Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387 results about "Dielectric surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

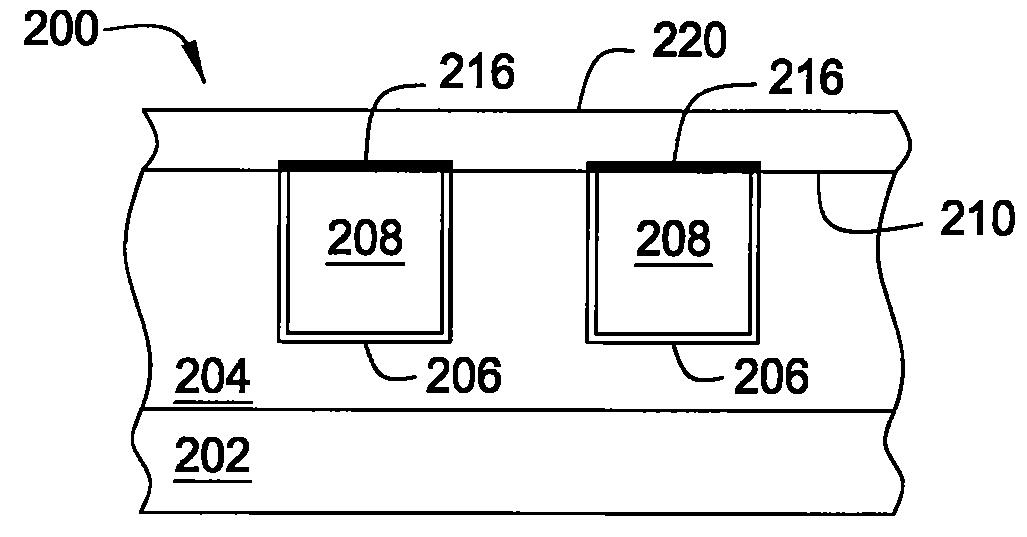

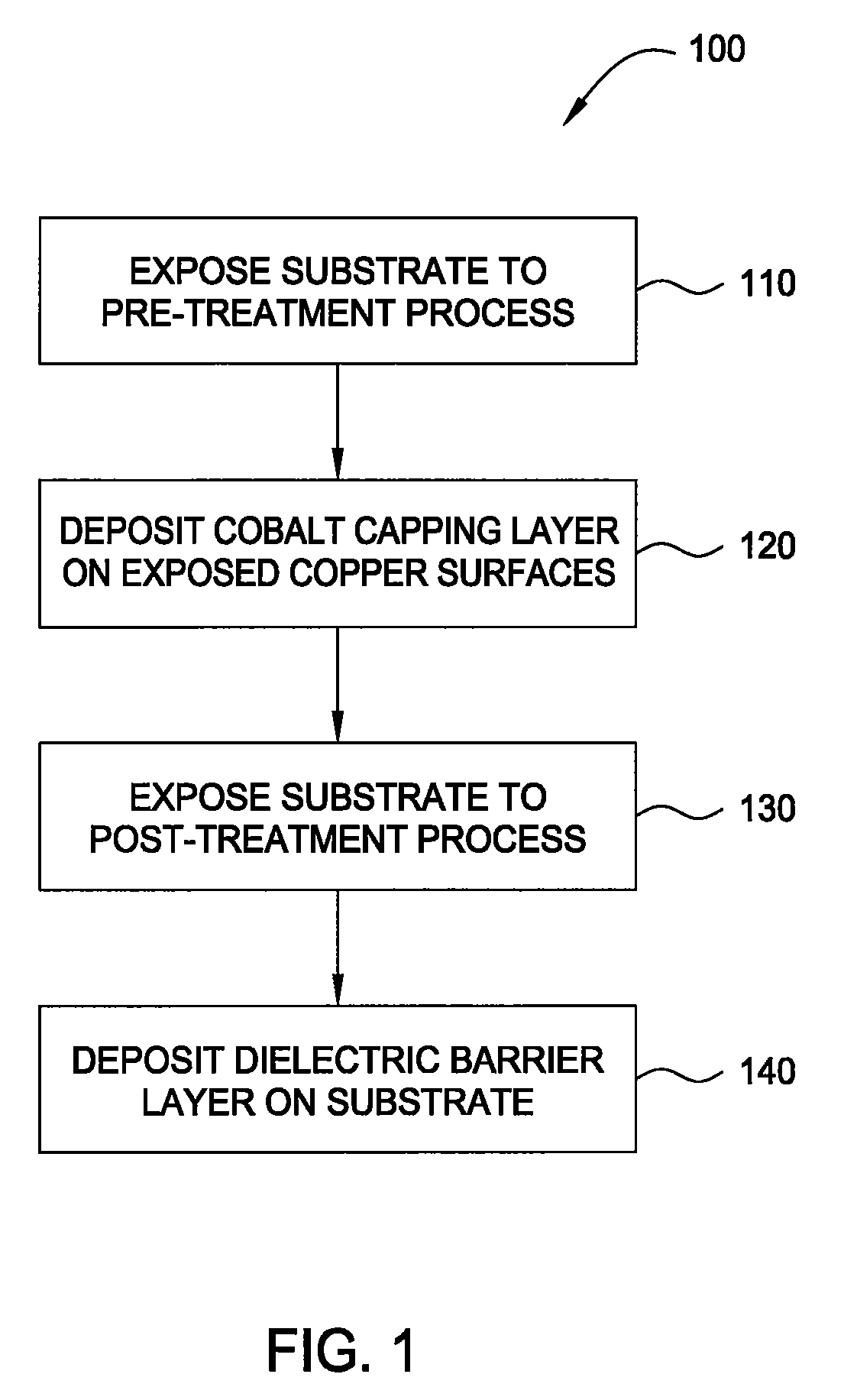

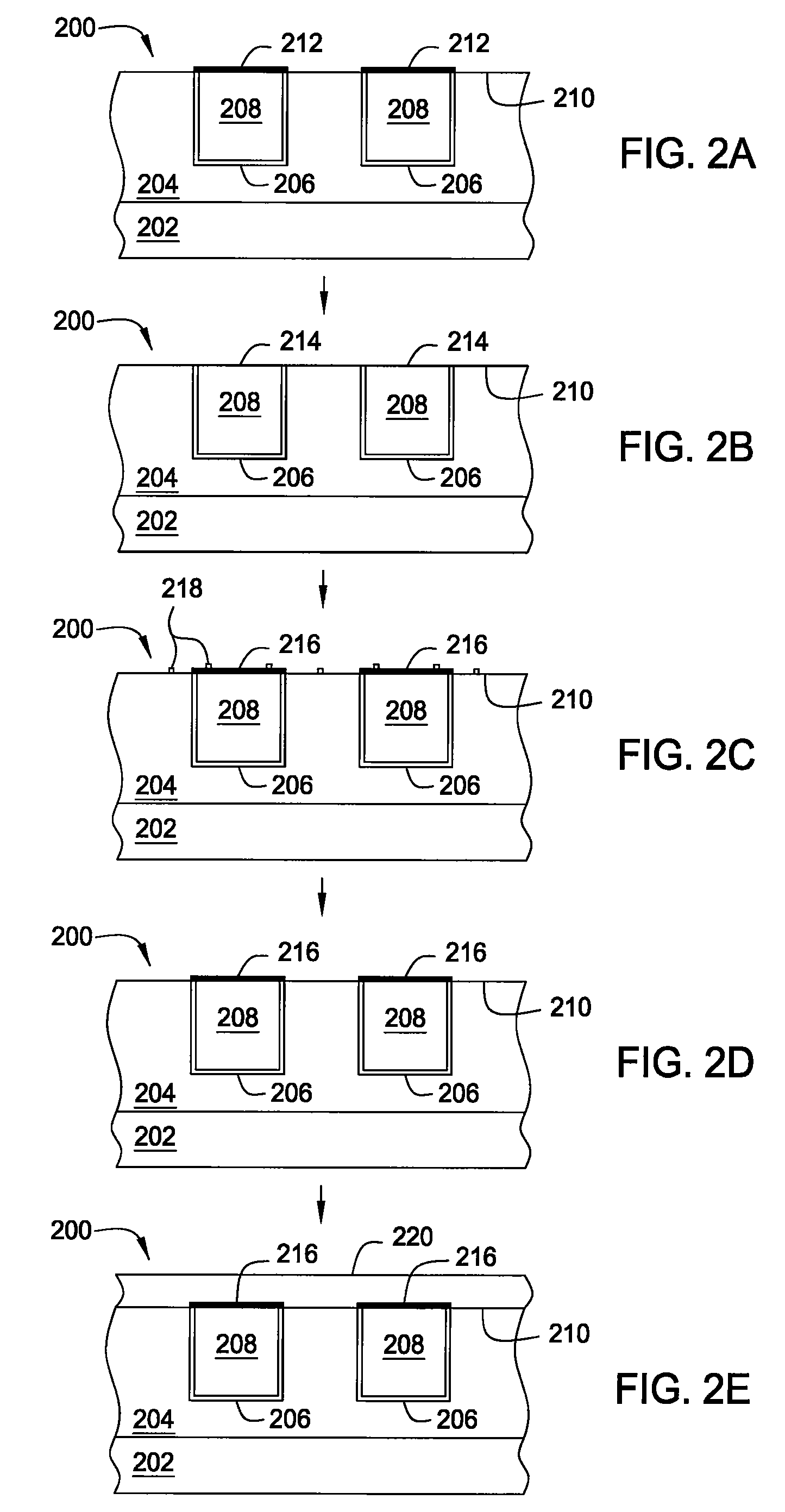

Selective cobalt deposition on copper surfaces

InactiveUS20090269507A1Pretreated surfacesSemiconductor/solid-state device manufacturingGas phaseDielectric surface

Embodiments of the invention provide processes to selectively form a cobalt layer on a copper surface over exposed dielectric surfaces. In one embodiment, a method for capping a copper surface on a substrate is provided which includes positioning a substrate within a processing chamber, wherein the substrate contains a contaminated copper surface and a dielectric surface, exposing the contaminated copper surface to a reducing agent while forming a copper surface during a pre-treatment process, exposing the substrate to a cobalt precursor gas to selectively form a cobalt capping layer over the copper surface while leaving exposed the dielectric surface during a vapor deposition process, and depositing a dielectric barrier layer over the cobalt capping layer and the dielectric surface. In another embodiment, a deposition-treatment cycle includes performing the vapor deposition process and subsequently a post-treatment process, which deposition-treatment cycle may be repeated to form multiple cobalt capping layers.

Owner:APPLIED MATERIALS INC

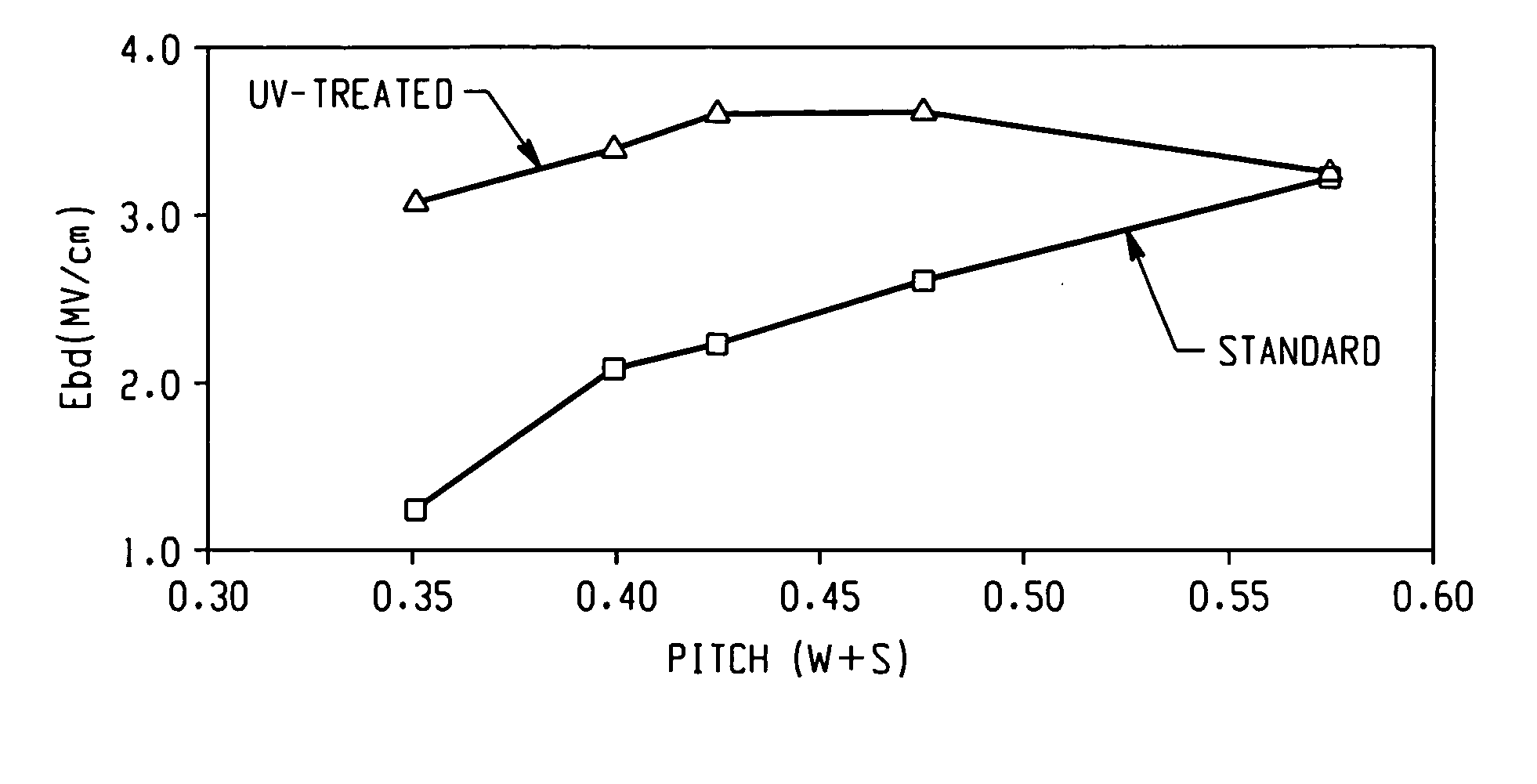

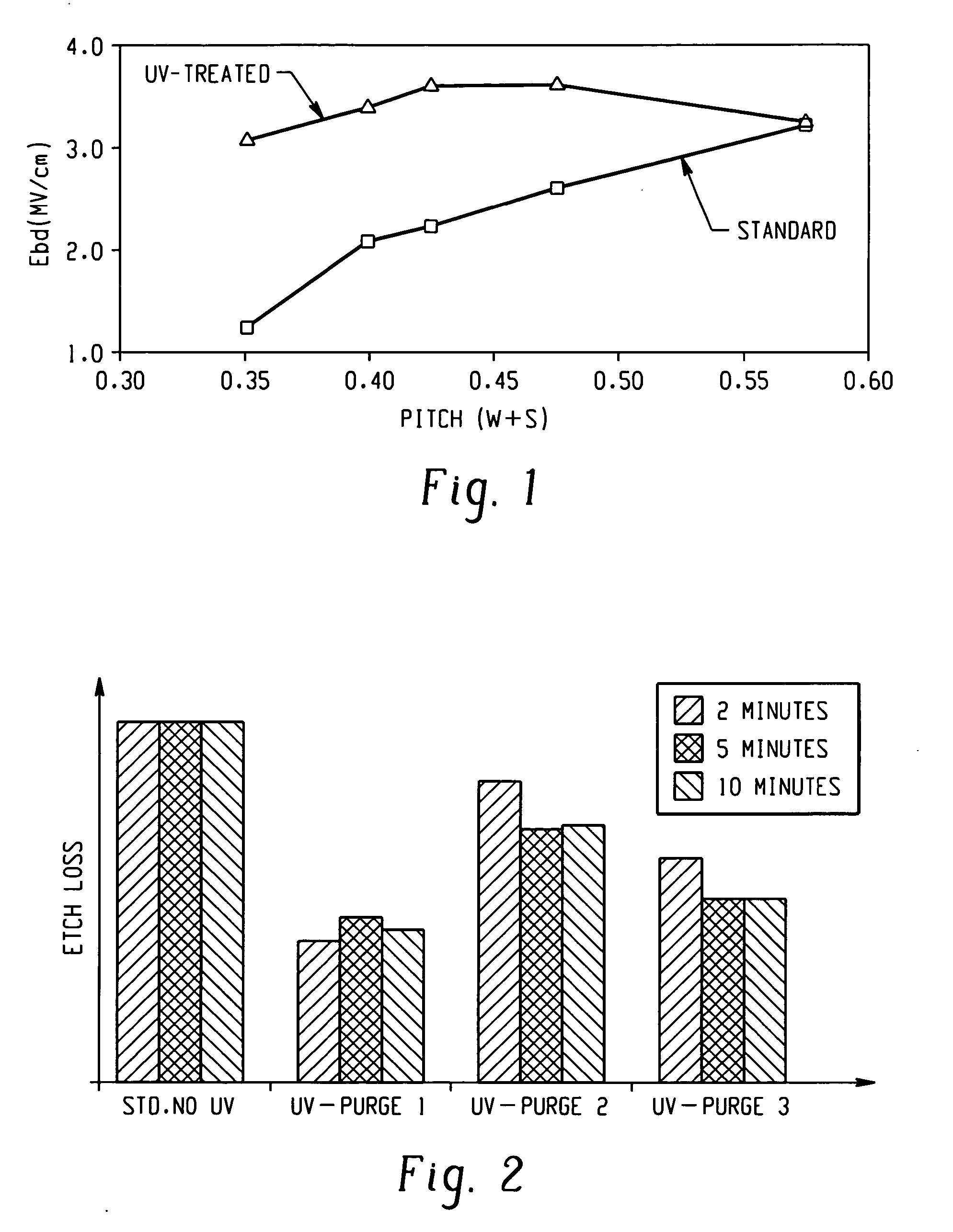

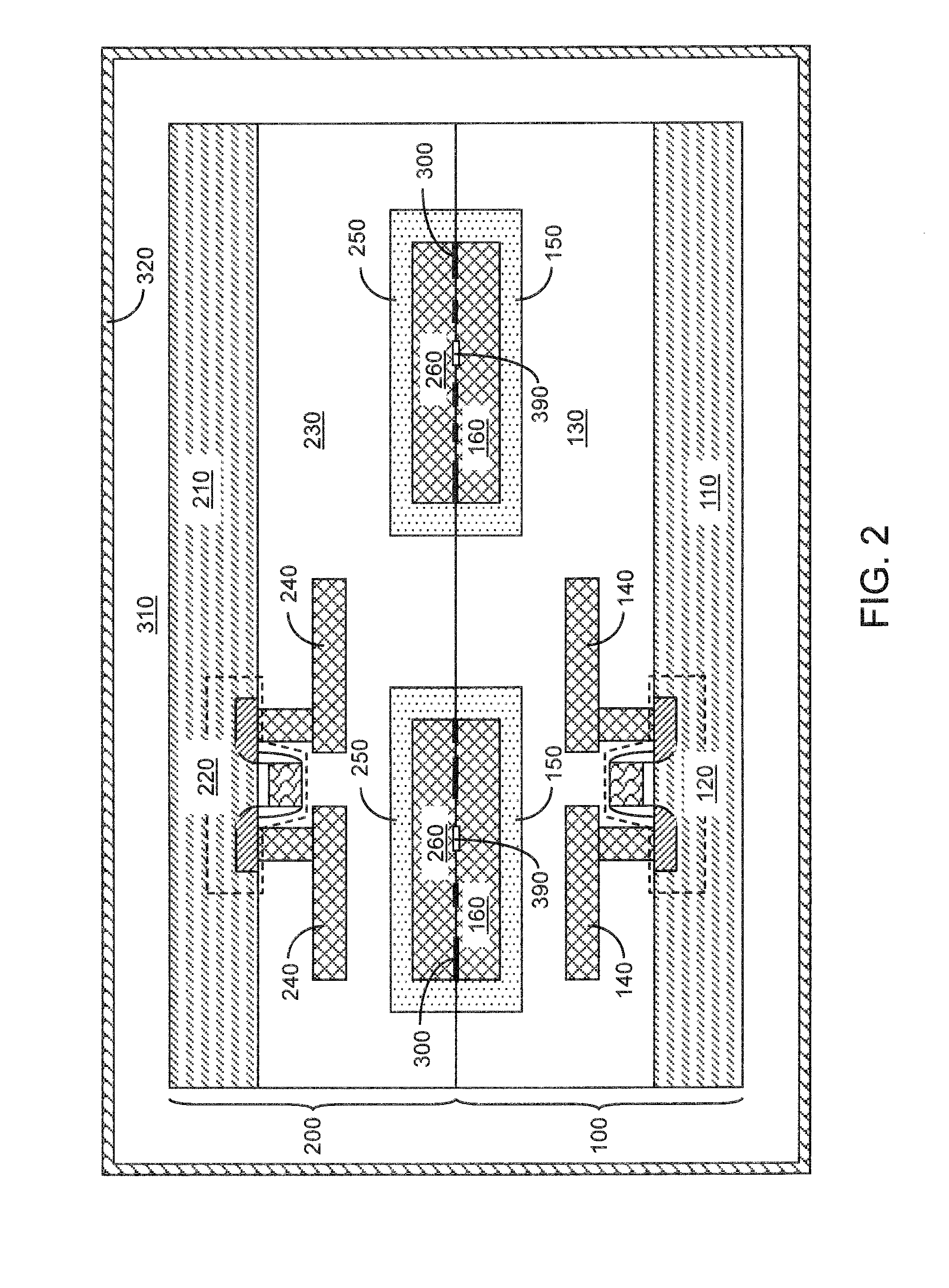

Ultraviolet assisted pore sealing of porous low k dielectric films

InactiveUS20060105566A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airCarbonization

Processes for sealing porous low k dielectric film generally comprises exposing the porous surface of the porous low k dielectric film to ultraviolet (UV) radiation at intensities, times, wavelengths and in an atmosphere effective to seal the porous dielectric surface by means of carbonization, oxidation, and / or film densification. The surface of the surface of the porous low k material is sealed to a depth less than or equal to about 20 nanometers, wherein the surface is substantially free of pores after the UV exposure.

Owner:AXCELIS TECHNOLOGIES

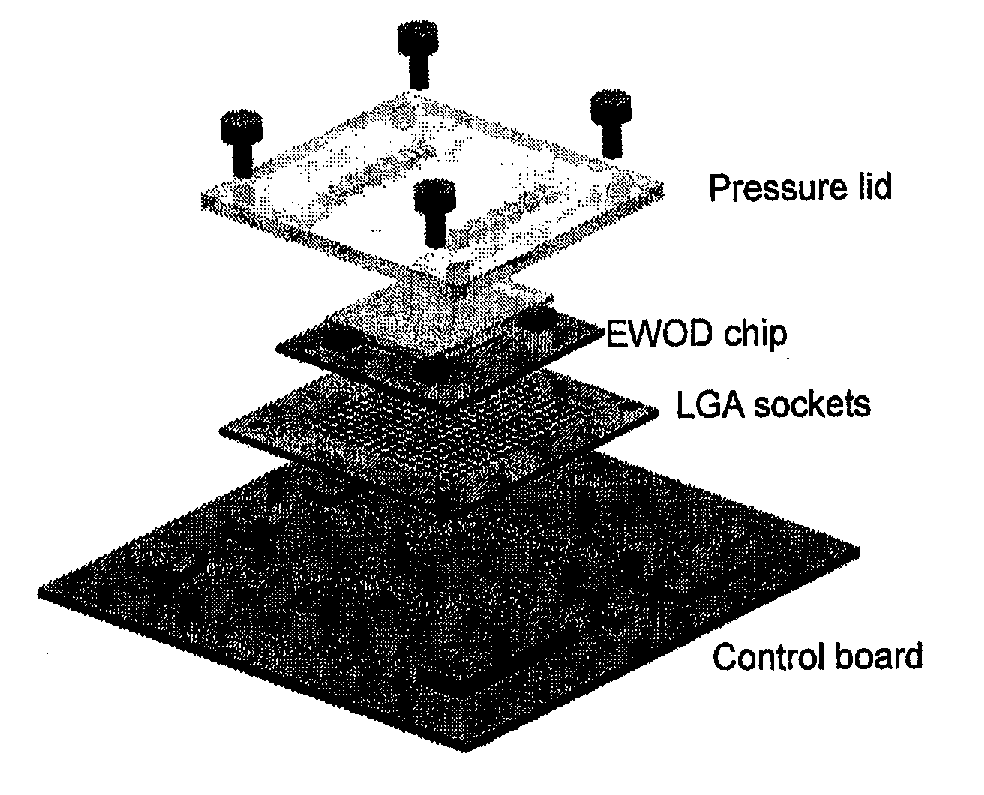

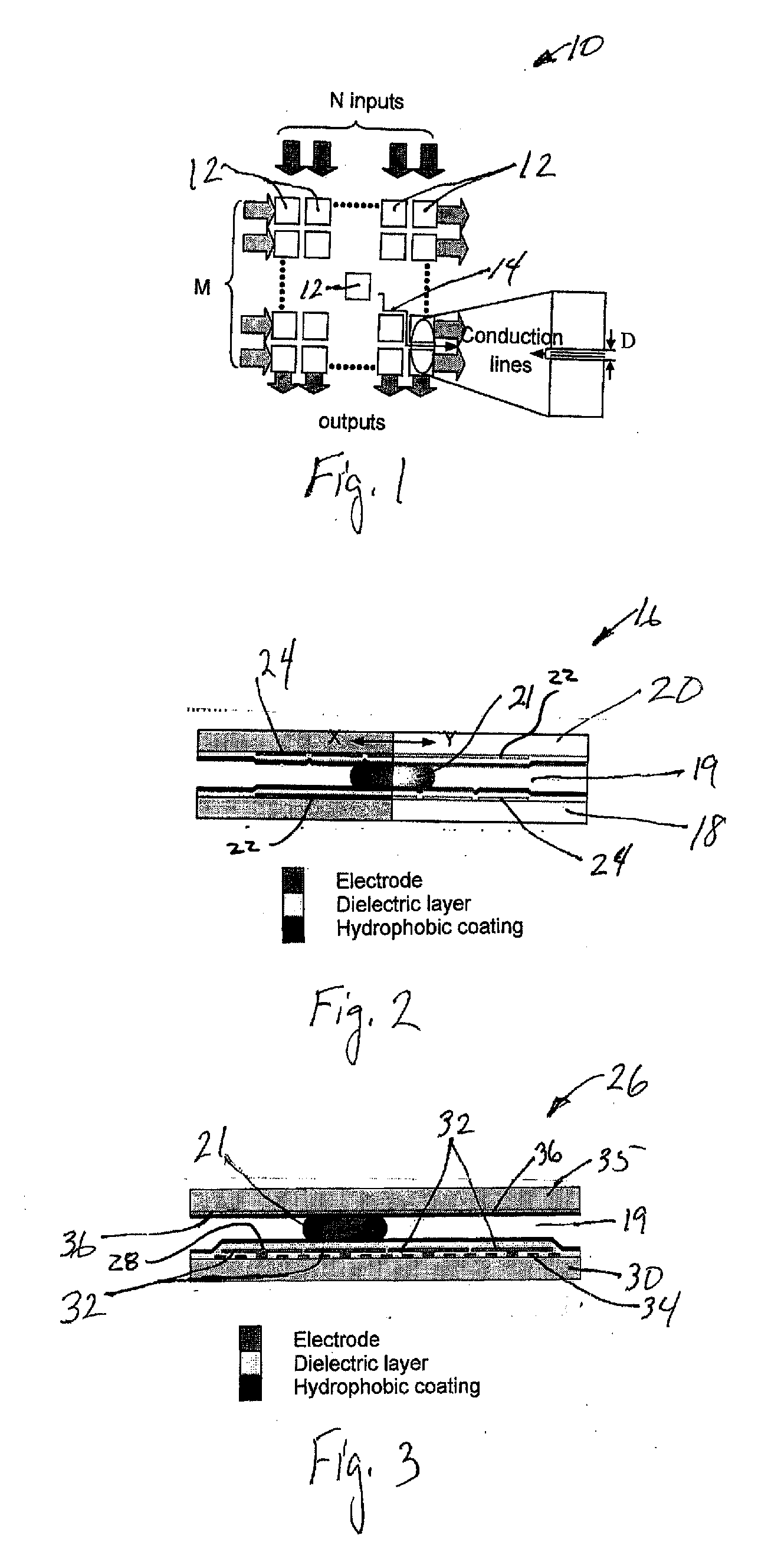

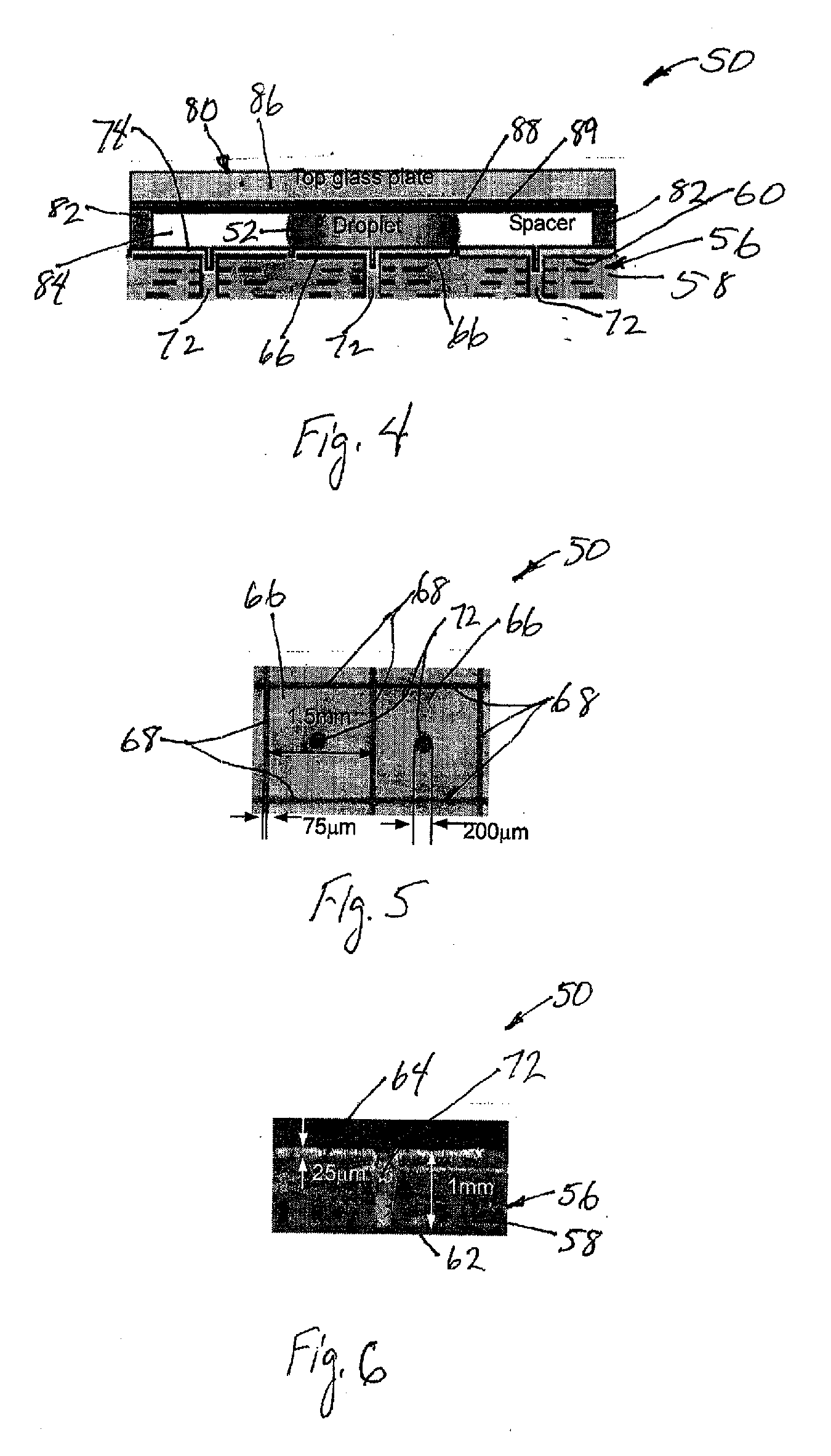

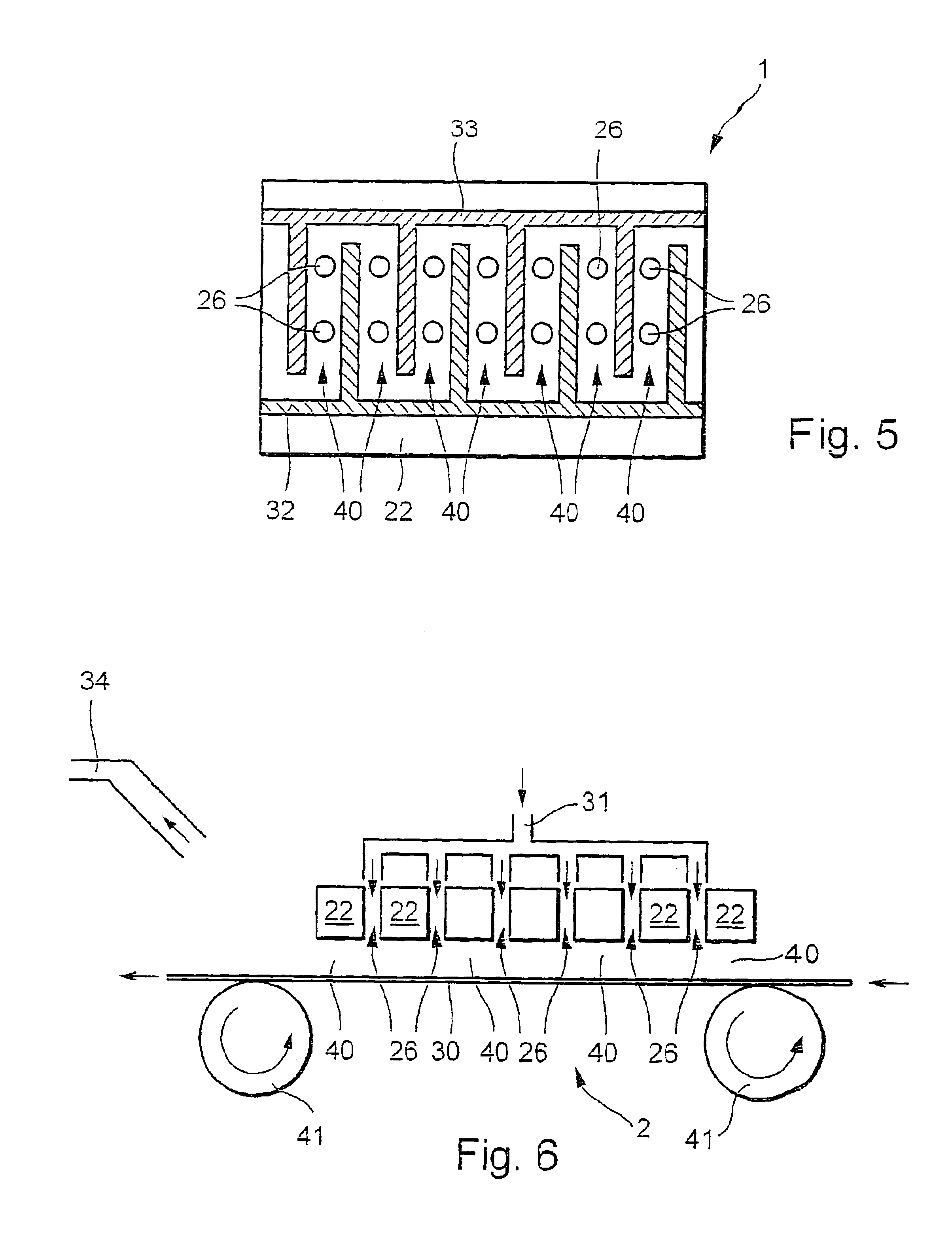

Small object moving on printed circuit board

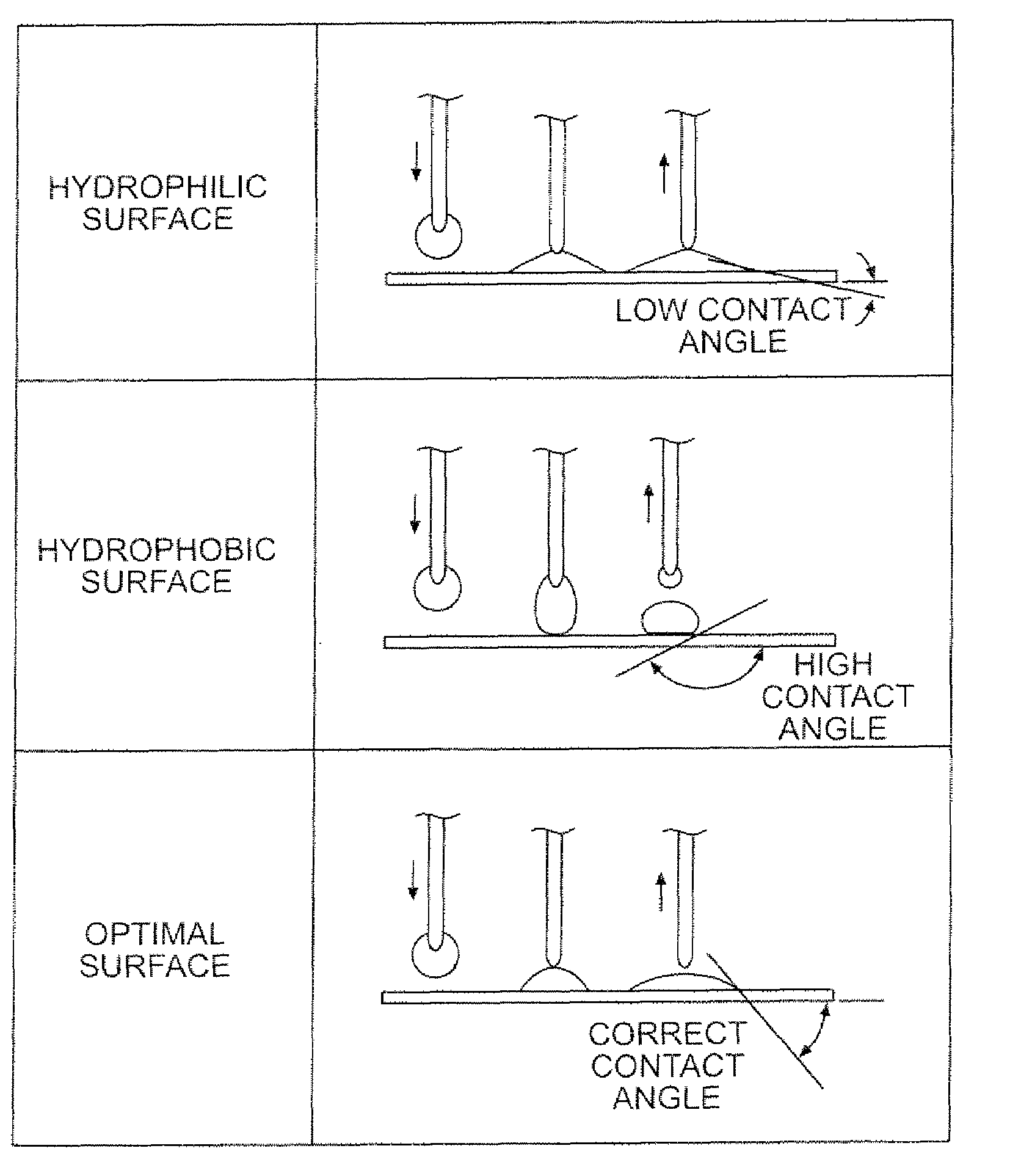

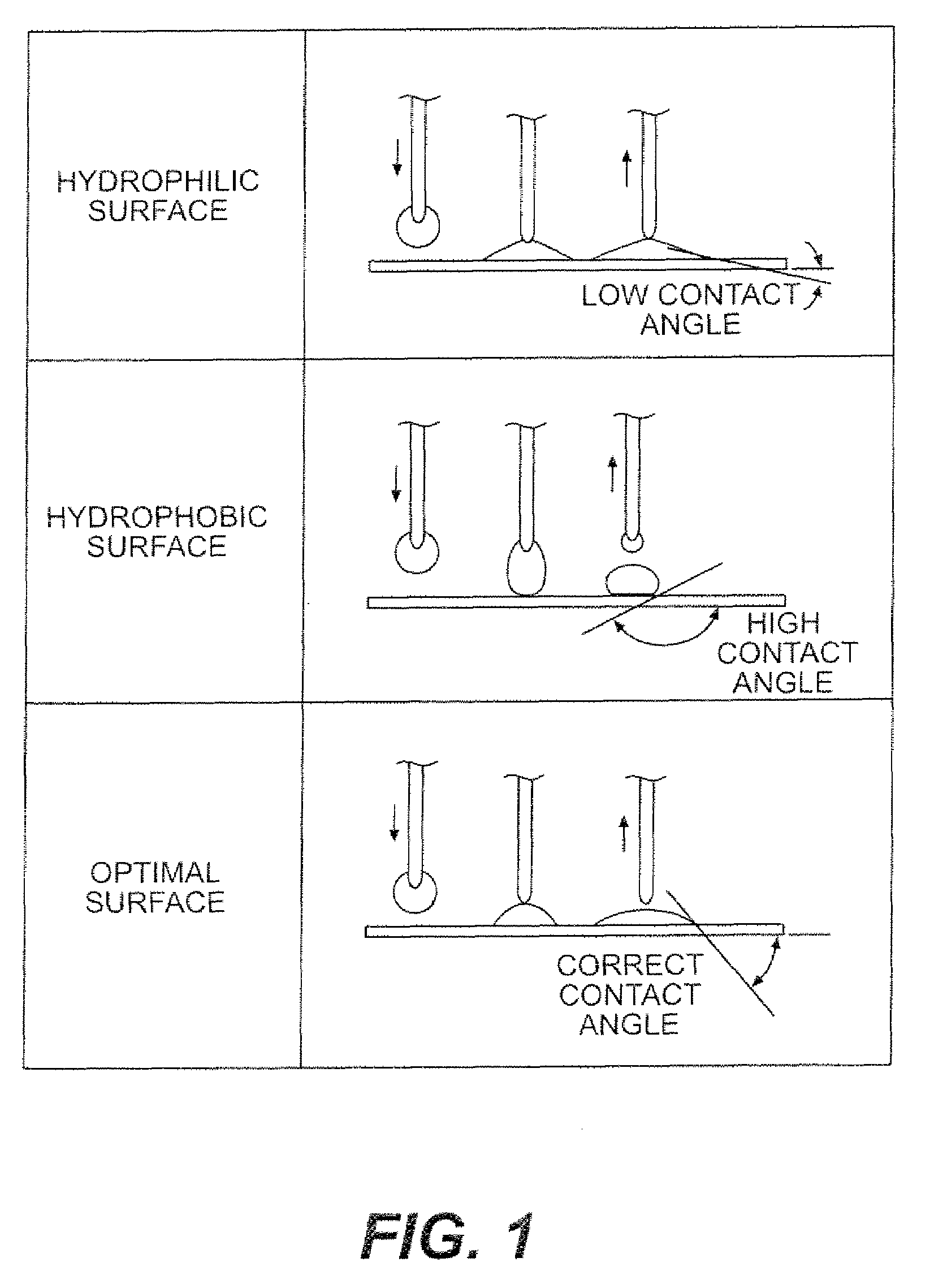

A printed circuit board based digital or droplet microfluidic system and method for producing such microfluidic system are disclosed. The digital microfluidic device comprises a printed circuit board having a substrate and a plurality of electrode pads disposed on the top surface of the substrate in a rectangular array. A via extends from each electrode pad through the substrate to other locations on the substrate . A dielectric layer is disposed on the electrode pads. Droplets may be manipulated using electrowetting principles and others by applying a voltage to the desired electrodes. Each electrode pad can be controlled directly and independently from the other electrode pads to modify the surface wettability of the dielectric layer in the vicinity of the electrode pad by applying a voltage to the desired electrode pad(s). In this way, droplets may be formed, moved, mixed, and / or divided or other small objects manipulated while in air or immersed in a liquid on the dielectric surface.

