Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2271results about How to "Improve biodegradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

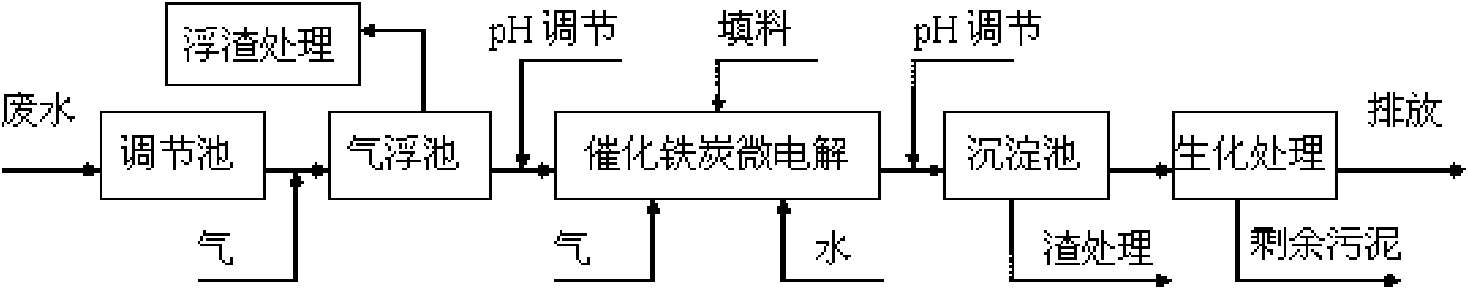

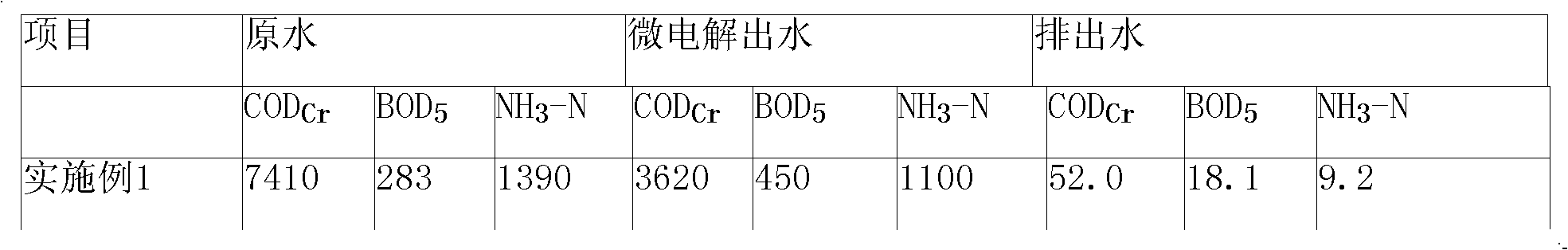

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

Water gel containing natural high molecule and its radiation preparing method

InactiveCN1944495AImprove water absorptionGood flexibilityOrganic active ingredientsAntipyreticCross-linkWound dressing

The present invention provides one kind of water gel containing natural high molecular material and its preparation process. The water gel has cross-linking degree of 70-95 % and water absorption of 500-80000 %, and contains natural high molecular material or its derivative selected from chitin, chitin derivative, chitosan, chitosan derivative, carrageenin, etc. The water gel may have synthetic high molecular material, inorganic filler, cross-linking sensitizer, medicine and other assistant added. It is prepared through radiation cross-linking, with the radiation dosage being 10-40 kGy. The water gel of the present invention has high water absorption, high flexibility, good medicine slow releasing performance, and may be used in wound dressing, etc.

Owner:厦门凝赋生物科技有限公司

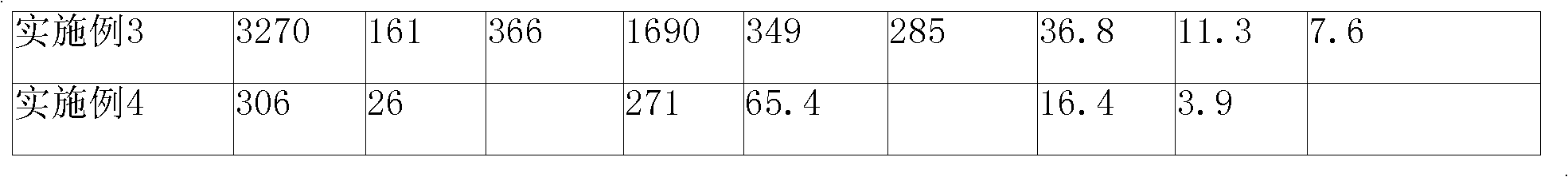

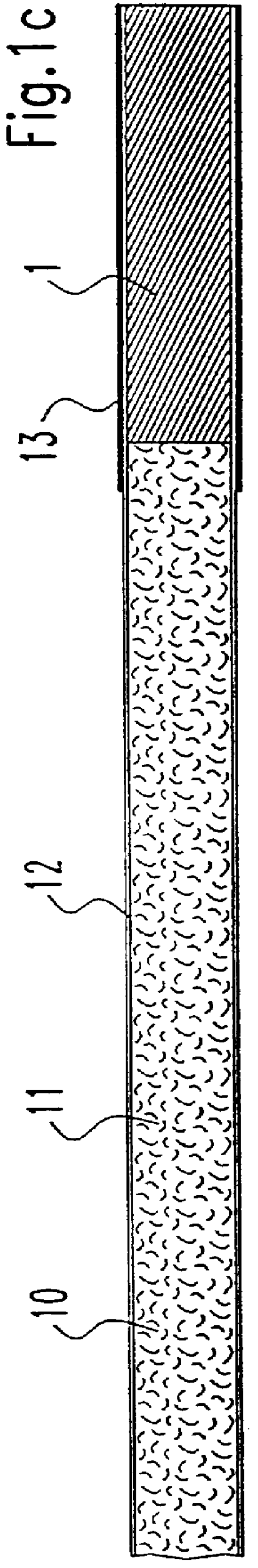

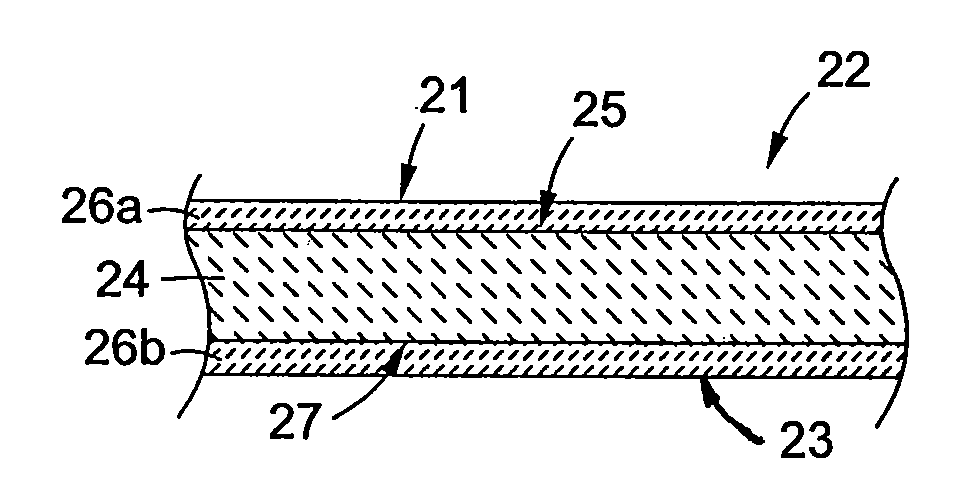

Biodegradable filter material and method for its manufacture

InactiveUS6062228AGood filtering propertyImprove biodegradabilityMechanical working/deformationTobacco treatmentFlavorFilter material

PCT No. PCT / EP96 / 04234 Sec. 371 Date Mar. 30, 1998 Sec. 102(e) Date Mar. 30, 1998 PCT Filed Sep. 27, 1996 PCT Pub. No. WO97 / 12528 PCT Pub. Date Apr. 10, 1997There is provided a biodegradable filter tow or filter material from renewable raw materials for the use as a tobacco smoke filter element of cigarettes, cigars or pipes as well as a method for preparing it, wherein fibers, films or foams prepared in an extrusion method from biopolymers based on thermoplastic starch or its polymer compositions are processed to the filter tow or filter material according to the present invention. The advantages of this invention reside in the use of mainly renewable raw materials, a fast and complete biodegradability of the natural biopolymer filter material, a pollutant-reducing flavor-increasing filtering effect and an economically favorable preparation method.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Method for preparing amylaceous fully degradable plastic

A starch-type fuel-degradable plastics is prepared from superfine starch, plasticizer, compatibilizer, cooxidanta nd synthetic degradating material. Its advantages are synergistic effect of the combination of optical degradation, thermal oxidizing degradation and biologic degradation and short degradation period (one year).

