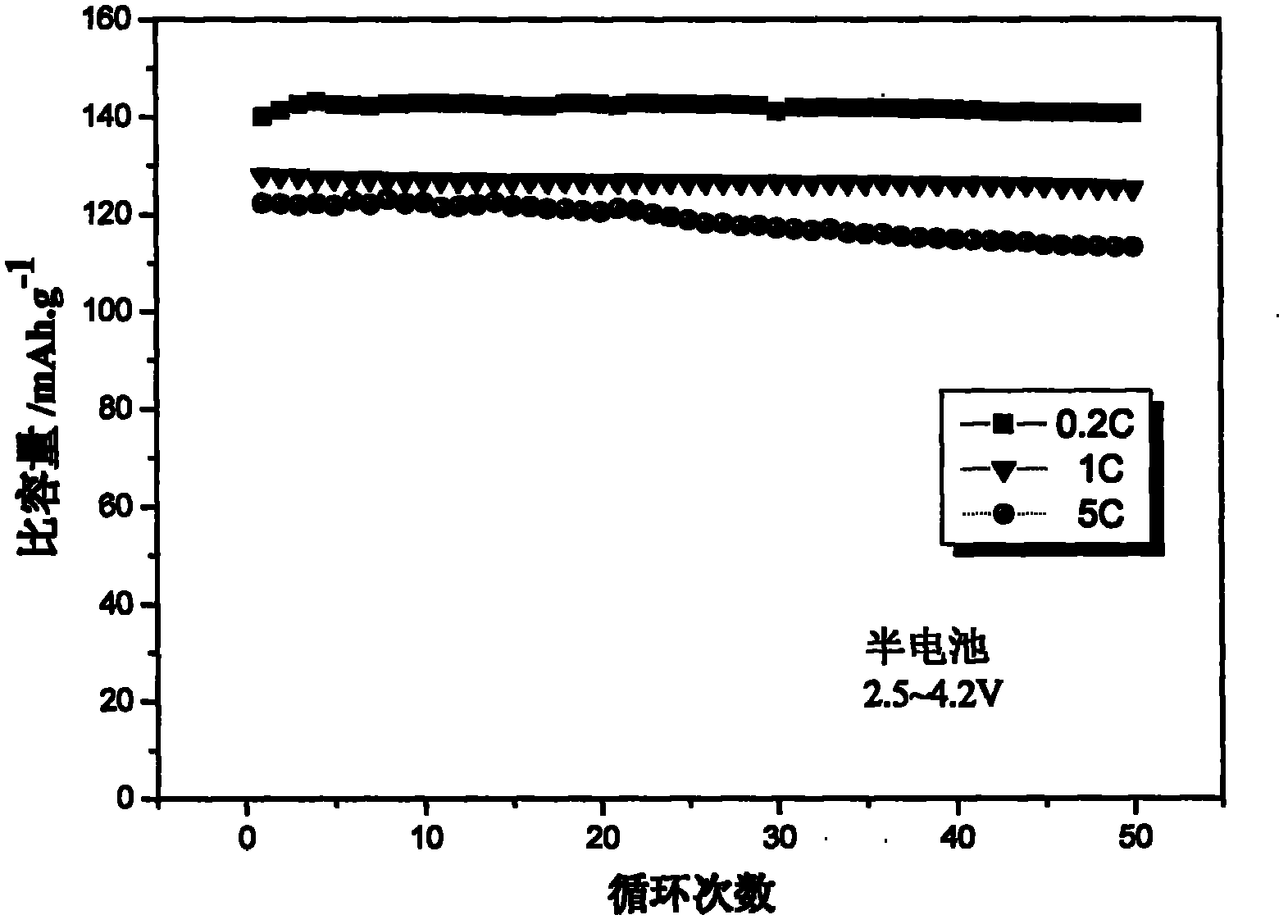

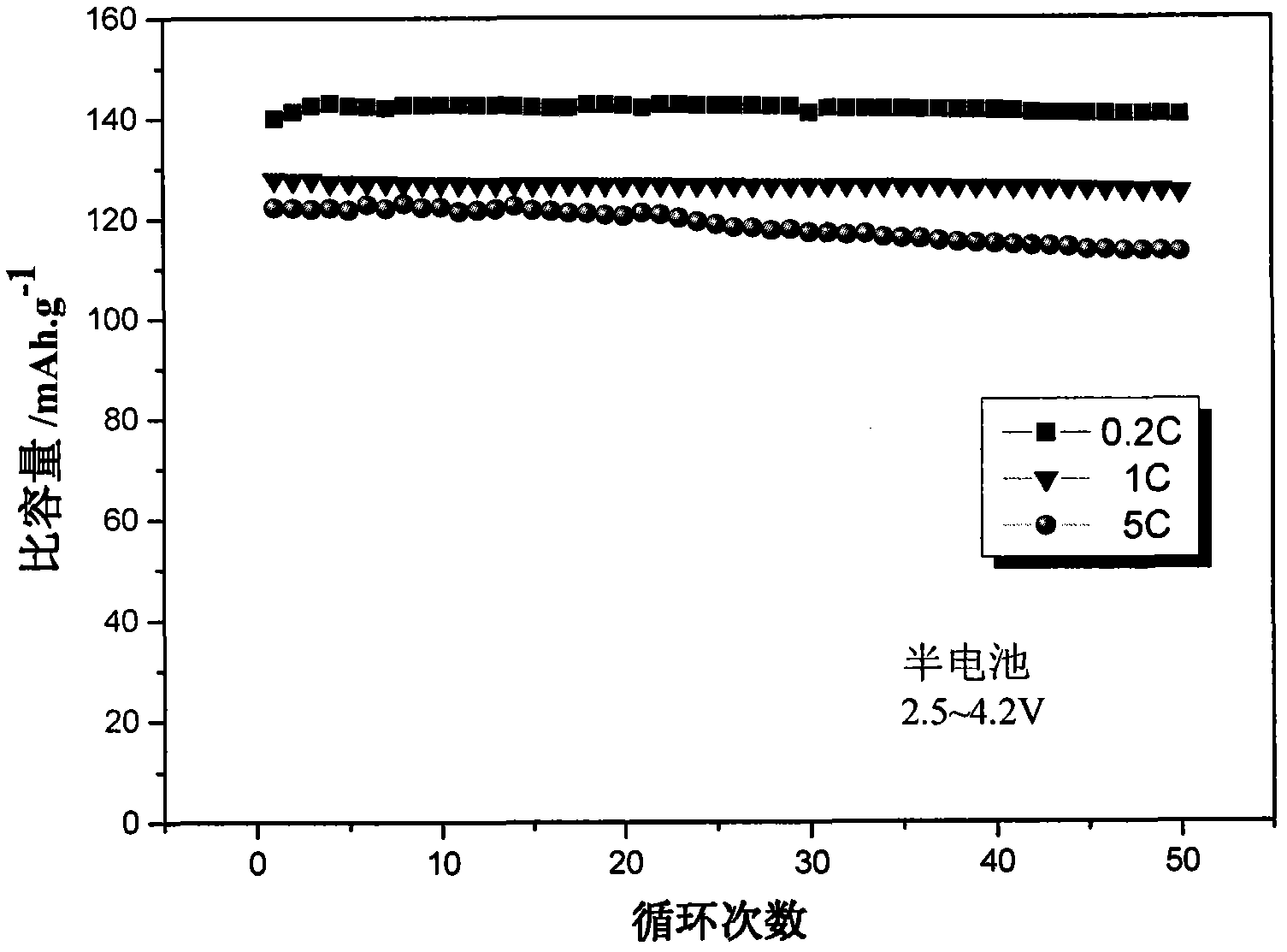

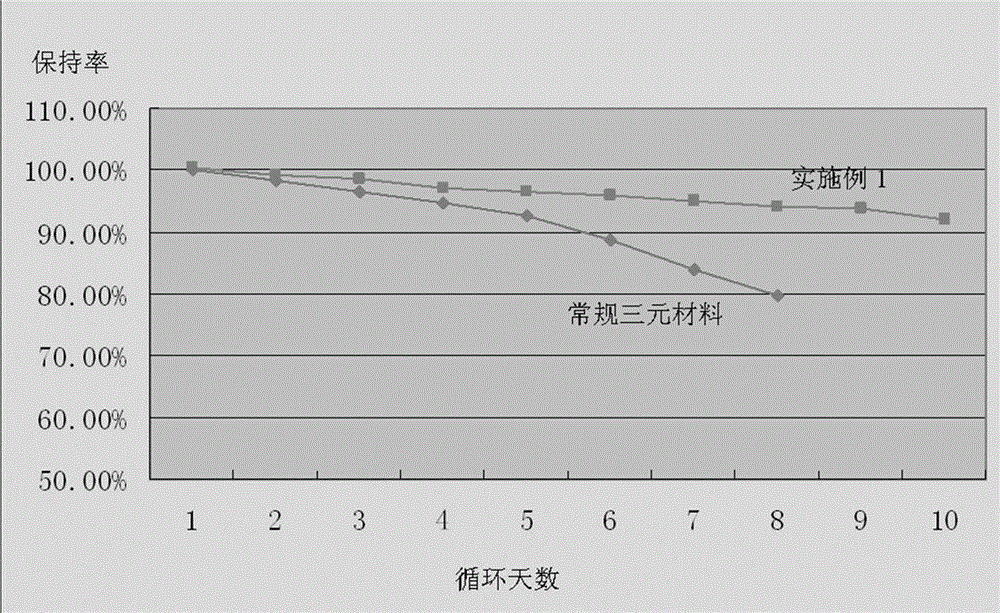

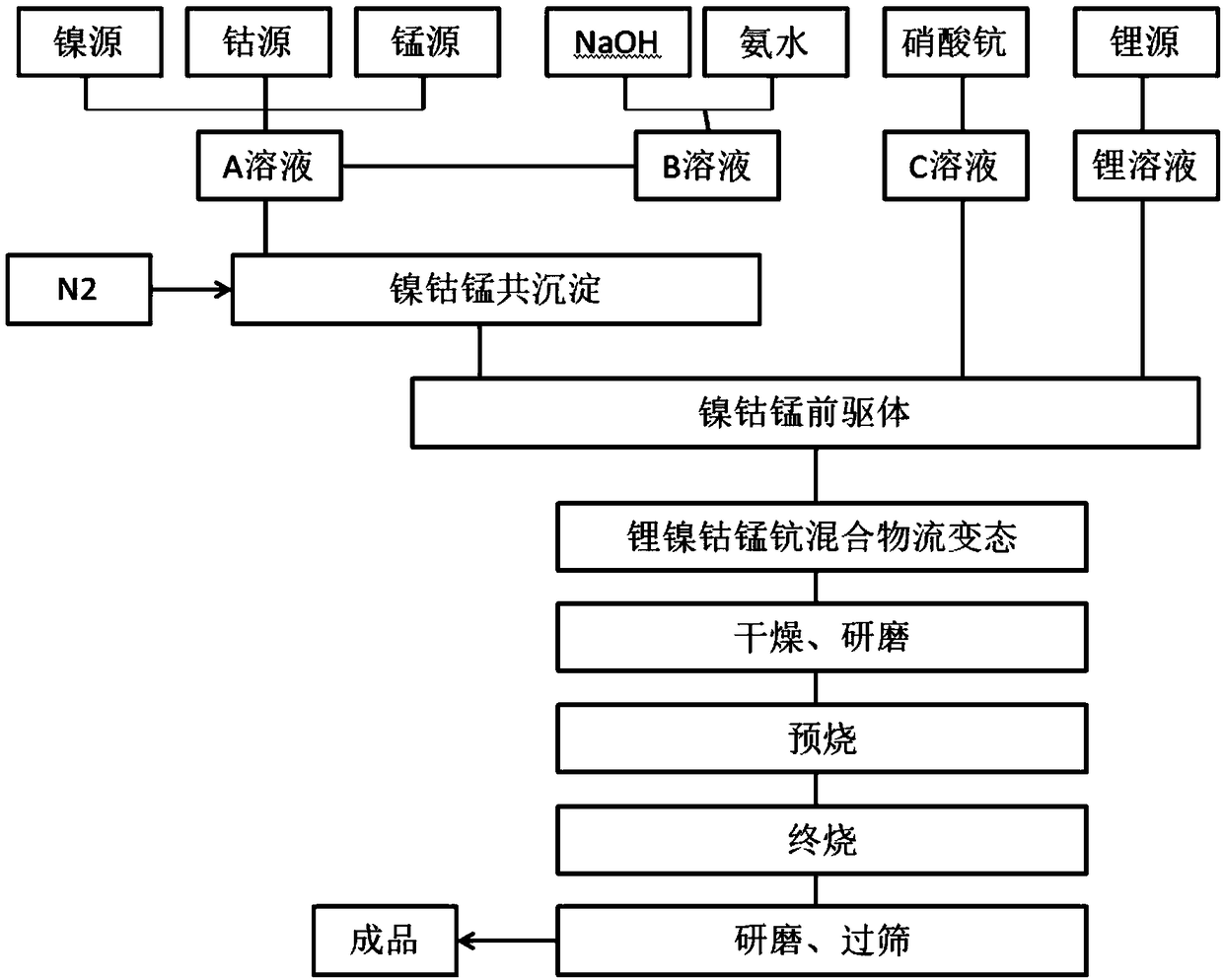

Preparation method of LiFePO4/C modified ternary positive electrode material

ActiveCN105355880AImprove charge and discharge performanceShorten the conduction pathCell electrodesSecondary cellsLithium iron phosphateActive electrode

The invention relates to a preparation method of a LiFePO4 / C modified ternary positive electrode material. Firstly, a ternary positive electrode material is prepared by a coprecipitation method; then a LiFePO4 / C composite material is grown on the surface of the ternary positive electrode material by a solid phase method, and the ternary positive electrode material is subjected to surface coating modification. The lithium iron phosphate active electrode material is adopted for modifying the ternary electrode material, on one hand, the advantages of the two active materials can be integrated to obtain the composite positive electrode material having better cycle performance, higher capacity and larger energy density; on the other hand, a traditional modification method for a ternary material is changed, and the cycle performance of the ternary positive electrode material is improved in the premise of almost no loss of material self capacity.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

