Selective cobalt deposition on copper surfaces

a cobalt deposition and copper surface technology, applied in the direction of chemical vapor deposition coating, coating, plasma technique, etc., can solve the problems reducing the probability of errors, so as to achieve the effect of increasing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

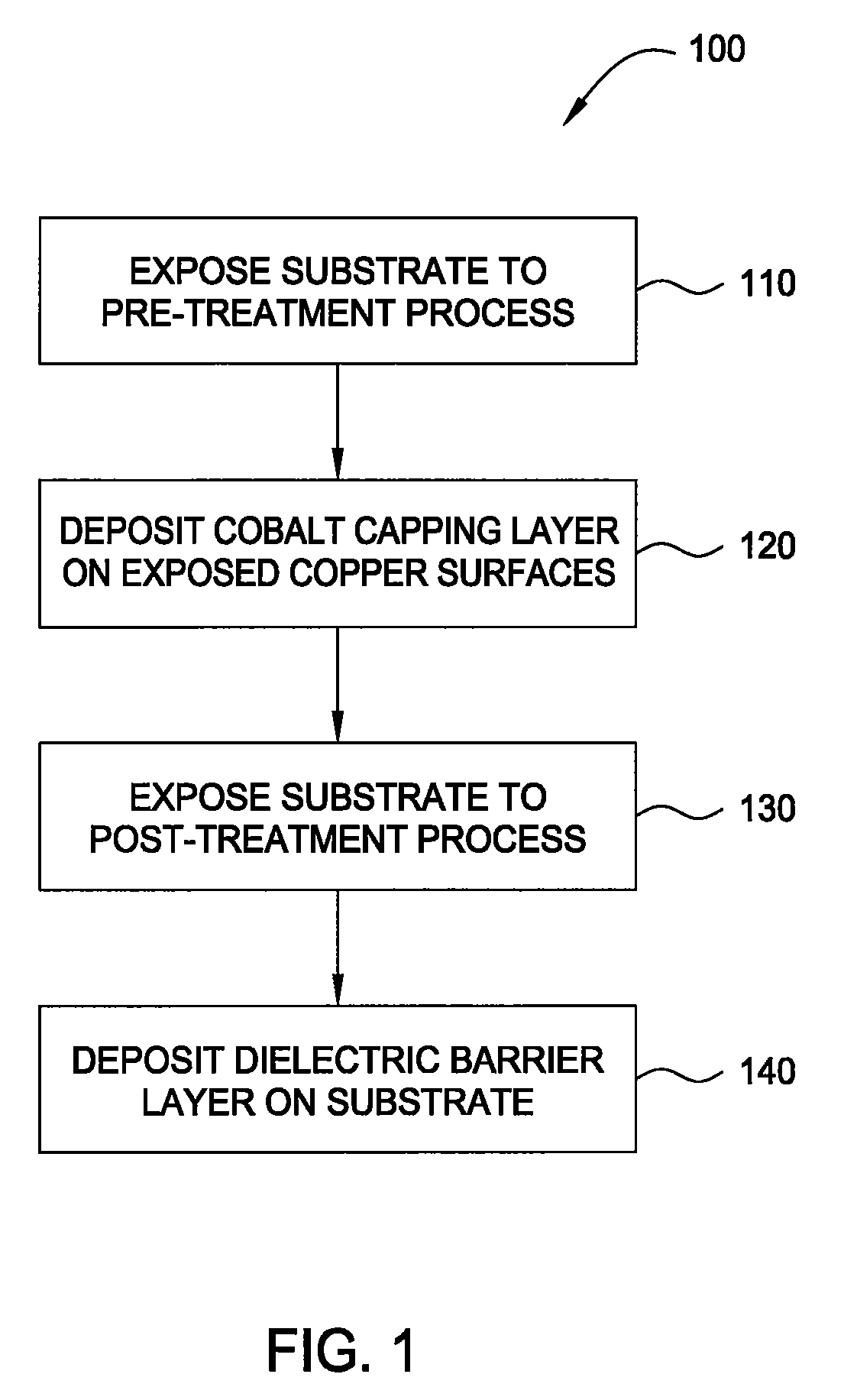

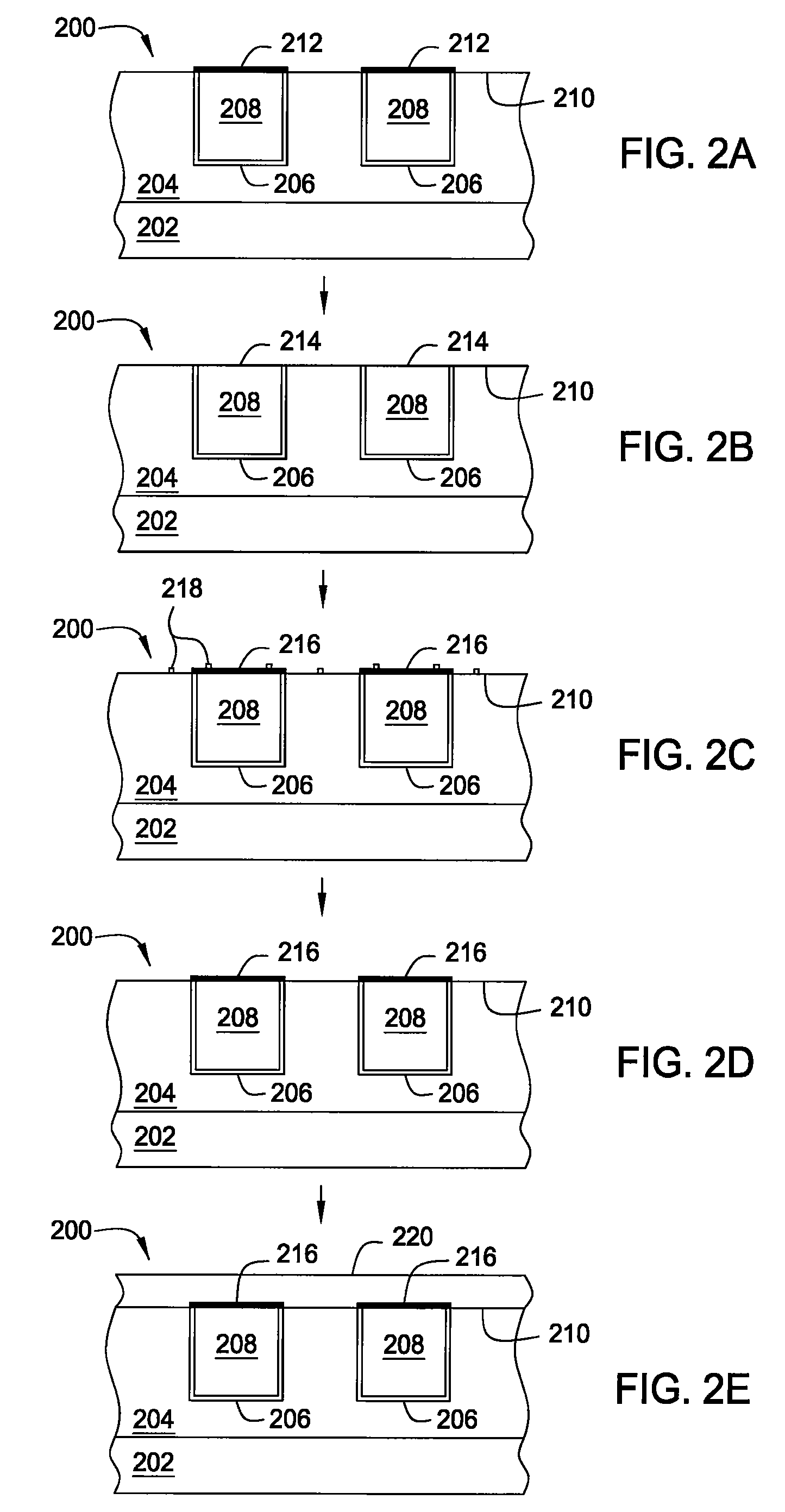

[0024]Embodiments of the invention provide a method that utilizes a cobalt capping layer or material to prevent copper diffusion and dewetting in interconnect boundary regions. The transition metal, for example, cobalt, improves copper boundary region properties to promote adhesion, decrease diffusion and agglomeration, and