Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4469 results about "Surface finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane).

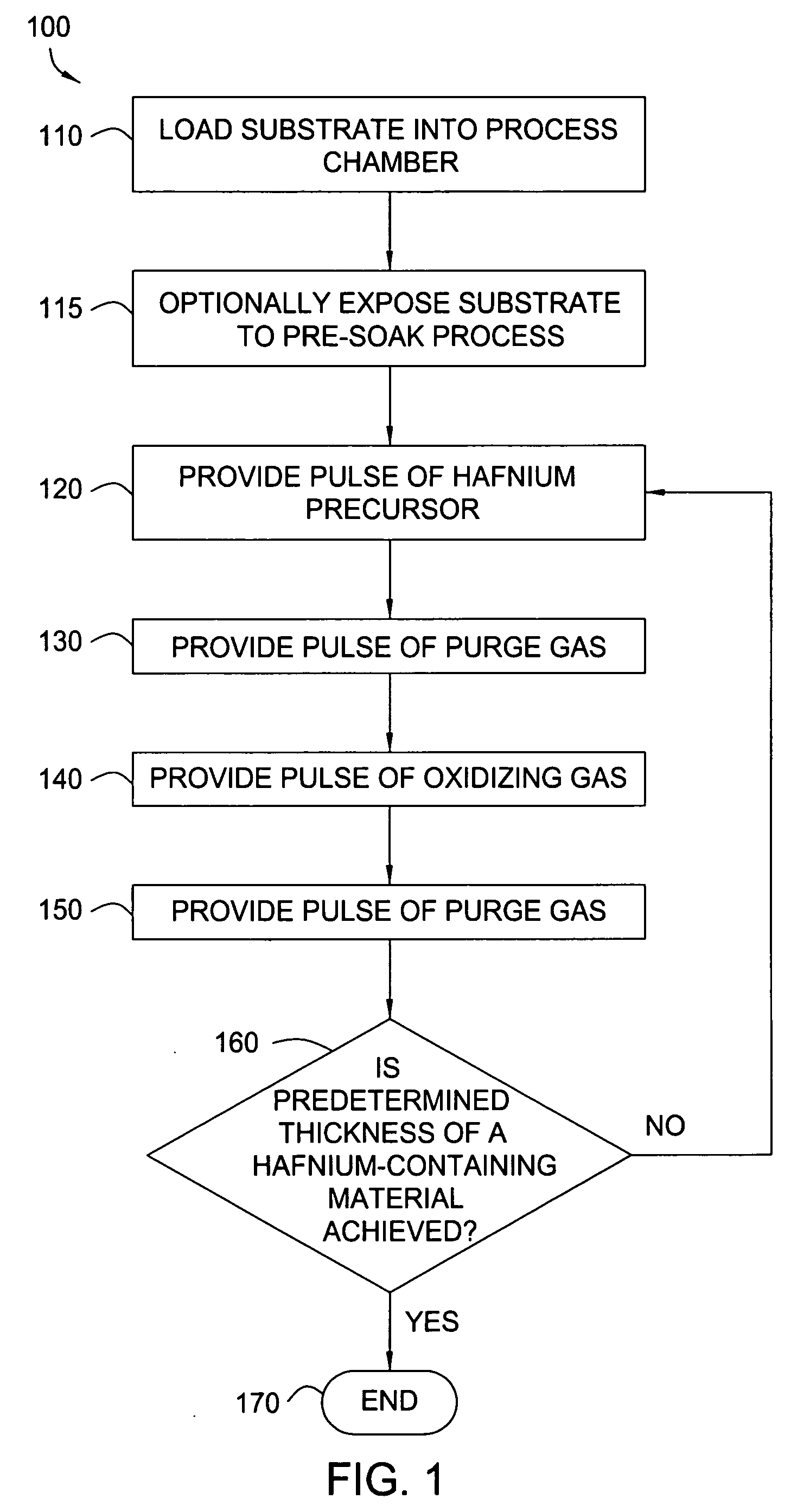

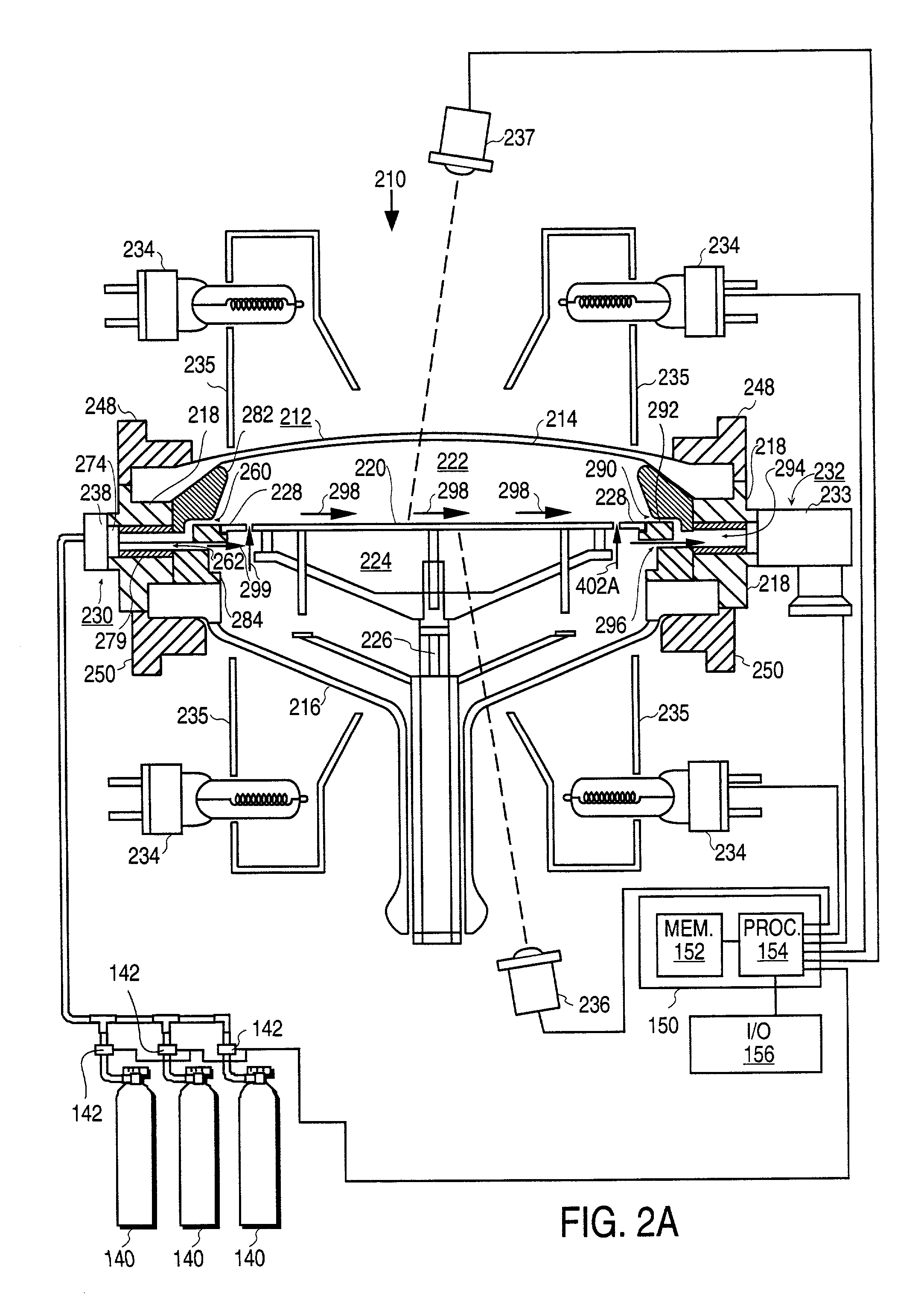

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

ActiveUS20050271812A1Steam generation heating methodsEfficient propulsion technologiesWater vaporGas phase

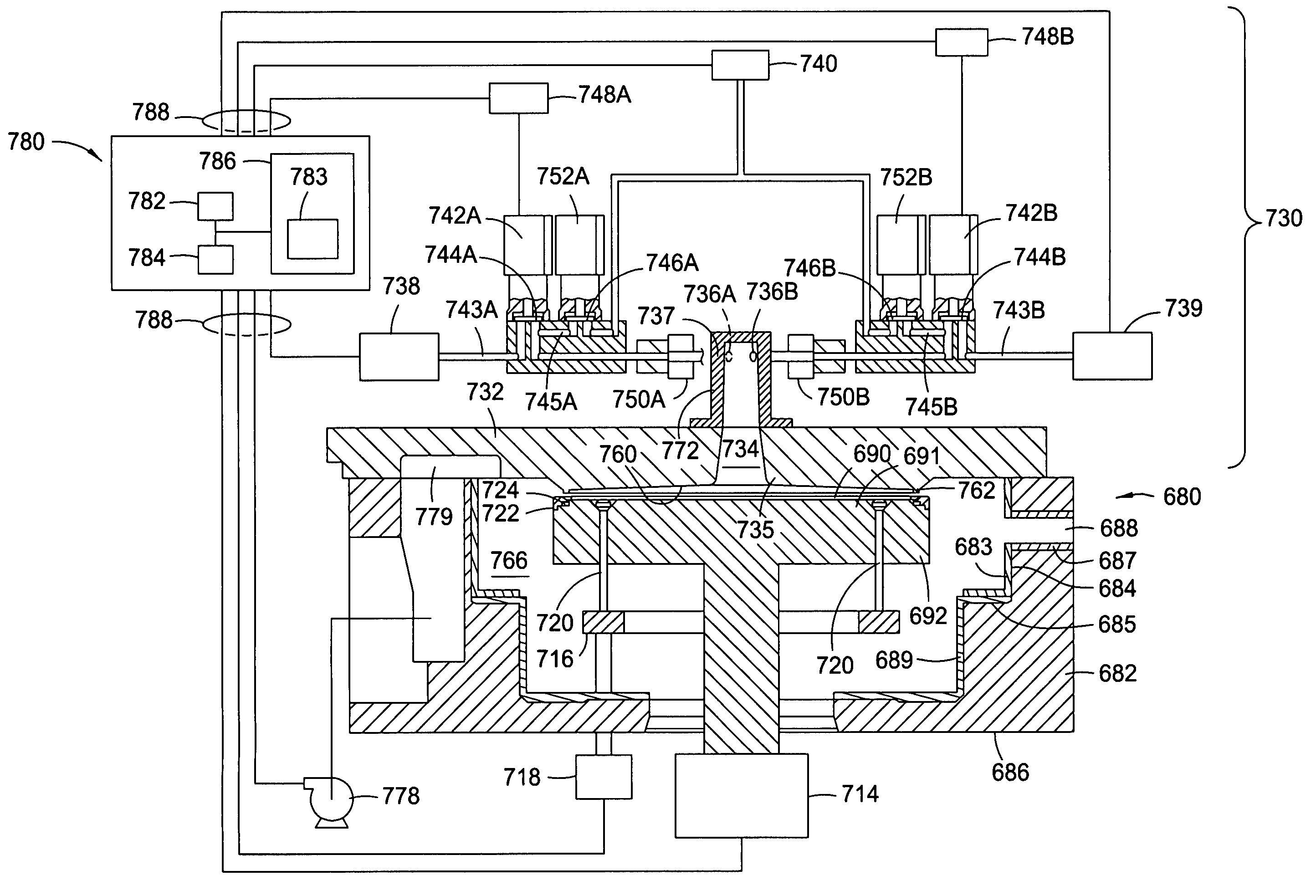

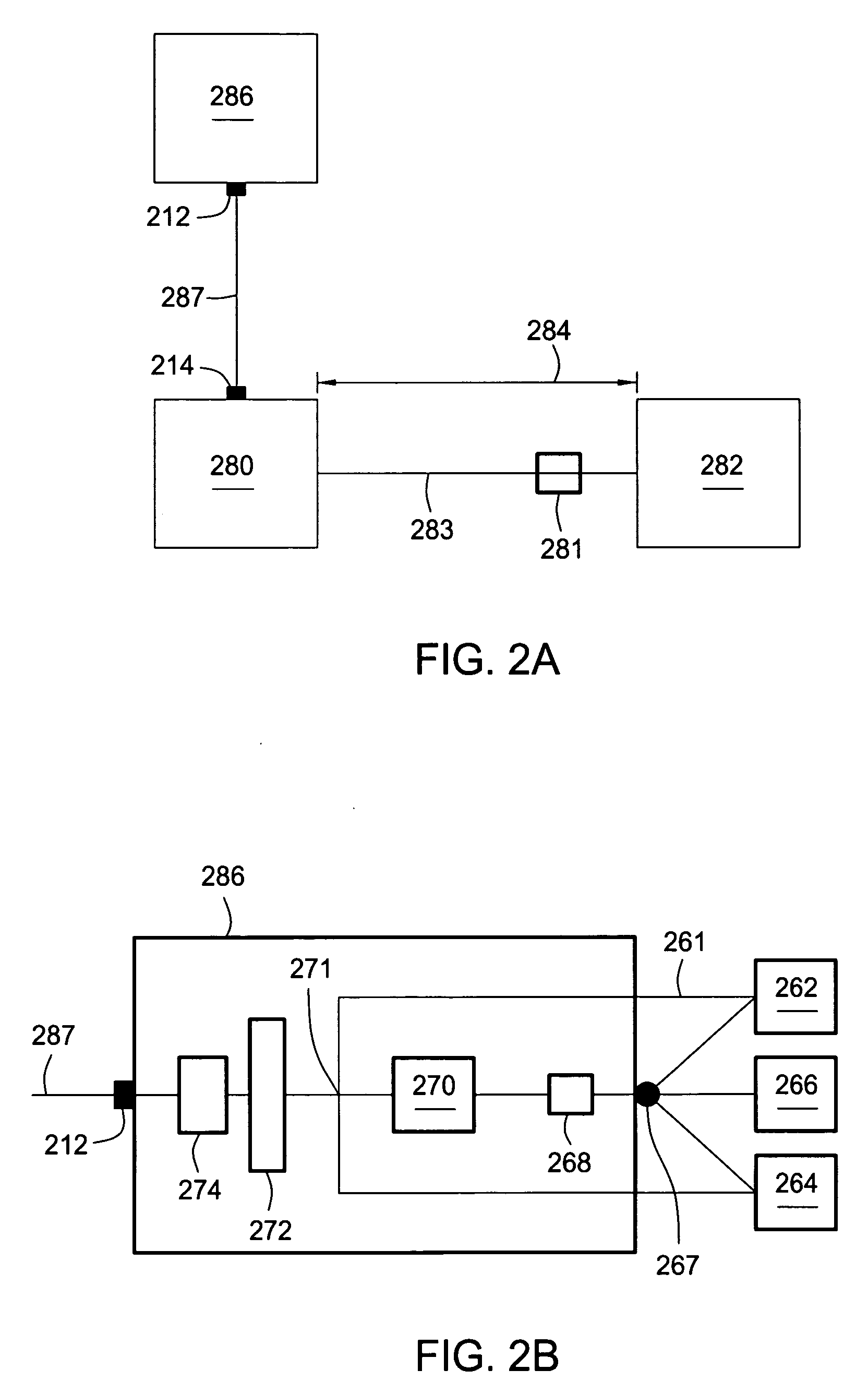

Embodiments of the invention provide apparatuses and methods for depositing materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one embodiment, a chamber contains a substrate support with a receiving surface and a chamber lid containing an expanding channel formed within a thermally insulating material. The chamber further includes at least one conduit coupled to a gas inlet within the expanding channel and positioned to provide a gas flow through the expanding channel in a circular direction, such as a vortex, a helix, a spiral or derivatives thereof. The expanding channel may be formed directly within the chamber lid or formed within a funnel liner attached thereon. The chamber may contain a retaining ring, an upper process liner, a lower process liner or a slip valve liner. Liners usually have a polished surface finish and contain a thermally insulating material such as fused quartz or ceramic. In an alternative embodiment, a deposition system contains a catalytic water vapor generator connected to an ALD chamber.

Owner:APPLIED MATERIALS INC

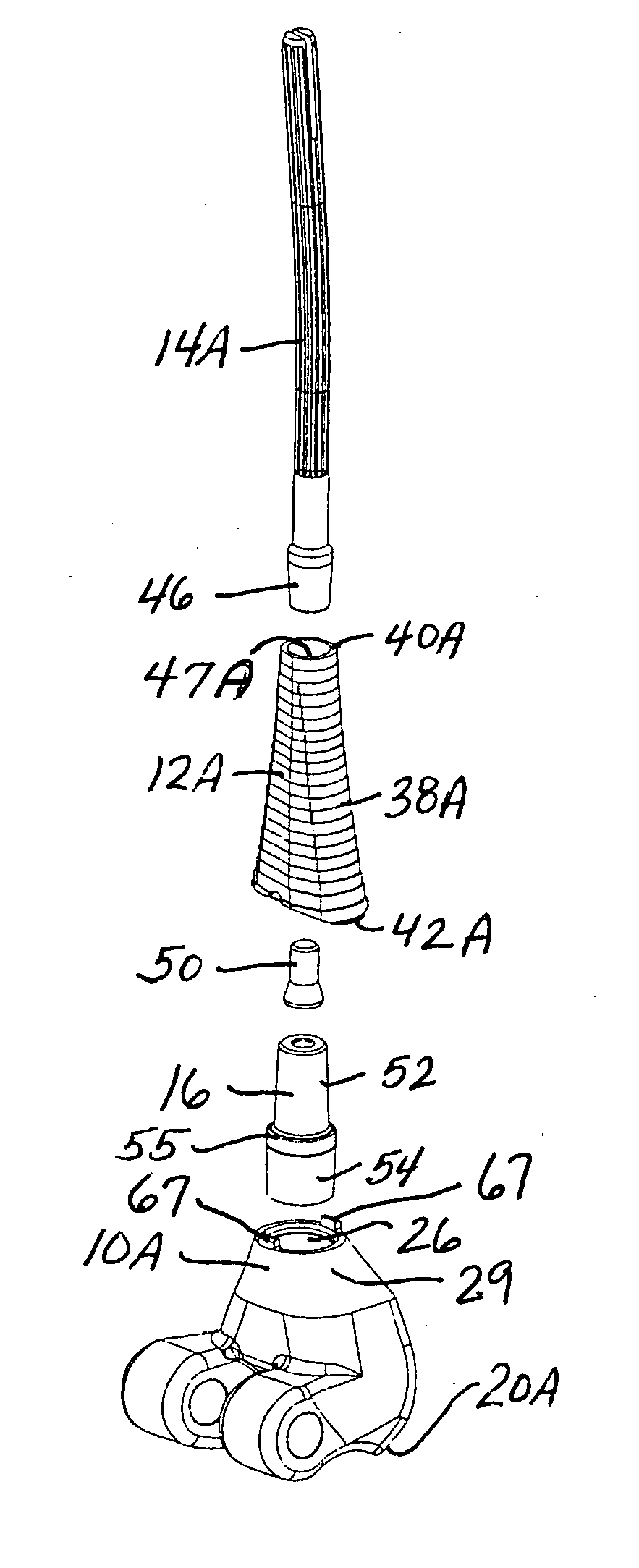

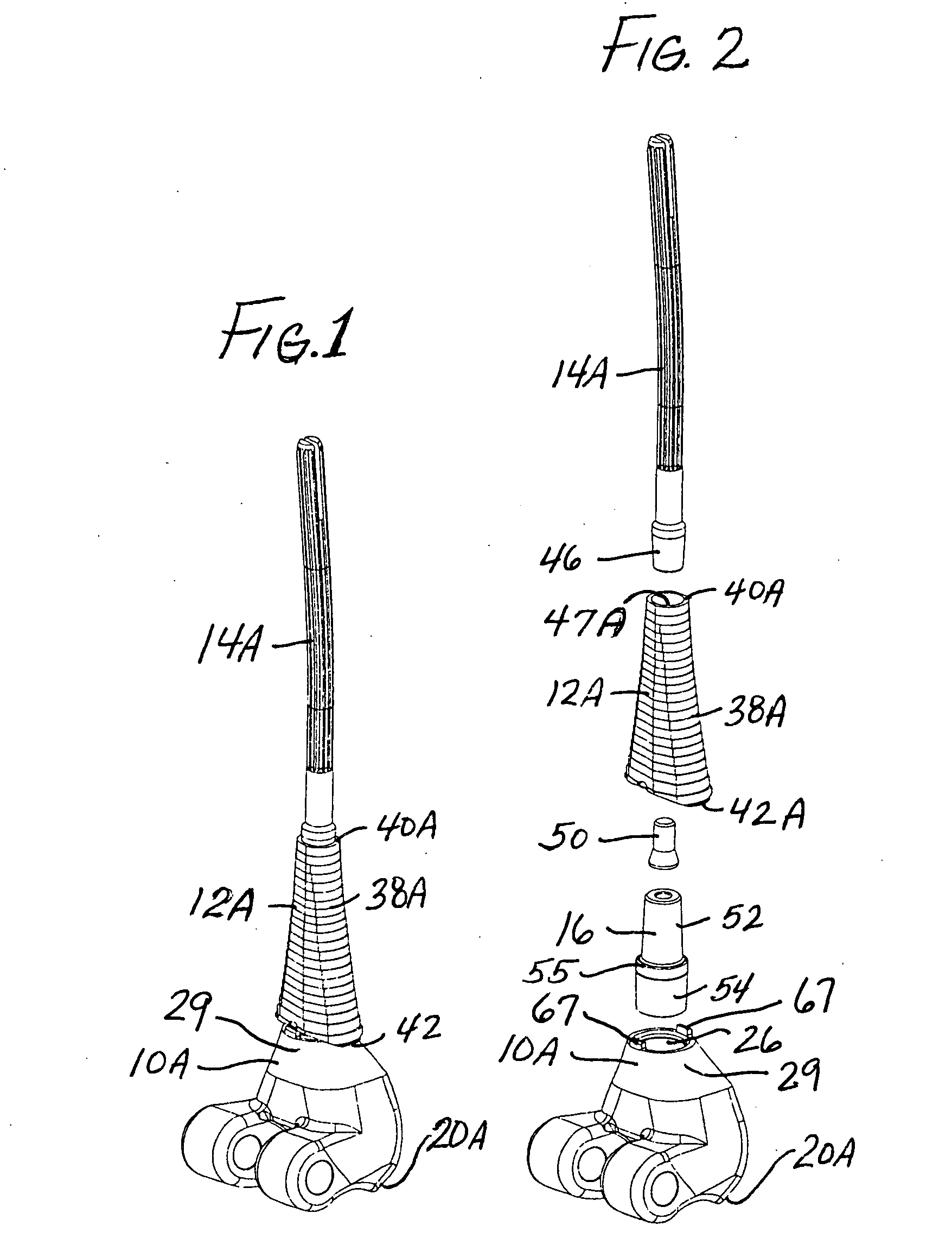

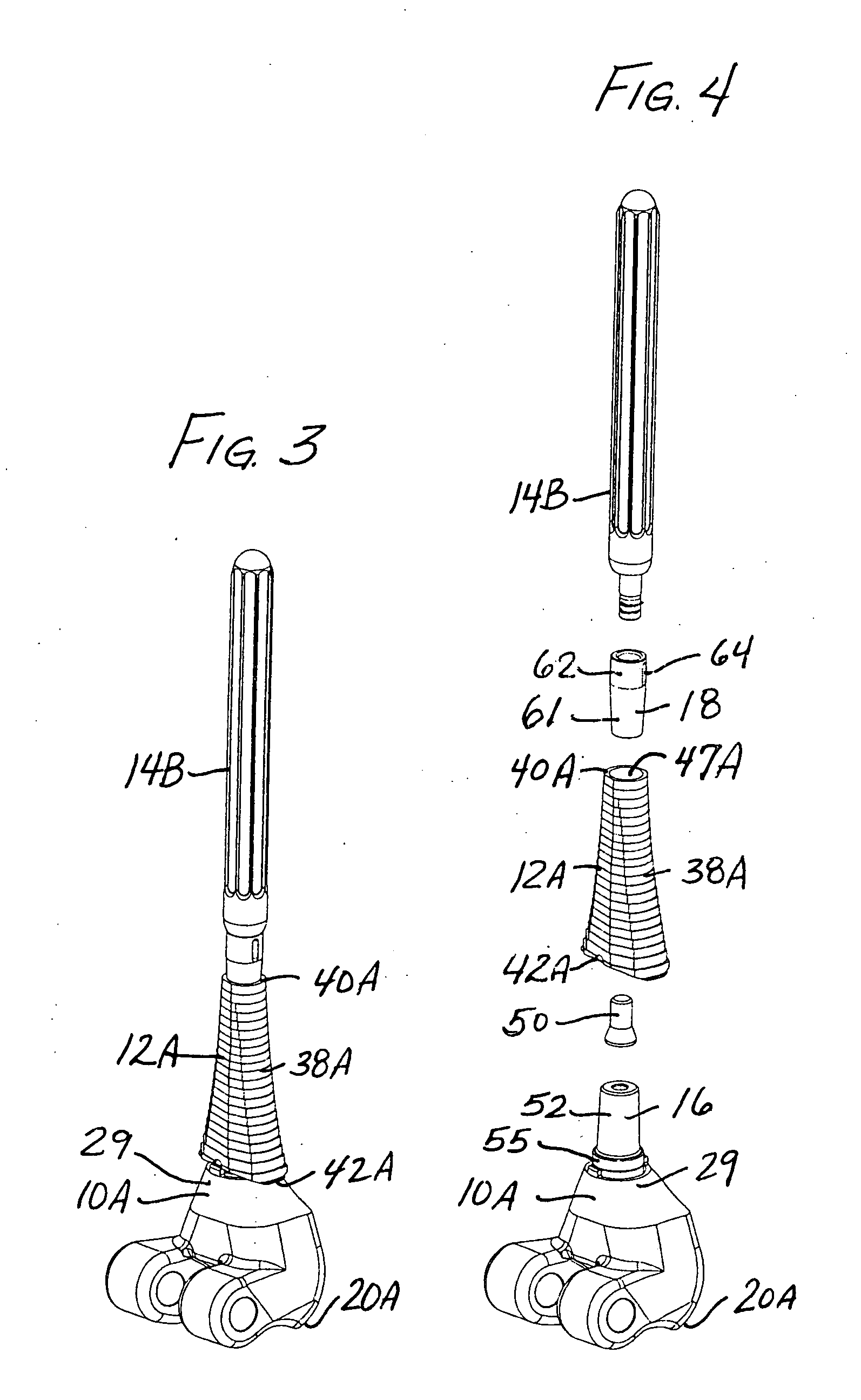

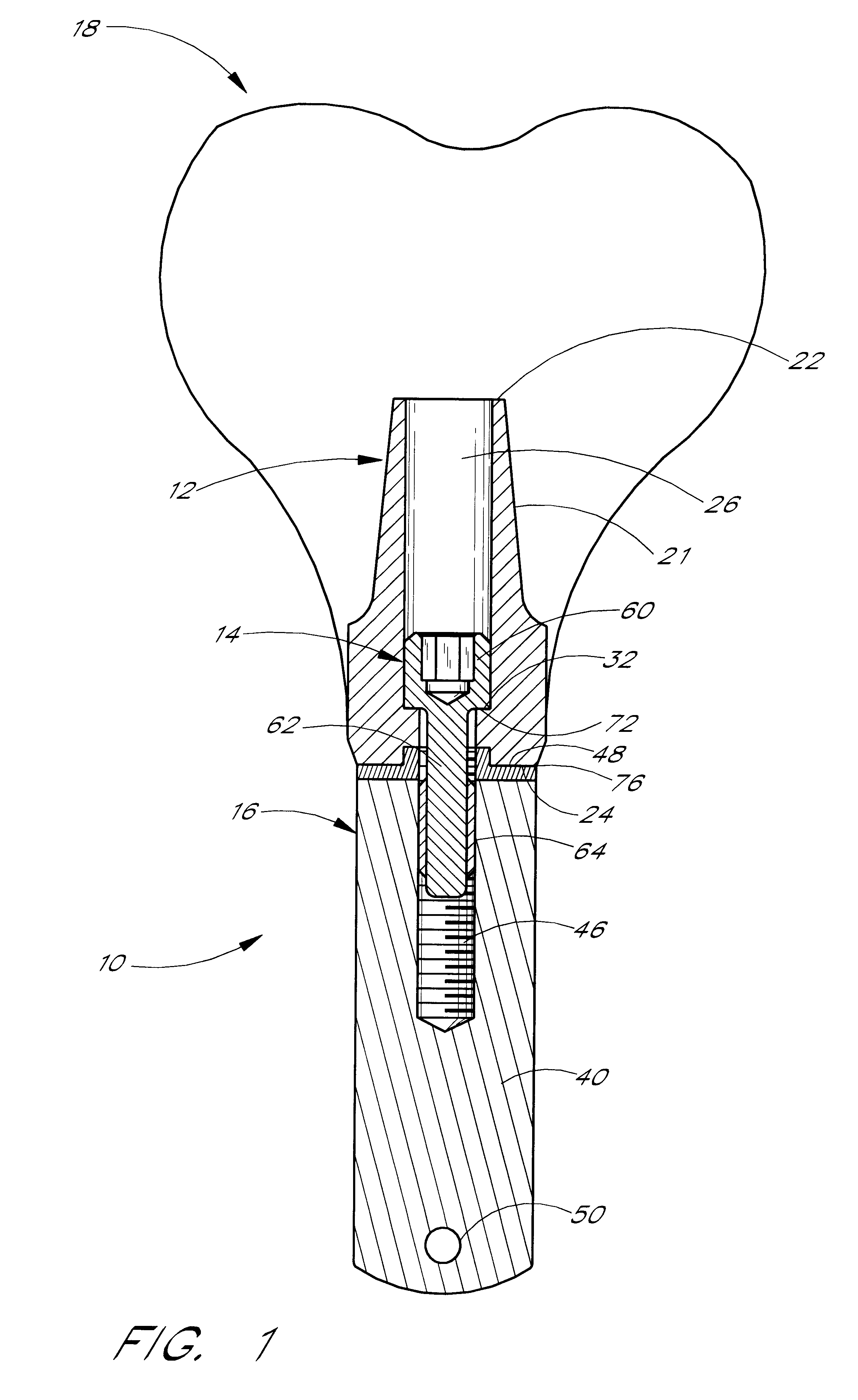

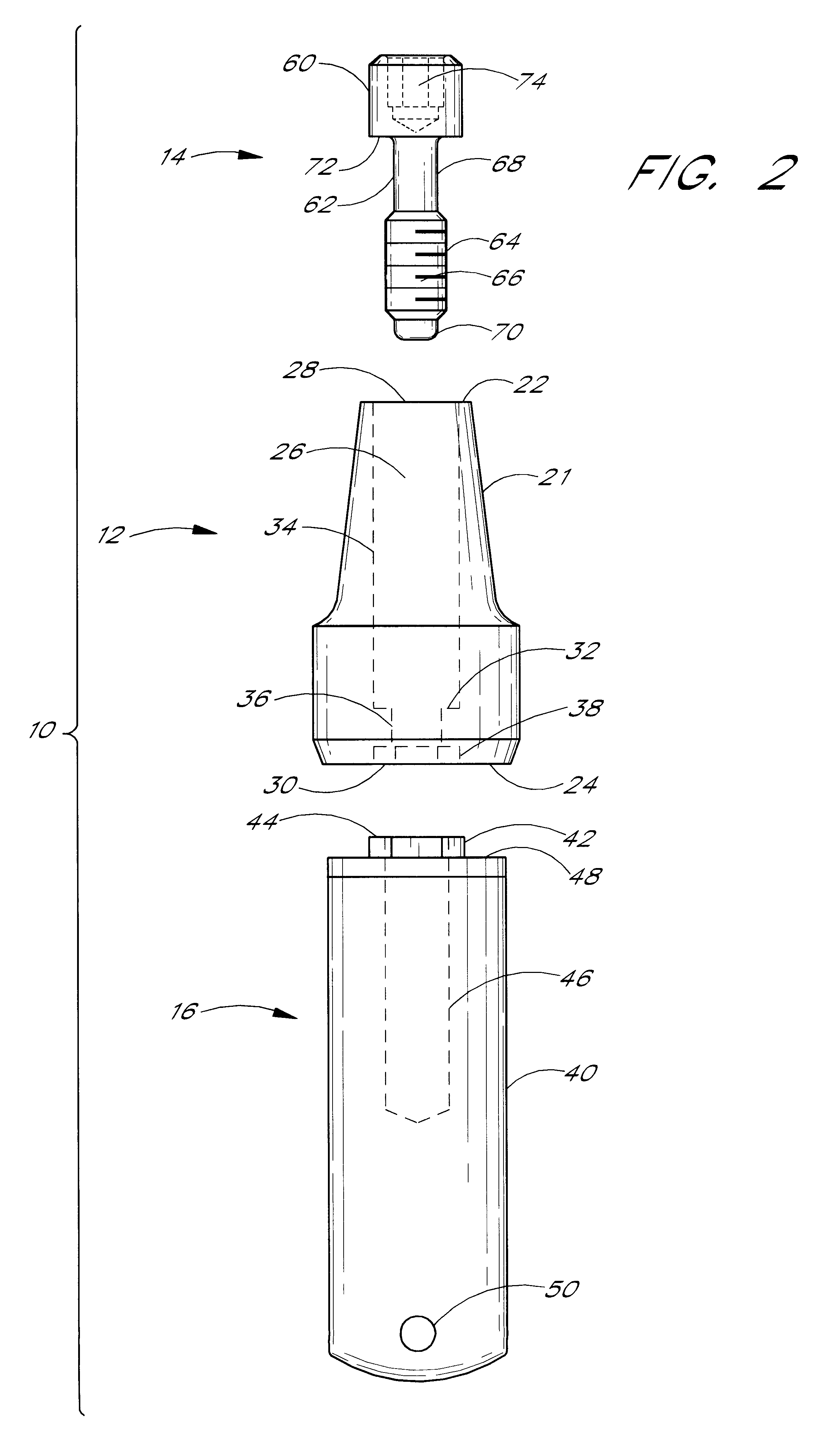

Modular implant system with fully porous coated sleeve

A modular knee implant system allows a surgeon to select between several different styles of distal femoral implant components and several different styles of stem extensions while also allowing for use of a metaphyseal component. The metaphyseal component can be a universal one that is usable with all of the styles of distal femoral implant components through use of an adapter. A second adapter allows for use of stem extensions with different types of connectors with the metaphyseal component. A separate metaphyseal component could also be provided with a distal Morse taper post to mate with a distal femoral component having a proximal Morse taper bore. The metaphyseal component may have an outer surface that is configured to maximize contact area with the patient's bone, and may have a surface finish over a substantial part of its overall length that is conducive to bone ingrowth.

