Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

926results about How to "Improve resistance to damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric constant insulating film and method for forming the same

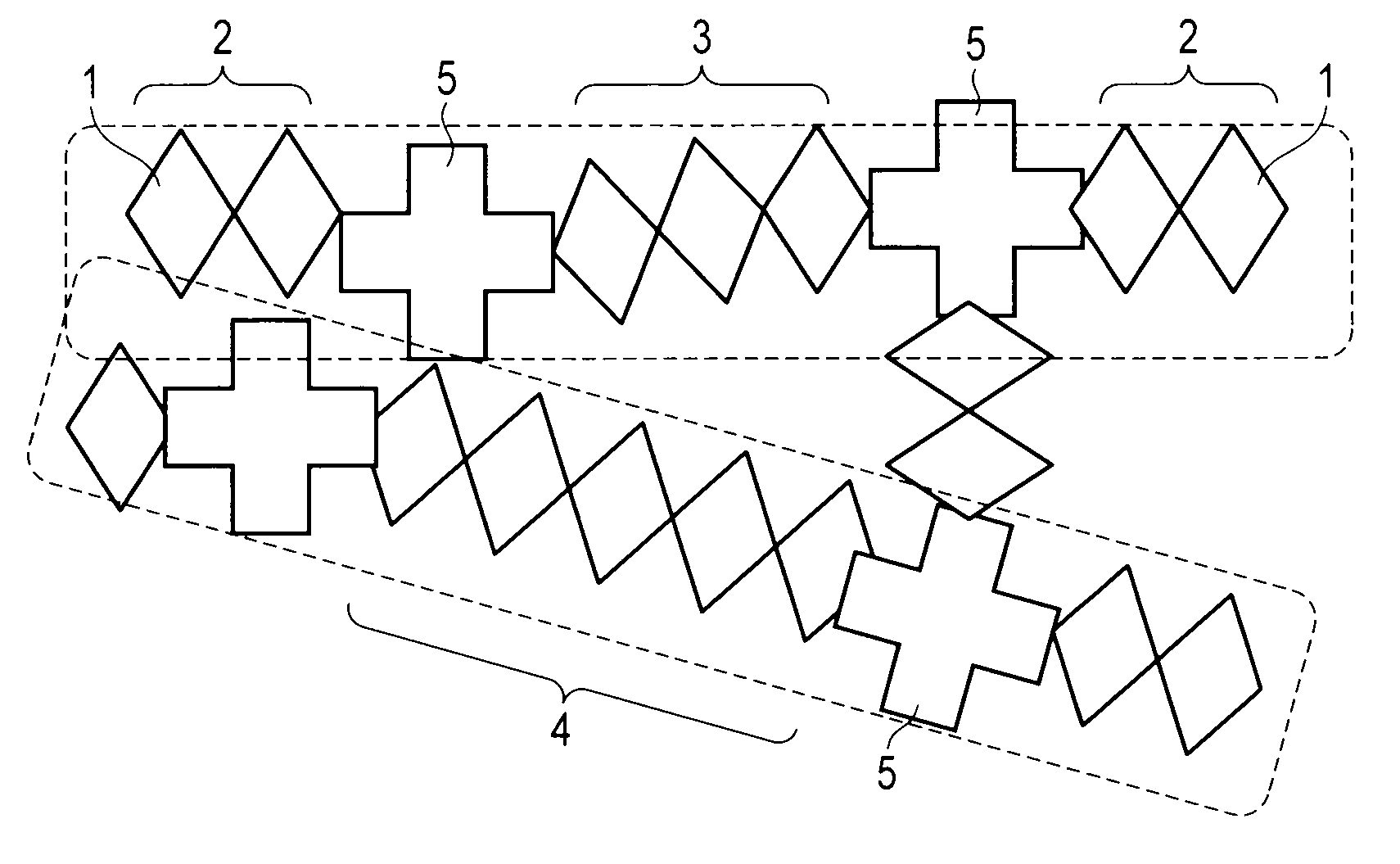

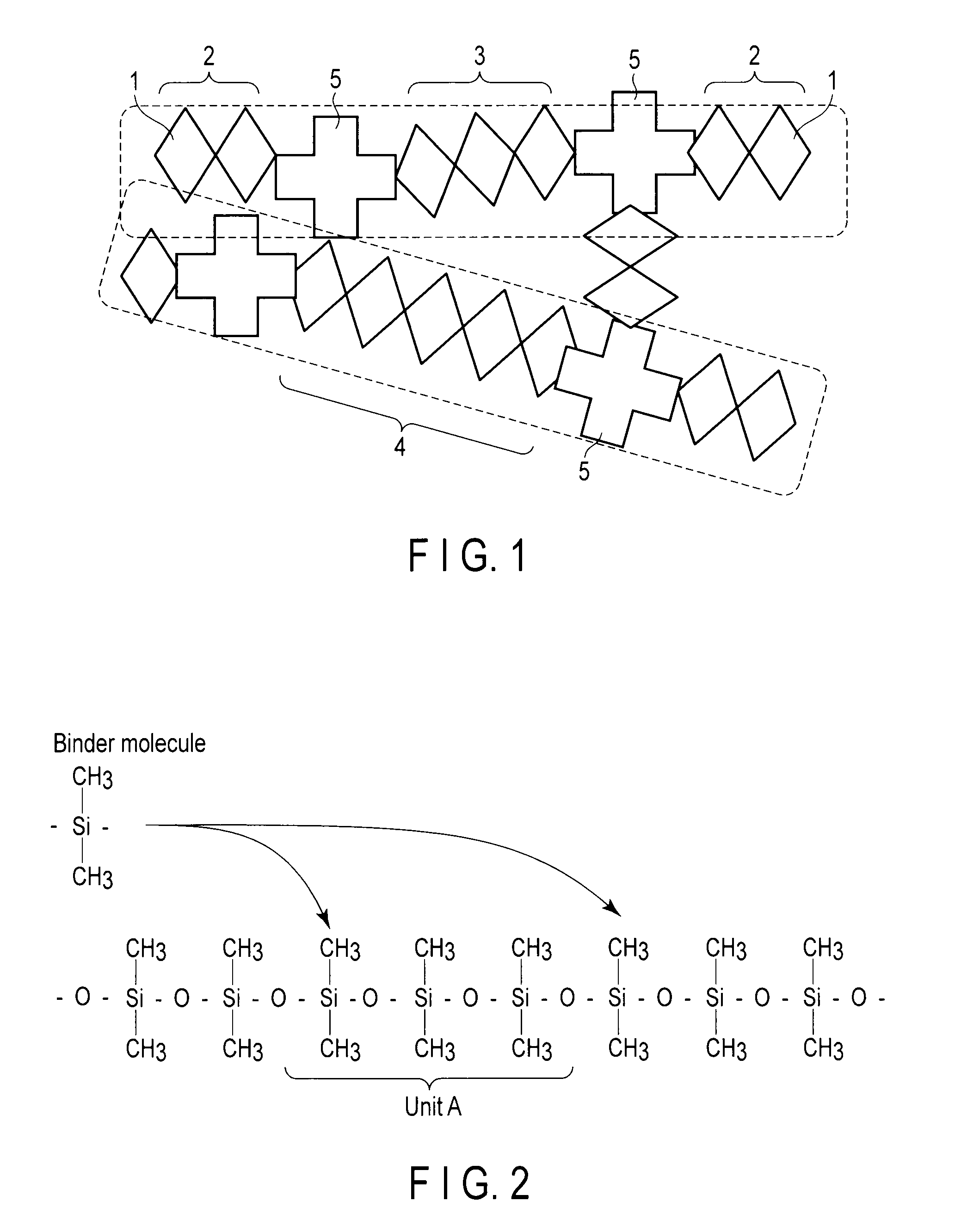

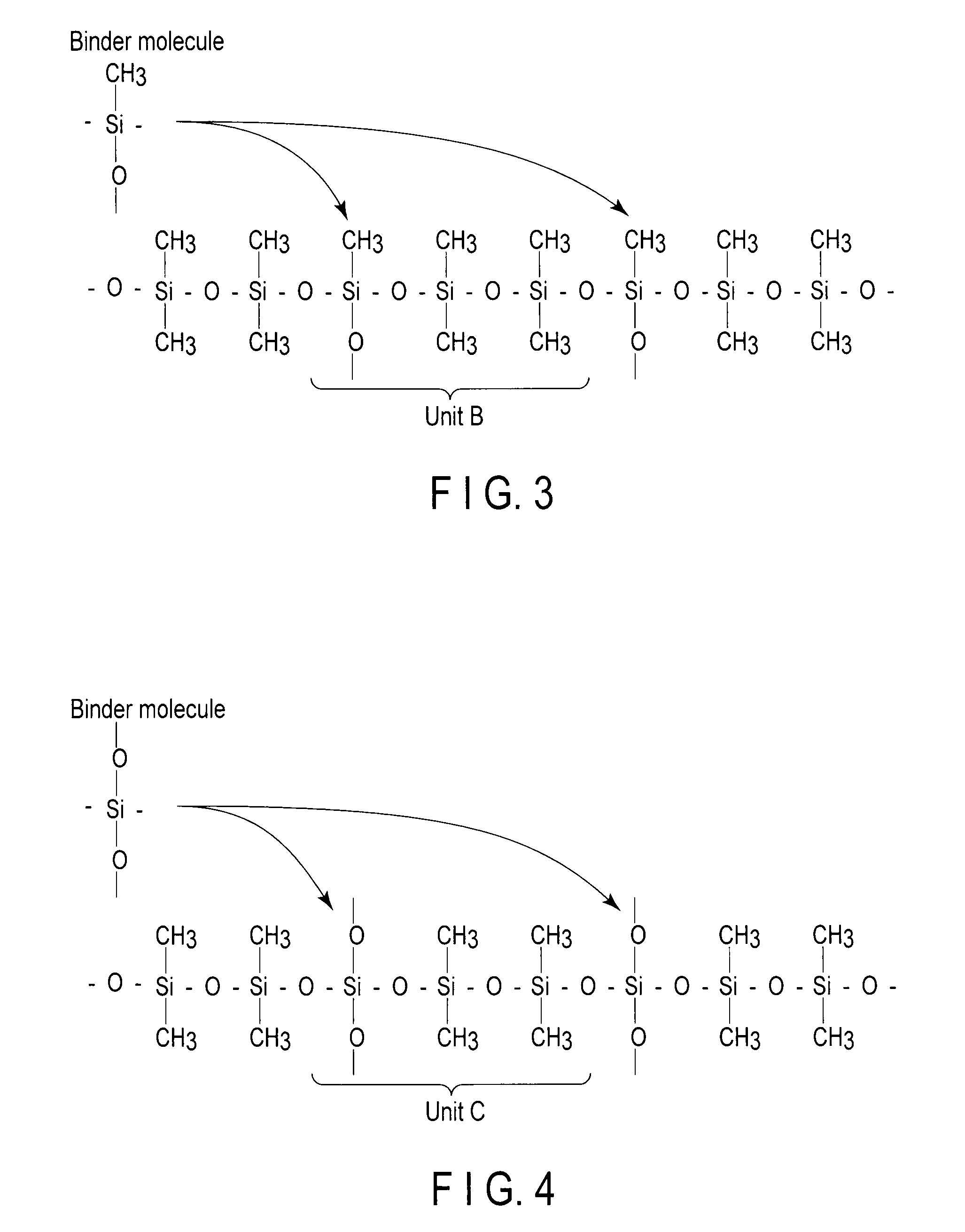

InactiveUS8828886B2Improve resistance to damageLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingArea ratioPolymer

Disclosed is a low dielectric constant insulating film formed of a polymer containing Si atoms, O atoms, C atoms, and H atoms, which includes straight chain molecules in which a plurality of basic molecules with an SiO structure are linked in a straight chain, binder molecules with an SiO structure linking a plurality of the straight chain molecules. The area ratio of a signal indicating a linear type SiO structure is 49% or more, and the signal amount of the signal indicating Si(CH3) is 66% or more.

Owner:TOHOKU UNIV

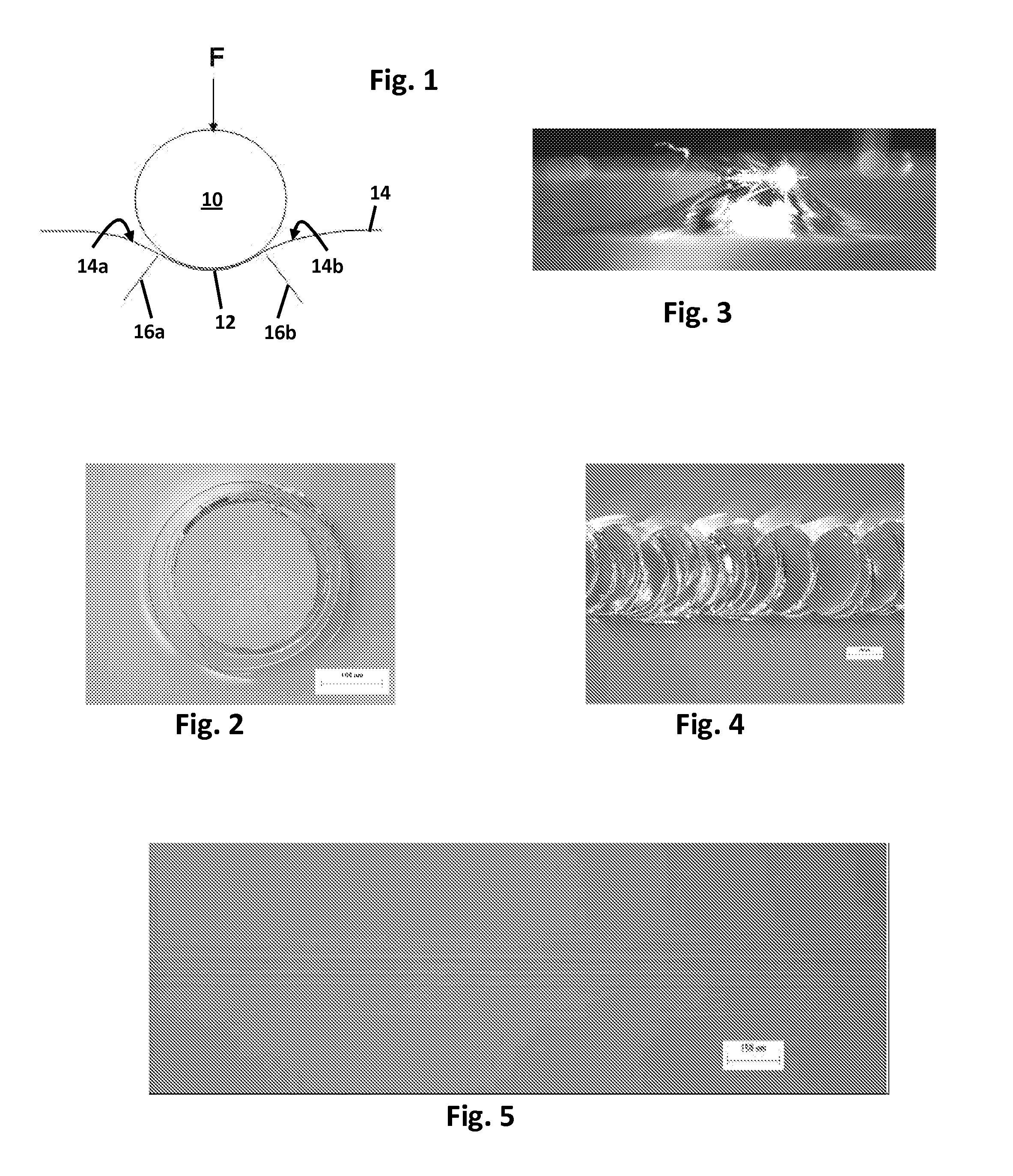

Glass with high frictive damage resistance

ActiveUS20120282449A1Improve initial strengthImprove the immunityDecorative surface effectsSynthetic resin layered productsPolymer scienceLayer thickness

A glass article exhibiting improved resistance to fictive surface damage and a method for making it, the method comprising removing a layer of glass from at least a portion of a surface of the article that is of a layer thickness at least effective to reduce the number and / or depth of flaws on the surface of the article, and then applying a friction-reducing coating to the portion of the article from which the layer of surface glass has been removed.