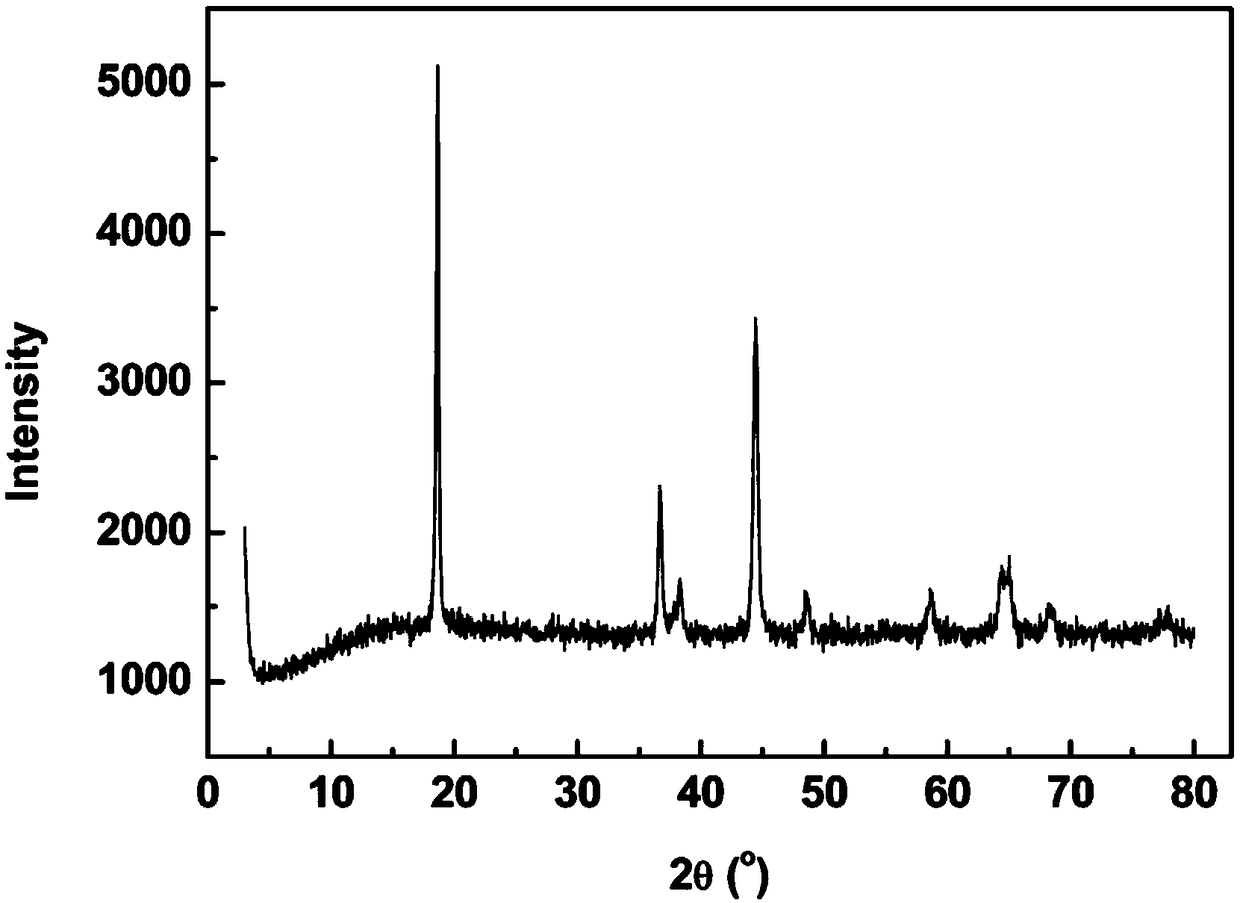

High-nickel and low-cobalt ternary cathode material and preparation method thereof

InactiveCN108767239AStable internal structureSimple internal structureCell electrodesSecondary cellsCrystallinityCobalt

The invention discloses a high-nickel and low-cobalt ternary cathode material and a preparation method thereof. The chemical general formula of the material is Li[Ni0.975Co0.0125Mn0.0125]1-xMxO2, wherein x is mole percent and is greater than or equal to 0.01 and is smaller than or equal to 0.05; M is one or a combination of Sc, Y, Zr, Ti, Mg or Al. The preparation method comprises the following steps: preparing a precursor by adopting a co-precipitation method; then synthesizing a cathode material which contains excessive lithium and is doped with M ions by adopting a simple solid phase method; the cost of a product is low; the preparation method of the high-nickel and low-cobalt ternary cathode material has the advantages of simplicity and easiness in control, wide source of raw materialsand easiness in industrial production; the prepared material has the advantages of good crystallinity, no impurity phase, fine and evenly-distributed particles as well as high discharge capacity andexcellent cycle performance.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

