Method and device for cutting machined object by using laser

A processing object, laser cutting technology, applied in glass cutting devices, laser welding equipment, metal processing equipment, etc., can solve the problems of inability to apply fine cutting, focus pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

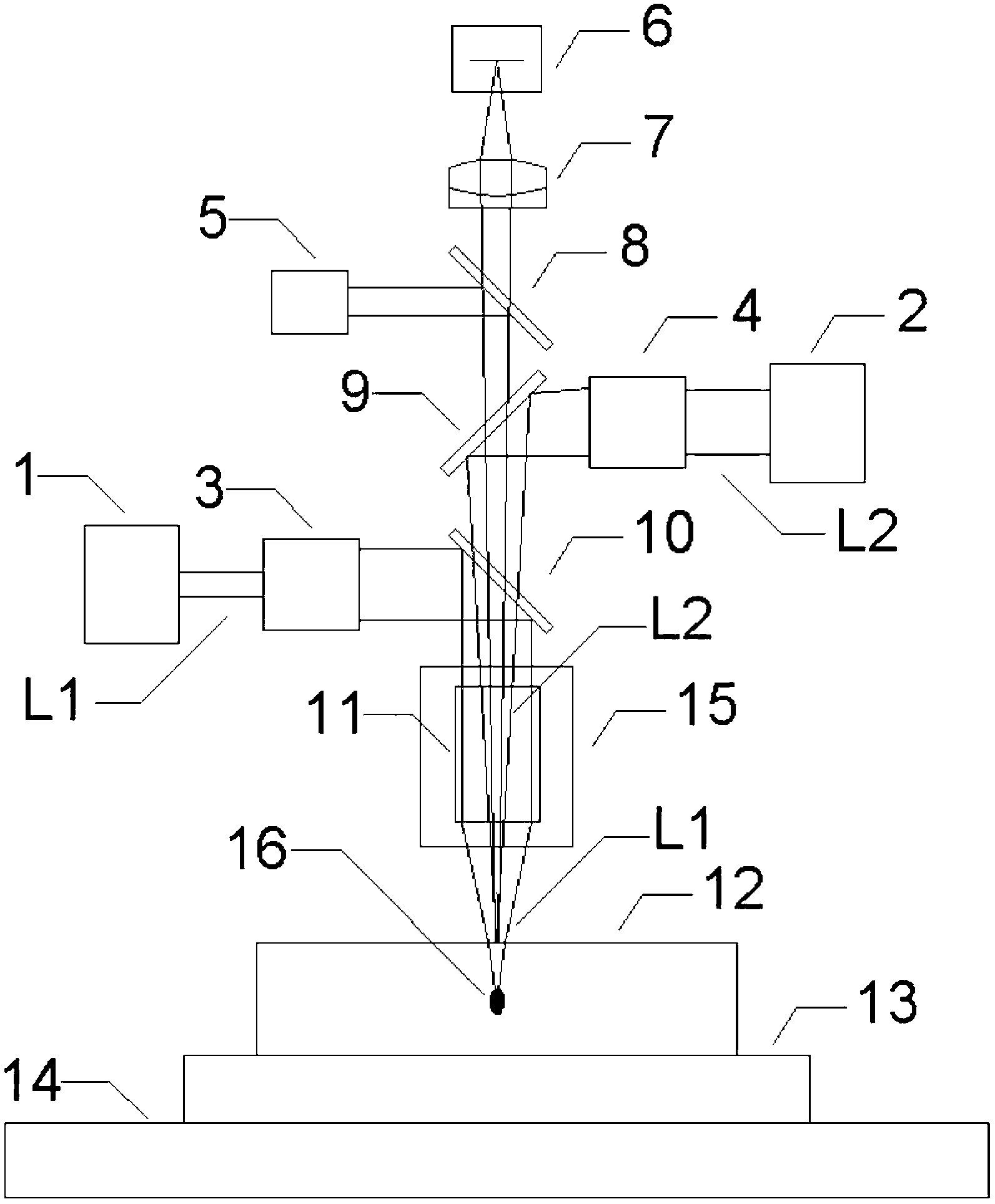

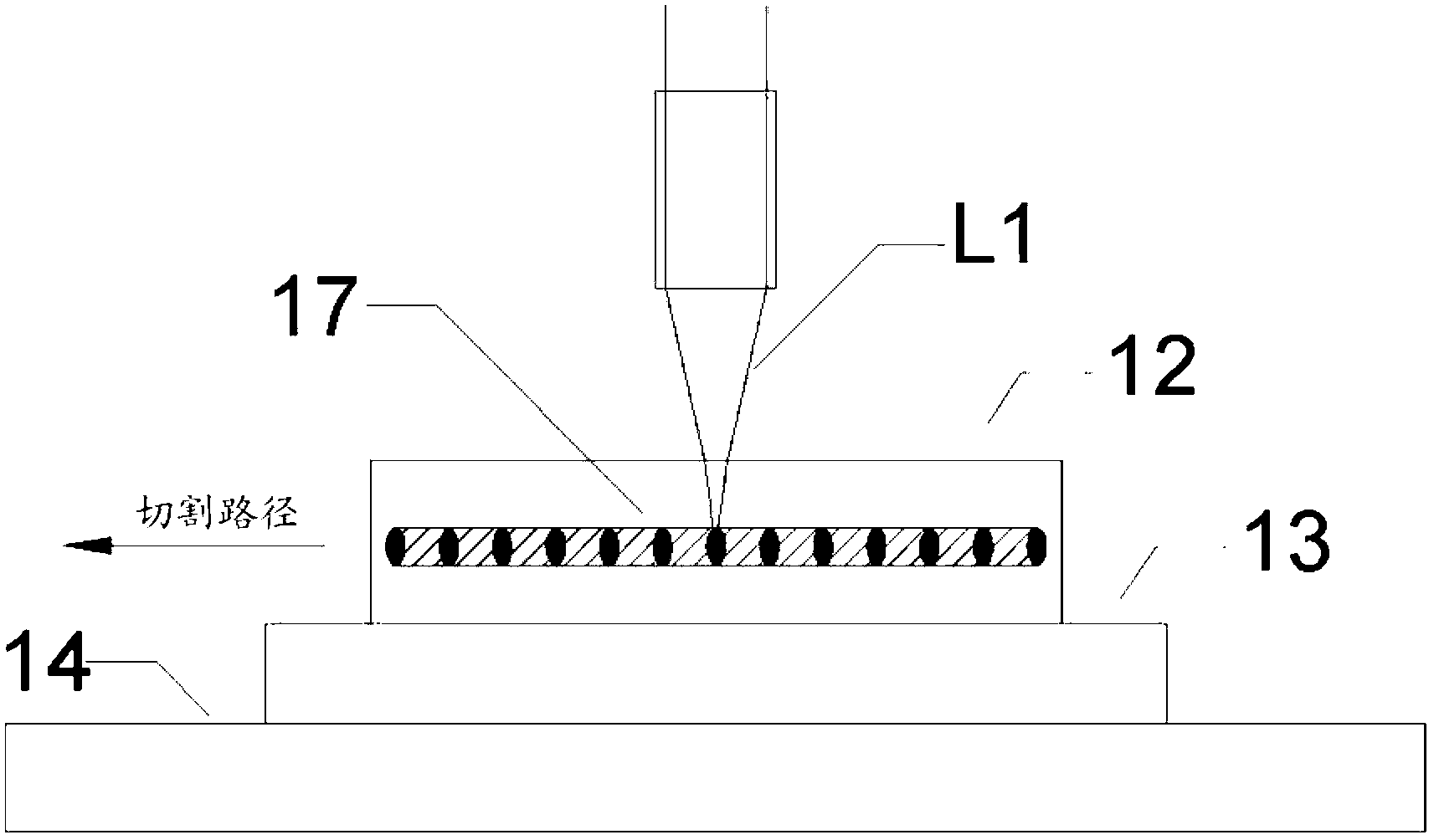

[0059] Embodiments of the laser cutting method of the present invention will now be further explained with reference to the schematic drawings. Moreover, the implementation apparatus of the laser cutting method of this invention is also schematically shown in the drawing of this specification.

[0060] figure 1 A schematic diagram of the optical path and system for implementing the laser cutting method of the present invention is shown. As an exemplary illustration, such as figure 1 As shown, the overall optical path system for implementing the laser cutting method of the present invention can be composed of three parts. The first part is emitted by the first laser source 1, the laser beam L1 is expanded and collimated by the laser beam expander 3, reflected by the laser mirror 10, enters the laser focusing mirror 11, and focuses on the inside of the object 12 to be processed. At this time, in a certain area near the laser focus inside the object 12, physical damage can occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com