Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6433results about "Water/sewage treatment by flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

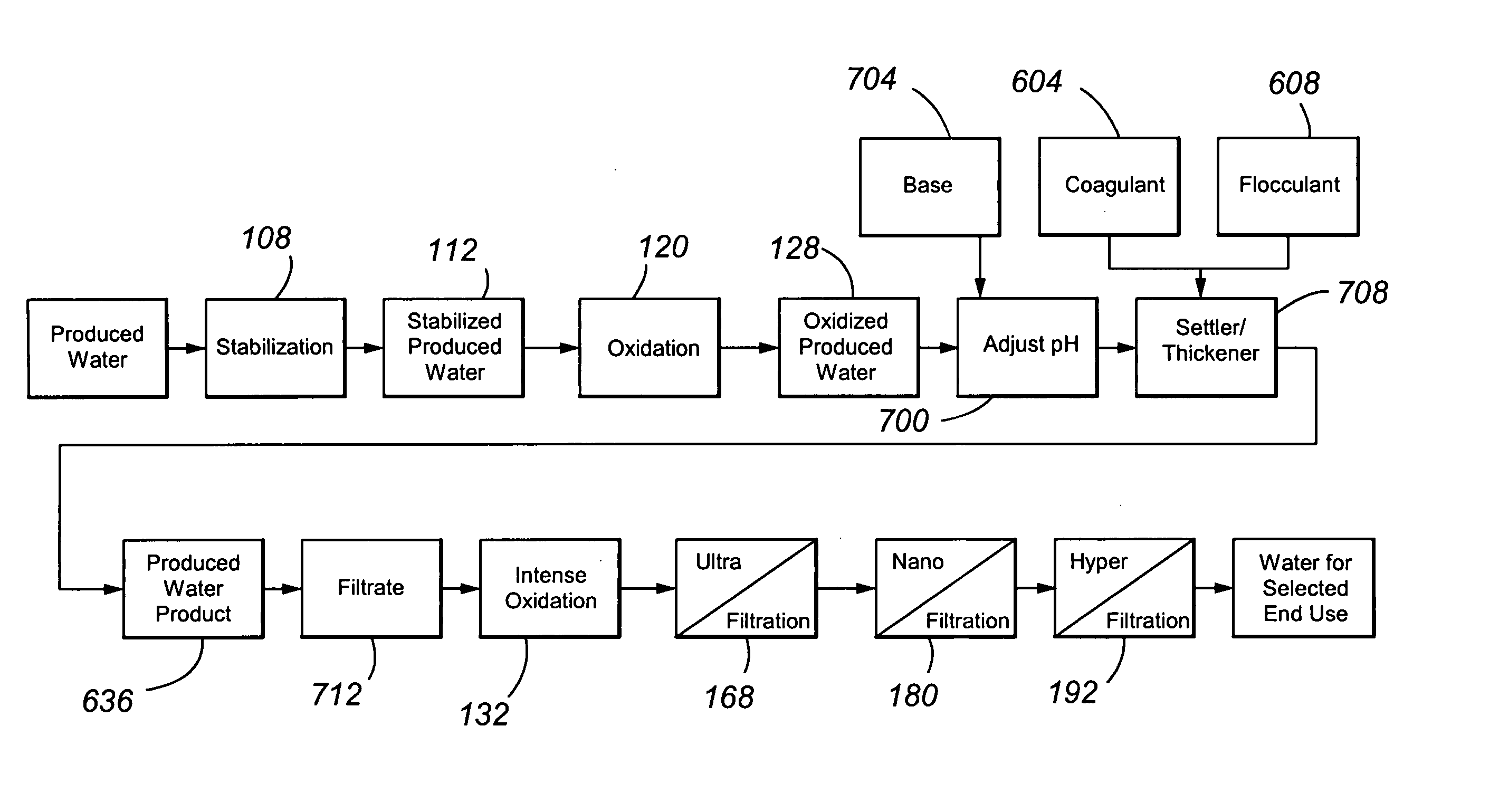

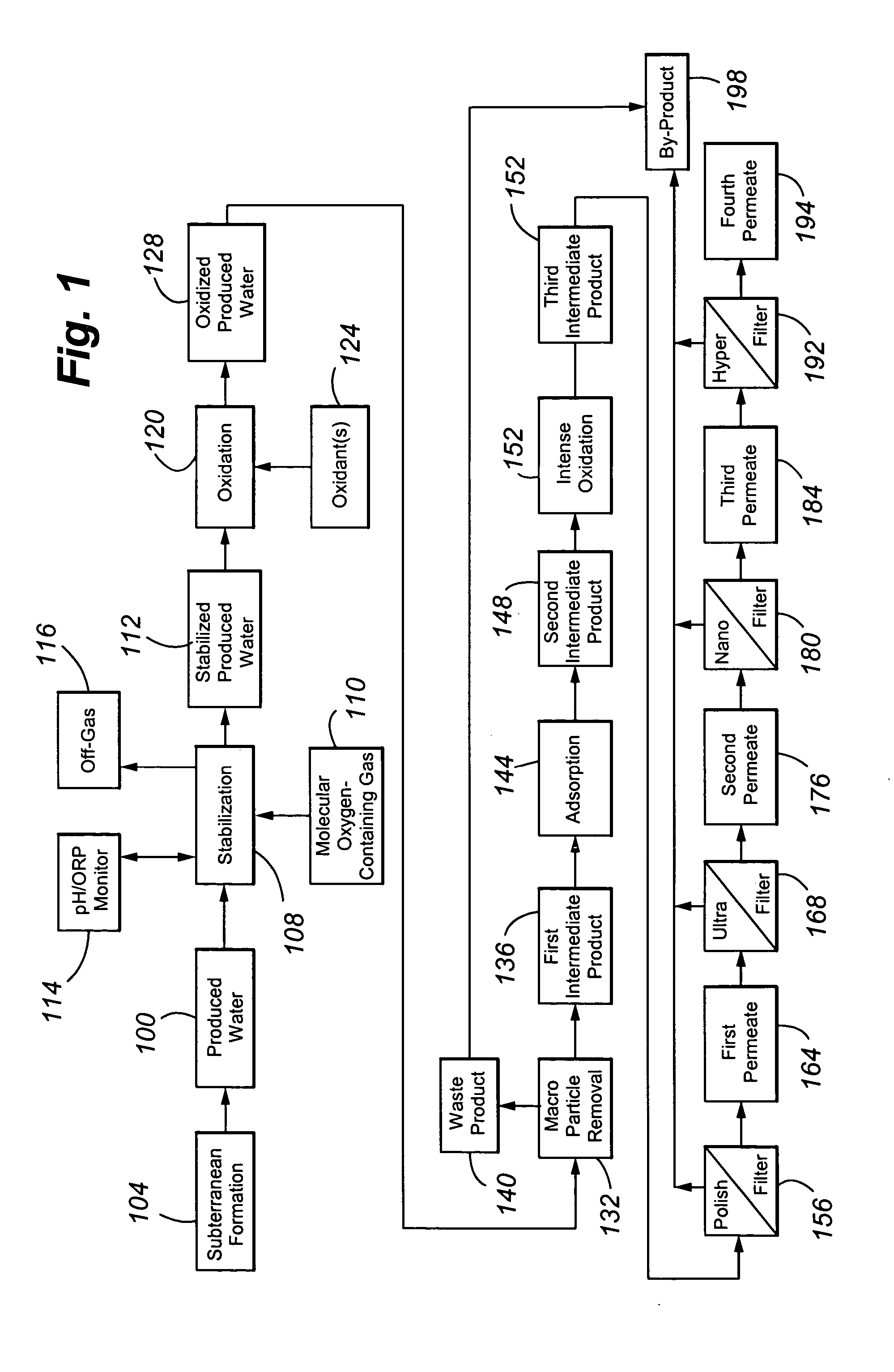

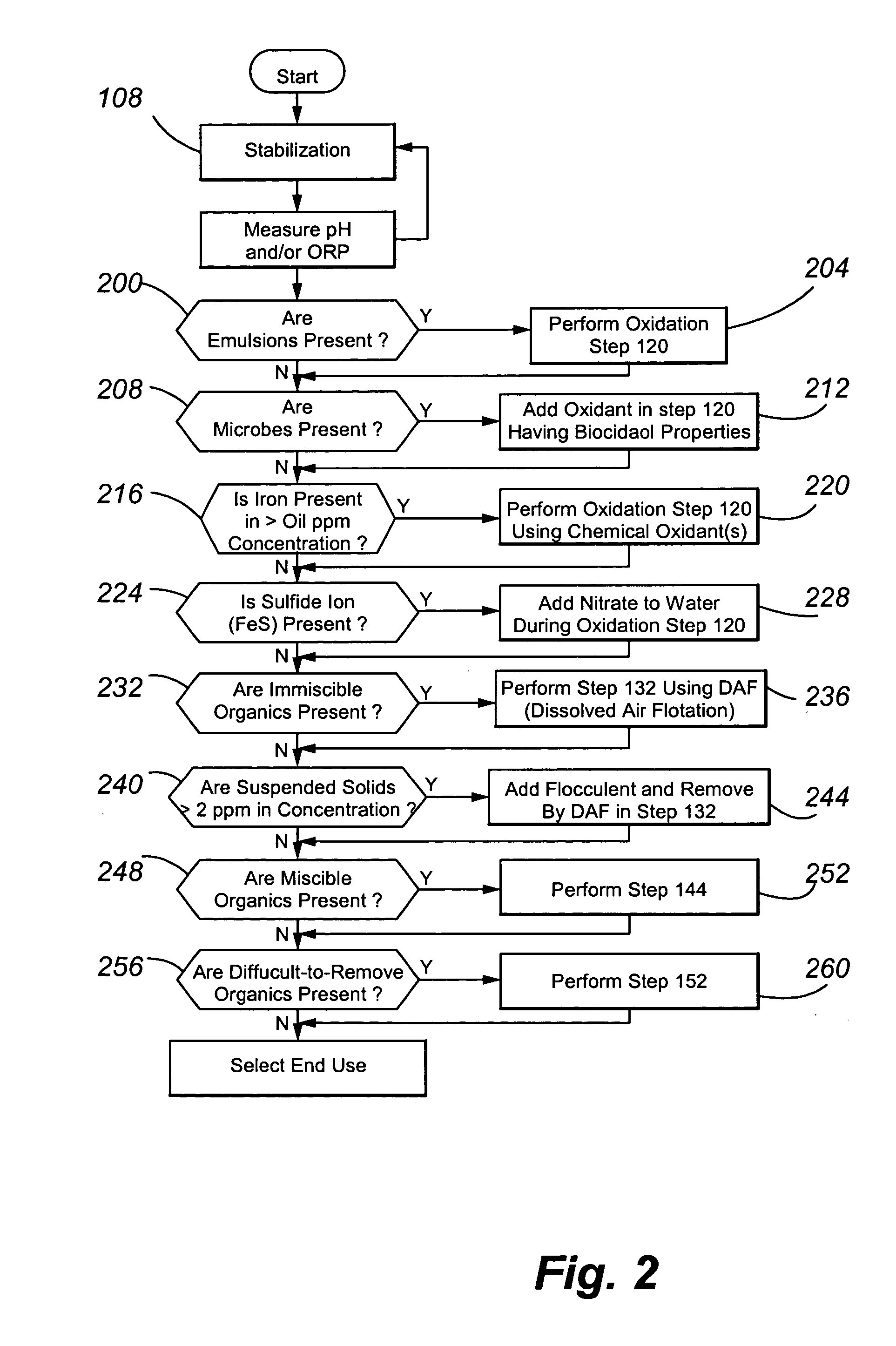

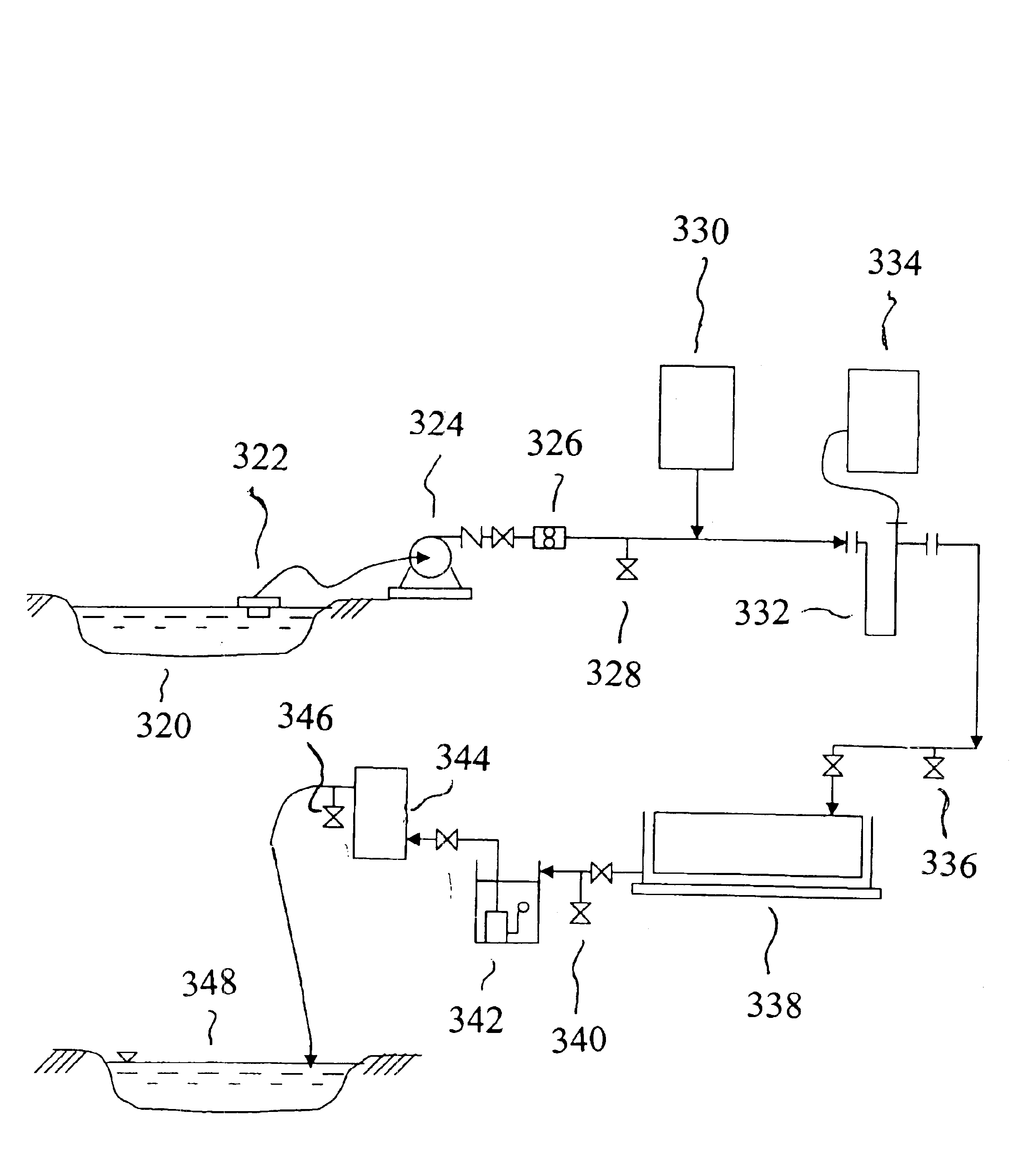

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

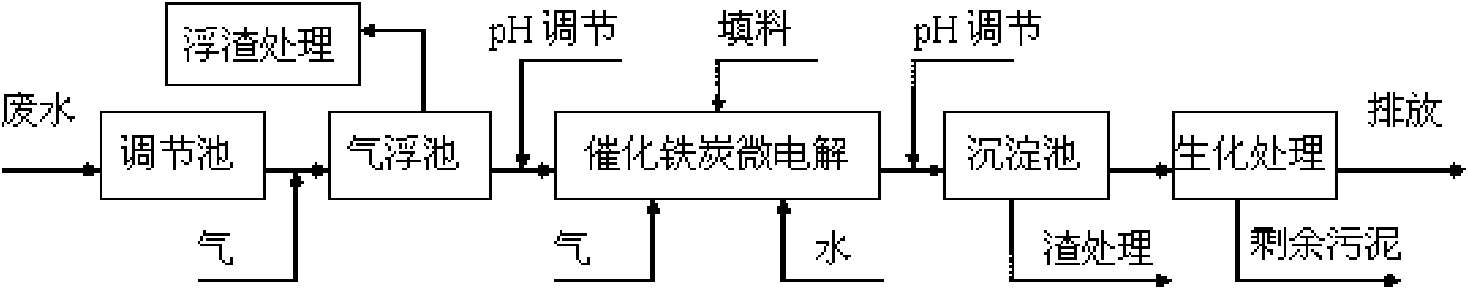

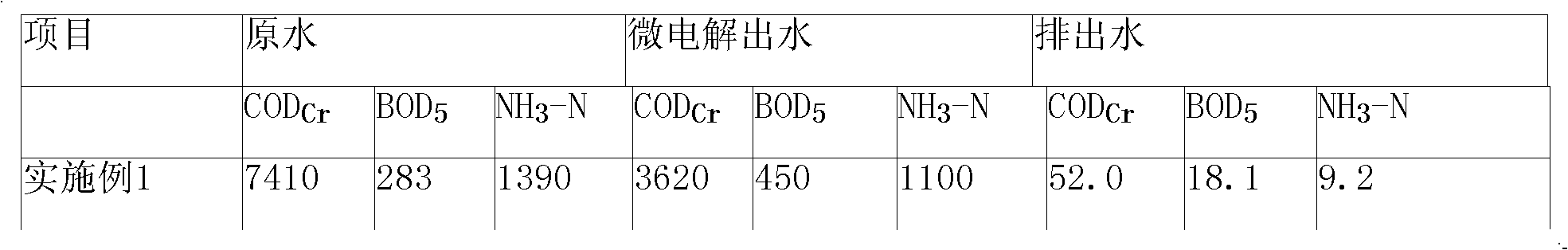

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

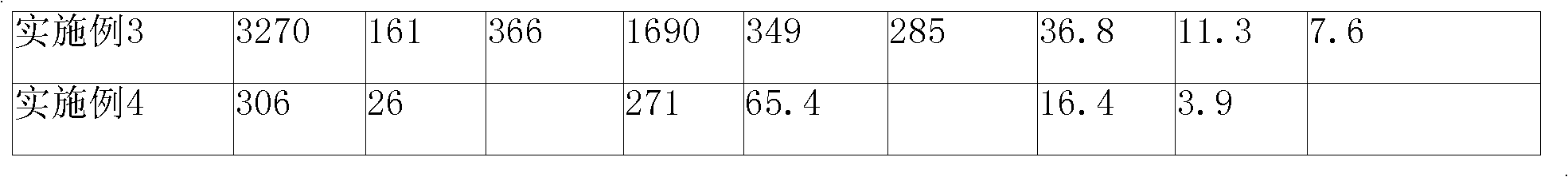

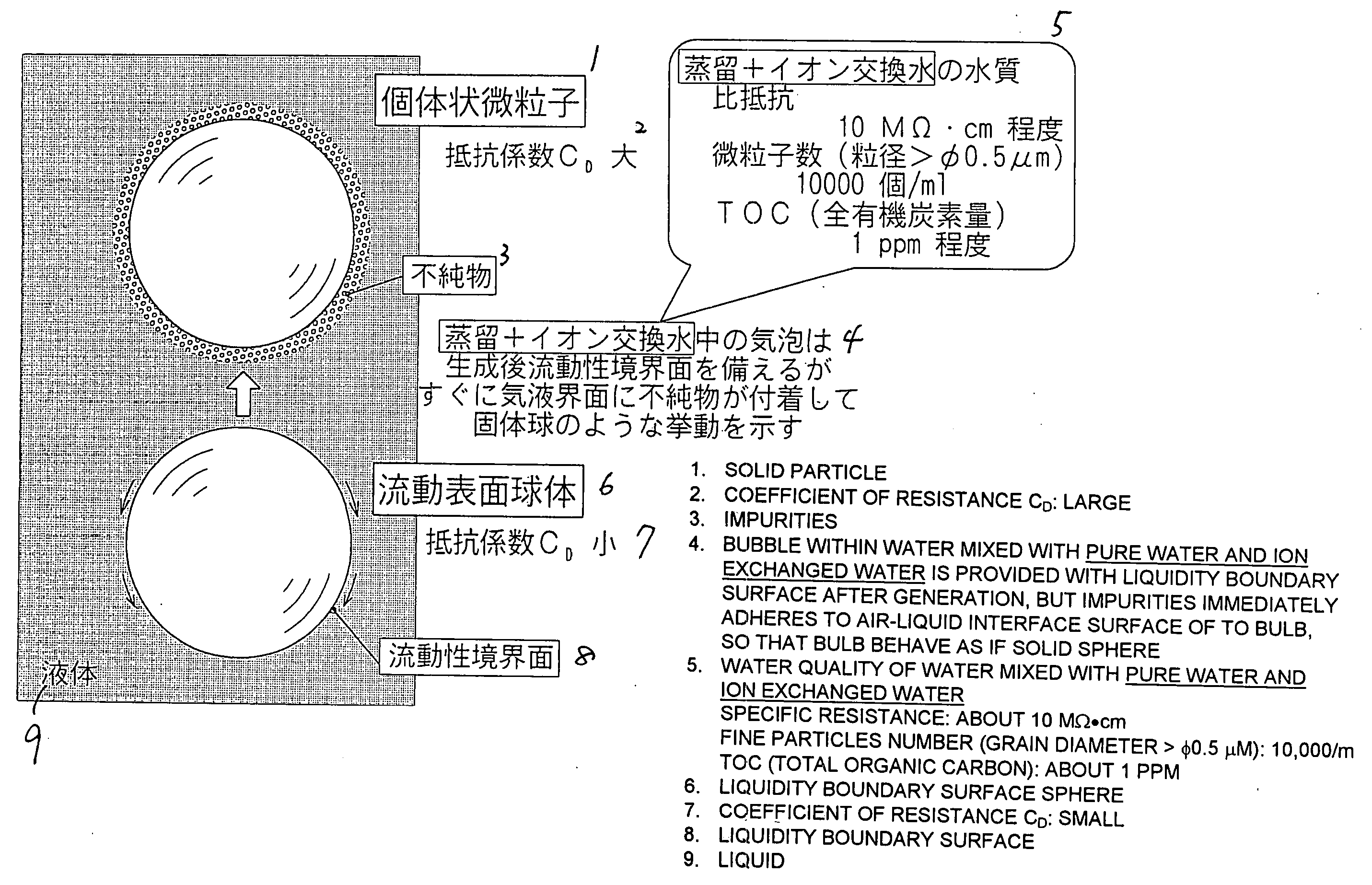

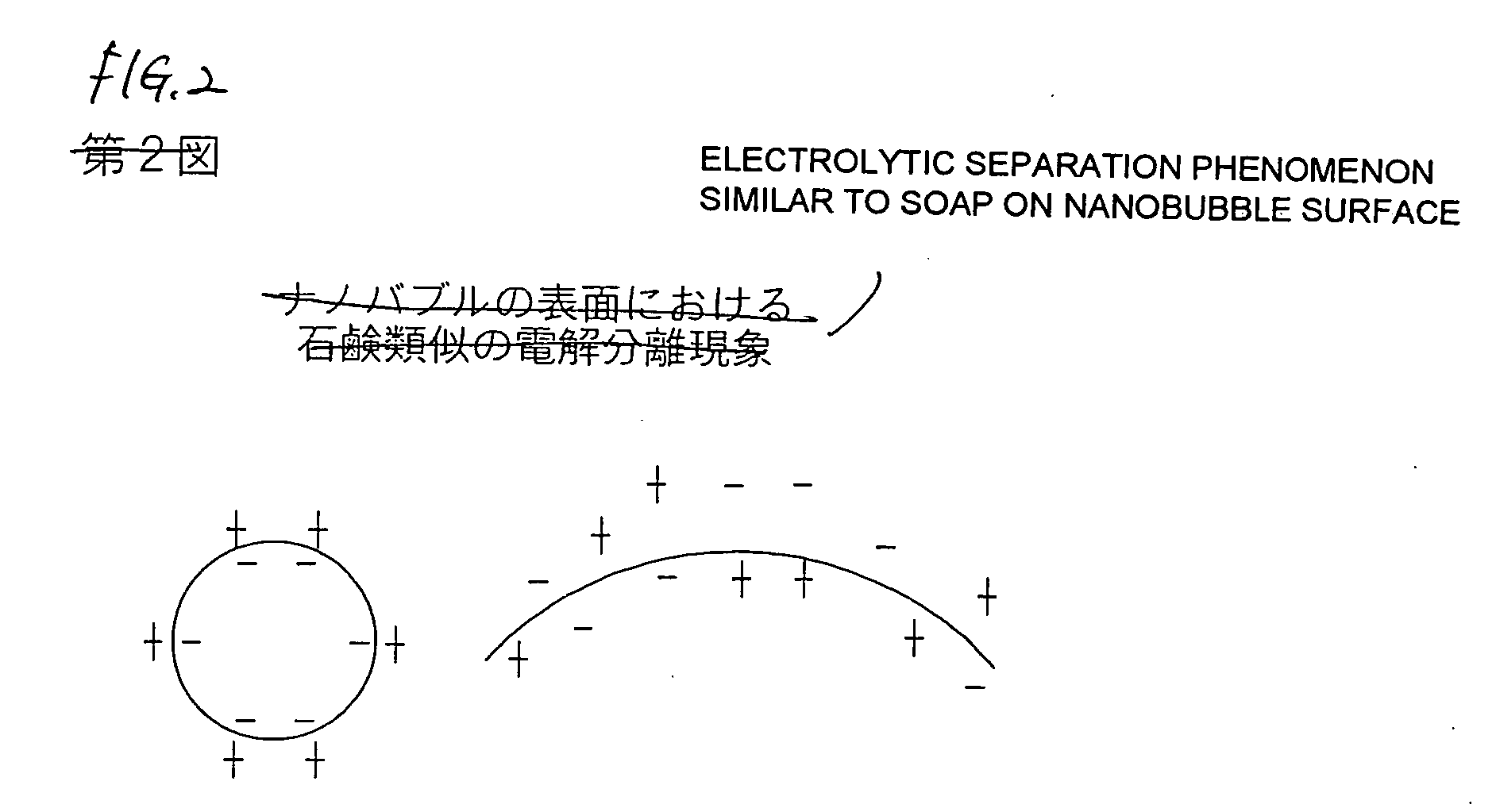

Nanobubble utilization method and device

InactiveUS20060054205A1Efficient use ofFast cleaningMaterial nanotechnologyVibration massageBiological bodyChemical reaction

The present inventors have found the presence of a nanobubble that has not been confirmed conventionally, and established a method for producing nanobubbles. The inventors have determined the theoretically expected characteristics of the produced nanobubbles, found new characteristics by analyzing data experimentally collected, and elucidated the relationship among the characters. Specifically, the inventors have found that a nanobubble has features such as decrease of the buoyant force, increase of the surface area, increase of the surface activity, generation of a local high-pressure field, interface activating action, and sterilizing action thanks to electrostatic polarization. By the association among the features, any of wide variety of objects can be cleaned with high performance and with light environmental load thanks to the function of adsorbing foul components, the function of cleaning the surface of an object quickly, and the sterilizing function, and polluted water can be purified. Nanobubbles can be applied to an organism to recover from fatigue and effectively used for chemical reactions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

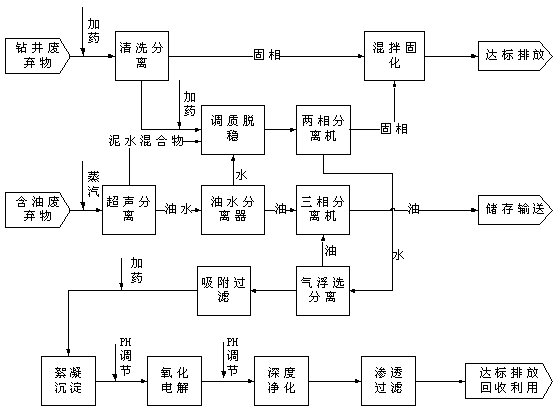

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Process for electrocoagulating waste fluids

An electrocoagulation process for removing organic and metal contaminants from a pressurized waste fluid is disclosed in which a clarified waste fluid is produced when the pressure is released.

