Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5001 results about "Manufacturing systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

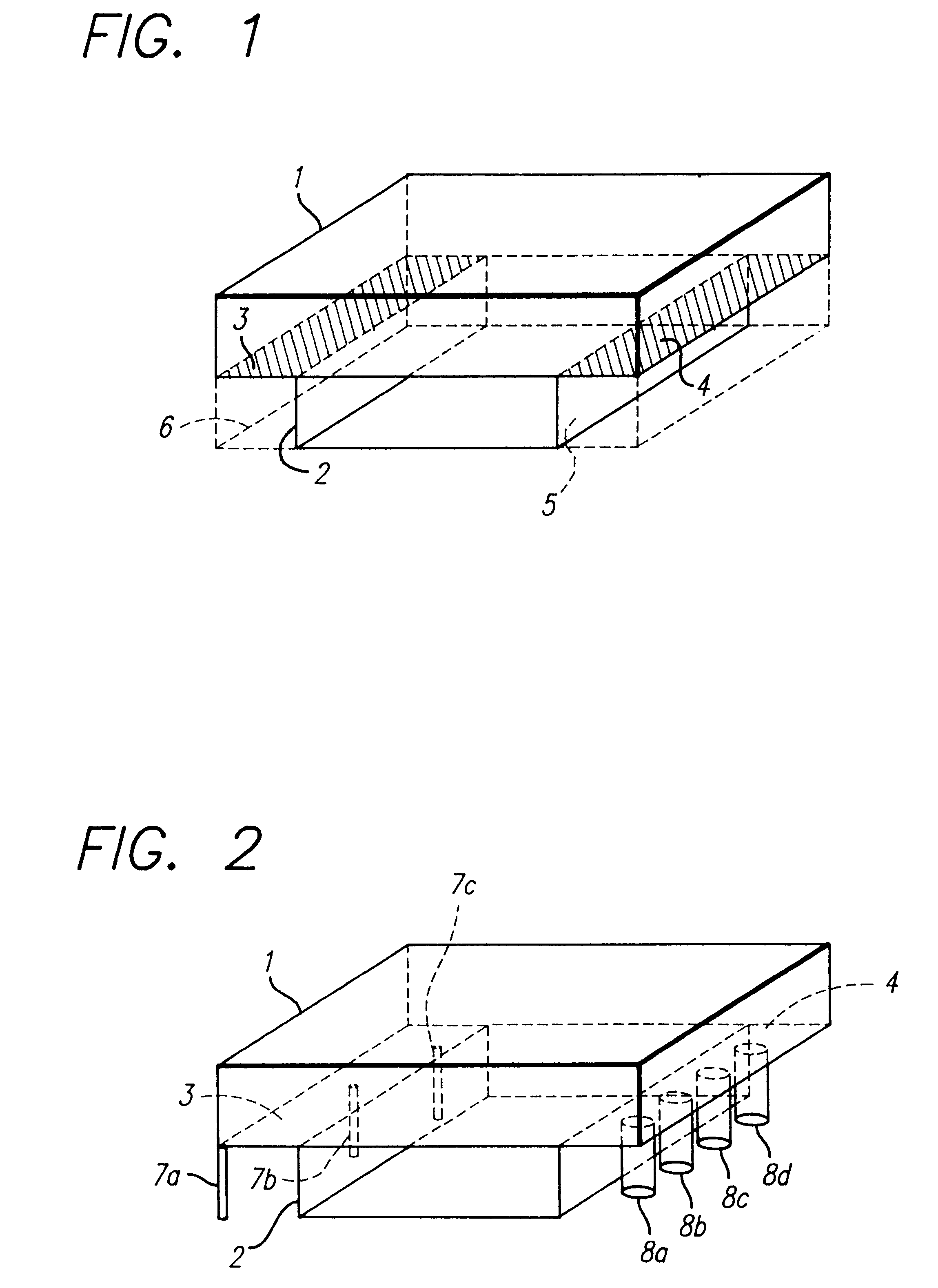

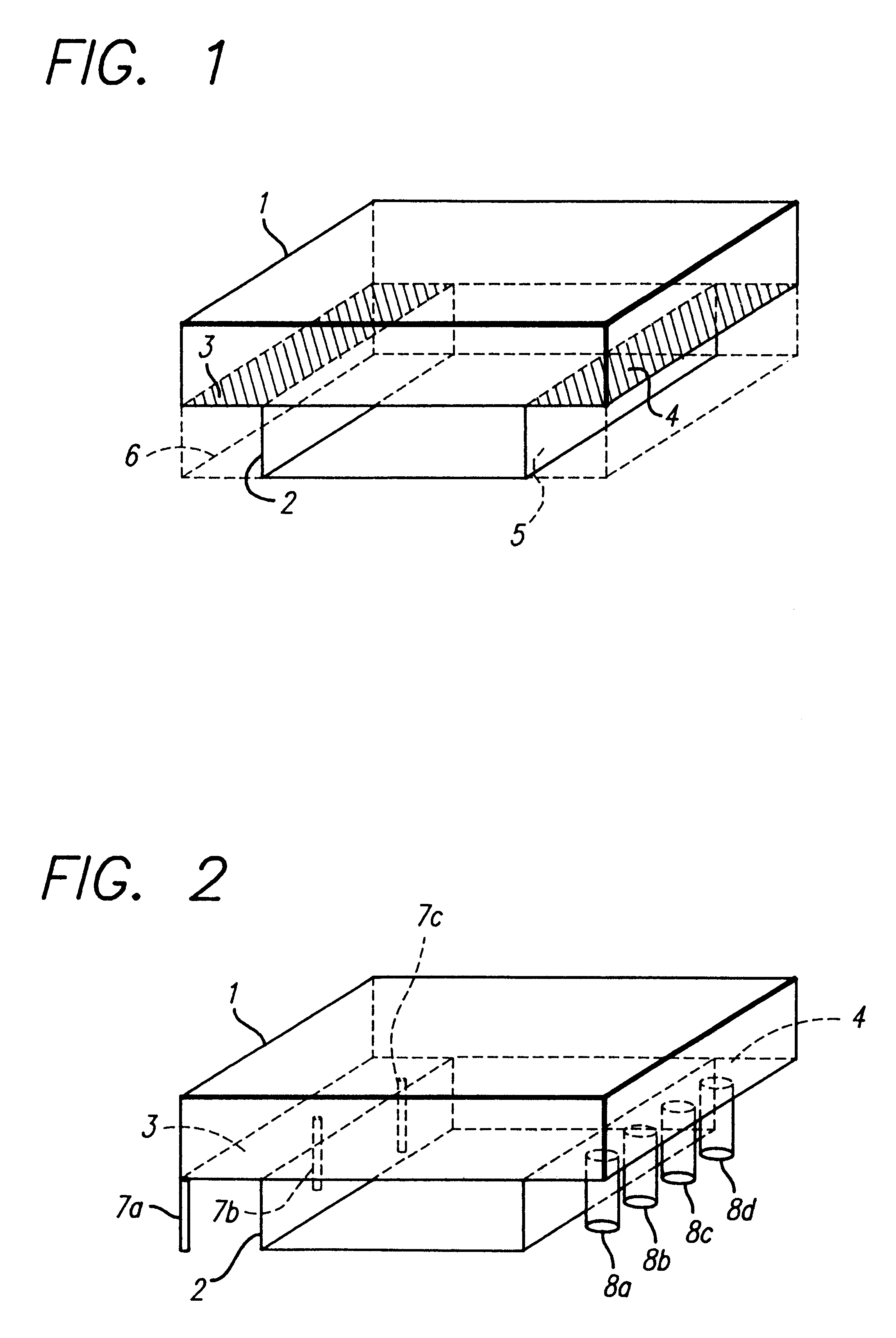

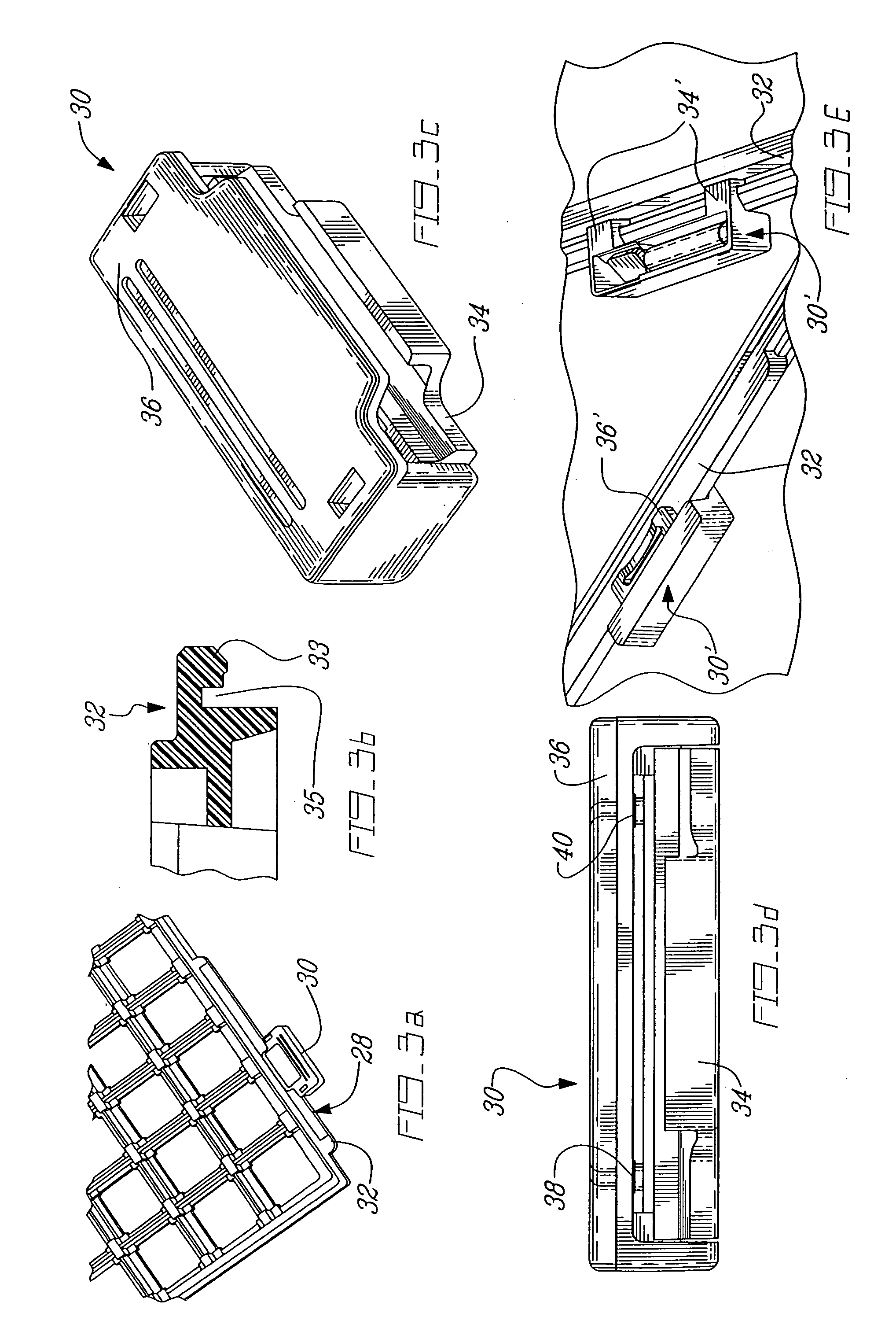

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6193923B1Easy to disassembleMinimal damageAdditive manufacturing apparatusCeramic shaping apparatusEngineeringSelective deposition

A variety of support structures and build styles for use in Rapid Prototyping and Manufacturing systems are described wherein particular emphasis is given to Thermal Stereolithography, Fused Deposition Modeling, and Selective Deposition Modeling systems, and wherein a 3D modeling system is presented which uses multijet dispensing and a single material for both object and support formation.