Owner:CORNING INC

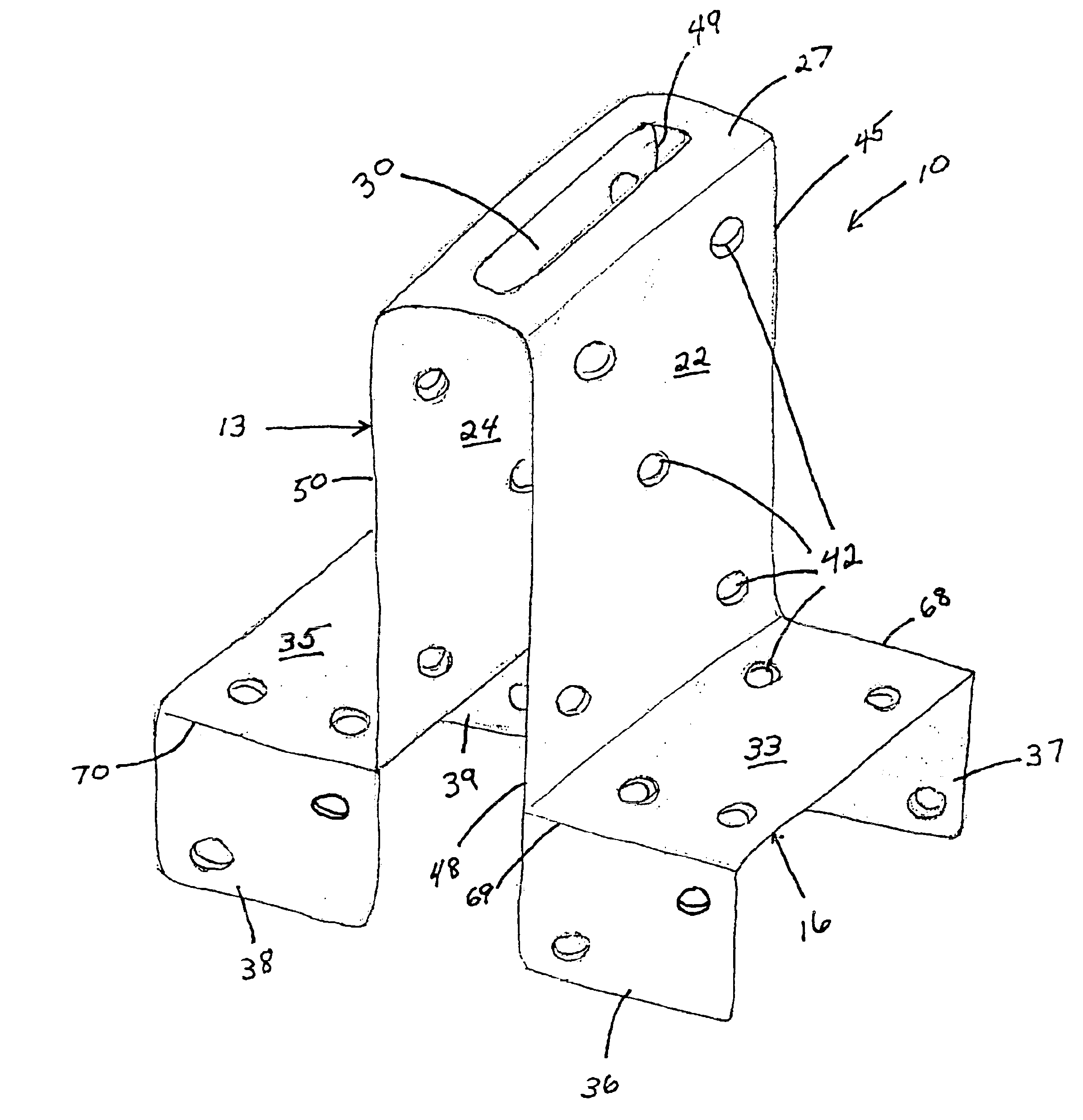

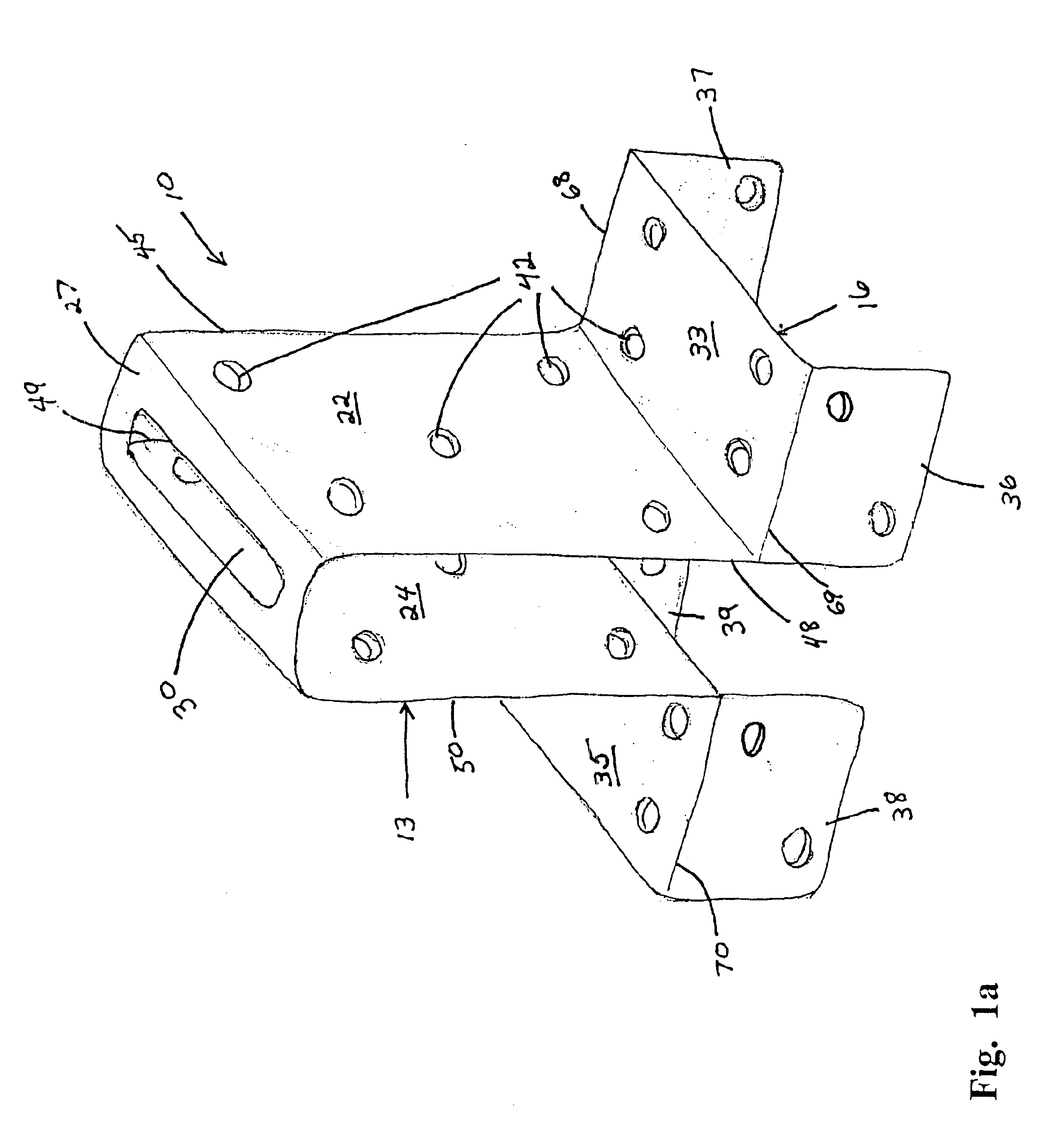

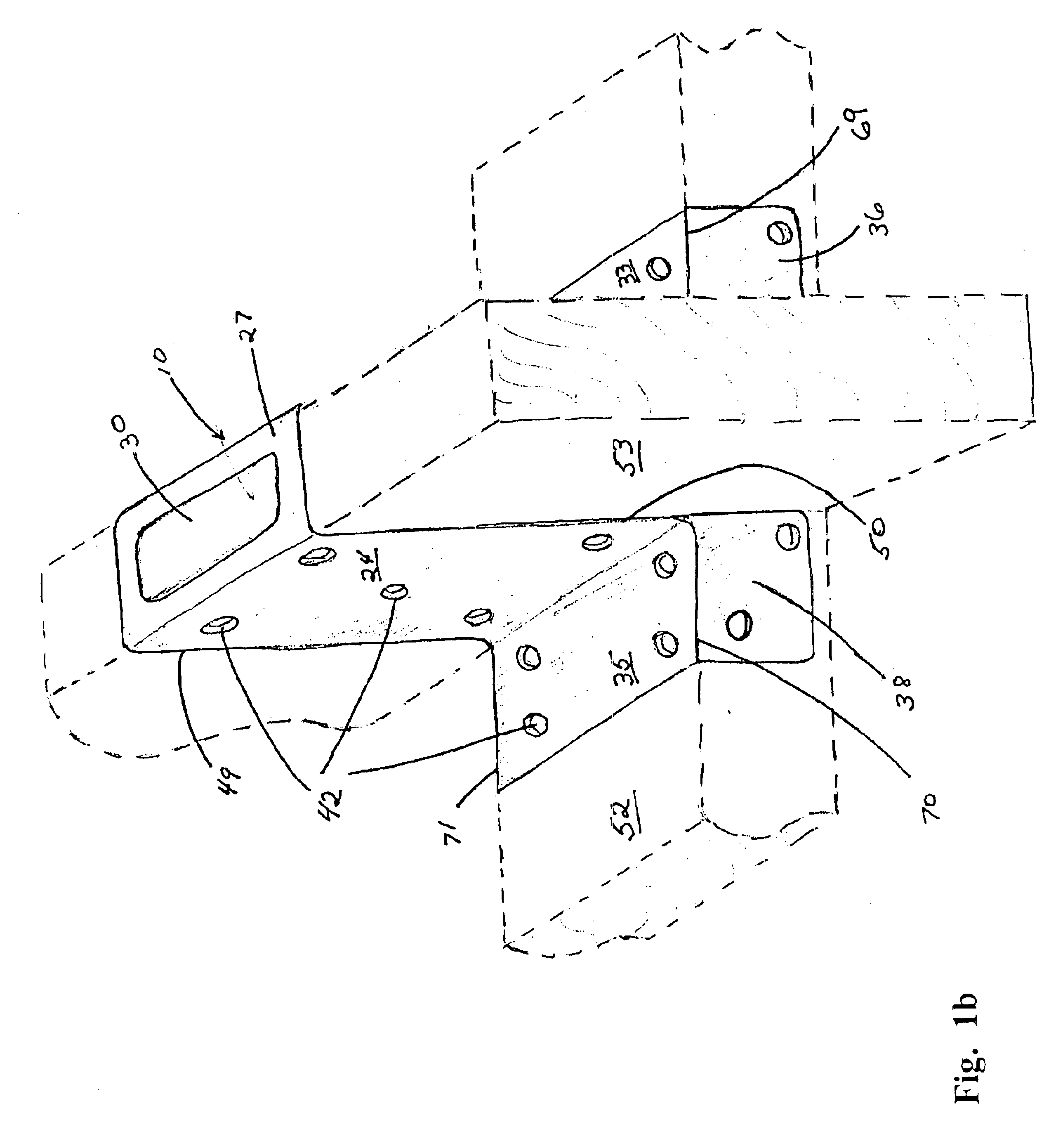

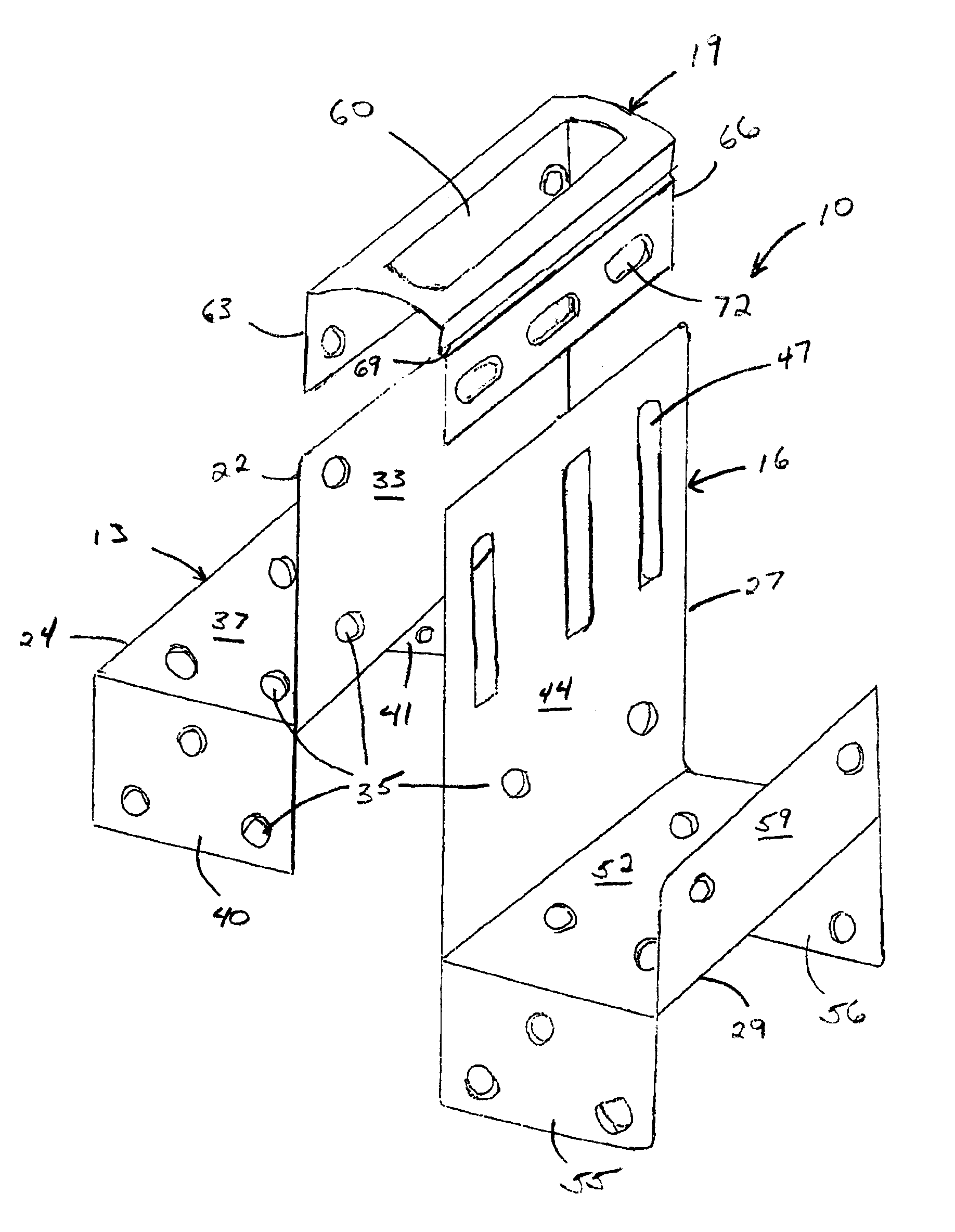

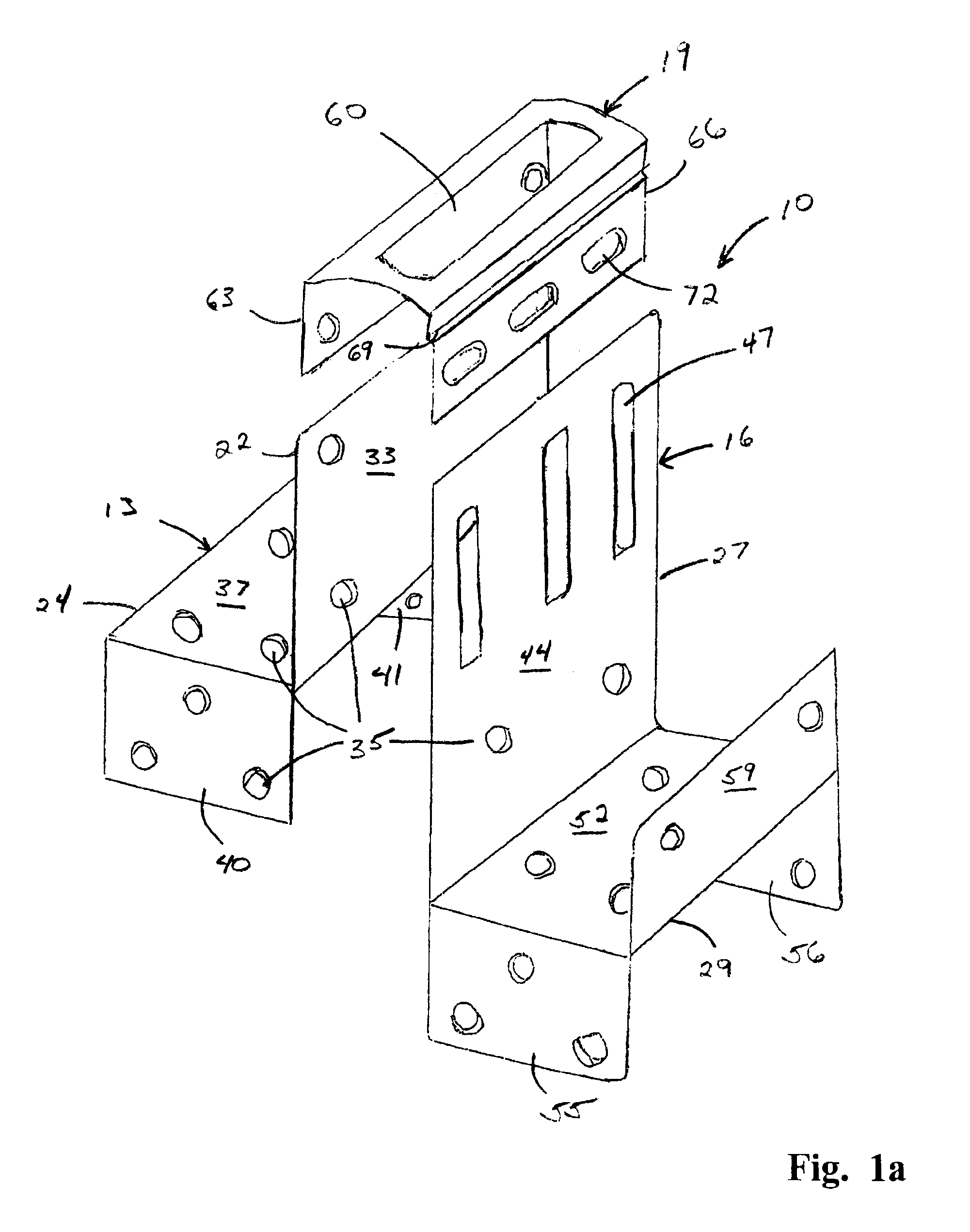

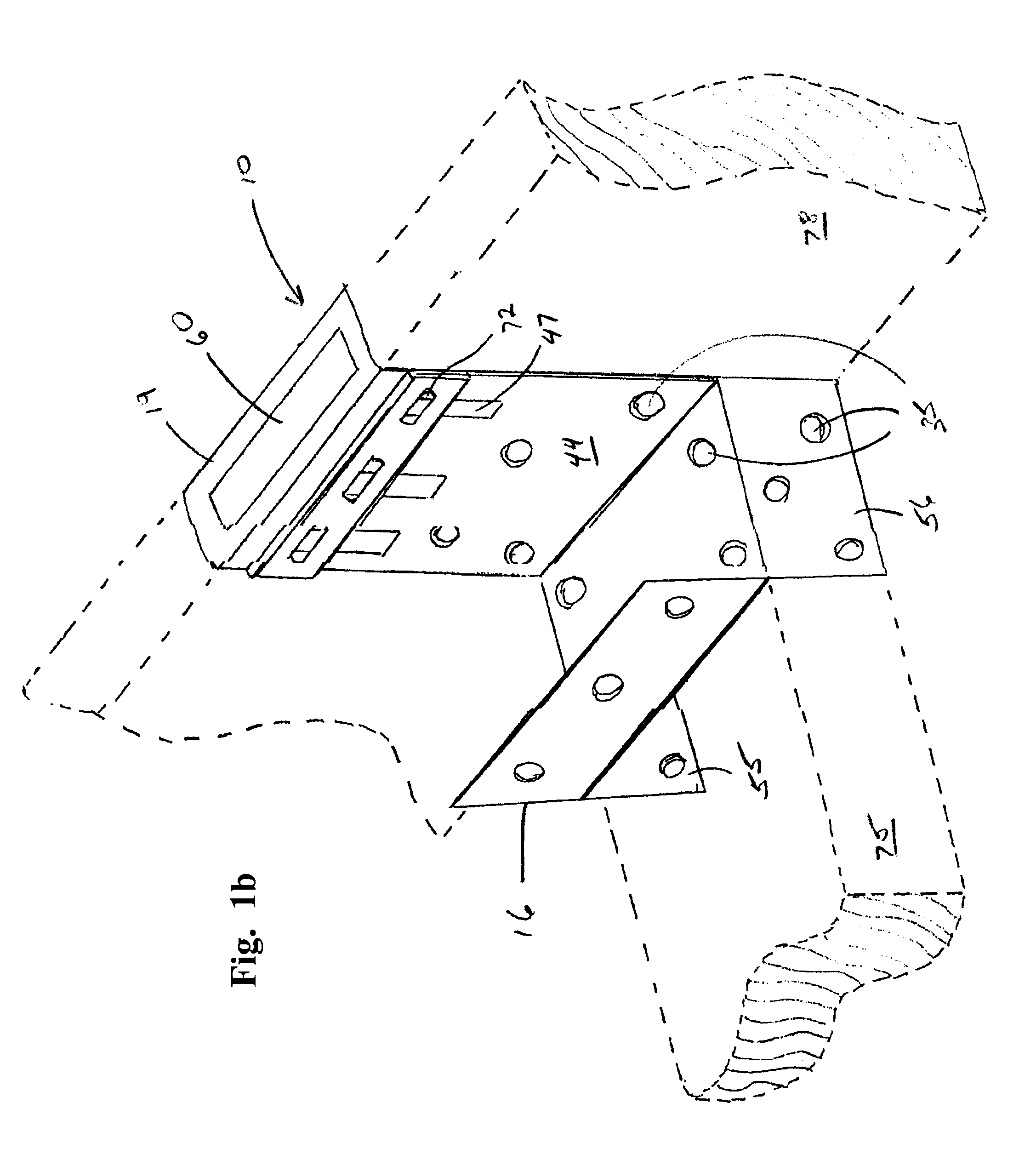

Tornado and hurricane roof tie

InactiveUS6837019B2Easily damagedBetter resist any upward liftBuilding roofsRoof covering using slabs/sheetsRafterFastener

Owner:COLLIE ANTHONY D

Tornado and hurricane roof tie

InactiveUS6931813B2Easily damagedResist upward liftBuilding roofsBuilding reinforcementsUltimate tensile strengthRafter

A building roof tie for attaching roof trusses and rafters to wood top plates in building structures, such roof tie having a sheet metal body with risers and a bridge for overlapping a rafter and flaps for wrapping on the sides of the top plate. A generally triangular shaped reinforcing wing provides strength and stability, and can also provide additional hold-down strength, allowing the roof tie to be manufactured from different weights of steel. Turnbuckles attached to the bridge provide additional hold-down strength against increased uplift forces. The roof ties are pitched to conform to a variety of framing applications. A plurality of apertures is formed in the roof tie to provide openings for fasteners for connecting the tie to the wood top plate and rafter.

Owner:COLLIE ANTHONY D

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

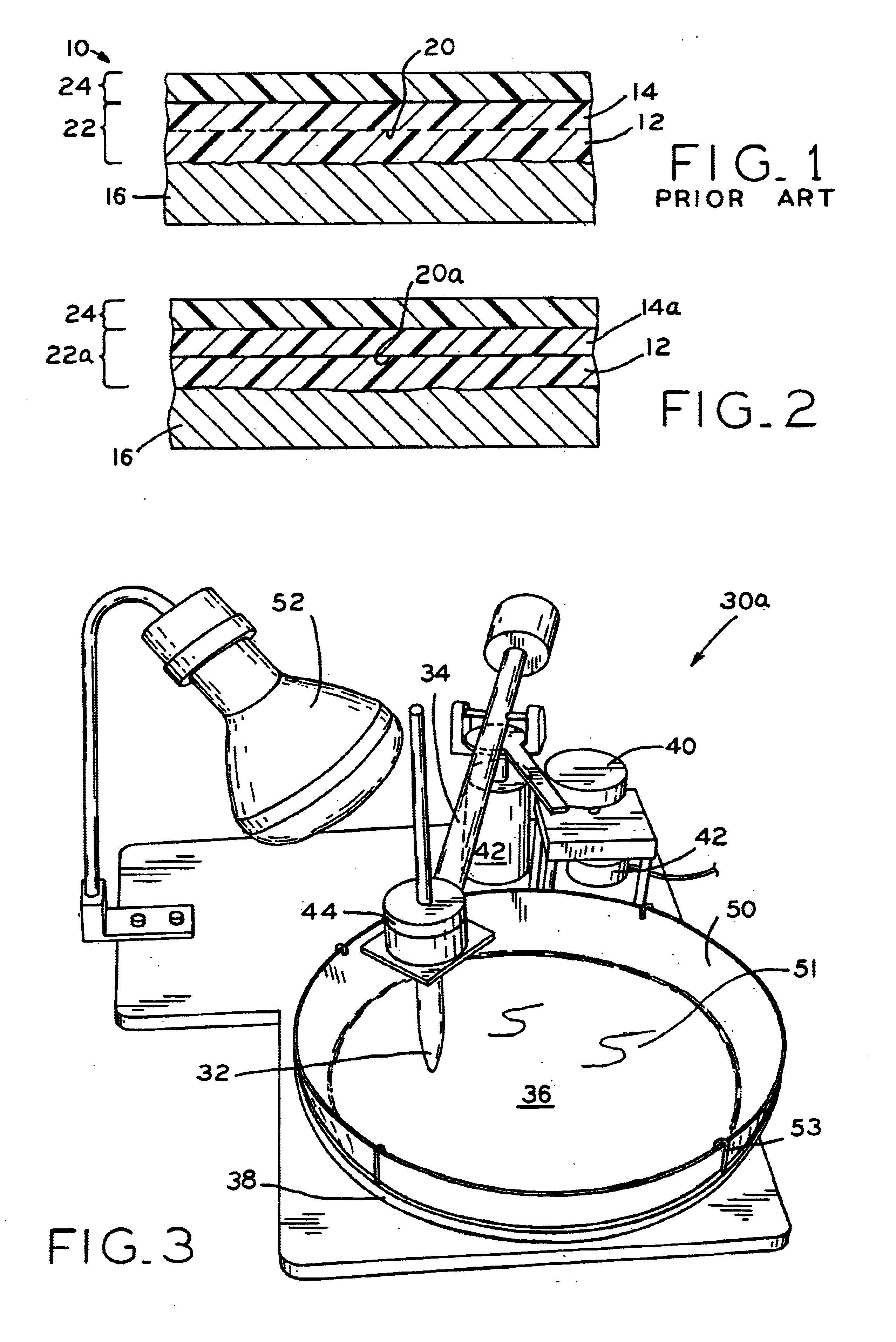

Multiple coat non-stick coating system and articles coated with same

InactiveUS6846570B2Improve adhesionImprove the level ofCooking-vessel materialsOther chemical processesPolymer scienceCoating system

Multiple coat non-stick coating systems, as well as articles coated with such non-stick coating systems, are provided. The primer (22a) of the multiple coat system includes a fluoropolymer (14a) copolymer, such as a fluoropolymer terpolymer including tetrafluoroethylene, hexafluoropropylene, and vinylidene fluoride monomers, which fluoropolymer copolymers are referred to collectively as THV. The multiple coat system exhibits excellent substrate adhesion and release properties, and the primer exhibits excellent primer-substrate adhesion and primer-topcoat adhesion. The multiple coat system is additionally resistant to separation failure at the interface between the binder (12) and fluoropolymer components of the primer, exhibits excellent adhesion to smooth substrates (16), and may also include a high level of fillers to provide increased damage resistance without compromising the above benefits.

Owner:PPG IND OHIO INC

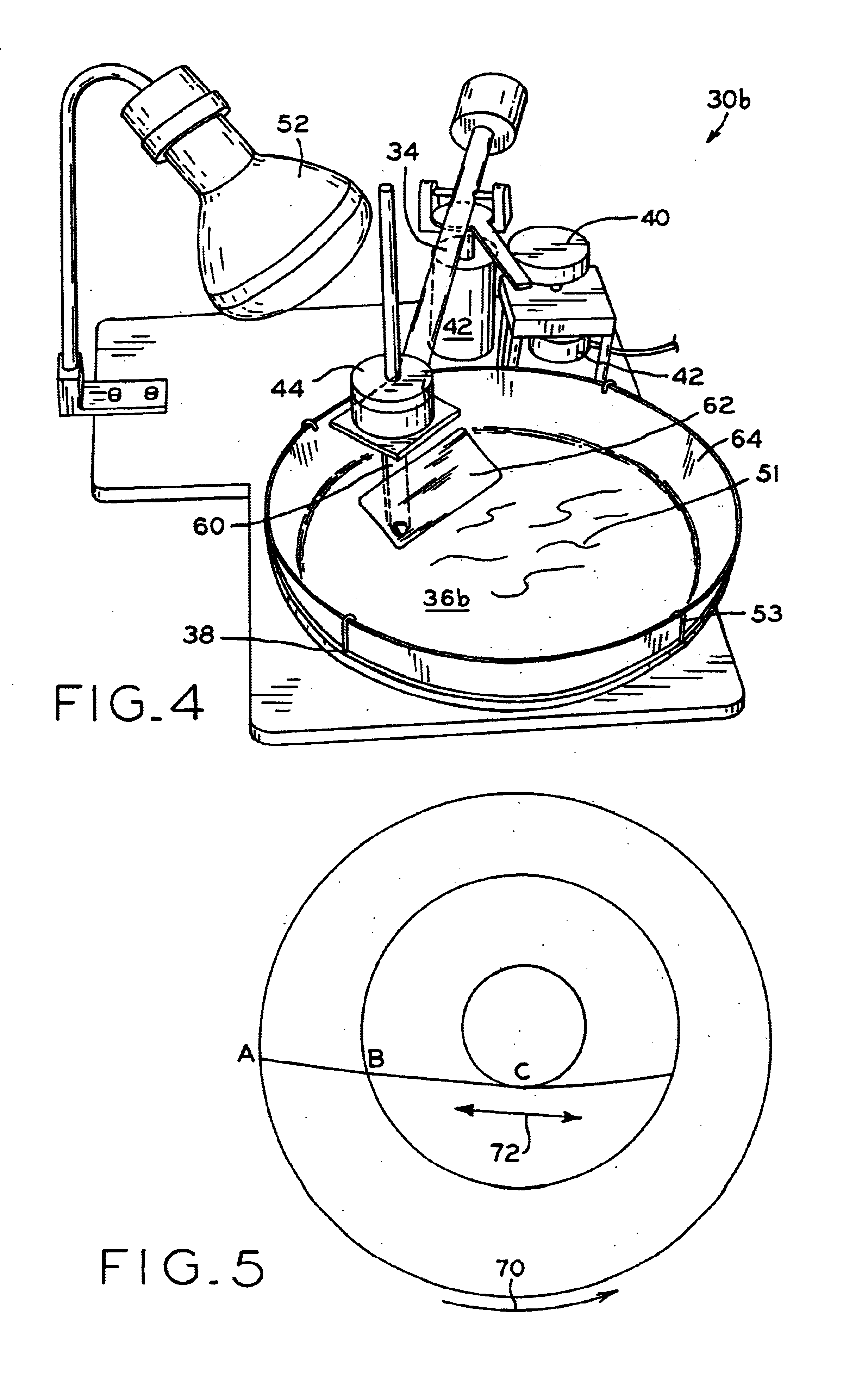

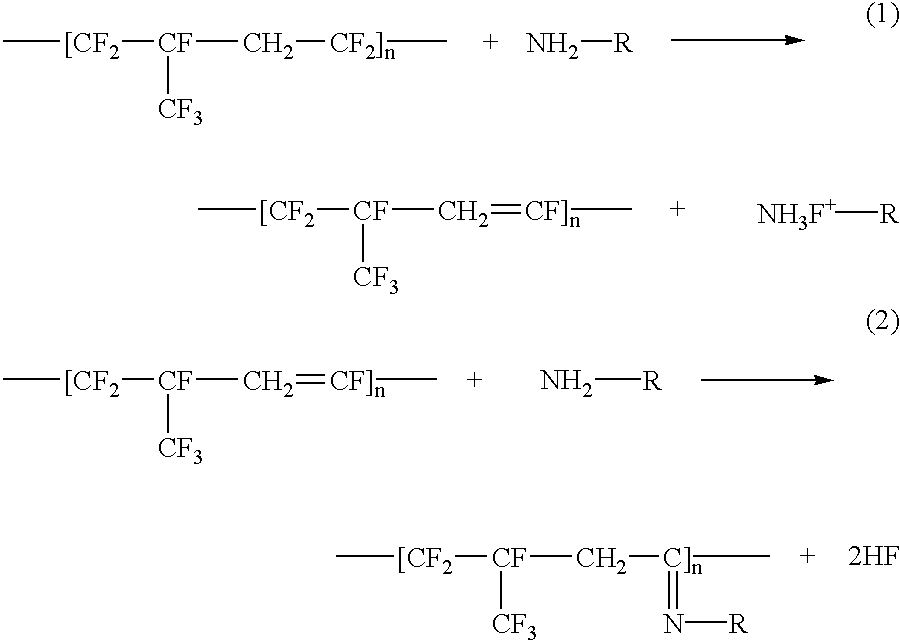

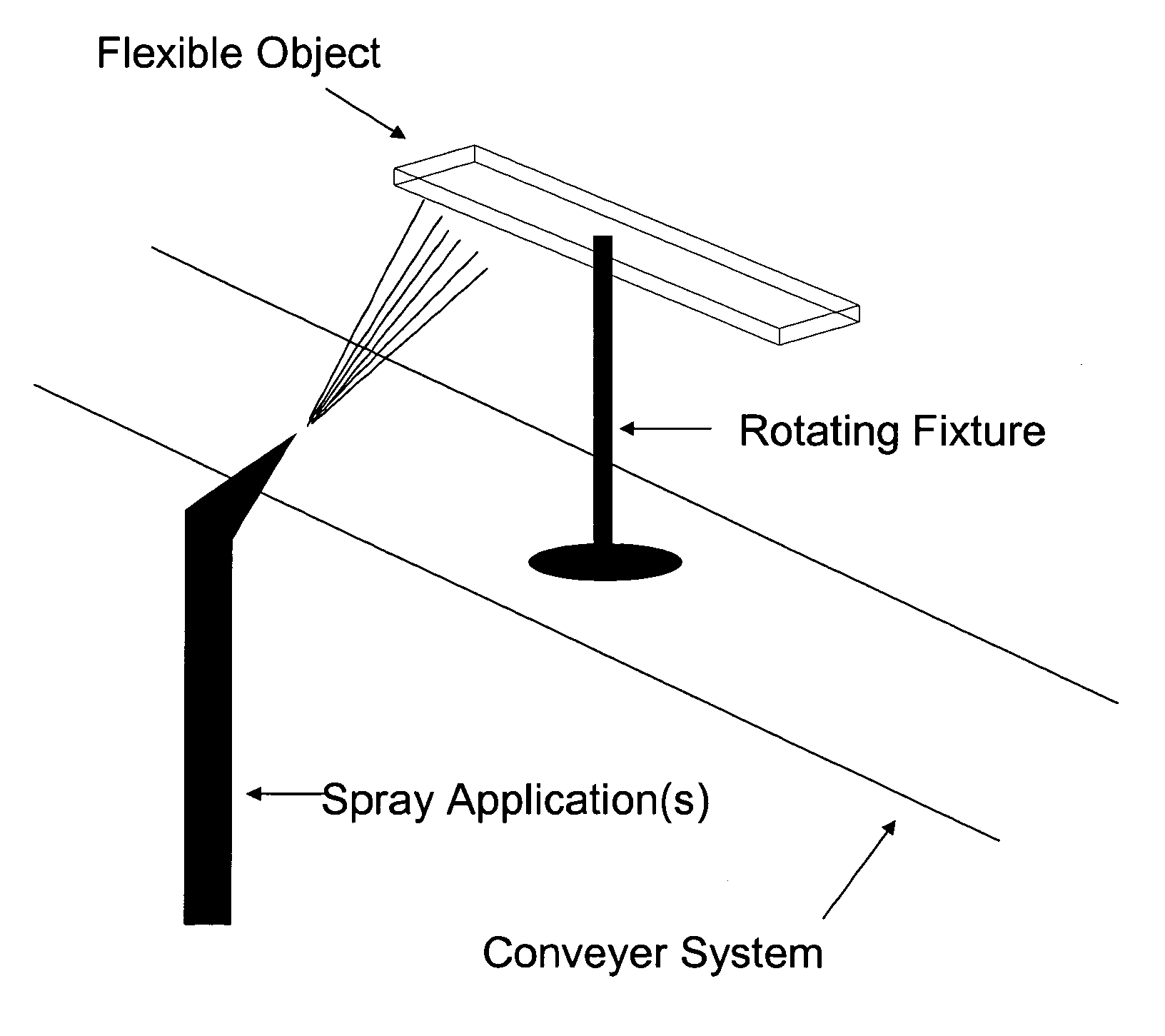

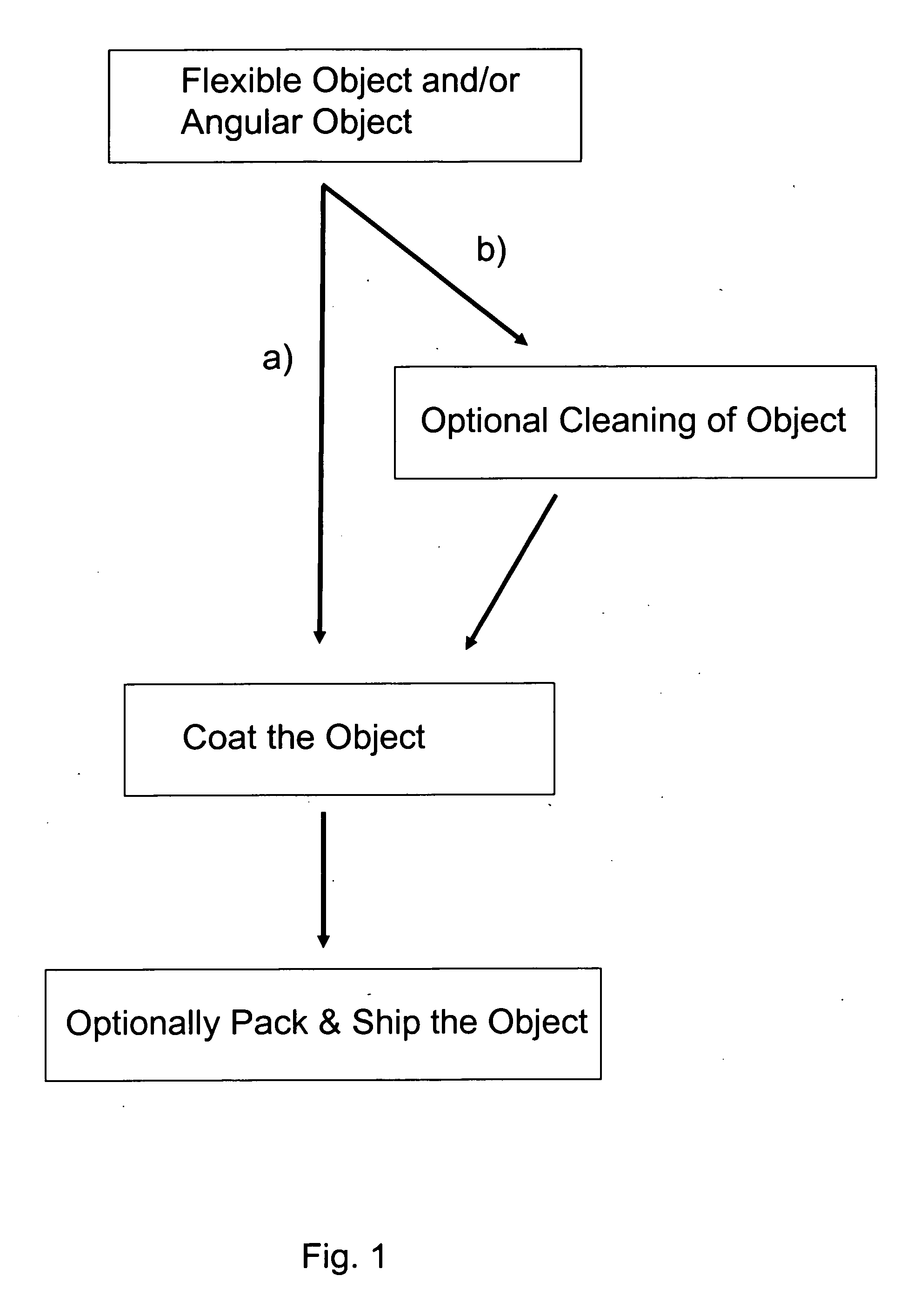

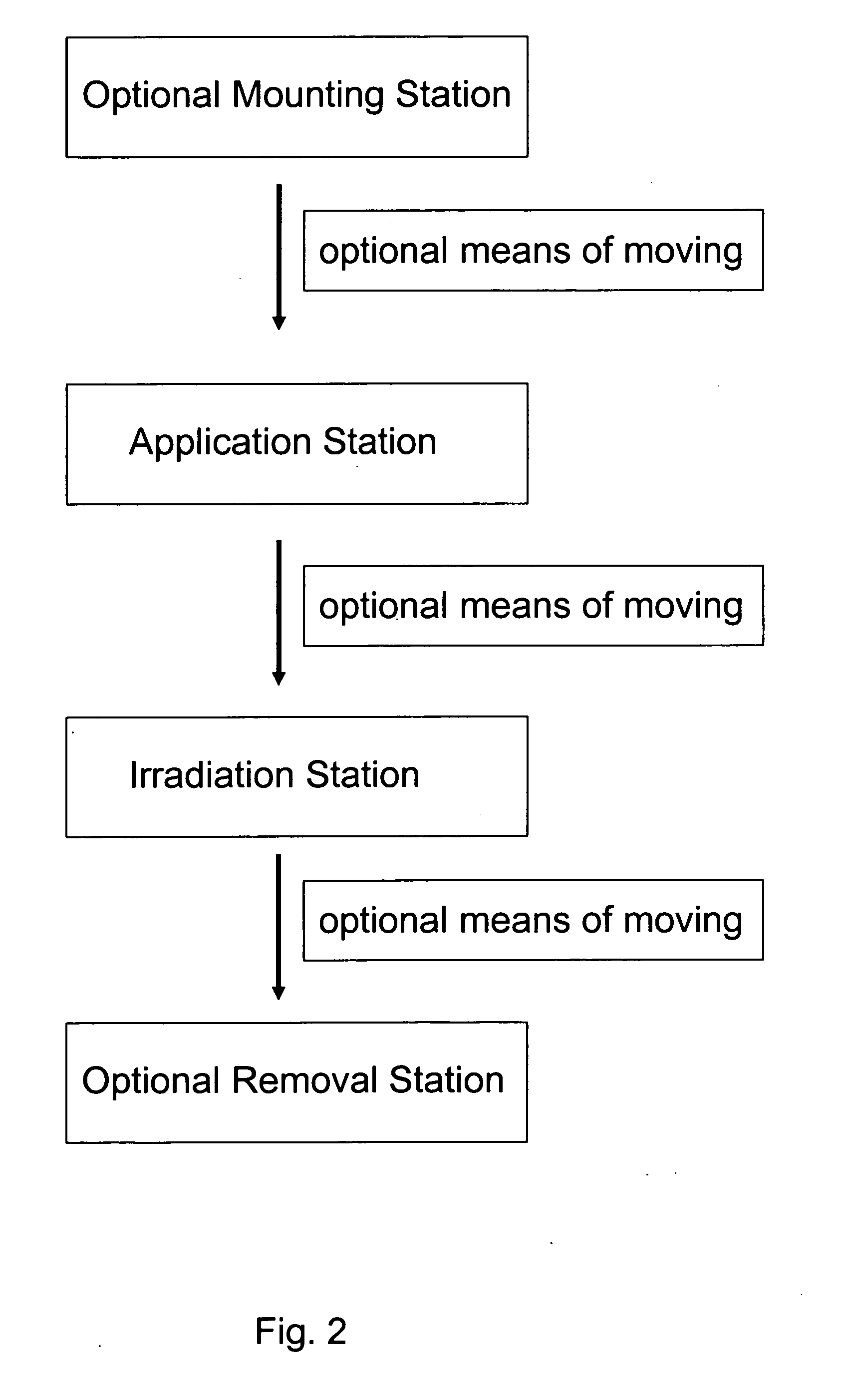

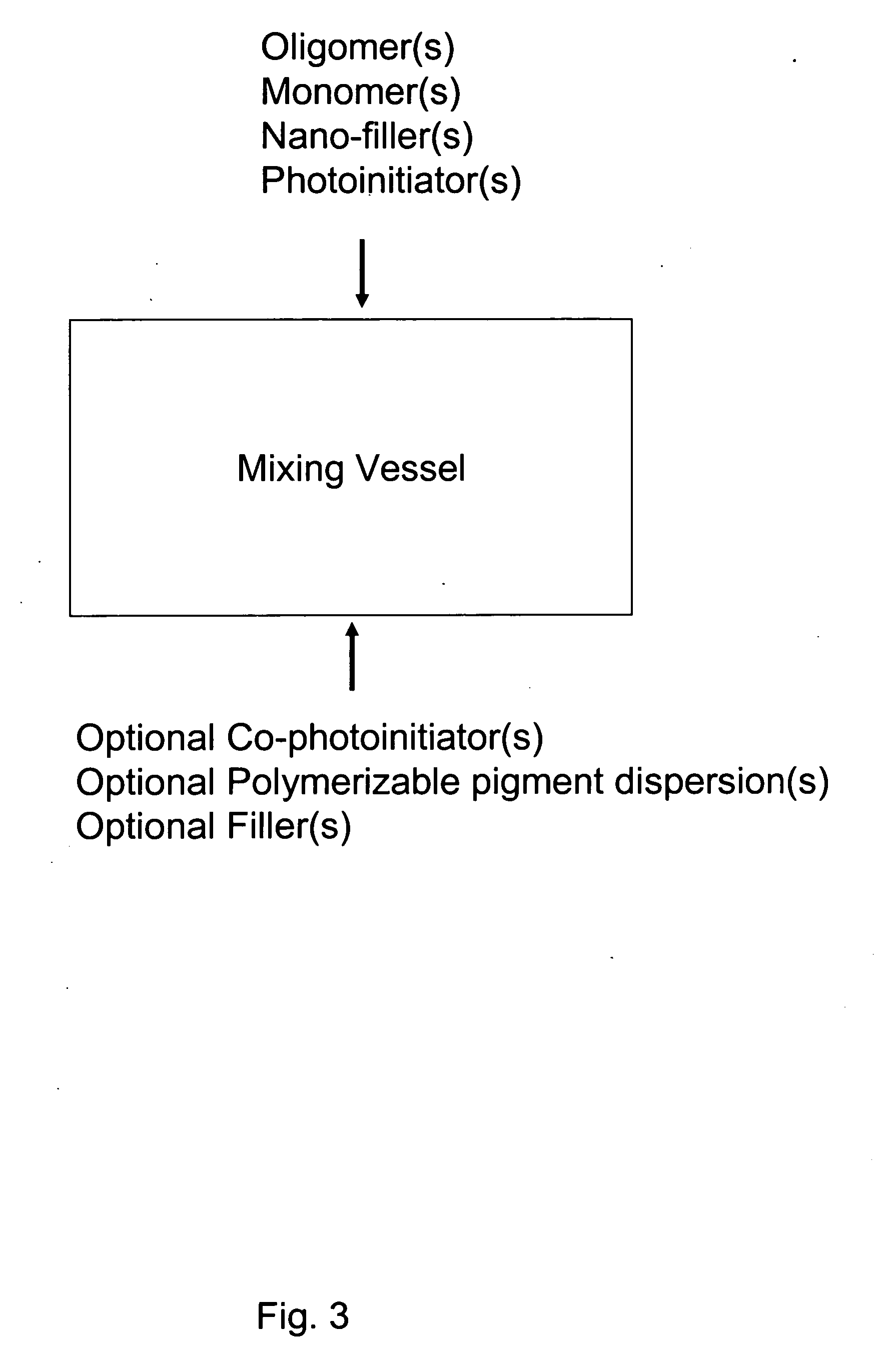

Environmentally friendly coating compositions for coating metal objects, coated objects therefrom, and methods, processes and assemblages for coating thereof

