Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

725 results about "Selective deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

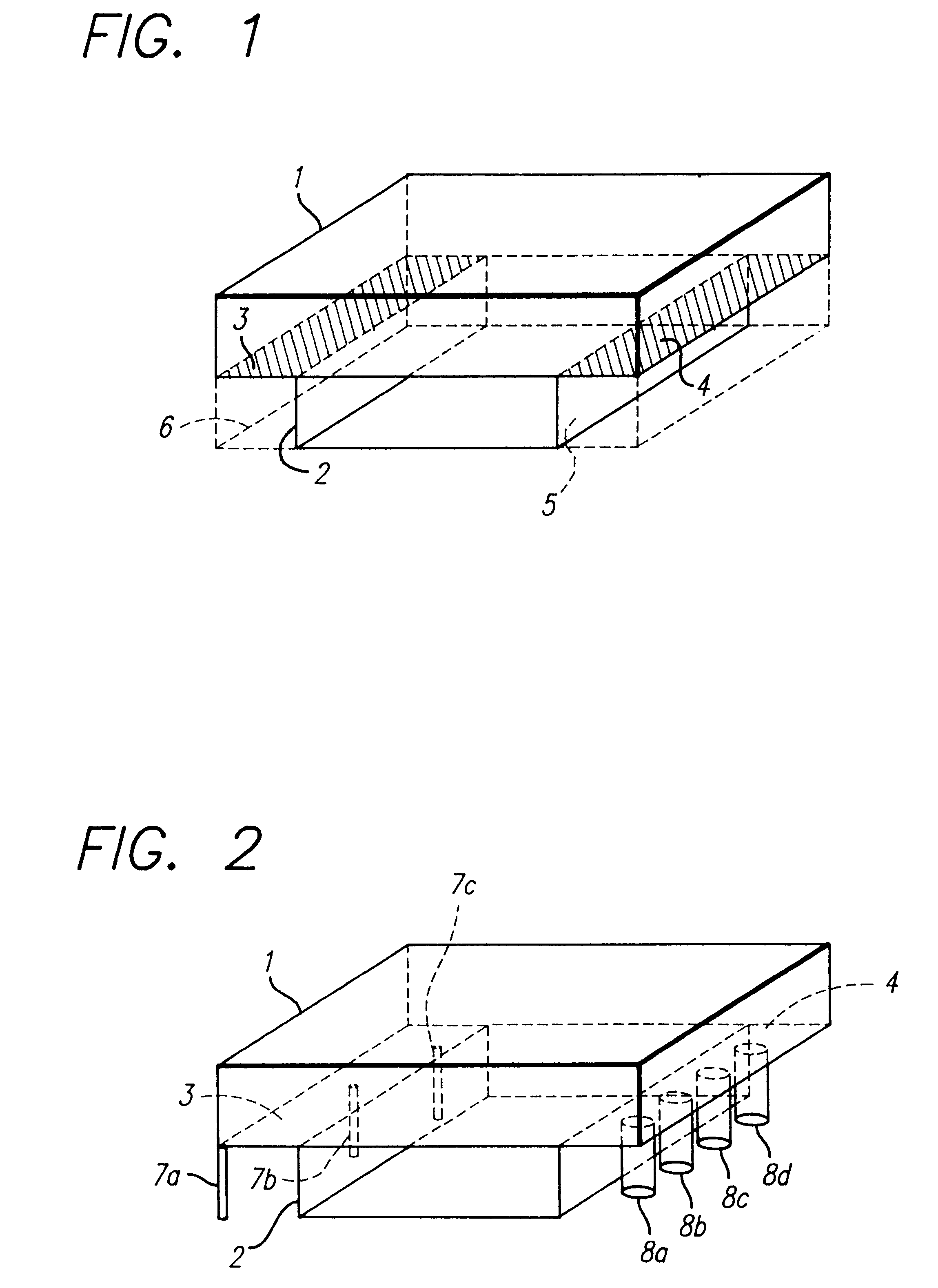

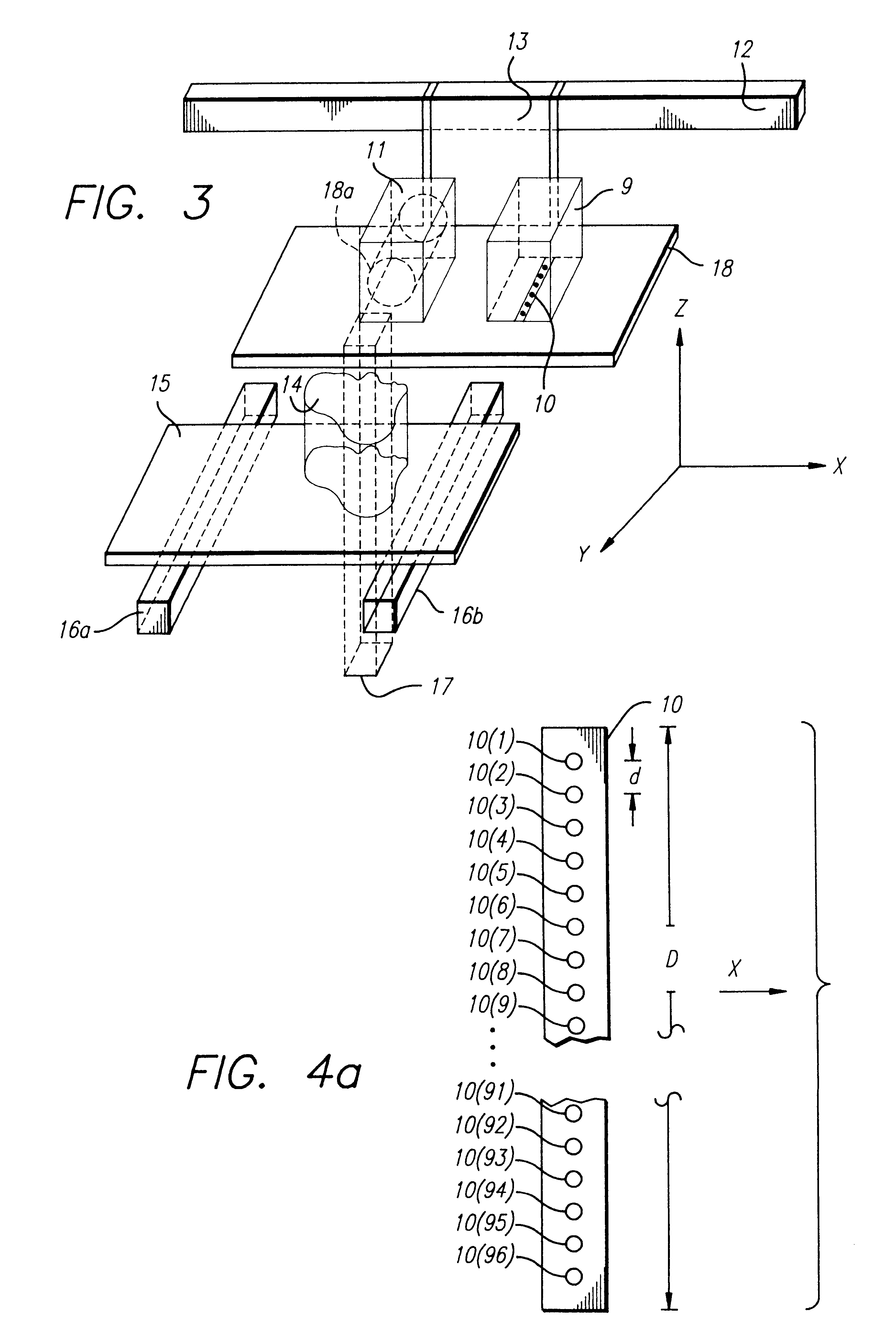

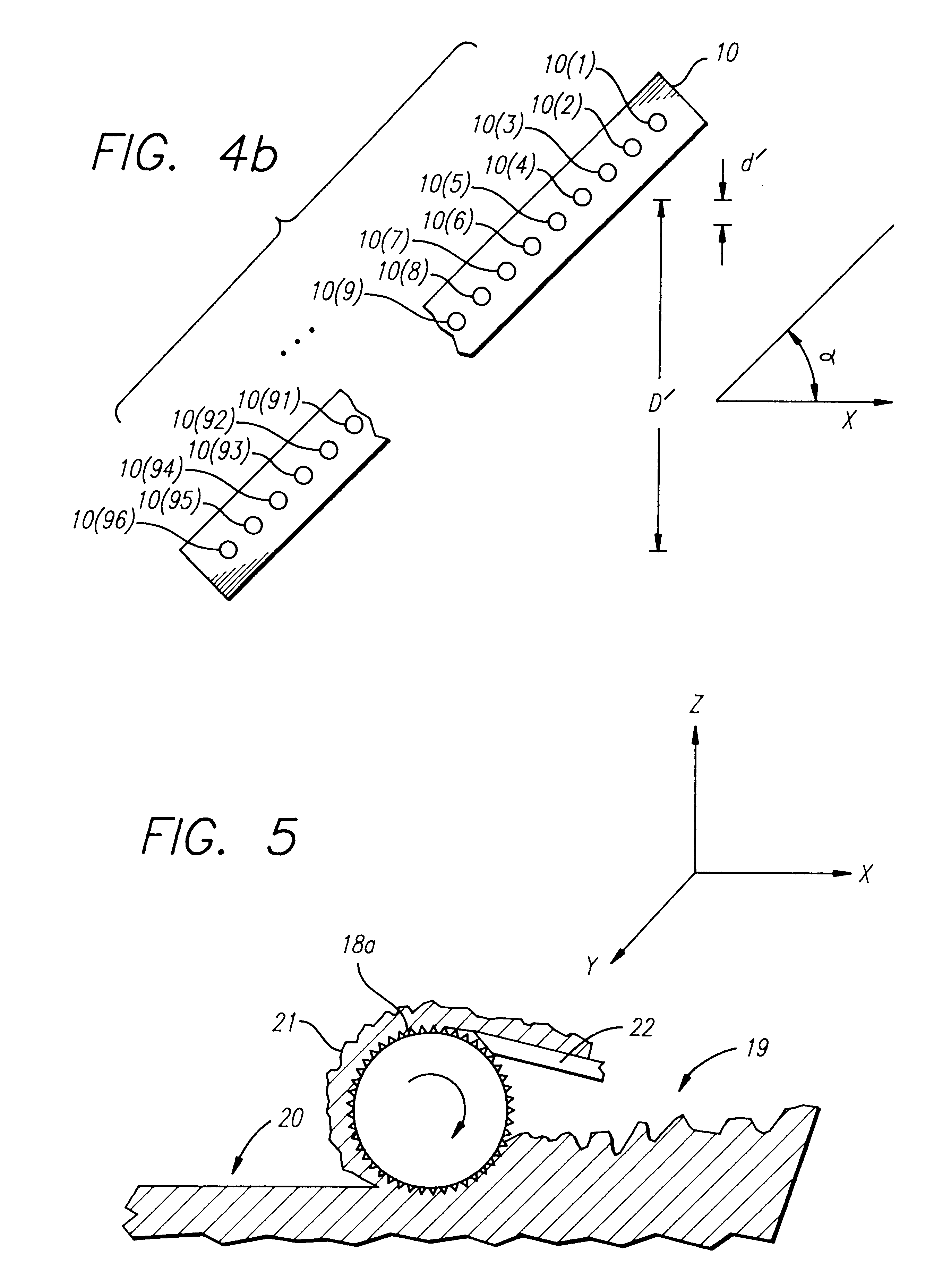

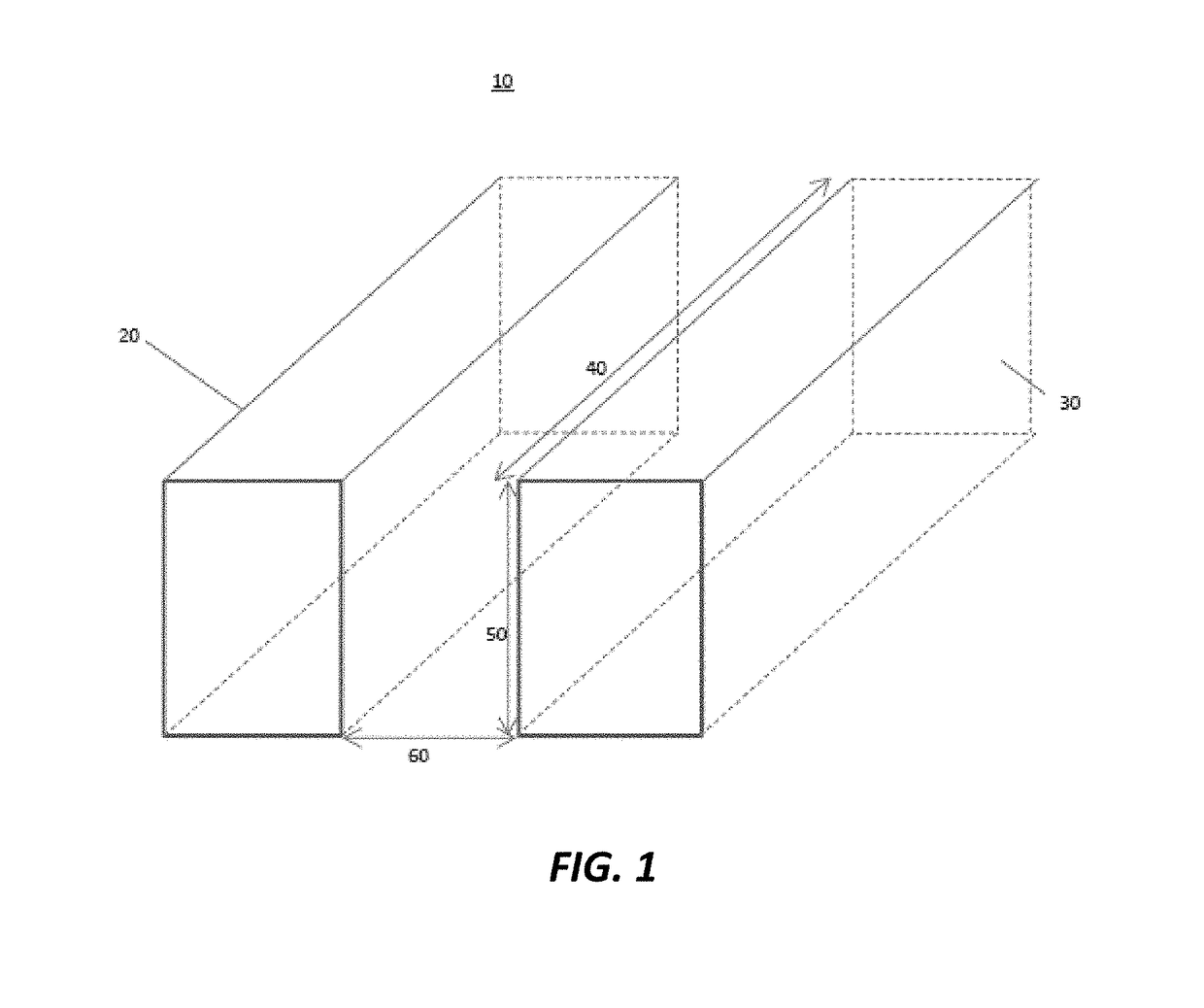

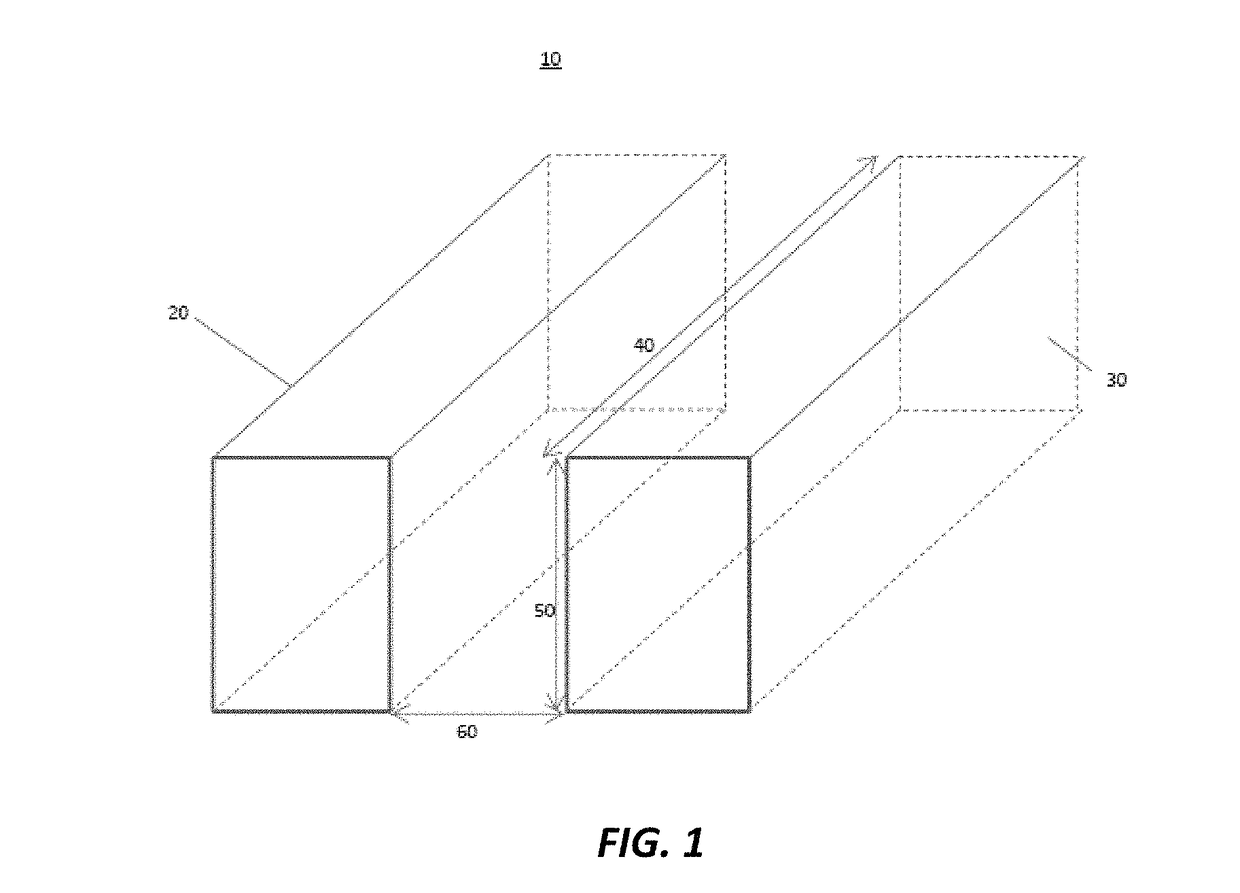

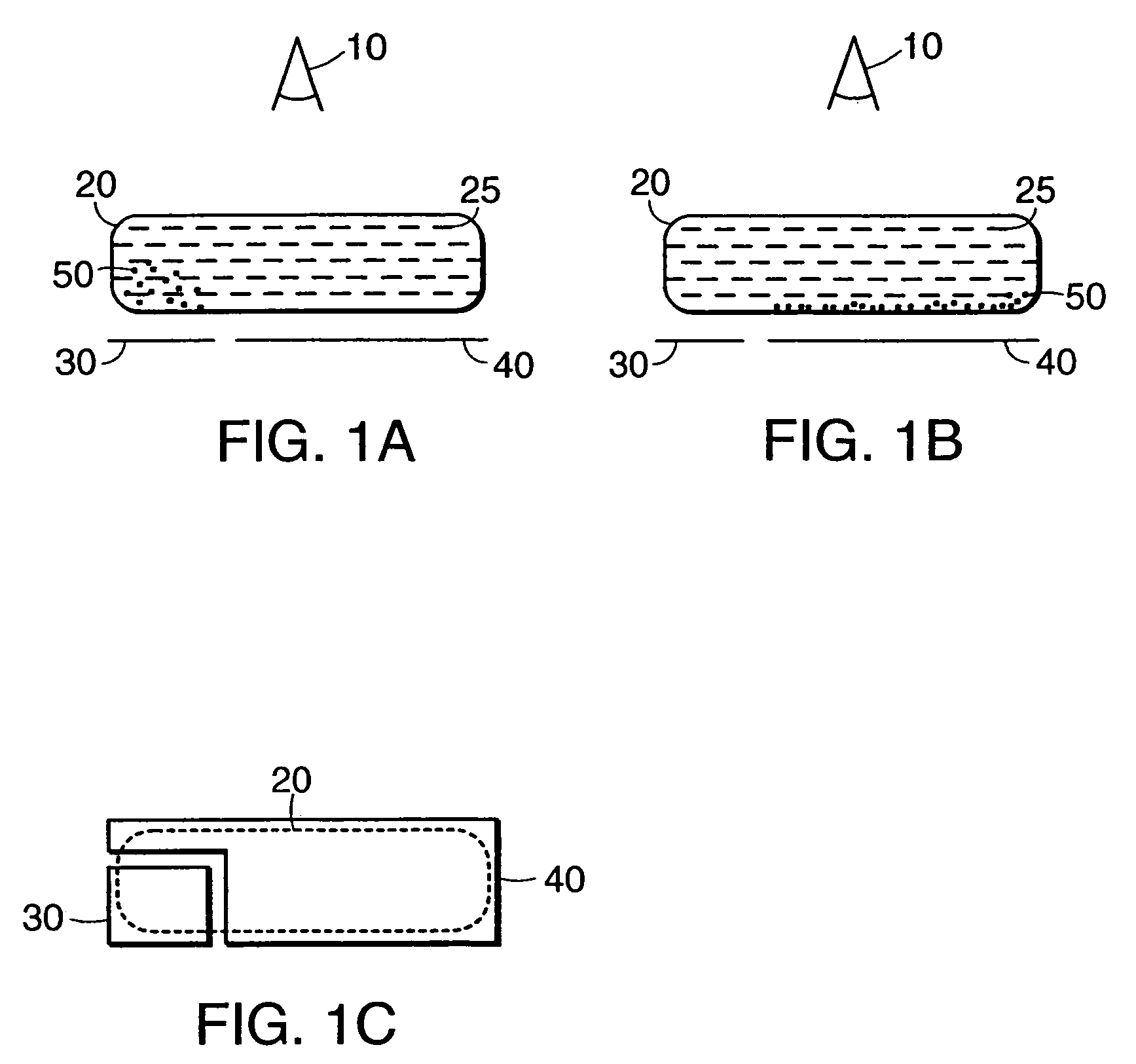

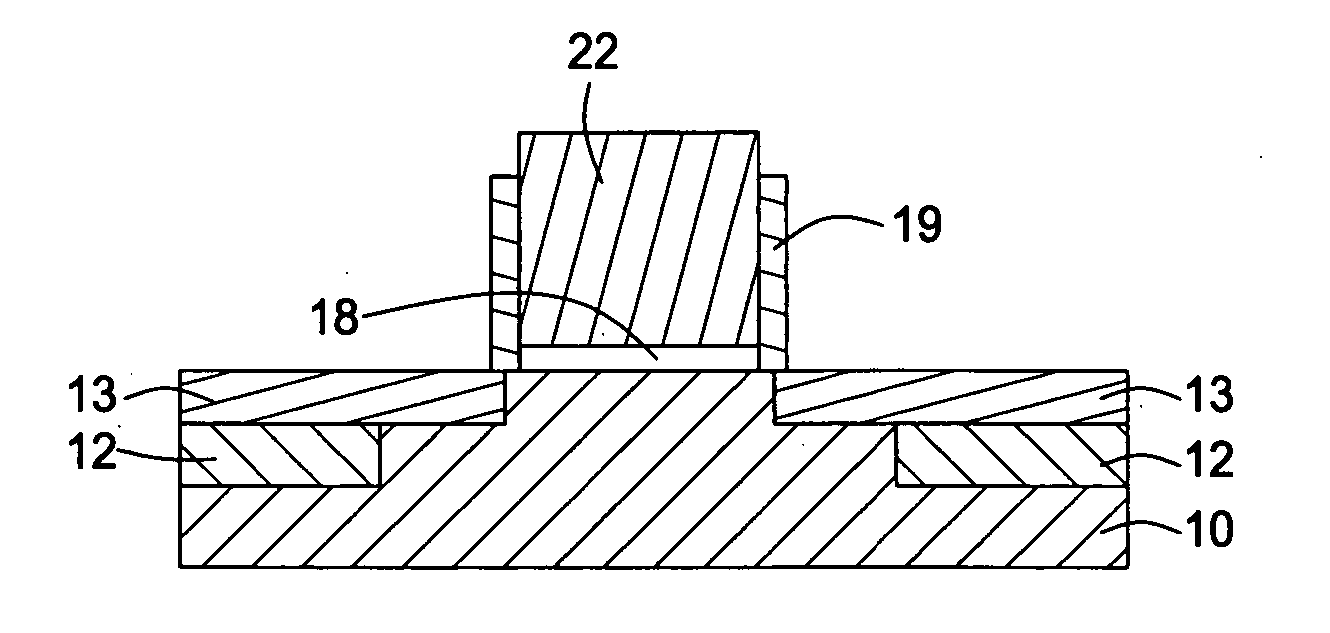

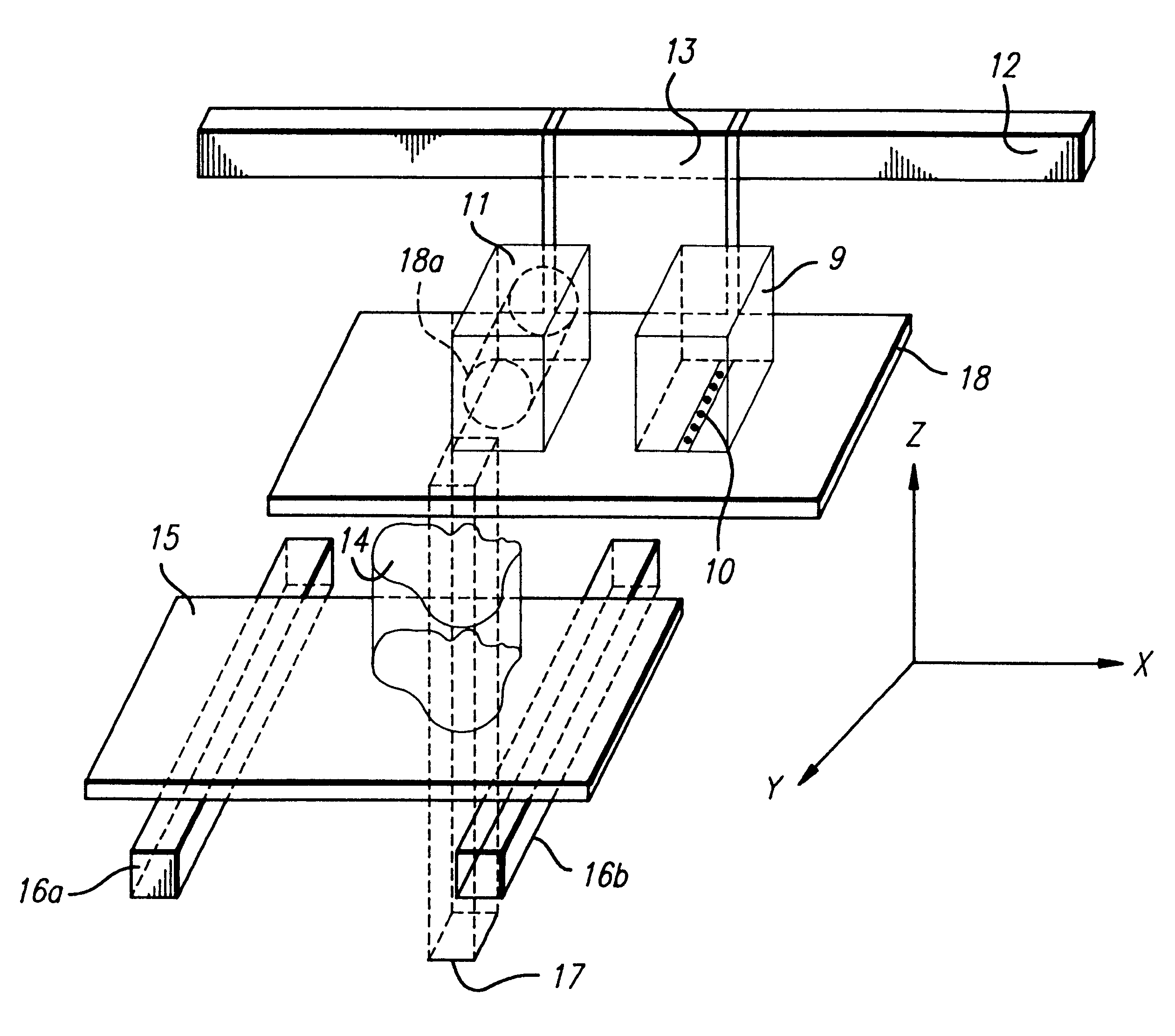

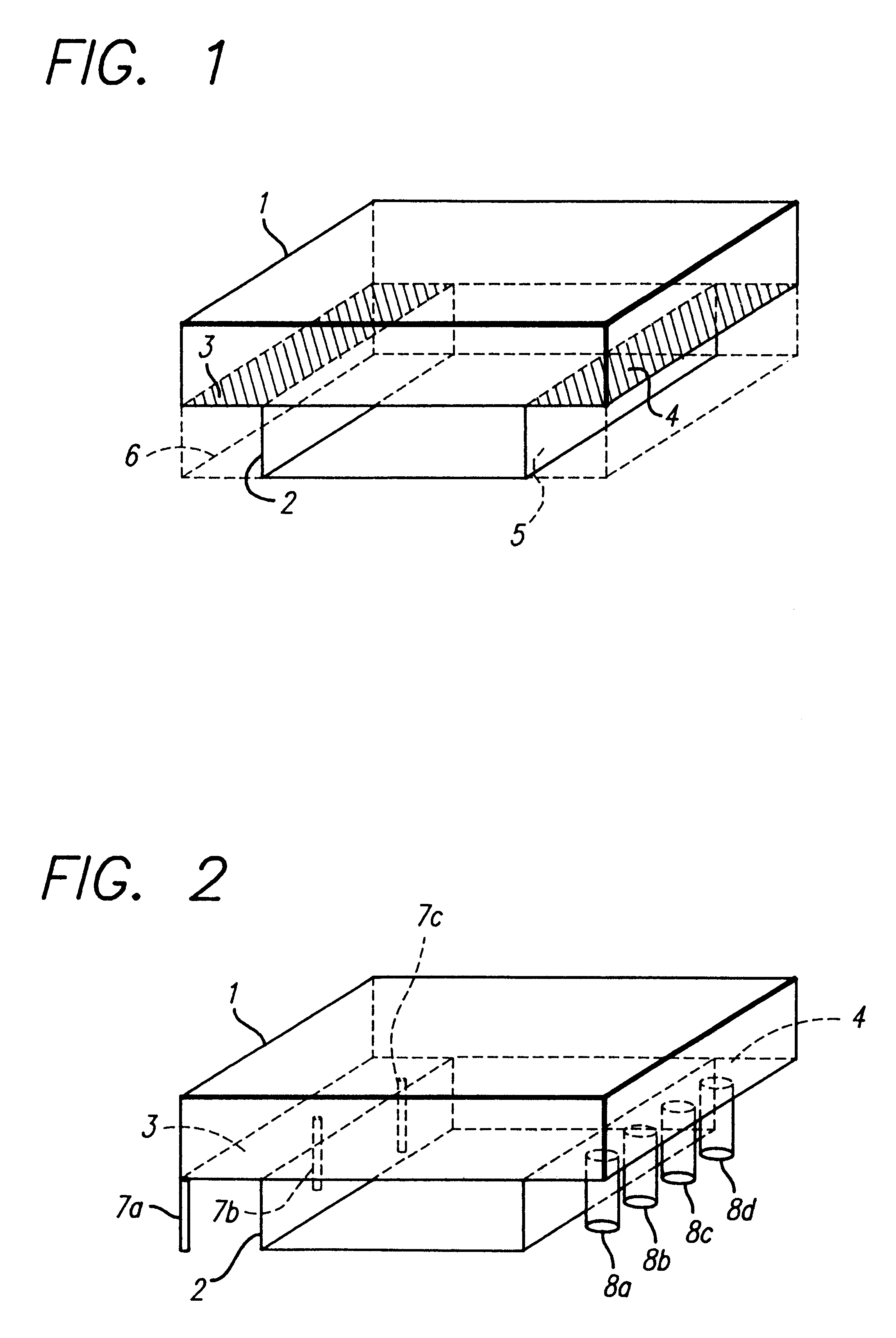

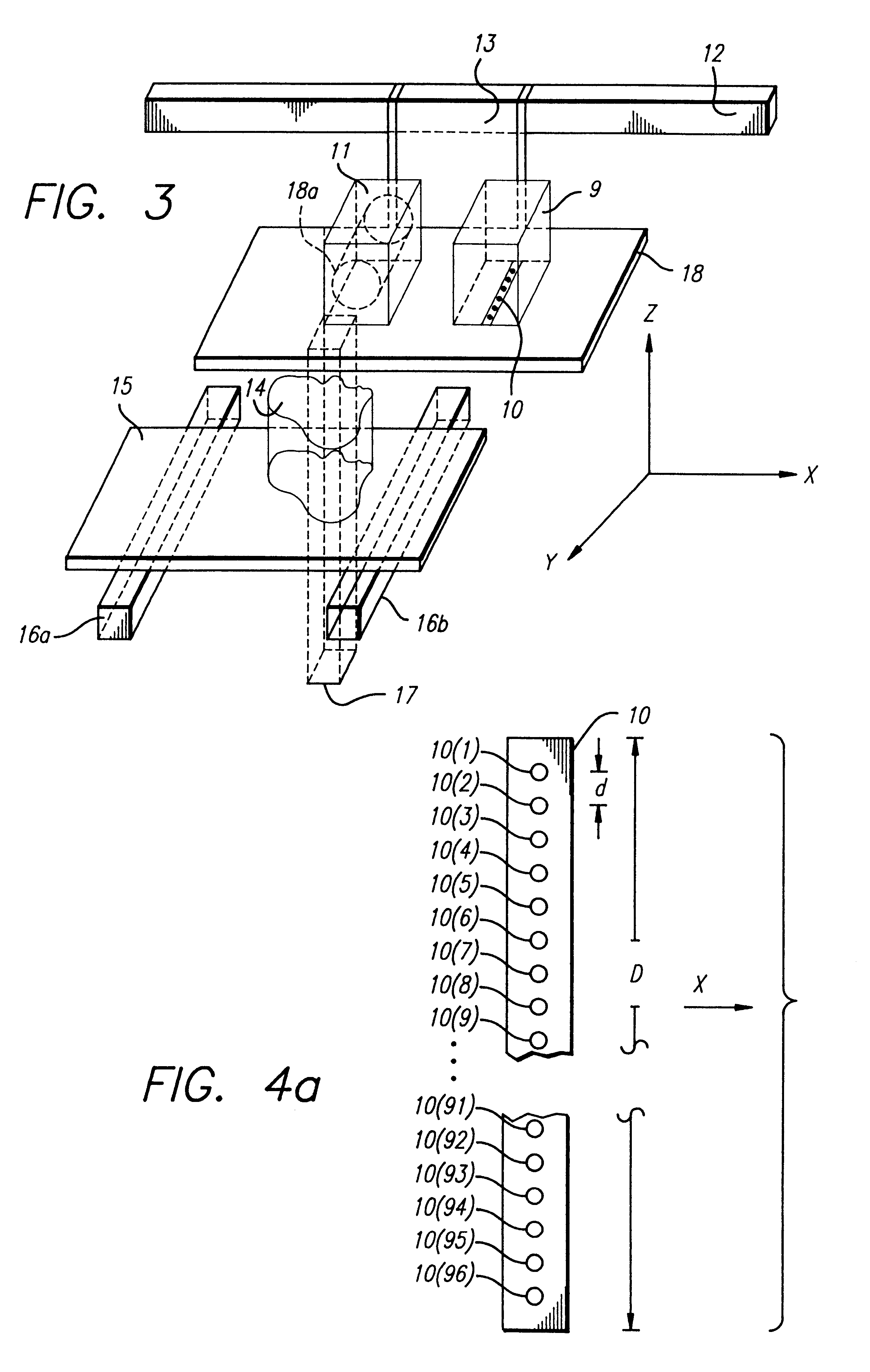

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6193923B1Easy to disassembleMinimal damageAdditive manufacturing apparatusCeramic shaping apparatusEngineeringSelective deposition

A variety of support structures and build styles for use in Rapid Prototyping and Manufacturing systems are described wherein particular emphasis is given to Thermal Stereolithography, Fused Deposition Modeling, and Selective Deposition Modeling systems, and wherein a 3D modeling system is presented which uses multijet dispensing and a single material for both object and support formation.

