Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1495 results about "Electrochemical corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

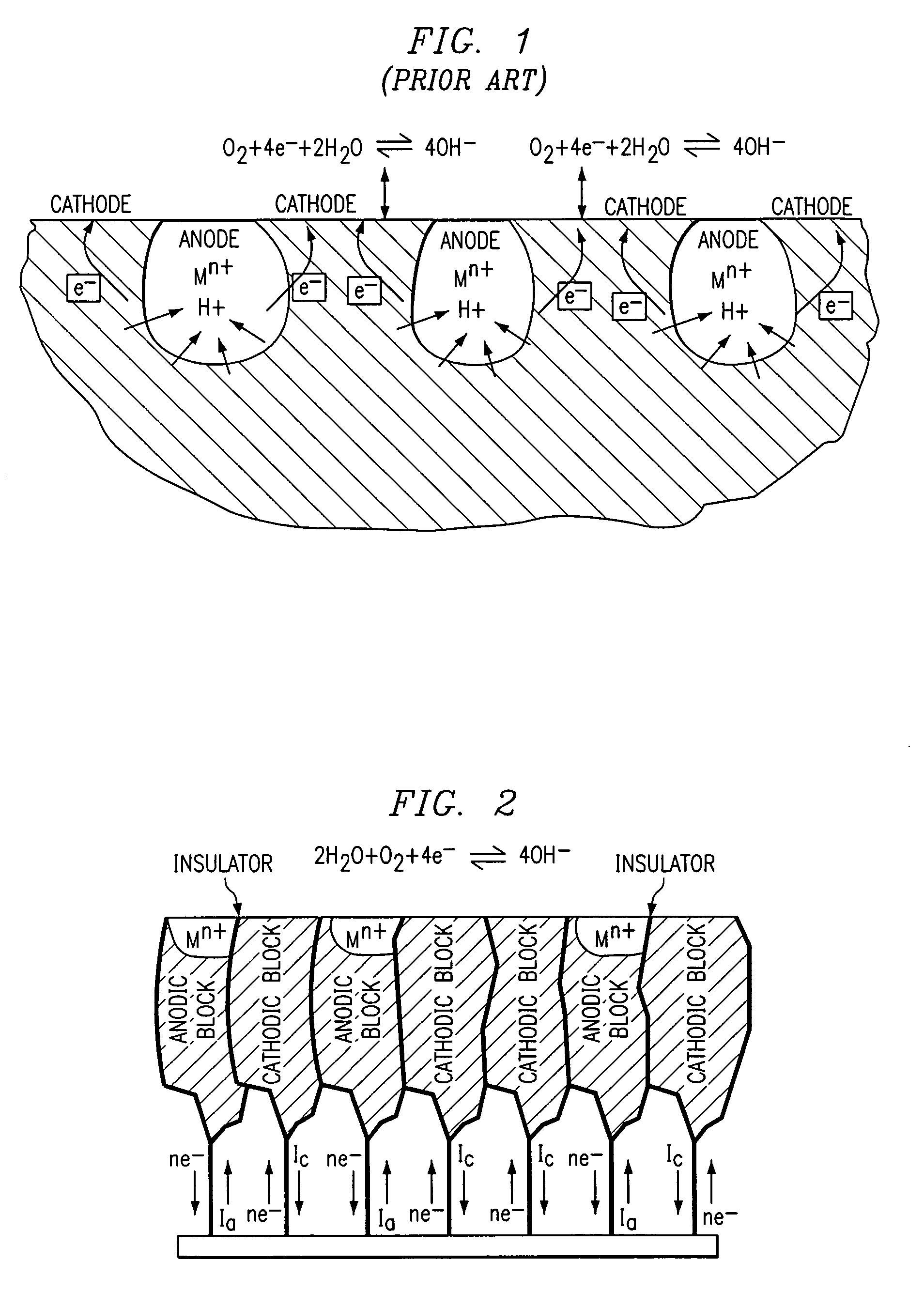

Electrochemical corrosion of metals occurs when electrons from atoms at the surface of the metal are transferred to a suitable electron acceptor or depolarizer.

