Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5501results about "Polishing compositions with abrasives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry compositions for chemical mechanical polishing of copper and barrier films

InactiveUS20050090104A1High selectivityShorten the counting processSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurryPolymer

Owner:INNOVATIUM TECH

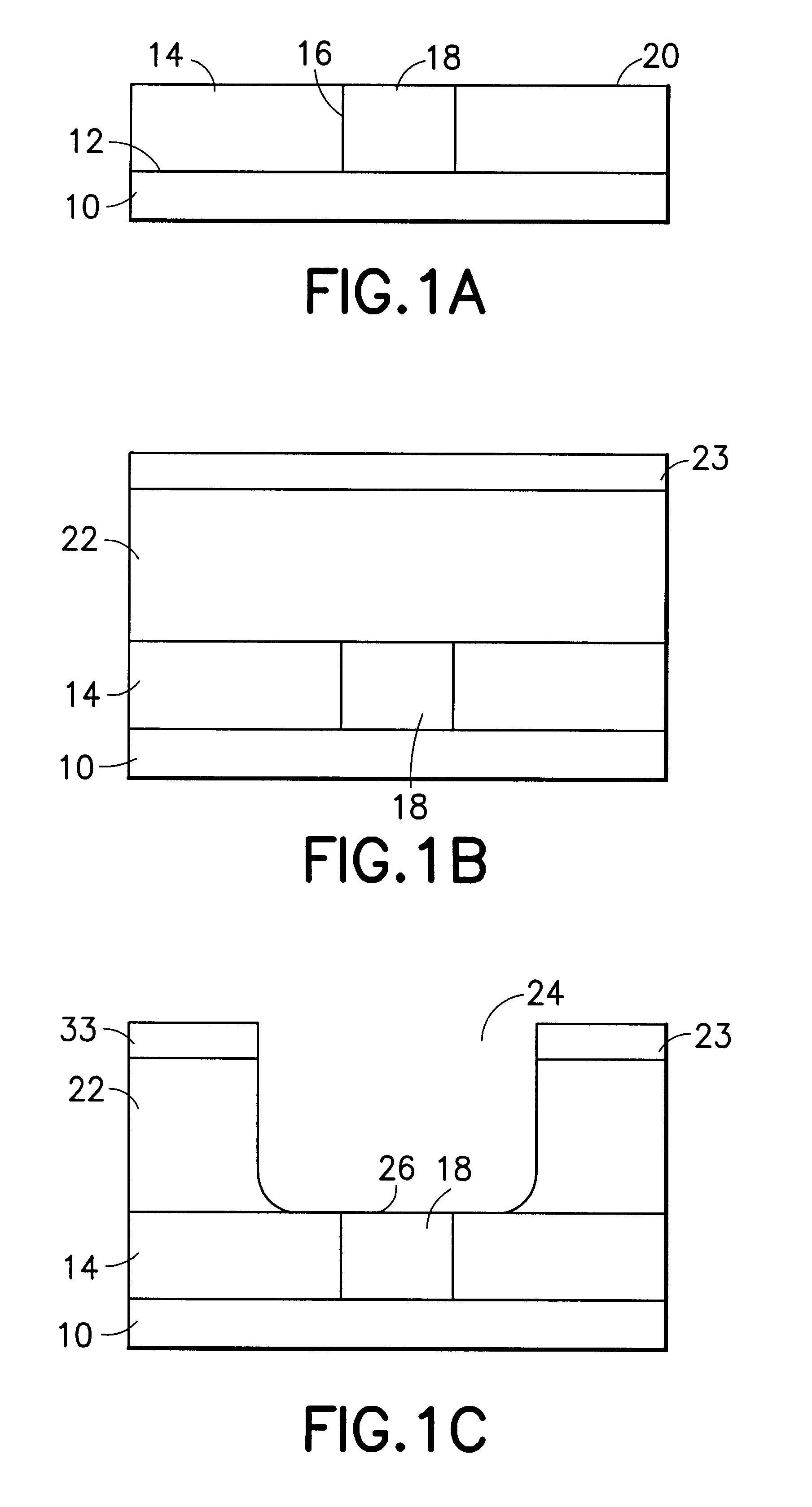

Compositions and structures for chemical mechanical polishing of FeRAM capacitors and method of fabricating FeRAM capacitors using same

InactiveUS6346741B1Easy to manufactureBig advantageOther chemical processesSemiconductor/solid-state device detailsLead zirconate titanateBarium strontium titanate

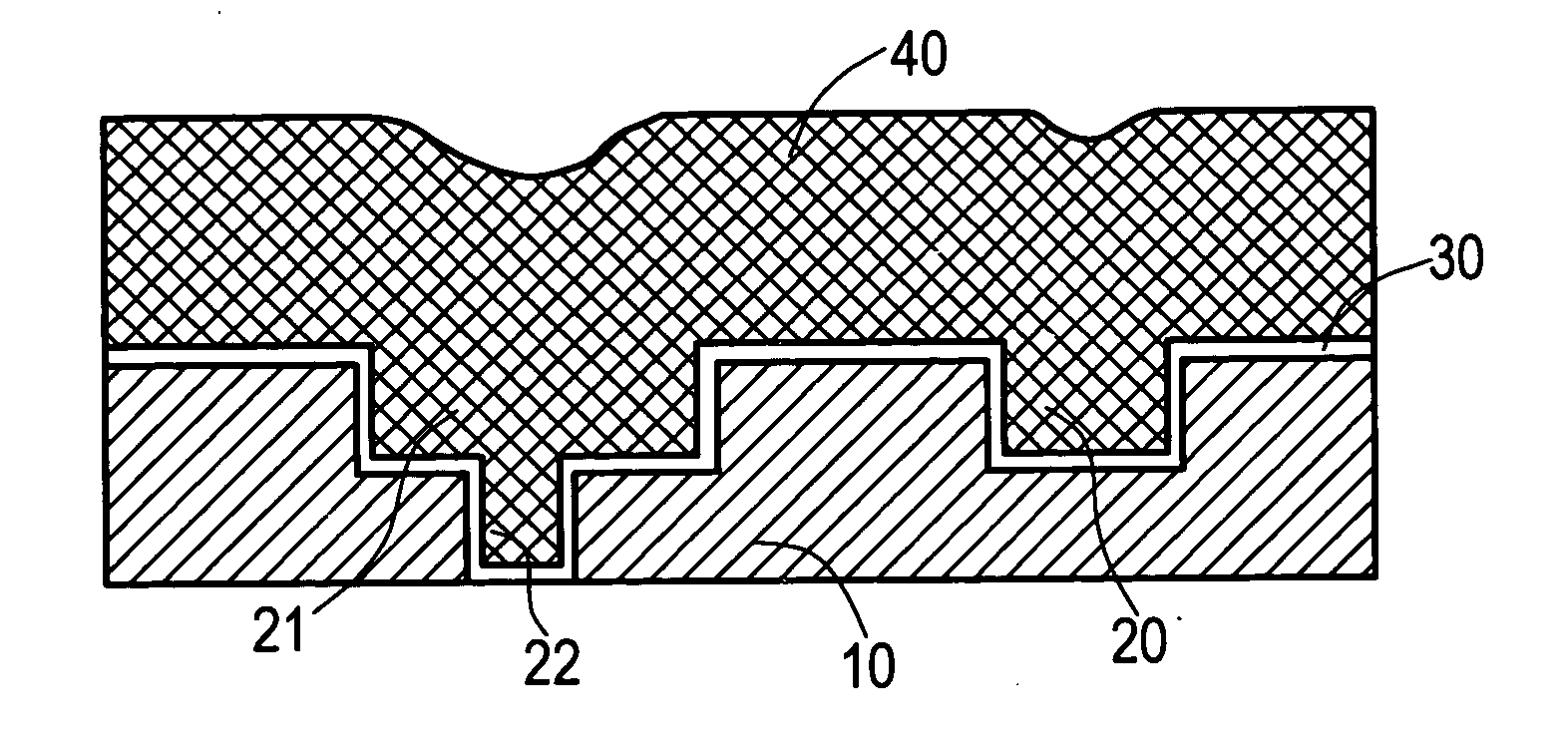

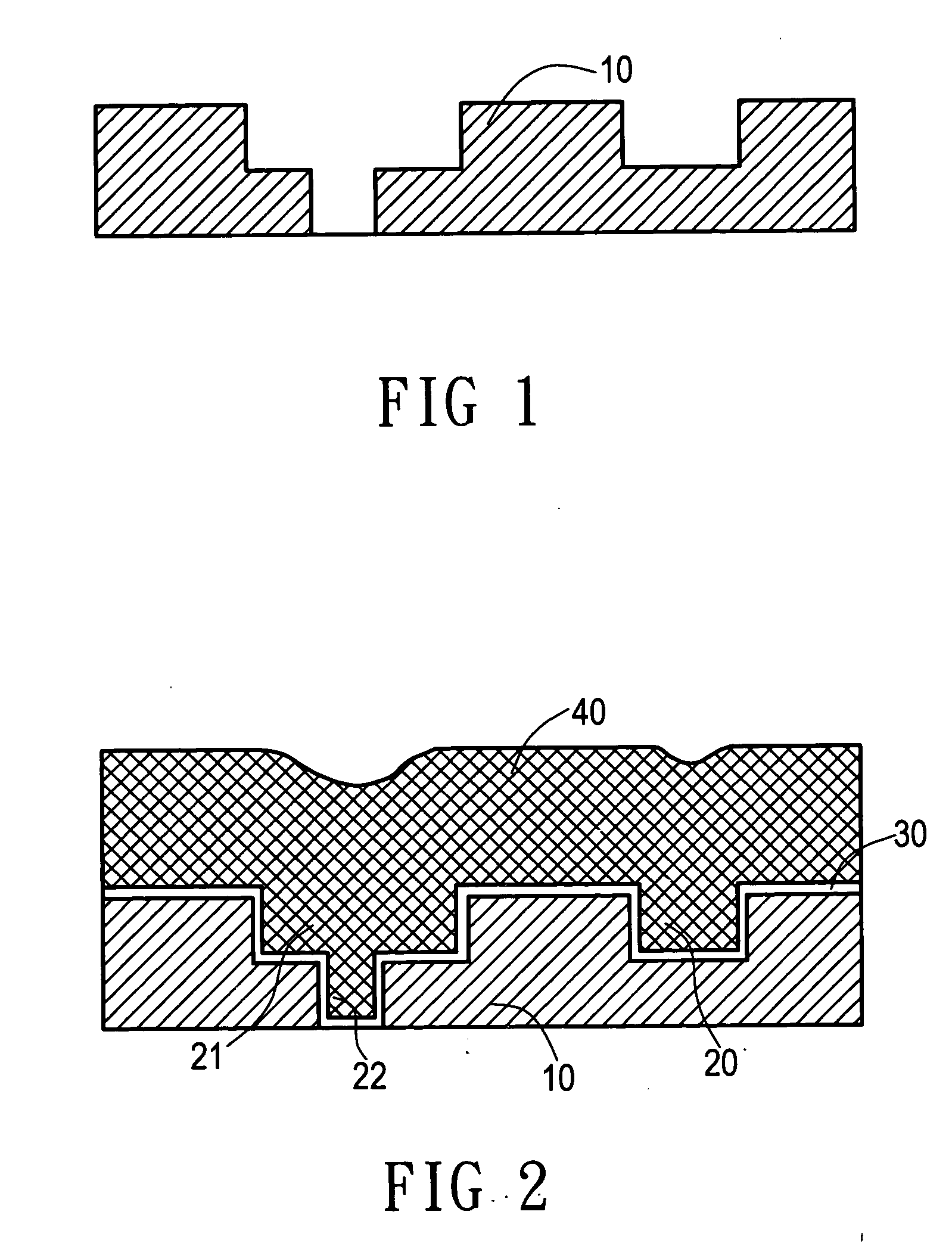

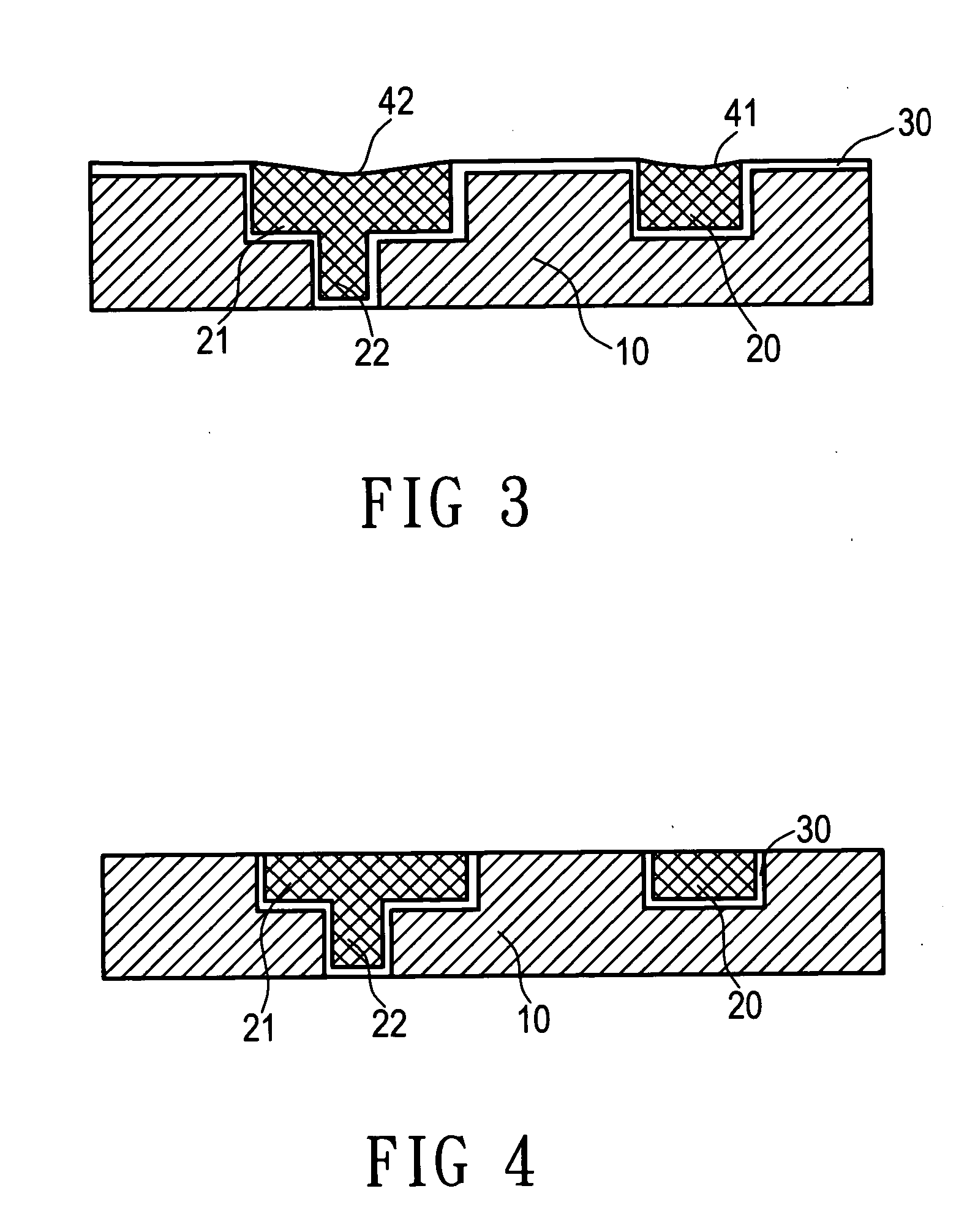

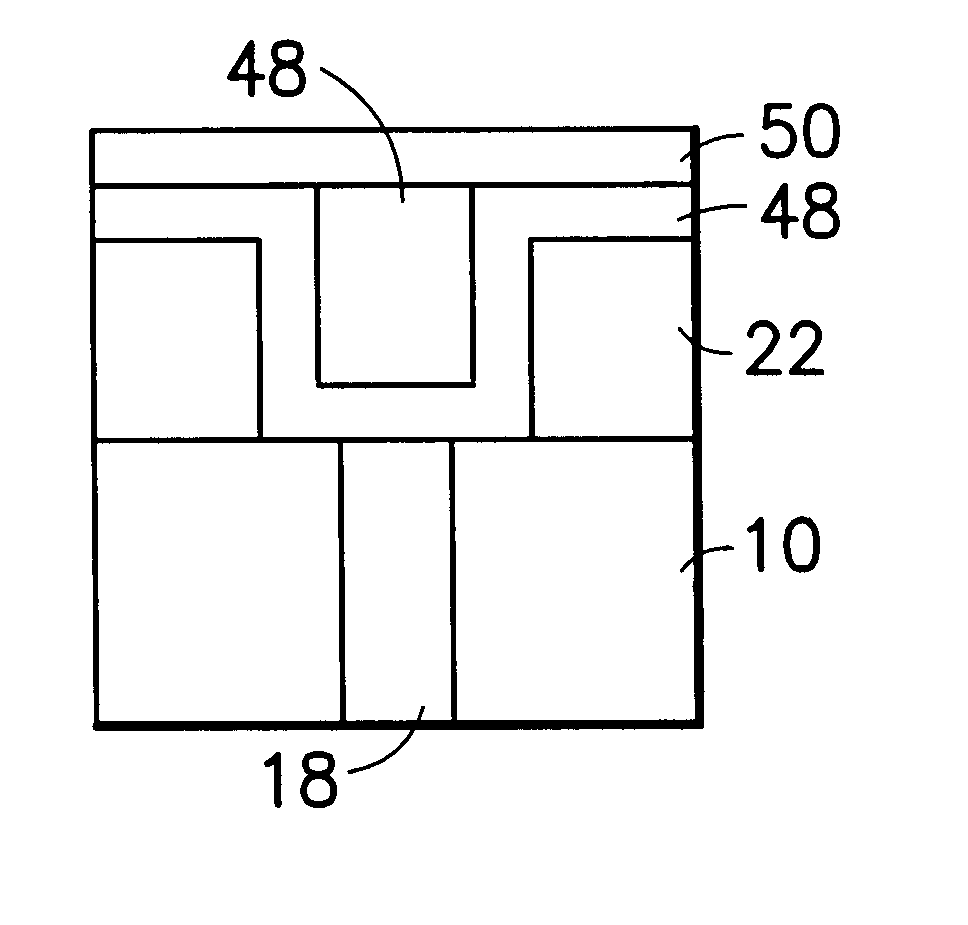

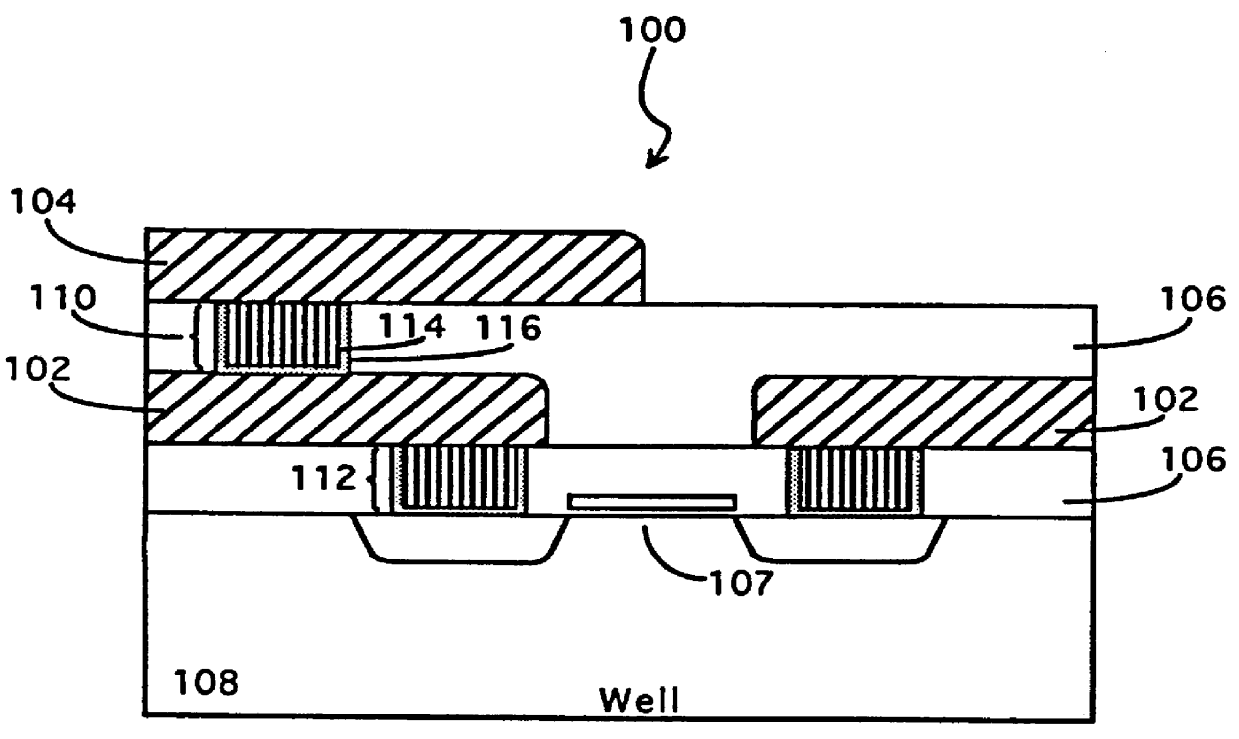

An integrated circuit structures formed by chemical mechanical polishing (CMP) process, which comprises a conductive pathway recessed in a dielectric substrate, wherein the conductive pathway comprises conductive transmission lines encapsulated in a transmission-enhancement material, and wherein the conductive pathway is filled sequentially by a first layer of the transmission-enhancement material followed by the conductive transmission line; a second layer of transmission-enhancement material encapsulating the conductive transmission line and contacting the first layer of the transmission-enhancement material, wherein the transmission-enhancement material is selected from the group consisting of high magnetic permeability material and high permittivity material. Such integrated circuit structure may comprise a device structure selected from the group consisting of capacitors, inductors, and resistors. Preferably, the transmission-enhancement material comprises MgMn ferrites, MgMnAl ferrites, barium strontium titanate, lead zirconium titanate, titanium oxide, tantalum oxide, etc.