Owner:3D SYST INC

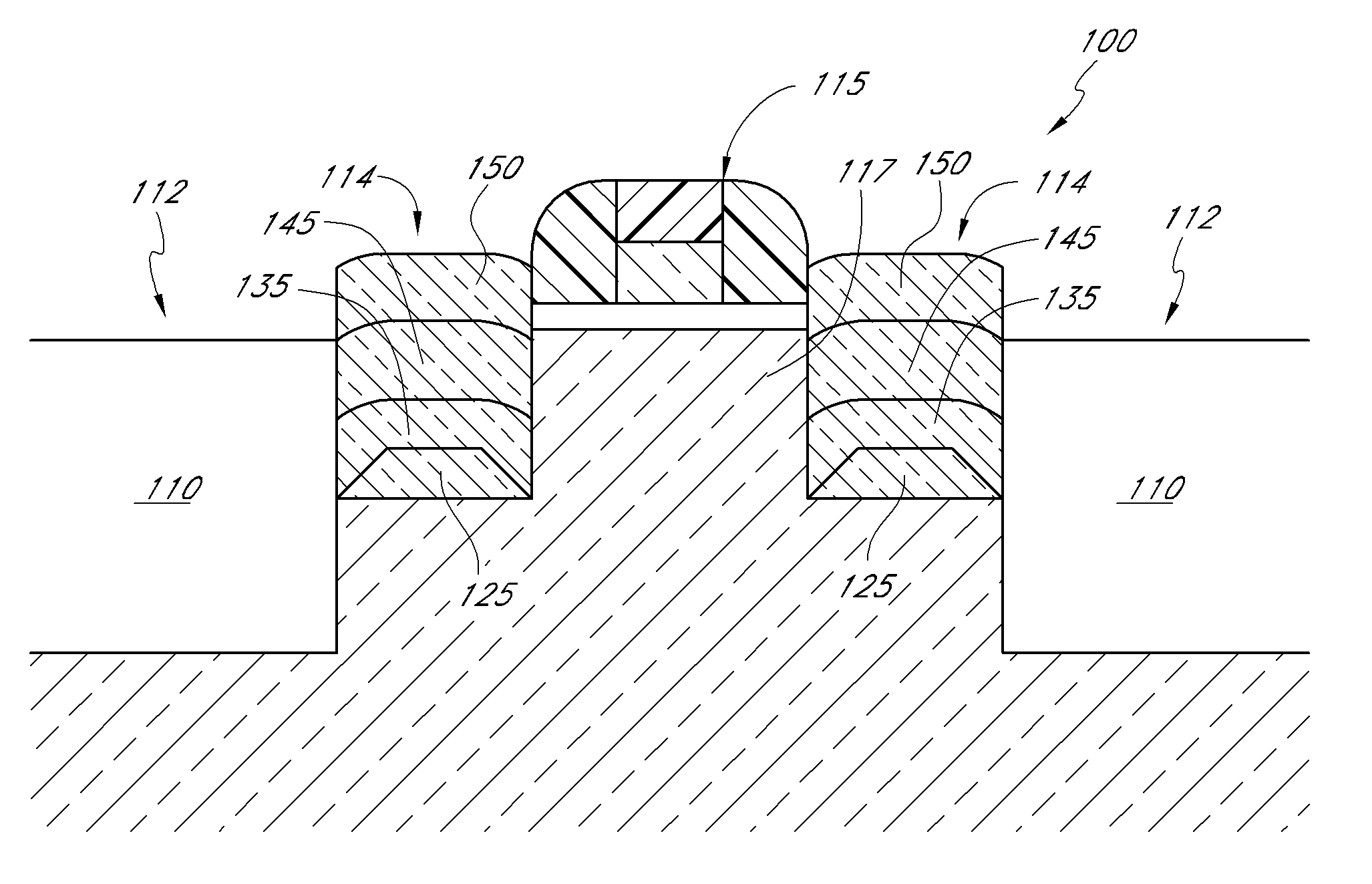

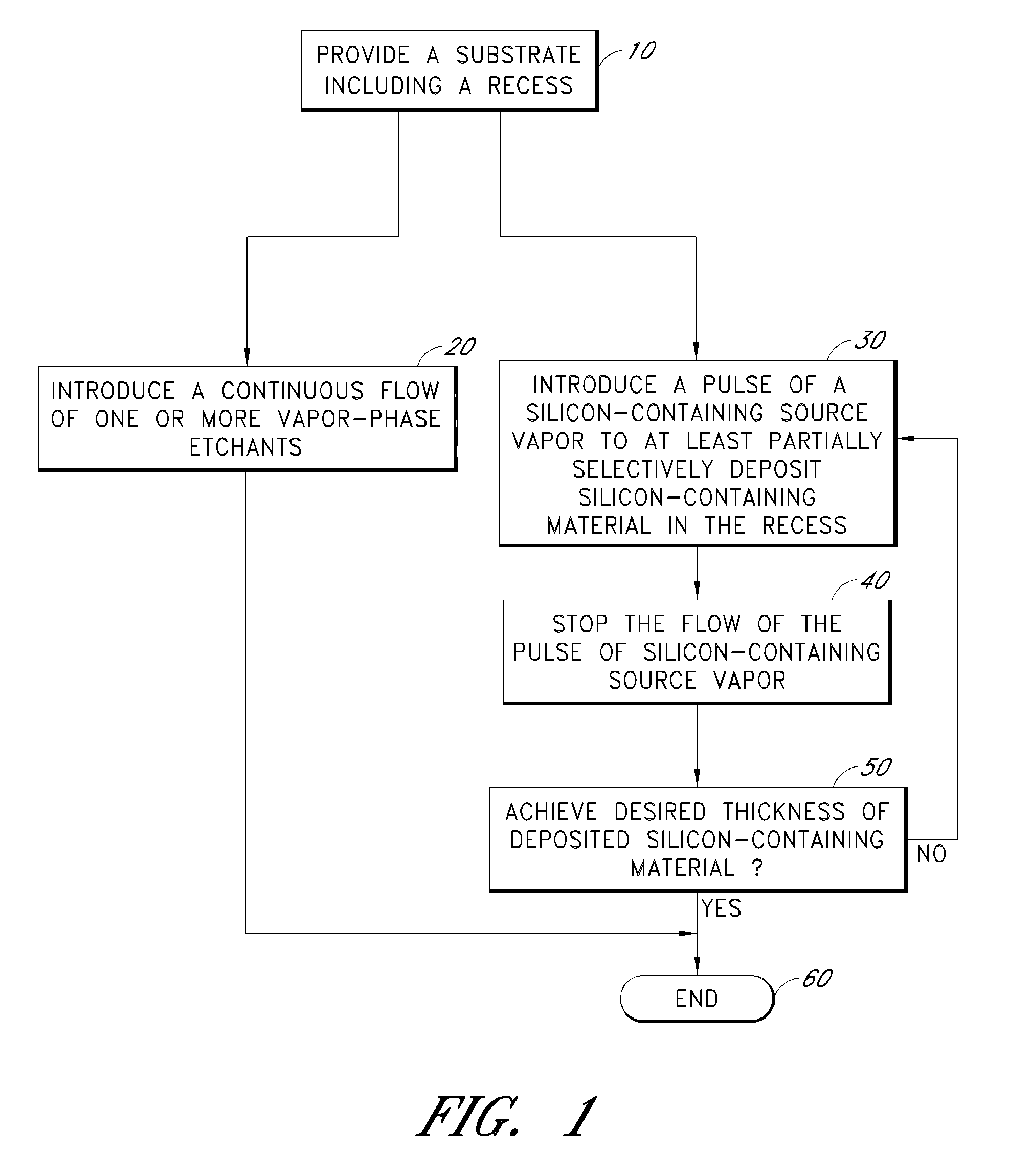

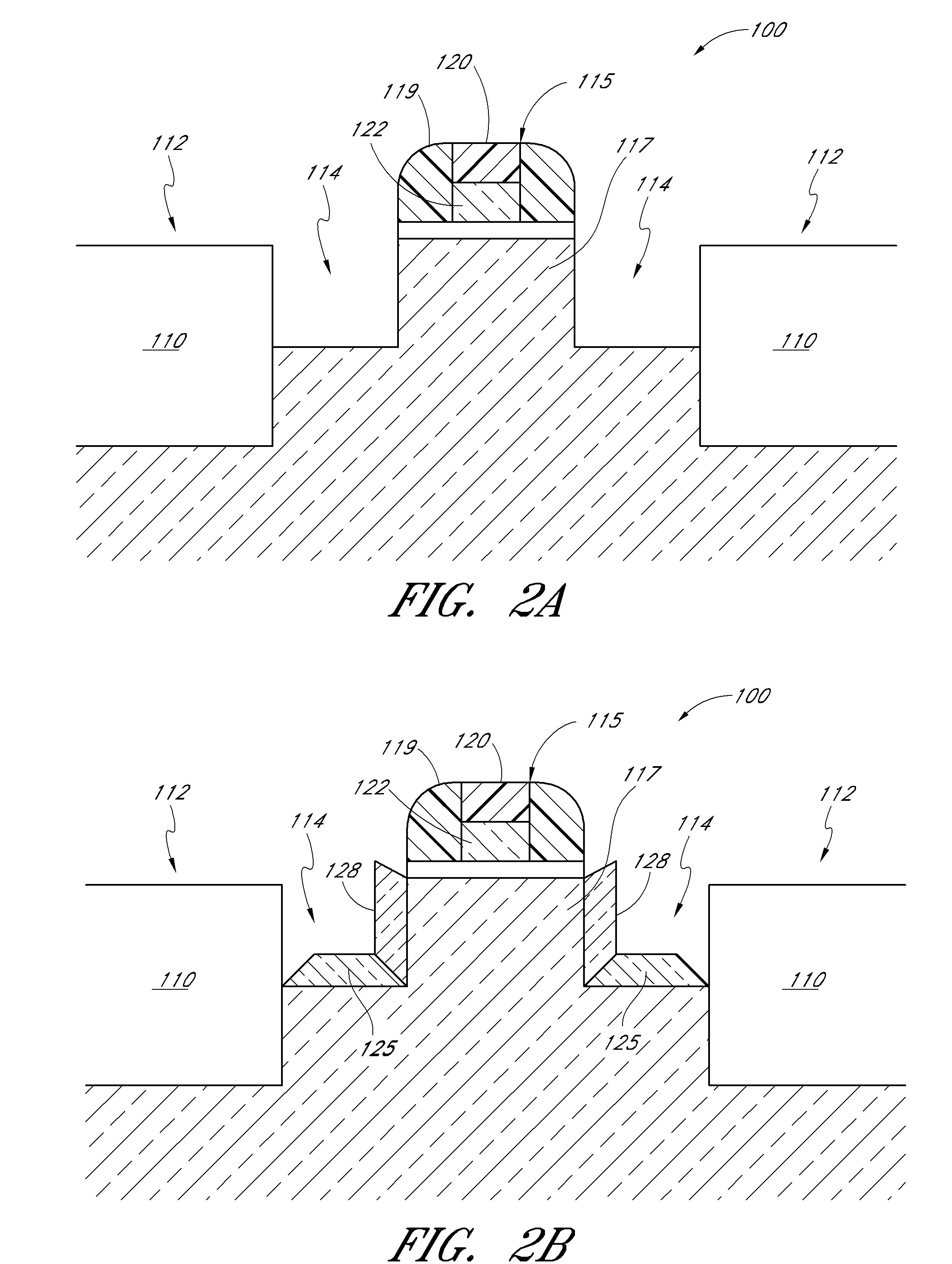

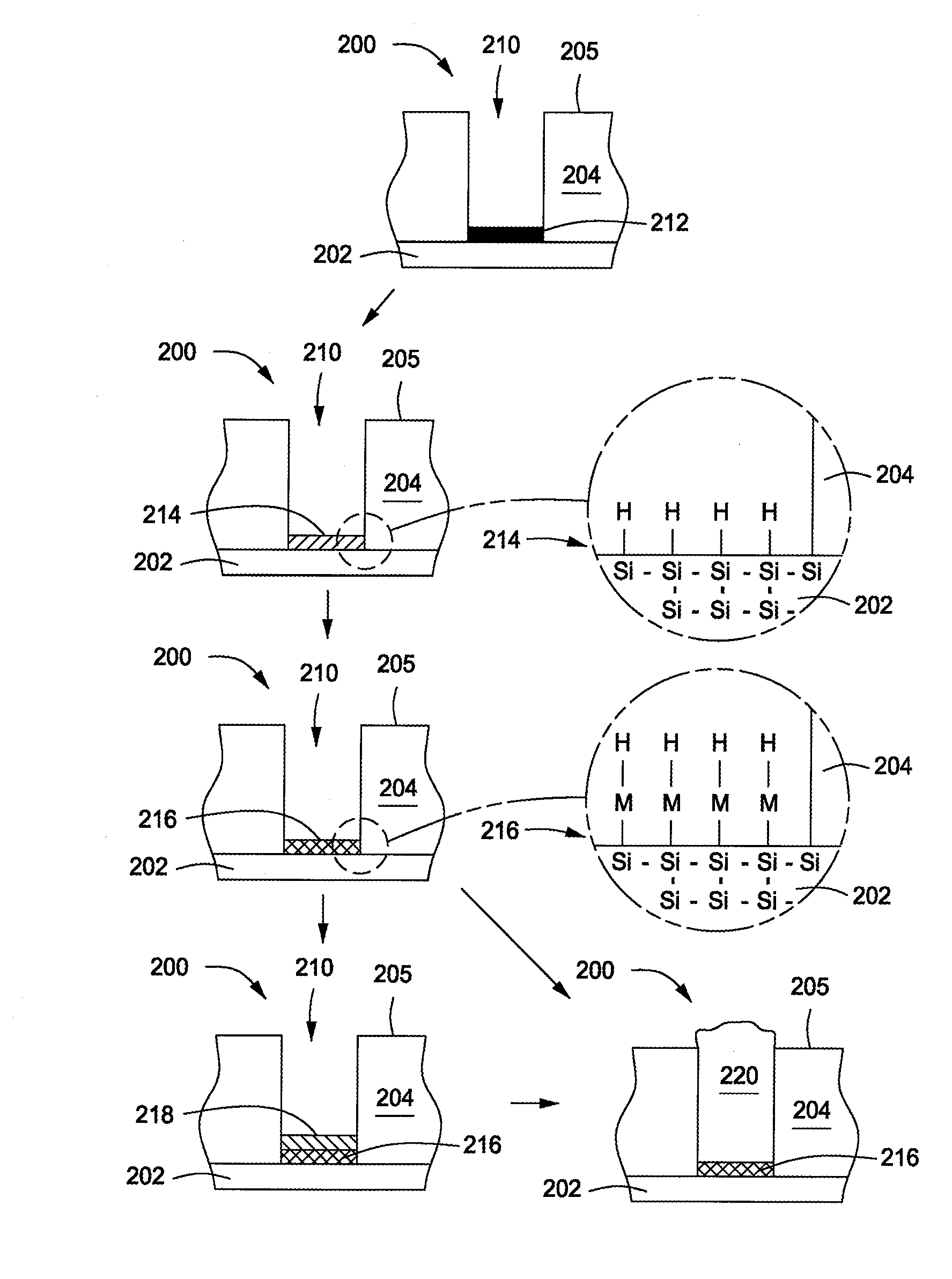

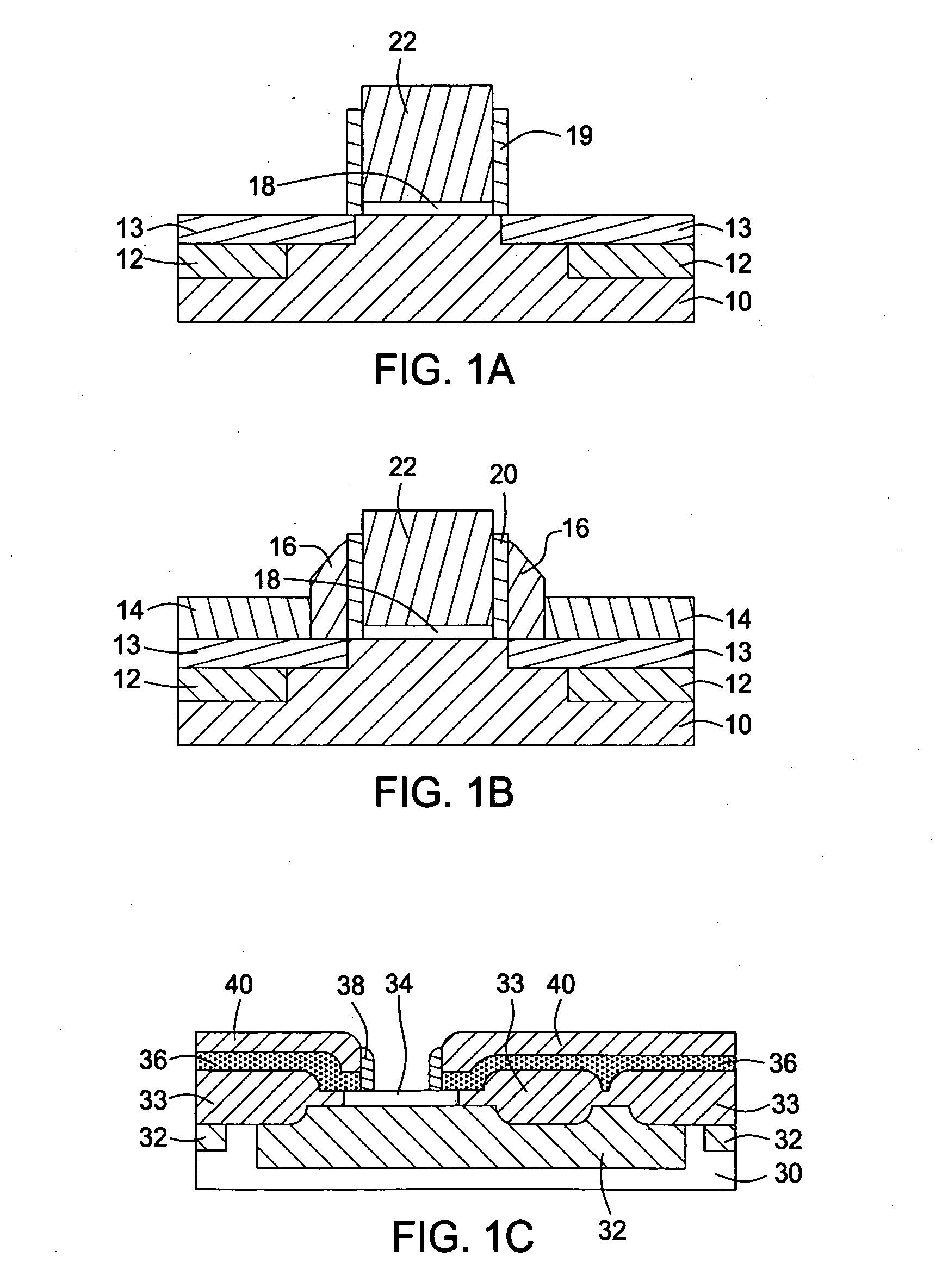

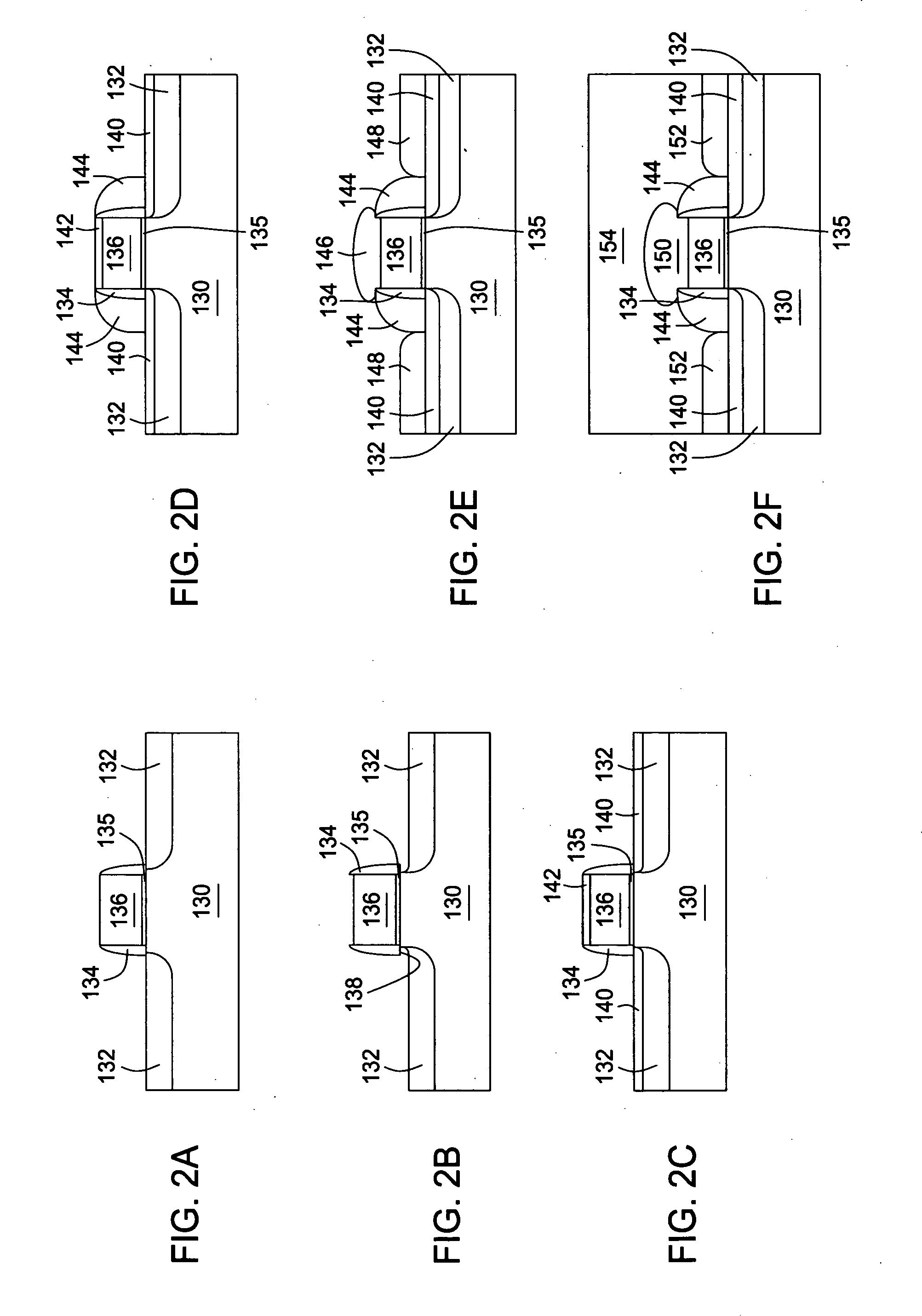

Cyclical epitaxial deposition and etch

ActiveUS20110117732A1Quality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesEpitaxial materialSemiconductor

Methods for selectively depositing high quality epitaxial material include introducing pulses of a silicon-source containing vapor while maintaining a continuous etchant flow. Epitaxial material is deposited on areas of a substrate, such as source and drain recesses. Between pulses, the etchant flow continues such that lower quality epitaxial material may be removed, as well as any non-epitaxial material that may have been deposited. The pulse of silicon-source containing vapor may be repeated until a desired thickness of epitaxial material is selectively achieved in semiconductor windows, such as recessed source / drain regions.

Owner:ASM IP HLDG BV

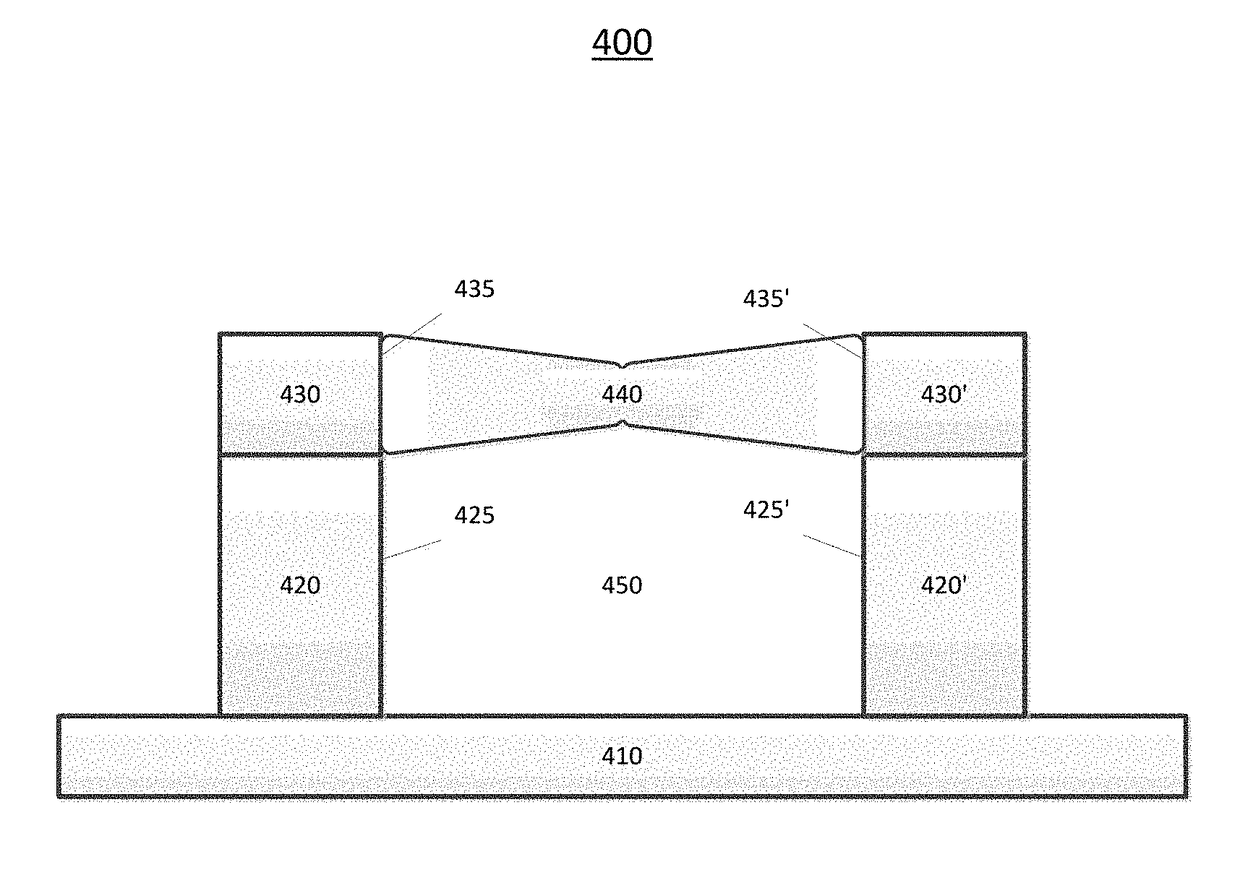

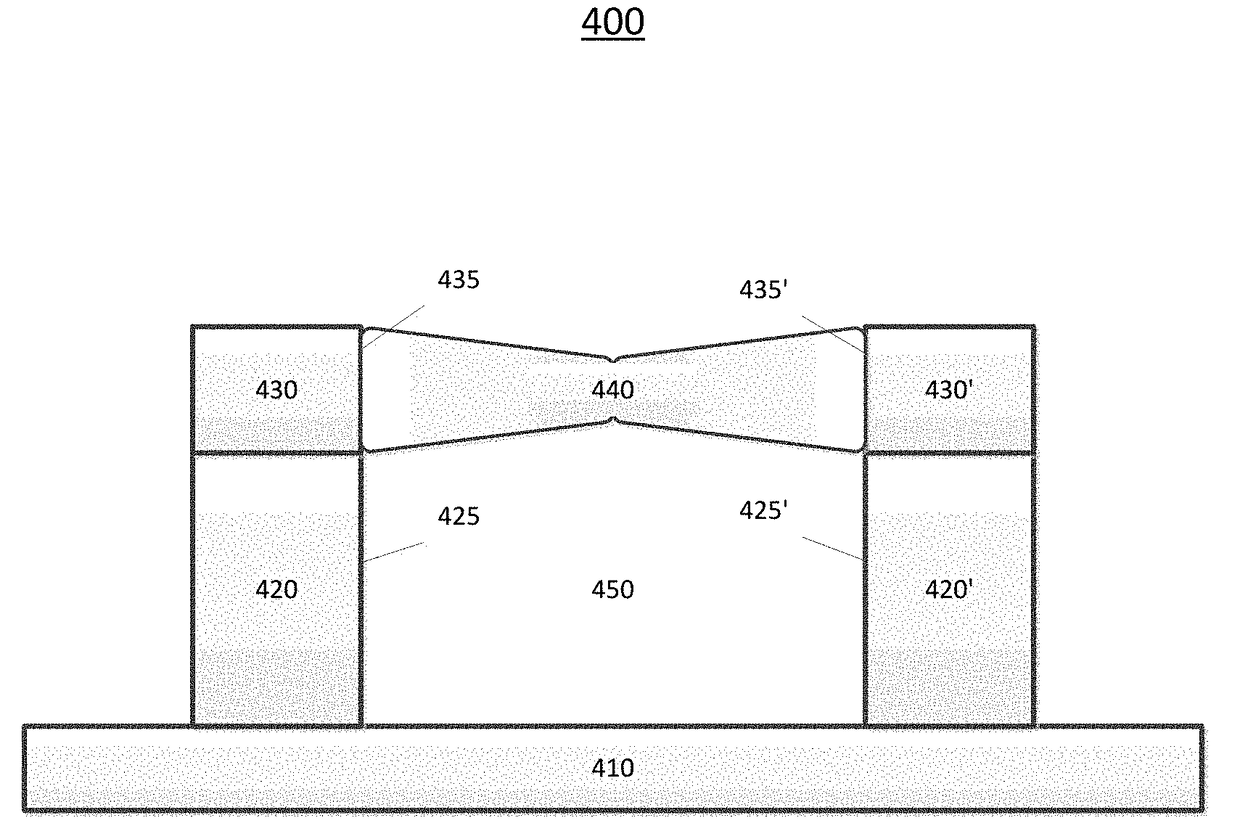

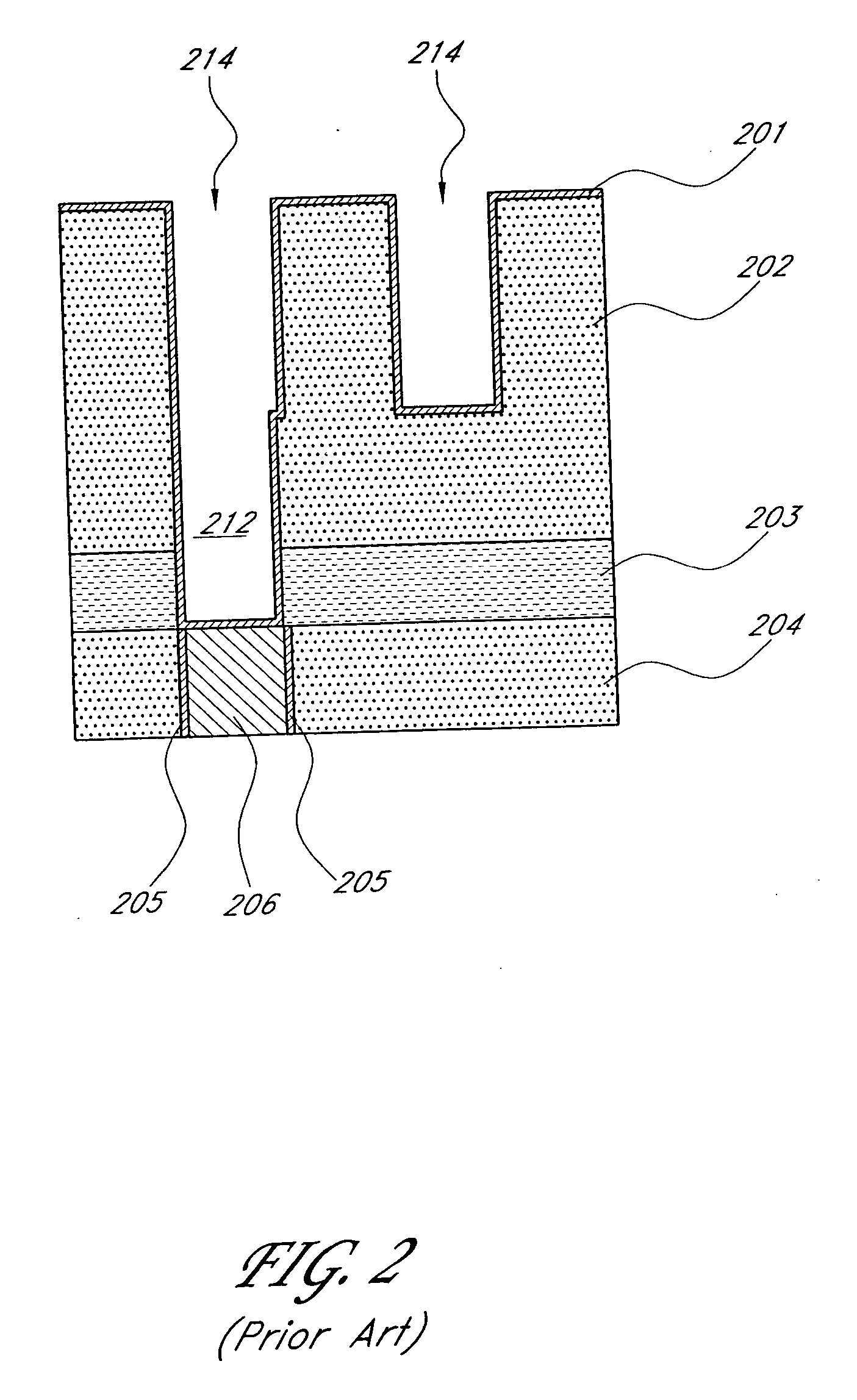

Selective deposition to form air gaps

A method for depositing a film to form an air gap within a semiconductor device is disclosed. An exemplary method comprises pulsing a metal halide precursor onto the substrate and pulsing an oxygen precursor onto a selective deposition surface. The method can be used to form an air gap to, for example, reduce a parasitic resistance of the semiconductor device.

Owner:ASM IP HLDG BV

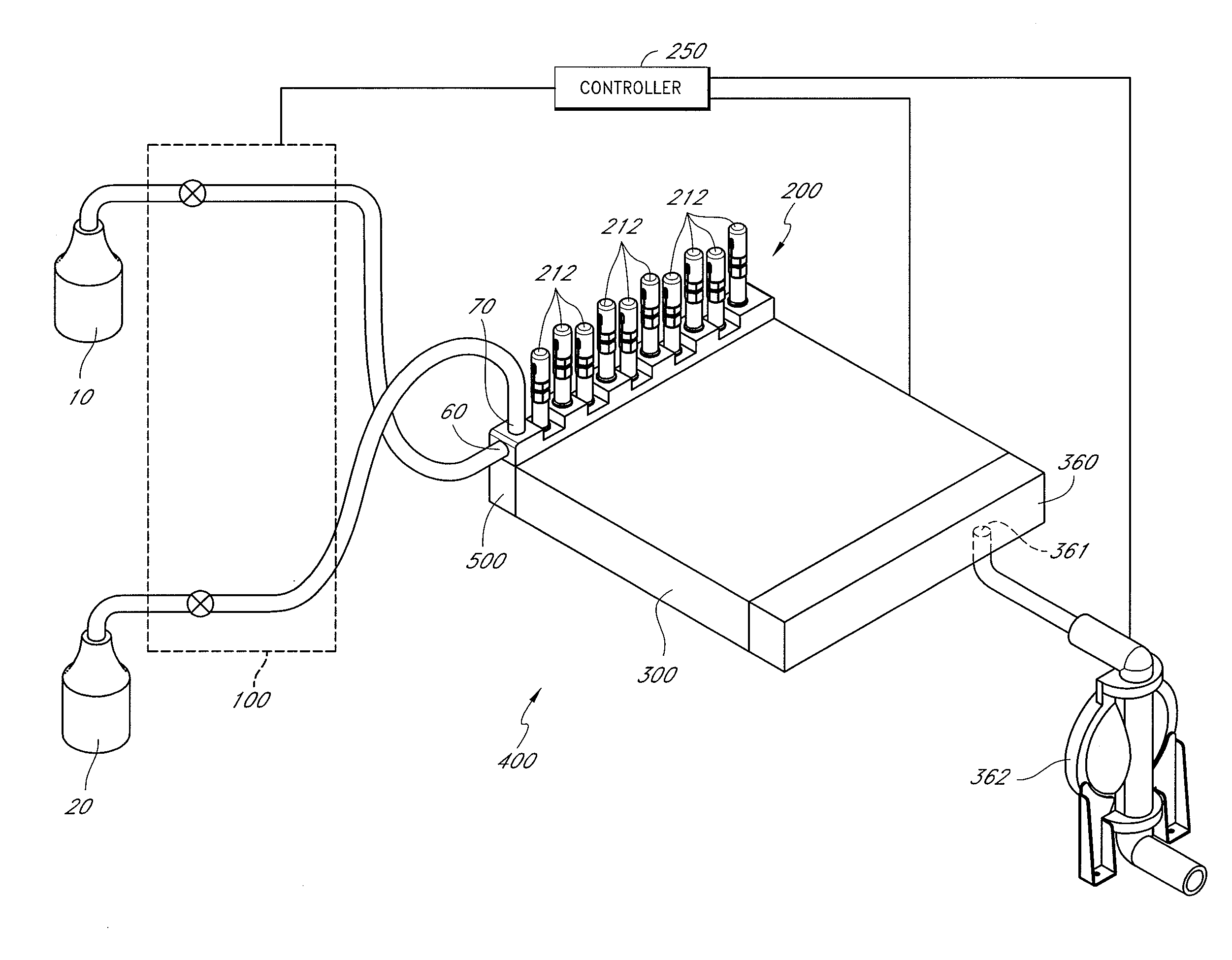

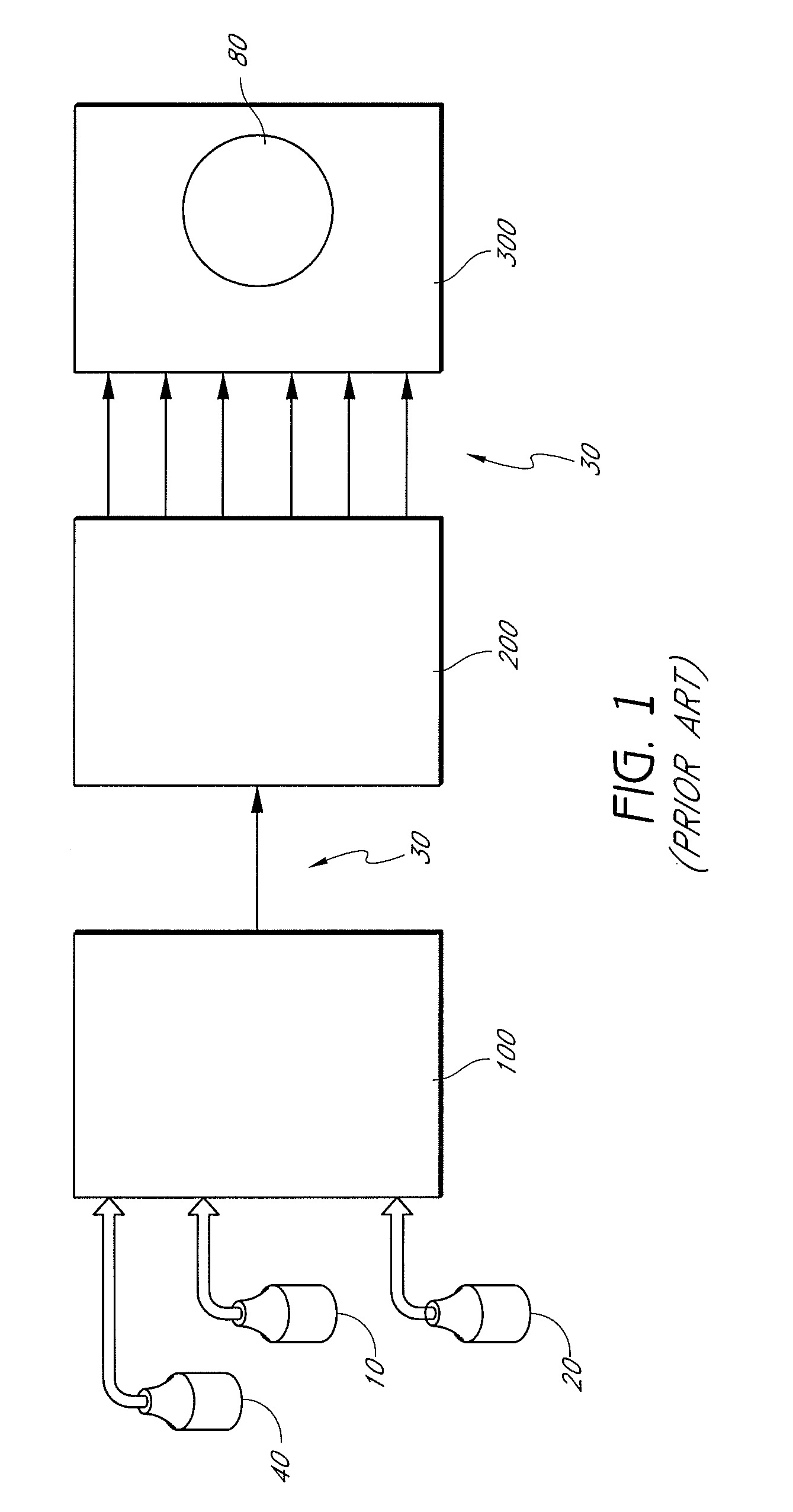

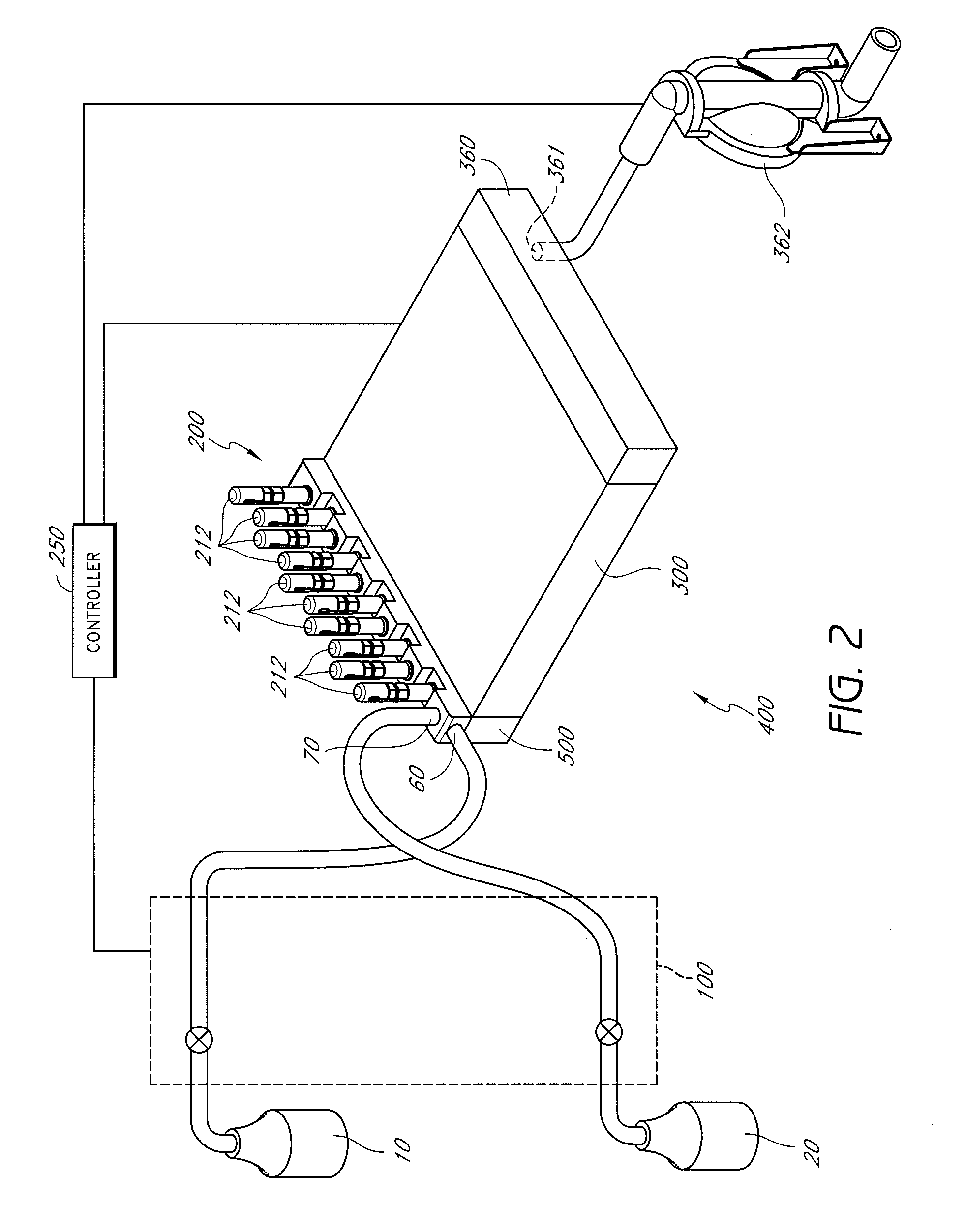

Substrate reactor with adjustable injectors for mixing gases within reaction chamber

ActiveUS20100255658A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasSelective deposition

Methods and apparatuses for separately injecting gases into a reactor for a substrate processing system. The flow profiles of the gases are controlled with two or more sets of adjustable gas flow injectors. The methods are particularly useful for selective deposition of gases in a CVD system using volatile combinations of precursors and etchants. In either case, the gases are provided along separate flow paths that intersect in a relatively open reaction space, rather than in more confined upstream locations.