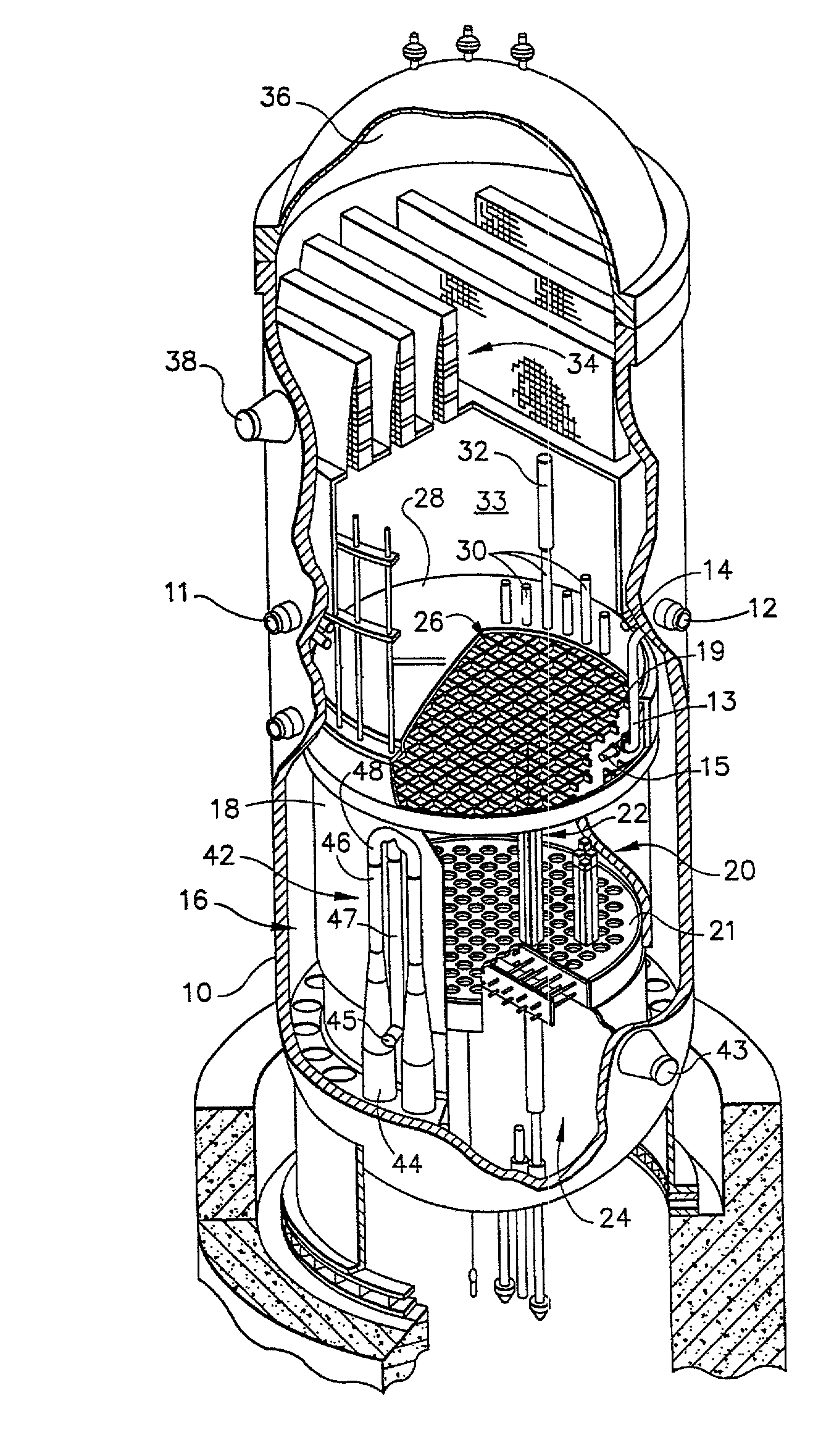

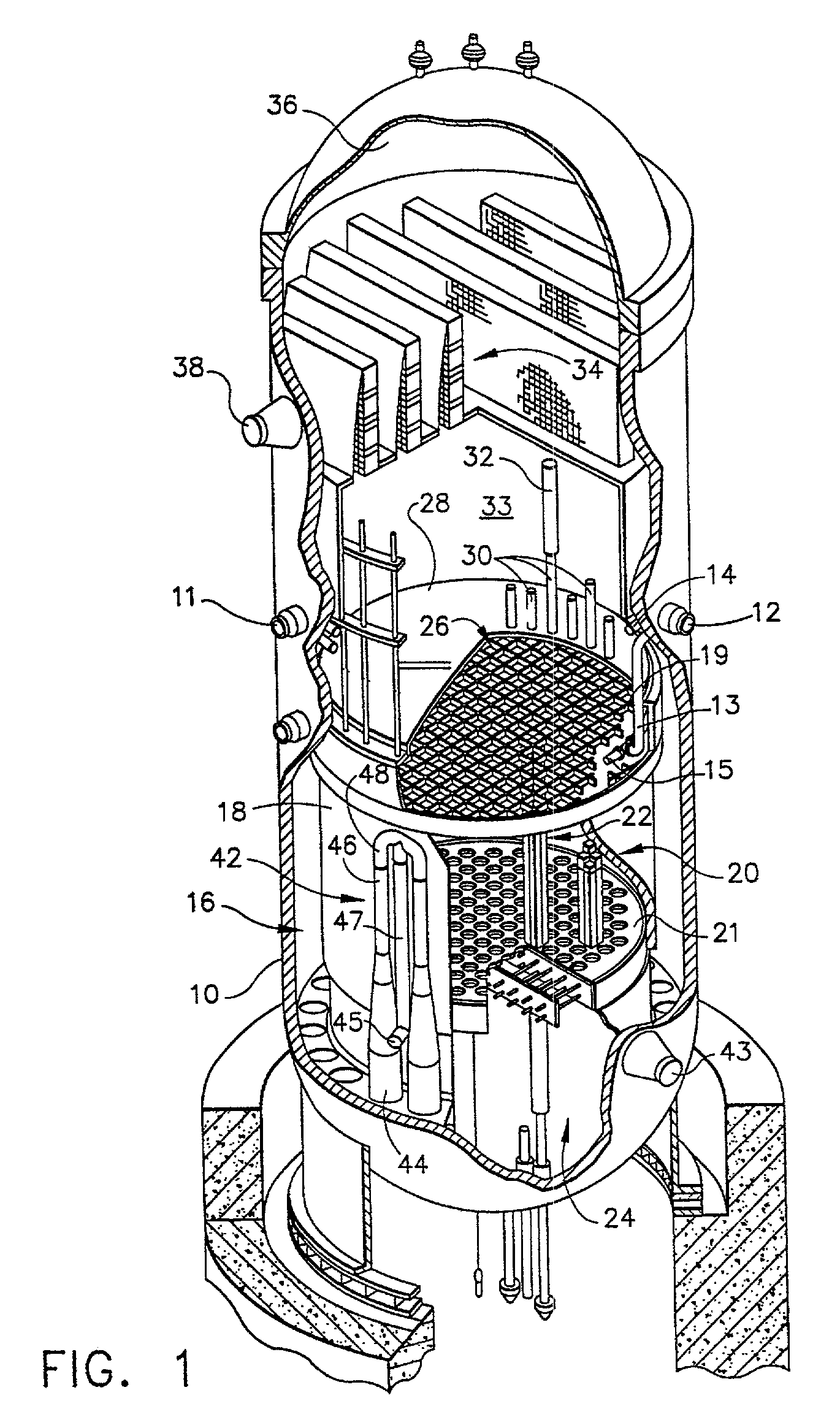

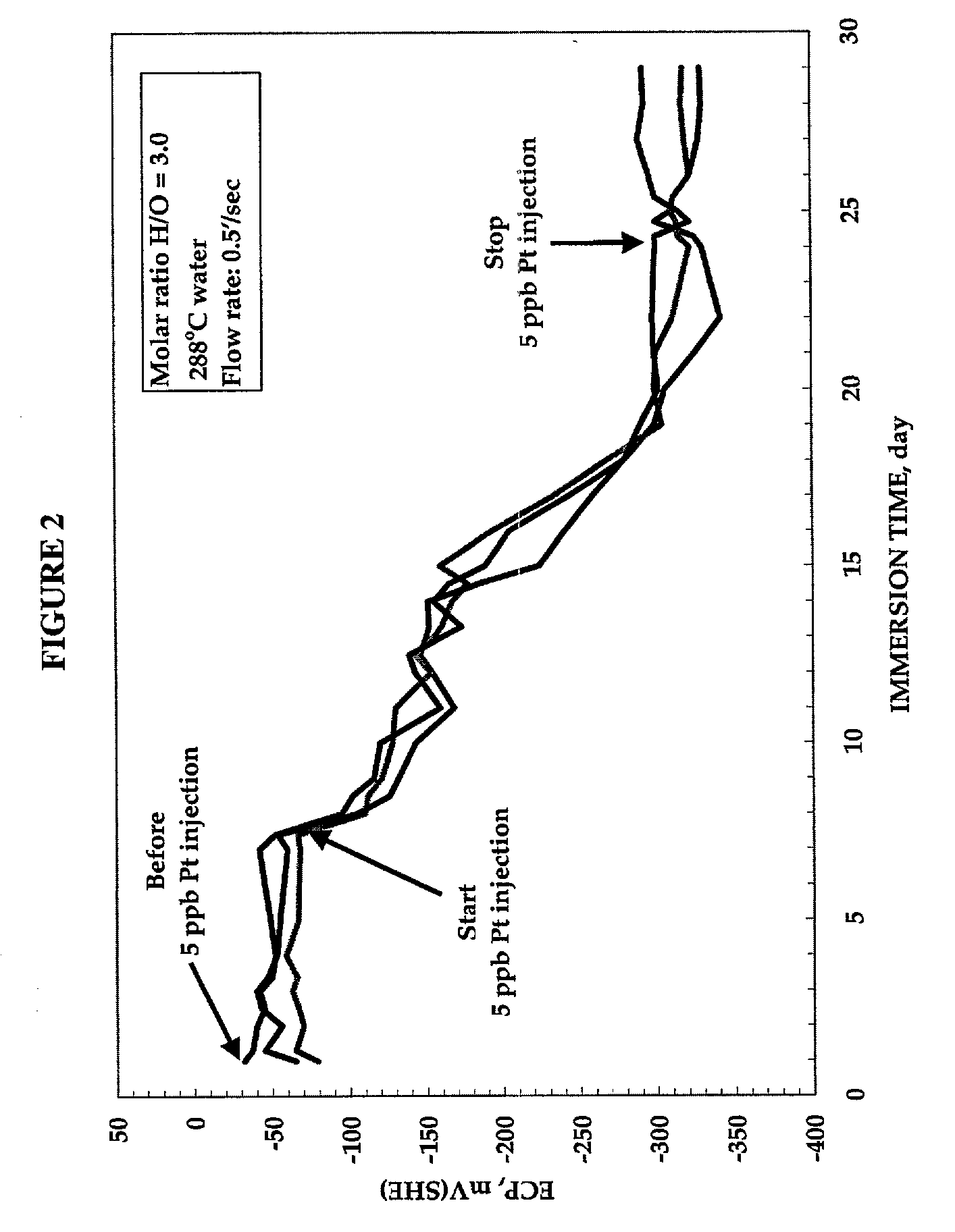

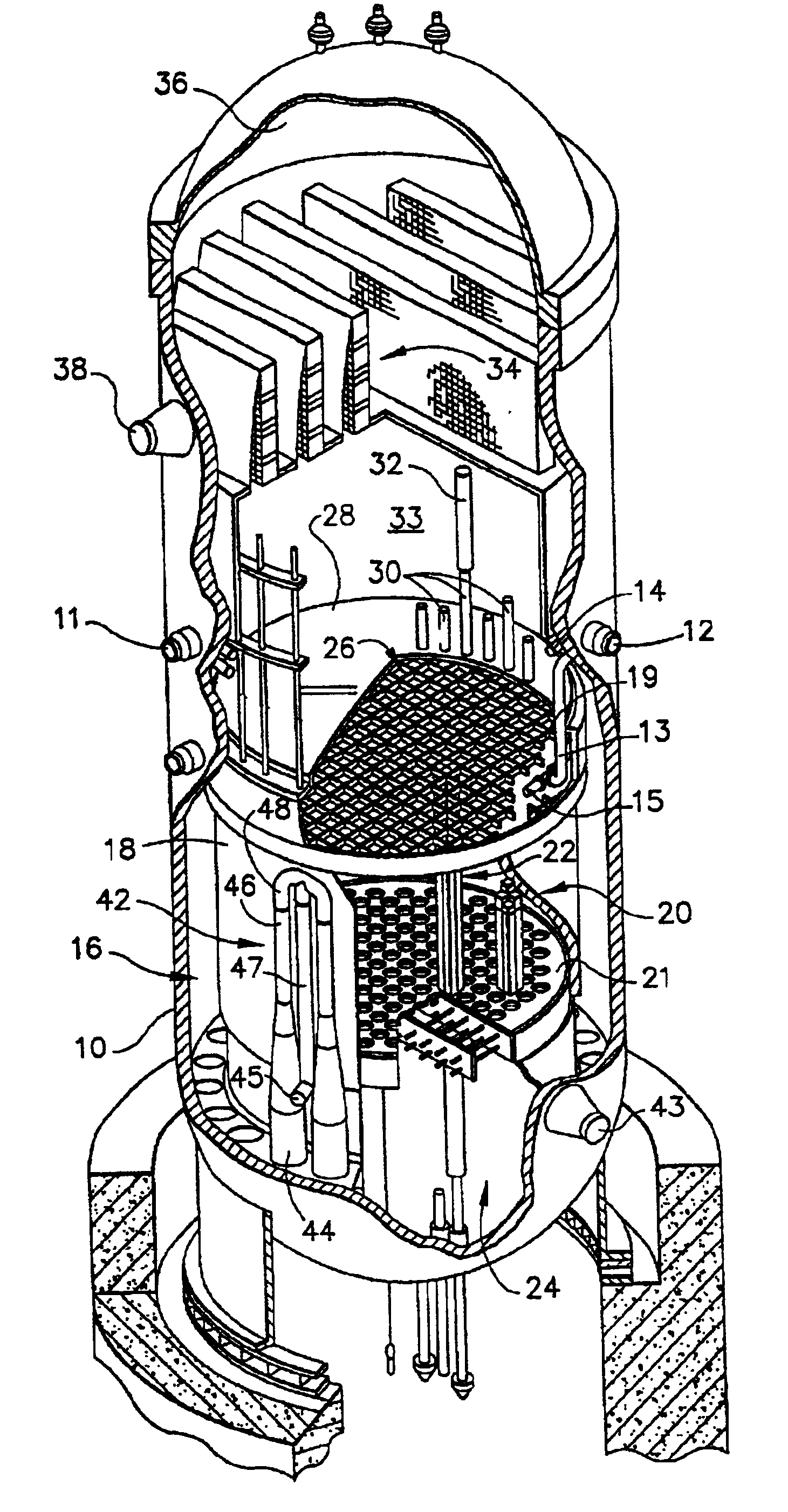

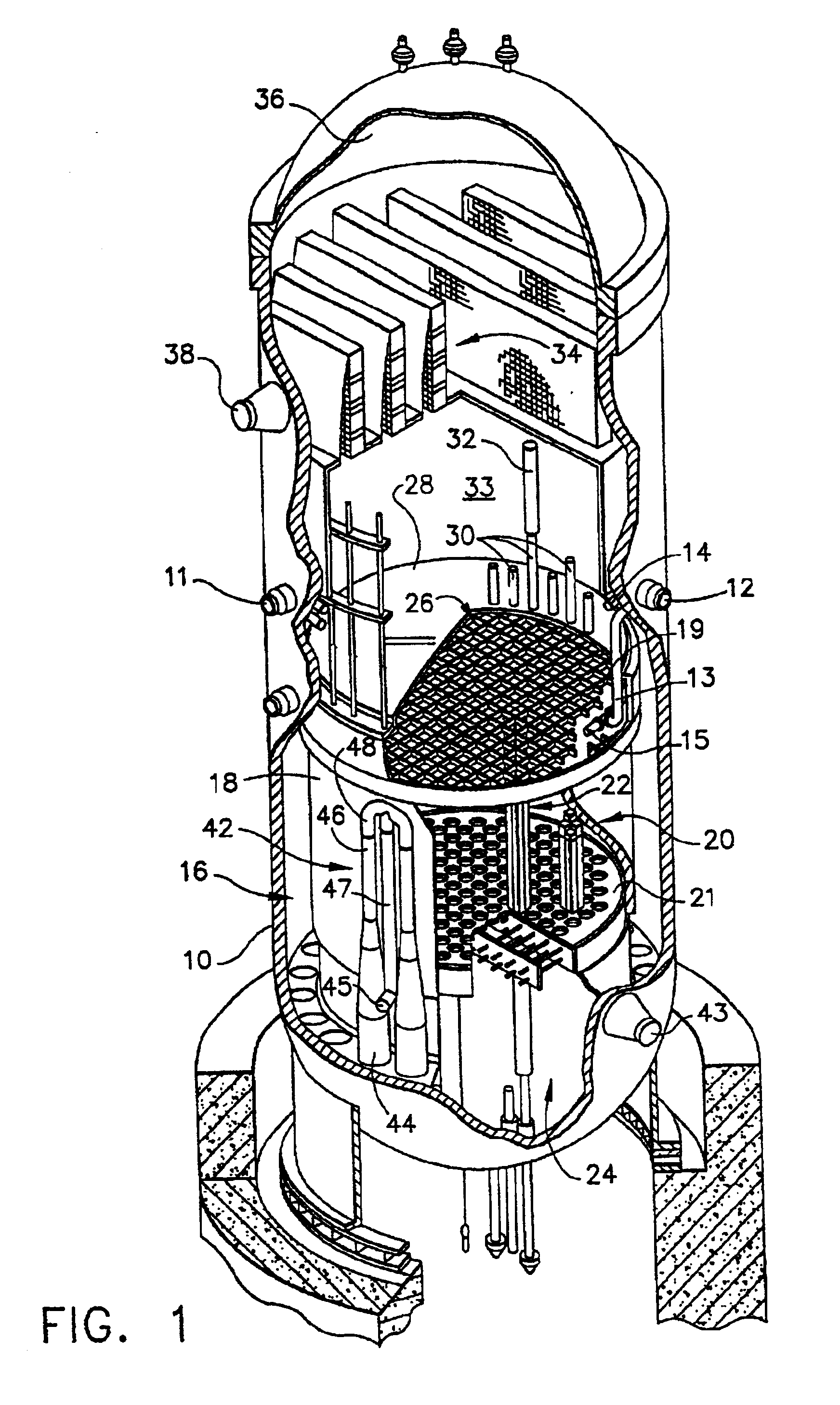

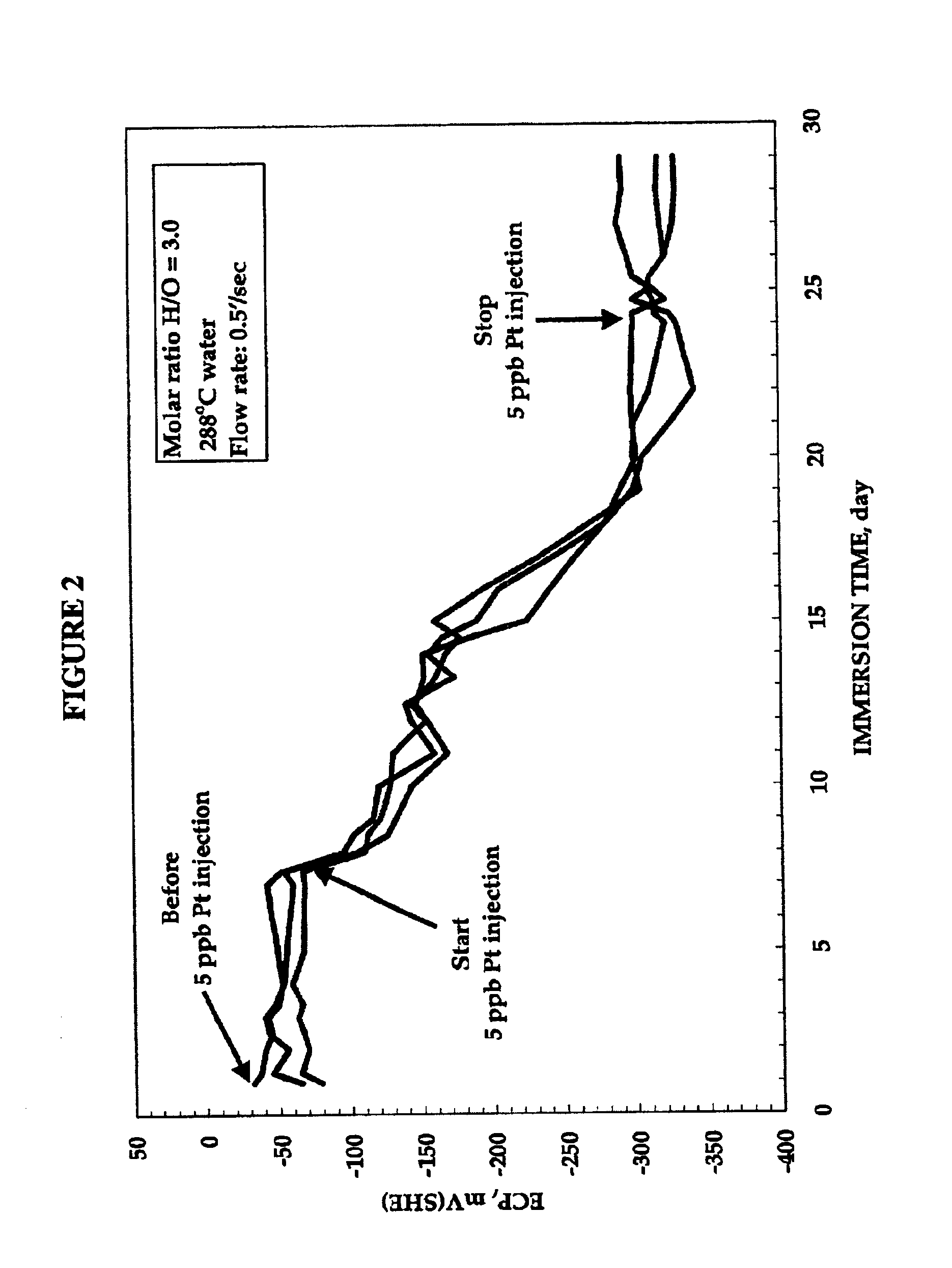

Process to mitigate stress corrosion cracking of structural materials in high temperature water

InactiveUS6724854B1Reduce crackingReducing the electrochemical corrosion potentialPlant parameters regulationNuclear energy generationNanoparticleStress corrosion cracking

A method for mitigating stress corrosion cracking in high temperature water includes introducing catalytic nanoparticles and dielectric nanoparticles to the high temperature water in an amount effective to reduce a electrochemical corrosion potential of the high temperature water.

Owner:GENERAL ELECTRIC CO

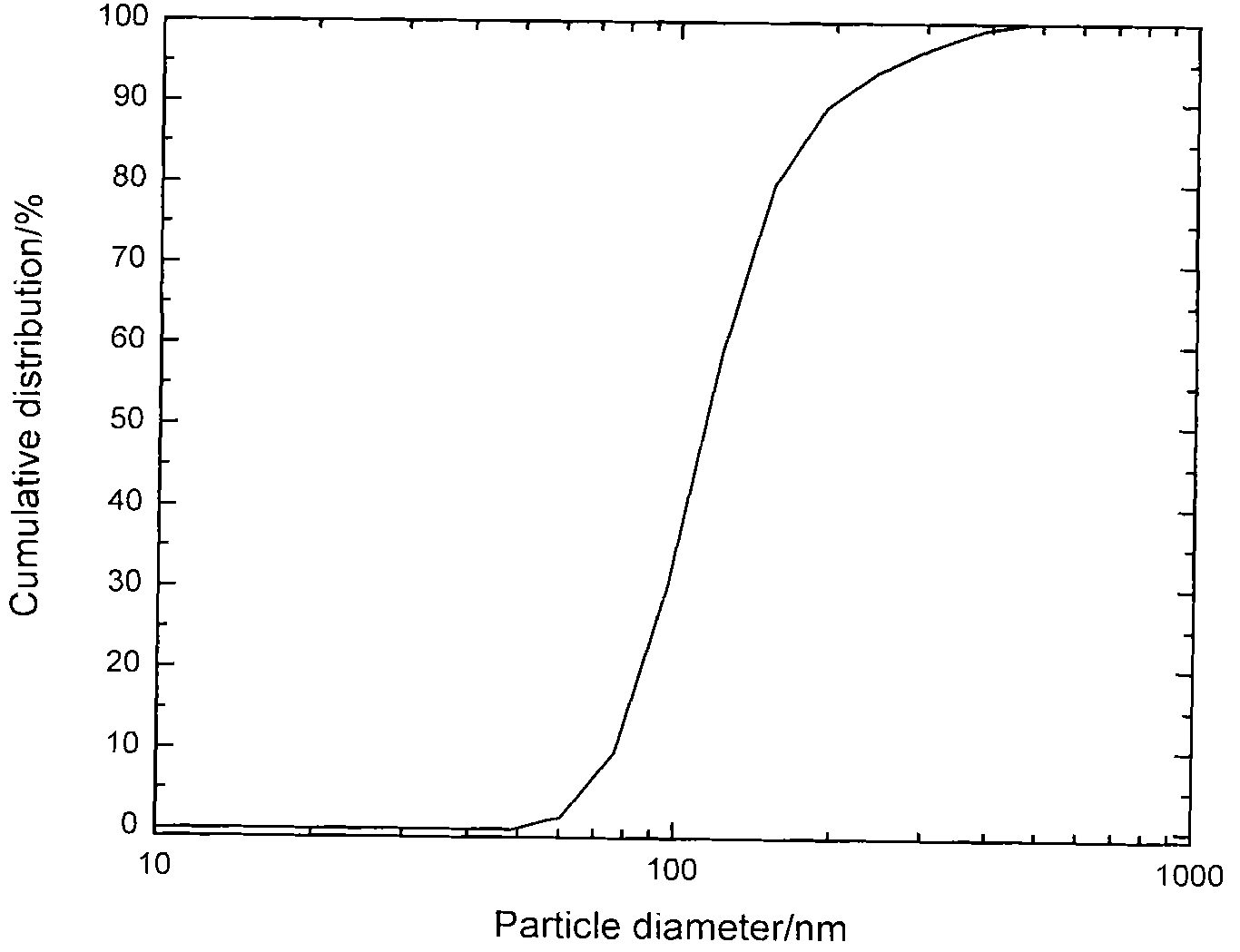

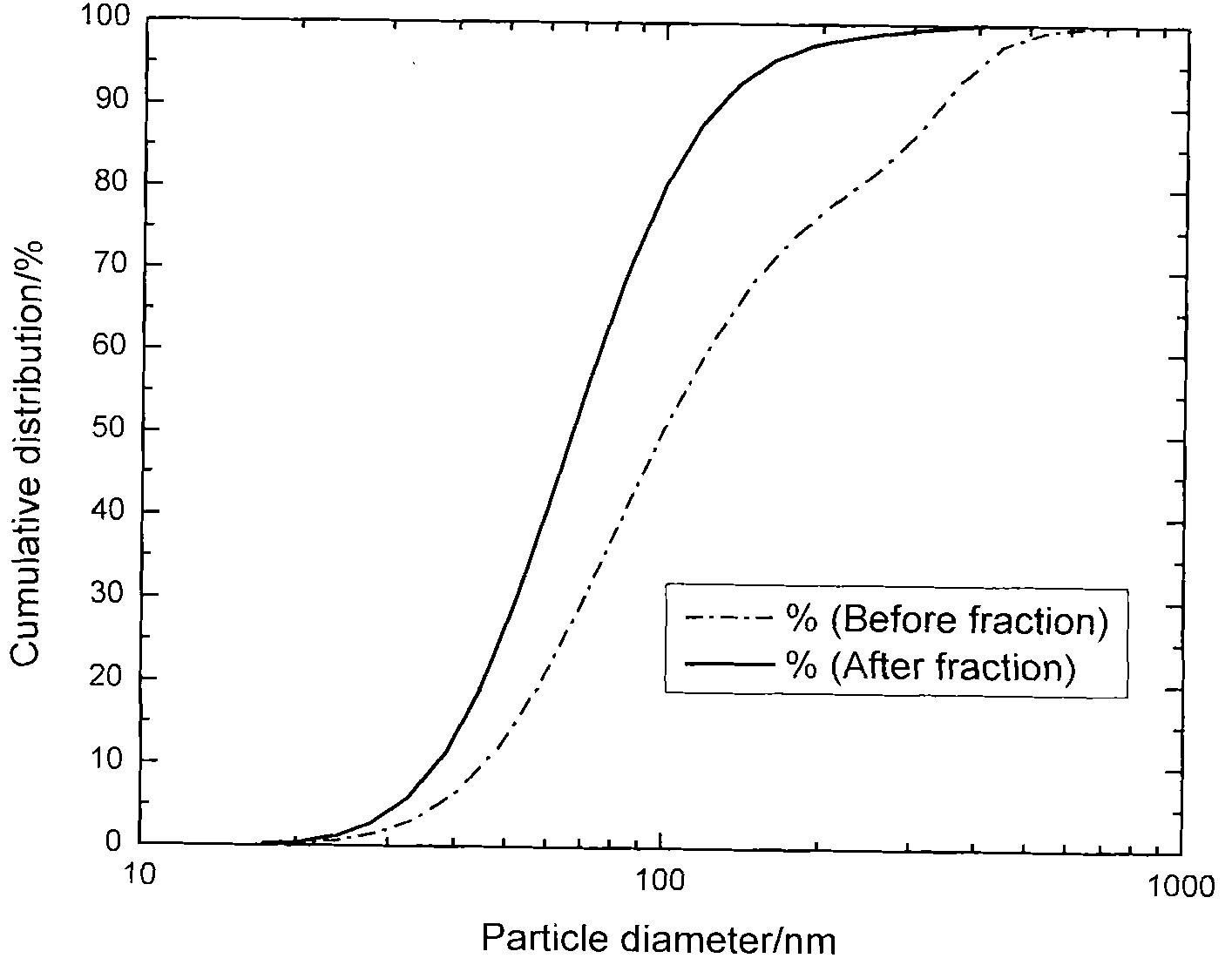

Application of catalytic nanoparticles to high temperature water systems to reduce stress corrosion cracking

InactiveUS20030012686A1Reducing electrochemical corrosion potentialReduce componentsNuclear energy generationNuclear monitoringNuclear reactorNanoparticle

A method and system for reducing stress corrosion cracking in a hot water system, such as a nuclear reactor, by reducing the electrochemical corrosion potential of components exposed to high temperature water within the structure. The method comprises the steps of: providing a reducing species to the high temperature water; and providing a plurality of noble metal nanoparticles having a mean particle size of up to about 100 nm to the high temperature water during operation of the hot water system. The catalytic nanoparticles, which may comprise at least one noble metal, form a colloidal suspension in the high temperature water and provide a catalytic surface on which a reducing species reacts with least one oxidizing species present in the high temperature water. The concentration of the oxidizing species is reduced by reaction with the reducing species on the catalytic surface, thereby reducing the electrochemical corrosion potential of the component.

Owner:GENERAL ELECTRIC CO

Application of catalytic nanoparticles to high temperature water systems to reduce stress corrosion cracking

InactiveUS6793883B2Reducing electrochemical corrosion potentialReduced dose rateNuclear energy generationNuclear monitoringNuclear reactorNanoparticle

A method and system for reducing stress corrosion cracking in a hot water system, such as a nuclear reactor, by reducing the electrochemical corrosion potential of components exposed to high temperature water within the structure. The method includes the steps of: providing a reducing species to the high temperature water; and providing a plurality of noble metal nanoparticles having a mean particle size of up to about 100 nm to the high temperature water during operation of the hot water system. The catalytic nanoparticles, which may contain at least one noble metal, form a colloidal suspension in the high temperature water and provide a catalytic surface on which a reducing species reacts with least one oxidizing species present in the high temperature water. The concentration of the oxidizing species is reduced by reaction with the reducing species on the catalytic surface, thereby reducing the electrochemical corrosion potential of the component.

Owner:GENERAL ELECTRIC CO

High-precision non-water-based nano-diamond grinding fluid and preparation method and application thereof

InactiveCN101831243AStrict control of particle size distributionTight control of particle morphologyPolishing compositions with abrasivesWater basedAlloy

The invention provides a high-precision non-water-based nano-diamond grinding fluid and a preparation method and application thereof. The high-precision non-water-based nano-diamond grinding fluid comprises main components of nano-diamond particles, a dispersion stabilizing agent, a suspension agent, a pH value regulator, an antistatic agent, an antioxidant, a dispersion medium and the like. In the invention, the particle size distribution is 130nm or smaller D50 particle size; the ratio of D10 to D50 is 50 percent or more; and the ratio of D90 to D50 is 200 percent or less. The preparation method comprises the following steps of: thinning diamond raw materials; carrying out modifying processing; deeply purifying; separating particle size; and finally mixing components according to a certain ratio. The invention has the advantages of completely eliminating deliquesce, hydrolization, chemical corrosion and electrochemical corrosion during the premise polishing and improving the polishing efficiency and the polishing quality to be maximum extent. The products have wide application to hard alloys, disk moulds, computer magnetic heads, computer disks, solar batteries and the like.

Owner:CHINA JILIANG UNIV

Fluorosilicone rubber nano composite alloy three-proof paint and production method thereof

InactiveCN101230224AImprove anti-corrosion performanceExcellent anti-fouling flashEpoxy resin coatingsCross-linkPolymer science

The invention discloses a fluorosilicone rubber nano-composite alloy triplicate-prevention paint and the production method. The organic silicon provided with hydroxyl is introduced into the carbon resin, and is dispersed into resin polymerize and cross-linked by a variety of polymer resin via nano-particle which is processed by nano-dispersion solution; and then the fluorosilicone rubber nano-composite alloy triplicate-prevention paint which can resist salt spray, acid, alkali and impact; has strong adhesive attraction, strong resistance to elements, and heavy corrosion resistance; can prevent pollution flashover , and can drain for anti-icing is produced by modifying the obtained resin. The invention has high reaction energy and ultra-low surface energy, can resist chemical corrosion and electrochemical corrosion, has ability for resisting strong corrosion medium, has strong adhesive attraction and high reliability between paint film layers, can prevent water, oxygen and other corrosion mediums from destructing, can resist ultraviolet radiation, can resist temperature change, has super resistance to elements, has long coating maintenance usage duration, and is applicable to bad weather conditions and all kinds of strong corrosive environments.

