Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6028results about How to "Improve scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

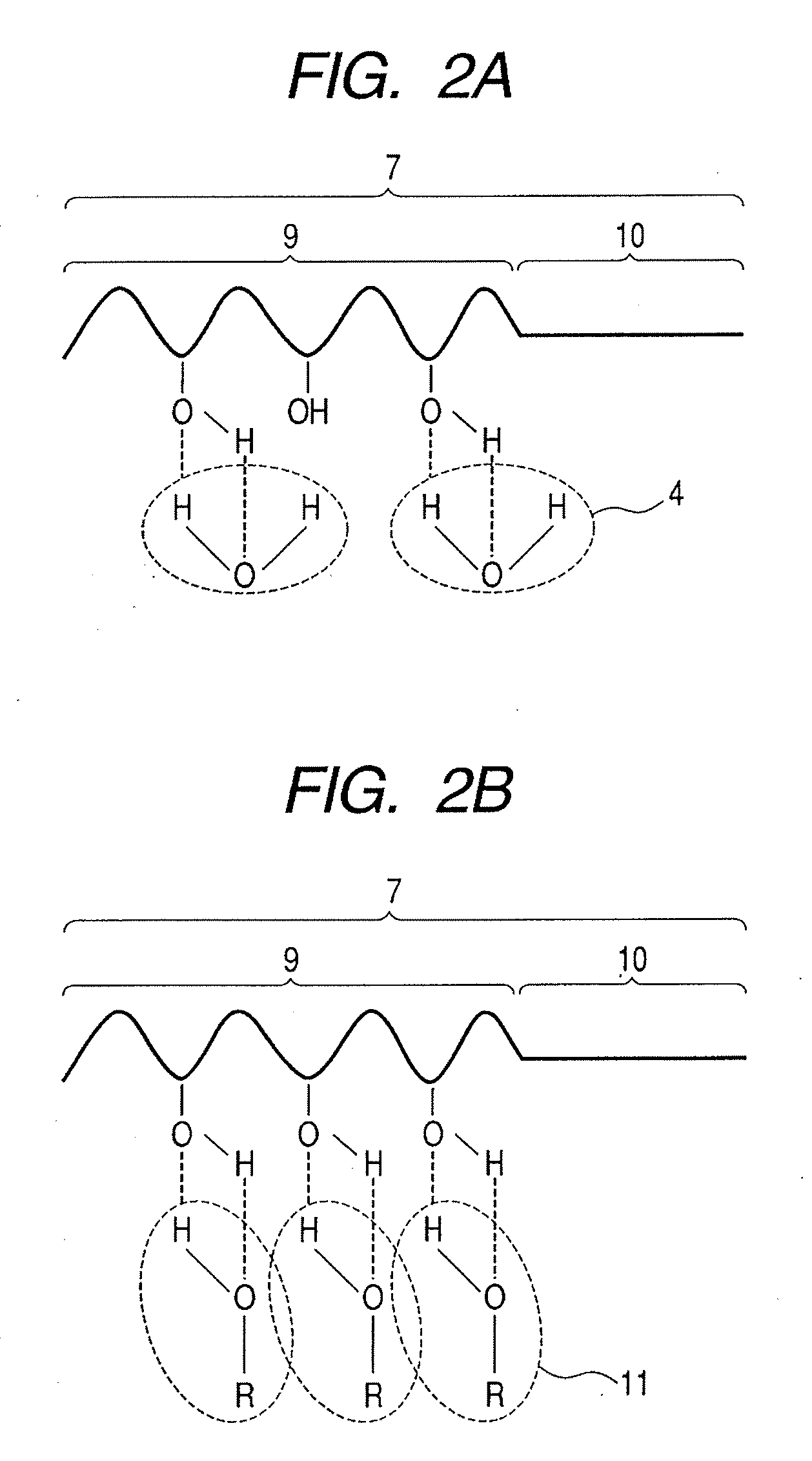

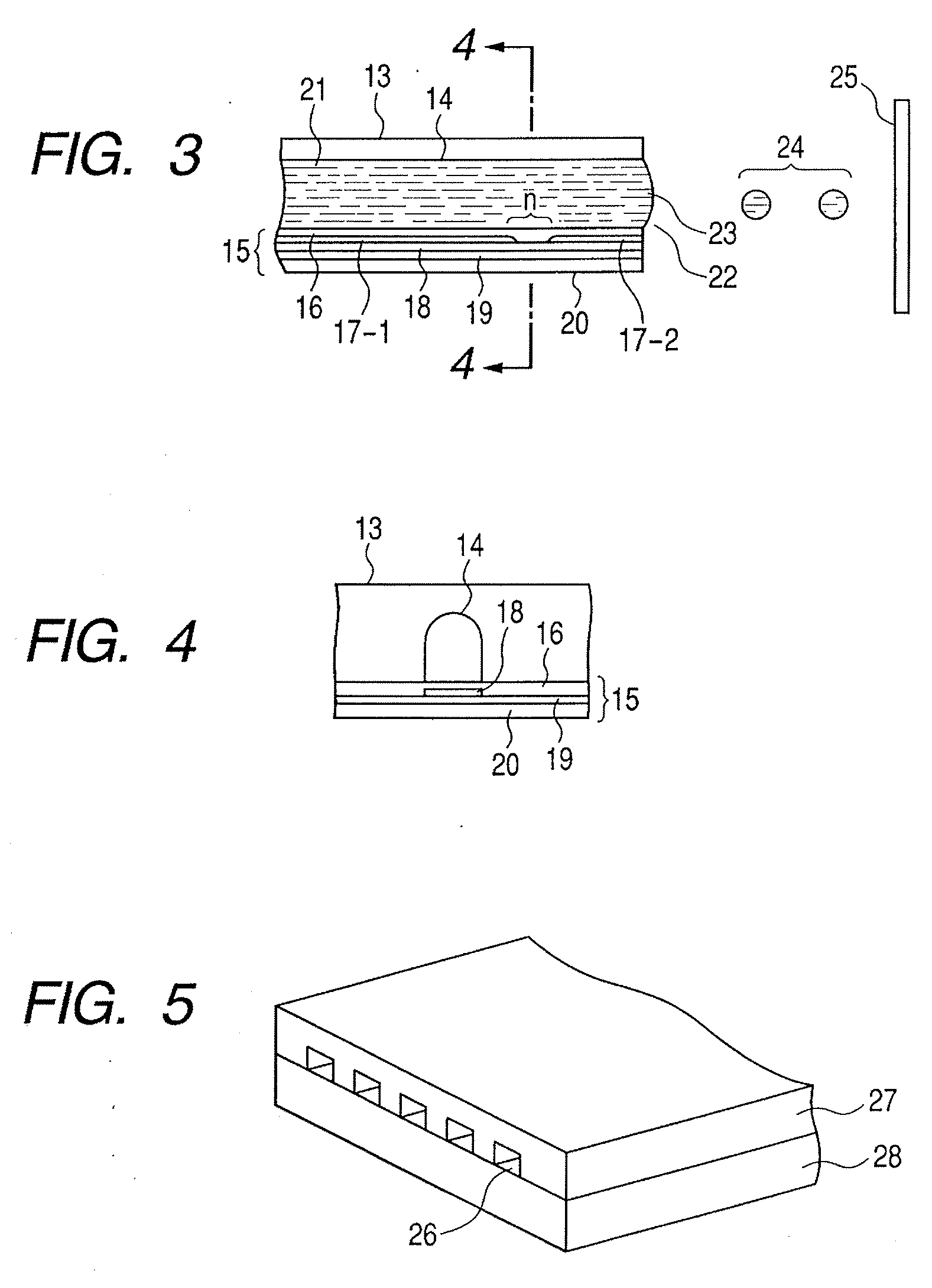

Antireflection film, polarizing plate, method for producing them, liquid cryatal display element, liquid crystal display device, and image display device

ActiveUS20070146887A1Reduce weightLow costLiquid crystal compositionsSynthetic resin layered productsSilica particleLiquid-crystal display

To provide an antireflection film which is easily and inexpensively producible and which has an antireflection property, a scratch resistance and a stain resistance in a sufficient level, and a polarizing plate and a liquid crystal display device utilizing the antireflection film of such excellent ability, the antireflection film includs a transparent support and a low-refractive index layer having a lower refractive index than the transparent support, wherein the low-refractive index layer is an outermost layer, and the low-refractive index layer contains a hollow silica particle and a compound that reduces a surface free energy of the outermost layer.

Owner:FUJIFILM CORP

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

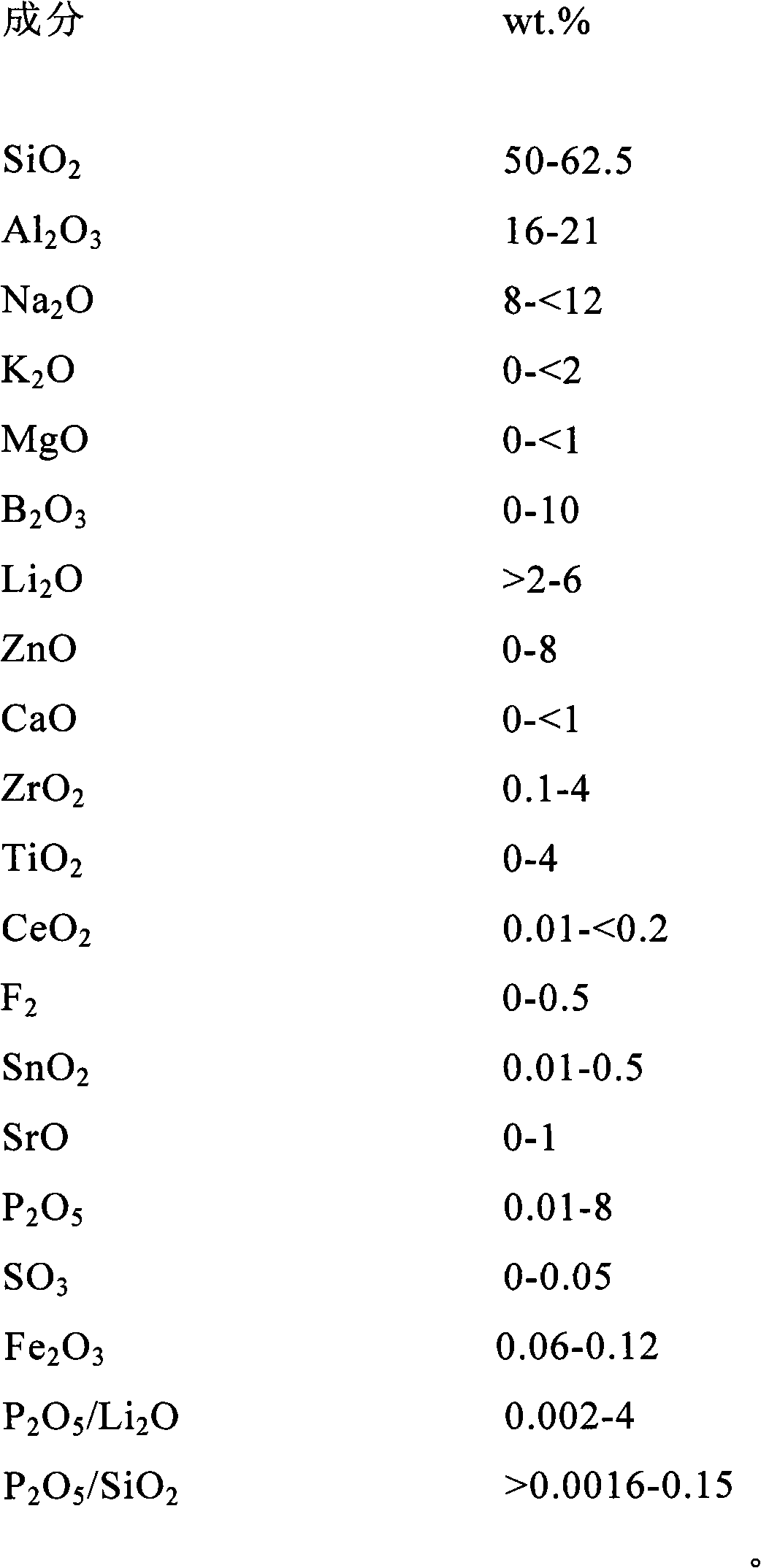

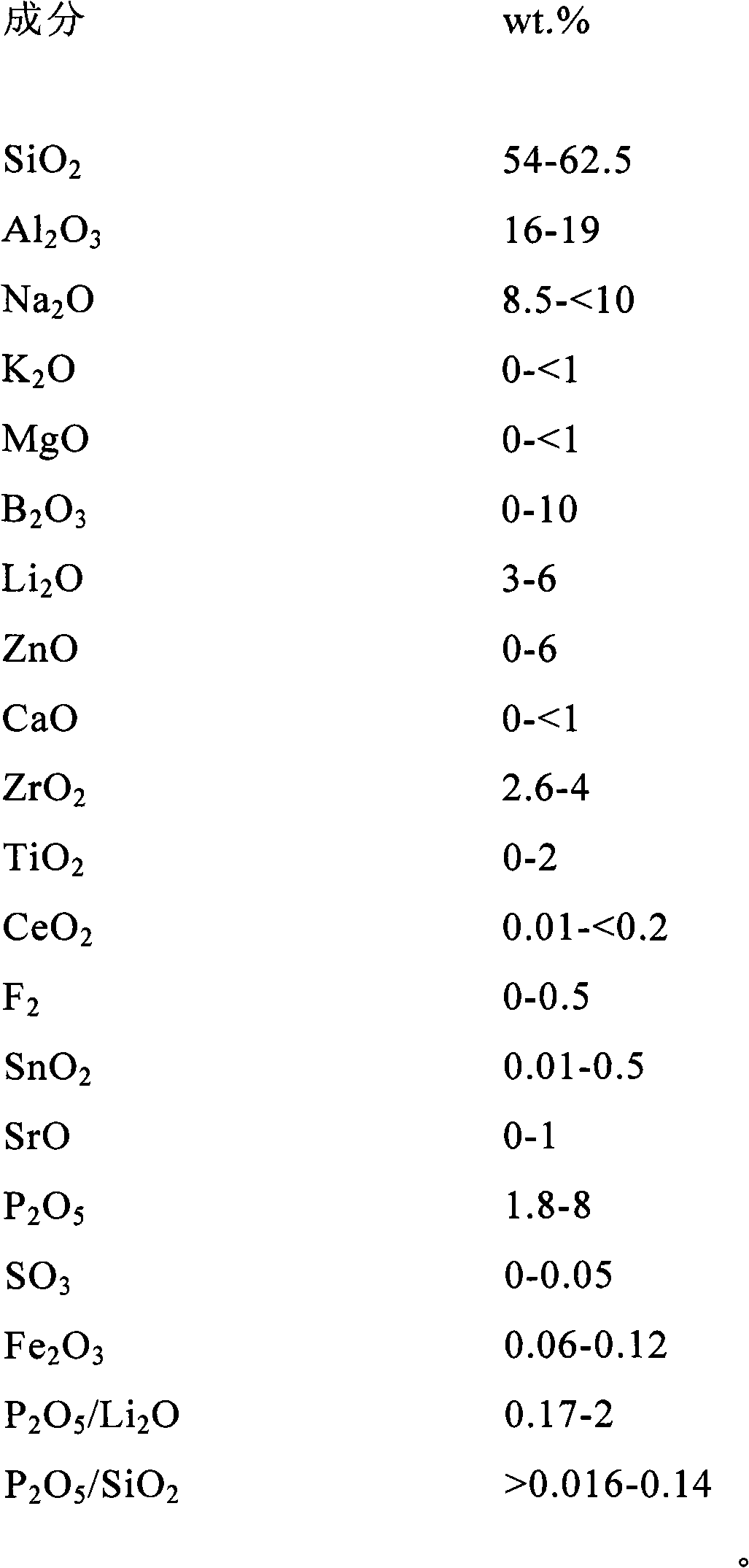

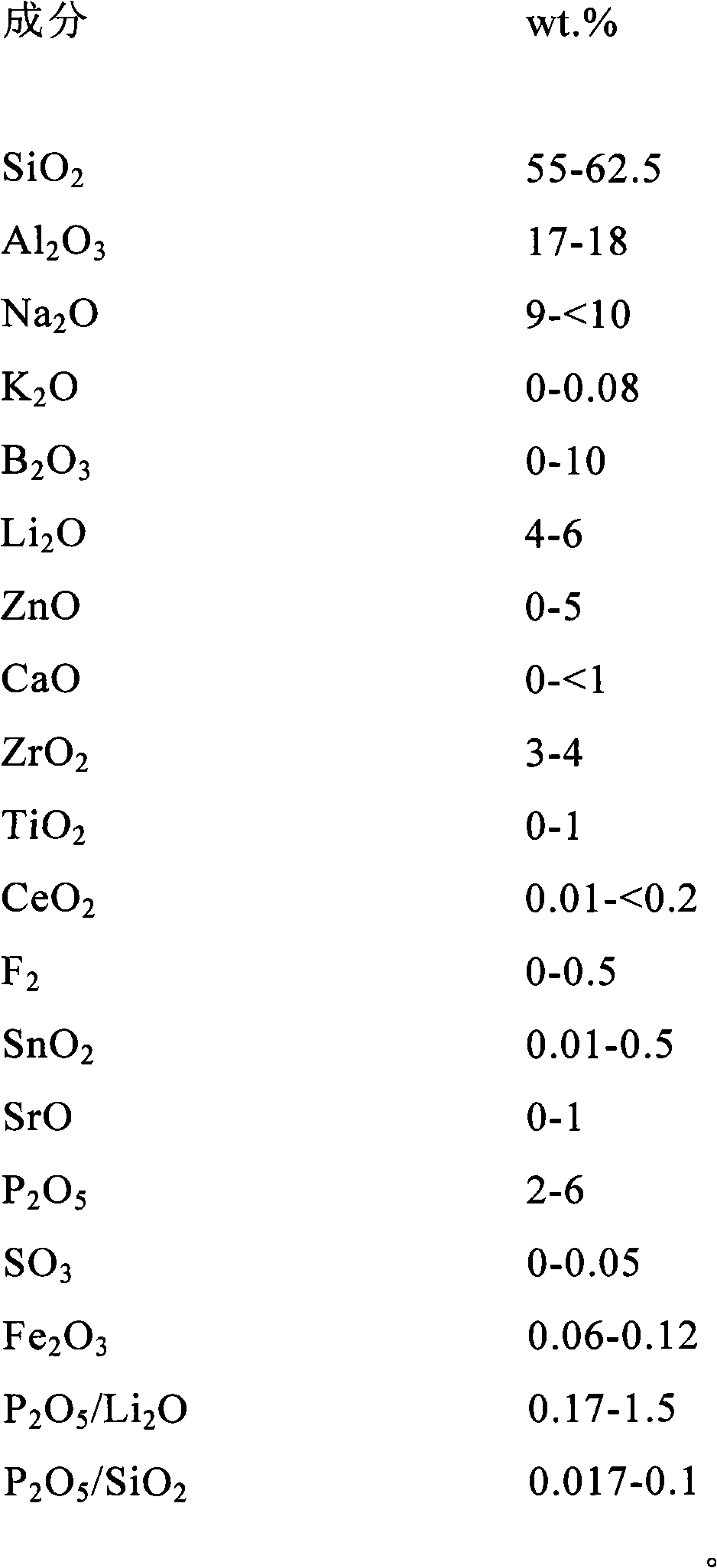

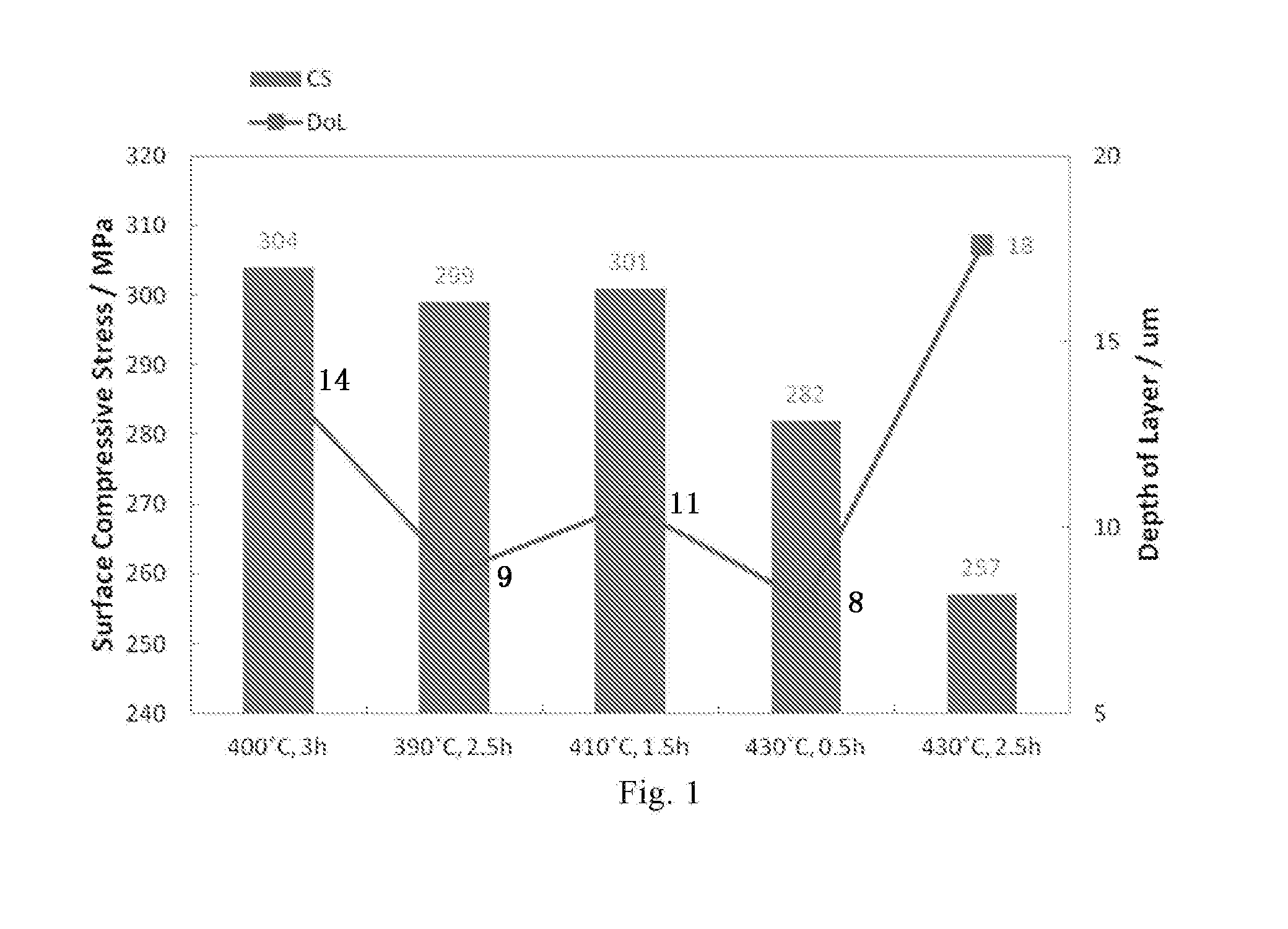

Aluminosilicate glass for chemical tempering and glass ceramics

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Polyolefin film containing cycloolefin polymer, process for the production thereof, and the use thereof

InactiveUS6068936AHigh strength valueGood barrier effectFlexible coversWrappersPolymer sciencePolyolefin

A polyolefin film which includes at least one layer containing polyolefin and cycloolefin polymer (COP), where the cycloolefin polymer is amorphous and has a mean molecular weight Mw in the range from 200 to 100,000, and this mean molecular weight Mw of the cycloolefin polymer is at most 50% of the mean molecular weight Mw of the polyolefin, and the cycloolefin polymer is a homopolymer or a copolymer containing at most 20% by weight of comonomer.