Owner:ASM IP HLDG BV

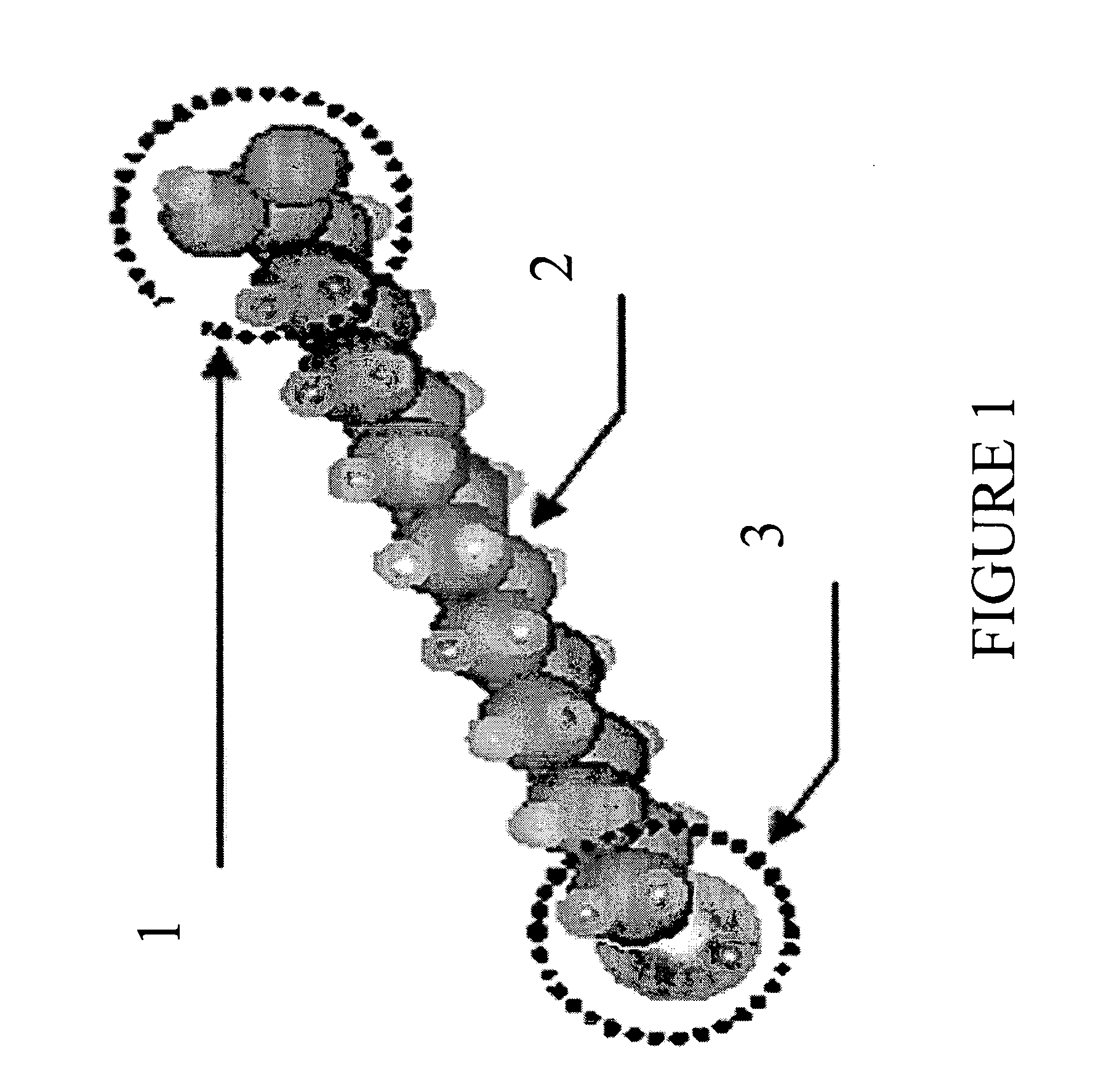

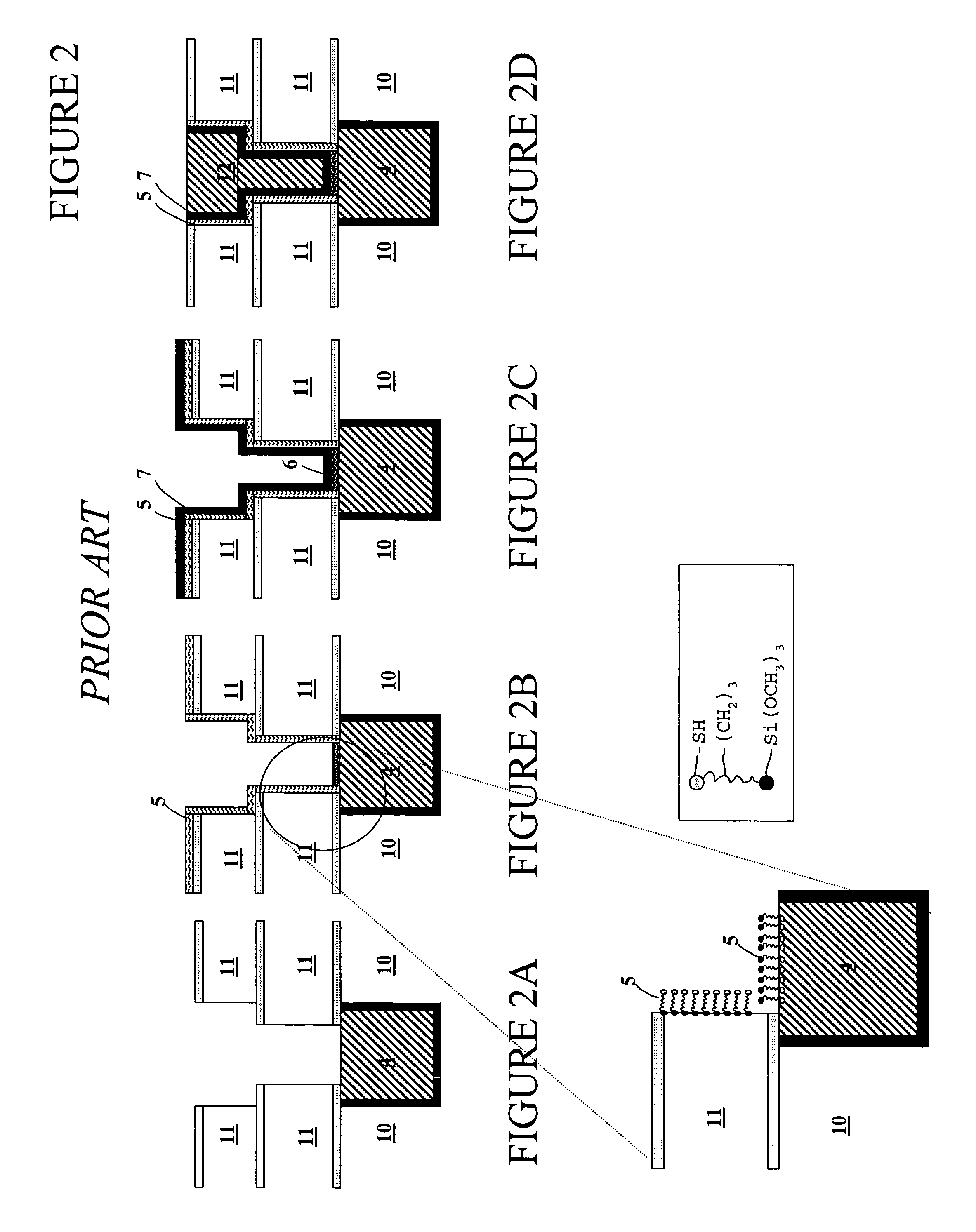

Method for selective deposition of a thin self-assembled monolayer

ActiveUS20060128142A1Material nanotechnologySemiconductor/solid-state device manufacturingSelf-assembled monolayerSelf assemble

A method for selective deposition of self-assembled monolayers to the surface of a substrate for use as a diffusion barrier layer in interconnect structures is provided comprising the steps of depositing a first self-assembled monolayer to said surface, depositing a second self-assembled monolayer to the non-covered parts of said surface and subsequently heating said substrate to remove the first self-assembled monolayer. The method of selective deposition of self-assembled monolayers is applied for the use as diffusion barrier layers in a (dual) damascene structure for integrated circuits.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

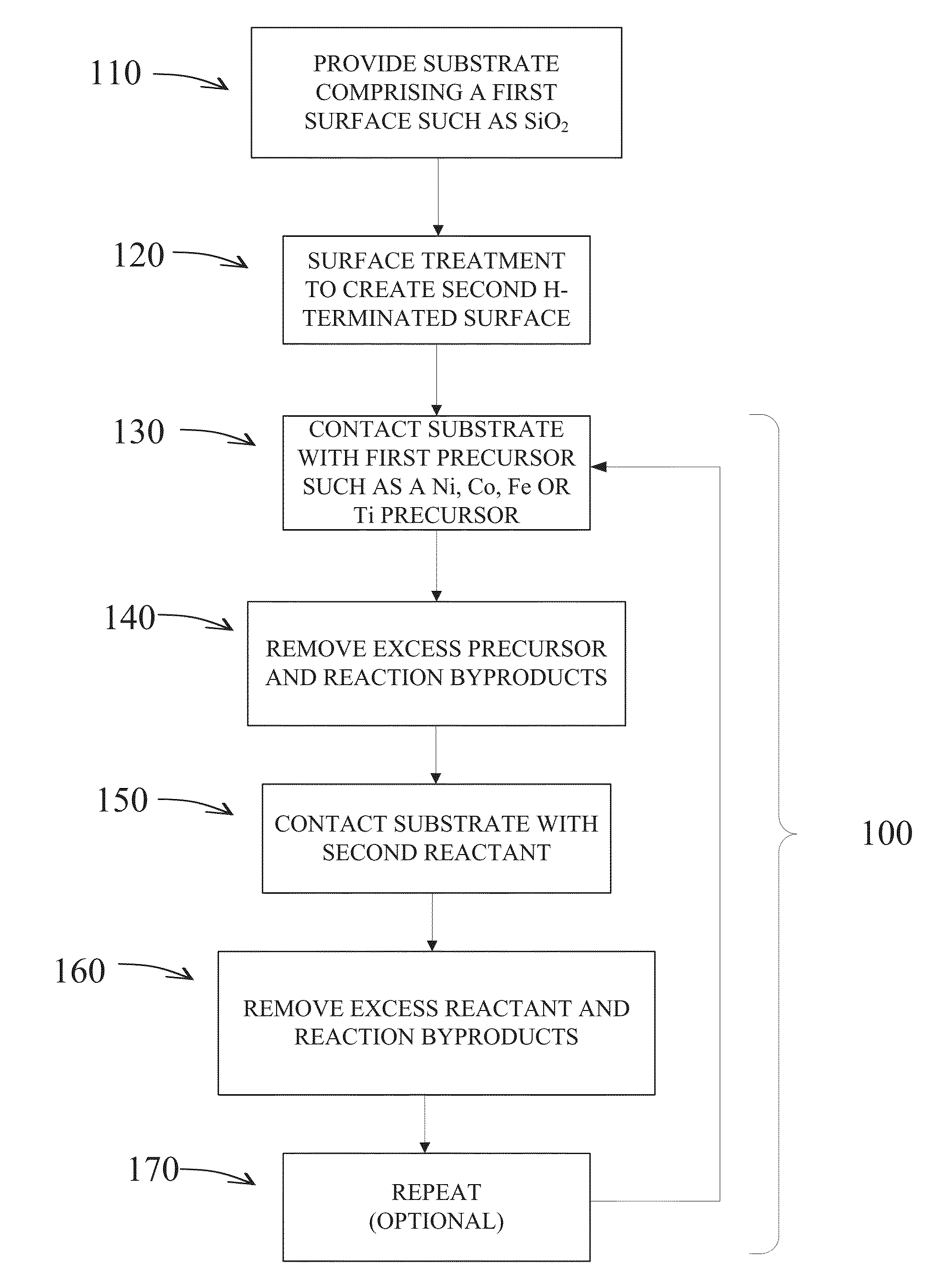

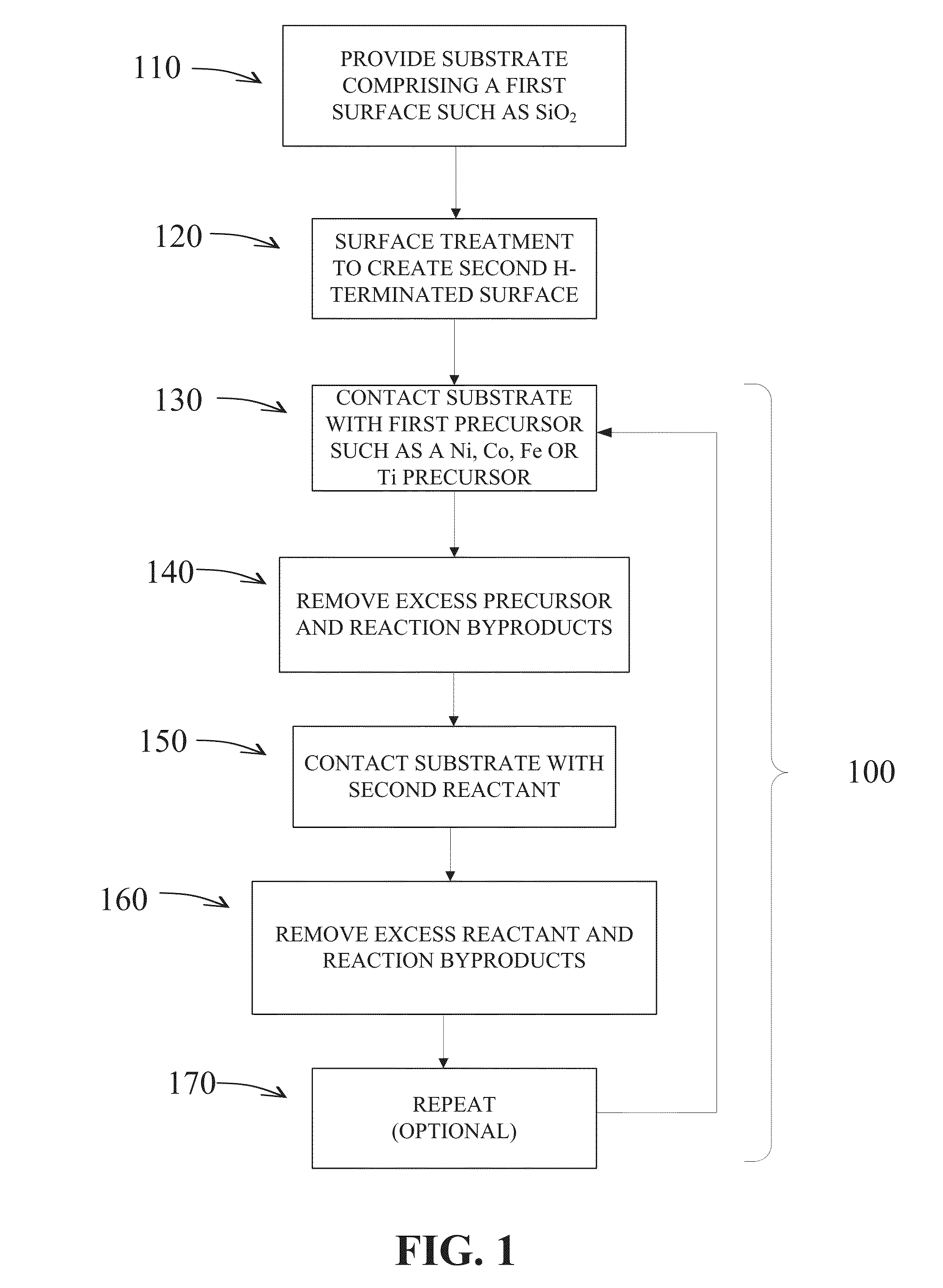

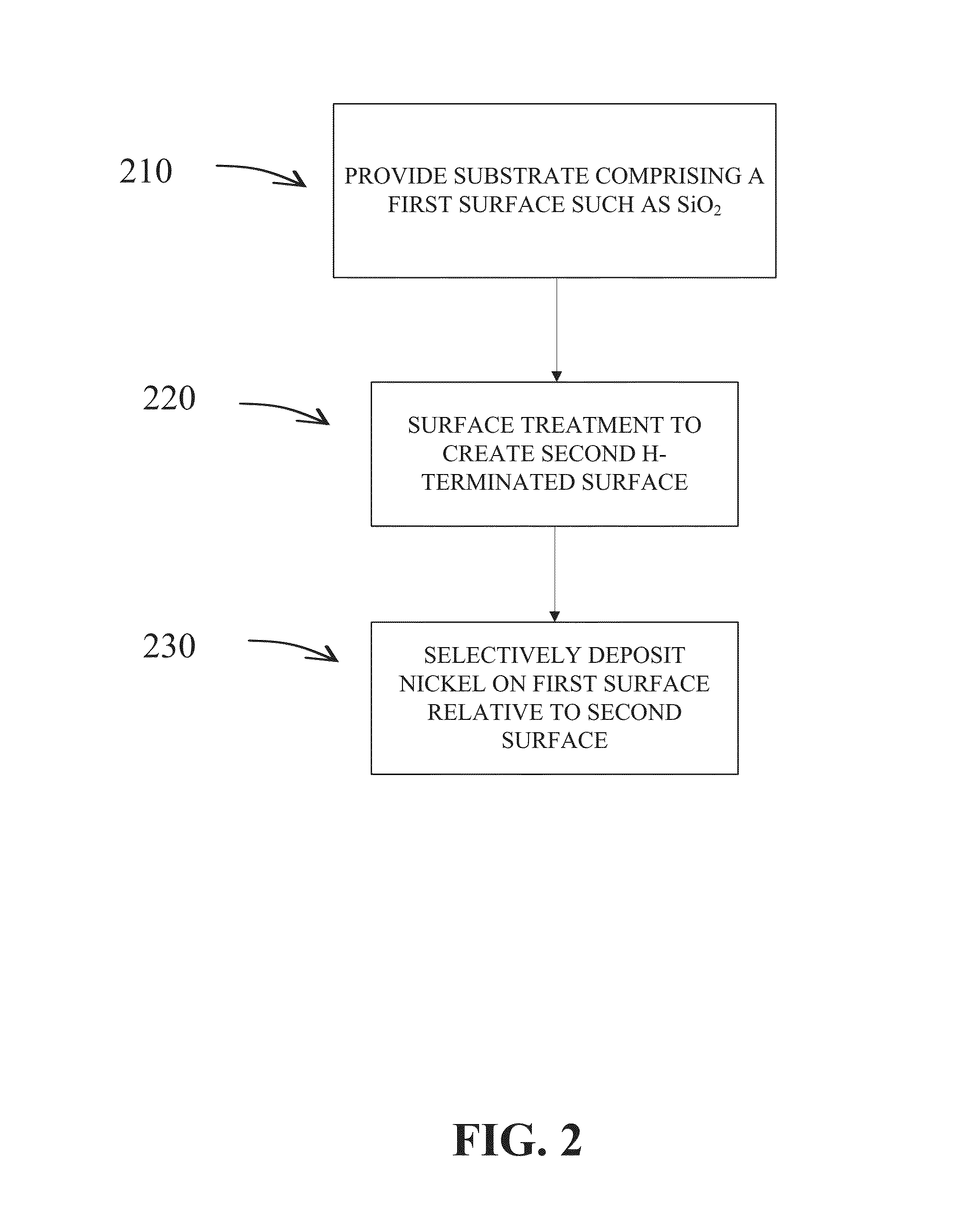

Selective deposition

Methods are provided for selectively depositing a surface of a substrate relative to a second, different surface. An exemplary deposition method can include selectively depositing a material, such as a material comprising nickel, nickel nitride, cobalt, iron, and / or titanium oxide on a first surface, such as a SiO2 surface, relative to a second, different surface, such as a H-terminated surface, of the same substrate. Methods can include treating a surface of the substrate to provide H-terminations prior to deposition.

Owner:ASM IP HLDG BV

Methods of selective deposition of heavily doped epitaxial SiGe

ActiveUS20050079691A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantSelective deposition

The invention generally teaches a method for depositing a silicon film or silicon germanium film on a substrate comprising placing the substrate within a process chamber and heating the substrate surface to a temperature in the range from about 600° C. to about 900° C. while maintaining a pressure in the range from about 0.1 Torr to about 200 Torr. A deposition gas is provided to the process chamber and includes SiH4, an optional germanium source gas, an etchant, a carrier gas and optionally at least one dopant gas. The silicon film or the silicon germanium film is selectively and epitaxially grown on the substrate. One embodiment teaches a method for depositing a silicon-containing film with an inert gas as the carrier gas. Methods may include the fabrication of electronic devices utilizing selective silicon germanium epitaxial films.

Owner:APPLIED MATERIALS INC

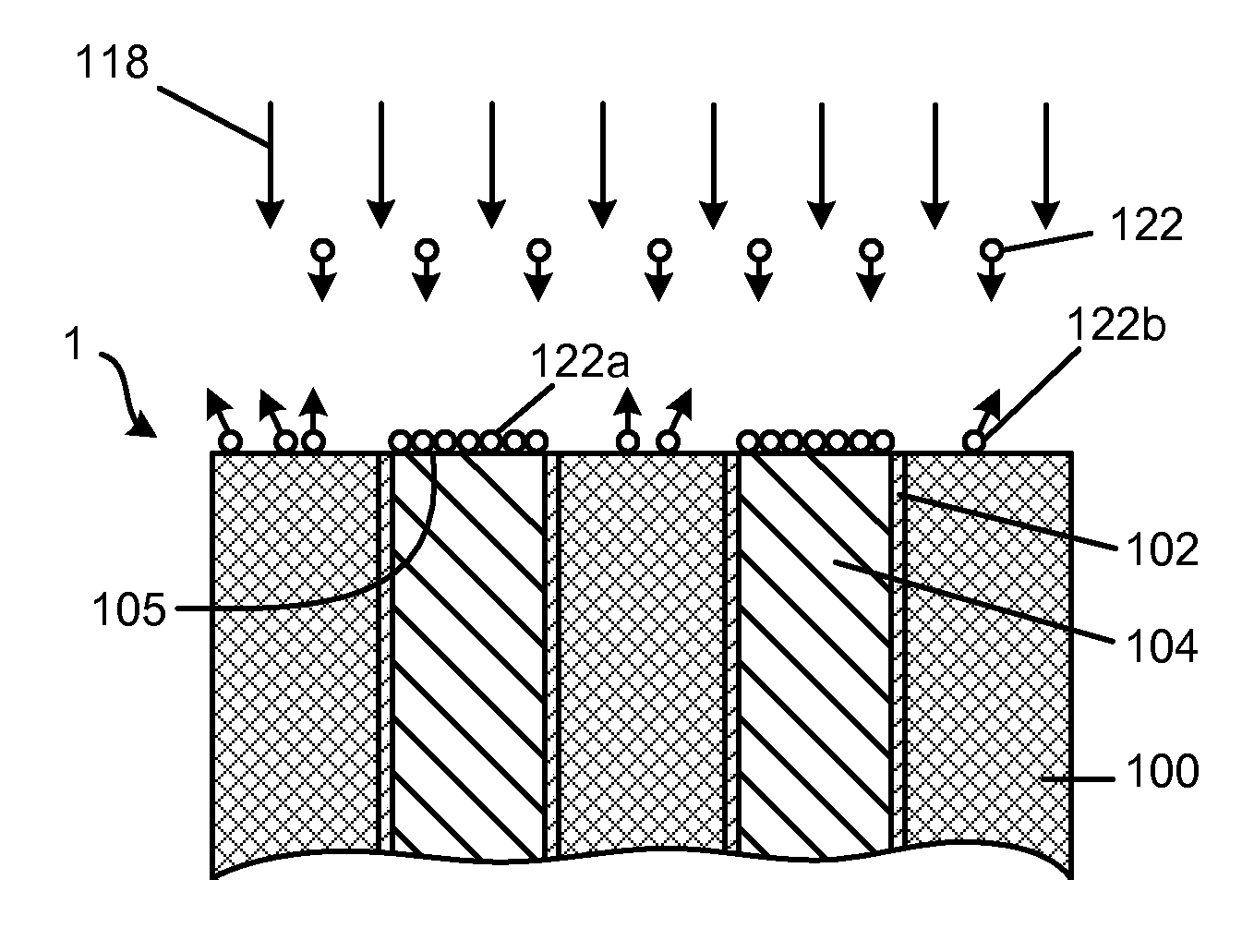

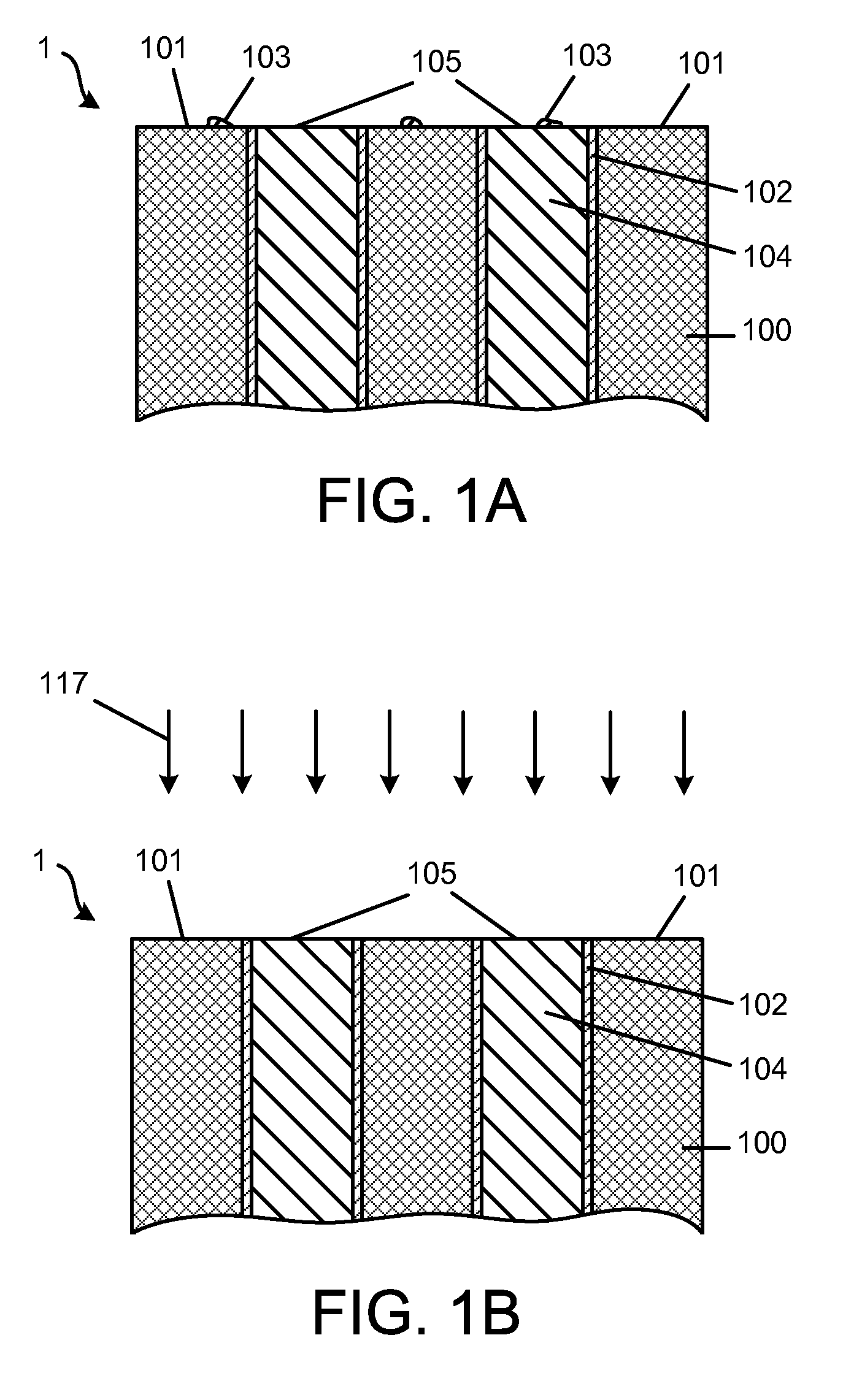

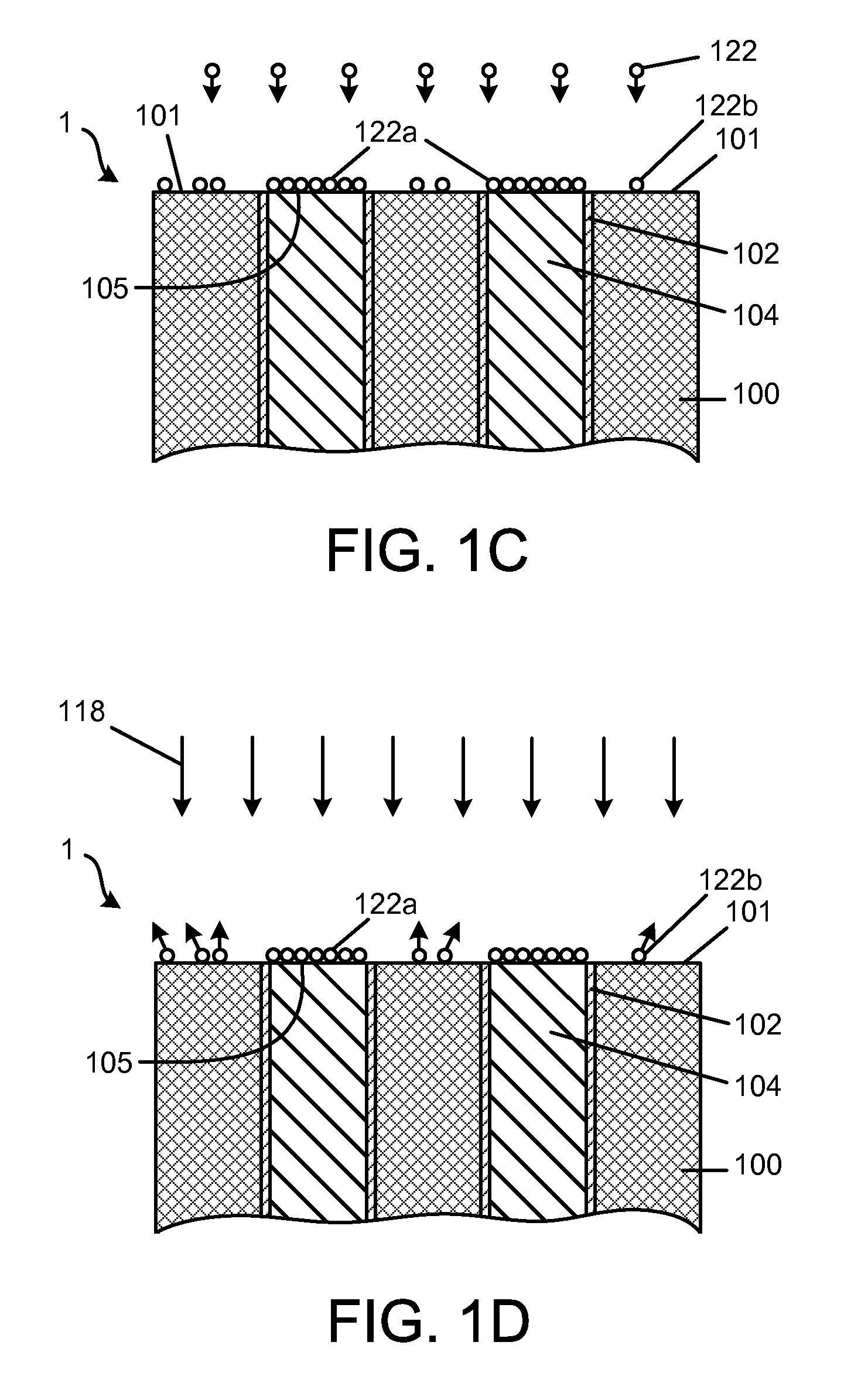

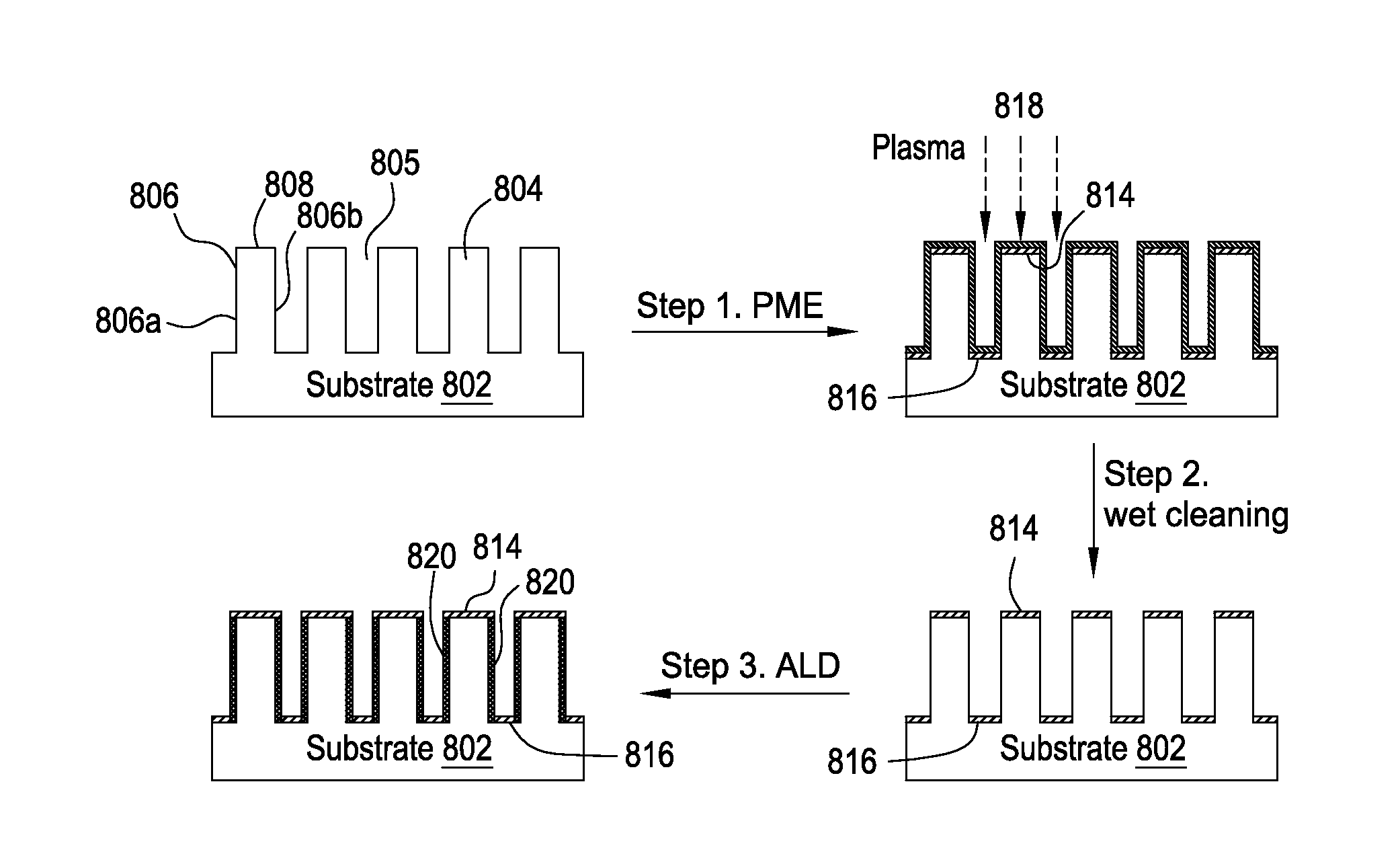

Methods of selectively forming a material using parylene coating

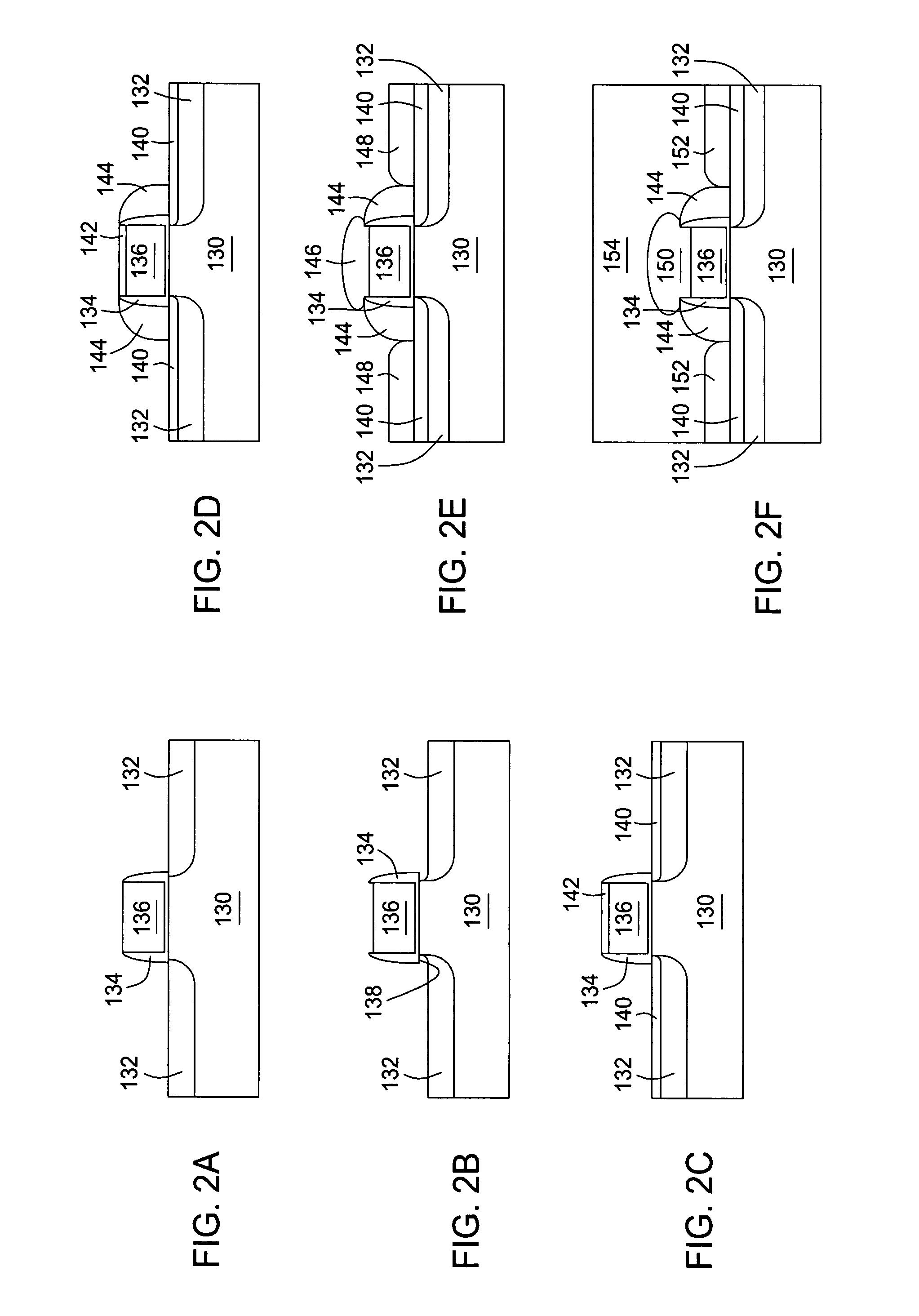

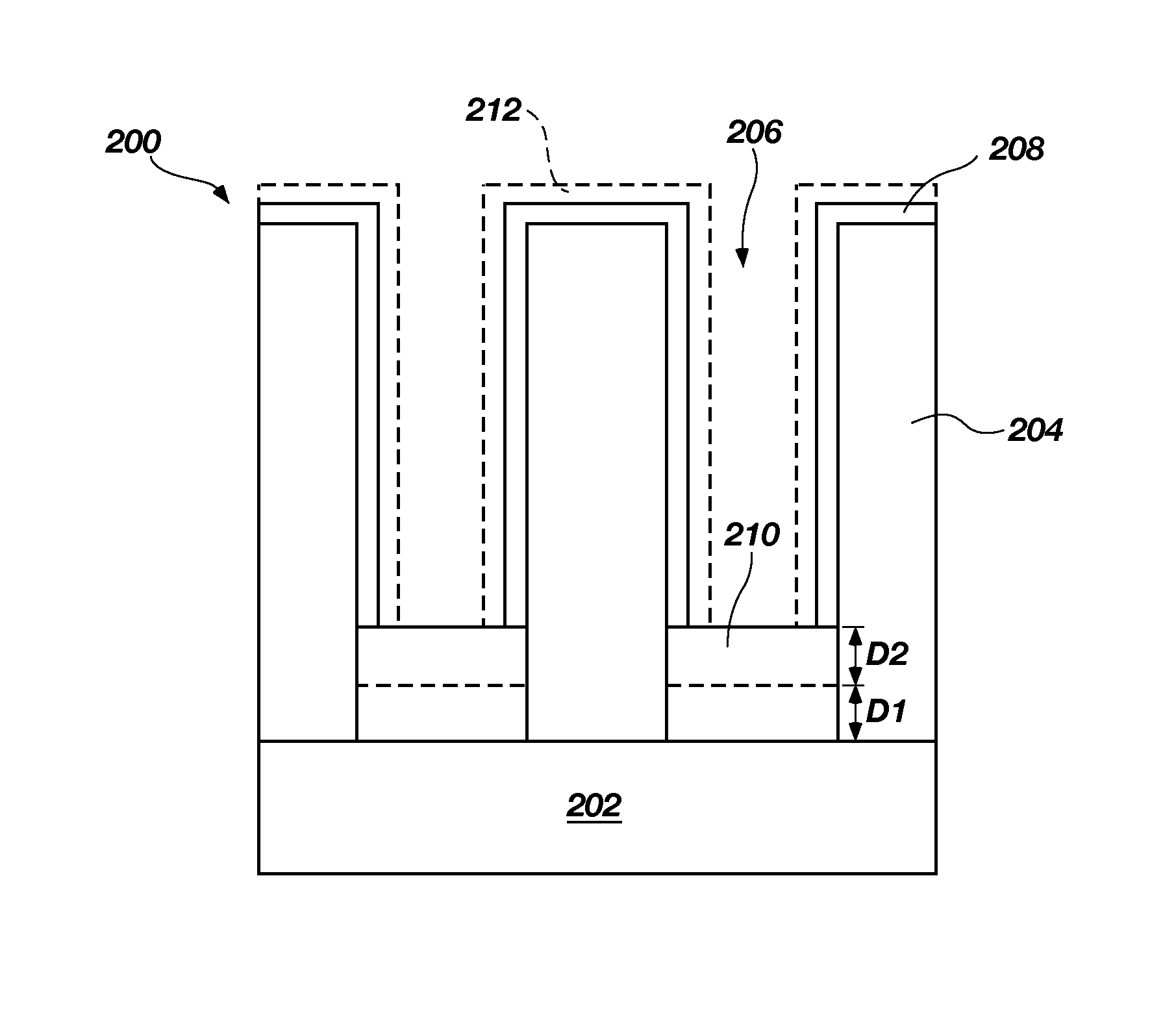

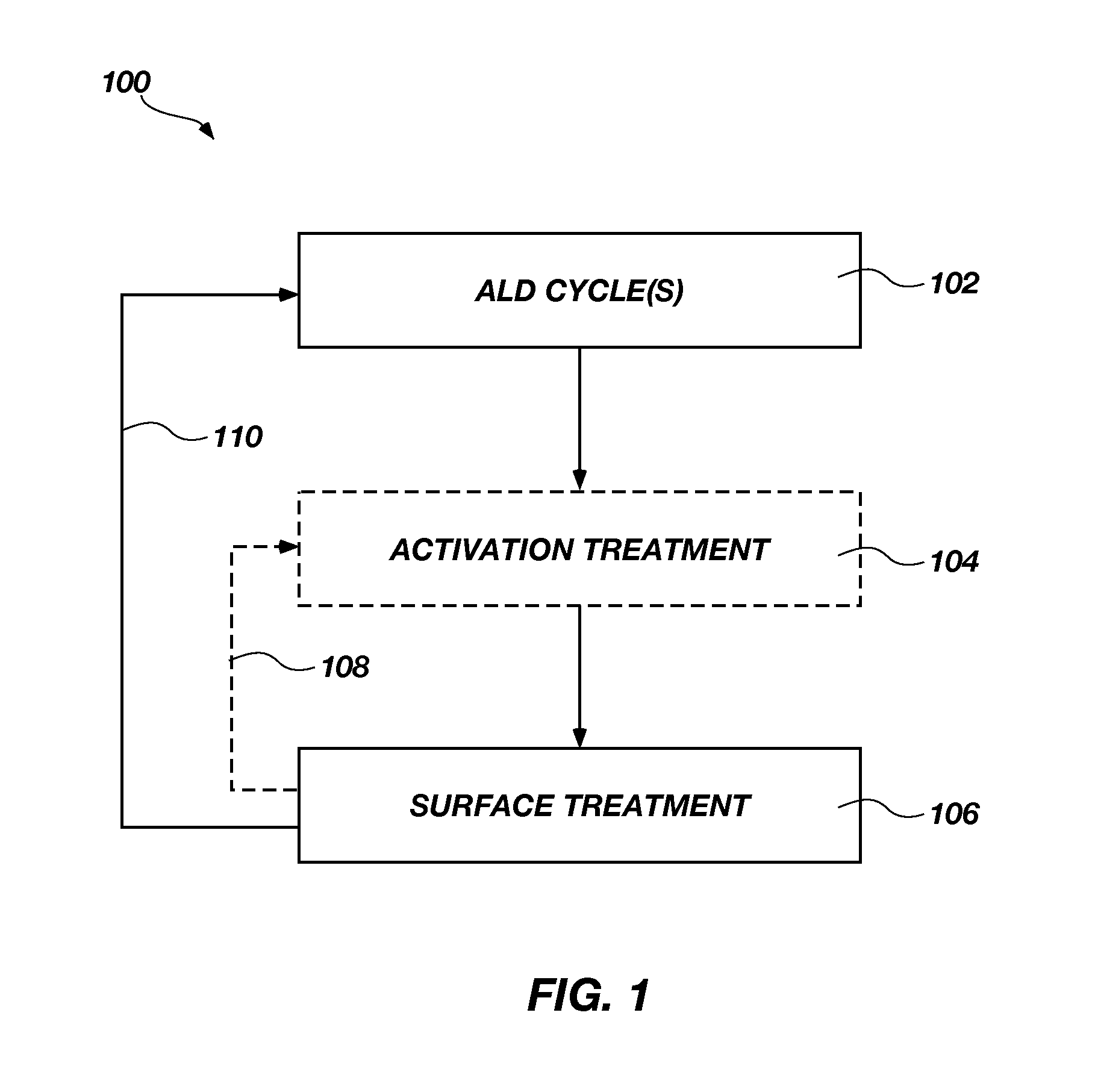

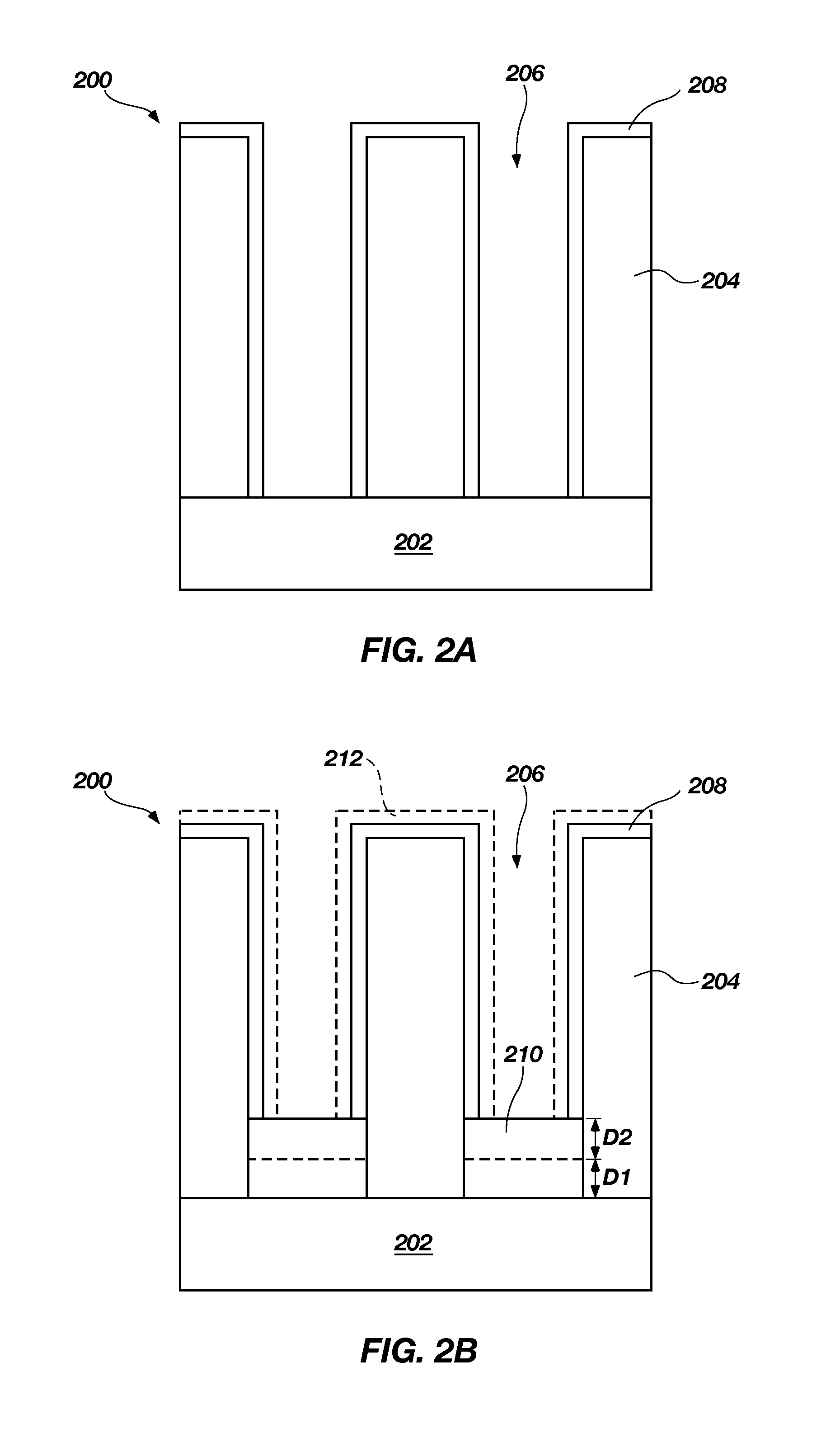

ActiveUS8945305B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor structureSelective deposition

Methods for depositing a material, such as a metal or a transition metal oxide, using an ALD (atomic layer deposition) process and resulting structures are disclosed. Such methods include treating a surface of a semiconductor structure periodically throughout the ALD process to regenerate a blocking material or to coat a blocking material that enables selective deposition of the material on a surface of a substrate. The surface treatment may reactivate a surface of the substrate toward the blocking material, may restore the blocking material after degradation occurs during the ALD process, and / or may coat the blocking material to prevent further degradation during the ALD process. For example, the surface treatment may be applied after performing one or more ALD cycles. Accordingly, the presently disclosed methods enable in situ restoration of blocking materials in ALD process that are generally incompatible with the blocking material and also enables selective deposition in recessed structures.