InactiveUS20050196605A1Improve propertiesLess materialImpression capsOrganic chemistryCoated surfaceProduction line

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In addition, the disclosed coating compositions are suitable for coating flexible objects and / or objects having angular features, such as, but not limited to, flexible metal objects with angular features. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example leaf springs. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING

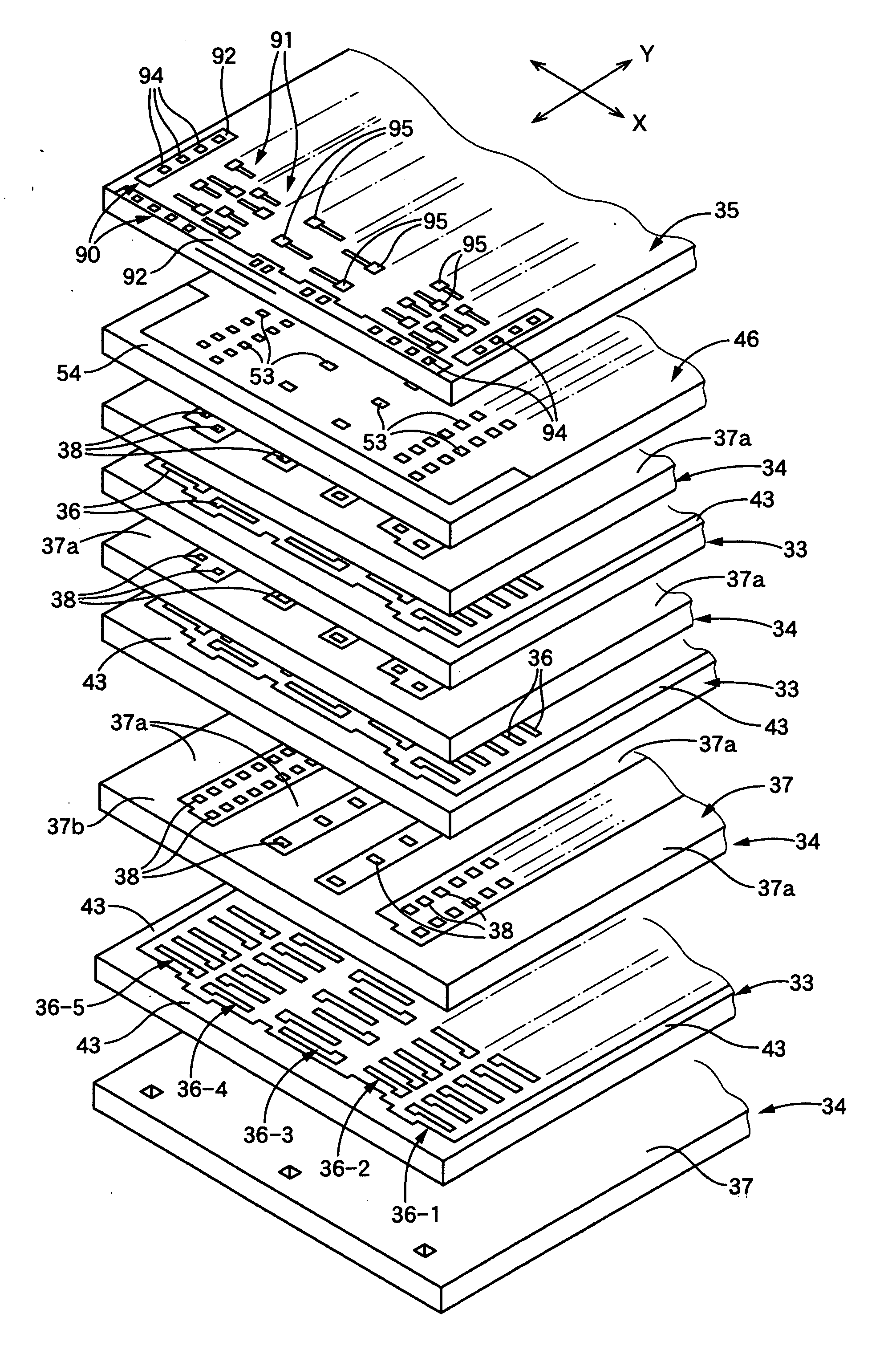

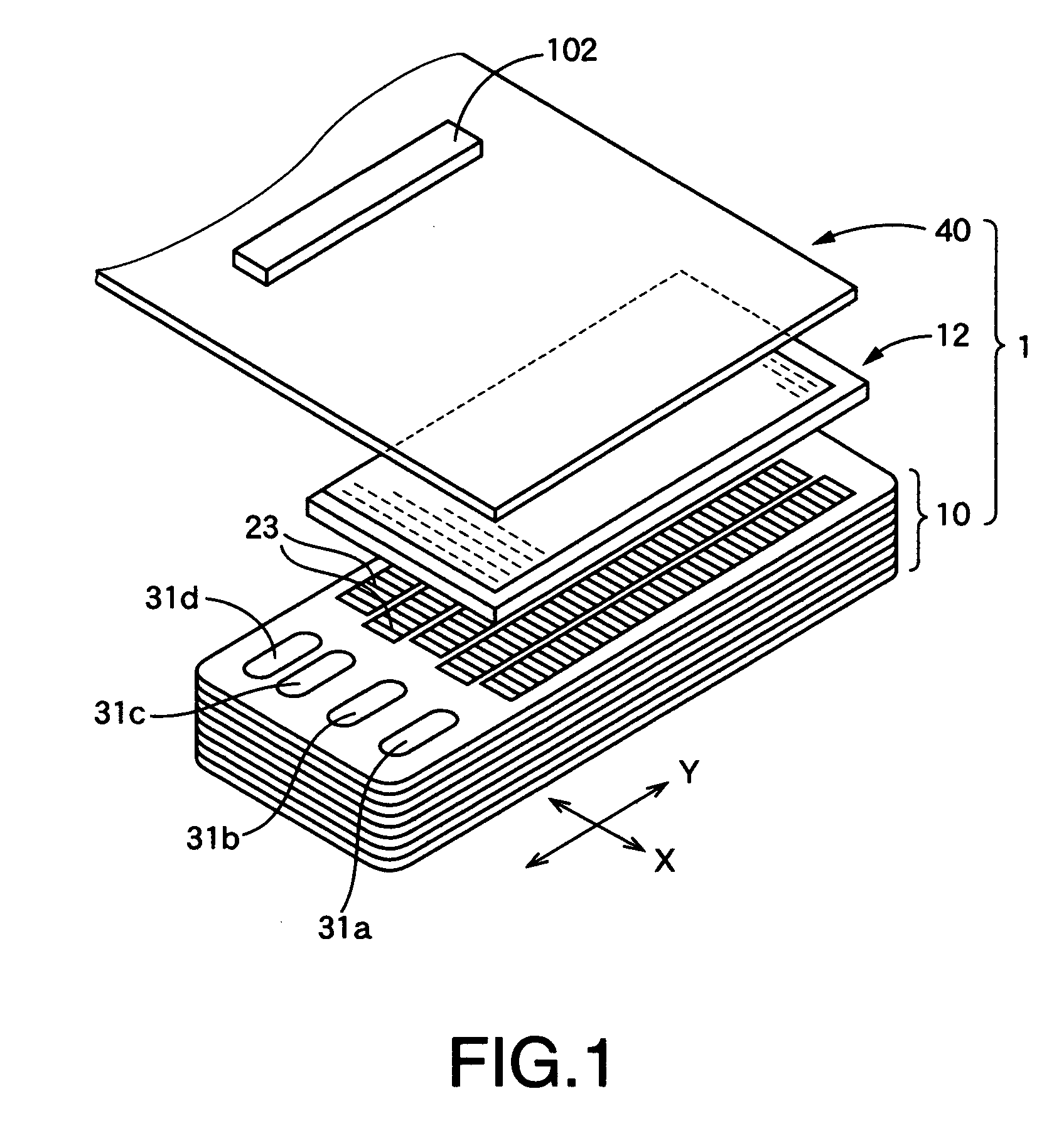

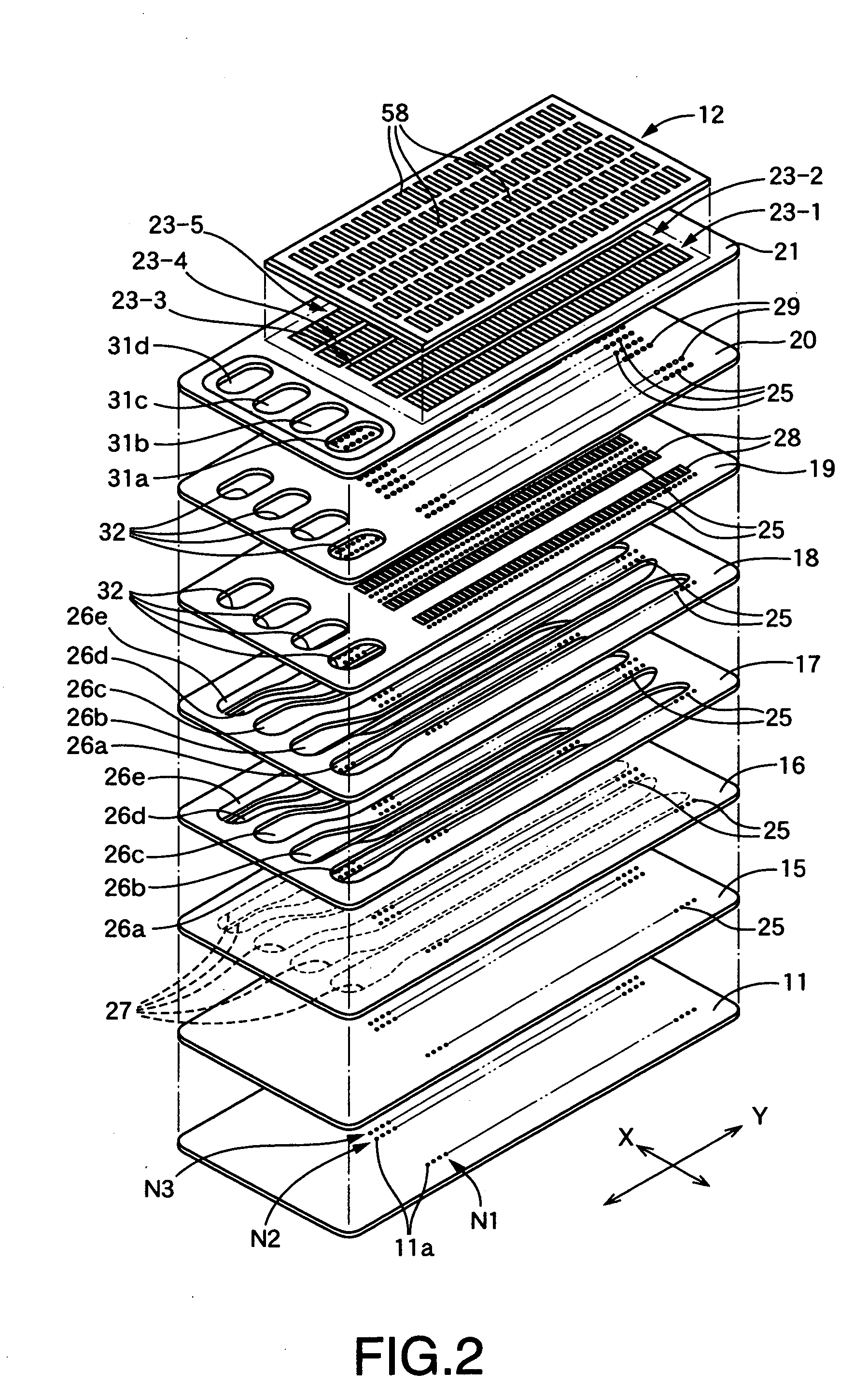

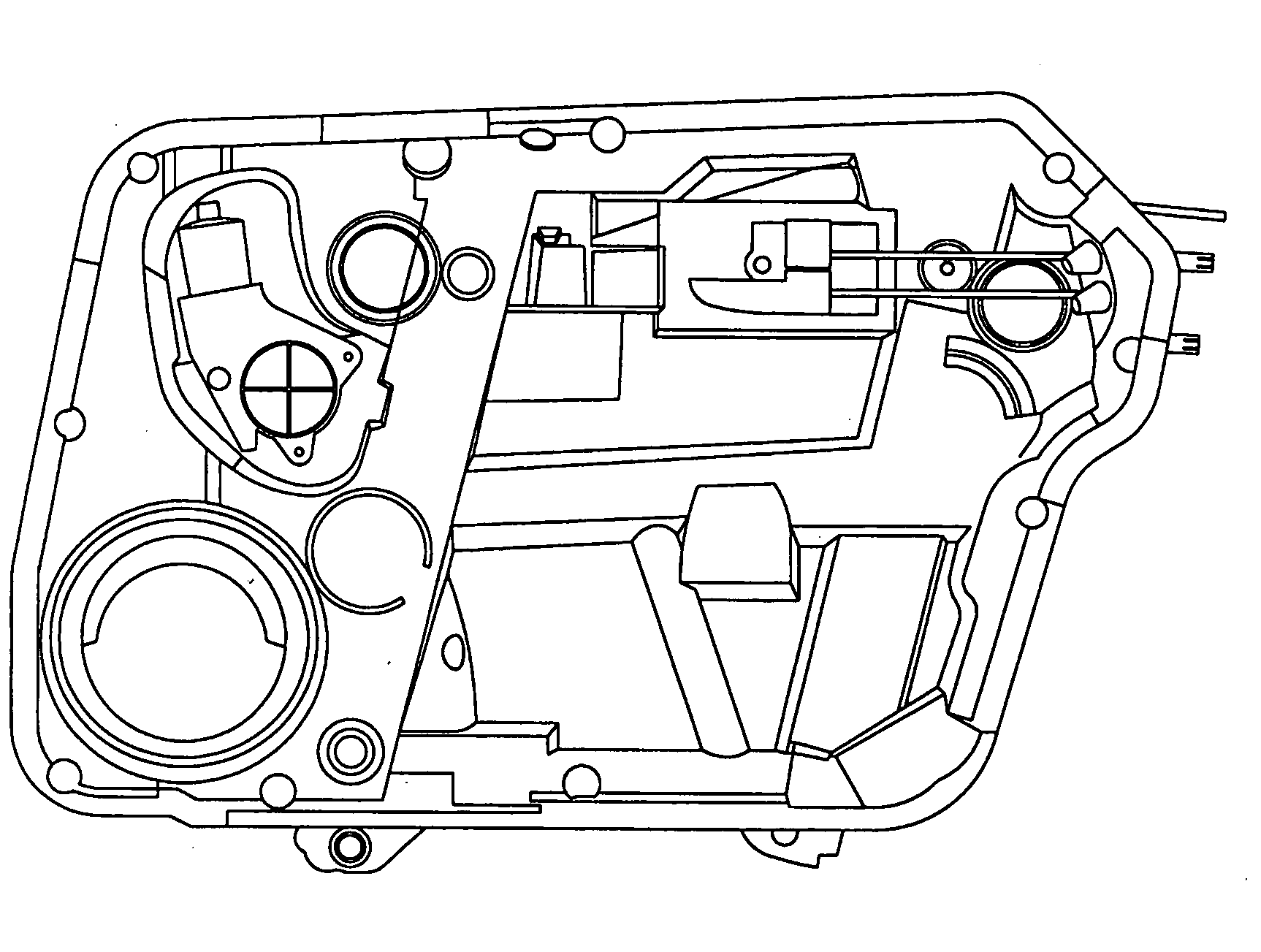

Injet printhead having externally-connected terminations structured to be resistant to damage

An inkjet printhead is disclosed which includes nozzles for ejecting ink droplets; a cavity unit incorporating pressure chambers; and an actuator in the form of a laminate of sheets. The actuator includes individual electrodes and a top sheet having bonding terminations. The inkjet printhead is bonded at the bonding terminations to a flexible flat cable. The bonding terminations include surface electrodes formed on the top sheet. The top sheet includes through holes, each of which is filled with a conductive material locally communicated with a corresponding one of the surface electrodes at a communication portion thereof. The top sheet includes external conductive areas, each formed on a surface of a corresponding one of the surface electrodes, and each having a thickness larger than that of the corresponding surface electrode. Each of the external conductive areas overlays an open end of the corresponding through hole located in the communication portion.

Owner:BROTHER KOGYO KK

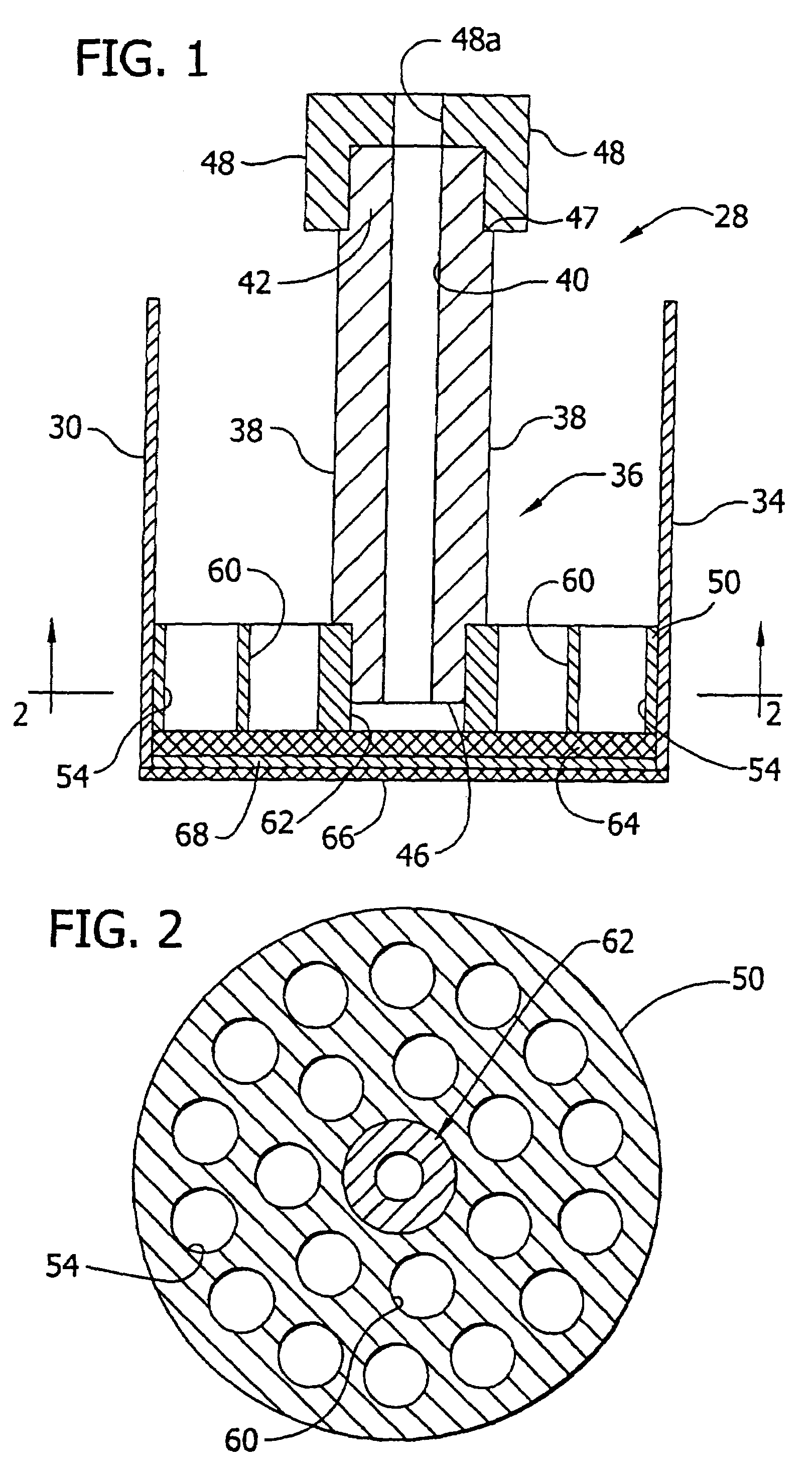

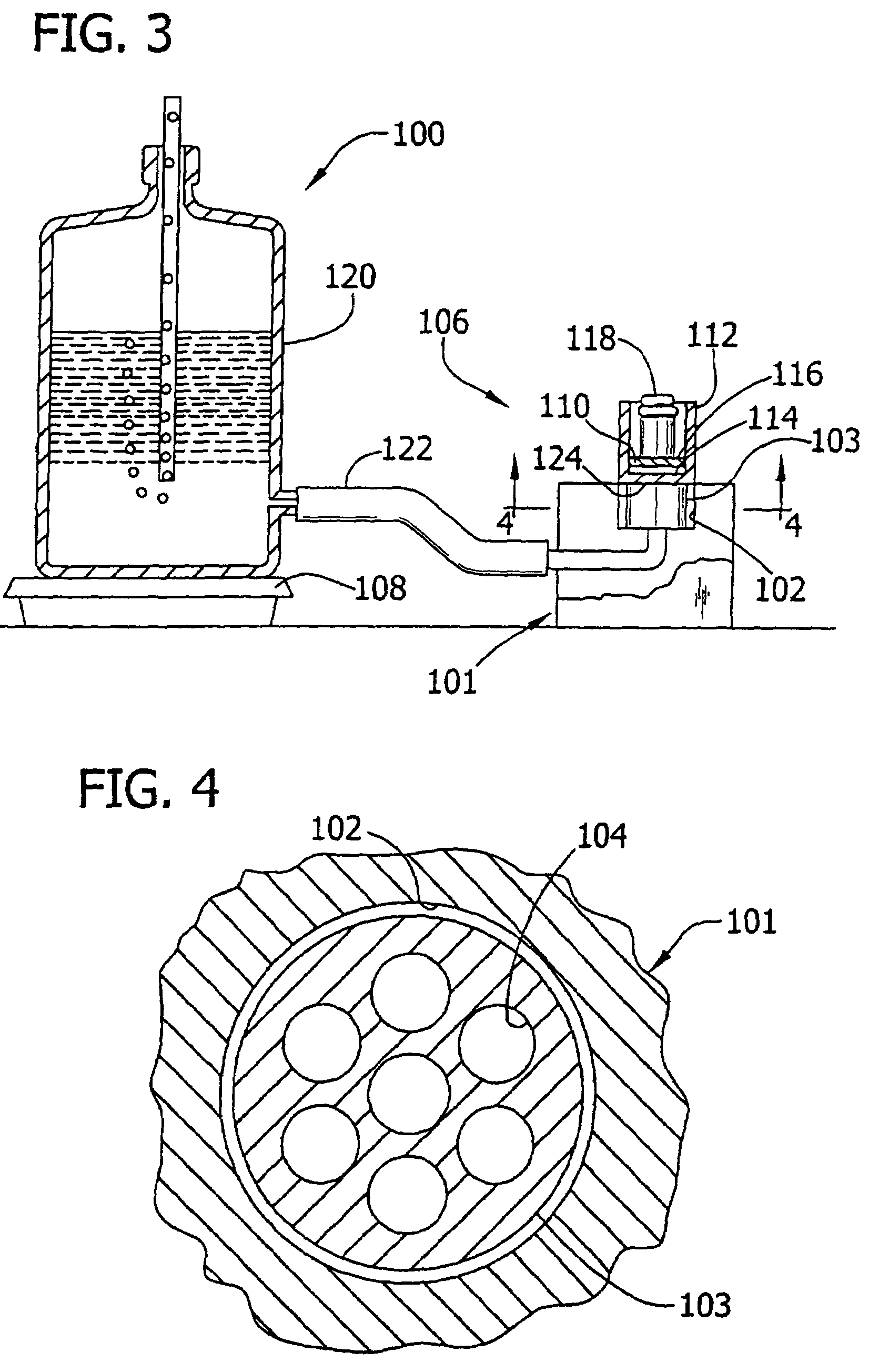

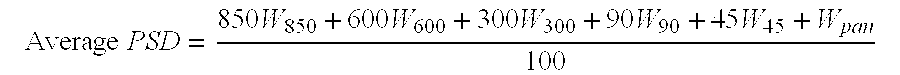

Damage-resistant superabsorbent materials

ActiveUS7179851B2Improve resistance to damageOrganic dyesAbsorbent padsPolymer sciencePercent sodium chloride

Superabsorbent material treated to resist damage when subjected to an Absorbent Product Processing Simulation Test, which simulates the mechanical damage that occurs during current commercial diaper manufacturing processes. The treated superabsorbent material has a centrifuge retention capacity of about 15 grams or greater of 0.9 weight percent sodium chloride per gram of the superabsorbent material and a gel bed permeability (GBP) at 0 psi swell pressure on pre-screened particles of about 200 (×10−9 cm2) or greater. After subjecting the treated superabsorbent material to the Absorbent Product Processing Simulation Test, the treated superabsorbent may exhibit minimal reduction in GBP of pre-screened or un-screened particles at 0 psi or at 0.3 psi swell pressure, as well as possibly exhibiting minimal reduction in average particle size diameter (PSD). The superabsorbent material can be treated by adding an aqueous solution of a hydrophilic soft polymer to the superabsorbent material, mixing the superabsorbent material with the aqueous solution, and drying the superabsorbent material.