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

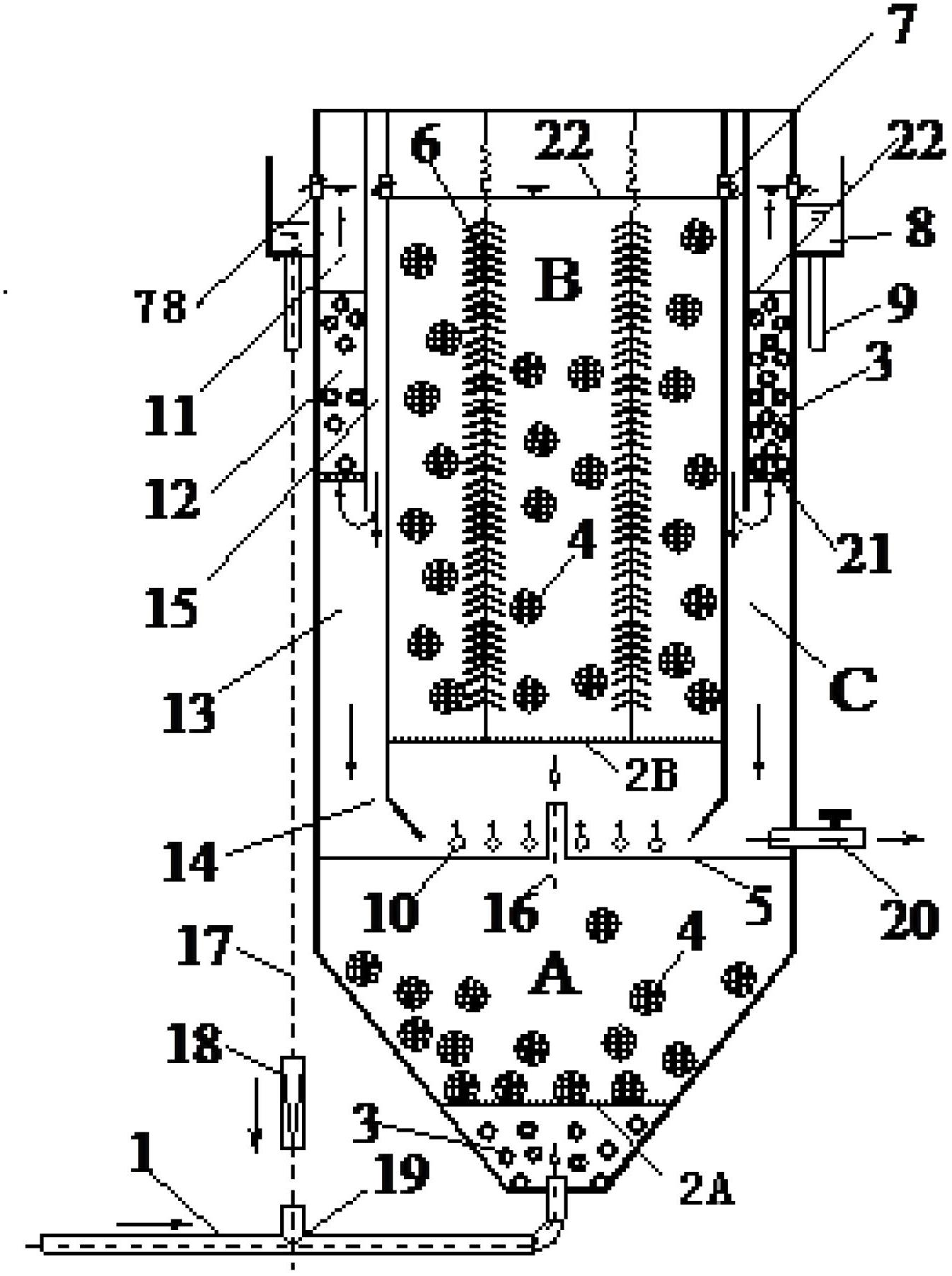

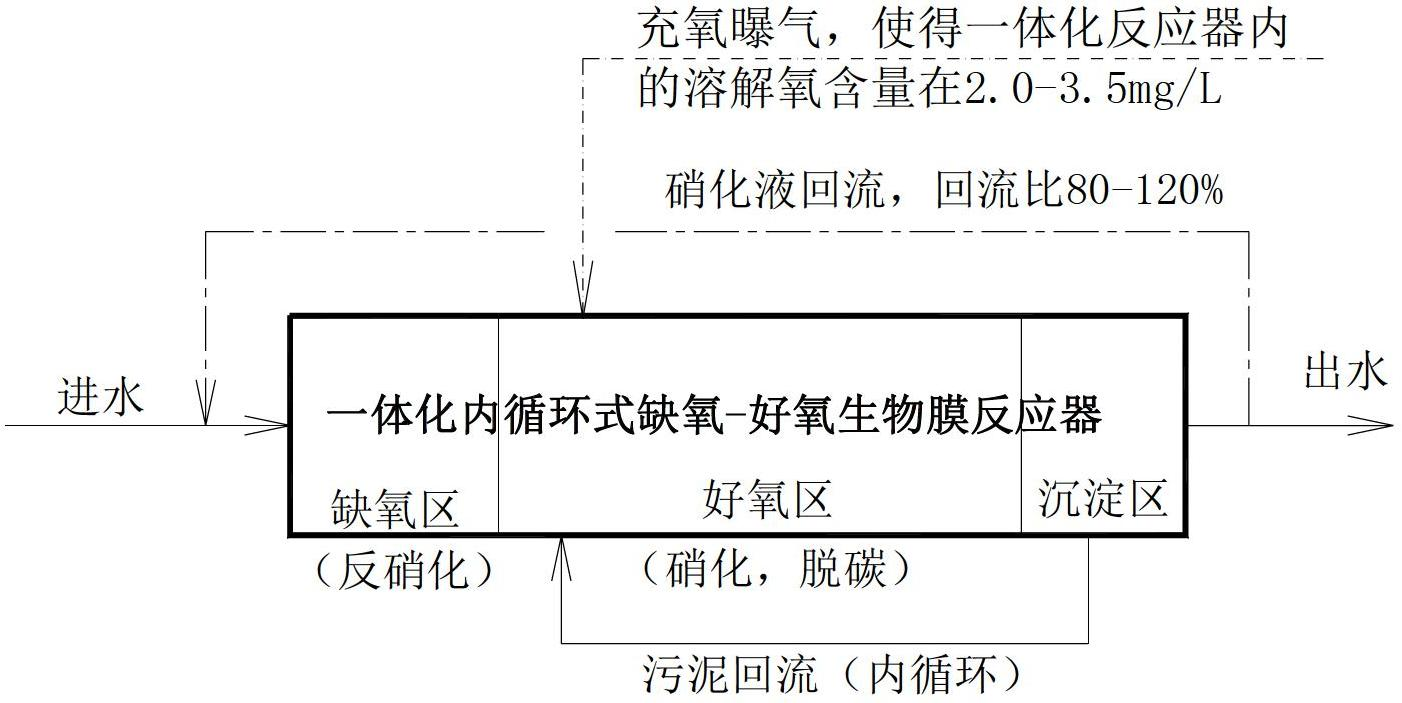

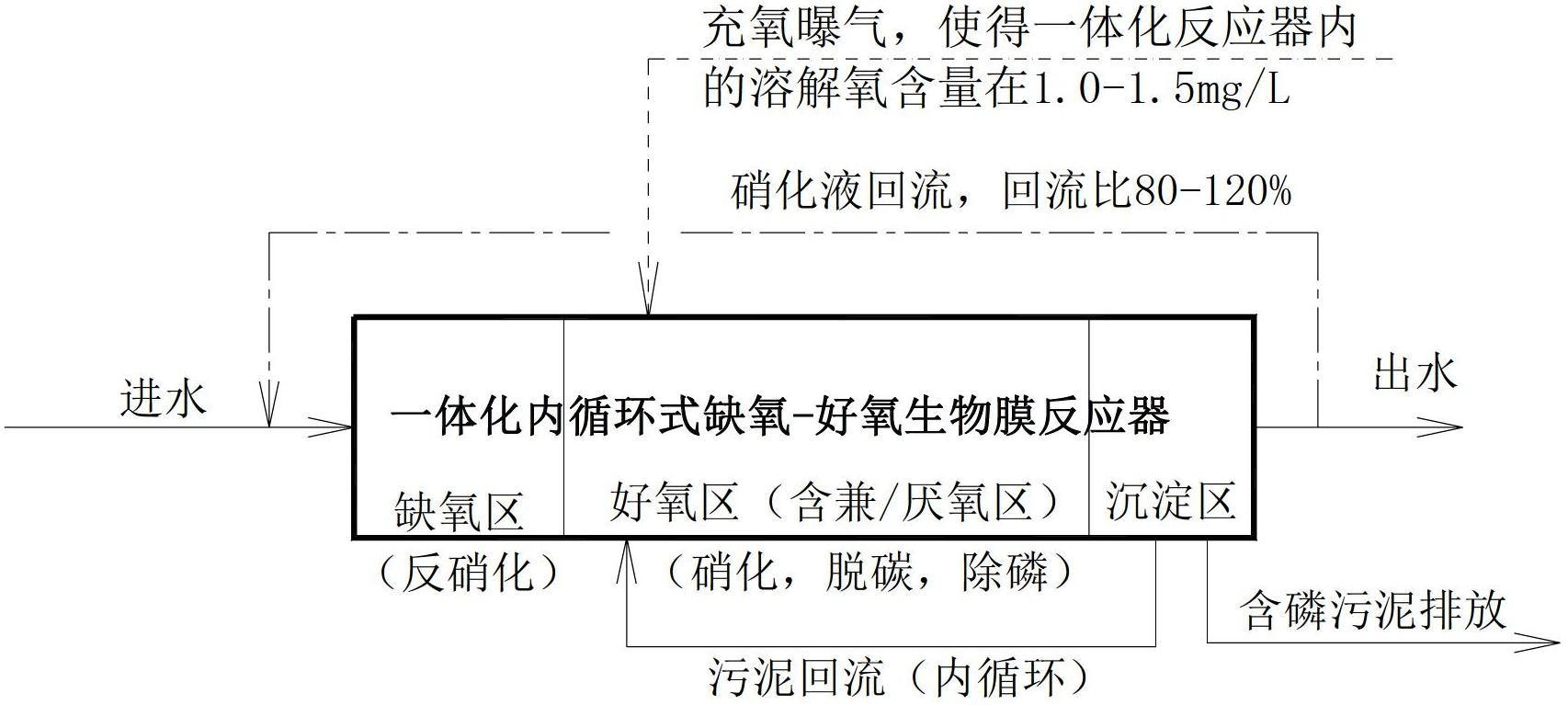

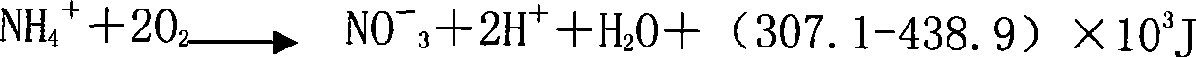

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

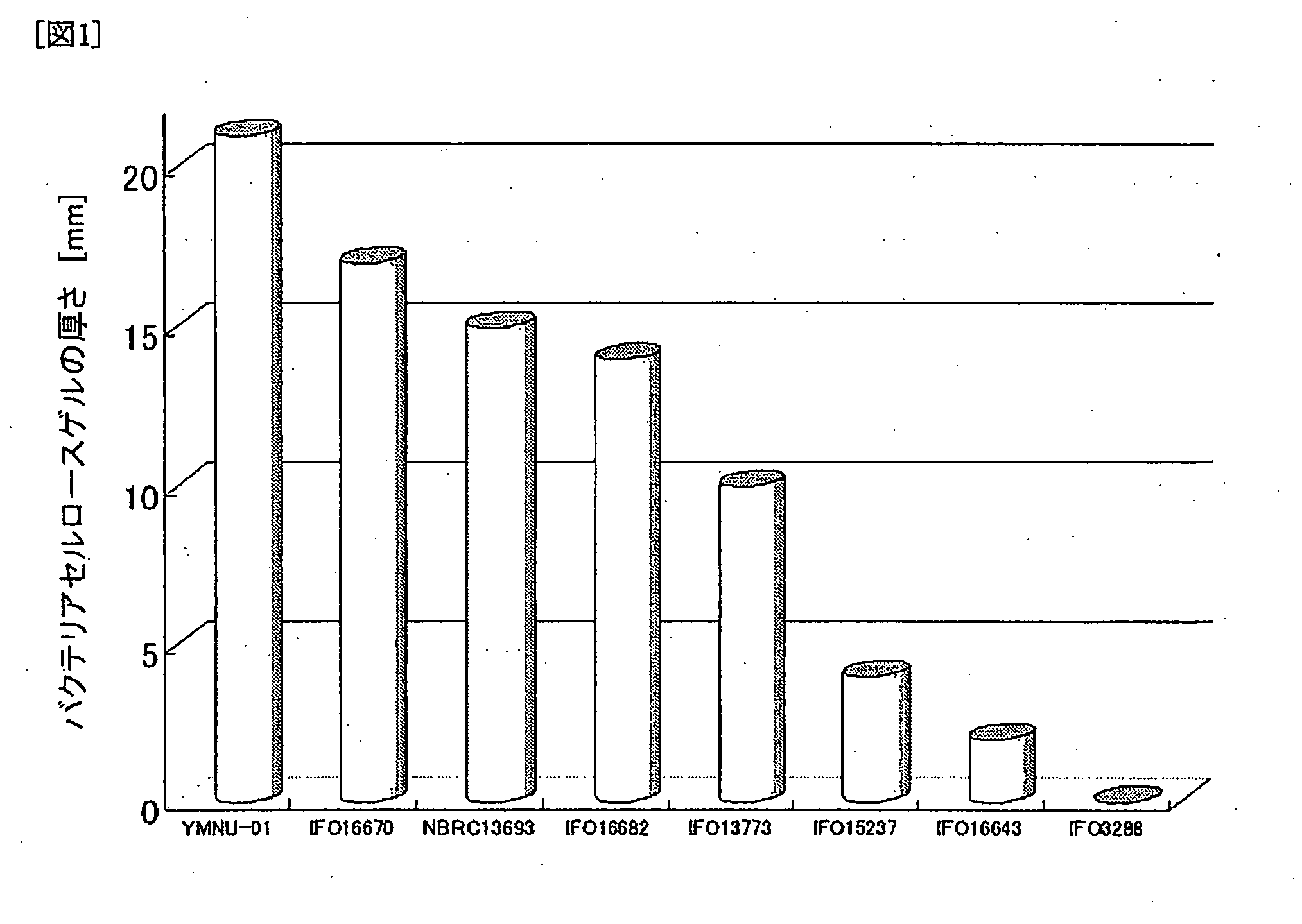

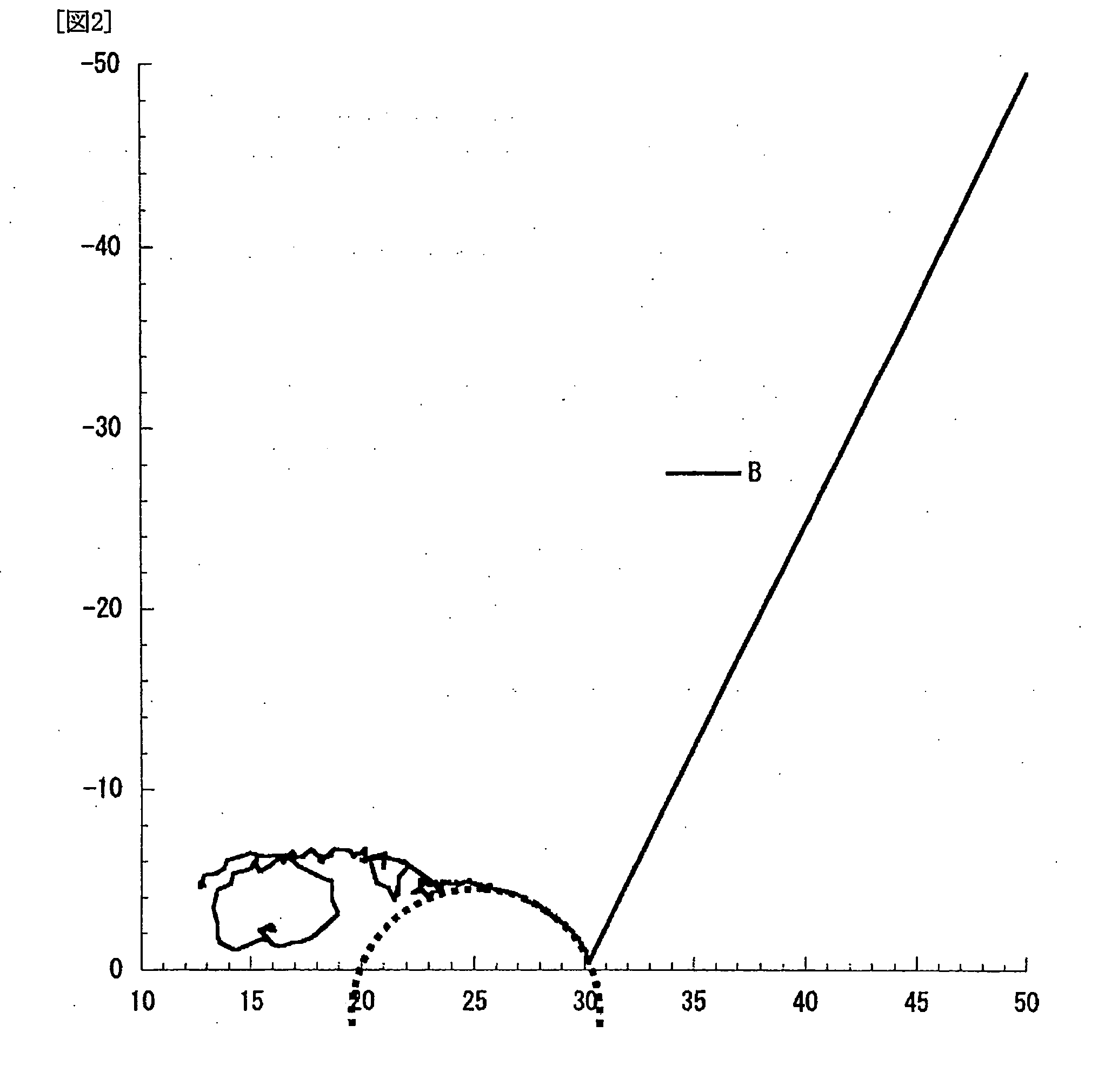

Lithium Ion Conductive Material Utilizing Bacterial Cellulose Organogel, Lithium Ion Battery Utilizing the Same and Bacterial Cellulose Aerogel

InactiveUS20080220333A1High mechanical strengthImprove performanceMaterial nanotechnologyConductive materialConductive materialsSolvent

A lithium ion conductive material that excels in mechanical strength, exhibiting high ion conductivity; a bacterial cellulose composite material having an inorganic material and / or organic material incorporated therein; and a bacterial cellulose aerogel. The water of bacterial cellulose hydrogel is replaced by a nonaqueous solvent containing a lithium compound. Bacterial cellulose producing bacteria are grown in a culture medium having an inorganic material and / or organic material added thereto. The bacterial cellulose hydrogel is dehydrated and dried.

Owner:YANO SHOICHIRO +5

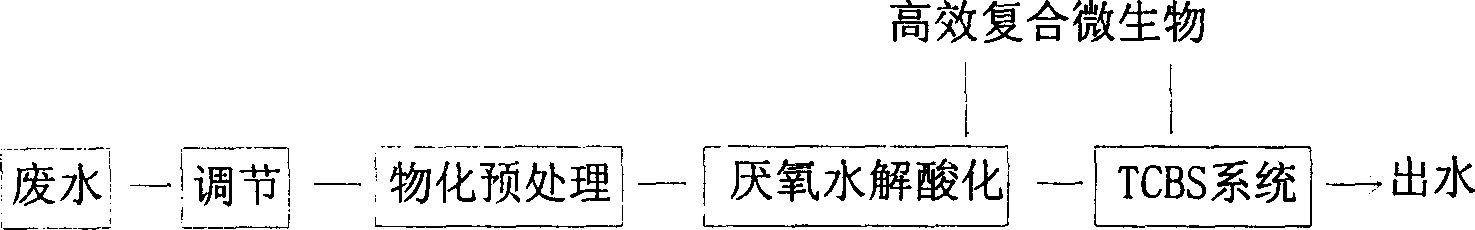

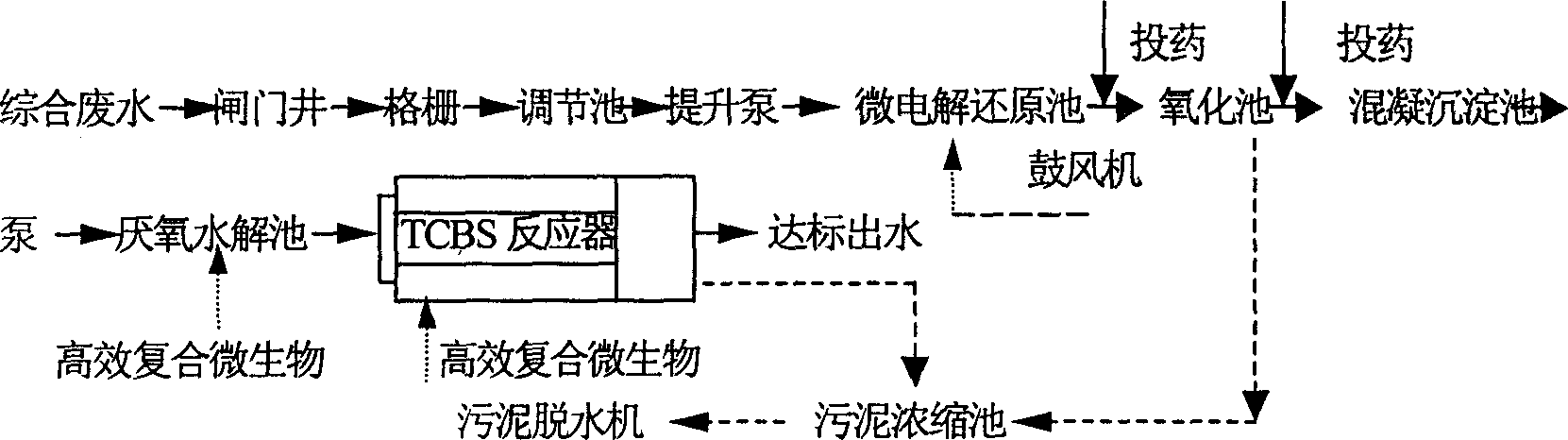

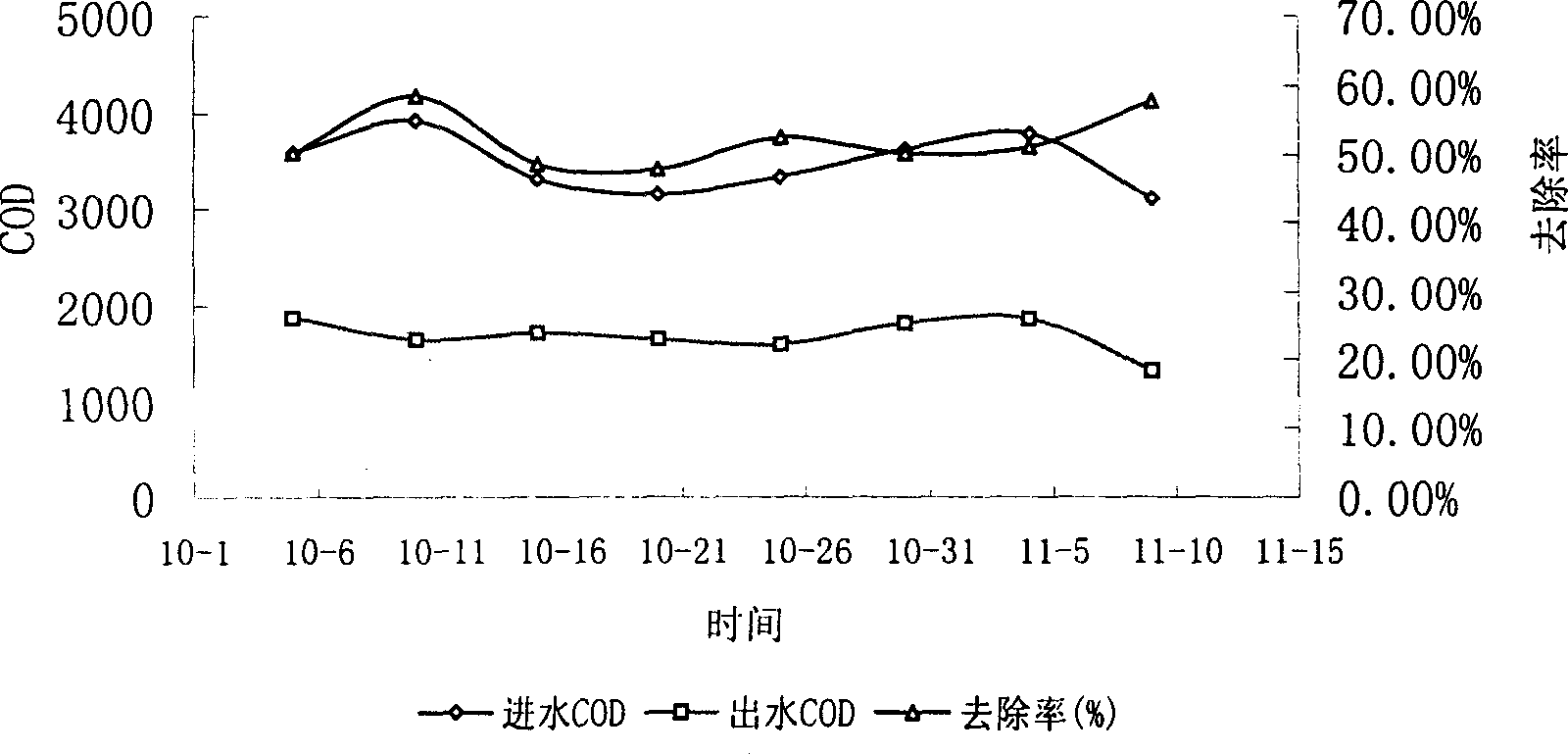

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

Copolyester resin composition and a process of preparation thereof

InactiveUS6399716B2Improve biodegradabilityEasy to processPhosphorus organic compoundsCopolyesterPolyester resin

An aromatic group containing copolyester resin composition which has good biodegradability and physical properties, wherein; (i) 0.1 wt % to 30 wt % of an aliphatic prepolymers having number average molecular weight of from 300 to 30,000; (ii) one or a plurality of aromatic dicarboxylic acid (or an acid anhydride thereof which containing aromatic group in the molecule; (iii) one or a plurality of aliphatic (including cyclic type) dicarboxylic acid (or an acid anhydride thereof); and (iv) one or a plurality of aliphatic (including cyclic type) glycol, wherein the copolyester resin has number average molecular weight of from 30,000 to 90,000, weight average molecular weight of from 100,000 to 600,000, melting point of from 70° C. to 150° C., and melt index of from 0.1 to 50 g / 10min. (190° C., 2,160 g), and the process for preparing and / or producing the same. The composition and preparation method provides a high molecular weight copolyester resin which has good biodegradability and physical properties required for packaging film, trash bags and agricultural film.

Owner:ANKOR BIOPLASTICS CO LTD

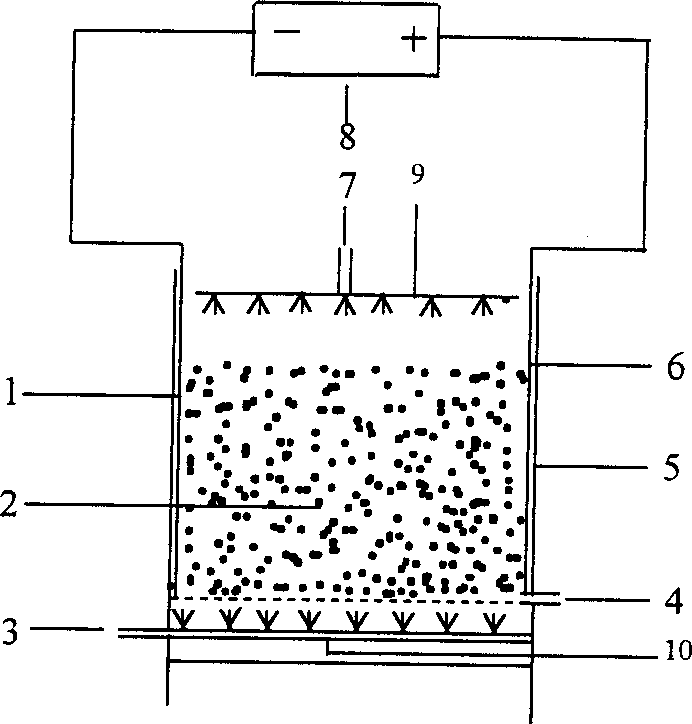

Three-dimension electrode reactor and use for treating organic waste water

InactiveCN1358672AImprove biodegradabilityGuaranteed emission standardsWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationDecompositionPollutant

The present invention relates to a three-D electrode reactor and its application for treating organic waste water. Said reactor is formed from bed body, feeder negative electrode, feeder positive electrode, particle electrode, water-distributing plate, aeration plate and D.C. power supply. It is a three-D electrode reactor using electric energy as excitation energy, air as raw material and particles electrode containing initiating agent as working electrode. Said reactor can produce strong oxidizing agents of H2O2 and OH, and can effectively make oxidation-decomposition, and can compltely mineralize organic pollutant into the inorganic materials of CO2 and water. It can be used for pretreating organic waste water, and can be used for making after treatment of waste water passed through biological chemical treatment so as to ensure standard discharge of waste water.