Owner:TICONA GMBH

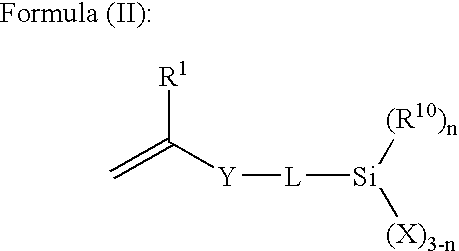

Coating compositions having improved scratch resistance, coated substrates and methods related thereto

InactiveUS7005472B2Improve scratch resistanceGood lookingMaterial nanotechnologyNanostructure manufacturePolymer sciencePolymer chemistry

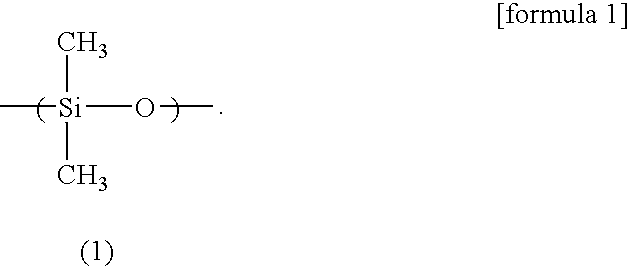

Coating compositions are provided which are formed from components comprising (a) at least one polysiloxane comprising at least one reactive functional group; (b) at least one reactant comprising at least one functional group that is reactive with at least one functional group selected from the at least one reactive functional group of the at least one polysiloxane and at least one functional group of at least one reactant; and (c) a plurality of particles, wherein each component is different, and wherein the at least one reactive functional group of the at least one polysiloxane and the at least one functional group of the at least one reactant are substantially nonreactive with the particles. A multi-component composite coating composition formed from a basecoat and a topcoat deposited from the curable coating composition also is provided. The multi-component composite coating compositions of the invention provide highly scratch resistant color-plus-clearcoatings capable of retaining scratch resistance after weathering.

Owner:PPG IND OHIO INC

Silsesquioxane derived hard, hydrophobic and thermally stable thin films and coatings for tailorable protective and multi-structured surfaces and interfaces

ActiveUS20110062619A1Attractive balanceImprove scratch resistanceNanoinformaticsPhotomechanical apparatusDiluentRare earth

A method of forming a coating comprising the steps of dissolving an silsesquioxane (e.g., one that is primarily a cage compound with 8, 10, 12, 14 or related complete cages or with partially condensed cages containing primarily Si(O)4 units in the cage) in a solvent to form an silsesquioxane solution; introducing (e.g., dissolving) an additive in the solution (e.g., the additive being selected from a rare earth compound, an acid, an organic moiety, a precious metal or compound thereof, a transition metal compound, or any combination thereof, or any of their ionic constituents); and optionally mixing a diluent with the solution to form a coating that is applied to a substrate, wherein the resulting coating forms crosslinks between resulting pendant Si(OH)x groups and a substrate surface. The present invention also contemplates coatings and coated articles consistent with the present teachings.

Owner:LAINE RICHARD M

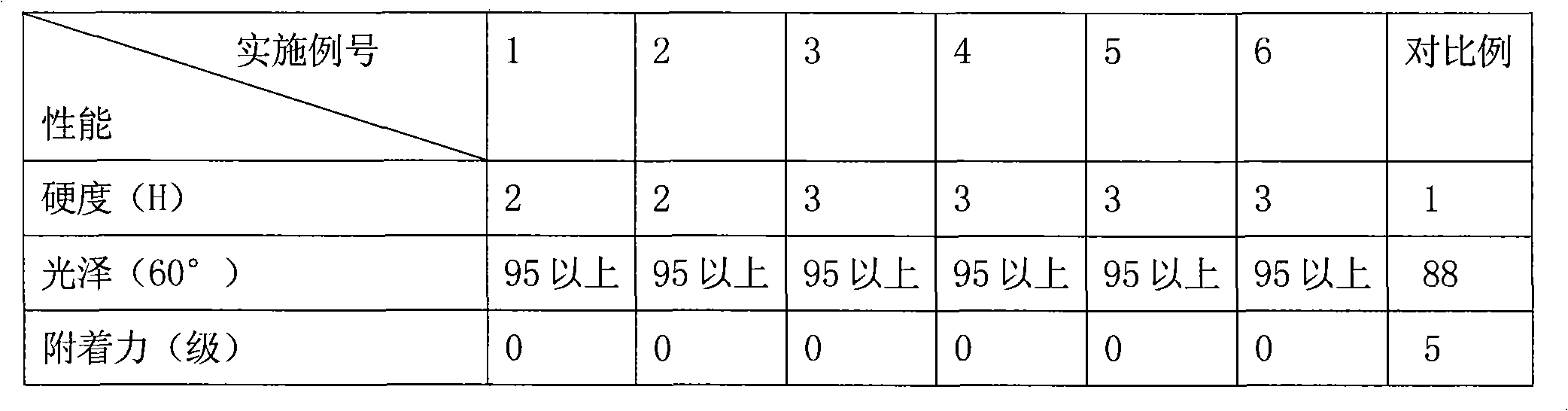

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

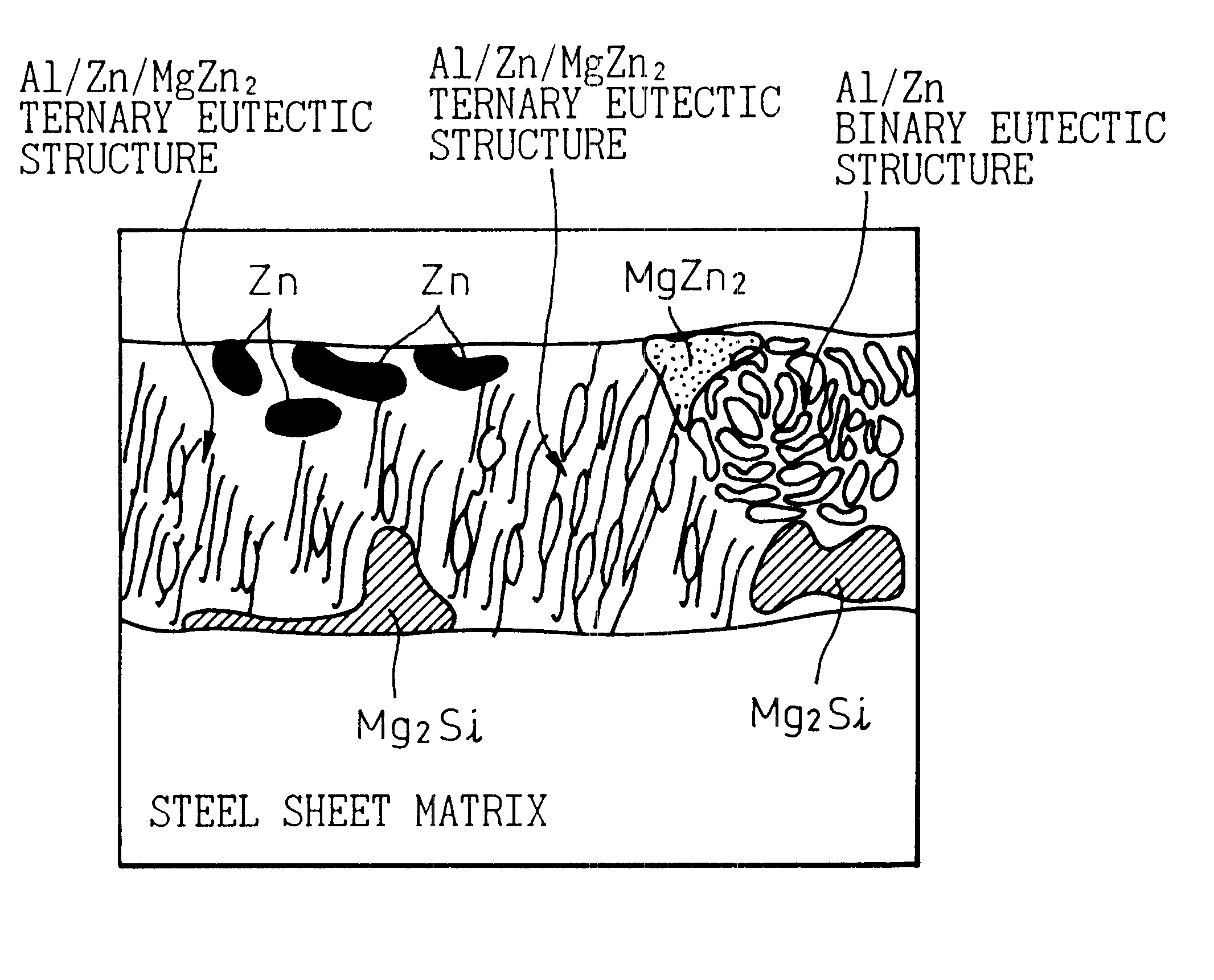

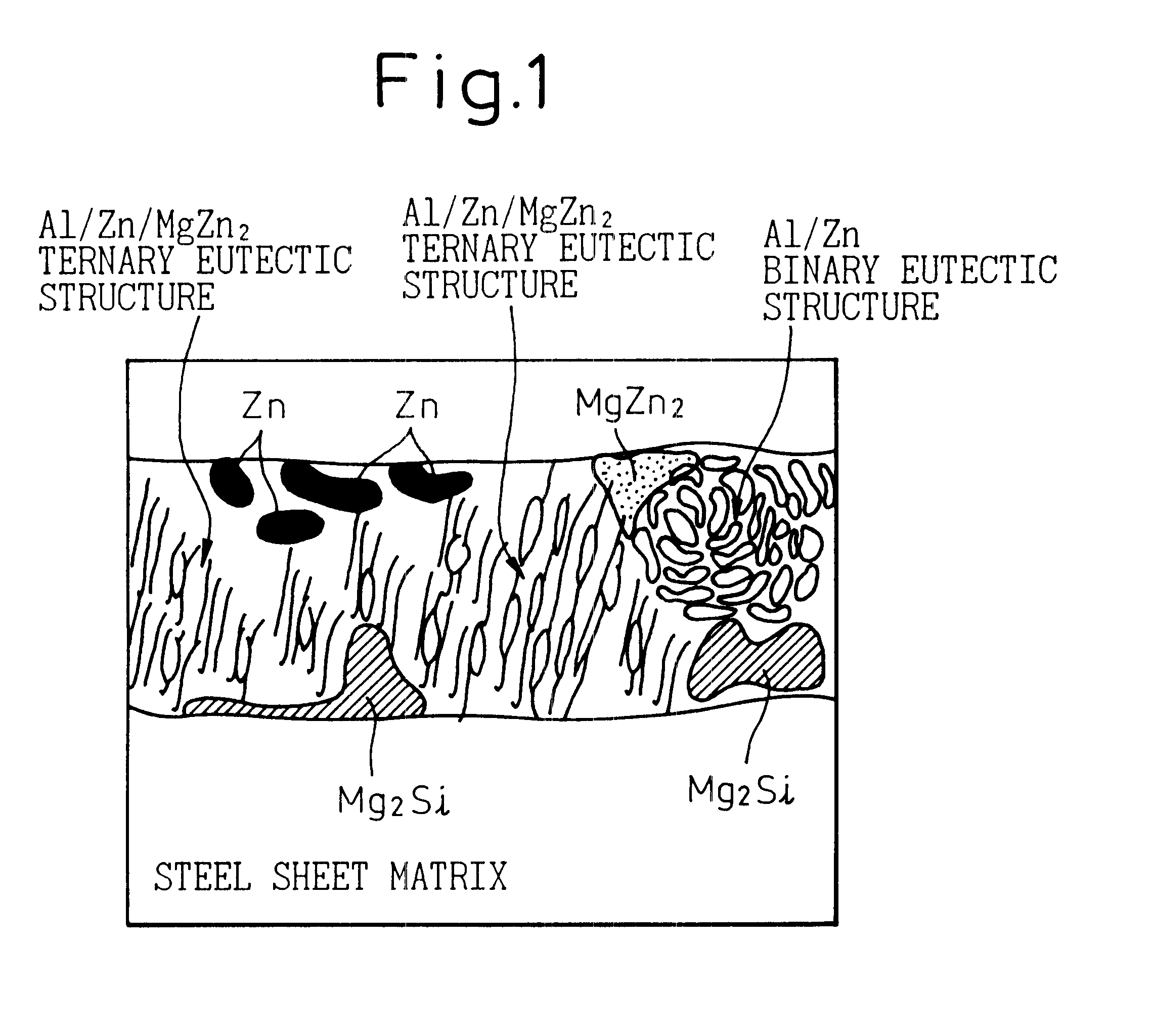

-Zn coated steel material, ZN coated steel sheet and painted steel sheet excellent in corrosion resistance, and method of producing the same

InactiveUS6465114B1Improve corrosion resistanceResistance to red rustHot-dipping/immersion processesLiquid surface applicatorsSheet steelAlloy coating

A coated steel material excellent in corrosion resistance and a method of producing the same, wherein a coated steel material has on the surface of the steel sheet a Zn-alloy coating layer containing 1-10 wt % of Mg, 2-19 wt % of Al and 0.01-2 wt % of Si, where Mg and Al satisfy Mg (%)+Al (%)<=20%, the balance being Zn and unavoidable impurities, and has a coating layer structure of a Mg intermetallic compound or the like. As a base metal treatment, it is preferably provided with a Ni coating layer. The coated Zn-alloy coated steel sheet may have provided on the coating layer, as an intermediate layer, a chromate film layer, and, as an upper layer, an organic coating layer. The Zn-alloy coating layer may further contain one or more of 0.01-1 wt % of In, 0.01-1 wt % of Bi and 1-10 wt % of Sn. The coated steel material may be painted.

Owner:NIPPON STEEL CORP

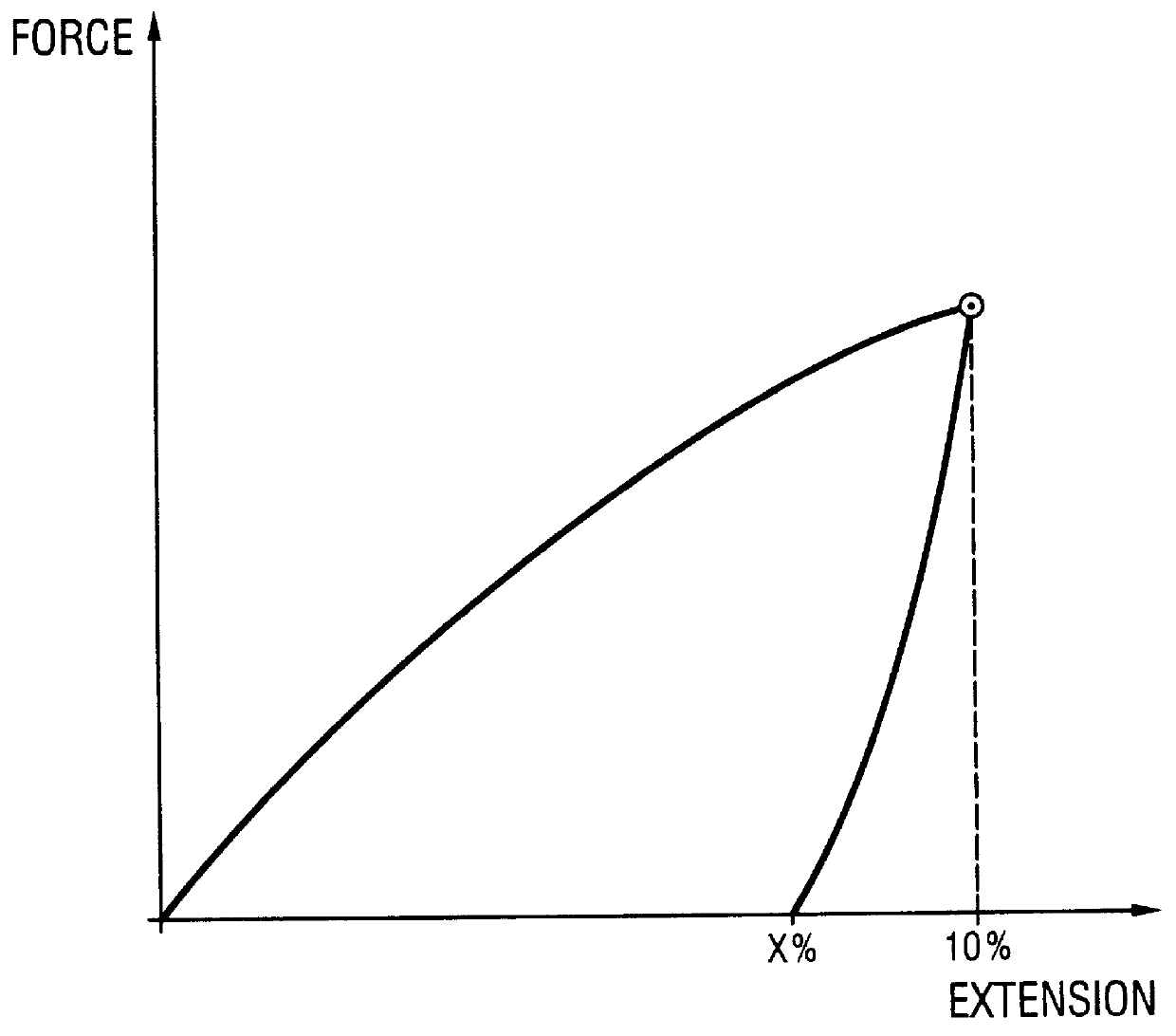

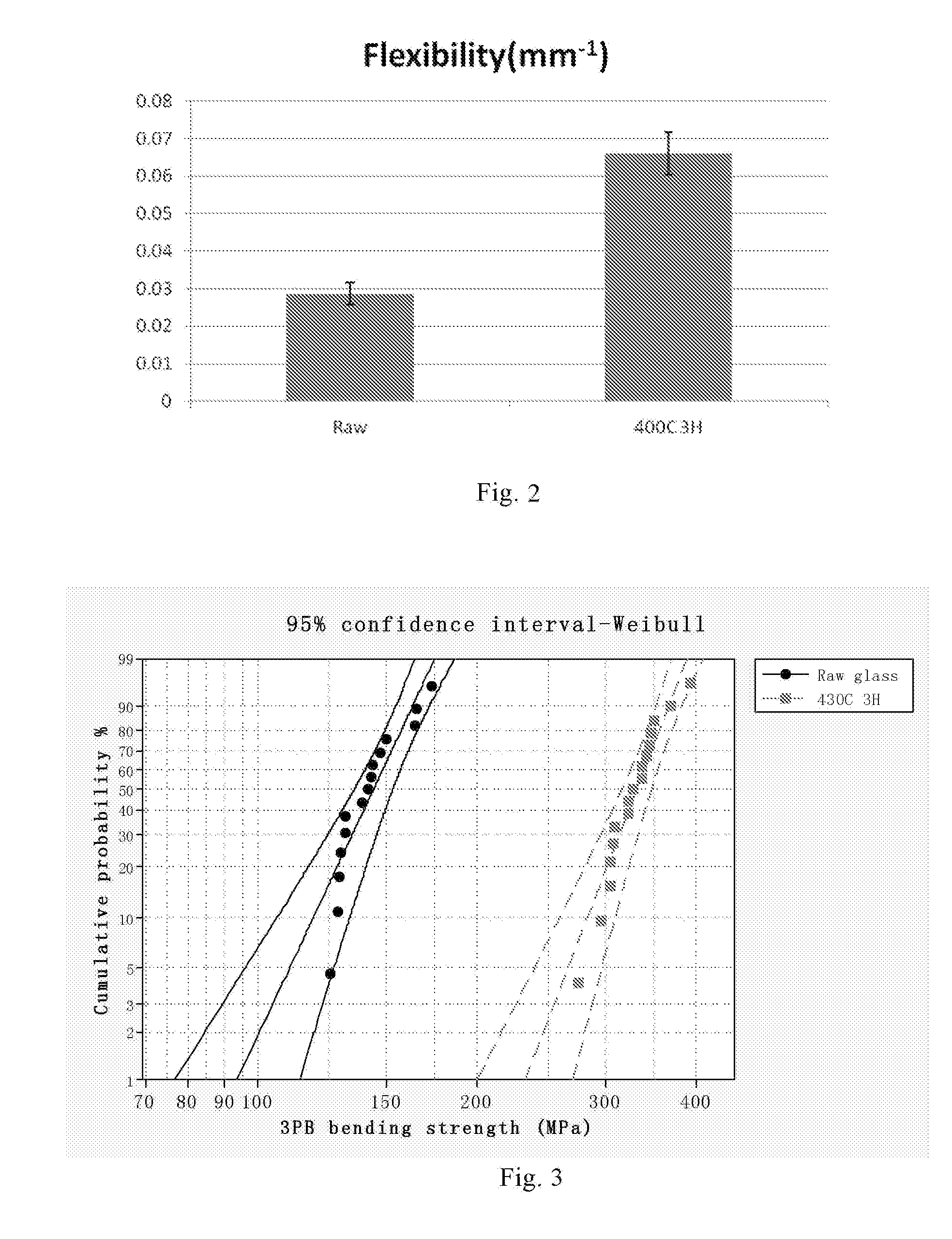

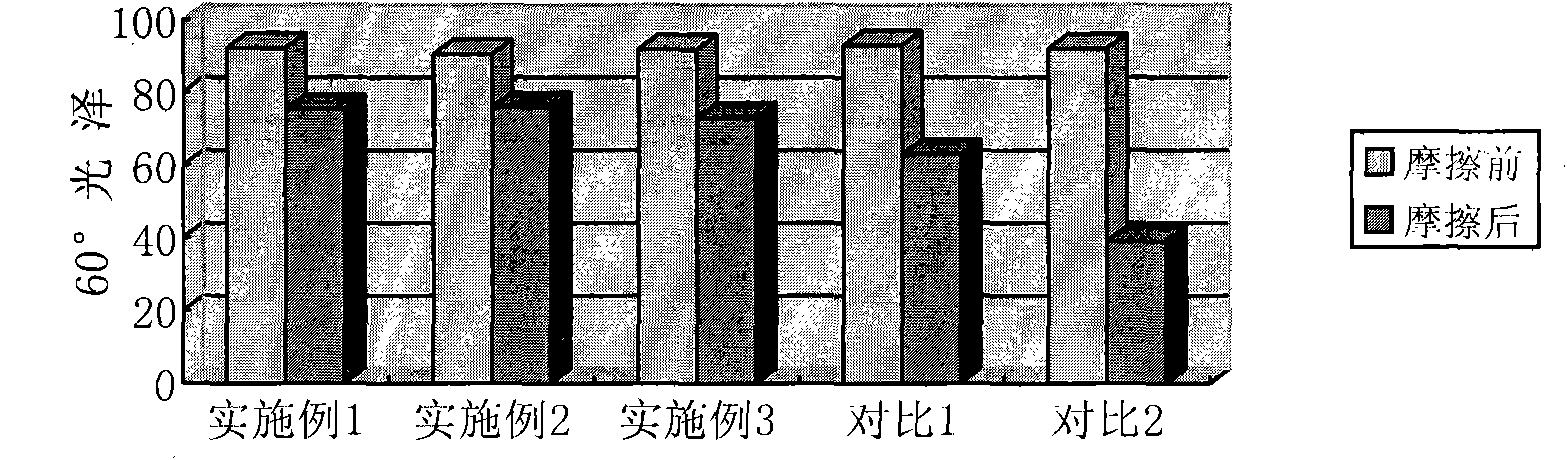

Chemically Toughened Flexible Ultrathin Glass

ActiveUS20160002103A1Reduce compressive stressIncrease flexibilityFilm/foil adhesivesSynthetic resin layered productsGlass sheetThermal shock

