Production of X-ray stress measuring calibrated sample

A stress measurement and X-ray technology, applied in the field of material analysis and testing, achieves the effects of portability, improved reliability, and easy on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Provide following embodiment in conjunction with content of the present invention:

[0023] (1) material quenching and tempering

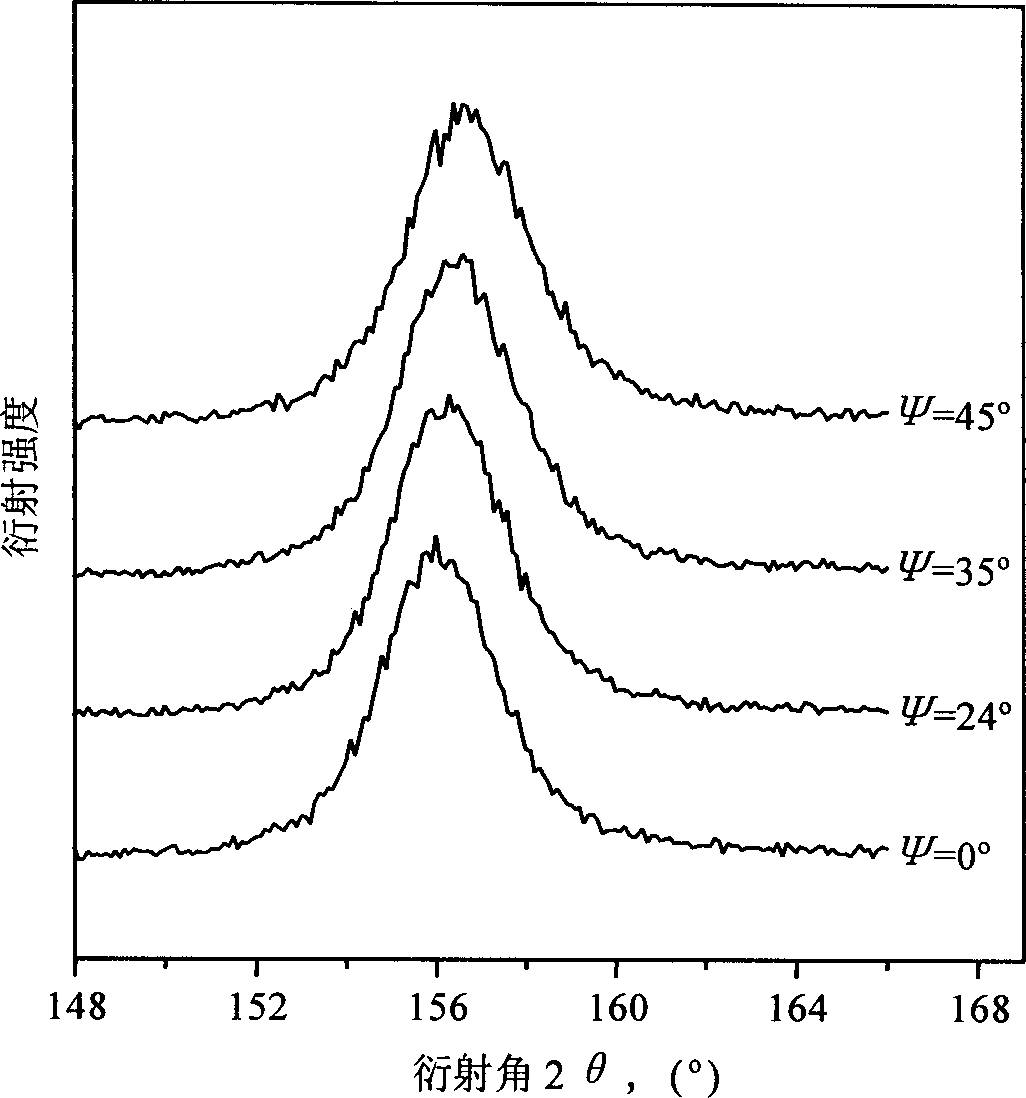

[0024] 2Cr13 ferritic stainless steel material is selected, and after forging, it is quenched and tempered. The quenching and tempering process is oil quenching at 1000°C and tempering at 660°C. Such as figure 1 As shown, the diffraction spectrum shows that the coarse grain and texture of the material are removed, and because the material contains 13% Cr element, the material does not rust in the atmospheric environment.