Owner:孟中

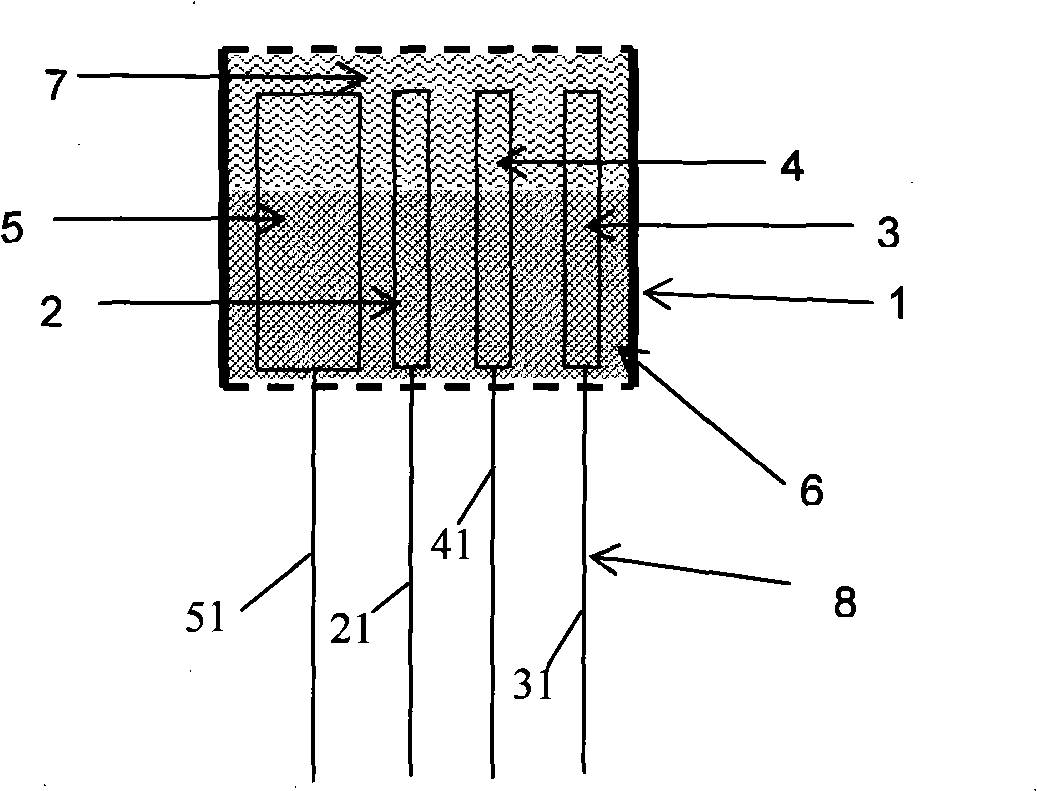

Multifunctional sensor for monitoring reinforced concrete structure erosion

InactiveCN101334353AImprove responsivenessImprove reliabilityWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionCarbonization

The invention discloses a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure, relating to a sensor, and provides a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure and can simultaneously monitor electrochemical corrosion parameters of carbonization of concretes, Cl<-> concentration, corrosion status and corrosion speed of reinforcement metals and the like on the spot, as well as a preparation method of the multifunctional sensor. The multifunctional sensor is provided with a metal shell, a Cl<-> probe, a pH probe, a reinforcement metal electrode, a MnO2 reference electrode and external guide lines. The Cl<-> probe, the pH probe, the reinforcement metal electrode and the MnO2 reference electrode are prepared separately, and then arranged in the shell. The external guide lines of each probe and each electrode are connected with and extend from the metal shell, each probe and each electrode are sealed and fixed with the metal shell, and insulating materials are exposed at the upper ends of each probe and each electrode and the ends exposing outside are covered by pervious materials; connecting parts between the external guide lines and the metal shell are sealed.

Owner:XIAMEN UNIV

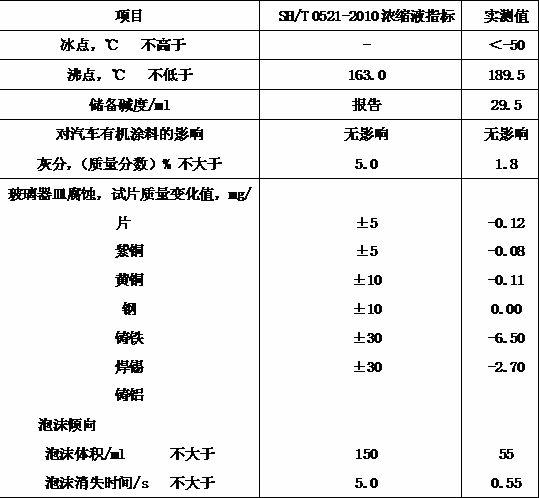

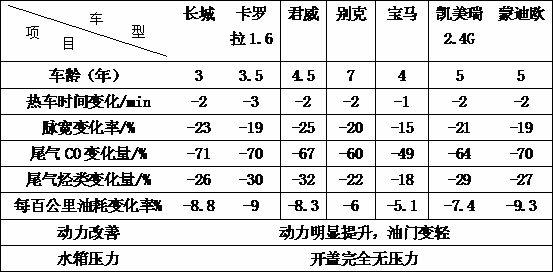

All-organic waterless engine coolant

InactiveCN102559152AImprove corrosion resistanceIncrease motivationHeat-exchange elementsCavitationElectrochemical corrosion

The invention aims at providing an all-organic waterless engine coolant with high storage alkalinity and long service life, which specifically contains the following components by weight percentage: 20-92% of propylene glycol, 0-60% of ethylene glycol, 0.6-5.5% of all-organic corrosion inhibitor, 5-20% of viscosity specific heat conditioning agents, 1.5-5.0% of potential of hydrogen (pH) conditioning agents, 0.01-0.1% of antifoaming agents and 0.001-0.01% of coloring agents. The boiling point of the all-organic waterless engine coolant reaches 180-190 DEG C, the freezing point reaches below -50 DEG C, and the all-organic waterless engine coolant is free of inorganic salt, so that defects of the traditional coolant of being low in boiling point, apt to have electrochemical corrosion and cavitation corrosion, apt to generate scale and the like are overcome, engine power is improved, noise is reduced, and fuel is saved. The all-organic waterless engine coolant has storage alkalinity larger than 25 ml and very long service life, can be used for a life time after being injected for once, does not need to be added with supplement annexing agents (SCA), and is good in market prospect.

Owner:GUANGZHOU BIAOBANG CAR CARE IND

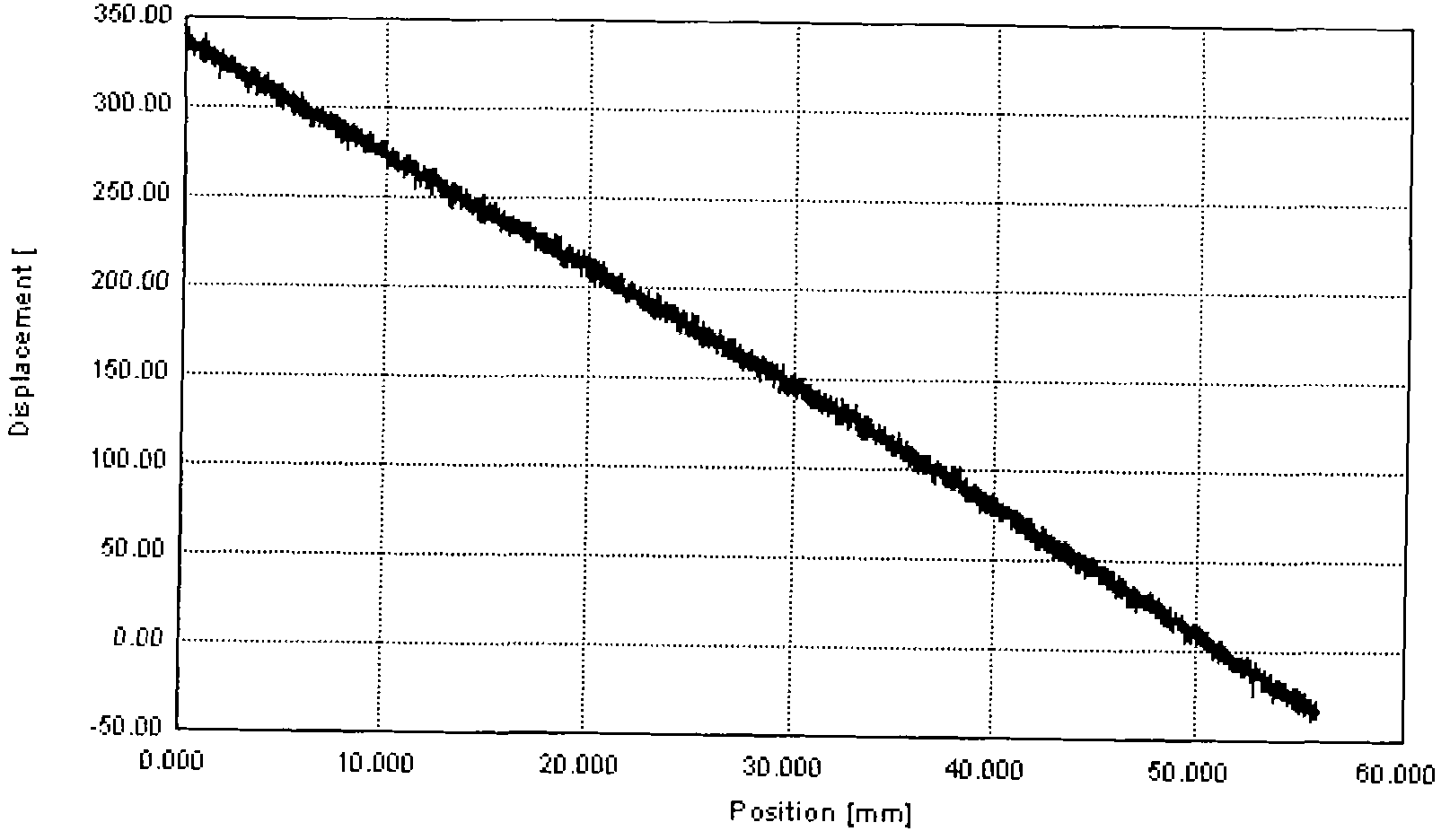

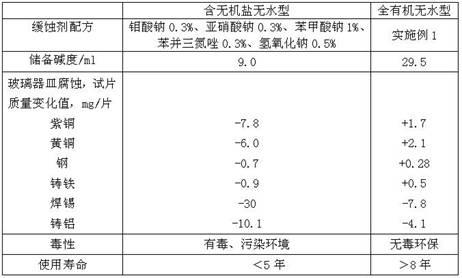

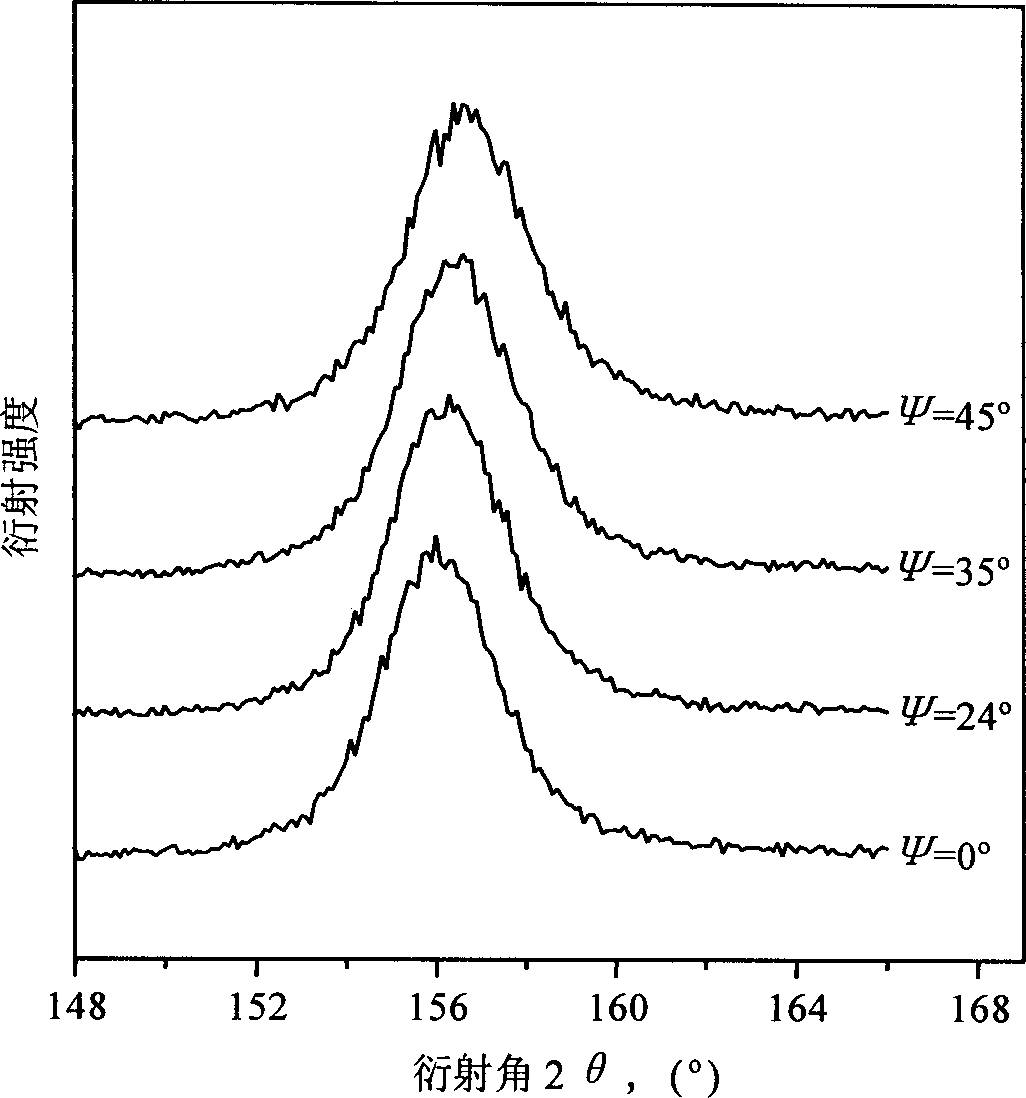

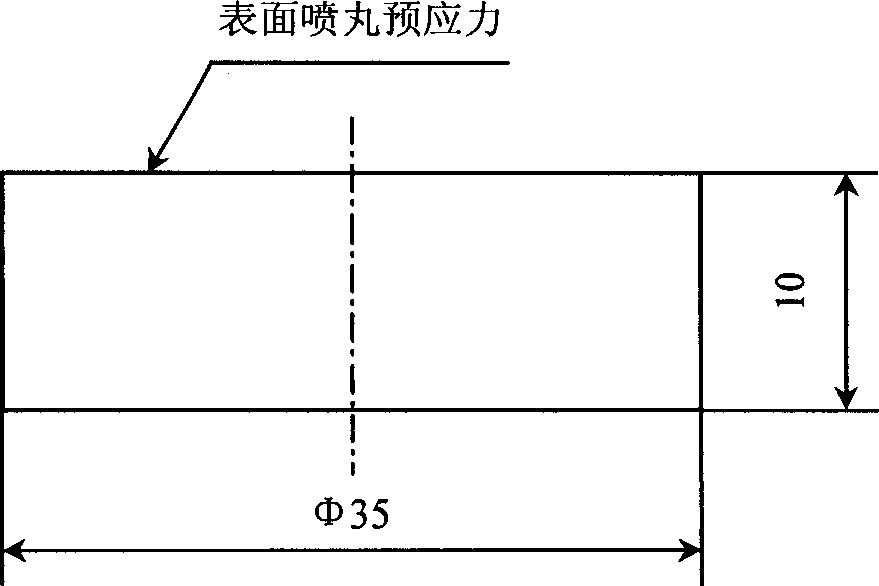

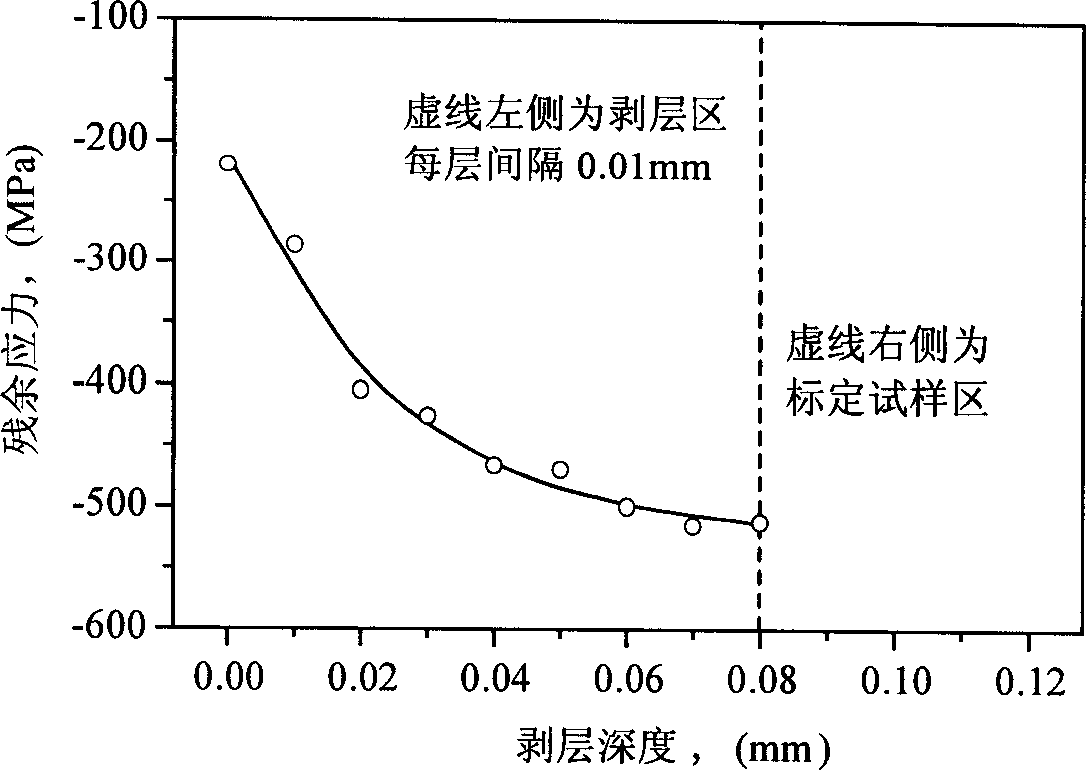

Production of X-ray stress measuring calibrated sample

InactiveCN1645091AEasy to carryBeautiful surfaceMaterial analysis using wave/particle radiationPreparing sample for investigationSurface stressStress measurement

A method for preparing calibration test sample of X ray stress measurement includes removing phenomenon of crystal particle coarsening and crystal face preferred orientation, carrying out short blasting treatment for semiproduct of the sample, stripping layer by layer for portion with greater stress gradient by electrochemical corrosion, carrying out X ray stress measurement and calibrating out work surface of the sample by utilizing relation curve of stress to layer depth.

Owner:SHANGHAI JIAO TONG UNIV

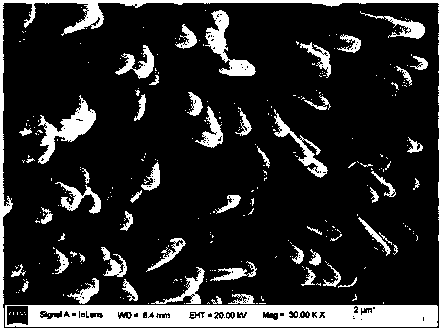

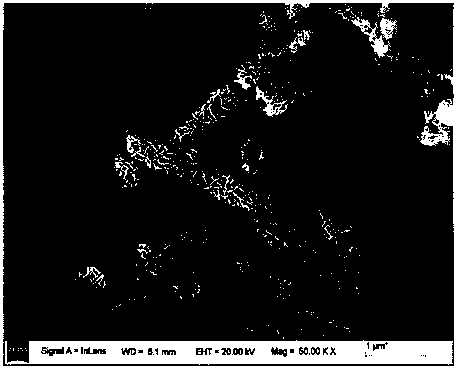

Preparation method of porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element

InactiveCN103424435ASimple methodLow process conditionsMaterial analysis by electric/magnetic meansGas detectorElectrochemical corrosion

The invention discloses a preparation method of a porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element. A porous silicon layer is prepared on a polished surface of a P-type single-side-polished monocrystalline wafer by double-channel electrochemical corrosion; tungsten oxide nanorods are grown in situ on porous silicon by hydrothermal process, so that composite-structure porous silicon-based tungsten trioxide nanorods are obtained; two platinum electrodes are deposited on the surface of the wafer by magnetron sputtering. The novel porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element which has excellent gas-sensitiveness features, such as simplicity in preparation process, ease of control, capability of detecting nitride oxide gas at the room temperature and high flexibility, is provided.