Owner:SUN YAT SEN UNIV

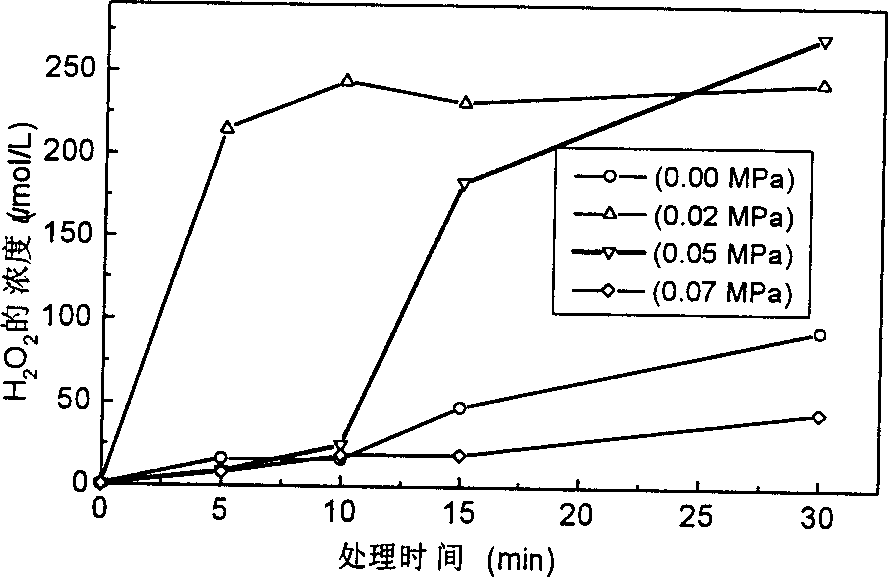

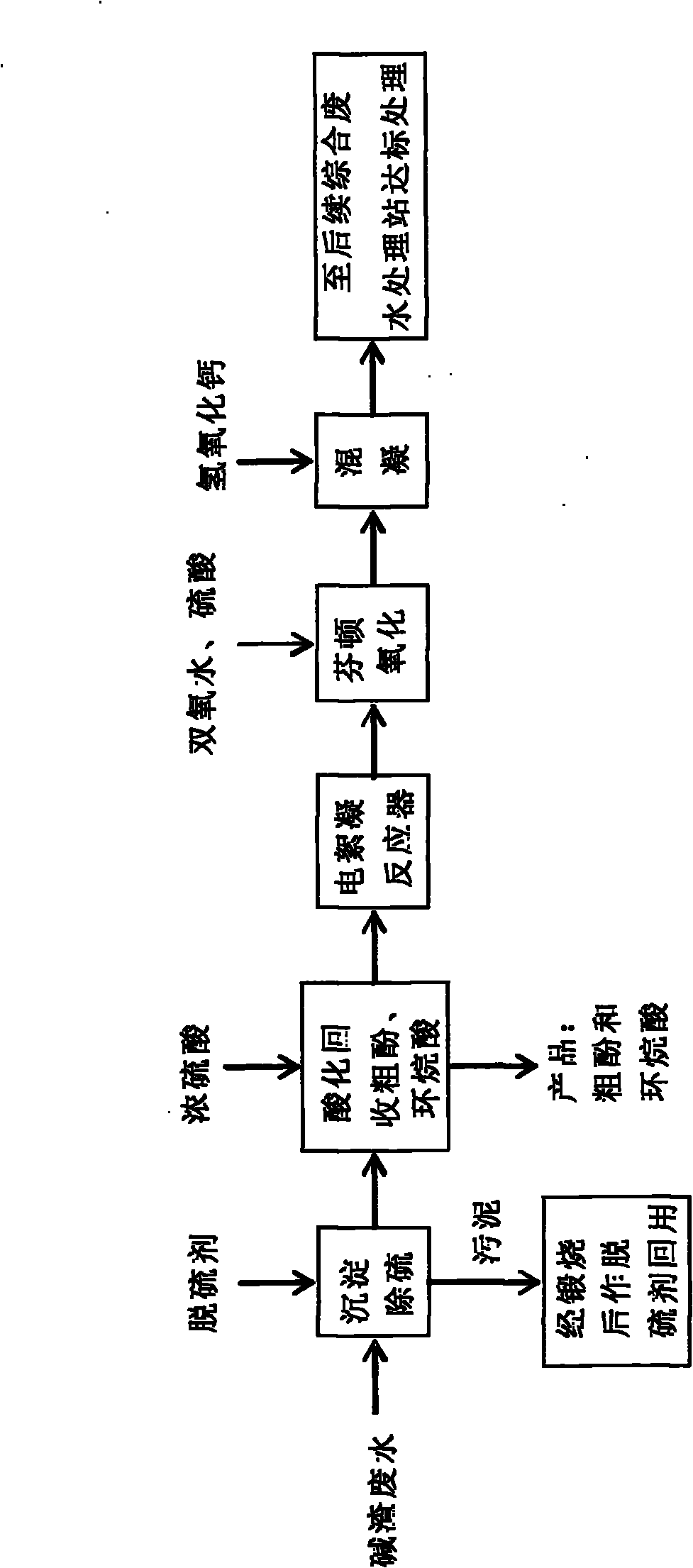

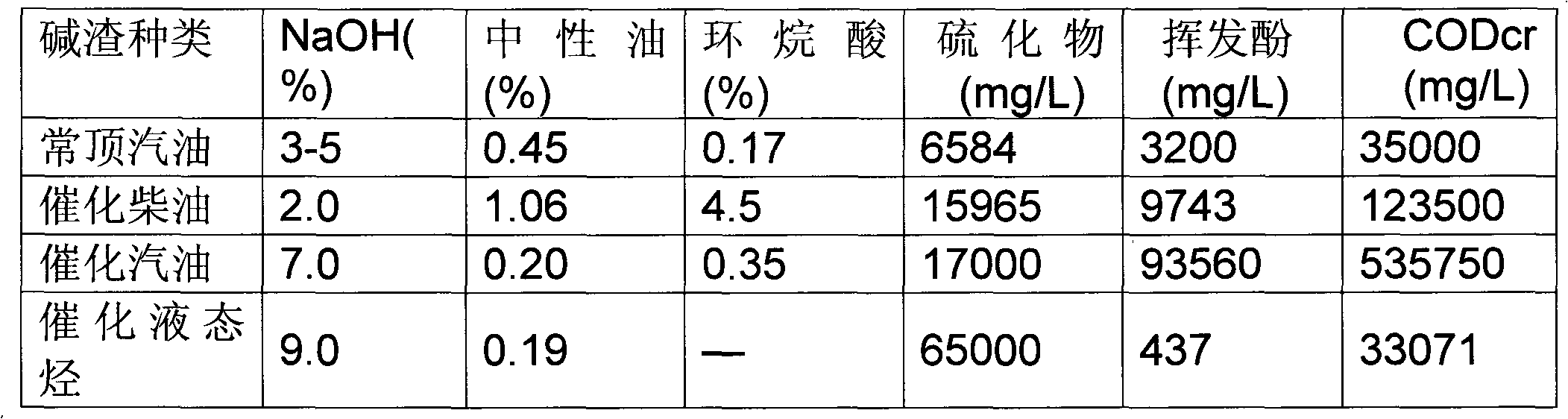

Treatment method for high-concentration sulfur-containing caustic sludge wastewater from oil refinery

InactiveCN101985379AGood biodegradabilitySimple processOrganic compound preparationMultistage water/sewage treatmentEnvironmental chemistrySulfide

The invention relates to a treatment method for high-concentration sulfur-containing caustic sludge wastewater from an oil refinery. The main process comprises precipitation, acidification, electrocoagulation and Fenton reagent oxidation. The method comprises the following steps of: adding a precipitator into the high-concentration sulfur-containing caustic sludge wastewater refined from the oil refinery so as to remove sulfide, sulfur ether, sulfur alcohol and other malodorants, greatly reduce odor of caustic residue and reduce toxicity of water body; then acidifying and recovering crude phenol and naphthenic acid; and performing oxidation treatment through an electrocoagulation-Fenton reagent so as to remove most of the polluted and nonbiodegradable organic matters from the wastewater. The limit of COD concentration and sulfur content of water inlet is improved to the greatest degree, the need of a large amount of dilution water is saved in the conventional operation process, the crude phenol and naphthenic acid in the caustic residue wastewater are effectively recovered, and no secondary pollution is produced in the operation process.

Owner:惠州TCL环境科技有限公司

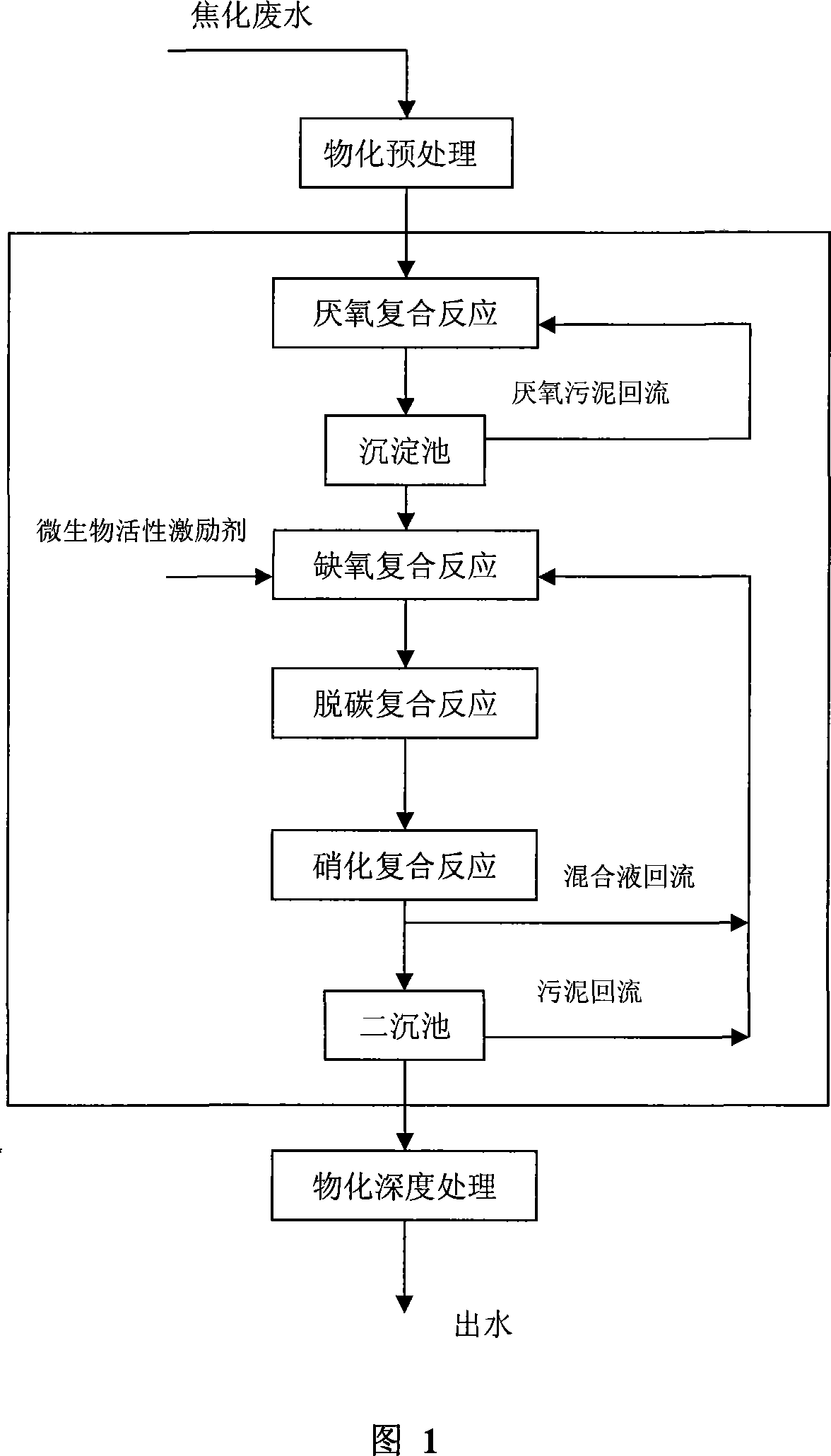

Impact-resistant multiplication combined type coking waste water treatment process

InactiveCN101113065AOptimize material compositionImprove biodegradabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater treatmentWater quality

An anti-impact multiplying combination coking wastewater treatment technique relates to a treatment method of coking wastewater. The coking wastewater is first qualified by a physical-chemical pretreatment to improve biodegradable property of wastewater; the composite technology of a biological carrier of active sludge is adopted to do anaerobic / hypoxia / aerobic decarbonization / aerobic nitrification biochemical combination treatment; suspended or floating folding ball-shaped fillings are arranged in biochemical reactors and when micro organism traits are abnormal or a great amount of foams existing in the reactor, micro organism active incentive agents are added to the reactor in interval to improve active sludge traits and organism film quantity; finally the water is treated by a physical-chemical advanced treatment to reach a top grade standard. The invention not only strengthens the removal of COD, ammonia-nitrogen, volatile phenol and other pollutants in the coking wastewater by biochemical treatment but also resists serious water quality impact and has the advantages of quick system startup, less foams in an aeration tank, small occupying space, low operation cost and stable and effective treatment to coking wastewater.

Owner:TONGJI UNIV +1

Dephosphorization and denitrification, mud decrement and phosphorus recovery integrated sewage treatment device and method thereof

InactiveCN101544453AImprove system synchronous denitrification and dephosphorization capacityReduce pool capacityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentContinuous flowChemistry

