Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

582 results about "Surface stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface stress was first defined by Josiah Willard Gibbs (1839-1903) as the amount of the reversible work per unit area needed to elastically stretch a pre-existing surface. A suggestion is surface stress define as association with the amount of the reversible work per unit area needed to elastically stretch a pre-existing surface instead of up definition. A similar term called “surface free energy”, which represents the excess free energy per unit area needed to create a new surface, is easily confused with “surface stress”. Although surface stress and surface free energy of liquid–gas or liquid–liquid interface are the same, they are very different in solid–gas or solid–solid interface, which will be discussed in details later. Since both terms represent a force per unit length, they have been referred to as “surface tension”, which contributes further to the confusion in the literature.

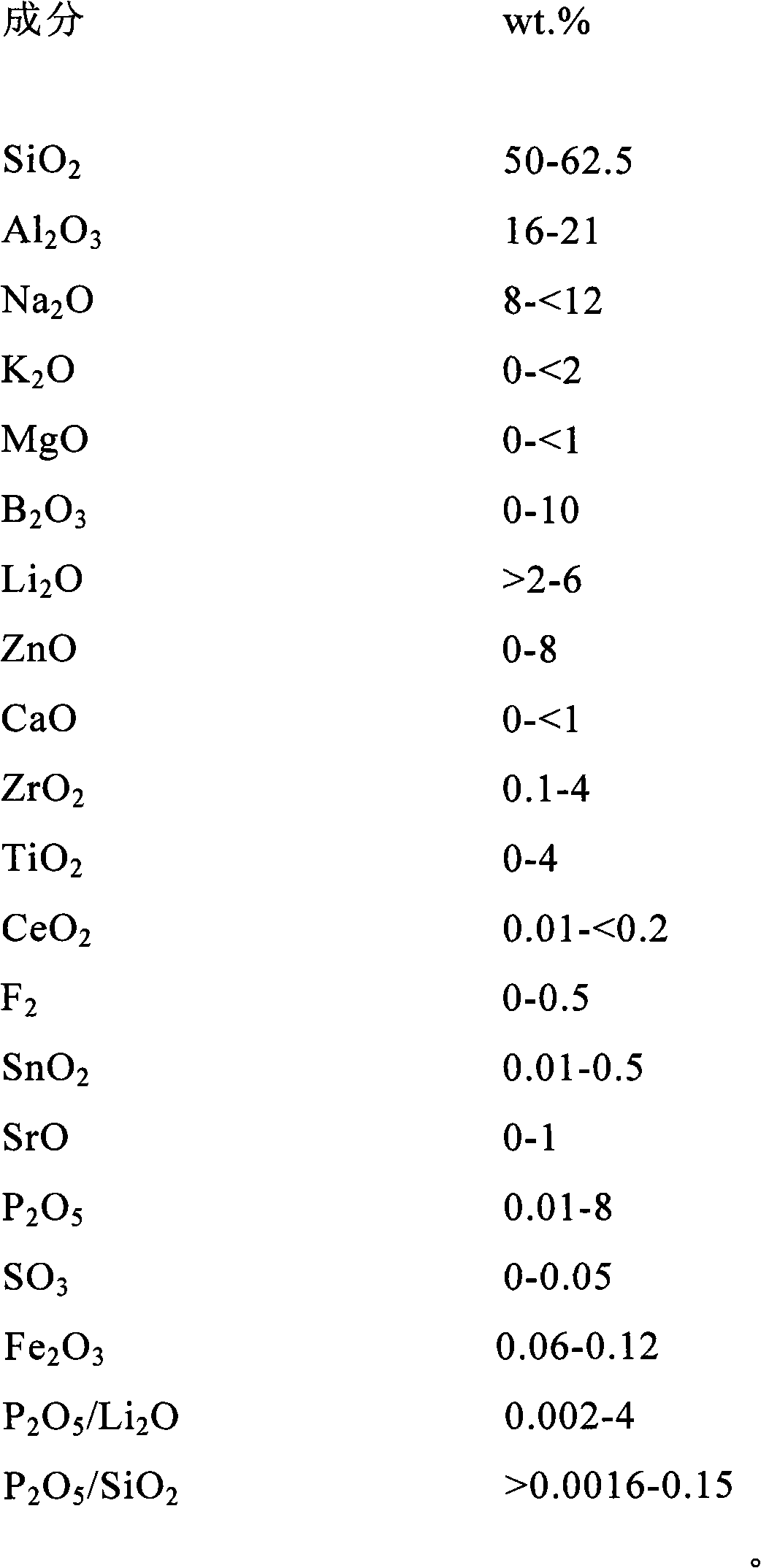

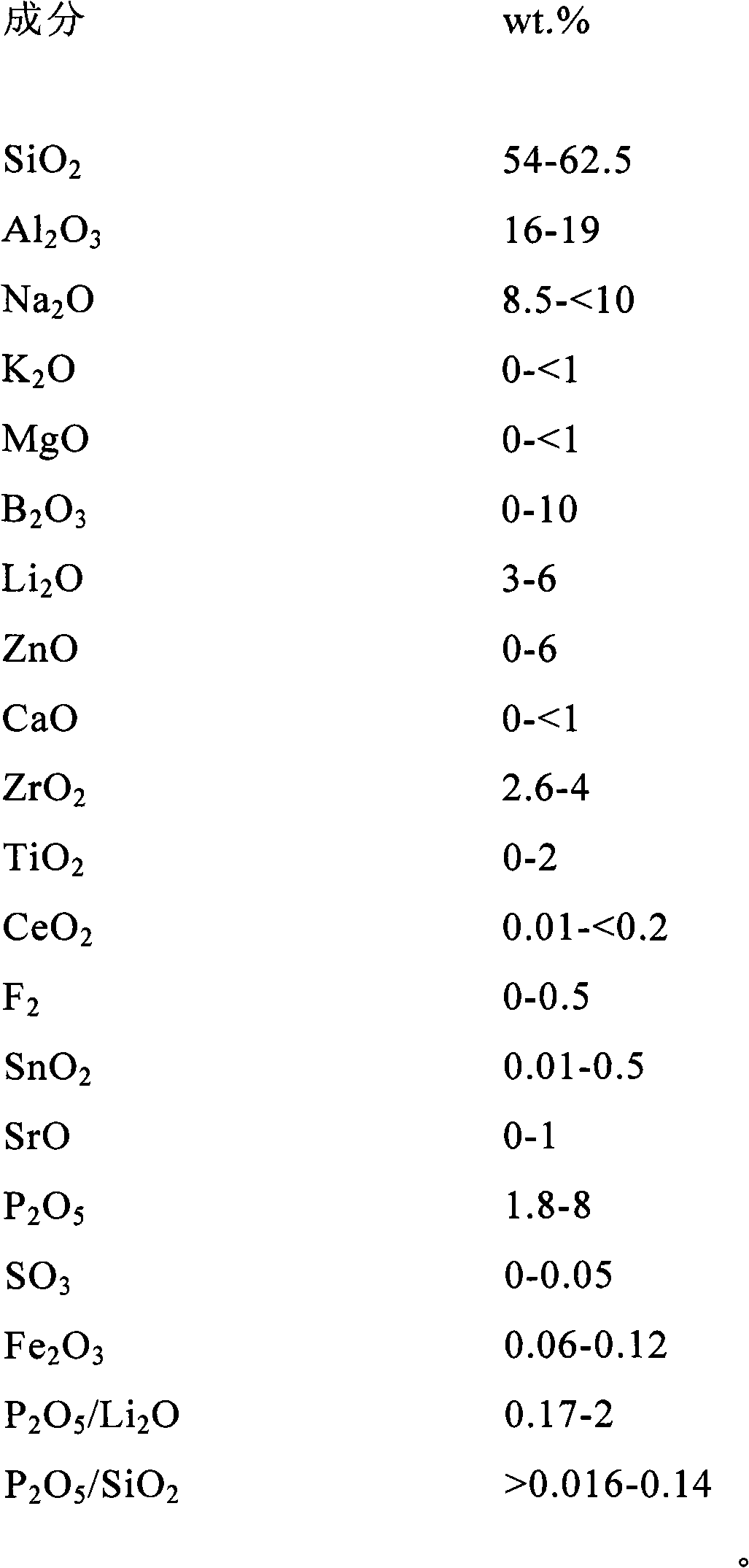

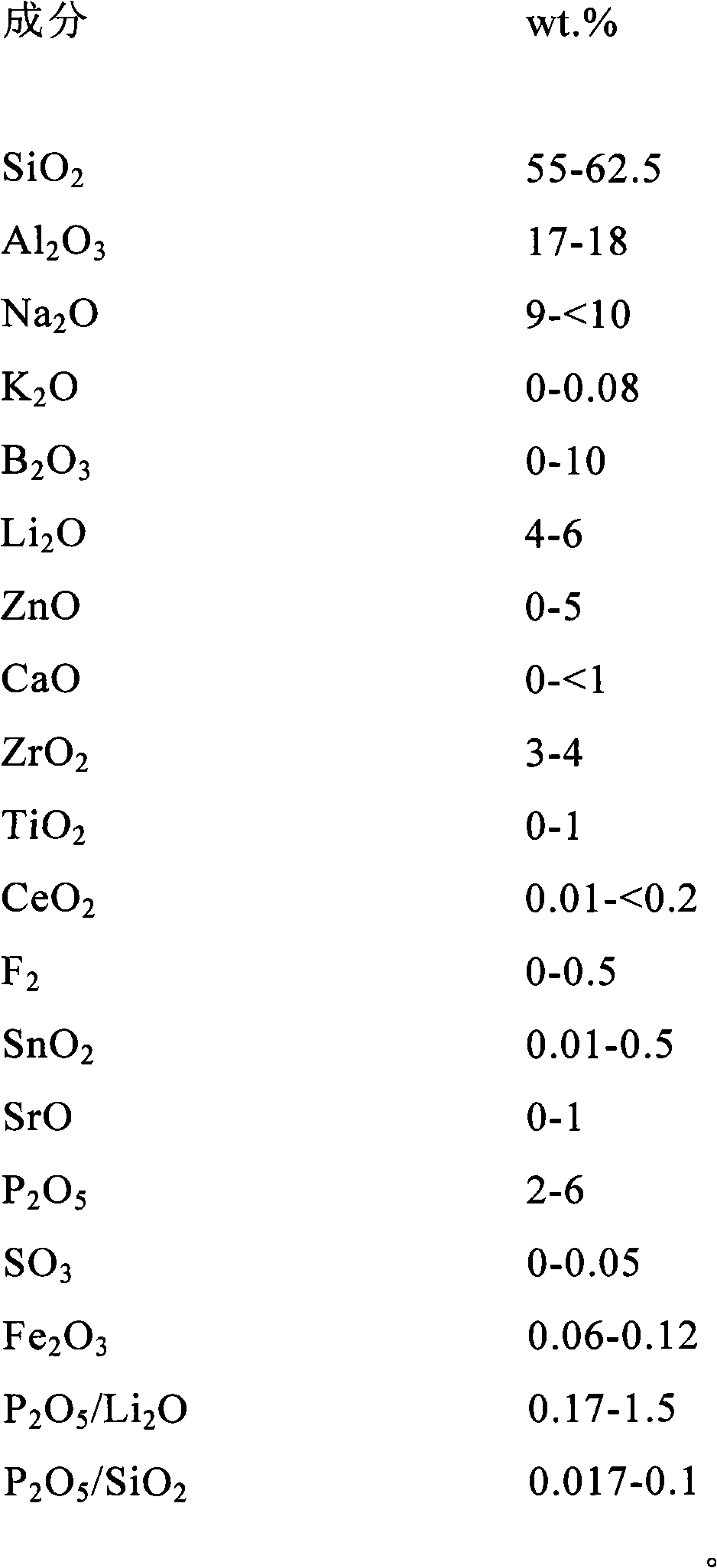

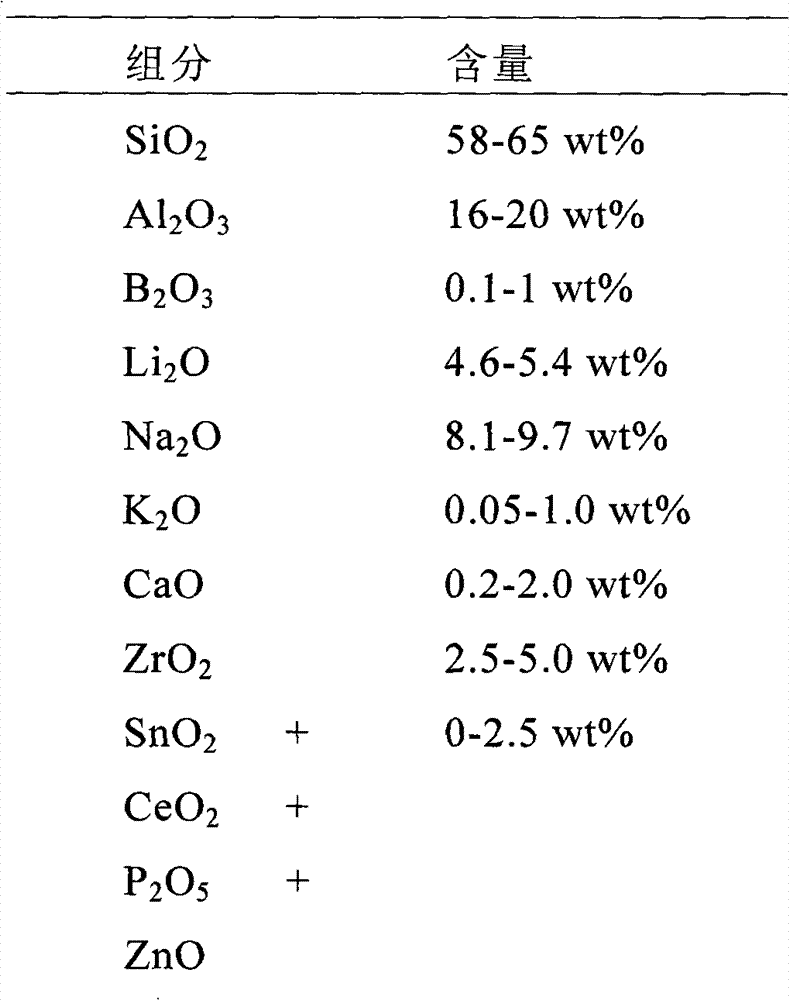

Aluminosilicate glass for chemical tempering and glass ceramics

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

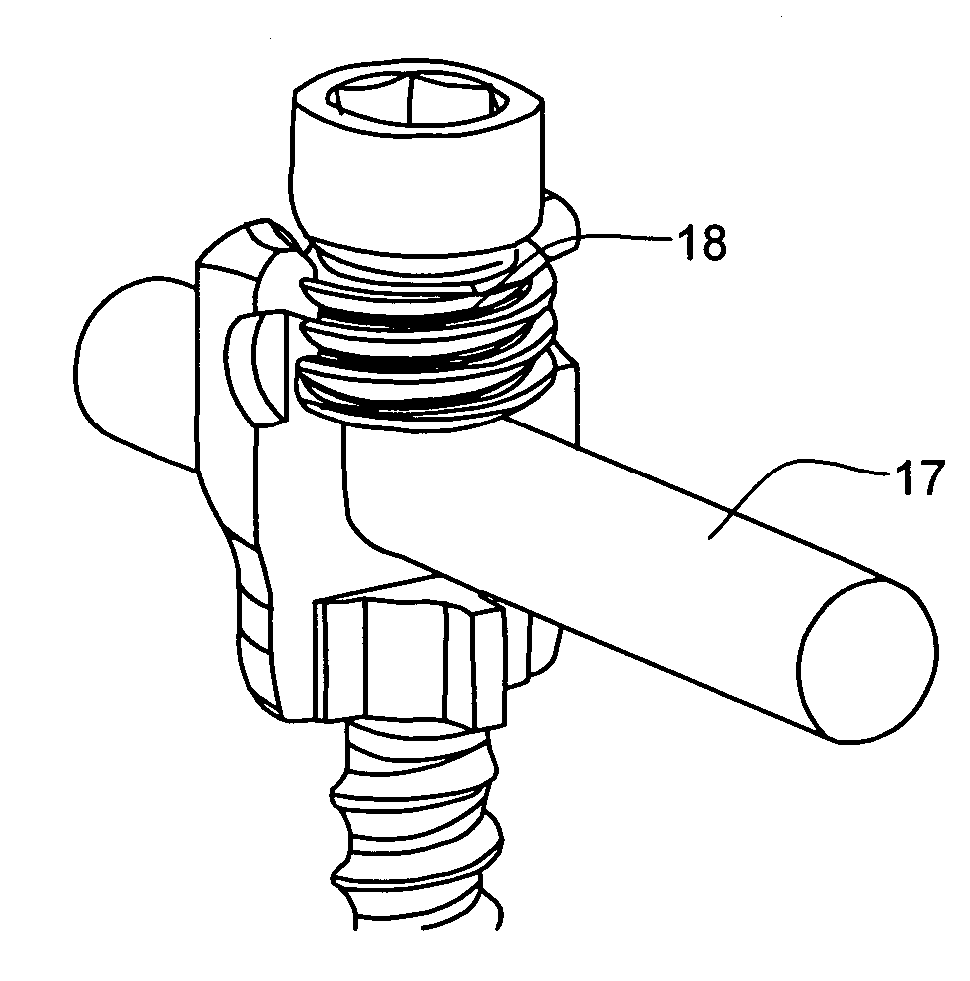

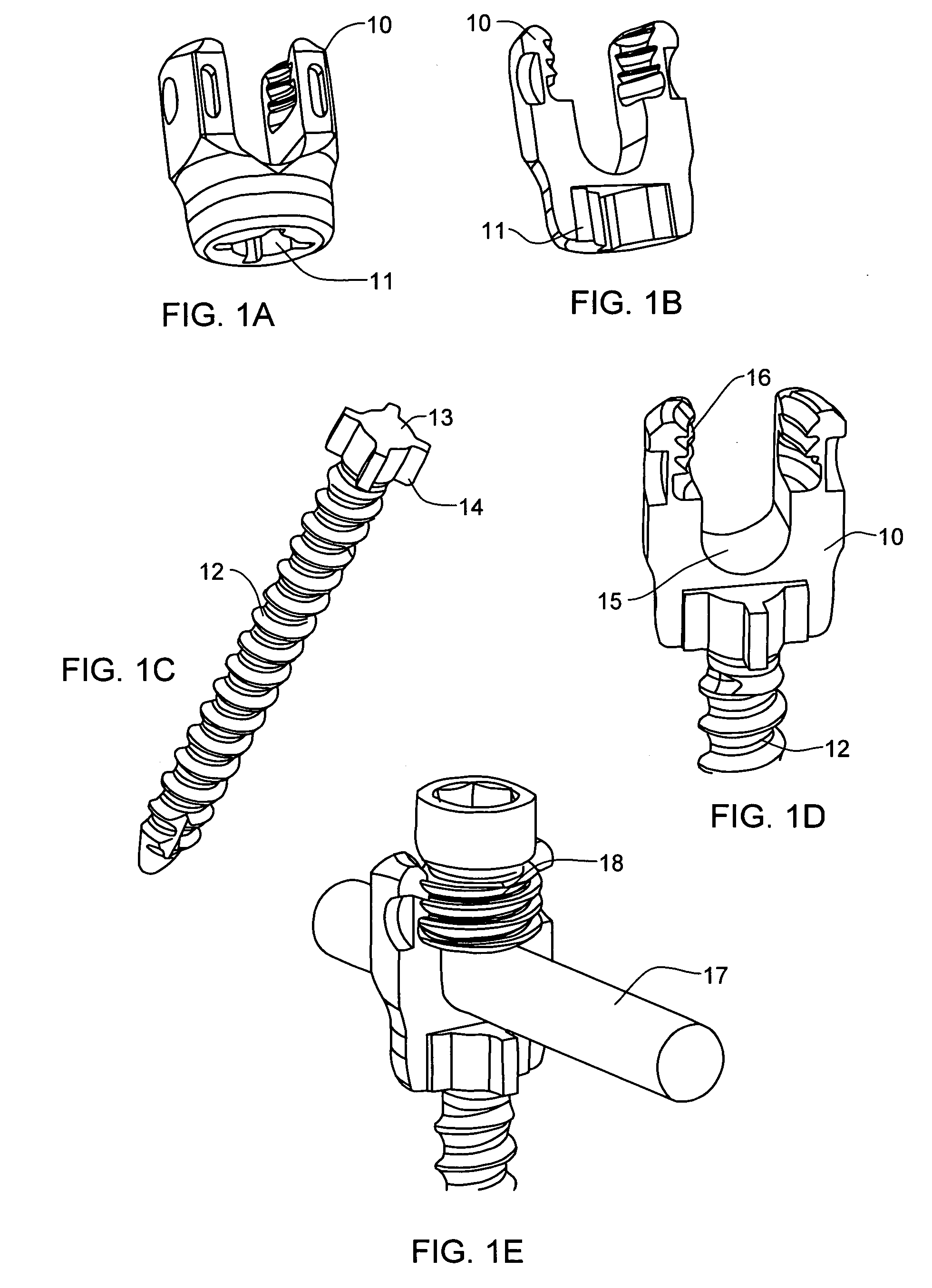

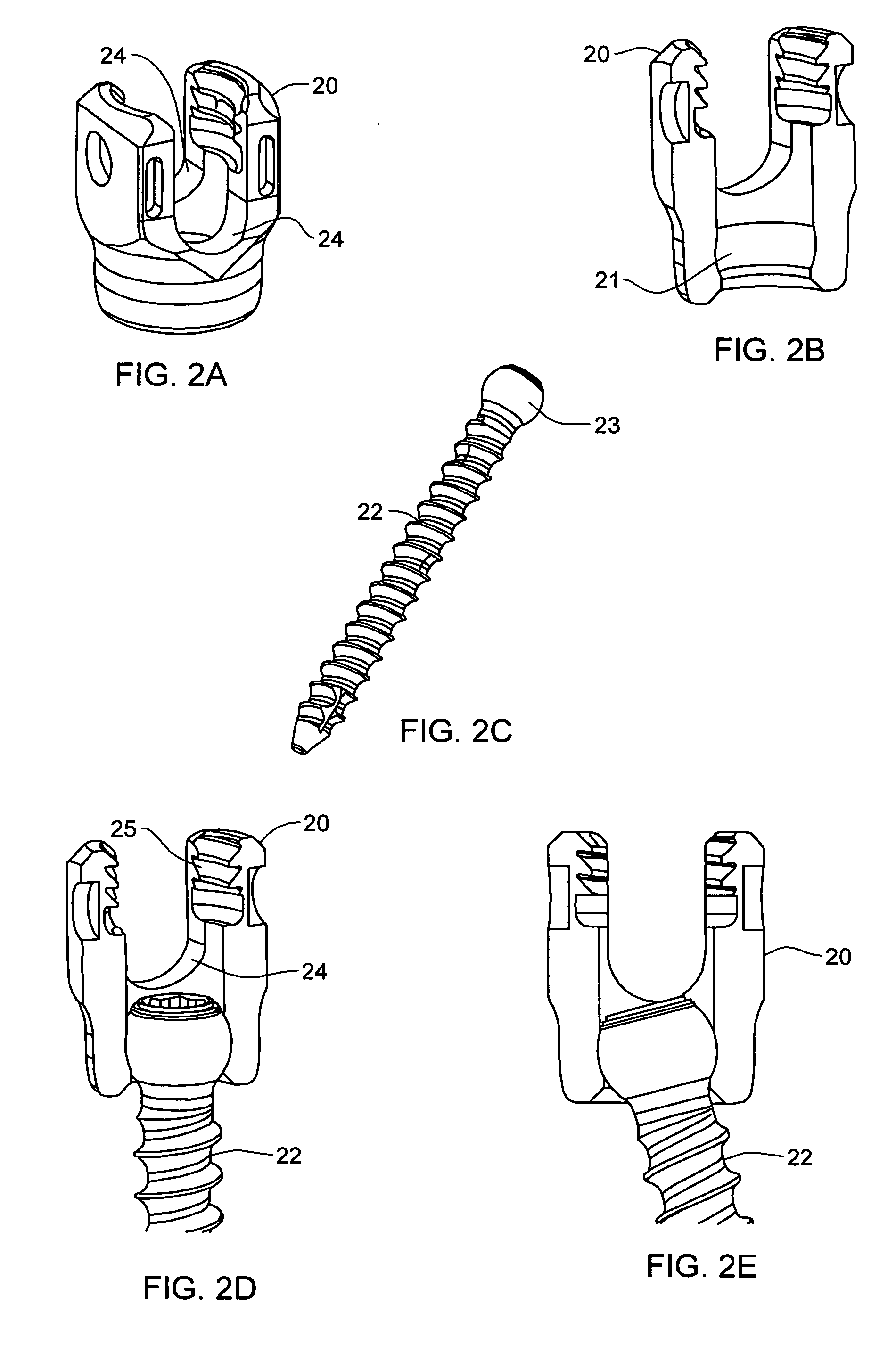

Bone anchor system utilizing a molded coupling member for coupling a bone anchor to a stabilization member and method therefor

A bone anchor system including a bone anchor having an integral head, a stabilization member, and a coupling member molded around the integral head of the bone anchor is provided for coupling the bone anchor to the stabilization member. The coupling member includes an interface to the stabilization member. Advantageously, the interface to the stabilization member is made of a deform able material to reduce surface stress concentration in the stabilization member. The interface of the coupling member may be integral to the coupling member, or the interface may be an interface piece that may be inserted into the coupling member. The integral head of a bone anchor may include a molded cap that is formed from a deformable material and configured to provide an interface to the stabilization member.

