Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2268 results about "Area ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The floor area ratio (FAR) is the relationship between the total amount of usable floor area that a building has, or has been permitted to have and the total area of the lot on which the building stands. The ratio is determined by dividing the total or gross floor area of the building by the gross area of the lot.

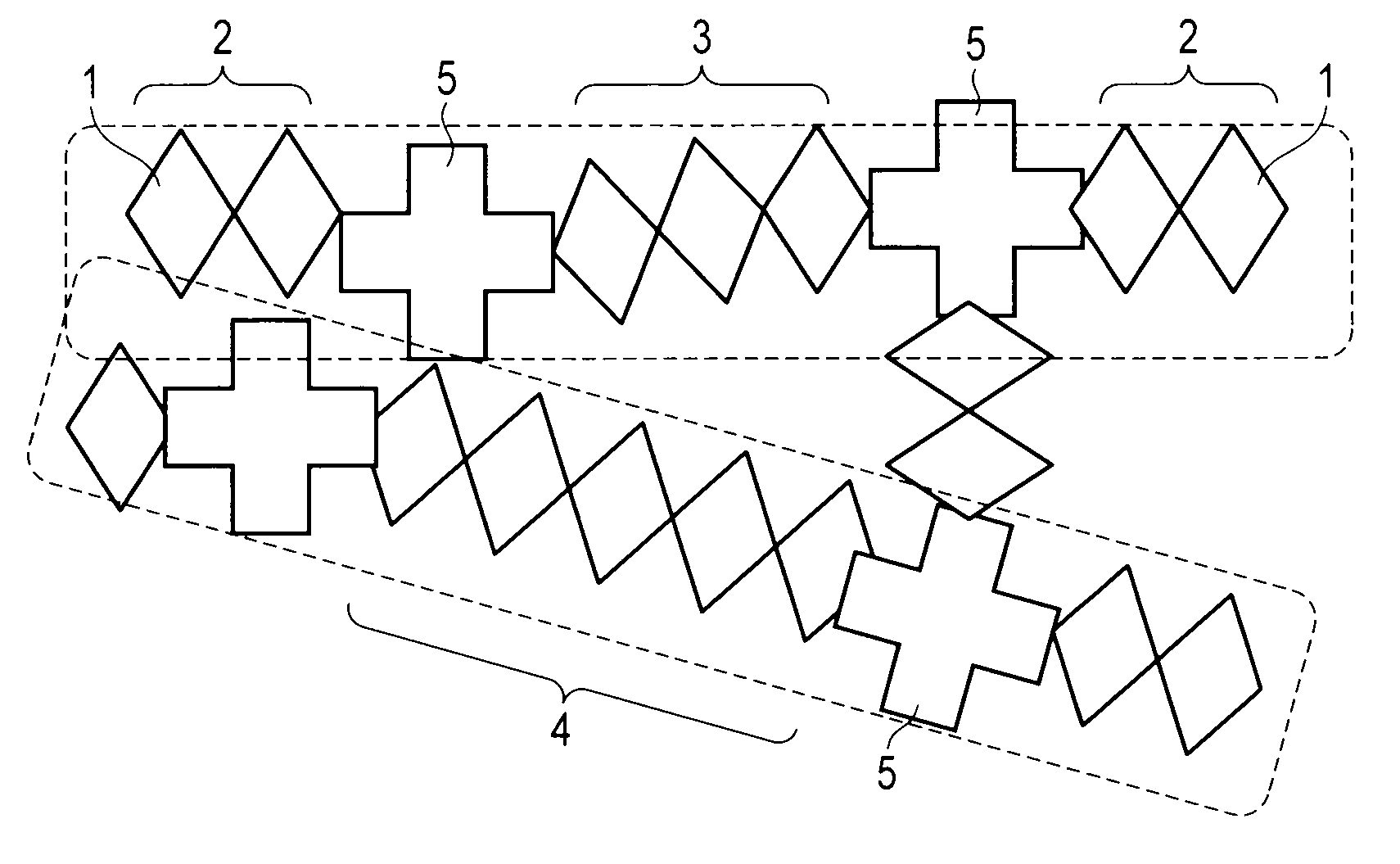

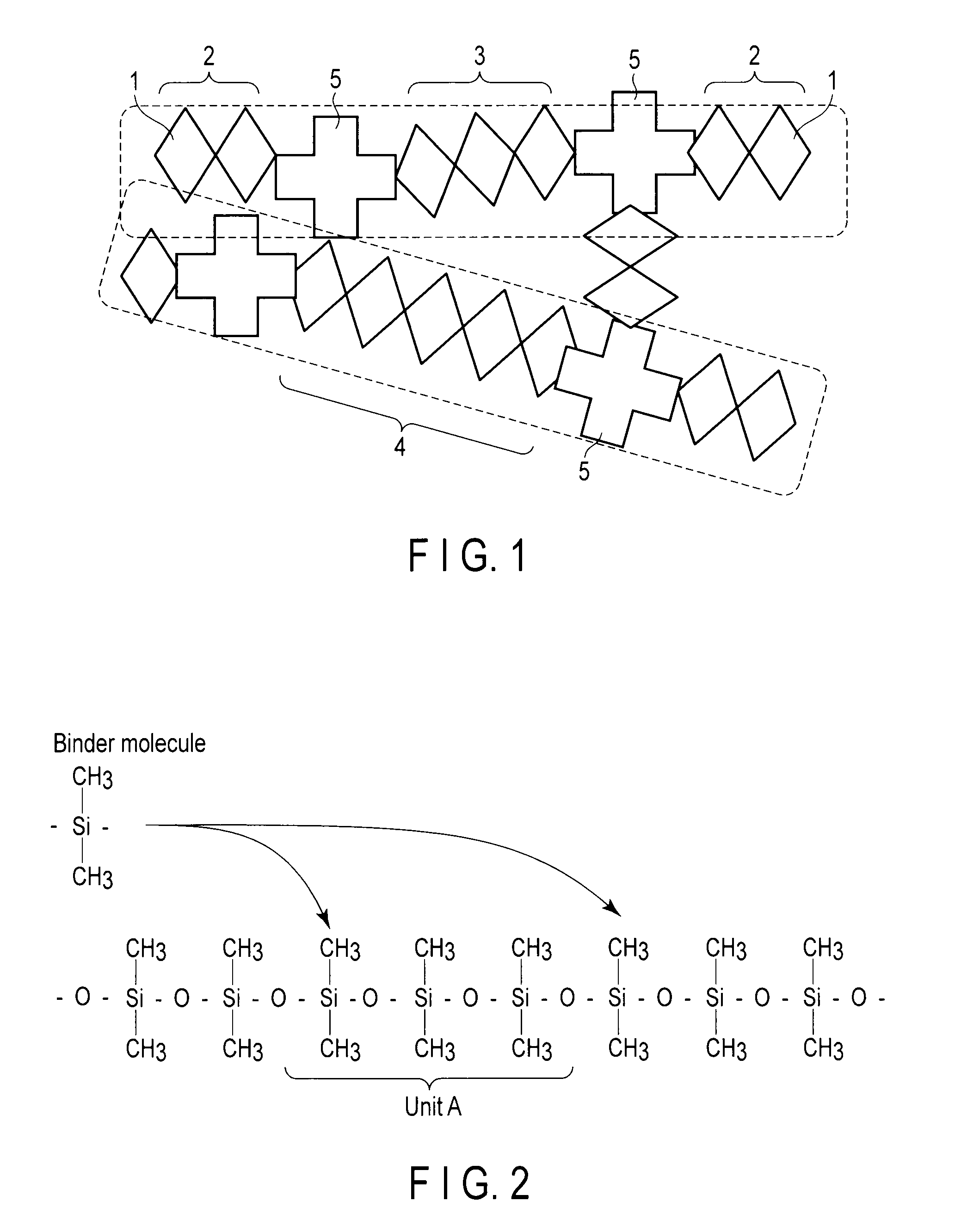

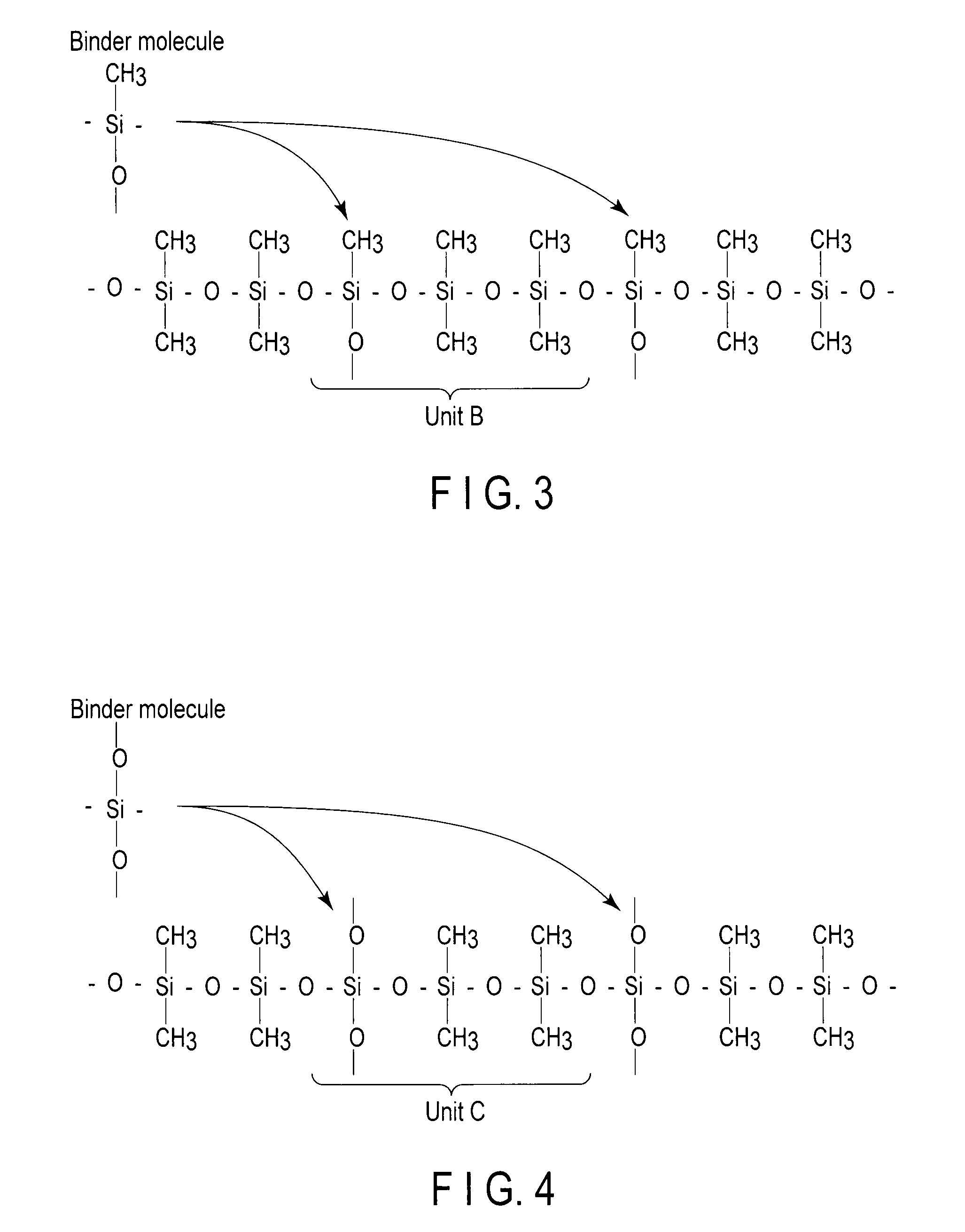

Low dielectric constant insulating film and method for forming the same

InactiveUS8828886B2Improve resistance to damageLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingArea ratioPolymer

Disclosed is a low dielectric constant insulating film formed of a polymer containing Si atoms, O atoms, C atoms, and H atoms, which includes straight chain molecules in which a plurality of basic molecules with an SiO structure are linked in a straight chain, binder molecules with an SiO structure linking a plurality of the straight chain molecules. The area ratio of a signal indicating a linear type SiO structure is 49% or more, and the signal amount of the signal indicating Si(CH3) is 66% or more.

Owner:TOHOKU UNIV

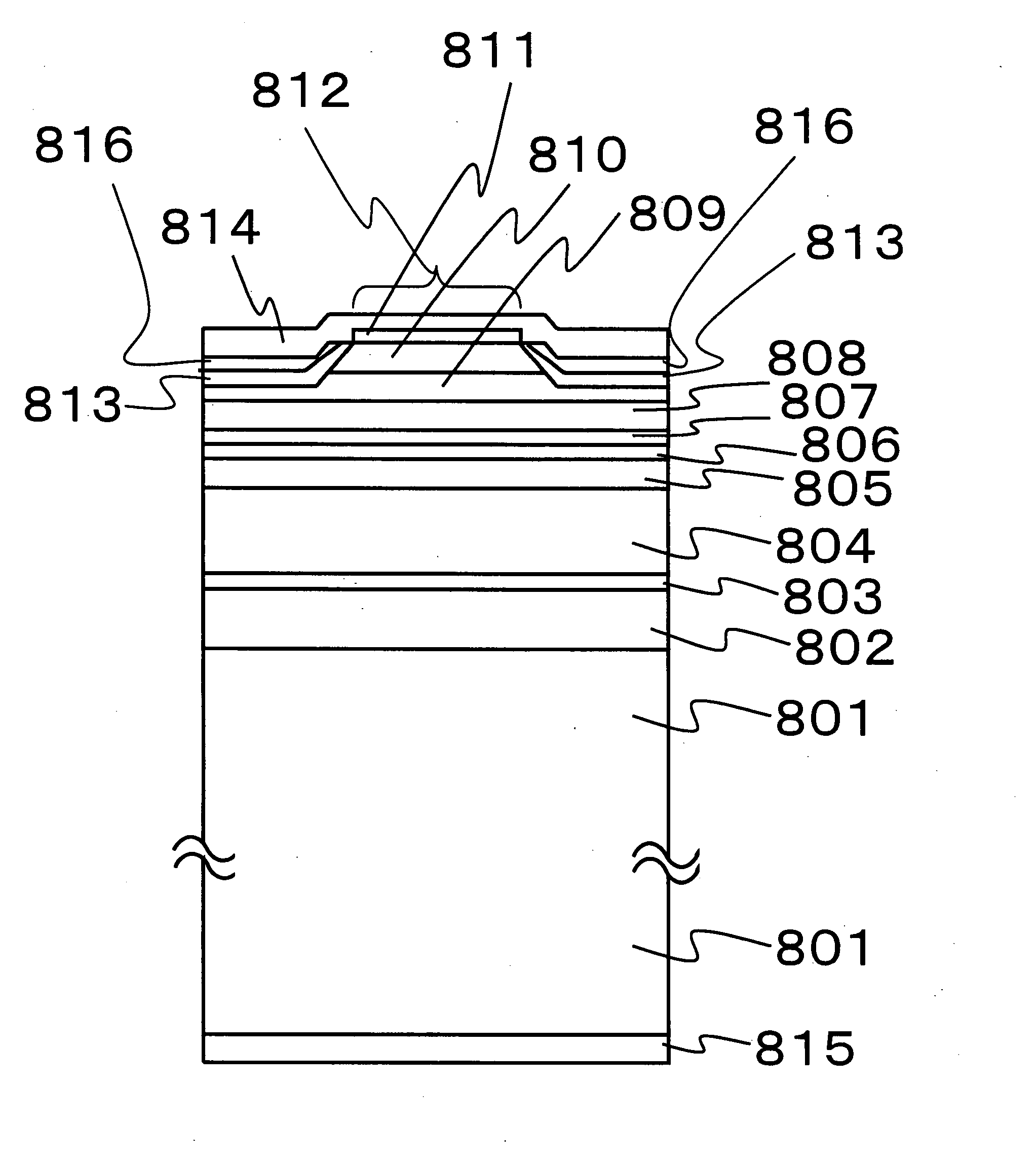

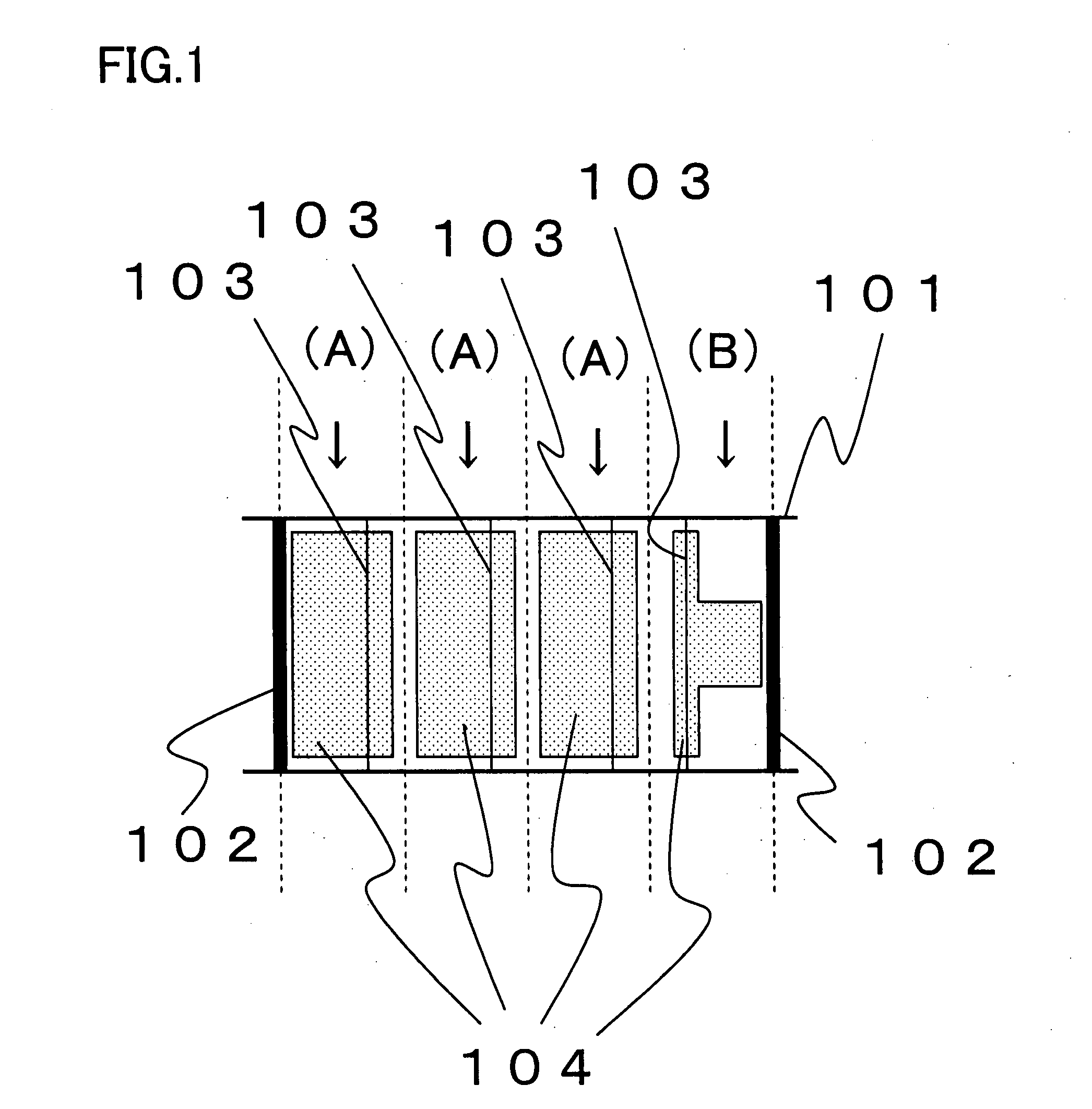

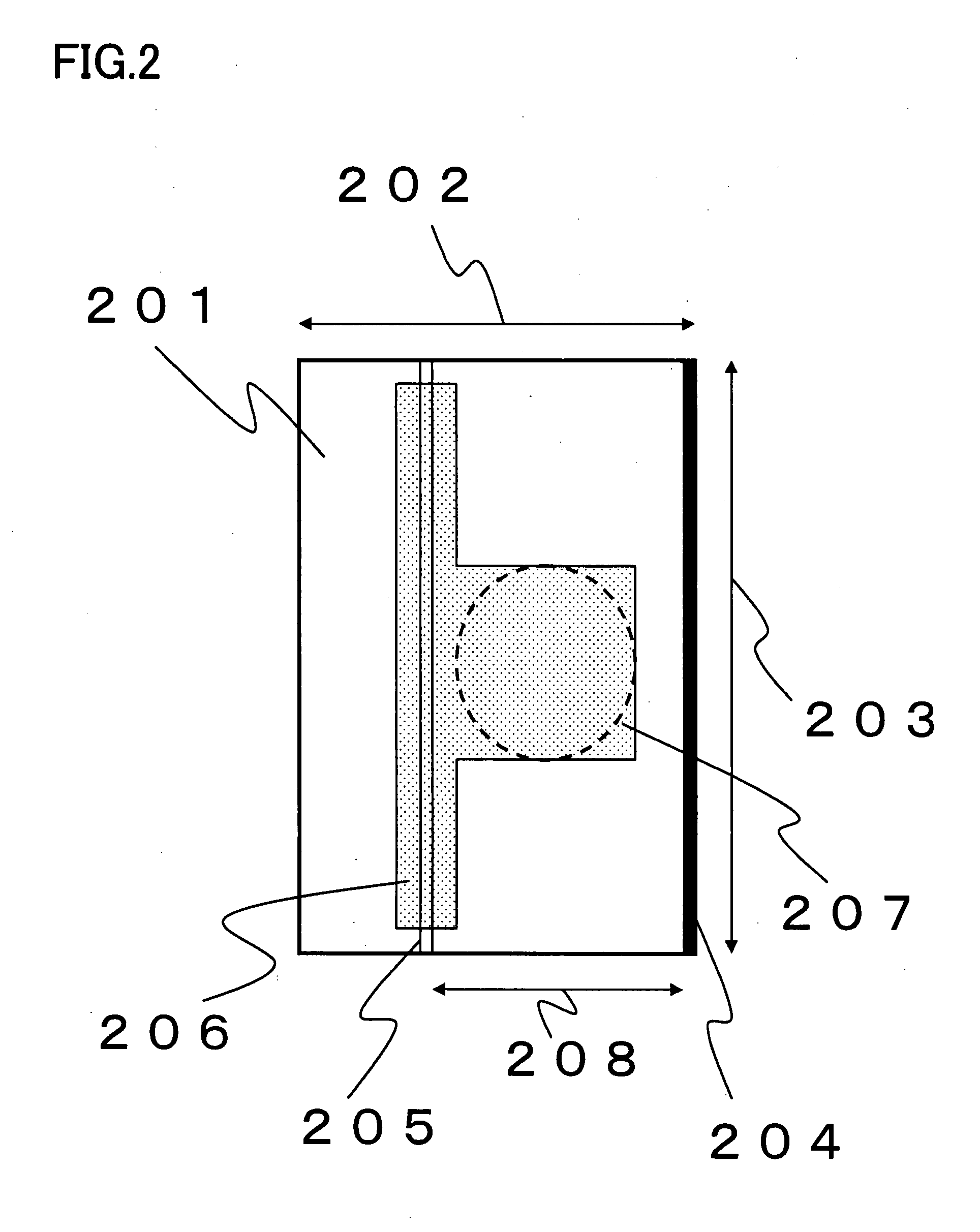

Nitride semiconductor laser device and method of producing the same

ActiveUS20070217462A1Avoid difficult choicesOptical wave guidanceLaser detailsActive layerArea ratio

A method of producing a nitride semiconductor laser device includes: forming a wafer including a nitride semiconductor layer of a first conductivity type, an active layer of a nitride semiconductor, a nitride semiconductor layer of a second conductivity type, and an electrode pad for the second conductivity type stacked in this order on a main surface of a conductive substrate and also including stripe-like waveguide structures parallel to the active layer; cutting the wafer to obtain a first type and a second type of laser device chips; and distinguishing between the first type and the second type of chips by automatic image recognition. The first type and the second type of chips are different from each other in position of the stripe-like waveguide structure with respect to a width direction of each chip and also in area ratio of the electrode pad to the main surface of the substrate.

Owner:SHARP FUKUYAMA LASER CO LTD

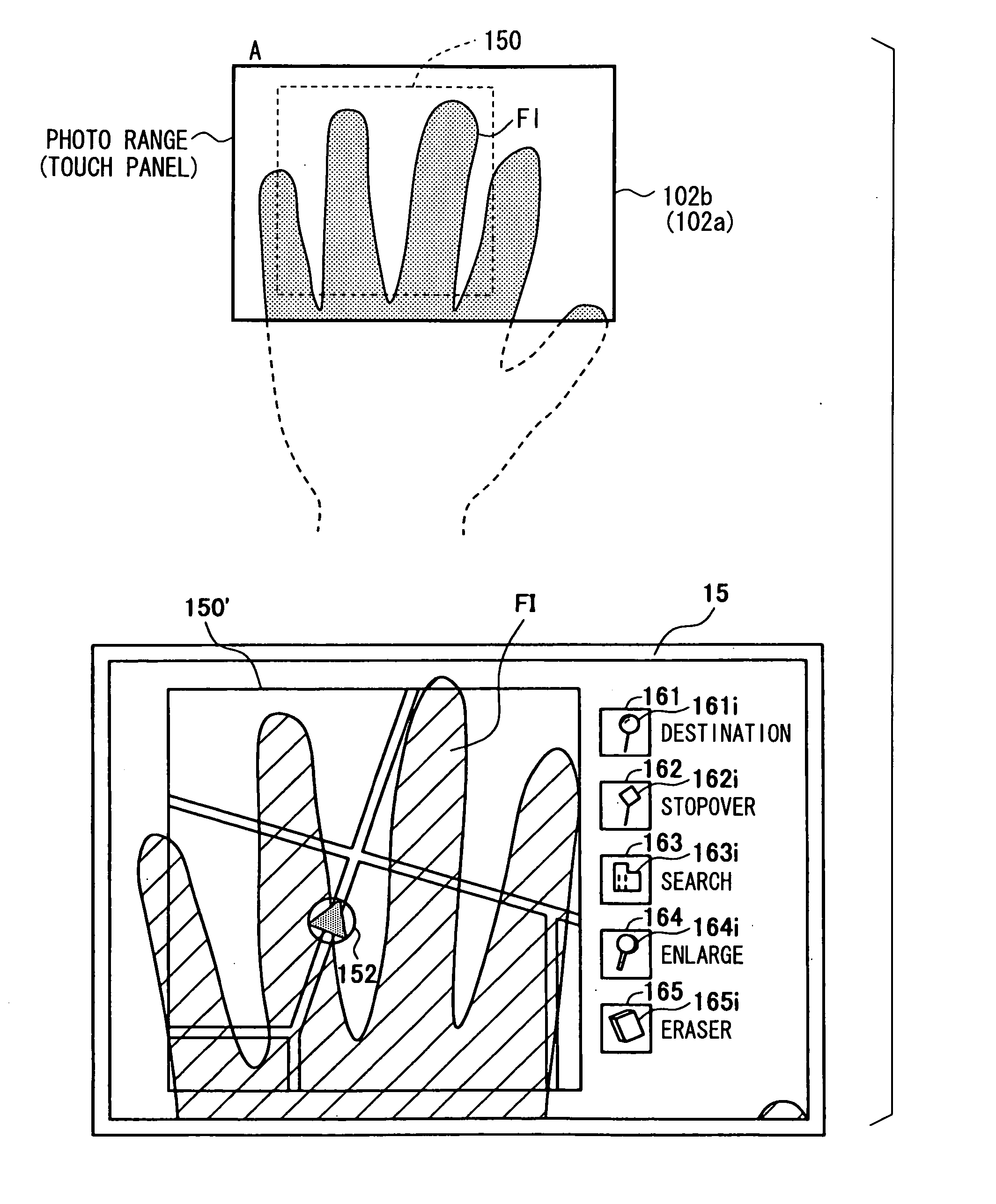

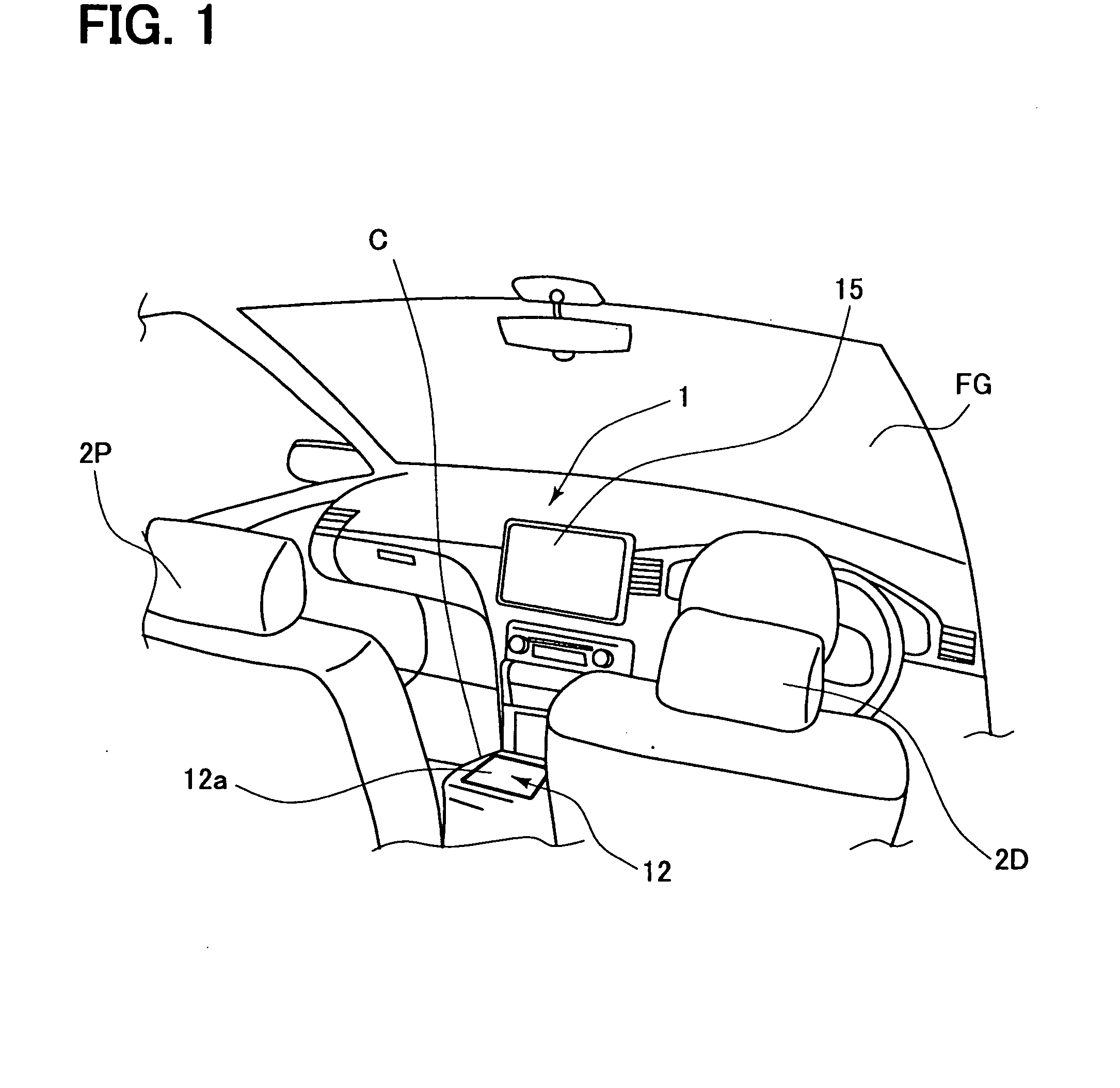

Control device

InactiveUS20100079413A1Effectively use such informationIncrease investmentInstruments for road network navigationDashboard fitting arrangementsIn vehicleArea ratio

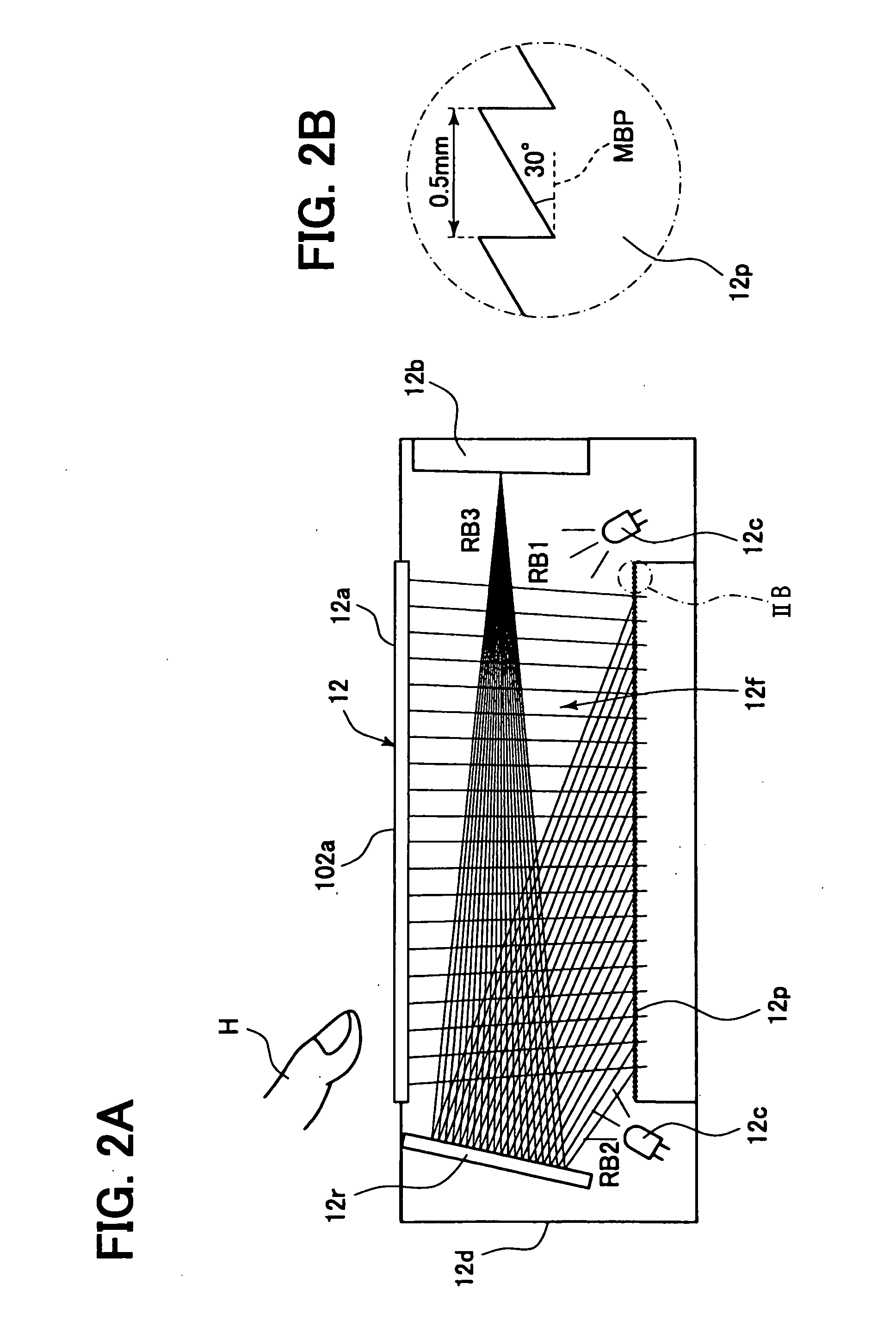

There is provided a control device for an in-vehicle electronic apparatus. The control device includes: a manipulation input element that has a manipulation input region having a predetermined area; an imaging device that has a photographing range covering the manipulation input region, and that captures an image including a hand image region representative of the hand; a hand image region identification section that identifies the hand image region in the image; an area ratio calculation section that calculates a value of hand image area ratio, which is area ratio of the hand image region to the manipulation input region; and an operation input information generation section that generates and outputs operation input information based on the calculated value of the hand image area ratio and a manipulation state of the manipulation input region, the operation input information being directed to the in-vehicle electronic apparatus.