Owner:GAVREL TOM G +1

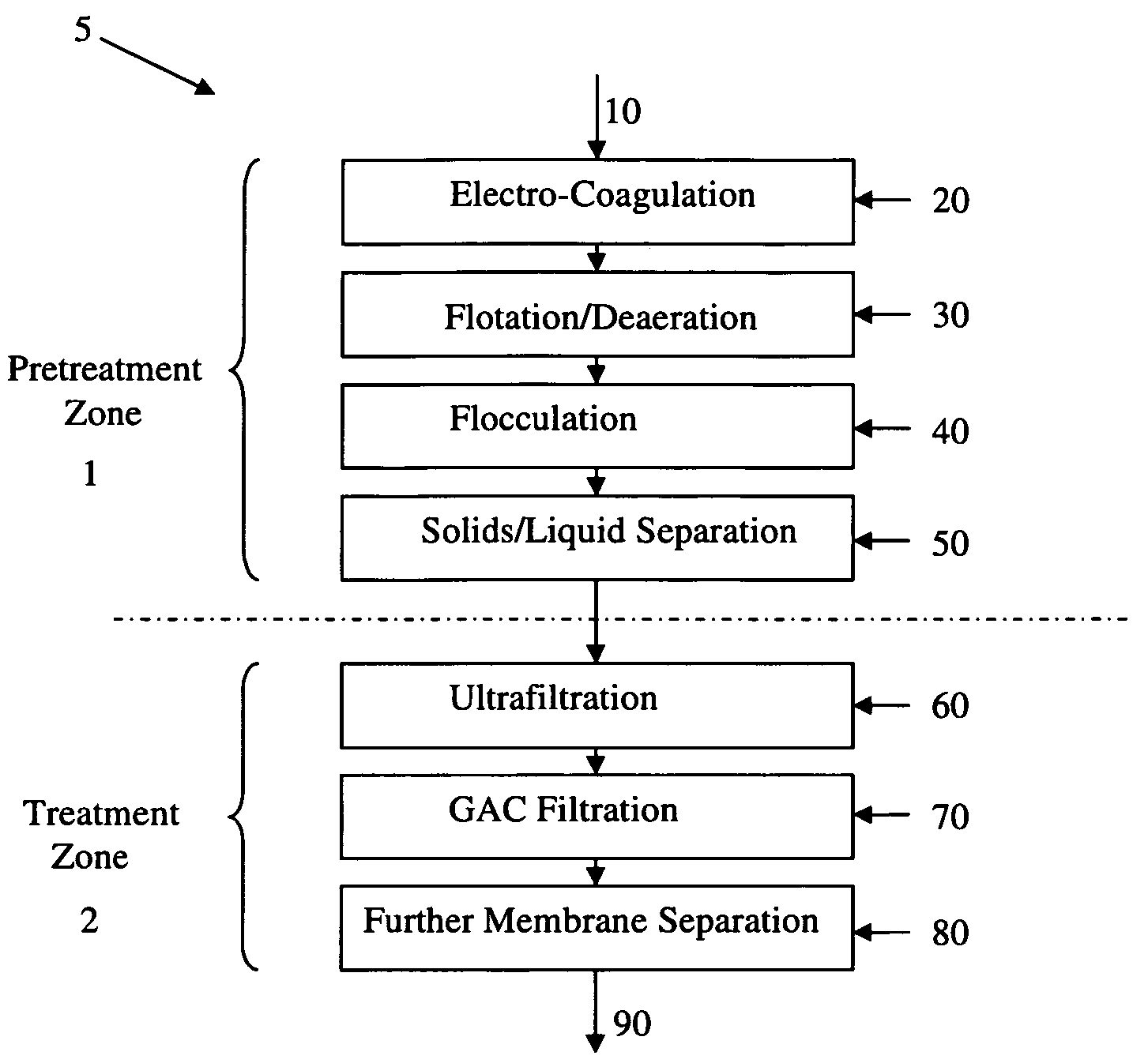

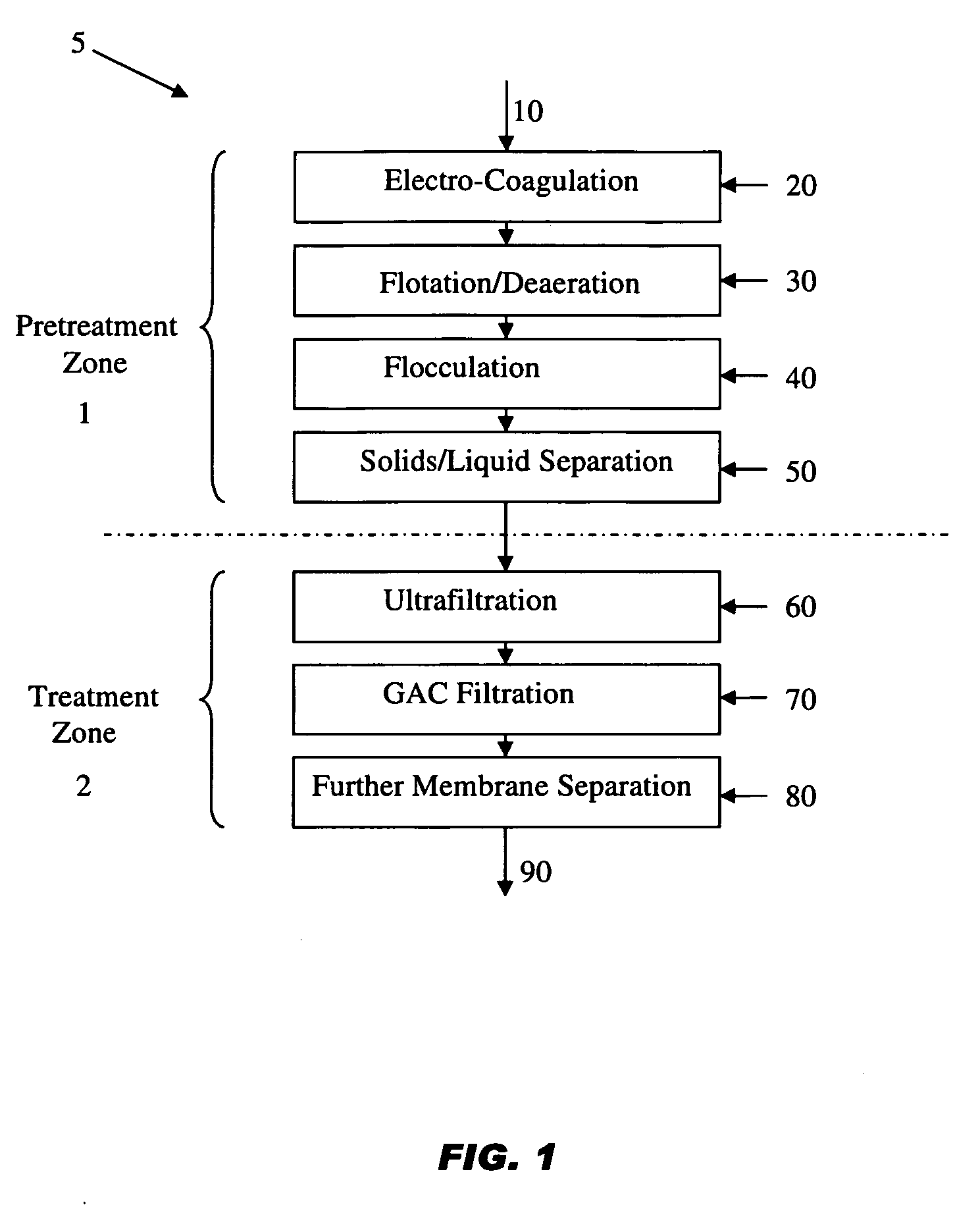

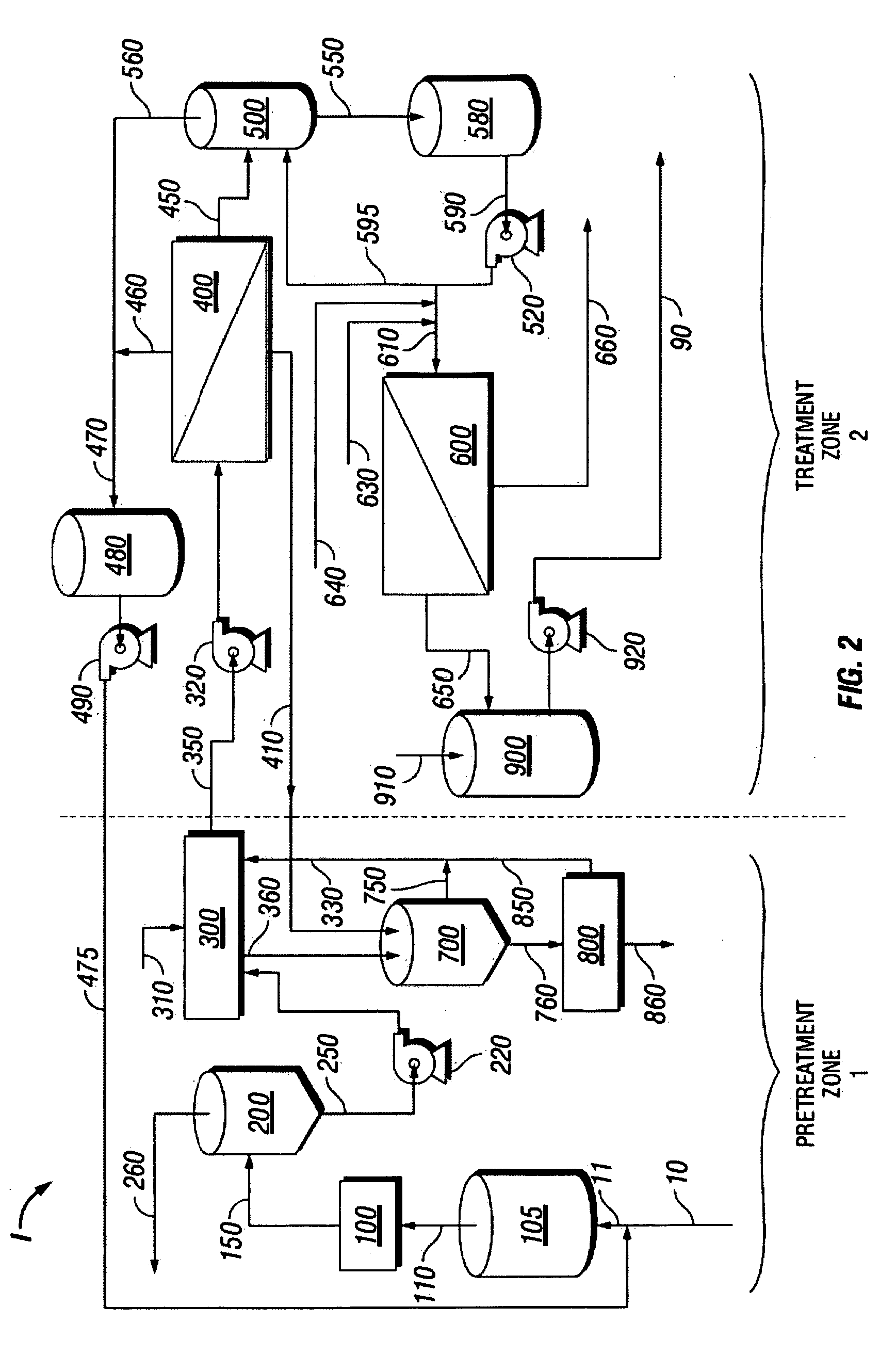

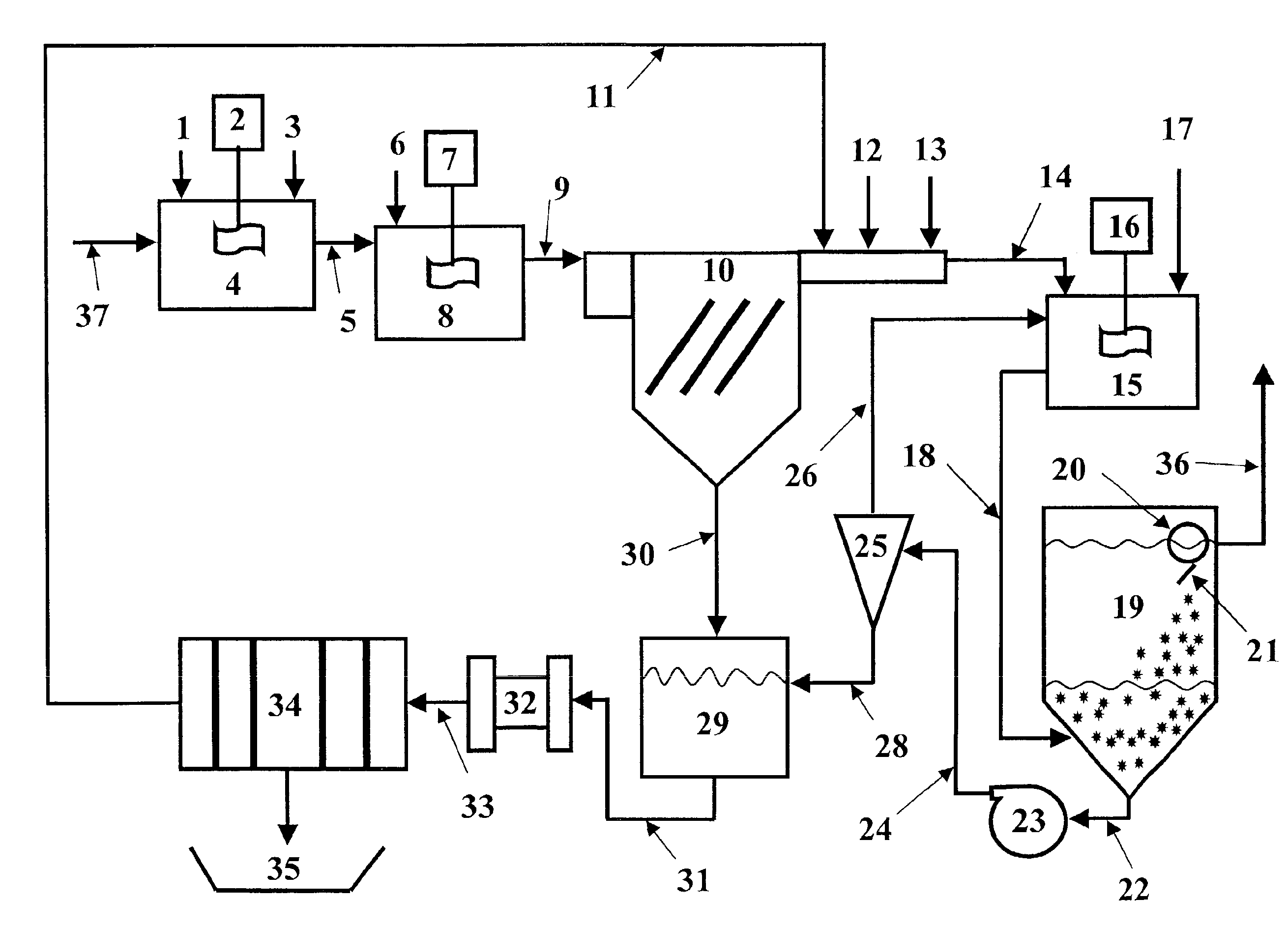

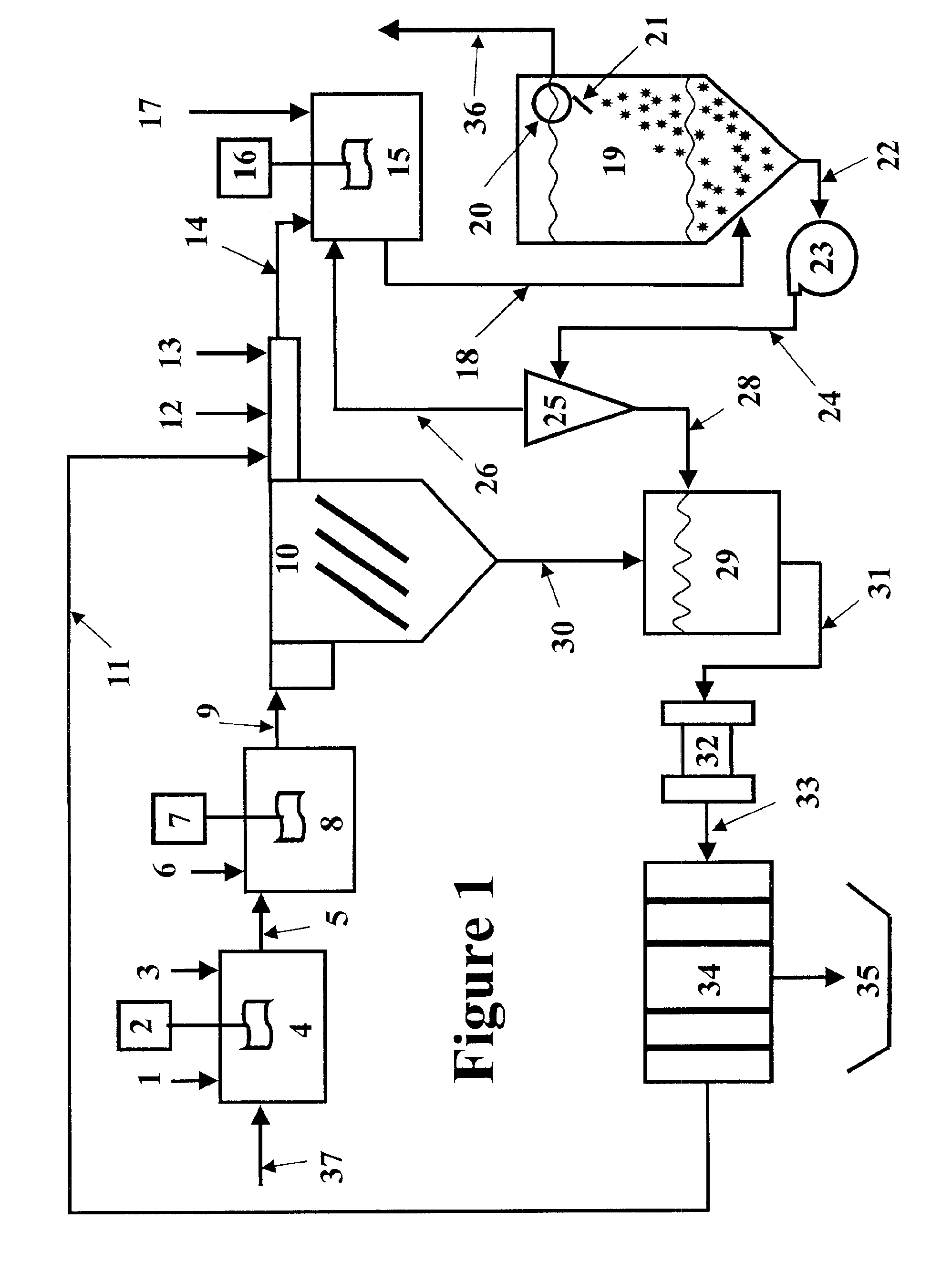

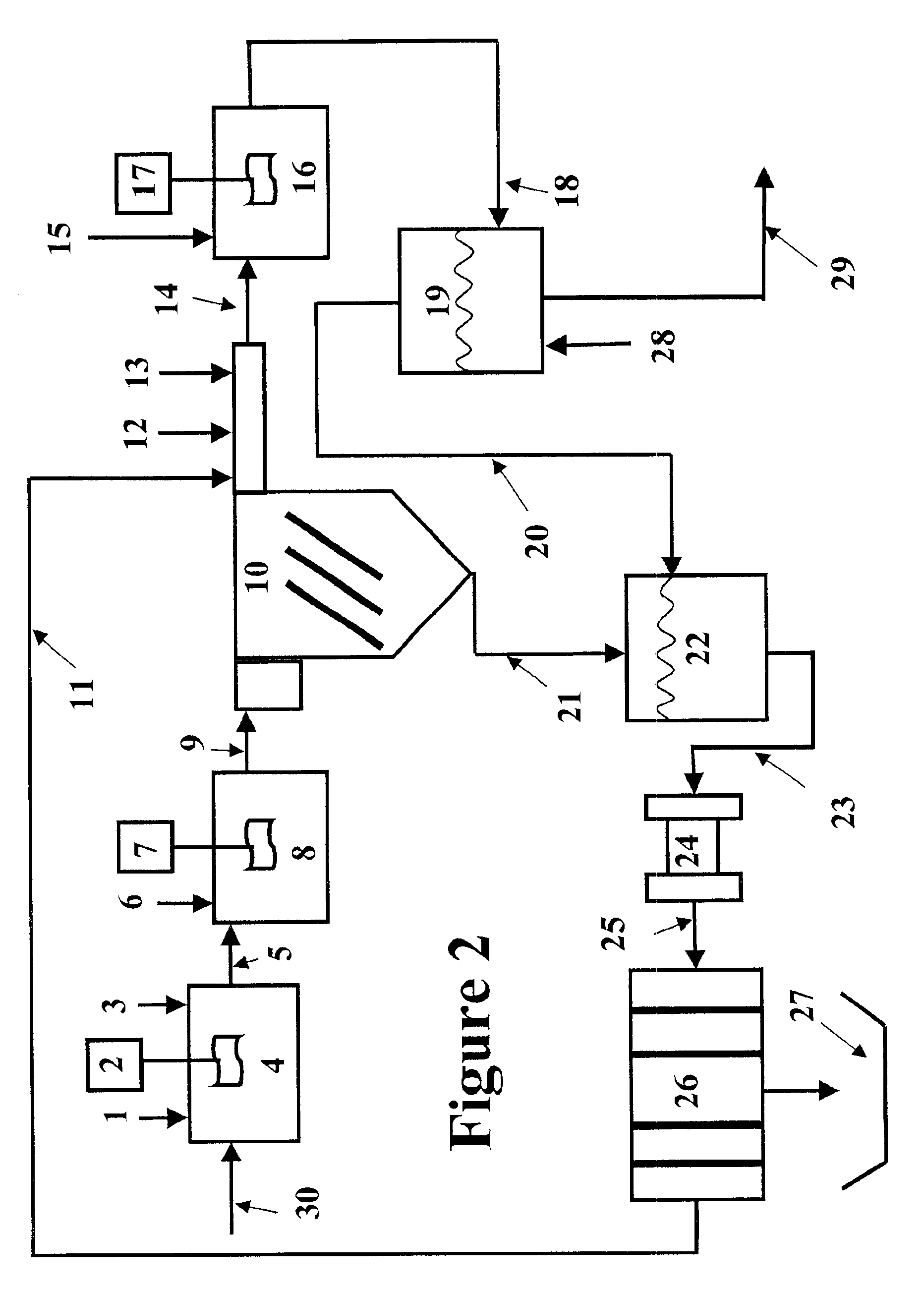

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS20050258103A1Efficient removalEasy to disassembleSedimentation separationDifferential sedimentationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

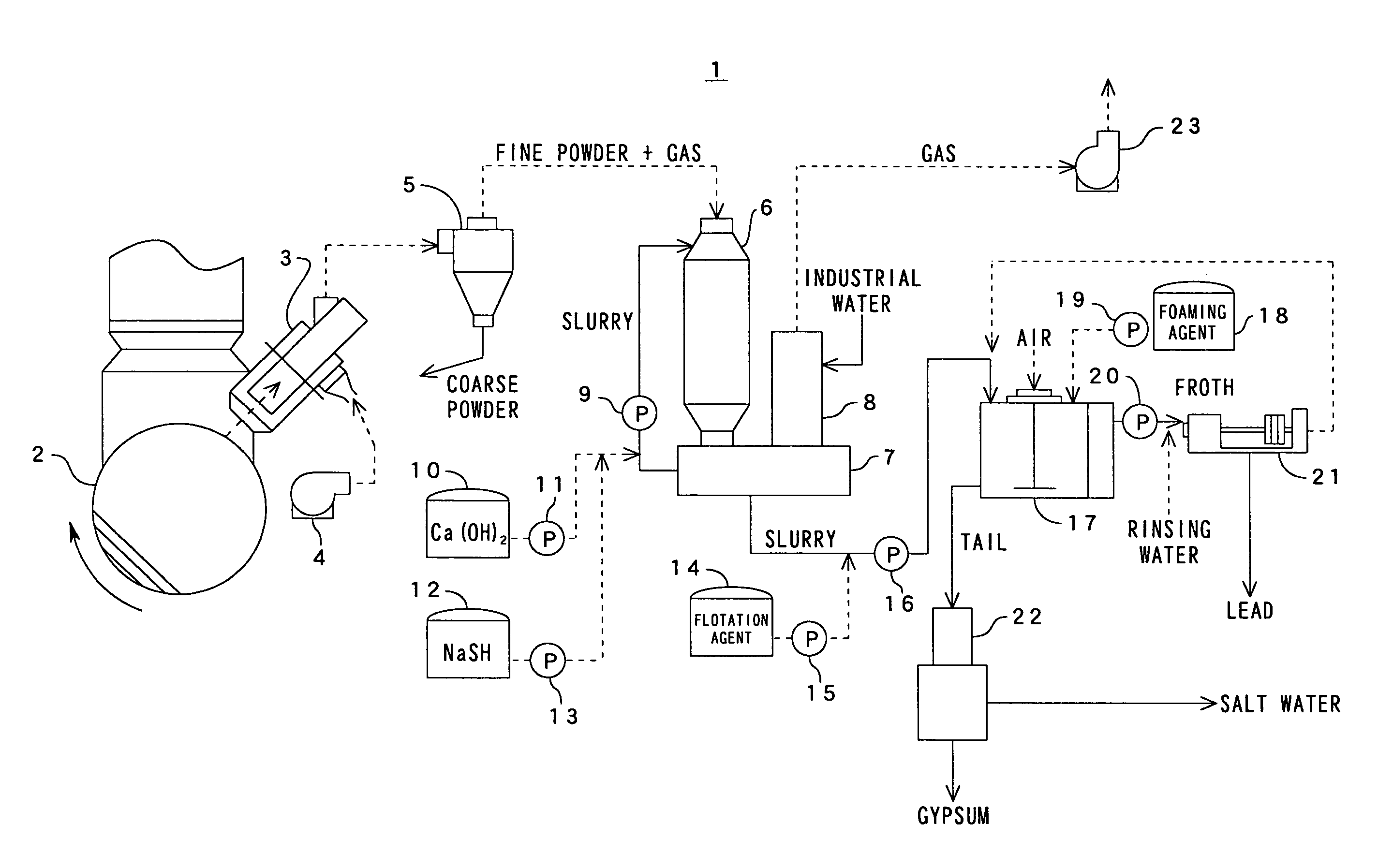

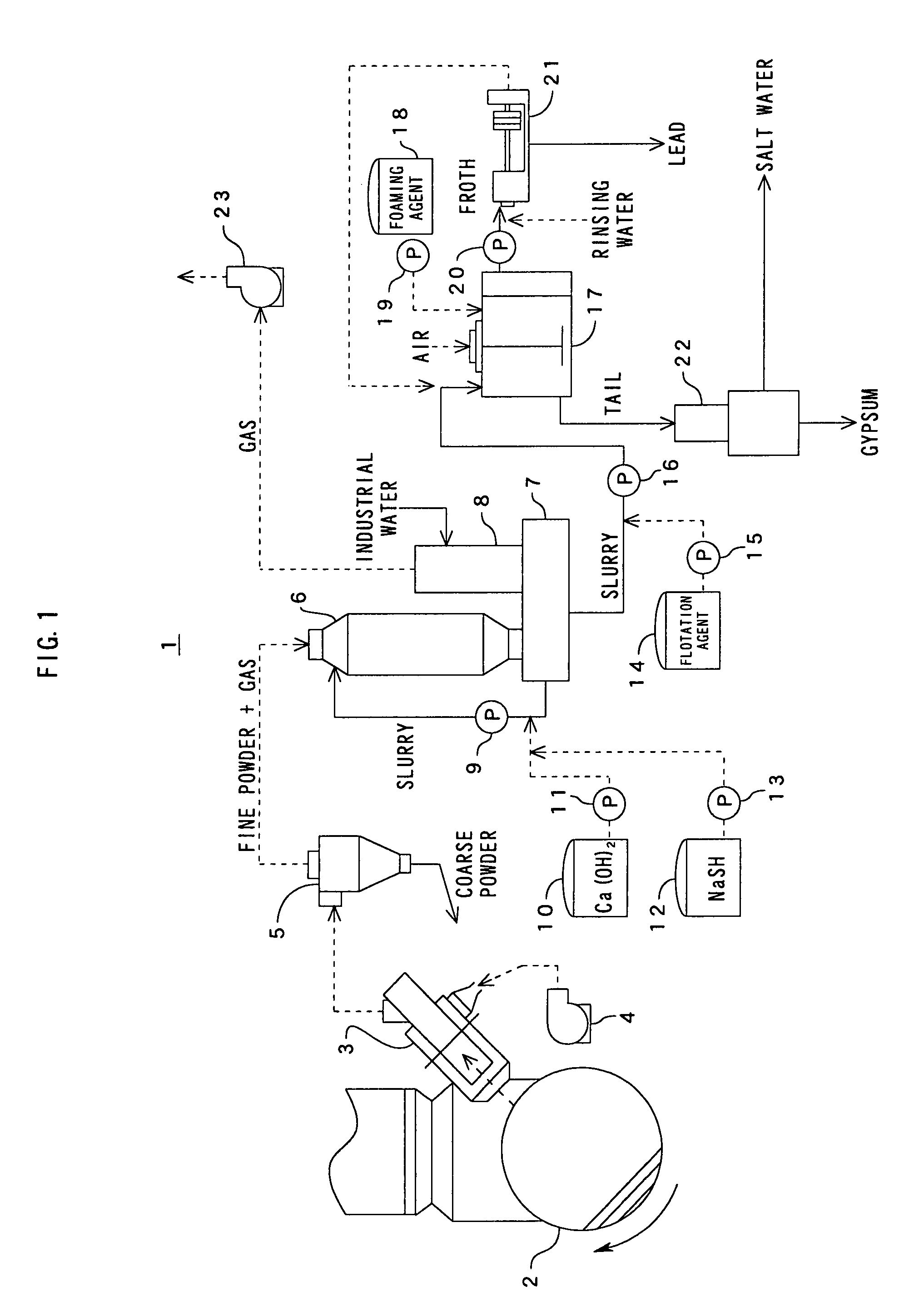

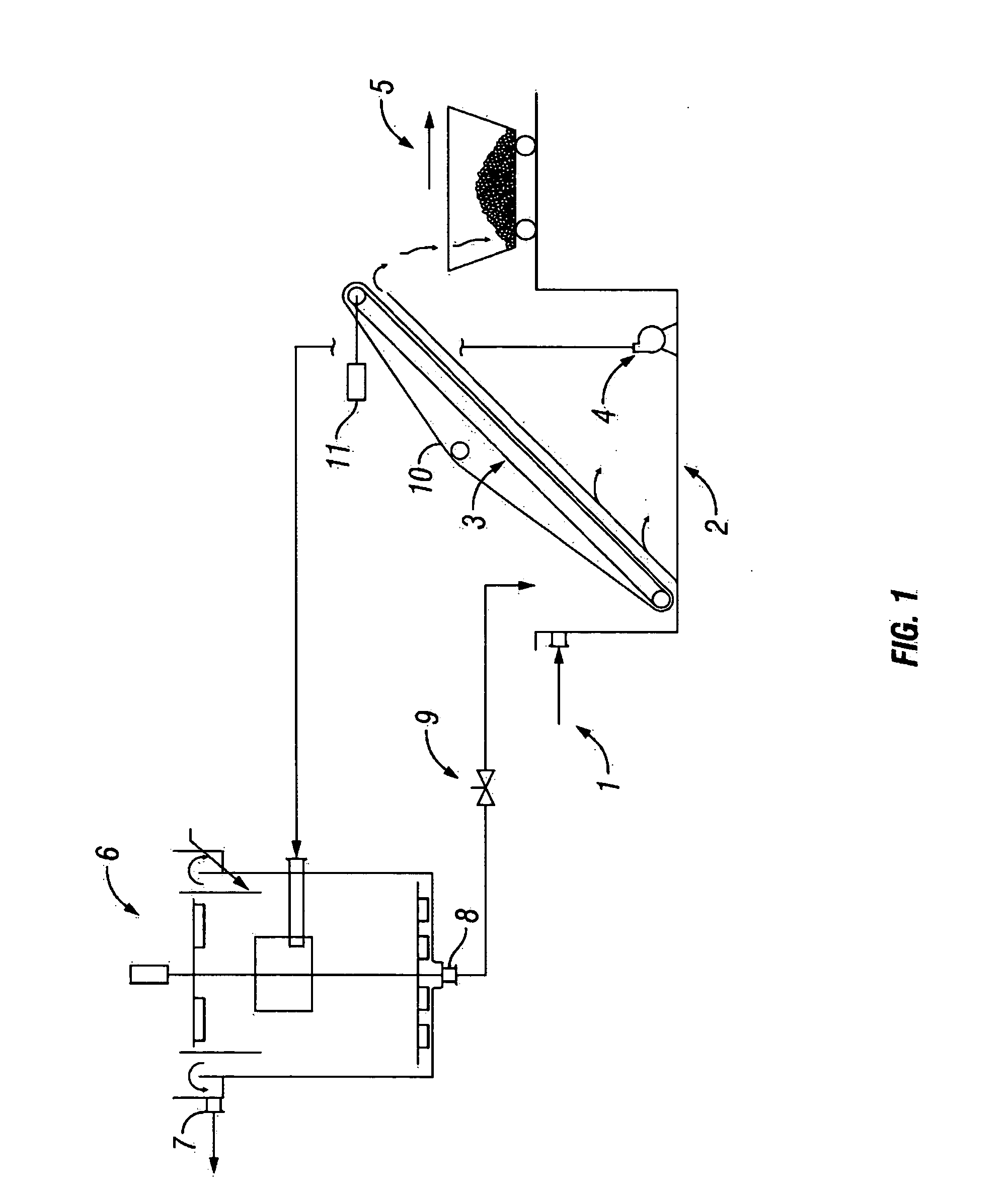

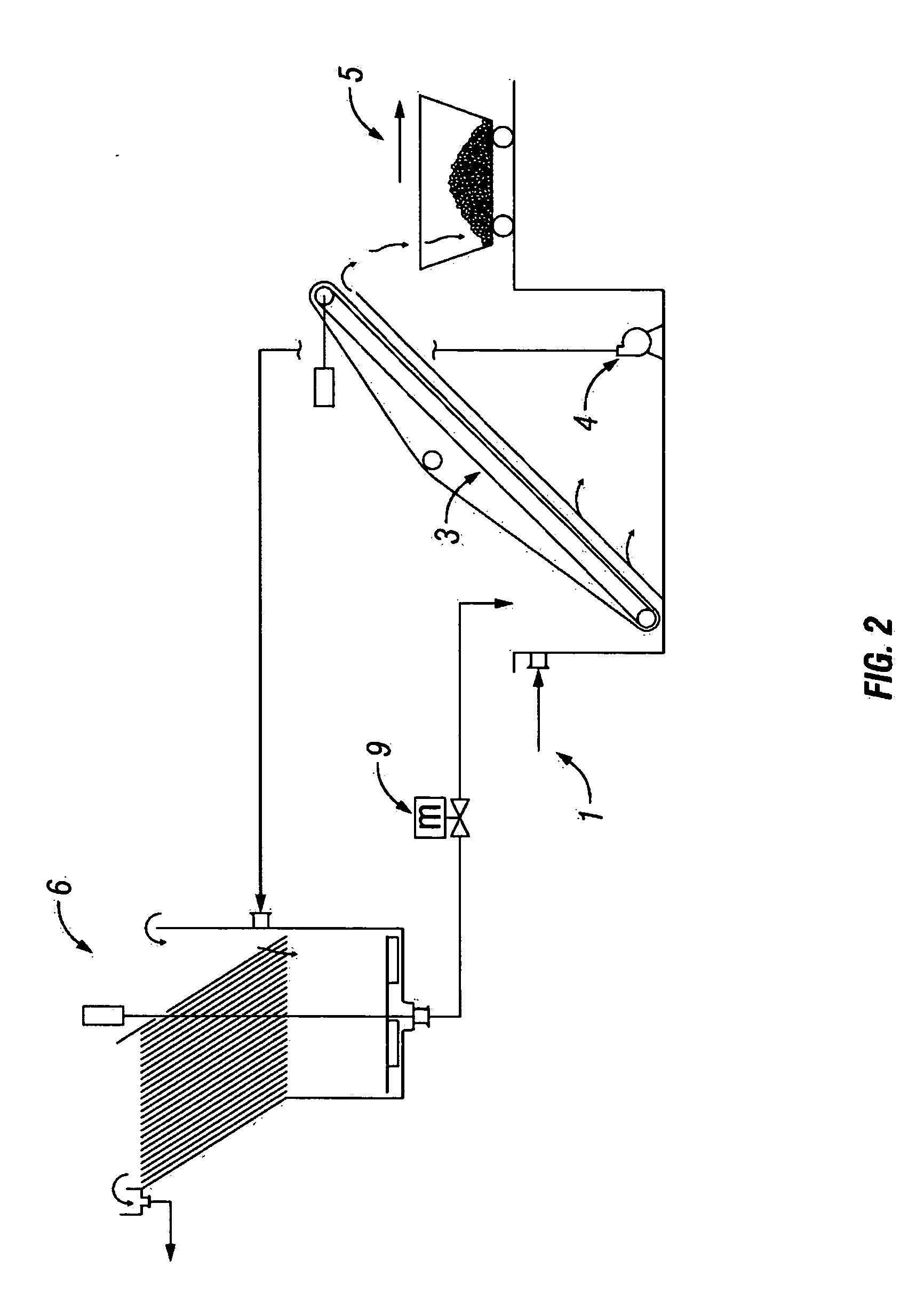

System and method for treating dust contained in extracted cement kiln combustion gas