Owner:KIMBERLY-CLARK WORLDWIDE INC

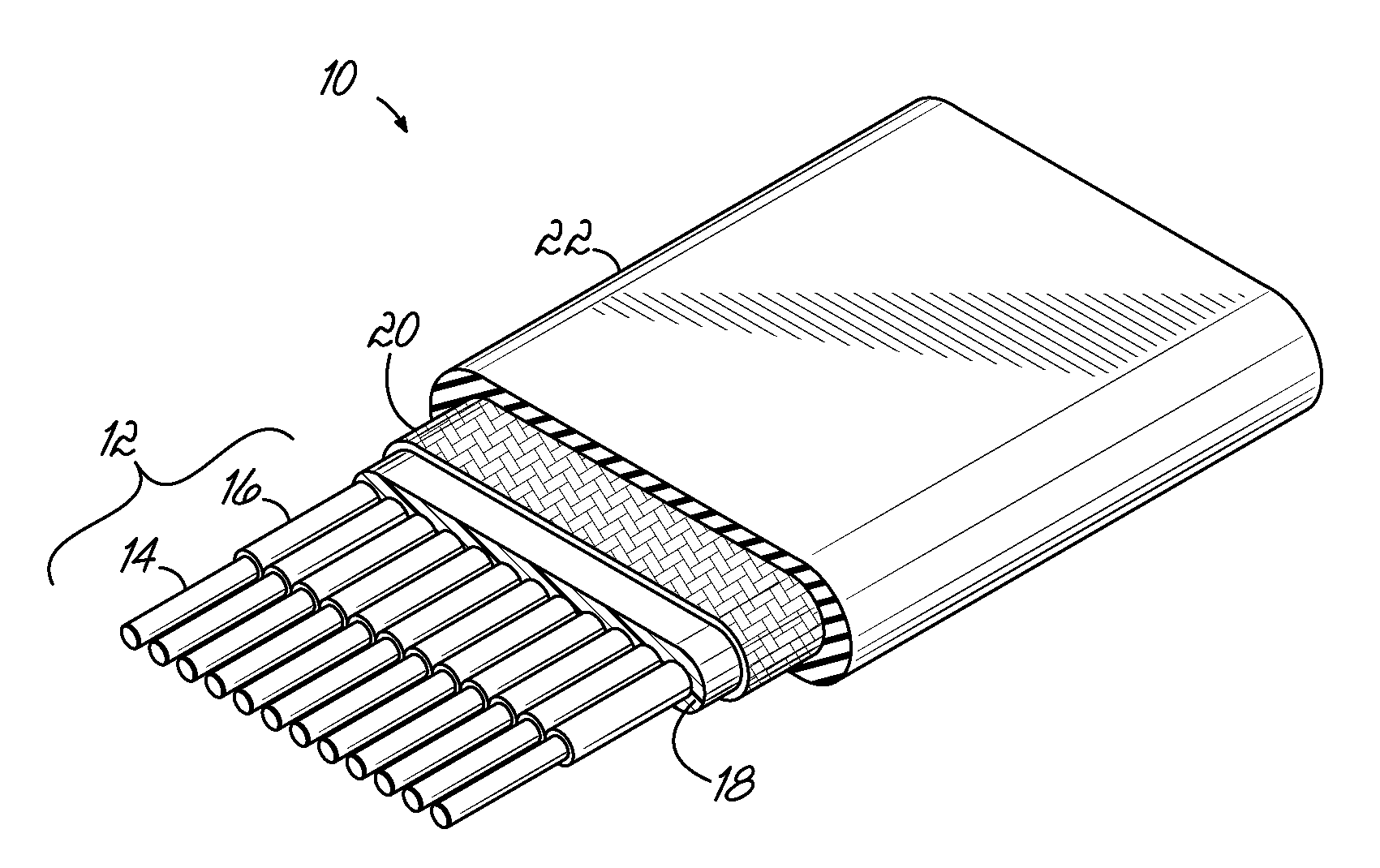

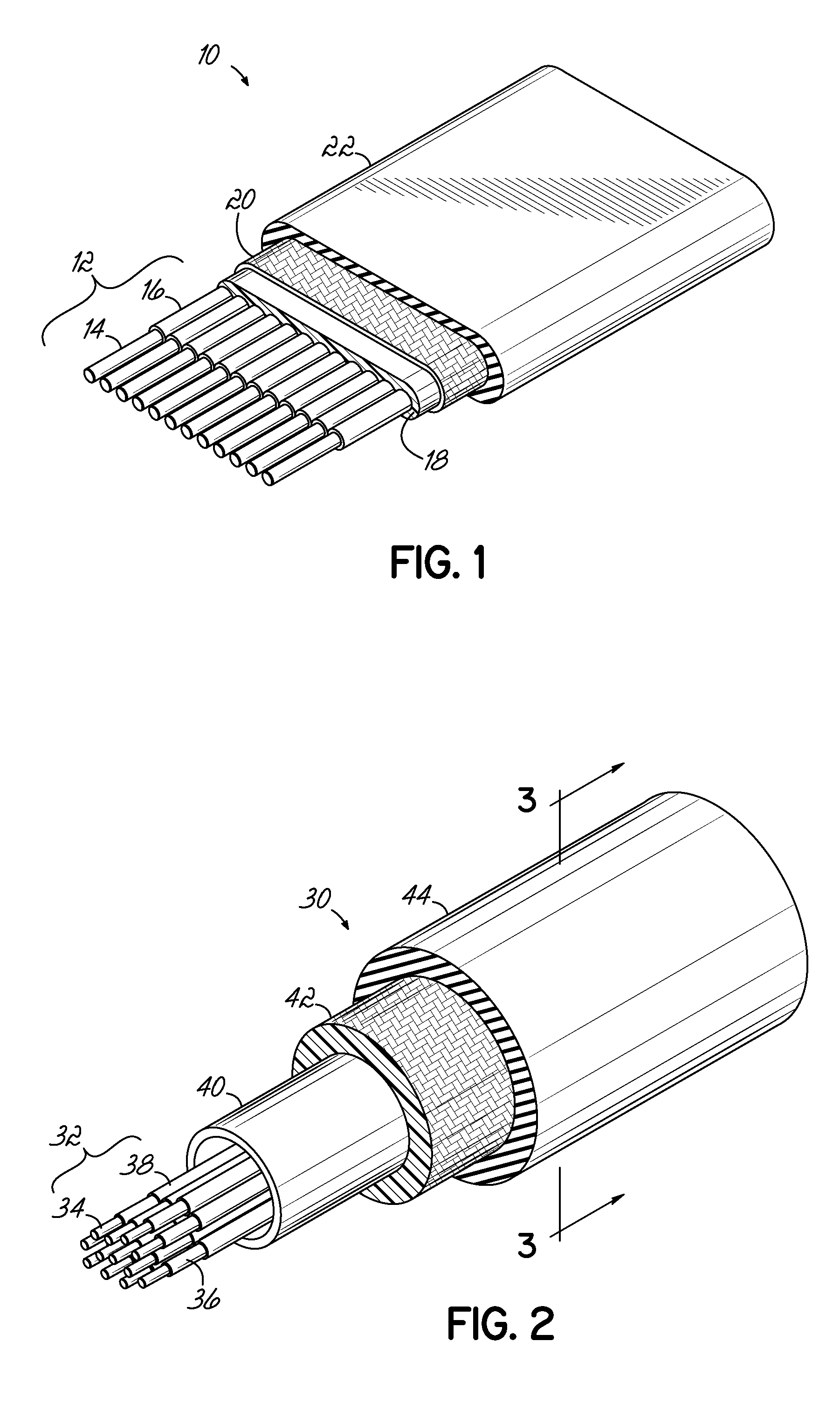

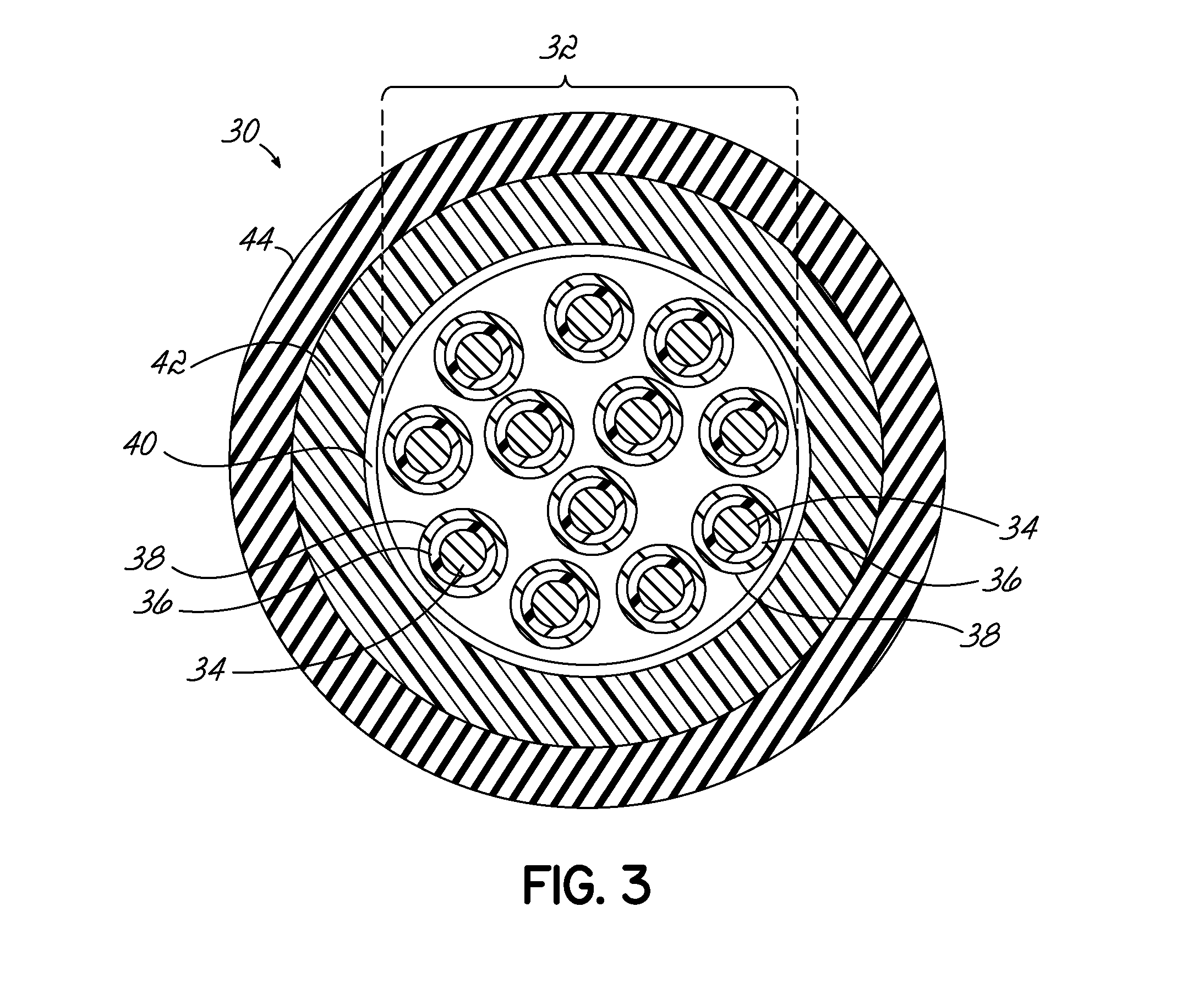

Fiber optic cable and method of manufacture

ActiveUS20120099825A1Low smokeHigh densityCladded optical fibreFibre mechanical structuresExtremes temperatureExtreme temperature

A fiber-optic cable for applications subject to extreme temperatures and high crushing and bending forces incorporating a loose fluoropolymer buffer material, a aramid / fiberglass strength member, and a fluoropolymer outer jacket compromising low smoke, low toxicity, and low flammability when exposed to flame.

Owner:CARLISLE INTERCONNECT TECH

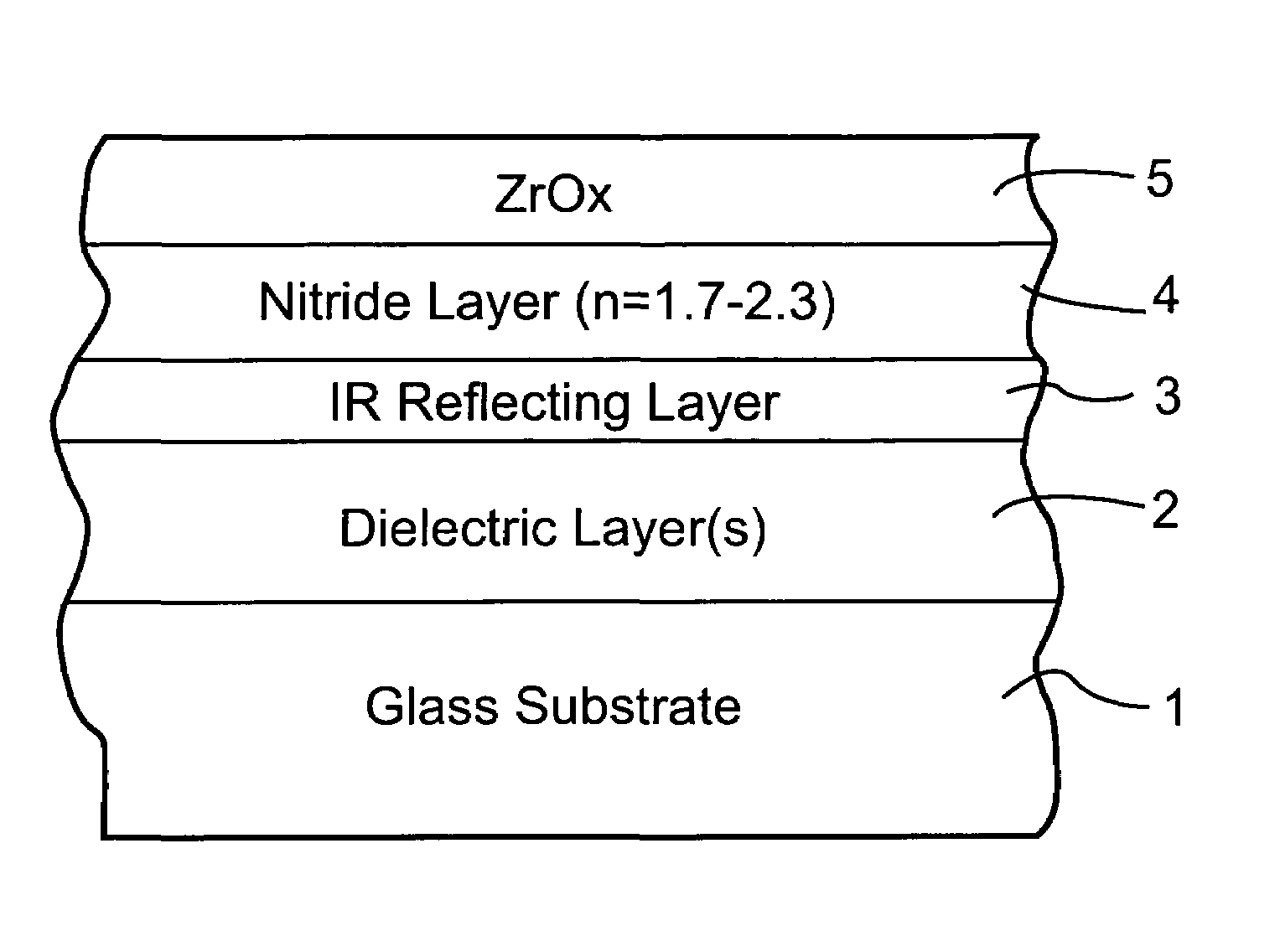

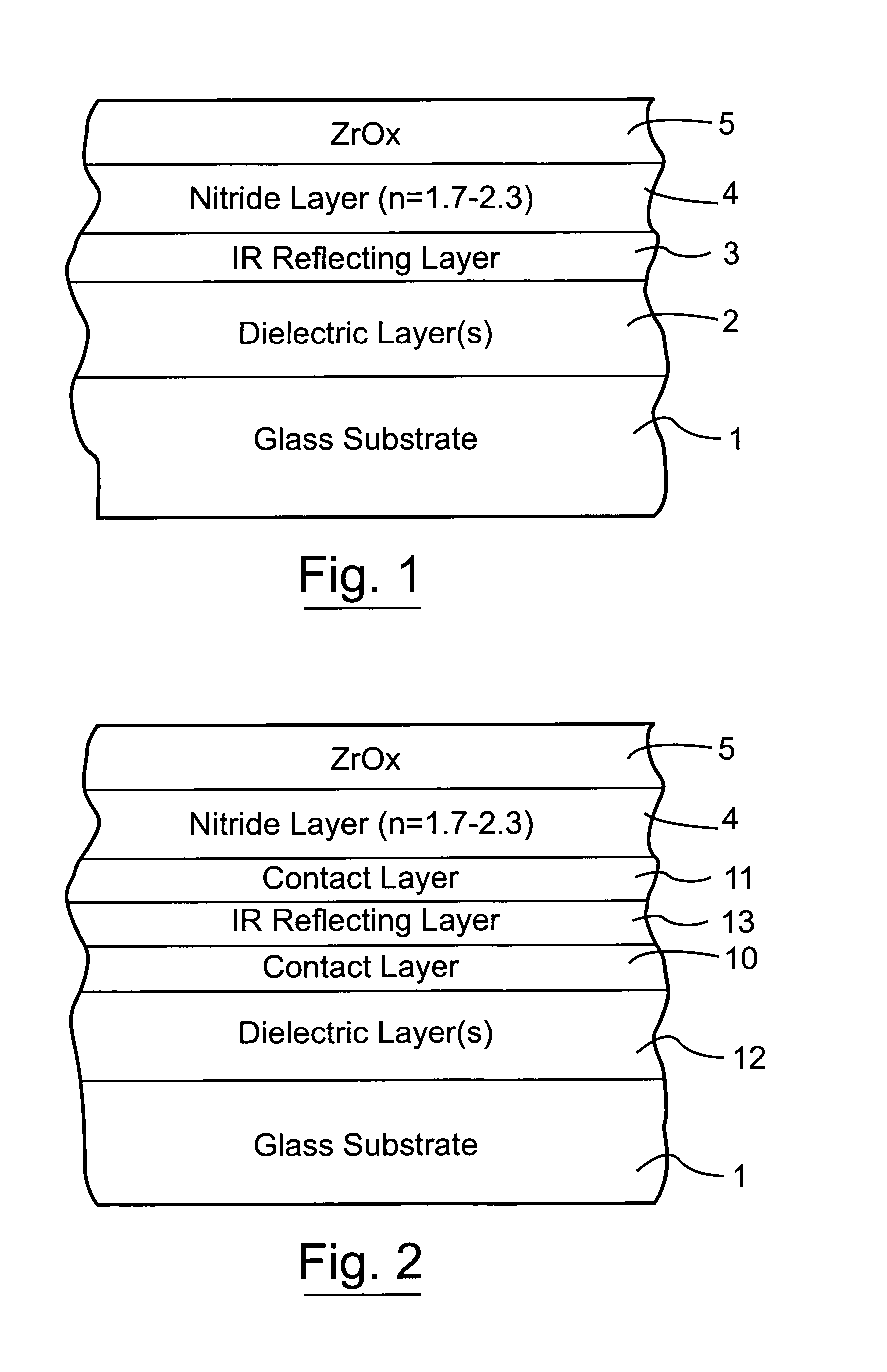

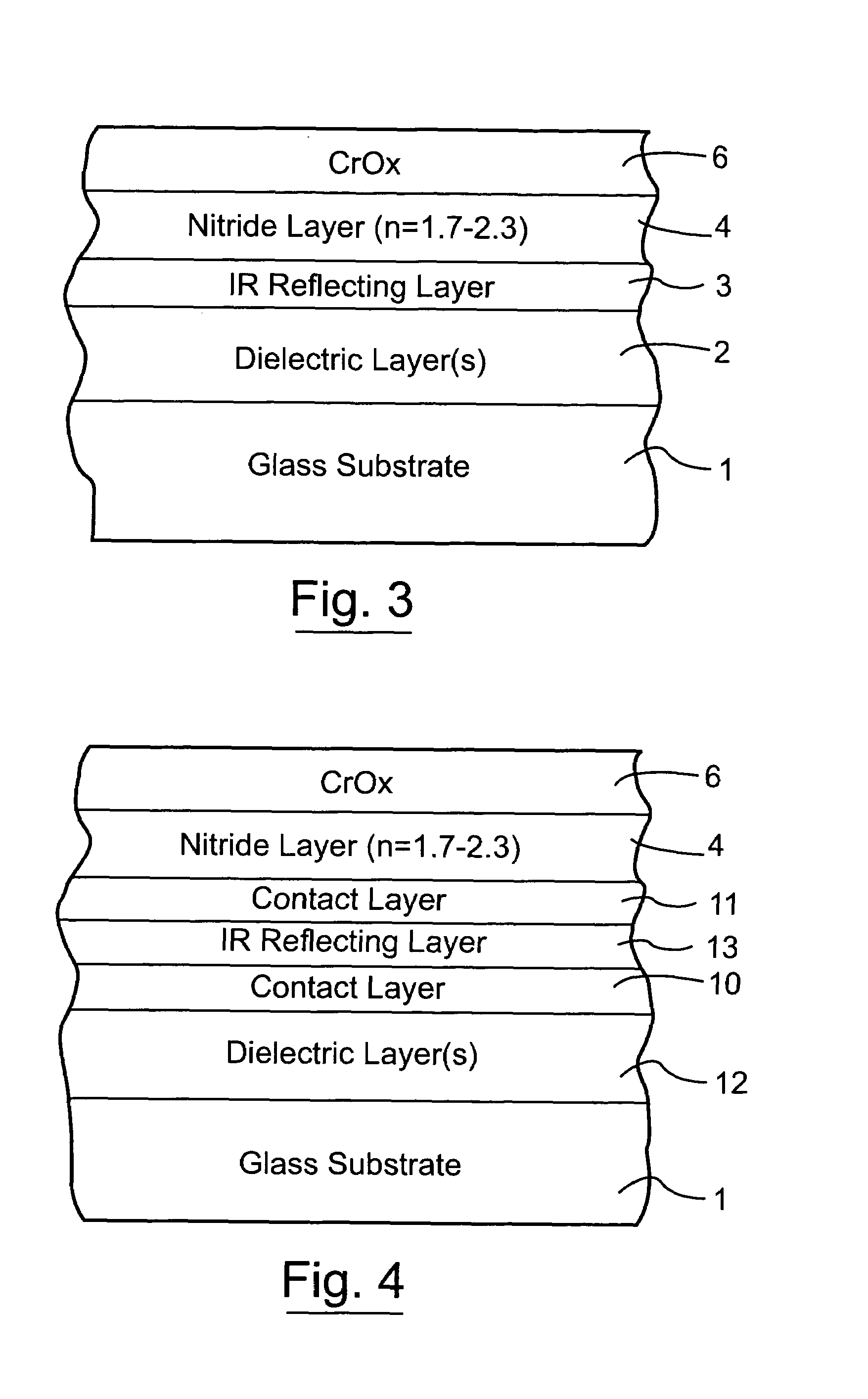

Coated article with dual-layer protective overcoat of nitride and zirconium or chromium oxide

InactiveUS7147924B2Inhibited DiffusionAcceptable optical propertyGlass/slag layered productsCoatingsNitrideZirconium oxide

A coated article is provided so as to include an overcoat including zirconium oxide or chromium oxide. In certain example embodiments, the overcoat includes a dual layer overcoat including a nitride inclusive layer which supports a zirconium oxide (ZrOX) layer. In certain example embodiments, the overcoat may be of chromium oxide, with or without such a nitride inclusive layer.

Owner:GUARDIAN GLASS LLC

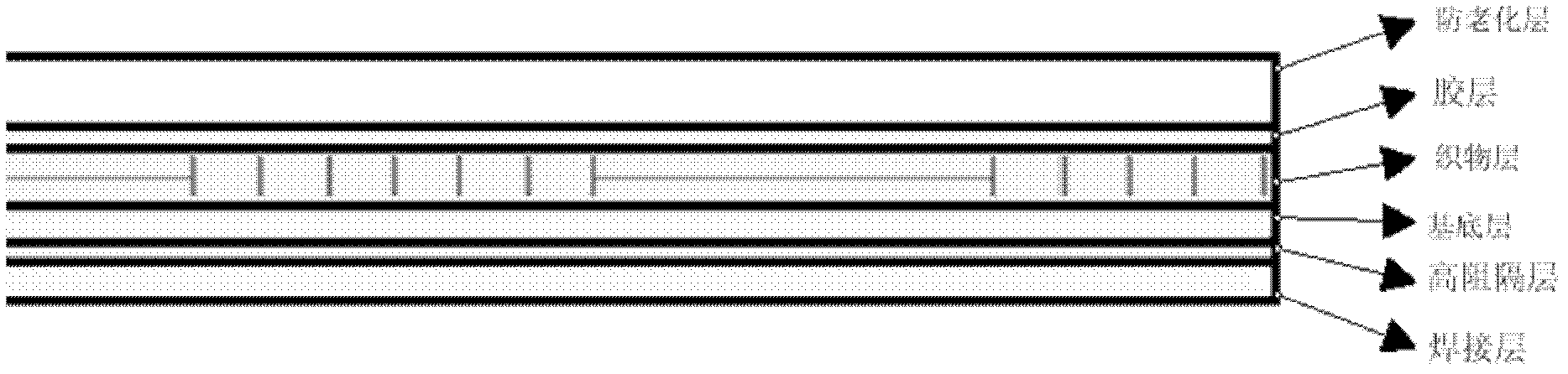

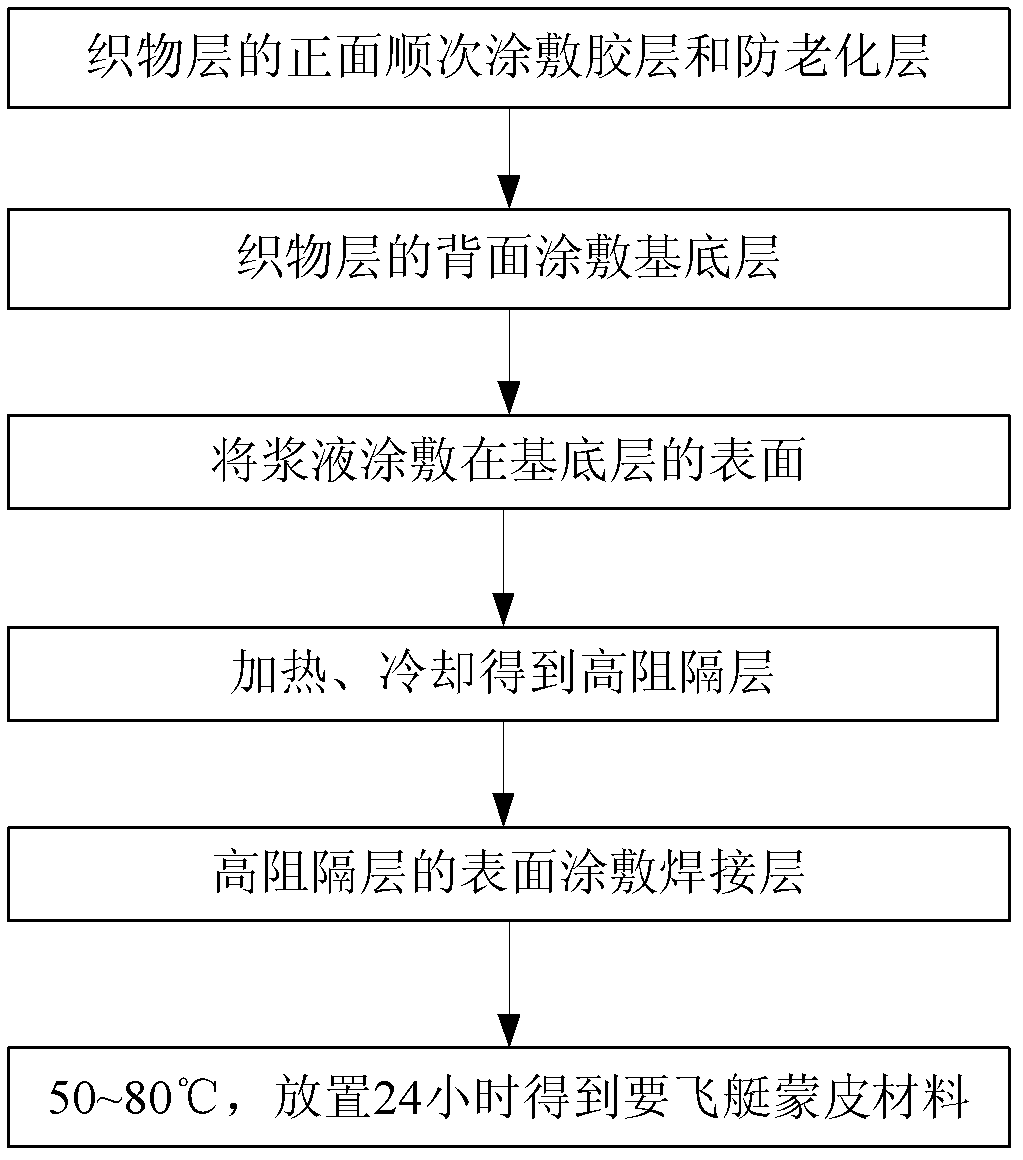

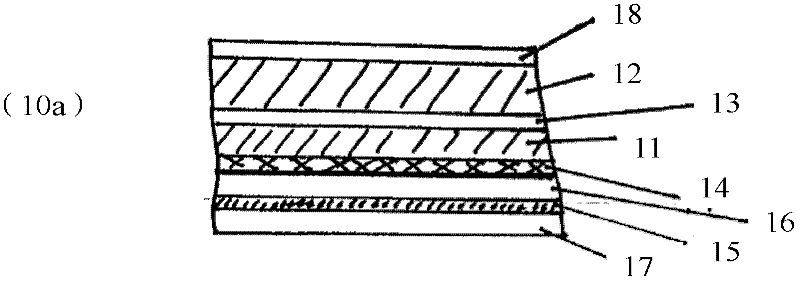

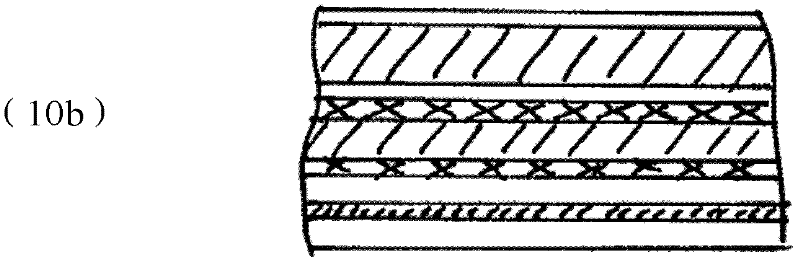

Airship sheath material and preparation method thereof

InactiveCN102416739AImprove barrier propertiesImprove rub resistanceSynthetic resin layered productsGas-bag arrangementsPolyvinyl alcoholNanoparticle

The invention provides an airship sheath material and a preparation method thereof. The sheath material comprises successively an anti-aging layer, a glue-line, a fabric layer, a basal layer, a high barrier layer and a weld layer. A material of the anti-aging layer is a thermoplastic polyurethane containing ZnO with a mass fraction of 1-3% and TiO2 with a mass fraction of 2.5-4% and having a thickness of 25-35 mum; a material of the high barrier layer is polyvinyl alcohol containing SiO2 nano particles with a mass fraction of 1.5-2.5%, a particle size of 20-70nm and a thickness of 1-3 mum. a material of the weld layer is thermoplastic polyurethane with a thickness of 20-30 mum. The high barrier layer of the airship sheath material is added with nano particles to gain a substantially enhanced obstruction effect and a helium permeation of 5-20ml / (m<2>.atm.24h). The preparation technology of the invention is simple; a coating technology and a simple applying technology are employed to realize a high obstruction effect.