Owner:DENSO CORP

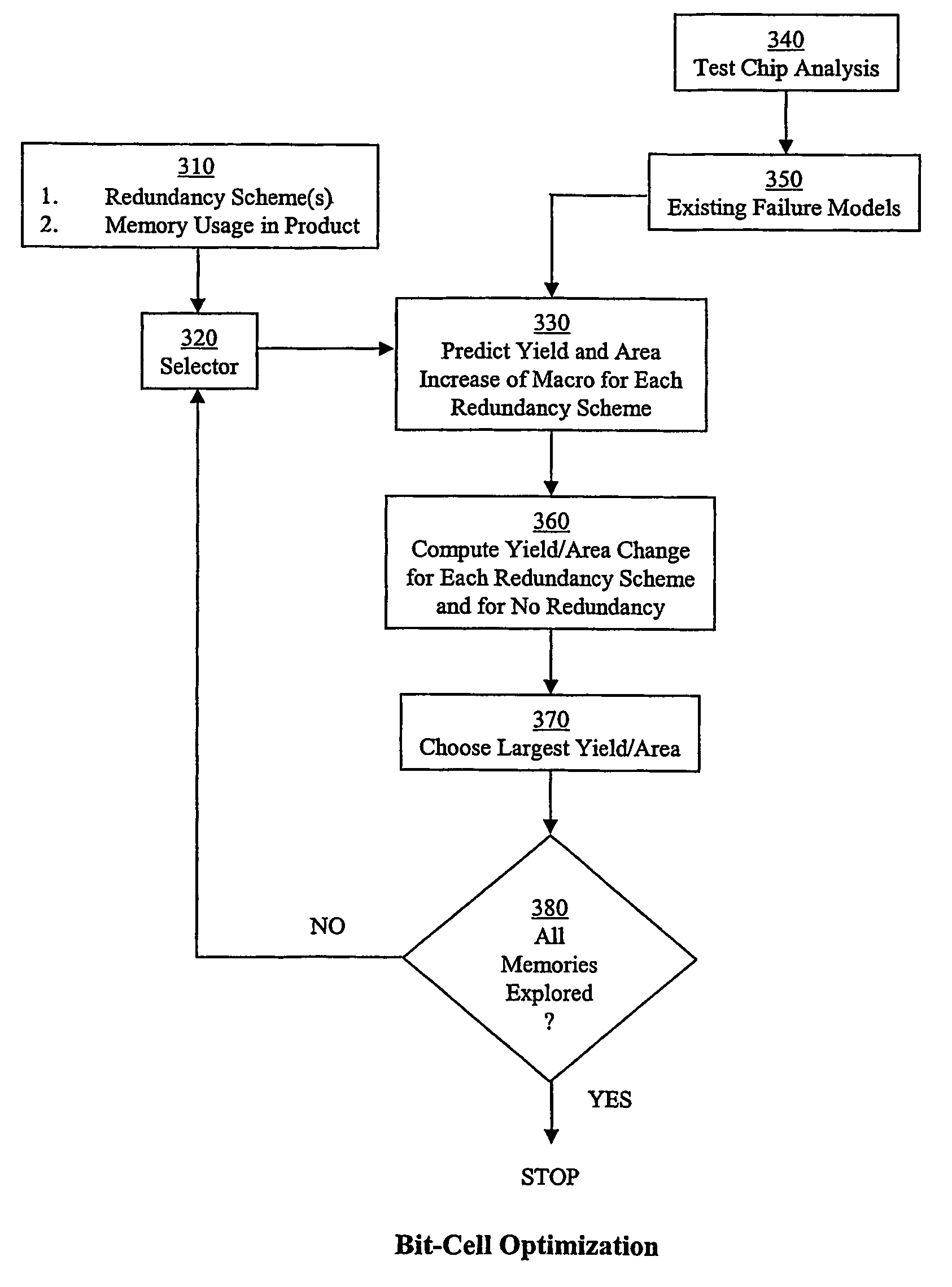

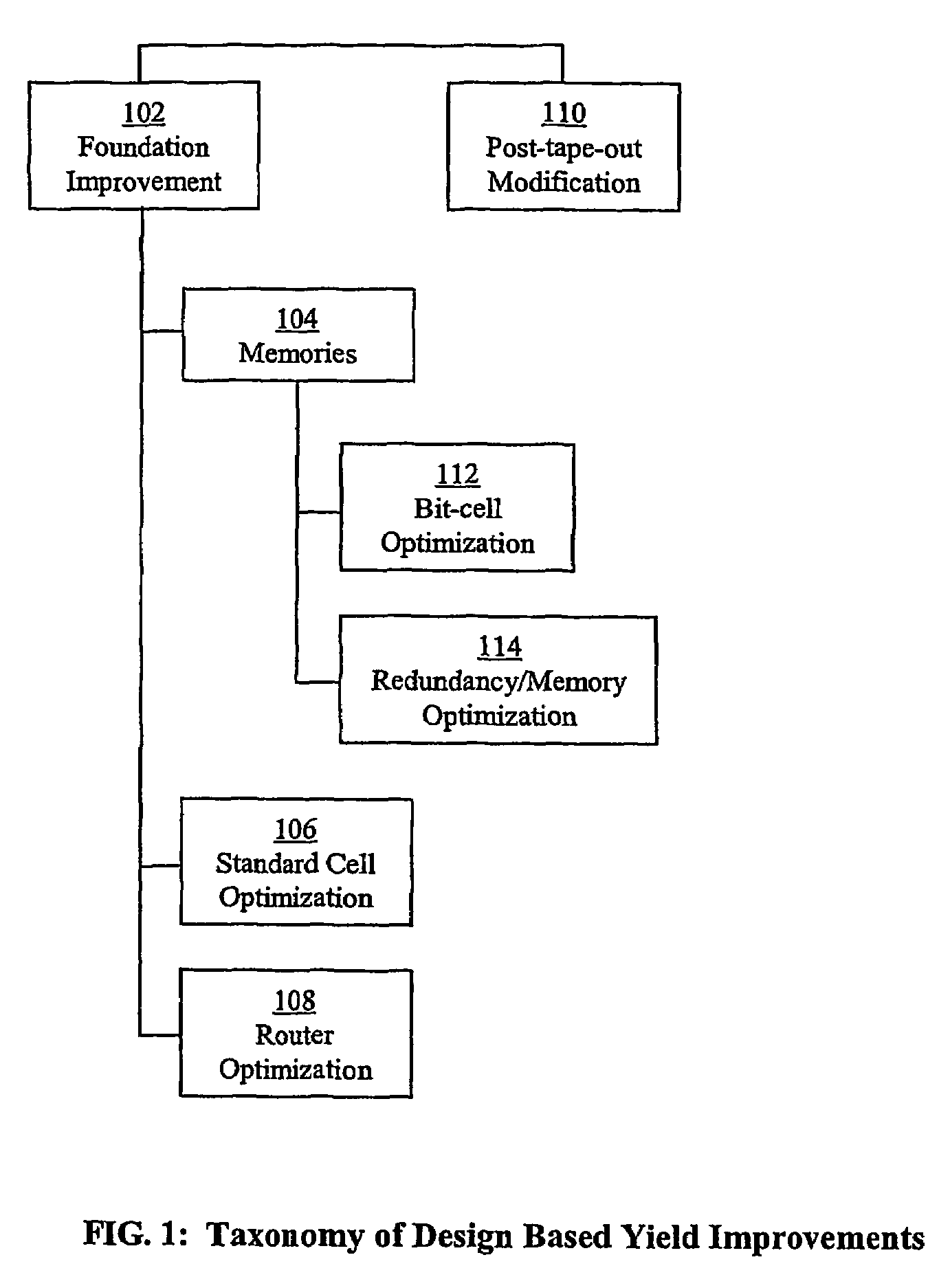

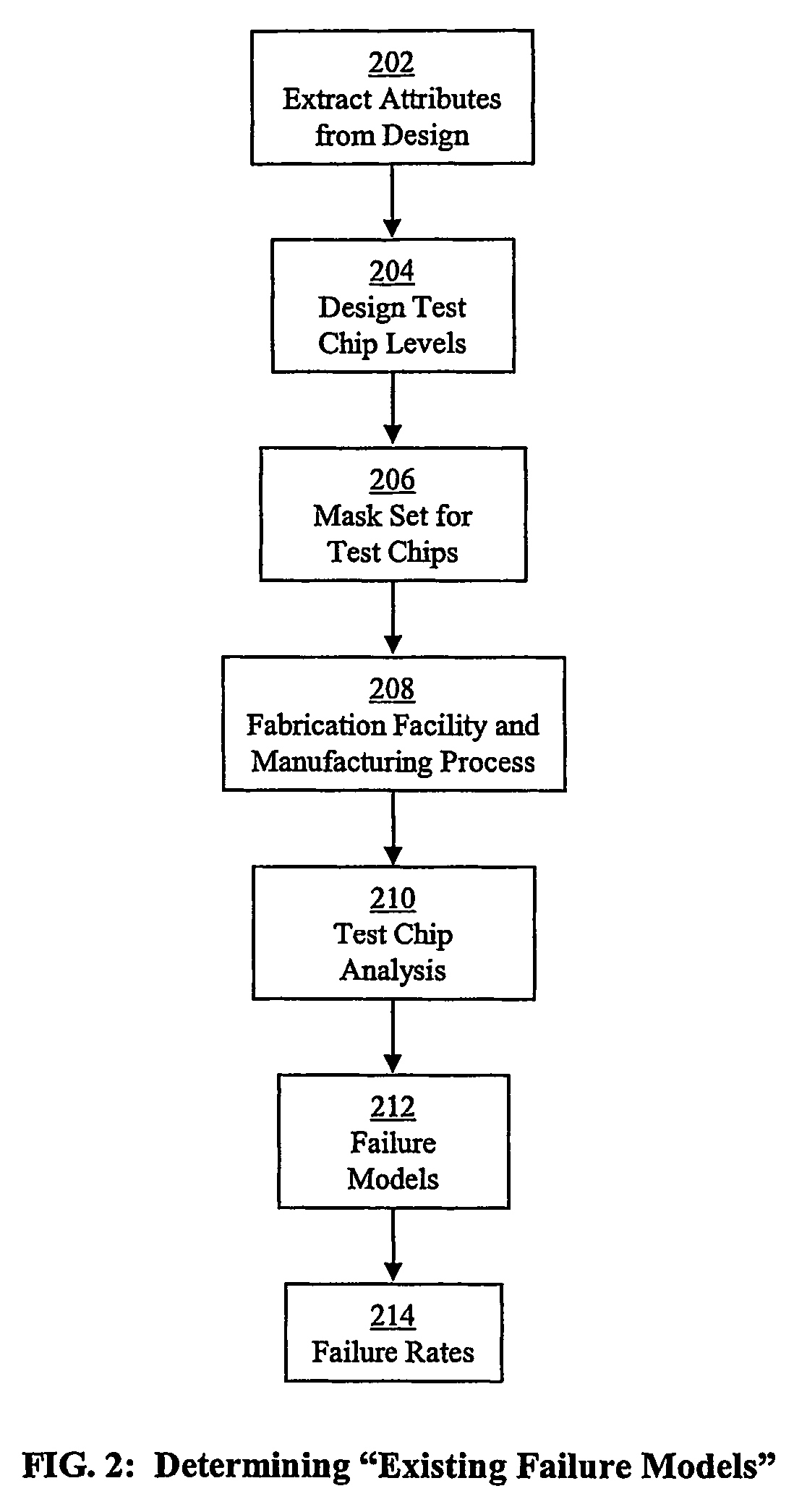

Designing an integrated circuit to improve yield using a variant design element

InactiveUS7487474B2Minimizes and eliminates relianceHigh yieldElectrical apparatusCAD circuit designIntegrated circuit layoutEngineering

An integrated circuit is designed to improve yield when manufacturing the integrated circuit, by obtaining a design element from a set of design elements used in designing integrated circuits. A variant design element is created based on the obtained design element, where a feature of the obtained design element is modified to create the variant design element. A yield to area ratio for the variant design element is determined. If the yield to area ratio of the variant design element is greater than a yield to area ratio of the obtained design element, the variant design element is retained to be used in designing the integrated circuit.

Owner:PDF SOLUTIONS INC

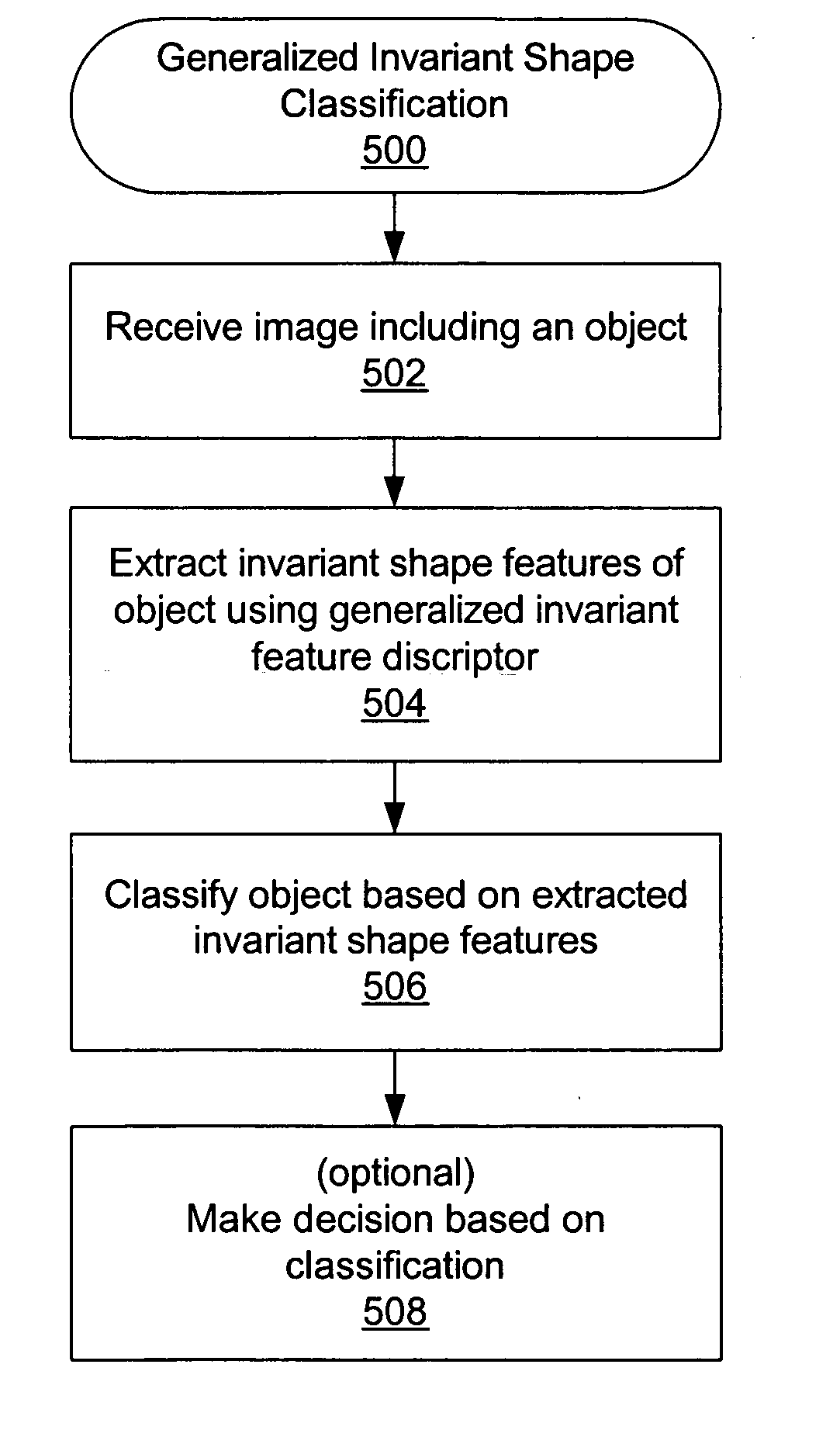

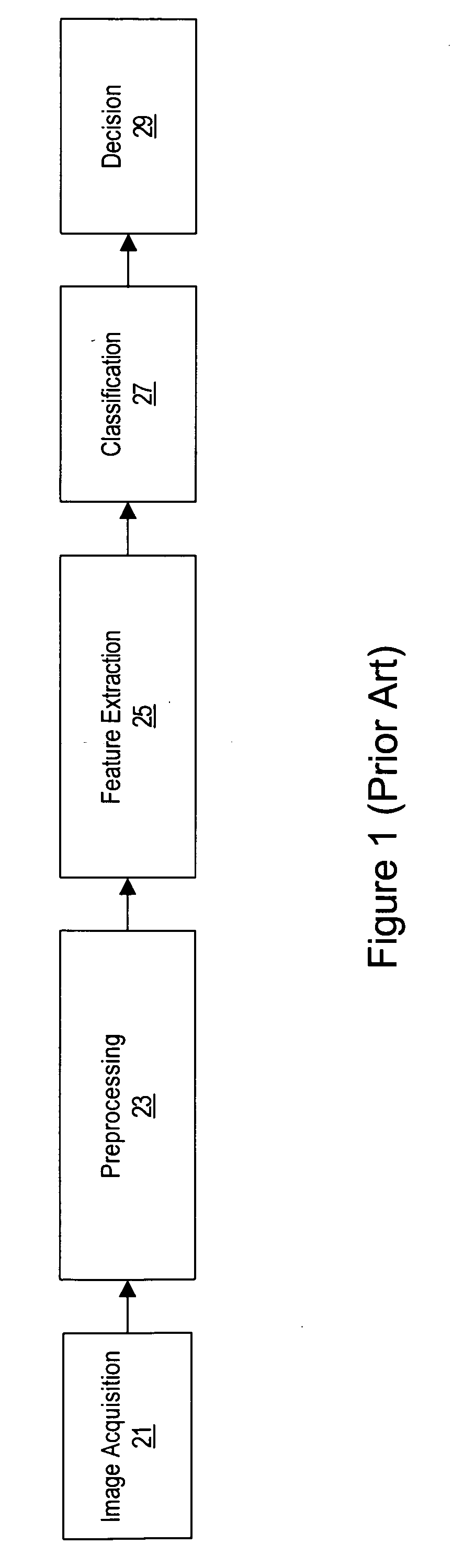

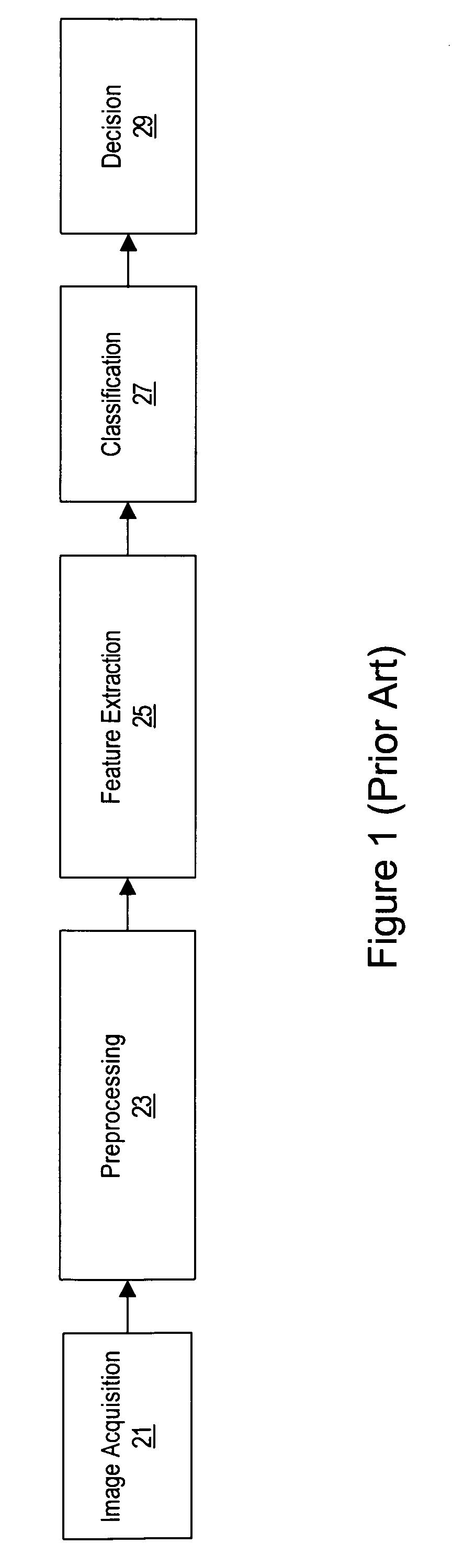

Shape feature extraction and classification

ActiveUS20060008151A1Facilitates characterizationFacilitates discriminationCharacter and pattern recognitionFeature vectorComputer science

System and method for analyzing an image. A received image, comprising an object or objects, is optionally preprocessed. Invariant shape features of the object(s) are extracted using a generalized invariant feature descriptor. The generalized invariant feature descriptor may comprise a generalized invariant feature vector comprising components corresponding to attributes of each object, e.g., related to circularity, elongation, perimeter-ratio-based convexity, area-ratio-based convexity, hole-perimeter-ratio, hole-area-ratio, and / or functions of Hu Moment 1 and / or Hu Moment 2. Non-invariant features, e.g., scale and reflection, may be extracted to form corresponding feature vectors. The object is classified by computing differences between the generalized invariant feature vector (and optionally, non-invariant feature vectors) and respective generalized invariant feature vectors corresponding to reference objects, determining a minimum difference corresponding to a closest reference object or class of reference objects of the plurality of reference objects, and outputting an indication of the closest reference object or class as the classification.

Owner:NATIONAL INSTRUMENTS

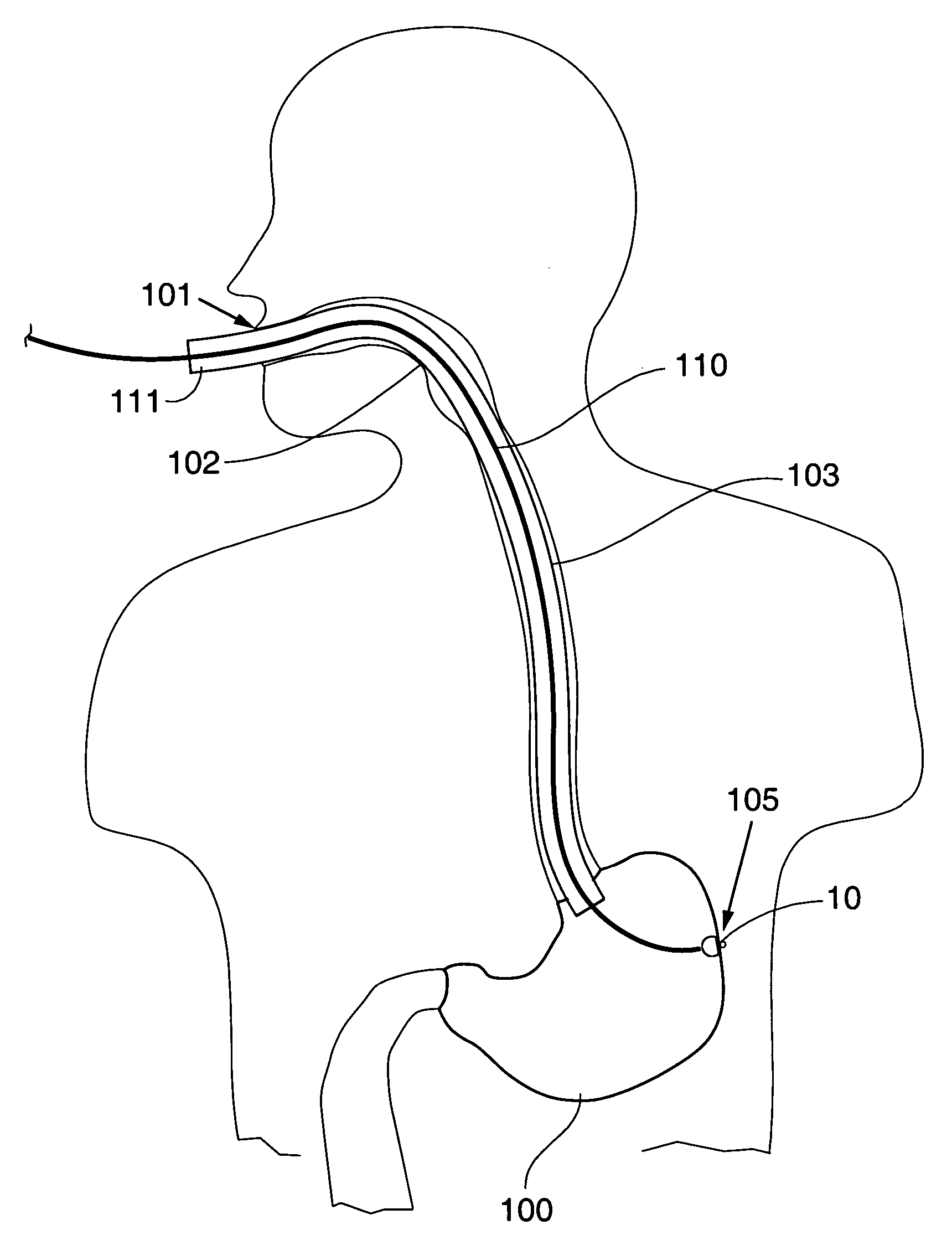

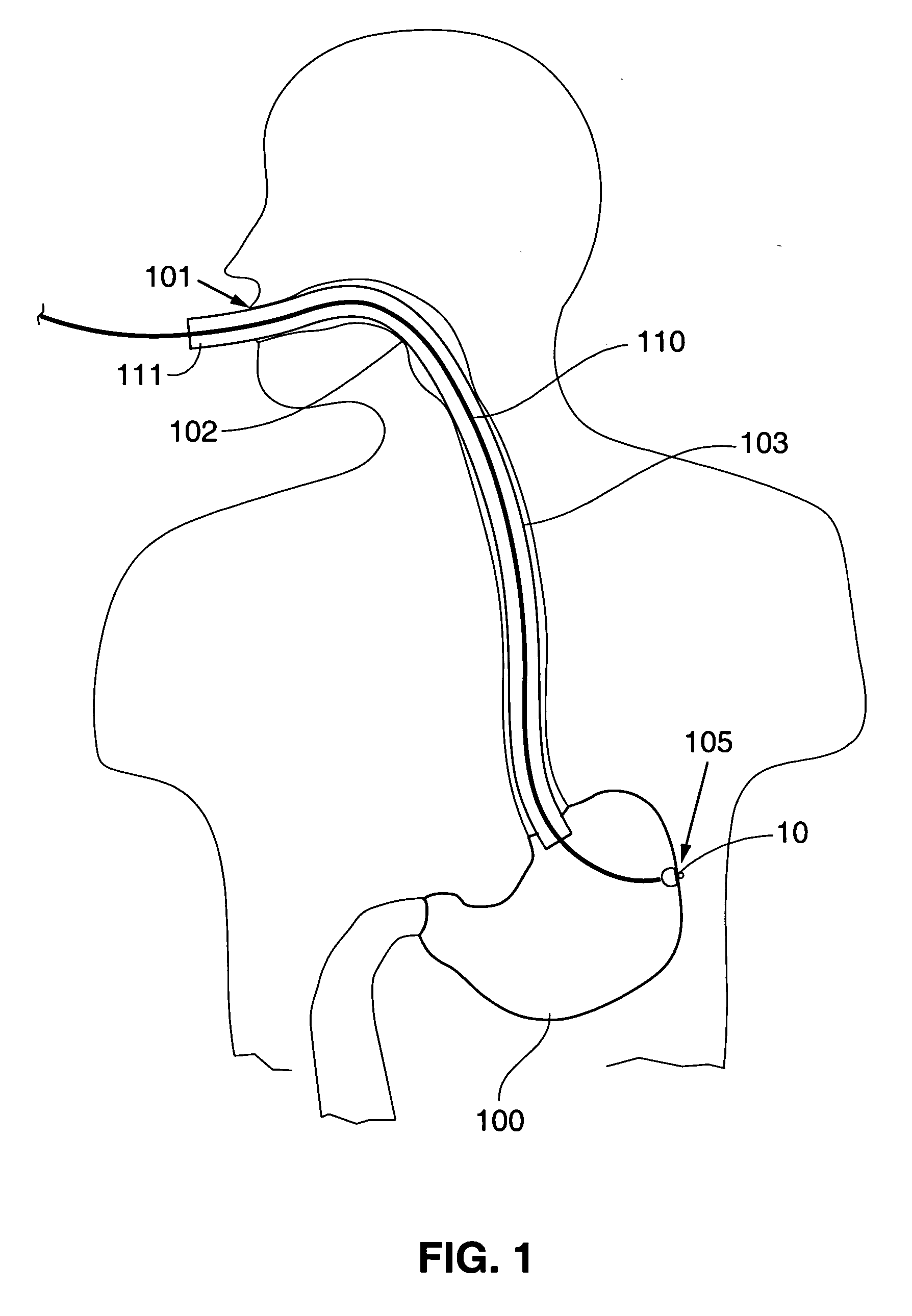

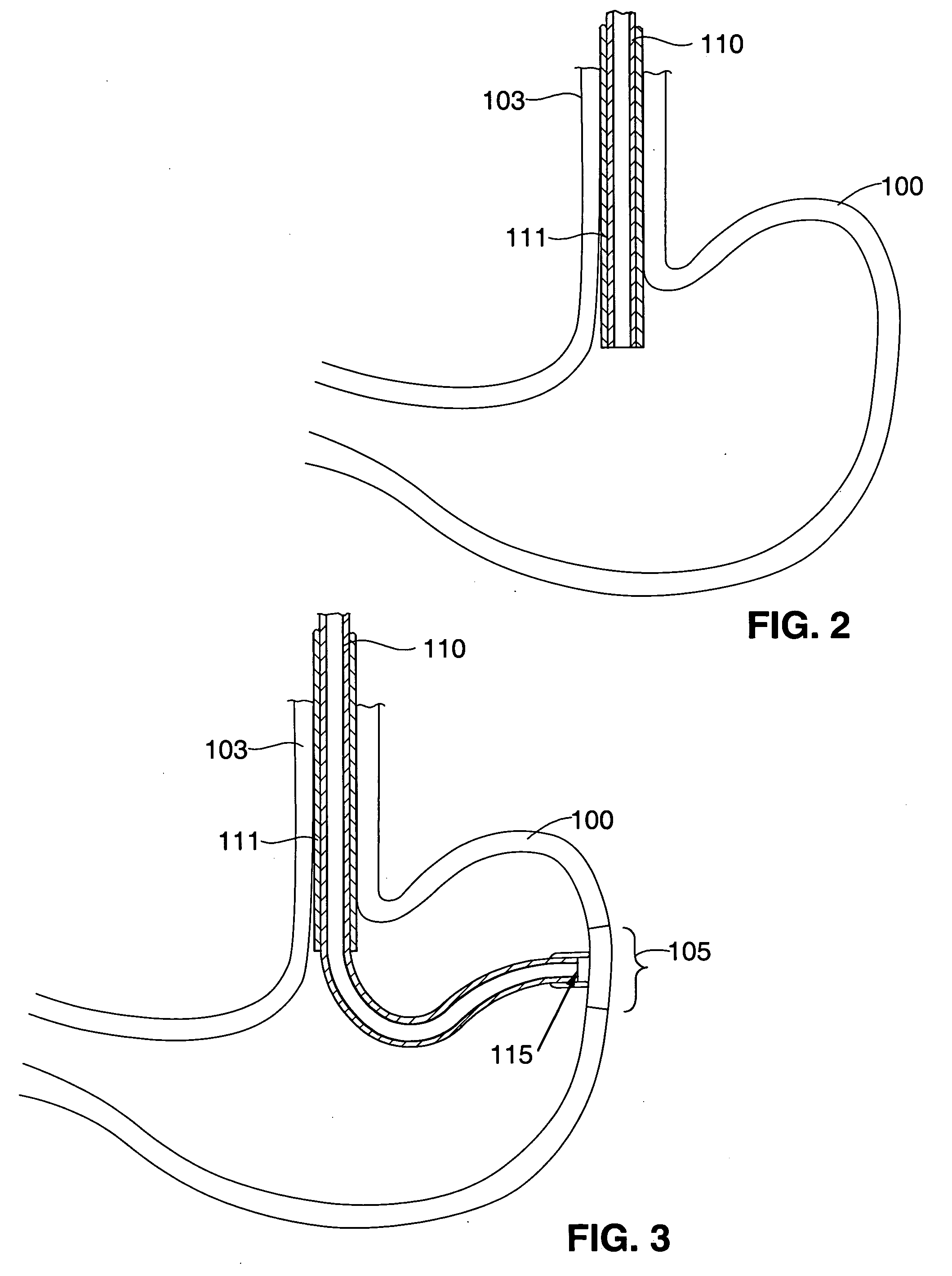

Gastrointestinal anchor with optimal surface area

InactiveUS20050143784A1Equally distributedUneven distributionCannulasSurgical needlesOptimal weightArea ratio

A device, system and method for anchoring a device to a stomach is provided. The device may be, among other things, a sensor for sensing various parameters of the stomach or stomach environment, or may be a therapeutic delivery device. The anchor of the device is constructed to resist pull out forces. An anchor has an optimal weight to surface area ratio.

