Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2471 results about "Dimensional precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

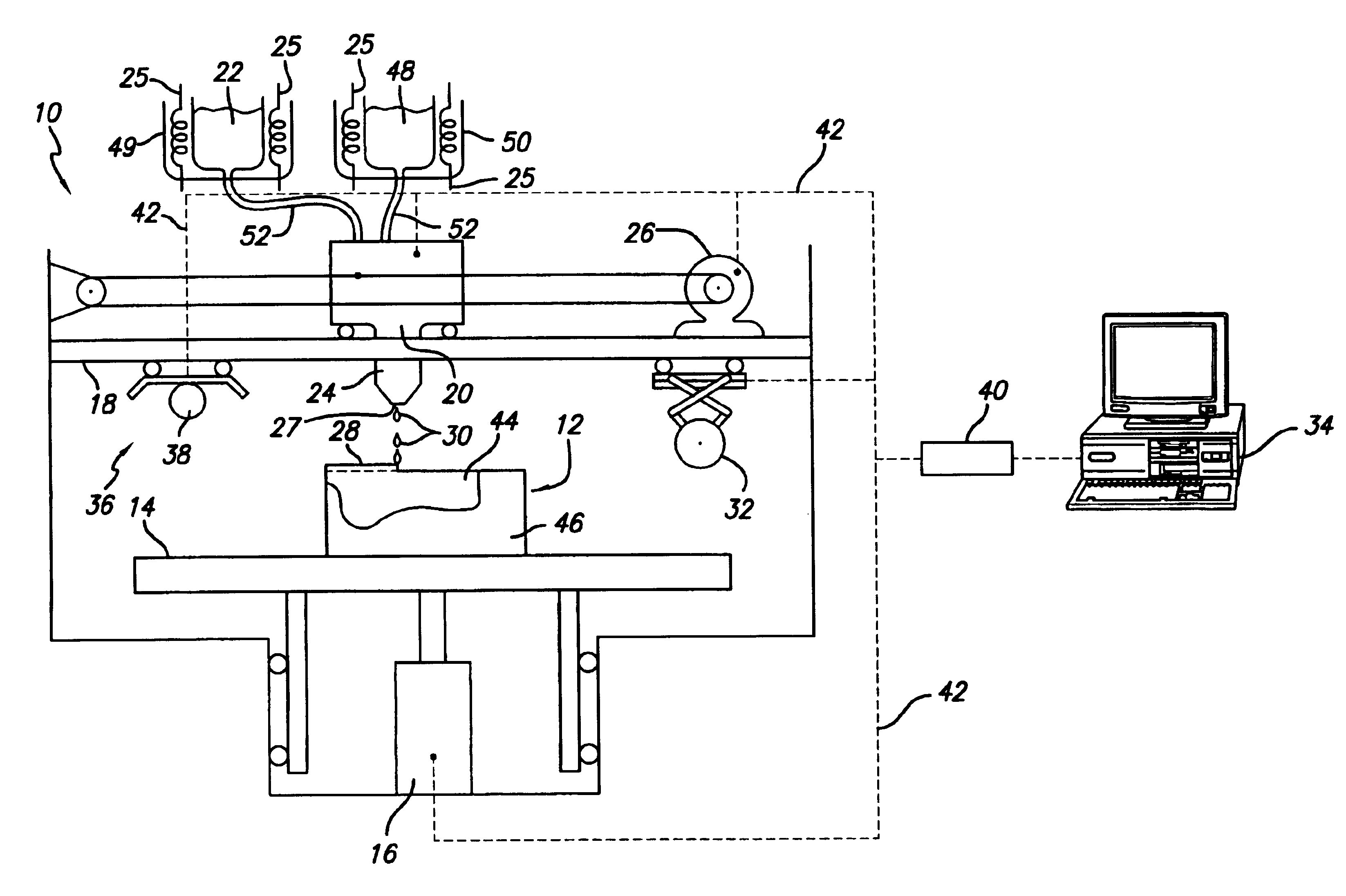

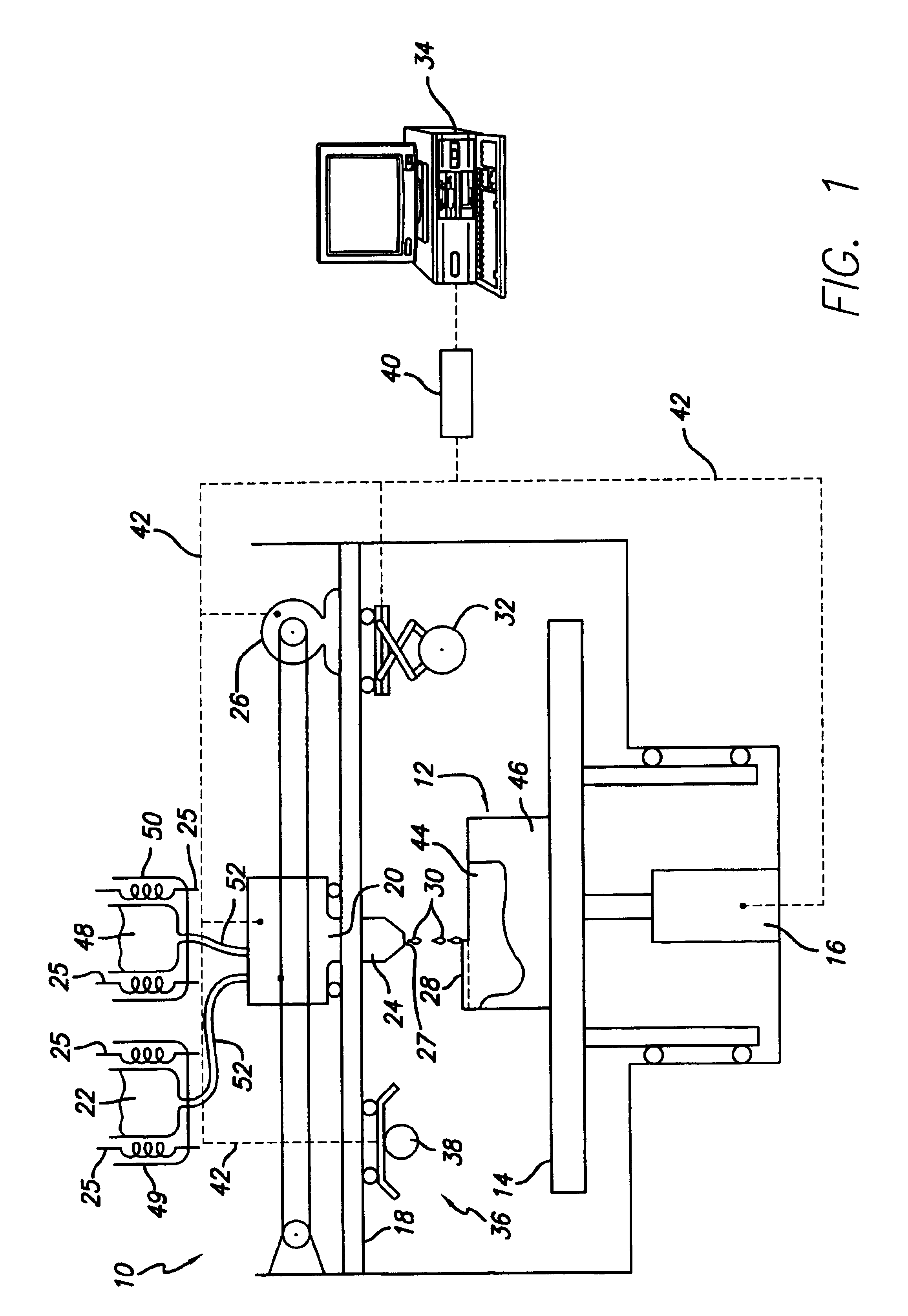

Selective deposition modeling build style providing enhanced dimensional accuracy

InactiveUS6936212B1High dimensional accuracyProduced cost-effectivelyAdditive manufacturing apparatusAuxillary shaping apparatusSelective depositionEngineering

A method of forming a three-dimensional object in a layerwise manner is disclosed. The object is formed in a manner-that substantially prevents non-uniform distortion to occur during the layerwise build process as the build material forming the object solidifies and shrinks. The formed object comprises an outer surface defined by a shell structure and an internal lattice structure residing within the internal volume of the object. The object may be formed by any selective deposition modeling apparatus from a wide variety of materials.

Owner:3D SYST INC

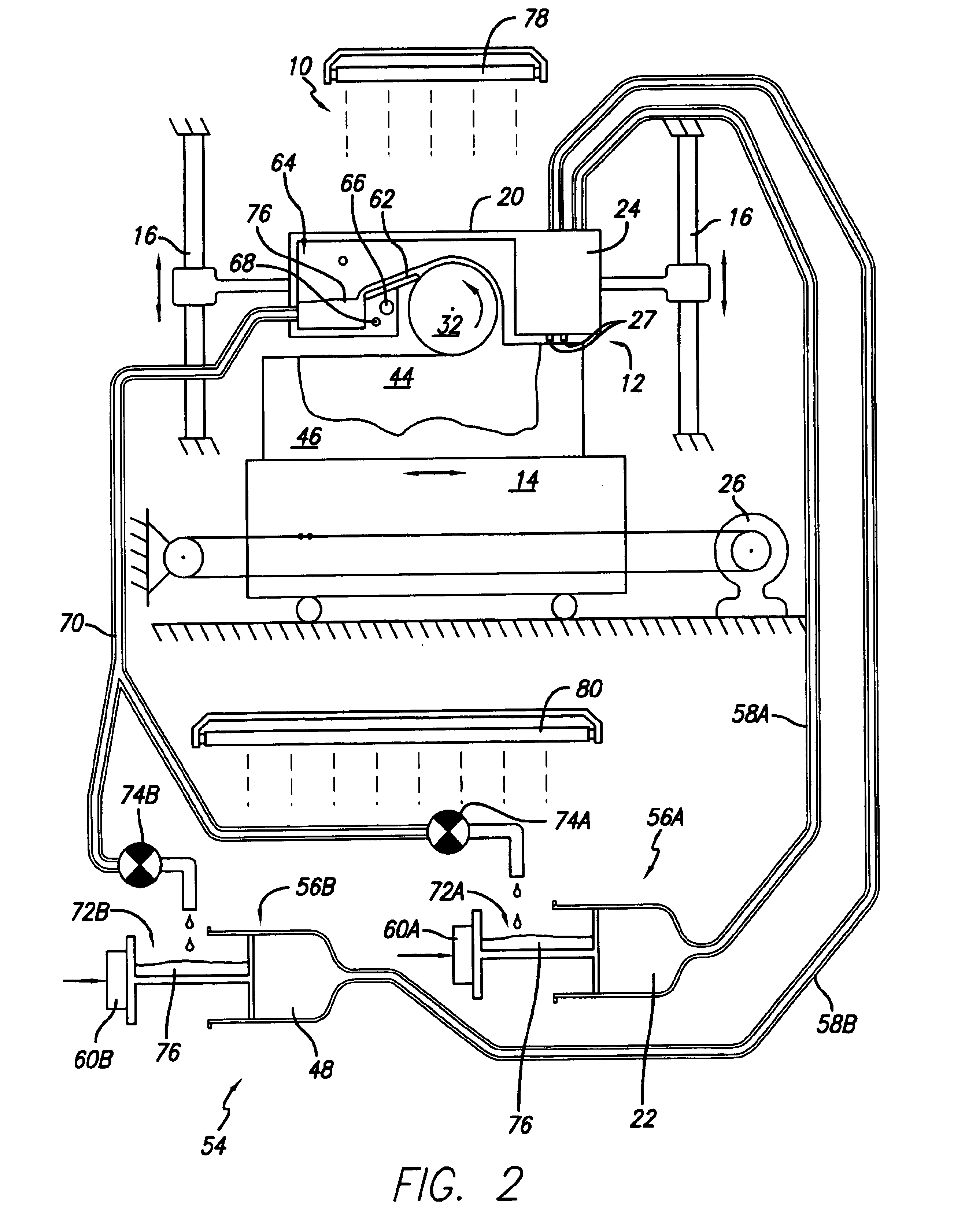

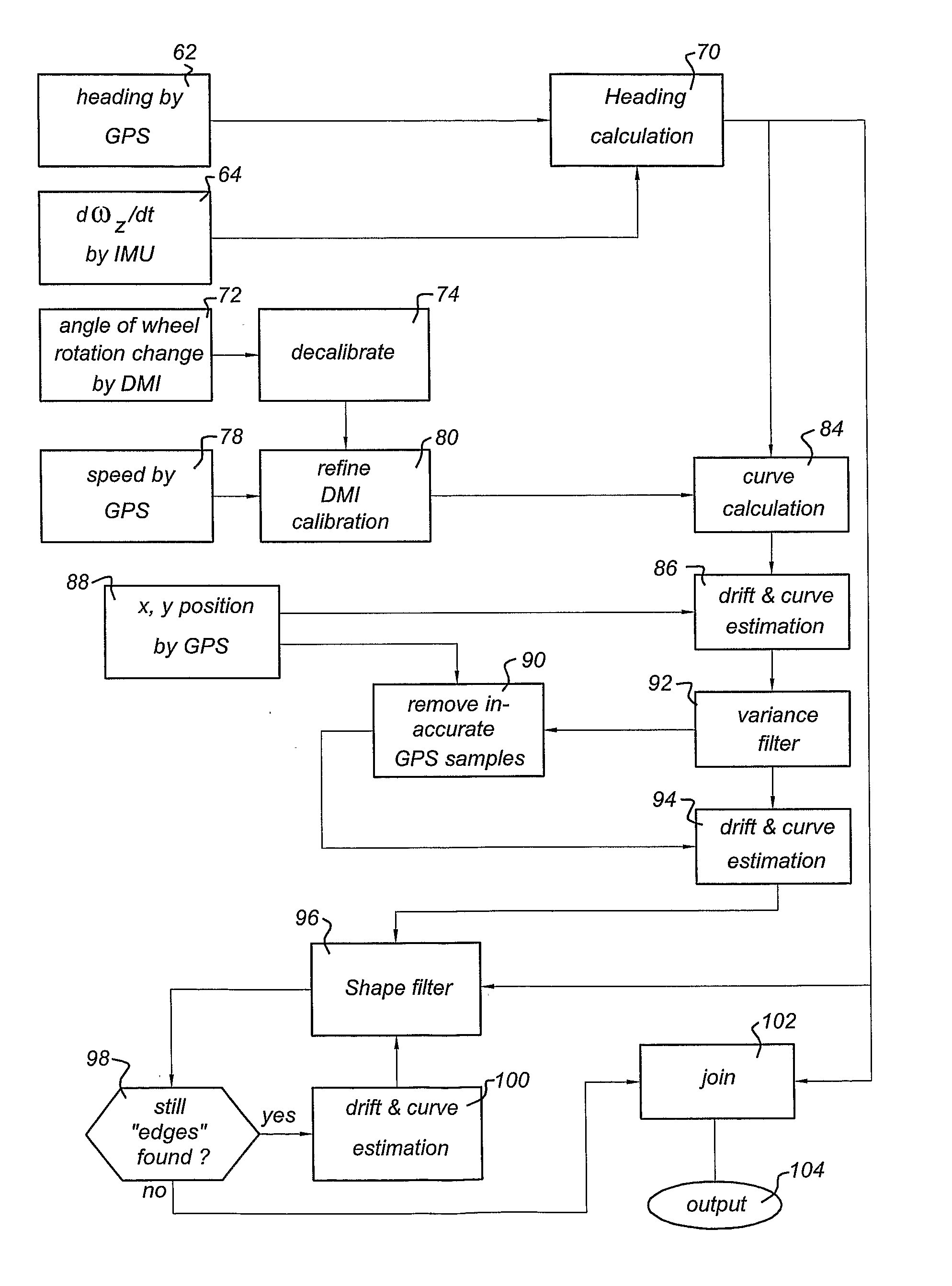

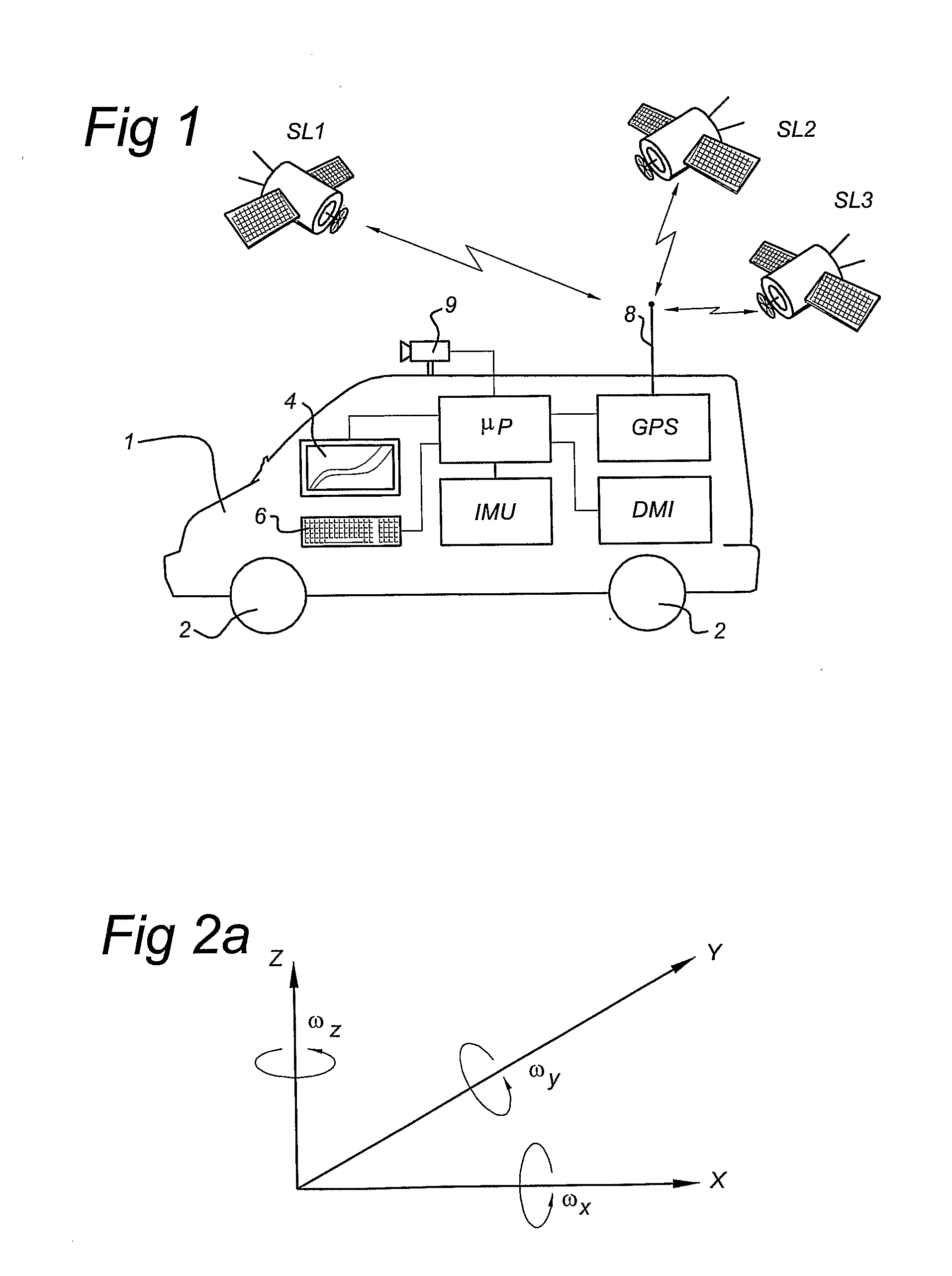

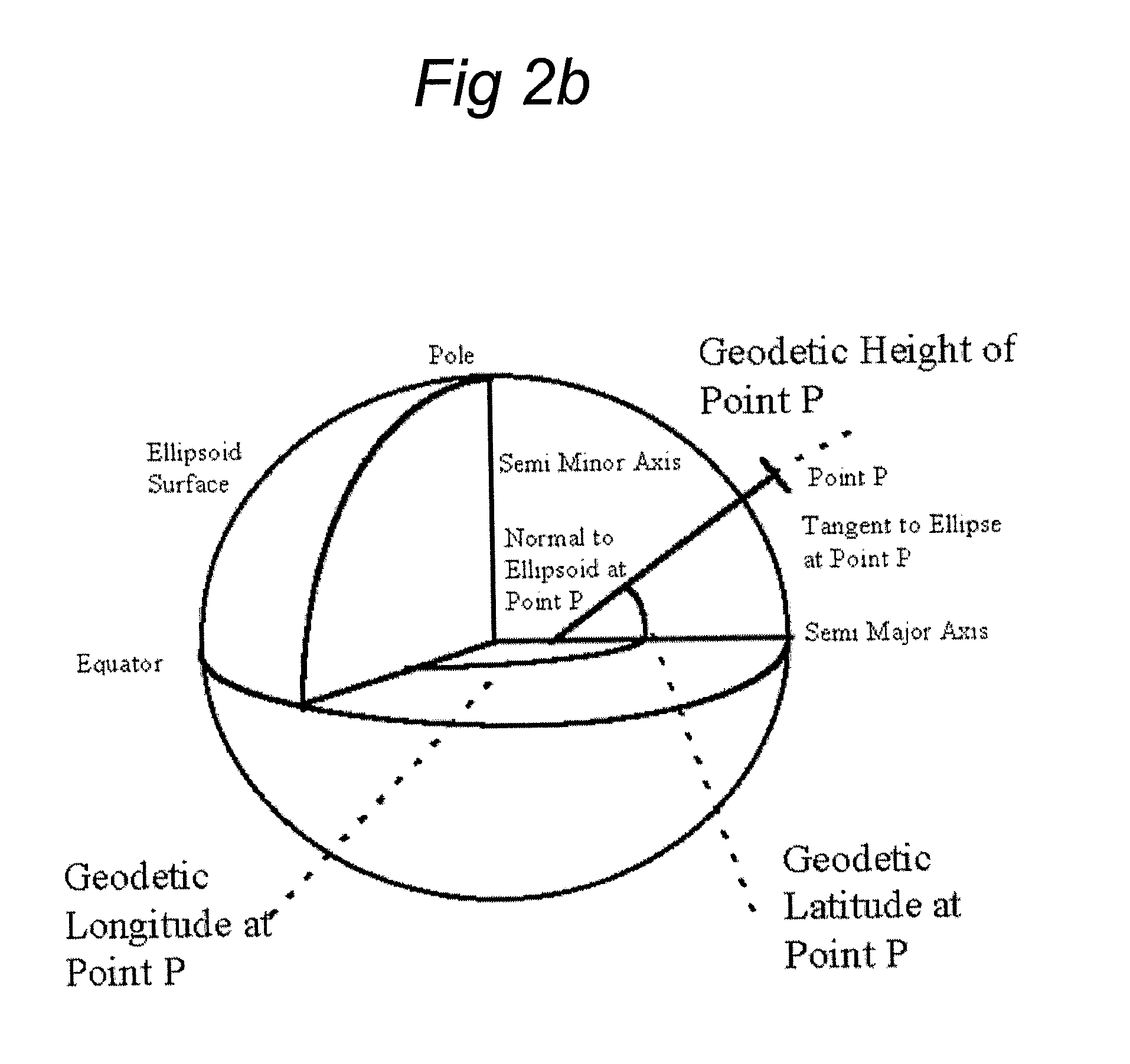

Arrangement for and method of two dimensional and three dimensional precision location and orientation determination

ActiveUS20100039318A1Improve of calculationsImprove positionInstruments for road network navigationPosition fixationOn boardPosition dependent

In one embodiment of the present invention, a method of and apparatus for determining inaccurate GPS samples in a set of GPS samples is disclosed, according to the following actions: a) obtaining GPS samples as taken by a global positioning system on board a vehicle when traveling along a trajectory; b) obtaining a first estimation of the trajectory based on the GPS samples; c) obtaining a second estimation of the trajectory at least based on measurements made by an inertial measurement unit on board vehicle when traveling along the trajectory; d) comparing the first and second estimations; e) establishing locations where the first estimation shows a variation compared with the second estimation above a predetermined threshold; f) if no such locations can be established continue with action j), otherwise continue with action g); g) removing GPS samples associated with the locations of high variation as being inaccurate GPS samples, thus forming a set of remaining GPS samples; h) calculating the first estimation anew of the trajectory based on the remaining GPS samples and calculating the second estimation anew; i) repeating actions d) to h); j) ending the actions.