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

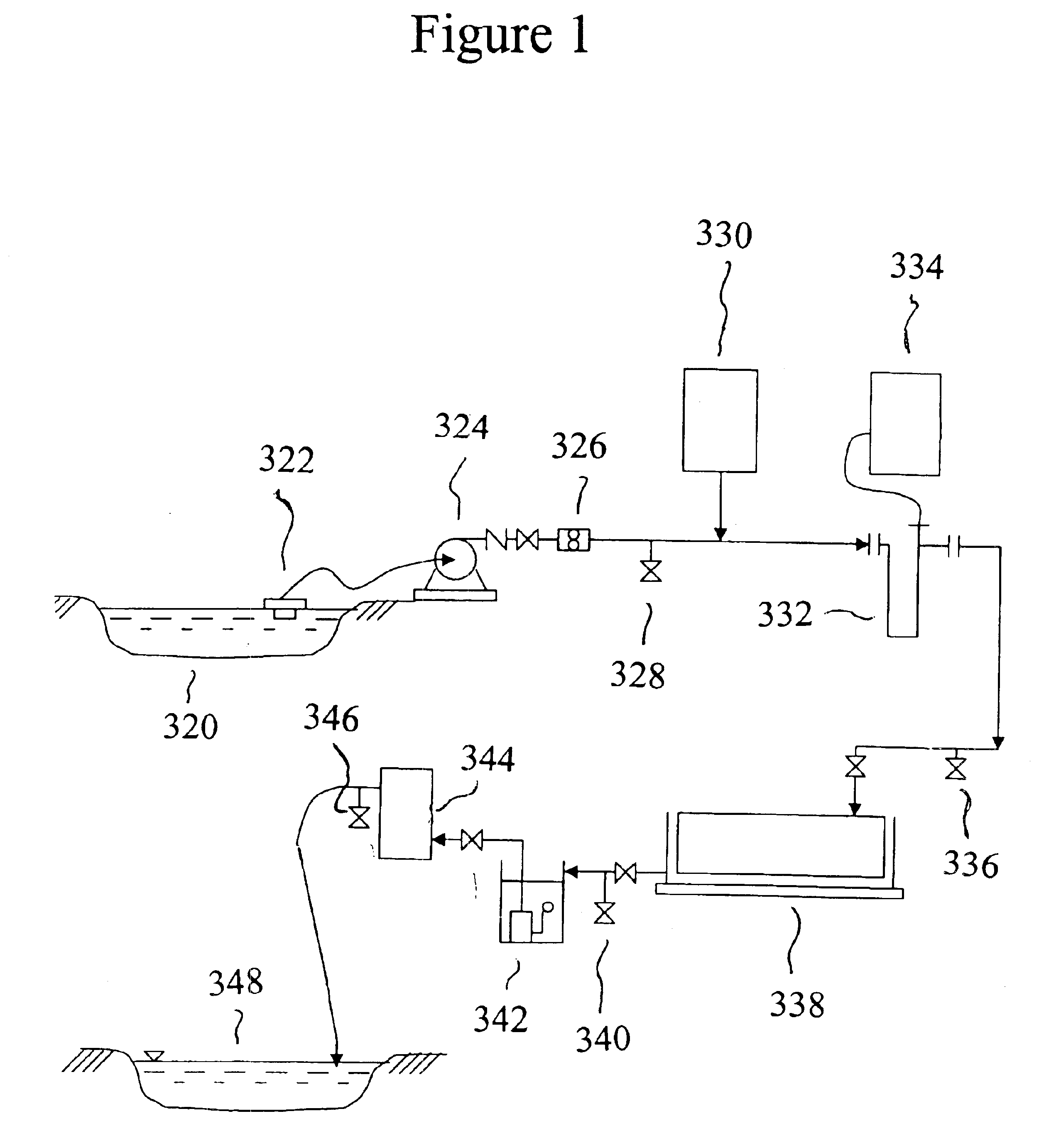

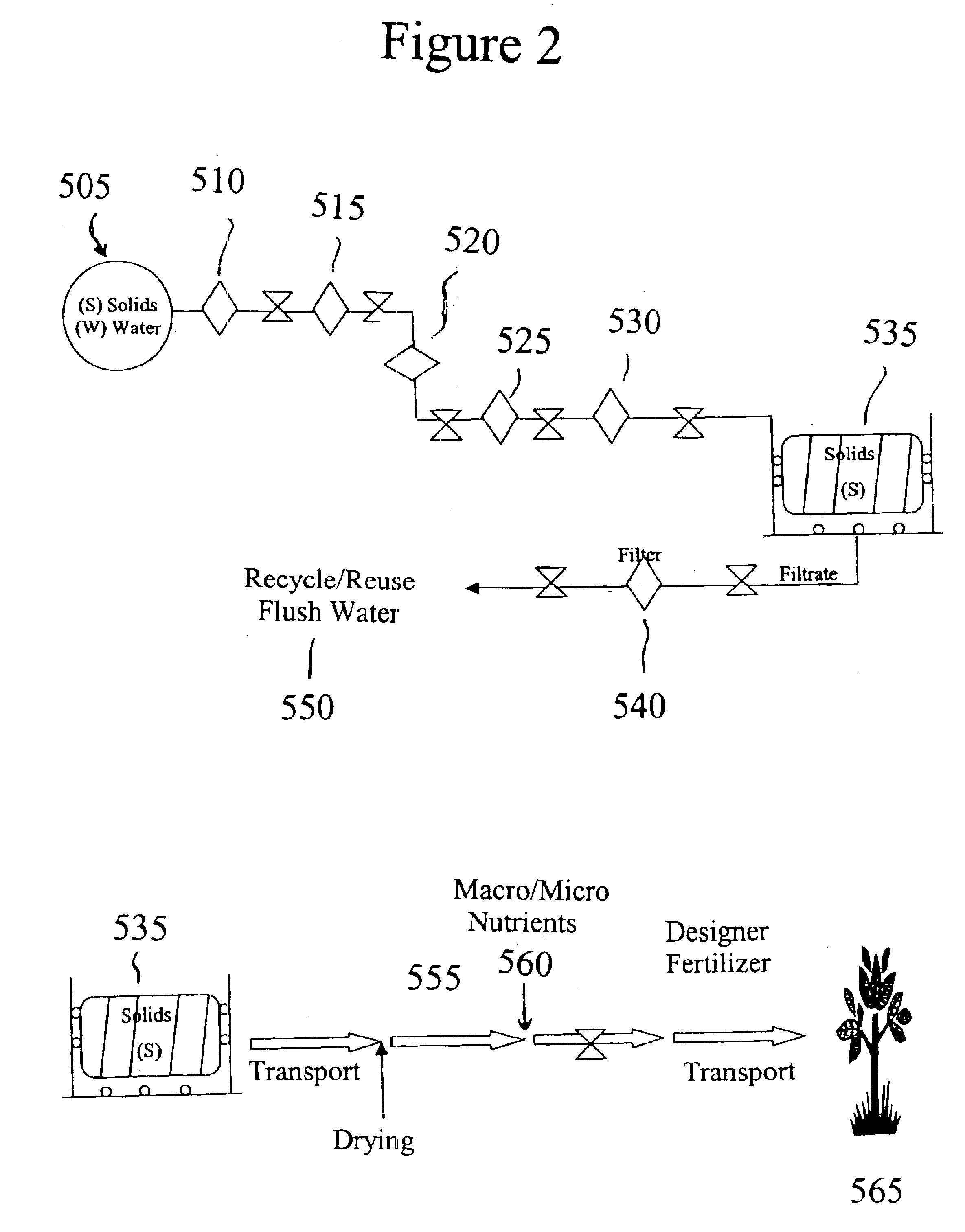

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

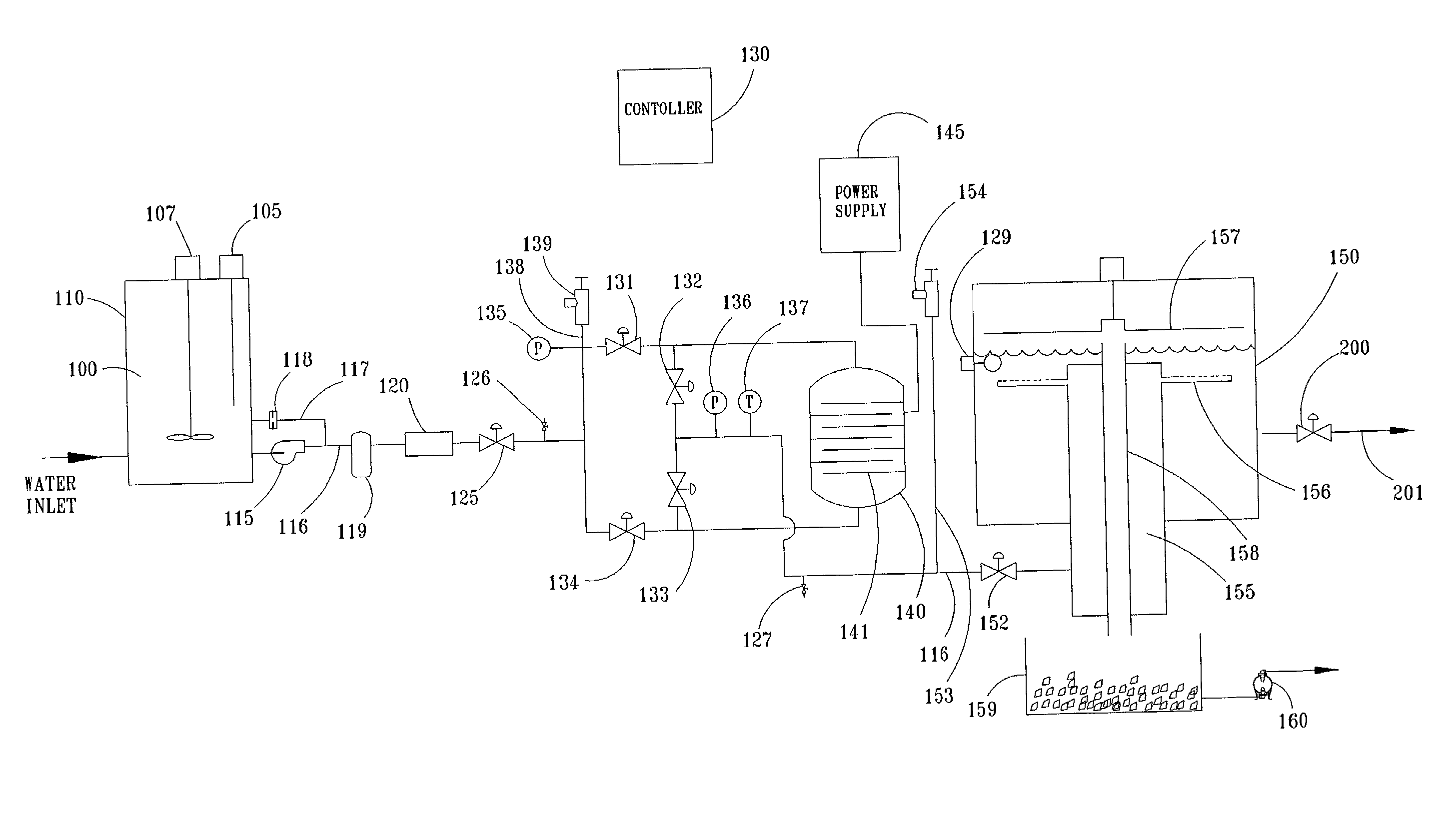

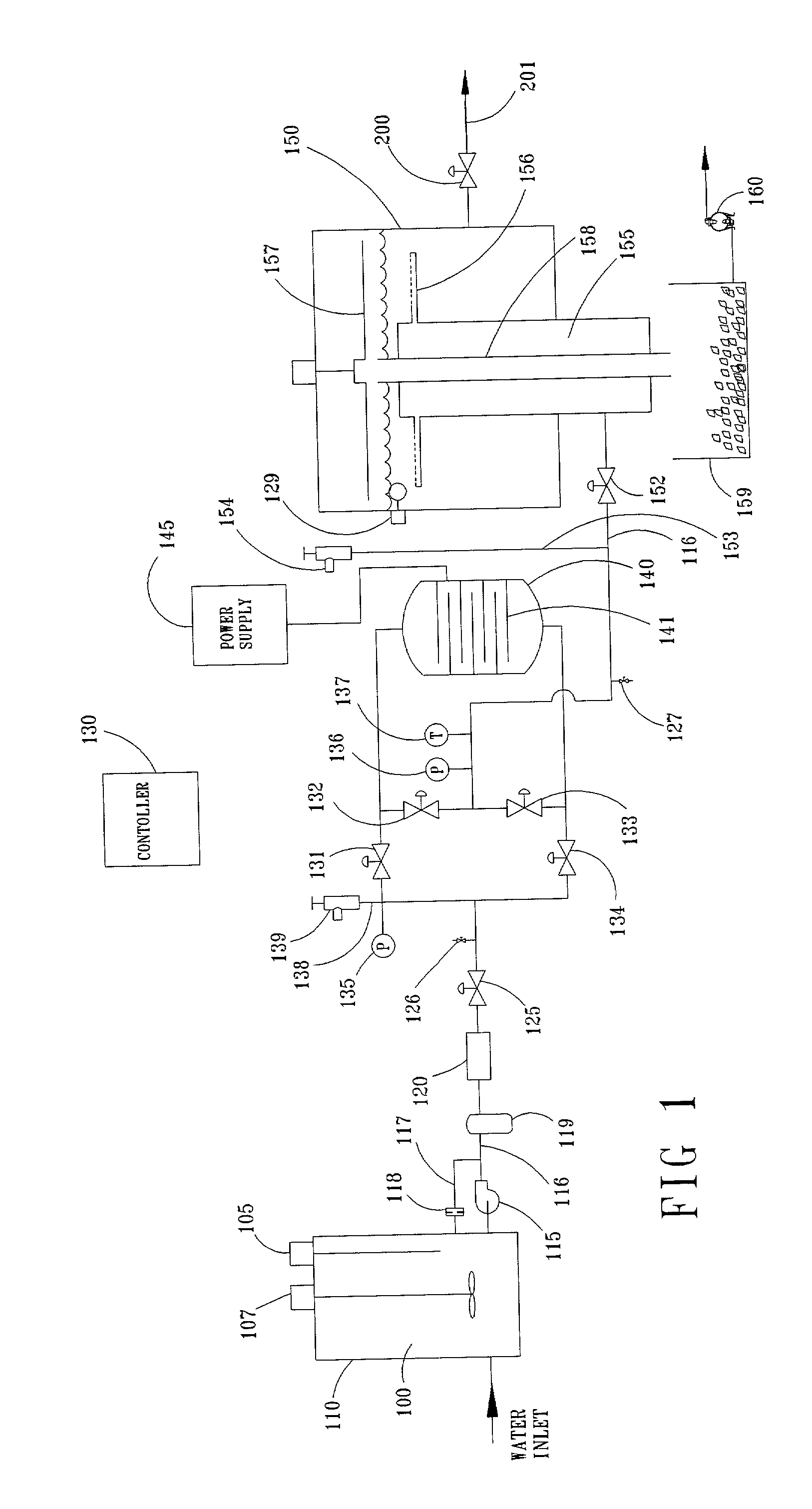

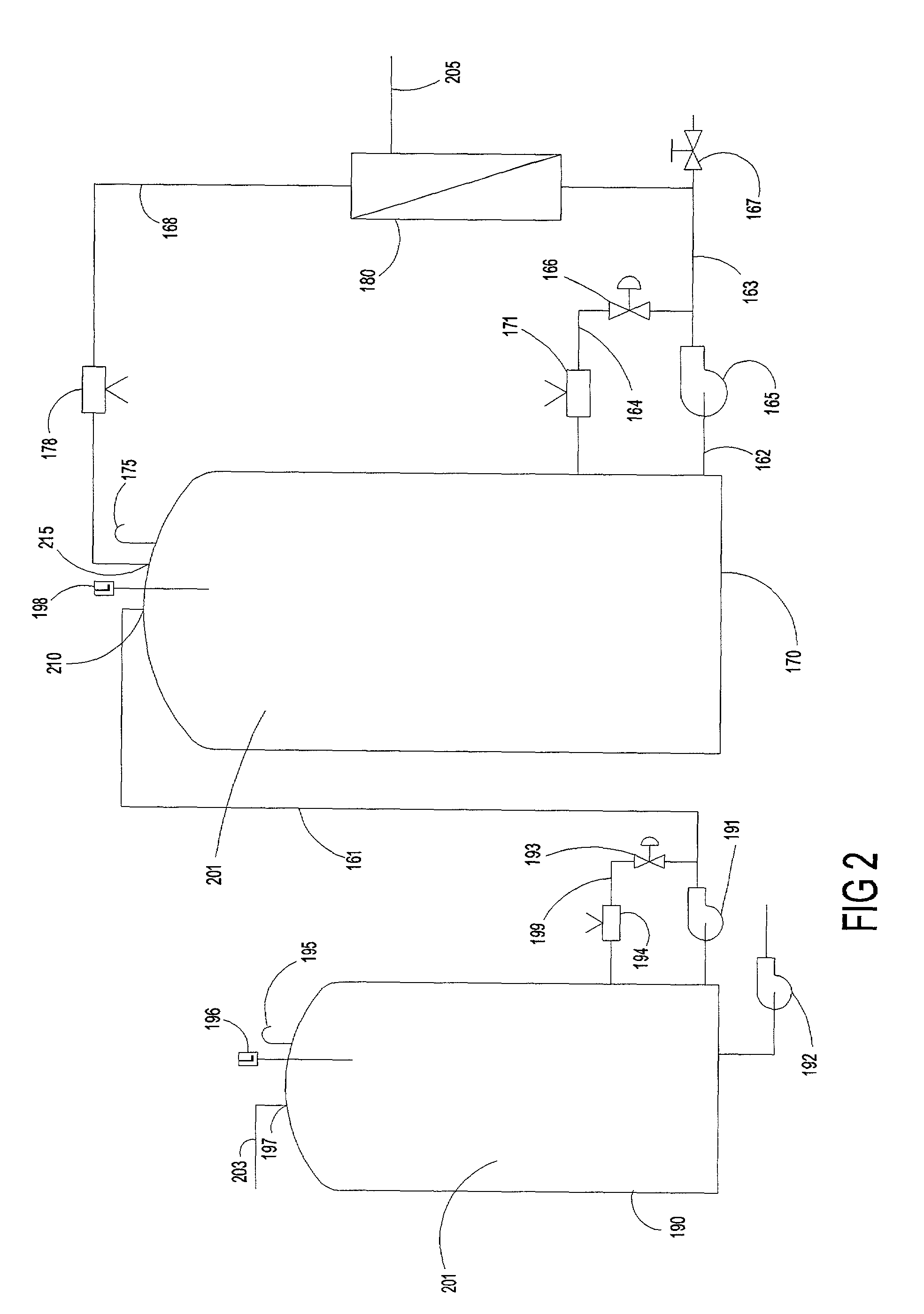

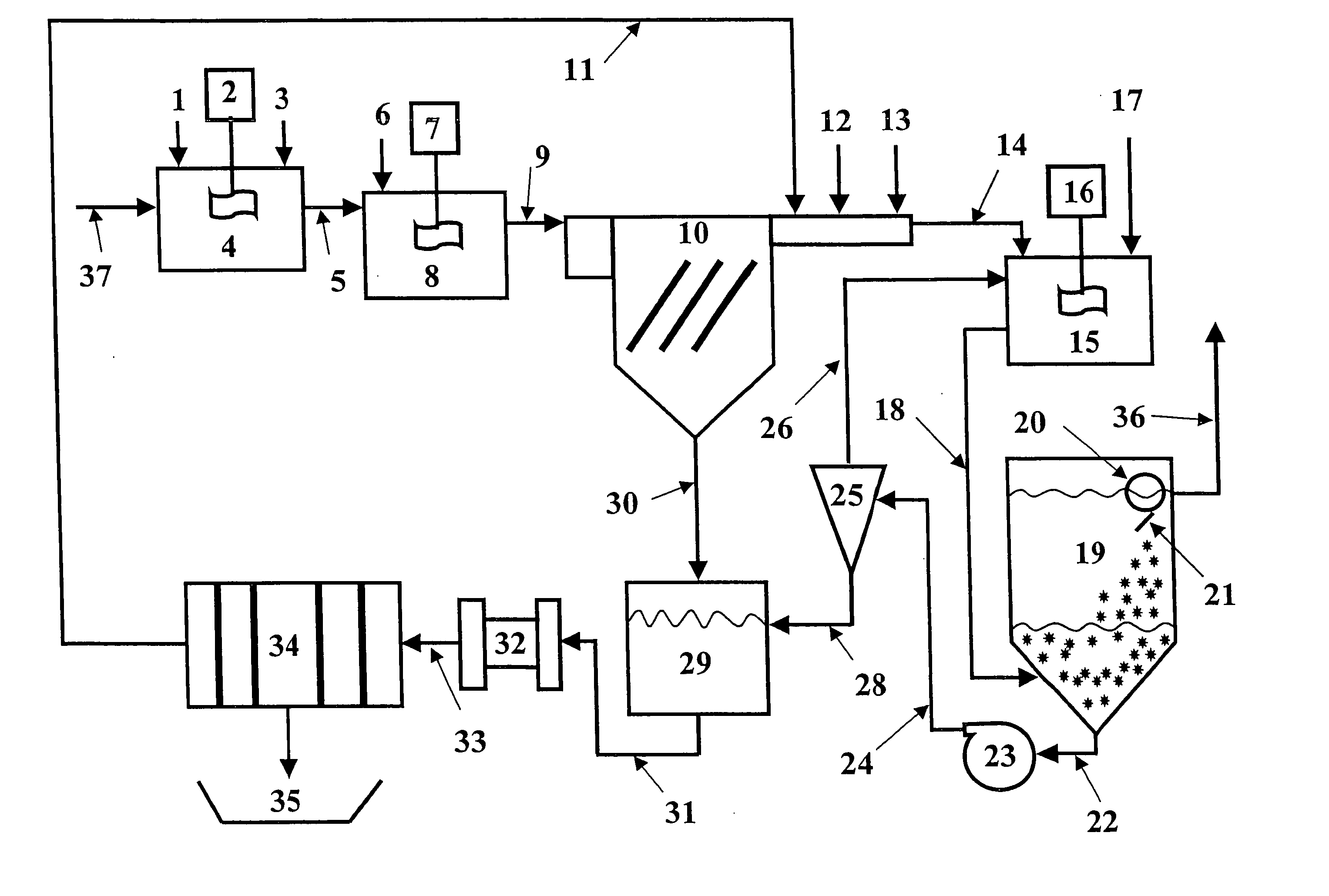

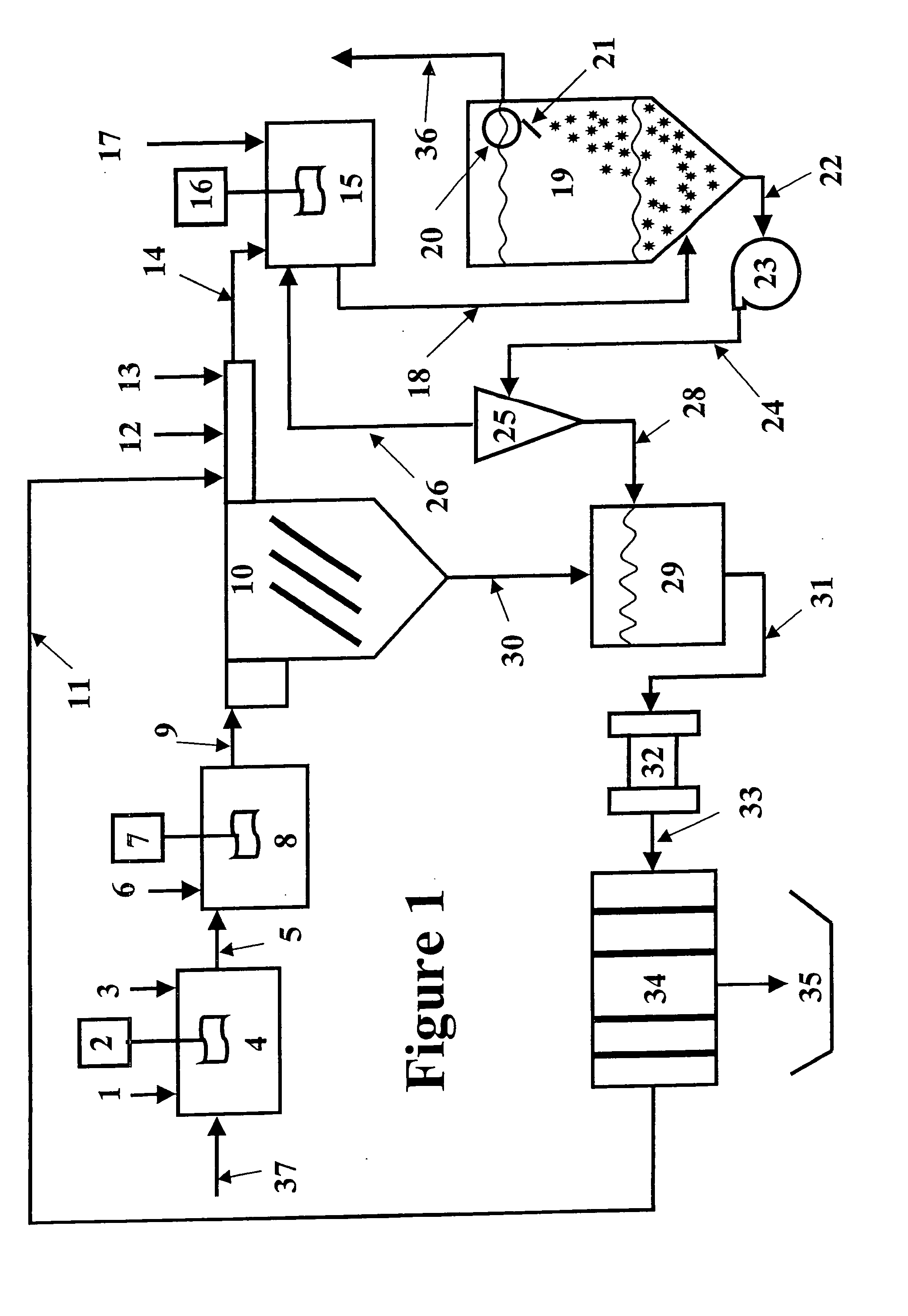

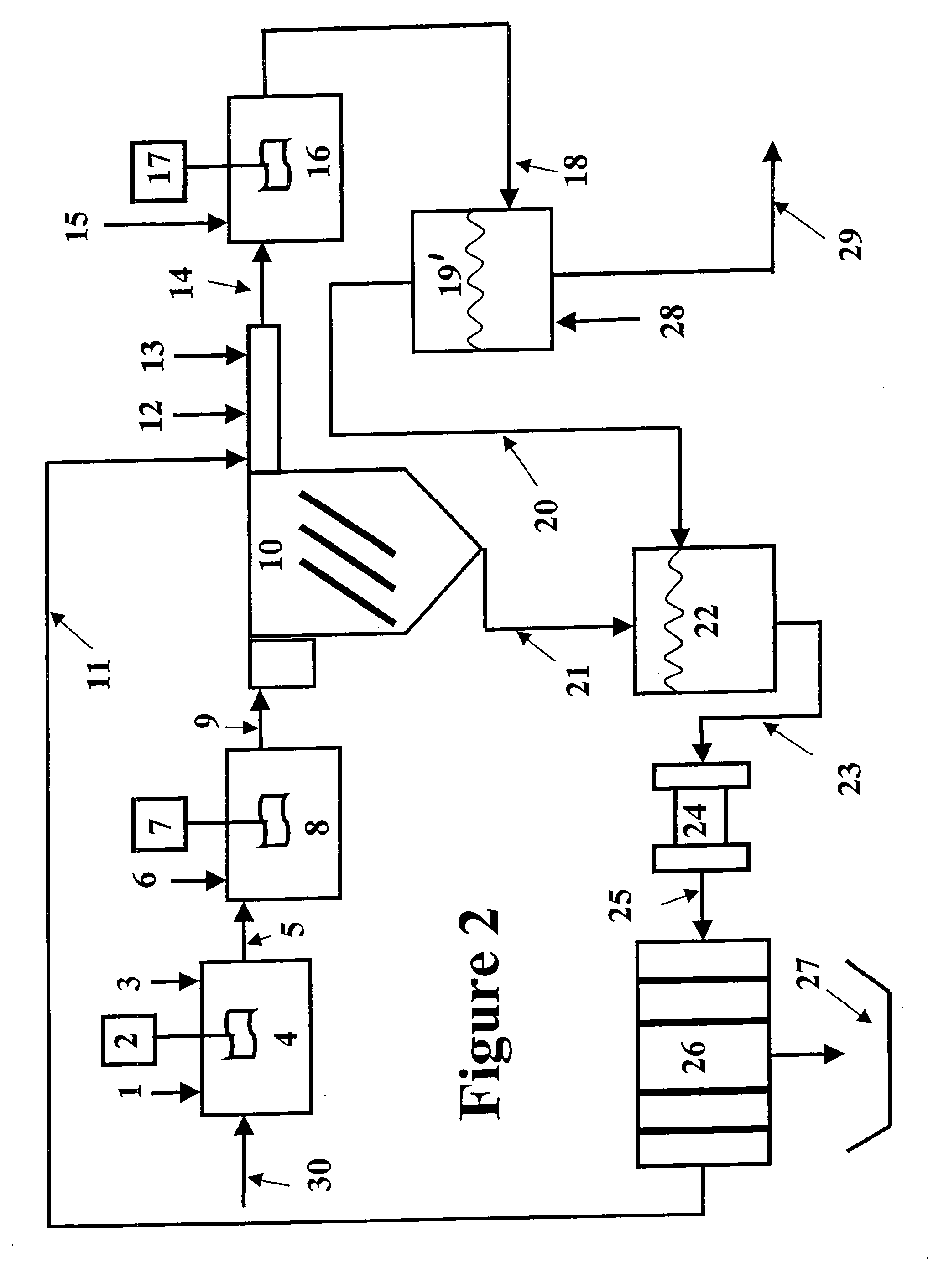

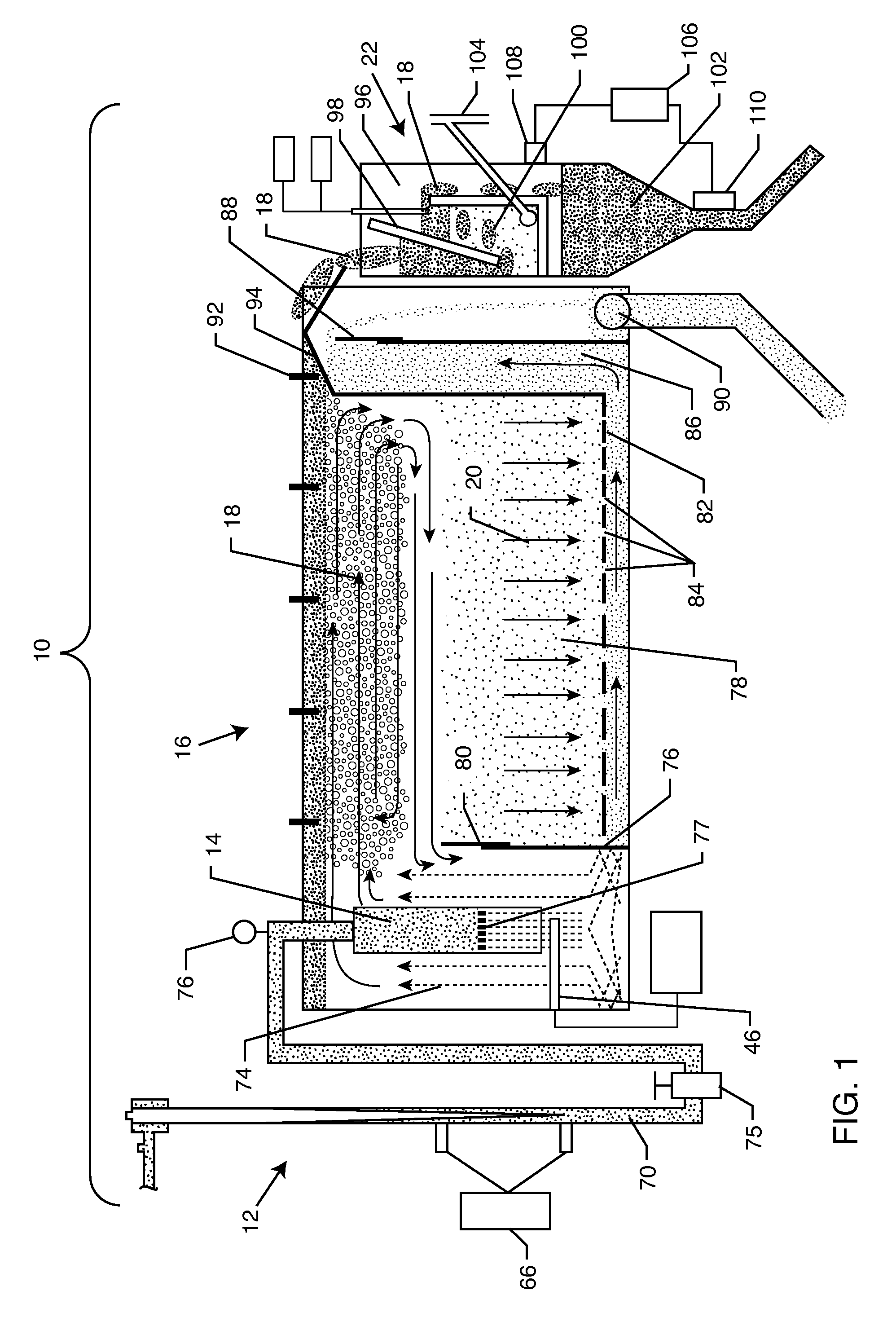

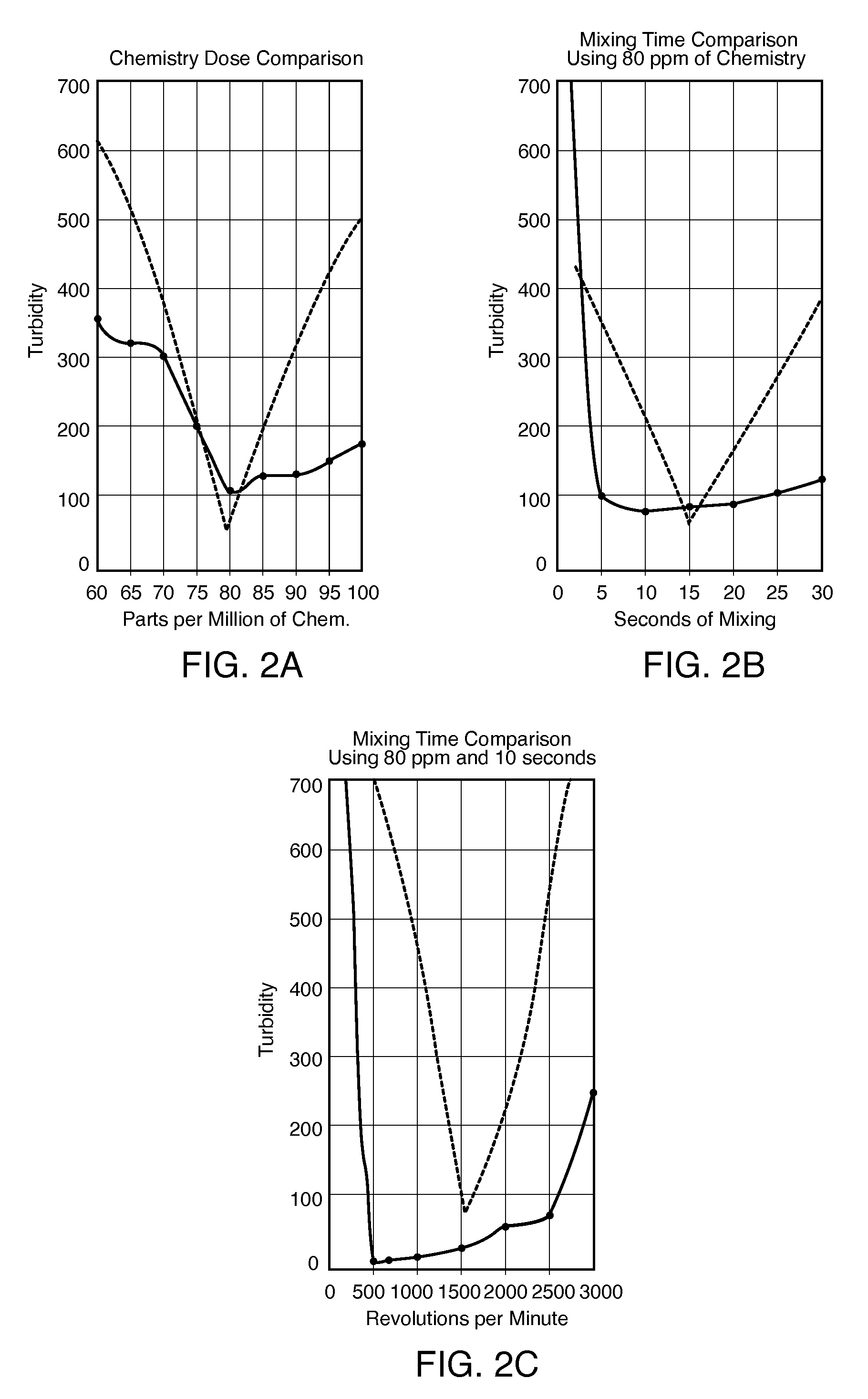

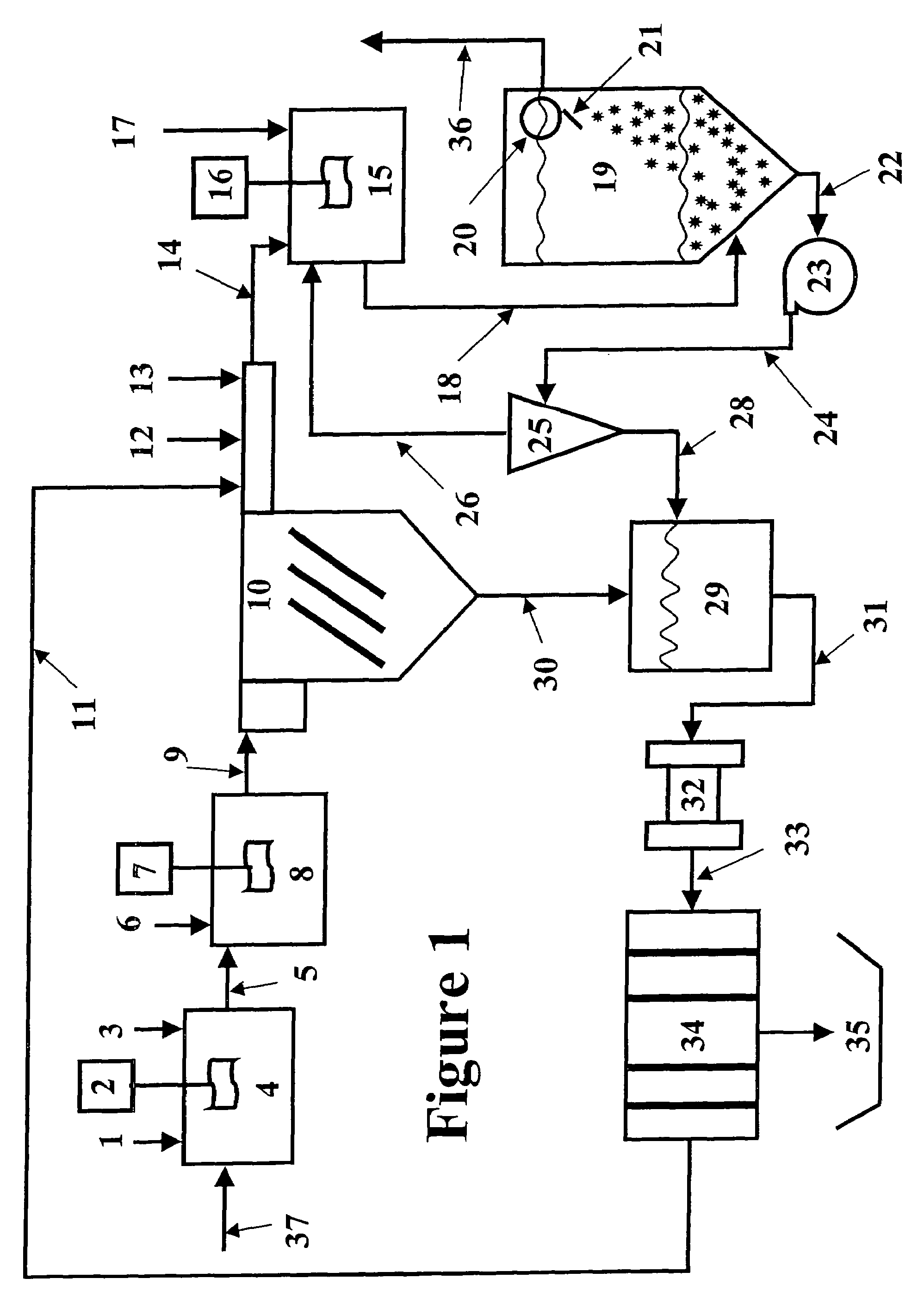

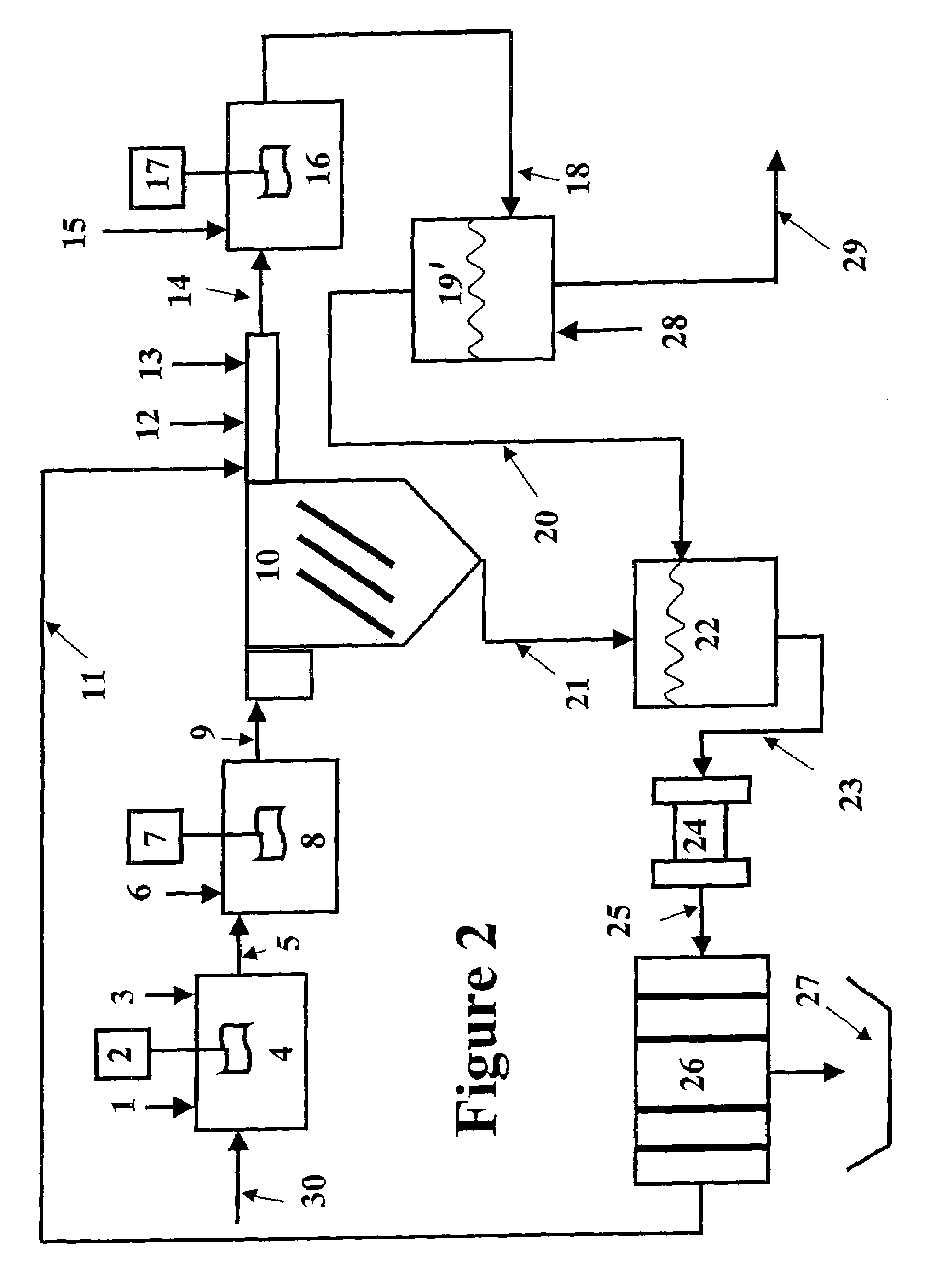

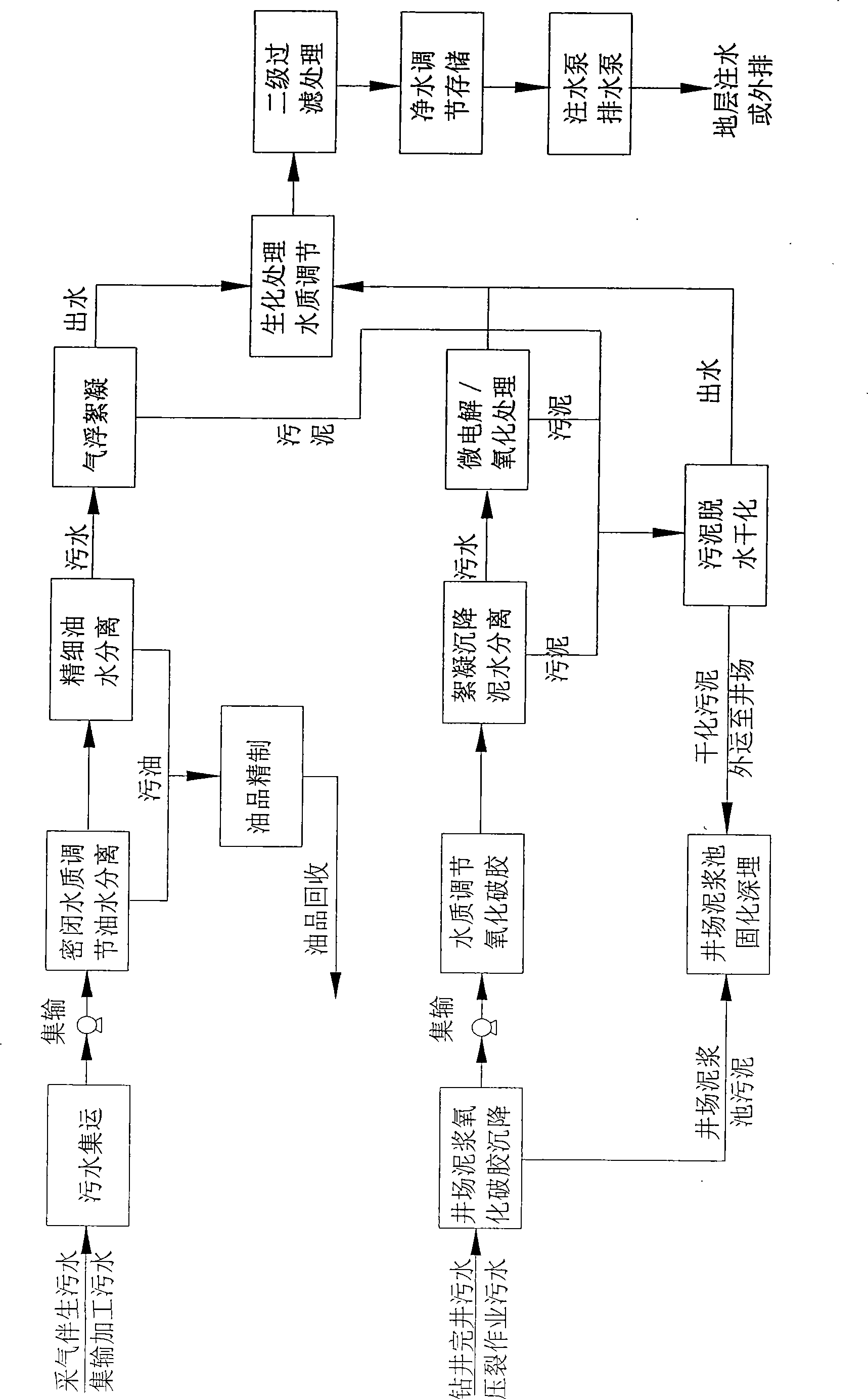

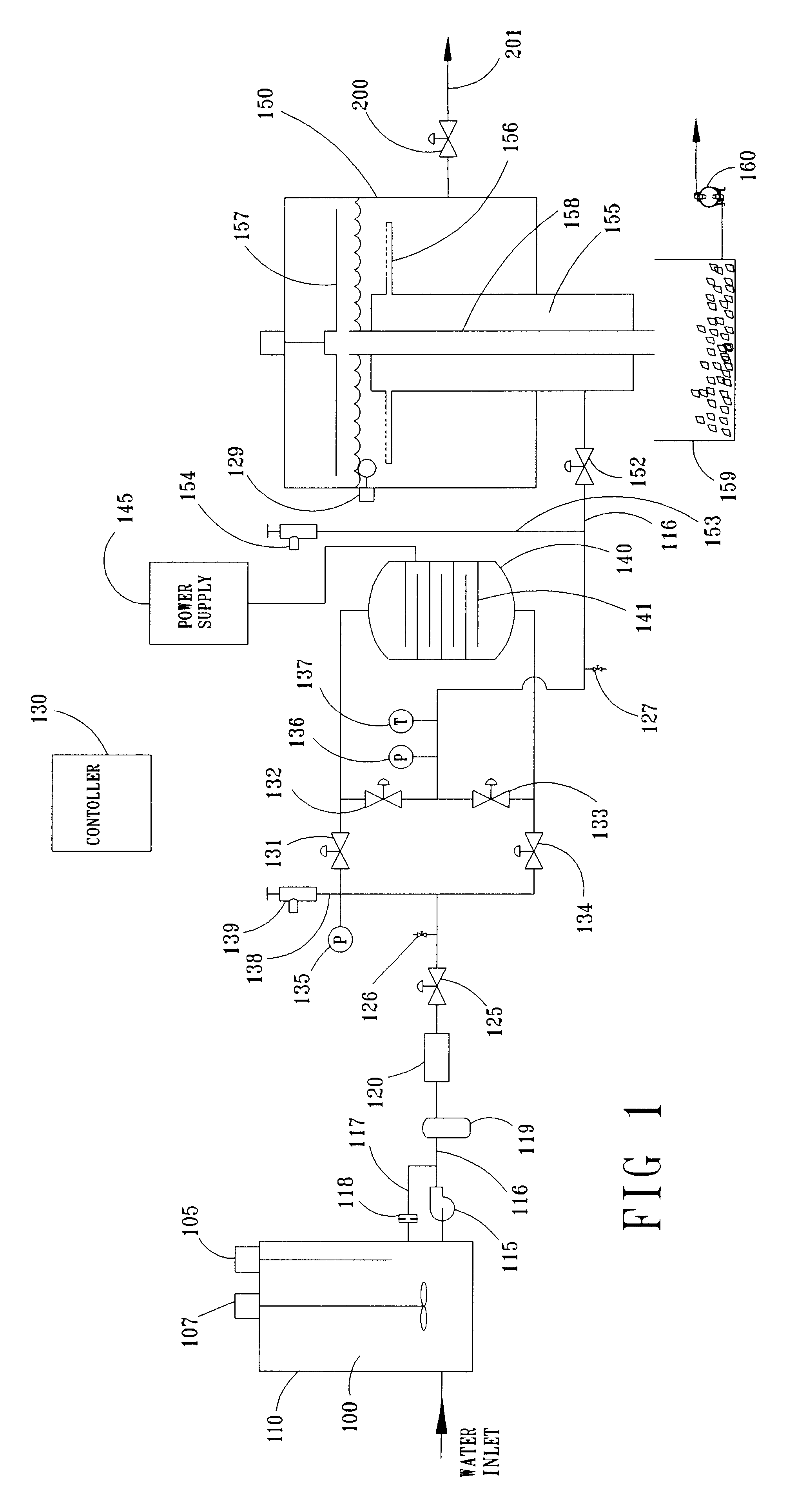

Control system and process for wastewater treatment

InactiveUS20080047903A1Effective positioningEasy to drainWater treatment parameter controlFlow mixersControl systemWastewater

A system and process is provided for optimizing chemical additions, mixing energy, mixing time, and other variables while treating a contaminated liquid stream. Samples from the contaminated liquid stream are tested to determine the optimal parameter for each variable, including type and amount of the chemicals to be added, chemical sequence, mixing energy, mixing time, temperature, and pressurization. A system of mixers, a flotation chamber, and a dewatering subsystem are designed to achieve optimal turbidity of the wastewater stream. The system can be modified in real-time in response to a continually changing contaminated liquid stream via a controller and set of sensors, valves, and ports.