Owner:CHONGQING UNIV

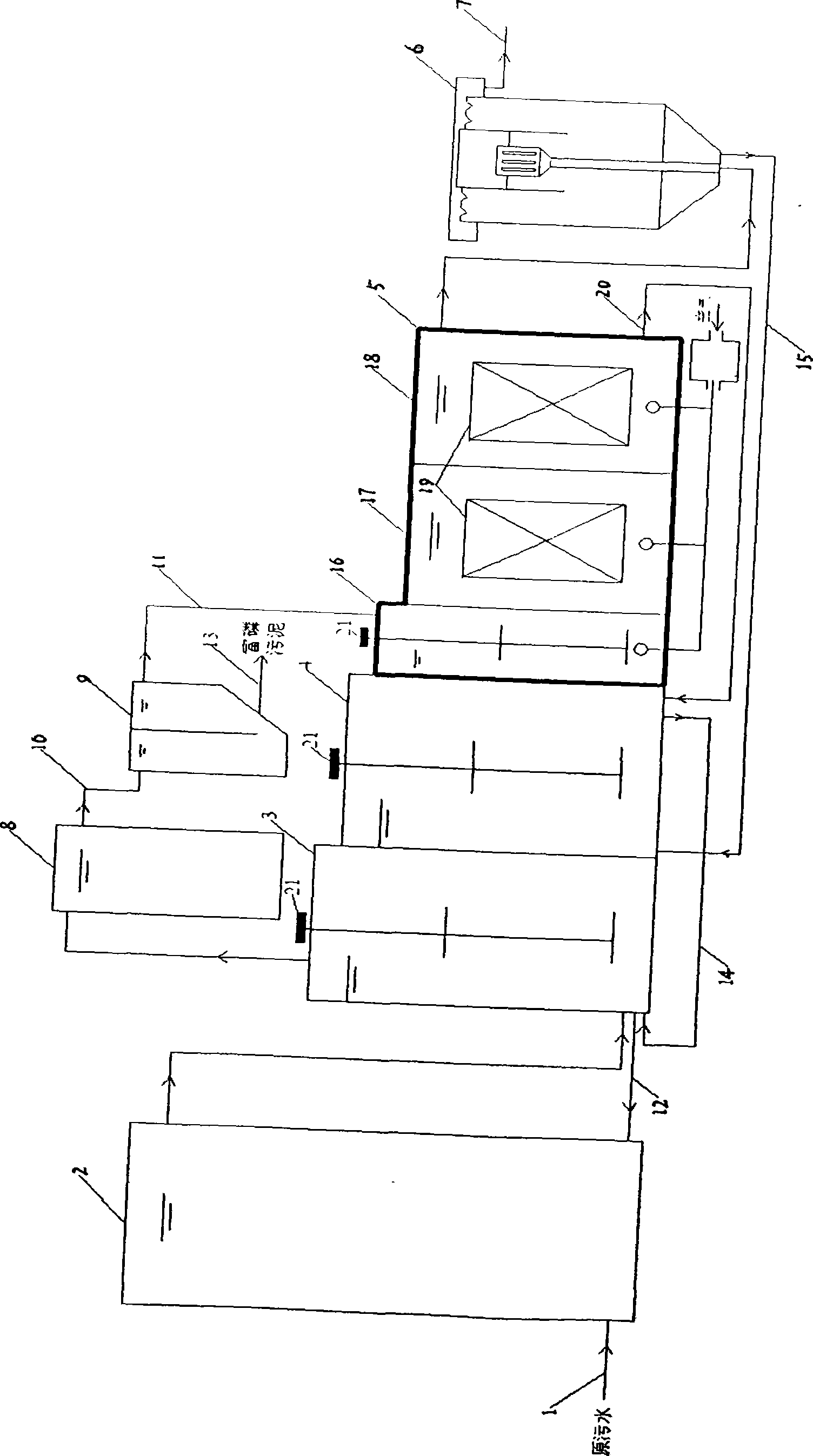

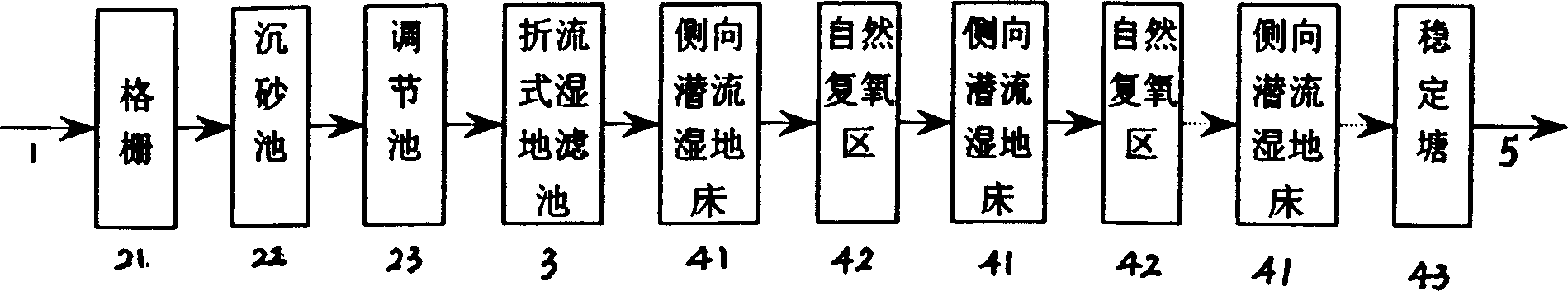

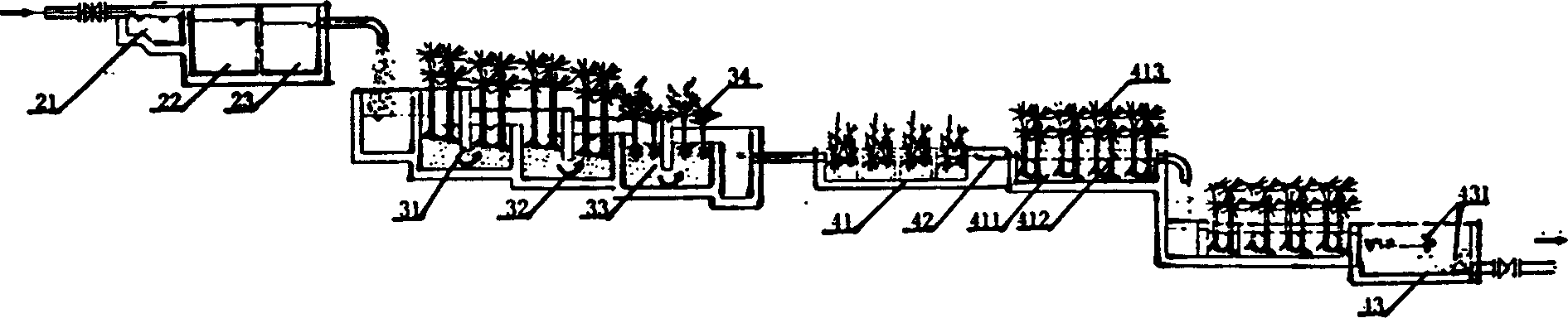

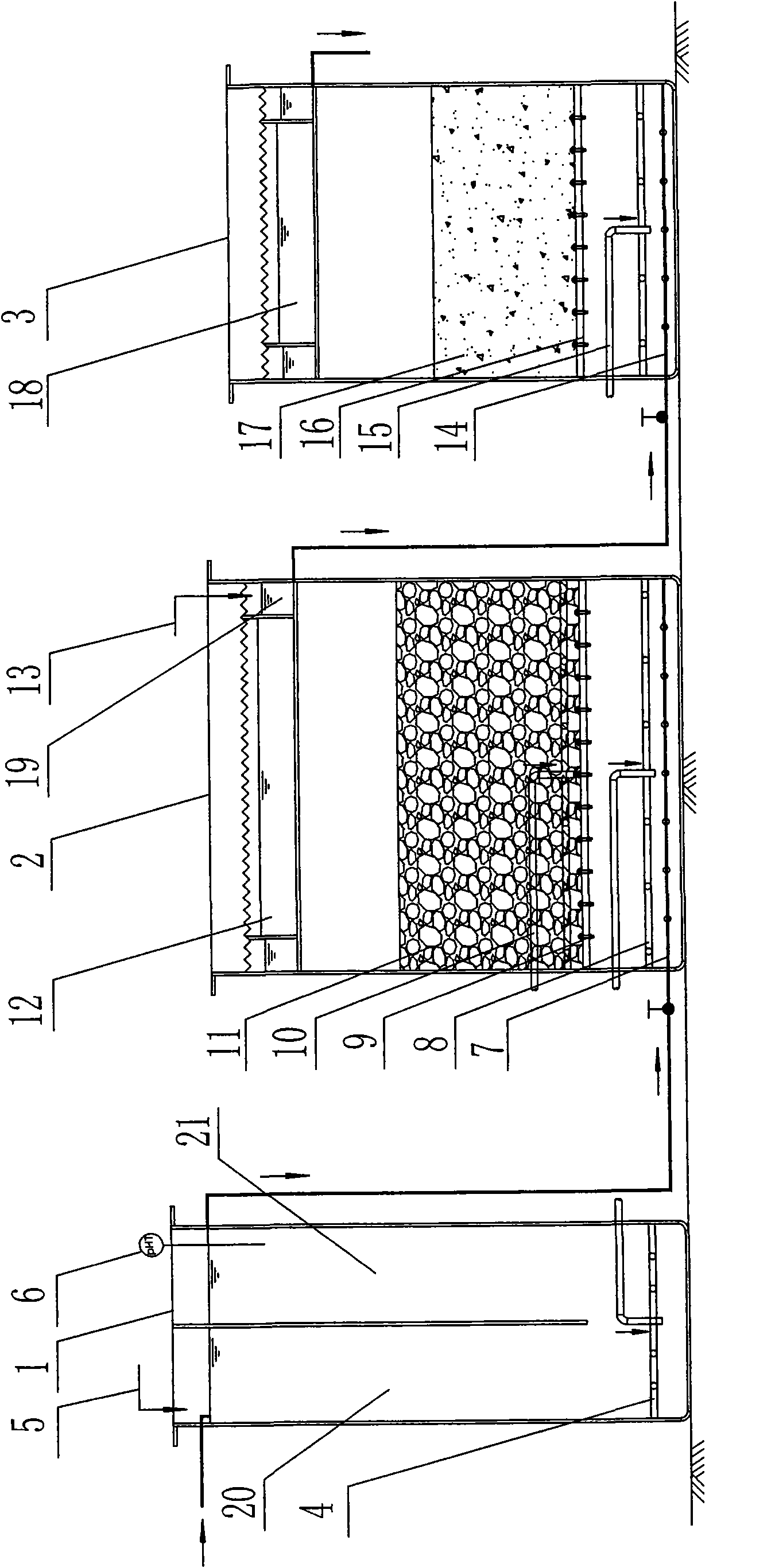

System and process for sawage treating with baffling wet land filtering tank and rateral underflow wet land bed

InactiveCN1693231AImprove biodegradabilityMake full use of interceptionTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater flowExpanded clay aggregate

A system for treating sewage is composed of a pretreating construction, a deflection-type nunja filter pool group and a lateral underflow nunja bed group, which are arranged in gradient mode from high level to low level. Each filter pool contains a vertical retention wall, filler (haydite or zeolite) and aquatic plant. Said lateral underflow nunja bed group consists of multi-stage lateral underflow nunja bed, natural oxygen-aerating area and anaerobic stabilizing pond. Its method is also disclosed.

Owner:CHONGQING UNIV

Particle electrode catalyst filling for three-dimensional electrode and preparation method thereof

InactiveCN1669942ALess investmentLower energy costsWater/sewage treatment by oxidationWastewaterCopper oxide

The invention discloses a particle electrode catalyst filling for three-dimensional electrode and preparation method, calculated by weight percent, the material comprises activated charcoal 50-54%, adhesive 14-19%, the initiating agent comprises 13-16% ferrum oxide, 12-15% copper oxide, 4-7% manganese oxide, 1-1.5% zinc oxide, 0.5-1% zirconium oxide, 0.5-1% cerium oxide.

Owner:SUN YAT SEN UNIV

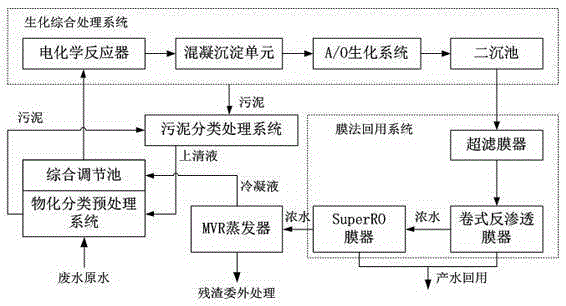

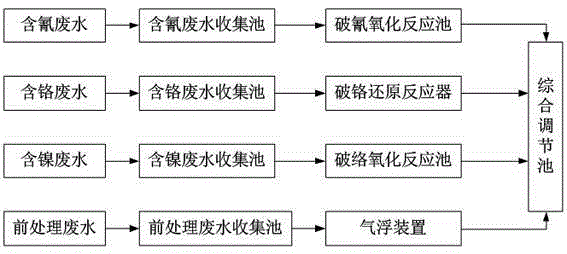

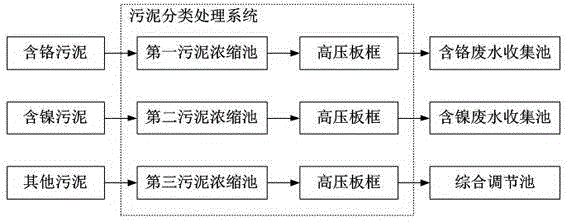

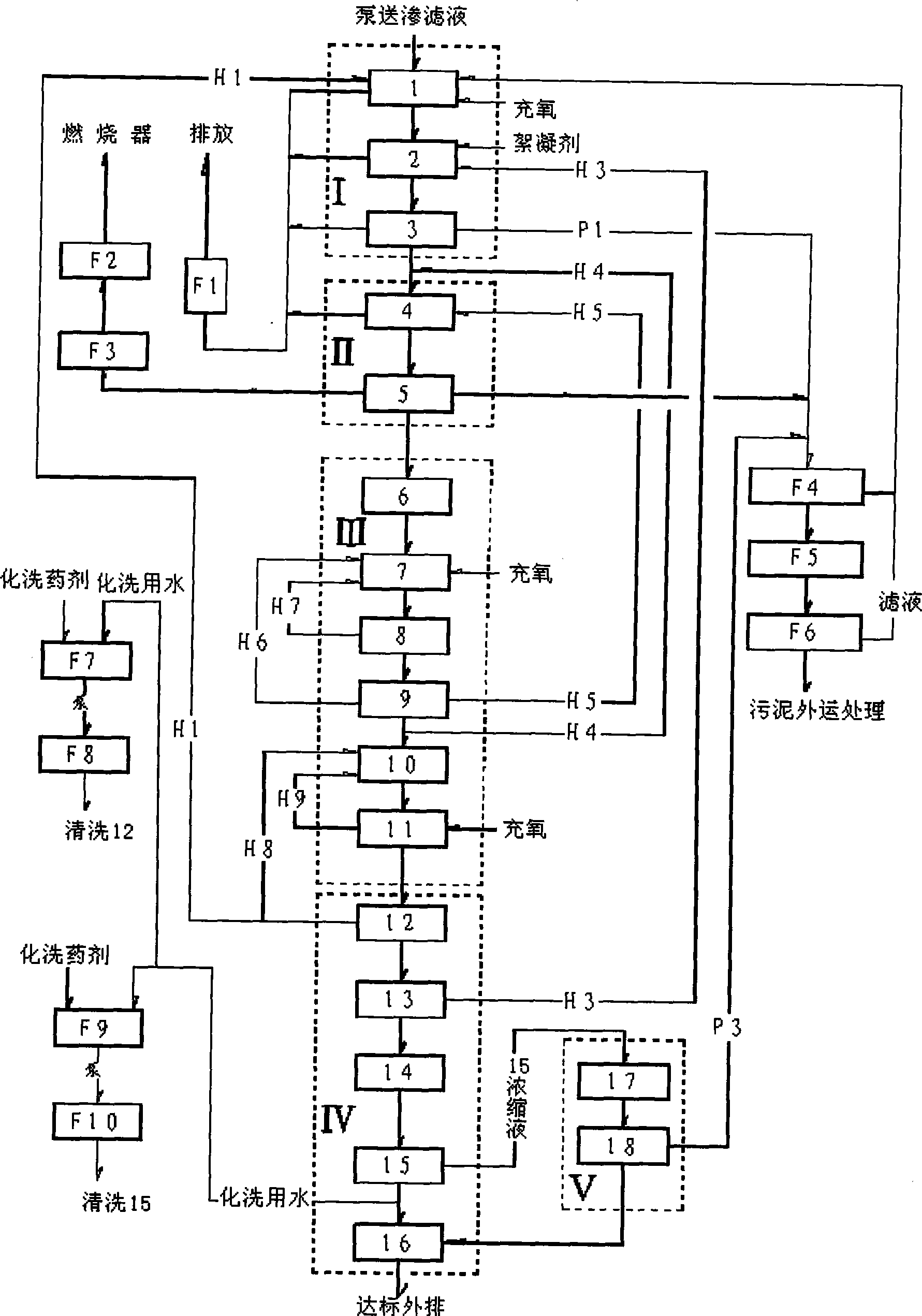

Technique and system for zero discharging treatment of electroplating effluent

ActiveCN105271622AReduce processing costsAvoid wastingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeWastewater

The invention discloses a technique and a system for zero discharging treatment of electroplating effluent. The system comprises a material classifying pre-treatment system, a biochemical comprehensive treatment system, a membrane method system, a membrane concentrated liquor vaporization system and a sludge classifying treatment system which are connected with each other in turn, wherein the sludge classifying treatment system is connected with the material classifying pre-treatment system and the biochemical comprehensive treatment system; the raw wastewater enters into the material classifying pre-treatment system; water generated by the membrane method system is recycled; the condensed liquid from the membrane concentrated liquor vaporization system is re-injected into the material classifying pre-treatment system. According to the technique provided by the invention, the wastewater is firstly treated in classifying form, so that the heavy pollution ions, such as, chromium, cyanogen, nickel, and the like, and the oily matters in the wastewater are effectively removed, and then the biochemical comprehensive treatment system is used for further treating, and lastly, the RO+SuperRo two-level combination mode is utilized to achieve the gross recovery at 94%, and meanwhile, the liquid amount for evaporation treatment is less than 6% of the gross wastewater quantity, the cost of the evaporation treatment is saved, the sludge is recycled, the waste of resources is avoided and the sludge treating cost is saved.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

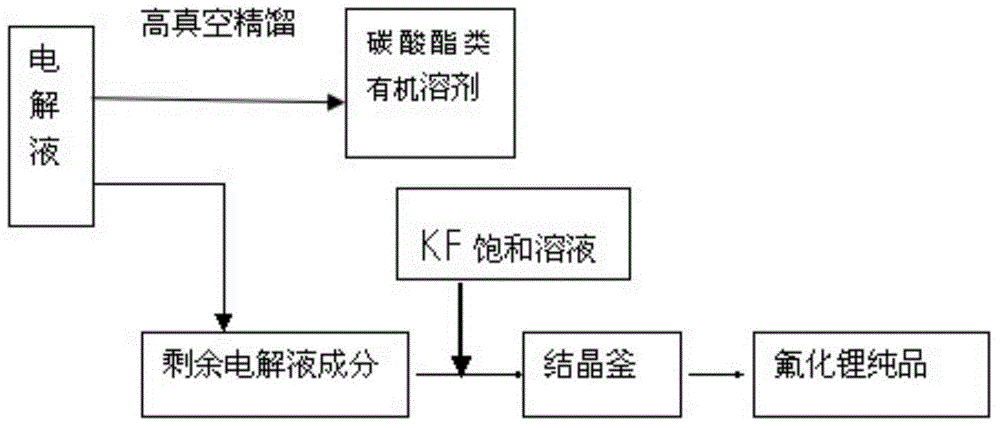

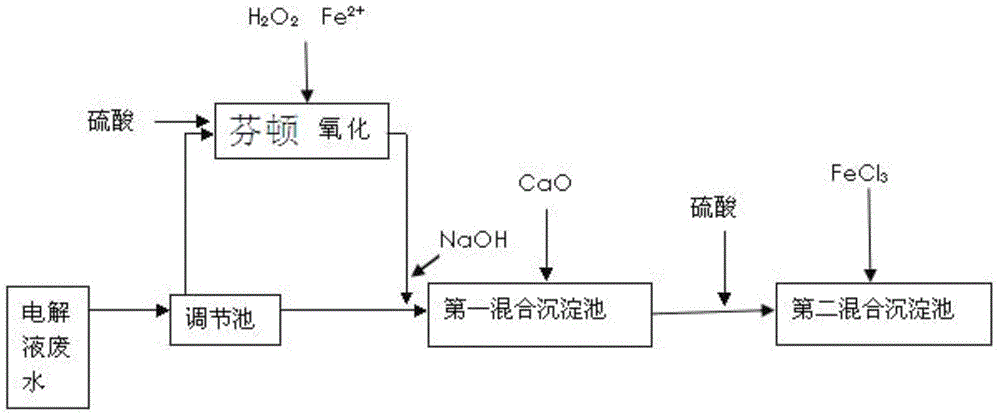

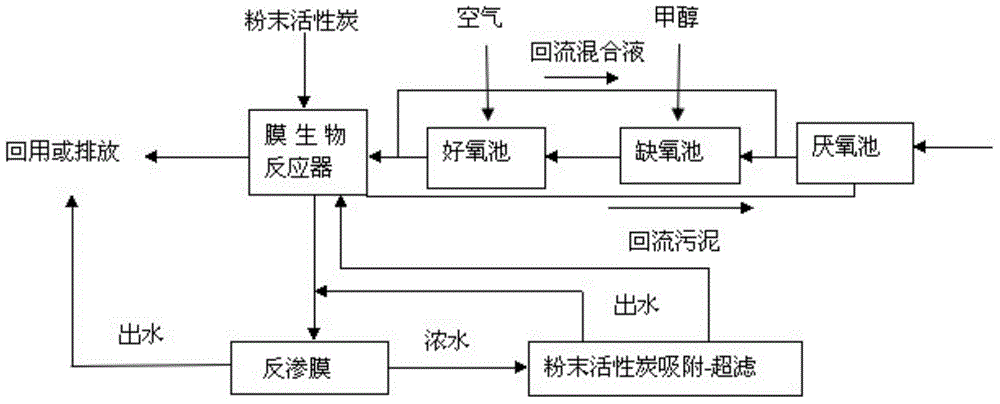

Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

InactiveCN104628217AImprove biodegradabilityOvercome incompletenessDispersed particle separationWater/sewage treatmentUltrafiltrationFiltration

The invention discloses a method for recovery treatment of a waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater. Three treatment units are employed for treatment. Firstly, the waste-and-old electrolyte is treated. Then, waste gas resulting from the reaction of the electrolyte is pumped into the waste water for absorption, so that the waste gas can be removed during a waste water treatment process; the lithium battery waste water is treated by a Fenton agent through oxidation to obtain improved biodegradability of the waste water; and reaction precipitates are removed through flocculent sedimentation and the obtained water is treated through combination of A2 / O and MBR membrane separation. Finally, the outlet water goes through a RO reverse osmosis unit to ensure the quality of the outlet water. Combination technology of active carbon powder adsorption and ultra-filtration is employed to remove organic pollutants of the concentrated water resulting from the RO unit, so that the water after treatment can meet the requirements of RO high-quality reuse water. According to the invention, imperfection of an existing technical method of waste-and-old lithium battery recovery and treatment is overcome, and quantitative reduction, harmlessness, and reutilization of waste water treatment of the waste-and-old electrolyte are realized.