Owner:WARSAW ORTHOPEDIC INC

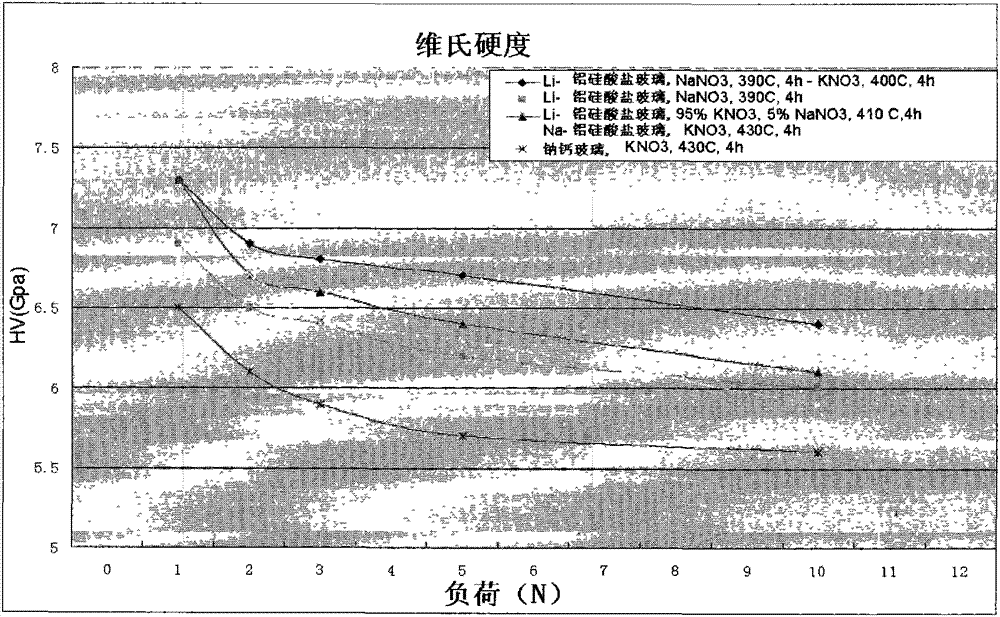

Method for producing tempered glass with plurality of surface stress layers and tempered glass product

The invention discloses a method for producing tempered glass with a plurality of surface stress layers and a tempered glass product and particularly relates to a method for producing tempered lithium glass with a plurality of surface stress layers. The method comprises that a mixed salt bath is used for conducting ion exchange in a step, or various mixed salt baths are used for conducting several ion exchange in a plurality of steps. By the aid of the novel chemical tempered lithium aluminosilicate glass and the treatment method of relative glass products, glass with the plurality of surface stress layers and products of the glass are obtained, and the product serves as a high-strength cover plate in electronic devices, household appliances and vehicles. Compared with the prior art, the tempered glass with the plurality of surface stress layers can protect electronic devices, household appliances and vehicles reliably.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

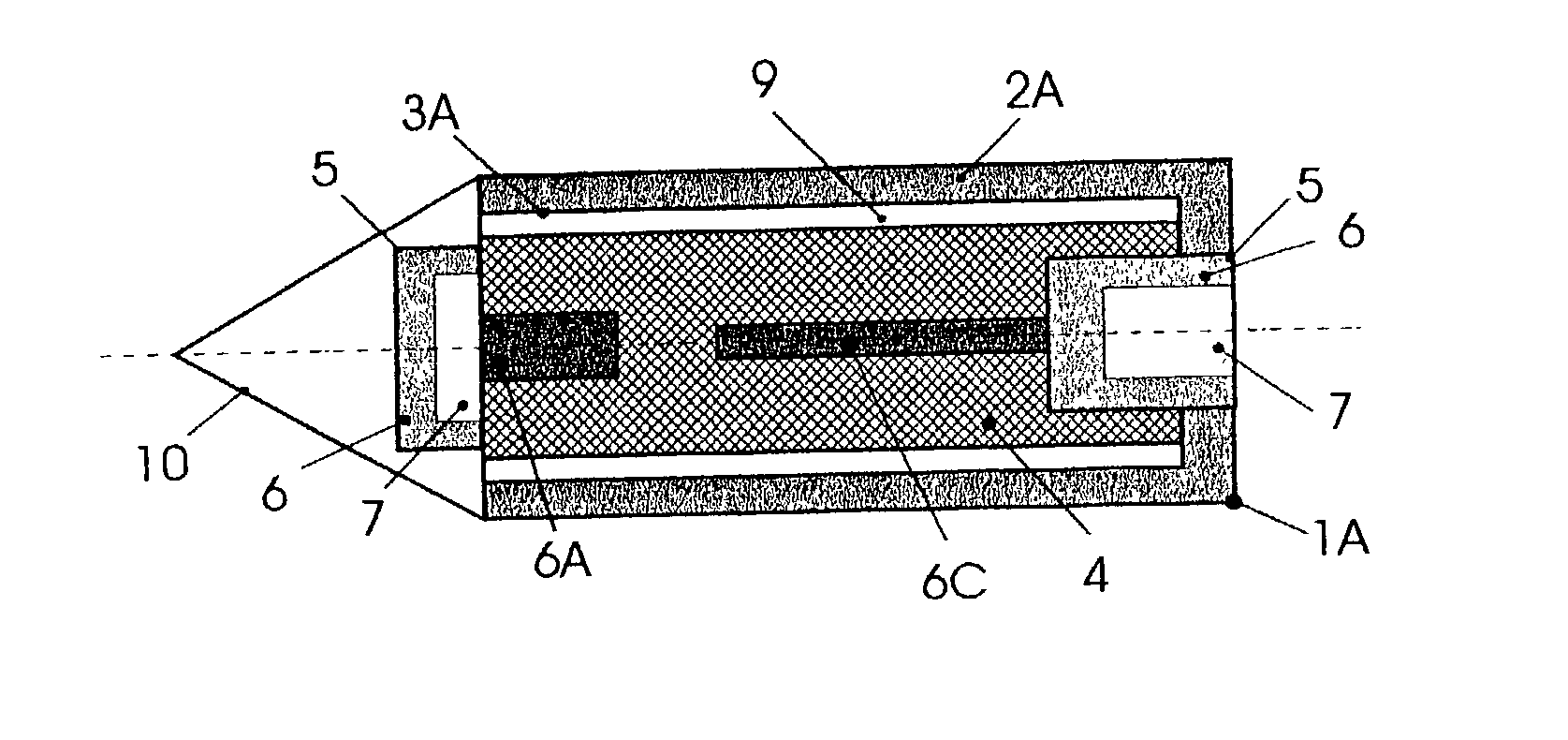

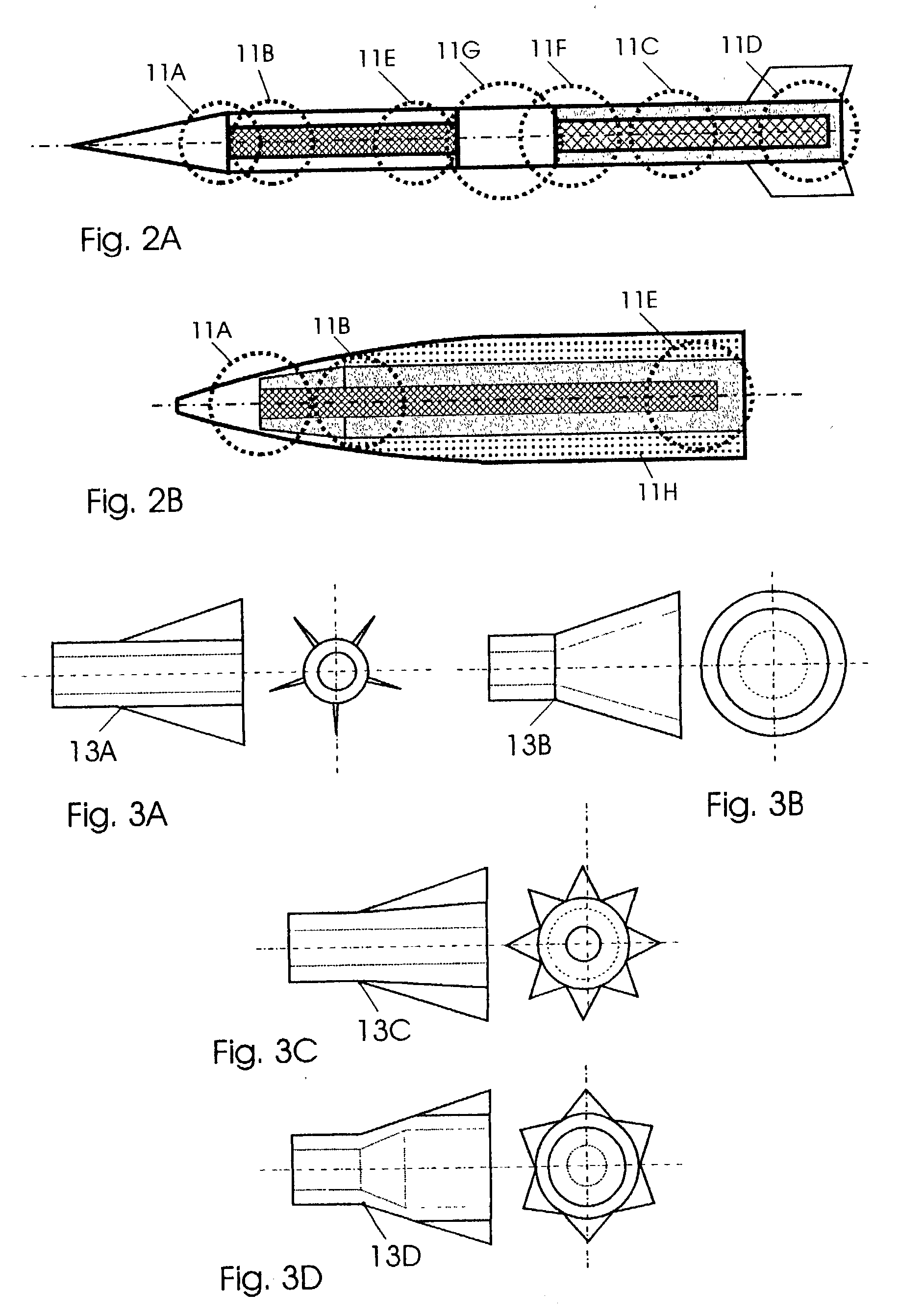

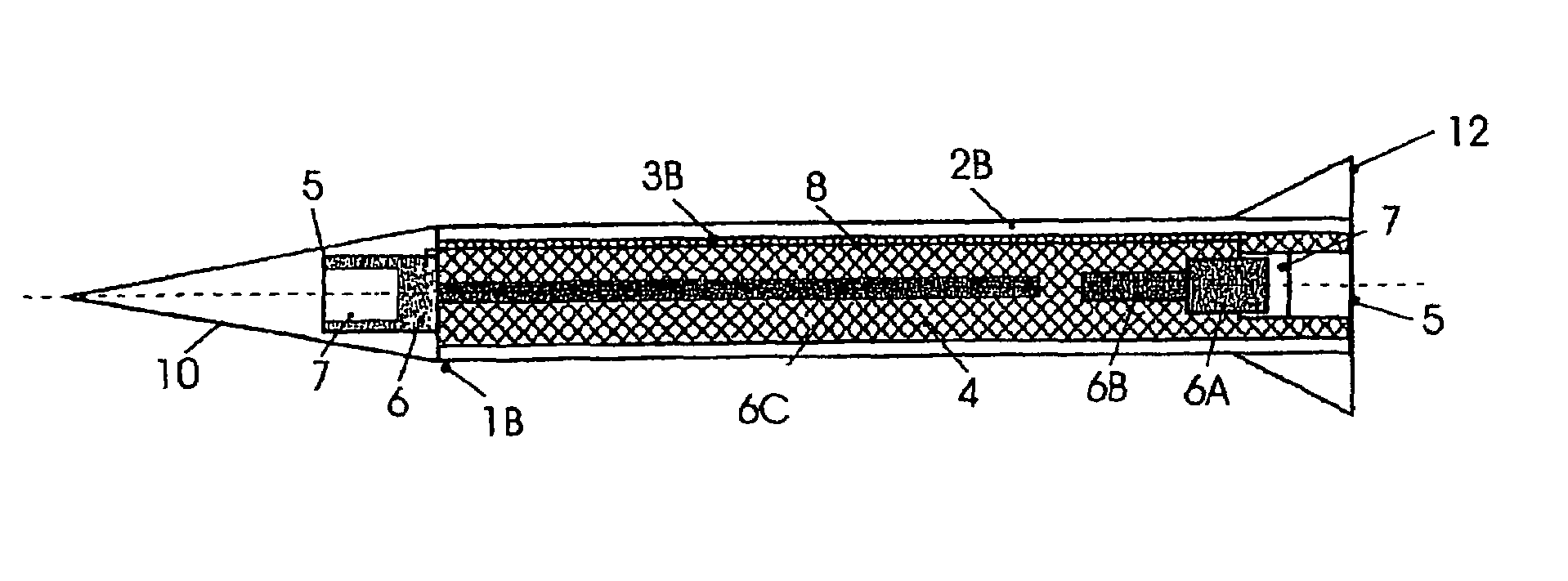

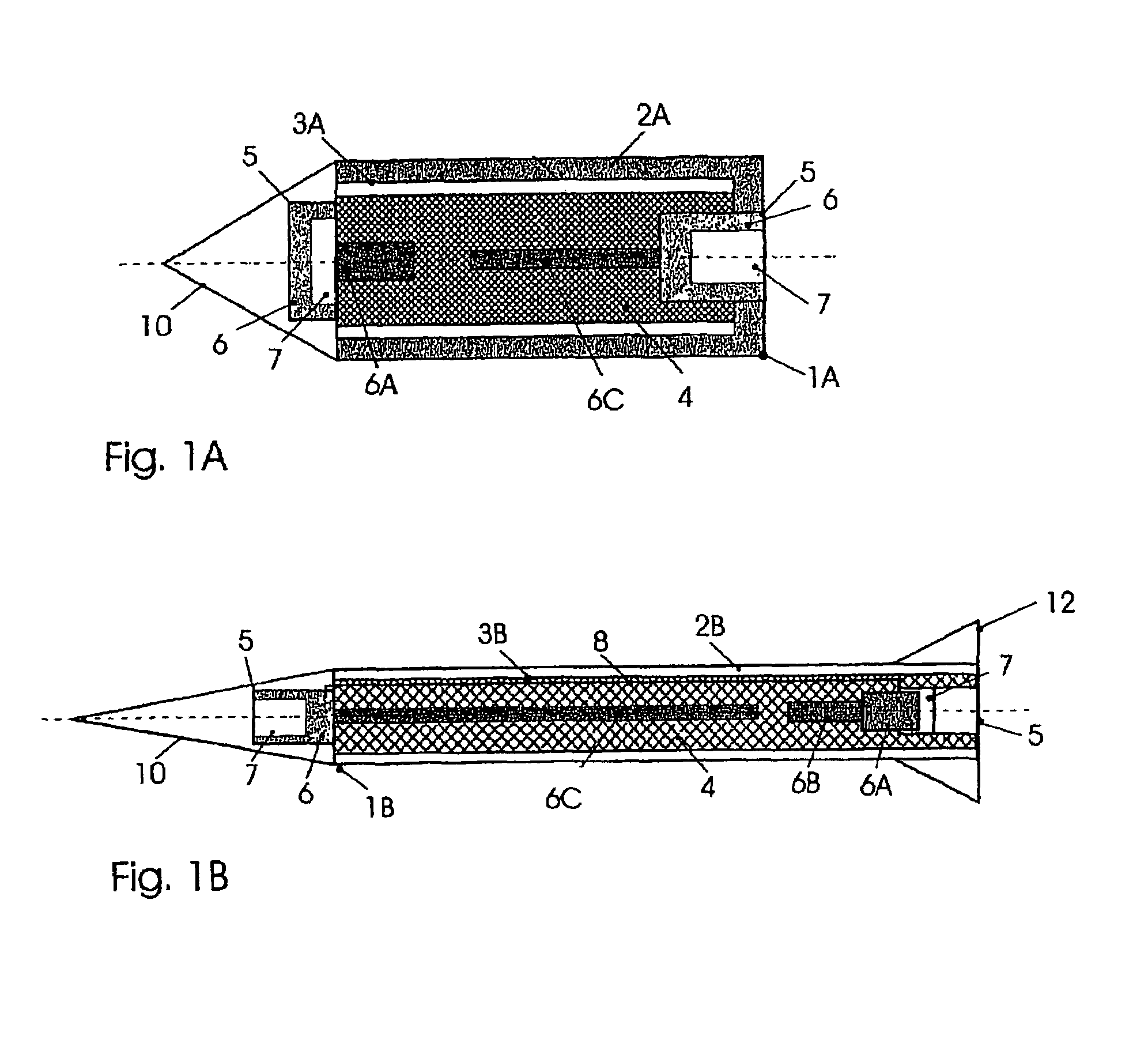

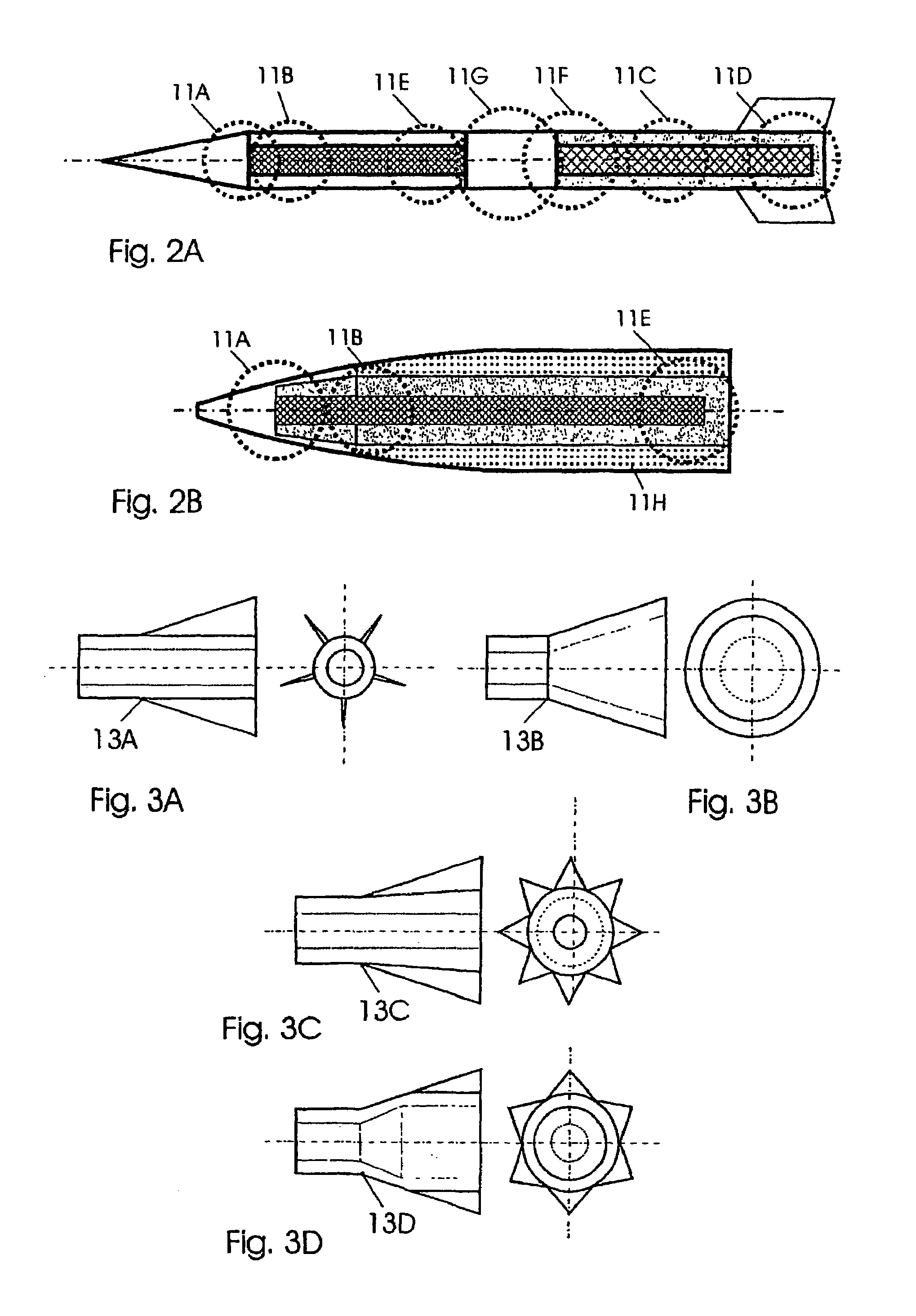

Projectiles possessing high penetration and lateral effect with integrated disintegration arrangement

InactiveUS20030167956A1Improve effectivenessSmall dimensionAmmunition projectilesSelf-propelled projectilesSurface stressEngineering

A highly effective and also inert active penetrator, an active projectile, an active airborne body or an active multipurpose projectile with a constructively adjustable or settable relationship between penetrating power and lateral effect. The end ballistic total effect which is obtained from the penetrating depth and covering the surface or stressing of the surface is initiated in an active case by means of a releasable arrangement or installation which is independent of the position of the active body.