Owner:MICRON TECH INC

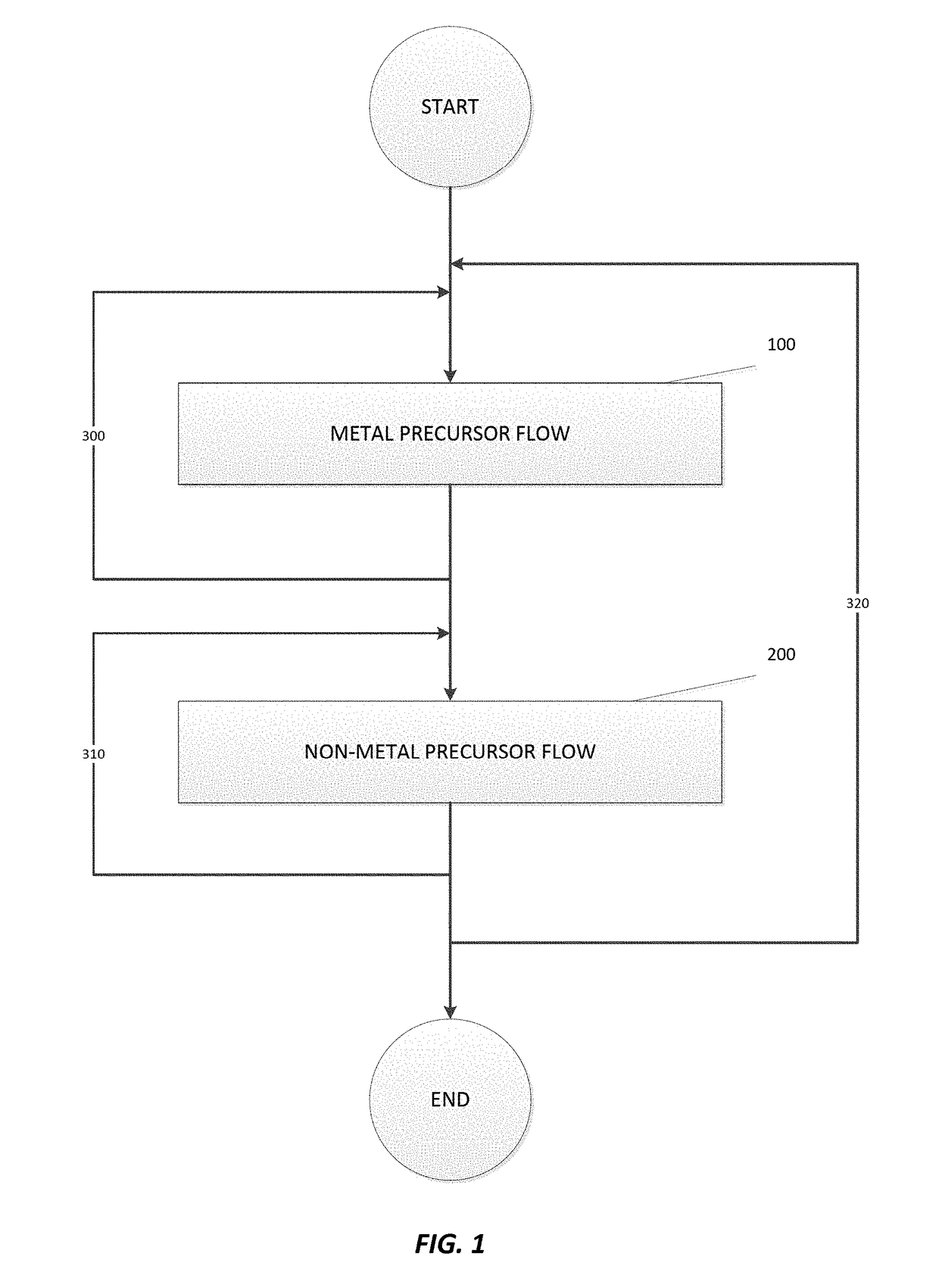

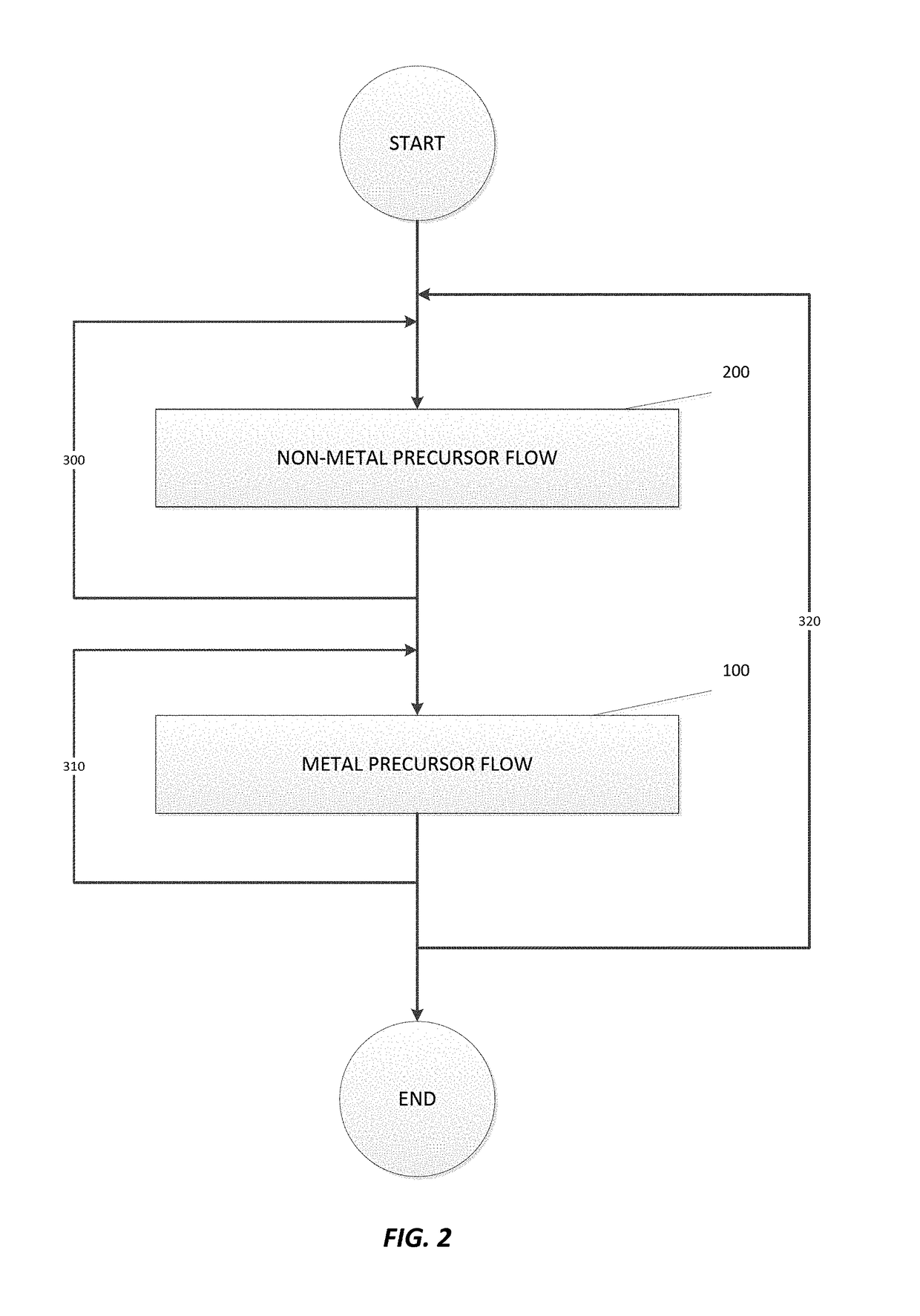

Selective deposition of tungsten

ActiveUS20180025939A1Semiconductor/solid-state device detailsSolid-state devicesHydrogenSelective deposition

A method for selectively depositing a metal film onto a substrate is disclosed. In particular, the method comprising flowing a metal precursor onto the substrate and flowing a non-metal precursor onto the substrate, while contacting the non-metal precursor with a hot wire. Specifically, a reaction between a tungsten precursor and a hydrogen precursor selectively forms a tungsten film, where the hydrogen precursor is excited by a tungsten hot wire.

Owner:ASM IP HLDG BV

Selective film deposition method to form air gaps

A method for depositing a film to form an air gap within a semiconductor device is disclosed. An exemplary method comprises pulsing a metal halide precursor onto the substrate and pulsing an oxygen precursor onto a selective deposition surface. The method can be used to form an air gap to, for example, reduce a parasitic resistance of the semiconductor device.

Owner:ASM IP HLDG BV

Method of selectively depositing a thin film material at a semiconductor interface

InactiveUS20070108404A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice formMetal silicide

Embodiments of the invention provide processes to form a high quality contact level connection to devices formed on a substrate. In one embodiment, a method for depositing a material on a substrate is provided which includes exposing the substrate to a buffered oxide etch solution to form a silicon hydride layer during a pretreatment process, depositing a metal silicide layer on the substrate, and depositing a first metal layer (e.g., tungsten) on the metal silicide layer. The buffered oxide etch solution may contain hydrogen fluoride and an alkanolamine compound, such as ethanolamine diethanolamine, or triethanolamine. The metal silicide layer may contain cobalt, nickel, or tungsten and may be deposited by an electroless deposition process. In one example, the substrate is exposed to an electroless deposition solution containing a solvent and a complexed metal compound.

Owner:APPLIED MATERIALS INC

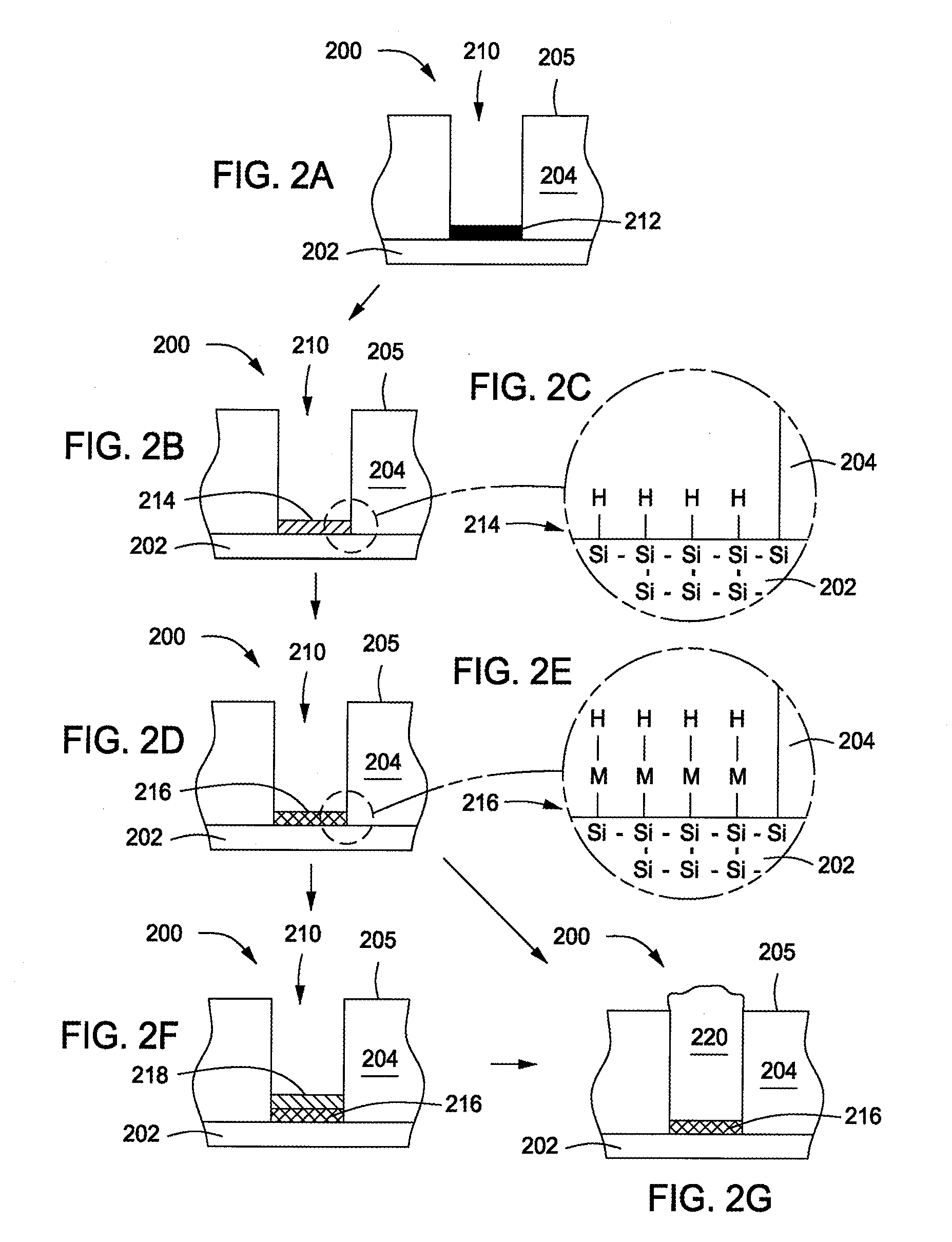

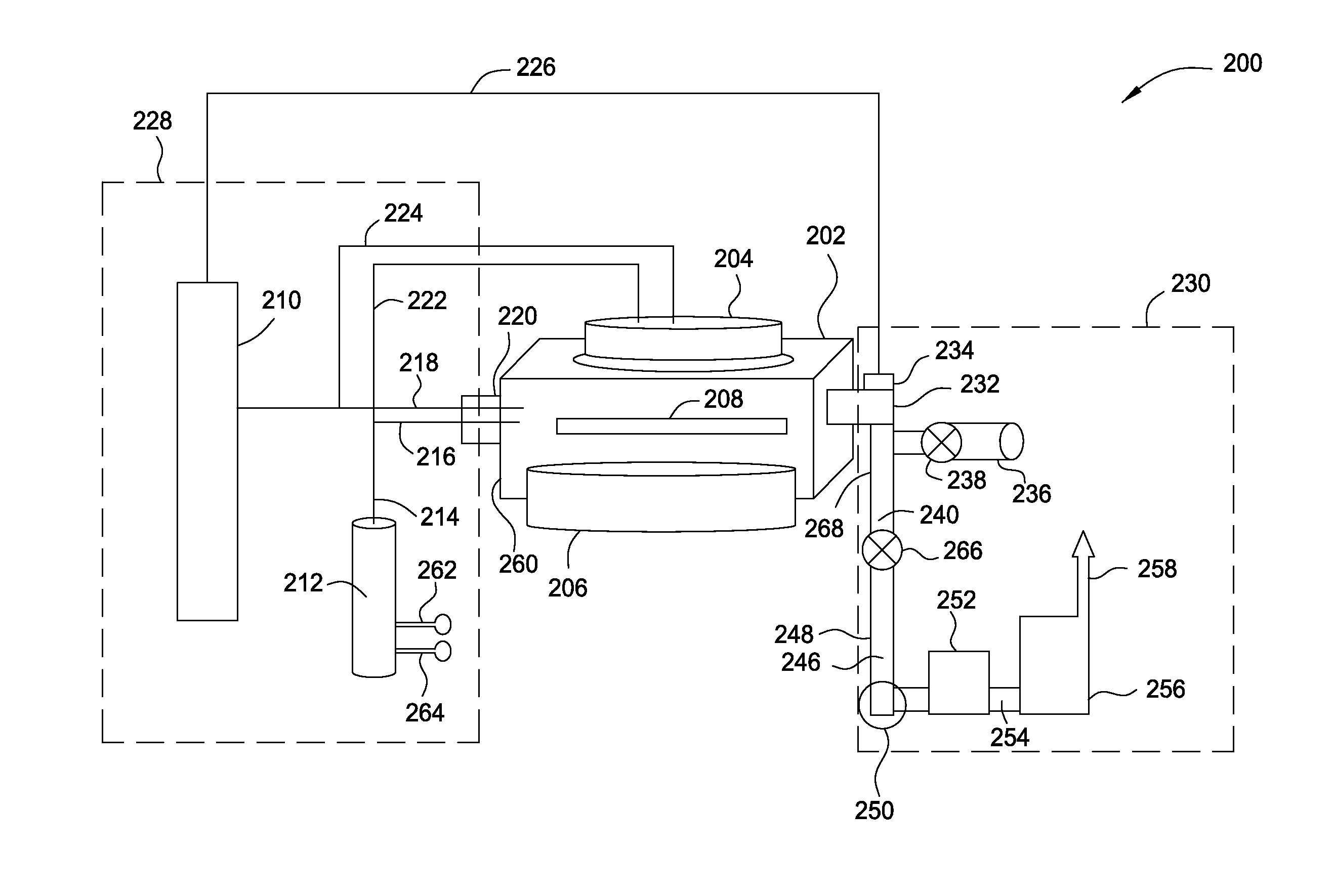

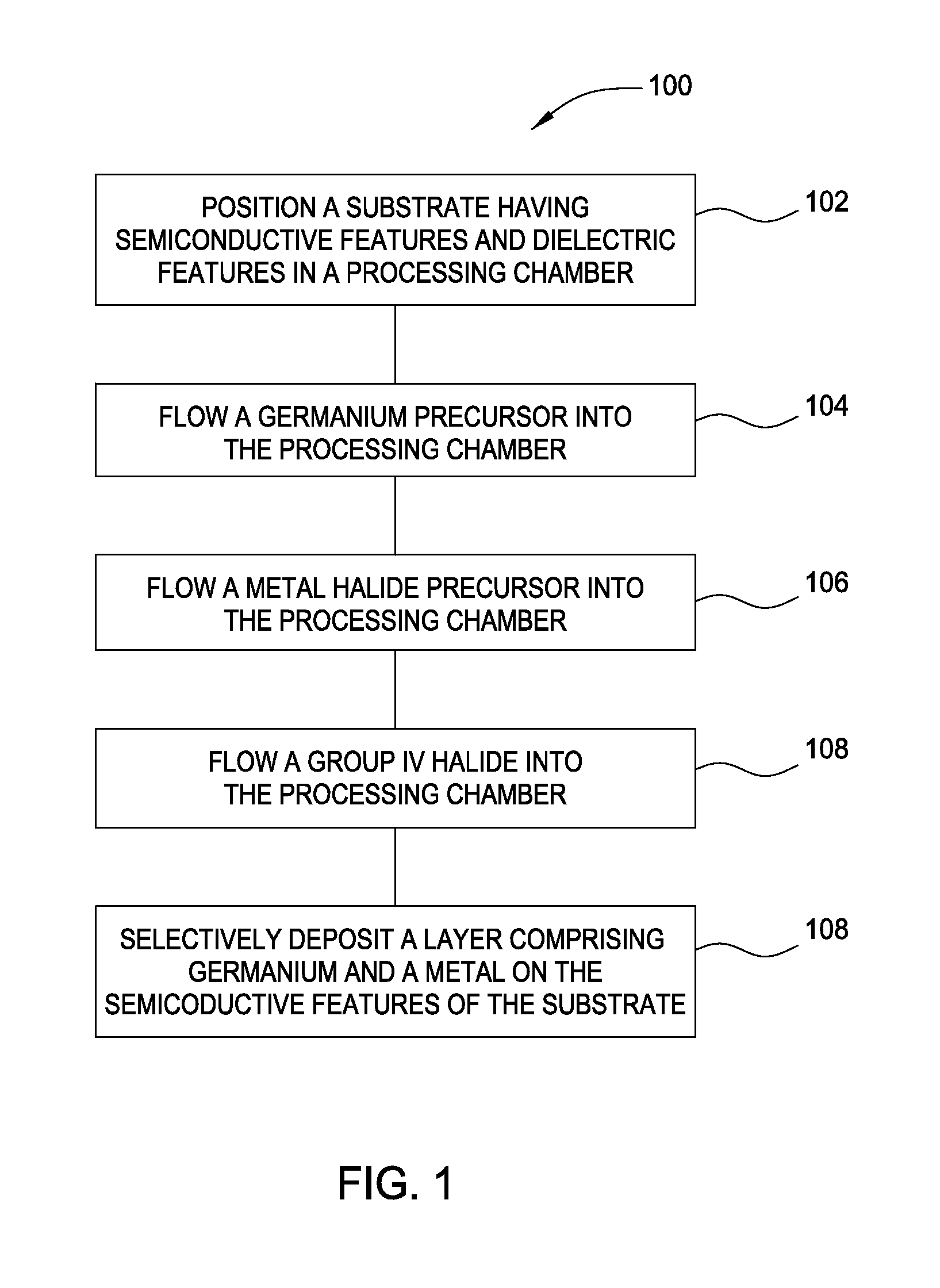

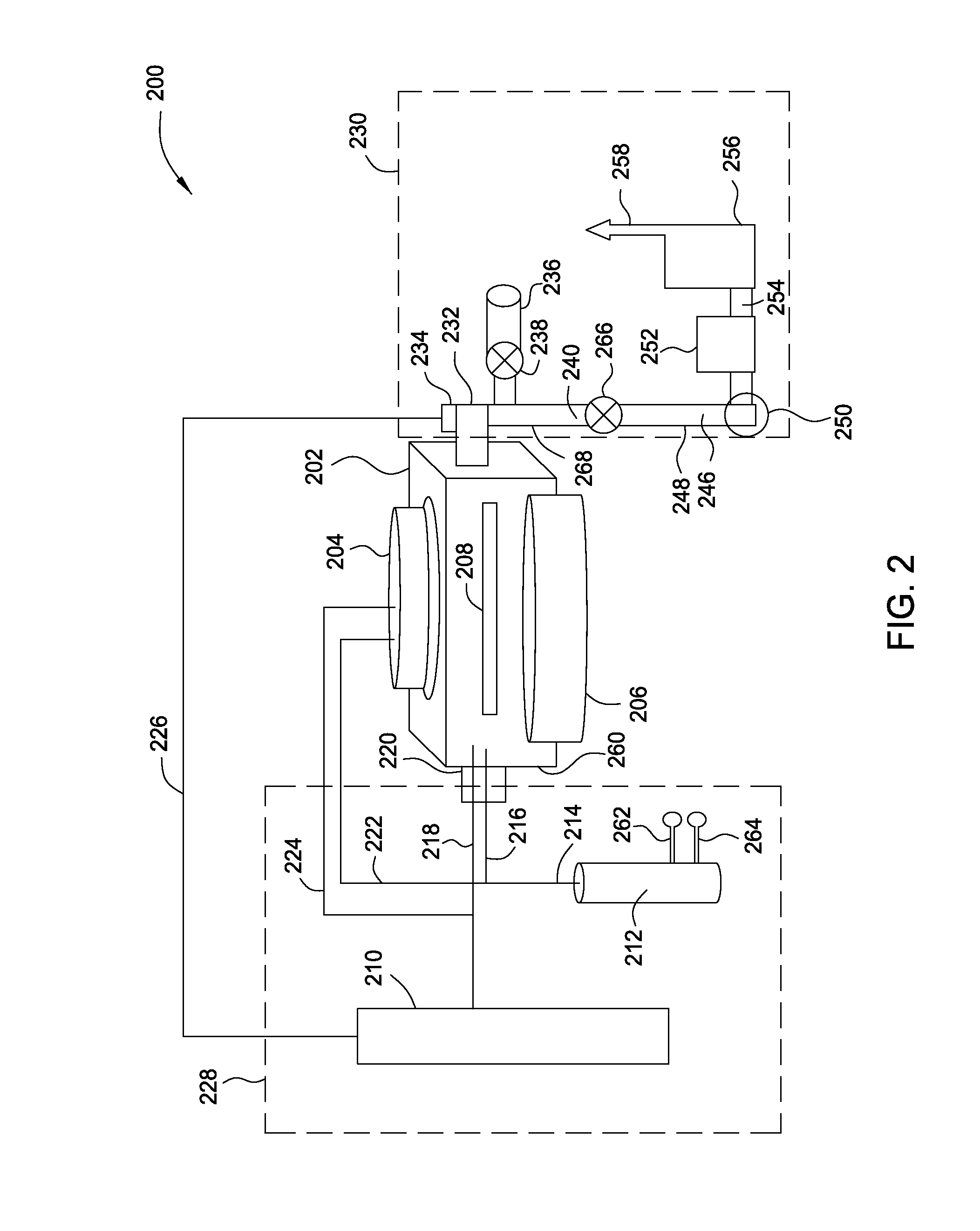

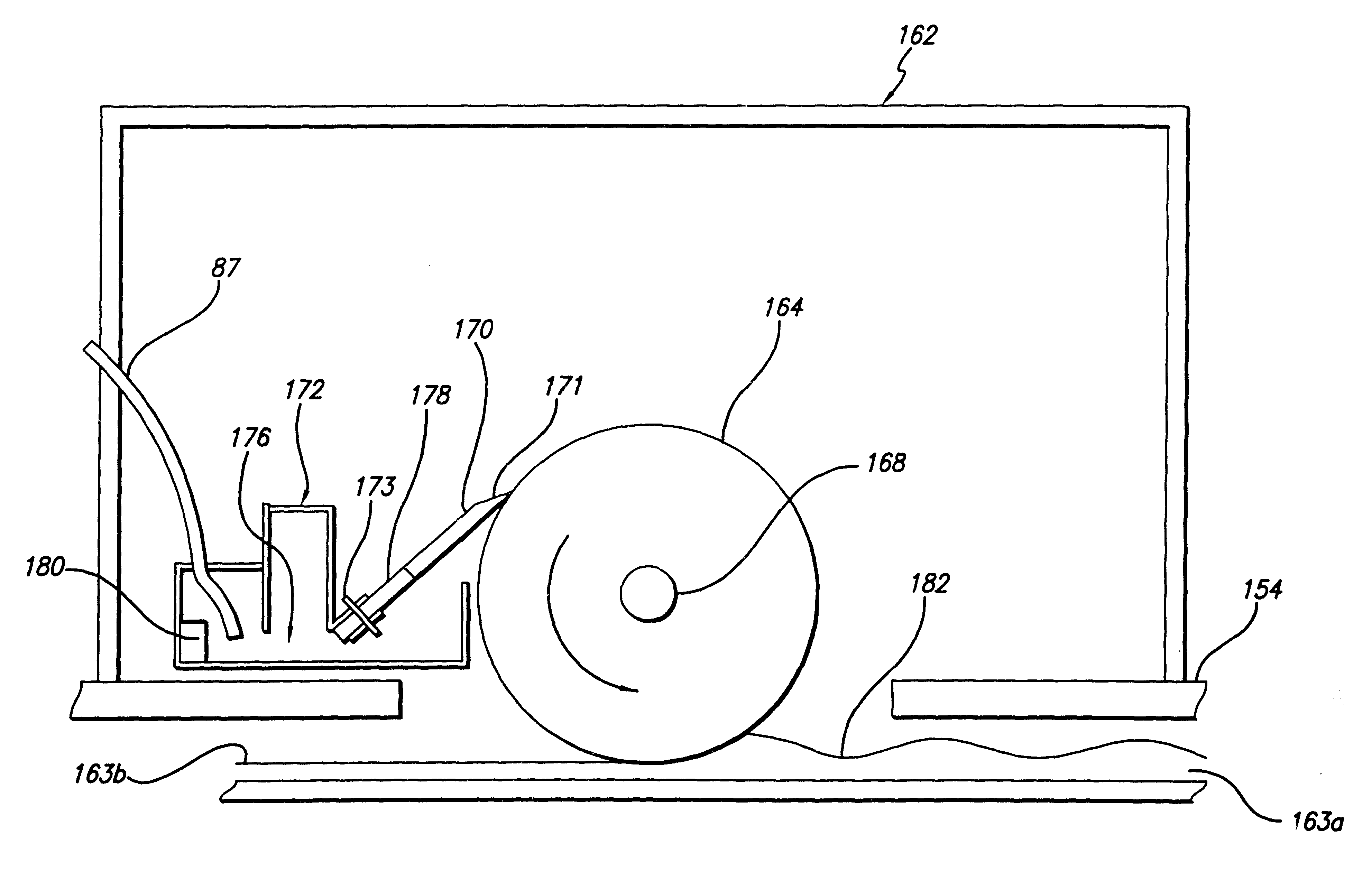

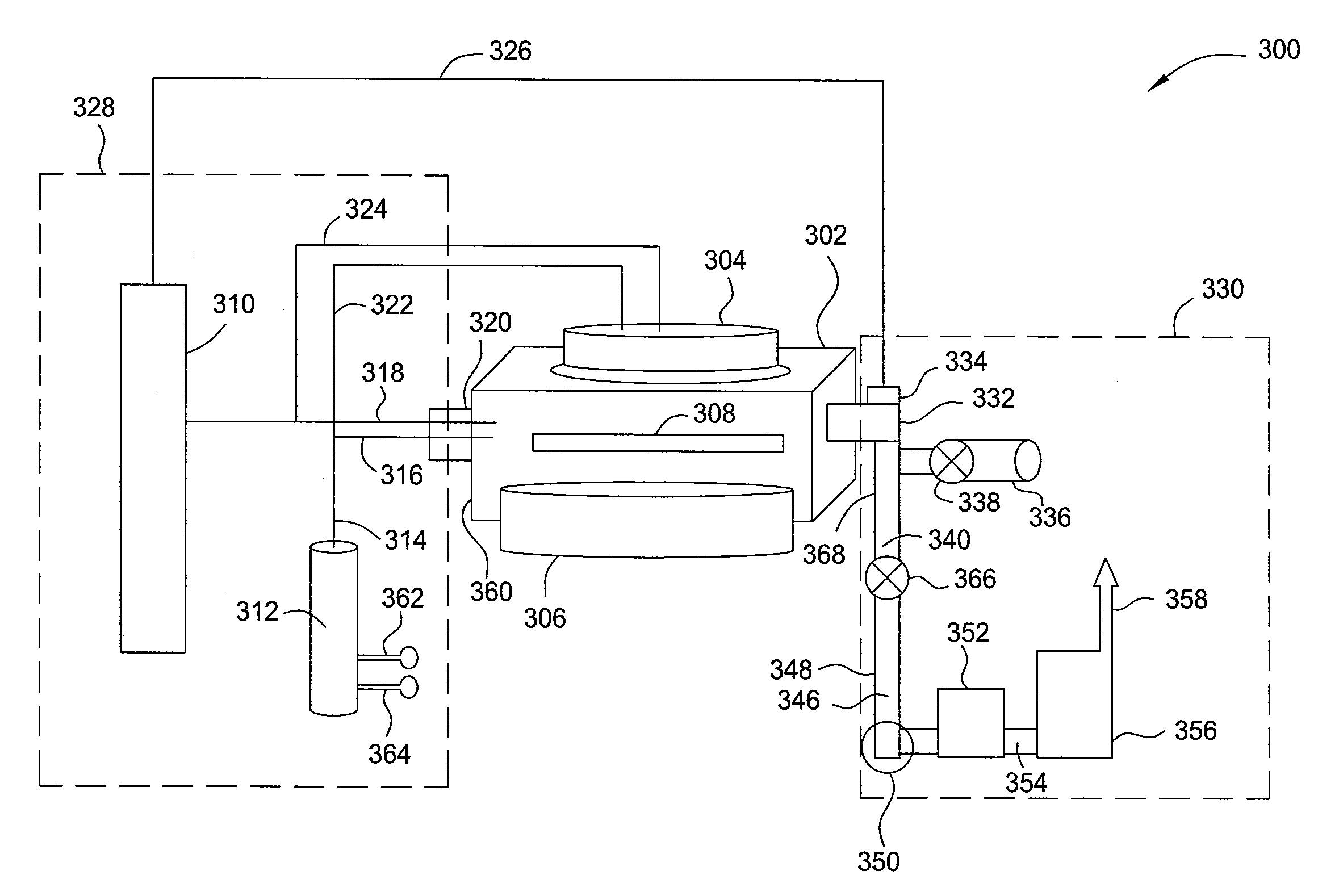

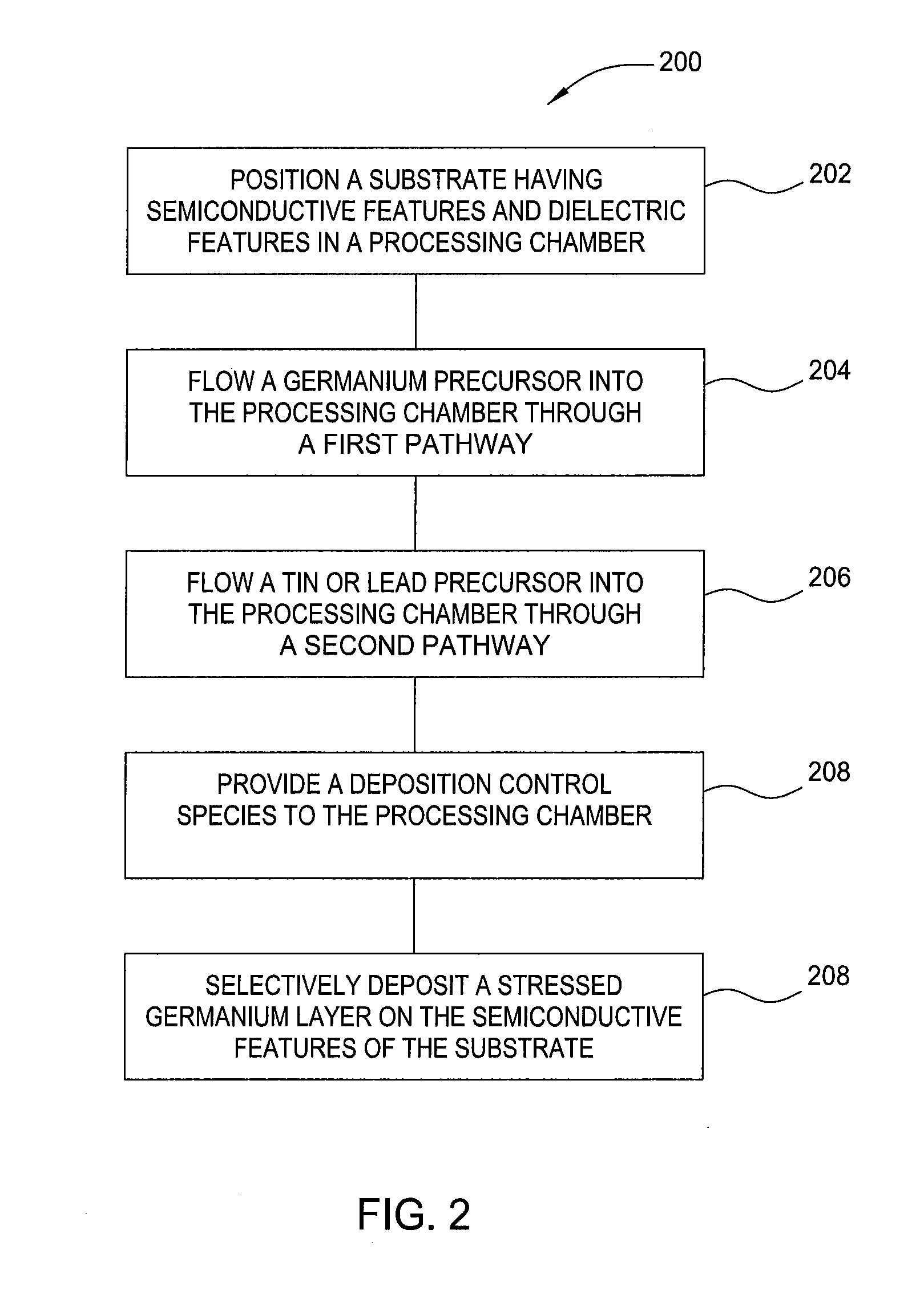

Method and apparatus for germanium tin alloy formation by thermal CVD

InactiveUS20130280891A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSelective depositionLiquid metal

A method and apparatus for forming semiconductive semiconductor-metal alloy layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy, optionally including silicon, is formed on the substrate. The metal precursor is typically a metal halide, which may be provided by evaporating a liquid metal halide, subliming a solid metal halide, or by contacting a pure metal with a halogen gas. A group IV halide deposition control agent is used to provide selective deposition on semiconductive regions of the substrate relative to dielectric regions. The semiconductive semiconductor-metal alloy layers may be doped, for example with boron, phosphorus, and / or arsenic. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

