Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4601 results about "Galvanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Galvanization or galvanizing is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are submerged in a bath of molten zinc.

Chromium-free passivation liquid for galvanized sheet and manufacture method thereof

InactiveCN101250699AImprove bindingImprove corrosion resistanceMetallic material coating processesChromium freeSealant

The invention in particular relates to passivation solution without chrome which is used for galvanized sheets and a method thereof. The technical scheme thereof comprises: firstly, dissolving inorganic salt corrosion inhibitor, then, adding the inorganic salt corrosion inhibitor into a stirred tank, adding dispersant, organic acid, sealant, silicone-acrylate emulsion and water while stirring, then, using inorganic acid or alkali to regulate the pH value to be 2.0-5.0, and then stirring for 1-2 hours under the condition that the temperature is 20-30 DEG C, the content of the components of each liter is: the inorganic salt corrosion inhibitor 10-55g, additive 4-10g, the organic acid 5-20g, the sealant 5-30g, the silicone-acrylate emulsion 150-300g, and the rest is the water. The method of the invention can additionally form a layer of organic resin separate layer on the basis of forming an inorganic metal compound precipitation film, additionally, since the silicon compound is added, not only the binding force between a passivation layer and zinc coating can be increased, but also the corrosion resistance, the scrubbing resistance and the wear resistance of the passivation layer can be increased, and the coating treatment after passivation can not be affected.

Owner:WUHAN UNIV OF SCI & TECH

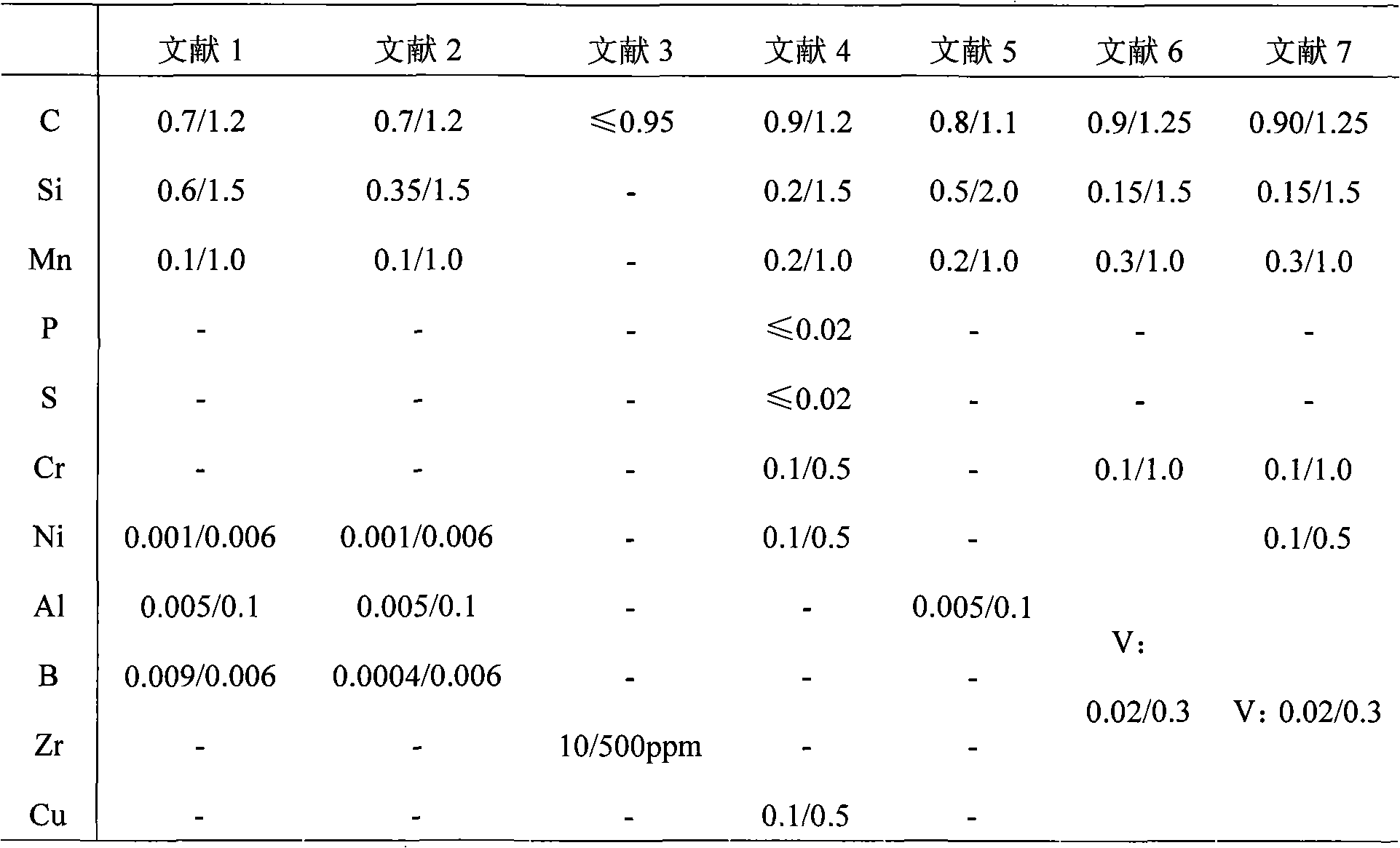

Laser fusing and coating process for wear resistant and etch-resistant coating of hydraulic support column cylinder and piston rod

ActiveCN101338427AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantRoom temperature

A laser cladding process of the wear-resisting anticorrosive coating of a hydraulic pressure support pillar cylinder barrel or a piston rod cylinder barrel comprises procedures as follows: the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are pretreated; the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are decreased, de-rusted and cleaned up by alcohol under room temperature; alloying powder is chosen and an automatic powder feeder is adjusted; the iron base alloying powder with good wear-resisting anticorrosive property and sound metallurgy compatibility with a matrix is selected and the iron base alloying powder contains major constituents, including Fe, C, Cr, Ni, Mo, Si, N, Nb, Ta and B; and at last, the automatic powder feeder is adjusted. Adjusting the automatic powder feeder can lead the alloying powder from an automatic feeding end to a laser melting pool and feeding amount is adjusted so that the thickness of the alloying coating reaches 0.6mm to1.2mm. The alloying coating of the invention is even and dense and has good wear-resisting anticorrosive property. Compared with galvanization, the wear-resisting anticorrosive property and the service life of the standing pillar cylinder barrel and the piston rod manufactured by the invention are greatly improved.

Owner:CHONGQING JIANGLU LASER TECH

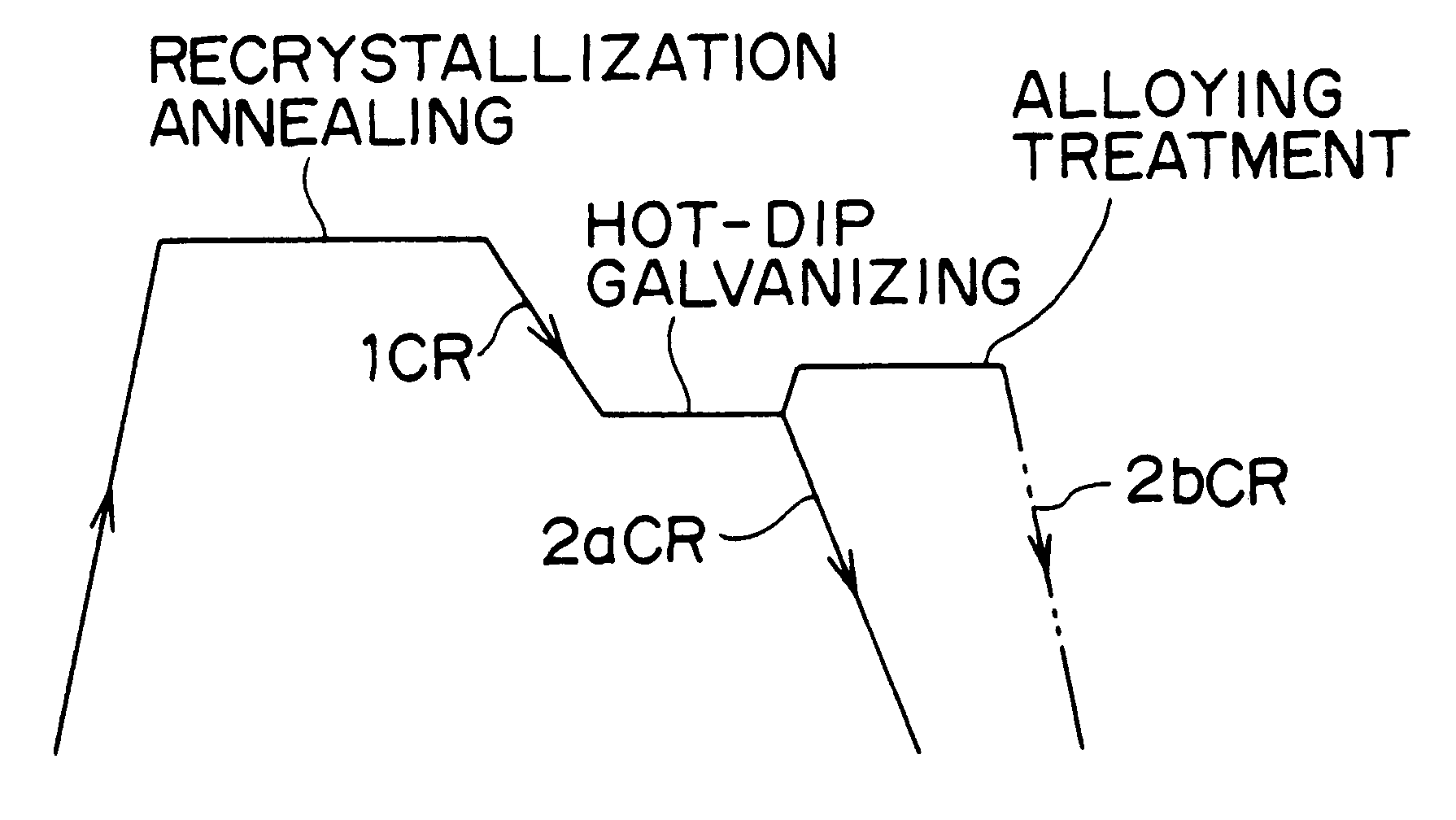

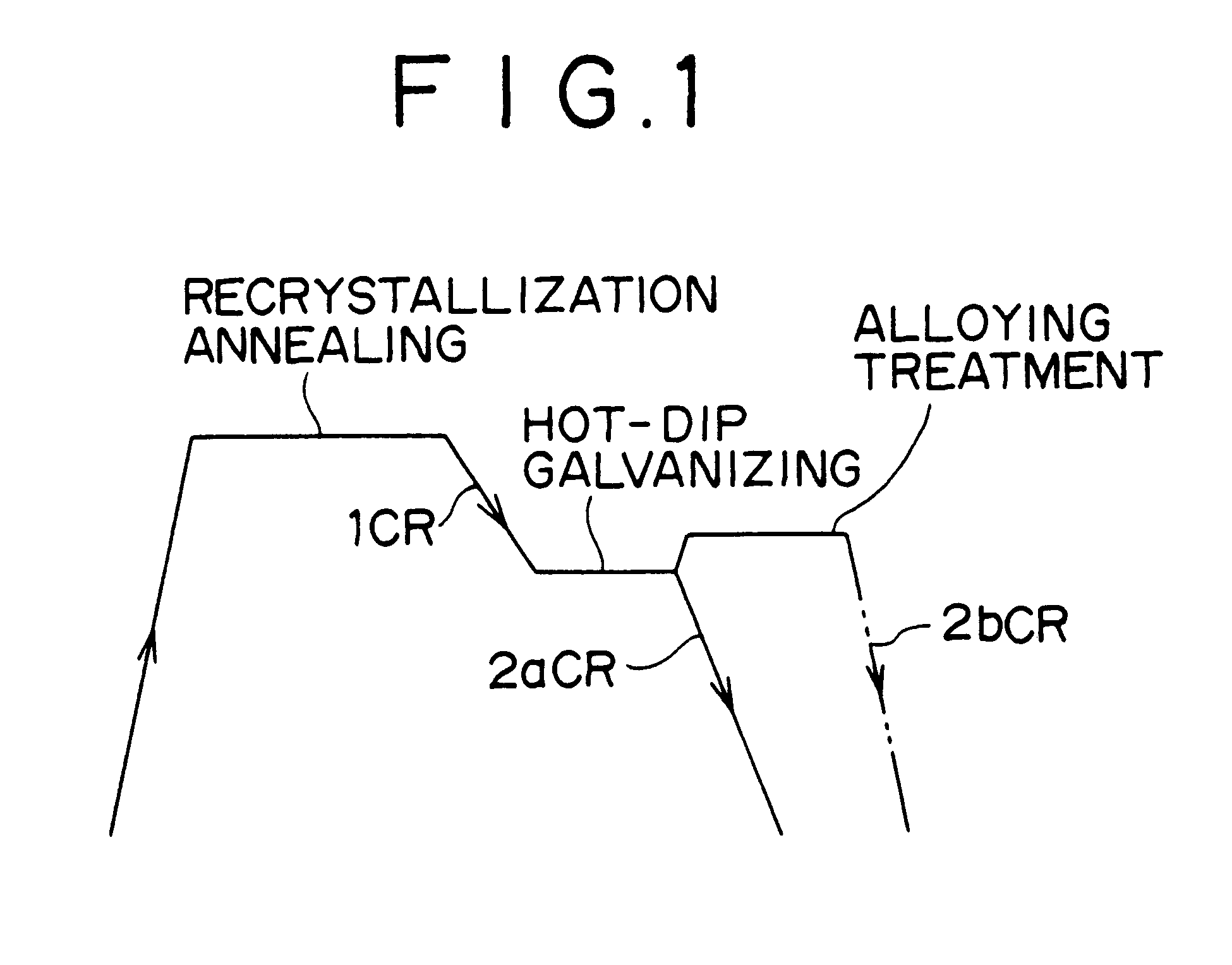

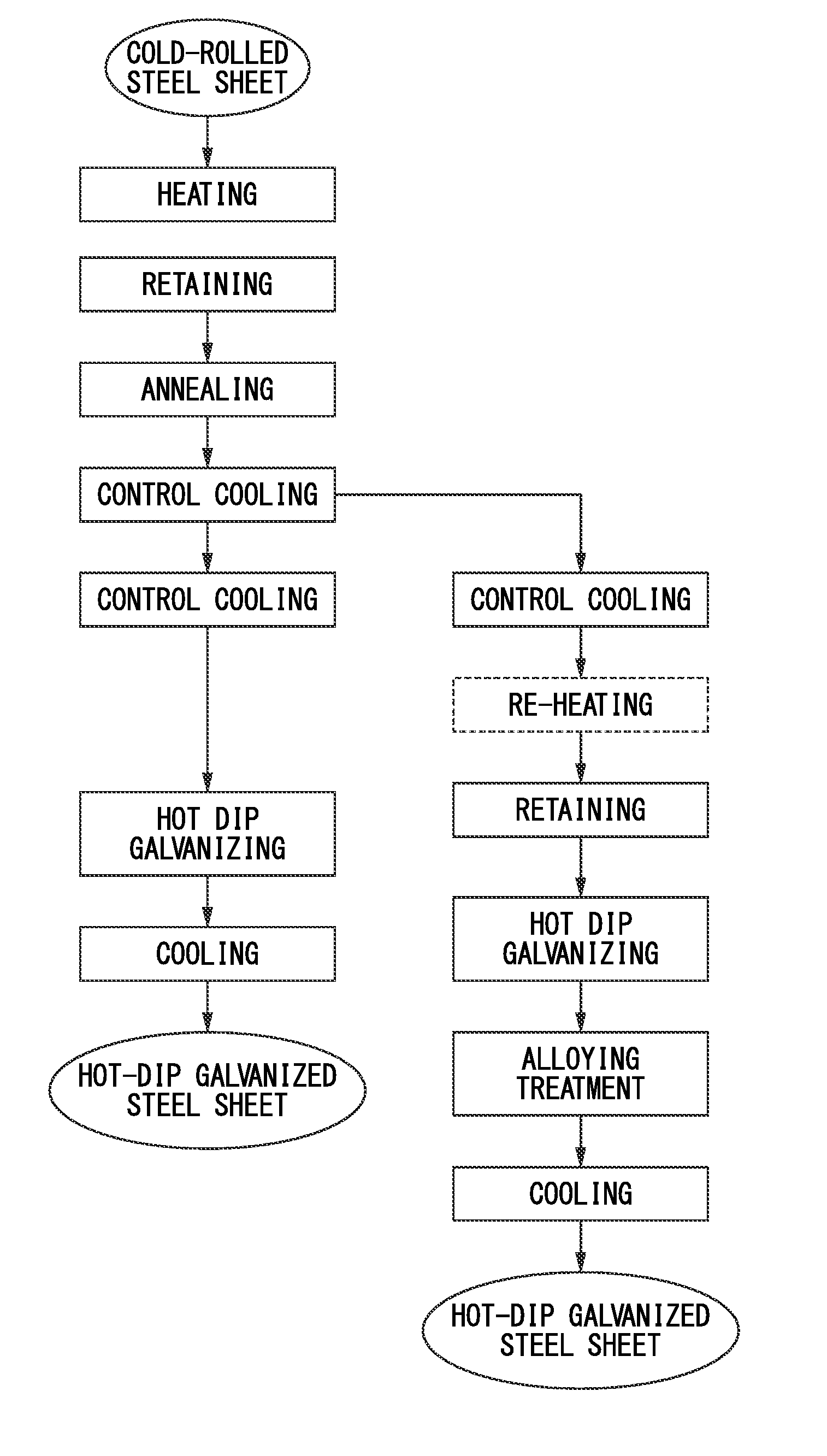

Hot-dip galvanized steel sheet and process for production thereof

InactiveUS6306527B1Ductility deterioratesImprove ductilityHot-dipping/immersion processesLiquid surface applicatorsHot-dip galvanizationDuctility