Owner:RHEINMETALL WAFFE MUNITION GMBH

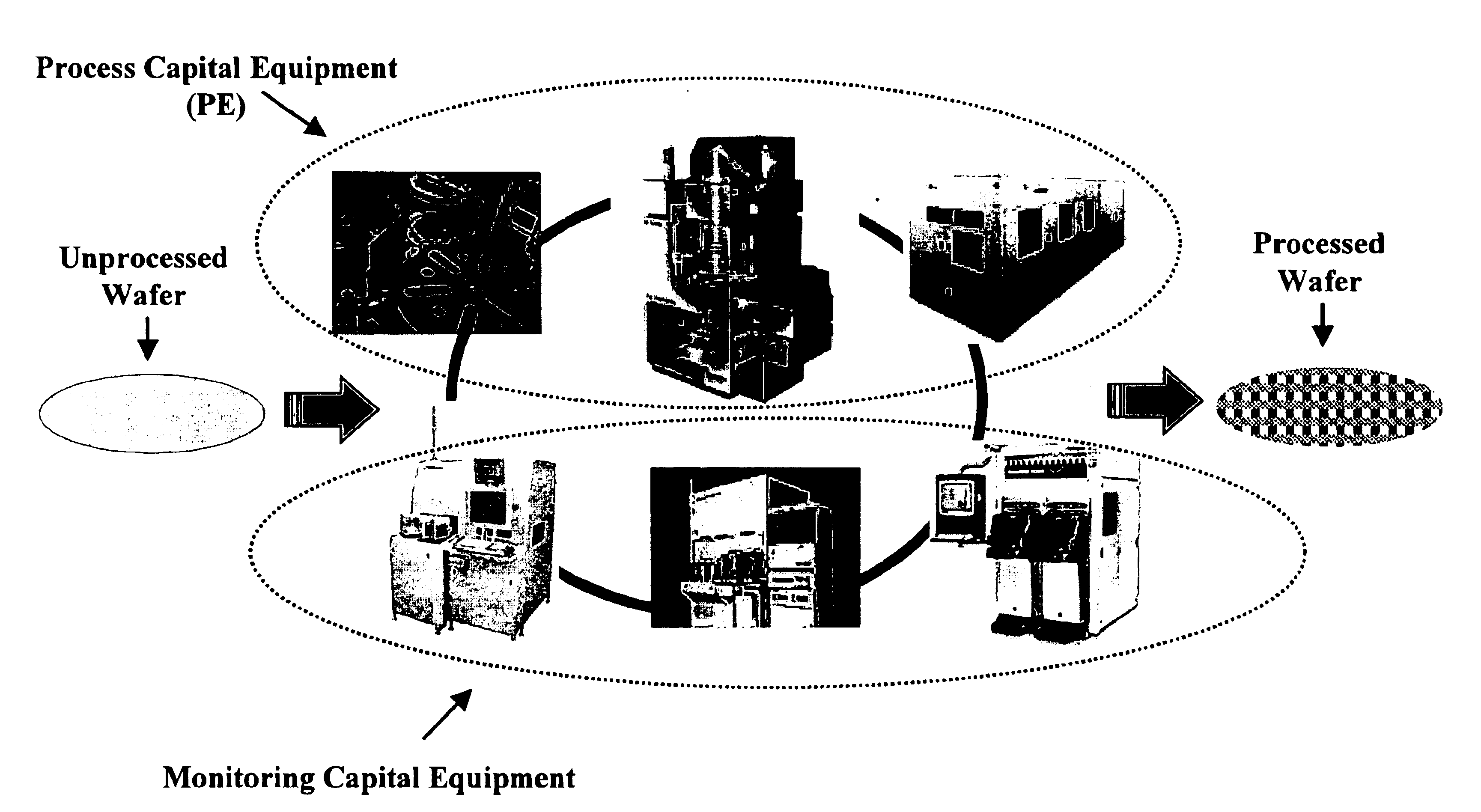

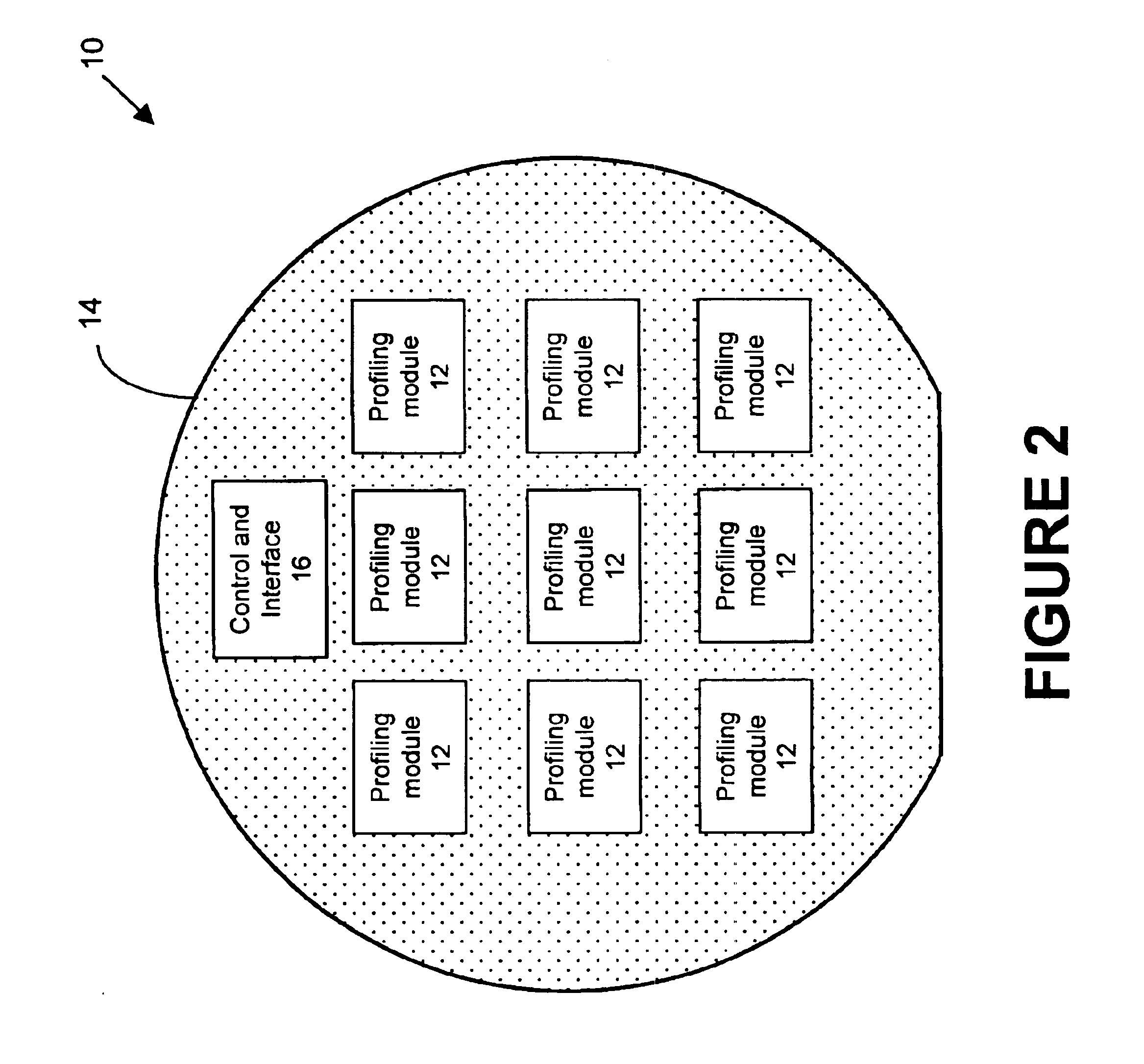

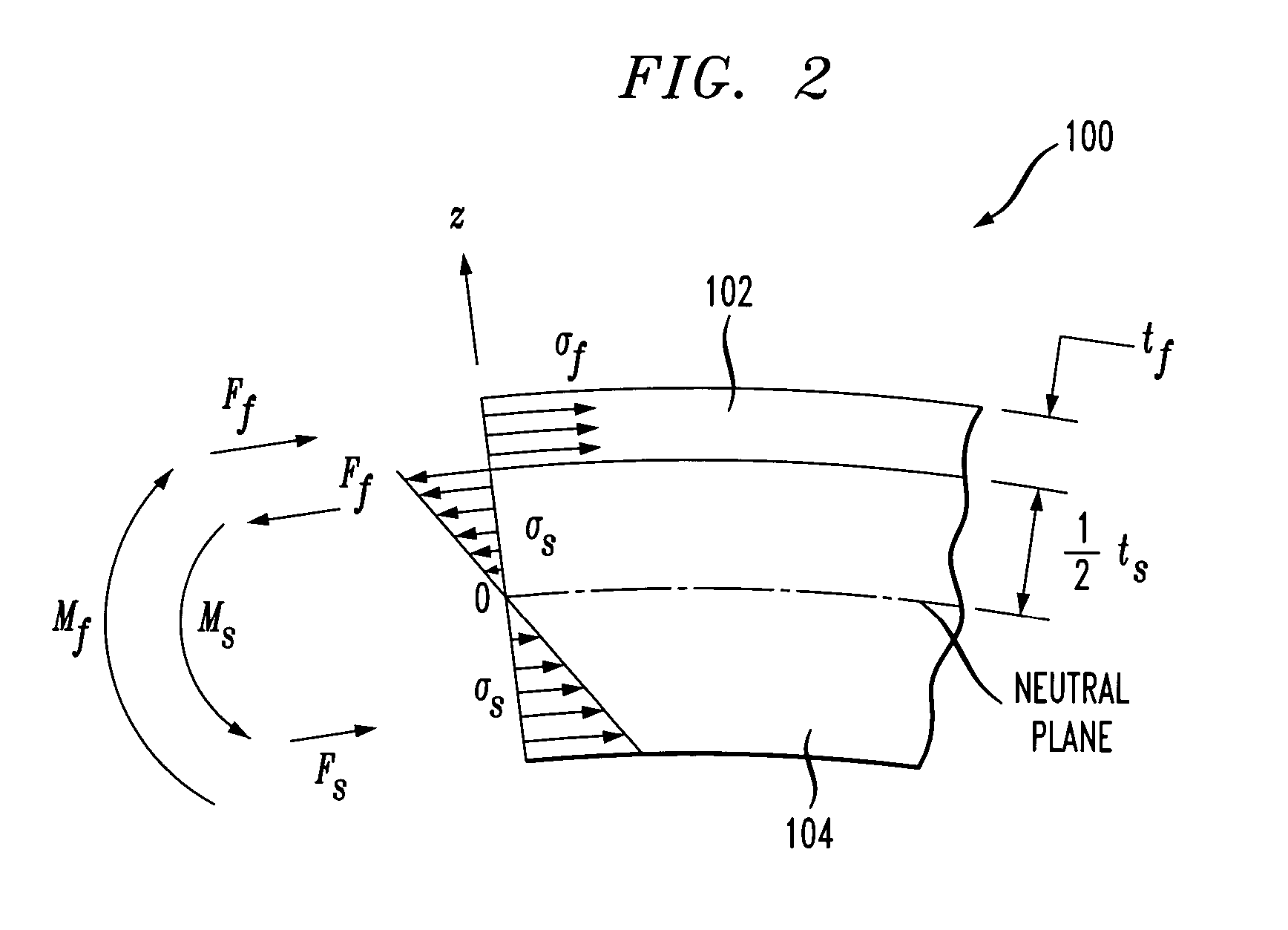

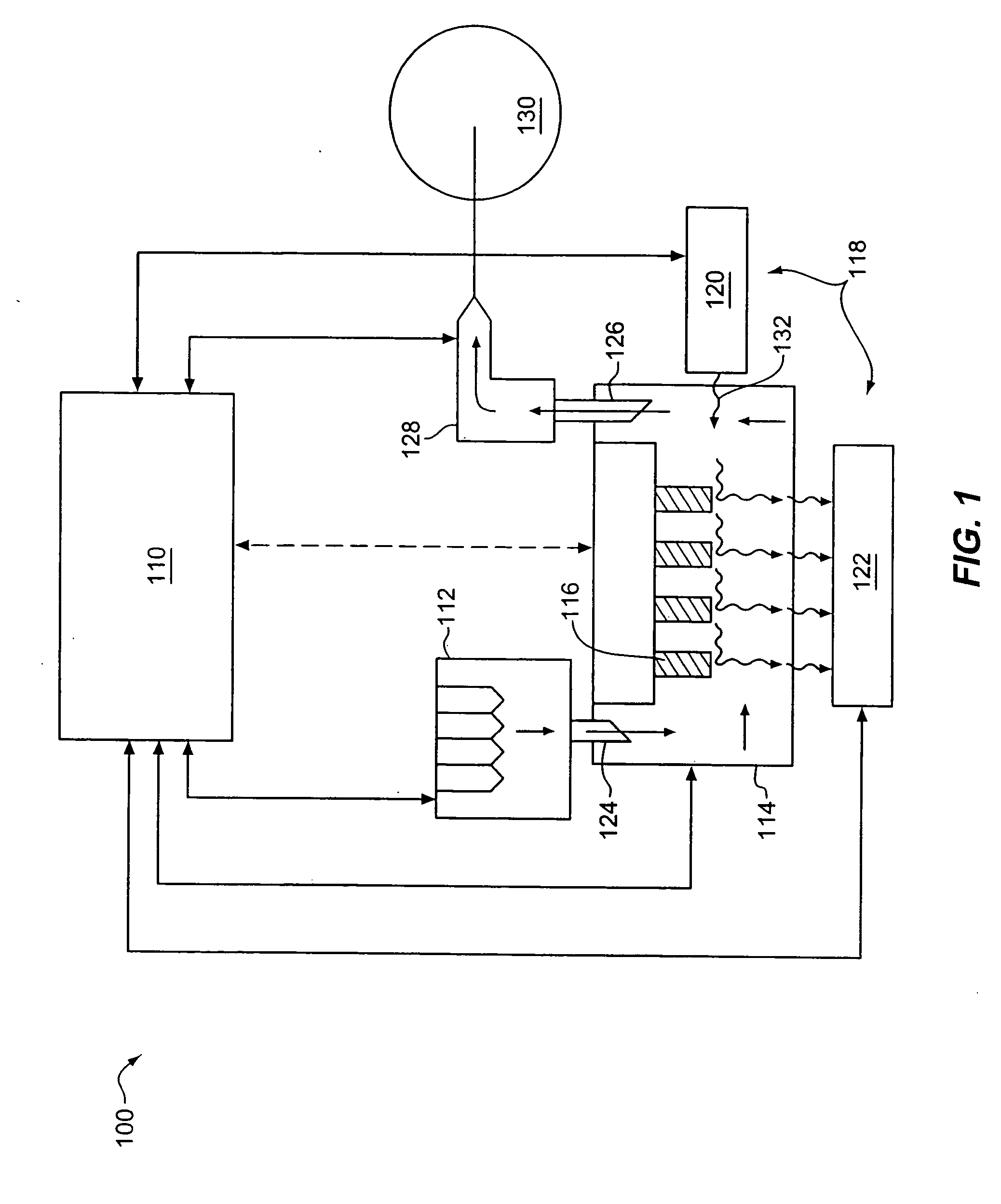

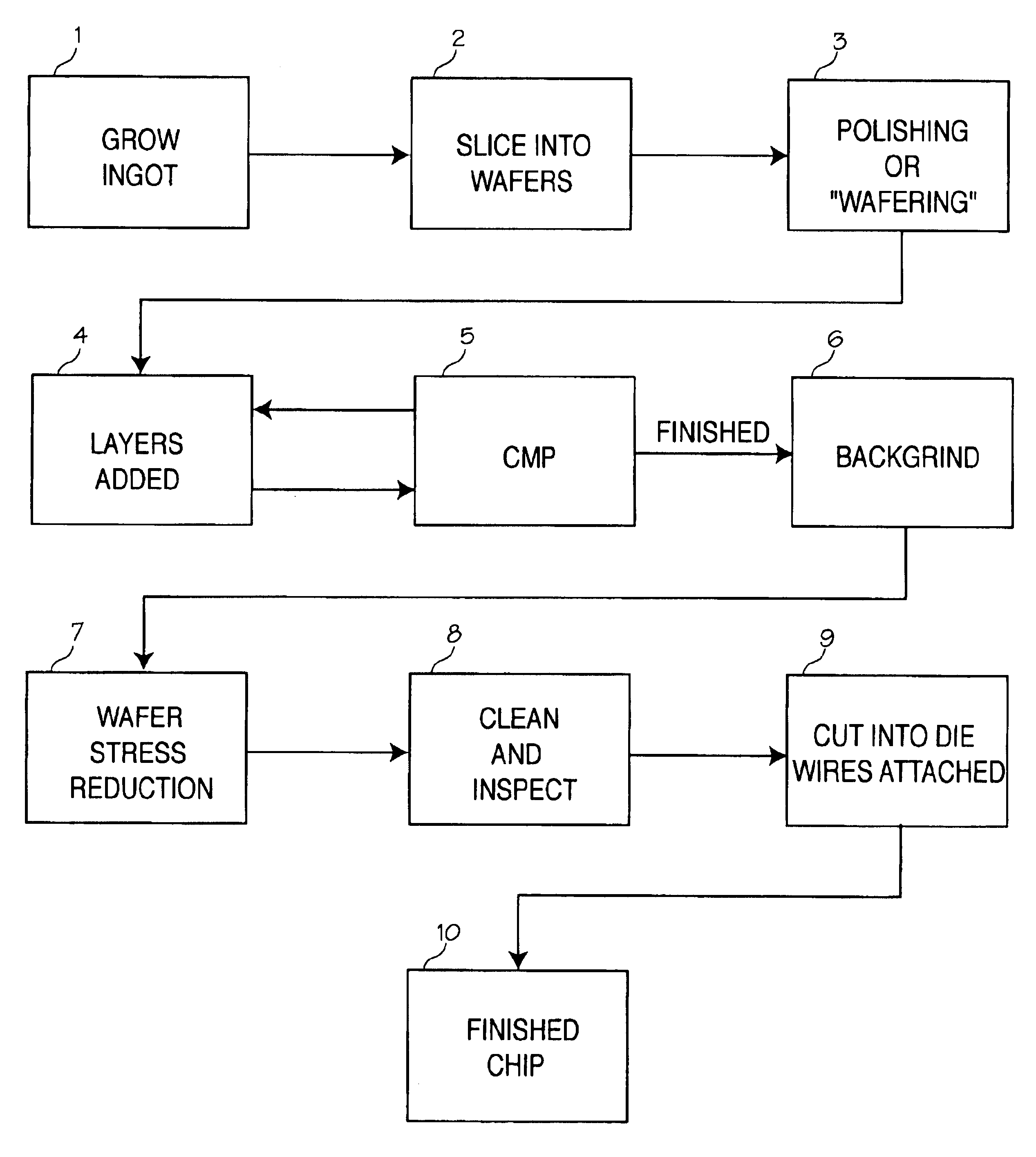

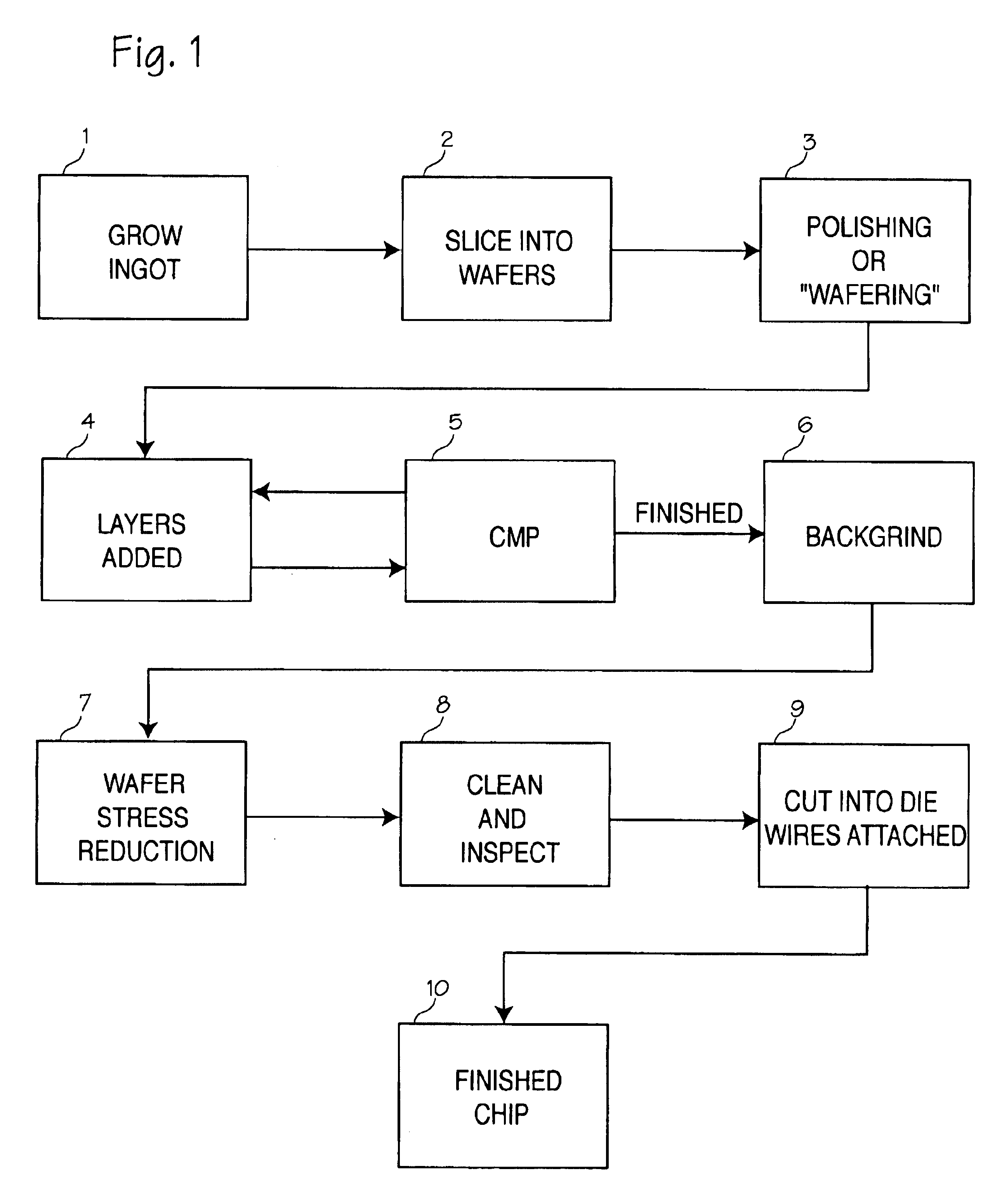

Method and apparatus for monitoring integrated circuit fabrication

ActiveUS6879924B2Accelerate lead optimization processChange is minimalSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceSurface stressEngineering

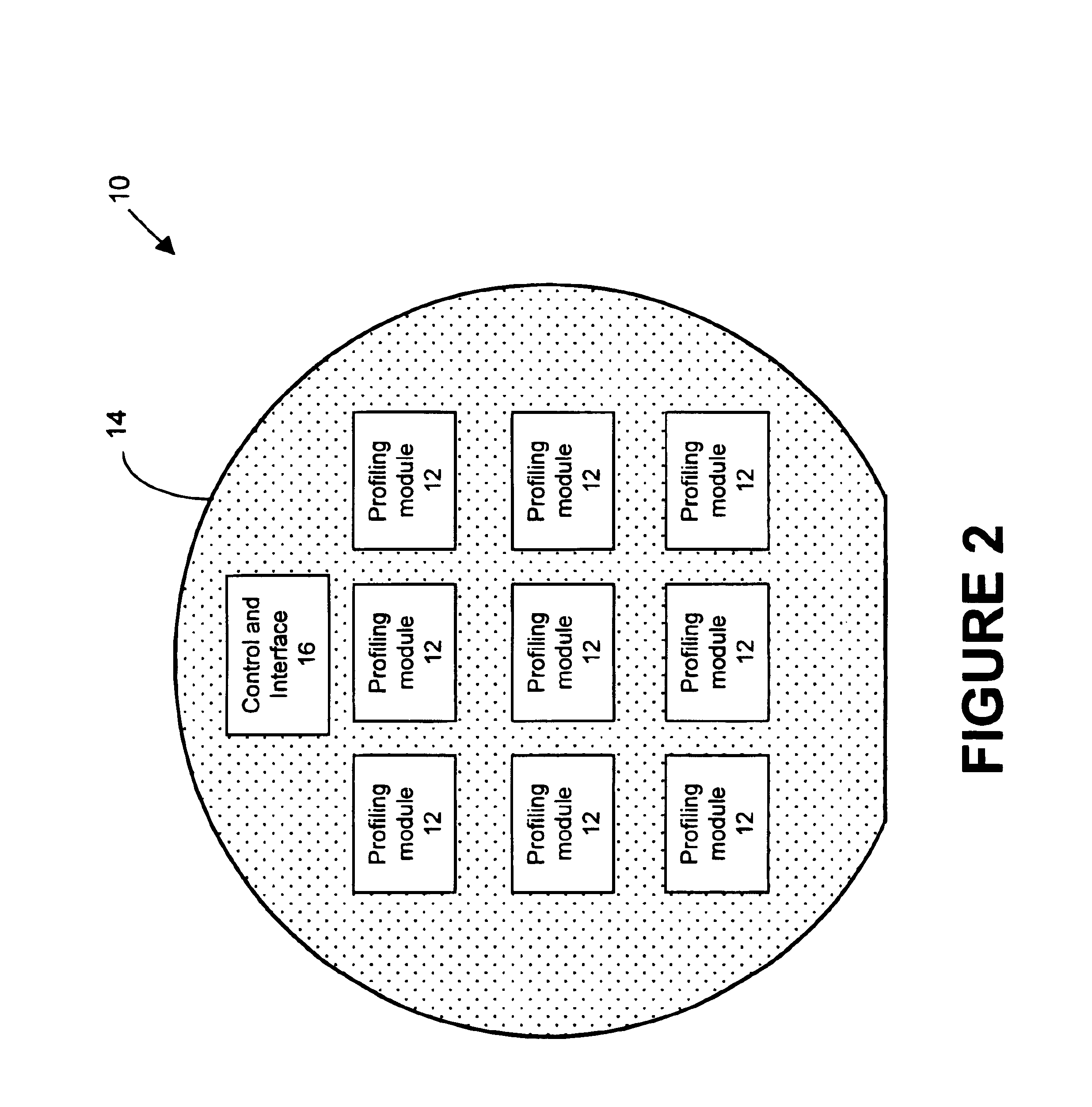

In one aspect, the present invention is a sensor unit for sensing process parameters of a process to manufacture an integrated circuit using integrated circuit processing equipment. In one embodiment, the sensor unit includes a substrate having a wafer-shaped profile and a first sensor, disposed on or in the substrate, to sample a first process parameter. The sensor unit of this embodiment also includes a second sensor, disposed on or in the substrate, to sample a second process parameter wherein the second process parameter is different from the first process parameter. In one embodiment, the sensor unit includes a first source, disposed on or in the substrate, wherein first source generates an interrogation signal and wherein the first sensor uses the interrogation signal from the first source to sample the first process parameter. The sensor unit may also include a second source, disposed on or in the substrate, wherein second source generates an interrogation signal and wherein the second sensor uses the interrogation signal from the second source to sample the second process parameter. The first sensor and the first source may operate in an end-point mode or in a real-time mode. In this regard, the first sensor samples the first parameter periodically or continuously while the sensor unit is disposed in the integrated circuit processing equipment and undergoing processing. In one embodiment, the first sensor is a temperature sensor and the second sensor is a pressure sensor, a chemical sensor, a surface tension sensor or a surface stress sensor.

Owner:ASML NETHERLANDS BV

Method and apparatus for monitoring integrated circuit fabrication

InactiveUS6892156B2Change is minimalSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceSurface stressPressure sensor

In one aspect, the present invention is a sensor unit for sensing process parameters of a process to manufacture an integrated circuit using integrated circuit processing equipment. In one embodiment, the sensor unit includes a substrate having a wafer-shaped profile and a first sensor, disposed on or in the substrate, to sample a first process parameter. The sensor unit of this embodiment also includes a second sensor, disposed on or in the substrate, to sample a second process parameter wherein the second process parameter is different from the first process parameter. In one embodiment, the sensor unit includes a first source, disposed on or in the substrate, wherein first source generates an interrogation signal and wherein the first sensor uses the interrogation signal from the first source to sample the first process parameter. The sensor unit may also include a second source, disposed on or in the substrate, wherein second source generates an interrogation signal and wherein the second sensor uses the interrogation signal from the second source to sample the second process parameter. The first sensor and the first source may operate in an end-point mode or in a real-time mode. In this regard, the first sensor samples the first parameter periodically or continuously while the sensor unit is disposed in the integrated circuit processing equipment and undergoing processing. In one embodiment, the first sensor is a temperature sensor and the second sensor is a pressure sensor, a chemical sensor, a surface tension sensor or a surface stress sensor.

Owner:ASML NETHERLANDS BV

Projectiles possessing high penetration and lateral effect with integrated disintegration arrangement

InactiveUS7231876B2Increase in significanceFacilitate transmissionAmmunition projectilesTraining ammunitionSurface stressEngineering

A highly effective and also inert active penetrator, an active projectile, an active airborne body or an active multipurpose projectile with a constructively adjustable or settable relationship between penetrating power and lateral effect. The end ballistic total effect which is obtained from the penetrating depth and covering the surface or stressing of the surface is initiated in an active case by means of a releasable arrangement or installation which is independent of the position of the active body.