Owner:INTRAPACE

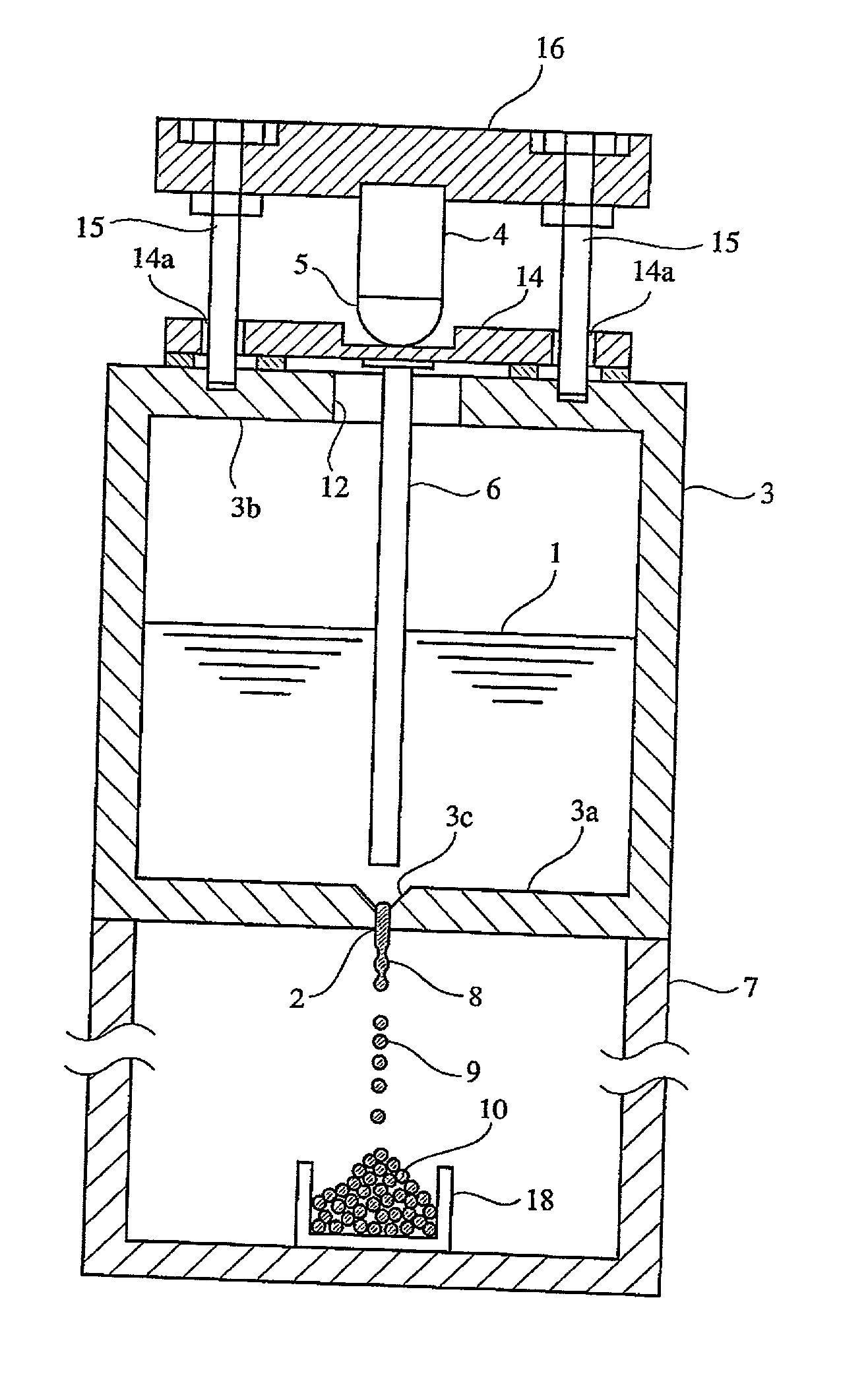

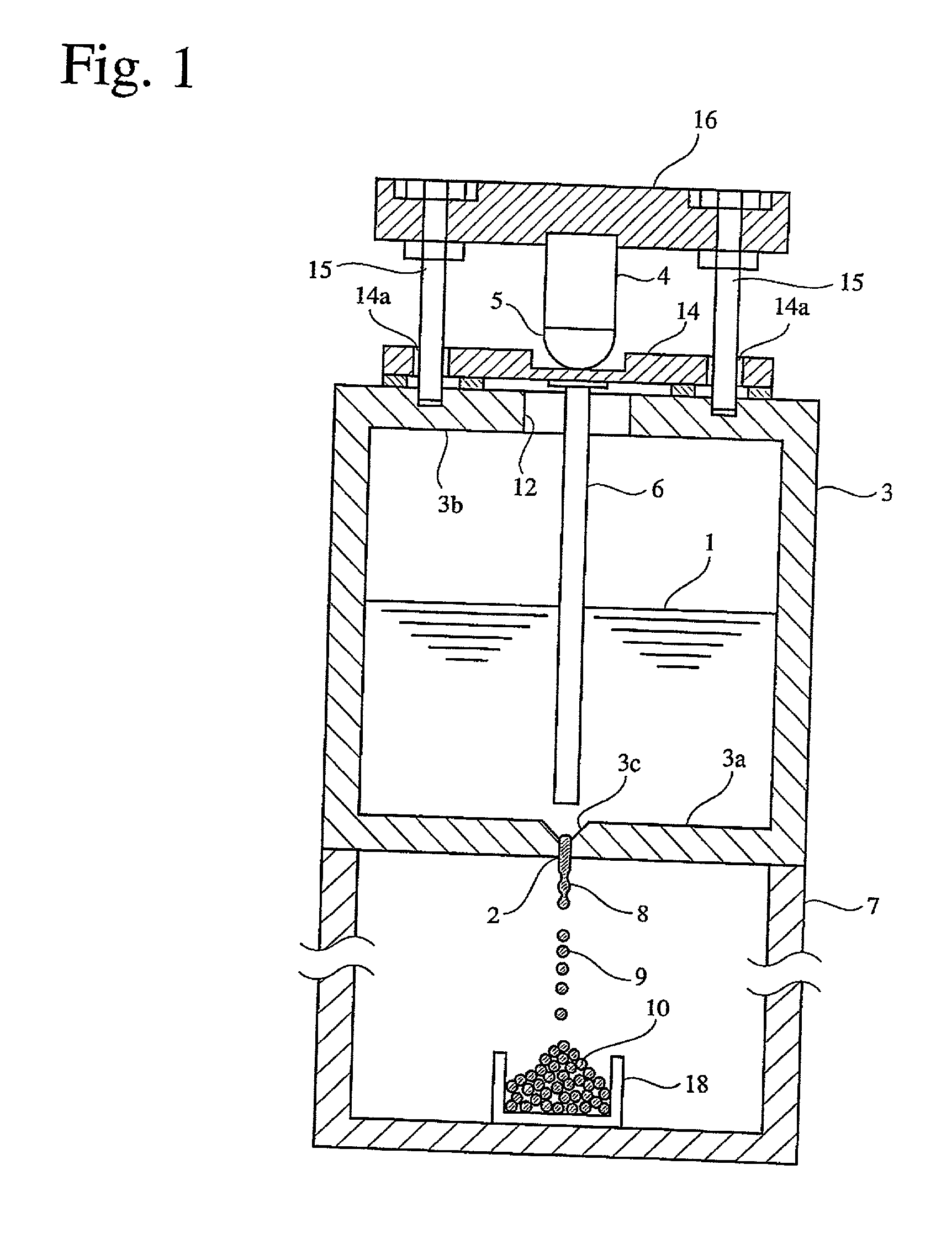

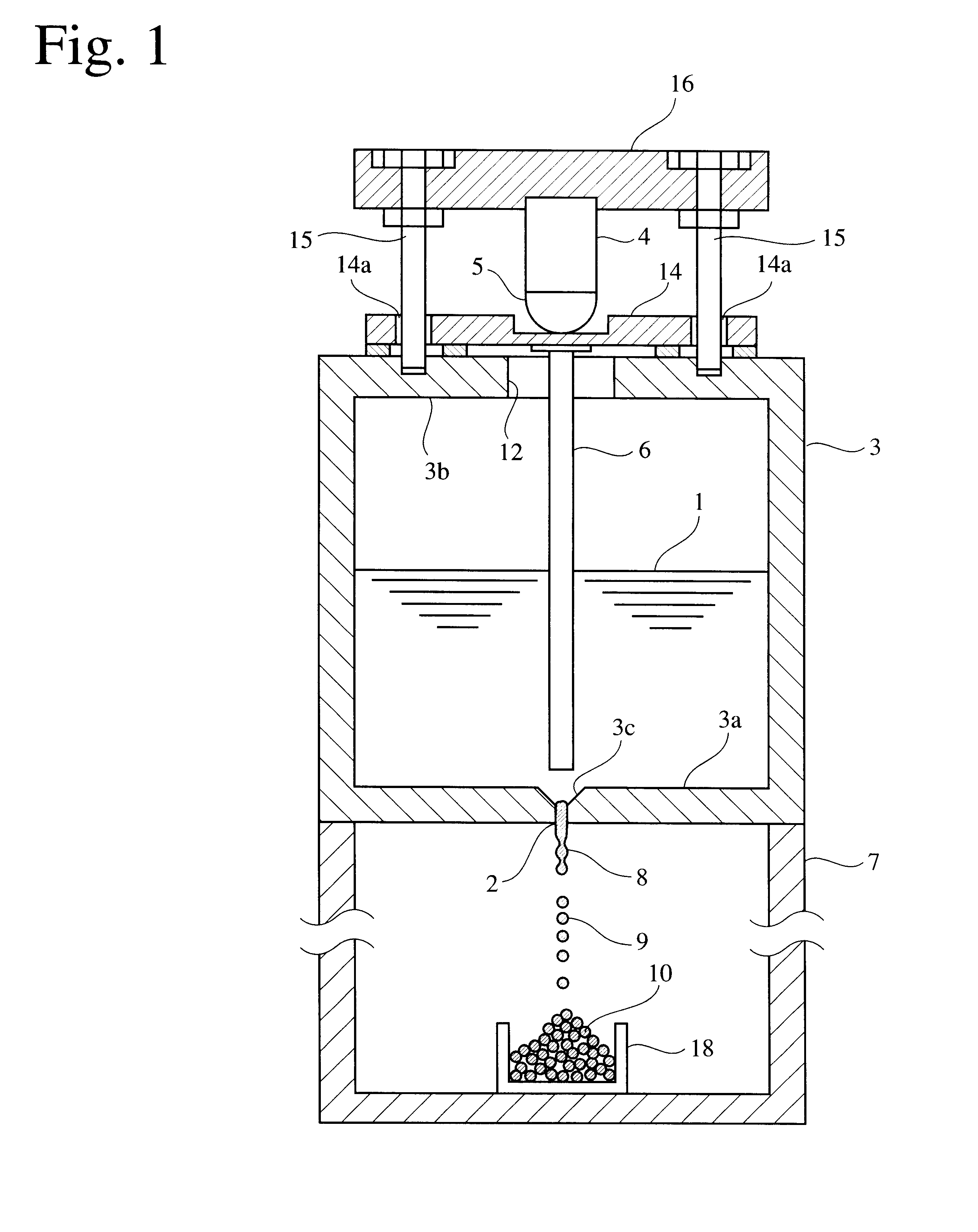

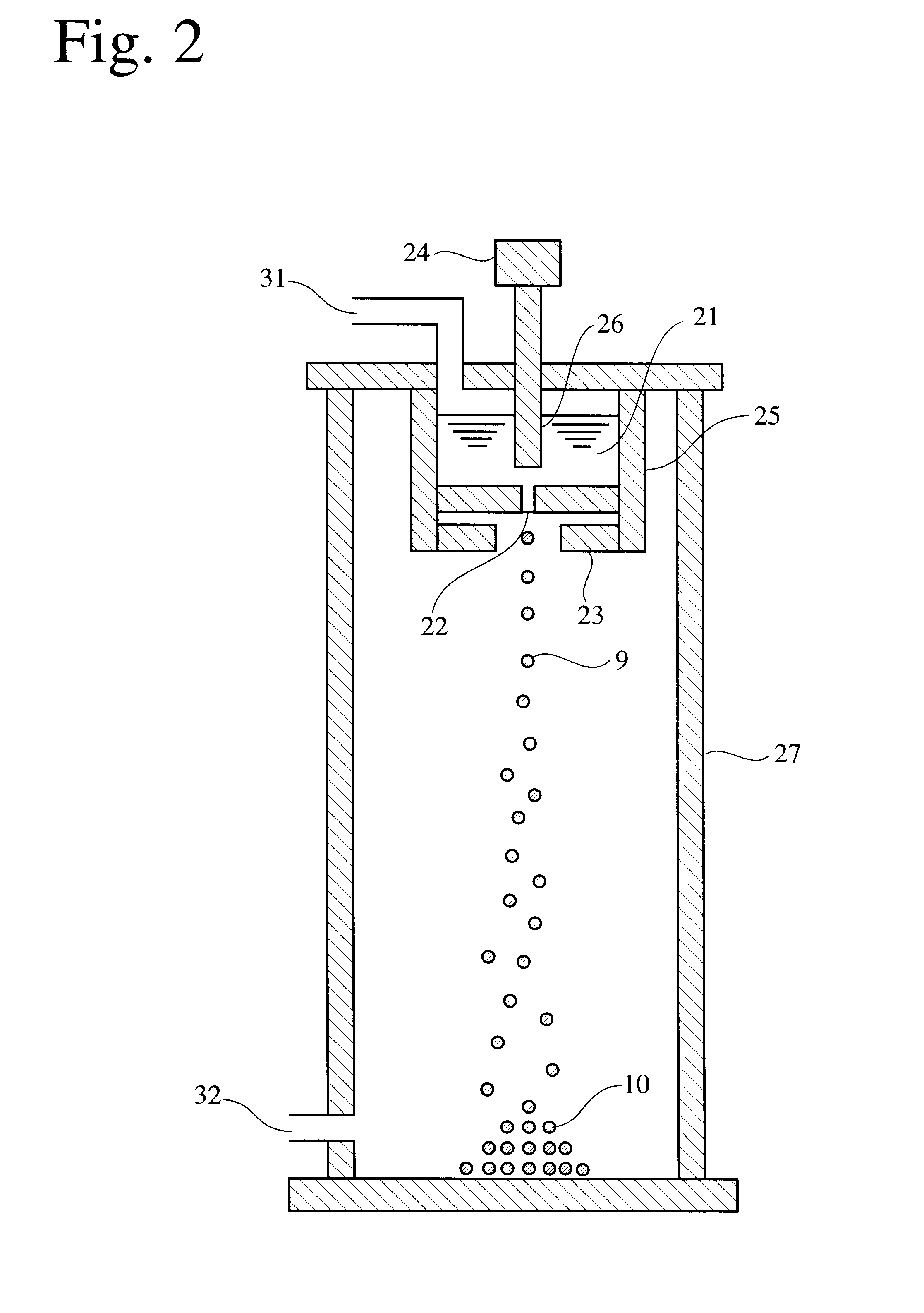

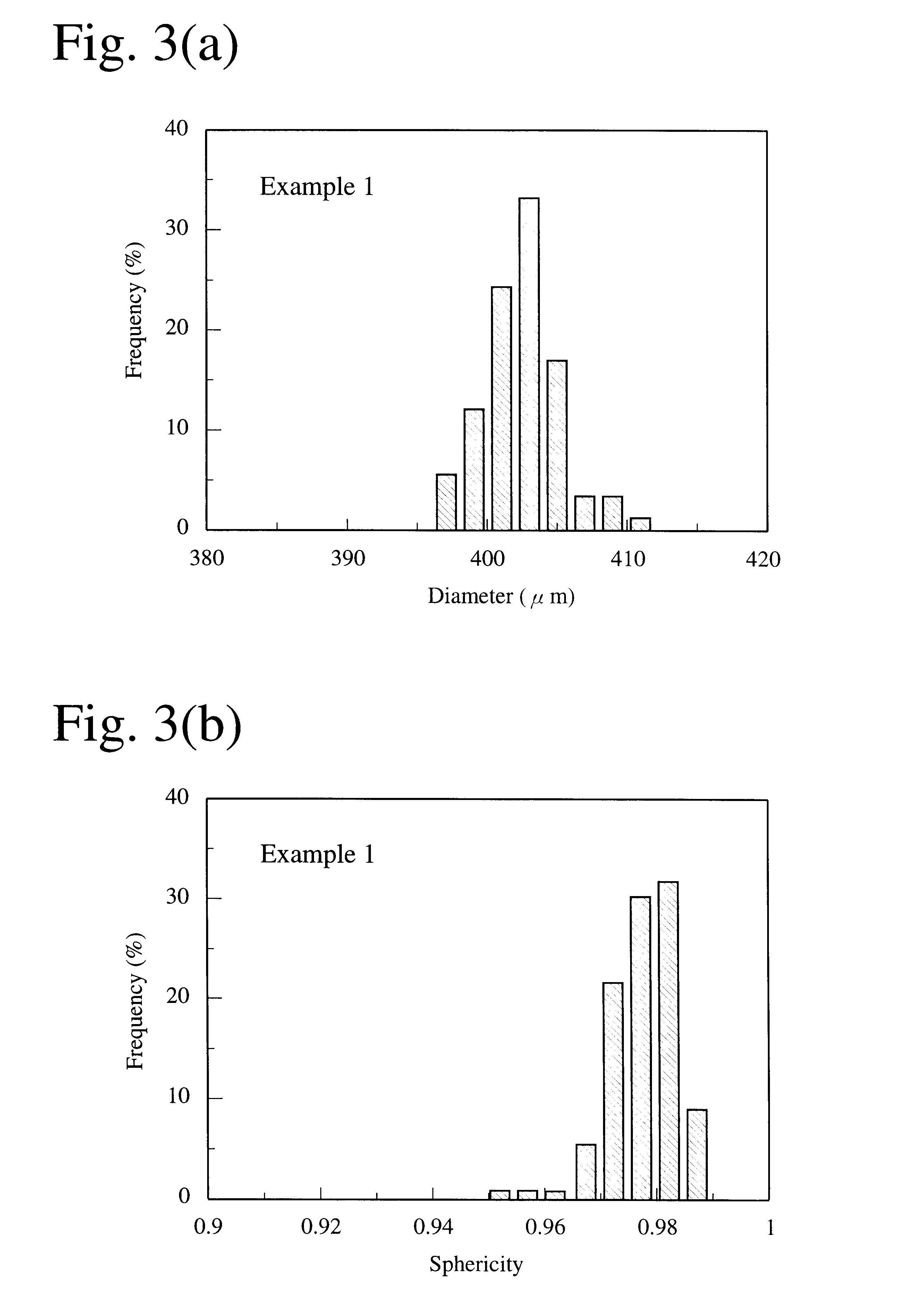

Solder ball and method for producing same

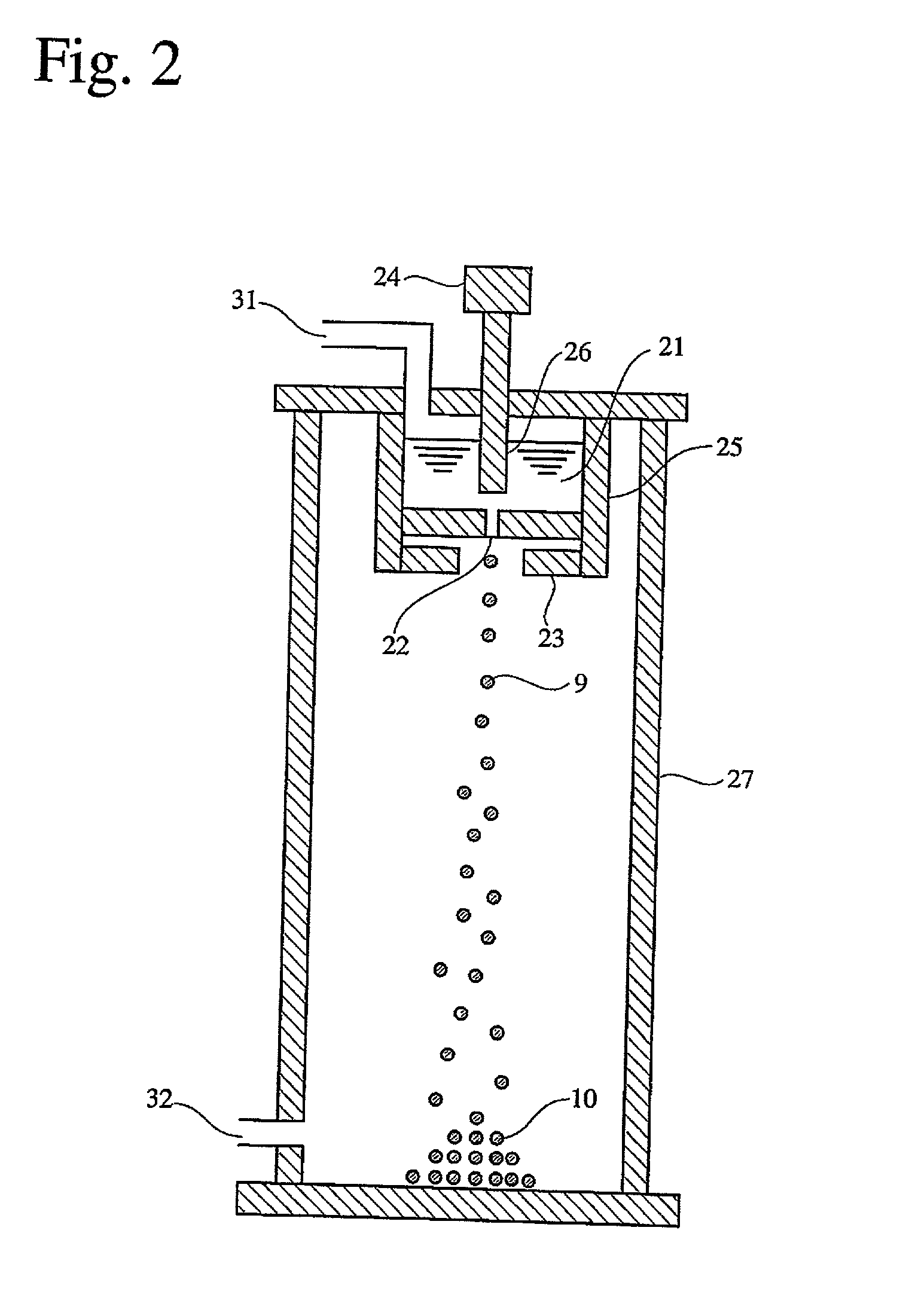

InactiveUS20020051728A1High degree of sphericityNarrow dimension distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass% of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

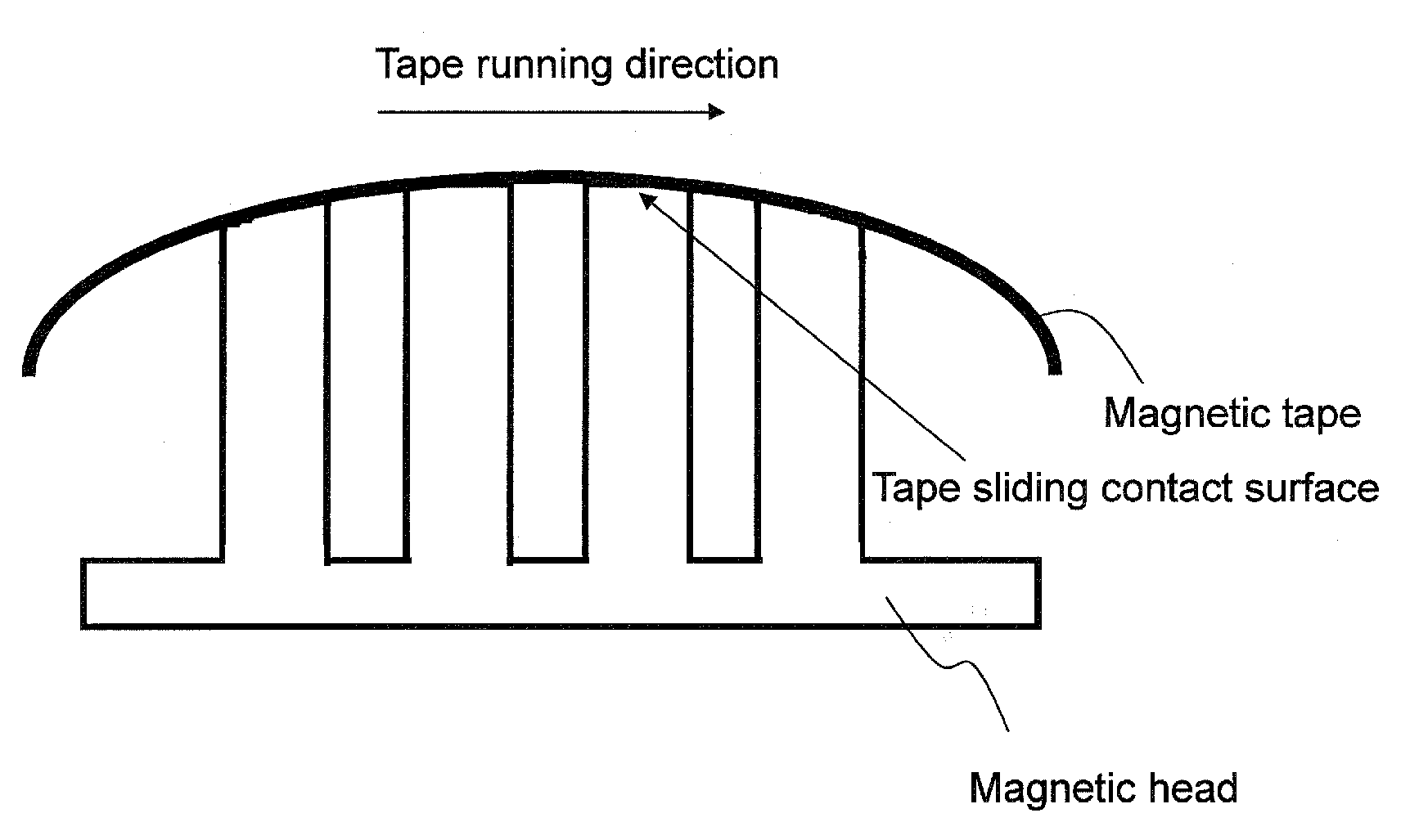

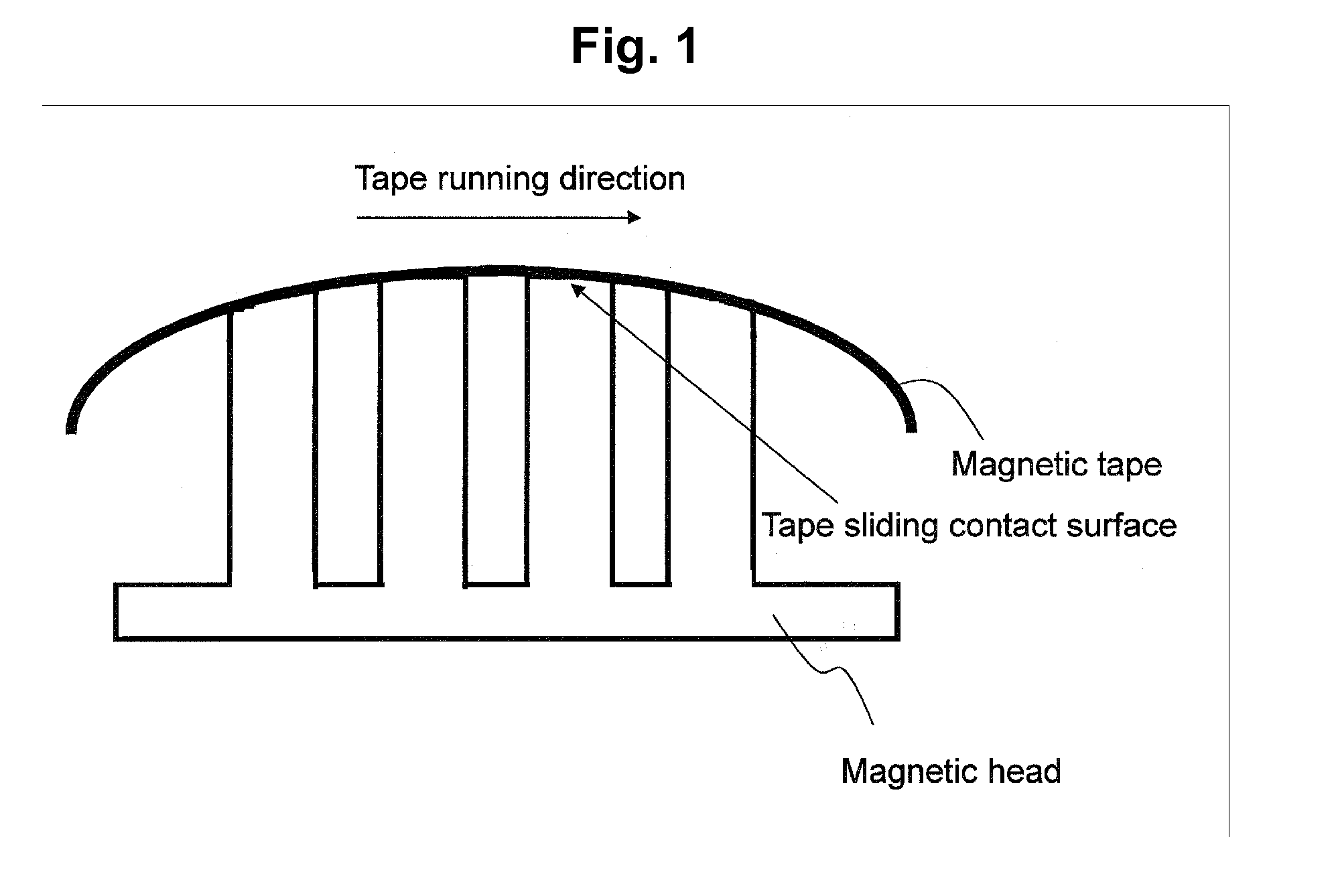

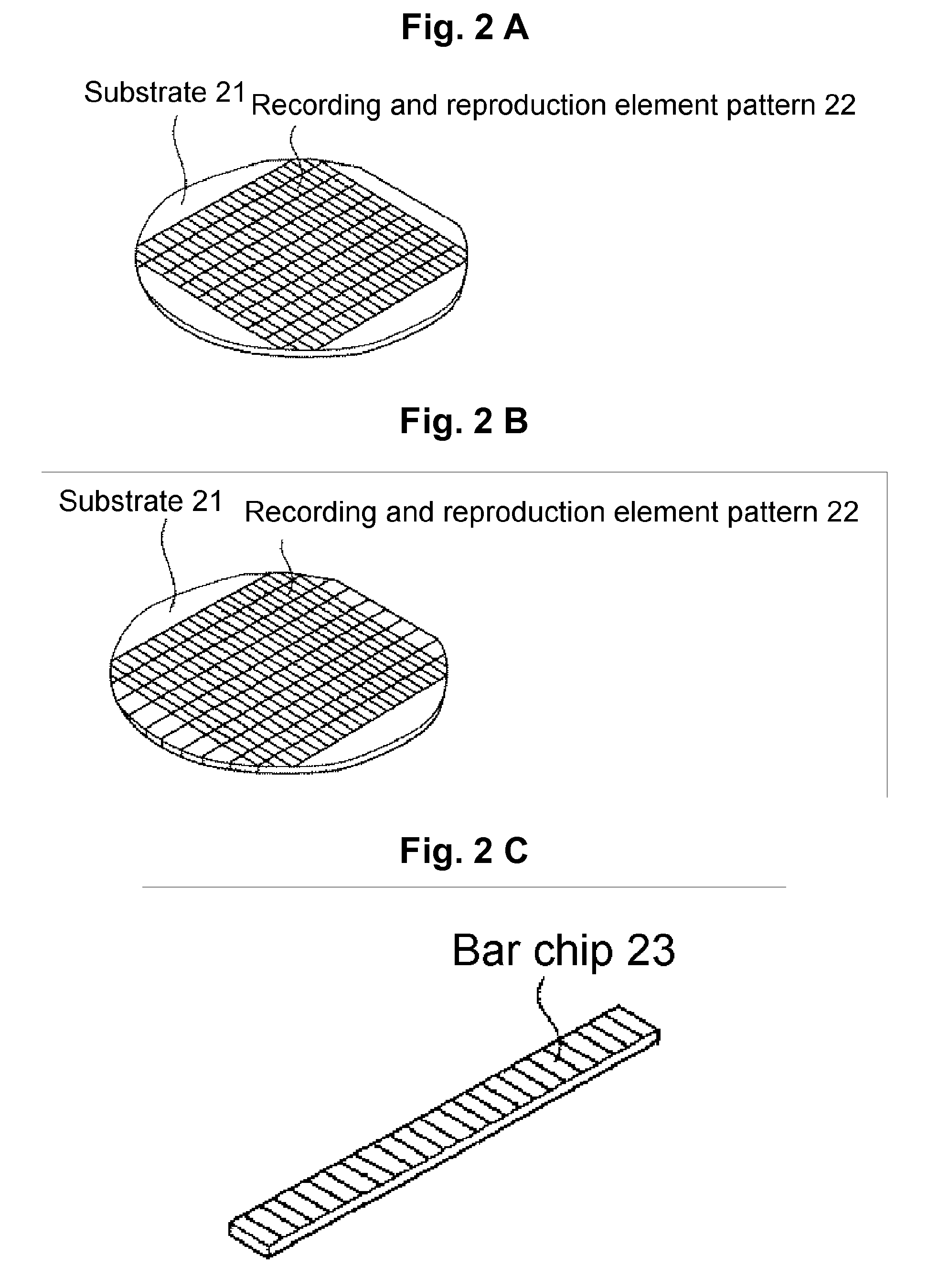

Magnetic head and method of manufacturing the same, linear tape drive apparatus, and magnetic recording and reproduction method

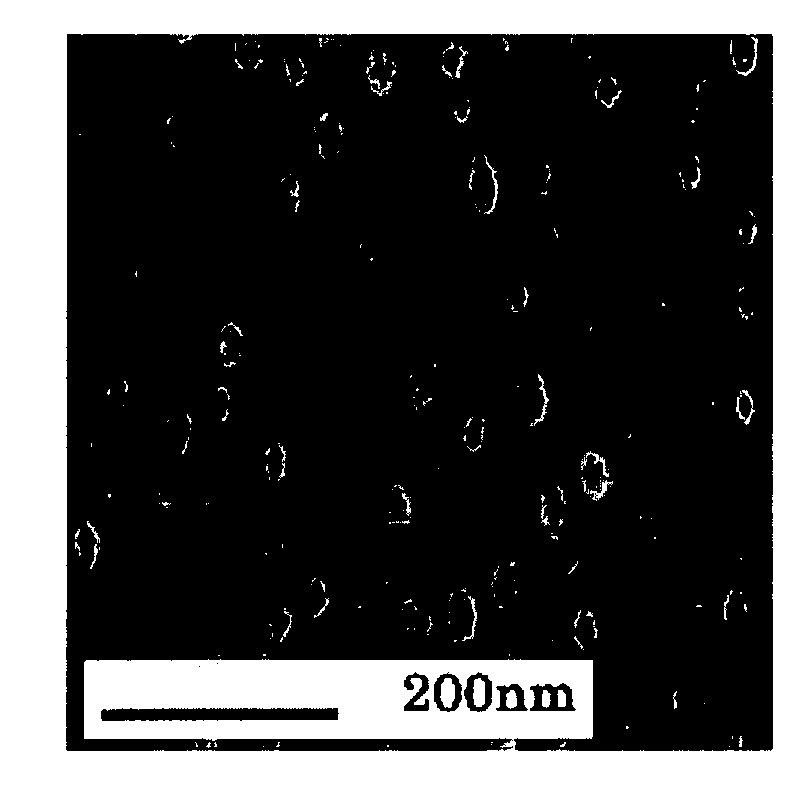

InactiveUS20100073816A1Excellent characteristicsImprove stabilityElectrical transducersRecord information storageMagnetic tapeImage View

An aspect of the present invention relates to a magnetic head employed in a linear tape drive in the form of a sliding-contact linear tape drive. The magnetic head comprises multiple indentations that are observed in a surface topographic image viewed by a scanning probe microscope on a surface (sliding contact surface) of sliding contact with a magnetic tape, and the multiple indentations satisfy (1) to (4) below:(1) an average area of the indentations in the sliding contact surface ranges from about 0.2 μm2 to about 1.0 μm2;(2) a standard deviation of an area of the indentations ranges from about 0.5 μm2 to about 2.0 μm2;(3) an area ratio of the indentations in the sliding contact surface ranges from about 20 percent to about 50 percent; and(4) an average depth of the indentations is equal to or greater than about 15 nm.