Owner:TOMTOM GLOBAL CONTENT

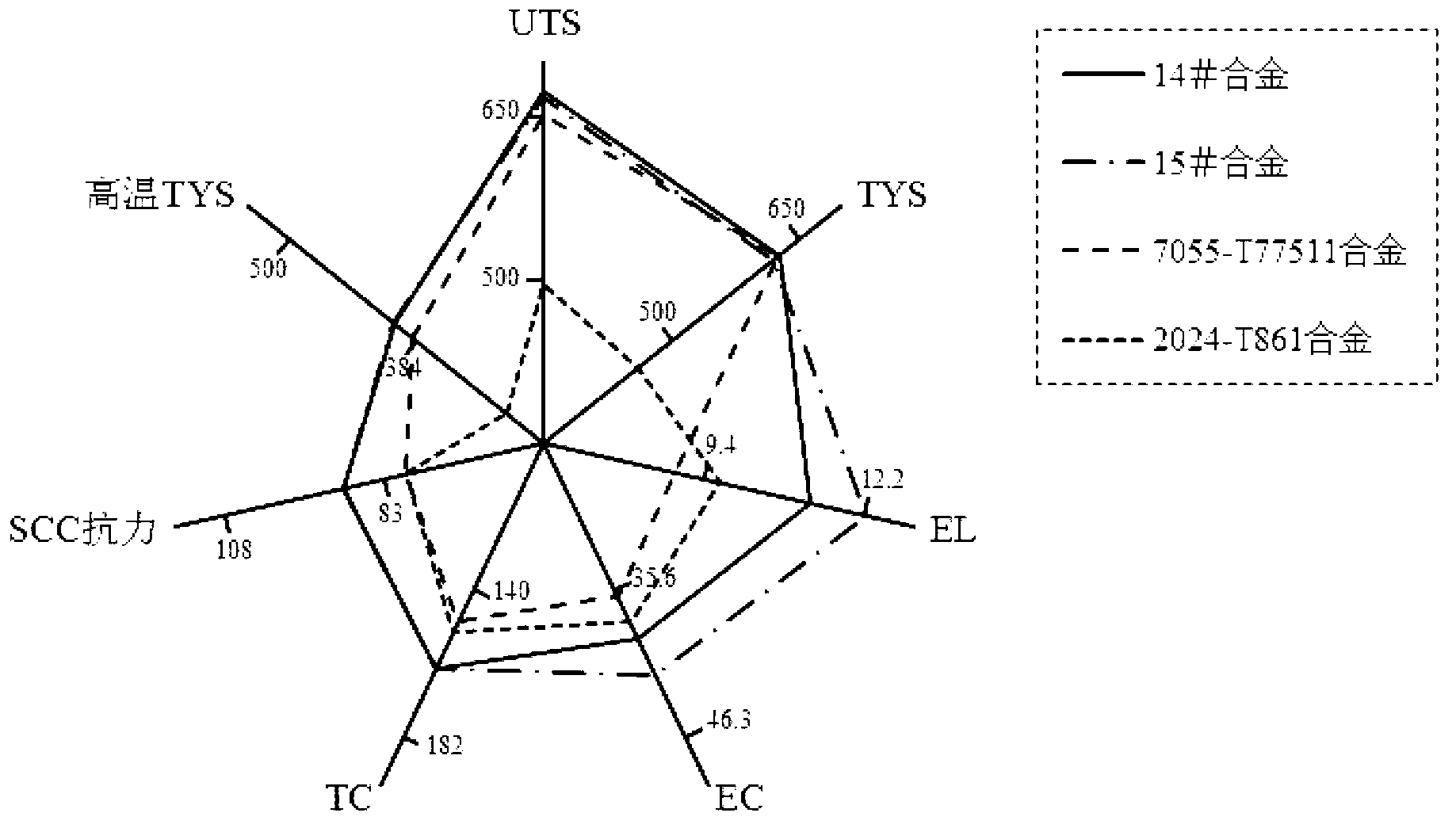

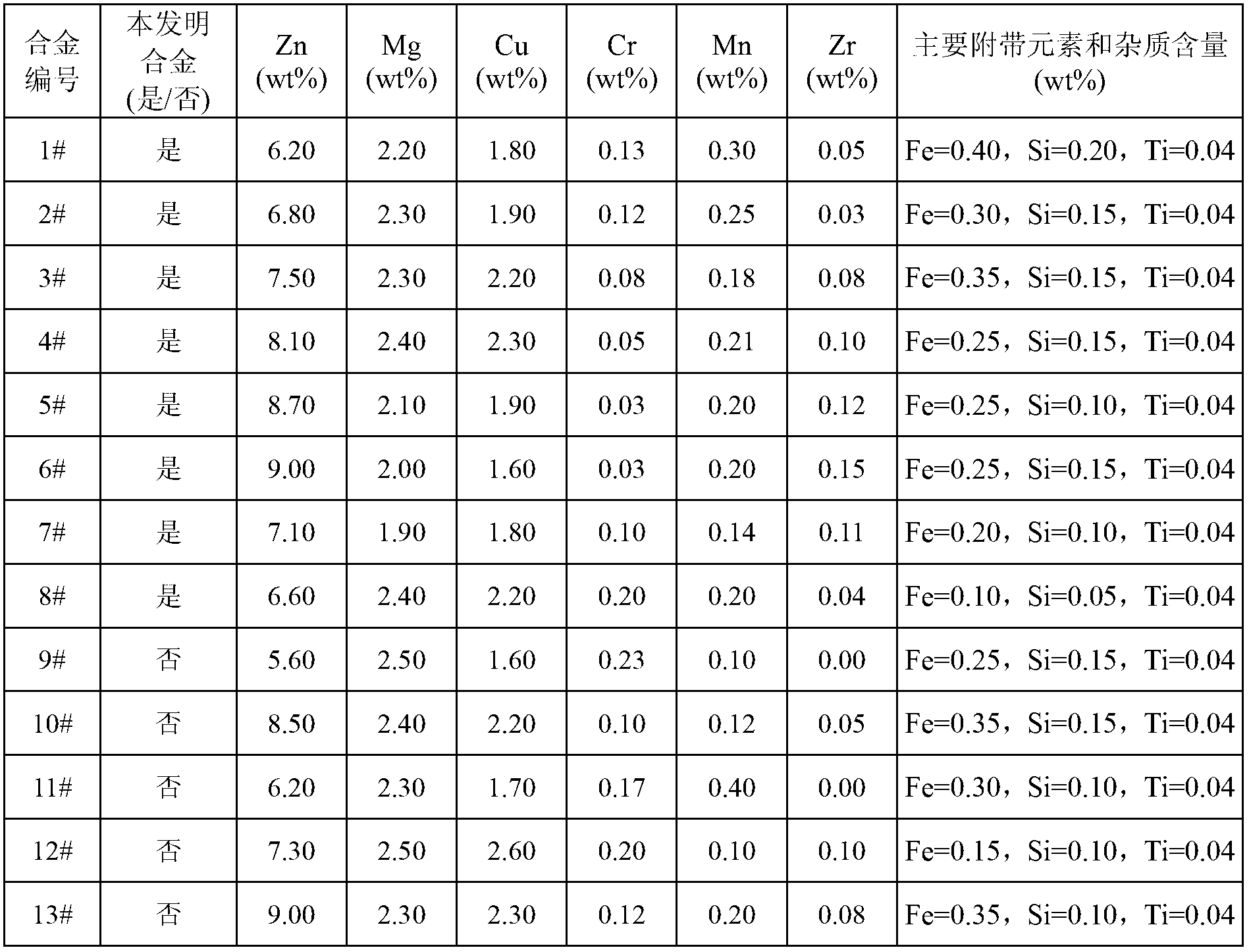

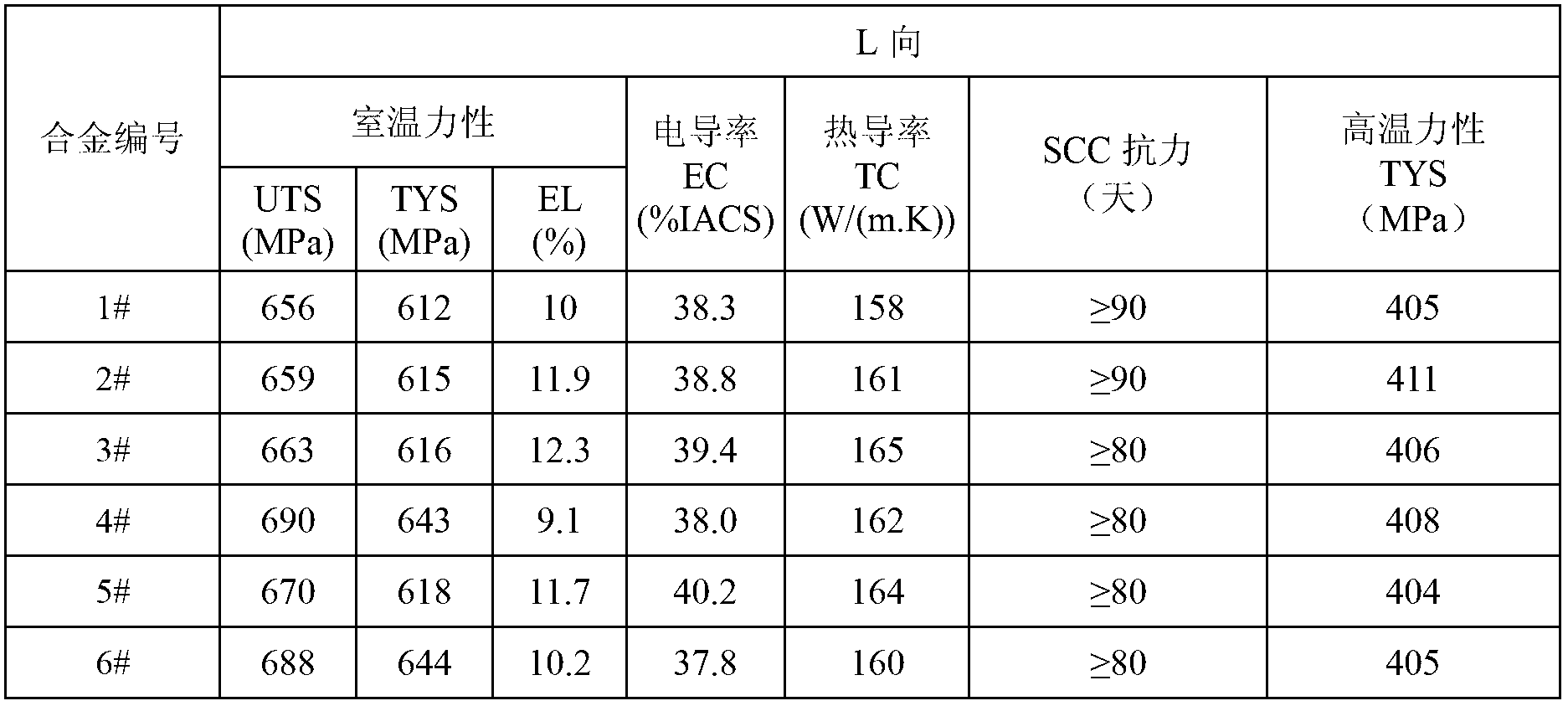

Aluminum alloy product suitable for structure and function integration, and preparation method thereof

The invention relates to an aluminum alloy product suitable for structure and function integration, and a preparation method thereof. The aluminum alloy product comprises the components of, by weight, 5.5-10.0% of Zn, 1.5-2.8% of Mg, 1.5-2.5% of Cu, 0.01-0.50% of Cr, 0.05-0.50% of Mn, 0.01-0.20% of Zr, and balance of of Al and incidental elements and impurities. In the aluminum alloy product: (a) Zn+Mg+Cu is no lower than 10.0% and no higher than 14.0%; (b) (Zn / Mg)+Cu is no lower than 4.4 and no higher than 6.5; (c) Cr+Mn+Zr is no lower than 0.10 and no higher than 0.60; and (d) the content of Cr is no higher than that of Mn, and content of Mn is no higher than that of Cr+0.20. The aluminum alloy product has high strength, high electric conductivity, and good thermal conductivity. Also, the aluminum alloy product has low residual stress, good surface quality, and good dimensional precision. The invention also relates to a preparation method of the aluminum alloy product.

Owner:GRIMAT ENG INST CO LTD

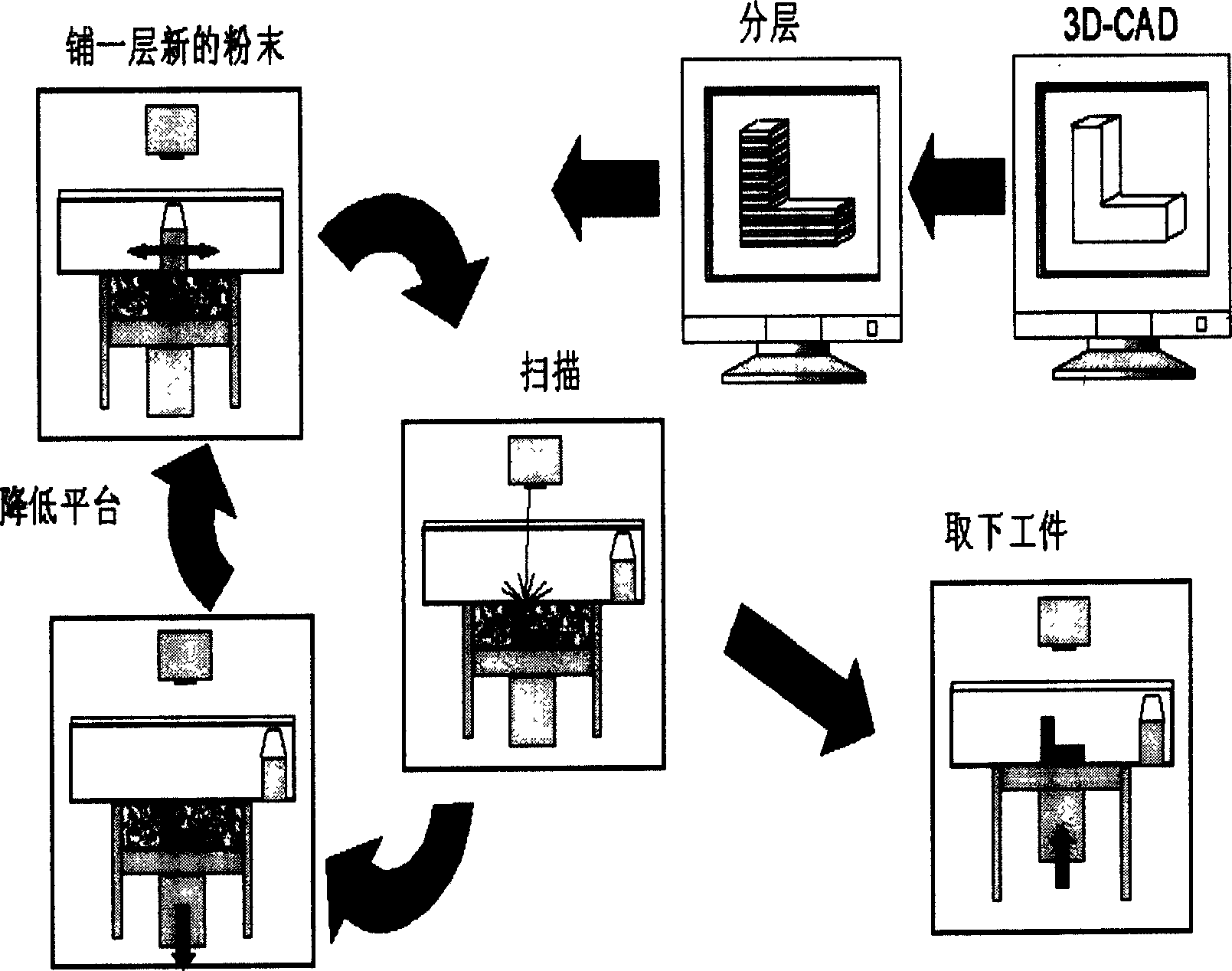

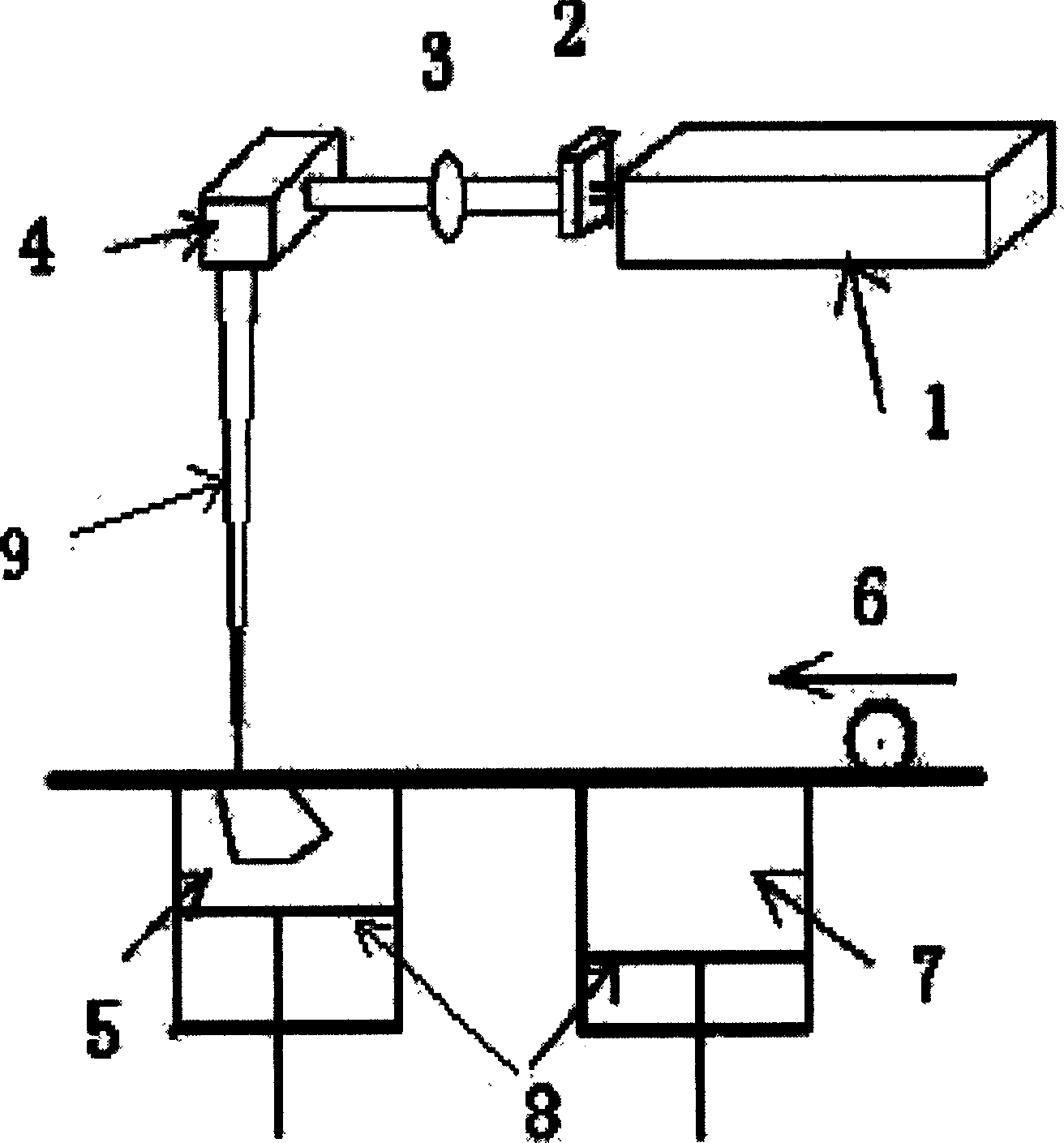

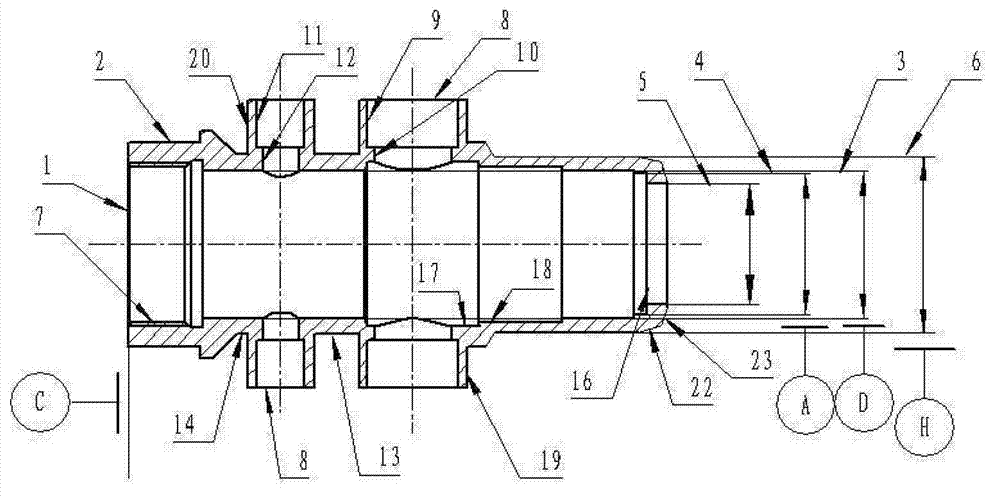

Selected zone laser melting and rapid forming method for metal parts and apparatus thereof

The invention relates to laser melting rapid forming method in the metal parts precinct and its installation. The method includes that setting CAD geometric model, doing stratification variance and laying powder layer by layer to the CAD geometric mode, adopting laser with high power density and high light speed factor of merit to form focusing facula with the diameter which is from thirty millimeter to fifty millimeter by focusing of beams system, melting the metal or alloy powder layer by layer, piling to a metallurgy unite, and forming to a compact solid mass. The installation is made up of semiconductor pumping YAG laser or fiber laser, focusing of beams system, shaped part jar, and powder jar. The semiconductor pumping YAG laser or fiber laser is light path connected to the focusing of beams system, and focalized and scanned at the shaped part jar. The shaped part jar is connected to the powder jar by powder laying roller. The powder laying roller is connected to the driving motor. And the driving motor is connected to the computer. The advantages of the invention are that the beam mode is good; mechanical features of the processed metal parts is well; the dimensional precision and the surface finish are high; and its range of application is wide.

Owner:SOUTH CHINA UNIV OF TECH

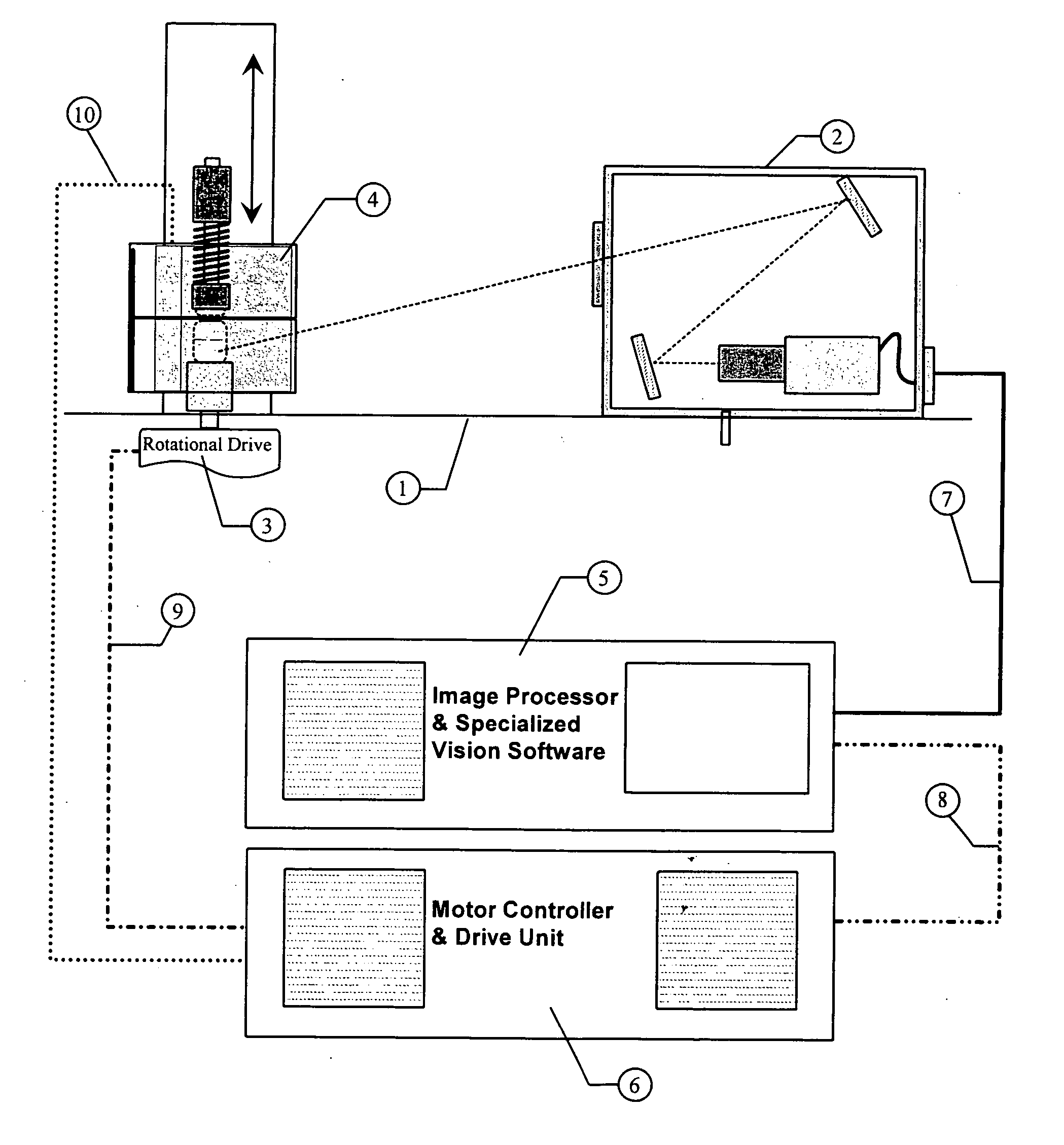

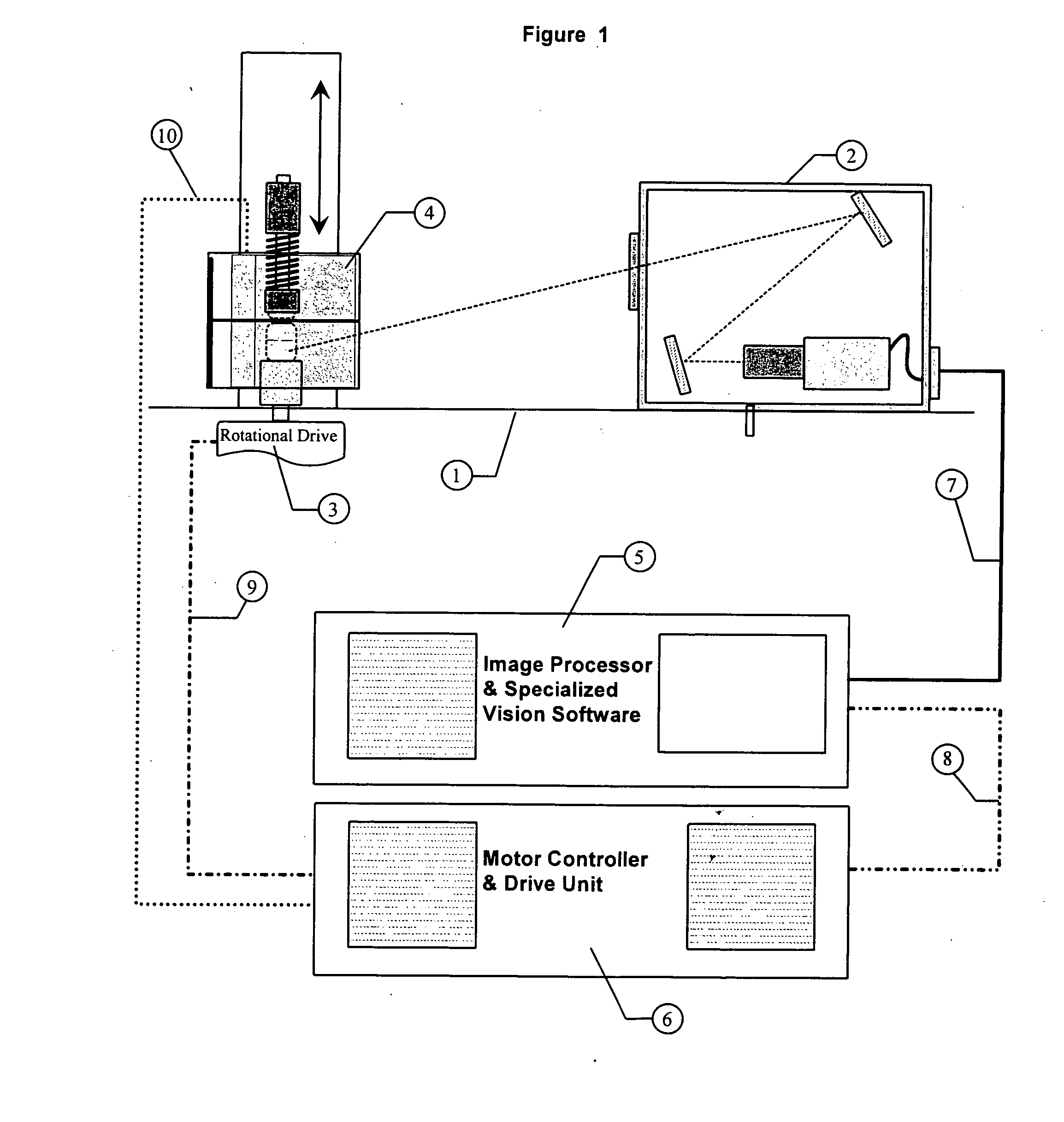

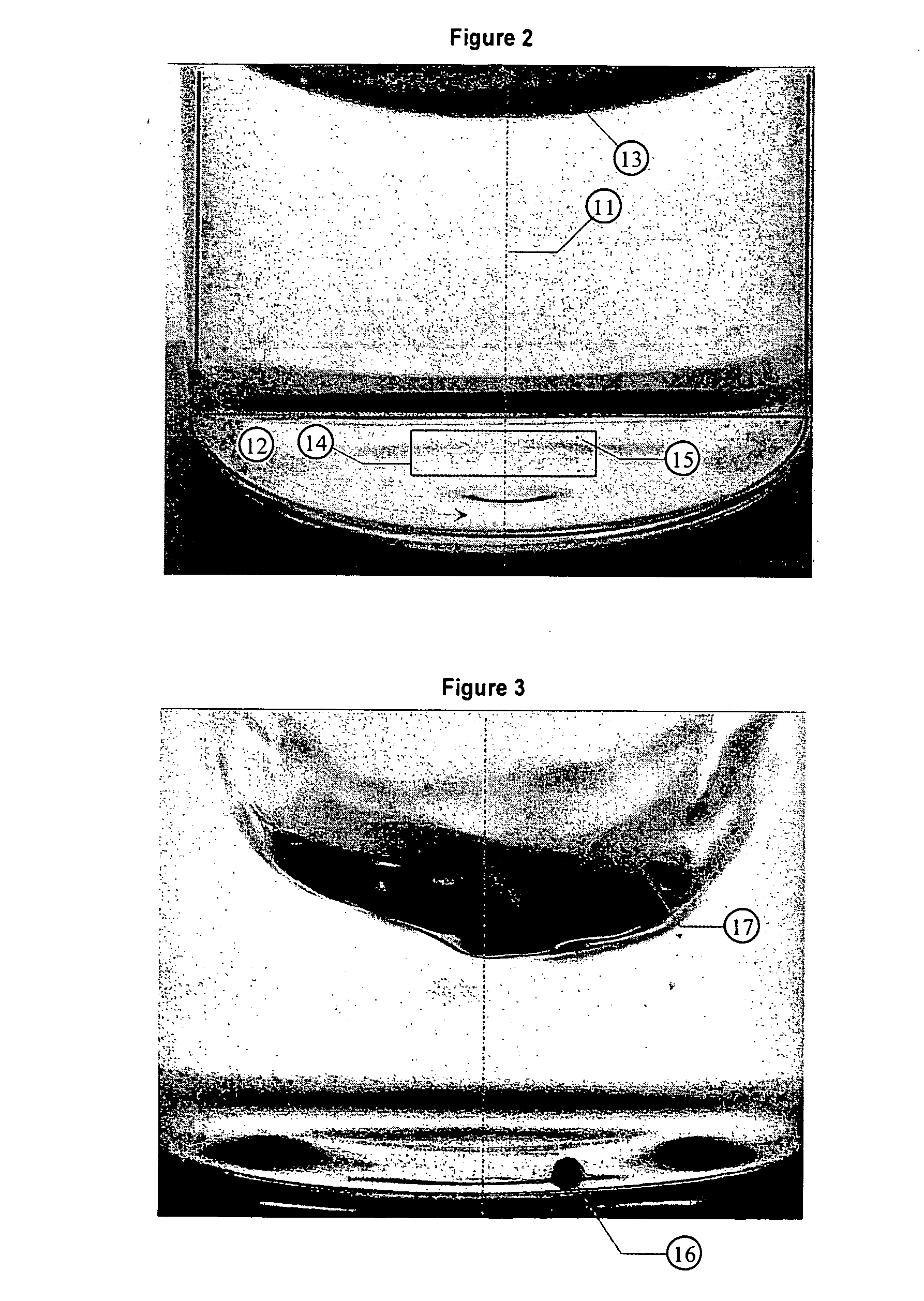

Small container fluid dynamics to produce optimized inspection conditions

ActiveUS20050248765A1Improve imaging characteristicReduce radiant energyOptically investigating flaws/contaminationIndividual particle analysisMeniscusEngineering

The generation of a desired non-linear resonance in the toroidal flow of liquid in a cylindrical injectable product is described. The resulting liquid flow pattern generated with an approximately smooth meniscus is down at the walls, across to the center of rotation, up on the center of rotation, across the meniscus to complete the pattern. The controlled flow pattern results in a predictable location for particle of varying mass and hydraulic shape. This predictability of location transforms the problem of particle detection from a chance occurrence to a deterministic task. The deterministic location of particle position is a contributor to the demonstrated capability to measure the size of visible particle range in a range from 33 μm to 1,000 μm with a median deviation of 1% and a maximum deviation from NIST dimensional accuracy of 3%.