Owner:DEPUY PROD INC

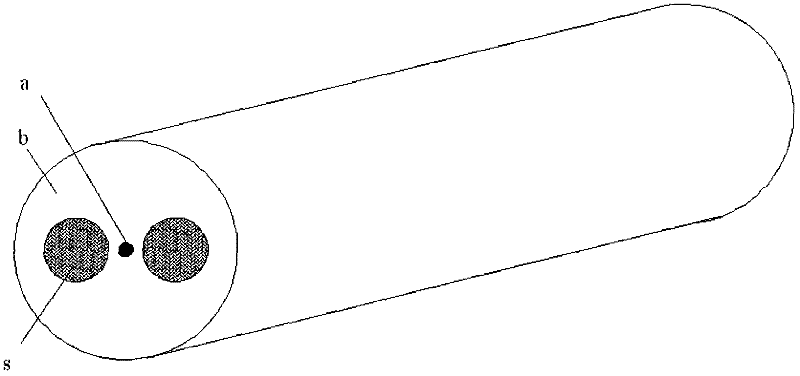

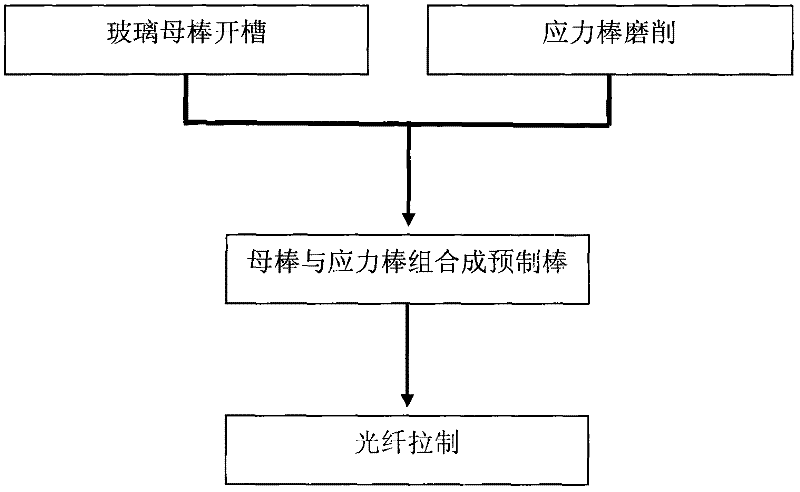

Manufacture method for polarization maintaining fiber and polarization maintaining fiber

InactiveCN102351415AImprove the finishImprove processing efficiencyGlass making apparatusOptical fibre with polarisationSurface finishPolarization-maintaining optical fiber

The invention provides a manufacture method for polarization maintaining fiber and a polarization maintaining fiber, and relates to optical waveguide fibers in the field of fiber-optical communication and fiber optical sensors. The method comprises the following steps that: (1) two oppositely arranged open slots with a same shape are inwardly provided at a side surface of a glass mother rod, stress rods are machined to obtain a shape matching the open slots, and the centers of the cross sections of the two open slots and the center of circle in the cross section of the glass mother rod are in a same line; (2) the stress rods are respectively inserted into each open slot on the glass mother rod, and the assembled glass mother rod and stress rods are put in a cannula to form a preformed rod of the polarization maintaining fiber; (3) the preformed rod of the polarization maintaining fiber is drew to form the polarization maintaining fiber. According to the invention, the glass mother rod is provided with the open slots, and the stress rods are embedded in the open slots, thereby obtaining high process repeatability; inner surfaces of the open slots have high fineness, and the open slots have good symmetry, thereby improving processing efficiency; therefore, the optical performance and reliability of the polarization maintaining fiber are substantially improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

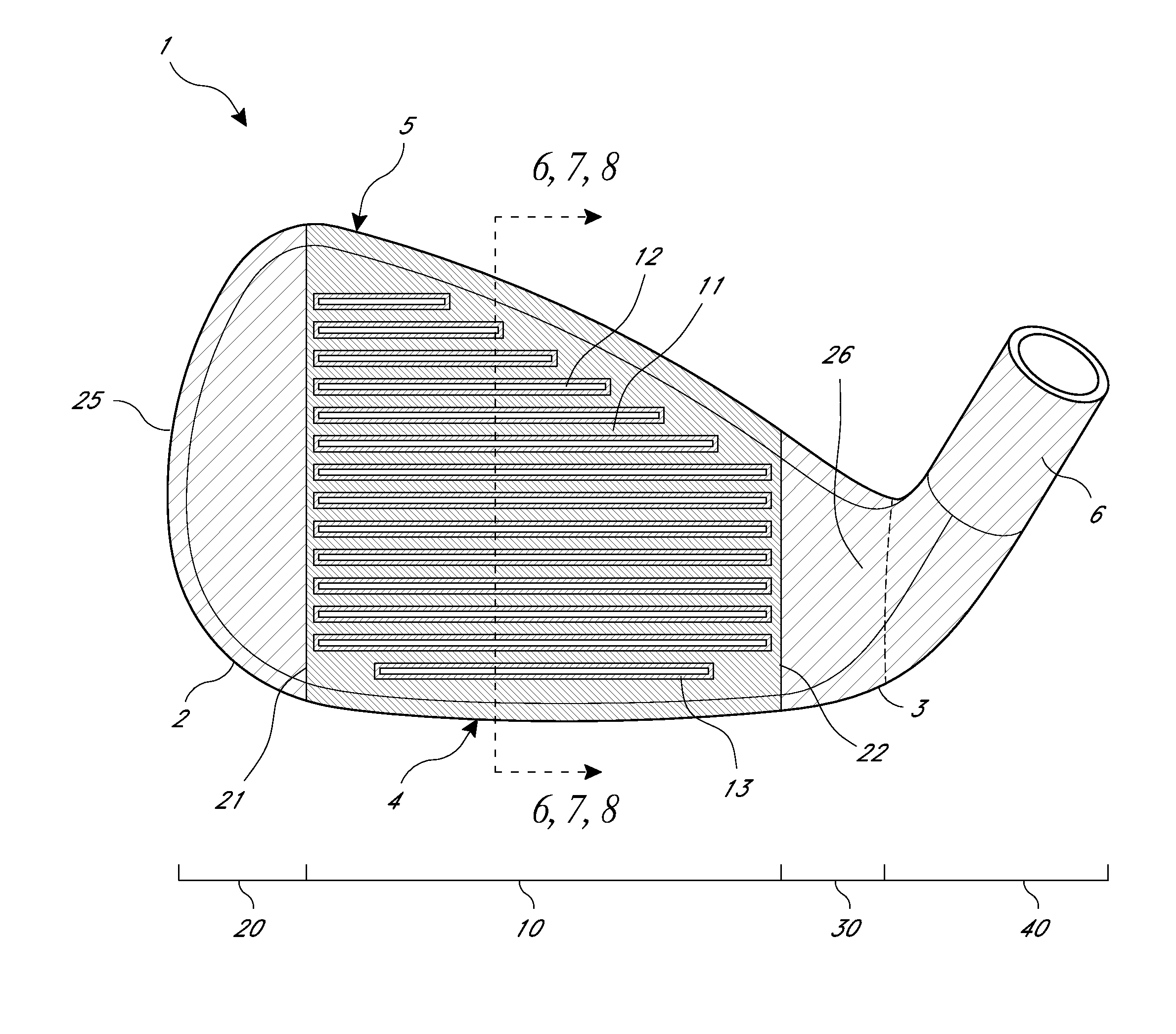

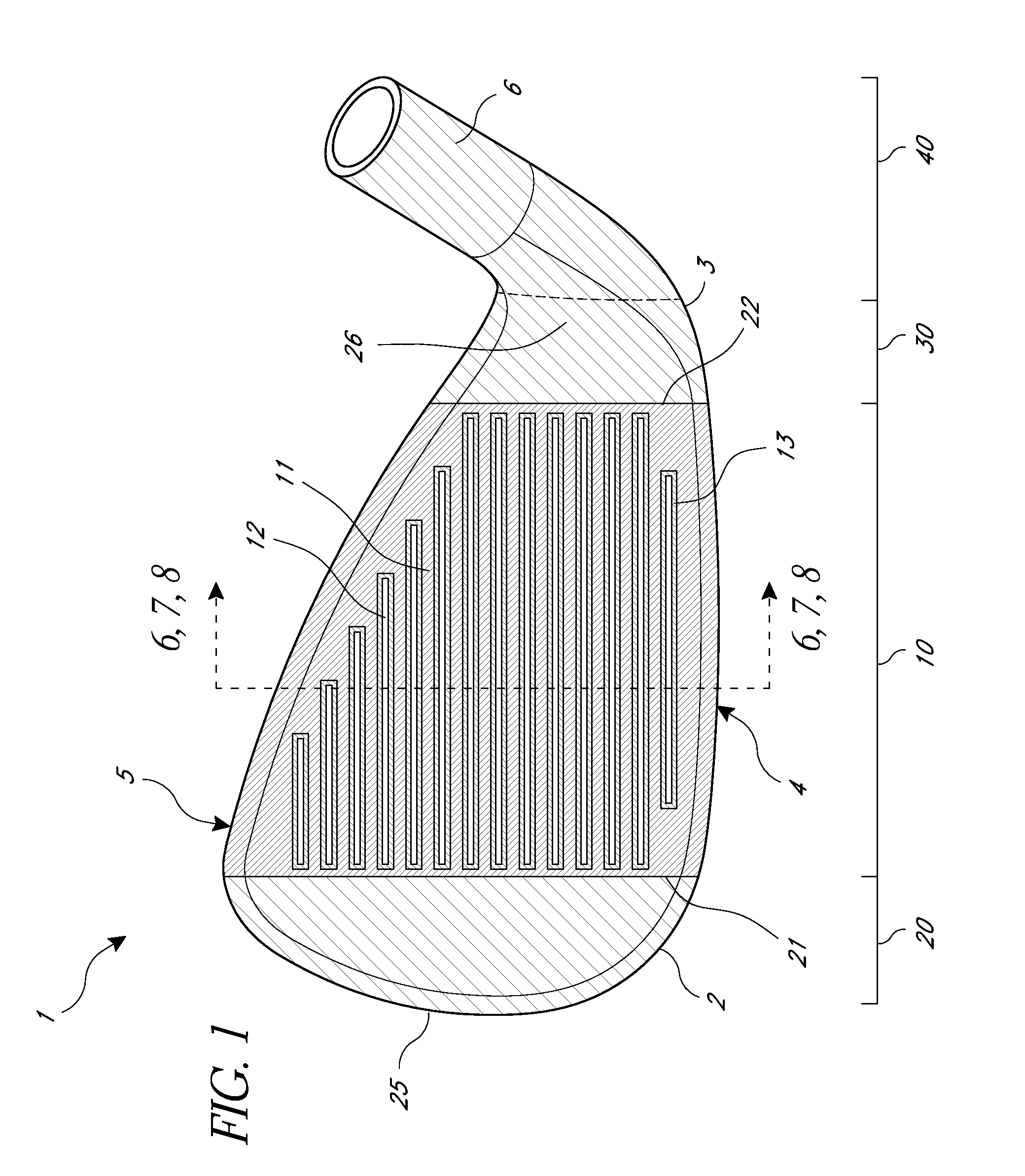

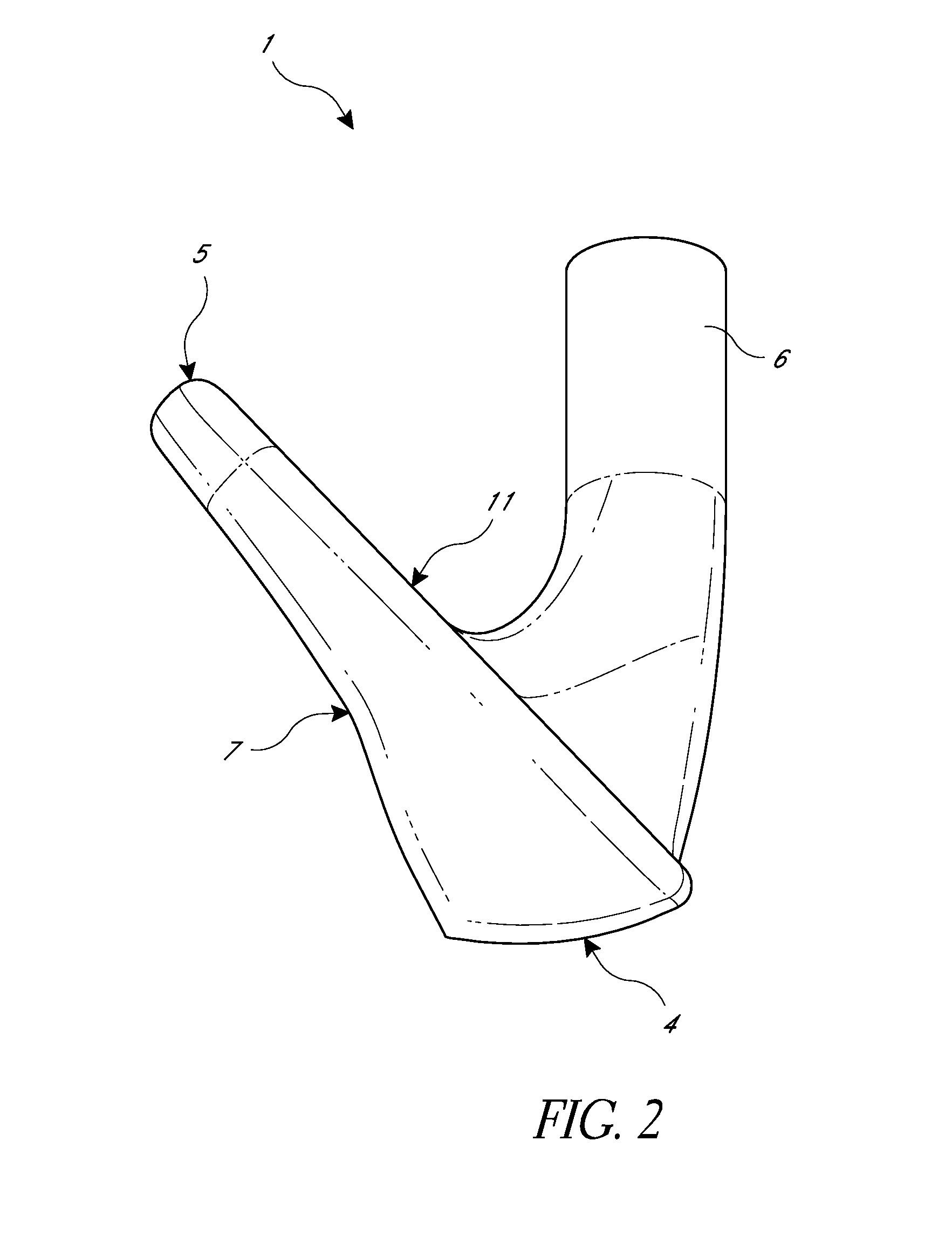

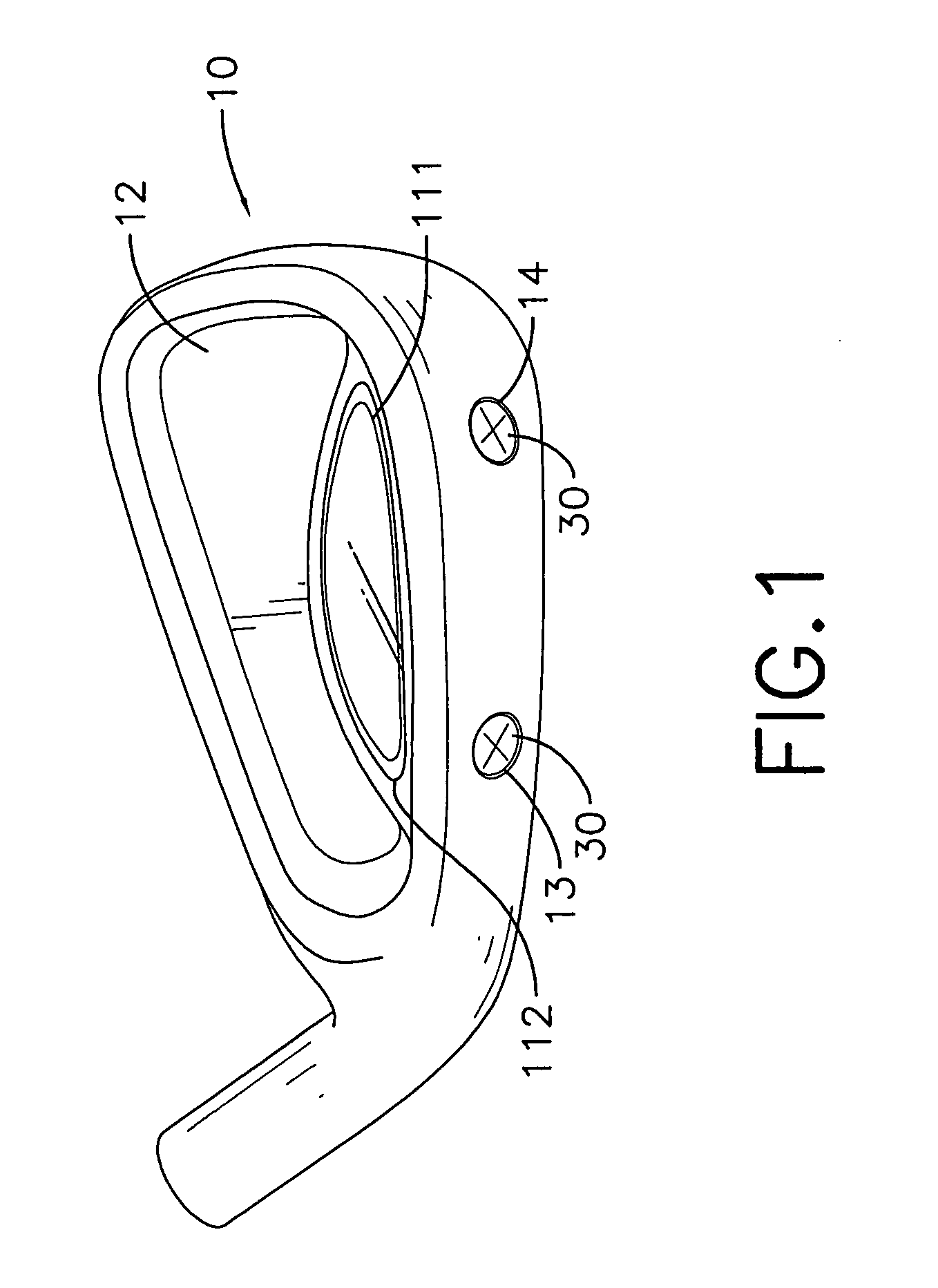

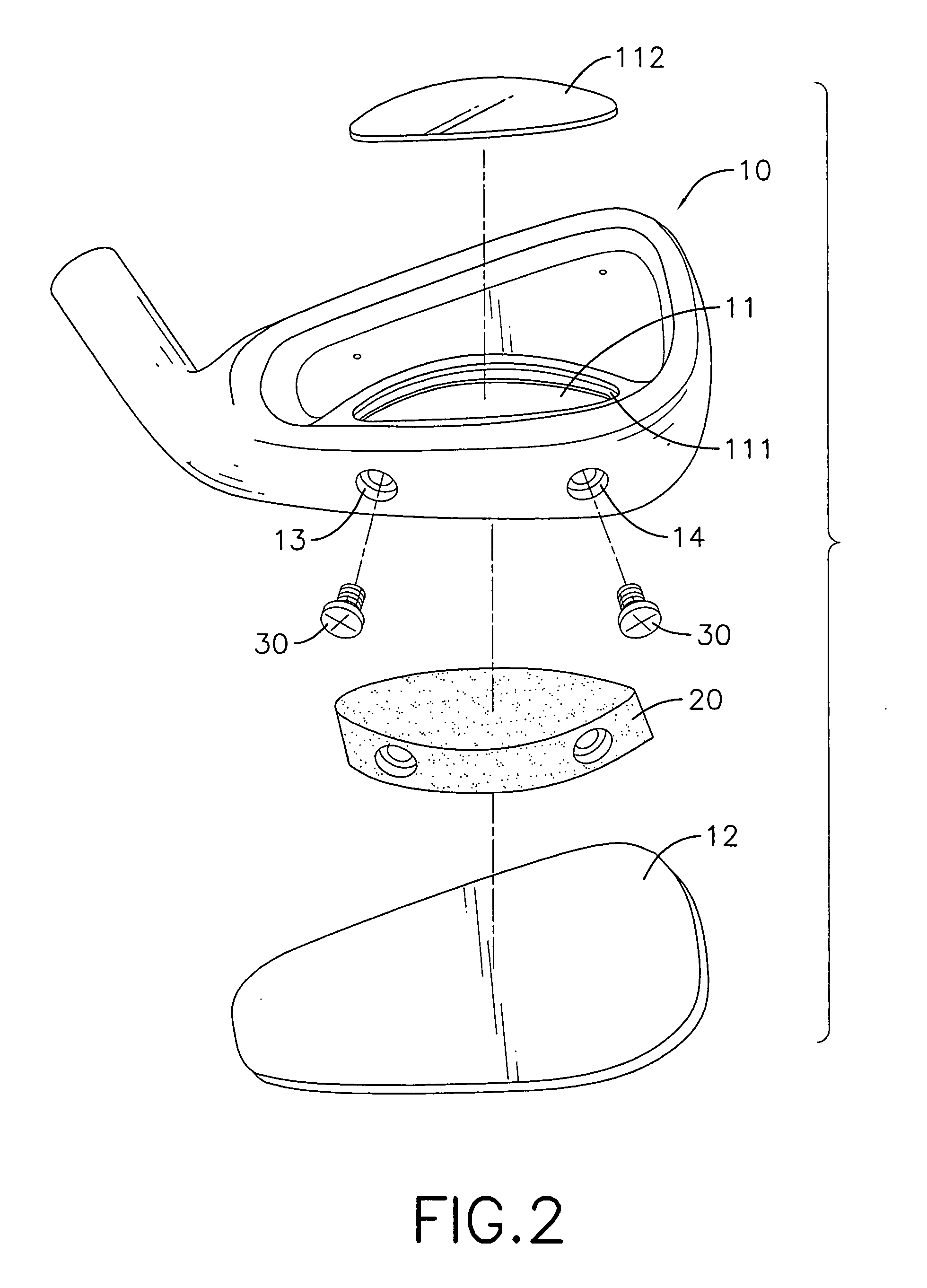

Golf club heads with enlarged grooves

Golf club heads with enlarged grooves, wherein a portion of the finish adjacent or within the groove is removed to create the visual appearance of enlarged grooves. The surface finish of the groove enhancement area surrounding the groove is matched to be the same as the surface finish of the groove, preferably a bright, smooth or shiny metallic finish. This surface finish of the remainder of the striking face of the golf club is a second surface finish, preferably a dark or black matte, or rough finish. The contrast between the two finishes gives the perception that the grooves are larger than they are physically.