Owner:FUJIFILM CORP

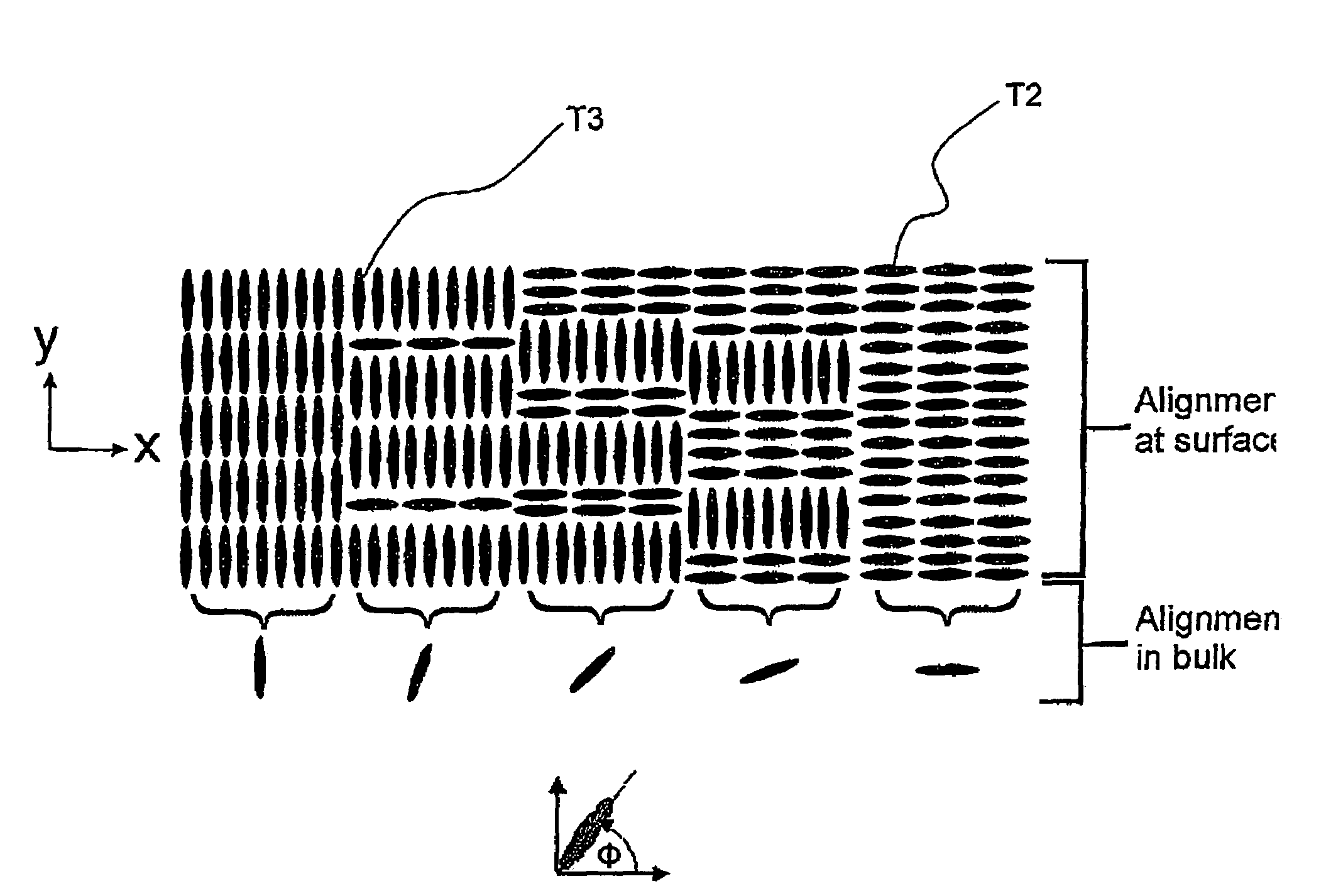

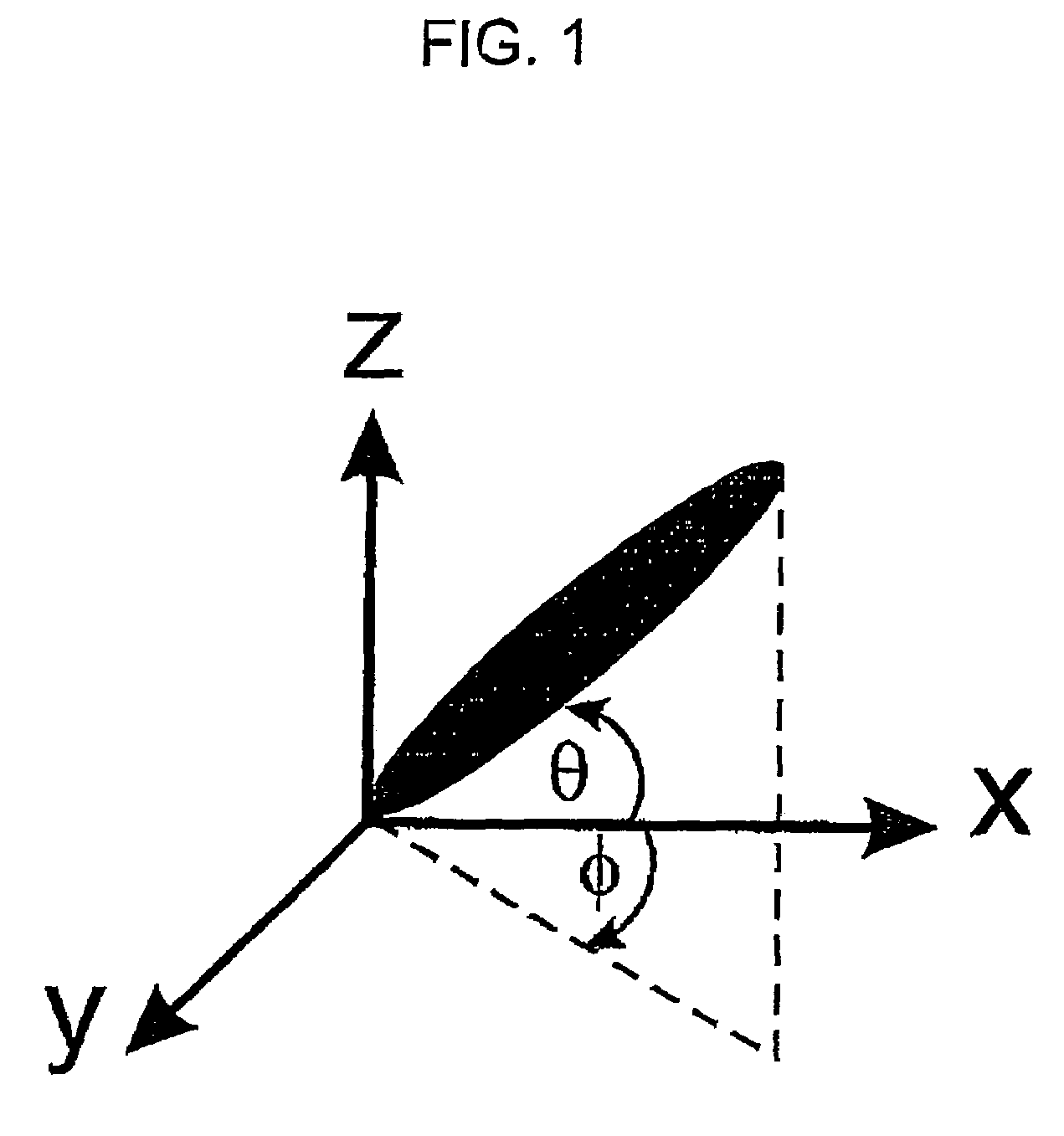

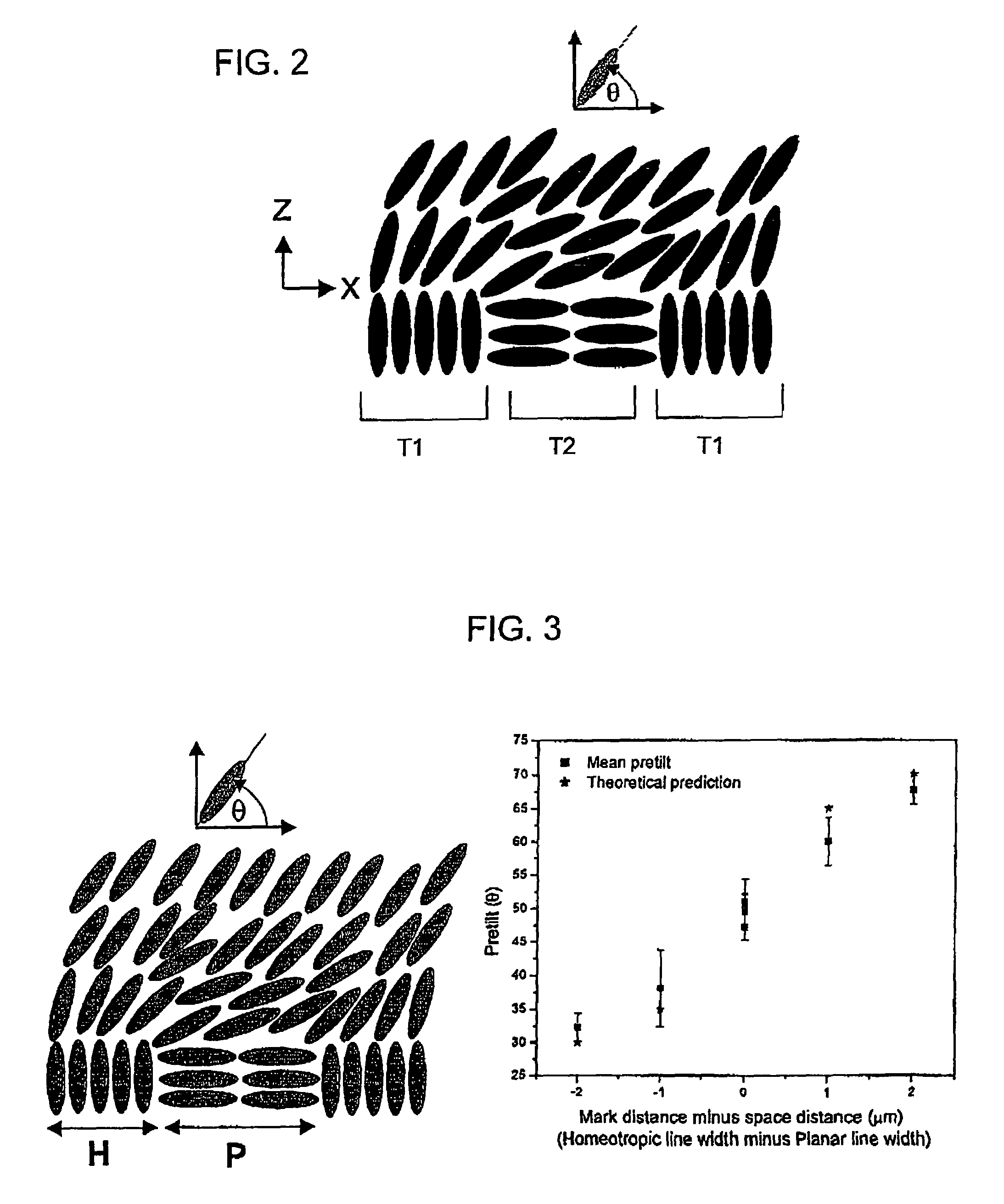

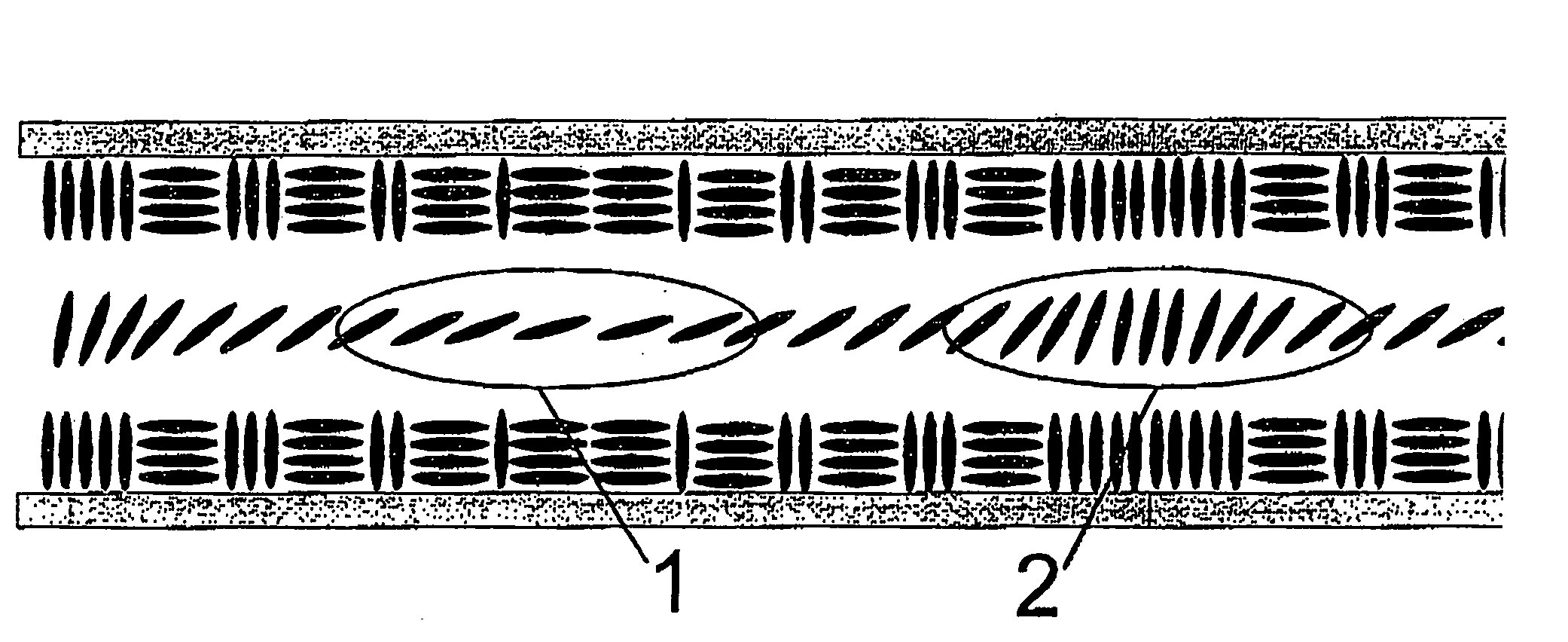

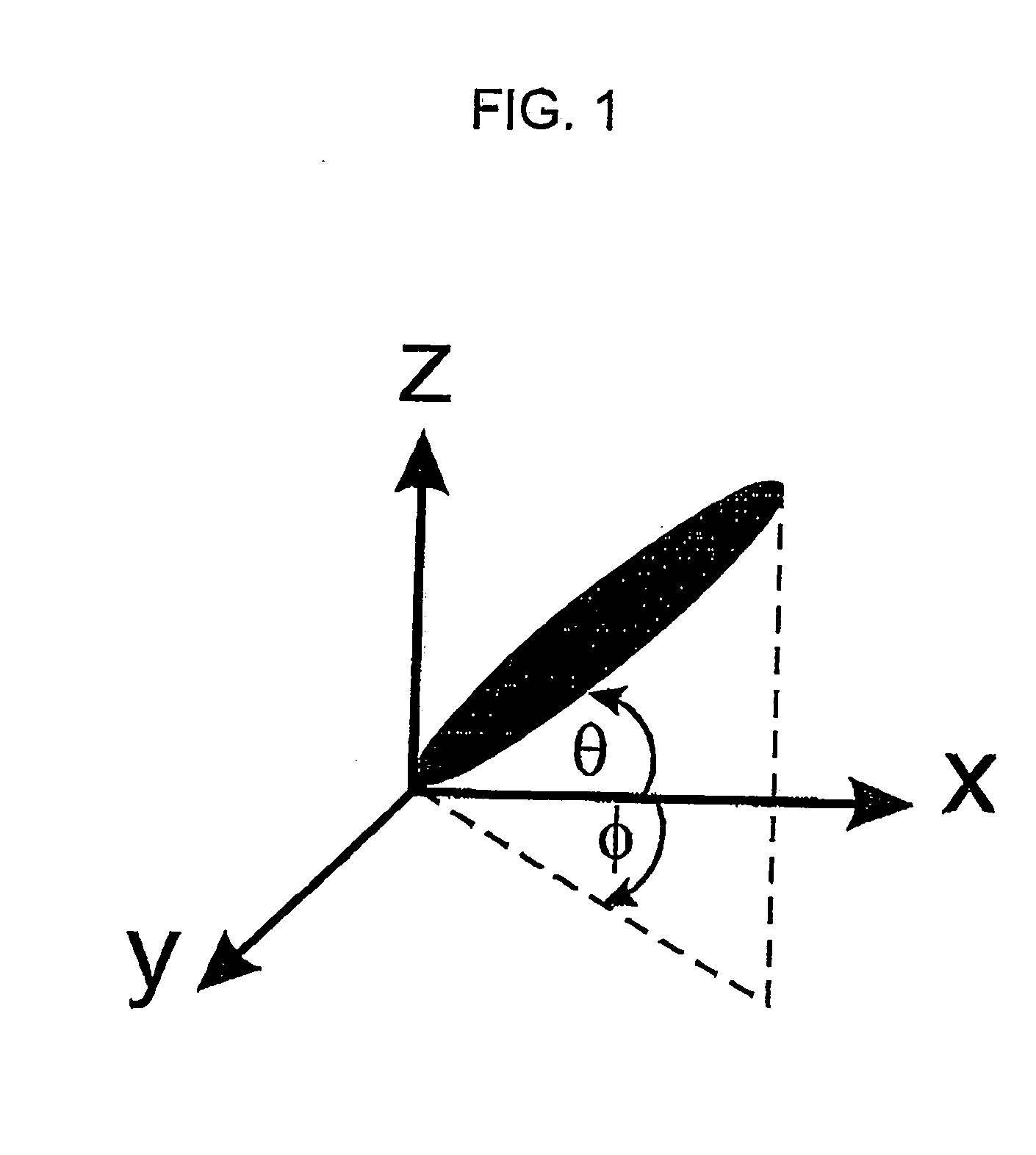

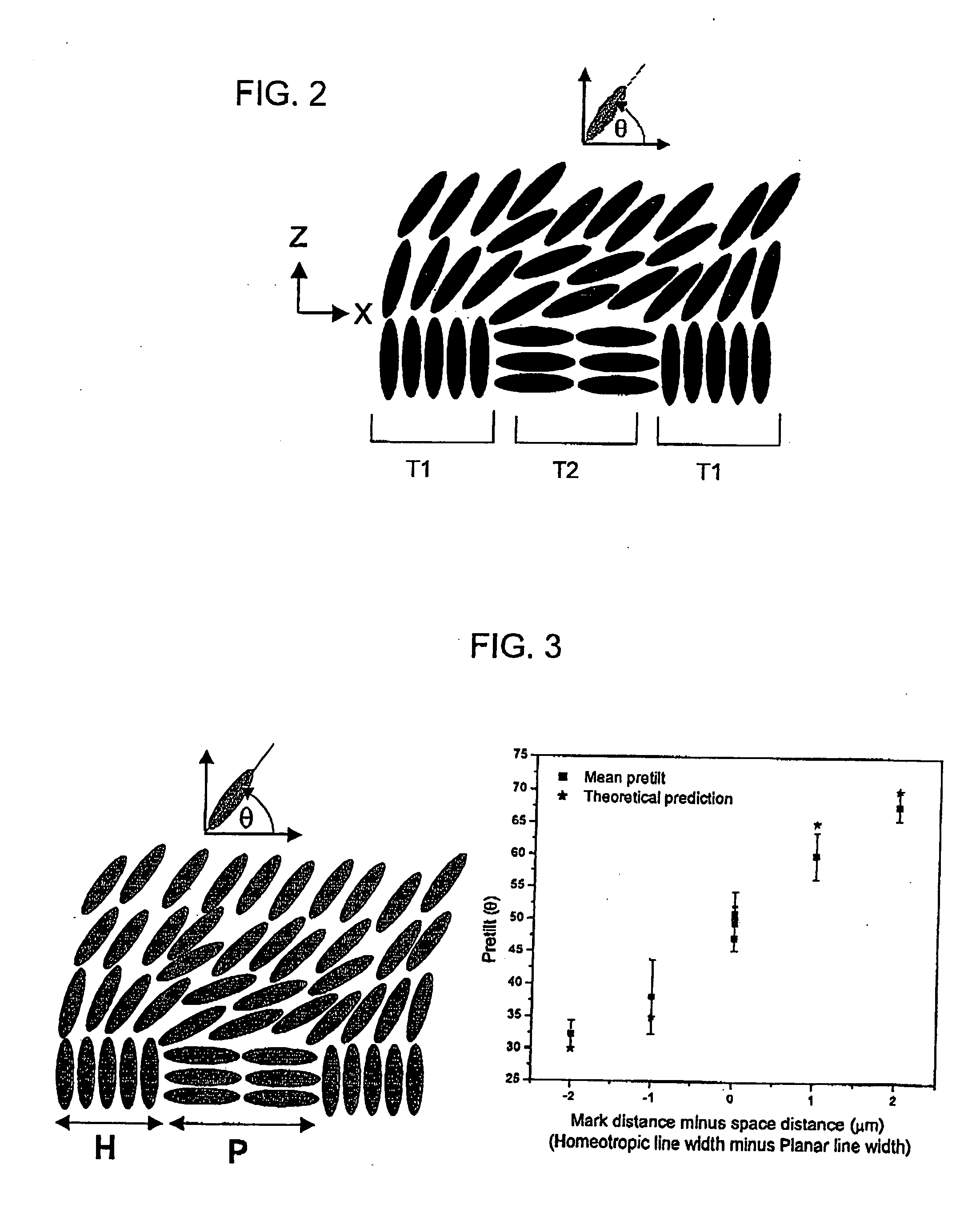

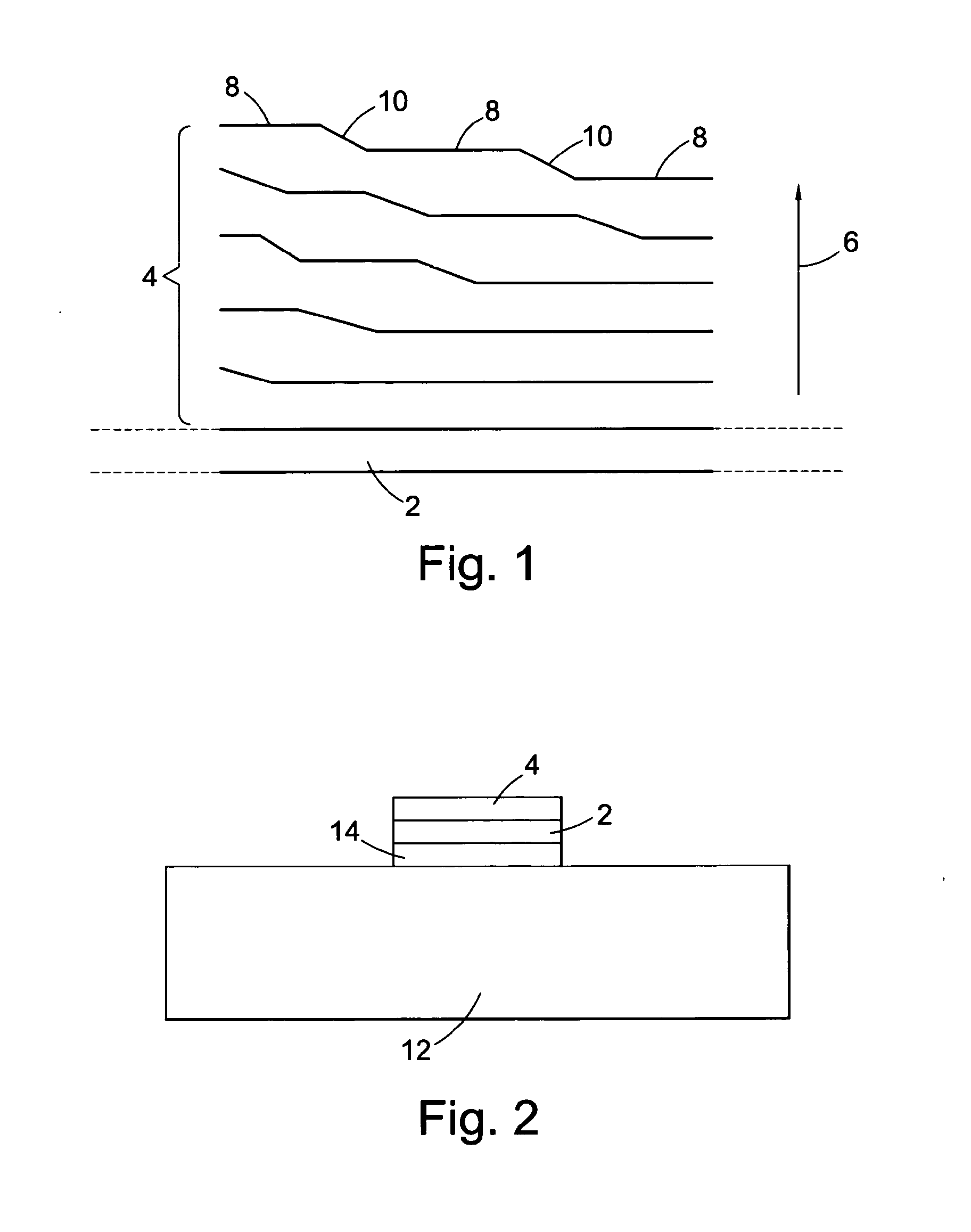

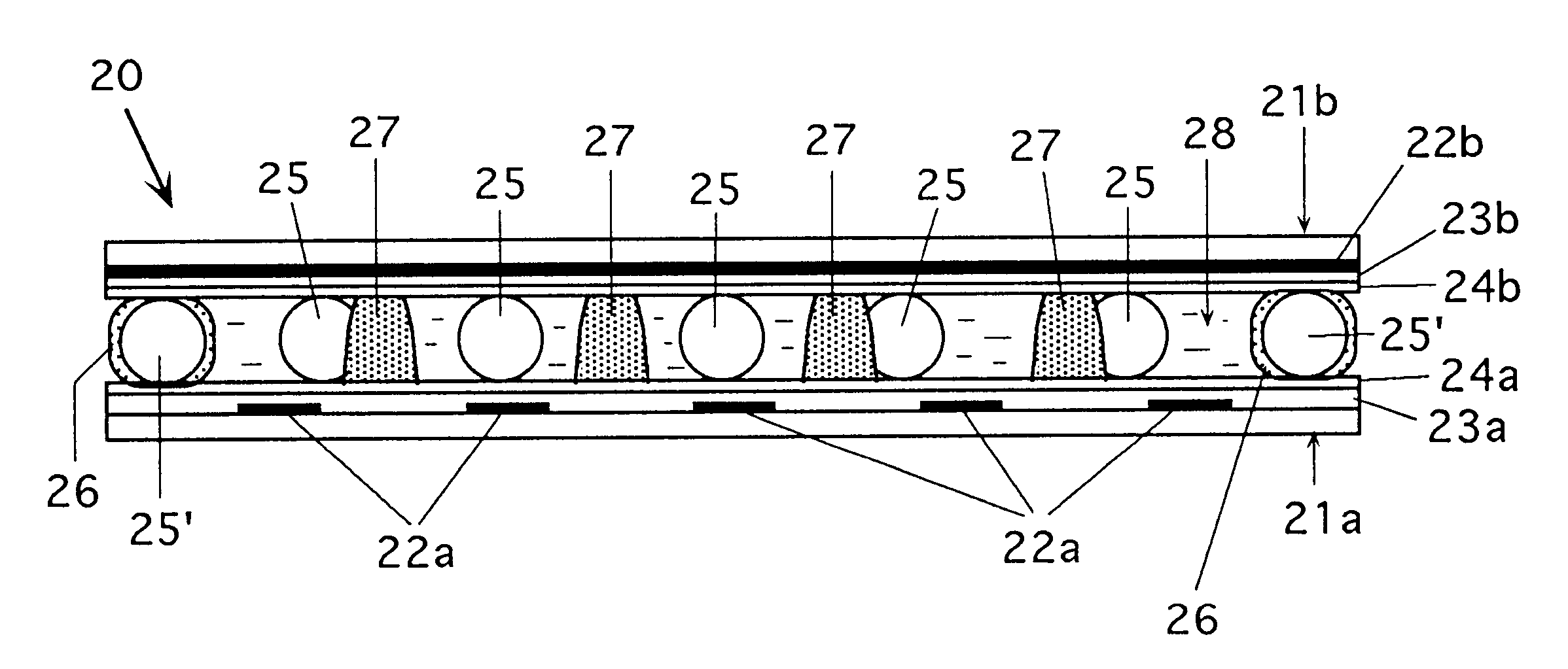

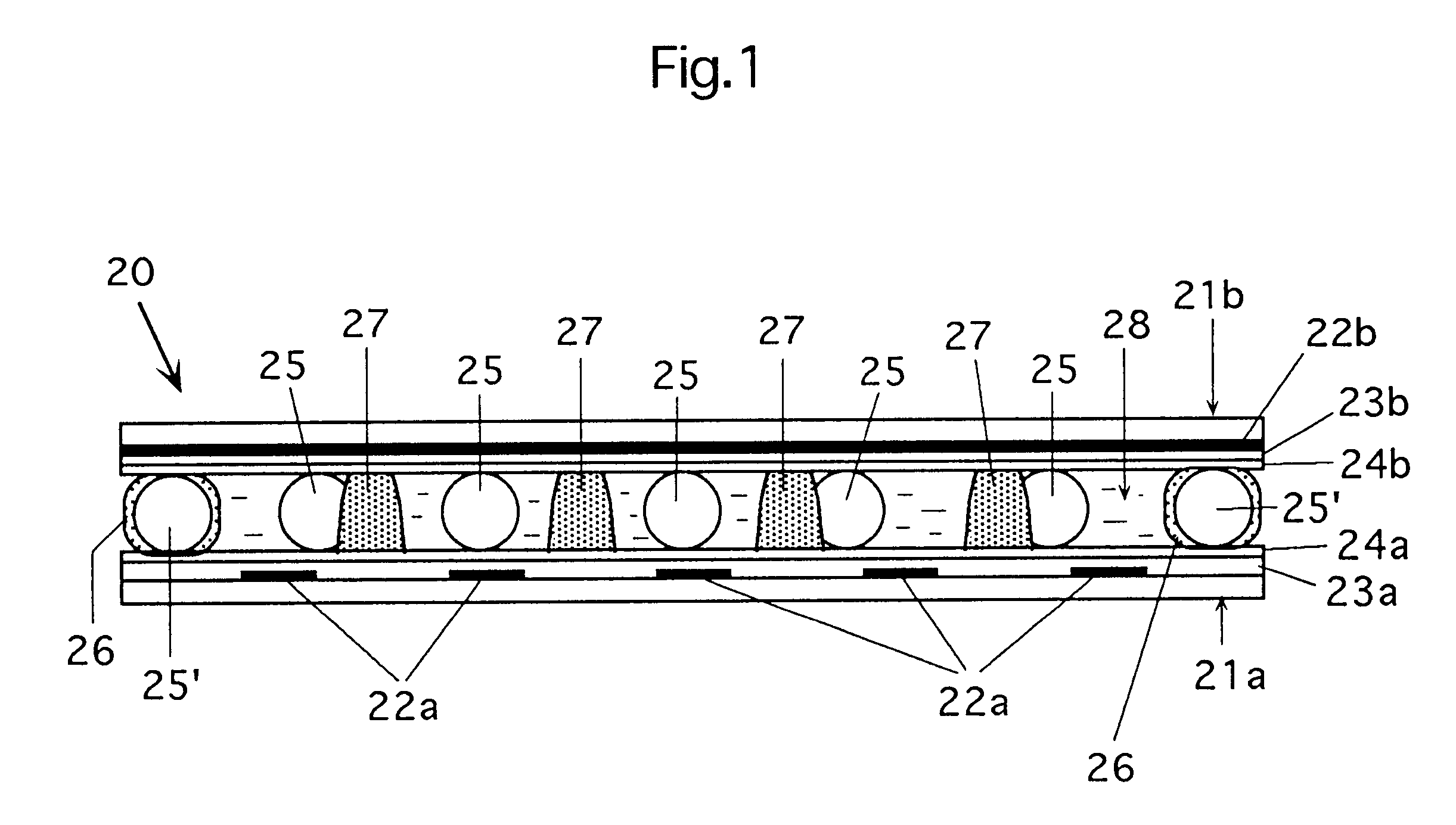

Control of liquid crystal alignment in an optical device

A method is provided that allows simultaneous control of macroscopic azimuthal and zenithal liquid crystal alignment (φ, θ) across a liquid crystal layer by controlling the area ratios between first, second and third different types of alignment region (T1, T2, T3) in a patterned alignment layer, the three different types of alignment region (T1, T2, T3) tending to induce liquid crystal alignment in the liquid crystal layer in three different respective, non-coplanar, principal orientations (z, x, y). In the illustrated example, the first type of alignment region (T1) tends to induce substantially homeotropic alignment (in the z direction) and the second and third types of alignment region (T2, T3) tend to induce substantially planar alignment in different, orthogonal, principal orientations (in the x and y directions). Control of macroscopic zenithal liquid crystal alignment (θ) is achieved by controlling the area ratios between the homeotropic (T1) and planar region types (T2, T3), and control of macroscopic azimuthal liquid crystal alignment (φ) is achieved by controlling the area ratio between the two planar region types (T2, T3).

Owner:SHARP KK

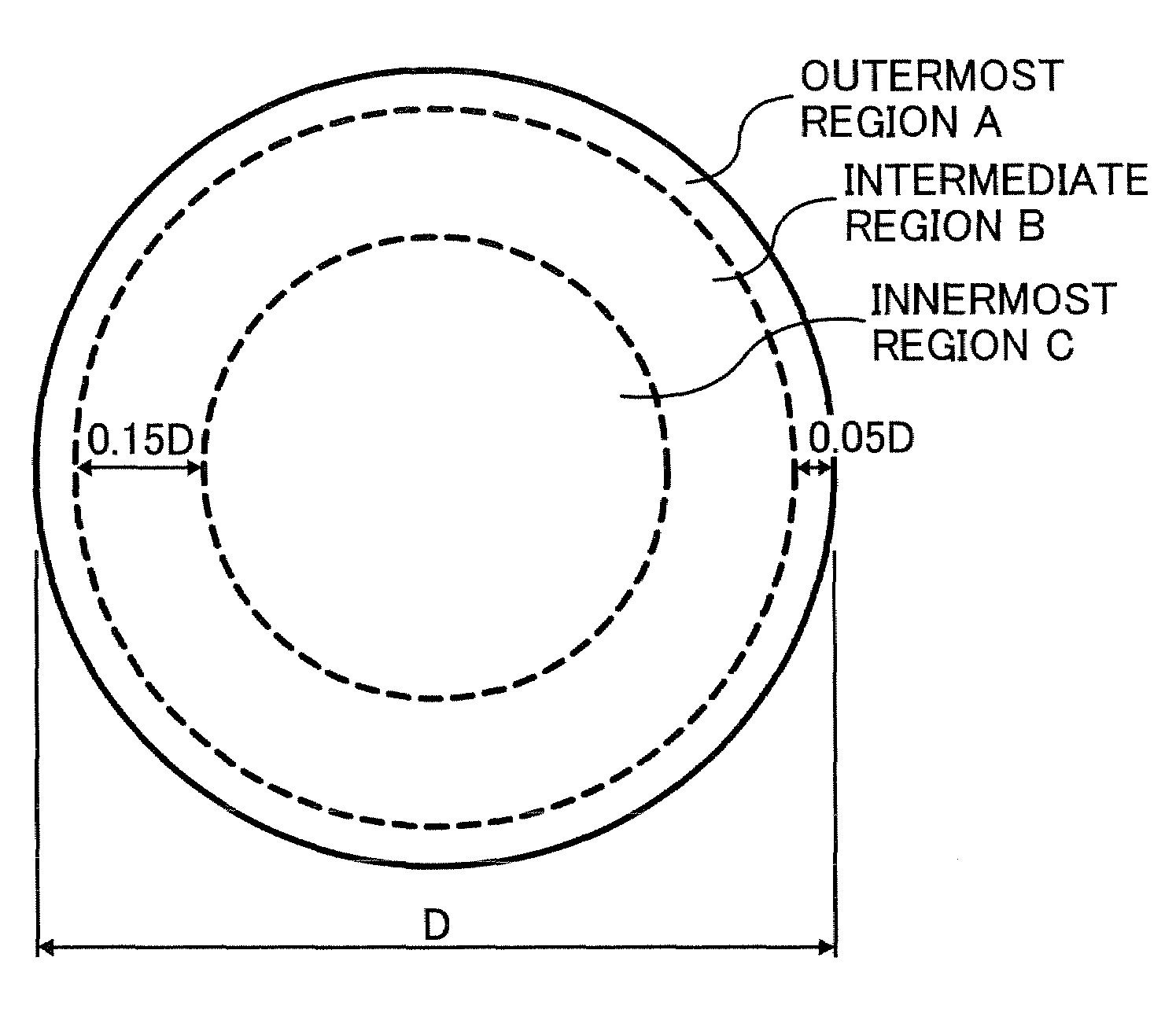

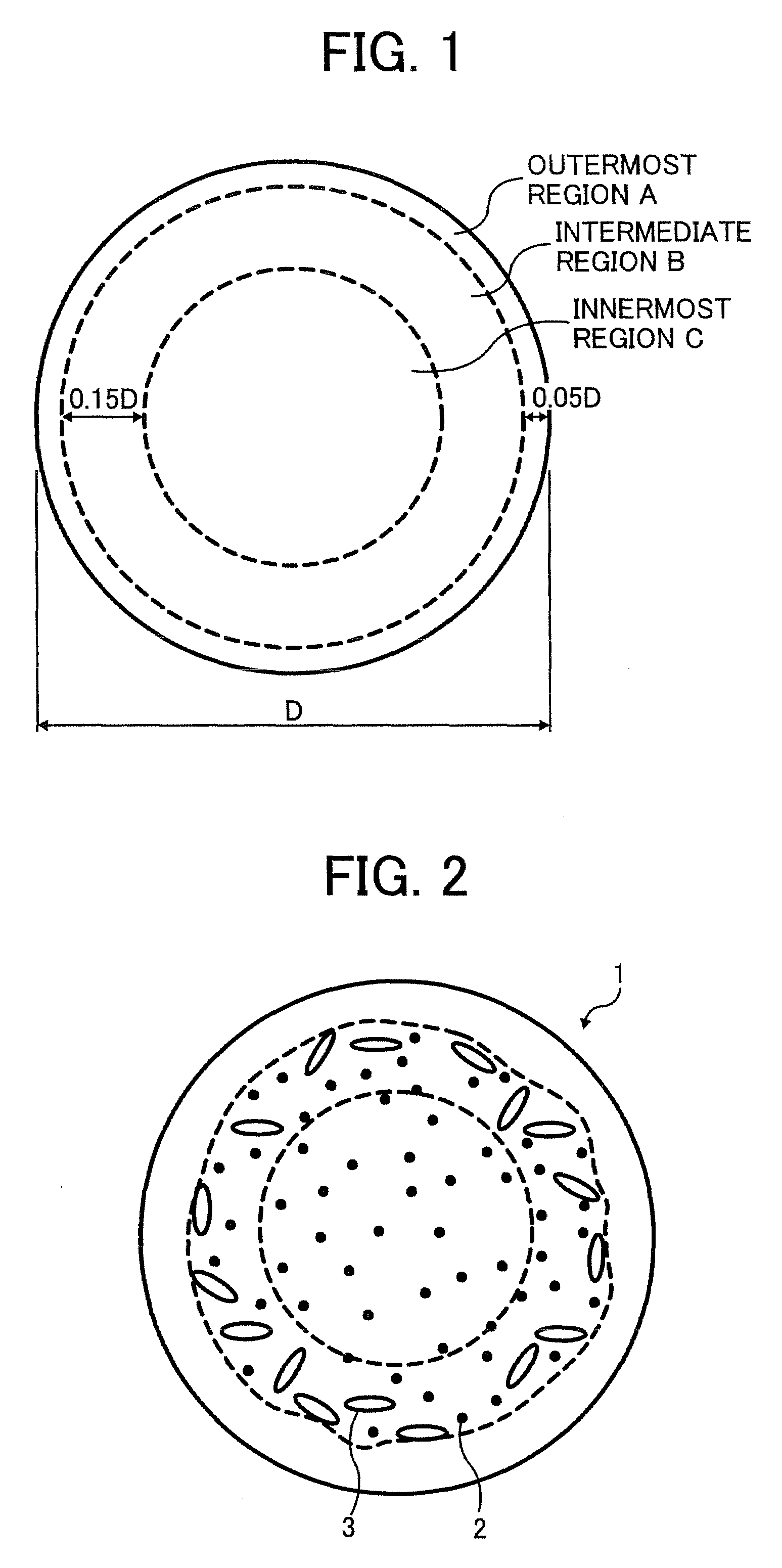

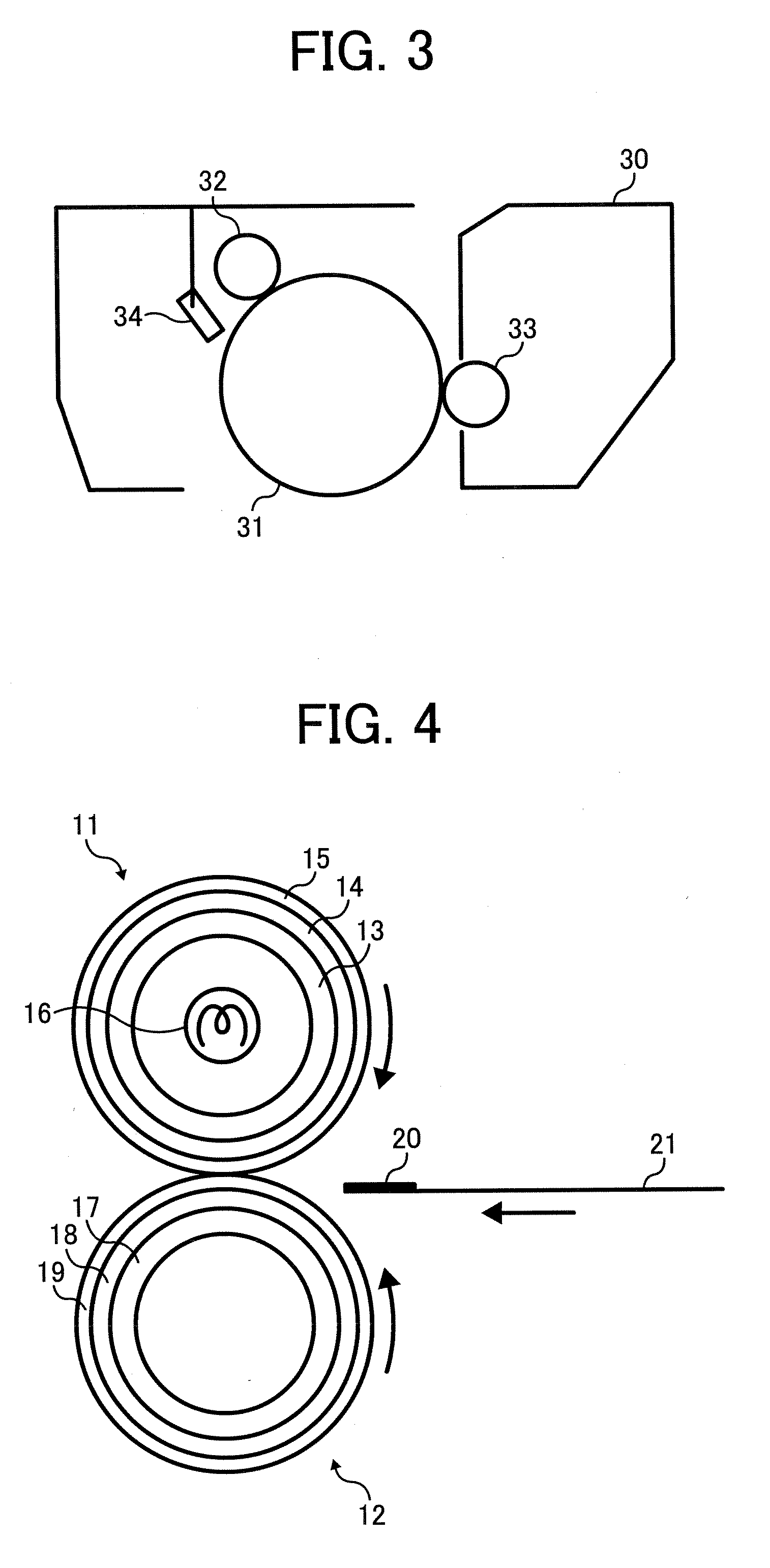

Toner and method of preparing the toner

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

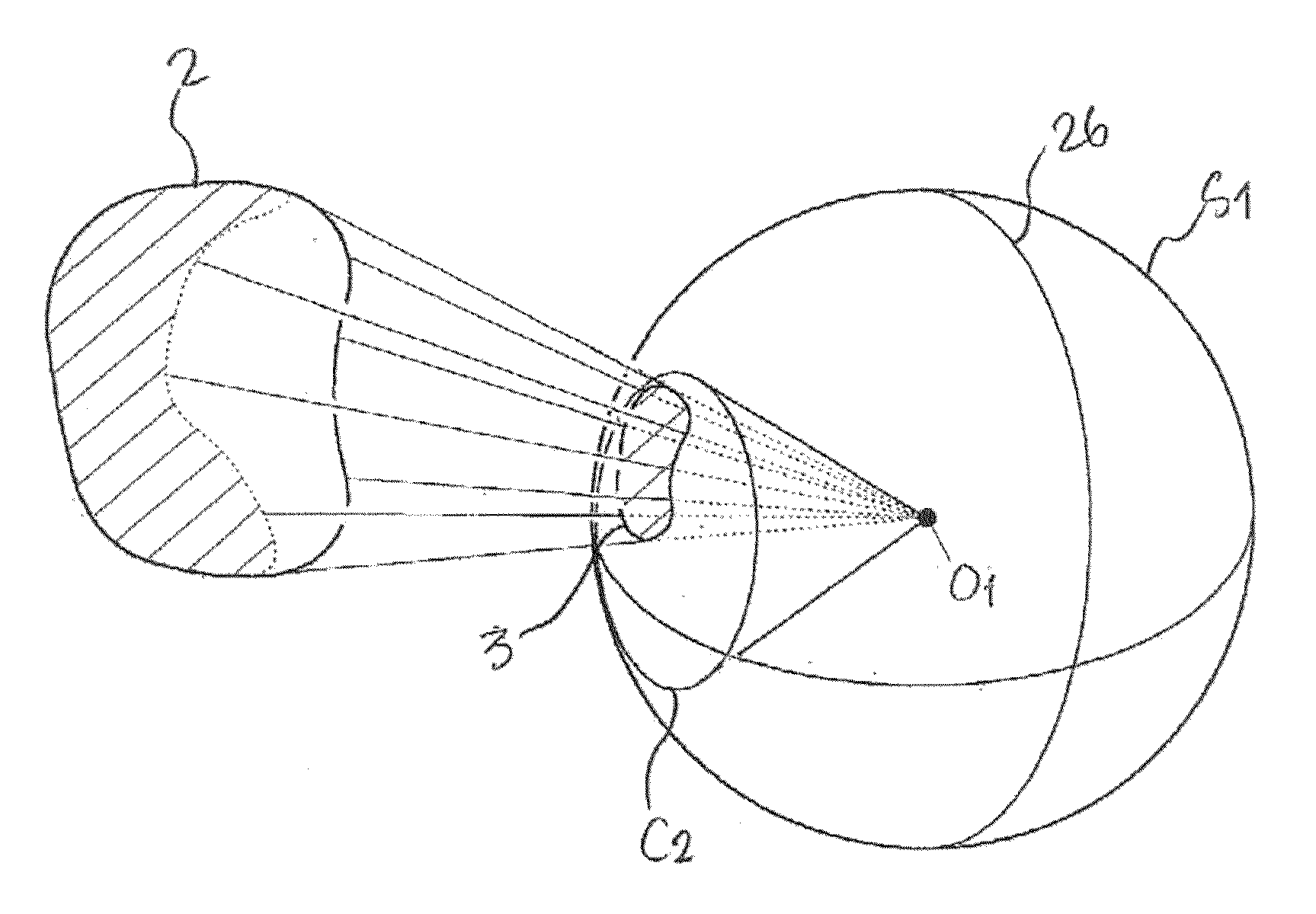

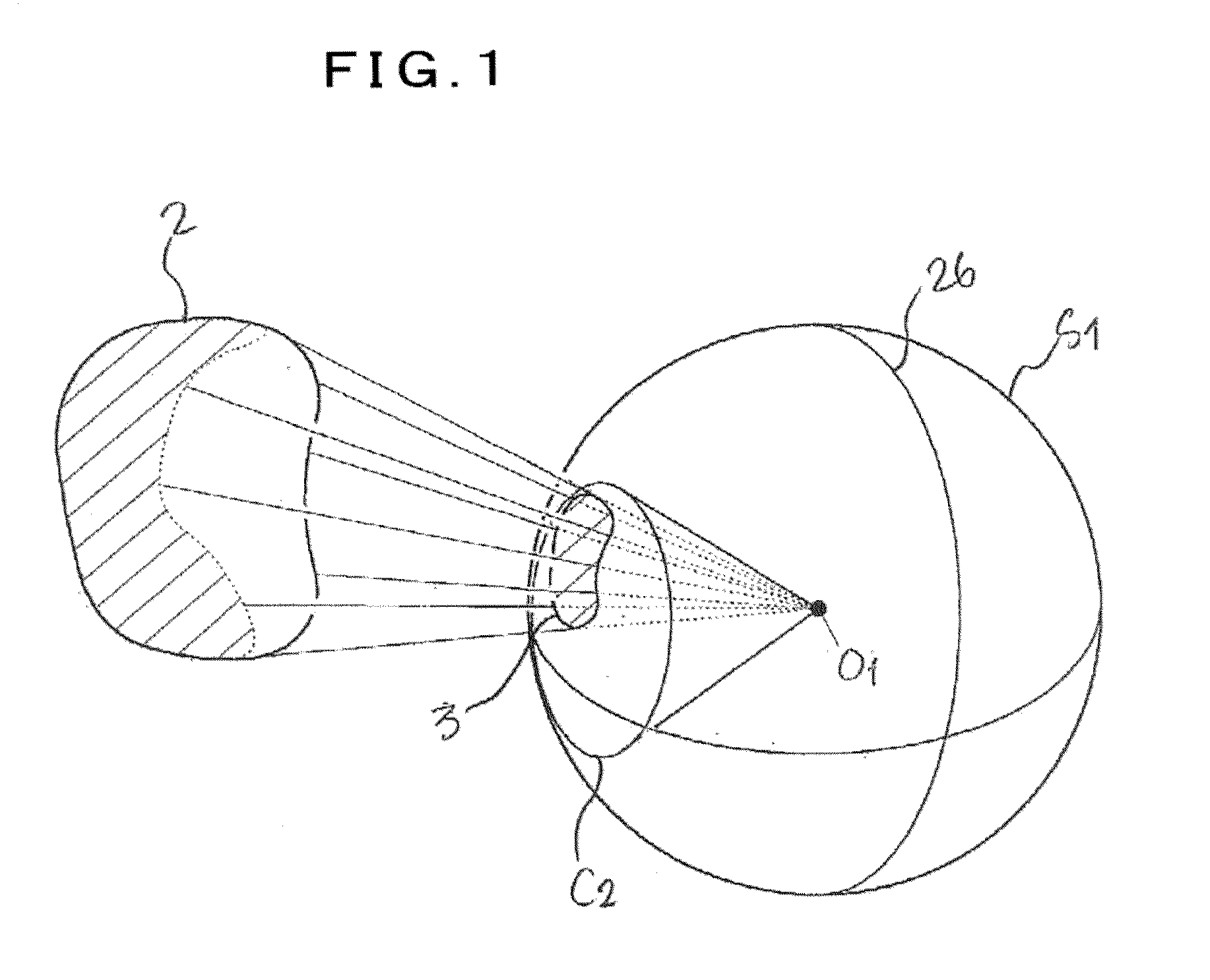

Information Processing Method

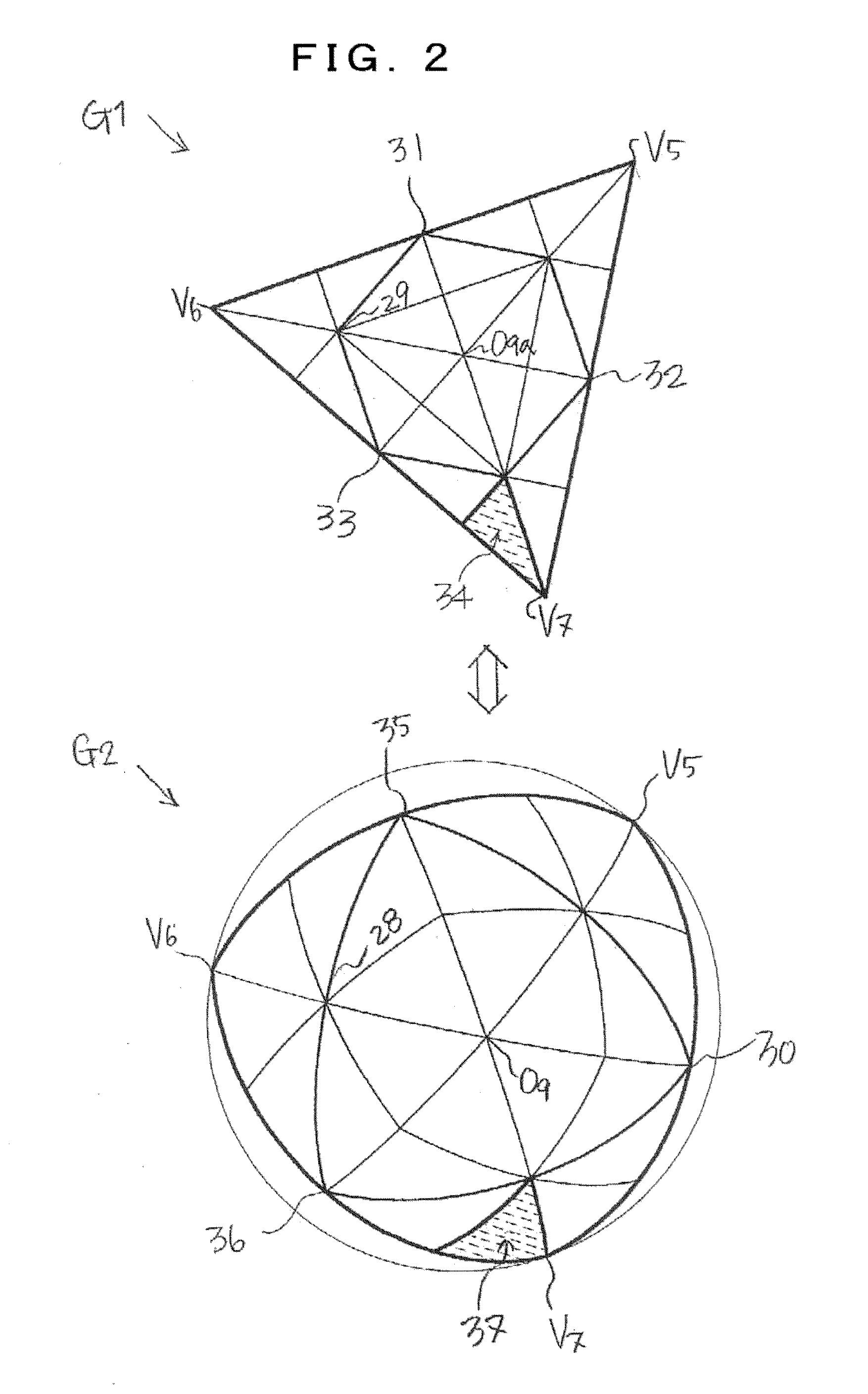

InactiveUS20100001997A1Reducing local distortionMaintaining their area ratio3D-image rendering3D modellingInformation processingComputer graphics (images)

An information processing method transfers information from a start face to an end face with a minimum local distortion by maintaining one-to-one correspondence between the original information on the start face and the transferred information on the end face. The method includes an operation of mapping information taken from a three-dimensional surface onto a rectangular plane, or vice versa, by dividing the start face into a plurality of divisional start faces and preparing divisional end faces that just fill the end face, then deforming each divisional start face to just fit a corresponding one of the divisional end faces, so as to maintain lines and points defining each divisional end face as lines and points also on the end face and to ensure that a first area ratio between each divisional start face relative to the entire start face and a second area ratio between each divisional end face relative to the entire end face is substantially equal.