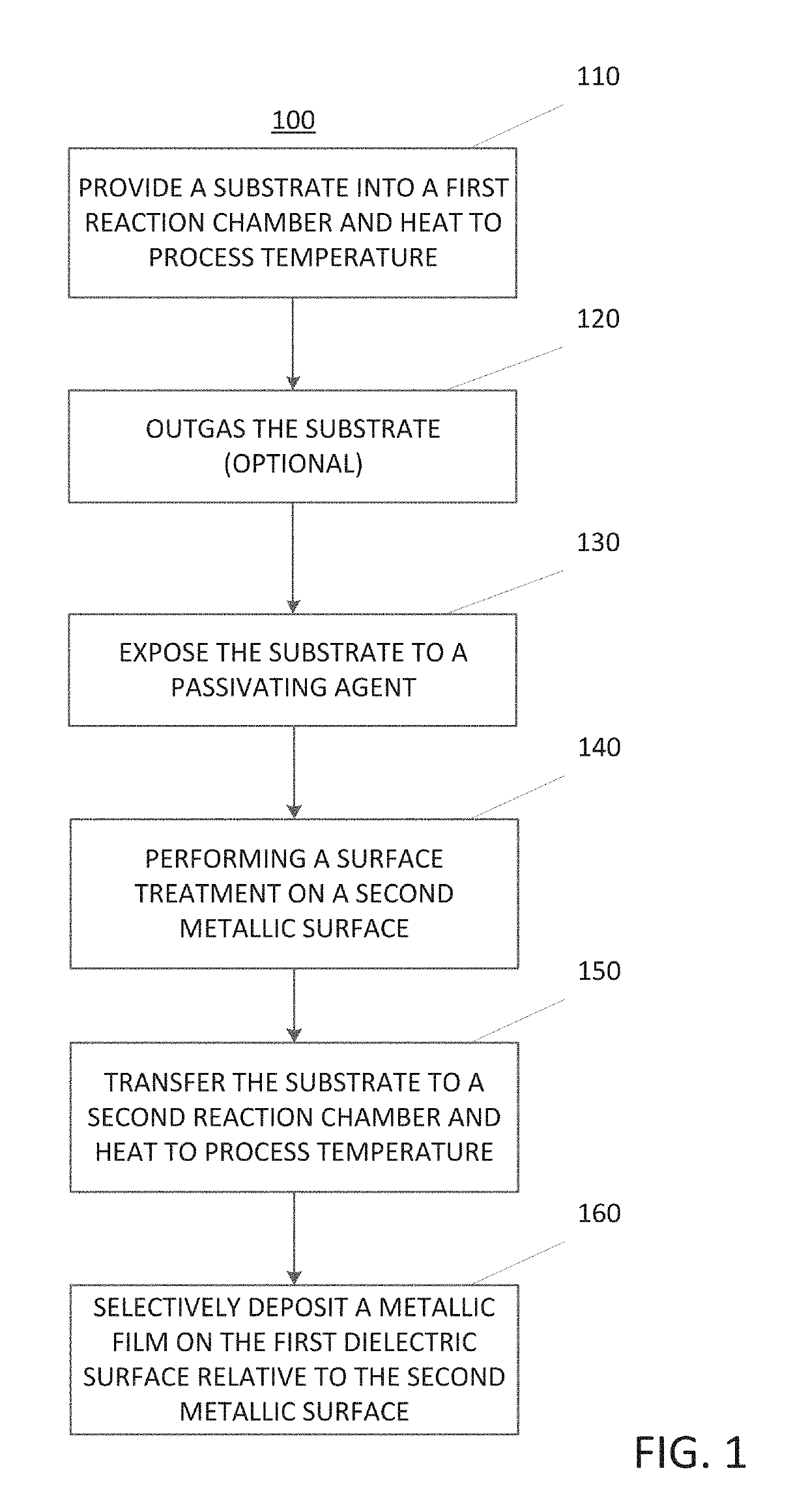

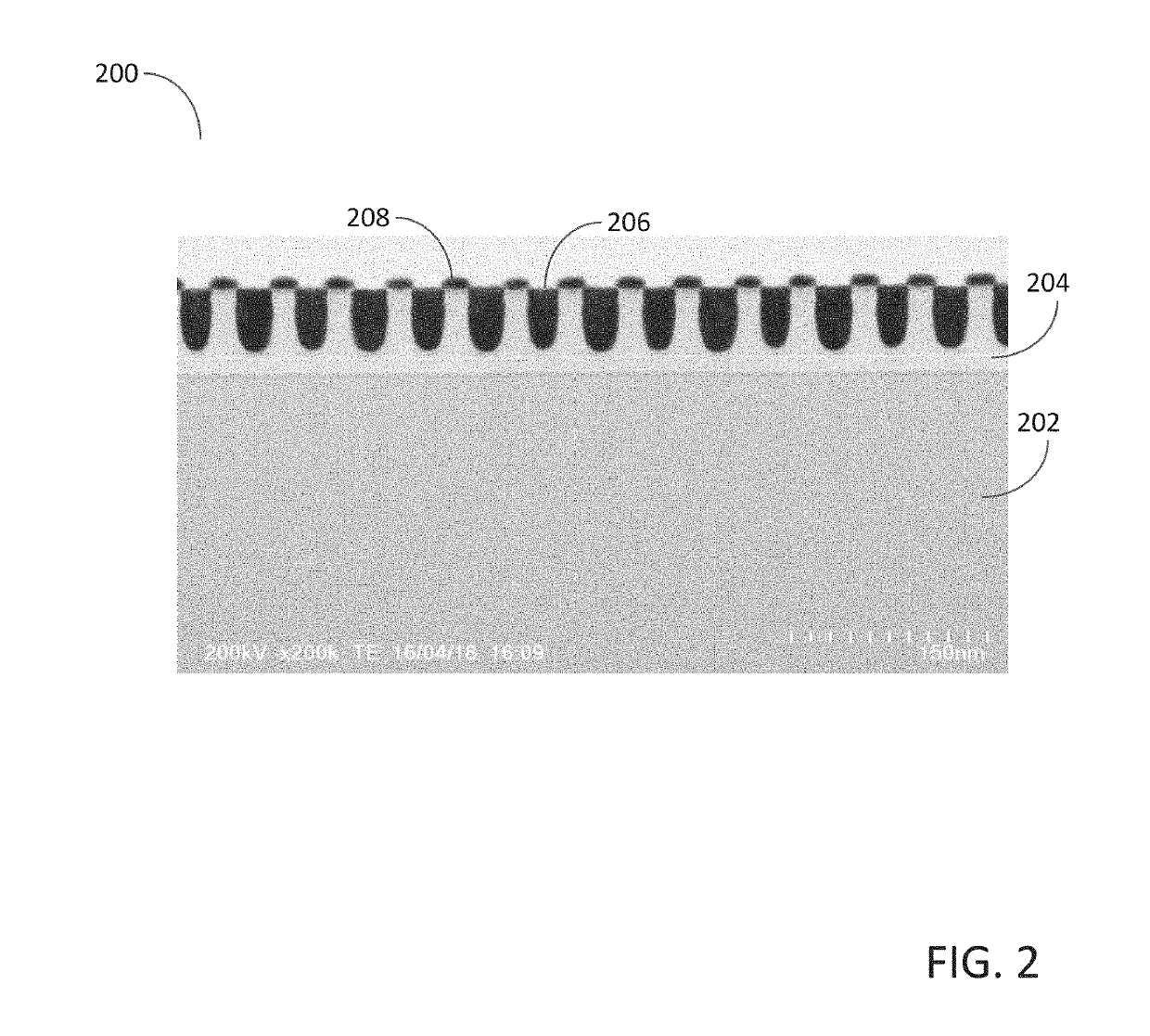

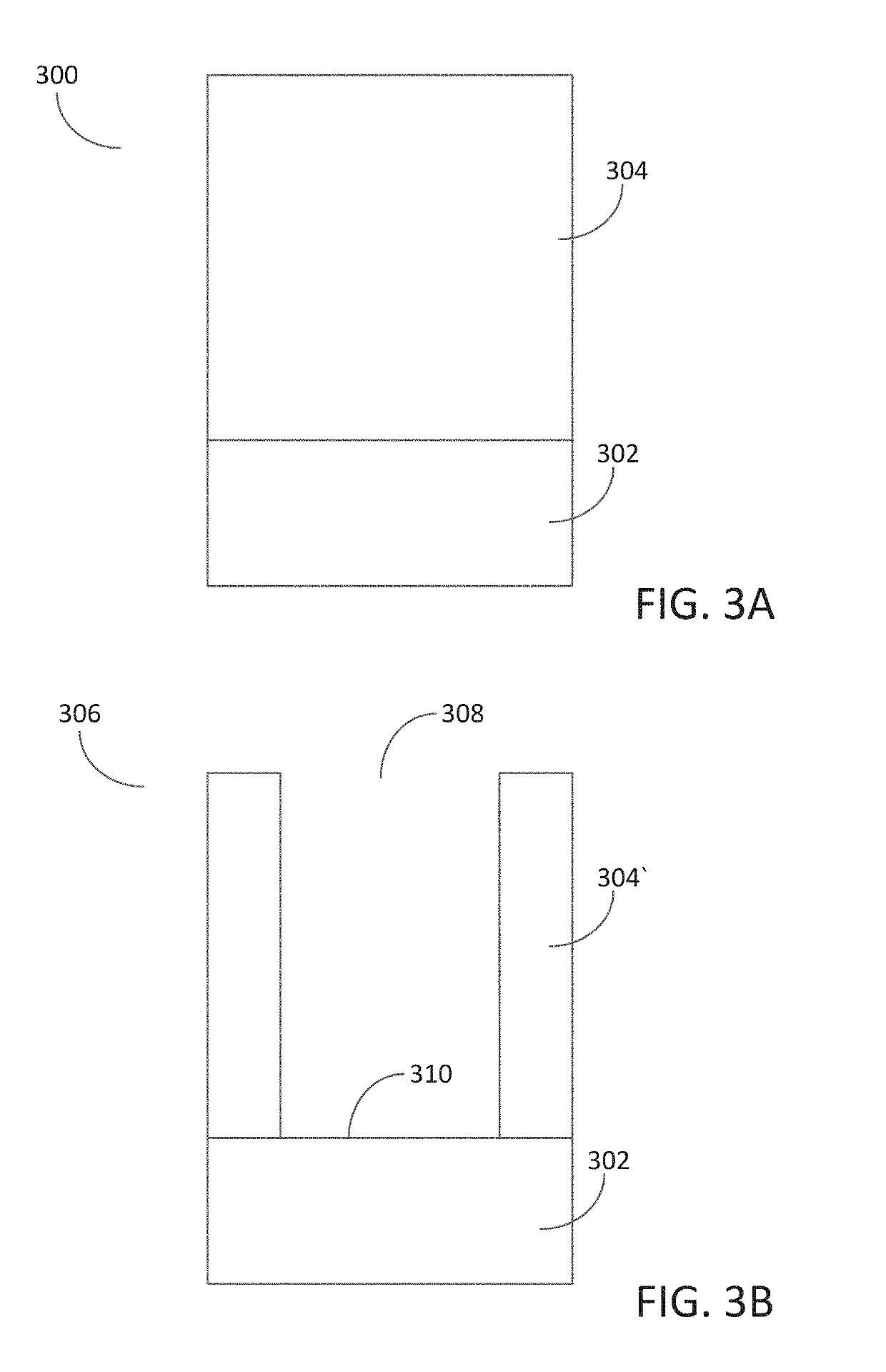

Method for selectively depositing a metallic film on a substrate

ActiveUS20190109009A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric surfaceSelective deposition

A method for selectively depositing a metallic film on a substrate comprising a first dielectric surface and a second metallic surface is disclosed. The method may include, exposing the substrate to a passivating agent, performing a surface treatment on the second metallic surface, and selectively depositing the metallic film on the first dielectric surface relative to the second metallic surface. Semiconductor device structures including a metallic film selectively deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

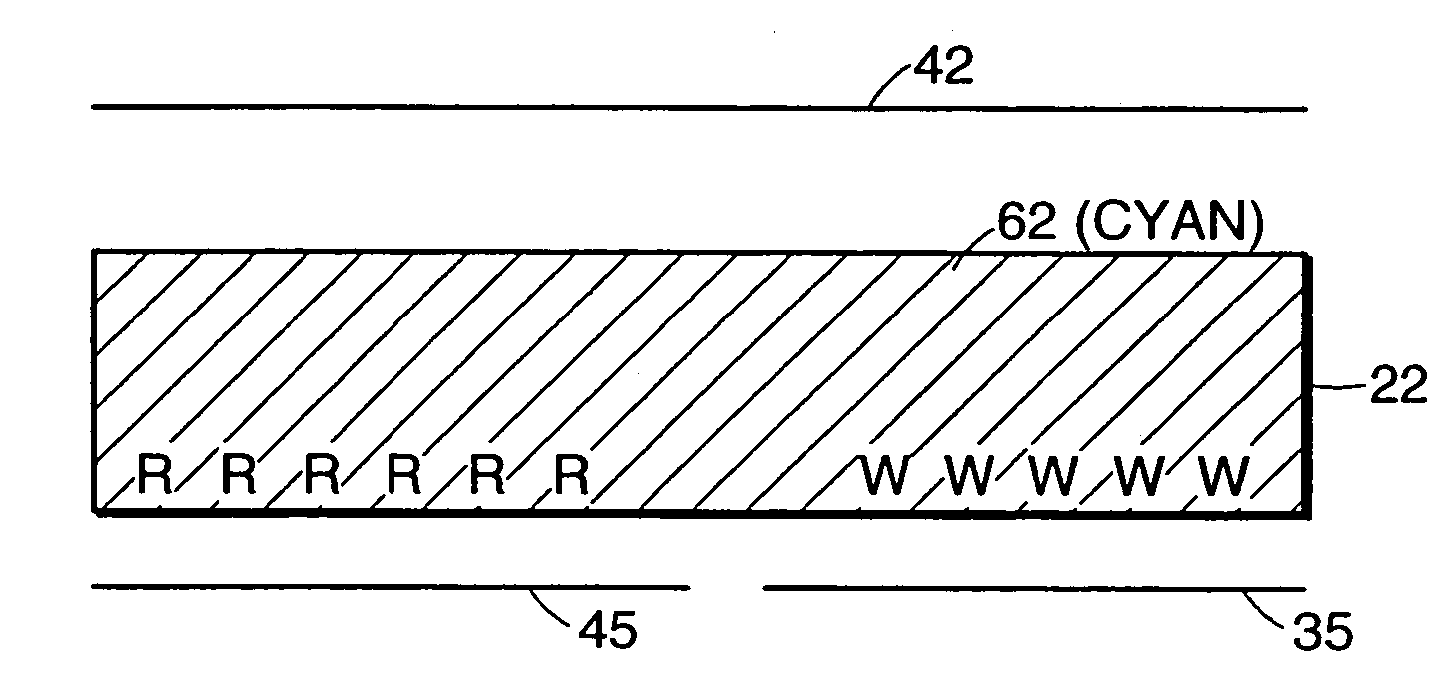

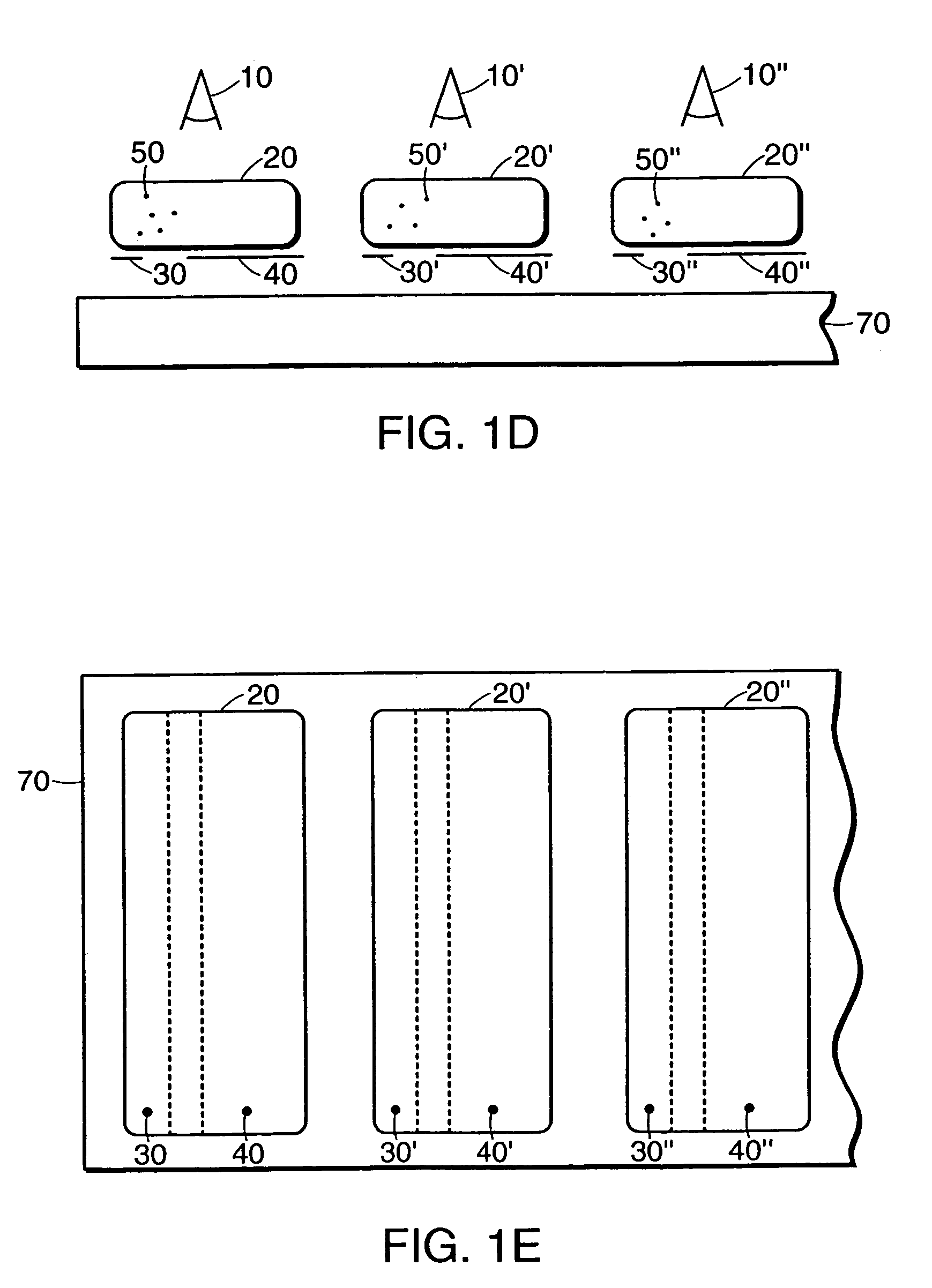

Methods for achieving improved color in microencapsulated electrophoretic devices

InactiveUS7667684B2Efficiently cheaply manufactureCheap to makeStatic indicating devicesSolid-state devicesScreen printingComputer graphics (images)

A method for manufacturing a full color, reflective display includes the steps of depositing a first plurality of electrophoretic display elements in substantial registration with a first electrode and a second plurality of electrophoretic display elements in substantial registration with a second electrode. The electrophoretic display elements include a capsule containing a species of particles dispersed in a suspending fluid. The selective deposition of the display elements can be achieved by ink-jet printing methods, screen printing methods or other printing methods. In some embodiments the electrodes are printed onto the substrate before selective deposition of the display elements, while in other embodiments the substrate is provided having the electrodes already disposed on it. In still other embodiments, the sequence of printing of electrodes and electrophoretic display elements can be varied.

Owner:E INK CORPORATION

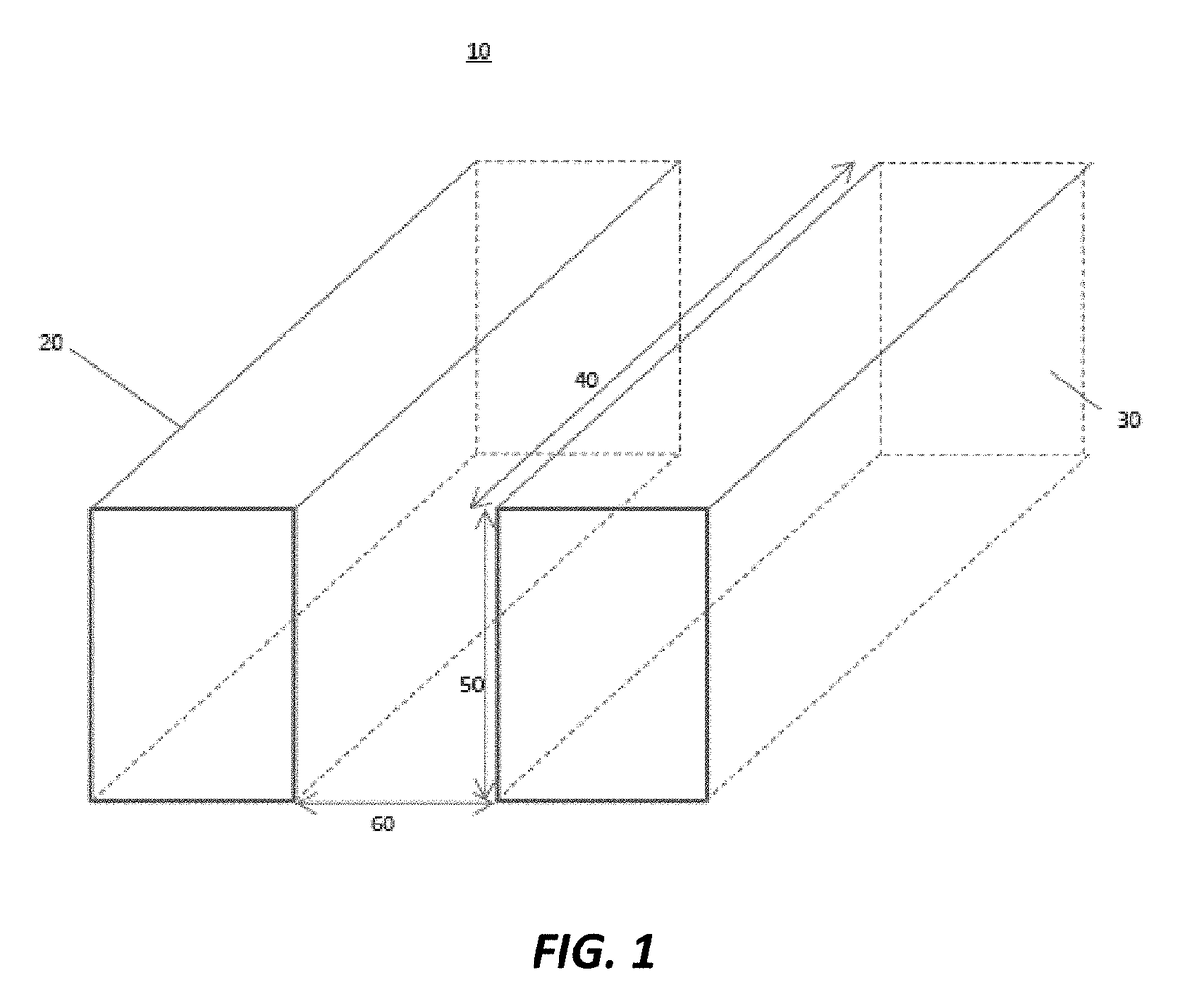

Selective deposition modeling system and method

InactiveUS6305769B1Additive manufacturing apparatus3D object support structuresEngineeringSelective deposition

A system and associated method for forming three-dimensional objects under computer control and from a material which may be rendered flowable and then dispensed on a layer-by-layer basis. The layers of the material solidify or otherwise physically transform upon being dispensed thereby forming successive cross-sections. The dispensing process is repeated whereby successive layers adhere to each other thereby forming the object.

Owner:3D SYST INC

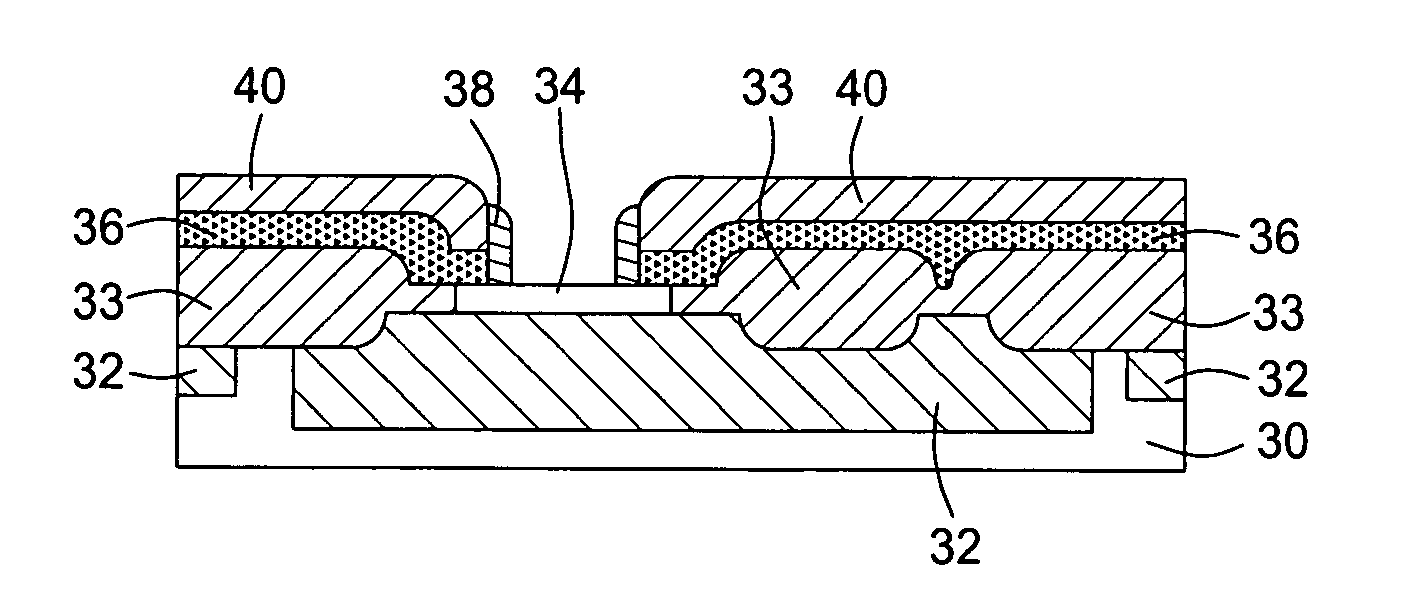

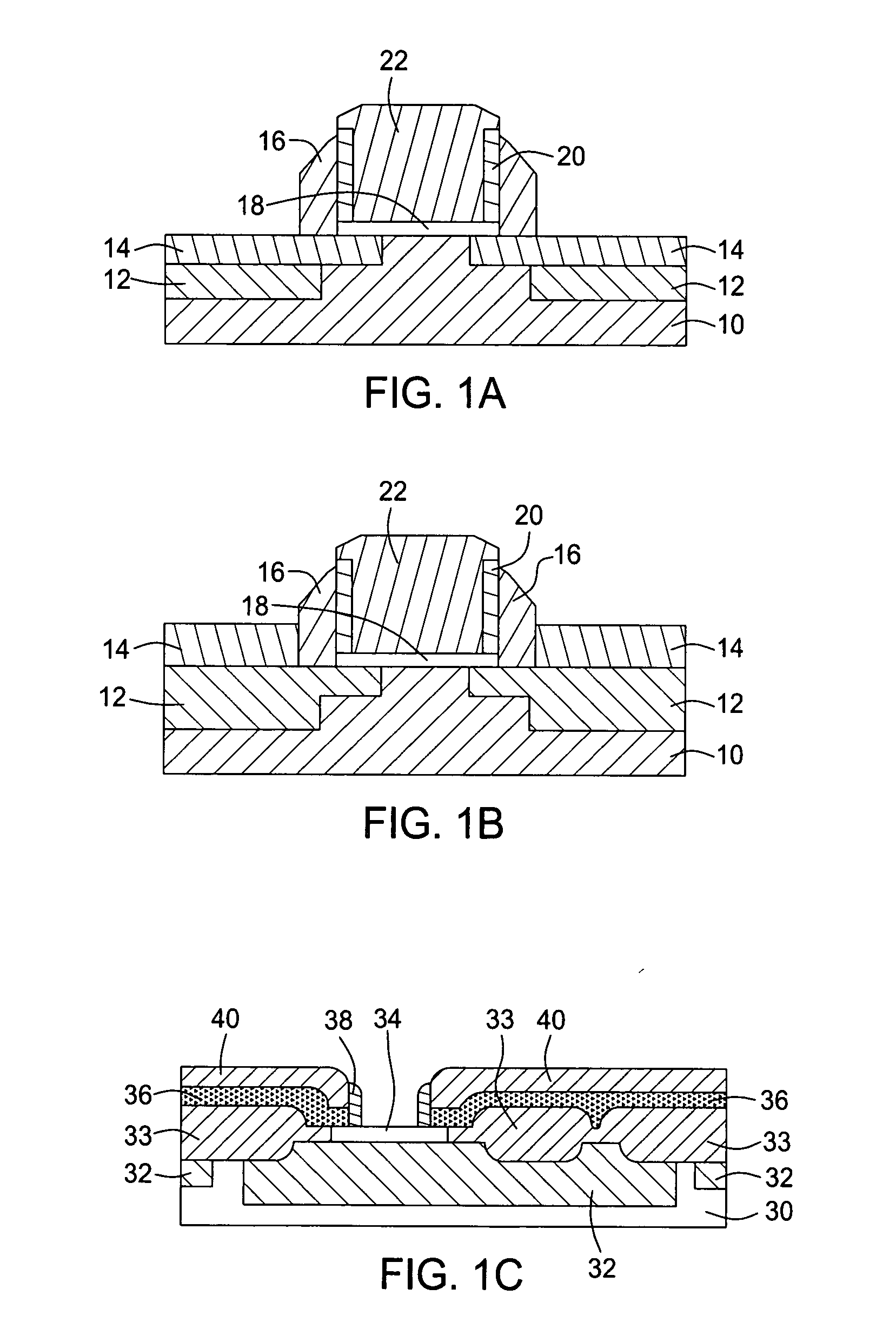

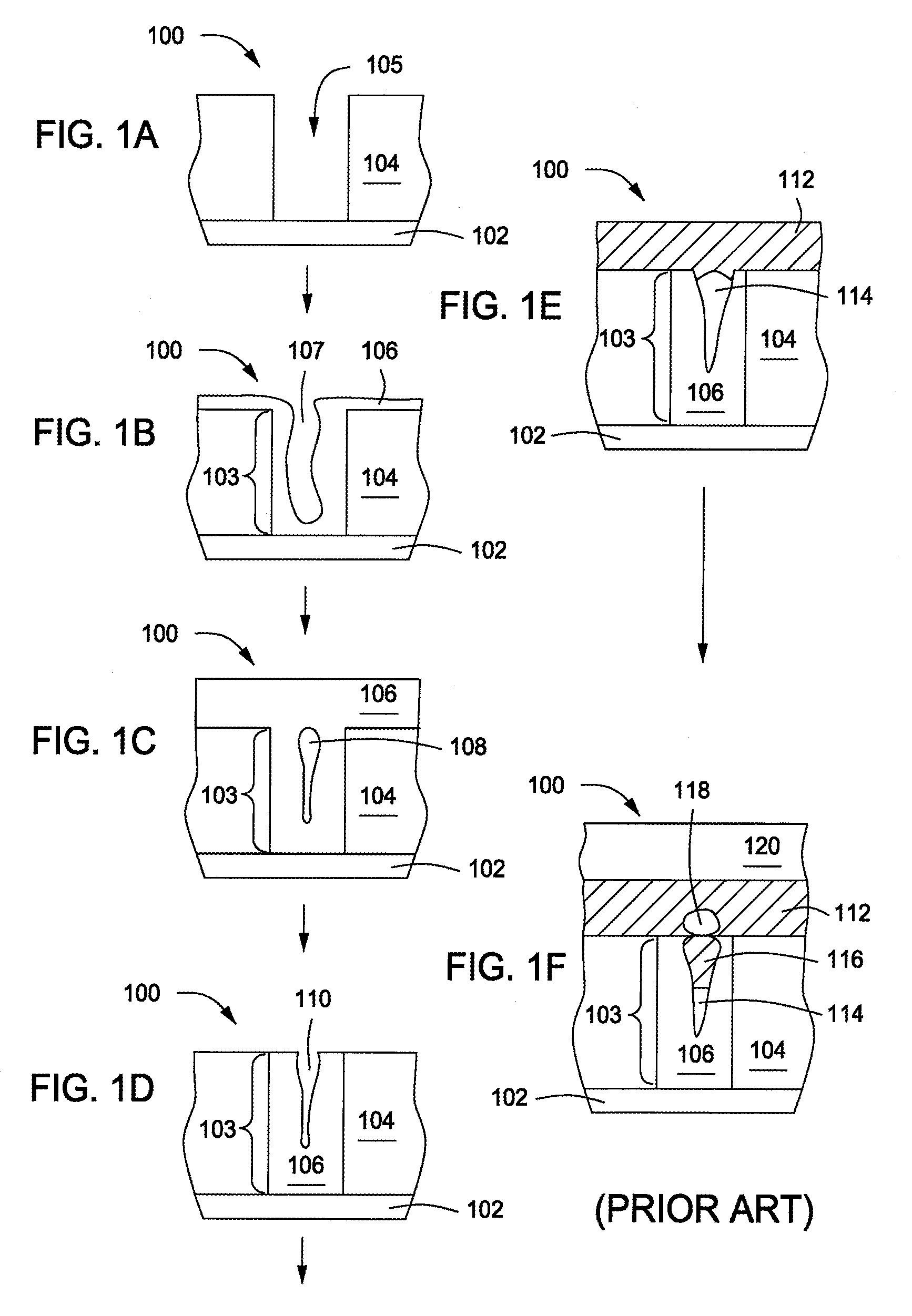

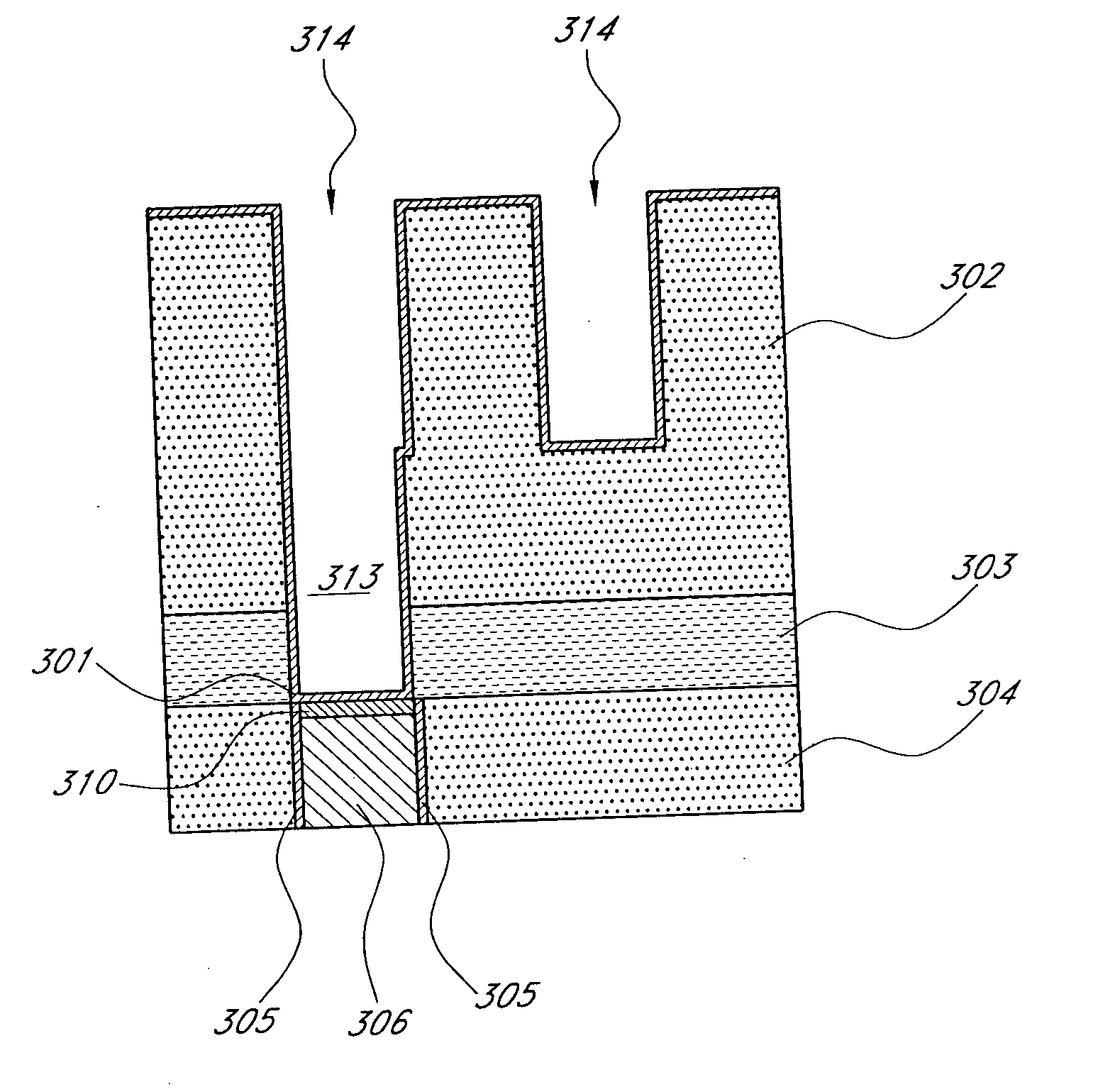

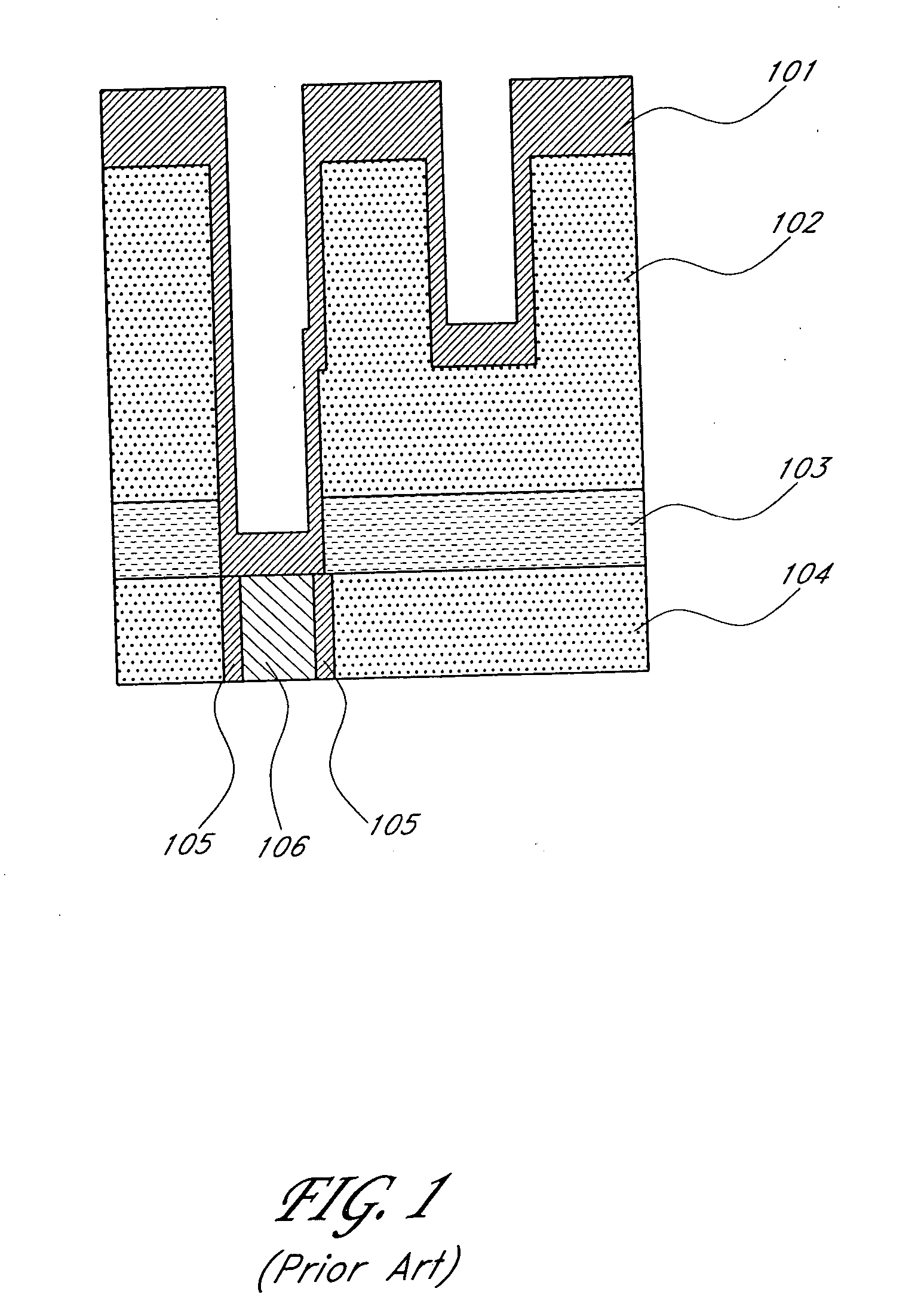

Methods to fabricate MOSFET devices using selective deposition process

ActiveUS20050079692A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMOSFETSelective deposition

In one embodiment, a method for fabricating a silicon-based device on a substrate surface is provided which includes depositing a first silicon-containing layer by exposing the substrate surface to a first process gas comprising Cl2SiH2, a germanium source, a first etchant and a carrier gas and depositing a second silicon-containing layer by exposing the first silicon-containing layer to a second process gas comprising SiH4 and a second etchant. In another embodiment, a method for depositing a silicon-containing material on a substrate surface is provided which includes depositing a first silicon-containing layer on the substrate surface with a first germanium concentration of about 15 at % or more. The method further provides depositing on the first silicon-containing layer a second silicon-containing layer wherein a second germanium concentration of about 15 at % or less, exposing the substrate surface to air to form a native oxide layer, removing the native oxide layer to expose the second silicon-containing layer, and depositing a third silicon-containing layer on the second silicon-containing layer. In another embodiment, a method for depositing a silicon-containing material on a substrate surface is provided which includes depositing epitaxially a first silicon-containing layer on the substrate surface with a first lattice strain, and depositing epitaxially on the first silicon-containing layer a second silicon-containing layer with a second lattice strain greater than the first lattice strain.

Owner:APPLIED MATERIALS INC

Selective film deposition method to form air gaps

A method for depositing a film to form an air gap within a semiconductor device is disclosed. An exemplary method comprises pulsing a metal halide precursor onto the substrate and pulsing an oxygen precursor onto a selective deposition surface. The method can be used to form an air gap to, for example, reduce a parasitic resistance of the semiconductor device.