Owner:3D SYST INC

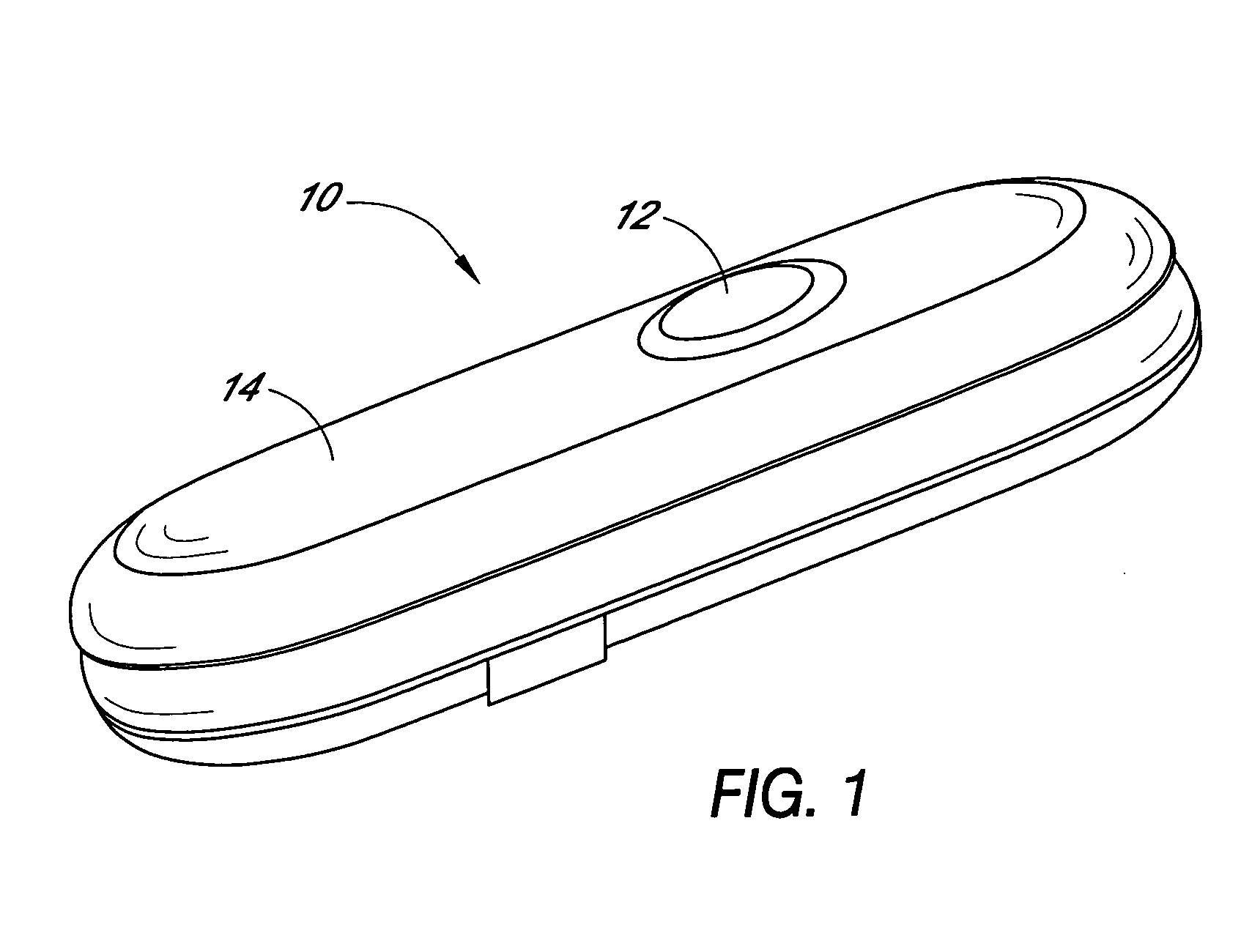

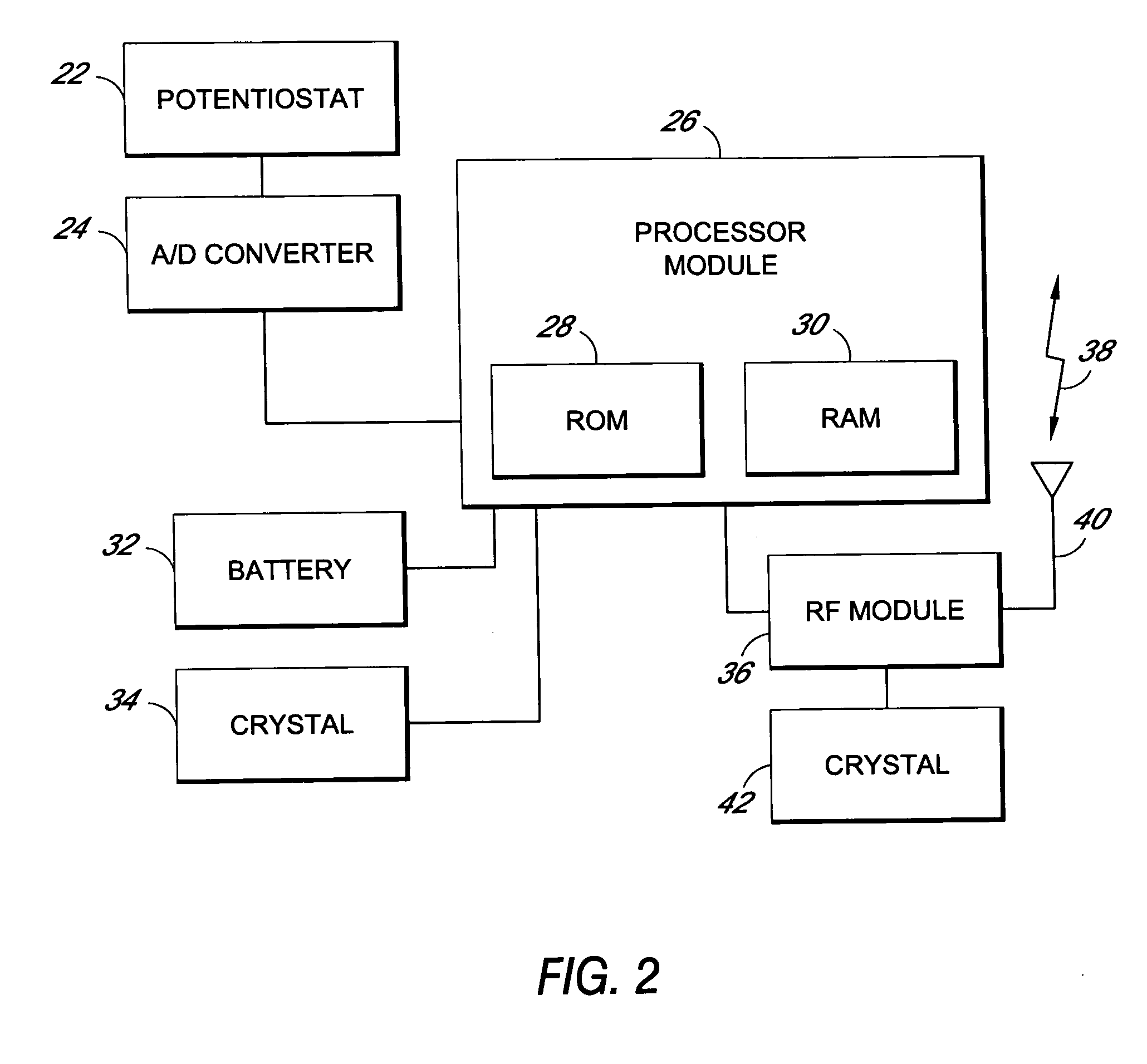

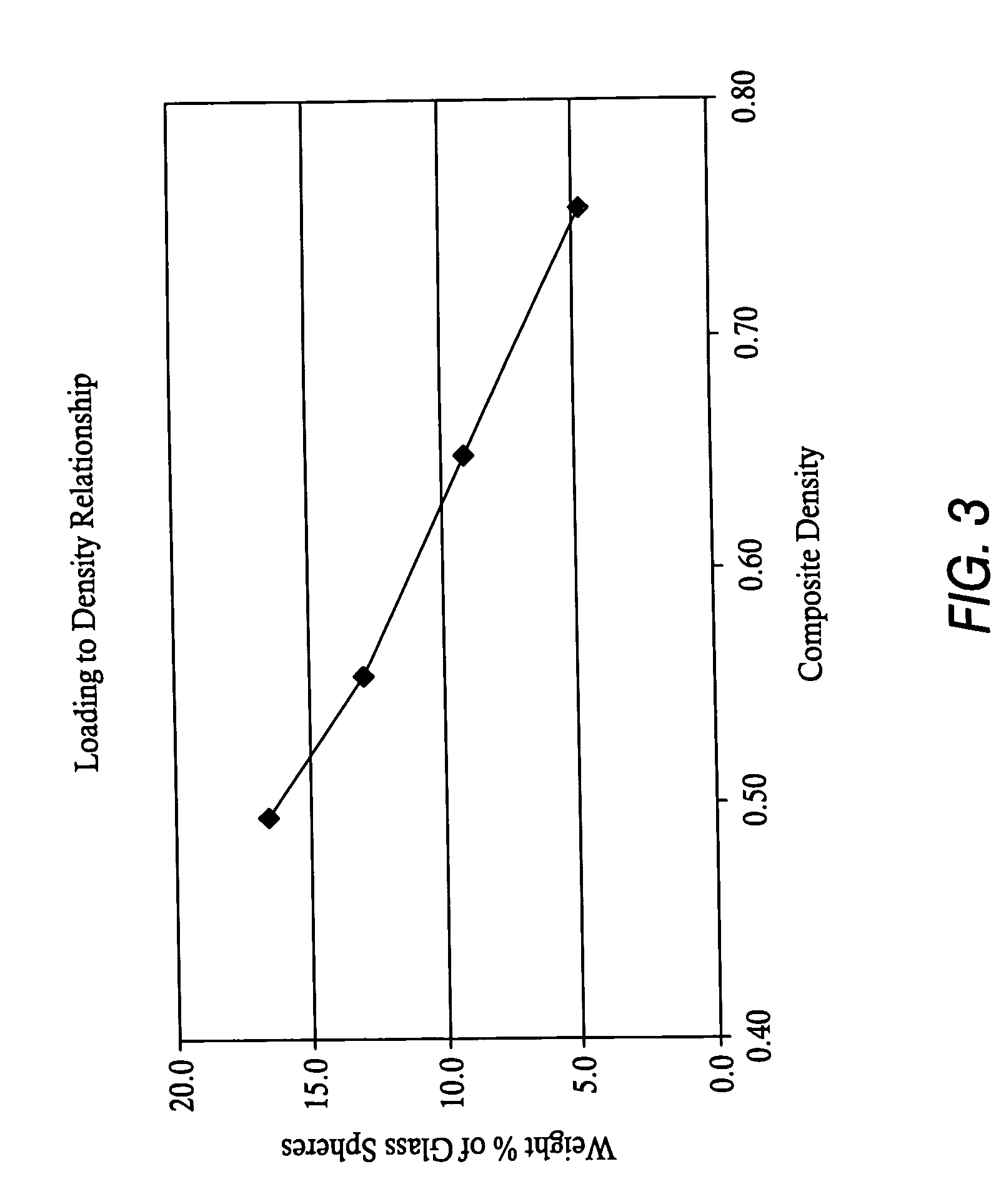

Composite material for implantable device

Devices suitable for implantation in a body of a host and systems and methods for their manufacture are provided. The implantable devices include a composite material formed at least from a matrix material and hollow gas-filled beads. In preferred embodiments, the composite material includes a polymeric matrix mixed with hollow air-filled glass beads, which are mixed and cured to form at least a portion of the body of the implantable device. Implantable devices including this composite material have decreased weight and / or overall density as compared to implantable devices without the beads incorporated therein, which is believed to improve the acceptance and function of the implantable device in vivo. Additionally, implantable devices concerned with transmitting and receiving via RF are believed to achieve improved RF performance due to a reduced dielectric constant provided by the incorporation of beads within the composite material.