Owner:NARUKAWA HAJIME

Control of liquid crystal alignment in an optical device

A method is provided that allows simultaneous control of macroscopic azimuthal and zenithal liquid crystal alignment (φ, θ) across a liquid crystal layer by controlling the area ratios between first, second and third different types of alignment region (T1, T2, T3) in a patterned alignment layer, the three different types of alignment region (T1, T2, T3) tending to induce liquid crystal alignment in the liquid crystal layer in three different respective, non-coplanar, principal orientations (z, x, y). In the illustrated example, the first type of alignment region (T1) tends to induce substantially homeotropic alignment (in the z direction) and the second and third types of alignment region (T2, T3) tend to induce substantially planar alignment in different, orthogonal, principal orientations (in the x and y directions). Control of macroscopic zenithal liquid crystal alignment (θ) is achieved by controlling the area ratios between the homeotropic (T1) and planar region types (T2, T3), and control of macroscopic azimuthal liquid crystal alignment (φ) is achieved by controlling the area ratio between the two planar region types (T2, T3).

Owner:SHARP KK

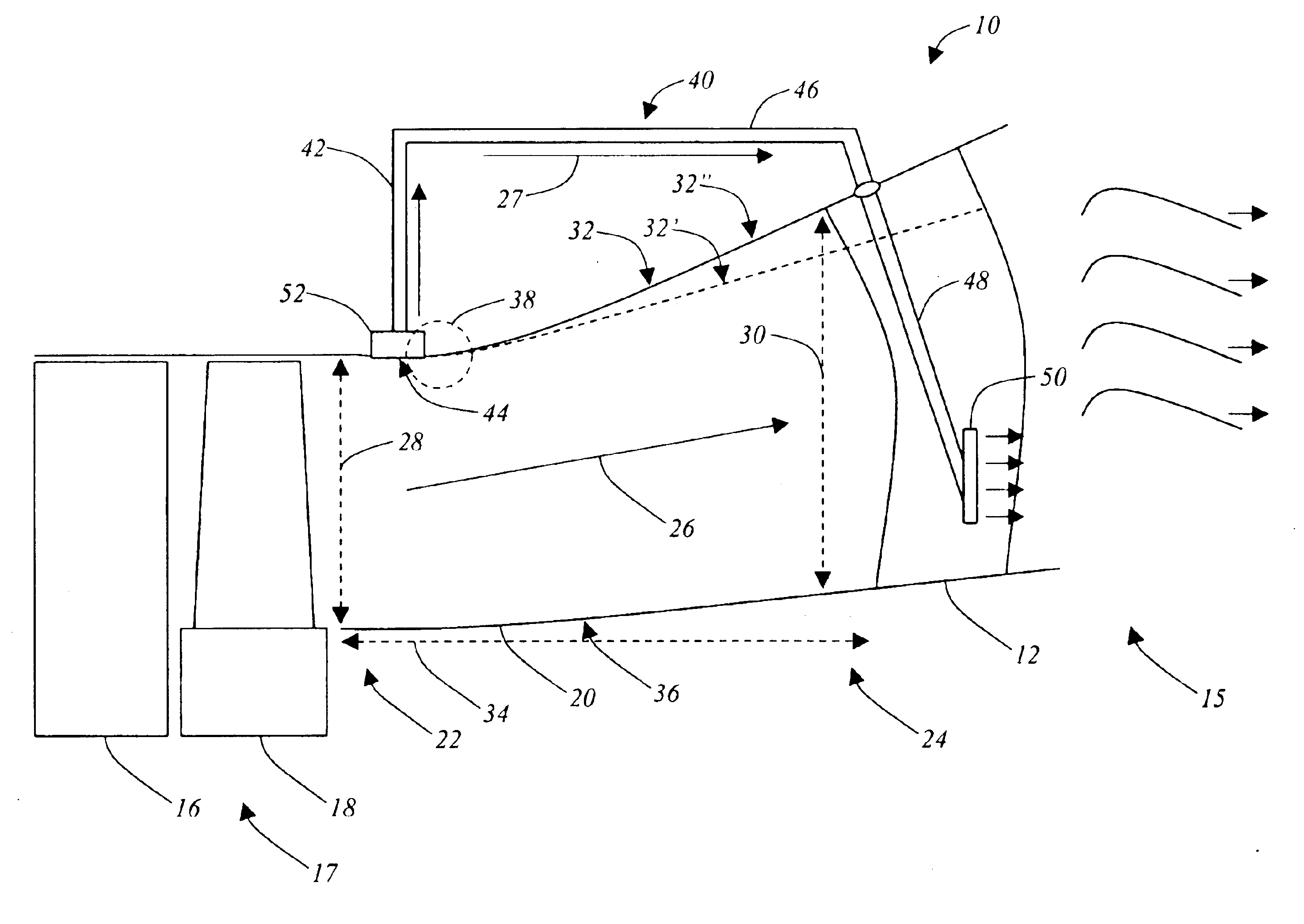

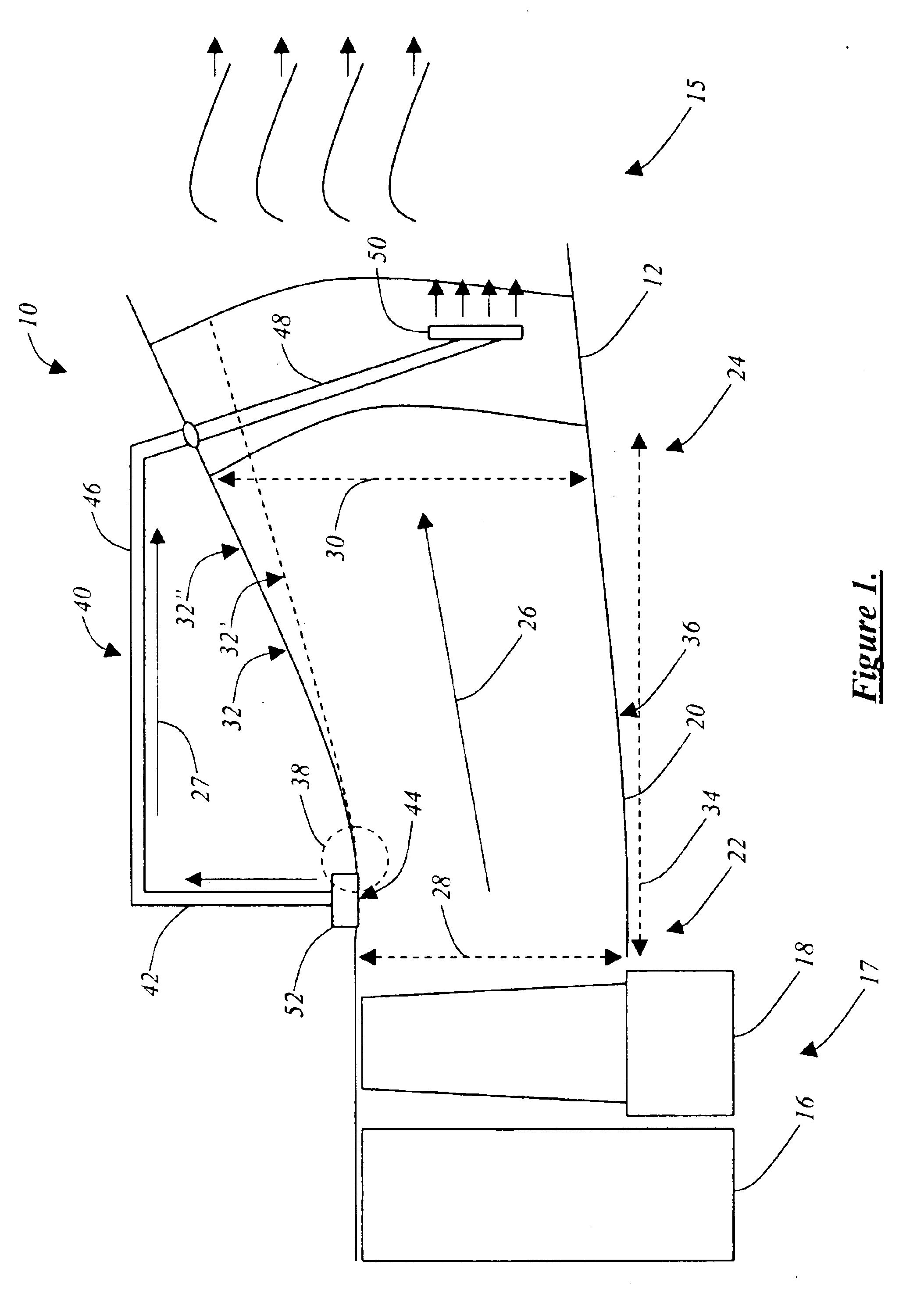

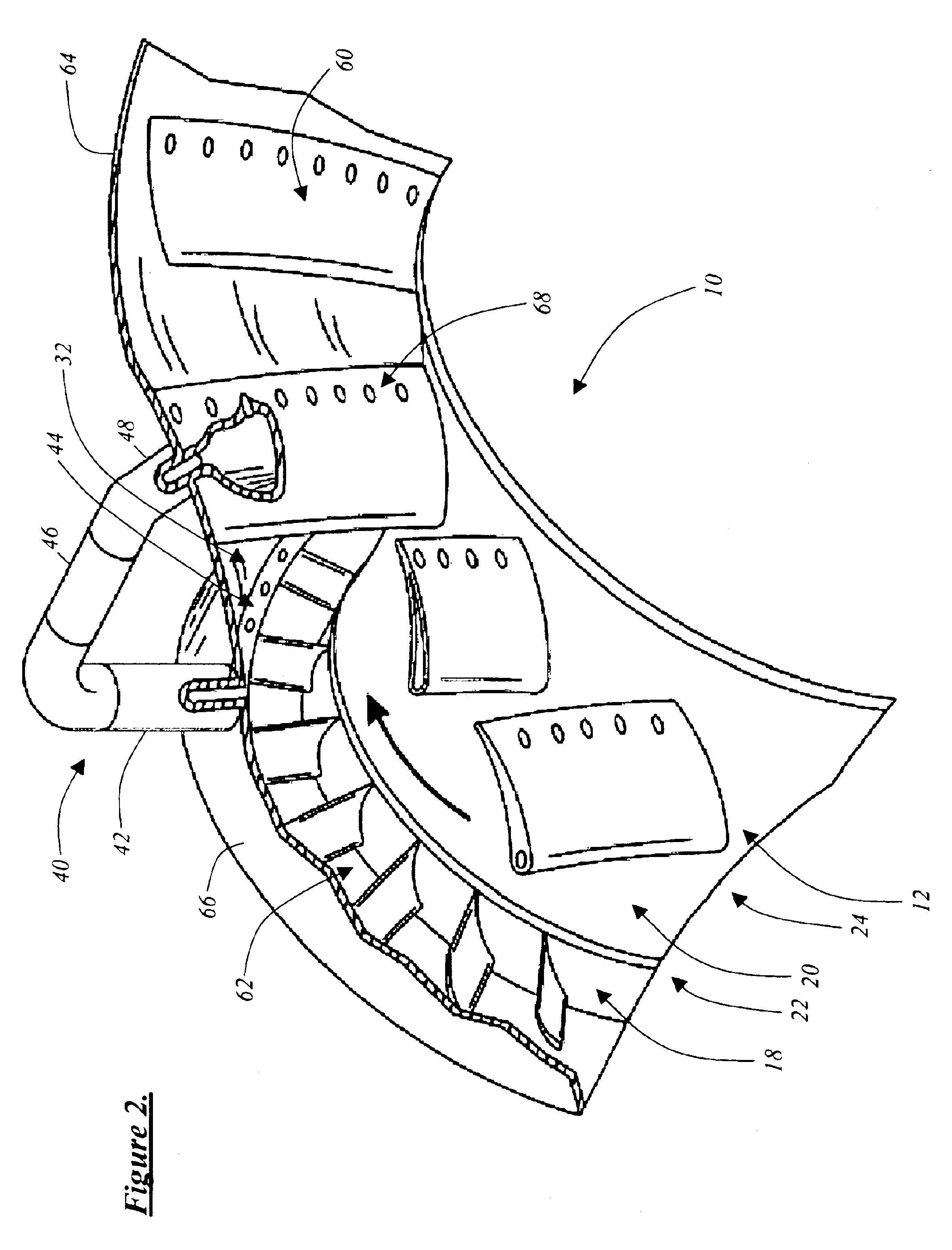

Self-aspirating high-area-ratio inter-turbine duct assembly for use in a gas turbine engine

InactiveUS6851264B2Improve performanceEnhanced aerodynamic benefitWind motor controlCombination enginesPressure differenceHigh pressure

In various embodiments, the present invention provides a means for improving gas turbine engine performance by applying fluid flow control to the inter-turbine duct joining a high-pressure turbine spool and an associated low-pressure turbine spool, allowing the low-pressure turbine spool to have a relatively larger diameter than the high-pressure turbine spool. One or more unobstructed fluid flow paths between one or more boundary layer suction ports disposed within the upstream end of the outer-body surface of the inter-turbine duct and the suction side of the associated low-pressure turbine nozzle are provided. Advantageously, the natural static pressure difference between these points results in a self-aspirating assembly. The fluid flow control provided by the respective suction and blowing forces generated allows for a relatively larger diameter low-pressure turbine spool and / or relatively fewer low-pressure turbine nozzles to be used than is possible with conventional systems, assemblies, and methods. Thus, a gas turbine engine weight savings and optimized performance may be achieved.

Owner:GENERAL ELECTRIC CO

Porous fiber

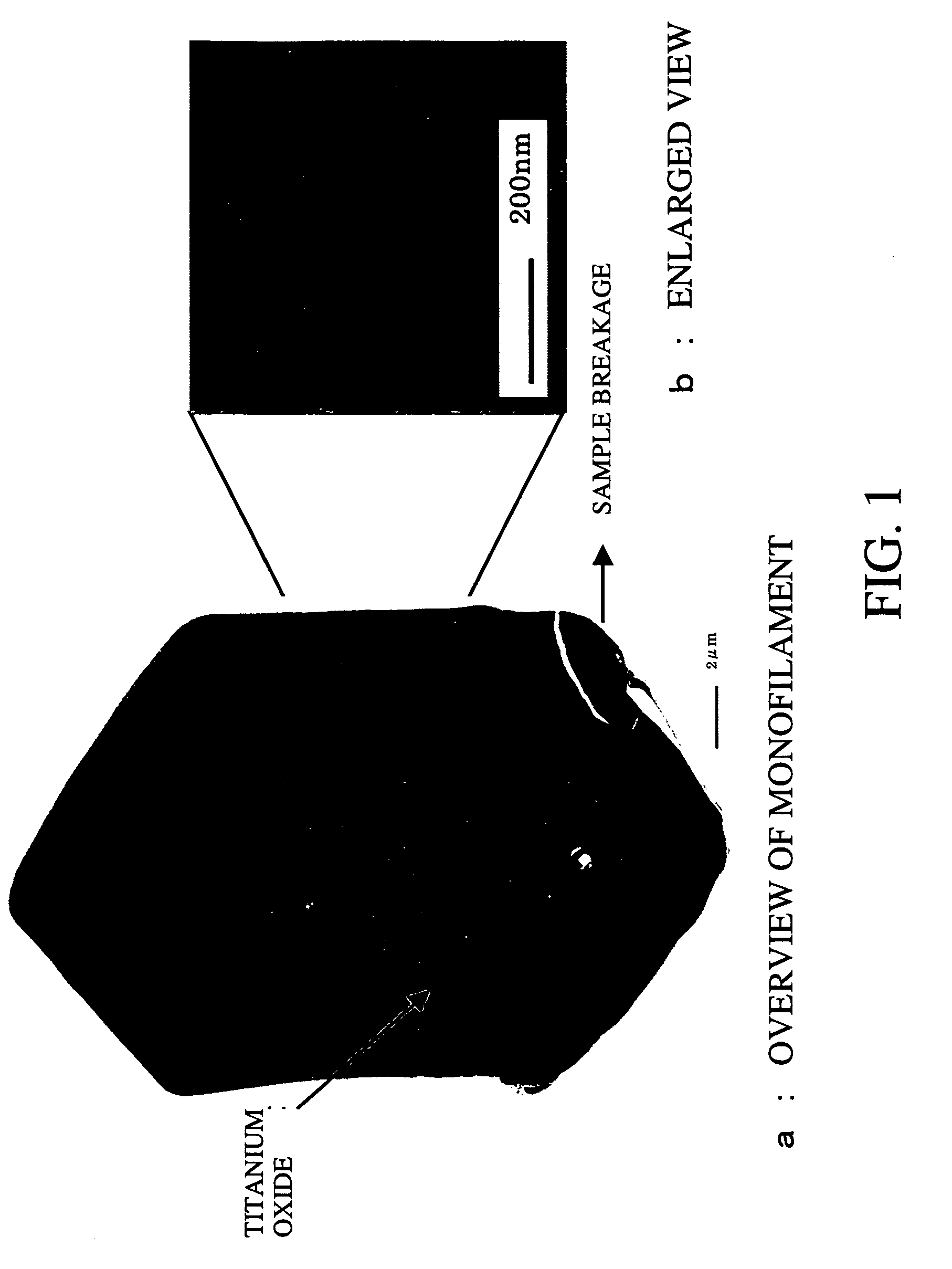

InactiveUS7097904B2Good color propertiesMaintain good propertiesFilament/thread formingNanotechnologyMetallurgyNanopore

The present invention provides a nanoporous fiber being substantially free from coarse pores and having homogeneously dispersed nanopores, unlike conventional porous fibers. A porous fiber has pores each having a diameter of 100 nm or less, in which the area ratio of pores each having a diameter of 200 nm or more to the total cross section of the fiber is 1.5% or less, and the pores are unconnected pores, or a porous fiber has pores each having a diameter of 100 nm or less, in which the area ratio of pores each having a diameter of 200 nm or more to the total cross section of the fiber is 1.5% or less, the pores are connected pores, and the fiber has a strength of 1.0 cN / dtex or more.

Owner:TORAY IND INC

Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

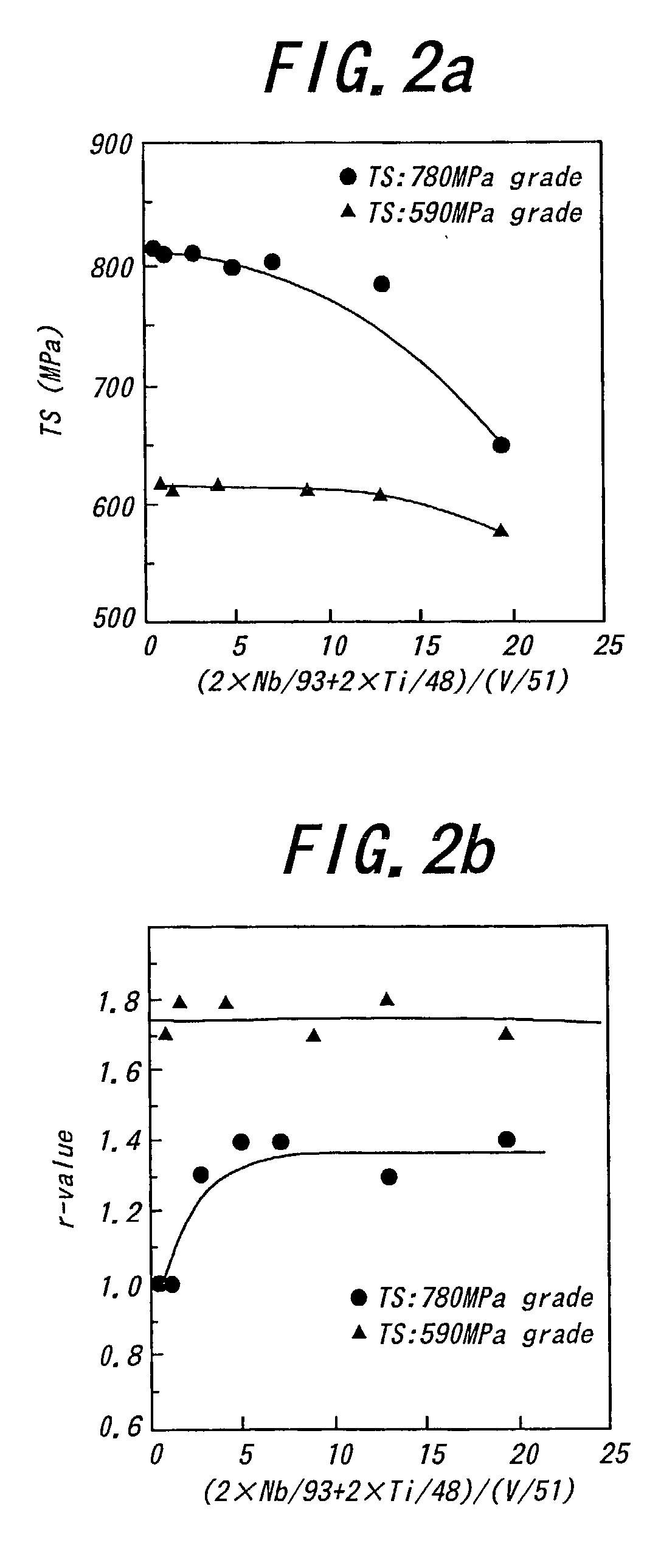

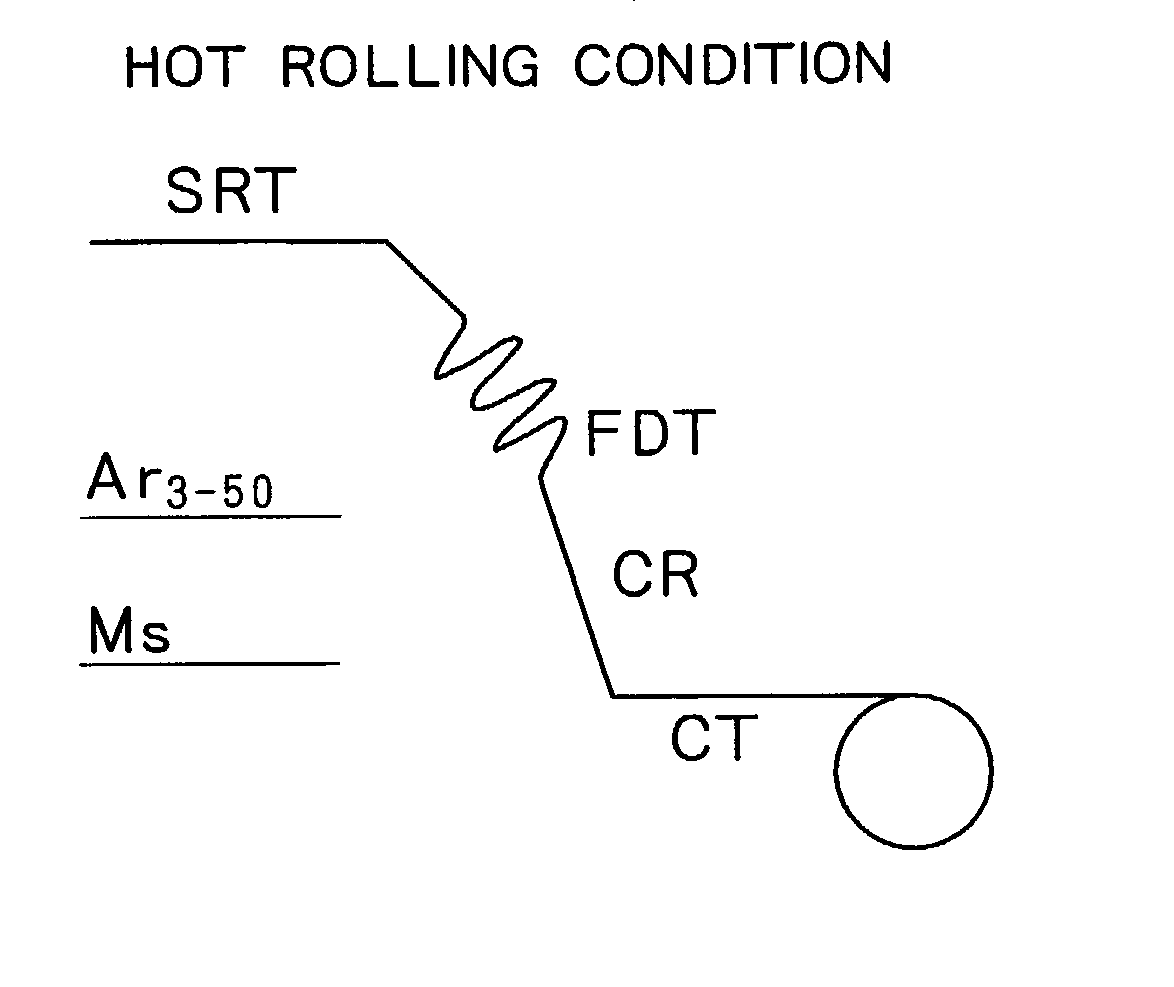

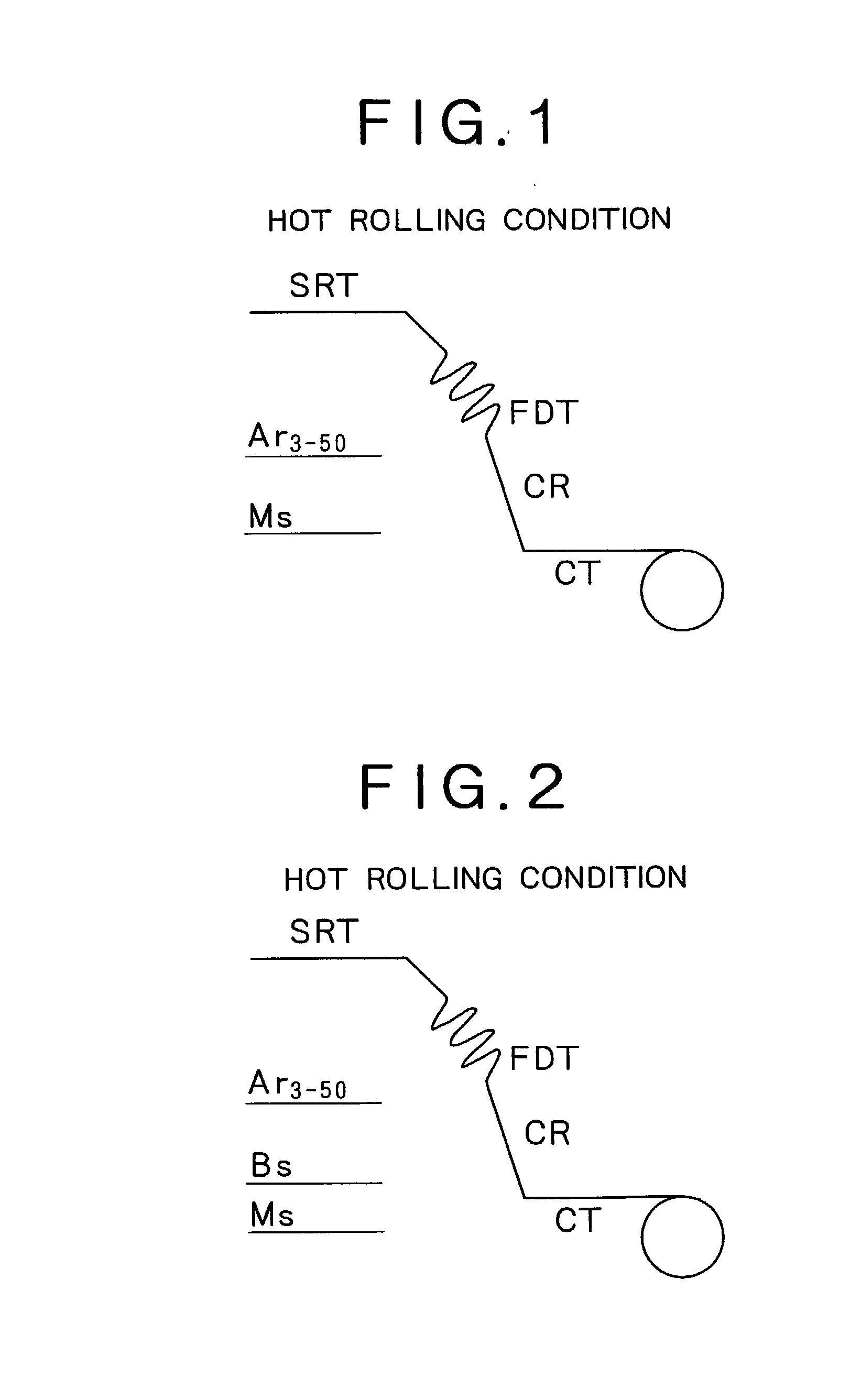

InactiveUS20030129444A1Lower yield stressImprove ductilityHot-dipping/immersion processesThin material handlingSheet steelHigh intensity

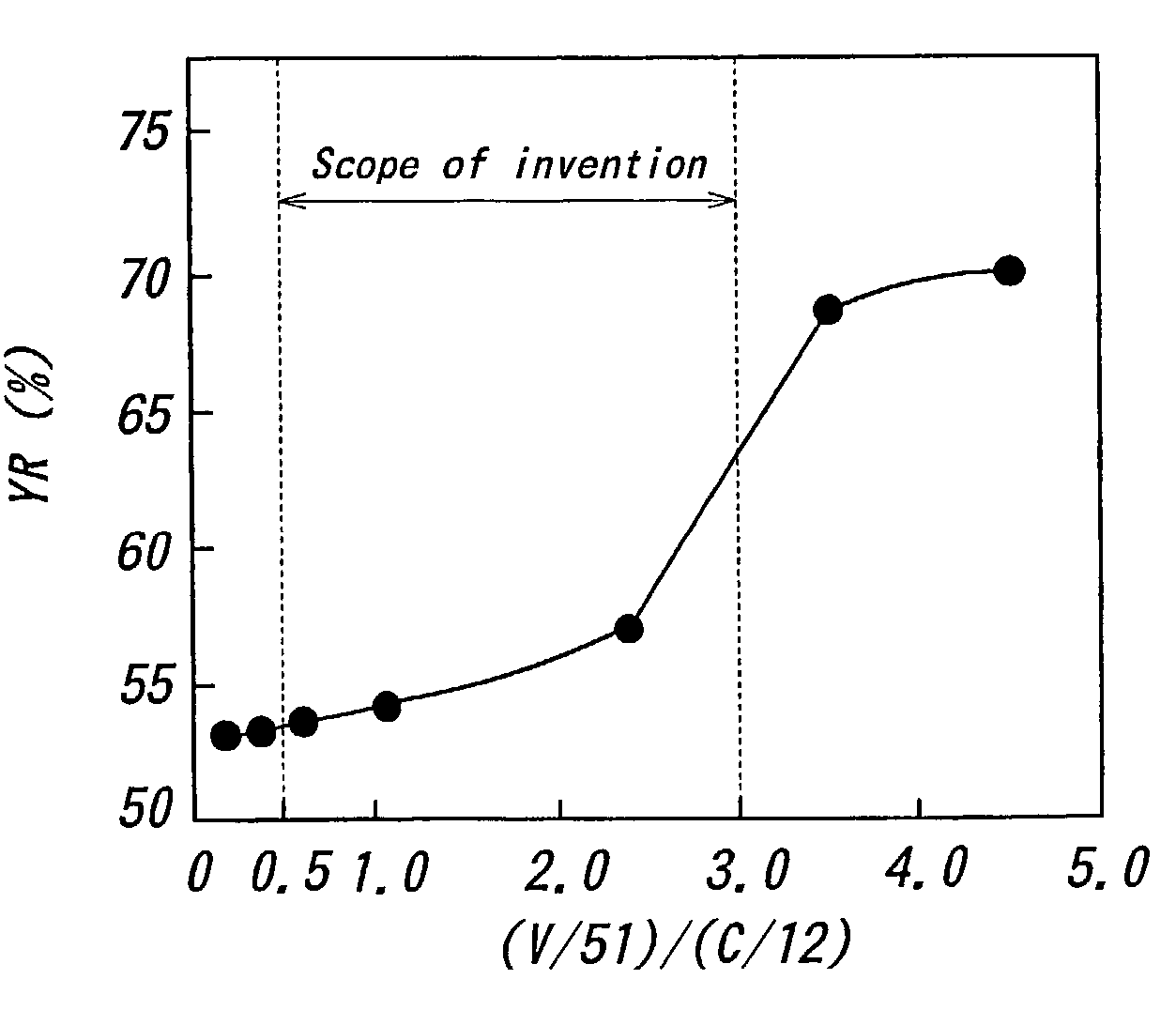

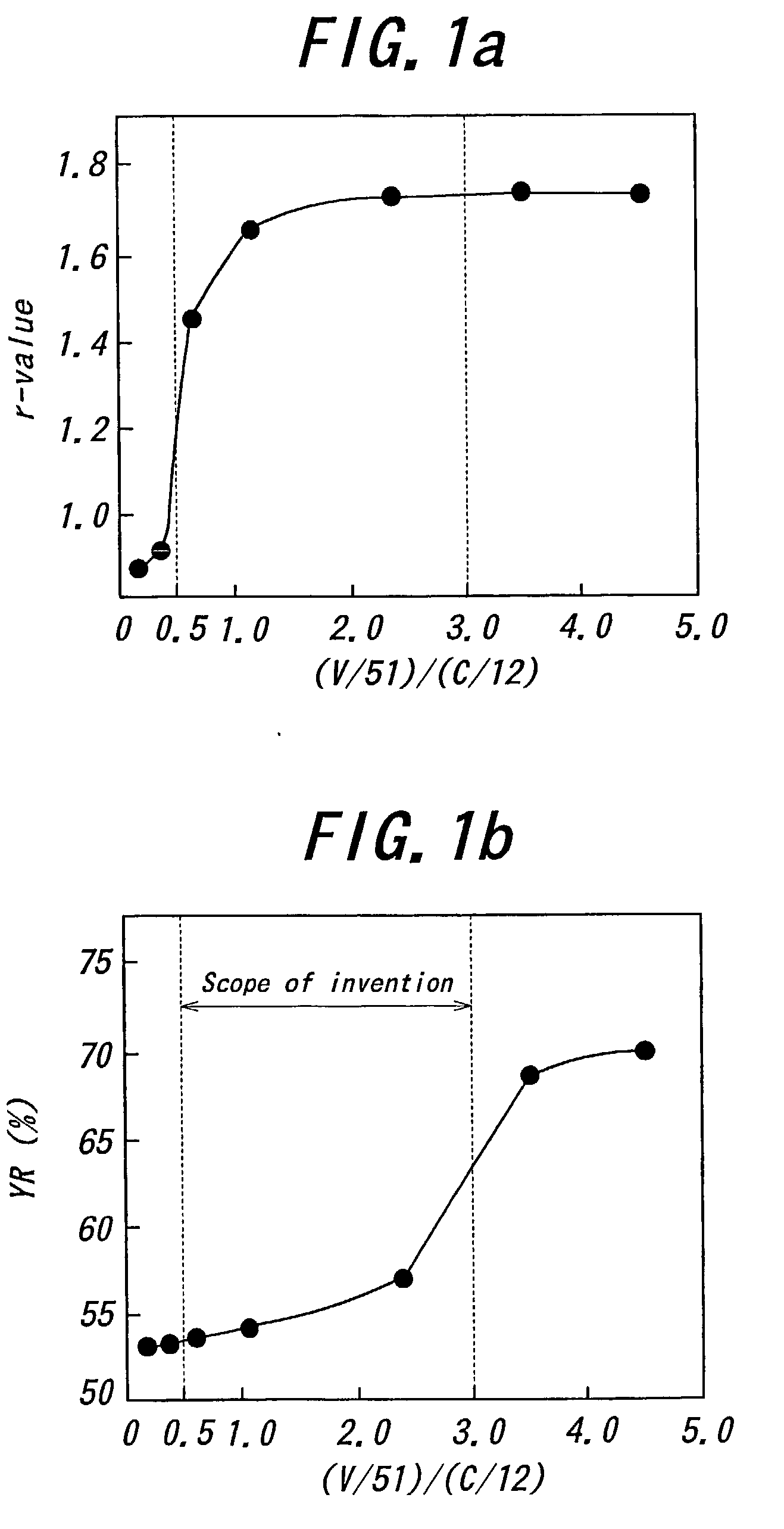

The invention proposes a high-strength dual-phase cold rolled steel sheet having an excellent deep drawability, wherein the steel sheet has a composition comprising C: 0.01-0.08 mass %, Si: not more than 2.0 mass %, Mn: not more than 3.0 mass %, P: not more than 0.10 mass %, S: not more than 0.02 mass %, A1: 0.005-0.20 mass %, N: not more than 0.02 mass % and V: 0.01-0.5 mass %, provided that V and C satisfy a relationship of 0.5xC / 12<=V / 51<=3xC / 12, and the remainder being Fe and inevitable impurities, and has a microstructure consisting of a ferrite phase as a primary phase and a secondary phase including martensite phase at an area ratio of not less than 1% to a whole of the microstructure and a high-strength dual-phase galvanized steel sheet comprising a galvanized coating on the above steel sheet as well as a method of producing the same.