Owner:BEIHANG UNIV

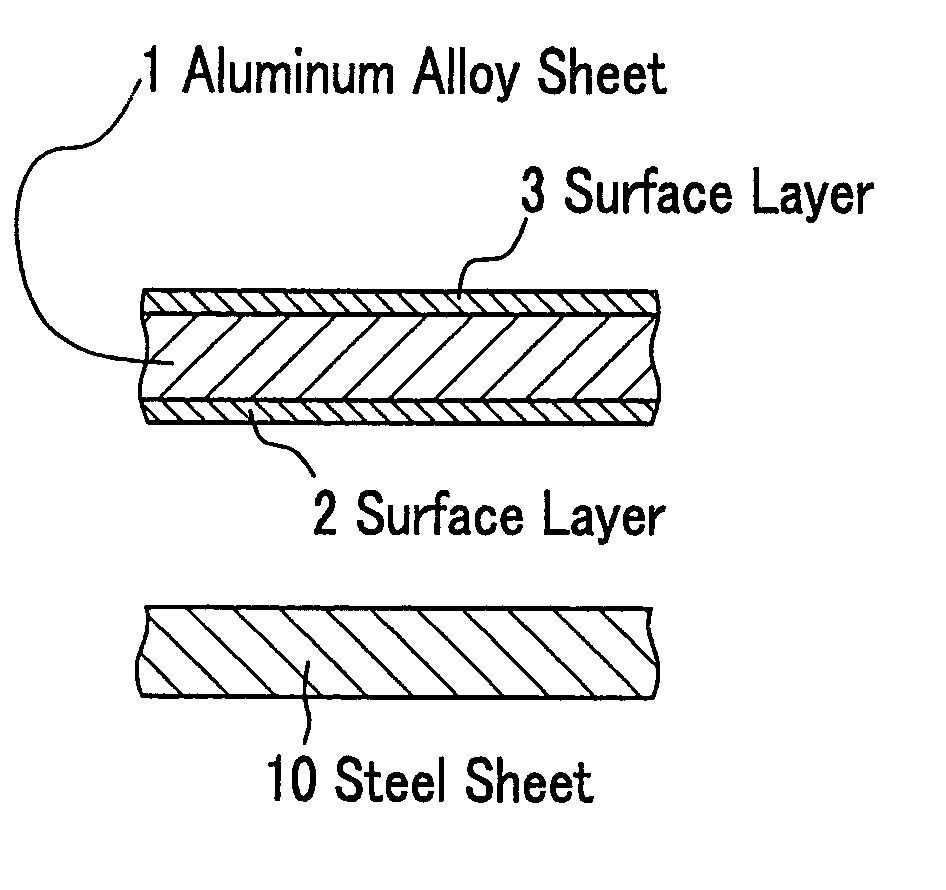

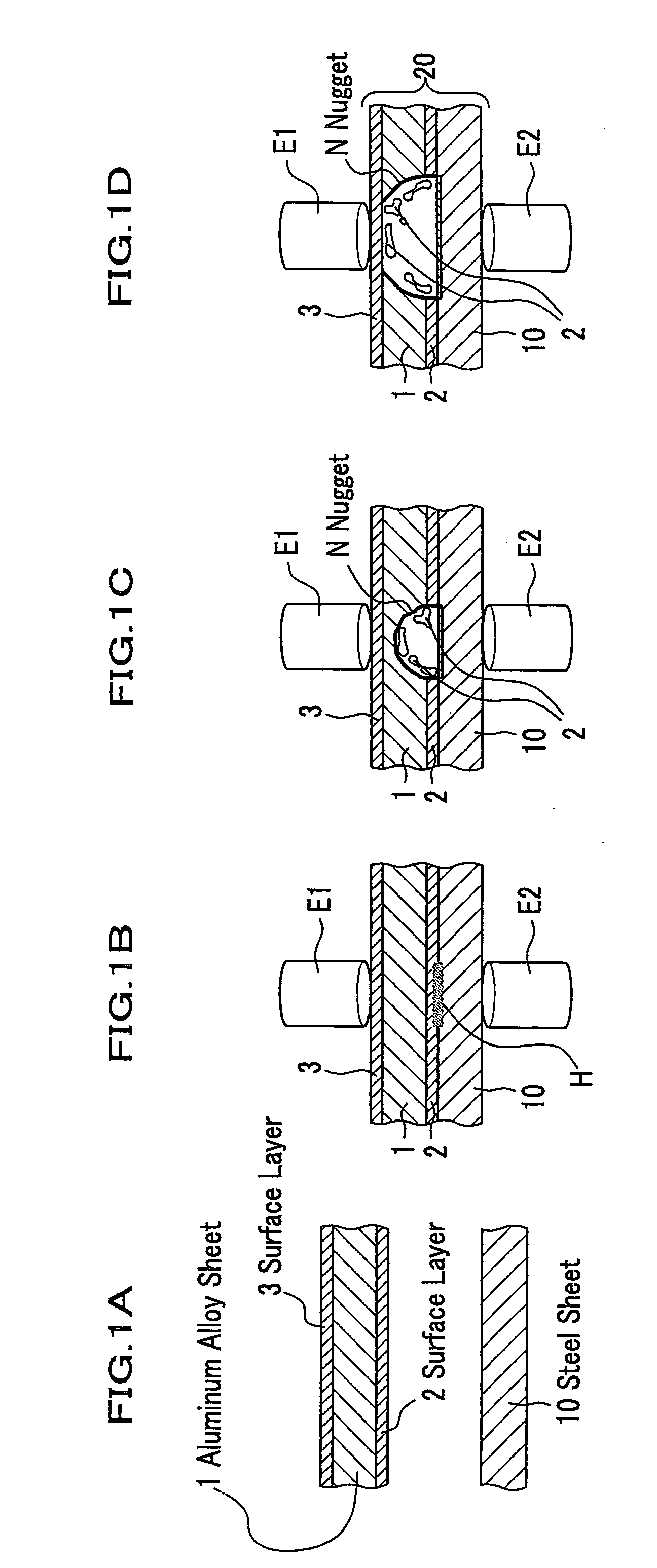

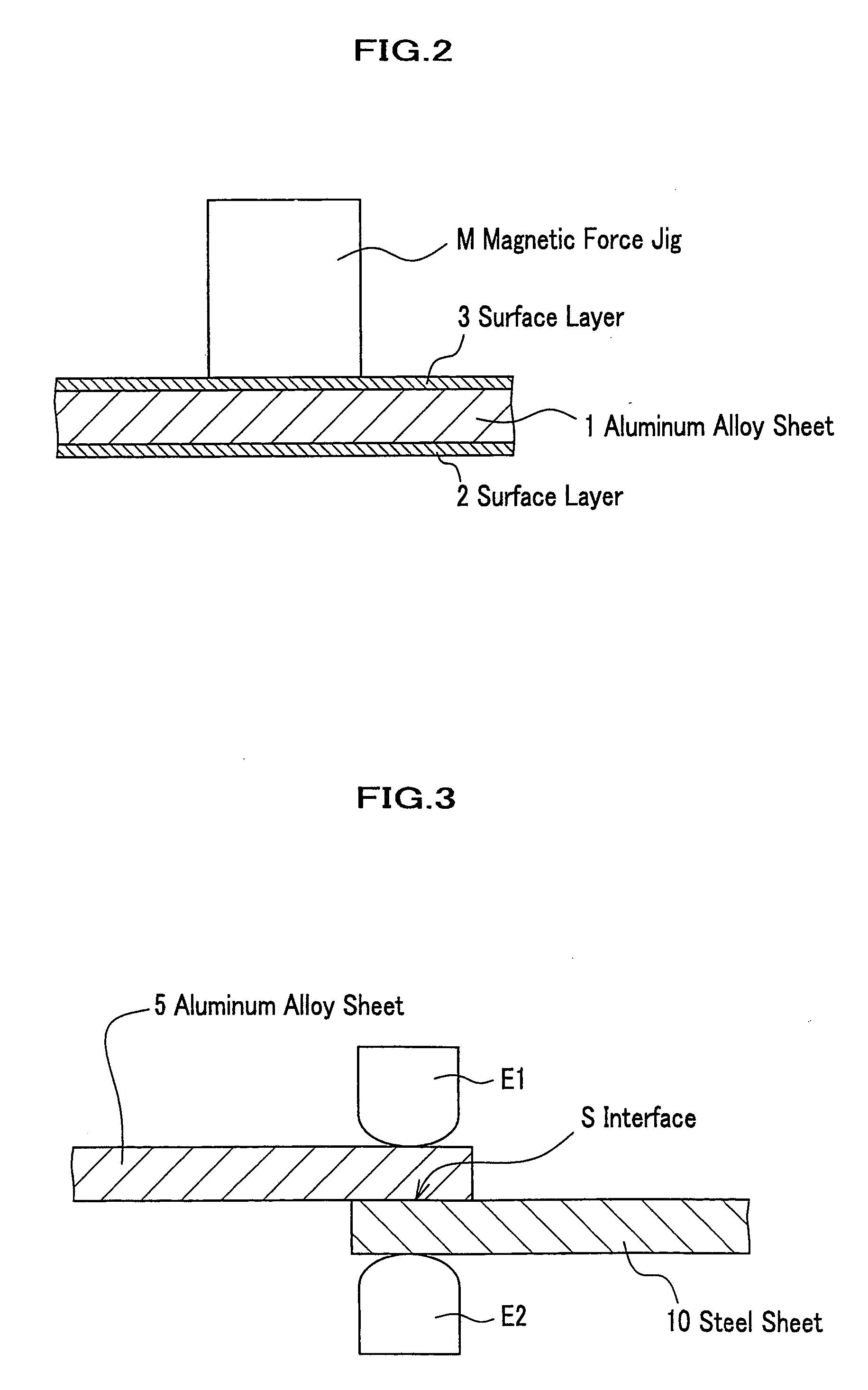

Resistance welding method of different kinds of materials, and resistance welding member of aluminum alloy material and different kind of material

InactiveUS20050218121A1Improve solderabilityEfficiency of manufacturing can not be realizedHot-dipping/immersion processesArc welding apparatusSurface layerSpot welding

The resistance welding method of different kinds of materials is the method for welding an iron material and an aluminum alloy material, and comprises the steps of: performing in advance a coating treatment at least to a portion of the aluminum alloy material, where resistance welding is performed, with any of iron and iron-base alloy and forming a surface layer; and performing resistance welding of the iron material and the aluminum alloy material through the surface layer, and the resistance welding may be any of spot welding and projection welding.

Owner:HONDA MOTOR CO LTD +1

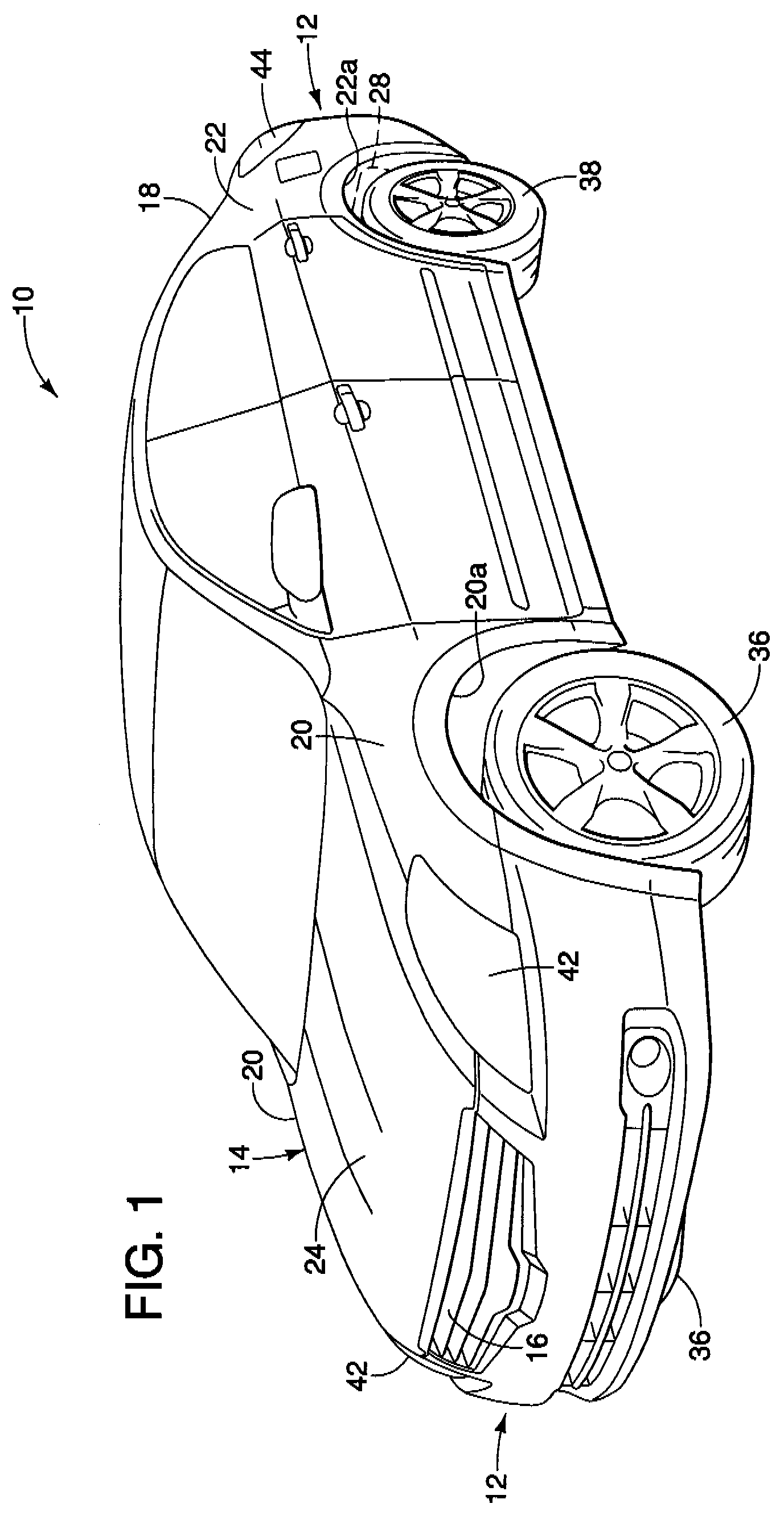

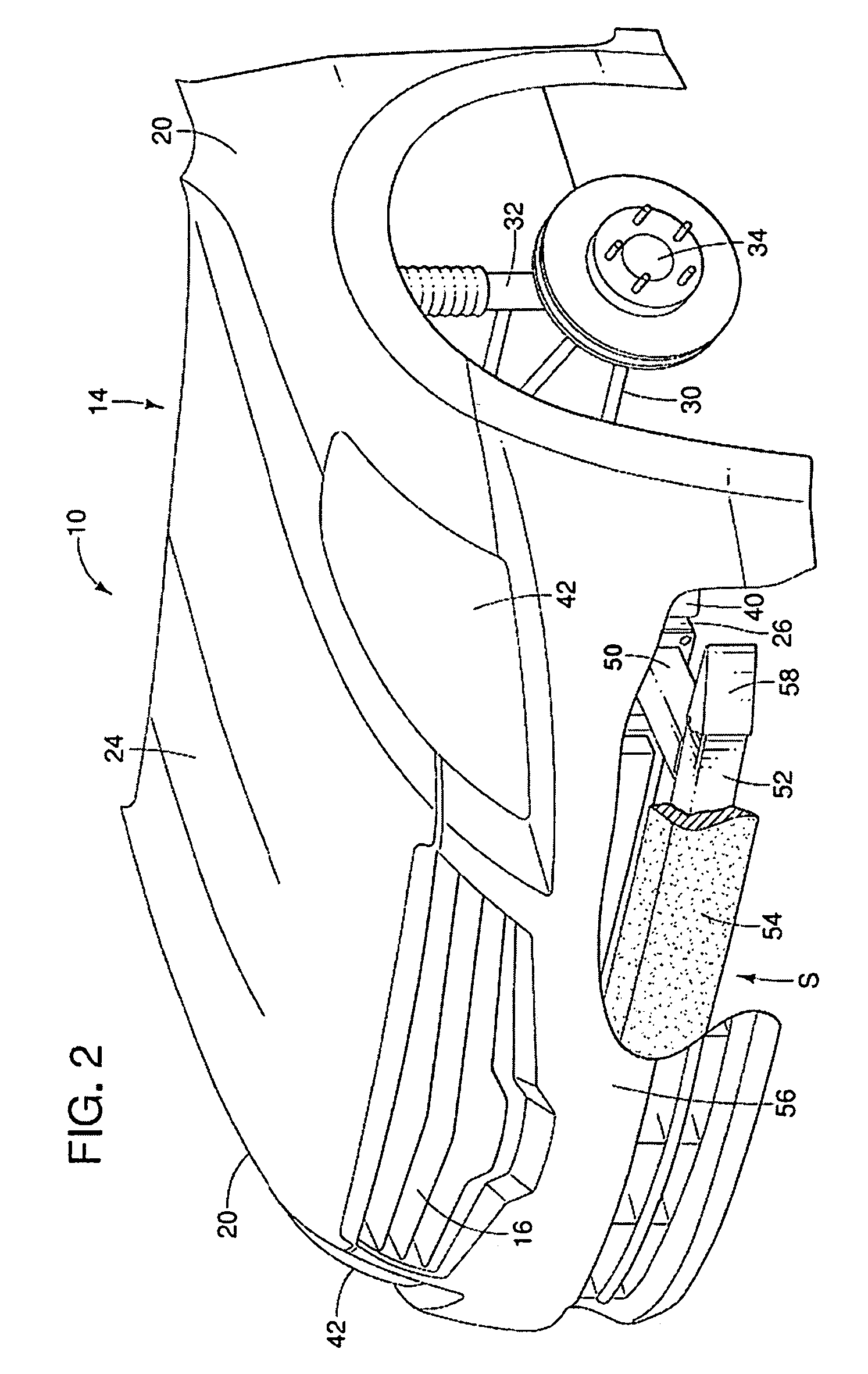

Vehicle bumper assembly

A vehicle bumper assembly includes a bumper reinforcement member, a corner bracket and a biasing member. The bumper reinforcement member has a first lateral end section, a second lateral end section, an outboard facing side extending between the first and second lateral end sections and an inboard facing side with a vehicle mounting structure. The corner bracket is pivotally supported to the first lateral end section of the bumper reinforcement member proximate the inboard facing side. The biasing member extends between the outboard facing side of the bumper reinforcement member and an outboard side of the corner bracket. The biasing member biases the corner bracket outwardly relative to the vehicle mounting structure to a normal rest position for absorption of low speed impact energy.

Owner:NISSAN MOTOR CO LTD

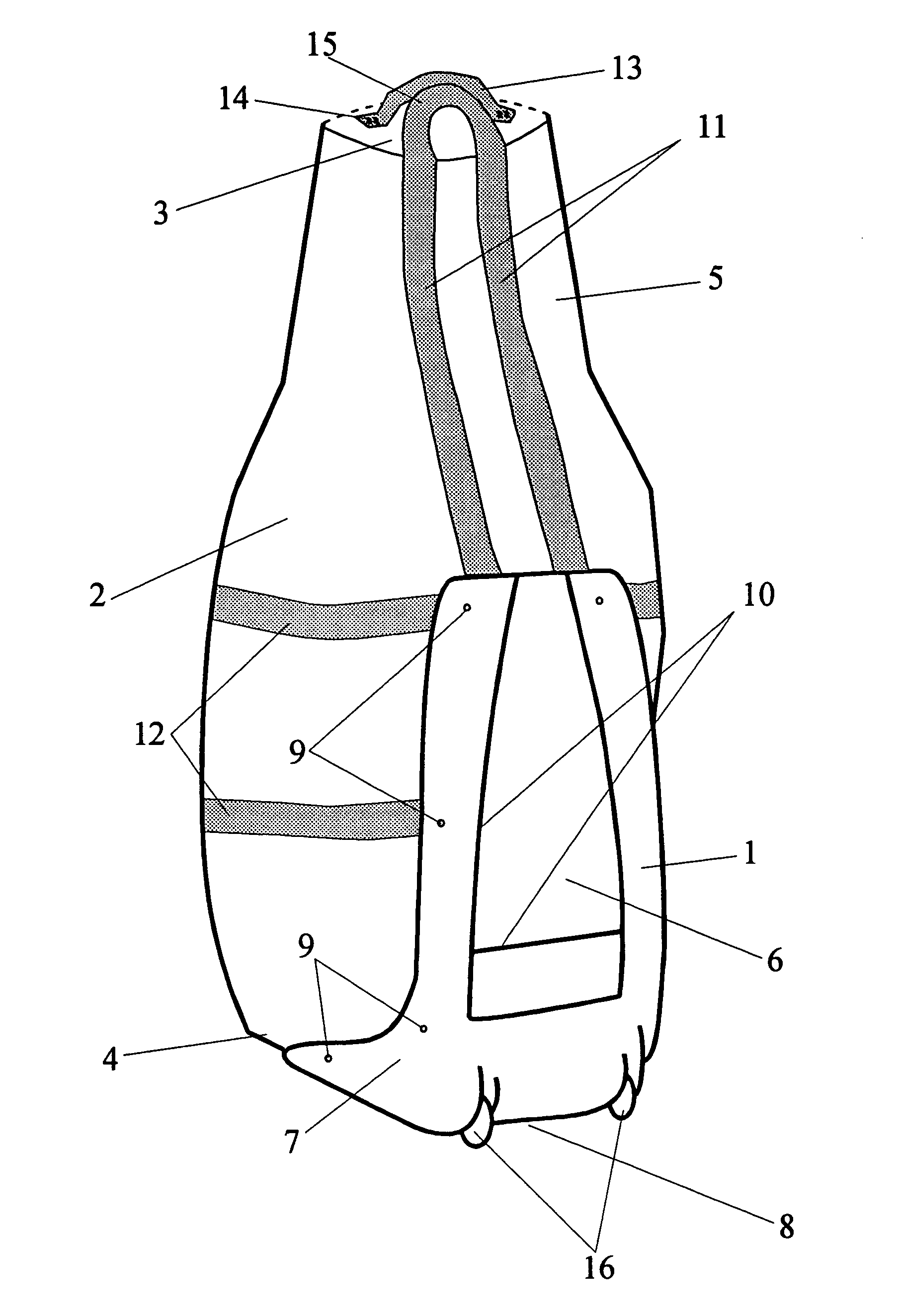

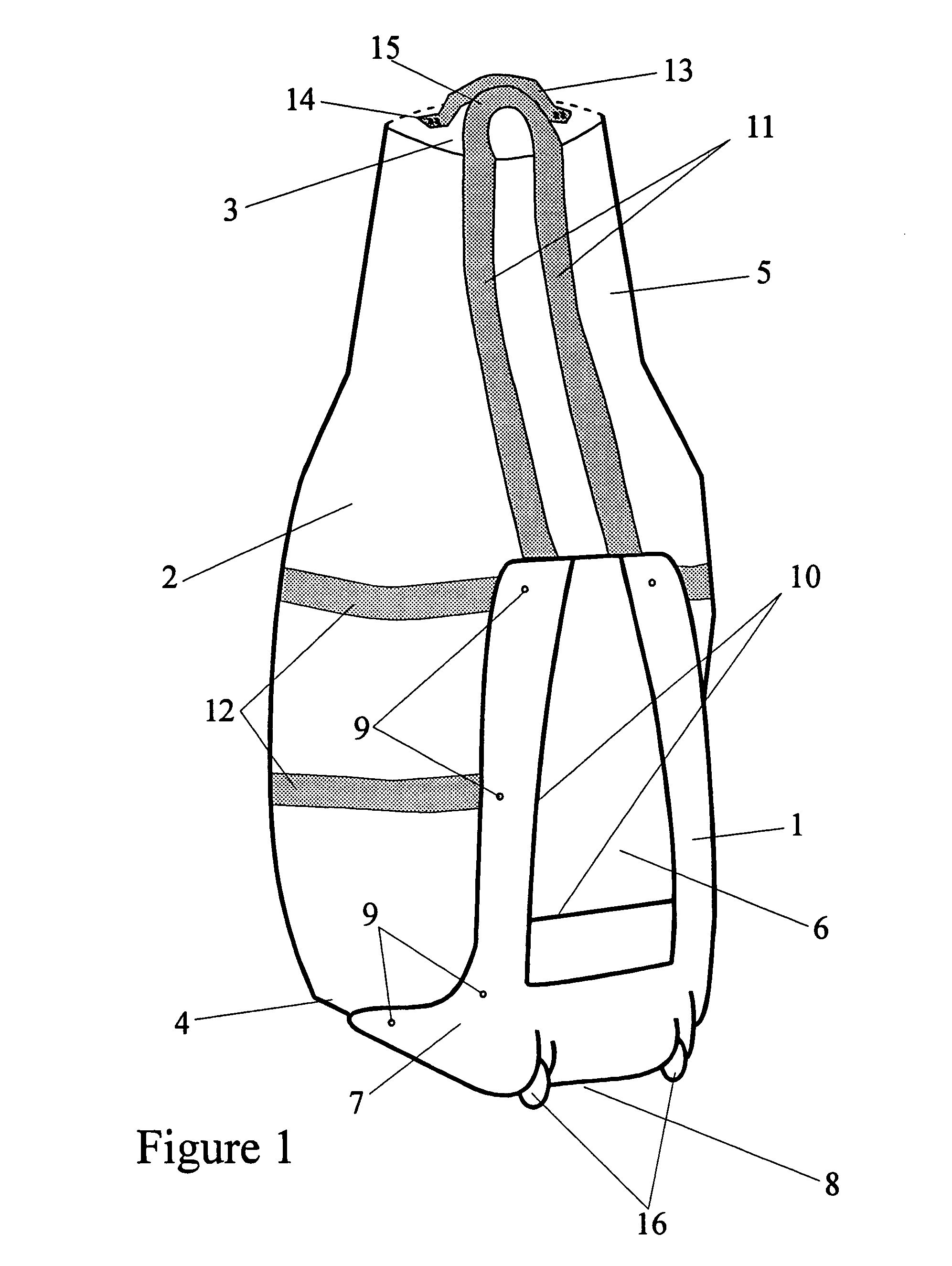

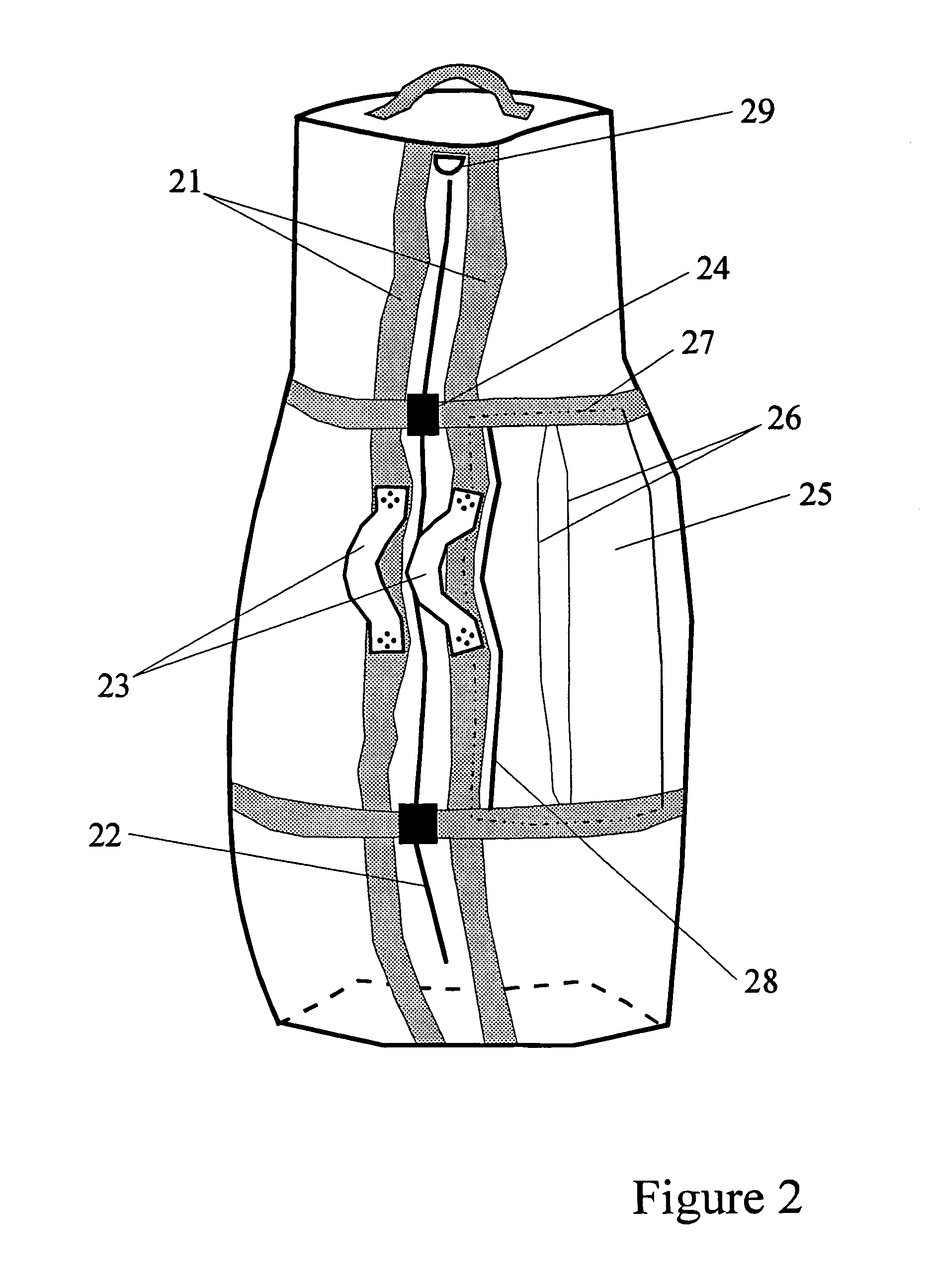

Travel bag with integrated support

InactiveUS7188714B1Improve resistance to damagePromote densificationTravelling sacksClosuresEngineeringSurface relief

A travel bag includes two major components; specifically, a bag member and a base member. These components are formed to matingly fit together and to be permanently attached to one another via rivets. The bag member incorporates additional features including a reinforcement system of webbing with longitudinal and circumferal portions. Also, the bag includes accessory pockets, a taper and padding, zippered opening, ‘D’-ring, among others. The base member features include wheels, reinforcement ribbing, seamless and cornerless joints, surface relief indicia among others. In addition, the travel bag as a whole enjoys a new arrangement of all parts and systems which provides for an extremely durable and rugged device.

Owner:ACUSHNET CO

Environmentally friendly coating compositions for coating metal objects, coated objects therefrom and methods, processes and assemblages for coating thereof

InactiveUS20060041047A1Improve propertiesLess materialMaterial nanotechnologyImpression capsCoated surfaceProduction line

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In certain embodiments, the disclosed coating compositions are suitable for coating flexible objects and / or objects having angular features, such as, but not limited to, flexible metal objects with angular features. In other embodiments, the cured coatings have improved slip properties and at least 6 H hardness. Such embodiments can served as substitutes for “hard chrome” coatings, TEFLON® coatings, coatings comprising TEFLON®, or TEFLON® like coatings. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example leaf springs, hydraulic rods and cylinders. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING +1

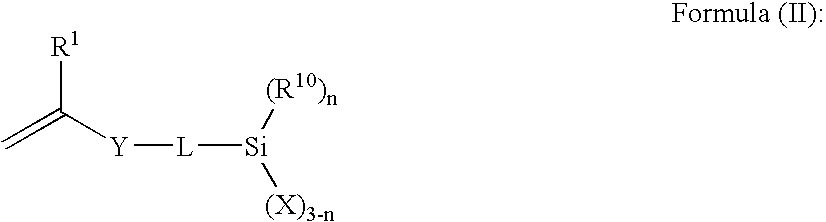

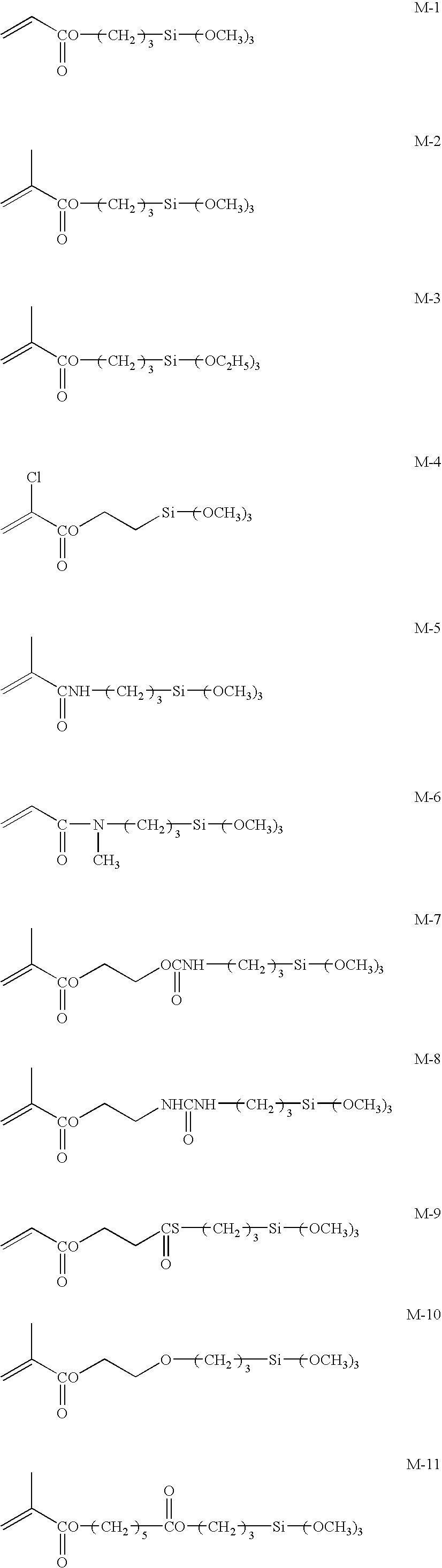

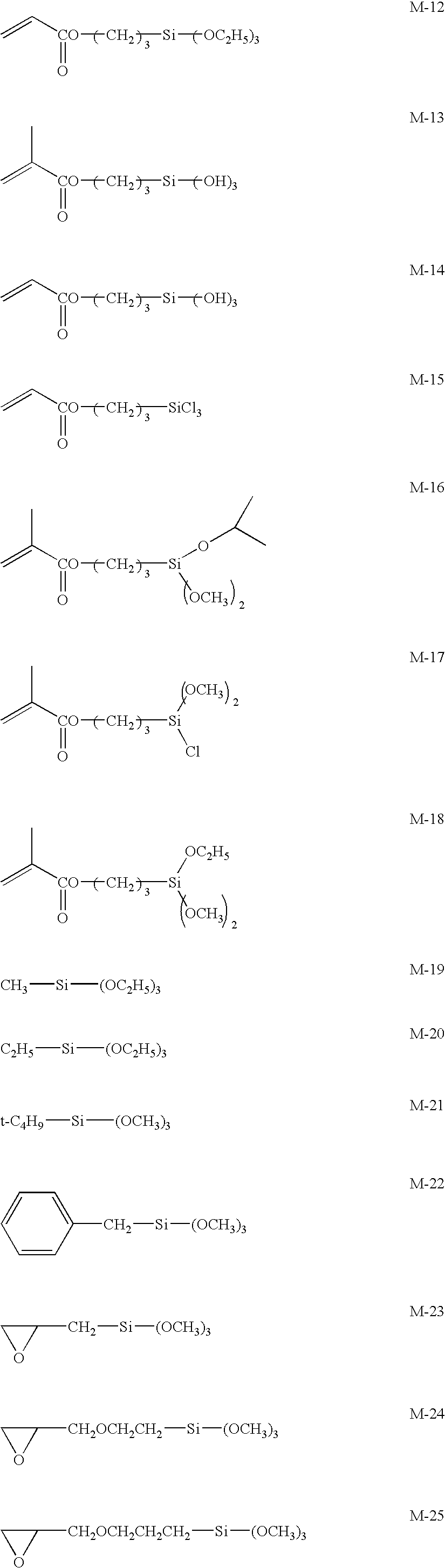

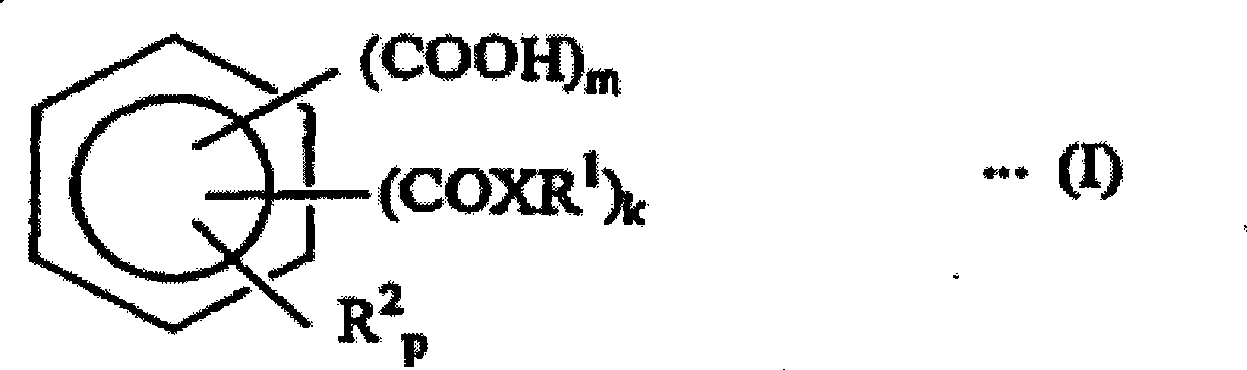

Inorganic fine particle-containing composition, optical film, antireflection film and polarizing film, and polarizing plate and display device using the same

ActiveUS20060216438A1Improve resistance to damageGood effectLiquid crystal compositionsSynthetic resin layered productsSilyleneDisplay device

An inorganic fine particle-containing composition comprising a silylation-treated inorganic oxide fine particle, which comprises 1.4 or more silyl groups per a surface area of 1 nm2 of the inorganic oxide fine particle.