Owner:BUDD GERALD WALTER +1

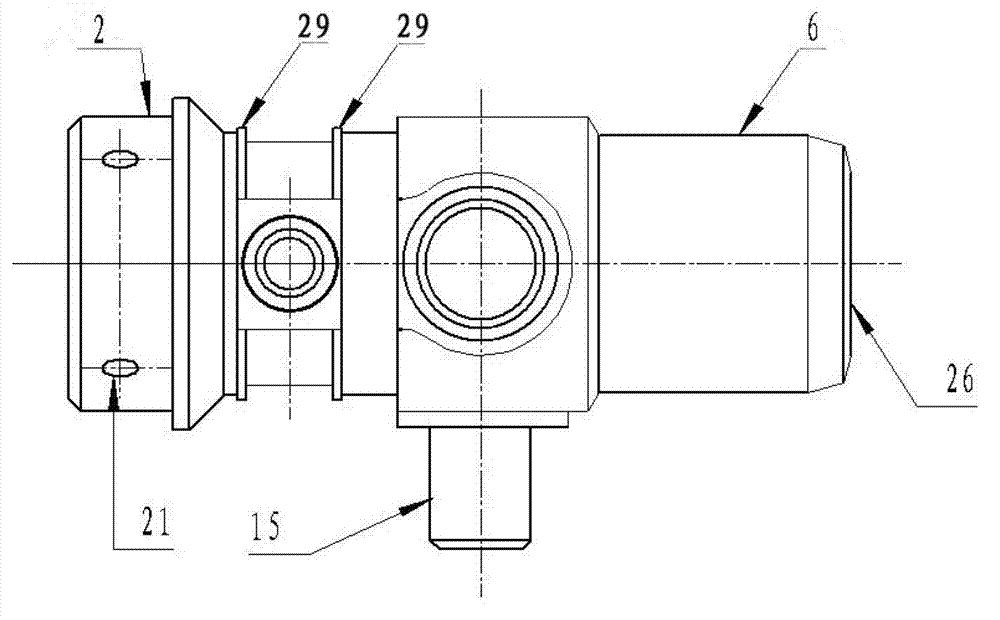

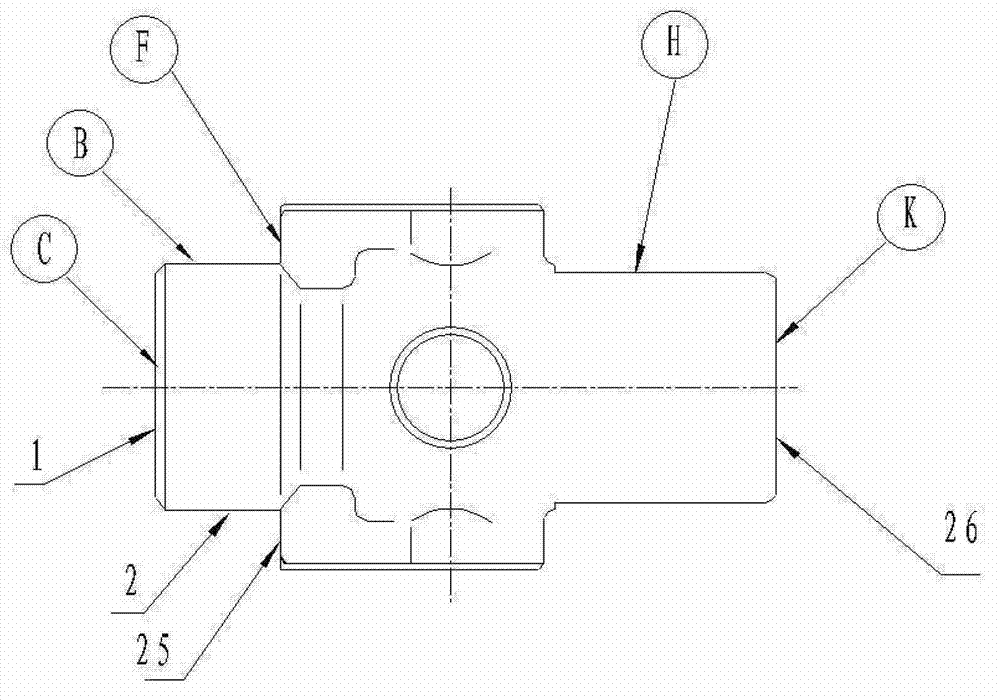

Numerically-controlled processing method of nozzle housing piece

The invention discloses a numerically-controlled processing method of a nozzle housing piece. According to the method, a numerically-controlled machining / milling combined processing center is adopted and comprises two main shafts and an on-line measurement device; the workblank of the nozzle housing piece is a die-forged part, and the die-forged part is made of a nickel-based high-temperature alloy. The method comprises the following steps: designing a nozzle housing processing path; performing polishing treatment on the die-forged part to remove burrs from the die-parting face and end-face die-drawing taper; coarsely machining the tail part of the work piece; performing numerically-controlled machining / milling on the whole work piece; performing numerically-controlled fine machining of the head part of the work piece; cleaning and marking the work piece; and inspecting. The method provides the reasonable designs of processing path and processing method of the work piece as well as the processing positioning reference of the work piece, and completes the processing of the inner cavity, the outer circle, the lateral adapter, the positioning pin and other parts of the nozzle housing piece within one-step loading process. The method solves the problem that the die-forged part has a complex structure and a thin wall and has strict requirements for dimensional precision and positional precision; and overcomes the defects of long processing period, low production efficiency and poor dimensional precision and positional precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

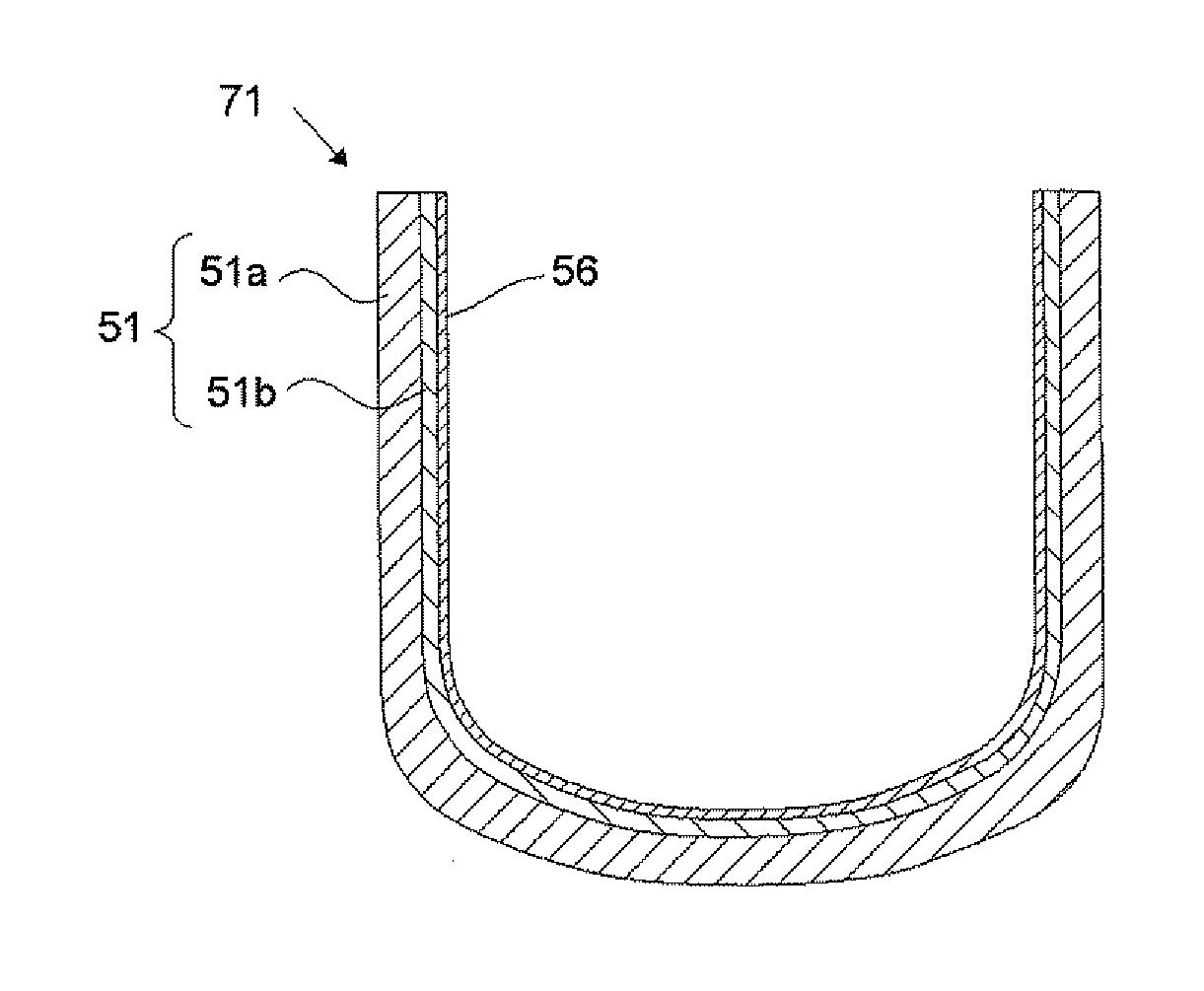

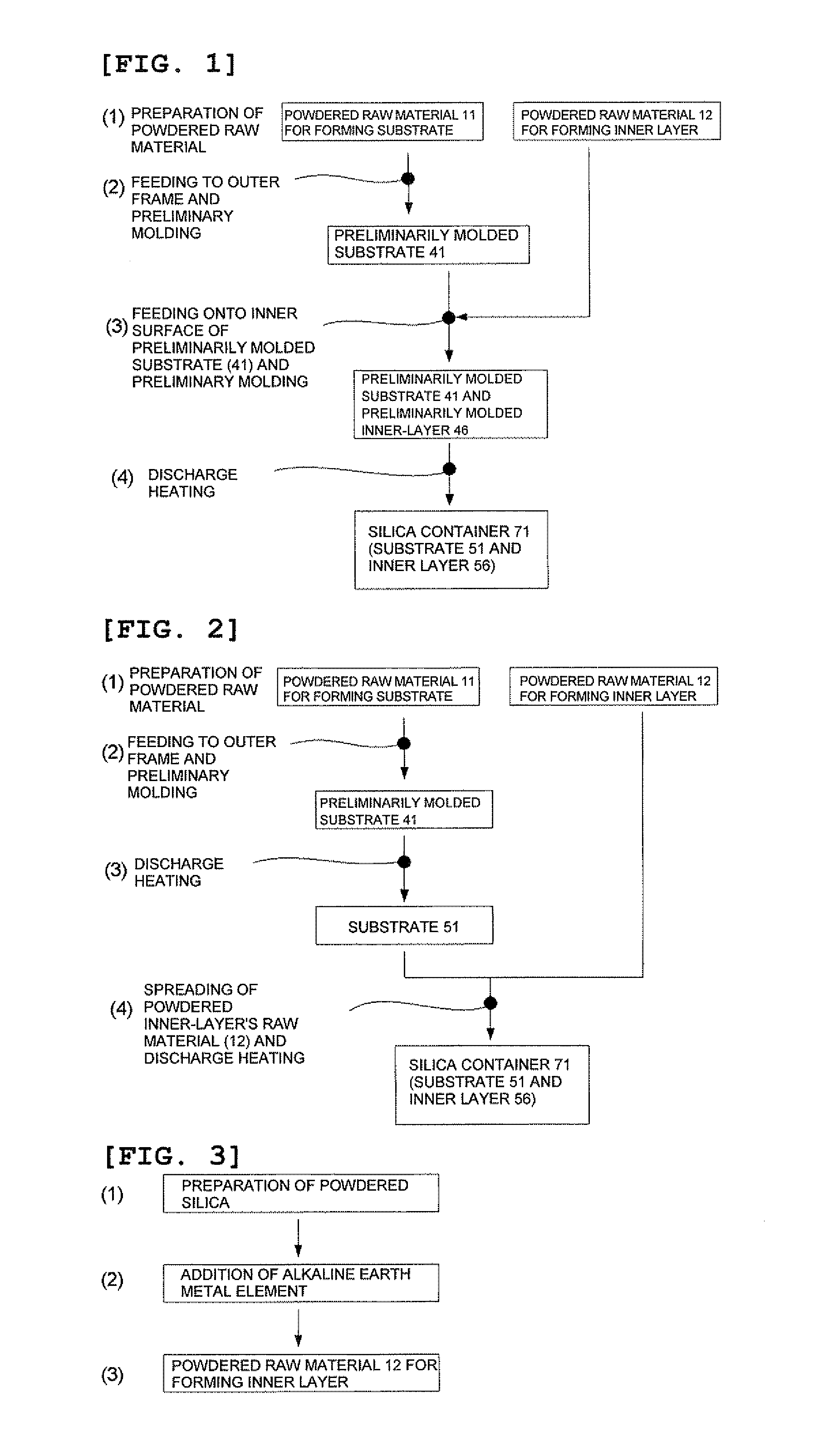

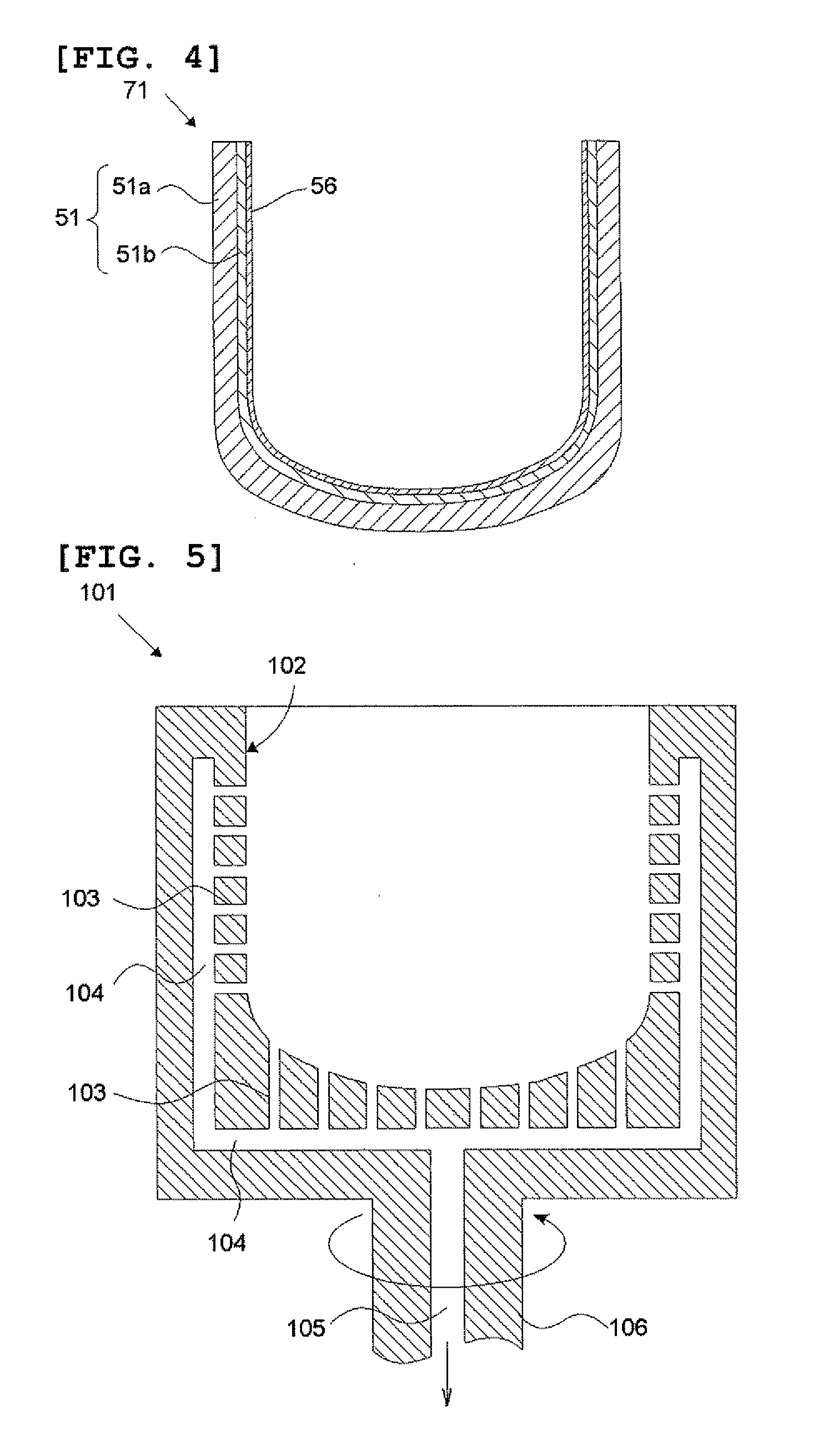

Silica container and method for producing the same

InactiveUS20110272322A1Increased durabilitySuppress generationAfter-treatment apparatusPolycrystalline material growthHydrogenFused glass

The present invention is a method for producing a silica container having a substrate containing gaseous bubbles in its outer peripheral part and an inner layer comprised of a transparent silica glass formed on an inner surface of the substrate, wherein a powdered raw material for forming a substrate containing Li, Na, and K with the total concentration of 50 or less ppm by weight and a powdered raw material for forming an inner layer containing Ca, Sr, and Ba with the total concentration of 50 to 2000 ppm by weight are prepared; a preliminarily molded substrate is formed in a frame; a preliminarily molded inner layer is formed on an inner surface of the preliminarily molded substrate; and the preliminarily molded substrate and molded inner layer are heated from inside thereof by a discharge-heat melting method under a gas atmosphere containing a hydrogen gas or a helium gas or a gas mixture thereof with the ratio of more than 10% by volume thereby making an outer peripheral part of the preliminarily molded substrate to a sintered body and an inner peripheral part of the preliminarily molded substrate and the preliminarily molded inner layer to a fused glass body. With this, a method for producing a silica container, producible with a low cost and having a high durability and dimensional precision, and a container of this sort can be provided.

Owner:SHIN ETABU QUARTZ PRODS

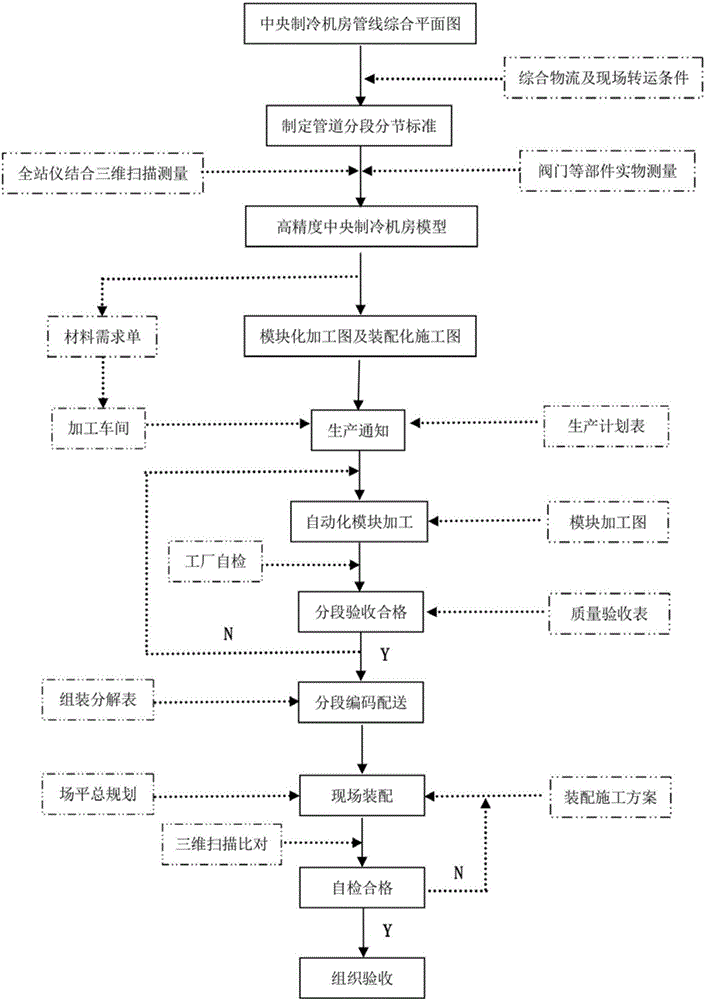

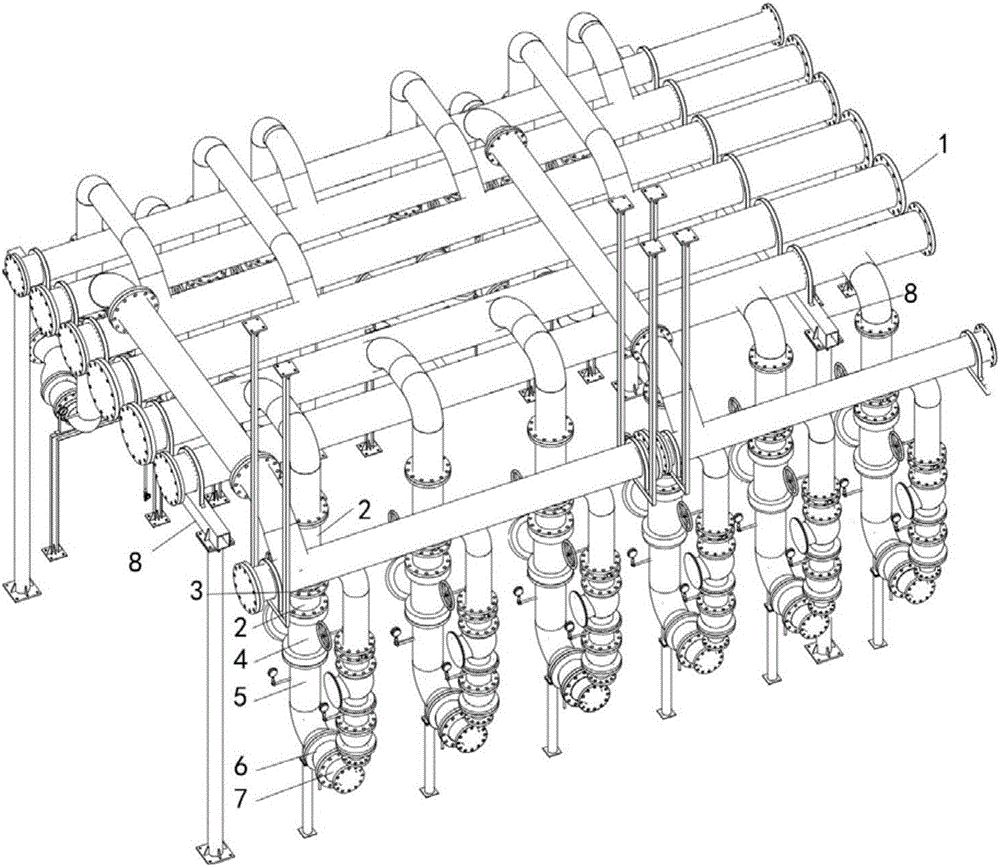

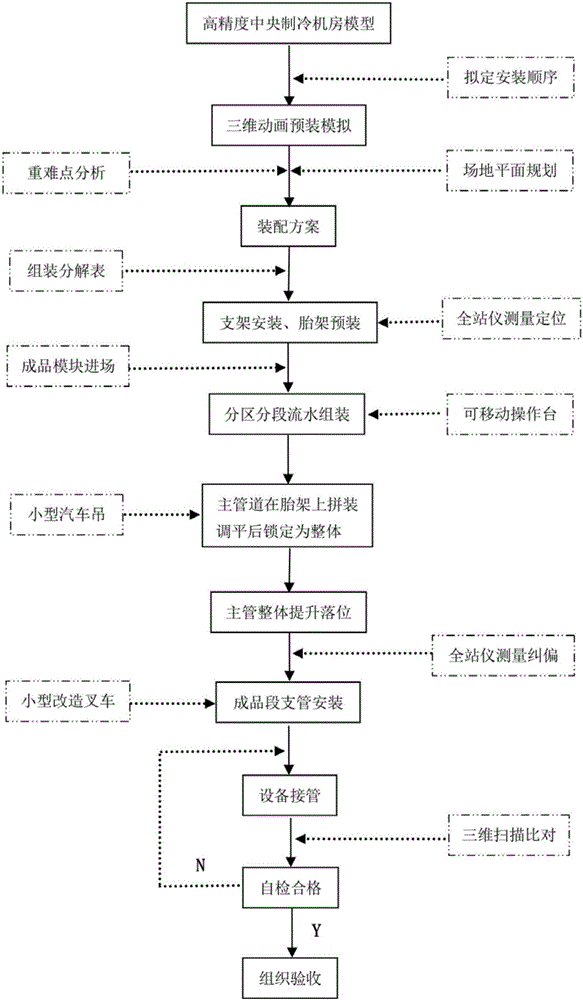

Central refrigeration machine room modular prefabrication and assembled construction method

ActiveCN105888317AError controllableImprove assembly efficiencyGeometric CADSpecial data processing applicationsComputer moduleRefrigeration

The invention discloses a central refrigeration machine room modular prefabrication and assembled construction method. The method comprises: refrigeration machine room standard family storehouse establishment, digital module design, three-dimensional precision control, factory full-automation prefabrication and assembled construction. A standard family storehouse is a central refrigeration machine room complete device, valve and component family storehouse created based on the size of an entity. A digital module is generated after a high-precision BIM model is subjected to scientific segmented encoding. The three-dimensional precision control comprises: rechecking and measuring a central refrigeration machine room building structure, constructing an absolute coordinate system, and ensuring that the model design precision, the processing precision and the field assembly precision are controlled uniformly and reliably. The factory full-automation prefabrication comprises factory production performed according to a digital module processing diagram. The assembled construction comprises segmented flange connection, and integrated lifting and mounting. The central refrigeration machine room modular prefabrication and assembled construction method has the advantages that mounting efficiency of a central refrigeration machine room can be improved, mounting quality and precision are improved, the reproduction and transplantation performances of a standard module design are high, and industrial production conditions are met.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Method for preparing complicated shape bonded magnet by utilizing 3D (three-dimensional) printing technology

ActiveCN103854844ASave raw materialsLow costInductances/transformers/magnets manufactureMagnetizationOperability

The invention relates to a method for a preparing complicated shape bonded magnet by utilizing a 3D (three-dimensional) printing technology, and belongs to the technical field of complicated shape bonded magnet preparation. According to the method, firstly, magnetic alloy powder, bonding agents and auxiliary agents are melted and mixed, then, a magnetic wire with a certain diameter is prepared through extrusion, next, a spray nozzle of 3D printing equipment is utilized for melting and accumulating the magnetic wire, in addition, orientation and curing are carried out, and finally, a required bonded magnet product with specific magnetism and complicated space shape is printed. The method has the advantages that the very thin bonded magnet (smaller than 0.4mm) with any complicated space shape can be prepared, the dimensional precision of the product is high, the product can be further subjected to magnetization and orientation control in the printing process, an isotropic or anisotropic permanent magnet product can be prepared, in addition, a blank and a mold are not needed in the printing process, raw materials can be greatly saved, the production efficiency can be improved, the process is stable and reliable, the operability is high, the repeatability is high, and the method is applicable to the batch production of the complicated shape bonded magnet.