[0025] (2) Shot peening prestress

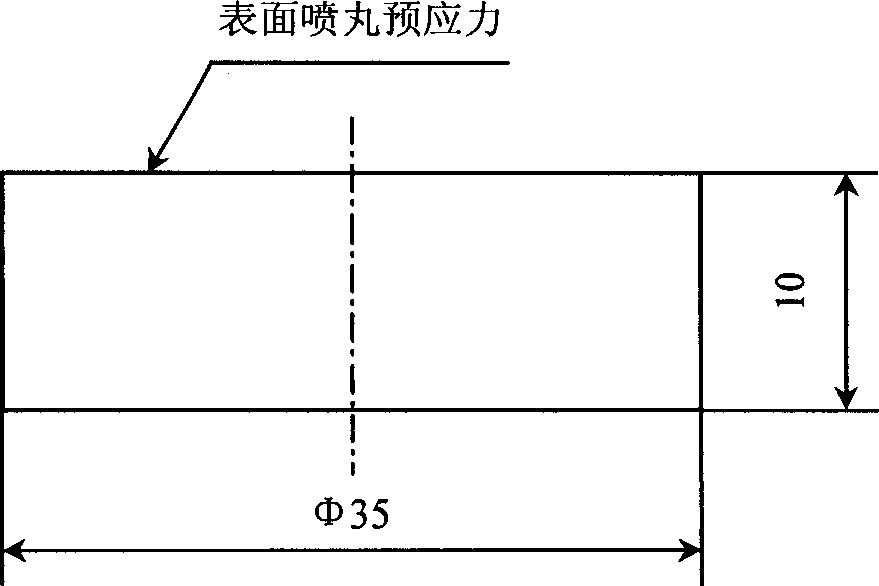

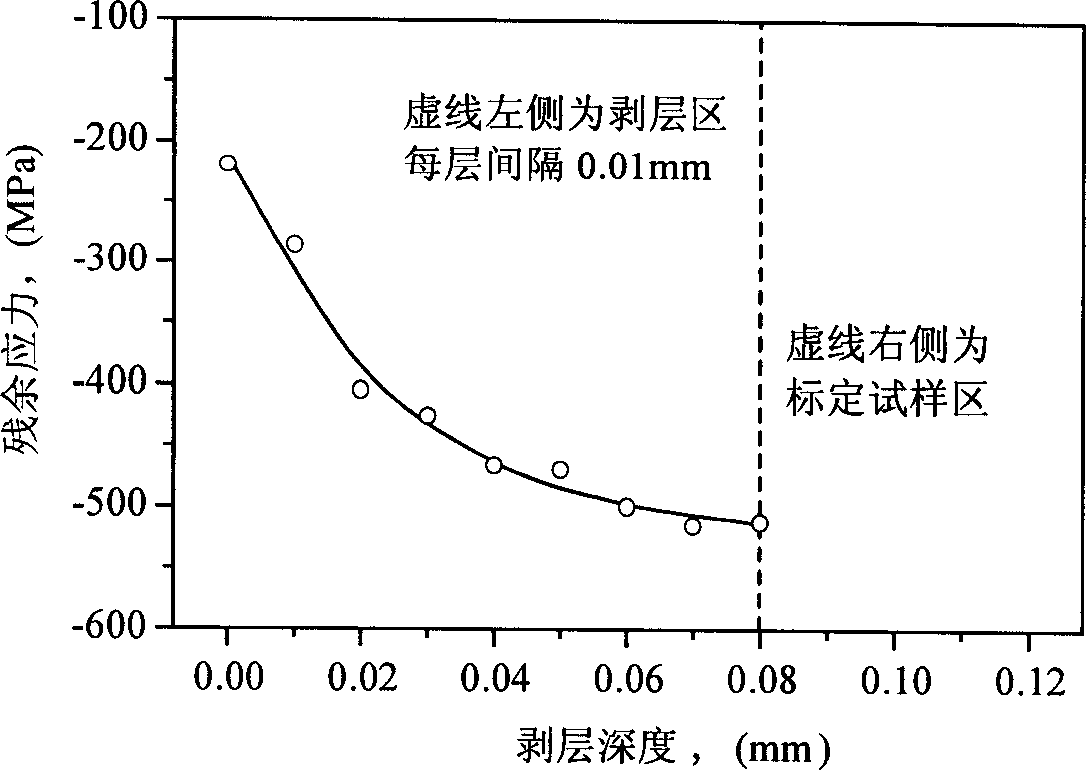

[0026] Such as figure 2 As shown, the end face of the calibration sample blank is subjected to shot peening prestressing treatment. The shot peening parameters are: the diameter of steel ball projectile is 0.15~0.25mm, the shot peening intensity is arc height 0.2mm, and the shot peening time is 10min. The outermost layer of the calibration sample obtained a residual stress of -218M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com