Owner:GULA CONSULTING LLC

Planarization composition

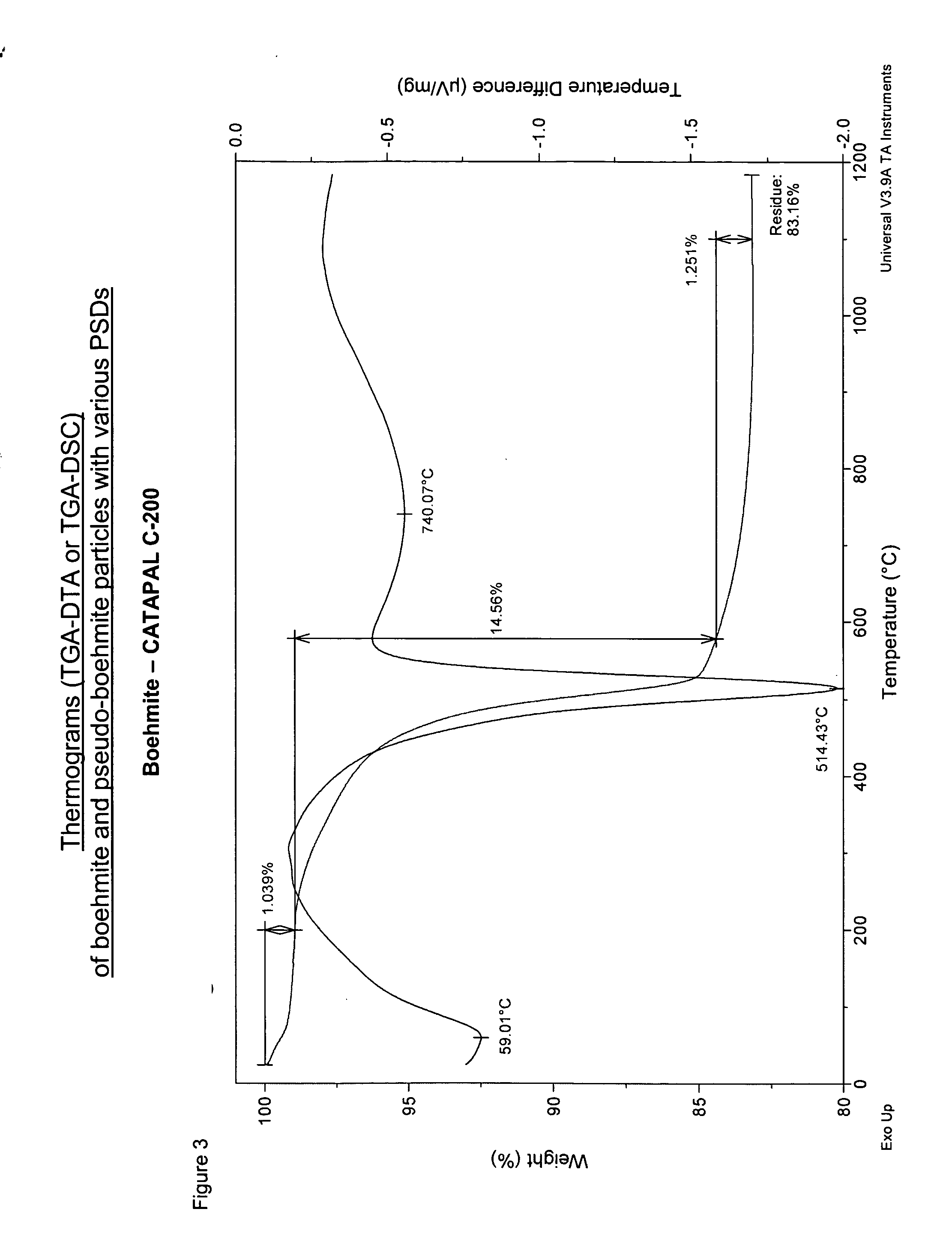

The present invention provides CMP abrasive slurry that is substantially free of aluminum oxide and comprises liquid and solids wherein the solids comprises: (a) in an amount of at least about 90 weight percent based on the solids, at least one non-spherical component having formula Al2O3.xH2O where x ranges from 1 to 3; and (b) up to about one weight percent based on the solids portion of submicron alpha-alumina. The CMP abrasive slurry may be used to polish metallic or dielectric surfaces in computer wafers.