Owner:DEXCOM

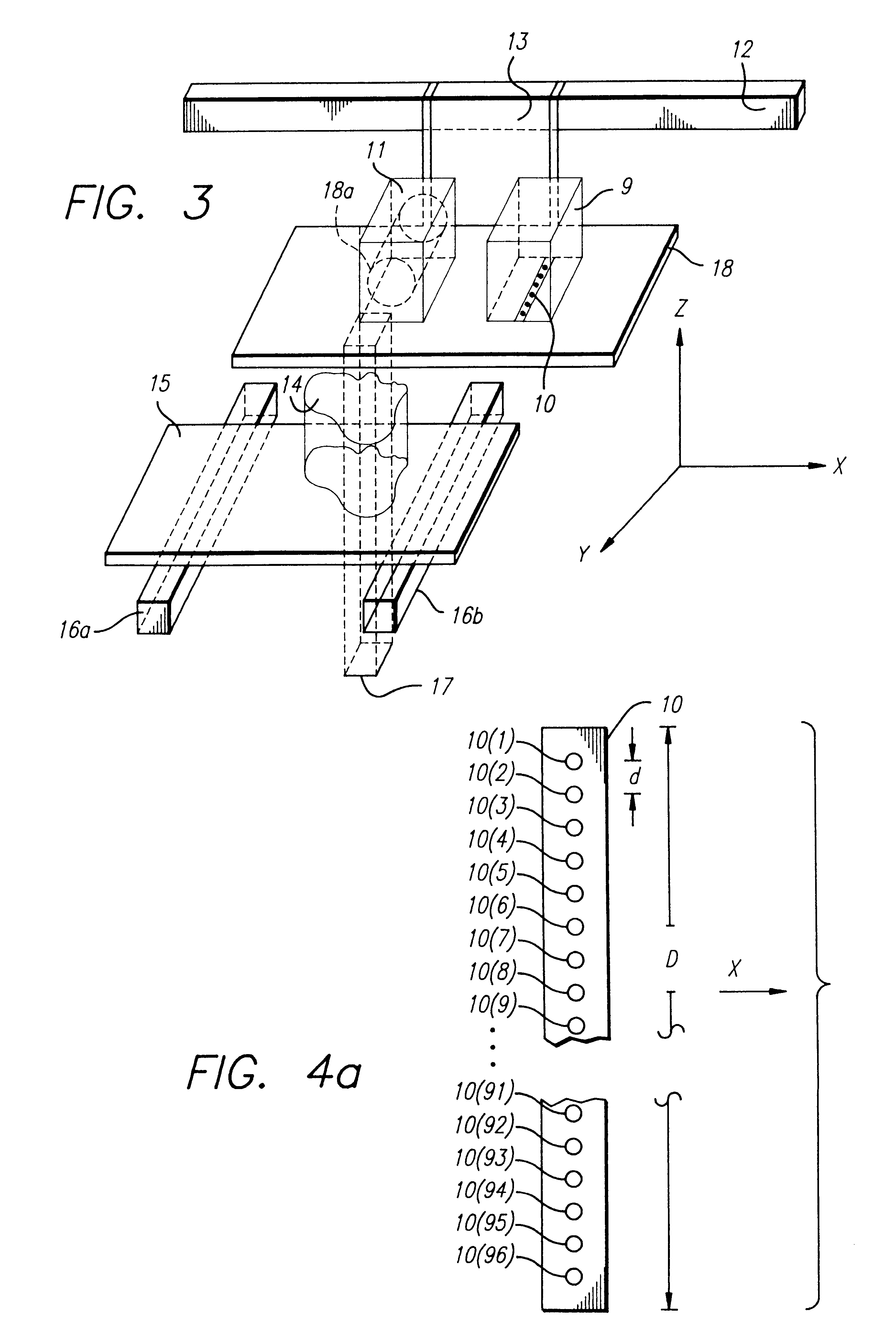

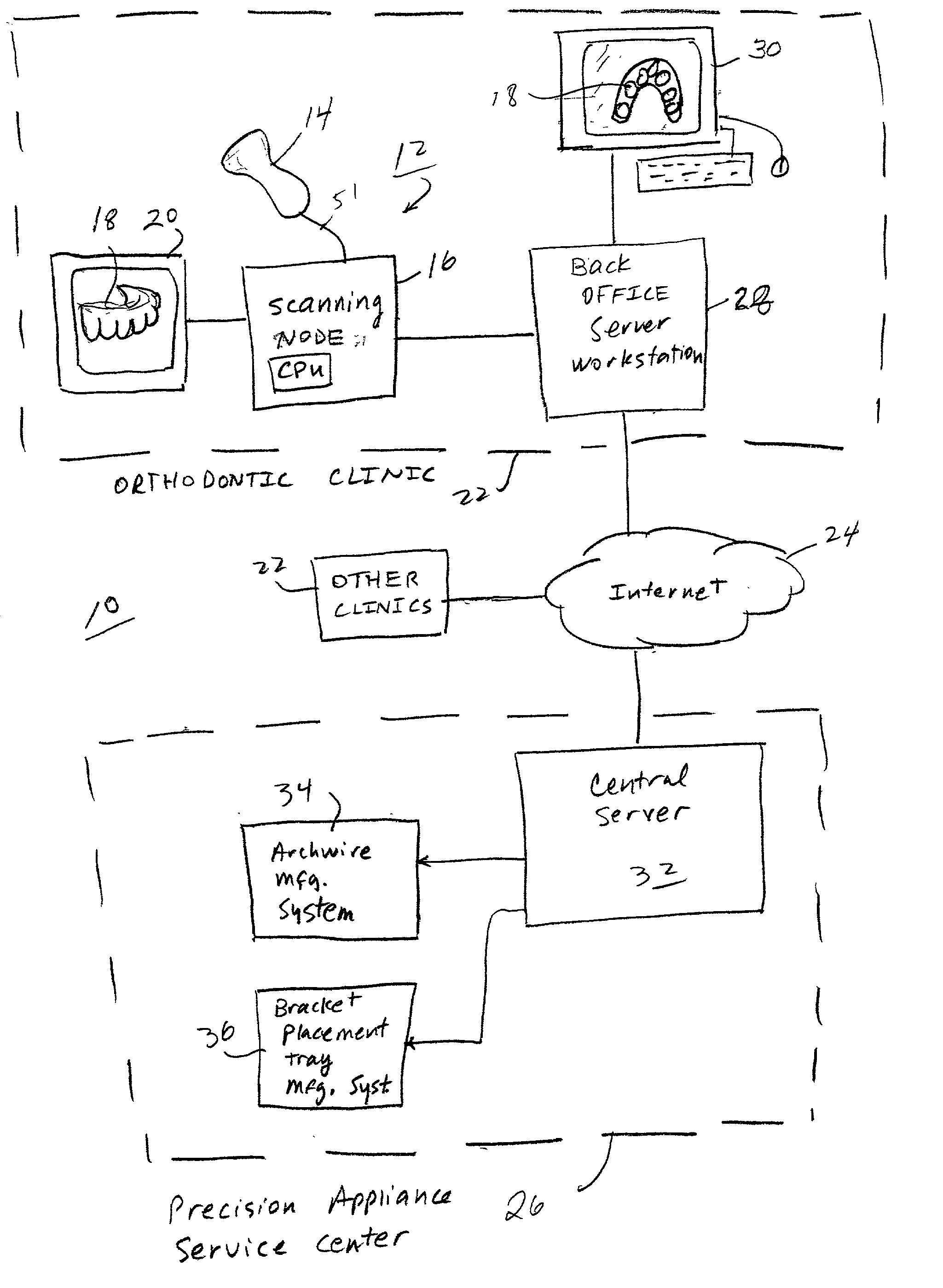