A chemically toughened ultrathin glass is provided. The glass has a thickness less than 500 μm and a surface compressive layer having a depth of at most 30 μm. The toughened ultrathin glass sheet is more flexible and has extraordinary thermal shock resistance with the glass being easier to handle for processing.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

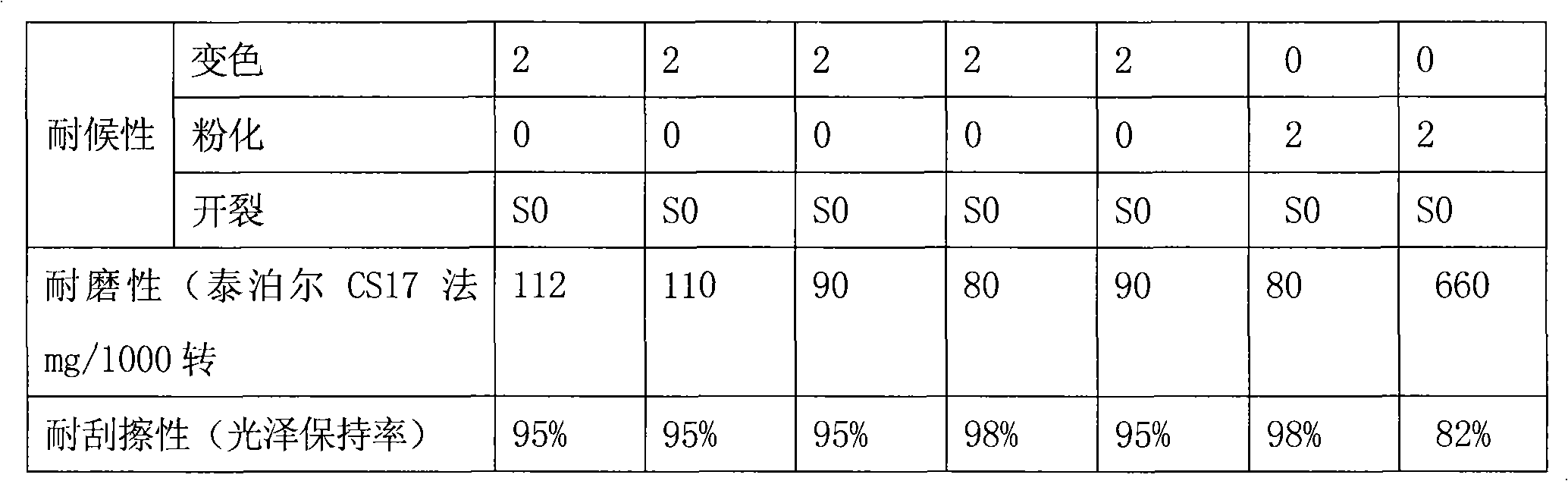

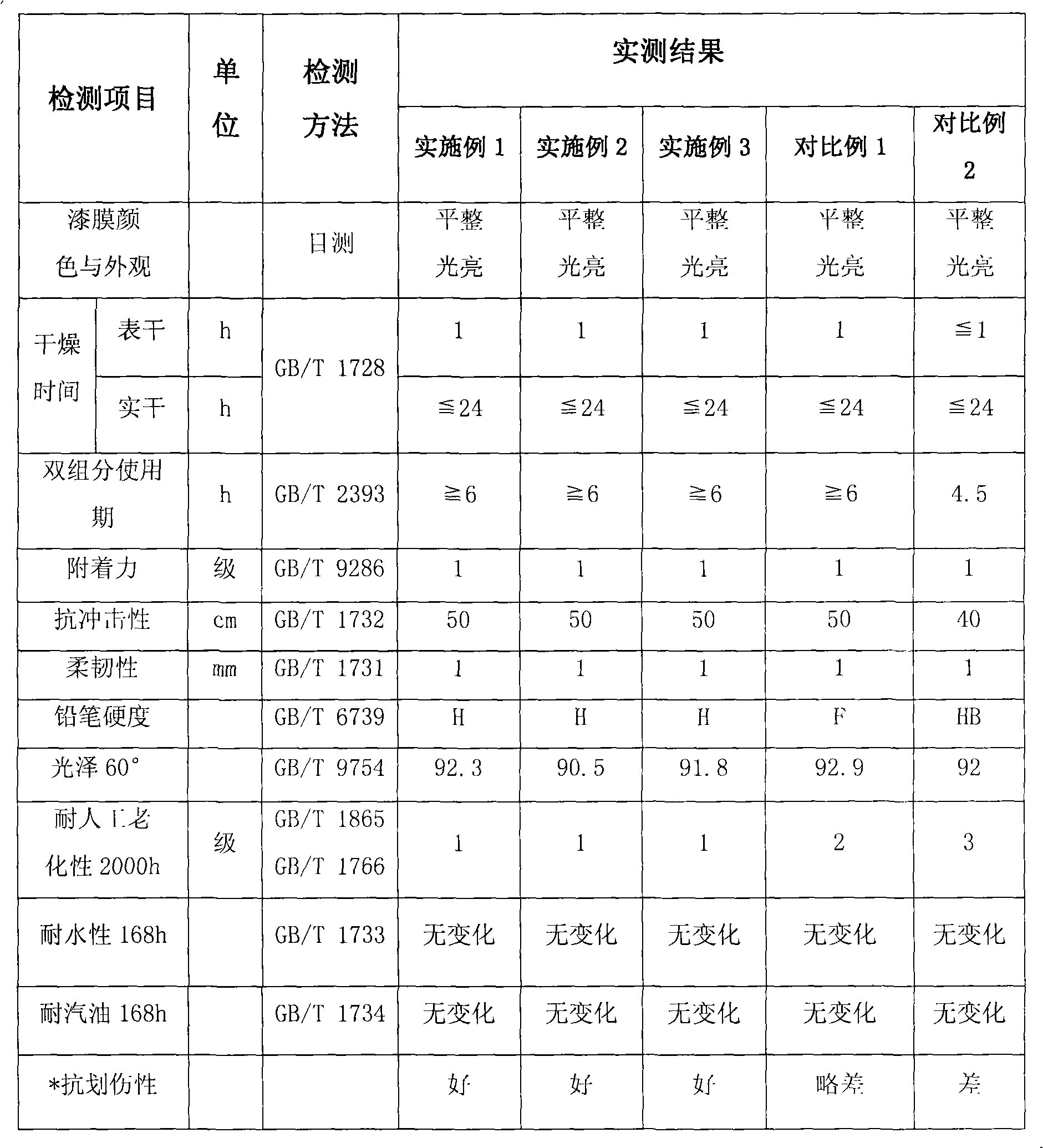

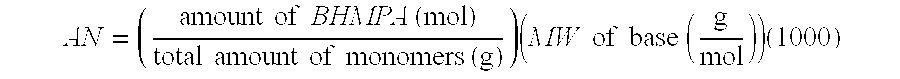

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

Ink jet composition containing microgel particles

InactiveUS20060100307A1Improve scratch resistanceImprove stain resistanceInksCoatingsWater insolubleCarboxylic acid

This invention relates to an ink jet ink composition comprising an aqueous medium and microgel particles, said particles comprising a crosslinked copolymer prepared from a monomer mixture comprising at least a crosslinking monomer, a polymerizable carboxylic acid monomer, and one or more polymerizable water insoluble vinyl type monomers. The ink composition may be a colorless ink or it may contain a colorant.

Owner:EASTMAN KODAK CO

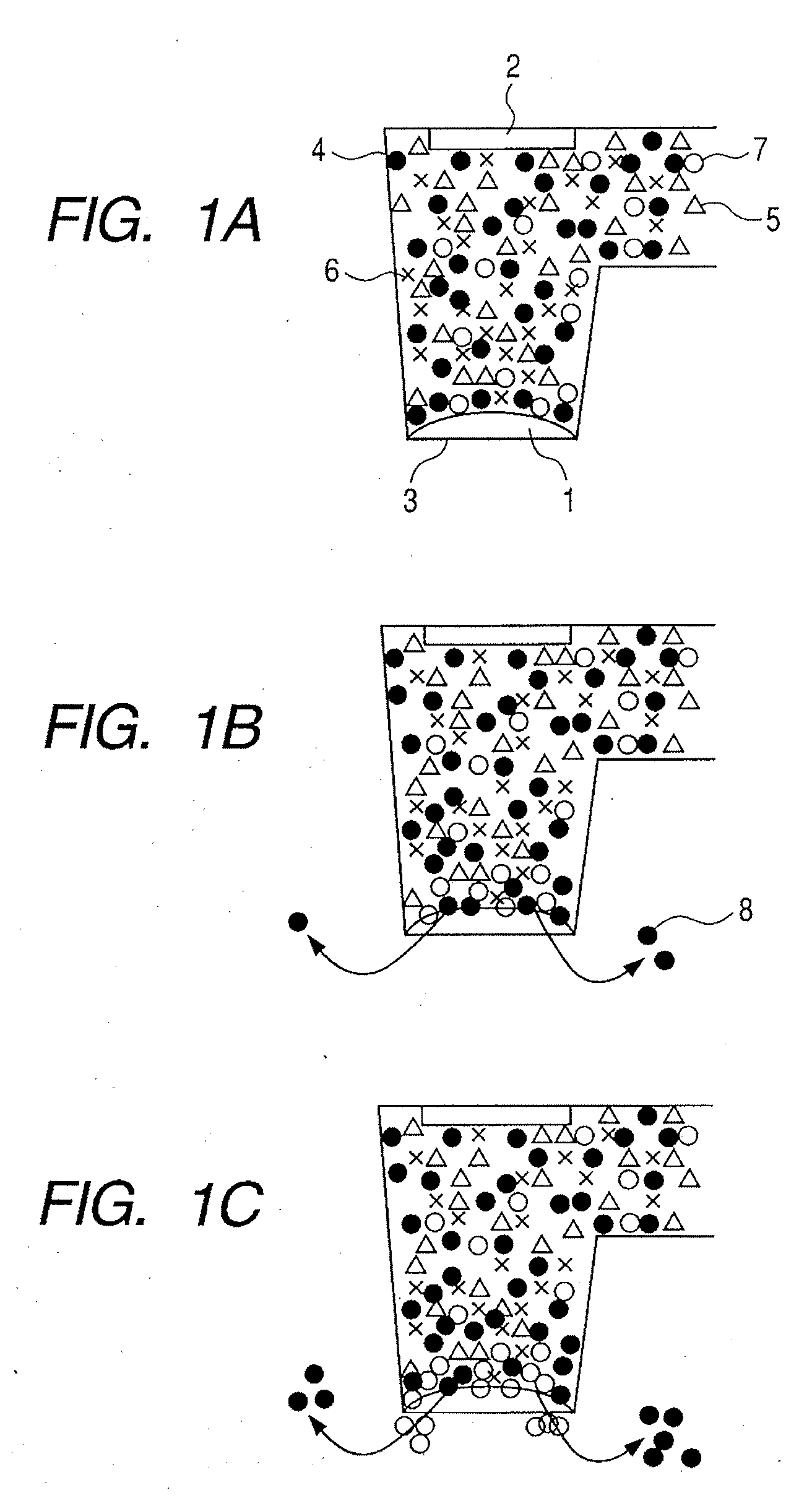

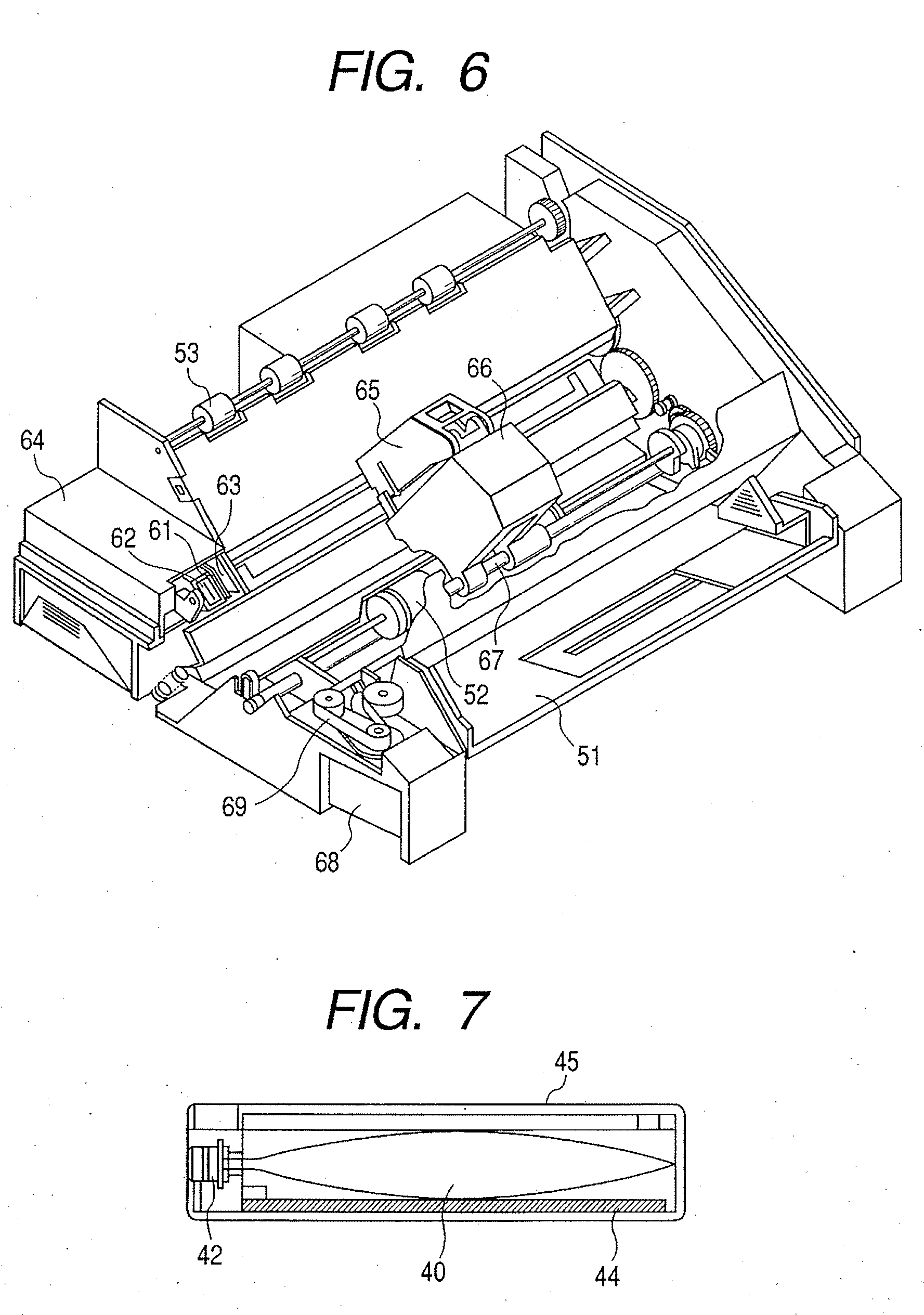

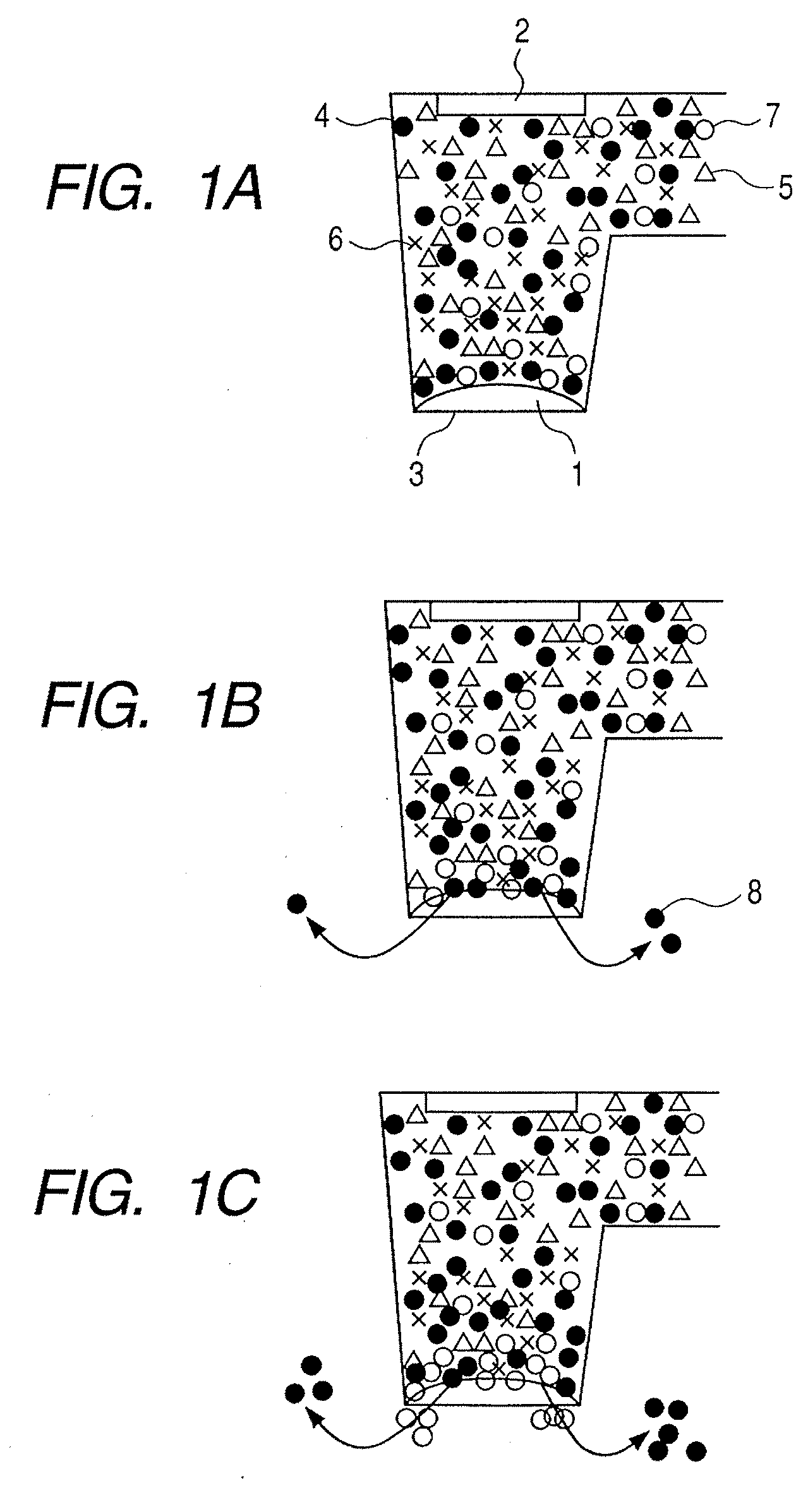

Aqueous ink, ink-jet recording method, ink cartridge, recording unit, ink-jet recording apparatus and image forming method

ActiveUS7276112B2Increase the areaHigh print densityDuplicating/marking methodsInksOrganic solventAtomic group

Disclosed is an aqueous ink comprising at least water, a plurality of water-soluble organic solvents and a coloring material. The coloring material is a pigment, and, it contains a pigment particle having at least one ionic group bonded to a surface of the pigment particle directly or via another atomic group. The plurality of water-soluble organic solvents have a good medium or good mediums for the pigment and a poor medium or poor mediums for the pigment. The poor medium does not solvate perfectly or substantially the pigment. The ionic group undergoes perfectly or substantially no ionic dissociation in the poor medium. Also, among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method, the Ka value of the poor medium is maximum.