Owner:TIANJIN UNIV

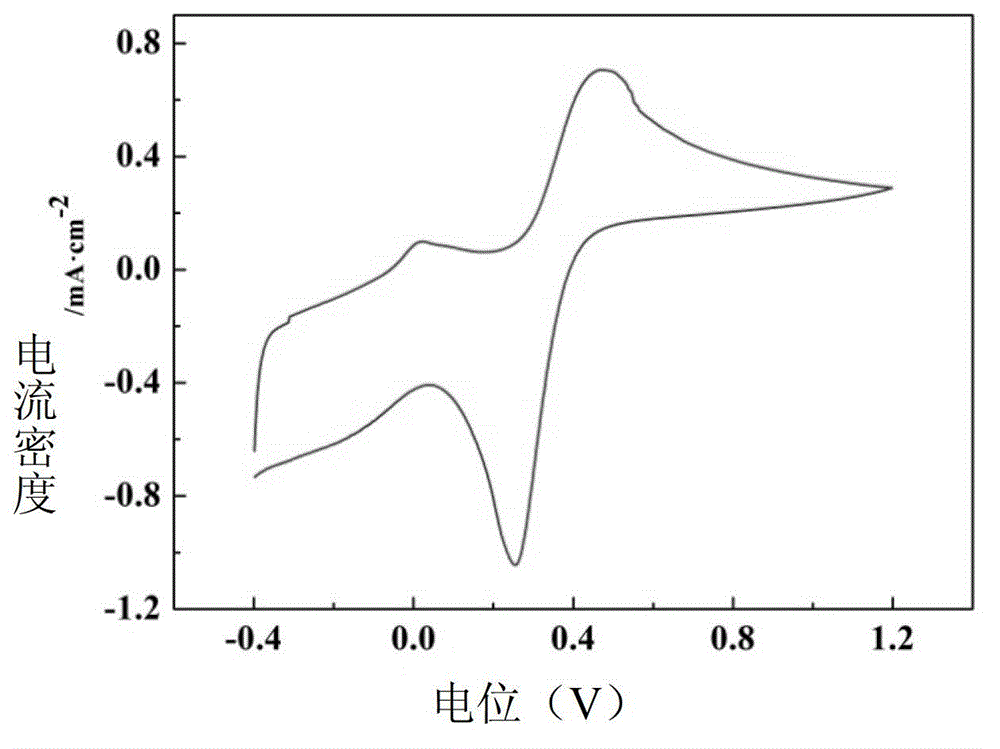

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

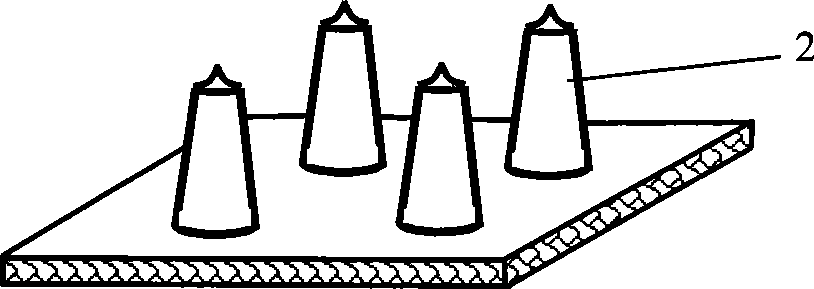

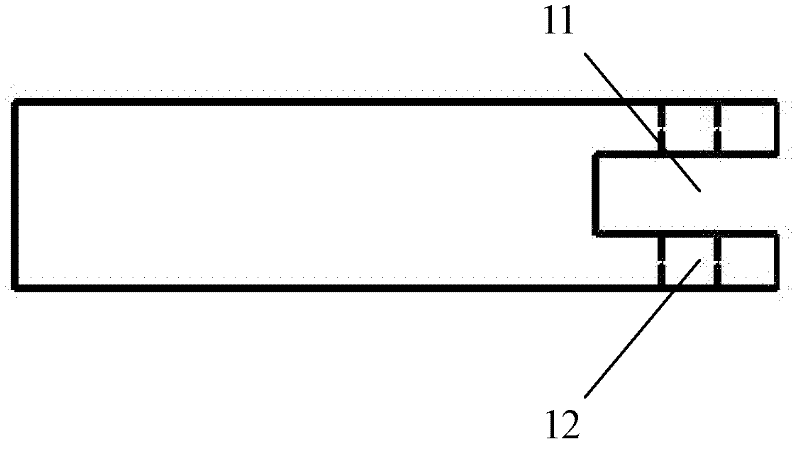

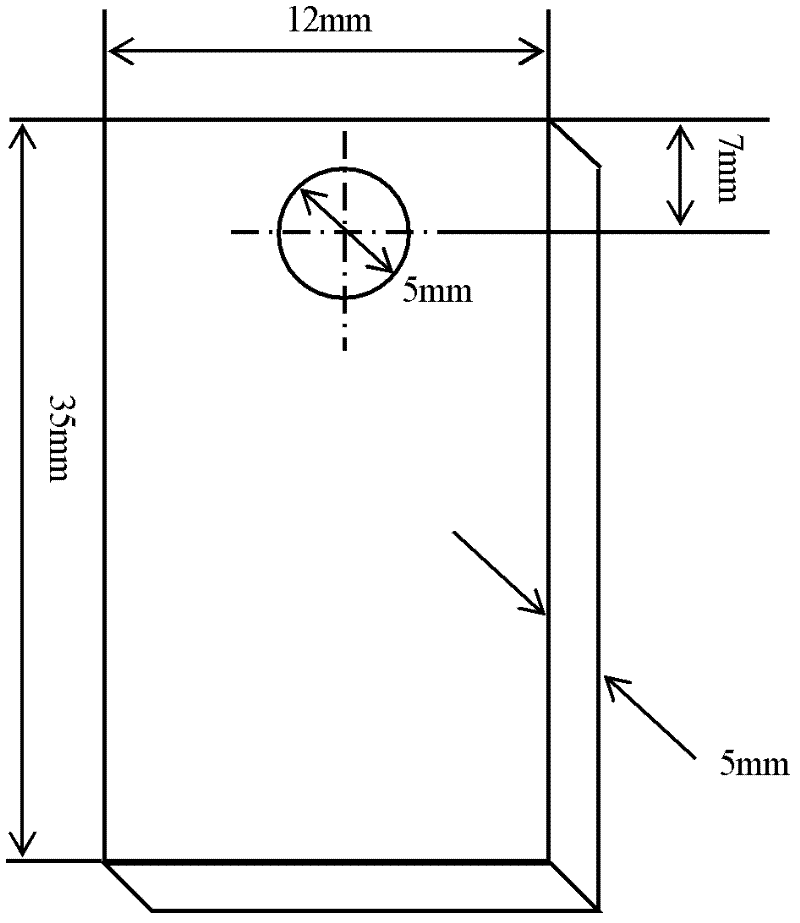

Micro-needle array chip, percutaneous administration device, percutaneous administration patch and preparation method thereof

The invention relates to a micro-needle array chip, a transdermal delivery device, a transdermal delivery patch and a preparation method thereof, wherein a micro-needle is obliquely fixed on a substrate at a set angle, the upper surface of the needle is an elliptic plane parallel to the substrate or obliquely provided with an acute angle, the needle is further treated to have more edge angles, a metal wire bar or tube penetrates a non-metallic material substrate such as polymer and the like along a certain angle, and then a nick of the metal wire bar or tube on the substrate is grinded and polished; and photosensitive resist patterns are formed nearby the nick at one end by adopting photoetching and etching technology, then the metal wire bar or tube is subjected to chemical or electrochemical corrosion to form a needle point and the photosensitive resist is removed, the surface of the manufactured solid micro-needle array chip can be covered with drugs, and the manufactured solid micro-needle array chip can deliver liquid medicine or extract body fluid. The method avoids the skin plugging a transfusion hole, is easy to adjust and control the maximum penetrating depth of the micro-needle, and is suitable for percutaneous transportation of biological macromolecular drugs and cosmetics and skincare and new percutaneous preparation of the prior drugs.