Owner:COBRA GOLF

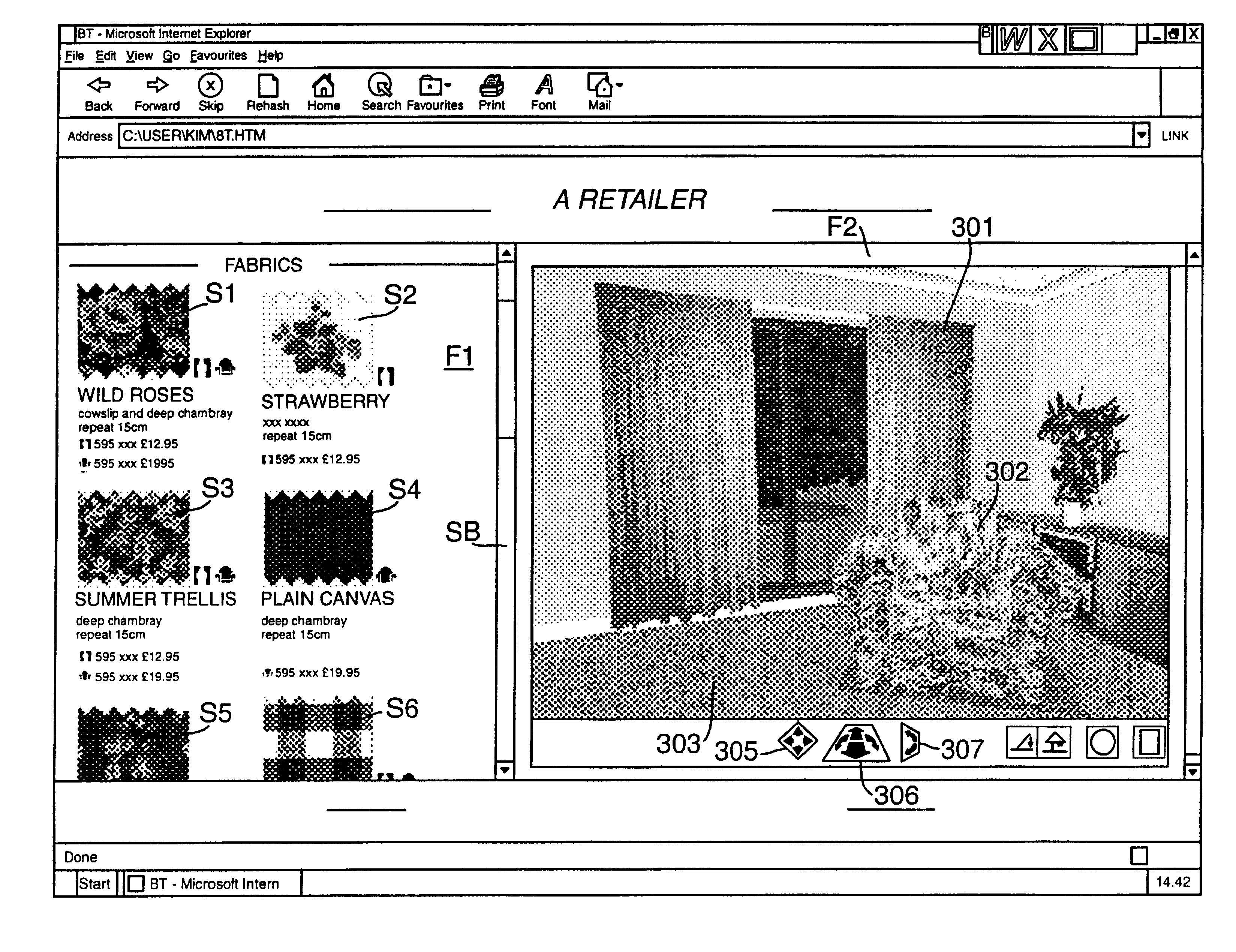

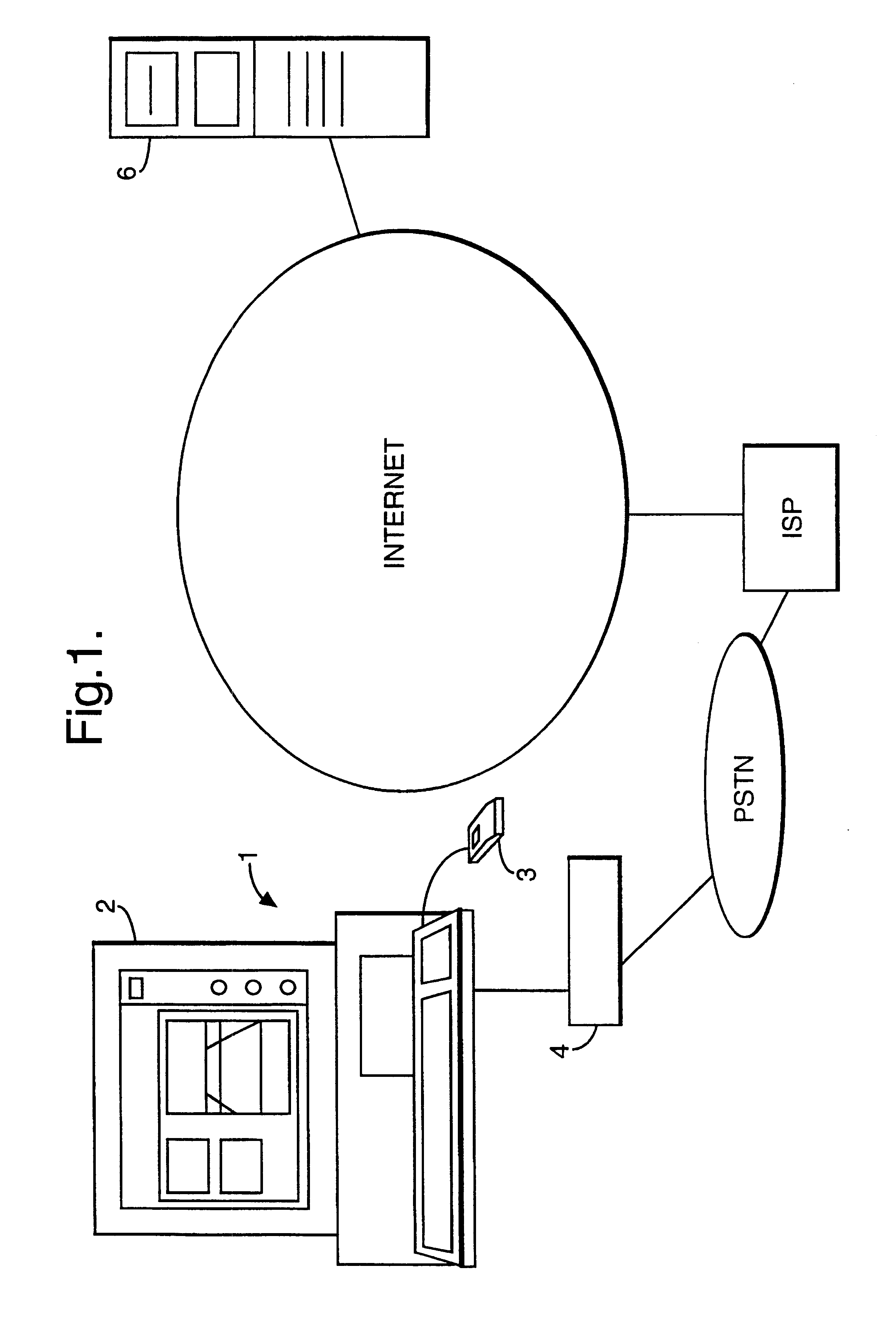

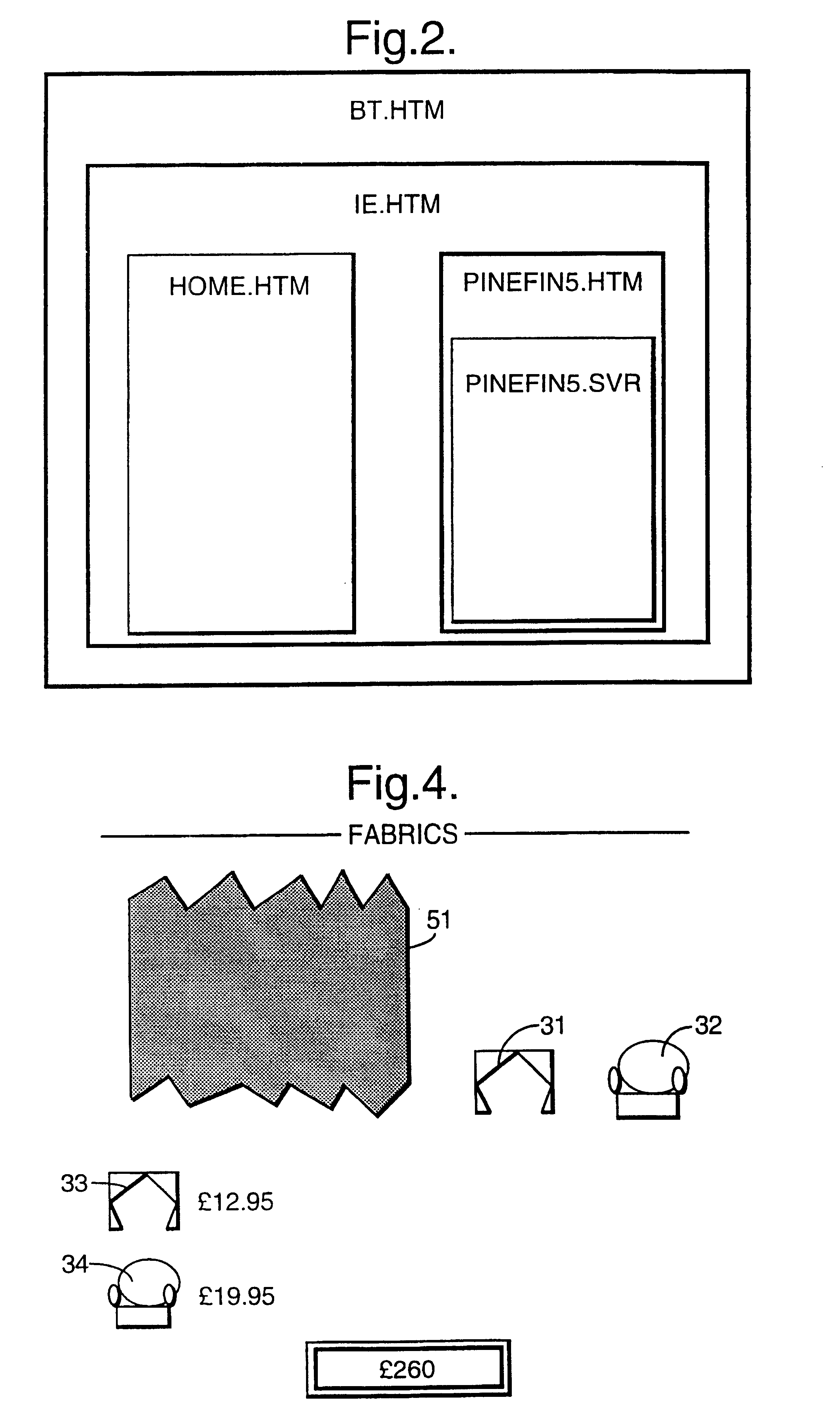

Display terminal user interface with ability to select remotely stored surface finish for mapping onto displayed 3-D surface

InactiveUS6331858B2Realistic assessmentCathode-ray tube indicatorsTwo-way working systemsViewpointsZoom

A user interface on a display terminal, such as a personal computer, includes a 3D display region which shows a scene incorporating a number of objects, such as items of furniture. A surface finish selector is also displayed and is used to select a surface finish from a number of alternatives. In the case of items of furniture, these finishes may correspond to different fabrics for upholstery. A surface texture data for a selected finish is automatically downloaded from a remote source and mapped onto the object in the 3D scene. In a preferred implementation, the surface finish selector is a frame of a web page and generates control data which is passed to another frame containing the 3D scene together with movement controls for changing the viewpoint in the scene.

Owner:BRITISH TELECOMM PLC

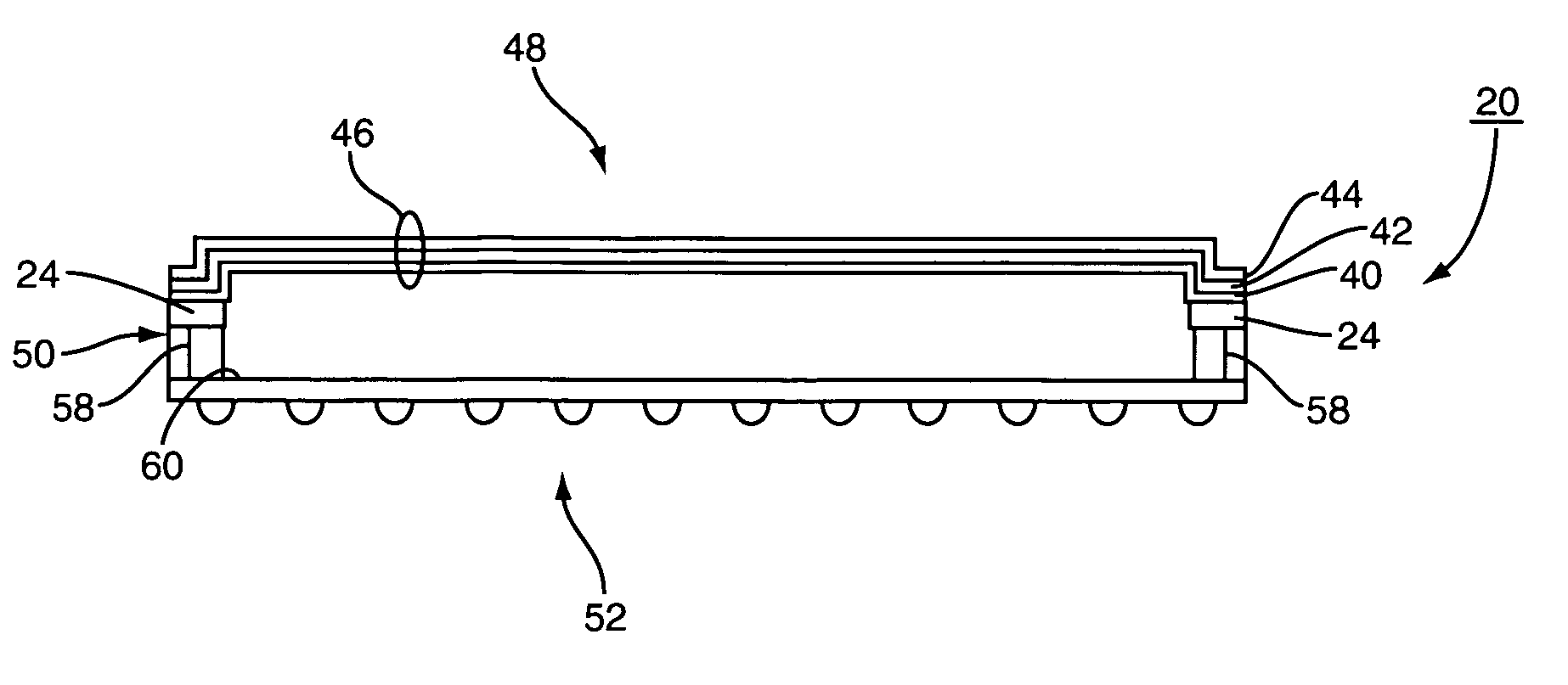

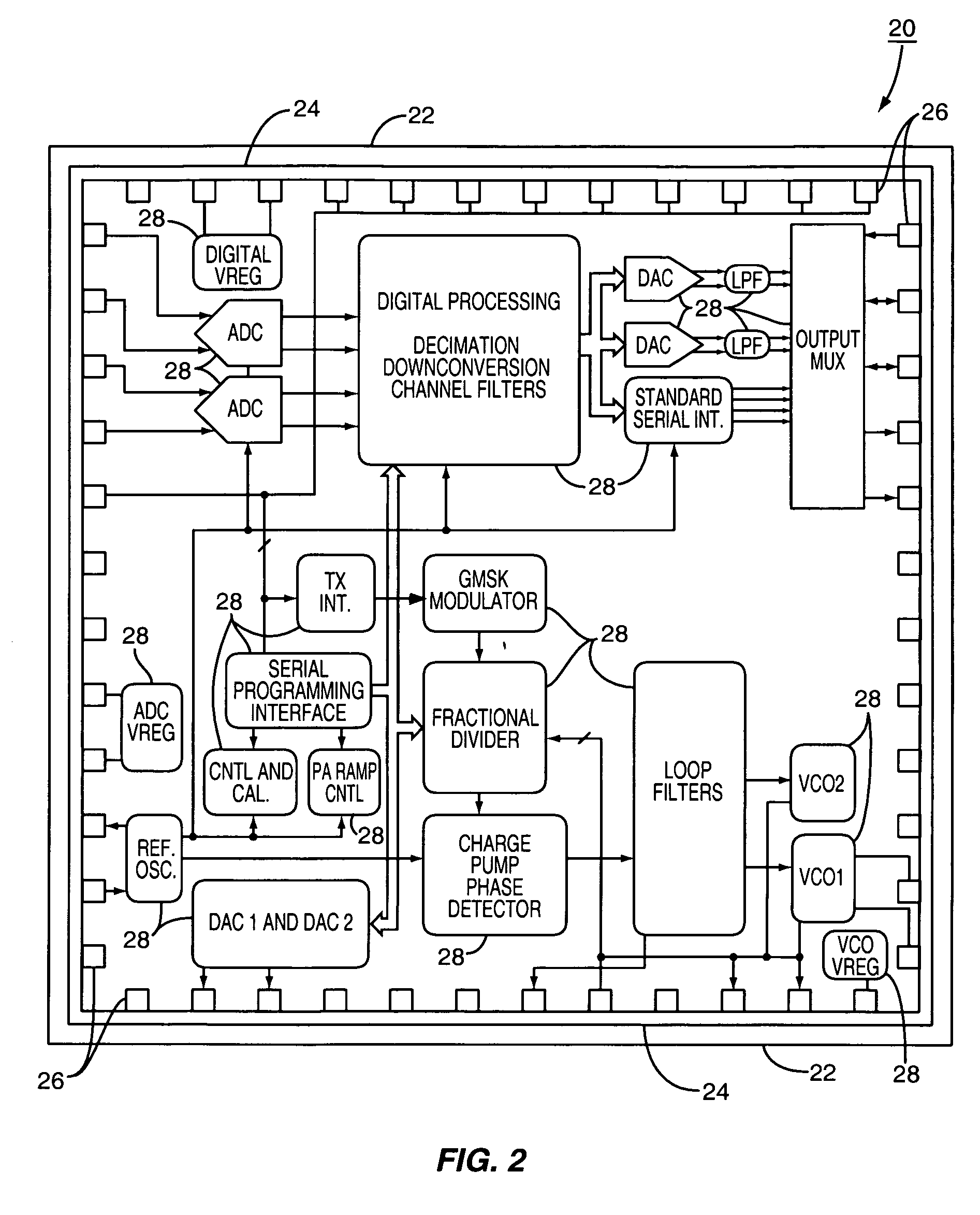

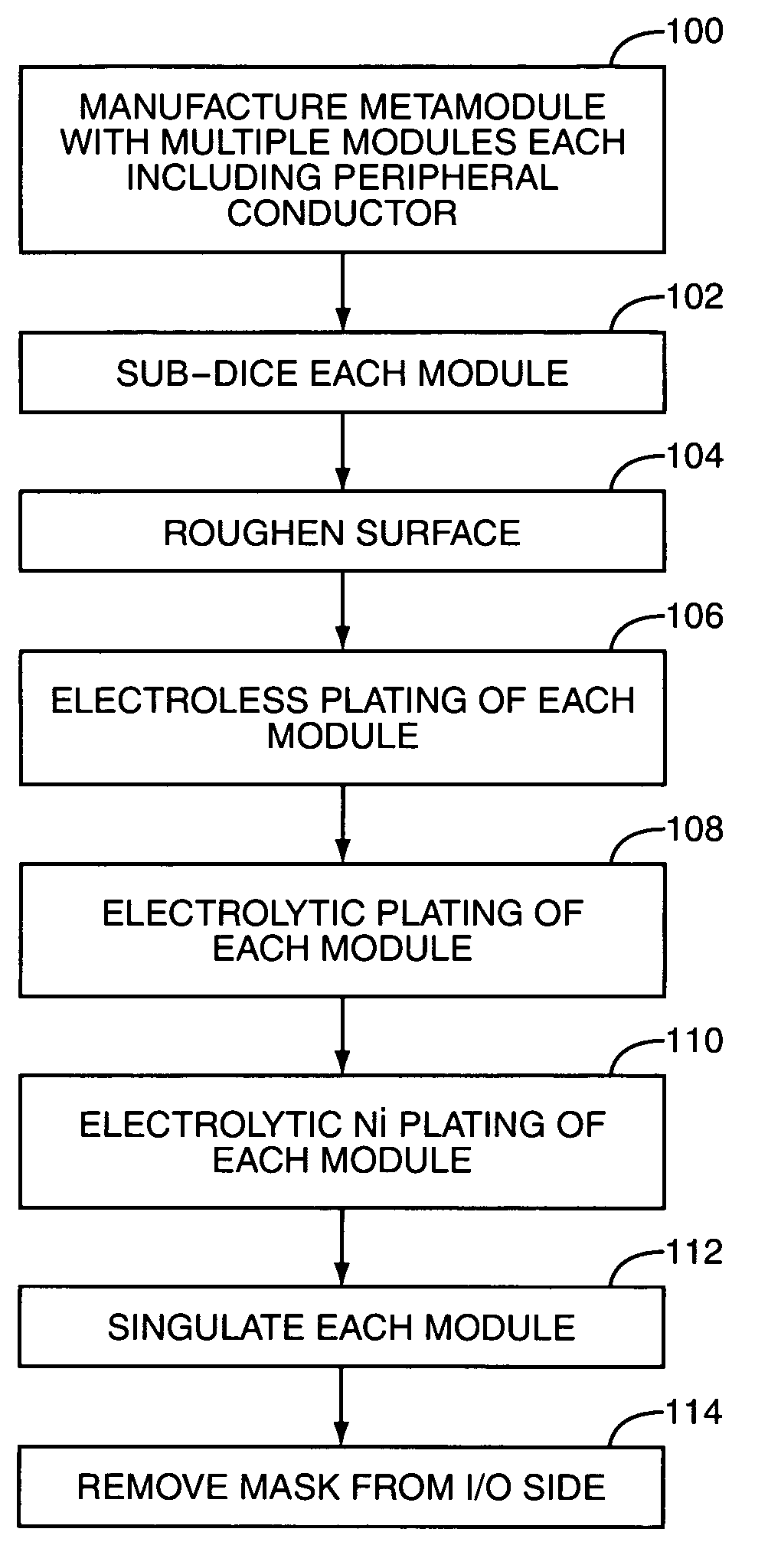

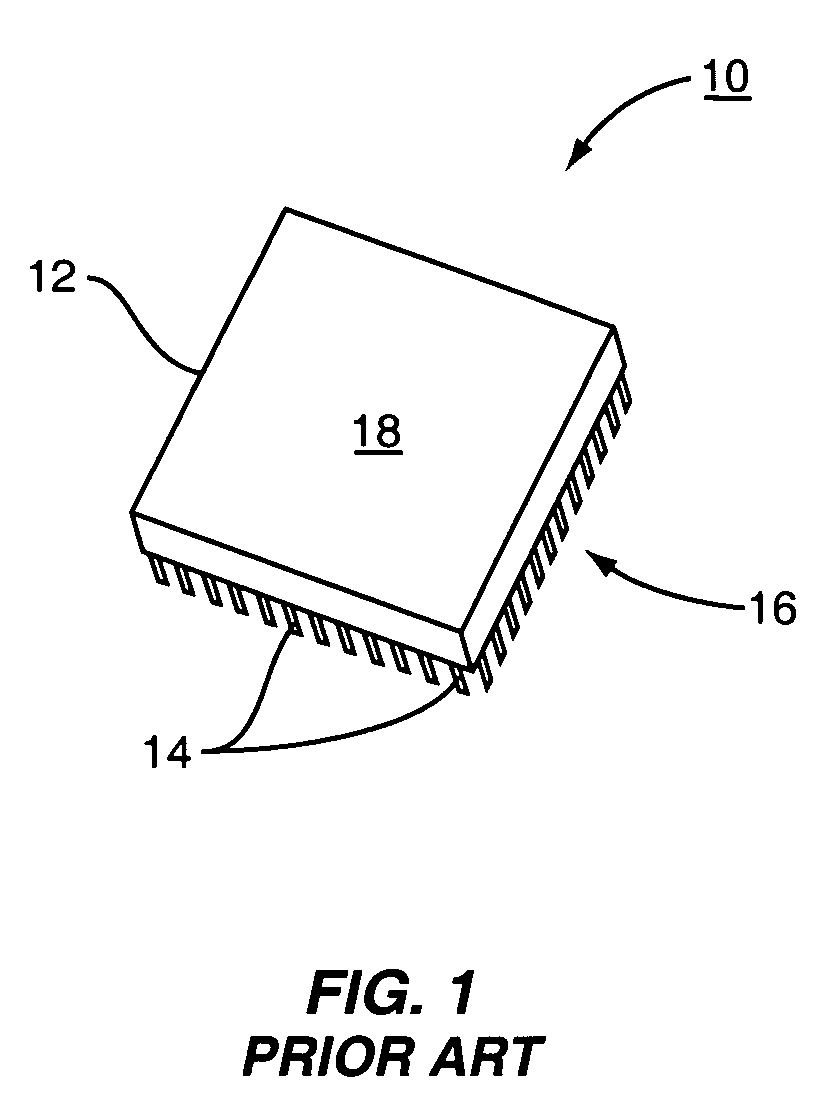

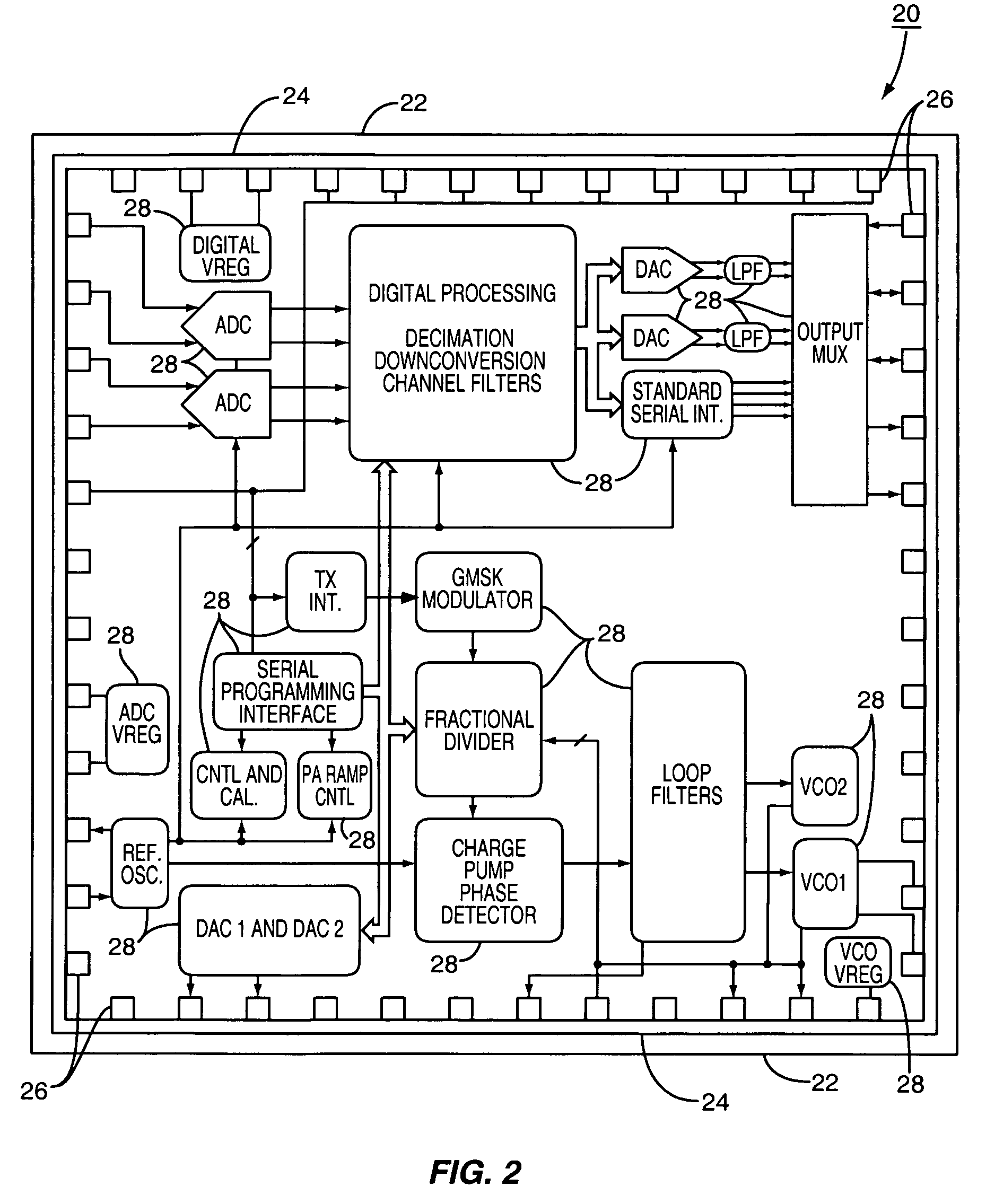

Conformal electromagnetic interference shield

An electromagnetic shield for an electronic module includes a surface finish that is applied to the surface of an electronic module so as to minimize the size of the shield. Once the shield is in place, the shield acts to address electromagnetic interference (EMI) concerns associated with the electronic module. An electronic module having a ring of conductive material embedded about its peripheral edge is formed. The electronic module is then sub-diced so as to expose the ring of conductive material. After sub-dicing, a conductive material may be applied through an electroless plating process followed by an electrolytic plating process. Alternatively, a conductive epoxy may be sprayed or painted onto the surface of the electronic module.