Owner:RHEINMETALL WAFFE MUNITION GMBH

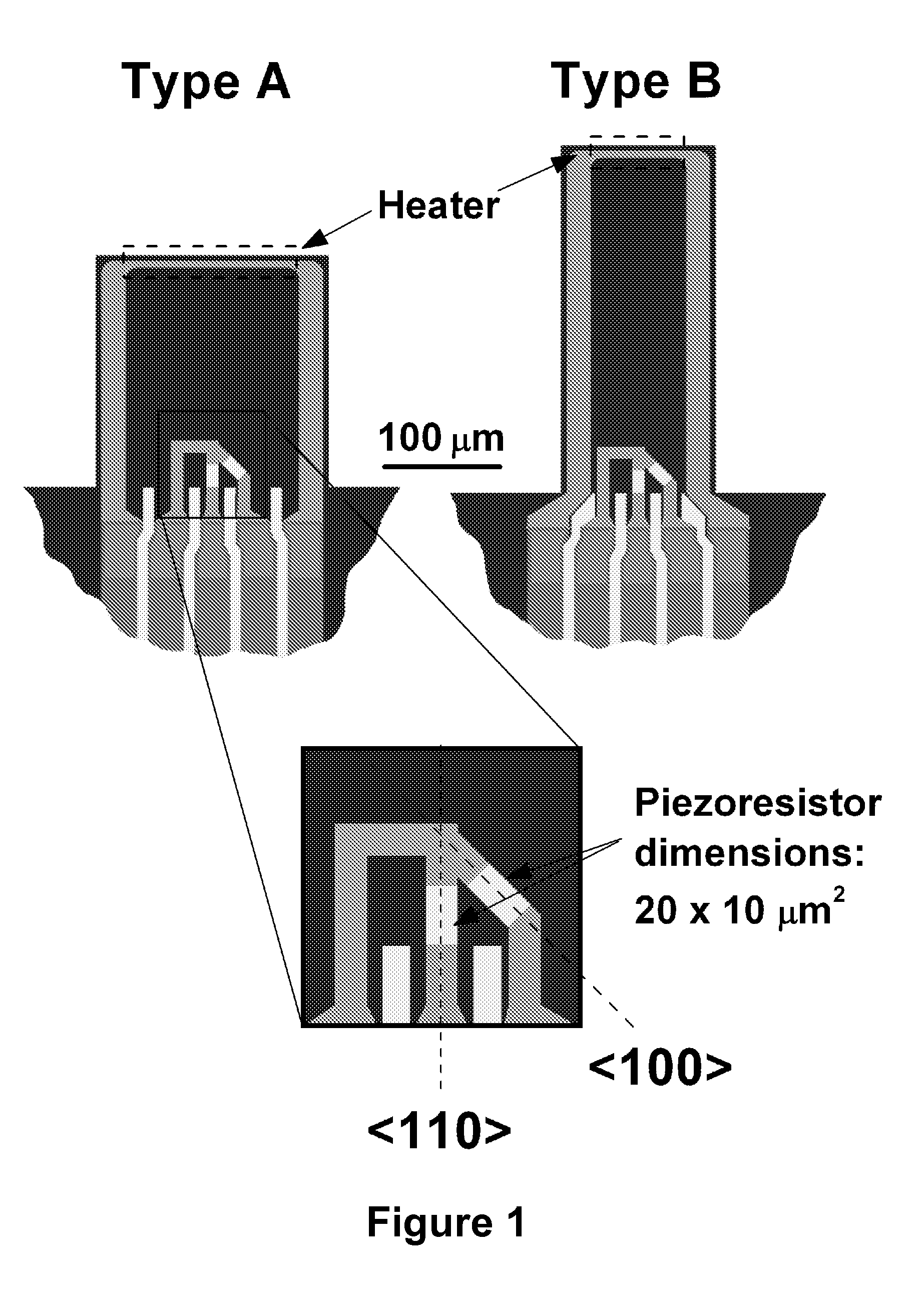

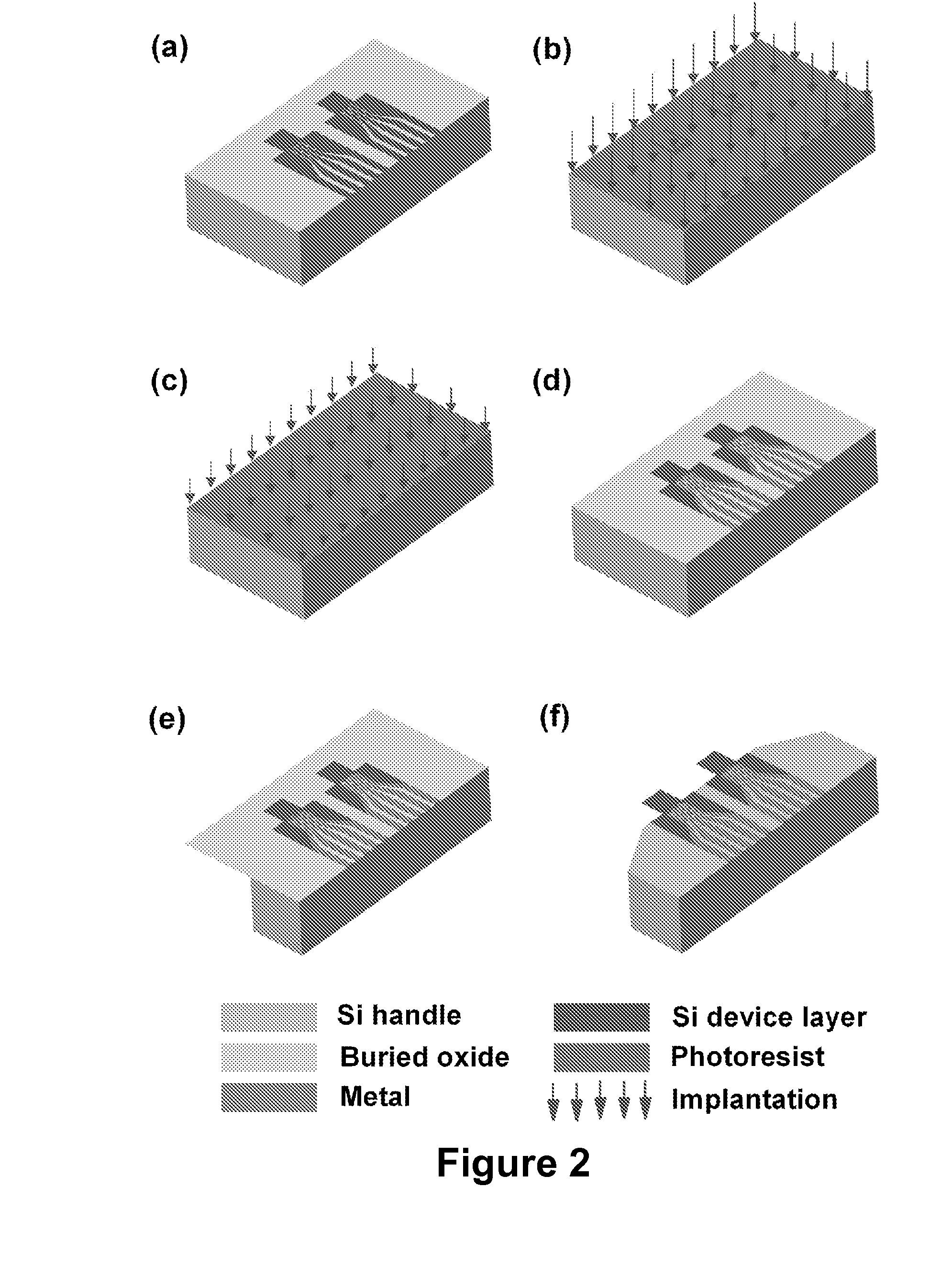

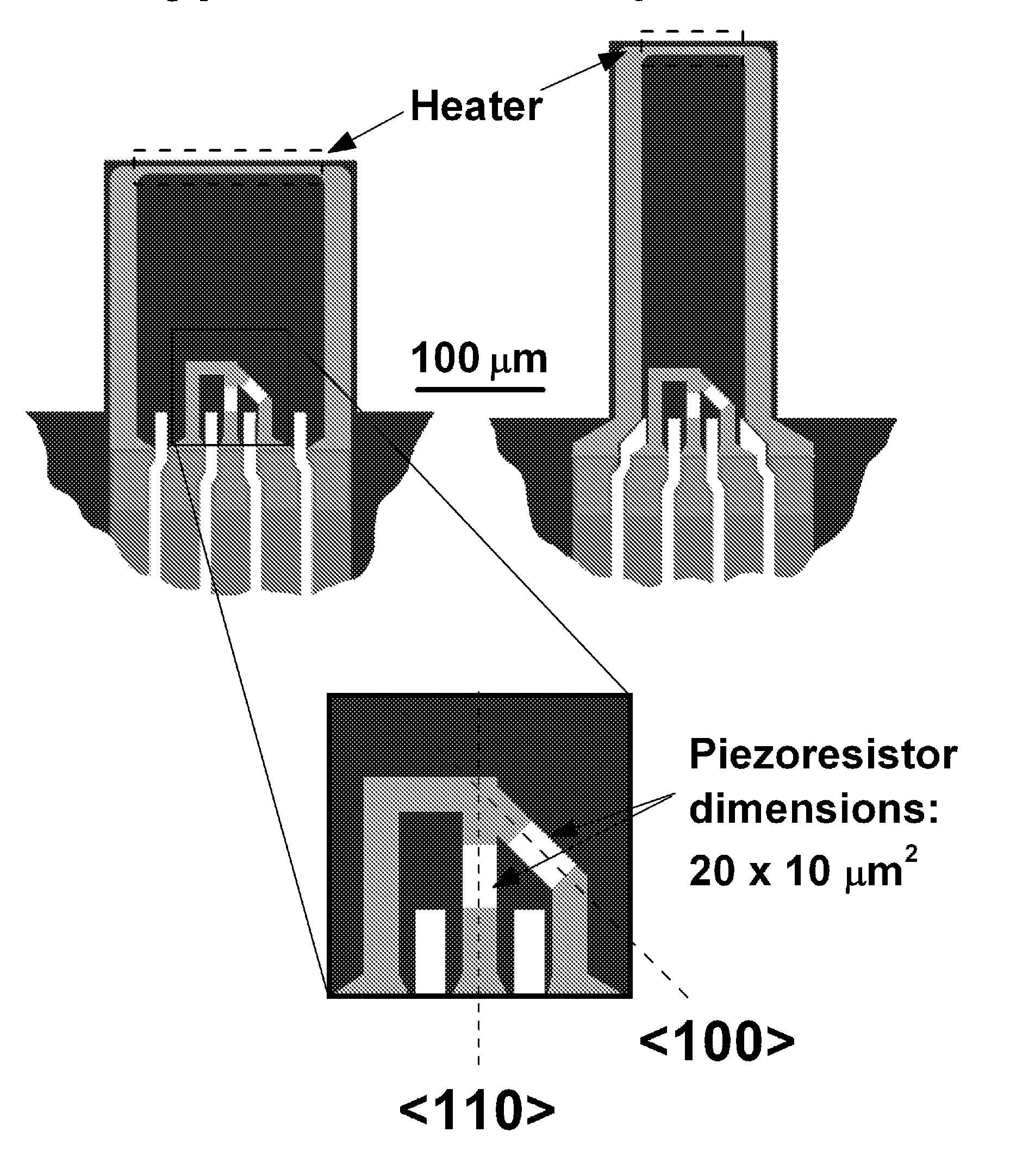

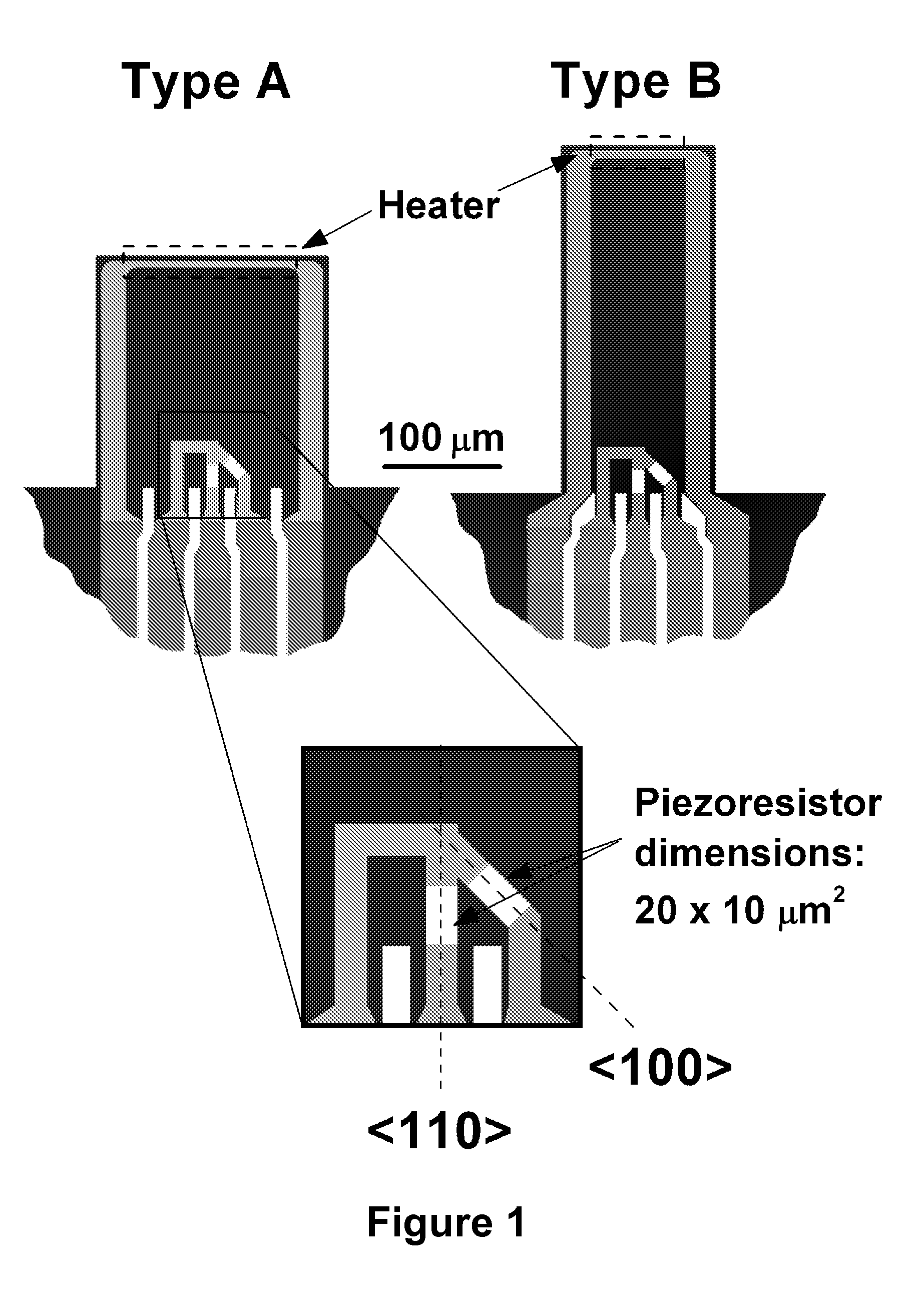

Microcantilever Heater-Thermometer With Integrated Temperature-Compensated Strain Sensor

InactiveUS20090139340A1Change resistanceWeighing by removing componentForce measurementSurface stressElectrical resistance and conductance

The present invention provides microcantilever hotplate devices which incorporate temperature compensating strain sensors. The microcantilever hotplate devices of the present invention comprise microcantilevers having temperature compensating strain sensors and resistive heaters. The present invention also provides methods for using a microcantilever hotplate for temperature compensated surface stress measurements, chemical / biochemical sensing, measuring various properties of compounds adhered to the microcantilever hotplate surface, or for temperature compensated deflection measurements.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

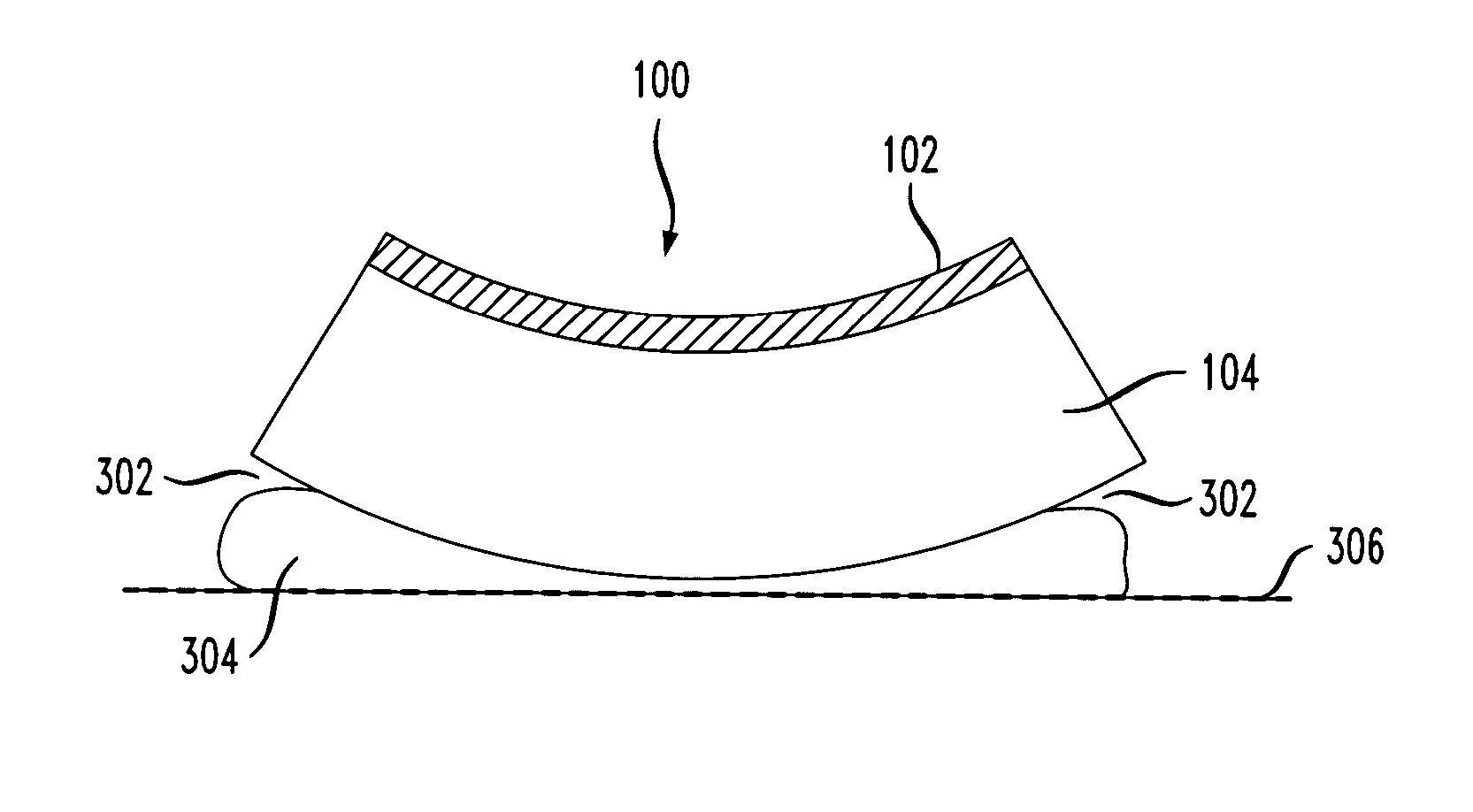

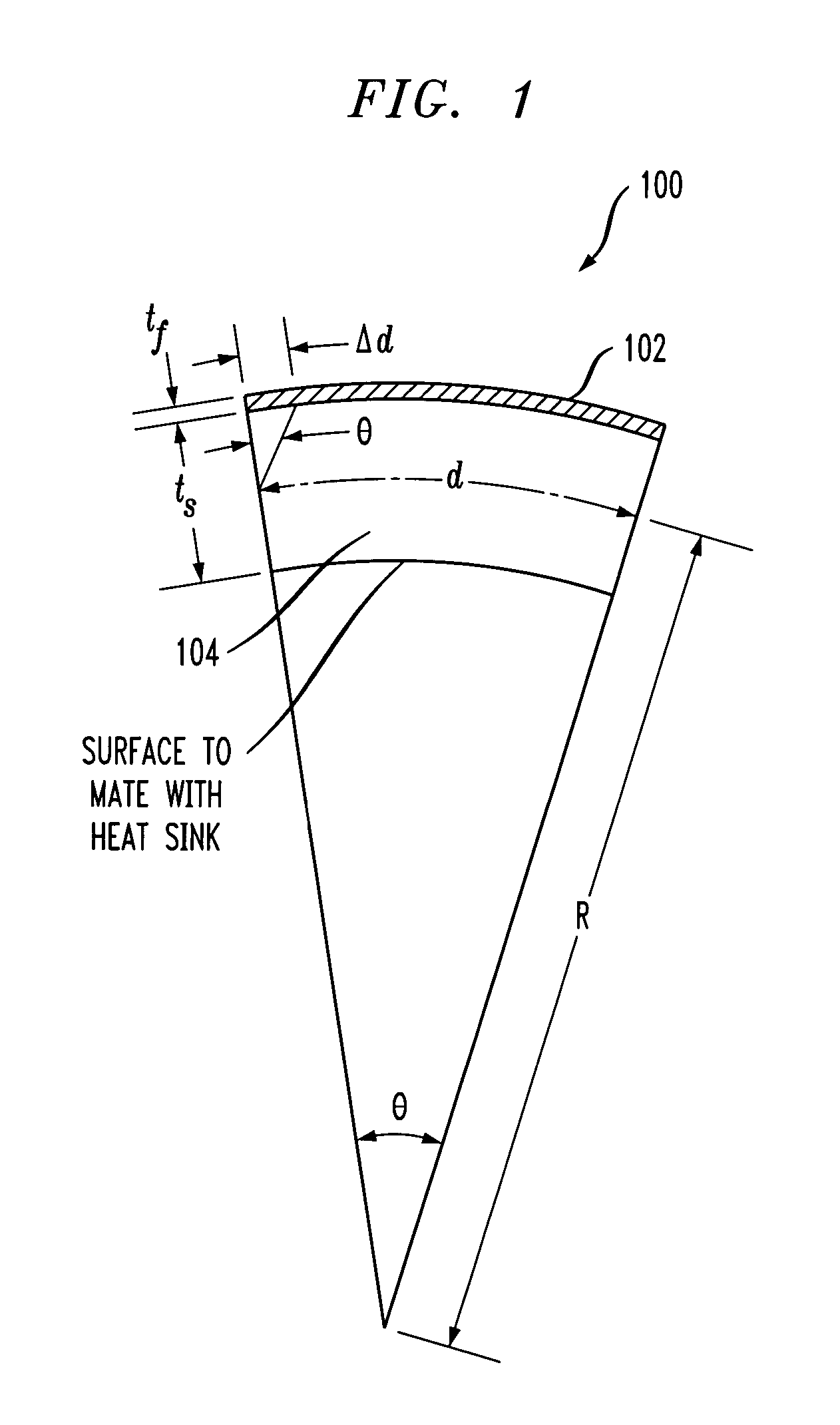

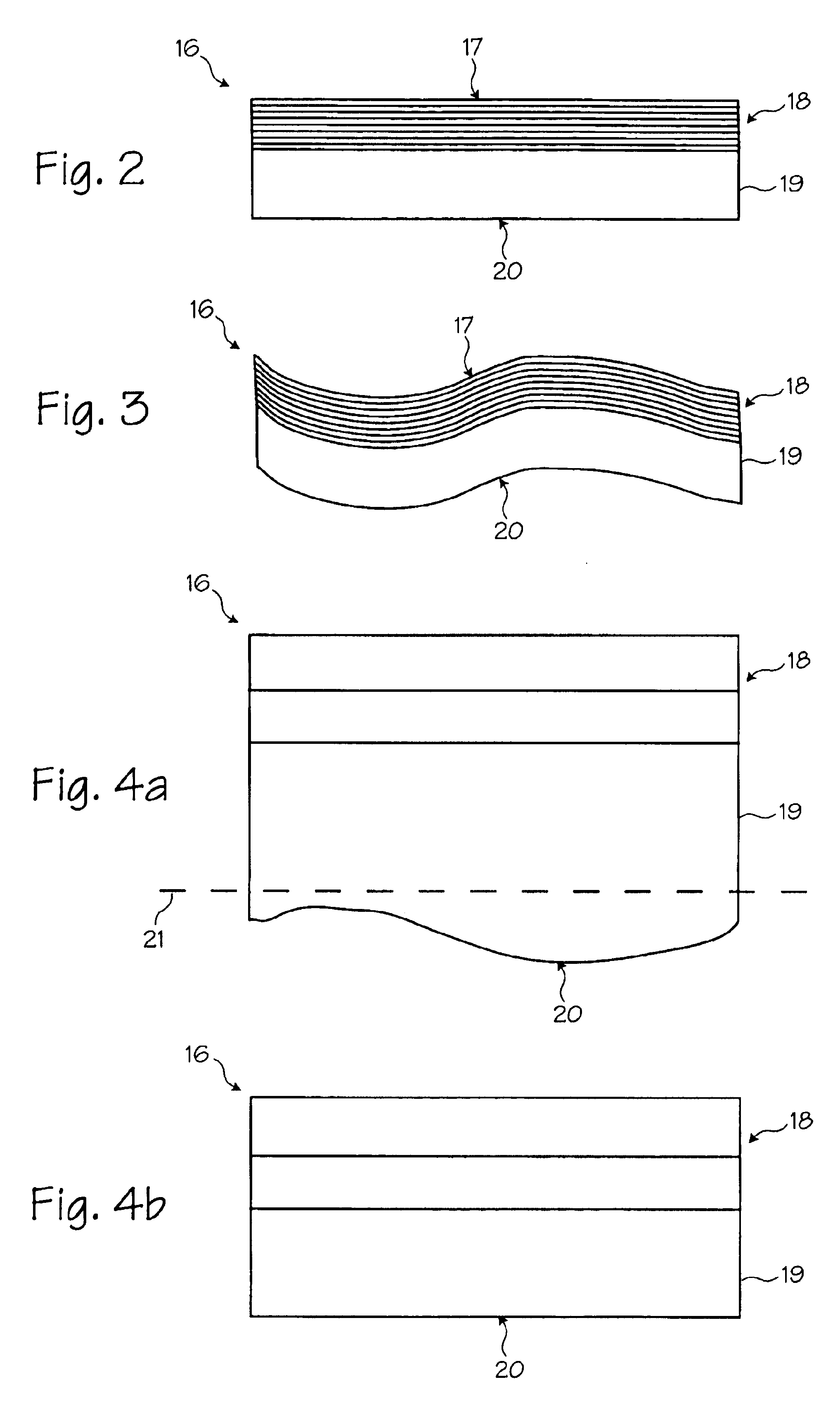

Techniques for curvature control in power transistor devices

InactiveUS20050026332A1Semiconductor/solid-state device detailsSolid-state devicesSurface stressEngineering

Techniques for processing power transistor devices are provided. In one aspect, the curvature of a power transistor device comprising a device film formed on a substrate is controlled by thinning the substrate, the device having an overall residual stress attributable at least in part to the thinning step, and applying a stress compensation layer to a surface of the device film, the stress compensation layer having a tensile stress sufficient to counterbalance at least a portion of the overall residual stress of the device. The resultant power transistor device may be part of an integrated circuit.

Owner:AGERE SYST LLC

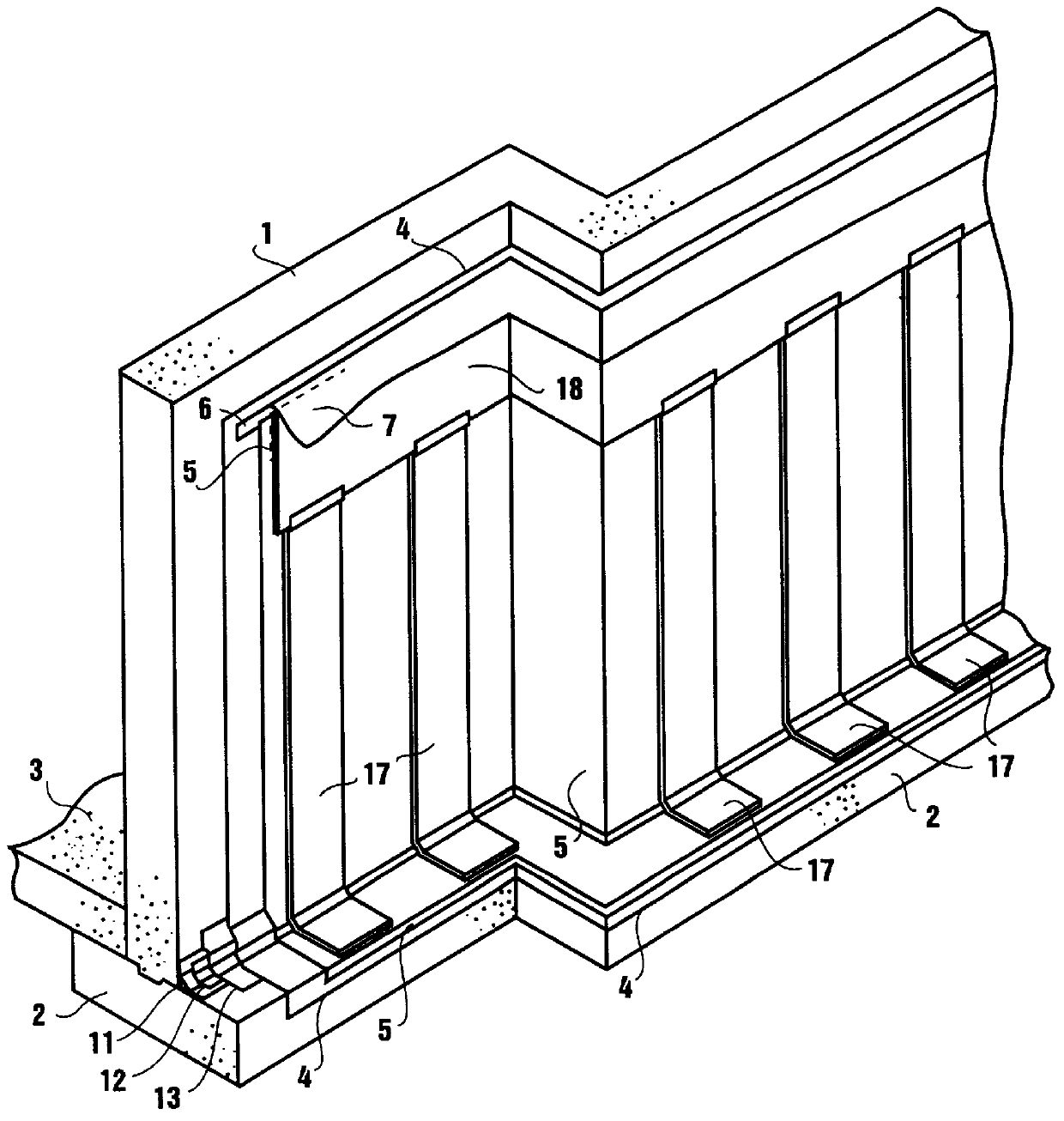

Moisture barrier protection system and method

InactiveUS6122887AImprove the immunityProtective foundationBuilding repairsSurface stressGeomembrane

A tough, high-strength geomembrane made from a custom blend of polyethylene copolymers, for protecting waterproofing courses from impact and pressure damage of debris resting against the waterproof course. A slip sheet configuration reduces surfaces stress due to earth movement and subsurface cracking thereby maintaining the protective course intact without any effect on the waterproofing layers. The geomembrane is available as lightweight rolls which can be easily be handled by one man. The film is installed horizontally in continuous sheets with few adhesive joints. Installation begins by applying a thick brush coat of the selected waterproofing membrane material (usually a rubber coat but may be any waterpoofing material). The film is unrolled along the wall, held up into position and secured using plastic self-sealing plugs and / or plastic termination bars. Concrete nails are used to attach the self-sealing plugs or termination bar to the wall. If termination bar is selected the film is extended up beyond the bar approximately 8'' and folded down over the termination bar after attachment. Staples into the termination bar can be used to hold the film down creating a nicely detailed upper edge.