Owner:JFE STEEL CORP

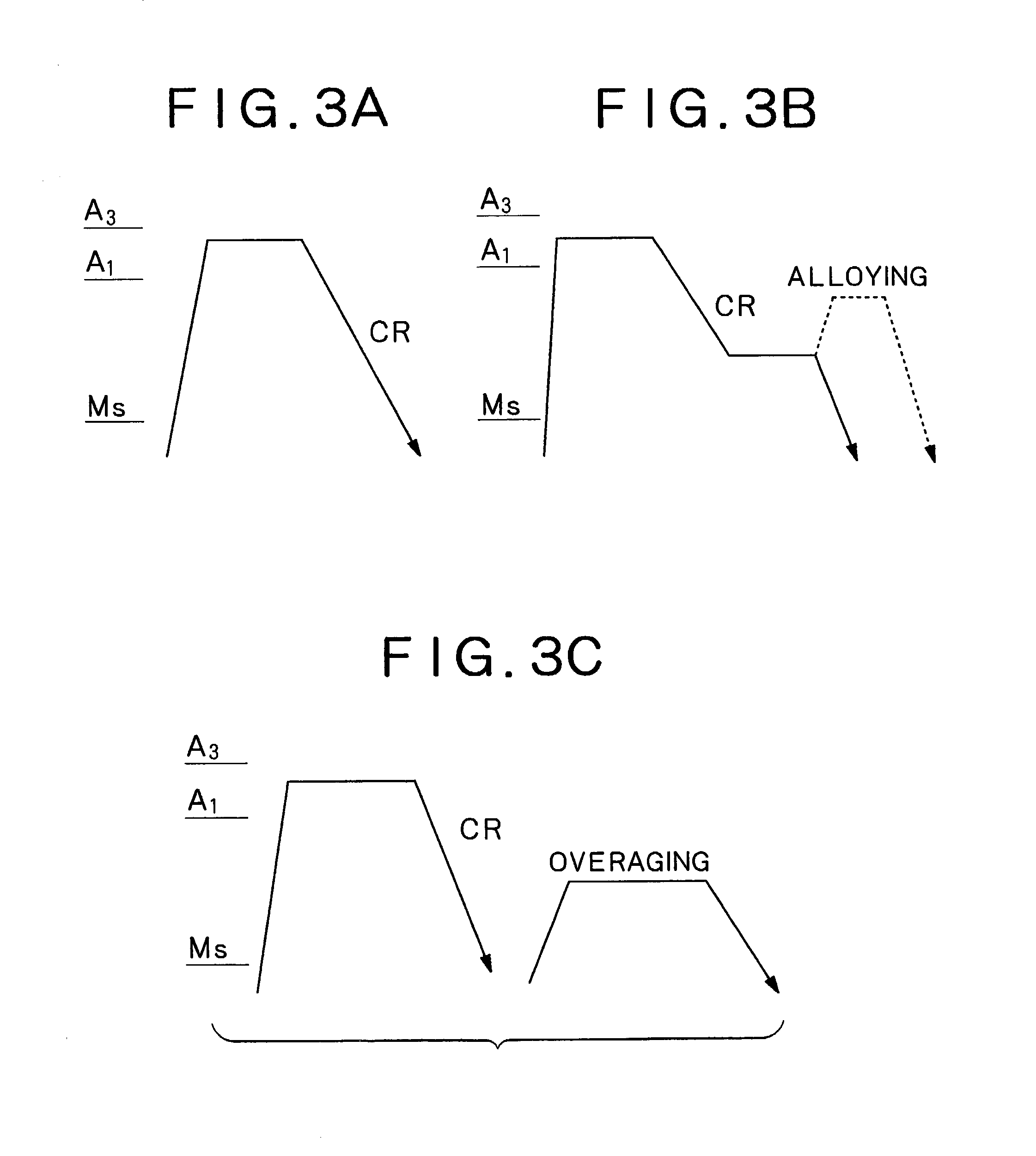

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

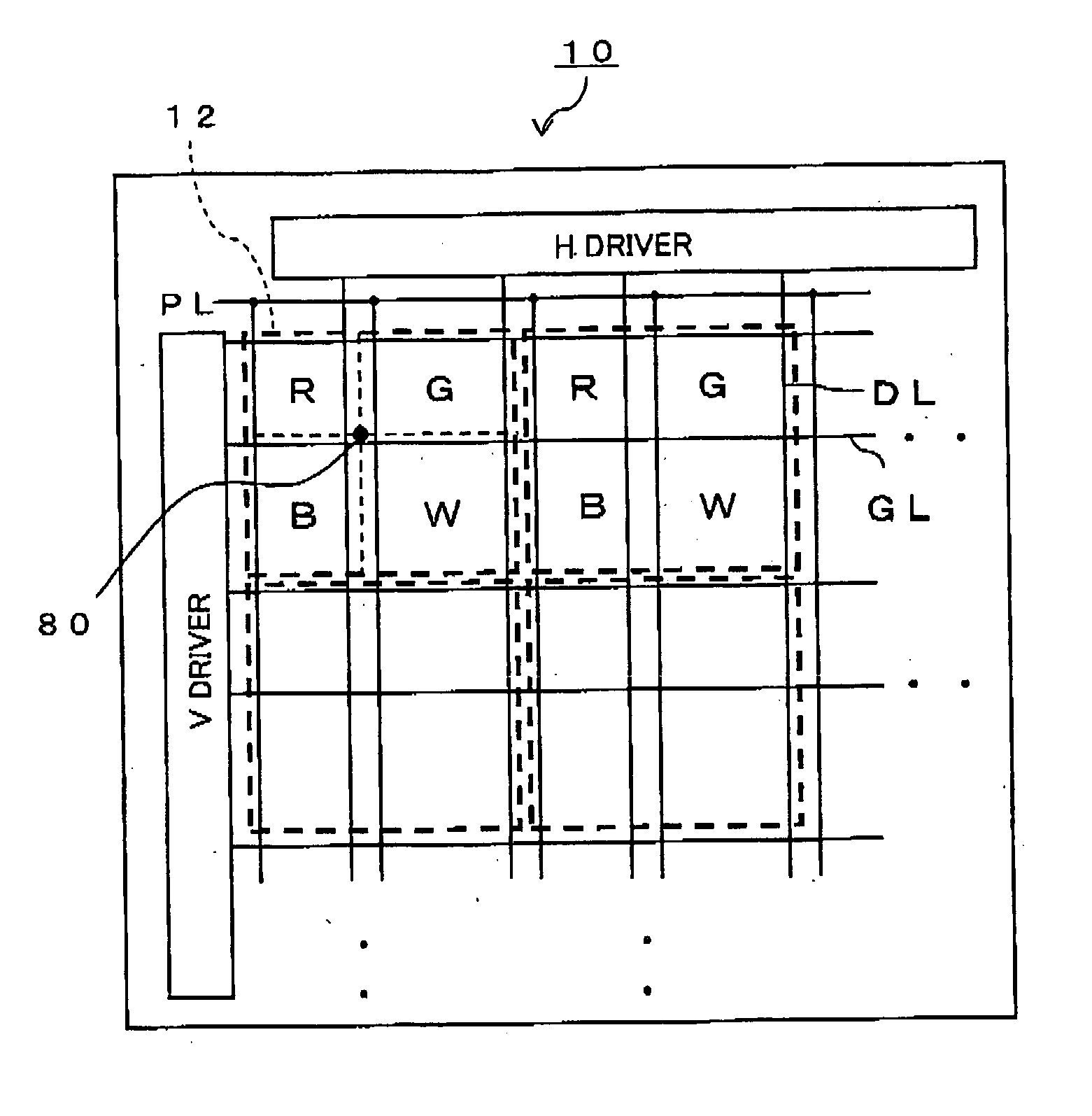

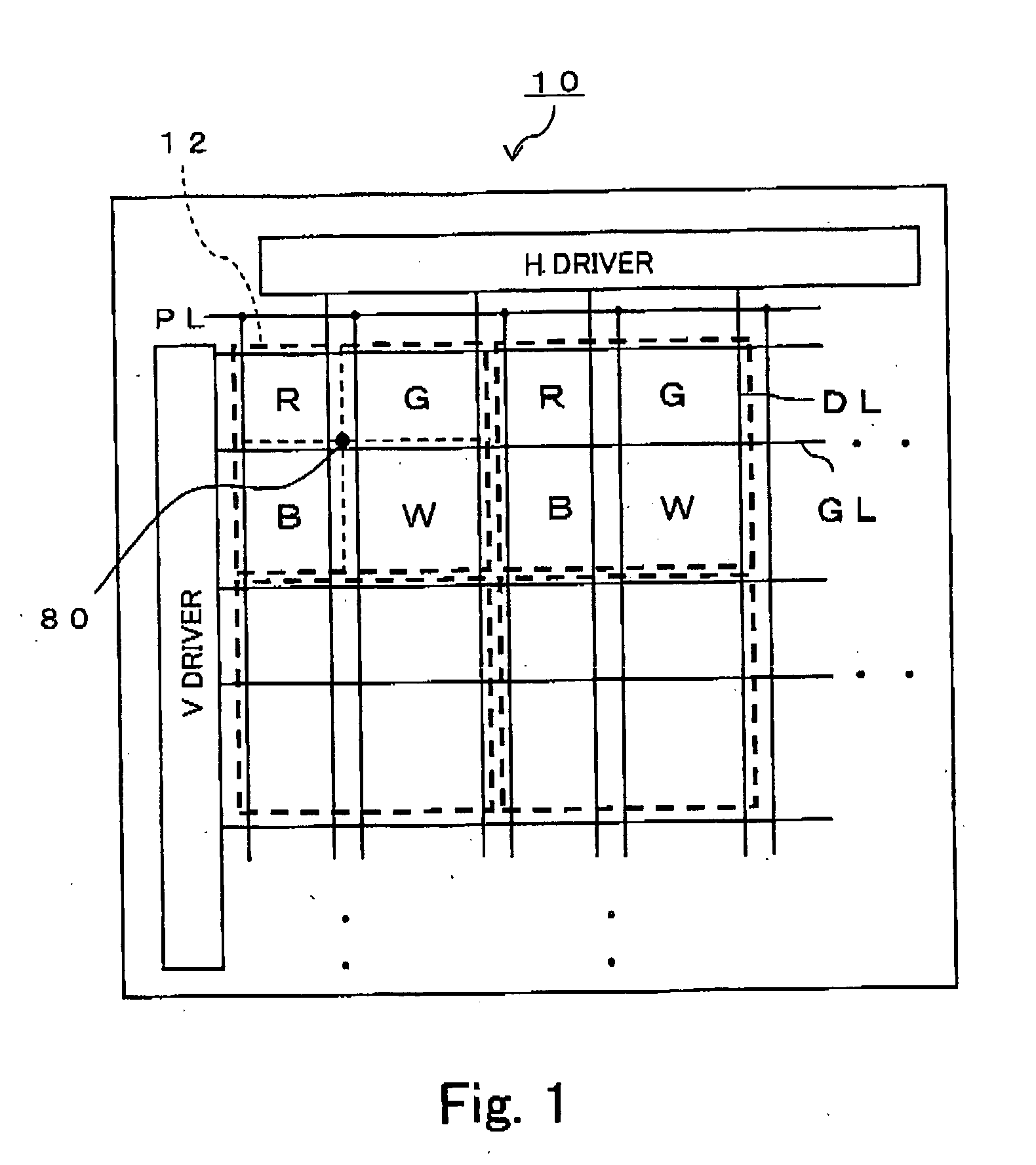

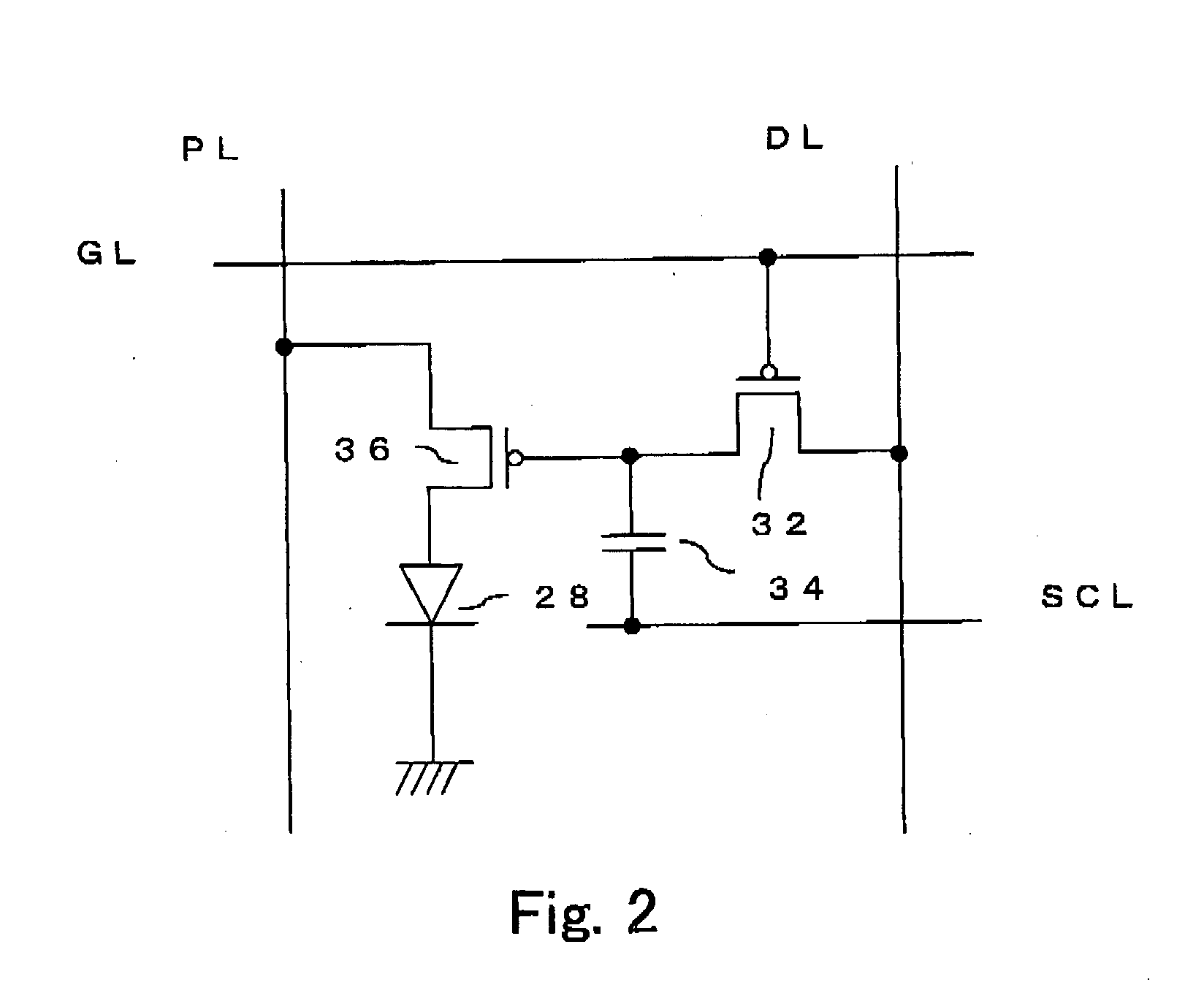

Light emissive display device

InactiveUS20050116615A1Facilitating circuit layout designIncrease opening ratioDischarge tube luminescnet screensLamp detailsDisplay deviceOptoelectronics

In a display device using, for example, an organic EL element as a light emissive element, a single pixel is formed of subpixels of four colors, R, G, B, and W, arranged in two rows and two columns. Each pixel is substantially quadrangular in shape, and at least one of the subpixels in the pixel has an area different from the areas of the other subpixels. The subpixels of the colors horizontally adjoining in the same row have the same height, and the subpixels of the colors vertically adjoining in the same column have the same width. Even when the area ratio of the subpixels is varied by changing the position of the intersecting point of divisional lines dividing a pixel into four subpixels, the design can easily be modified by satisfying the above relationship, and a display device with a high luminance and a long life can easily be obtained with any area ratio.

Owner:SANYO ELECTRIC CO LTD

Single crystal CVD synthetic diamond material

ActiveUS20140335339A1Improve optical qualityReduce concentrationPolycrystalline material growthSynthetic resin layered productsPhotoluminescenceSingle crystal

A single crystal CVD synthetic diamond material comprising: a total as-grown nitrogen concentration equal to or greater than 5 ppm, and a uniform distribution of defects, wherein said uniform distribution of defects is defined by one or more of the following characteristics: (i) the total nitrogen concentration, when mapped by secondary ion mass spectrometry (SIMS) over an area equal to or greater than 50×50 μm using an analysis area of 10 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value, or when mapped by SIMS over an area equal to or greater than 200×200 μm using an analysis area of 60 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value; (ii) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein the nitrogen-vacancy defects are uniformly distributed through the synthetic single crystal CVD diamond material such that, when excited using a 514 nm laser excitation source of spot size equal to or less than 10 μm at room temperature using a 50 mW 46 continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm there is a low point-to-point variation wherein the intensity area ratio of nitrogen vacancy photoluminescence peaks between regions of high photoluminescent intensity and regions of low photolominescent intensity is <2× for either the 575 nm photoluminescent peak (NV0) or the 637 nm photoluminescent peak (NV); (iii) a variation in Raman intensity such that, when excited using a 514 nm laser excitation source (resulting in a Raman peak at 552.4 nm) of spot size equal to or less than 10 μm at room temperature using a 50 mW continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm, there is a low point-to-point variation wherein the ratio of Raman peak areas between regions of low Raman intensity and high Raman intensity is <1.25×; (iv) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein, when excited using a 514 nm excitation source of spot size equal to or less than 10 μm at 77K using a 50 mW continuous wave laser, gives an intensity at 575 nm corresponding to NV0 greater than 120 times a Raman intensity at 552.4 nm, and / or an intensity at 637 nm corresponding to NV− greater than 200 times the Raman intensity at 552.4 nm; (v) a single substitutional nitrogen defect (Ns) concentration equal to or greater than 5 ppm, wherein the single substitutional nitrogen defects are uniformly distributed through the synthetic single crystal CVD diamond material such that by using a 1344 cm−1 infrared absorption feature and sampling an area greater than an area of 0.5 mm2, the variation is lower than 80%, as deduced by dividing the standard deviation by the mean value; (vi) a variation in red luminescence intensity, as defined by a standard deviation divided by a mean value, is less than 15%; (vii) a mean standard deviation in neutral single substitutional nitrogen concentration of less than 80%; and (viii) a colour intensity as measured using a histogram from a microscopy image with a mean gray value of greater than 50, wherein the colour intensity is uniform through the single crystal CVD synthetic diamond material such that the variation in gray colour, as characterised by the gray value standard deviation divided by the gray value mean, is less than 40%.

Owner:ELEMENT SIX LTD

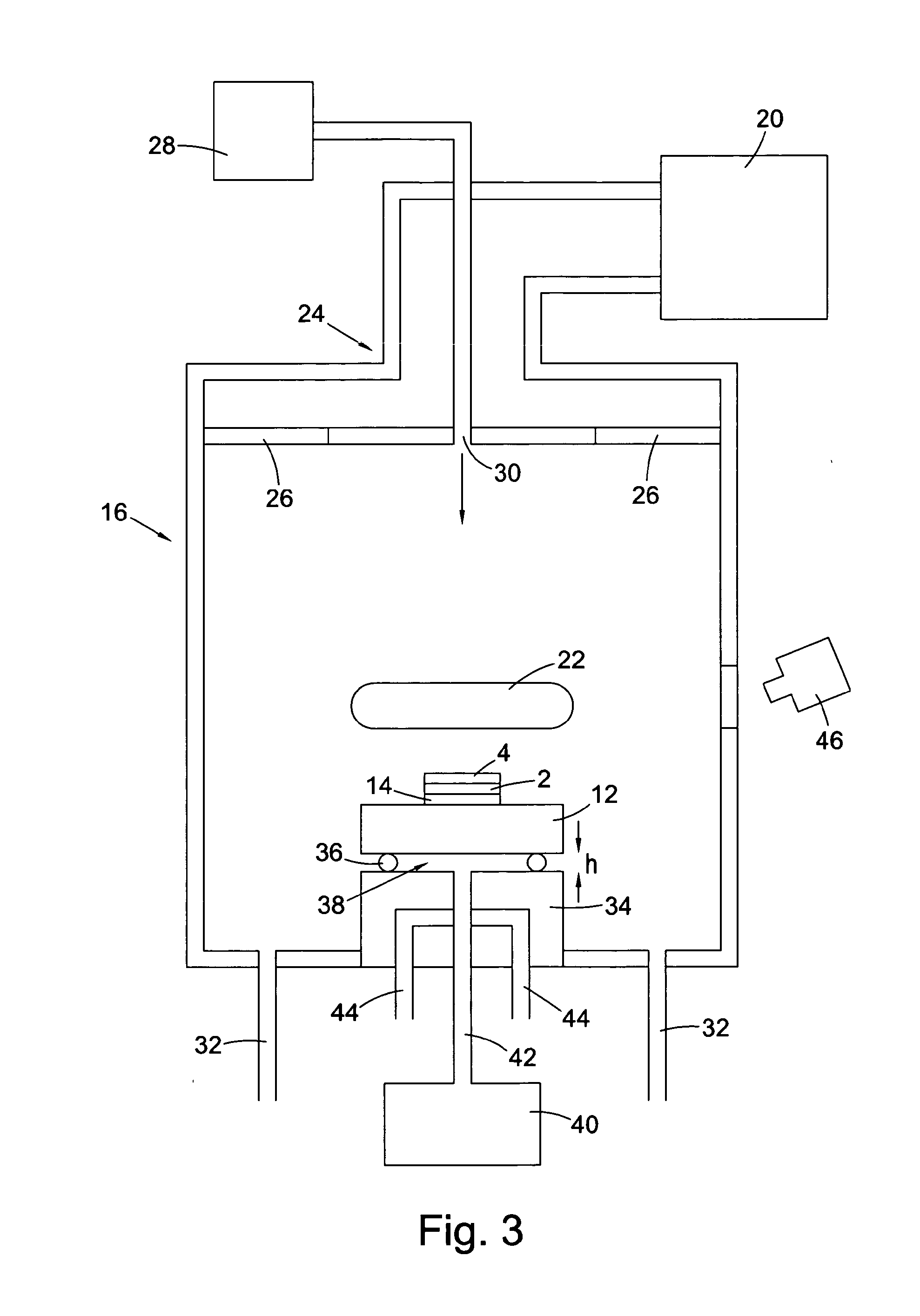

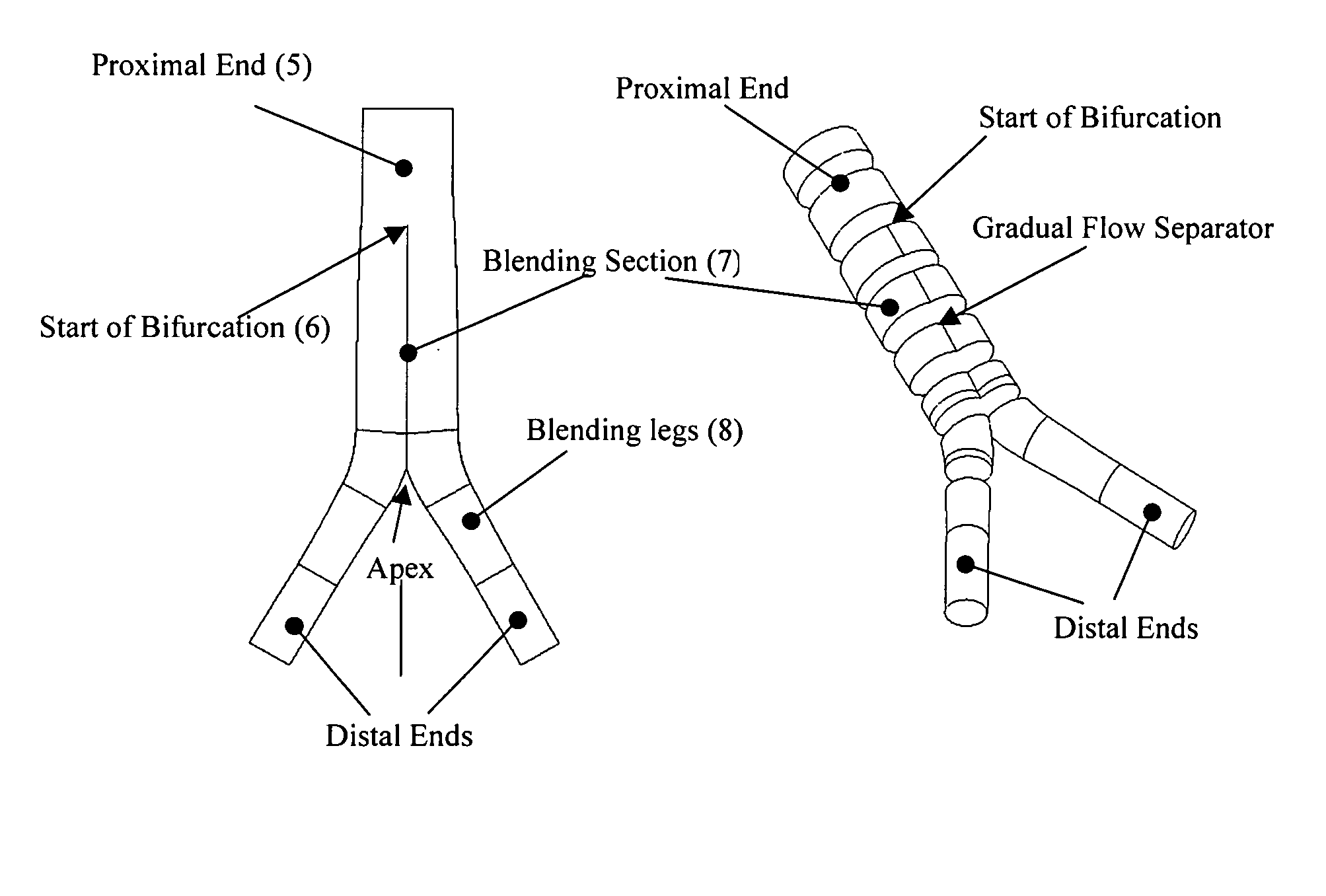

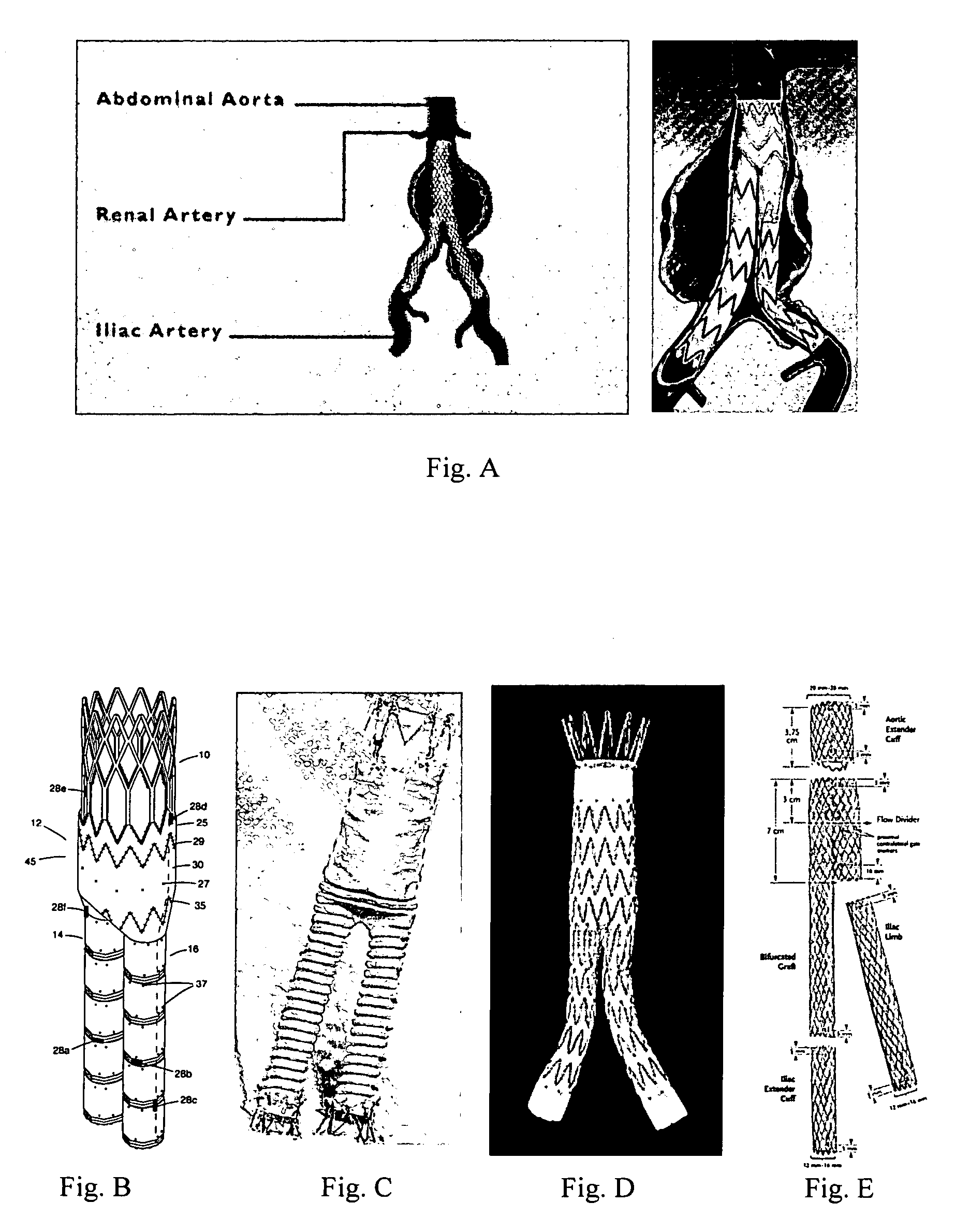

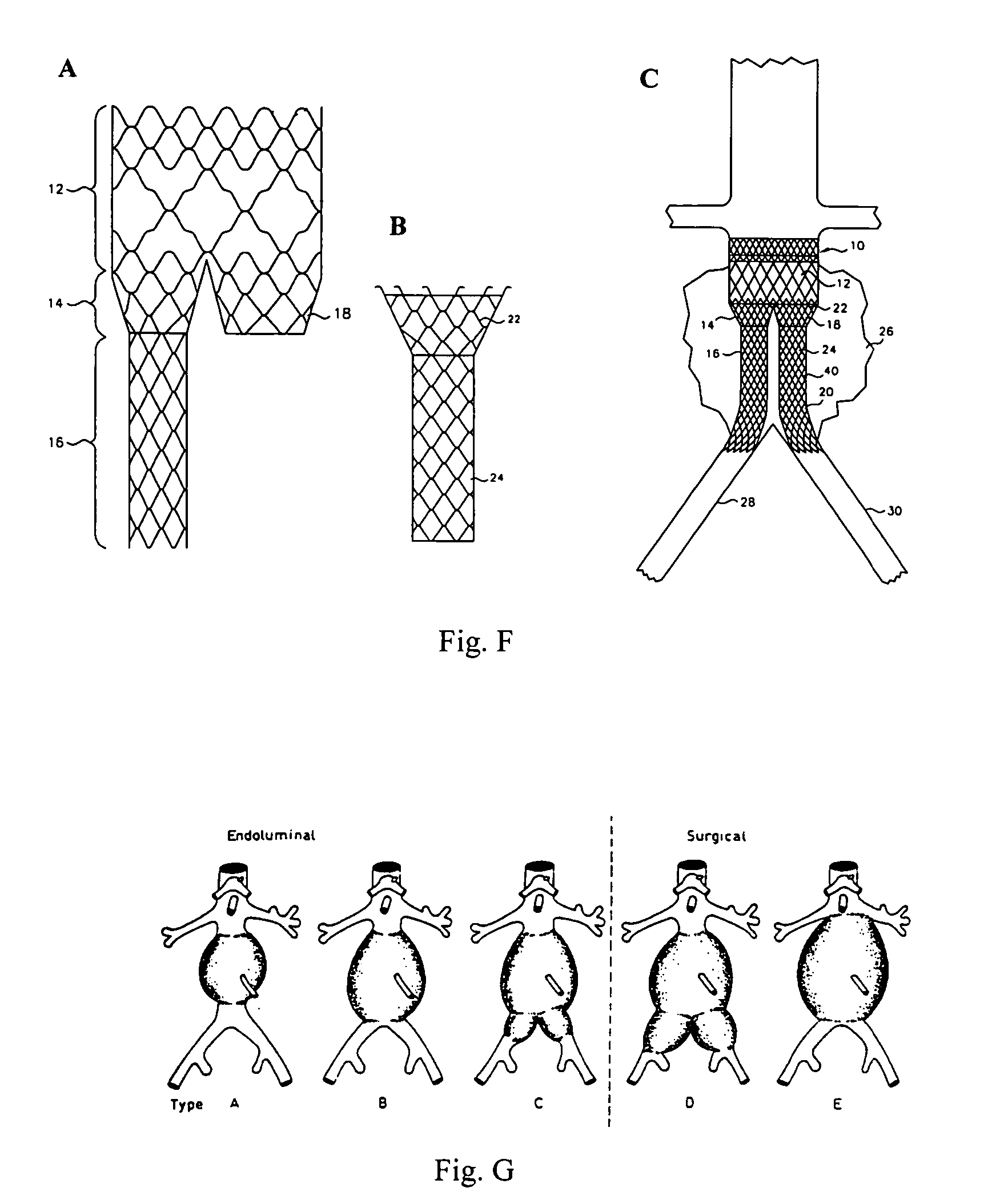

Vascular graft

InactiveUS20060229709A1Reduce the cross-sectional areaEliminate needStentsBlood vesselsVascular graftingVascular graft

A vascular graft comprising a proximal section, iliac distal legs and a bifurcation blending section (7) between the proximal section and the distal legs. The cross-sectional area of the proximal section at the bifurcation point is less than or equal to the sum of the two cross sectional areas of both iliac legs. The blending section (7) generates a smooth transition from the proximal section to both iliac legs which minimizes wave reflections by ensuring that the area ratio at the bifurcated junction (7) is as close to unity or greater than unity as possible. The blending section (7) defines a first lumen for fluid flow from the proximal section into the first distal leg, and a separate second lumen for fluid flow from the proximal section into the second distal leg. The two lumen are separated by means of a gradual flow which separates the fluid flow from the proximal section into each lumen. The distal legs are connected to the blending section (7) at the bifurcation region to form a substantially “Y”-shaped graft.

Owner:LIMERICK UNIV OF

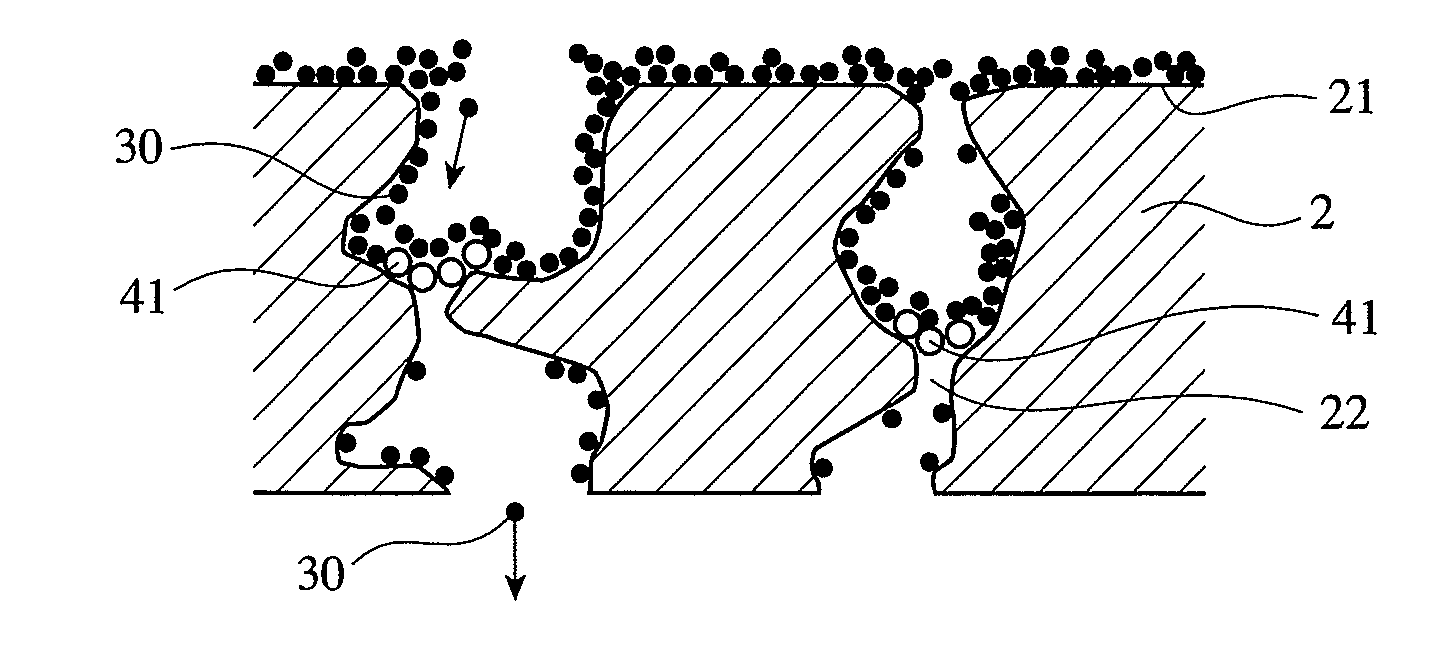

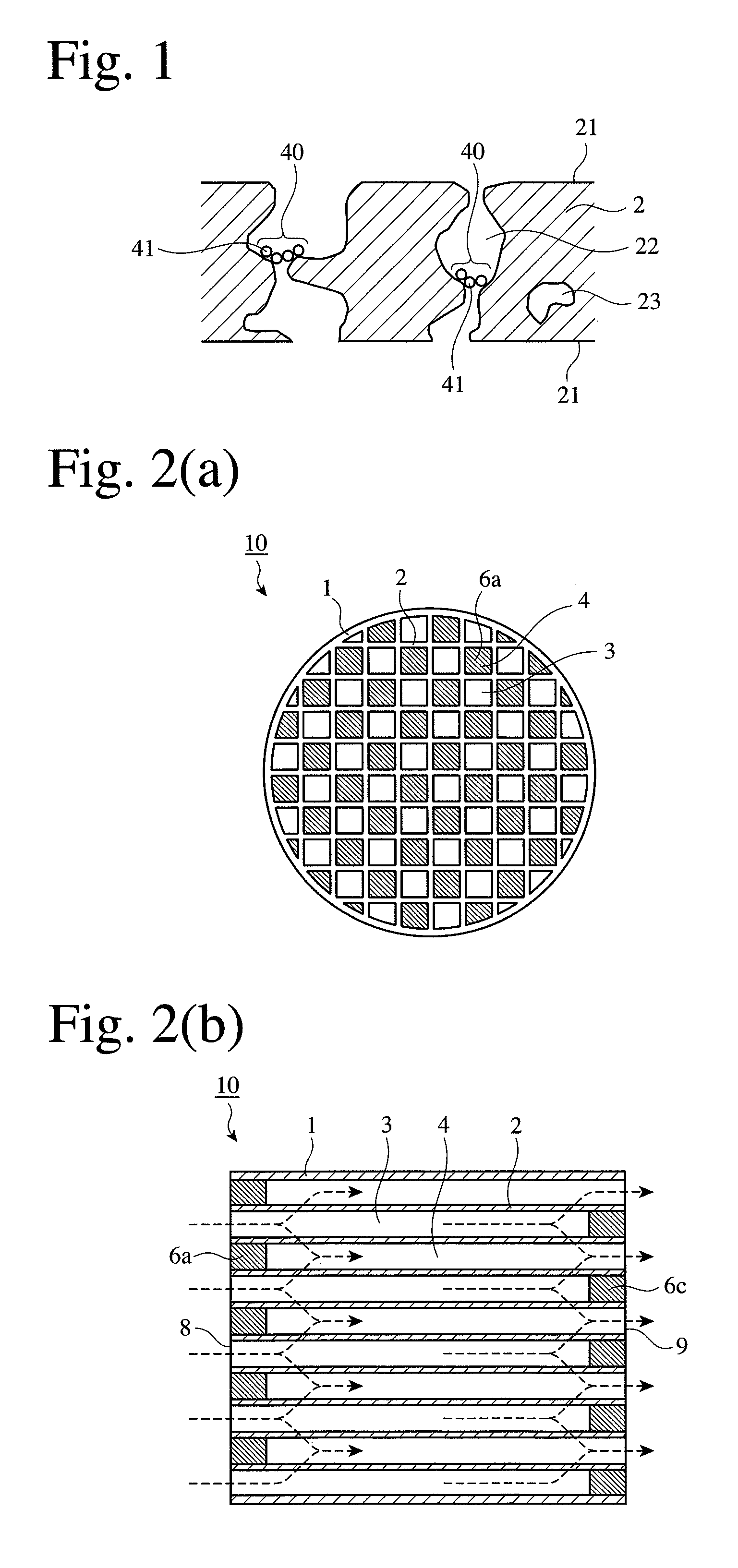

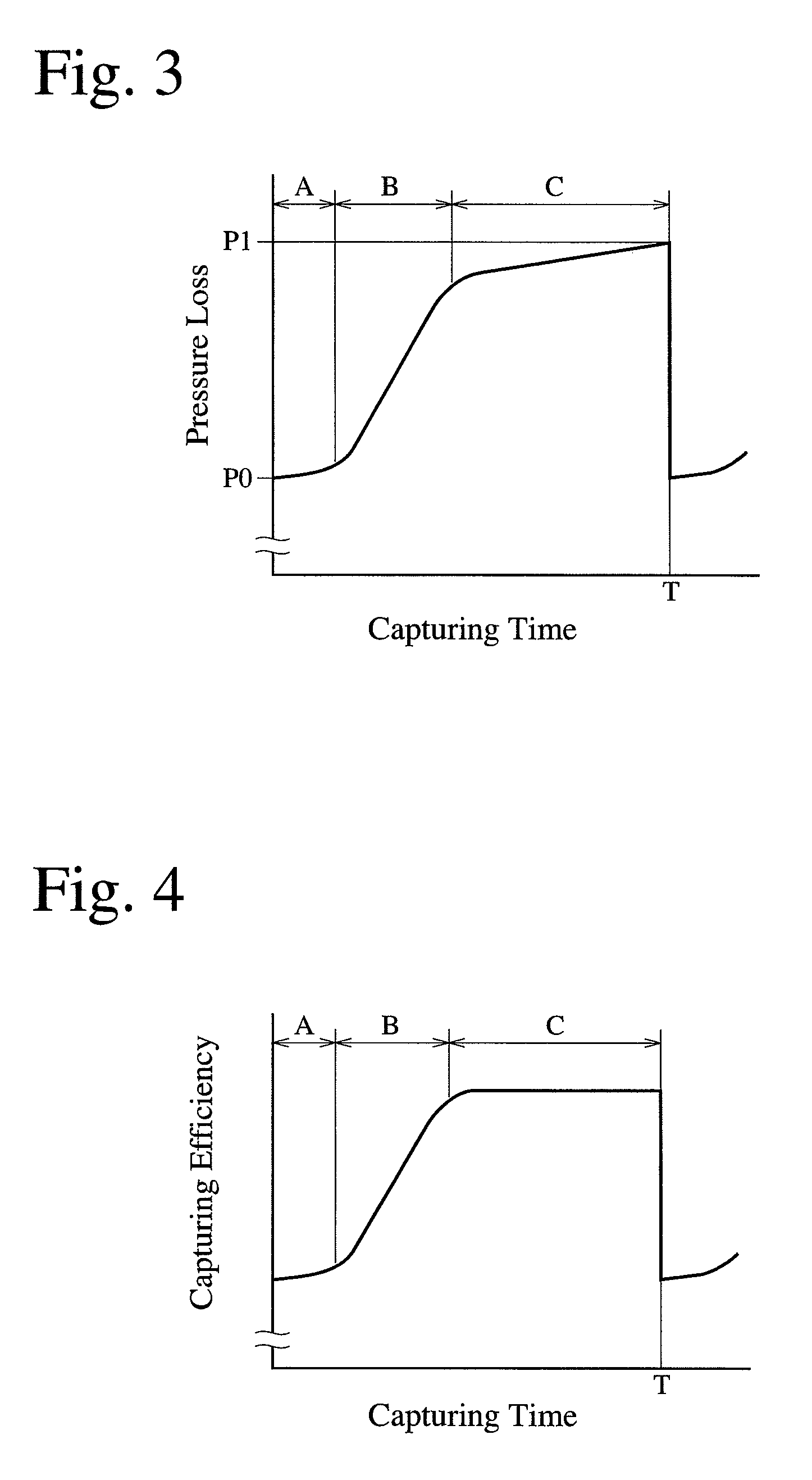

Ceramic honeycomb filter and its production method

ActiveUS8388721B2High PM-capturing efficiencyEasy to optimizeCombination devicesLiquid surface applicatorsCross-linkHoneycomb structure

A ceramic honeycomb filter comprising a honeycomb structure having large numbers of flow paths partitioned by porous cell walls, and plugs alternately formed in the flow paths on the exhaust-gas-inlet and outlet sides, the area ratio of pores opening at the cell wall surfaces being 20% or more, porous, cross-linked structures being formed by heat-resistant particles introduced together with a gas into penetrating holes constituted by communicating pores in the cell walls, such that they clog the penetrating holes, and the cross-linked structures being formed more on the exhaust-gas-outlet side of the ceramic honeycomb filter than on the exhaust-gas-inlet side.