Owner:ASM IP HLDG BV

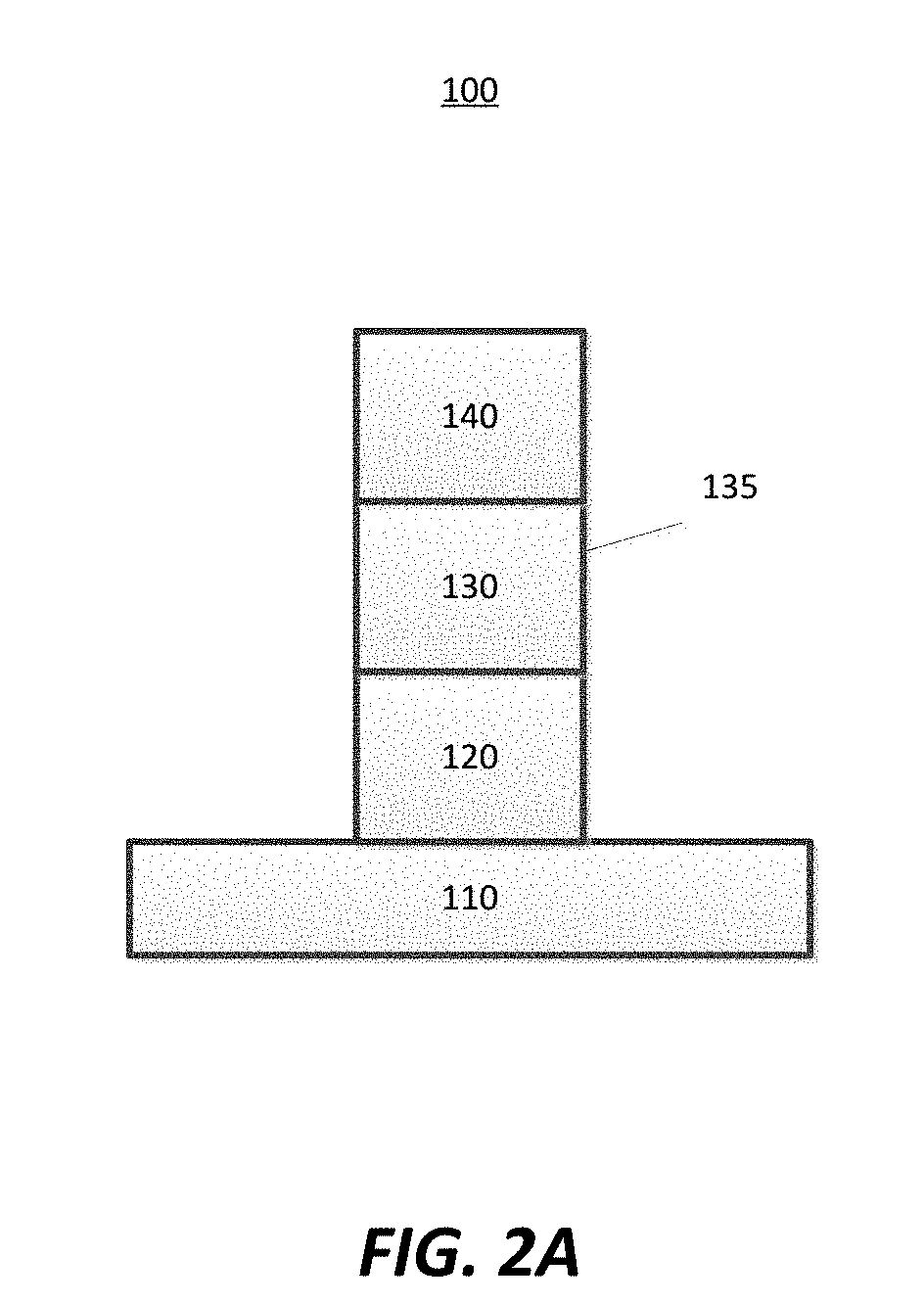

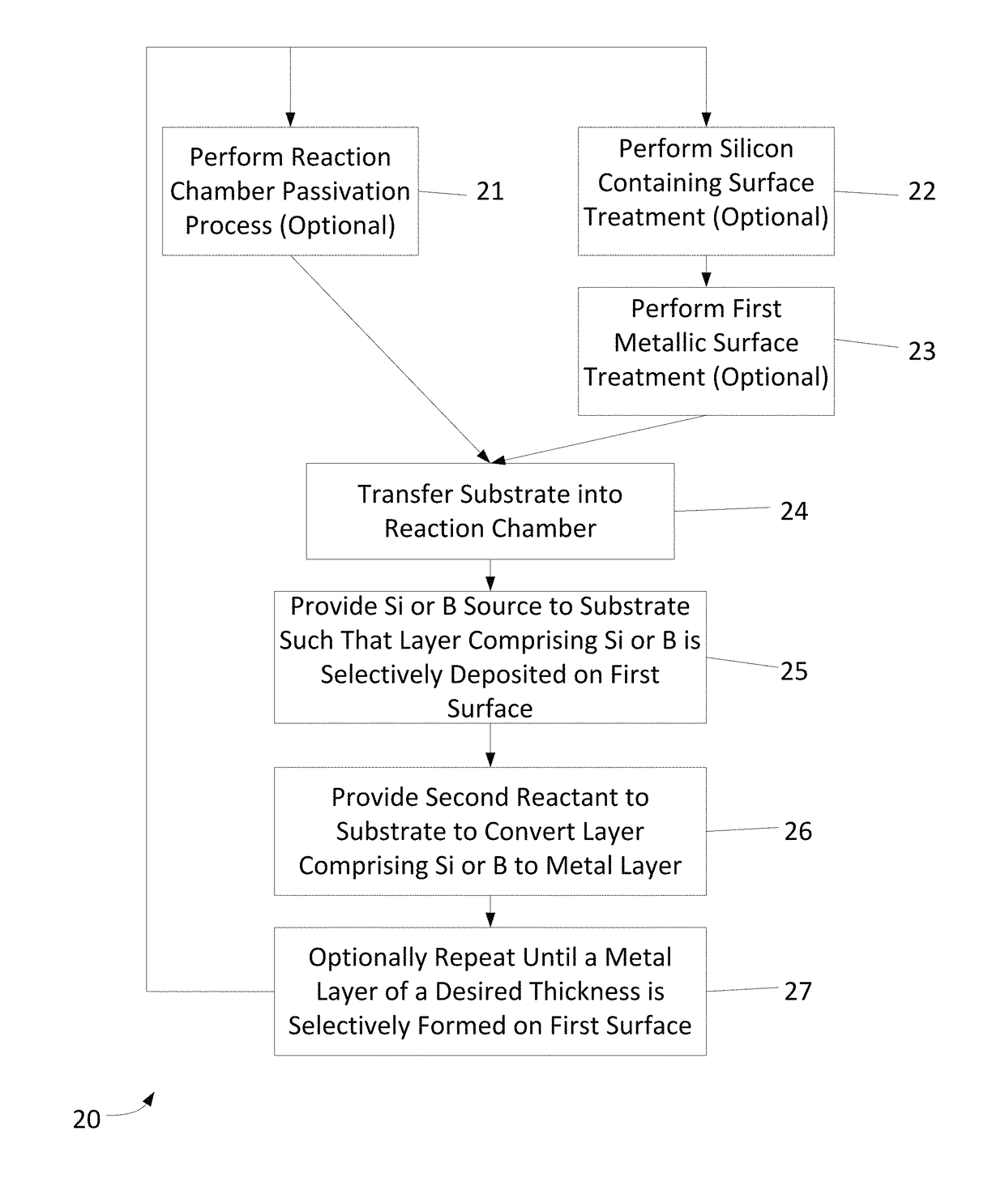

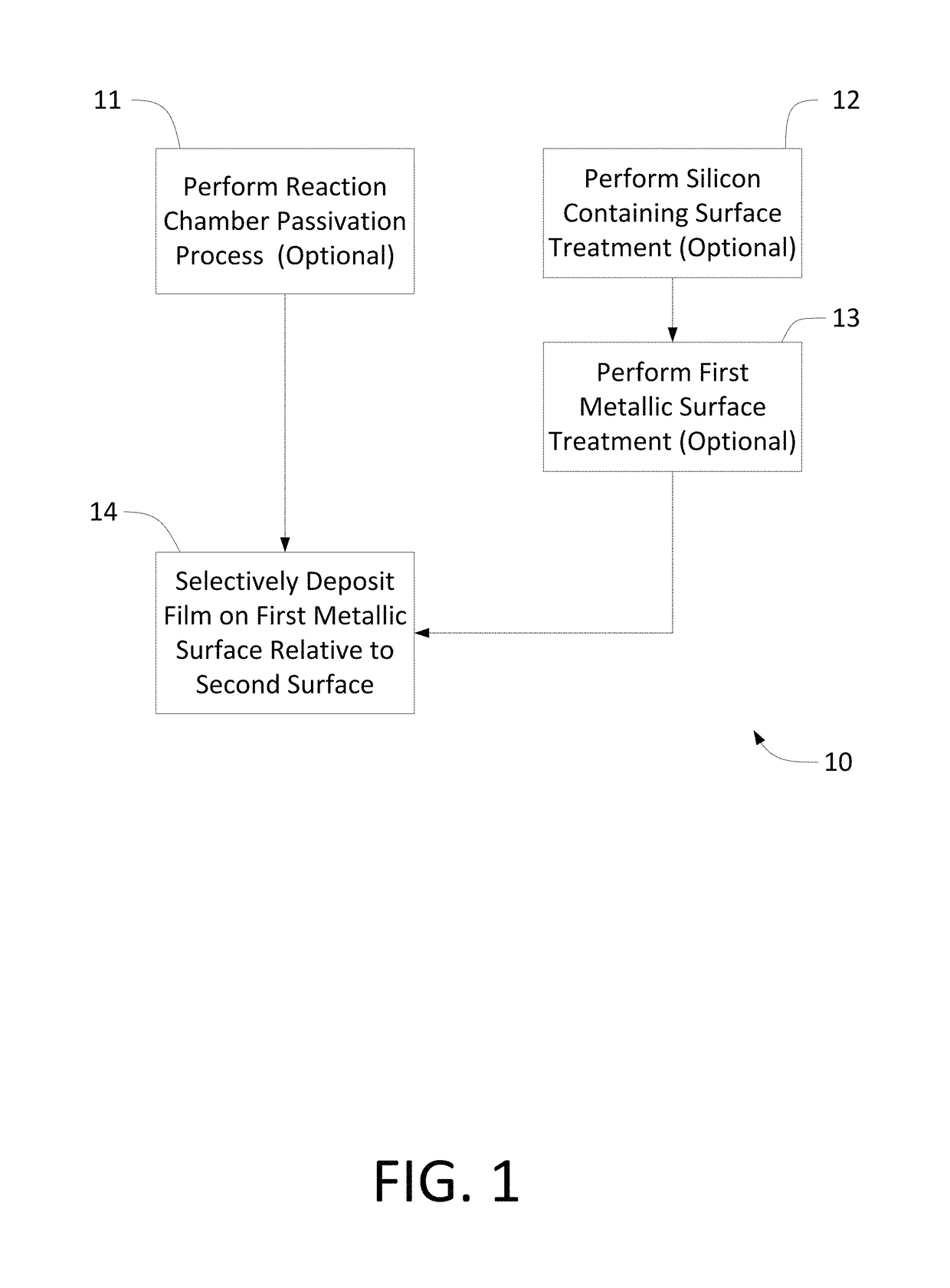

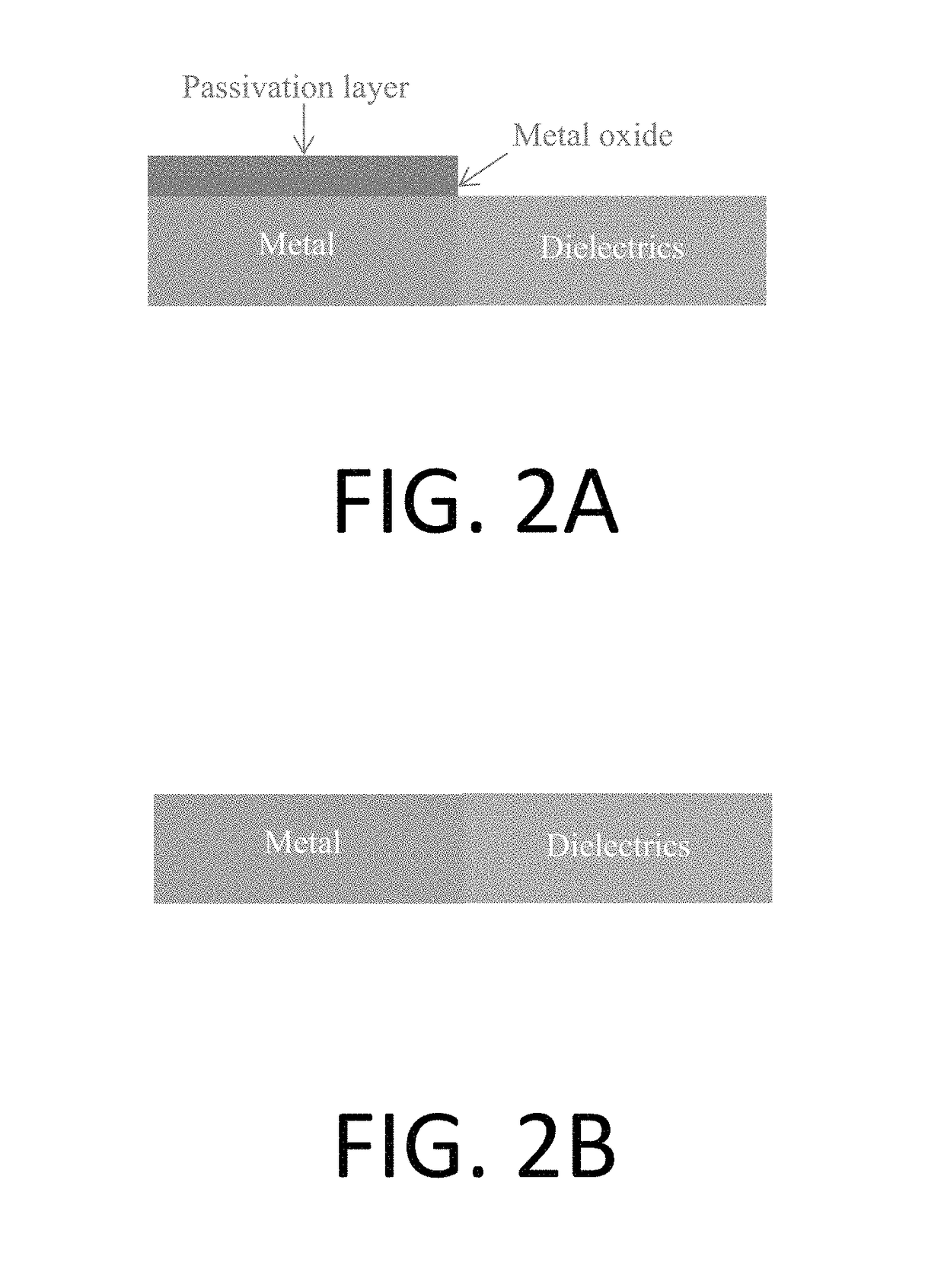

Selective deposition of metallic films

ActiveUS10014212B2Enhanced vapor depositionEnhance layeringSemiconductor/solid-state device detailsSolid-state devicesSelective depositionSilicon

Metallic layers can be selectively deposited on one surface of a substrate relative to a second surface of the substrate. In some embodiments, the metallic layers are selectively deposited on a first metallic surface relative to a second surface comprising silicon. In some embodiments the reaction chamber in which the selective deposition occurs may optionally be passivated prior to carrying out the selective deposition process. In some embodiments selectivity of above about 50% or even about 90% is achieved.

Owner:ASM IP HLDG BV

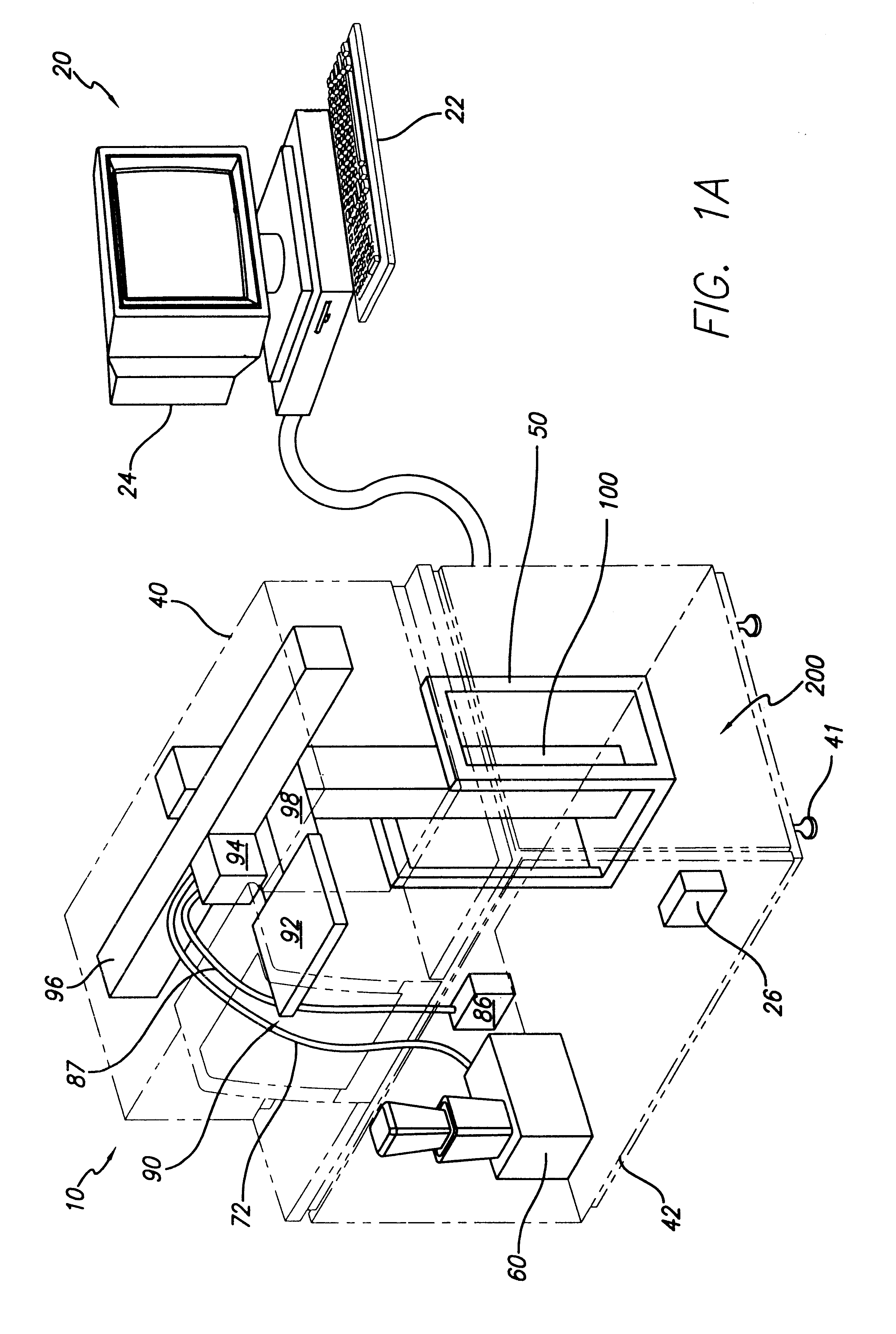

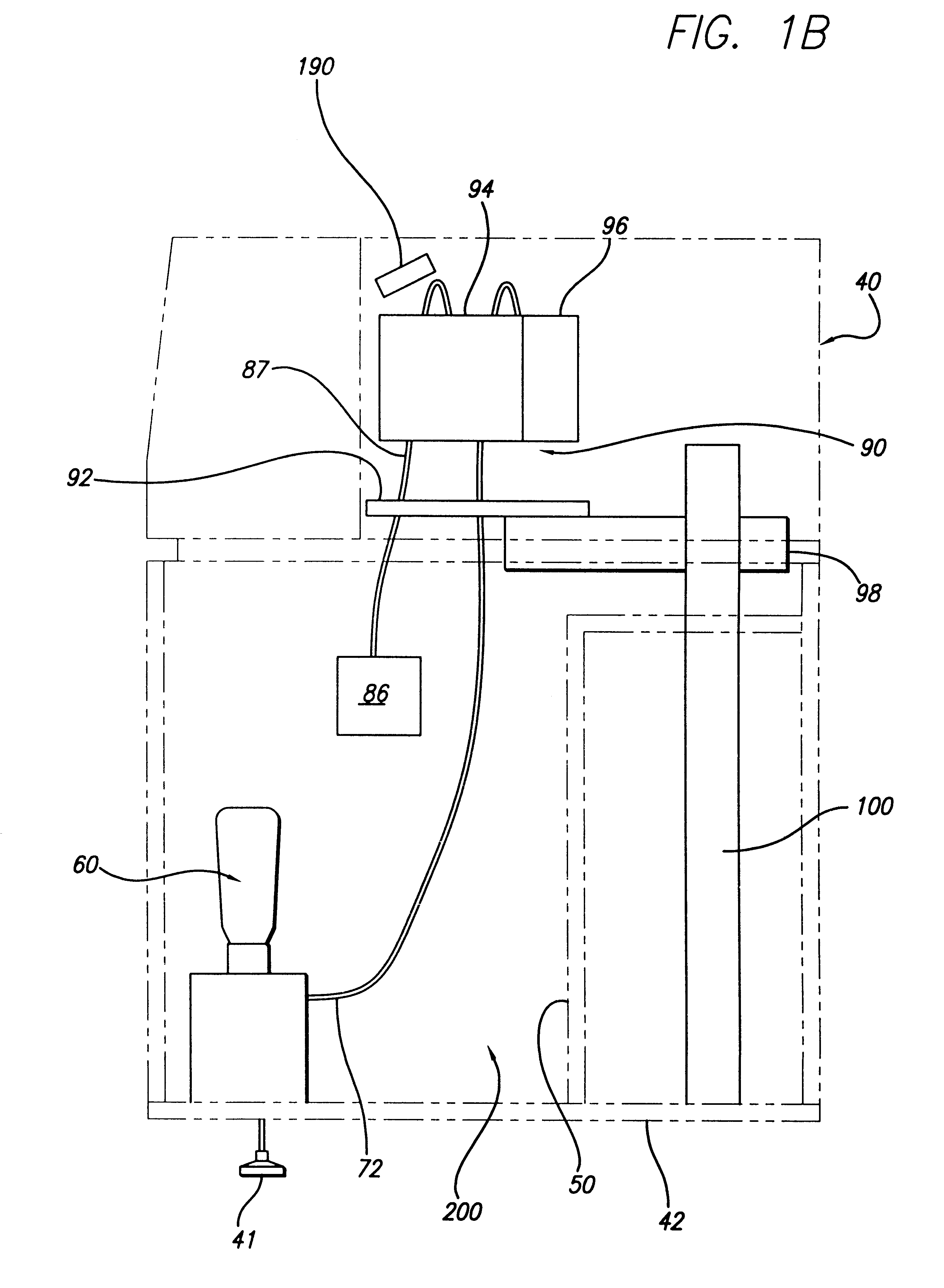

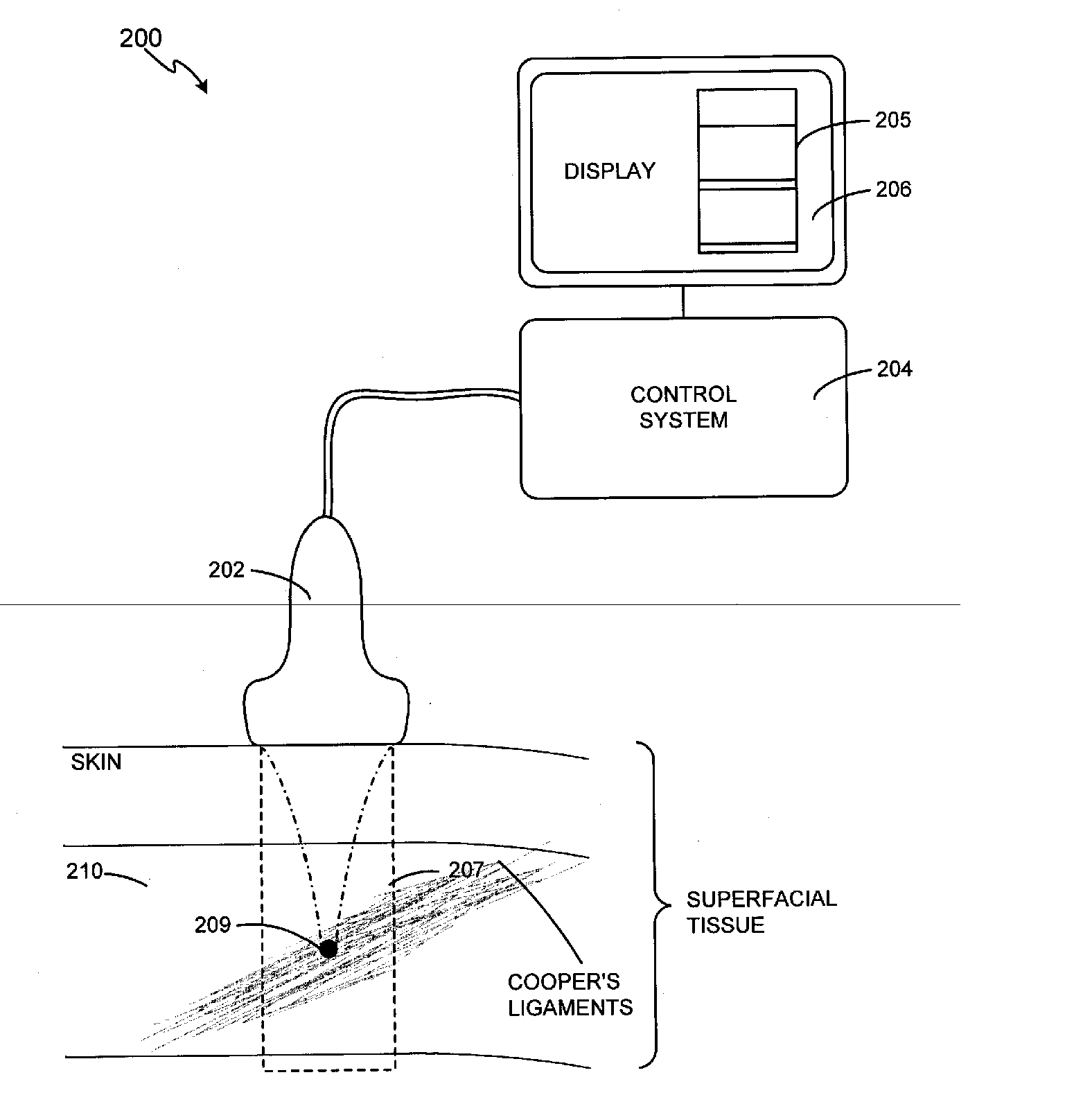

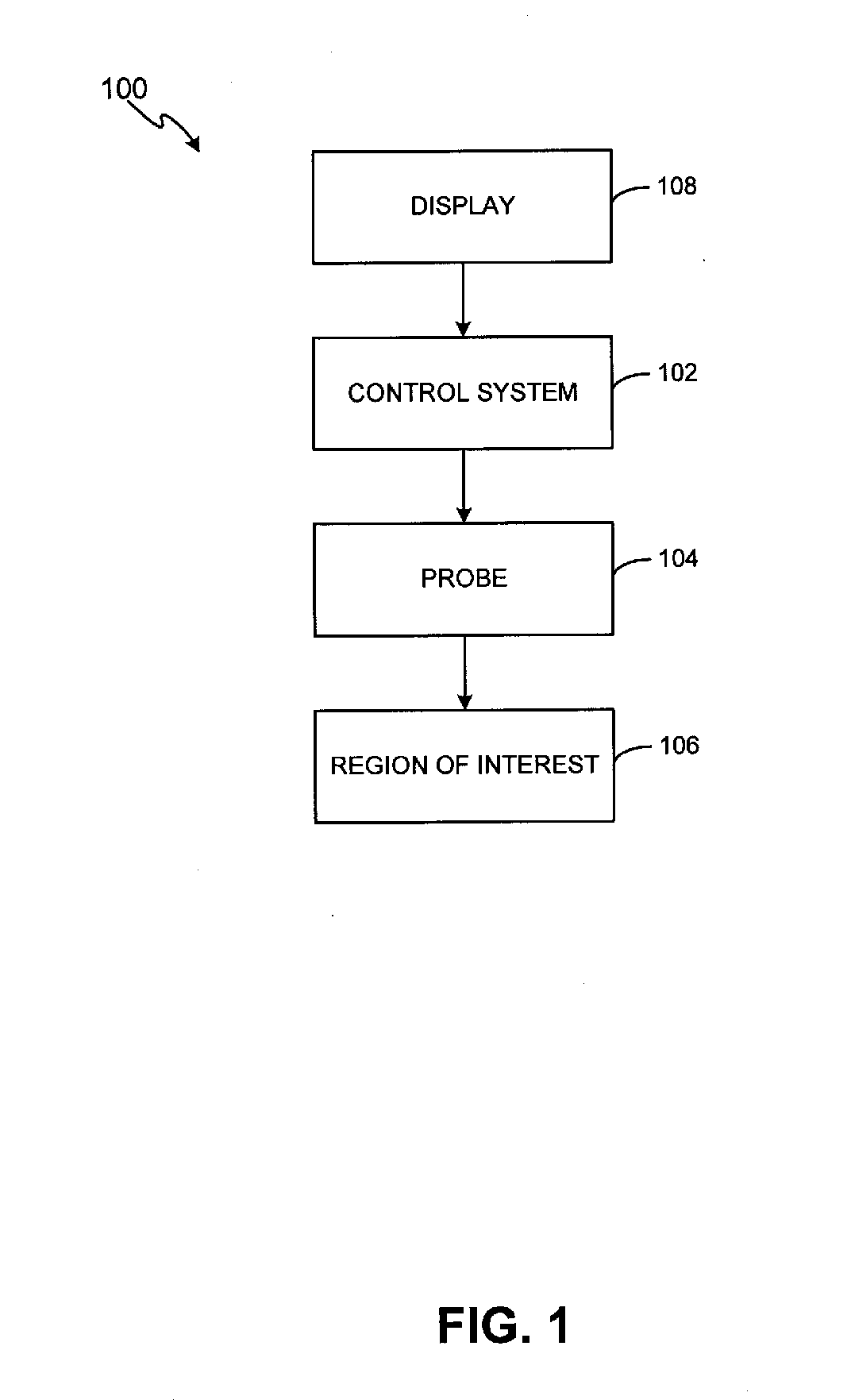

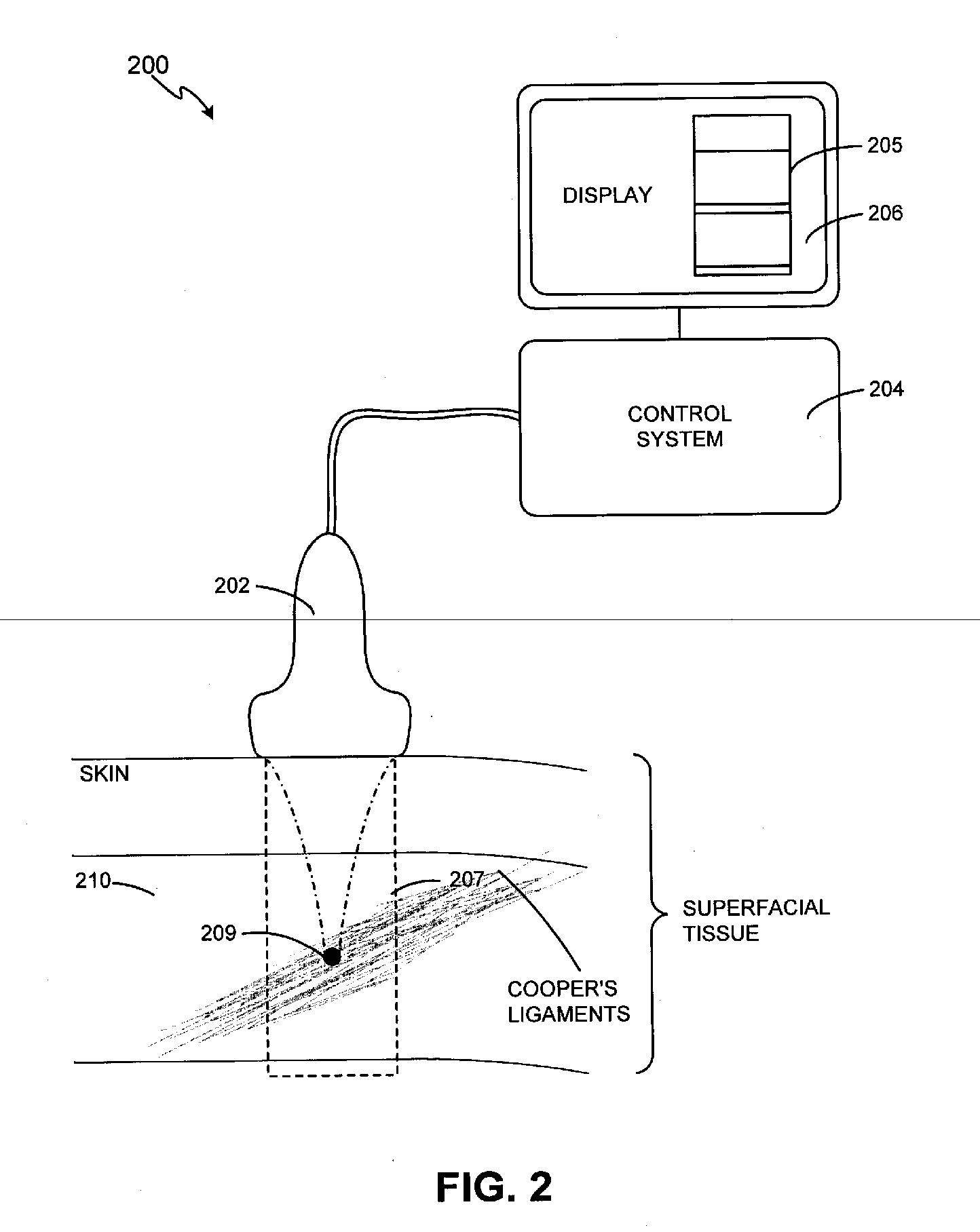

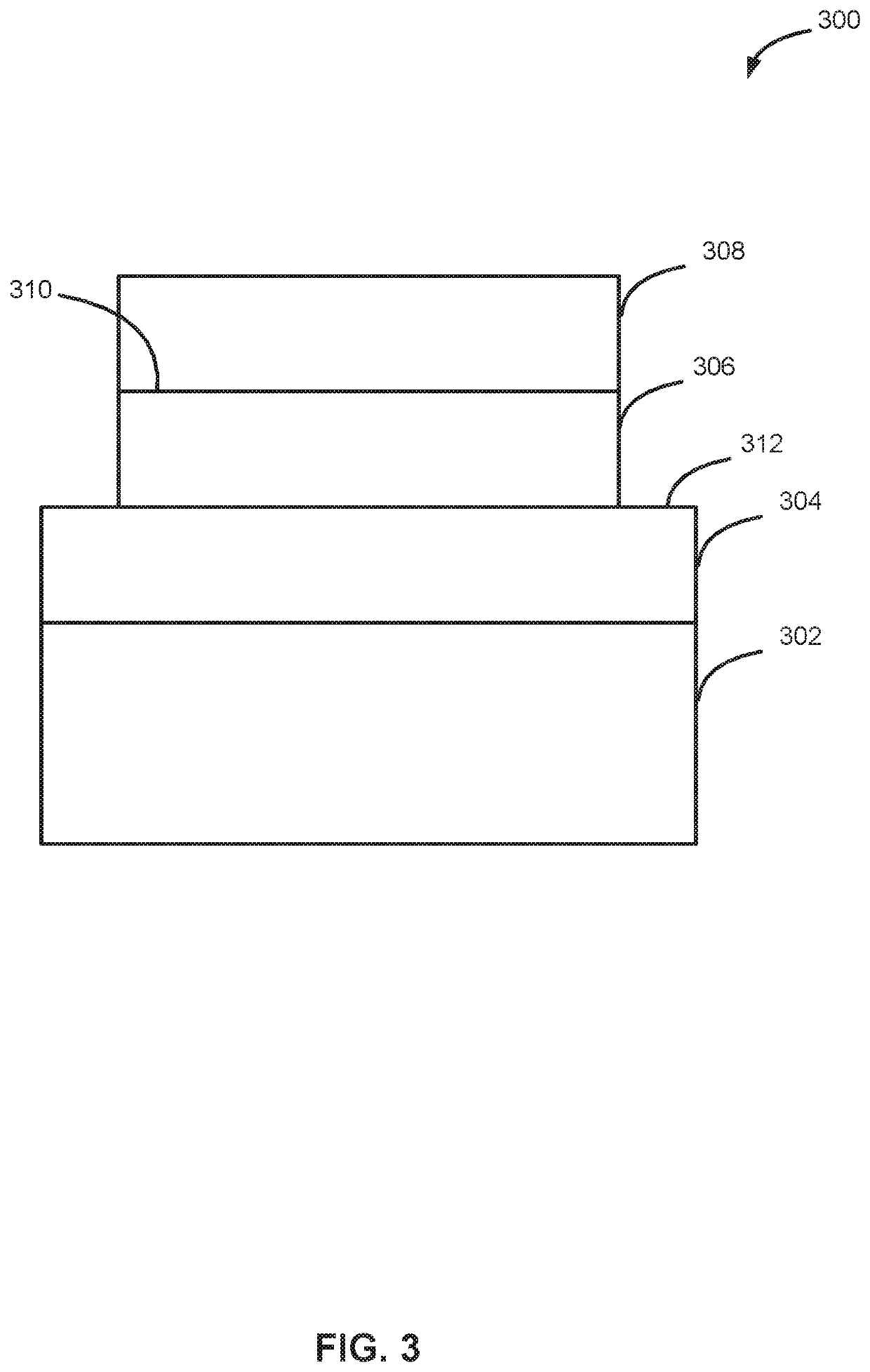

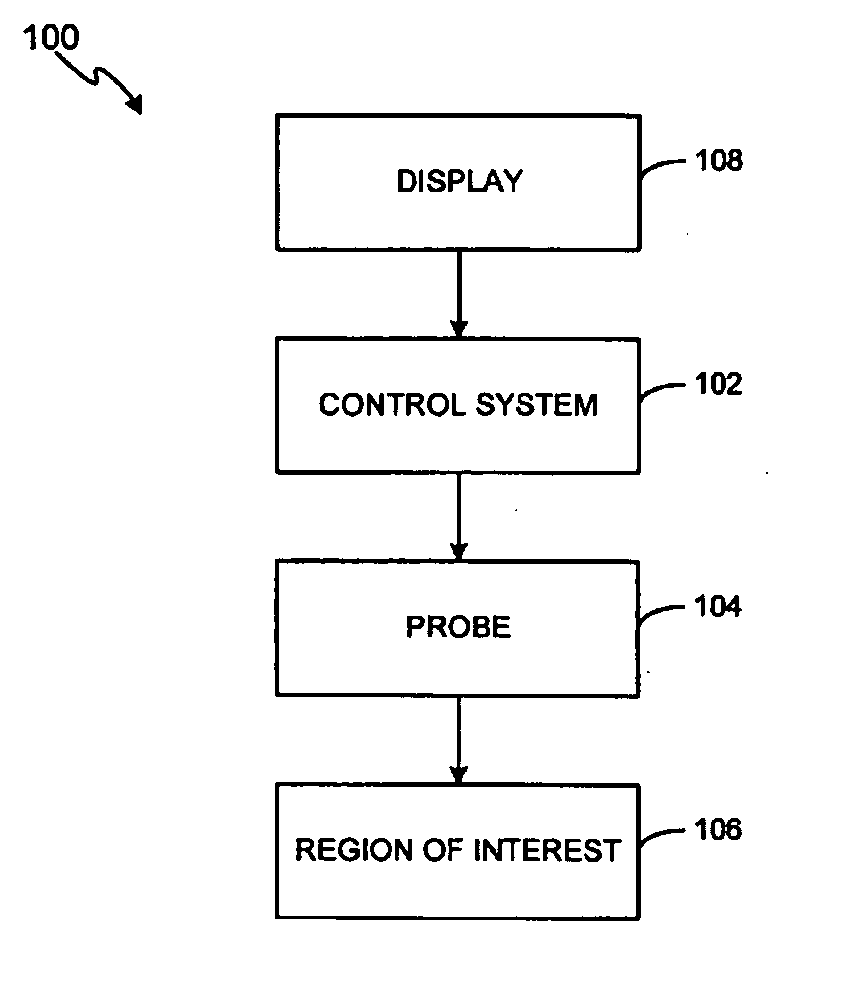

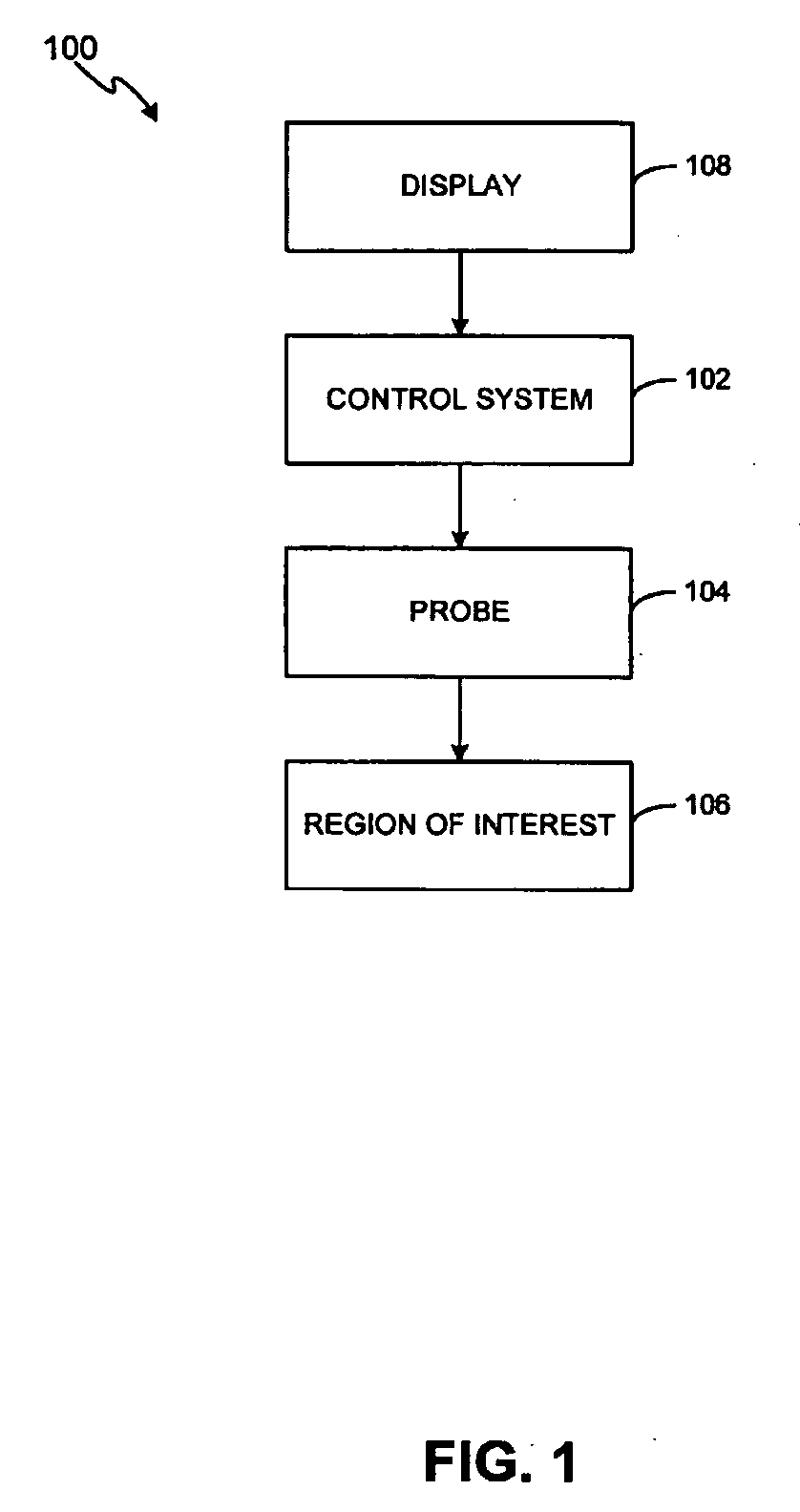

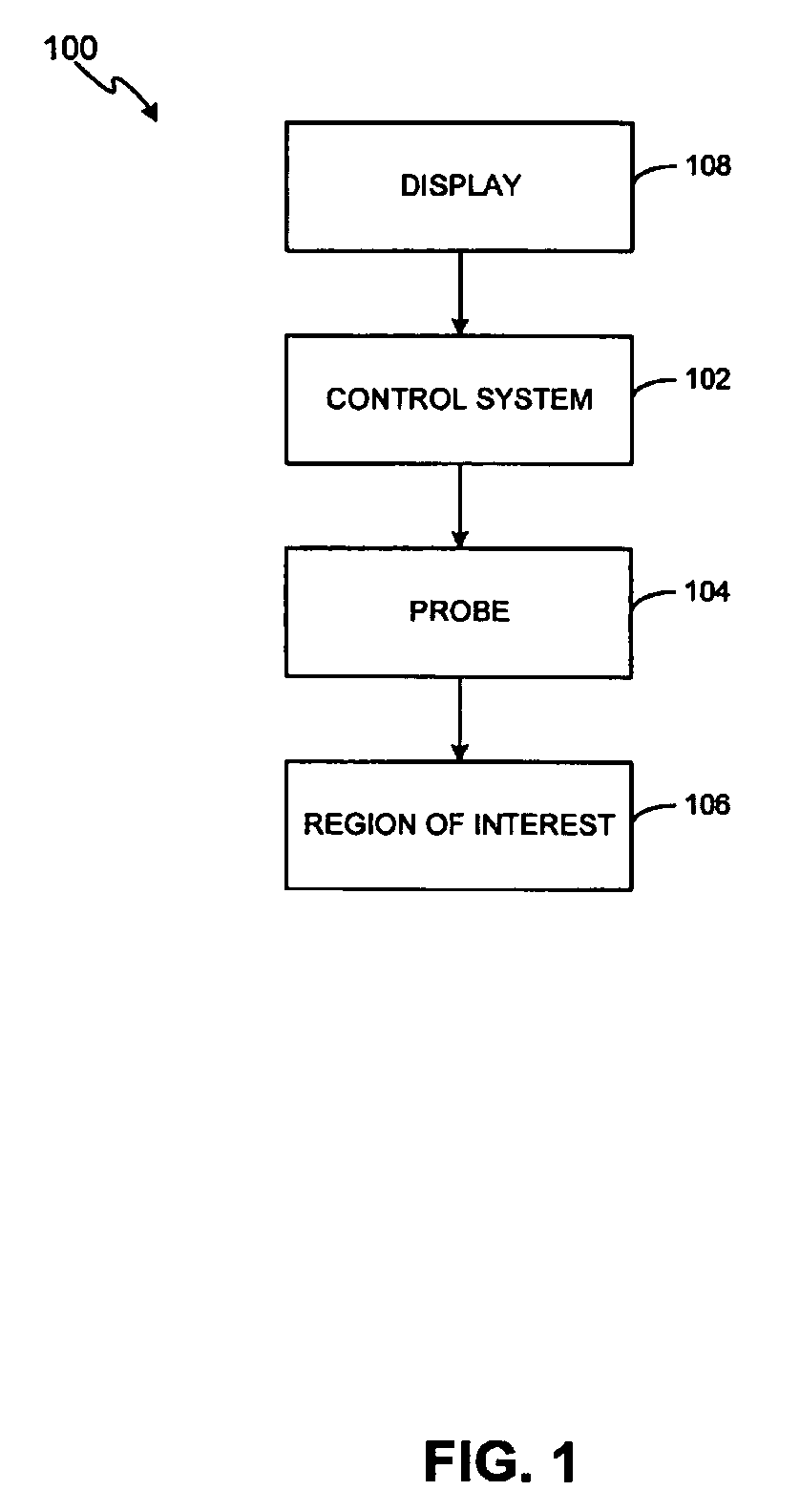

Method and system for noninvasive mastopexy

ActiveUS20060074314A1Avoid cavitationUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasound imagingMastopexy

Methods and systems for noninvasive mastopexy through deep tissue tightening with ultrasound are provided. An exemplary method and system comprise a therapeutic ultrasound system configured for providing ultrasound treatment to a deep tissue region, such as a region comprising muscular fascia and ligaments. In accordance with various exemplary embodiments, a therapeutic ultrasound system can be configured to achieve depth from 1 mm to 4 cm with a conformal selective deposition of ultrasound energy without damaging an intervening tissue in the range of frequencies from 1 to 15 MHz. In addition, a therapeutic ultrasound can also be configured in combination with ultrasound imaging or imaging / monitoring capabilities, either separately configured with imaging, therapy and monitoring systems or any level of integration thereof.