Owner:SOCOPAC

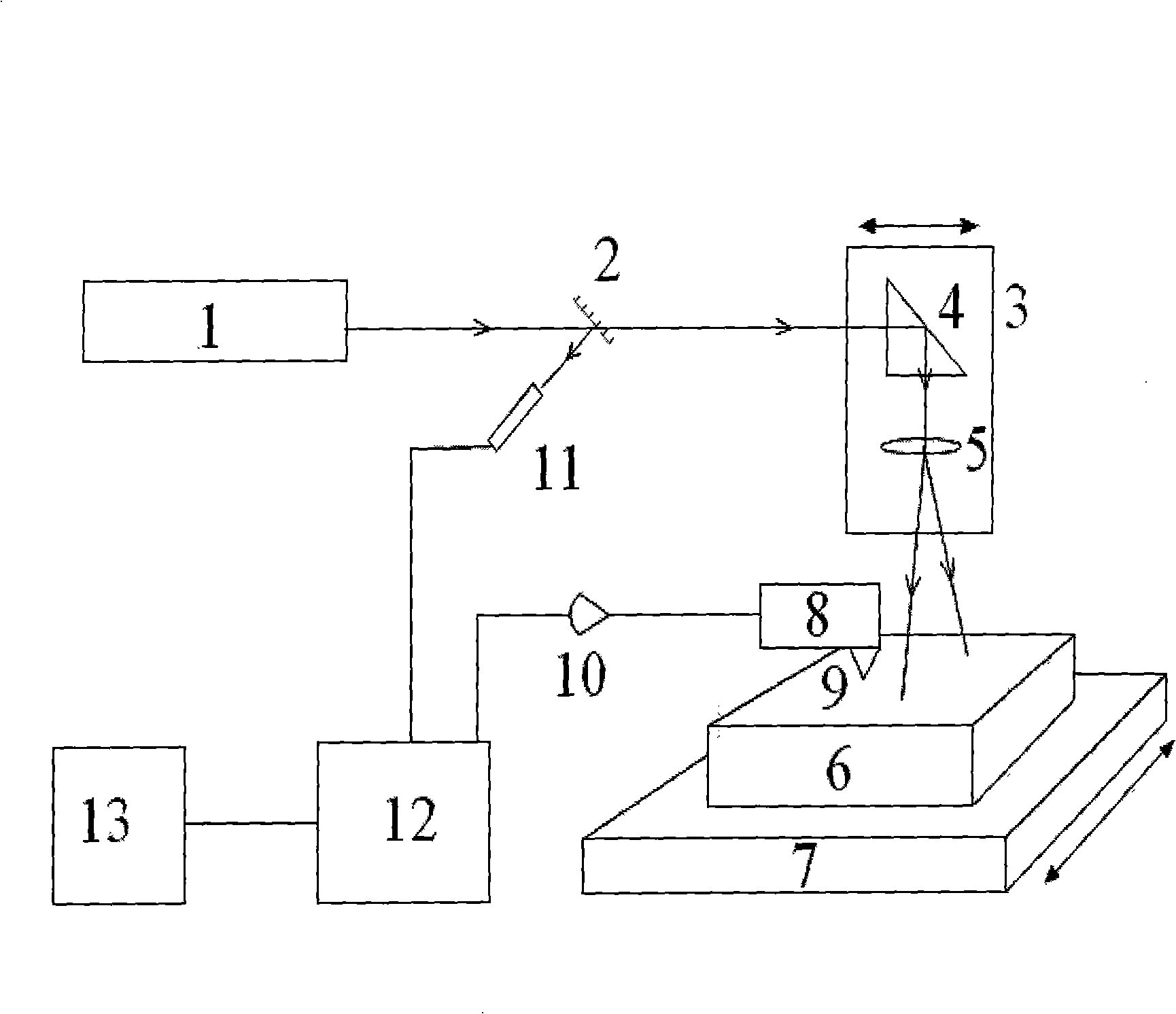

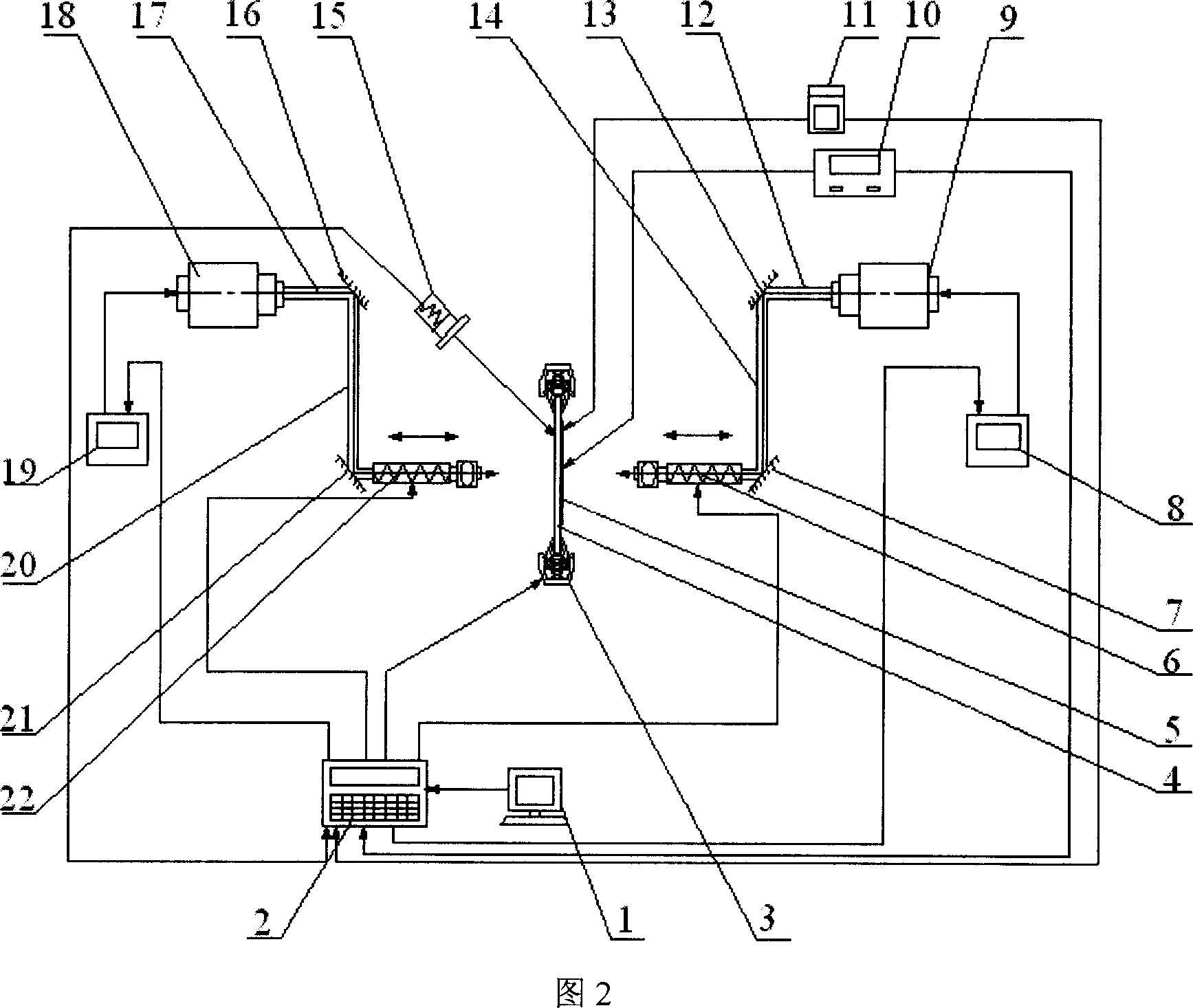

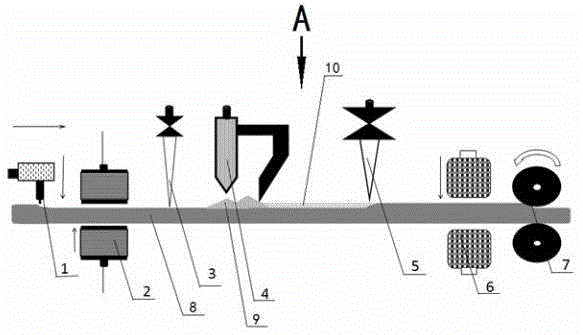

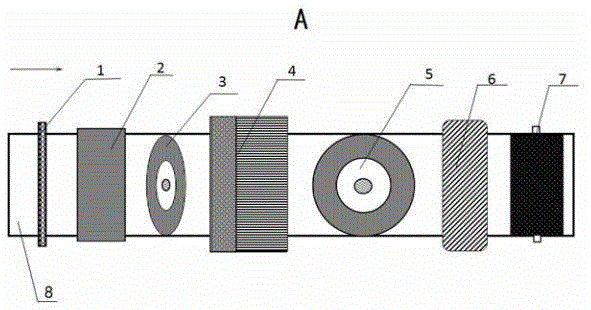

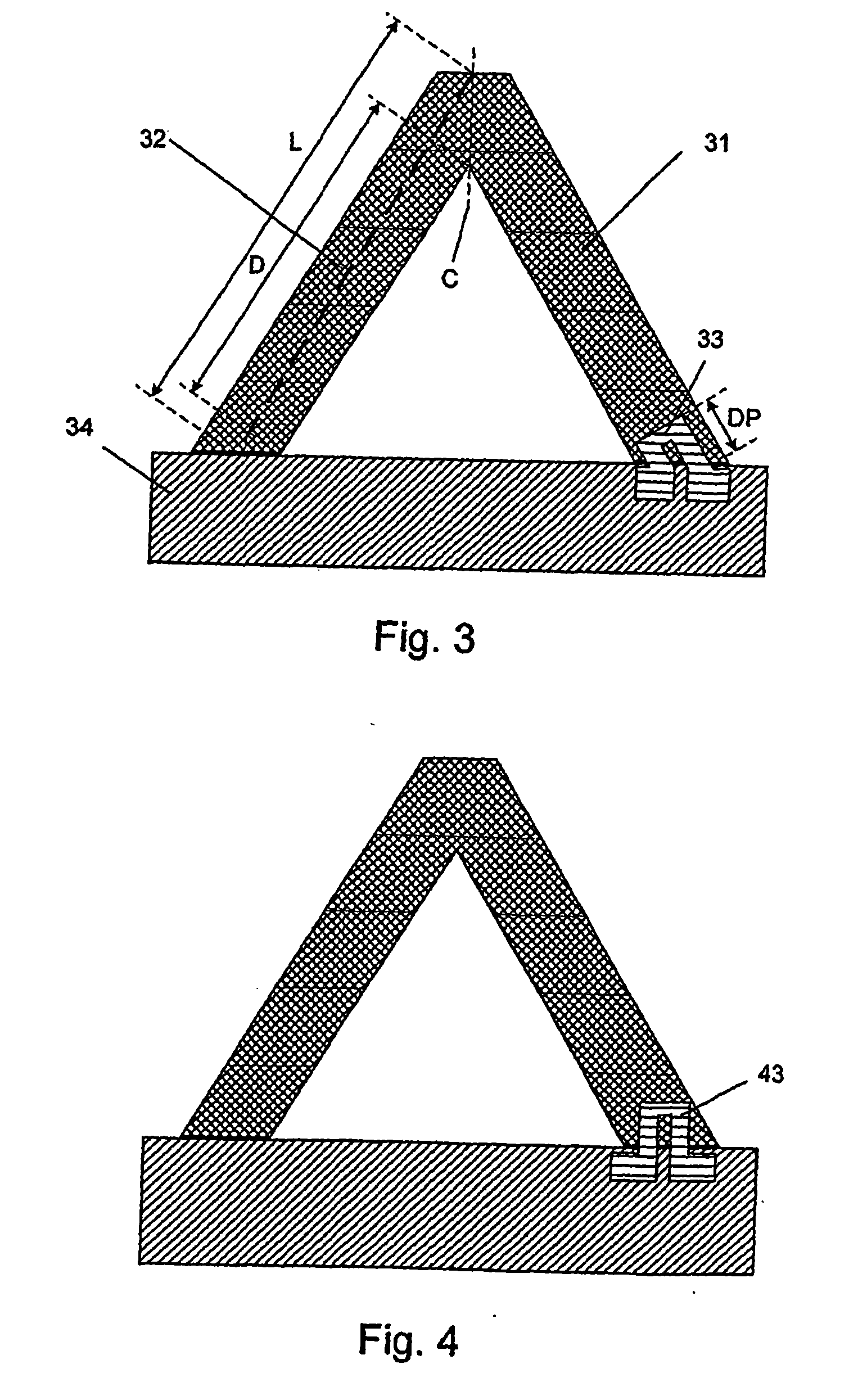

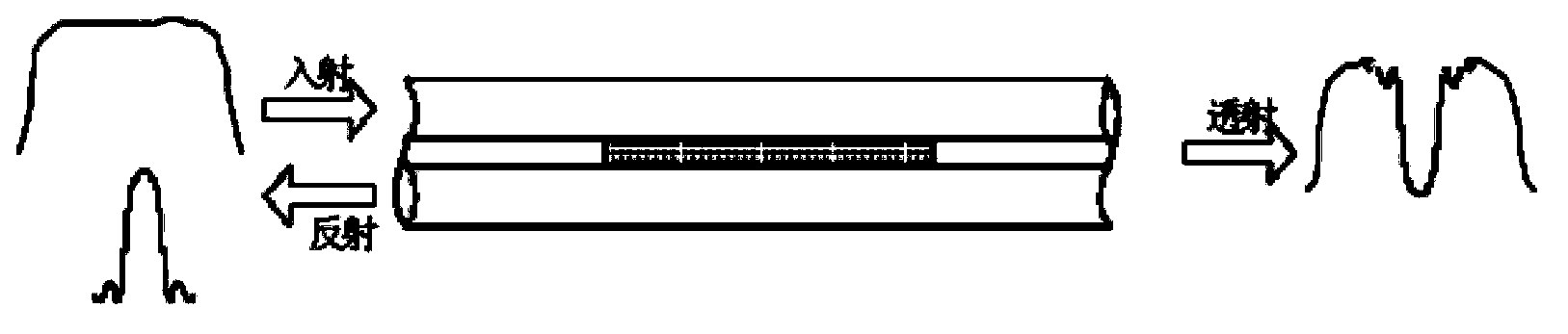

Laser sonic surface wave stress test system

InactiveCN101281172AFast 2D scanningHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationMetallic materials

The invention discloses a laser acoustic surface wave stress test system, which is mainly comprises an ultrasound surface wave excitation part composed of a short-pulse laser, a spectroscope, a triple prism and a cylindrical convex lens, and an ultrasound surface wave detection part composed of a PVDF piezoelectric film and a high-frequency pre-amplifier. The invention uses the short-pulse laser to generate a high-frequency ultrasound surface wave on the surface of the samples to be tested, a stress value is obtained according to the principle of acoustic elasticity, the PVDF piezoelectric film is served as the receiver of the ultrasound surface wave, fast two-dimensional scanning is realized on the surface of the samples in the way that the PVDF piezoelectric film is fixed, the excitation source and the samples to be tested are in two-dimensional translation motion, the obtained ultrasound surface wave signals are transmitted to an electronic computer, and the measurement of the stress distribution on the surface and the sun-surface of the samples is realized through fast computing and processing by programming according to the principle of acoustic elasticity. The system has the advantages of simple structure and low cost, which can be widely used in the stress distribution measurement on the surface and the sun-surface of metal materials.

Owner:NANJING UNIV OF SCI & TECH

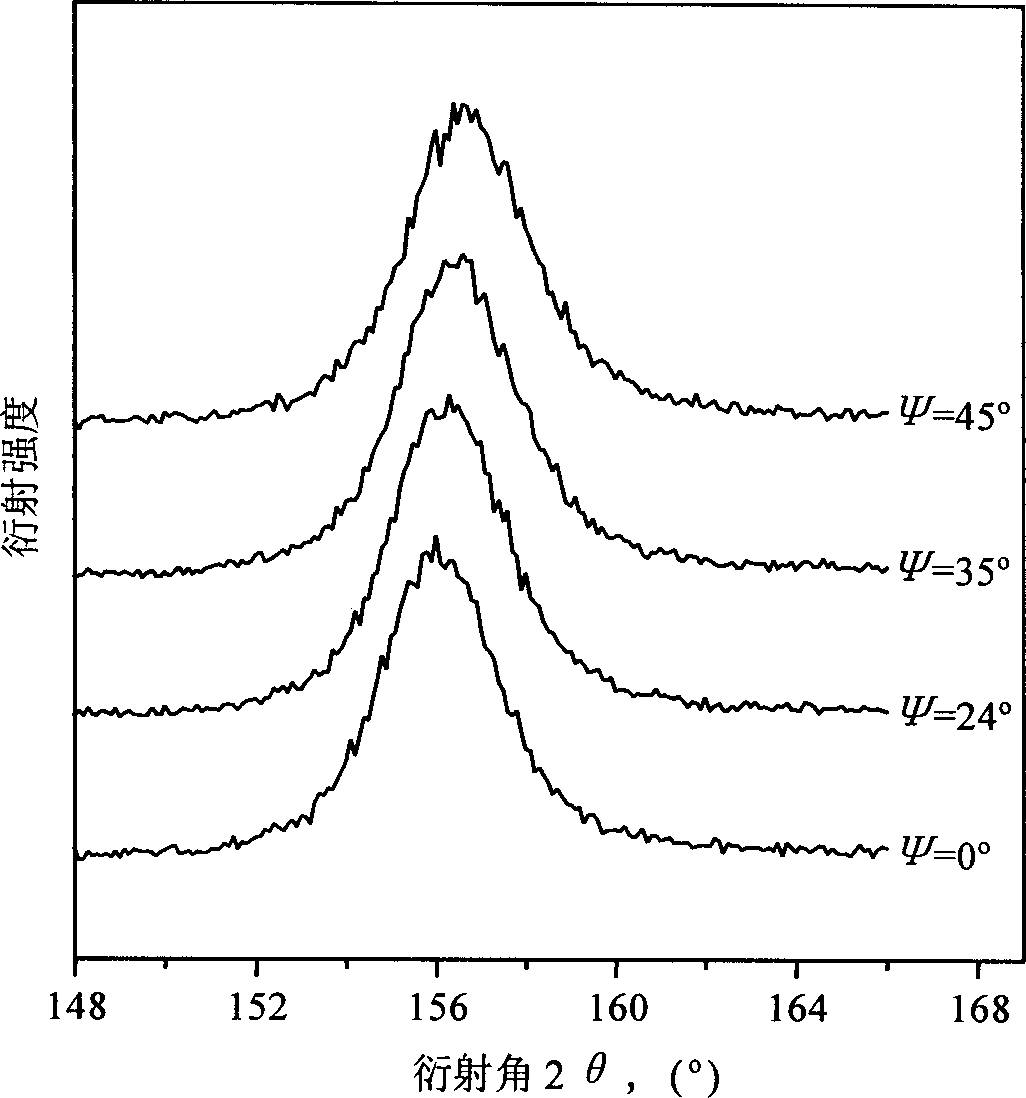

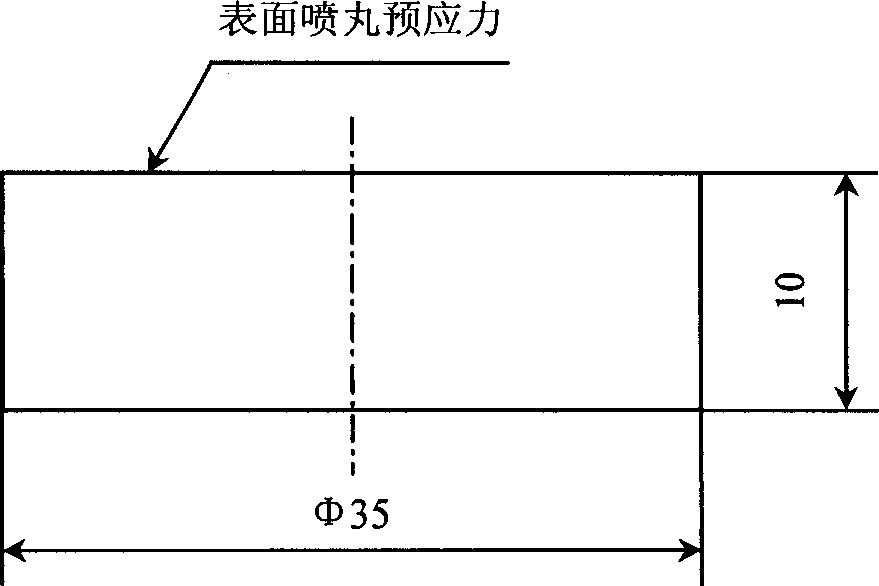

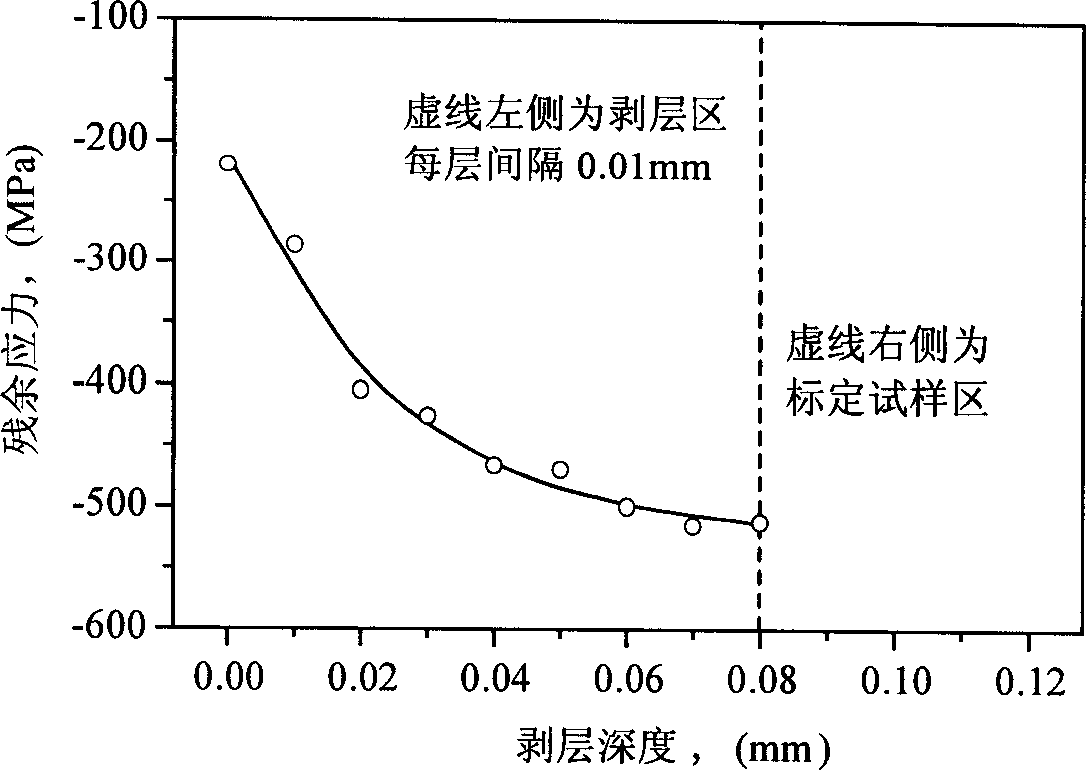

Production of X-ray stress measuring calibrated sample

InactiveCN1645091AEasy to carryBeautiful surfaceMaterial analysis using wave/particle radiationPreparing sample for investigationSurface stressStress measurement

A method for preparing calibration test sample of X ray stress measurement includes removing phenomenon of crystal particle coarsening and crystal face preferred orientation, carrying out short blasting treatment for semiproduct of the sample, stripping layer by layer for portion with greater stress gradient by electrochemical corrosion, carrying out X ray stress measurement and calibrating out work surface of the sample by utilizing relation curve of stress to layer depth.

Owner:SHANGHAI JIAO TONG UNIV

Microcantilever heater-thermometer with integrated temperature-compensated strain sensor

InactiveUS7928343B2Change resistanceWeighing by removing componentForce measurementSurface stressEngineering

The present invention provides microcantilever hotplate devices which incorporate temperature compensating strain sensors. The microcantilever hotplate devices of the present invention comprise microcantilevers having temperature compensating strain sensors and resistive heaters. The present invention also provides methods for using a microcantilever hotplate for temperature compensated surface stress measurements, chemical / biochemical sensing, measuring various properties of compounds adhered to the microcantilever hotplate surface, or for temperature compensated deflection measurements.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

GaAs-based LED chip cutting method

ActiveCN105226143AGuaranteed FusionImprove appearance qualitySemiconductor/solid-state device manufacturingFine working devicesSurface stressSurface mounting

The invention discloses a GaAs-based LED chip cutting method. The method comprises the following steps: (1) semi-cutting is carried out on a P surface, criss-cross cutting grooves are formed, and chip P surface electrodes are separated at equal intervals; (2) the chip P electrodes face a white film downwardly, N electrodes face upwardly and are attached to the white film; (3) chip N surface scribing is carried out along the cutting grooves formed by P surface semi-cutting, and chip N surface stress is relieved; (4) film inverting is carried out on the scribed chip, and the chip is transferred to a blue film from the white film; and (5) on the chip N surface, a bonding tool of a chip breaking machine is used for chip breaking along scratches, and the chip is processed into independent crystal grains. The improved surface mount method is used, a cutting method which combines advantages of a chip sawing machine and a laser chip scribing machine is adopted, the chip P surface stress and the N surface stress are relieved maximally, deformation stress effects caused by film laminating can be reduced and edge collapse and pipe core breaking phenomena after the chip is cut are reduced, and the appearance quality after the chip is cut is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