Owner:RGT UNIV OF CALIFORNIA

Method and apparatus for controlling contact of biomedical electrodes with patient skin

A method of monitoring the contact of a biomedical electrode to skin of a patient is disclosed, where the phase angle of current flow through one portion of the electrode is compared to the phase angle of current flow through another portion of the electrode. The two portions are both electrical conductors, one having a lossy dielectric surface and the other bare metal. Any monitoring of an electrical interface is possible based on the difference in phase angle. Lift of any portion of the electrode from contact with skin of a patient can be monitored more easily than using conventional Contact Quality Monitoring circuitry and "split plate patient plates."

Owner:3M INNOVATIVE PROPERTIES CO

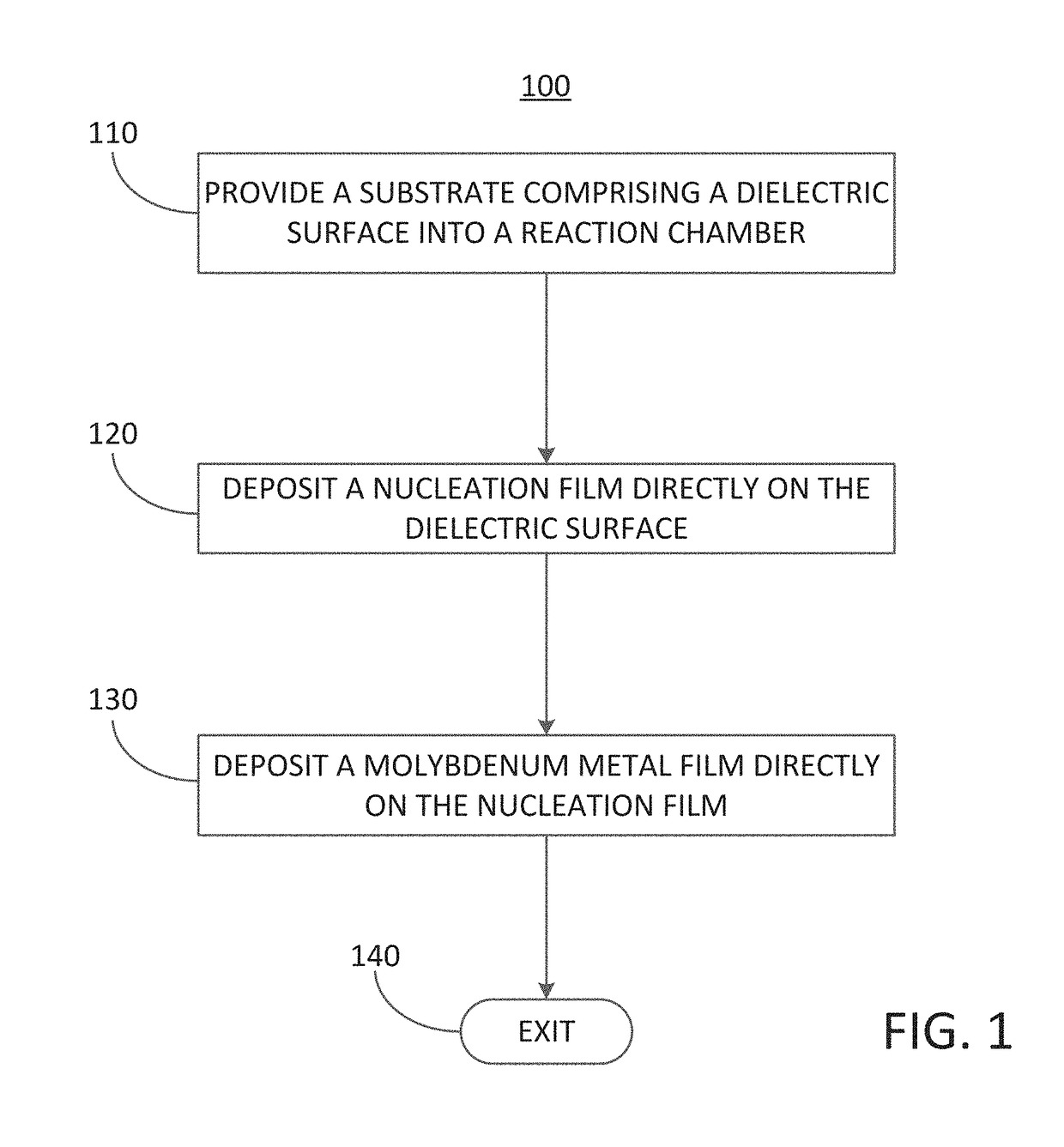

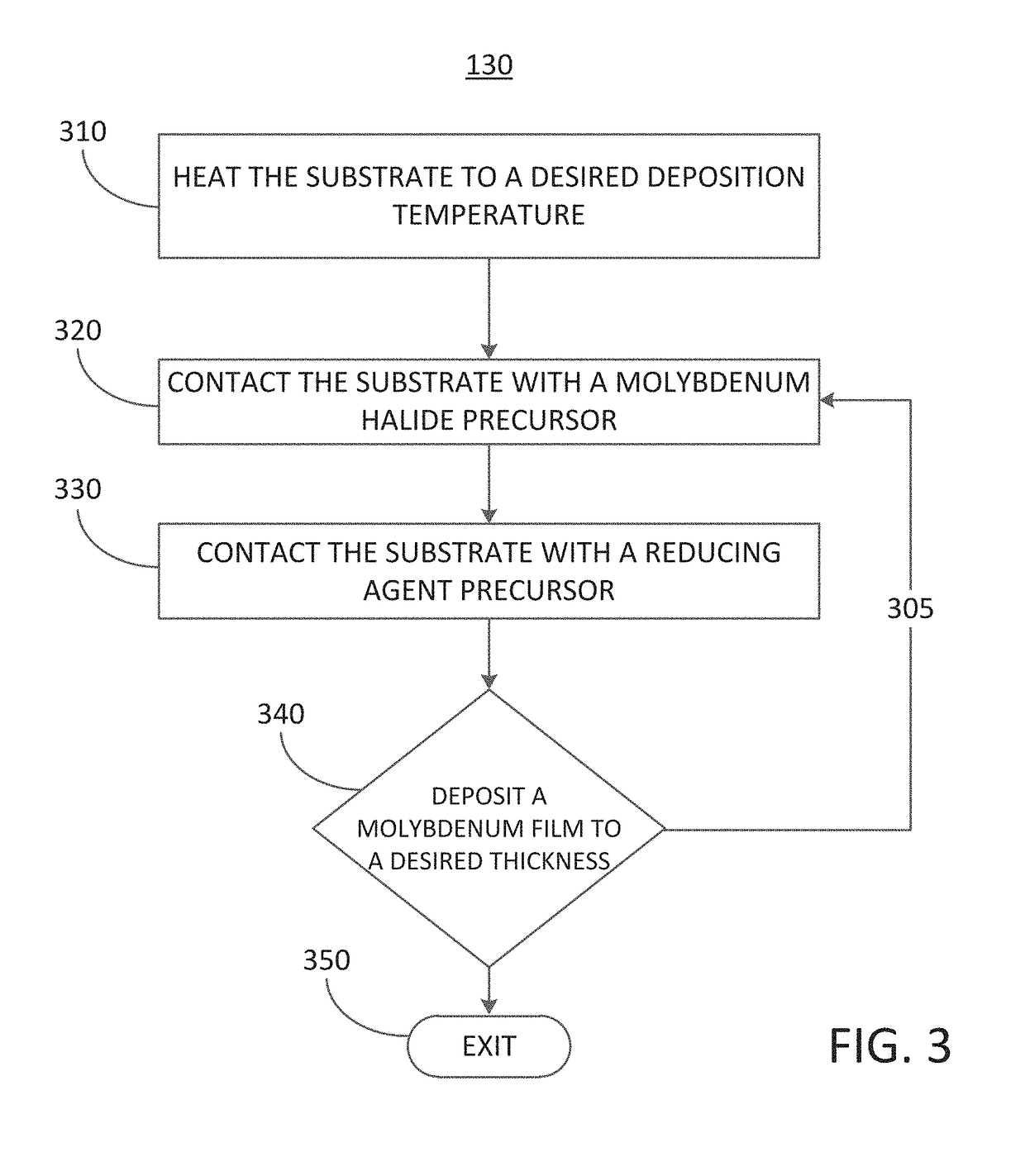

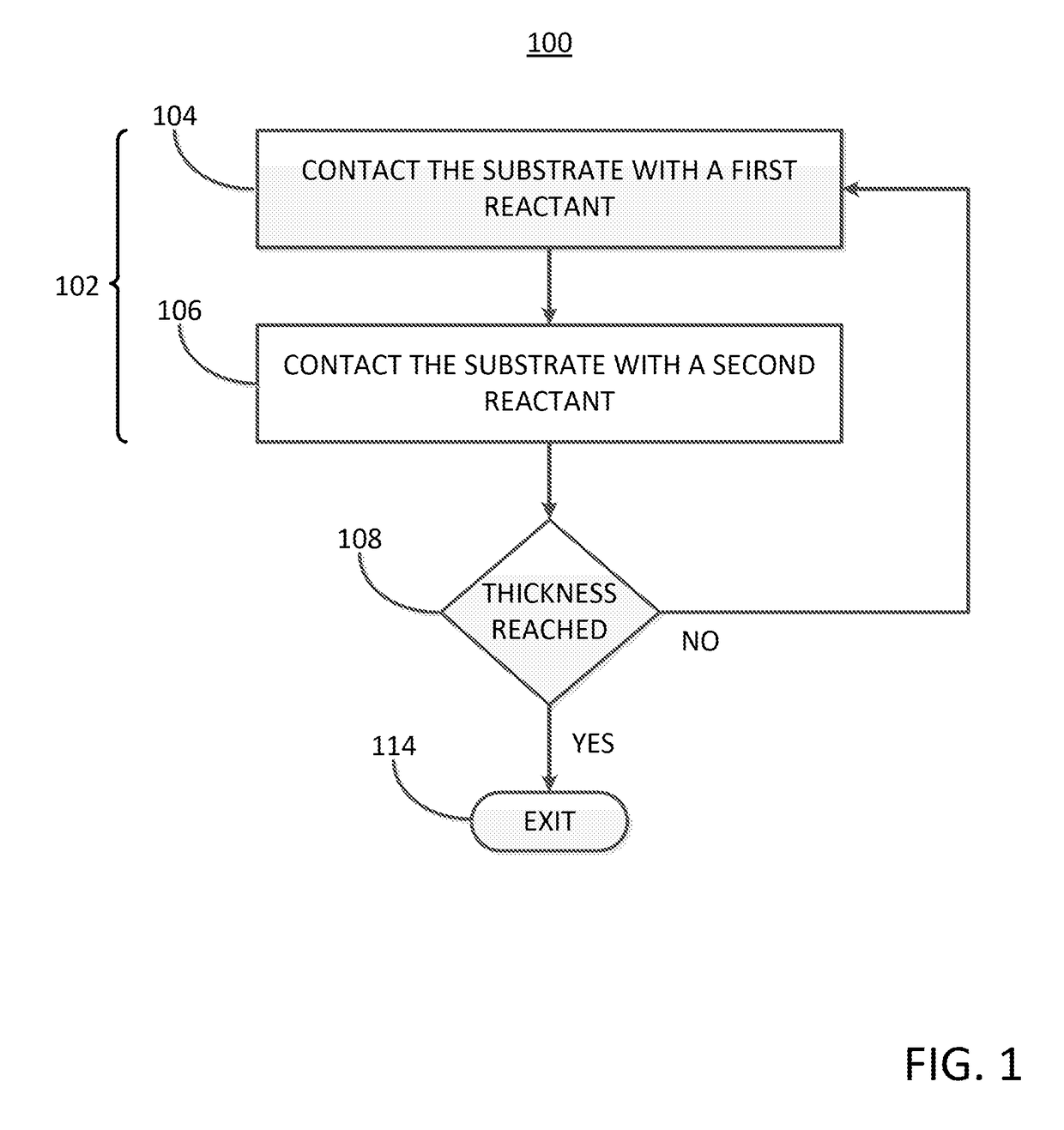

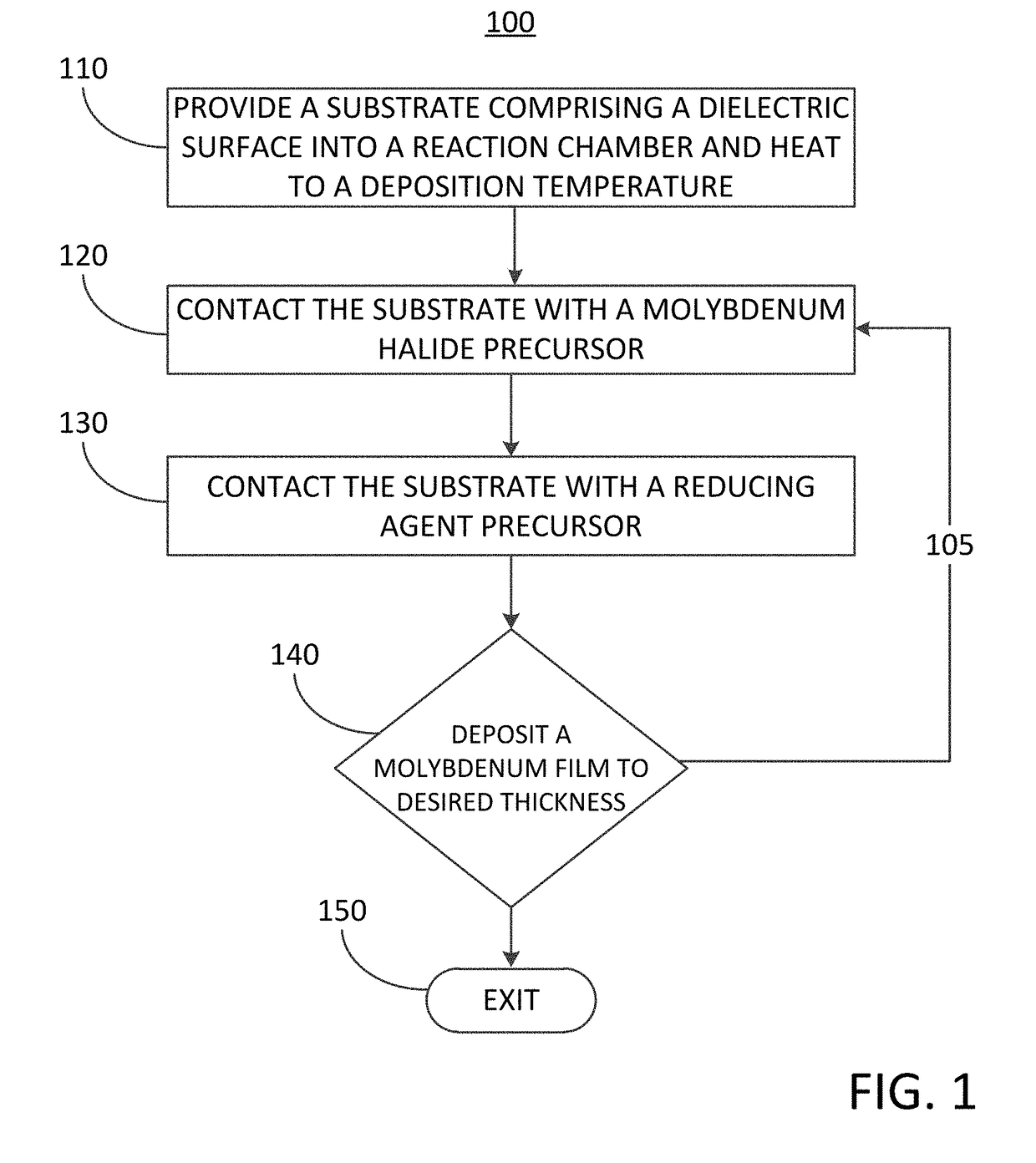

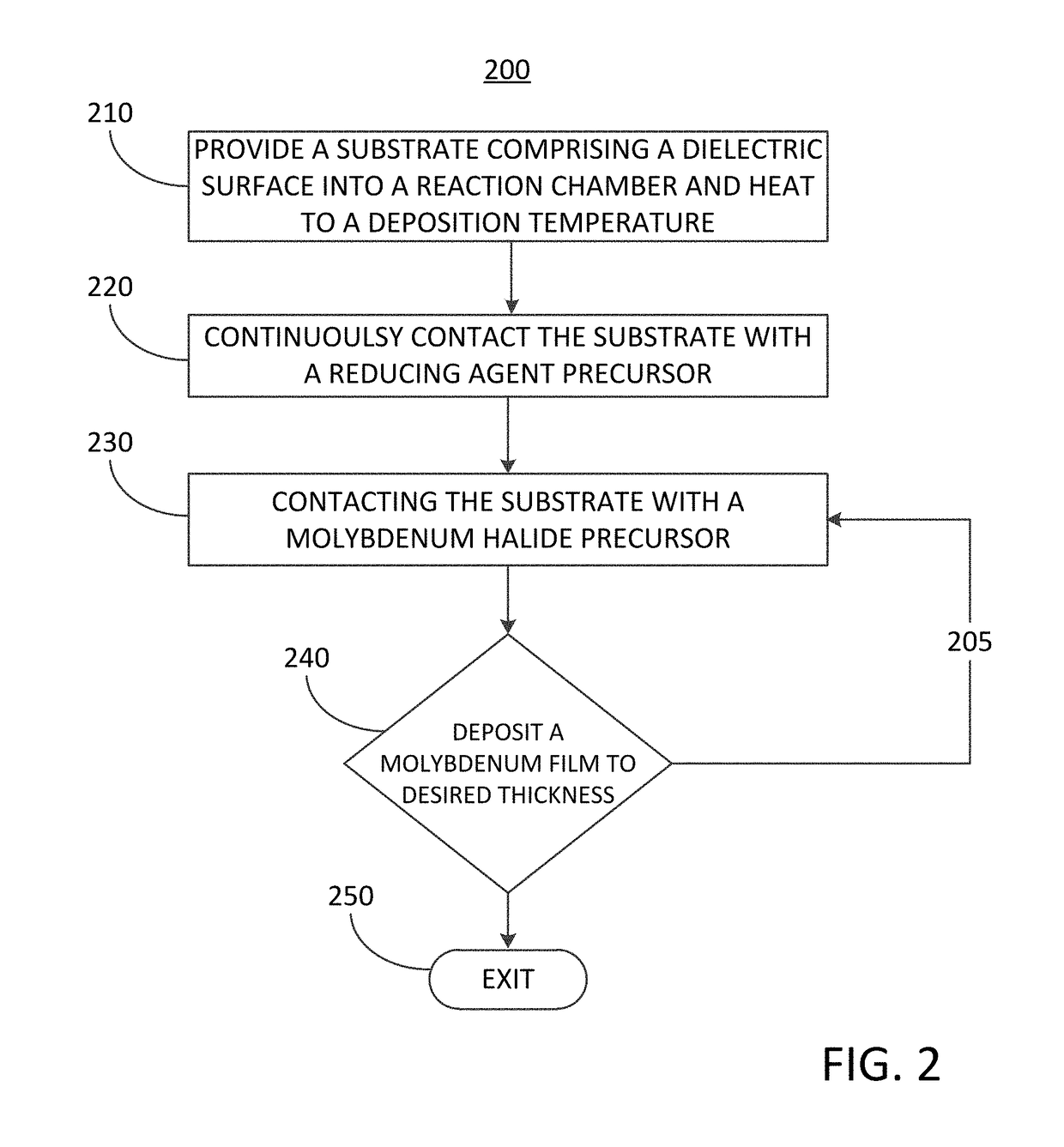

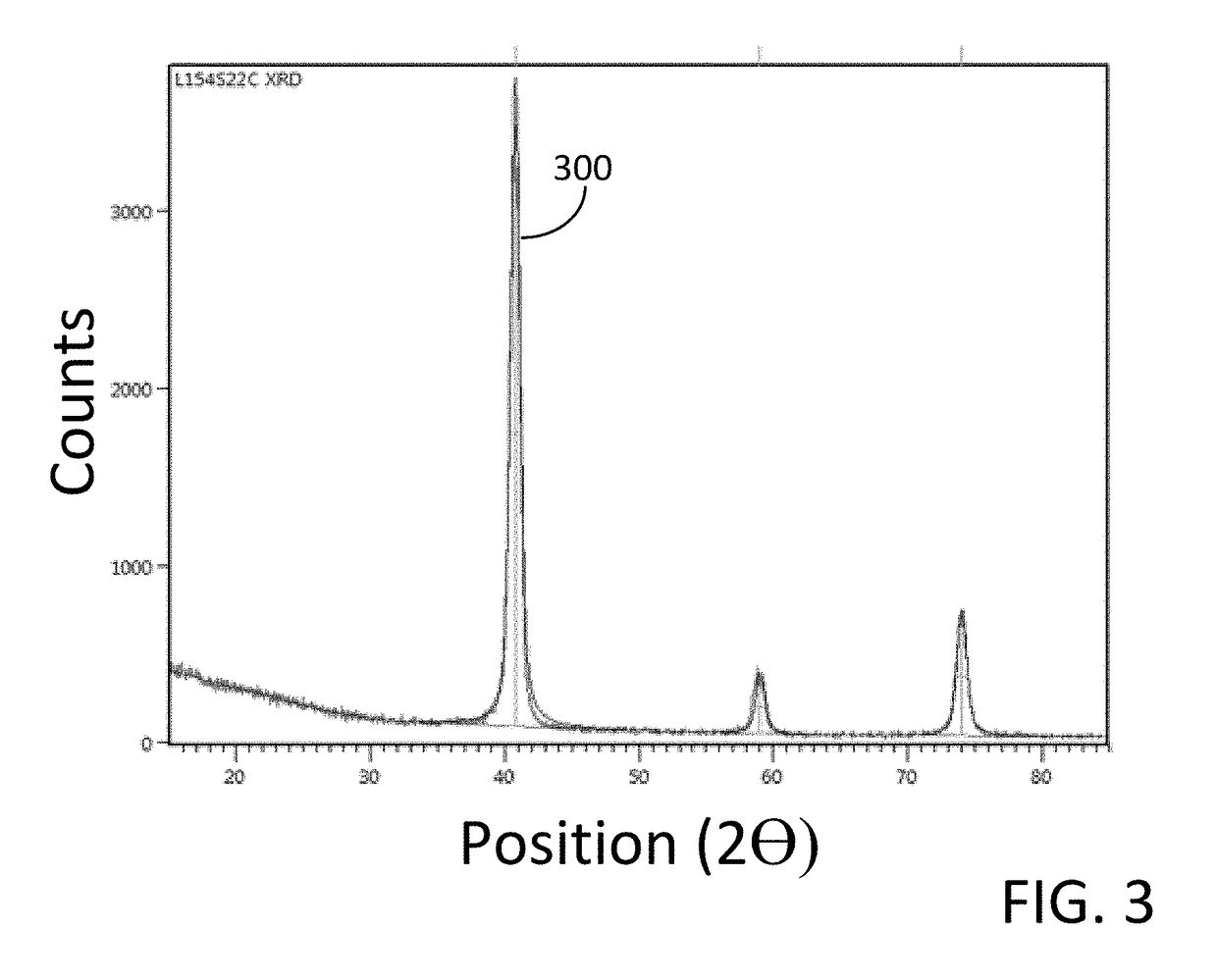

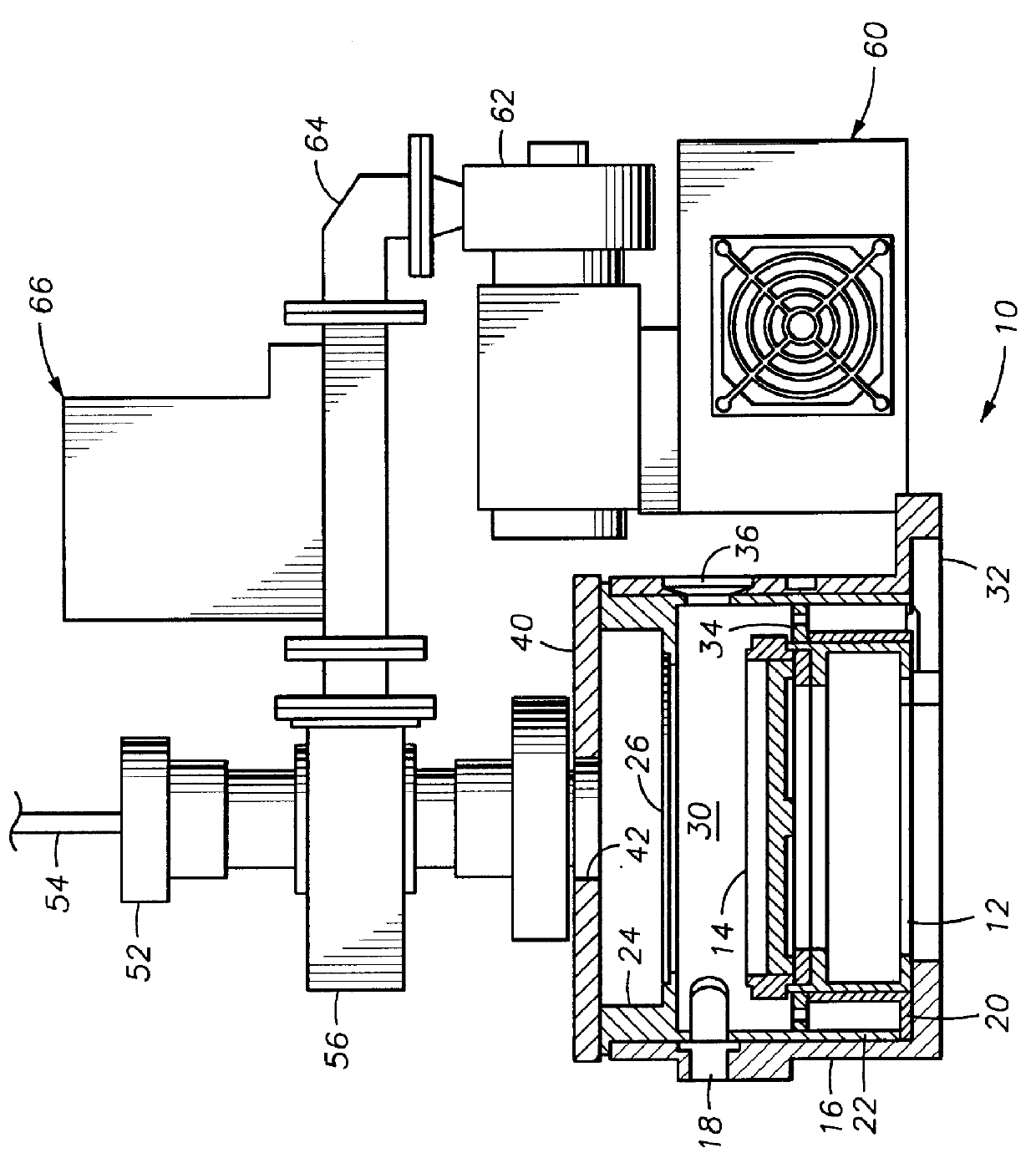

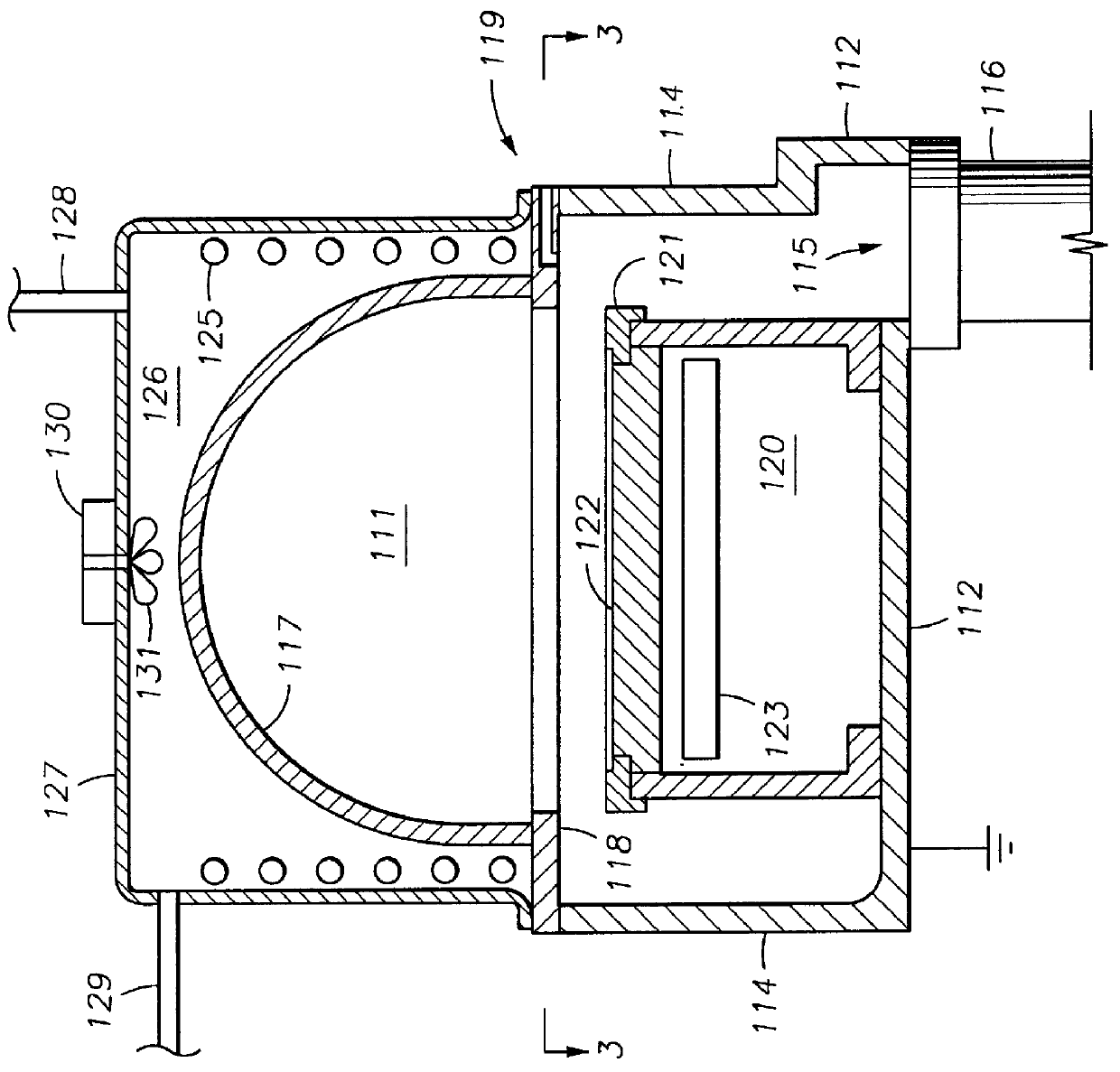

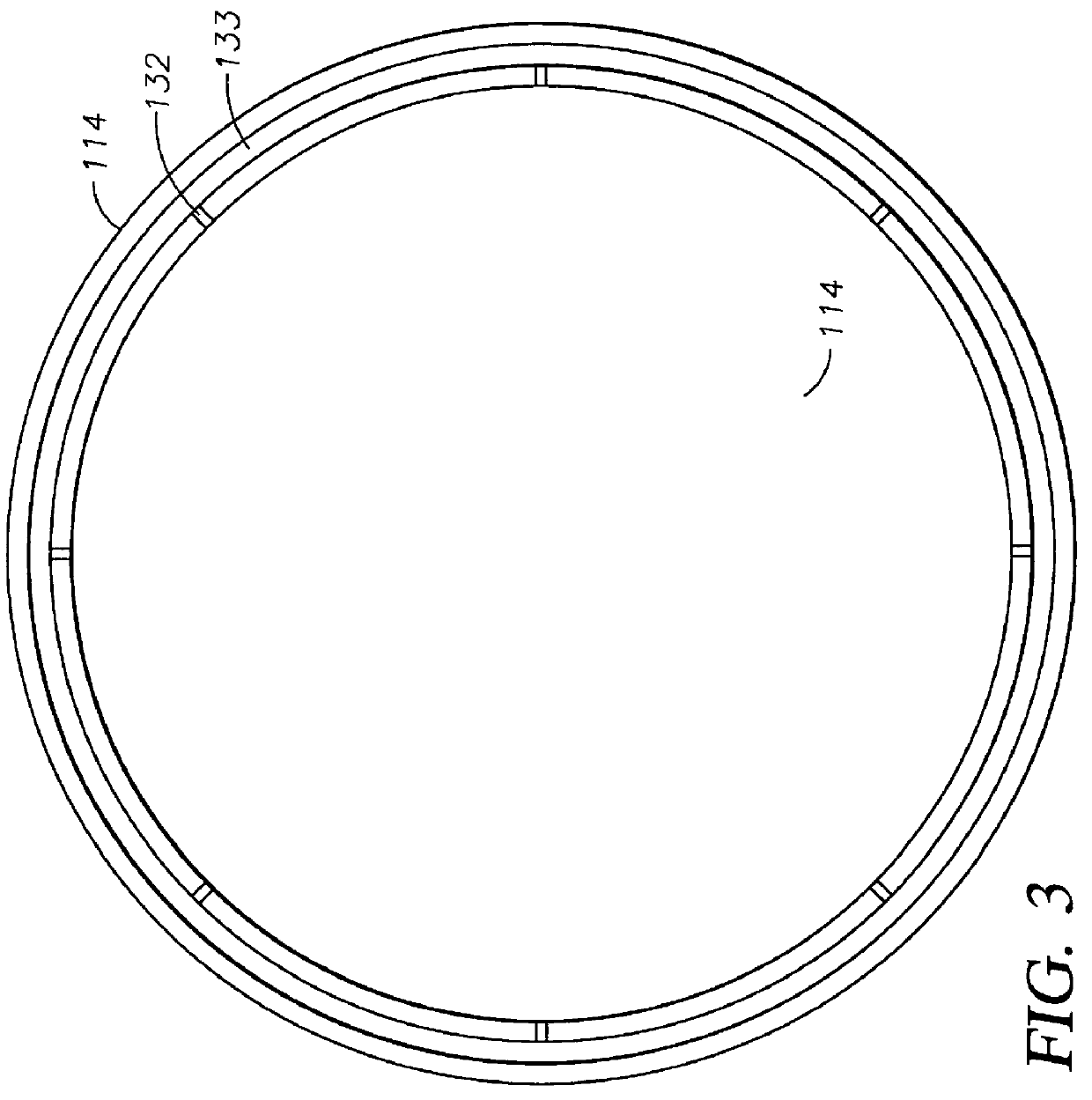

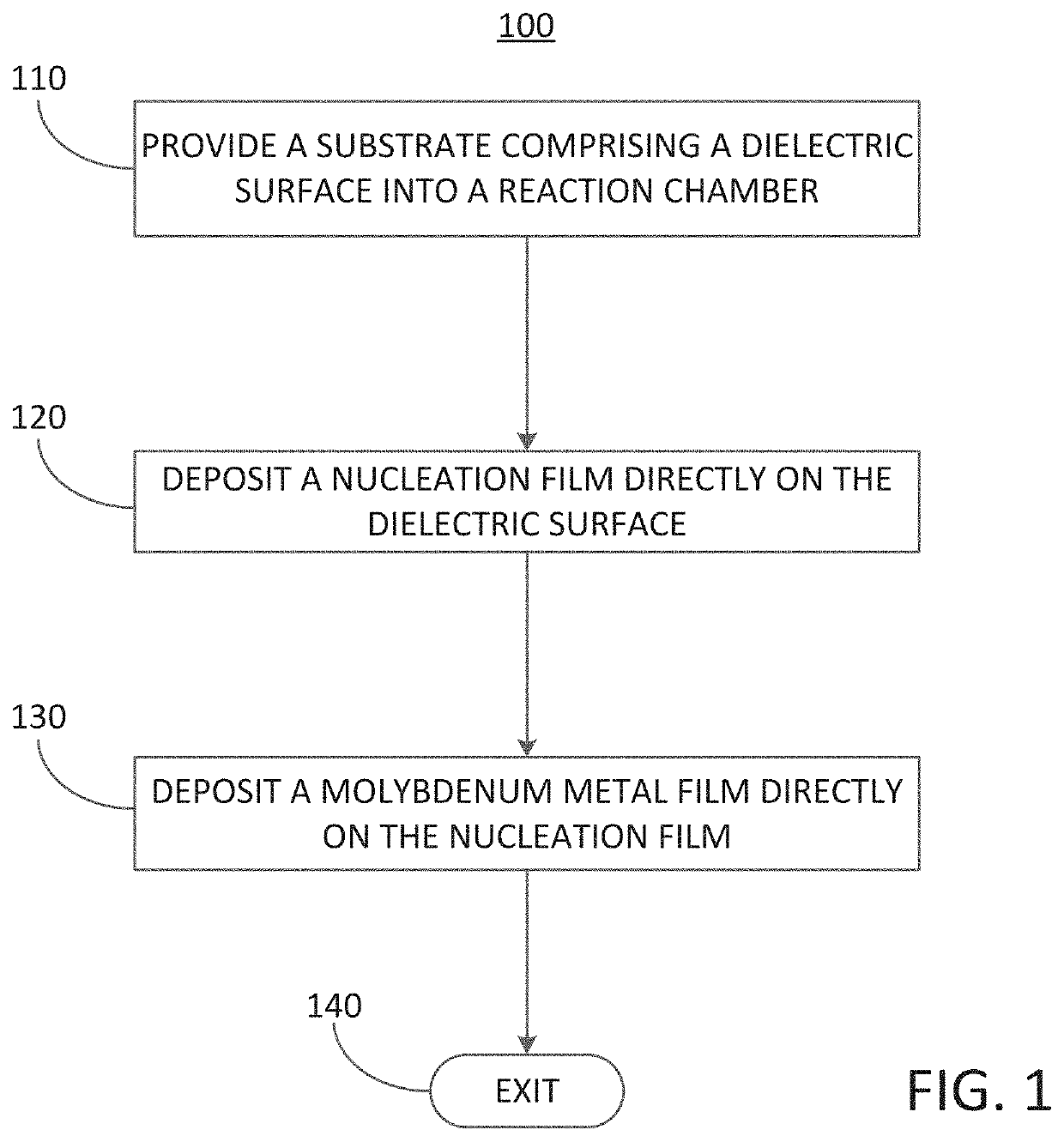

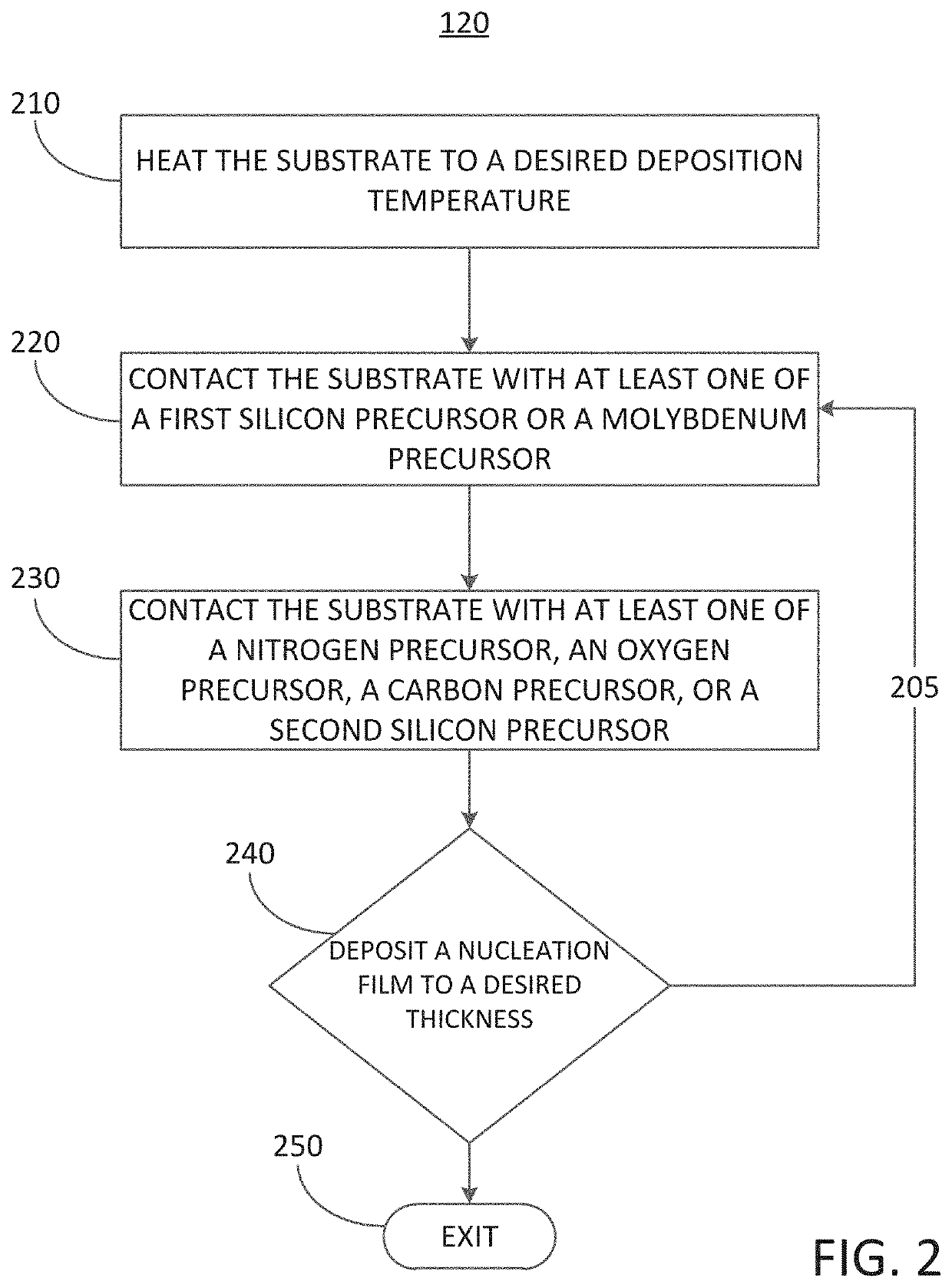

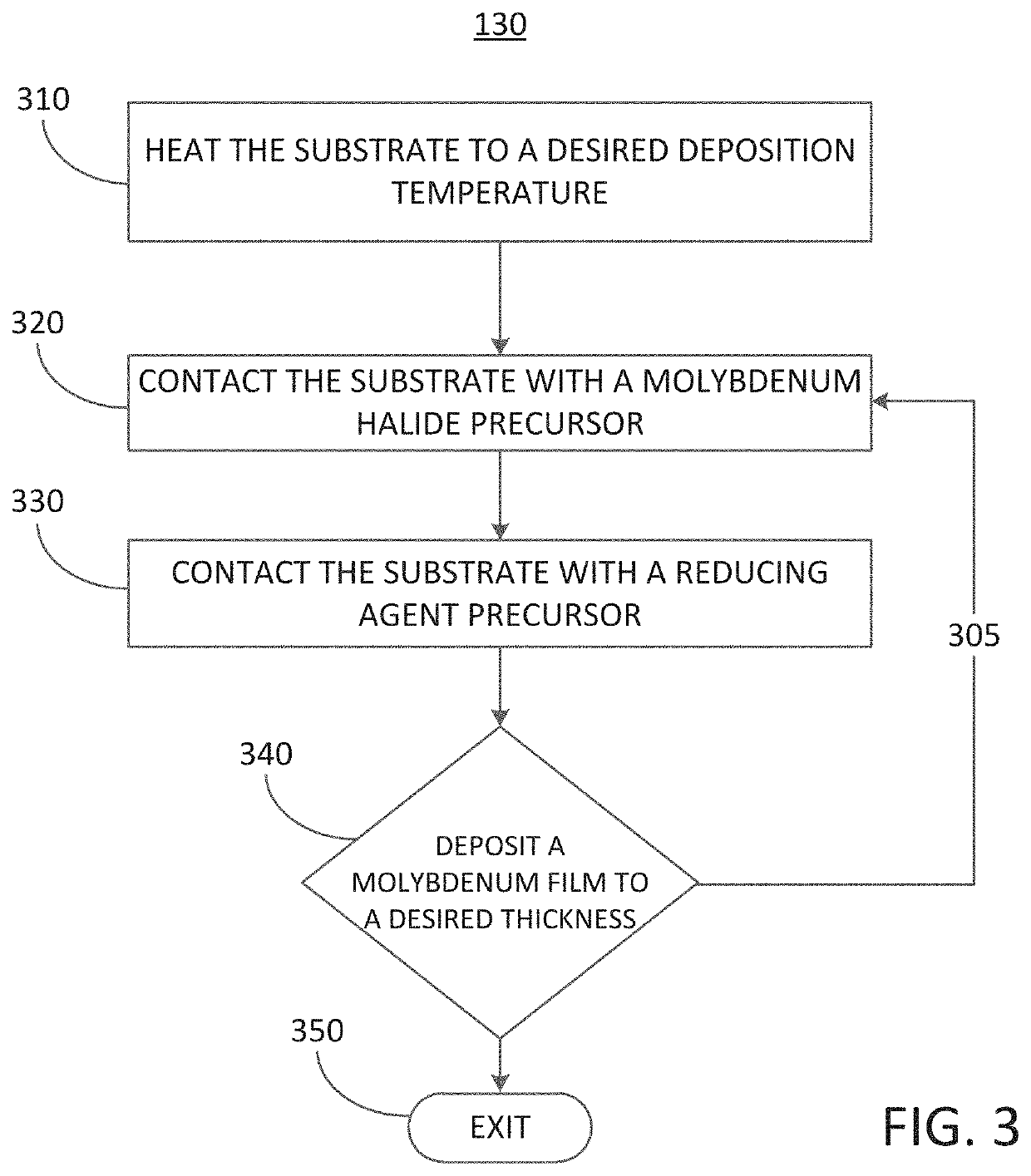

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process and related semiconductor device structures

ActiveUS20190067094A1Semiconductor/solid-state device detailsSolid-state devicesGas phaseDielectric surface

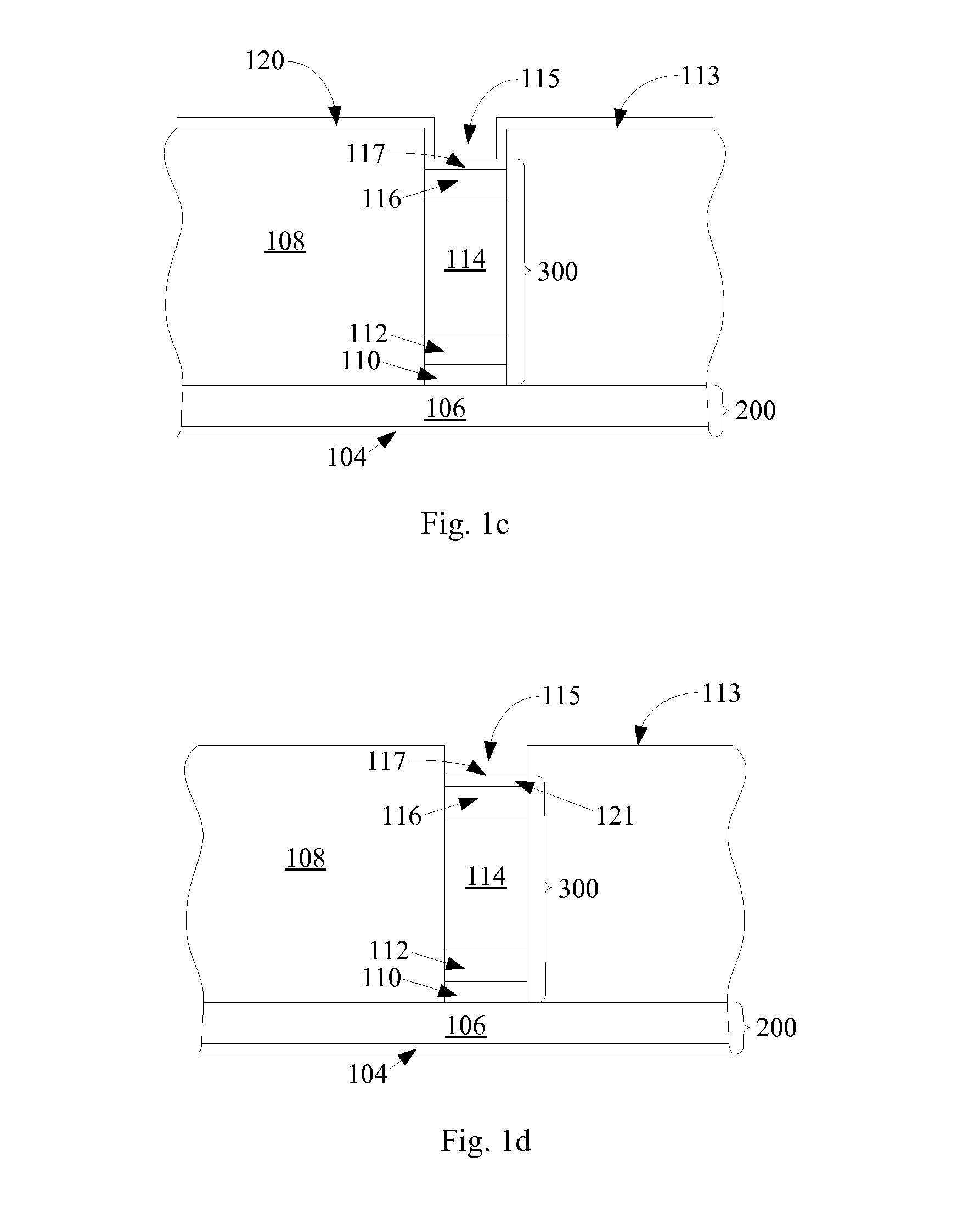

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process are disclosed. The methods may include: providing a substrate comprising a dielectric surface into a reaction chamber; depositing a nucleation film directly on the dielectric surface; and depositing a molybdenum metal film directly on the nucleation film, wherein depositing the molybdenum metal film includes: contacting the substrate with a first vapor phase reactant comprising a molybdenum halide precursor; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. Semiconductor device structures including a molybdenum metal film disposed over a surface of a dielectric material with an intermediate nucleation film are also disclosed.