Owner:UNIV OF SCI & TECH BEIJING

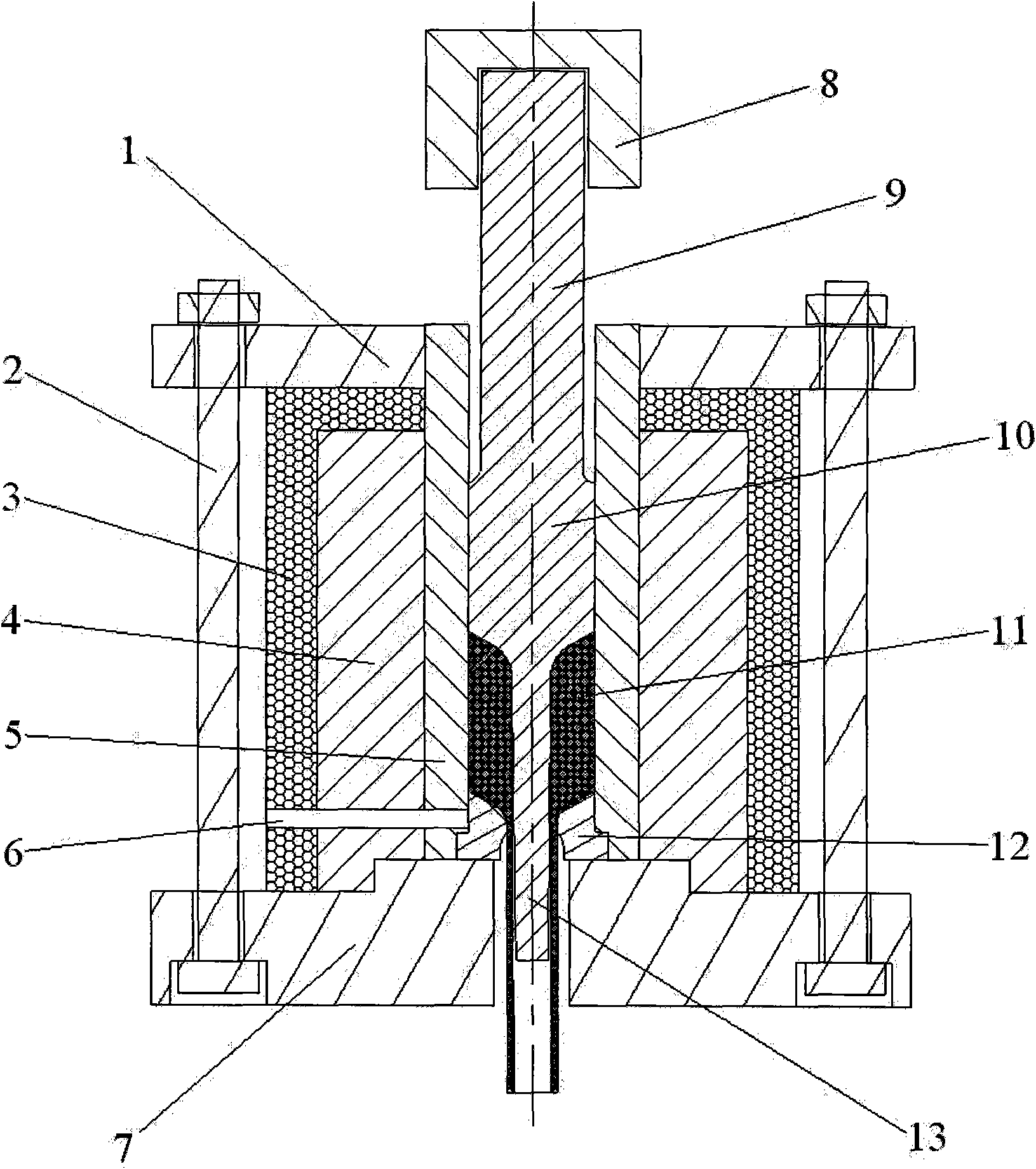

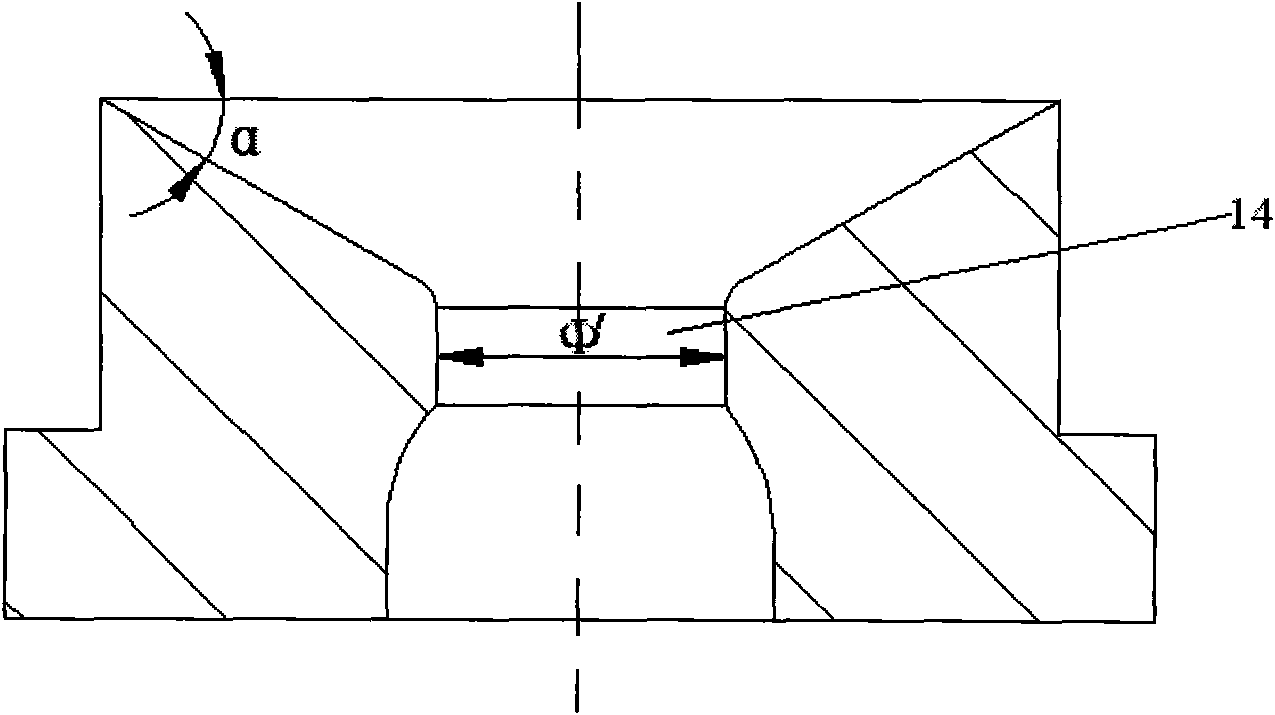

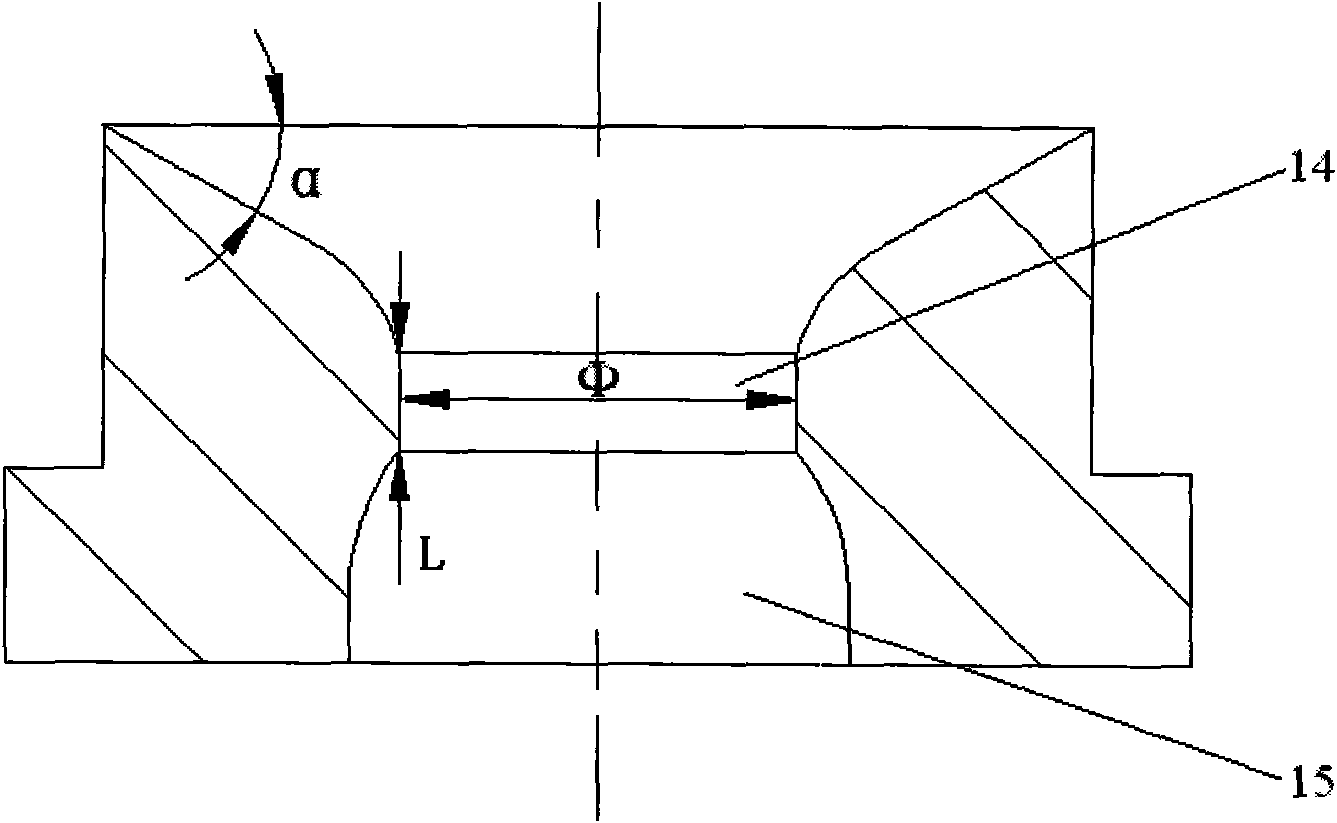

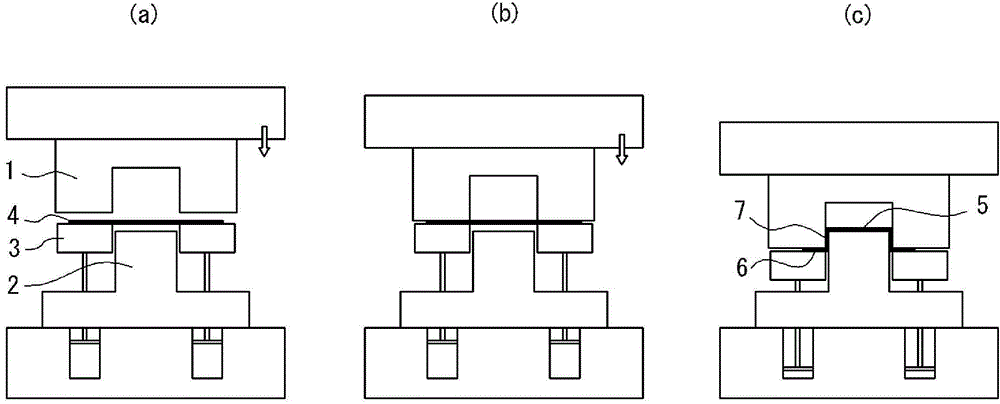

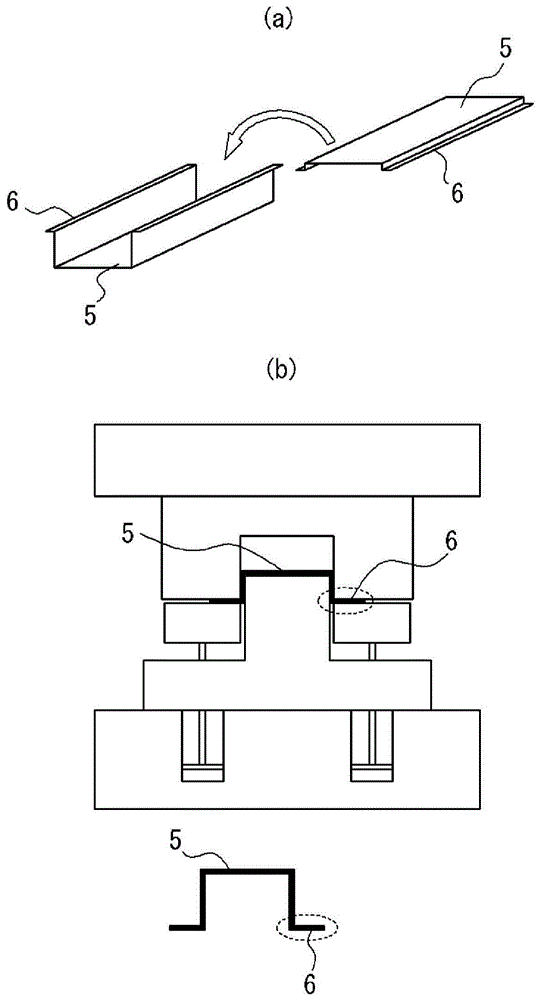

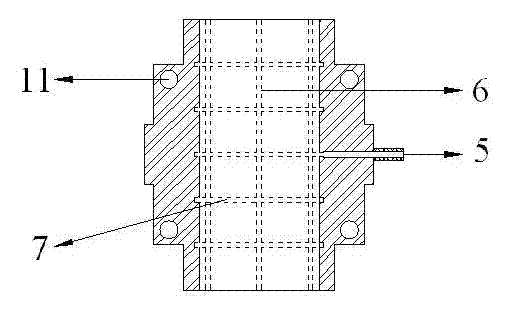

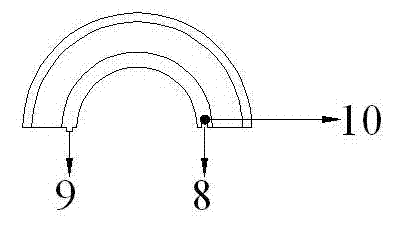

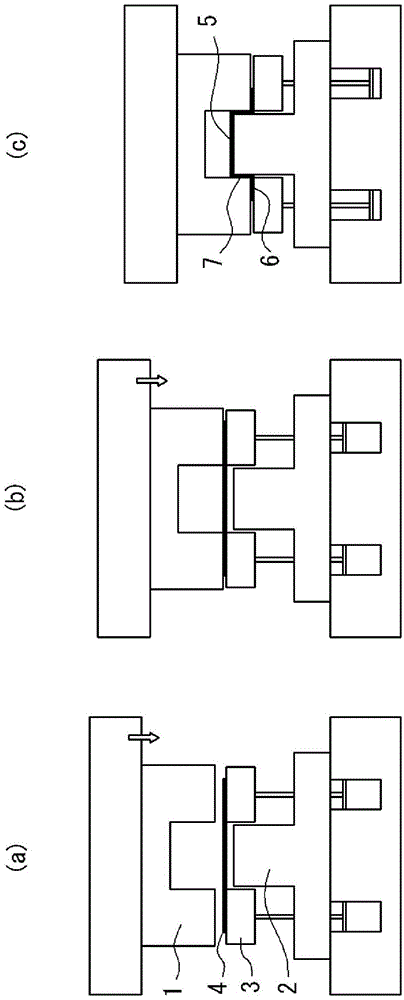

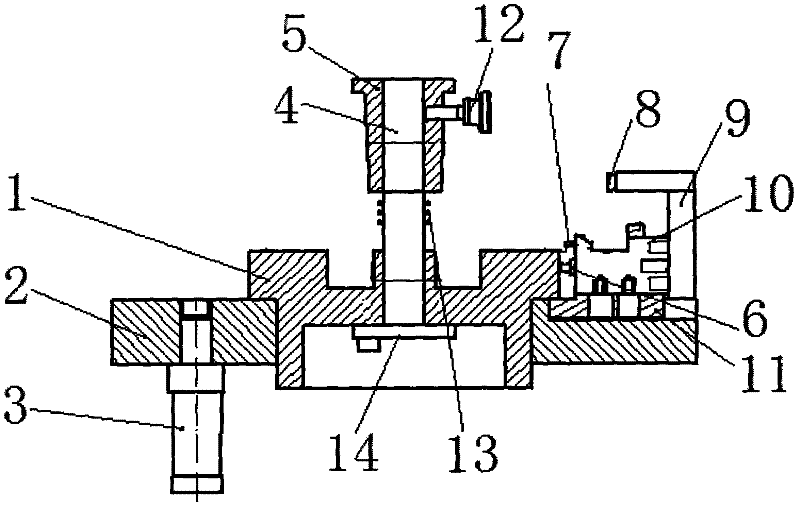

Rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold

InactiveCN101549361AIncrease profitReduce extrusion pressureExtrusion diesExtrusion containersThermal insulationRare earth

The invention relates to a rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold. The method includes: machine-tooling after casting ingot homogenization treatment into a hollow blank, performing pre-extrusion in the mold, extrusion molding after die change, and performing solid dissolving aging treatment for further improving the tube dynamics performance. The invention relates to a special mold, including an upper and a lower die holders, a thermal insulation sleeve, a squeezing barrel, a male die and a concave die, wherein, the concave die is composed of a pre-extrusion concave die and a shaping concave die, one of the pre-extrusion concave die and the shaping concave die is selected and interchangeable with the other, and is fixed on the lower die holder through a squeezing barrel. The invention can extrude a rare-earth magnesium alloy seamless thin wall tubule with the external diameter of 5-10mm and internal diameter of 4-8mm, which has features of high material utilization, small extruding force, high products dimensional precision, good surface accuracy, good dynamics performance and the like features. The inventive mold simultaneously has advantages of simple structure, easy operation, low cost, long life and so on.

Owner:CHONGQING UNIV

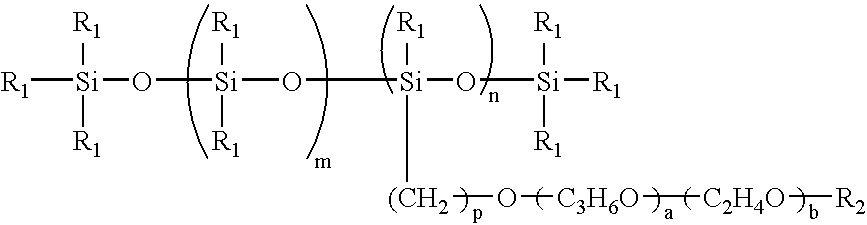

Dental impression material composition

ActiveUS6861457B2Improve hydrophilicityPromote recoveryImpression capsDental impression compositionsNonionic surfactantDimensional precision

To provide a dental impression material composition having high hydrophilicity comparable to that of polyether rubber-made impression materials, being superior in recovery from deformation caused by removal out of an oral cavity, which are similar to silicone rubber-made impression materials, the dental impression material composition being superior in dimensional precision, and good in storage stability. The dental impression material composition includes (A) 100 parts by weight of the sum of (1) an organopolysiloxane containing at least two aliphatic unsaturated hydrocarbons in one molecule and (2) a polyether containing at least one aliphatic unsaturated hydrocarbon in one molecule, in a weight ratio of (1) to (2) of 1:0.01˜1:5, having (B) 0.1˜100 parts by weight of an organohydrogenpolysiloxane containing at least three hydrogen atoms directly bonded to a silicon atom in one molecule, (C) 10˜500 ppm, based on the sum of (A) and (B), of a silicone-soluble platinum compound, (D) 10˜800 parts by weight of an inorganic filler, and (E) 0.5˜5 parts by weight of a nonionic surfactant and / or a polyether-modified silicone oil, compounded therewith.

Owner:GC CORP

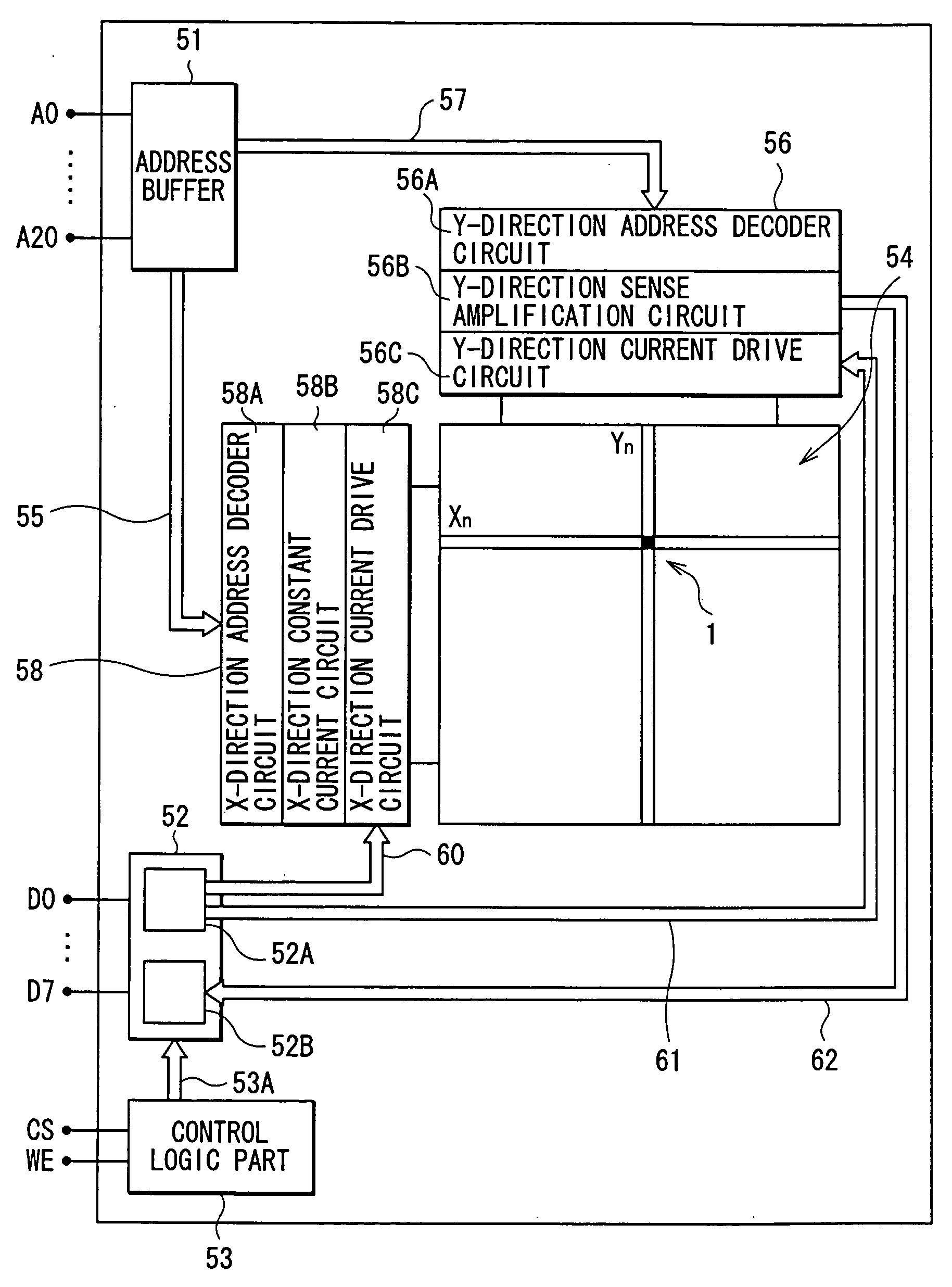

Magnetoresistive element, magnetic memory cell, and magnetic memory device, and method for manufacturing the same

InactiveUS20050018476A1Stable writingEasy to useMagnetic-field-controlled resistorsSolid-state devicesMagnetic memoryVolumetric Mass Density

The present invention provides a magnetic memory device capable of performing stable operation efficiently using a magnetic field generated by write current and formed with high precision while realizing a compact configuration. Since a plating film is used for at least a part of a magnetic yoke, as compared with the case of formation by a dry film forming method, sufficient thickness and higher dimensional precision can be obtained. Consequently, a more stabilized return magnetic field can be generated and high reliability can be assured. Neighboring memory cells can be disposed at narrower intervals, so that the invention is suitable for realizing higher integration and higher packing density.

