Method for preparing nano porous titanium dioxide thin film doped with Pd by constant voltage dealloying method on amorphous alloy stripe

A technology of amorphous alloy and dealloying method, which is applied in the field of preparation of new nanoporous thin film electrodes, can solve the problems of easy falling off, decreased catalytic ability, weak binding force, etc., and achieves strong controllability, simple operation, and low implementation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

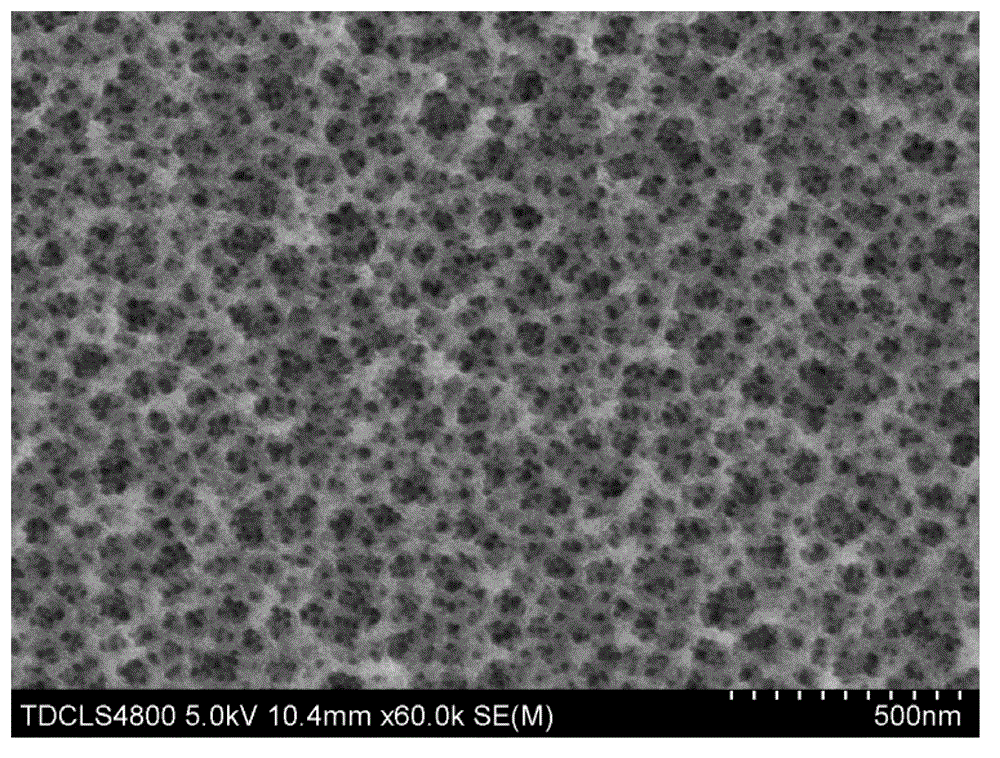

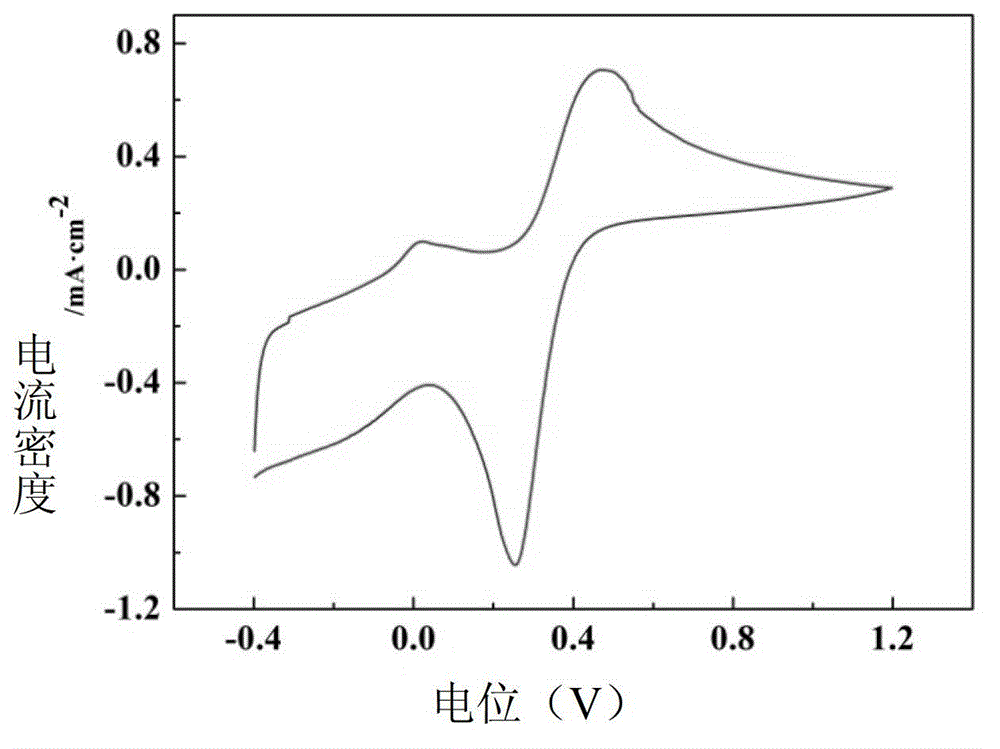

[0019] Embodiment 1: A kind of novel nanoporous material, it is characterized in that: Utilize constant voltage dealloying method to prepare nanoporous TiO doped with Pd on the surface of amorphous Ti-Cu-Pd alloy strip 2 thin film electrodes.

[0020] The so-called constant voltage dealloying method uses the Gamry Reference600 electrochemical workstation, adopts the traditional electrochemical three-electrode system, in which the Pt mesh electrode (2cm×2cm) is used as the counter electrode, and the saturated calomel electrode (SCE) is used as the reference electrode. Ti-Cu-Pd amorphous alloy strips coated with silica gel are used as working electrodes and prepared by electrochemical dealloying in nitric acid solution.

[0021] The process parameters used in the constant voltage dealloying corrosion process are:

[0022] Composition of Ti-Cu-Pd amorphous alloy (alloy element composition is calculated by atomic percentage): Ti: 30%; Cu: 69%; Pd: 1%

[0023] Electrolyte concent...

Embodiment 2

[0034] Embodiment 2: A kind of novel nanoporous material, it is characterized in that: Utilize constant voltage dealloying method to prepare nanoporous TiO doped with Pd on the surface of amorphous Ti-Cu-Pd alloy strip 2 thin film electrodes.