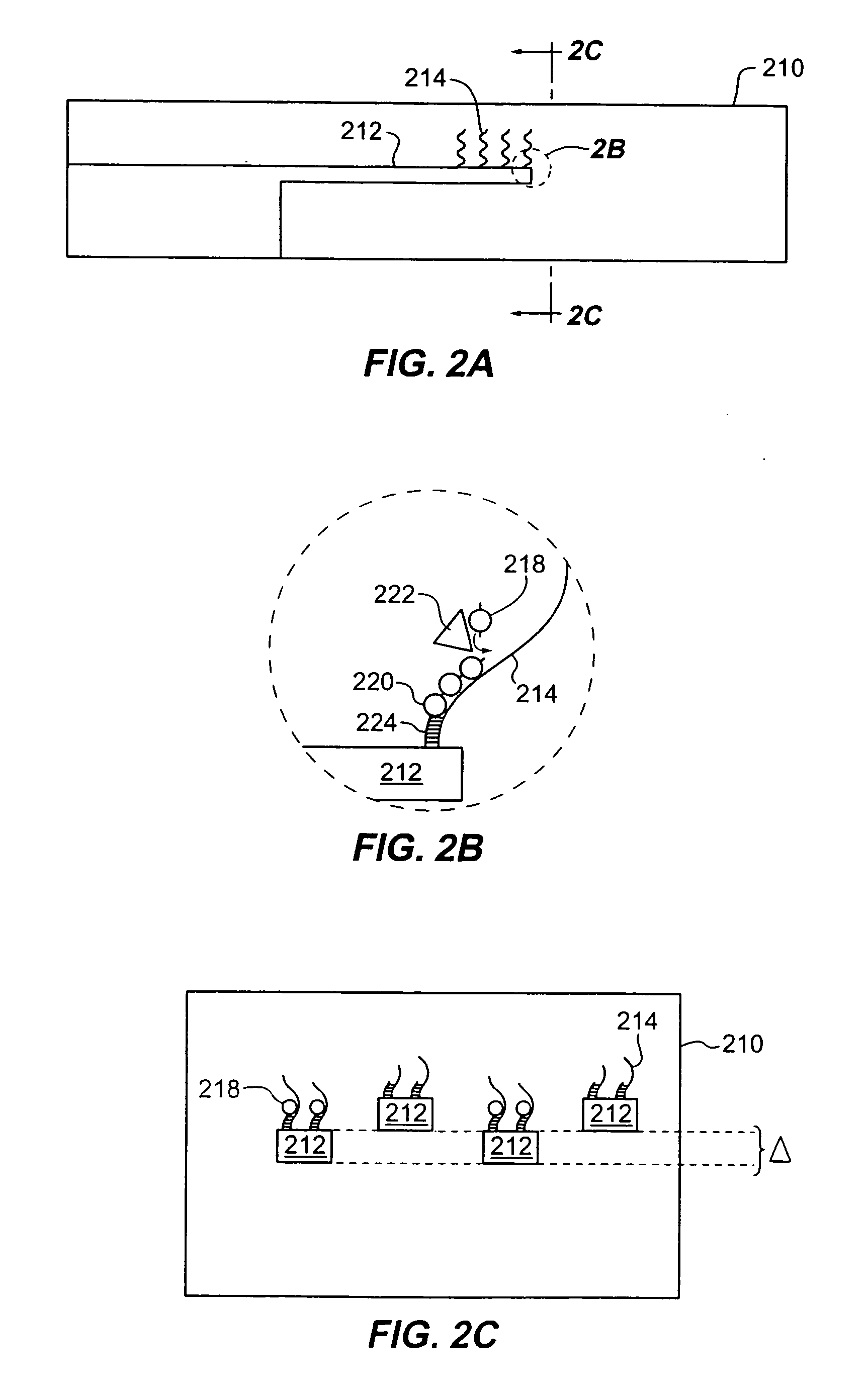

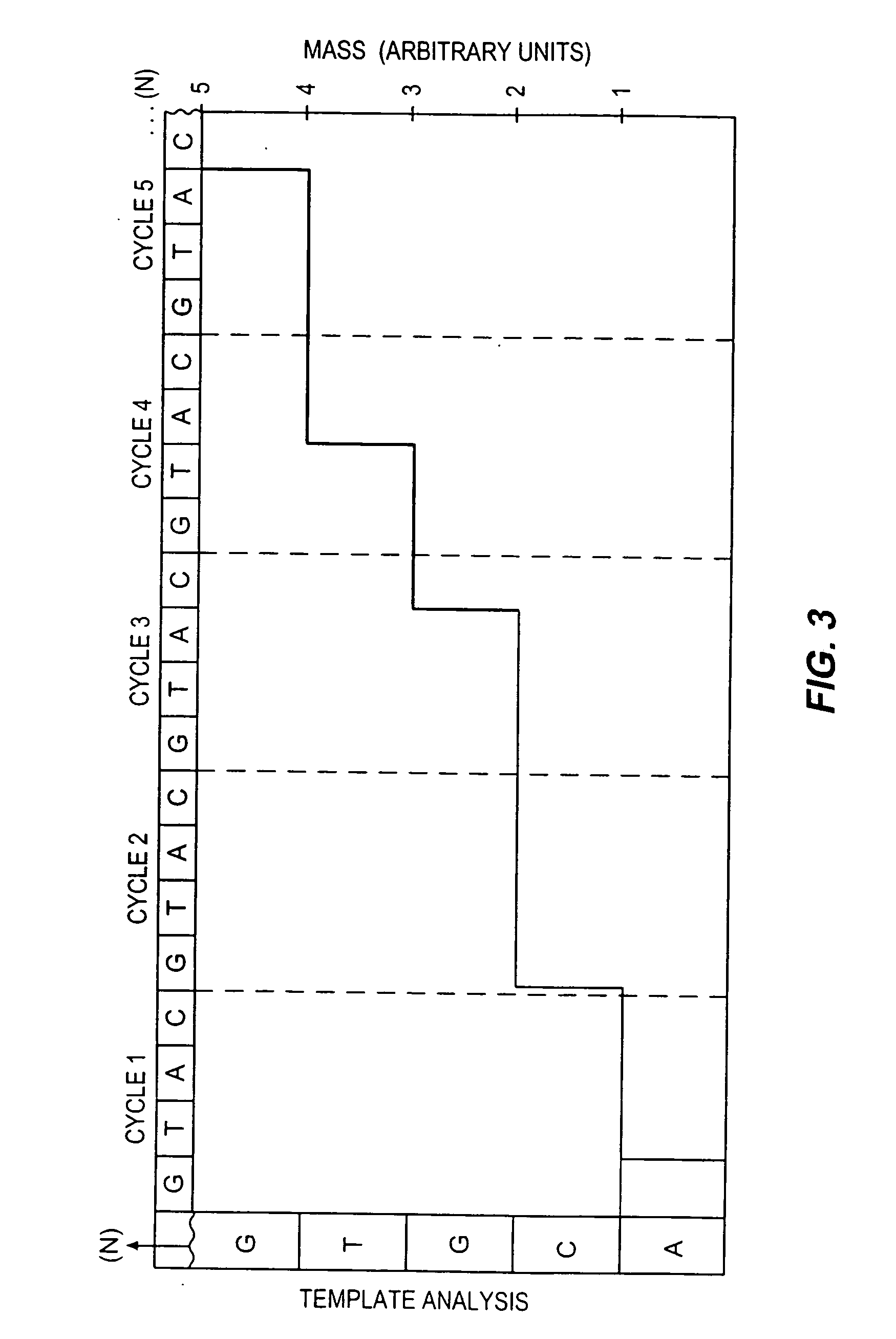

Method for sequencing nucleic acids by observing the uptake of nucleotides modified with bulky groups

InactiveUS20070059733A1Bioreactor/fermenter combinationsMaterial nanotechnologySurface stressPresent method

The present methods and apparatus concern nucleic acid sequencing by incorporation of nucleotides into nucleic acid strands. The incorporation of nucleotides is detected by changes in the mass and / or surface stress of the structure. In some embodiments of the invention, the structure comprises one or more nanoscale or microscale cantilevers. In certain embodiments of the invention, each different type of nucleotide is distinguishably labeled with a bulky group and each incorporated nucleotide is identified by the changes in mass and / or surface stress of the structure upon incorporation of the nucleotide. In alternative embodiments of the invention only one type of nucleotide is exposed at a time to the nucleic acids. Changes in the properties of the structure may be detected by a variety of methods, such as piezoelectric detection, shifts in resonant frequency of the structure, and / or position sensitive photodetection.

Owner:INTEL CORP

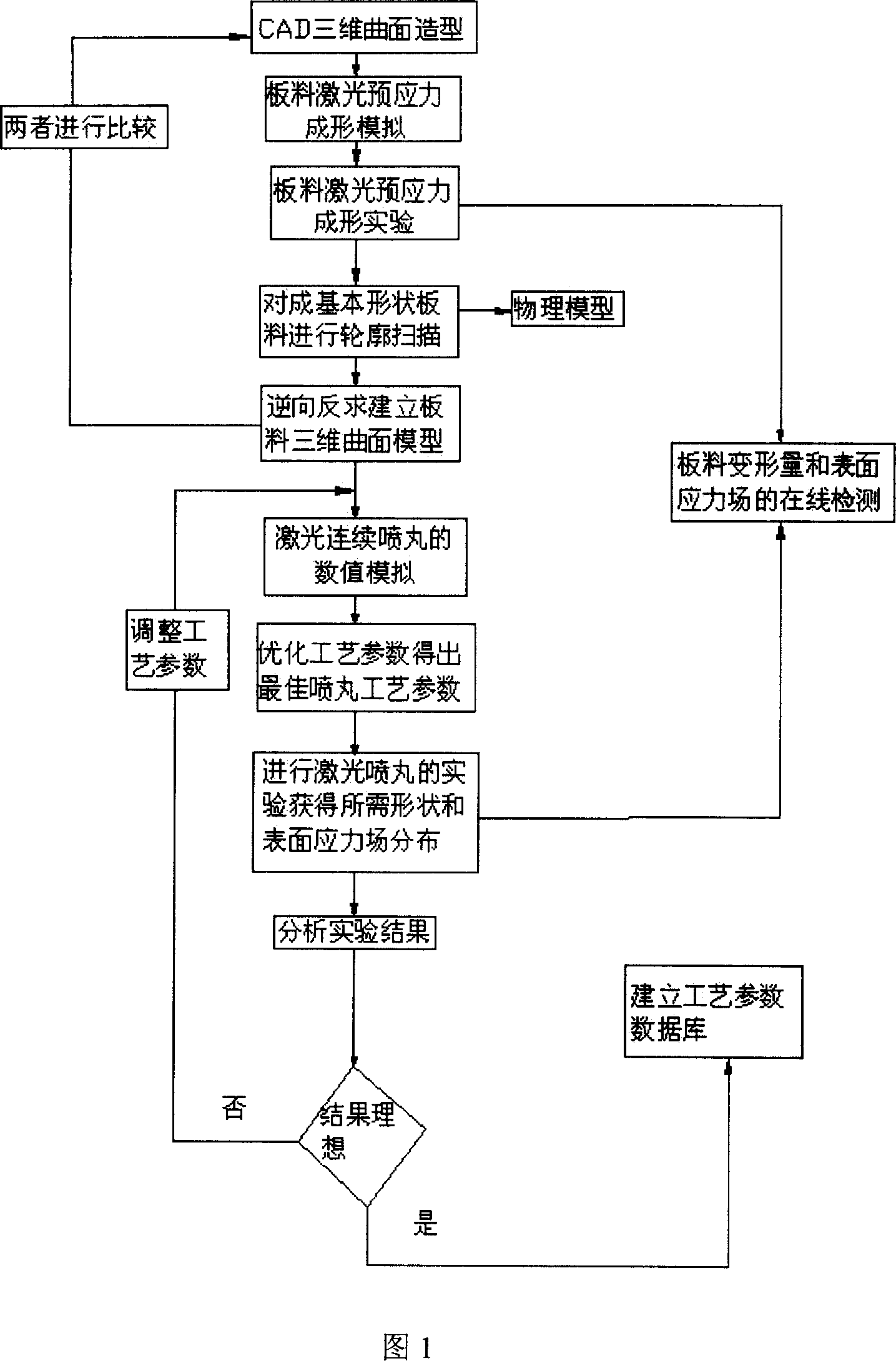

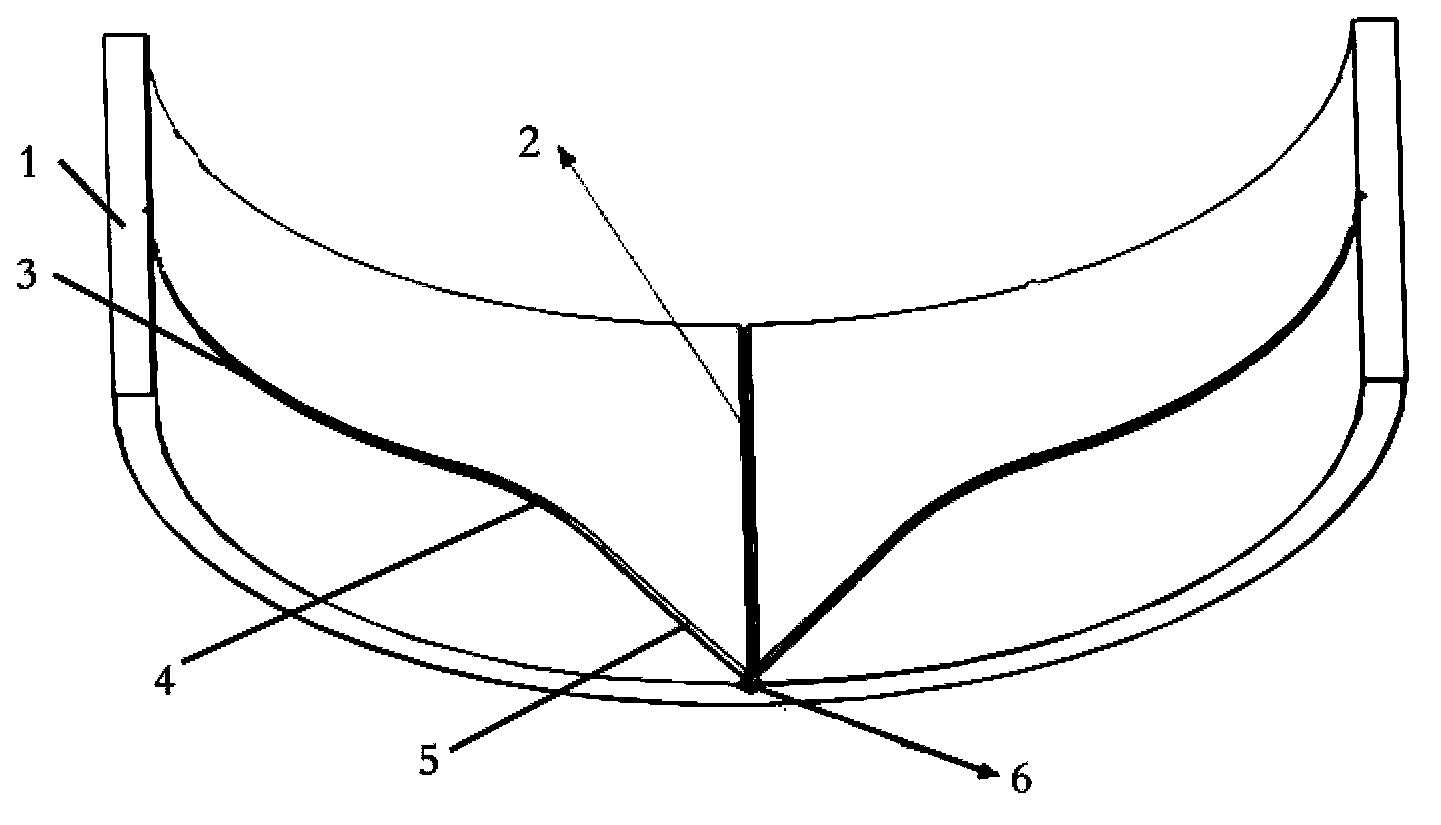

Method and apparatus of forming cut deal laser prestress composite shot blasting

InactiveCN101011777AImprove surface qualityImprove fatigue resistanceNumerical controlLaser beam welding apparatusSurface stressLaser light

A cut deal laser inherent stress composite peen forming features in the clipper using robot, using carbon dioxide to realize the basic formation, profile measuring feedback system controlling the deformation quantity, left stress meter measuring the surface stress of the board, optical scanning the pre formation, realizing board through model analog software, getting optimized process parameter instructing laser consecutive peen formation, using neodymium glass laser providing short pulse strong laser light, laser impact wave as the force source of precise forming, using the profile feedback device and on line measuring board surface stress left stress to control the deformation quantity to realize precision forming with complex shapes.

Owner:JIANGSU UNIV

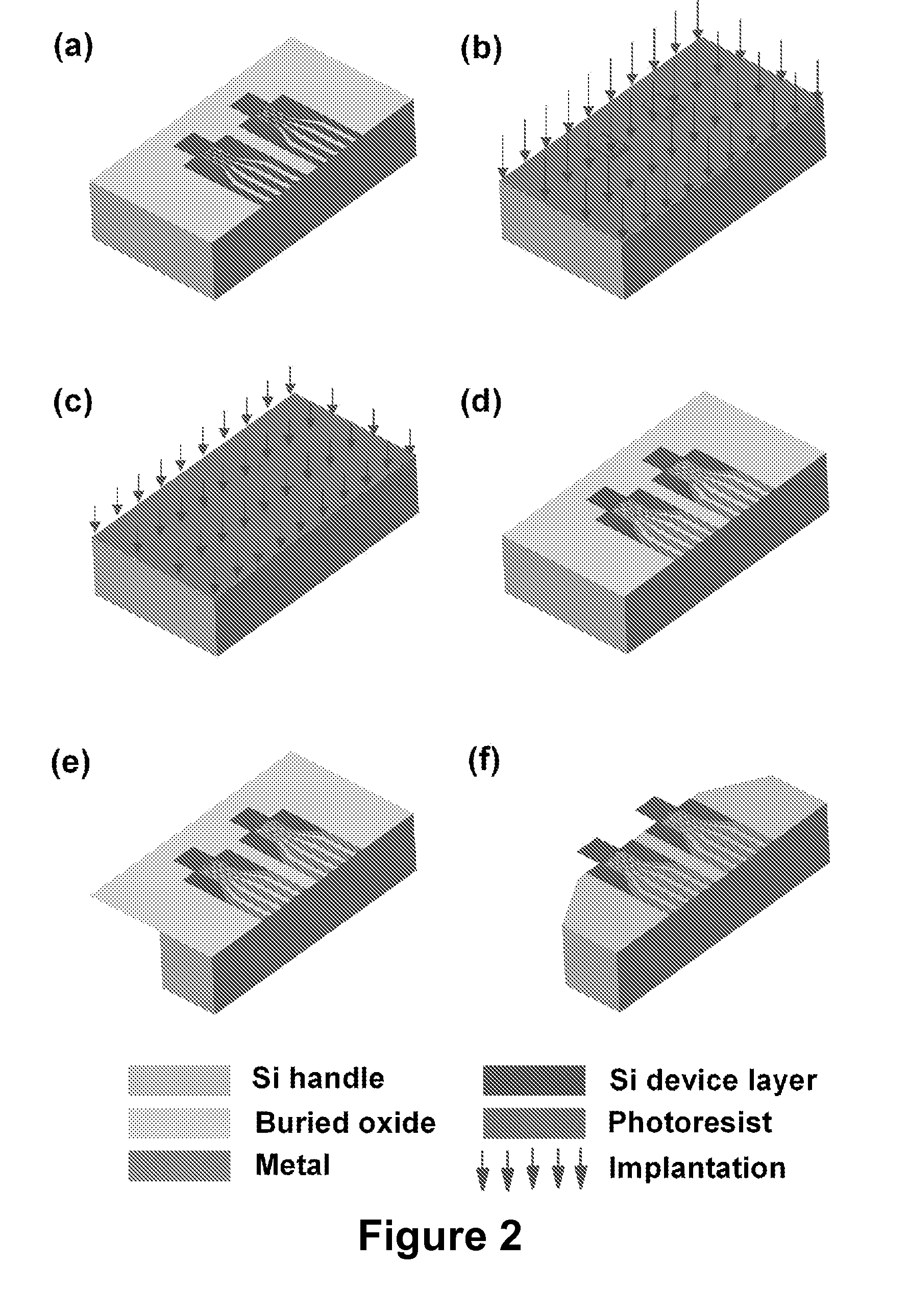

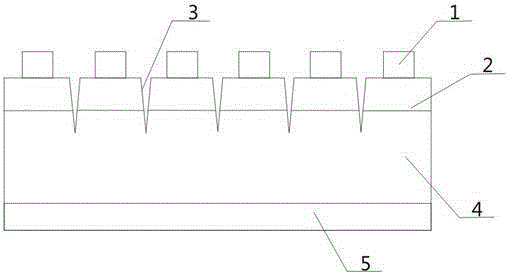

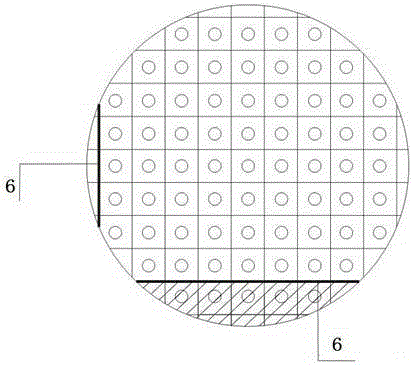

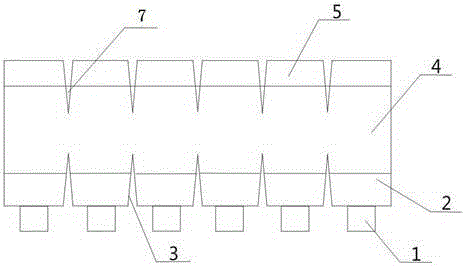

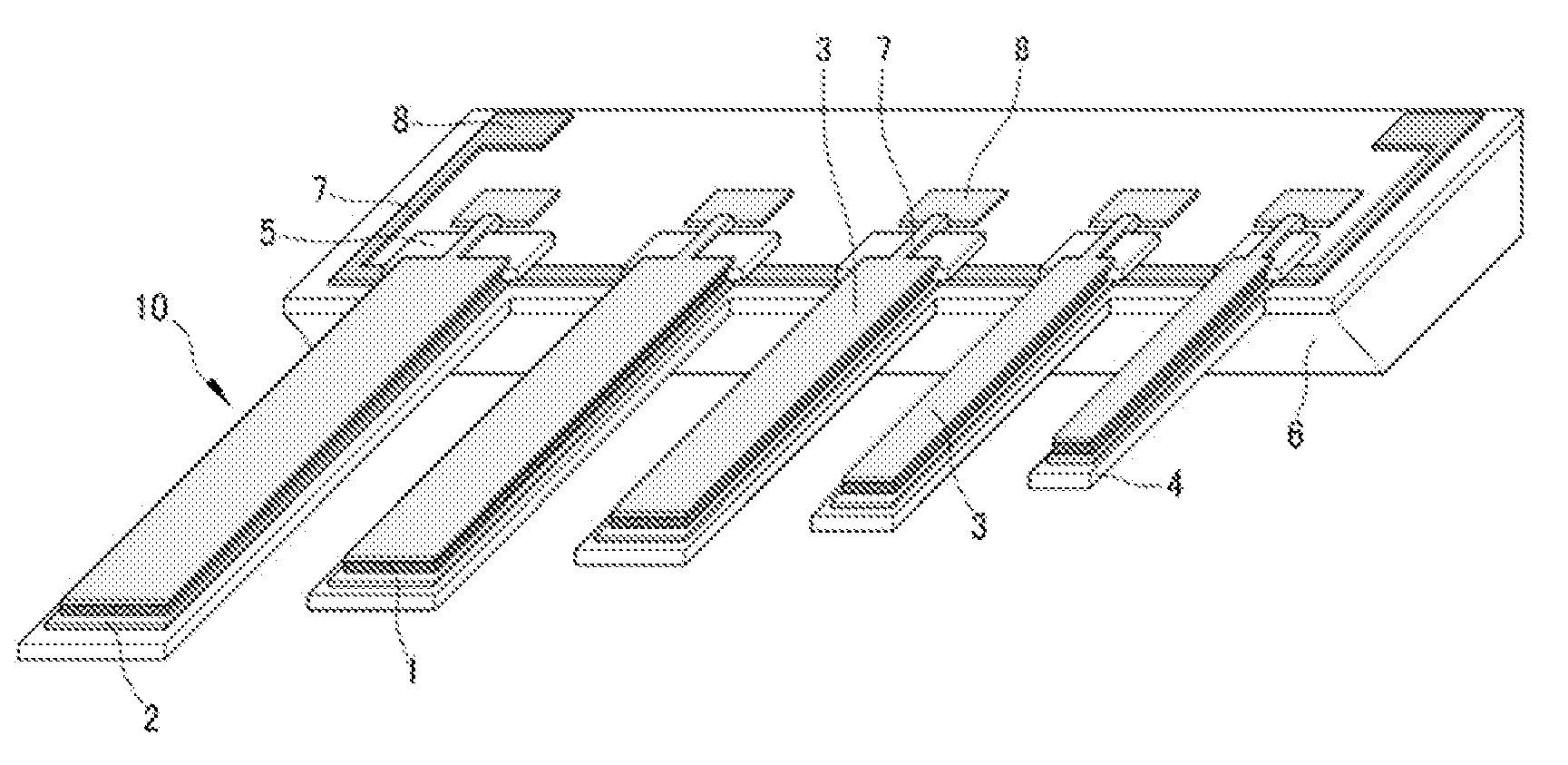

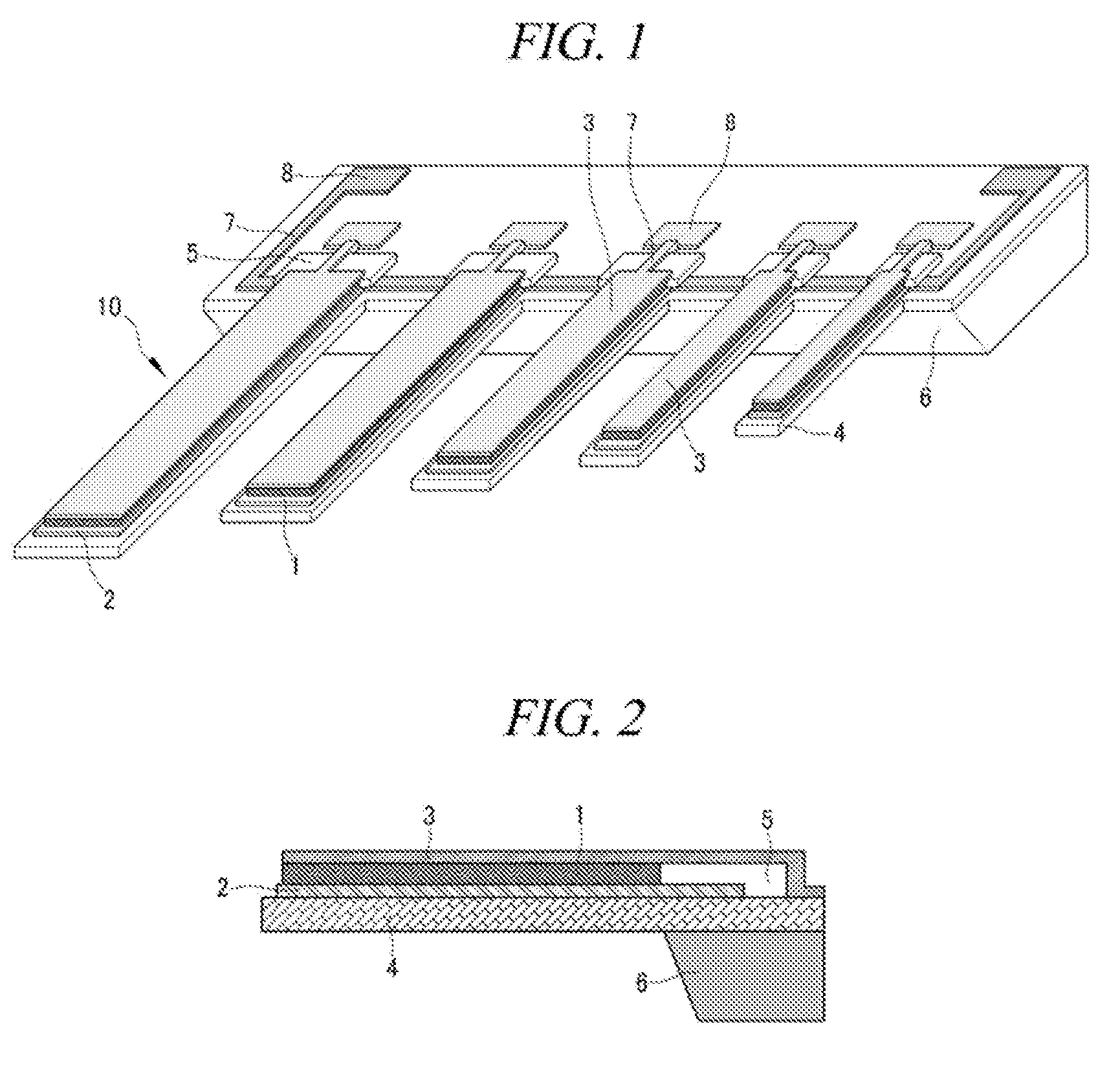

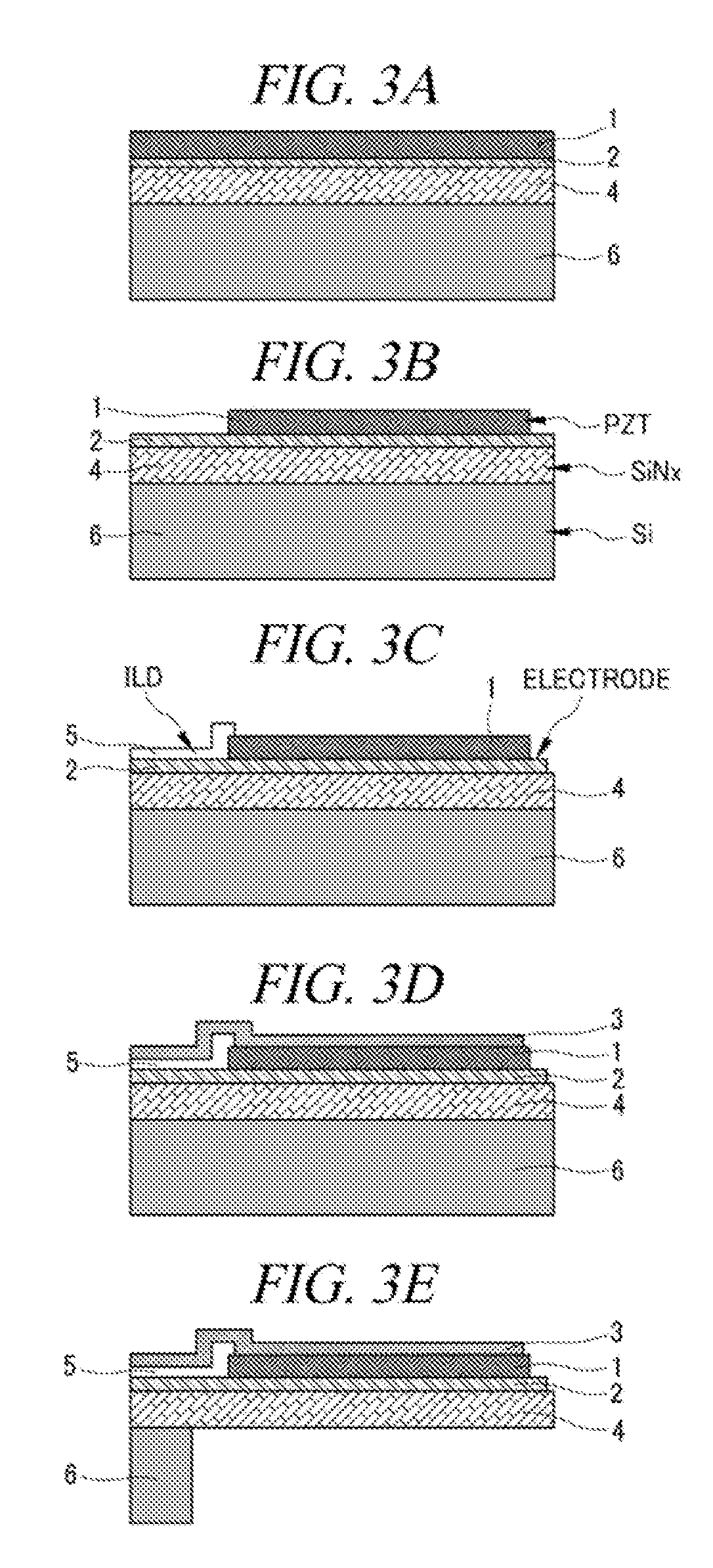

Physical/Biochemical Sensor Using Piezoelectric Microcantilever And Manufacturing Method Thereof