Owner:WORLD WATER TECH

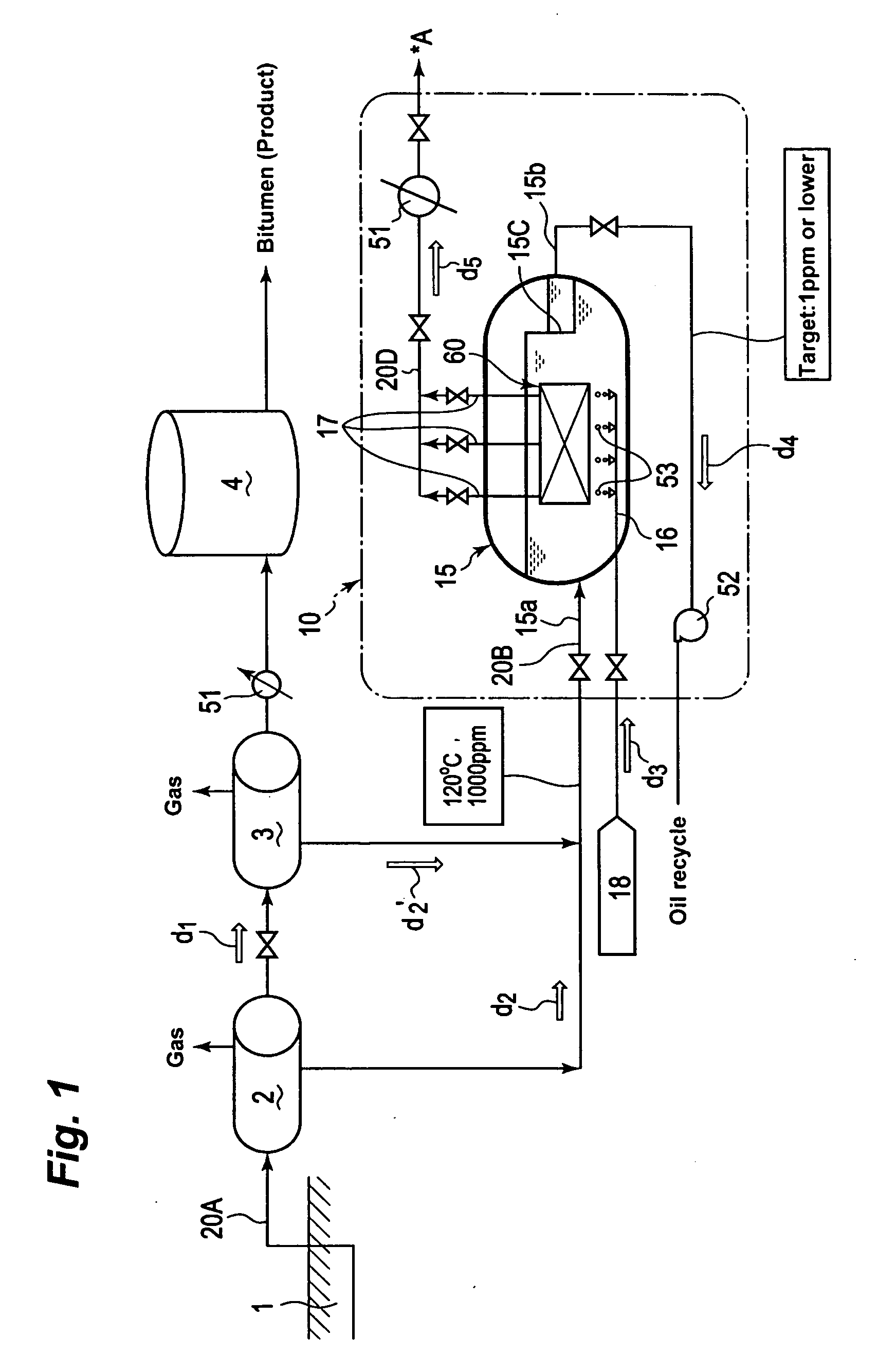

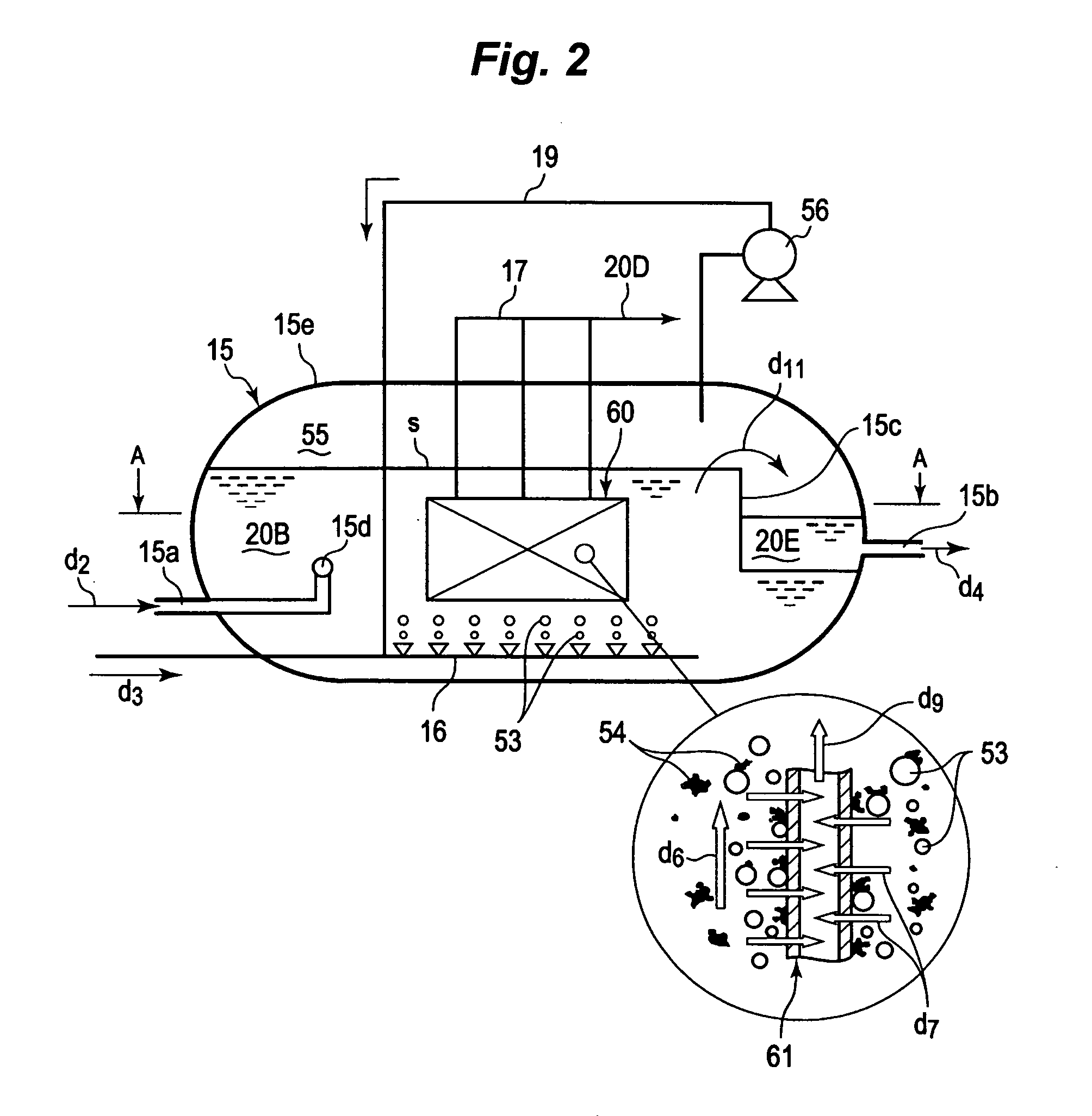

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

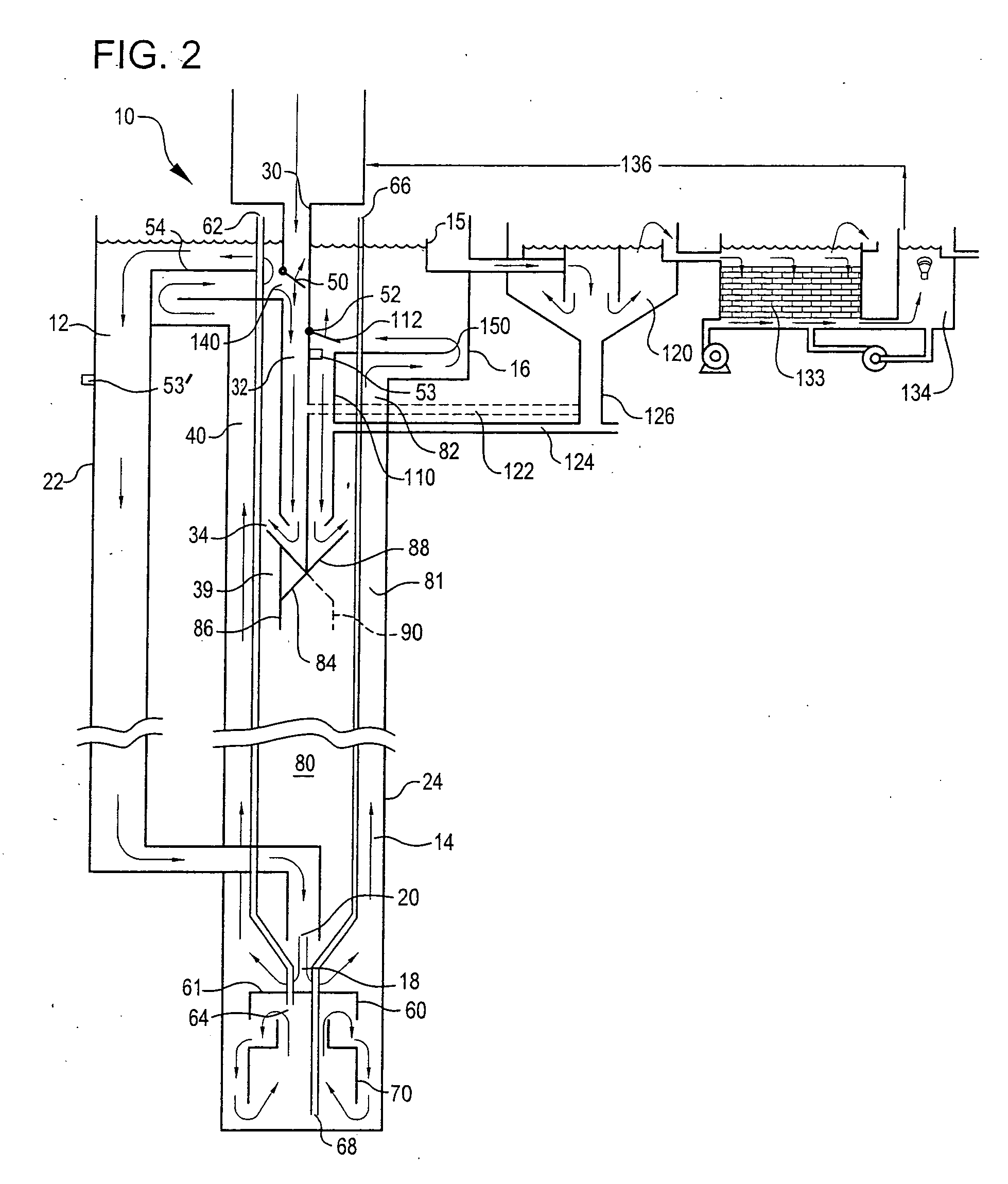

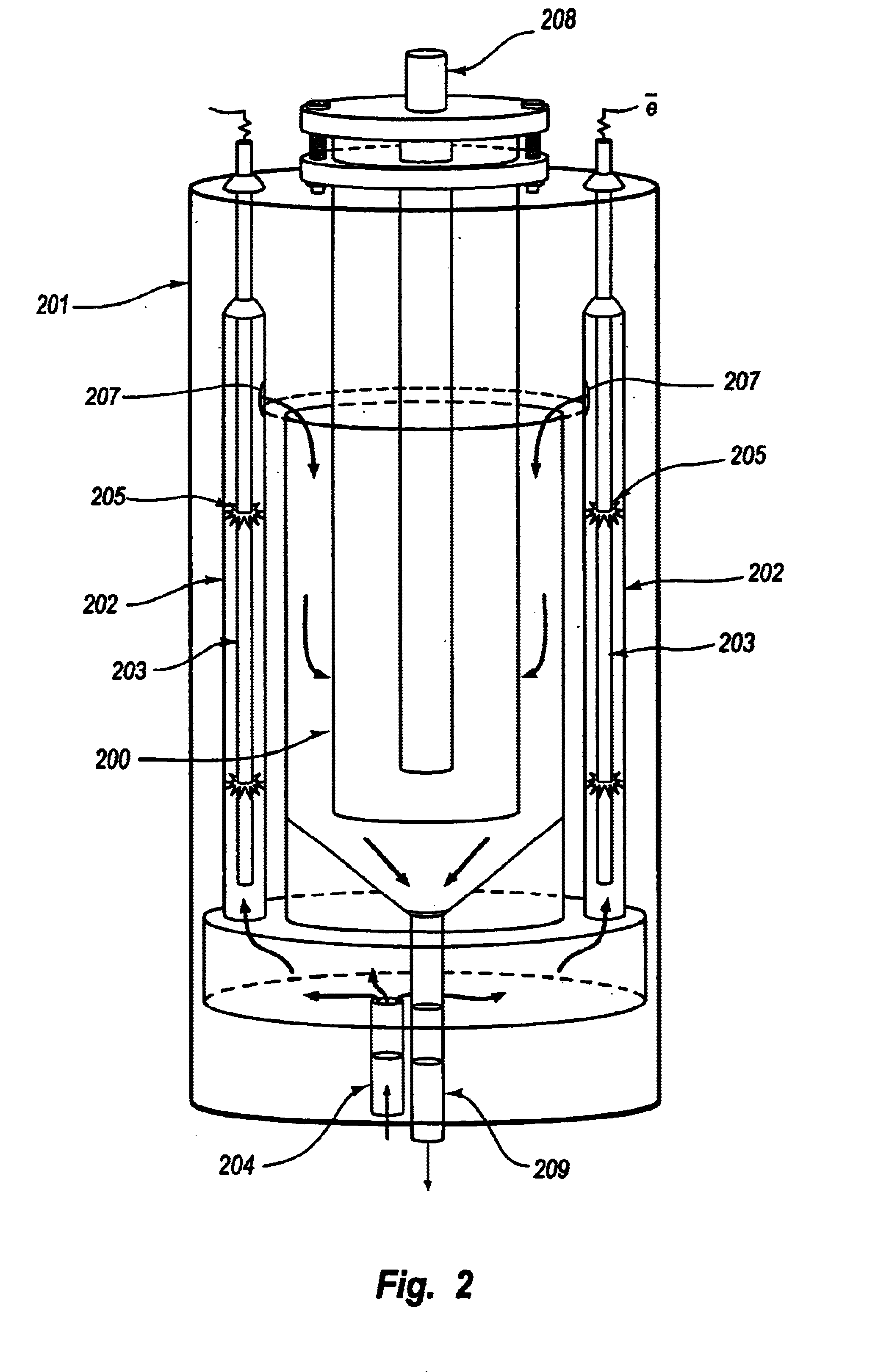

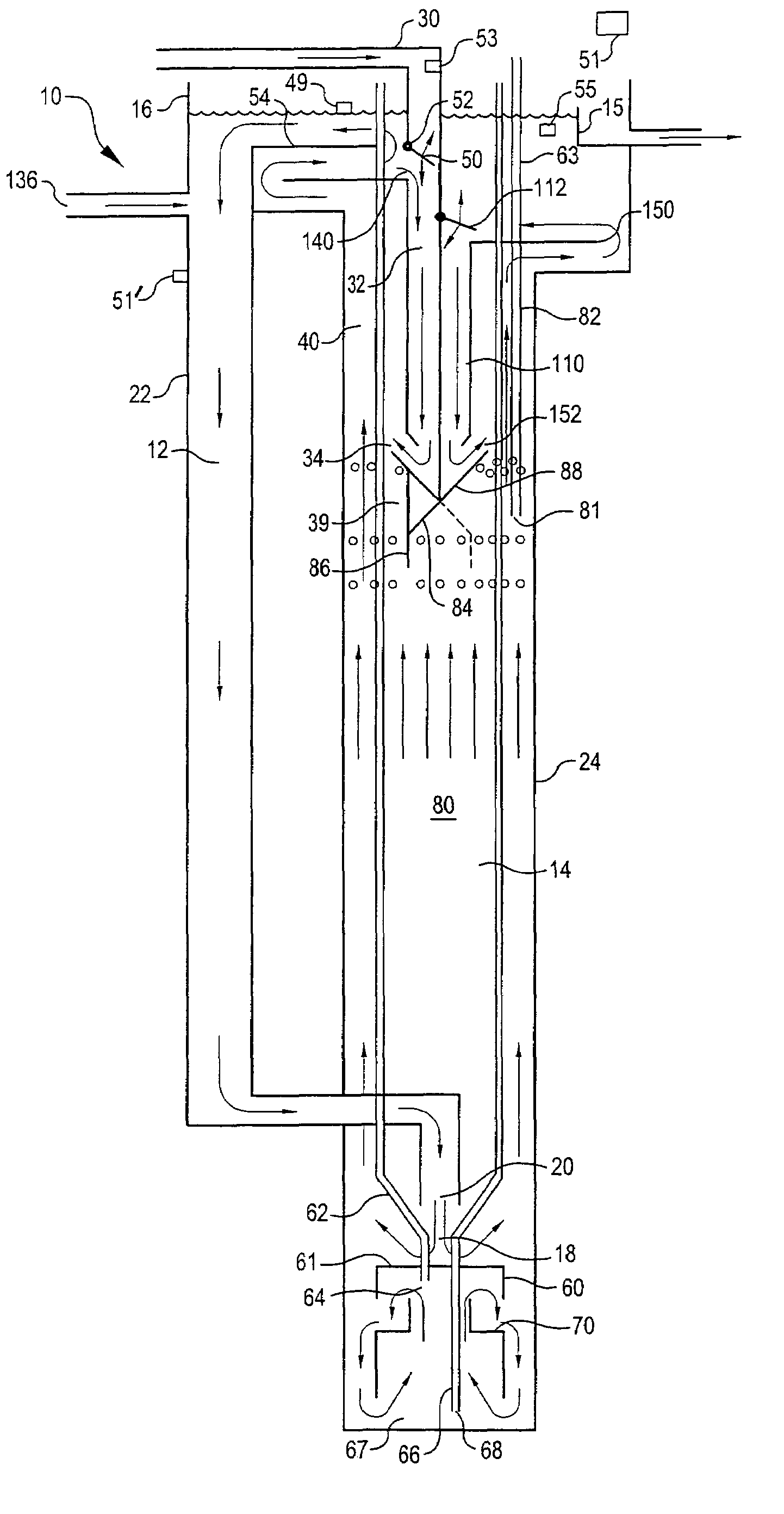

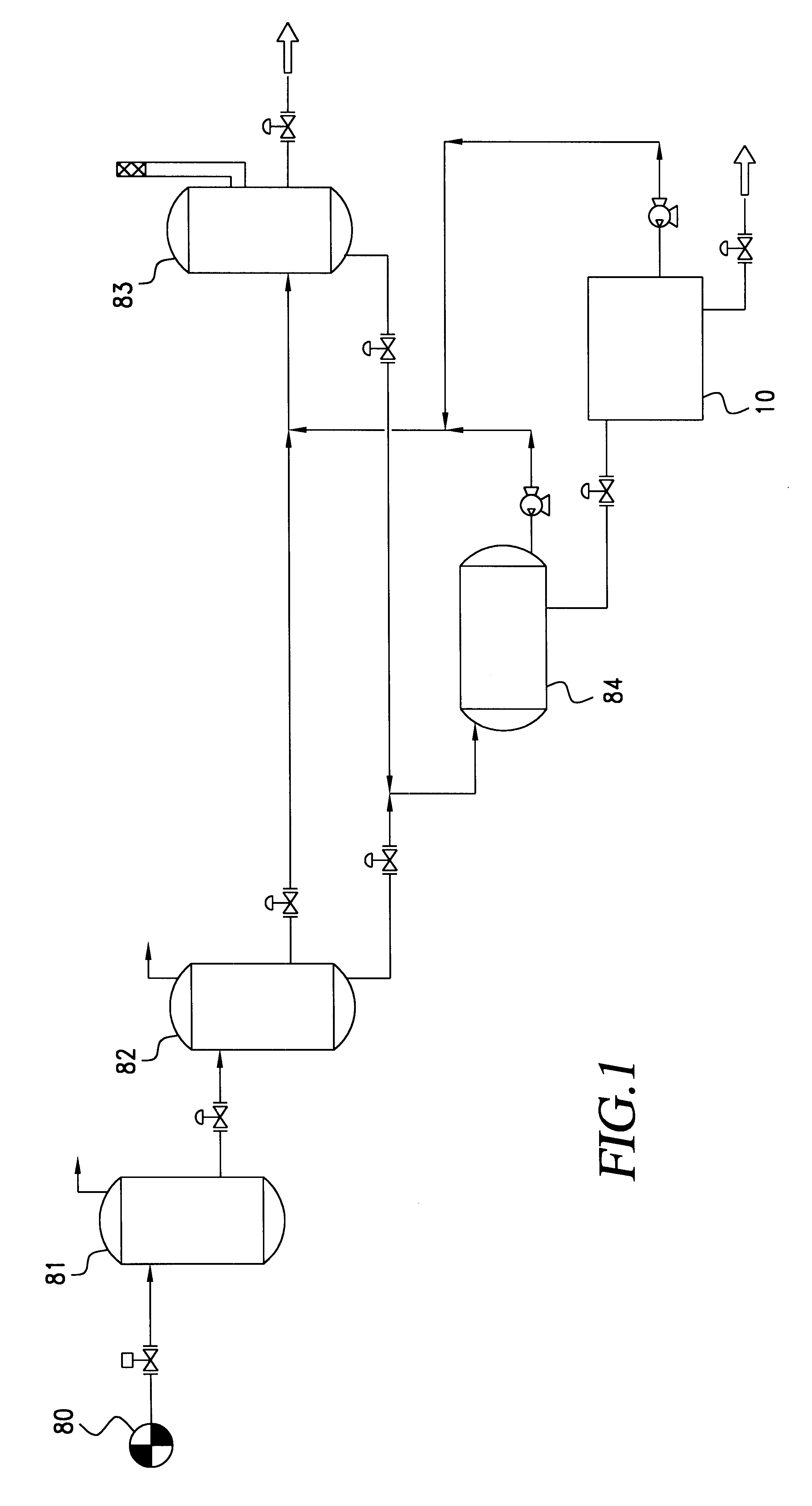

Methods and apparatus for biological treatment of waste waters

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

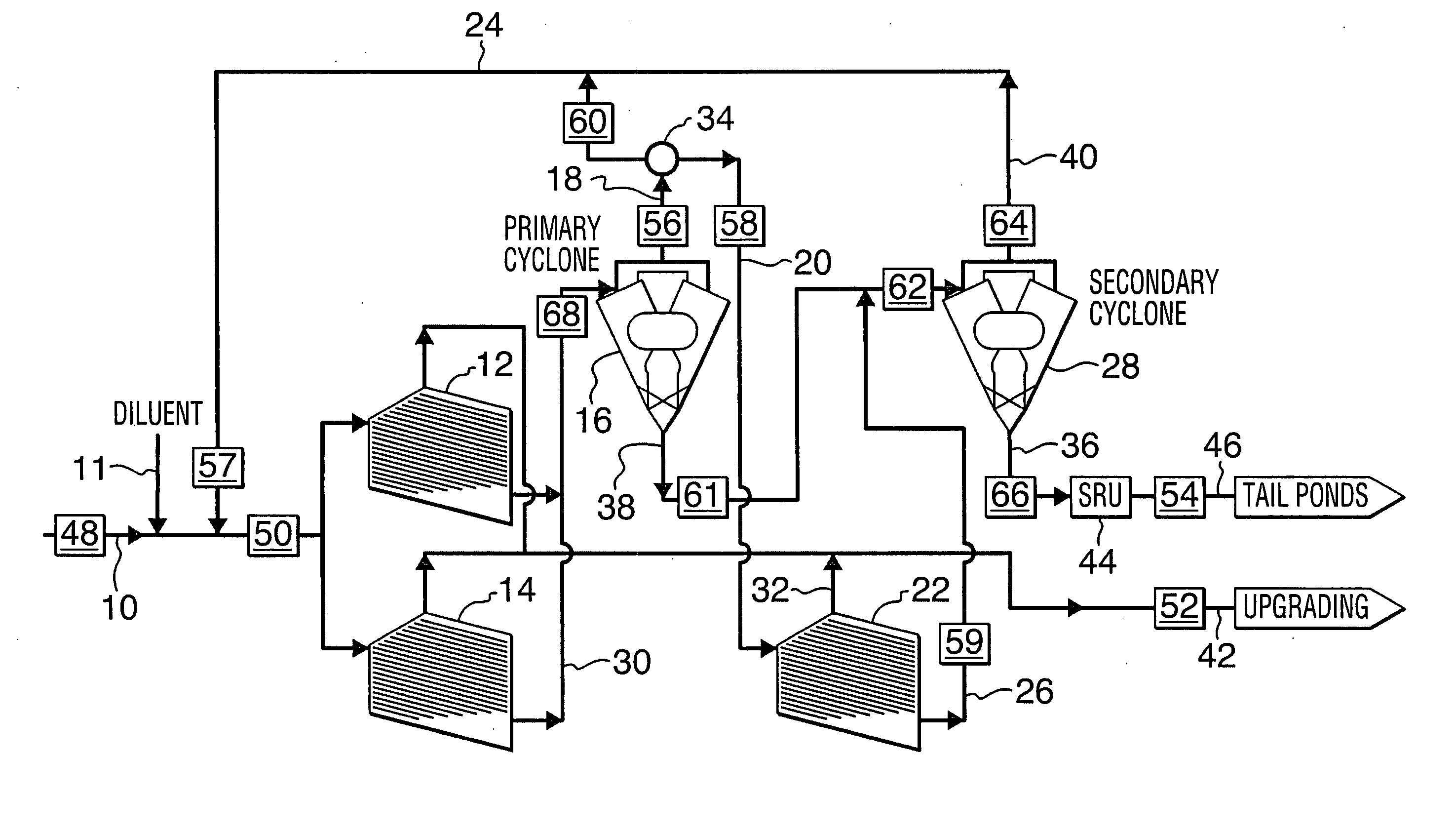

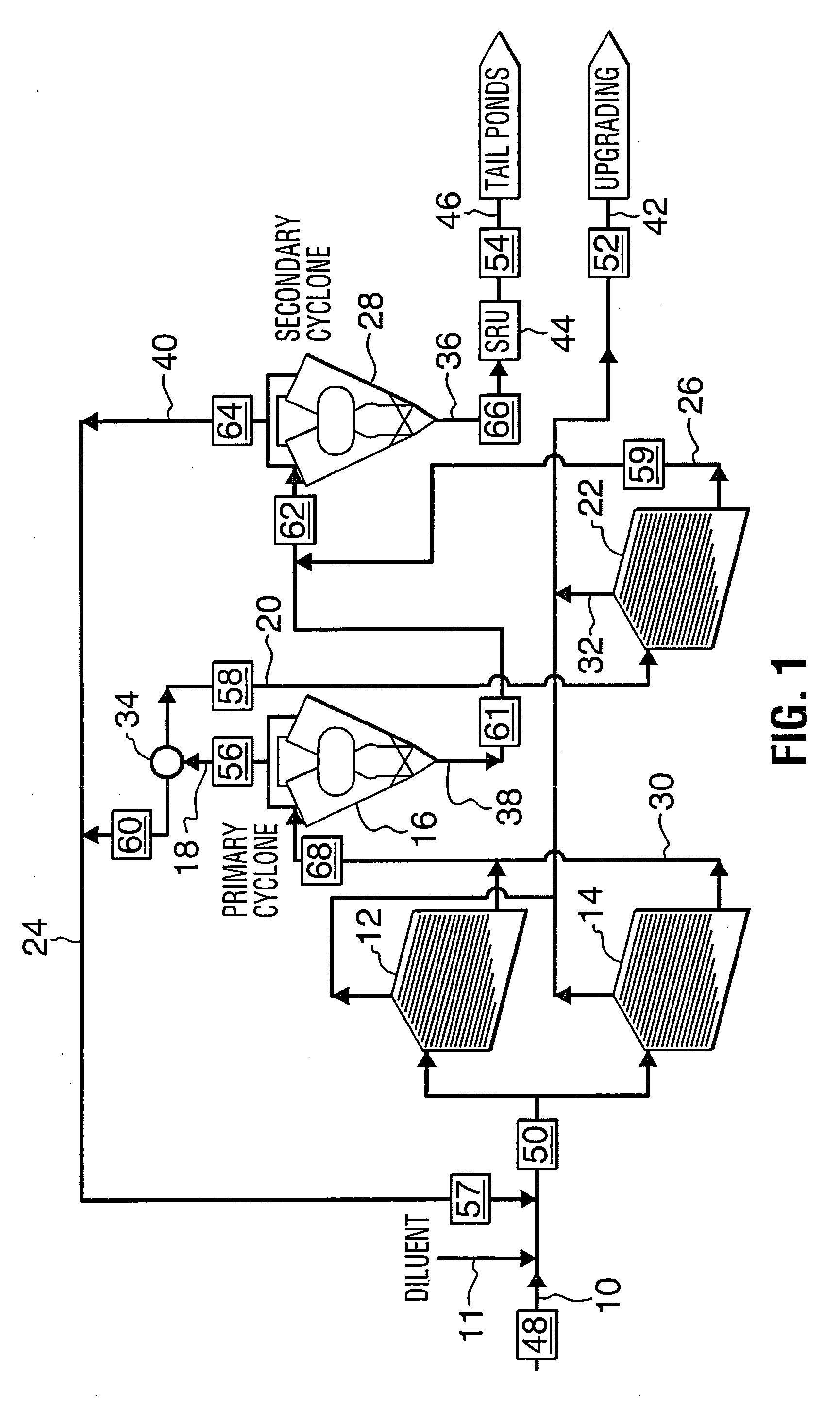

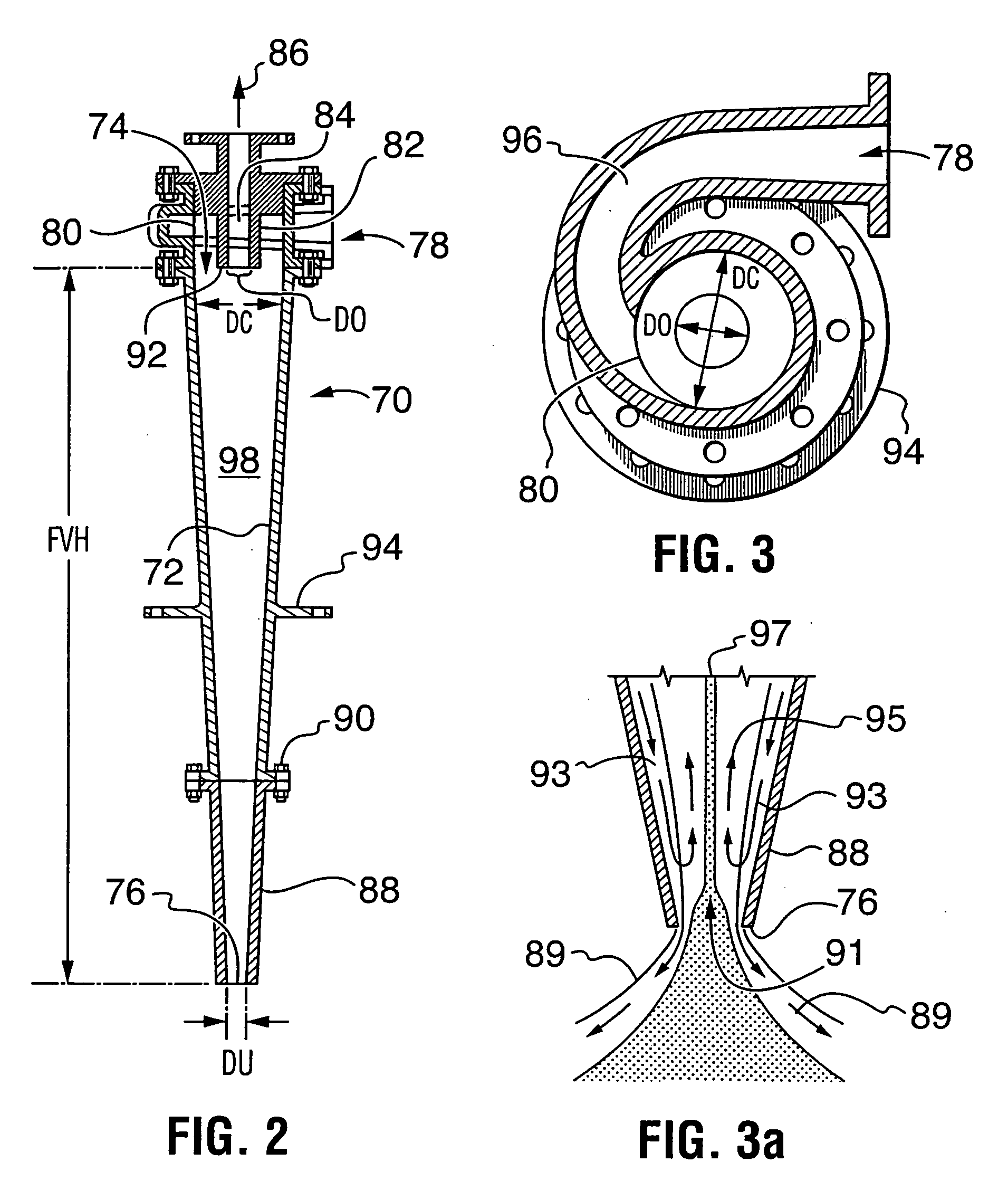

Bituminous froth hydrocarbon cyclone

InactiveUS20060138055A1Poor separationEasy to separateReversed direction vortexCentrifugal force sediment separationCycloneHydrocotyle bowlesioides

An apparatus to perform a process to remove water and minerals from a bitumen froth output of a oil sands hot water extraction process comprises: (i) a cyclone body having an elongated conical inner surface defining a cyclone cavity extending from an upper inlet region with a diameter DC to a lower apex outlet with a diameter DU; (ii) an inlet means forming an inlet channel extending into the upper inlet region of the cyclone cavity; and (iii) a vortex finder forming an overflow outlet of a diameter (DO) extending into the upper inlet region of the cyclone cavity toward the lower apex outlet and having a lower end extending an excursion distance below the inlet channel; wherein a fluid composition entering the inlet channel into the cyclone cavity is urged by force of gravity and velocity pressure downward toward the lower apex and variations in density of the constituent components of the fluid composition cause the lighter component materials to be directed toward the overflow outlet of the vortex finder.

Owner:GARNER WILLIAM NICHOLAS +2

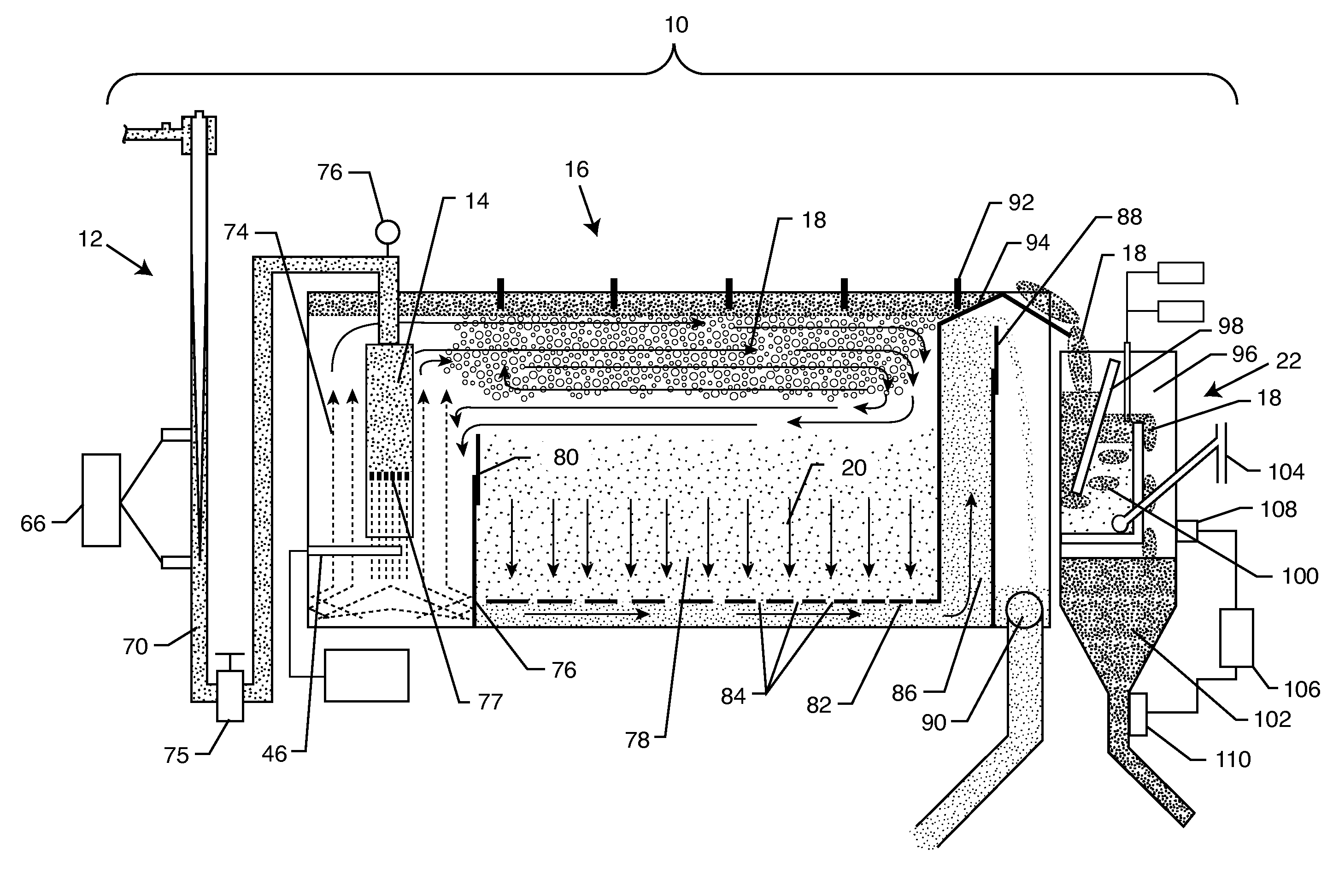

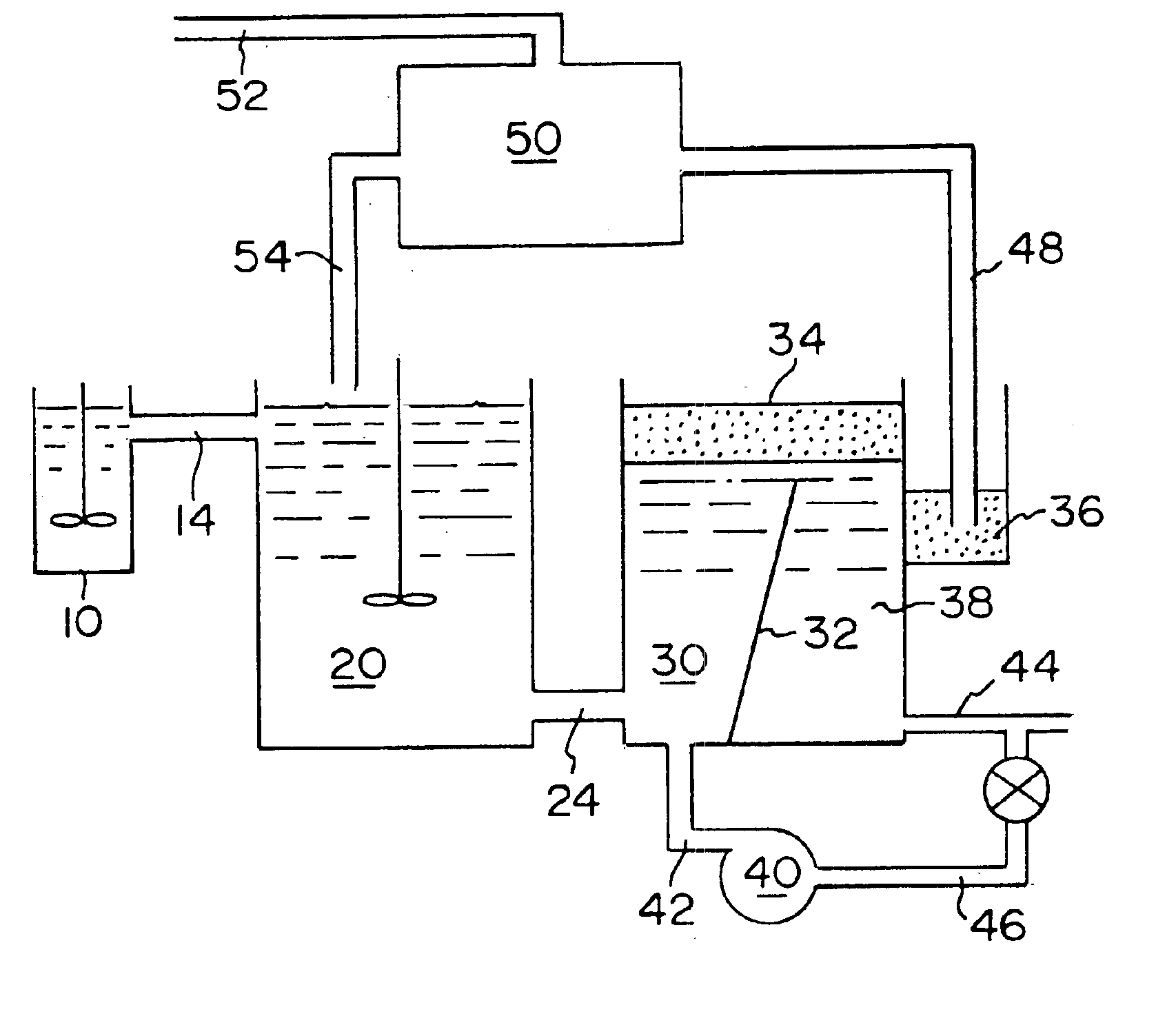

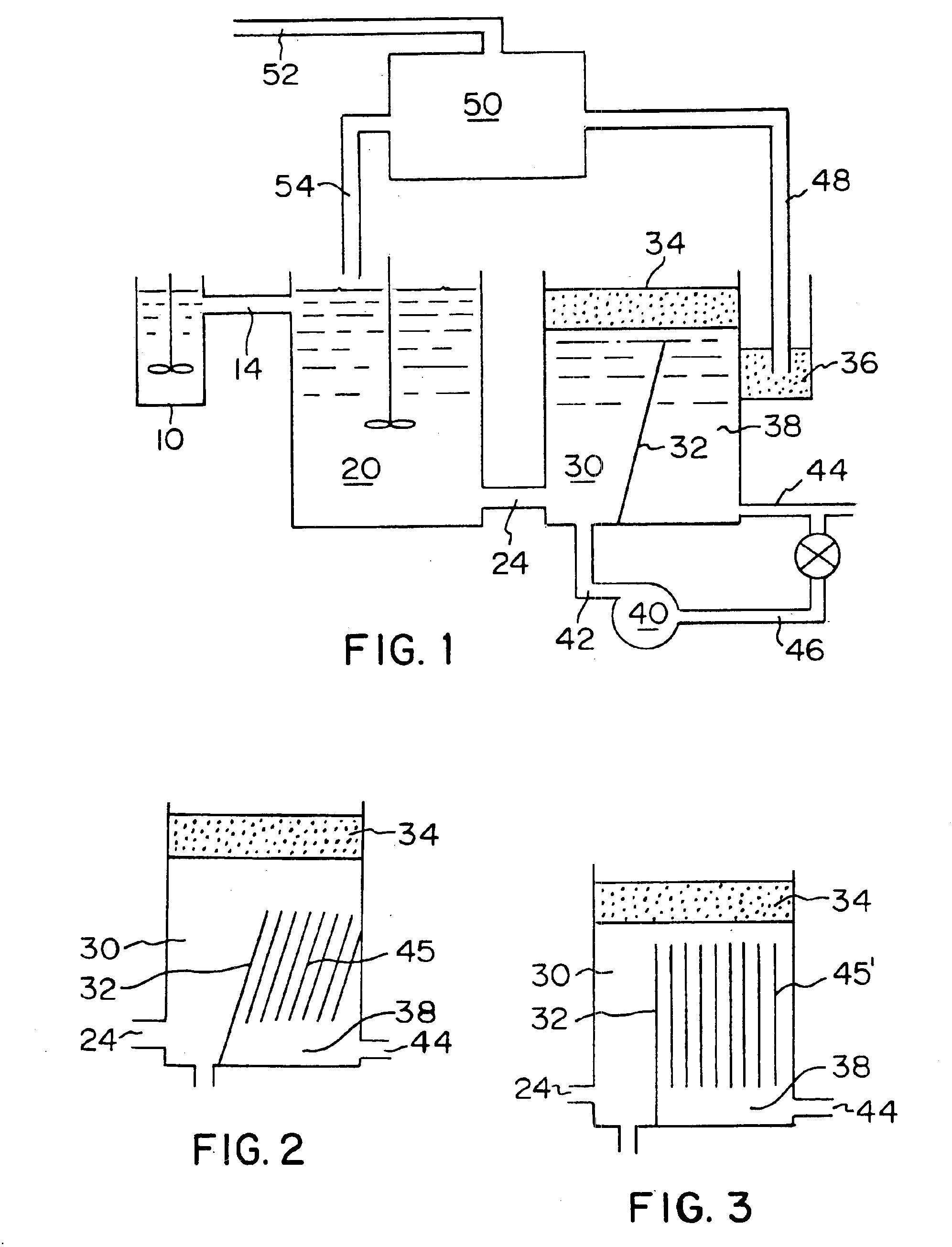

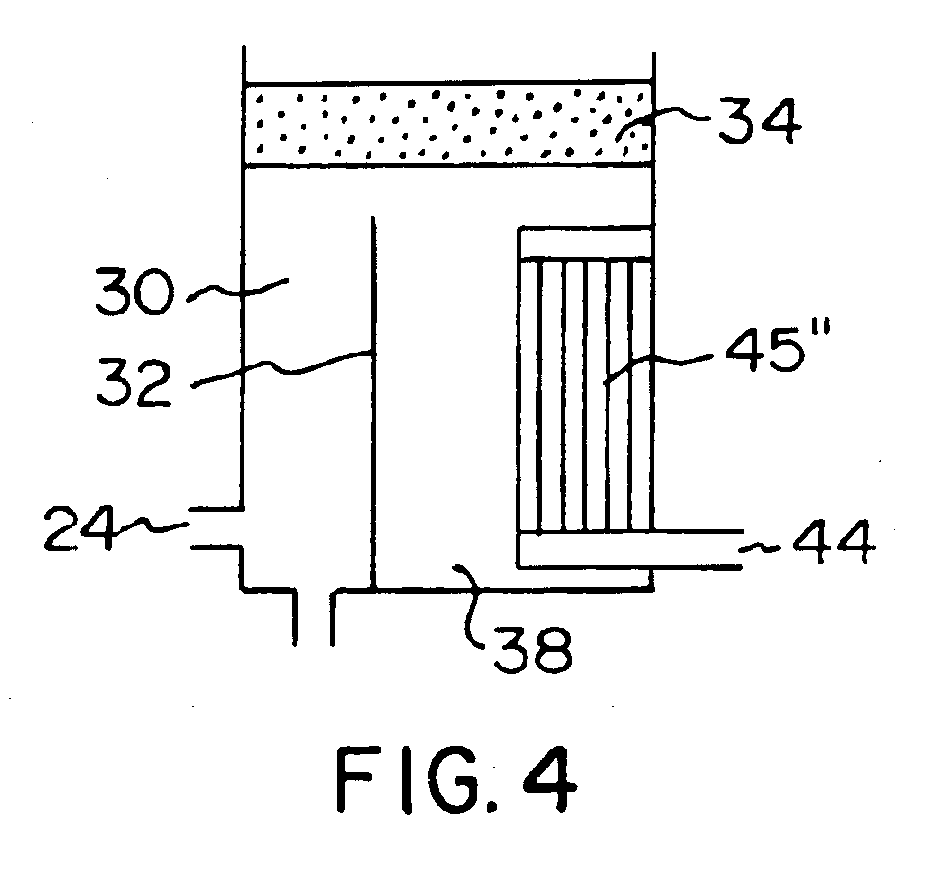

Buoyant media flotation