Owner:QORVO US INC

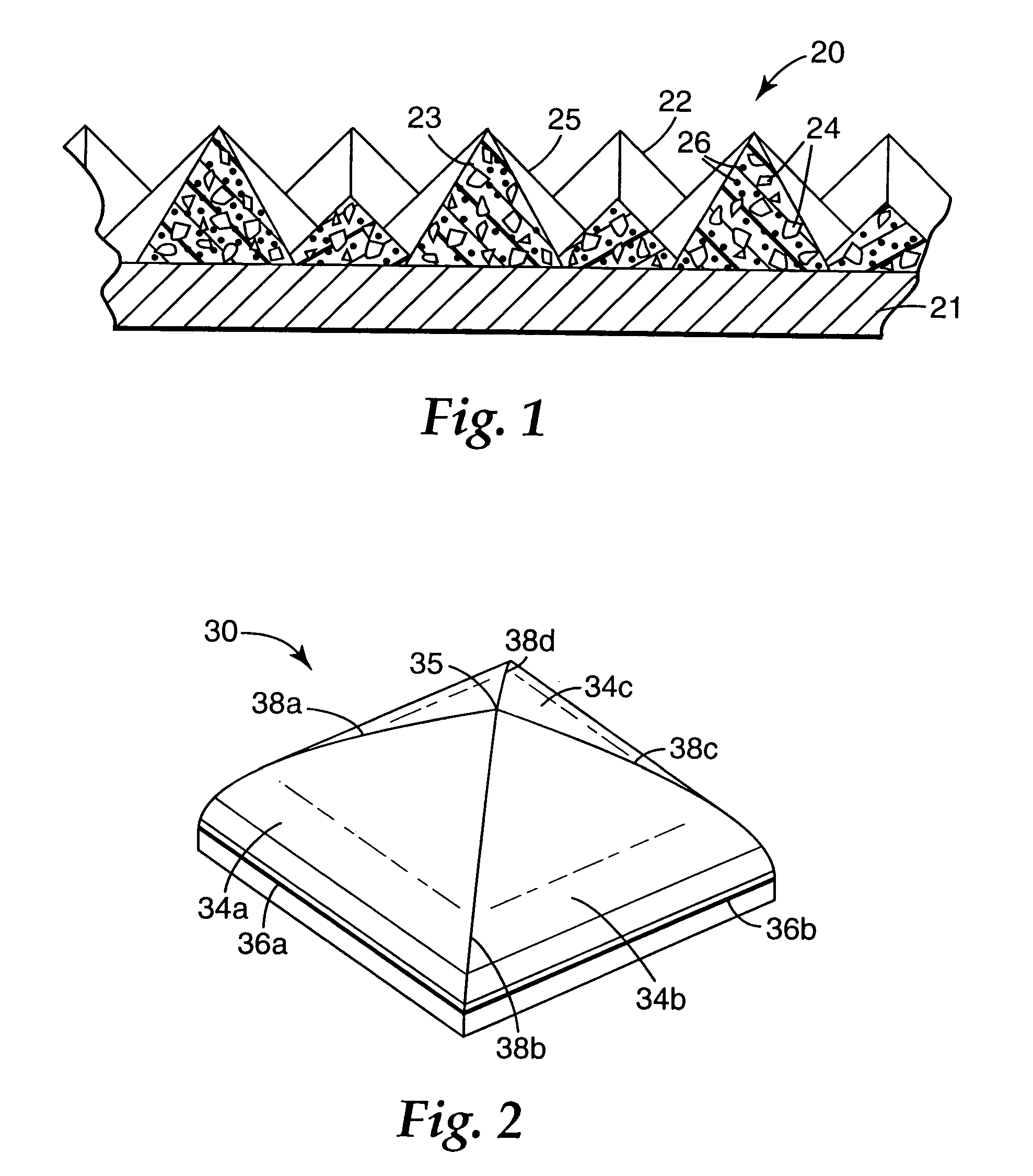

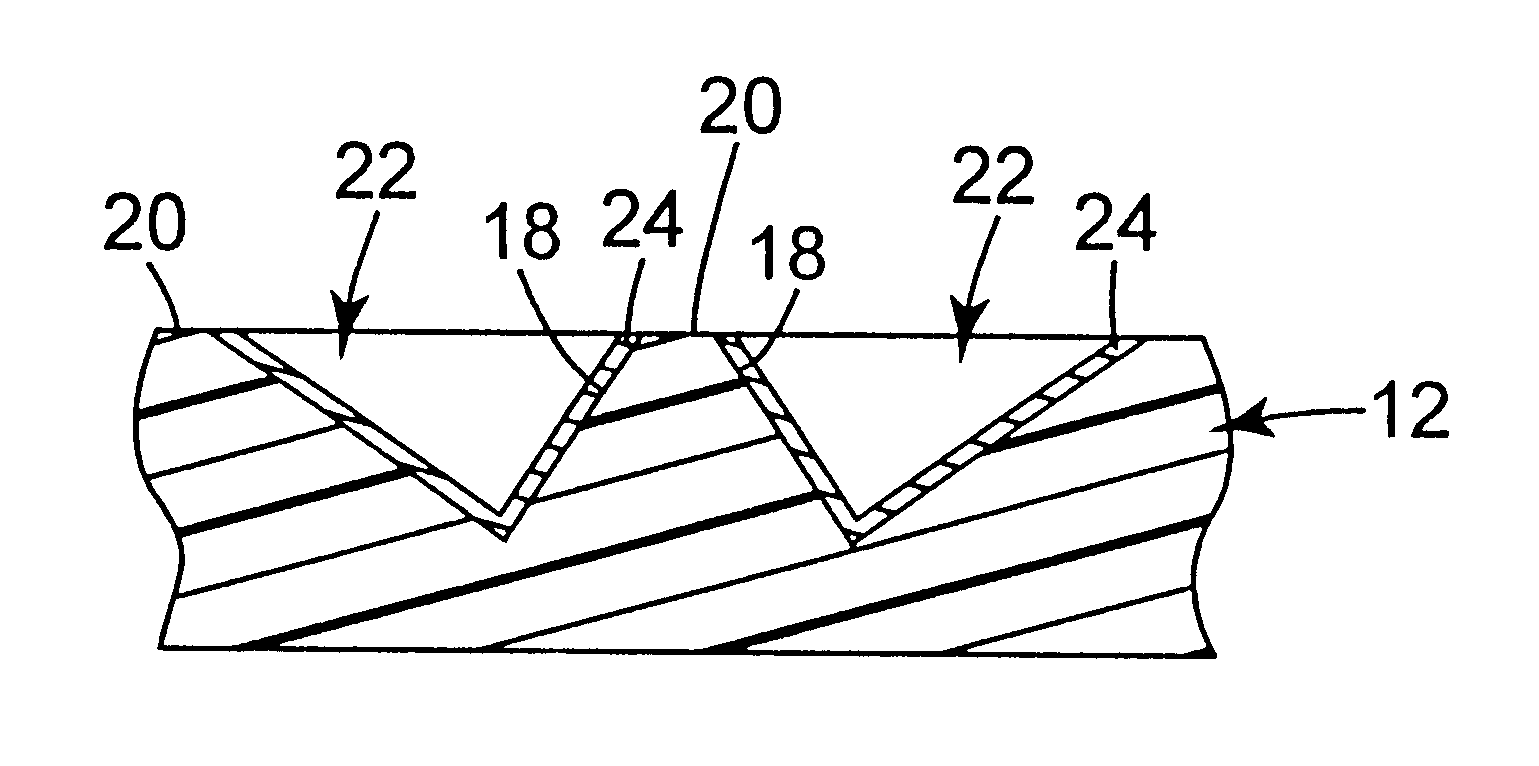

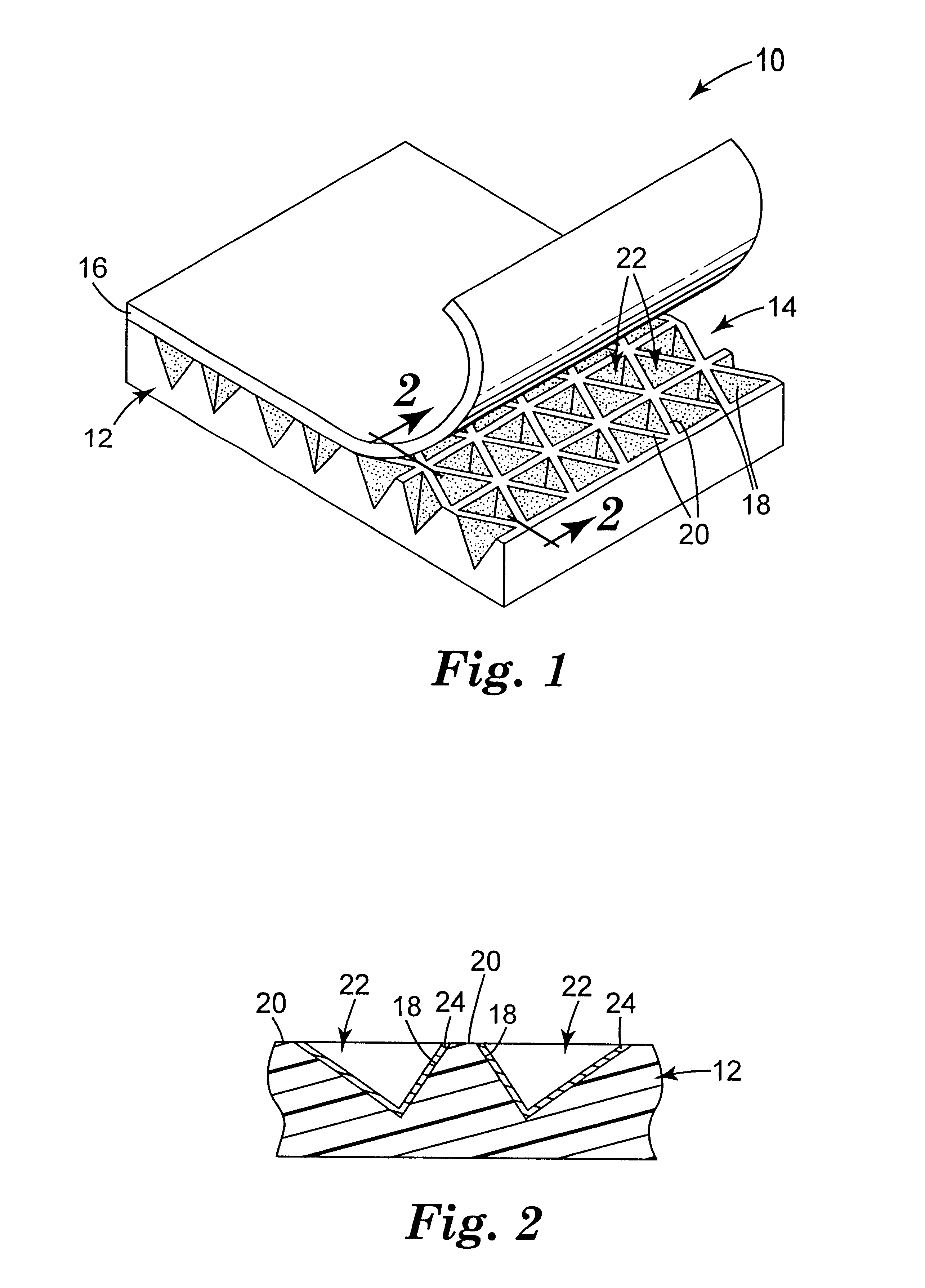

Compositions for abrasive articles

ActiveUS20050060947A1Attenuation consistentImprove cutting lifePigmenting treatmentOther chemical processesSurface finishMicrometer

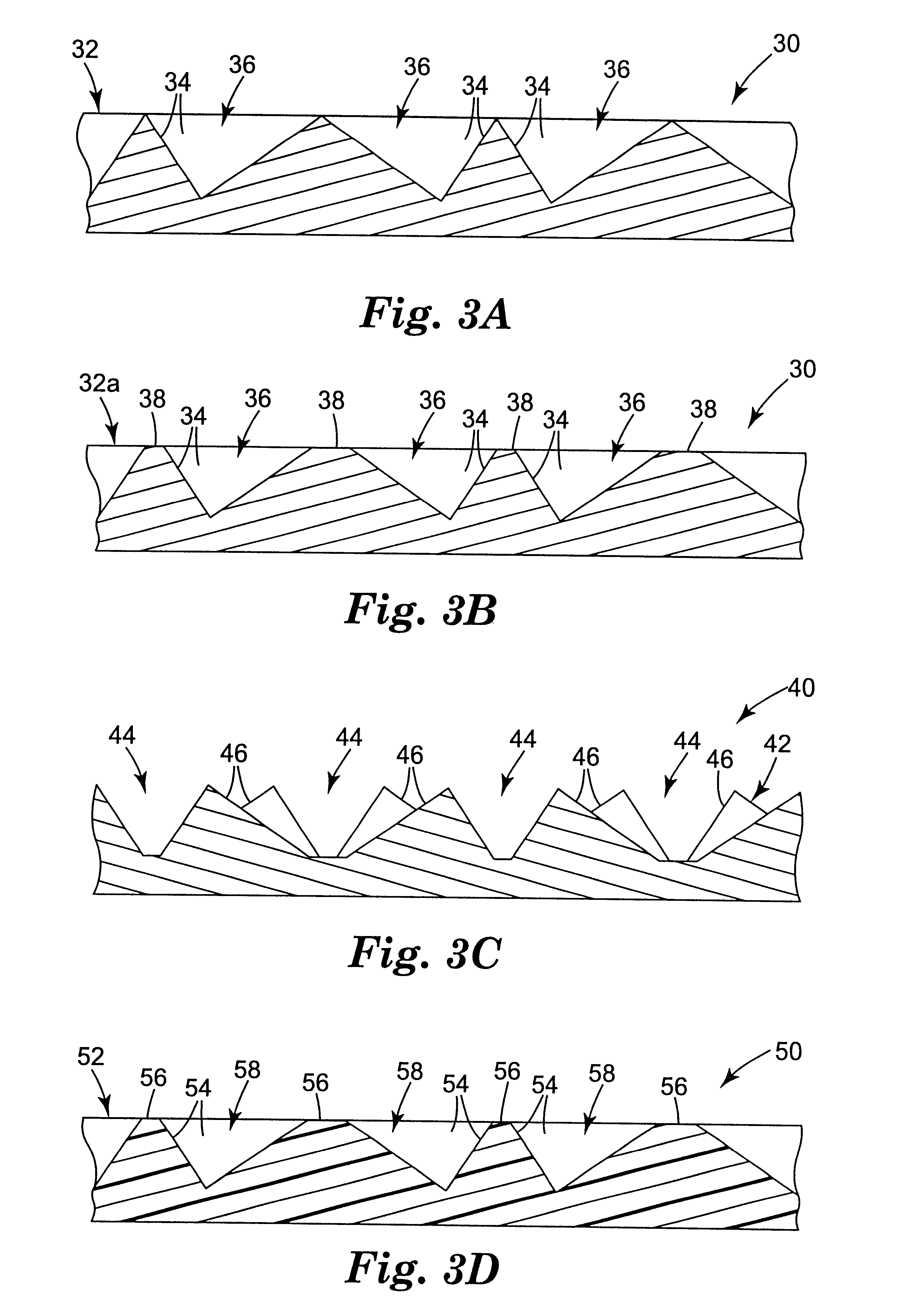

A structured abrasive article, methods of making an abrasive article, and methods of using an abrasive article. The abrasive composites forming the abrasive article have a height of at least 500 micrometers, and the abrasive particles in the composites have an average particle size of at least 40 micrometers, in some embodiments, at least about 85 micrometers. The large topography composites, together with the large ceramic abrasive particles, provides an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than conventional make / coat abrasive articles with the same size and type of abrasive particles. Additionally, the large topography composites, together with the large ceramic abrasive particles, provide an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than structured abrasive articles having a smaller topography, even with the same abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

Diamond-like carbon coated dental retaining screws

The invention relates to a coated dental screw for retaining and securing components of a dental prosthetic implant stack. The screw is coated with a hard carbon coating / film to provide a low friction surface finish which advantageously results in improved preloading of the screw, and hence a high clamping force between the components of the dental prosthetic implant stack. The coating can comprise diamond-like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof. The dental screw can include abutment retaining screws and prosthesis retaining screws. Other advantages provided by the hard carbon coating include high mechanical surface hardness, biocompatibilty, corrosion resistance, chemical inertness and low cost.