Owner:ASM IP HLDG BV

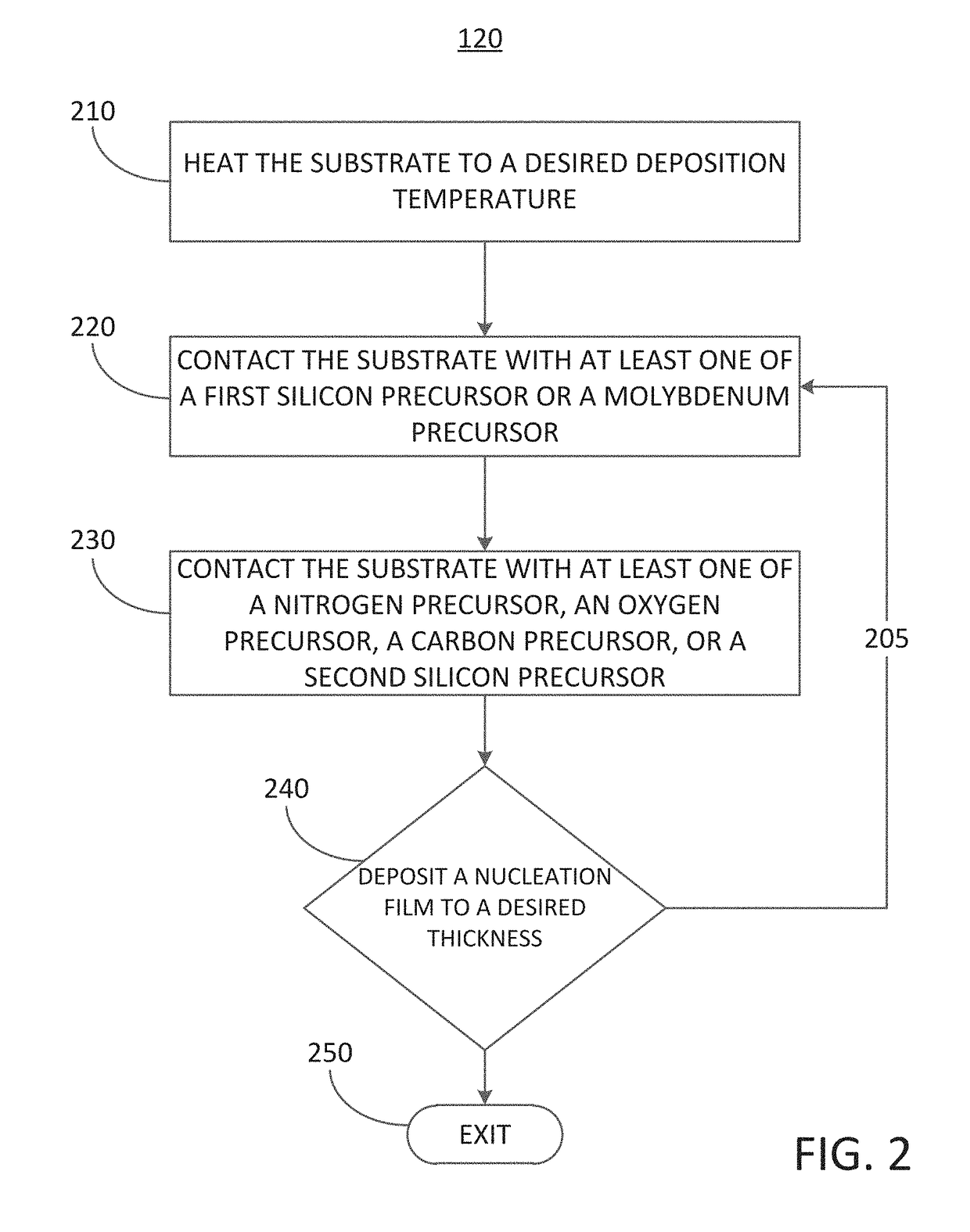

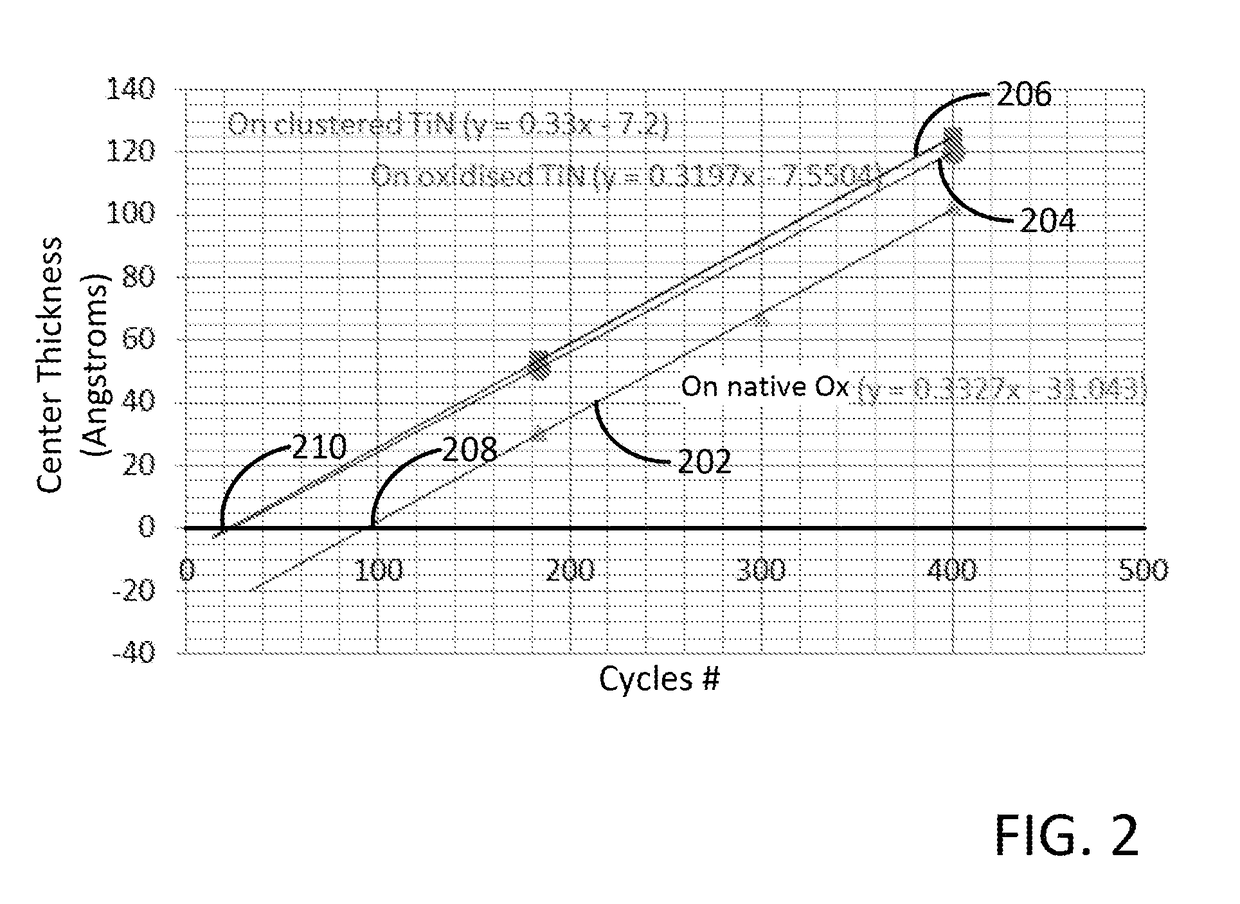

Methods for selectively forming a silicon nitride film on a substrate and related semiconductor device structures

ActiveUS20180323055A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDielectric surfaceNitrogen source

A method for selectively forming a silicon nitride film on a substrate comprising a first metallic surface and a second dielectric surface by a cyclical deposition process is disclosed. The method may comprise contacting the substrate with a first reactant comprising a silicon halide source and contacting the substrate with a second reactant comprising a nitrogen source, wherein the incubation period for the first metallic surface is less than the incubation period for the second dielectric surface. Semiconductor device structures comprising a selective silicon nitride film are also disclosed.

Owner:ASM IP HLDG BV

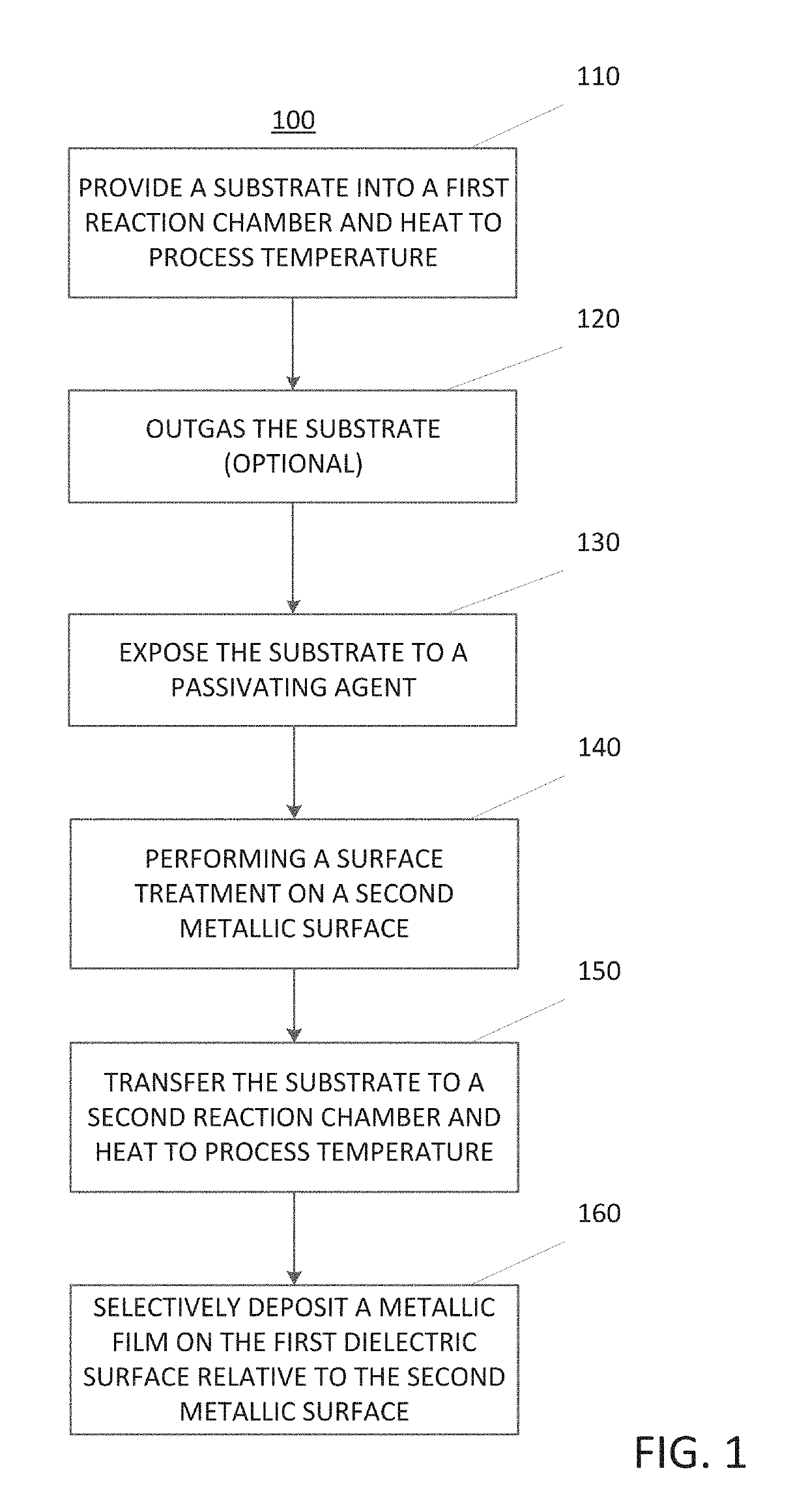

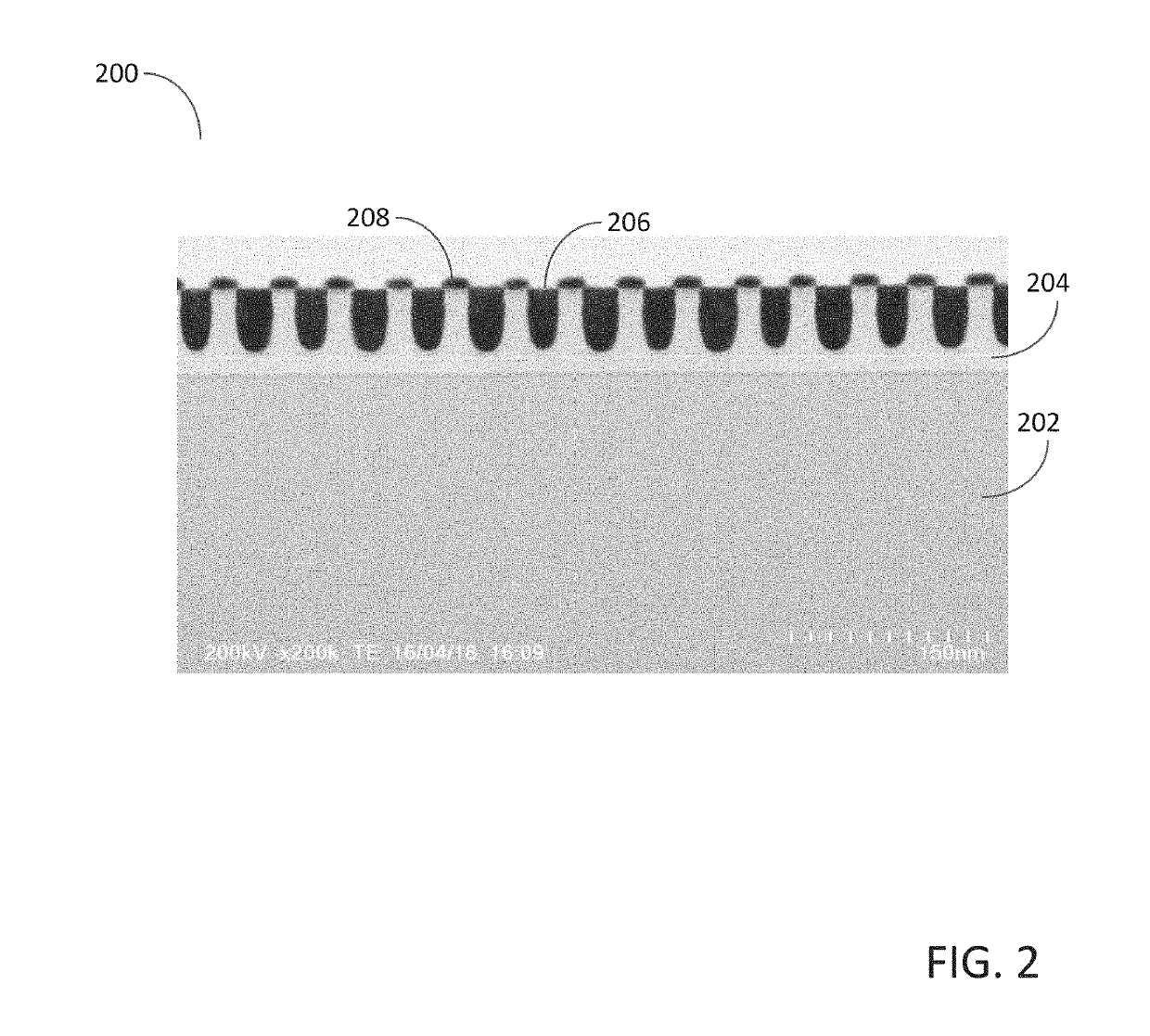

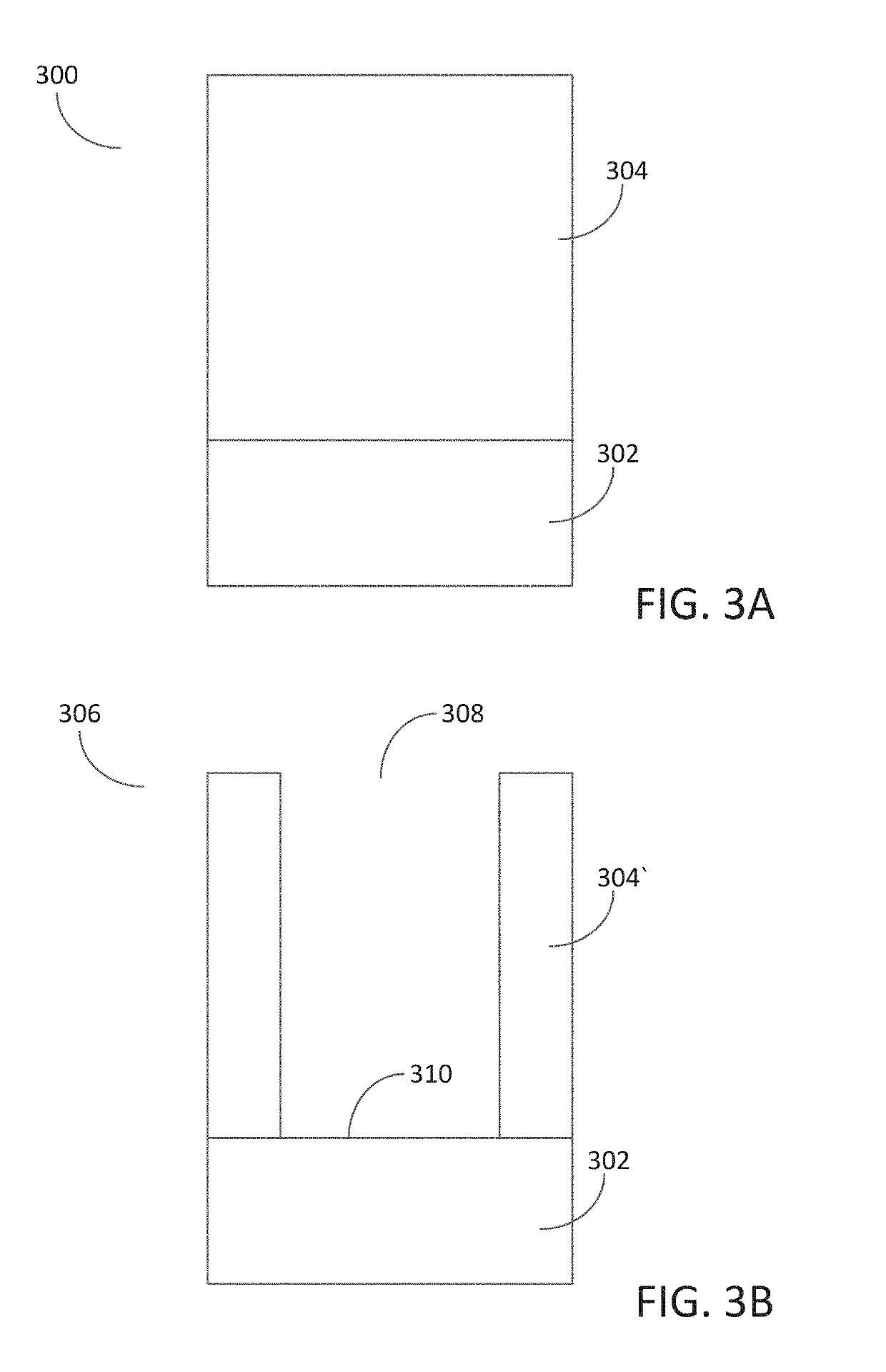

Method for selectively depositing a metallic film on a substrate

ActiveUS20190109009A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric surfaceSelective deposition

A method for selectively depositing a metallic film on a substrate comprising a first dielectric surface and a second metallic surface is disclosed. The method may include, exposing the substrate to a passivating agent, performing a surface treatment on the second metallic surface, and selectively depositing the metallic film on the first dielectric surface relative to the second metallic surface. Semiconductor device structures including a metallic film selectively deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