Owner:CANON KK

Antireflection film, manufacturing method thereof, and polarizing plate using the same, and image display device

InactiveUS20070042173A1Achieve the wholeHigh in suitability for manufacturingSynthetic resin layered productsPretreated surfacesBoiling pointOrganic base

An antireflection film comprising a support and a layer formed by coating a composition containing at least one salt formed from an organic base whose conjugate acid has a pKa of from 5.0 to 10.5 and an acid, wherein the antireflection film has a haze value due to surface scattering of 1% or more and less than 10%, or an antireflection film comprising a support and a layer formed by coating a composition containing at least one salt formed from a nitrogen-containing organic base having a boiling point of from 35° C. to 85° C. and an acid, wherein the antireflection film has a haze value due to surface scattering of 1% or more and less than 10%.

Owner:FUJIFILM CORP

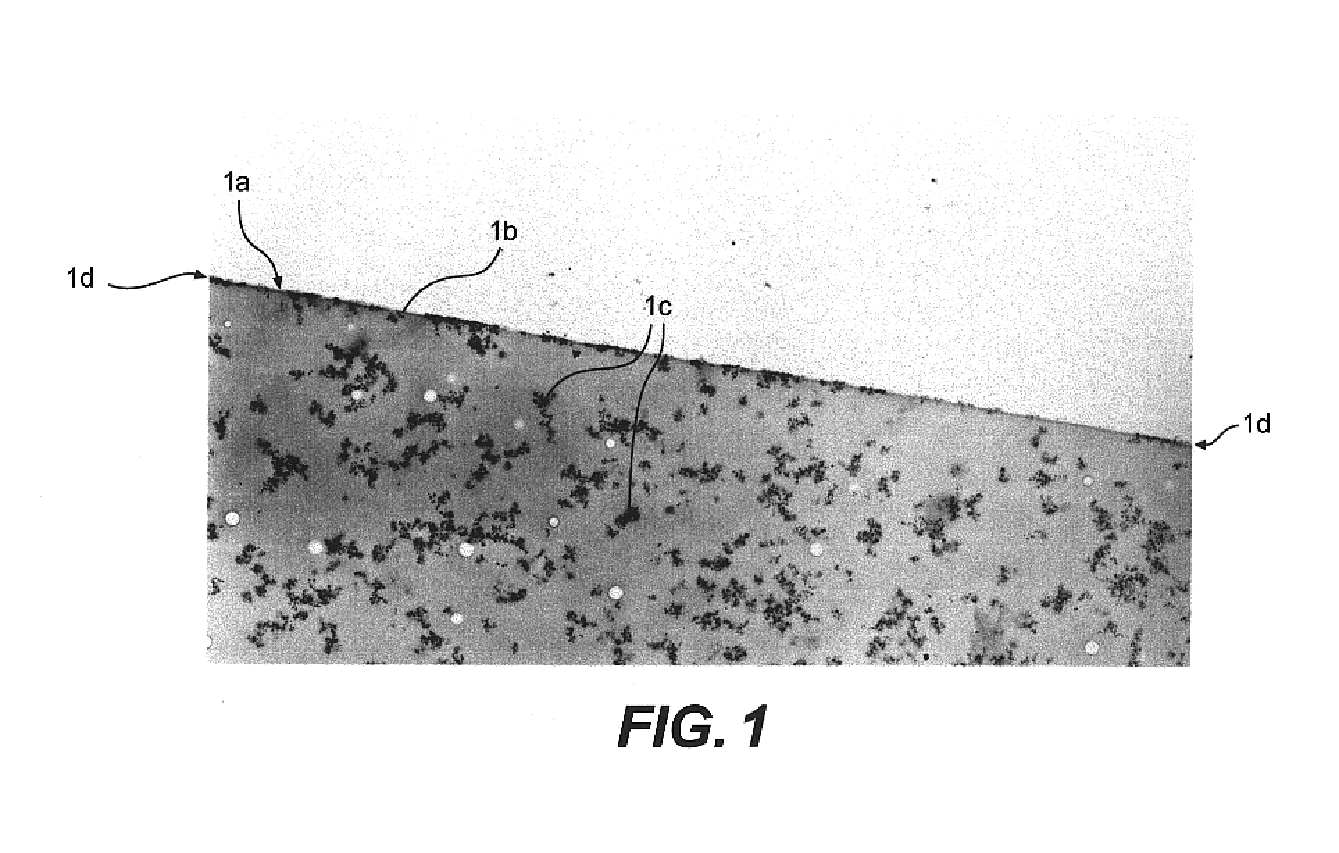

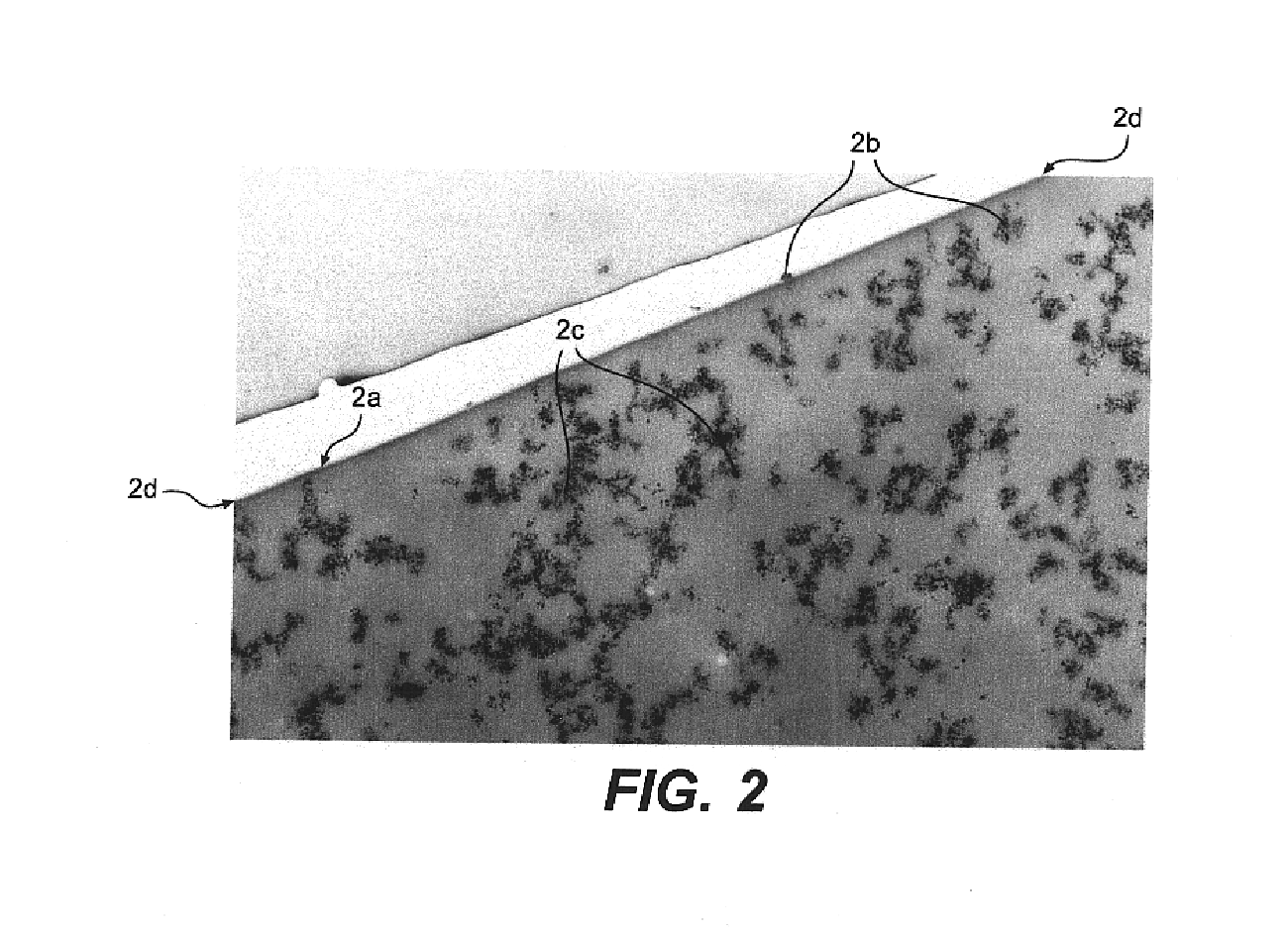

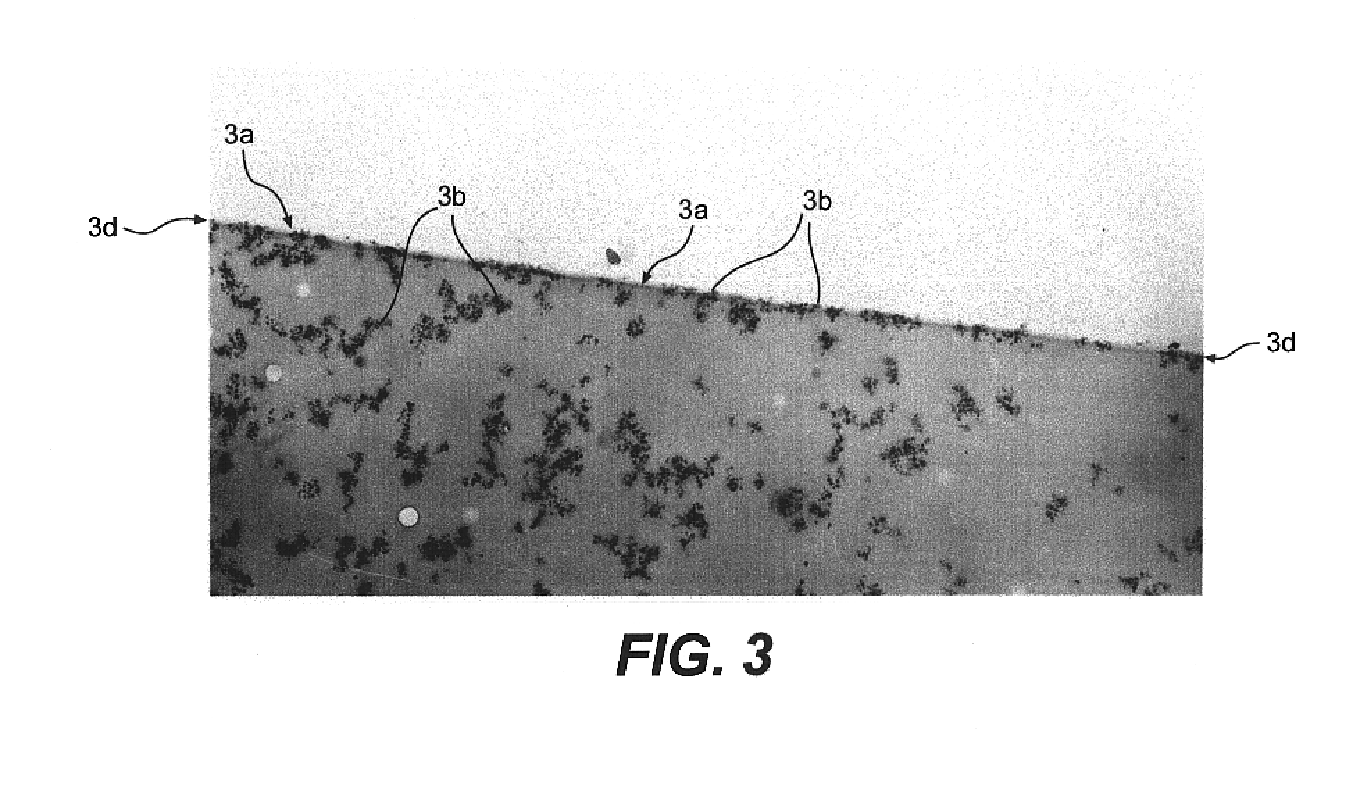