A hot-dip galvanized steel sheet which is produced from a cold-rolled steel sheet, as a base steel sheet, consisting essentially of C: 0.010-0.06 wt %, Si: no more than 0.5 wt %, Mn: no less than 0.5 wt % and less than 2.0 wt %, P: no more than 0.20 wt %, S: no more than 0.01 wt %, Al: 0.005-0.10 wt %, N: no more than 0.005 wt %, Cr: no more than 1.0 wt %, Mn+1.3Cr: 1.9-2.3 wt %, Fe: remainder, and having a structure composed of ferrite and a second phase containing martensite, said second phase in the structure accounting for no more than 20% in terms of area and martensite in the second phase accounting for no less than 50%, and which has a zinc-plated layer formed on the surface thereof by hot-dip galvanizing or hot-dip galvannealing. A process for production of said hot-dip galvanized steel sheet. This steel sheet has a composite structure containing martensite and yet it has a low strength (no higher than 500 MPa) and also has good strength-ductility balance.

Owner:KOBE STEEL LTD

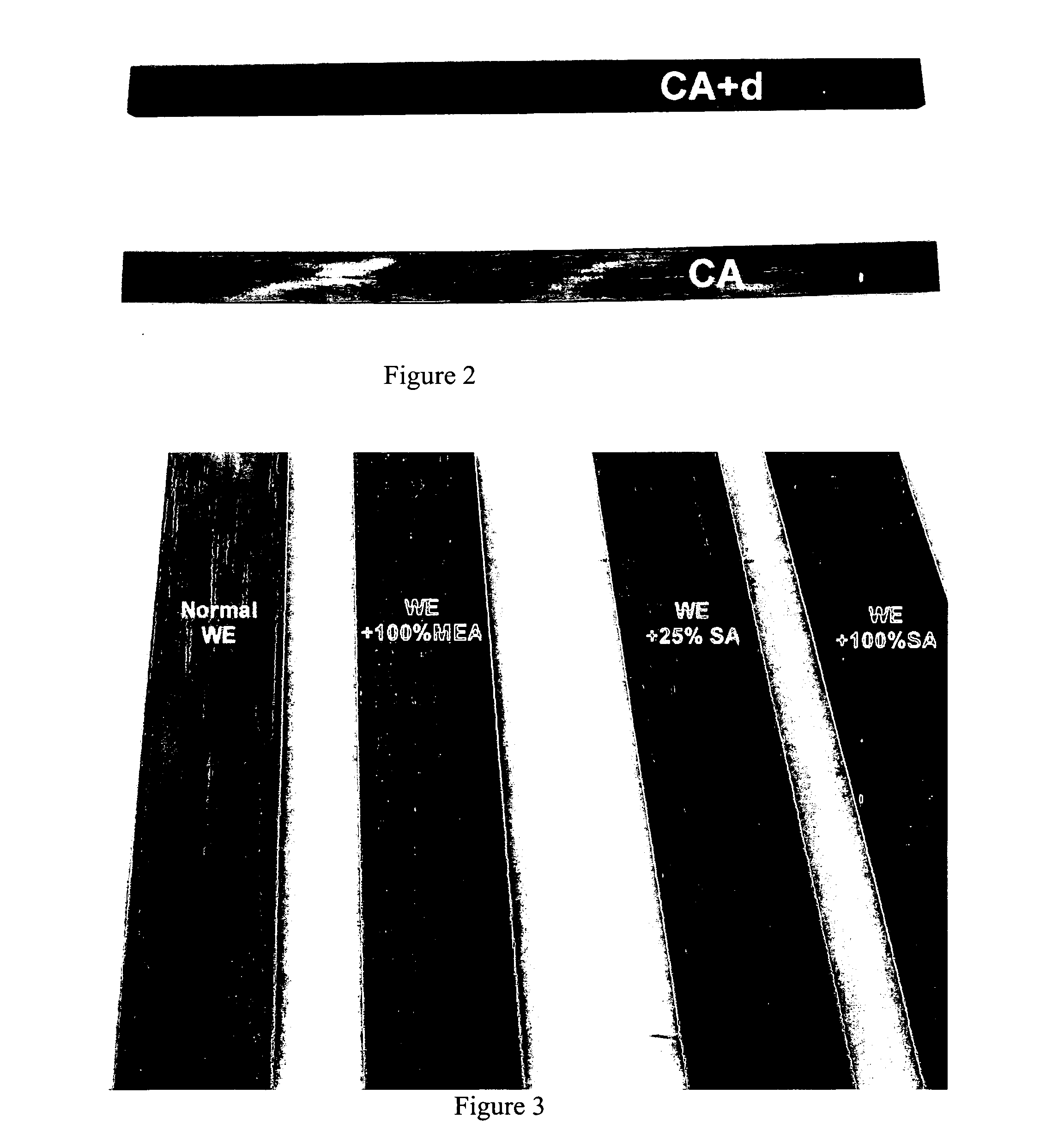

Penetration of copper-ethanolamine complex in wood

InactiveUS20060078686A1Reduce premature precipitationPretreated surfacesCoatingsPhosphatePreservative

Addition of base improves the homogeneity of aqueous copper amine complex preservatives injected into wood. The base includes at least a portion of alkali metal hydroxides, alkali metal carbonates, alkali metal phosphates, alkali metal borates, and / or alkali metal pyrophosphates, the corrosivity of the composition to steel and galvanized steel is reduced, and the leach rate of the copper from the wood is also reduced.

Owner:OSMOSE

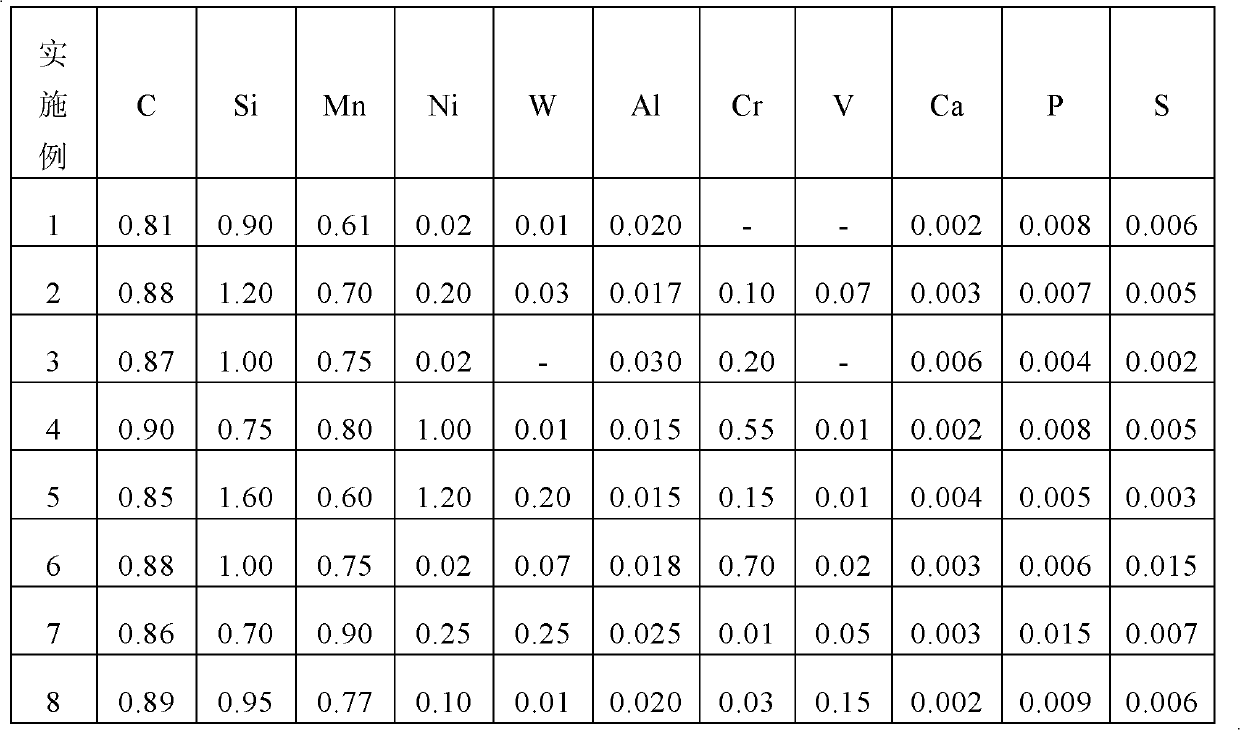

Steel wire rod for 1860MPa-level bridge cable galvanized steel wire and manufacturing method thereof

The invention relates to a steel wire rod for an 1860MPa-level bridge cable galvanized steel wire and a manufacturing method of the steel wire rod. The steel wire rod for the 1860MPa-level bridge cable galvanized steel wire comprises the following raw materials by weight percent: 0.81-0.90% of C, 0.70-1.60% of Si, 0.60-0.90% of Mn, 0.02-1.20% of Ni, 0.00-0.25% of W, 0.015-0.030 of Al, 0.00-0.70% of Cr, 0.00-0.15% of V, 0.002-0.006% of Ca, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurities, wherein the total quantity of the impurity elements is lower than 0.05%. For the steel wire rod and the preparation method of the steel wire rod, the steel wire rod is not required for salt bath processing, and can be produced by adopting conventional drawing technique, the finished steel wire after being drawn and galvanized has the strength higher than 1860MPa, has 14 times of torsion values, and can be applicable to the need for construction of extra big span bridge.