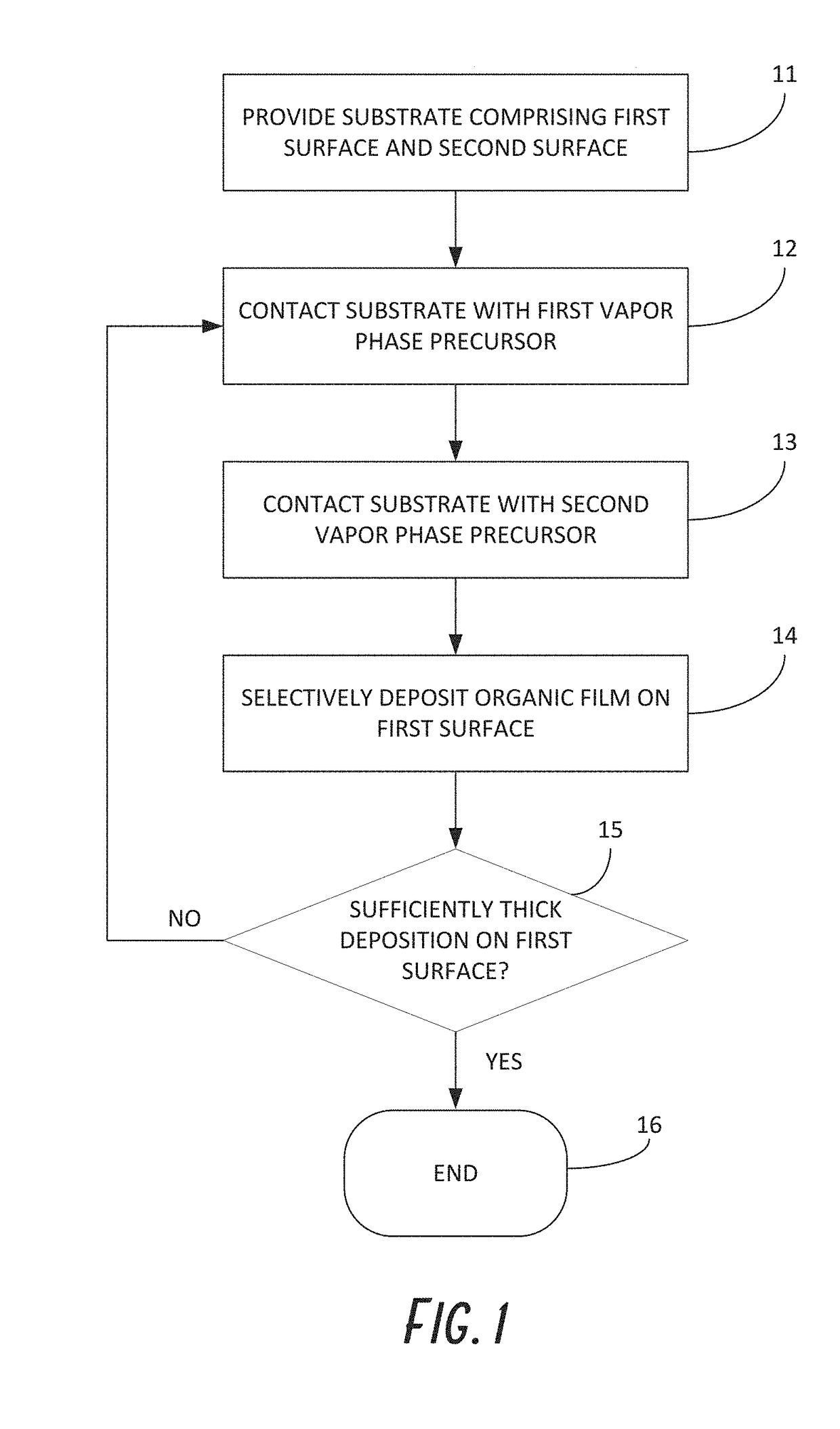

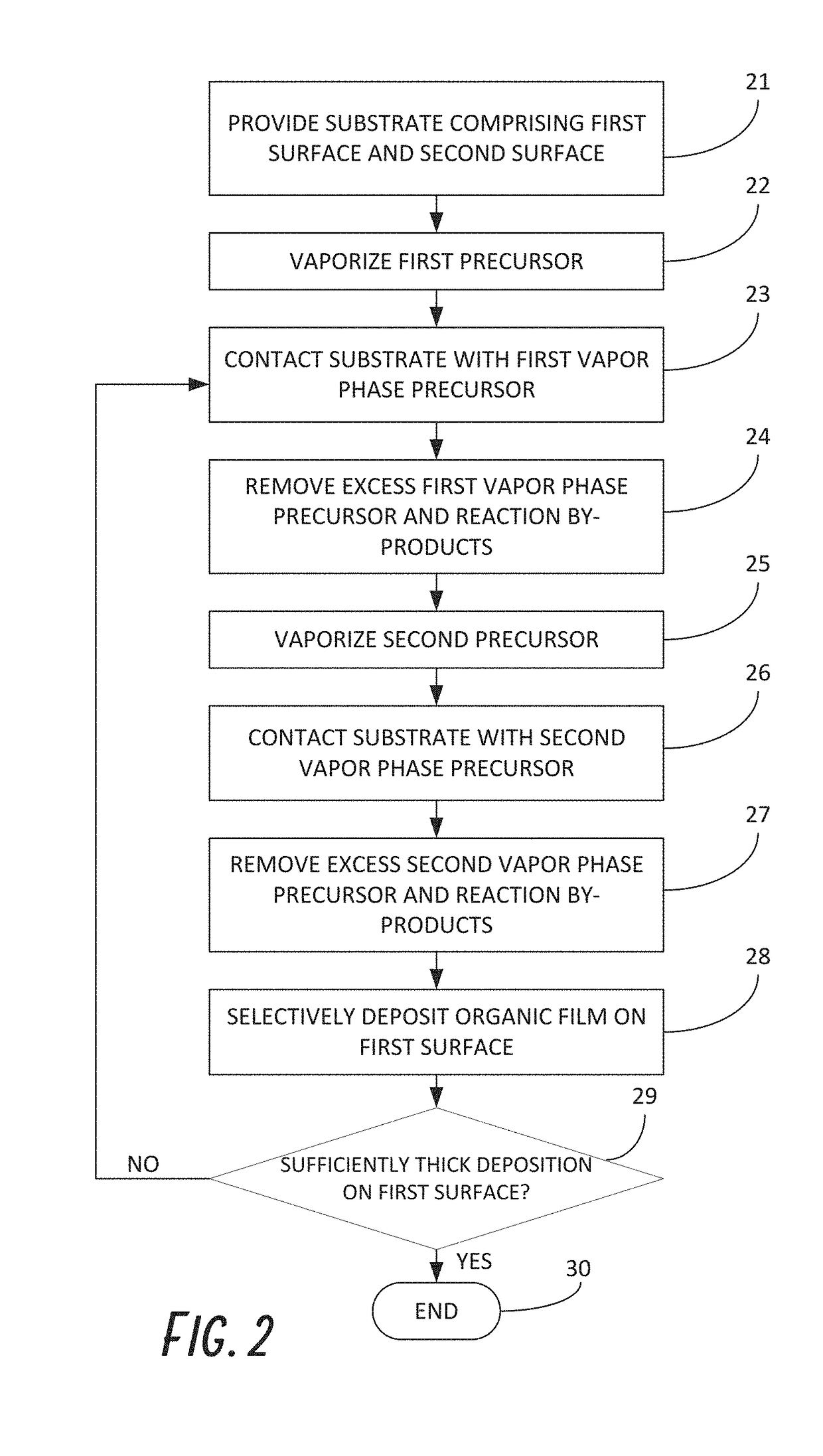

Methods for depositing a molybdenum metal film on a dielectric surface of a substrate and related semiconductor device structures

PendingUS20190067003A1Semiconductor/solid-state device detailsSolid-state devicesGas phaseDielectric surface

Methods for depositing a molybdenum metal film directly on a dielectric material surface of a substrate by a cyclical deposition process are disclosed. The methods may include: providing a substrate comprising a dielectric surface into a reaction chamber; and depositing a molybdenum metal film directly on the dielectric surface, wherein depositing comprises: contacting the substrate with a first vapor phase reactant comprising a molybdenum halide precursor; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. Semiconductor device structures including a molybdenum metal film disposed directly on a surface of a dielectric material deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

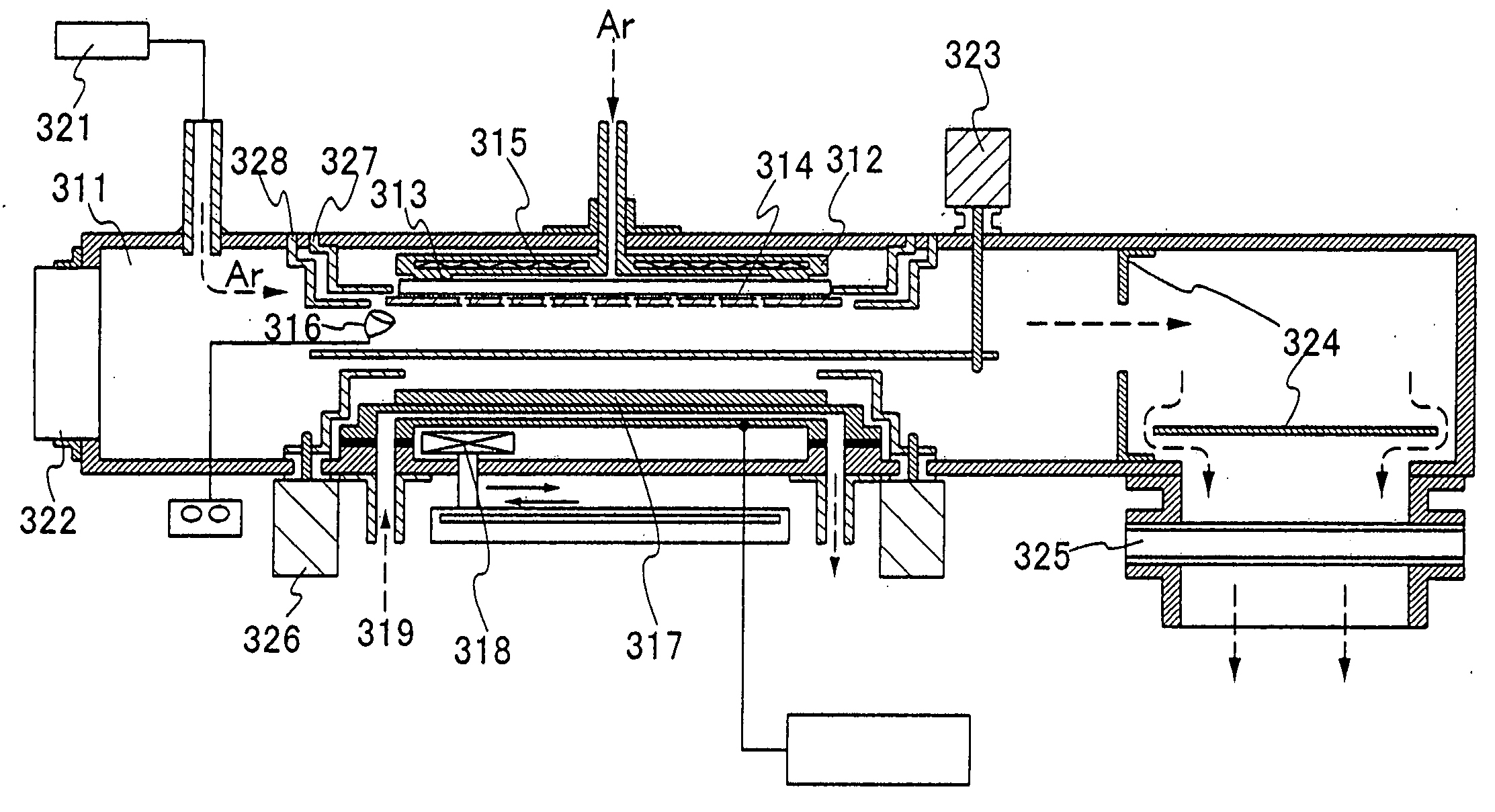

Reactive preclean prior to metallization for sub-quarter micron application

InactiveUS6107192AReduce the amount requiredIncrease resistanceVacuum evaporation coatingSputtering coatingRemote plasmaHydrogen

The present invention generally provides a precleaning process prior to metallization for submicron features on substrates. The method includes cleaning the submicron features with radicals from a plasma of a reactive gas such as oxygen, a mixture of CF4 / O2, or a mixture of He / NF3, wherein the plasma is preferably generated by a remote plasma source and the radicals are delivered to a chamber in which the substrate is disposed. Native oxides remaining in the submicron features are preferably reduced in a second step by treatment with radicals from a plasma containing hydrogen. Following the first or both precleaning steps, the features can be filled with metal by available metallization techniques which typically include depositing a barrier / liner layer on exposed dielectric surfaces prior to deposition of aluminum, copper, or tungsten. The precleaning and metallization steps can be conducted on available integrated processing platforms.

Owner:APPLIED MATERIALS INC

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process and related semiconductor device structures

ActiveUS20210151352A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialPhysical chemistry

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process are disclosed. The methods may include: providing a substrate comprising a dielectric surface into a reaction chamber; depositing a nucleation film directly on the dielectric surface; and depositing a molybdenum metal film directly on the nucleation film, wherein depositing the molybdenum metal film includes: contacting the substrate with a first vapor phase reactant comprising a molybdenum halide precursor; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. Semiconductor device structures including a molybdenum metal film disposed over a surface of a dielectric material with an intermediate nucleation film are also disclosed.

Owner:ASM IP HLDG BV

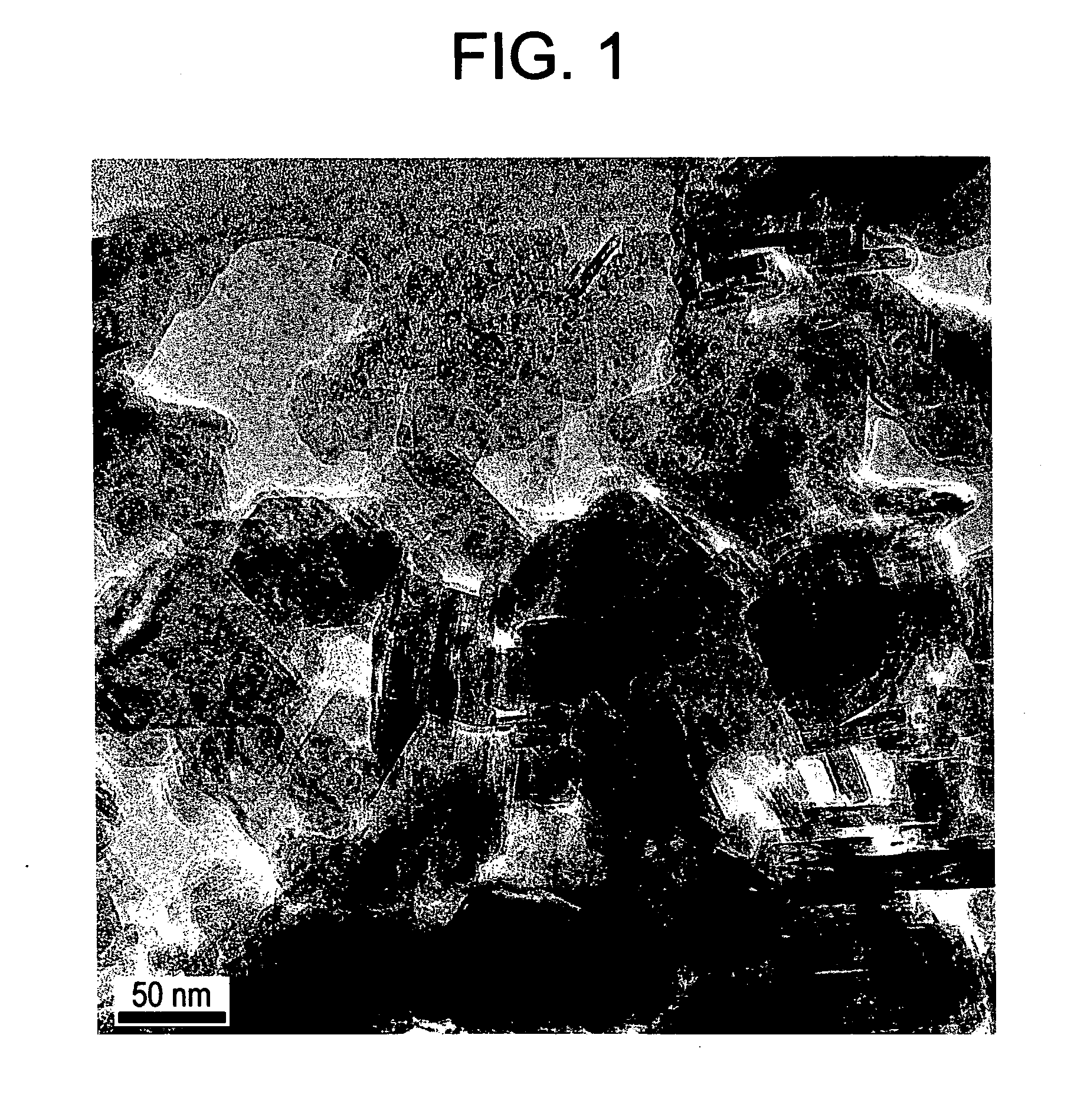

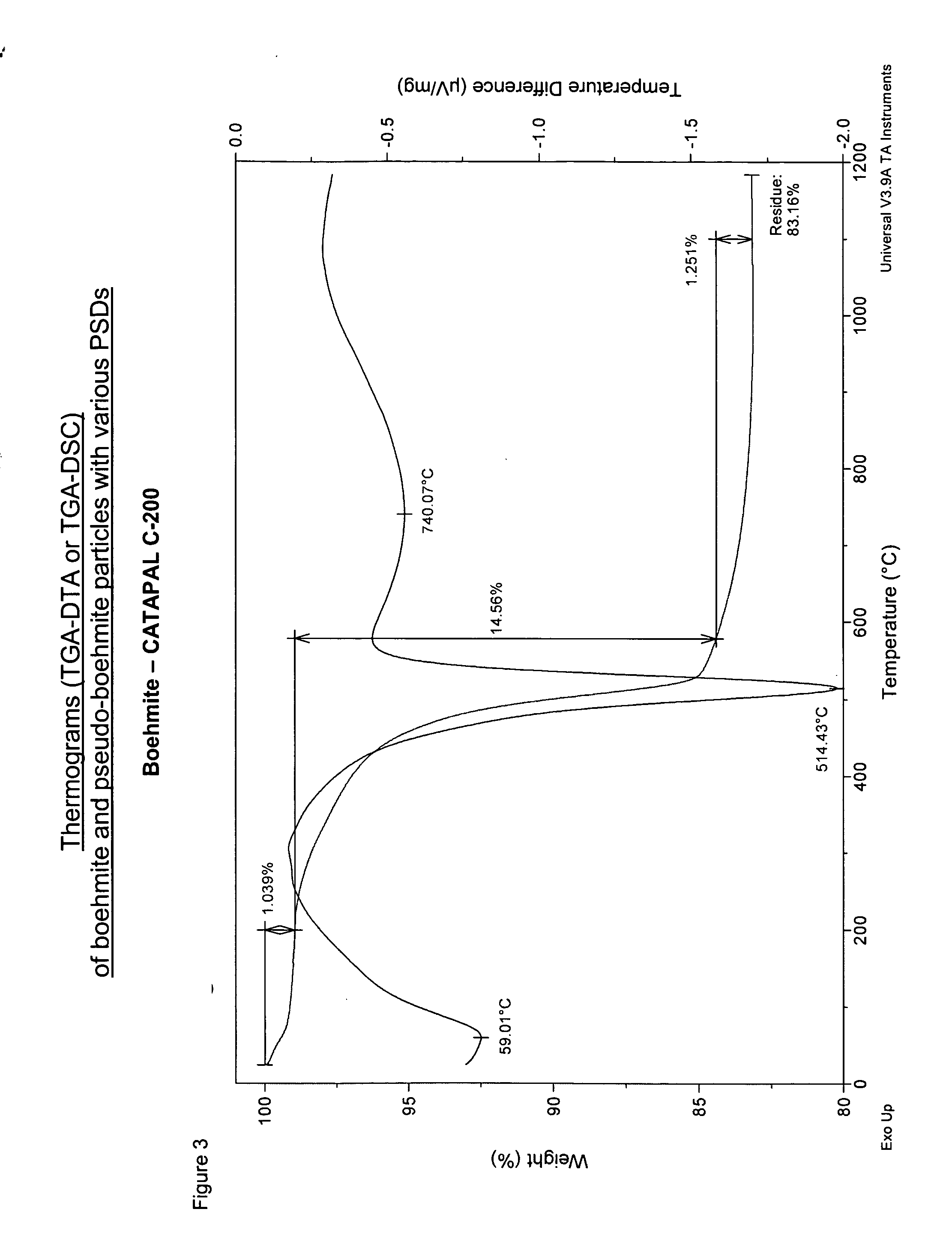

Planarization composition

The present invention provides CMP abrasive slurry that is substantially free of aluminum oxide and comprises liquid and solids wherein the solids comprises: (a) in an amount of at least about 90 weight percent based on the solids, at least one non-spherical component having formula Al2O3.xH2O where x ranges from 1 to 3; and (b) up to about one weight percent based on the solids portion of submicron alpha-alumina. The CMP abrasive slurry may be used to polish metallic or dielectric surfaces in computer wafers.

Owner:BASF AG +1

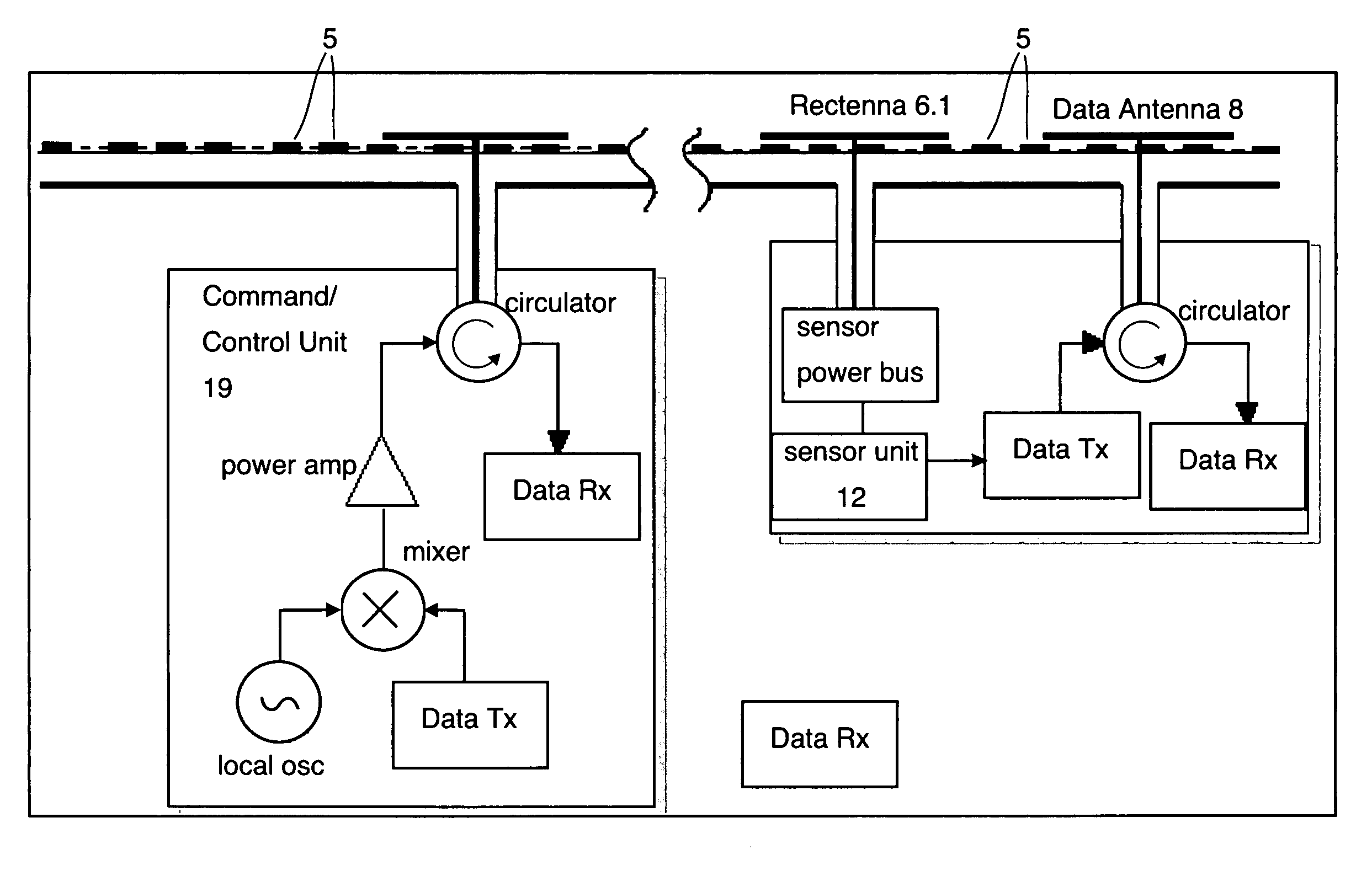

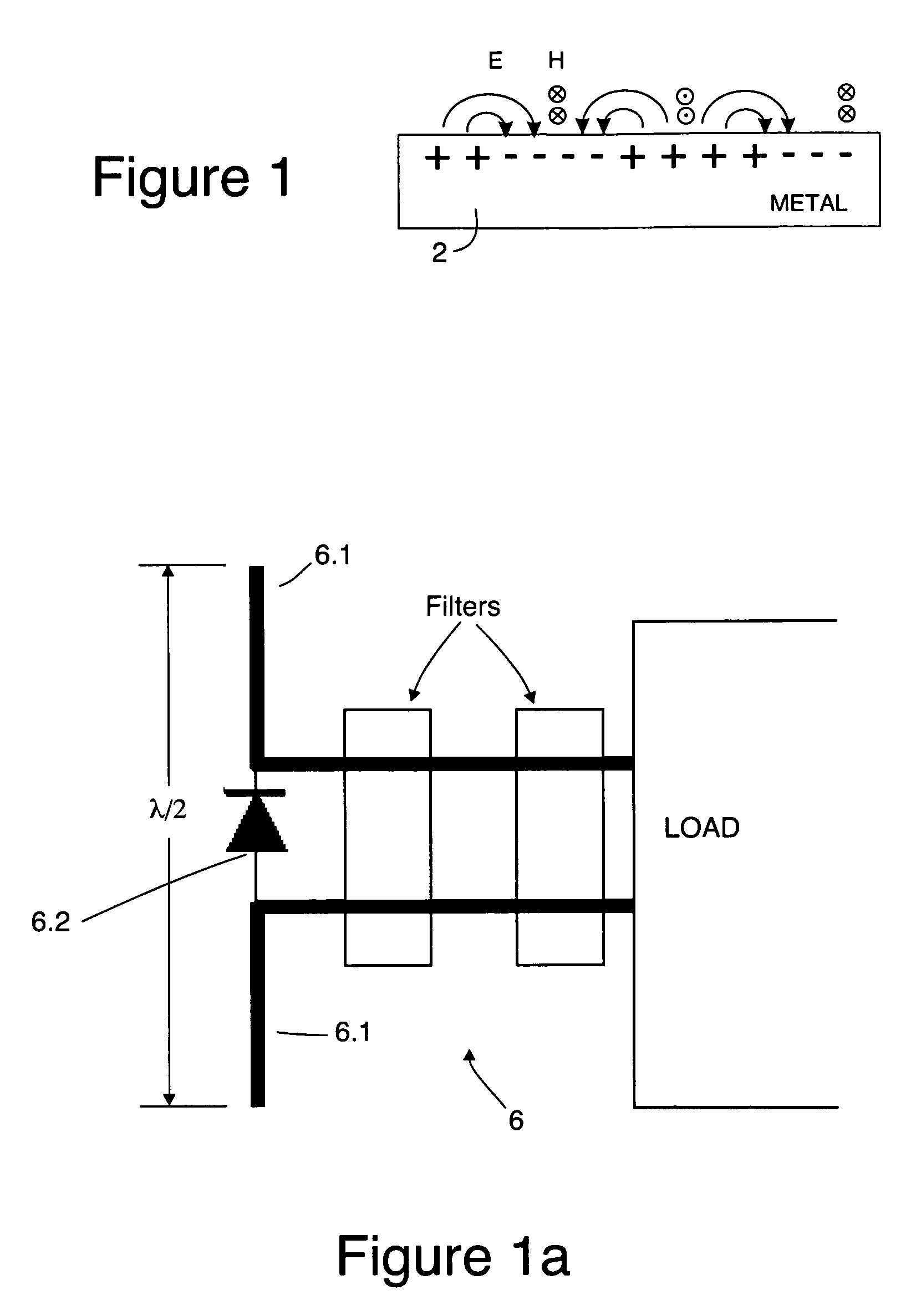

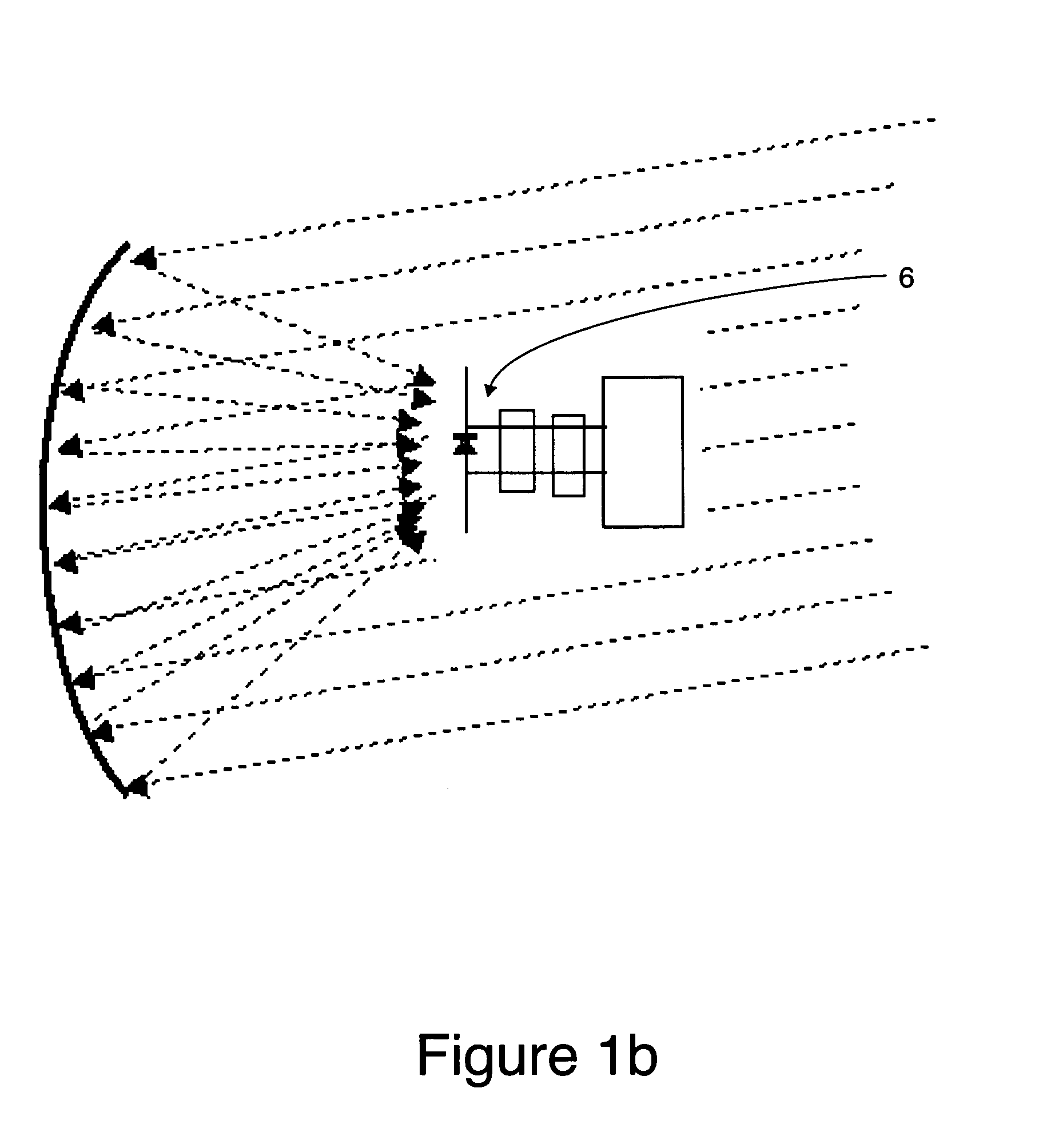

Large-scale adaptive surface sensor arrays

An adaptive surface has a dielectric surface with a repeating pattern of electrically conductive structures disposed thereon or therein, the dielectric surface in combination with repeating pattern of electrically conductive structures forming a metasurface for binding surface waves thereto. A plurality of actuators on the dielectric surface alter the shape of the metasurface in response to control signals. A plurality of sensors on the dielectric surface for measuring a desired parameter and converting it to data. A plurality of rectennae disposed on the dielectric surface for providing electrical power to said actuators and to said sensors. A plurality of data antennas are disposed on or in the dielectric surface, the data antennas being coupled with data receivers and data transmitters for receiving data from an external source for controlling the actuators and for transmitting data from said sensors to an external receiver.