Owner:TDK CORPARATION

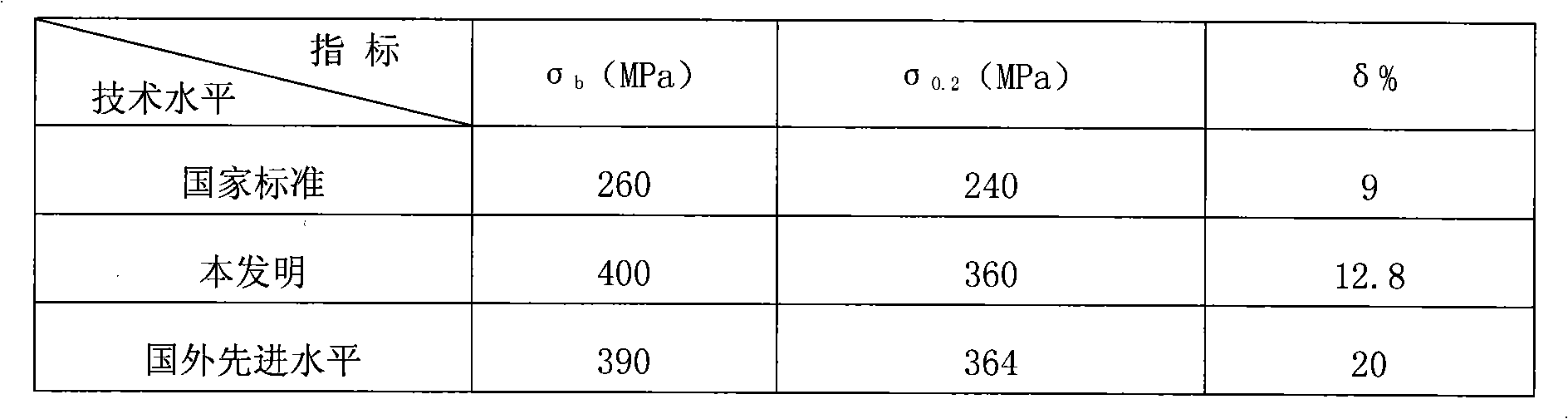

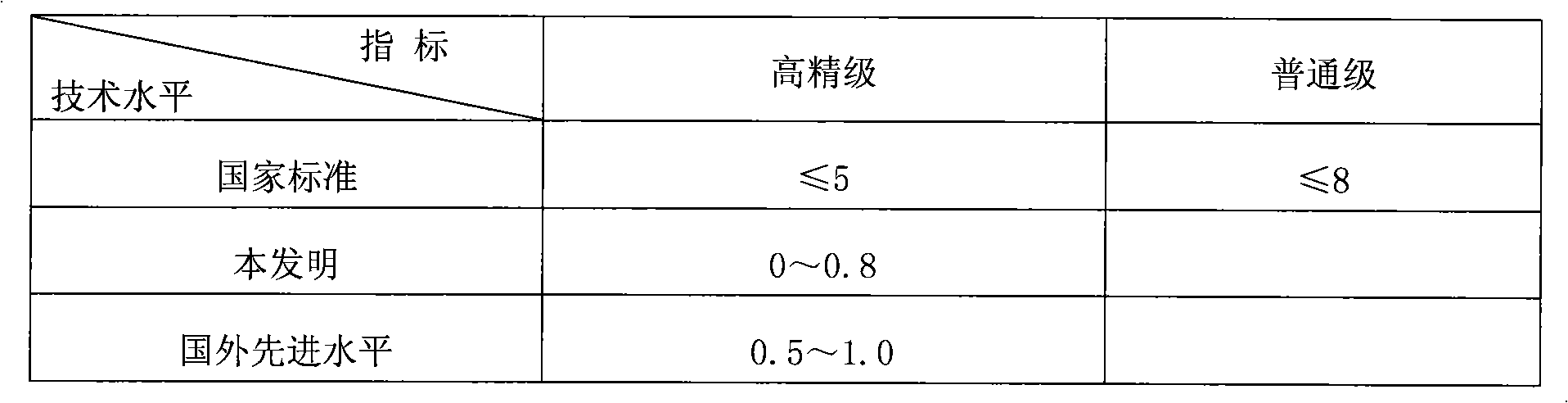

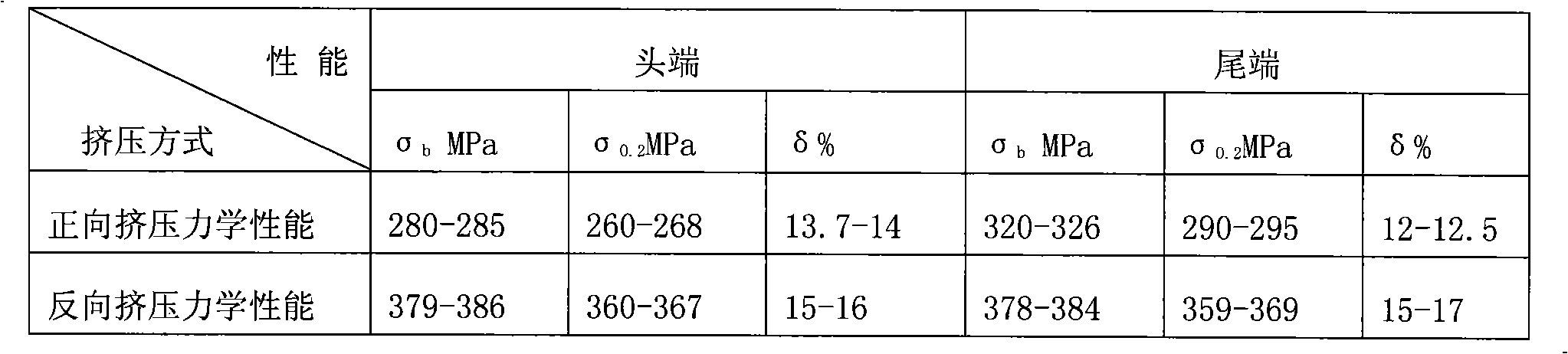

Production process of ABS valve body material for cars

The invention provides a production process of the automobile ABS valve body material, which includes the following steps: preparing raw materials, melting, refining and standing, filtering and casting, homogenizing, ingot processing, ingot heating, indirect extruding, on-line water quenching, stretch rolling, artificial aging and finished product inspecting. By adopting the optimized alloy component in combination with indirect extrusion technology and on-line heat treatment technology, particularly the indirect extrusion technology, the inventive production process achieves the high uniformity of material structure, head-and-tail measures and mechanical property, thereby solving the problems of 6061 alloy coarse grain zone and mechanical property, increasing the production yield index, reducing the energy consumption of unit product, obtaining the material of which the mechanical property, metallographic structure, dimensional precision and the surface quality reach the advanced level of foreign similar products, achieving the import substitution of the material and laying the foundation of automobile localization.

Owner:西北铝业有限责任公司

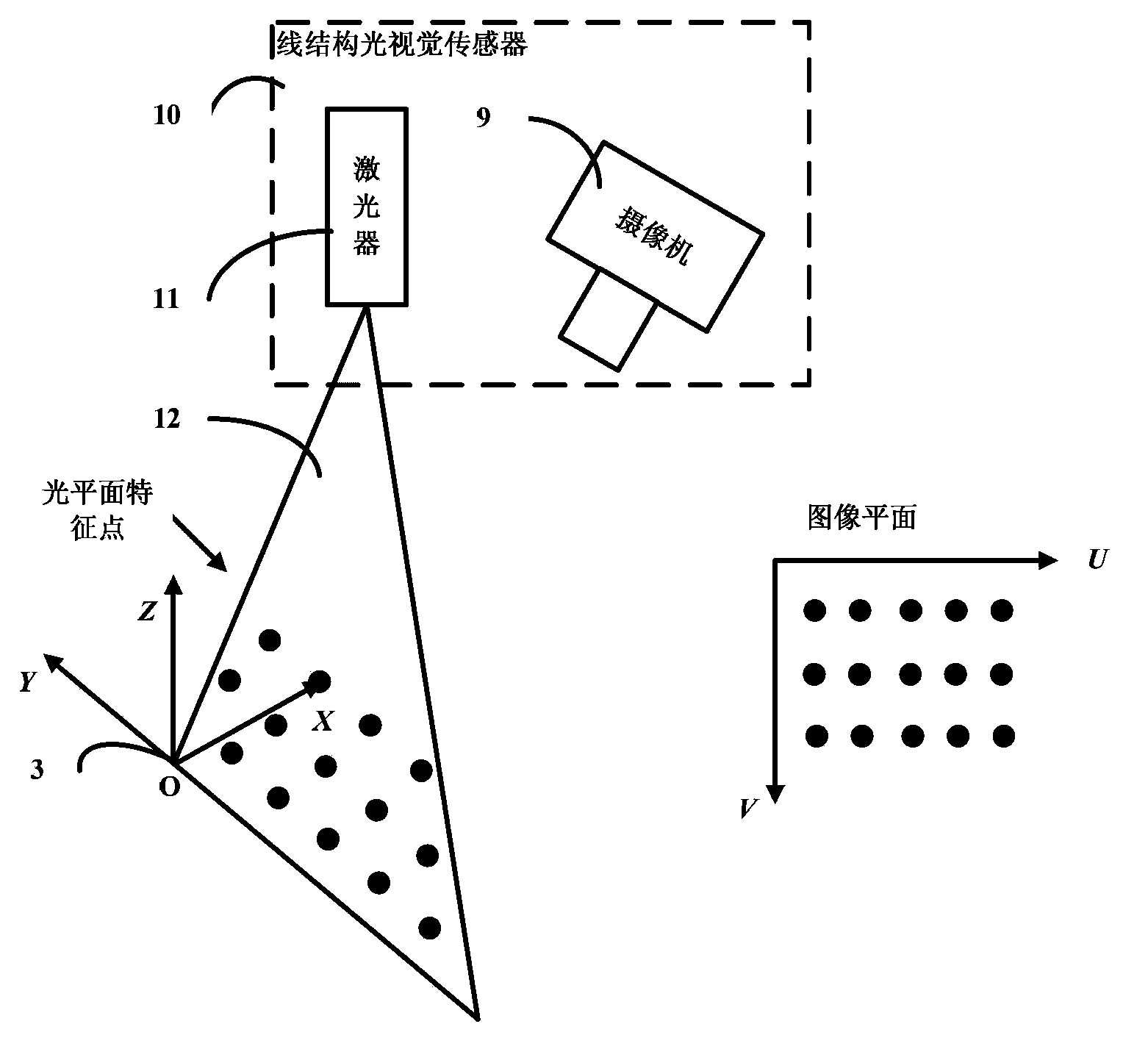

Direct calibration method for line structured light vision sensor

The invention relates to a direct calibration method for a line structured light vision sensor. The method comprises the following steps: establishing a target formed through standard gauge blocks and by utilizing a three-dimensional precision translation bench; projecting structured light plane to the target through the line structured light vision sensor to form feature points on the target; establishing a space coordinate system on the target; collecting target images and extracting the feature points; establishing a search index table including establishing a direct mapping relation between image coordinates of the feature points and space coordinate system coordinates of the feature points; carrying out calibration on the line structured light vision sensor; and based on the image coordinate of a point to be calibrated, searching the space coordinate system coordinate, which is obtained directly or obtained by utilizing a least squares fitting method, of the point in the search index table, so that the direct calibration of the line structured light vision sensor can be realized. The calibration method is used for the line structured light vision sensor which belongs to the small vision field high precision measurement application field. The calibration method is simple and direct, easy to realize, high in precision and can meet the need of measurement.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Manufacturing process for aluminum-containing die-casting shell capable of anodic oxidation

The invention provides a manufacturing process for an aluminum-containing die-casting shell capable of anodic oxidation. The die-casting shell is designed into two portions, one is an internal structural component, and the other is an exterior component which encircles the outer periphery of the internal component. Firstly, machine shaping is conducted on the exterior component, the exterior component is arranged in a die-casting mold, metal liquid is poured so that the exterior component and the internal component are casted into a whole to be the shell, and the anodic oxidation process is conducted on the die-casting shell. The manufacturing process for the aluminum-containing die-casting shell capable of anodic oxidation has the advantages of applying the technology of the anodic oxidation to the aluminum-containing die-casting shell, reducing the manufacturing procedures of CNC, saving the production cost, improving the product yield and the dimensional precision, and reducing the waste of aluminum alloy material, the equipment of CNC and the investment of human resources.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Warm press forming method and automobile frame component

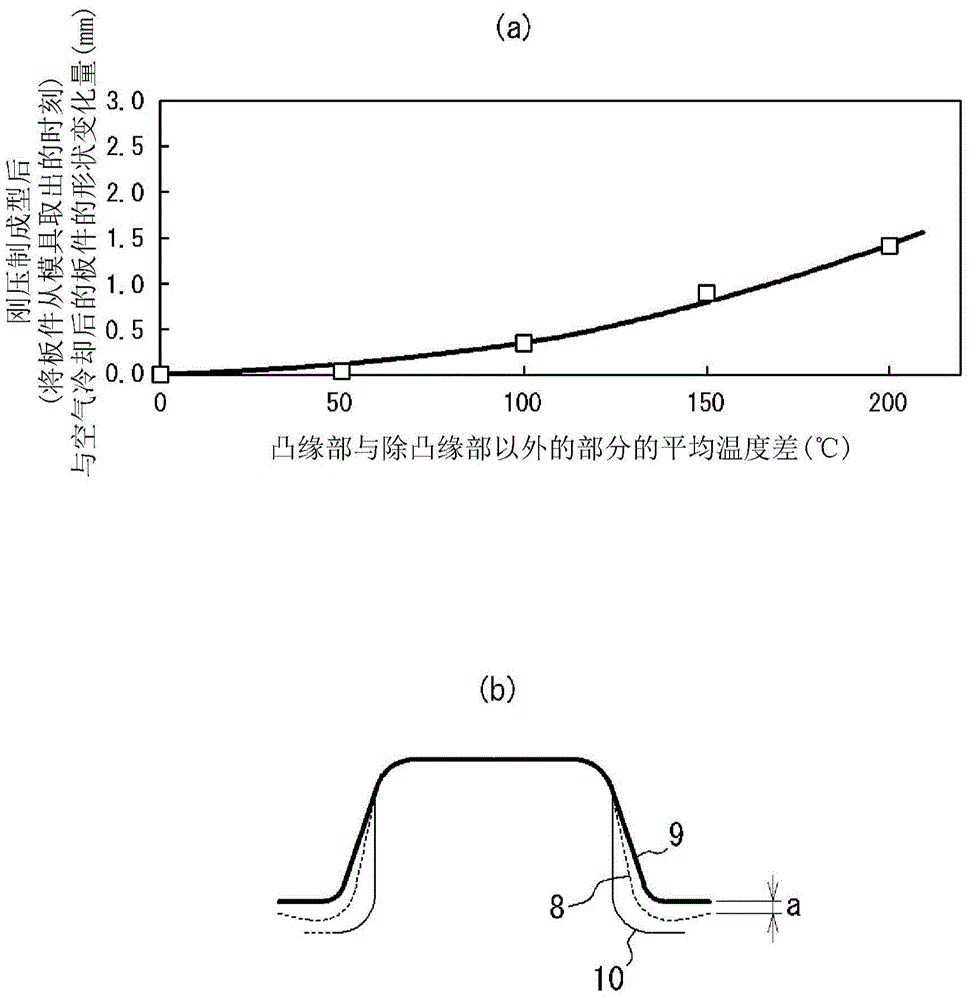

ActiveCN104159681ASuppresses shape changeHigh dimensional accuracyHot-dipping/immersion processesRailway componentsSheet steelShape change

By the present invention, during forming of a steel sheet having a tensile strength of 400 MPa or greater into a press-formed part comprising a flange part and other portions by press forming, by heating the steel sheet to a temperature range of 400-700°C and then press forming the heated steel sheet using draw forming, at which time this state is maintained for 1 to 5 seconds at the bottom dead center of forming, shape changes such as springback can be suppressed, the dimensional precision of a panel can be enhanced, and the desired mechanical characteristics can easily be obtained in the press-formed part.

Owner:JFE STEEL CORP

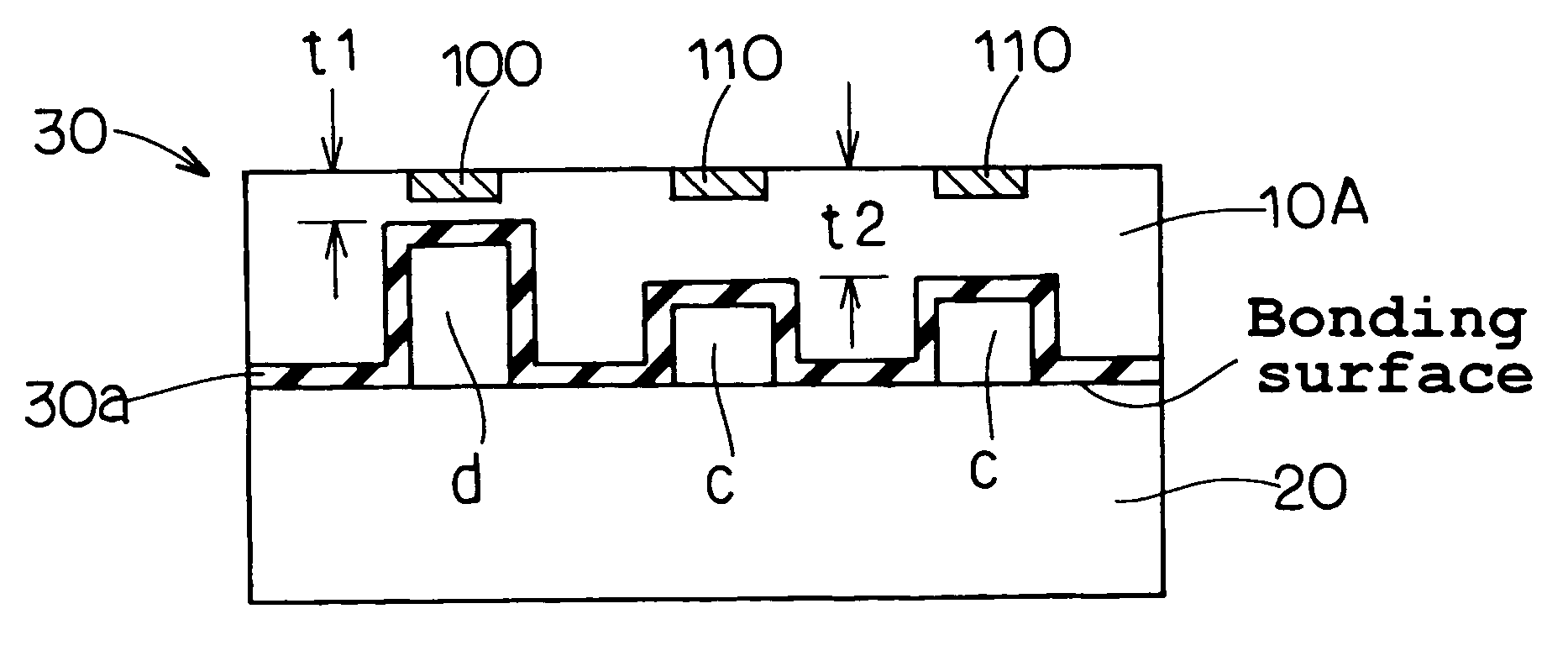

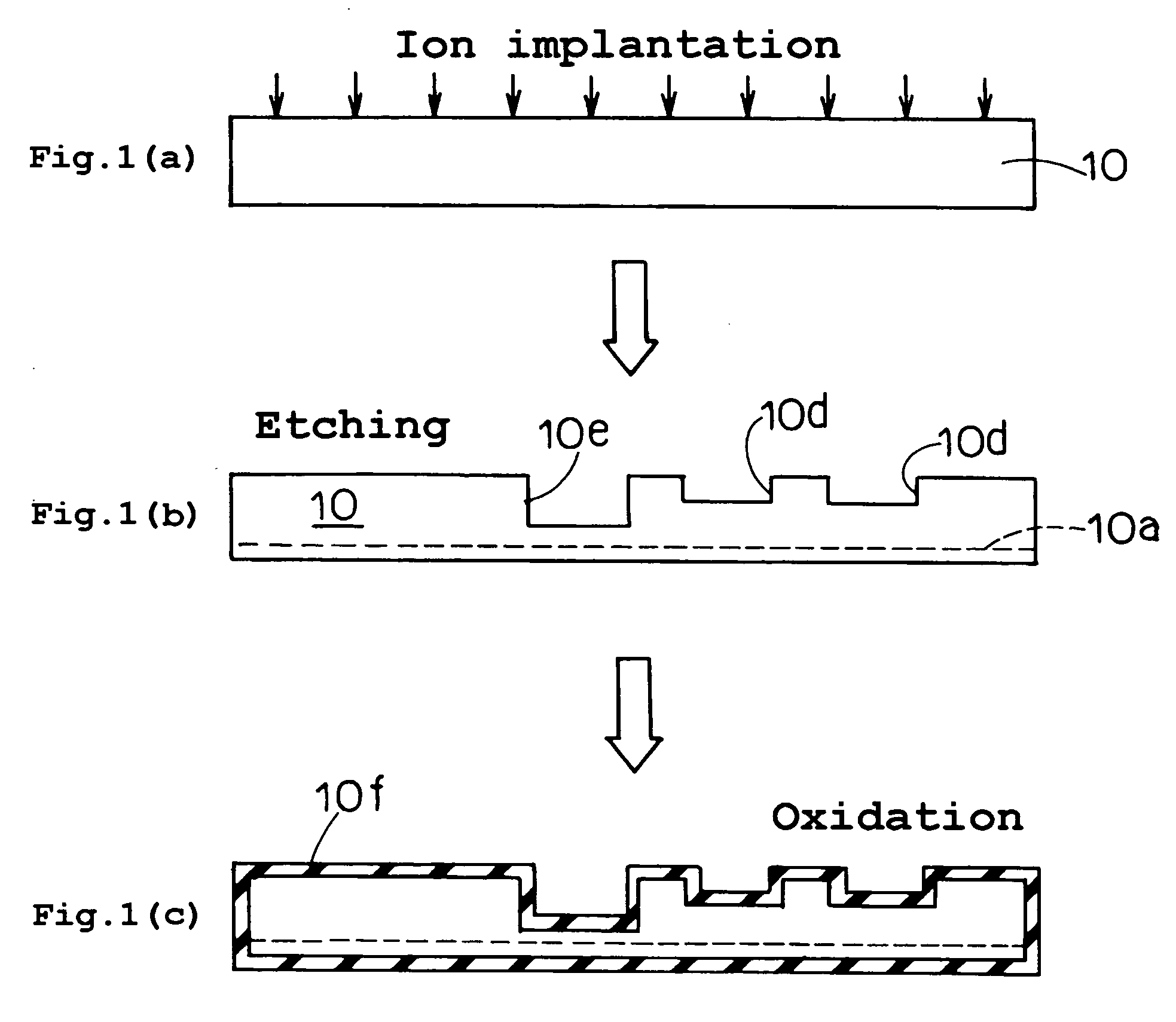

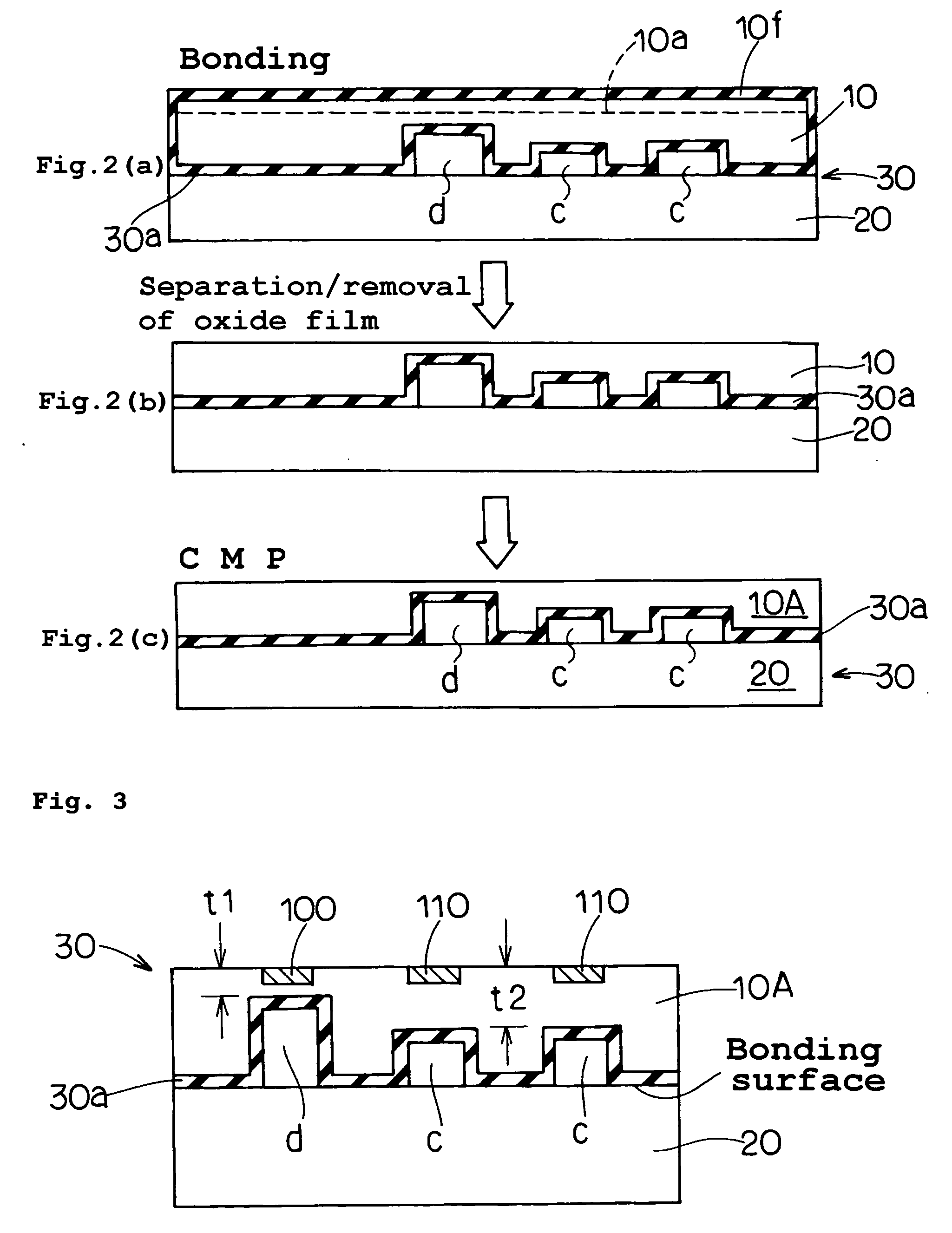

Pasted soi substrate, process for producing the same and semiconductor device

ActiveUS20050081958A1Advantageously effectiveEasy to makeTransistorSolid-state devicesDevice materialSoi substrate

A plurality of recessed portions having different depths is formed in a surface of the active layer wafer or in a bonding surface of the supporting substrate wafer. Those wafers are bonded to each other with an insulation film interposed therebetween. This allows a cavity of higher dimensional precision to be buried therein. A plurality of cavities may be formed simultaneously in a plurality of locations within the plane of the substrate, which allows the thickness of the SOI layer to be set arbitrarily. Accordingly, such a semiconductor device can be fabricated easily in which a MOS type element and a bipolar element are formed on the same chip in a mixed manner.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Abrasive belt grinding processing method and device capable of automatic repair and maintain for workpiece

InactiveCN101234479ARealize automatic profile grindingRealize profile grindingBelt grinding machinesAutomatic grinding controlExecution unitHigh dimensional

The invention relates to a belt grinding processing method which can dress workpiece automation and a device thereof. And the invention is a dressing and grinding system formed by a set of automation equipments, adopts intelligent process to control, and realizes the automation dressing and grinding processing of the complex profile workpiece in the manner of grinding belts. The device of the invention comprises a control unit, an execution unit, a grinding unit, etc., sections; wherein, the control unit comprises a plurality of software modules; the grinding and dressing knowledge base is the key software module, which can generate automatically all the grinding parameters according to the grinding amounts of all the input points; and other software modules, for example, path correction module, generate actual processing path finally according to the parameters; the execution unit is a robot or a digital machine tool, which can receive the actual processing path of the control unit, and can generate machining track; the grinding unit is a belt grinder which can receive commands from the execution unit, and can finish the dressing grinding of the workpieces. The belt grinding processing method can be widely applied in the dressing grinding processing of the workpieces with variety of high-dimensional accuracy and complex profile.