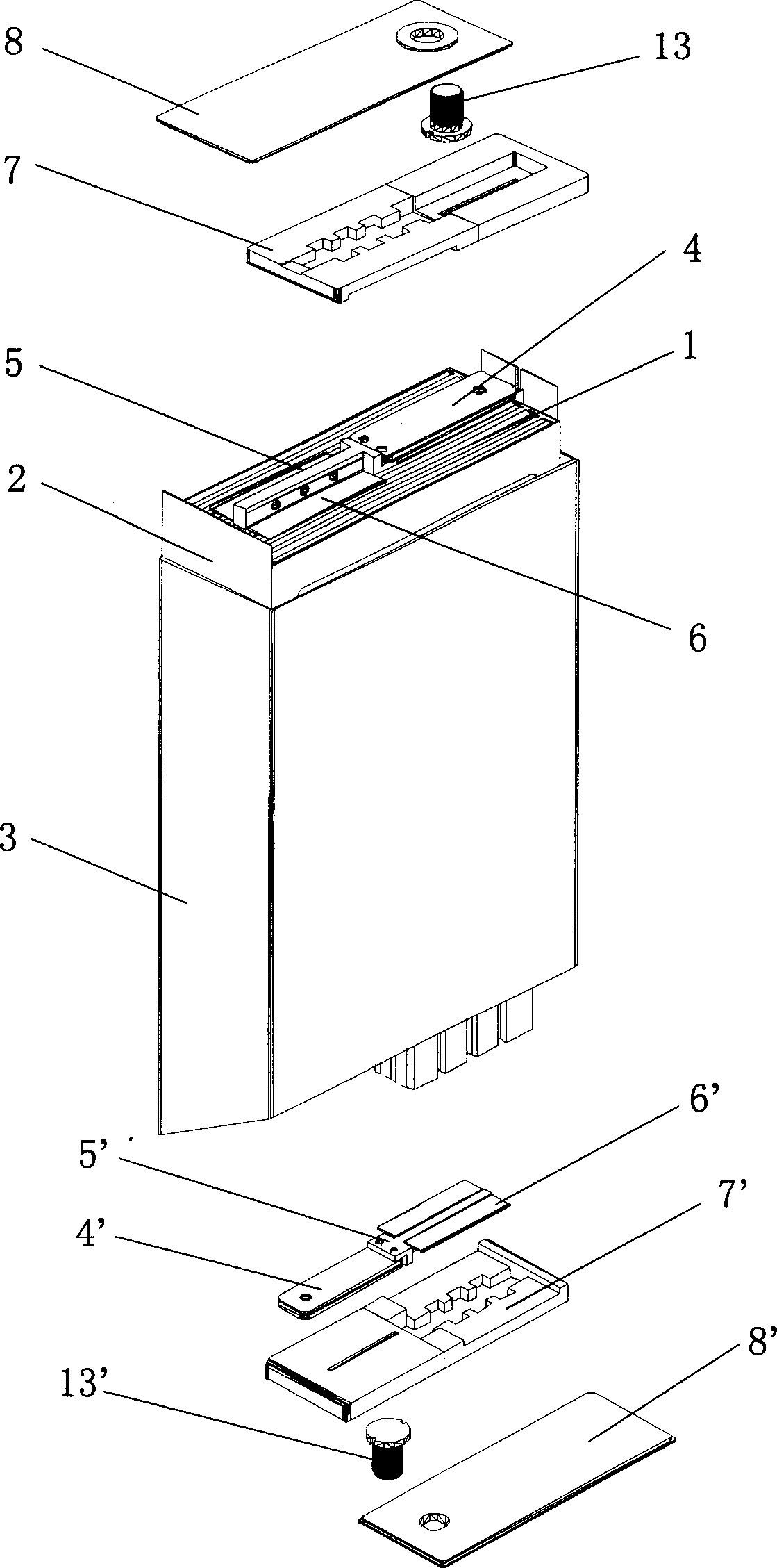

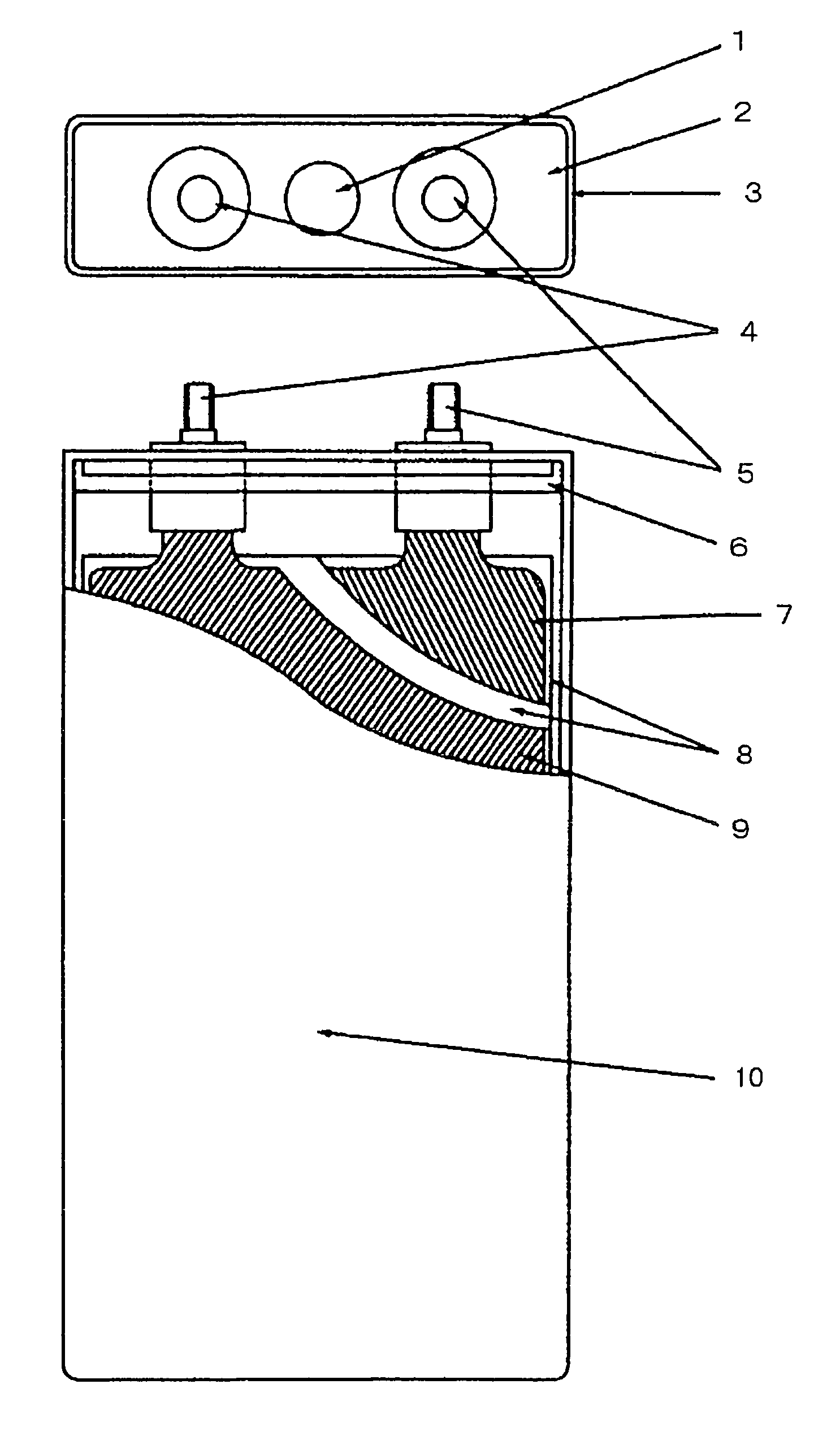

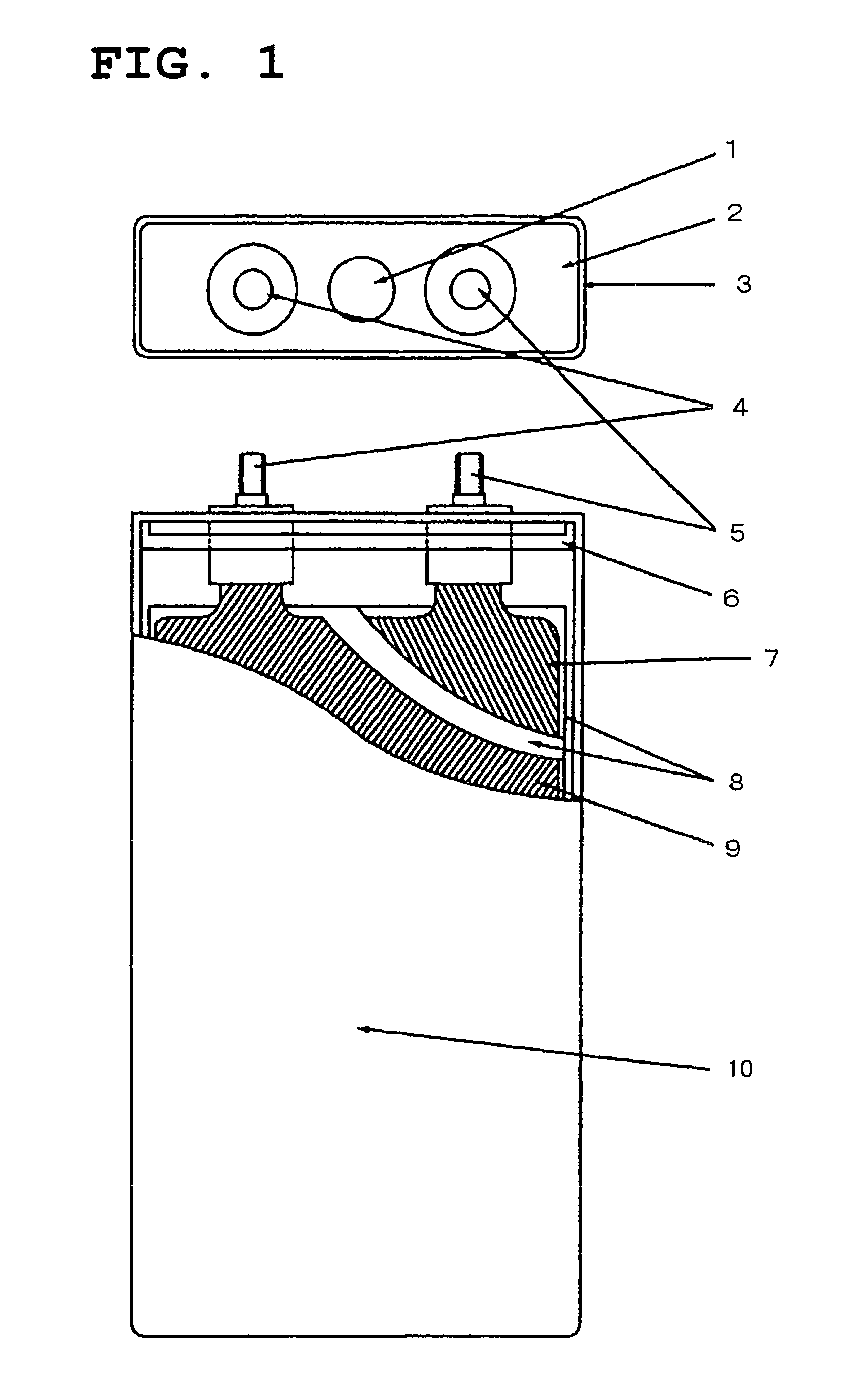

Lithium ion secondary cell

InactiveCN1521882ALower internal resistanceHigh rate discharge performance is goodFinal product manufactureSecondary cellsLithiumCoupling

A lithium ion secondary battery comprises a positive electrode, a negative electrode, electrolytic solution and barrier diaphragm, wherein the battery pole core is laminated by inserting the positive and negative electrode sheets of the bag type barrier diaphragm, the positive and negative electrodes are in current collecting arrangement fixed by screws or rivets, and are connected through the top and bottom covering plates through specific coupling pieces, the pole piece member, the battery case and the battery cover plate are in close fit so as to form a battery member having a secured pole piece. The lithium ion secondary battery provided by the invention has the advantages of high safety, high magnification of flash-over characteristic and simple manufacturing process.