Owner:HRL LAB

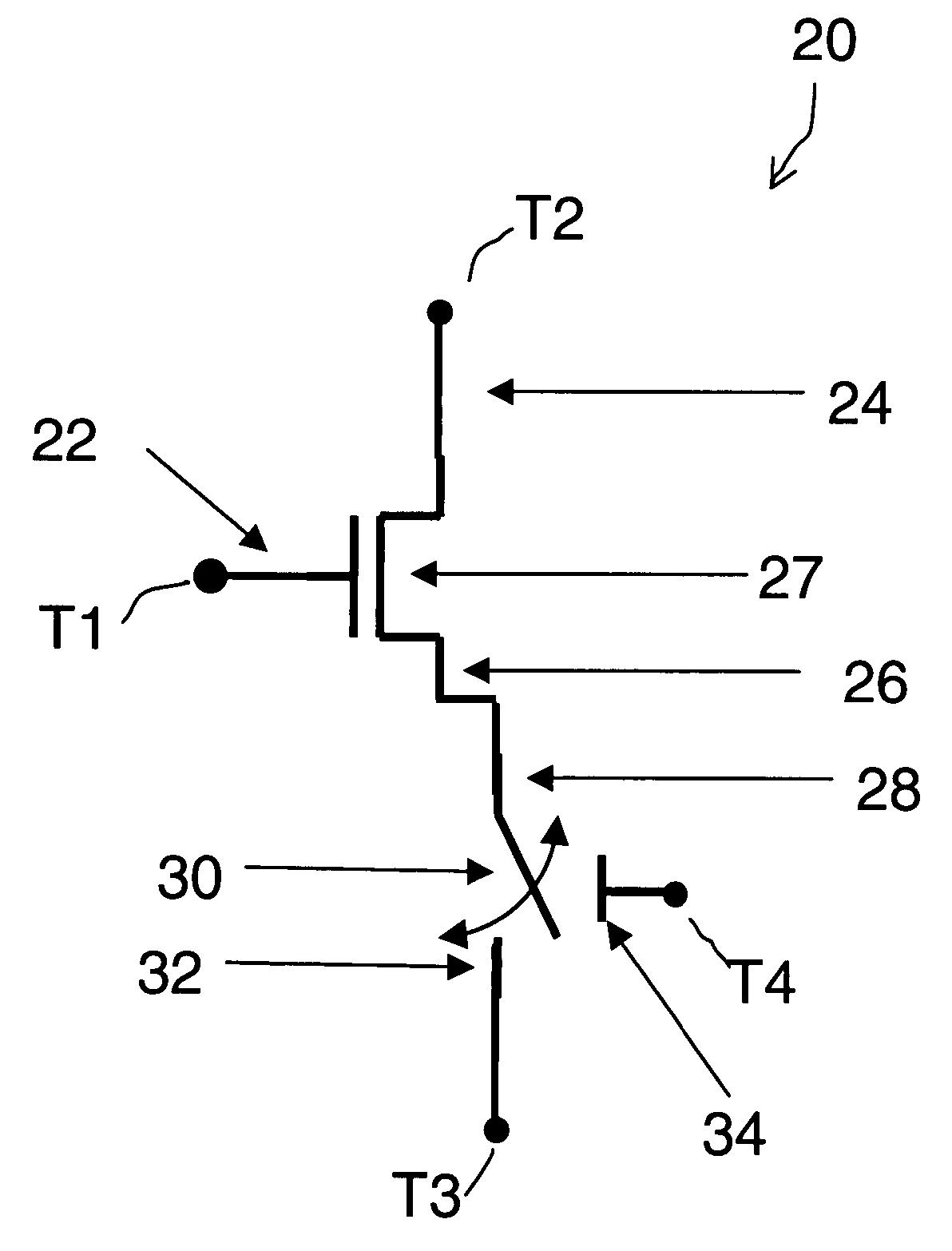

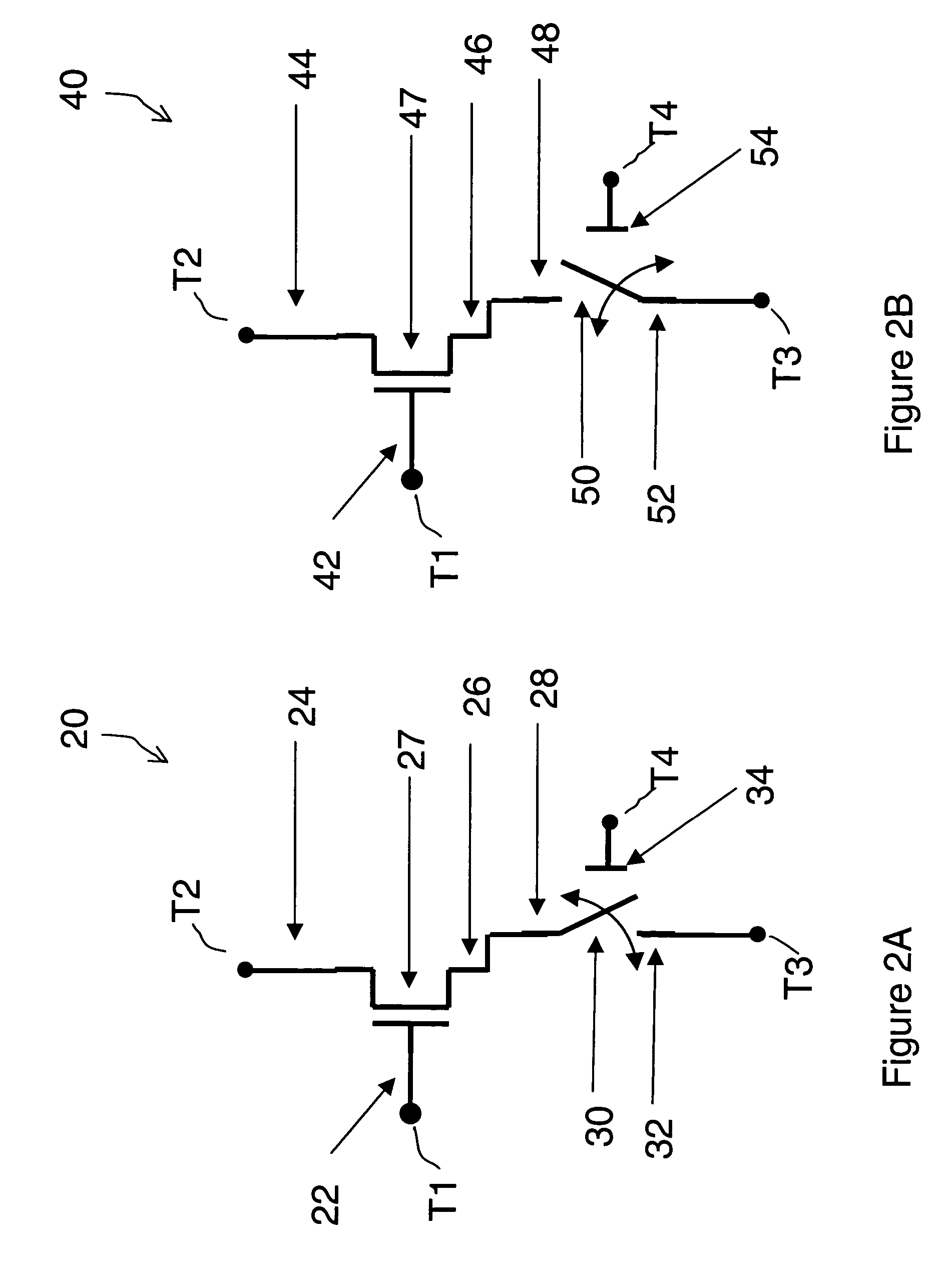

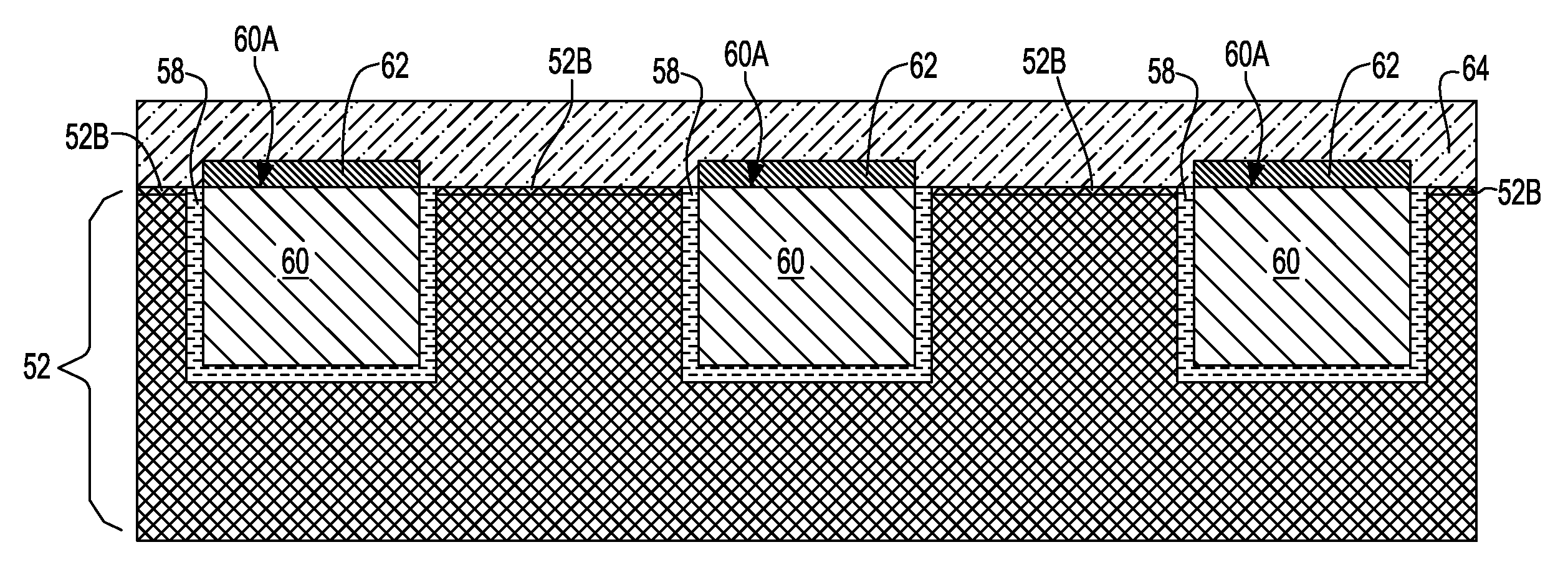

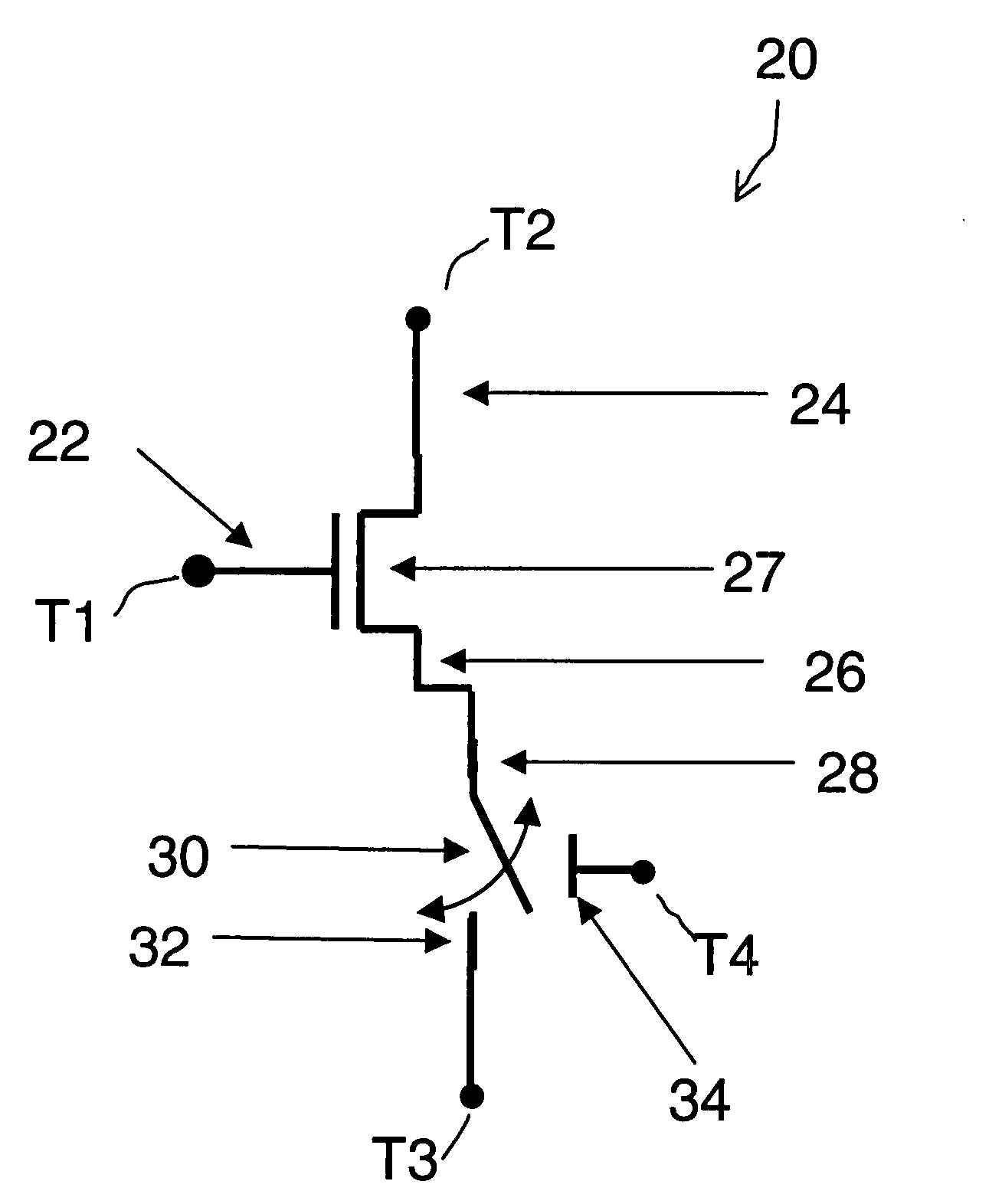

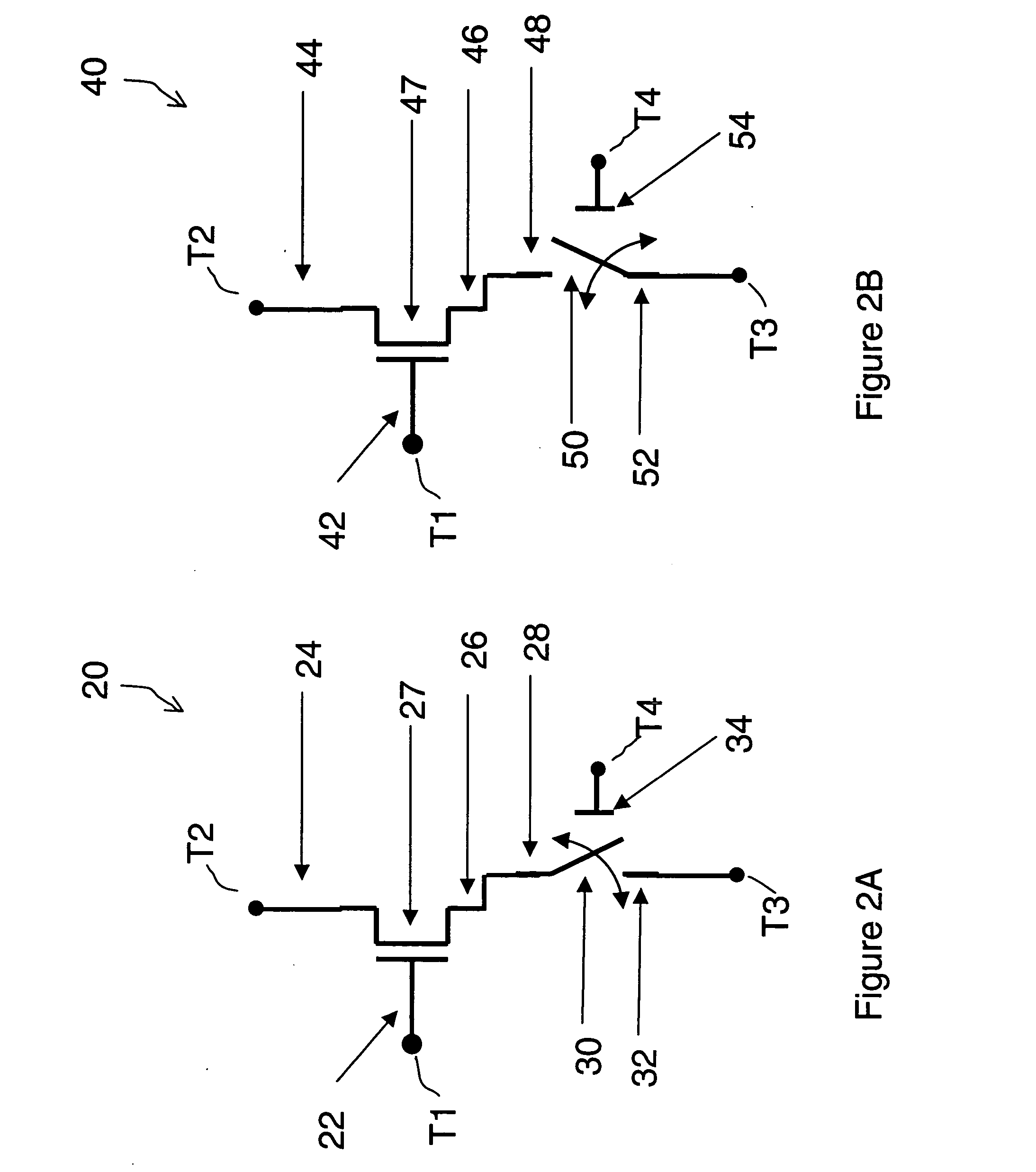

Non-volatile electromechanical field effect devices and circuits using same and methods of forming same

Non-volatile field effect devices and circuits using same. A non-volatile field effect device includes a source, drain and gate with a field-modulatable channel between the source and drain. Each of the source, drain, and gate have a corresponding terminal. An electromechanically-deflectable, nanotube switching element is electrically positioned between one of the source, drain and gate and its corresponding terminal. The others of the source, drain and gate are directly connected to their corresponding terminals. The nanotube switching element is electromechanically-deflectable in response to electrical stimulation at two control terminals to create one of a non-volatile open and non-volatile closed electrical communication state between the one of the source, drain and gate and its corresponding terminal. Under one embodiment, one of the two control terminals has a dielectric surface for contact with the nanotube switching element when creating a non-volatile open state. Under one embodiment, the source, drain and gate may be stimulated at any voltage level from ground to supply voltage, and wherein the two control terminals are stimulated at any voltage level from ground to a switching threshold voltage larger in magnitude than the supply voltage. Under one embodiment, the nanotube switching element includes an article made from nanofabric that is positioned between the two control terminals. Under one embodiment, one of the two control terminals is a release electrode for electrostatically pulling the nanotube article out of contact with the one of the source, drain and gate so as to form a non-volatile open state. Under one embodiment, the other of the two control terminals is a set electrode for electrostatically pulling the nanotube article into contact with the one of the source, drain and gate so as to form a non-volatile closed state.

Owner:NANTERO

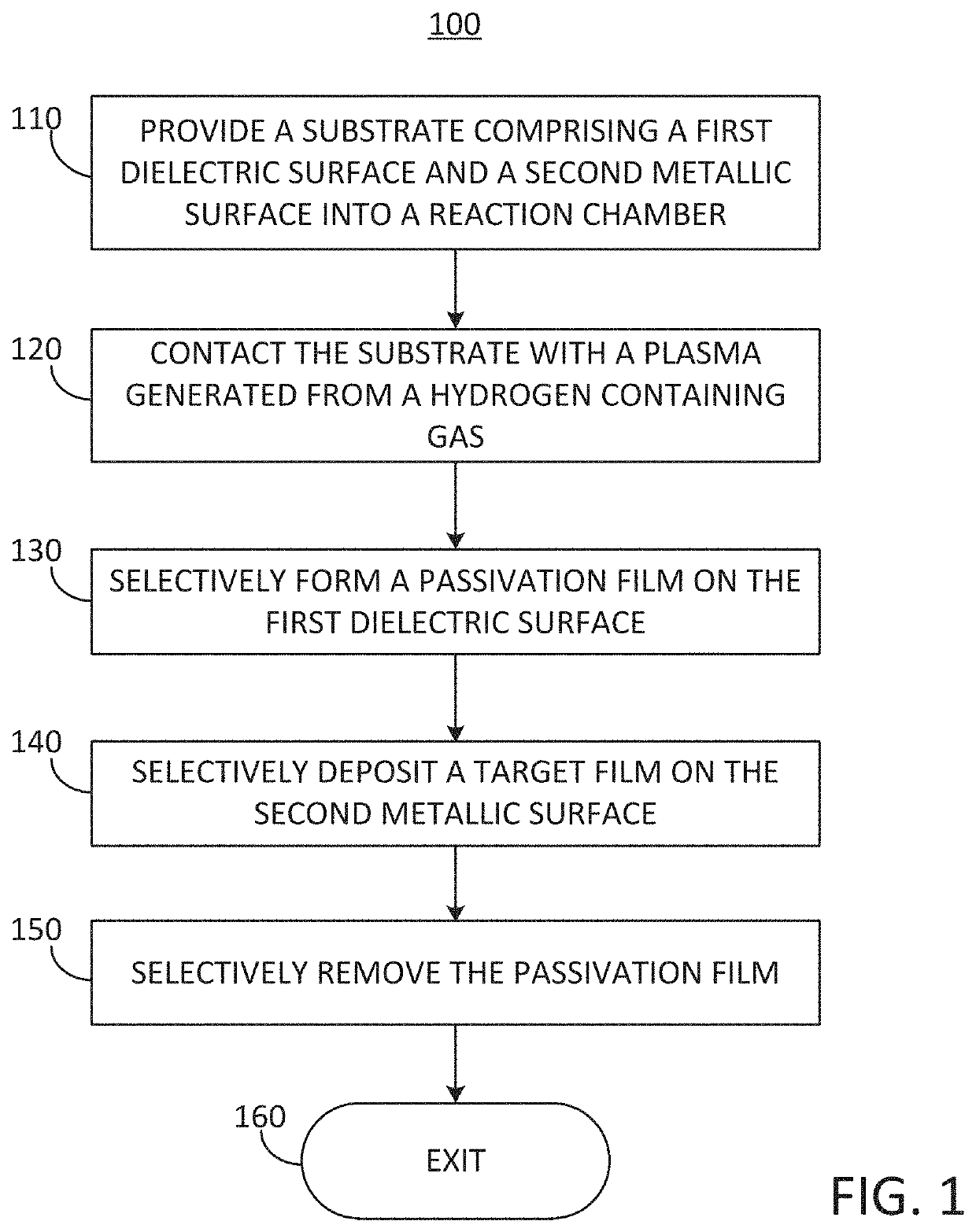

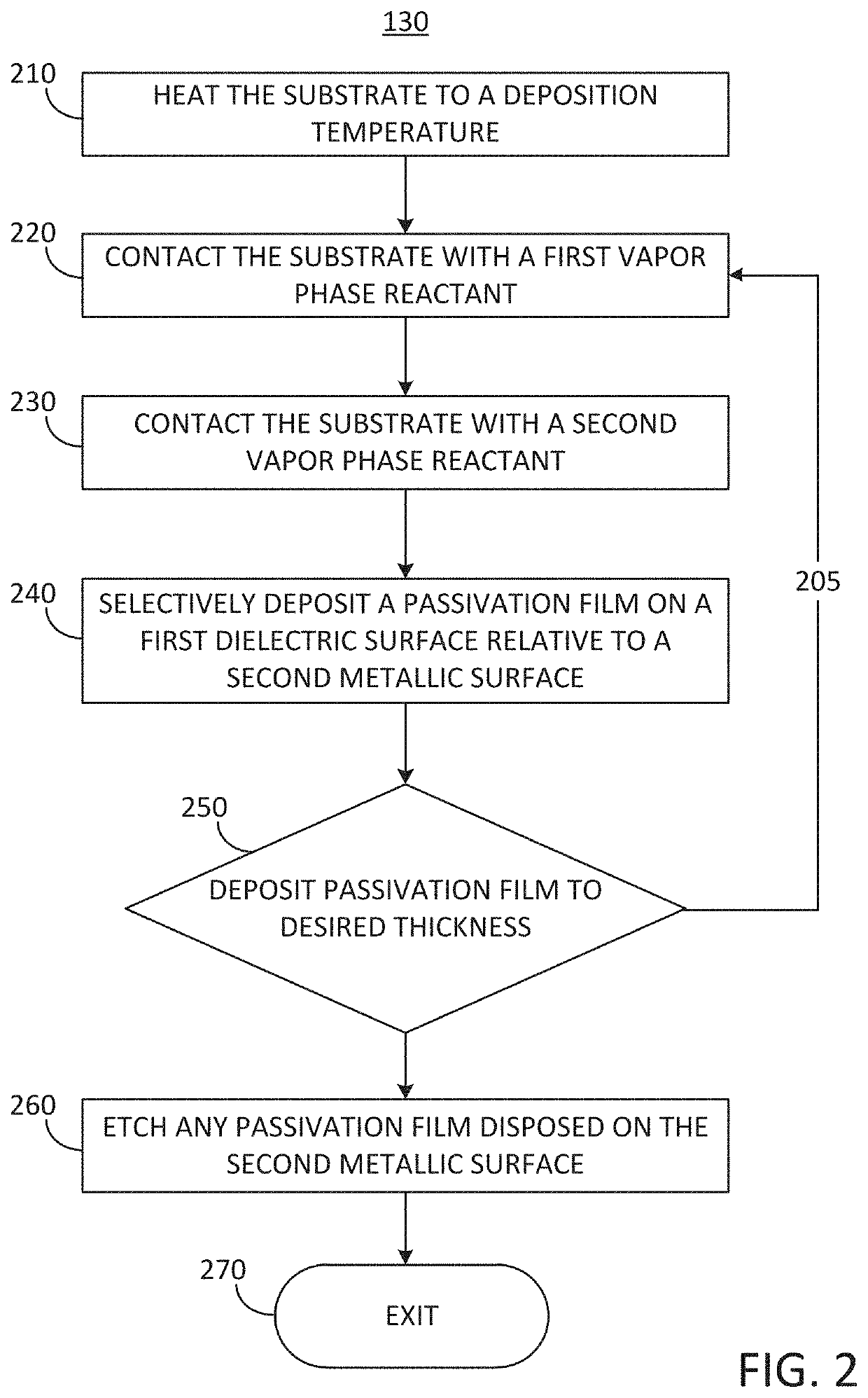

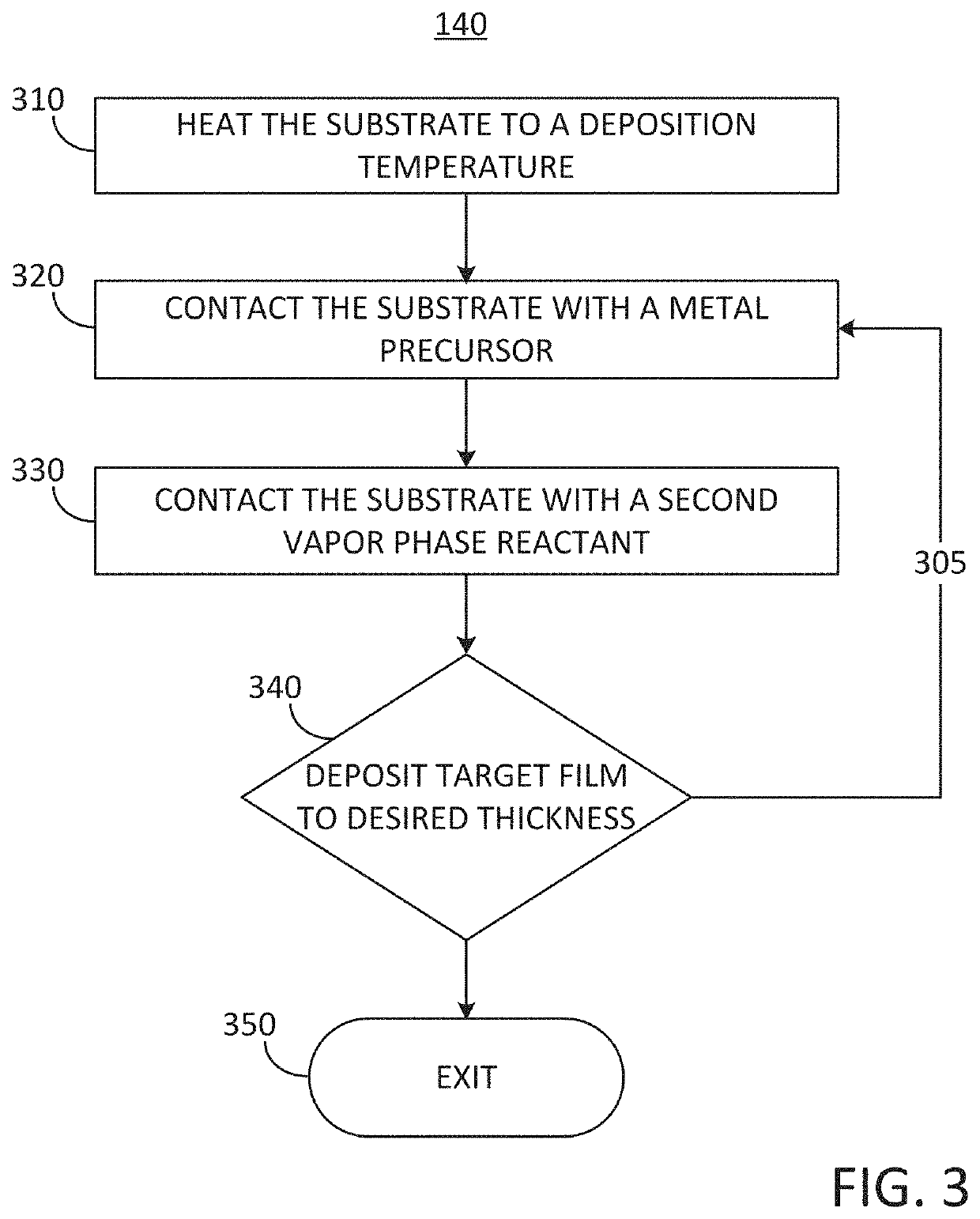

Methods for selectively forming a target film on a substrate comprising a first dielectric surface and a second metallic surface

ActiveUS20210159077A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDielectric surfaceVapor phase

Methods for selectively forming a target film on a substrate comprising a first dielectric surface and a second metallic surface are disclosed. The methods may include: contacting the substrate with a plasma generated from a hydrogen containing gas, selectively forming a passivation film from vapor phase reactants on the first dielectric surface while leaving the second metallic surface free from the passivation film, and selectively depositing the target film from vapor phase reactants on the second metallic surface relative to the passivation film.

Owner:ASM IP HLDG BV

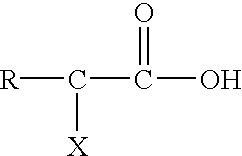

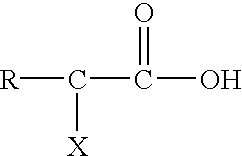

Post clean treatment

InactiveUS6546939B1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydroxylamineHydrazine compound

A composition for removal of chemical residues from metal or dielectric surfaces or for chemical mechanical polishing of a copper or aluminum surface is an aqueous solution with a pH between about 3.5 and about 7. The composition contains a monofunctional, difunctional or trifunctional organic acid and a buffering amount of a quaternary amine, ammonium hydroxide, hydroxylamine, hydroxylamine salt, hydrazine or hydrazine salt base. A method in accordance with the invention for removal of chemical residues from a metal or dielectric surface comprises contacting the metal or dielectric surface with the above composition for a time sufficient to remove the chemical residues. A method in accordance with the invention for chemical mechanical polishing of a copper or aluminum surface comprises applying the above composition to the copper or aluminum surface, and polishing the surface in the presence of the composition.

Owner:DUPONT AIR PRODS NANOMATERIALS

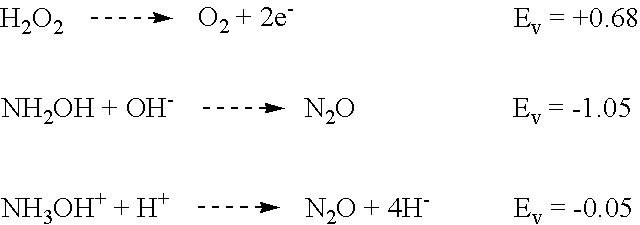

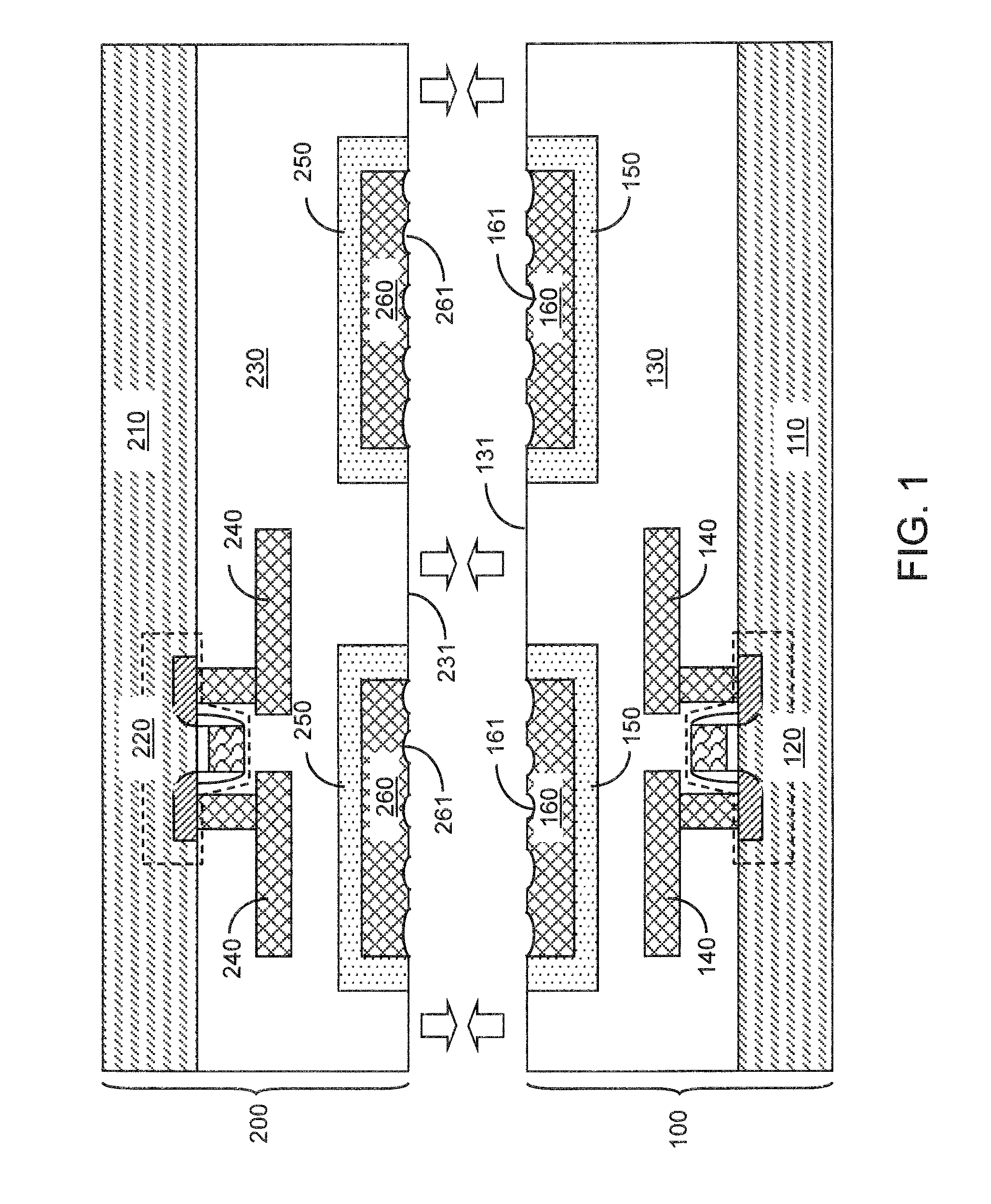

Pad bonding employing a self-aligned plated liner for adhesion enhancement

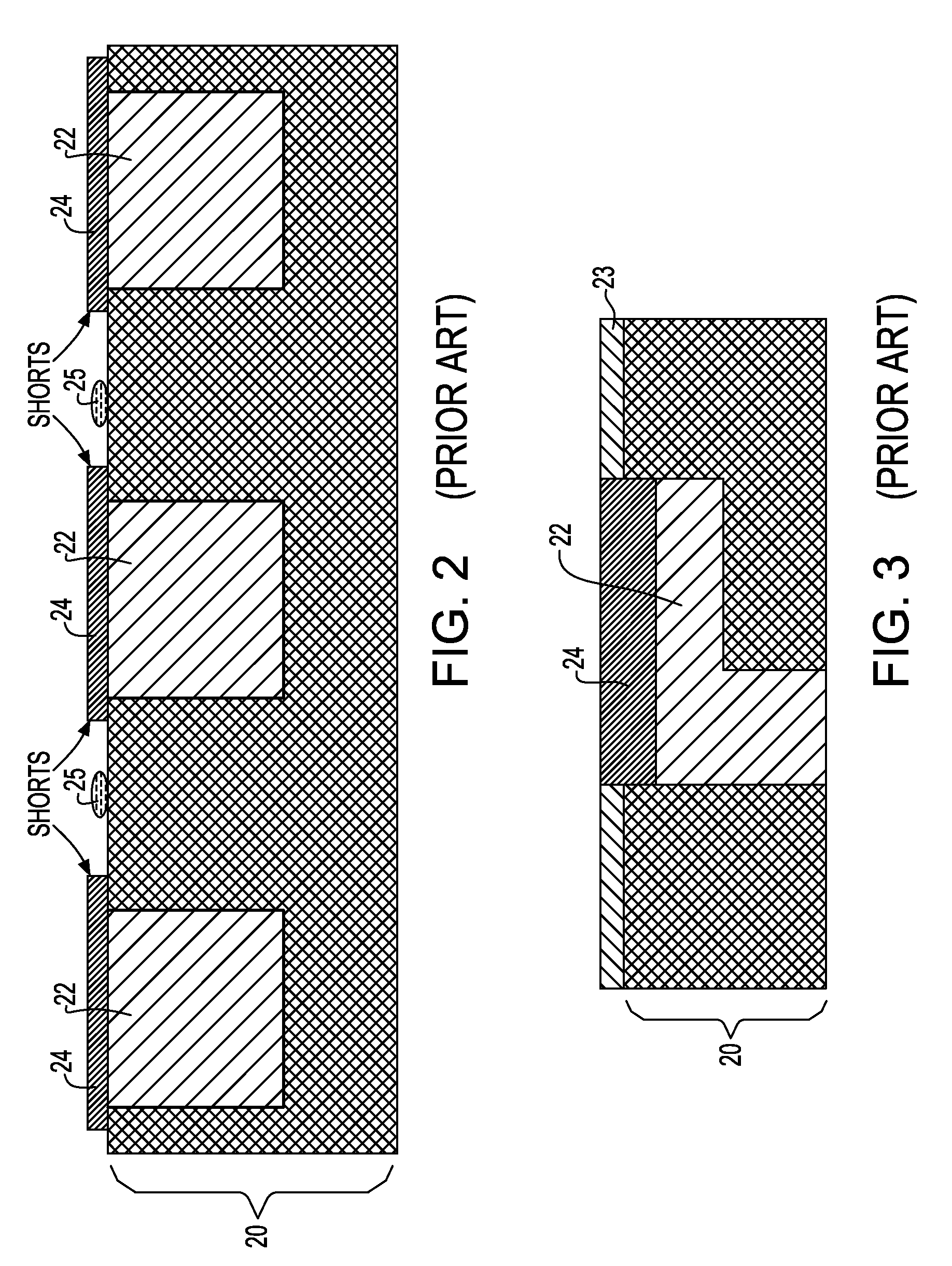

ActiveUS8482132B2Improve adhesionSemiconductor/solid-state device detailsSolid-state devicesDielectric surfaceConductive materials

Owner:TAIWAN SEMICON MFG CO LTD

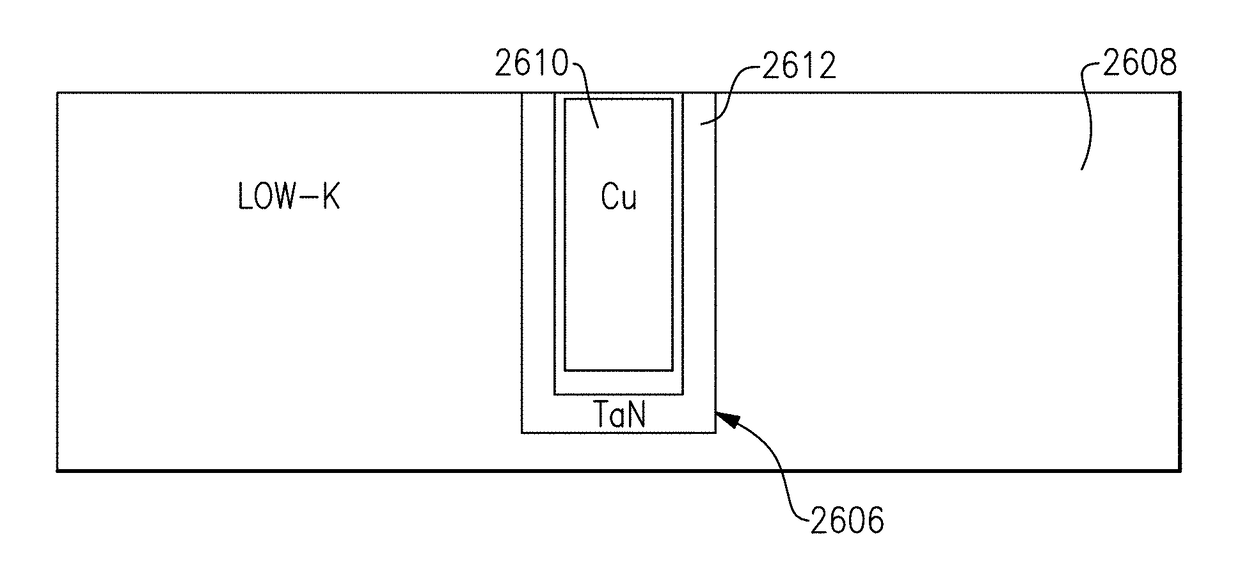

Noble metal cap for interconnect structures

InactiveUS20090189287A1Improved EM reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface layerDielectric surface

An interconnect structure that includes a dielectric material having a dielectric constant of about 3.0 or less is provided. This low k dielectric material has at least one conductive material having an upper surface embedded therein. The dielectric material also has a surface layer that is made hydrophobic prior to the formation of the noble metal cap. The noble metal cap is located directly on the upper surface of the at least one conductive material. Because of the presence of the hydrophobic surface layer on the dielectric material, the noble metal cap does not substantially extend onto the hydrophobic surface layer of the dielectric material that is adjacent to the at least one conductive material and no metal residues from the noble metal cap deposition form on this hydrophobic dielectric surface.

Owner:GLOBALFOUNDRIES INC

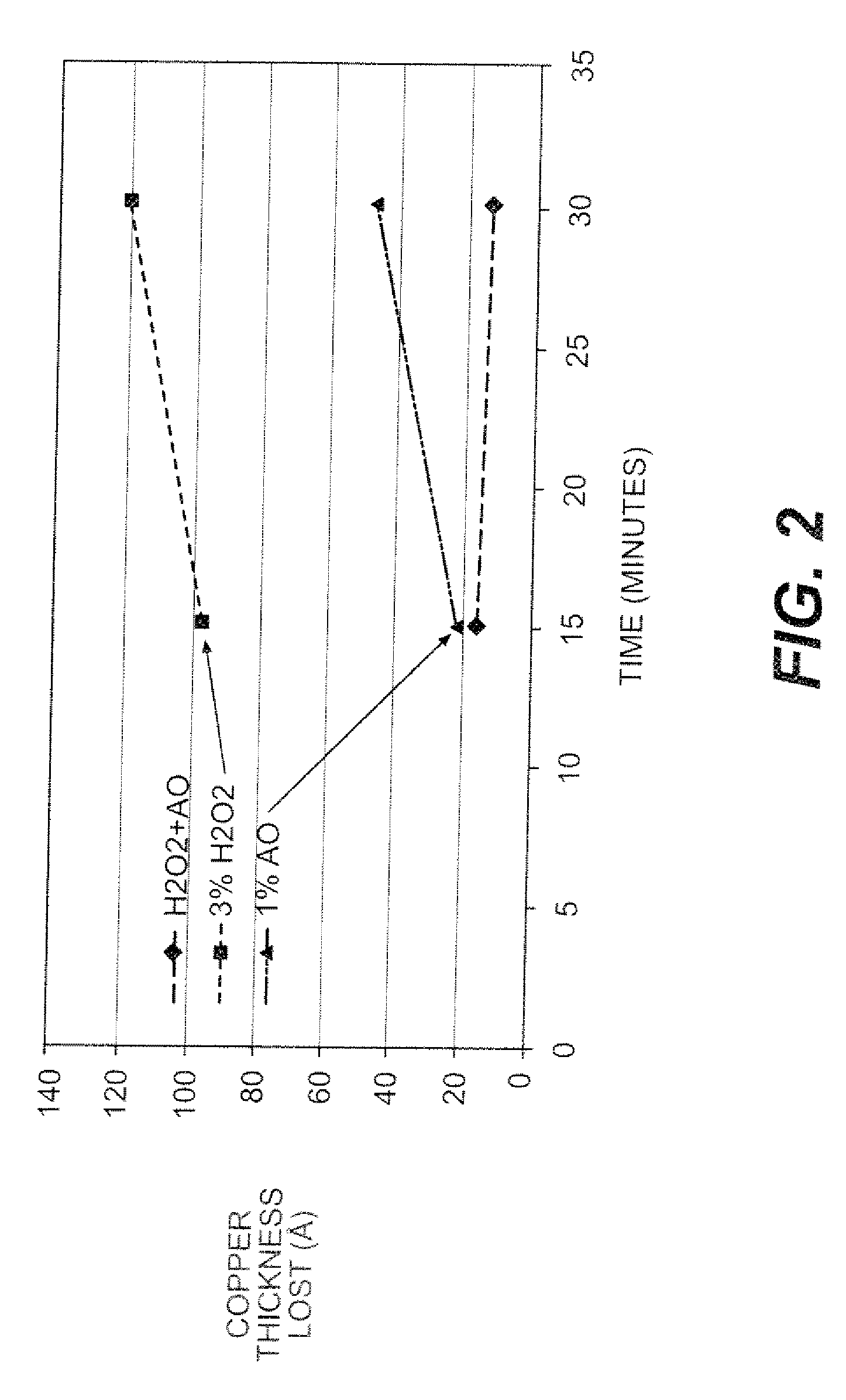

Methods of post chemical mechanical polishing and wafer cleaning using amidoxime compositions

InactiveUS20090133716A1Reducing and eliminating corrosion problemSignificant to useOrganic detergent compounding agentsNon-surface-active detergent compositionsDielectric surfaceCompound (substance)

The invention relates to a method for the removal of residues and contaminants from metal or dielectric surfaces and to a method for chemical mechanical polishing of a copper or aluminum surface. The methods of the invention include using an aqueous amidoxime complex agent. Optionally, the pH of the solution can be adjusted with an acid or base. The method includes applying the above composition to the copper or aluminum surface and polishing the surface in the presence of the composition.