Owner:天津智通信息系统集成有限公司

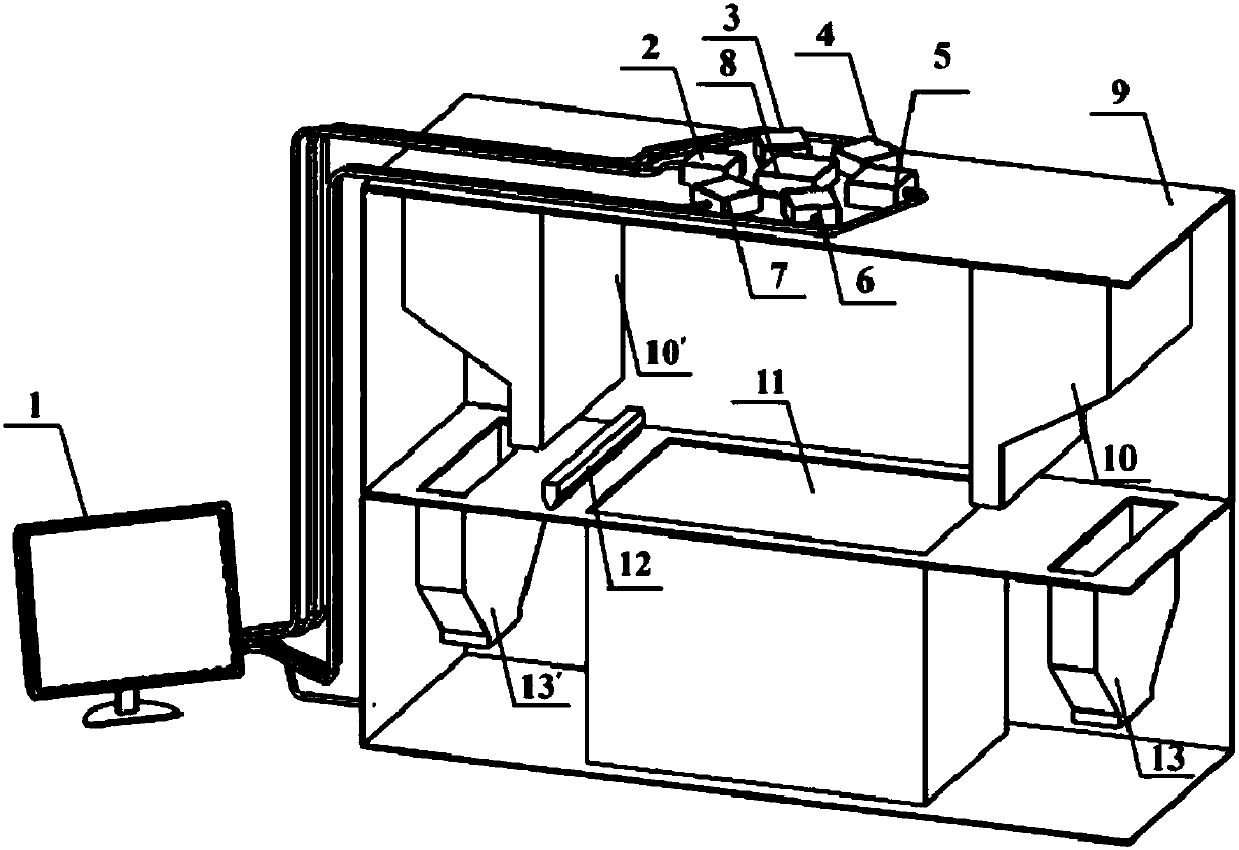

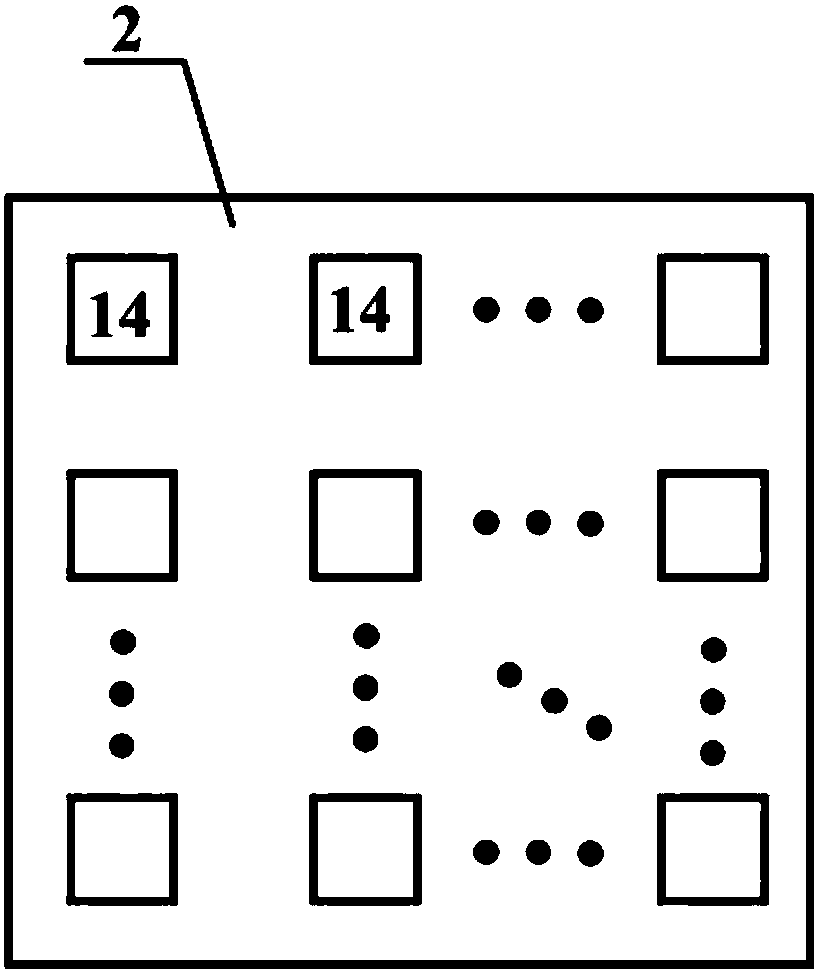

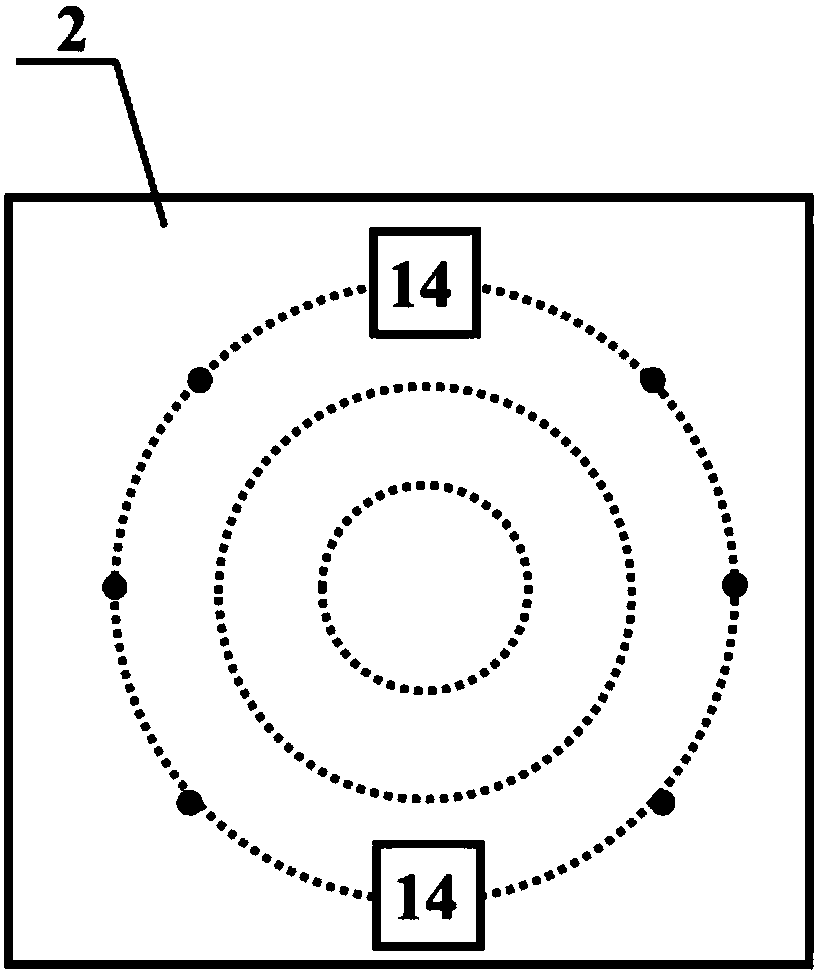

Nondestructive on-line quality inspection equipment and method applicable to powder spreading type additive manufacturing

ActiveCN107598163AFlexible combinationFlexible selectionAdditive manufacturing apparatusCeramic shaping apparatusAdditive layer manufacturingElectron

The invention discloses nondestructive on-line quality inspection equipment and method applicable to powder spreading type additive manufacturing and belongs to the field of nondestructive inspection.A forming assembly of the equipment is provided with a power spreading quality inspection module, a constituent inspection module, a defect inspection module, a deformation inspection module, a stress inspection module and a dimensional precision inspection module. All the modules can work separately and simultaneously; and the nondestructive on-line quality inspection equipment is high in use flexibility. By means of the equipment, comprehensive integrated inspection is conducted on powder spreading quality, component constituents, defects, deformation, the stress and dimensional precision in the powder spreading type additive manufacturing and forming process; powerful guarantee can be provided for the forming process of metal components of different materials, dimensions and structuresand in different shapes, and thus the excellent-quality metal components are manufactured one time efficiently; the yield can be increased to a certain extent; and economic losses are reduced. The nondestructive on-line quality inspection equipment and method can be widely applied to manufacturing of various types of powder spreading type additives of heat sources utilizing laser, electron beams,plasmas and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

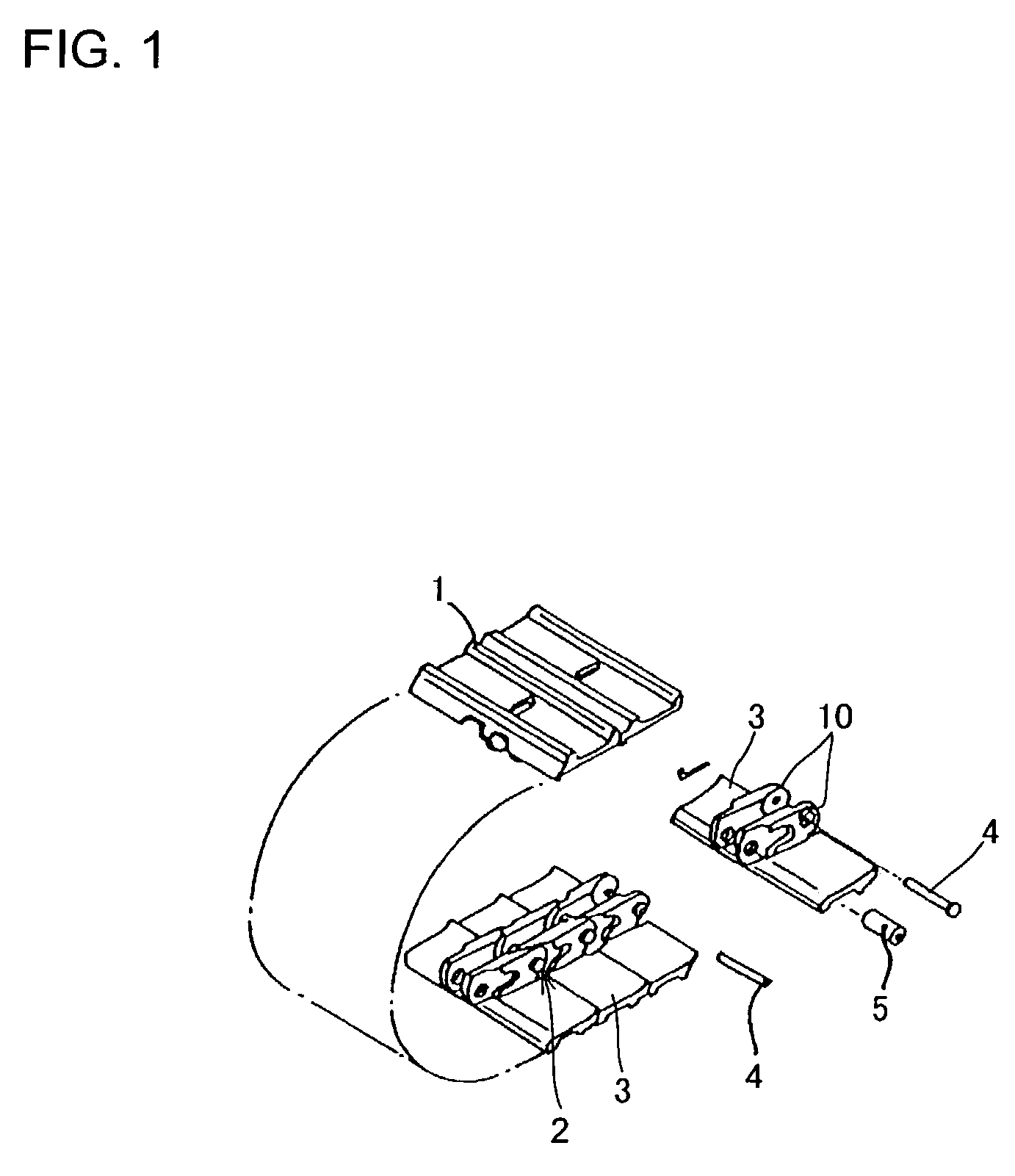

Track link production method and track link produced by the same

InactiveUS7040080B2Delayed failureIncrease pressureConnecting rodsMetal-working apparatusHigh dimensionalMachining process

There are proposed a track link production method capable of providing markedly improved wear life with good cost performance and a track link produced by this method. To this end, the track link production method includes a heat treatment process (Steps 4, 5) of applying quenching and low temperature tempering treatment to a whole link material after hot forging (Step 2), and is designed such that desired machining is applied to the link material (Step 3) before the heat treatment process (Steps 4, 5) and such that after the heat treatment process (Steps 4, 5), tempering (Step 6) and finish machining (Step 7) are sequentially applied to some of the parts which have undergone the machining process, the some parts including at least parts where high dimensional accuracy is required.

Owner:KOMATSU LTD

Small-Sized Electronic Casing and Method of Manufacturing Small-Sized Electronic Casing

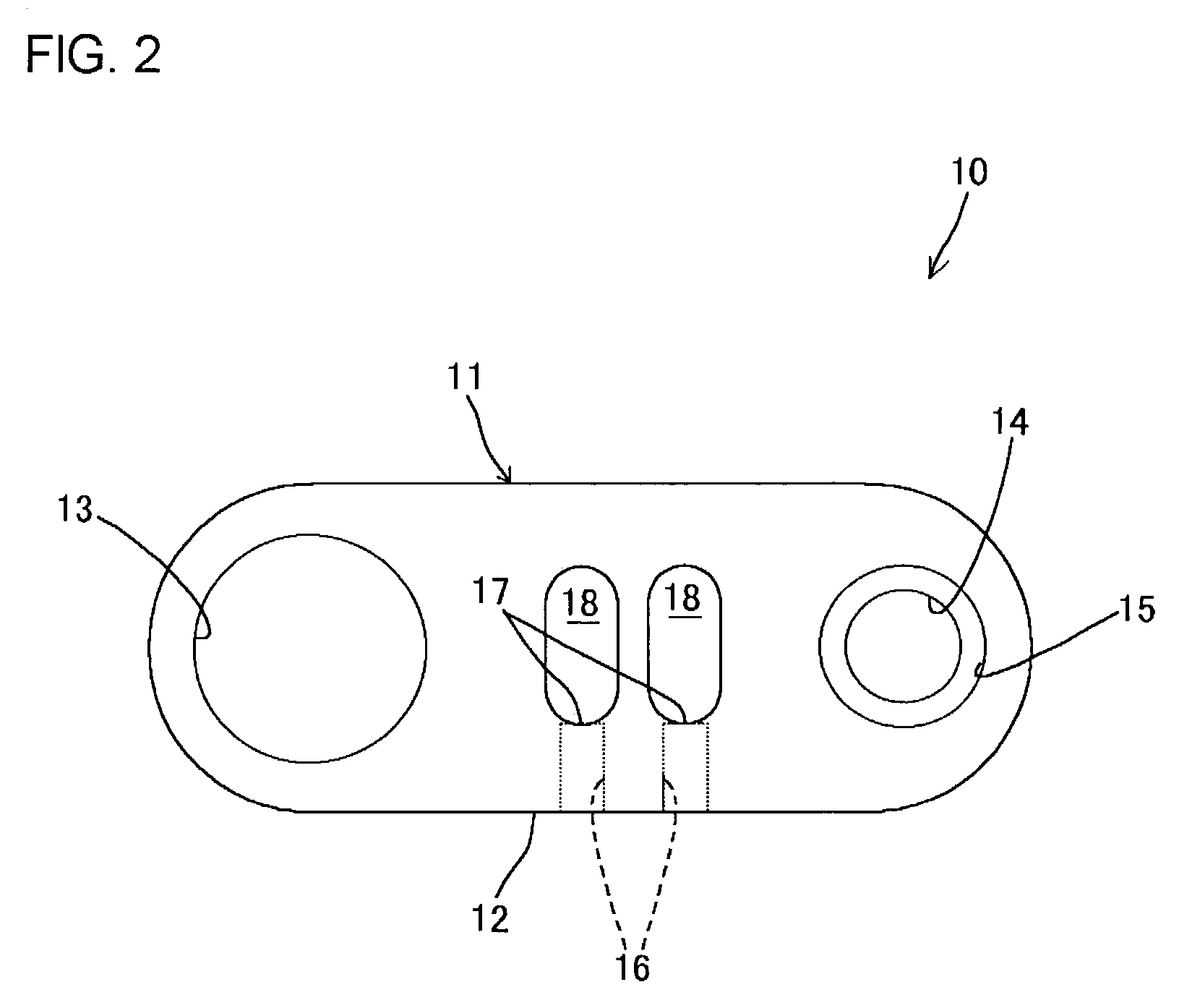

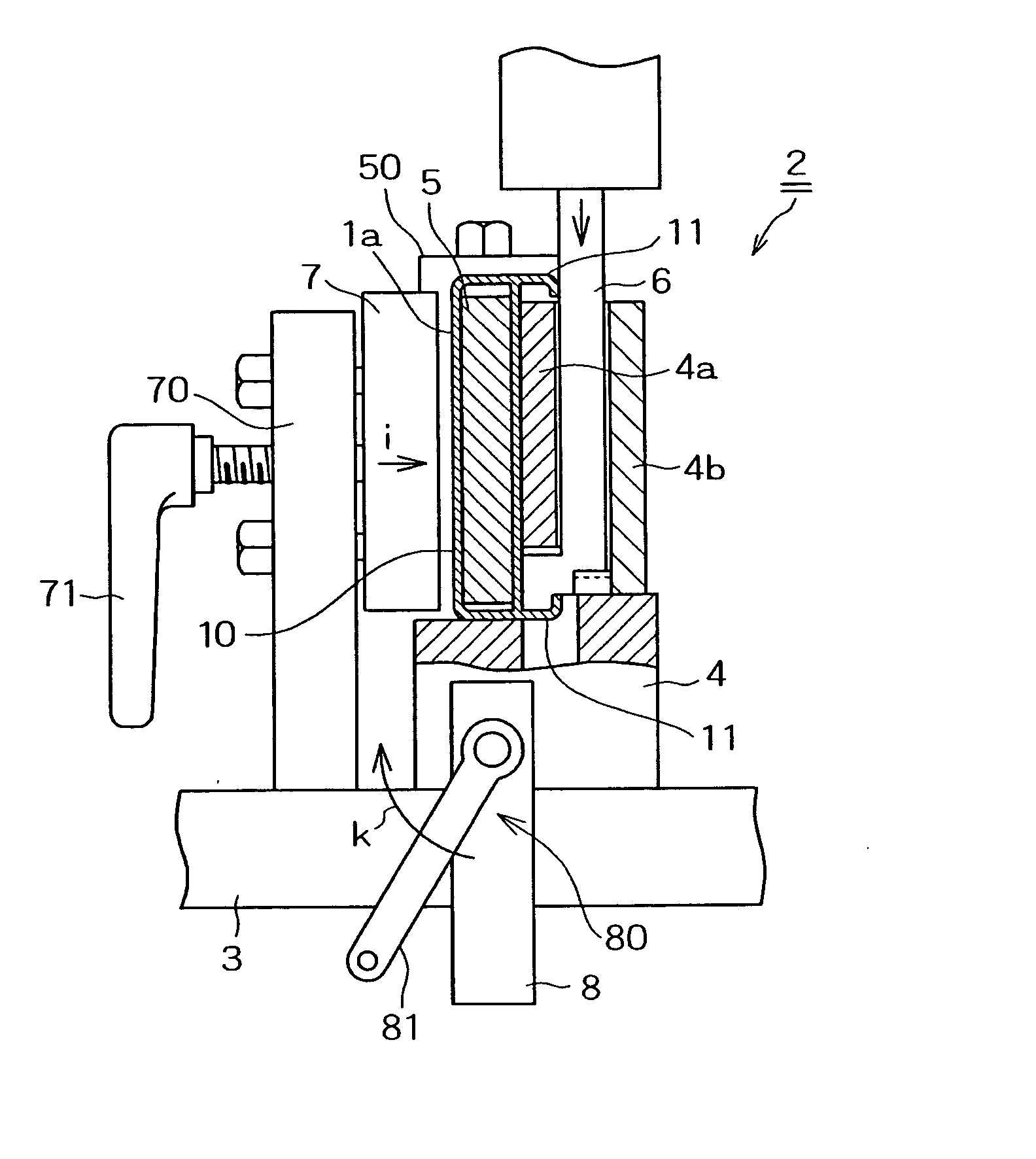

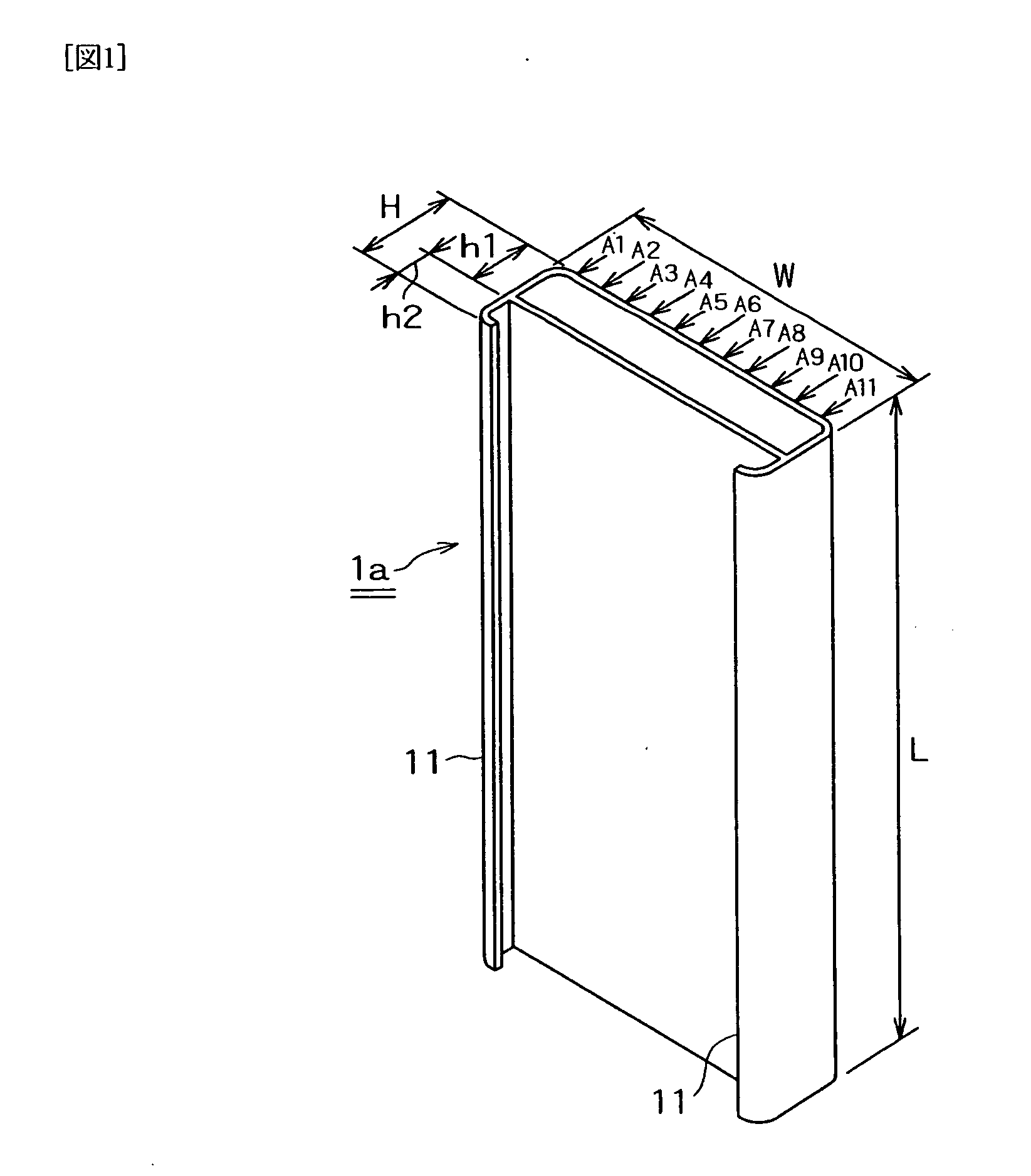

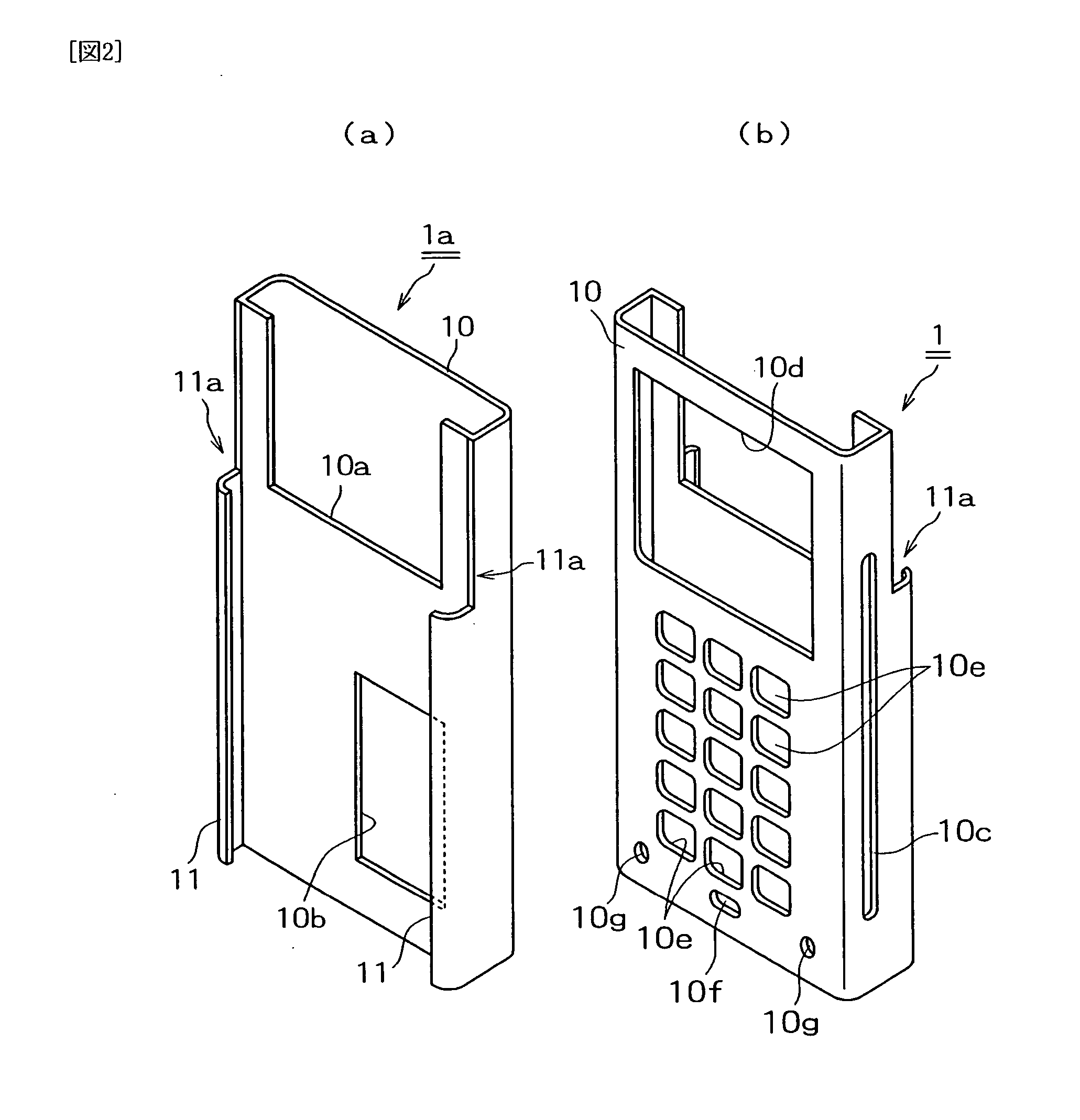

InactiveUS20070236870A1Small thicknessGood formabilityWave amplification devicesDigital data processing detailsEngineeringStructural engineering

One mode of the present invention relates to a small-sized electronic casing comprising an aluminum alloy extruded shape having a hollow sectional part at least contained in a main part, wherein the extruded shape has at least either component-mounting holes or notches. Another mode of the present invention relates to a small-sized electronic casing manufacturing method that comprises a press punching process of forming at least either component-mounting holes or notches in an aluminum alloy extruded shape of a prescribed length having a hollow sectional part. The present invention may provide an aluminum alloy casing that is excellent in formability and productivity, has a smaller thickness and provides higher dimensional precision.