Owner:GUIDED THERAPY SYSTEMS LLC

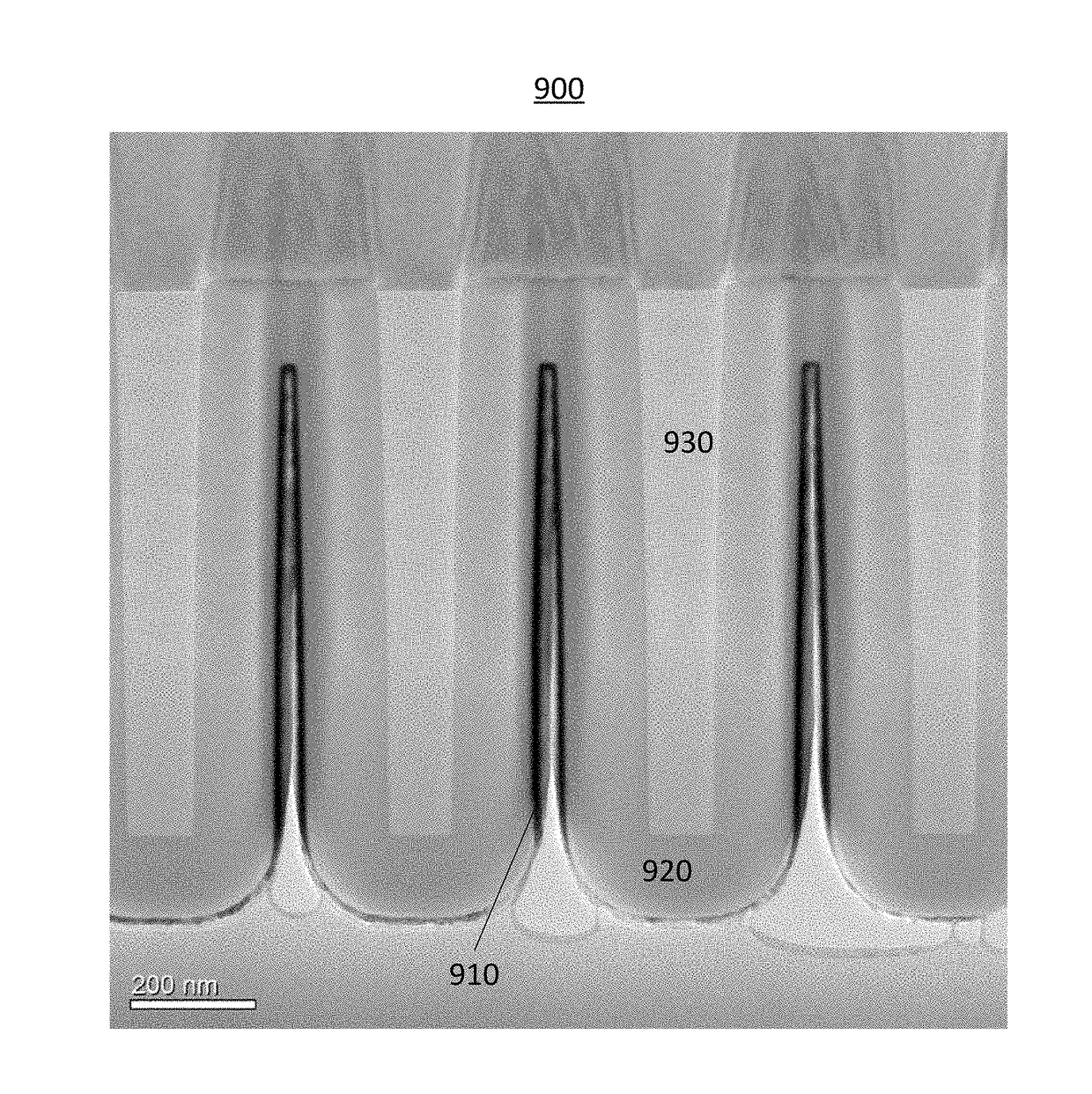

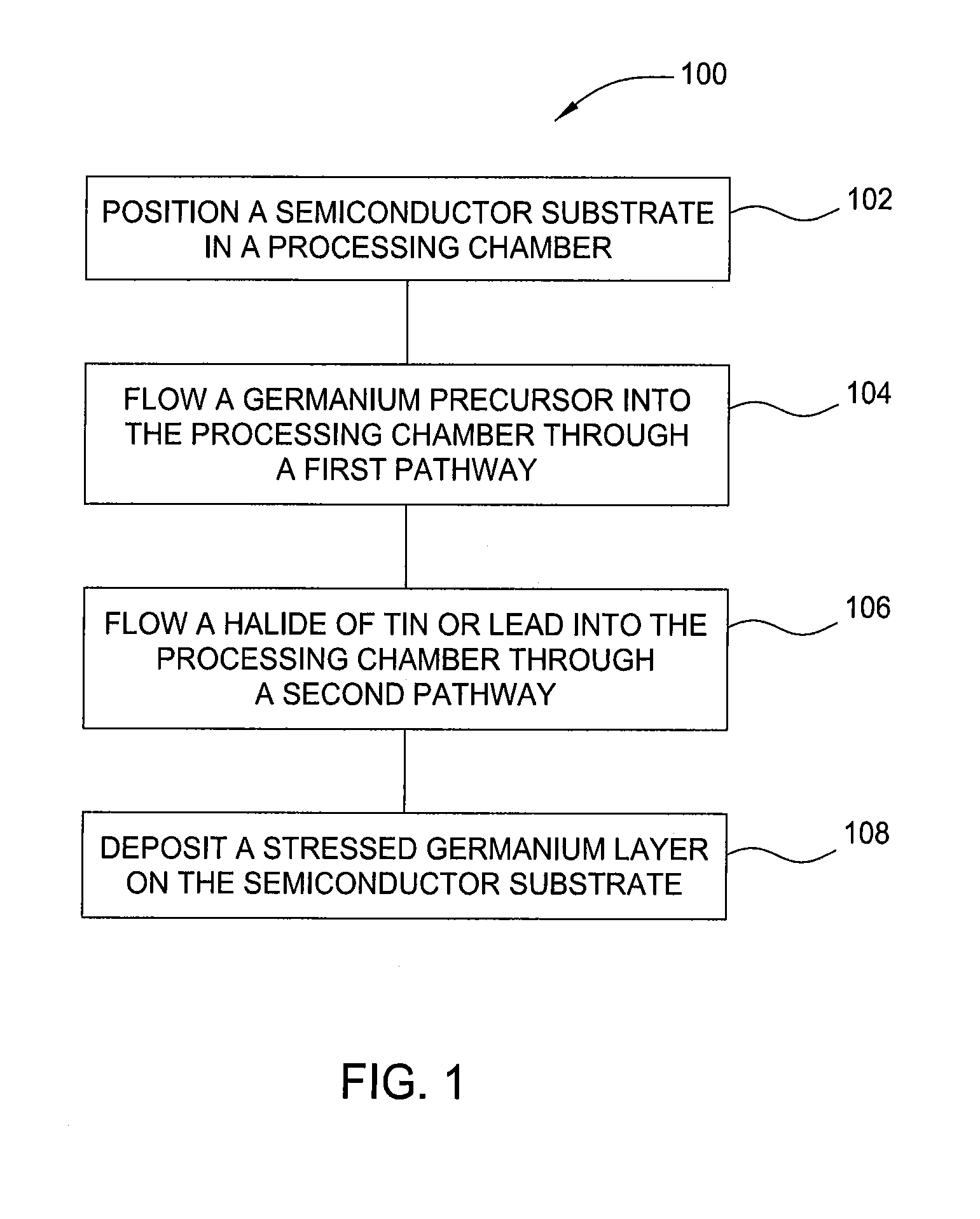

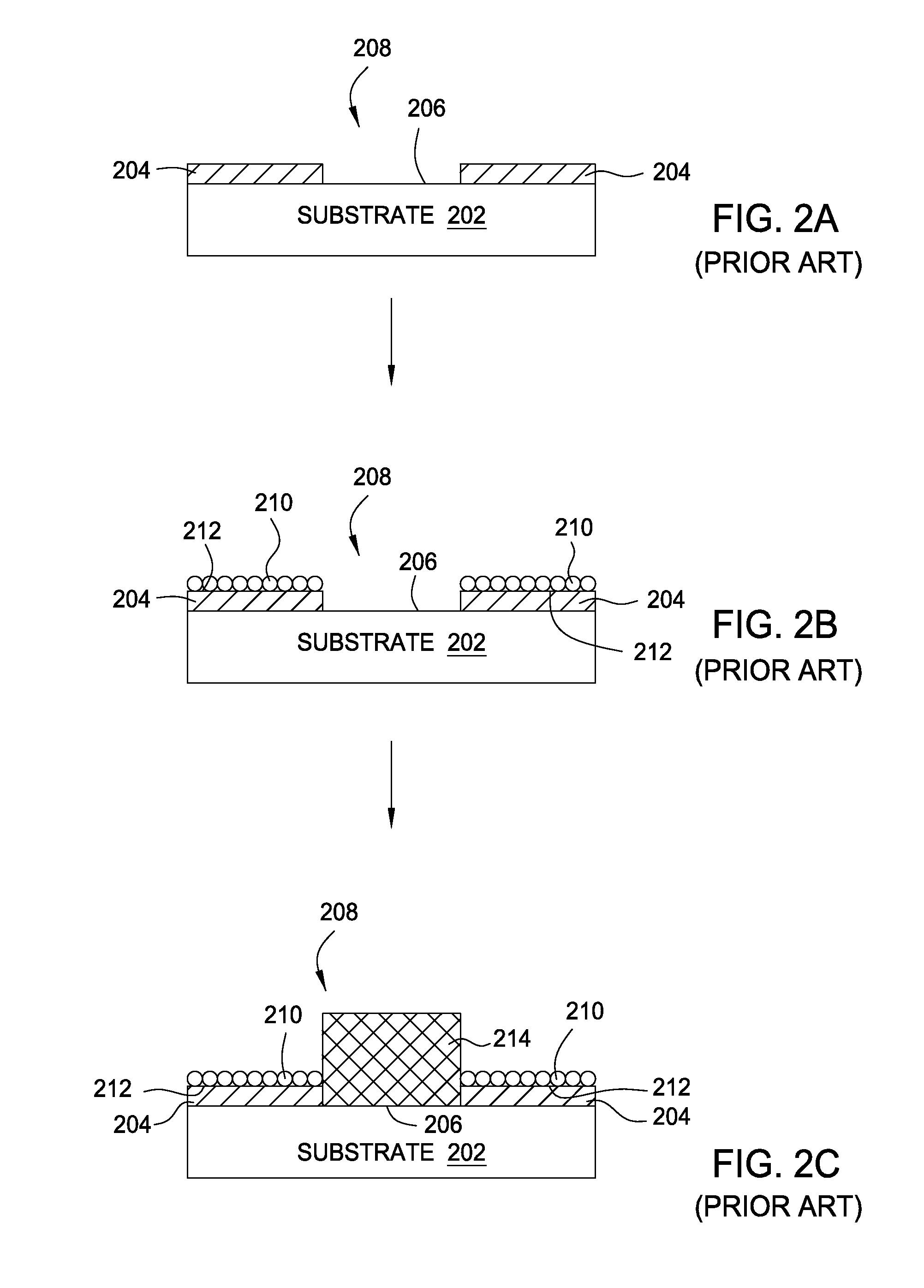

Method and apparatus for the selective deposition of epitaxial germanium stressor alloys

ActiveUS20120247386A1Reduce adhesionPolycrystalline material growthSemiconductor/solid-state device manufacturingHeterojunctionHalogen

A method and apparatus for forming heterojunction stressor layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy formed on the substrate. The metal precursor is typically a metal halide, which may be provided by subliming a solid metal halide or by contacting a pure metal with a halogen gas. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

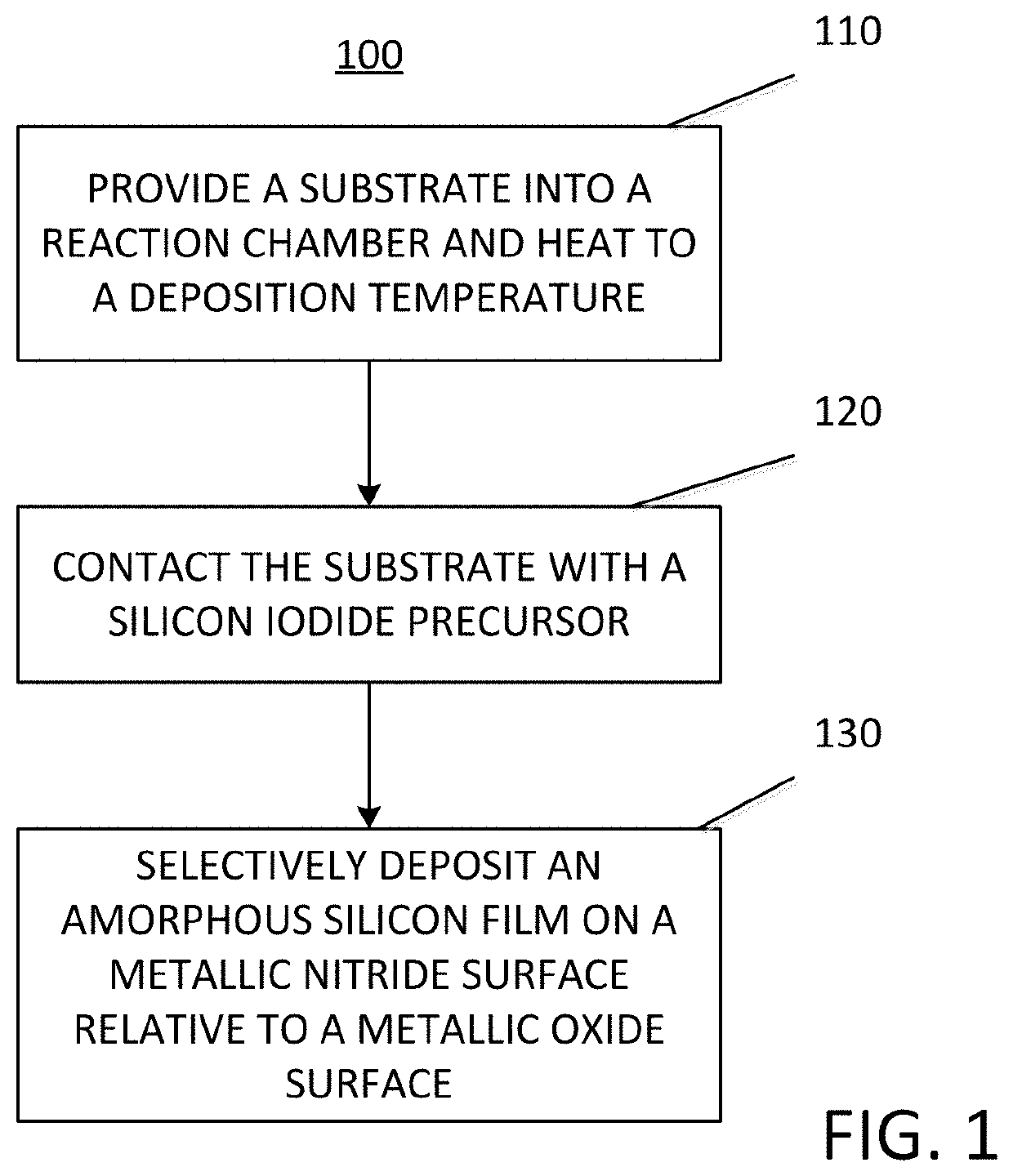

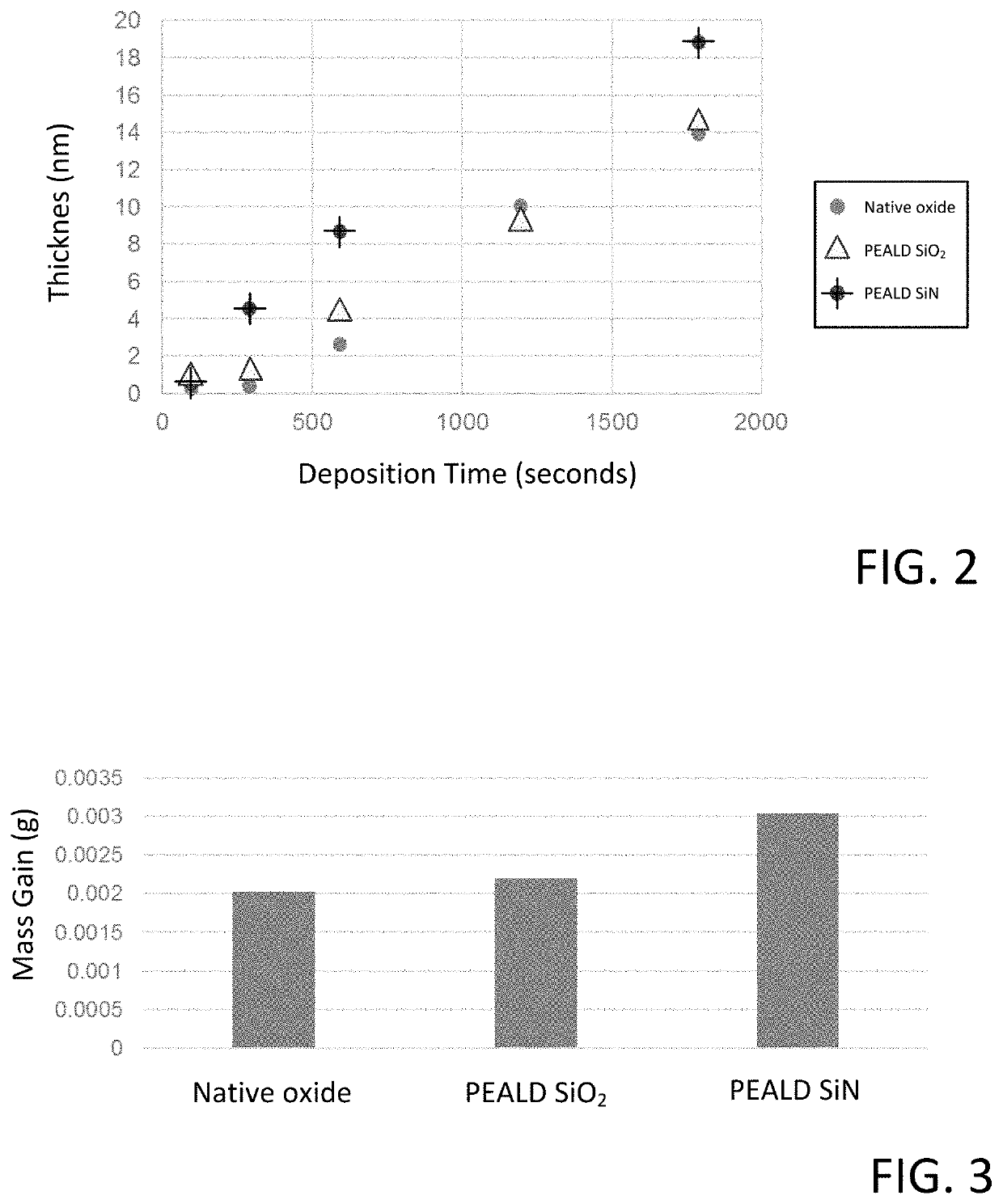

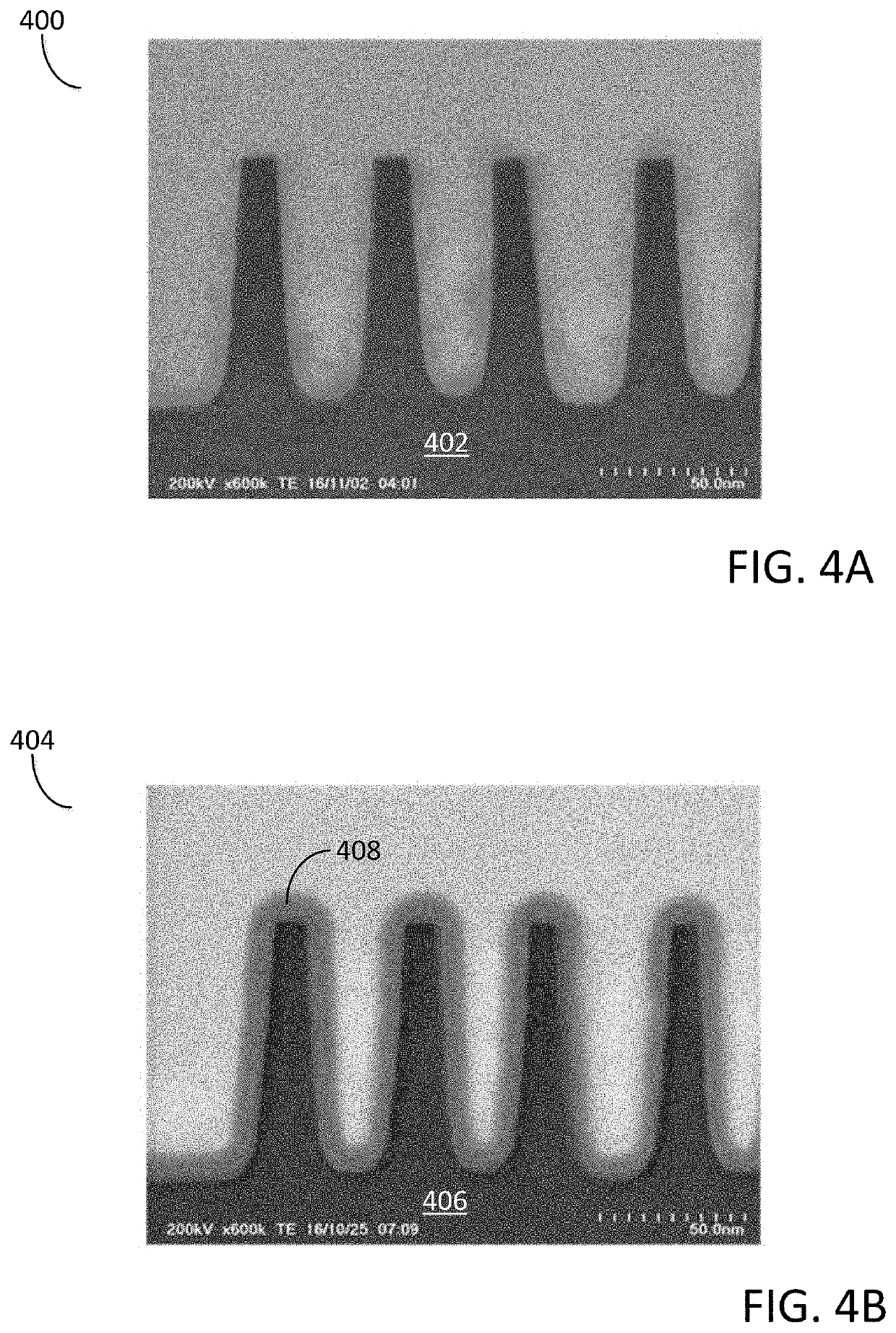

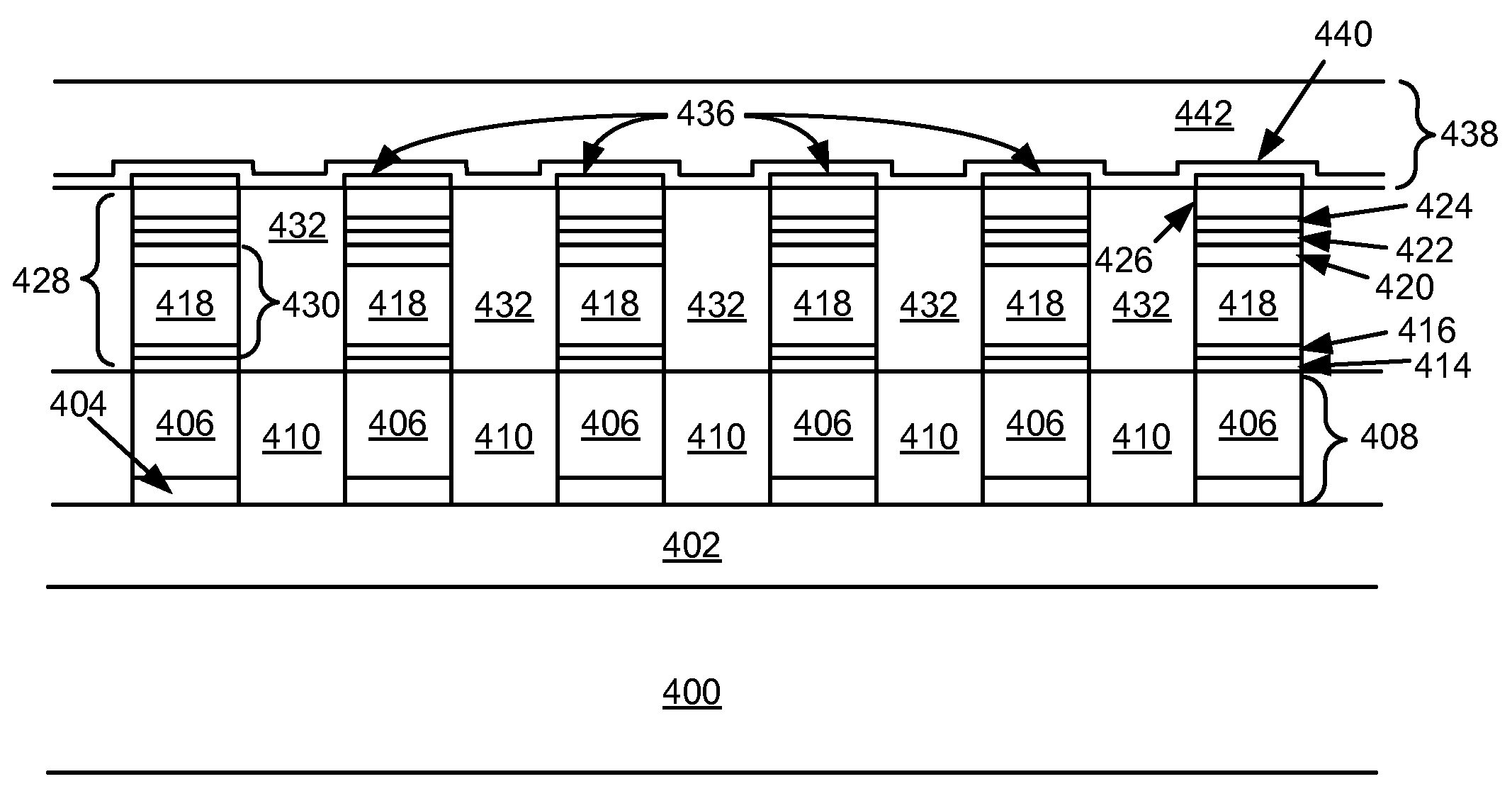

Methods for selectively depositing an amorphous silicon film on a substrate

ActiveUS20200140995A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDeposition temperatureDevice material

A method for selectively depositing an amorphous silicon film on a substrate comprising a metallic nitride surface and a metallic oxide surface is disclosed. The method may include; providing a substrate within a reaction chamber, heating the substrate to a deposition temperature, contacting the substrate with silicon iodide precursor, and selectively depositing the amorphous silicon film on the metallic nitride surface relative to the metallic oxide surface. Semiconductor device structures including an amorphous silicon film deposited by selective deposition methods are also disclosed.

Owner:ASM IP HLDG BV

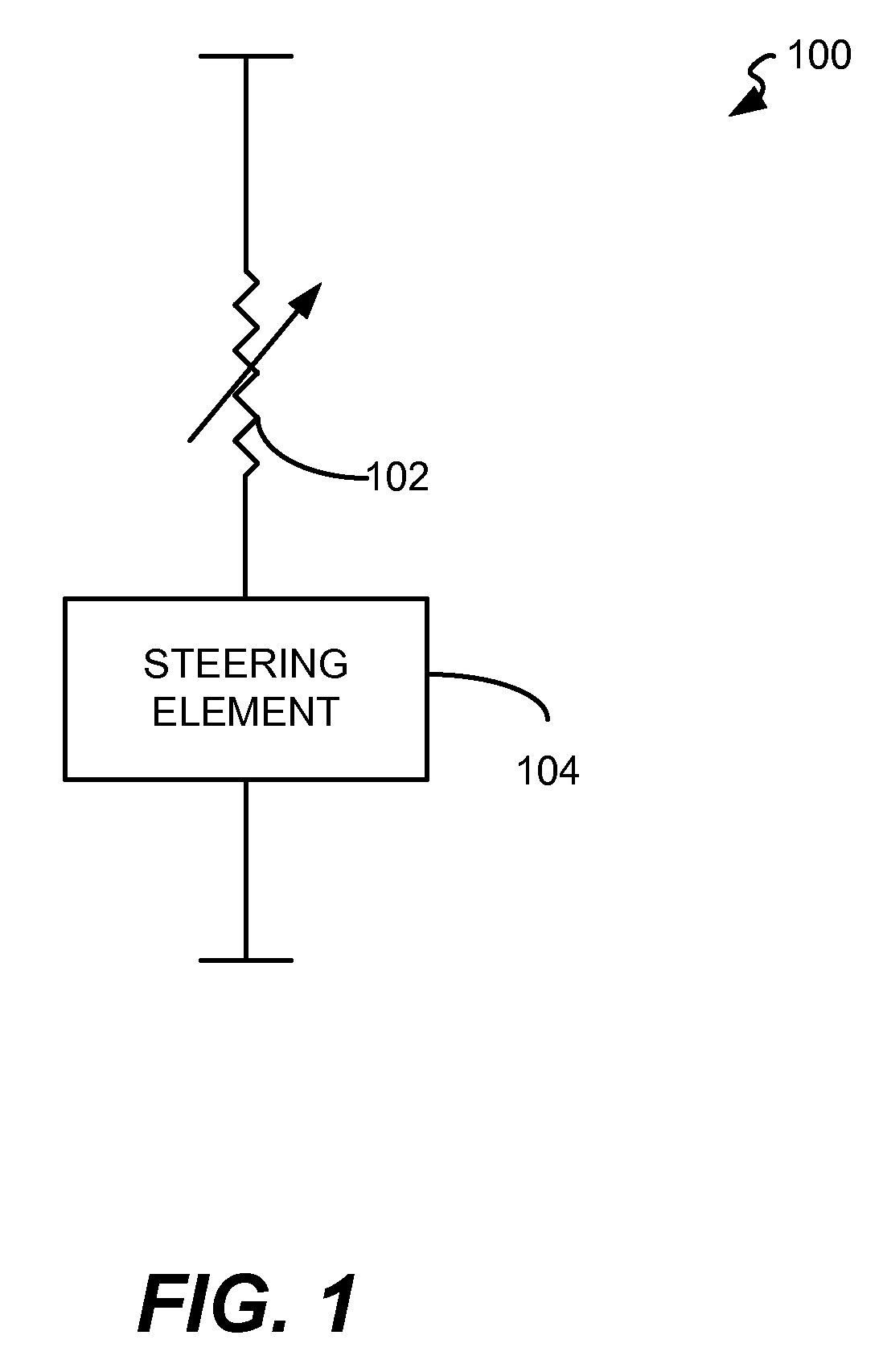

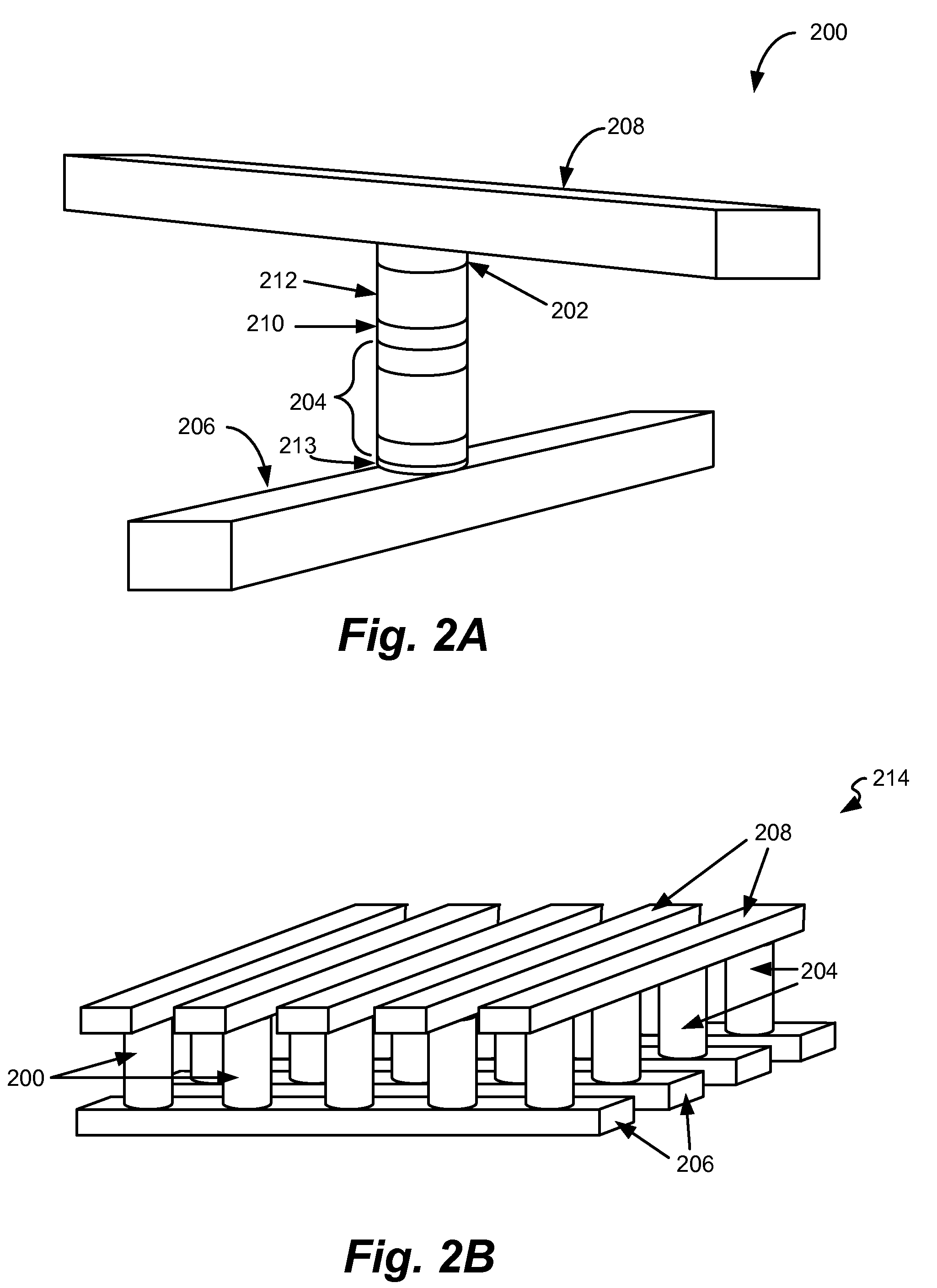

Memory cell that employs a selectively deposited reversible resistance-switching element and methods of forming the same

In some aspects, a method of forming a memory cell is provided that includes (1) forming a first conductor above a substrate; (2) forming a diode above the first conductor; (3) forming a reversible resistance-switching element above the first conductor using a selective deposition process; and (4) forming a second conductor above the diode and the reversible resistance-switching element. Numerous other aspects are provided.