Owner:BAOSHAN IRON & STEEL CO LTD

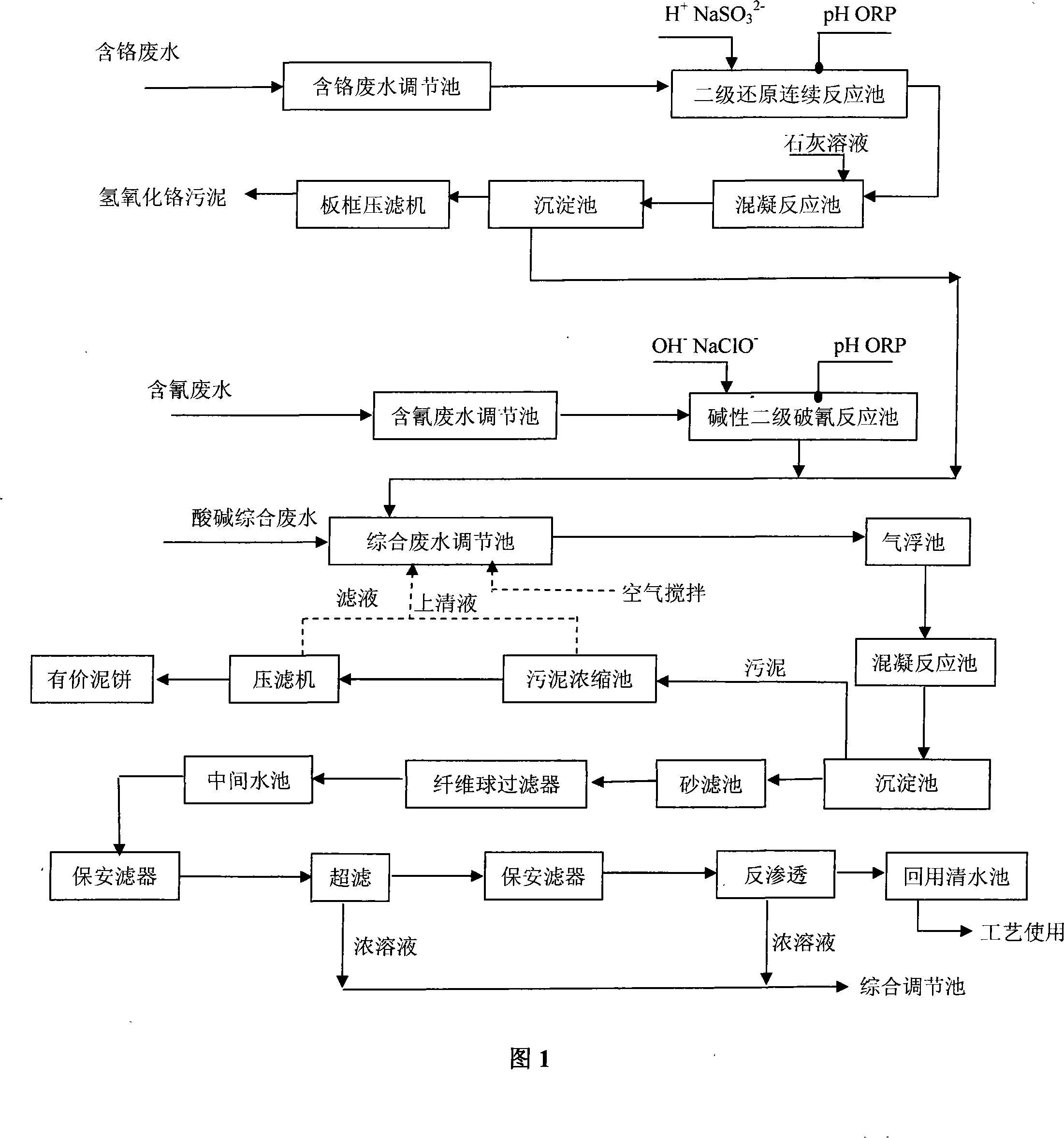

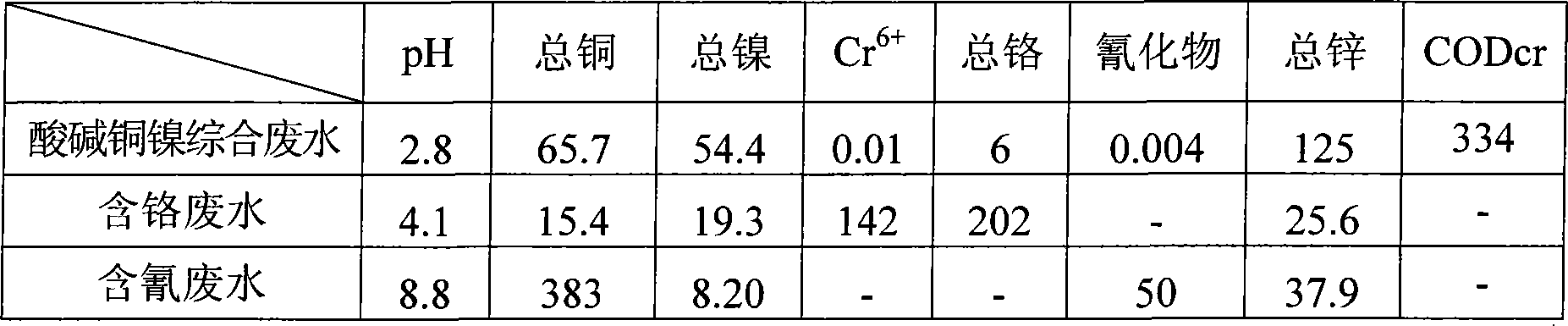

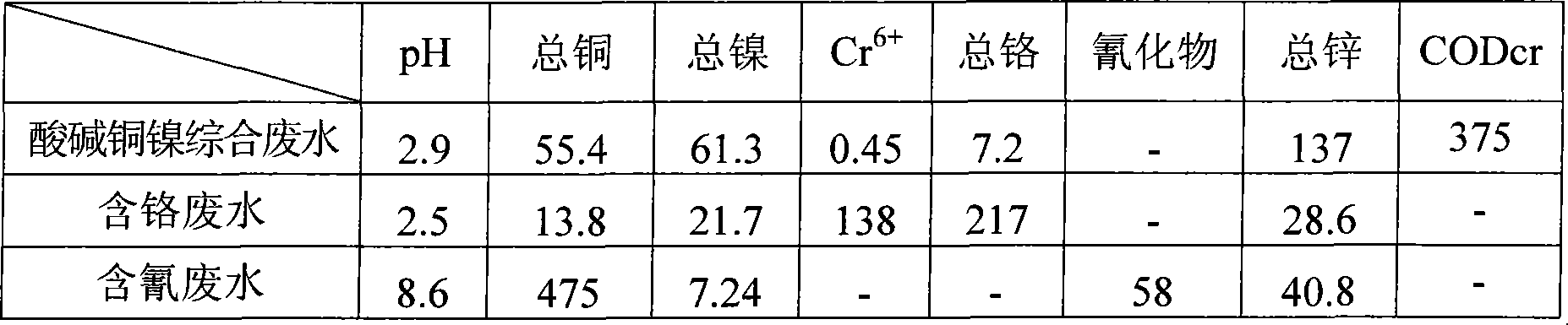

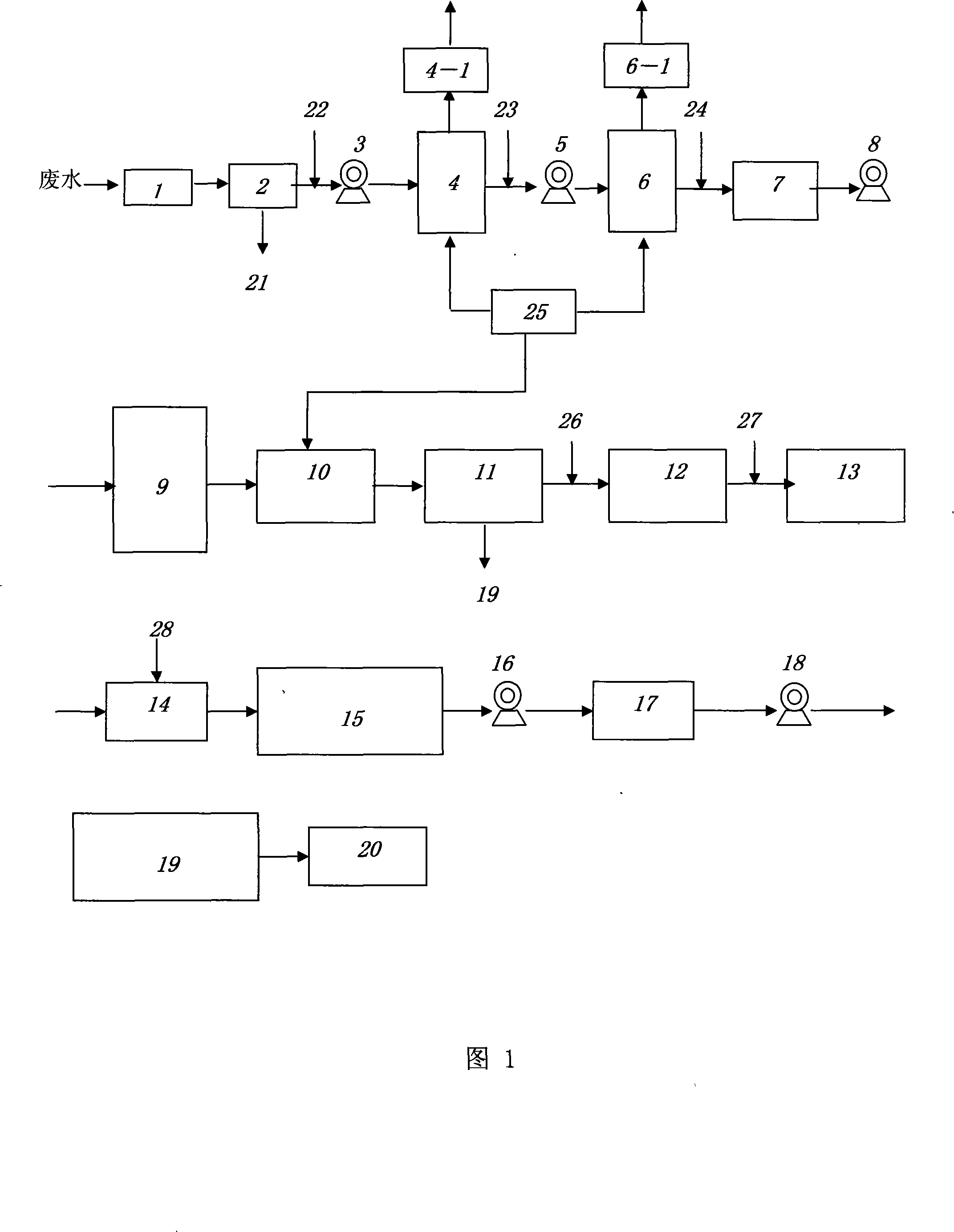

Integrated electroplating treatment method for waste water

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

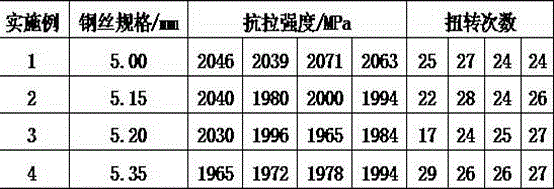

Hot-rolled wire rod for 1,960MPa-level cable rope galvanized steel wire and production method

ActiveCN105671443AGuaranteed torsional performanceHigh tensile strengthWire rodUltimate tensile strength

The invention discloses a hot-rolled wire rod for a 1,960MPa-level cable rope galvanized steel wire and a production method. The hot-rolled wire rod is prepared from, by weight percent, 0.85%-0.91% of C, 0.20%-1.00% of Si, 0.60%-0.90% of Mn, 0.25%-0.35% of Cr, 0.015%-0.040% of Al, not larger than 0.025% of P, not larger than 0.025% of S, 0.02%-0.07% of V, not larger than 0.20% of Cu, not larger than 0.0030% of Ca and the balance Fe and inevitable impurity elements. Reasonable component contents are adopted in the wire rod, the wire rod has the beneficial effects of being high in tensile strength and plasticity, the situation of hardening during machining in the drawing process can be effectively reduced, and the torsional property of the steel wire obtained through drawing is effectively guaranteed. In the wire rod obtained through the method, the sorbite structure proportion reaches 90% to 93%, the tensile strength of the wire rod is larger than or equal to 1,320 MPa, and the area reduction rate is larger than or equal to 40%. After the wire rod obtained through the method is subjected to drawing, galvanizing and stabilizing treatment, the tensile strength of the steel wire is larger than or equal to 1,960 MPa, the torsion index is larger than or equal to 14 times, and the wire rod can be used for producing the 1,960MPa-level bridge cable rope galvanized steel wire and is suitable for ultra-large-span bridges with the ultrahigh requirement for strength.

Owner:XINGTAI IRON & STEEL

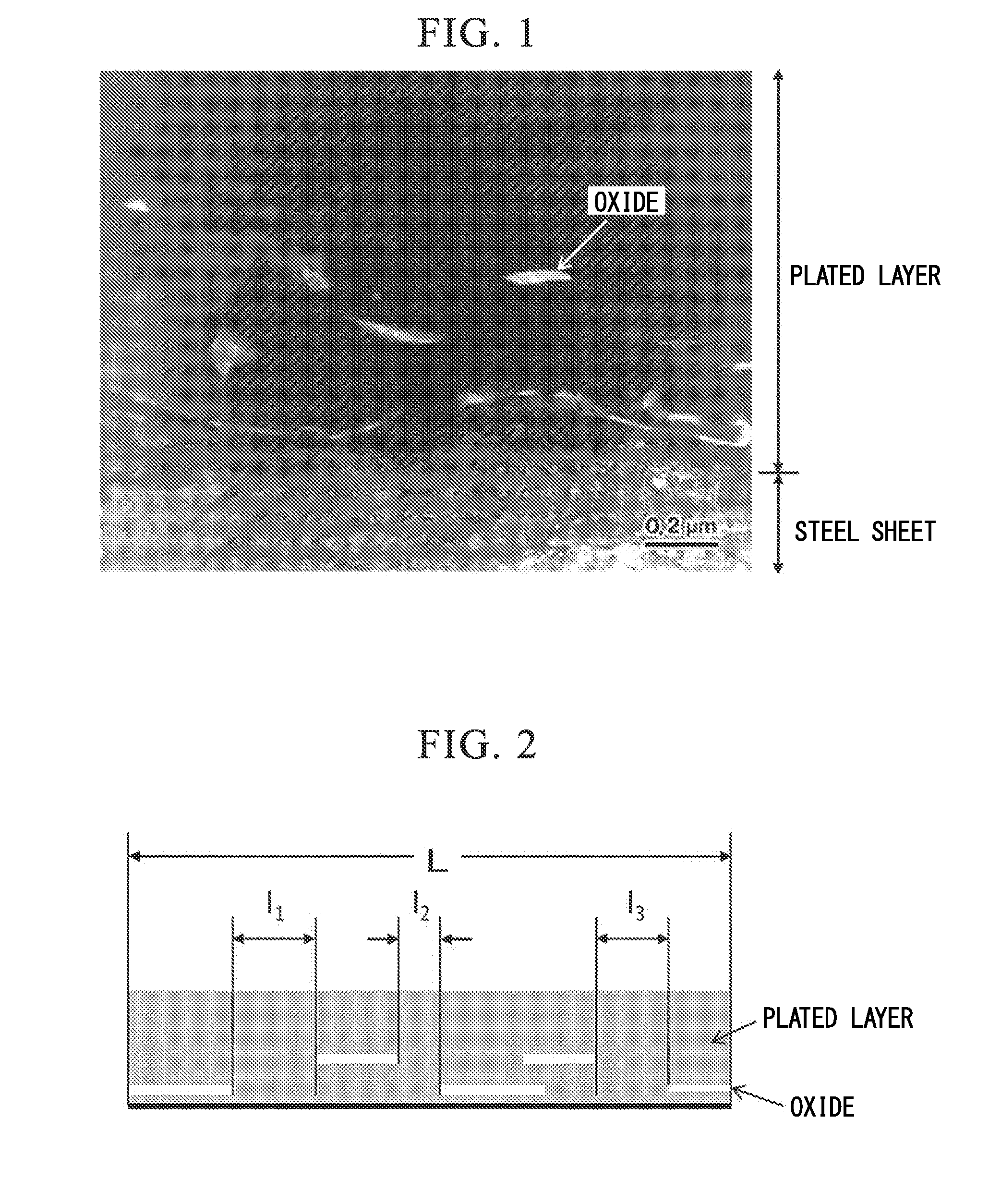

Hot-dip galvanized steel sheet and manufacturing method thereof

ActiveUS20140234657A1Low costImprove adhesionHot-dipping/immersion processesFurnace typesPearliteBainite

A hot-dip galvanized steel sheet includes: a steel sheet; and a plated layer on a surface of the steel sheet, a microstructure contains, by volume fraction, equal to or more than 20% and equal to or less than 99% in total of one or two of martensite and bainite, a residual structure contains one or two of ferrite, residual austenite of less than 8% by volume fraction, and pearlite of equal to or less than 10% by volume fraction, tensile strength is equal to or greater than 980 MPa, the plated layer is a hot-dip galvanized layer which contains oxides including one or two or more of Si, Mn, and Al, contains equal to or less than 15 mass % of Fe, and a remainder including Zn, Al, and unavoidable impurities, and when a cross section including the steel sheet and the hot-dip galvanized layer is seen in a sheet thickness direction, a projected area ratio is equal to or more than 10% and equal to or less than 90%.

Owner:NIPPON STEEL CORP

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

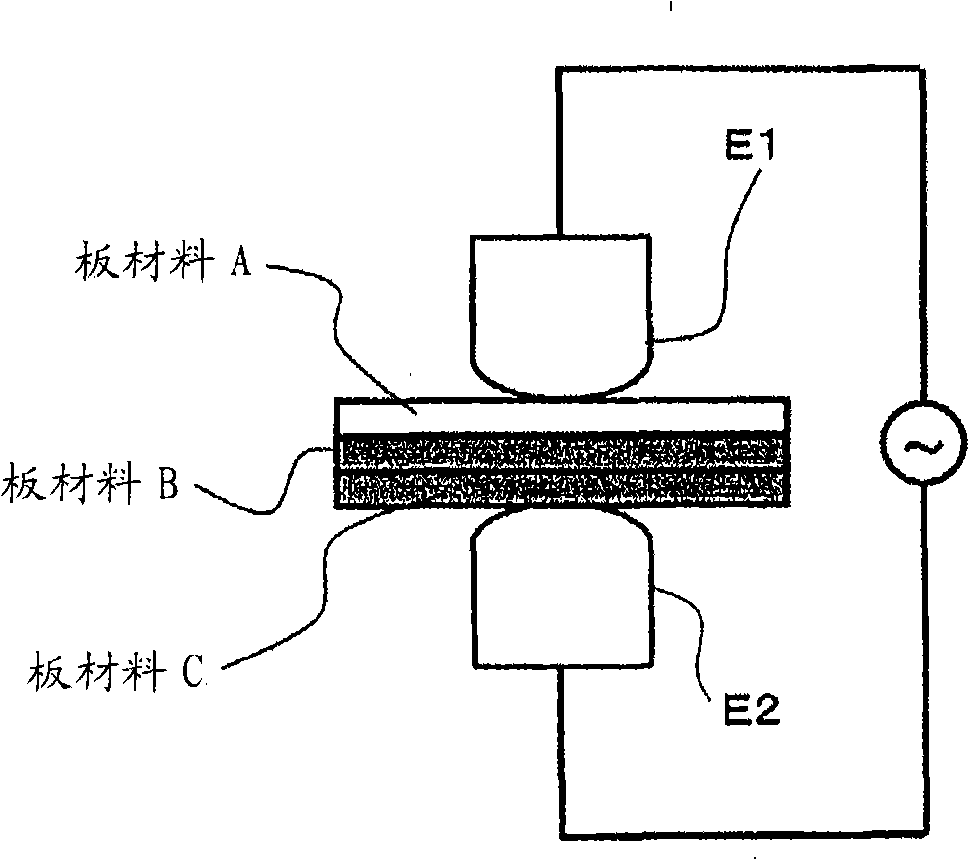

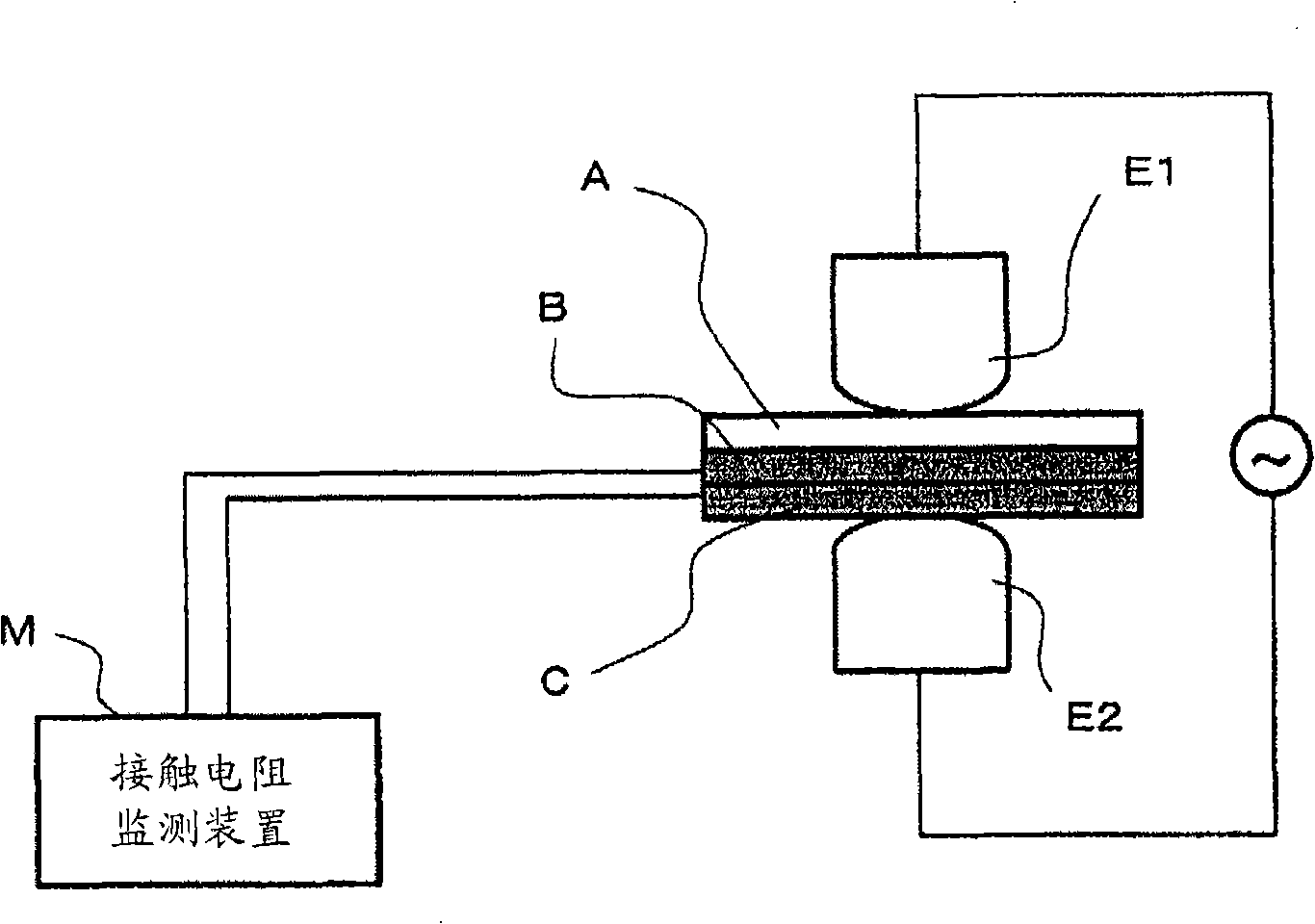

Bonding method of dissimilar materials made from metals and bonding structure thereof