Owner:BASF AG +1

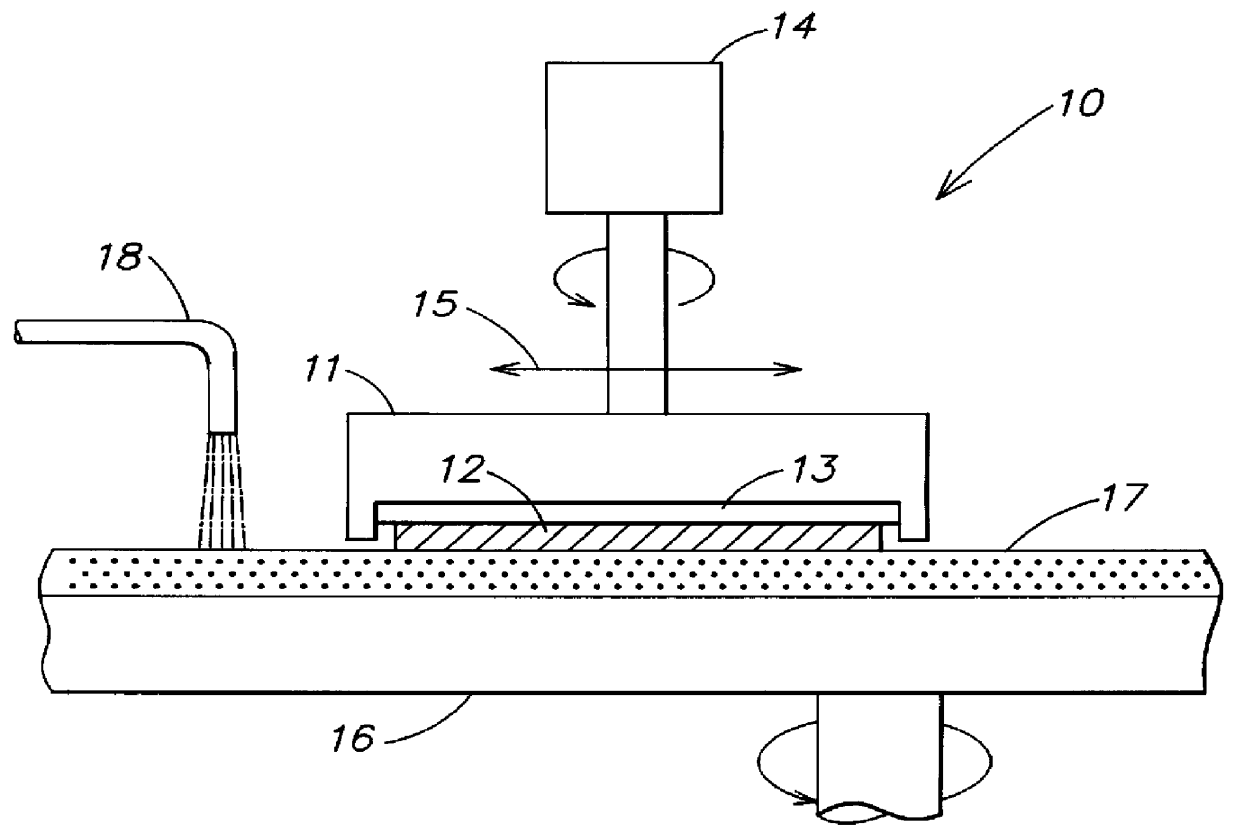

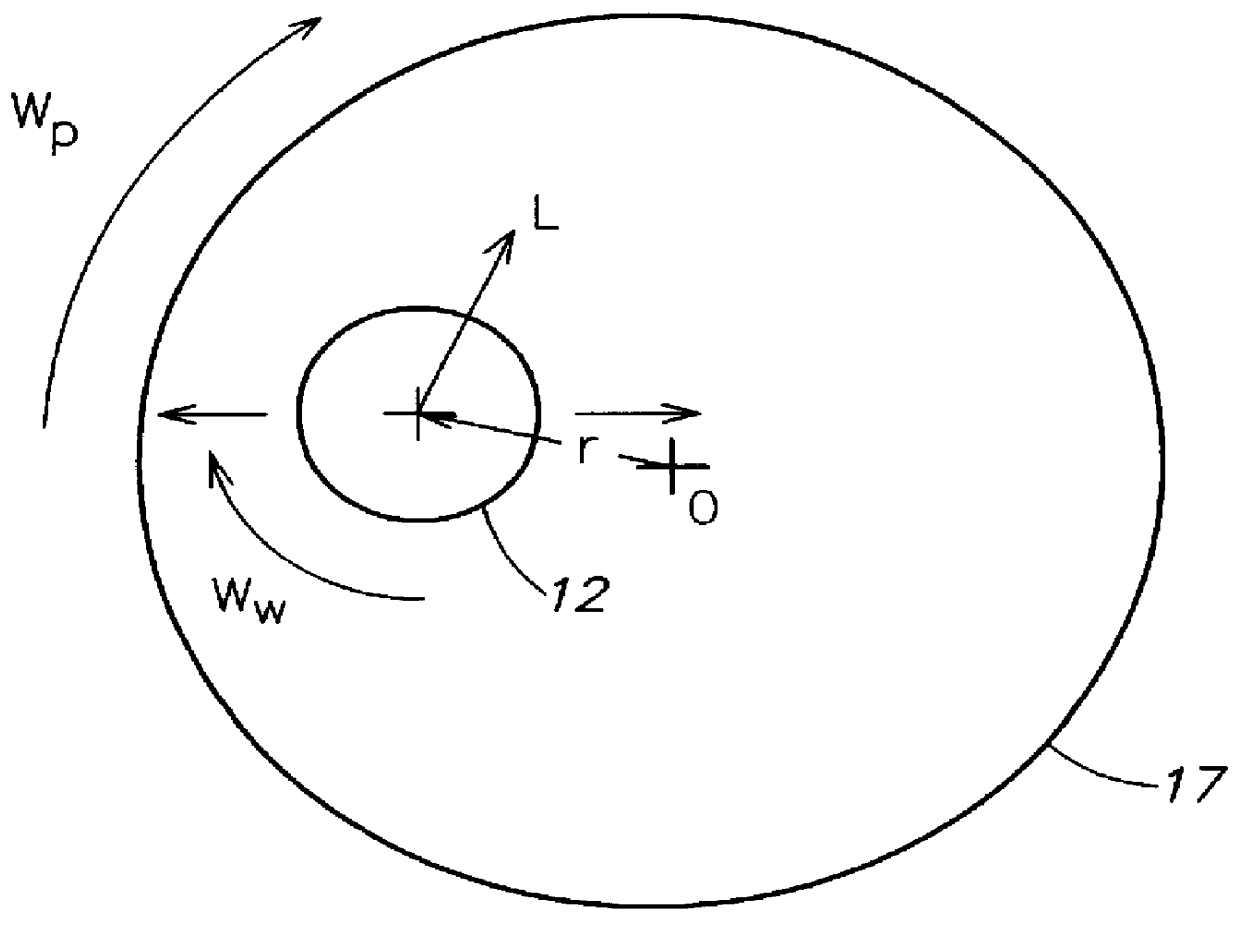

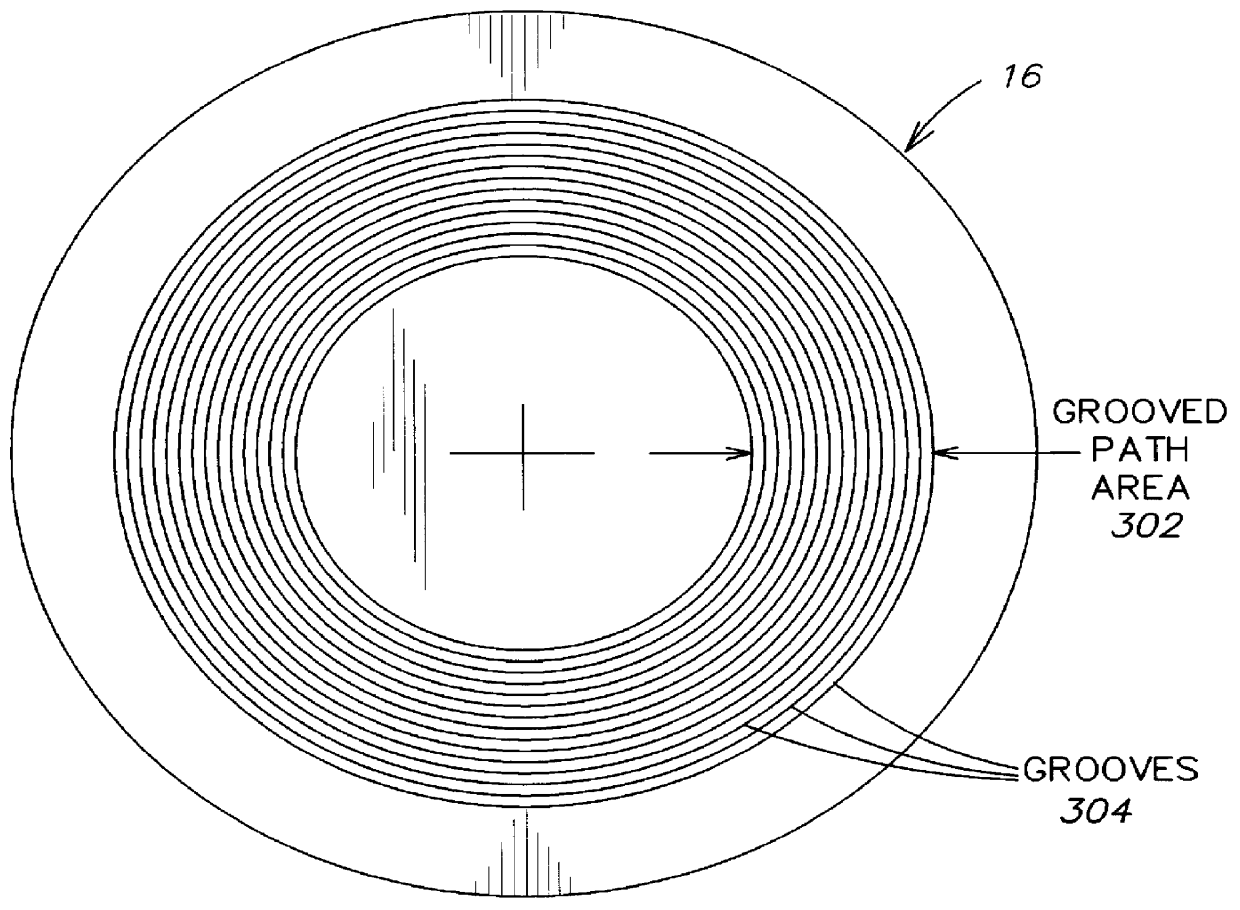

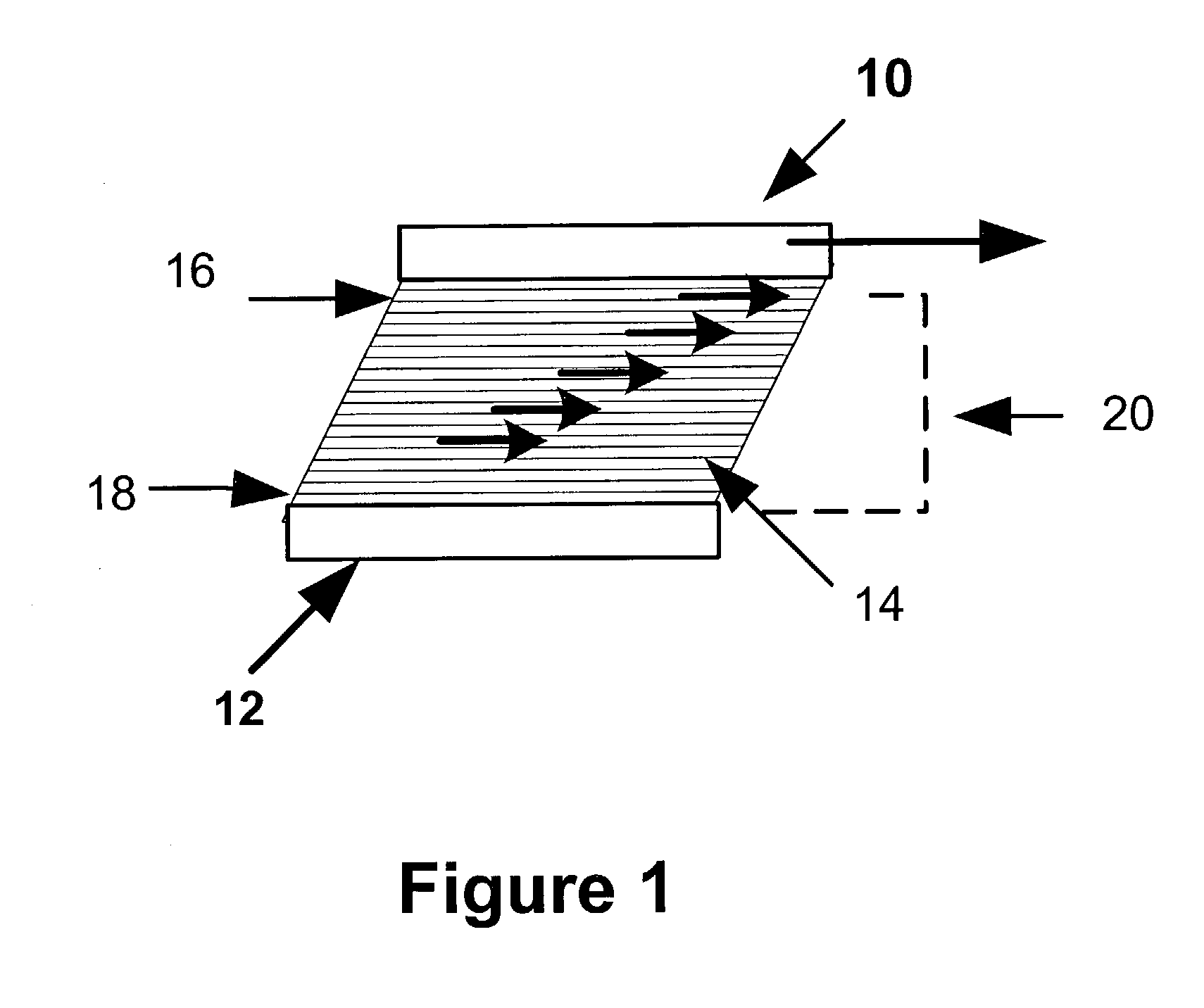

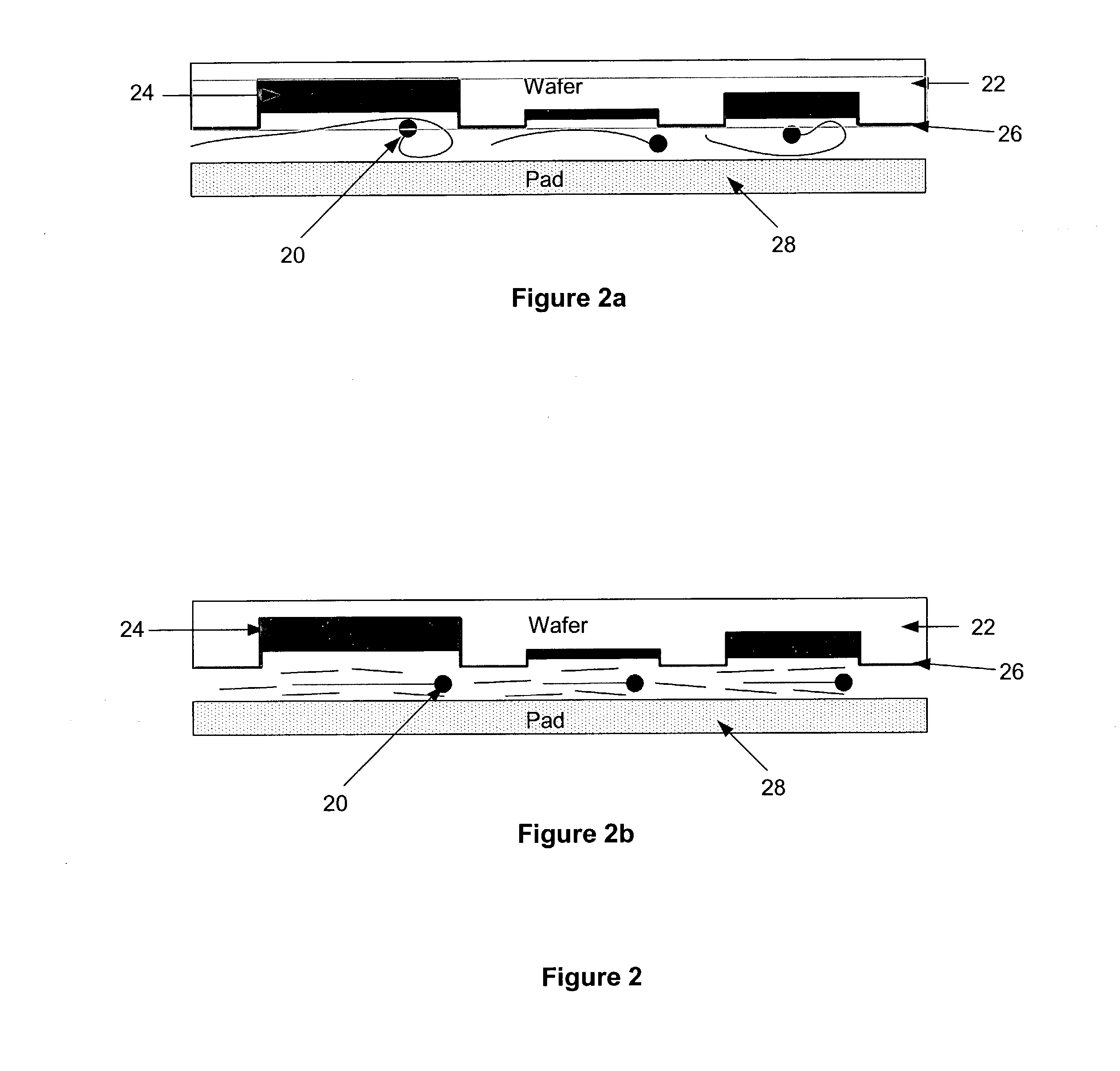

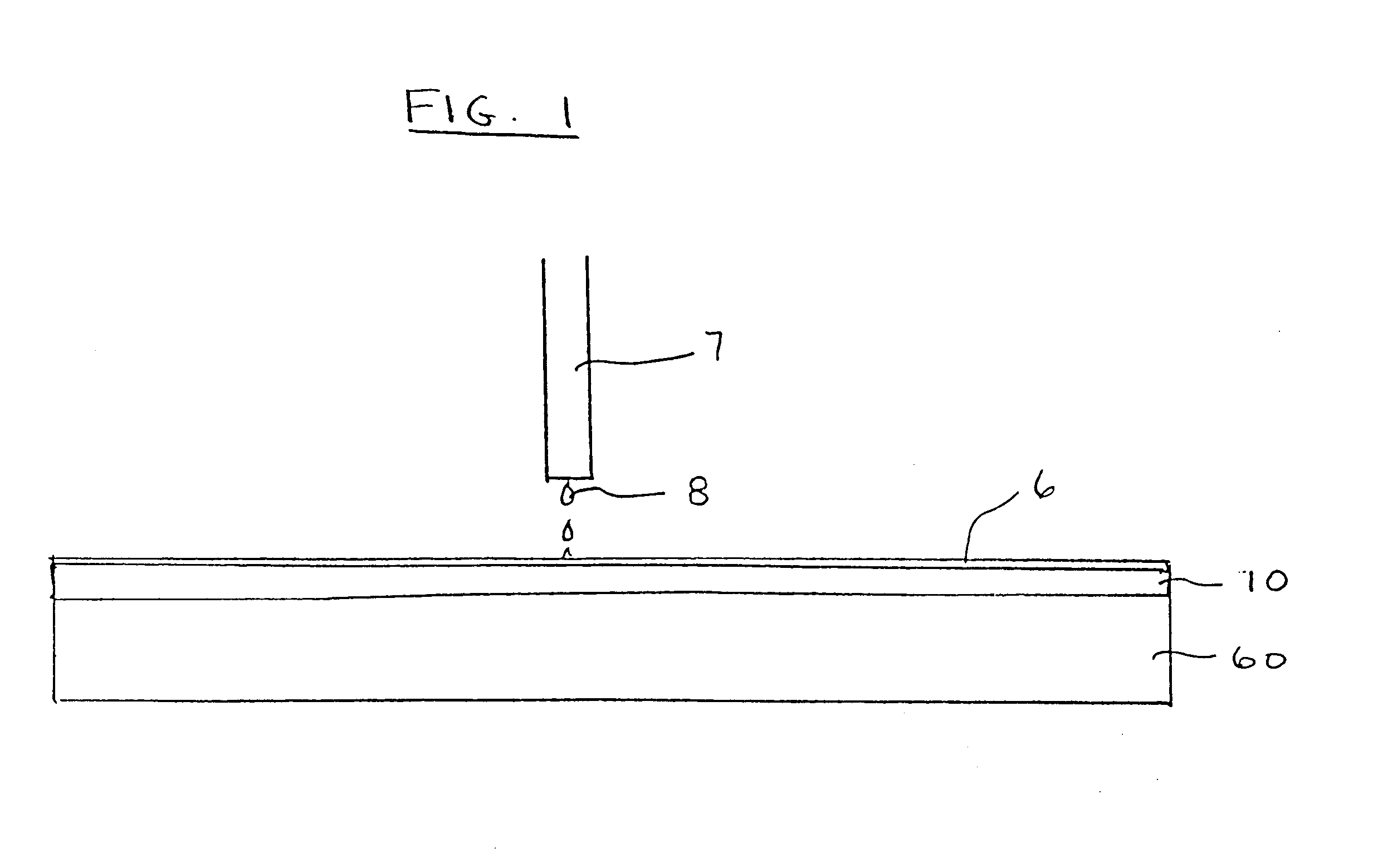

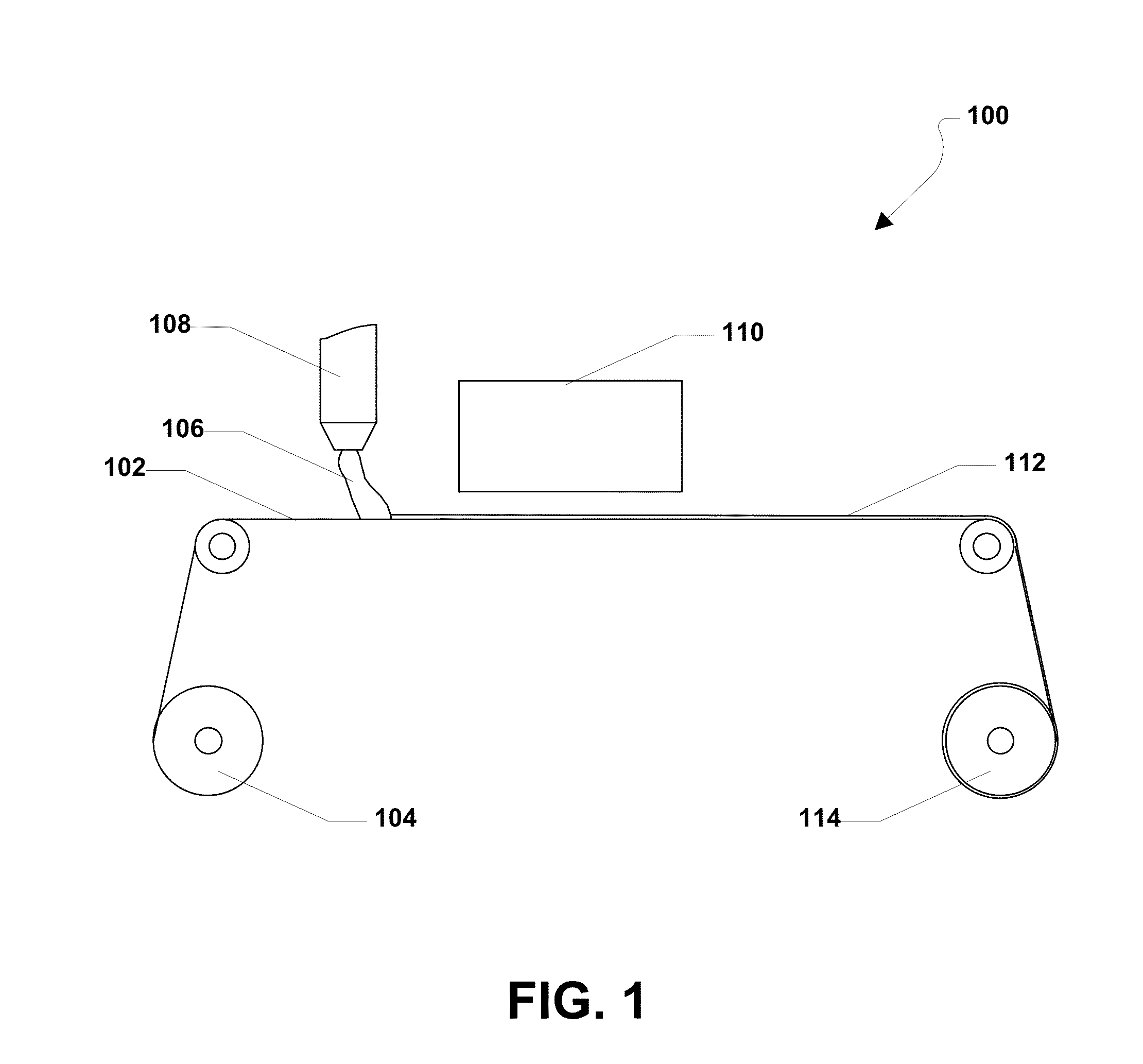

Method and apparatus for slurry polishing

InactiveUS6110832AHigh viscosityDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringSlurry

A method and apparatus for Chemical-Mechanical Polishing of semiconductor wafers using various formulations of high viscosity slurry.

Owner:GLOBALFOUNDRIES INC

High surface quality GaN wafer and method of fabricating same

InactiveUS6951695B2Improve surface qualityPolycrystalline material growthAfter-treatment detailsSurface roughnessHigh surface

AlxGayInzN, wherein 0≦x≦1, 0≦y≦1, 0≦z≦1, and x+y+z=1, characterized by a root mean square surface roughness of less than 1 nm in a 10×10 μm2 area. The AlxGayInzN may be in the form of a wafer, which is chemically mechanically polished (CMP) using a CMP slurry comprising abrasive particles, such as silica or alumina, and an acid or a base. High quality AlxGayInzN wafers can be fabricated by steps including lapping, mechanical polishing, and reducing internal stress of said wafer by thermal annealing or chemical etching for further enhancement of its surface quality. CMP processing may be usefully employed to highlight crystal defects of an AlxGayInzN wafer.

Owner:WOLFSPEED INC

Passivative chemical mechanical polishing composition for copper film planarization

ActiveUS20040108302A1Decorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Copper

A CMP composition containing 5-aminotetrazole, e.g., in combination with oxidizing agent, chelating agent, abrasive and solvent. Such CMP composition advantageously is devoid of BTA, and is useful for polishing surfaces of copper elements on semiconductor substrates, without the occurrence of dishing or other adverse planarization deficiencies in the polished copper, even in the presence of substantial levels of copper ions, e.g., Cu<2+>, in the bulk CMP composition at the copper / CMP composition interface during CMP processing.

Owner:ENTEGRIS INC

Chemical mechanical polishing compositions for copper and associated materials and method of using same

A CMP composition containing a rheology agent, e.g., in combination with oxidizing agent, chelating agent, inhibiting agent, abrasive and solvent. Such CMP composition advantageously increases the materials selectivity in the CMP process and is useful for polishing surfaces of copper elements on semiconductor substrates, without the occurrence of dishing or other adverse planarization deficiencies in the polished copper.

Owner:ADVANCED TECH MATERIALS INC

Compositions and methods for rapidly removing overfilled substrates

InactiveUS20050178742A1Decorative surface effectsNon-surface-active detergent compositionsAcetic acidOxidizing agent

This invention relates to compositions and methods for removing overfilled substrates, preferably at a relatively high removal rates. Advantageously, a composition according to the invention can contain an oxidizer, preferably a per-type oxidizer such as a peroxide, periodic acid, and peracetic acid, and may also optionally contain an abrasive.

Owner:DUPONT AIR PRODS NANOMATERIALS +1

Planarization compositions and methods for removing interlayer dielectric films

InactiveUS6322600B1Improve planarization qualityQuality improvementPigmenting treatmentOther chemical processesThinningDielectric thin films