Owner:NOBEL BIOCARE SERVICES AG

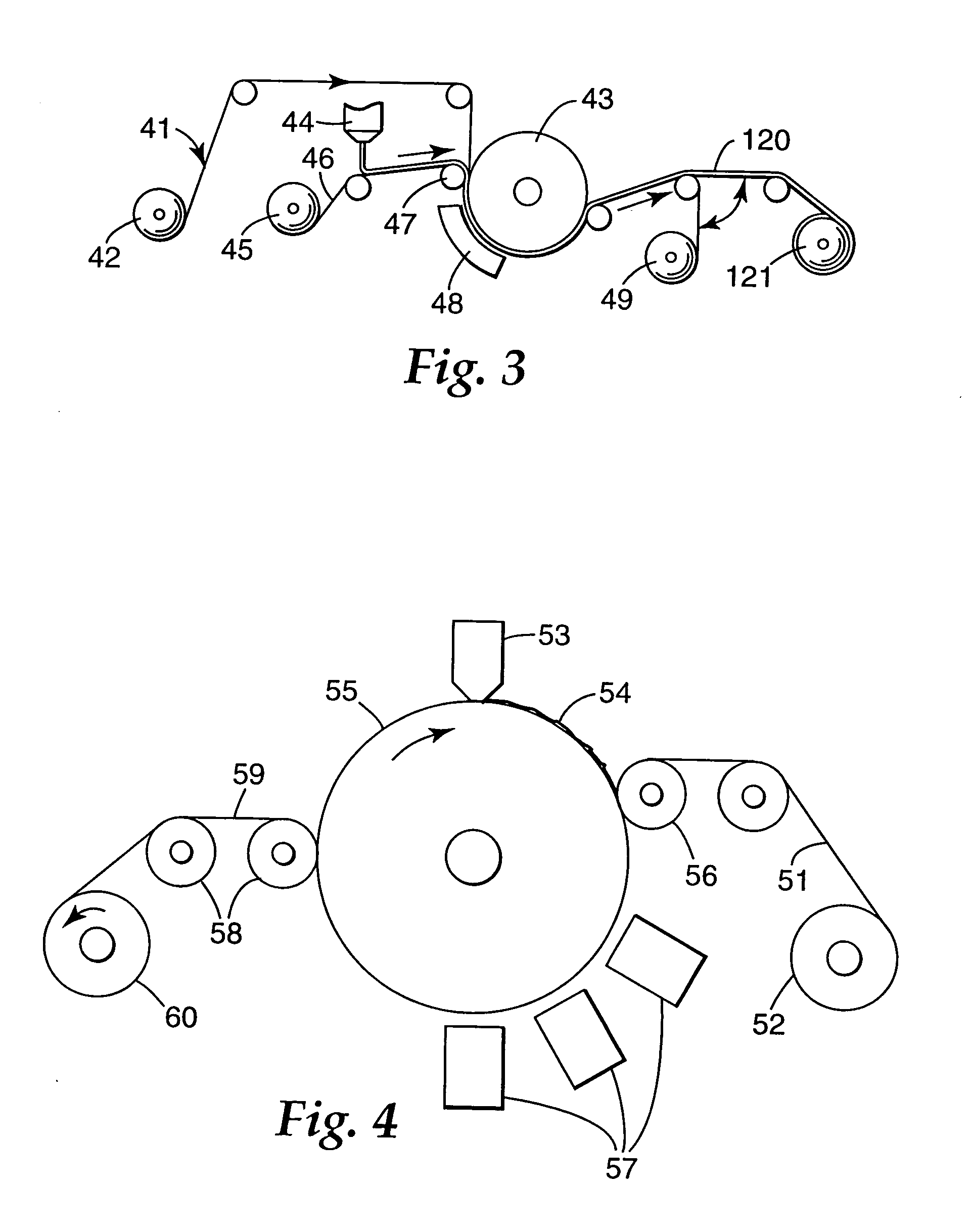

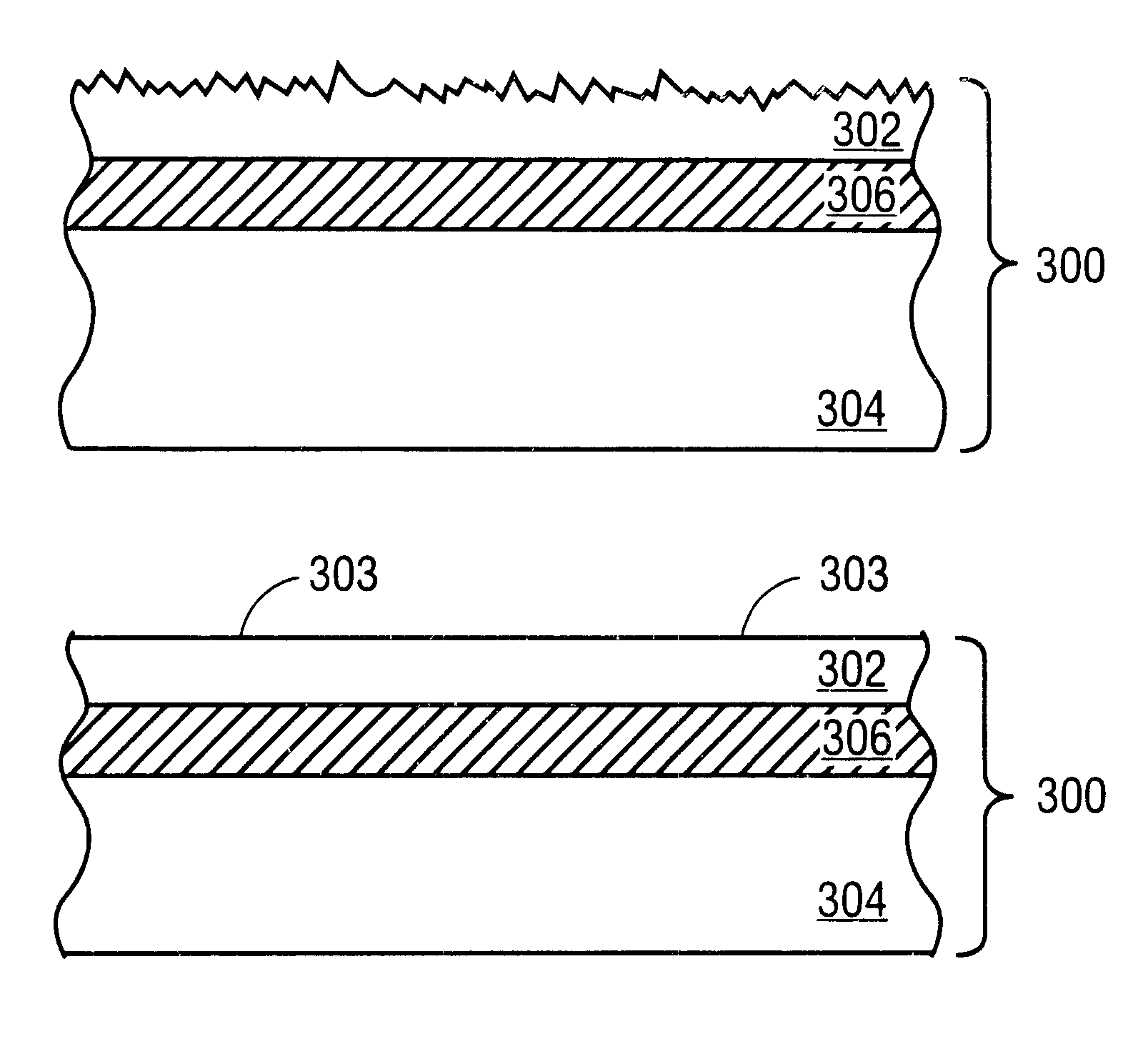

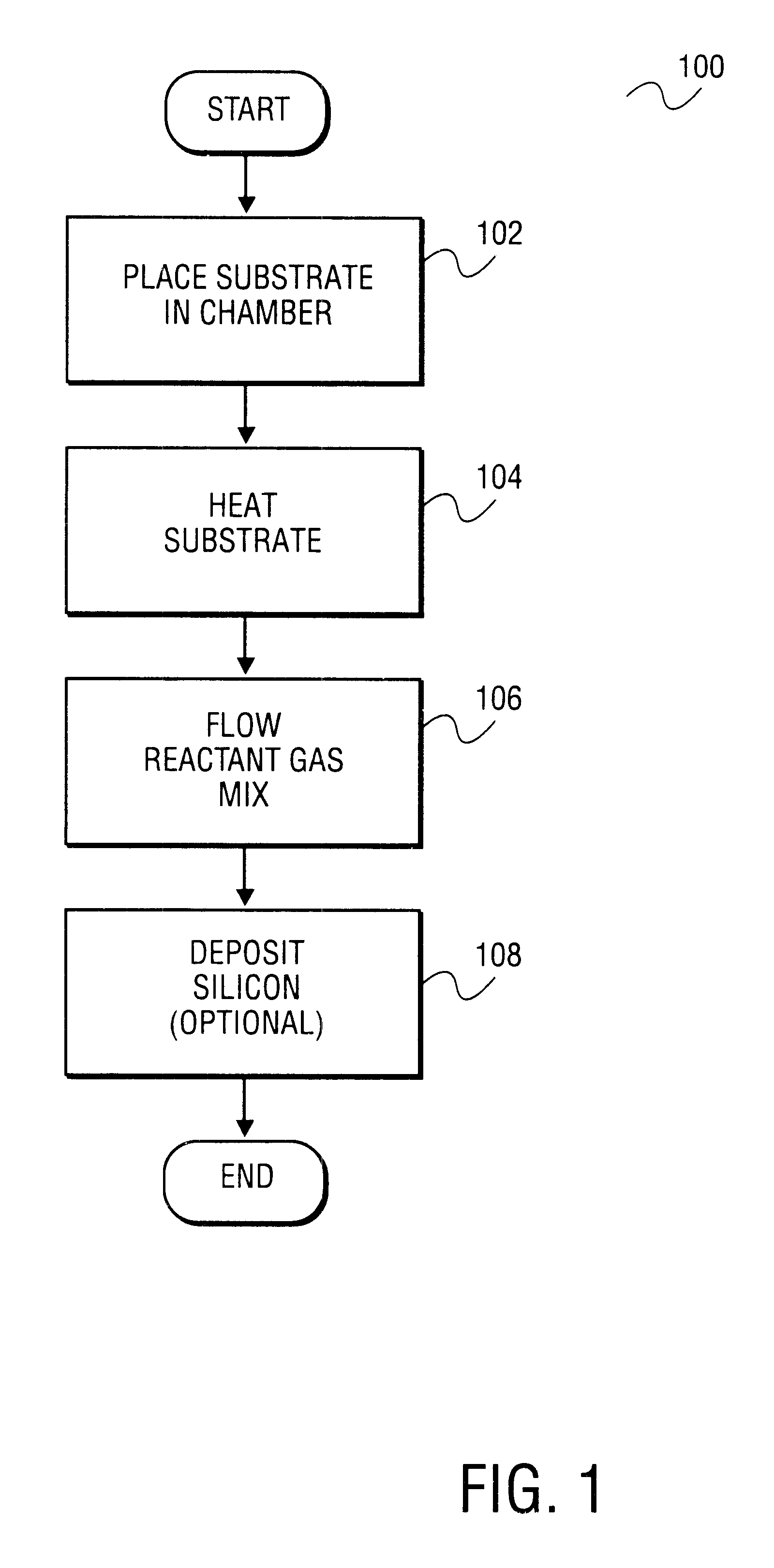

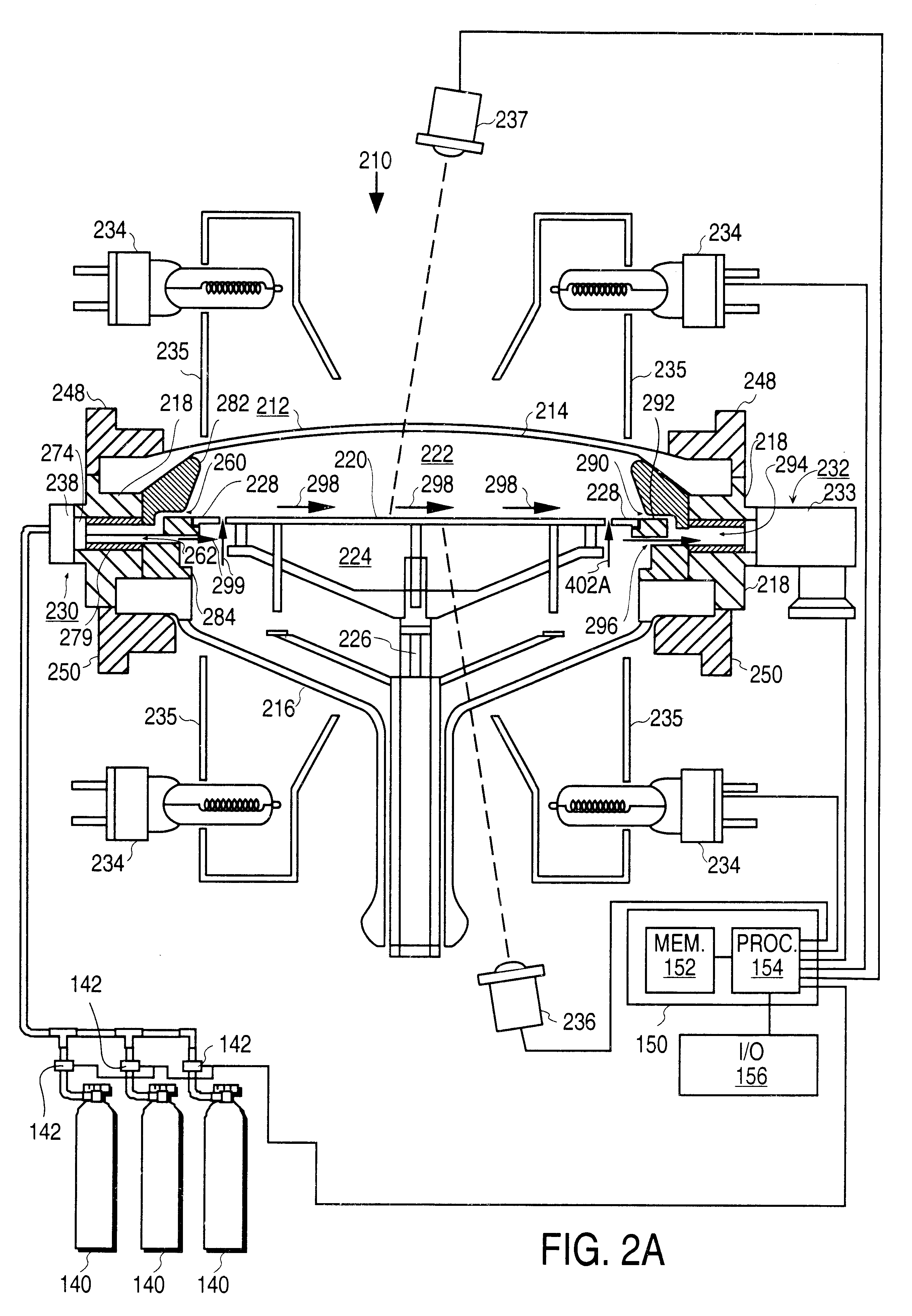

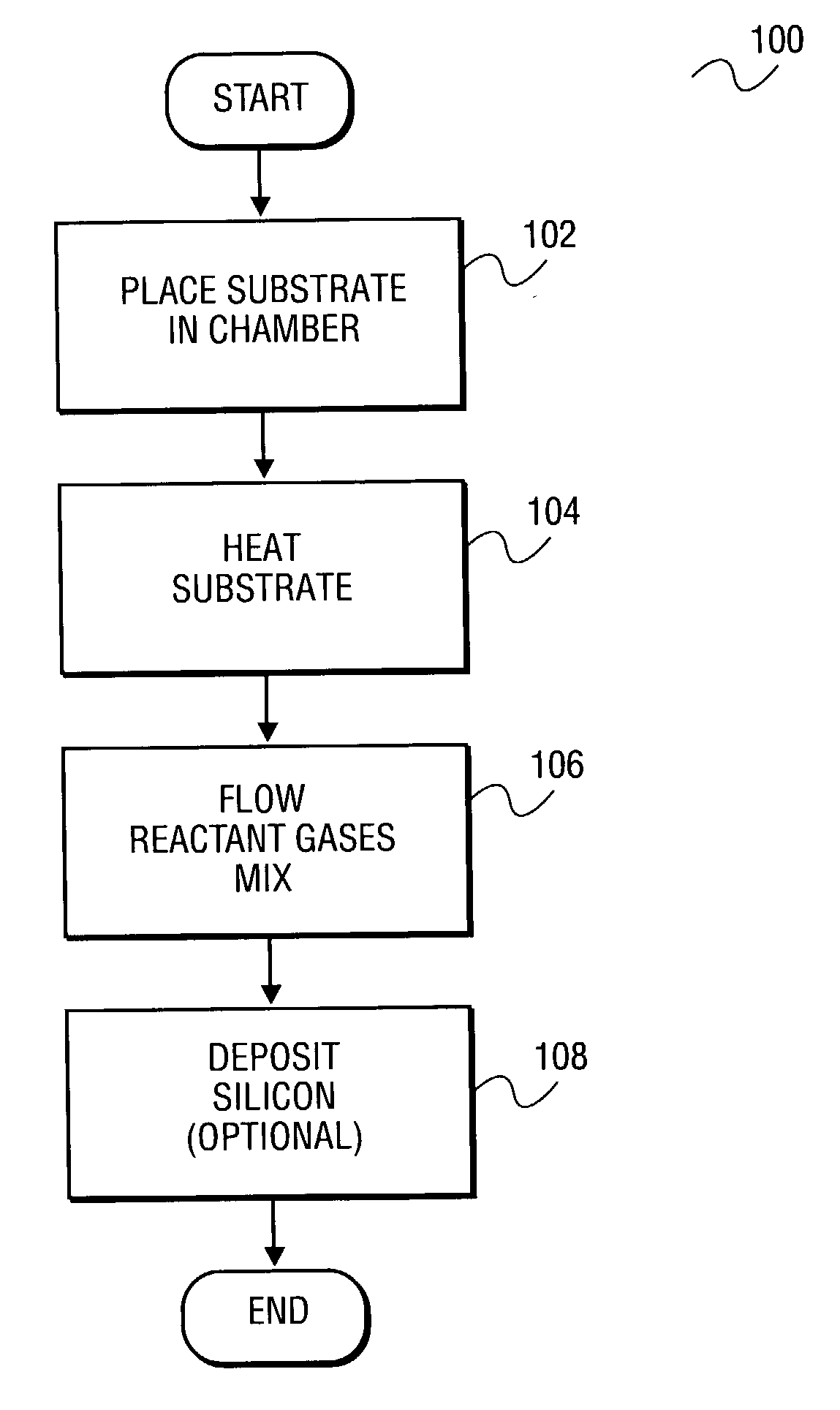

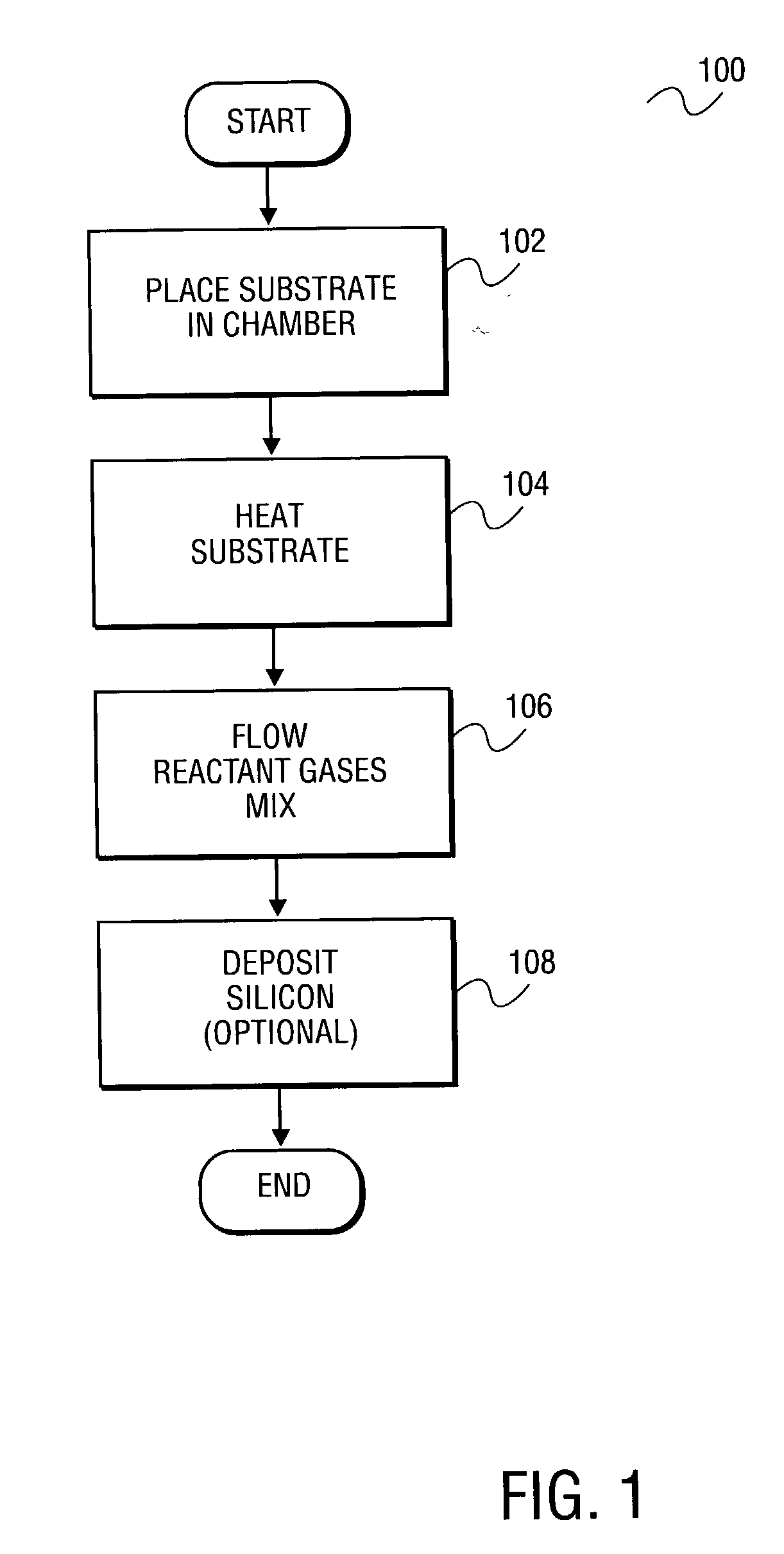

Apparatus and method for surface finishing a silicon film

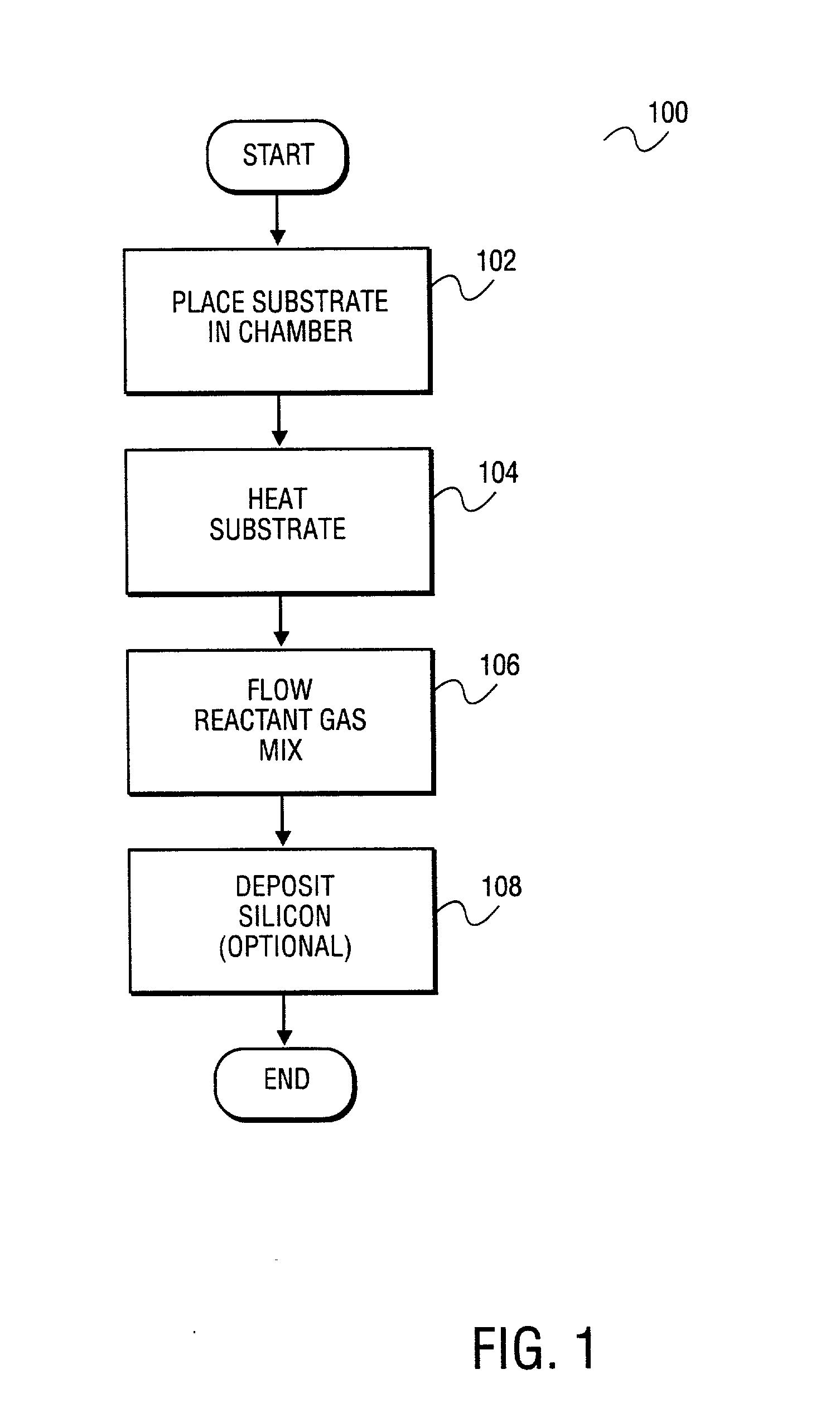

A method of smoothing a silicon surface formed on a substrate. According to the present invention a substrate having a silicon surface is placed into a chamber and heated to a temperature of between 1000°-1300° C. While the substrate is heated to a temperature between 1000°-1300° C., the silicon surface is exposed to a gas mix comprising H2 and HCl in the chamber to smooth the silicon surface.

Owner:SILICON GENERAL CORPORATION +1

Apparatus and method for surface finishing a silicon film

InactiveUS20020090818A1Polycrystalline material growthAfter-treatment detailsSurface finishSilicon membrane

A method of smoothing a silicon surface formed on a substrate. According to the present invention a substrate having a silicon surface is placed into a chamber and heated to a temperature of between 1000°-1300° C. While the substrate is heated to a temperature between 1000°-1300° C., the silicon surface is exposed to a gas mix comprising H2 and HCl in the chamber to smooth the silicon surface.

Owner:APPLIED MATERIALS INC +1

Laser sinter powder with a metal salt and a fatty acid derivative, process for its production, and moldings produced from this laser sinter powder

InactiveUS20050027050A1Improve the immunityMaintain good propertiesAdditive manufacturing apparatusFibre treatmentSelective laser sinteringPolyamide

The present invention relates to a sinter powder composed of polyamide which also comprises metal salts of weak acids, in particular metal carbonates, and fatty acid derivatives, in particular fatty acid esters or fatty acid amides, to a process for laser sintering, and also to moldings produced from this sinter powder. The moldings formed using the powder of the invention have marked advantages in appearance and in surface finish when compared with conventional products, especially when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder of the invention moreover also have markedly improved mechanical properties when compared with moldings based on recycled conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strain at break. These moldings also have a density approaching that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

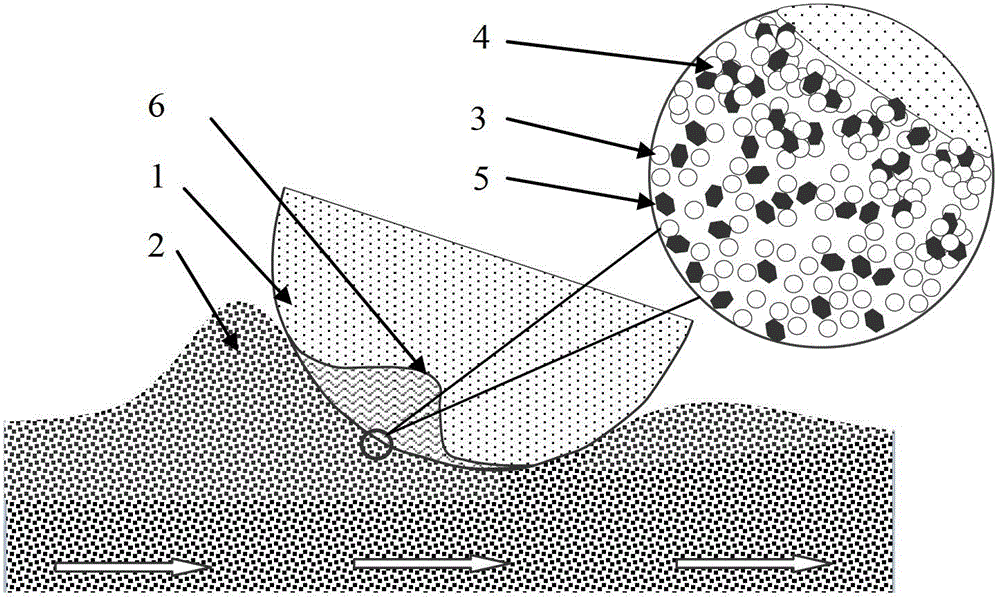

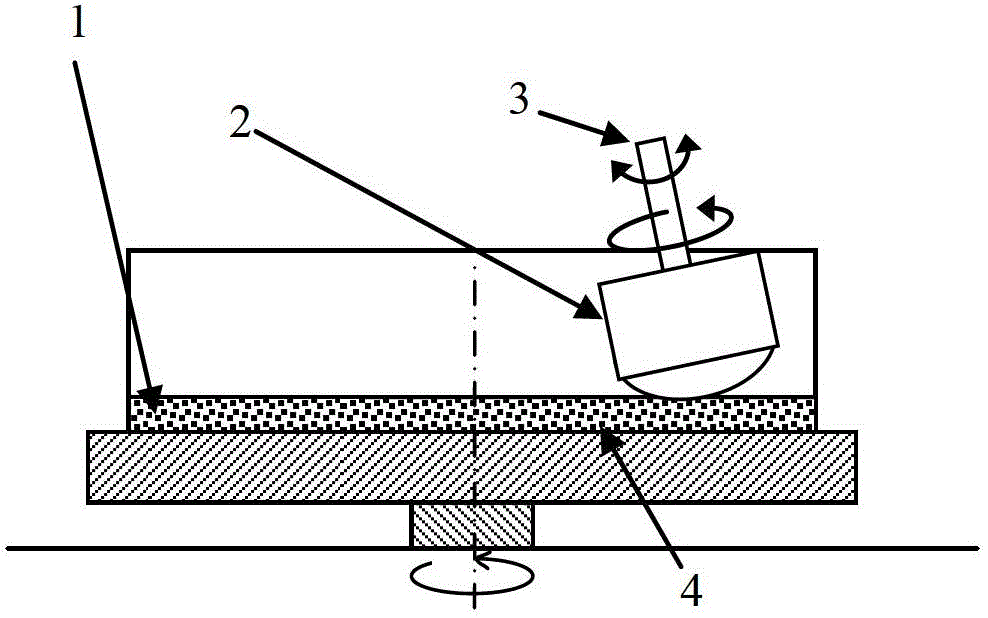

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

Self-leveling polymer cement base repair mortar and preparation method thereof

The invention provides a self-leveling polymer cement base repair mortar which is used for repairing cracks of a concrete building. The self-leveling polymer cement base repair mortar comprises the following components in part by weight: 25 to 60 parts of cement, 40 to 70 parts of sand, 1 to 5 parts of redispersible rubber powder, 0.2 to 1.0 part of interface reinforcing agent, 0.1 to 0.5 part of water-retaining agent, and 0.1 to 1 part of water reducing agent; the self-leveling polymer cement base repair mortar has high self-leveling performance; after the building is repaired by the mortar, the whole flatness is high, surface finishment is uniform, and the decoration performance is high; the mortar has high crack infiltration capacity, can infiltrate the crack with the length of less than 1mm, has high bonding strength between the mortar and the original concrete, and does not fall off after being dried and hardened; and after being hardened, the mortar has micro expansion performance, and can compensate the partial shrinkage of concrete, improve the impermeability of the concrete, and is suitable for crack repairing of the concrete.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

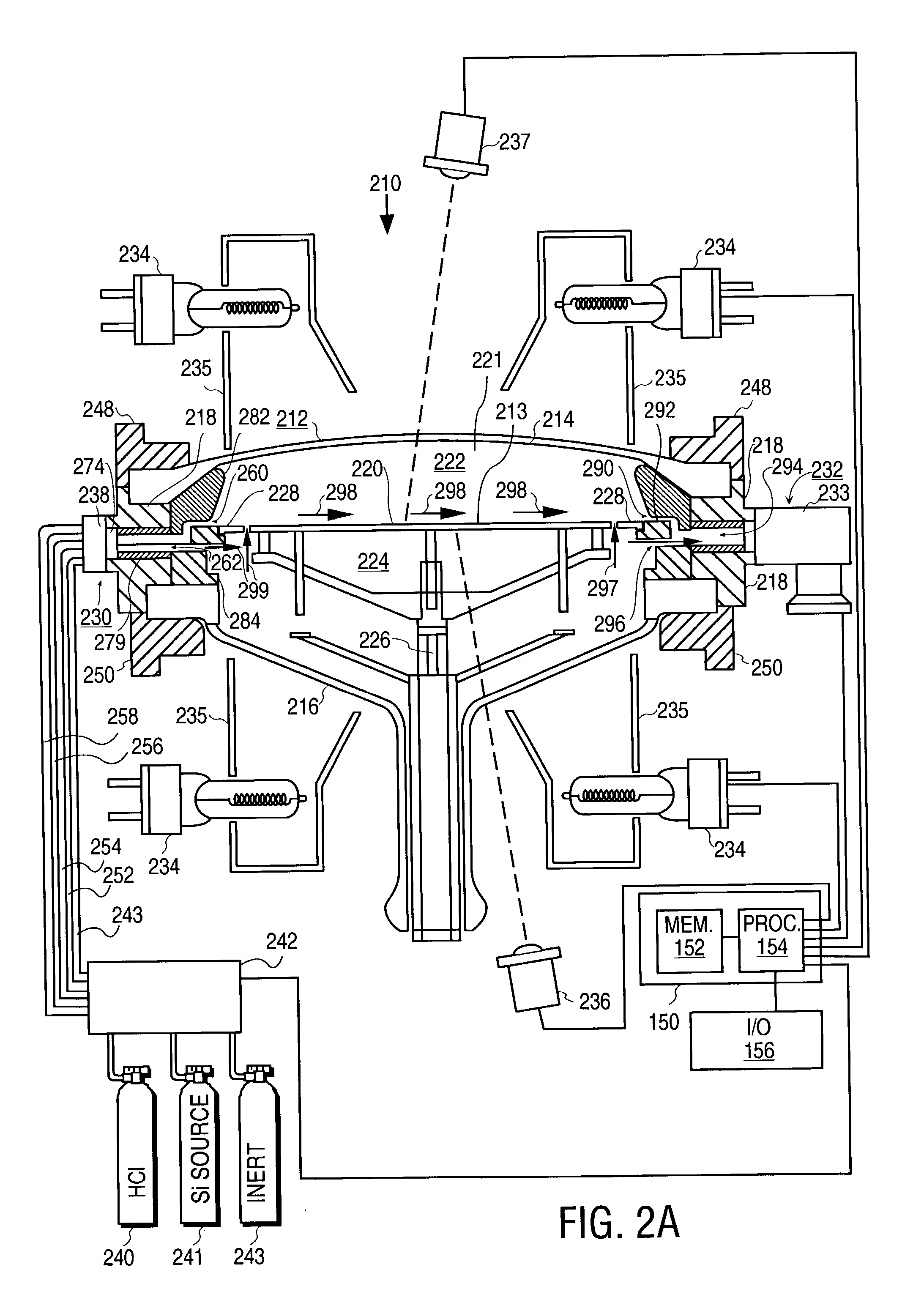

Apparatus and method for surface finishing a silicon film

InactiveUS20040053515A1Polycrystalline material growthAfter-treatment detailsSurface finishSilicon membrane

A method of treating a silicon surface of a substrate that includes heating the substrate in a process chamber to a temperature, exposing a first area adjacent to the silicon surface to a first gas mixture comprising an etchant, a silicon source gas, and a carrier, exposing a second area adjacent to the silicon surface to a second gas mixture, wherein the second gas mixture is different from the first gas mixture.

Owner:APPLIED MATERIALS INC

Method of making a conformal electromagnetic interference shield

An electromagnetic shield for an electronic module includes a surface finish that is applied to the surface of an electronic module so as to minimize the size of the shield. Once the shield is in place, the shield acts to address electromagnetic interference (EMI) concerns associated with the electronic module. An electronic module having a ring of conductive material embedded about its peripheral edge is formed. The electronic module is then sub-diced so as to expose the ring of conductive material. After sub-dicing, a conductive material may be applied through an electroless plating process followed by an electrolytic plating process. Alternatively, a conductive epoxy may be sprayed or painted onto the surface of the electronic module.

Owner:QORVO US INC

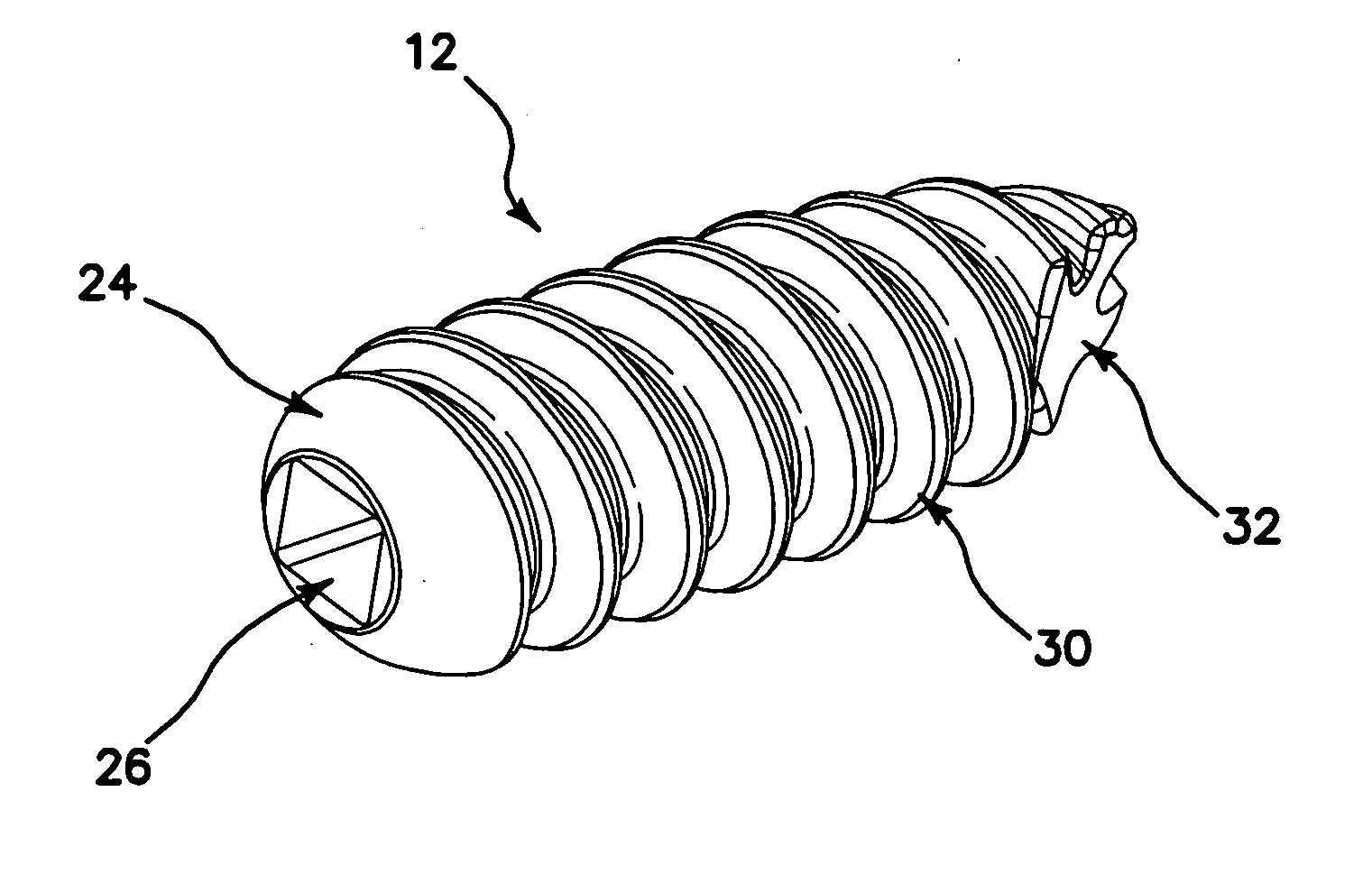

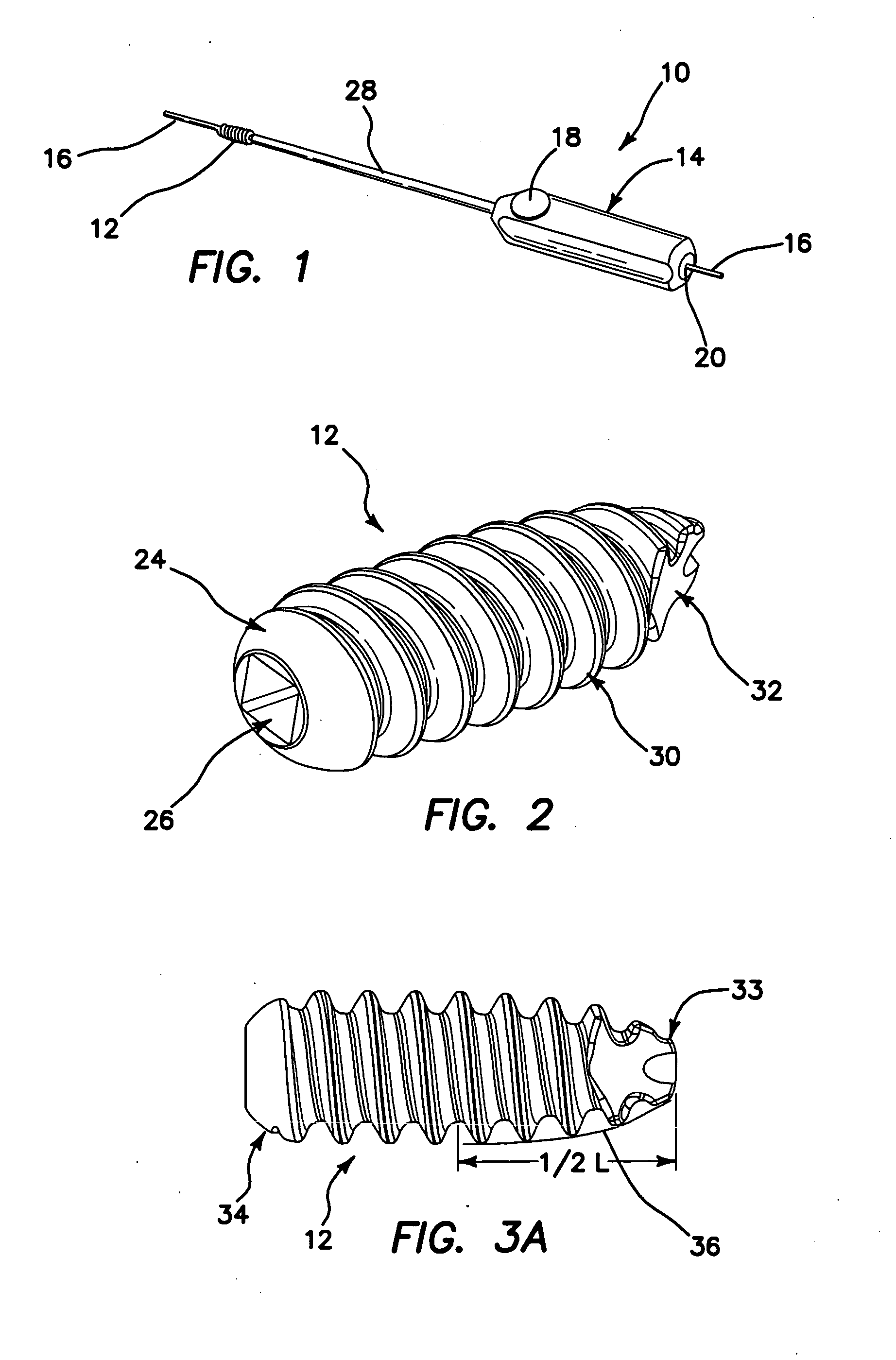

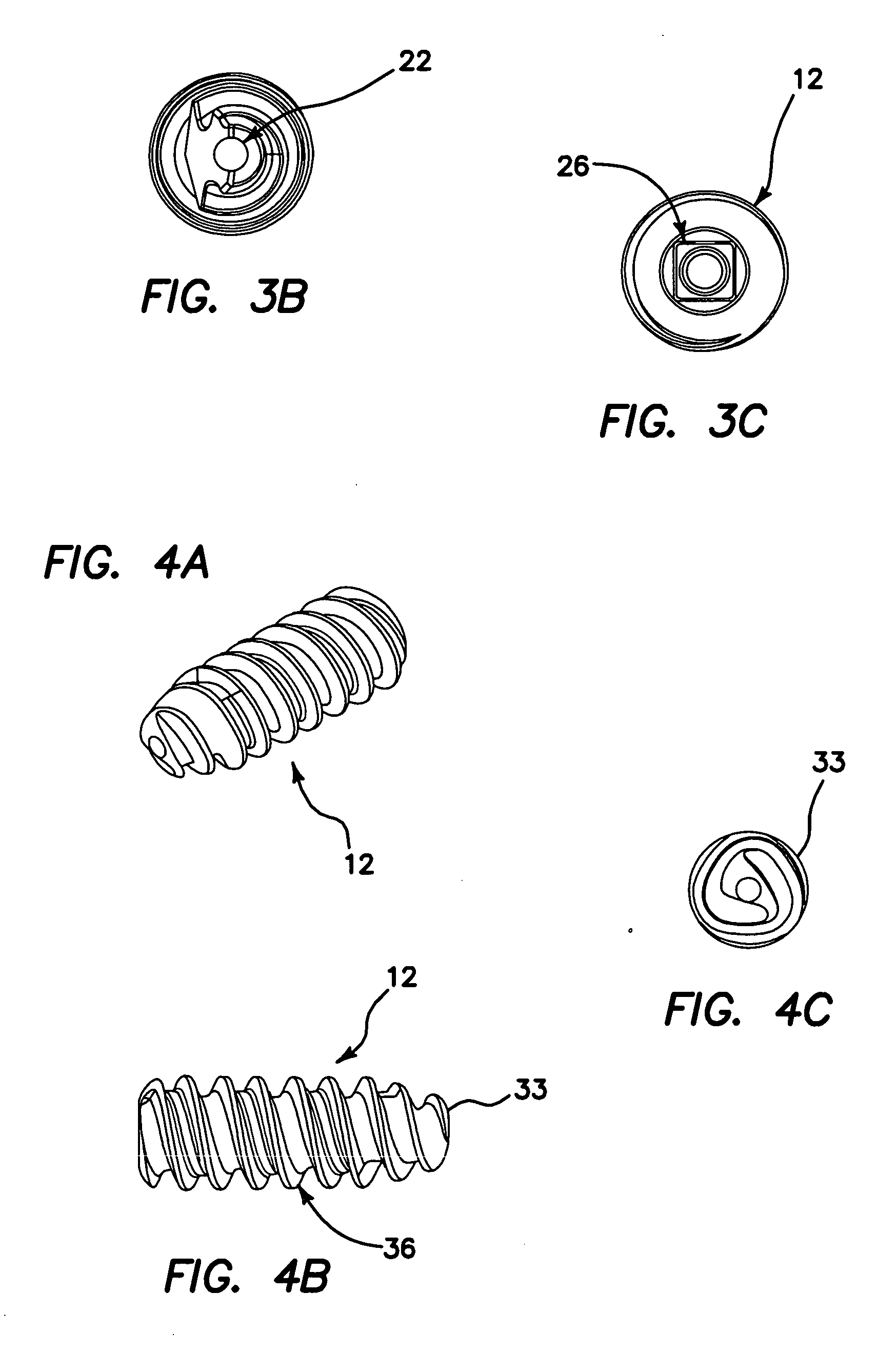

Self-tapping biocompatible interference bone screw

A biocompatible interference screw for soft tissue or bone-to-bone fixation comprises a screw body extending from a screw head to a distal tip of the screw. The screw body has an outer surface, and comprises polyether-ether-ketone (PEEK) material. Advantageously, the body outer surface has a textured surface finish for substantially improving pull-out strength of the interference screw. The textured surface finish is textured, in preferred embodiments, with a minimum of approximately 16 micro inches of surface roughness. The screw head comprises a tapered square keyhole for receiving a distal end of a driver instrument. The screw comprises a series of threads, which have a relatively smooth profile, in order to prevent graft tissue laceration as the screw is being inserted. The distal tip of the screw body comprises a narrow tip, and a distal end of the screw body is angled inwardly toward the narrow distal tip.