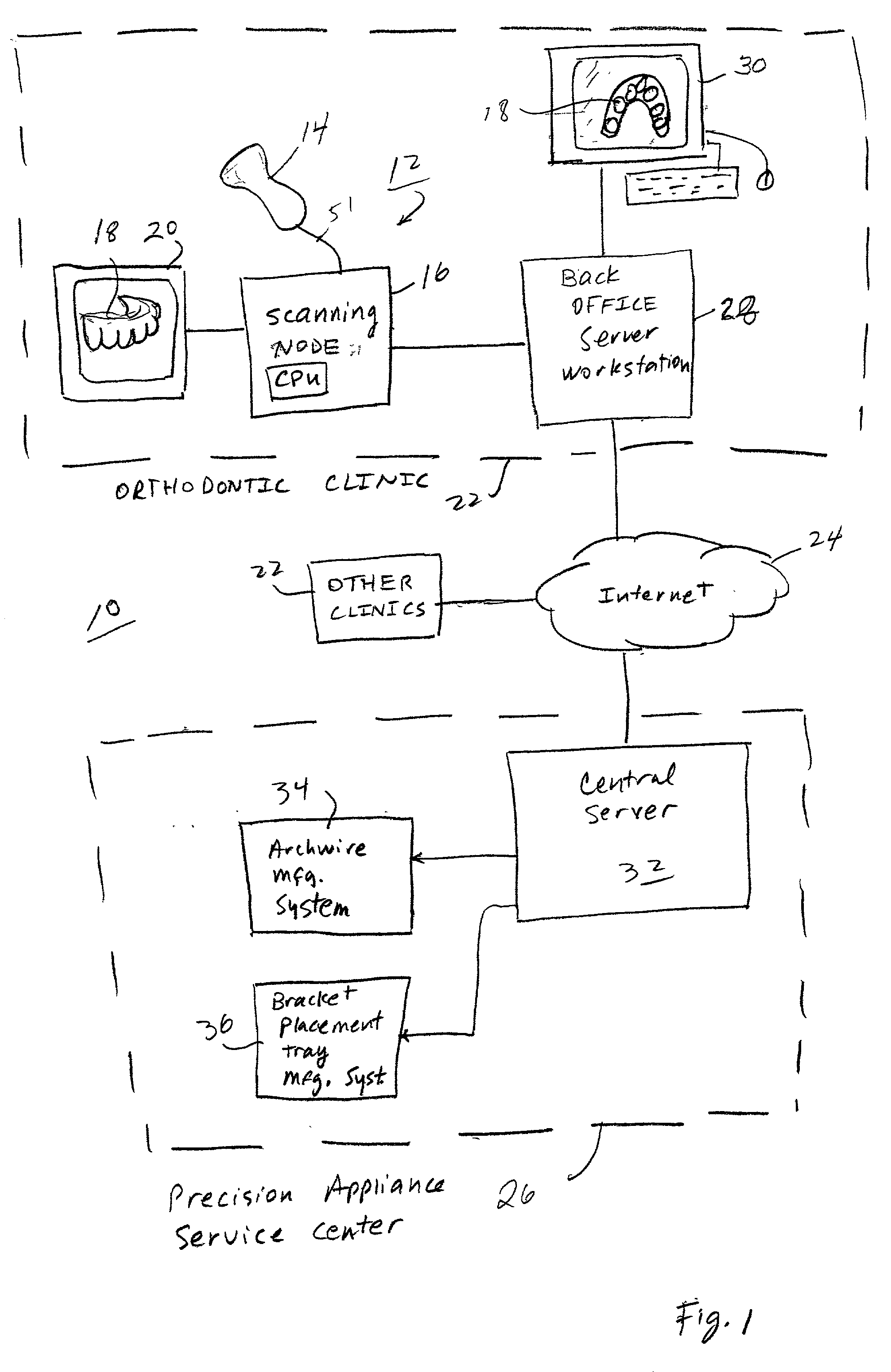

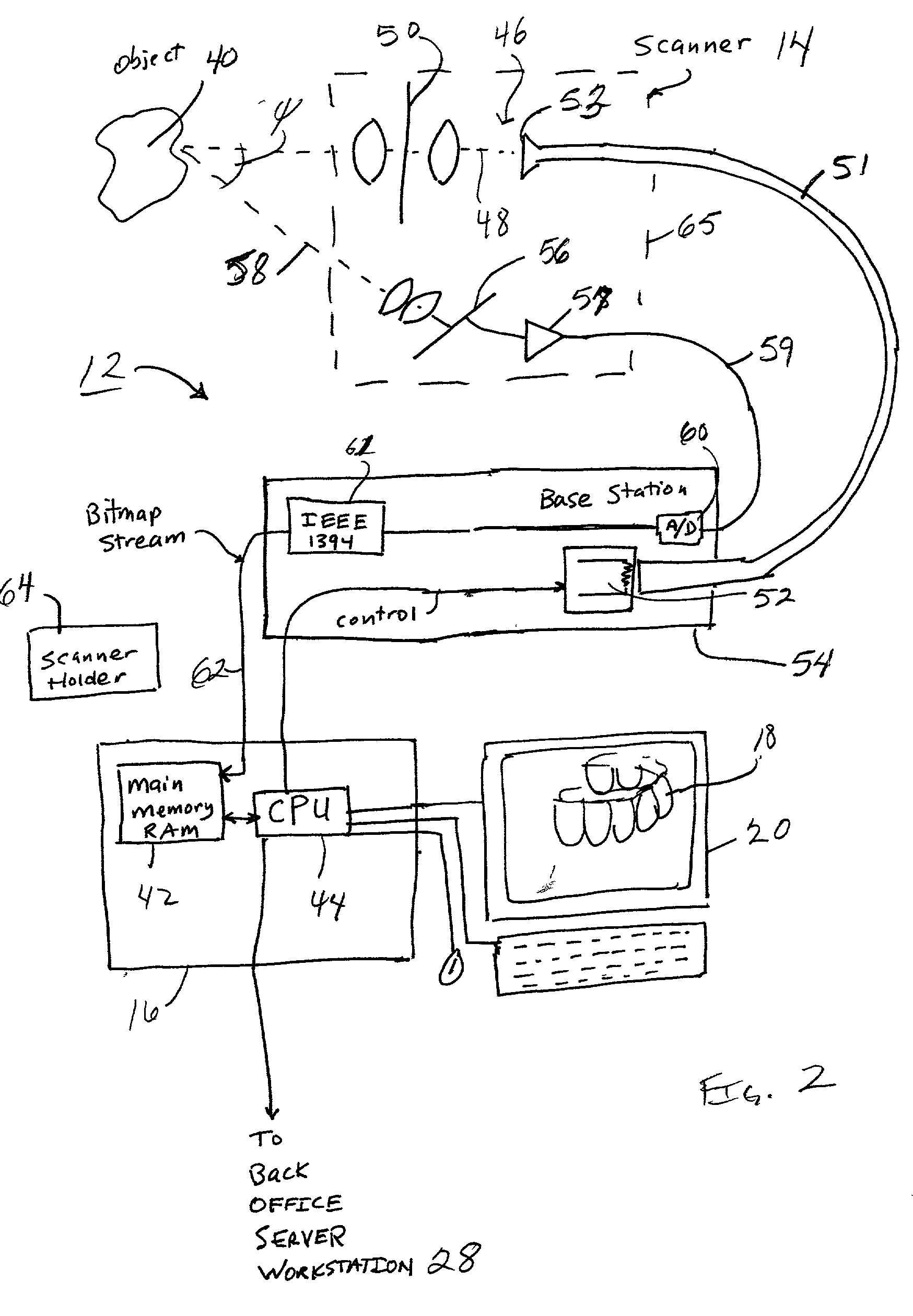