Owner:HITACHI METALS LTD

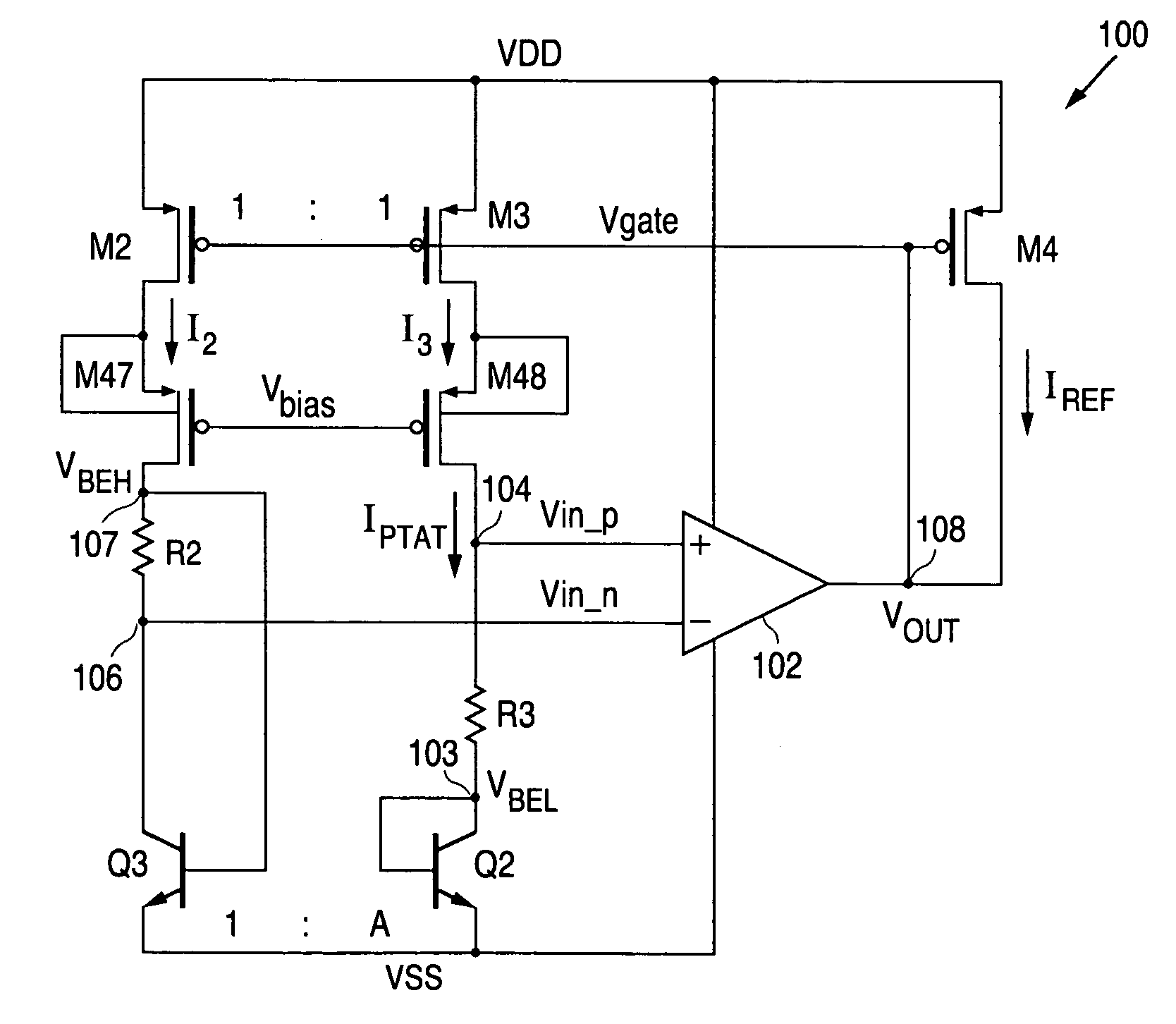

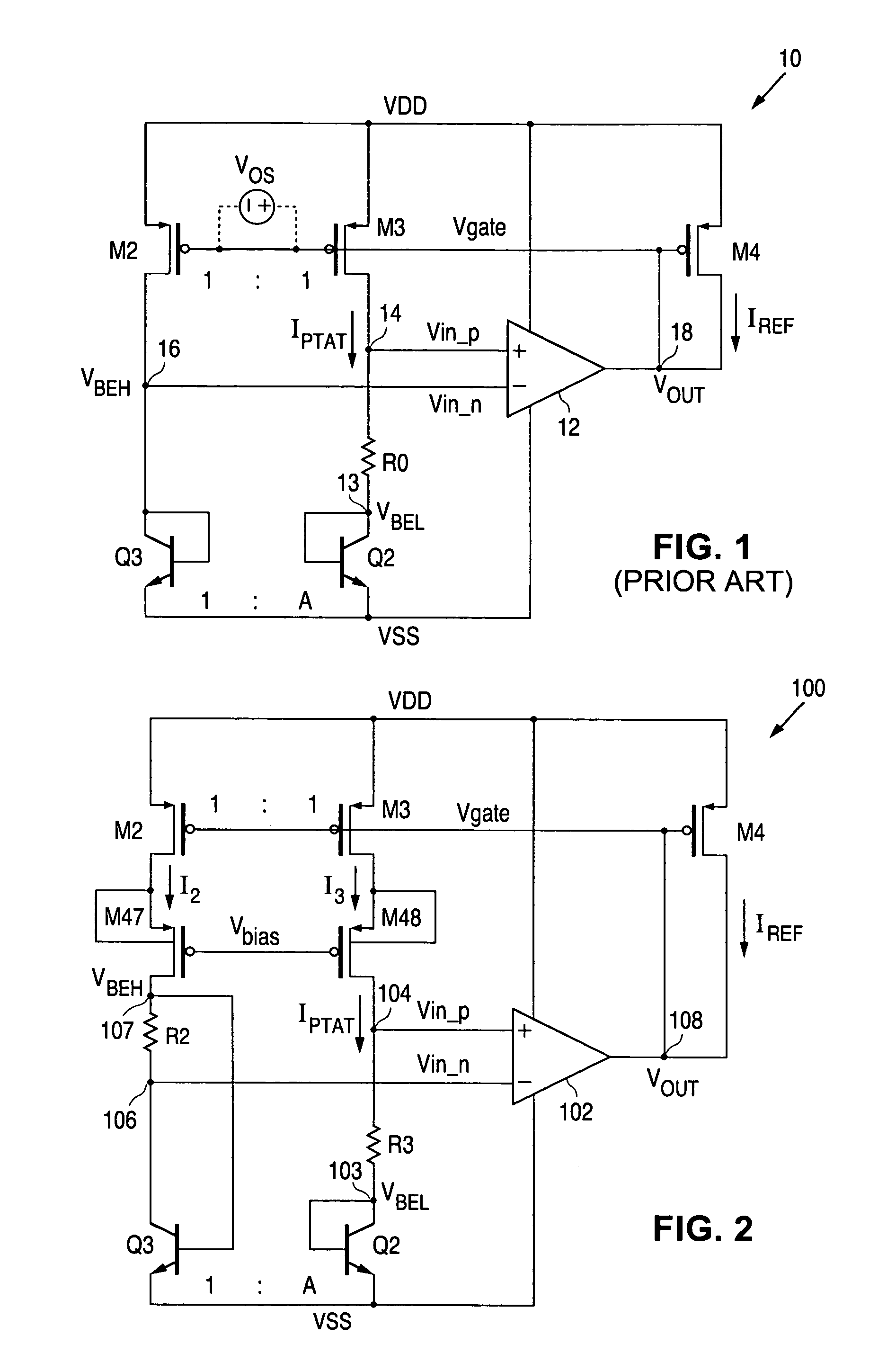

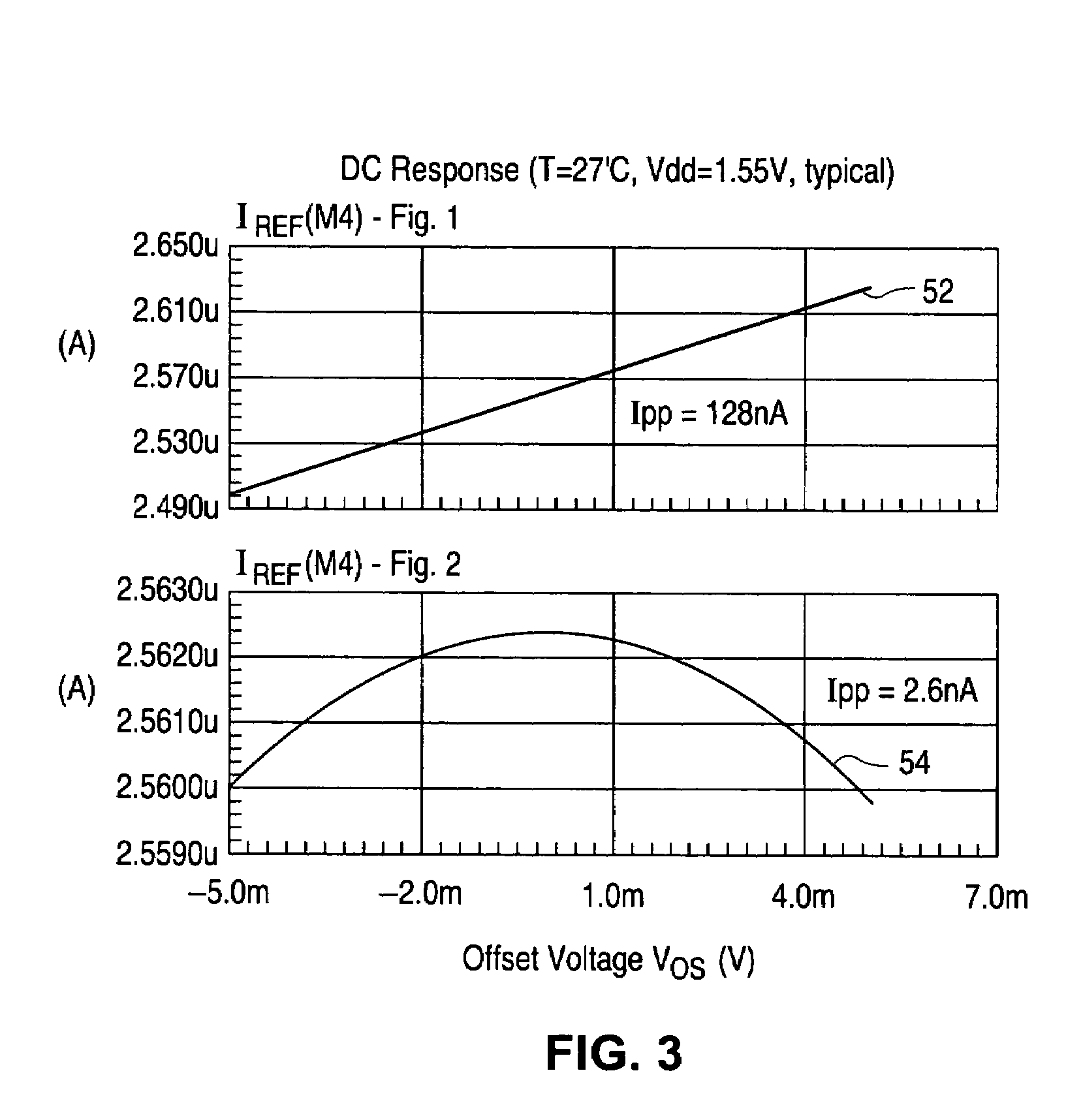

Self-regulating process-error trimmable PTAT current source

ActiveUS7236048B1Electronic switchingPulse generation by opto-electronic devicesElectrical resistance and conductanceProcess error

A current source for generating a PTAT current using two bipolar transistors with an 1:A emitter area ratio implements a split resistor architecture to cancel mismatch errors in the current mirror of the current source. In one embodiment, a first resistor is coupled to the unit area bipolar transistor and a second resistor is coupled to the A-ratio-area bipolar transistor. The first resistor has a resistance value indicative of the emitter resistance re of the bipolar transistors while the second resistor has a resistance value satisfying the equation re*(lnA−1). In another embodiment, an emitter area trim scheme is applied in a PTAT current source to cancel, in one trim operation, both bipolar transistor area mismatch error and sheet resistance variations. The emitter area trim scheme operates to modify the emitter area of the A-ratio-area bipolar transistor to select the best effective emitter area that provides the most accurate PTAT current.

Owner:NAT SEMICON CORP

Shape feature extraction and classification

ActiveUS7668376B2Subsequent processing of the image more effective or easierCancel noiseColor television with pulse code modulationColor television with bandwidth reductionFeature vectorComputer science

System and method for analyzing an image. A received image, comprising an object or objects, is optionally preprocessed. Invariant shape features of the object(s) are extracted using a generalized invariant feature descriptor. The generalized invariant feature descriptor may comprise a generalized invariant feature vector comprising components corresponding to attributes of each object, e.g., related to circularity, elongation, perimeter-ratio-based convexity, area-ratio-based convexity, hole-perimeter-ratio, hole-area-ratio, and / or functions of Hu Moment 1 and / or Hu Moment 2. Non-invariant features, e.g., scale and reflection, may be extracted to form corresponding feature vectors. The object is classified by computing differences between the generalized invariant feature vector (and optionally, non-invariant feature vectors) and respective generalized invariant feature vectors corresponding to reference objects, determining a minimum difference corresponding to a closest reference object or class of reference objects of the plurality of reference objects, and outputting an indication of the closest reference object or class as the classification.

Owner:NATIONAL INSTRUMENTS

Method of manufacturing liquid crystal display element

InactiveUS6392736B1Simplify manufacturing stepsShort manufacturing timeStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

Method of manufacturing liquid crystal display element includes disposing adhesive on at least one of first and second substrates; disposing spacer particles on at least one substrate; supplying liquid crystal material onto at least one substrate; and fixing the substrates together with adhesive spacer particles and liquid crystal material therebetween. The substrates are fixed together by applying pressure and / or heat to the substrates from an end portion toward the other end portion thereof. An impulse applied to each spacer particle can be between 0.001 gf.sec and 0.1 gf.sec in substrate fixing step. Parameter X relating to heating in fixing step can satisfy 200<=X<=3000, where X=(T-20) / (V.D), T is temperature (°C), V is fixing speed (mm / sec) of substrates, and D is diameter of spacer particles (mm). The spacer particles can occupy an area ratio of 0.003 or more to unit area of the substrate.

Owner:MINOLTA CO LTD

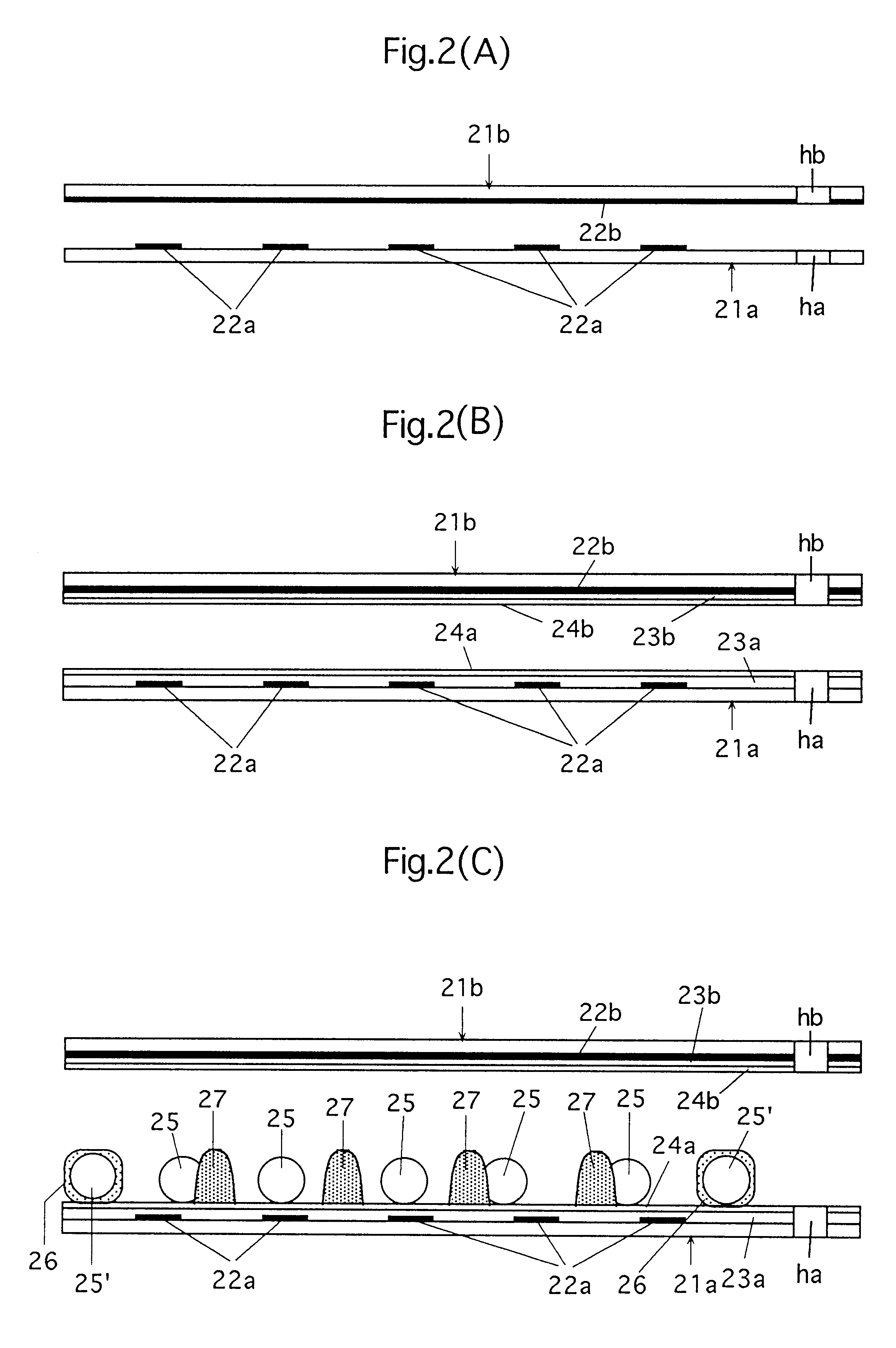

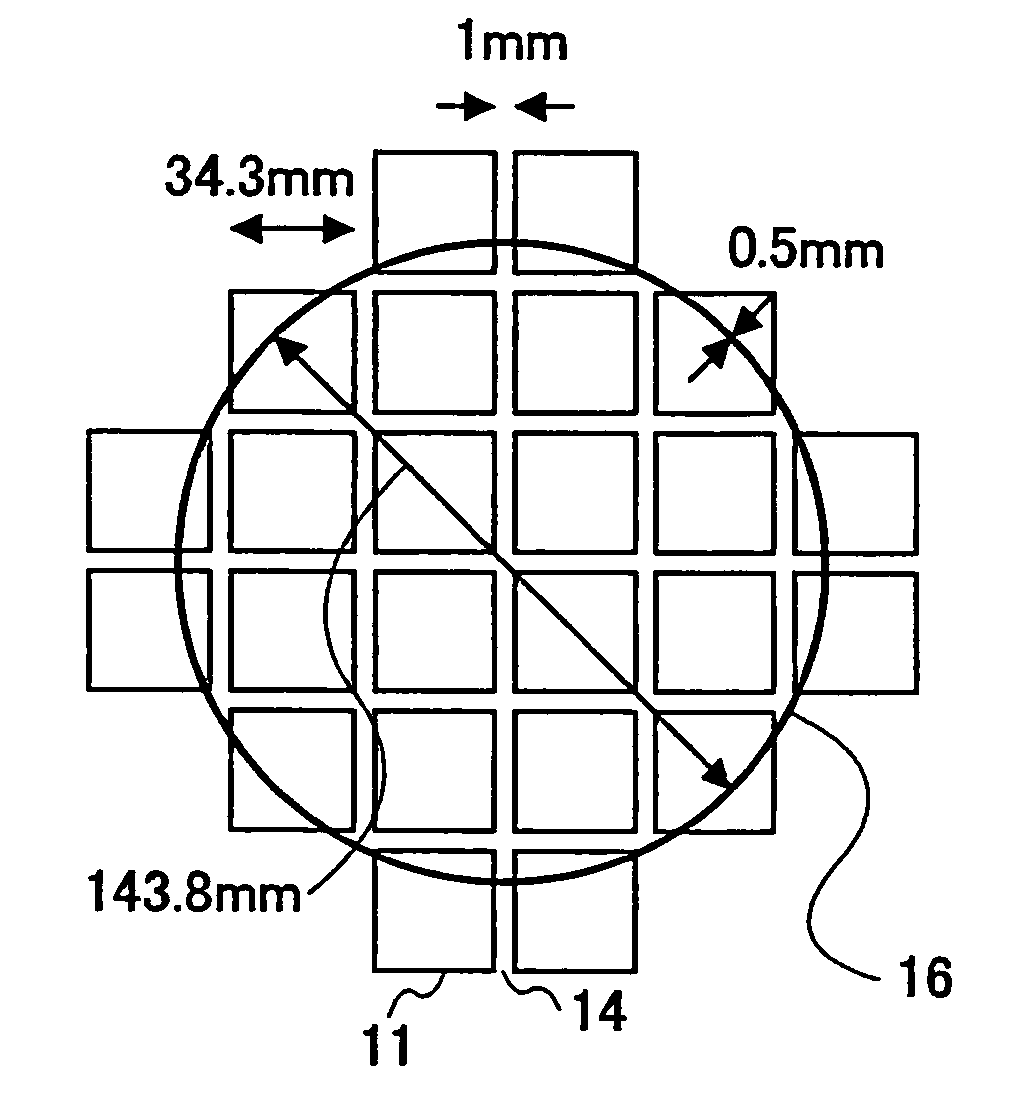

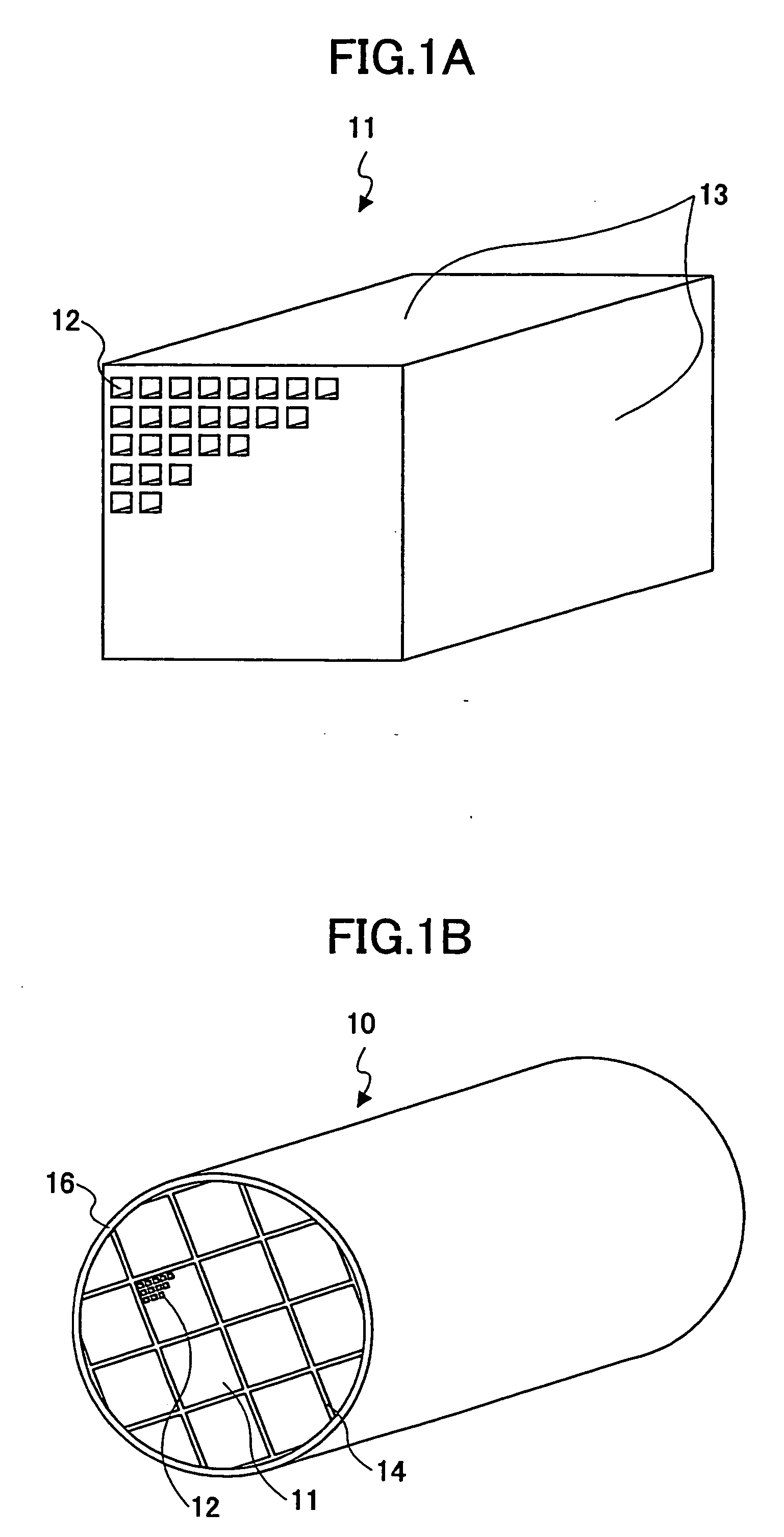

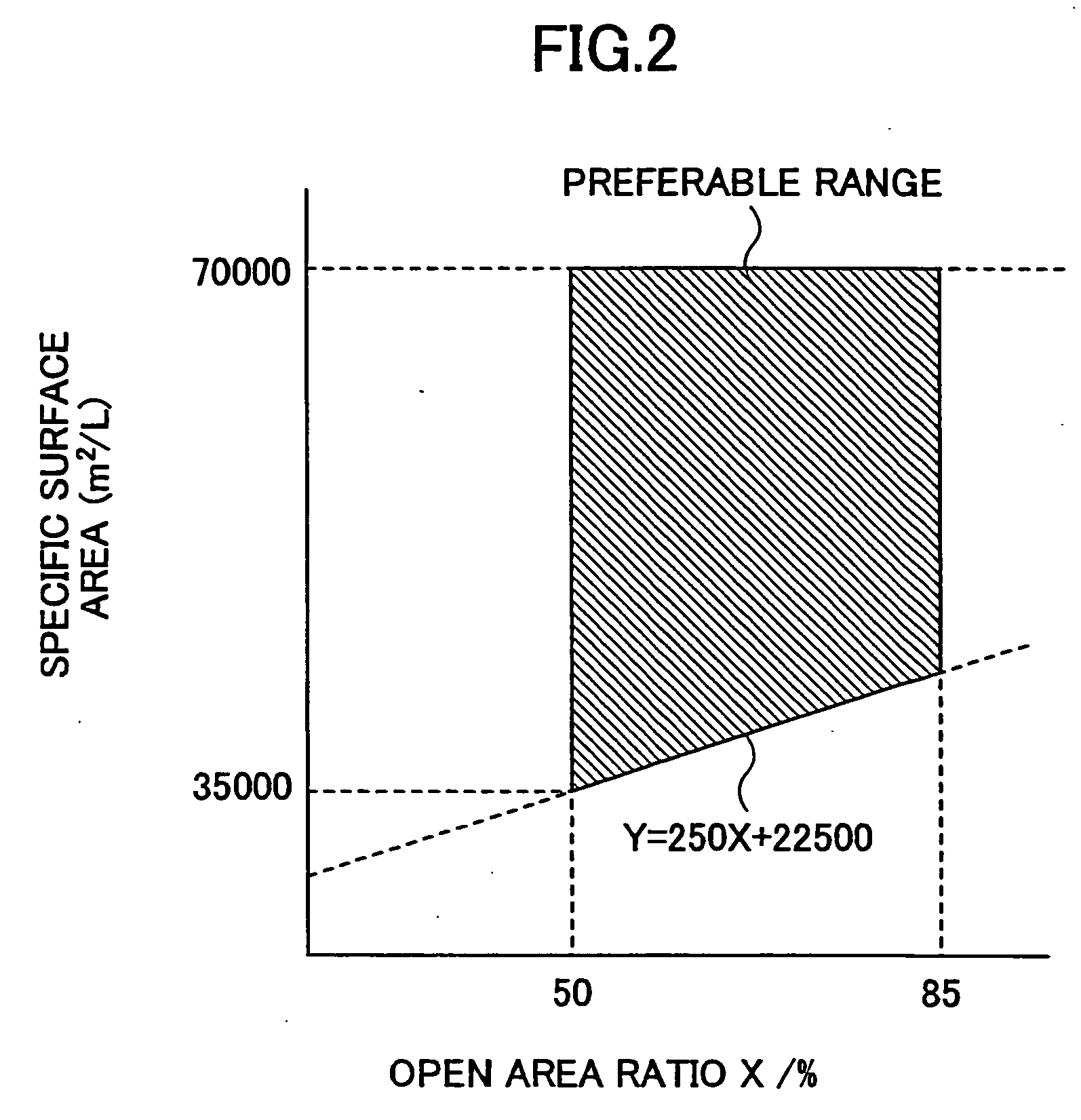

Honeycomb structure, honeycomb structure aggregate, and honeycomb structure catalyst

ActiveUS20060292340A1Internal combustion piston enginesDispersed particle filtrationHoneycomb structureArea ratio

A honeycomb structure is disclosed that includes plural through-holes separated by plural partition walls and provided in parallel along a longitudinal direction, wherein the thickness of each of the partition walls is less than or equal to about 0.25 mm, the length of each of the through-holes is equal to or greater than about 50-fold of a hydraulic diameter of each of the through-holes and less than or equal to about 350-fold of the hydraulic diameter of each of the through-holes, and an open area ratio (X) % of a cross section of the honeycomb structure perpendicular to the through-holes and a surface area per unit volume (Y(m2 / L)) satisfy Y≧250×X+22500 (about 50≦X≦about 85).

Owner:IBIDEN CO LTD

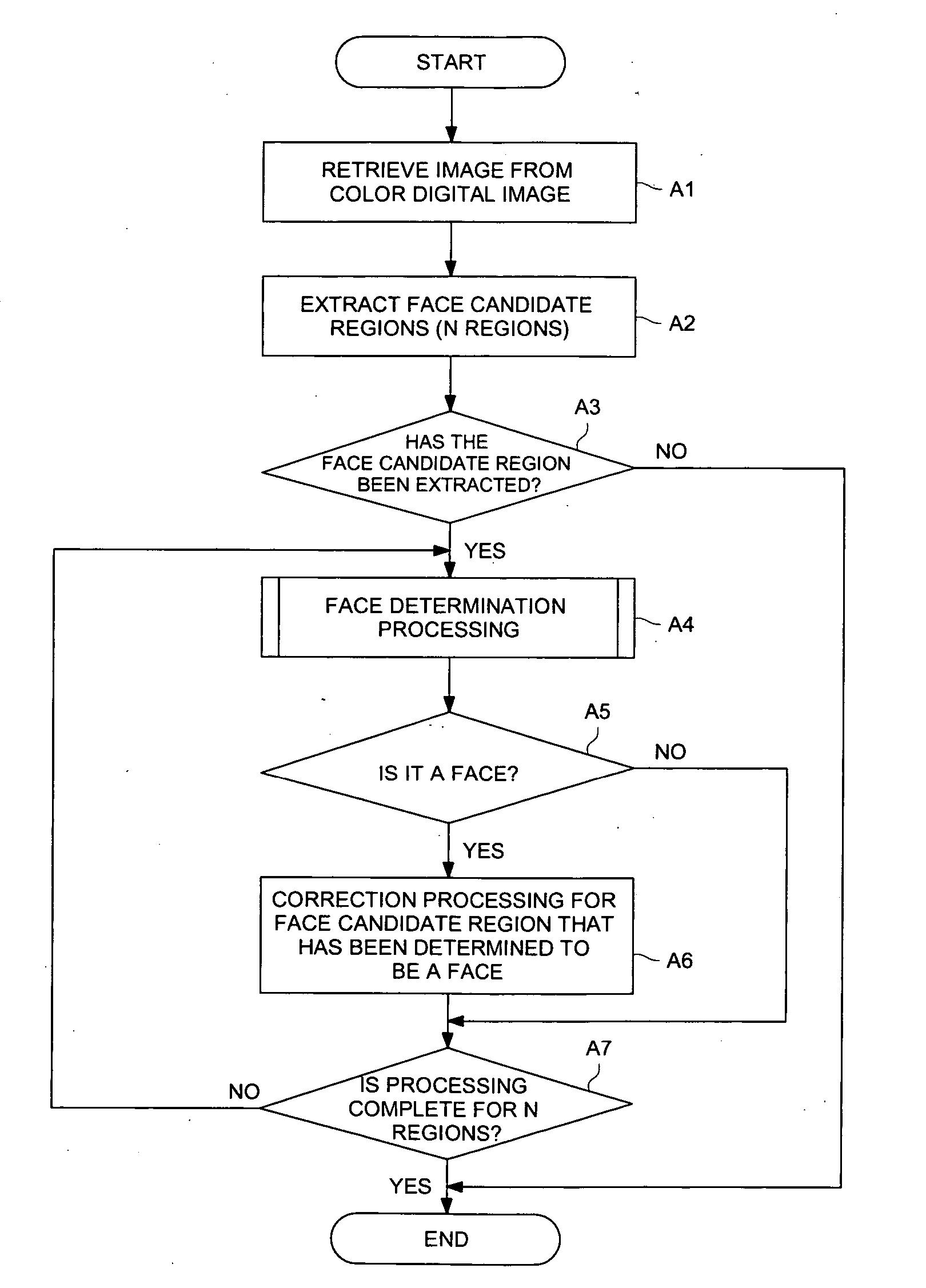

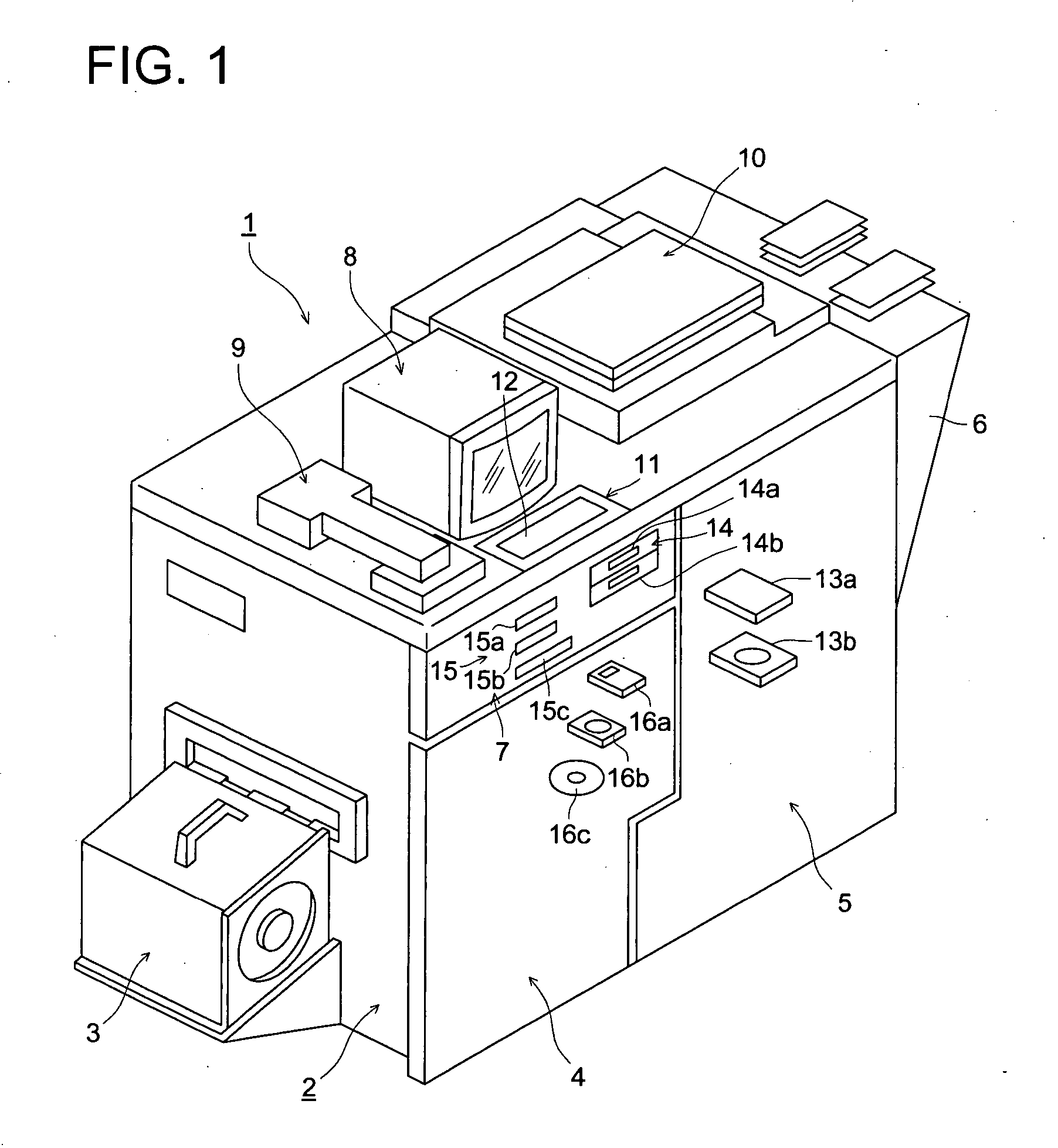

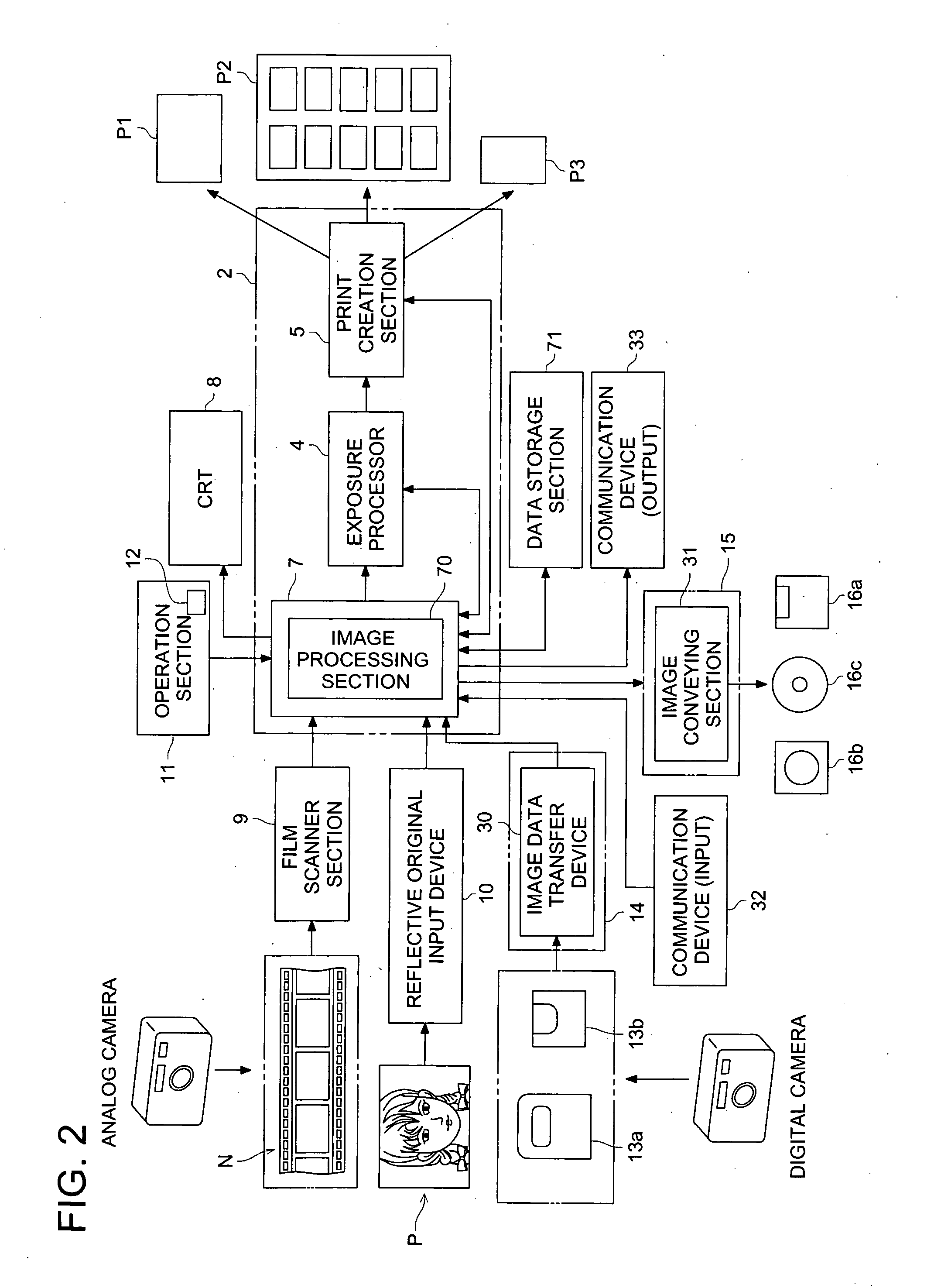

Image processing method, image processing apparatus and image processing program

InactiveUS20050232482A1Improve accuracyImage analysisCharacter and pattern recognitionPattern recognitionImaging processing

The image for the face candidate region is obtained, extraction conditions are determined for extracting the eye and the mouth pixels from the candidate region based on the size of the face candidate region. The eye pixels and the mouth pixels are then extracted from the face candidate region based on the determined extraction conditions, and then the area ratio of the eyes and the area ratio of mouth are calculated for the face candidate region based on the eye pixels and the mouth pixels. Next the area ratio for the eyes and mouth is input into the neural network and a determinations is made as to whether the face candidate region is the face of a person using the neural network.