Owner:天津卡特化工技术有限公司

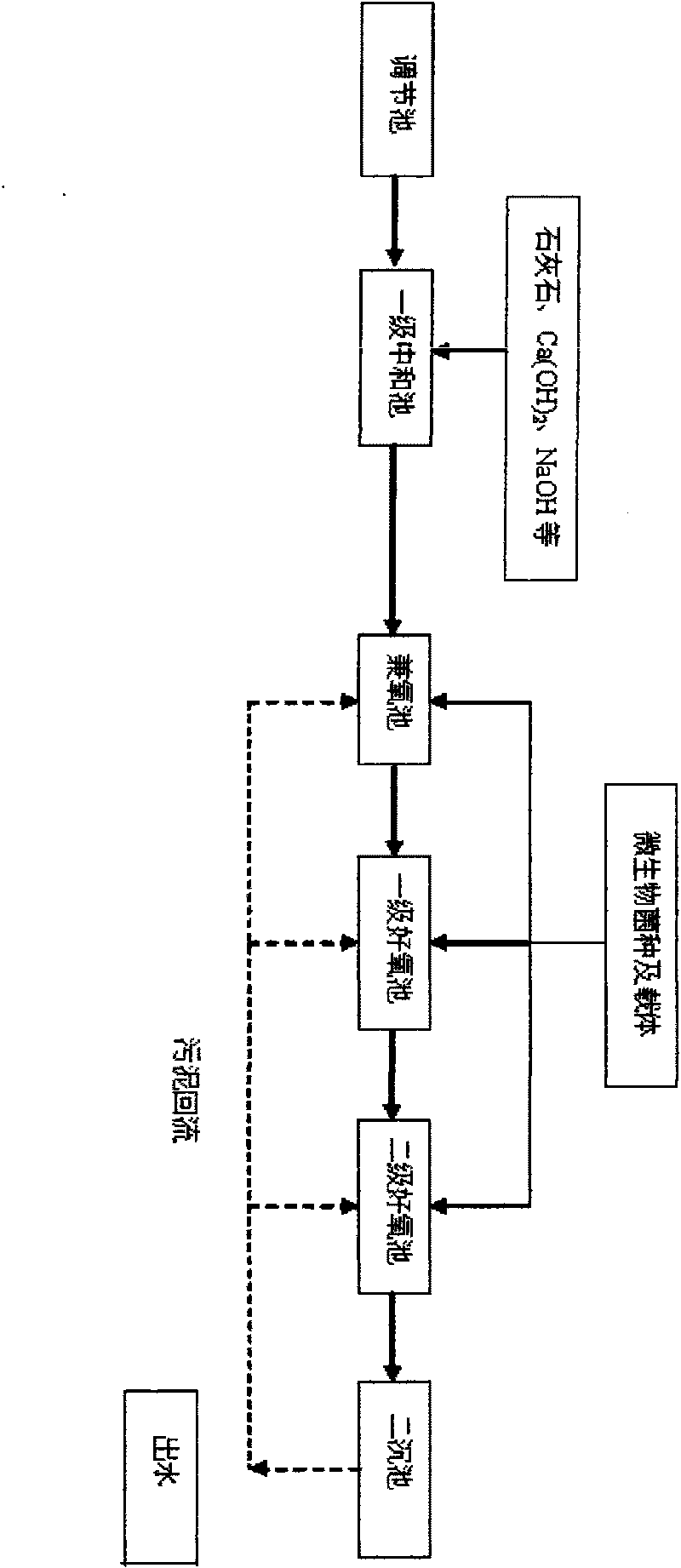

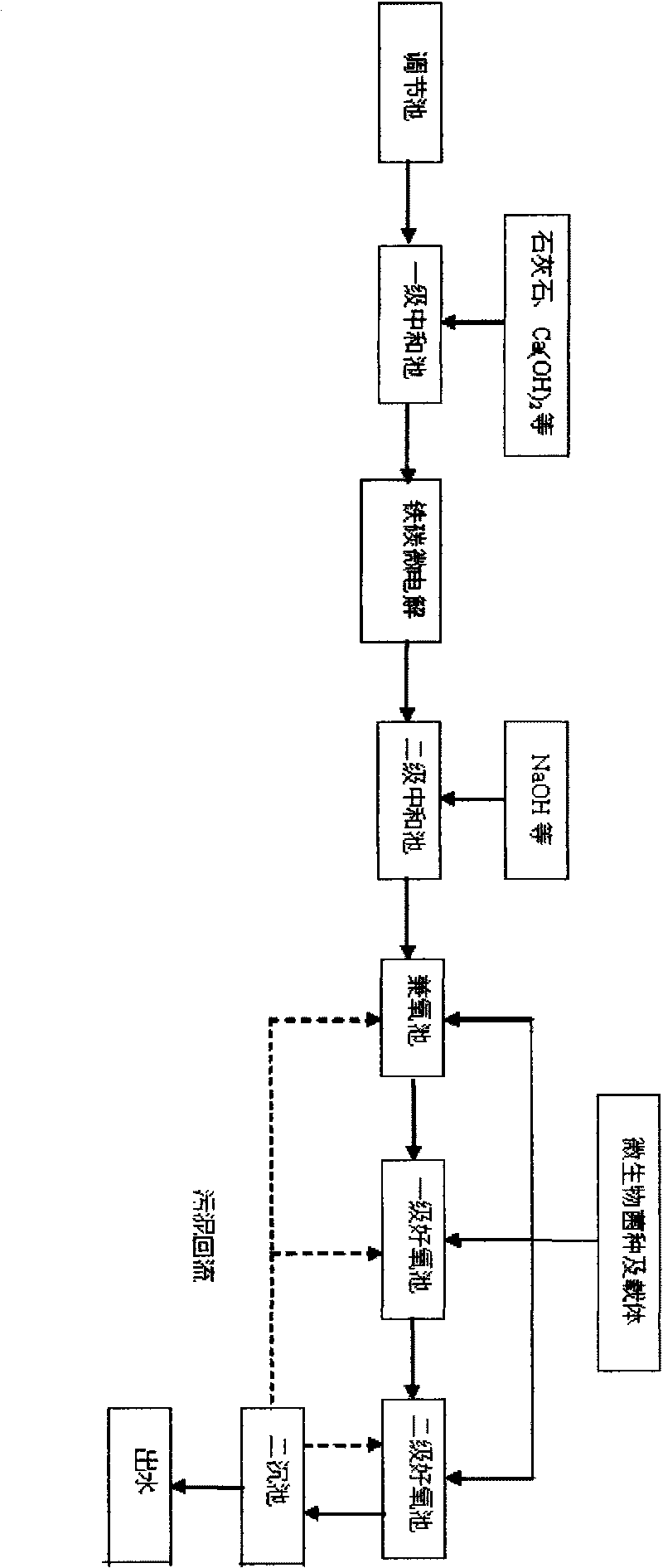

Method for processing organosilicon waste water

ActiveCN101759329AImprove biodegradabilityReduce processing costsWater contaminantsTreatment with aerobic and anaerobic processesElectrolysisWater volume

The invention relates to a method for processing organosilicon waste water. The method optimizes and combines a preprocessing unit and a biochemistry unit, aiming at the properties of high salt and difficult degradation of the organosilicon waste water. The method can process the organosilicon waste water to the second grade standard of integrated wastewater discharge standard (GB8978-1996). The organosilicon waste water is strongly acidic. A preneutralization pool is arranged at the front end of technological process and neutralizes the PH of the waste water to about 1 to 2. The waste water enters a micro-electrolysis reactor which is filled with micro-electrolysis stuffing. The effluent enters a secondary neutralization pool, and water volume and PH value are adjusted further. The waste water enters a biochemistry processing establishment and at last enters a secondary sedimentation tank. The biochemistry processing system of the waste water comprises a primary oxygen compatibility pool, a primary aerobic pool and a secondary aerobic pool. Microbial flora and relative carriers are added to the pools. The invention has the advantages that the processed organic waste water is guaranteed to meet the specified standard and the processing cost is reduced greatly. The win-win solution of economy and environment is realized.