Owner:BYD CO LTD

Electrolyte of lithium ion battery discharging at ultra-low temperature

ActiveCN107069094AGood low temperature performance and high rate discharge performanceLow freezing pointSecondary cellsOrganic electrolytesSingle useLithium electrode

The invention relates to the technical field of lithium ion battery, and particularly relates to an electrolyte of a lithium ion battery discharging at an ultra-low temperature. The electrolyte is composed of a lithium electrolyte salt, a cyclic ether compound, an organic carbonate, an ethylene glycol dimethyl ether, and a N,N-dimethyl trifluoroacetamide, wherein the lithium electrolyte salt is prepared by mixing lithium hexafluorophosphate, lithium bisoxalatoborate(LiBOB) and lithium oxalate difluoro borate(LiODFB) by a mass ratio of 3:1:1. According to the invention, the freezing point of the mixed solvent can be decreased obviously by mixing the organic additive N,N-dimethyl trifluoroacetamide with an organic carbonate, so that a low temperature electrolyte can be formed; and with the electrolyte prepared from lithium hexafluorophosphate, lithium bisoxalatoborate and lithium oxalate difluoro borate in a reasonable proportion, not only the weakness that the single use of the lithium hexafluorophosphate lacks temperature stability is overcome, but better low-temperature performance and better high-rate discharge performance are exhibited.

Owner:福建省劲德电源科技有限公司

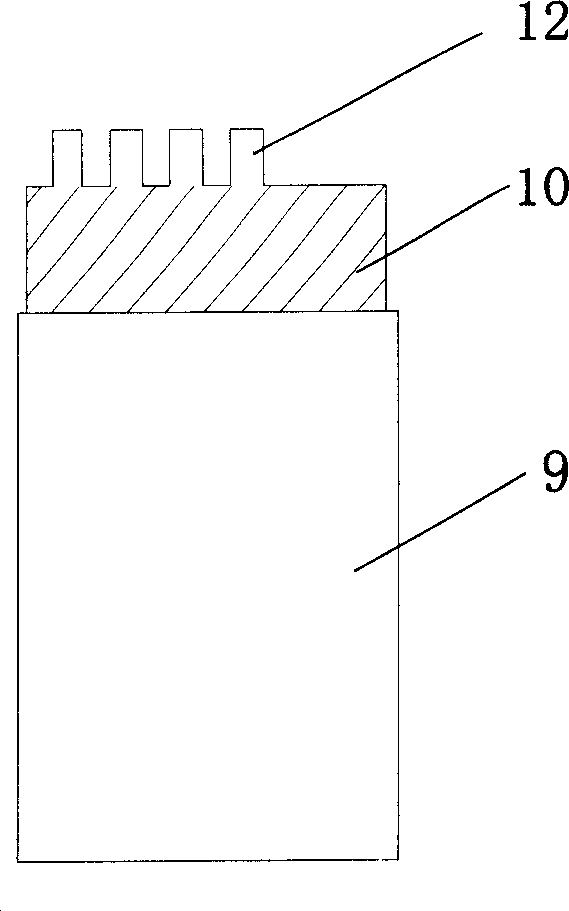

Anode and lithium-ion secondary battery

ActiveUS20080241685A1Improve high rate discharge performanceLarge capacityActive material electrodesAlkaline accumulator electrodesLithiumHigh rate

An anode for lithium-ion secondary battery is provided as one capable of ensuring sufficient safety (suppression of dendrites) while achieving a higher capacity (higher density of the electrode), and permitting formation of a lithium-ion secondary battery with excellent high-rate discharge performance. An anode for lithium-ion secondary battery has a current collector, and an active material-containing layer formed on the current collector, the active material-containing layer is comprised of an outermost layer disposed on the farthest side from the current collector, and a lower layer composed of at least one layer disposed between the outermost layer and the current collector, and a degree of flexion of the outermost layer is smaller than that of the lower layer.

