Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2528 results about "Hafnium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hafnium is a chemical element with the symbol Hf and atomic number 72. A lustrous, silvery gray, tetravalent transition metal, hafnium chemically resembles zirconium and is found in many zirconium minerals. Its existence was predicted by Dmitri Mendeleev in 1869, though it was not identified until 1923, by Coster and Hevesy, making it the last stable element to be discovered. Hafnium is named after Hafnia, the Latin name for Copenhagen, where it was discovered.

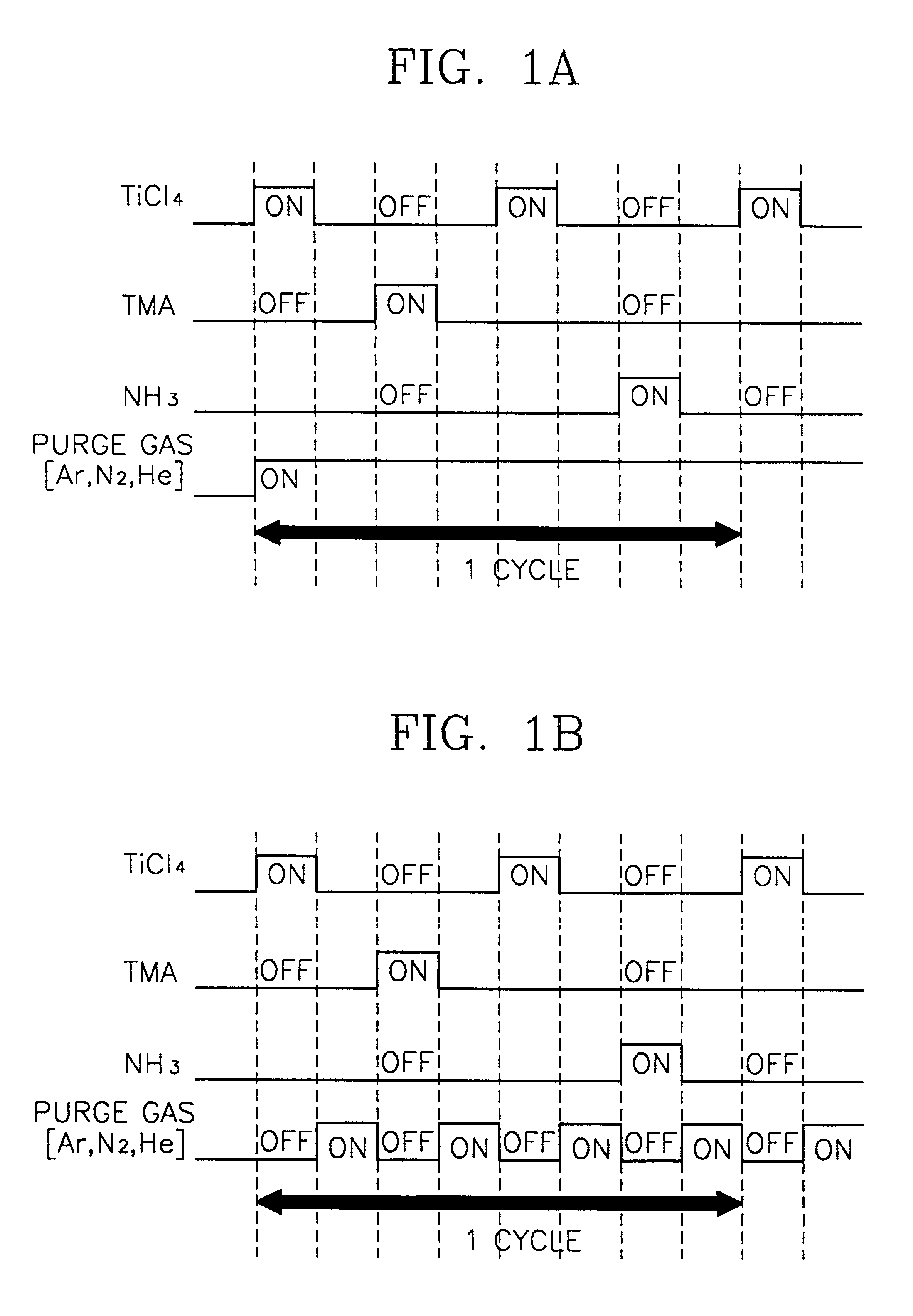

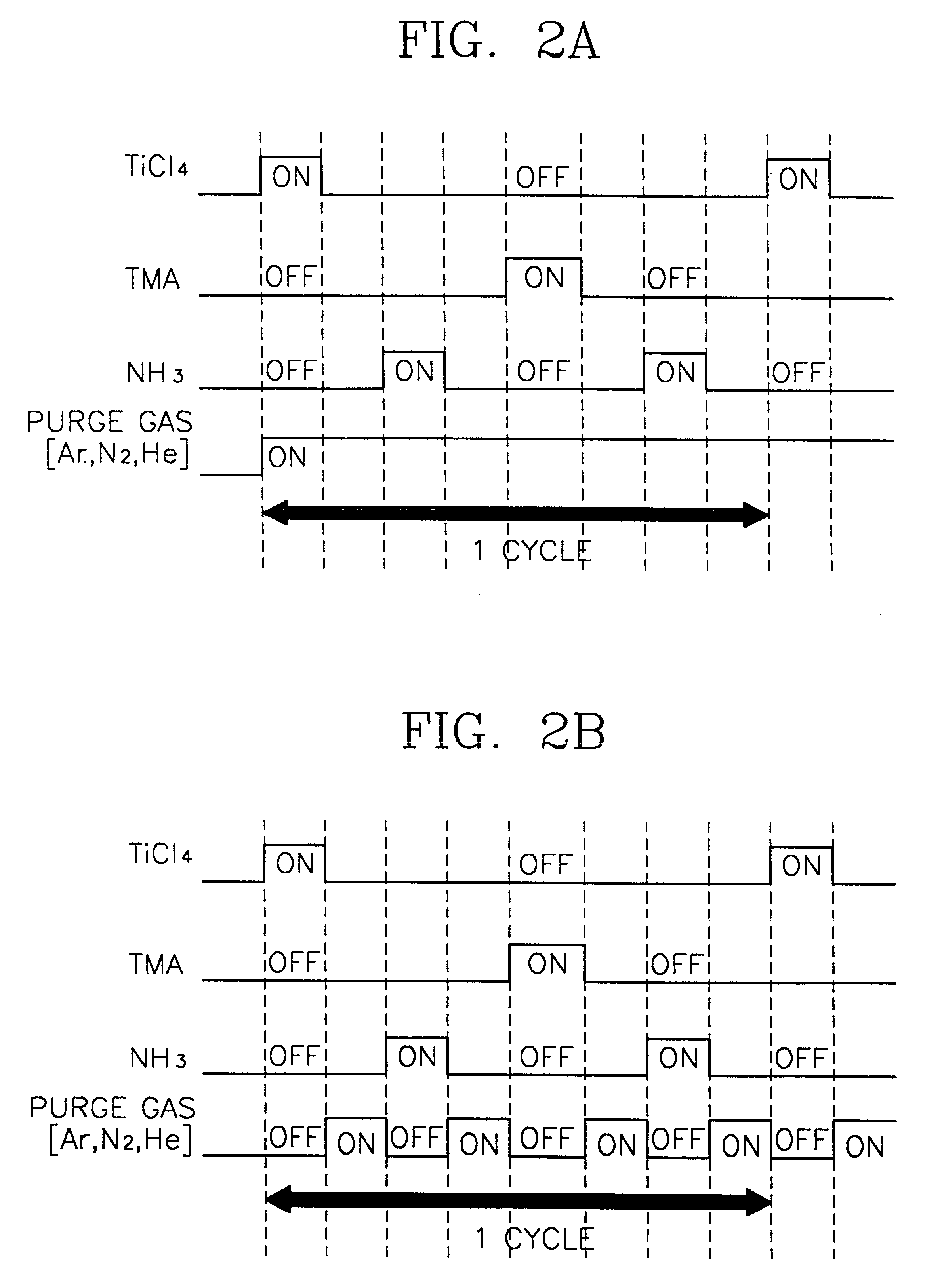

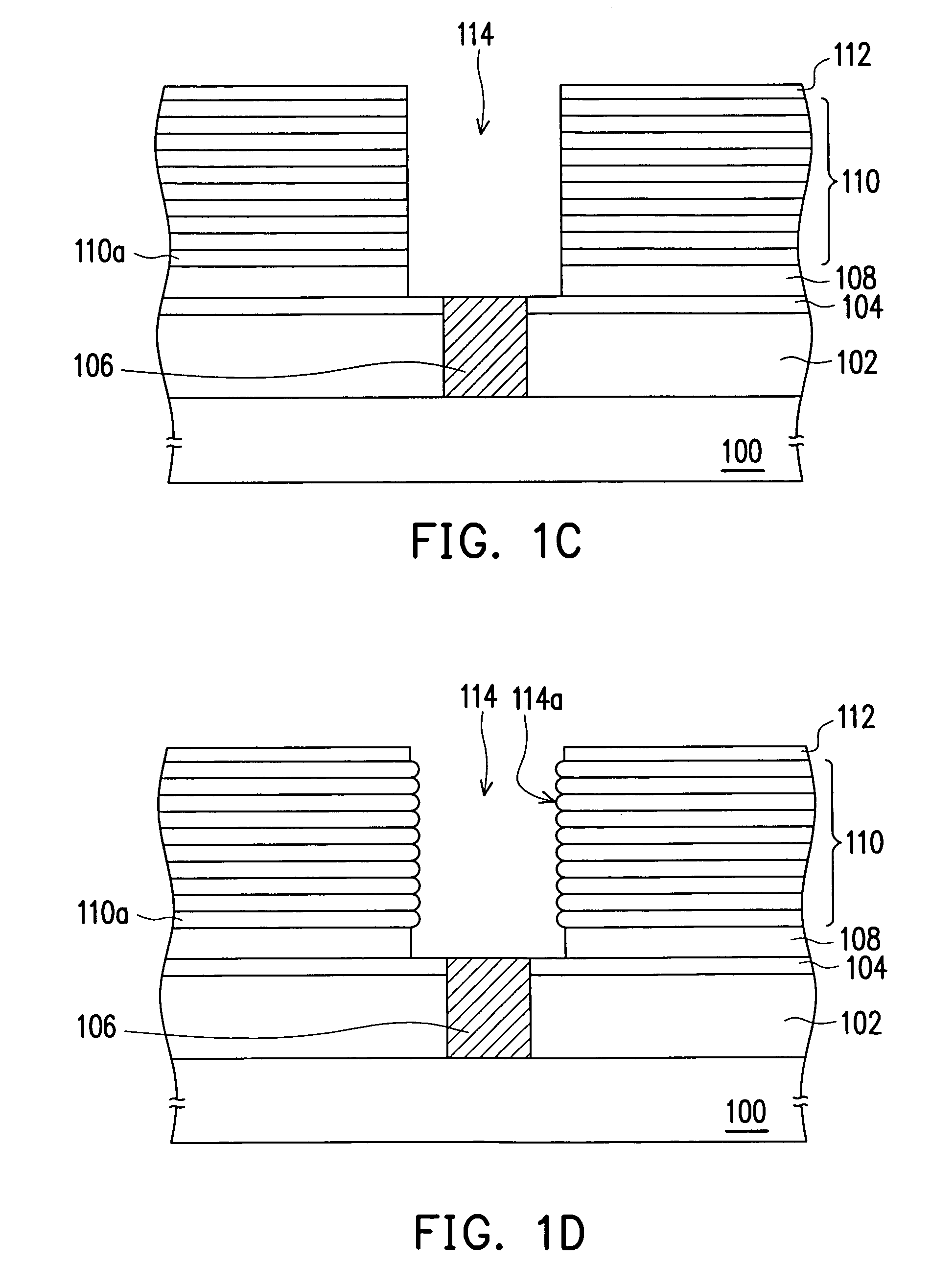

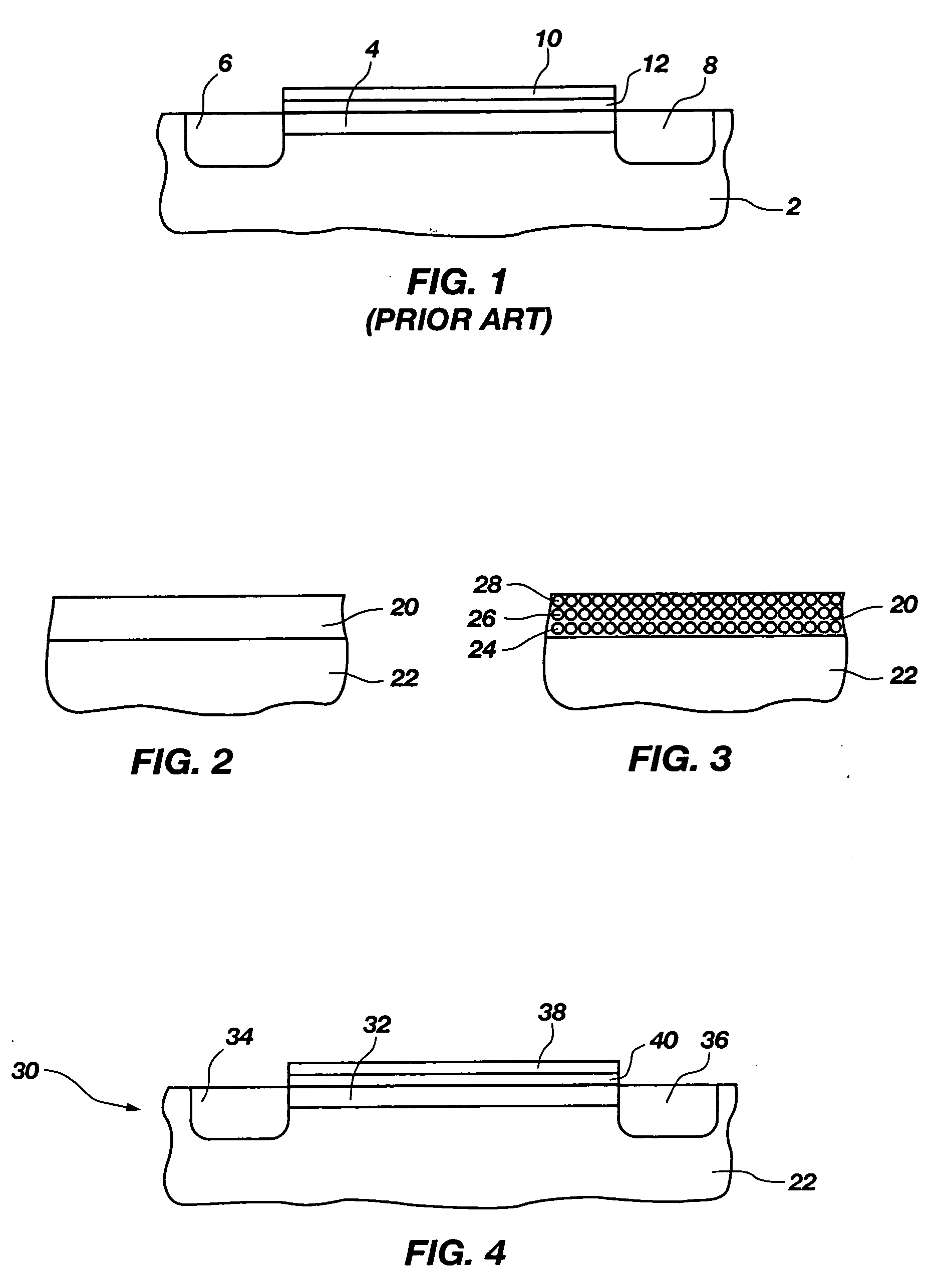

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

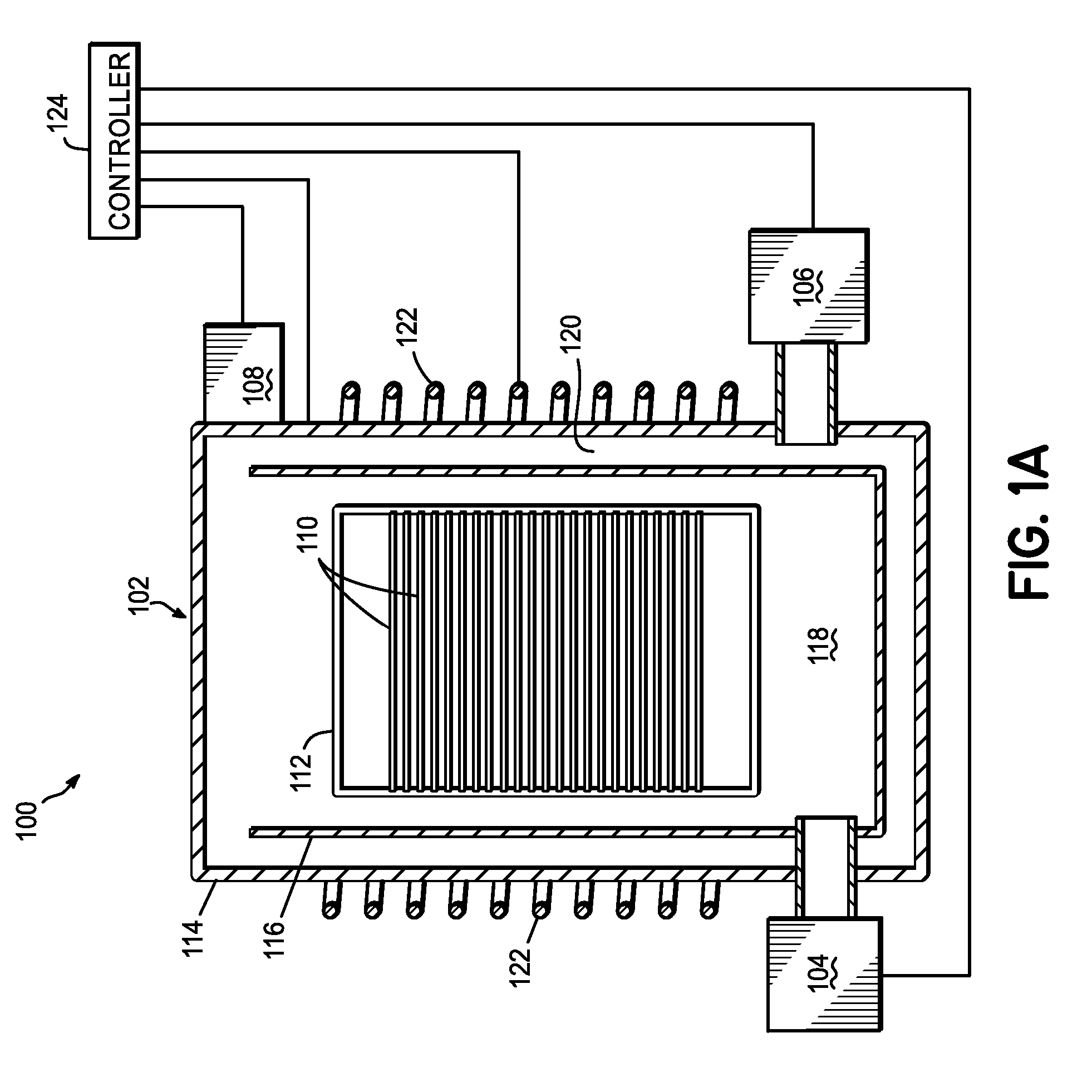

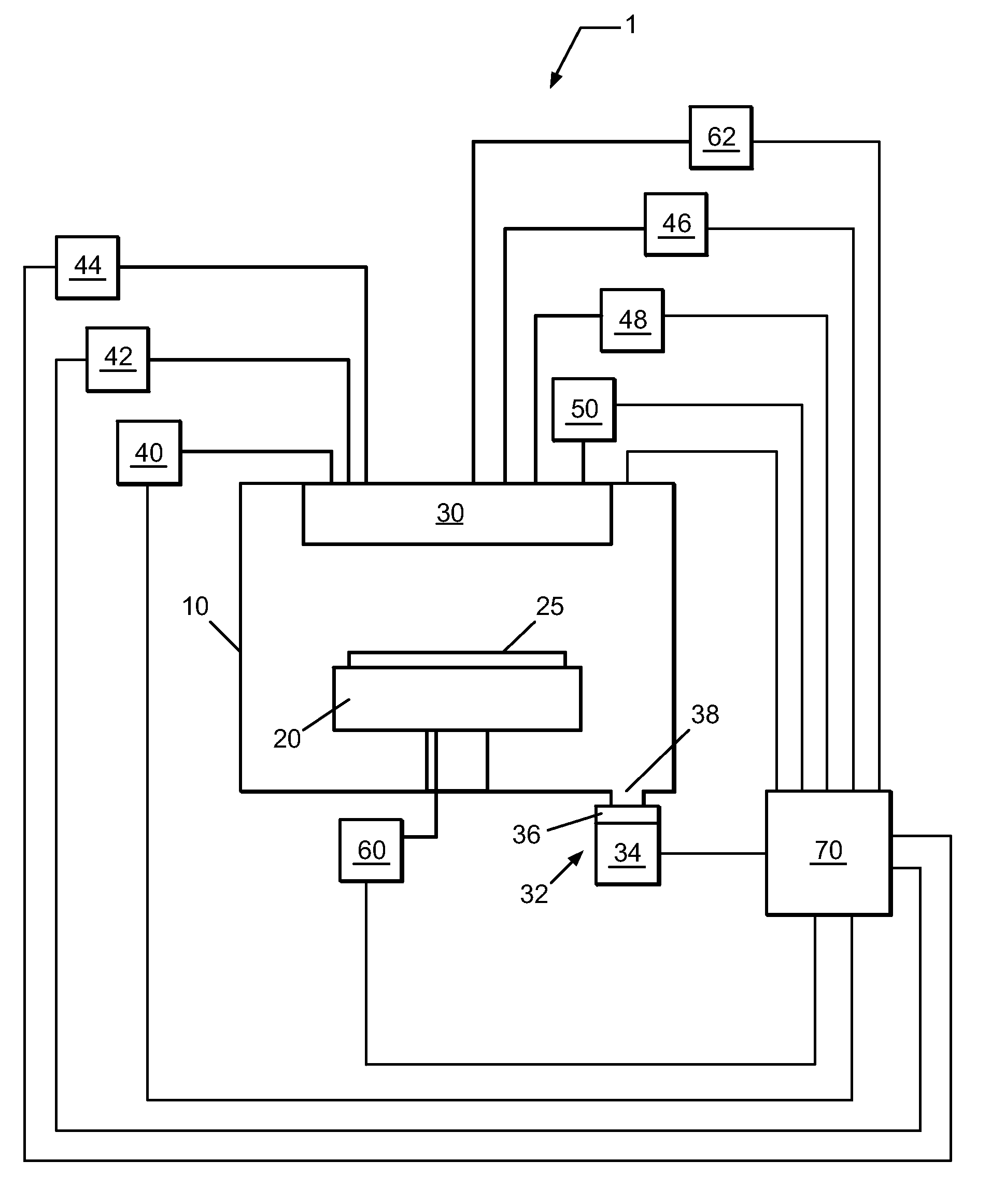

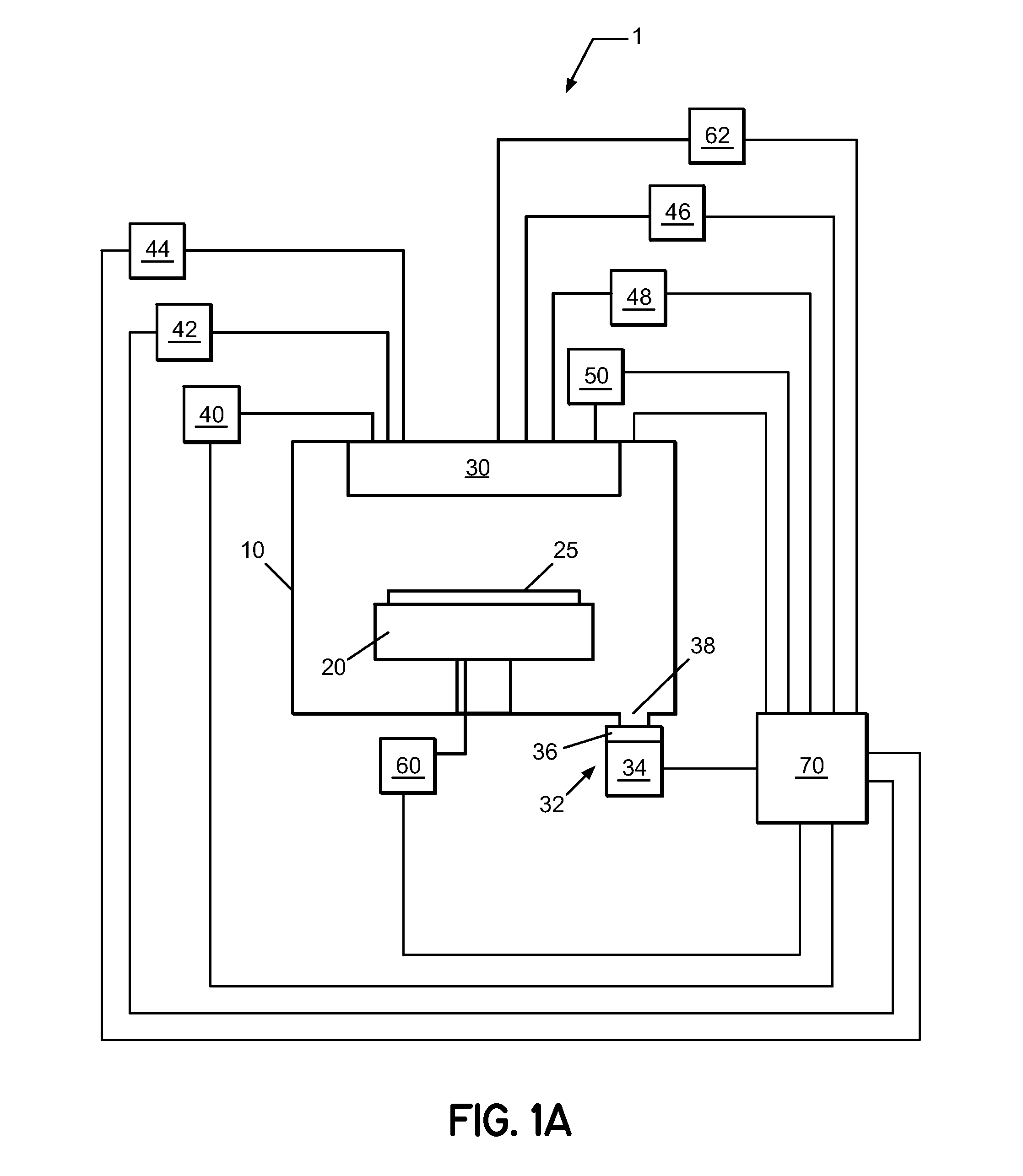