ActiveUS20100033058A1Accurate informationQuick responseMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesSurface stressMass loading

The present invention discloses a physical / biochemical sensor using a multisized piezoelectric microcantilever resonator array which enables to quantitatively and simultaneously analyze a mass loading effect and a surface stress change effect and a manufacturing method thereof. In the physical / biochemical sensor using the multisized piezoelectric microcantilever resonator array, a plurality of piezoelectric micro-cantilever resonators having different sizes is arrayed so as to quantitatively and discriminately analyze a surface stress change as well as a sensor surface mass change induced by an adsorbed sensing-target material occurring in a sensing process. Thus, the mass loading effect and the surface stress change effect can be quantitatively and simultaneously analyzed.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

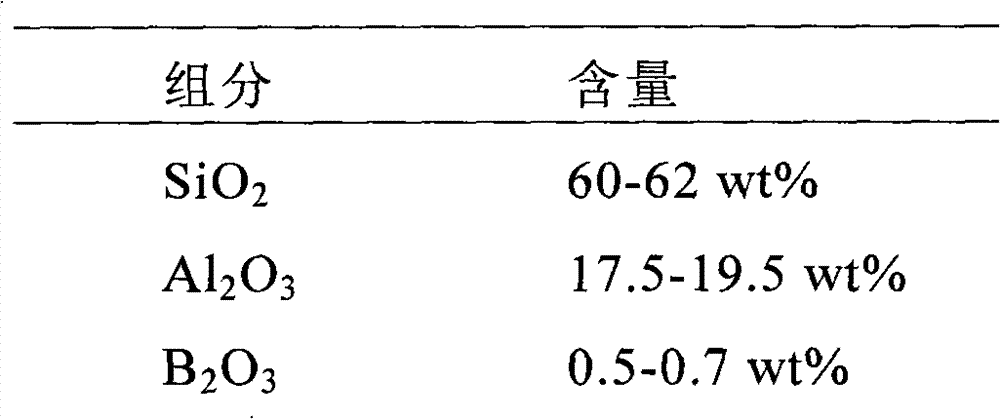

Deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass

ActiveCN103359934ALow densityHigh elastic modulusGlass forming apparatusSurface stressSilicate glass

The invention relates to deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass and particularly relates to alumina silicate glass containing ZrO2 and B2O3. The glass has the characteristics that the elasticity modulus E is more than or equal to 60 GPa and less than or equal to 78 GPa after the glass is chemically tempered; the yield point At is more than or equal to 620 DEG C and less than or equal to 850 DEG C; the coefficient of thermal expansion (CET) is more than or equal to 7.5*10<-6> / K and less than or equal to 9.8*10<-6> / K; the density is less than or equal to 2.5 g / cm<3>; the surface pressure stress is at least 700 MPa; and the thickness of a surface stress layer is at least 25 microns. The glass has deformation resistance, is high in yield point and is light in weight.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

ActiveCN105643215AHigh bonding strengthEliminate surface stressRoll force/gap control deviceMetal rolling arrangementsHigh energyBound property

The invention discloses a direct forming manufacturing method of a metal-based multilayer / gradient composite board and a process unit of the direct forming manufacturing method. Scale, corrosion materials and other impurities on the joint surface of a base board are removed through chemical cleaning, the cleaned surface is subjected to gradient power electromagnetic induction heating or laser bombardment surface treatment, all phases near the joint surface are fully dissolved, a solid solution is enhanced, toughness and corrosion resistance are improved, the surface stress of the board is eliminated, and surface laser treatment is conducted to improve the binding property of a composite layer; raw materials of the composite layer are added and injected through powder laying, a high-energy heat source is adopted for irradiation or induction heating to melt powder, metallurgical bonding is formed between the composite layer and a base, and control over the final shape of a cold / hot-rolled board is conducted. The obtained multilayer / gradient composite board is compact in surface structure, bonding between the composite layer and the base and between layers is good, and the interlayer bonding performance of the composite board is remarkably improved. The process is high in flexibility, and the production period of the metal-based composite board can be greatly shortened after the process is combined with an existing continuous casting technology.

Owner:SHANGHAI UNIV

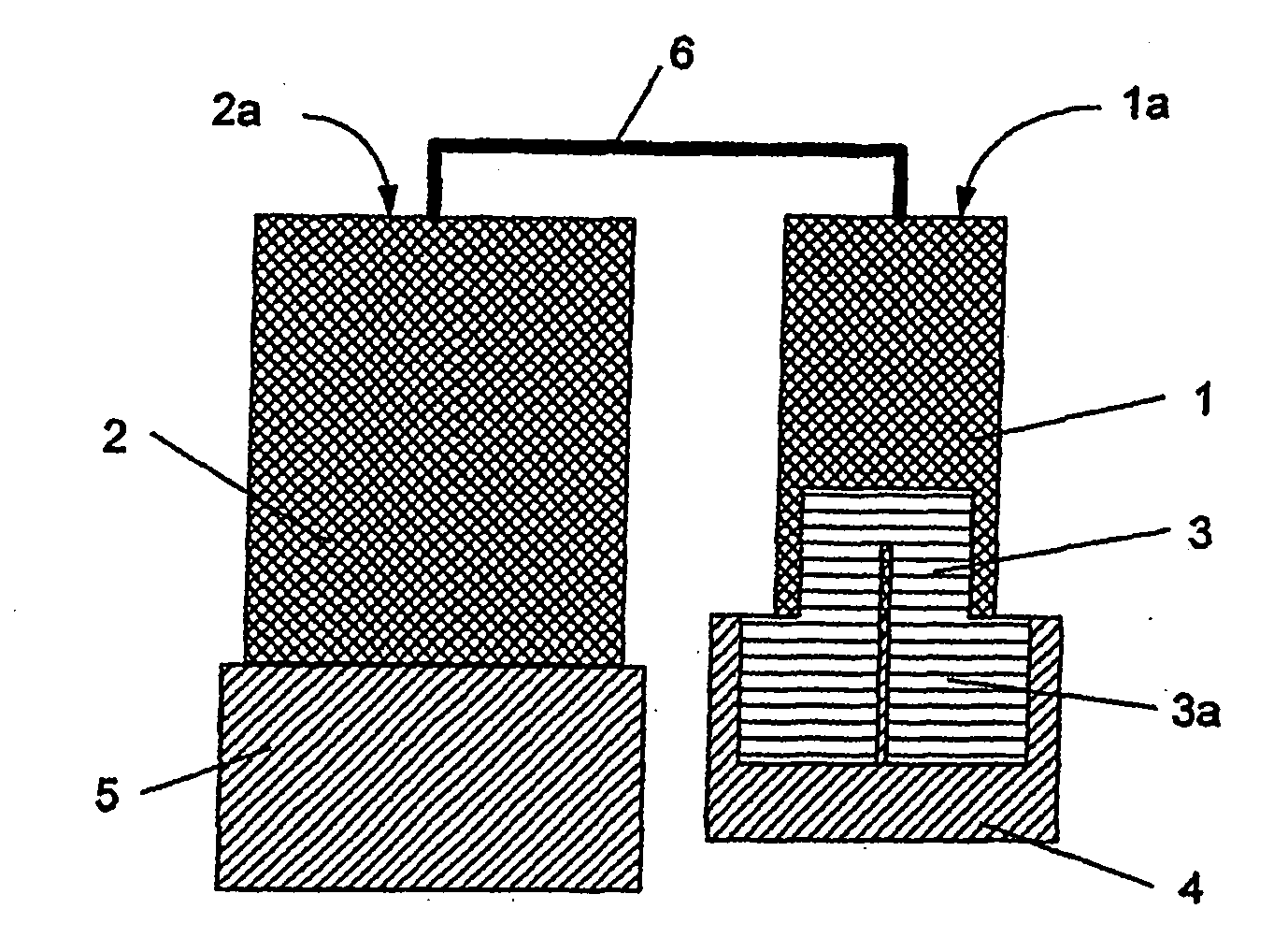

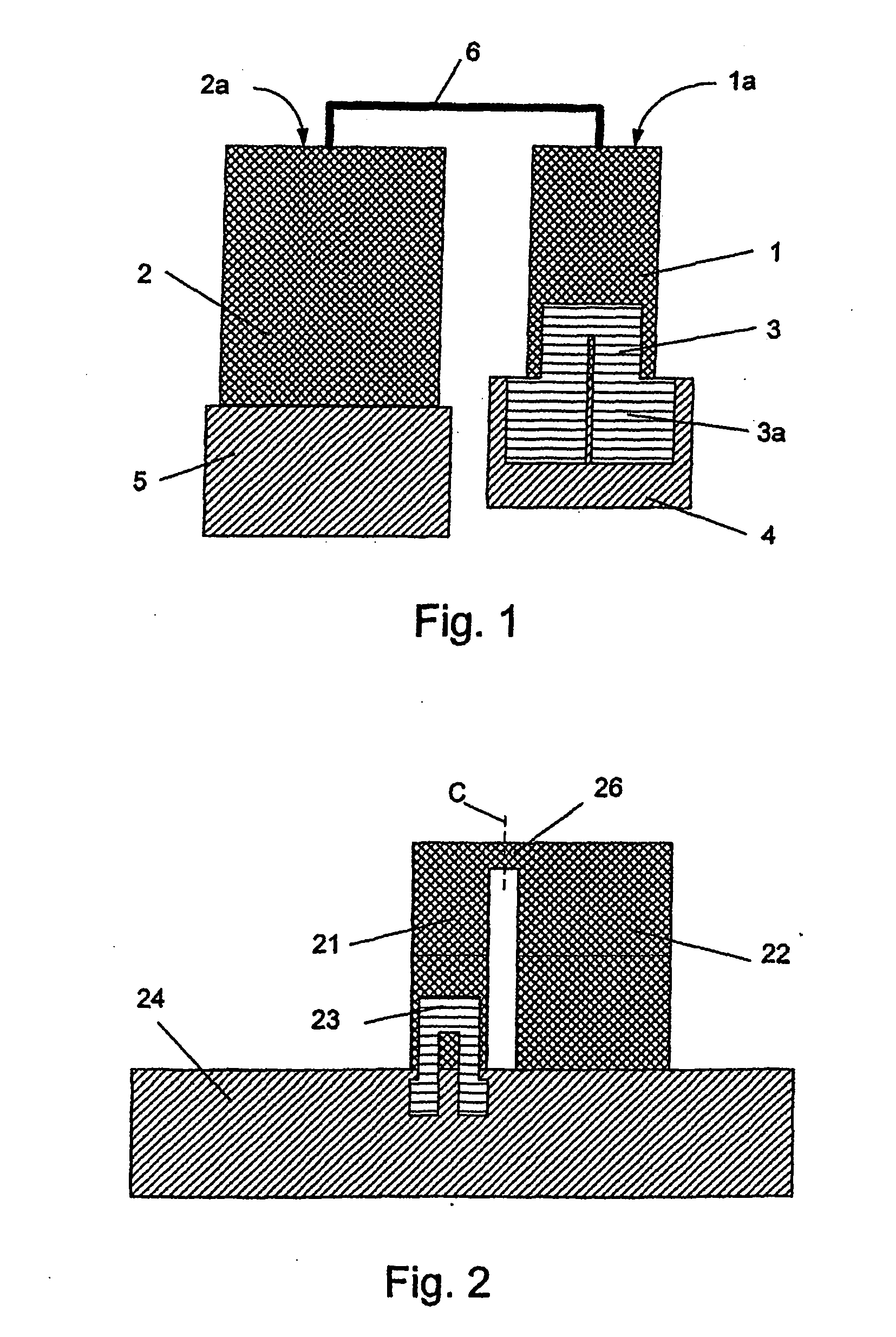

Sensor comprising mechanical amplification of surface stress sensitive cantilever

InactiveUS20050034542A1Prevent short-circuitingIncrease flexibilityForce measurement using piezo-resistive materialsApparatus for force/torque/work measurementSurface stressCantilevered beam

The invention relates to a sensor comprising one or more sensor units, wherein at least one of the sensor units is in the form of a poly-cantilever structure. The poly-cantilever structure comprise two or more cantilever-like structures, at least one of the cantilever-like structures comprises a piezoresistive element, and at least one of the cantilever-like structures comprises a capture surface, at least one cantilever-like structure with a piezoresistive element designated a piezoresistive cantilever being connected in an amplifying connection to at least one of the cantilever-like structure with a capture surface designated a capture surface cantilever. The amplifying connection being provided so that a deflection of said capture surface cantilever due to a stress generated at said capture surface being capable of deflecting the connected piezoresistive cantilever. The sensor can be used for detection of a target substance in a fluid, such as a gas or a liquid.

Owner:CANTION

Method for preparing AuNPs-PDMS composite micro film biosensor

The invention discloses a method for preparing AuNPs (nanogold)-PDMS (polydimethylsiloxane) composite micro film surface stress biosensor. The method comprises the following steps: by taking a PDMS film as a substrate and using a chloroauric acid solution as a first-step reducing agent, reducing to generate a gold seed; by utilizing the gold seed generated on the film and taking glucose and potassium bicarbonate as auxiliary reducing agents, performing second-step reduction on the composite film by using the chloroauric acid; by utilizing an AuNPs-PDMS composite film as a sensitive element of the sensor and taking PDMS as a substrate, preparing a gold electrode of the sensor by adopting a sputtering technology, and finishing preparation of the sensor. The electric conductivity of the AuNPs-PDMS composite film generated by the method is obviously improved, so that the sensitivity of the sensor is improved. Moreover, the preparation method is simple, and possibility is provided for miniature, low-cost batch production.

Owner:TAIYUAN UNIV OF TECH

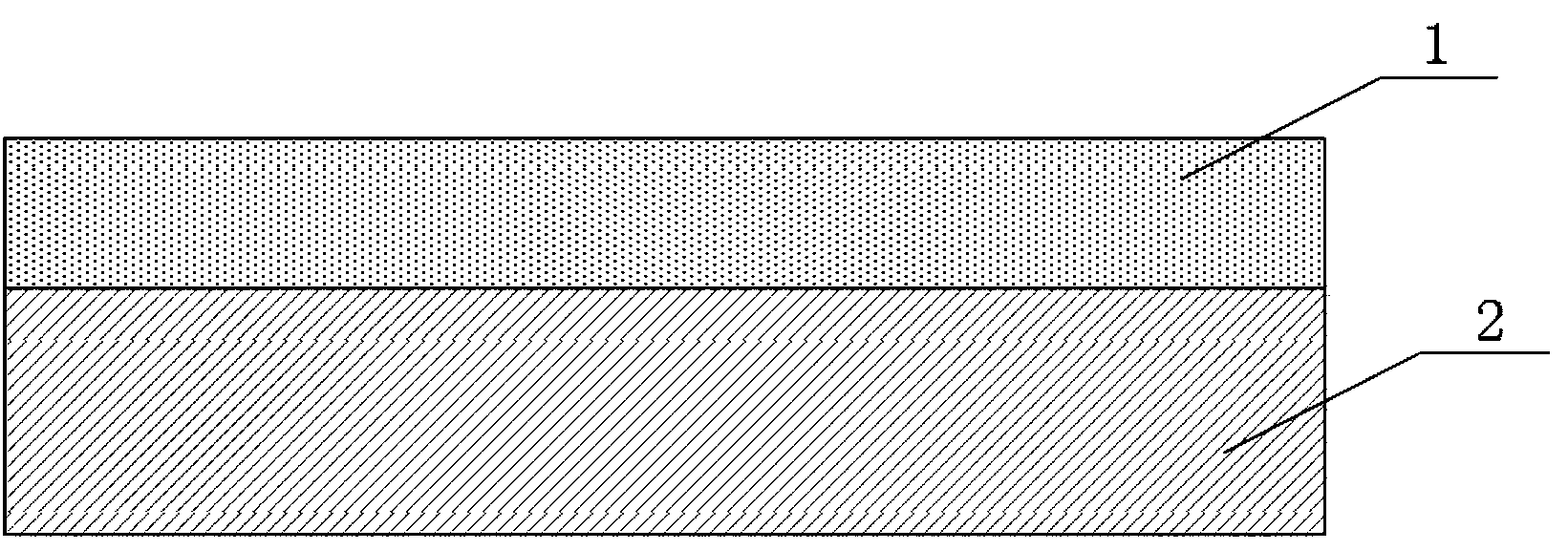

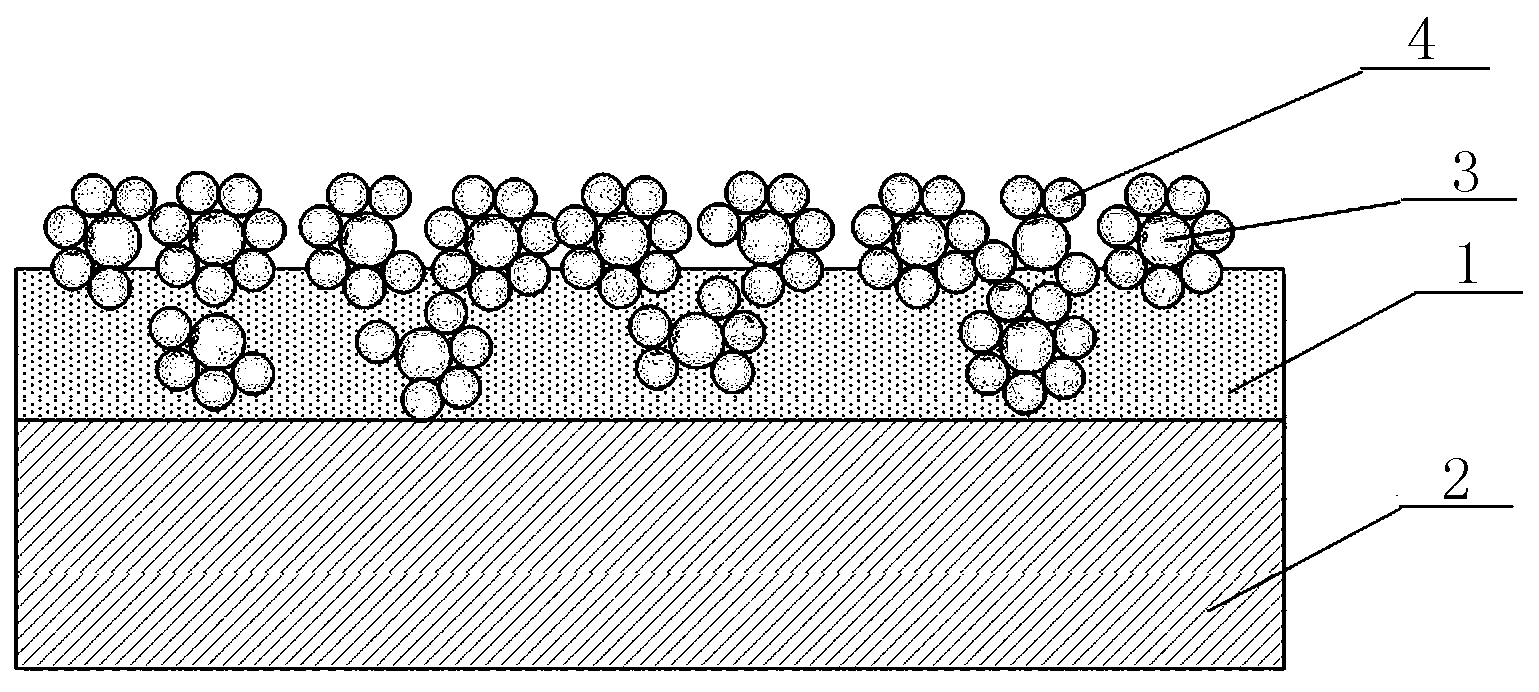

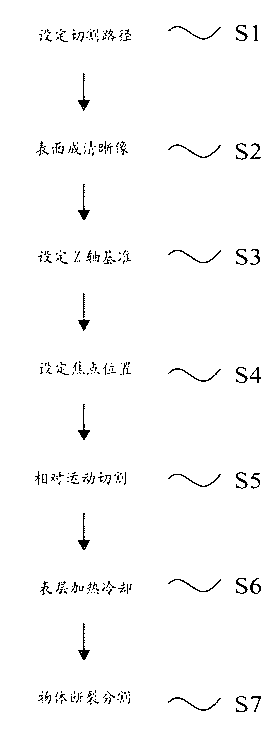

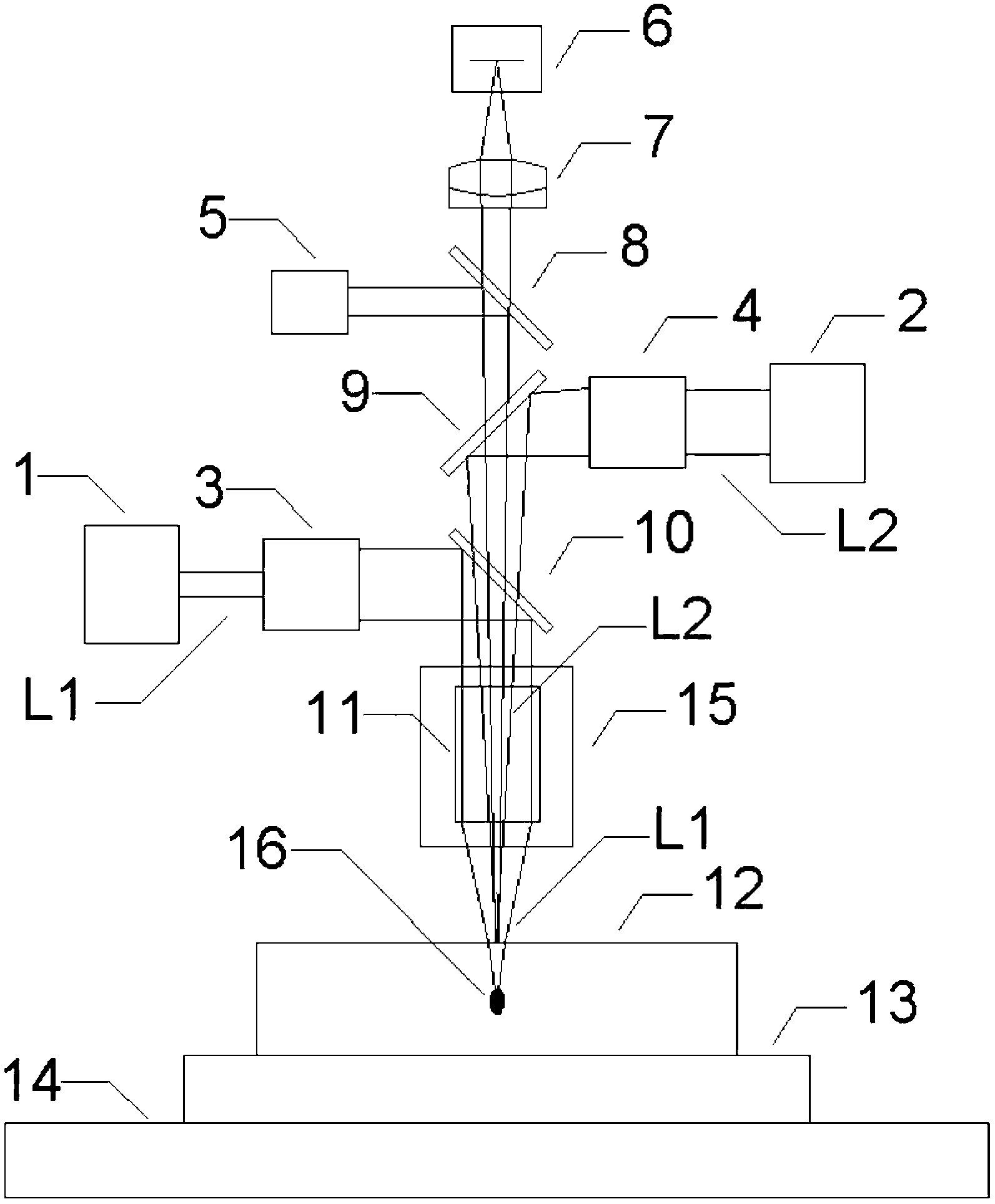

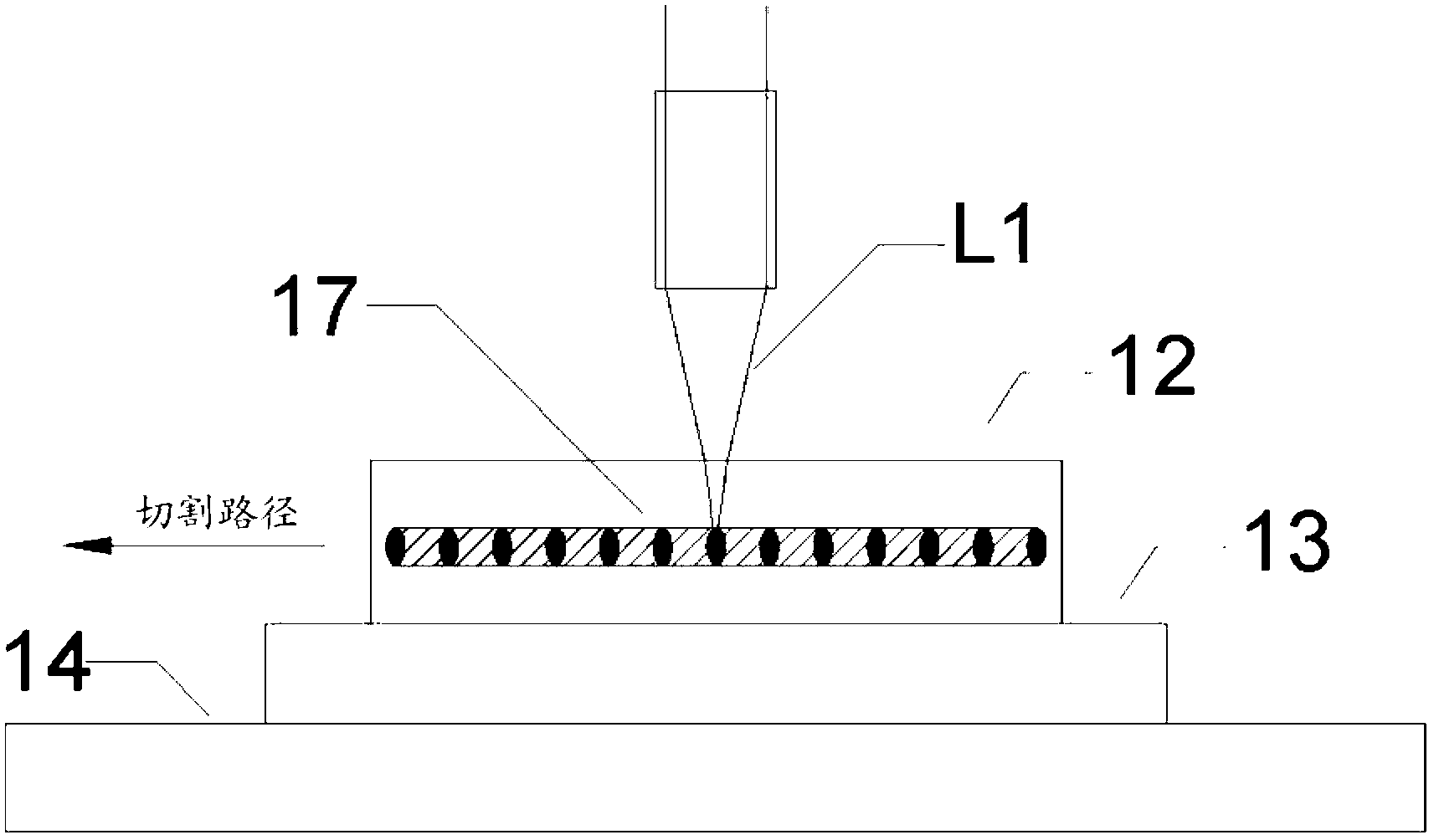

Method and device for cutting machined object by using laser

The invention relates to a method for cutting a machined object by using laser, which comprises the following steps of: providing at least two laser beams, wherein the two laser beams comprises a first laser beam and a second laser beam; focusing the first laser beam inside the machined object, and producing an internal stress layer inside the machined object by means of the action of the first laser beam on the machined object; focusing the second laser beam on the surface of the machined object, and producing an surface stress layer on the surface of the machined object by means of the action of the second laser beam on the machined object; and at least partially utilizing the superposition of stresses released by the internal stress layer and the surface stress layer, so that the machined object is at least partially fractured and further segmented. The invention also relates to a device for cutting the machined object by using the method.