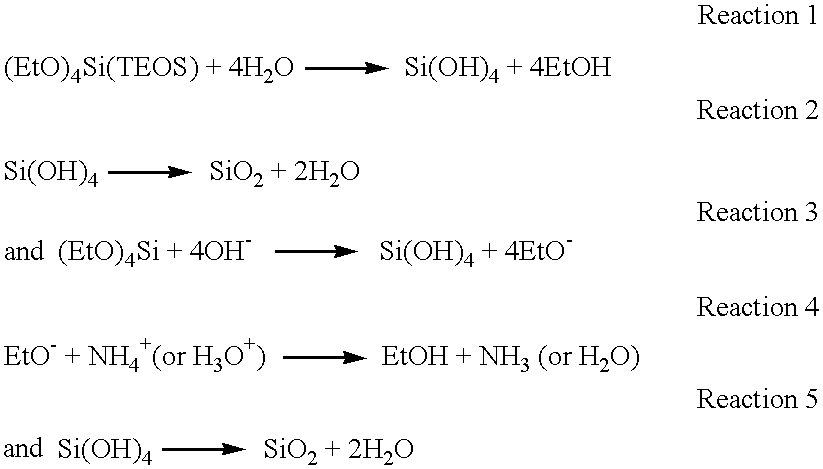

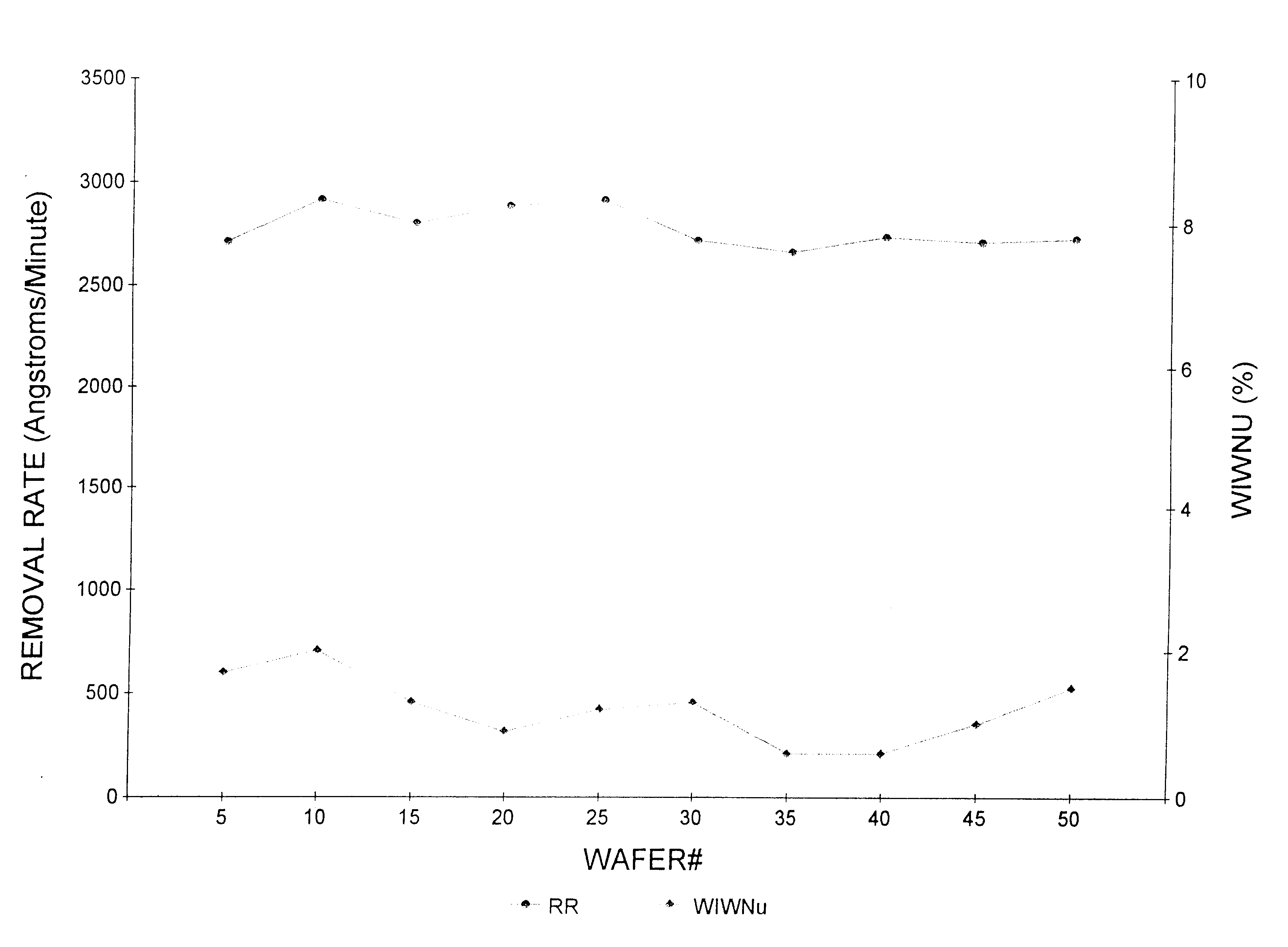

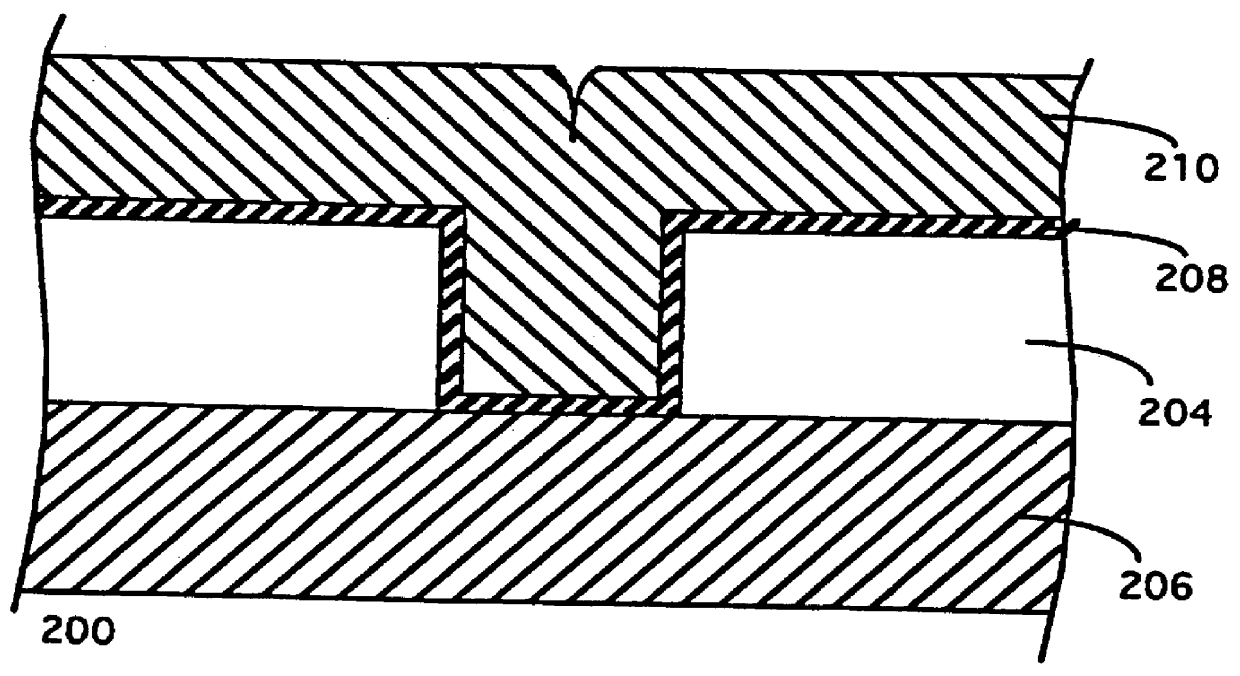

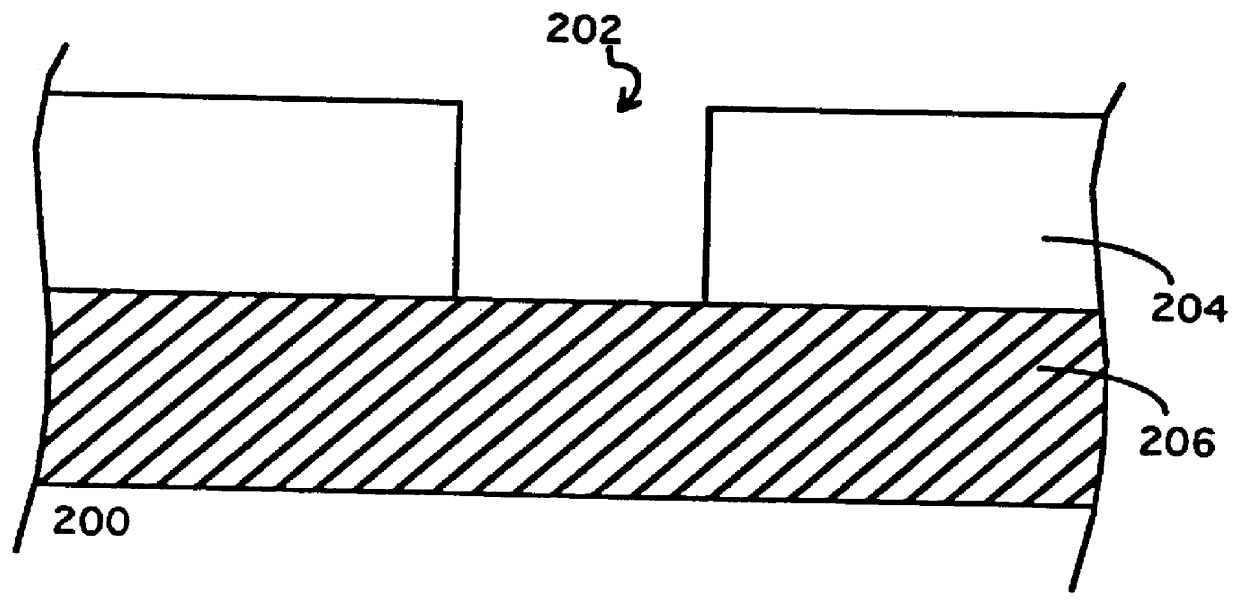

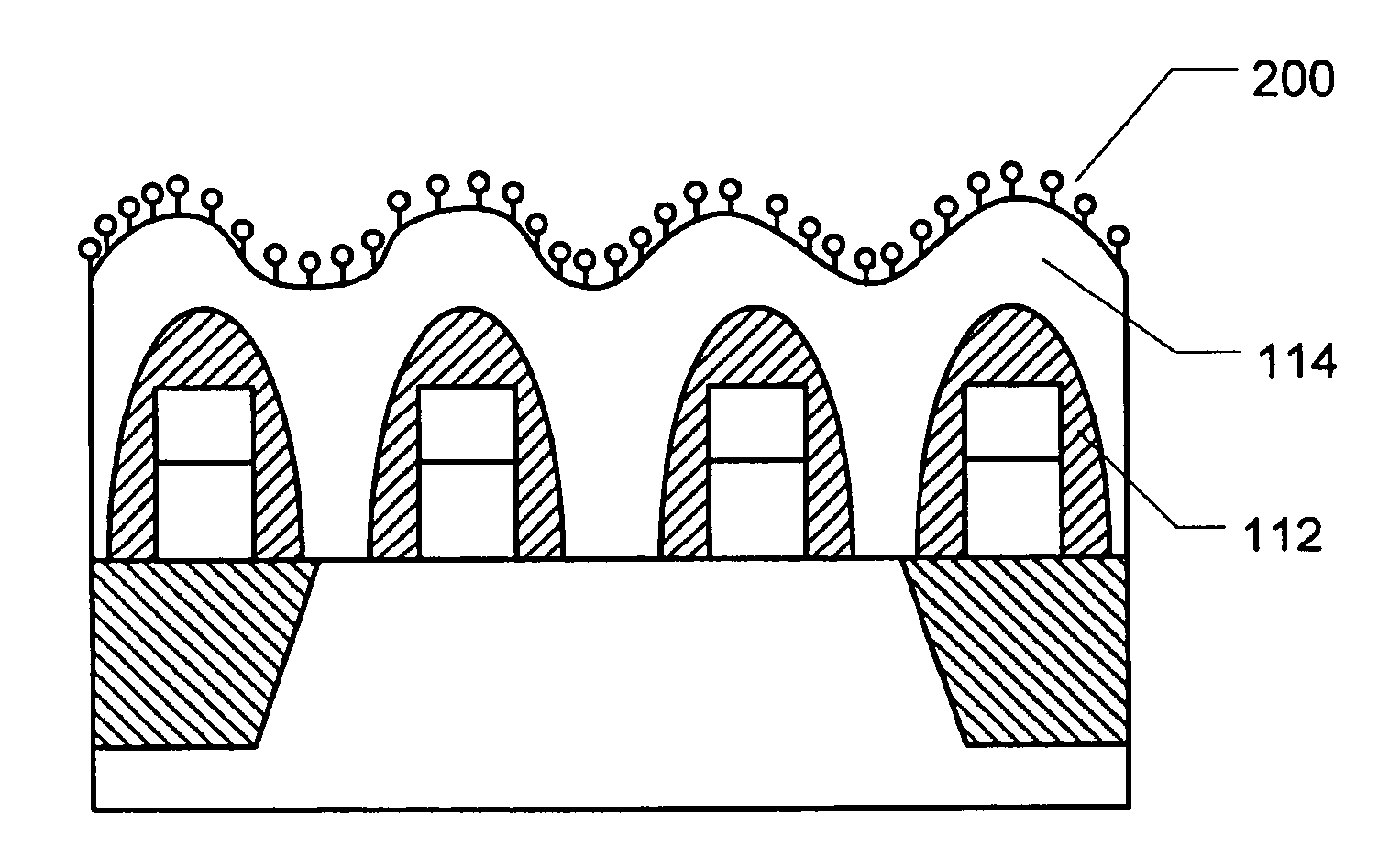

A planarization composition is set forth for chemical mechanical planarization of dielectric layers for semiconductor manufacture. The composition comprises spherical silica particles having an average diameter of from 30 nm to about 400 nm, and a narrow range of particle sizes, wherein about 90% of the particles is within 20% of the average particle diameter. The composition includes a liquid carrier comprising up to about 9% alcohol and an amine hydroxide in the amount of about 0.2 to about 9% by weight. The pH of the composition is in the range of about 9 to about 11.5, and the remainder of the solution is water. The composition has low amounts of metal ions, and the composition is used for thinning, polishing and planarizing interlayer dielectric thin films, shallow trench isolation structures, and isolation of gate structures. The invention also comprises methods for using the planarization composition in the manufacture of semiconductor devices.

Owner:ADVANCED TECH MATERIALS INC

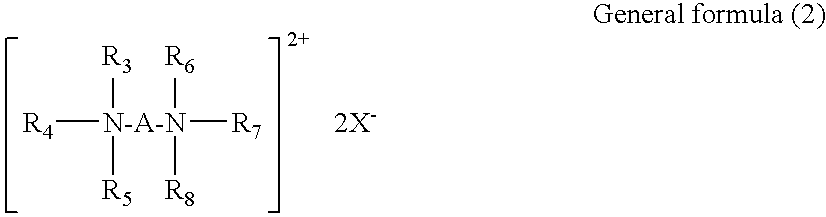

Methods of post chemical mechanical polishing and wafer cleaning using amidoxime compositions

InactiveUS20090133716A1Reducing and eliminating corrosion problemSignificant to useOrganic detergent compounding agentsNon-surface-active detergent compositionsDielectric surfaceCompound (substance)

The invention relates to a method for the removal of residues and contaminants from metal or dielectric surfaces and to a method for chemical mechanical polishing of a copper or aluminum surface. The methods of the invention include using an aqueous amidoxime complex agent. Optionally, the pH of the solution can be adjusted with an acid or base. The method includes applying the above composition to the copper or aluminum surface and polishing the surface in the presence of the composition.

Owner:EKC TECH

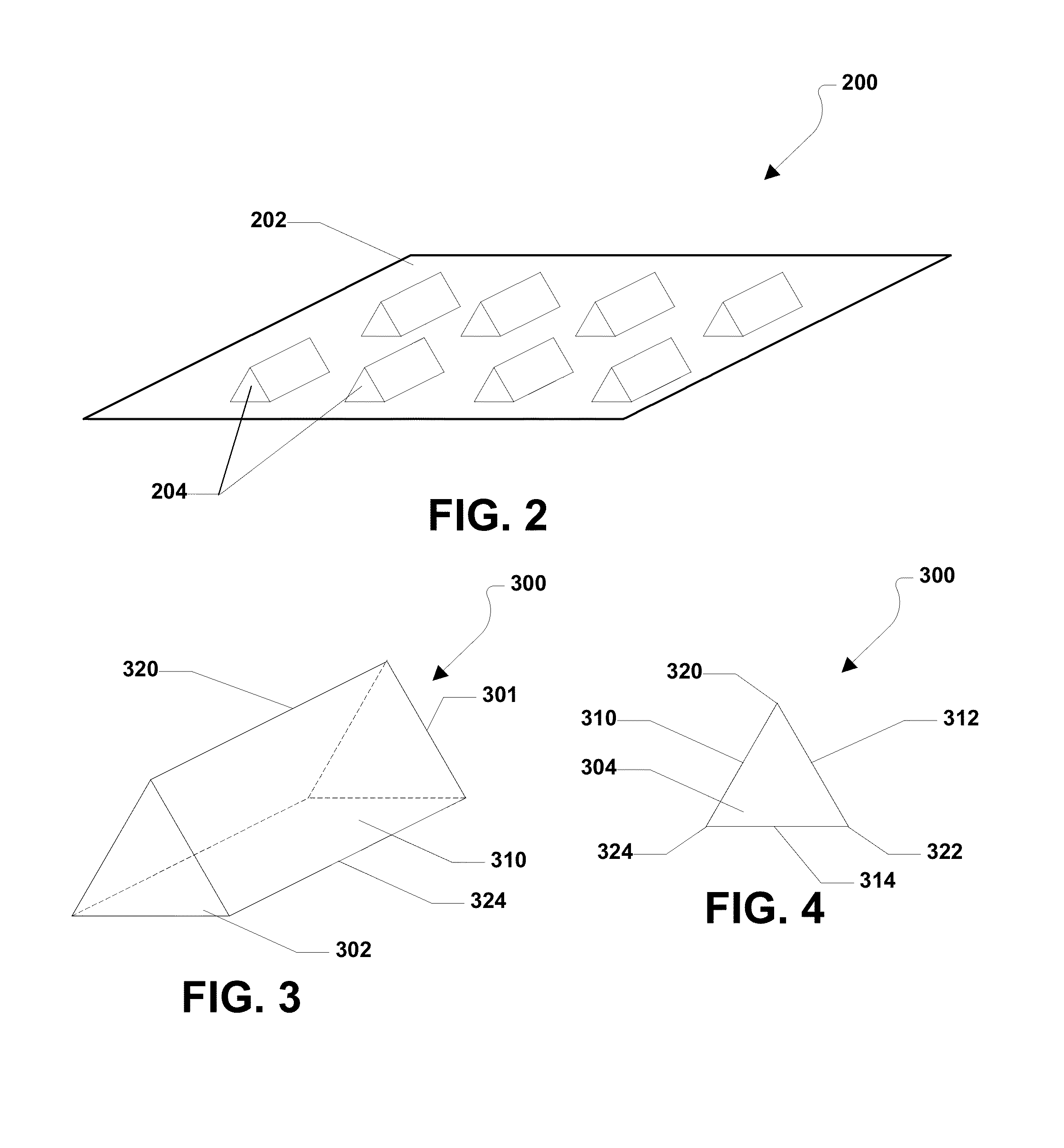

Abrasive particles having complex shapes and methods of forming same

An abrasive grain is disclosed and may include a body. The body may define a length (l), a height (h), and a width (w). In a particular aspect, the length is greater than or equal to the height and the height is greater than or equal to the width. Further, in a particular aspect, the body may include a primary aspect ratio defined by the ratio of length:height of at least about 2:1. The body may also include an upright orientation probability of at least about 50%.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