Owner:TSINGHUA UNIV

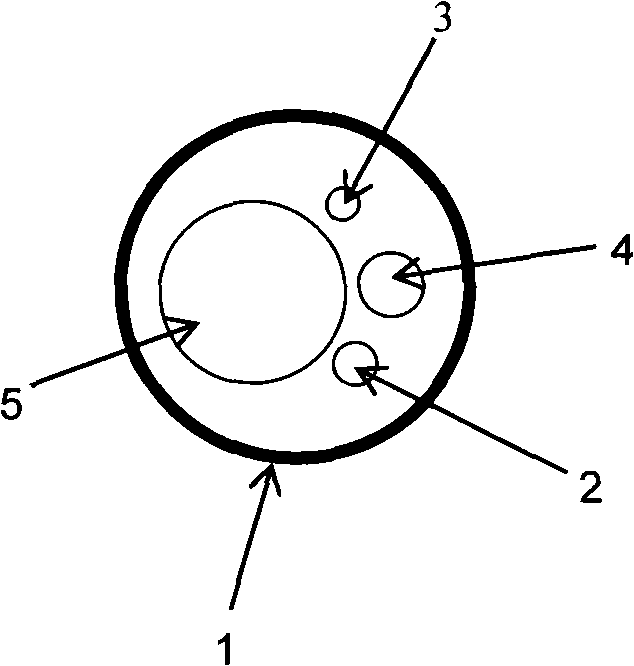

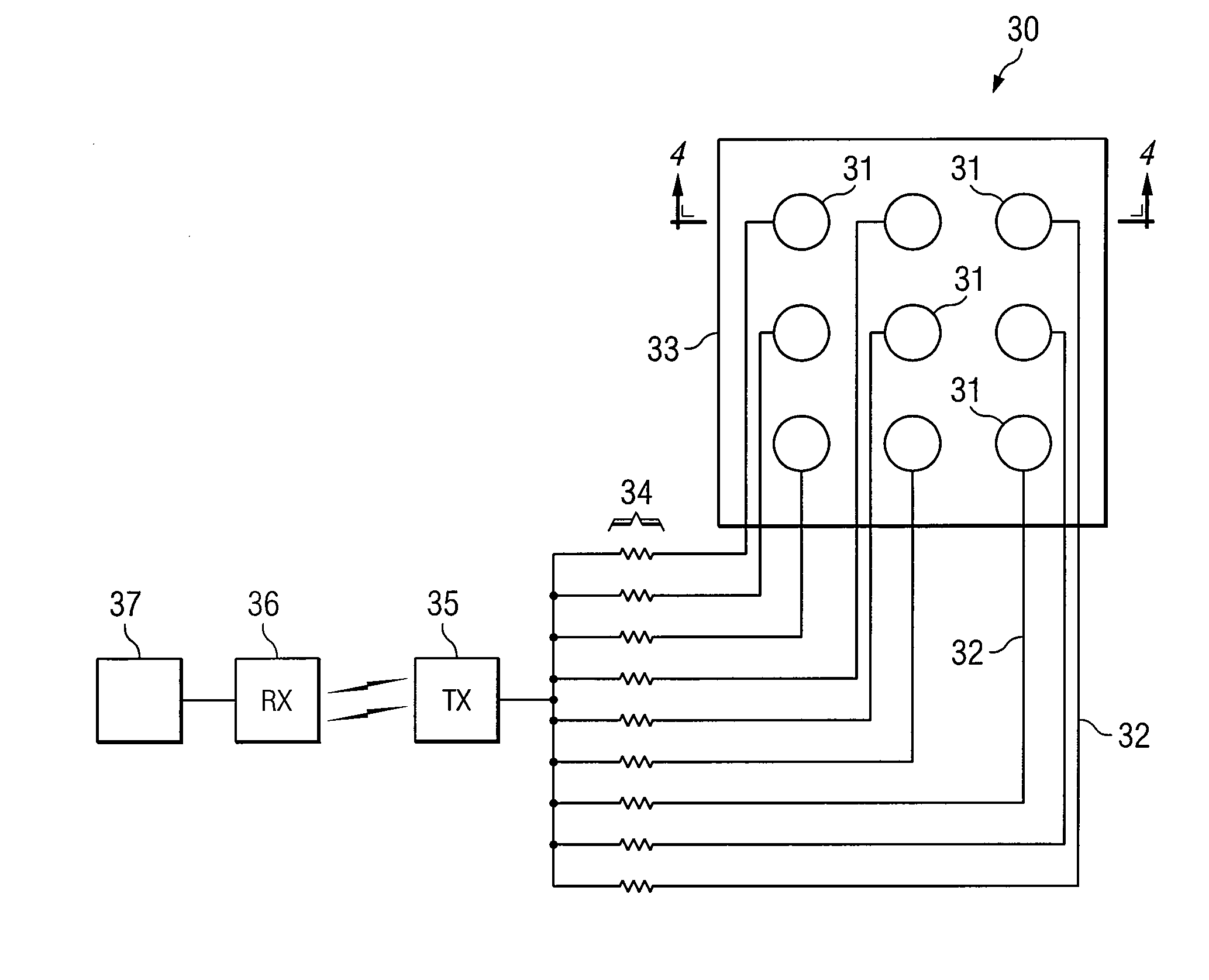

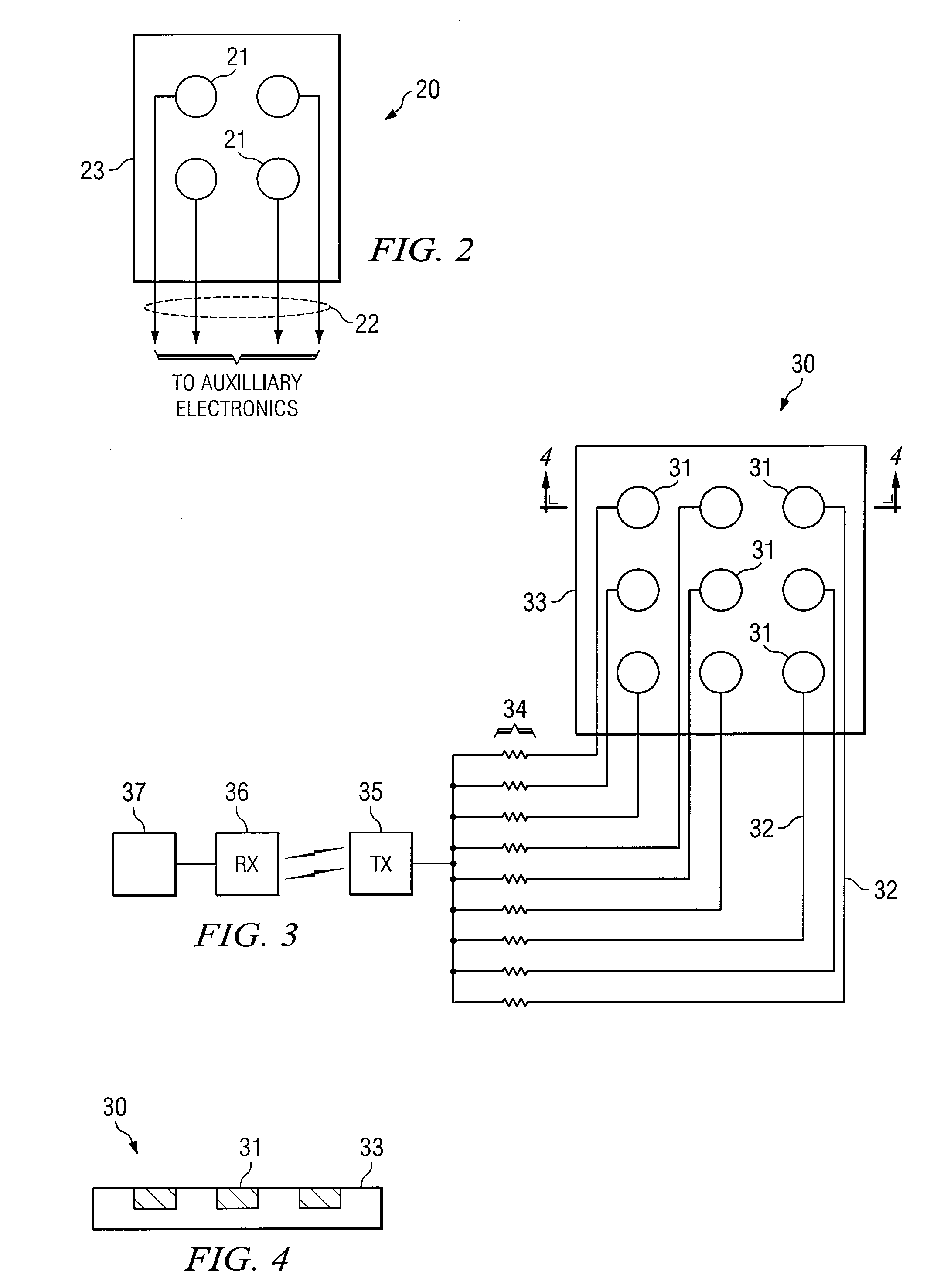

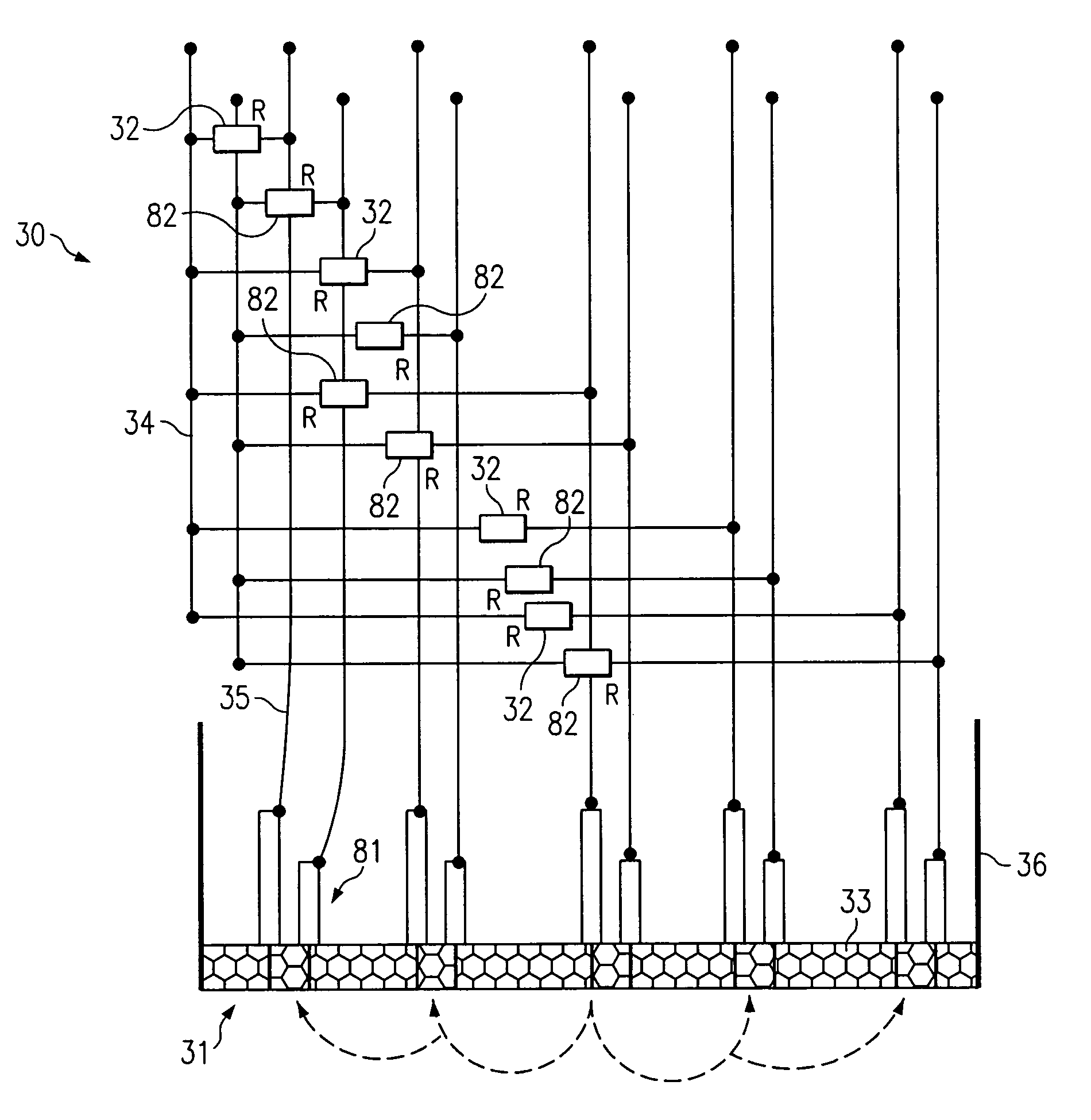

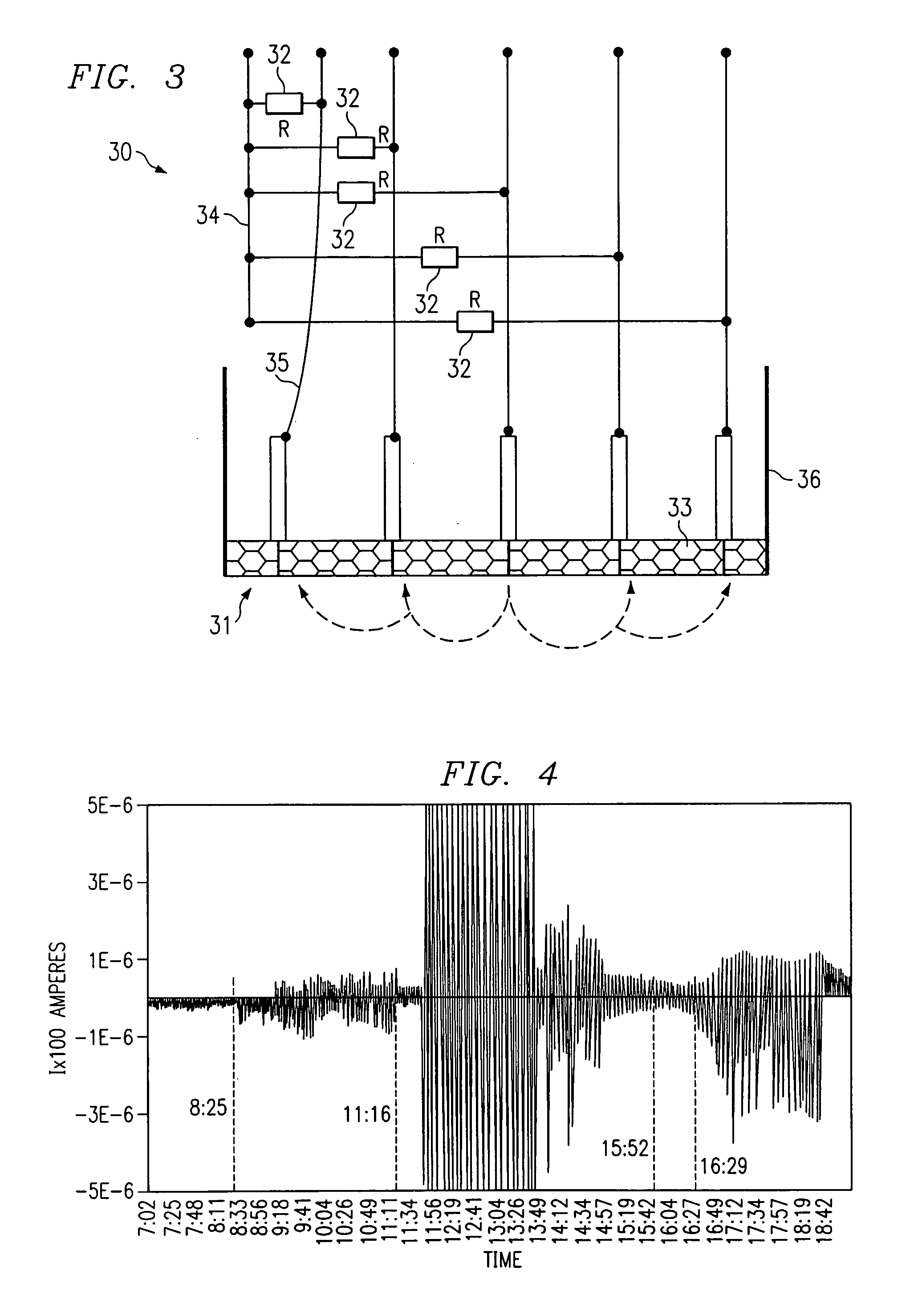

Planar multi-electrode array sensor for localized electrochemical corrosion detection

ActiveUS20070193887A1Easy to useReliable measurementCellsWeather/light/corrosion resistanceEngineeringElectrode array

A planarized type of coupled multi-electrode corrosion sensing device. Electrode pads are fabricated on a thin backing, such as a thin film. Each pad has an associated electrical lead for connection to auxiliary electronic circuitry, which may include a resistor associated with each electrical pad. The design permits the device to be easily placed in small crevices or under coatings such as paint.

Owner:SOUTHWEST RES INST

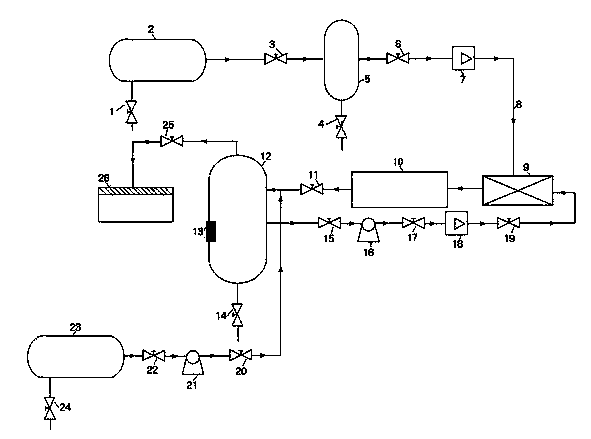

Gas and liquid two-phase flow loop corrosion experiment device

The invention relates to the field of oil and gas field corrosion research, in particular to a gas and liquid two-phase flow loop corrosion experiment device, which is applicable to coupon corrosion experiment and in-situ corrosion electrochemical test of gas and liquid two-phase flow of an oil and gas field production system on an oil pipe under the simulated working condition. An experiment testing module is arranged in a horizontal pipeline, and oil and gas field high-temperature and high-pressure fluid simulated by an experiment device is subjected to loop corrosion experiment by using an electrochemical workstation and a three-electrode electrochemical corrosion measuring device, so that flow accelerated corrosion weight loss and appearance features are obtained; an 'in-situ' electrochemical signal of a working electrode in simulated high-temperature and high-pressure fluid is monitored, so that the corrosion behavior and mechanism of the gas and liquid two-phase flow loop are mastered.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

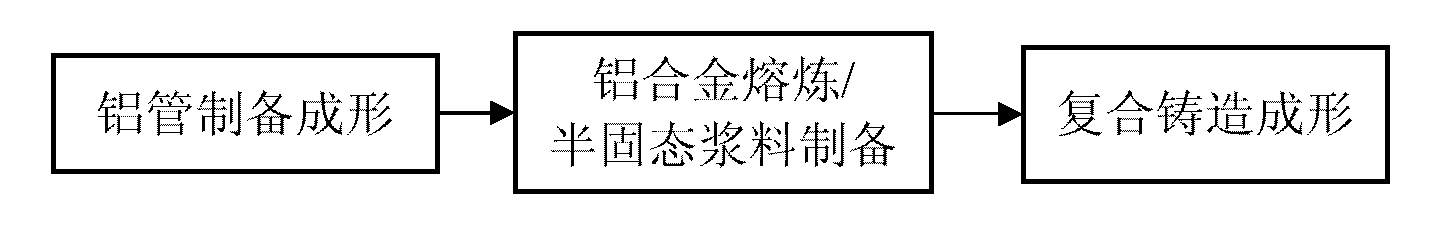

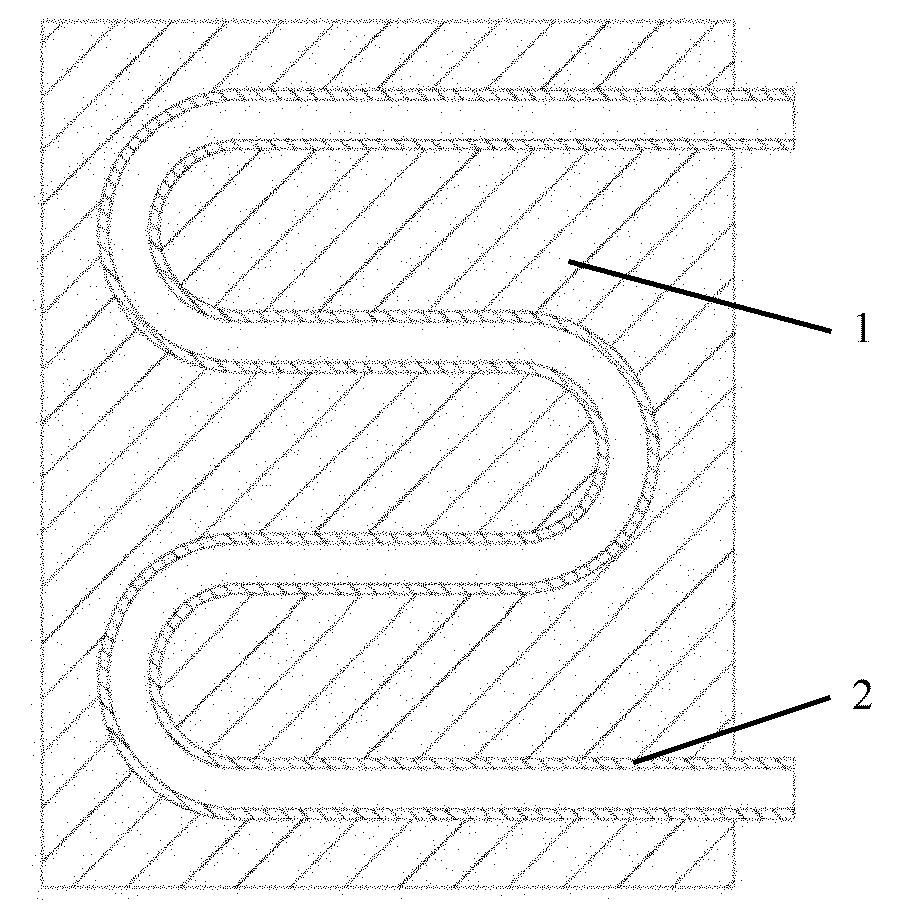

Composite casting method of aluminum cooling plate

InactiveCN102069172AAchieve near net shapeReduce consumptionSemiconductor/solid-state device detailsSolid-state devicesAviationMetallic materials

The invention relates to a composite casting method of an aluminum cooling plate, belonging to the field of metal materials. The composite casting method comprises the following steps: fixing industrial pure aluminum or an aluminum alloy pipe which is used as a cooling liquid passageway in a mold cavity; and then fully filling liquid or semi-solid aluminum alloy melt in the mold cavity and coagulating, so as to prepare the aluminum cooling plate. By using the composite casting method, the problem that when the aluminum alloy is casted in an aluminum tube, a casting is wasted because the aluminum tube is melted and deformed is solved, thereby achieving the near-net forming of the aluminum cooling plate, reducing the consumption of materials for subsequent processing procedures and improving the production efficiency. Because the aluminum tube and an aluminum cooling plate substrate are made of aluminum materials, thereby eliminating an electrochemical corrosion phenomenon; and the aluminum cooling plate can be integrally retrained or recycled, thereby reducing the waste of the material and lowering the production cost. The total density of the casting is the same as that of an aluminum casting, thus the casting can be applied to the fields of aviation, ships and the like which have strict requirements on the weights of parts.

Owner:UNIV OF SCI & TECH BEIJING

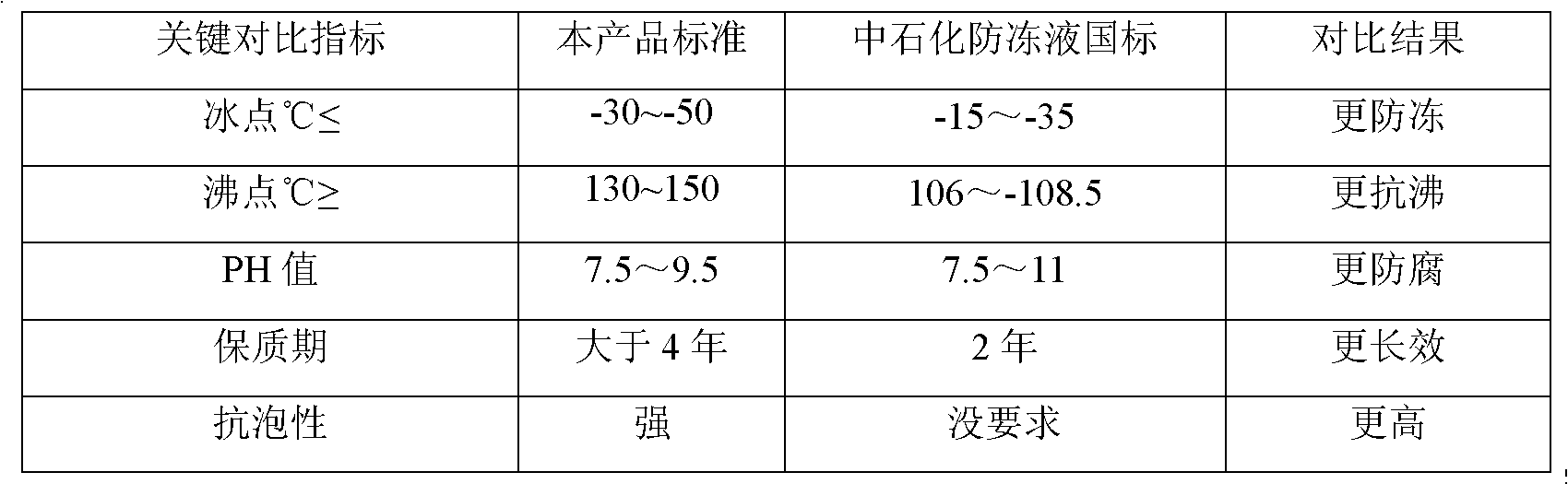

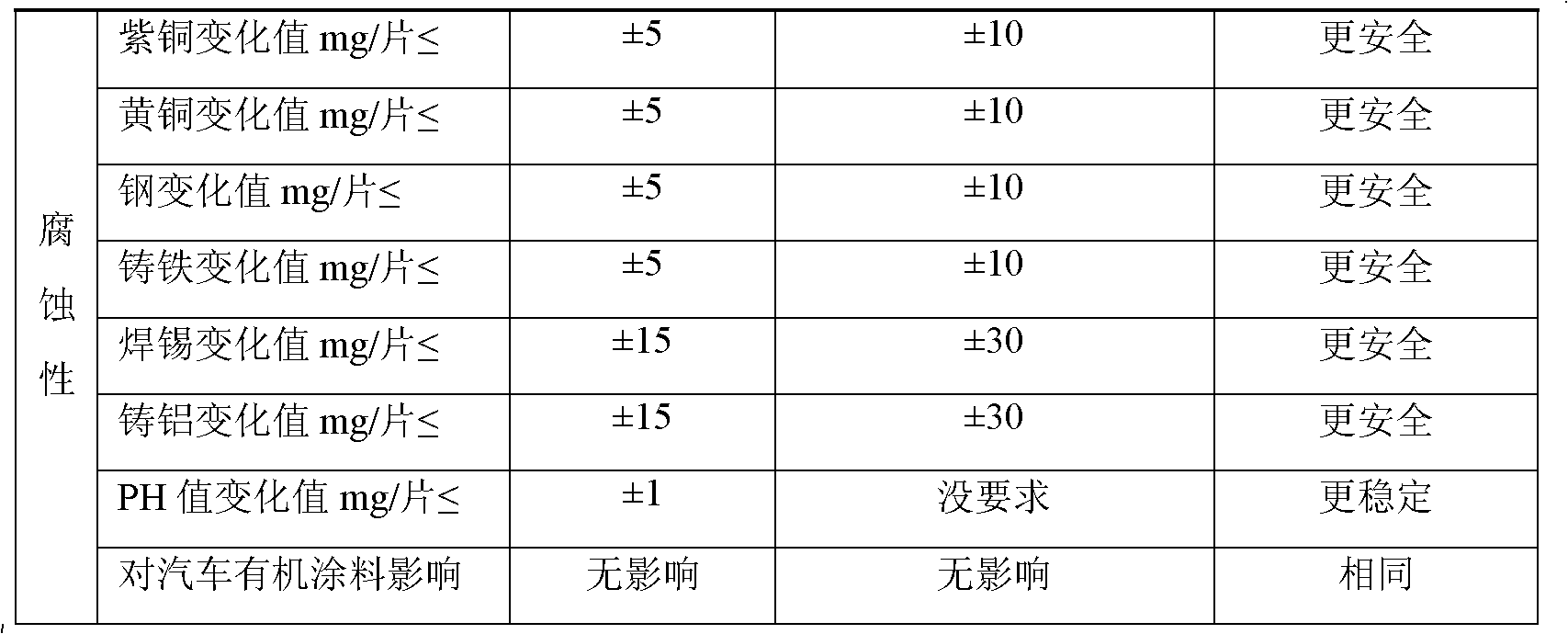

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

Method for preparing nano porous titanium dioxide thin film doped with Pd by constant voltage dealloying method on amorphous alloy stripe

InactiveCN103055891ALow implementation costSimple and fast operationCell electrodesCatalyst activation/preparationPore distributionSynthesis methods

The invention discloses a method for preparing a nano porous titanium dioxide thin film doped with Pd by a constant voltage dealloying method on a Ti-Cu-Pd amorphous alloy stripe, in order to provide a novel Pd-TiO2 composite electrode catalyst. A nano porous thin film structure with uniform pore distribution is prepared by steps of adopting a traditional electrochemical three-electrode system, using nitric acid solution as an electrolyte solution, and respectively applying a constant voltage to the amorphous alloy stripe to realize constant voltage electrochemical corrosion by Gamry Reference 600 electrochemical workstation. The method is low in implementation cost, simple and convenient to operate, strong in controllability, good in repeatability and low in reaction temperature, so that the method is an efficient and economic synthesis method.