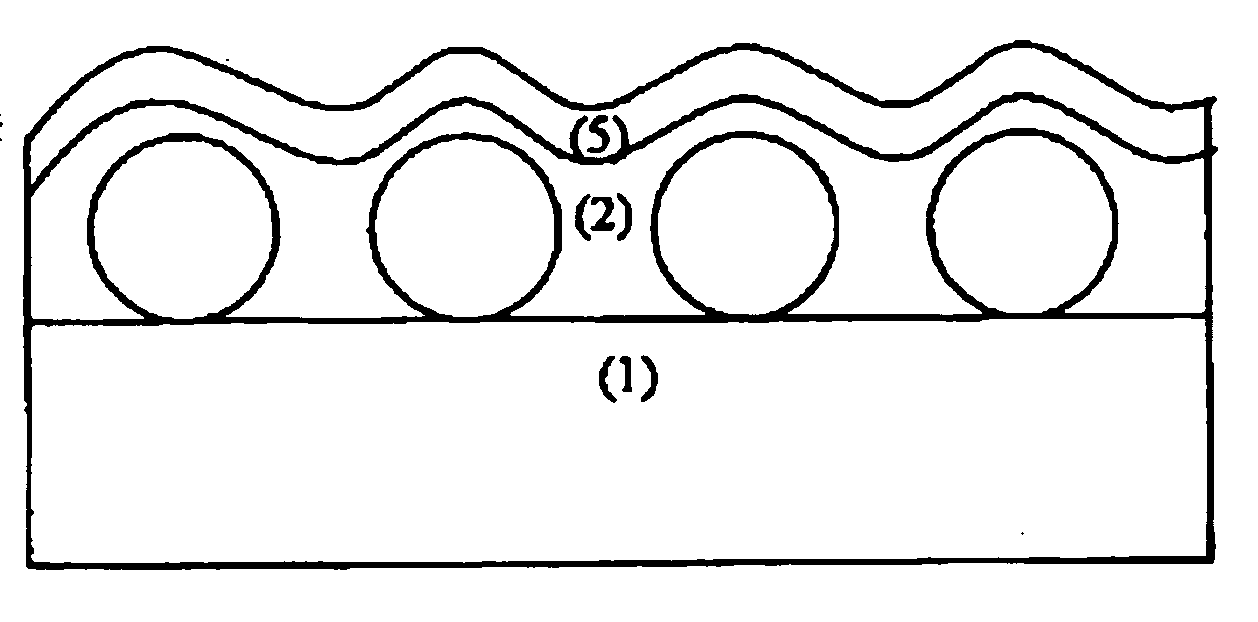

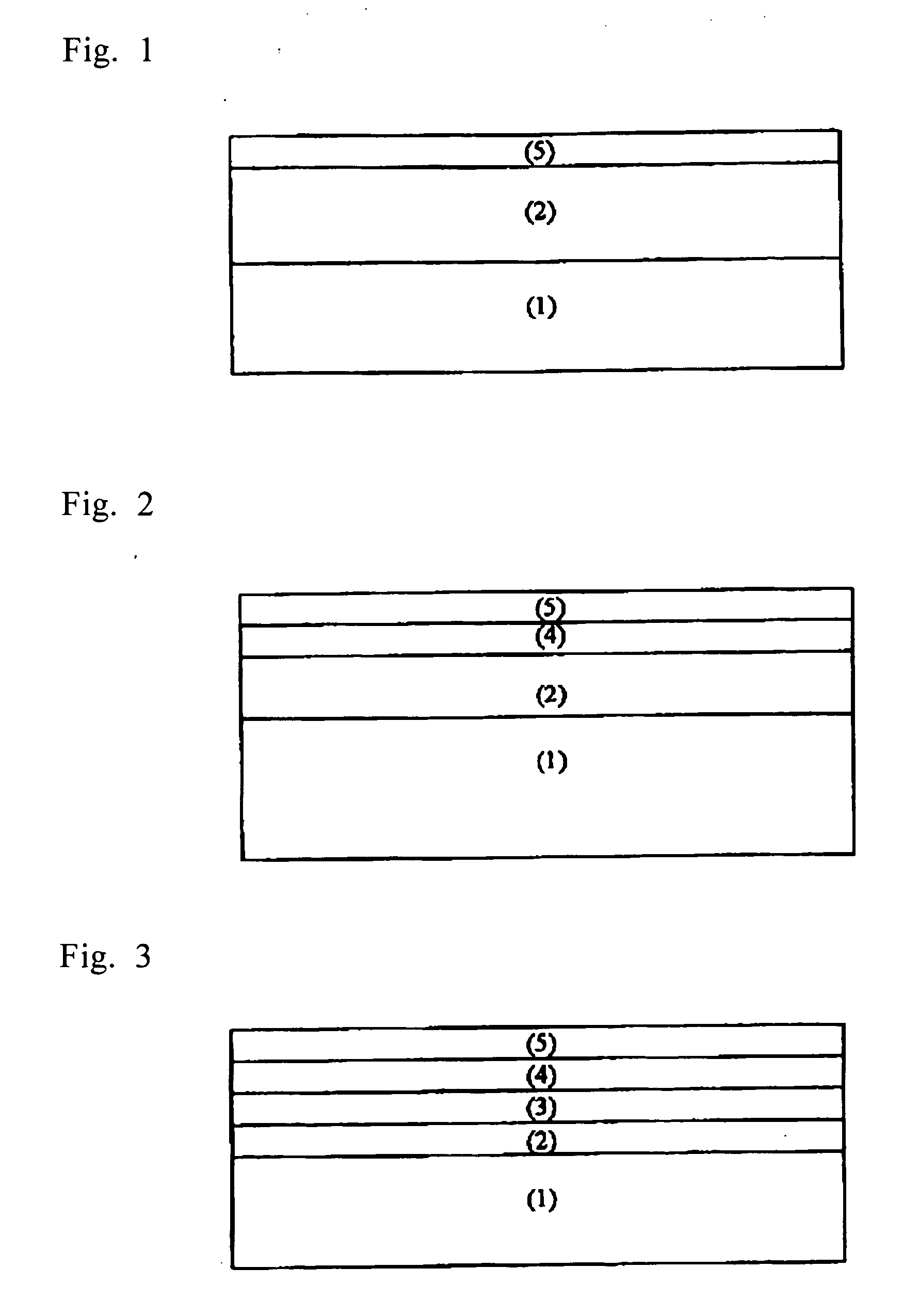

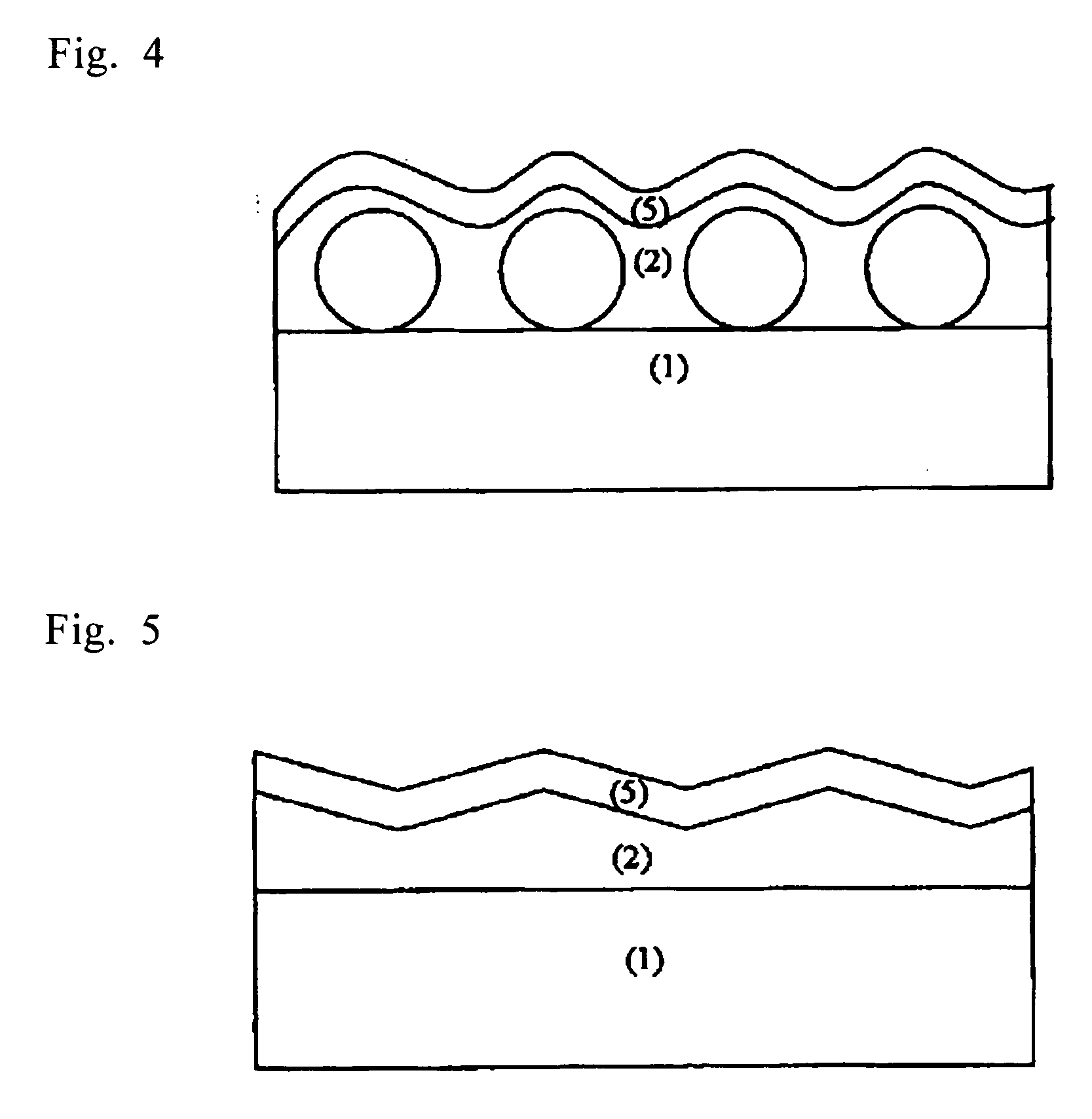

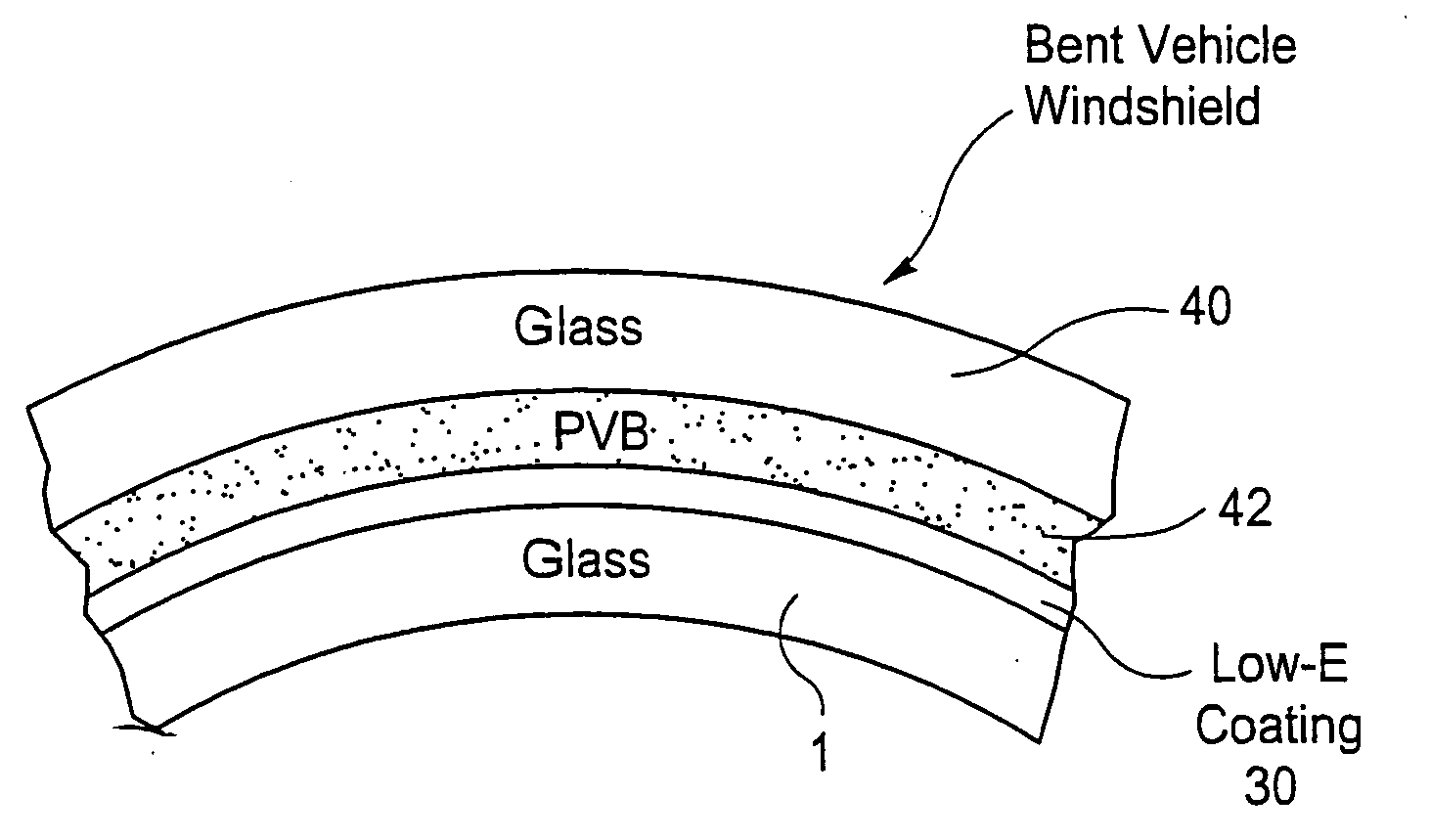

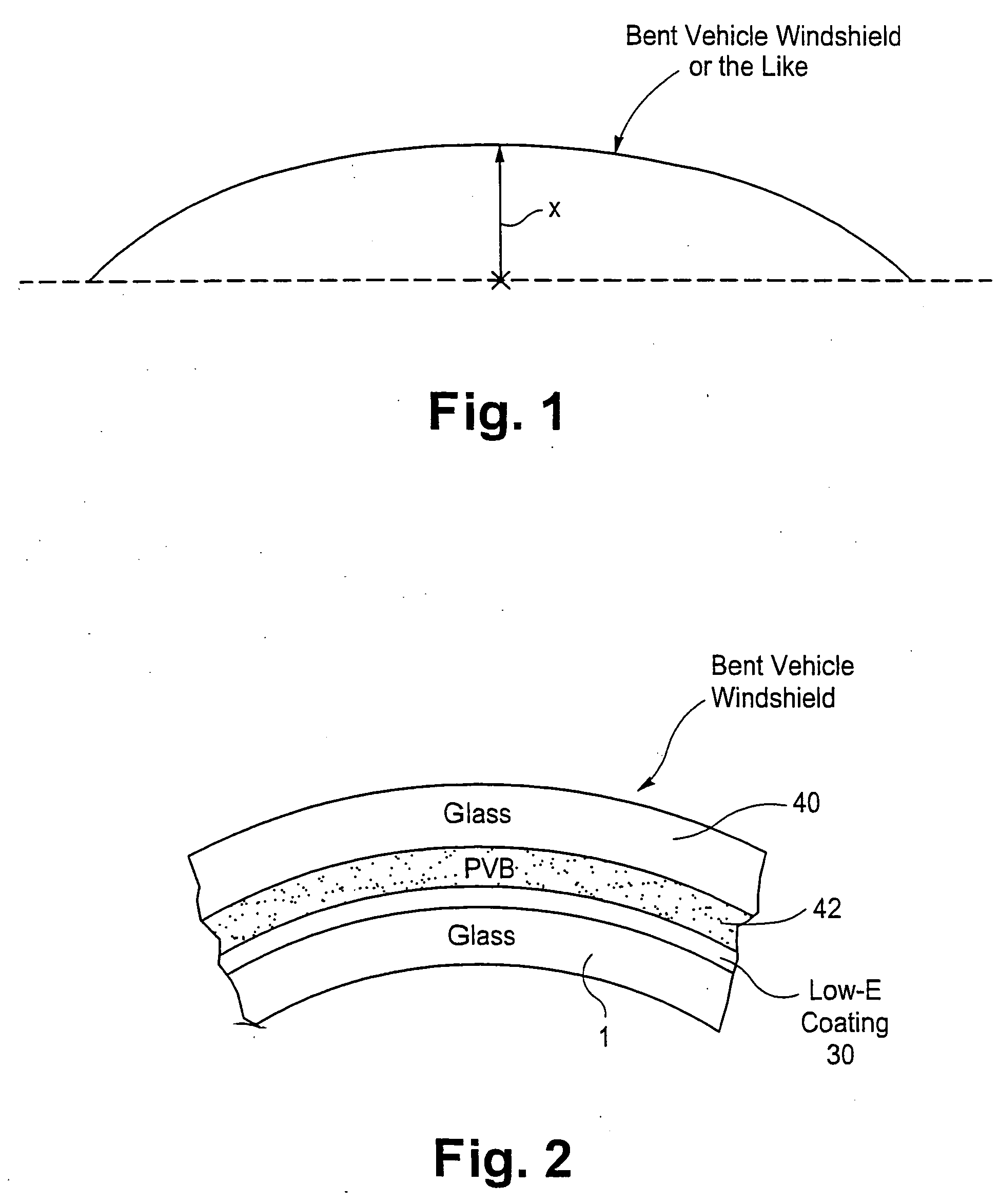

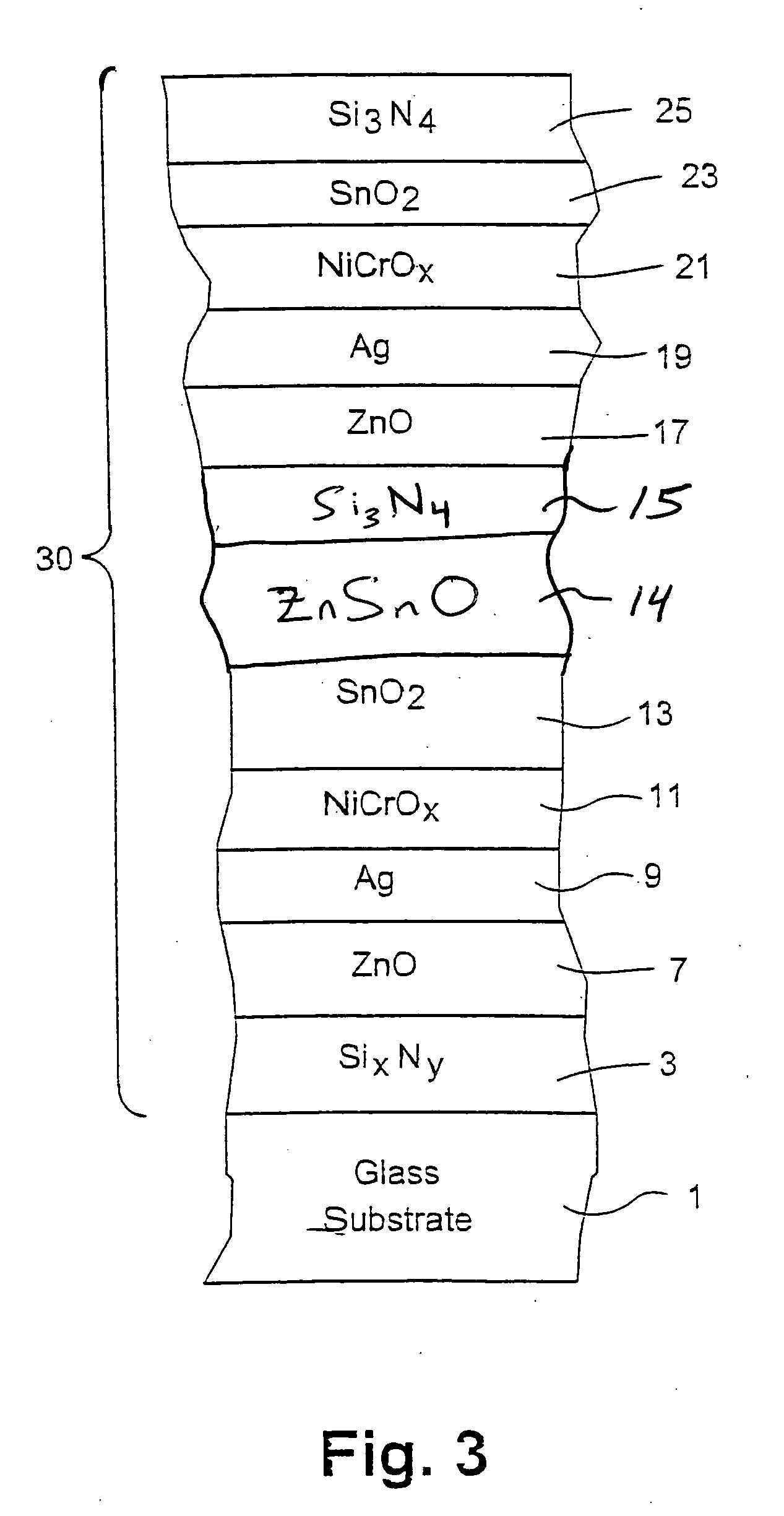

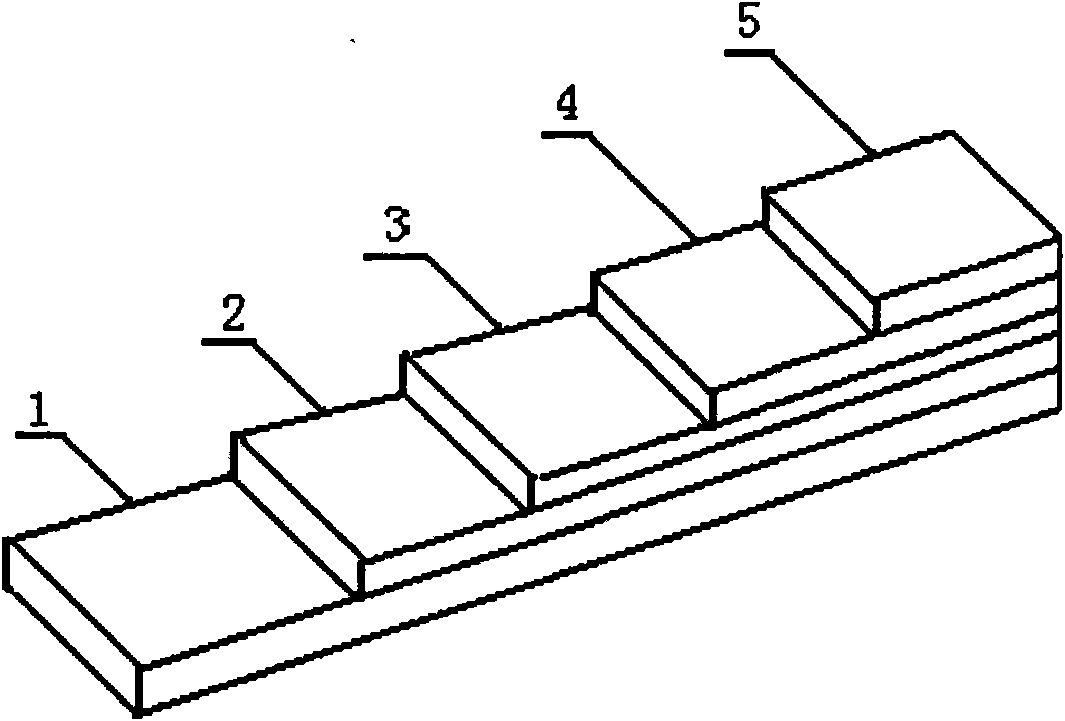

Coated article with low-e coating having zinc stannate based layer between IR reflecting layers for reduced mottling and corresponding method

ActiveUS20100295330A1Improve mechanical durabilityReduction in mottling damageWindowsWindscreensReflective layerStannate

A coated article is provided which may be heat treated (e.g., thermally tempered) and / or heat bent in certain example instances. In certain example embodiments, a zinc stannate based layer is provided between a tin oxide based layer and a silicon nitride based layer, and this has been found to significantly reduce undesirable mottling damage upon heat treatment / bending. This results in significantly improved bendability of the coated article in applications such as vehicle windshields and the like.