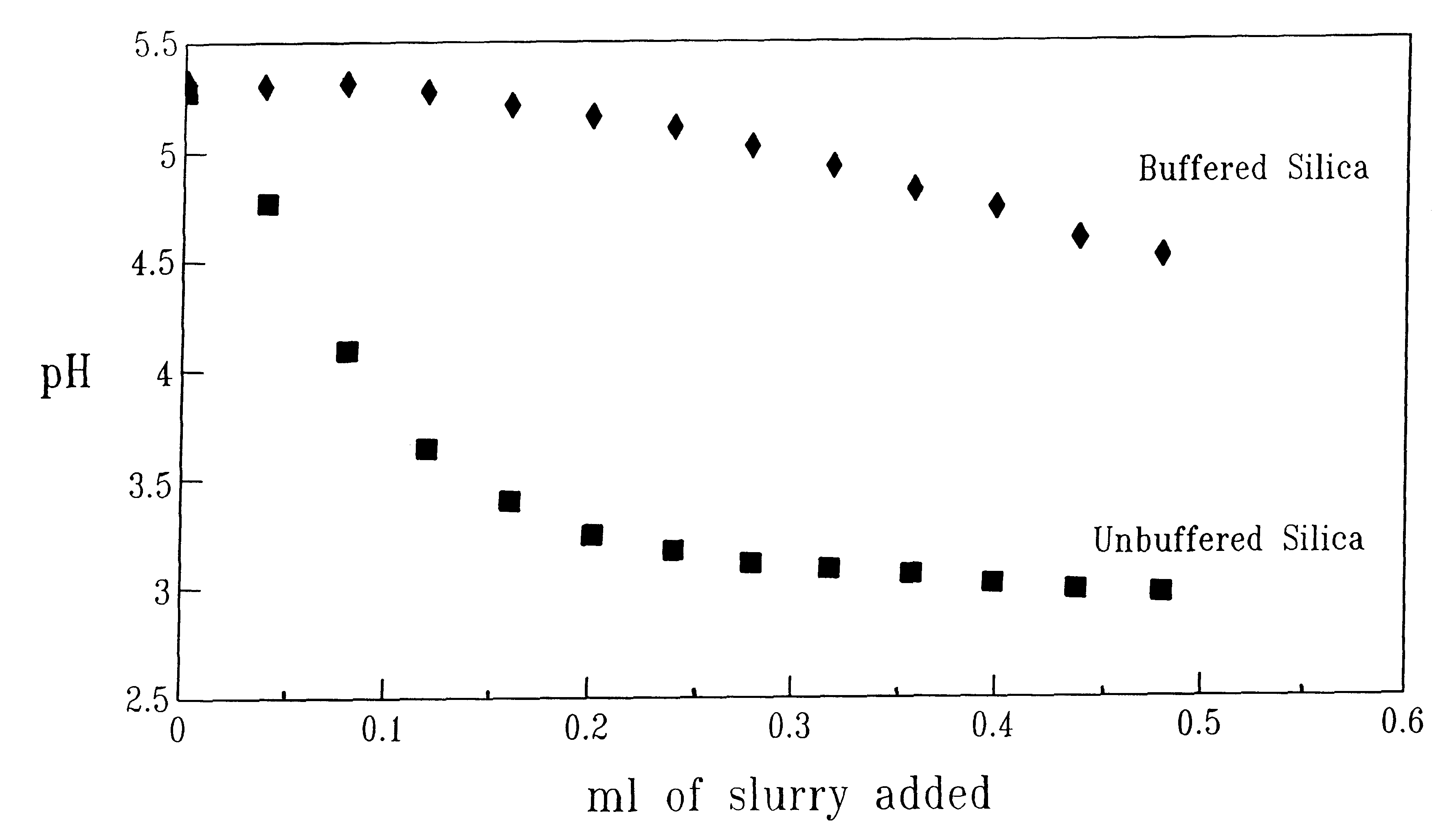

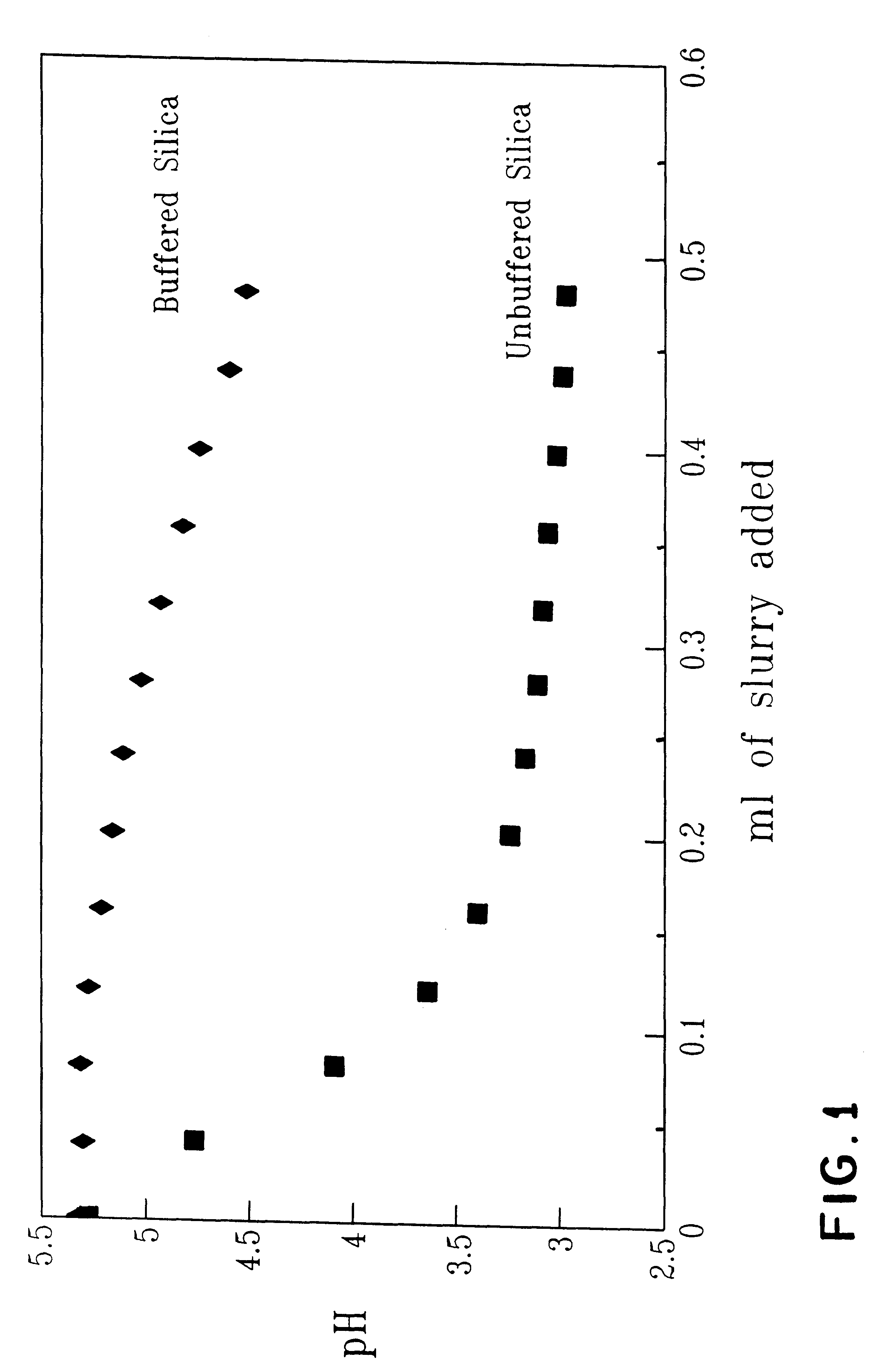

pH-buffered slurry and use thereof for polishing

InactiveUS6190237B1Other chemical processesSemiconductor/solid-state device manufacturingPh bufferingSlurry

A slurry containing abrasive particles and a pH buffering component comprising at least one acid or salt thereof and at least one base is especially useful for polishing surfaces, including those used in microelectronics.

Owner:IBM CORP

Polishing composition and method utilizing abrasive particles treated with an aminosilane

ActiveUS20090081927A1Other chemical processesSemiconductor/solid-state device manufacturingMaterials science

Owner:CMC MATERIALS INC

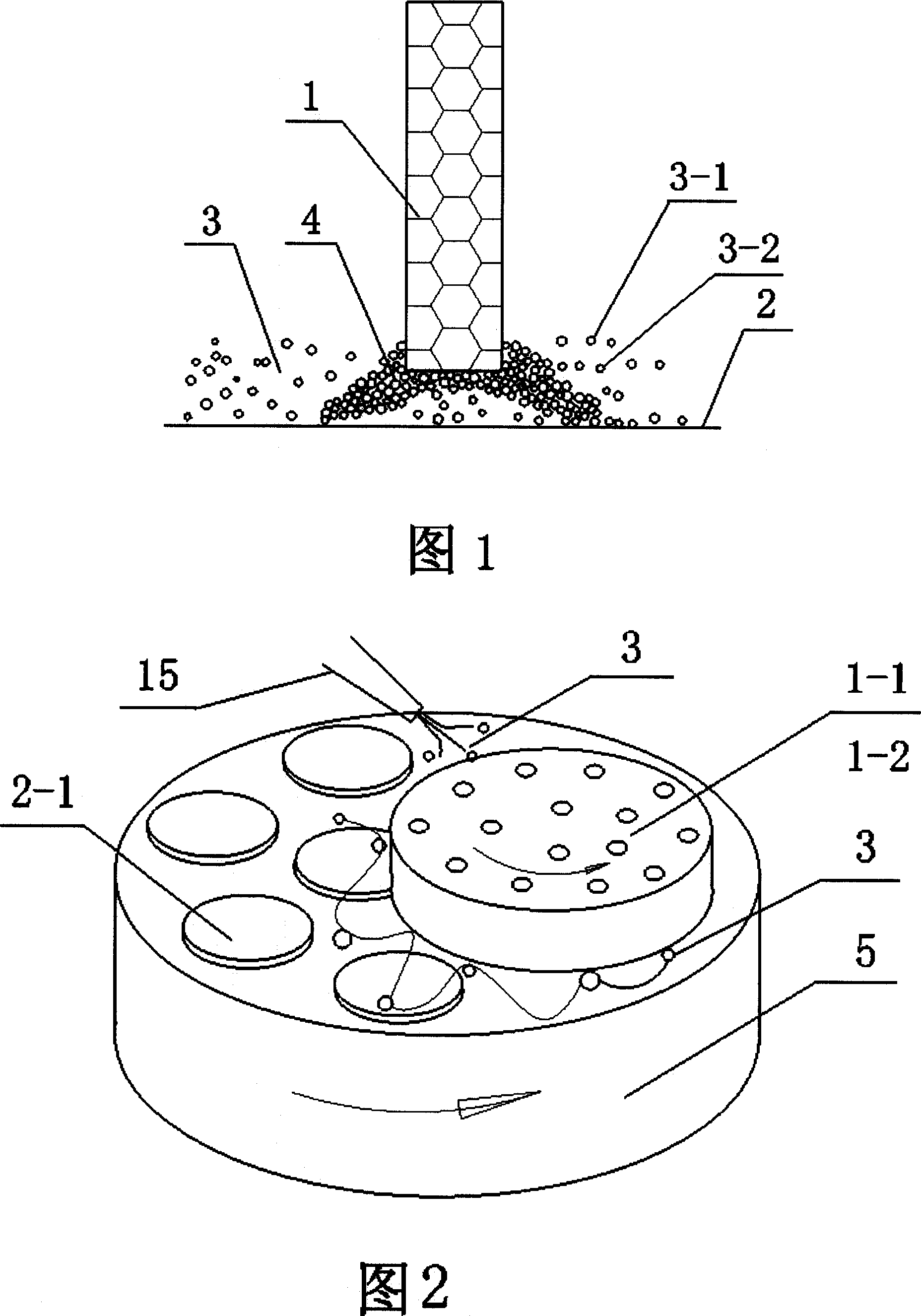

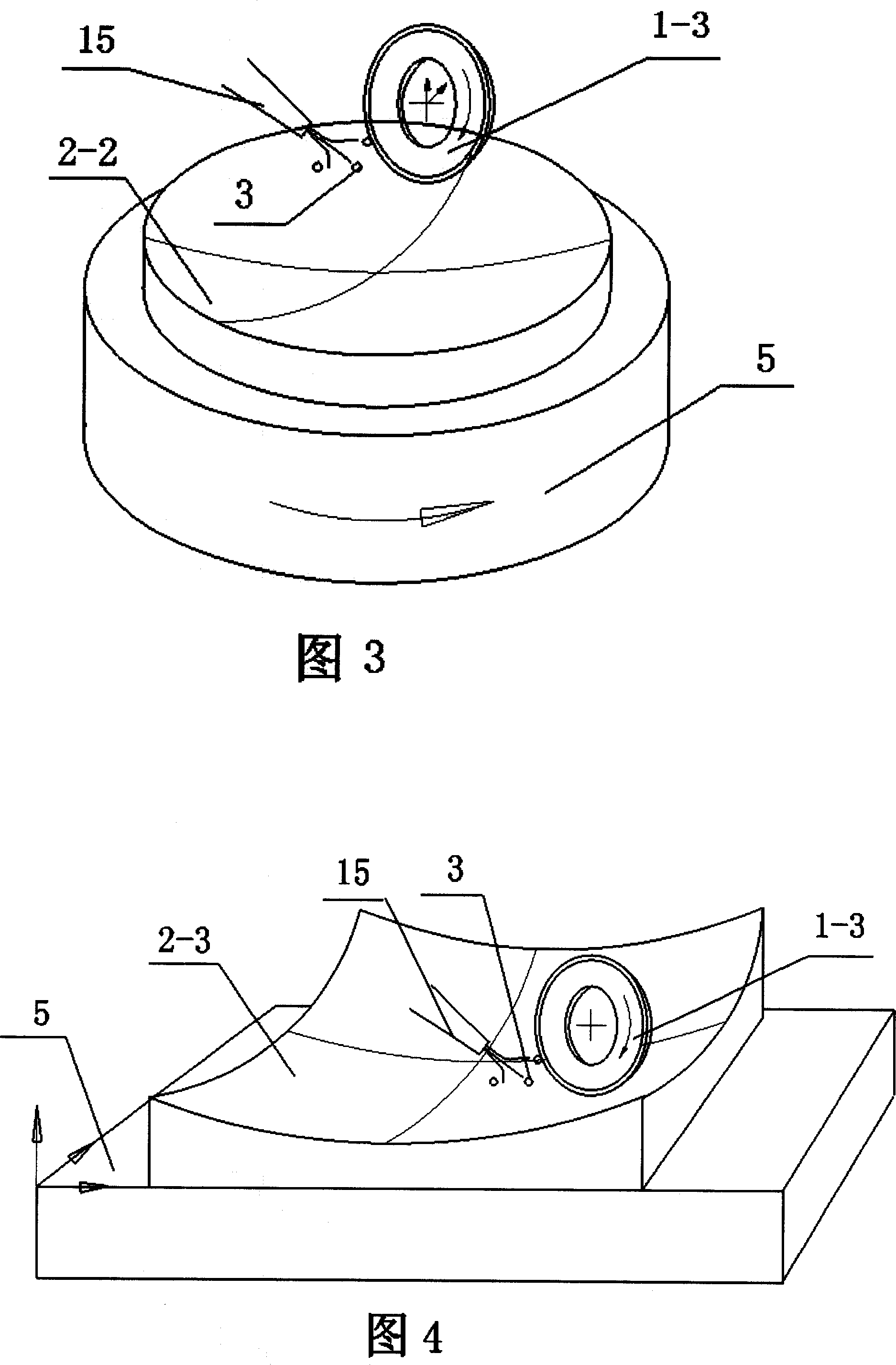

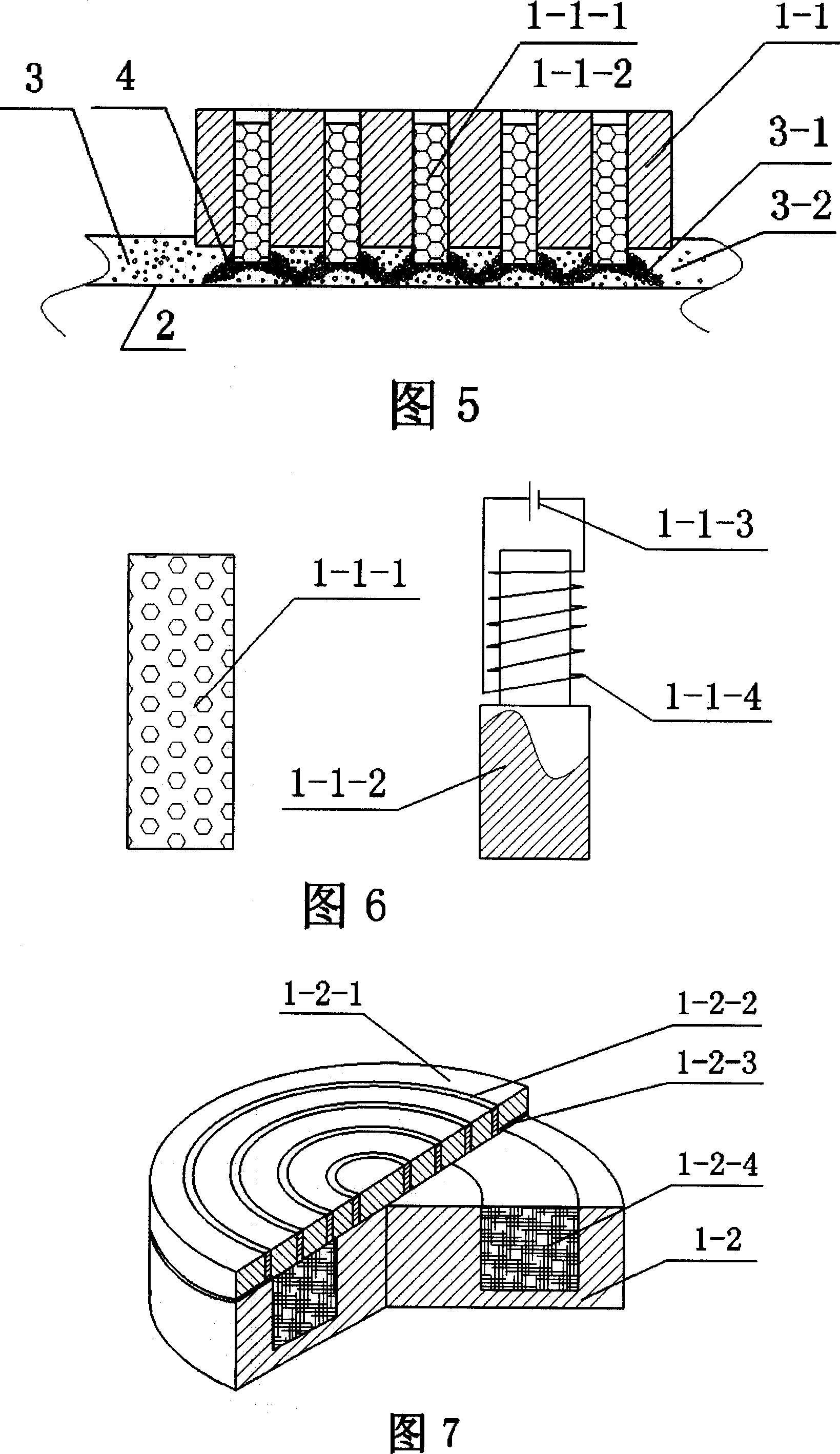

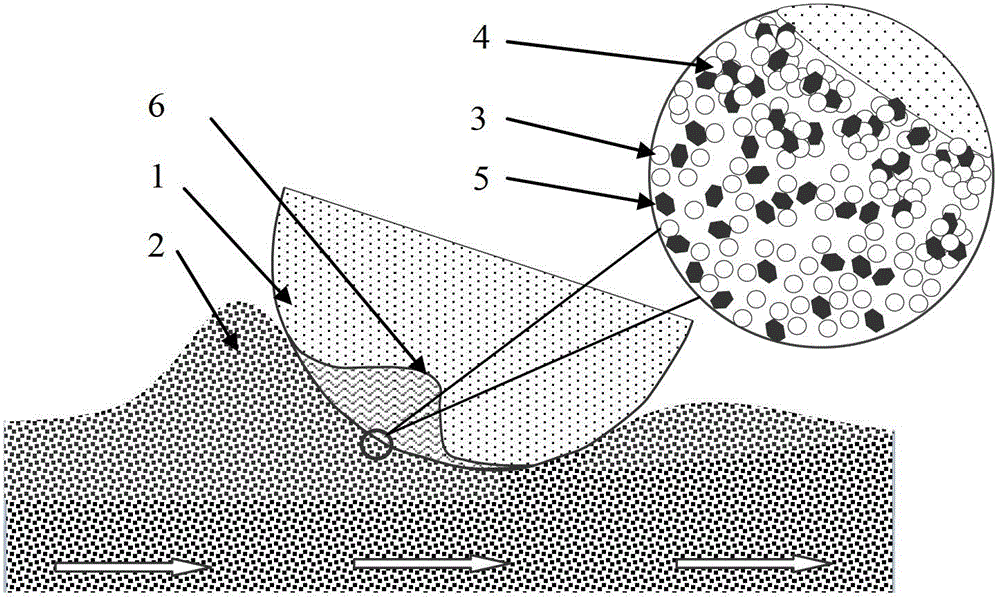

Grinding polishing method based on magnetic rheology effect and its polishing device

InactiveCN100999061AReduce removal rateReduce machining accuracyPolishing machinesPolishing compositions with abrasivesMagnetorheological fluidMaterials science

The present invention discloses a grinding-polishing method based on magnetorheological effect. Said method is characterized by that in the magnetorheological fluid a kind of free abrasive material is added, used as grinding-polishing liquor and injected into the between of magnetic body and workpiece surface, under the action of magnetic field the ferromagnetic particles in the magnetorheological fluid can be arranged by strings to cover the abrasive material pacticles and can be constrained in the end face of magnetic body to form magnetic grinding brush, said magnetic grinding brush can be used for grinding-polishing workpiece surface. Said invention also provides a grinding-polishing device for implementing said grinding-polishing method. Said device includes grinding tool mounted on main shaft connected with motor and working table for mounting workpiece.

Owner:GUANGDONG UNIV OF TECH

Catalyst attached to solid and used to promote free radical formation in CMP formulations

InactiveUS7029508B2Promote formationFacilitates and accelerates reactionOther chemical processesAbrasion apparatusCompound (substance)Free Radical Formation

The present invention provides a composition for chemical-mechanical polishing which comprises at least one abrasive particle having a surface at least partially coated by a activator. The activator comprises a metal other than a metal of Group 4(b), Group 5(b) or Group 6(b). The composition further comprises at least one oxidizing agent. The composition is believed to be effective by virtue of the interaction between the activator coated on the surface of the abrasive particles and the oxidizing agent, at the activator surface, to form free radicals. The invention further provides a method that employs the composition in the polishing of a feature or layer, such as a metal film, on a substrate surface. The invention additionally provides a substrate produced this method.