Owner:TIANJIN UNIV

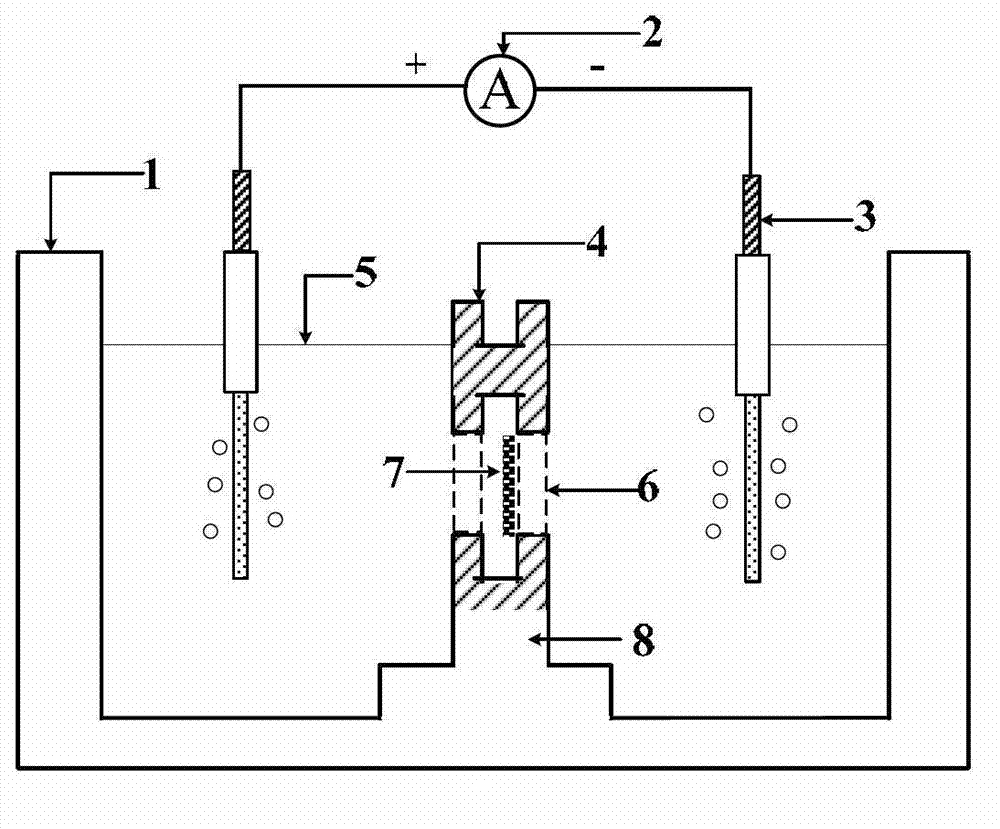

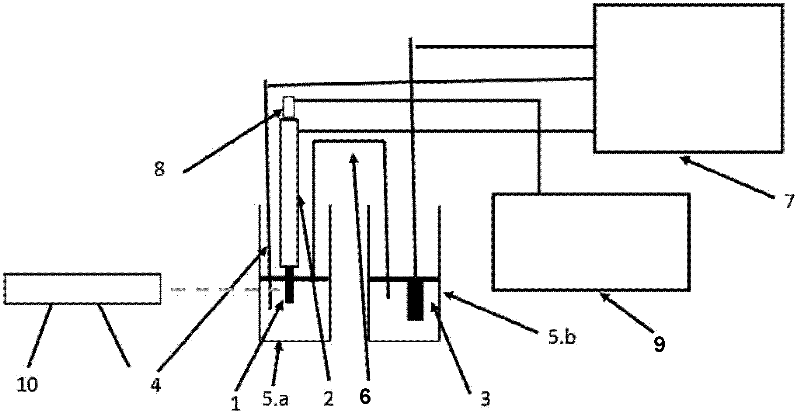

In situ observation experiment apparatus for electrochemical corrosion measurement

InactiveCN103630488AEasy to analyzeSufficient informationWeather/light/corrosion resistanceMetallic materialsAuxiliary electrode

The invention relates to the field of electrochemical corrosion measurements, particularly to an in situ observation experiment apparatus for an electrochemical corrosion measurement, wherein a purpose of the present invention is to solve problems that the electrochemical corrosion measurement in the prior art can not observe changes generated on the metal material surface during the experiment process and the like. According to the in situ observation experiment apparatus, a transparent corrosive liquid is filled in a container, a metal sample, an auxiliary electrode and a reference electrode are connected with an electrochemical workstation through conducting wires, and a miniature digital microscope is arranged above the metal sample. According to the present invention, the miniature digital microscope can observe the change of the metal surface in the transparent corrosive solution along with changes of the experiment time, the polarization potential and other parameters at any time so as to acquire the metal surface topography image in real time; and the electrochemical measurement result can be corresponded to the metal surface topography image to acquire sufficient information and data so as to well analyze the corrosion mechanism of the metal material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

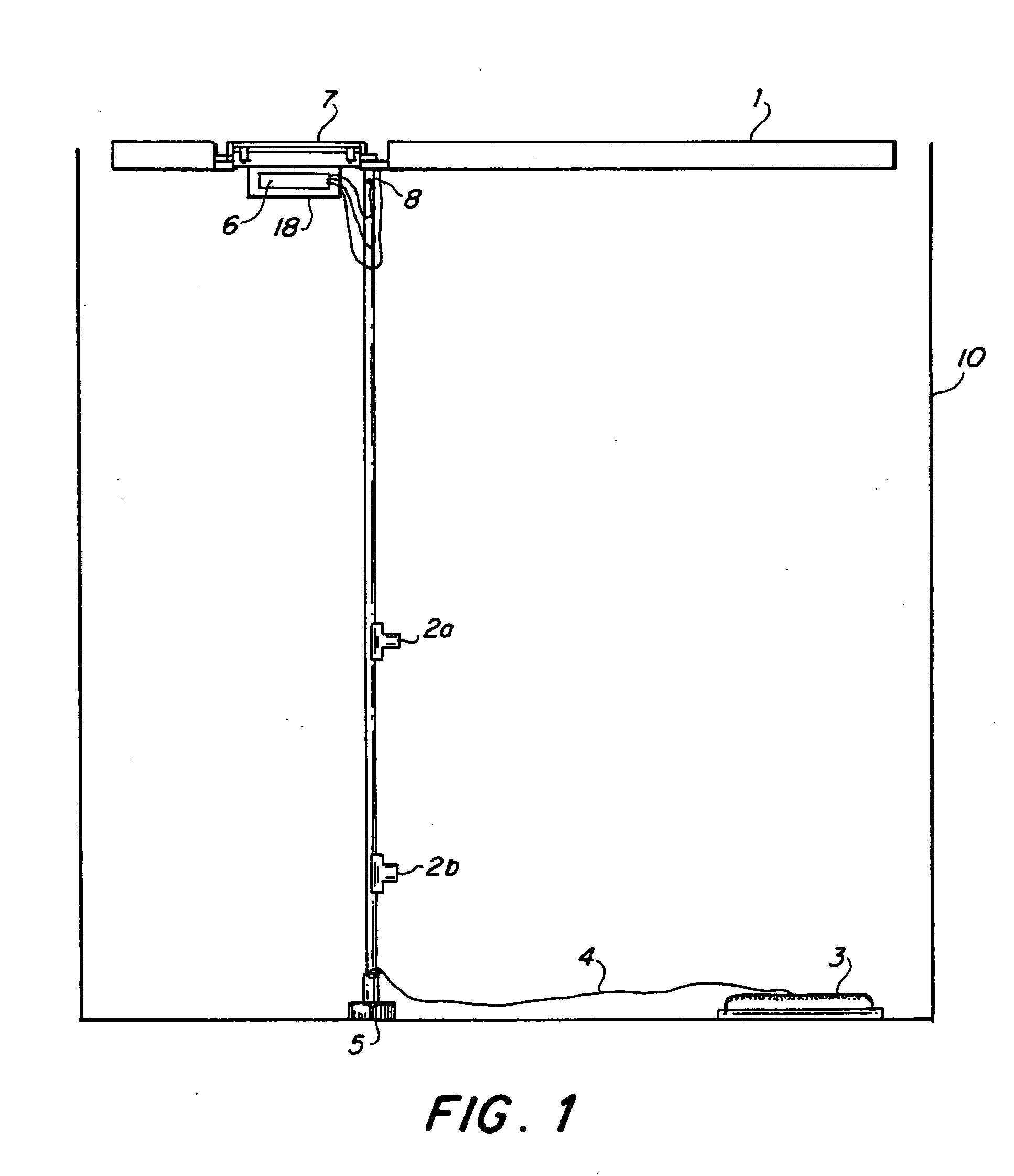

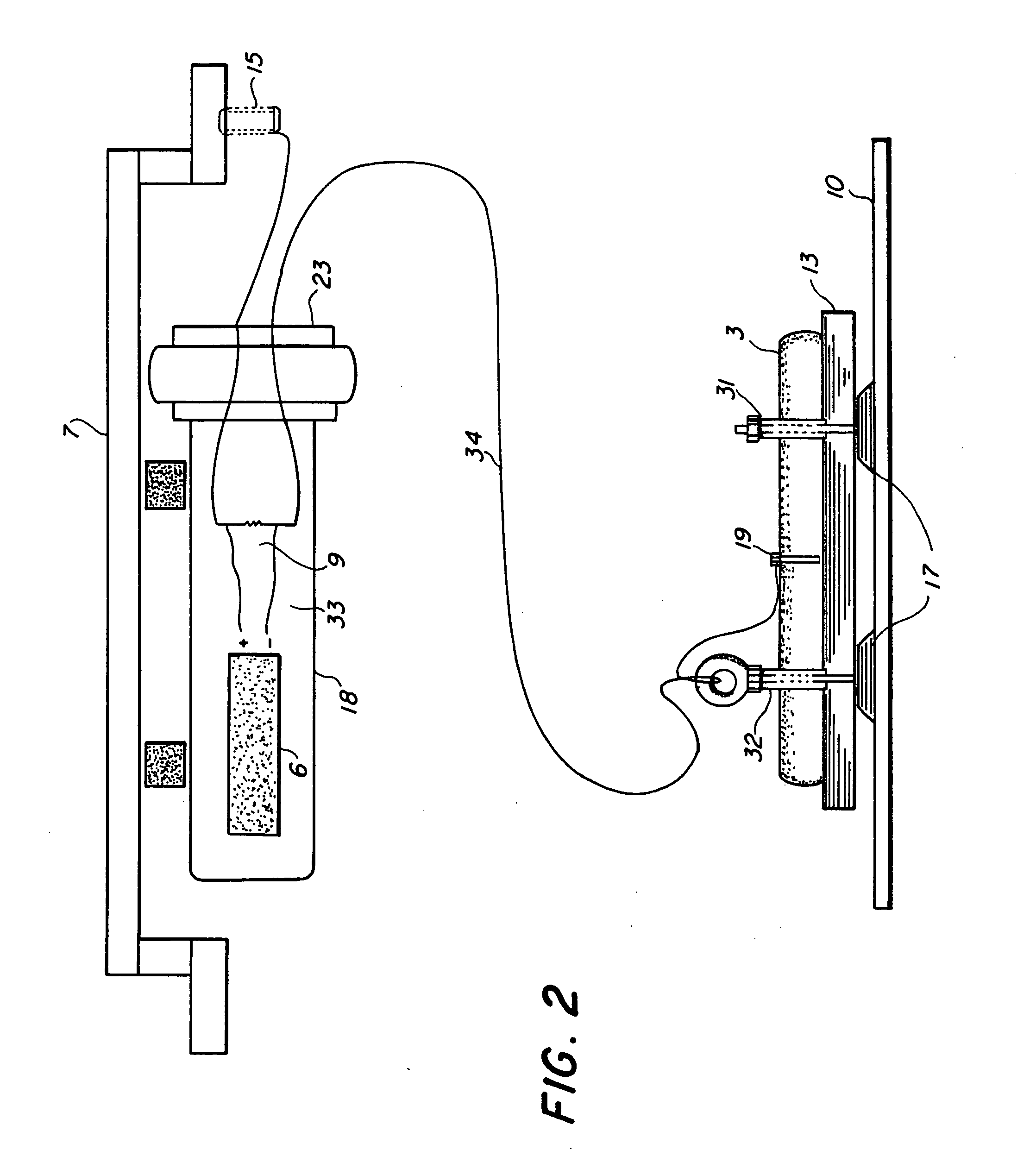

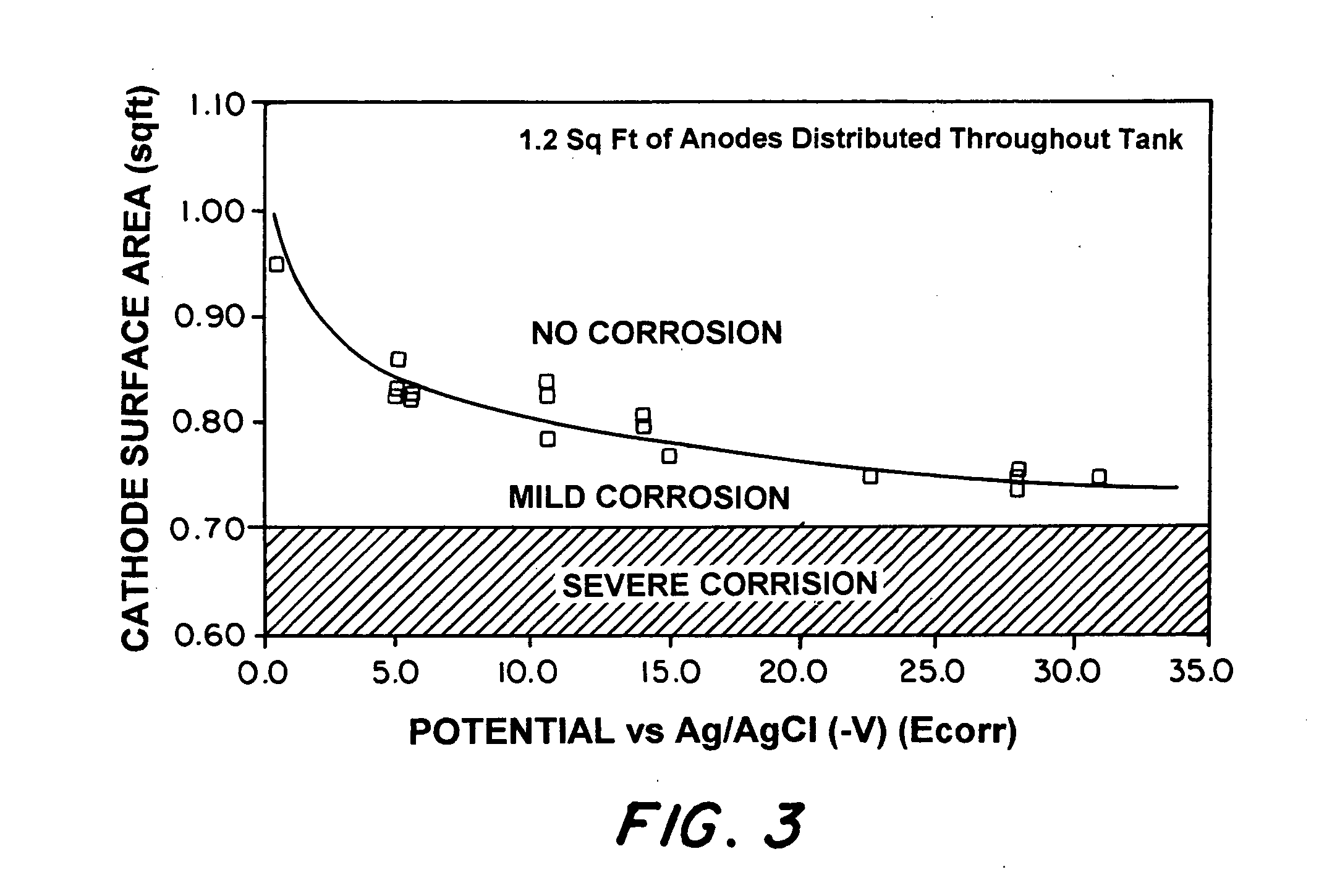

Corrosion sensor

InactiveUS20050006251A1Fast, objective, effectiveEasy to compareWeather/light/corrosion resistanceVolume/mass flow measurementFuel tankEngineering

A system using tank corrosion sensors to provide for an overall assessment and monitoring of the electro-chemical corrosion and coatings condition in ships' tanks, and particularly in ships' seawater or compensated fuel tanks. The system includes reference half-cells mounted along a suspended cable and one instrumented sacrificial anode at the end of the cable to provide optimal sensing capability within a tank structure. The reference half-cells and the sacrificial anode measure a potential and current output, respectively. Together the measurements provide objective information that can be used to predict corrosion damage and coating deterioration occurring throughout the structure of the tank. The system may be used for an overall assessment and monitoring of the electrochemical corrosion and coatings condition. In a preferred embodiment, the measurements are stored in a datalogger that is optimally contained within an associated instrument housing. If used with other systems in other tanks, the system may be used to monitor the relative tank condition, trend tank condition changes over time, range tank behavior into three categories and provide a direct analysis methodology for making tank maintenance decisions.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

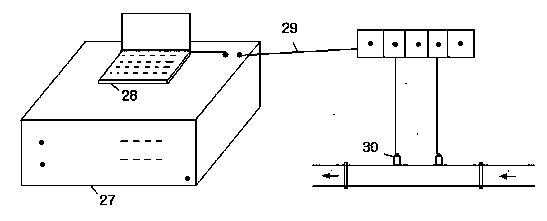

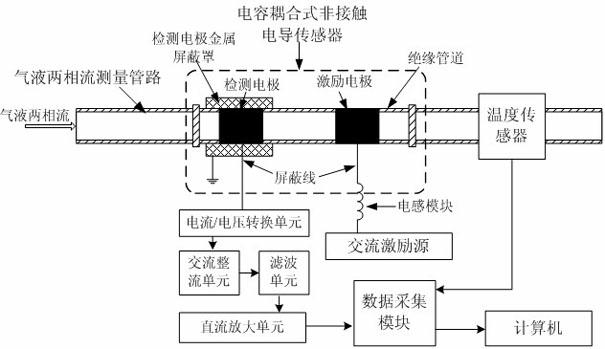

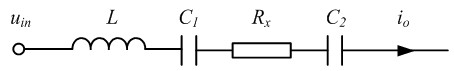

Non-contact conductive gas/liquid two-phase flow pattern identifying device and method

InactiveCN102109451AAvoid Phenomena That Degrade Measurement PerformanceImprove reliabilityFlow propertiesCapacitanceData acquisition

The invention discloses a non-contact conductive gas / liquid two-phase flow pattern identifying device and method thereof. The device comprises a gas / liquid two-phase flow measuring pipeline, an alternating-current excitation source, a capacitive coupling non-contact conductive sensor, a temperature sensor, a current / voltage conversion unit, an alternating-current rectifying unit, a filter unit, a direct-current amplifying unit, a data acquisition module and a computer. The method comprises the following steps: firstly, the capacitive coupling non-contact conductive sensor obtains conductance signals of flows of the gas / liquid two phases; then, characteristic values of the obtained conductance signals are extracted via a time domain collection method and a Fourier transformation method; and finally, the characteristic values are input to a flow pattern classifier for online identification. The device and method provided by the invention can effectively prevent reduction of the conductivity measurement performance caused by polarization effects and electrochemical corrosion effects, and improve the reliability and robustness of a flow pattern identification system; furthermore, the device is simple in structure, easy to mount, low in cost and the like. The invention provides a novel effective path for measuring parameters of the gas / liquid two phases in the fields such as energy source, petrochemical industry and the like.