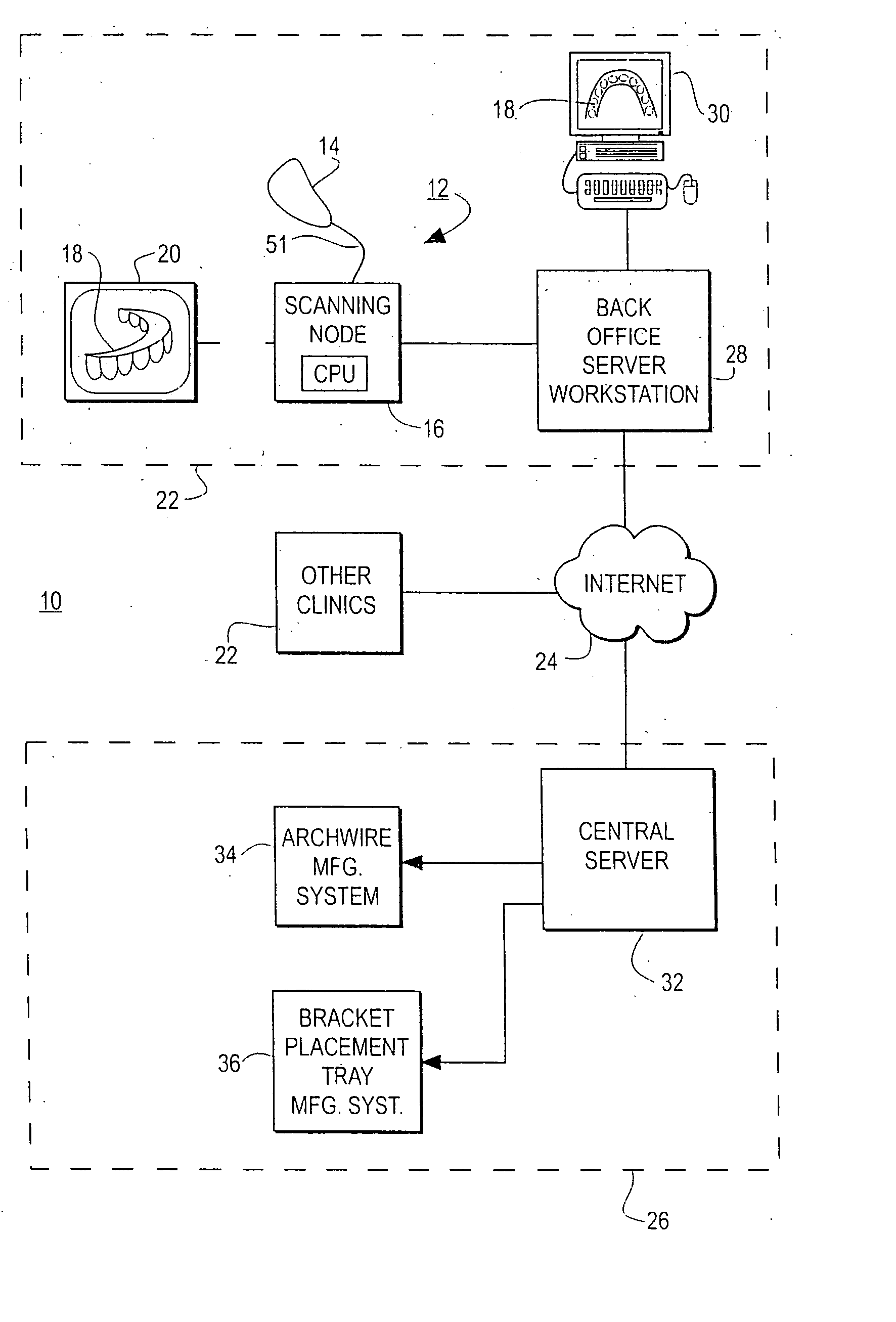

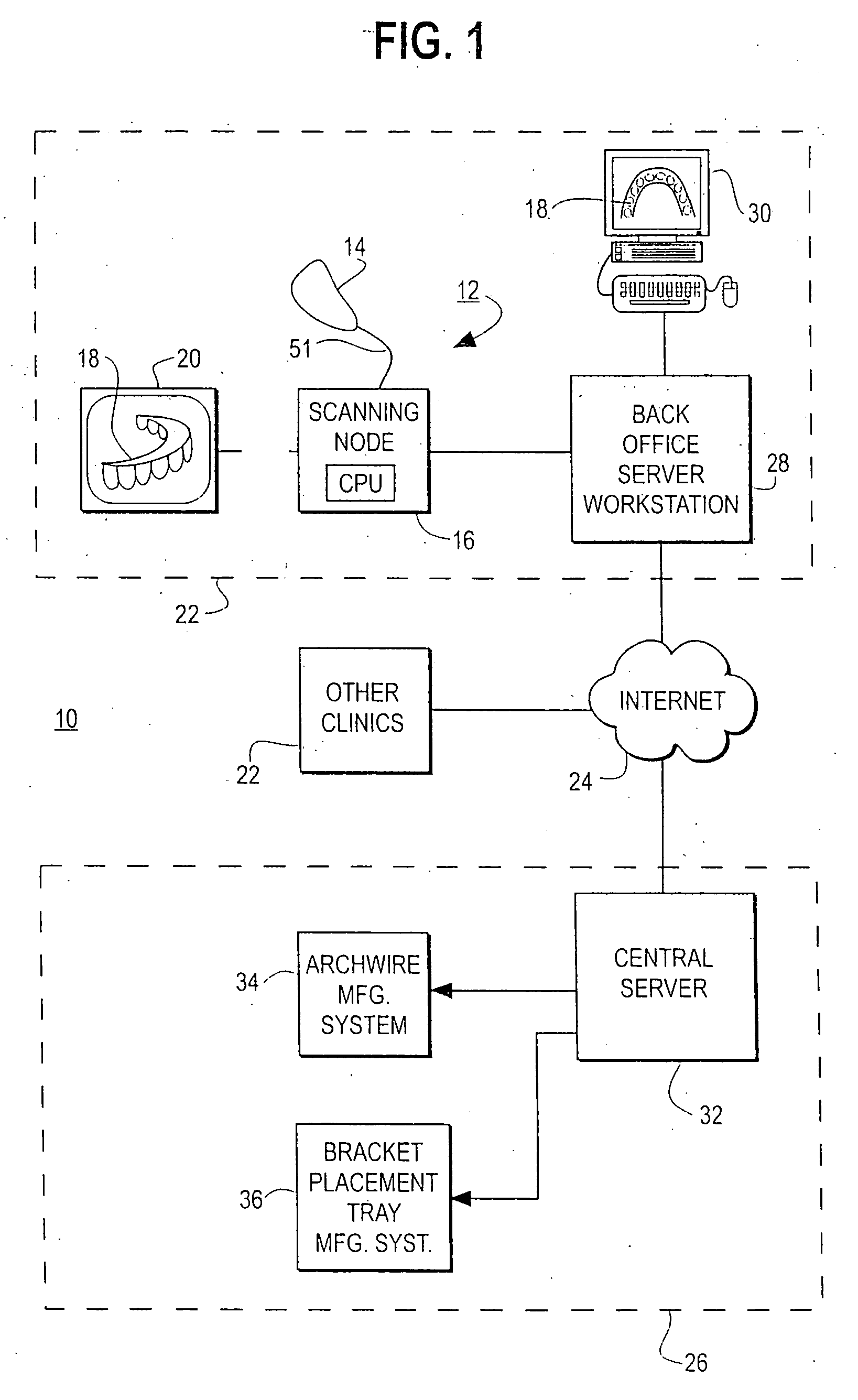