InactiveUS6890431B1Less energyLower the volumeOther chemical processesSolid sorbent liquid separationEngineeringBuoyancy

A clarification system for fluids in which particles are separated from the fluid by flotation and in which the buoyant media inducing the flotation is recycled. Flotation can be assisted by a flotation assistance device, such as dissolved air flotation.

Owner:XYLEM WATER SOLUTIONS ZELIENOPLE LLC

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS7255793B2Cost- and chemically-effectiveSedimentation separationWater/sewage treatment by neutralisationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

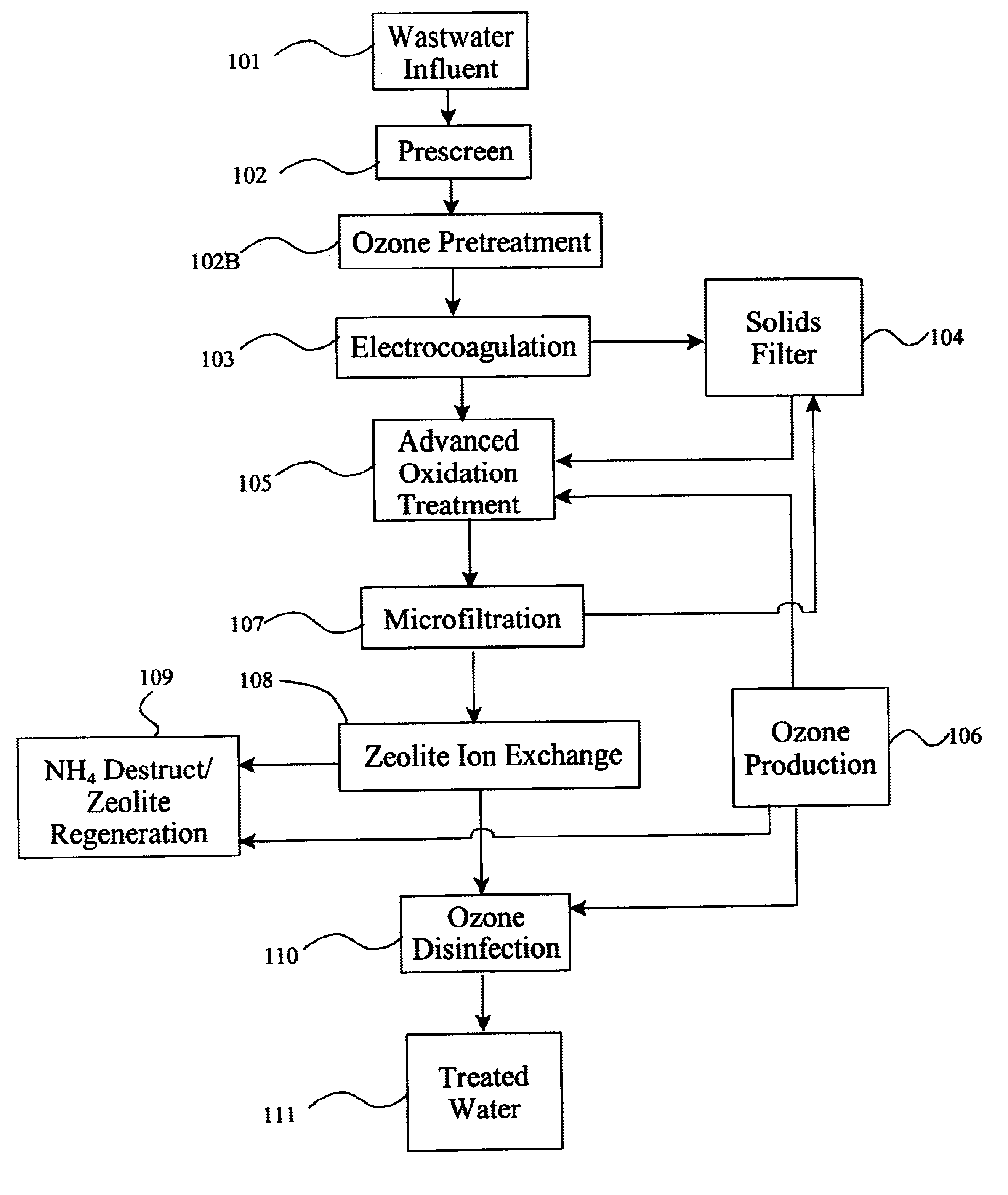

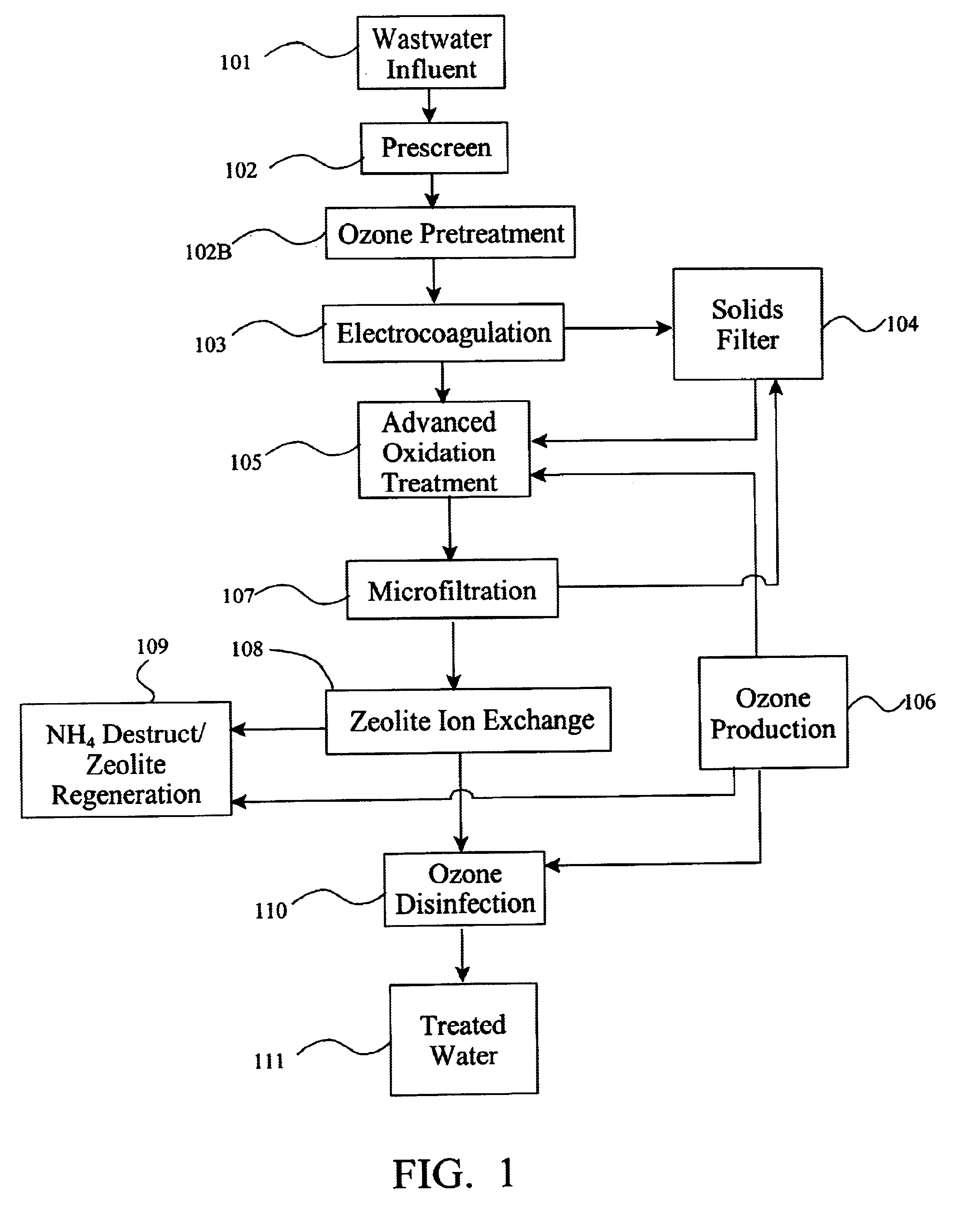

Leachate and wastewater remediation system

InactiveUS6960301B2Effective amount of reactionMany difficultyLiquid separation by electricityFlow mixersAdvanced oxidation processFiltration

A compact portable modular wastewater treatment system which integrates several processing technologies to provide a substantially purified water source. A wastewater stream is sent through an initial filtration step. The filtered wastewater is then subjected to electrocoagulation and then further filtered. The resulting stream containing substantially only organics is then treated in an advanced oxidation process which can include passing an electrical current through the water during the oxidation process. The partially treated water is then passed through ion-exchange columns to polish ammonium and other contaminants. The ion-exchange columns are cycled through regeneration cycles to provide continuous ion-exchange medium. The ammonium rich brine solution used in regeneration is subjected to an ammonium destruct process and then reused in regenerating ion-exchange columns. The water can then be sent through a final disinfection oxidation process to destroy or inactivate pathogens and / or remove any remaining colorants or odor to provide a water source suitable for almost any use.