Owner:GUARDIAN EURO S A R L +1

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

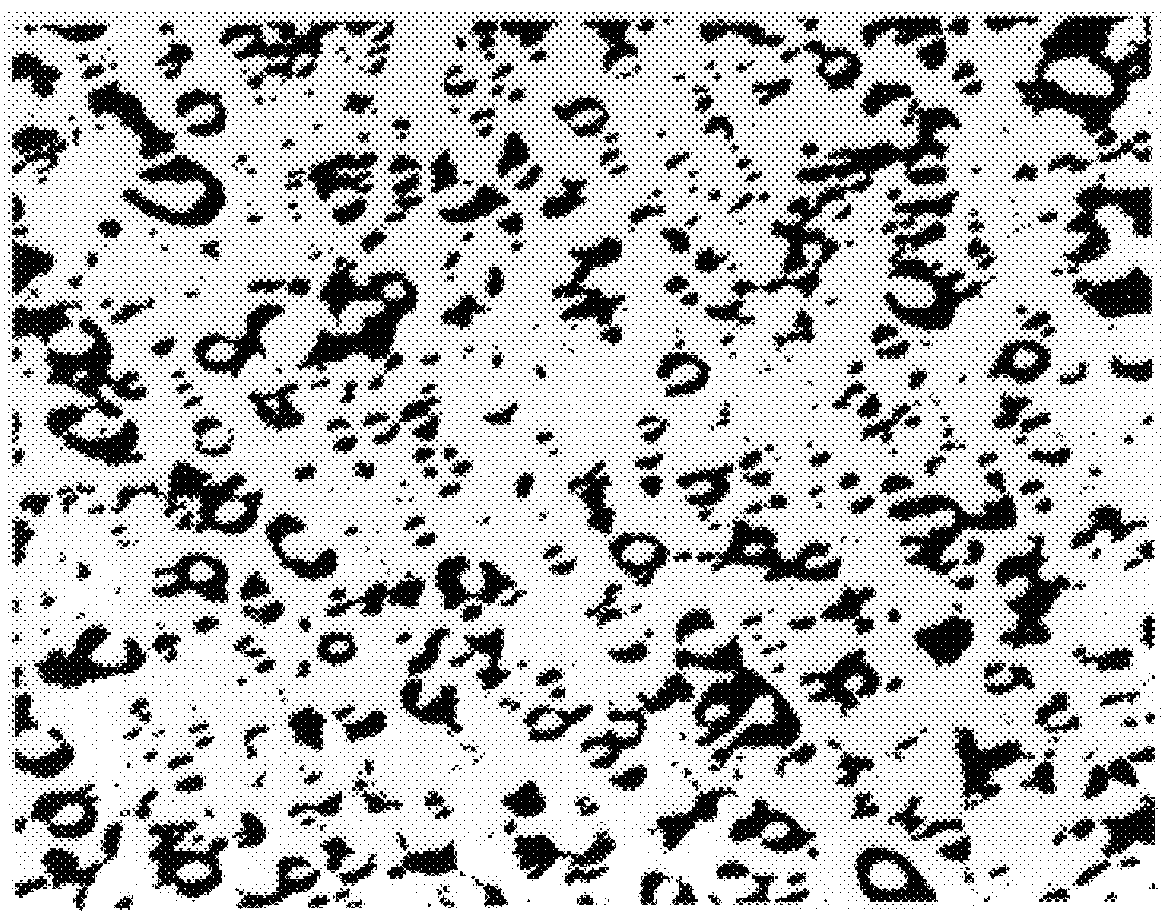

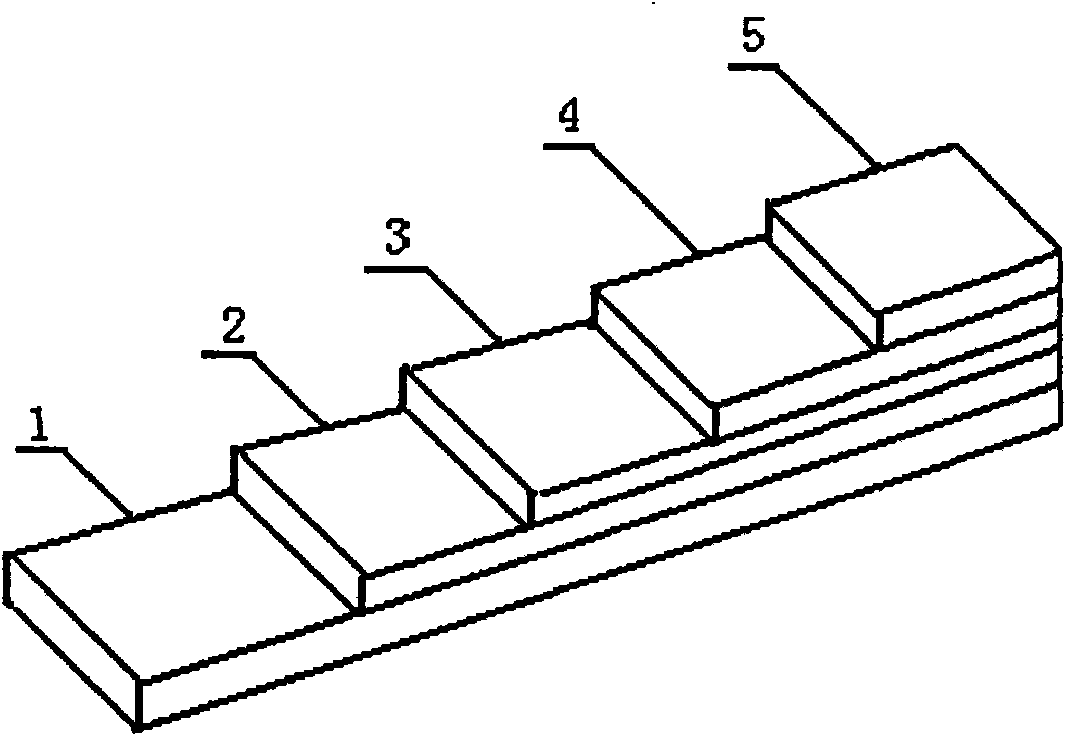

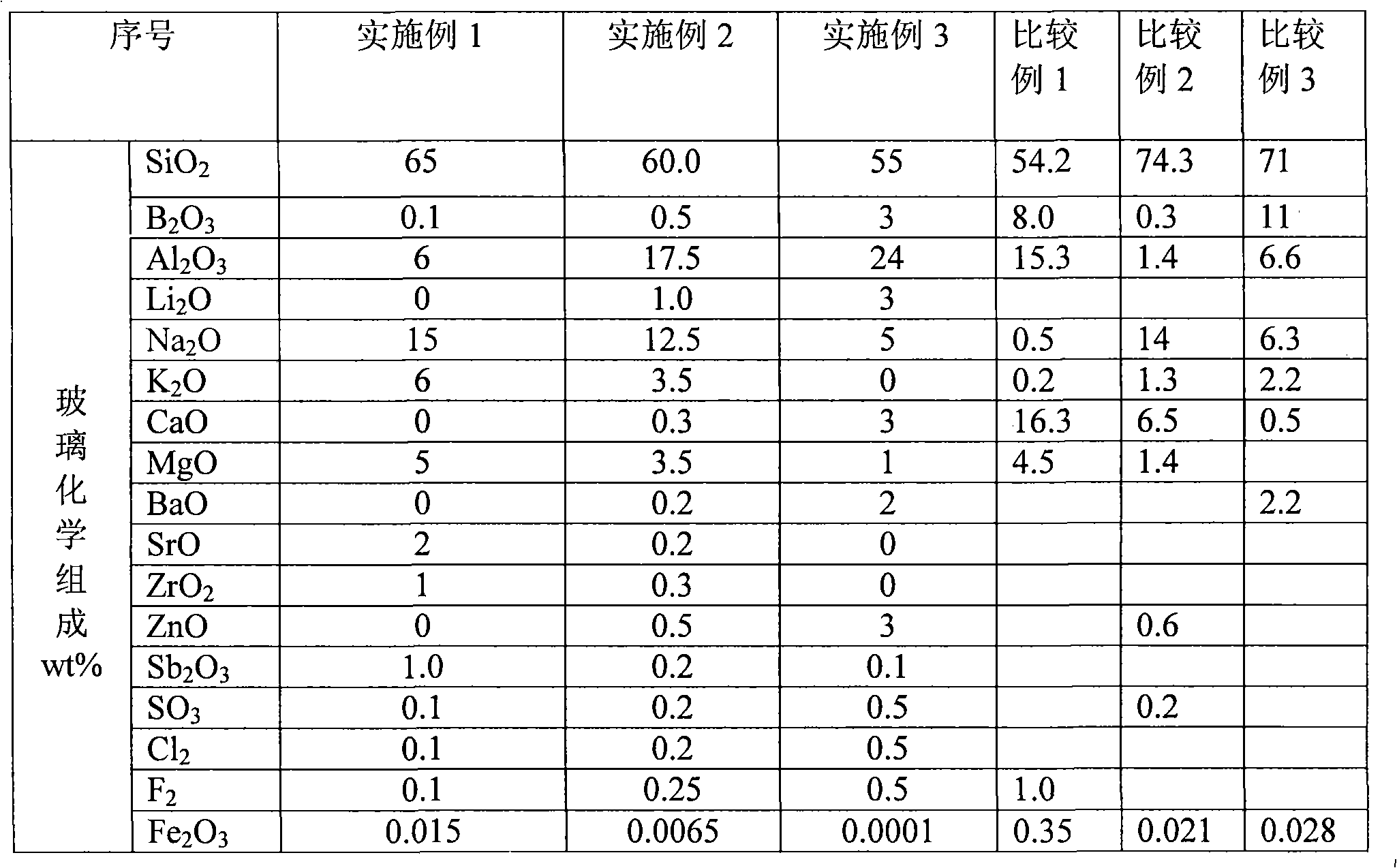

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

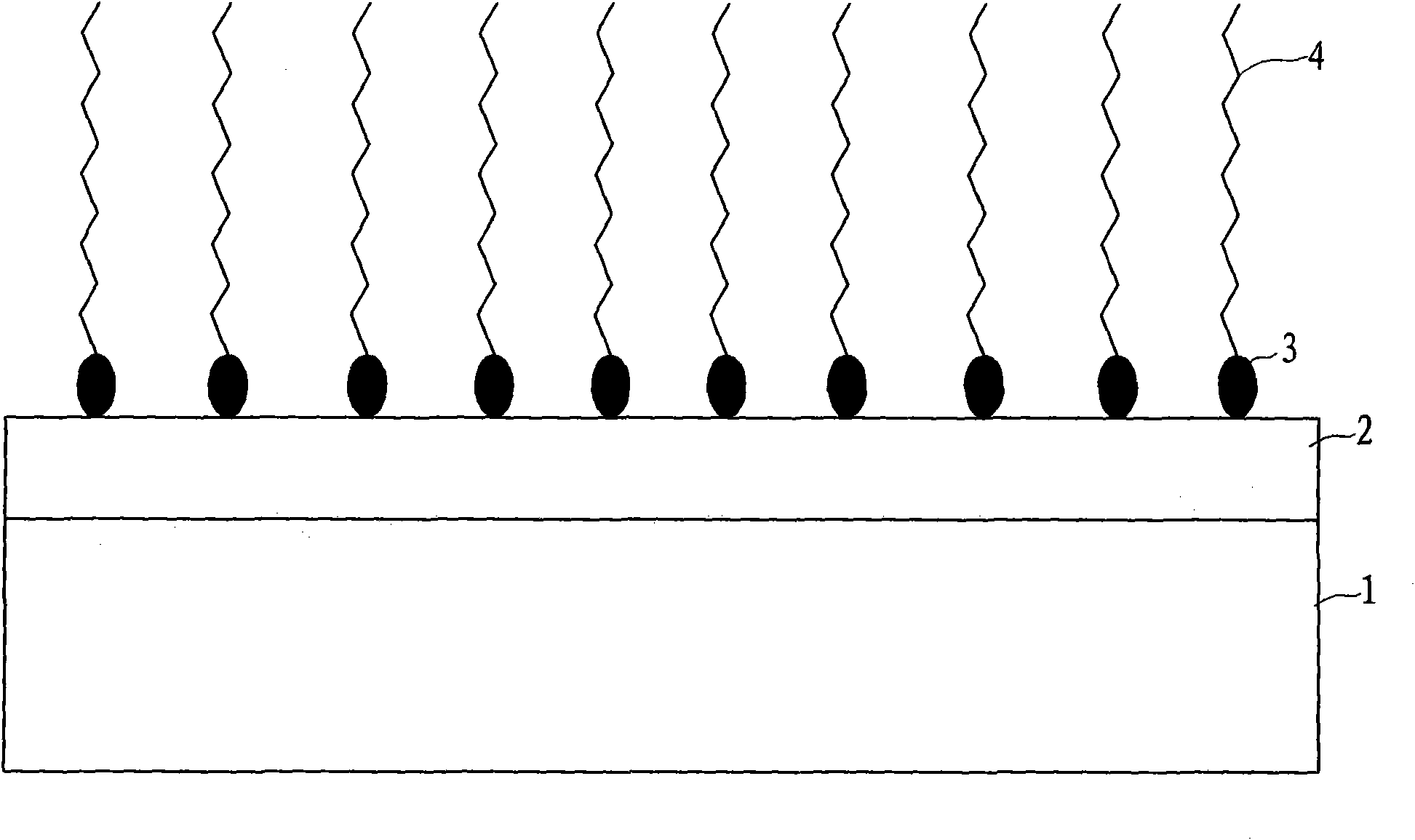

Antireflection Hard Coating Film, Optical Element and Image Display

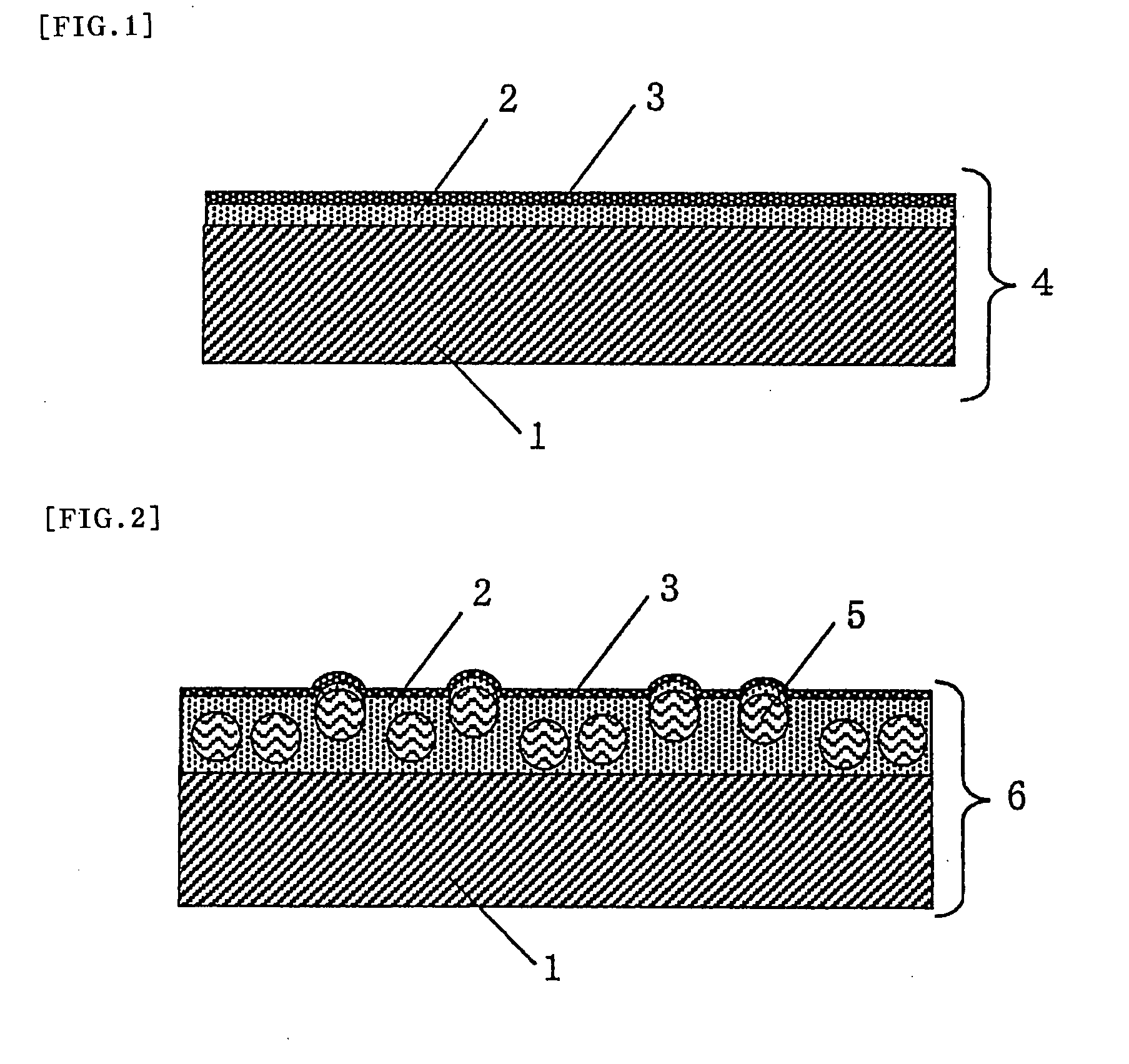

ActiveUS20080160257A1Improve suppression propertiesImprove adhesionRoof covering using sealantsSynthetic resin layered productsMeth-Display device

An antireflection hard coating film of the invention comprises: a transparent plastic film substrate; and at least one hard coating layer of a cured coating layer and at least one antireflection layer that are formed in this order on at least one side of the transparent plastic film substrate, wherein a hard coating layer-forming material contains 100 parts by weight of a (meth)acrylate group-containing curable compound (A) and 0.01 to 3 parts by weight of a (meth)acrylate group-containing reactive silicone (B), and an antireflection layer-forming material contains a siloxane component-containing compound, at the interface between the hard coating layer and the antireflection layer being in direct contact with each other. The antireflection hard coating film has good adhesion between the hard coating layer and the antireflection layer, high hardness, and good scratch resistance without a reduction in antireflection properties.

Owner:NITTO DENKO CORP

Preparation method of photovoltaic glass surface antireflection film

The invention discloses a preparation method of a photovoltaic glass surface antireflection film, which is characterized by comprising the following steps of firstly, preparing inorganic-organic hybrid silicasol; secondly, coating; thirdly, hydrophobic treatment; and fourthly, solidification treatment. Compared with the prior art, the invention has the advantages that the film-substrate cohesion between an antireflection film and substrate photovoltaic glass is stronger, and therefore, the wiping resistance of the coated photovoltaic glass surface antireflection film is enhanced; a layer of hydrophobic group with low surface energy is formed on the surface of the antireflection film, and therefore, the corrosion of moisture to a film microstructure is reduced, and the long service life of the coated photovoltaic glass is ensured; and the invention has low whole process cost and simple technical route and is suitable for industrial and large-scale application.

Owner:CHANGZHOU ALMADEN

Treatment Liquid for Plastic Film, Primer Liquid for Printing, Ink Composition, and Method for Ink Jet Recording Using Them

InactiveUS20080152825A1Improve rub resistanceImprove scratch resistanceLiquid surface applicatorsWater-repelling agents additionPlastic filmPolymer chemistry

This invention provides a treatment liquid for an ink jet recording medium having a recording face of a plastic film, wherein the treatment liquid including at least a specific cyclic ester compound or a specific cyclic amide compound, a primer liquid for printing, and an ink composition. According to the present invention, a plastic recorded matter possessing excellent adhesion and waterfastness can be formed on a recording medium having a recording face of a plastic film.

Owner:SEIKO EPSON CORP

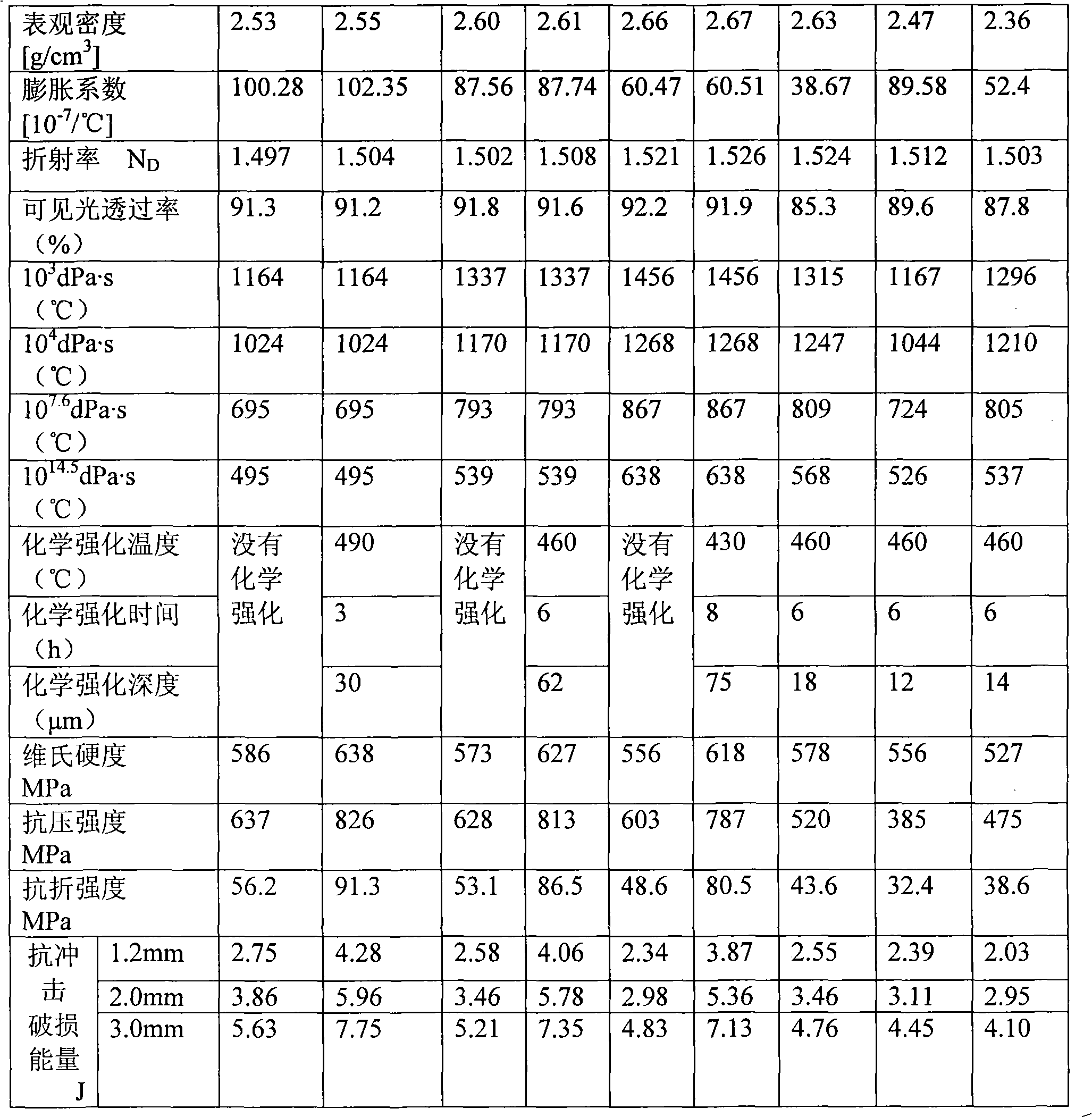

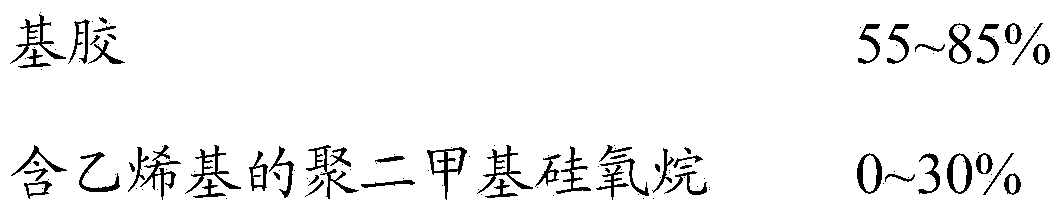

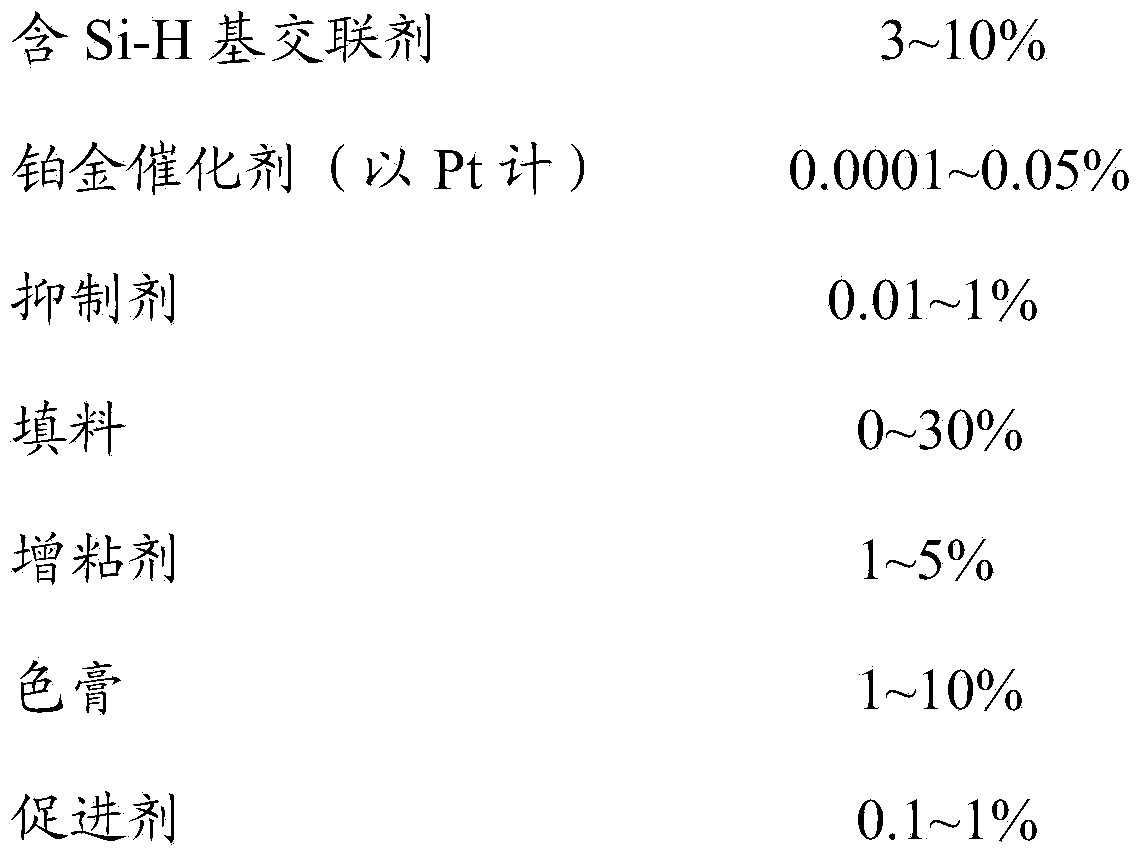

Organosilicon synthetic leather adopting three-layer structure and preparation method thereof

ActiveCN103821008AImprove wear resistanceImprove scratch resistanceLamination ancillary operationsSynthetic resin layered productsChemical reactionWear resistance

The invention discloses organosilicon synthetic leather adopting a three-layer structure and a preparation method thereof. The organosilicon synthetic leather is bonded by a base material, bottom layer glue and surface layer glue in sequence. According to the organosilicon synthetic leather adopting the three-layer structure, through the reasonable design of the chemical composition of the bottom layer glue and the surface layer glue, the bottom layer glue provides a firm interlamination bonding function for the two connecting surfaces under the combined action of various chemical reactions, and is endowed with the characteristics of softness and smoothness of the organosilicon synthetic leather, the surface layer glue is endowed with the characteristics of being dry, comfortable and wearable of the organosilicon synthetic leather, so that the organosilicon synthetic leather has the characteristics that dust adsorption is reduced, and the wear resistance, the scrape resistance and the scratch resistance are improved.