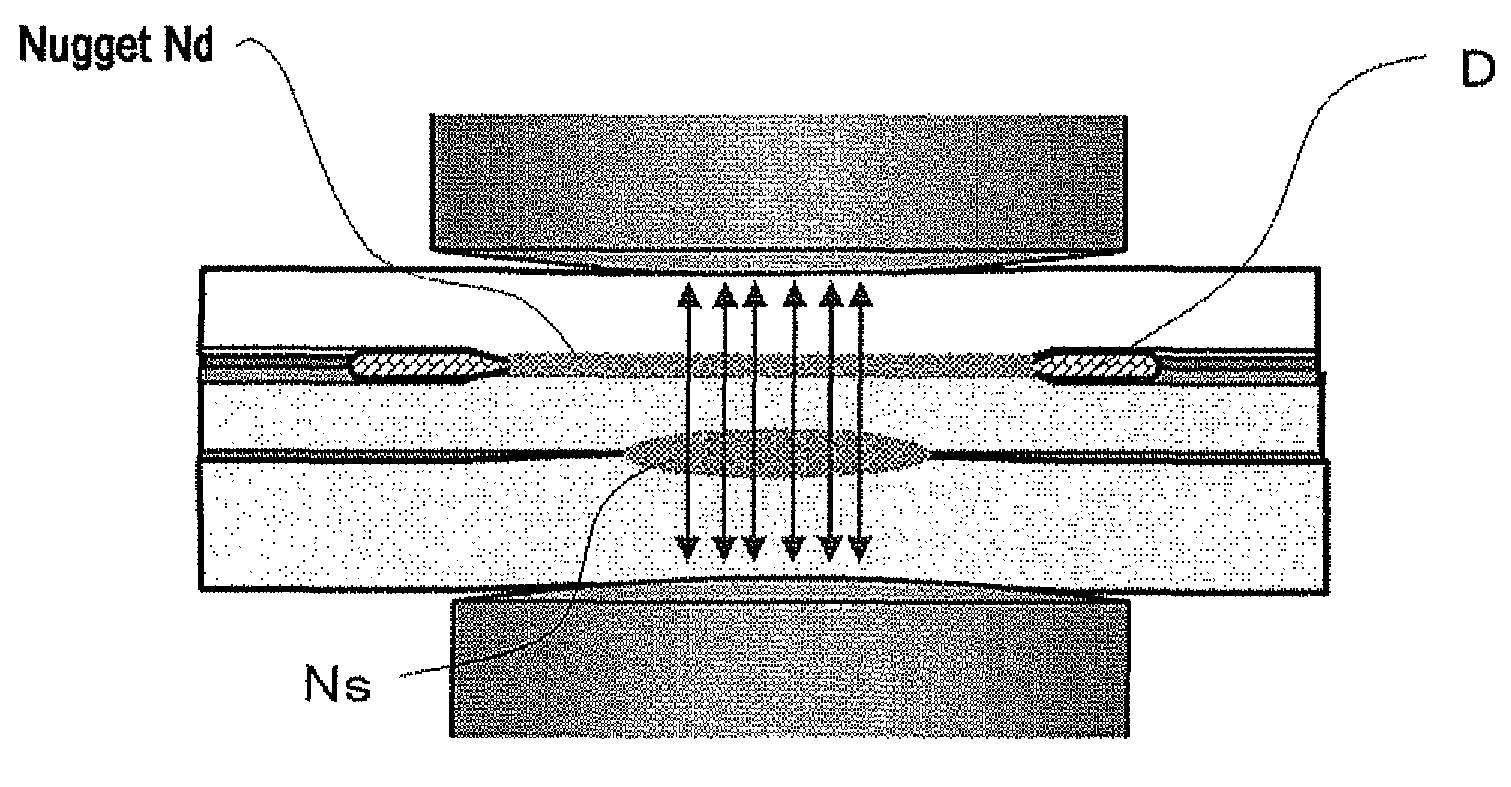

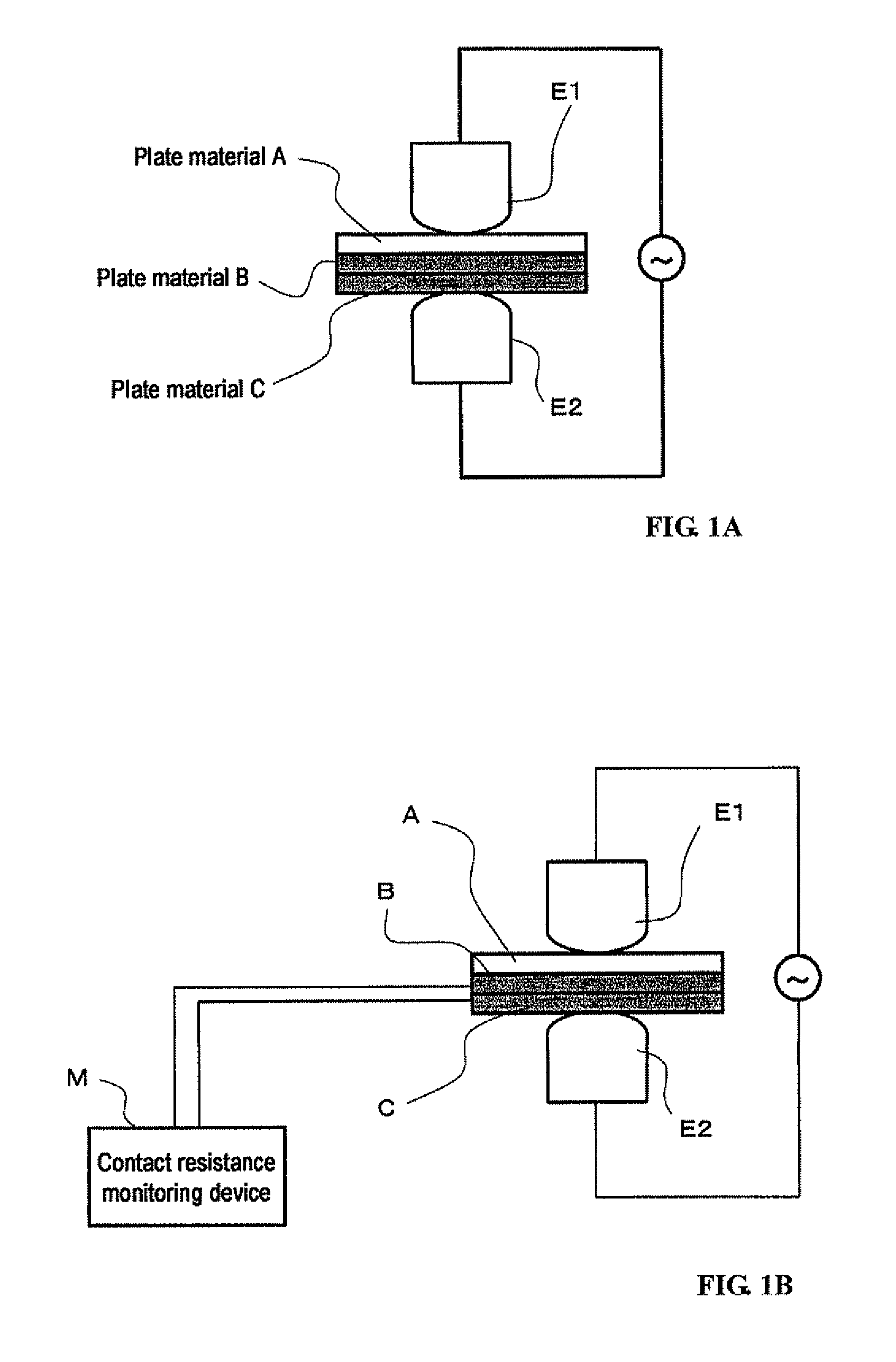

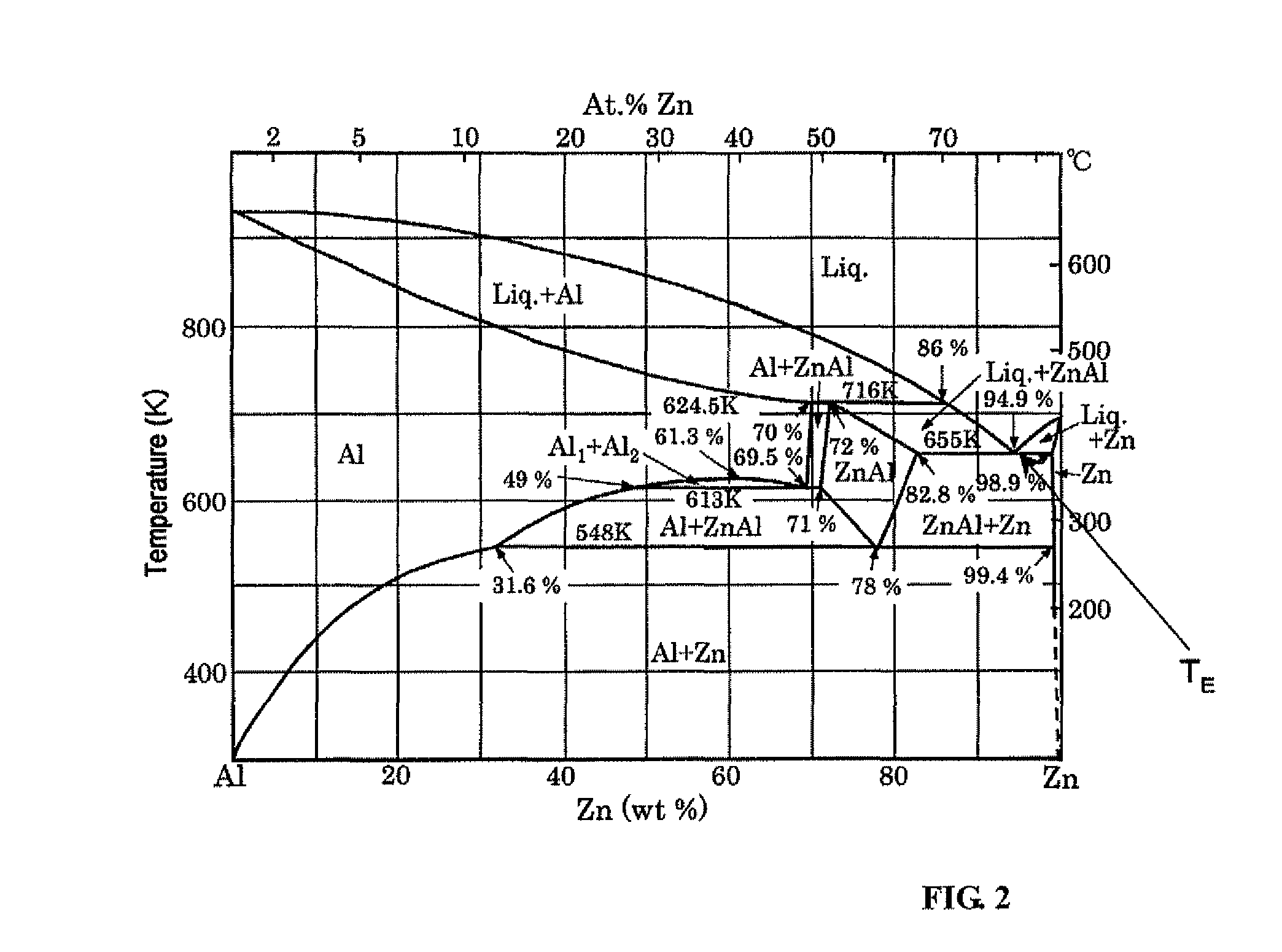

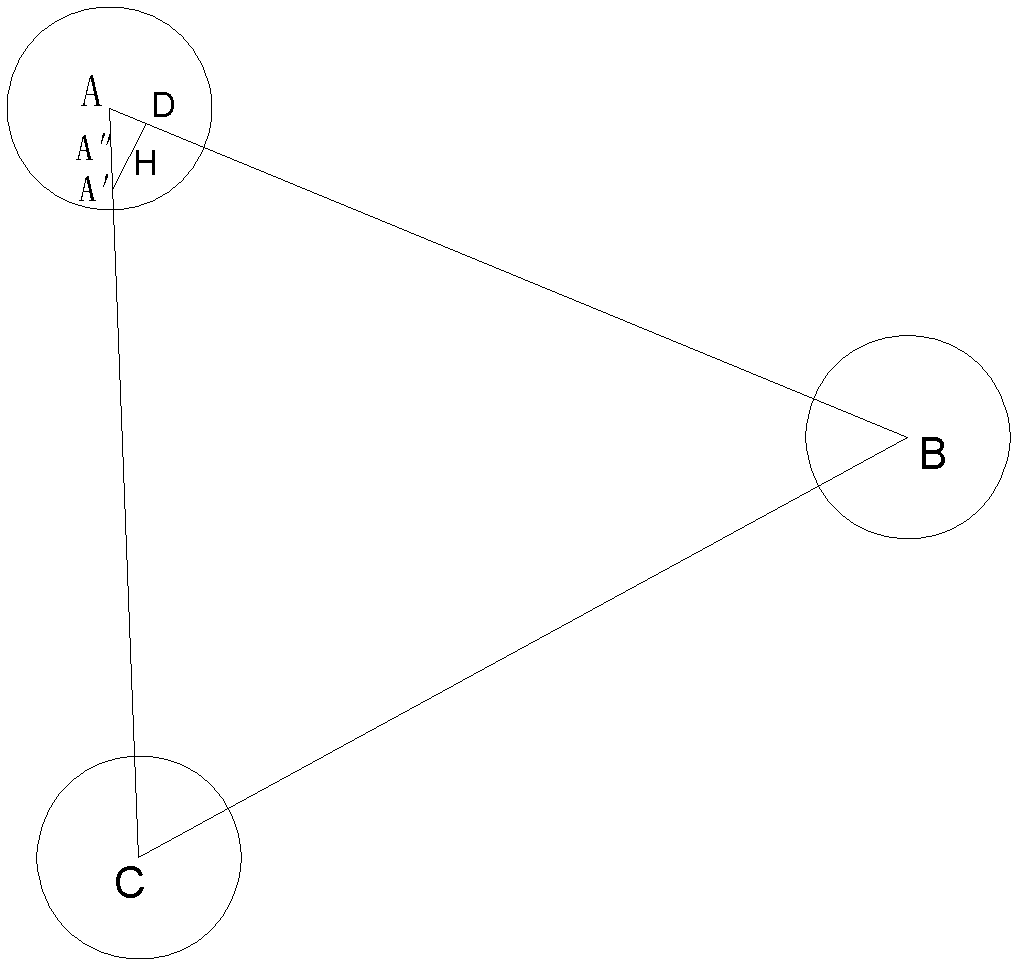

Disclosed is a bonding method for dissimilar materials made from metals and its resulting structures. The materials to be bonded are formed by layering three or more sheets such that a dissimilar material interface and a same material interface are formed. A first current is conducted between a three-sheet layered plate material wherein an aluminum alloy plate, a zinc plated steel plate and a bare steel plate, for example, are layered in order. A nugget is formed in an interface between the zinc plated steel plate and the bare steel plate, which are the same materials. Then, a second current greater than the first current is conducted, and a nugget is formed in an interface between the aluminum alloy plate and the zinc plated steel plate.