Owner:VERSUM MATERIALS US LLC

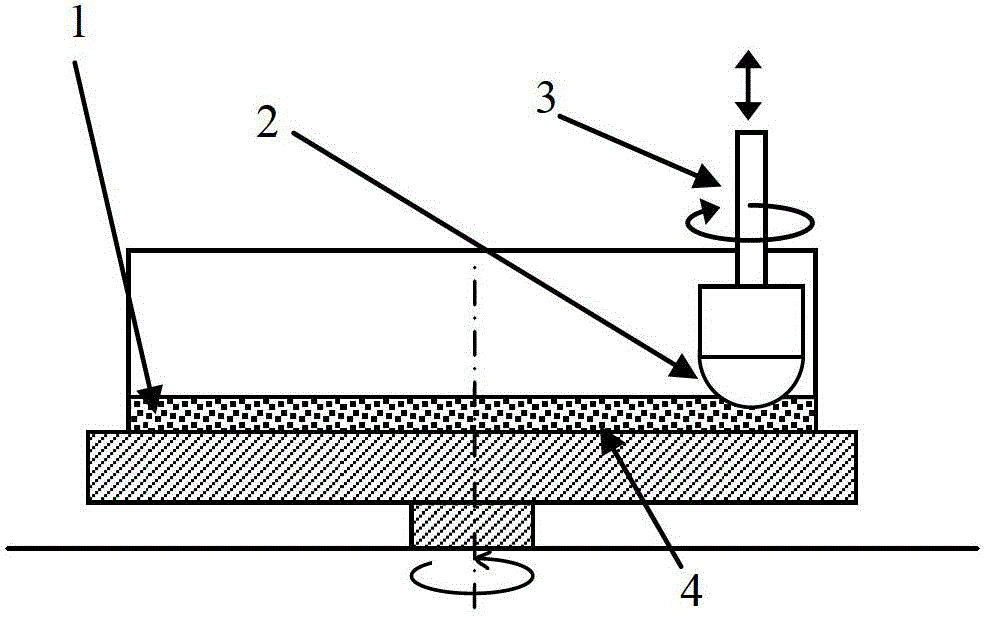

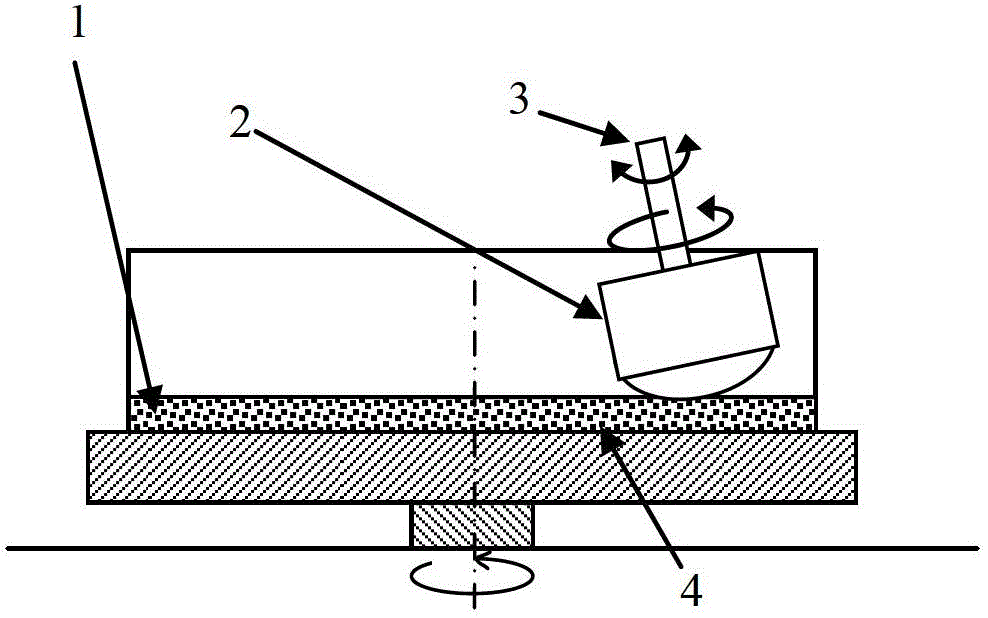

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

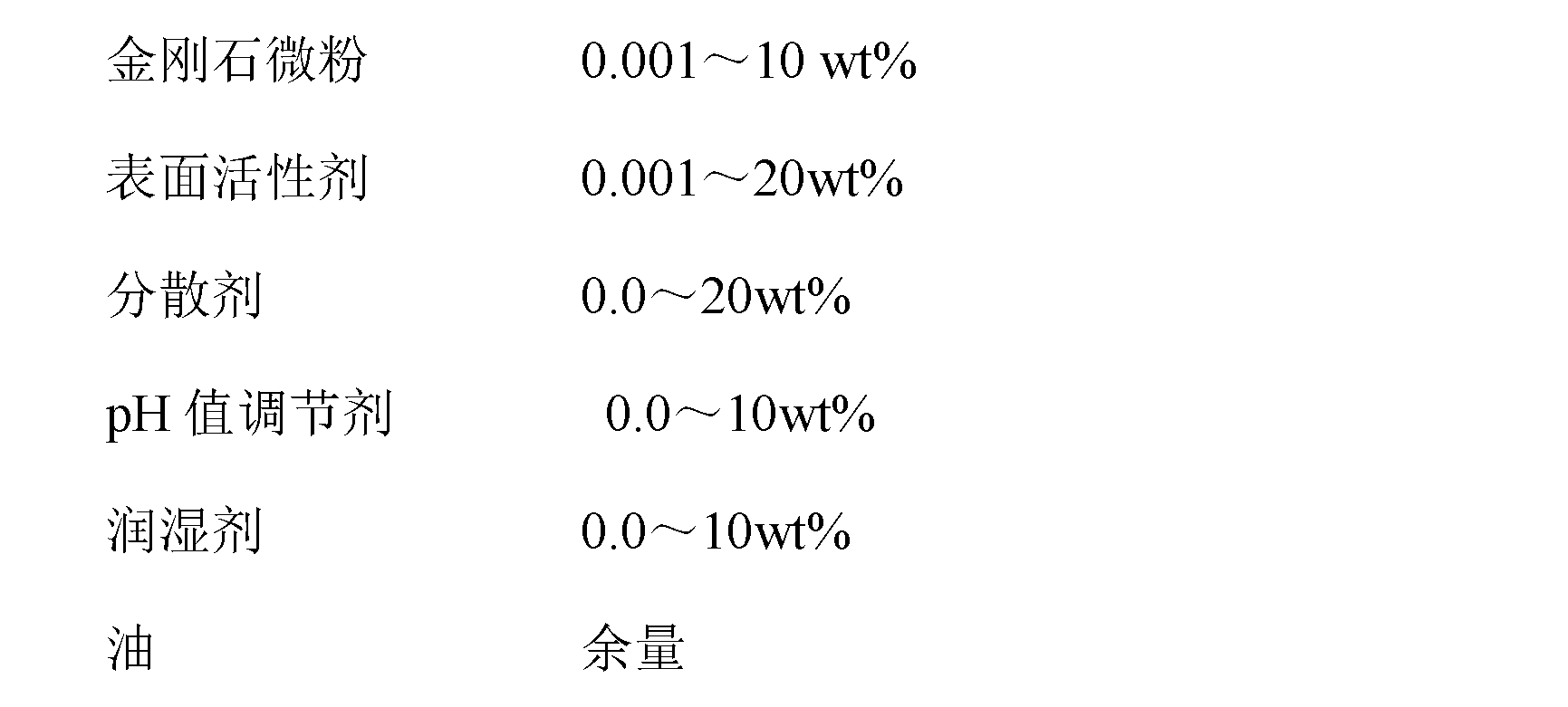

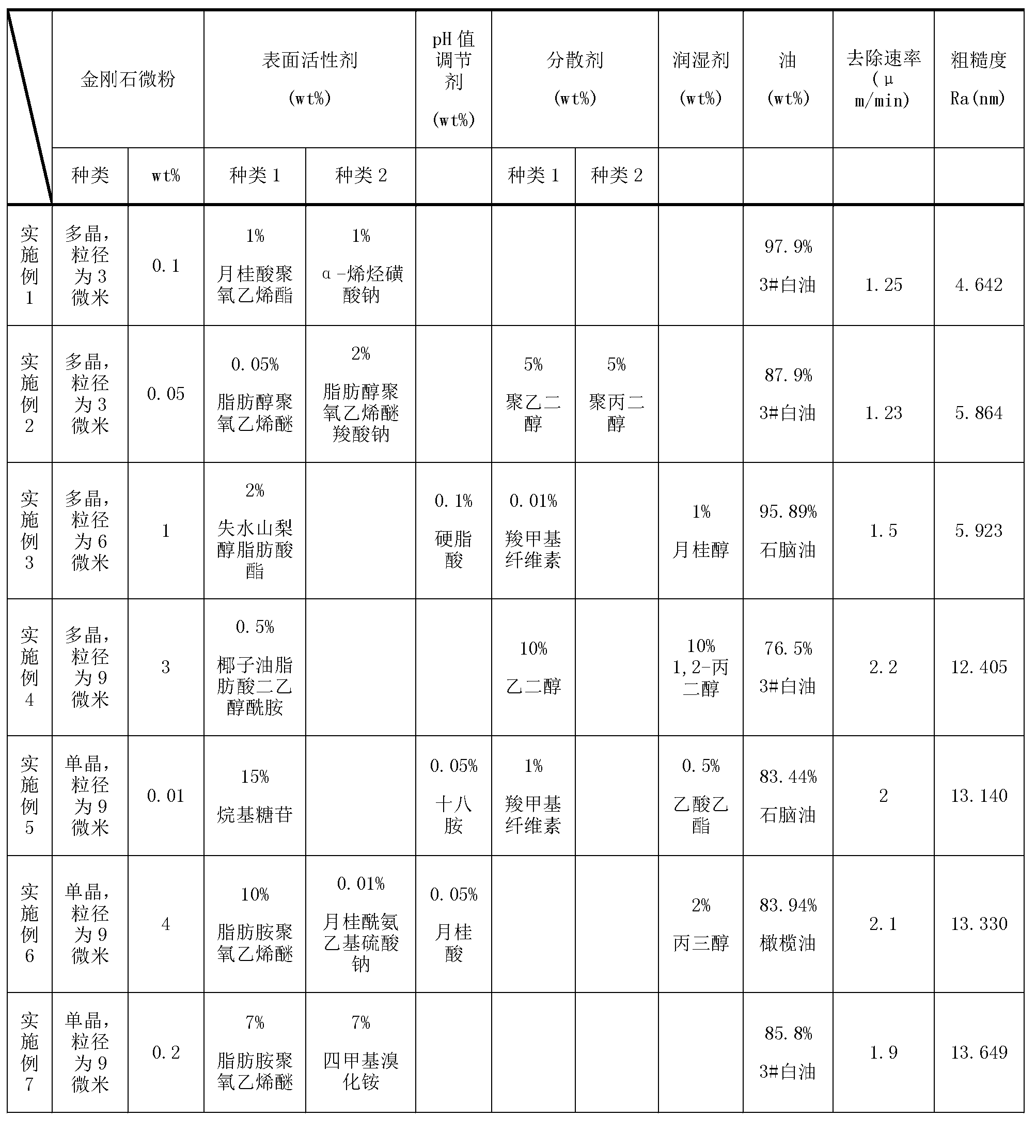

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

Method of polishing a silicon-containing dielectric

InactiveUS7071105B2Other chemical processesSemiconductor/solid-state device manufacturingThiolHydroxamic acid

The invention is directed to a method of polishing a silicon-containing dielectric layer involving the use of a chemical-mechanical polishing system comprising (a) an inorganic abrasive, (b) a polishing additive, and (c) a liquid carrier, wherein the polishing composition has a pH of about 4 to about 6. The polishing additive comprises a functional group having a pKa of about 4 to about 9 and is selected from the group consisting of arylamines, aminoalcohols, aliphatic amines, heterocyclic amines, hydroxamic acids, aminocarboxylic acids, cyclic monocarboxylic acids, unsaturated monocarboxylic acids, substituted phenols, sulfonamides, thiols, salts thereof, and combinations thereof. The invention is further directed to the chemical-mechanical polishing system, wherein the inorganic abrasive is ceria.

Owner:CABOT MICROELECTRONICS CORP

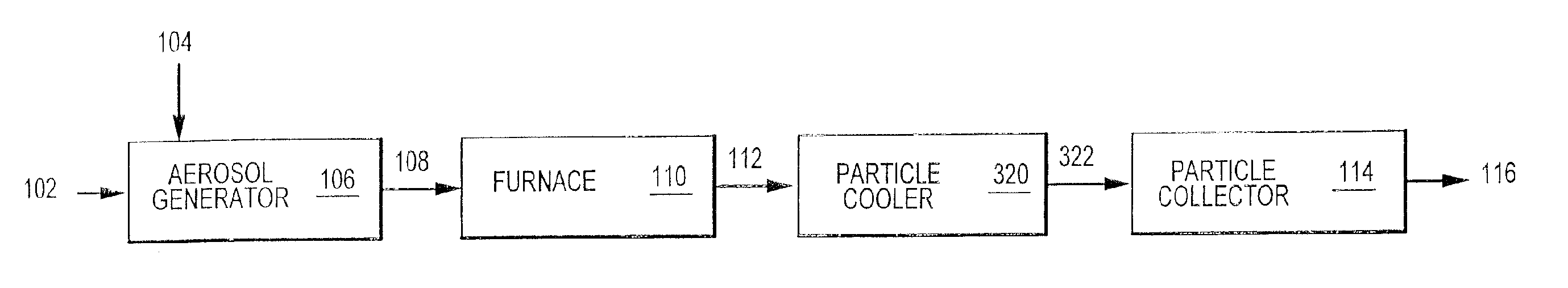

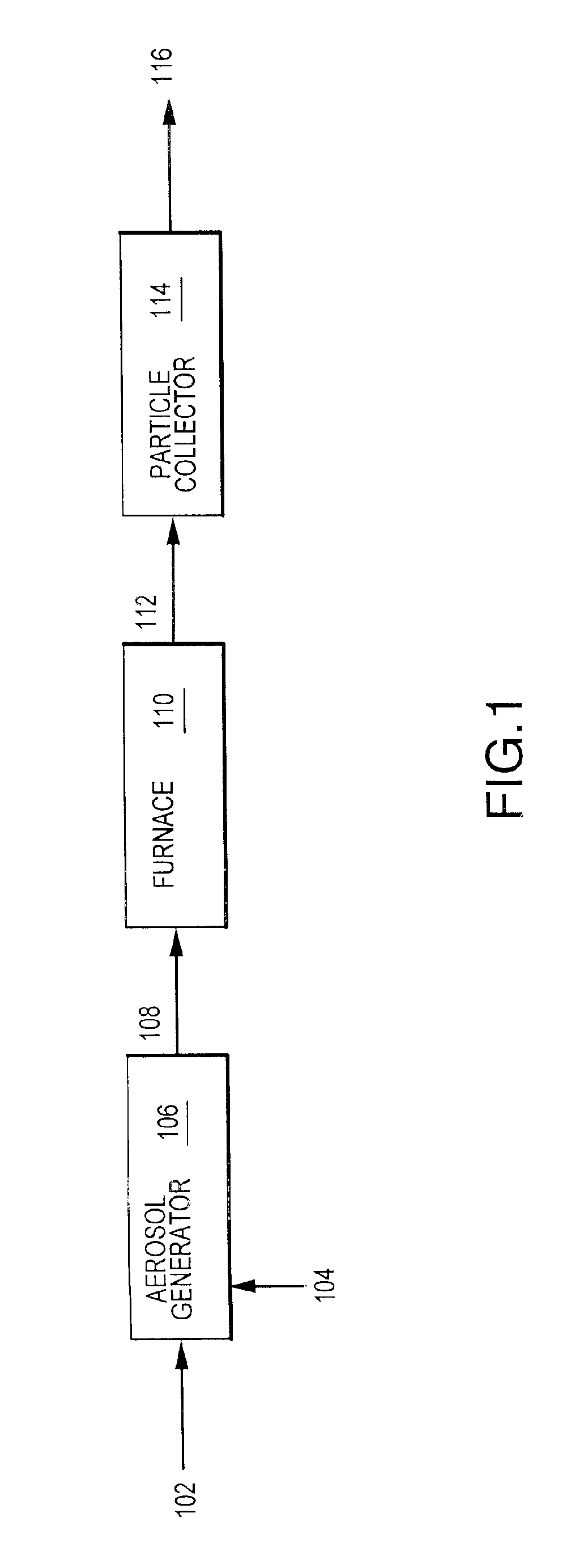

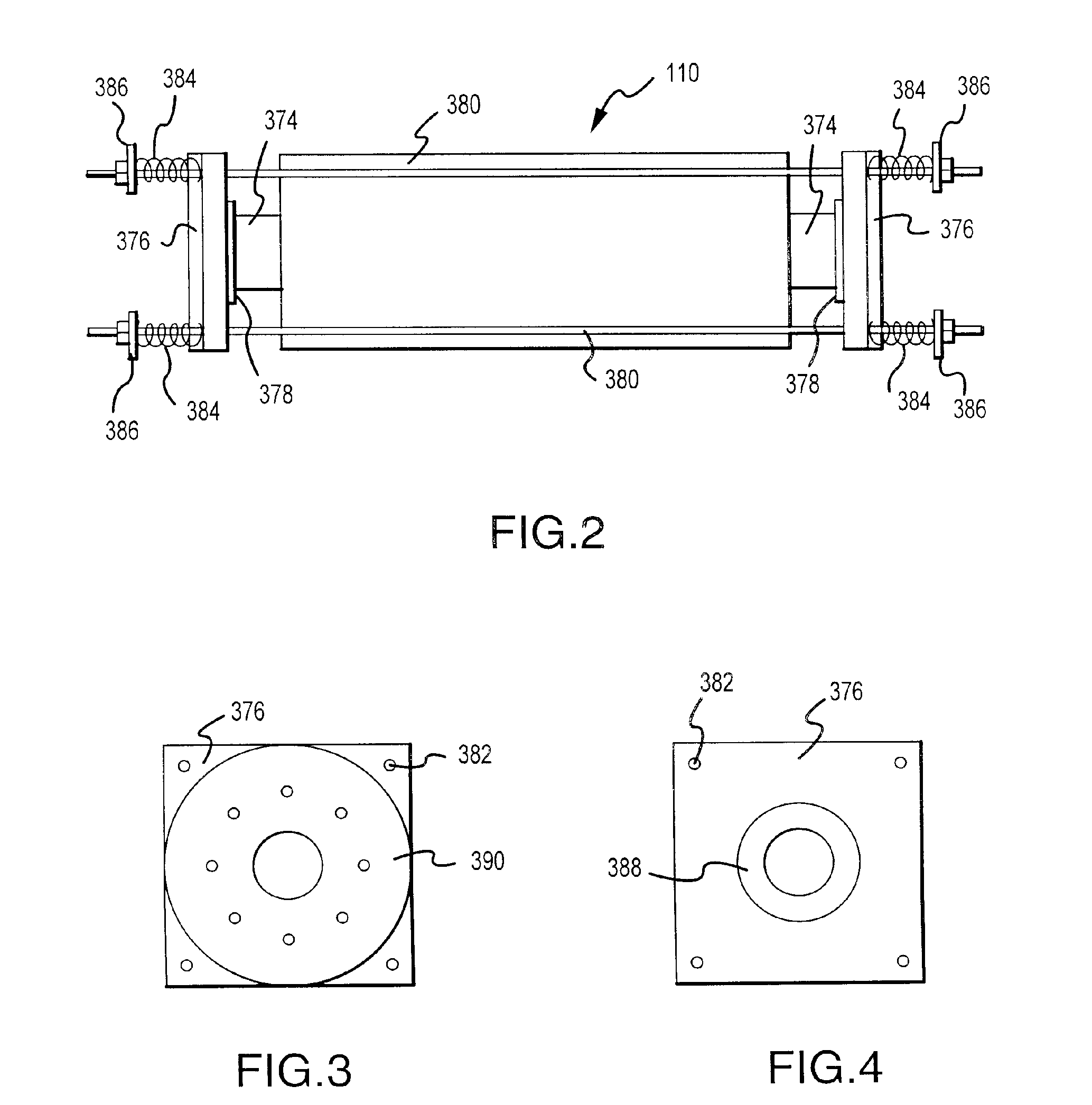

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

Surface modified colloidal abrasives, including stable bimetallic surface coated silica sols for chemical mechanical planarization

A composition and an associated method for chemical mechanical planarization (or other polishing) are described. The composition includes a surface-modified abrasive modified with at least one stabilizer and at least one catalyst differing from the at least one stabilizer. The composition can further include a medium containing the abrasive and an oxidizing agent (e.g., hydrogen peroxide), wherein the at least one catalyst is adapted to catalyze oxidation of a substrate by the oxidizing agent. Preferably, the abrasive is alumina, titania, zirconia, germania, silica, ceria and / or mixtures thereof, the stabilizer includes B, W and / or Al, and the catalyst is Cu, Fe, Mn, Ti, W and / or V. Both the stabilizer and the catalyst are immobilized on the abrasive surface. The method includes applying the composition to a substrate to be polished, such as substrates containing W, Cu and / or dielectrics.