Owner:NEW EARTH SYST

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS6896815B2Small sizeChemical cost reductionSolid sorbent liquid separationGold compoundsWater useSludge

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation” technology such as magnetic separation, dissolved air flotation, vortex separation or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment.

Owner:CORT STEVEN L

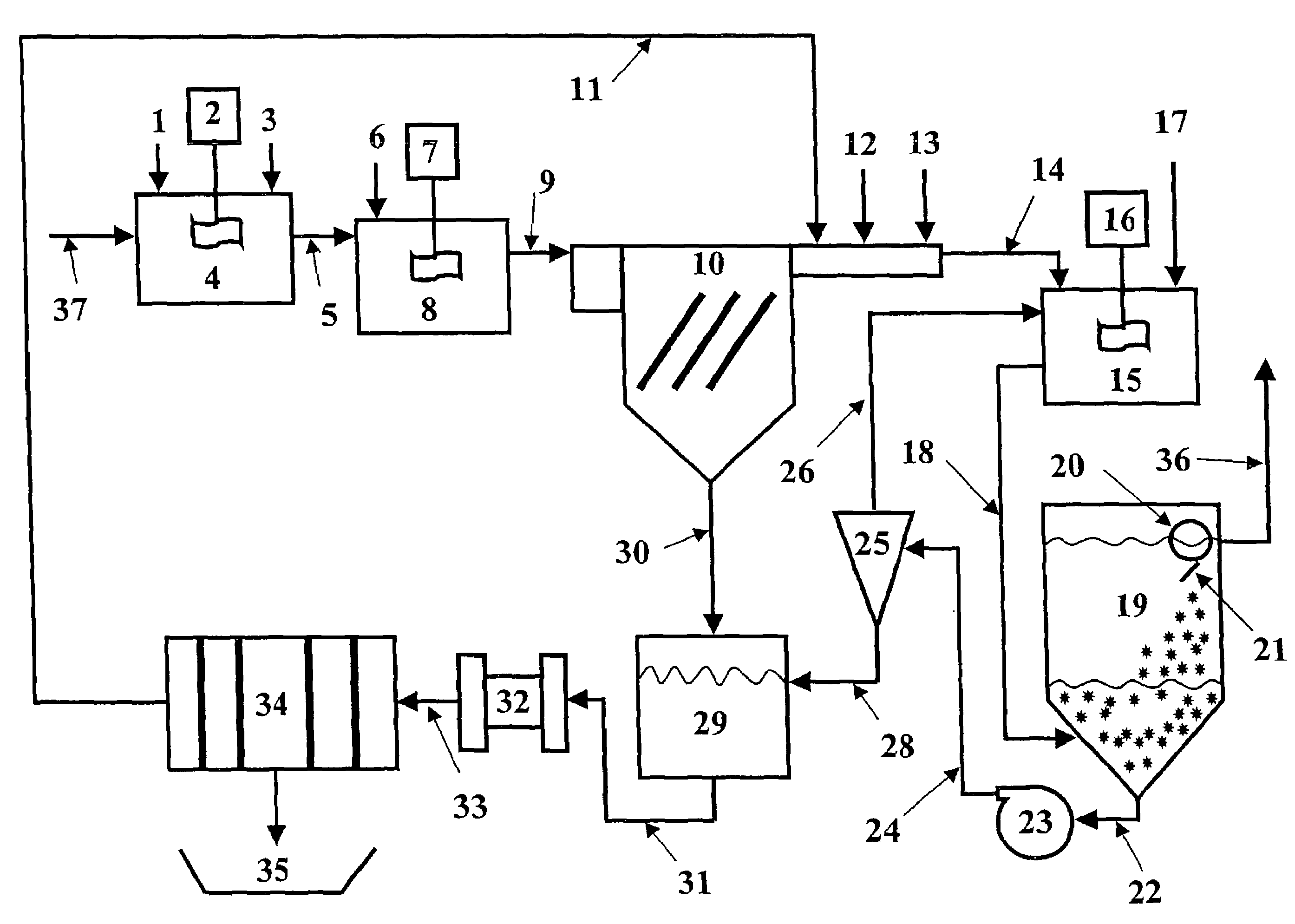

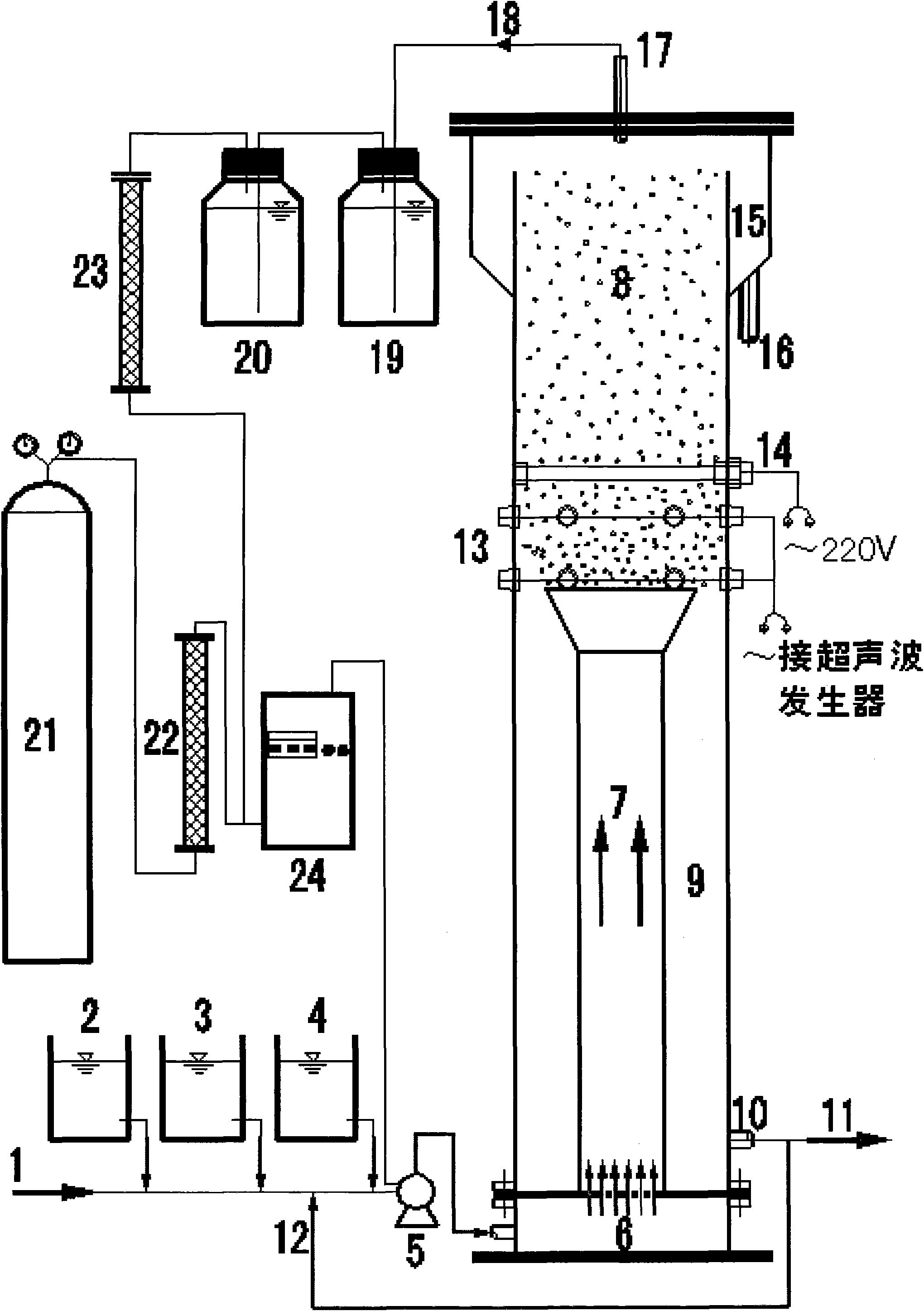

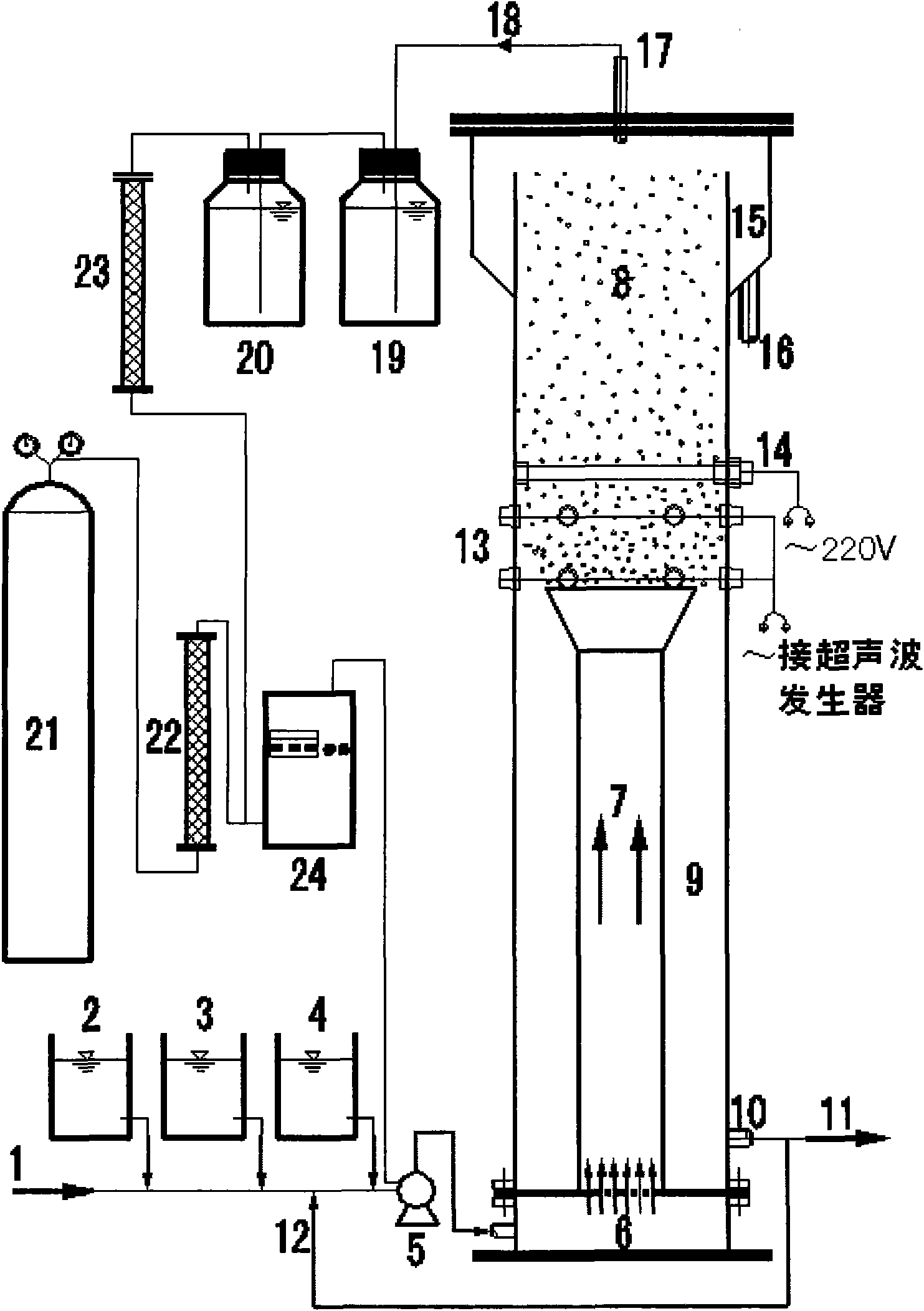

Novel multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower

ActiveCN102115253AReduce pollutionImprove efficiencyWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsOzone generatorActivated carbon

The invention belongs to a multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower mainly aiming at the treatment of refractory industrial wastewater. Influent (1) and O3 generated by an ozone generator (24) are injected into a water distribution cabin through a dissolved gas pump (5) and enter a micro-bubble release contact area (7) through a pore plate to release dissolved gas; Liquid which contains slag flows upwards and enters a floating slag separation area (8), liquid which contains no slag flows downwards and enters a gas-liquid separator (9), one part of effluent (10) is drained from a drain hole (11), and one part of the effluent (10) is refluxed to a dissolved gas pump intake pipe (12); an ultrasonic vibrator (13) and an ultraviolet light source (14) provide an ultrasonic and ultraviolet synergetic catalysis action; floating slag overflows to a collecting groove (15) and is drained through a drain hole (16); and a coagulant, powder activated carbon and hydrogen peroxide are added by adding systems (2, 3, 4) to provide a coagulation action and the synergetic catalysis action of PAC (powdered activated carbon) and H2O2. Tail gas is refluxed to the ozone generator through a drain hole (17), a one-way valve (18), gas suction tanks (19 and 20) and a dryer (23). The oxidation tower is compact in structure and has high treatment efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

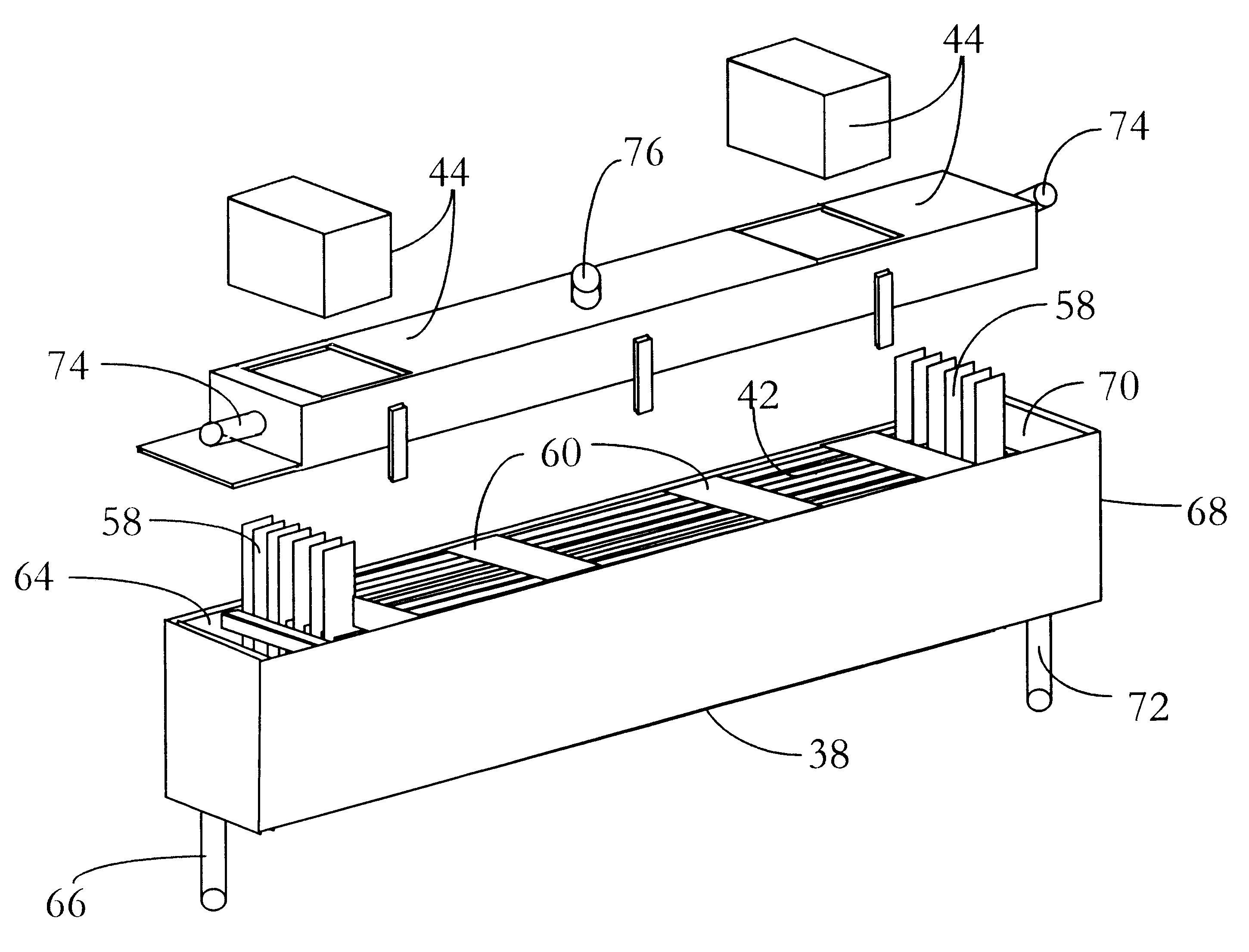

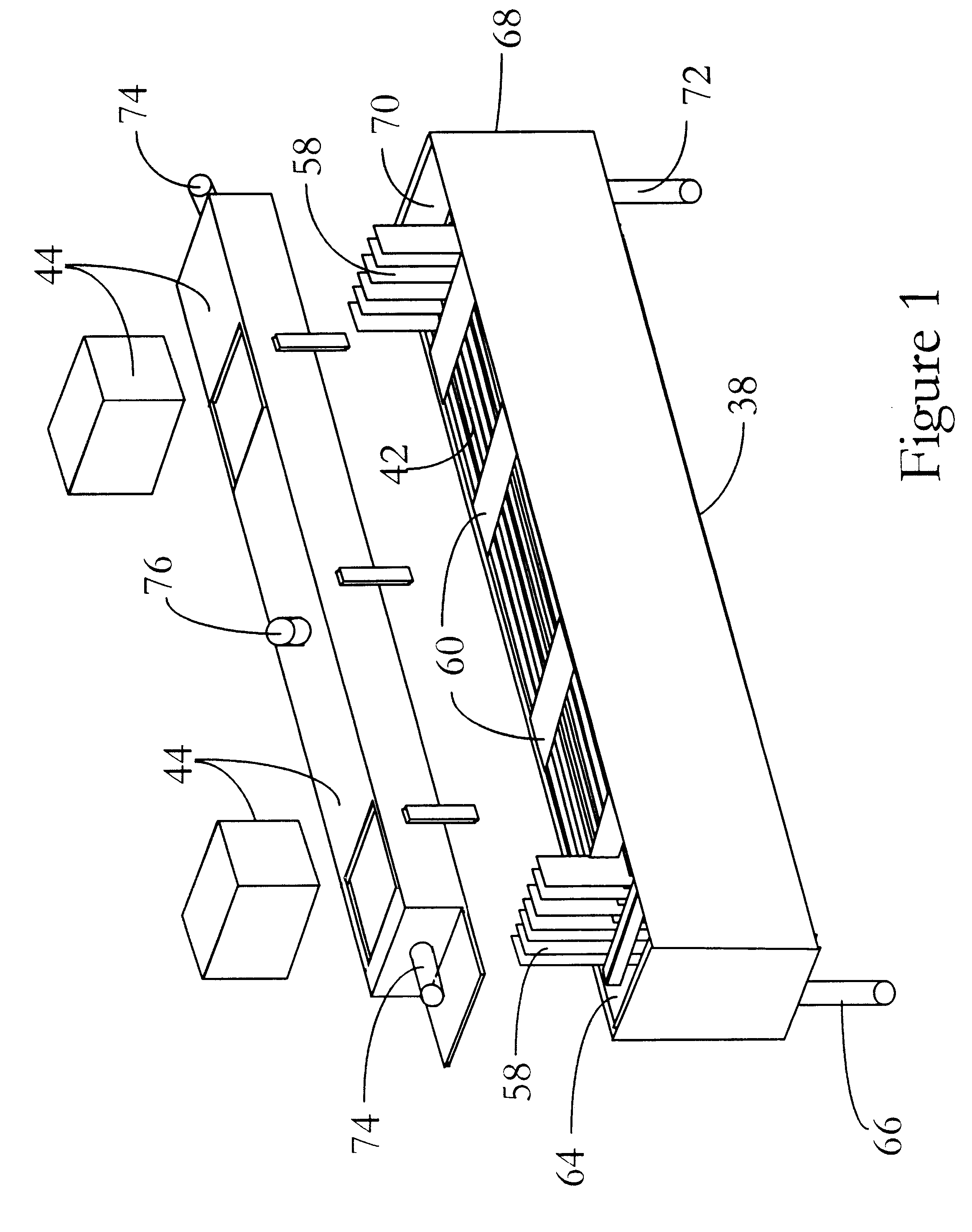

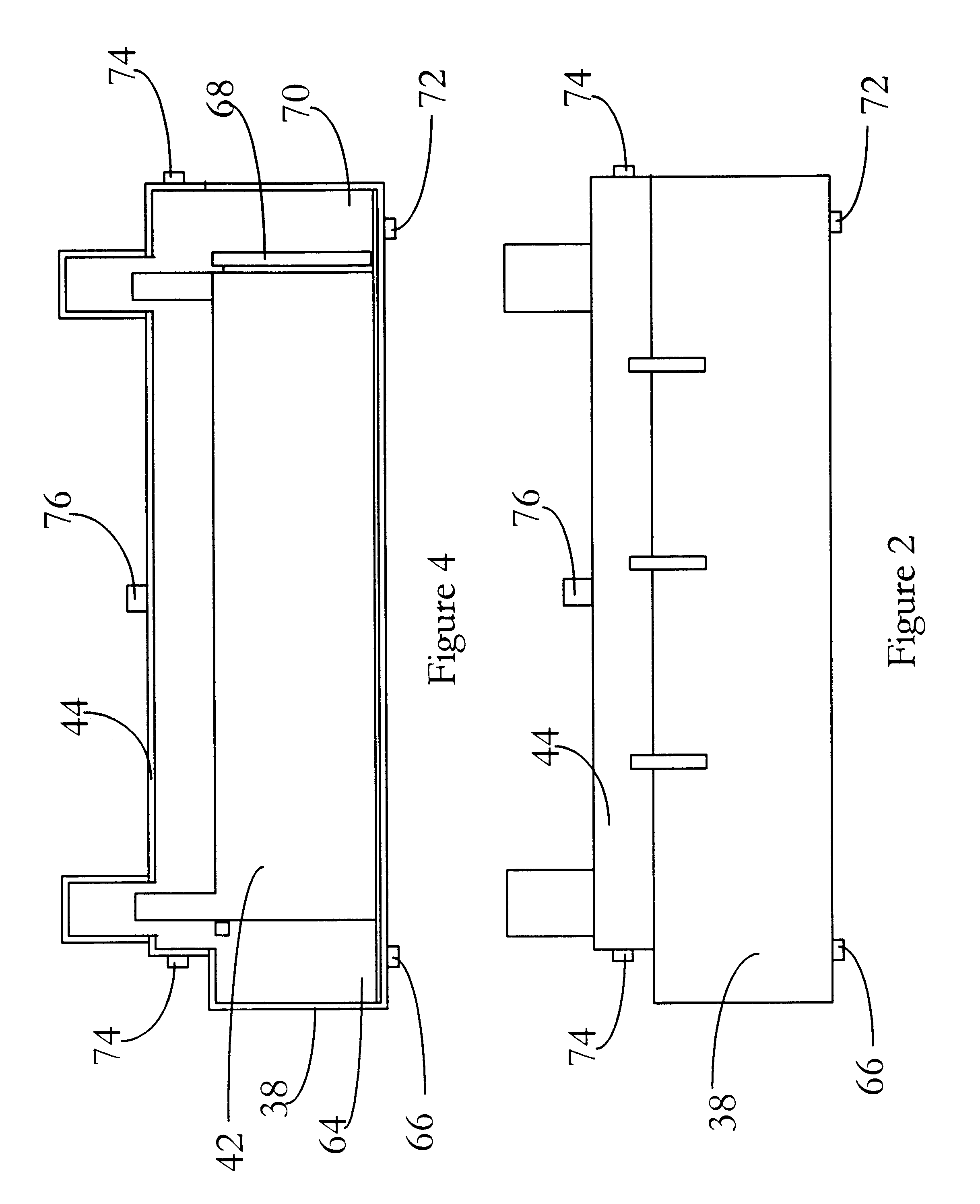

Electrocoagulation chamber and method

InactiveUS6613217B1Improve efficiencyLow costSludge treatmentElectrostatic separatorsElectrocoagulationEngineering

A stream of process liquid is treated while flowing through in a horizontally elongated chamber having an open top. Longitudinally elongated electrode blades are aligned with the longitudinal dimension of the chamber. An overhead disbursement chamber supplies a sweeping air stream over the open top of the chamber for removing foam and gas reaction by-products. The electrode blades are separated and held at a desired spacing by small portable guides located below and above the blades.