Owner:ZHEJIANG UNIV

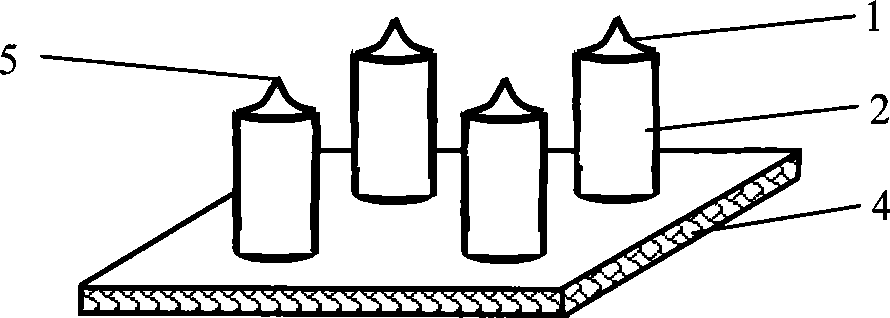

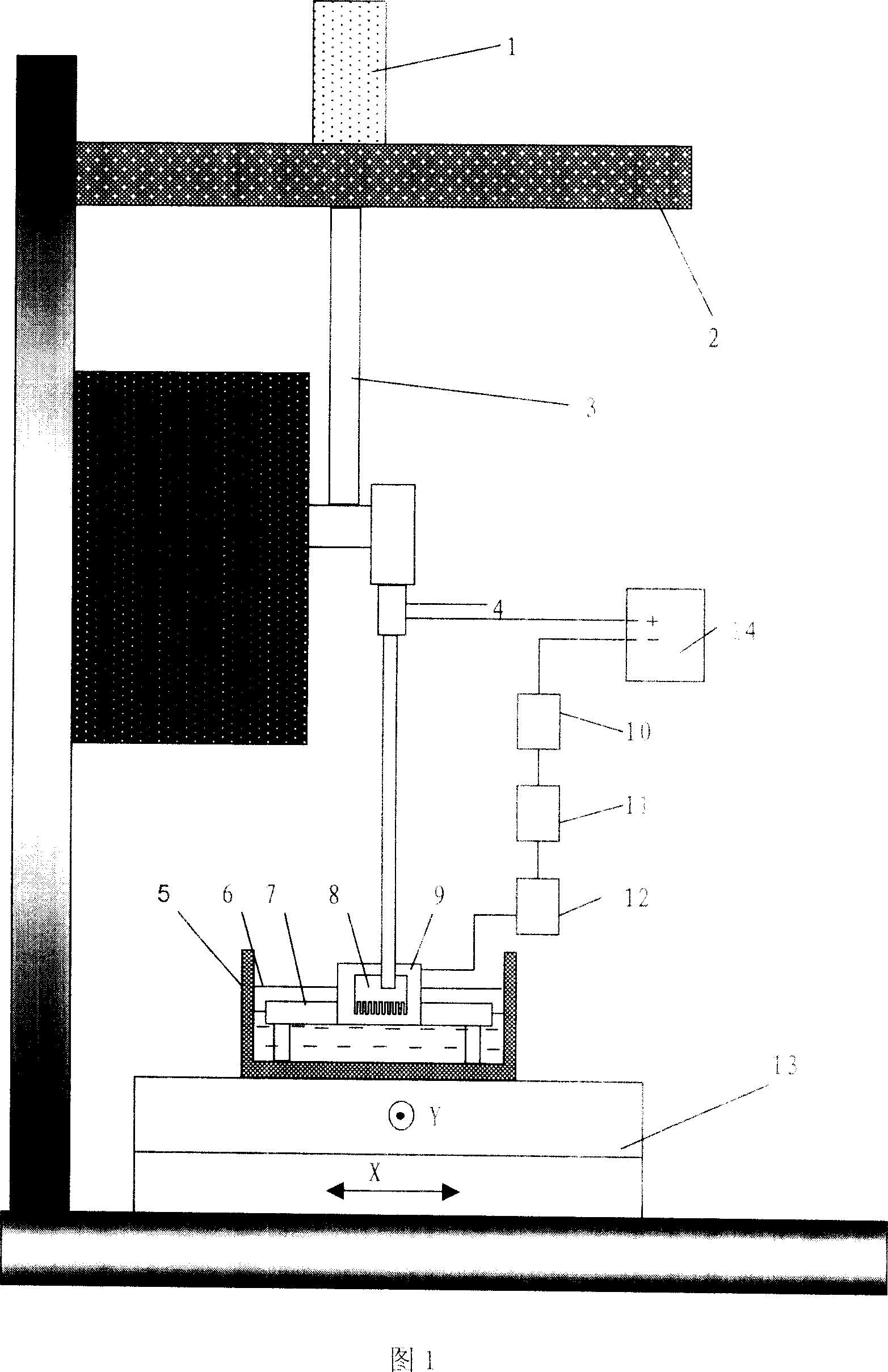

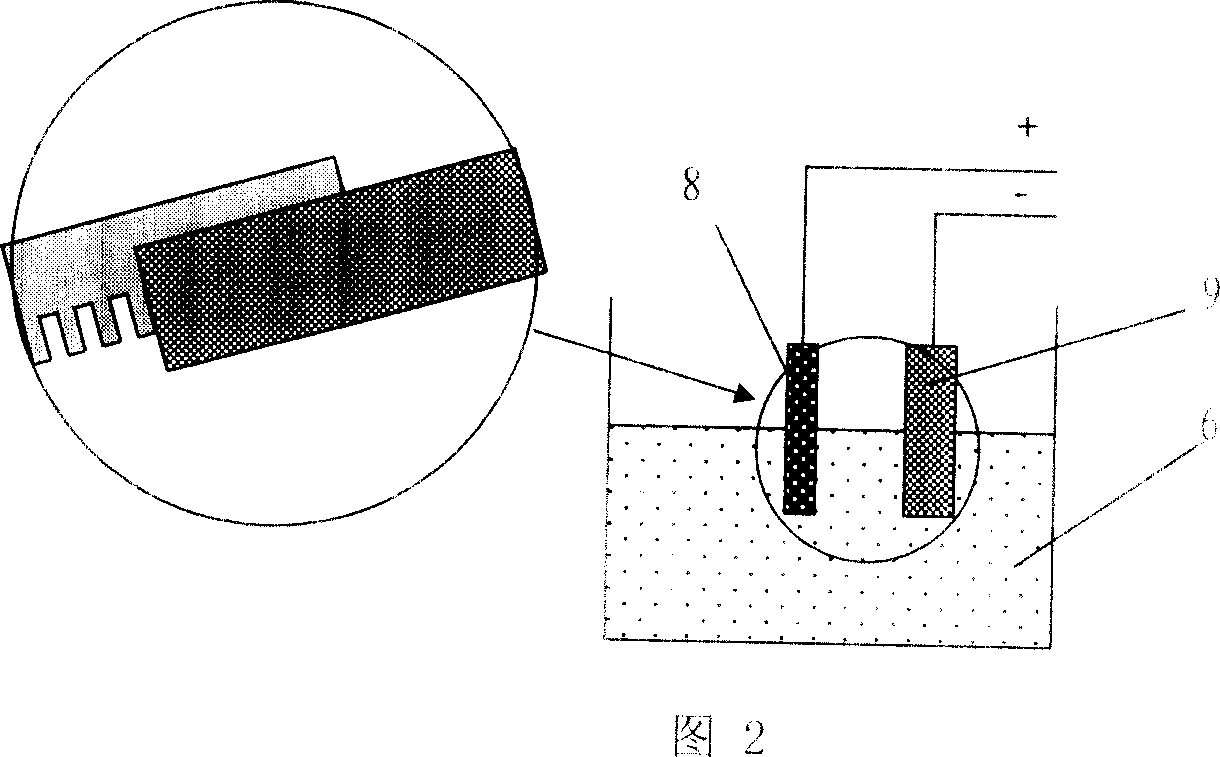

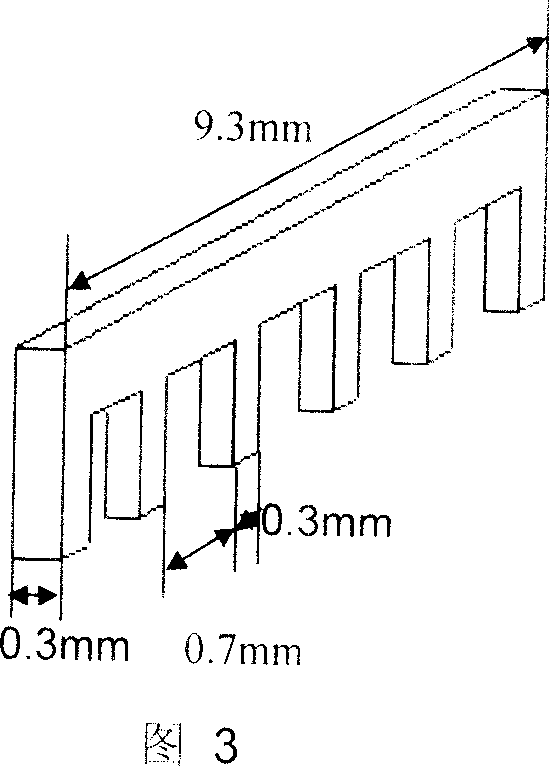

Electrochemical corrosion processing method with micro fine cylindrical group electrode

ActiveCN1943950AUniform current densityImprove processing efficiencyMachining electrodesElectrical-based machining electrodesElectrolysisControl manner

The electrochemical corrosion processing method for micro cylindrical group electrode belongs to the field of electrolysis processing technology. The method includes the following steps: 1. making group electrode blank with several single electrodes through wire electric cutting or micro milling; 2. designing and making tool cathode for electrochemical erosion in finite element method; 3. soaking the group electrode blank as the anode for electrochemical erosion and the cathode into electrolyte vertically and parallelly; and 4. applying voltage for processing the group electrode blank via electrochemical erosion and controlling the shape and size of the group electrode via constant voltage method and the charge method. The present invention has simple processing apparatus and control, high processing efficiency, high processing quality and low production cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

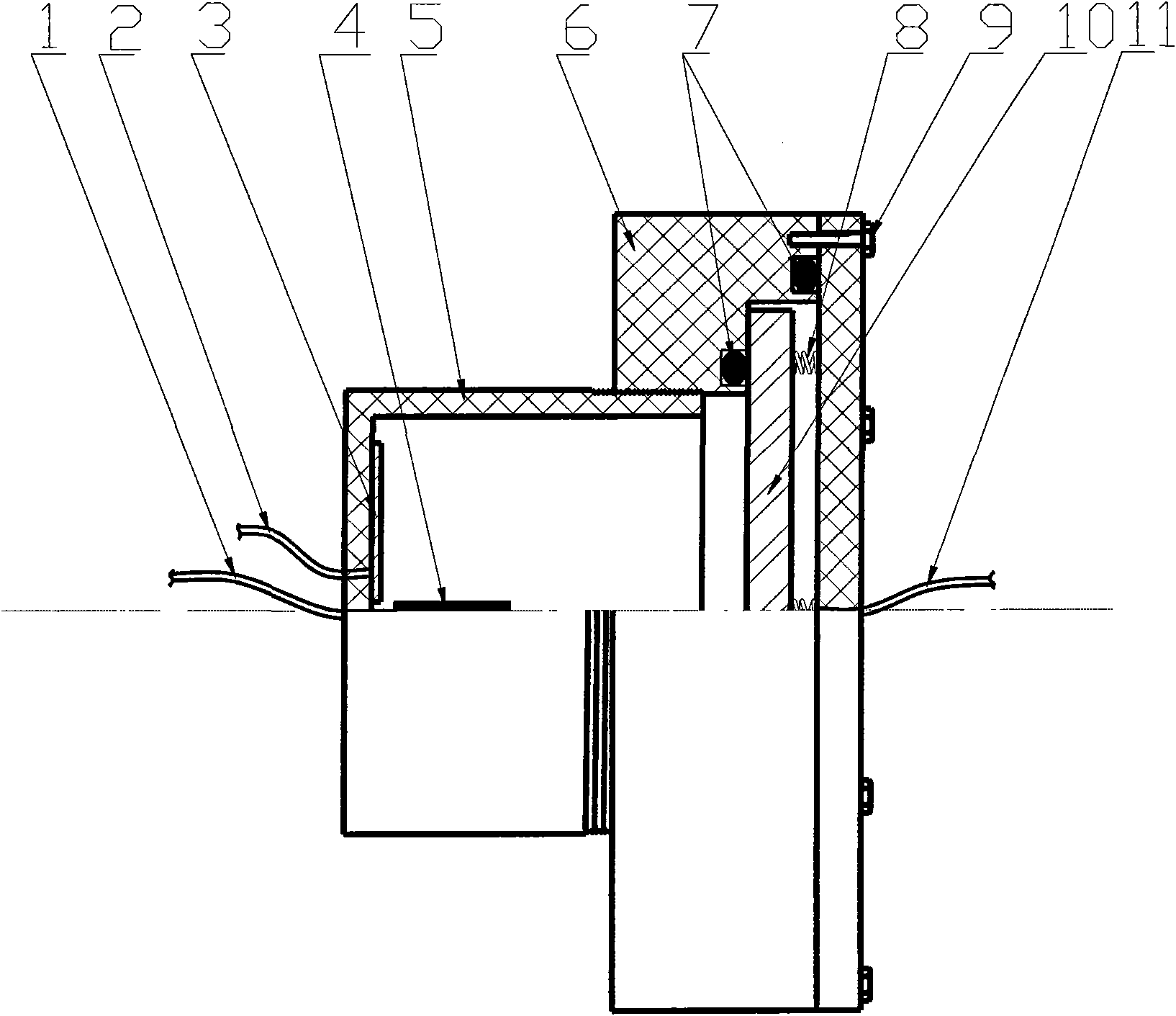

Corrosion test device with in-situ electrochemical test function

InactiveCN101644653AReduce distractionsReduce adverse effectsWeather/light/corrosion resistanceMetallic materialsAuxiliary electrode

The invention relates to a corrosion test device with a field in-situ electrochemical test function in a natural sea area environment, belonging to the technical field of electrochemical corrosion tests. The main structure of the corrosion test device comprises a reference electrode lead wire, an auxiliary electrode lead wire, an auxiliary electrode, a reference electrode, a probe shell, a samplesealing structure shell, a sealing ring, a pressure spring, a fastening bolt, a sample and a sample lead wire, wherein an electrochemical test probe and a sample sealing structure are designed into split type structures; the electrochemical test probe consists of the reference electrode, the reference electrode lead wire, the auxiliary electrode and the probe shell and is rotated to the sample sealing structure through screw threads positioned at the front of the probe shell; the sample sealing structure shell is processed by and made of plastic and nylon or other non-metal materials; and thesample or the researched electrode is hermetically fixed by the O-shaped sealing ring and sealing stuffing. The invention has simple and reliable structural principle, convenient use and operation andgood test accuracy.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

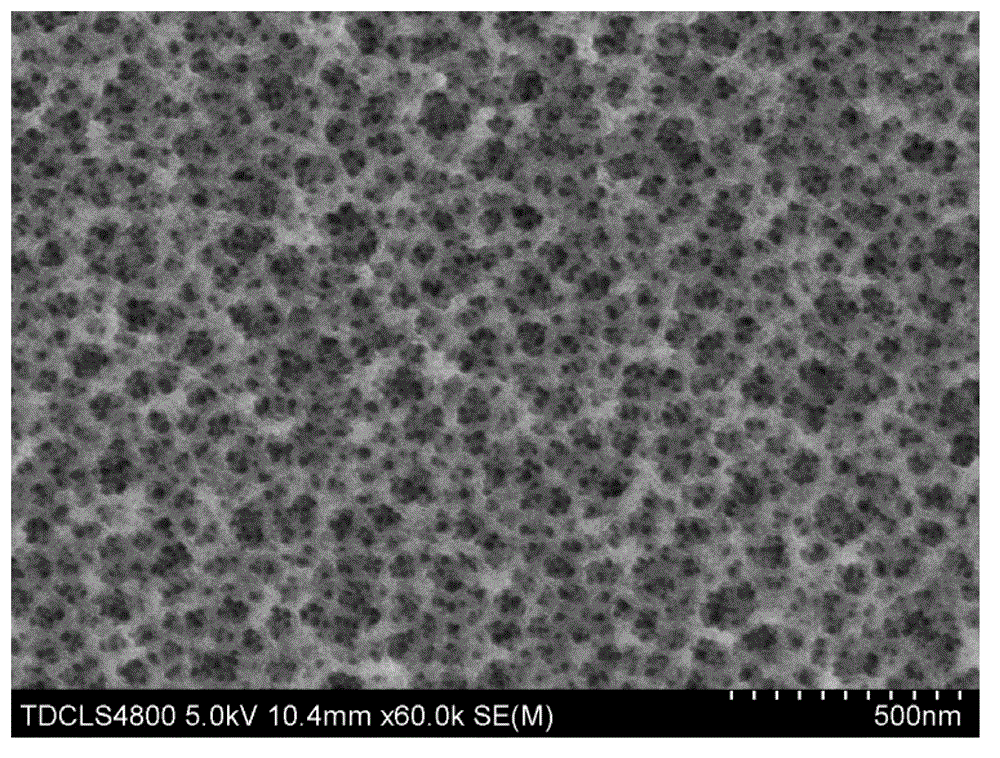

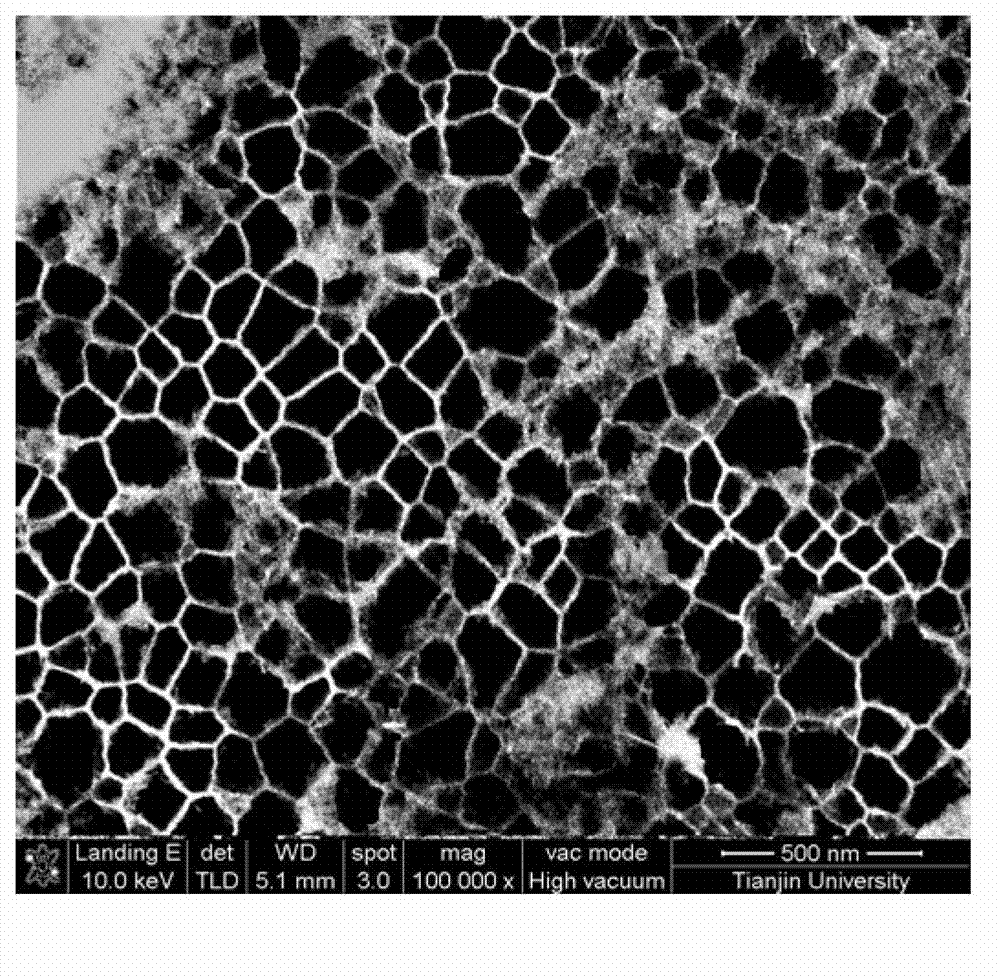

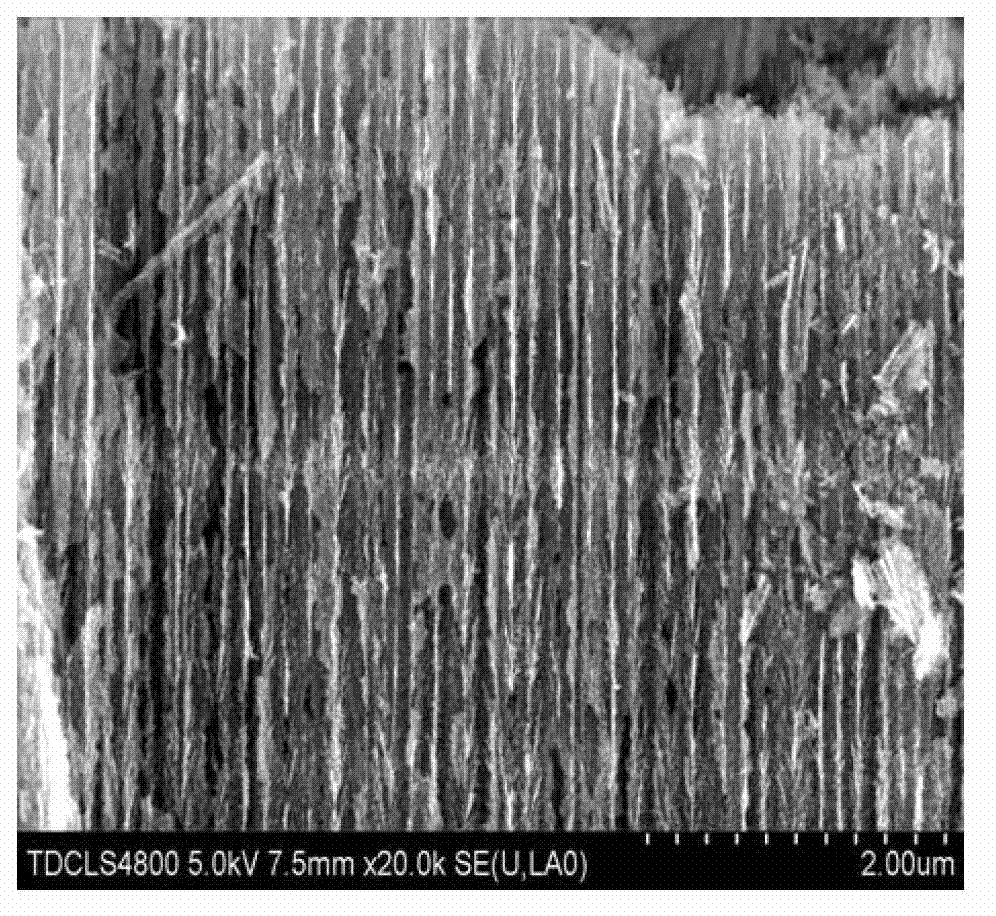

Method for preparing silicon-based nano-scale ordered porous silicon

InactiveCN102953113ALarge specific surface areaInsufficient improvementVolumetric Mass DensitySolvent