Owner:EKC TECH

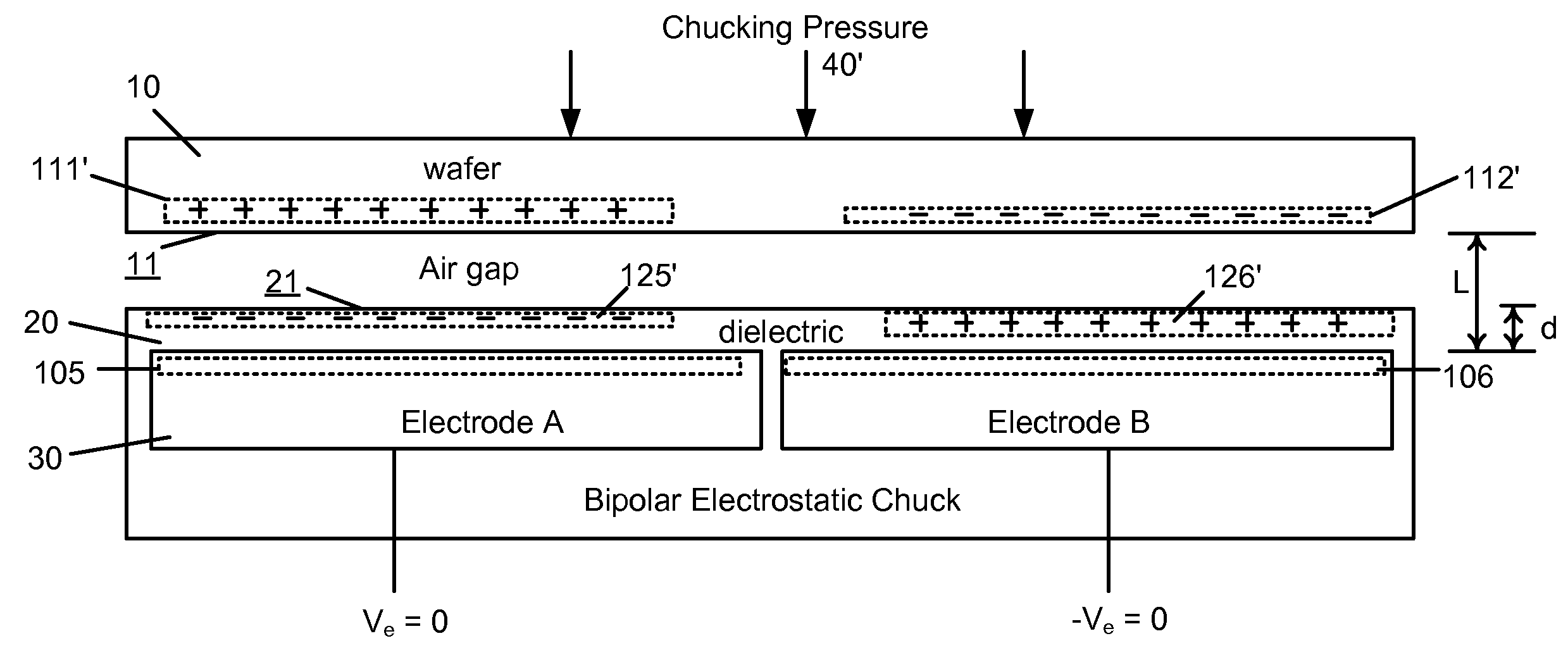

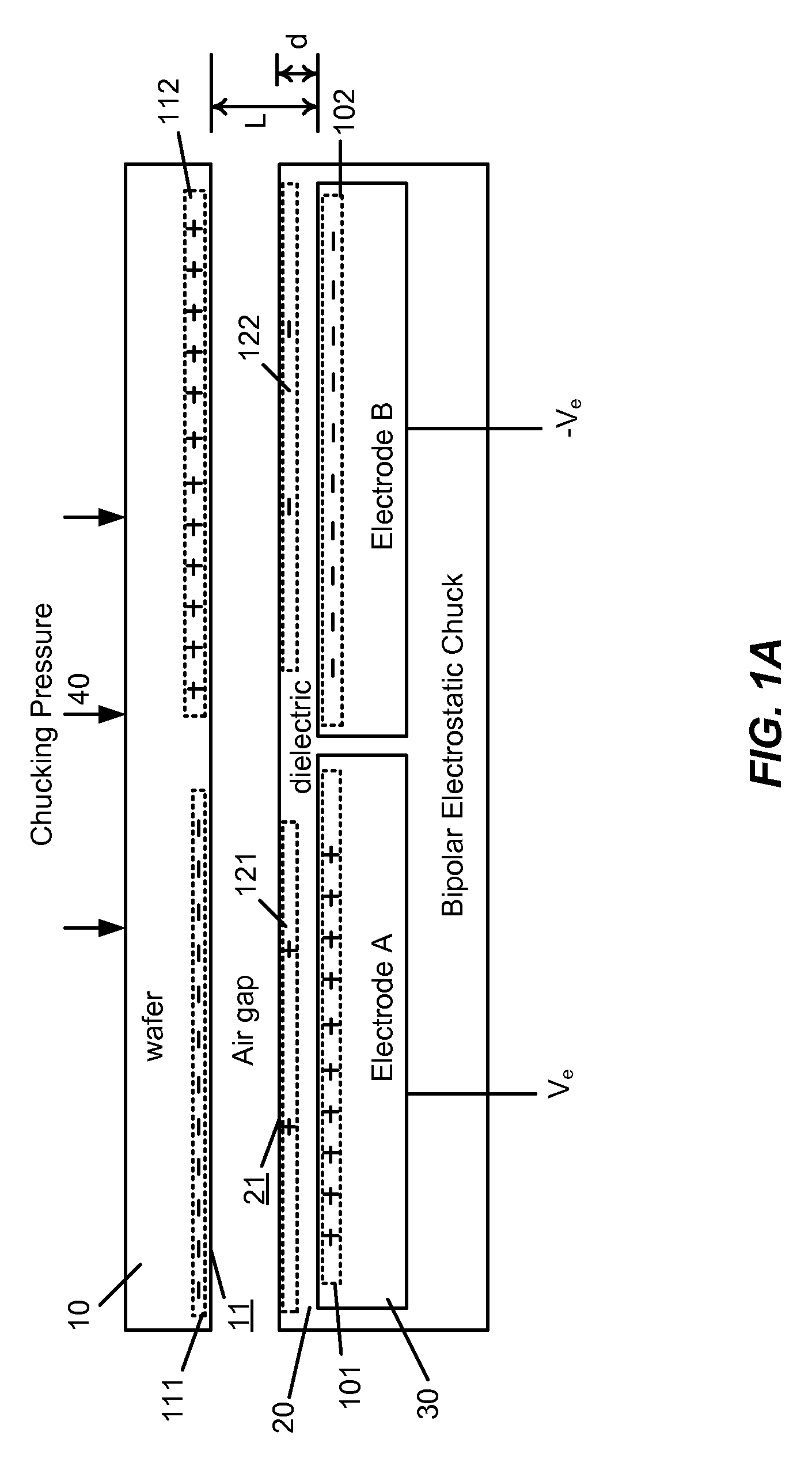

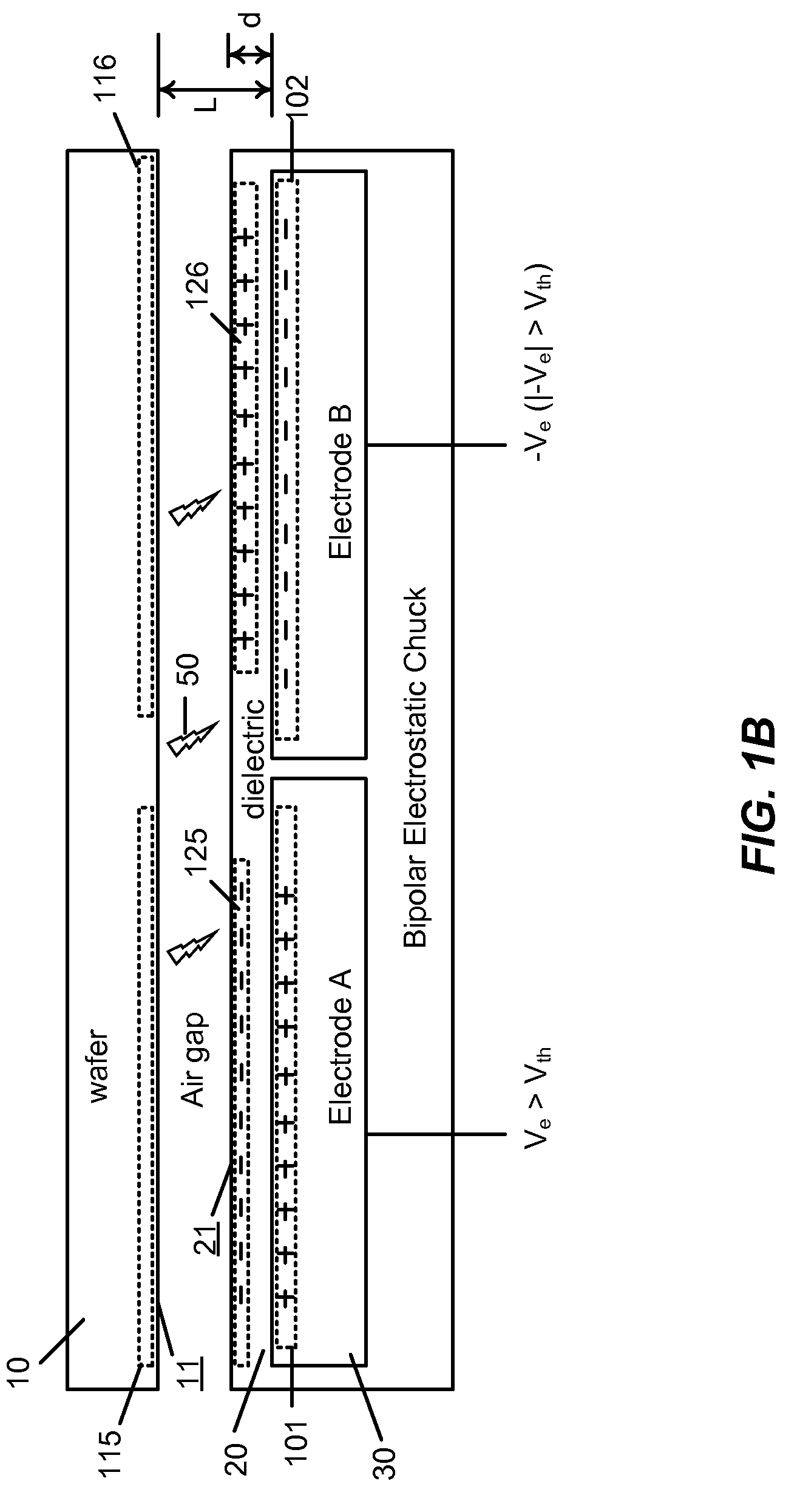

Method and system for performing electrostatic chuck clamping in track lithography tools

InactiveUS20090109595A1Enhanced chucking pressureIncrease pressureSemiconductor/solid-state device manufacturingLithographic artistTime segment

A method of clamping / declamping a semiconductor wafer on an electrostatic chuck in ambient air includes disposing the semiconductor wafer at a predetermined distance above a dielectric surface of the electrostatic chuck having one or more electrodes and applying a first voltage greater than a predetermined threshold to the one or more electrodes of the electrostatic chuck for a first time period. The method includes reducing the first voltage to a second voltage substantially equal to a self bias potential of the semiconductor wafer after the first time period. The method includes maintaining the second voltage for a second time period and adjusting the second voltage to a third voltage characterized by a polarity opposite to that of the first voltage and a magnitude smaller than the predetermined threshold. The method includes reducing the third voltage to a fourth voltage substantially equal to the second voltage after a third time period.

Owner:SOKUDO CO LTD

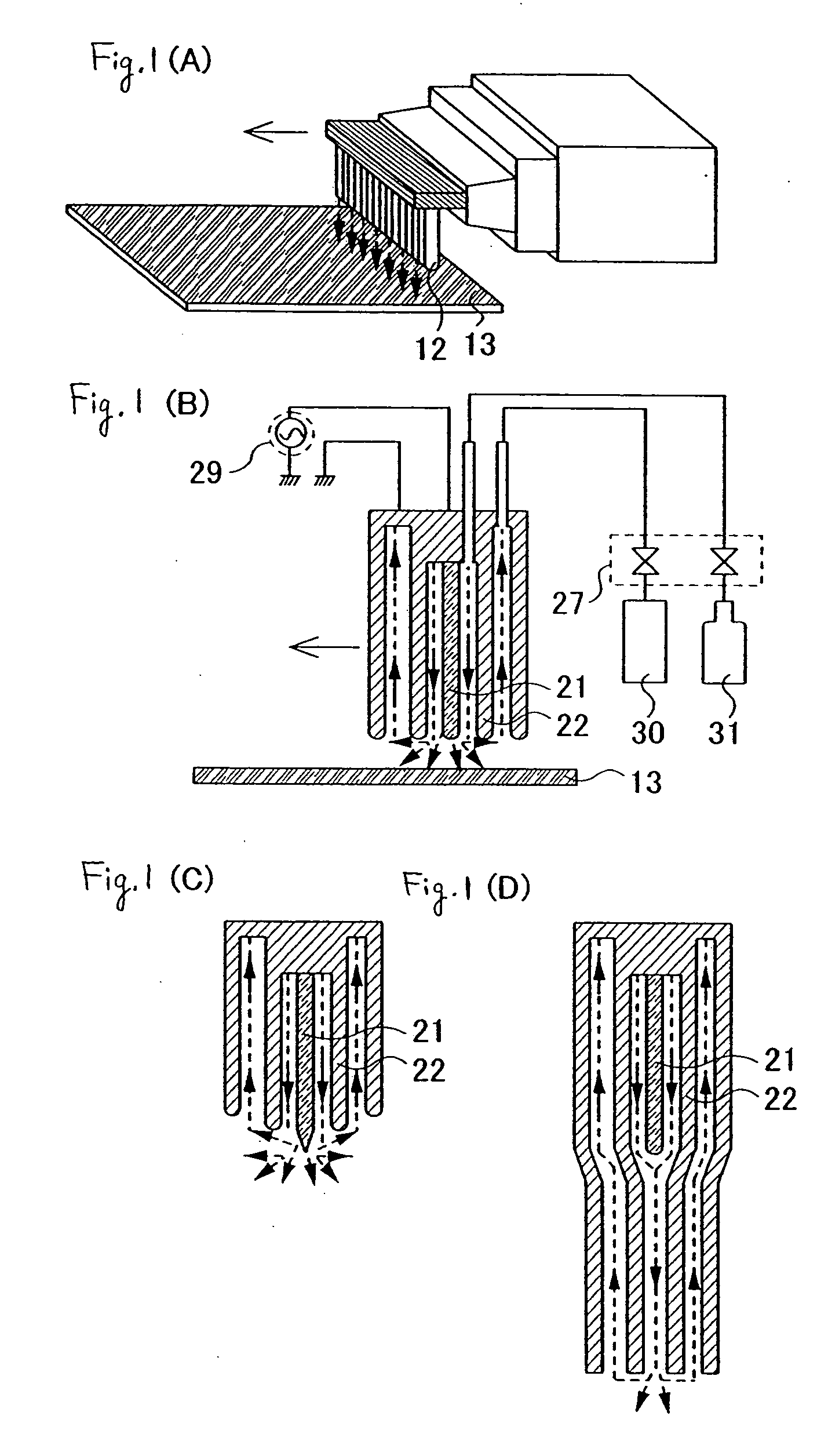

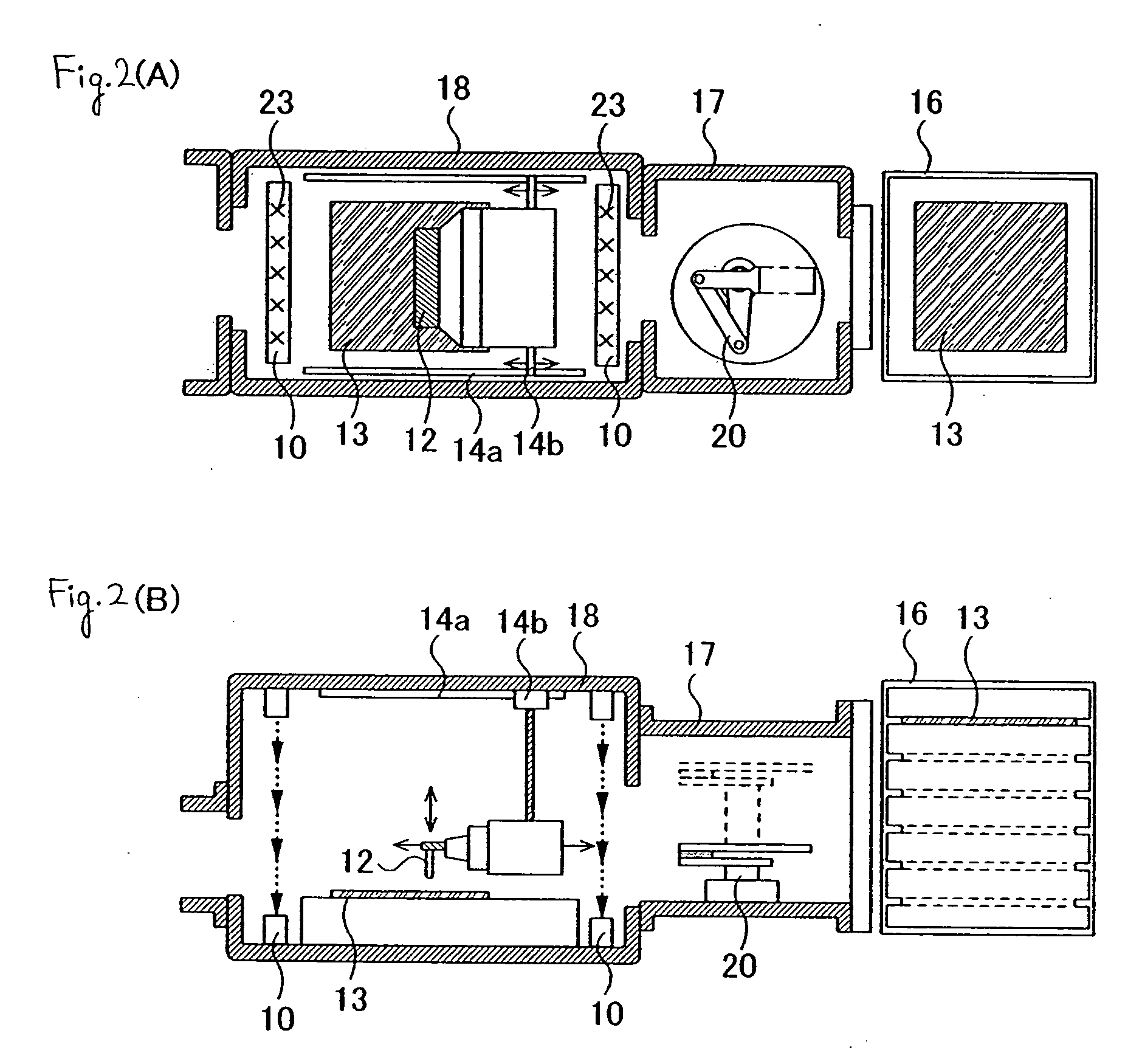

Manufacturing method for wiring

InactiveUS20050011752A1Improve throughputEfficient use ofElectric discharge tubesVacuum evaporation coatingResistEvaporation

In the case in which a film for a resist is formed by spin coating, there is a resist material to be wasted, and the process of edge cleaning is added as required. Further, when a thin film is formed on a substrate using a vacuum apparatus, a special apparatus or equipment to evacuate the inside of a chamber vacuum is necessary, which increases manufacturing cost. The invention is characterized by including: a step of forming conductive layers on a substrate having a dielectric surface in a selective manner with a CVD method, an evaporation method, or a sputtering method; a step of discharging a compound to form resist masks so as to come into contact with the conductive layer; a step of etching the conductive layers with plasma generating means using the resist masks under the atmospheric pressure or a pressure close to the atmospheric pressure; and a step of ashing the resist masks with the plasma generating means under the atmospheric pressure or a pressure close to the atmospheric pressure. With the above-mentioned characteristics, efficiency in use of a material is improved, and a reduction in manufacturing cost is realized.

Owner:SEMICON ENERGY LAB CO LTD

Nonvolatile phase change memory cell having a reduced contact area

InactiveUS7728318B2Solid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryDielectric surface

Owner:SANDISK CORP

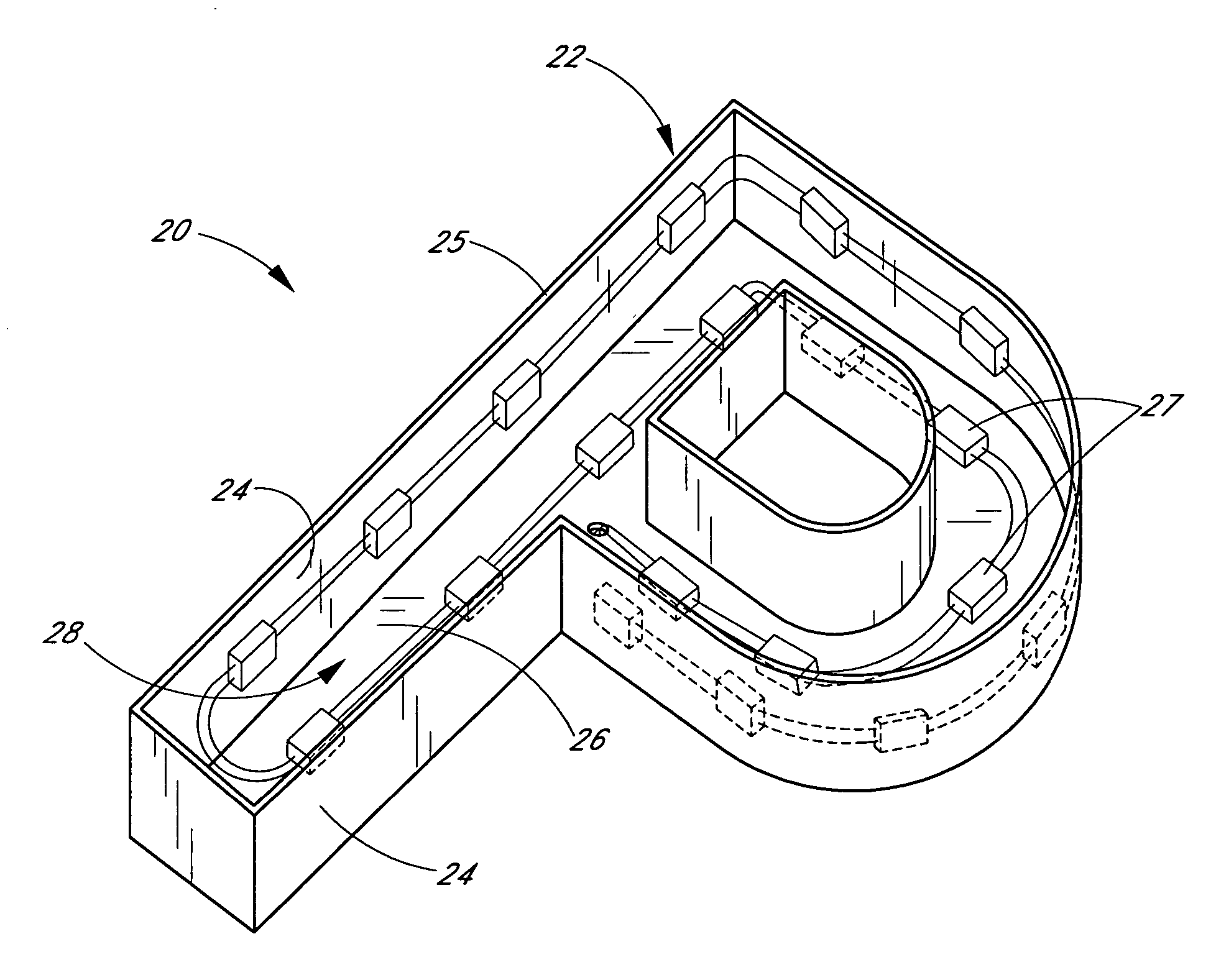

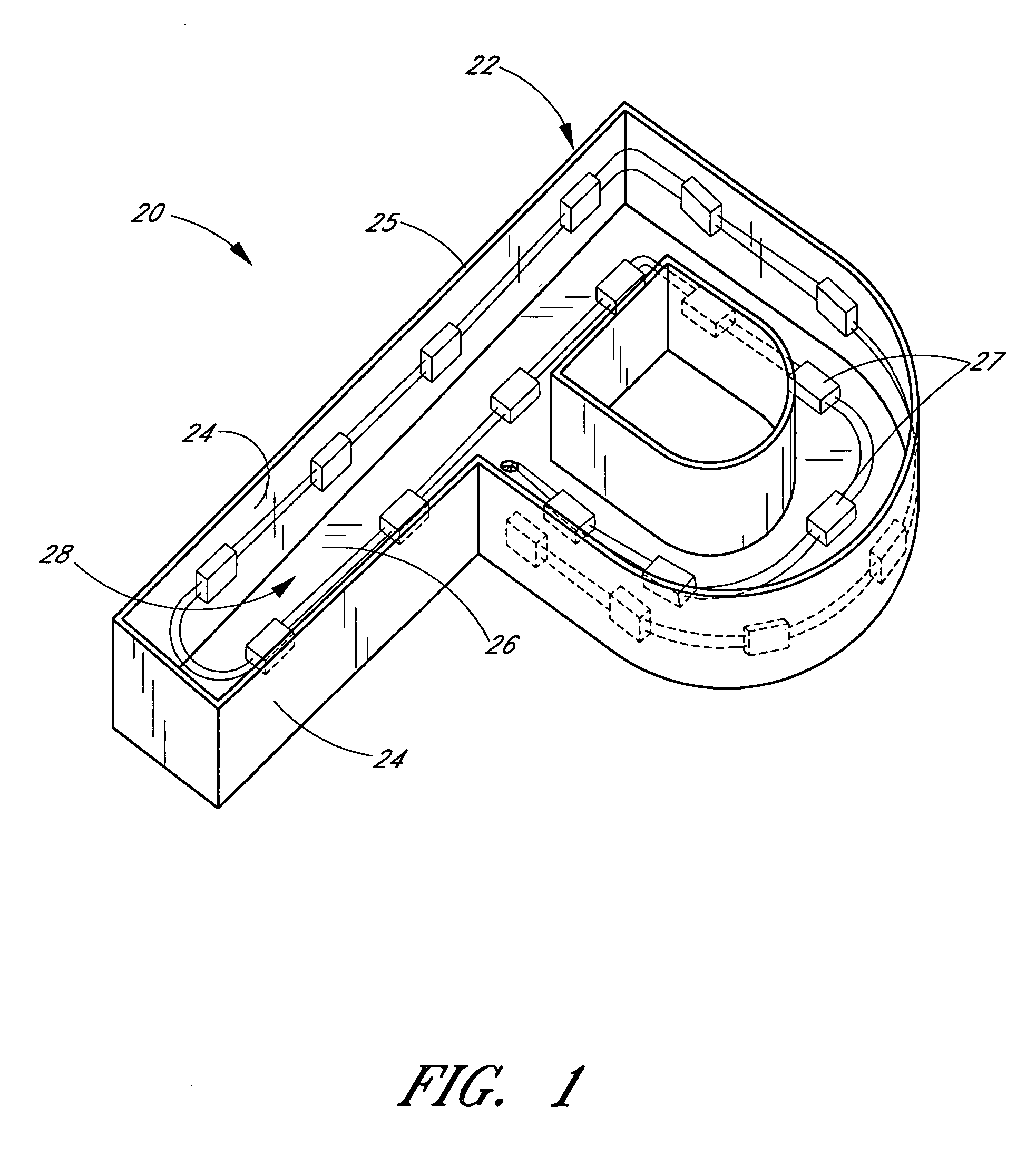

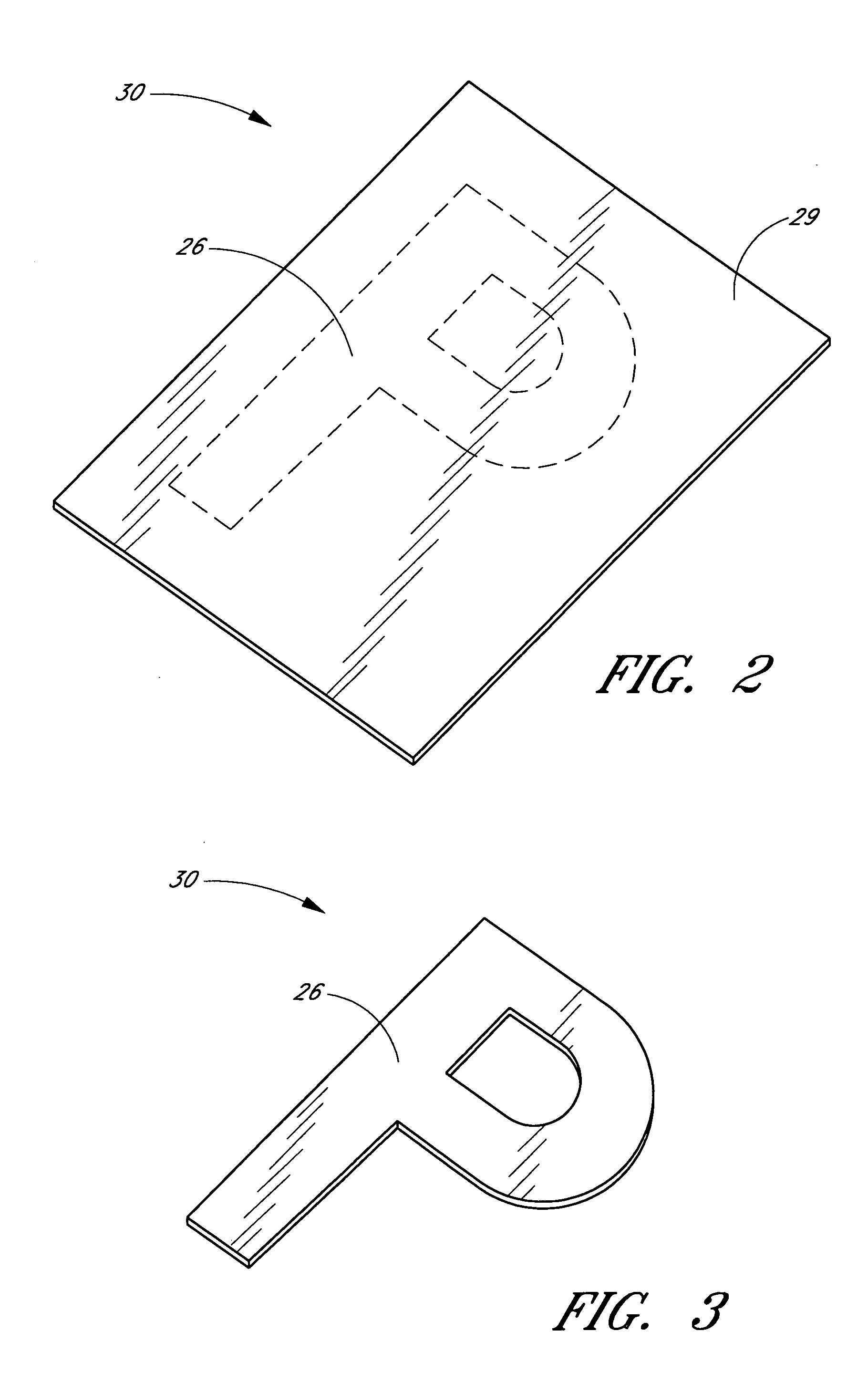

Cuttable illuminated panel

InactiveUS20050251698A1Minimizing assembly effortReduce the amount requiredVolume/mass flow measurementLighting elementsLight equipmentDielectric surface

An illumination apparatus is provided having a panel including a plurality of circuit units on a dielectric surface. The circuit units include electrically conductive traces and at least one light emitting diode (LED). At least some of the circuit units have contacts for supplying power to the LED. The circuit units are preferably electrically interconnected so that power provided to one circuit unit also supplied power to at least a group of the circuit units. The apparatus with the circuit units may be cut or shaped to a predetermined or desired shape. Also provided are methods of manufacturing, assembling, and using the illumination apparatus.