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

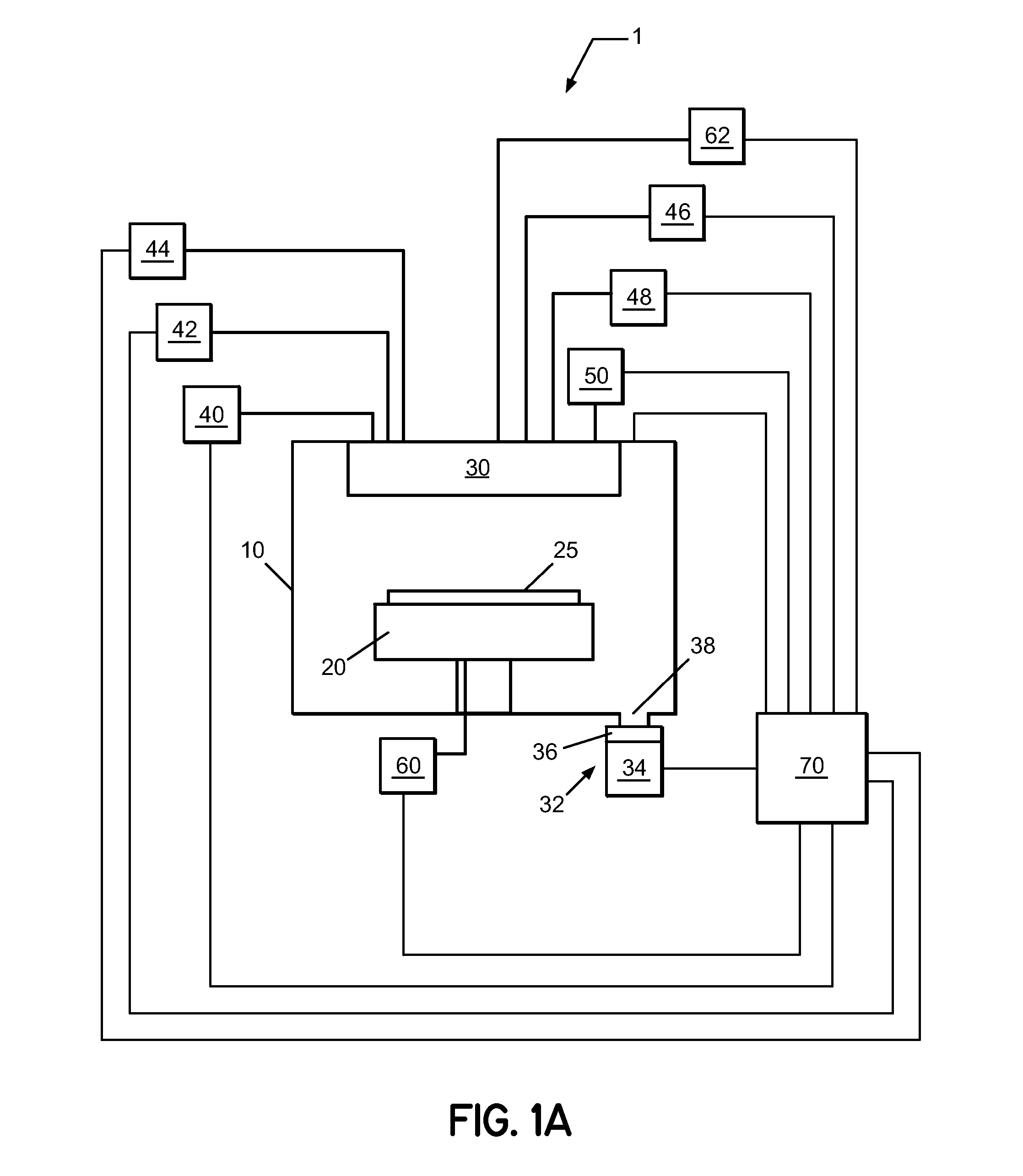

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

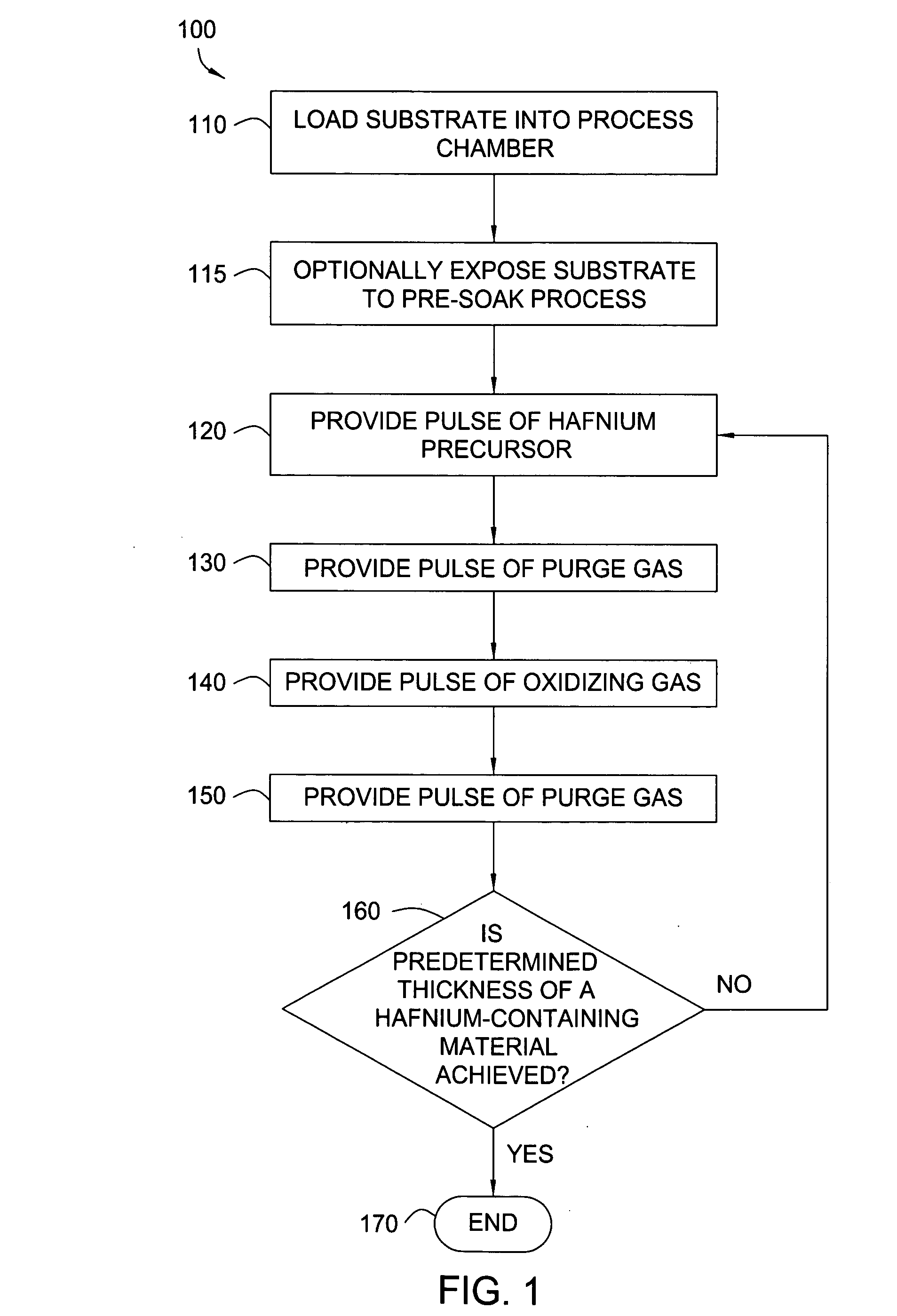

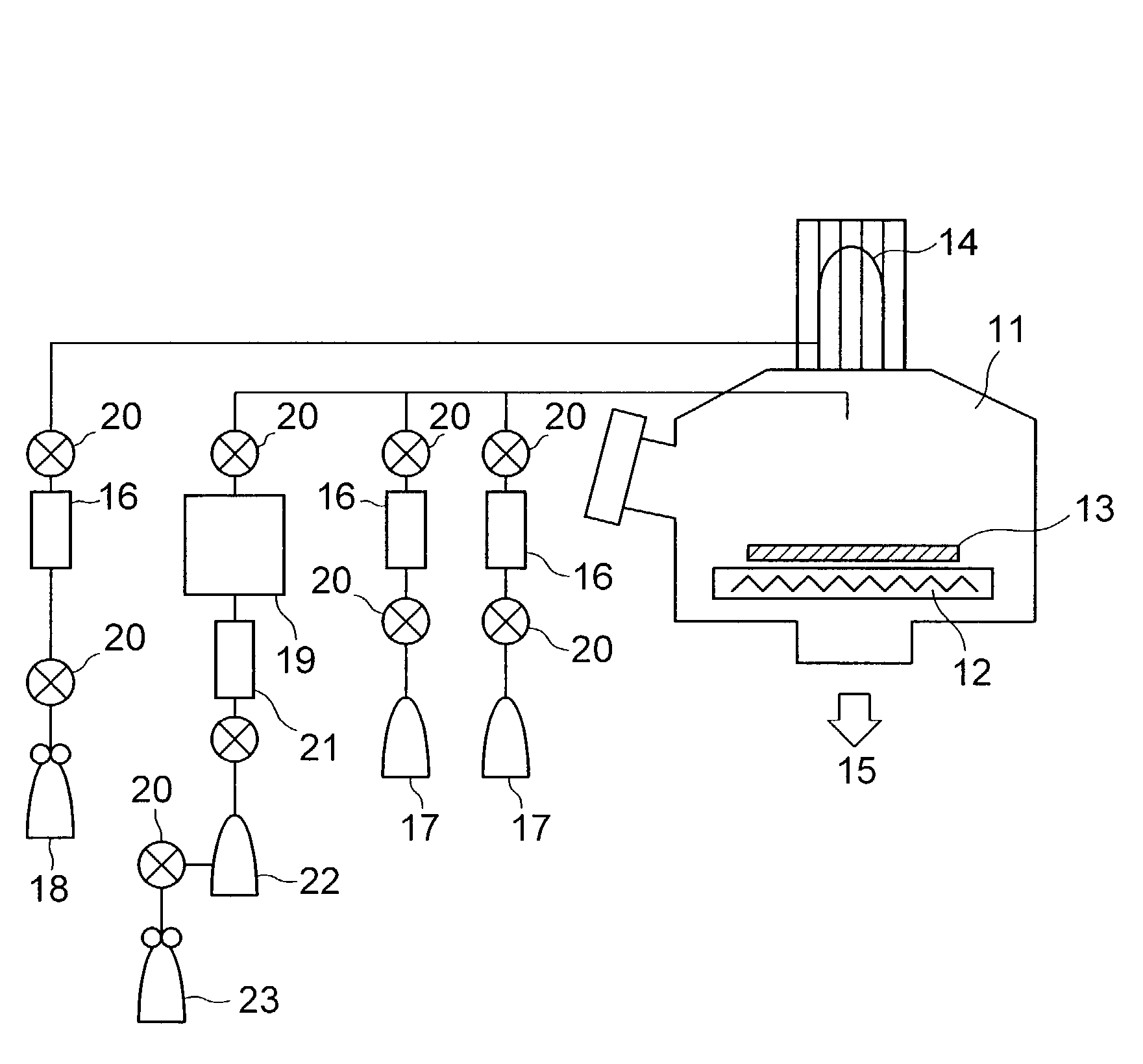

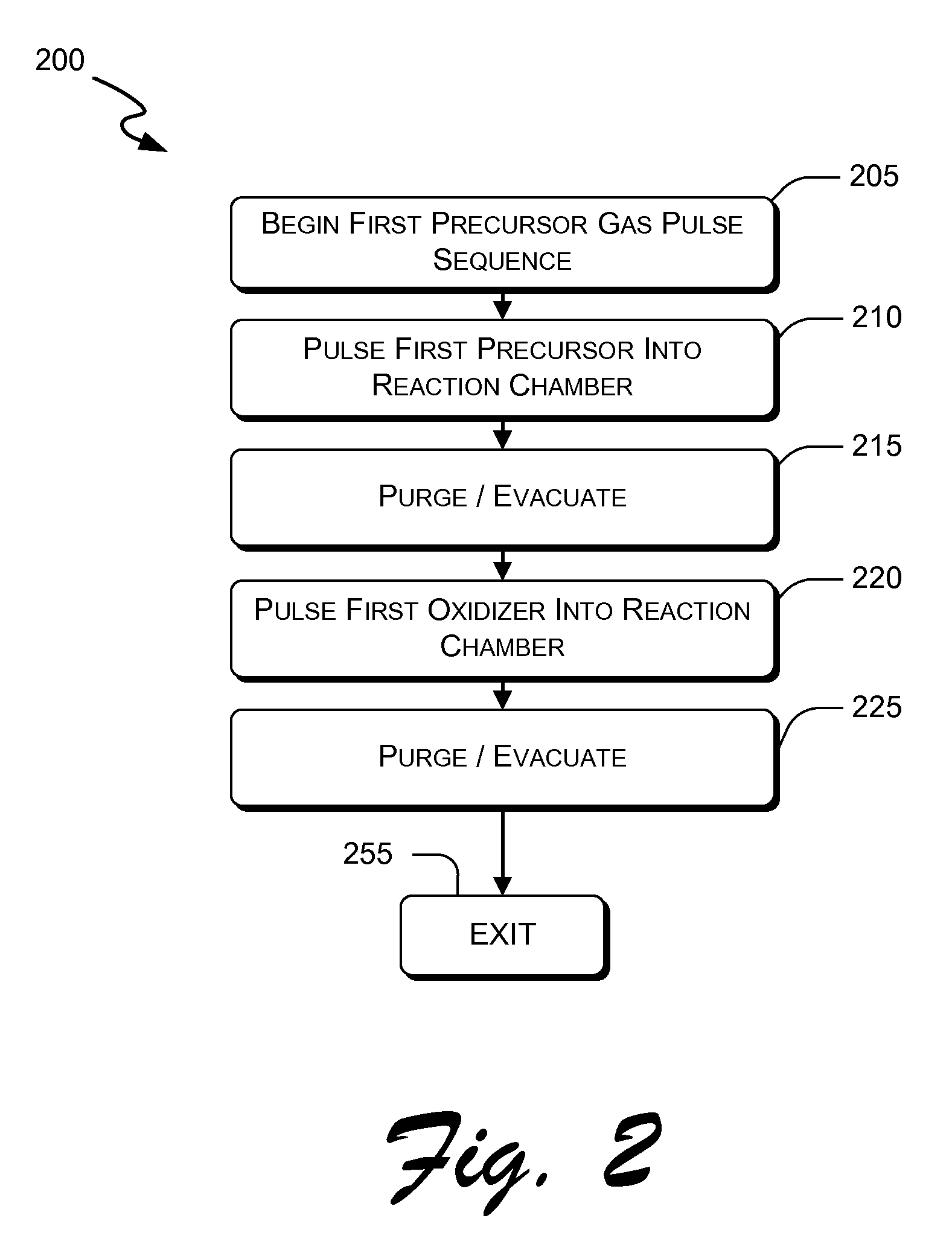

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

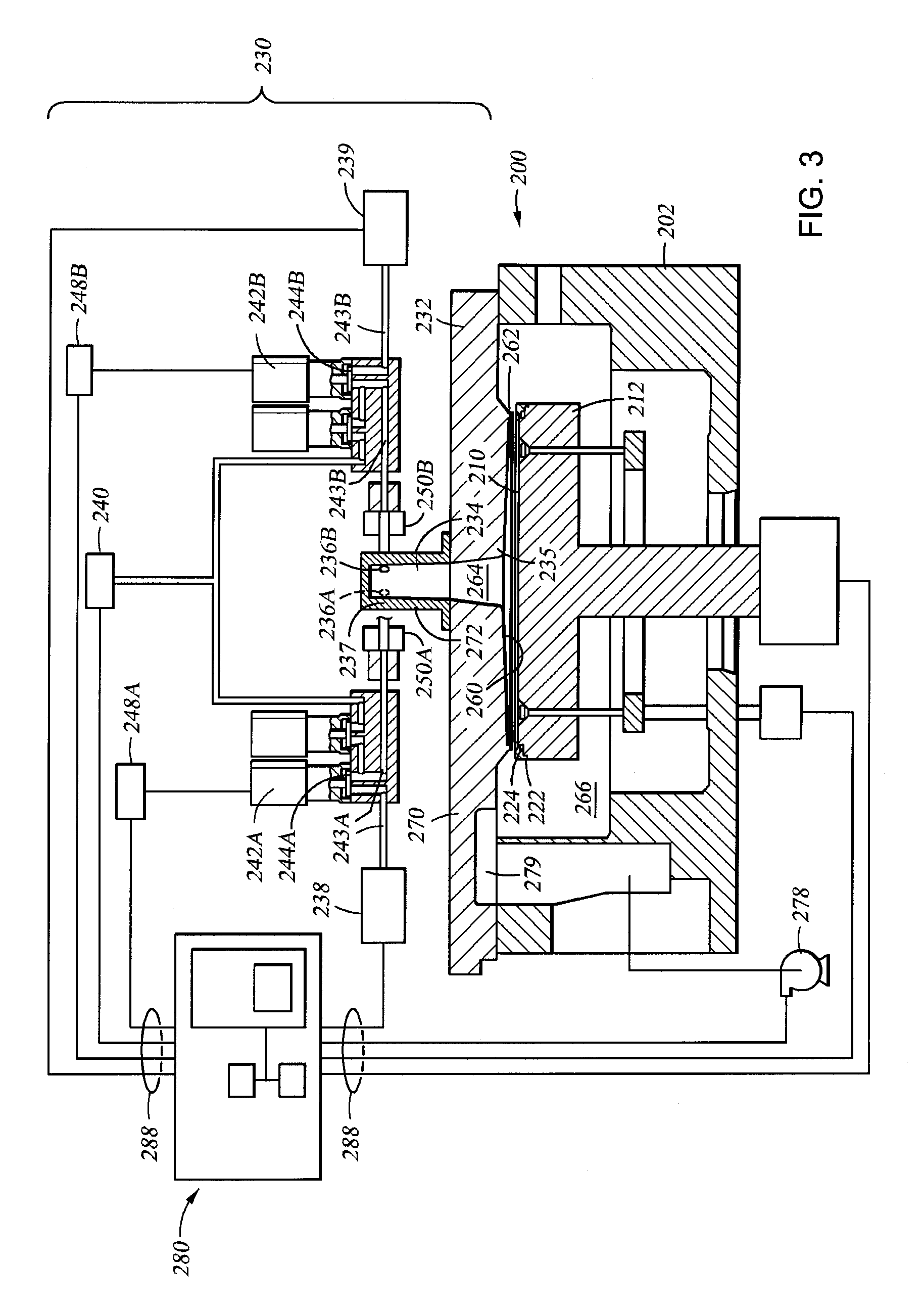

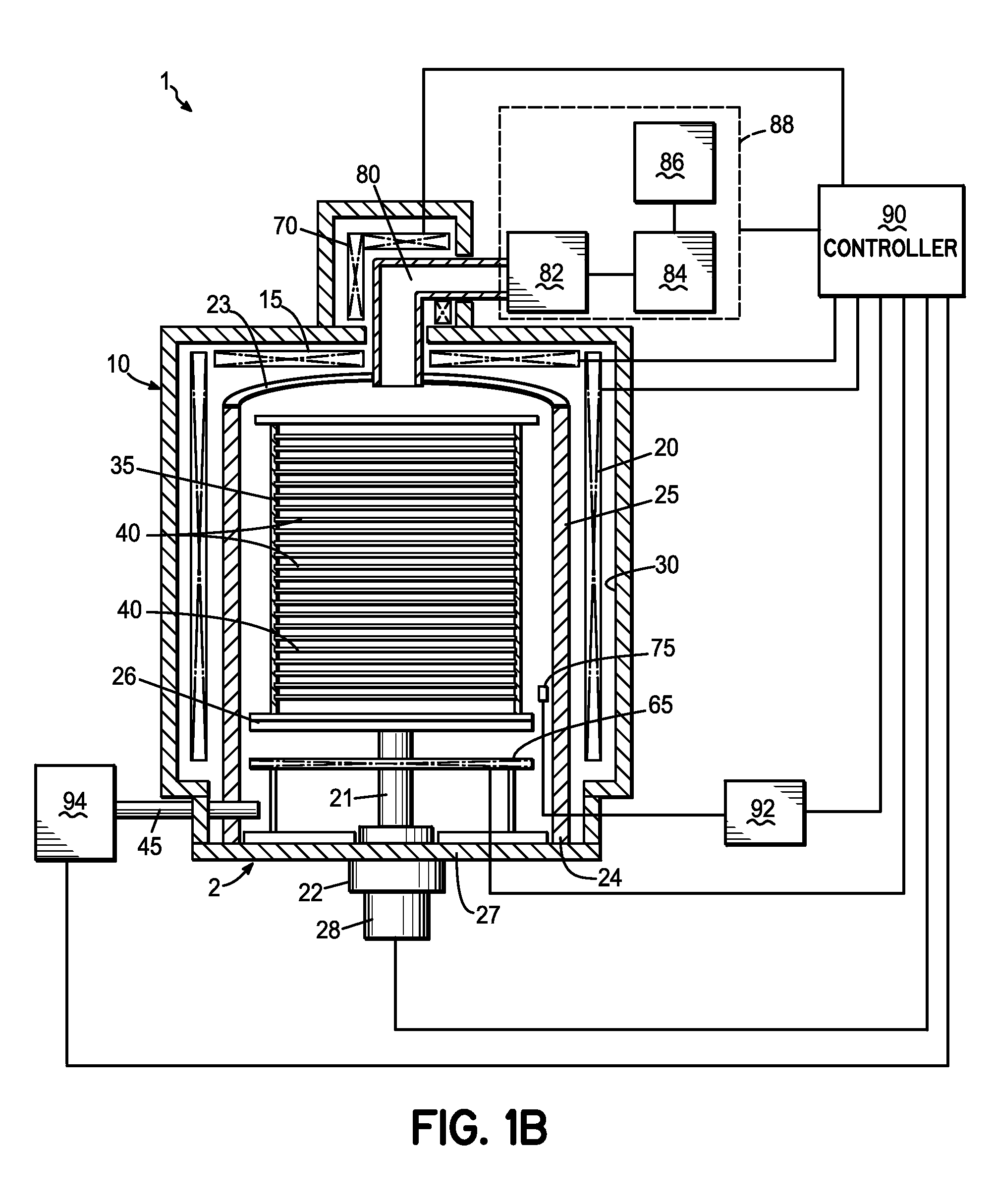

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

ActiveUS20050271812A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

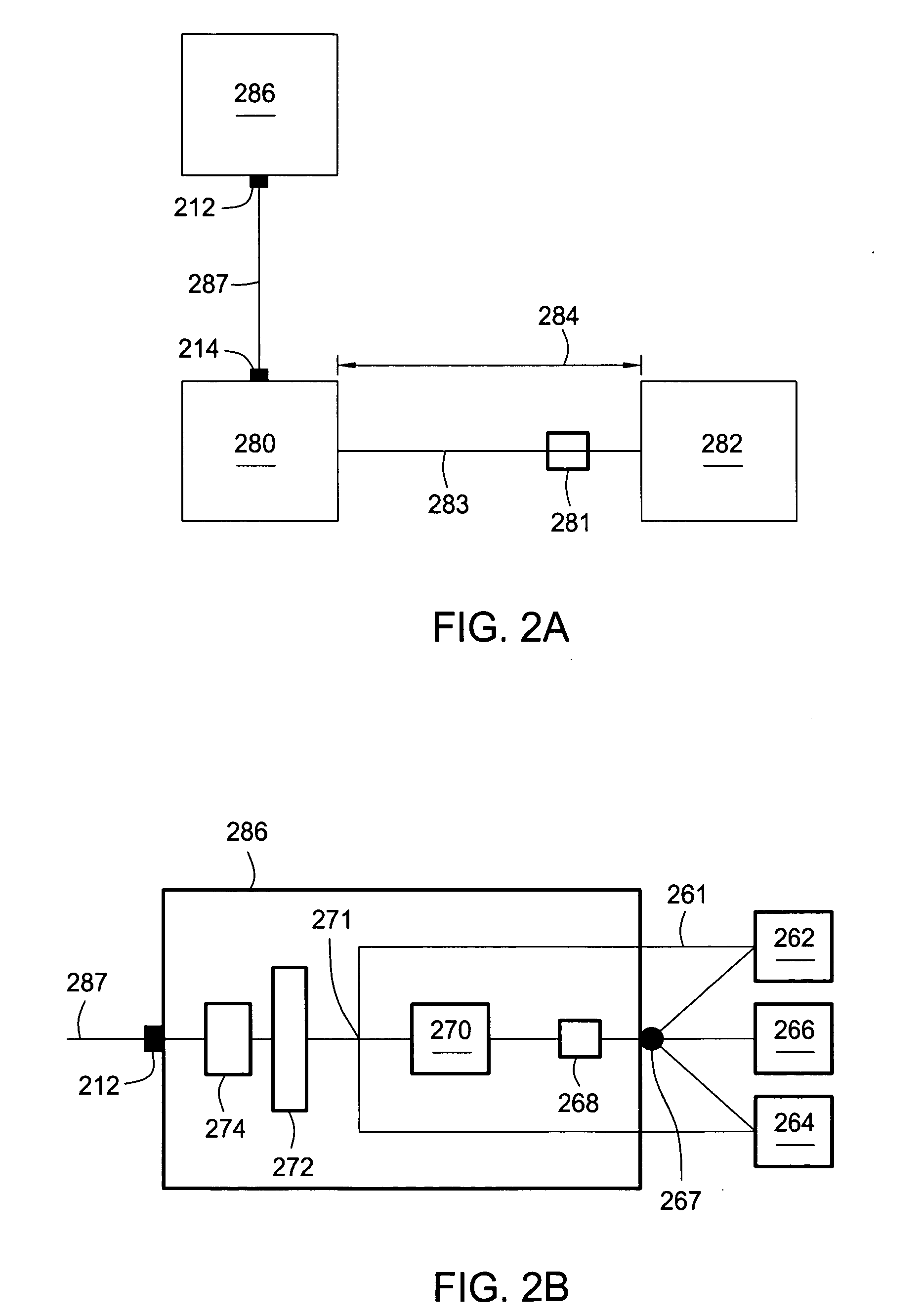

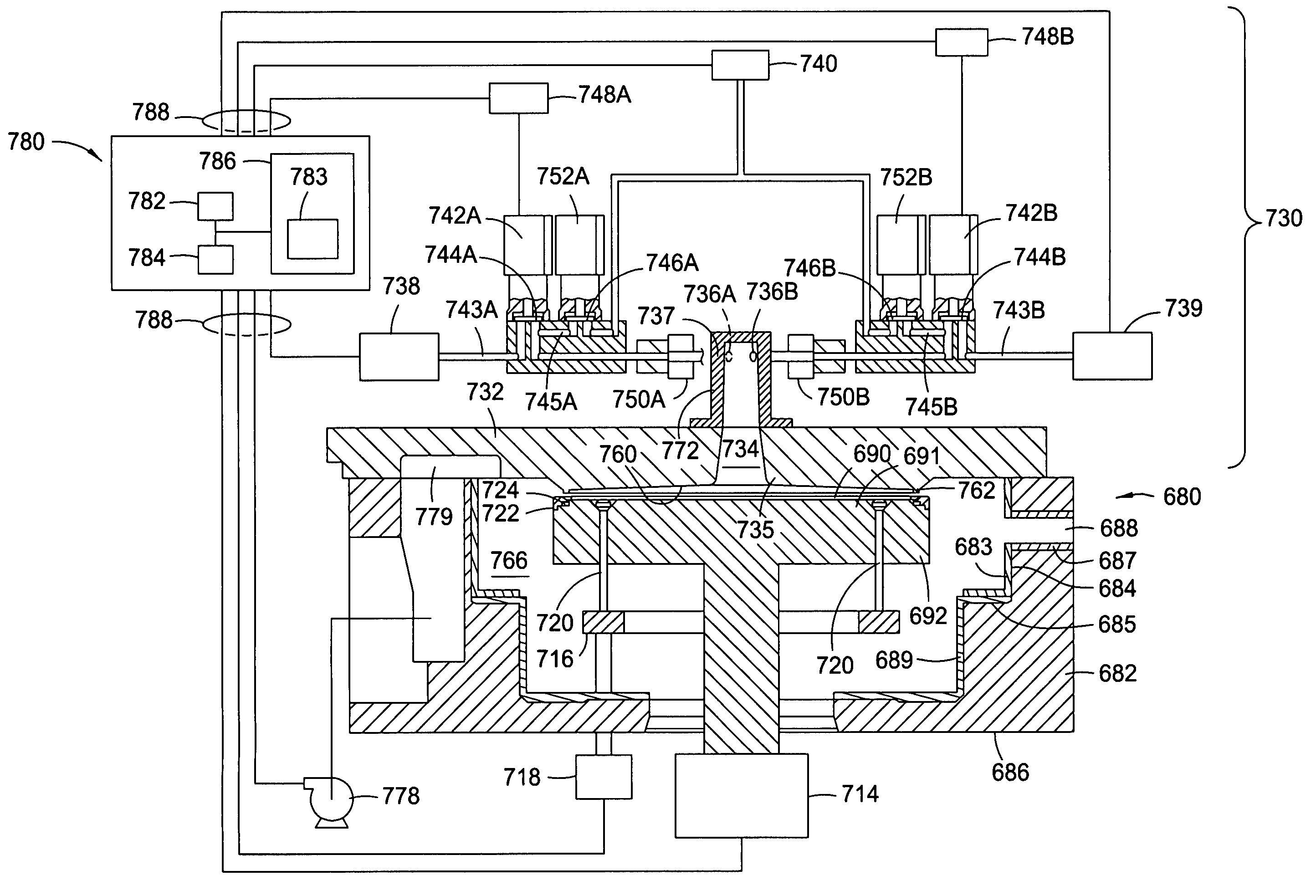

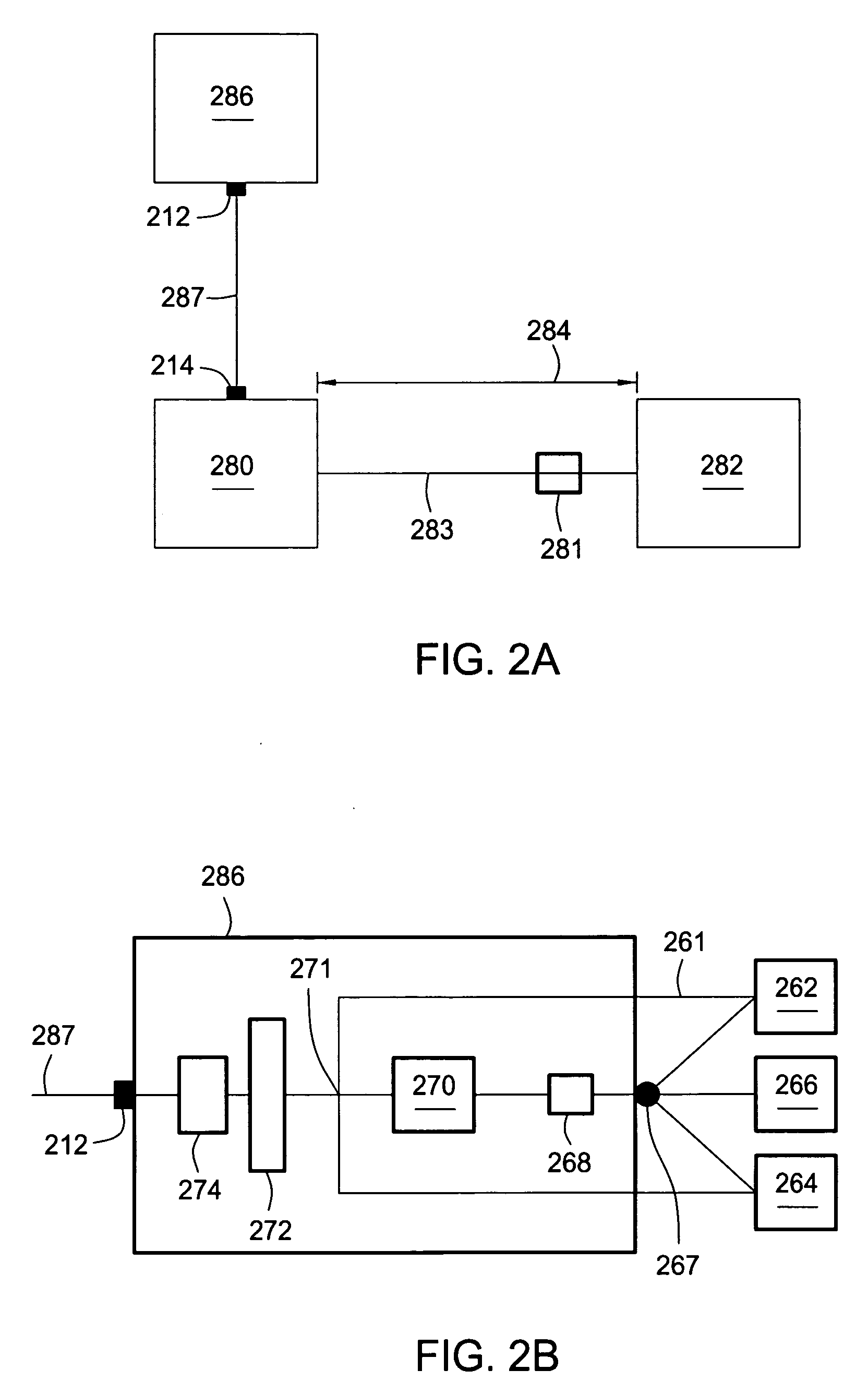

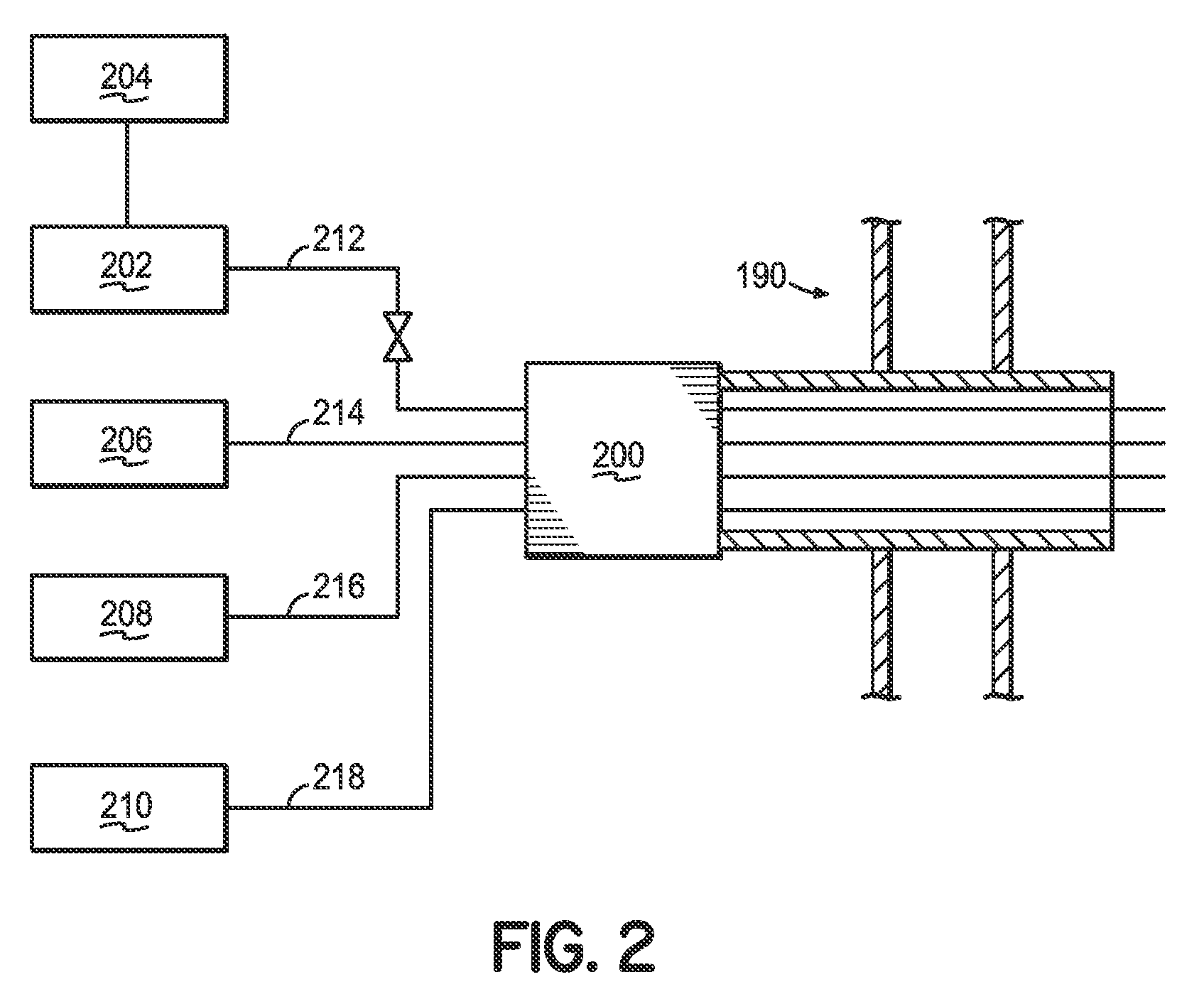

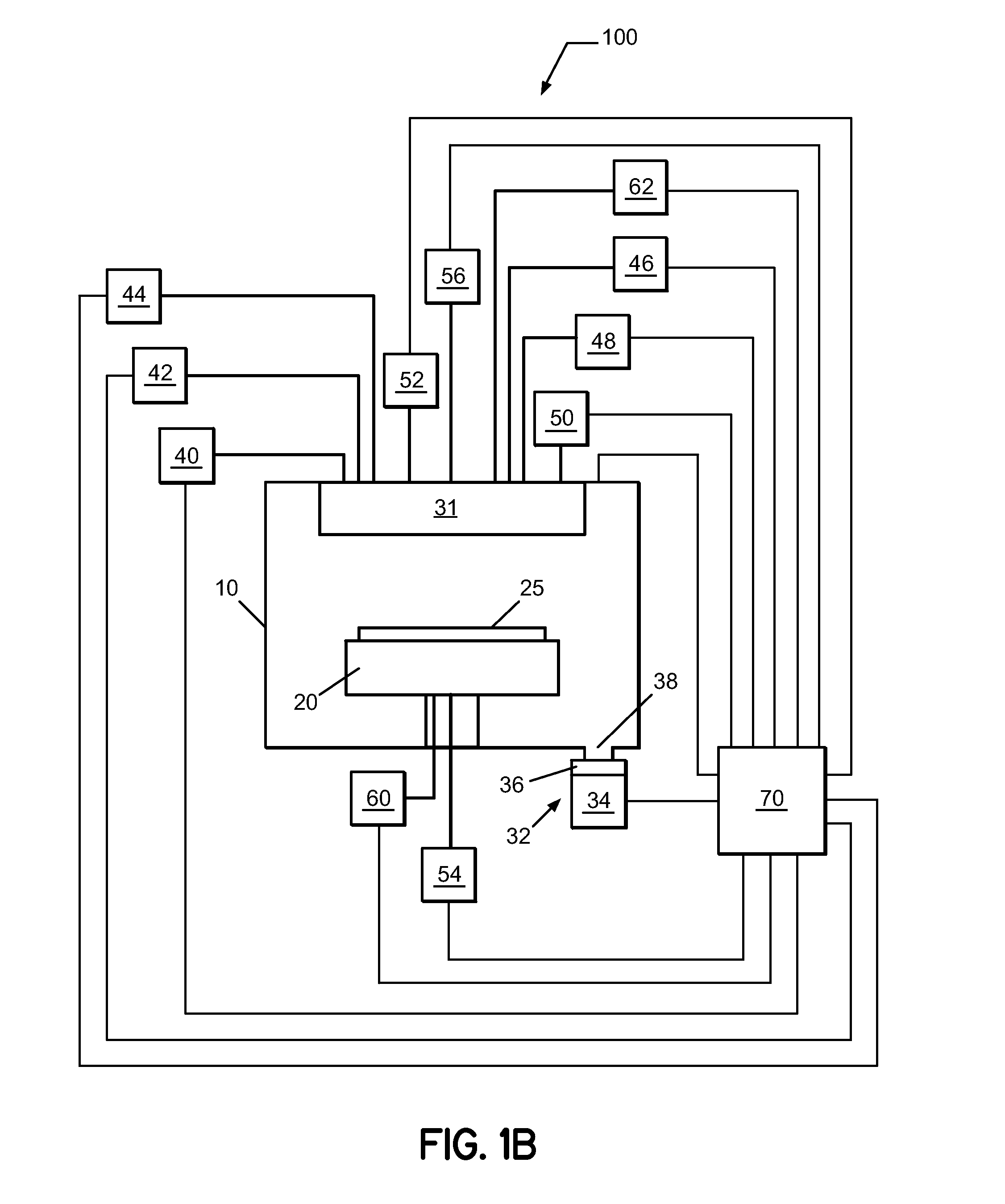

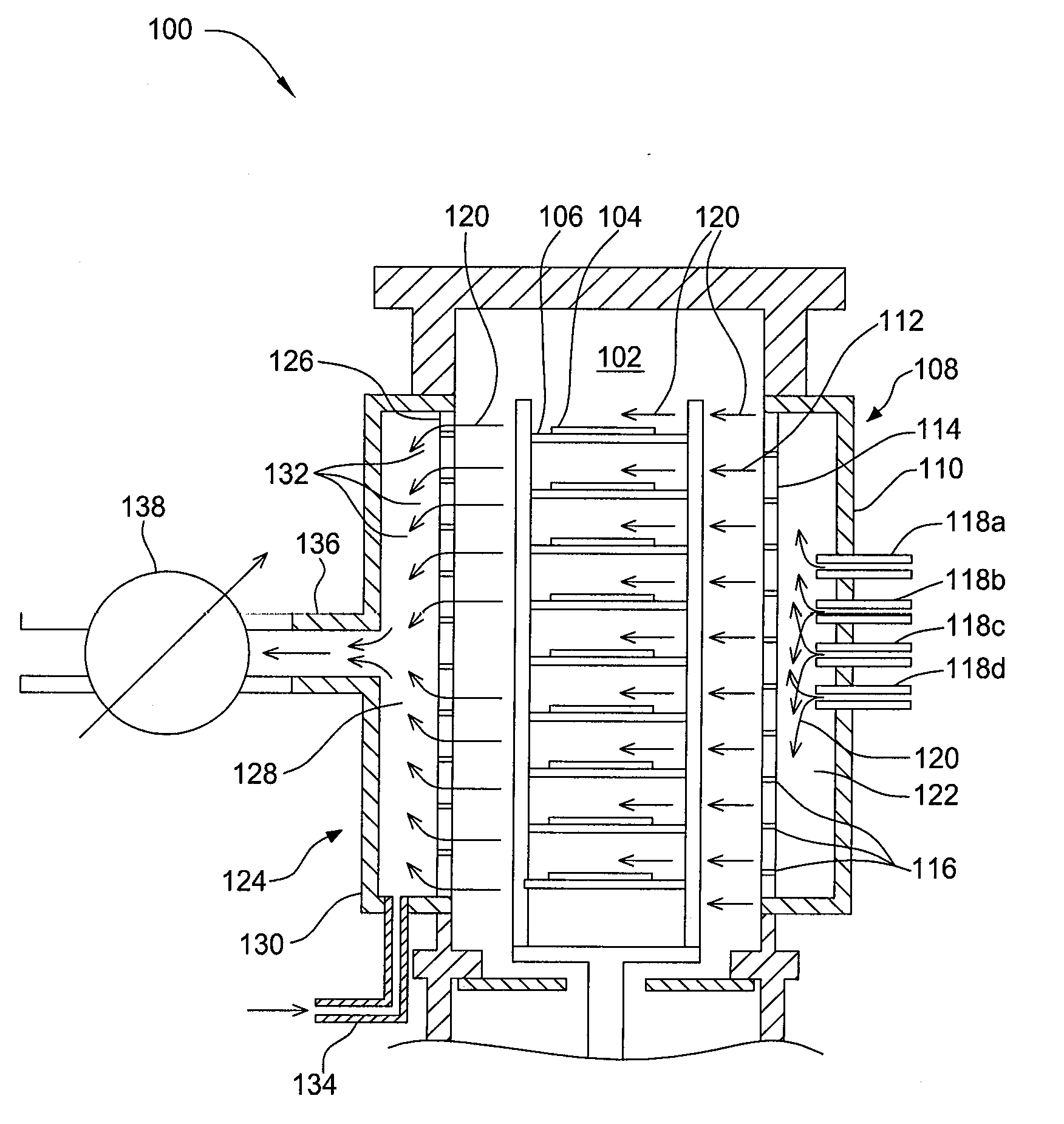

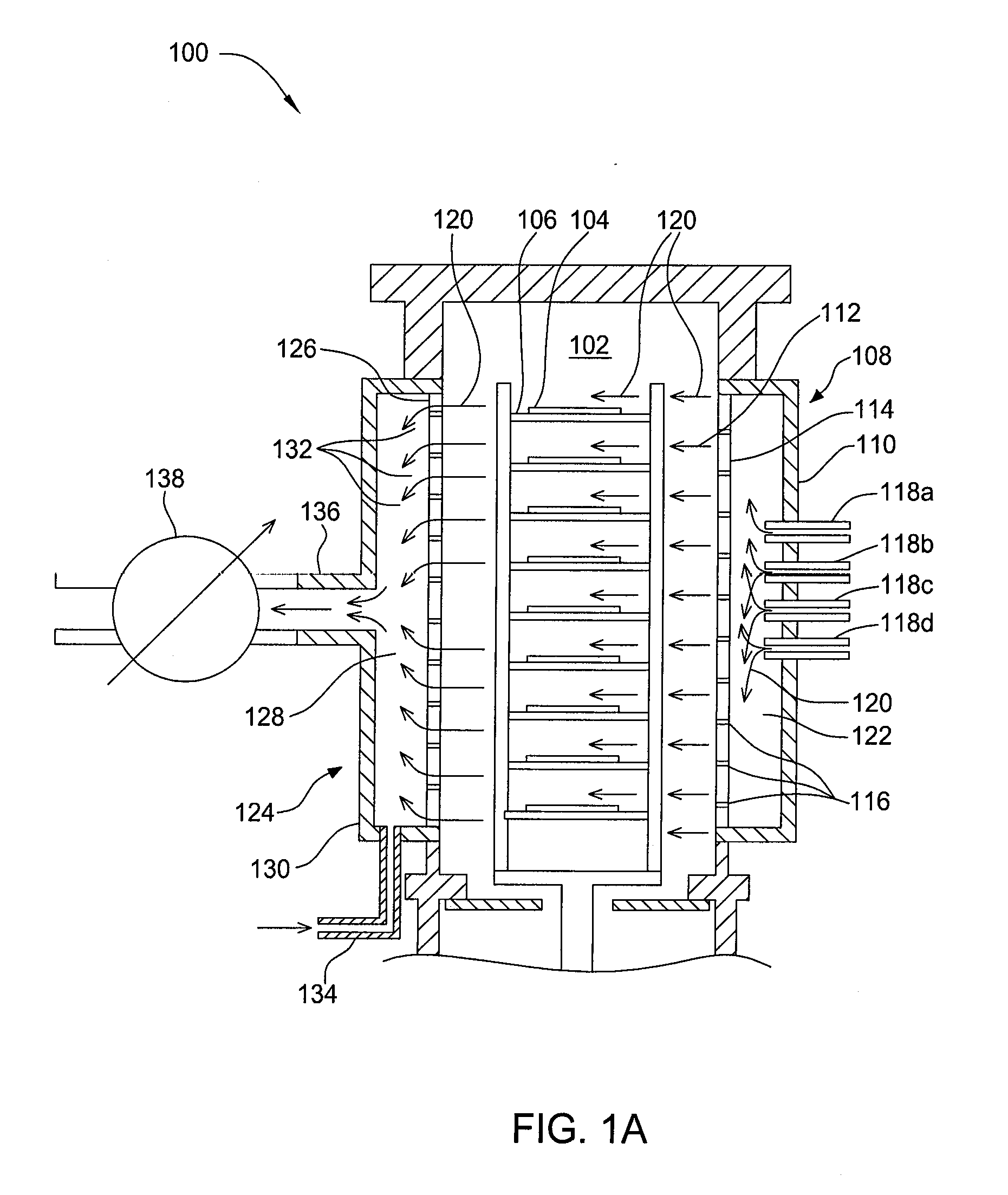

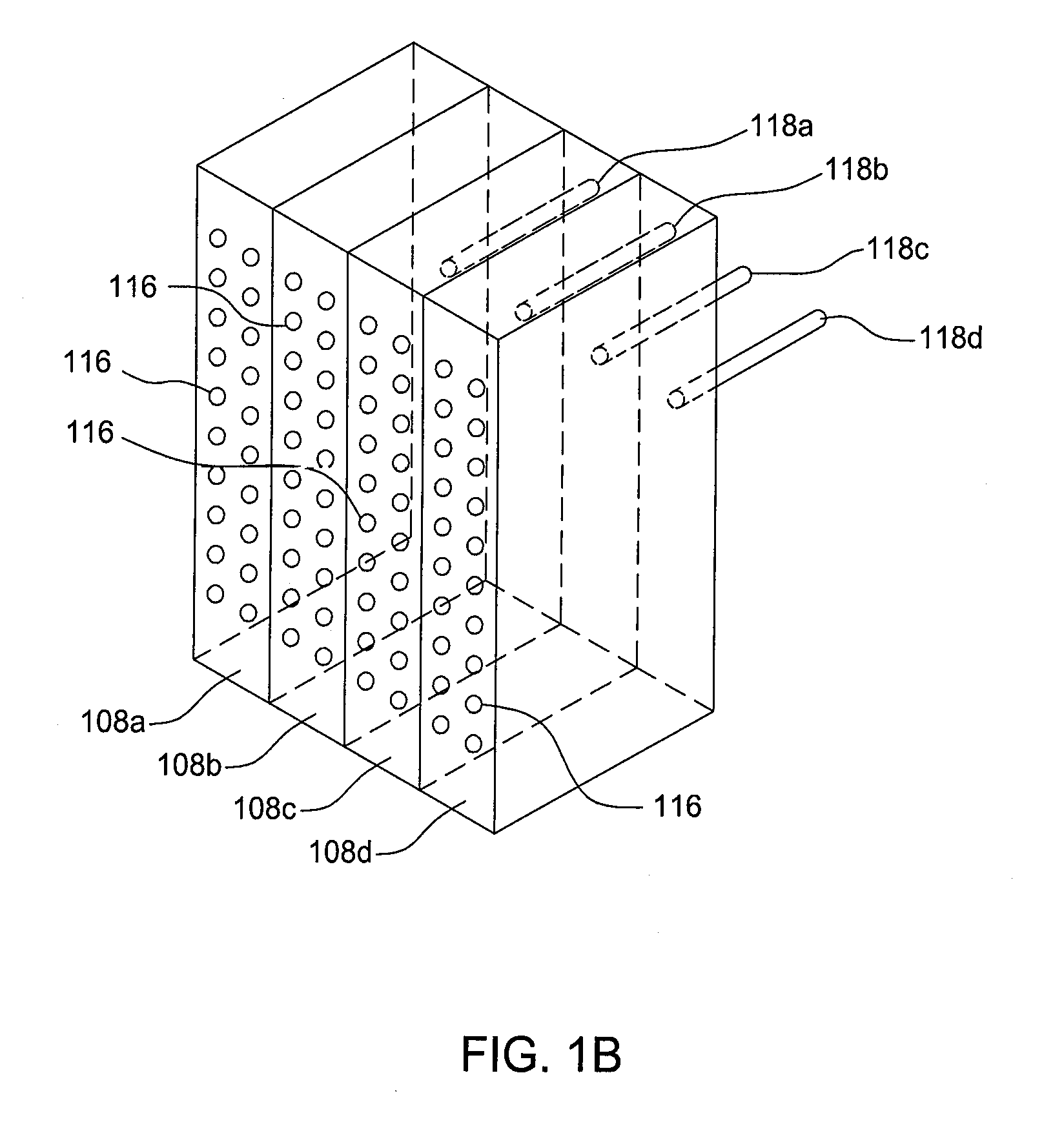

Embodiments of the invention provide apparatuses and methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

