An anode material for compound lithium ion battery

A technology for ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity, achieve good rate performance, high discharge specific capacity, and improved discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

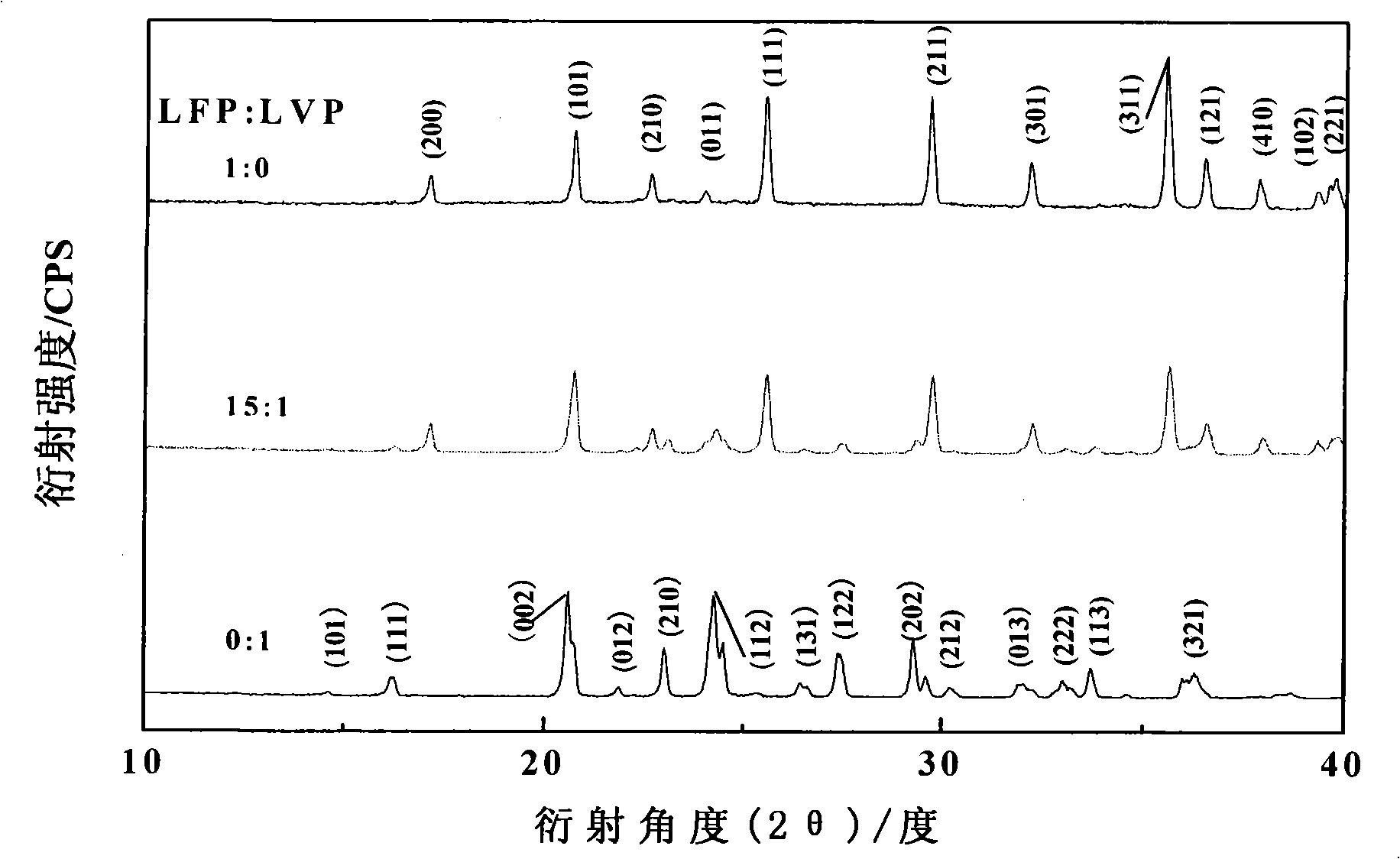

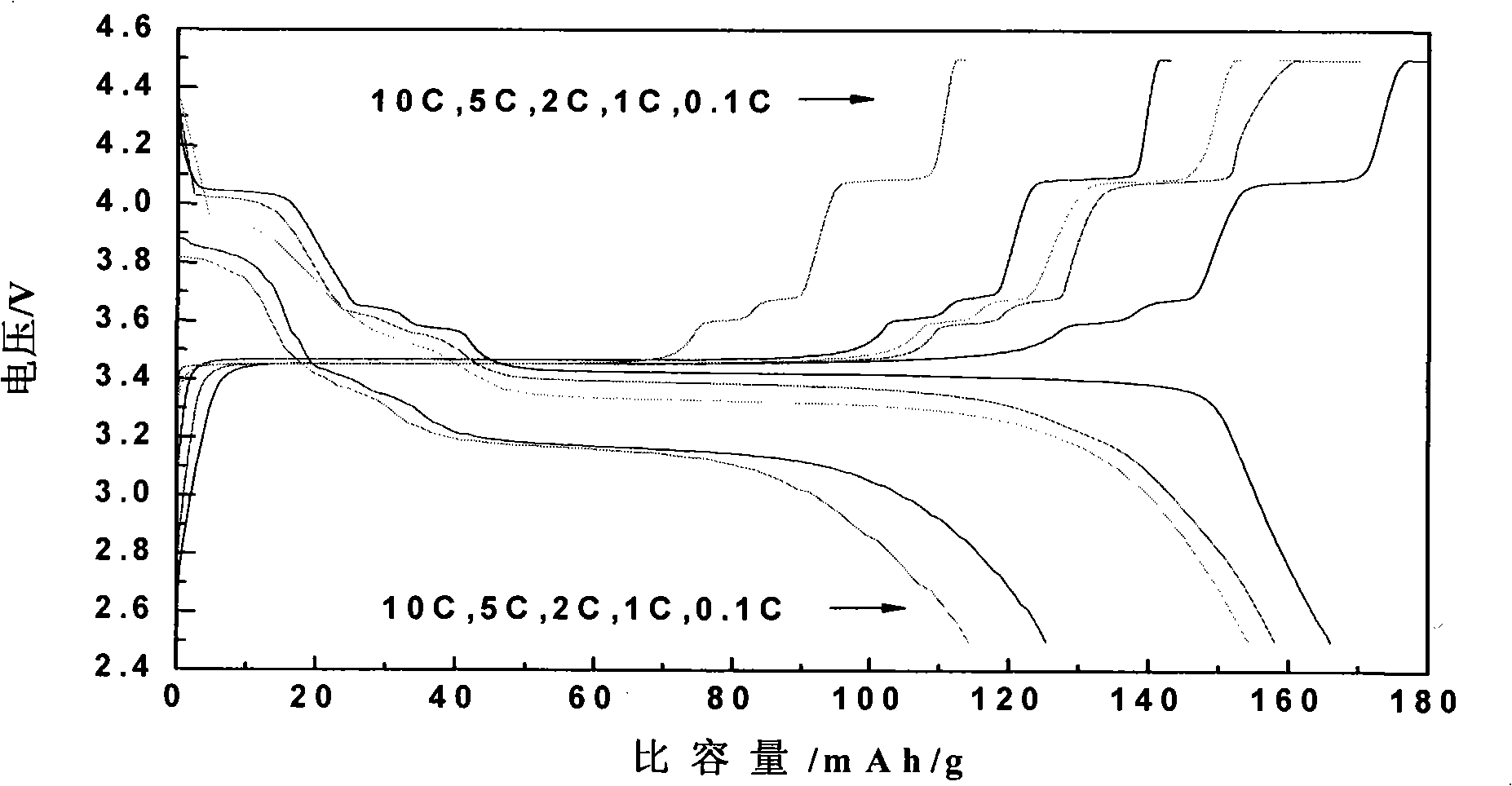

Embodiment 1

[0013] FePO 4 ·xH 2 O. Li 2 CO 3 , V 2 o 5 and NH 4 h 2 PO 4 As a raw material, according to the obtained composite cathode material composition M=15LiFePO 4 +Li 3 V 2 (PO 4 ) 3 The molar ratio of ingredients, and mixed evenly, after mechanical activation, into the tube furnace, under the condition of argon atmosphere temperature of 600 ℃, constant temperature for 12 hours. The obtained composite cathode material was analyzed by X-ray diffraction as LiFePO 4 and Li 3 V 2 (PO 4 ) 3 Both phases coexist. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The first charge-discharge capacity and the discharge capacity after 50 cycles of discharge at the rate of 0.1C, 1C, 2C, 5C and 10C are as follows:

[0014] Sample charge and discharge test results in table 1 example 1

[0015]

Embodiment 2

[0017] FeC 2 o 4 2H 2 O. Li 2 CO 3 , LiF, V 2 o 5 and (NH 4 ) 2 HPO 4 As a raw material, according to the obtained composite cathode material composition M=25LiFePO 4 +LiVPO 4 F molar ratio ingredients, and mixed evenly, after mechanical activation, put into tube furnace, under the condition of argon atmosphere temperature of 700 ℃, keep the temperature constant for 5 hours. The obtained composite cathode material was analyzed by X-ray diffraction as LiFePO 4 and LiVPO 4 F two phases coexist. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. When the charge-discharge test was performed at 0.1C, the discharge specific capacity reached 165mAh·g -1 , the discharge specific capacity after 50 cycles is 164.6mAh·g -1 , The capacity retention rate reaches 99.76%.

Embodiment 3

[0019] LiFePO 4 as the matrix, Li 3 V 2 (PO 4 ) 3 coated in LiFePO 4 Particle surface, LiFePO 4 with Li 3 V 2 (PO 4 ) 3 The molar ratio is 100:1. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. When the charge-discharge test was performed at 0.1C, the discharge specific capacity reached 155mAh·g -1 , after 50 cycles, the discharge specific capacity is 150mAh·g -1 , The capacity retention rate reaches 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com