Owner:NISSAN MOTOR CO LTD

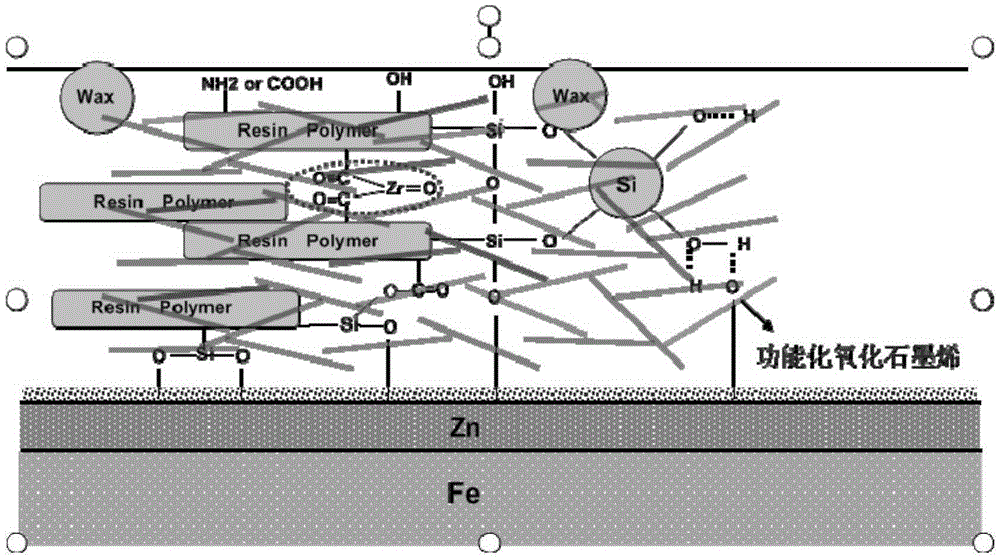

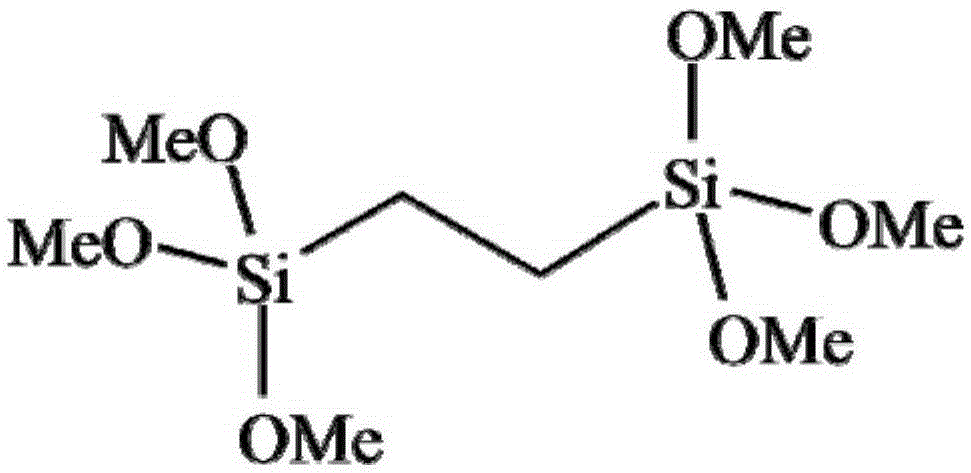

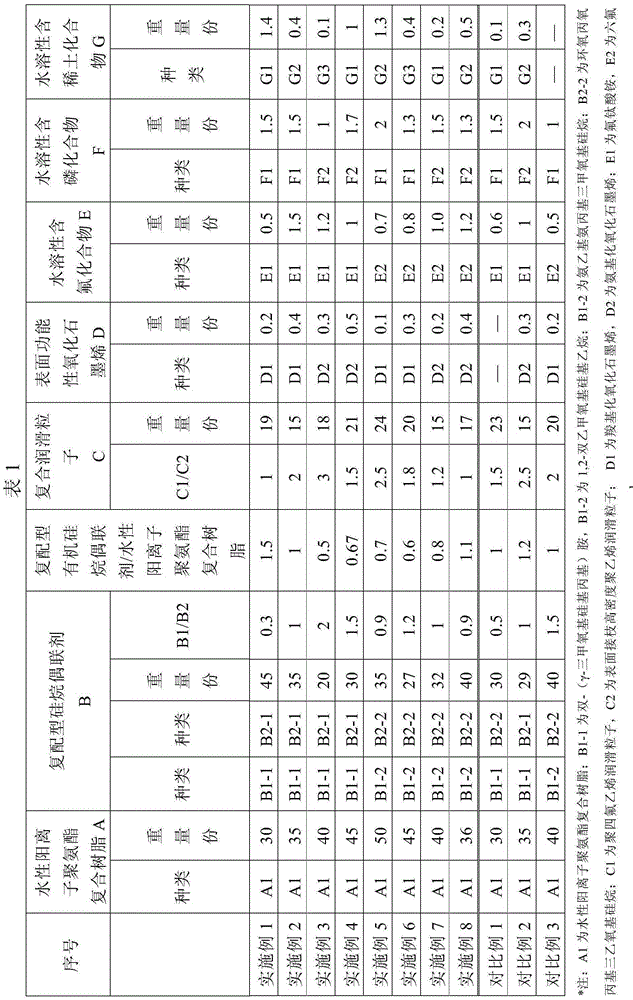

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

Wire rod for producting1770Mpa bridge cable galvanized steel wire and method for manufacturing same

ActiveCN101311288AHigh Dynamic Load Fatigue TestImprove toughnessRoll mill control devicesHeat treatment process controlWire rodToughness

The invention provides a wire rod for a galvanized steel wire of a 1770MPa bridge stay cable comprising the following chemical elements (by wt percentage): C, 0.85 to 0.9; Si, 0.12 to 0.32; Mn, 0.6 to 0.9; P, less than or equal to 0.025; S, less than or equal to 0.025; Cr, 0.1 to 0.25; V, less than or equal to 0.06; Cu, less than or equal to 0.1; the rest, inevitable impurity elements. The invention also provides a manufacturing method of the wire rod. The wire rod provided by the invention has the tensile strength Rm of 1300 to 1400 MPa, the elongation after fracture A which is more than or equal to 8 percent, and the contraction of area Z which is more than or equal to 30 percent (after aging, the contraction of area is more than or equal to 35 percent). The galvanized steel wire made of the wire rod can completely meet the technical requirements of the galvanized steel wire of the 1770MPa bridge stay cable, such as fatigue tests of high dynamic load (more than or equal to two million cycle-index), high toughness and high torsion (more than or equal to eleven times), etc.