Owner:FUJIFILM CORP

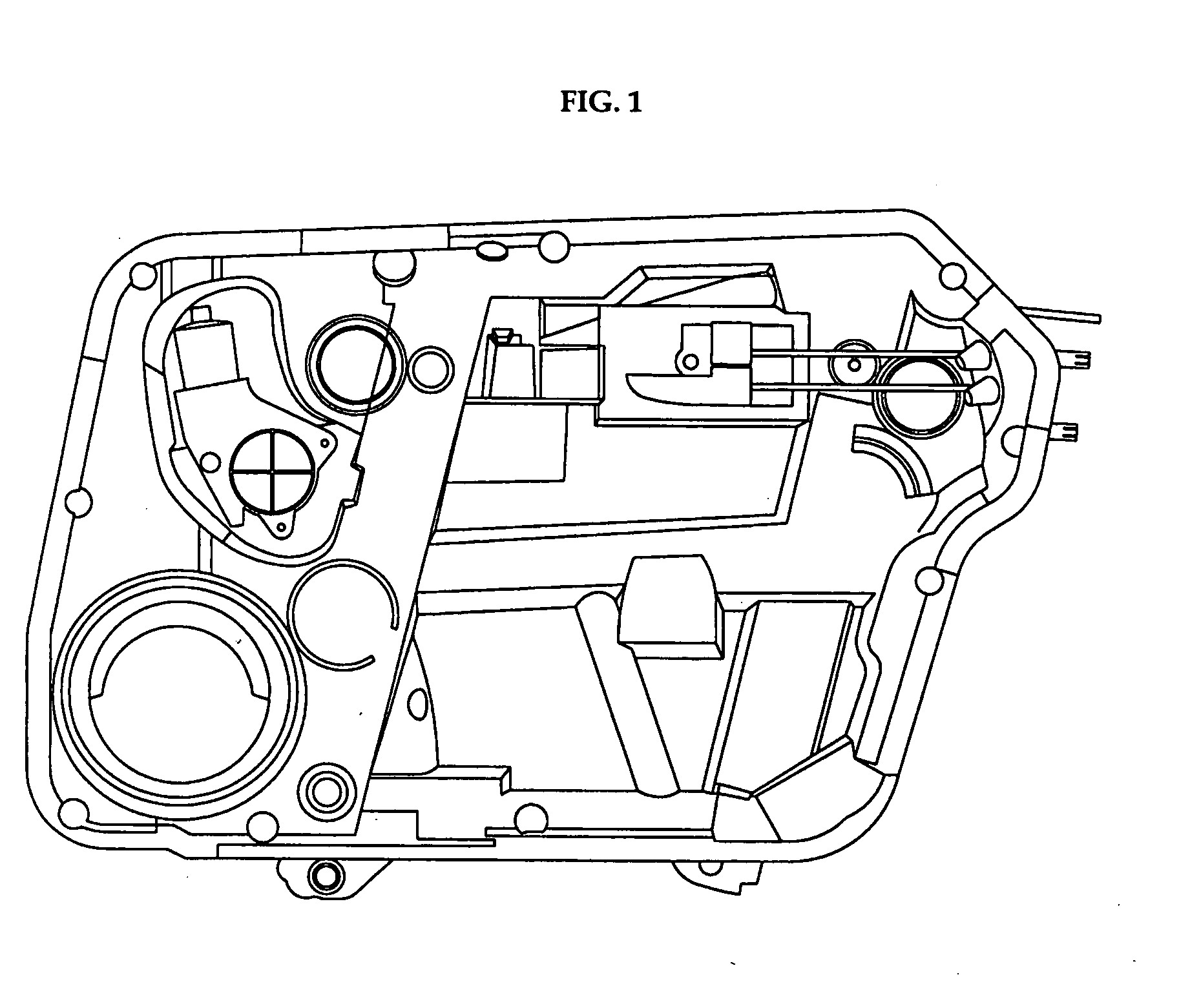

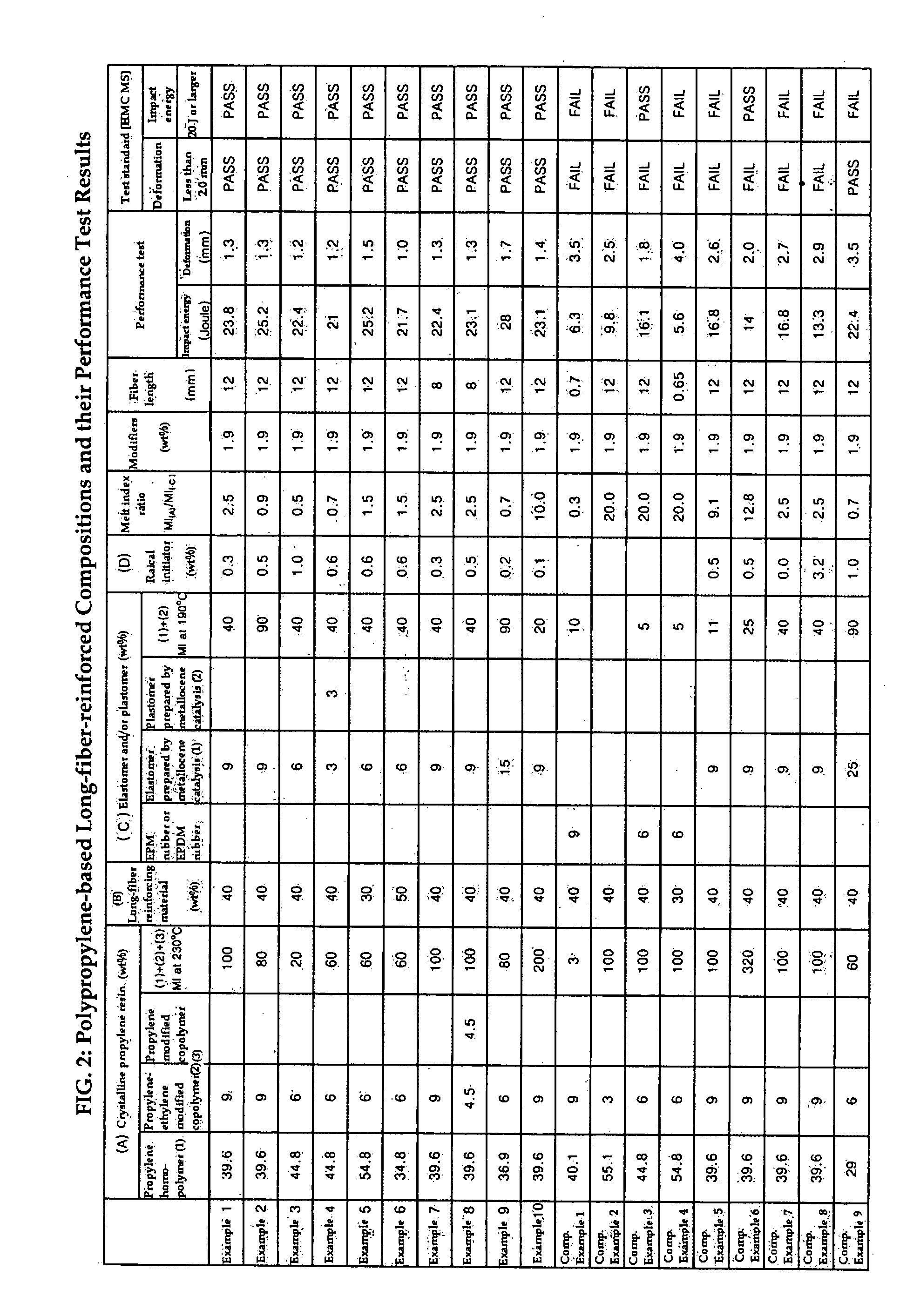

Long-fiber-reinforced polypropylene compositions and door shield module plate produced with the same

ActiveUS20070087193A1Improve resistance to damageImprove impact resistanceFilm/foil adhesivesSynthetic resin layered productsElastomerPlastomer

The present invention provides long-fiber reinforced polypropylene compositions comprising: (a) about 29-77 wt % of a crystalline polypropylene resin comprising about 50-100 wt % of a propylene homopolymer; (b) about 20-50 wt % of a long-fiber reinforcing material having an average fiber length of about 3-50 mm and an average diameter of about 4-30 μm; (c) about 2-20 wt % of an elastomer, a plastomer, or a mixture thereof having a melt index as measured at 190° C. of about 20-150 g / 10 min, wherein said elastomer, plastomer, or mixture thereof was polymerized by a metallocene-based catalyst; and (d) about 0.01-3 wt % of a radical initiator, wherein the ratio of the melt index as measured at 230° C. of the crystalline polypropylene resin to the melt index as measured at 190° C. of the elastomer, the plastomer, or the mixture thereof is in the range of about 0.5 to about 10.

Owner:HYUNDAI MOTOR CO LTD +1

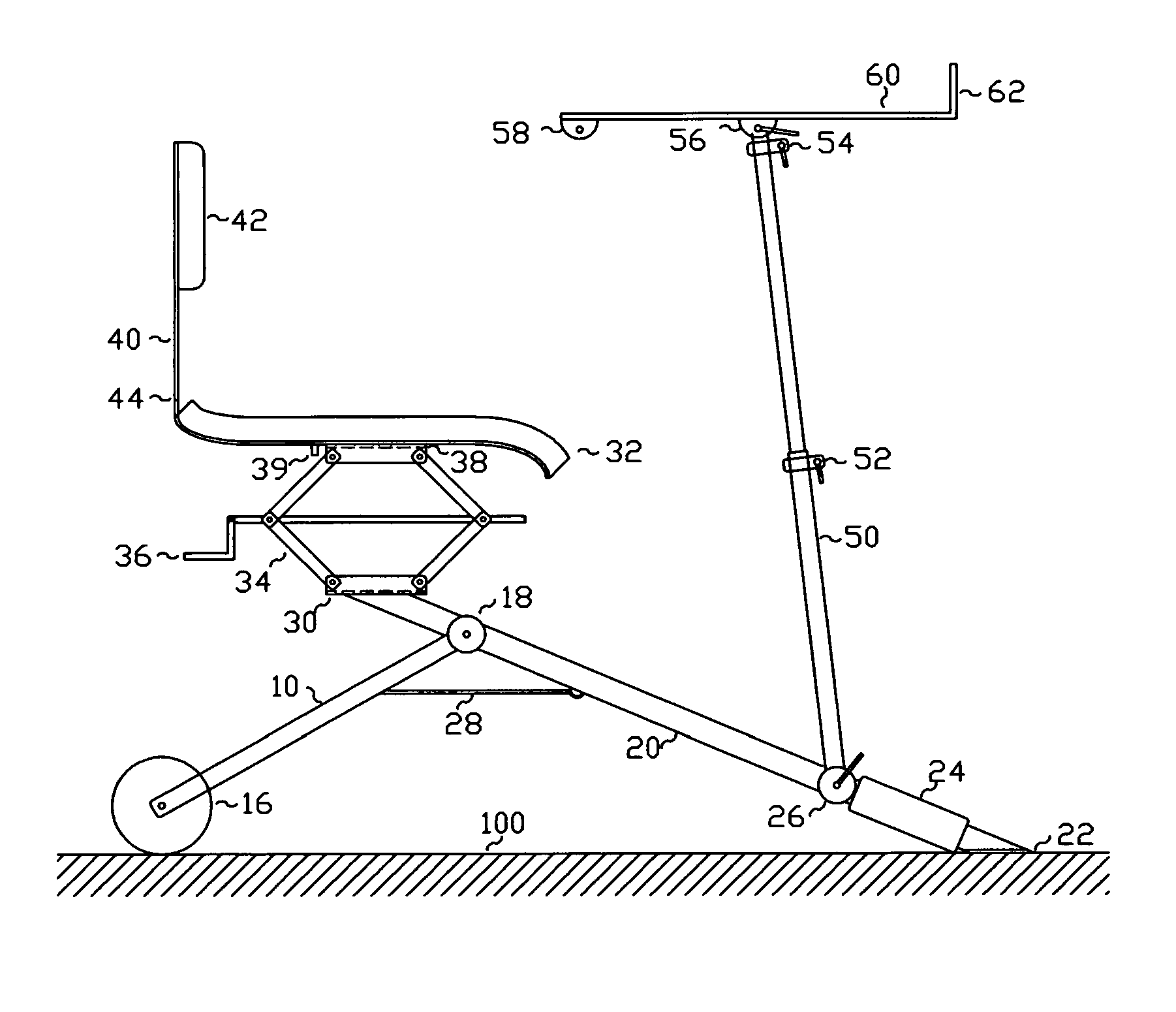

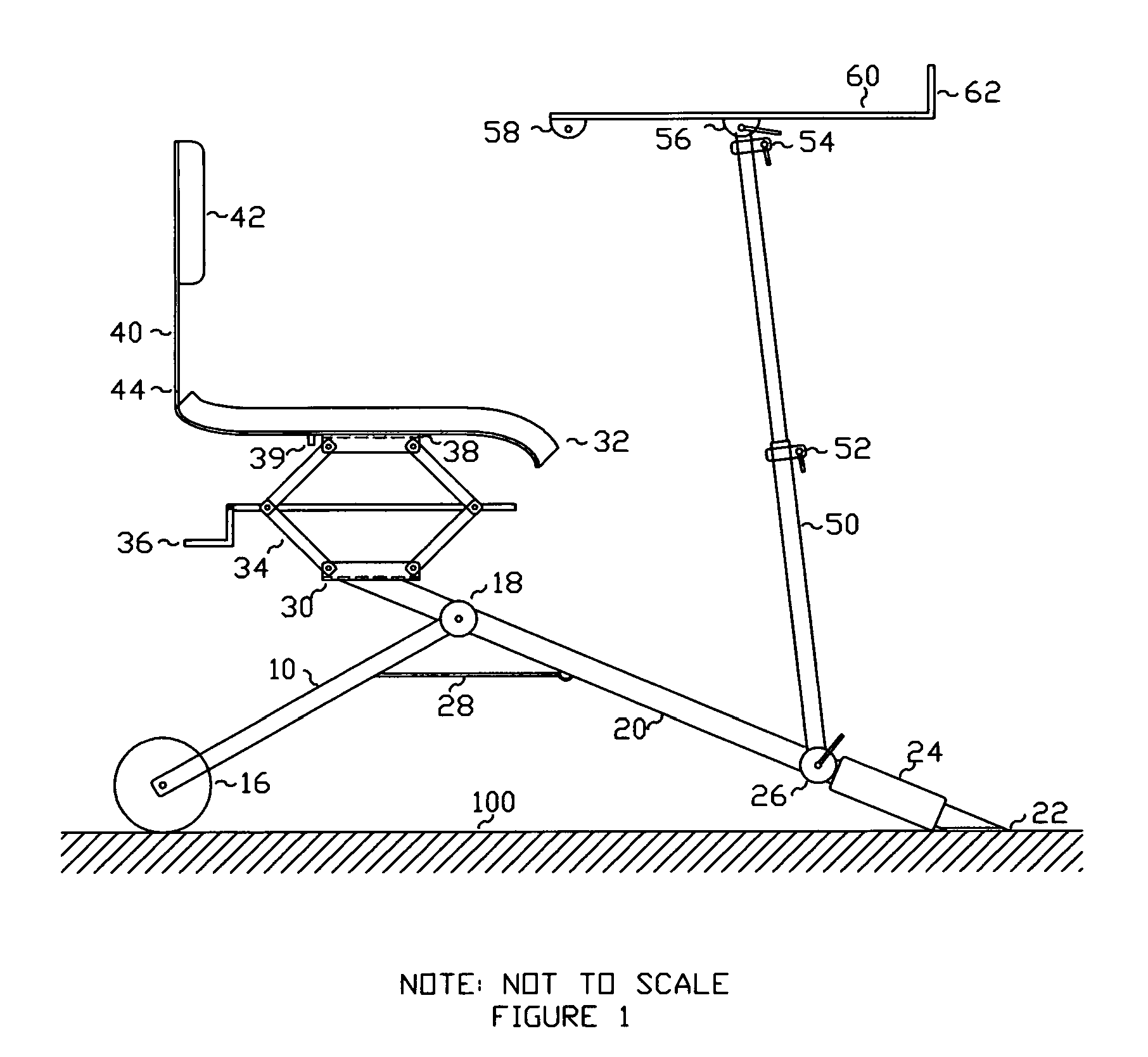

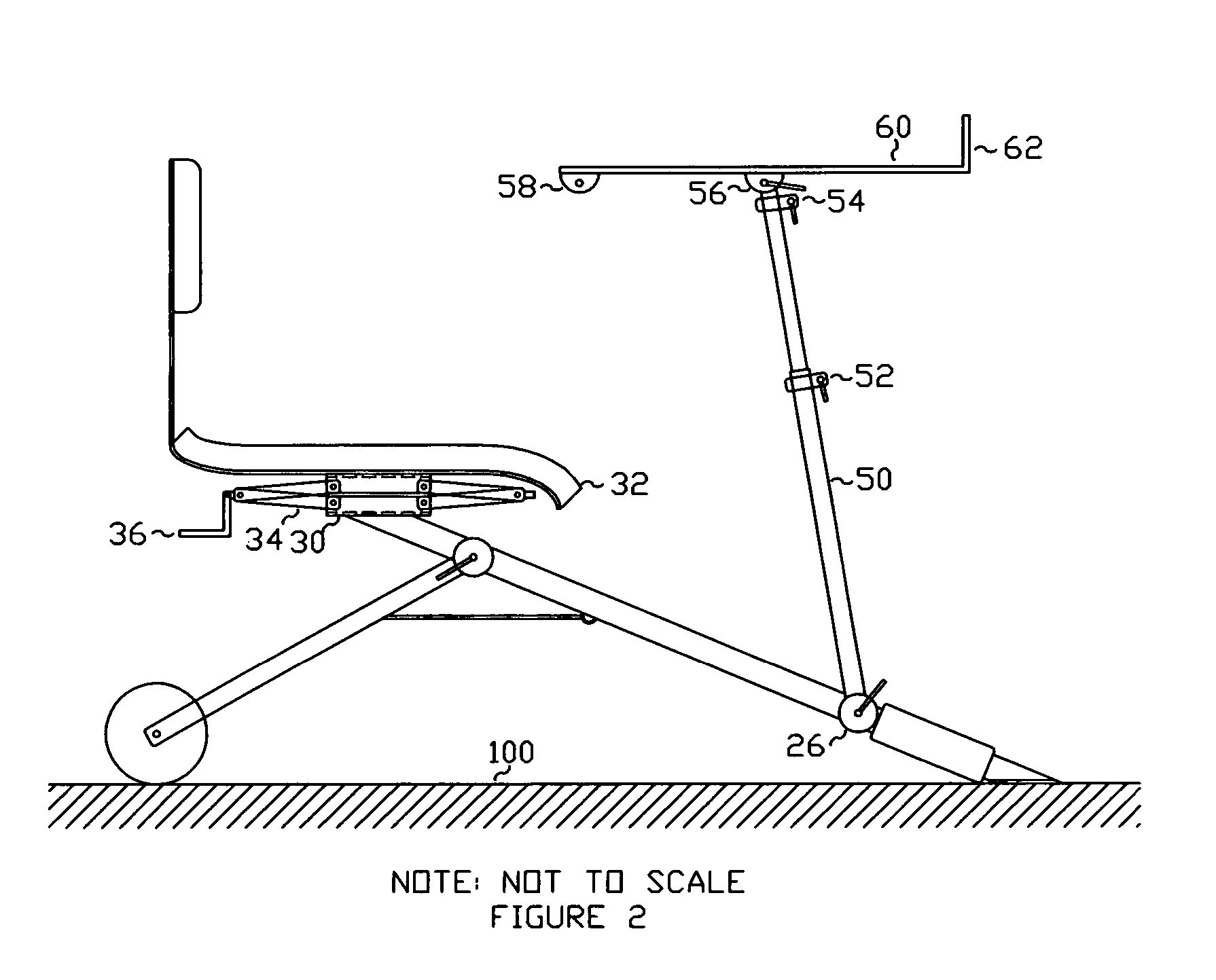

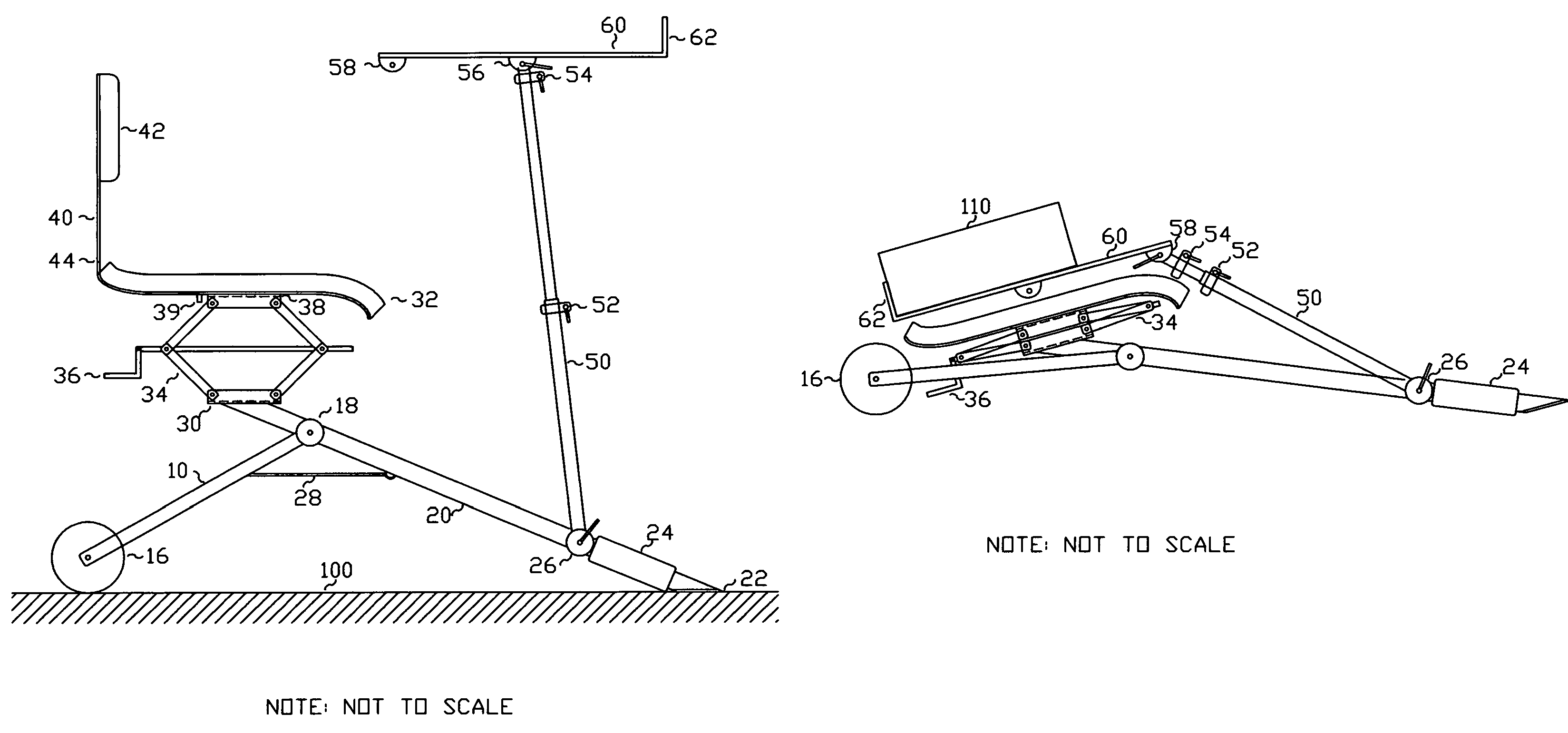

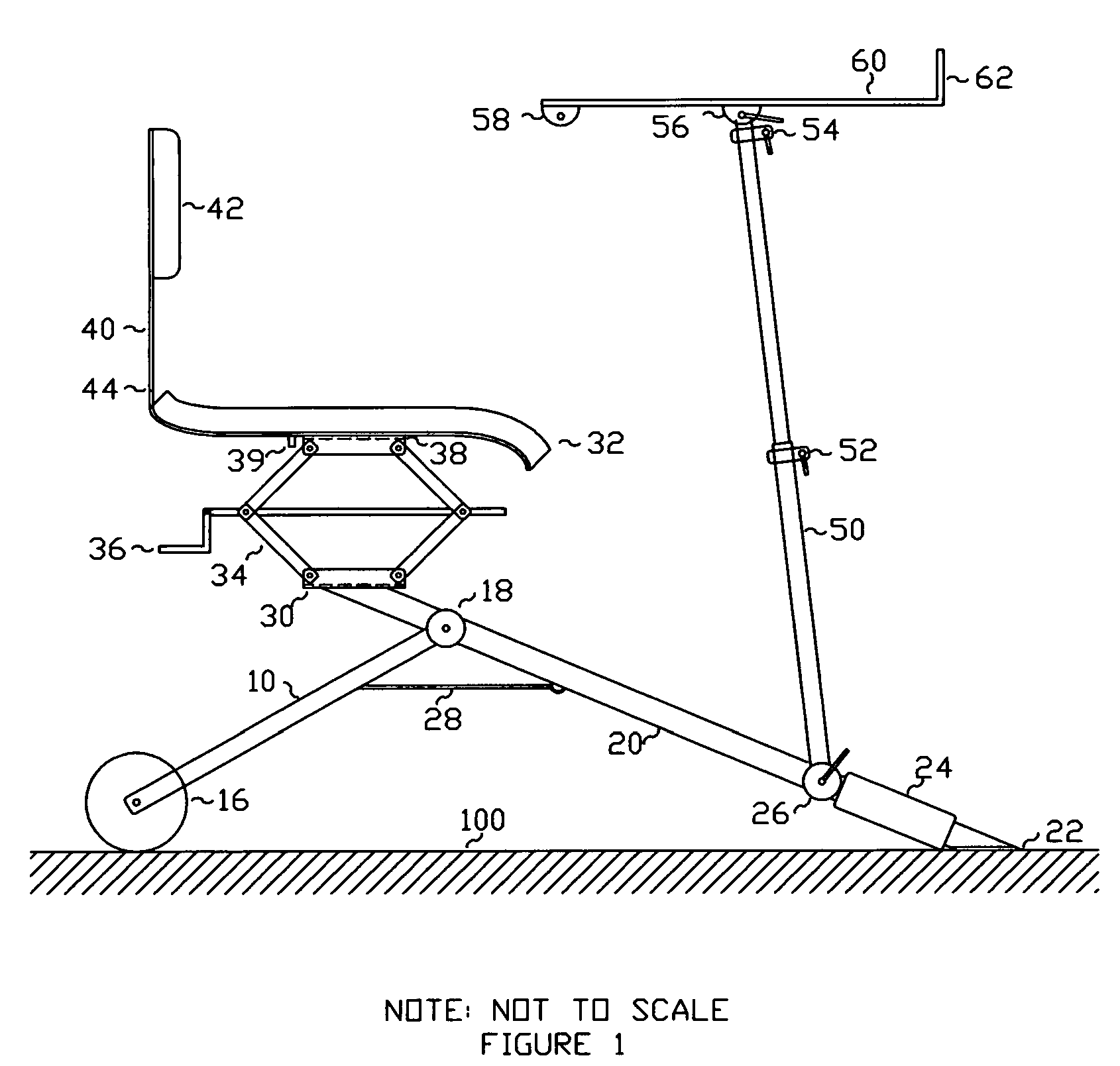

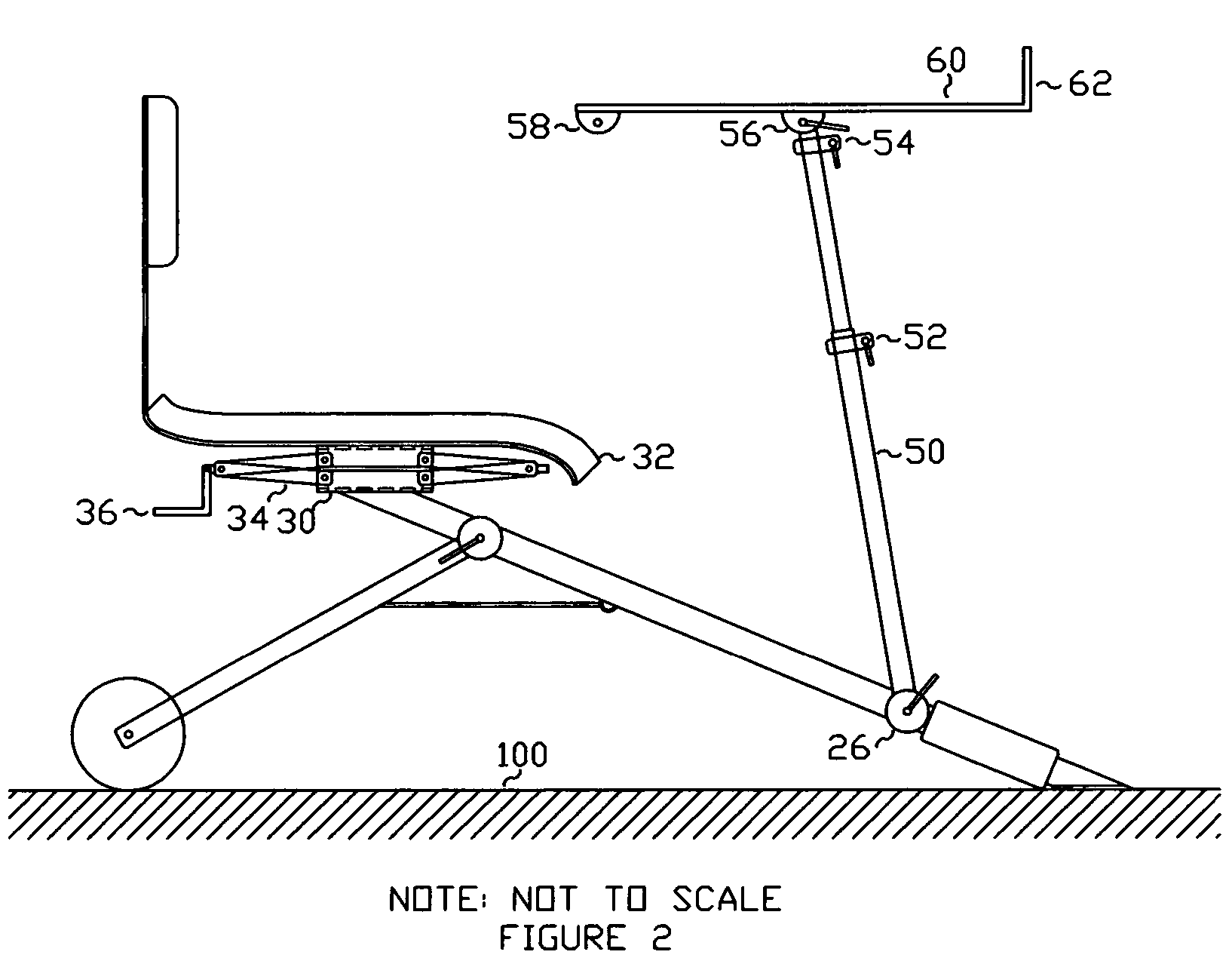

Portable workstation

ActiveUS20060197362A1Great productivityLess fatigueVehicle seatsFoldable tablesLoad carryingBuilding material

This invention describes a wheeled, portable, collapsible workstation with integral seating, work surface, and equipment transportation capability. Also described is a method of assembly, disassembly, operation and transportation. The device consists of a tripod like frame section, wheel(s) and axle(s), adjustable seating (vertical displacement, and rotation about the vertical axis), adjustable work surface (vertical and horizontal displacement, tilt about the horizontal plane) transportation handle, and load carrying / transportation capability. The workstation work surface provides a storage location, and attachment means for equipment, luggage, toolboxes, instrumentation, computing devices, and the like. The user attaches said equipment to the work surface. Using the integral handle and wheels, the user pulls / pushes the workstation and said equipment to a work site. The user removes said equipment from said work surface, and unfolds the workstation, adjusting the seat and work surface as desired. The user replaces the equipment on the work surface. The user now has an ergonomically adjusted workstation allowing for greater productivity and less fatigue. Additionally, equipment damage due to falls from unstable or makeshift work surfaces is minimized. Variations in construction materials provide for increased resistance to damage from the elements, chemical or physical abuse. Various instrumentation devices such as photographic equipment may be substituted for the work surface. Additionally, the work surface converts to an artist's easel. Two or more workstations may be combined forming a larger table work surface.