Owner:CAYENNE MEDICAL INC

Cube corner cavity based retroreflectors and methods for making same

InactiveUS6287670B1High specular reflectivityEfficient retroreflectionMirrorsDiffusing elementsSurface finishEngineering

Retroreflective sheeting includes a body layer having a structured surface with recessed faces and top surfaces, the recessed faces forming cube corner cavities. The recessed faces have a high specular reflectivity, while the top surfaces have a low specular reflectivity. In some embodiments a substantially continuous film of reflective material covers the structured surface, and a masking substance is provided over the reflective material at the top surfaces. Alternatively, the top surfaces are given a non-smooth surface finish so that the film of reflective material on those portions has a diffuse reflectivity. In other embodiments the film of reflective material is discontinuous, disposed selectively on the recessed faces and not on the top surfaces. A cover layer is also provided, and can bond at least to the top surfaces. Keeping the top surfaces substantially free of reflective material inhibits corrosion and can enhance the bond integrity. The top surfaces are preferably flat, and diffusely reflective to enhance the daytime whiteness of the sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

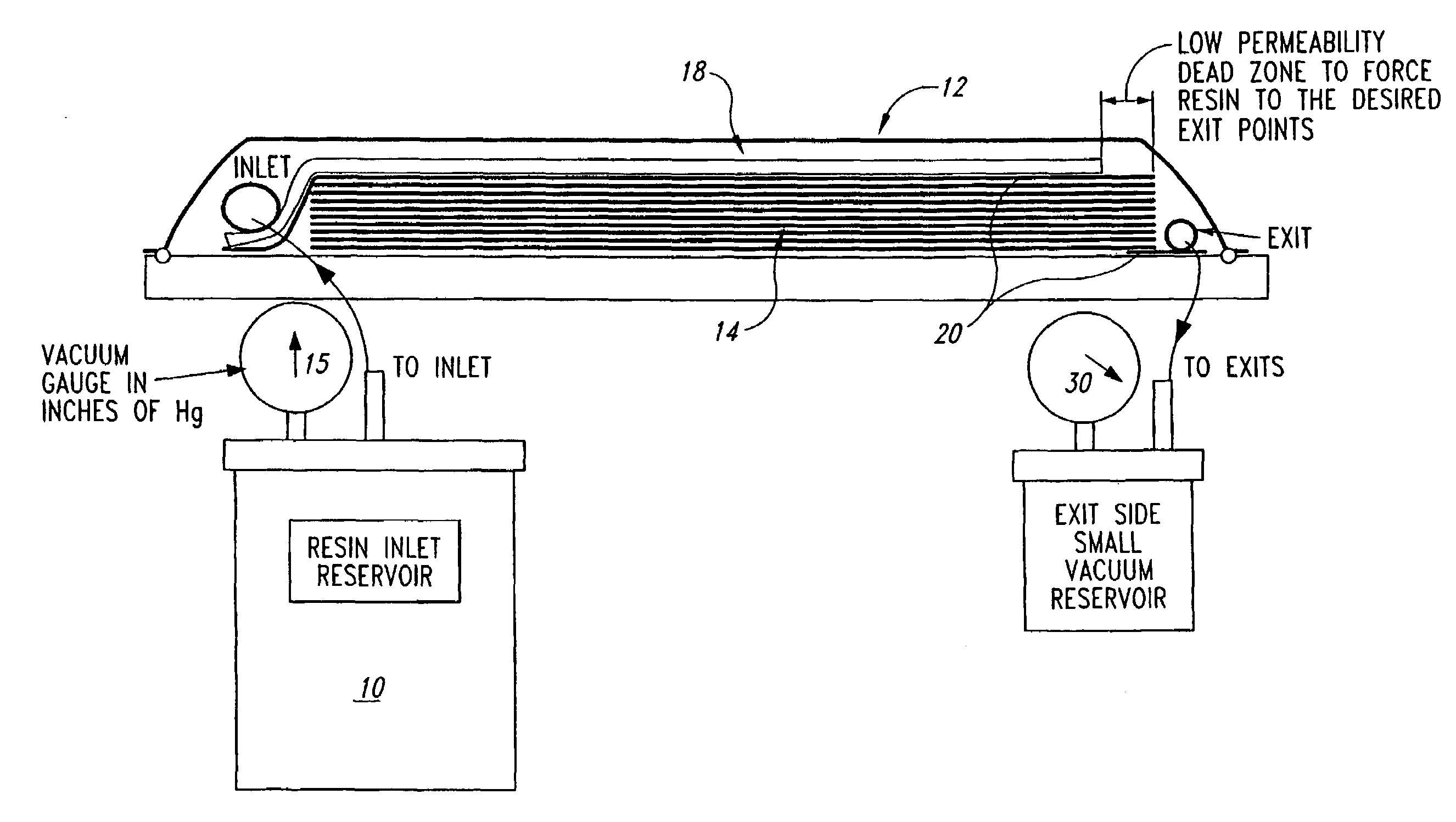

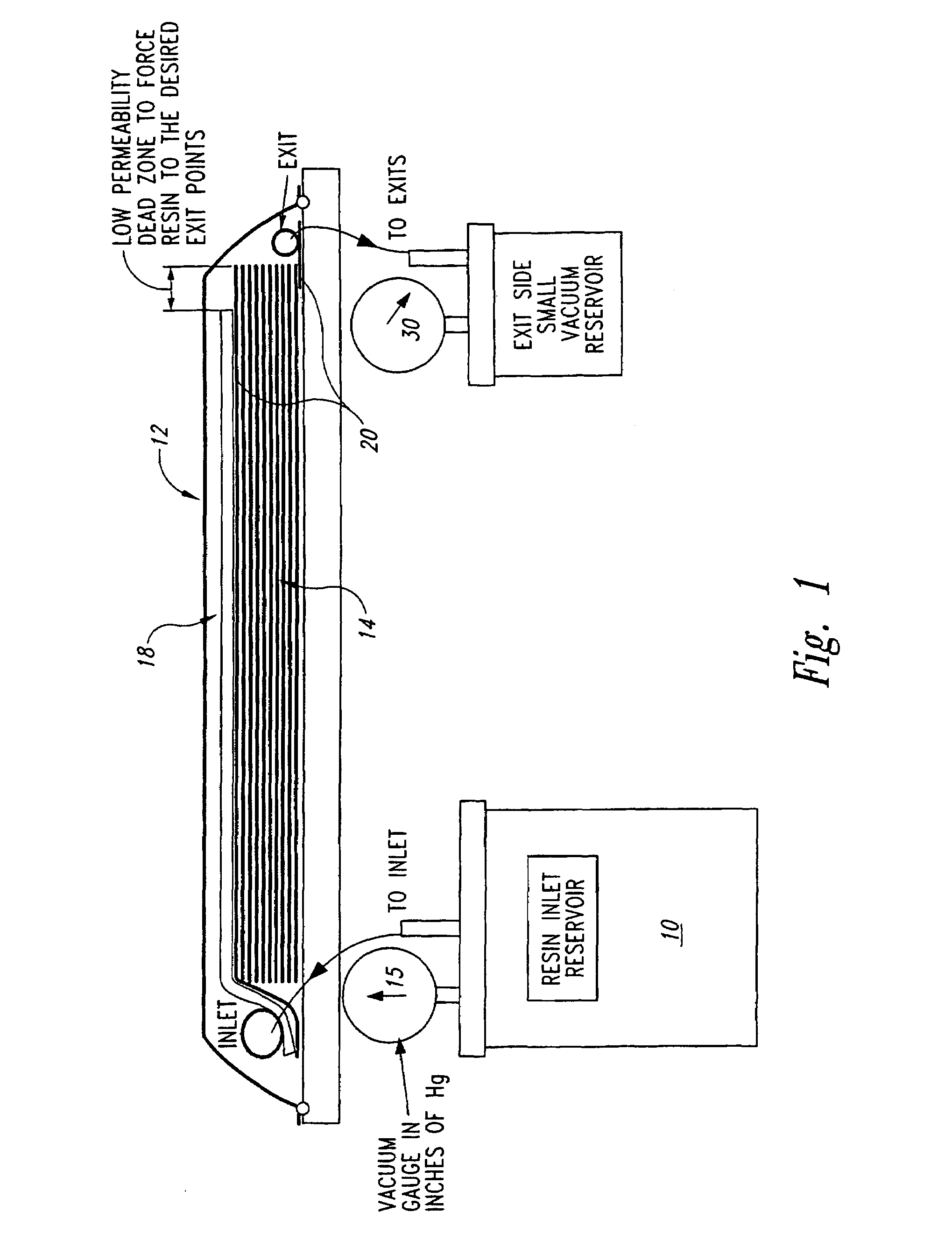

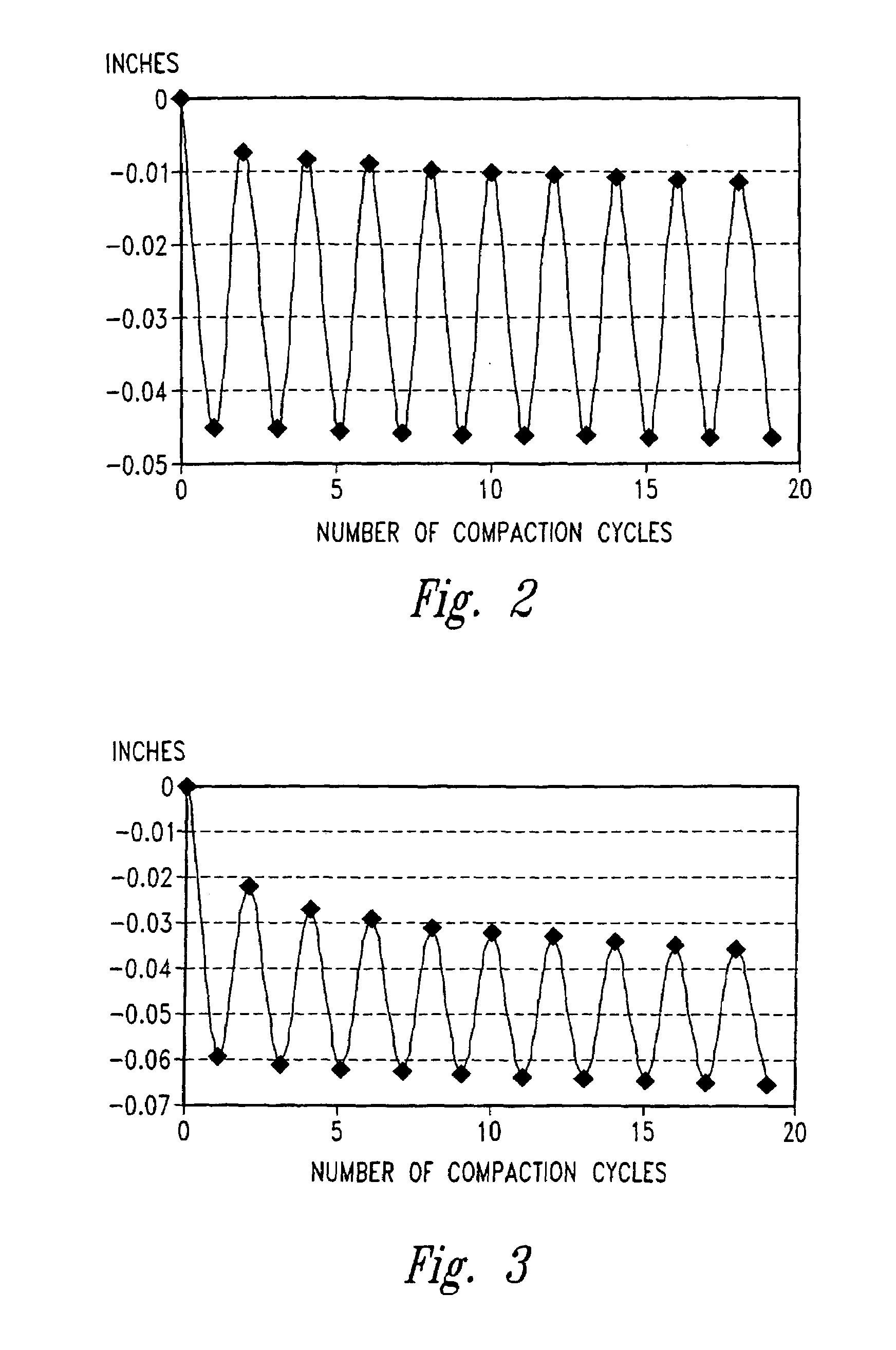

Controlled atmospheric pressure resin infusion process

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

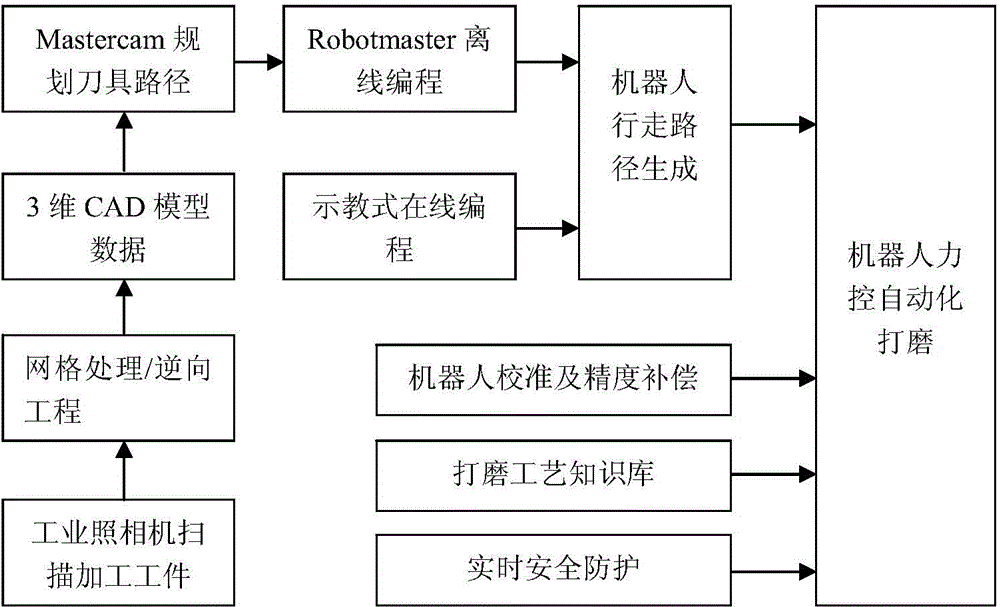

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

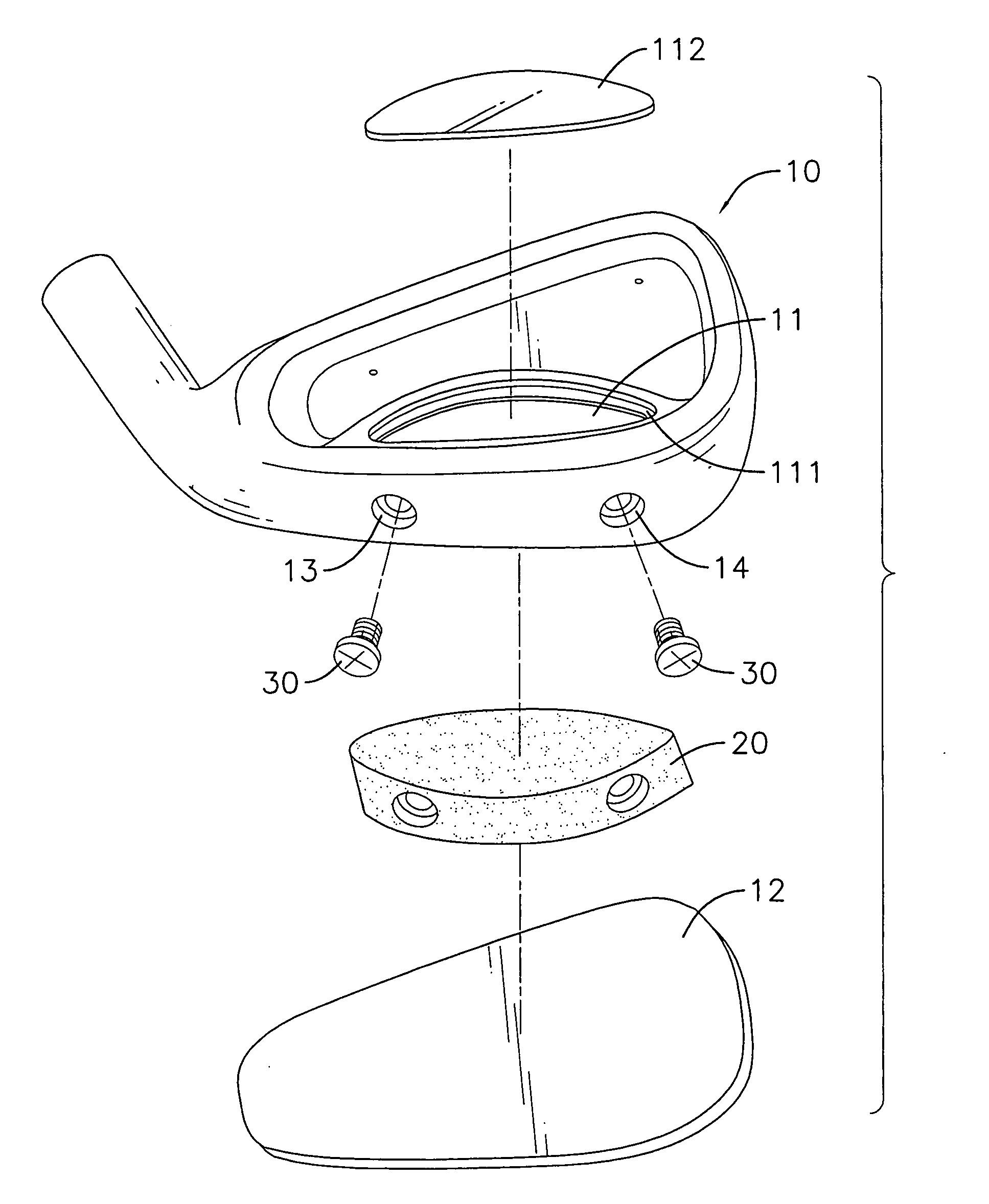

Method for producing a golf club head

A method for producing a golf club head has a molding step, an injecting step, a surface finishing step and a sealing step. The molding step has obtaining a base and a striking faceplate and punching a recess formed in a front surface of the base and having an opening receiving the striking faceplate, a window and multiple through holes in the base. The injecting step has blocking the window by a stopper and injecting vibration-absorbing material into the recess. The surface finishing step has removing the stopper when the vibration-absorbing material is foamed and molded and then mounting at least one sealing element to block up the at least one through hole. The sealing step has adhering a transparent panel on the recess to seal the window to obtain a golf club head with vibration-absorbing effect. Users can see the vibration-absorbing material from the transparent panel.