Method for vapor deposition of a metal compound film

InactiveUS20020172768A1Improve film propertiesEfficiently stackedTransistorSemiconductor/solid-state device detailsLanthanideNitrogen

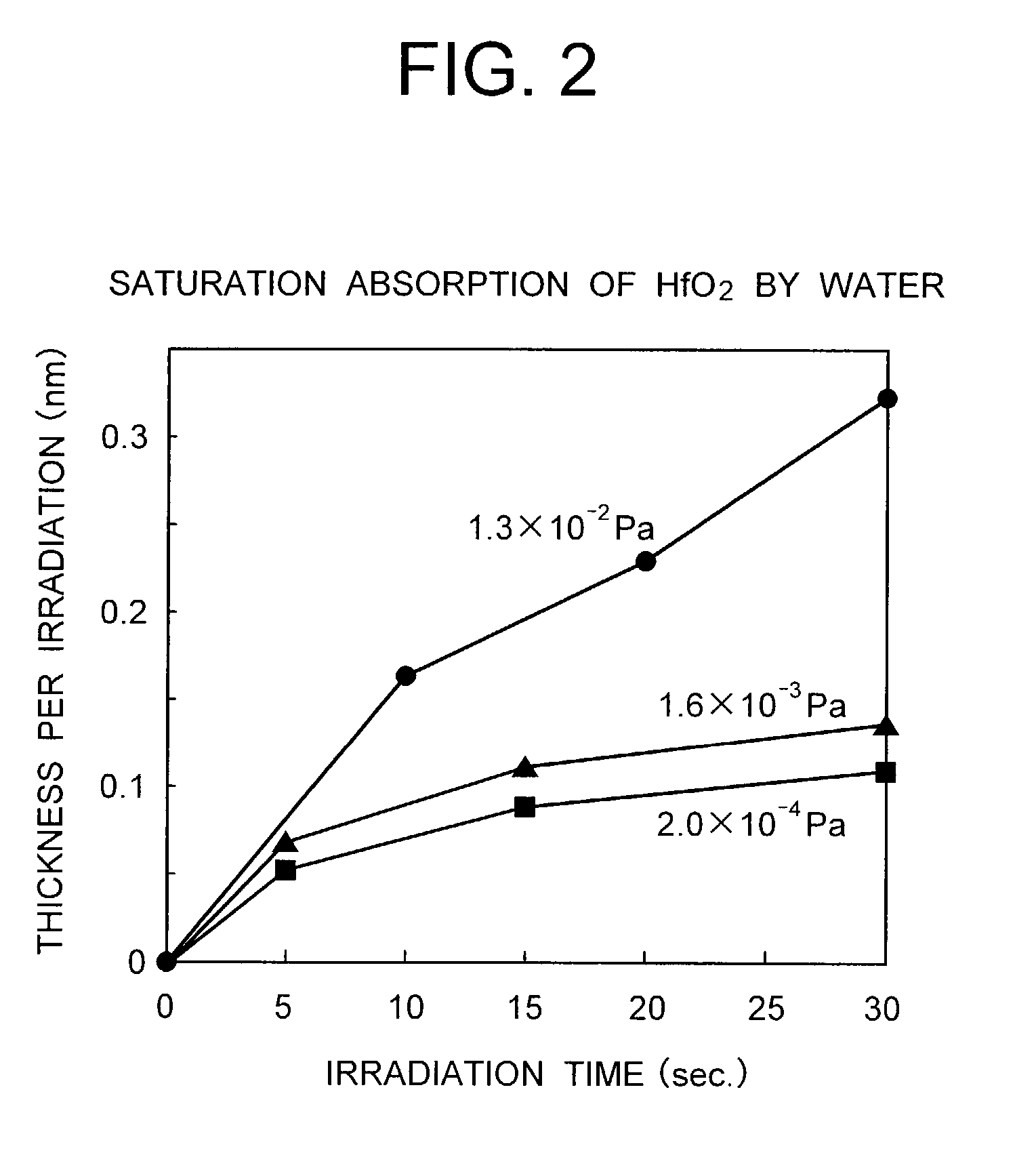

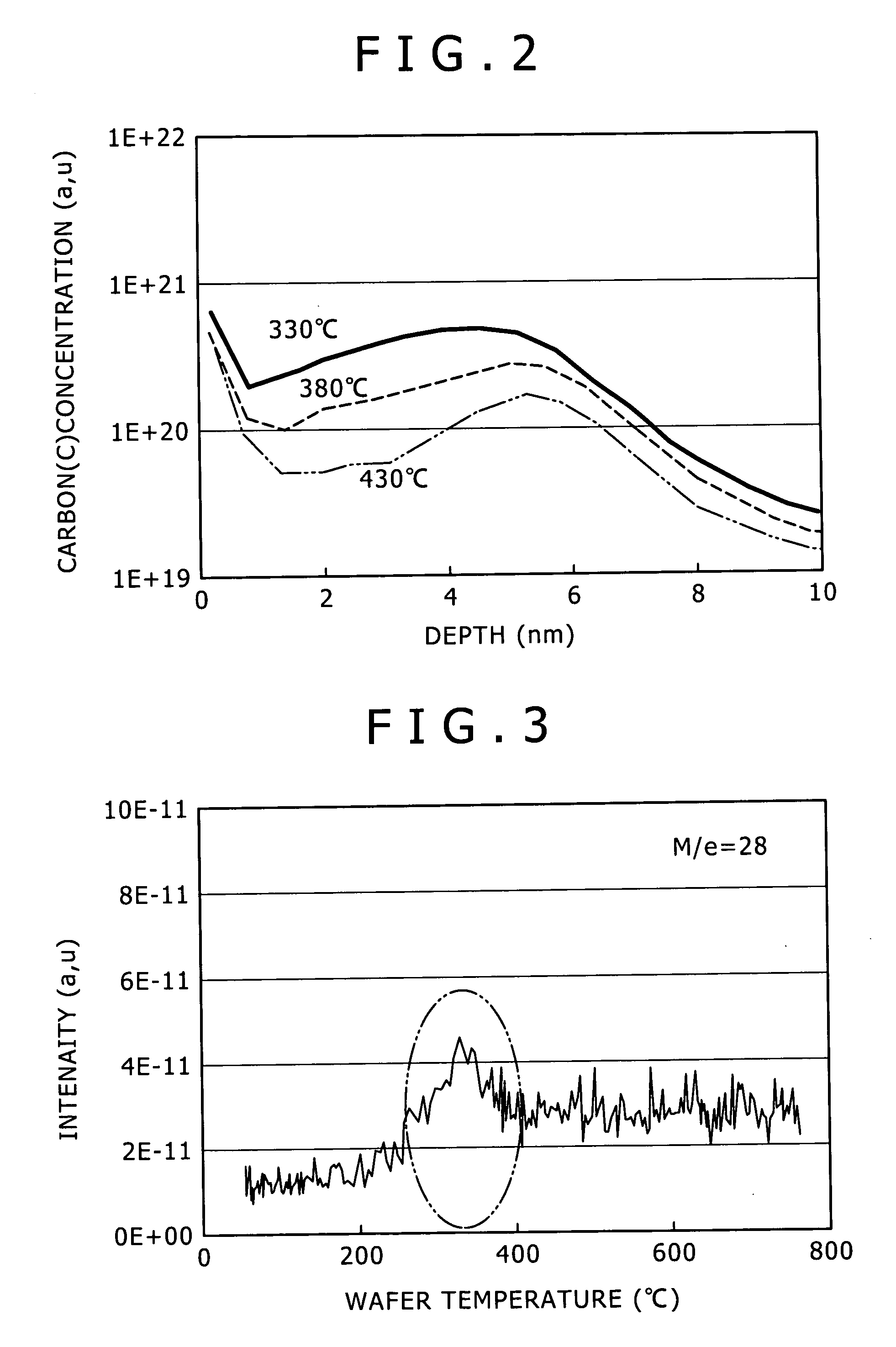

A method for forming a metal compound film includes alternate irradiation of an organometal compound and oxygen or nitrogen radicals to deposit monoatomic layers of the metal compound. The organometal compound includes zirconium, hafnium, lanthanide compounds. The resultant film includes little residual carbon and has excellent film characteristic with respect to leakage current.

Owner:RENESAS ELECTRONICS CORP

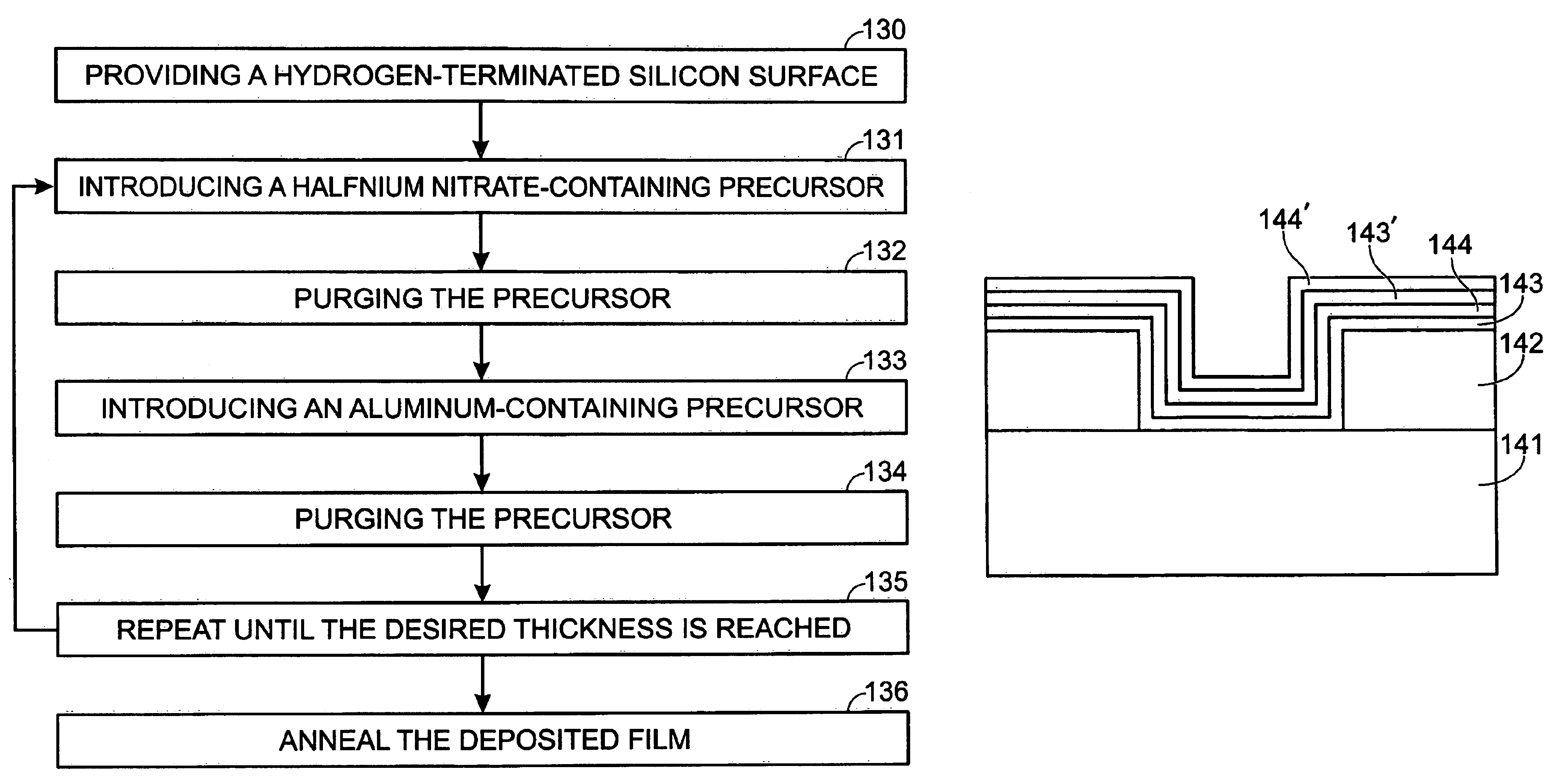

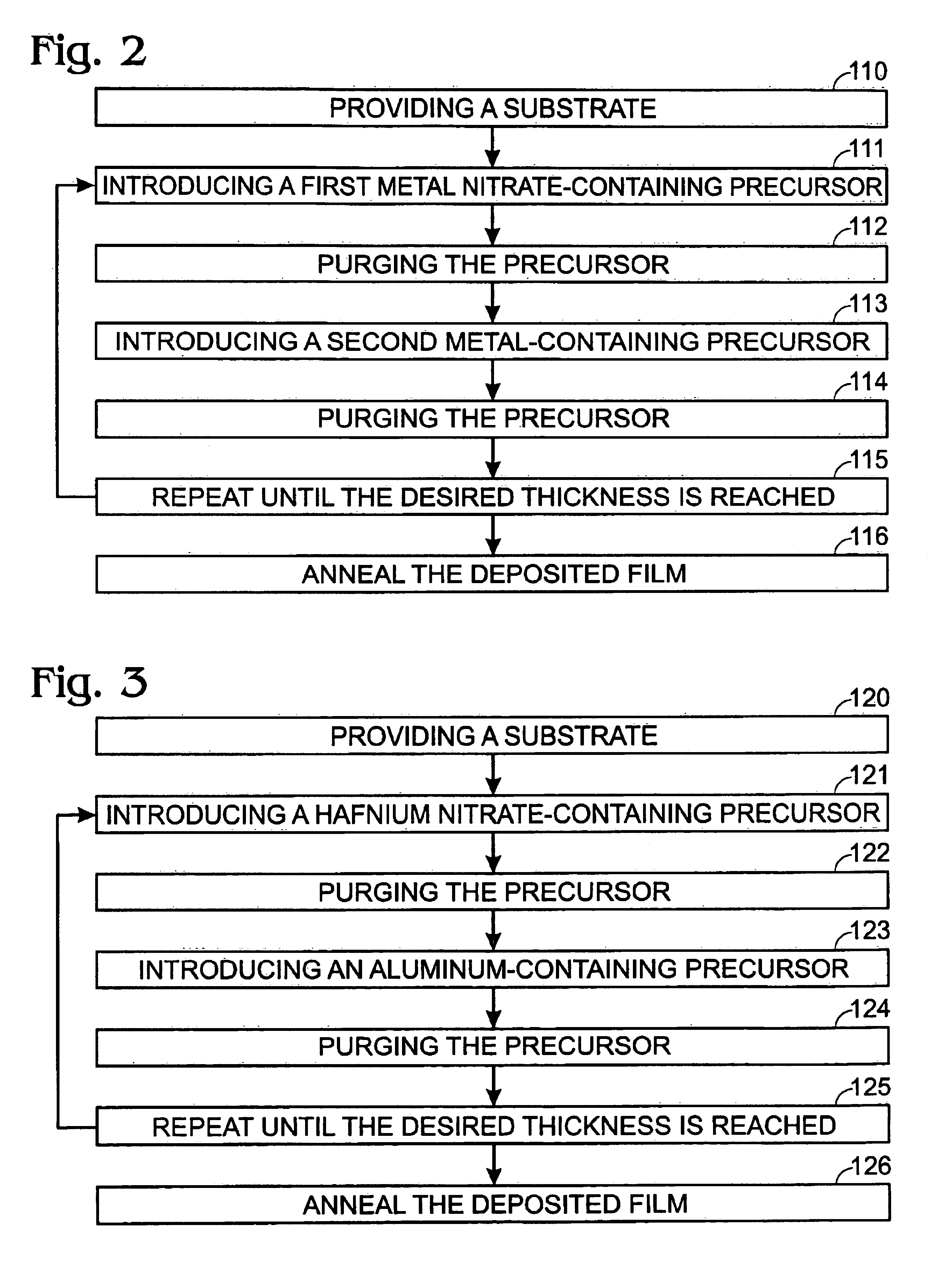

Method for depositing a nanolaminate film by atomic layer deposition

InactiveUS6930059B2Simple methodQuality improvementTransistorSemiconductor/solid-state device manufacturingGate dielectricHafnium

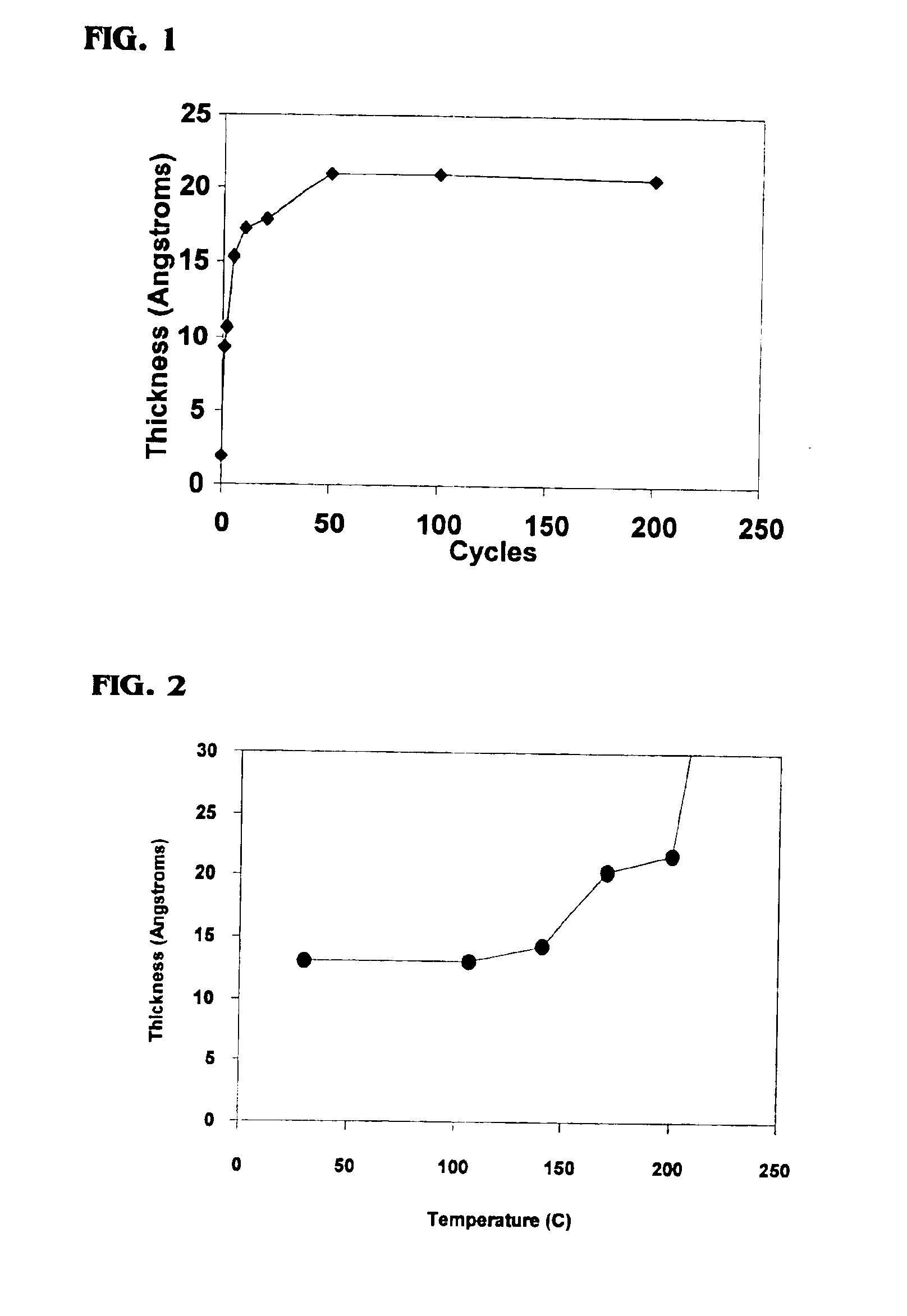

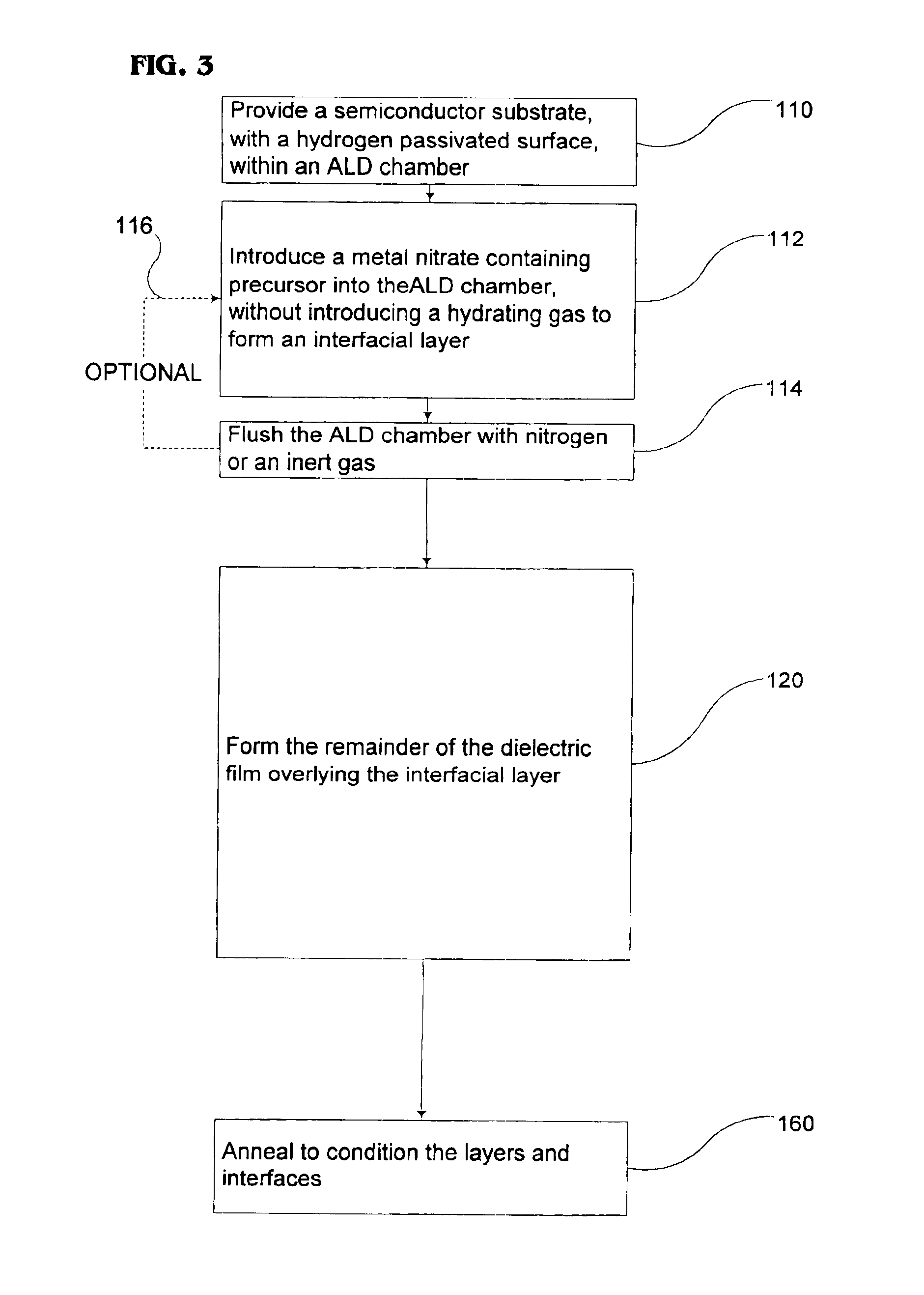

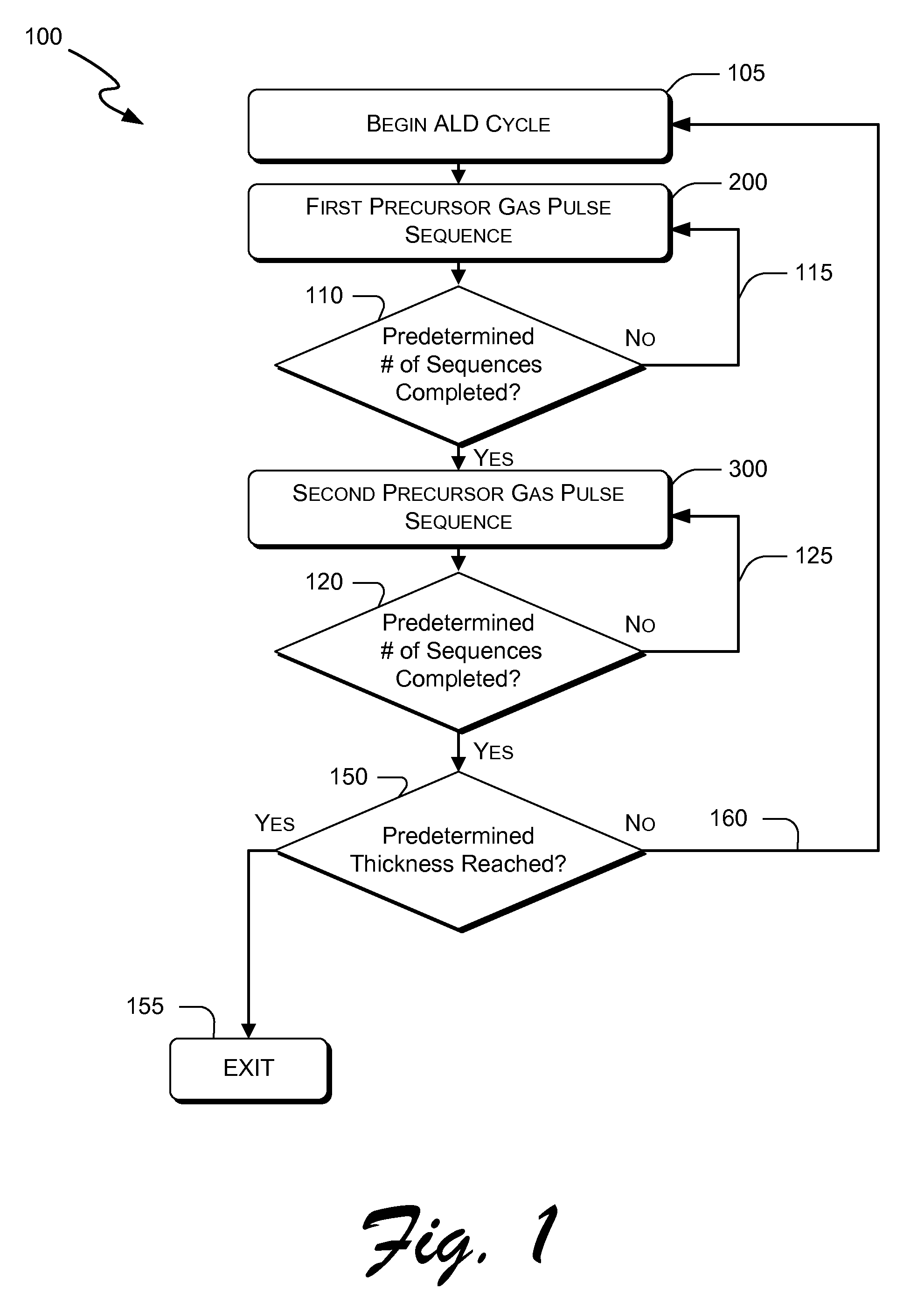

An atomic layer deposition method to deposit an oxide nanolaminate thin film is provided. The method employs a nitrate ligand in a first precursor as an oxidizer for a second precursor to form the oxide nanolaminates. Using a hafnium nitrate precursor and an aluminum precursor, the method is well suited for the deposition of a high k hafnium oxide / aluminum oxide nanolaminate dielectric for gate dielectric or capacitor dielectric applications on a hydrogen-terminated silicon surface.