The invention discloses a method for preparing silicon-based nano-scale ordered porous silicon, comprising the following steps of: (1) ultrasonically washing an n-shaped one-side polished monocrystalline silicon piece in an acetone solvent, absolute ethyl alcohol and de-ionized water sequentially; and (2) preparing a porous silicon layer on the polished surface of the silicon piece by a double-tank electrochemical corrosion method, taking the aqueous solution of hydrofluoric acid having the mass fraction of 5-9% as corrosive liquid, and applying corrosion current, wherein the density of the corrosion current is 75-155 mA / cm<2>, and the corrosion time is 5-30 min; and the process is performed at the room temperature without illumination. The method disclosed by the invention is simple, quick, effective and practicable, and high in operability; and the bore diameter of the obtained porous silicon is at hundred-nanometer scale, and has the characteristics of high porosity and highly ordered pore canals. The method is capable of achieving the purpose of the silicon-based nano-scale ordered porous silicon by controlling the concentration of the hydrofluoric acid, the corrosion current density and the corrosion time; and the silicon-based nano-scale ordered porous silicon is an ideal material for preparing biological and chemical sensor elements.

Owner:TIANJIN UNIV

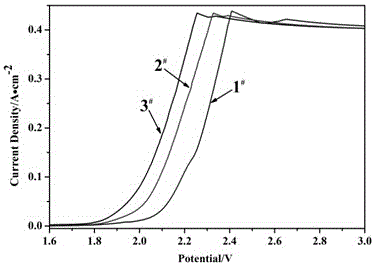

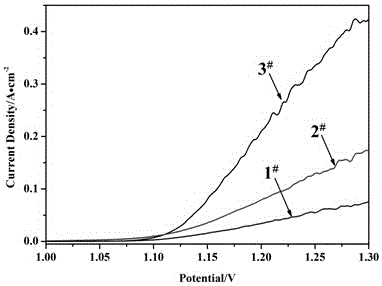

Electrode material with intermediate Ti4O7 coating

InactiveCN105058916AImprove product qualityImprove bonded stateMetal layered productsElectrode potentialAlloy

Owner:KUNMING UNIV OF SCI & TECH

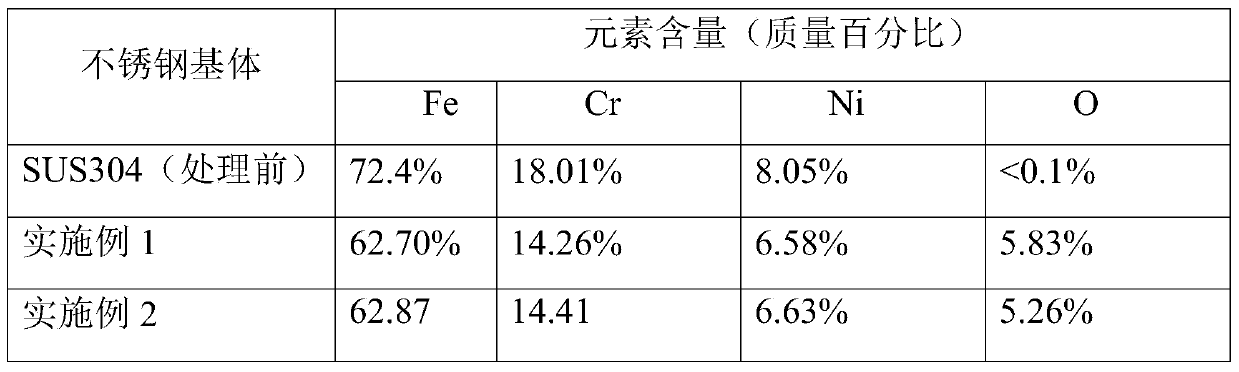

Surface treatment method for metal substrate, the metal substrate, and metal-resin composite and production method of same

ActiveCN105500600AImprove the decorative effectImprove bindingCoatingsPhosphorus acidPhosphoric acid

The invention discloses a surface treatment method for a metal substrate, the metal substrate prepared therethrough, and a metal-resin composite and a production method of the same. The surface treatment method includes the steps of (1) pre-treating the metal substrate with a mixed acid solution composed of two or more of sulfuric acid, citric acid and phosphorus acid to form irregular corroded holes in the surface of the metal substrate; and (2) performing electrochemical corrosion to the metal substrate in an alkaline solution or chemically soaking the metal substrate in an acidic solution. The metal substrate subjected to the surface treatment is placed into a die to perform injection moulding through a thermoplastic resin composition to obtain the integrated metal-resin composite. The invention also provides the production method of the integrated metal-resin composite which is excellent in binding force. The production method is easy to carry out and low in cost.

Owner:BYD CO LTD

Preparation method of stainless steel-resin composite and stainless steel-resin composite prepared by same

InactiveCN103895161ASize has little effectEasy injection moldingMetal layered productsPolymer scienceSS - Stainless steel

The invention relates to a preparation method of a stainless steel-resin composite and a stainless steel-resin composite prepared by the same. The preparation method comprises the following steps: S1. putting a pretreated stainless steel substrate in a corrosive solution to perform electrochemical corrosion, wherein the corrosive solution is a 2-25 wt% hydrochloric acid and / or 5-35 wt% iron trichloride solution; and S2. carrying out injection molding on a resin composition to the surface of the stainless steel substrate obtained in the step S1, and forming to obtain the stainless steel-resin composite. The stainless steel-resin composite has the advantages of high binding force between stainless steel and resin, simple technique, low requirements for resin, wide application range and no pollution, and can easily implement large-scale production.

Owner:BYD CO LTD

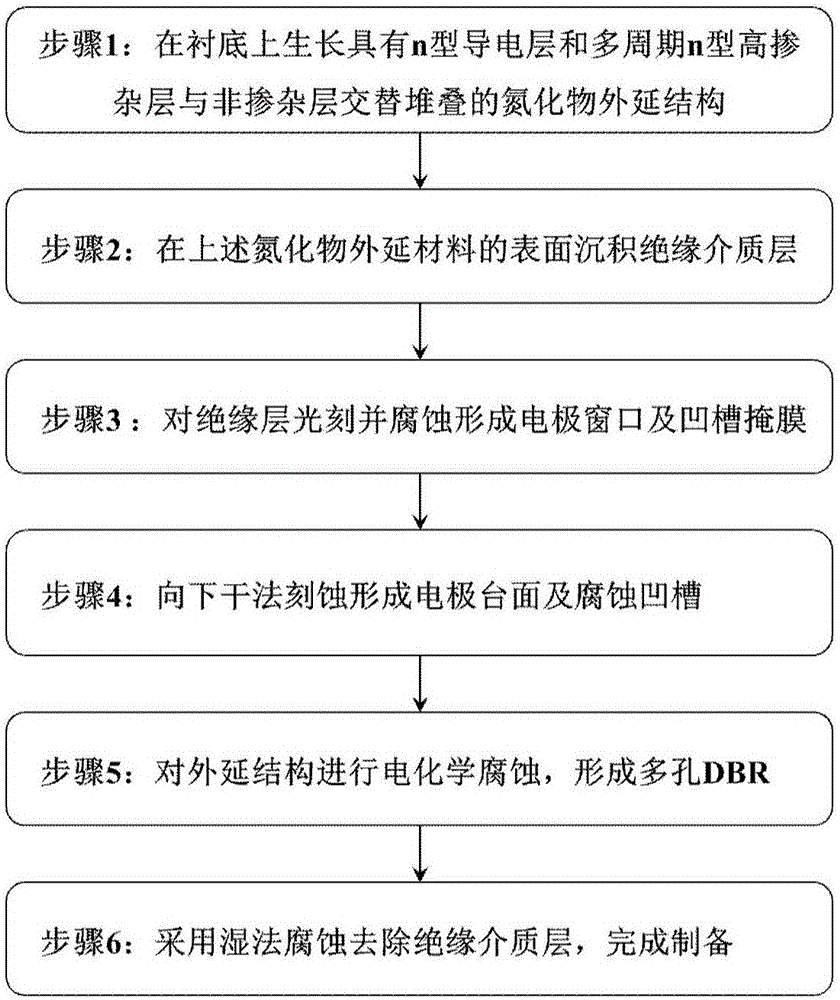

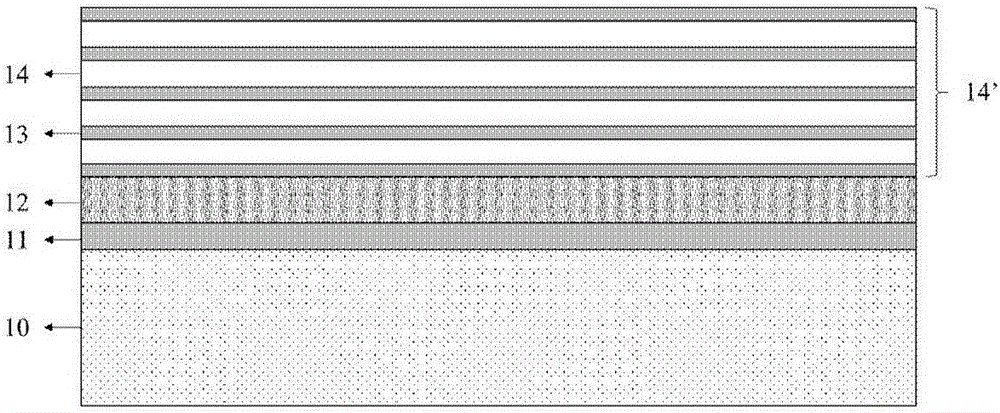

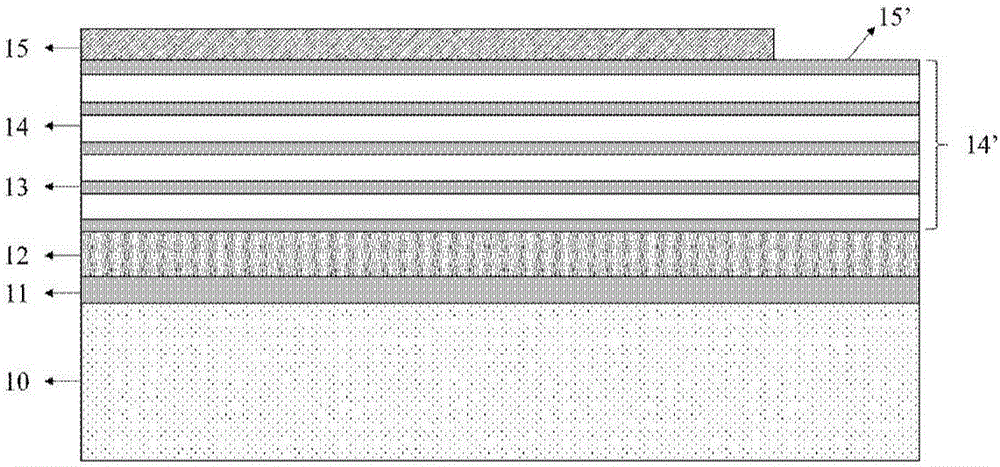

Preparation method of GaN-based porous DBR

ActiveCN106848016AControllable reflectivityAvoiding the Difficulty of ExtensionLaser detailsSemiconductor lasersNon dopedElectrochemical corrosion

The invention discloses a preparation method of a GaN-based porous DBR. The method comprises the following steps of (1) sequentially growing a buffer layer, an n-type GaN conductive layer, n-type high-doped layers and non-doped layers on a substrate, wherein the n-type high-doped layers and the non-doped layers are alternately stacked to form a multi-period nitride epitaxial structure; (2) depositing an insulating dielectric layer on the upper surface of the nitride epitaxial structure; (3) forming an electrode window in one side of the upper surface of the insulated dielectric layer through photolithography and corrosion, and forming a groove in the area except for an electrode window; (4) etching the electrode window downwards by adopting a dry etching technology to form an electrode table and etching a groove downwards to expose the side wall of the nitride epitaxial structure to form a corrosion groove; and (5) carrying out electrochemical corrosion on the nitride epitaxial structure of which the side wall is exposed to form a periodical porous DBR; and (6) removing the insulated dielectric layer by employing wet corrosion and completing preparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Sensor array for electrochemical corrosion monitoring

InactiveUS6987396B2Accurate measurementEliminate needWeather/light/corrosion resistanceResistance/reactance/impedenceSensor arrayElectricity

A sensor array for measuring localized corrosion based on electrochemical reactions is disclosed. The sensor has an array of electrodes that are made from the material of interest. The electrodes are electrically insulated from each other and arranged so that a small area of the electrode contacts a corrosive environment. The voltage outputs across the electrodes connected to the electrodes are measured and used as the signals to indicate localized corrosion.

Owner:SOUTHWEST RES INST

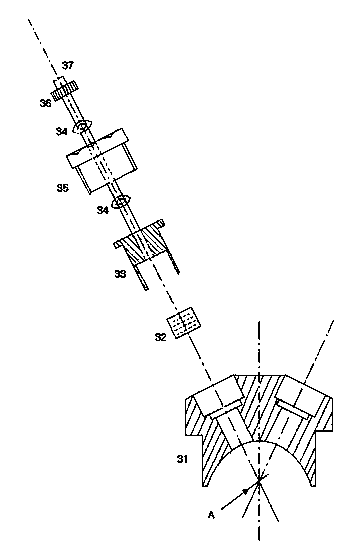

An electrochemical corrosion test device that realizes multiple in-situ monitoring

InactiveCN102288536ACorrosivity researchResearch FeaturesWeather/light/corrosion resistanceSpectroscopyOptical observation

The invention belongs to the field of material electrochemical corrosion test monitoring, more precisely, relates to a kind of electrochemical corrosion test device for realizing multiple in-situ monitoring, and solves the in-situ in-situ monitoring of material surface corrosion morphology existing in the prior art. information, and is not suitable for issues such as long-term online monitoring. The device is mainly composed of three parts: electrochemical test device, acoustic emission test device, and optical observation system. The working electrode is connected to the waveguide rod, and forms a three-electrode system with the counter electrode and reference electrode. Electrochemical (polarization curve, impedance spectrum, etc.) tests can be performed through the electrochemical workstation; the acoustic emission probe is fixed on the waveguide rod and can be collected synchronously. The acoustic emission signal during the corrosion process of the working electrode; the long focal length microscope can observe the corrosion morphology of the surface of the working electrode in situ. The device can realize various in-situ monitoring such as electrochemistry, acoustic emission, and long-focus microscope at the same time, and realize electrochemical corrosion monitoring of materials at room temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Hot rolling roller for rolling nonferrous metal, and manufacturing method thereof

The present invention discloses a hot rolling roller for rolling a nonferrous metal, and a manufacturing method thereof. Chemical components of the roller comprise, by weight, 0.50-0.80% of C, 0.30-1.20% of Si, 0.20-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 4.50-6.00% of Cr, 0.20-0.80% of Ni, 0.20-1.00% of Mo, 0.10-0.50% of V, and the balance of Fe and unavoidable impurities. The manufacturing method of the roller comprises the following process steps: a, refining a steel ingot; b, forging a roller blank; c, carrying out quenching and tempering, and carrying out mechanical processing; d, carrying out a quenching heat treatment; and e, carrying out a tempering treatment. The hot rolling roller has characteristics of high wear resistance, good thermal cracking resistance and good electrochemical corrosion resistance, and a service life of the hot rolling roller can be increased by more than 50% compared with the ordinary Cr3 roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

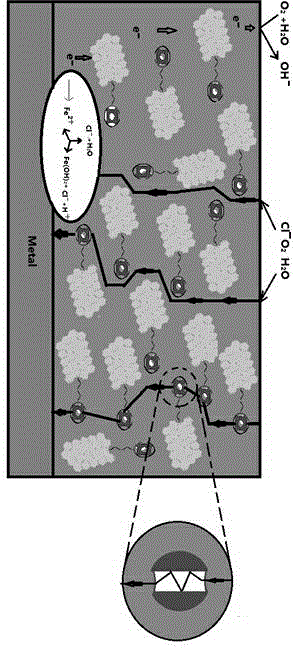

Preparation method of waterborne epoxy composite anticorrosive coating

InactiveCN104877517APrevent restackingAvoid gatheringAnti-corrosive paintsEpoxy resin coatingsEpoxyElectrochemical corrosion

The invention provides a preparation method of a waterborne epoxy composite anticorrosive coating and relates to a preparation method of a composite coating material. The waterborne epoxy composite anticorrosive coating provided by the invention is prepared by adopting carbodiimide (EDC) mediated condensation reaction to integrate zeolite and graphene, and then filling the integrated zeolite and graphene into waterborne epoxy resin. By adopting the method, the characteristics of more pore passages and large specific surface area of zeolite are combined with high strength and electron mobility of graphene; corrosive particles can be blocked from passing through a coating layer to reach a metal matrix and the time for the corrosive particles to pass through the coating layer to reach the metal matrix can be prolonged in the process of anticorrosive application of the coating; and the cathode reaction during corrosion can be transferred to an interface between the coating layer and air by virtue of the electrical conductivity of graphene, thereby slowing down the happening of electrochemical corrosion reaction. By adopting the method, the defects that the current waterborne anticorrosive coating layer is generally poor in barrier property and short in anticorrosion cycle are overcome, and the anticorrosion performance of the waterborne coating layer is greatly improved.

Owner:蓬莱禄源漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com