Owner:BAOSHAN IRON & STEEL CO LTD

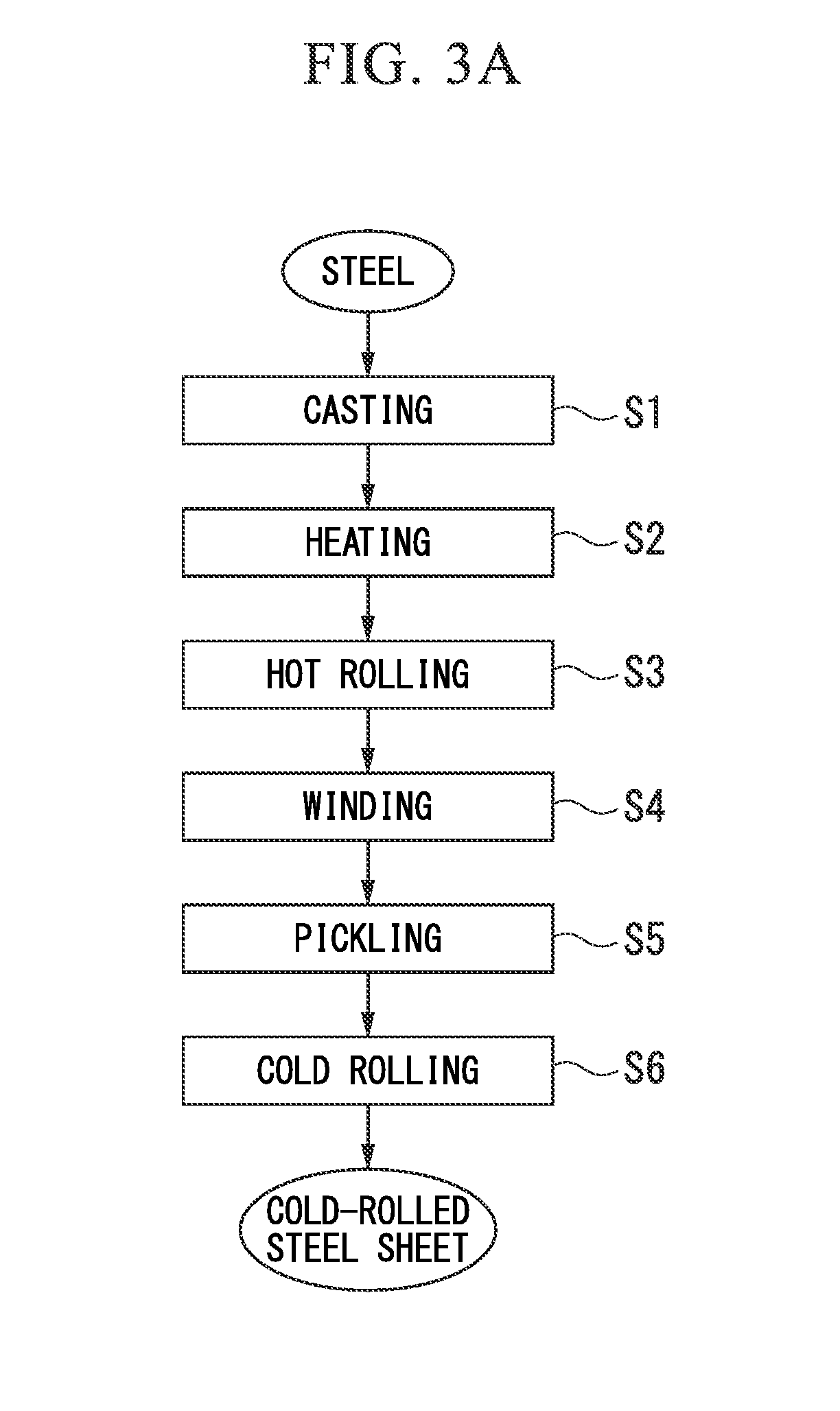

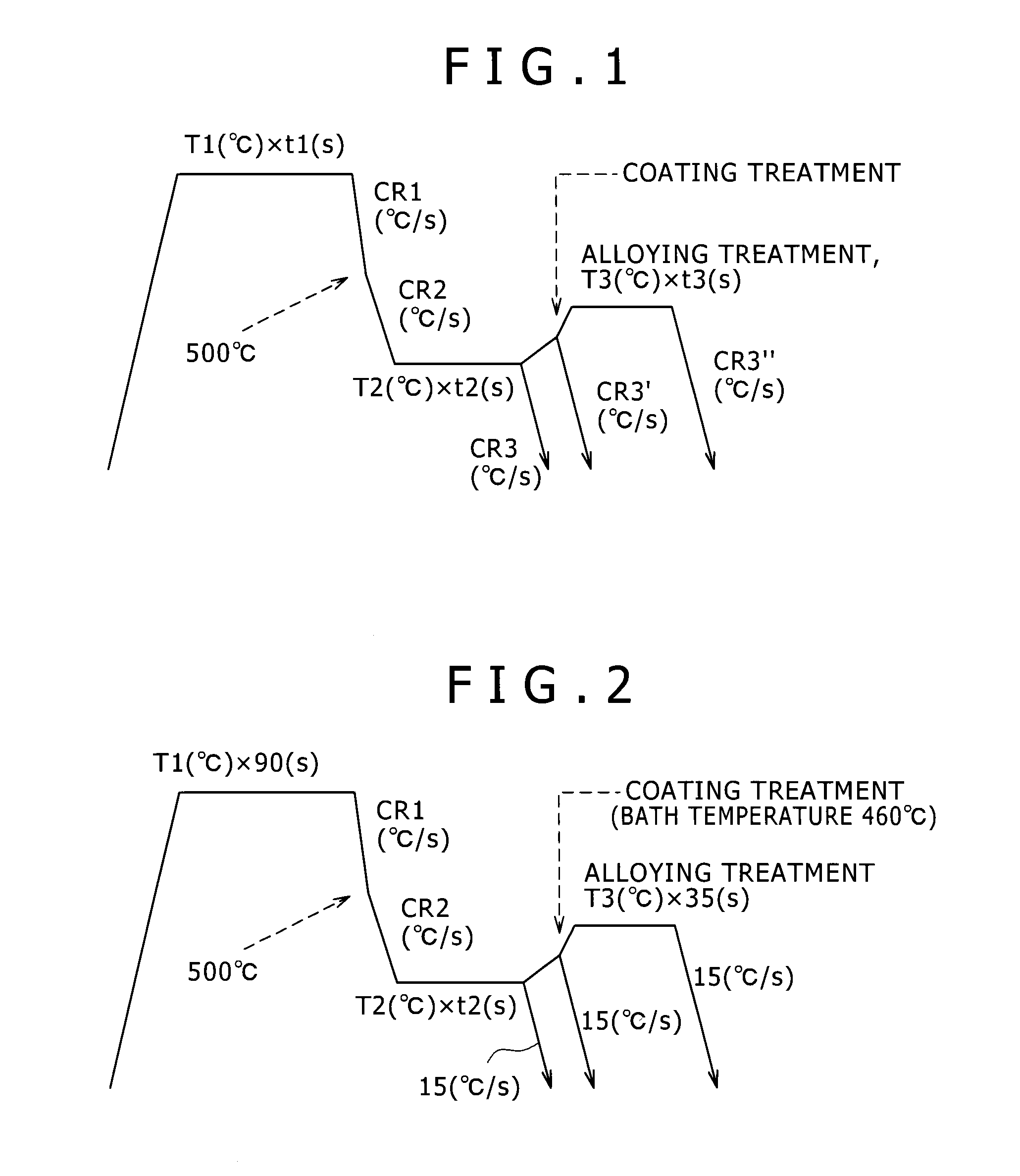

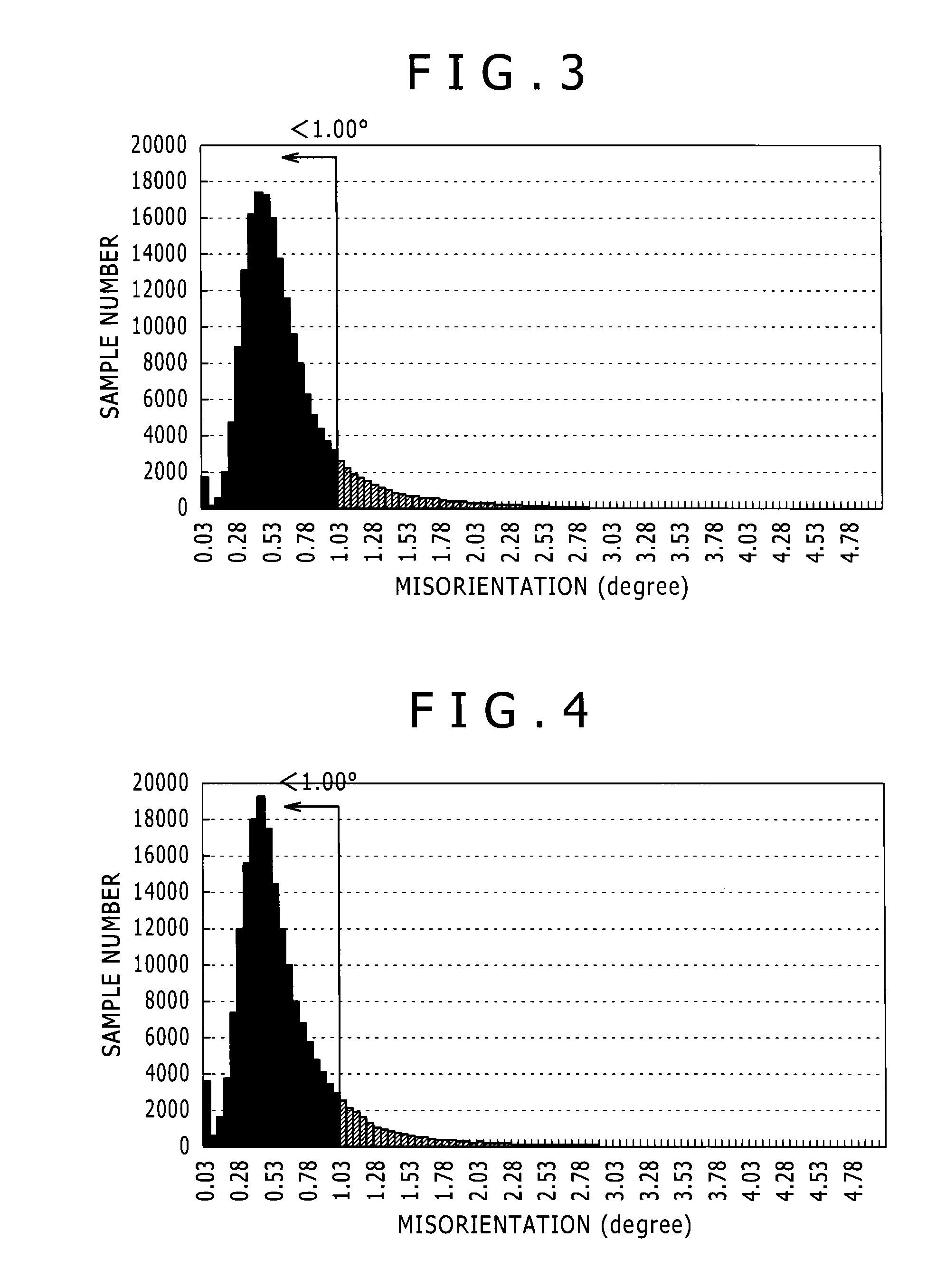

High-strength cold-rolled steel sheet, high-strength hot-dip galvanized steel sheet, and high-strength hot-dip galvannealed steel sheet excellent in formability and shape fixability, and methods for manufacturing them

InactiveUS20150086808A1Good formabilityEasy to shapeHot-dipping/immersion processesFurnace typesChemical compositionBainite

A high-strength cold-rolled steel sheet has a specific chemical composition and has a steel microstructure meeting conditions: a total content of bainitic ferrite (BF) and tempered martensite (TM) is 65% (in area percent, hereinafter the same for steel microstructure) or more; a fresh martensite (M) content is 3% to 18%; a retained austenite content is 5% or more; and a polygonal ferrite (F) content is 5% or less. The steel sheet has a specific average KAM<1.00° of 0.50° or more and has a tensile strength of 980 MPa or more. The high-strength cold-rolled steel sheet excels in formability and shape fixability.

Owner:KOBE STEEL LTD

High-strength hot-dipped galvanized steel sheet having excellent formability and impact resistance, and method for producing same

ActiveUS20140377584A1Good molding effectPartly suitableHot-dipping/immersion processesFurnace typesMartensiteAustenite

A galvanized steel sheet has a composition containing, by mass %, C: 0.05% or more and 0.5% or less, Si: 0.01% or more and 2.5% or less, Mn: 0.5% or more and 3.5% or less, P: 0.003% or more and 0.100% or less, S: 0.02% or less, Al: 0.010% or more and 0.5% or less, B: 0.0002% or more and 0.005% or less, Ti: 0.05% or less, a relationship of Ti>4N being satisfied, and the balance comprising Fe and inevitable impurities, and a microstructure containing 60% or more and 95% or less of tempered martensite in terms of area ratio and 5% or more and 20% or less of retained austenite in terms of area ratio, or further containing 10% or less (including 0%) of ferrite in terms of area ratio and / or 10% or less (including 0%) of martensite in terms of area ratio, the tempered martensite having an average grain diameter of 5 μm or less.

Owner:JFE STEEL CORP

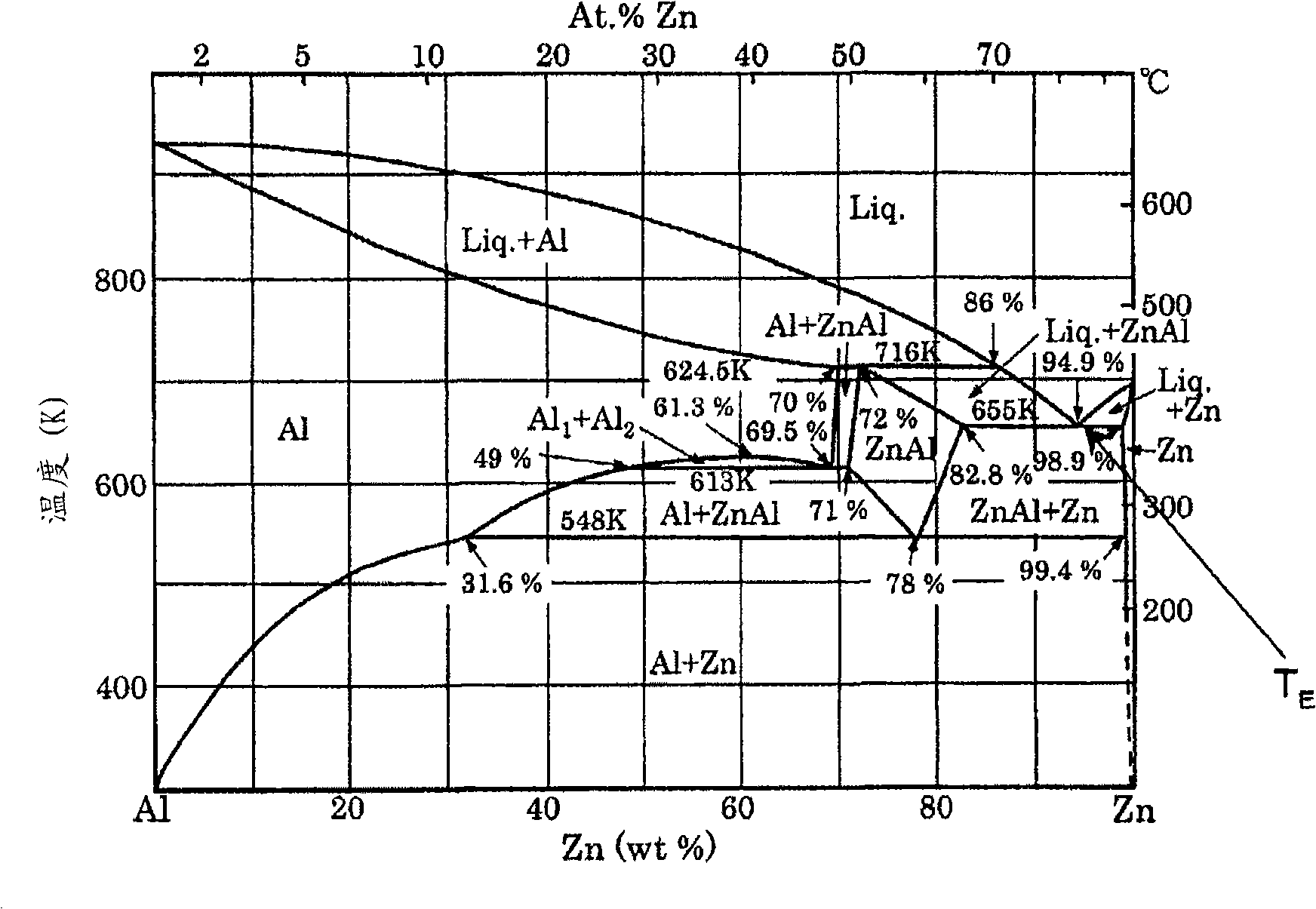

High Corrosion Resistance Hot dip Galvanized Steel Material

InactiveUS20090053555A1Improve corrosion resistanceSuppressing degradationHot-dipping/immersion processesThin material handlingAmorphous phaseAlloy

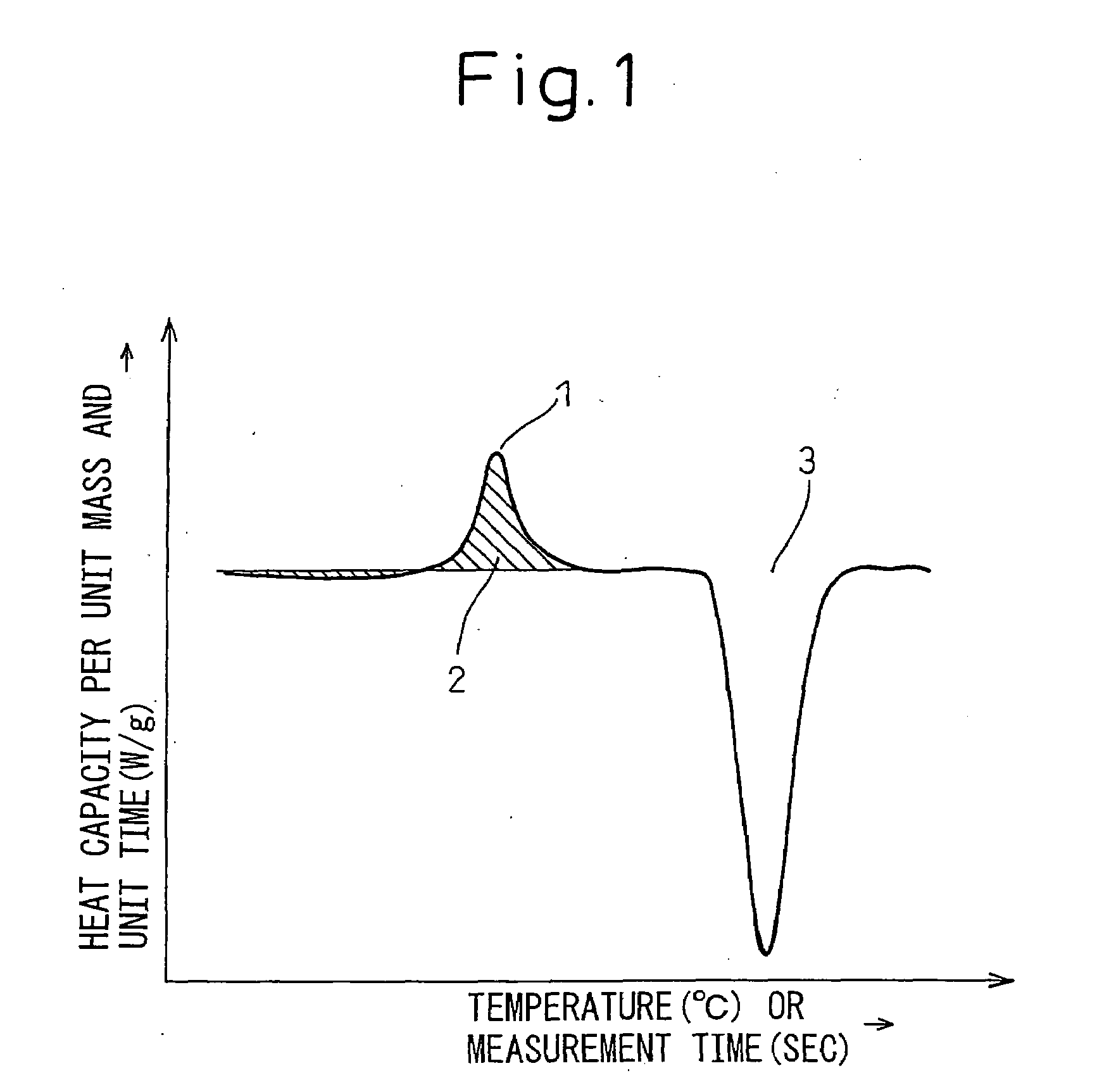

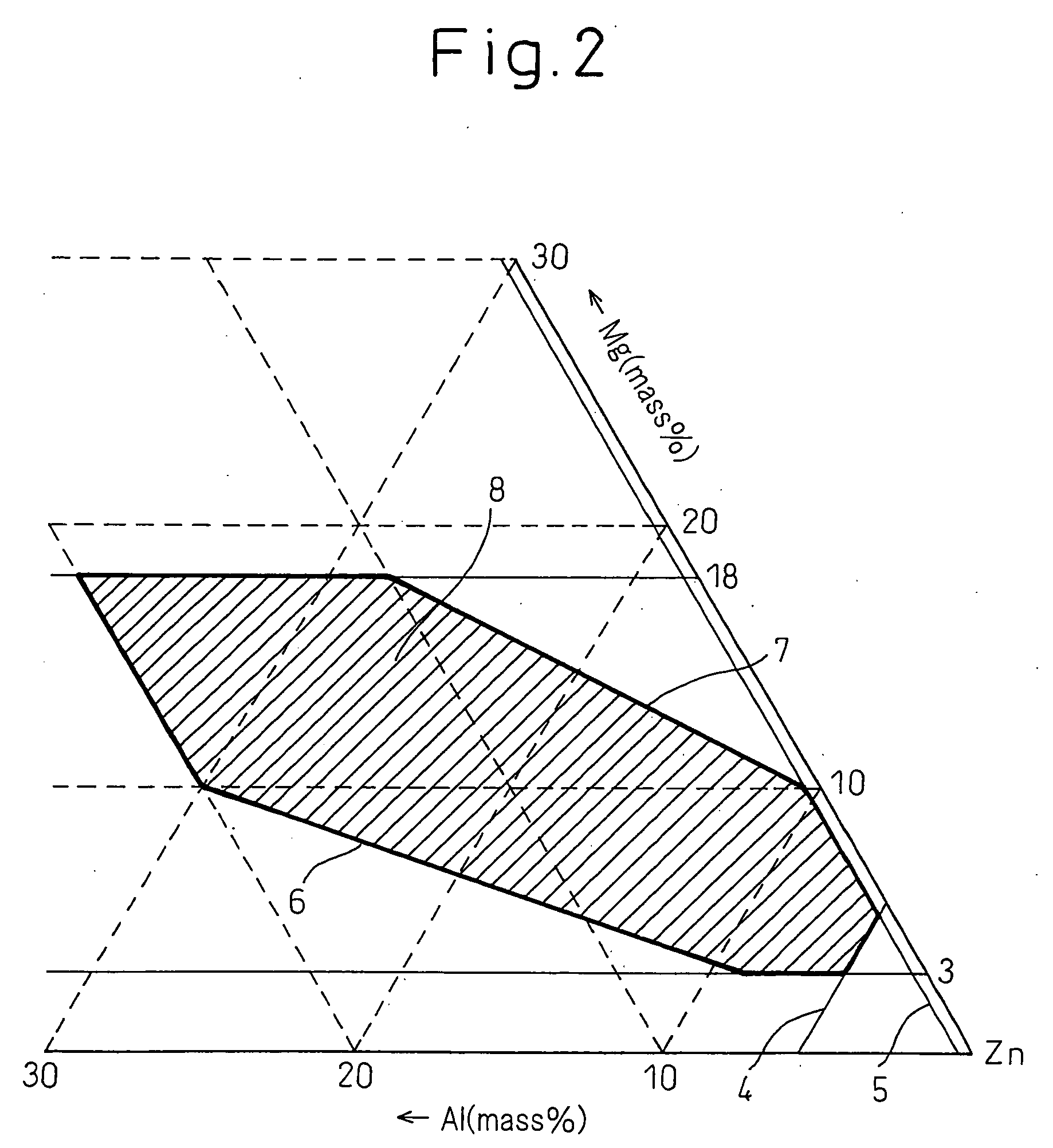

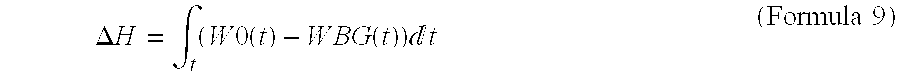

The present invention provides a high corrosion resistance hot dip galvannealed steel material comprised of a Zn-based hot dip plated steel material achieving both a higher corrosion resistance of the plated layer itself by the added elements and sacrificial protection of iron metal by the plated layer or workability free of degradation caused of formation of intermetallic compounds by added elements, that is, a high corrosion resistance hot dip Zn plated steel material characterized in that an alloy plated layer containing Zn: 35 mass % or more, preferably 40 mass % or more, contains a non-equilibrium phase having a heat capacity by differential scanning calorimetry of 1 J / g or more. Furthermore, 5% or more, preferably 50% or more in terms of vol % is an amorphous phase. The alloy layer may contain, by mass %, Mg: 1 to 60% and Al: 0.07 to 59%, may further contain one or more elements selected from Cr, Mn, Fe, Co, Ni, and Cu in a total of 0.1 to 10%, and may in addition contain one or more elements of 0.1 to 10% of La, 0.1 to 10% of Ce, 0.1 to 10% of Ca, 0.1 to 10% of Sn, 0.005 to 2% of P, and 0.02 to 7% of Si.