Owner:SHARP LAB OF AMERICA INC

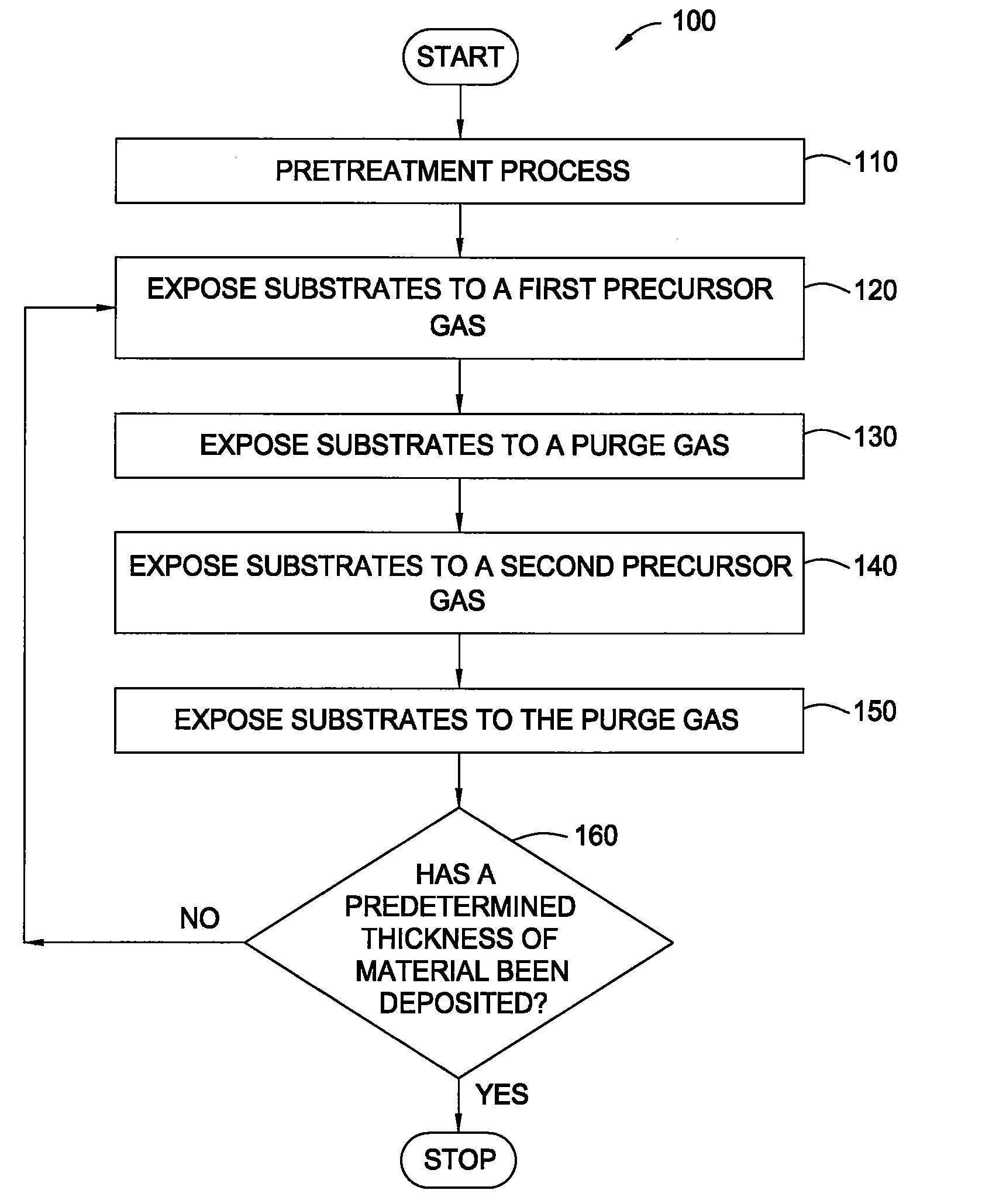

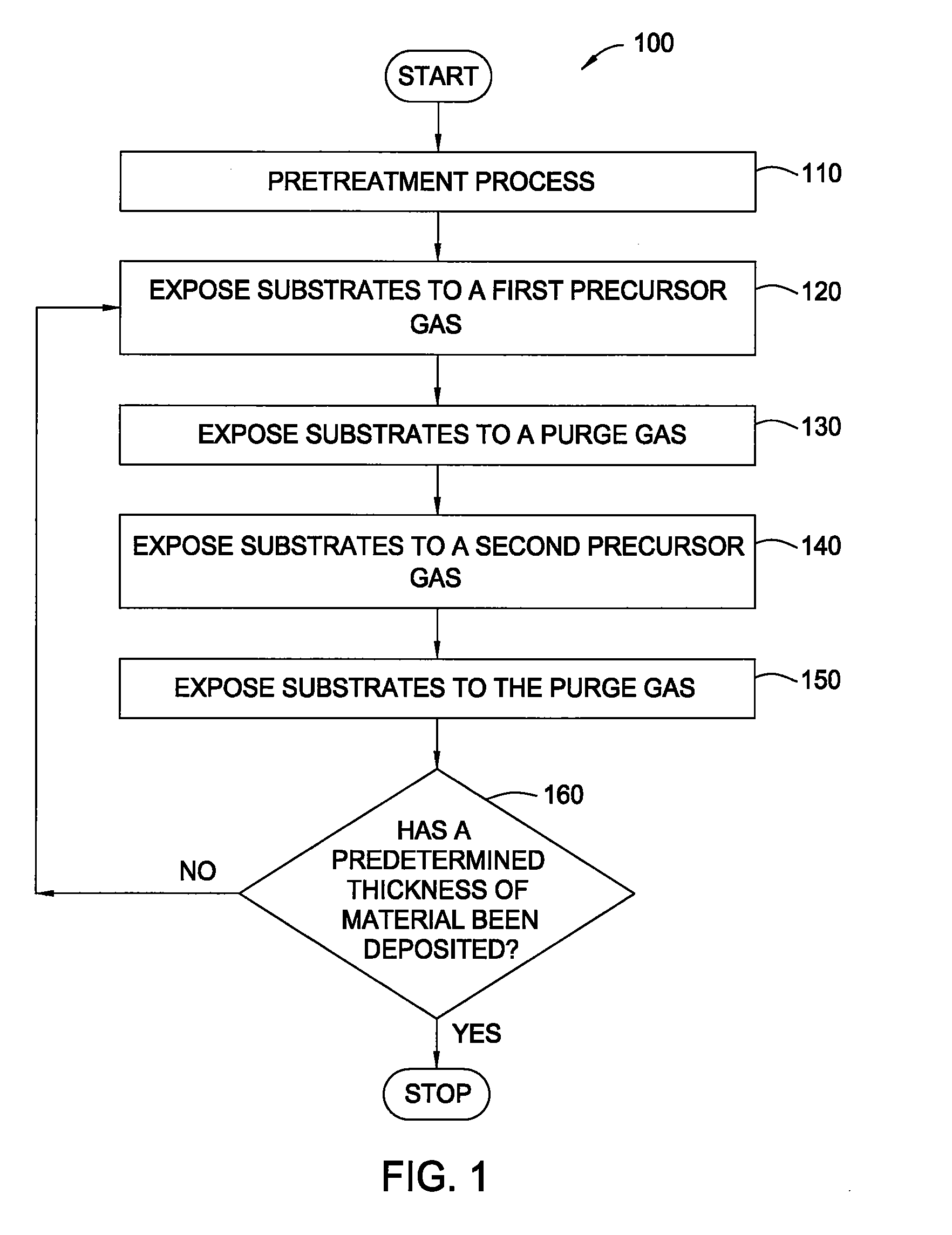

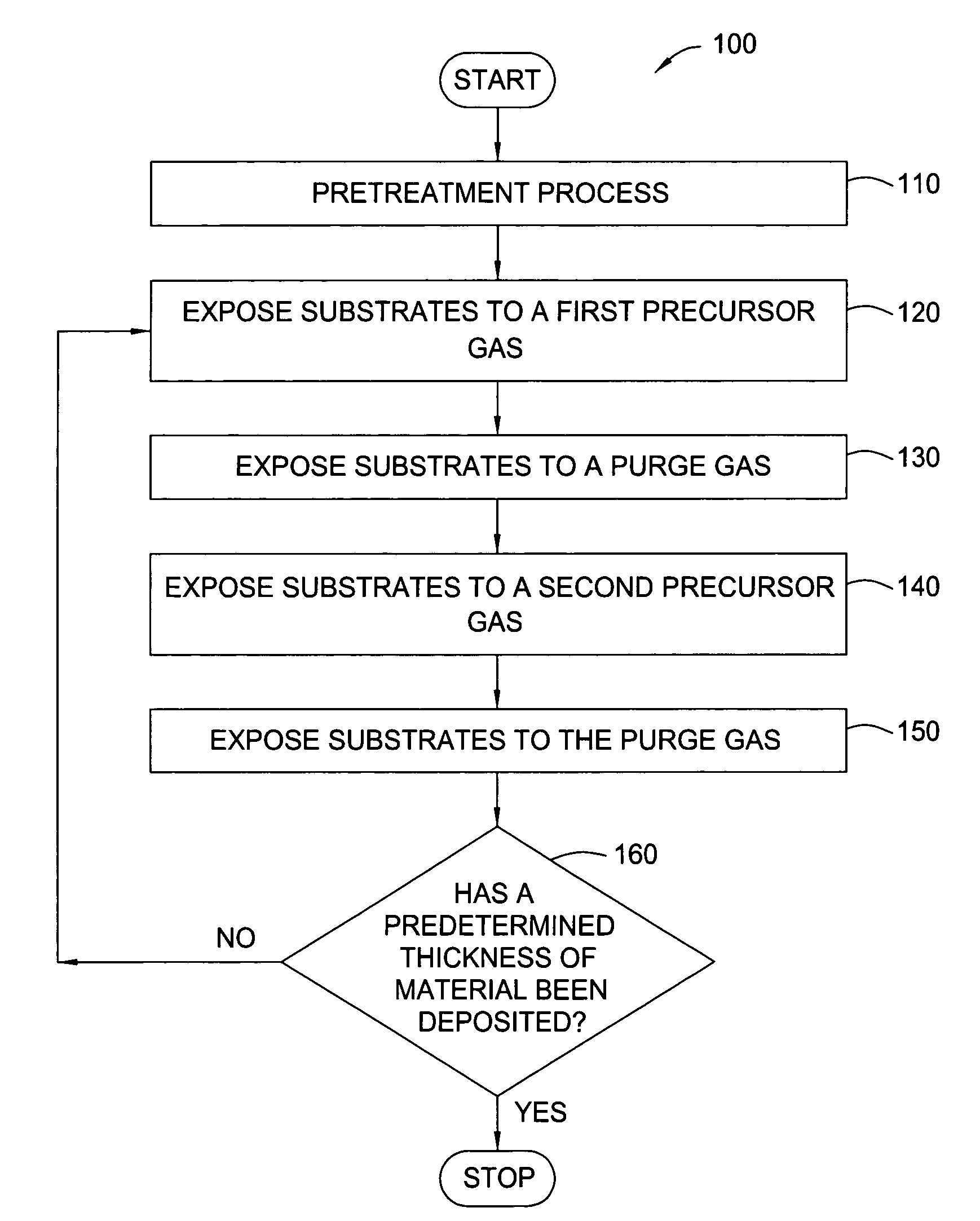

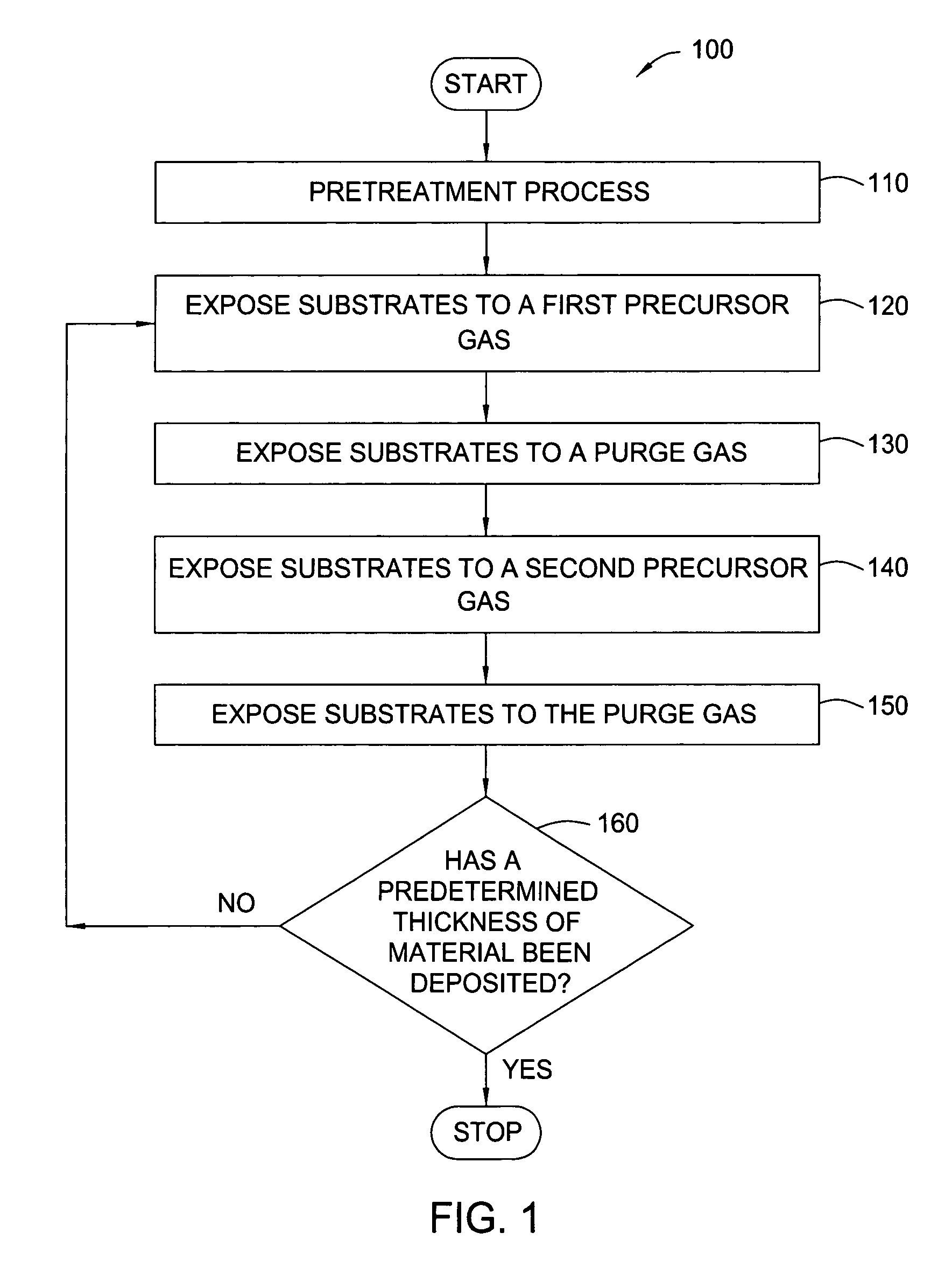

Pretreatment processes within a batch ald reactor

InactiveUS20080261413A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHafniumAtomic layer deposition

Embodiments of the invention provide methods for forming a hafnium material on a substrate within a processing chamber. In one embodiment, a method is provided which includes exposing the substrate within the processing chamber to a first oxidizing gas during a pretreatment process, exposing the substrate sequentially to a second oxidizing gas and a deposition gas during an atomic layer deposition (ALD) cycle, wherein the second oxidizing gas contains water and the deposition gas contains a hafnium amino compound, and repeating the ALD cycle to form a hafnium-containing layer having a thickness within a range from about 5 Å to about 300 Å. In one example, the first oxidizing gas contains an O3 / O2 mixture having an ozone concentration within a range from about 5 atomic percent to about 30 atomic percent.

Owner:APPLIED MATERIALS INC

Ald metal oxide deposition process using direct oxidation

InactiveUS20070059948A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenHafnium

Embodiments of the invention provide methods for forming hafnium materials, such as oxides and nitrides, by sequentially exposing a substrate to hafnium precursors and active oxygen or nitrogen species (e.g., ozone, oxygen radicals, or nitrogen radicals). The deposited hafnium materials have significantly improved uniformity when deposited by these atomic layer deposition (ALD) processes. In one embodiment, an ALD chamber contains an expanding channel having a bottom surface that is sized and shaped to substantially cover a substrate positioned on a substrate pedestal. During an ALD process for forming hafnium materials, process gases form a vortex flow pattern while passing through the expanding channel and sweep across the substrate surface. The substrate is sequentially exposed to chemical precursors that are pulsed into the process chamber having the vortex flow.

Owner:APPLIED MATERIALS INC

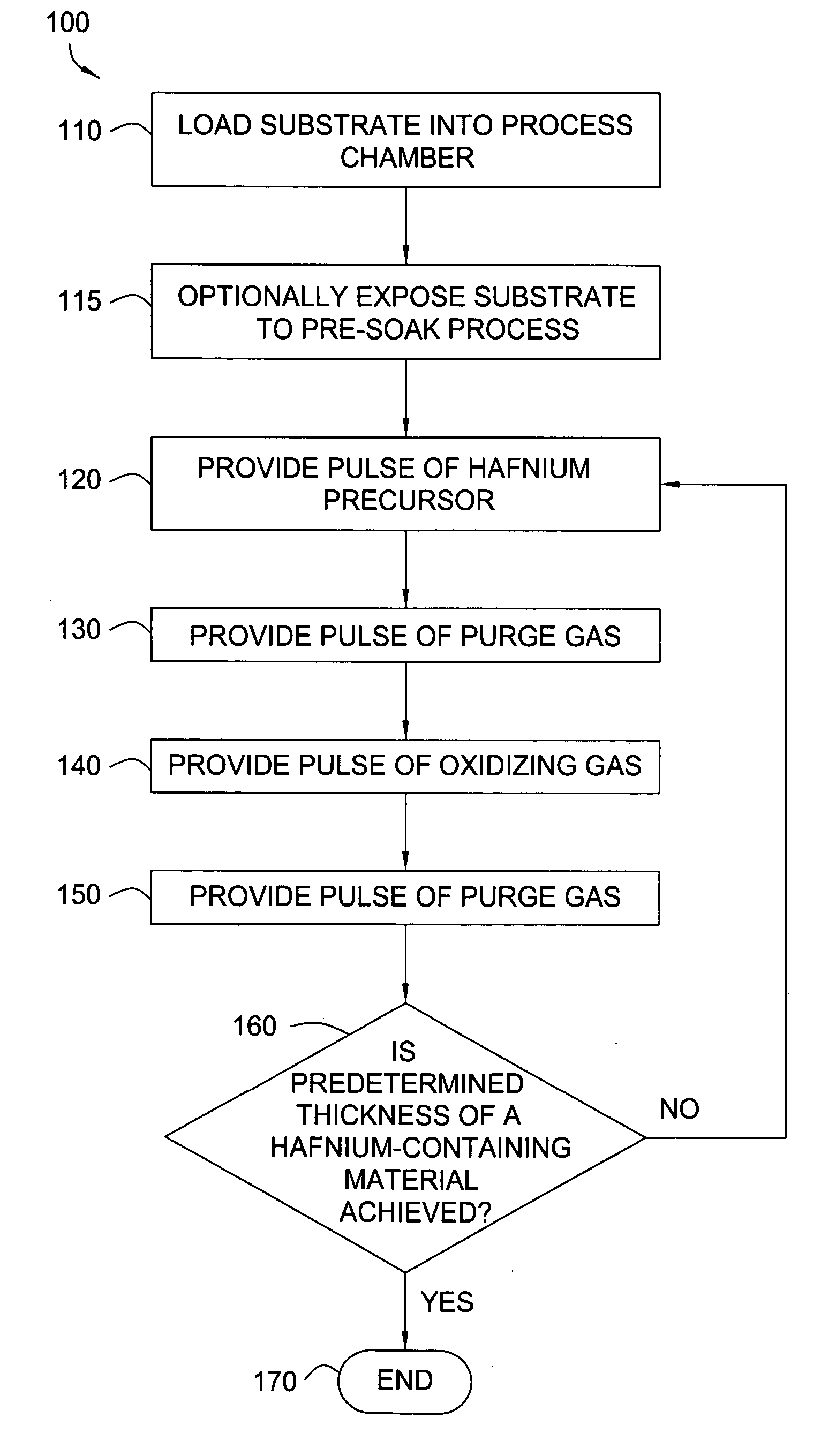

Pretreatment processes within a batch ALD reactor

InactiveUS20070049053A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingWater vaporHafnium

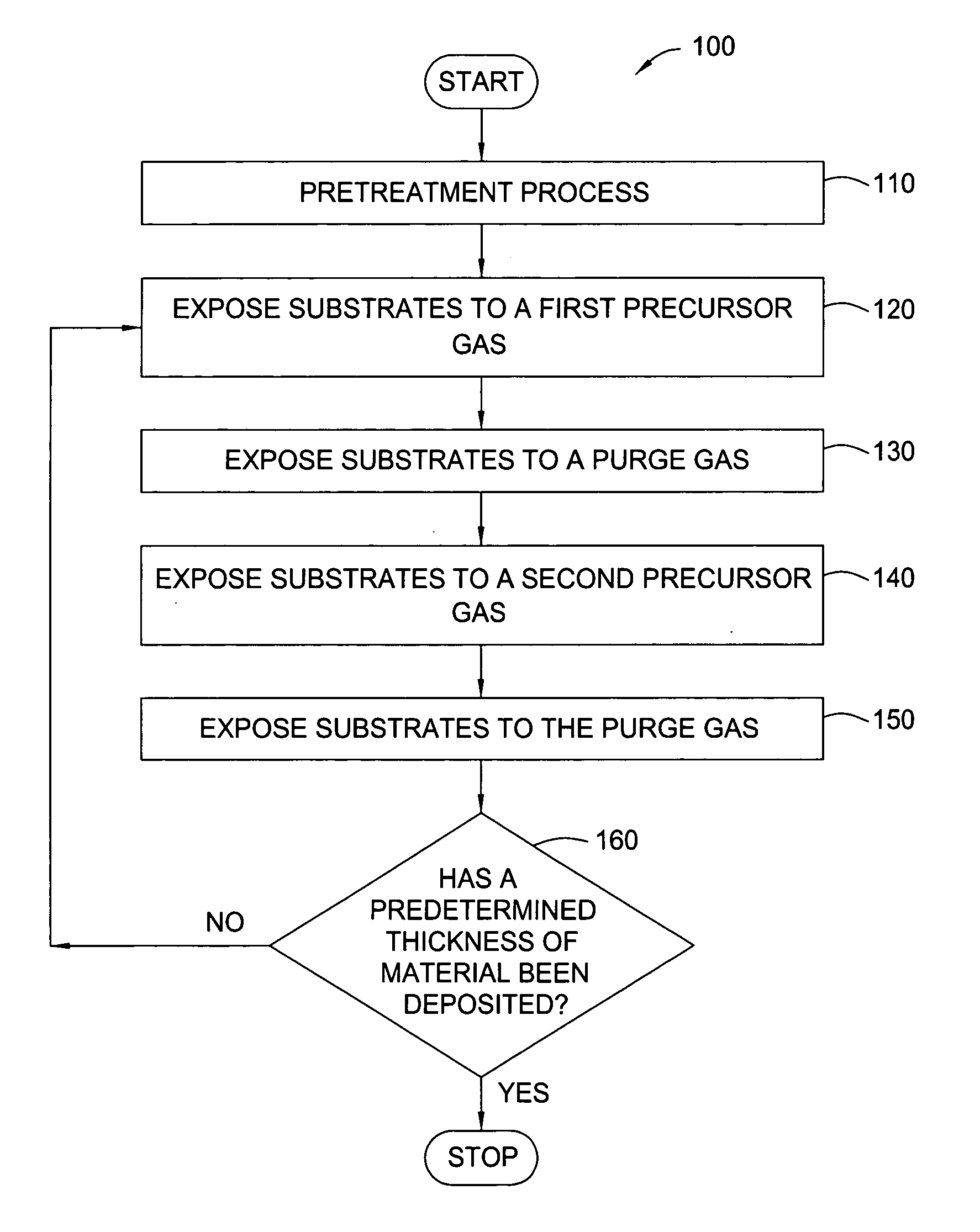

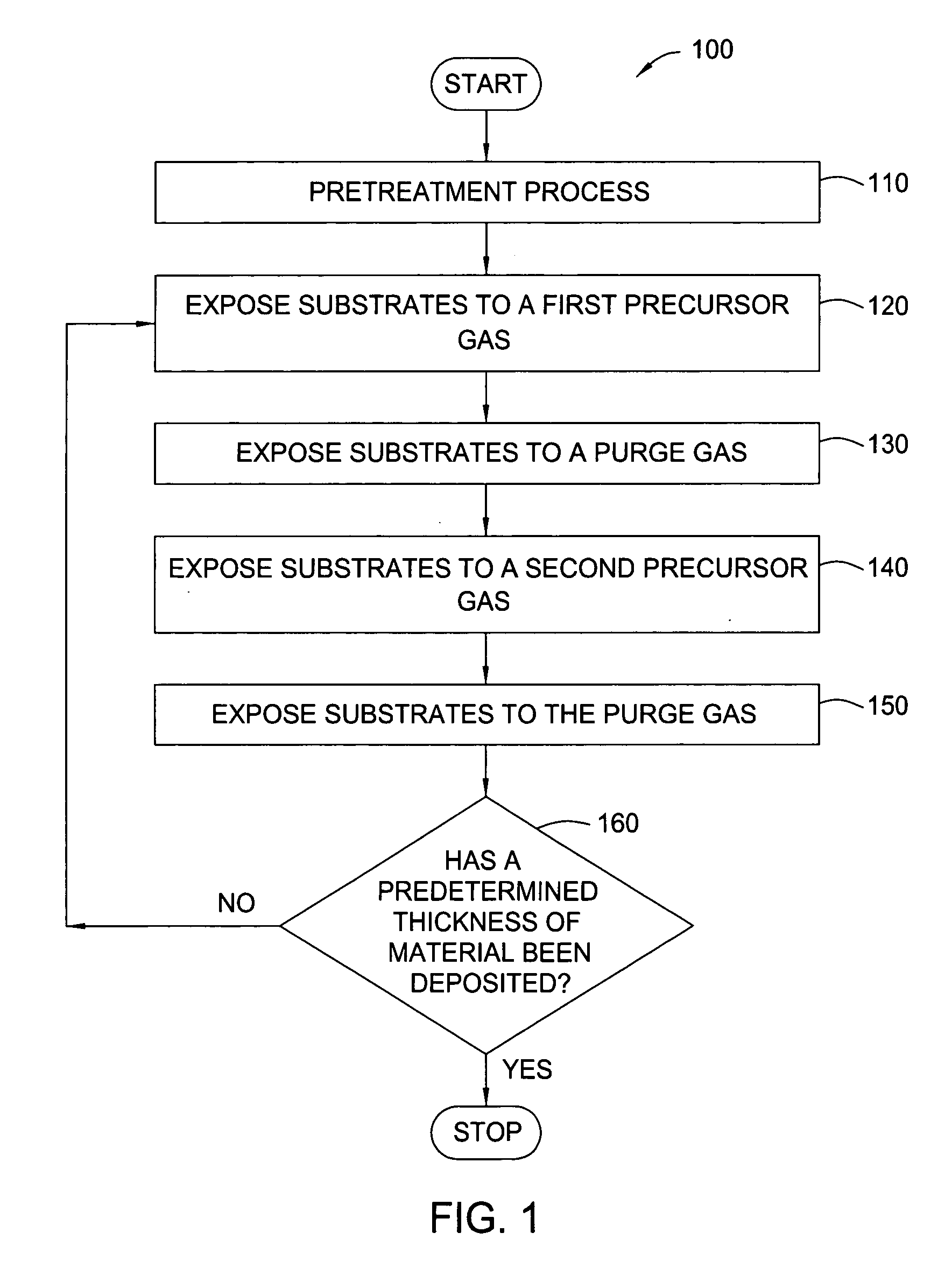

Embodiments of the invention provide methods for forming a material on a substrate which includes exposing a plurality of substrates within a batch process chamber to a first oxidizing gas during a pretreatment process, exposing the substrates sequentially to a precursor and a second oxidizing gas during an ALD cycle and repeating the ALD cycle to form a material on the substrates. In a preferred example, a hafnium precursor is used during the ALD process to form a hafnium-containing material, such as hafnium oxide. In one example, the first and second oxidizing gases are the same oxidizing gases. In a preferred example, the first and second oxidizing gases are different oxidizing gases, such that the pretreatment process contains ozone and the ALD process contains water vapor.

Owner:APPLIED MATERIALS INC

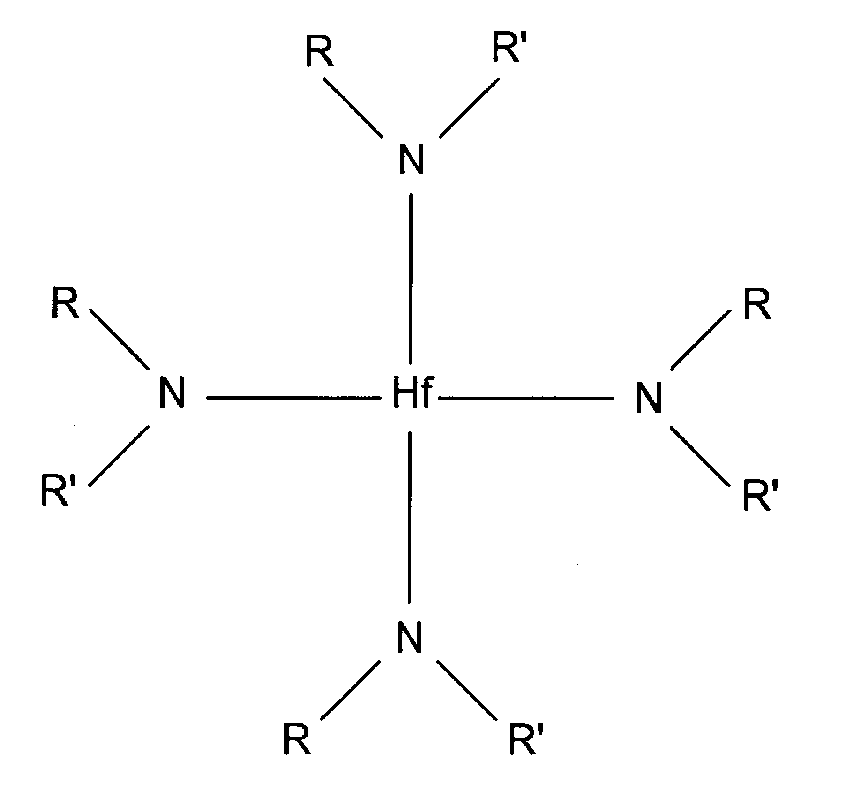

Low zirconium, hafnium-containing compositions, processes for the preparation thereof and methods of use thereof

InactiveUS20060193979A1Improve propertiesDesired morphologyGroup 4/14 organic compounds without C-metal linkagesPretreated surfacesHafniumChemical vapor deposition

This invention relates to hafnium-containing compositions having a zirconium concentration of less than about 500 parts per million, a process for producing the hafnium-containing compositions, organometallic precursor compositions containing a hafnium-containing compound and having a zirconium concentration of less than about 500 parts per million, a process for producing the organometallic precursor compositions, and a method for producing a film or coating from the organometallic precursor compositions. The organometallic precursor compositions are useful in semiconductor applications as chemical vapor deposition (CVD) or atomic layer deposition (ALD) precursors for film depositions.

Owner:PRAXAIR TECH INC

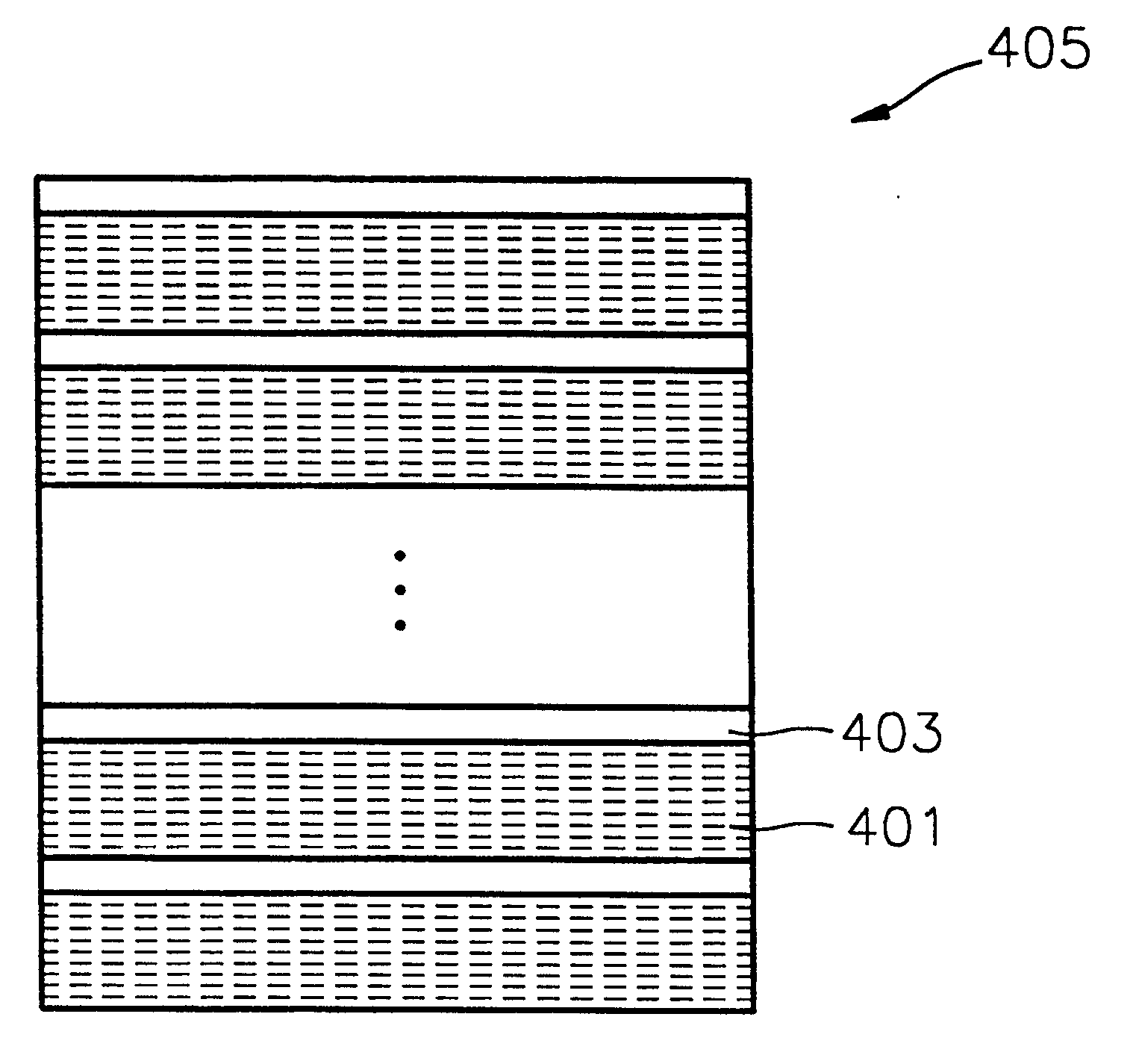

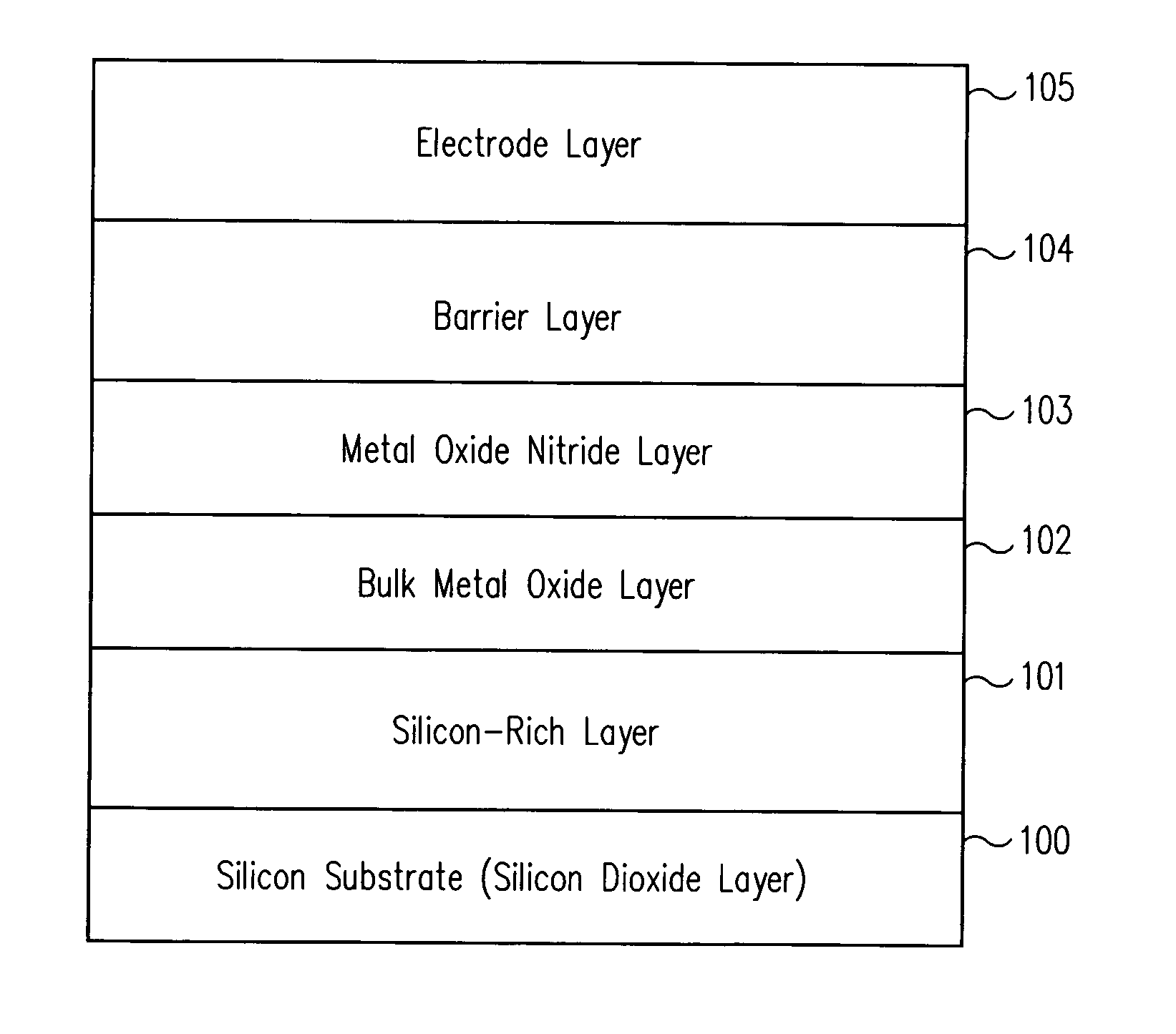

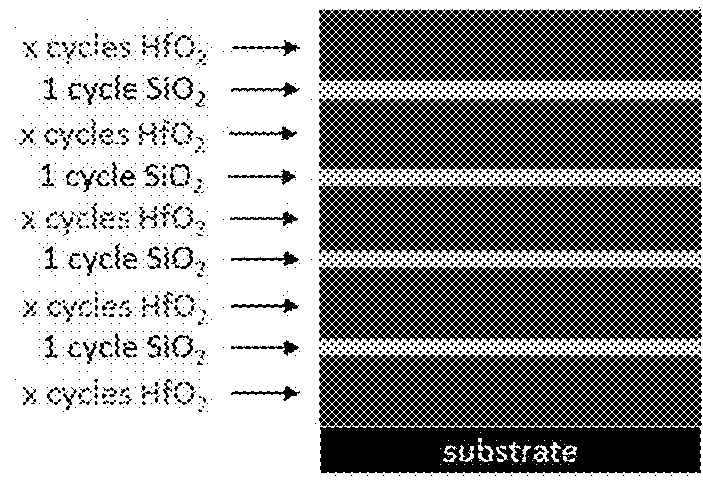

Multilayer multicomponent high-k films and methods for depositing the same

InactiveUS20060264066A1Improve performanceSemiconductor/solid-state device detailsSolid-state devicesDielectricNitrogen

The present invention provides systems and methods for forming a multi-layer, multi-component high-k dielectric film. In some embodiments, the present invention provides systems and methods for forming high-k dielectric films that comprise hafnium, titanium, oxygen, nitrogen, and other components. In a further aspect of the present invention, the dielectric films are formed having composition gradients.