Owner:TDK CORPARATION

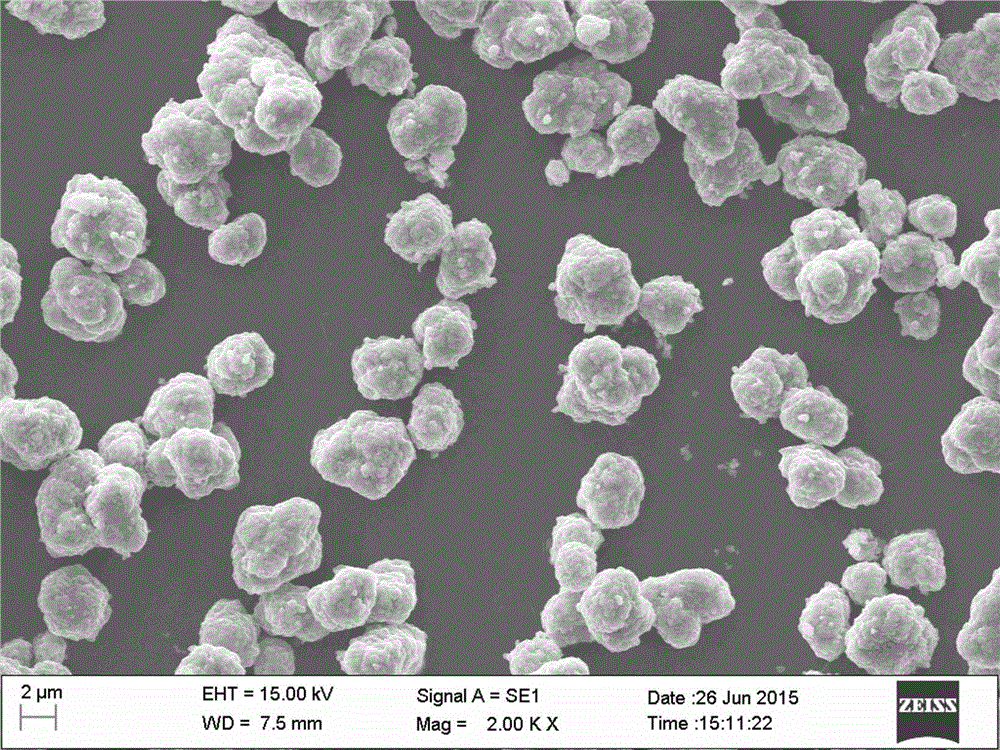

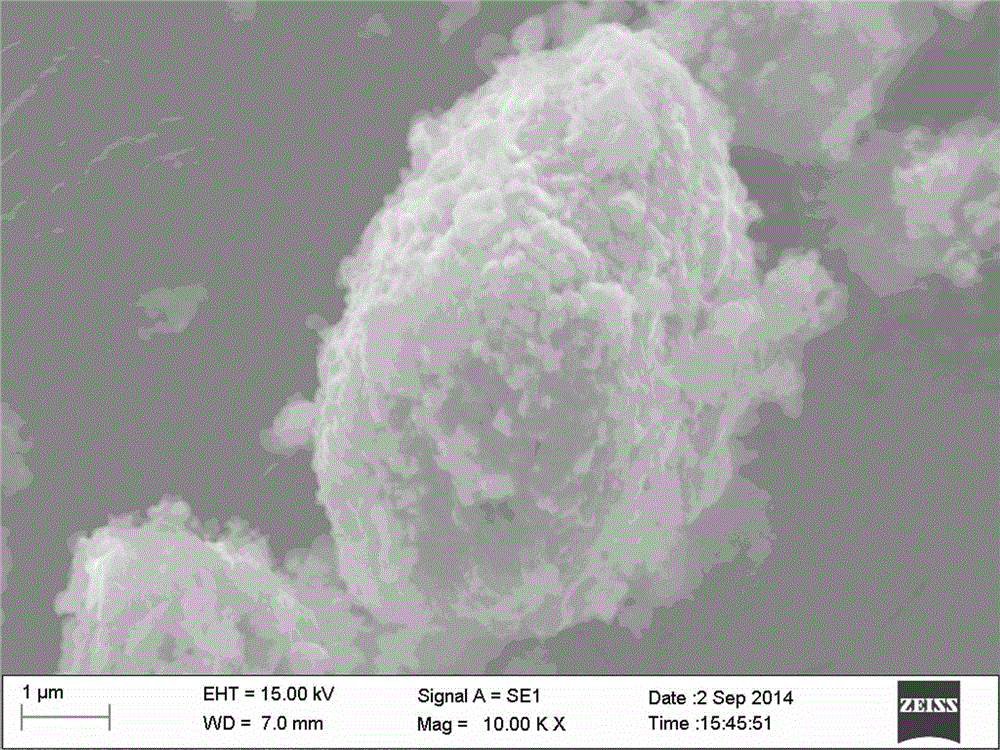

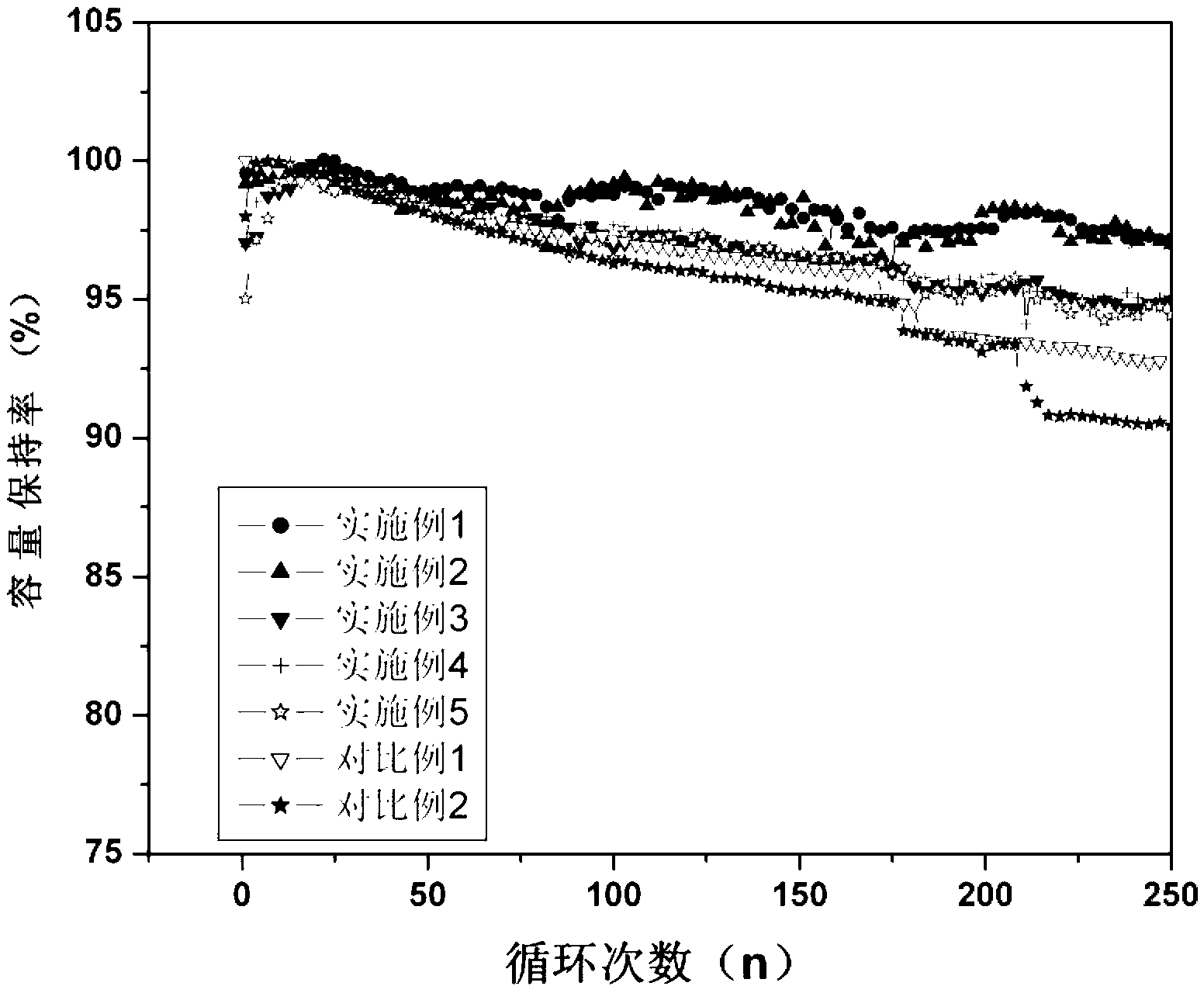

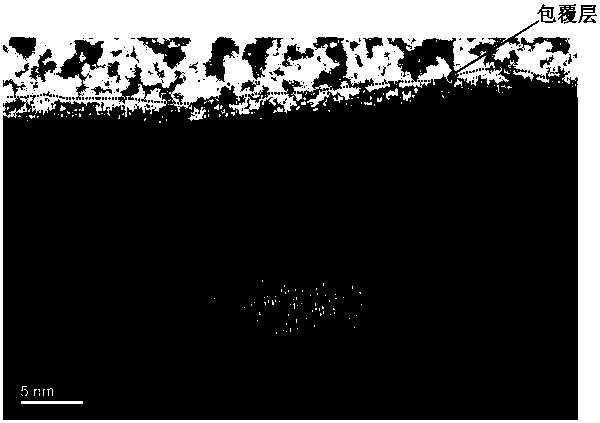

Preparation method of N-doped mesoporous carbon-coated ternary cathode material of lithium ion battery

ActiveCN107732220AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSodium-ion batteryLithium-ion battery

The invention provides a preparation method of an N-doped mesoporous carbon-coated ternary cathode material of a lithium ion battery. The preparation method comprises the following steps: (1) performing ultrasonic dispersion on a ternary cathode material into water, adding a phenylamine monomer, performing ultrasonic dispersion and adding acid solution, so as to obtain precursor solution; (2) adding ammonium persulfate solution into the precursor solution, heating and stirring the mixture, washing and settling twice or more than twice after centrifugal separation and performing vacuum drying,so as to obtain a polyaniline-coated ternary cathode material of the lithium ion battery; (3) placing the polyaniline-coated ternary cathode material into a tube furnace, calcining the polyaniline-coated ternary cathode material in an inert atmosphere, and naturally cooling to room temperature, so as to obtain the N-doped mesoporous carbon-coated ternary cathode material. The particle size of theN-doped mesoporous carbon-coated ternary cathode material of the lithium ion battery, which is obtained by the method, is 5-15mum, and an N-doped mesoporous carbon-coated layer is uniform and is 3-20nm in thickness; the N-doped mesoporous carbon-coated ternary cathode material is assembled into the battery and has comparatively good cycling stability and large rate discharge performance. The method is low in cost and simple in process, therefore, the method is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

Wet method of preparing lithium ferrous phosphate and its prepared lithium ferrous phosphate

The present invention provides a method for preparing ferrous lithium phosphate by using wet method. Said method includes the following steps: making required water-soluble compounds containing Li, Fe and P and containing alloying element M respectively be dissolved in water; stirring them and placing them into a reactor to obtain a suspension, in which the Li content, Fe content and P content must be met with the following formula: [mLi+n(1-m) / n M]; pFe:qPO4=1:1:1, in said formula n is chemical valence of alloying element M, m is mole number of Li, (1-m) / n is mole number of alloying element M and the P and q respectively are mole numbers of Fe and PO4; adding reduction electro-conductive additive, spray drying suspension, roasting and pulverizing so as to obtain the invented product.

Owner:北京环宇赛尔新能源科技有限公司

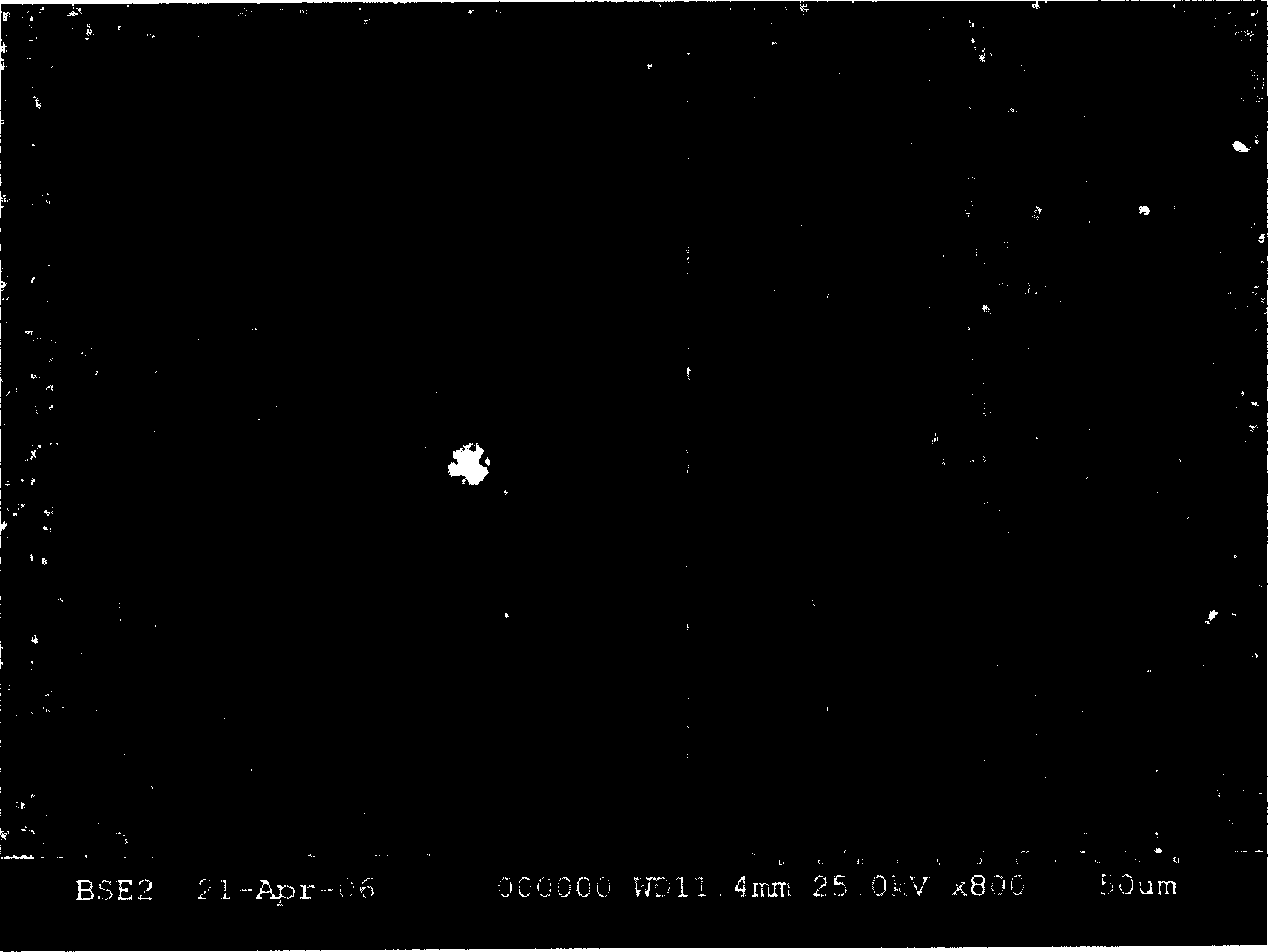

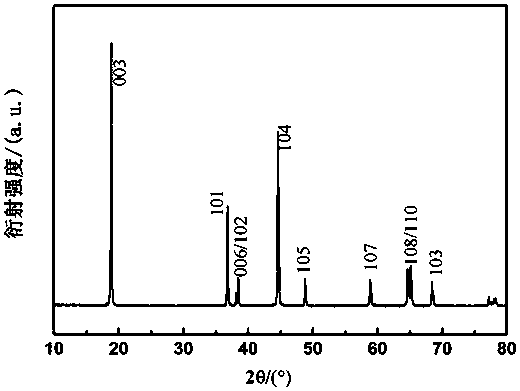

Positive active material for lithium secondary battery, manufacturing method thereof, lithium secondary battery electrode, and lithium secondary battery

InactiveUS20140038053A1Improve high rate discharge performanceElectrode thermal treatmentSecondary cellsSpace groupX-ray

A positive active material for a lithium secondary battery contains a lithium-transition metal composite oxide represented by a composition formula of Li1+αMe1−αO2 (Me is a transition metal element including Co, Ni, and Mn; 1.2<(1+α) / (1−α)<1.6). A molar ratio (Co / Me) of Co contained in the Me ranges from 0.24 to 0.36, and when a space group R3-m is used for a crystal structure model based on an X-ray diffraction pattern, a half width of a diffraction peak that attributes to a (003) line ranges from 0.204° to 0.303°, or a half width of a diffraction peak that attributes to a (104) line ranges from 0.278° to 0.424°.