Owner:GILMORE F WILLIAM

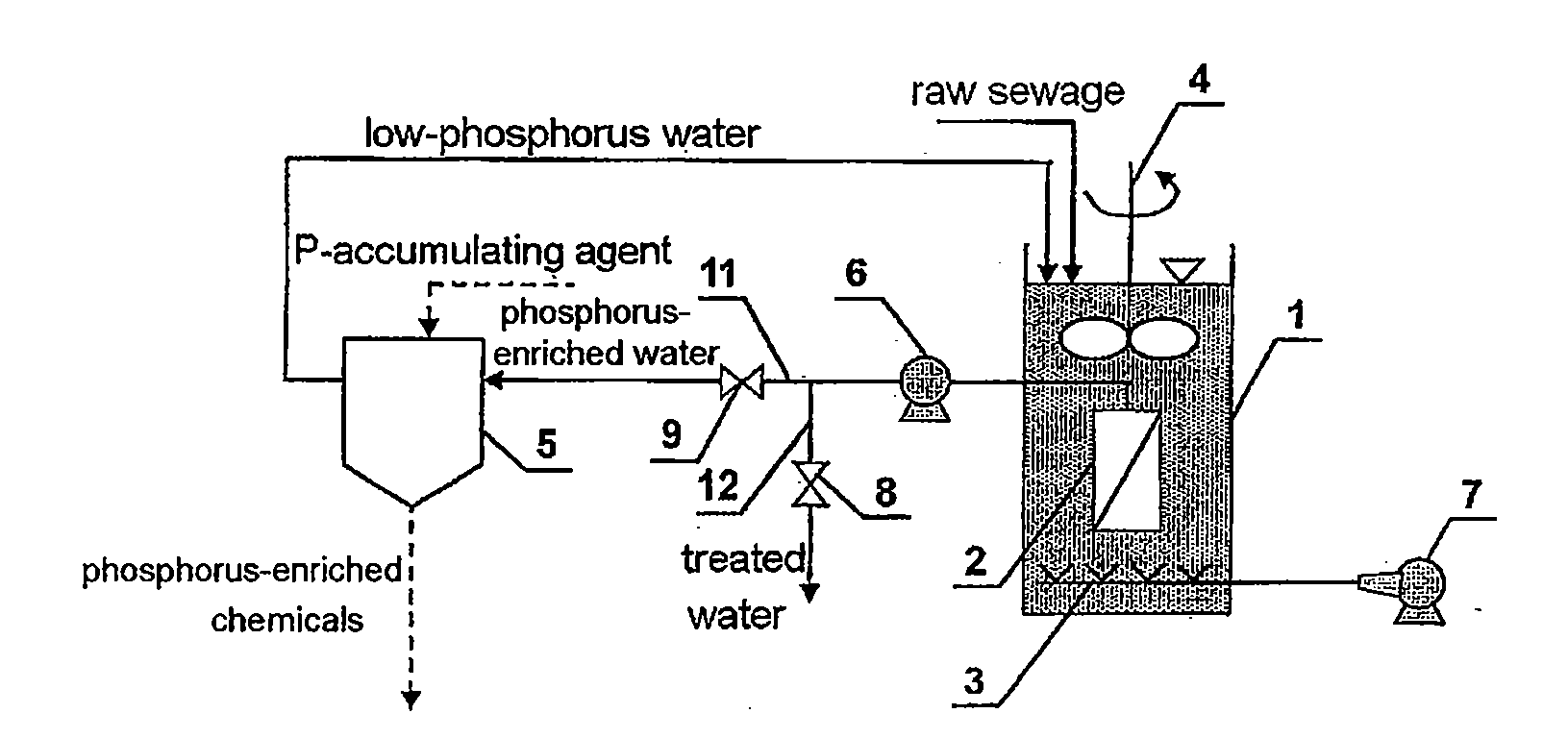

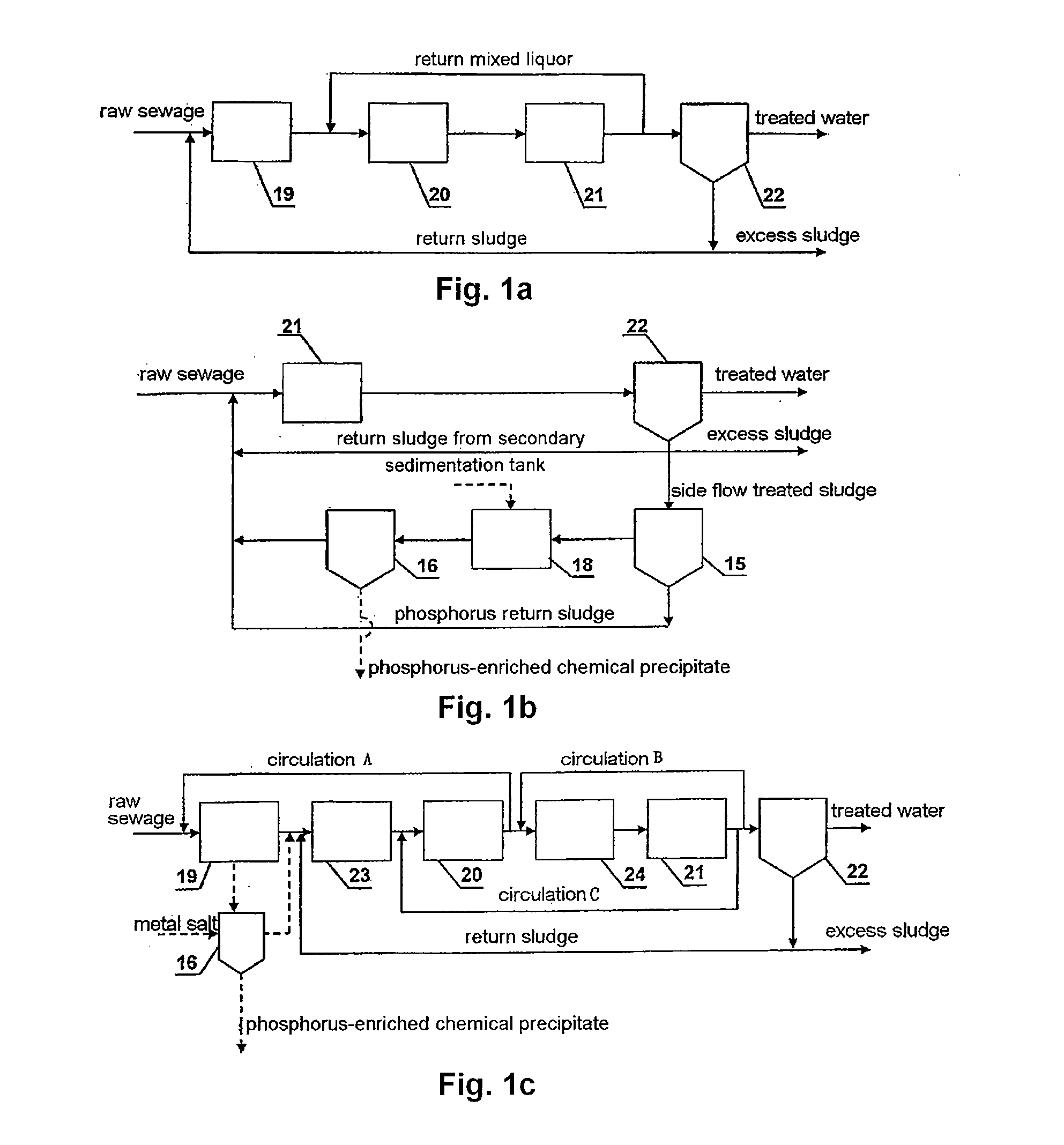

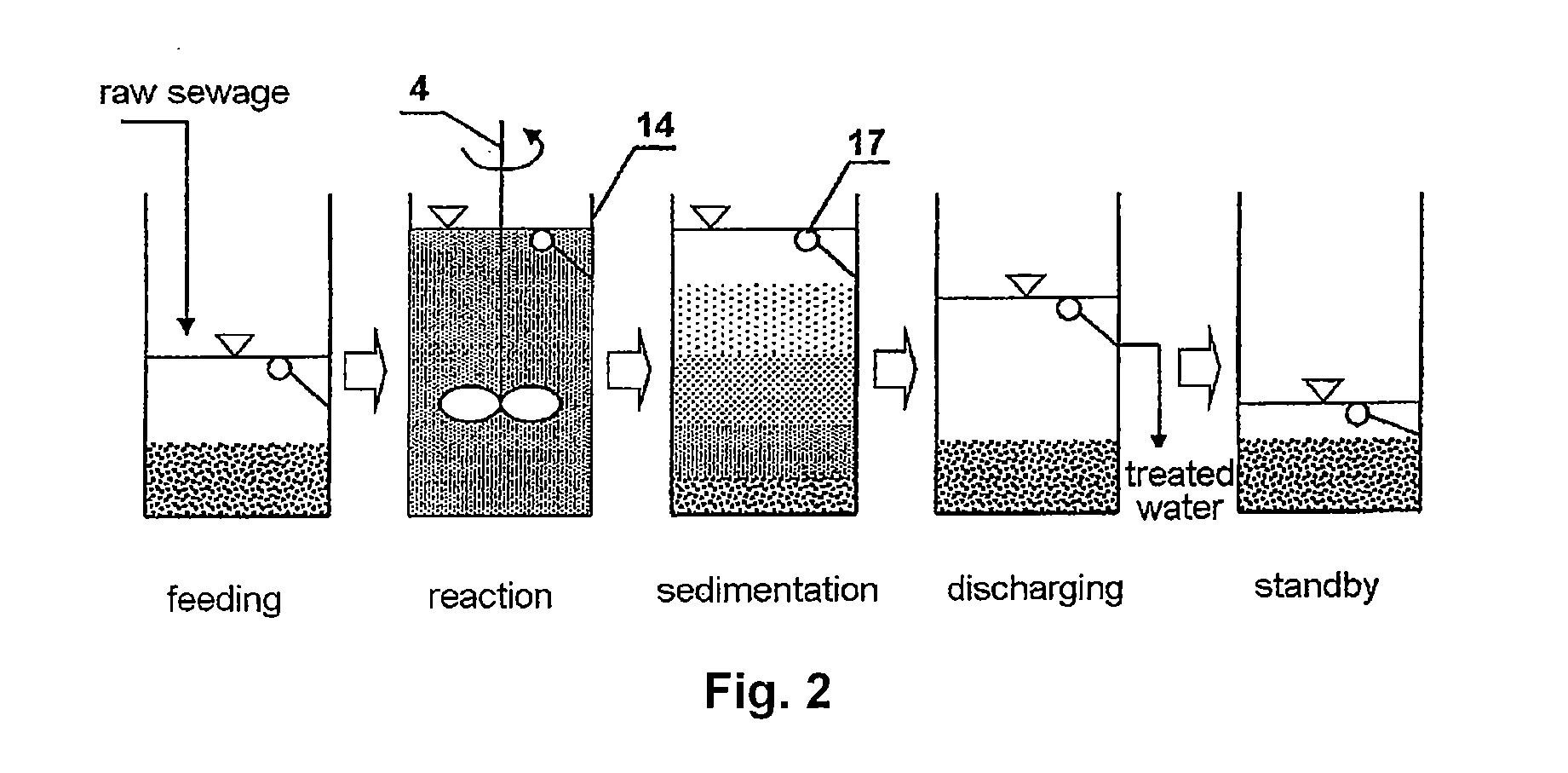

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

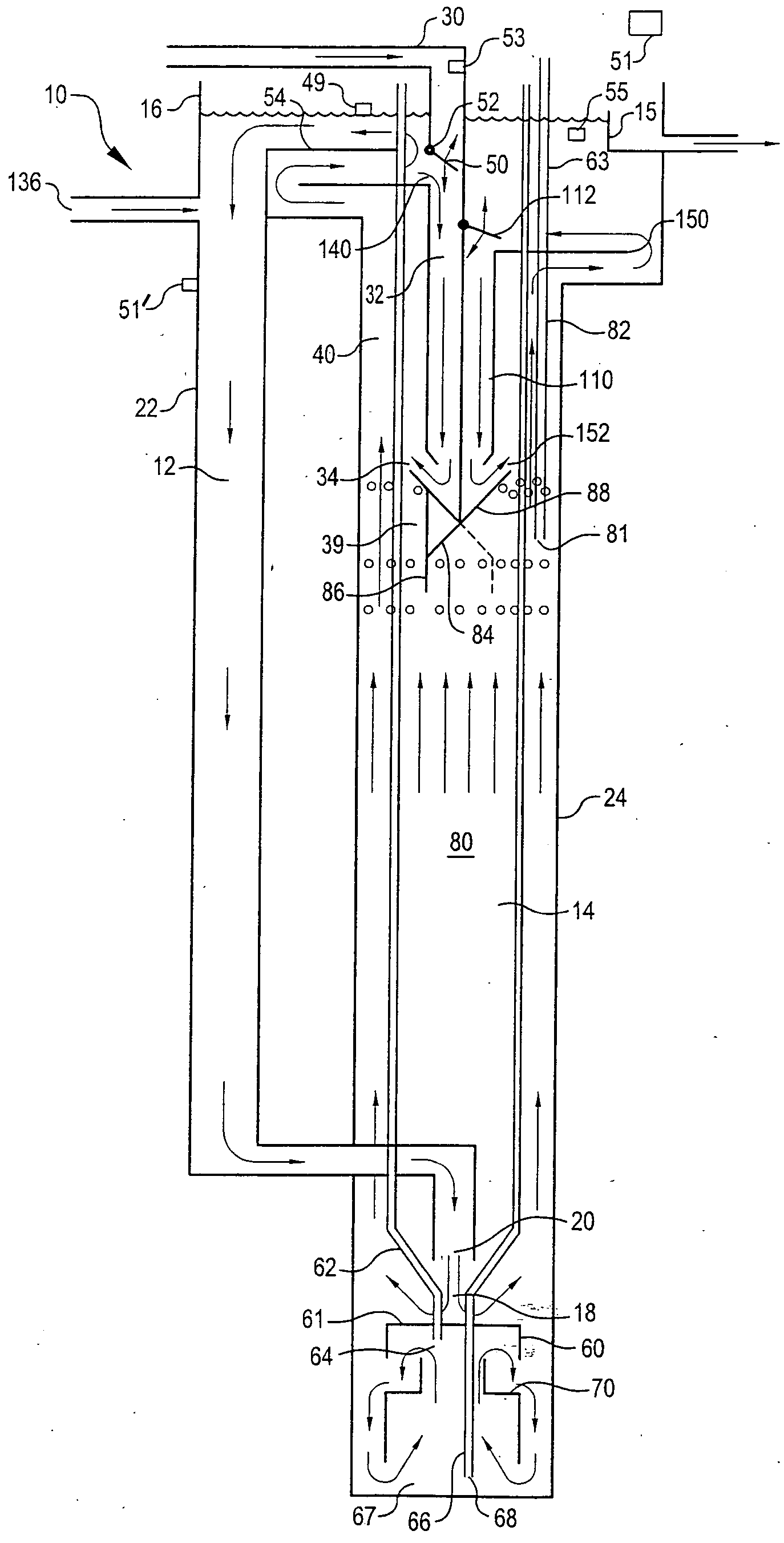

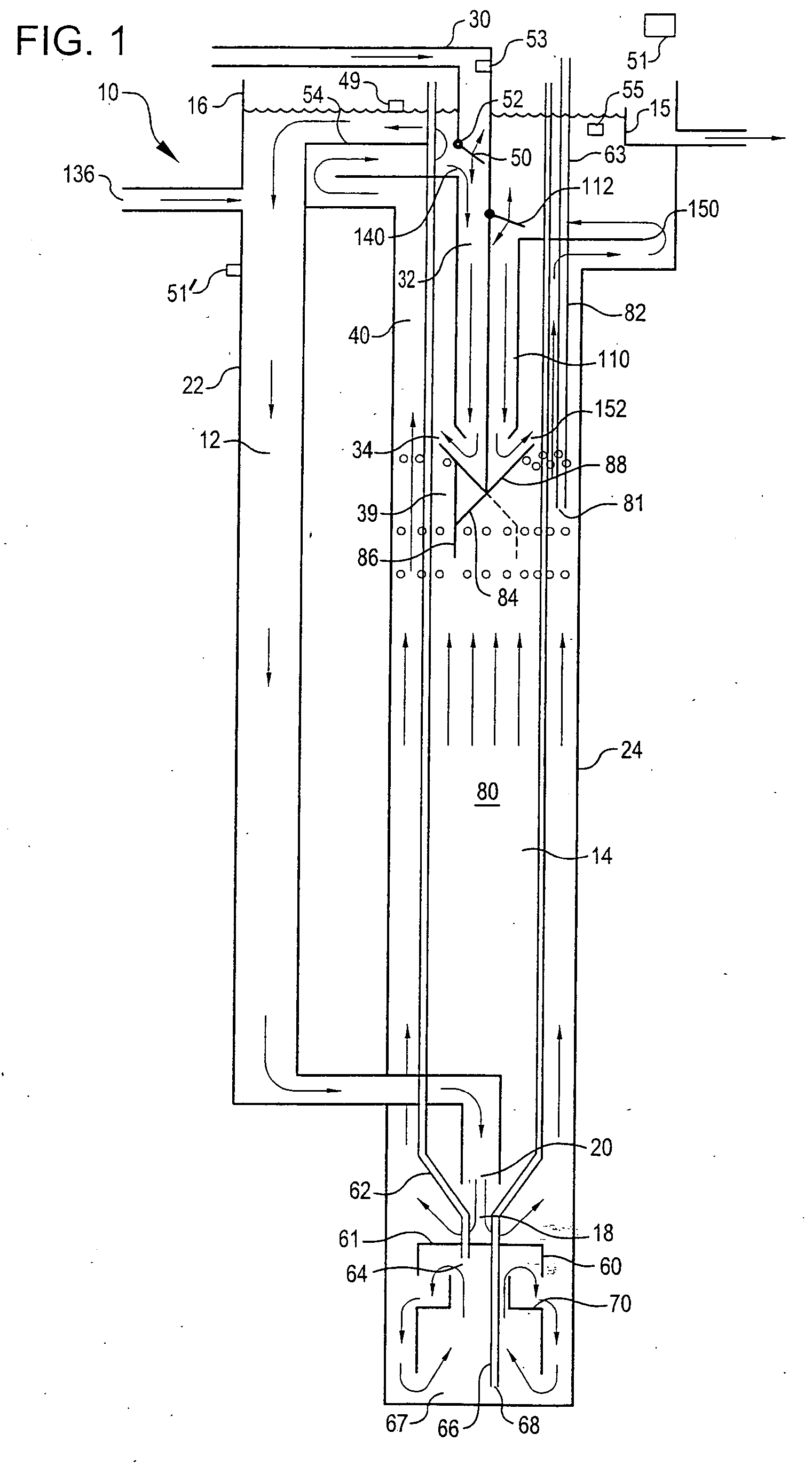

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

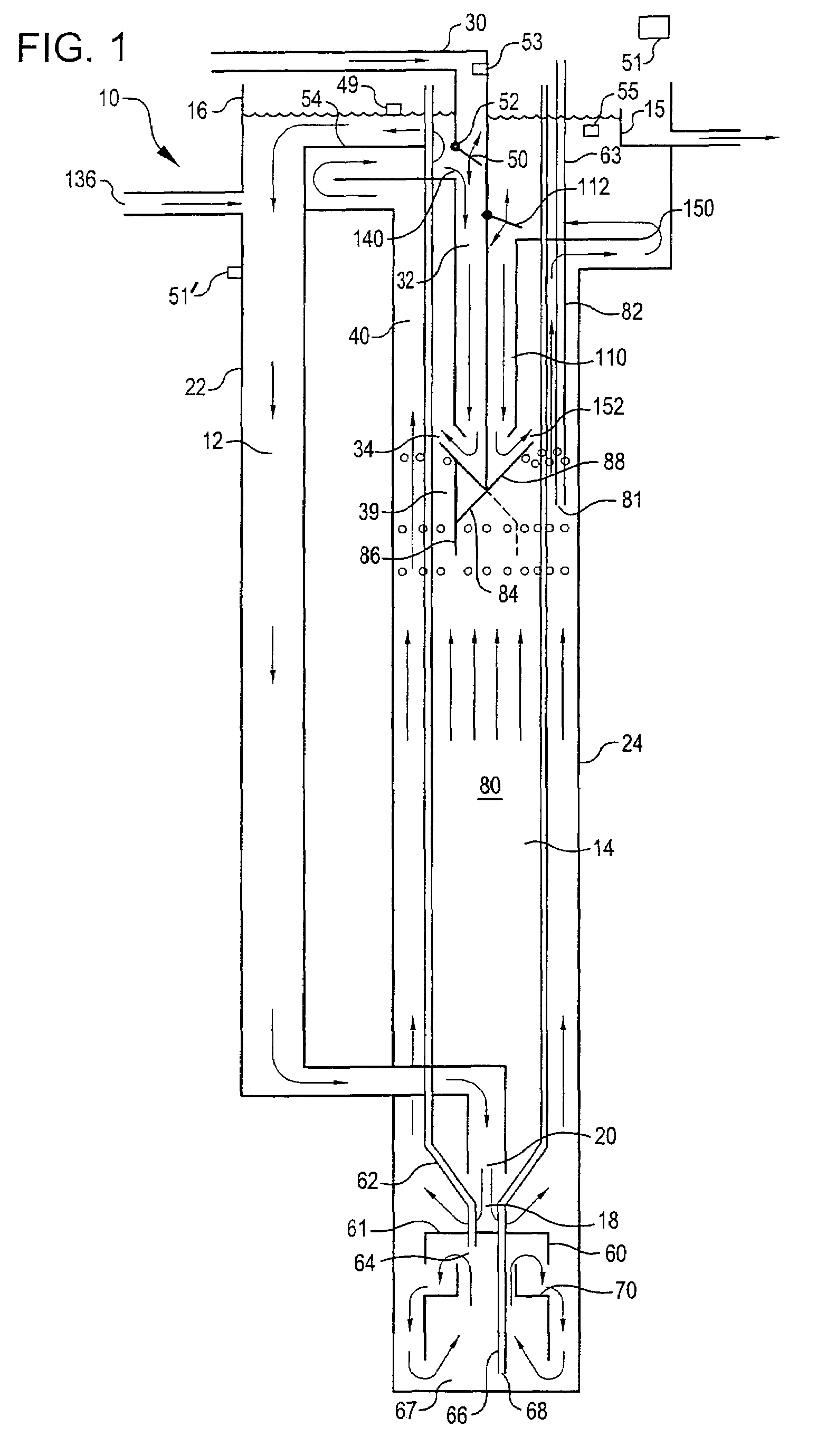

Gas field sewerage and solid pollutant comprehensive processing technological process

InactiveCN101475285AEasy to handleReduce pollutionSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSocial benefitsSludge

The invention relates to a comprehensive treatment process method for sewage and solid pollutants in a natural gas field. The process method comprises five process units, namely, purification treatment for gas production accompanying sewage, purification treatment for drilling mud sewage, biochemical treatment for yielding water and water quality adjustment, fine filtering discharge of the yielding water, mud purification and solidification treatment for the solid pollutants. From the reality of development and production of the natural gas field, the comprehensive treatment process method for the sewage and the solid pollutants in the natural gas field combines environmental protection requirement, has strong comprehensiveness and practicality, is easy to execute, can effectively treat the sewage and the solid pollutants in the natural gas field, changes waste into valuable, effectively reduces environment pollution, and acquires good economic and social benefits.

Owner:LIAONING TIANYI IND CO LTD

Process for electrocoagulating waste fluids

InactiveUS6719894B2CellsWater/sewage treatment by centrifugal separationLiquid wasteElectrocoagulation

An electrocoagulation process for removing organic and metal contaminants from a pressurized waste fluid is disclosed in which a clarified waste fluid is produced when the pressure is released.

Owner:GAVREL TOM G +1

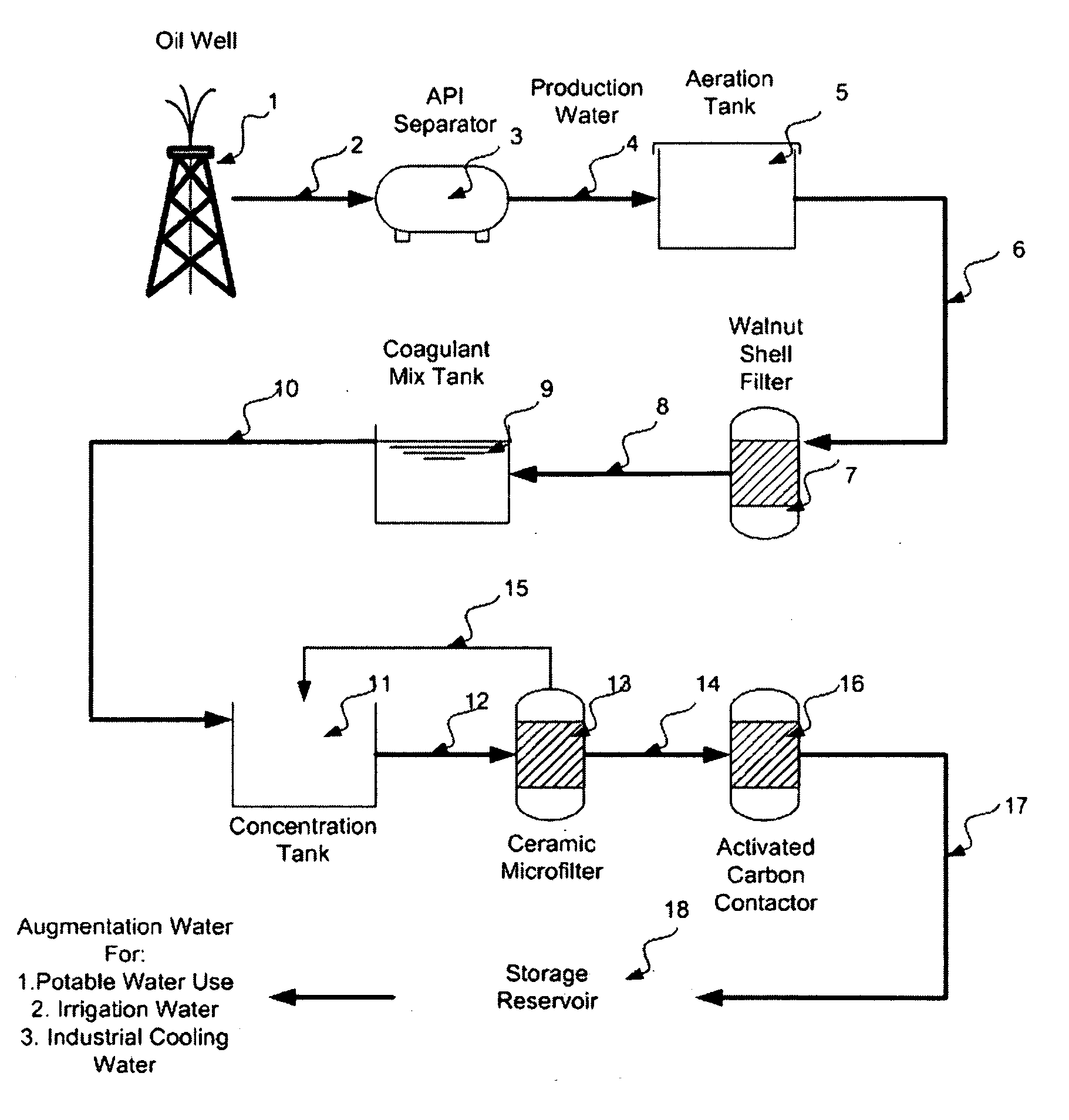

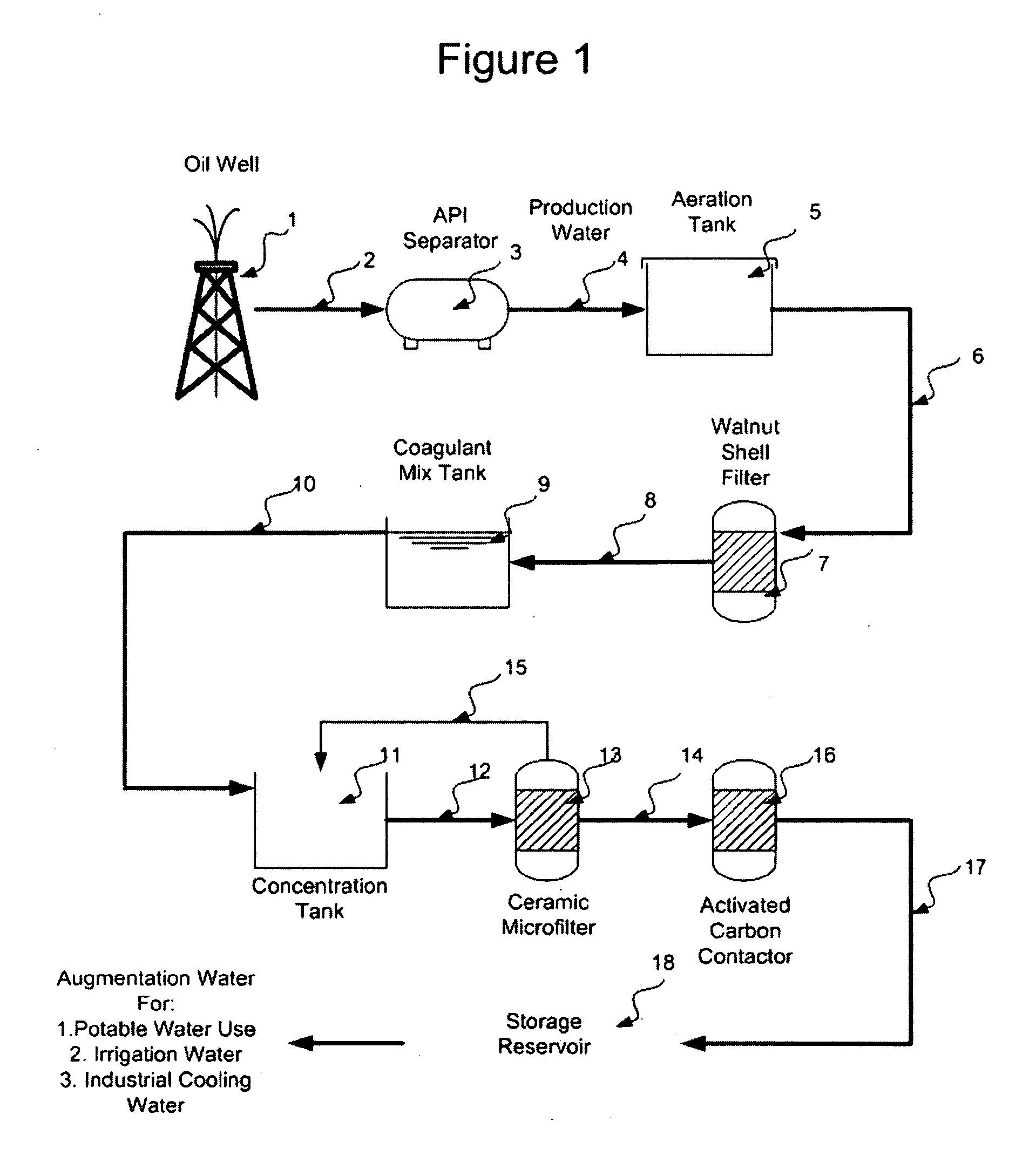

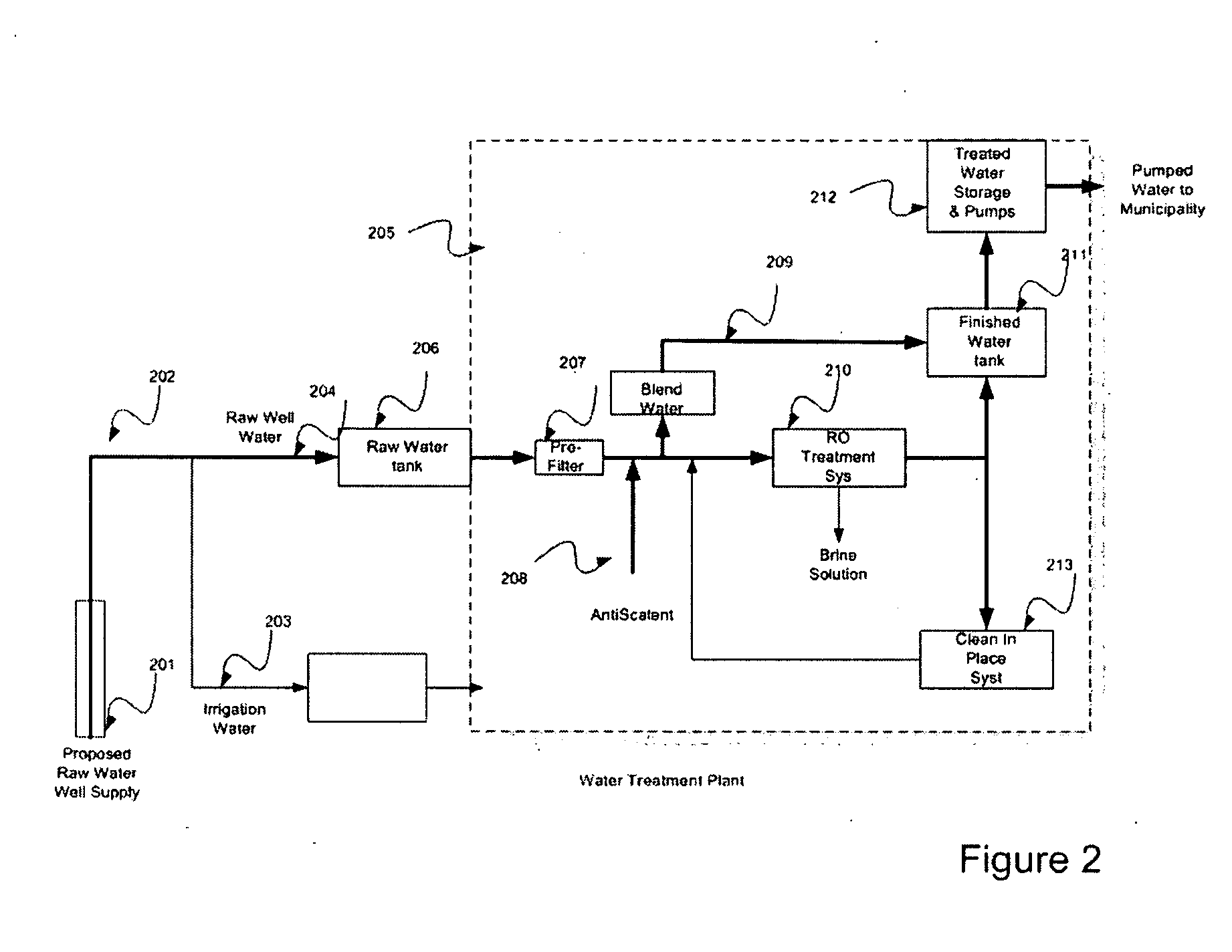

Purification of Oil Field Production Water for Beneficial Use

A method for generating new water with attached water rights comprising identifying a source of production water and treating the water in appropriate ways to provide water appropriate for beneficial use such as agriculture, irrigation, industrial or municipal or potable applications. Appropriate permits are obtained to create the new water with attached water rights.