Owner:VERSUM MATERIALS US LLC

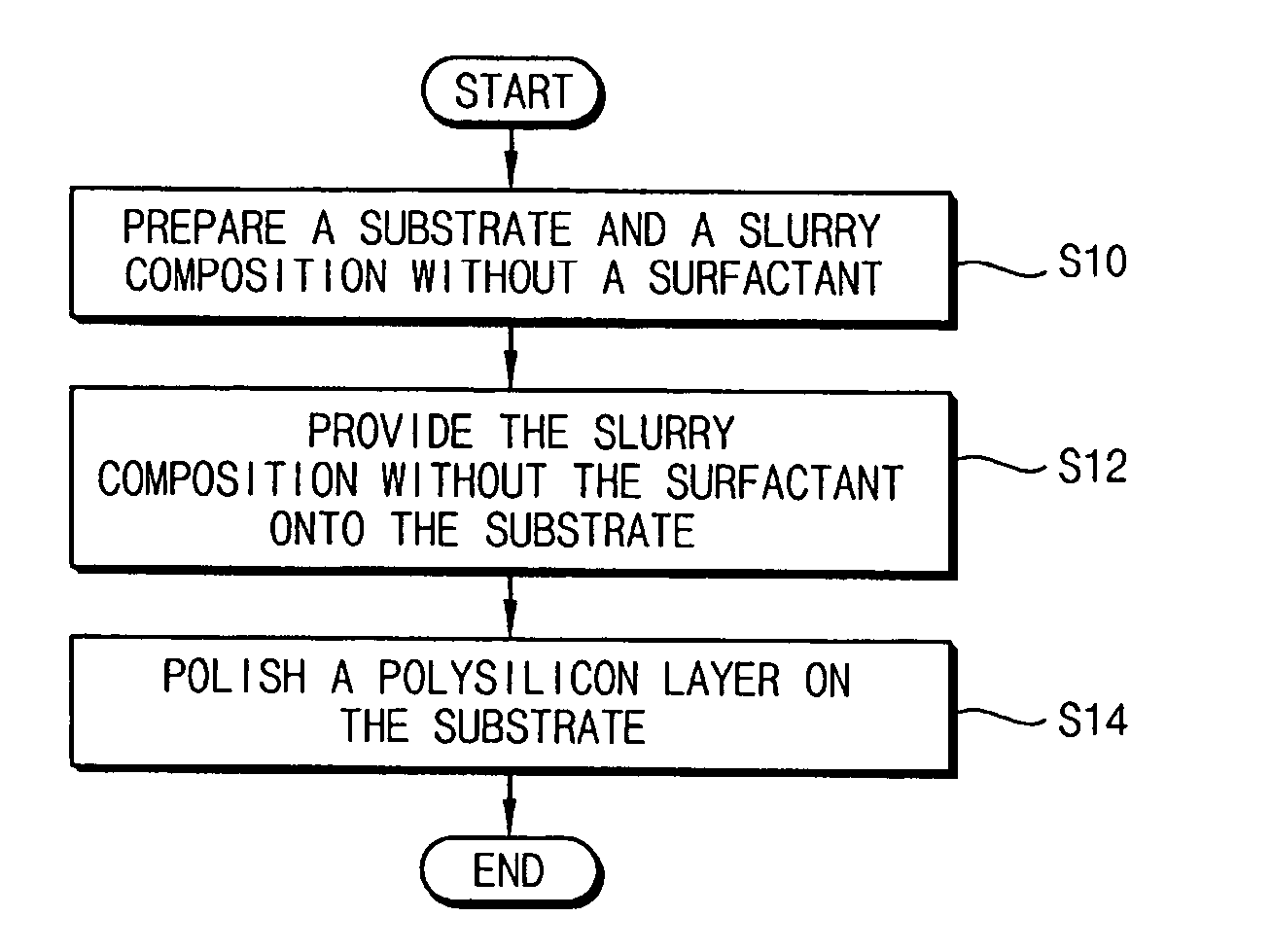

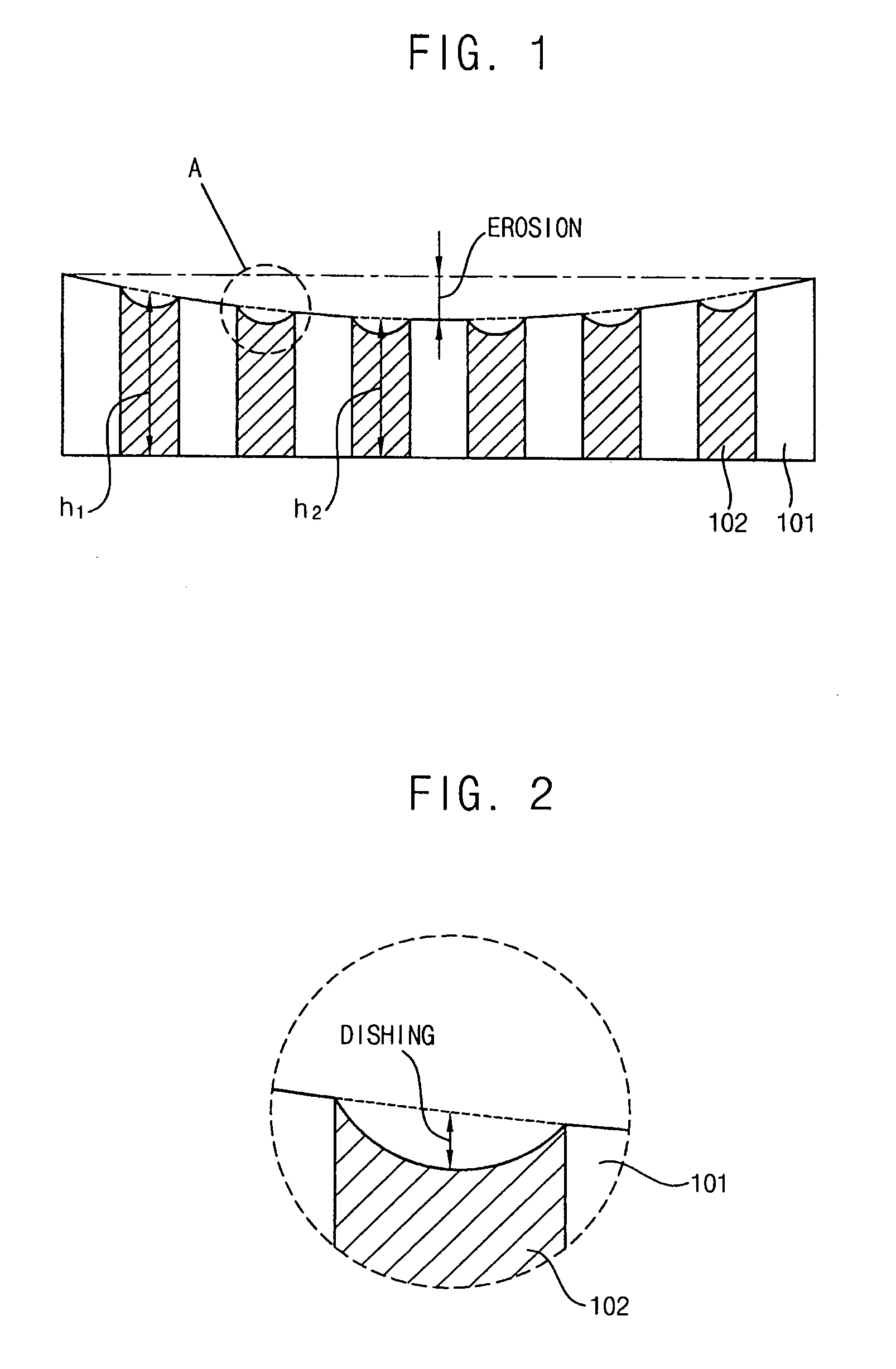

Slurry composition, polishing method using the slurry composition and method of forming a gate pattern using the slurry composition

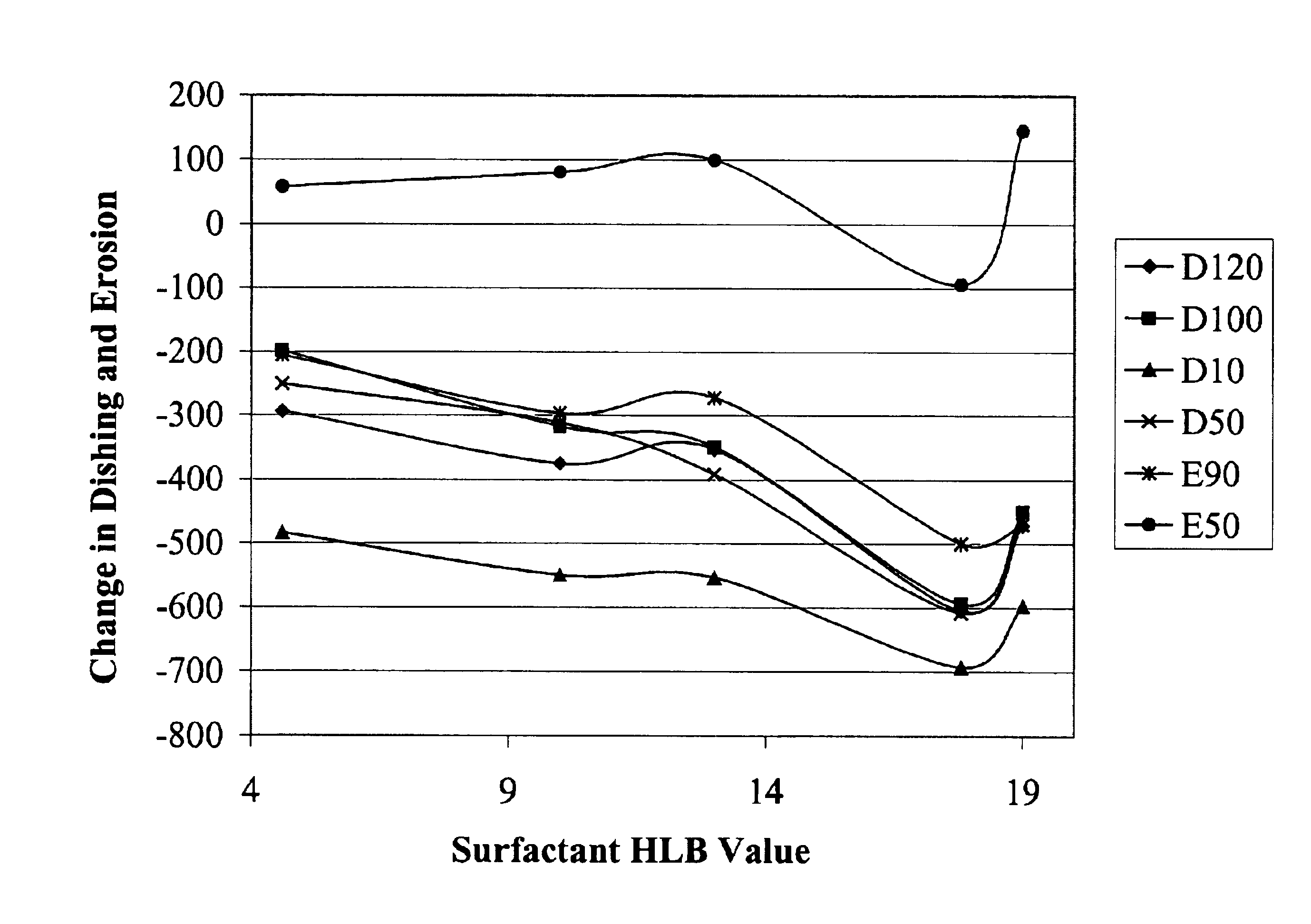

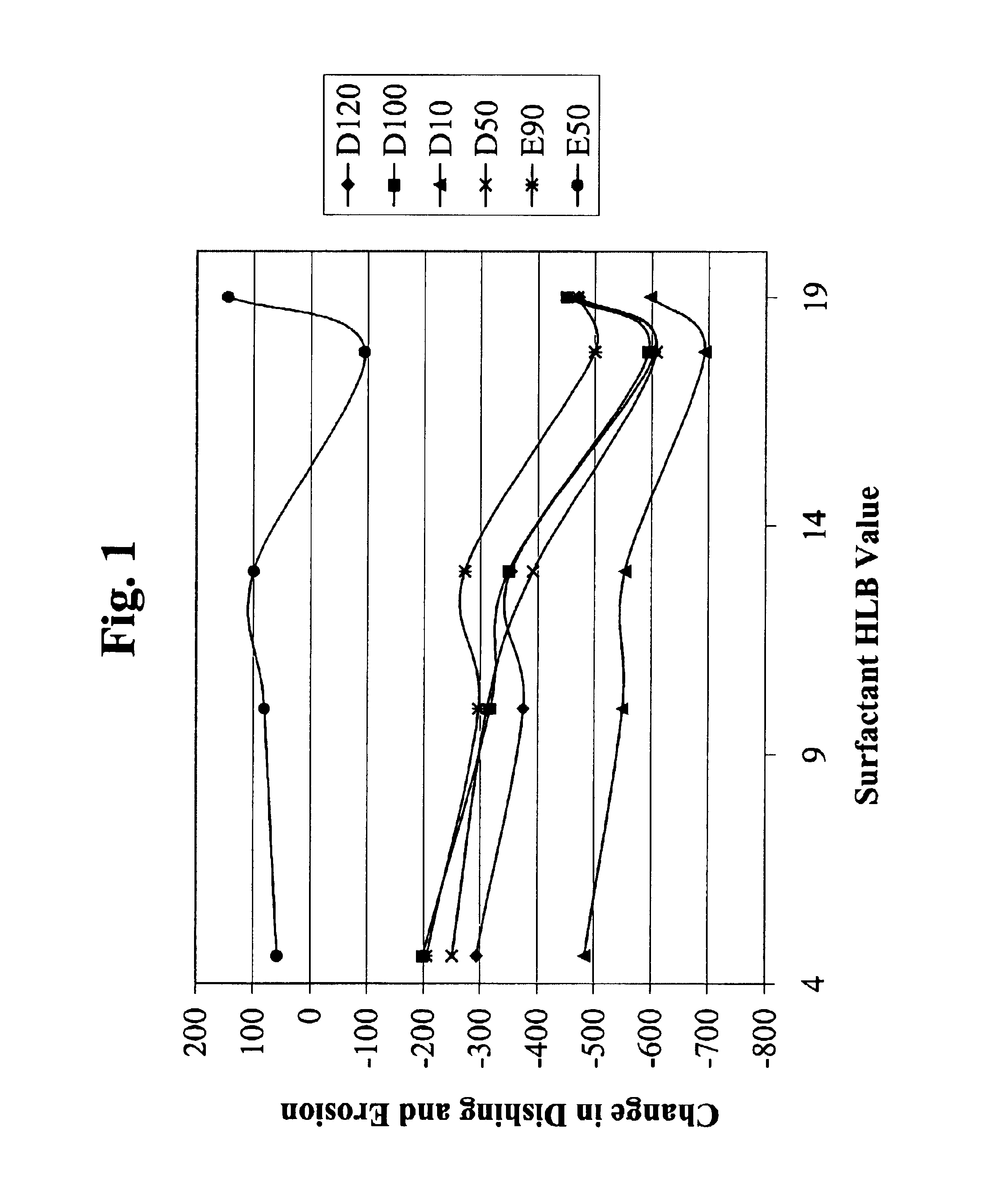

InactiveUS20060014390A1High removal rateOther chemical processesSemiconductor/solid-state device manufacturingSlurrySURFACTANT BLEND

A slurry composition includes about 4.25 to about 18.5 weight percent of an abrasive, about 80 to about 95 weight percent of deionized water, and about 0.05 to about 1.5 weight percent of an additive. The slurry composition may further include a surfactant. In a polishing method using the slurry composition, a polysilicon layer may be rapidly polished, and also dishing and erosion of the polysilicon layer may be suppressed.

Owner:SAMSUNG ELECTRONICS CO LTD

Plug or via formation using novel slurries for chemical mechanical polishing

InactiveUS6046099AOther chemical processesSemiconductor/solid-state device manufacturingIntegrated circuit manufacturingPotassium ferricyanide

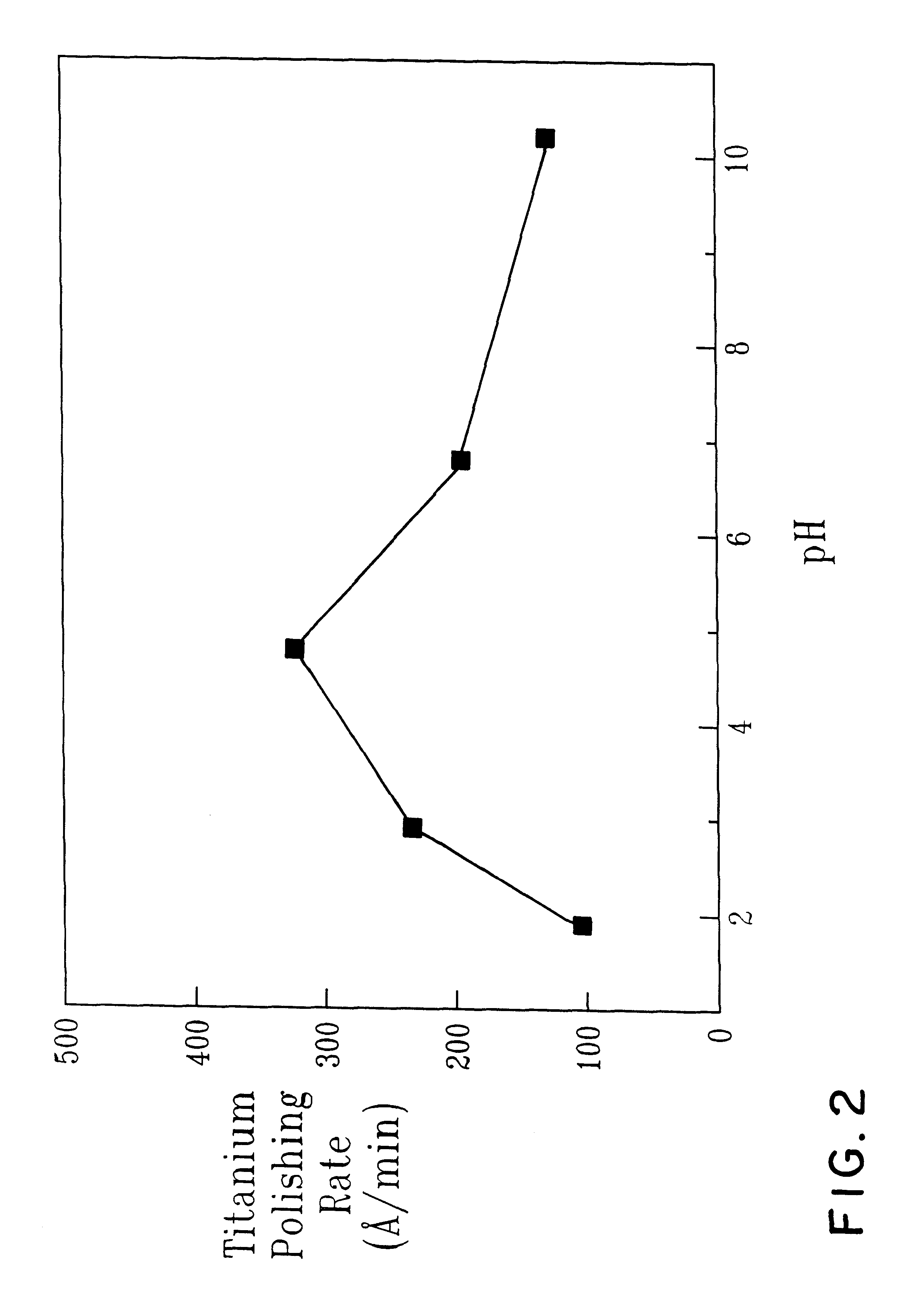

Novel slurries for the chemical mechanical polishing of thin films used in integrated circuit manufacturing. A tungsten slurry of the present invention comprises an oxidizing agent, such as potassium ferricyanide, an abrasive such as silica, and has a pH between two and four. The tungsten slurry of the present invention can be used in a chemical mechanical planarization process to polish back a blanket deposited tungsten film to form plugs or vias. The tungsten slurry can also be used to polish copper, tungsten silicide, and titanium nitride. A second slurry, which is a 9:1 dilution of the tungsten slurry is ideal for chemical mechanical polishing of titanium nitride films. A third slurry of the present invention comprises a fluoride salt, an abrasive such as silica and has a pH< / =8. The third slurry can be used to polish titanium films.