Owner:GS YUASA INT LTD

AB5-base hydrogen storage alloy, electrode for Ni-MH battery, secondary battery and method for preparing hydrogen storage alloy

ActiveCN109585790AMeet overcharge performanceSatisfy the charging and discharging dynamic performanceNegative electrodesAlkaline accumulator electrodesHigh rateCerium

The invention relates to a hydrogen storage alloy, an electrode for a Ni-MH battery, a secondary battery and a method for preparing the hydrogen storage alloy. The chemical composition of the hydrogenstorage alloy is represented by the general formula La(3.0-3.2)x CexZrySm (1- (4.0~4.2)x-y)NizCouMnvAlw, wherein x, y, z, u, v, w are molar ratios; 0.14 <= x <= 0.17; 0.02 <= y <= 0 .03; 4.60 <= z +u + v + w <= 5.33; 0.10 <= u <= 0.20; 0.25 <= v <= 0.30; and 0.30 <= w <= 0.40. The overcharge performance of the electrode material is satisfied by fixing a ratio of lanthanum (La) to cerium (Ce) to3.0 - 3.2. A large number of samarium (Sm) elements on a side A are replaced, namely, the ratio of Sm atoms accounts for 25.6 to 42% of the side A to overcome a decrease in service life caused by lowcobalt (Co). The equilibrium pressure is adjusted by changing the ratios of Sm and La to Ce in order to satisfy the charge and discharge dynamics performance of the electrode material. The nucleationrate of a solidification process is increased by adding zirconium (Zr) having an atomic ratio of 2 to 3% relative to the elements at the side A to the elements at the side A. The Ni-MH battery anode material obtained by using the hydrogen storage alloy has high overcharge resistance, high rate discharge performance and good cycle stability.

Owner:SOUTH CHINA UNIV OF TECH +2

Improved type lithium-ferrous disulfide battery and manufacturing method of the same

InactiveCN101383419AImprove high current discharge capabilityExtended use timePrimary cellsElectrode carriers/collectorsCopper foilPositive current

The invention relates to an improved lithium- ferrous disulfide battery which comprises a shell; a positive pole piece and a negative pole piece in the shell are wound together through a porous isolating film, and organic electrolyte is filled in the shell. The positive pole piece comprises a positive active material and a positive current collector, and the positive active material is ferrous disulfide. The negative pole piece comprises a negative active material and a negative current collector, wherein the negative active material is metal lithium foil, and the negative current collector is selected form a copper net, a hole-shaped aluminum foil, an aluminum net, a hole-shaped copper foil, foamed nickel, a hole-shaped nickel foil or nickel net. The positive pole piece is manufactured by the positive active material, conductive agent and binding agent which are evenly mixed and applied to a metallic matrix; and the negative pole piece is manufactured by pressing the metal lithium foil and the metal net or the hole-shaped foil. Then the organic electrolyte is infused, and the battery is obtained after the packaging. The invention has the advantages of small internal resistance, good large current discharge performance, good pulse discharge performance, high discharge platform, no voltage sag and good consistence of performance.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

Method for making electric core of lithium ion battery

InactiveCN101267050AGood discharge performanceLower battery internal resistanceFinal product manufactureElectrolyte accumulators manufactureAirplaneWrinkle

The present invention is an improvement of the preparing method of a lithium ion battery electrical core, characterized in that a diaphragm and / or electrode plate binding face has adhesive which is capable of resisting electrolyte, redox reaction and solid content is 2-30%, voltage attaching after mutually stacking, and the diaphragm voidage is above 30%. A gap does not exist between the diaphragm and the electrode pate, the battery has large rate discharge ability, especially for a battery product of a power battery, an electrical tool battery, a model airplane battery which has requirement to large rate discharge; the battery has a small internal resistance, small self-consumption power. The diaphragm is patched with the electrode plate at the same time, not only reducing the alignment degree adjustment of the diaphragm and the electrode plate under the winding or overlapping course, greatly enhancing the battery preparing production efficiency; the diaphragm and the electrode plate not easy wrinkle, benefit to improve the battery life service, the capability is more stable and credible.

Owner:JIANGSU DIO ENERGY SCI TECH

Active substance of positive electrode and non-aqueous electrolyte battery containing the same

ActiveUS7691535B2Increase energy densityImprove high rate discharge performanceSecondary cellsAlkali metal oxidesHigh energyPhysical chemistry

A positive active material is provided which can give a battery having a high energy density and excellent high-rate discharge performance and inhibited from decreasing in battery performance even in the case of high-temperature charge. Also provided is a non-aqueous electrolyte battery employing the positive active material. The positive active material contains a composite oxide which is constituted of at least lithium (Li), manganese (Mn), nickel (Ni), cobalt (Co), and oxygen (O) and is represented by the following chemical composition formula: LiaMnbNicCodOe (wherein 0<a≦1.3, |b−c|≦0.05, 0.6≦d<1, 1.7≦e≦2.3, and b+c+d=1). The non-aqueous electrolyte battery has a positive electrode containing the positive active material, a negative electrode, and a non-aqueous electrolyte.

Owner:GS YUASA INT LTD

Nitrogen-doped porous carbon ball/manganic manganous oxide nanometer composite electrode material and preparation method thereof

InactiveCN105355874AAbundant and easy to get resourcesLow costMaterial nanotechnologyCell electrodesPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material and a preparation method thereof. The preparation method comprises that chitosan and its derivative as carbon source and nitrogen source predecessors and porous silica as a hard template are carbonized, then silica is removed so that nitrogen-doped porous carbon balls are obtained, manganic manganous oxide nanometer particles grow on the nitrogen-doped porous carbon balls by a mild solvothermal method, and the nitrogen-doped porous carbon balls with the manganic manganous oxide nanometer particles are subjected to centrifugation washing and drying so that the nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material is obtained. The prepared material as a lithium ion battery negative electrode material has a high reversible specific capacity, good cycling stability and excellent multiplying power discharge performances. The preparation method can be operated easily, has mild preparation conditions and no harsh requirement on equipment and is suitable for industrial production. The nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material has a wide application prospect in the electrochemistry fields of high performance lithium ion batteries and super capacitors.

Owner:HUBEI ENG UNIV

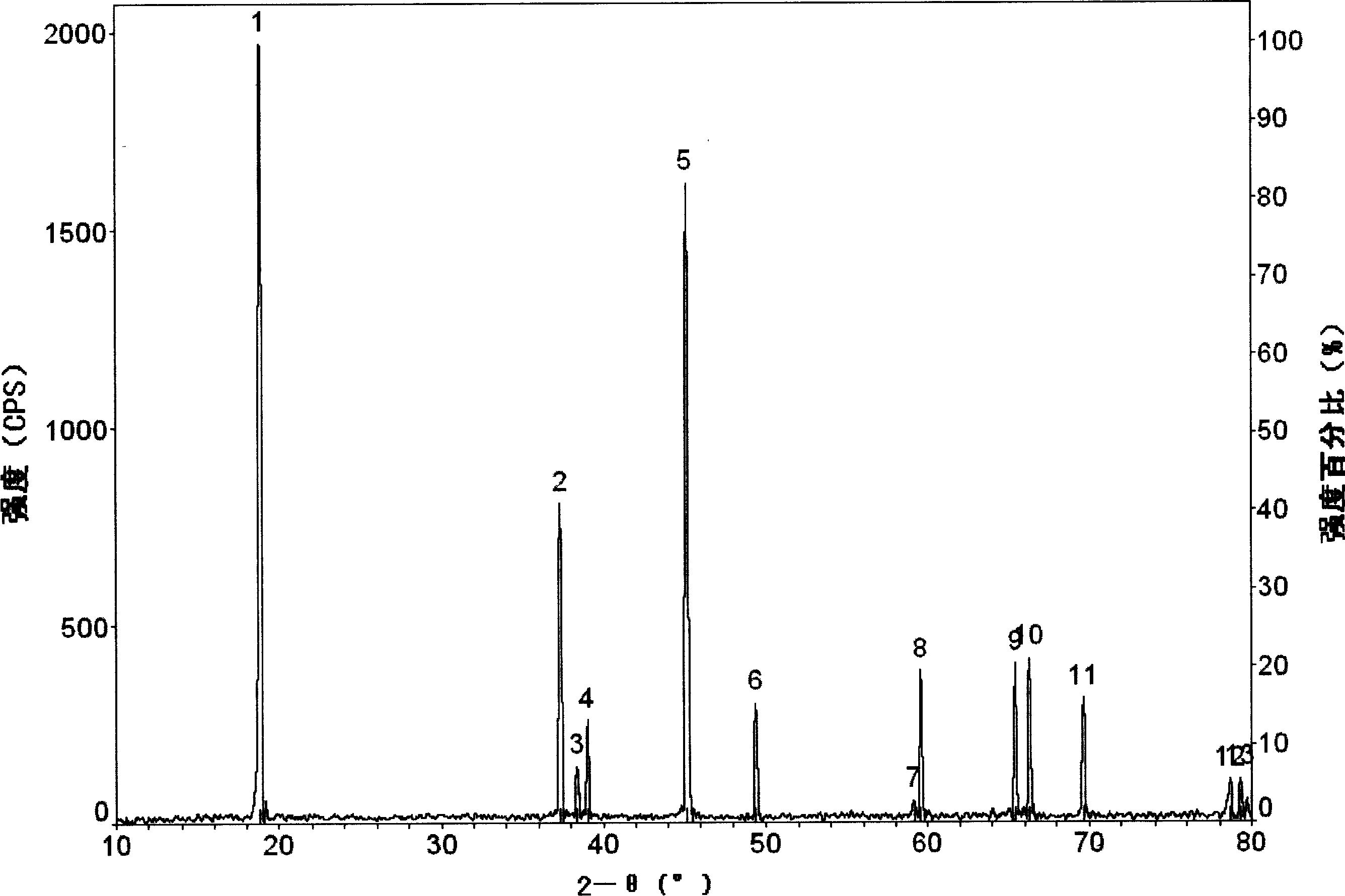

Preparation method of lithium titanate/carbon nano tube composite cathode material

The invention discloses a preparation method of a lithium titanate / carbon nano tube composite cathode material and belongs to the technical field of battery materials. A carbon nano tube grows on the surface of lithium titanate by a chemical vapour deposition method, and has the characteristics of uniform dispersion, high binding force and the like compared with a carbon nano tube directly doped in lithium titanate, the growing carbon nano tube can form a network structure on the surface of lithium titanate, and an important effect is exerted on improving structural stability of the material under the condition of high-rate discharge of a battery. The contact probability of the lithium ion battery with lithium titanate is increased and the internal resistance and polarization are reduced by using high conductivity of the carbon nano tube and the network structure formed by the carbon nano tube, the liquid absorption and keeping ability of the cathode material can be improved due to larger specific surface area of the carbon nano tube, and the high-rate discharge ability and recyclability of the battery are improved.