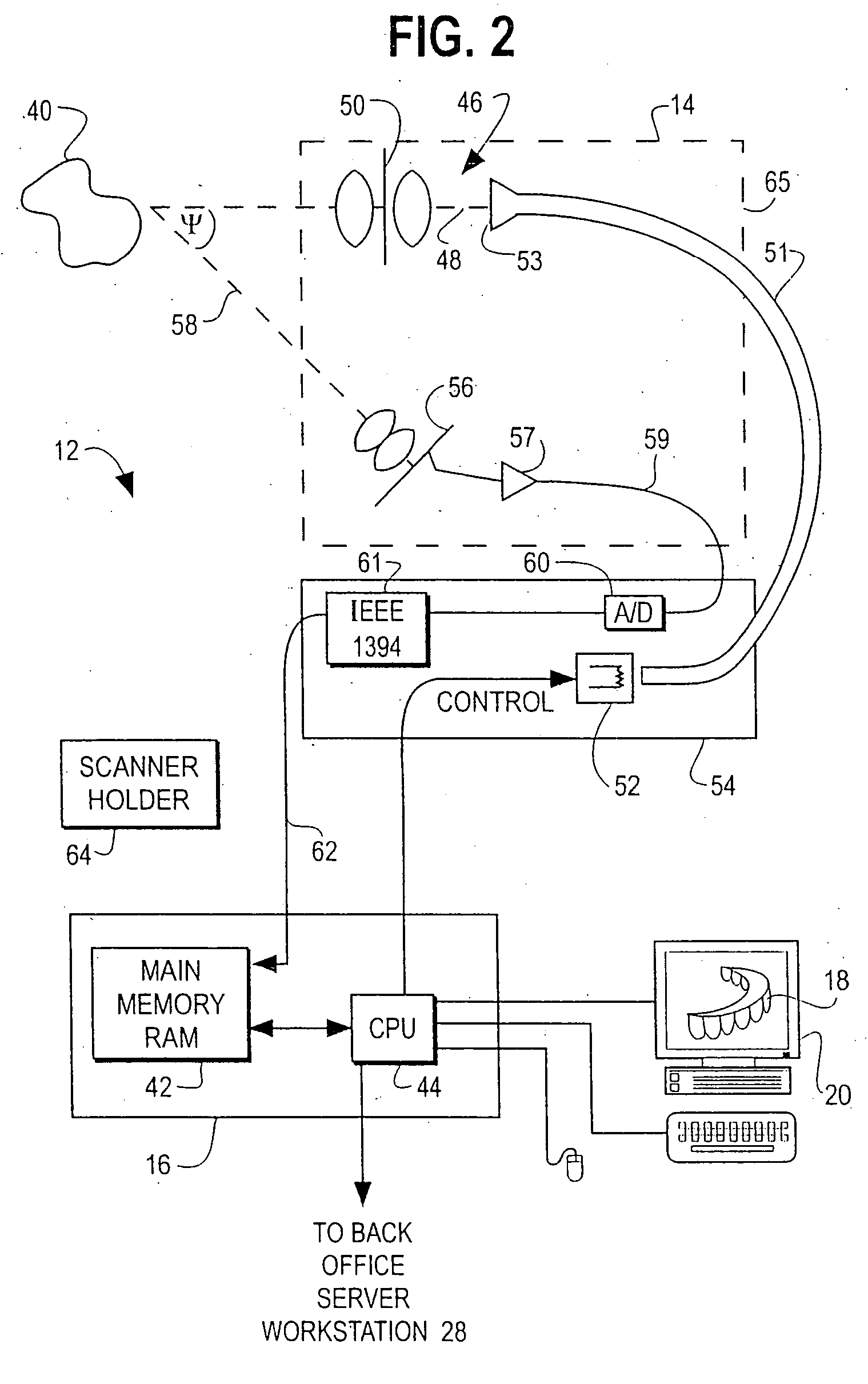

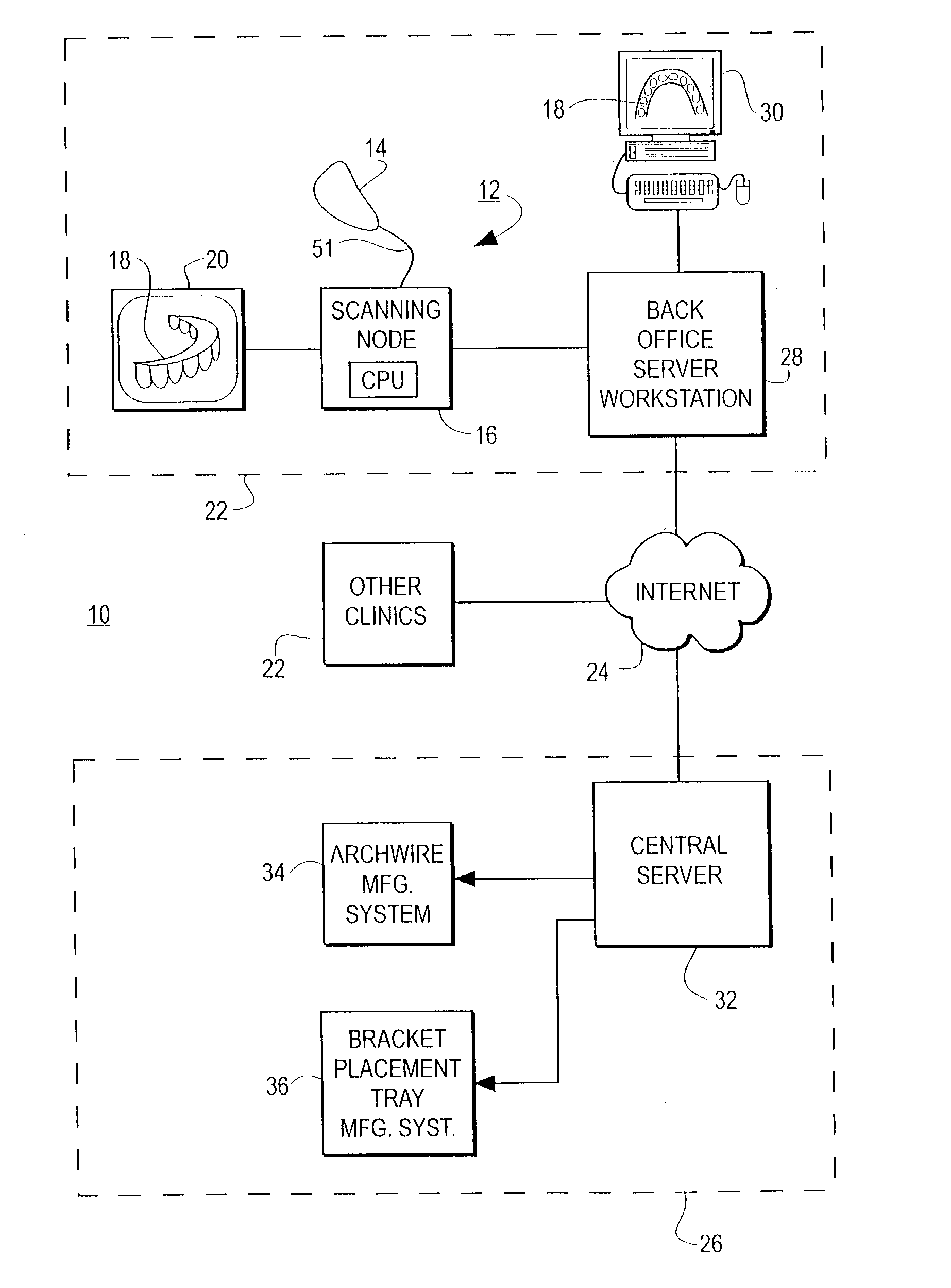