Owner:KONICA MINOLTA PHOTO IMAGING

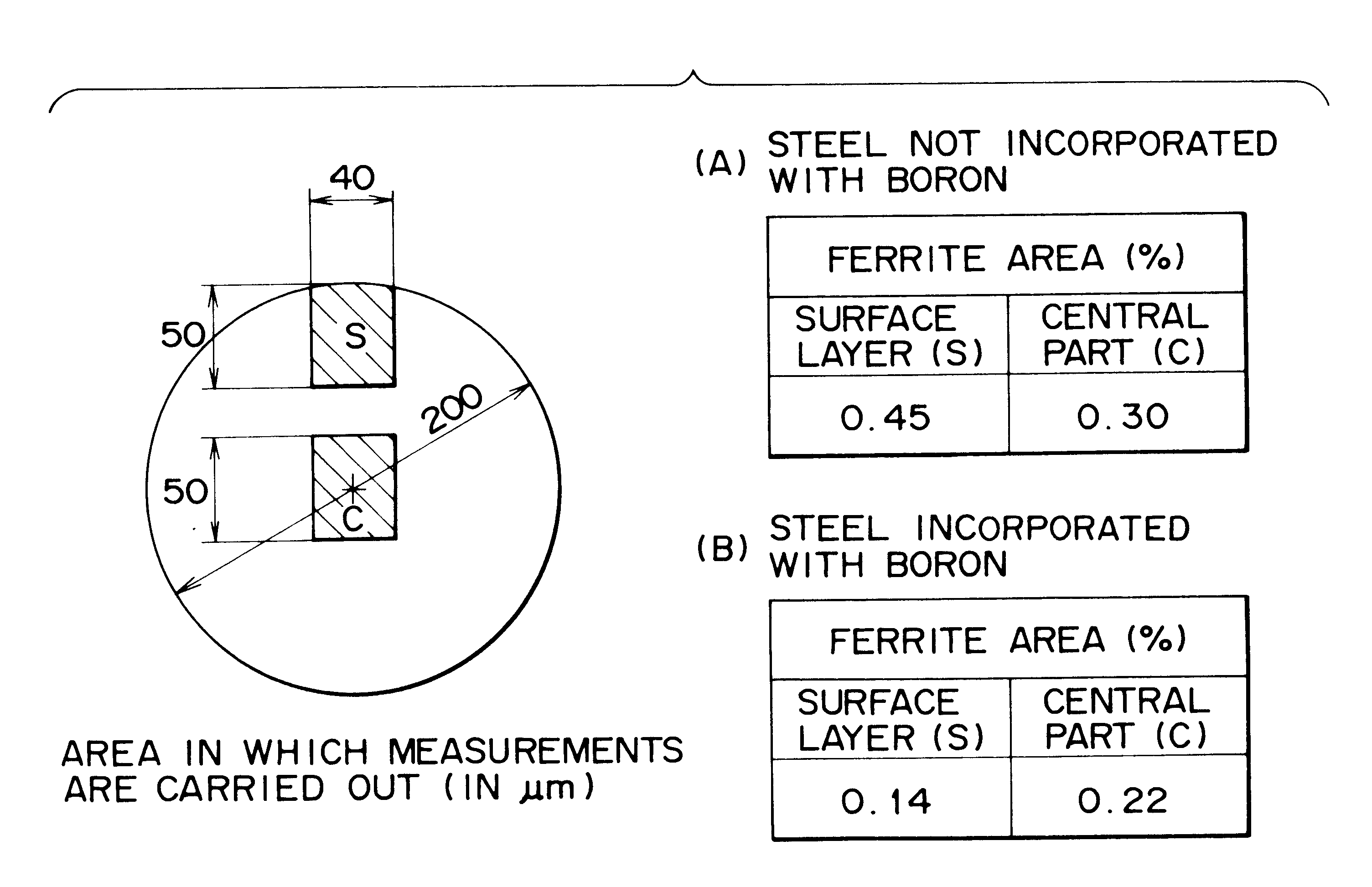

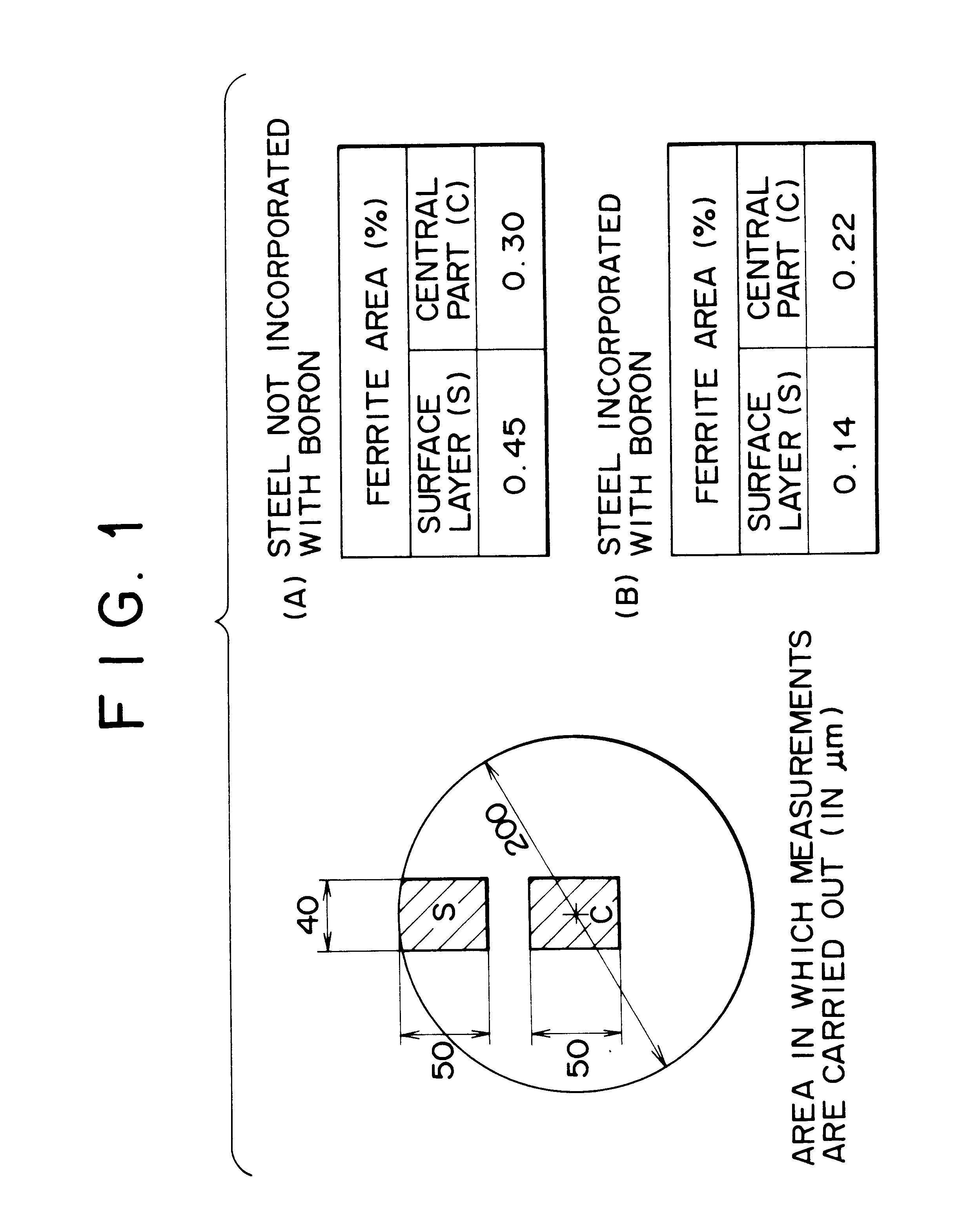

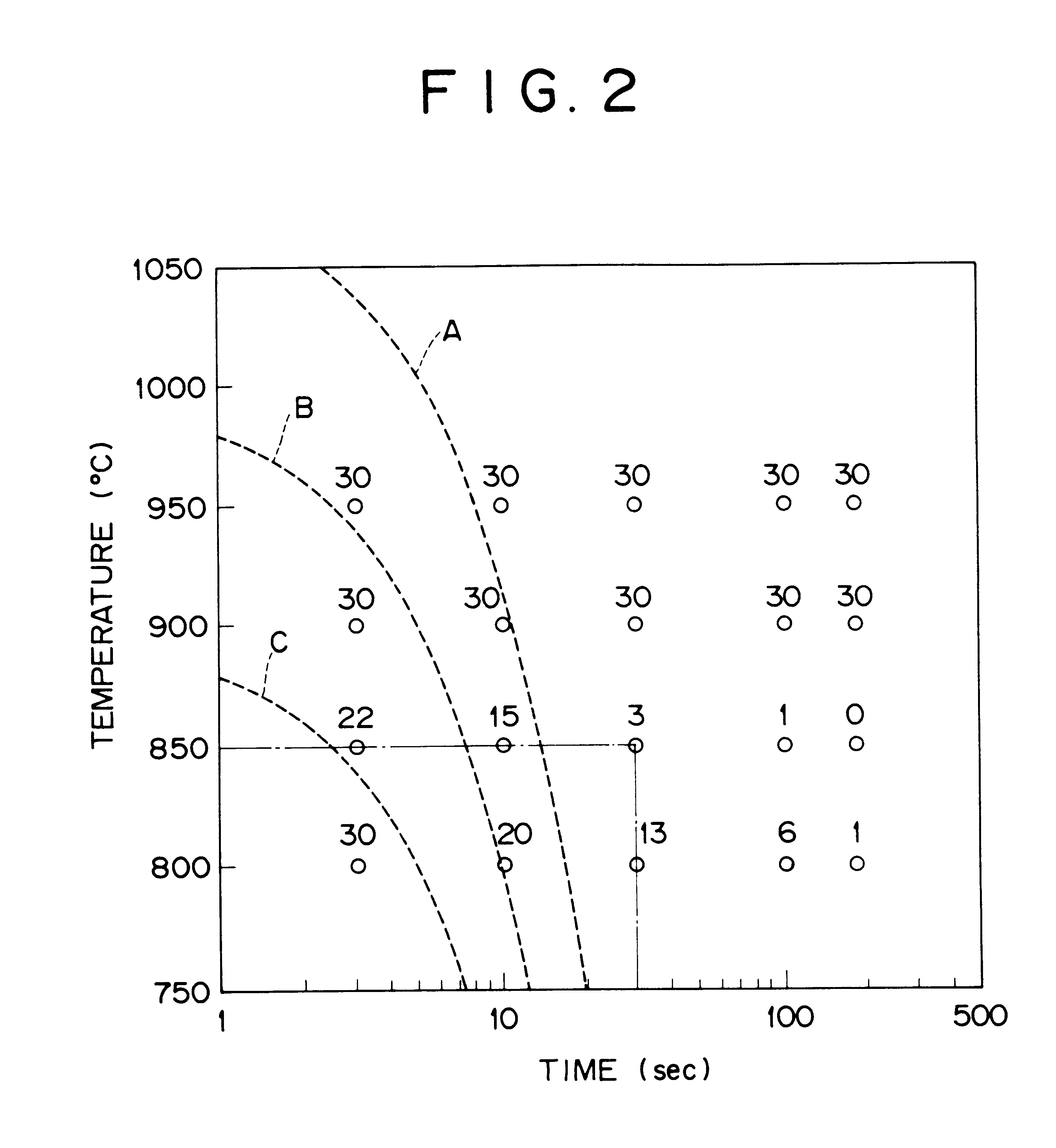

High-carbon steel wire superior in resistance to longitudinal cracking, steel product for the same, and process for production of the same

Disclosed herein are a high-carbon steel wire having high strength and superior in resistance to longitudinal cracking, a steel for said high-carbons steel wire, and a process for producing said steel. The high-carbon steel wire is characterized in that the essential components are C (0.65-1.2 wt %), Si (0.1-2.0 wt %), Mn (0.2-2.0 wt %), and Fe, the main phase is pearlite, and the ferrite area ratio is less than 0.40 % in the surface layer up to a depth of 50 mum from the surface. The high-carbon steel may further contain B (0.0003-0.0050 wt %), Ti (less than 0.030 wt %), and N (less than 0.0050 wt %), with the amount of B, Ti, and N satisfying the following equationThe resulting steel wire produced in the usual way contains ferrite in an amount less than 0.40 wt % in its surface layer. This low ferrite content is responsible for good resistance to longitudinal cracking because ferrite causes longitudinal cracking to start from it.

Owner:KOBE STEEL LTD

Aluminum alloy forgings and process for production thereof

There are provided an aluminum alloy forging having high strength, toughness, and resistance to corrosion in response to the thinning of automotive underbody parts, and a process for production thereof.The aluminum alloy forging includes an aluminum alloy containing predetermined amounts of Mg, Si, Mn, Fe, Zn, Cu, Cr, Zr, and Ti with the balance being composed of Al and inevitable impurities, and having a hydrogen gas concentration of 0.25 ml / 100 g of Al. In the aluminum alloy forging mentioned above, the area ratio of Mg2Si having a maximum length of 0.1 μm or above is 0.15% or below, the recrystallization ratio of the aluminum alloy is 20% or below, and a size distribution index value defined by V / r of dispersed particles of the aluminum alloy (V: the area ratio [%] of the dispersed particles, and r: the average radius [nm] of the dispersed particles) is 0.20 or above.

Owner:KOBE STEEL LTD

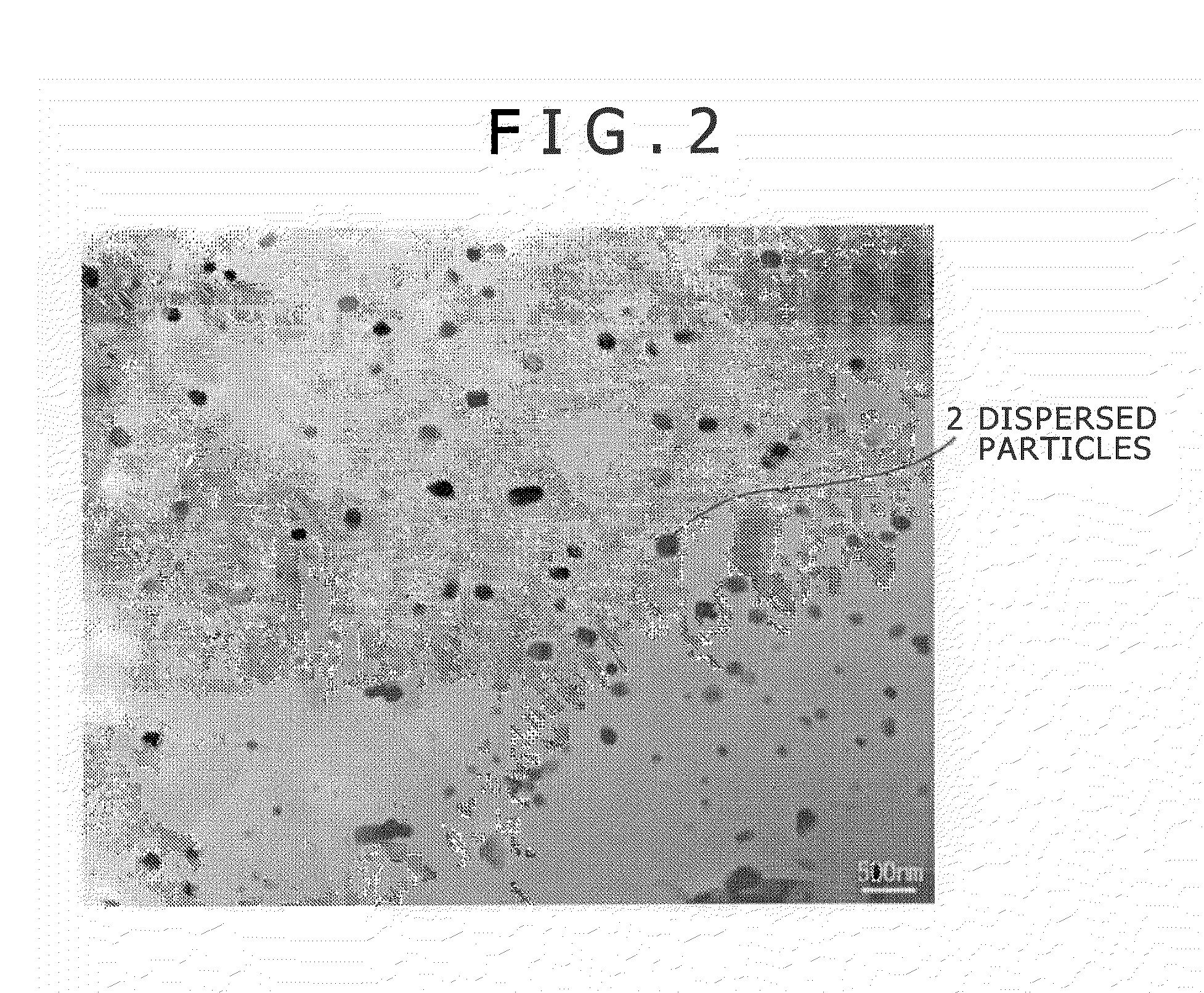

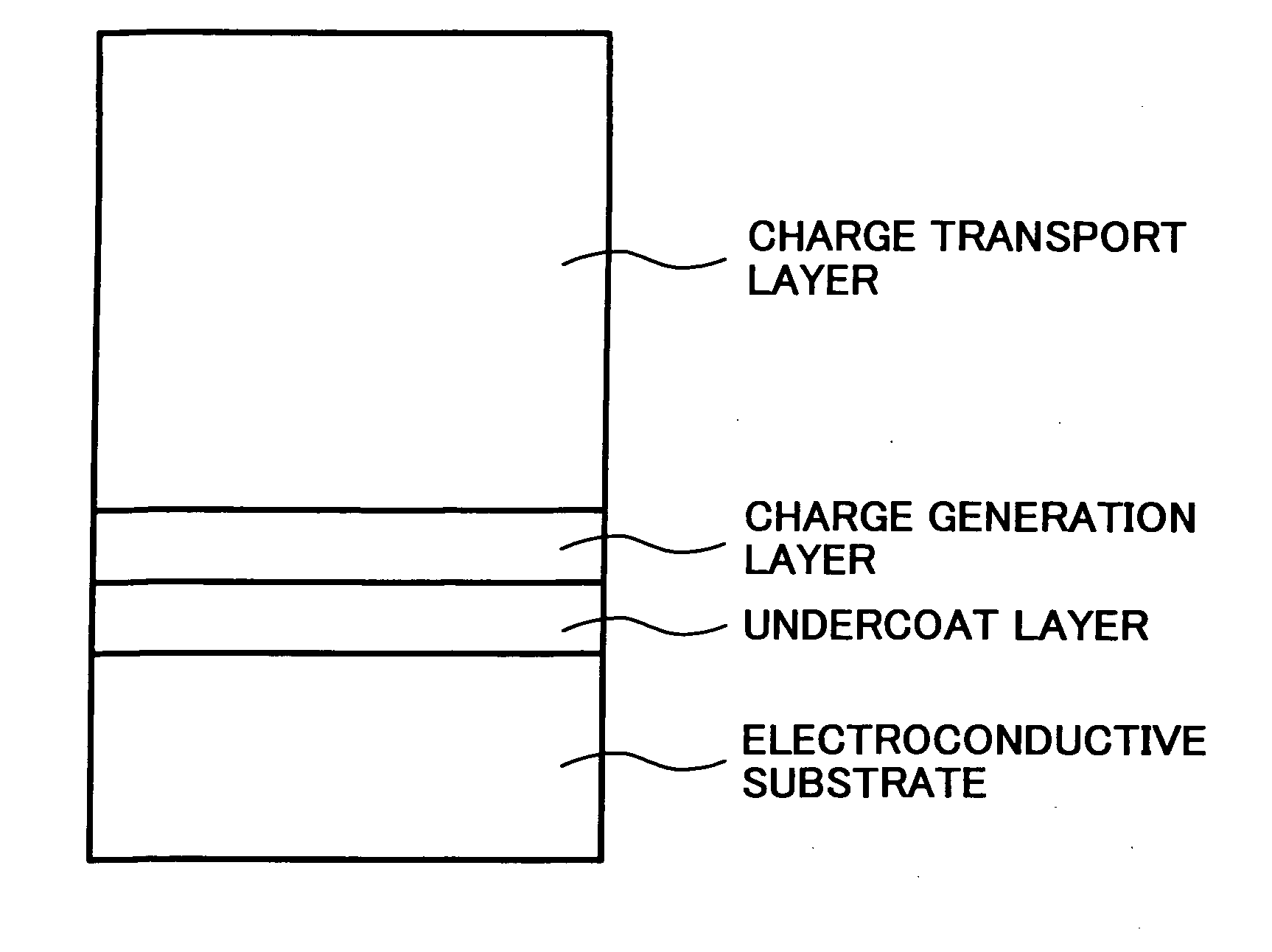

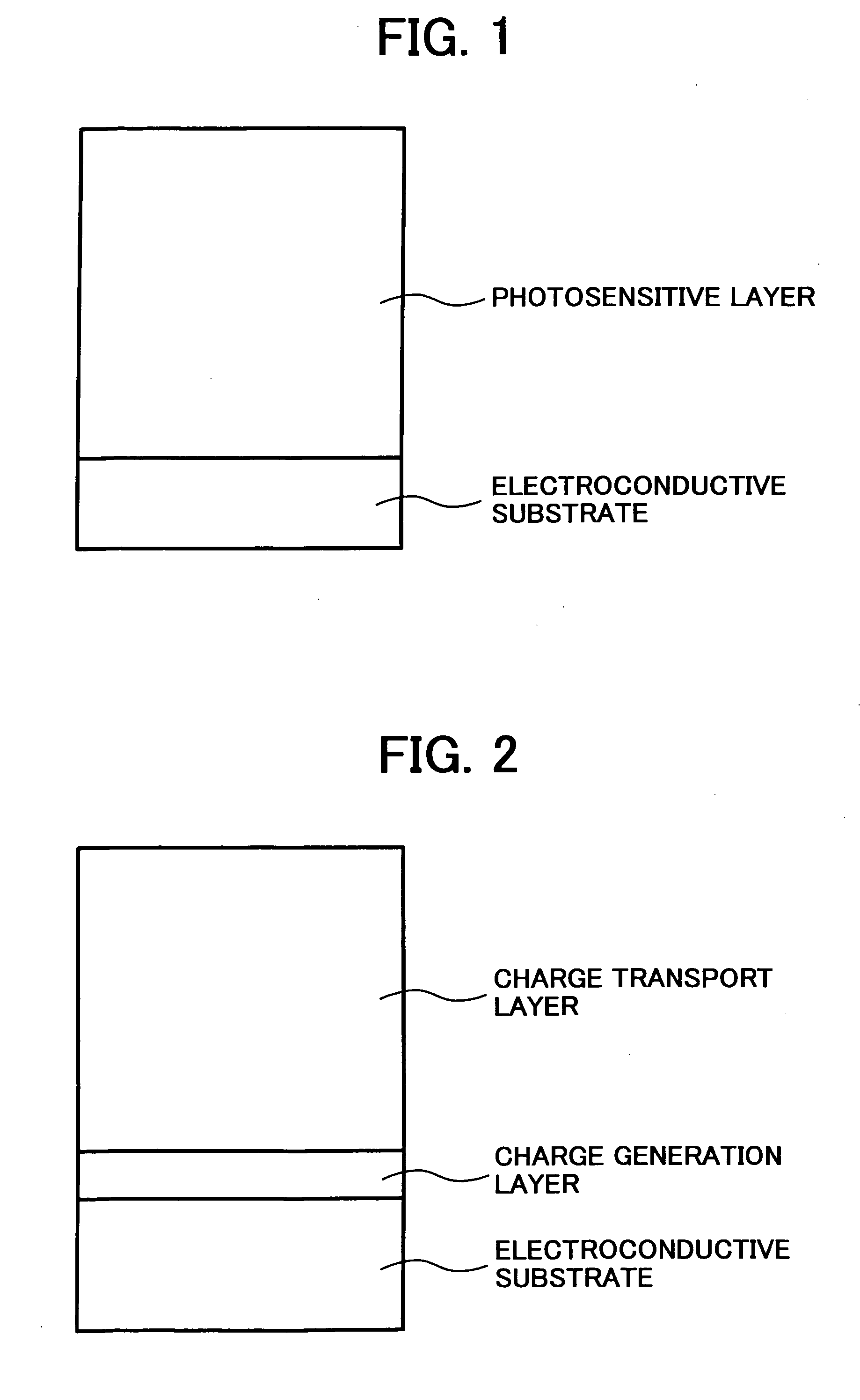

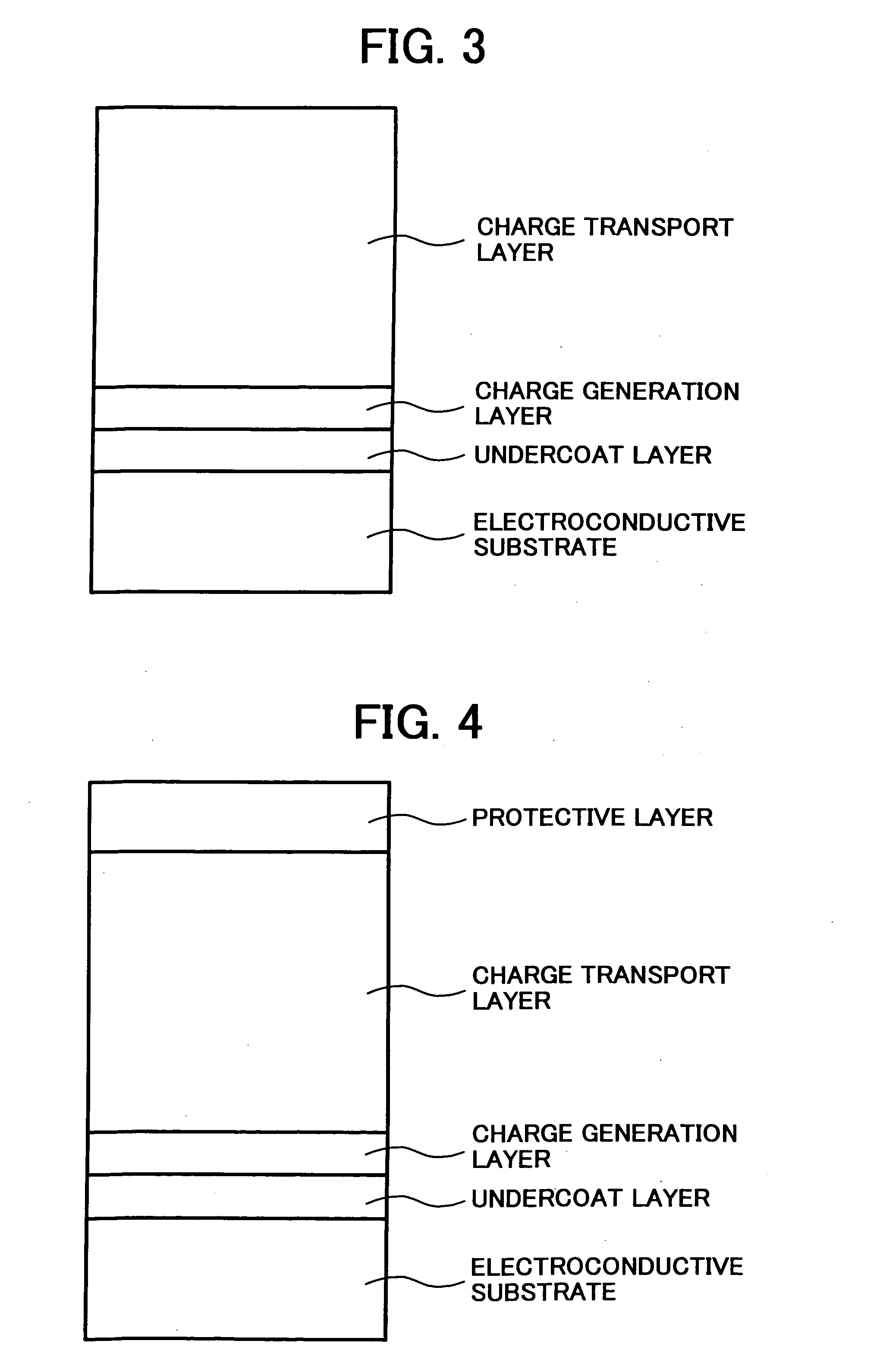

Electrophotographic photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the electrophotographic photoreceptor

ActiveUS20050053853A1Stably producing quality imageReduce coefficient of frictionElectrographic process apparatusElectrographic processes using charge patternParticulatesImage formation

An electrophotographic photoreceptor including an electroconductive substrate and a photosensitive layer located overlying the electroconductive substrate, wherein an outermost layer of the electrophotographic photoreceptor includes a particulate fluorine-containing resin, and wherein a primary particle of the particulate fluorine-containing resin and a secondary particle formed of agglomerated primary particles thereof, which are projected from a surface of the outermost layer and have an average particle diameter of from 0.15 to 3 μm, are present in an area ratio not less than 10% based on total surface area of the outermost layer.

Owner:RICOH KK

Solder ball and method for producing same

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

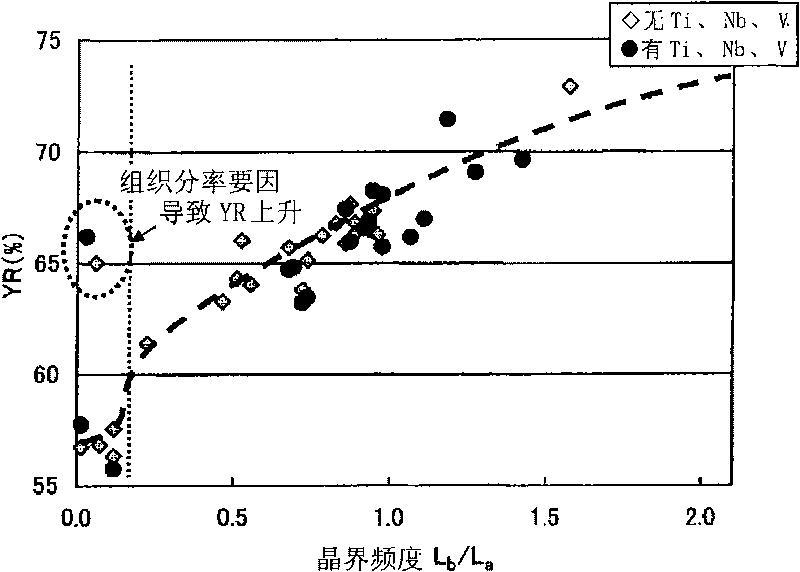

High yield ratio and high-strength hot-dip galvanized steel sheet excellent in workability and production method thereof

InactiveCN101724776AHigh yield ratioHigh elongationHot-dipping/immersion processesFurnace typesSheet steelCrystal orientation

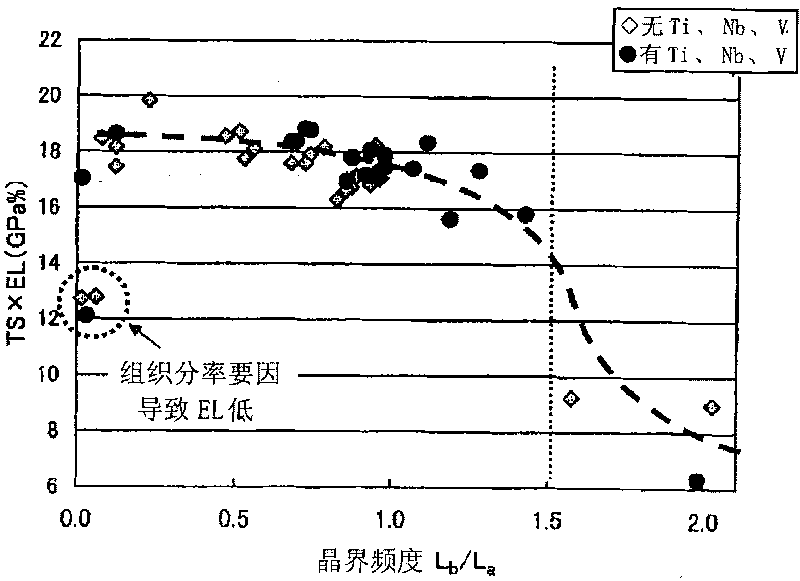

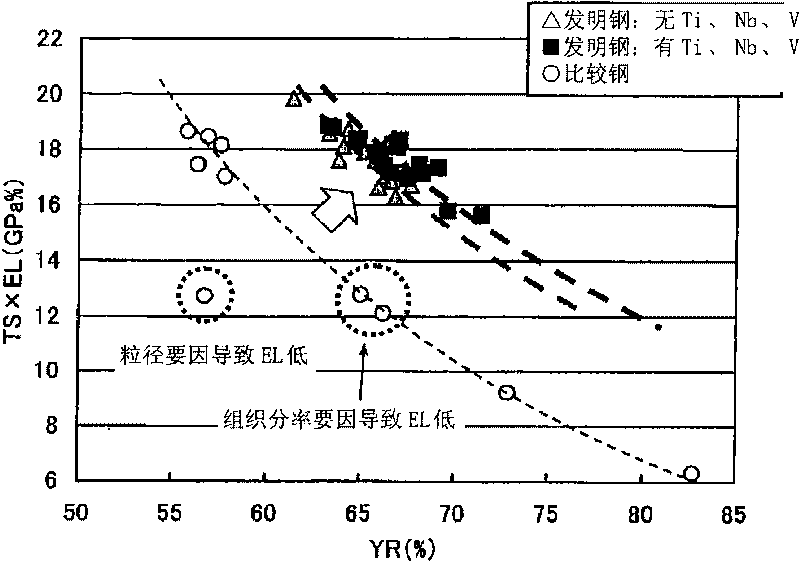

A high-strength hot-dip galvanized steel sheet excellent in workability according to the present invention: contains C, Si, Mn and other elements; has a dual phase structure containing ferrite and martensite as the metallographic structure; and, in the ferrite structure, satisfies the expression 0.2<=(Lb / La)<=1.5 when the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as La and the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are less than 10 degrees is defined as Lb and further satisfies the requirements that the average value of D is 25 [mu]m or less and the area ratio of crystal grains satisfying the expression D<=30 [mu]m in the ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is 50% or more when the circle equivalent diameter of each of ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as D; and has a tensile strength of 980 MPa or more.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com