Owner:MABON ROBERT ALAN +1

Neodymium iron boron magnetic materials and preparation method of the same

The invention discloses neodymium iron boron magnetic materials and a preparation method of the neodymium iron boron magnetic materials. The neodymium iron boron magnetic materials comprise, by weight, 27-34.5 % of neodymium (Nd), 4.5-5.75 % of praseodymium (Pr), 0.45-0.575 of gadolinium (Gd), 2-4% of boron (B), 0.08-0.16 % of niobium (Nb), 0.01-0.02 % of hafnium (Hf), 0.01-0.02 % of wolfram (W) and 0.045-0.0575 % of scandium (Sc), and the rest is ferrum (Fe). The neodymium iron boron magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance to some extent. The preparation method of the neodymium iron boron magnetic materials fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

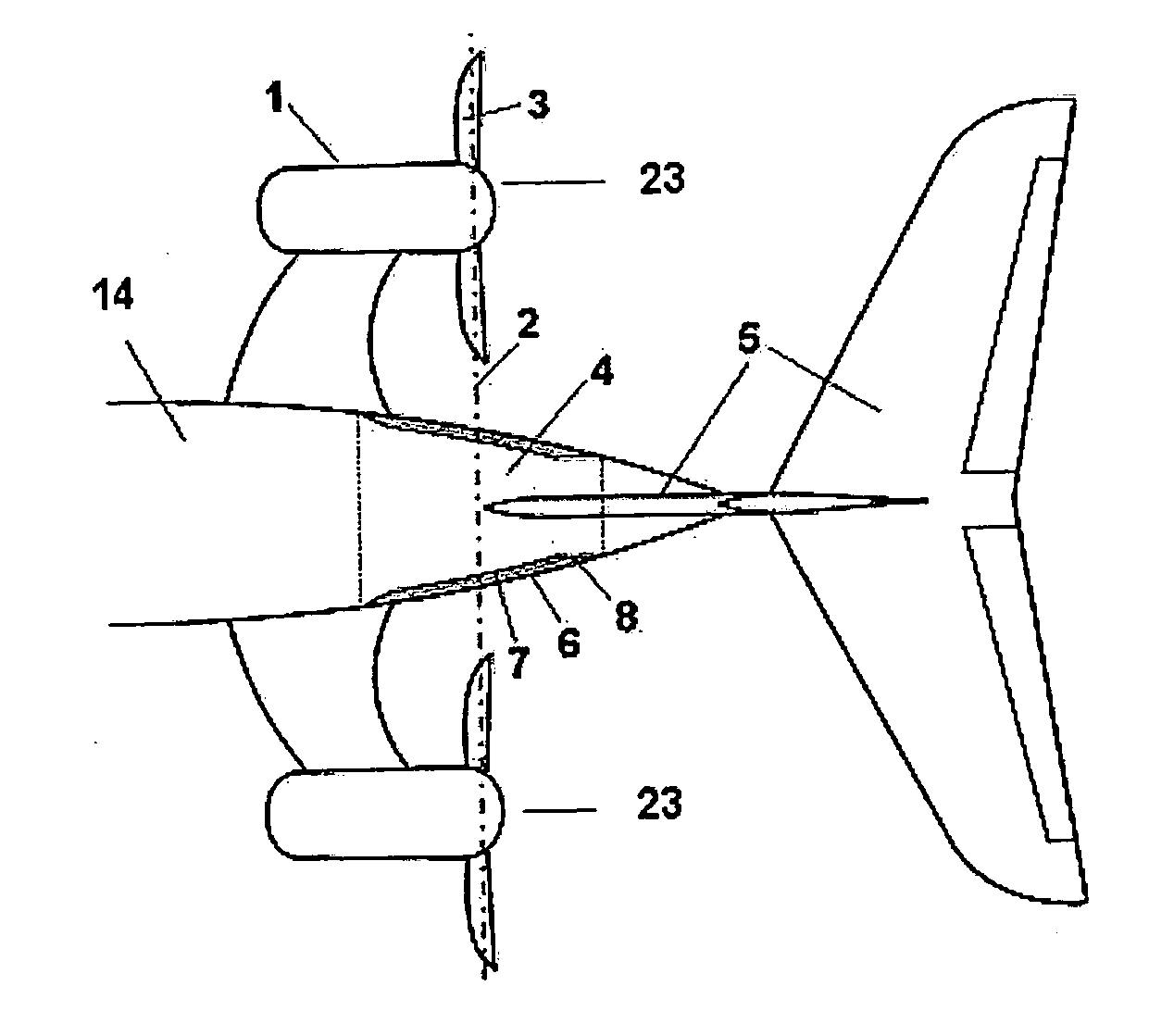

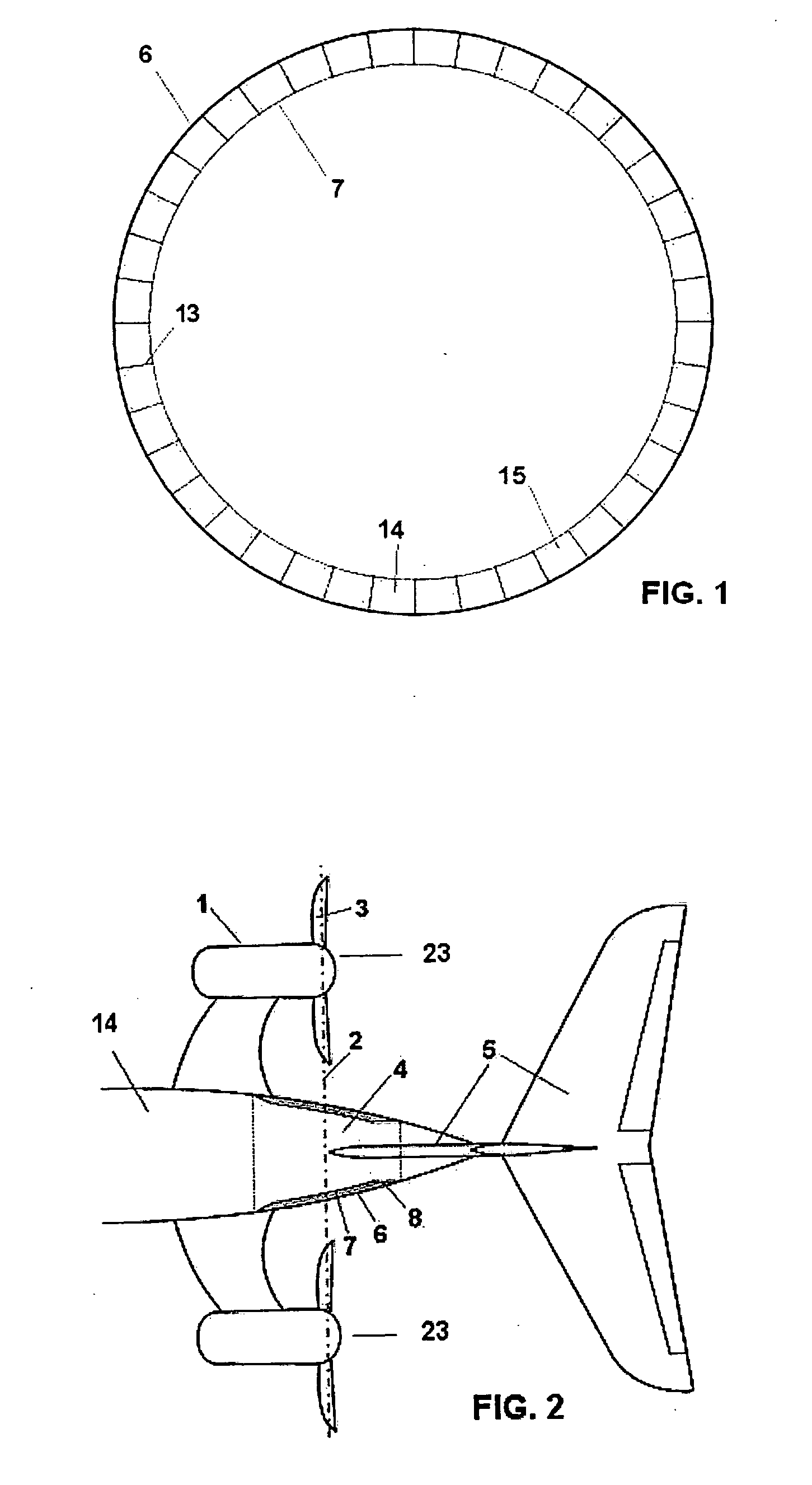

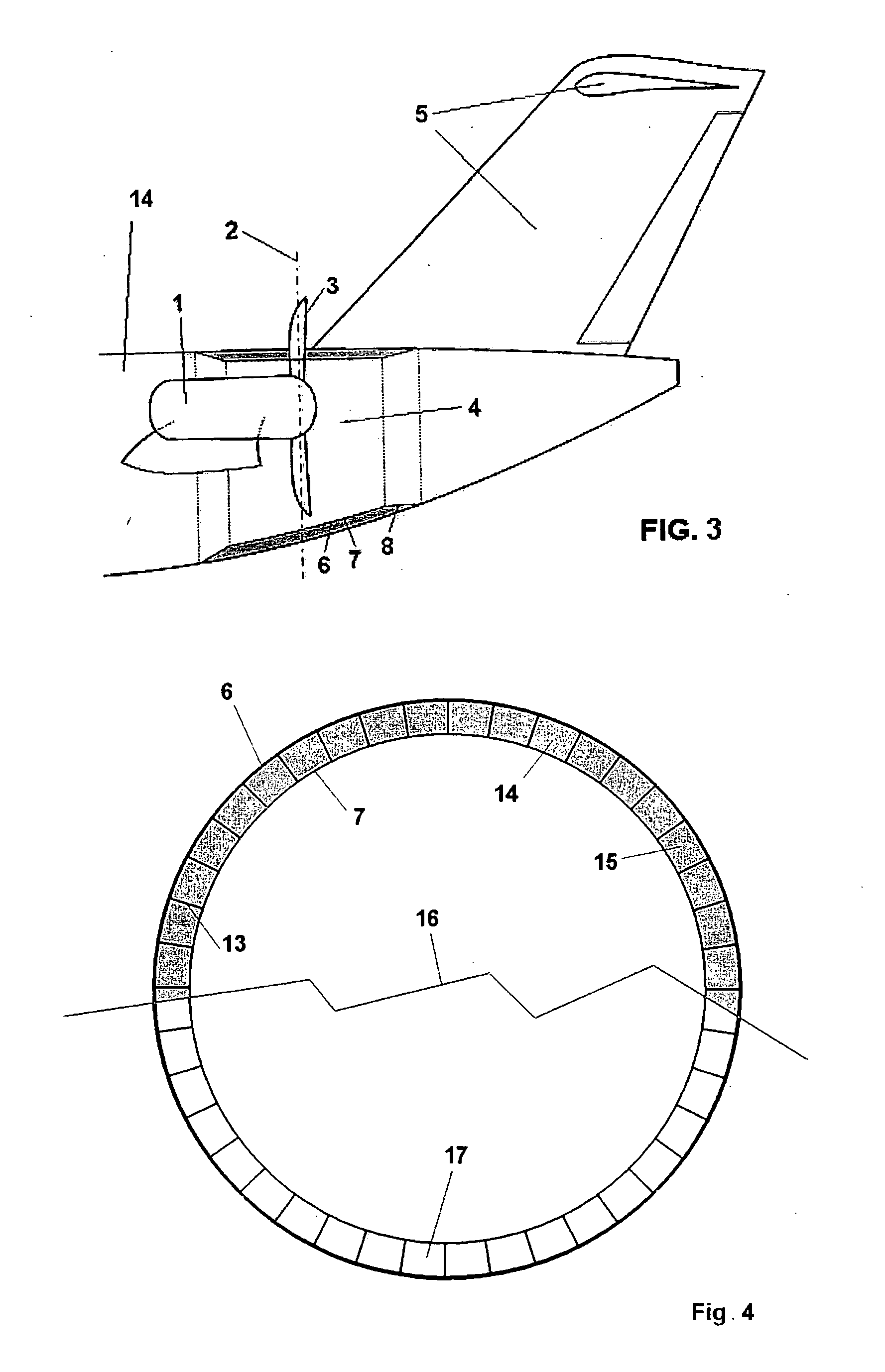

Impact resistant aircraft fuselage

ActiveUS20090140096A1Sufficient residual torsional strengthIncreasing resistance to damageGas turbine type power plantsPiston type power plantsPropellerTorsional strength

The invention relates to a structural configuration of the rear fuselage (4) of an aircraft with propeller engines (1) comprising propellers (23) formed in turn by blades (3), the mentioned propeller engines (1) being located at the rear part of the aircraft and the empennage (5) of the aircraft in turn being located behind the plane of the propellers (23), characterized in that the structural configuration of the rear fuselage (4) comprises an outer skin (6) and an inner skin (7), both skins (6, 7) being joined by means of radial elements (13) configuring cells (14), such that the obtained structural configuration maximizes the torsional strength of the rear fuselage (4) of the aircraft in the event of damage of the mentioned rear fuselage (4) due to the detachment of one of the blades (3) of the propeller engines (1).

Owner:AIRBUS OPERATIONS SL

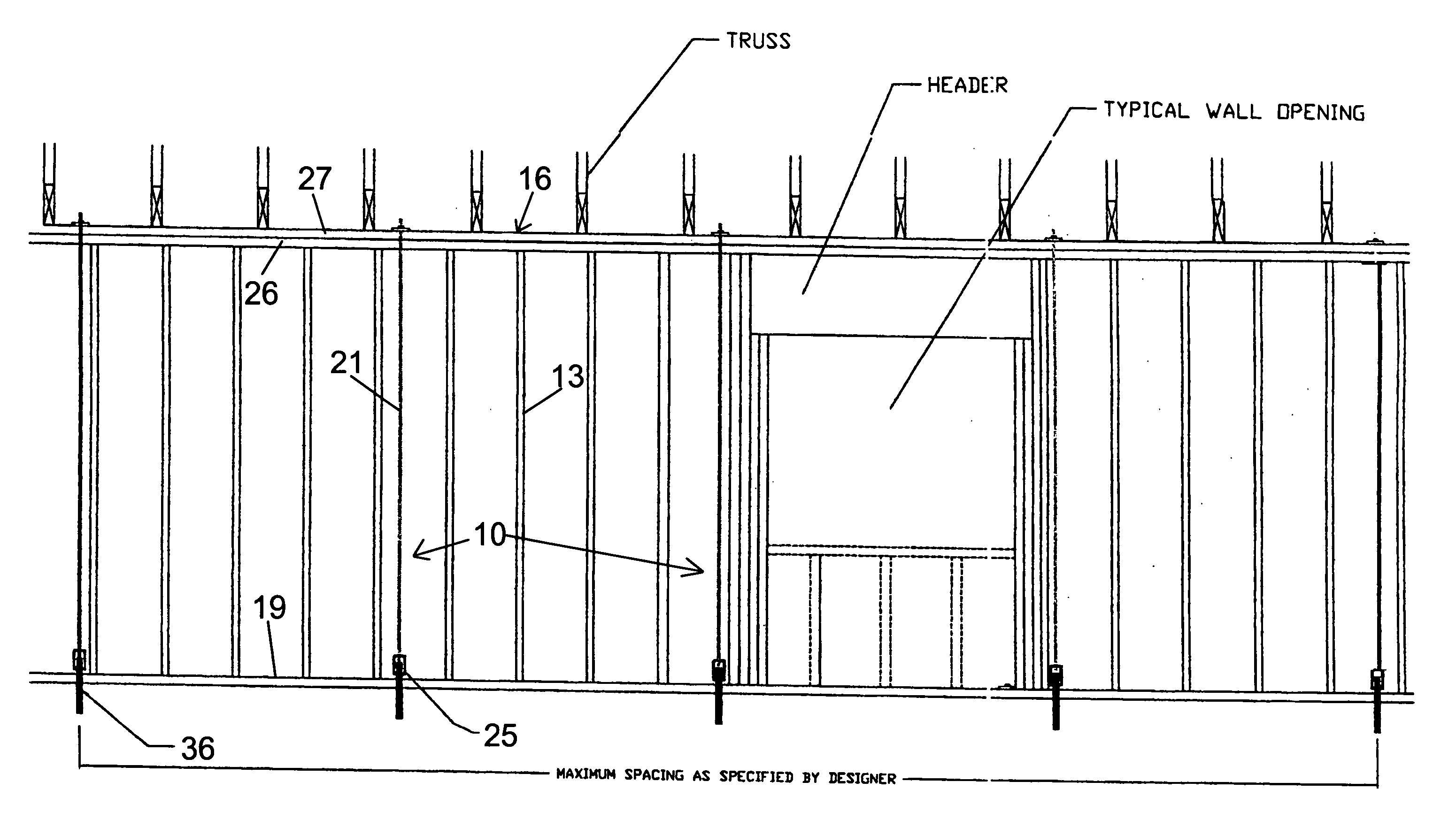

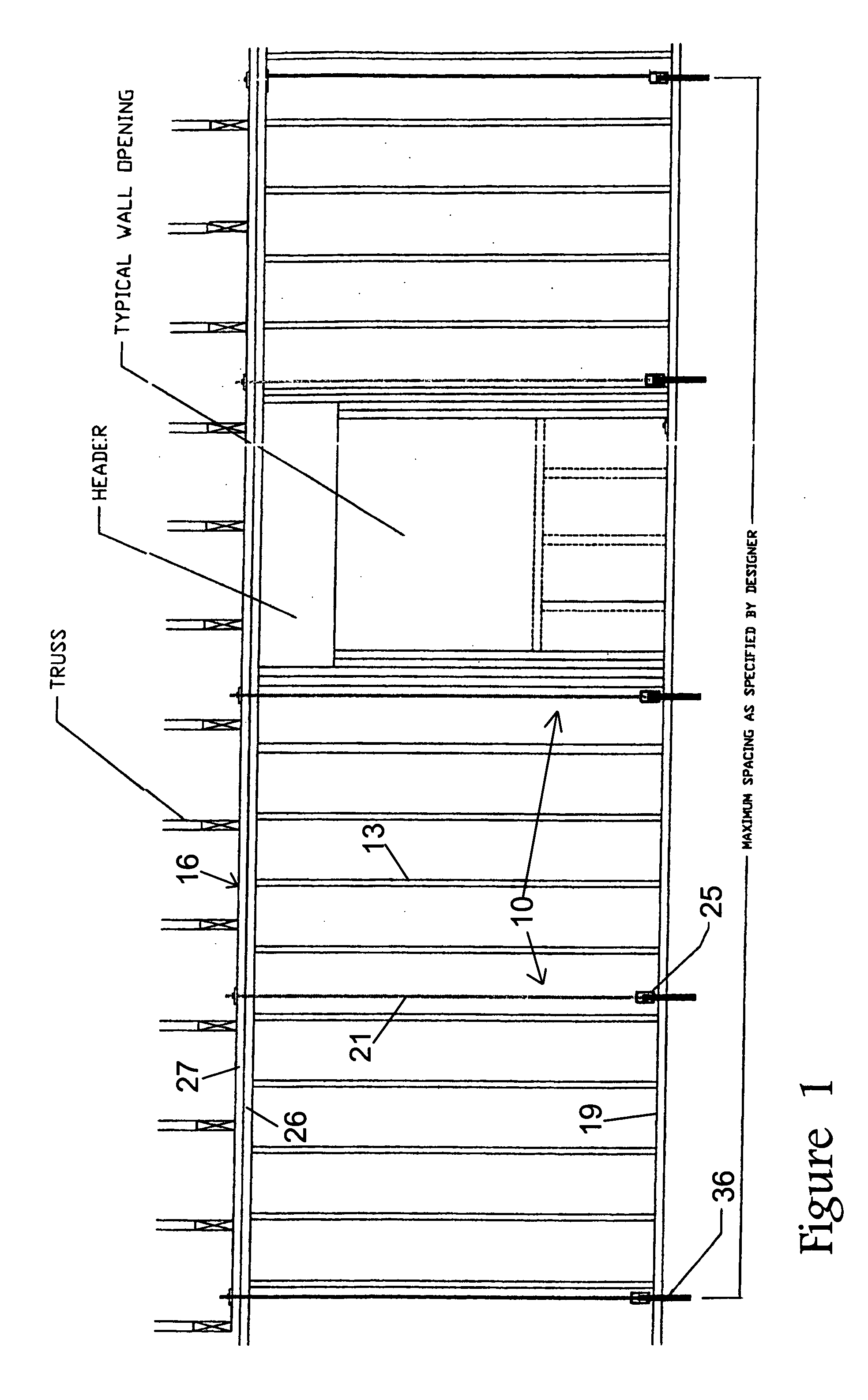

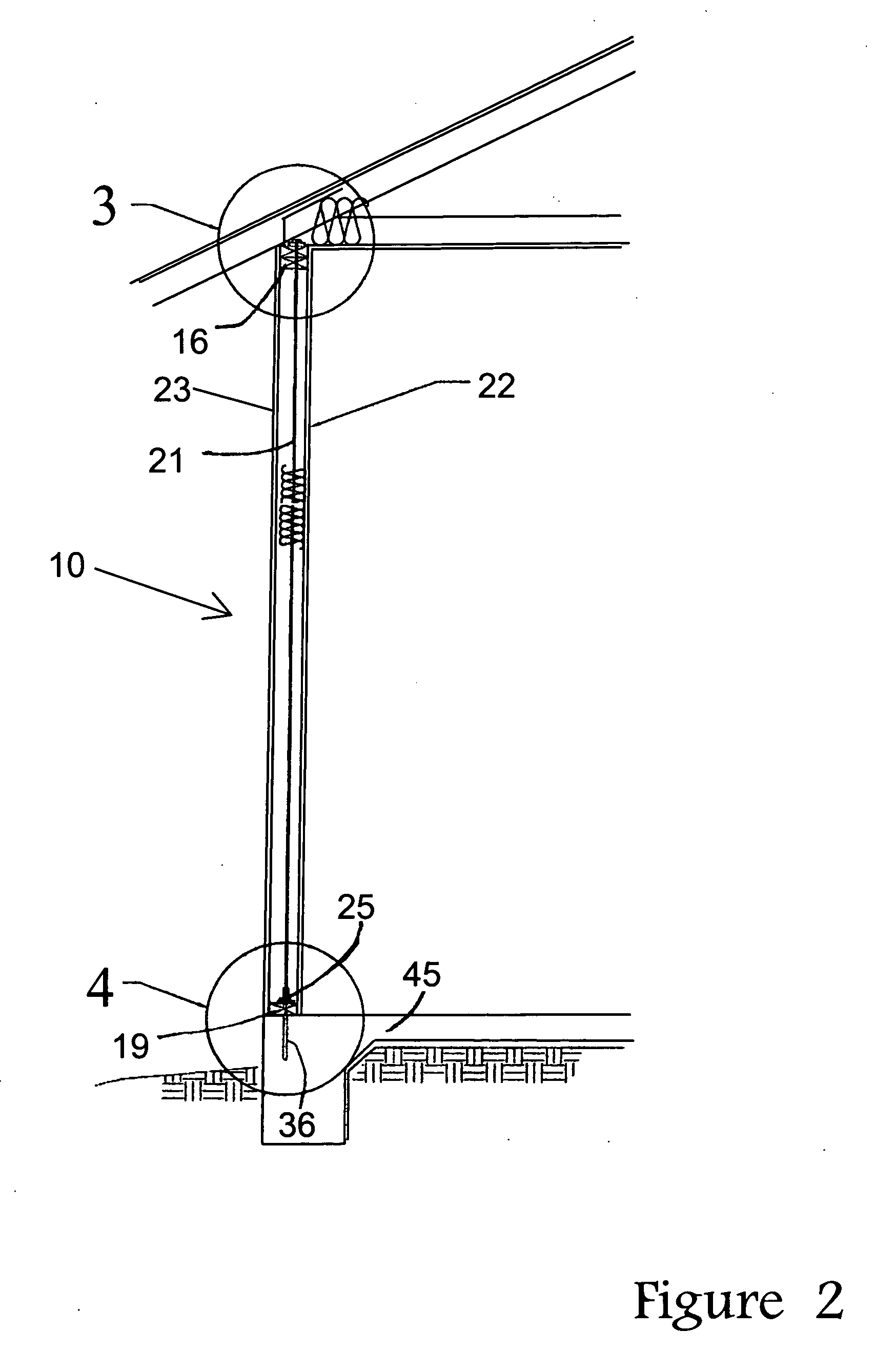

Threaded rod wind and seismic resistance system

InactiveUS20050193681A1Low costAvoid corrosionFoundation engineeringProtective buildings/sheltersCorrosionJoist

Wood framed walls of buildings are strengthened against destructive wind and seismic forces by a threaded hold-down rod attached to the structure top plate and anchored to the building foundation. The foundation structure may be concrete or other floor joist or the like. The threaded rod is normally used in a system that attaches at top and bottom of studs at approximately every fourth or fifth stud along all load-bearing walls. The threaded rod system comprises two sections of threaded rod connected to the structure by way of a nut and washer at the top plate and embedded in the foundation at the bottom. A short section of threaded rod is embedded in the foundation and a coupling nut connects the short section to the remaining threaded rod section near the bottom plate. The short section may be manufactured of galvanized steel or stainless steel to avoid corrosion where fastened to a pressure treated bottom plate. In an alternate embodiment, an elongated wire bolt rod can be attached to the foundation and directly to a roof truss and ceiling plate. The described system can be installed during initial construction of a structure or retrofit into existing structures.