Owner:RIGHTFUL TECH

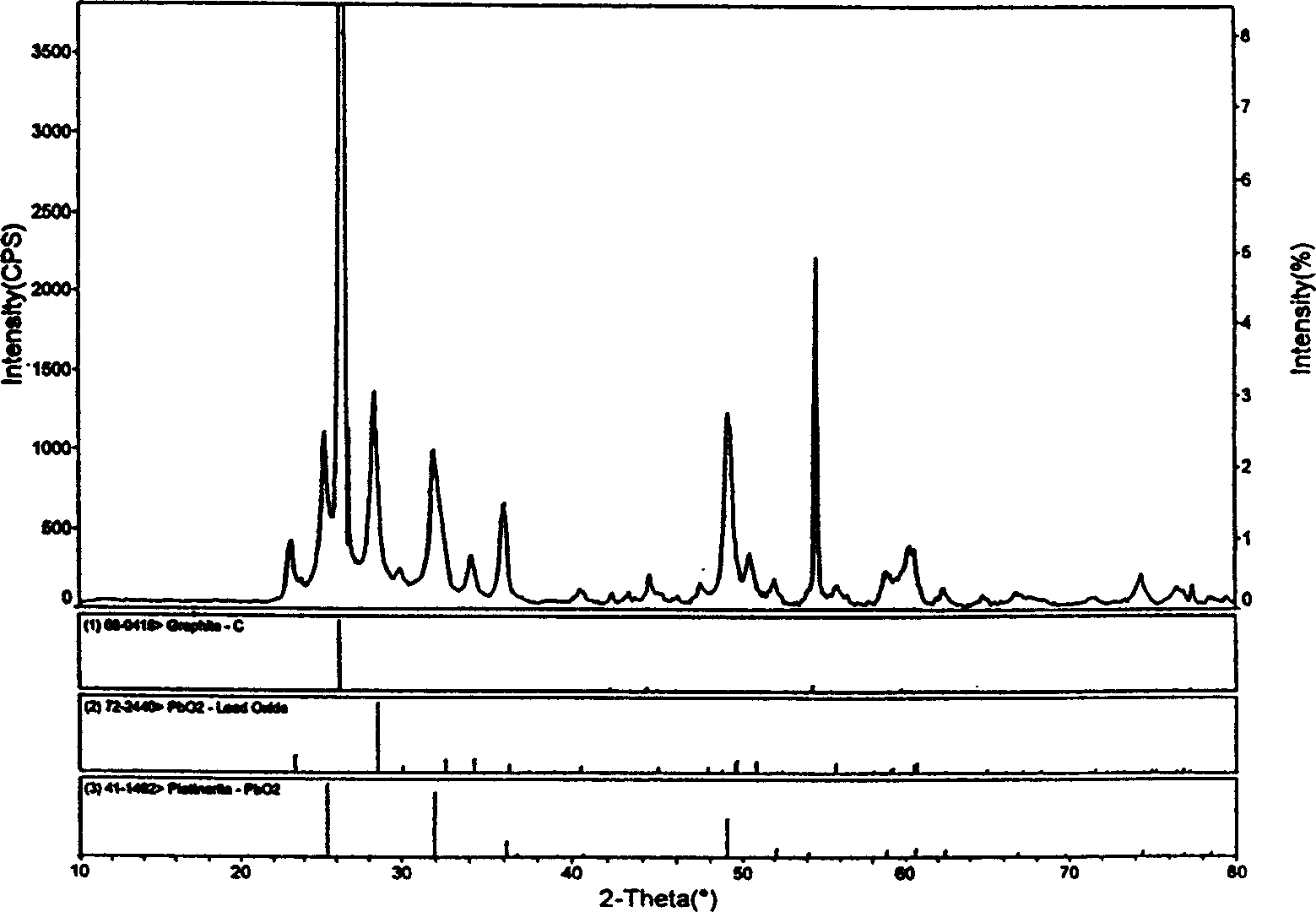

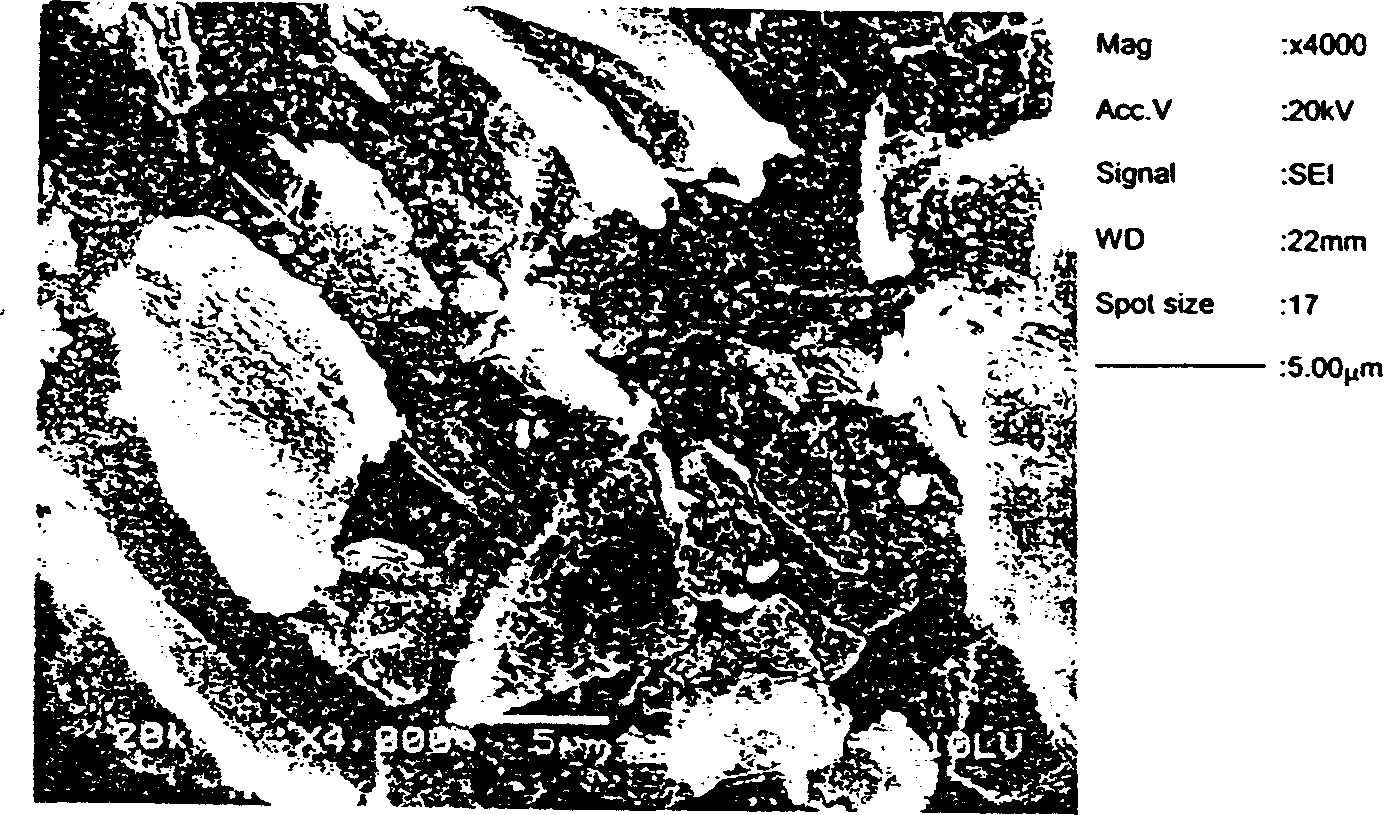

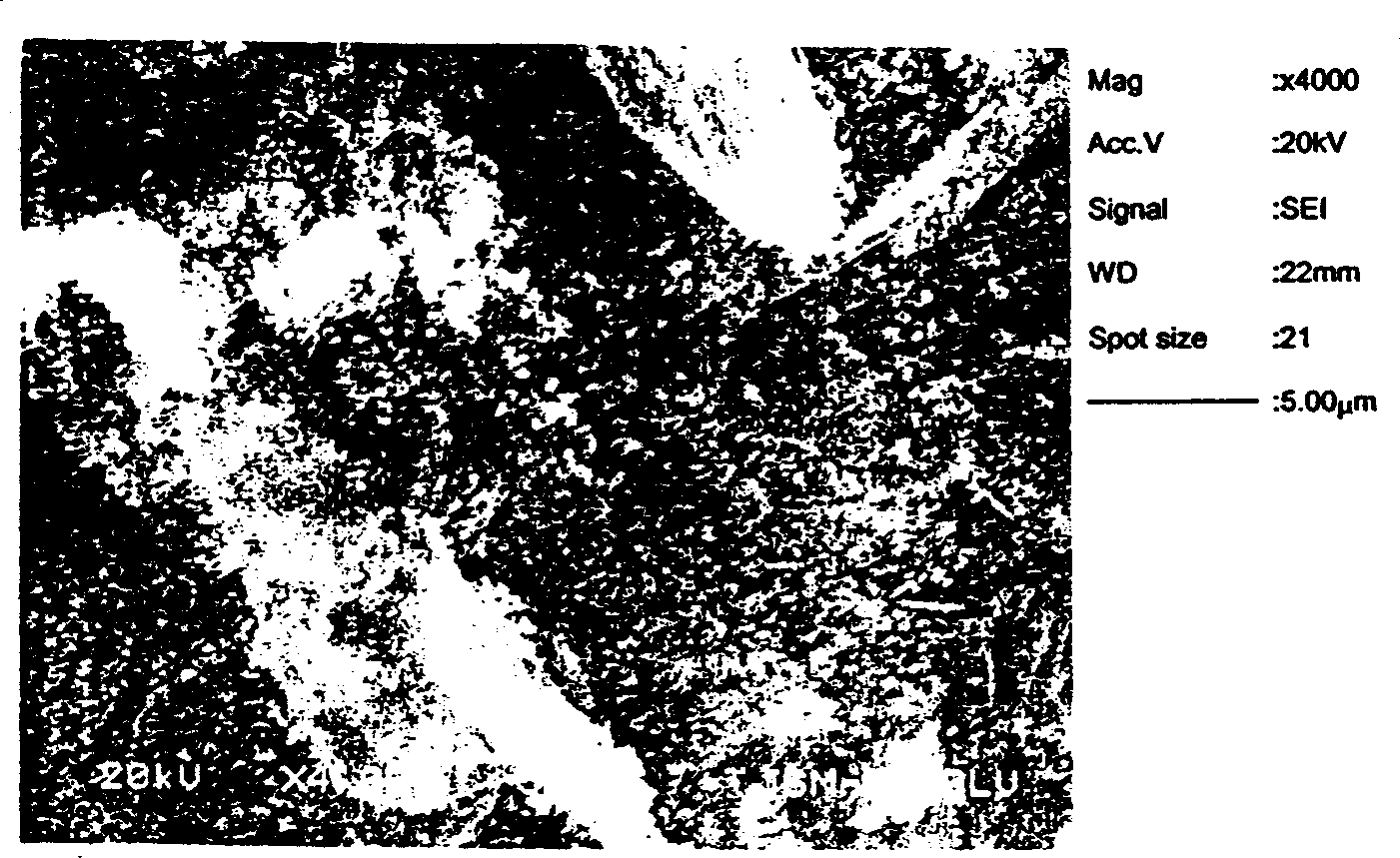

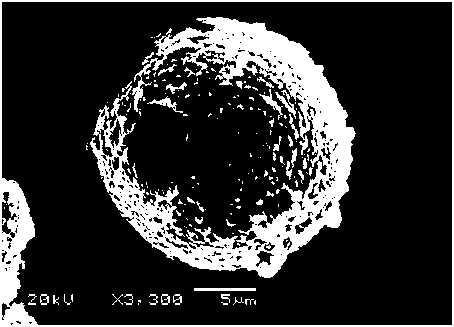

Lead dioxide coated carbon material, making method and zinc-nickel battery containing the same