Owner:SANDISK TECH LLC

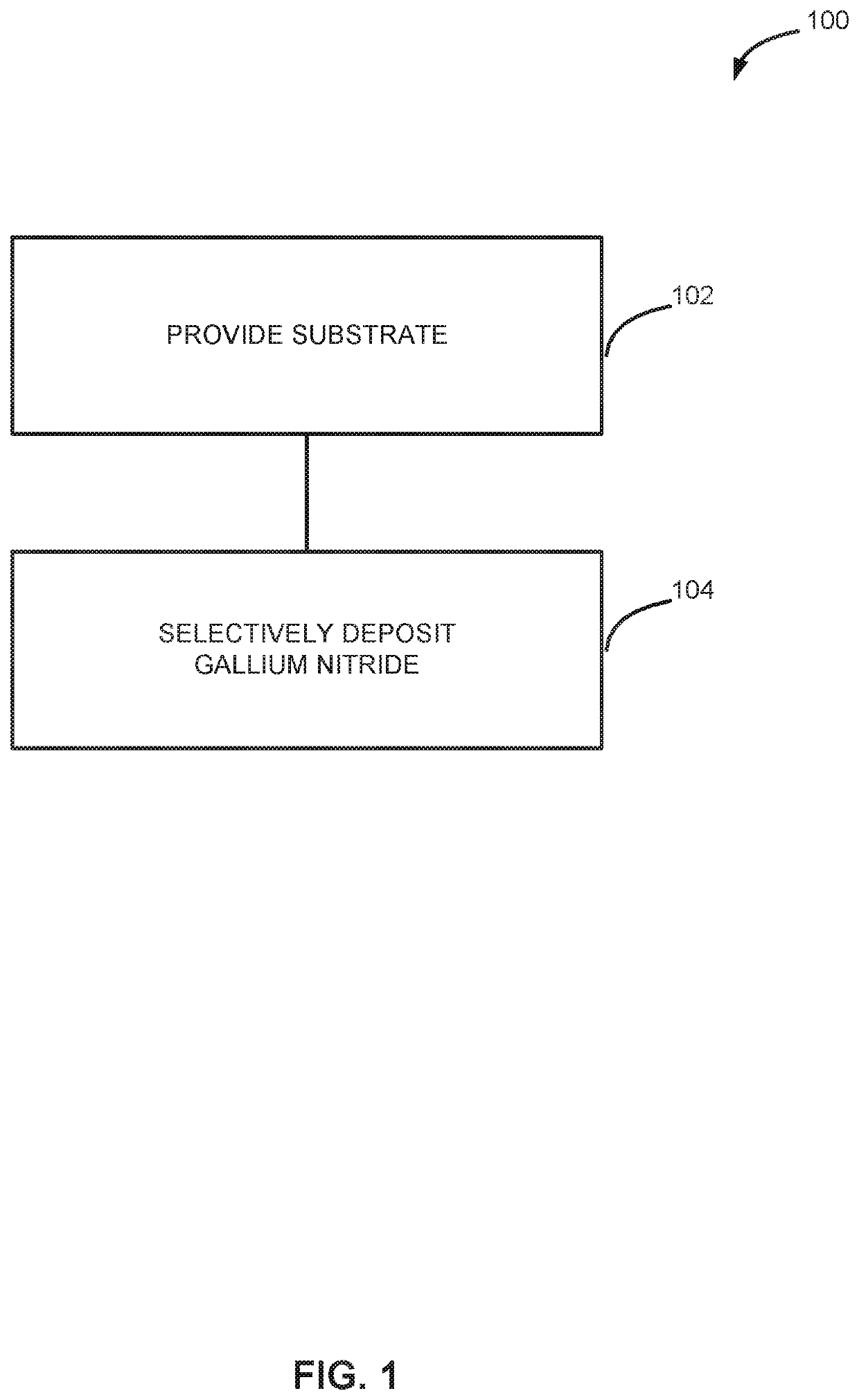

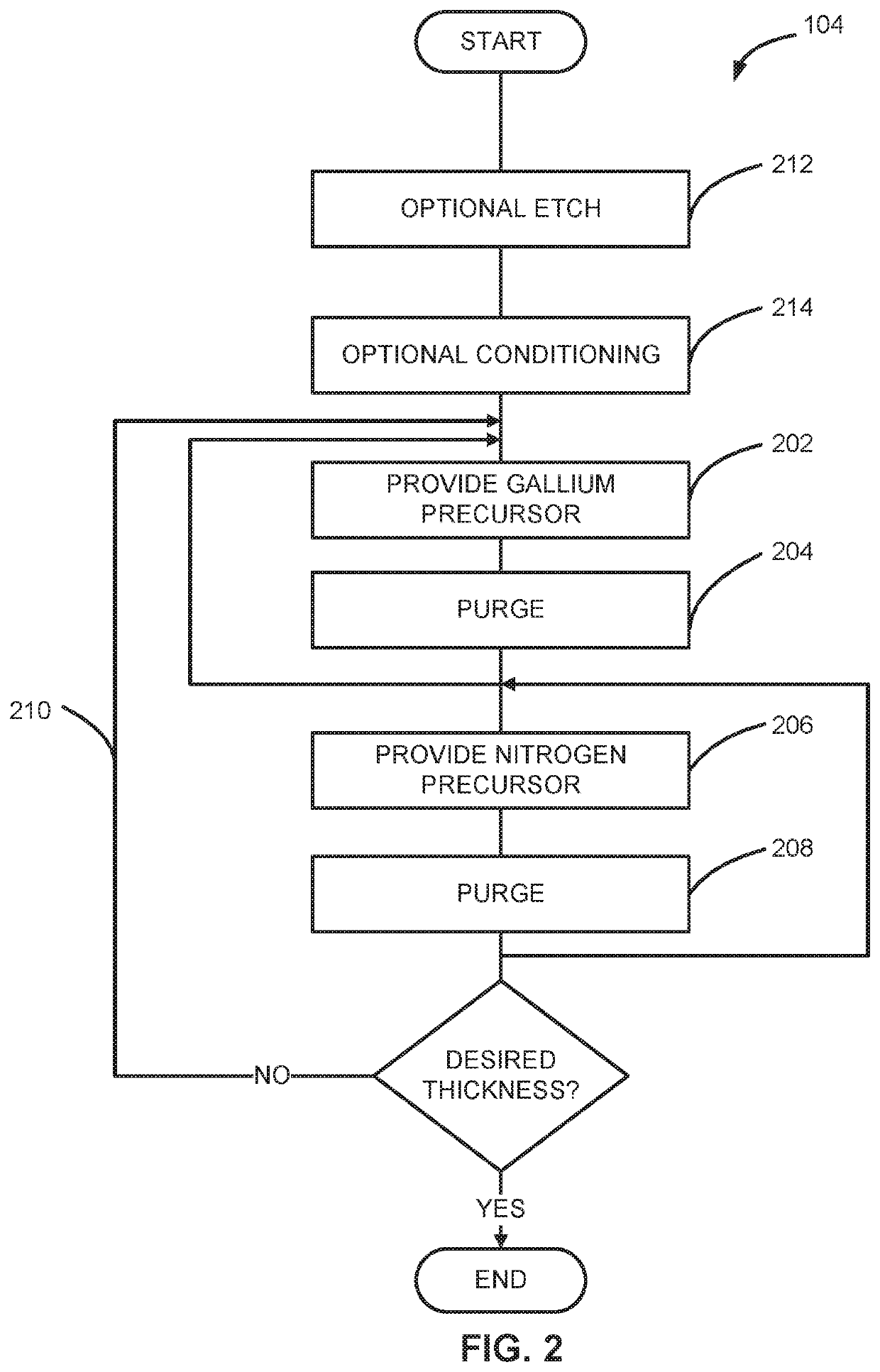

Method of forming a device structure using selective deposition of gallium nitride and system for same

ActiveUS20200194253A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringSelective deposition

Owner:ASM IP HLDG BV

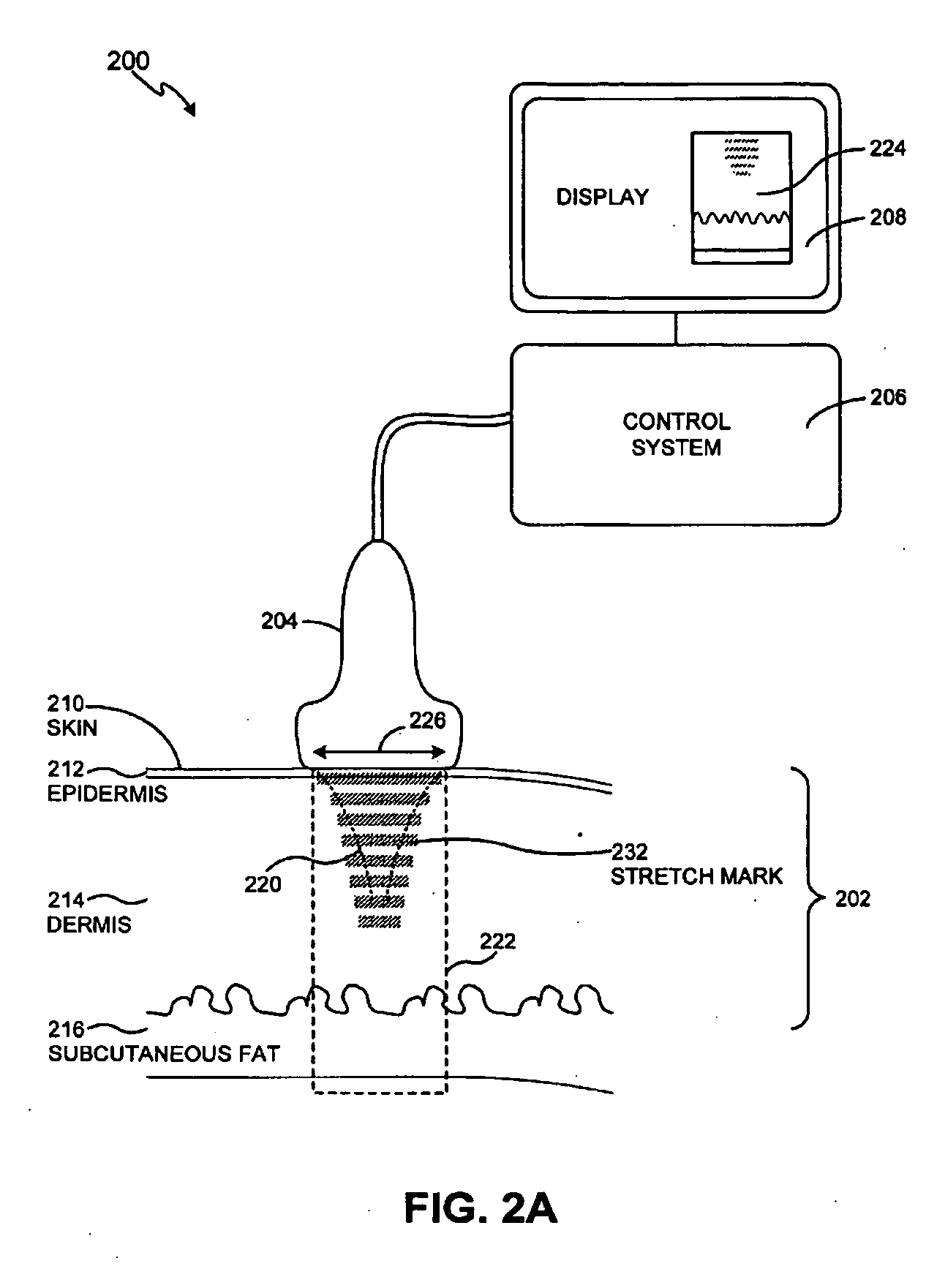

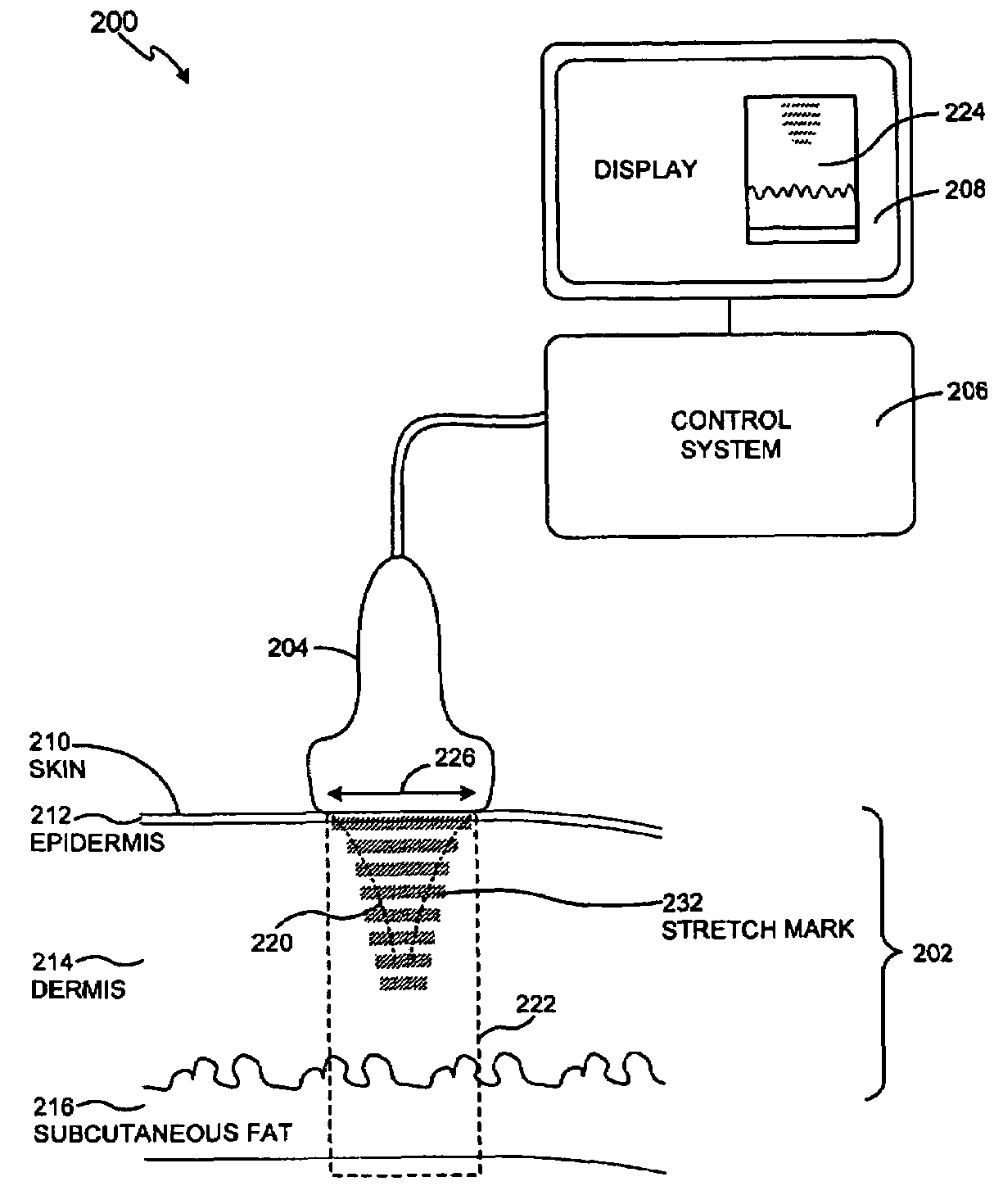

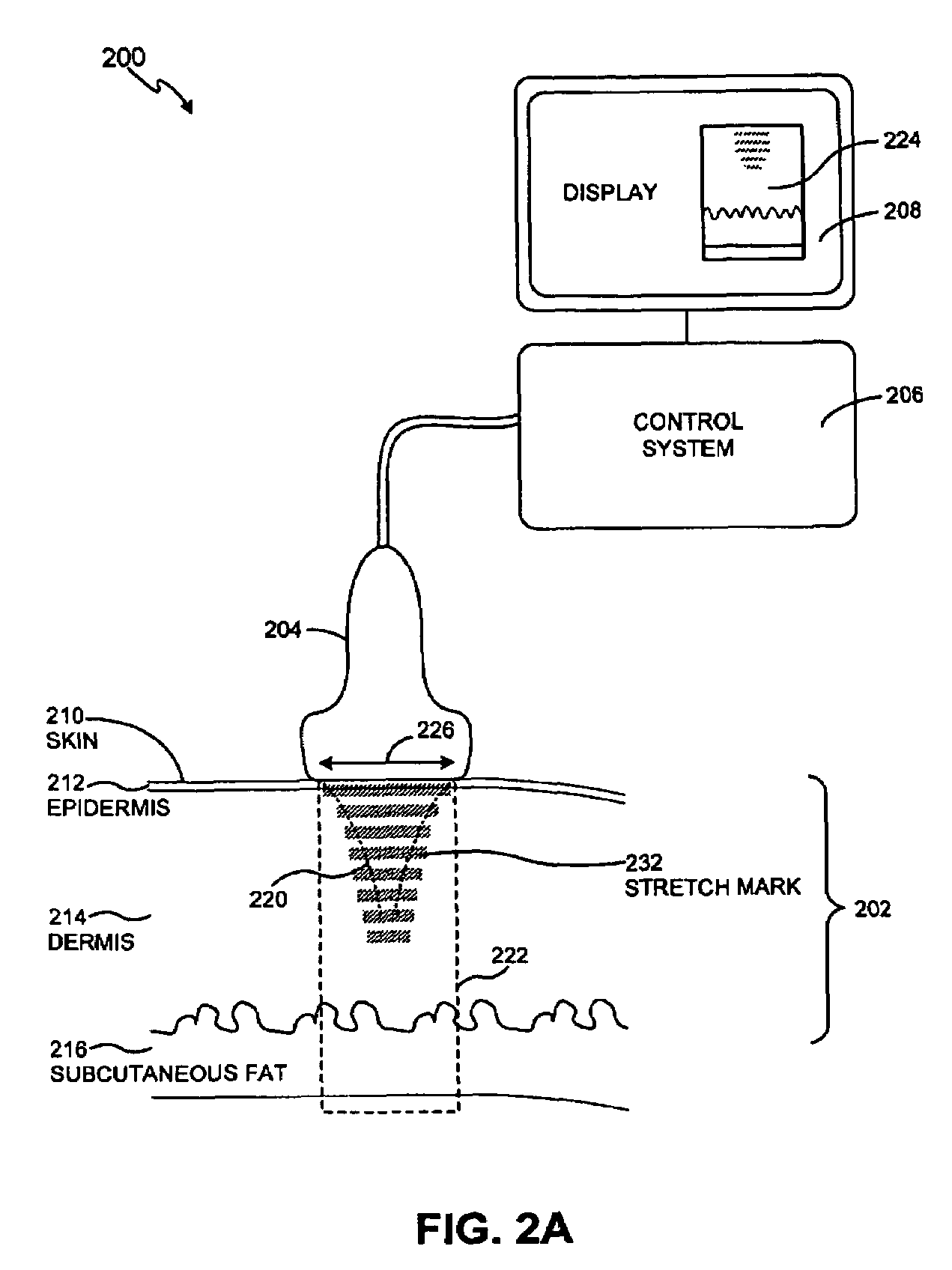

Method and system for treating stretch marks

Methods and systems for treating stretch marks through deep tissue tightening with ultrasound are provided. An exemplary method and system comprise a therapeutic ultrasound system configured for providing ultrasound treatment to a shallow tissue region, such as a region comprising an epidermis, a dermis and a deep dermis. In accordance with various exemplary embodiments, a therapeutic ultrasound system can be configured to achieve depth from 0 mm to 1 cm with a conformal selective deposition of ultrasound energy without damaging an intervening tissue in the range of frequencies from 2 to 50 MHz. In addition, a therapeutic ultrasound can also be configured in combination with ultrasound imaging or imaging / monitoring capabilities, either separately configured with imaging, therapy and monitoring systems or any level of integration thereof.

Owner:GUIDED THERAPY SYSTEMS LLC

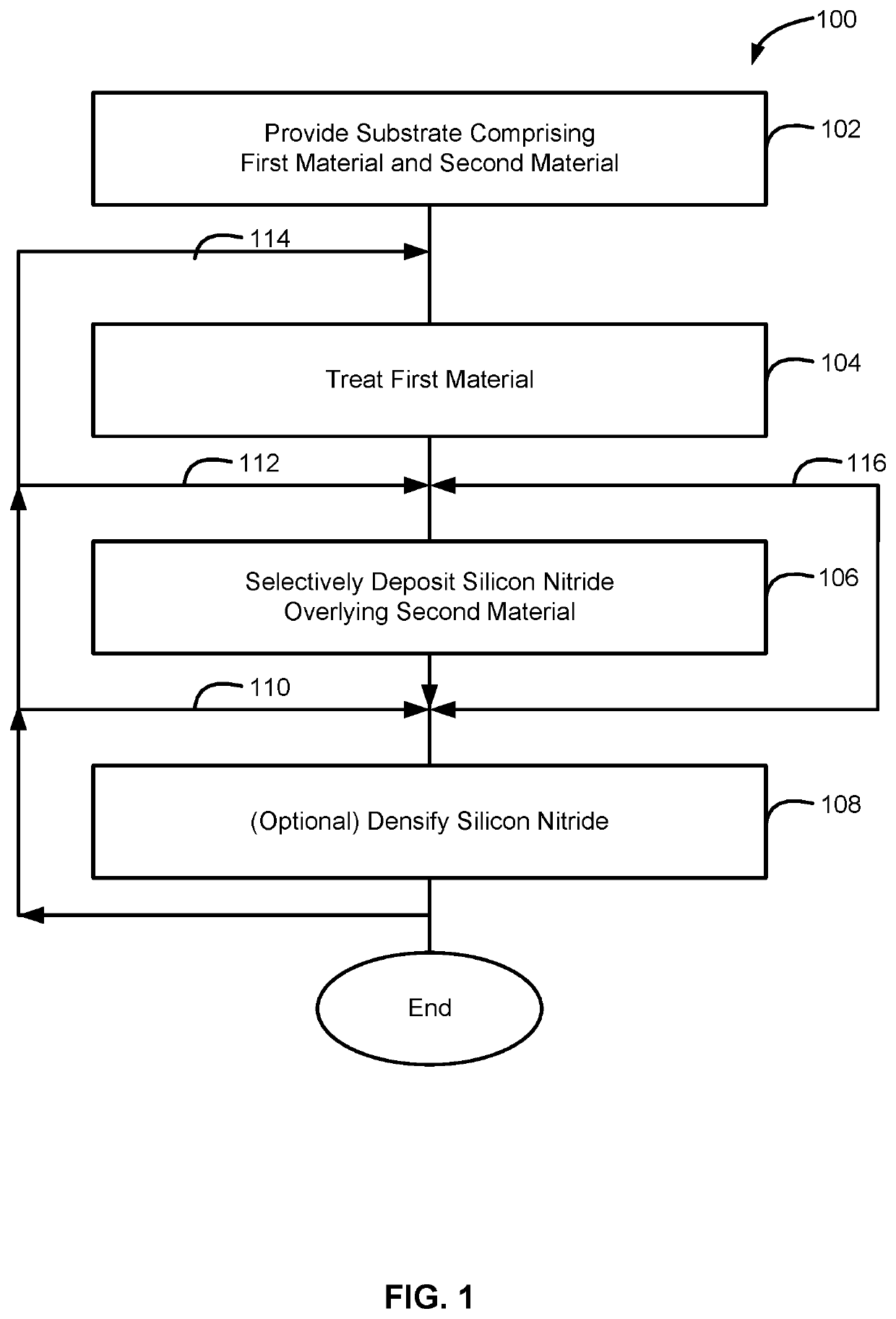

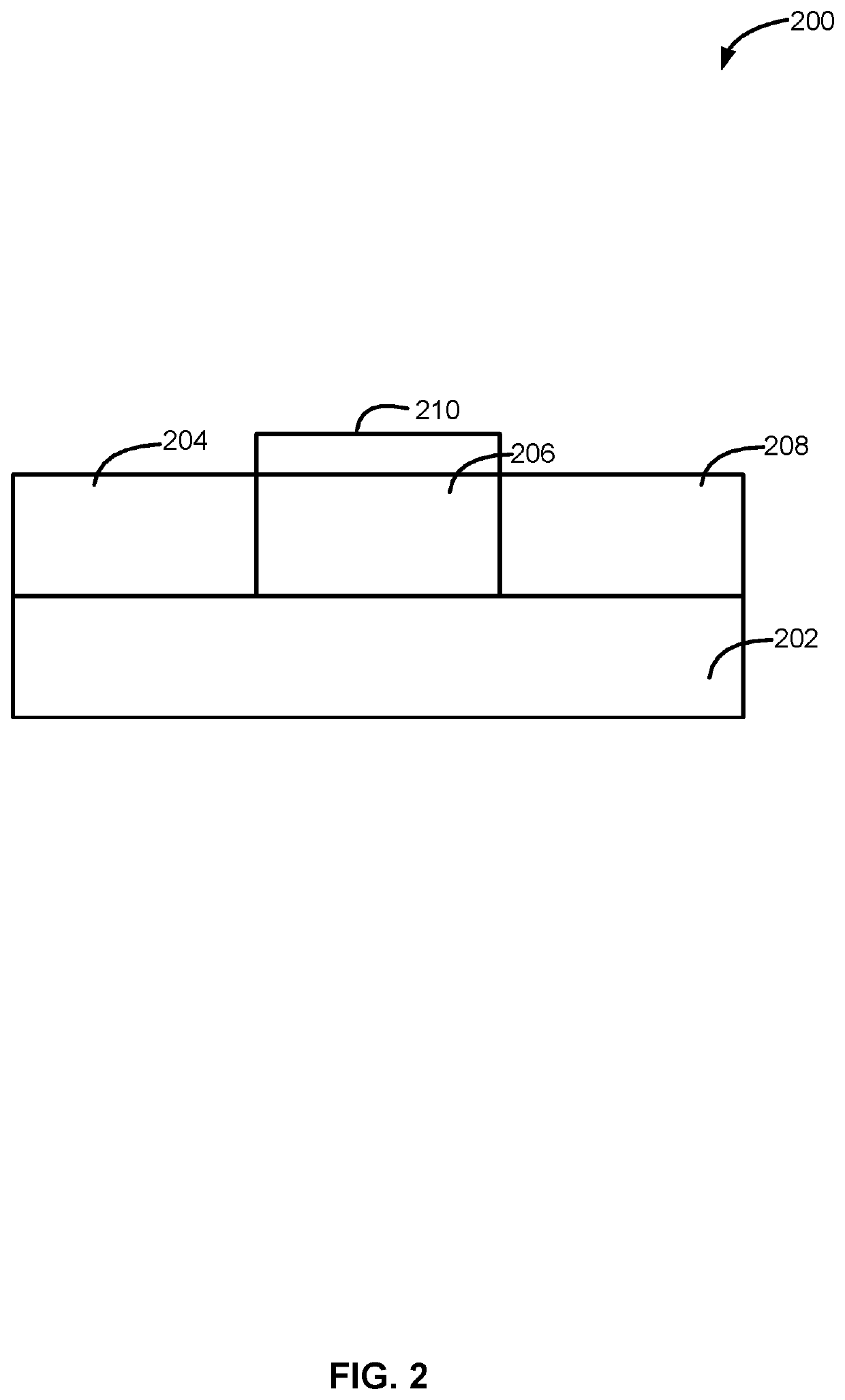

Method for selective deposition of silicon nitride layer and structure including selectively-deposited silicon nitride layer

ActiveUS20200286726A1Electric discharge tubesSemiconductor/solid-state device manufacturingSelective depositionMaterials science

A method for selectively depositing silicon nitride on a first material relative to a second material is disclosed. An exemplary method includes treating the first material, and then selectively depositing a layer comprising silicon nitride on the second material relative to the first material. Exemplary methods can further include treating the deposited silicon nitride.

Owner:ASM IP HLDG BV

Selective formation of metal layers in an integrated circuit

ActiveUS20060121733A1Improve reliabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingCopper interconnectSelective deposition

A method for enhancing the reliability of copper interconnects and / or contacts, such as the bottom of vias exposing top surfaces of buried copper, or at the top of copper lines just after CMP. The method comprises contacting the exposed copper surface with a vapor phase compound of a noble metal and selectively forming a layer of the noble metal on the exposed copper surface, either by a copper replacement reaction or selective deposition (e.g., ALD or CVD) of the noble metal.

Owner:ASM JAPAN

Radiation-assisted selective deposition of metal-containing cap layers

InactiveUS20100210108A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialSelective deposition

A method for integrating metal-containing cap layers into copper (Cu) metallization of semiconductor devices to improve electromigration and stress migration in bulk Cu metal. In one embodiment, the method includes providing a patterned substrate containing Cu metal surfaces and dielectric layer surfaces, exposing the patterned substrate to a process gas comprising a metal-containing precursor, and irradiating the patterned substrate with electromagnetic radiation, where selective metal-containing cap layer formation on the Cu metal surfaces is facilitated by the electromagnetic radiation. In some embodiments, the method further includes pre-treating the patterned substrate with additional electromagnetic radiation and optionally a cleaning gas prior to forming the metal-containing cap layer.

Owner:TOKYO ELECTRON LTD

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6270335B2Less distortionReduce the risk of bridgingAdditive manufacturing apparatusConfectioneryEngineeringSelective deposition

Owner:3D SYST INC

Method and system for treating stretch marks

Methods and systems for treating stretch marks through deep tissue tightening with ultrasound are provided. An exemplary method and system comprise a therapeutic ultrasound system configured for providing ultrasound treatment to a shallow tissue region, such as a region comprising an epidermis, a dermis and a deep dermis. In accordance with various exemplary embodiments, a therapeutic ultrasound system can be configured to achieve depth from 0 mm to 1 cm with a conformal selective deposition of ultrasound energy without damaging an intervening tissue in the range of frequencies from 2 to 50 MHz. In addition, a therapeutic ultrasound can also be configured in combination with ultrasound imaging or imaging / monitoring capabilities, either separately configured with imaging, therapy and monitoring systems or any level of integration thereof.

Owner:GUIDED THERAPY SYSTEMS LLC

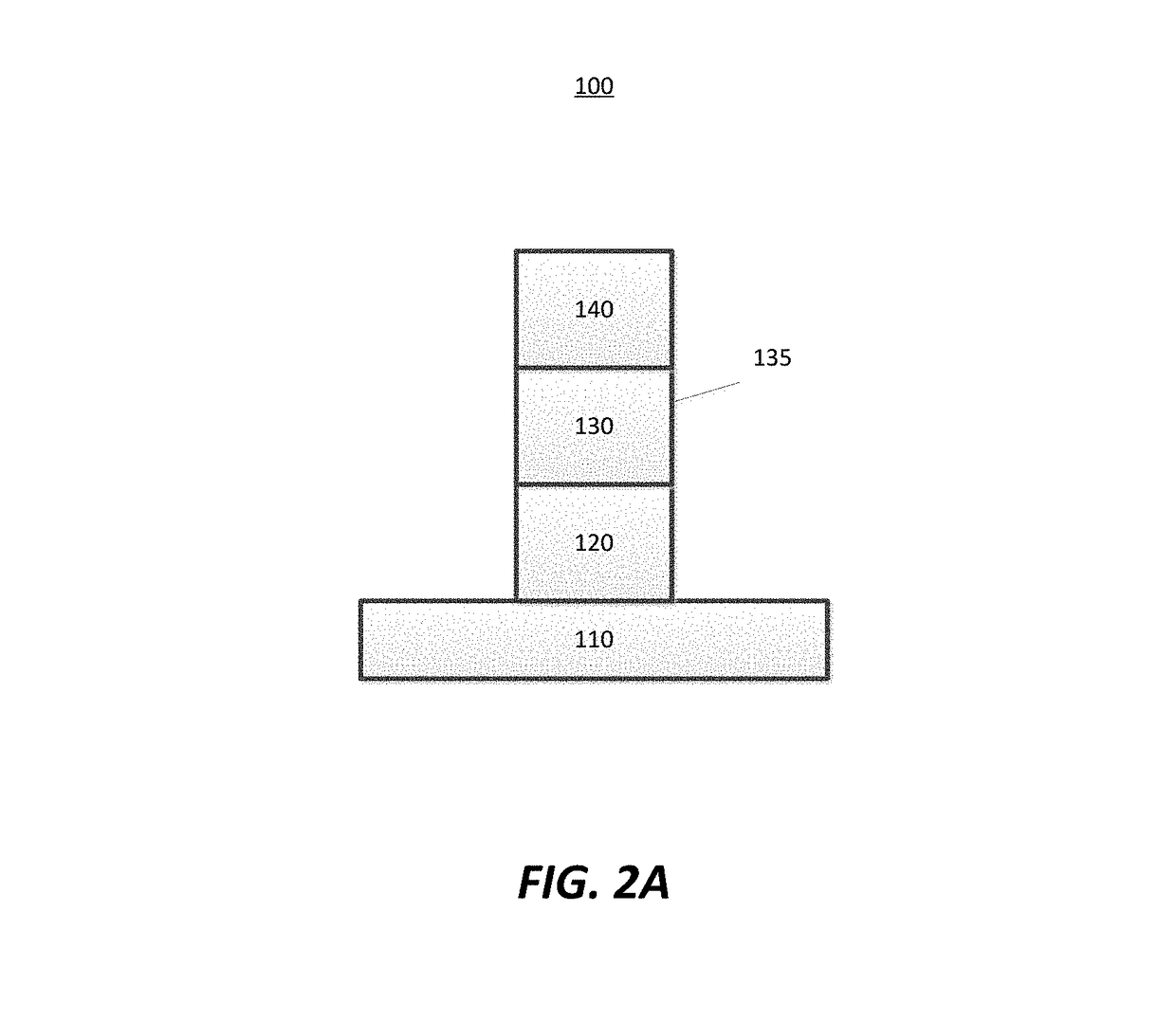

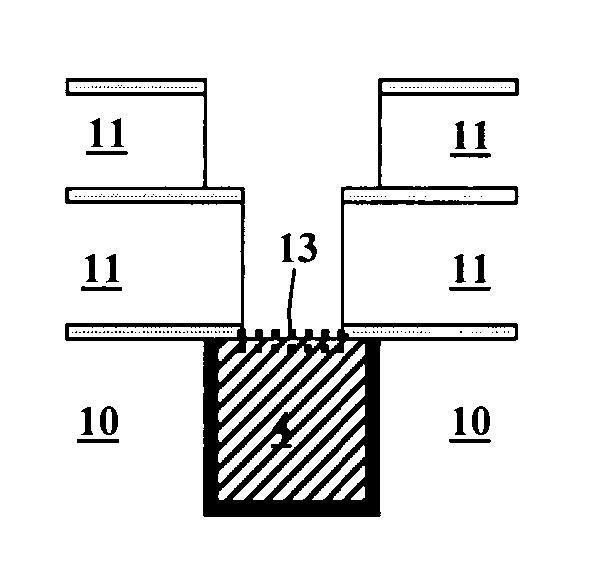

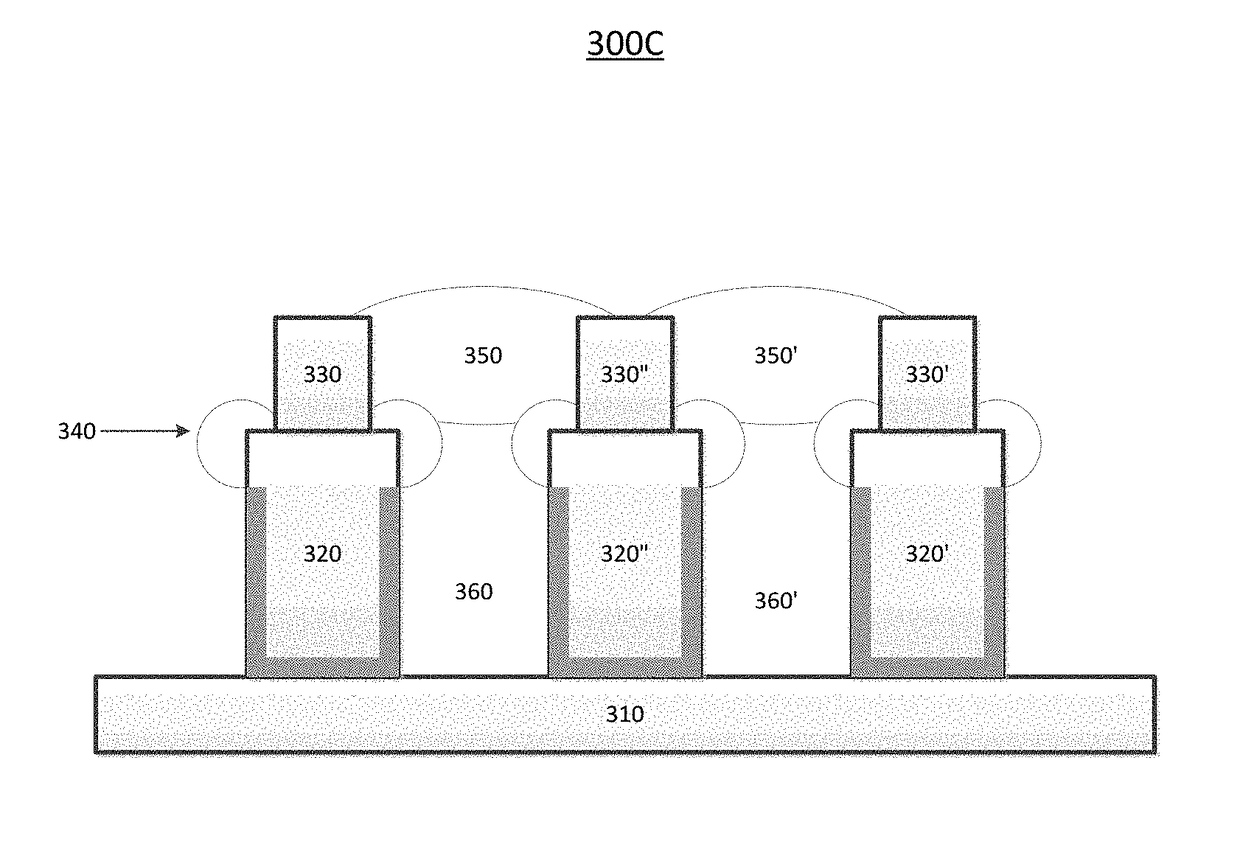

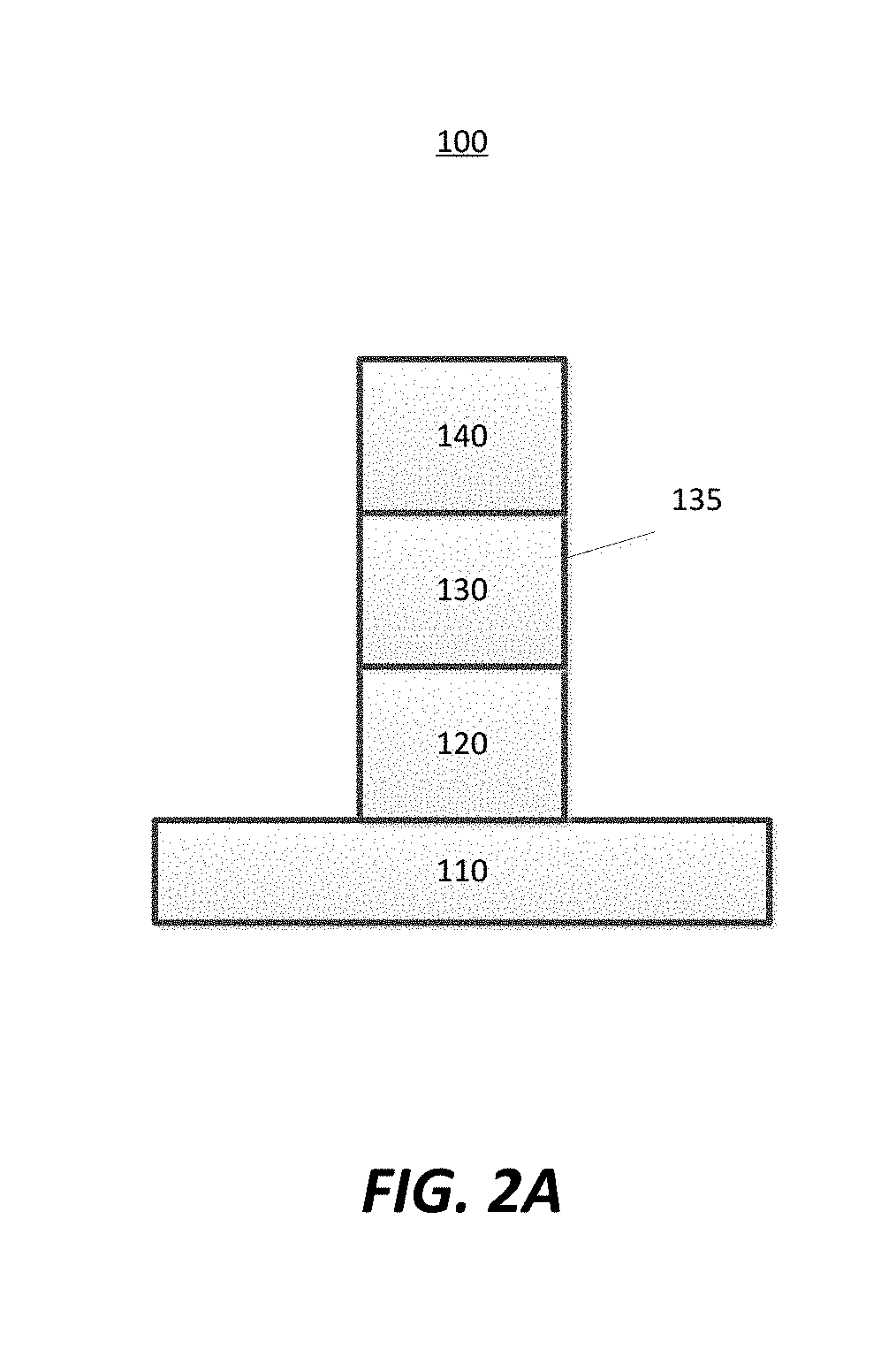

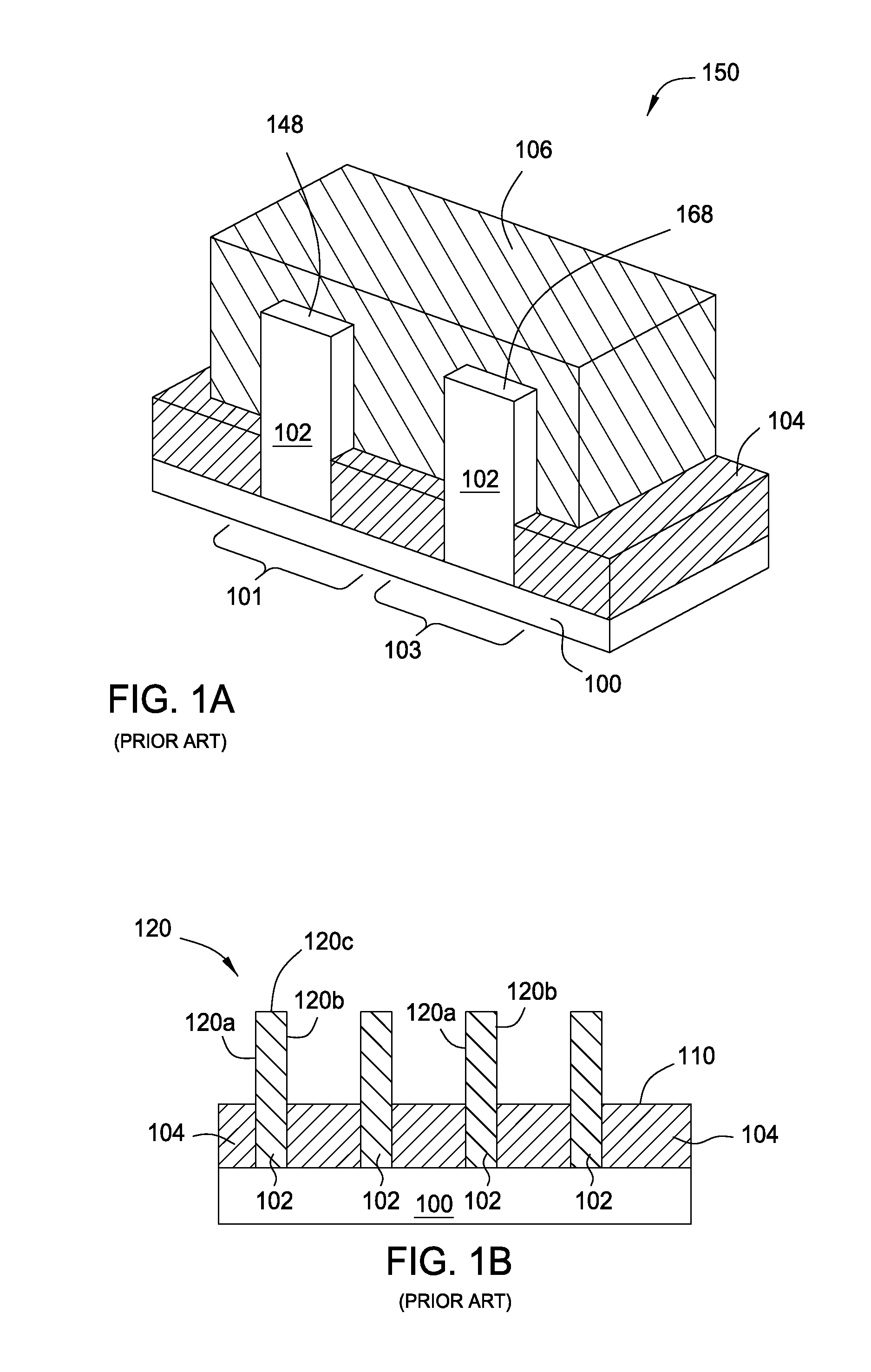

Method and apparatus for selective deposition

ActiveUS20160005839A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSelective deposition

Methods for forming fin structures with desired materials formed on different locations of the fin structure using a selective deposition process for fin field effect transistors (FinFETs) are provided. In one embodiment, a method of forming a structure with desired materials on a substrate includes depositing a first material on a substrate having a three-dimensional (3D) structure formed thereon while performing an implantation process to dope a first region of the 3D structure. The first material may be removed and a second material may be deposited on the 3D structure. The second material may selectively grow on a second region of the 3D structure.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com