Owner:AVIZA TECHNOLOGY INC

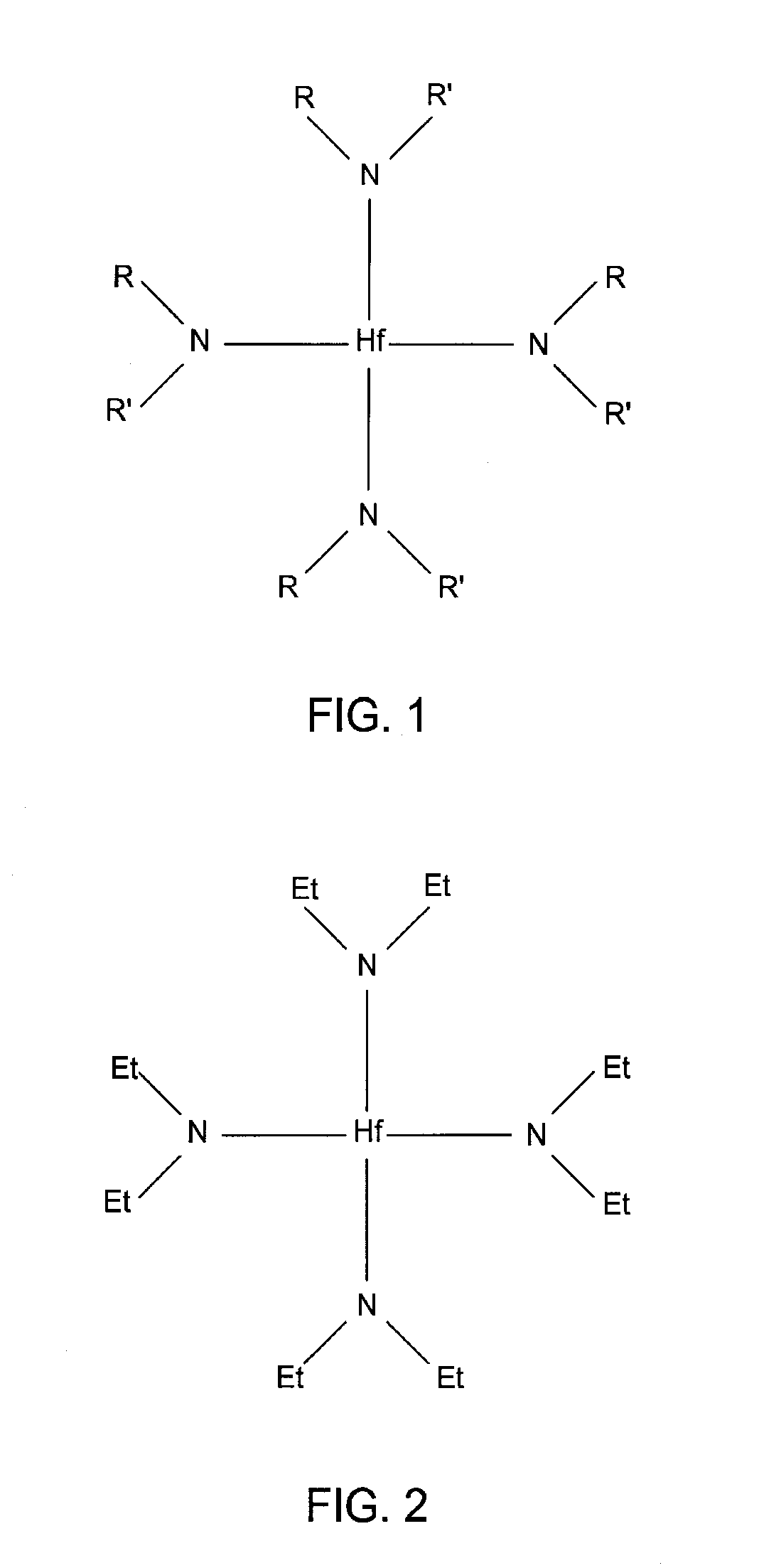

In-situ atomic layer deposition

InactiveUS20070037412A1Improve uniformityImprove electrical performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingWaferingHafnium

An in situ method for forming a HfO2 high-k dielectric layer in a batch wafer processing system. The method comprises first loading a plurality of wafers into a process chamber, and then pre-treating the plurality of wafers in the process chamber with a first oxidizer. After pre-treating the wafers, and without removing the wafers from the process chamber, the method then comprises depositing HfO2 on the plurality of wafers by atomic layer deposition, which comprises a plurality of deposition cycles, each cycle comprising alternating exposure of the plurality of wafers in the process chamber to a second oxidizer and a hafnium precursor. The hafnium precursor is selected from hafnium tert-butoxide (HTB) or hafnium tetra-diethylamide (TDEAH).

Owner:TOKYO ELECTRON LTD

Atomic layer deposition of high k metal silicates

InactiveUS20060228888A1Reduce carbon pollutionReduce stepsSolid-state devicesSemiconductor/solid-state device manufacturingHafniumAtomic layer deposition

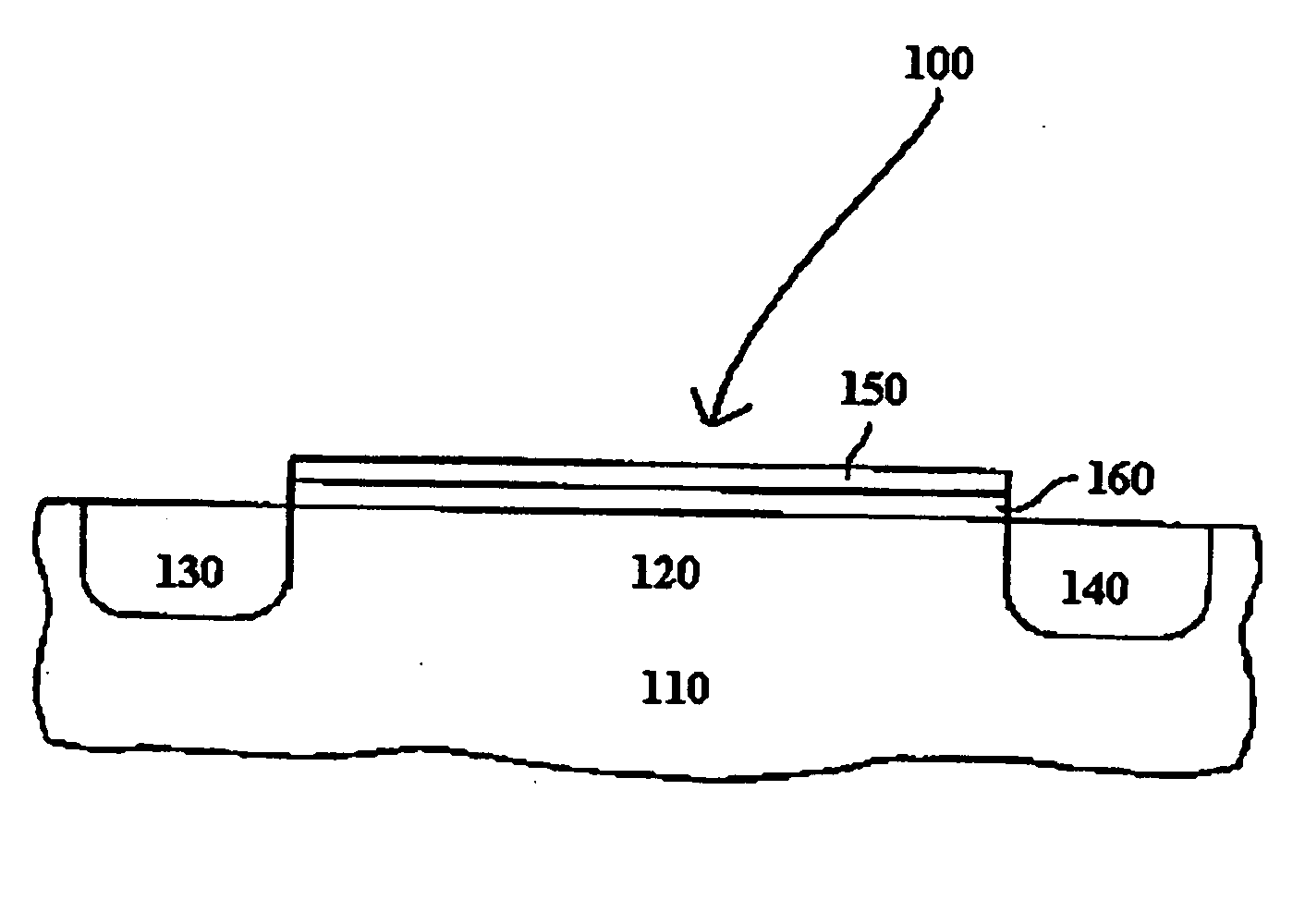

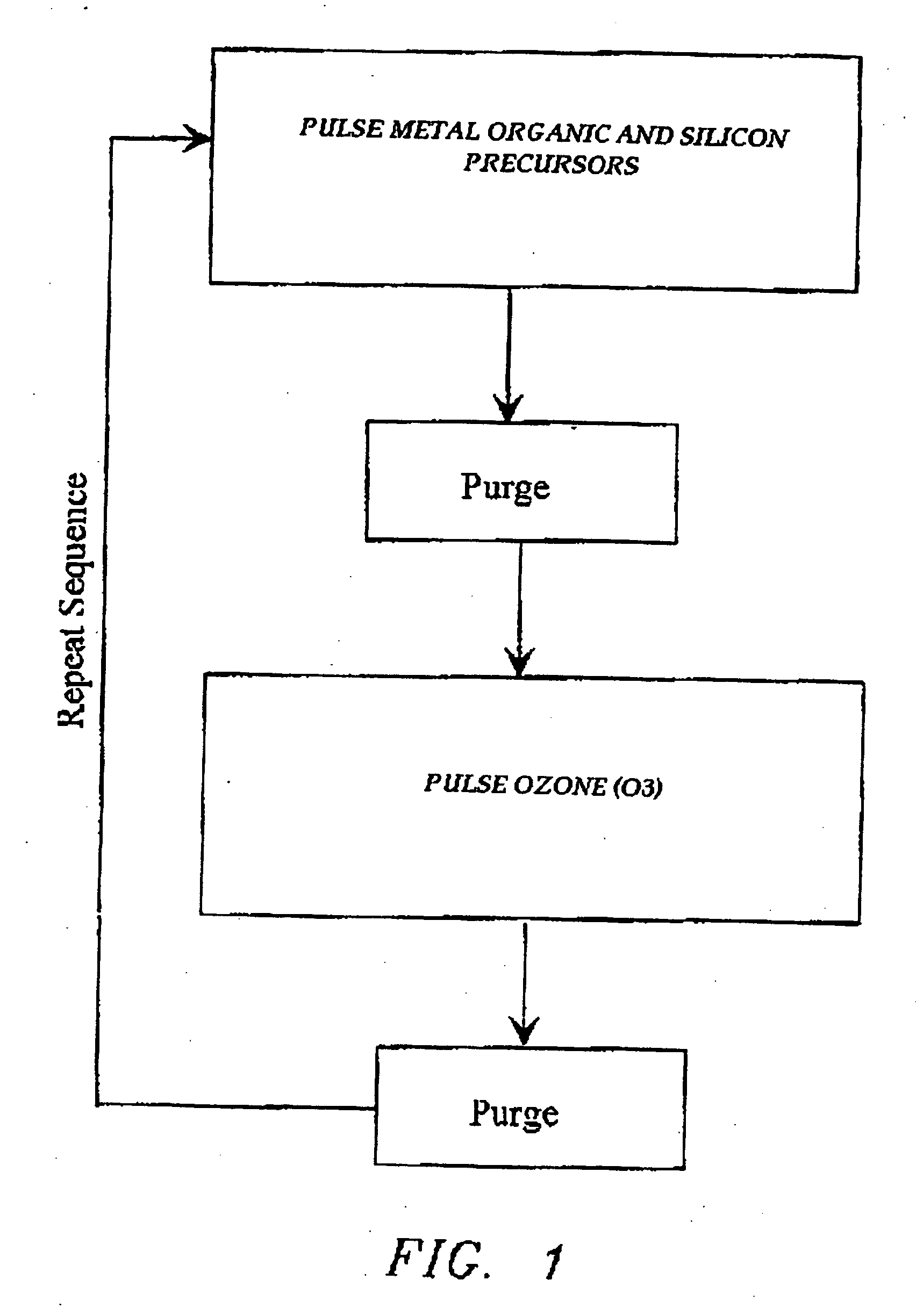

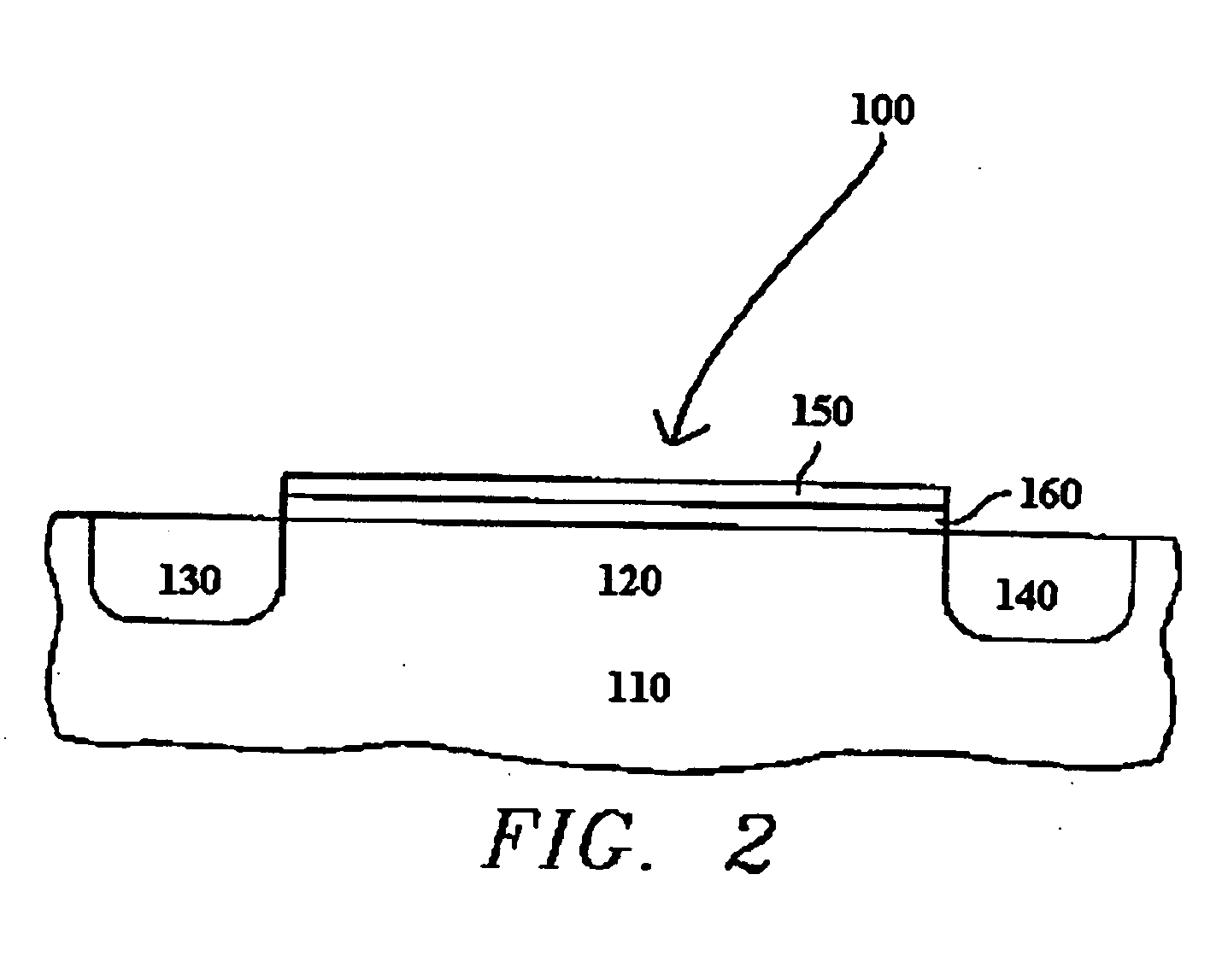

The present invention relates to the atomic layer deposition (“ALD”) of high k dielectric layers of metal silicates, including hafnium silicate. More particularly, the present invention relates to the ALD formation of metal silicates using metal organic precursors, silicon organic precursors and ozone. Preferably, the metal organic precursor is a metal alkyl amide and the silicon organic precursor is a silicon alkyl amide.

Owner:AVIZA TECHNOLOGY INC +1

Pretreatment processes within a batch ALD reactor

InactiveUS7402534B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBatch processingWater vapor

Embodiments of the invention provide methods for forming a material on a substrate which includes exposing a plurality of substrates within a batch process chamber to a first oxidizing gas during a pretreatment process, exposing the substrates sequentially to a precursor and a second oxidizing gas during an ALD cycle and repeating the ALD cycle to form a material on the substrates. In a preferred example, a hafnium precursor is used during the ALD process to form a hafnium-containing material, such as hafnium oxide. In one example, the first and second oxidizing gases are the same oxidizing gases. In a preferred example, the first and second oxidizing gases are different oxidizing gases, such that the pretreatment process contains ozone and the ALD process contains water vapor.

Owner:APPLIED MATERIALS INC

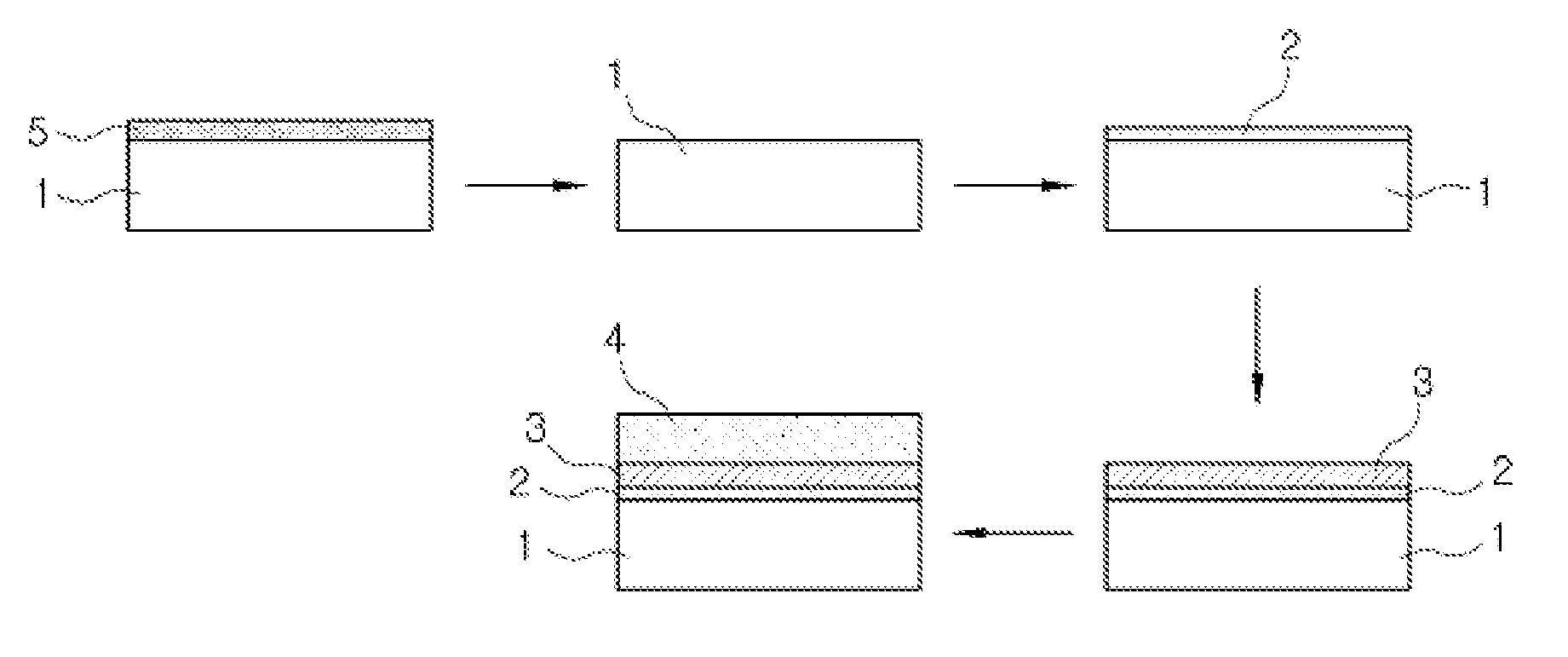

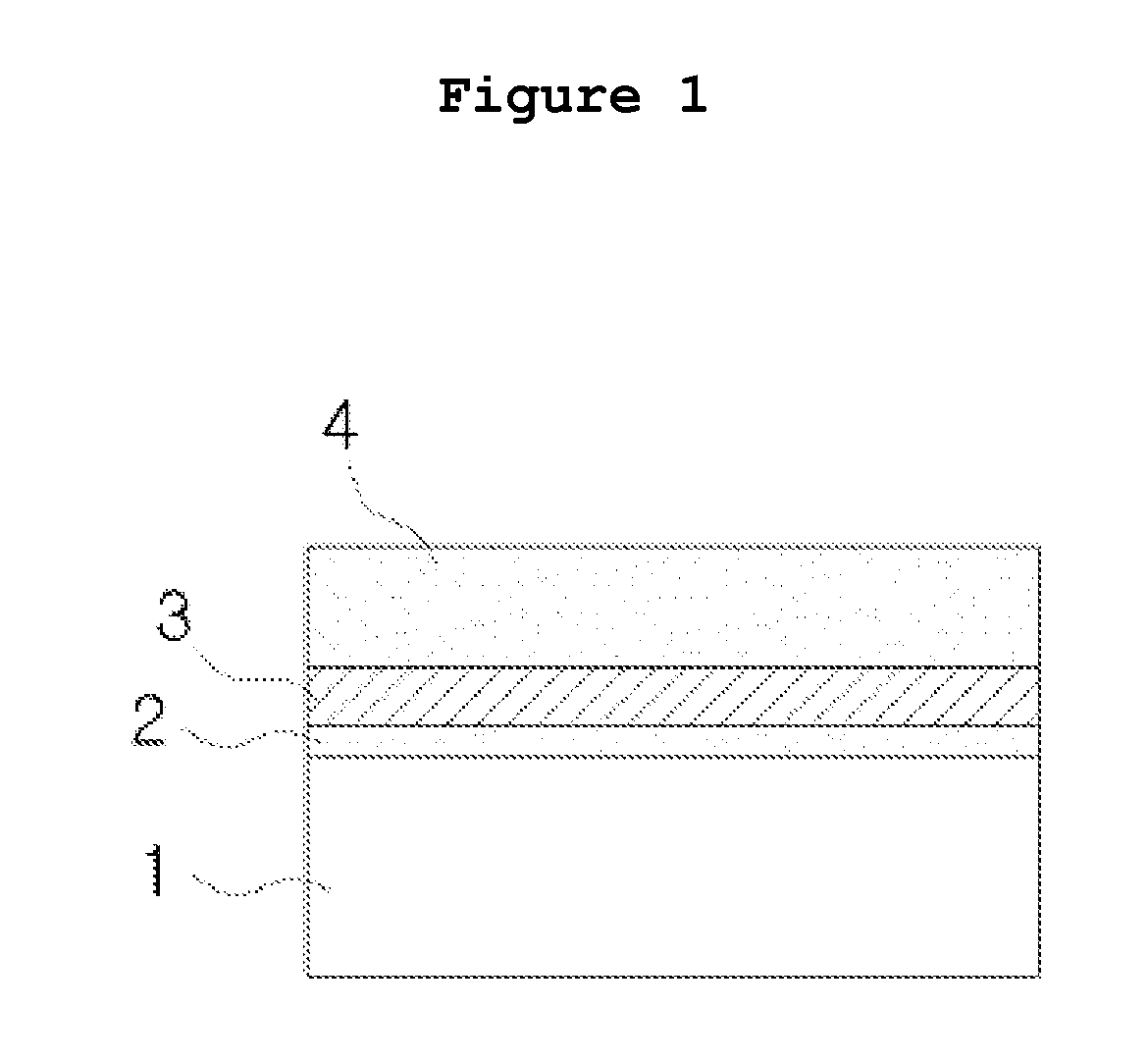

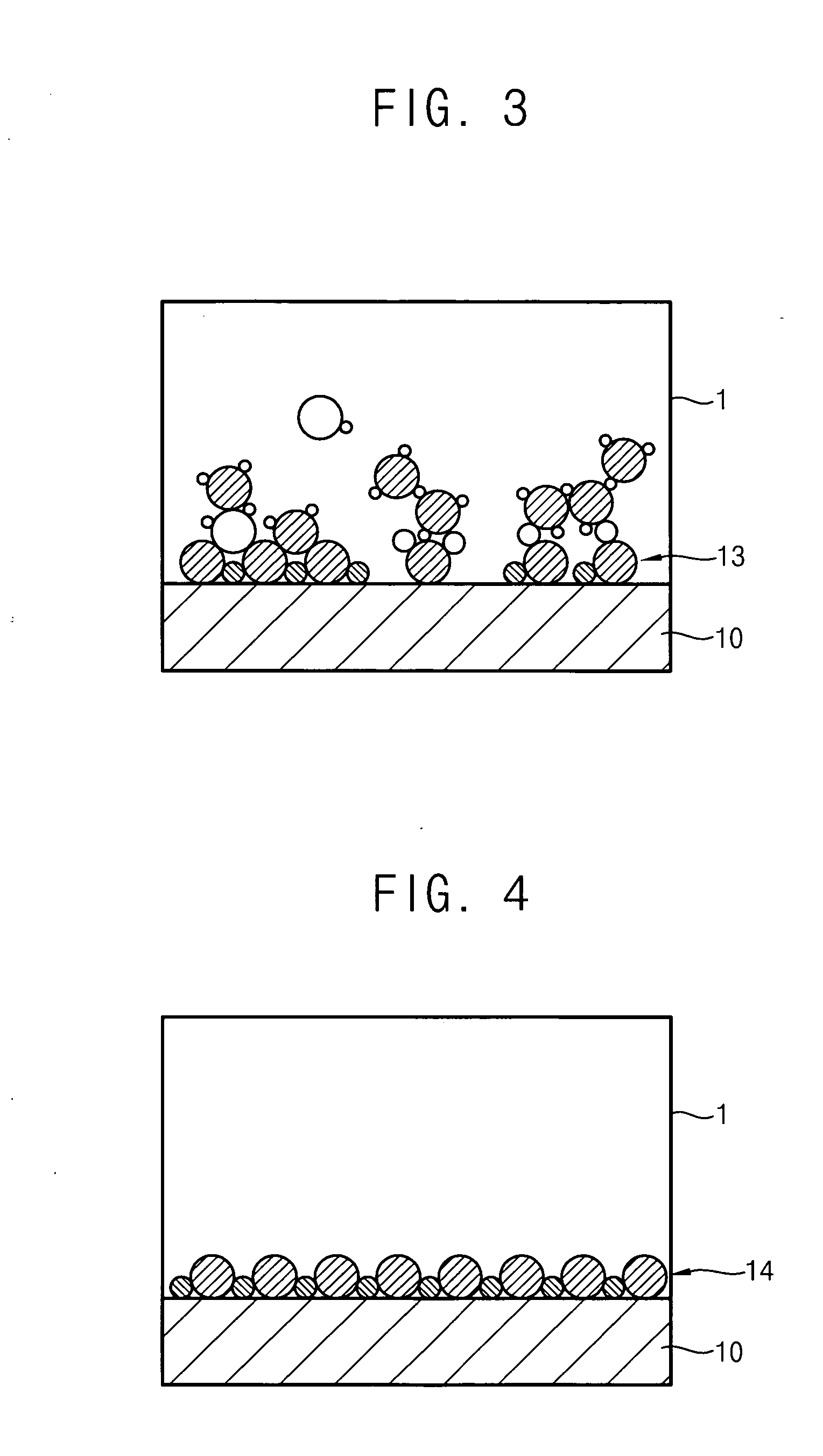

Method of manufacturing charge storage device

InactiveUS7405166B2Increase electrode areaEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceHydrogen fluoride

Owner:IND TECH RES INST

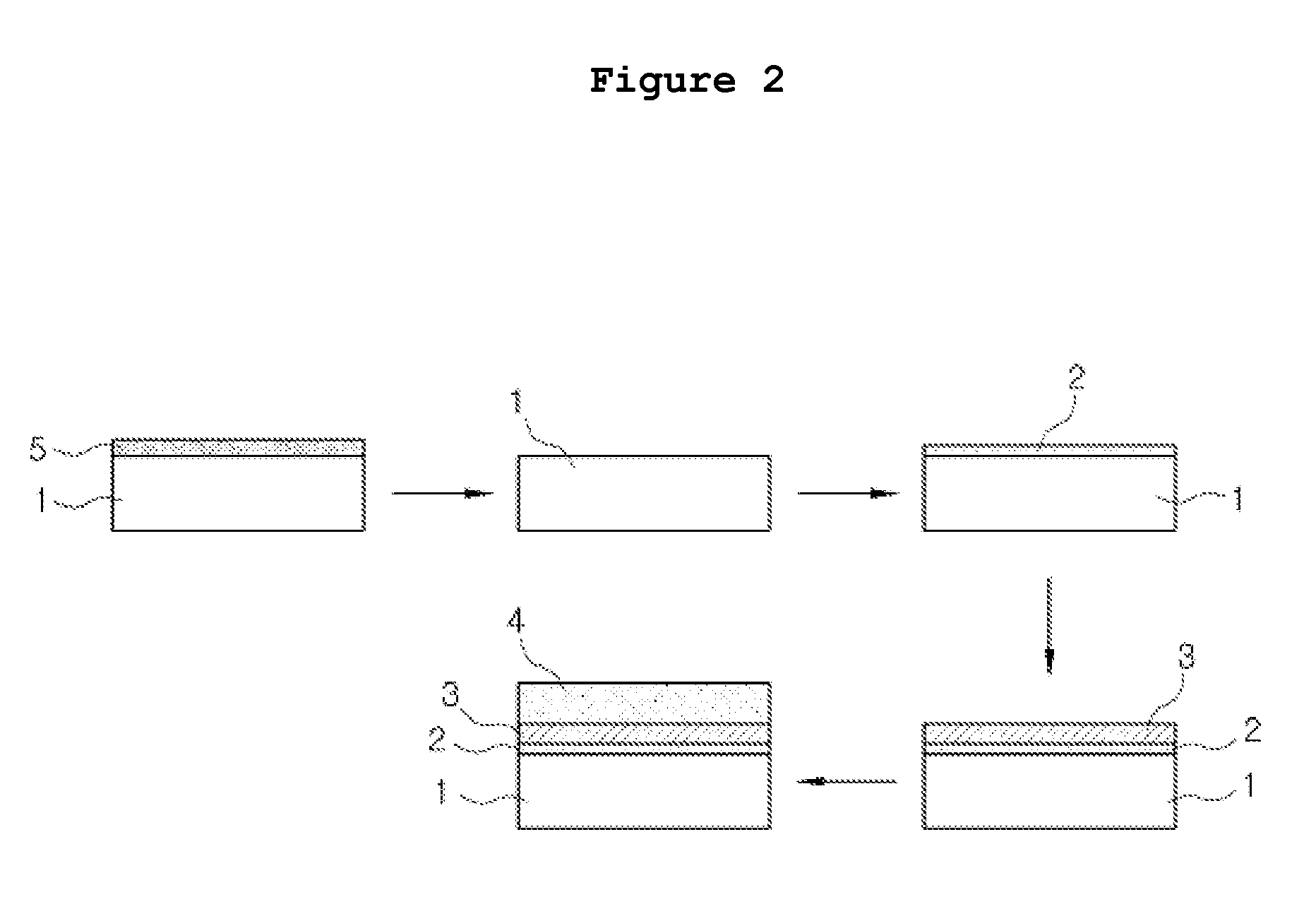

Method of depositing nanolaminate film for non-volatile floating gate memory devices by atomic layer deposition

Disclosed herein is a method of depositing a nanolaminate film for next-generation non-volatile floating gate memory devices by atomic layer deposition. The method includes the steps of: introducing a substrate into an atomic layer deposition reactor; forming on the substrate a first high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source; forming on the first high-dielectric-constant layer a nickel oxide layer by alternately supplying a nickel source and an oxygen source; and forming on the nickel oxide layer a second high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source. The nanolaminate film deposited according to the method shows good memory window characteristics compared to those of memory devices fabricated using nanocrystal floating gates according to the prior physical vapor deposition methods, and thus can be applied to non-volatile floating gate memory devices.

Owner:KOREA RES INST OF CHEM TECH

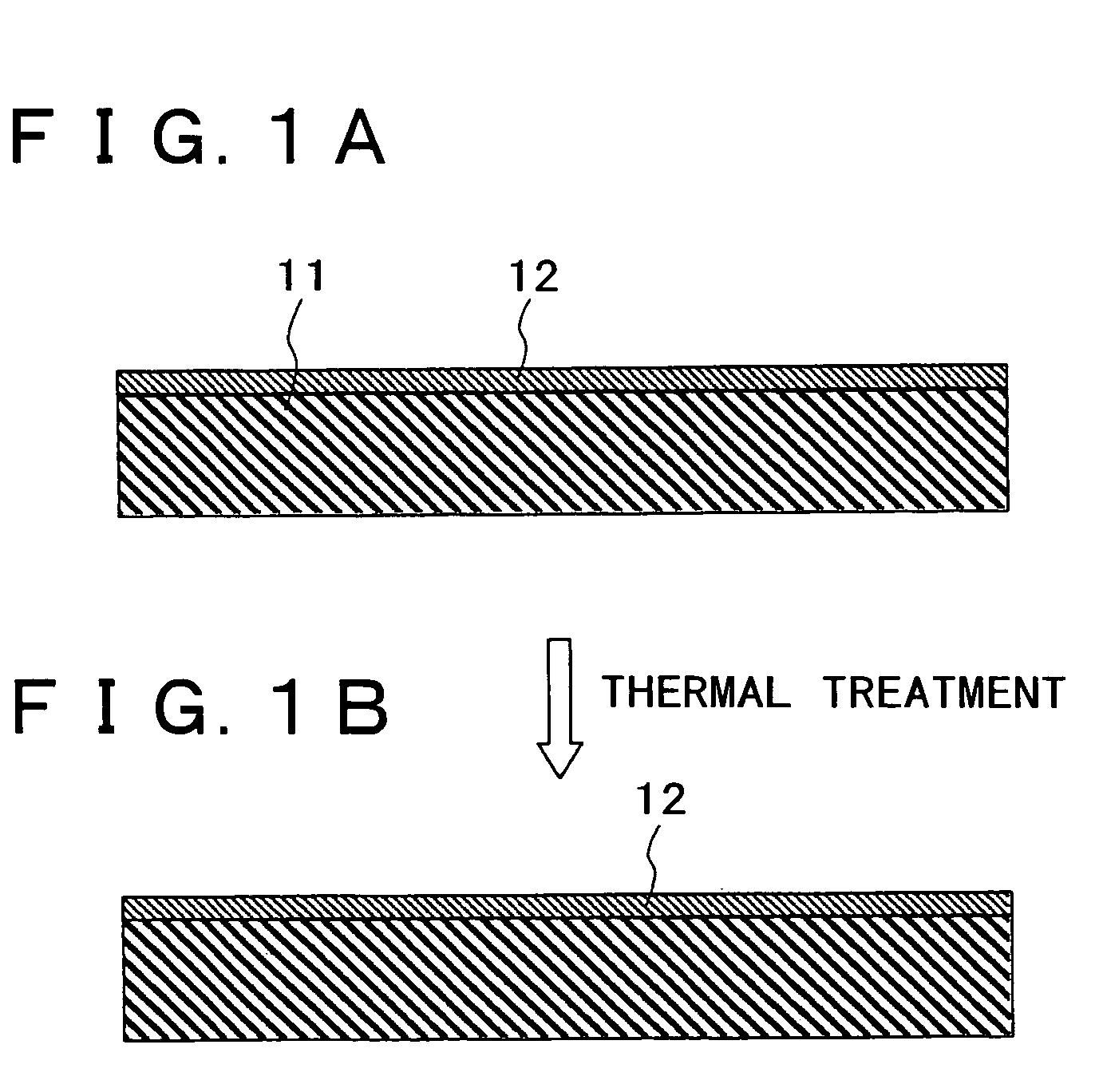

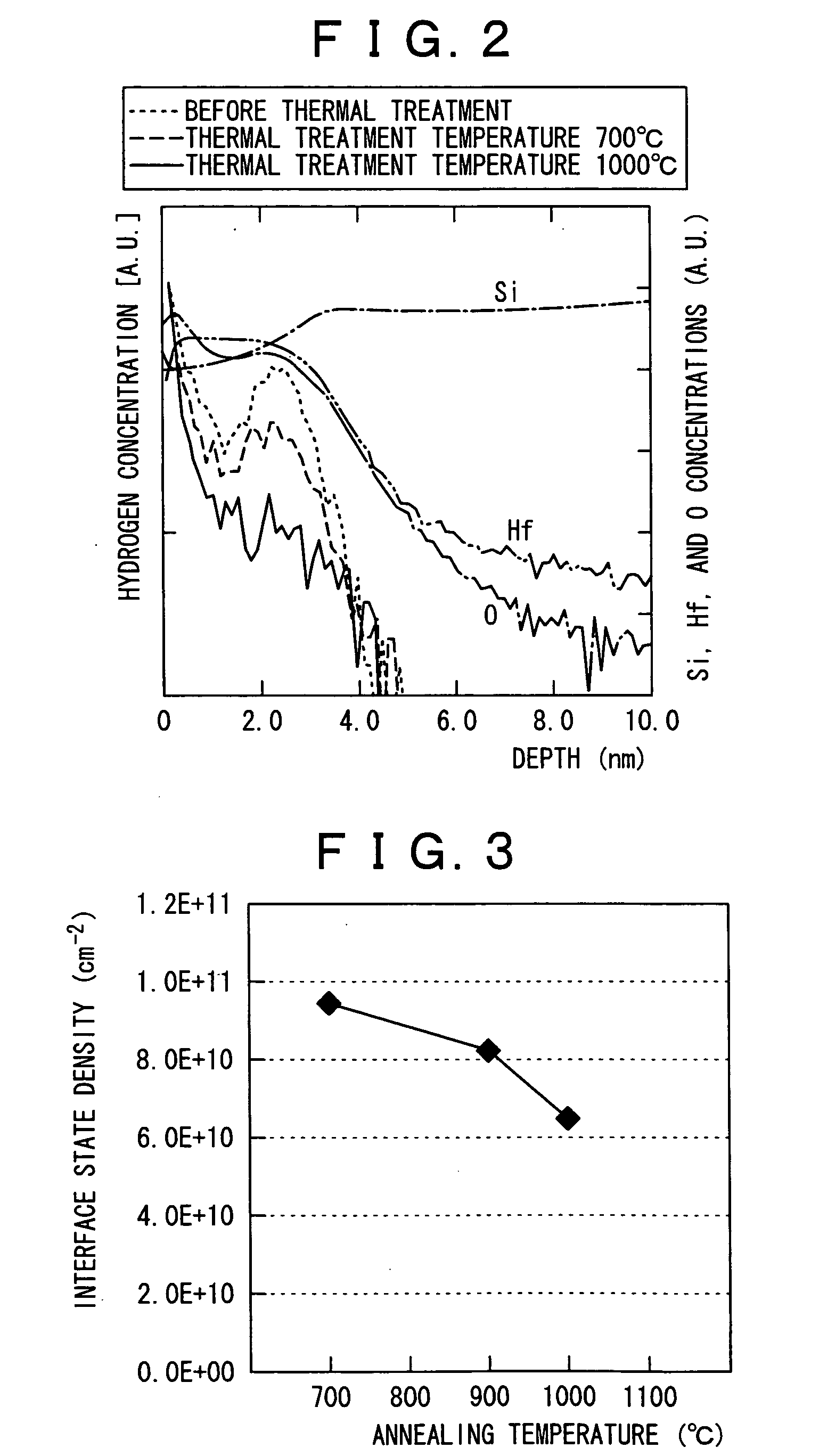

Method for forming a thin film and method for fabricating a semiconductor device

InactiveUS20050070123A1Improve mobility and reliabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricHafnium

By conducting a high temperature annealing in a nitrogen atmosphere at a temperature at which a hafnium silicate film undergoes no phase separation, hydrogen contained in the film is removed and prevention of boron penetration is made possible. The present invention provides a method for forming a thin film including a step of forming a hafnium silicate film on a substrate by an atomic layer deposition method and a step of carrying out thermal treatment on the hafnium silicate film at a thermal treatment temperature equal to or higher than a temperature at which hydrogen contained in the hafnium silicate film is removed and lower than a temperature at which the hafnium silicate film undergoes no phase separation, and a method for fabricating a semiconductor device for forming a gate dielectric film using the method for forming a thin film.