Owner:江西赛欧特科新材料有限公司

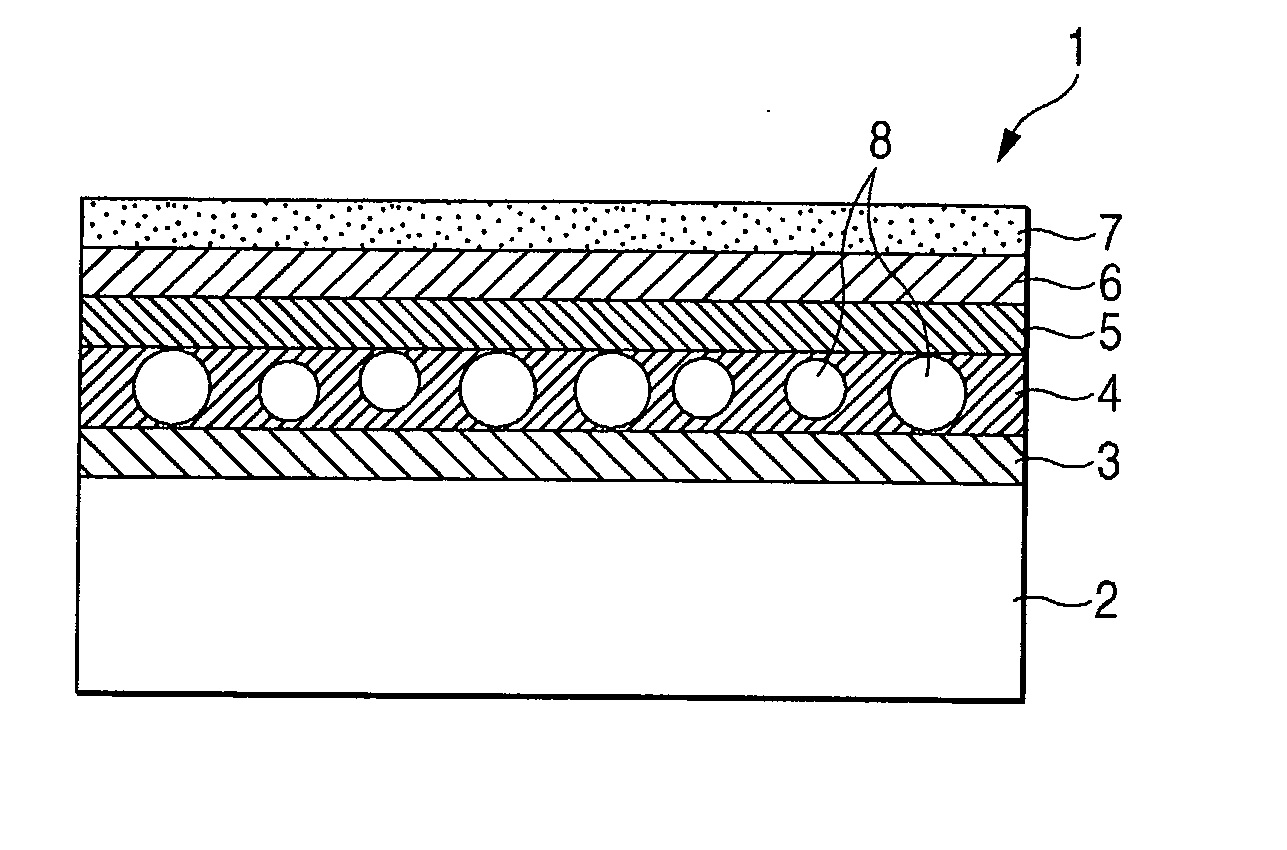

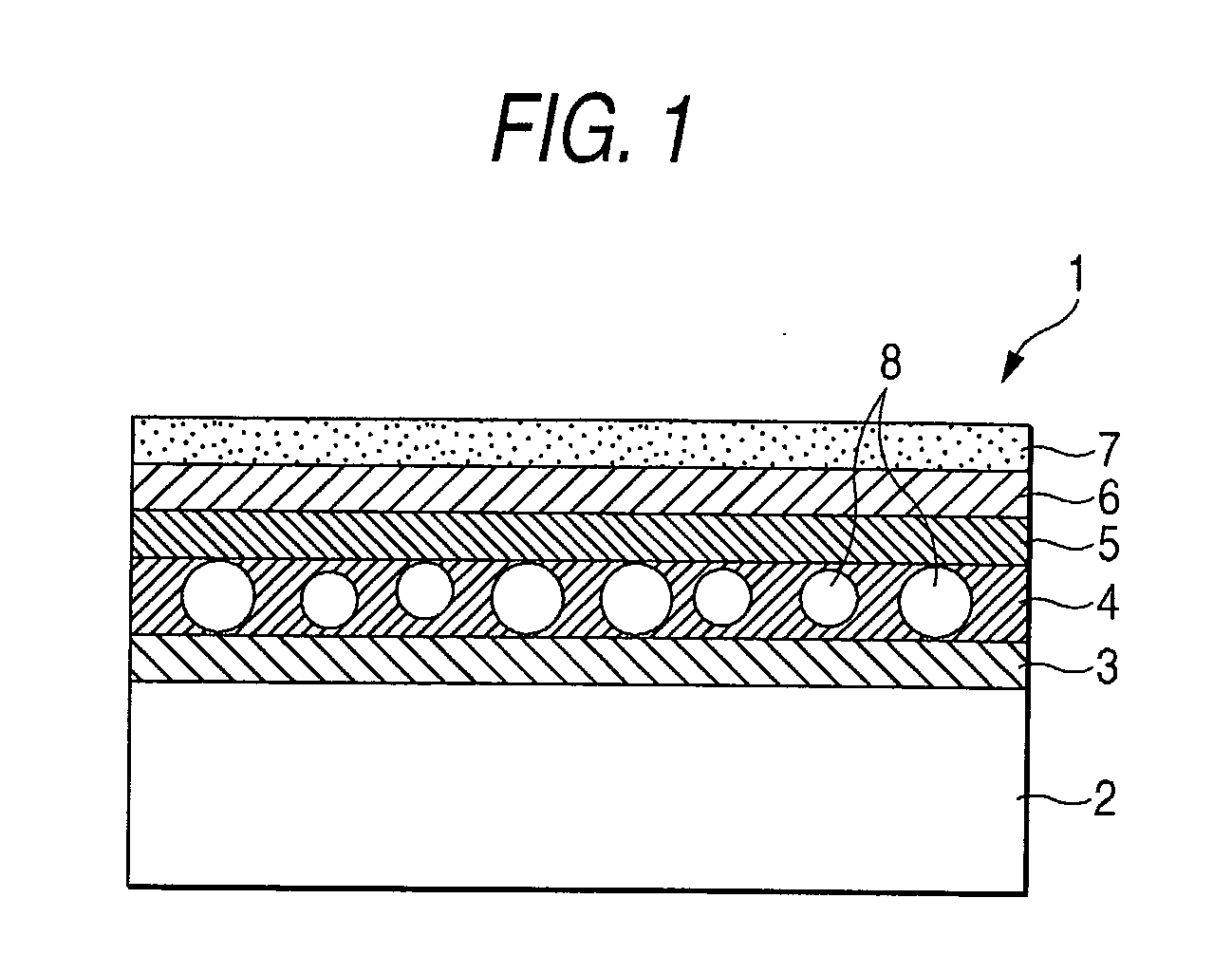

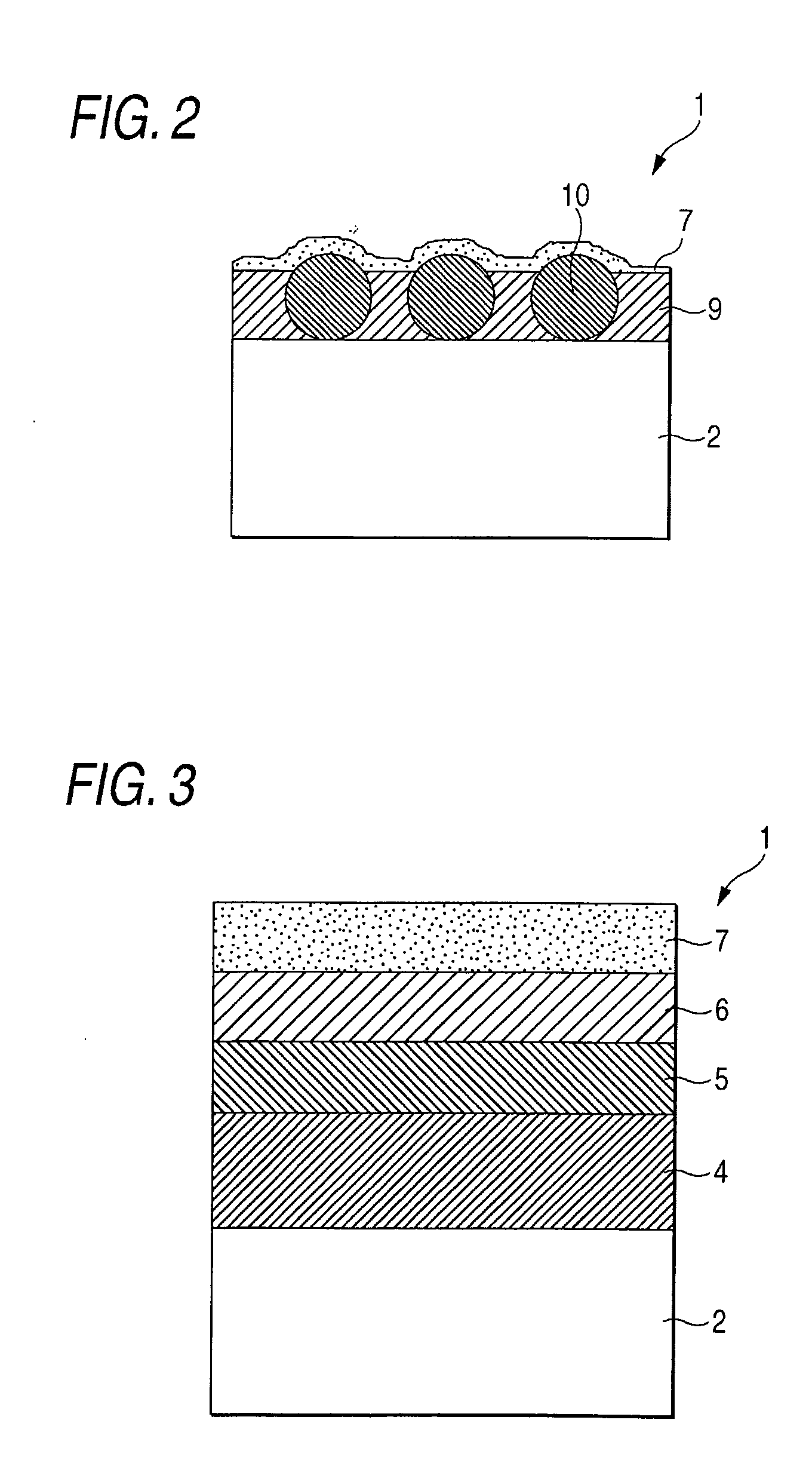

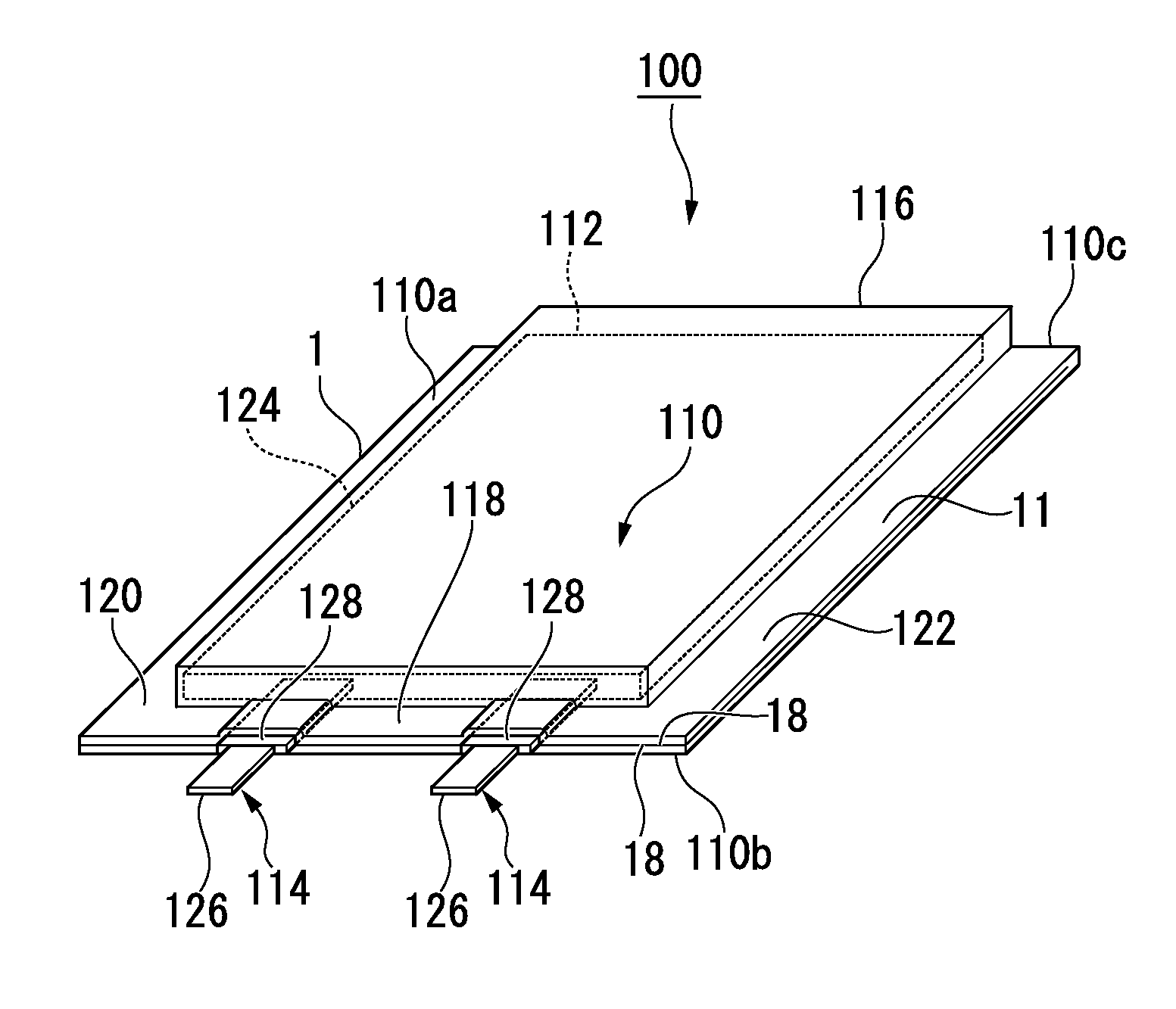

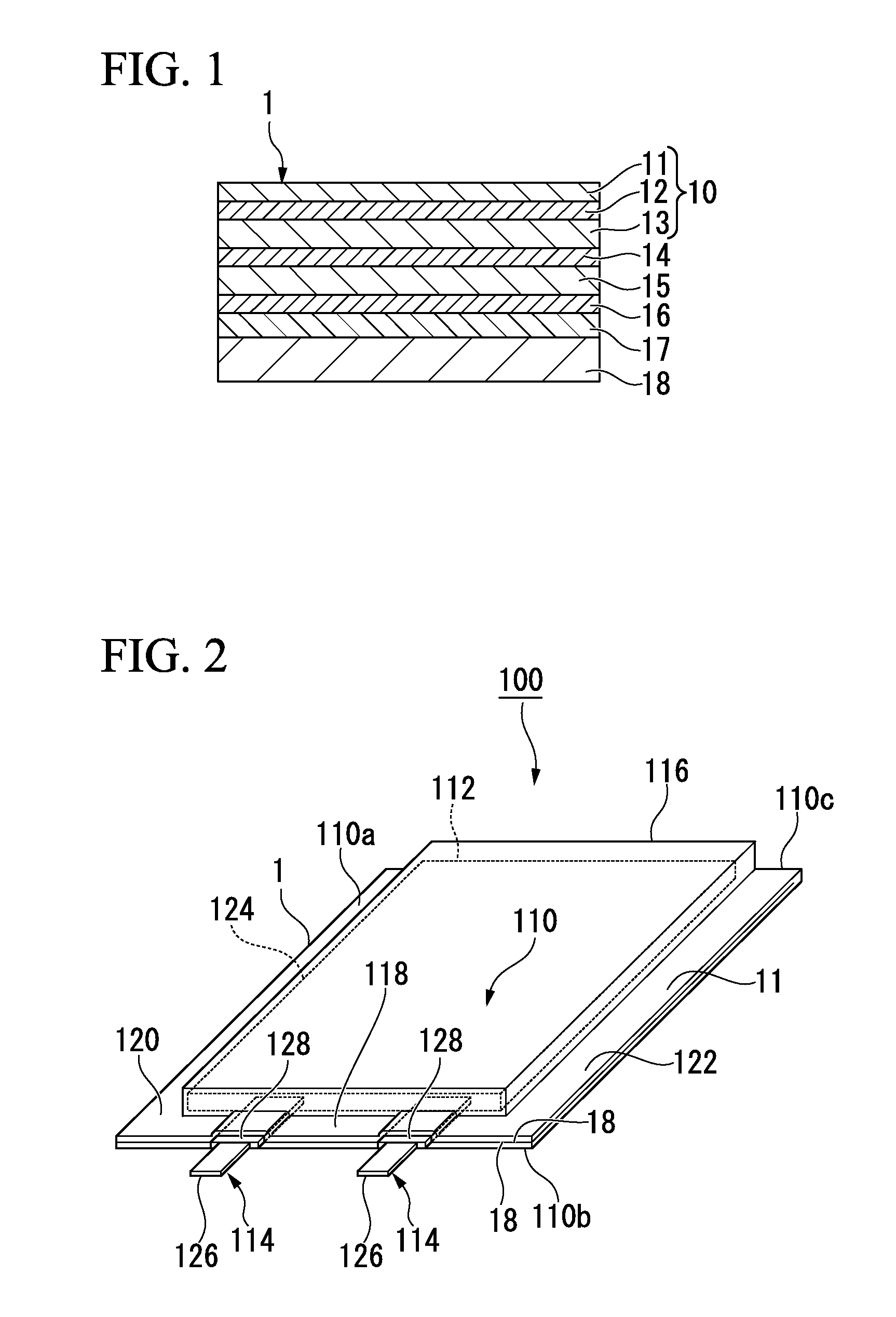

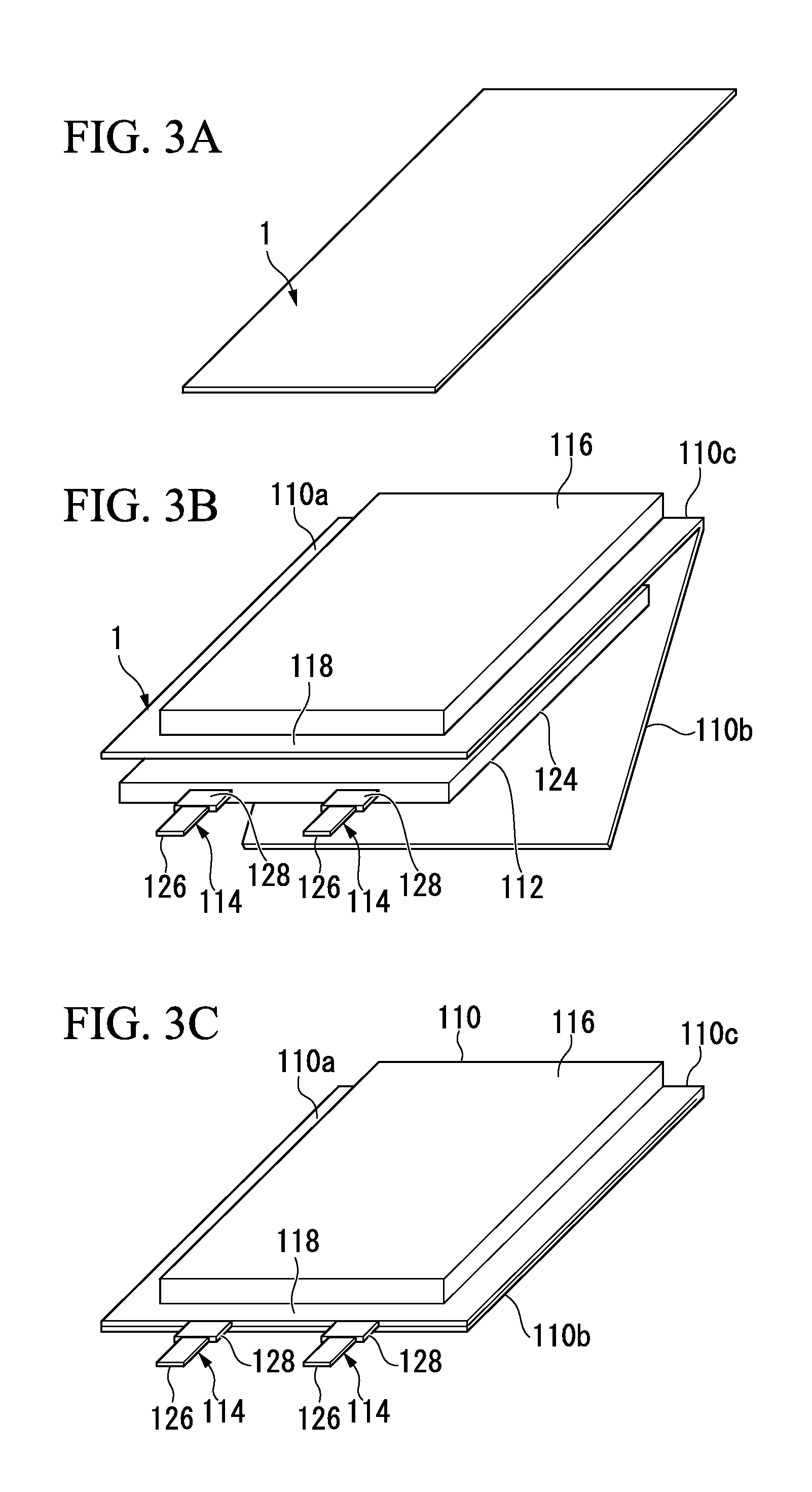

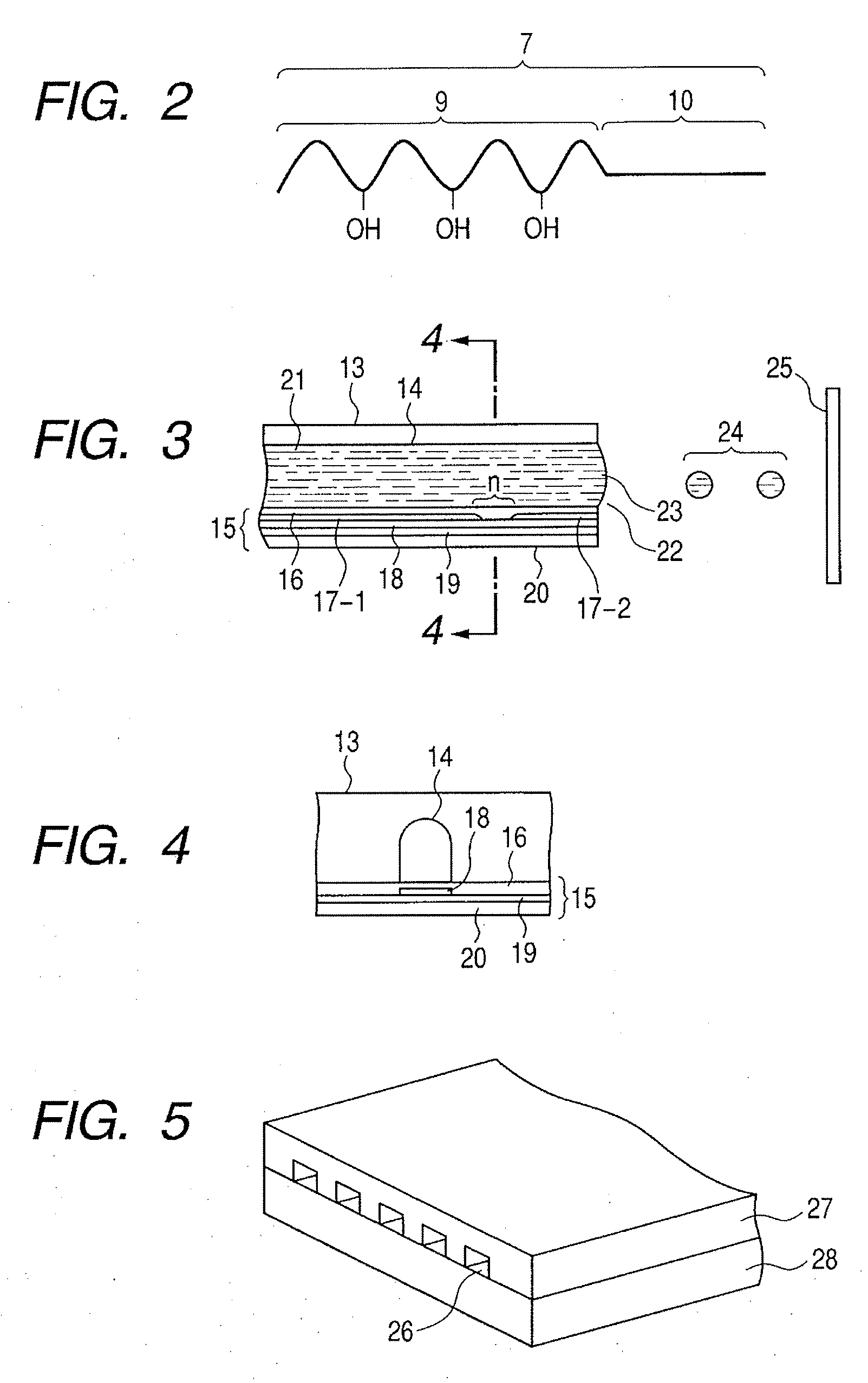

Packaging material for lithium ion battery, lithium ion battery, and method for manufacturing lithium ion battery

ActiveUS20140072864A1Good molding effectStay in shapeFinal product manufactureElectrode carriers/collectorsMetal foilPack material

A packaging material for a lithium ion battery includes: a base material layer that is formed from a film obtained by biaxially stretching a multi-layered coextruded film including a first thermoplastic resin layer having rigidity and chemical resistance and being disposed at an outer side thereof, a second thermoplastic resin layer having a capability of propagating stress and adhesiveness, and a third thermoplastic resin layer having toughness; a metal foil layer that is laminated on one surface of the base material layer; an anti-corrosion-treated layer that is laminated on the metal foil layer; an inner adhesive layer that is laminated on the anti-corrosion-treated layer; and a sealant layer that is laminated on the inner adhesive layer.