Owner:DIAMOND CREEK CAPITAL LLC

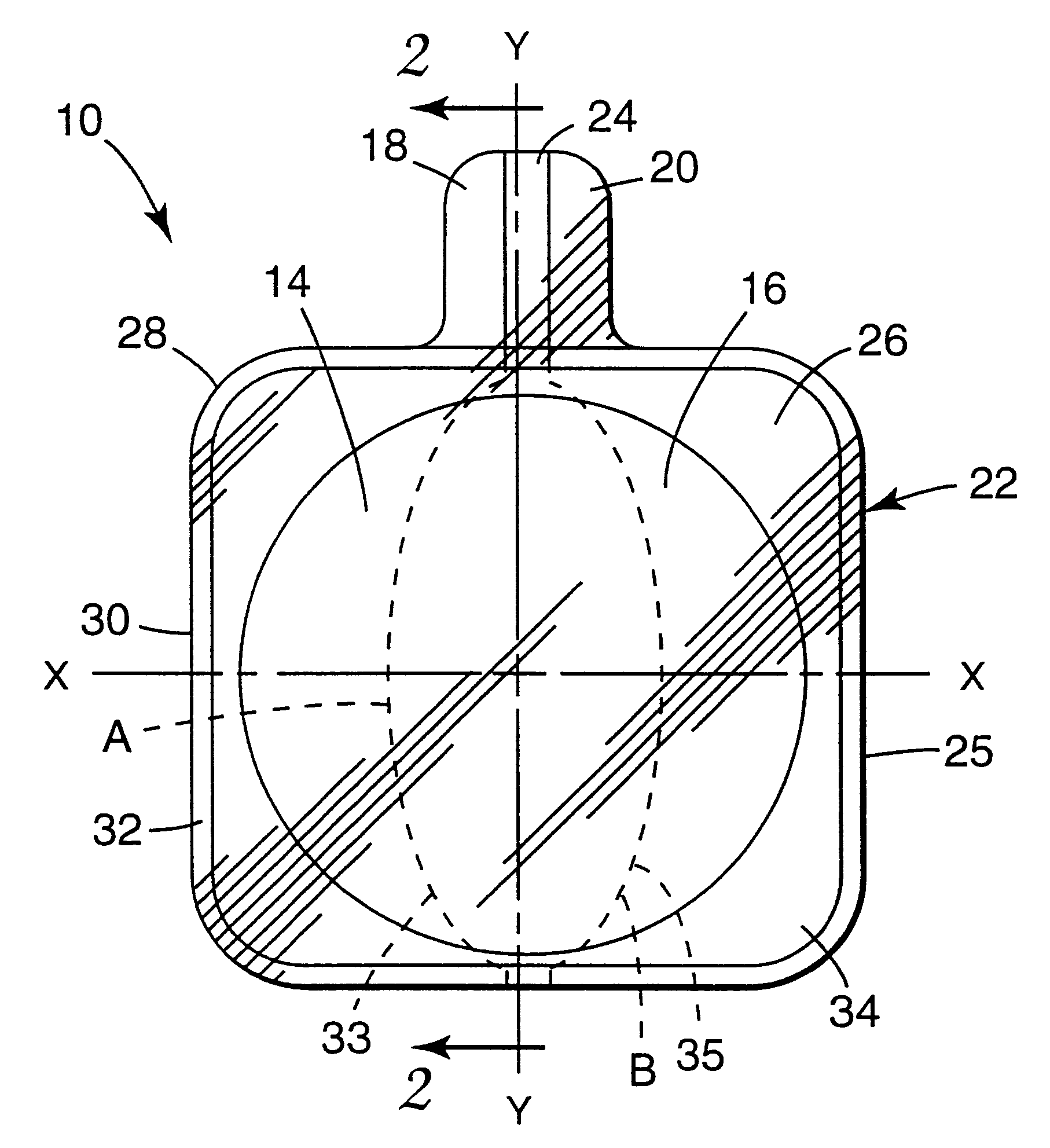

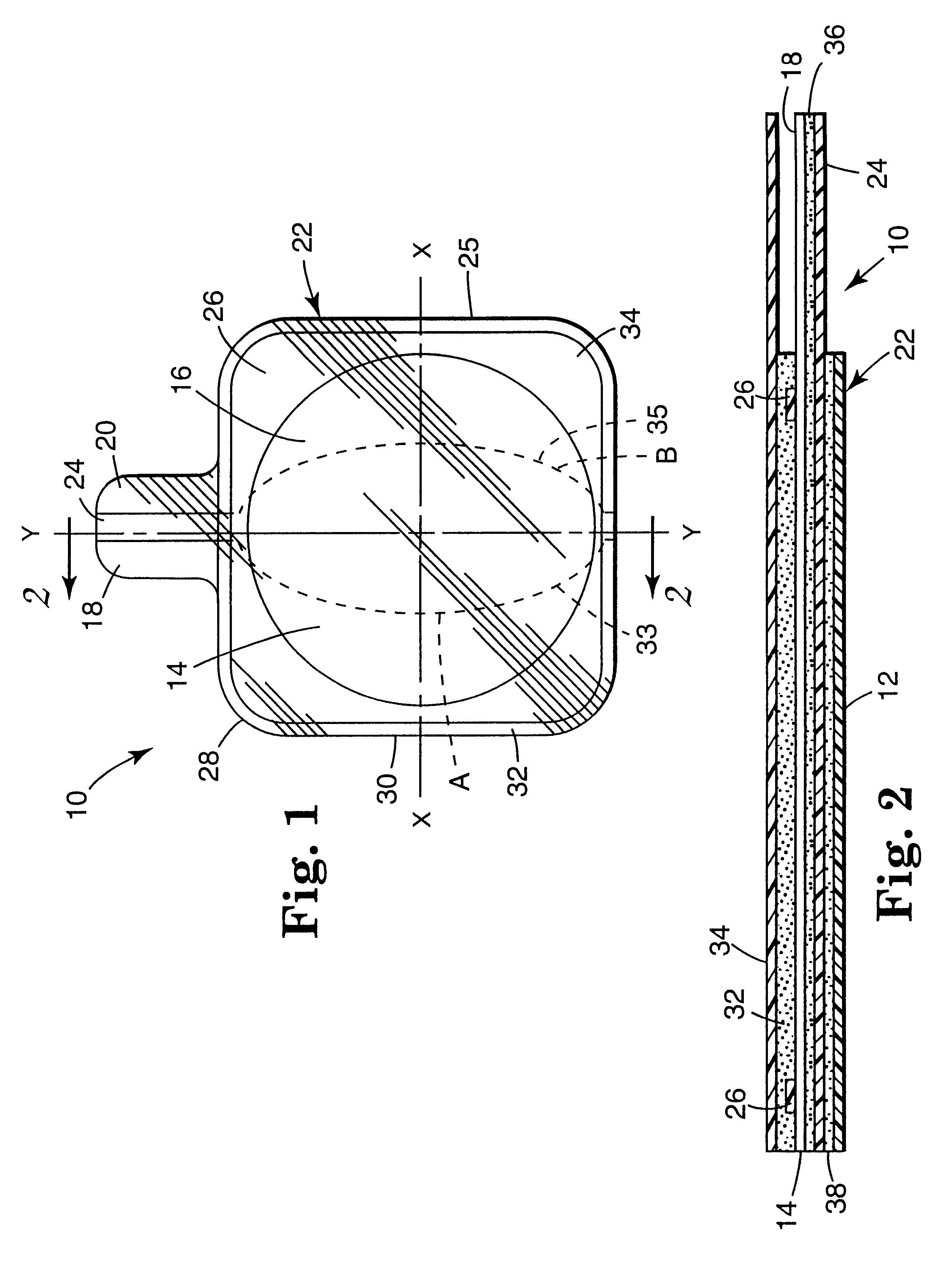

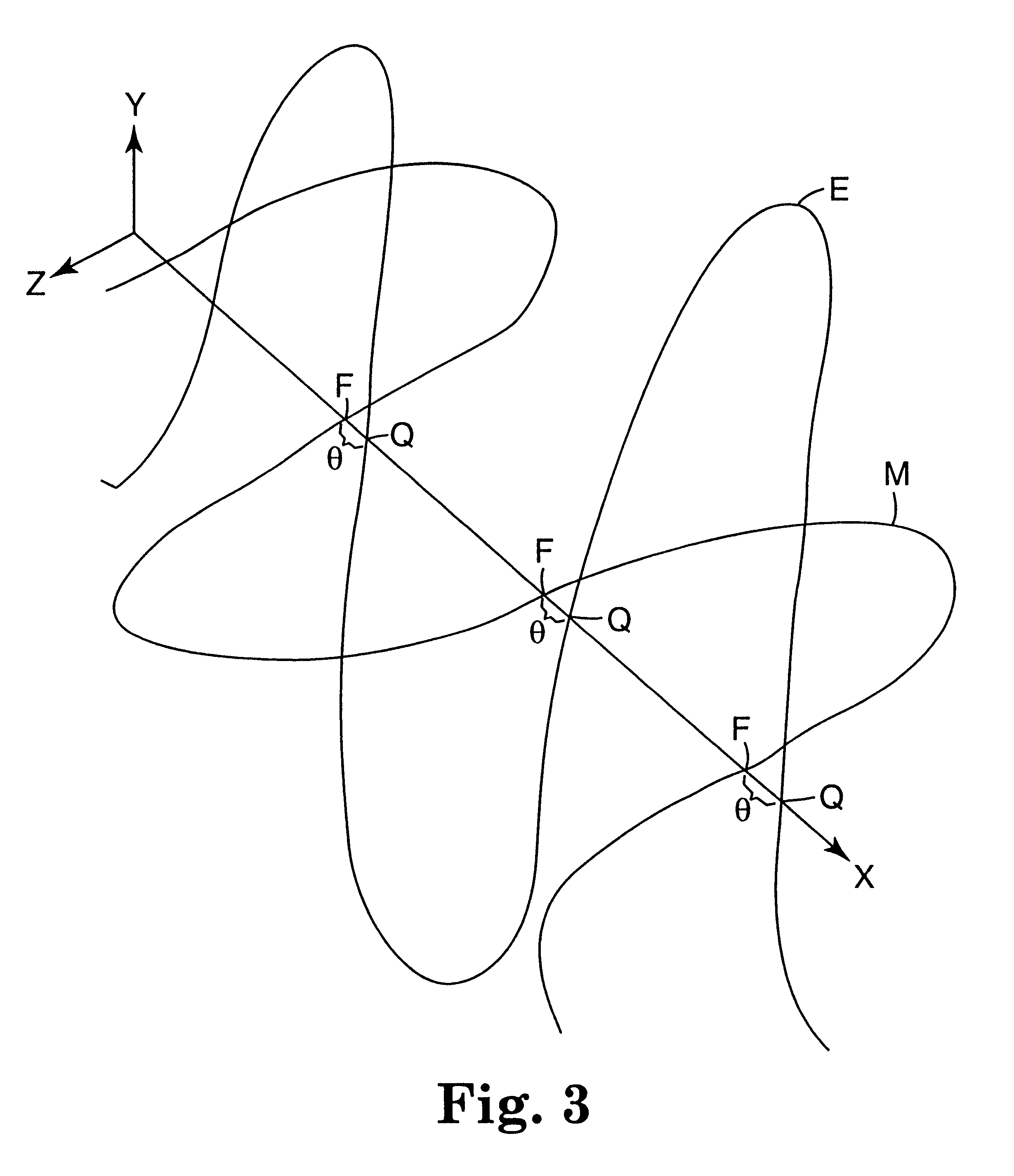

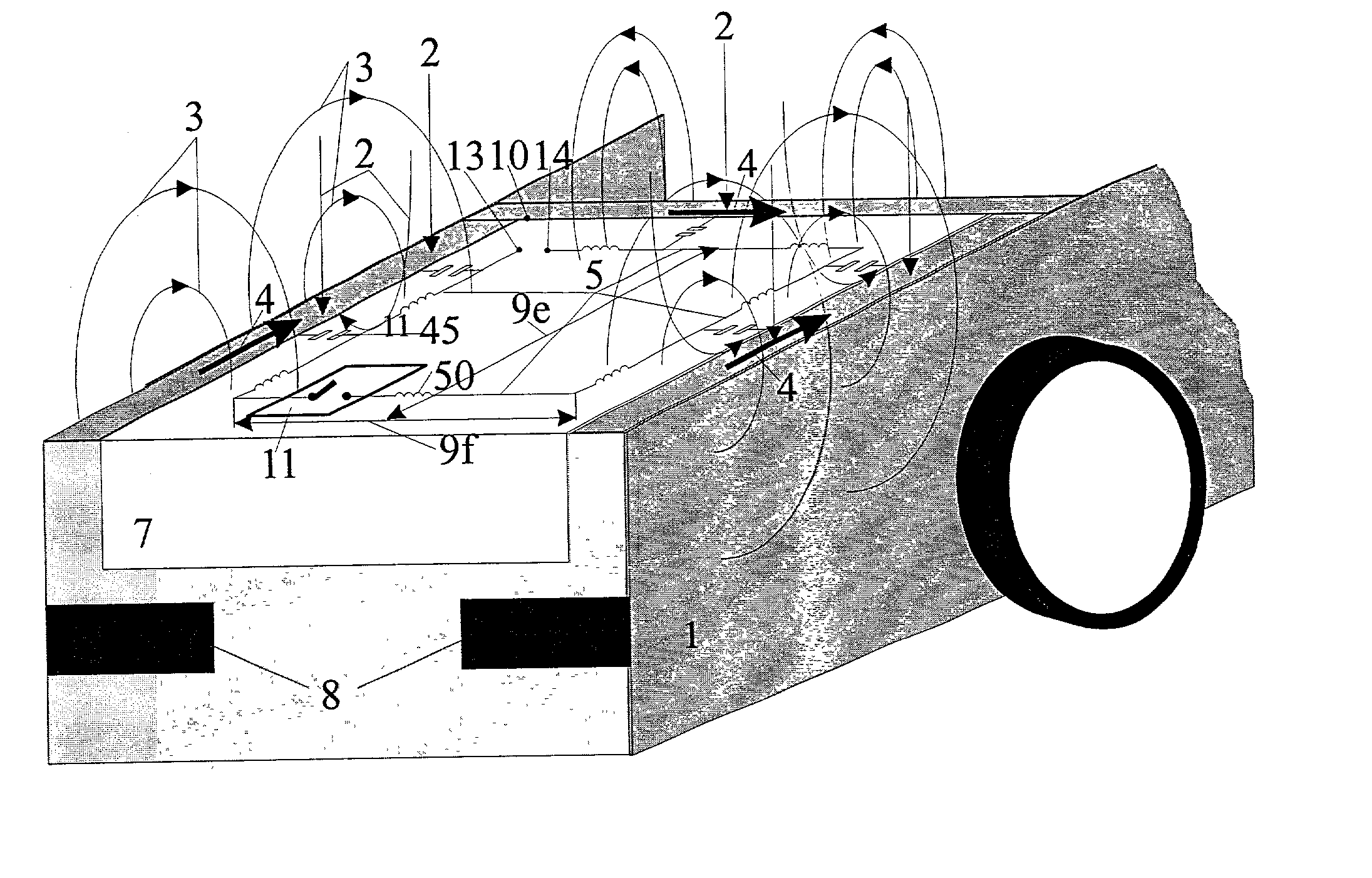

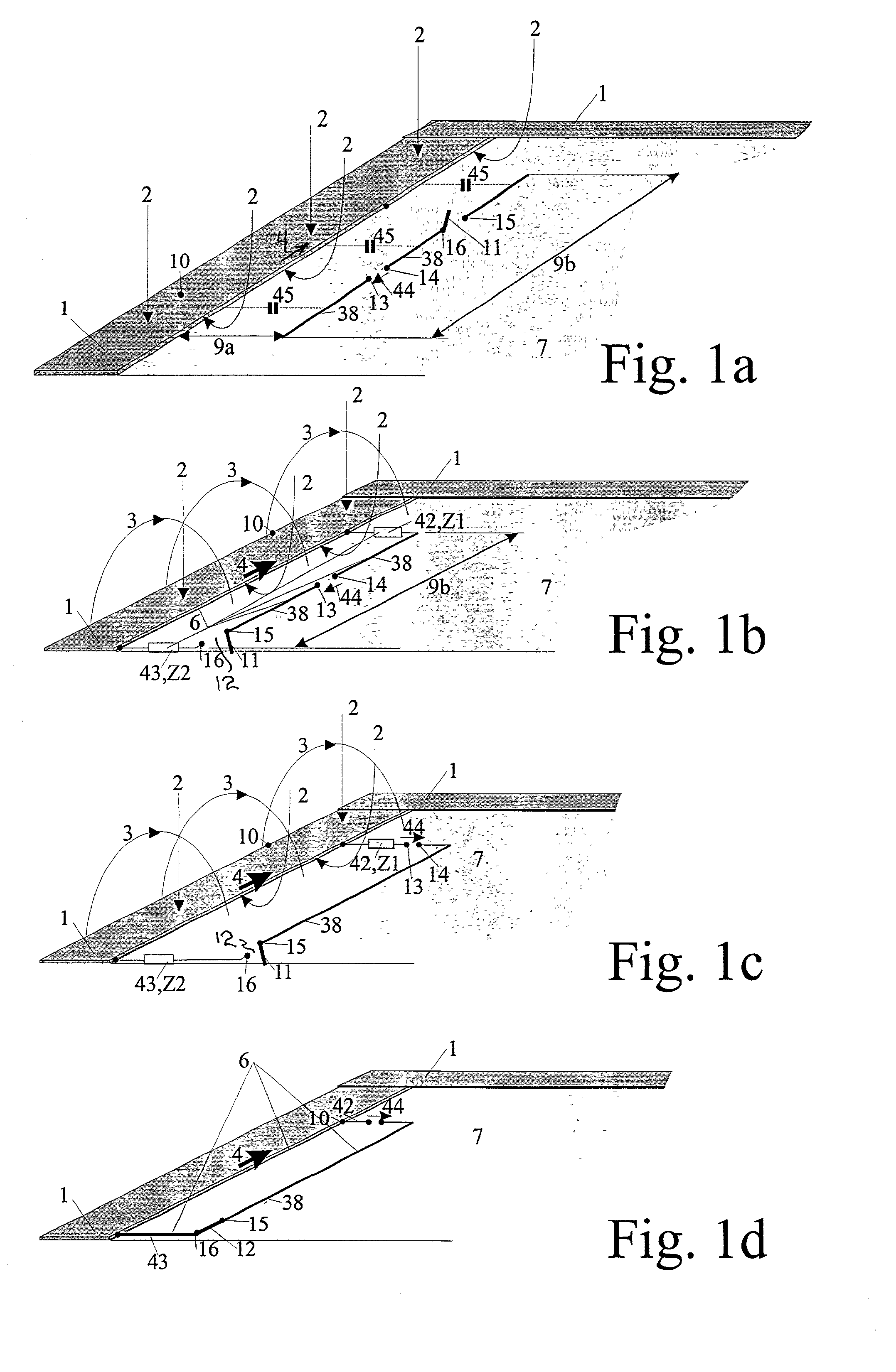

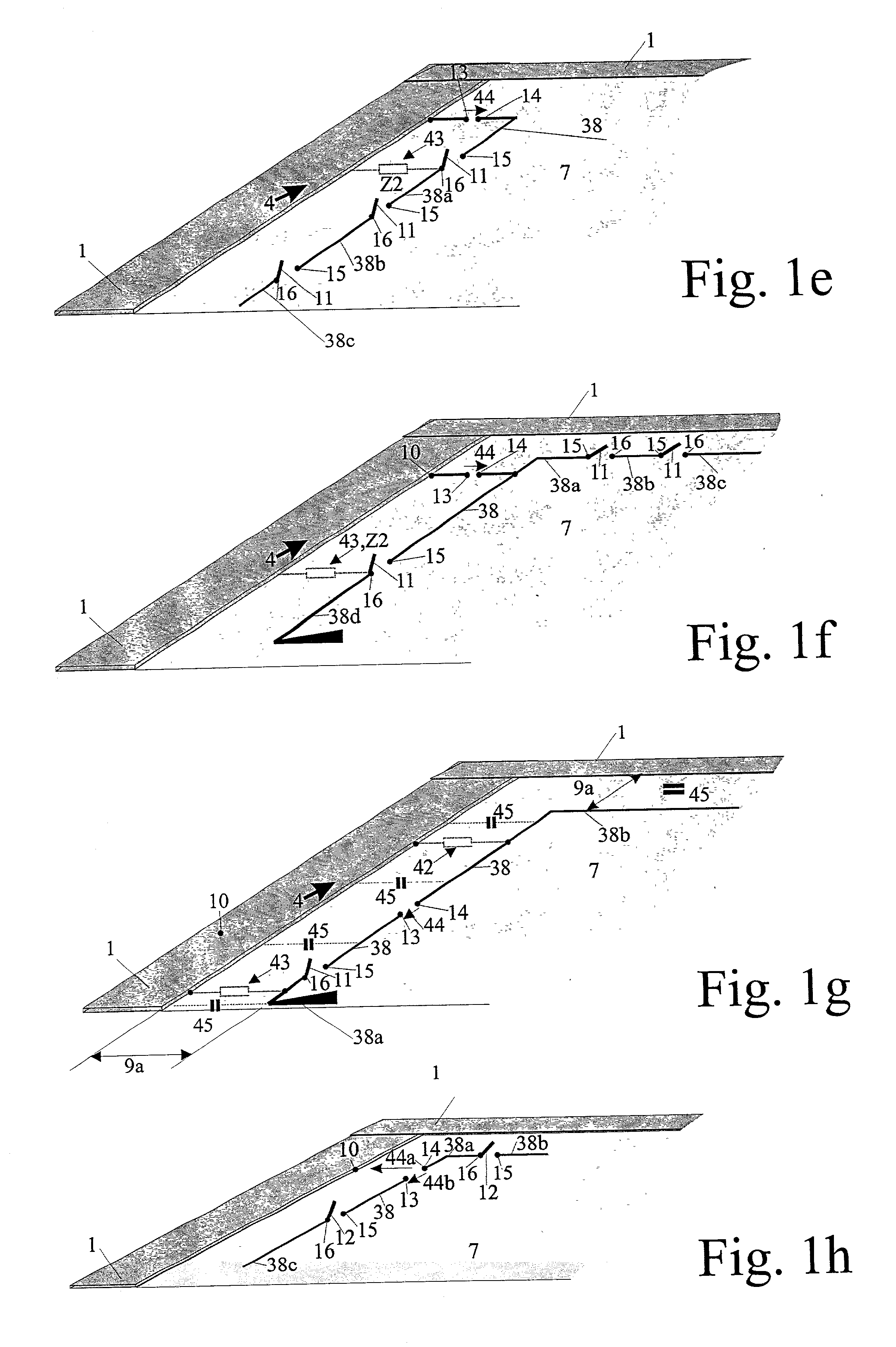

Diversity antenna on a dielectric surface in a motor vehicle body

InactiveUS20020126055A1Improve reception qualitySave installation spaceWindowsSpatial transmit diversityElectricityElectrical conductor

A diversity antenna for the meter and decimeter wave ranges installed on a conductively framed dielectric surface in the body of a motor vehicle and substantially assembled from rectangular part surfaces, for example in a roof cutout or trunk with a dielectric trunk lid. A substantially wire-shaped antenna conductor is installed parallel with the conductive frame and spaced from a part thereof of the dielectric surface less than one fourth of the width of the dielectric surface. The wire-shaped antenna conductor has an interruption site which define a pair of antenna connection terminals. A two-pole, electronically controllable impedance network is incorporated in series in at least one additional interruption site. The position of the interruption site with the pair of antenna connection terminals, and the position of the additional interruption site are selected so that the antenna signals available at the different settings of the controllable impedance network are adequately decoupled in terms of diversity.

Owner:DELPHI DELCO ELECTRONICS EUROPE GMBH

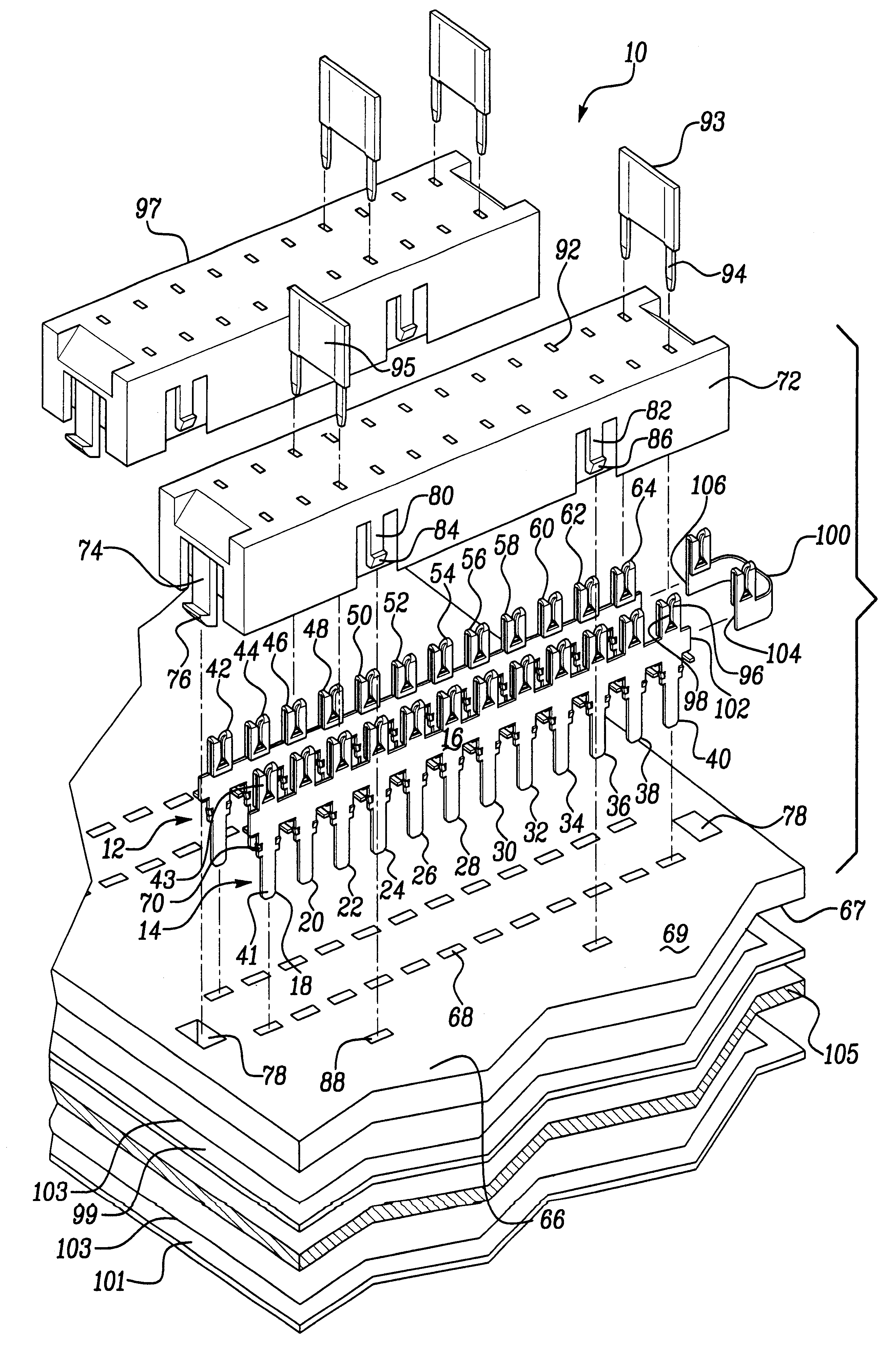

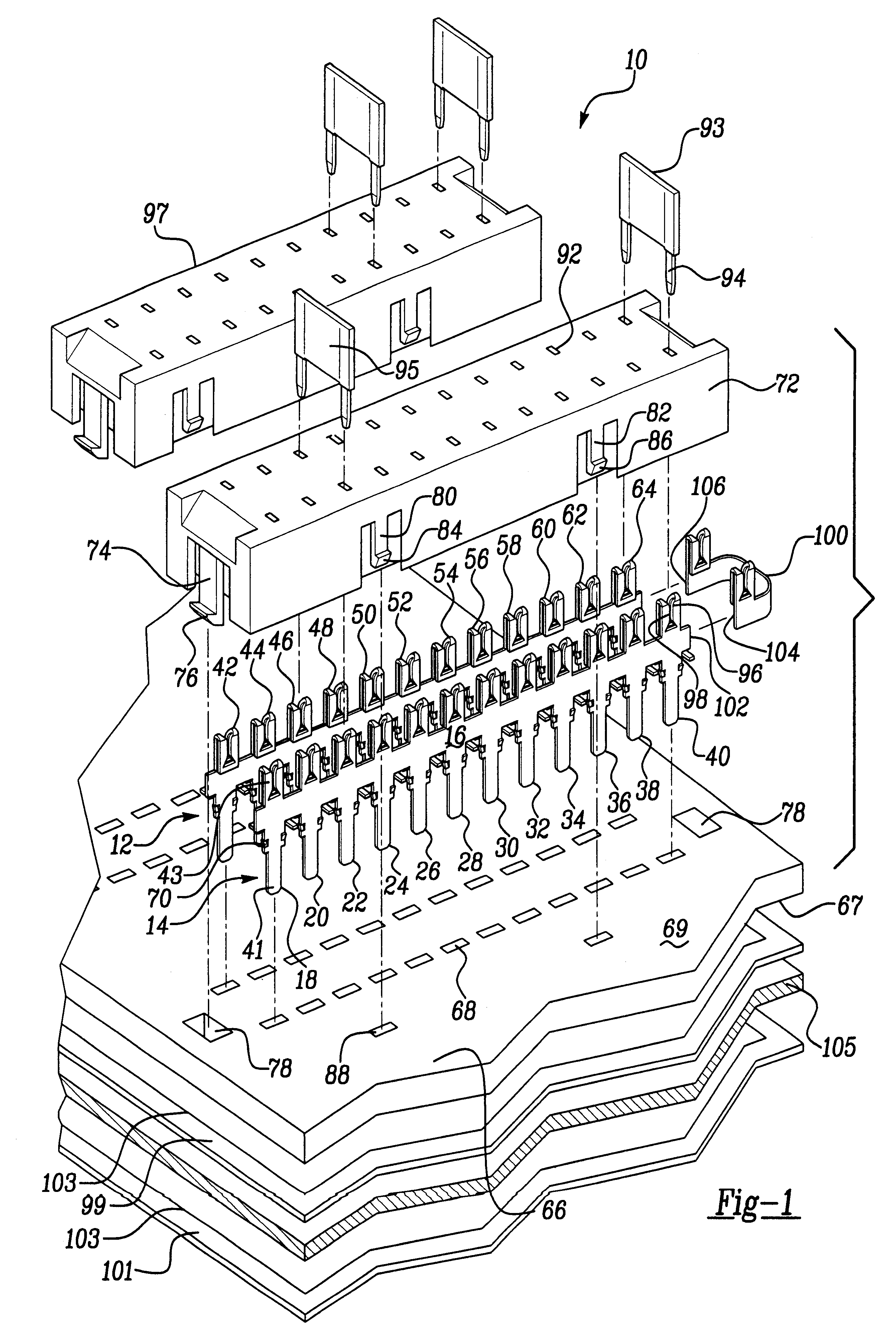

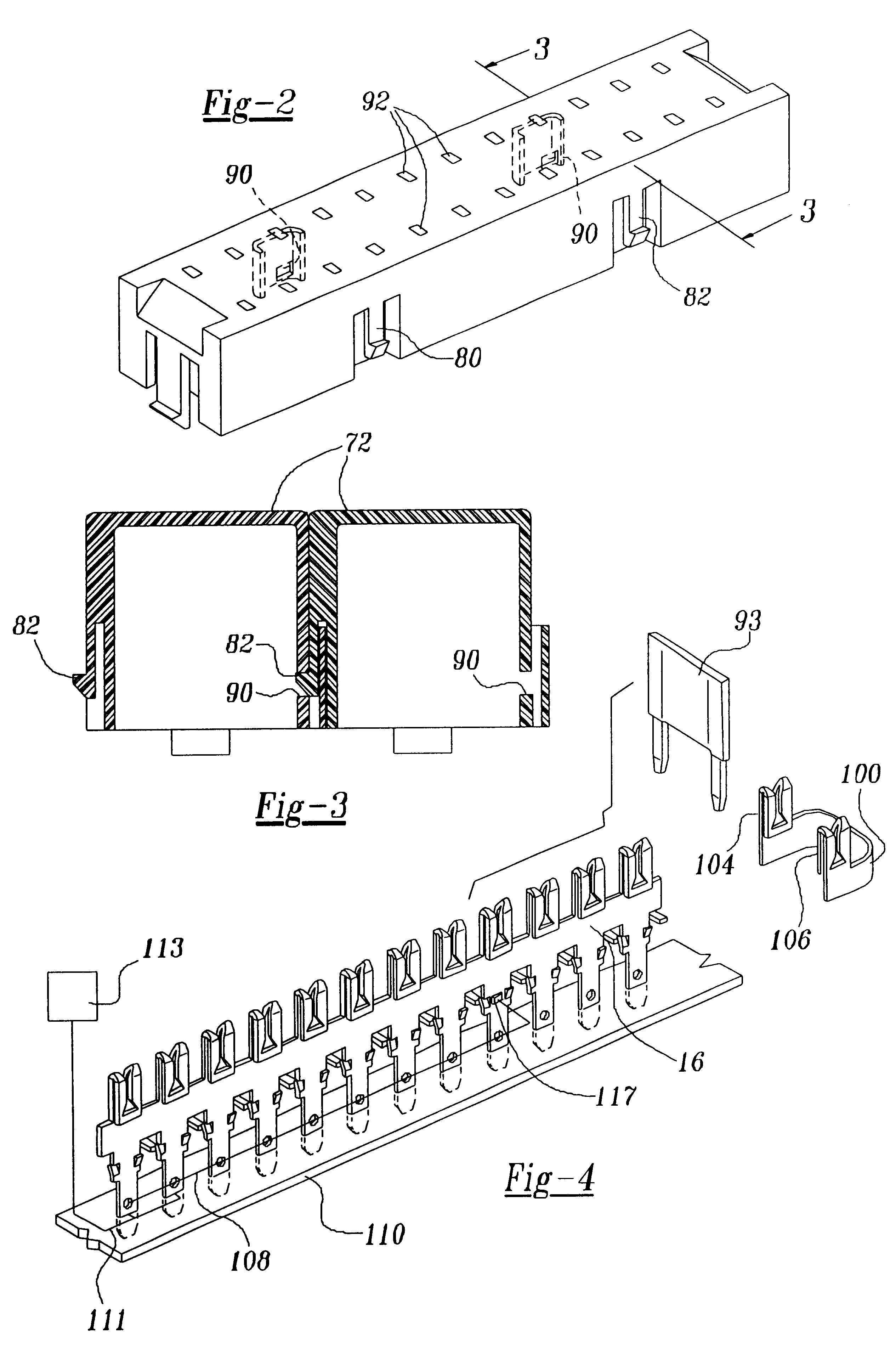

Method and apparatus for selectively connecting electrical circuits and components

InactiveUS6280253B1Efficient and cost-effectiveElectrically conductive connectionsElectric discharge tubesElectricityDielectric surface

An electrical connection and power distribution assembly 10 including a dynamically configurable array of substantially identical terminal members 12, 14 which are disposed upon a dielectric surface 66, which may be selectively connected to a plurality of automobile circuit assemblies 99, 101, and 110; which may selectively receive fuses 93 or other components; and which may be selectively interconnected and / or selectively severed to form a desired and / or required circuit and component interconnection scheme.