Owner:蓝星环境工程有限公司

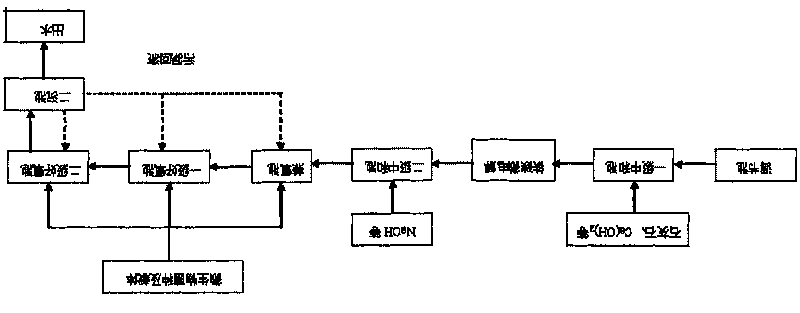

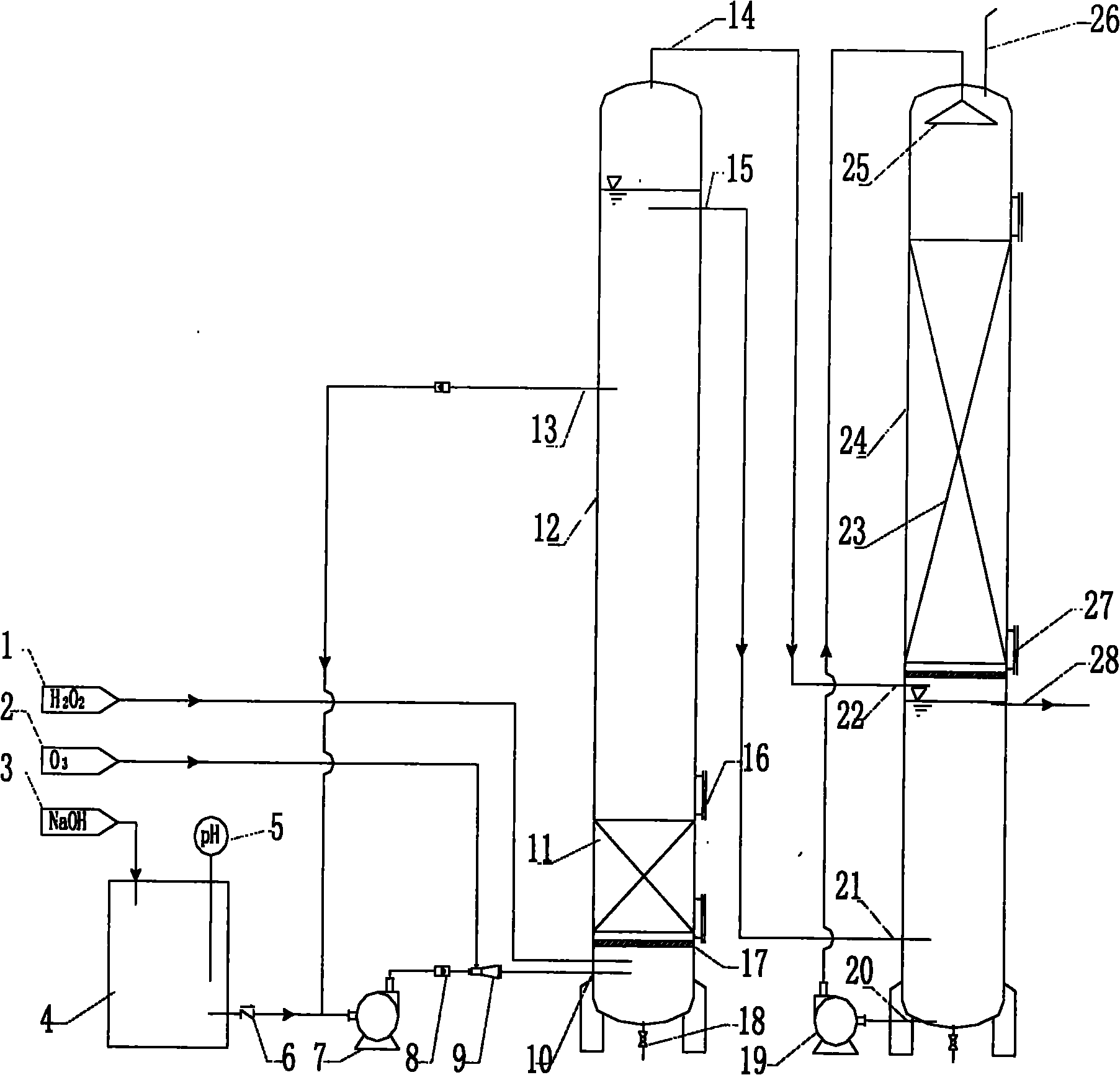

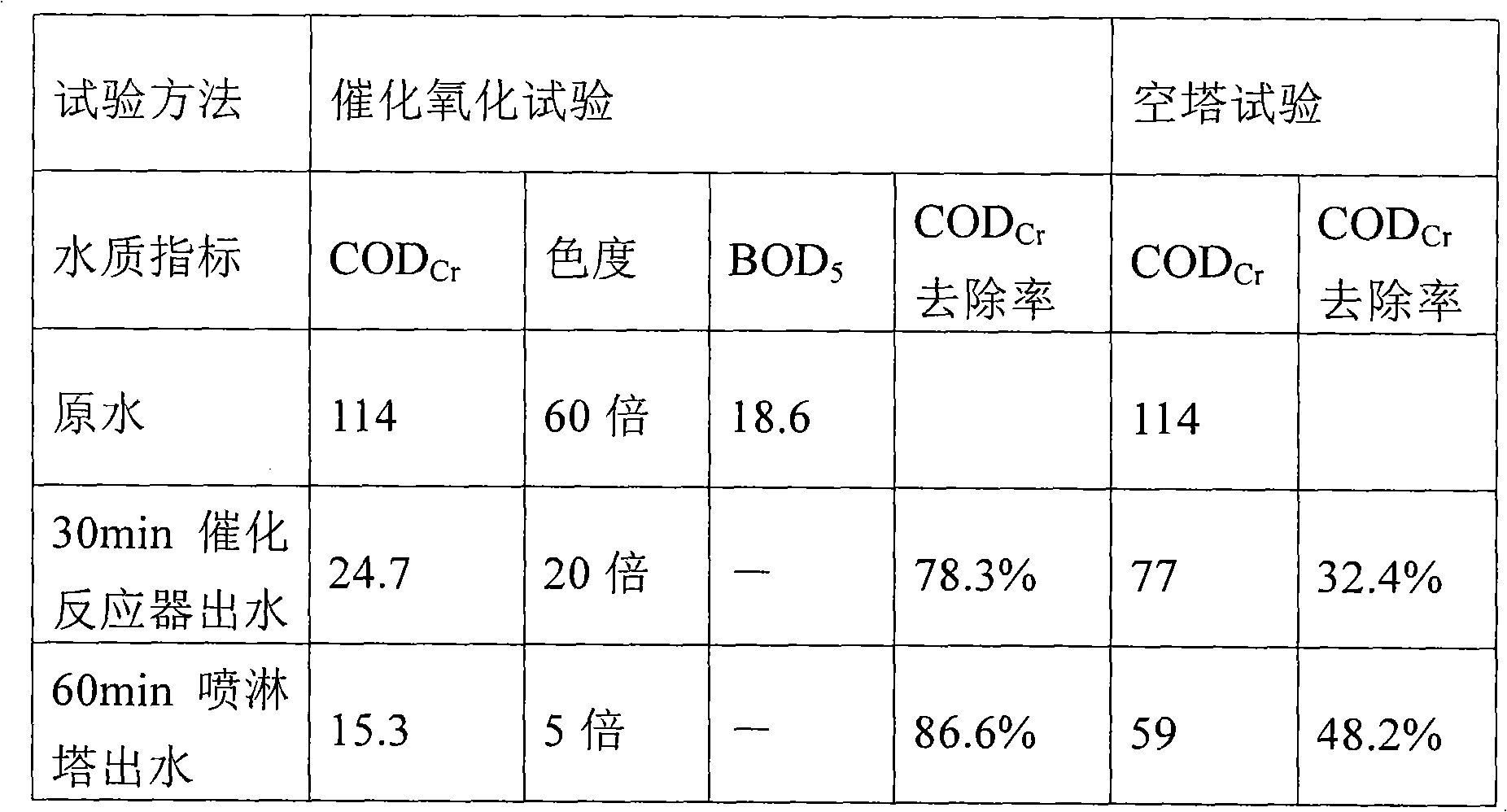

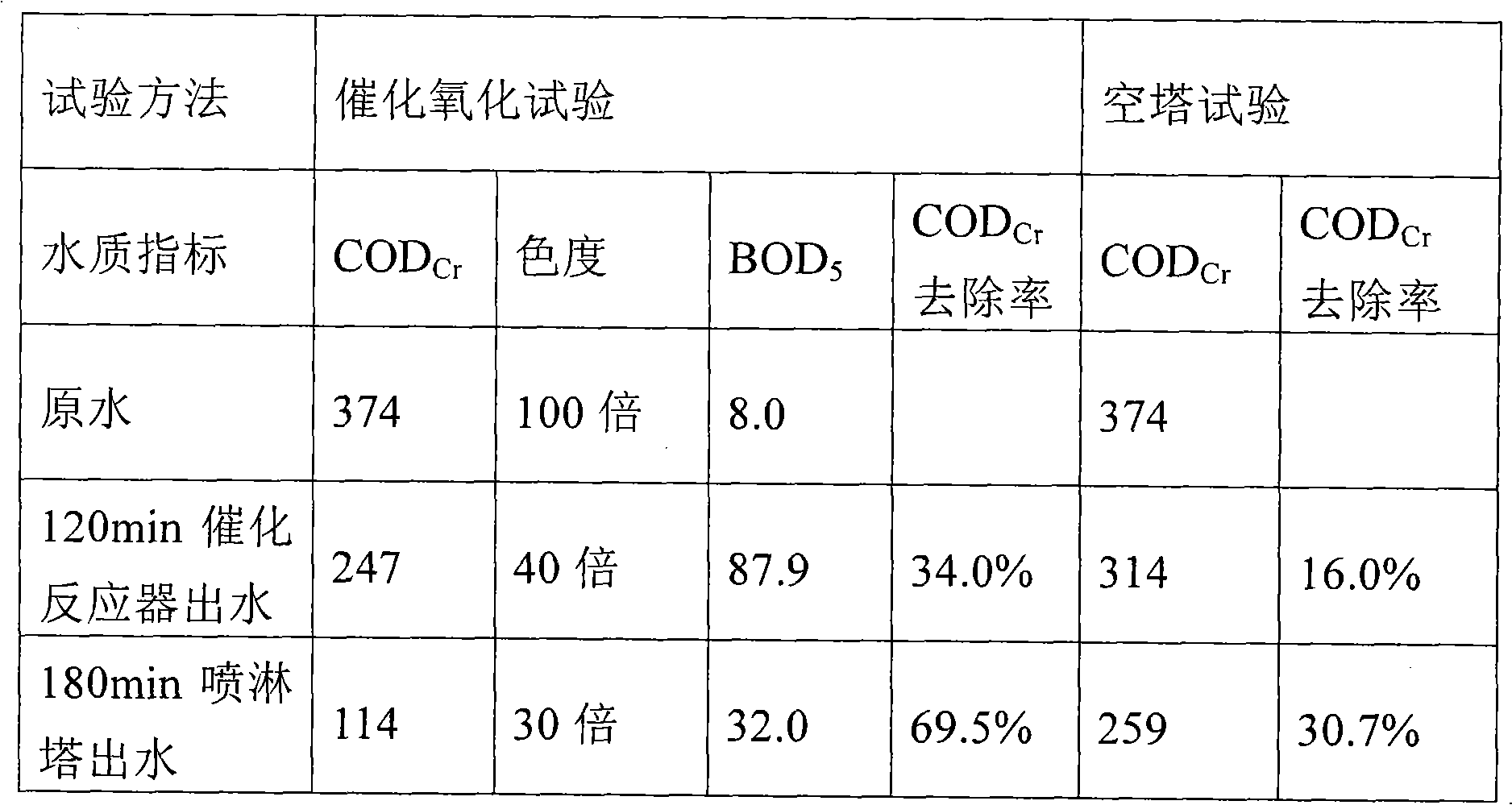

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

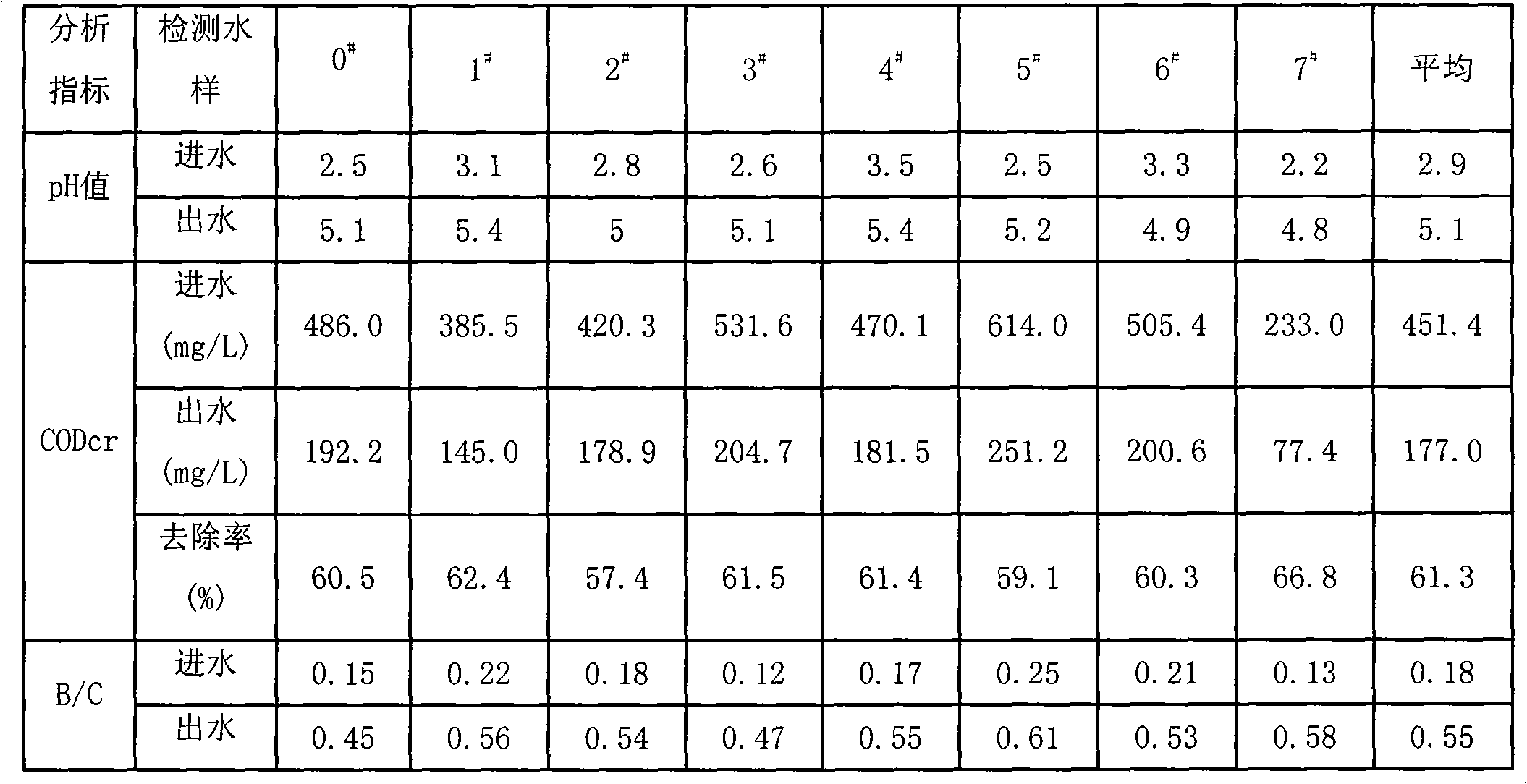

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

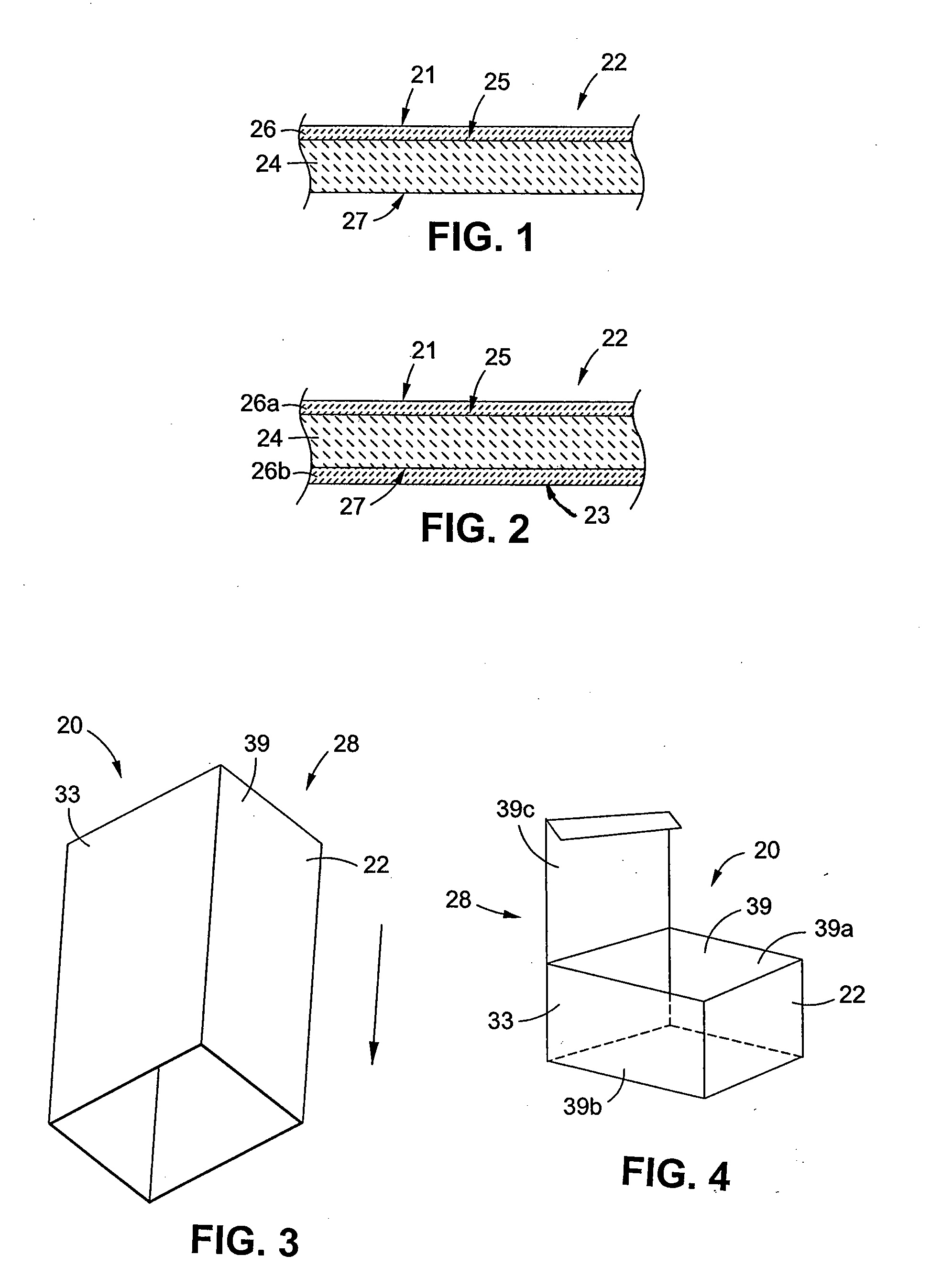

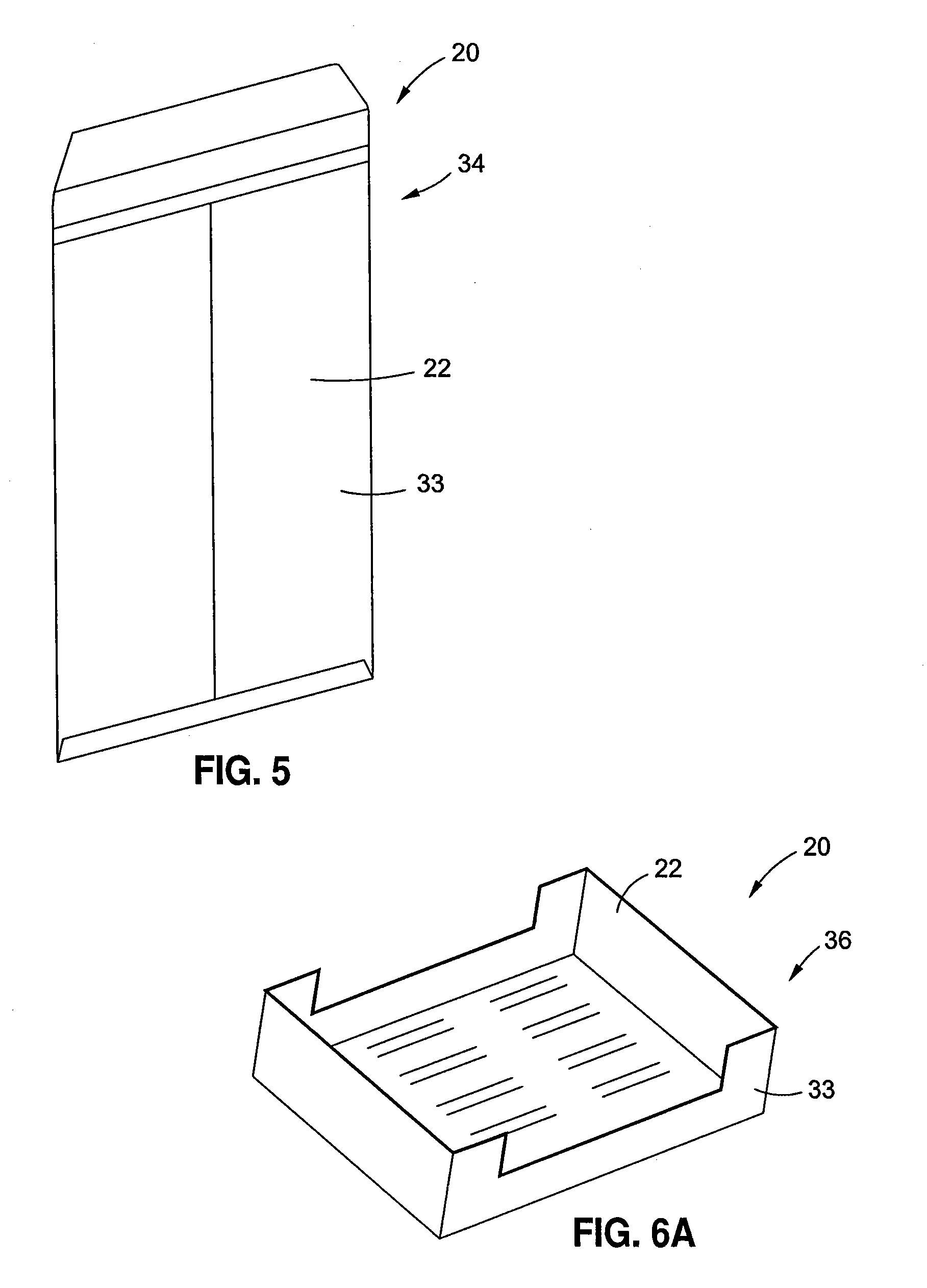

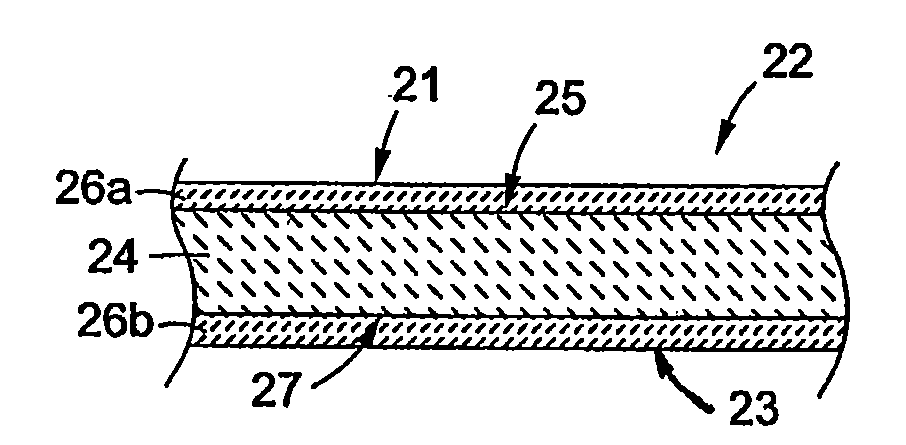

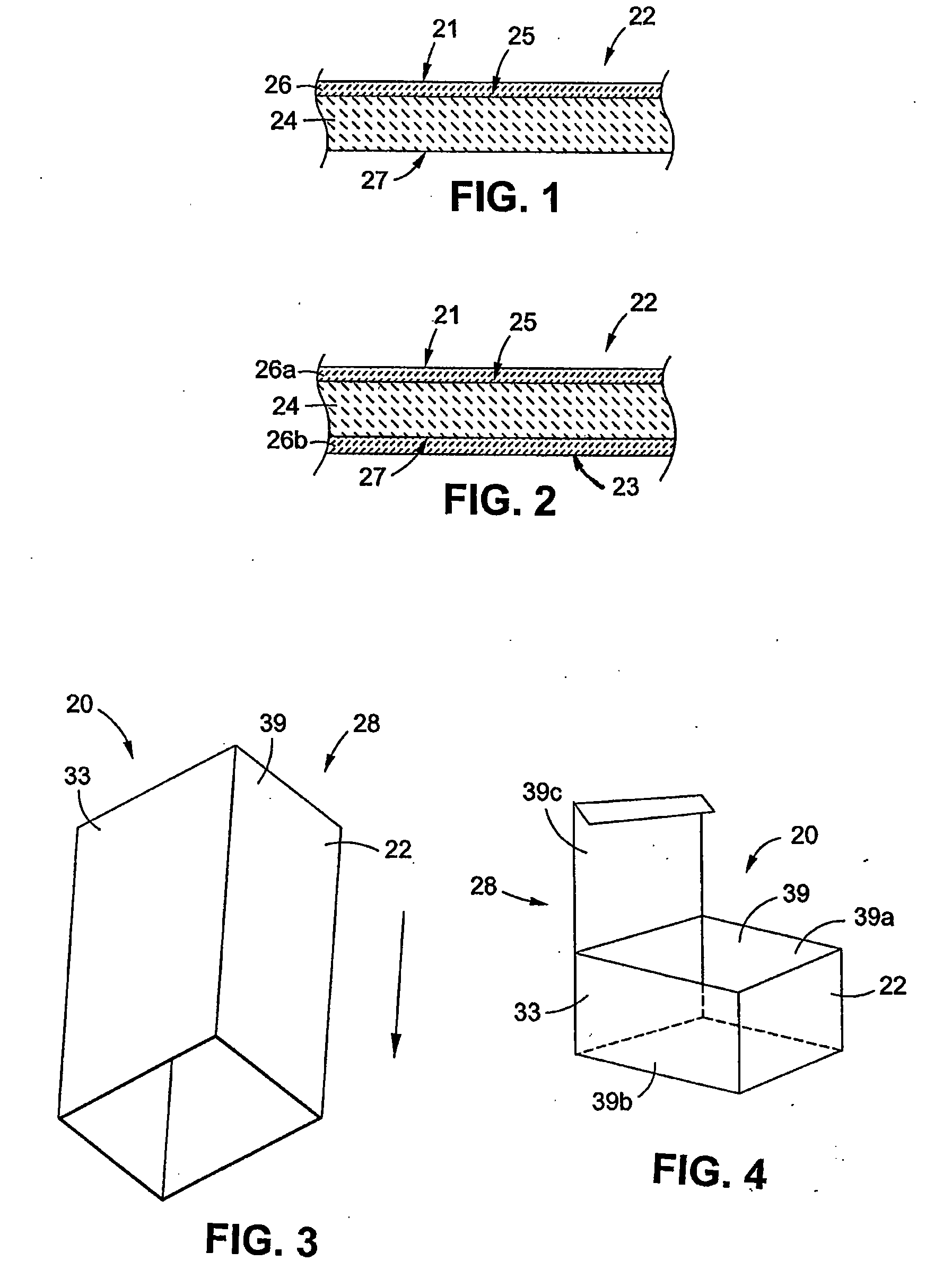

Composites for packaging articles and method of making same

InactiveUS20090047511A1Improve featuresAttractive printing surfaceEnvelopesFilm/foil adhesivesCartonPliability

The present invention is directed to an unexpectedly unique environmentally friendly composite material structure and storage article fabricated therefrom. The composite structure includes a fiber-containing layer, such as a fiberboard layer or other layer having fibers from natural and / or synthetic sources, and a mineral-containing layer covering the fiber-containing layer. The mineral-containing layer is substantially continuously bonded to the fiber-containing layer along the surface of the fiber-containing layer. The fiber-containing layer and mineral-containing layer can be shaped, sized and manufactured such that the composite structure formed therefrom is capable of being machined to form the storage article. The composite structure has advantages in that it has a high degree of pliability and flexibility that is increased over the pliability of the fiber-containing layer alone, which renders it highly attractive to consumers. The composite structure further has tensile strength and other characteristics that allow it to be readily machined into desired storage article forms, such as box and carton forms. Further advantages include environmentally attractive features such as less water, bleaching agent, formaldehyde usage and discharge as well as 50% or better use of recycled or post consumer recycled fibers.