Owner:SUPER WAY TECH

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

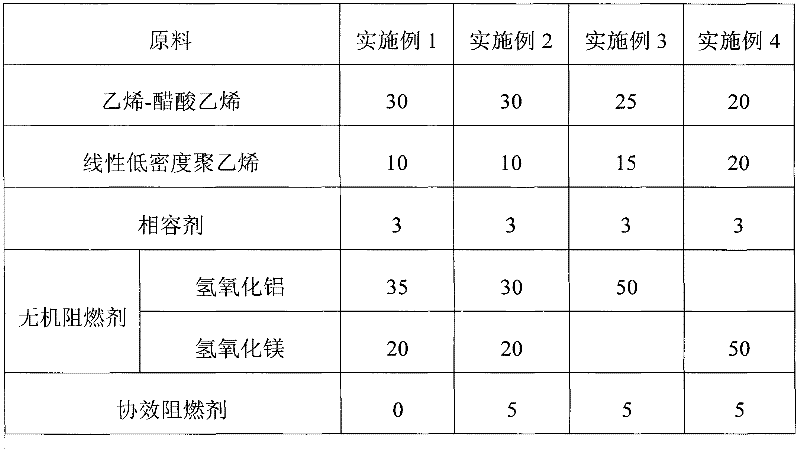

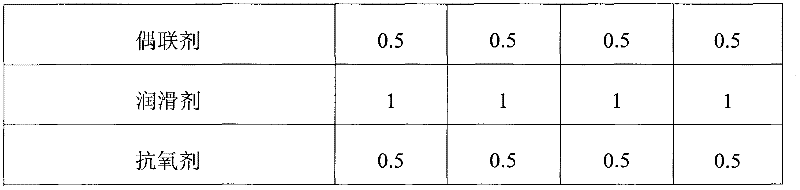

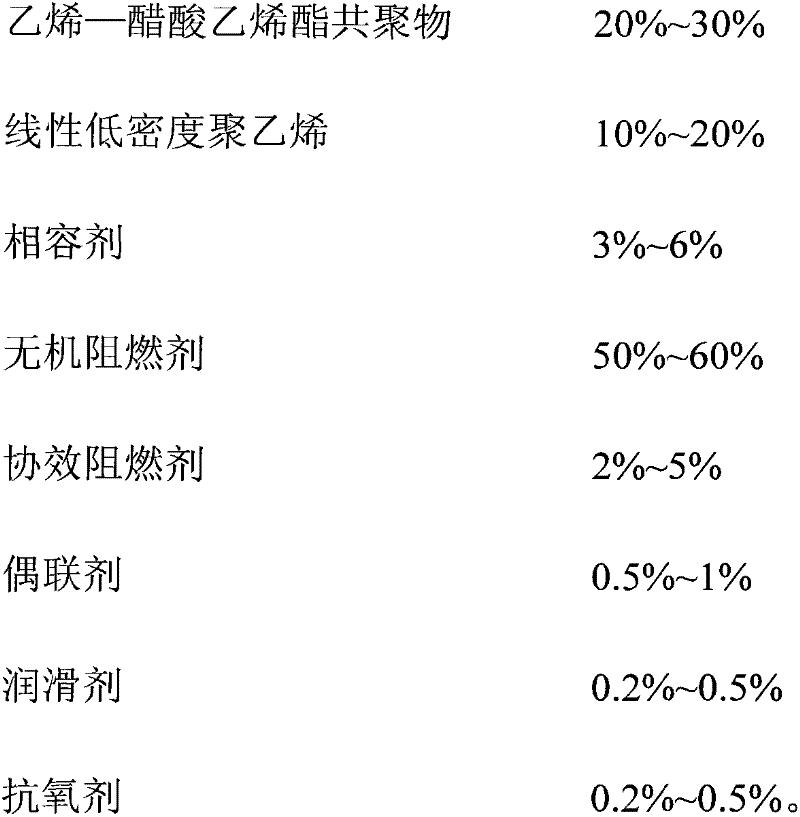

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

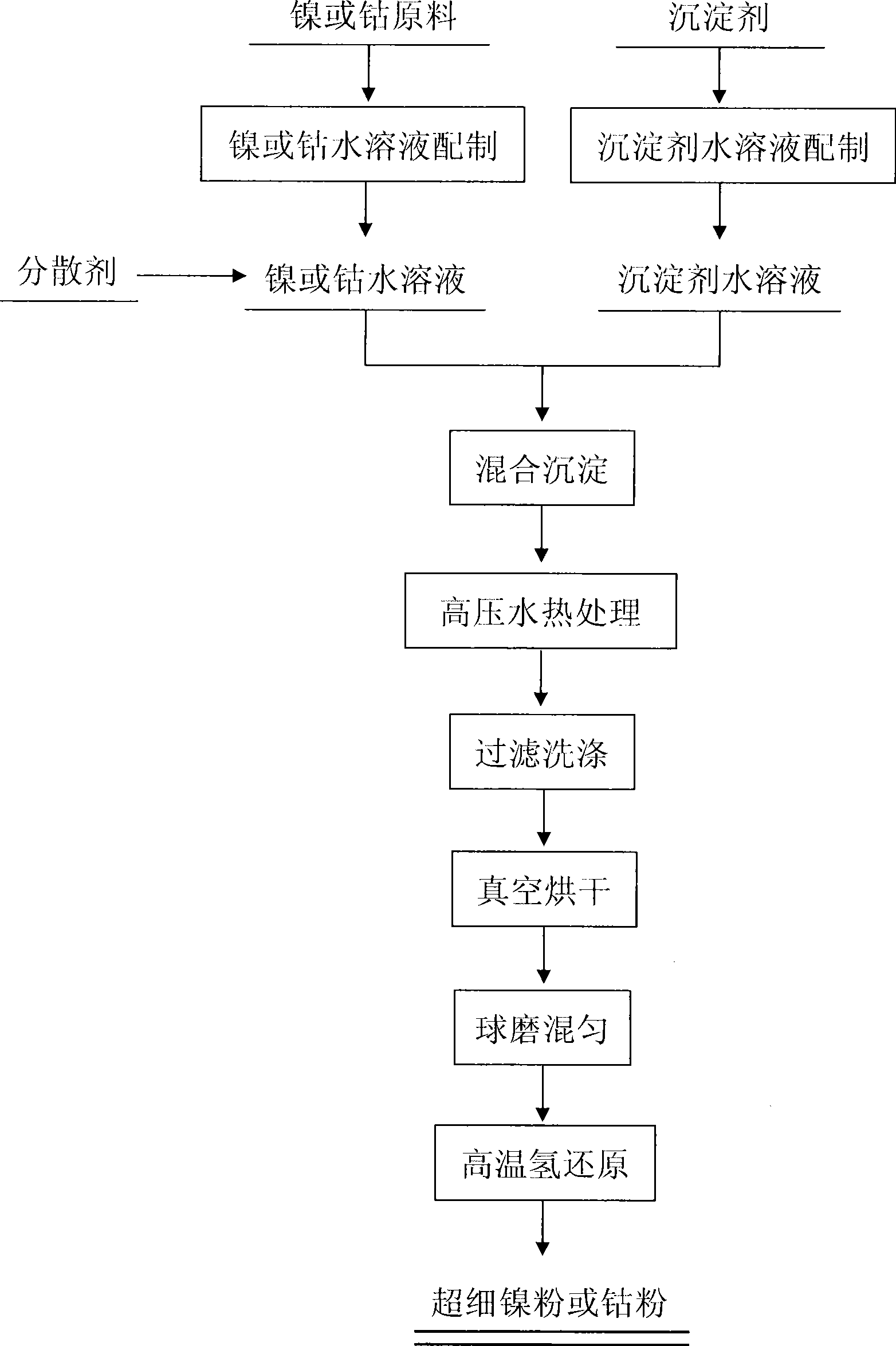

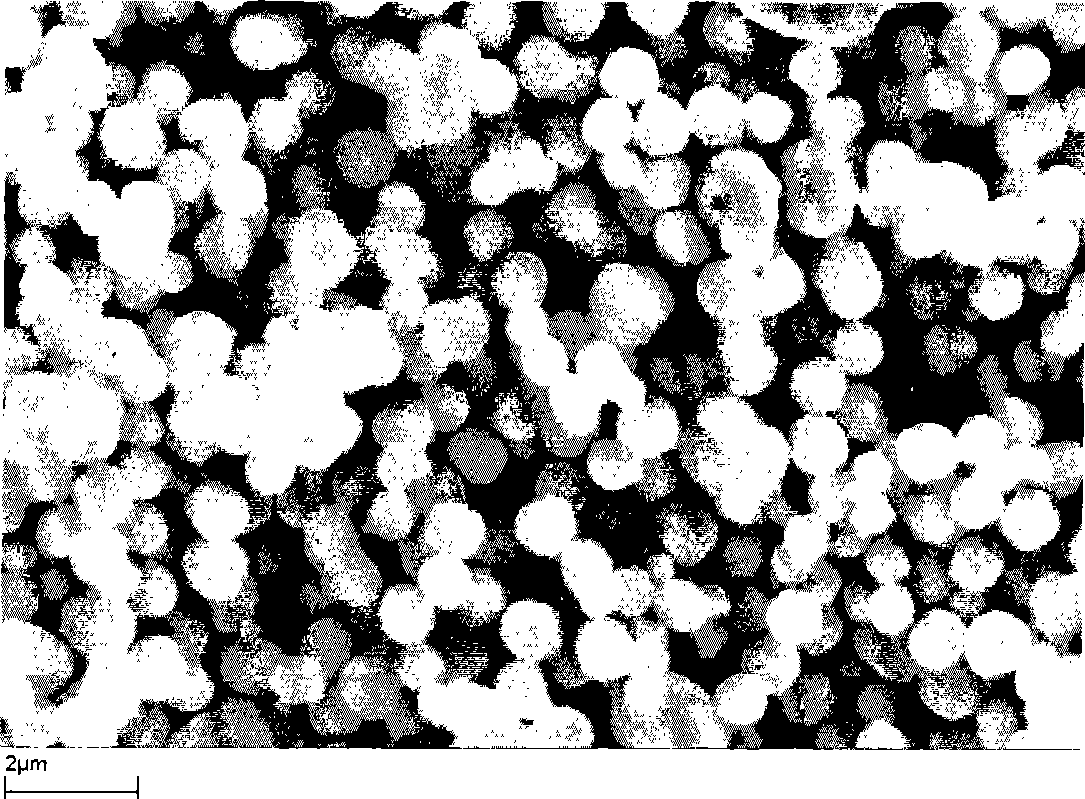

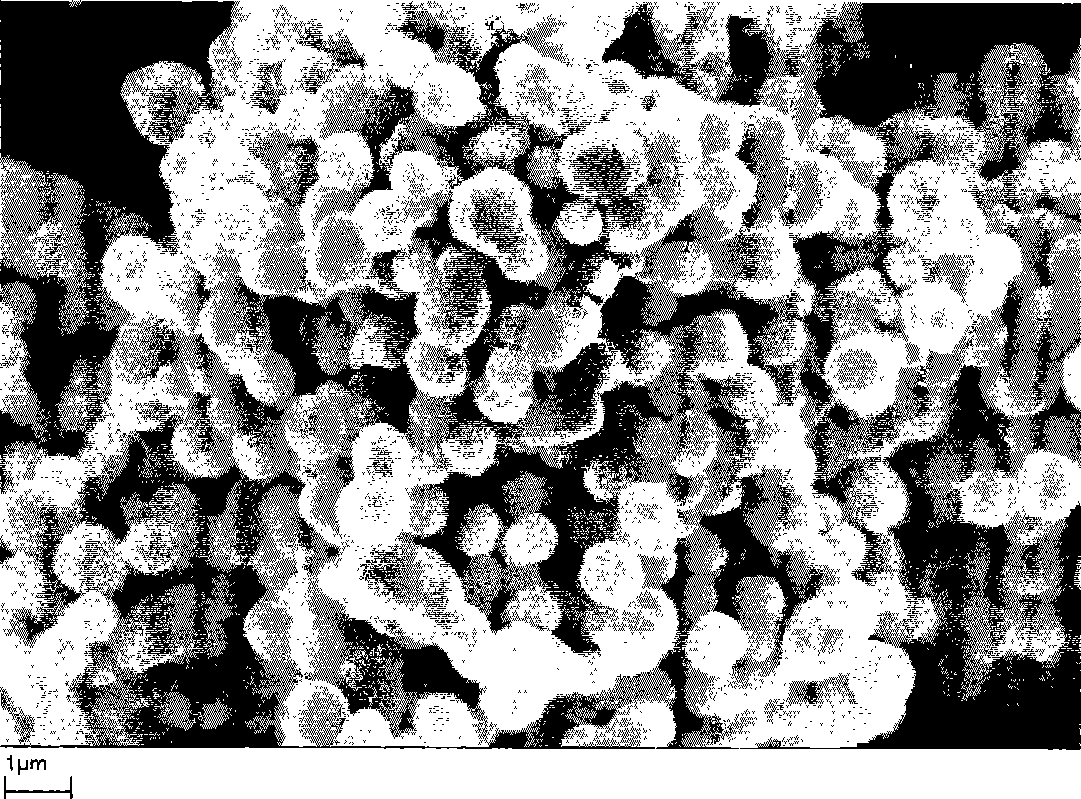

Process for producing spherical submicron metal with hydro-thermal treatment

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

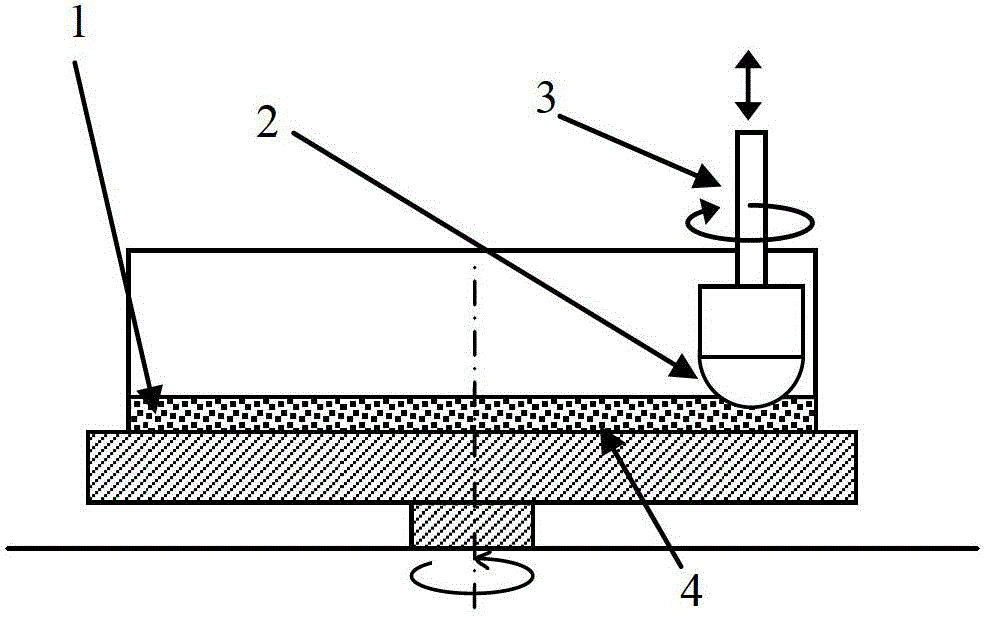

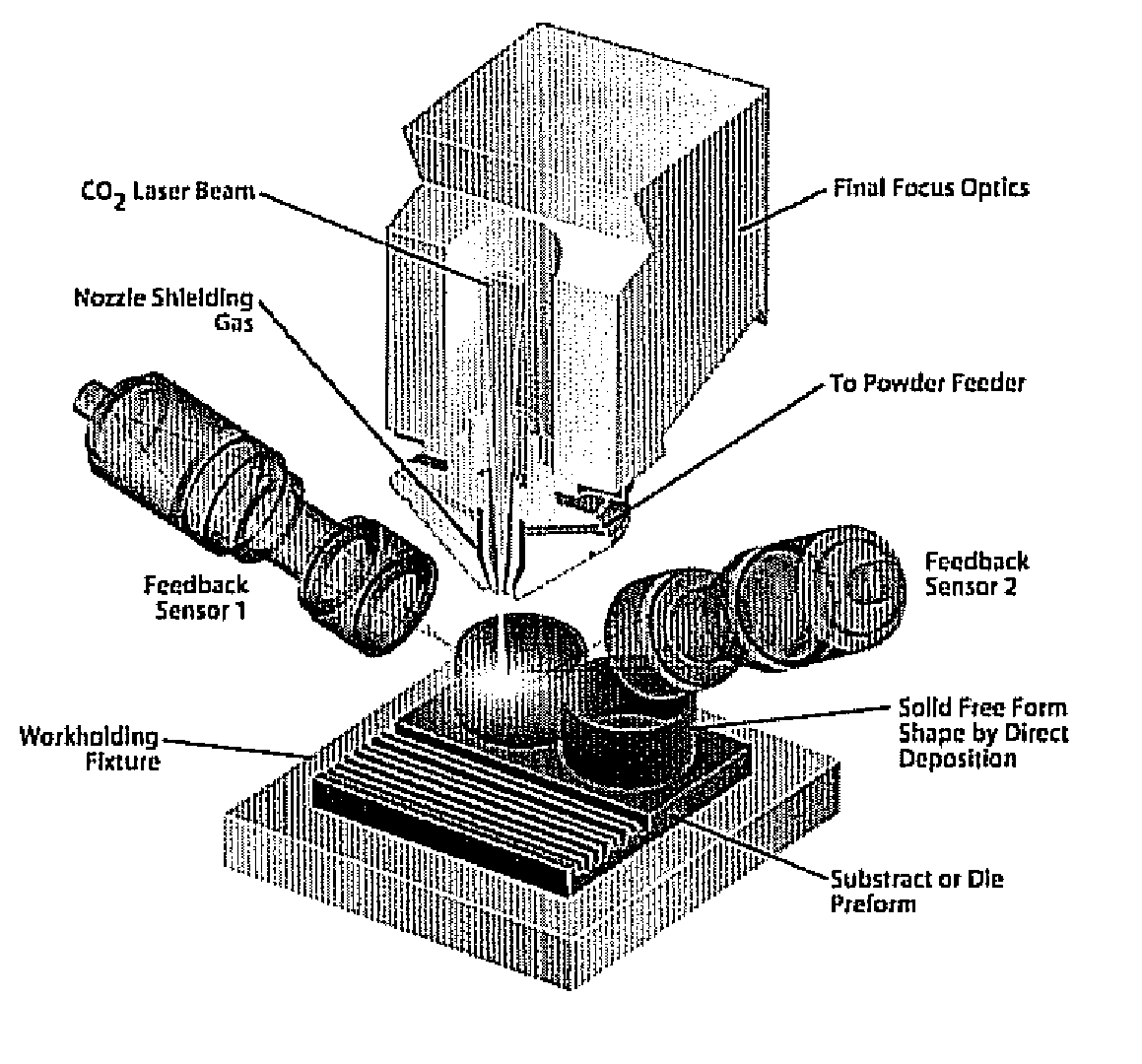

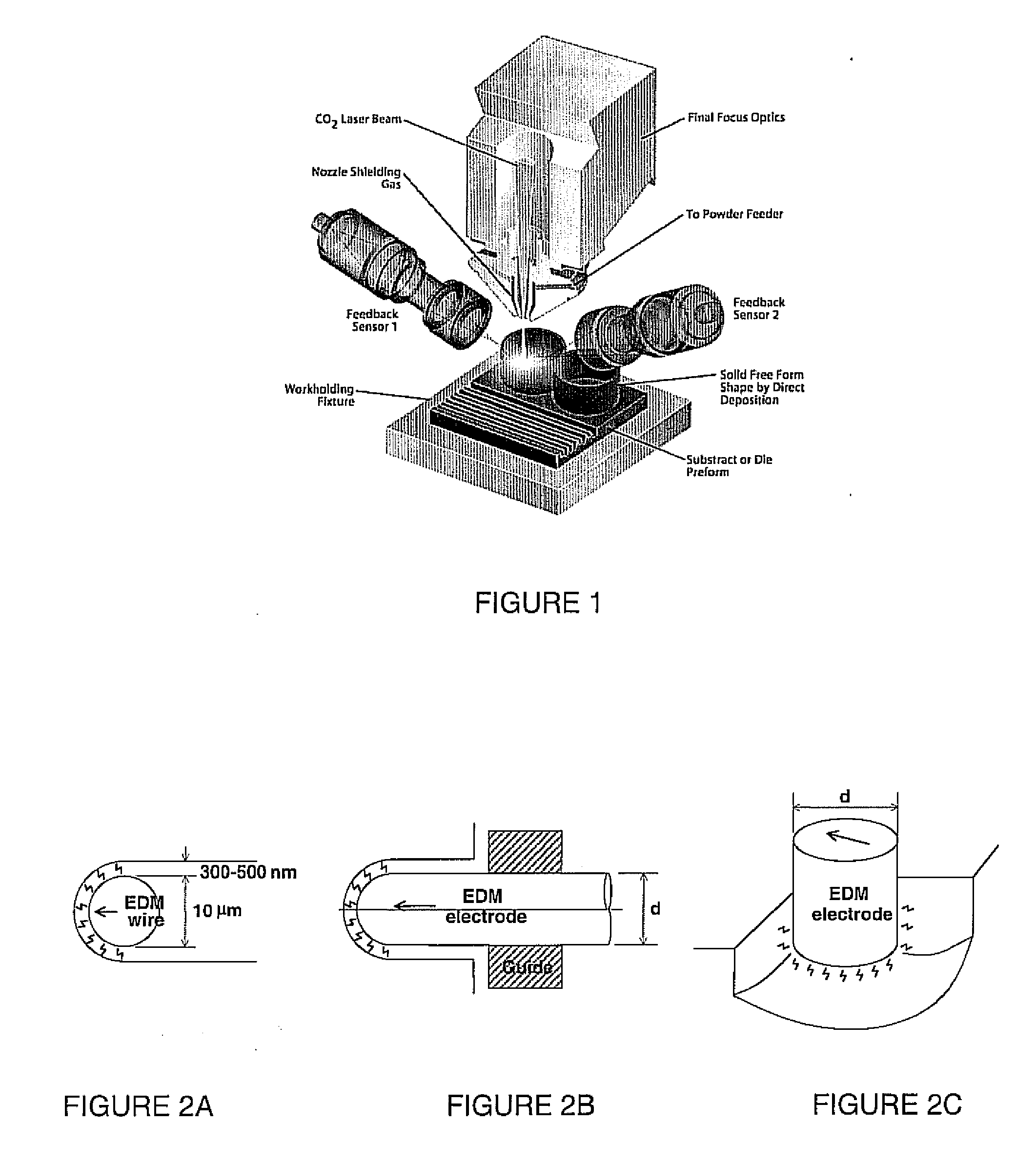

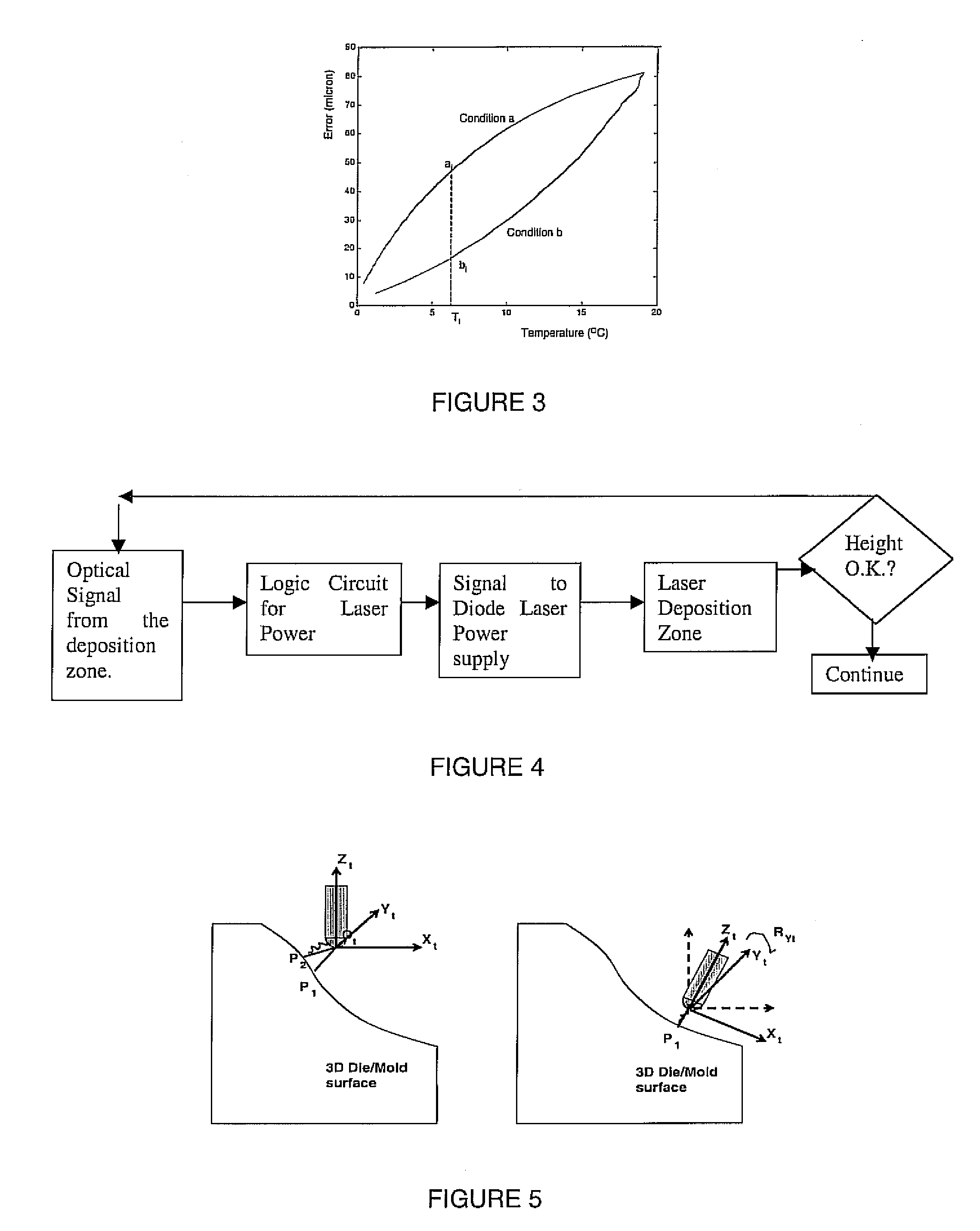

High-speed, ultra precision manufacturing station that combines direct metal deposition and edm

ActiveUS20070205184A1Fast transferImprove efficiencyAdditive manufacturing apparatusElectric discharge heatingEngineeringWorkstation

A direct-metal deposition (DMD) processing stage and a 5DOF (degree of freedom) dry micro-EDM (mEDM) stage are integrated to provide the submicron scale resolution necessary for the ultra-precision processing of work pieces. The DMD processing stage includes optical feedback for dimensional control utilizing a high-power, fiber-coupled diode laser with fast response time and small beam parameter product. The electrical discharge machining (EDM) stage is a dry EDM stage using an inert gas with appropriate dielectric properties to perform the surface finishing operations. The system further includes one or more surface treatment operations to obtain a desired level of surface hardness or wear resistance and / or to minimize the distortion induced in treating the surface.

Owner:DM3D TECH

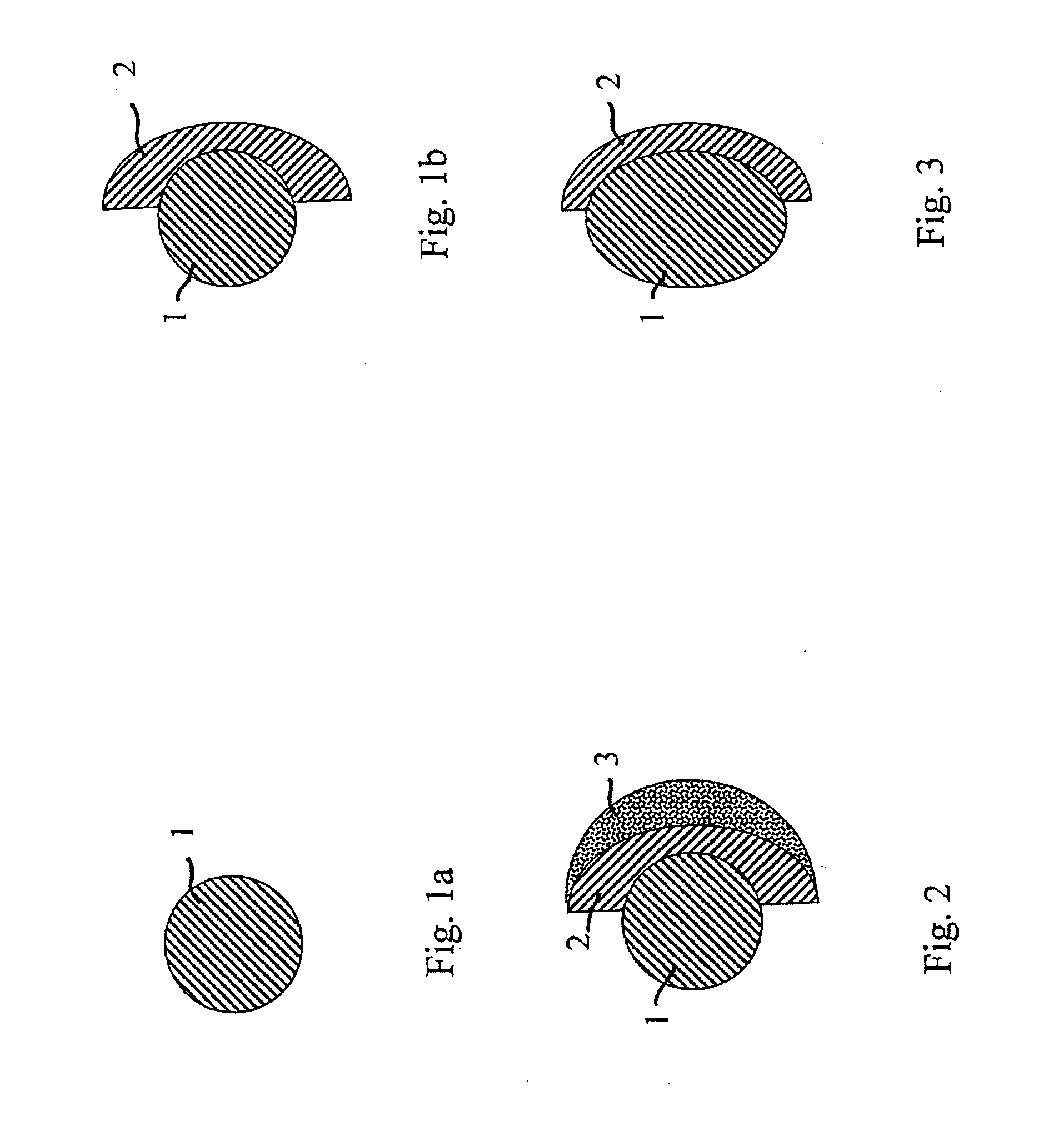

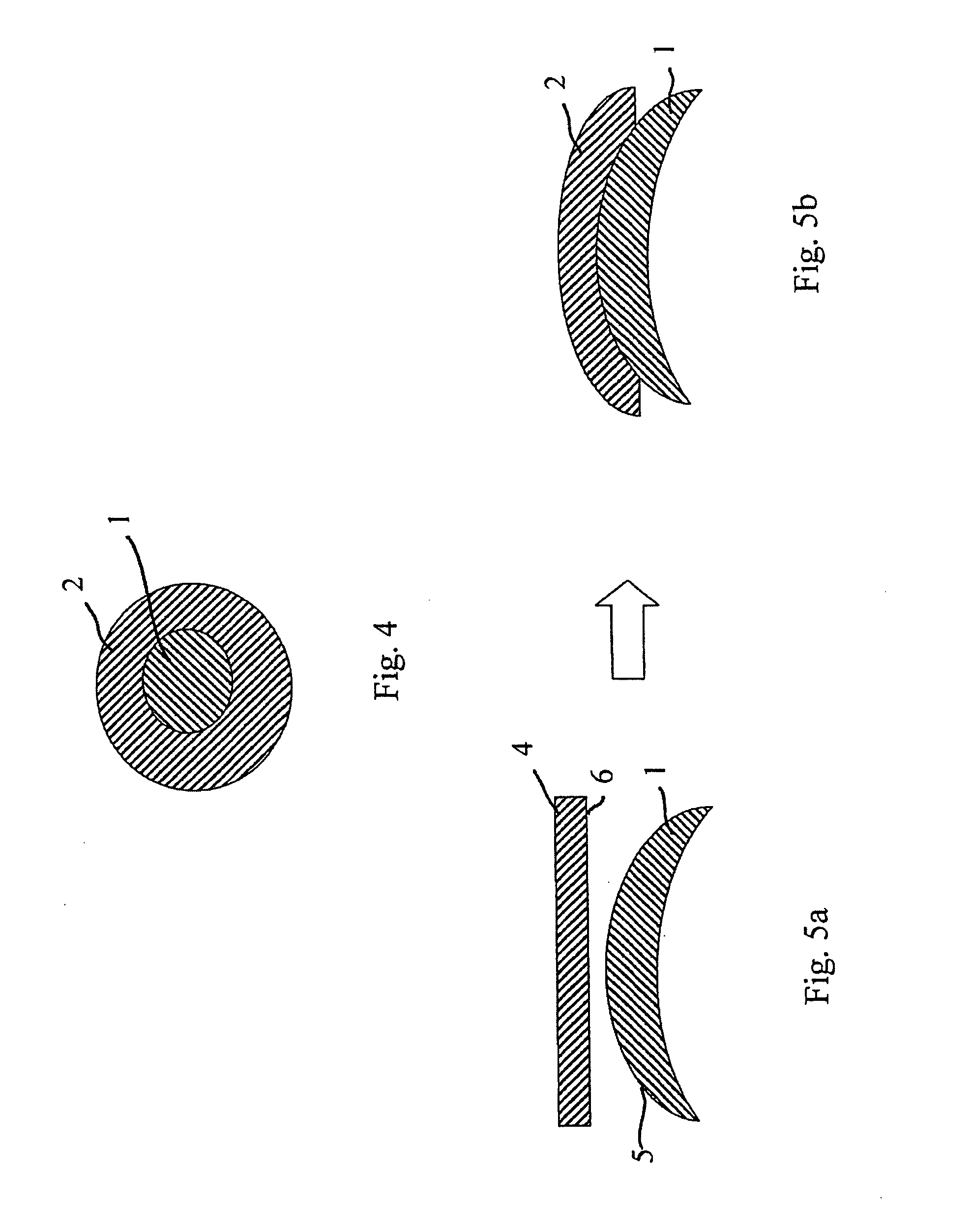

Optical lens or lens group, process for the production thereof, as well as optical image acquisition device

InactiveUS20070091472A1Simple and economical production processHigh resolutionLensSurface finishRefractive index

The invention relates to an optical hybrid lens. According to the invention, the lens consists of a substrate (1) that consists of a ceramic having a predetermined shape and at least another material (2), which covers a surface of the substrate (1) at least in certain sections in order to form a lens surface. Use of an optical ceramic as a material enables an additional degree of freedom for adjusting the imaging properties of the hybrid lens. The optical ceramic may have a high refractive index and a low dispersion. The other material can be a material that can be deformed or recast at temperatures that are low in comparison to those of the optical ceramic. In particular the other material can be a low-TG glass or a polymer. The other material is directly applied onto the substrate without a further surface finishing being necessarily required. Other aspects of the invention relate to an optical lens group, an optical image acquisition device, and a process for manufacturing a hybrid lens.

Owner:SCHOTT AG

Bi-component aqueous ground hardening agent and preparation method thereof

The invention belongs to the field of construction materials, in particular to a bi-component aqueous ground hardening agent and a preparation method thereof. The bi-component aqueous ground hardening agent comprises the following components in percentage by weight: 12-35 percent of first component and 65-88 percent of second component, wherein the first component is a lithium silicate solution, and the second component contains magnesium fluosilicate, silane emulsion, crylic acid resin emulsion, petrolin and water. The bi-component aqueous ground hardening agent has favorable effects of abrasion resistance, reinforcement, compactness, water prevention and seal and can improve the surface smoothness; and after being applied to the concrete ground, the bi-component aqueous ground hardening agent can improve the surface smoothness of concrete and reduce the dust.