Owner:TOPPAN PRINTING CO LTD

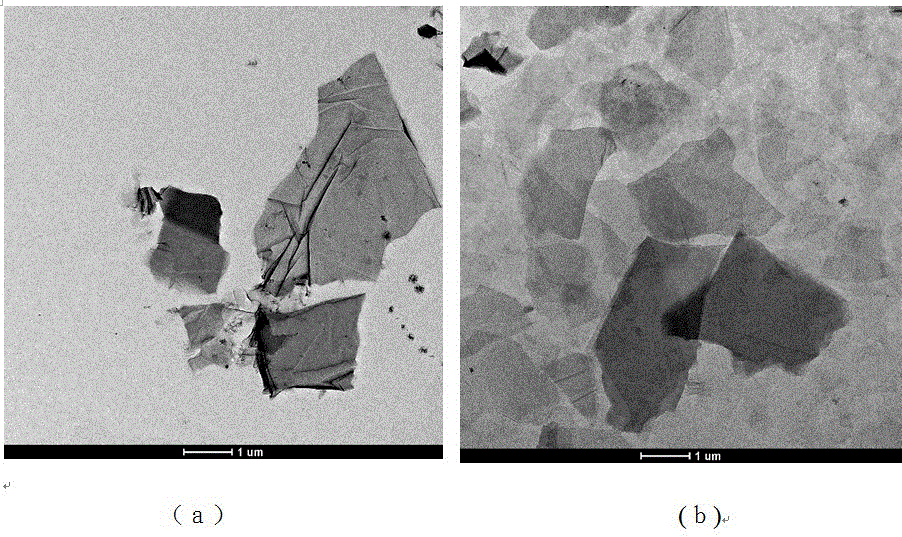

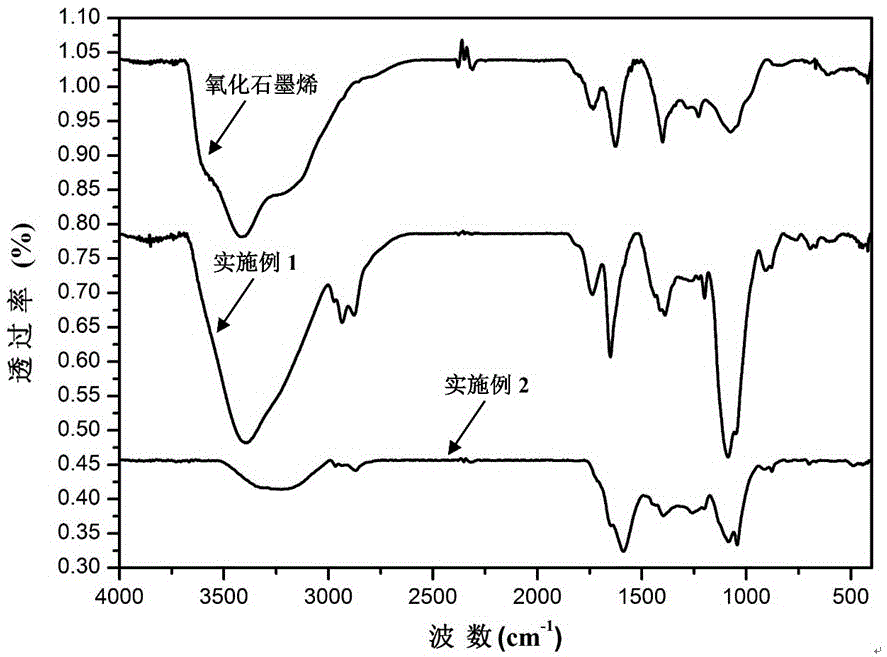

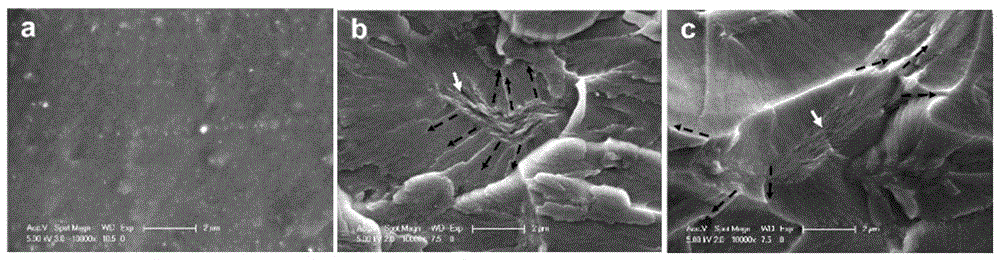

Graphene/polysiloxane composite coating material and preparation method thereof

ActiveCN106752926AImprove scratch resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyResin-Based Composite

The invention provides a graphene / polysiloxane composite coating material and a preparation method thereof. The method comprises the following steps: modifying the graphene surface with active groups by a chemical modification technique to obtain modified graphene, mixing the modified graphene with a silane compound, a dispersion medium, a non-essential comonomer and a non-essential accelerator, and carrying out hydrolytic condensation or hydrolytic condensation-free radical polymerization to generate a graphene / polysiloxane composite resin in situ; and mixing the resin with a non-essential blend resin, a non-essential curing agent, a non-essential solvent, a non-essential pigment and filler and a non-essential aid, and carrying out physical blending, amino epoxy addition reaction, Michael addition reaction and the like to form a film, thereby obtaining the graphene / polysiloxane composite coating material. The uniformly dispersed graphene lamellae and polysiloxane have strong interface effects, also have the gas / liquid barrier and heat shielding effects, and endow the coating with excellent corrosion resistance, flame retardancy and the like, thereby greatly enhancing the mechanical properties, corrosion resistance, scratch resistance, wear resistance and the like of the coating.

Owner:FUDAN UNIV

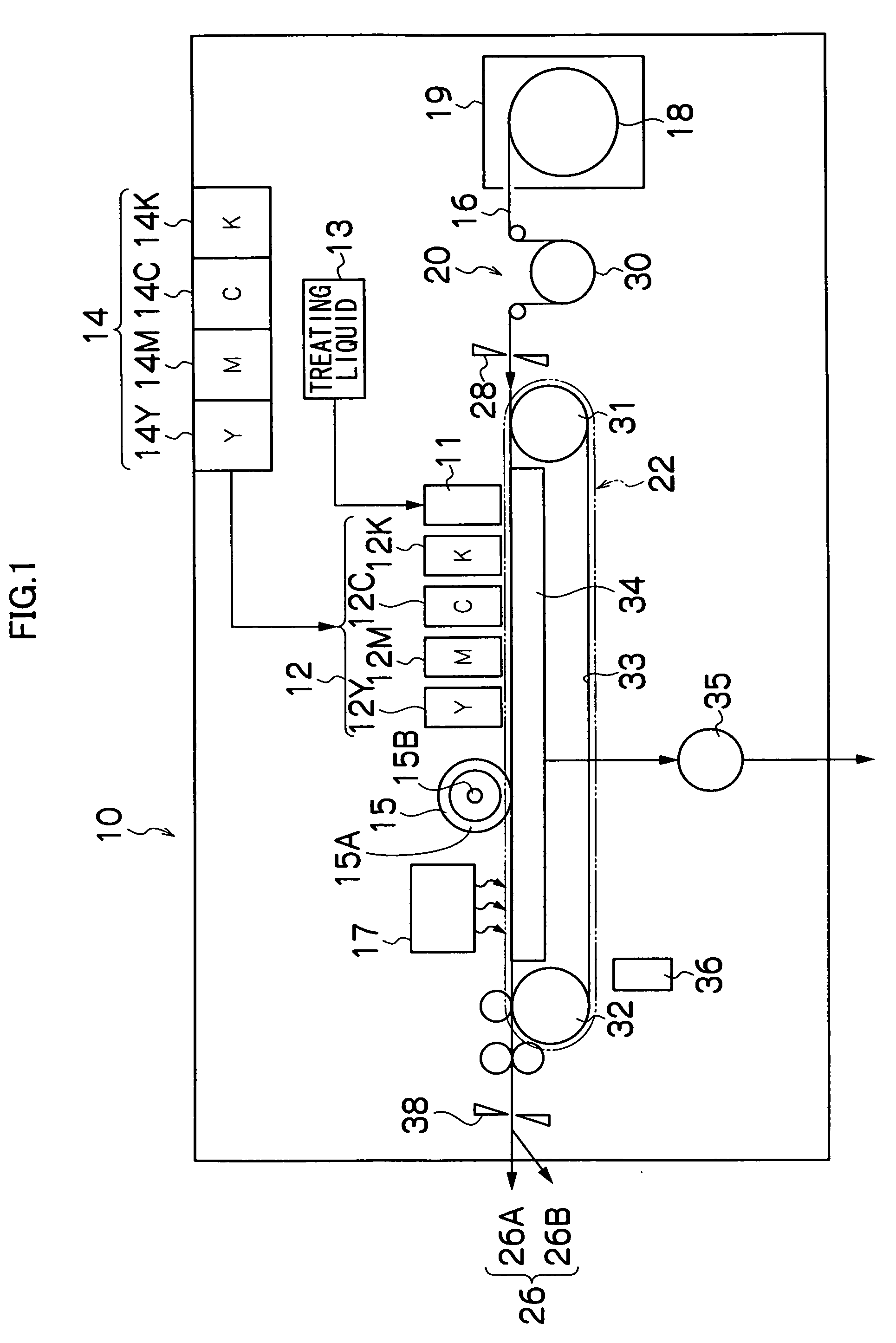

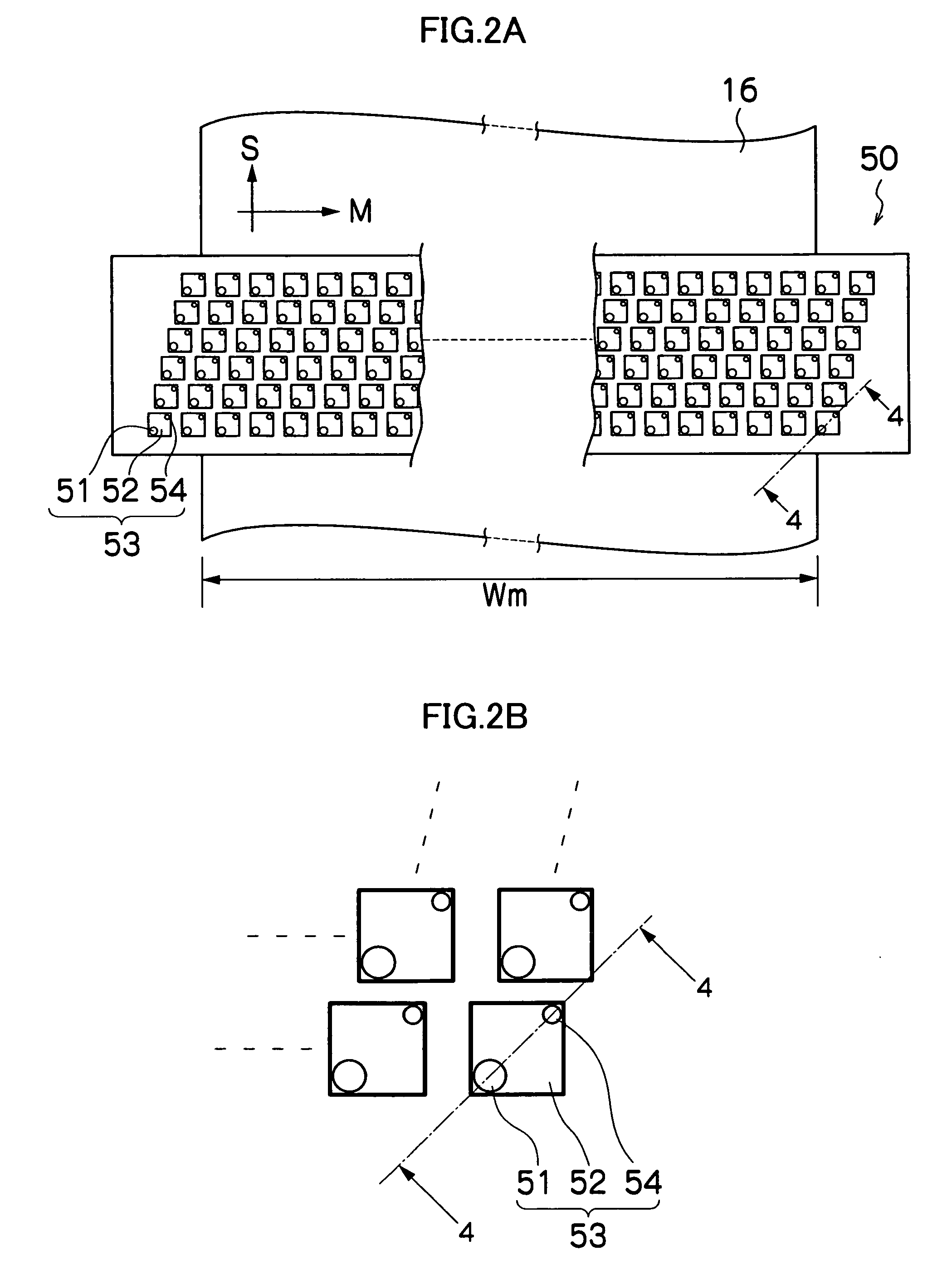

Ink set and method and apparatus for recording image

InactiveUS20070054981A1Improve scratch resistanceImprove waterproof performanceInksCoatingsOrganic solventWater soluble

An ink set comprising an ink containing at least an organic pigment, a water-soluble organic solvent and water and a treating liquid which is applied to a recording medium before applying the ink to the recording medium and produces an agglomerate upon contact with the ink, the ink containing a low molecular weight dispersant having a molecular weight of 2000 or lower and polymer fine particles.

Owner:FUJIFILM CORP

Aqueous ink, ink-jet recording method, ink cartridge, recording unit, ink-jet recording apparatus and image forming method

ActiveUS20060100311A1Large area factorSuperior stabilityDuplicating/marking methodsInksWater solubleIonic dissociation

Disclosed is an aqueous ink comprising at least water, a plurality of water-soluble organic solvents and a coloring material. The coloring material is a pigment, and, it contains a pigment particle having at least one ionic group bonded to a surface of the pigment particle directly or via another atomic group. The plurality of water-soluble organic solvents have a good medium or good mediums for the pigment and a poor medium or poor mediums for the pigment. The poor medium does not solvate perfectly or substantially the pigment. The ionic group undergoes perfectly or substantially no ionic dissociation in the poor medium. Also, among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method, the Ka value of the poor medium is maximum.

Owner:CANON KK

High-performance jet ink

The invention relates to a high-performance jet ink. The jet ink comprises the following components by weight percent: 20-80% of solvent, 1-45% of cosolvent, 4-20% of adhesive, 0.5-20% of colorant, 0-5% of adhesion force promoter, 0.01-2% of wax powder, 0-2% of brightening agent and 0-5% of other additives. As adhesion force promoter is added in the jet ink, the adhesion performance on base materials such as glass, metal, polypropylene or polyethylene is increased. In addition, wax is added to increase wear resistance and scratch resistance, and brightening agent is added to increase the lustrousness, brilliance and definition of the ink. The product has high adhesion force, good wear resistance, high lustrousness and definition and good compatibility, thus the defects of the existing ink such as low lustrousness, poor wear resistance and low definition can be greatly improved and the jet ink has good market prospect.

Owner:王学珍

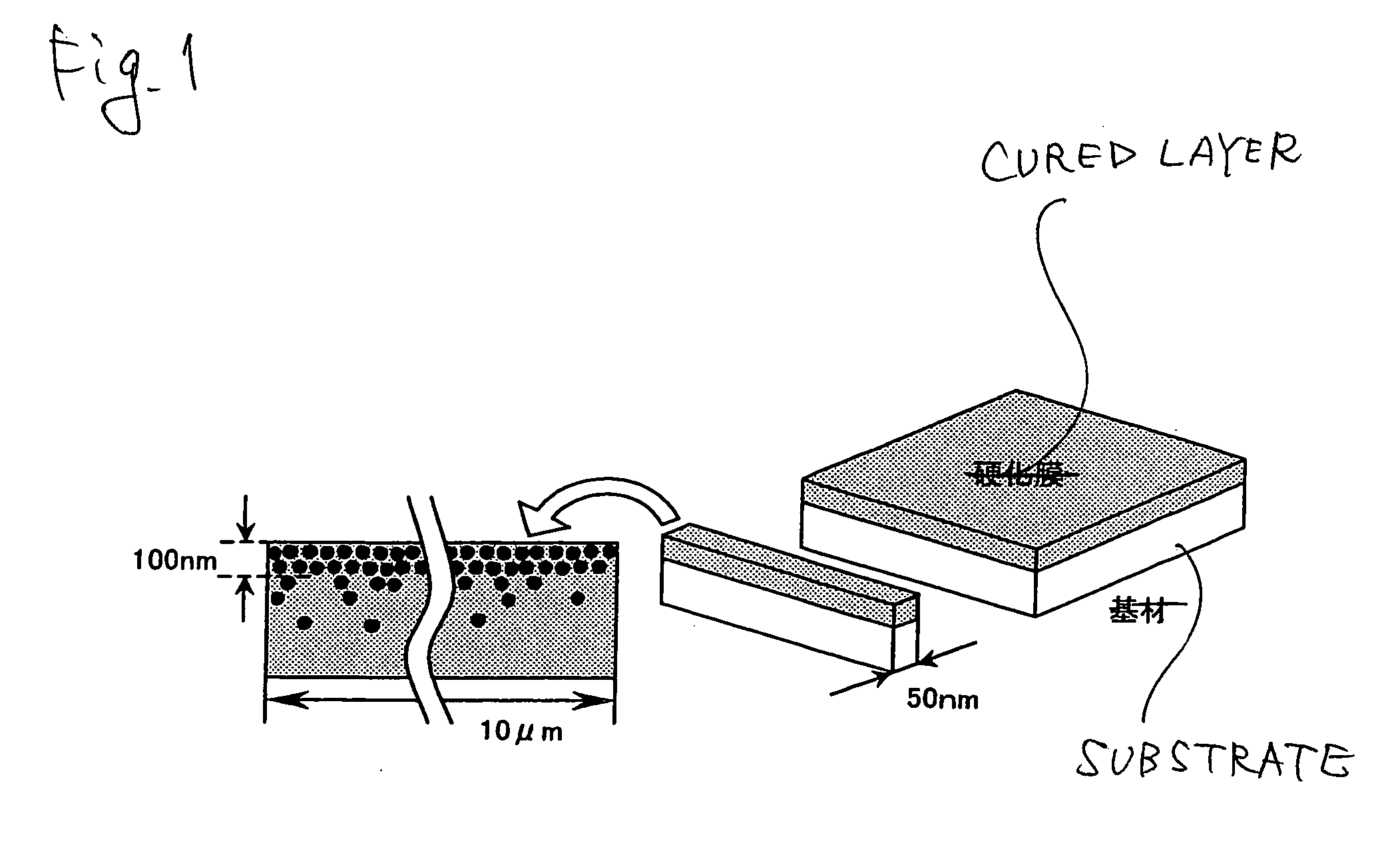

Optical film, polarizing plate and image display device

InactiveUS20070047087A1Improve anti-reflection effectImprove scratch resistanceOptical elementsRefractive indexPlastic film

An optical film comprises: a transparent plastic film substrate; and a cured layer having a dry thickness of 100 nm or more, formed by coating a curable composition comprising: a low refractive index fine particle having a refractive index of 1.50 or less; and a binder, wherein the low refractive index fine particle is unevenly distributed in the cured layer to a surface portion on the side opposite the transparent plastic film substrate.

Owner:FUJIFILM CORP

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

InactiveUS20070097155A1Excellent in resistance highlighterImprove scratch resistanceInksCoatingsOrganic solventWater soluble

The invention provides an aqueous ink comprising a polymer having hydroxyl groups and a pigment, which can provide images excellent in scratch resistance and highlighter resistance and can inhibit the seeping out phenomenon of the polymer and the deterioration of ejection characteristics even when it is stored for a long period of time. The aqueous ink comprises a polymer having hydroxyl groups, a pigment and a water-soluble organic solvent, wherein the water-soluble organic solvent comprises a poor medium for a polymer that is not adsorbed on the pigment of the polymer having hydroxyl groups, and wherein when the segment constituting the polymer that is not adsorbed on the pigment of the polymer having hydroxyl groups is comprised of a segment A having hydroxyl groups and a segment B having no hydroxyl group, at least one of the poor medium is a good medium for either one of the segment A and the Segment B.

Owner:CANON KK

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS20070112095A1Excellent in resistance highlighterImprove scratch resistanceInksCoatingsOrganic solventAlcohol

The invention provides an aqueous ink comprising a polymer having hydroxyl groups and a pigment, which can provide images excellent in scratch resistance and highlighter resistance and can inhibit the seeping out phenomenon of the polymer and the deterioration of ejection characteristics even when it is stored for a long period of time. The aqueous ink comprises a polymer having hydroxyl groups, a pigment and a water-soluble organic solvent, wherein the water-soluble organic solvent comprises a polyhydric alcohol having a value of number of hydroxyl groups / number of carbon atoms in its molecule of 0.50 or less.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com