Owner:SMART PLANET TECH

Method for processing garbage leachate

InactiveCN102786183AImprove biodegradabilityReduce CODGeneral water supply conservationTreatment with aerobic and anaerobic processesChemistryCapacitance

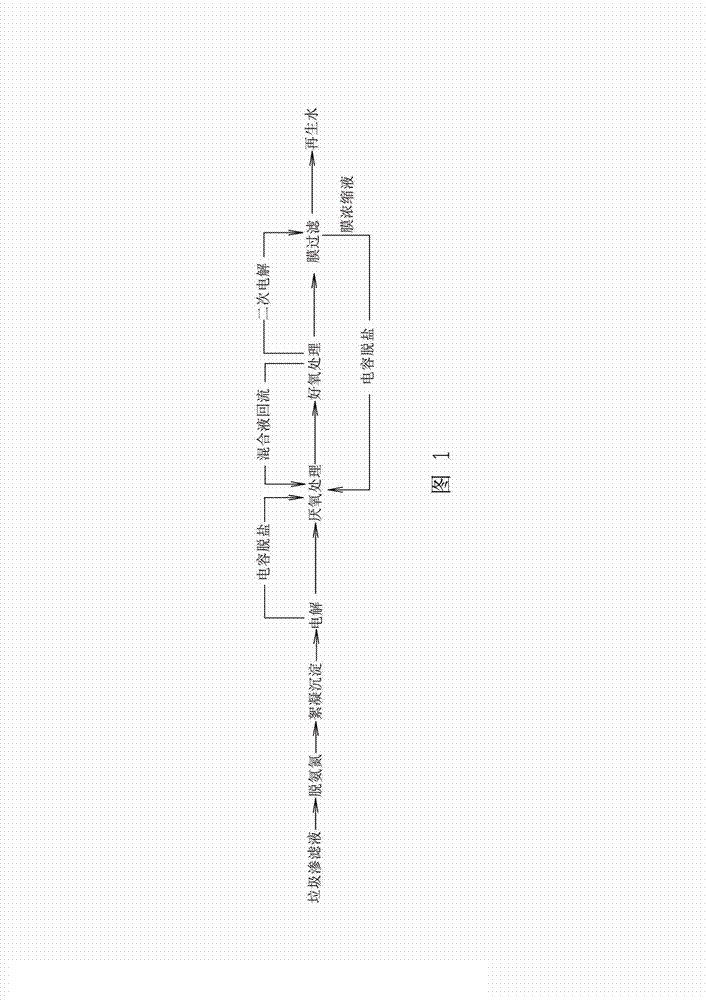

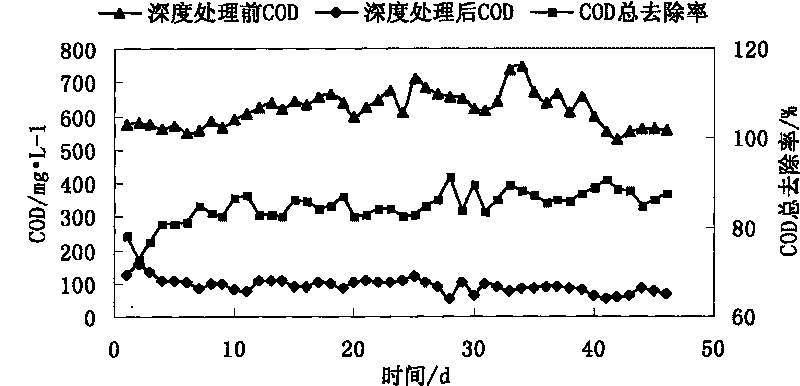

The invention discloses a method for processing a landfill leachate, which comprises the following steps of ammonia nitrogen removal, flocculent precipitate, electrolysis, capacitance desalination, anaerobic treatment, aerobic treatment, membrane filtration and membrane concentrate treatment. The method for processing the landfill leachate has the advantages that an electrolysis technology, a membrane technology and a bio-chemical technology are combined to form a method for processing the landfill leachate, the method has the characteristics of stable operation, strong adaptive capacity on water quality change, low cost, high treatment efficiency, effective reduction of index of ammonia nitrogen, COD, SS, chromaticity in the landfill leachate and standard discharge of effluent.

Owner:BOYING XIAMEN SCI & TECH

Advanced treating method of landfill leachate

InactiveCN101698550AImprove biodegradabilityReduce concentrationMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeLitter

The invention discloses an advanced treating method of landfill leachate, which comprises the steps of: discharging eobiont-treated landfill leachate waste water into an adjusting pond; pumping the waste water in the adjusting pond into a polymeric ferrum reaction precipitation pond with a waste water metering pump to evenly mix polymeric ferrum agent with the waste water, and treating liquid supernatant which flows into an Fento oxidation pond by means of advanced oxidation after coagulating polymeric ferrum; leading the water to flow into a neutralization pond after the advanced oxidation to adjust the pH value of the waste water at 6-8, and adding PAM into the precipitation pond to carry out coagulation precipitation after neutralizing the waste water; and pumping liquid supernatant of the precipitation pond into a biological filler filter to carry out biological treatment, putting filler into the pond, sufficiently aerating to carry out aerobic treatment, and draining at the top of the pond through a water outlet weir, wherein the quality of the outlet water achieves landfill leachate state first-grade discharge standard. Sludge in the polymeric ferrum reaction pond and the precipitation pond can be directly transported to landfill areas to be landfilled after dehydration treatment.

Owner:SOUTH CHINA UNIV OF TECH

Composites for packaging articles and method of making same

InactiveUS20090142528A1Improve featuresBright and attractive printing surfaceBio-packagingSynthetic resin layered productsPaperboardCarton

A composite structure comprises a fiber-containing layer, such as a layer of paperboard or other layer having fibers from natural and / or synthetic sources, and a mineral-containing layer covering the fiber-containing layer. The mineral-containing layer is substantially continuously bonded to the fiber-containing layer along the surface of the fiber-containing layer and provide a printing surface. The fiber-containing layer and mineral-containing layer can be shaped, sized, and manufactured such that the composite structure formed therefrom is capable of being machined to form a storage article. The composite structure further has tensile strength and other characteristics that allow it to be readily machined into desired storage article forms, such as box, carton, and other forms.

Owner:SMART PLANET TECH

High mineral content film for sealing

InactiveUS20100137493A1Improve biodegradabilityImprove moisture resistanceAlkaline-earth metal silicatesSpecial tyresPolyolefinPolymer chemistry

A composition used to form thermoplastic films and coatings comprising a thermoplastic polyolefin and a ground natural mineral material wherein a film or coating formed of said composition heat seals at or above 200 degrees F. with a dwell time exceeding approximately 0.5 seconds, has a TAPPI T-525 Whiteness % over 78, a TAPPI T-425 Opacity % over 78, a post corona treated ASTM D-2578 dyne level over 38, a minimum moisture barrier transmission rate of 4.0 g / mil / 100 sq. in. / 24 hrs. at 100 degrees F. at 90% relative humidity, and a minimum oxygen barrier of 350 cc / mil / 100 sq. in / 24 hrs. at 23 degrees C.

Owner:SMART PLANET TECH

Method for treating wastewater containing molasses alcohol

ActiveCN101759316AImprove biodegradabilityReduce concentrationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAlcoholPre treatment

The invention discloses a method for treating wastewater containing molasses alcohol. The specific process of the method comprises the following steps: firstly, carrying out the coagulation sedimentation pretreatment on the wastewater; further carrying out the two-stage anaerobic treatment on the pre-treated wastewater; then, carrying out the aerobic treatment on the treated wastewater; and finally, carrying out the advanced oxidation treatment on the treated wastewater on the basis of the Fenton advanced oxidation method and air floatation method. The method of the invention has the advantages of simple operation, low treatment cost and high biochemical efficiency, and guarantees that the effluent subjected to the advanced treatment can meet the standards.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

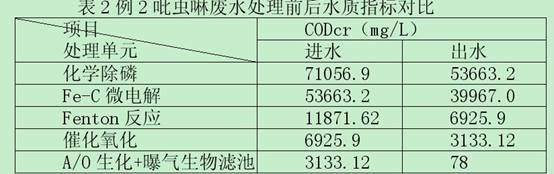

Imidacloprid pesticide wastewater treatment method

ActiveCN102040318AImprove biodegradabilityImprove the overall physical and chemical treatment effectMultistage water/sewage treatmentChemical treatmentPretreatment method

The invention relates to improvement on an imidacloprid pesticide wastewater treatment method. The imidacloprid pesticide wastewater treatment method is characterized by comprising the following steps of: performing physical and chemical pretreatment, namely performing chemical phosphorus removal and ferrum-carbon (Fe-C) micro-electrolysis sequentially and then performing Fenton oxidation and catalytic oxidation respectively; and performing biochemical treatment, namely performing aerobic biochemical treatment in the presence of salt-tolerant aerobic bacteria. By the imidacloprid pesticide wastewater treatment method, the total physical and chemical treatment effect is greatly improved; physical and chemical pretreatment can be performed at normal temperature and normal pressure; organic matters difficult to biochemically degrade is degraded and the biochemical property of the wastewater is improved under the condition of low cost; the dilution factor of the wastewater is greatly reduced; and the using amount of diluting water is reduced by 50 to 80 percent, so that the treatment is more economic. The imidacloprid pesticide wastewater treatment method is simple in pretreatment method, mild and stable in process reaction condition, simple in operation (for example, the catalytic oxidation can be performed at normal temperature and normal pressure and a catalyst can be recycled), low in operating cost, good in treatment effect, low in the using amount of the diluting water during the subsequent biochemical treatment and low in total treatment cost, and the water from the biochemical treatment can reach a national level 1 of discharge standard.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

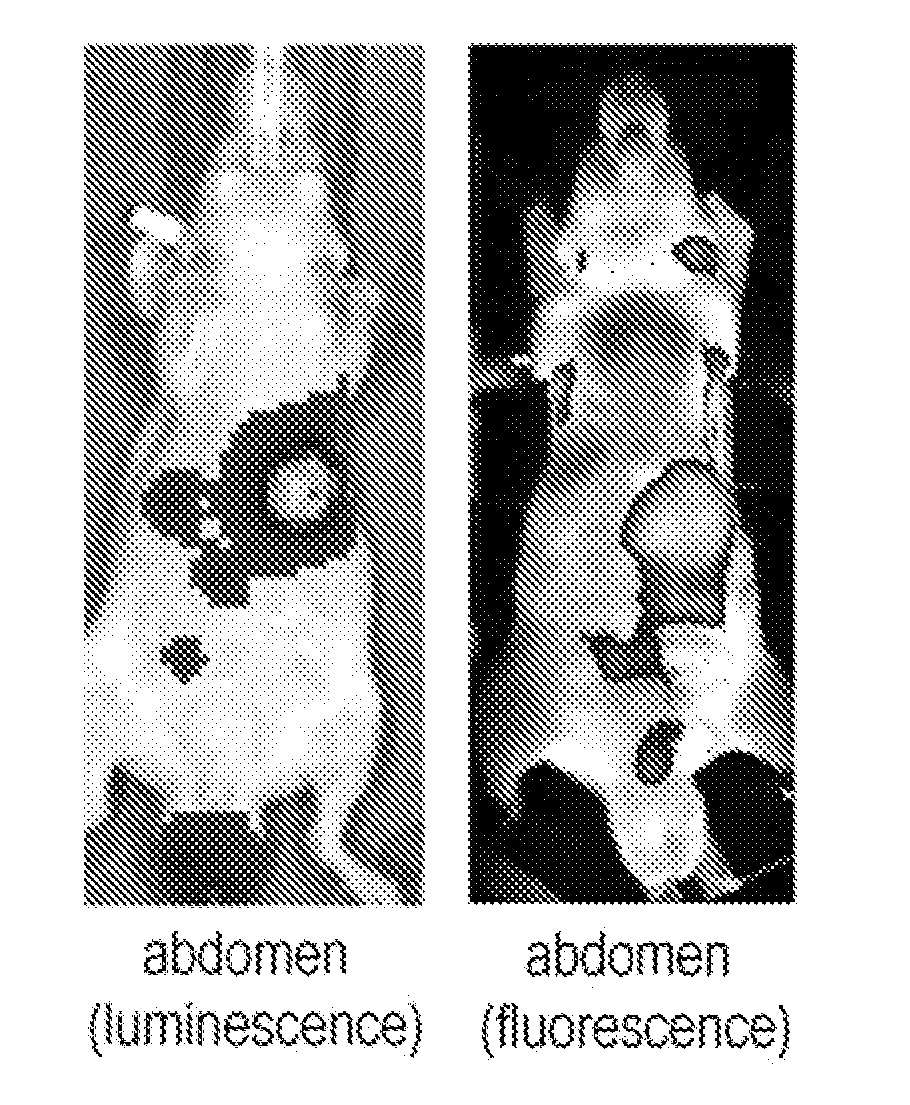

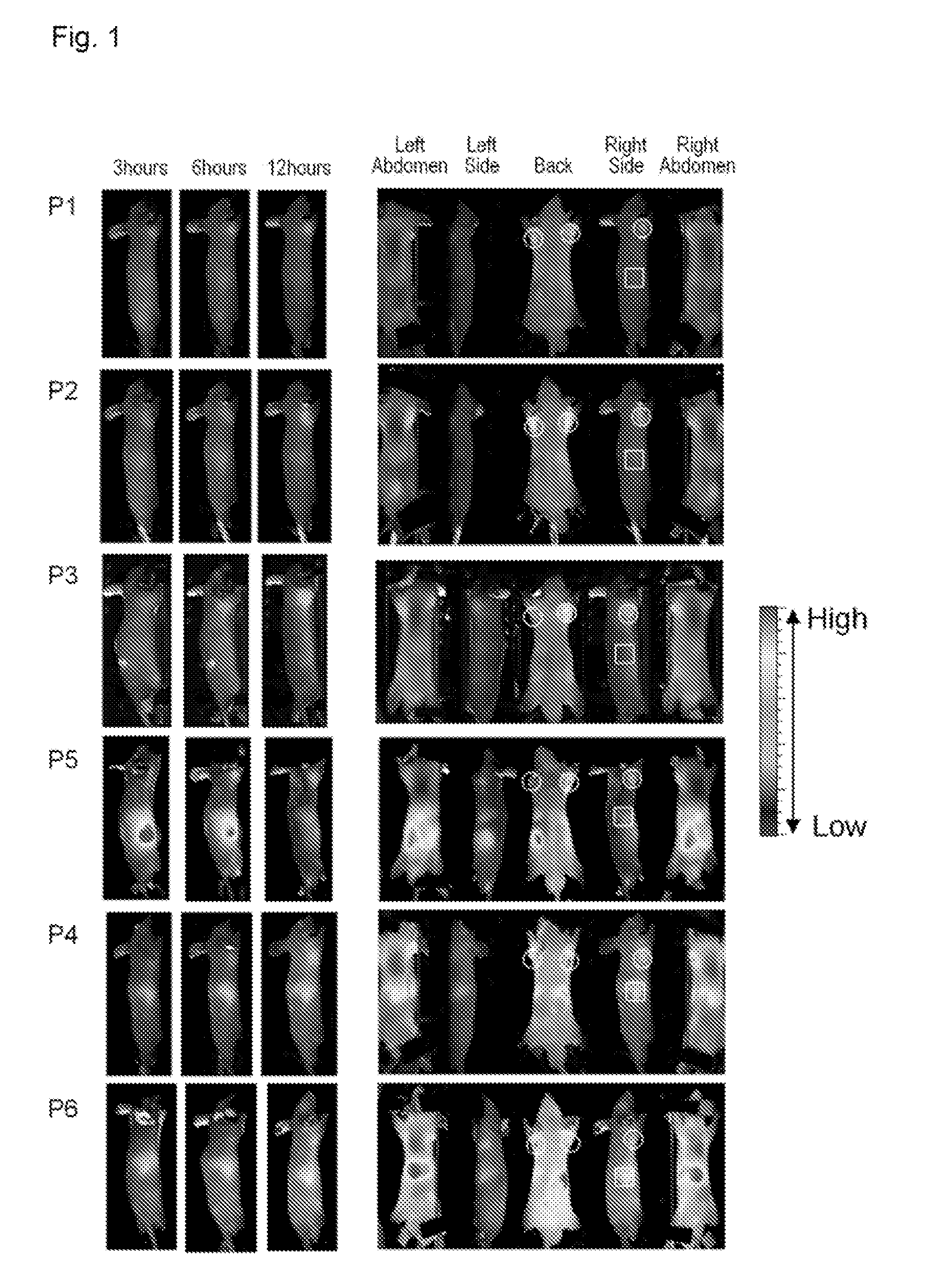

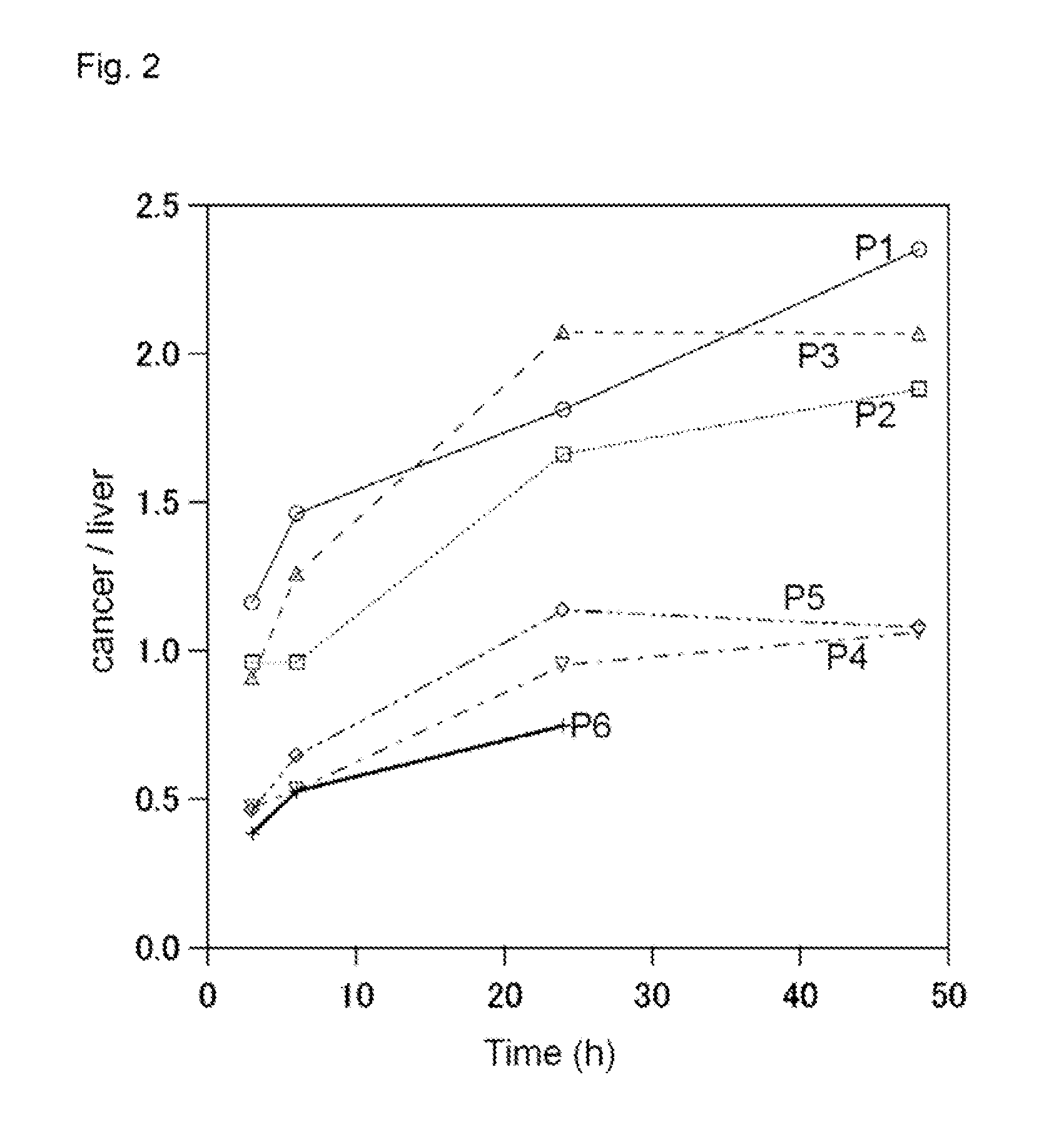

Novel molecular assembly, molecular probe for molecular imaging and molecular probe for drug delivery system using the same, and molecular imaging system and drug delivery system