Owner:TONGJI UNIV

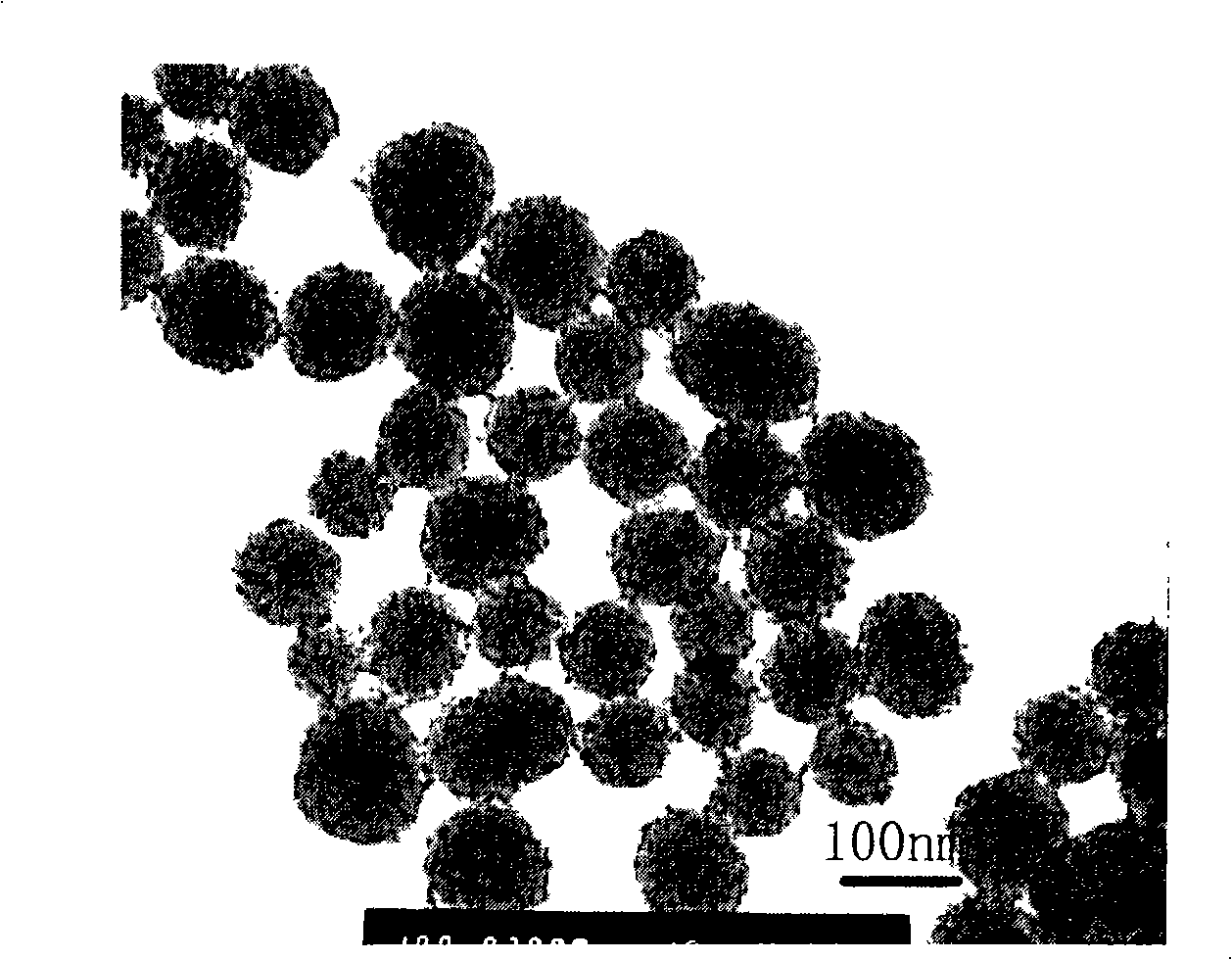

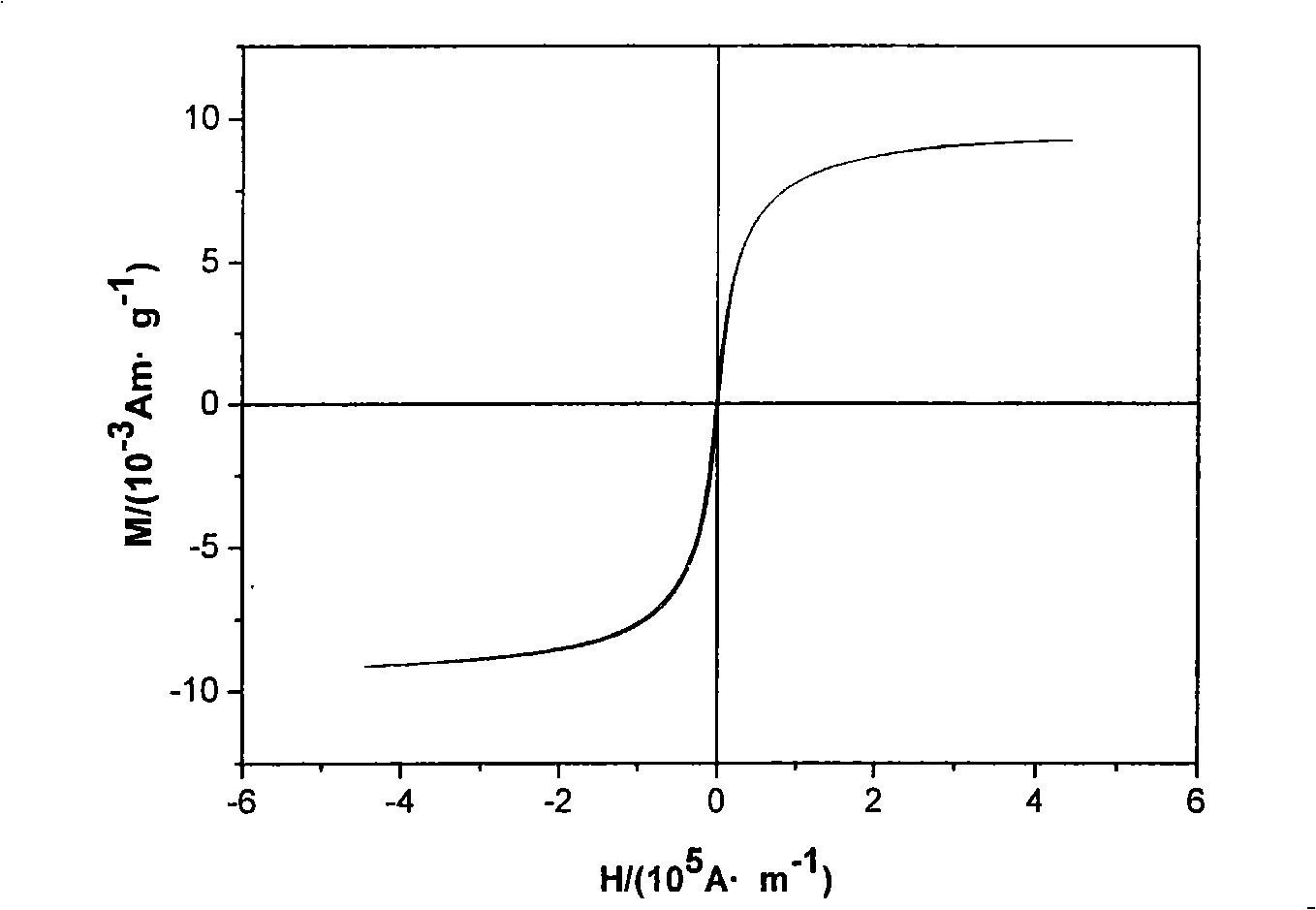

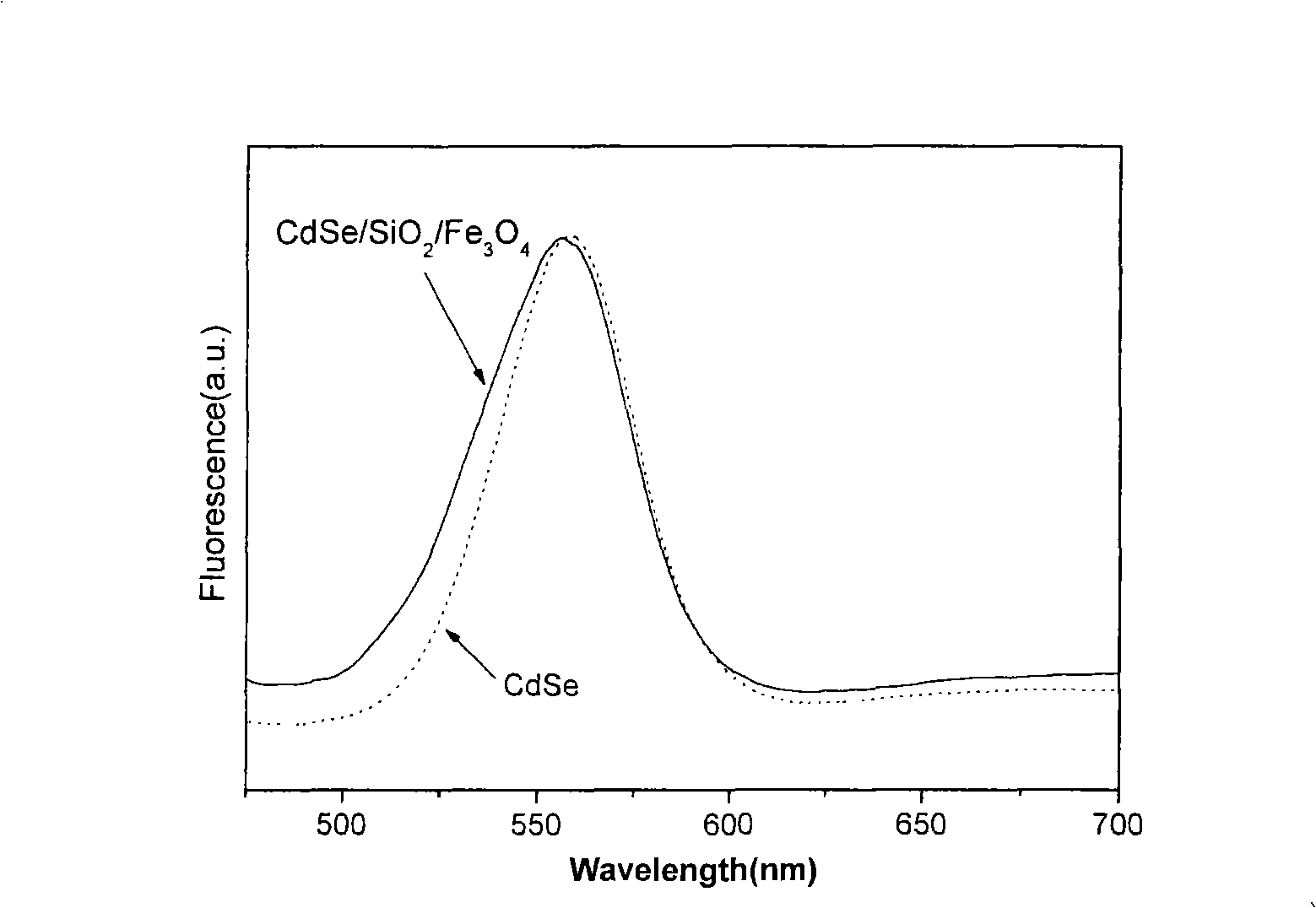

Magnetic composite nano microsphere capable of emitting fluorescence and preparation thereof

The invention discloses a magnetic composite nano microsphere capable of emitting fluorescent light and a preparation method thereof, which belong to the inorganic nanophase material field. The preparation method comprises the following steps: firstly, the sol-gel method or the reversed phase microemulsion method is adopted for performing base catalysis on alkyl silicate, and a layer of silicon dioxide is uniformly coated on the surface of inorganic magnetic nano particles; secondly, an amino silane coupling agent is adopted for performing surface finish on silicone dioxide; thirdly, semiconductor quantum dots are absorbed on the surface of the silicone dioxide through the electrostatic action between an amino group and a carboxyl group on the surface of the amino silane coupling agent; and fourthly, the magnetic composite nano microsphere with a core-shell structure capable of emitting the fluorescent light is obtained. The preparation method has easy obtained raw materials and low cost. The composite nano microsphere obtained has good stability, controllable grain size, narrow distribution, and has good magnetic responsivity and performance of being capable of emitting the fluorescent light, and the two performances are controllable. The magnetic composite nano microsphere and the preparation method can be applied in the fields of biomedicine, bioengineering, etc. including immunoassay, biological labeling and separation, cell imaging and so on.

Owner:TONGJI UNIV

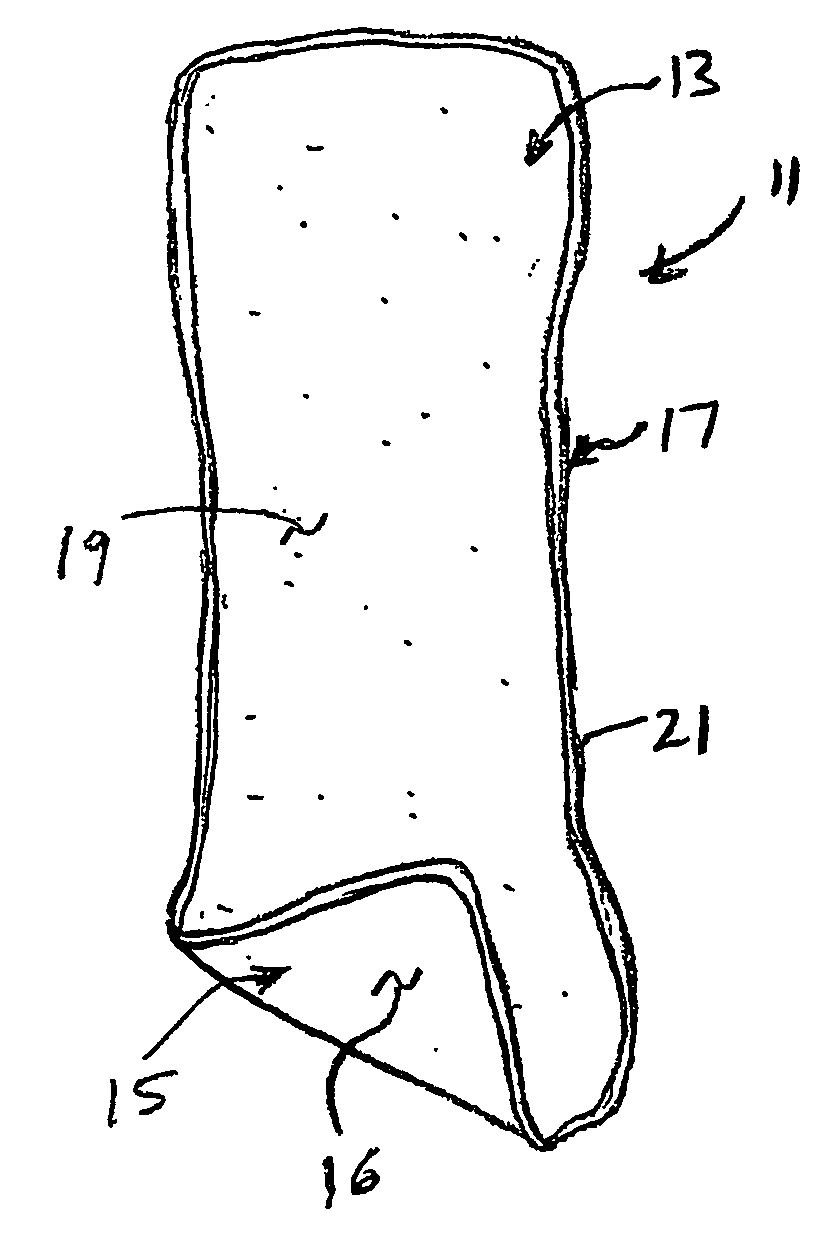

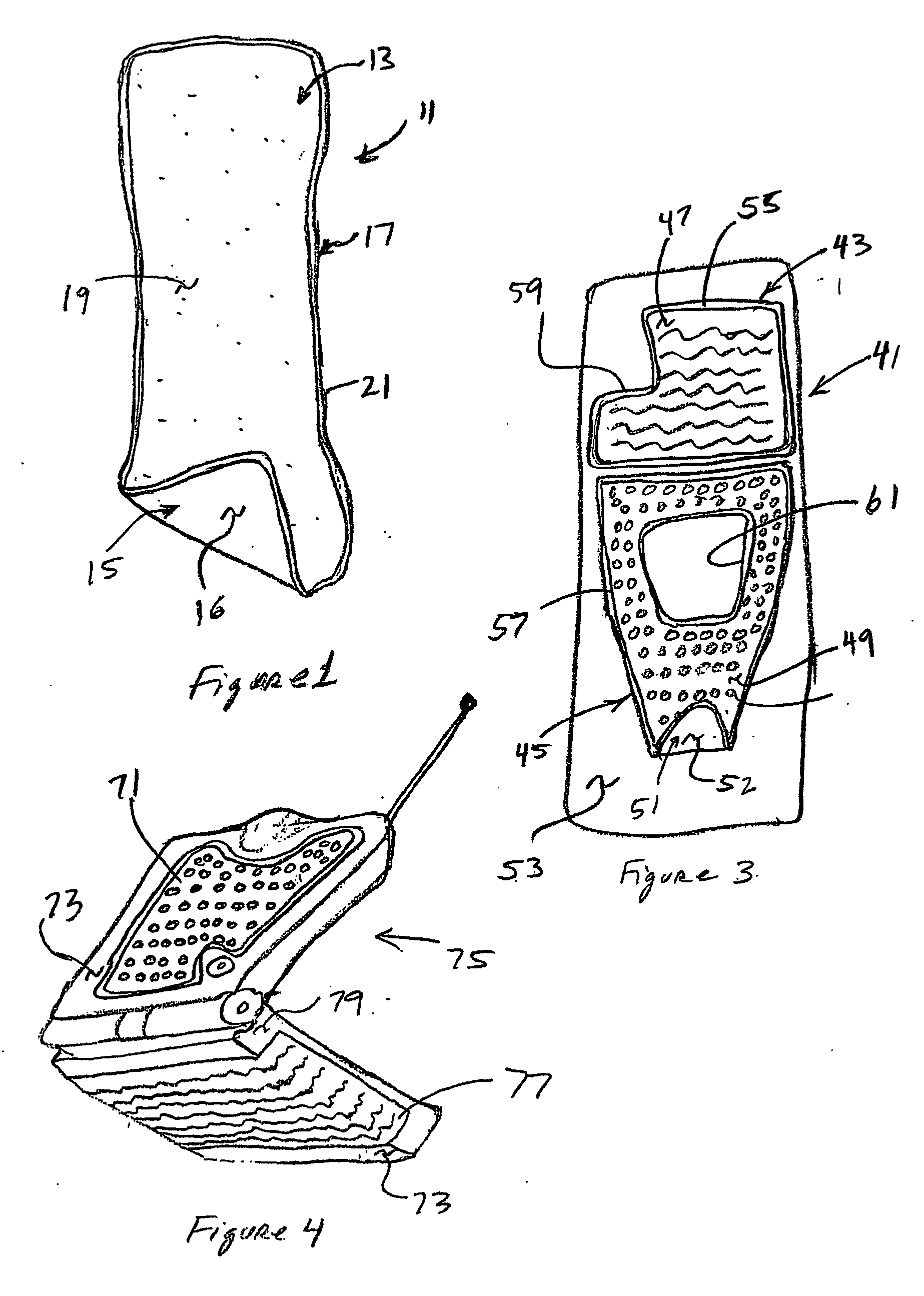

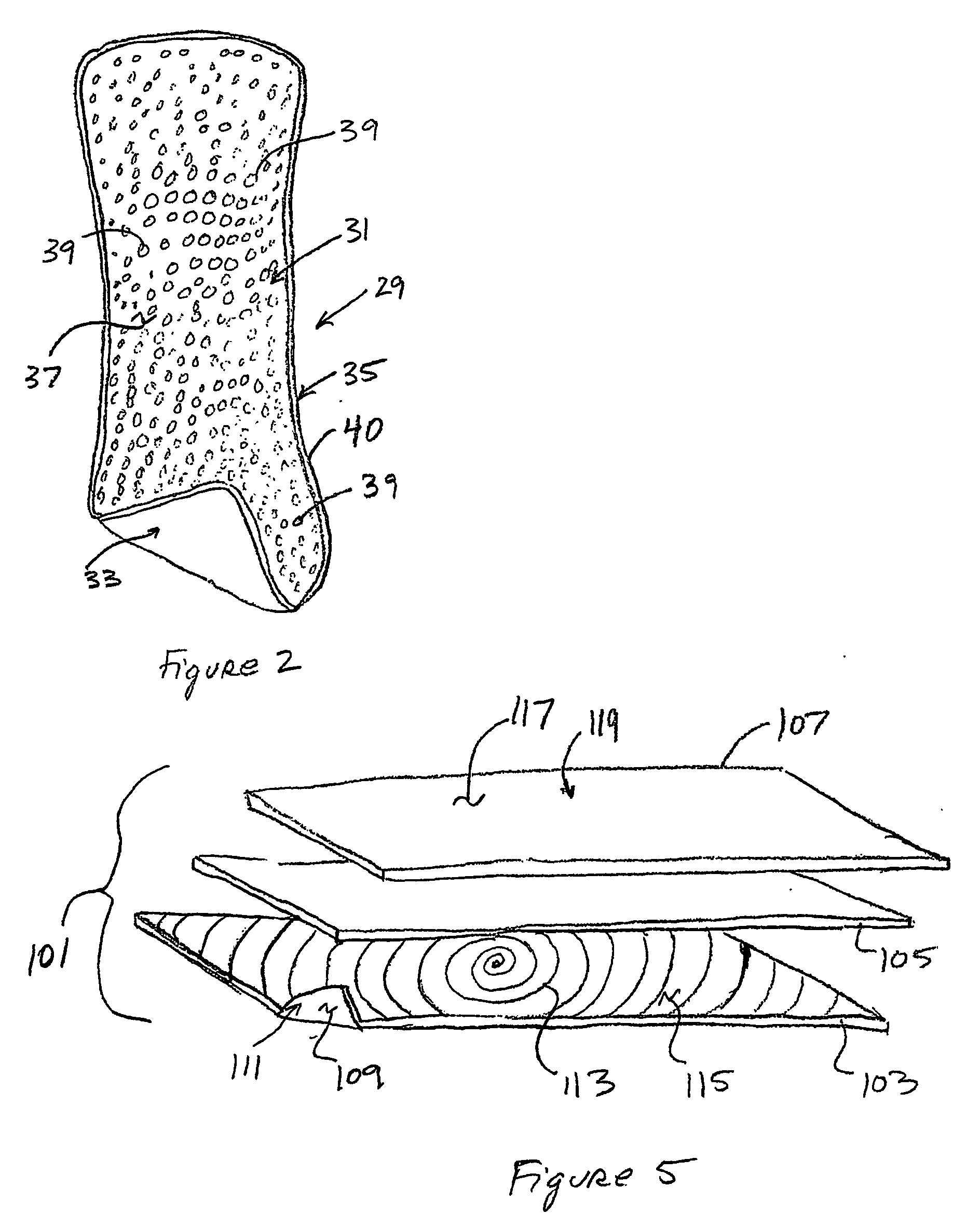

Adhesive backed skins and grips for handheld devices

A skin (11) for use with a handheld electronic device is disclosed. The skin (11) includes a decorative layer, an anti-slip layer adhered over the decorative layer, and an adhesive layer disposed between the decorative layer and the anti-slip layer. The anti-slip layer has a surface finish (19) having a high coefficient of friction. The skin (11) is attached to the handheld electronic device by a layer of adhesive (16) on the back of the decorative layer. The skin (11) is selectively shapped to conform to the contours, shape, and components of the handheld electronic device. The skin (11) provides anti-slip and shock absorption fucntionalities to the handheld electronic device, but does not prevent or impede the handheld electronic device from mating with or connecting to corresponding accessory components.

Owner:ANTONINI FRED A

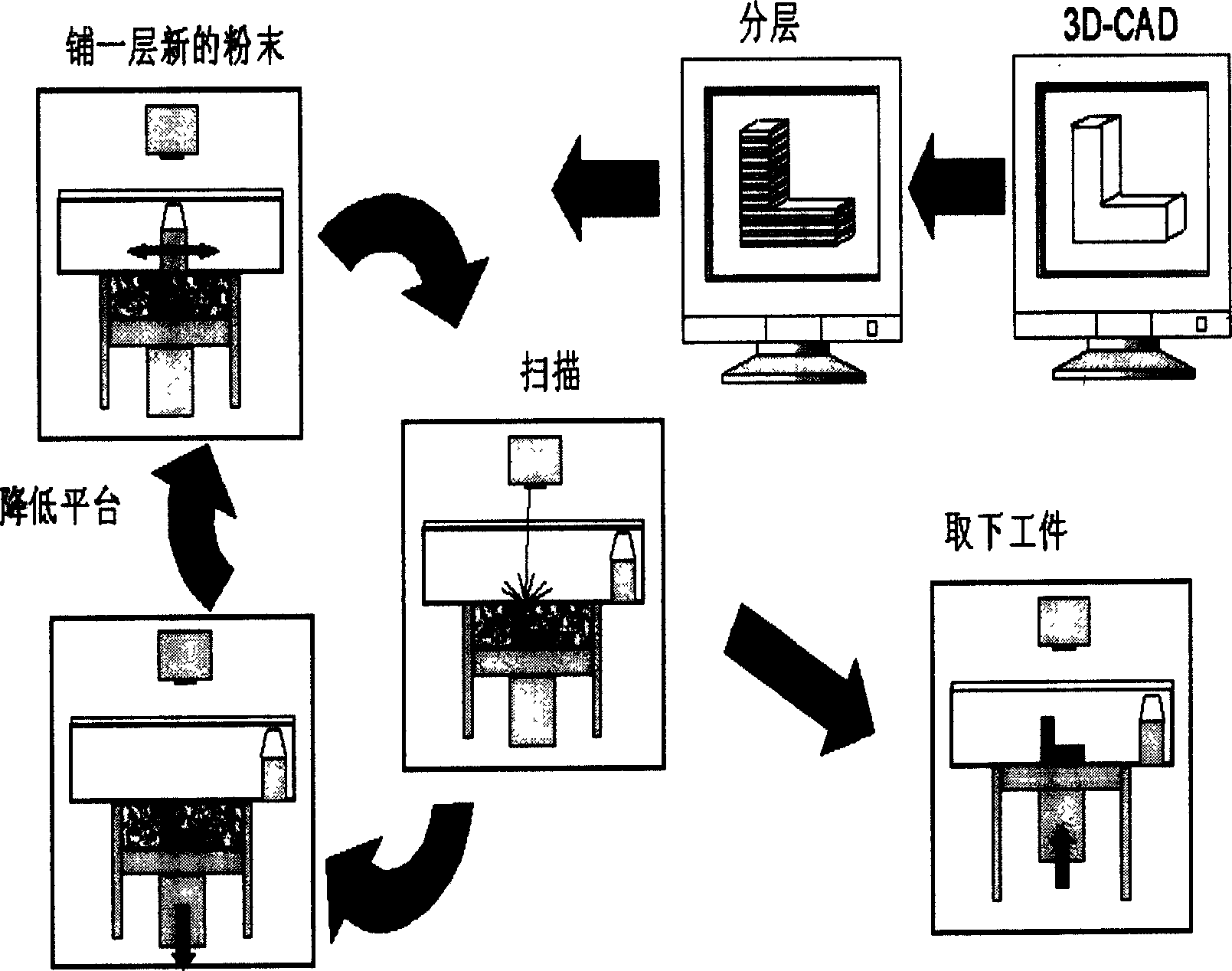

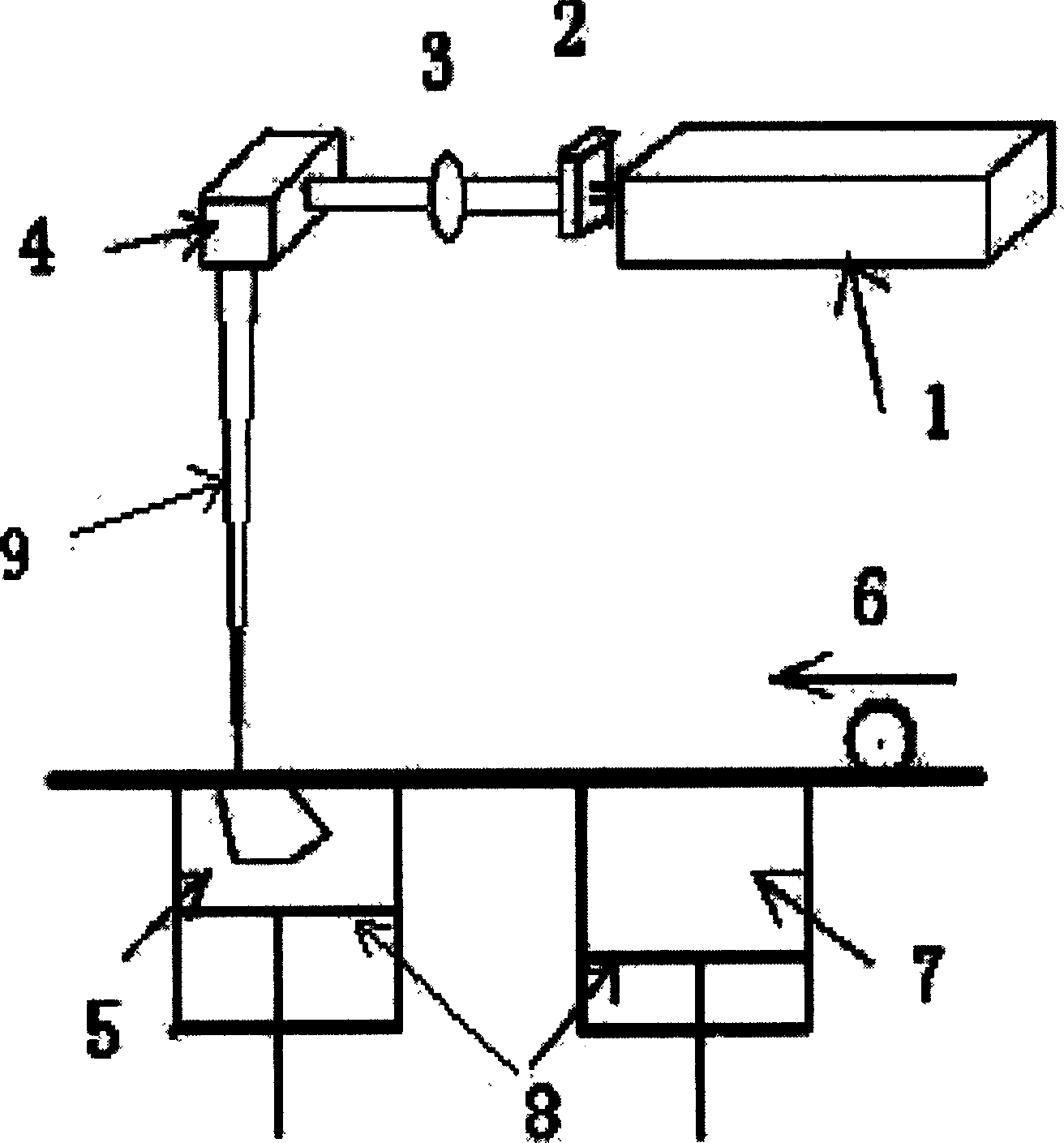

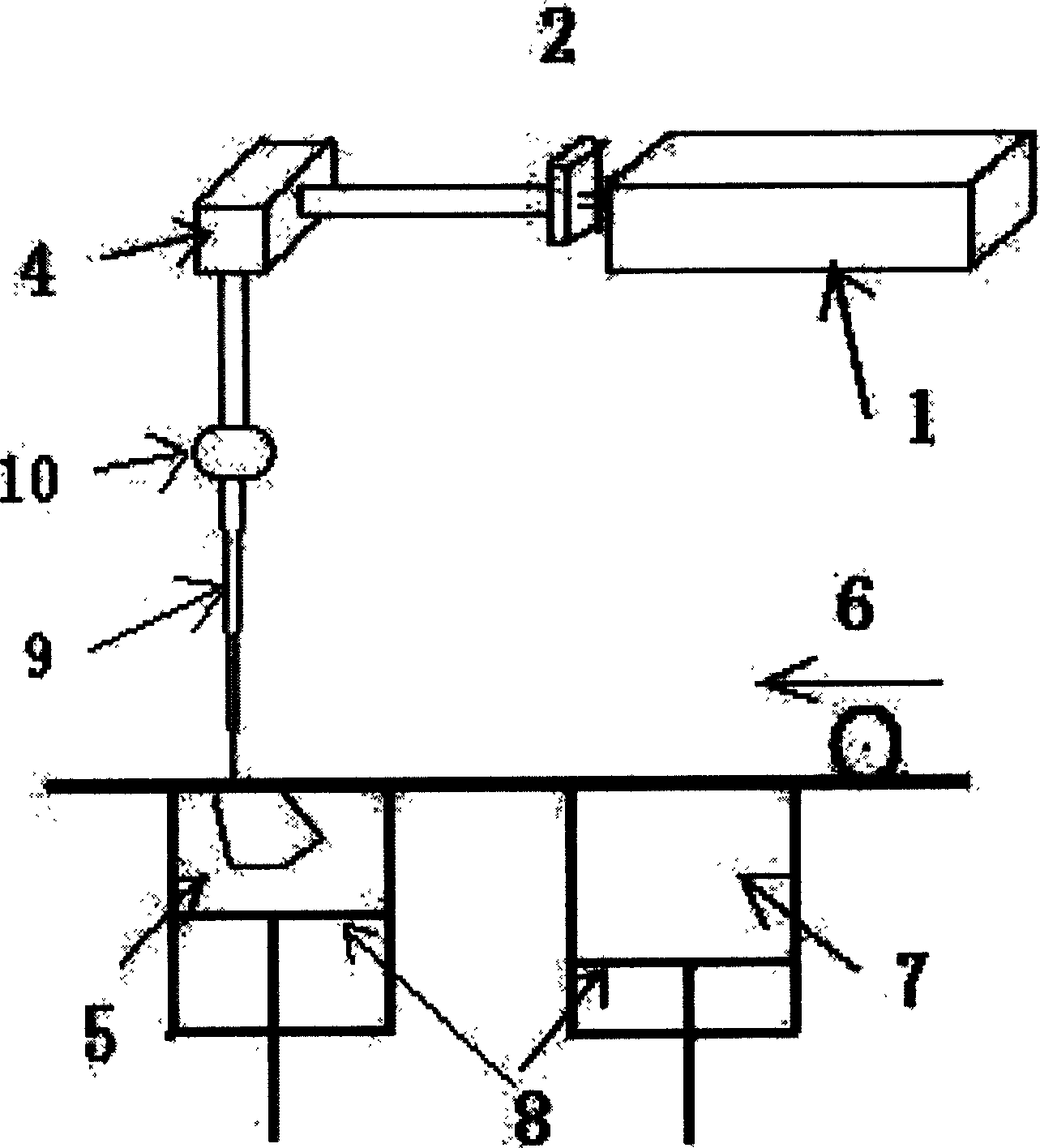

Selected zone laser melting and rapid forming method for metal parts and apparatus thereof

The invention relates to laser melting rapid forming method in the metal parts precinct and its installation. The method includes that setting CAD geometric model, doing stratification variance and laying powder layer by layer to the CAD geometric mode, adopting laser with high power density and high light speed factor of merit to form focusing facula with the diameter which is from thirty millimeter to fifty millimeter by focusing of beams system, melting the metal or alloy powder layer by layer, piling to a metallurgy unite, and forming to a compact solid mass. The installation is made up of semiconductor pumping YAG laser or fiber laser, focusing of beams system, shaped part jar, and powder jar. The semiconductor pumping YAG laser or fiber laser is light path connected to the focusing of beams system, and focalized and scanned at the shaped part jar. The shaped part jar is connected to the powder jar by powder laying roller. The powder laying roller is connected to the driving motor. And the driving motor is connected to the computer. The advantages of the invention are that the beam mode is good; mechanical features of the processed metal parts is well; the dimensional precision and the surface finish are high; and its range of application is wide.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com