Owner:NIPPON STEEL CORP

High-strength galvanized steel sheet excellent in bendability and manufacturing method thereof

ActiveUS20140212684A1Improve bending performanceHigh tensile strengthHot-dipping/immersion processesFurnace typesAlloyHardness

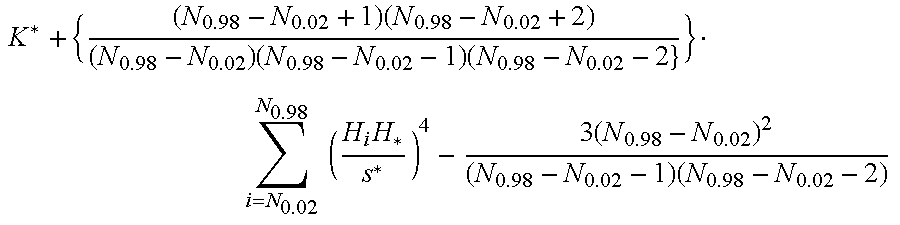

The present invention provides a high-strength galvanized steel sheet with maximum tensile strength of 900 MPa or more. The high-strength galvanized steel sheet has an alloyed galvanized layer formed on a surface of a base steel sheet containing predetermined amounts of C, Si, Mn, P, S, Al, N, O with a balance being constituted of iron and inevitable impurities, in which in a structure of the base steel sheet, retained austenite is limited to 8% or less in volume fraction, kurtosis K* of the hardness distribution between 2% hardness and 98% hardness is −0.30 or less, a ratio between Vickers hardness of surface layer of the base steel sheet and Vickers hardness of ¼ thickness of the base steel sheet is 0.35 to 0.70, and a content of iron in the alloyed galvanized layer is 8 to 12% in mass %.

Owner:NIPPON STEEL CORP

Trivalent-chromium blue-white passivator for zinc-plated permanent magnetic material and passivation method thereof

InactiveCN102041497AAvoid pollutionAvoid damageMetallic material coating processesRare-earth elementNickel salt

The invention provides a trivalent-chromium blue-white passivator for a zinc-plated permanent magnetic material and a passivation method thereof. The trivalent-chromium blue-white passivator contains a main film-forming agent, an auxiliary film-forming agent, a stabilizer, an oxidant and a surfactant, wherein the main film-forming agent is a soluble salt of trivalent chromium, the stabilizer is selected from at least one of fluoride, citric acid and oxalic acid, the auxiliary film-forming agent is selected from at least one of soluble cobalt salt, soluble nickel salt or soluble salts of rare-earth elements, the oxidant is nitrate ions or hydrogen peroxide, and the surfactant is NPE (Nonylphenol Polyoxyethylene Ether) or sodium dodecyl benzene sulfonate. The trivalent-chromium blue-white passivator provided by the invention has a low cost, does not pollute the environment, and also does not cause damage to the health of operators.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Bonding method of dissimilar materials made from metals and bonding structure thereof

Disclosed is a bonding method for dissimilar materials made from metals and its resulting structures. The materials to be bonded are formed by layering three or more sheets such that a dissimilar material interface and a same material interface are formed. A first current is conducted between a three-sheet layered plate material wherein an aluminum alloy plate, a zinc plated steel plate and a bare steel plate, for example, are layered in order. A nugget is formed in an interface between the zinc plated steel plate and the bare steel plate, which are the same materials. Then, a second current greater than the first current is conducted, and a nugget is formed in an interface between the aluminum alloy plate and the zinc plated steel plate.

Owner:NISSAN MOTOR CO LTD

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

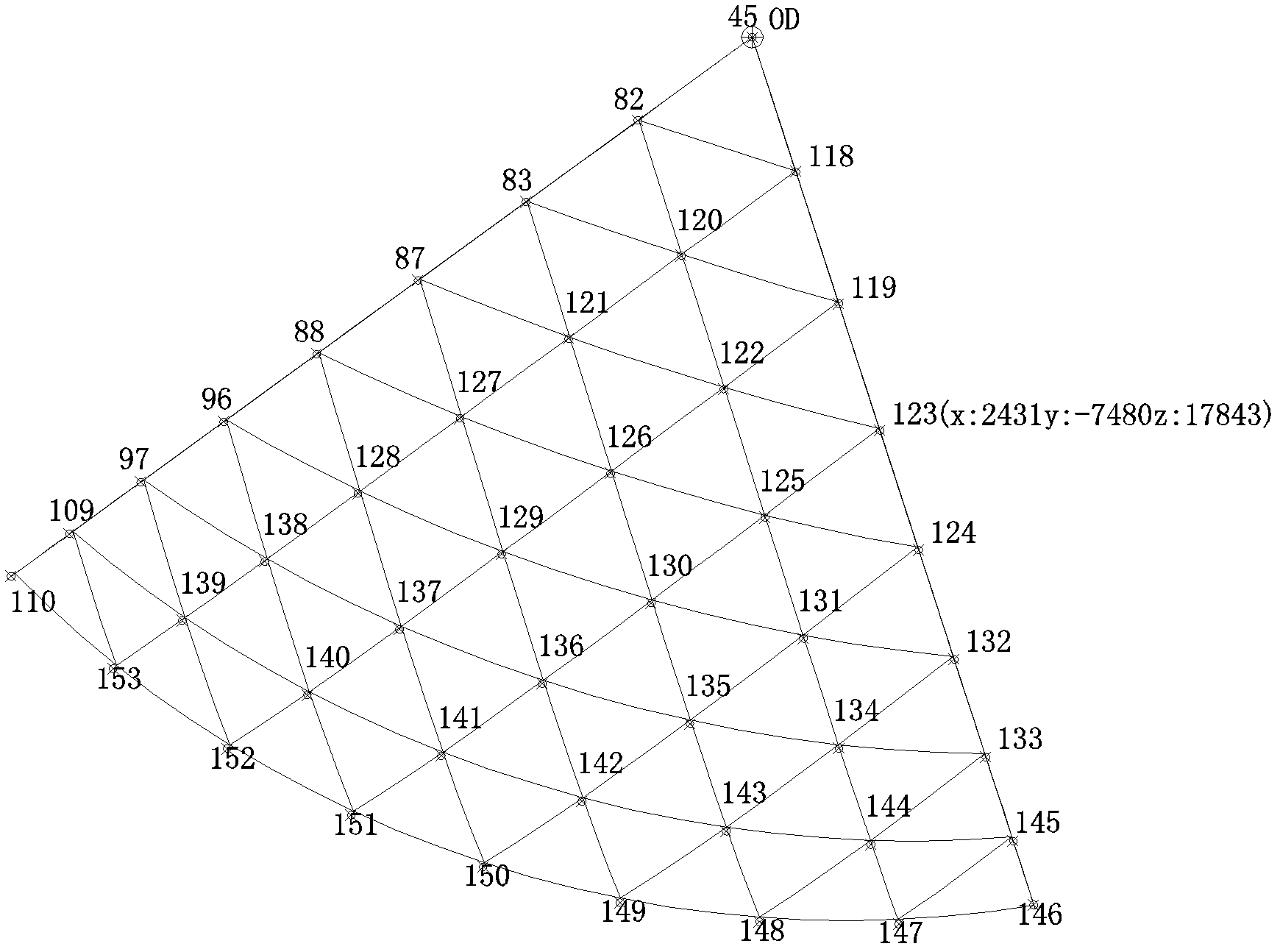

Construction method for spherical curved surface stainless steel curtain wall

ActiveCN102535844ARealize spherical hyperboloid modelingAccurate spatial positioningWallsBuilding material handlingSurface finishFalsework

The invention relates to a construction method for a spherical curved surface stainless steel curtain wall. The method comprises the following steps of: performing construction setting-out, erecting an operating scaffold, installing steel supports, steel keels and backing galvanized iron sheets, constructing fireproof layers and thermal insulation layers, installing waterproof aluminum plates, aluminum alloy keel supports and double curved surface stainless steel panels, injecting glue, performing a spray test, constructing sound absorbing layers, and the like on the outer side of the finished spherical building structure, so that a spherical mirror surface stainless steel plate curtain wall which has strong metal texture and high surface finish and is convenient to clean is formed on the surface. The fireproof layers and the thermal insulation layers are constructed in a spraying mode, so that a reinforcement measure in the conventional mode for the fireproof layers and the thermal insulation layers is eliminated, and engineering cost is saved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Thermal treatment wire rod for 2000MPa-grade cable steel wire and production method

ActiveCN107299280AImprove mechanical propertiesImprove uniformityQuenching agentsWire rodSpecial design

The invention provides a thermal treatment wire rod for a 2000MPa-grade cable steel wire and a production method. The thermal treatment wire rod is prepared from the following components in percentage by weight: 0.85 to 1.0 percent of C, 0.80 to 1.5 percent of Si, 0.30 to 0.80 percent of Mn, 0.20 to 0.80 percent of Cr, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.01 to 0.08 percent of Al, and the balance of Fe and inevitable impurities. According to the thermal treatment wire rod for the 2000MPa-grade cable steel wire and the production method disclosed by the invention, through special design of the components, the wire rod is produced through processes of smelting, continuous casting, blank casting and grinding, steel rolling and off-line thermal treatment, and the sorbitizing rate of the wire rod is greater than 95 percent, tissues are homogenized, and quenching tissues such as network carbide and martensite are avoided. After the wire rod is subjected to drawing, zinc (aluminum) plating, and stabilization treatment, the strength of the steel wire is greater than or equal to 2000MPa, so that the wire rod can be used for producing the 2000MPa-grade cable zinc (aluminum) plating steel wire for bridges, and is applied to bridges requiring extra long-span and ultrahigh strength.

Owner:QINGDAO SPECIAL STEEL CO LTD

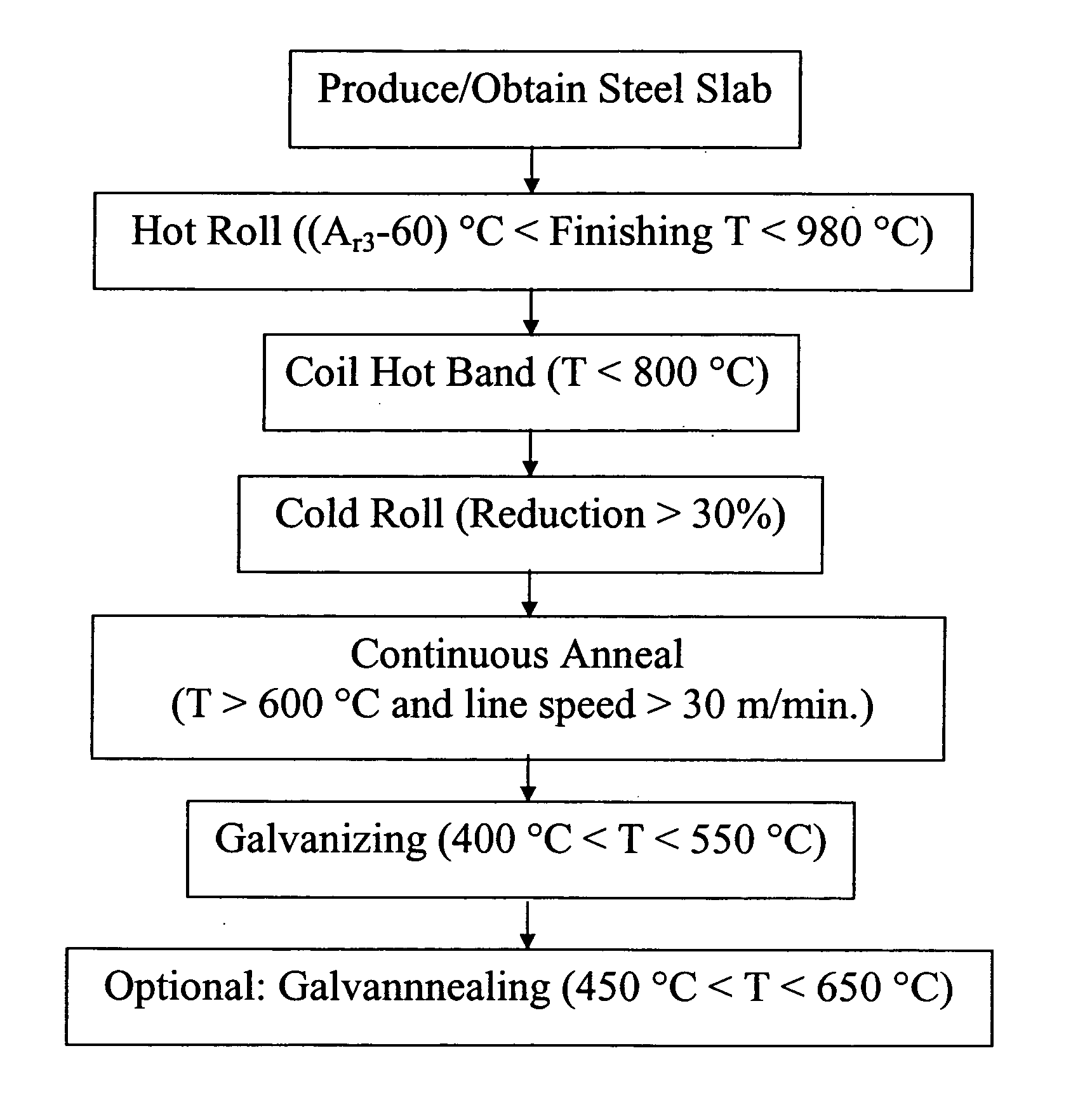

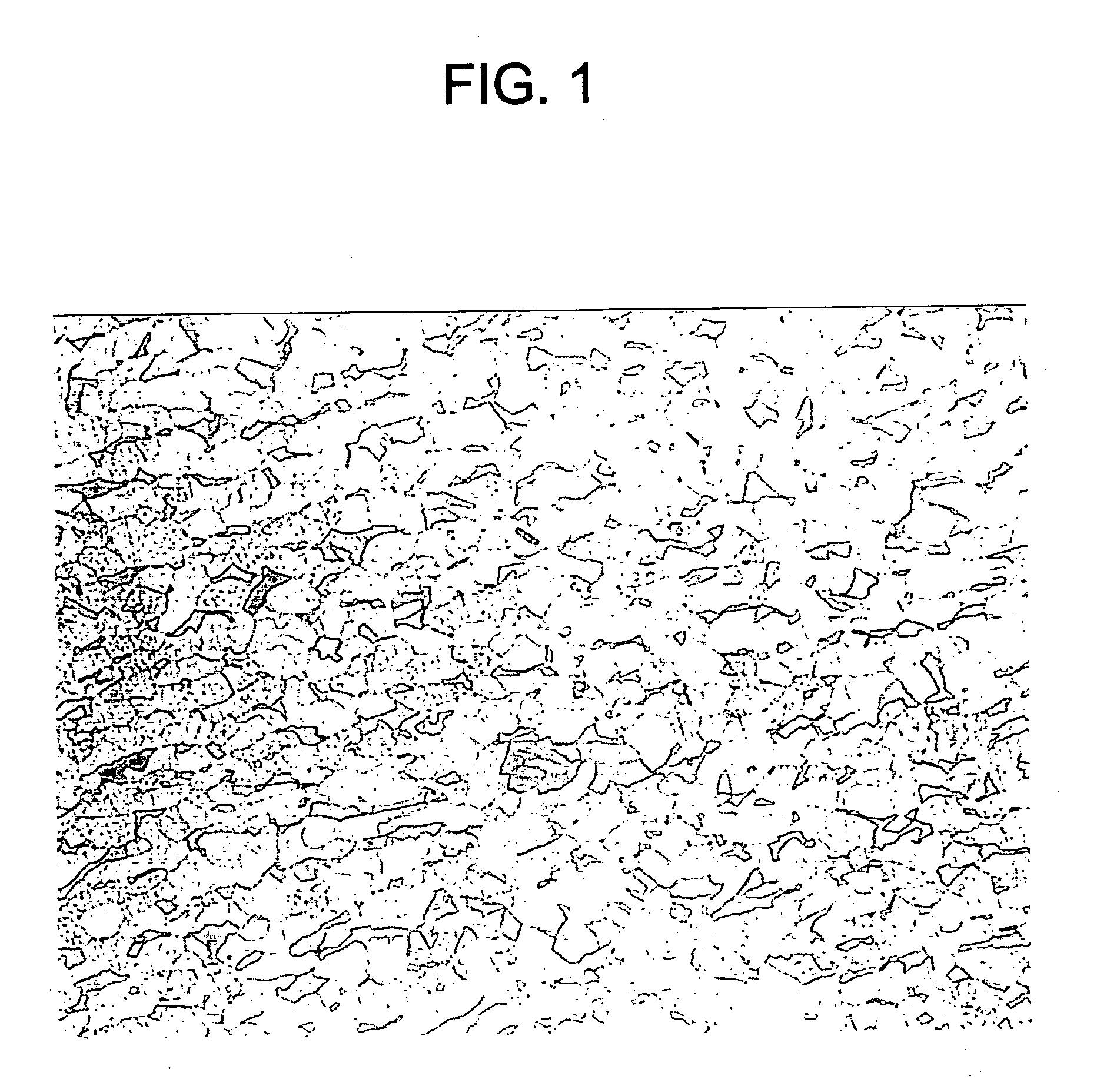

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20080075971A1Good energyGood formabilityHot-dipping/immersion processesFurnace typesNiobiumManganese