encourage uniform roughness and wetting of the substrate surface during processing. Embodiments provide that a cobalt capping layer may be selectively deposited on a copper contact or surface on a substrate while leaving exposed dielectric surfaces on the substrate.

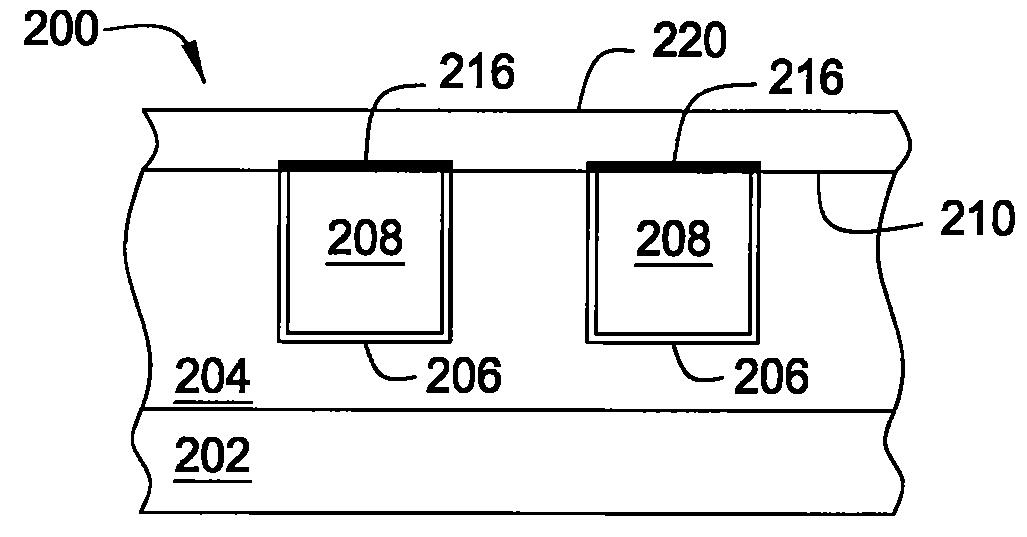

[0025]FIG. 1 depicts a flow chart illustrating process 100 according to an embodiment of the invention. Process 100 may be used to clean and cap a copper contact surface on a substrate post a polishing process. In one embodiment, steps 110-140 of process 100 may be used on substrate 200, depicted in FIGS. 2A-2E. Process 100 includes exposing a substrate to pre-treatment process (step 110), depositing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com