InactiveCN1501530AImprove high rate discharge performanceImprove conductivityAlkaline accumulatorsCell electrodesLead dioxideHydrogen

The invention relates to a carbon material, wherein the carbon material is used as a core whose skin layer is covered by lead dioxide, the weight ratio of lead dioxide is 1%-80%. The invention also relates to the method for preparing the material which comprises, filling carbon material into alkaline solution with dissolved oxidant, instilling solution containing diatomic lead ion, transforming it into lead dioxide in the alkaline solution which attaches to the carbon material surface evenly. The invention further relates to a zinc-nickel battery having high discharging performance.

Owner:BYD CO LTD

Lithium manganate-coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

ActiveCN107946579AImprove cycle stabilityImprove high rate discharge performanceMaterial nanotechnologyCell electrodesAir atmosphereCobalt hydroxide

Disclosed are a lithium manganate-coated lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. Lithium manganate accounts for 1-10wt% of the material based on mass percentage composition; lithium manganate forms a coating layer with thickness of 2-20nm to coat lithium nickel cobalt aluminate; and the positive electrode material is spherical particles with the grain diameter of 5-15[mu]m. The preparation method comprises the following steps of (1) dissolving a surfactant into water, and performing heating and stirring; (2) adding a manganese source, performing stirring and dissolving, and then adding aluminum nickel cobalt hydroxide, and performing heating, stirring and evaporating to dryness; (3) performing calcining in air atmosphere, and cooling; and (4) adding a lithium salt, and performing two-stage sintering in flowing oxidizing atmosphere. The positive electrode material disclosed in the invention has relatively high cycle stability and high-rate discharging performance; by virtue of the coating layer, the material structure can be stabilized, and the secondary reaction between an electrolyte and an active material can be suppressed effectively; and the method is low in cost, simple in process and suitable for massive industrial production.

Owner:CENT SOUTH UNIV

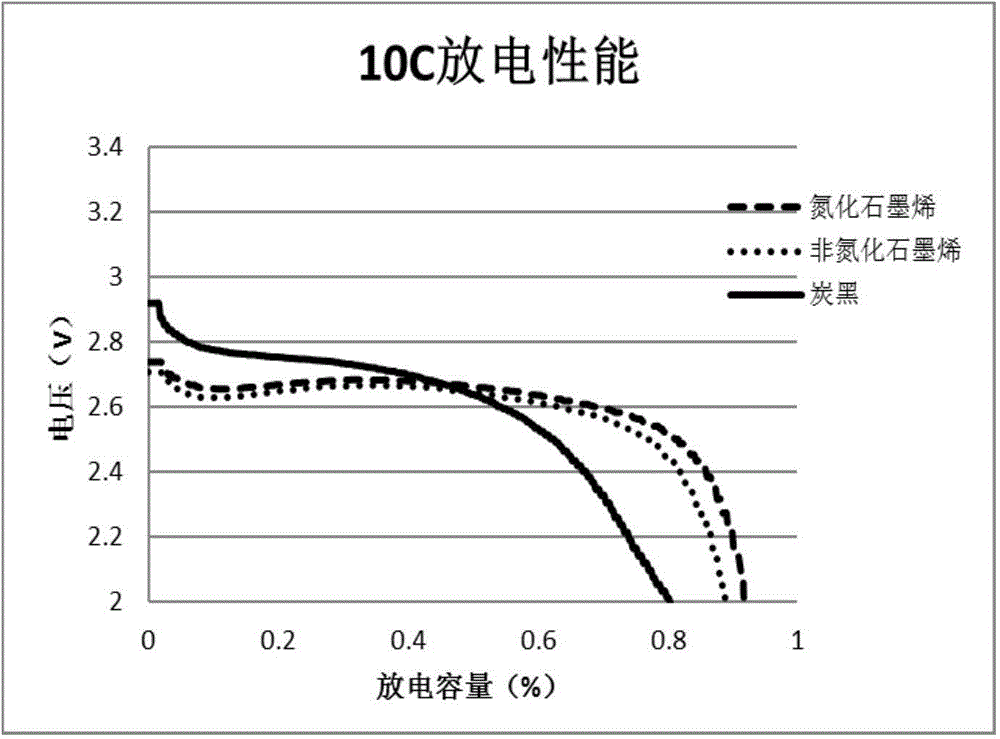

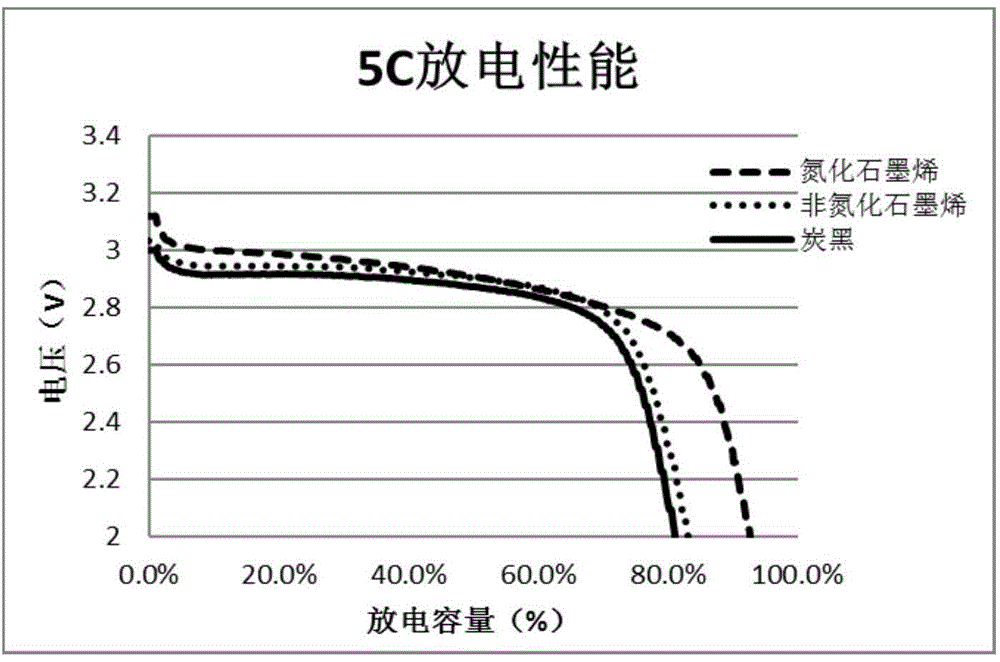

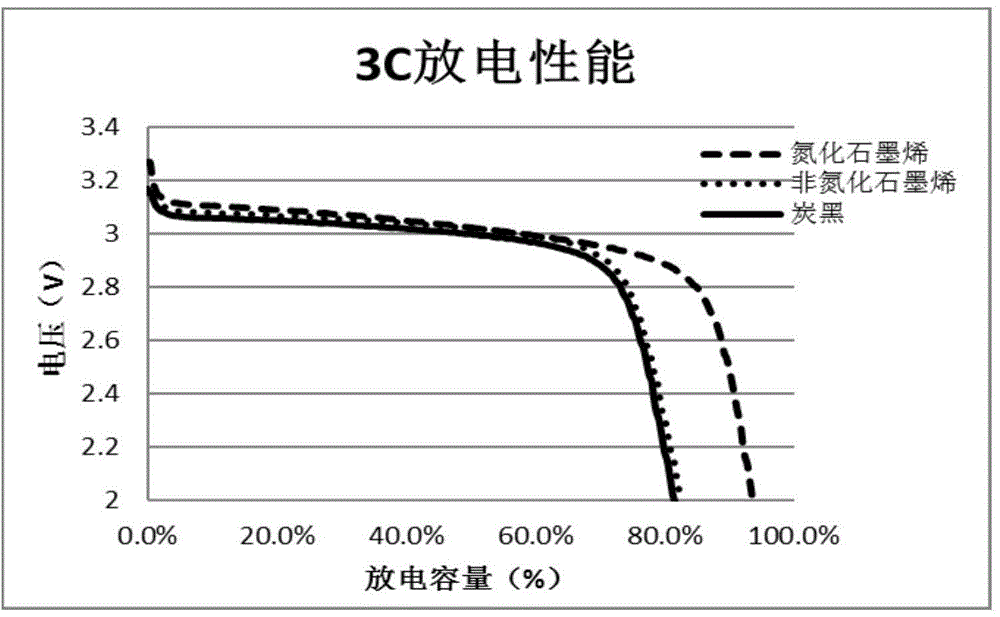

Preparation method of azotized graphene lithium ion power battery slurry

The invention relates to a preparation method of azotized graphene lithium ion power battery slurry. The preparation method mainly comprises the preparation of azotized expanded graphite and azotized graphene lithium ion power battery slurry. The preparation method comprises the steps of firstly, introducing a nitrogen increasing agent in the expandable graphite and expanded graphite preparation process, and azotizing to obtain azotized expanded graphite; and secondly, preparing azotized graphene by taking the azotized expanded graphite as the raw material, and introducing substances such as a dispersing agent, a conductive agent, active materials and a binder in the preparation process so as to obtain the azotized graphene lithium ion power battery slurry. According to the preparation method, azotized graphene or the compound of azotized graphene and other conductive additives is adopted as the conductive additive of the lithium ion power battery slurry, the high-temperature cycle performance, high-temperature storage performance and high-rate discharge performance are further improved; on the other hand, the preparation of azotized graphene and the dispersion of the lithium ion power battery slurry are implemented simultaneously, and the problem that graphene cannot be dispersed easily in the application process can be solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com