A galvanized steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: carbon in a range from about 0.01% to about 0.18%; manganese in a range from about 0.2% to about 3%; silicon ≦ about 1.2%; aluminum in a range from about 0.01% to about 0.1%; one or both of chromium and nickel in a range from about 0.1% to about 3.5%; calcium in a range from about 0.0003% to about 0.01%; phosphorus ≦ about 0.01%; sulfur ≦ about 0.03%; nitrogen ≦ about 0.02%; molybdenum ≦ about 1%; copper ≦ about 0.8%; one or more of niobium, titanium, and vanadium ≦ about 1%; and boron ≦ about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. In one embodiment, the steel sheet is both galvanized and galvannealed.

Owner:NUCOR CORP

Plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and production method thereof

The invention discloses plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and a production method thereof. The dual-phase steel comprises the chemical components of, by weight, 0.12-0.18% of C, 0.3-0.6% of Si, 1.3-2.3% of Mn, 0-0.01% of P, 0-0.01% of S, 0.4-0.9% of Al, and the balance Fe and inevitable impurities. The technical problems of how to reduce the alloy or process cost and improve the galvanized surface quality on the basis of meeting the intensity requirement are solved, and the technical effects of reducing the alloy cost and improving the galvanized surface quality are achieved.

Owner:SHOUGANG CORPORATION

Ultrahigh-strength vanadium-titanium composite microalloyed high carbon steel wire rod and preparation method thereof

ActiveCN102352469ASimple production processLow costHeat treatment process controlElectric furnaceTitaniumPre stress

The invention discloses an ultrahigh-strength vanadium-titanium composite microalloyed high carbon steel wire rod and a preparation method thereof. The wire rod is prepared by the vanadium-titanium composite microalloying technology. The high carbon steel wire rod contains basic components such as C, Si, Mn, P, S, V, Ti, Cr, Cu, Ni, O and N and optional components such as Al, Ca, B and Mg and also contains the balance of iron and impurities. The preparation method comprises the following working procedures of: performing electric furnace smelting, refining, performing continuous casting, rolling and cooling. The diameter of the wire rod is 11-15mm, the tensile strength Rm is 1330-1410MPa, the average tensile strength is 1380MPa and the section shrinkage rate Z is no less than 32%. The tensile strength of the 15.2mm prestressed steel strand produced by the low-alloyed high carbon steel wire rod is more than 2140MPa, the tensile strength of the 15.2mm galvanized steel strand is more than 1960MPa and the tensile strength of the 7mm galvanized steel wire is more than 1860MPa.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Surface treating agent with excellent alkali resistance and solvent resistance and for zinc coated steel plate

ActiveCN1887449AEasy to handleGood alkali resistancePretreated surfacesAnti-corrosive paintsTectorial membraneSolvent

The present invention relates to surface treating agent for zinc coated steel plate, and is especially one kind of surface treating agent with excellent alkali resistance and solvent resistance for zinc coated steel plate. The surface treating agent is water solution, which consists of fluoric acid with 4 or more fluorine atoms and at least one of Ti, Zr and Si atome in 0.1-5.0 wt%; phsosphorus containing compounding 0.01-0.5 wt%; one or more organic silicon coupling agent with amino group containing at least one active hydrogen atom 10-20 wt%, one or more organic silane coupling agent with at least one epoxy group 25-50 wt%; at least one kind of cationic or non-ionic water soluble polyurethane resin 30-60 wt% and vanadium compound 0.1-1.0 wt%. It is used in forming protecting film with excellent performance on the surface of zinc coated steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Rustproofing agent for zinc plated steel sheet

A rustproofing agent for a zinc plated steel sheet is provided which contains (A) a chromium aqueous solution containing an organic substance and (B) an acid metal such as a metal salt of nitric acid or phosphoric acid. All of the chromium in the chromium aqueous solution of component. A is trivalent chromium. It is preferable if the organic substance in component A contains at least one type of oxy acid or oxide thereof. The metal in the acid metal salt of component B is an alkaline earth metal, cobalt, nickel, iron, zirconium, titanium, etc. It is also preferable if (C) a water-dispersible silica is contained as an additional component. The present invention also provides a zinc plated steel sheet, in which at least one side of the surface of a zinc plated steel sheet is coated with the zinc plated steel sheet rustproofing agent and the rustproofing agent dried to form a coating with a dry coating weight of 0.01 to 3 g / m<2>.

Owner:HENKEL KGAA

Process for magnesium alloy surface micro-arc oxidation

InactiveCN1772968ASmall coefficient of thermal expansionStrong corrosion resistanceAnodisationAluminateMicro arc oxidation

The present invention relates to a magnesium alloy surface microarc oxidation method. Said method includes the following steps: (1), pretreatment; (2), preparing alkaline silicate electrolyte or alkaline aluminate electrolyte; and (3), placing the pretreated magnesium alloy in the alkaline silicate electrolyte or alkaline aluminate electrolyte and making microarc oxidation; applying DC current, continuously rising voltage, constant current, current density is 1-15 A / sq.dm, galvanization time is 5-90 min and electrolyte temperature is less than 40 deg.C.

Owner:HARBIN INST OF TECH

Hot press-formed article and a method for its manufacture

ActiveUS20060121305A1Improve corrosion resistanceNot readily peel offAnodisationHot-dipping/immersion processesSolderabilitySolid solution

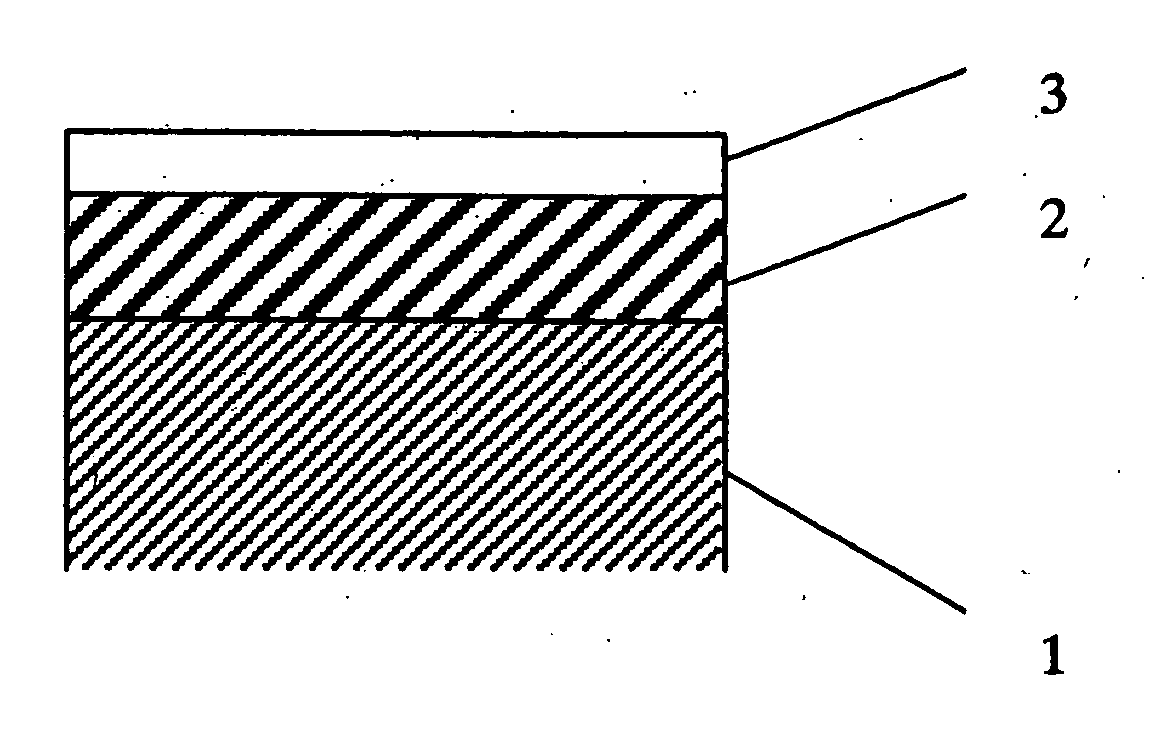

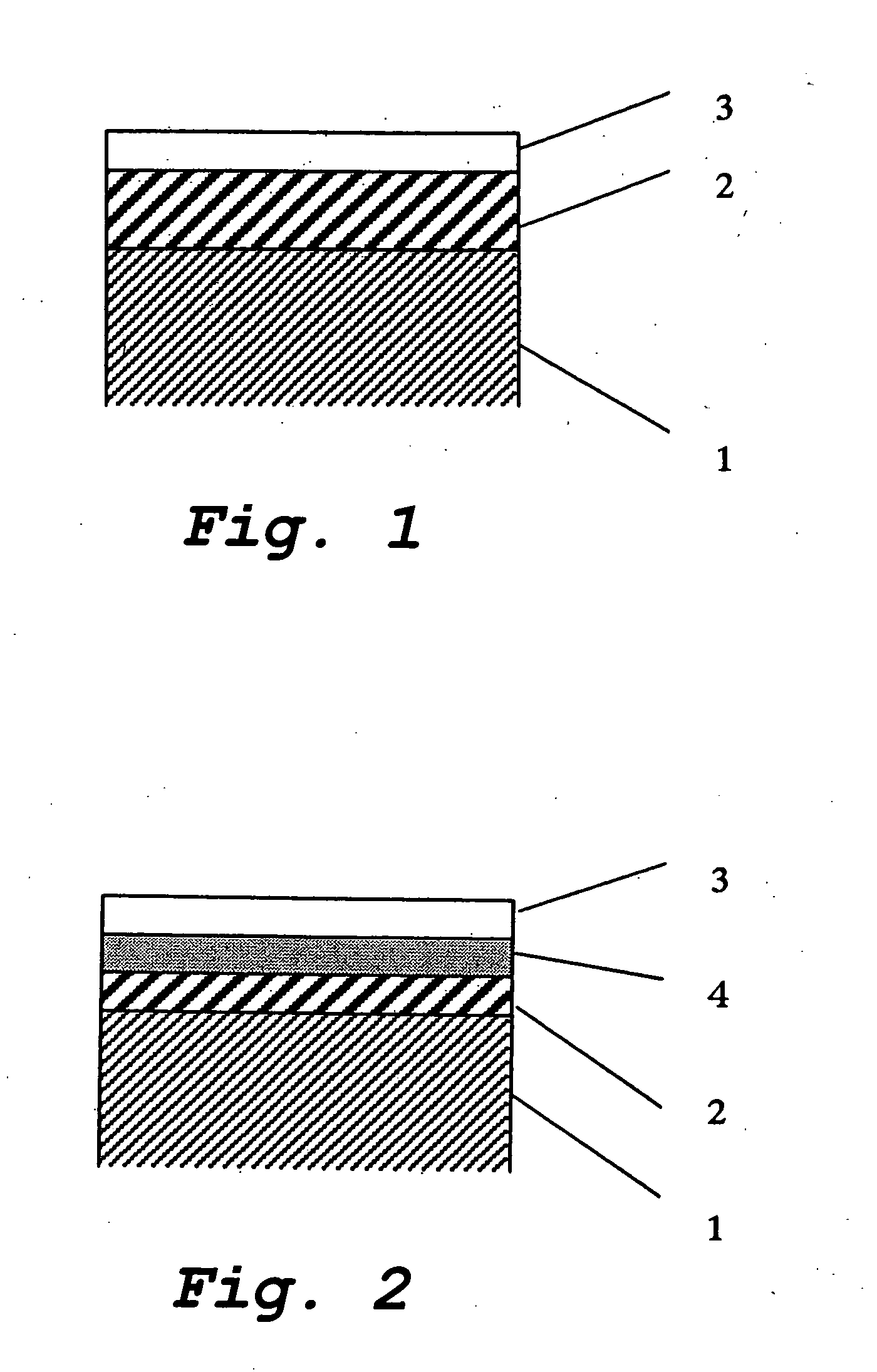

A hot press-formed article having improved corrosion resistance and coating adhesion when coated is obtained by hot press forming of a zinc-based plated steel material. It has a zinc-based plating layer comprising an iron-zinc solid solution phase and atop it a zinc oxide layer. The average thickness of the zinc oxide layer which is the outermost layer is at most 2 μm. A hot press-formed article having a good appearance and excellent corrosion resistance, coating adhesion, post-coating corrosion resistance, and weldability has a layer (2) consisting essentially of an iron-zinc solid solution phase atop a base material steel sheet (1). It also has a zinc oxide layer (3) with an average thickness of at most 5 μm as an uppermost layer, but it does not have a substantial amount of an iron-zinc intermetallic compound phase. The total amount of Al contained in the iron-zinc solid solution layer (2) and the zinc oxide layer (3) is at most 0.5 g / m2, and / or the total amount of Al oxides contained in these layers is at most 5 mg / m2.

Owner:NIPPON STEEL CORP +2

Production method of high-strength steel rope

InactiveCN103352381AMeet the standard requirementsUniform tissueFurnace typesQuenching agentsWater bathsQuenching

The invention provides a production method of a high-strength steel rope. The production method of the high-strength steel rope is characterized that low carbon is selected and used as raw materials of the steel rope, and the production technology comprises a first step of surface processing, wherein wire materials are placed on a pay-off rack, the diameter of the wire materials is 5.5mm, hot-rolled oxide-scale is eliminated through mechanical dephophorization equipment, high-power ultrasonic cleaning is conducted on the wire materials, the wire materials enter phosphating equipment, phosphating is conducted on the wire materials, the wire materials enter drying equipment and are dried finally, and preprocessed wire materials are obtained; a second step of drawing, wherein the preprocessed wire materials obtained from the first step are placed on a drawing machine, multi-pass drawing is conducted on the preprocessed wire materials, semi-finished wire materials are obtained, and winding up is conducted through a spool; a third step of water bath heat treatment and galvanization, wherein the semi-finished wire materials obtained in the second step are placed on the pay-off rack, the semi-finished wire materials are heated in a four-section form heat treatment furnace, quenching, drying, galvanization and cooling are conducted on the semi-finished wire materials, semi-finished wire materials are obtained, and winding up is conducted; a fourth step of wet type drawing, wherein the semi-finished wire materials obtained in the third step are placed on the drawing machine, multi-pass drawing is conducted on the semi-finished wire materials, the compression angle of a wire-drawing die of each pass is 13-14 degrees, dedicated lubricating agent is used as lubricating agent, the concentration of the dedicated lubricating agent is 2%-3%, finished wire materials are obtained, and winding up is conducted through a spool; a fifth step of stranding and rope forming, wherein the finished wire materials are placed on a stranding machine, stranding and laying-up are conducted, and the finished steel stranded rope is obtained.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com