Owner:FURUKAWA SKY ALUMINUM CORP

Fiber-reinforced thermoplastic resin molded article

ActiveUS20100009158A1High dimensional accuracyImprovement of outward appearanceSynthetic resin layered productsCeramic shaping apparatusPolymer sciencePolymer chemistry

Provided is a fiber-reinforced thermoplastic resin molded article, which contains reinforcing fibers having a given flattened cross-sectional profile, in which the fiber length distribution of the reinforcing fibers is shifted on the side of long fibers, and which is excellent in mechanical strength, heat resistance, dimensional accuracy such as warpage resistance, and surface appearance.A fiber-reinforced thermoplastic resin molded article of a thermoplastic resin composition comprising from 70 to 35% by weight of a thermoplastic resin (A), and from 30 to 65% by weight of reinforcing fibers (B) of which the cross section is flattened to have a degree of flatness, as expressed by the formula mentioned below, of at least 2.3, wherein the weight-average fiber length of the reinforcing fibers in the molded article is at least 1 mm:Degree of flatness=major diameter of reinforcing fiber (a) / minor diameter of reinforcing fiber (b).

Owner:MITSUBISHI ENG PLASTICS CORP

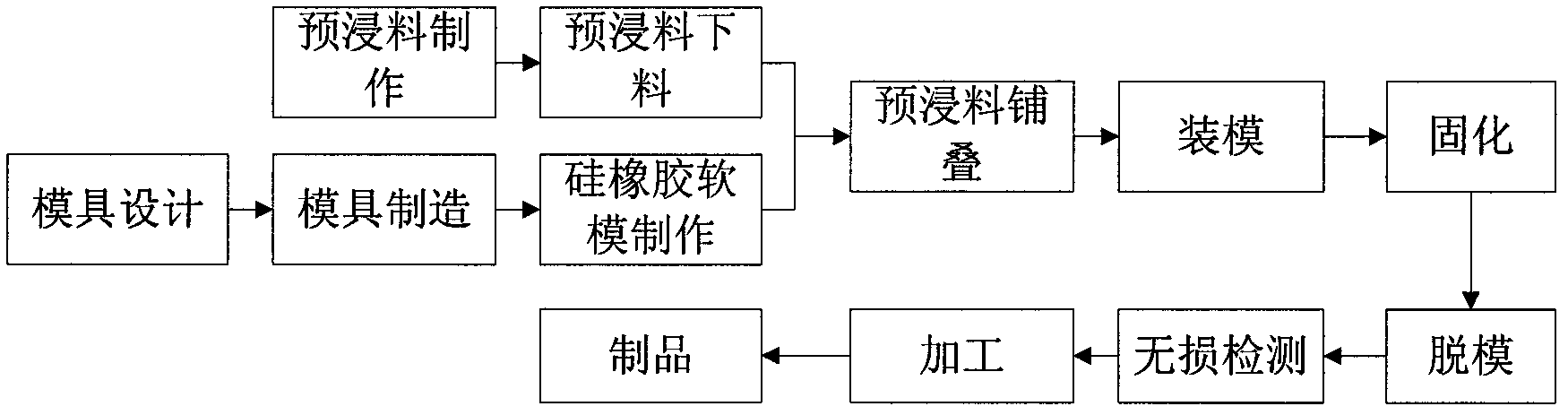

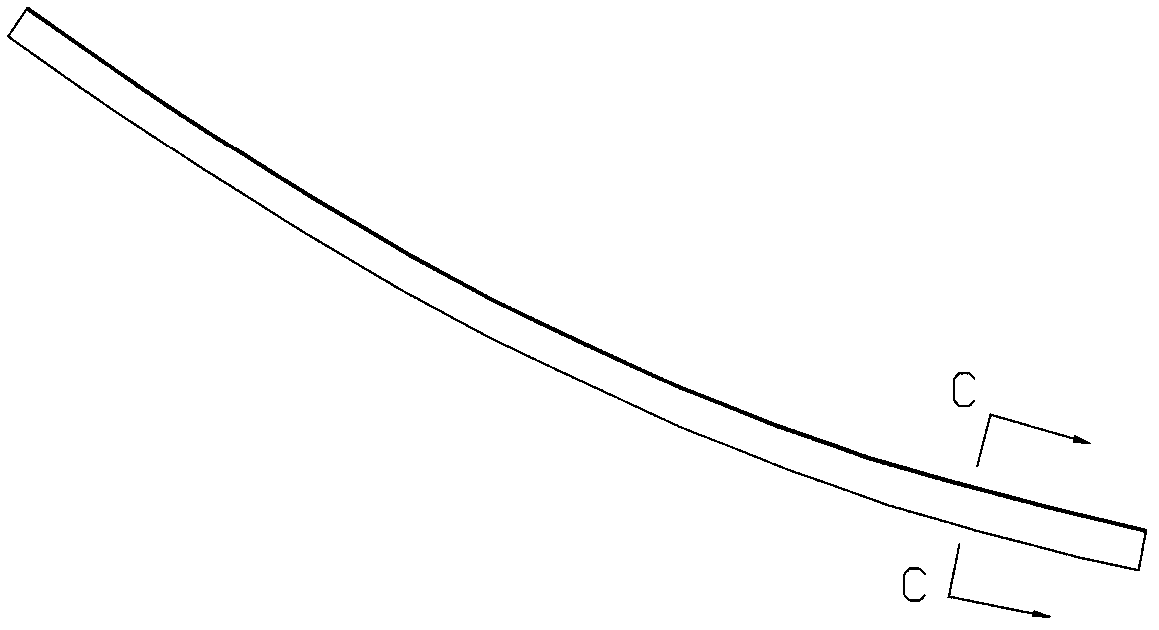

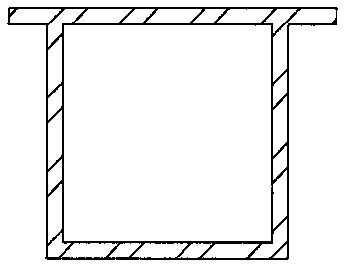

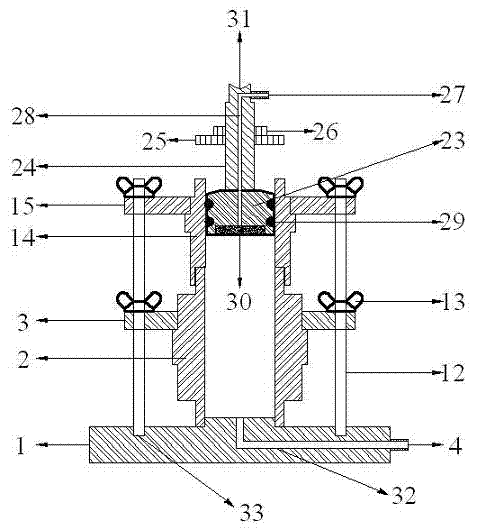

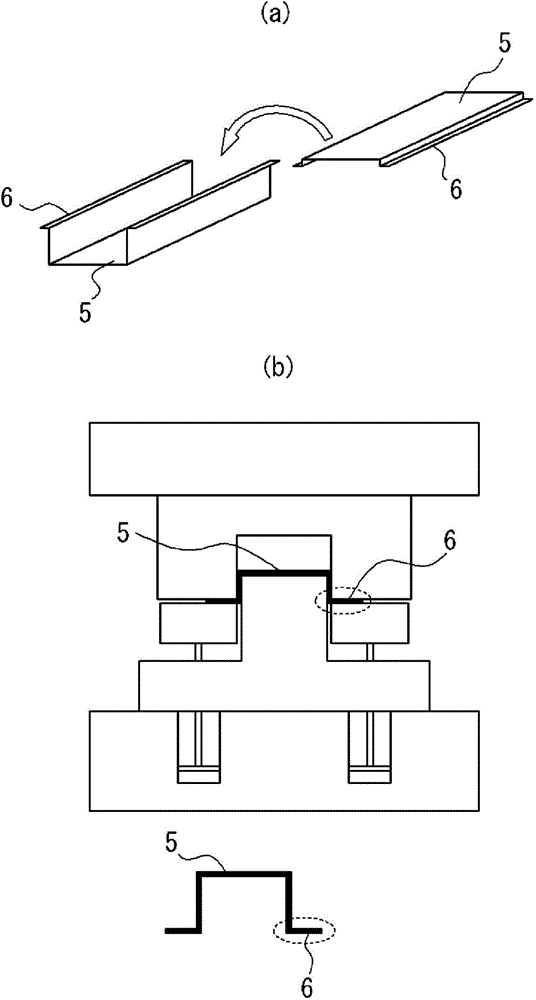

Forming process of curved composite tube

ActiveCN102320139ASolve the difficulty of demouldingSolve sizeTubular articlesCavity sizeHigh dimensional

The invention provides a forming process of a curved composite tube. The forming process comprises the following steps of: manufacturing a forming die; preparing prepregs; laying up the prepregs; assembling the die; curing; and de-molding. The forming process has the beneficial effects that a closed and combined hard die is utilized as the forming die, a silicon rubber flexible die is utilized asthe inner cavity of the curved composite tube, and the size of the silicon rubber flexible die is determined by means of the forming pressure and the swelling property of silicon rubber, which solvesthe difficulties of the curved composite tube such as difficult de-molding process and difficult control of the cavity size of the product and ensures that the size of the inner cavity meets the requirements after the formed product is smoothly de-molded; the integral informing technology is adopted so as to solve the difficulties of extension positions at two sides of the curved composite tube such as difficult pressurization, difficult control of overall quality and the like, thus achieving the purpose of one-time forming of the product and meeting the requirements for dimensional precision; and by means of layering design and forming process control of a composite material, the problem of easiness in deformation of the formed curved composite tube is solved so as to meet the requirements for accuracy control of the product. The curved composite tube formed by the forming process has the advantages of better structural quality, higher performance, higher dimensional precision and higher curvature forming precision.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Triaxial sample preparation device for low-liquid limit silty soil and sample preparation method

InactiveCN103048174AHigh dimensional accuracyImprove sealingPreparing sample for investigationSoil scienceConsolidation process

The invention relates to the technical field of preparation of triaxial experiment samples in rock mechanics and discloses a triaxial sample preparation device for low-liquid limit silty soil and a sample preparation method. The device comprises a sample tube, a smoothening device, a vibrator and a loading device. The method comprises the following steps: sleeving a rubber diaphragm in a split cavity; gradually pouring soil sample; controlling the initial dry density through the smoothening device and the vibrator; filling carbon dioxide and air-free water from a base until saturation; and carrying out sample consolidation process according to a secondary dry density. According to the invention, the problem of producing uniform silty soil sample is solved, the split cavity integrates the functions of positioning and sealing so as to improve the dimensional precision and the sealing effect of the sample; a rubber-steel combined vibrating head is adopted to improve the vibration and densification effect; and the matching with a current triaxial apparatus is realized, which reduces the equipment investment; and through the two-stage control of the initial dry density and the secondary dry density, the density of the sample can be optionally appointed within a certain range.

Owner:DALIAN UNIV OF TECH

Warm press forming method and automobile frame component

ActiveCN104159680ASuppresses shape changeHigh dimensional accuracyFurnace typesHeat treatment furnacesShape changeTemperature difference

By the present invention, during forming of a steel sheet having a tensile strength of 400 MPa or greater into a press-formed part comprising a flange part and other portions by press forming, by heating the steel sheet to a temperature range of 400-700°C and then press forming the heated steel sheet using crash forming, at which time the average temperature difference between the flange part and the other portions of the press-formed part immediately after forming is kept to within 100°C, shape changes such as springback can be suppressed, the dimensional precision of a panel can be enhanced, and the desired mechanical characteristics can easily be obtained in the press-formed part.

Owner:JFE STEEL CORP

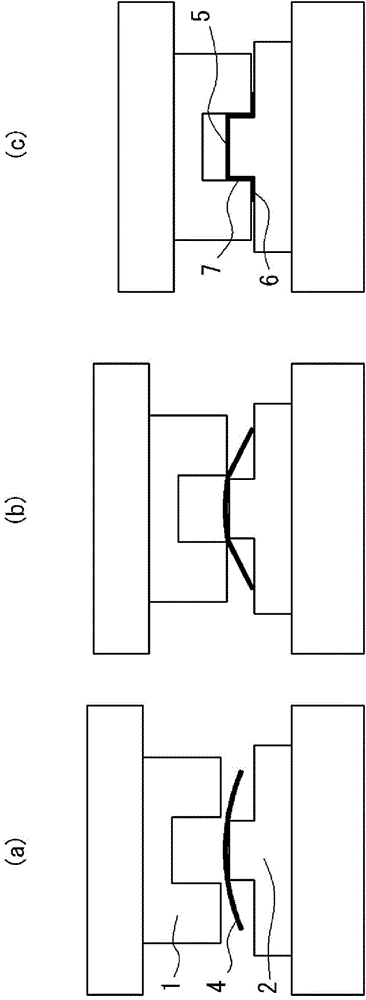

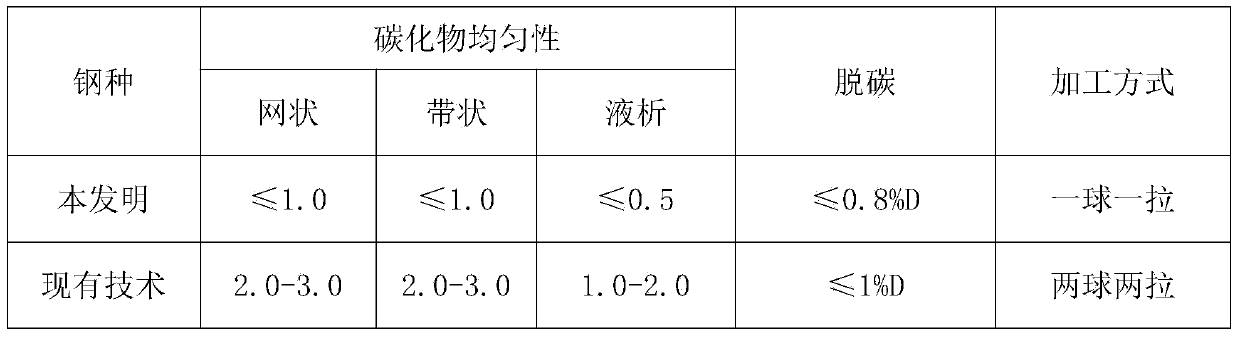

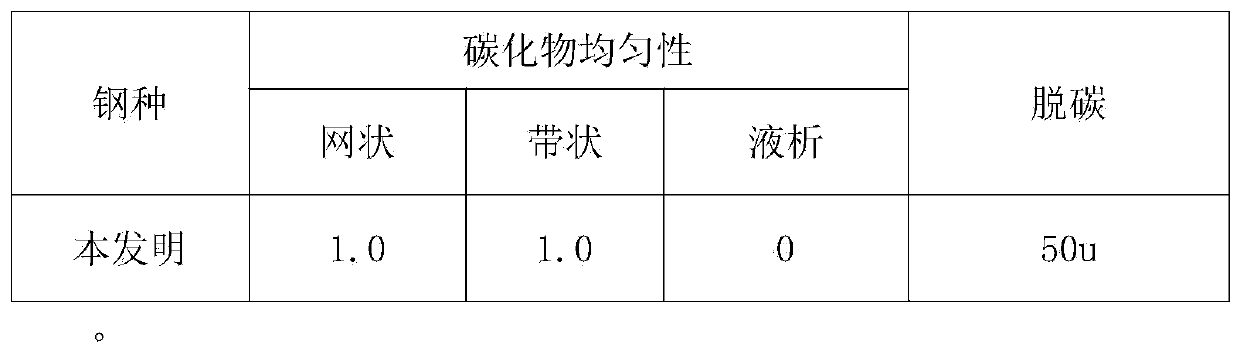

Production technology for bearing steel wire rod

InactiveCN104190705AChemically stableSlight surface decarburizationMetal rolling arrangementsHigh pressureAir cooling

The invention discloses a production technology for a bearing steel wire rod. The production technology comprises the following working procedures of blank pretreatment, billet steel heating, high-pressure water de-scaling, rough and intermediate rolling and pre-finishing rolling, finish rolling, reducing and sizing rolling, on-line finish product diameter measurement, spinning, air-cooling and finishing. Bearing steel is composed of, by weight, 0.95 percent-1.05 percent of C, 0.25 percent-0.45 percent of Mn, 0.15 percent-0.35 percent of Si, less than or equal to 0.02 percent of P, less than or equal to 0.006 percent of S, 1.45 percent -1.6 percent of Cr, less than or equal to 0.1 percent of Ni, less than or equal to 0.13 percent of Cu, less than or equal to 0.002 percent of Ti, less than or equal to 0.04 percent of Al, 0.05 percent of Mo, less than or equal to 0.001 percent of Ca and the balance being Fe. By the adoption of the controlled rolling and cooling technology, the process control over the bearing steel wire rod is performed to obtain properly spheroidized granular P texture. Good Carbide uniformity is achieved, and surface quality and dimension accuracy are stable. In a bearing steel wiredrawing factory, one ball can be drawn to form the finished steel wire in a one-off mode, so that production efficiency is substantially enhanced, and meanwhile the production cost is lowered.

Owner:NANJING IRON & STEEL CO LTD

Manufacturing method and fixture of integral bladed-disk wax mold

ActiveCN102363199AImprove consistencyHigh dimensional accuracyFoundry moulding apparatusWaxPrimary standard

The invention discloses a manufacturing method and a fixture of an integral bladed-disk wax mold. According to the invention, an integral bladed-disk wax pattern is divided into single blades and a disk shaft. Processes of separated pressing, precise fixture positioning and wax mold welding assembling are adopted. The integral wax pattern is precisely cast. According to the invention, the disk shaft is fixed on an assembling fixture; the blades are sequentially positioned on positioning points on the fixture, and are welded onto the disk shaft. Blade bodies and channel inner walls with high precisions are adopted in the positioning of the blades, such that good consistency is provided for the blades. When the wax pattern is assembled, positioning points are positioned on the blade bodies;blade body positioning points are consistent with processing positioning points, primary standards of cold and hot processing are consistent, such that blade dimensional precision of the whole cast is optimally improved, throat areas between blades are ensured, and flow rate homogeneity is ensured. Positioning parts of the fixture can be adjusted according to measured dimensions of parts, such that the volume of flow rate can be changed according to directional positions of angles of the blades. Therefore, repairing or even rejecting risks caused by unqualified integral mold dimensions are avoided, production period is saved, and production cost is reduced. With the method provided by the invention, hard processes are turned easy, product precision is improved, and production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

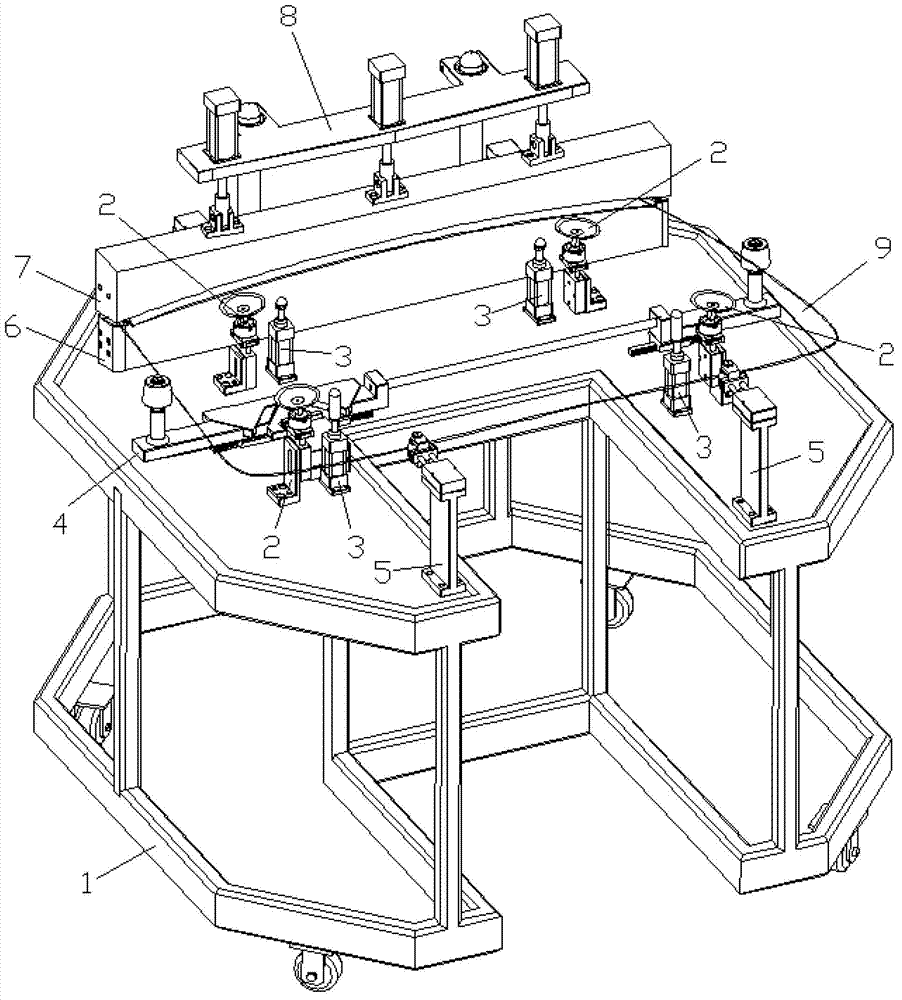

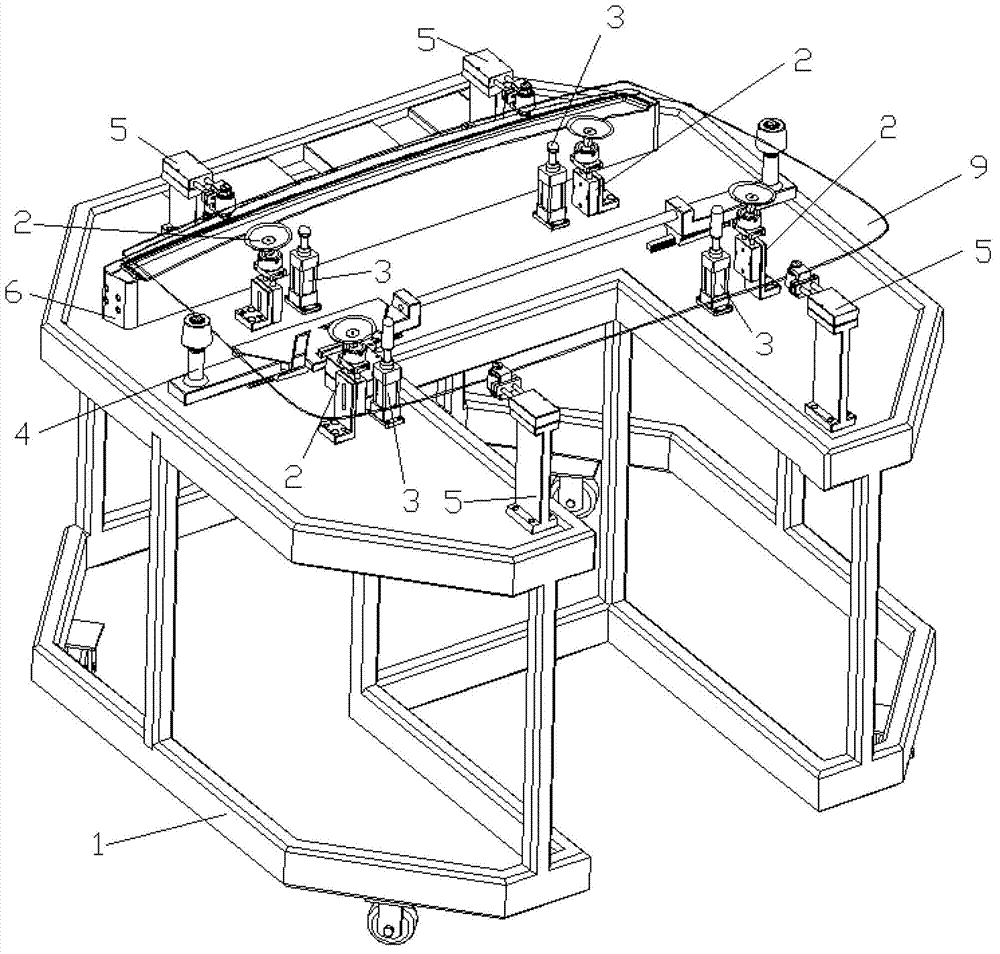

Frock device used for mounting glazing tapes and method thereof

InactiveCN102774447AHigh bonding strengthSimple processVehiclesBonding processTemperature and pressure

The invention relates to the technical field of glass accessories mounting, and particularly relates to a frock device used for mounting glazing tapes and a method of the frock device. The device comprises a sucker device, a mandril device, a lateral positioning device, a longitudinal positioning device, a glazing tape fixing block, a glazing tape pressing block and a pressing block lifting device, wherein the glazing tape fixing block is provided with a locating groove corresponding to the glazing tape in shape; a vacuum hole which is communicated with a gas-type fitting at the side surface of the glazing tape fixing block is formed in the locating groove; and the device is characterized in that the glazing tape fixing block is internally provided with a heating device. The surfaces to be bonded of the glass and the glazing tape are coated with the same first coat, according to the frock device, the glazing tape and the glass are firmly bonded through the first coats under certain temperature and pressure control. The frock device has the advantages of being simple in structure, low in cost, simple in bonding process and good in bond performance, and having low requirements on glass dimensional precision and high yield.