Owner:INTEL CORP

Particulate or particle-bound chelating agents

The invention generally relates to compositions and methods for chemically mechanically polishing a substrate, including a polishing accelerator, which is normally one or more oxidizers, an abrasive material, and chelating particles and / or metal-absorbent clay material. In addition, the invention can also involve methods of forming chelator particles and methods of separating metal-containing ions from polishing and / or etching solutions after polishing and / or etching.

Owner:VERSUM MATERIALS US LLC

Raspberry-type metal oxide nanostructures coated with ceo2 nanoparticles for chemical mechanical planarization (CMP)

InactiveUS20120077419A1Efficient processCost-effective and convenient processMaterial nanotechnologySilicaCeo2 nanoparticlesWater soluble

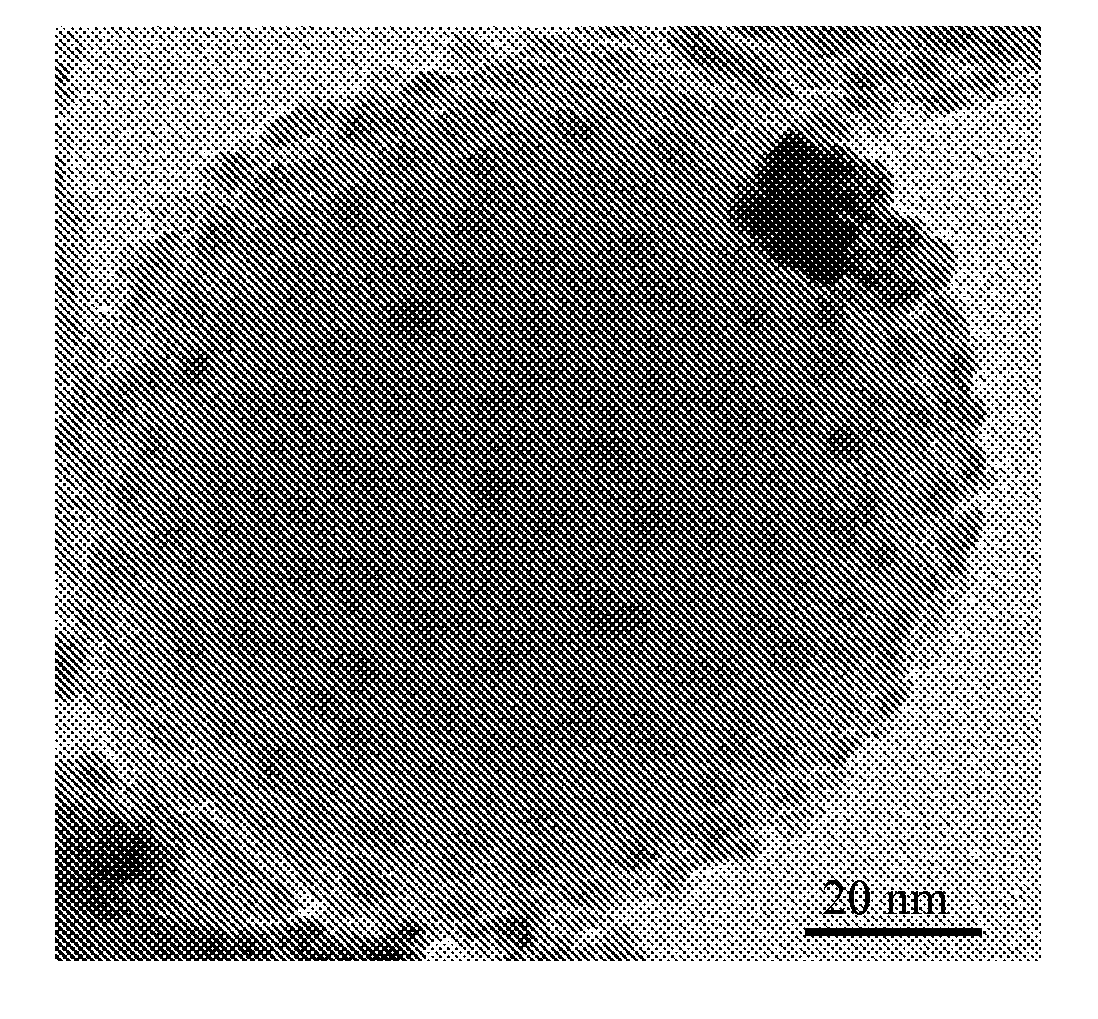

Raspberry-type coated particles comprising a core selected from the group consisting of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof with a core size of from 20 to 100 nm wherein the core is coated with CeCO2 particles having a particle size below 10 nm; process for preparing raspberry type coated particles comprising the steps of i) providing a mixture containing: a) core particles selected from the group of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof, with a particle size of from 20 to 100 nm; b) a water soluble Ce-salt and c) water; ii) adding an organic or inorganic base to the mixture of step i) at temperatures of from 10 to 90° C. and iii) aging the mixture at temperatures of from 10 to 90° C.; and polishing agents containing the particles and their use for polishing surfaces.

Owner:BASF AG

Polishing slurry

ActiveUS20090311864A1Avoid corrosionLow costMaterial nanotechnologyOther chemical processesMetallurgySlurry

A polishing slurry used in chemical mechanical polishing of a barrier layer and an interlayer dielectric film in a semiconductor integrated circuit includes an abrasive, an oxidizer, an anticorrosive, an acid, a surfactant and an inclusion compound. The polishing slurry has a pH of less than 5. The resulting polishing slurry contains a solid abrasive used in barrier CMP for polishing a barrier layer made of a metallic barrier material, has excellent storage stability, achieves a good polishing rate in various films to be polished such as the barrier layer, and is capable of independently controlling the polishing rate with respect to the various films to be polished while further suppressing agglomeration of the abrasive particles.

Owner:FUJIFILM CORP

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

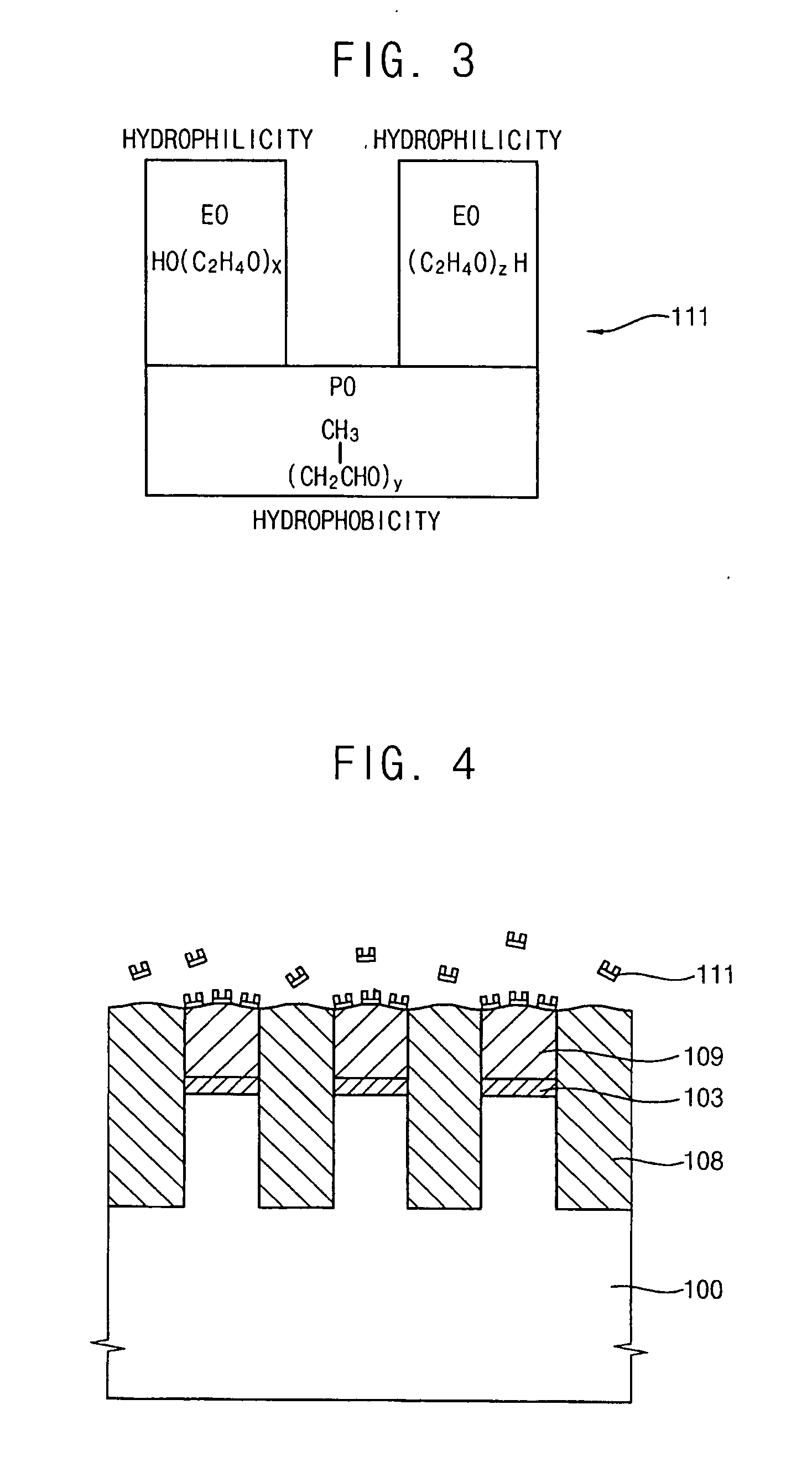

Slurry compositions and CMP methods using the same

InactiveUS20050130428A1Reduce and eliminate excessive removalOther chemical processesSemiconductor/solid-state device manufacturingArylSlurry

The exemplary embodiments of the present invention providing new slurry compositions suitable for use in processes involving the chemical mechanical polishing (CMP) of a polysilicon layer. The slurry compositions include one or more non-ionic polymeric surfactants that will selectively form a passivation layer on an exposed polysilicon surface in order to suppress the polysilicon removal rate relative to silicon oxide and silicon nitride and improve the planarity of the polished substrate. Exemplary surfactants include alkyl and aryl alcohols of ethylene oxide (EO) and propylene oxide (PO) block copolymers and may be present in the slurry compositions in an amount of up to about 5 wt %, although much smaller concentrations may be effective. Other slurry additives may include viscosity modifiers, pH modifiers, dispersion agents, chelating agents, and amine or imine surfactants suitable for modifying the relative removal rates of silicon nitride and silicon oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

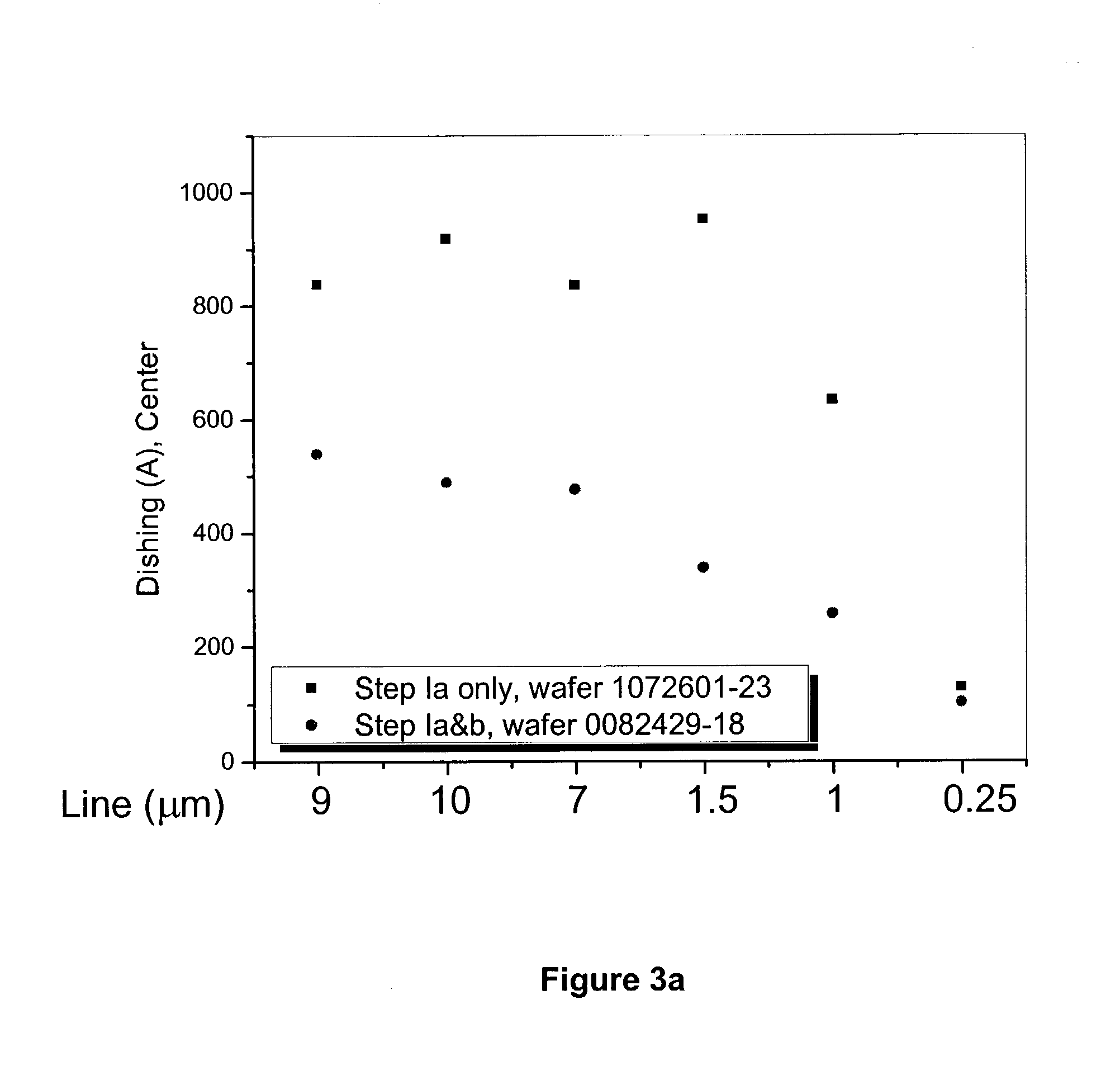

CMP method utilizing amphiphilic nonionic surfactants

InactiveUS6936543B2Other chemical processesSemiconductor/solid-state device manufacturingOrganic acidCopper

The invention provides methods of polishing a substrate comprising (i) contacting a substrate comprising at least one metal layer comprising copper with a chemical-mechanical polishing (CMP) system and (ii) abrading at least a portion of the metal layer comprising copper to polish the substrate. The CMP system comprises (a) an abrasive, (b) an amphiphilic nonionic surfactant, (c) a means for oxidizing the metal layer, (d) an organic acid, (e) a corrosion inhibitor, and (f) a liquid carrier. The invention further provides a two-step method of polishing a substrate comprising a first metal layer and a second, different metal layer. The first metal layer is polishing with a first CMP system comprising an abrasive and a liquid carrier, and the second metal layer is polished with a second CMP system comprising (a) an abrasive, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier.

Owner:CMC MATERIALS INC

High throughput chemical mechanical polishing composition for metal film planarization

InactiveUS20080254628A1Semiconductor/solid-state device manufacturingLapping machinesMaterial removalHigh flux

A chemical mechanical polishing process including a single copper removal CMP slurry formulation for planarization of a microelectronic device structure preferably having copper deposited thereon. The process includes the bulk removal of a copper layer using a first CMP slurry formulation having oxidizing agent, passivating agent, abrasive and solvent, and the soft polishing and over-polishing of the microelectronic device structure using a formulation including the first CMP slurry formulation and at least one additional additive. The CMP process described herein provides a high copper removal rate, a comparatively low barrier material removal rate, appropriate material selectivity ranges to minimize copper dishing at the onset of barrier material exposure, and good planarization efficiency.

Owner:ADVANCED TECH MATERIALS INC

Polishing slurry for silicon oxide, additive liquid and polishing method

InactiveUS20070175104A1Increase speedInhibit progressPigmenting treatmentOther chemical processesPolyethylene glycolSlurry

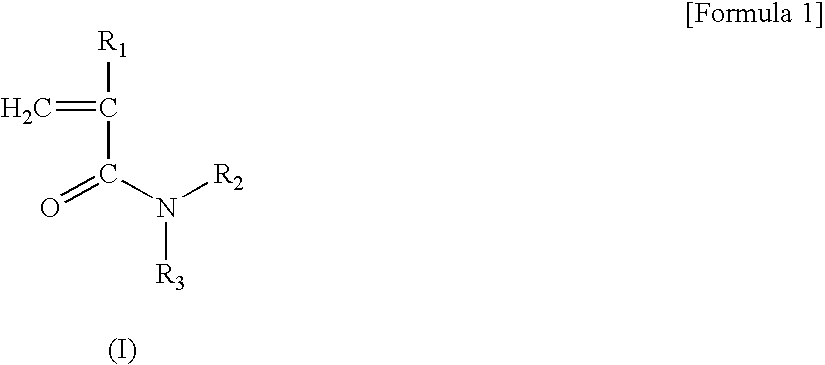

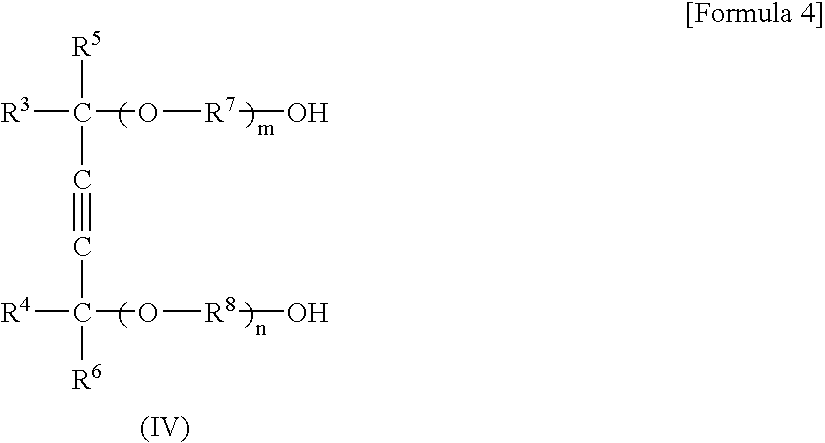

The polishing slurry of the invention is a polishing slurry for polishing a silicon oxide film on polysilicon, which contains an abrasive, polysilicon polishing inhibitor, and water. As the polishing inhibitor, it is preferable to use (1) a water-soluble polymer having a N-monosubstituted or N,N-disubstituted skeleton substituted by any member selected from the group consisting of acrylamide, methacrylamide, and α-substituted derivatives thereof, (2) polyethylene glycol, (3) an oxyethylene adduct of an acetylene-based diol, (4) a water-soluble organic compound having an acetylene bond, (5) an alkoxylated linear aliphatic alcohol, or (6) a copolymer containing polyvinyl pyrrolidone or vinyl pyrrolidone. There is provided a polishing method which is capable of polishing a silicon oxide film on a polysilicon film at a high speed, and inhibiting the progress of polishing of a polysilicon film in exposed parts in the manufacturing method for a semiconductor.

Owner:HITACHI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com