[0035] The so-called constant voltage dealloying method uses the Gamry Reference600 electrochemical workstation, adopts the traditional electrochemical three-electrode system, in which the Pt mesh electrode (2cm×2cm) is used as the counter electrode, and the saturated calomel electrode (SCE) is used as the reference electrode. Ti-Cu-Pd amorphous alloy strips coated with silica gel are used as working electrodes and prepared by electrochemical dealloying in nitric acid solution.

[0036]The process parameters used in the constant voltage dealloying corrosion process are:

[0037] Composition of Ti-Cu-Pd amorphous alloy (alloy element composition is calculated by atomic percentage): Ti: 30%; Cu: 67%; Pd: 3%

[0038] Electrolyte concentr...

Embodiment 3

[0049] Embodiment 3: A kind of novel nanoporous material is characterized in that: Utilize constant voltage dealloying method to prepare nanoporous TiO doped with Pd on the surface of amorphous Ti-Cu-Pd alloy strip 2 thin film electrodes.

[0050] The so-called constant voltage dealloying method uses the Gamry Reference600 electrochemical workstation, adopts the traditional electrochemical three-electrode system, in which the Pt mesh electrode (2cm×2cm) is used as the counter electrode, and the saturated calomel electrode (SCE) is used as the reference electrode. Ti-Cu-Pd amorphous alloy strips coated with silica gel are used as working electrodes and prepared by electrochemical dealloying in nitric acid solution.

[0051] The process parameters used in the constant voltage dealloying corrosion process are:

[0052] Composition of Ti-Cu-Pd amorphous alloy (alloy element composition is calculated by atomic percentage): Ti: 30%; Cu: 67%; Pd: 3%

[0053] Electrolyte concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com