Owner:FUYAO GLASS IND GROUP CO LTD

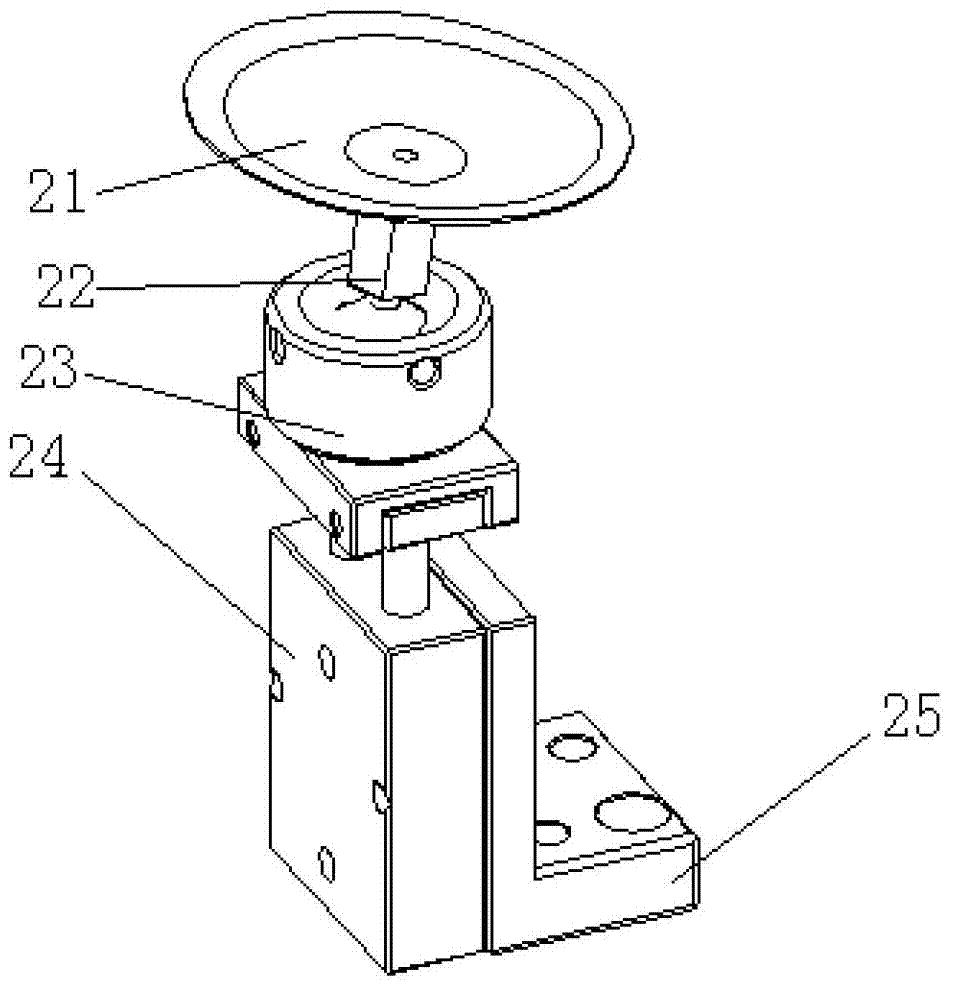

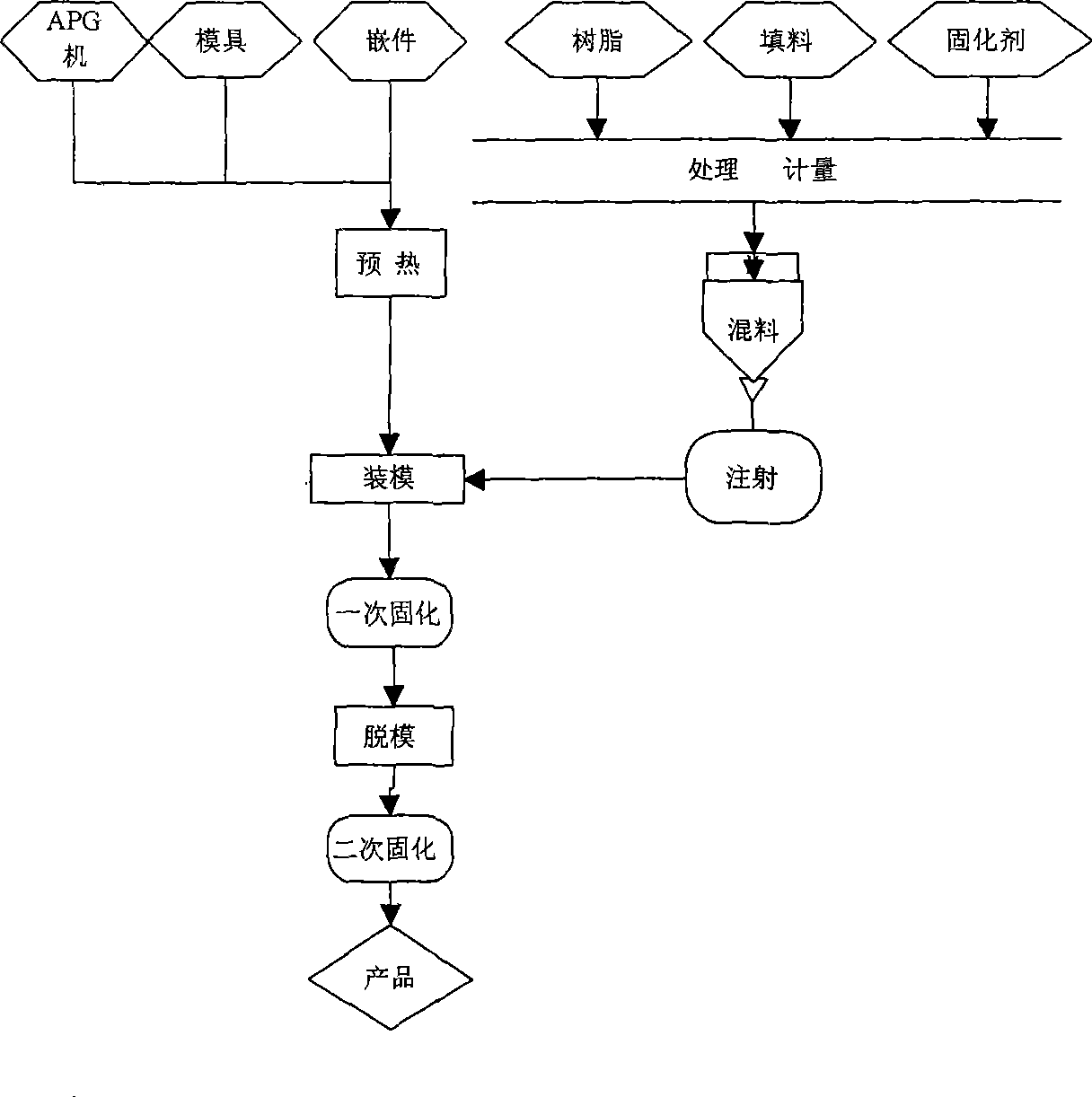

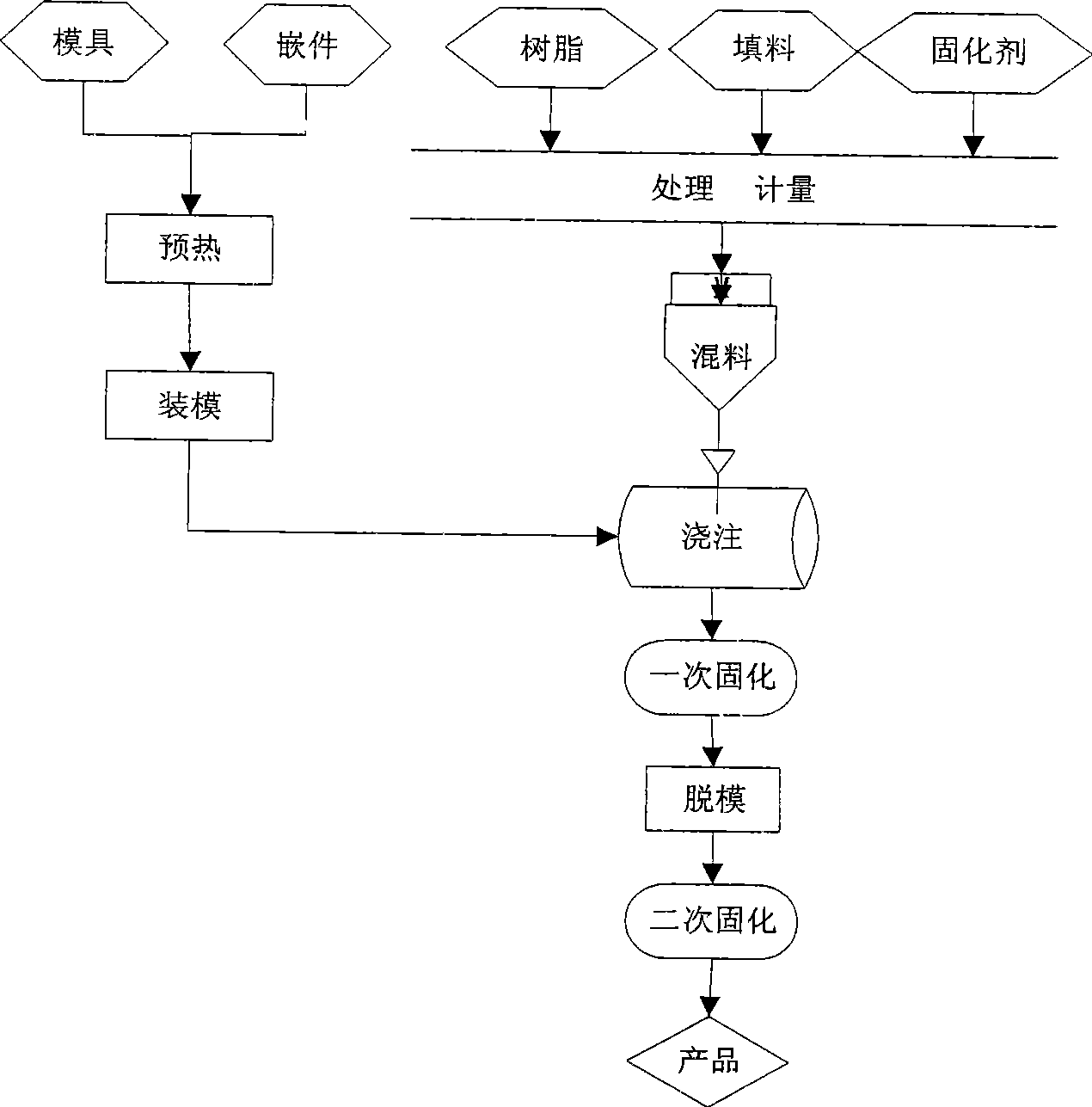

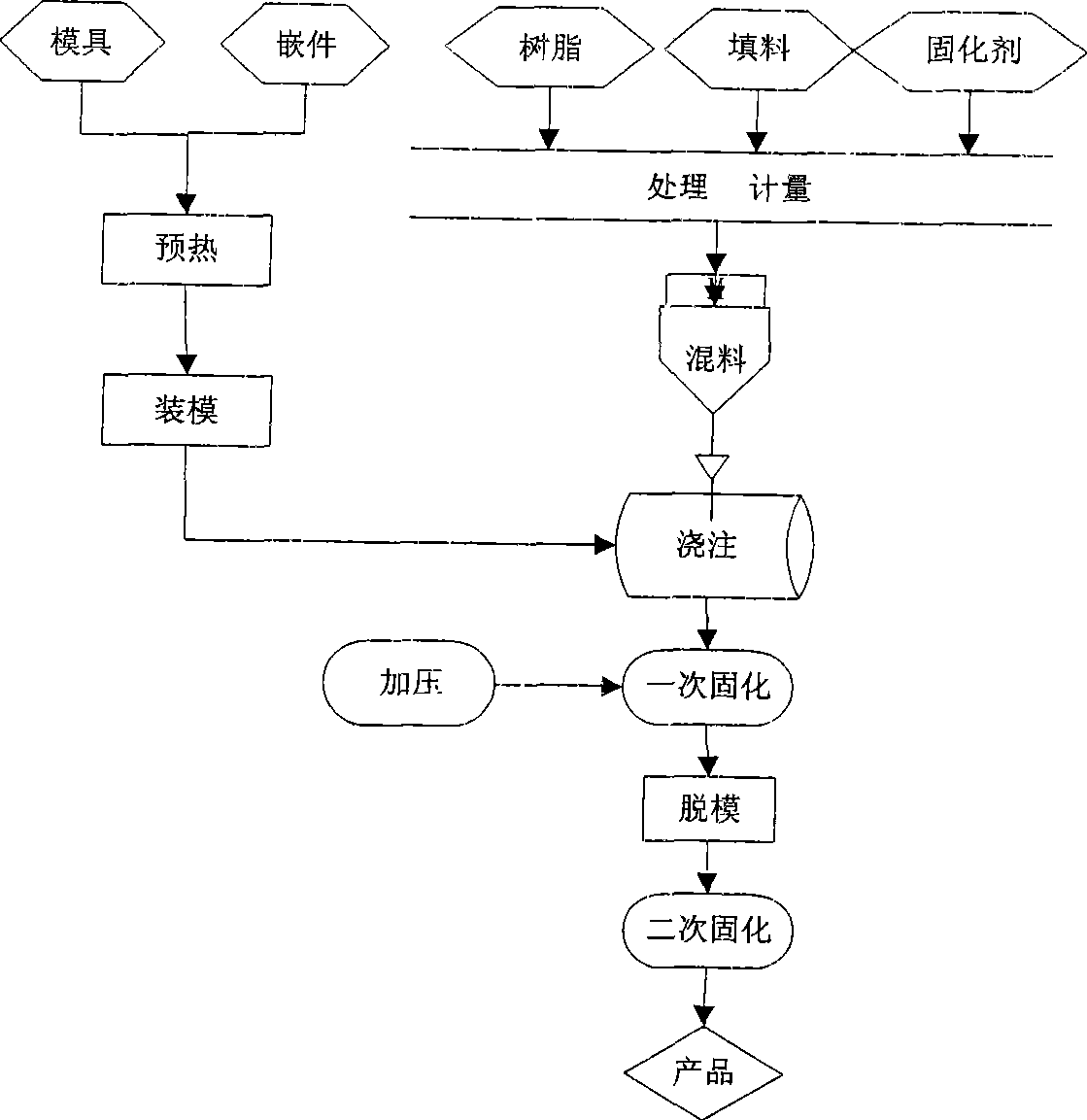

Vacuum pressure pouring process for epoxy resins insulation pouring piece of high voltage electric appliance

The invention discloses a vacuum pressure pouring process of an epoxide resin insulation pouring piece for high-voltage appliances, comprising three procedures of material mixing, pouring and curing; firstly epoxide resin insulation pouring material is heated and evenly mixed in a vacuumized mixing bowl; then the mixed material is poured into a heated mould in a pouring tank, the pouring tank is vacuumized and the temperature of the pouring tank is equivalent to the temperature of the mixing bowl; under heating and pressuring, the mould is released after a primary curing, finally a corresponding secondary curing is carried out under heating, as the process of pressuring on pouring material is added in the primary curing, the obtained product eliminates or reduces sink marks and bubbles, and the insulation pouring piece finally obtained by curing has stable dimensional precision and excellent electric and mechanic properties.

Owner:麦克奥迪(厦门)智能电气有限公司

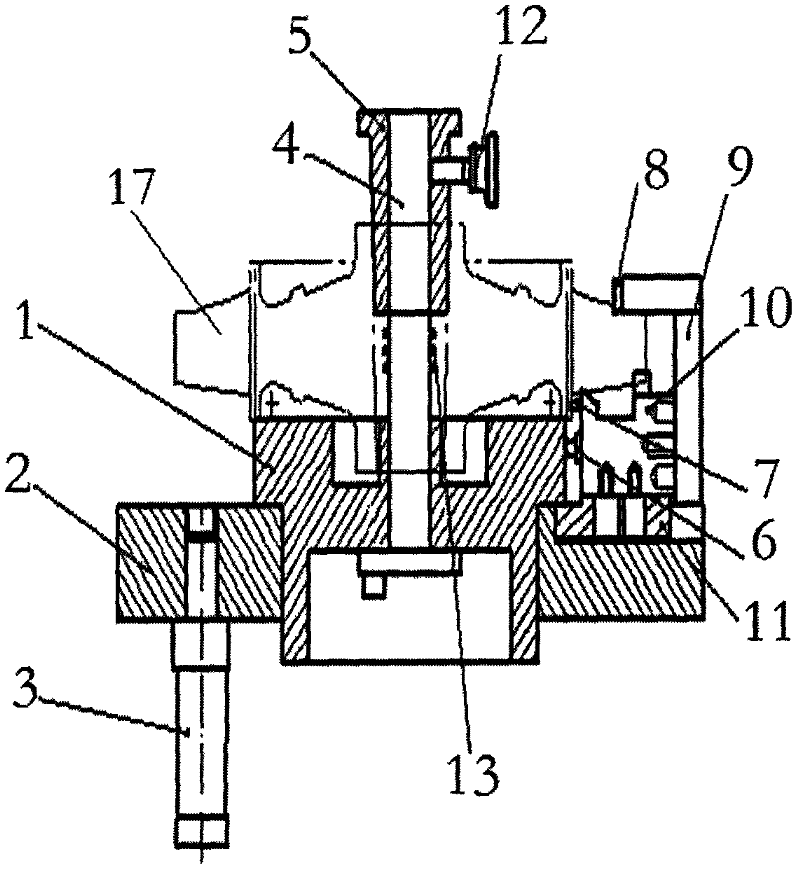

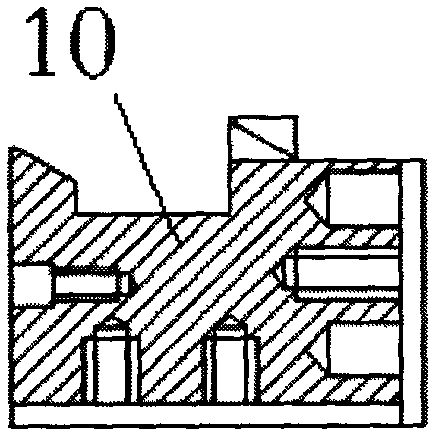

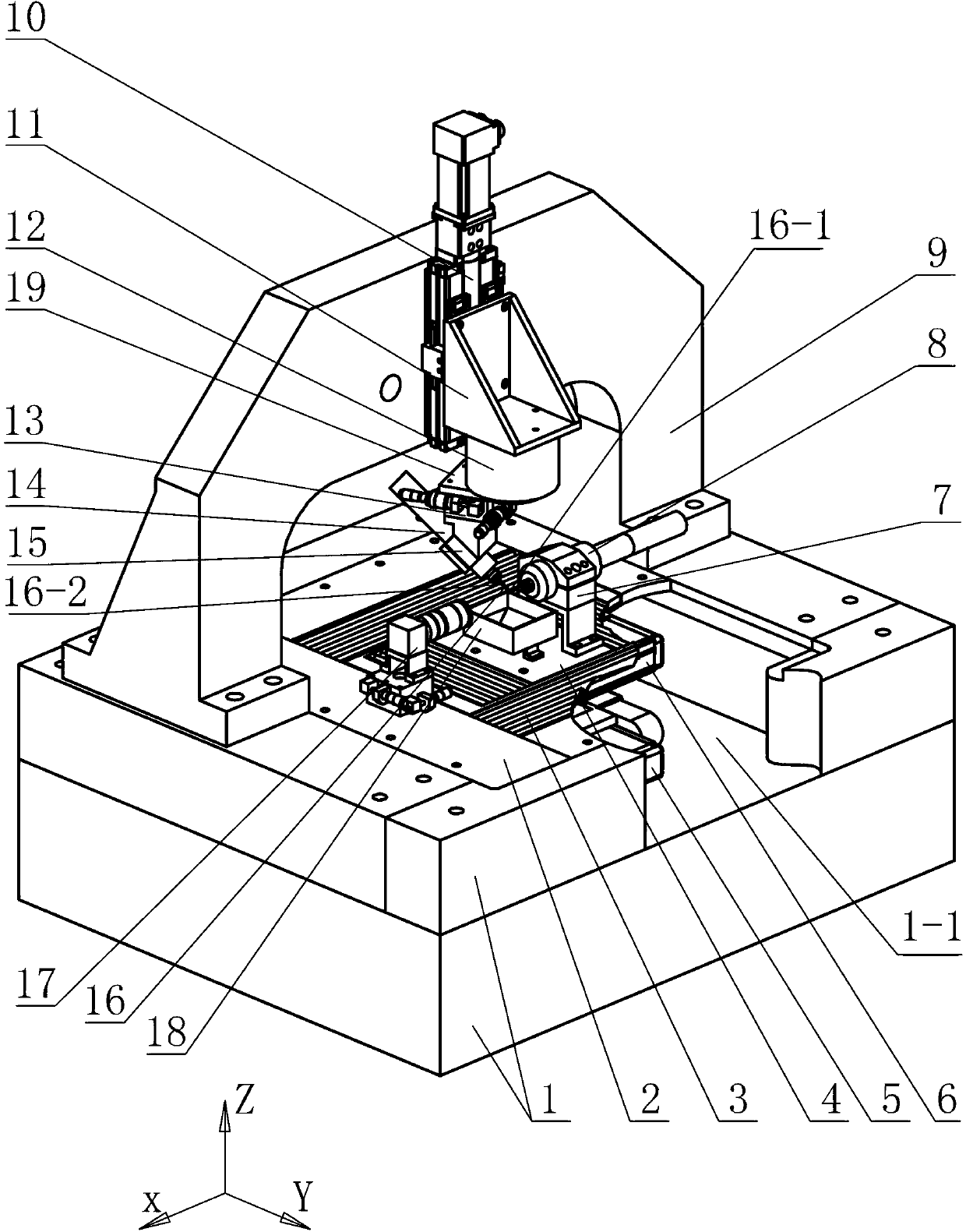

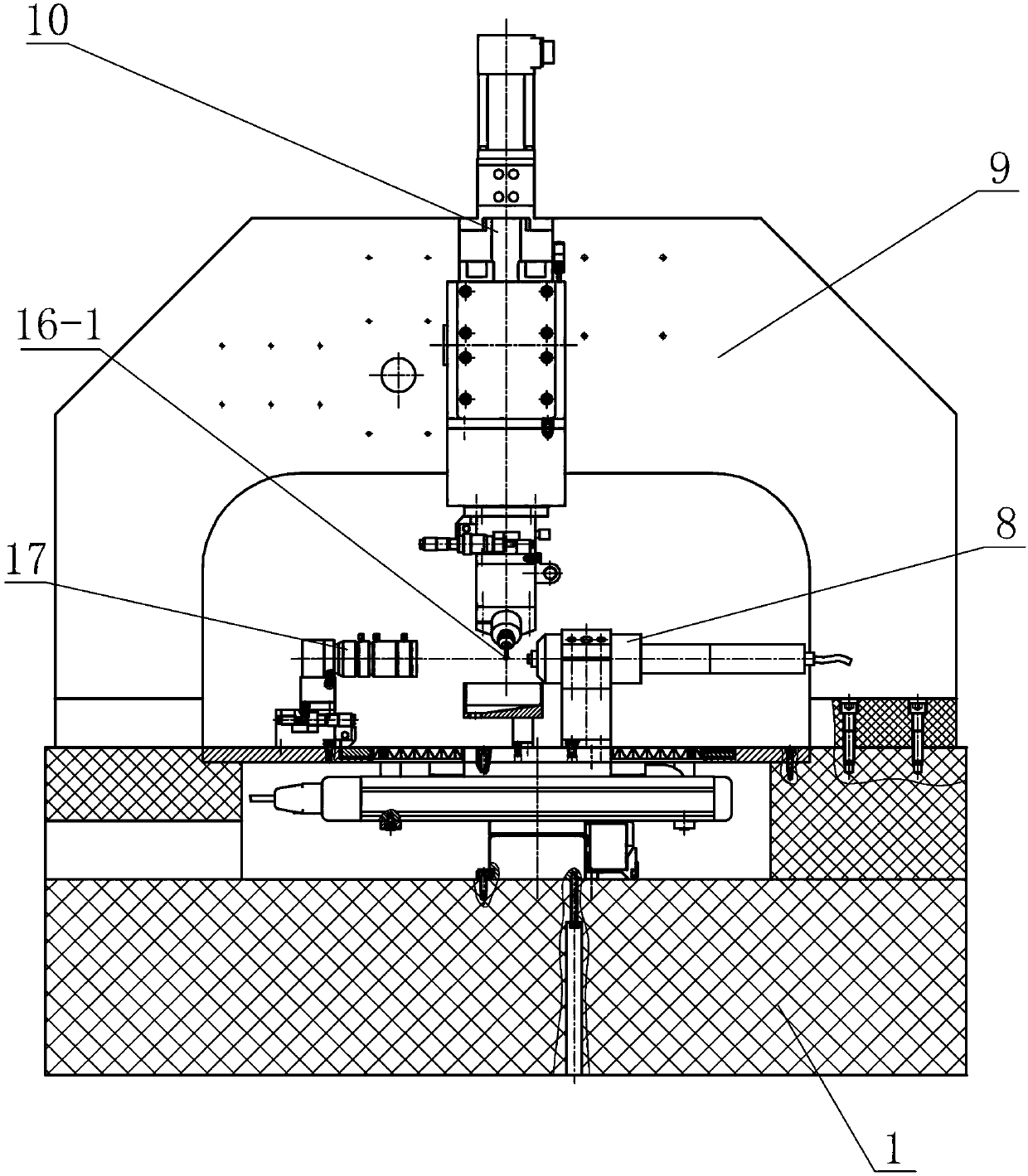

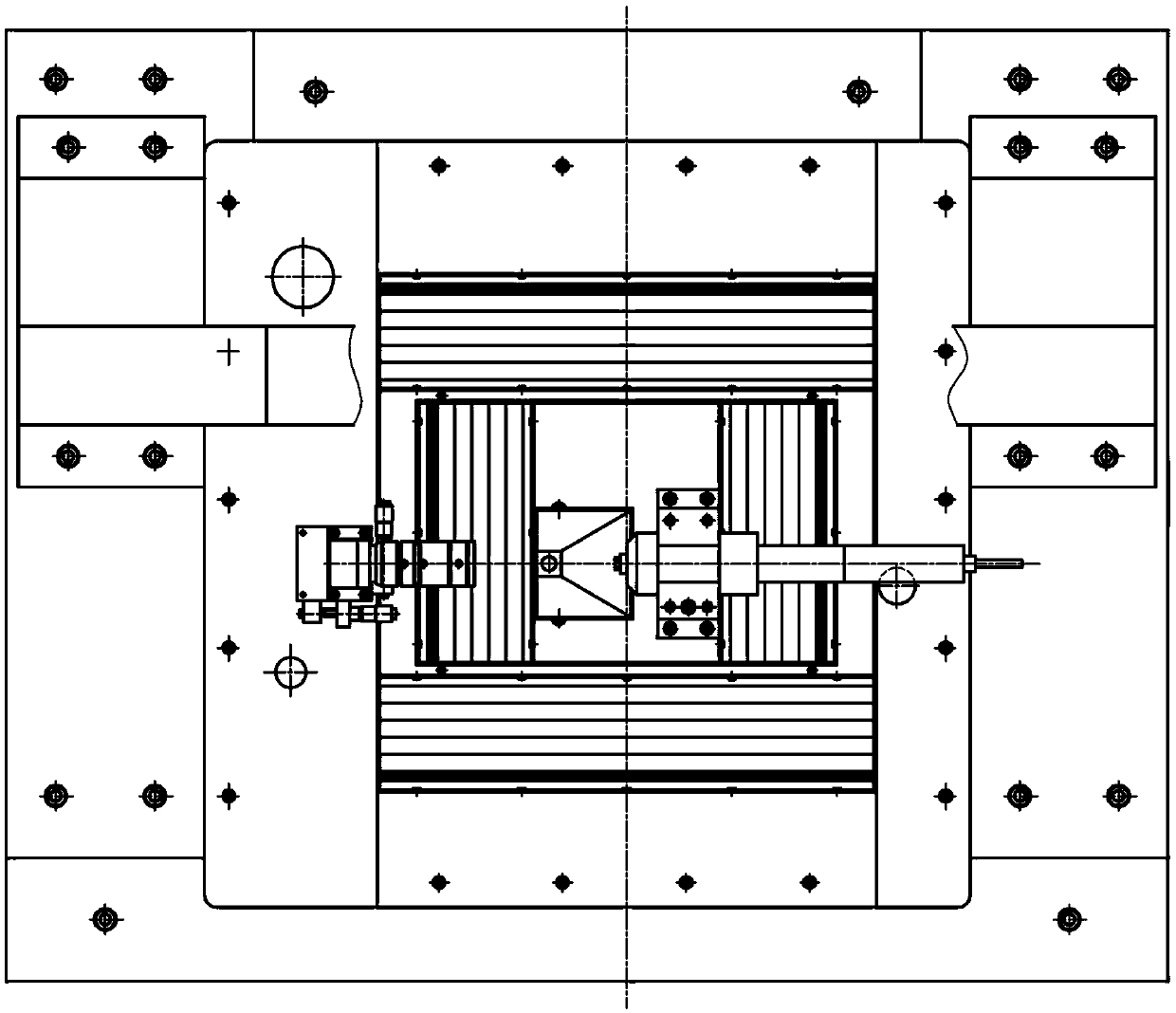

Small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool

ActiveCN103072047AIncrease contactAvoid interferenceGrinding machine componentsMachine toolComputer science

The invention discloses a small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool, which belongs to the technical field of grinding-polishing processing, and is used for solving the problem that the shape and size accuracy requirements of a processed part cannot be met since each position of a small-caliber non-spherical curved surface to be processed cannot be contacted during processing of workpieces with the conventional polishing processing equipment. A workbench is arranged on an X axis linear unit of an XY precision movable platform; an organ protection cover is arranged between the edge of the workbench and a cover plate; a workpiece main shaft is arranged on the workbench through a workpiece main shaft bracket; a Z axis linear unit is arranged on a portal frame; a revolving table is arranged on the Z axis linear unit through a right-angle connecting frame; the shaft end of a rotating shaft in the revolving table is connected with a polishing head main shaft bracket through a two-dimensional precision fine adjustment displacement table; and the polishing head main shaft bracket has a certain inclination angle, so that an included angle between a polishing head main shaft on the polishing head main shaft bracket and a horizontal plane is 40-45 degrees. The machine tool is suitable for ultra-precision polishing processing of high-accuracy small-caliber non-spherical parts.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com