Owner:SUZHOU DELPHI LASER

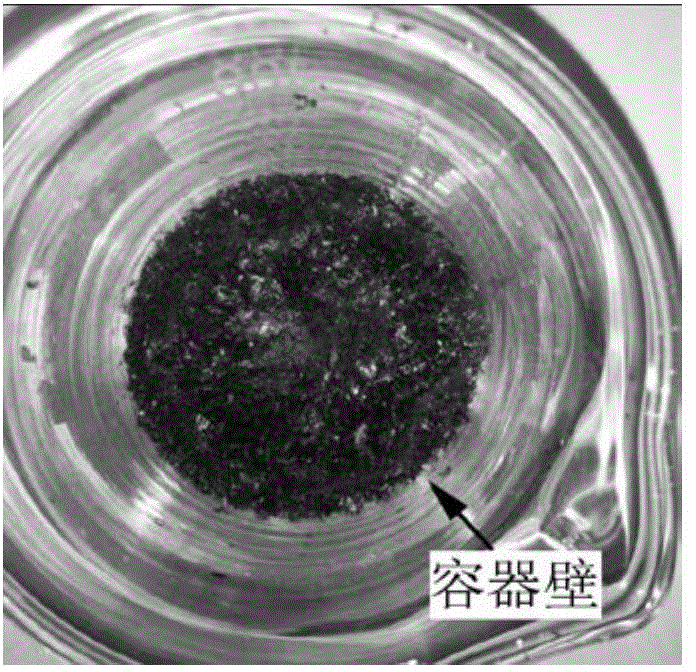

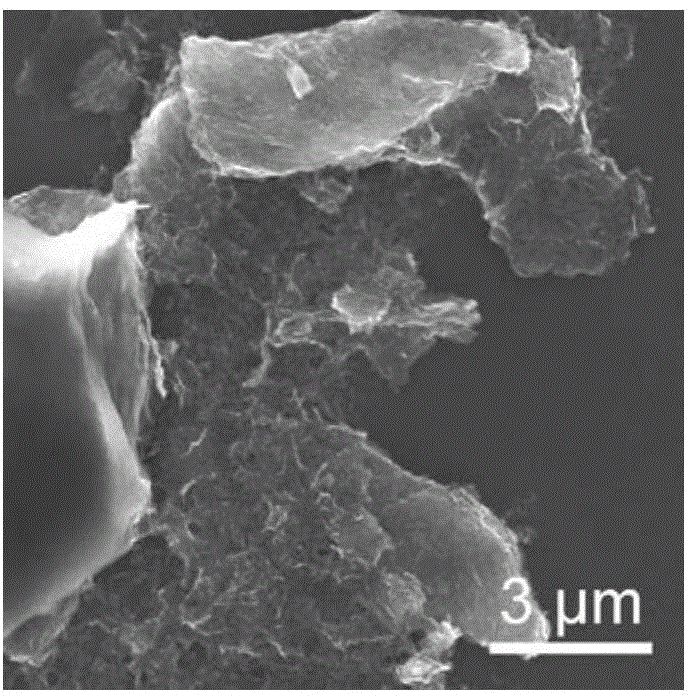

Preparation method for doped graphene foams

The invention discloses a preparation method for doped graphene foams. The preparation method comprises the following steps: adopting the hydrothermal method to enable nano particles to dope with and generate on oxidized graphene sheets to obtain oxidized graphene aerogel; reducing the oxidized graphene aerogel doped with the nano particles in a controllable manner at the low-temperature gaseous phase condition to obtain the doped graphene foams. According to the preparation method, a reductant is not used in the growing process of the nano particles, and liquid is not introduced into the reaction system, so that excessive overlap of the graphene layers is avoided, porosity of the graphene foams is maintained, polyporous shrinkage caused by surface stress is prevented, and the uniformly doped graphene foam material with the controllable appearance is obtained. The preparation method is convenient to operate, uniform in doping, controllable in product size, economical and fast, is adopted as the novel technology for the large-scale preparation of the doped graphene foam material, and is expected to provide novel materials for graphene adsorbents, graphene capacitors, graphene catalysts and the like.

Owner:四川烯城环保科技有限公司

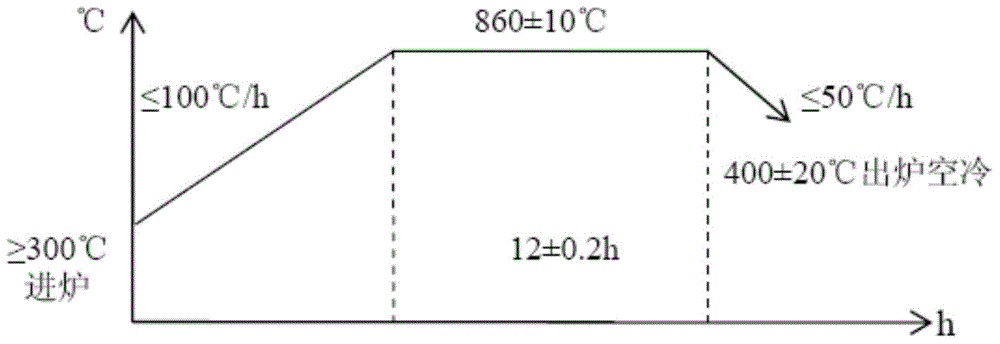

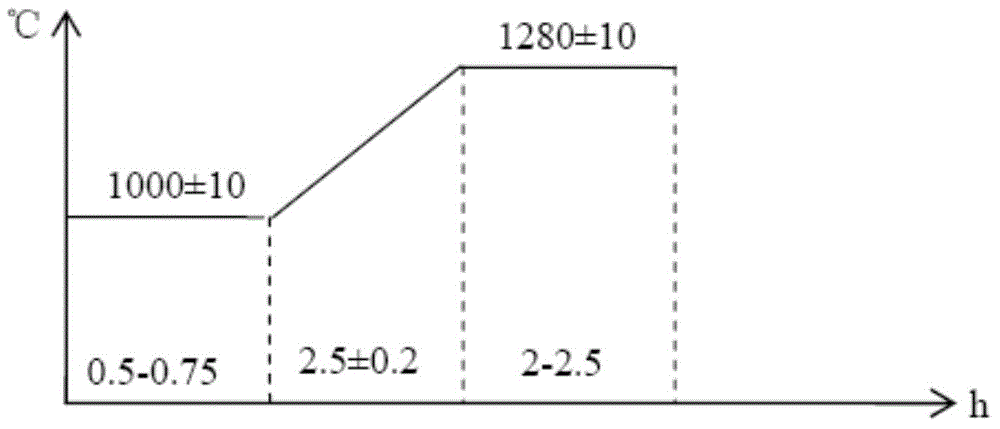

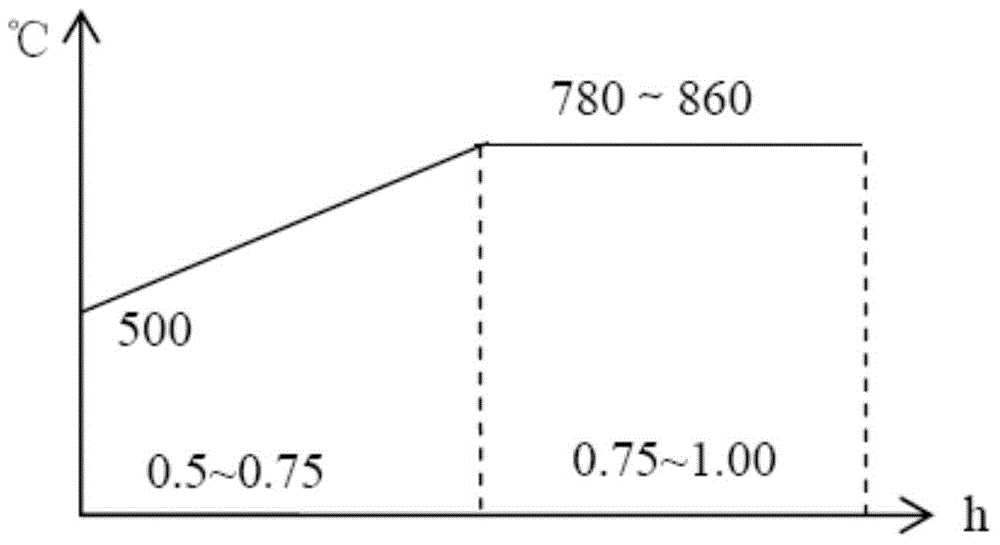

Martensitic stainless steel wire rod and production method thereof

The invention relates to a martensitic stainless steel wire rod and a production method thereof. The martensitic stainless steel wire rod is prepared from the following chemical components in weight percent: 0.30-0.65% of carbon, 0.20-0.50% of silicon, less than or equal to 0.60% of manganese, less than or equal to 0.30% of nickel, 11.50-17.00% of chromium, 0.20-0.50% of molybdenum, less than or equal to 0.25% of copper, less than or equal to 0.030% of sulfur, less than or equal to 0.040% of phosphorus, 0.02-0.20% of nitrogen, and the balance being ferrum and unavoidable impurities. The martensitic stainless steel wire rod which is excellent in surface, steady in performance and uniform in texture can be obtained by adopting the steps of smelting, casting, rolling, online hot charging annealing, salt bath, pickling, finishing to finished product inspecting and packaging, and the martensitic stainless steel wire rod has tensile strength of more than 600MPa, yield strength of more than 300MPa, elongation of more than 25%, percentage reduction of area of more than 50% and qualified product ratio of more than 85%. According to the invention, the comprehensive utilization performance of steel is improved, and the problem that surface stress cracking is easy to cause in annealing of high-carbon martensitic stainless steel in the prior art is solved on the basis of not increasing the smelting and rolling cost.

Owner:宝钢特钢有限公司

Multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts

InactiveCN104109860AAchieving Surface Quality Polishing IssuesQuick polishSurface stressLaser scanning

The invention discloses a multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts, and the polishing on the surfaces of the additive manufacturing metal parts can be realized by repeatedly scanning and processing the surfaces of the additive manufacturing metal parts through utilizing millisecond pulse laser and nanosecond pulse laser; during the multi-laser scanning polishing process, the additive manufacturing metal parts are subjected to thermal preservation treatment, so that the stress on the surfaces of the additive manufacturing metal parts can be evenly distributed; laser scanning reinforcement is carried out on the surfaces of the laser-polished additive manufacturing metal parts, so that the stress state on the surfaces of the additive manufacturing metal parts can be changed into pressure stress from tensile stress, the anti-fatigue property of the additive manufacturing metal parts can be enhanced, and the usage performance of the metal parts can be met; compared with a manual polishing method, the multi-laser polishing and reinforcement efficiency of the additive manufacturing metal parts is high and is as 20 times as that of the manual polishing, the non-contact rapid polishing of the additive manufacturing metal parts can be realized, the tensile stress, caused by the laser polishing, of the additive manufacturing metal parts can be eliminated, and the anti-fatigue property of the additive manufacturing metal parts can be enhanced.

Owner:XI AN JIAOTONG UNIV

Method of spin etching wafers with an alkali solution

InactiveUS6743722B2Semiconductor/solid-state device manufacturingSemiconductor devicesSurface stressWafering

A method of relieving surface stress on a thin wafer by removing a small portion of the wafer substrate, the substrate being removed by applying a solution of KOH to the wafer while the wafer spins.

Owner:STRASBAUGH +1

Method for mfg. high strength fireproof signle sheet cesium potash glass

ActiveCN1559942AImprove cooling effectIncrease compressive stressGlass tempering apparatusGlass productionSurface stressThermal spraying

The invention relates to a making process and method of a single piece of Cs-K fireproof glass, implemented by simultaneously making physical and chemical toughening in a horizontal toughening furnace, where the chemical toughening is implemented by hot-spraying a salt solution with specific components. The made product has surface stress not less than 140 MPa and not greater than 180 MPa and advantageous fire-proofing function, and overcomes the defects of grout fireproof glass in bad weatherability, easy foaming under ultraviolet irradiation, low strength, and unability of being used to outer walls of buildings.

Owner:甘肃金刚光伏股份有限公司

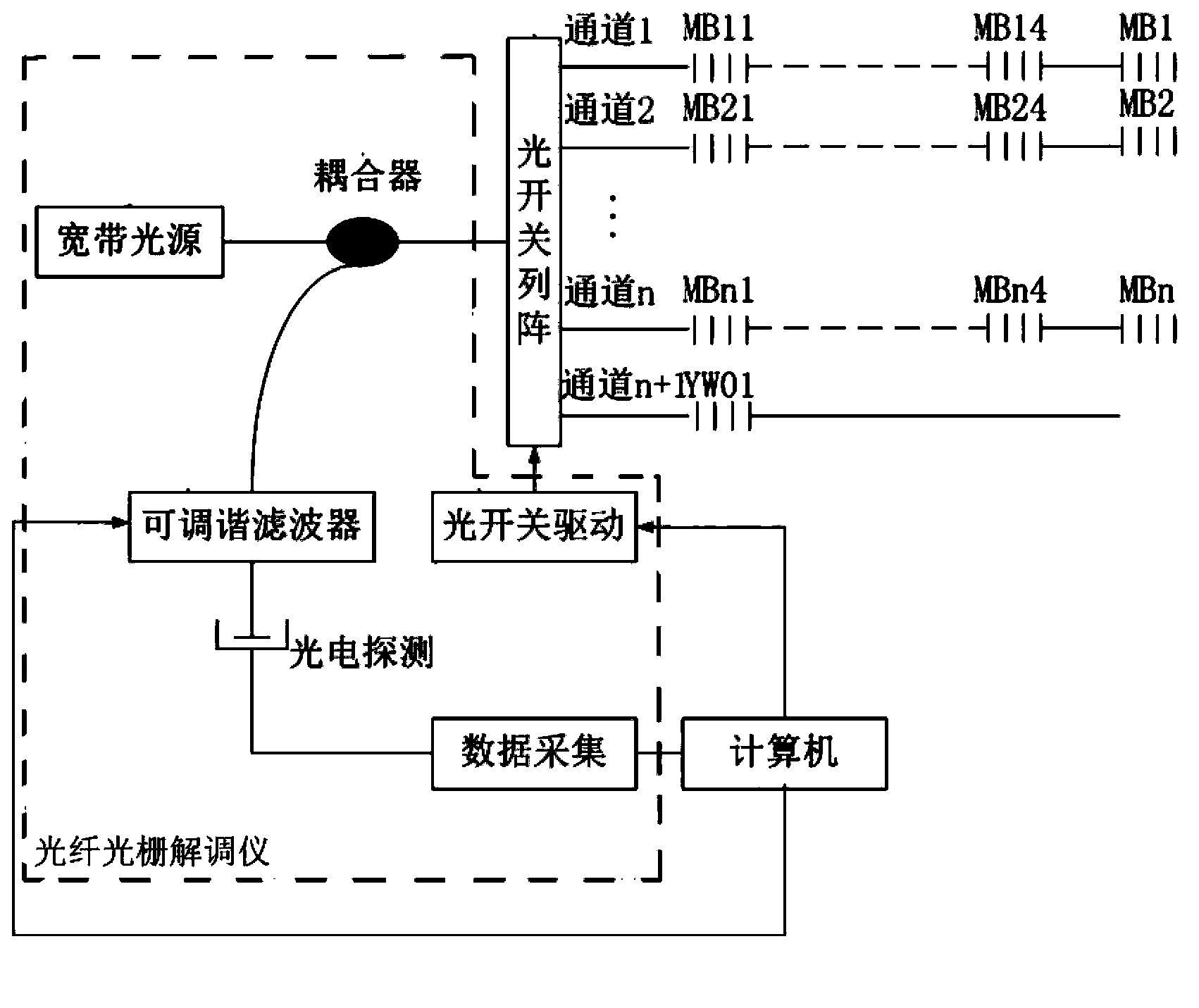

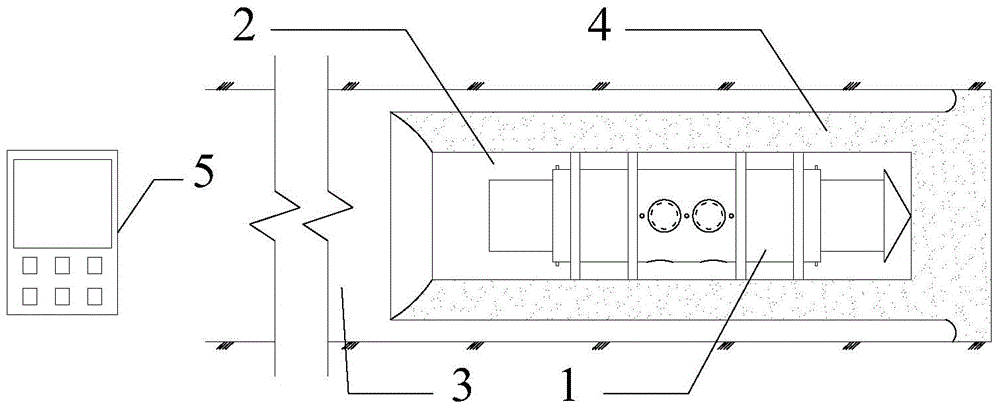

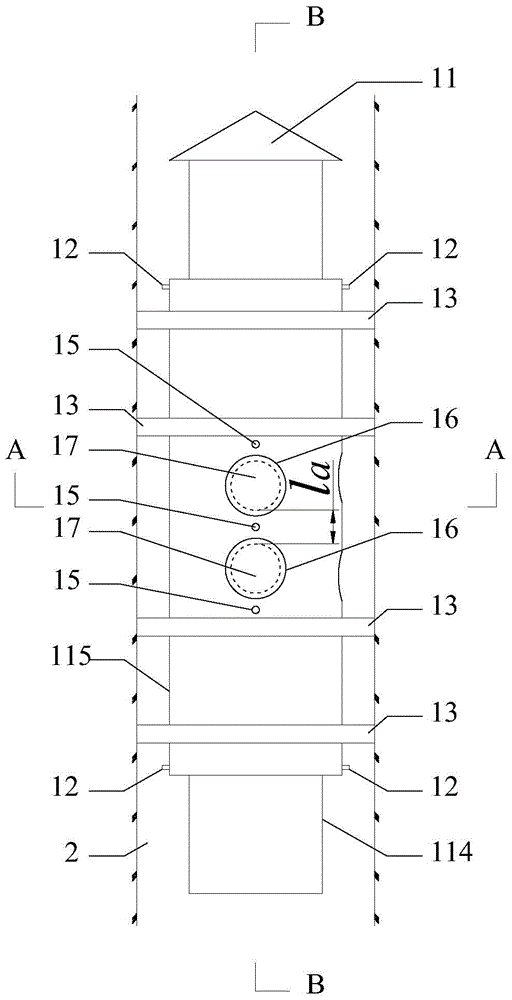

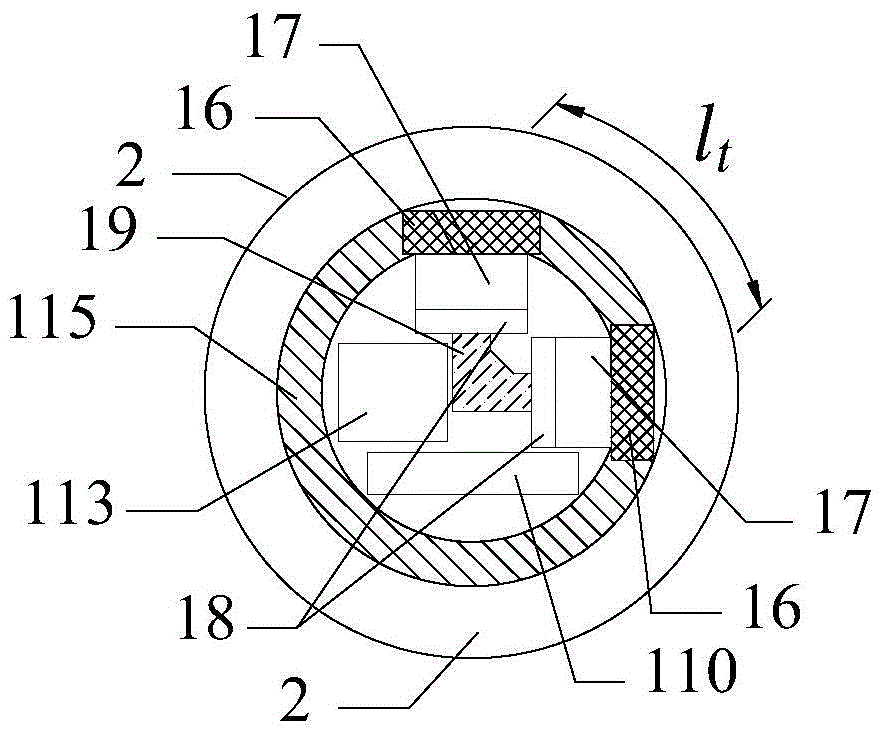

Inner surface stress and temperature monitoring method of internal combustion engine main bearing based on fiber bragg grating

ActiveCN103411550ASimultaneously monitor temperatureSimultaneous monitoring of strain changesThermometers using physical/chemical changesUsing optical meansFiberGrating

The invention provides an inner surface stress and temperature monitoring method of an internal combustion engine main bearing based on a fiber bragg grating. Fiber bragg grating strain sensors and fiber bragg grating temperature sensors for temperature compensation are respectively arranged on an internal surface of a to-be-tested main bearing so as to obtain strain changes of a bearing working surface; the fiber bragg grating strain sensors are arranged at all directions of the inner surface of a bearing so as to obtain the strain changes of the bearing at each direction; an engine oil temperature sensor is arranged in a waste engine oil pipe of the internal combustion engine so as to obtain engine oil temperature data; a fiber Bragg grating demodulation instrument is used to obtain center wavelength changes of the engine oil temperature sensor, and to convert the center wavelength changes into electrical signals; and engine oil temperature changes when the internal combustion engine works can be calculated. With the use of characteristics that the fiber bragg grating can simultaneously measure the strain and temperature and is small-sized and one-line-multi-point, the inner surface stress and temperature monitoring method of the internal combustion engine main bearing based on the fiber bragg grating can simultaneously monitor the temperature and strain distribution of the main bearing working when the internal combustion engine works, so as to provide accurate data to support optimization of the structural design of the internal combustion engine main bearing.

Owner:WUHAN UNIV OF TECH

Non-contact ground stress testing device and method based on drilling microscopy digital photography

The invention relates to a non-contact ground stress testing device and method based on drilling microscopy digital photography and belongs to ground stress measuring device and method of geotechnical engineering. The device comprises an electronic microscopy camera, a signal processing and control module, a signal transmission module, a gyroscope, a signal collecting module, a portable power source and a device shell. The method includes: fixing the testing device in a device mounting hole, using the electronic microscopy camera to collect the hole wall digital images of the hole during a whole stress relieving process, selecting the representative images before and after the stress relieving, acquiring sub-pixel images through image interpolation, optimizing sub-pixel image analyzing areas and points, setting analyzing traces, calculating to obtain strain values, and calculating the ground stress values and the azimuth angles thereof by the hole partial wall surface stress relieving method theory. The non-contact ground stress testing device and method has the advantages that simple operation and high adaptability are achieved, testing precision can reach one micro strain, strain measuring mark points and analyzing traces are optimized, influence of temperature, rock viscosity and electromagnetic interference is avoided, a probe can be reused, and low cost is achieved.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing Ni cementing WC base cemented carbide

The invention disclose a method for preparing a hard alloy by bonding WC group with Ni, which is characterized by comprising the steps that: firstly, the mixing powder of WC and Ni is subjected to wet grinding, drying and pressing in absolute ethyl alcohol, and then subjected to vacuum sintering at the temperature of 1440 DEG C to 1480 DEG C; when the sintering is finished, nitrogen is introduced to a furnace simultaneously for carrying out vacuum quenching, the pressure of the nitrogen is 0.1MPa to 0.4MPa, and the quenching time is 5min to 10min; after tapping, deep cooling treatment is carried out in liquid nitrogen, the treatment temperature is 150 DEG C to 196 DEG C, and the heat-preservation time is: the hard alloy weight multiplied by weight factor plus the Ni percent content of the hard alloy weight multiplied by component factor, wherein, the weight factor is 5min / g to 25min / g and the component factor is 10min to 20 min; and drawing temper is carried out in a vacuum furnace at the temperature of 120 DEG C to 200 DEG C, the temperature-preservation time is 1h to 3h. By adopting the method for preparing the hard alloy by bonding the WC group with Ni, the contact ratio of the WC can be controlled, the solubility of the WC in Ni is improved, furthermore, the surface stress condition of the alloy after treatment is compressive stress which improves the shock resistance capability of the alloy, thus being capable of realizing the substitution of Ni to Co and obtaining the performances corresponding to WC-Co series hard alloys.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com