Owner:SONY CORP

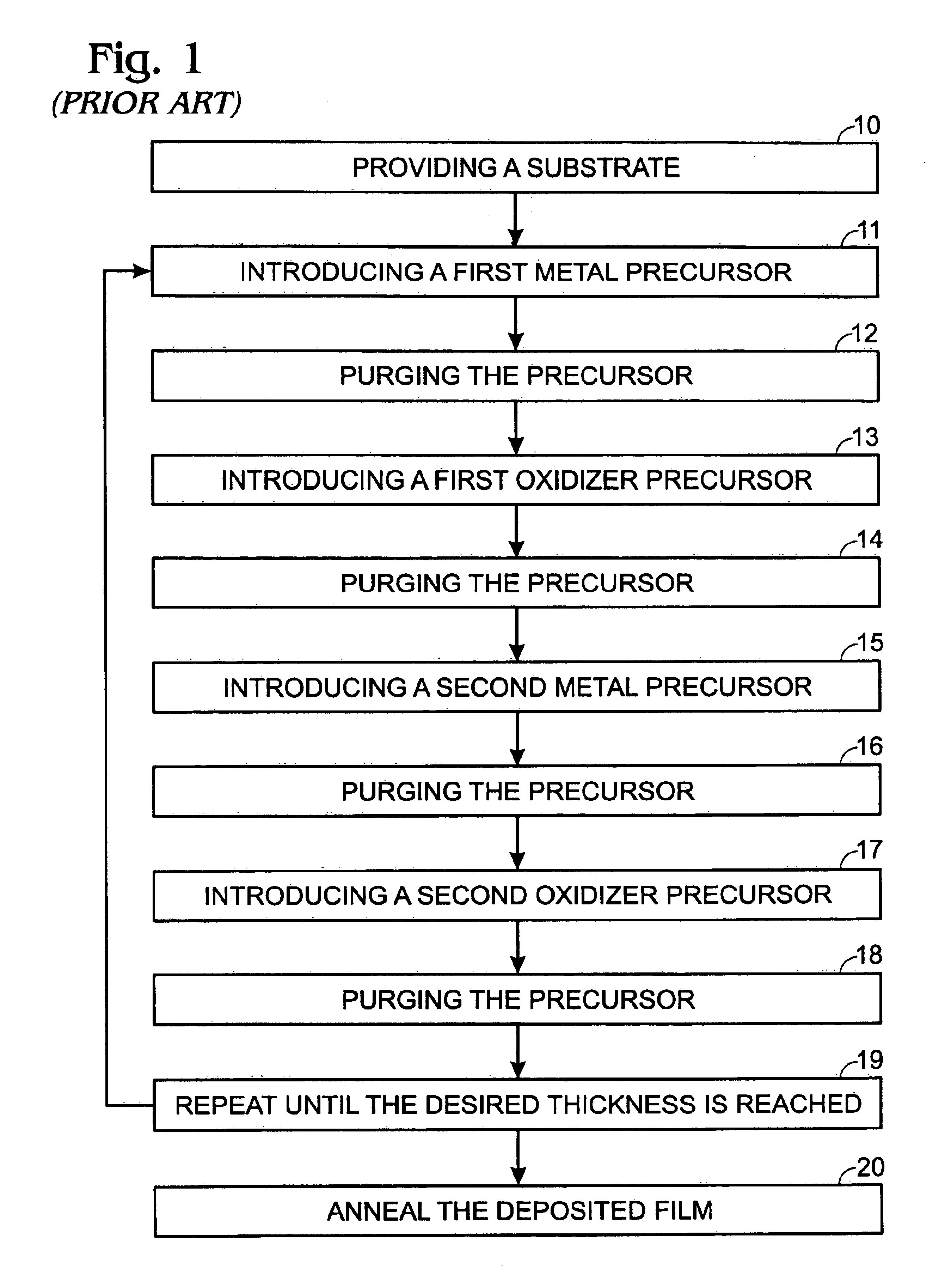

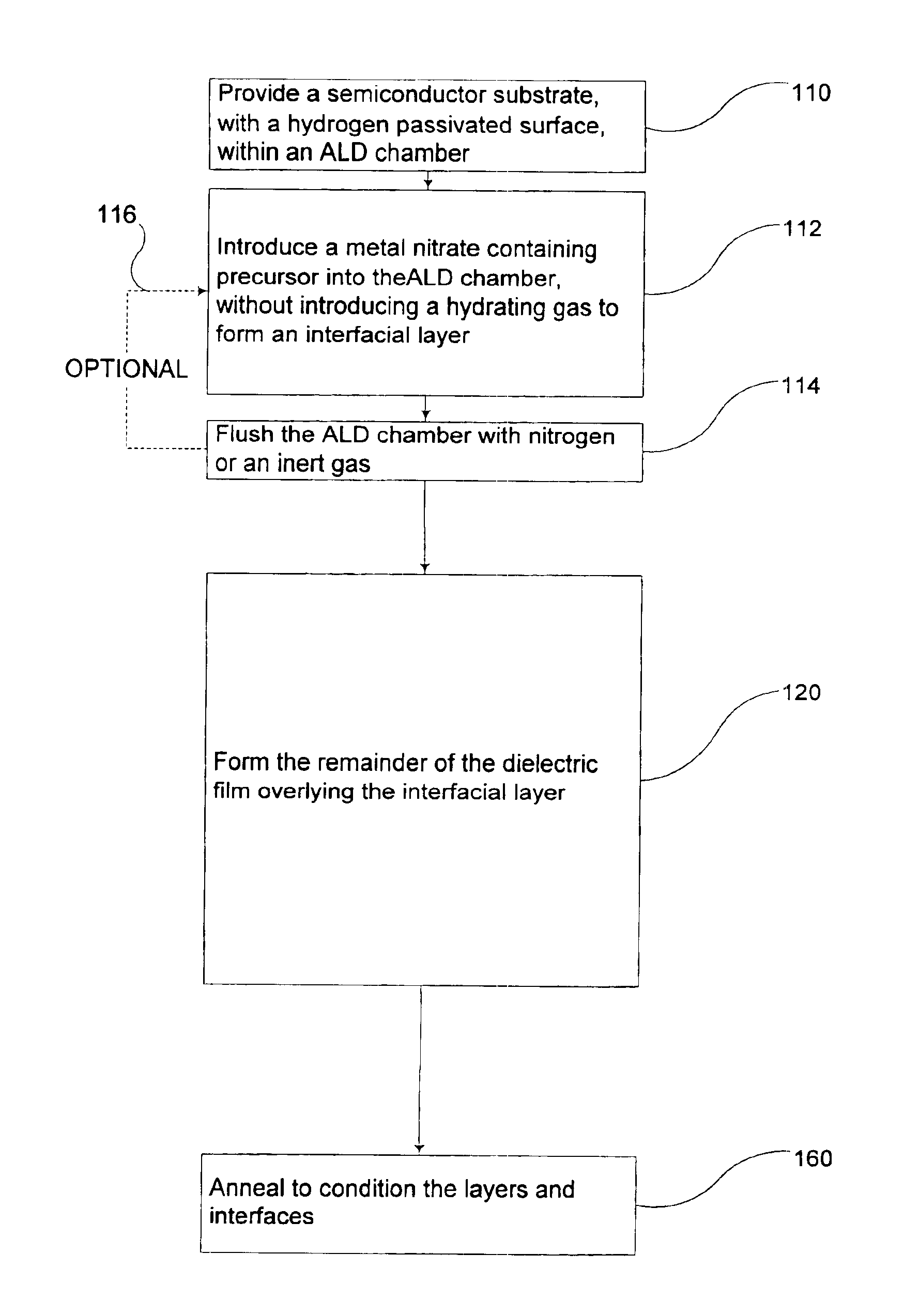

Method to control the interfacial layer for deposition of high dielectric constant films

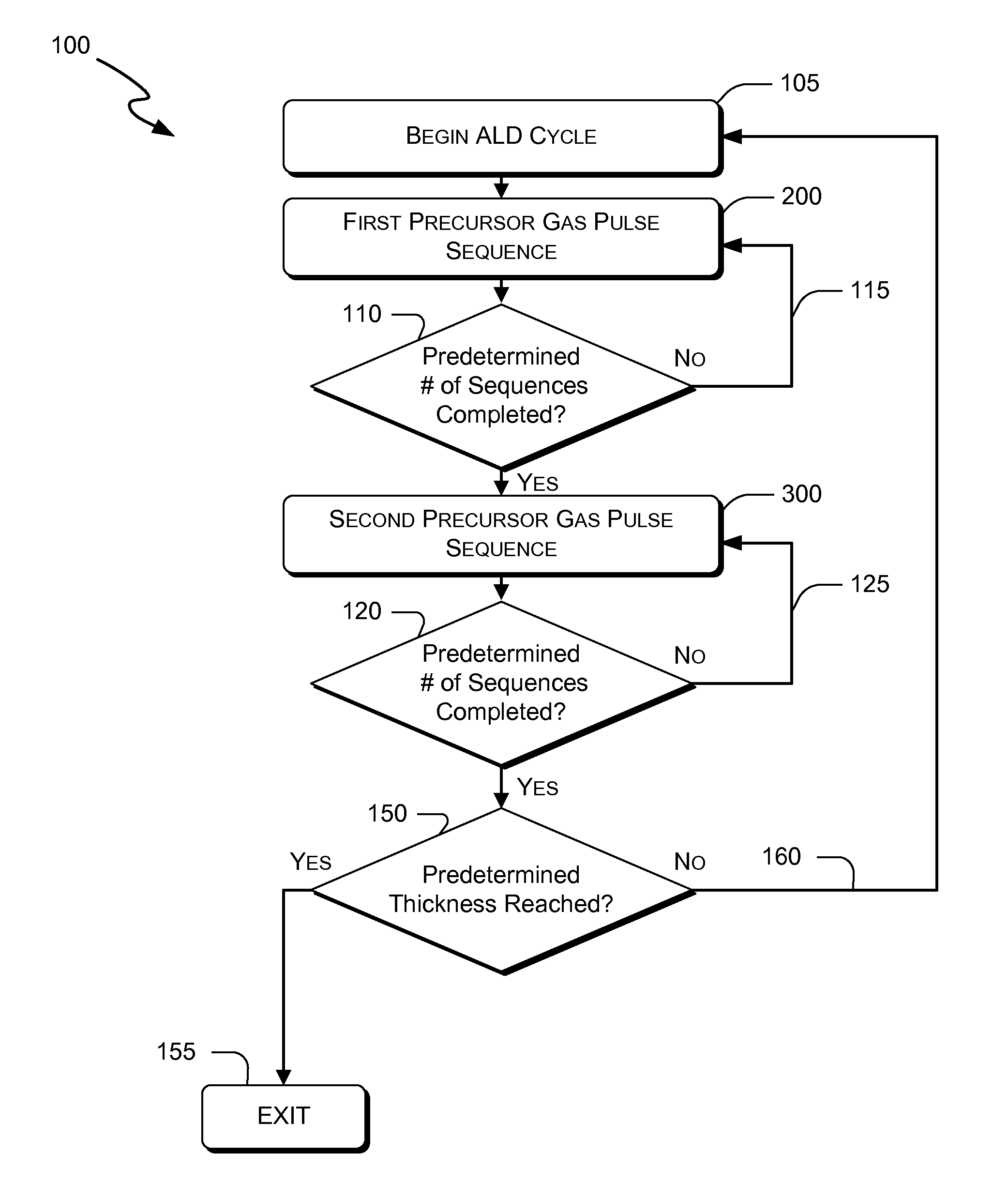

Methods of forming an interfacial layer on a hydrogen-passivated substrate are provided. These methods utilize atomic layer deposition techniques incorporating metal nitrate-based precursors, such as hafnium nitrate or zirconium nitrate, without introducing a hydrating agent, or oxidizing agent, such as water, during the formation of the interfacial layer. Also provided are methods of forming high-k films, by first forming an interfacial layer on the surface of a hydrogen-passivated substrate, and then depositing one, or more, high-k dielectric films.

Owner:SHARP LAB OF AMERICA INC

Atomic layer deposition of hafnium lanthanum oxides

There is provided an improved method for depositing thin films using precursors to deposit binary oxides by atomic layer deposition (ALD) techniques. Also disclosed is an ALD method for depositing a high-k dielectric such as hafnium lanthanum oxide (HfLaO) on a substrate. Embodiments of the present invention utilize a combination of ALD precursor elements and cycles to deposit a film with desired physical and electrical characteristics. Electronic components and systems that integrate devices fabricated with methods consistent with the present invention are also disclosed.

Owner:ASM IP HLDG BV

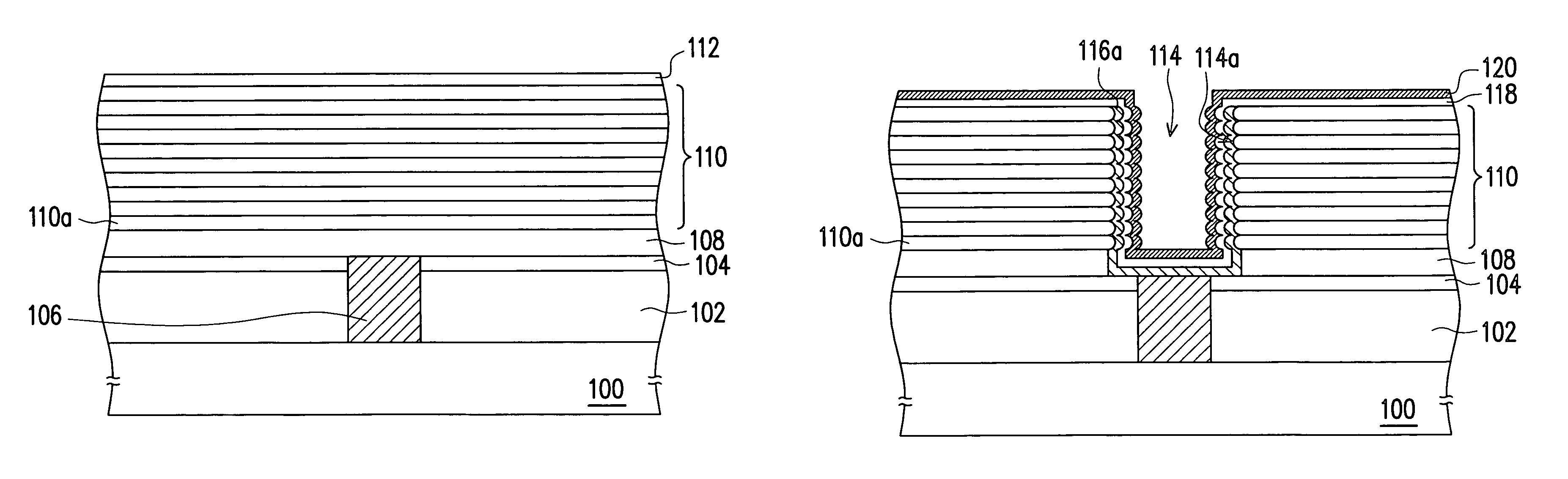

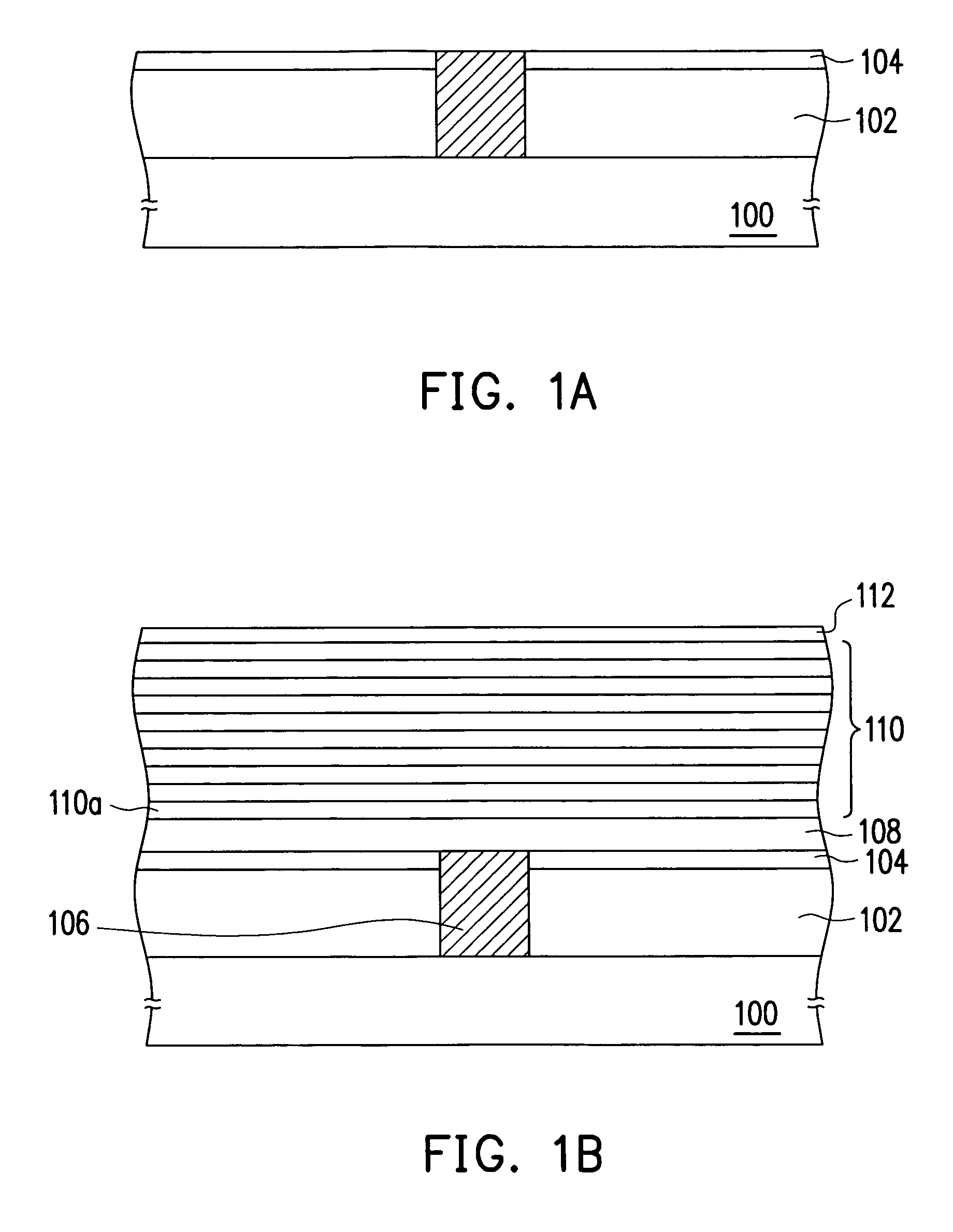

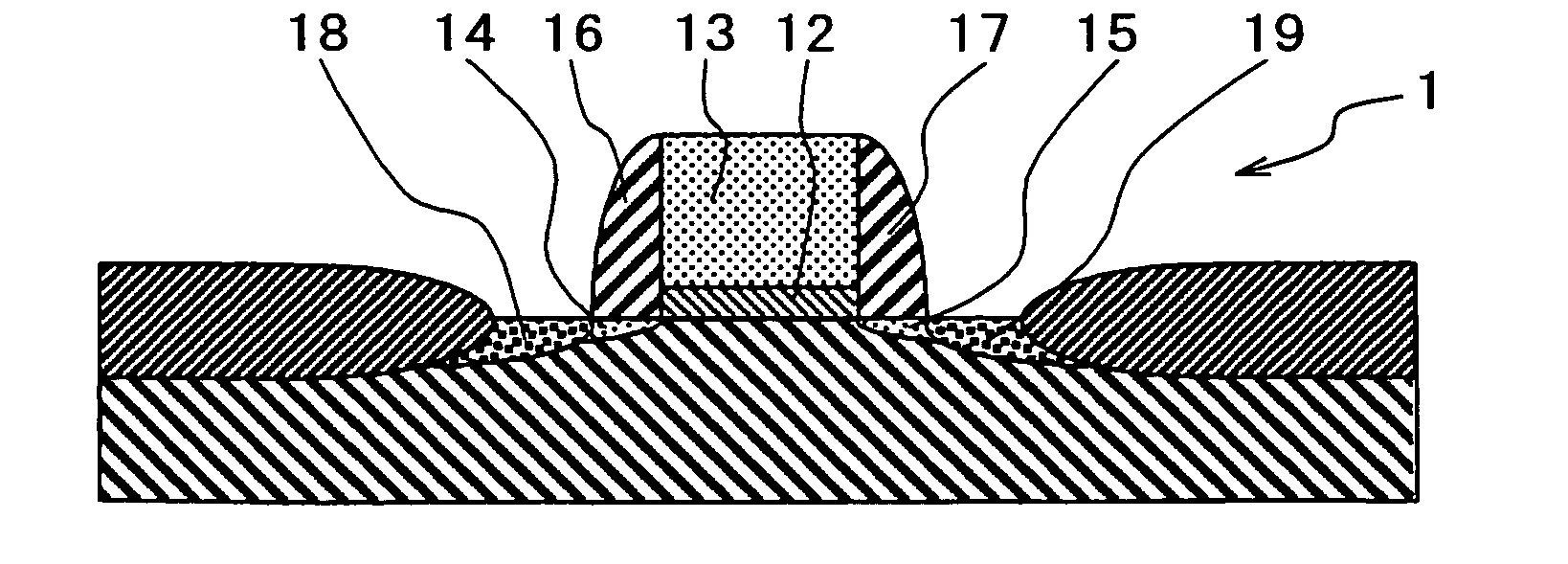

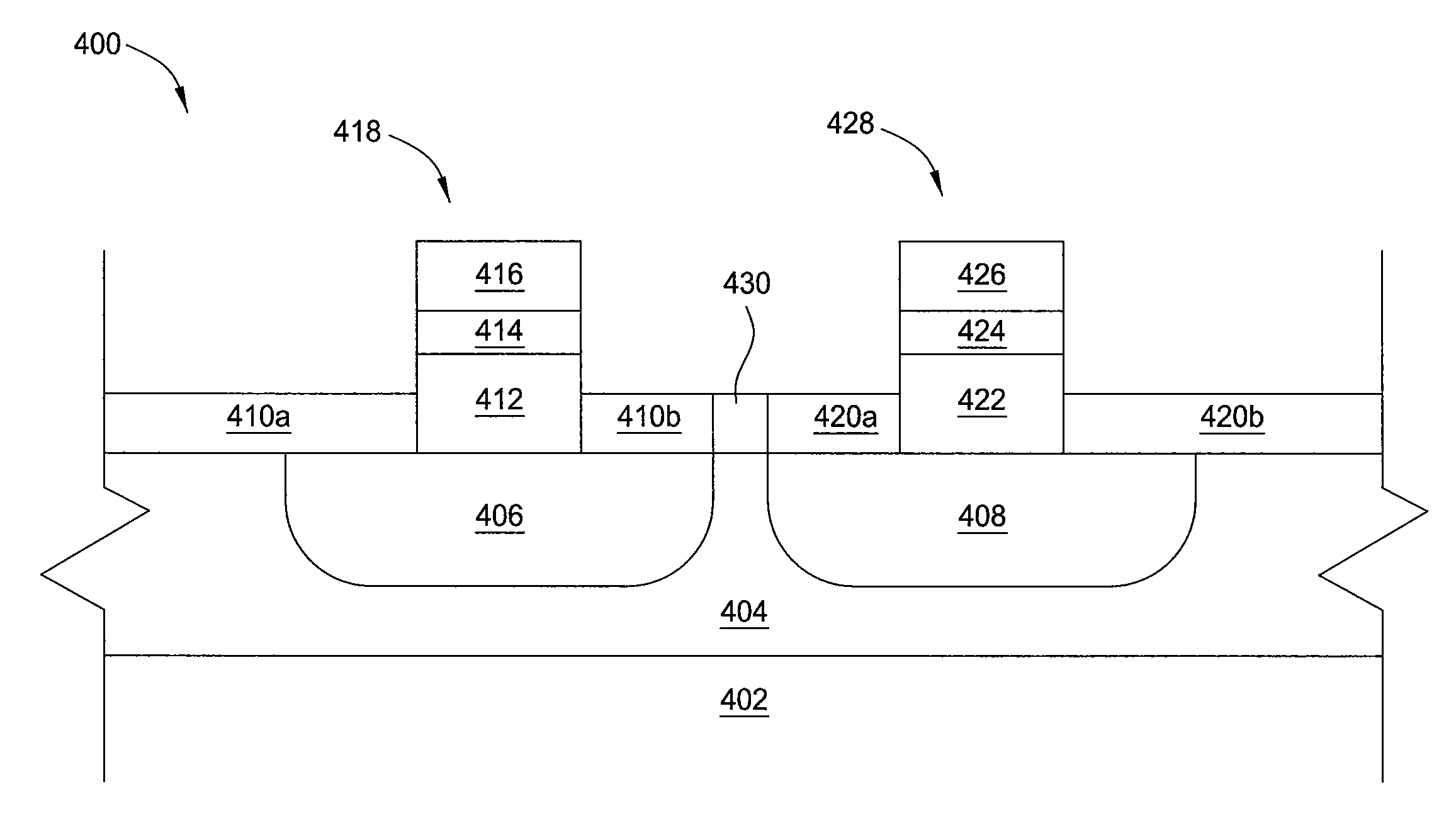

Method of manufacturing semiconductor device

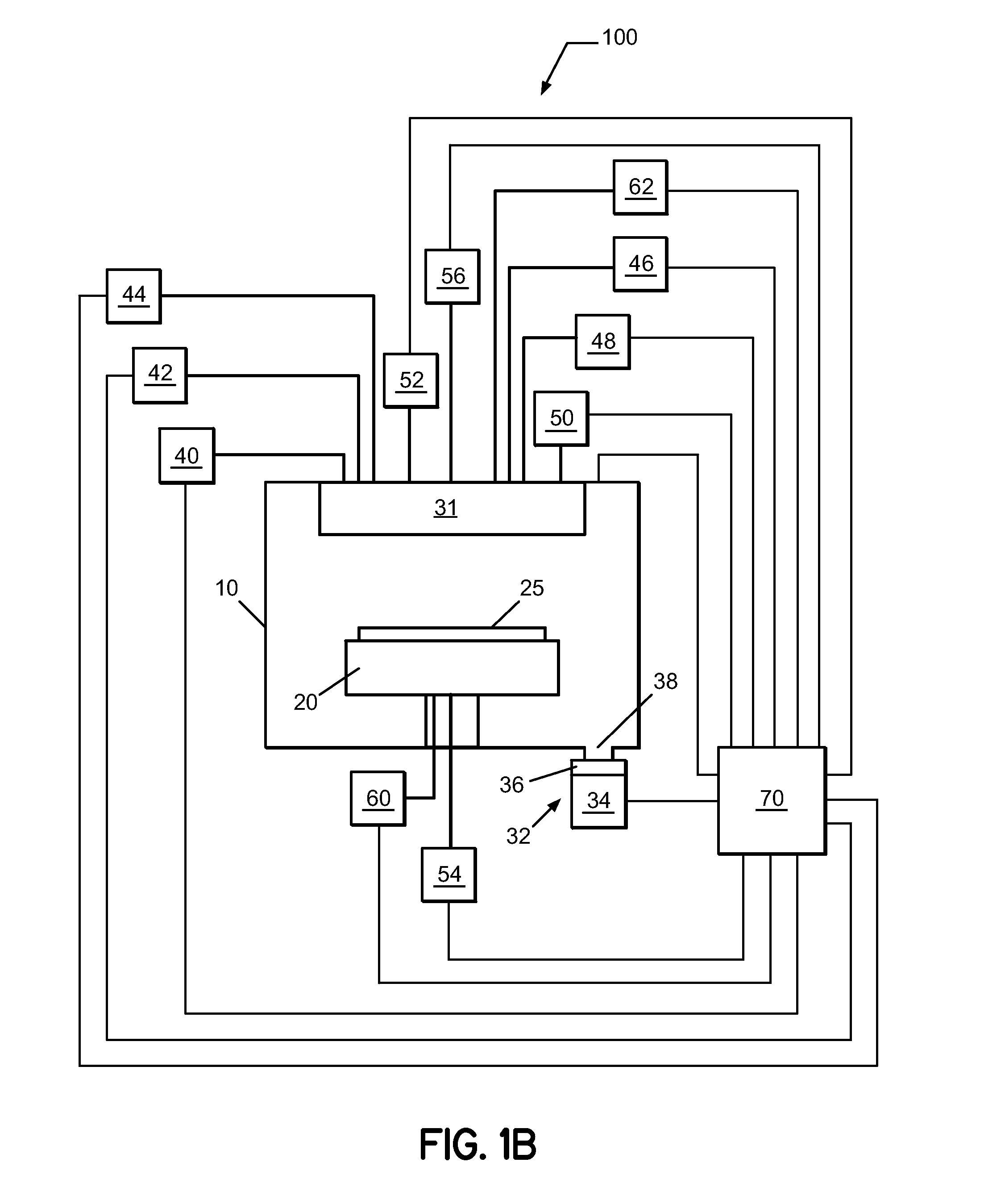

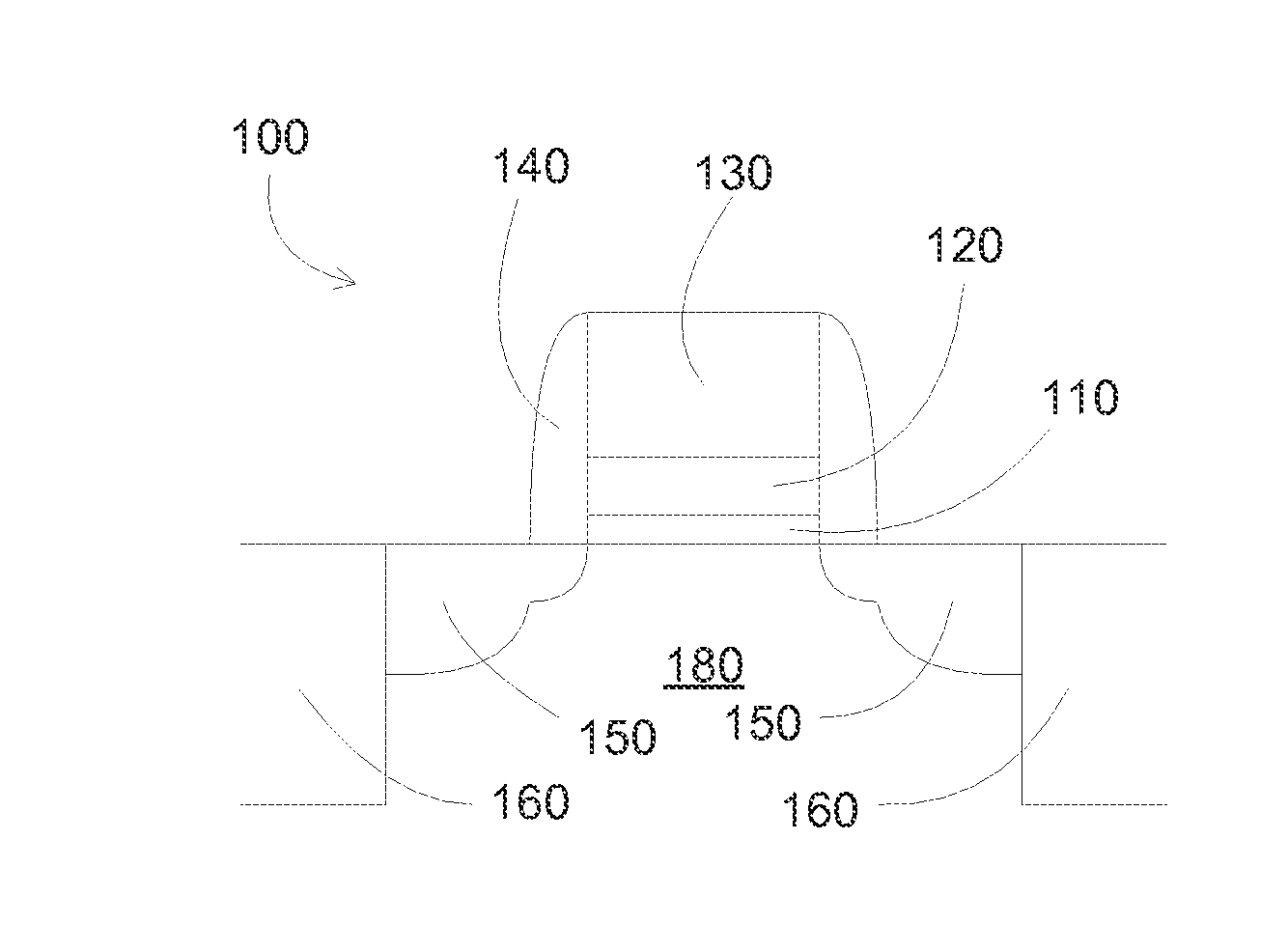

InactiveUS20070066010A1Good step coverageReduce leakage levelTransistorSolid-state devicesDevice materialEvaporation