Owner:BRACKETT CHARLES T

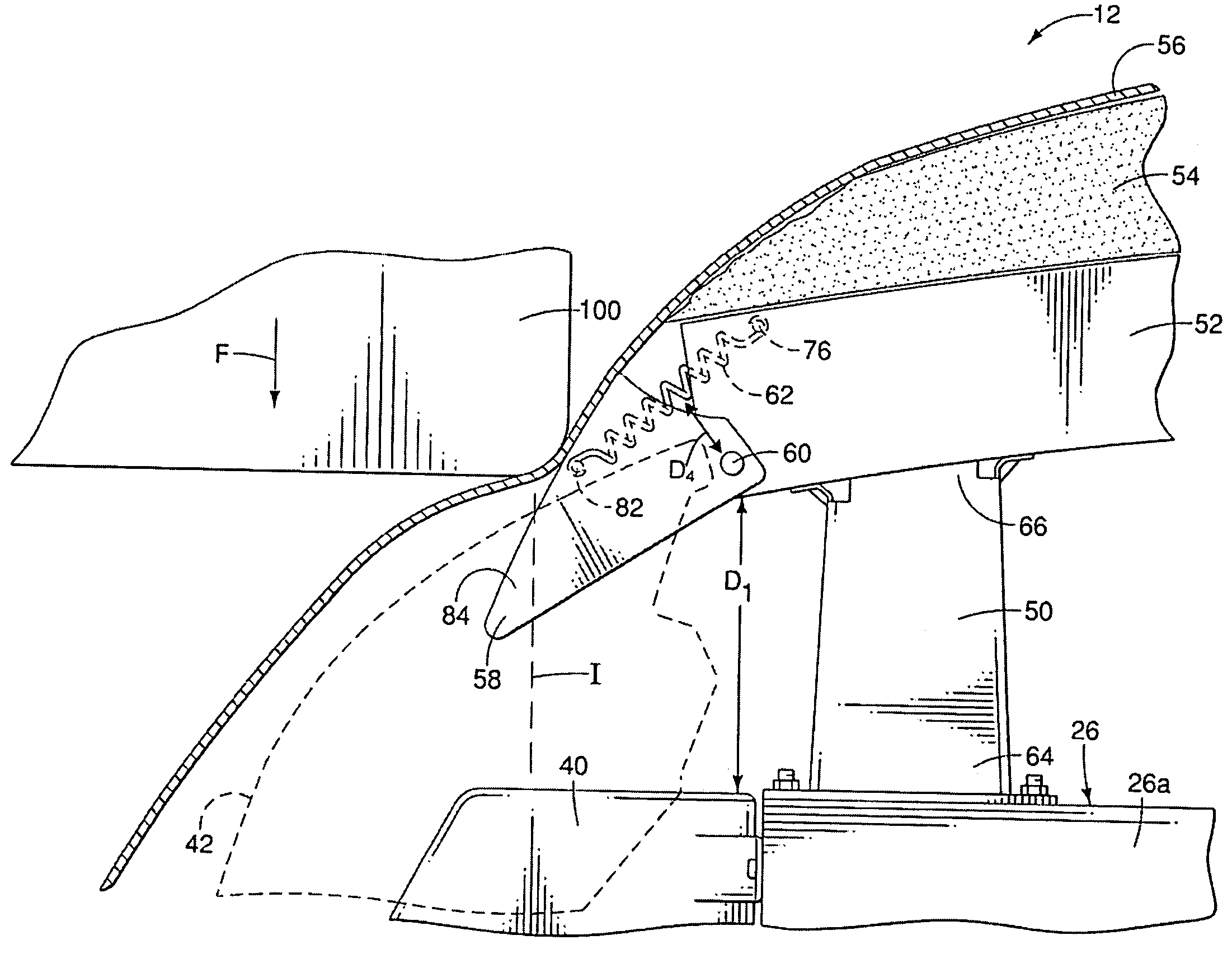

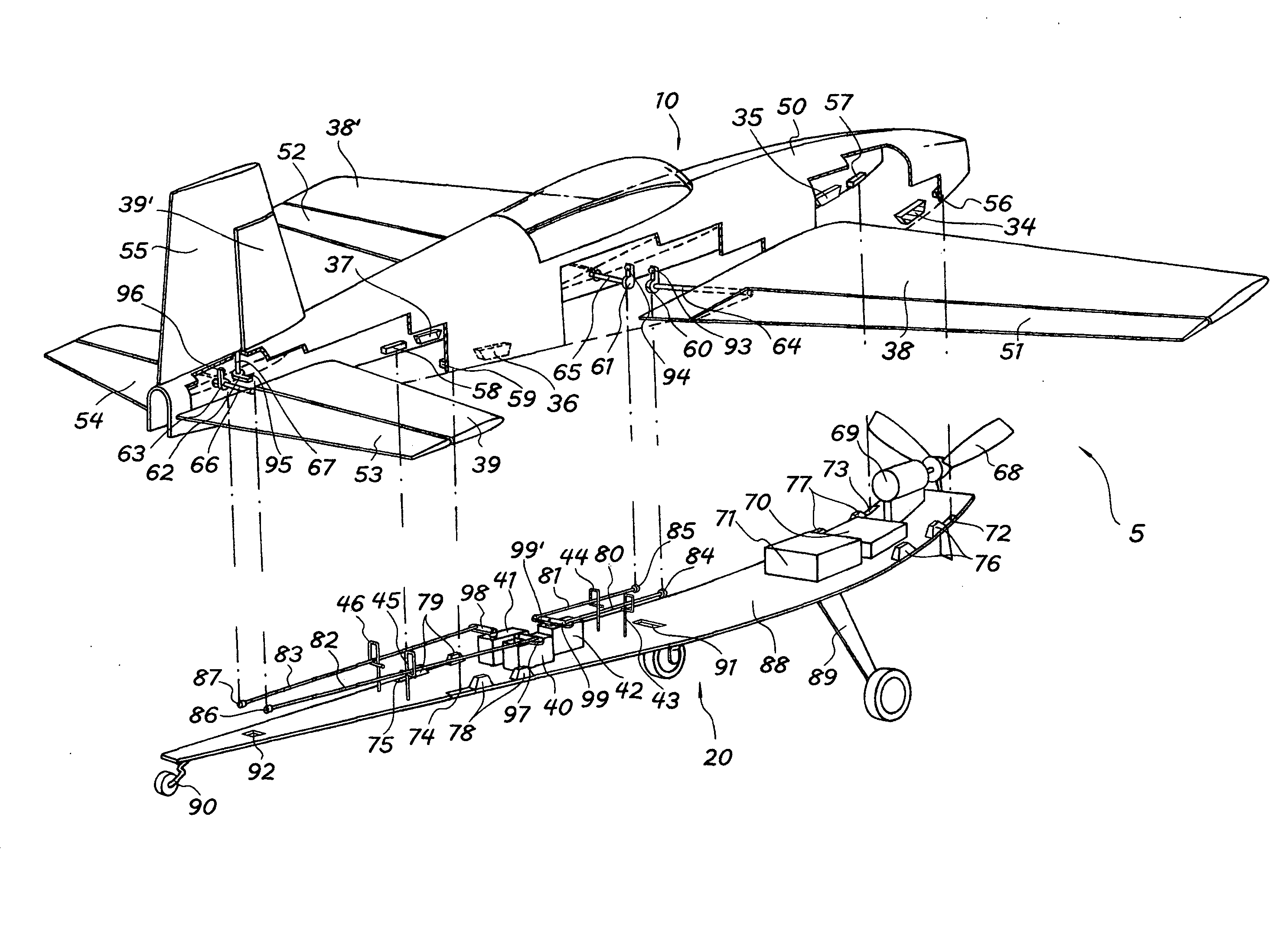

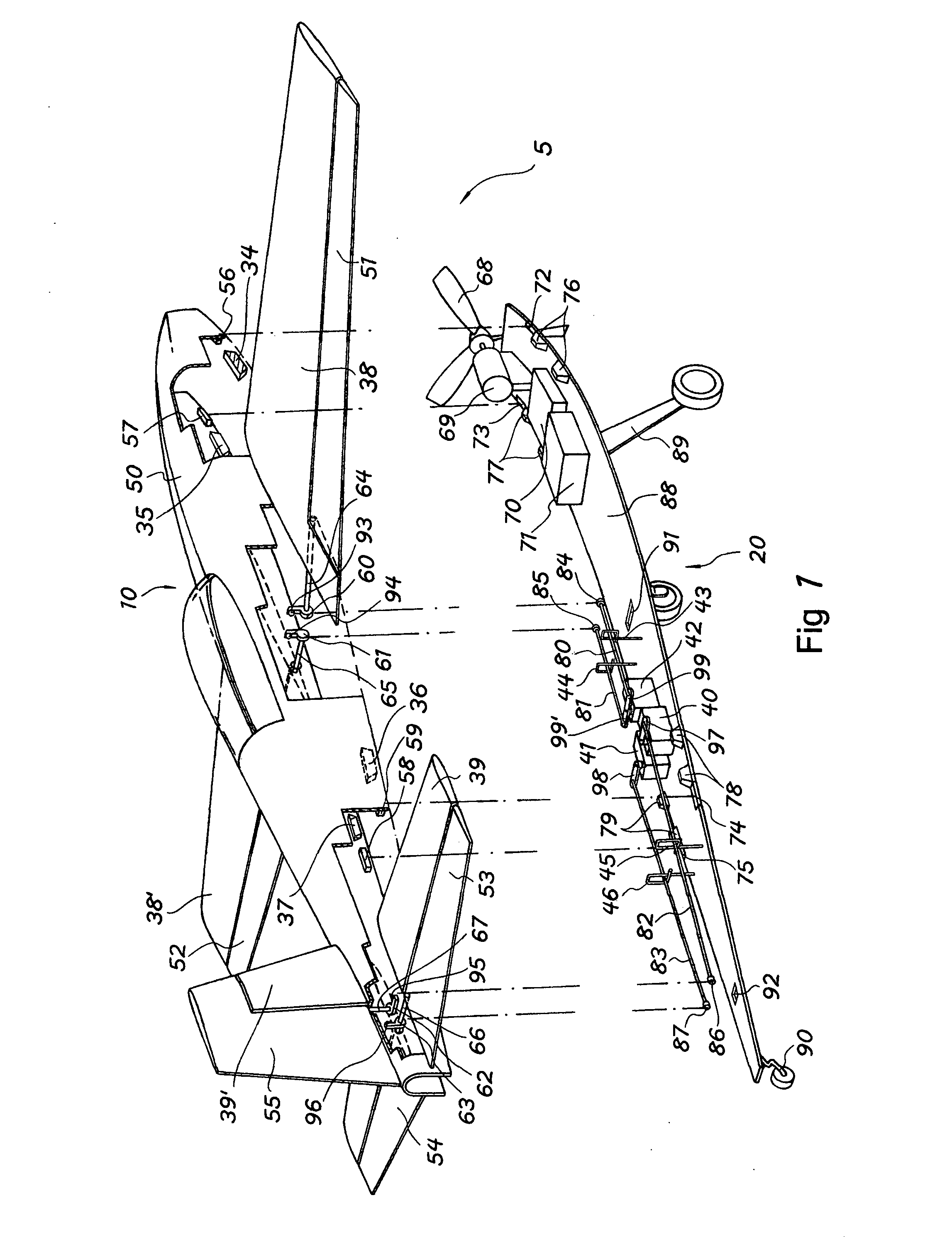

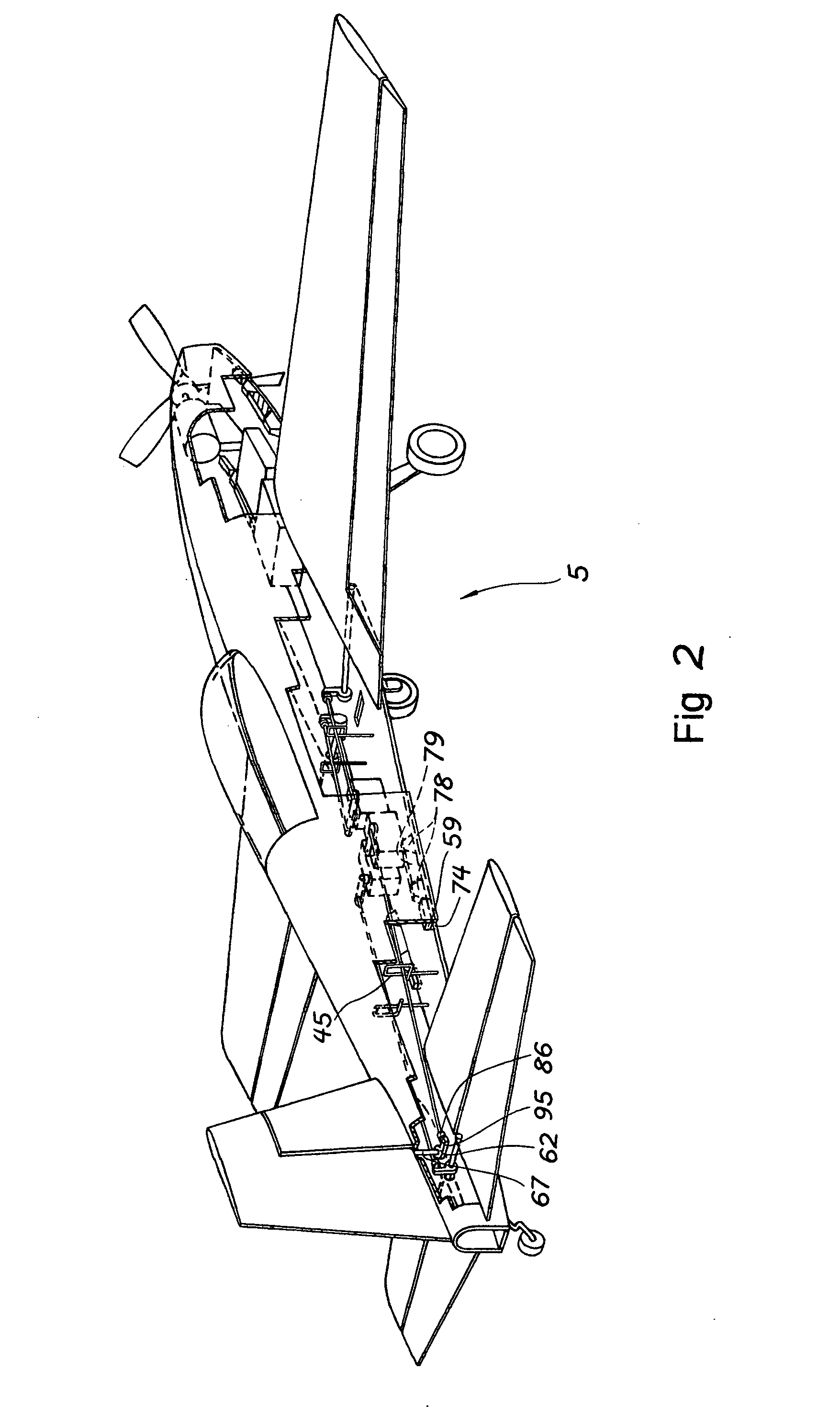

Modularized airplane structures and methods

ActiveUS20080217470A1Improving crash damage resistanceHighly practicalAircraft stabilisationWing adjustmentsRadio receptionRadio receiver

A modularized airplane includes two separably interconnected modules. The first module, incorporating substantial airplane style characteristics, comprises wings and stabilizers having at least one associated control surface joined with a fuselage portion. The second module carries a set of essential airplane components interconnected to suffice airplane operations including a propulsion unit, radio receiver and / or auto-piloting electronics unit, control servo devices, and power means mounted on provided support structures. At least one pair of mutually magnetically attractive connectors oppositely affixed on said two module members provide means for inter-modular structural connection. An alignment mechanism having oppositely provided complementary structures on said two modules facilitate alignment as well as lateral interlocking for inter-modular structural connection. A linkage means includes two linkage portions separably connected by two mutually magnetically attractive elements oppositely mounted thereon to form a linkage assembly for linking between control surfaces and associated servo devices, a linkage guide means, and a stress isolation mechanism. The structural connection and the control linkage means facilitate substantially effortless inter-modular connections to form a functional modularized airplane as well as excessive parting tension induced nondestructive inter-modular disconnection. Multiple modules of differing styles and aerodynamic specifications can be made as the first module to be interconnected with the second module to form differing airplanes, sharing essential components, for various applications.

Owner:ZHAO JIE

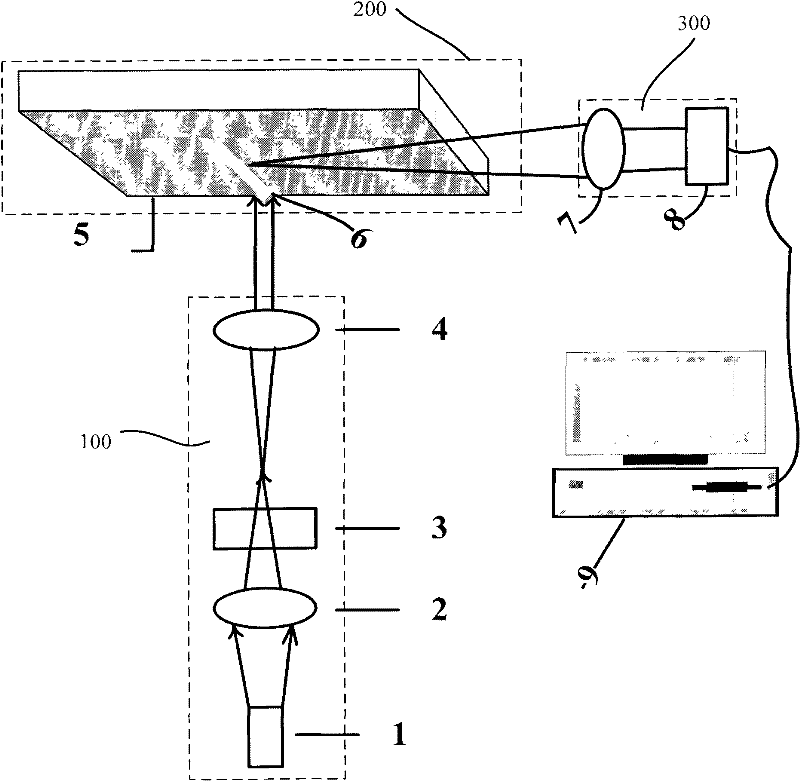

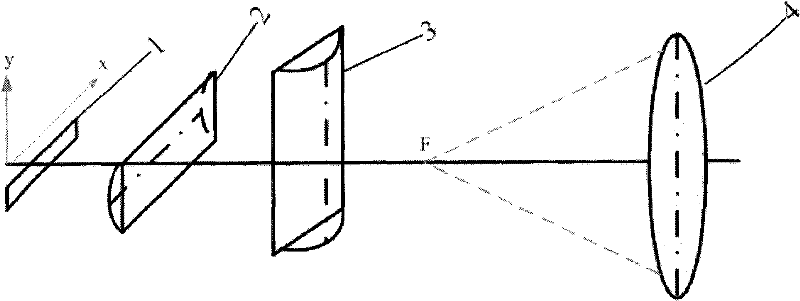

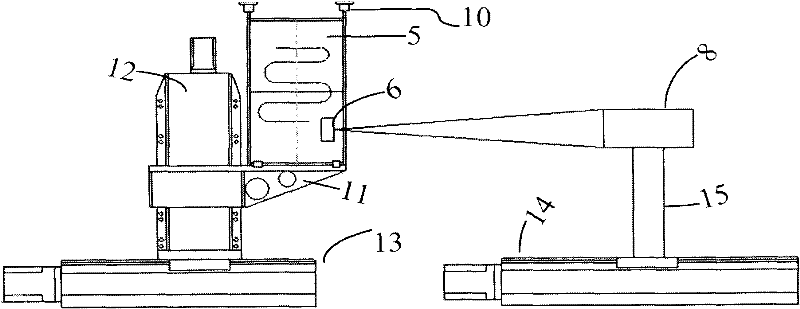

Method and device for detecting internal defects of optical components

InactiveCN102288622AEfficient detectionEffective uniformityMaterial analysis by optical meansLight beamLighting system

A detection device for internal defects of an optical element, comprising: a stage, an illumination system, and an imaging system; wherein, the position of the illumination system relative to the stage is set in the following manner: when the optical element to be tested is placed on the stage After being mounted, the illumination beam emitted by the illumination system can irradiate the surface of the optical element in a normal incidence mode; the imaging system is arranged outside the side of the optical element on the stage, and can obtain the illumination beam emitted by the illumination system on the optical element. A 2D image of an illuminated section formed in the thickness direction. The device can be used to detect the internal defect of the optical element, and can also distinguish the surface defect from the internal defect. The invention also provides a detection method of the optical element.

Owner:ZHEJIANG NORMAL UNIVERSITY

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

High barrier packaging laminate, method for manufacturing of the packaging laminate and packaging container

ActiveCN102470642AImprove resistance to damageFull strengthSynthetic resin layered productsPaper/cardboard layered productsPolymer scienceFood packaging

Owner:TETRA LAVAL HLDG & FINANCE SA

Portable workstation

ActiveUS7314248B2Improve resistance to damageIncrease production capacityVehicle seatsFoldable tablesWorkstationTruck

A portable workstation apparatus having a collapsible frame, wheels, a seat, and work surface, whereby collapsing the frame and manipulating an articulated work surface attachment, permits the apparatus to be utilized as a hand truck. Also described is an enhanced version of the collapsible portable workstation apparatus having a scissors linkage lift mechanism allowing adjustment of the seating height.

Owner:MABON ROBERT ALAN +1

Fabric treatment for stain release

ActiveUS7893014B2Extended service lifeFeel goodCationic surface-active compoundsOrganic detergent compounding agentsWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Treatment compositions can be used as a pretreatment prior to washing, through soaking, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, to first provide and then maintain and restore the beneficial fabric protection benefits imparted to the fabrics during a first treatment operation. The fabric treatment is complete when the fabric is cured by drying and / or heating. Following use of a first treatment composition, protective benefits are maintained and restored by means of a second treatment operation employing a second treatment composition with lower active levels of the protective agents to provide for economical and continual maintenance of the imparted fabric protection benefits through a delivered second fabric treatment benefit with each subsequent treatment operation employing the fabric treatment compositions.

Owner:VAN BUSKIRK GREGORY

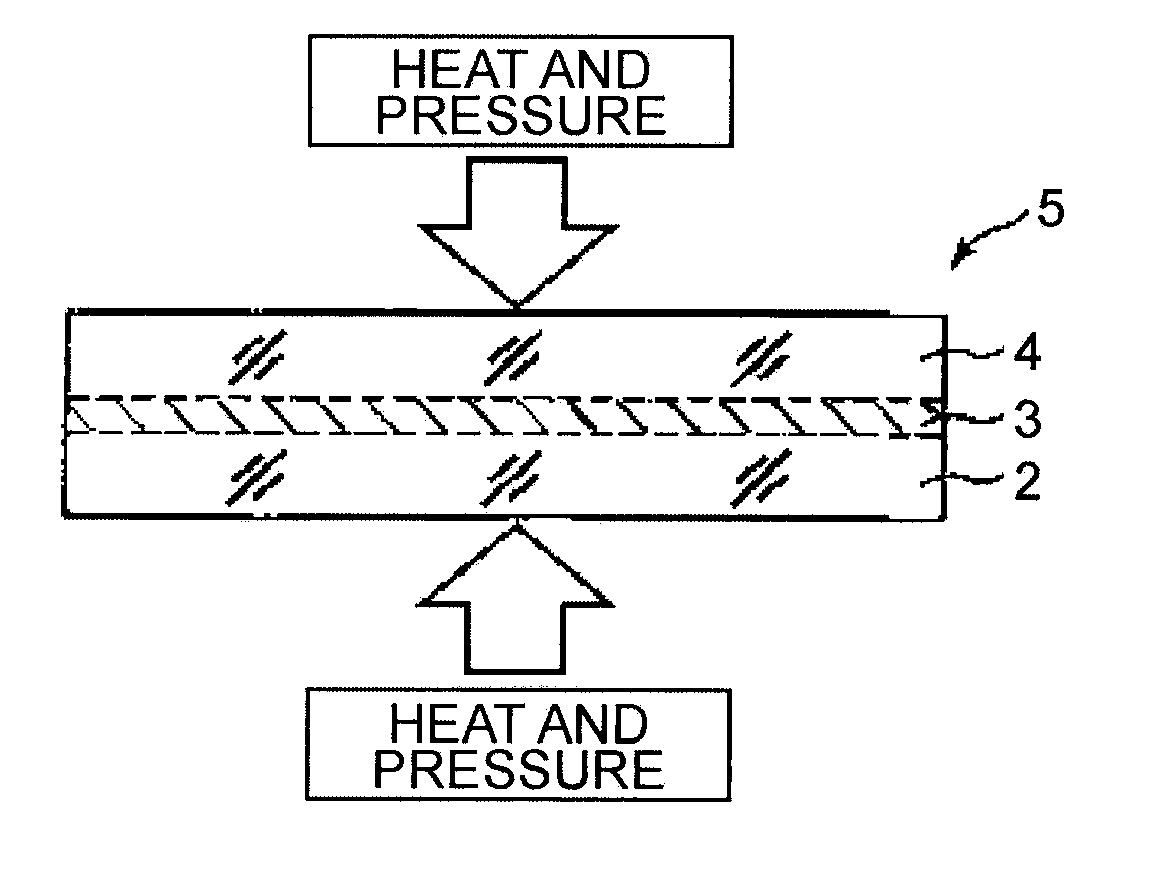

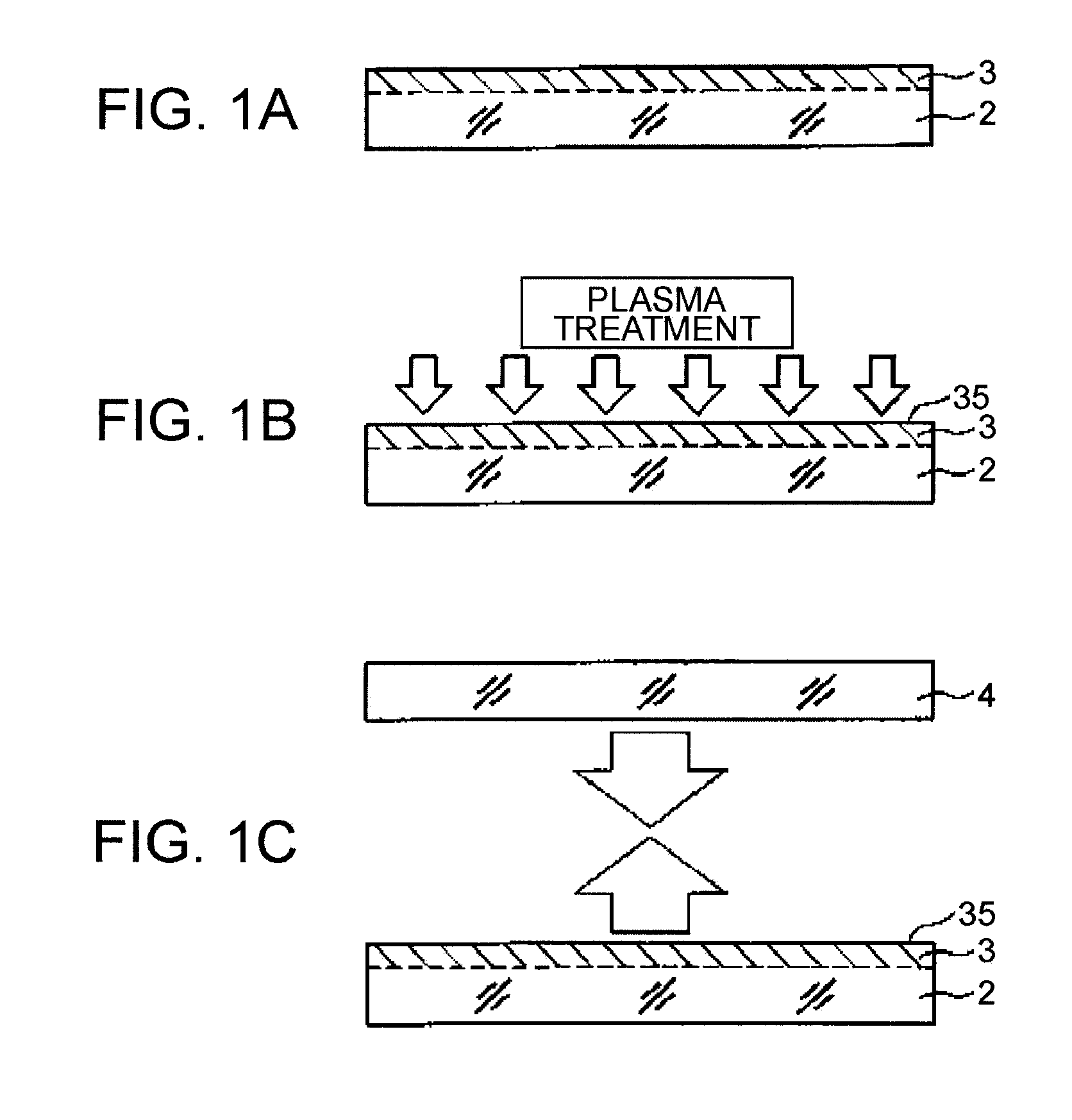

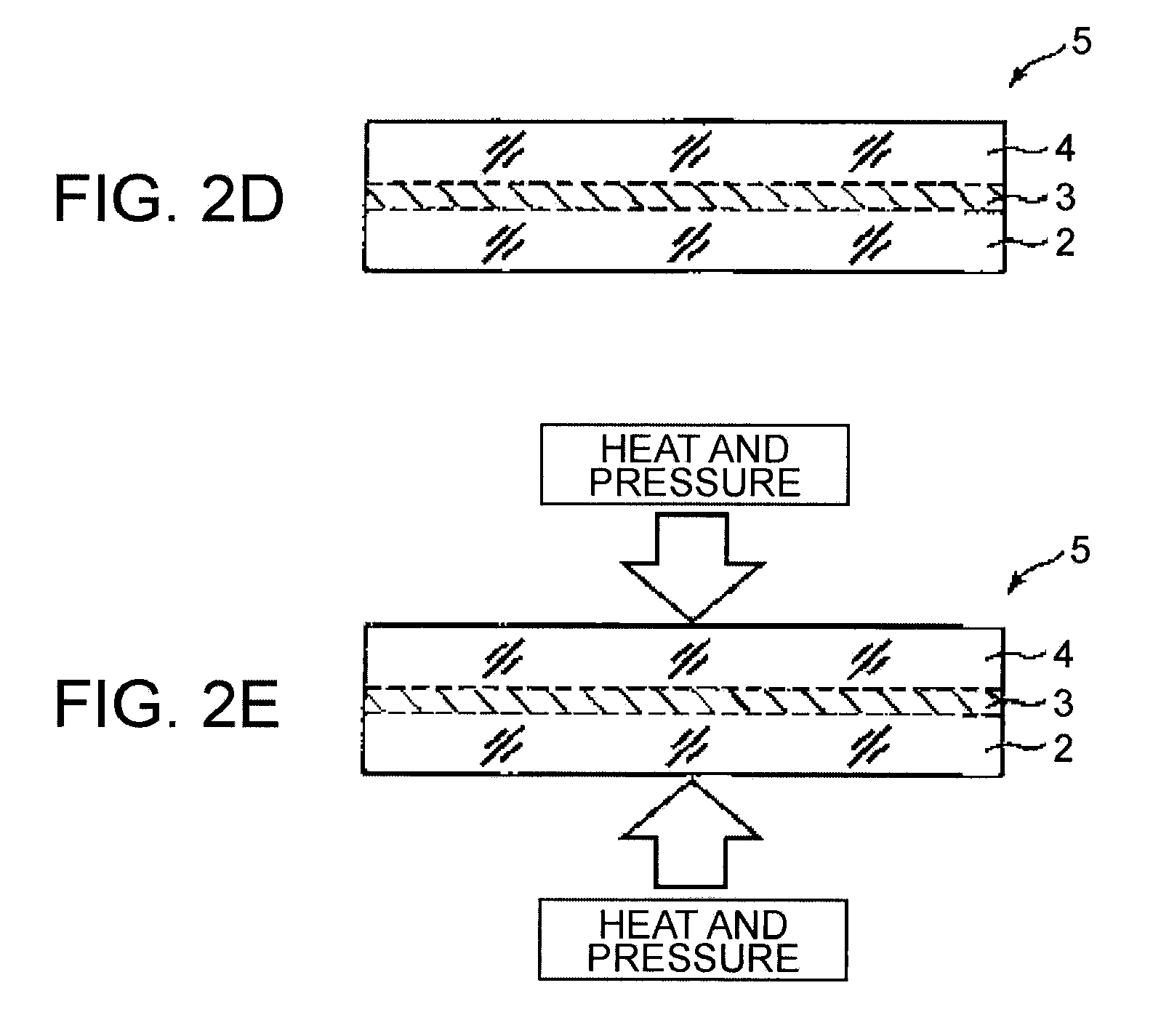

Optical element and method for producing same

InactiveUS20100101719A1Improve light resistanceHigh dimensional accuracyLamination ancillary operationsLaminationLeaving groupRefractive index

An optical element includes a first optical component and a second optical component each having light transmission properties; and a bonding film bonding together the first and the second optical components. The bonding film is formed by plasma polymerization and includes an Si skeleton having a random atomic structure including a siloxane (Si—O) bond and leaving groups binding to the Si skeleton. The first and the second optical components are bonded together by the bonding film having adhesive properties provided by applying energy to at least a part of the bonding film to eliminate the leaving groups from the Si skeleton at a surface of the bonding film. Additionally, the bonding film is formed so as to have approximately the same refractive index as that of at least one of the first and the second optical components by adjusting a film forming condition of the plasma polymerization.

Owner:SEIKO EPSON CORP

Rubber composition

InactiveCN101107296AImprove resistance to damageImprove crack growth resistanceMasterbatchPolymer science

A natural rubber wet masterbatch rubber composition comprising a mixture of a natural rubber latex with a slurry solution containing a carbon black dispersed therein, which satisfies the followings: (1) a CATB specific surface area (m<2> / g) in the range of 60 < CTAB < 110, (2) a 24M4DBP (m<3> / 100g) in the range of 55 < 24M4DBP < 75, (3) a CATB specific surface area and a tint strength (TINT) having the relationship of TINT > 0.41 x CTAB + 81, and (4) a compounding amount of 10 to 100 parts by mass relative to 100 parts by mass of natural rubber. The natural rubber wet masterbatch rubber composition can be suitably used for improving the resistance to fracture and to crack propagation of a tire, a steel coating rubber for a rubber product for industrial use, and the like.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com