Owner:VISTEON GLOBAL TECH INC

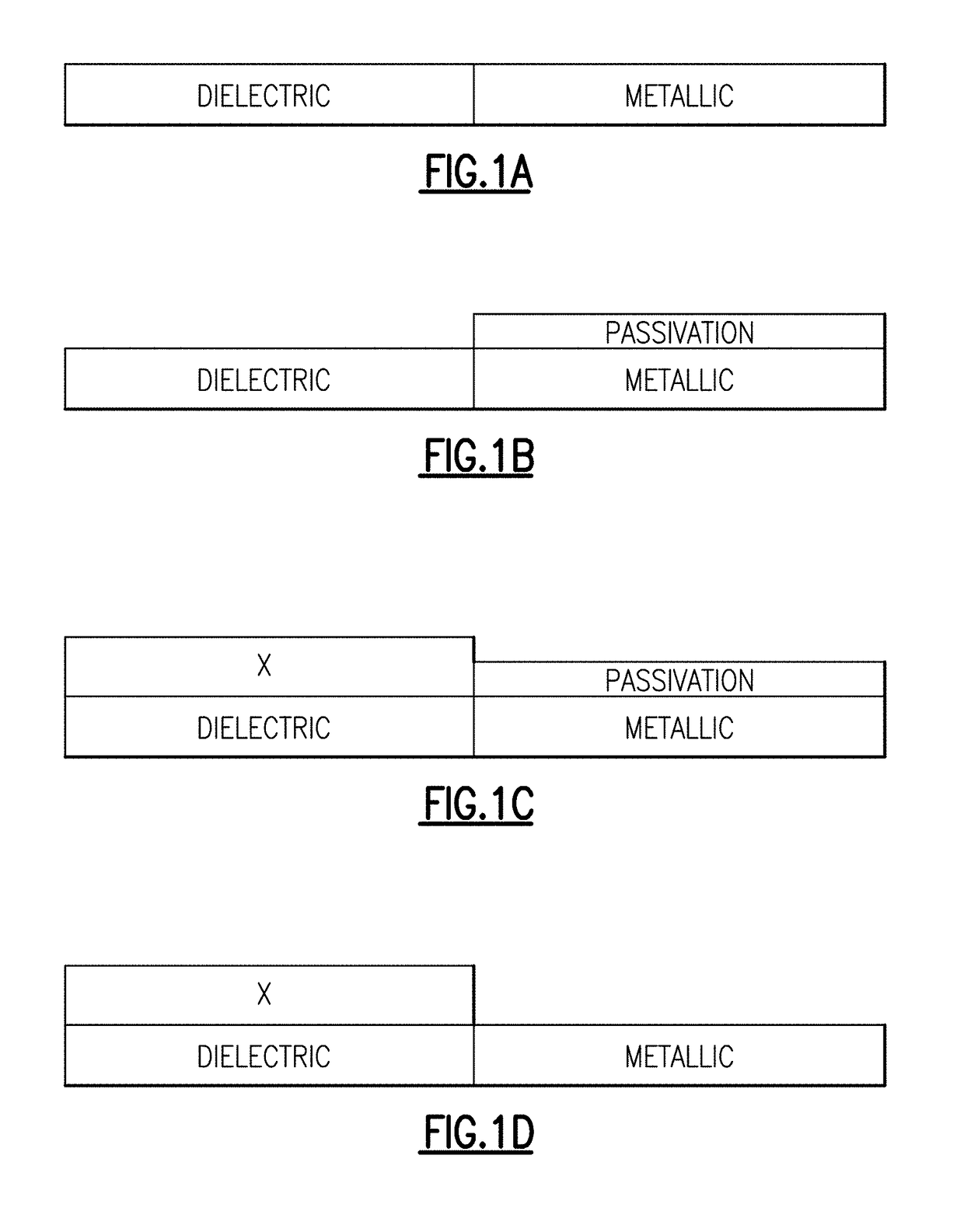

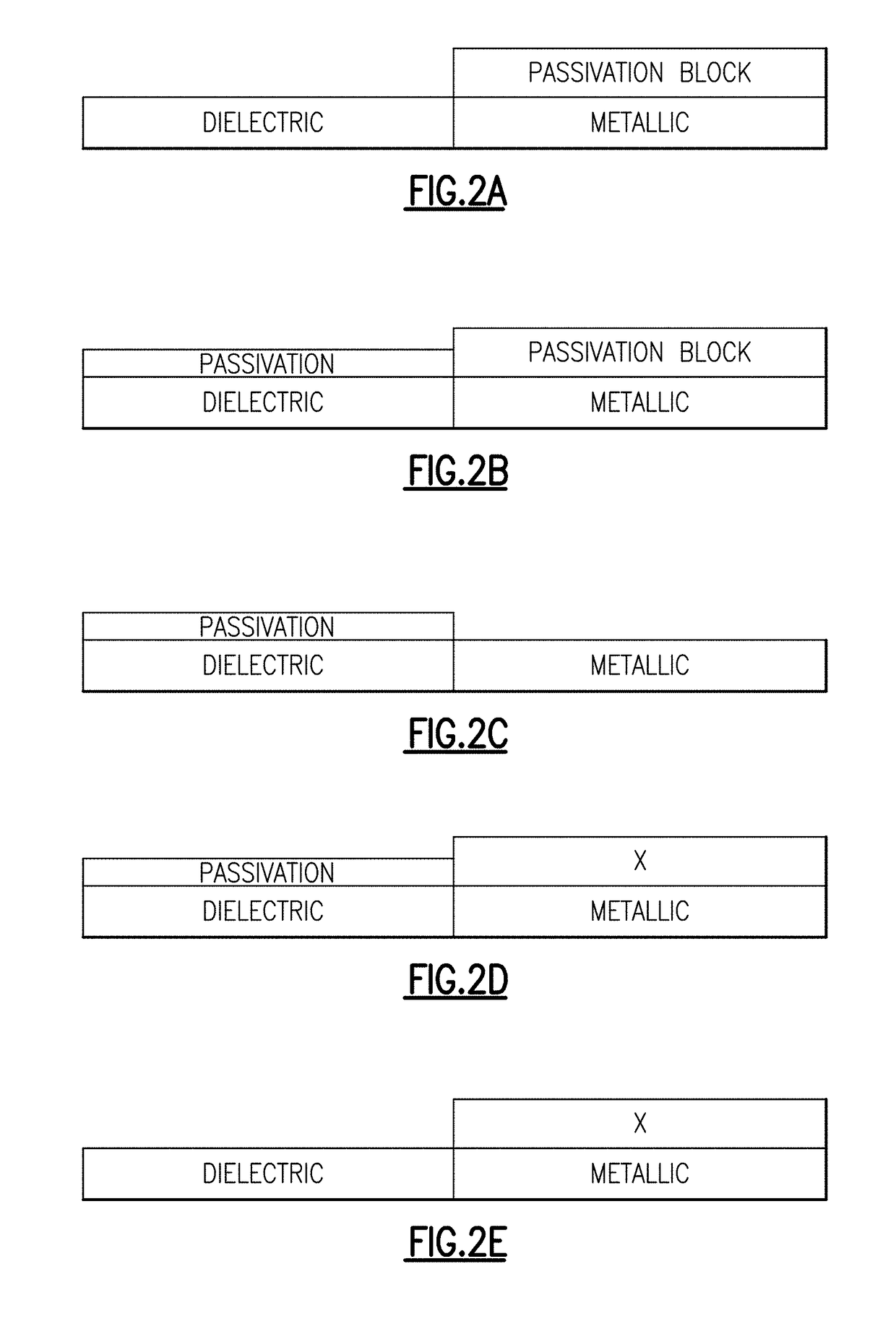

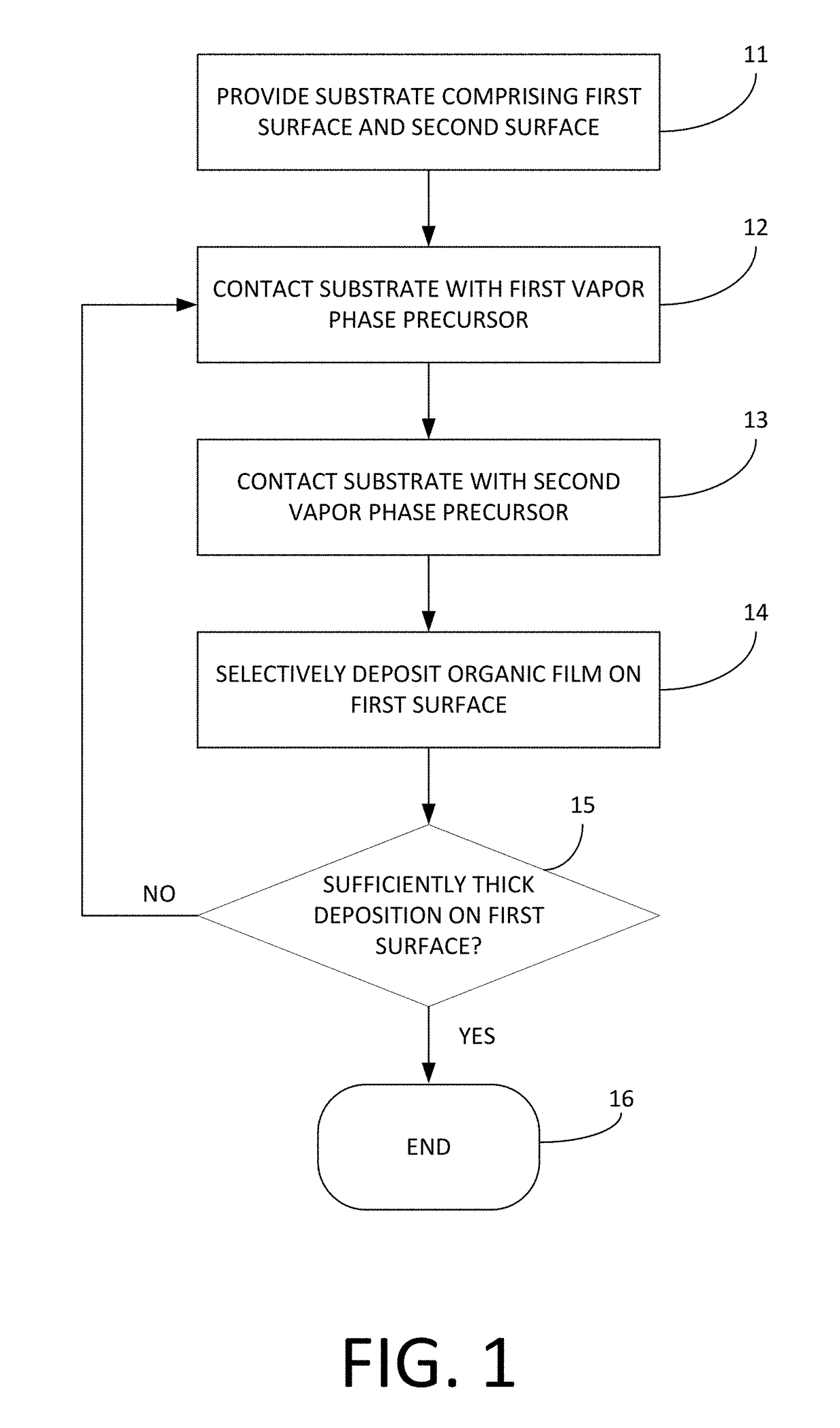

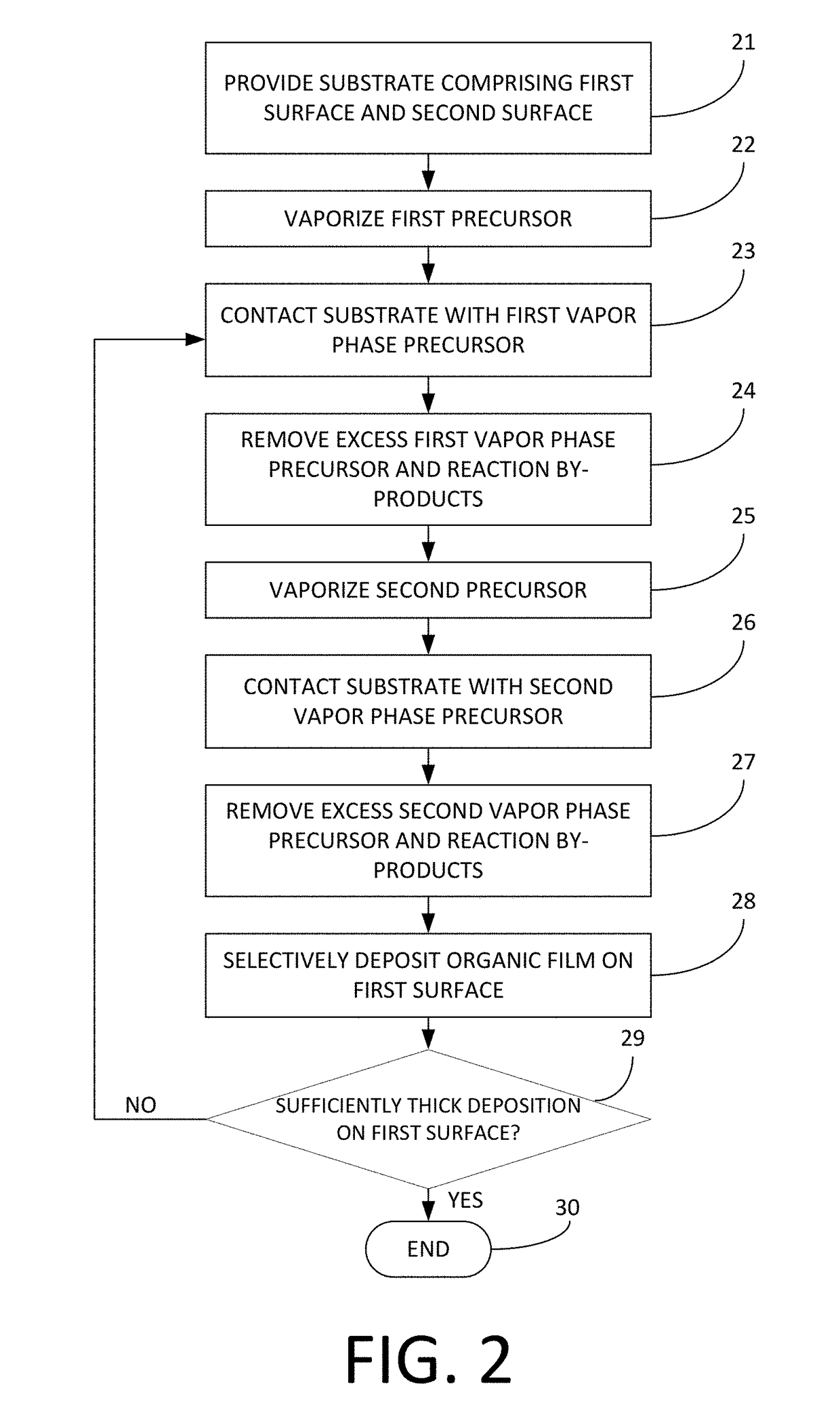

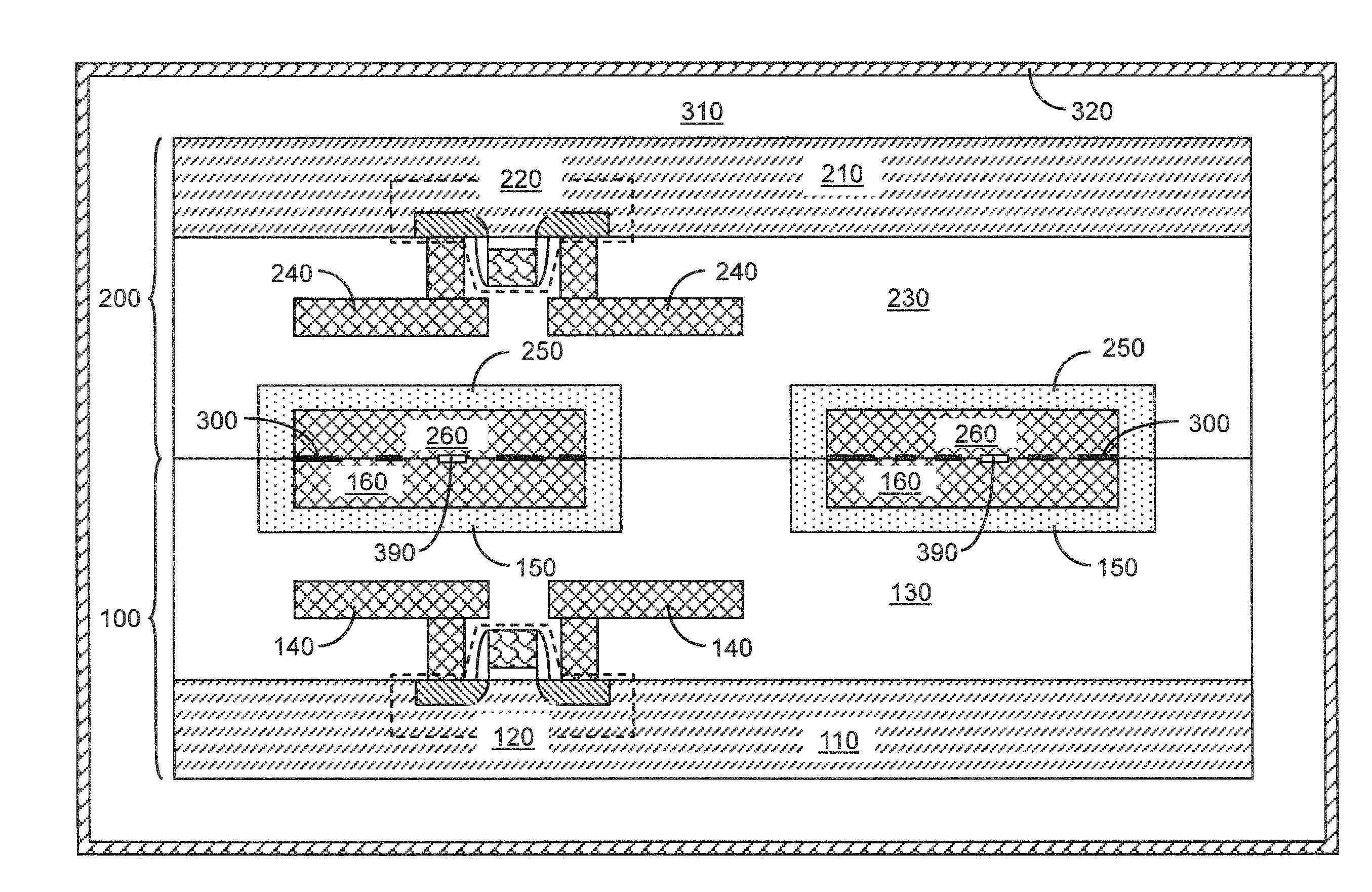

Selective passivation and selective deposition

ActiveUS20180233350A1Semiconductor/solid-state device detailsSolid-state devicesDielectric surfaceSelective deposition

Methods for selective deposition, and structures thereof, are provided. Material is selectively deposited on a first surface of a substrate relative to a second surface of a different material composition. A passivation layer is selectively formed from vapor phase reactants on the first surface while leaving the second surface without the passivation layer. A layer of interest is selectively deposited from vapor phase reactants on the second surface relative to the passivation layer. The first surface can be metallic while the second surface is dielectric, or the second surface is dielectric while the second surface is metallic. Accordingly, material, such as a dielectric, can be selectively deposited on either metallic or dielectric surfaces relative to the other type of surface using techniques described herein. Techniques and resultant structures are also disclosed for control of positioning and shape of layer edges relative to boundaries between underlying disparate materials.

Owner:ASM IP HLDG BV

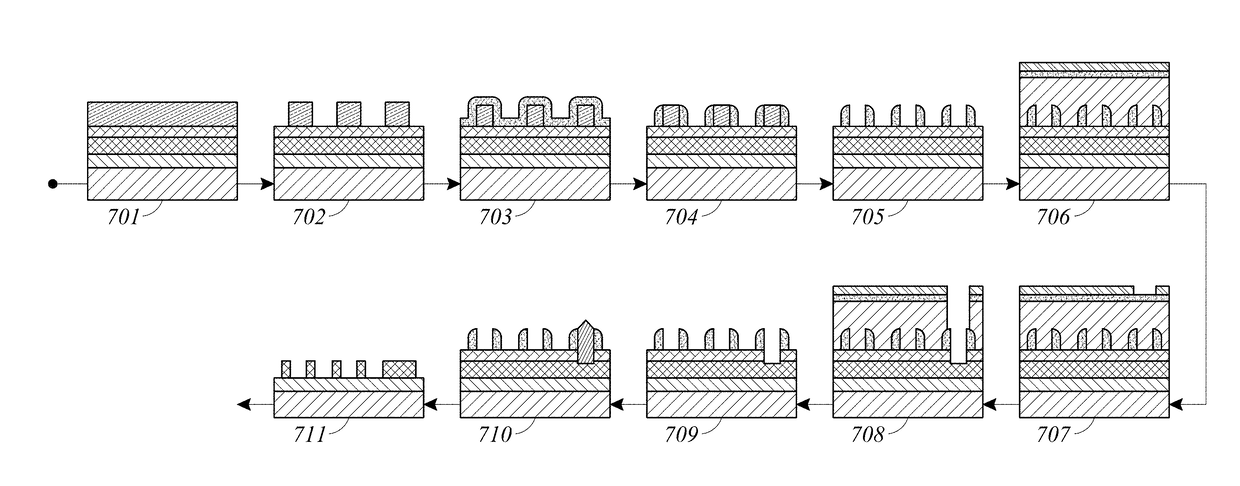

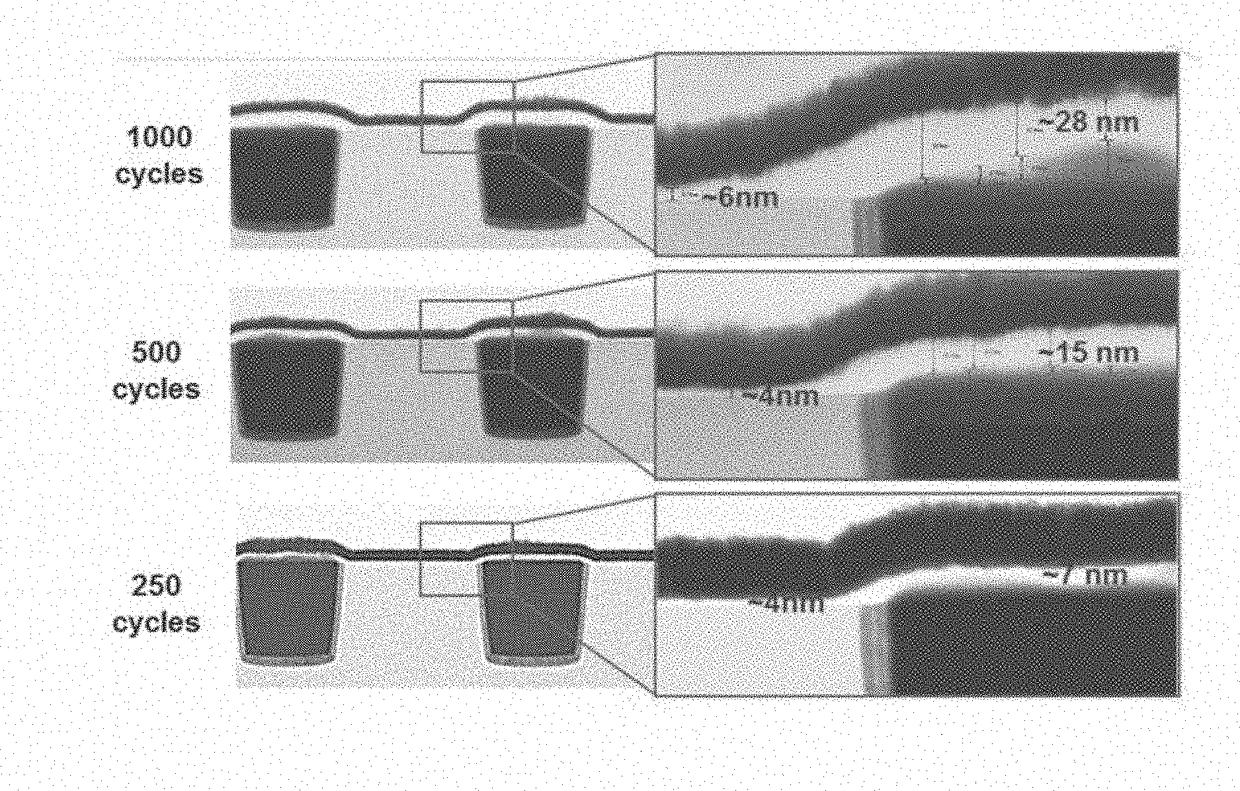

Deposition of organic films

ActiveUS20170352550A1Increased resistance to HFSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity. Masking applications employing selective organic films are provided. Post-deposition modification of the organic films, such as metallic infiltration and / or carbon removal, is also disclosed.

Owner:ASM IP HLDG BV

Deposition of organic films

ActiveUS20170352533A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity.

Owner:ASM IP HLDG BV

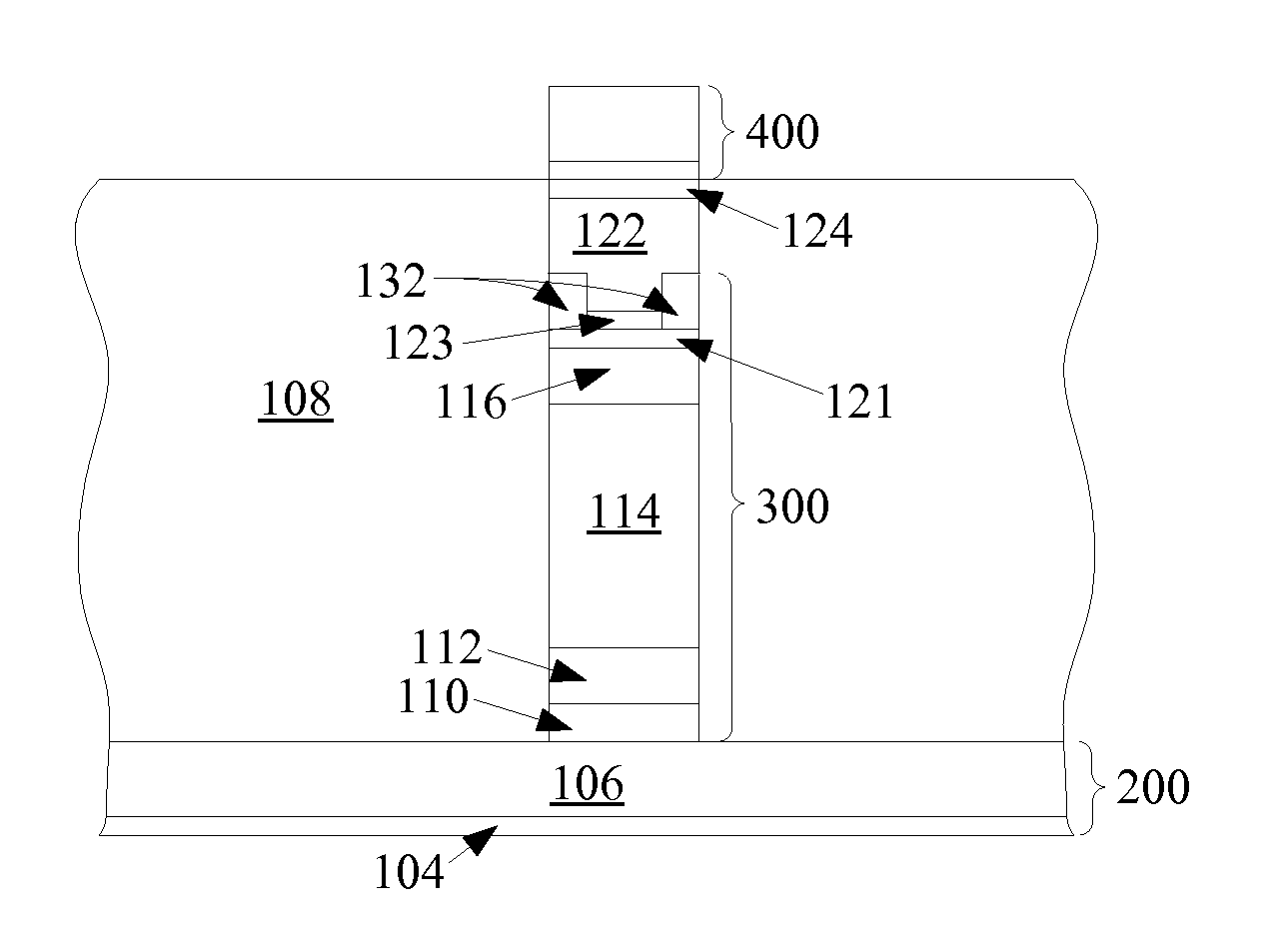

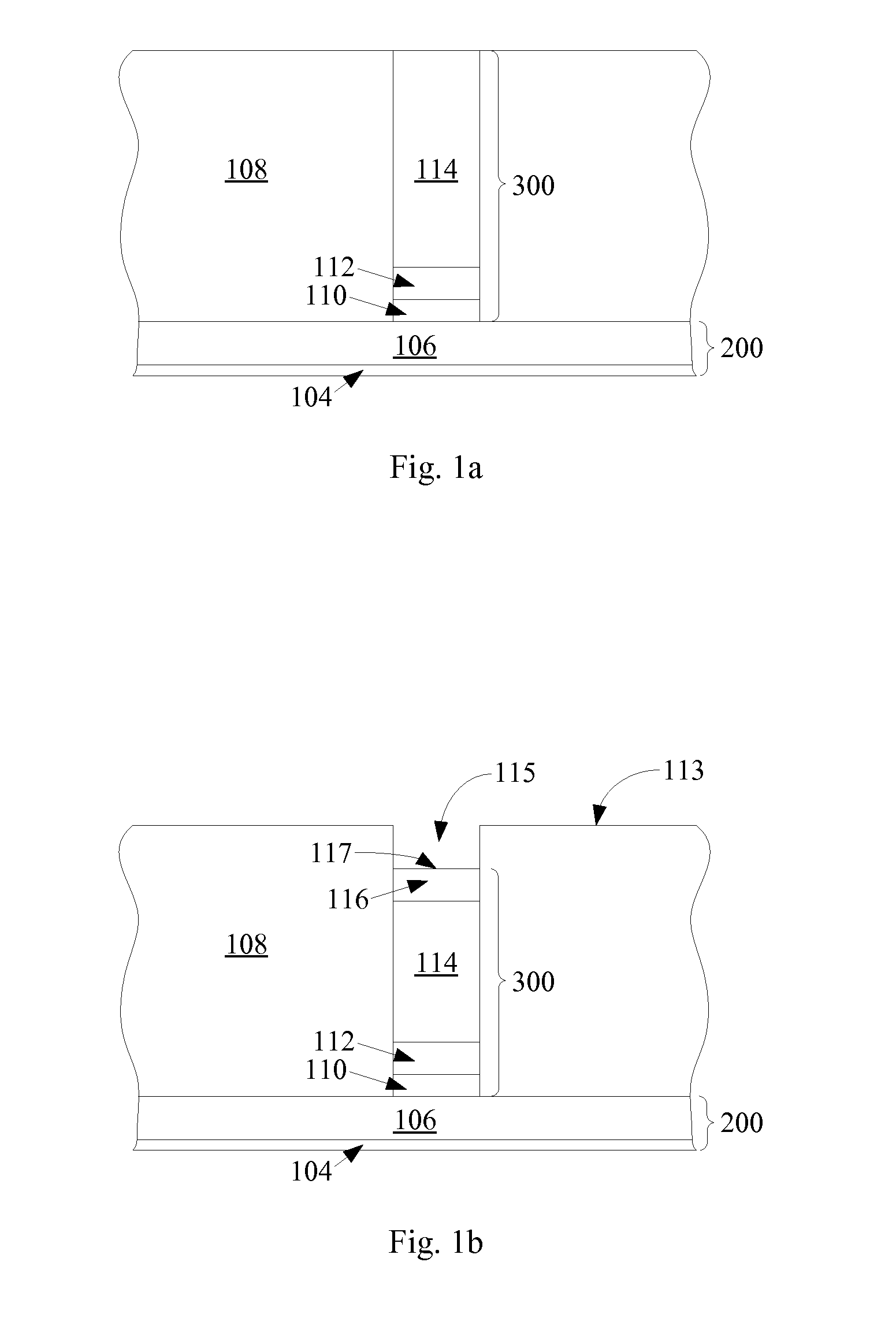

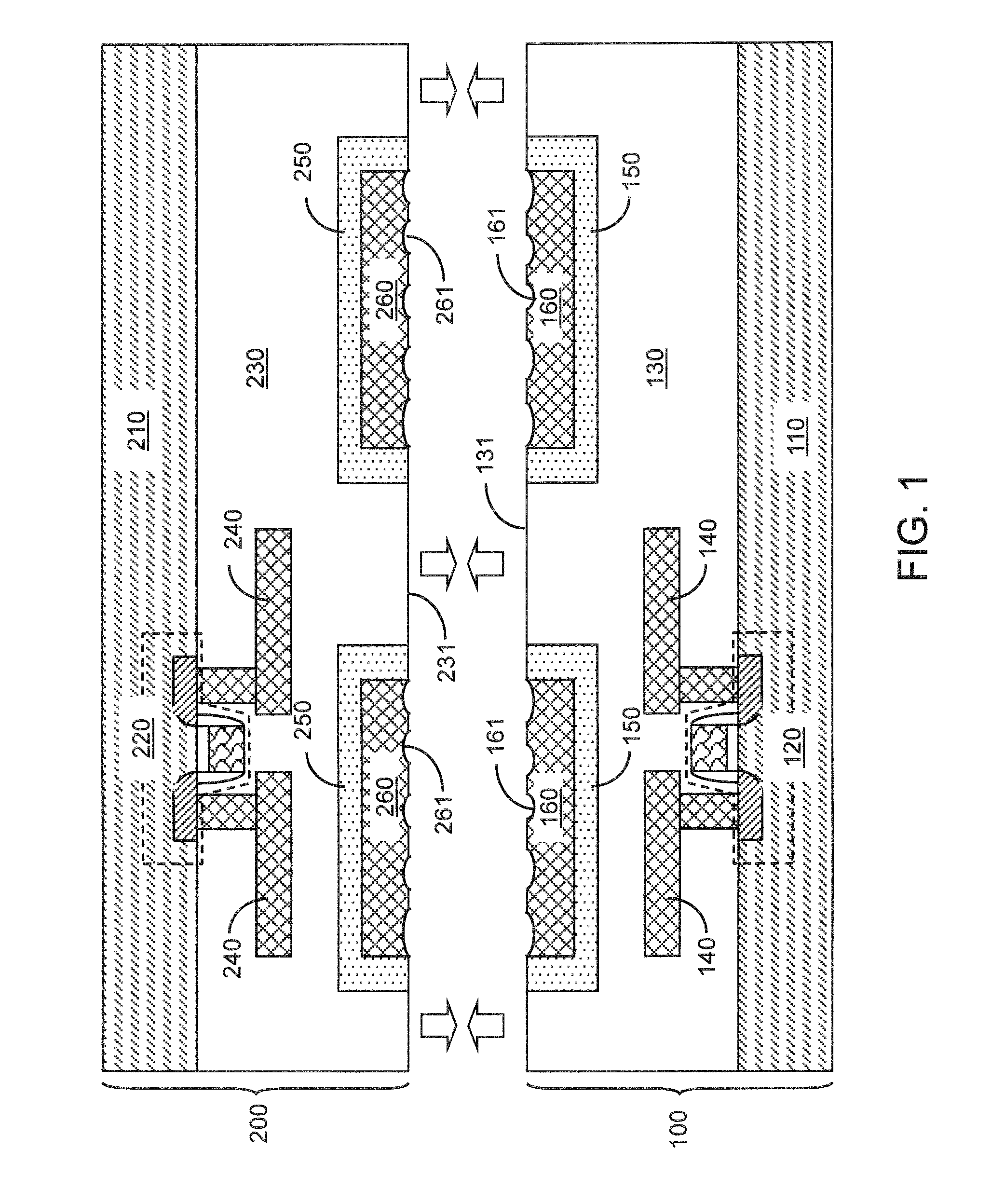

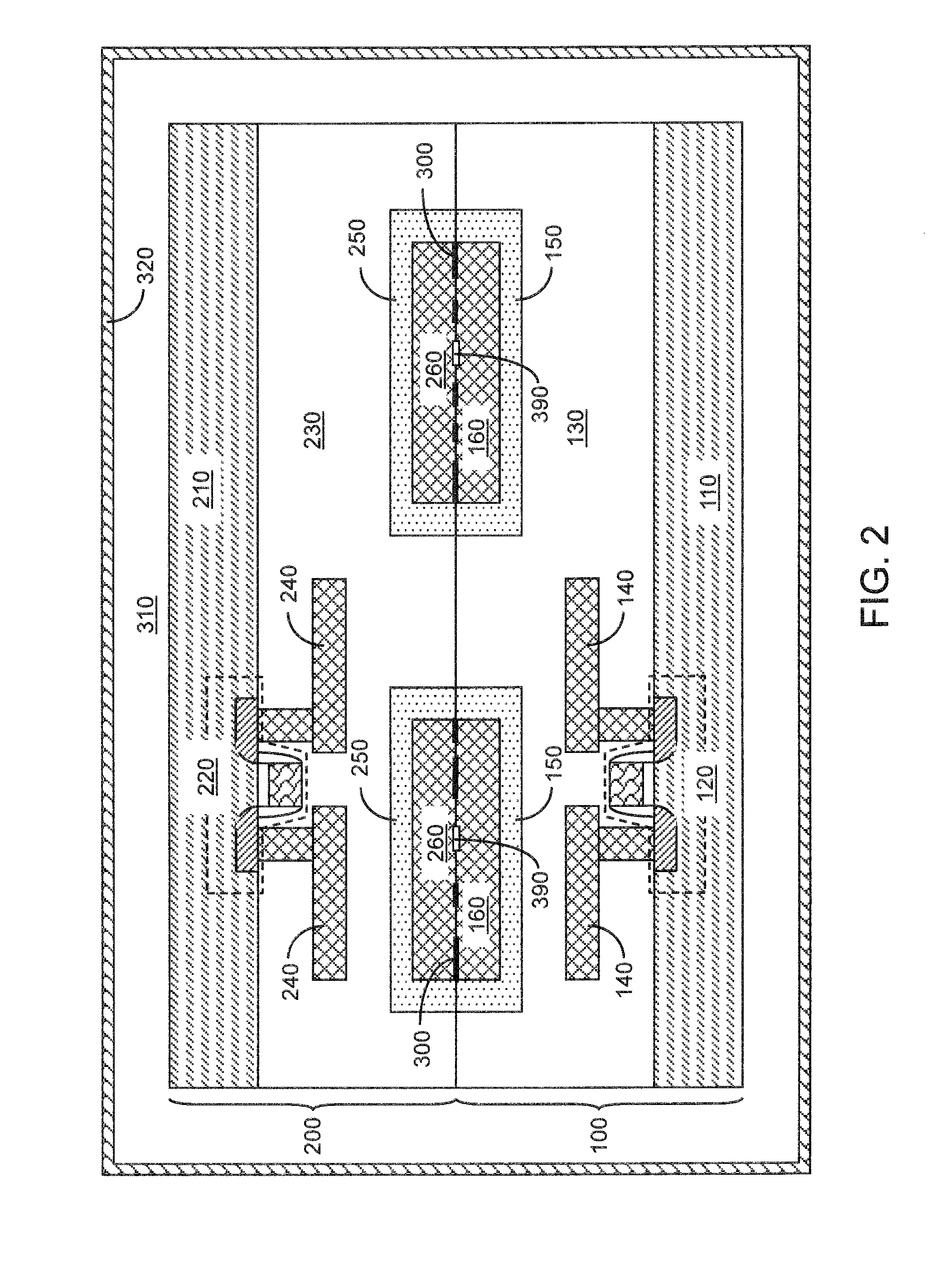

Pad bonding employing a self-aligned plated liner for adhesion enhancement

ActiveUS20110084403A1Enhanced mechanical adhesionImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesDielectric surfaceConductive materials

Two substrates are brought together and placed in a plating bath. In one embodiment, a conductive material is plated in microscopic cavities present at the interface between a first metal pad and a second metal pad to form at least one interfacial plated metal liner portion that adheres to a surface of the first metal pad and a surface of the second metal pad. In another embodiment, at least one metal pad is recessed relative to a dielectric surface before being brought together. The two substrates are placed in a plating bath and a conductive material is plated in the cavity between the first metal pad and the second metal pad to form a contiguous plated metal liner layer that adheres to a surface of the first metal pad and a surface of the second metal pad.

Owner:TAIWAN SEMICON MFG CO LTD

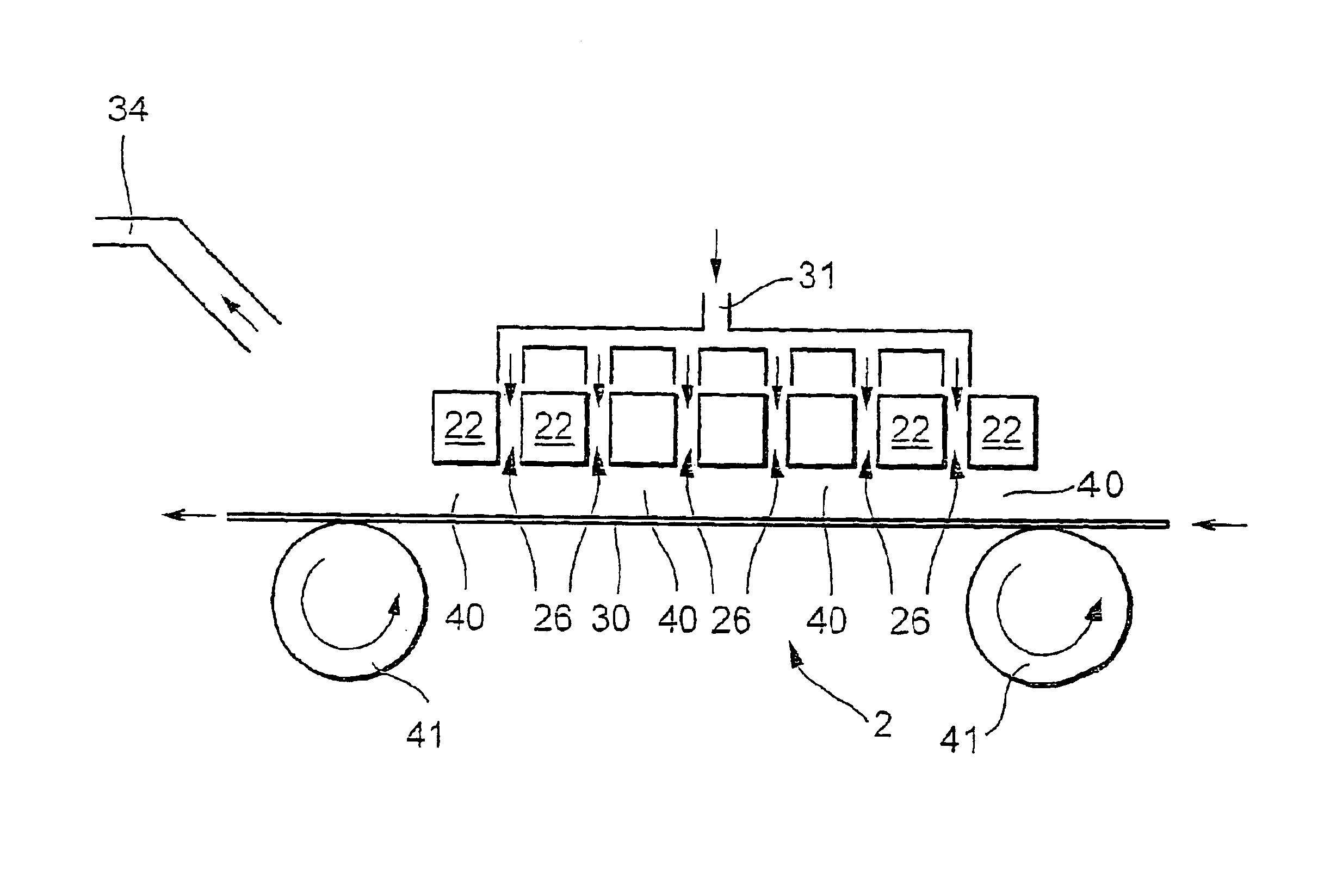

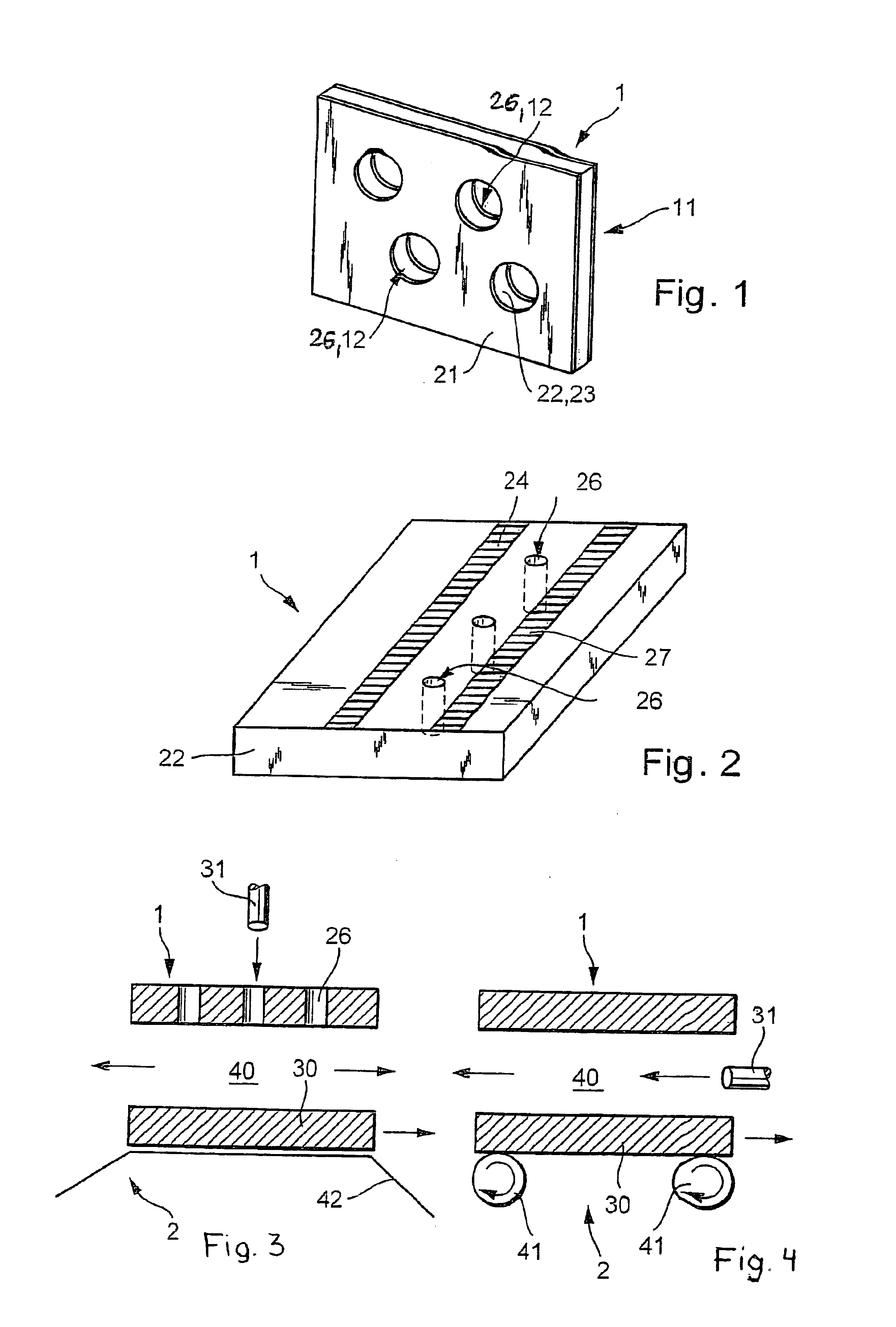

Device and method for charge removal from dielectric surfaces

InactiveUS6934142B2Optimized charge removalEasy to operateElectric discharge tubesEmergency protective arrangements for automatic disconnectionElectricityDielectric surface

A device and a method for at least partial removal of electric charges from dielectric surfaces, in particular surfaces of plastic films, paper webs or plastic fibers are described. First, a plasma is generated through microstructure discharges with a plasma device in at least one plasma region. In addition, the dielectric surface is introduced into the plasma region with a feed mechanism and is temporarily exposed to electrically charged particles generated by the plasma there.

Owner:ROBERT BOSCH GMBH

Non-volatile electromechanical field effect devices and circuits using same and methods of forming same

Non-volatile field effect devices and circuits using same. A non-volatile field effect device includes a source, drain and gate with a field-modulatable channel between the source and drain. Each of the source, drain, and gate have a corresponding terminal. An electromechanically-deflectable, nanotube switching element is electrically positioned between one of the source, drain and gate and its corresponding terminal. The others of the source, drain and gate are directly connected to their corresponding terminals. The nanotube switching element is electromechanically-deflectable in response to electrical stimulation at two control terminals to create one of a non-volatile open and non-volatile closed electrical communication state between the one of the source, drain and gate and its corresponding terminal. Under one embodiment, one of the two control terminals has a dielectric surface for contact with the nanotube switching element when creating a non-volatile open state. Under one embodiment, the source, drain and gate may be stimulated at any voltage level from ground to supply voltage, and wherein the two control terminals are stimulated at any voltage level from ground to a switching threshold voltage larger in magnitude than the supply voltage. Under one embodiment, the nanotube switching element includes an article made from nanofabric that is positioned between the two control terminals. Under one embodiment, one of the two control terminals is a release electrode for electrostatically pulling the nanotube article out of contact with the one of the source, drain and gate so as to form a non-volatile open state. Under one embodiment, the other of the two control terminals is a set electrode for electrostatically pulling the nanotube article into contact with the one of the source, drain and gate so as to form a non-volatile closed state.

Owner:NANTERO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com