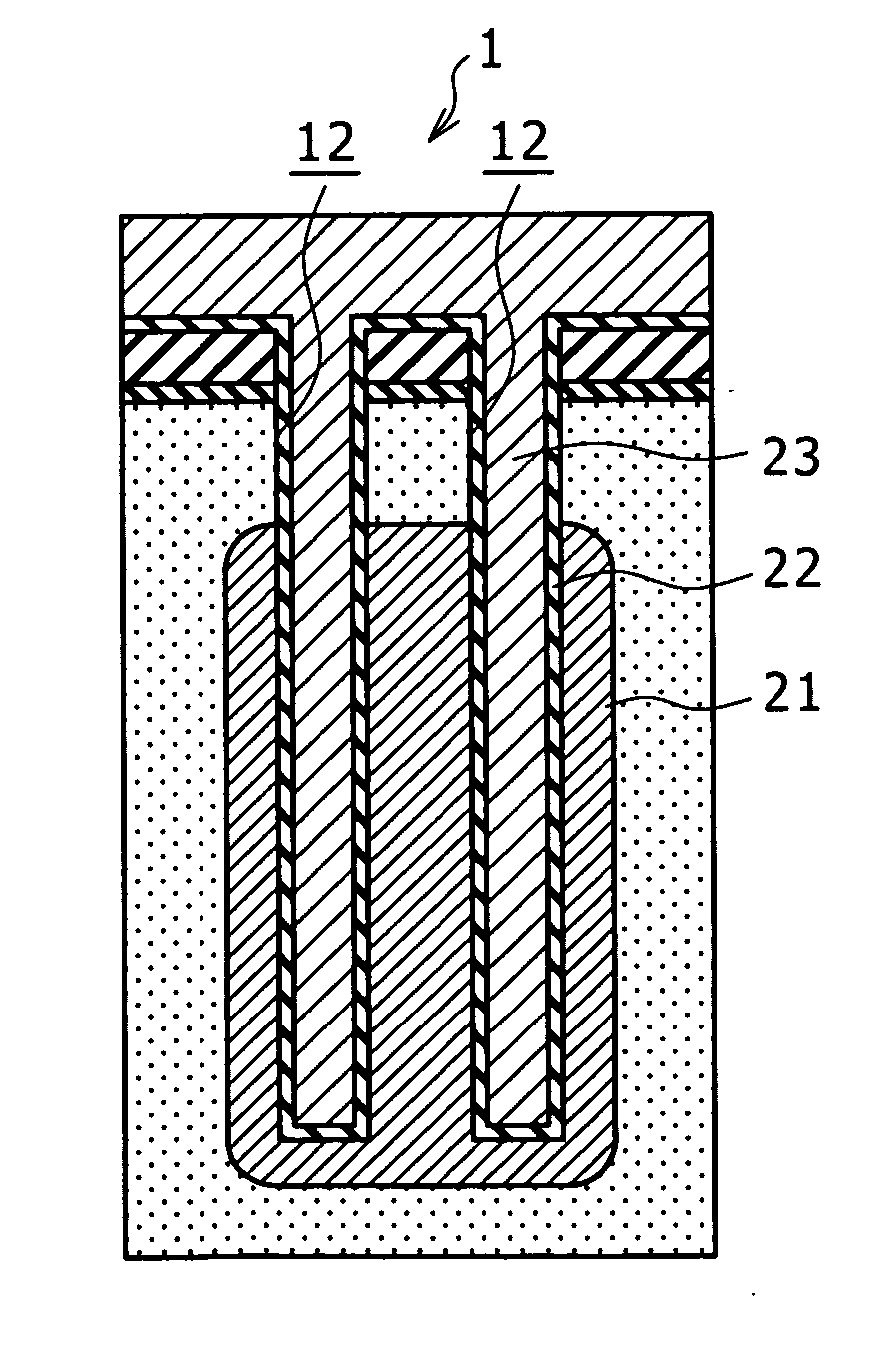

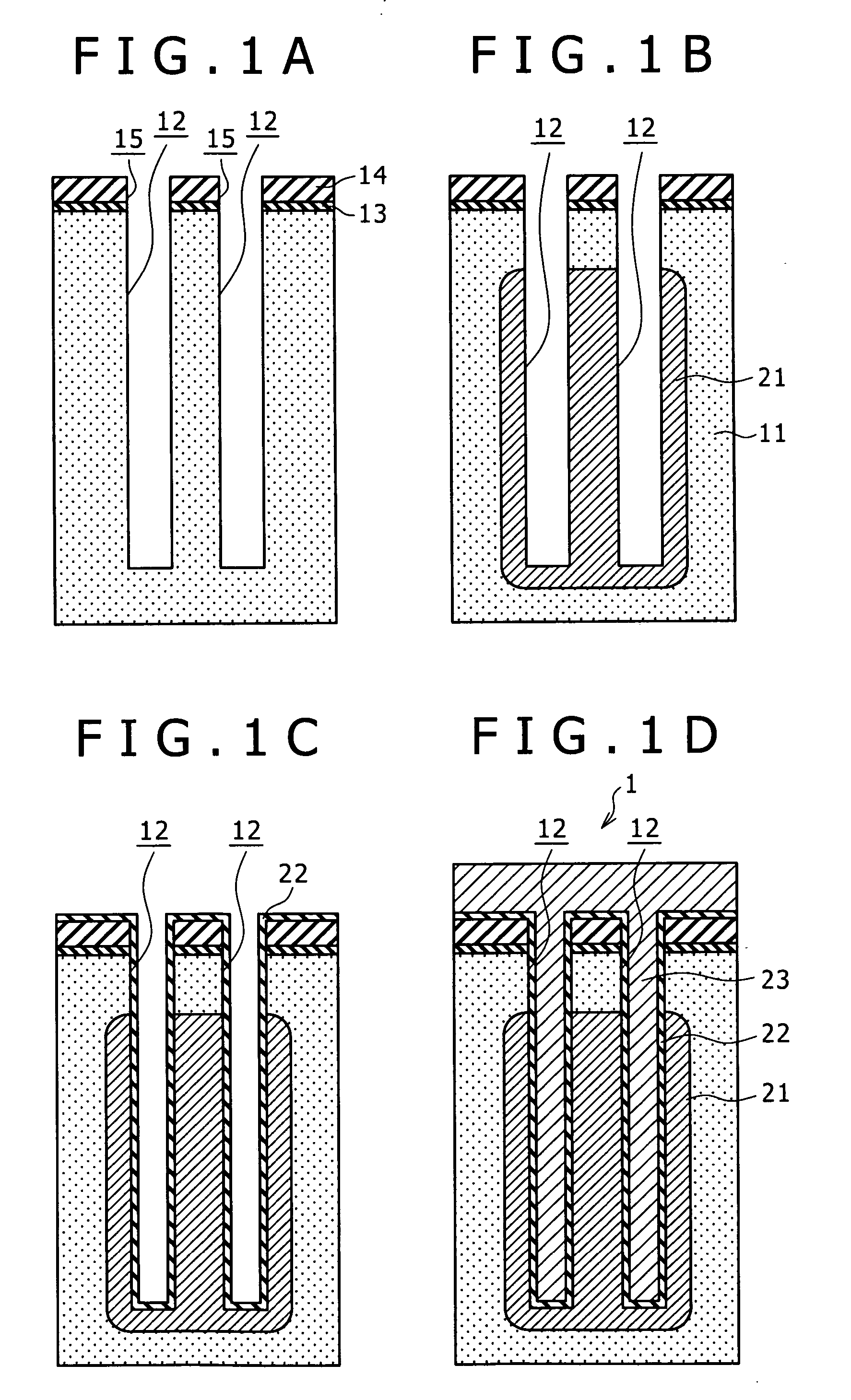

The invention aims at enabling leakage current characteristics and a step coverage property to be improved by depositing a hafnium silicate film by utilizing an atomic layer evaporation method using a hafnium raw material, a silicon raw material and an oxidizing agent. Disclosed herein is a method of manufacturing a semiconductor device having a trench capacitor including a first electrode formed on an inner surface of a trench, a capacitor insulating film formed on a surface of the first electrode, and a second electrode formed on a surface of the capacitor insulating film. The method includes the step of depositing the capacitor insulating film in a form of a hafnium silicate film by utilizing an atomic layer deposition method using a hafnium raw material, a silicon raw material and an oxidizing agent.

Owner:SONY CORP

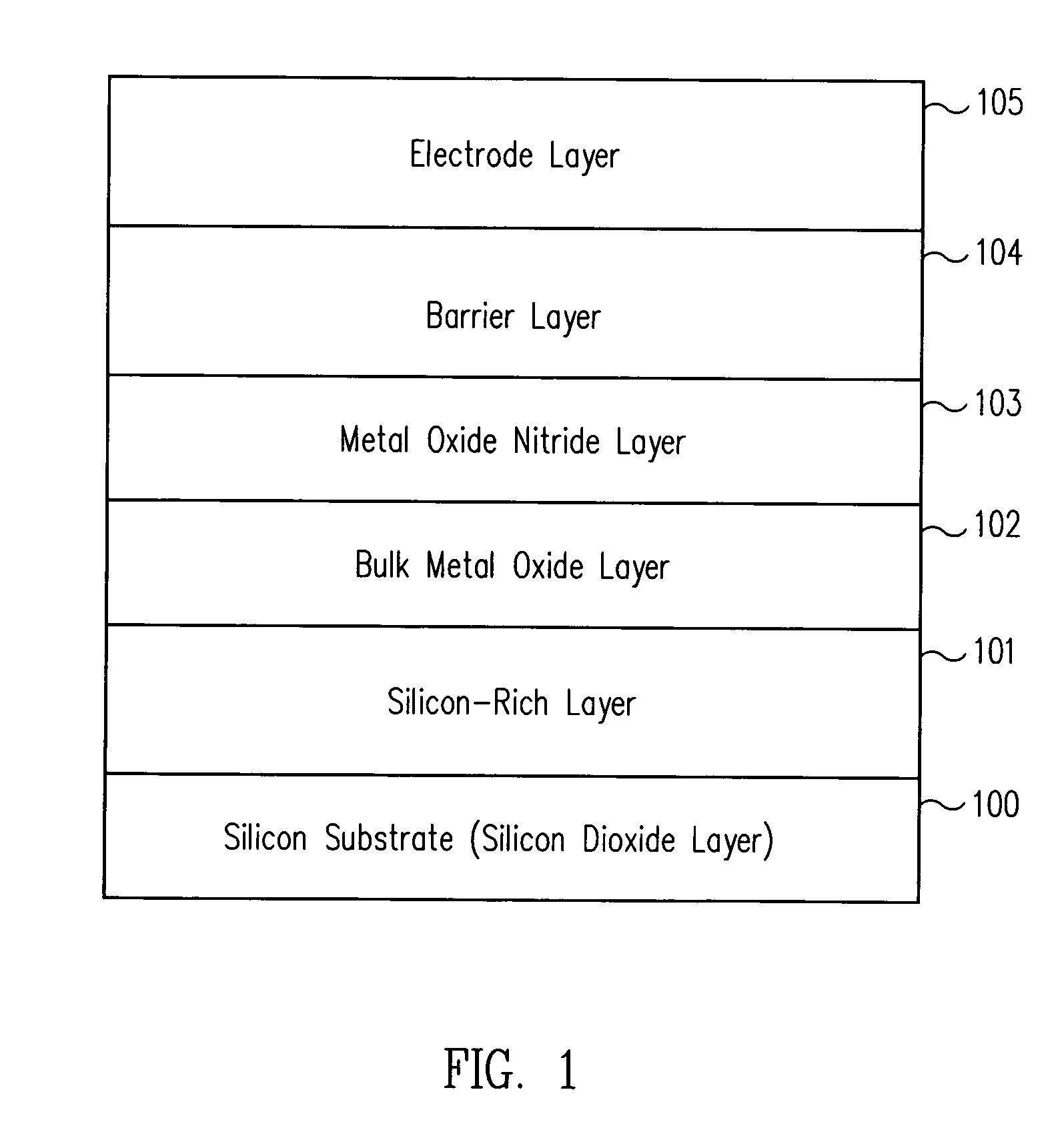

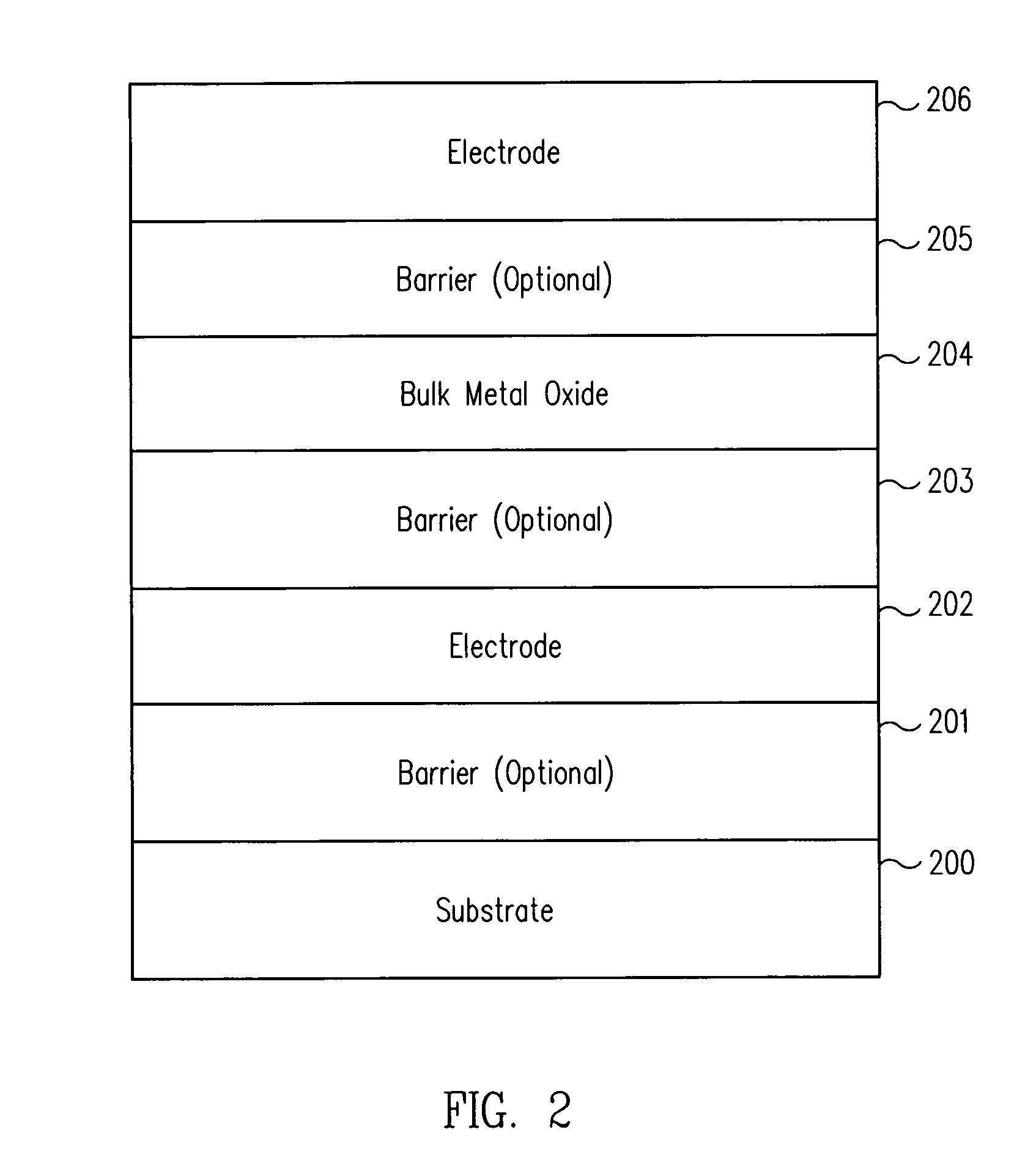

Atomic layer deposition of metal oxynitride layers as gate dielectrics

InactiveUS20060051925A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricHafnium

A metal oxynitride layer formed by atomic layer deposition of a plurality of reacted monolayers, the monolayers comprising at least one each of a metal, an oxide and a nitride. The metal oxynitride layer is formed from zirconium oxynitride, hafnium oxynitride, tantalum oxynitride, or mixtures thereof. The metal oxynitride layer is used in gate dielectrics as a replacement material for silicon dioxide. A semiconductor device structure having a gate dielectric formed from a metal oxynitride layer is also disclosed.

Owner:AHN KIE Y +1

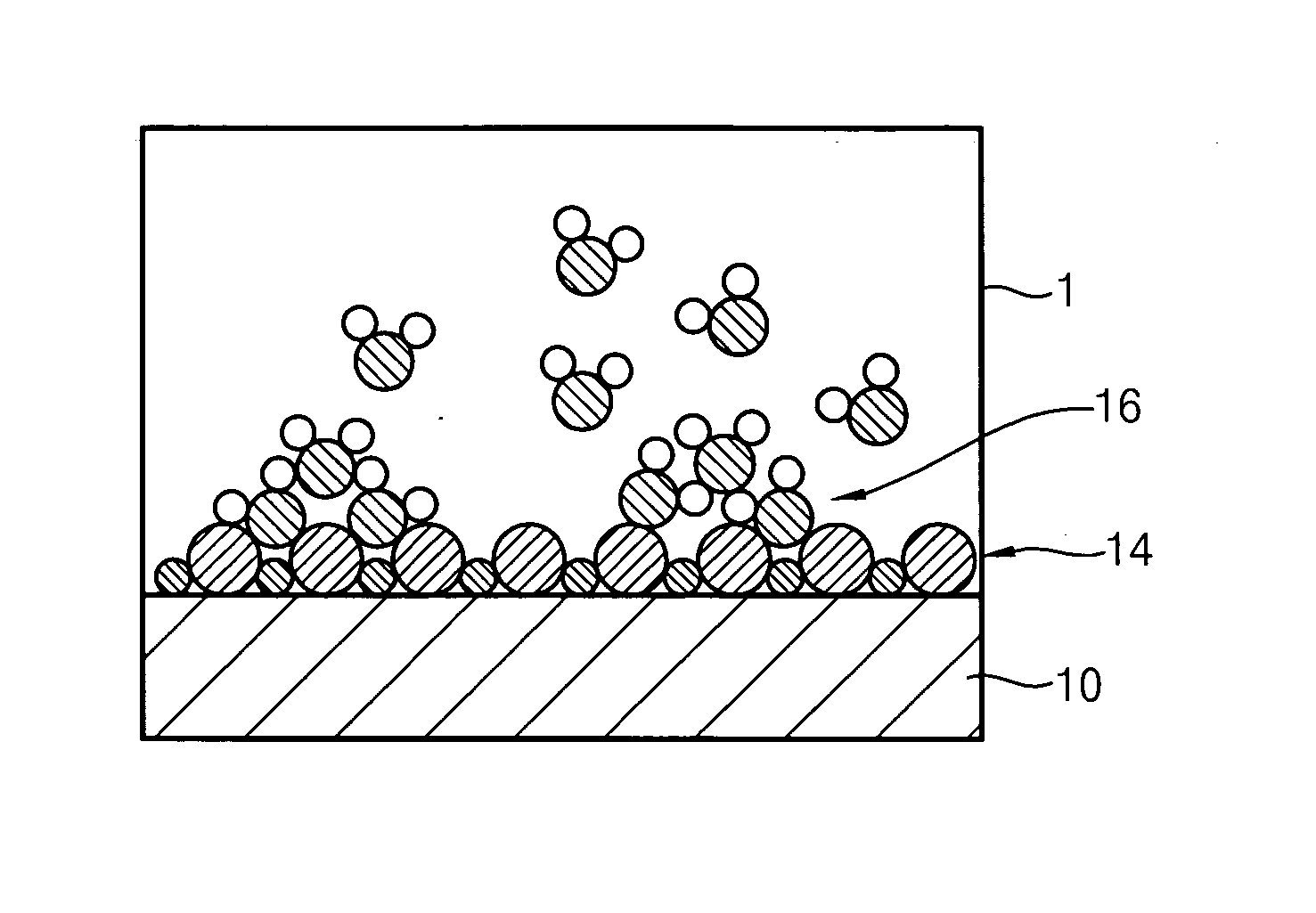

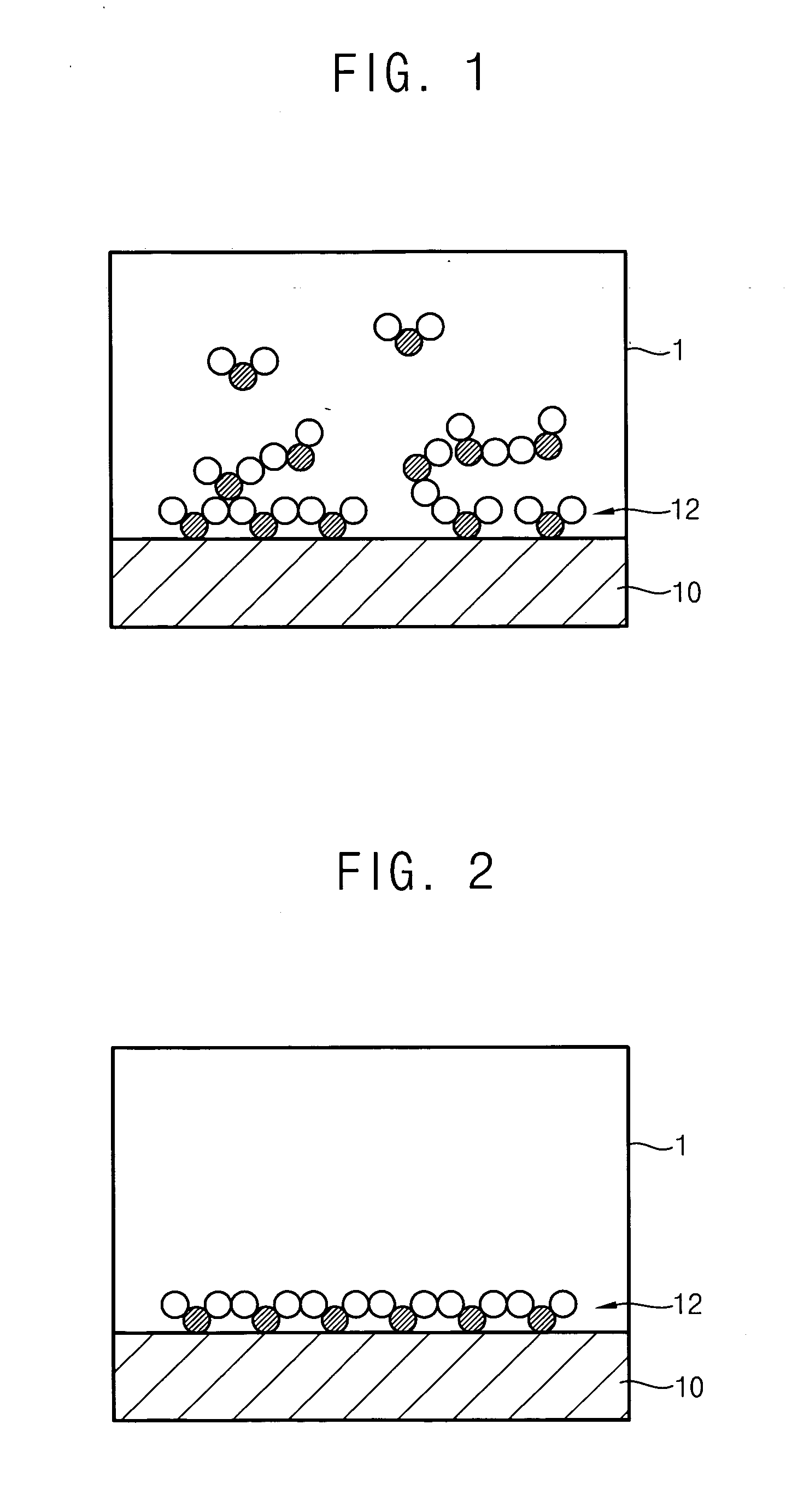

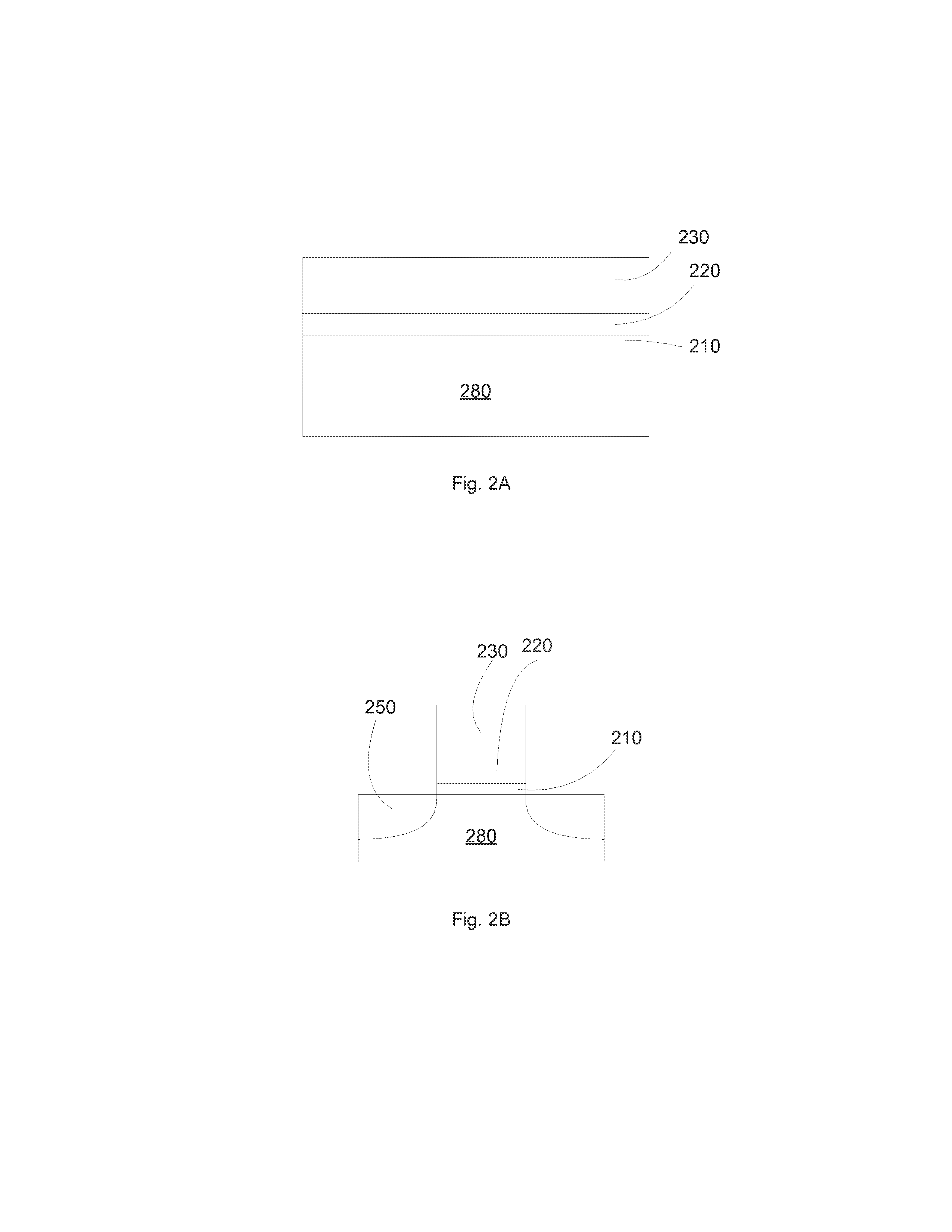

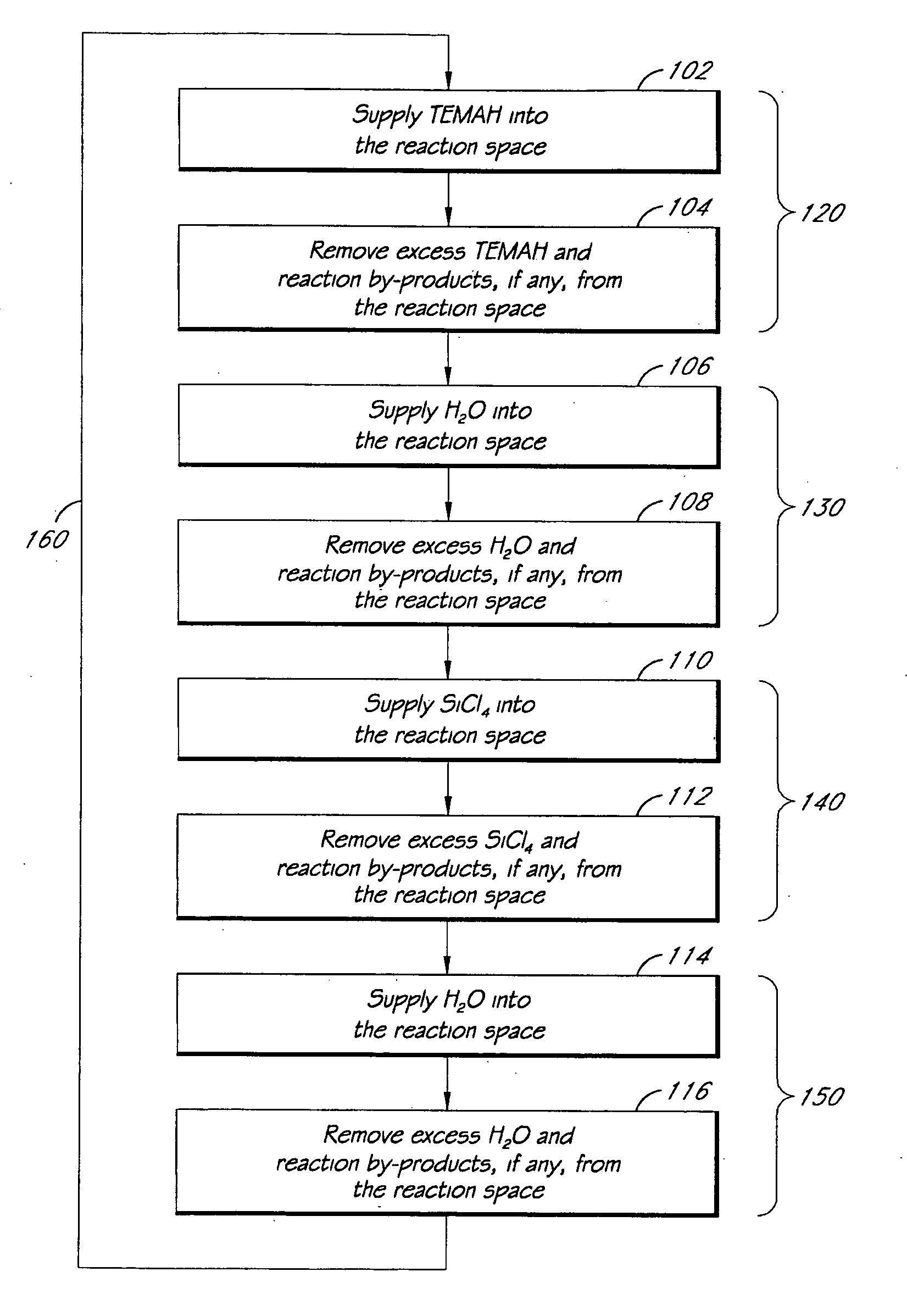

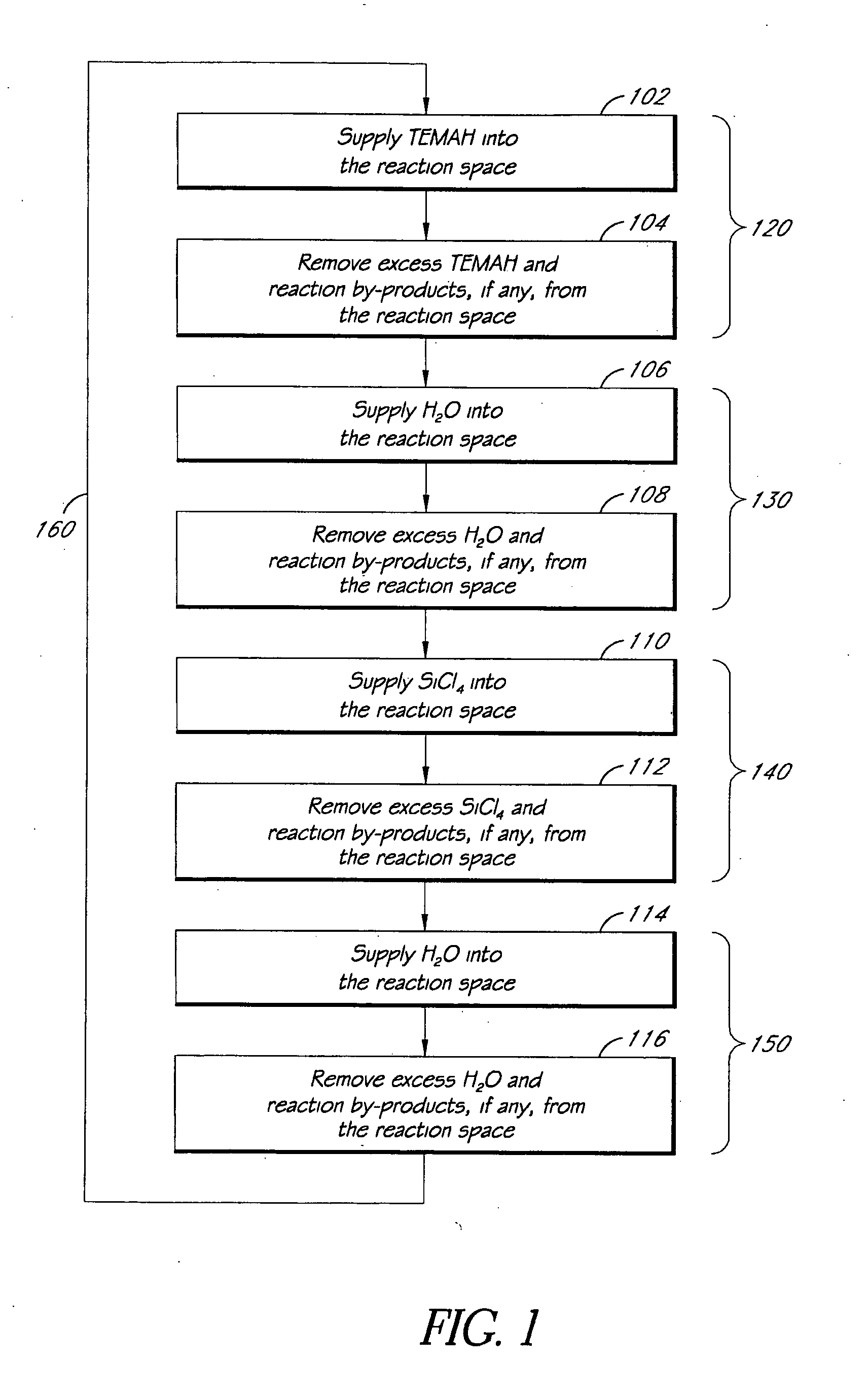

Methods of forming a thin film structure, and a gate structure and a capacitor including the thin film structure

InactiveUS20060013946A1Well formedHigh dielectric constantSemiconductor/solid-state device manufacturingSpecial surfacesChemical reactionSilicon oxide

A thin film structure is formed that includes hafnium silicon oxide using an atomic layer deposition process. A first reactant including tetrakis ethyl methyl amino hafnium (TEMAH) is introduced onto a substrate. A first portion of the first reactant is chemisorbed to the substrate, whereas a second portion of the first reactant is physorbed to the first portion of the first reactant. A first oxidant is provided onto the substrate. A first thin film including hafnium oxide is formed on the substrate by chemically reacting the first oxidant with the first portion of the first reactant. A second reactant including amino propyl tri ethoxy silane (APTES) is introduced onto the first thin film. A first portion of the second reactant is chemisorbed to the first thin film, whereas a second portion of the second reactant is physorbed to the first portion of the second reactant. A second oxidant is provided onto the first thin film. A second thin film including silicon oxide is formed on the first thin film by chemically reacting the second oxidant with the first portion of the second reactant.

