Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

An organic wastewater and combined process technology, applied in the field of environmental engineering, can solve the problems of poor electrochemical reaction efficiency and organic matter degradation ability, high cost, and hydrogen peroxide to increase the cost of wastewater treatment, so as to improve electrochemical treatment capacity and efficiency, improve treatment Ability and efficiency, the effect of improving redox efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

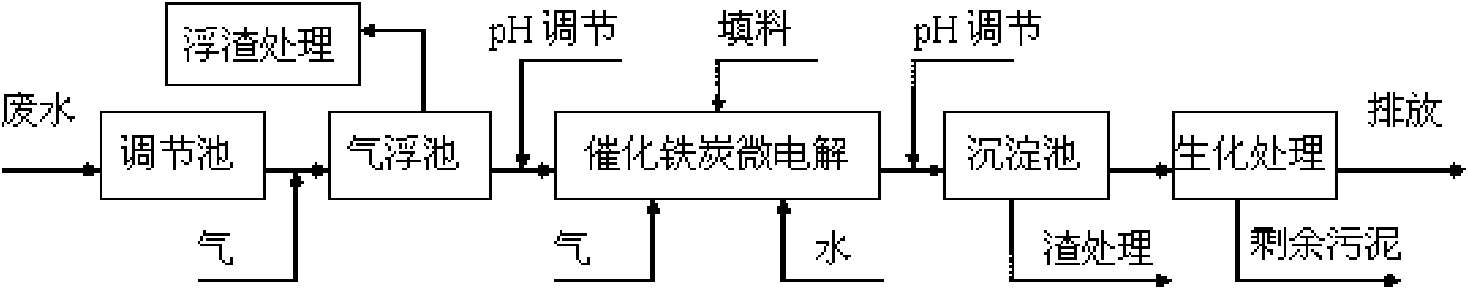

Method used

Image

Examples

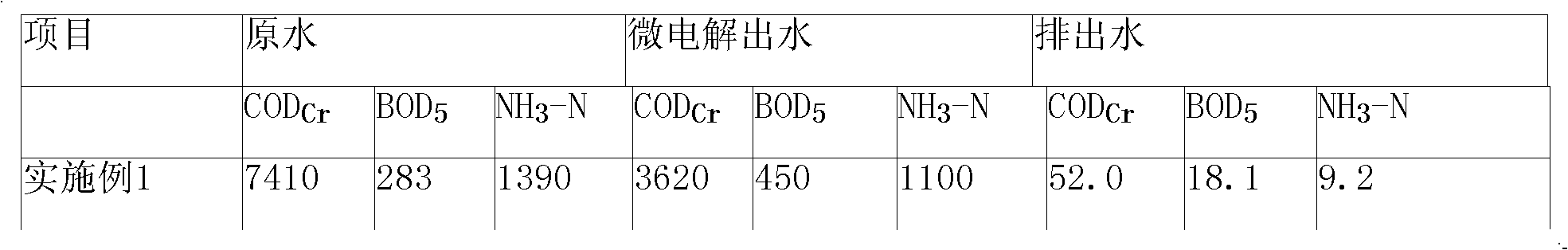

Embodiment 1

[0025] Implementation steps of high-concentration organic wastewater treatment from caprolactam production in a petrochemical company.

[0026] ① The raw water in the adjustment tank is fed into the diffused air flotation tank with a flow rate of 5L / h by a micro pump for air flotation treatment, and the designed residence time of the air flotation tank is 18 minutes.

[0027]② Use 5% sulfuric acid solution to adjust the pH of the wastewater to 3.0, and treat it with a catalytic iron-carbon micro-electrolysis column with a ratio of iron: carbon: catalyst of 2:1:0.02. The residence time of wastewater is 1.5h, and the volume ratio of water to filler is 2. : 3, the backwashing method of the catalytic iron-carbon micro-electrolytic column is air-water combined backwashing, and the backwashing time interval is 8h.

[0028] ③ The effluent of the catalytic iron-carbon micro-electrolysis column uses 10% milk of lime to adjust the pH to 8.0, then enters the advection sedimentation tank,...

Embodiment 2

[0031] Implementation steps of organic wastewater treatment in a chemical enterprise.

[0032] ① The raw water in the adjustment tank is pumped into the air flotation treatment system at a flow rate of 5L / h. The air flotation adopts the method of dissolved air and advection floating pool. The pressure of dissolved air water is 0.3MPa, and the residence time is 15mim.

[0033] ②Using 10% sulfuric acid solution to adjust the pH of the wastewater to 1.8, the effluent from the air flotation tank is treated with a catalytic iron-carbon micro-electrolysis column with a ratio of iron, carbon and catalyst of 3:2:0.1. : 1, the backwashing method is high pressure water backwashing.

[0034] ③The effluent of the catalytic iron-carbon micro-electrolysis column is adjusted to pH 7.5 with 10% milk of lime, and then enters the advection sedimentation tank, and the residence time of the sedimentation tank is 1.5h.

[0035] ④ The effluent from the sedimentation tank enters the biochemical tre...

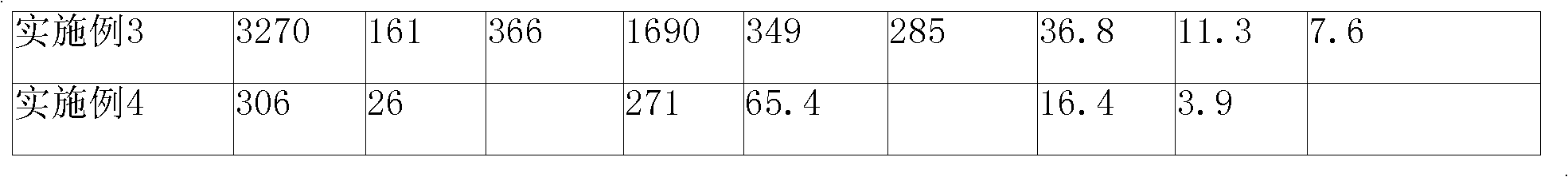

Embodiment 3

[0037] Implementation steps for the treatment of simulated liquid containing toluene wastewater.

[0038] ① The raw water in the adjustment pool is pumped into the diffused air flotation pool for air flotation treatment at a flow rate of 3L / h, and the air flotation time is 16 minutes.

[0039] ② Use 5% sulfuric acid solution to adjust the pH of the wastewater to 2.5, and treat it with a catalytic iron-carbon micro-electrolysis column with a ratio of iron, carbon and catalyst of 2:1:0.2. The residence time of wastewater is 1.5h, and the volume ratio of water to filler is 1. : 1, the backwashing method is air-water combined backwashing.

[0040] ③ The effluent from the catalytic iron-carbon micro-electrolysis column uses 10% lime milk to adjust the pH to 7.5 and then enters the biochemical treatment system. The biochemical system adopts the hydrolytic acidification-aerobic aeration (HAT / O) process. The HAT section has a built-in YDT elastic three-dimensional filler, and the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com