InactiveUS20110104056A1The method is simple and safeHighly safe for a living bodyUltrasonic/sonic/infrasonic diagnosticsSurgeryBiological bodyMolecular imaging

The present invention provides a molecular assembly which is less likely to accumulate in tissue other than cancer tissue, is highly safe for a living body, and can be prepared by a simple and safe method and whose particle size can be easily controlled. The present invention provides a molecular imaging system and a molecular probe useful for the system, and a drug delivery system and a molecular probe useful for the system. The present invention provides a method for preparing molecular assembly, by which the particle size of molecular assembly having a signal group or a drug can be arbitrarily controlled in order to allow the molecular assembly to effectively accumulate in cancer tissue by utilizing EPR effect. A molecular assembly comprising: an amphiphilic block polymer A comprising a hydrophilic block chain and a hydrophobic block chain having 10 or more lactic acid units; a hydrophobic polymer A2 having at least 10 or more lactic acid units; and / or a labeled polymer B comprising at least 10 or more lactic acid units and a labeling group.

Owner:SHIMADZU CORP

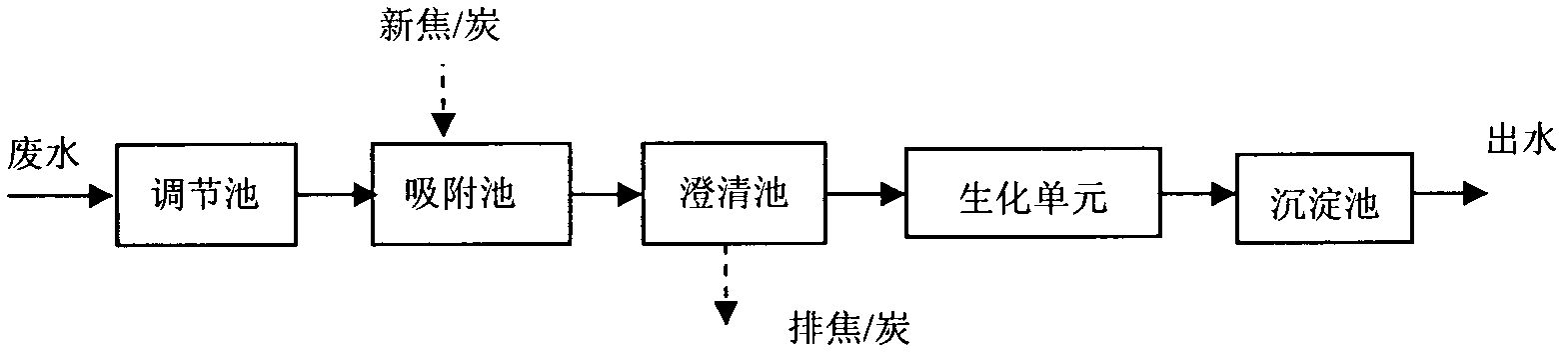

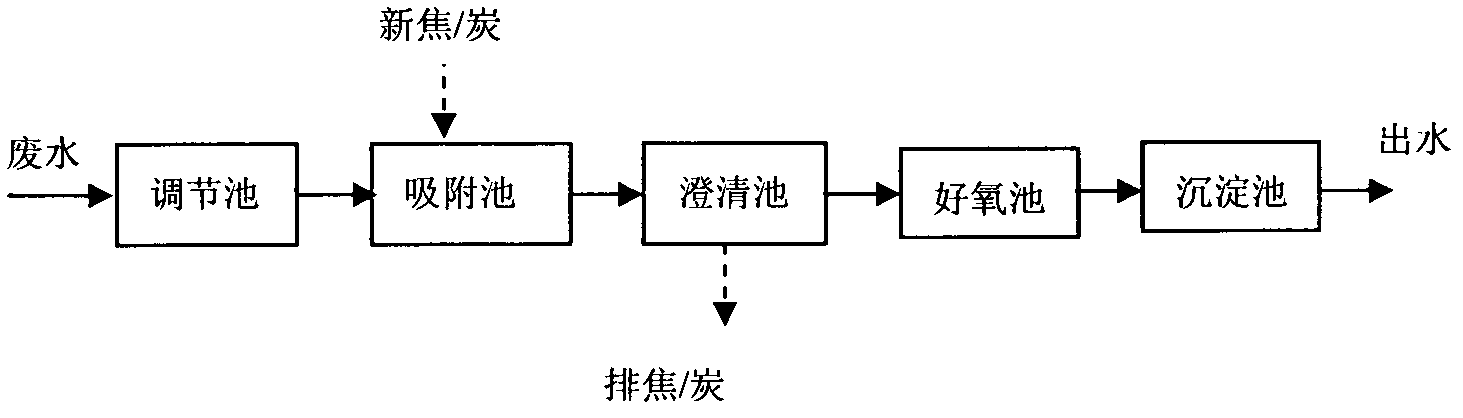

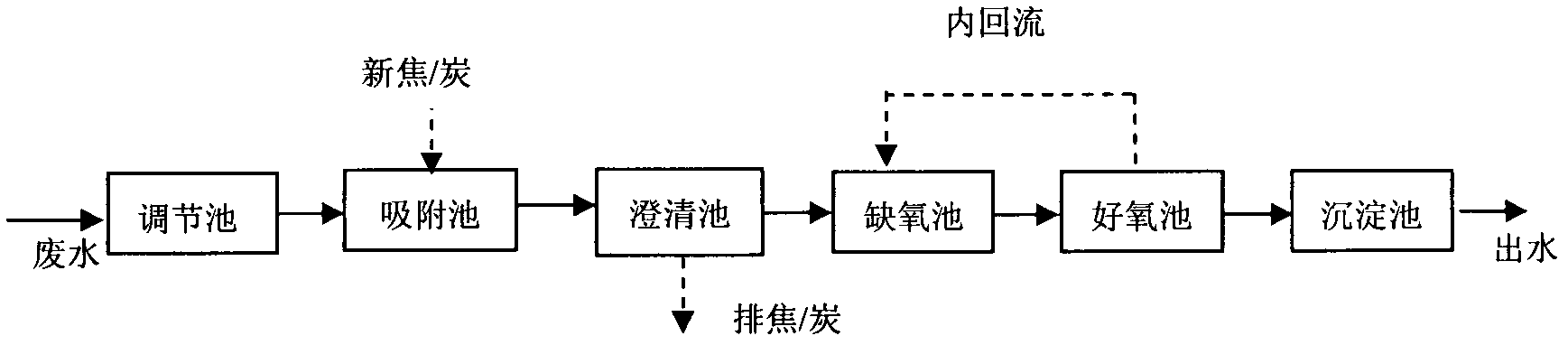

Process for treating coal chemical waste water

ActiveCN102001789AImprove biodegradabilityEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbonActivated sludge

The invention relates to a process for treating coal chemical waste water, wherein a method combining active material adsorption and biochemical treatment is adopted. The method comprises the following steps of: firstly, introducing coal chemical waste water in a waste water regulating reservoir; secondly, introducing the waste water subjected to adsorption treatment by an adsorption tank into a clarification reservoir for sedimentation; then introducing the waste water subjected to the treatment of the clarification reservoir into a biochemical unit for biochemical treatment; and finally, introducing the waste water subjected to the biochemical treatment into a sedimentation reservoir for sedimentation treatment. In the technical scheme, macromolecular organic pollutants are removed through adsorption, therefore, the requirement of the subsequent biochemical treatment is met, and the problems of insufficient utilization of pores of activated carbon and incomplete exertion of the adsorbability of the activated carbon due to the influence of sludge when the activated carbon is added into an activated sludge aeration tank in the prior art are solved; and the process for treating coal chemical waste water has high efficiency and can sufficiently utilize the pores of the activated carbon and ensure the full exertion of the adsorbability of the activated carbon.

Owner:北京国能普华环保工程技术有限公司 +1

Preparation method of catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater

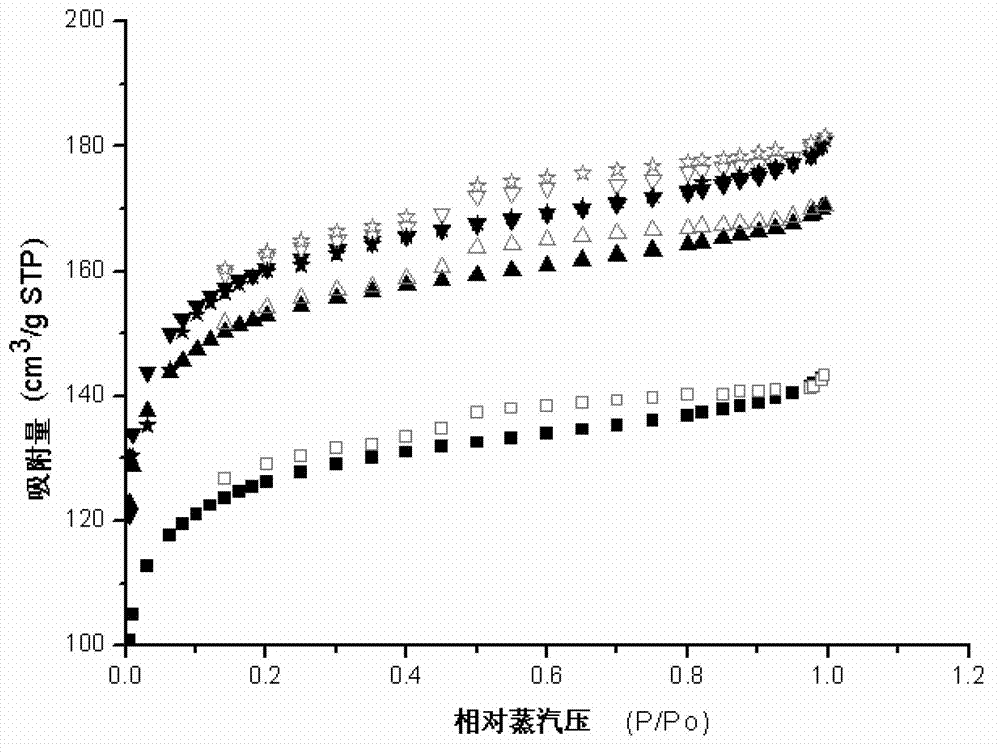

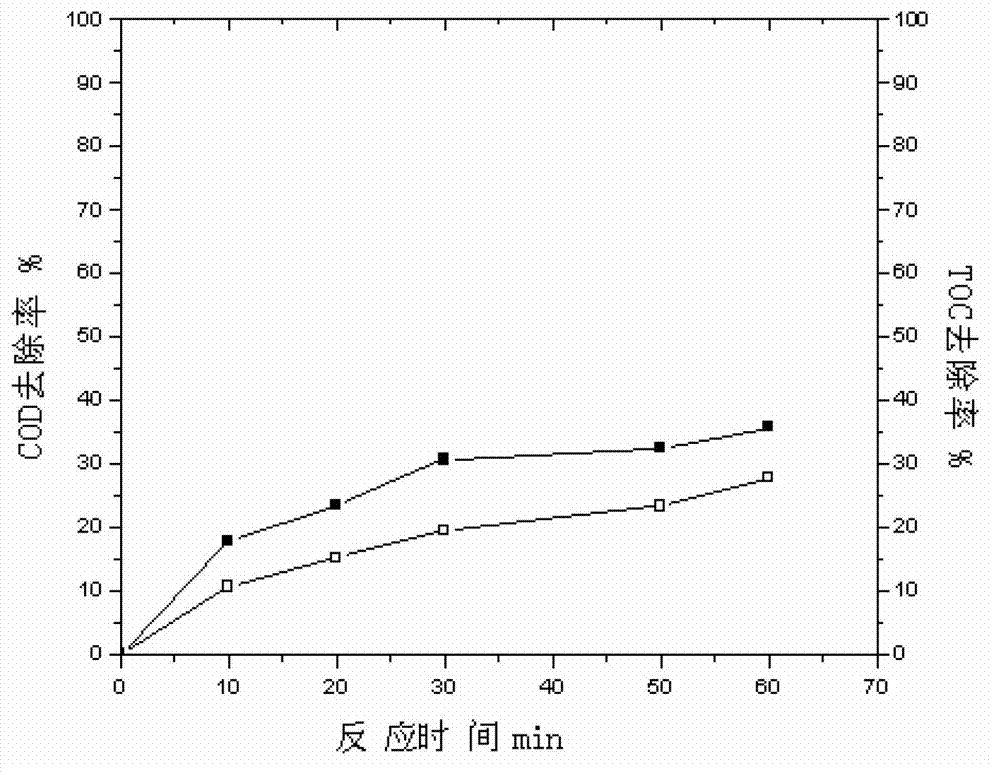

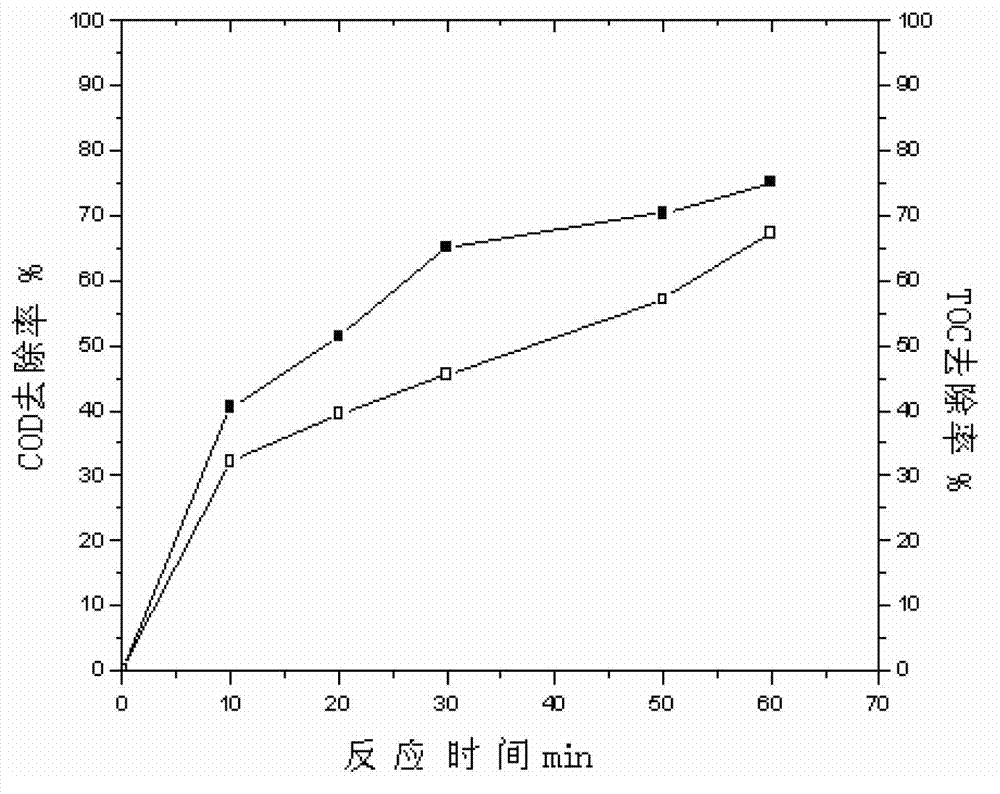

InactiveCN103111290AReduce pollution pressureLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSolubilityHazardous substance

The invention discloses a preparation method of a catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater and relates to a preparation method for the catalyst. The preparation method is used for solving the technical problems that the existing ozonation method is poor in ozone water solubility and low in degradation rate, successfully applied to the advanced treatment of the coal chemical wastewater, and capable of removing the degradation-resistant hazardous substances in water, improving the biodegradability of the wastewater and enabling the quality of the outlet water to reach the first-grade national emission standards. The preparation method comprises the following steps of: firstly, washing active carbon particles; secondly, soaking the active carbon in a metal nitrate solution, shaking for mixing and reacting, and taking out the active carbon 12 hours later; and thirdly, drying the active carbon and putting the dried active carbon to a muffle furnace, heating the muffle furnace to 200 DEG C by adopting nitrogen gas as the protective gas, roasting for one hour, continuing heating the muffle furnace to 600 DEG C and roasting for 3 hours at 600 DEG C to obtain the catalyst for treating the coal chemical wastewater. By using the catalyst prepared by the preparation method disclosed by the invention, the utilization rate of ozone is greatly improved, and the catalyst is very suitable for the field of coal chemical wastewater treatment.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com