Owner:PRODD WATER DEV

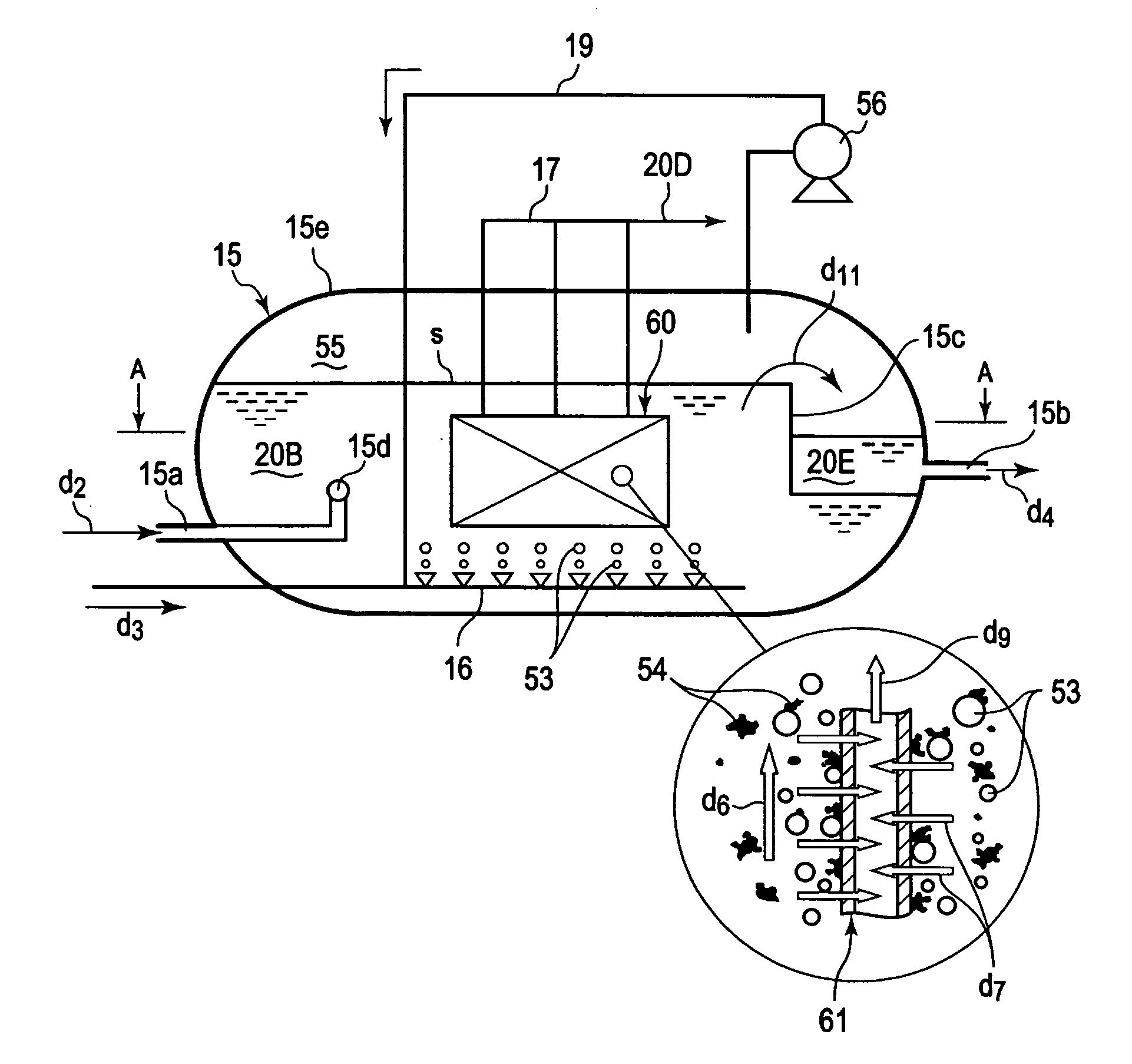

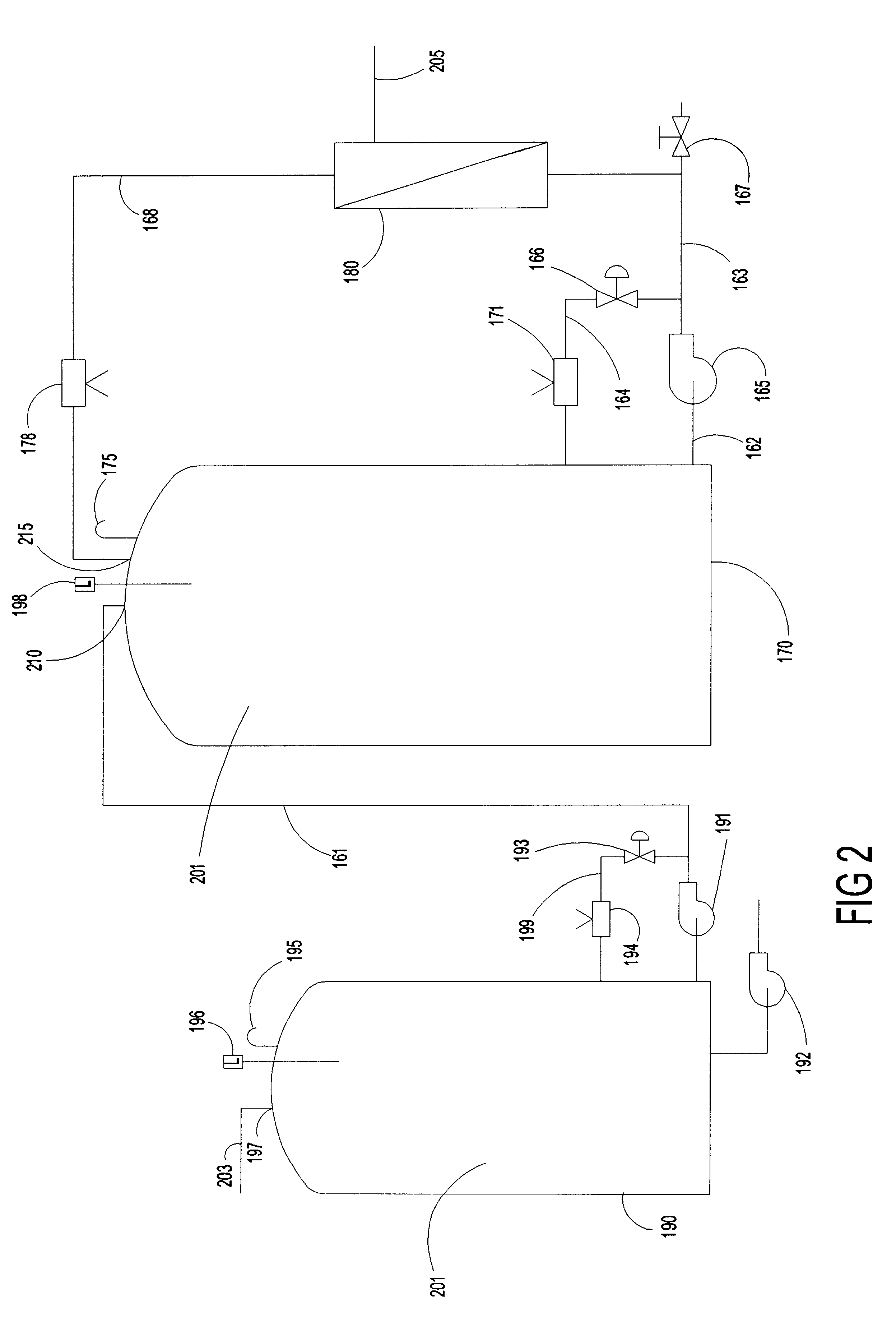

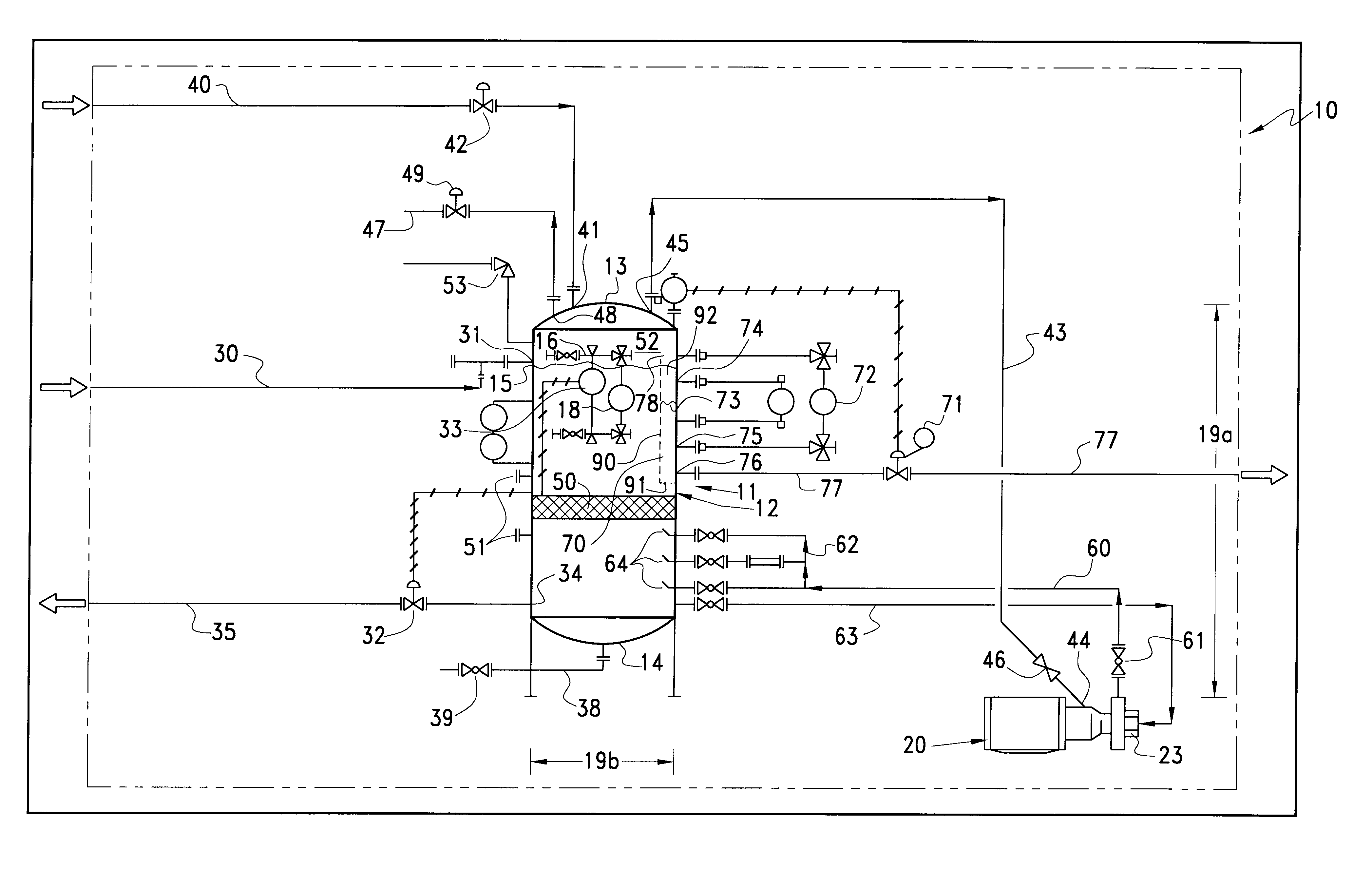

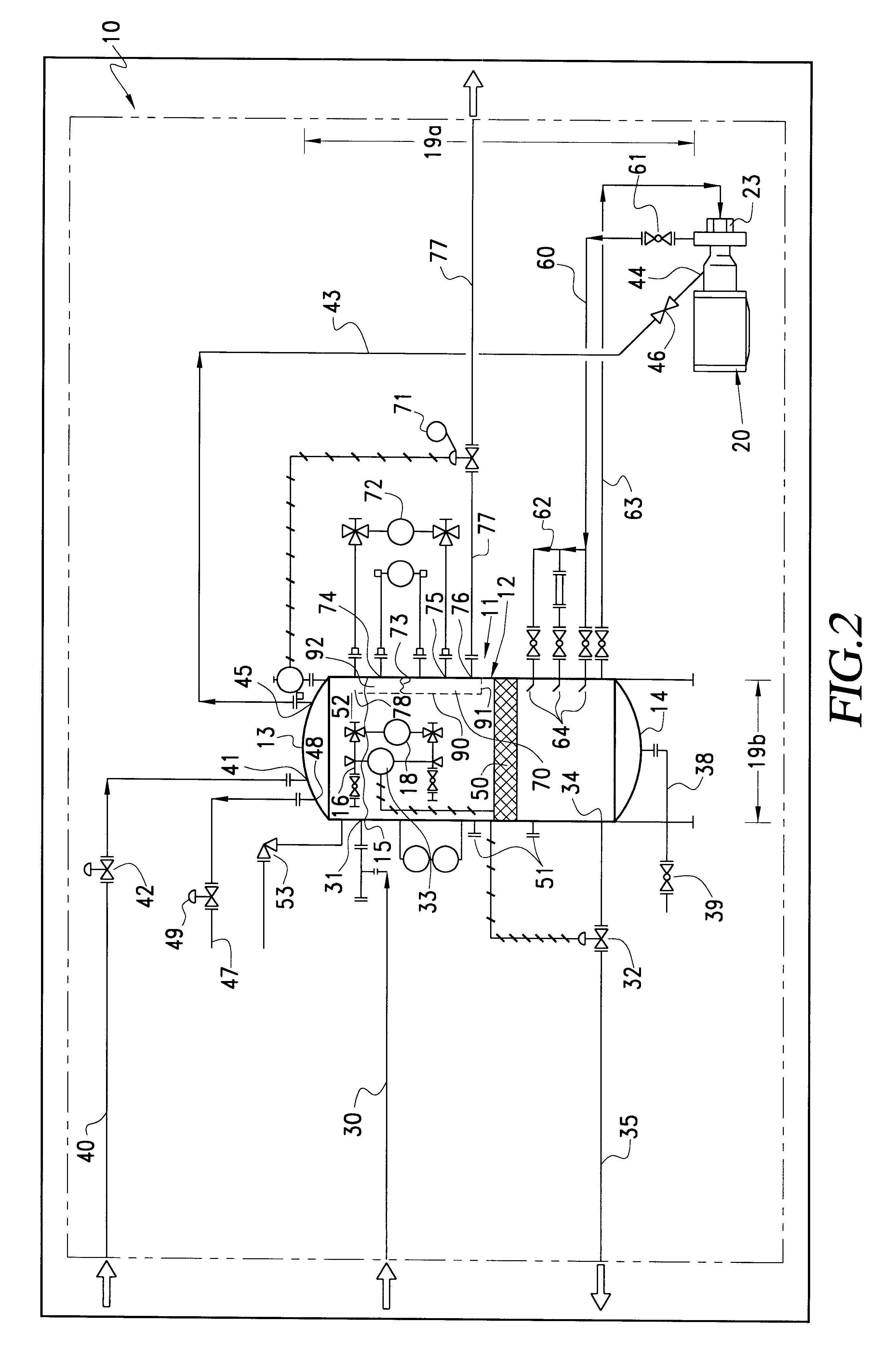

Flotation apparatus for clarifying produced water

InactiveUS6337023B1Fast oil separationWiden meansLiquid separation auxillary apparatusSettling tanks feed/dischargeDissolved gas flotationEngineering

A dissolved gas flotation apparatus and process for removing oils and other contaminants from produced water generated in the production of crude petroleum and natural gas. The invention is particularly designed for offshore applications, where space is limited and natural gas is readily available. The invention includes a vessel for receiving and maintaining a liquid level therein and a circulating pump for introducing tiny flotation gas bubbles into the vessel. Natural gas is used as a blanket gas for the vessel and as a source of gas fed into the pump, wherein the gas is mixed with the pumped liquid. The liquid / gas mixture is transferred into the vessel, wherein the gas releases from the liquid, thereby forming tiny, finely dispersed gas bubbles. The tiny gas bubbles rise vertically through the vessel and attach themselves to the oil and other contaminants suspended in the liquid and buoyantly transport the oil and other contaminants to the top of the vessel, where the gas is released and either recycled back to the recirculating pump or transferred out of the vessel for further processing, and the oil and other contaminants are collected in a reservoir for recovery. The clarified water is removed from the vessel through a liquid outlet line located near the bottom of the vessel.

Owner:SIEMENS ENERGY INC

Method and apparatus for treating animal waste and wastewater

InactiveUS20060060525A1Solid waste disposalWaste water treatment from animal husbandryEvaporationWastewater

Novel methods and apparatuses are disclosed for the treatment of wastewater to reduce, often associated, offensive odors. Irrigation of oxygenated liquid on top of a permeable cover effectively creates an aerobic treatment zone at the top of the lagoon whereby odorous gases being produced anaerobically below the cover are metabolized within this zone before being released to the atmosphere. This same system also serves to increase evaporation from the overall waste handling system therefore substantially reducing or eliminating the need for land application of treated wastewater.

Owner:HOFFLAND ROBERT O

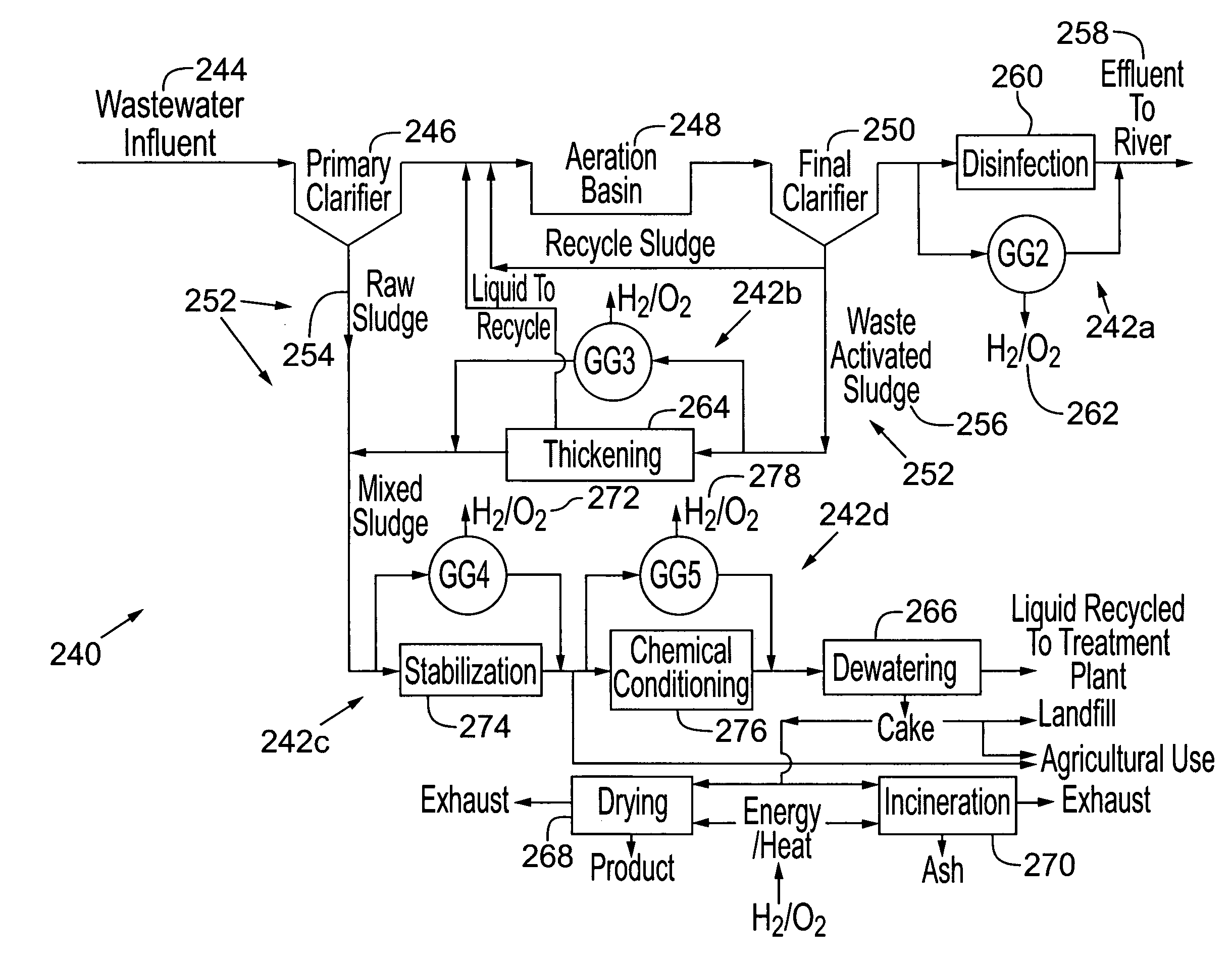

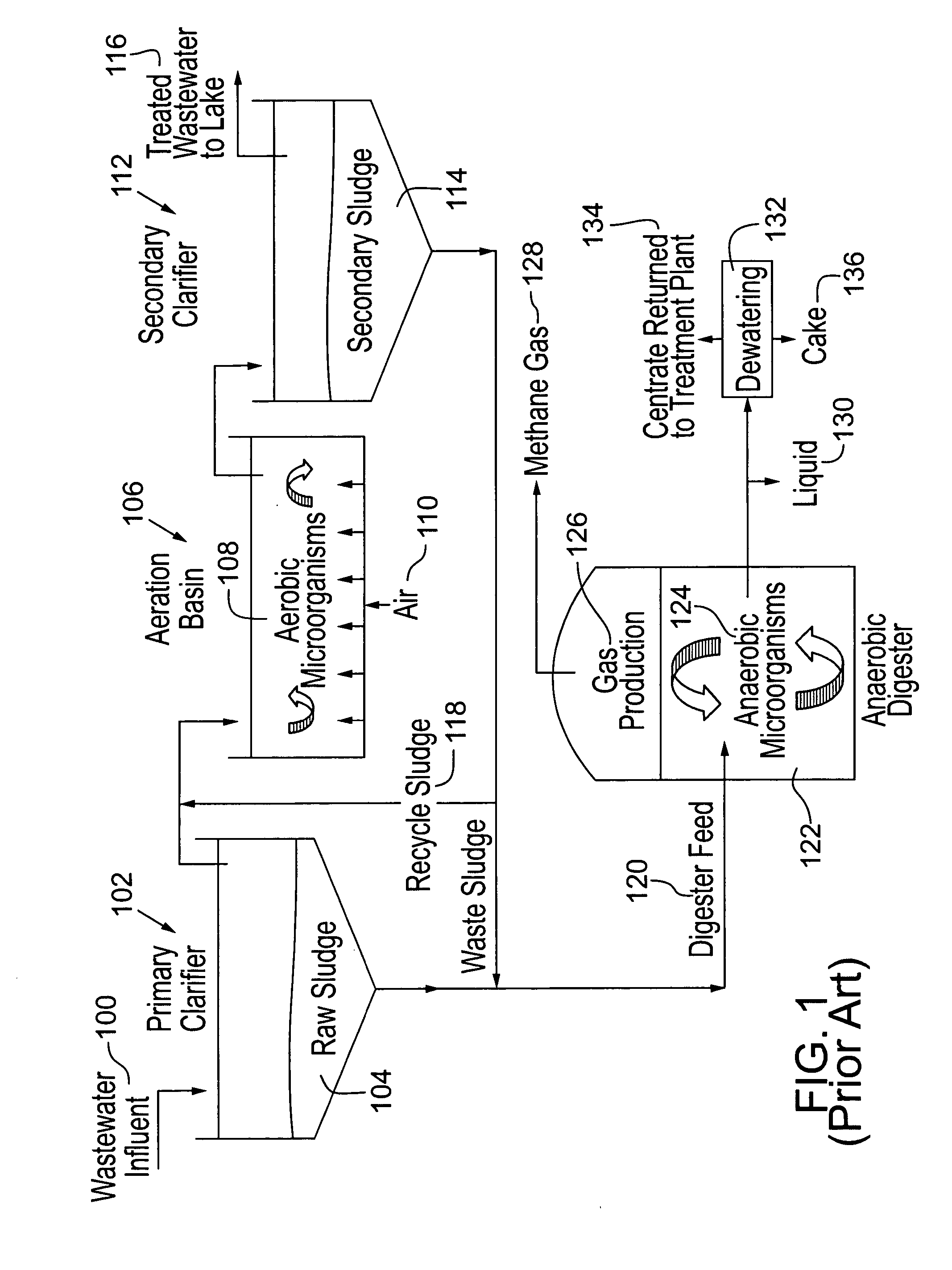

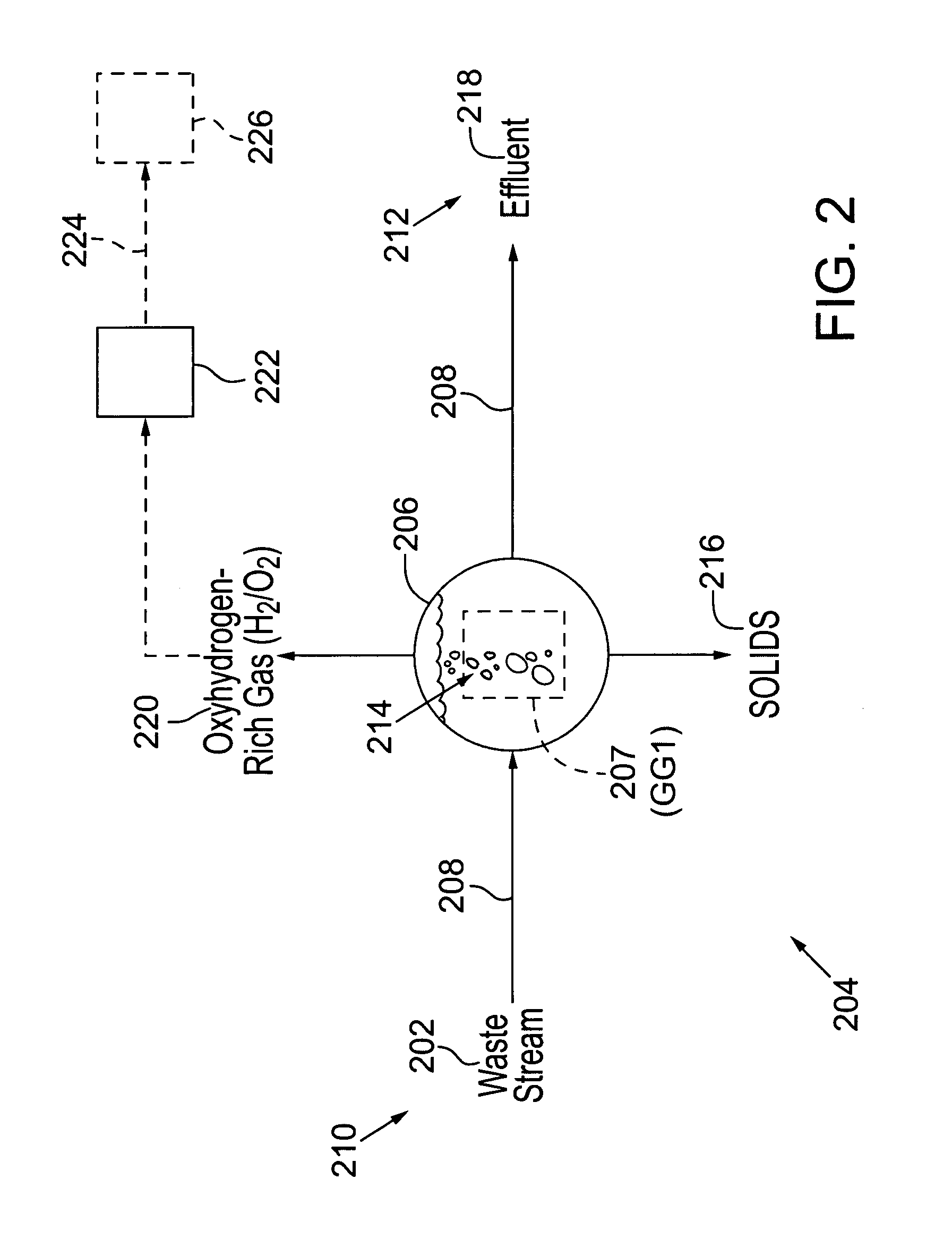

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

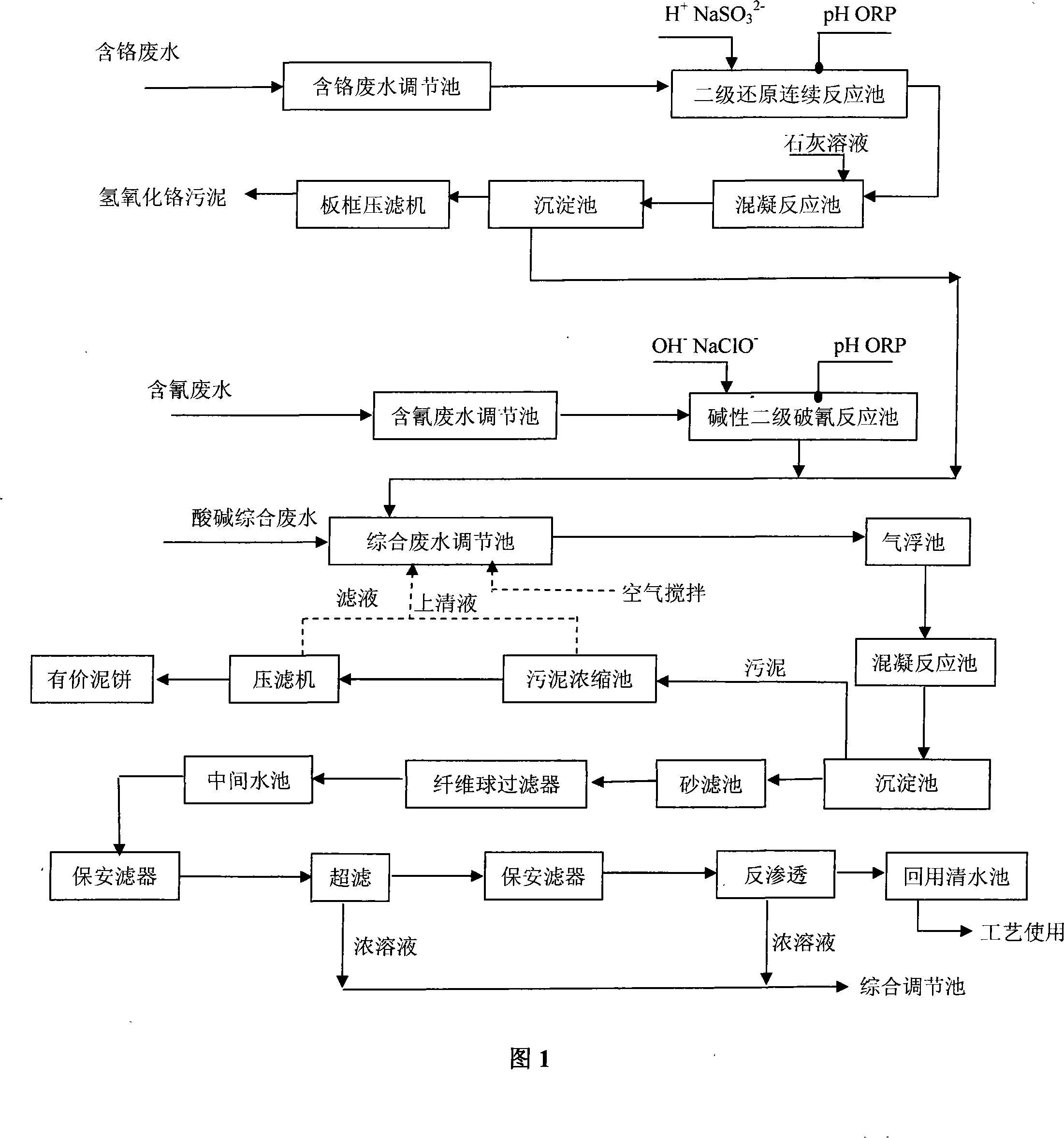

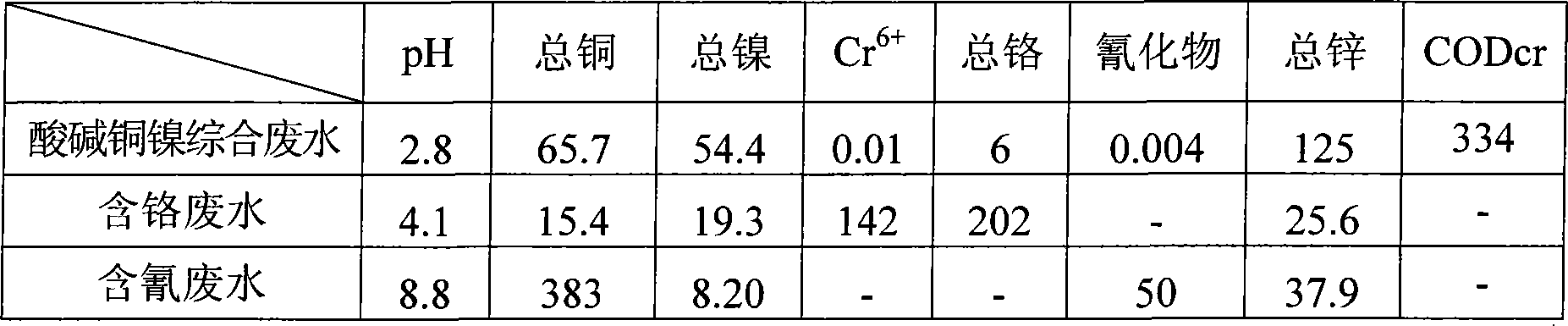

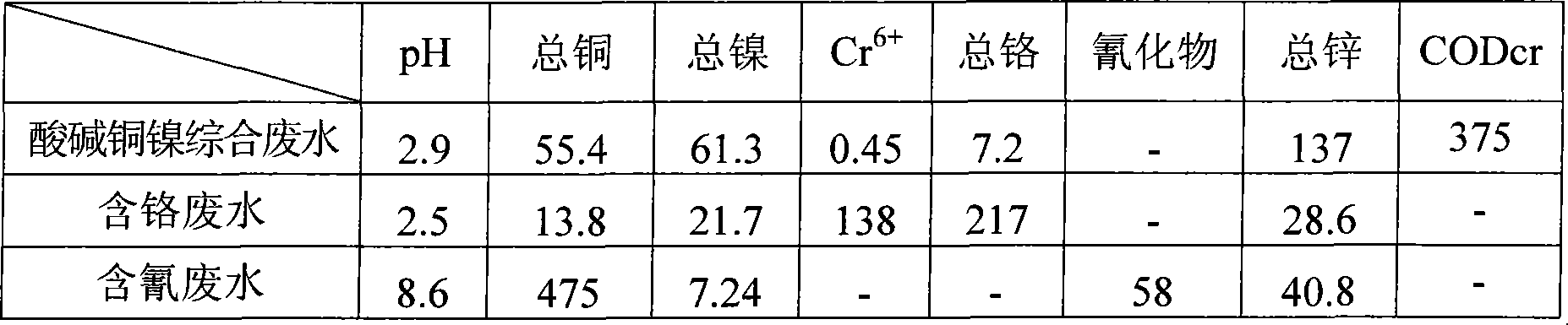

Integrated electroplating treatment method for waste water

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

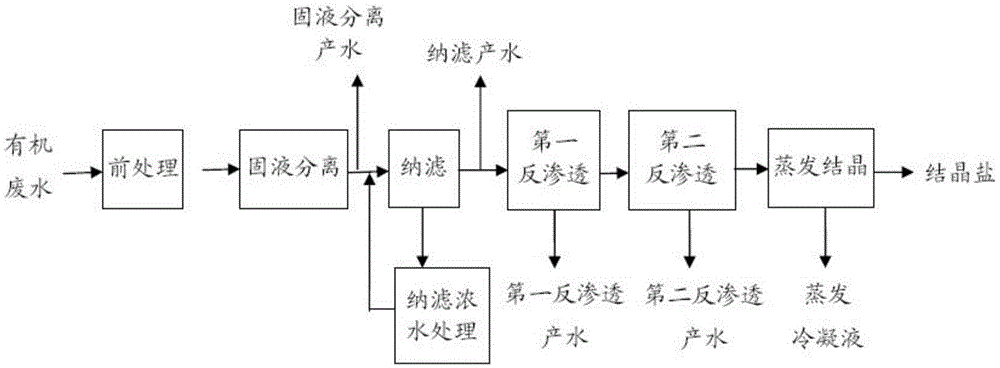

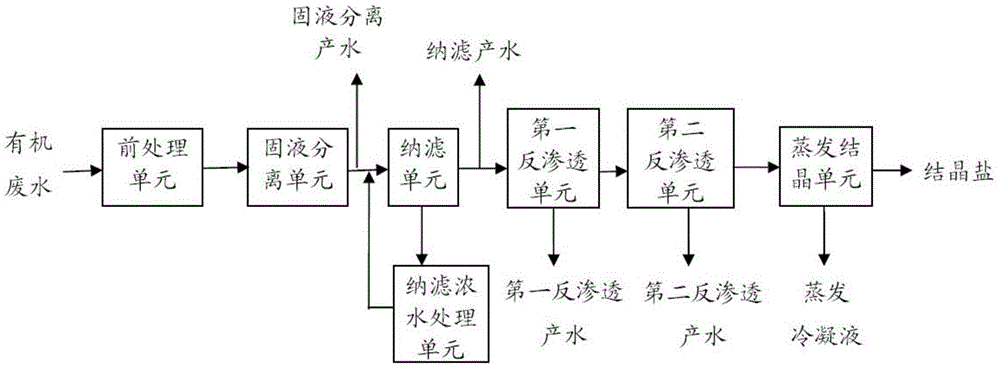

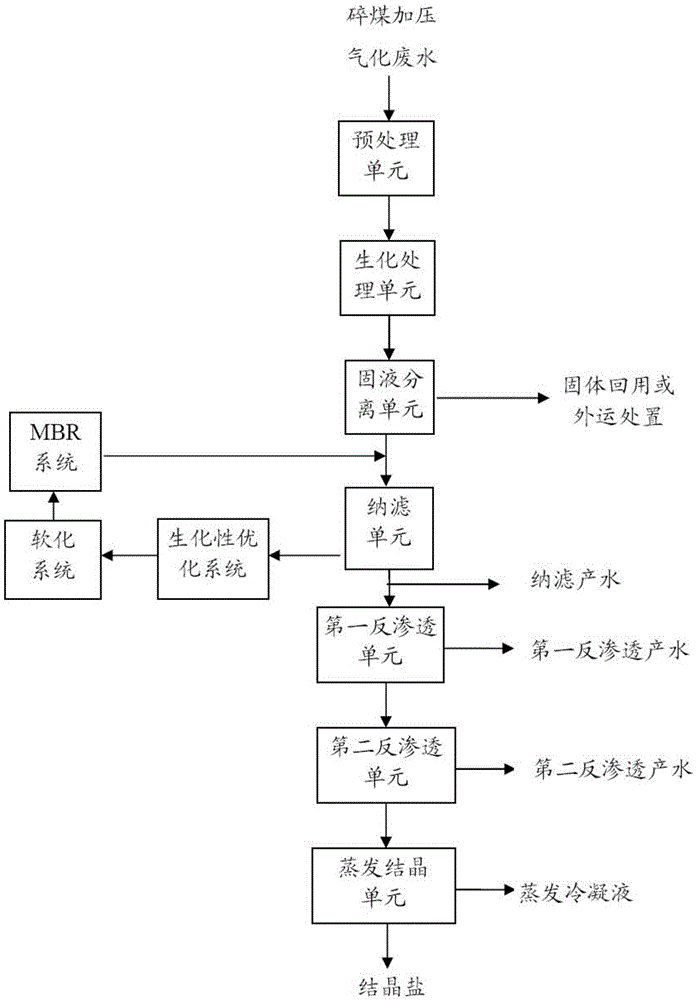

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

Popular searches

Water/sewage treatment by substance addition Liquid separation Water/sewage treatment by flocculation/precipitation Contaminated groundwater/leachate treatment Water/sewage treatment by oxidation Membranes Water treatment compounds Water/sewage treatment by ion-exchange Water/sewage treatment bu osmosis/dialysis Water/sewage treatment by degassing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com