Owner:SAMSUNG ELECTRONICS CO LTD

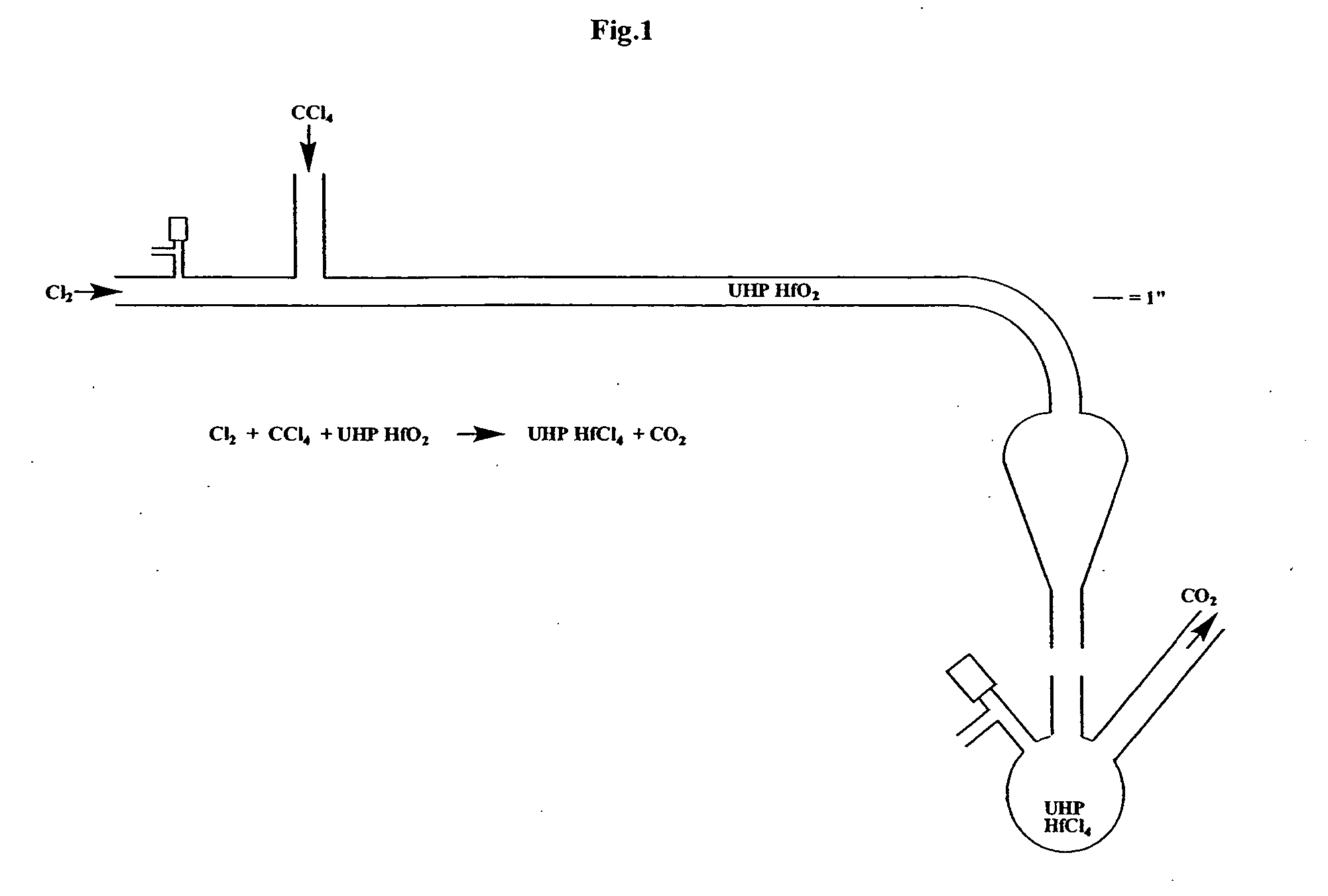

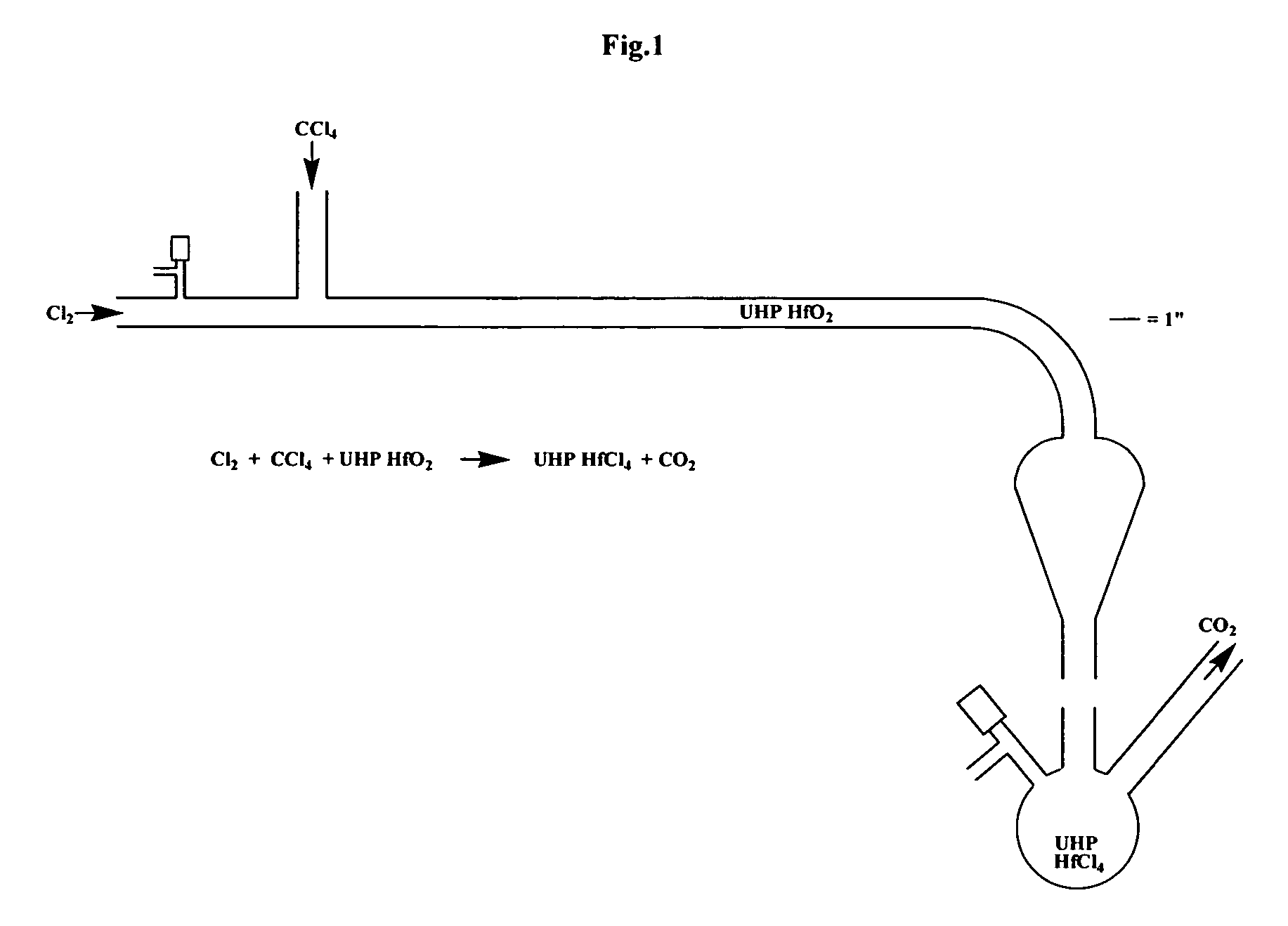

Low zirconium hafnium halide compositions

InactiveUS20050214458A1Improve smoothnessShort incubation timeSemiconductor/solid-state device manufacturingTitanium organic compoundsGas phaseHafnium

This invention relates to hafnium halide compositions having a zirconium concentration of less than about 1000 parts per million, a process for producing the hafnium halide compositions having a zirconium concentration of less than about 1000 parts per million, organometallic compound precursors, a process for producing the organometallic compound precursors, and a method for producing a film or coating from the organometallic compound precursors. The organometallic compounds are useful in semiconductor applications as chemical vapor or atomic layer deposition precursors for film depositions.

Owner:PRAXAIR INC

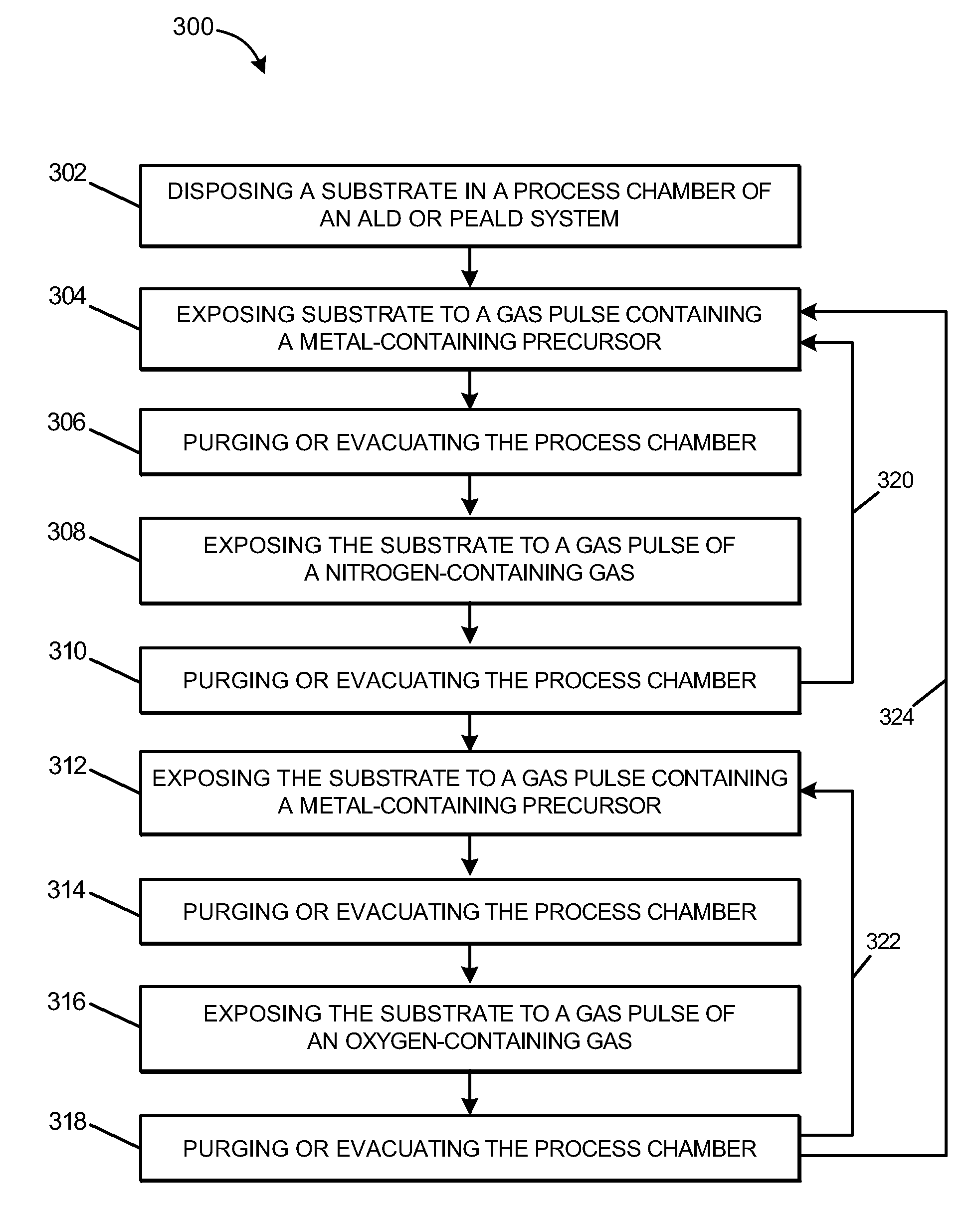

Nitrogen profile engineering in nitrided high dielectric constant films

InactiveUS7767262B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementNitrogen

A method of forming a nitrided high-k film by disposing a substrate in a process chamber and forming the nitrided high-k film on the substrate by a) depositing a nitrogen-containing film, and b) depositing an oxygen-containing film, wherein steps a) and b) are performed in any order, any number of times, so as to oxidize at least a portion of the thickness of the nitrogen-containing film. The oxygen-containing film and the nitrogen-containing film contain the same one or more metal elements selected from alkaline earth elements, rare earth elements, and Group IVB elements of the Periodic Table, and optionally aluminum, silicon, or aluminum and silicon. According to one embodiment, the method includes forming a nitrided hafnium based high-k film. The nitrided high-k film can be formed by atomic layer deposition (ALD) or plasma-enhanced ALD (PEALD).

Owner:TOKYO ELECTRON LTD

Method of depositing catalyst assisted silicates of high-k materials

InactiveUS20080113096A1Reduce the temperatureSilicon organic compoundsChemical vapor deposition coatingSoaking ProcedureHafnium

A high-k silicate atomic layer deposition method is disclosed. To produce a hafnium silicate layer, a substrate may be exposed to a pulse of a hafnium precursor, a pulse of an oxidizer, a pulse of a silicon precursor, and a pulse of another oxidizer. A catalyst may additionally be co-flowed with one or more reactants into the chamber through a separate inlet. Alternatively, the catalyst may be flowed to the chamber before the reactant is introduced in a soaking procedure. By either co-flowing the catalyst through separate inlets or by performing a catalyst soak, hafnium silicate formation may proceed at a fast rate and / or at a low temperature.

Owner:APPLIED MATERIALS INC

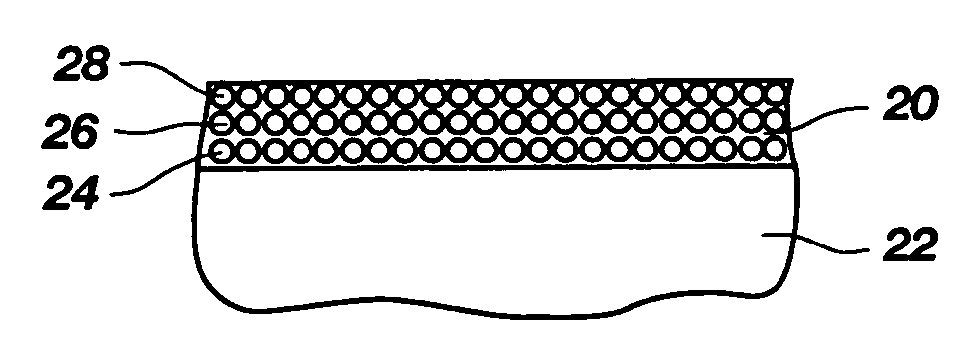

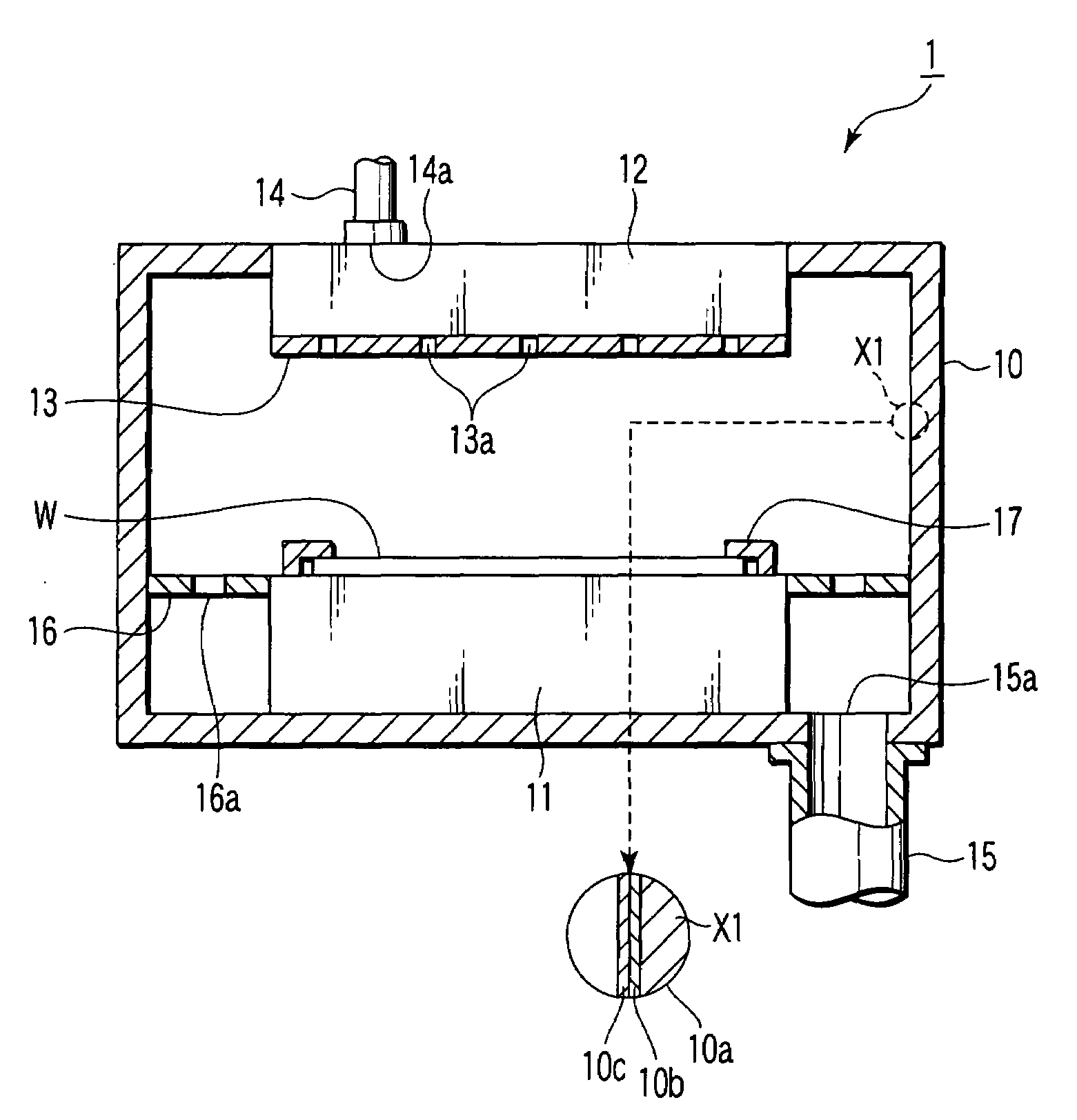

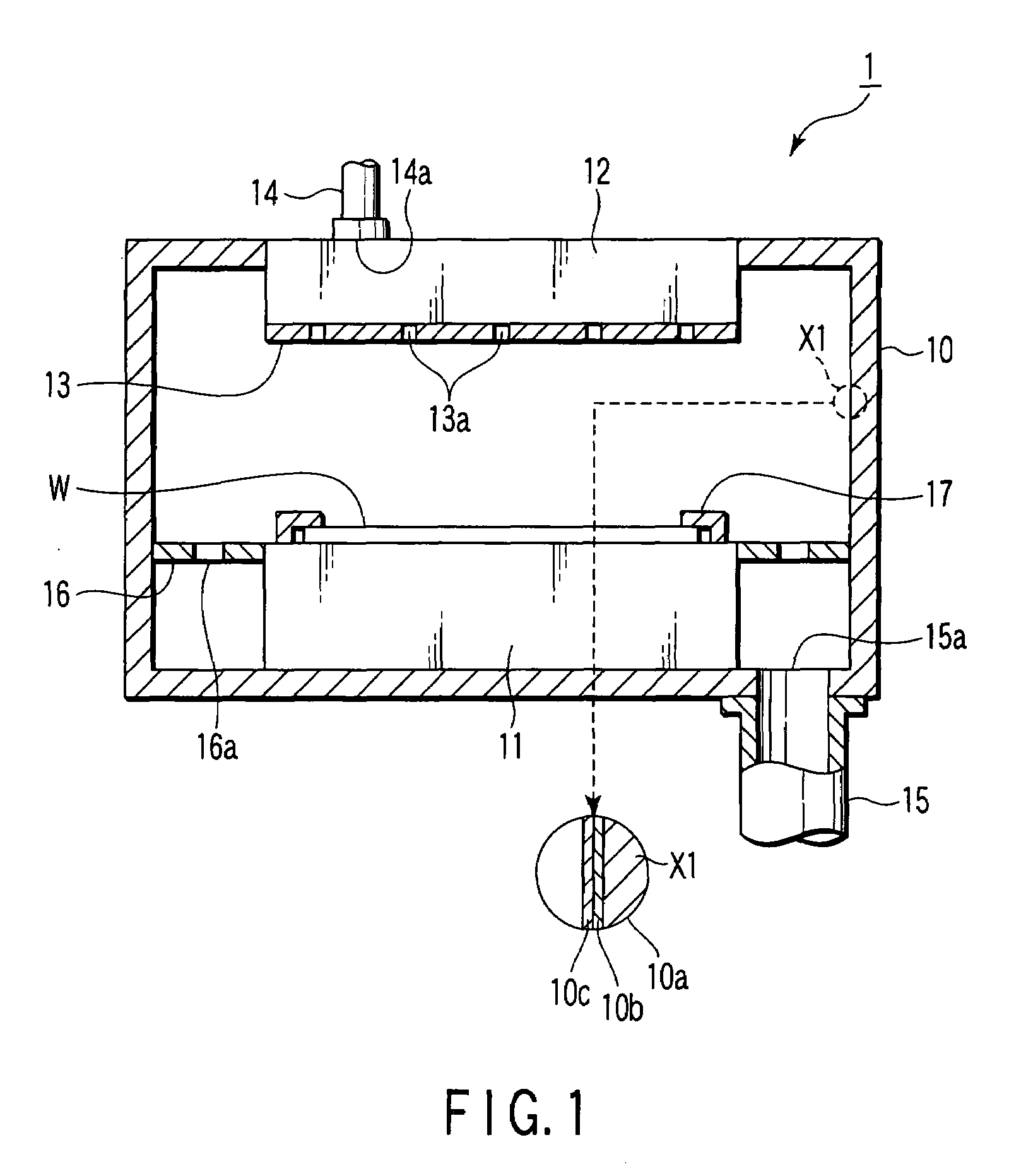

Component for semicondutor processing apparatus and manufacturing method thereof

InactiveUS20090194233A1Increased durabilityLiquid surface applicatorsSemiconductor/solid-state device manufacturingTectorial membranePorosity

A component (10) for a semiconductor processing apparatus includes a matrix (10a) defining a shape of the component, and a protection film (10c) covering a predetermined surface of the matrix. The protection film (10c) consists essentially of an amorphous oxide of a first element selected from the group consisting of aluminum, silicon, hafnium, zirconium, and yttrium. The protection film (10c) has a porosity of less than 1% and a thickness of 1 nm to 10 μm.

Owner:TOKYO ELECTRON LTD

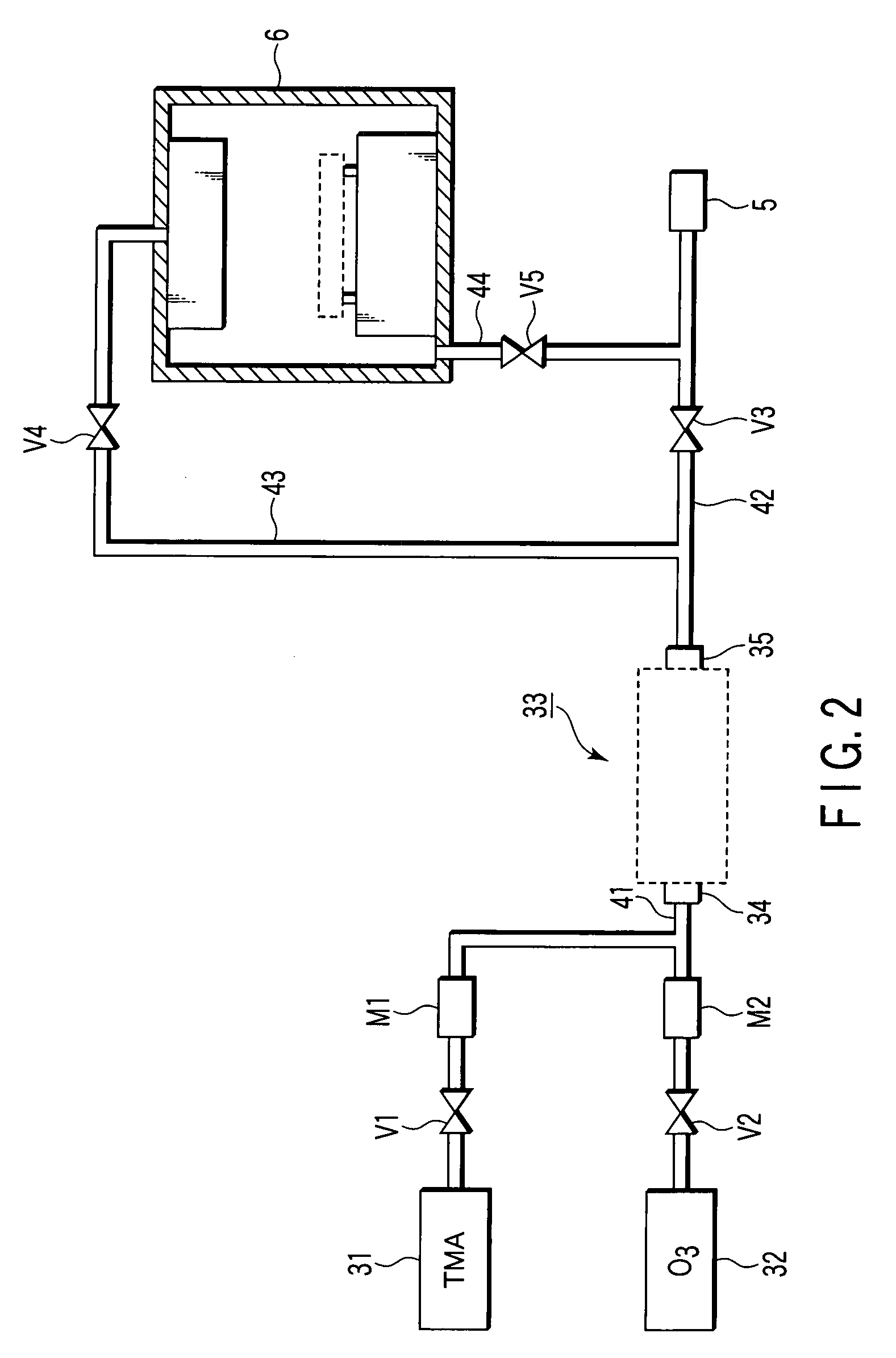

Nitrogen profile engineering in nitrided high dielectric constant films

InactiveUS20080081113A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementNitrogen

A method of forming a nitrided high-k film by disposing a substrate in a process chamber and forming the nitrided high-k film on the substrate by a) depositing a nitrogen-containing film, and b) depositing an oxygen-containing film, wherein steps a) and b) are performed in any order, any number of times, so as to oxidize at least a portion of the thickness of the nitrogen-containing film. The oxygen-containing film and the nitrogen-containing film contain the same one or more metal elements selected from alkaline earth elements, rare earth elements, and Group IVB elements of the Periodic Table, and optionally aluminum, silicon, or aluminum and silicon. According to one embodiment, the method includes forming a nitrided hafnium based high-k film. The nitrided high-k film can be formed by atomic layer deposition (ALD) or plasma-enhanced ALD (PEALD).

Owner:TOKYO ELECTRON LTD

Methods of atomic layer deposition of hafnium oxide / erbium oxide bi-layer as advanced gate dielectrics

InactiveUS20130313656A1Improve electrical performanceFew defectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricHafnium

Provided is a two-step ALD deposition process for forming a gate dielectric involving an erbium oxide layer deposition followed by a hafnium oxide layer deposition. Hafnium oxide can provide a high dielectric constant, high density, large bandgap and good thermal stability. Erbium oxide can act as a barrier against oxygen diffusion, which can lead to increasing an effective oxide thickness of the gate dielectric and preventing hafnium-silicon reactions that may lead to higher leakage current.

Owner:INTERMOLECULAR

ALD of metal silicate films

ActiveUS20080020593A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Methods for forming metal silicate films are provided. The methods comprise contacting a substrate with alternating and sequential vapor phase pulses of a metal source chemical, a silicon source chemical and an oxidizing agent. In preferred embodiments, an alkyl amide metal compound and a silicon halide compound are used. Methods according to preferred embodiments can be used to form hafnium silicate and zirconium silicate films with substantially uniform film coverages on substrate surfaces comprising high aspect ratio features (e.g., vias and / or trenches).

Owner:ASM IP HLDG BV

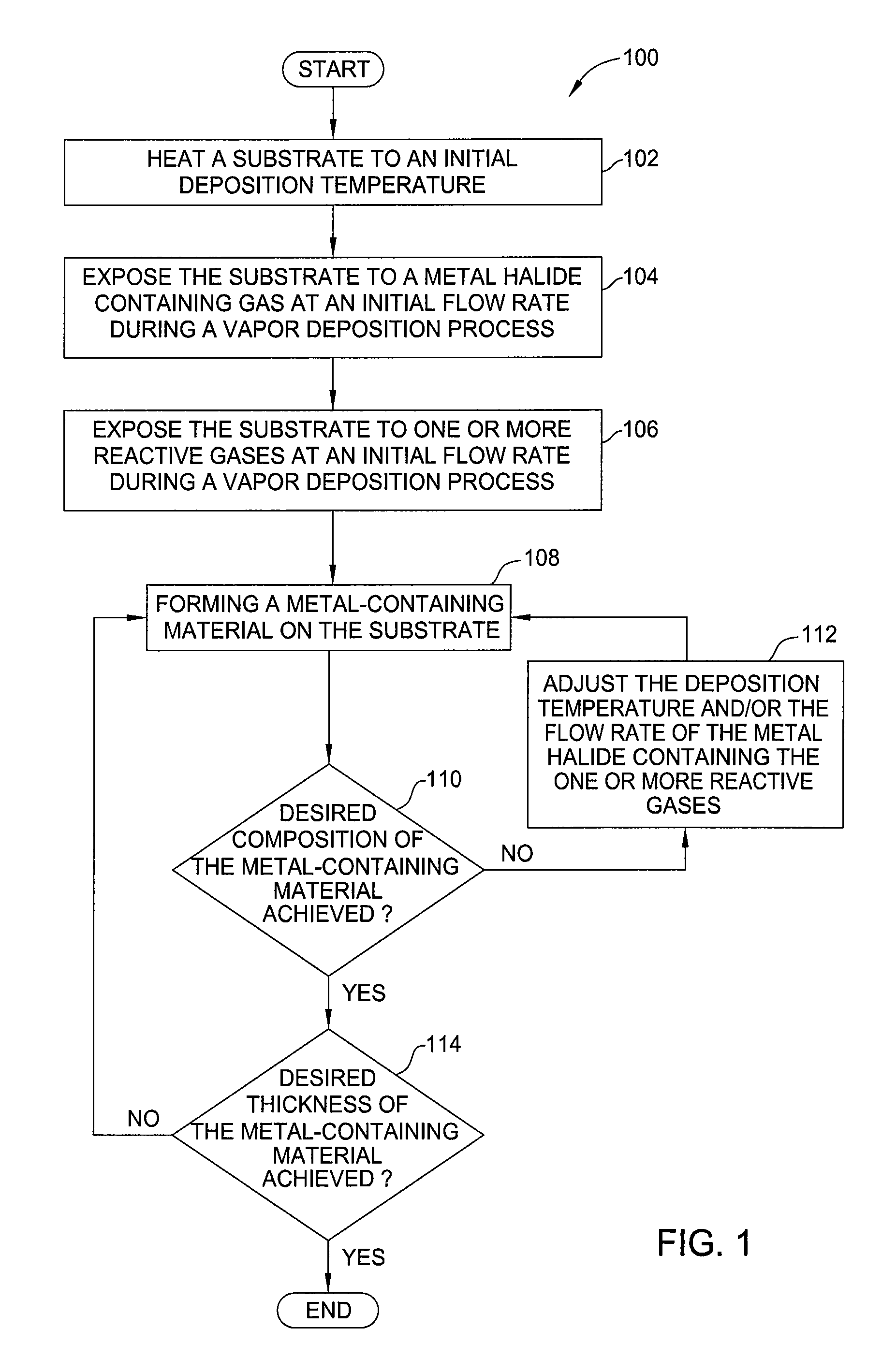

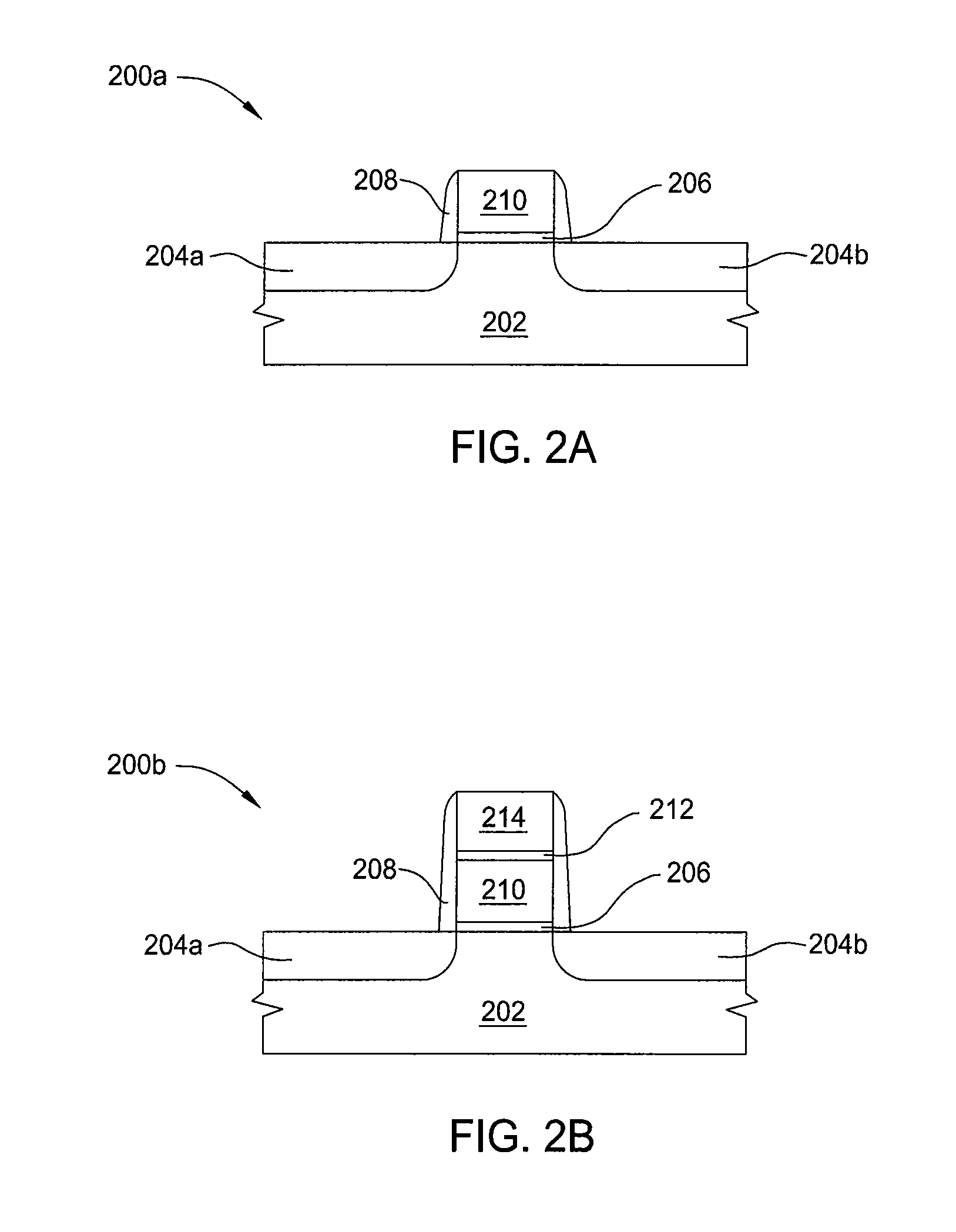

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

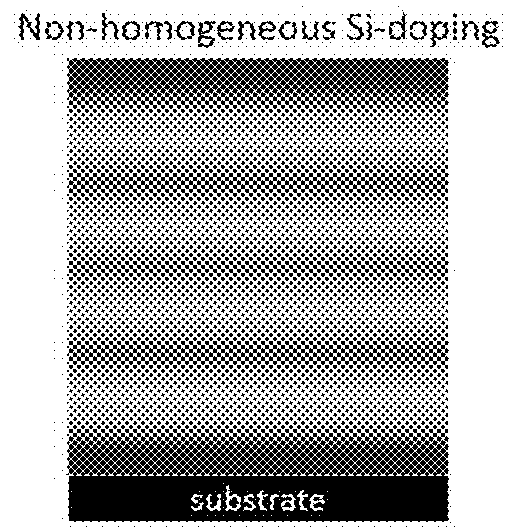

Formulation for Deposition of Silicon Doped Hafnium Oxide as Ferroelectric Materials

ActiveUS20180269057A1Reduce and increase reactivityEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingHafniumSilicon

In one aspect, the invention is formulations comprising both organoaminohafnium and organoaminosilane precursors that allows anchoring both silicon-containing fragments and hafnium-containing fragments onto a given surface having hydroxyl groups to deposit silicon doped hafnium oxide having a silicon doping level ranging from 0.5 to 8 mol %, preferably 2 to 6 mol %, most preferably 3 to 5 mol %, suitable as ferroelectric material. In another aspect, the invention is methods and systems for depositing the silicon doped hafnium oxide films using the formulations.

Owner:VERSUM MATERIALS US LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com