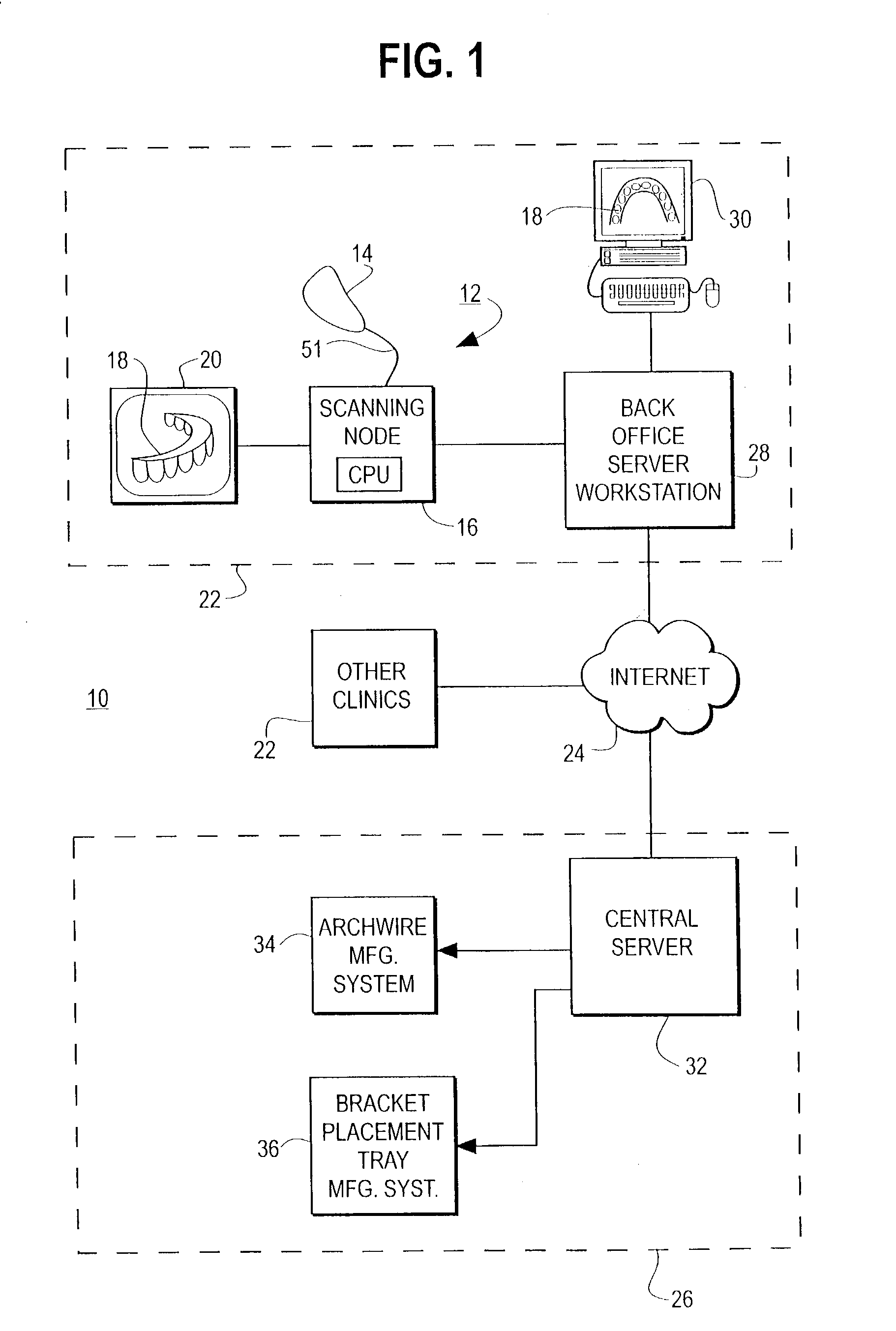

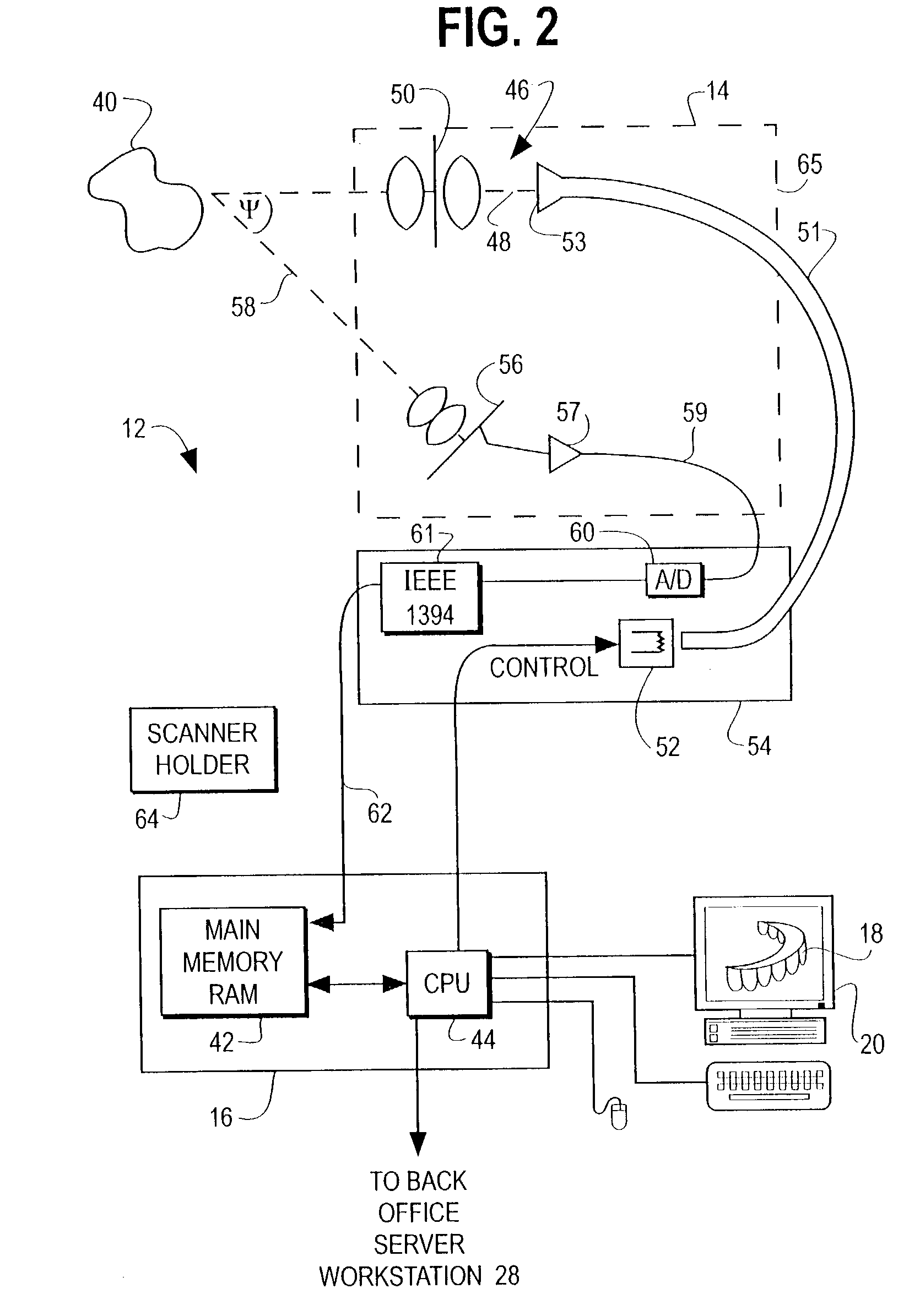

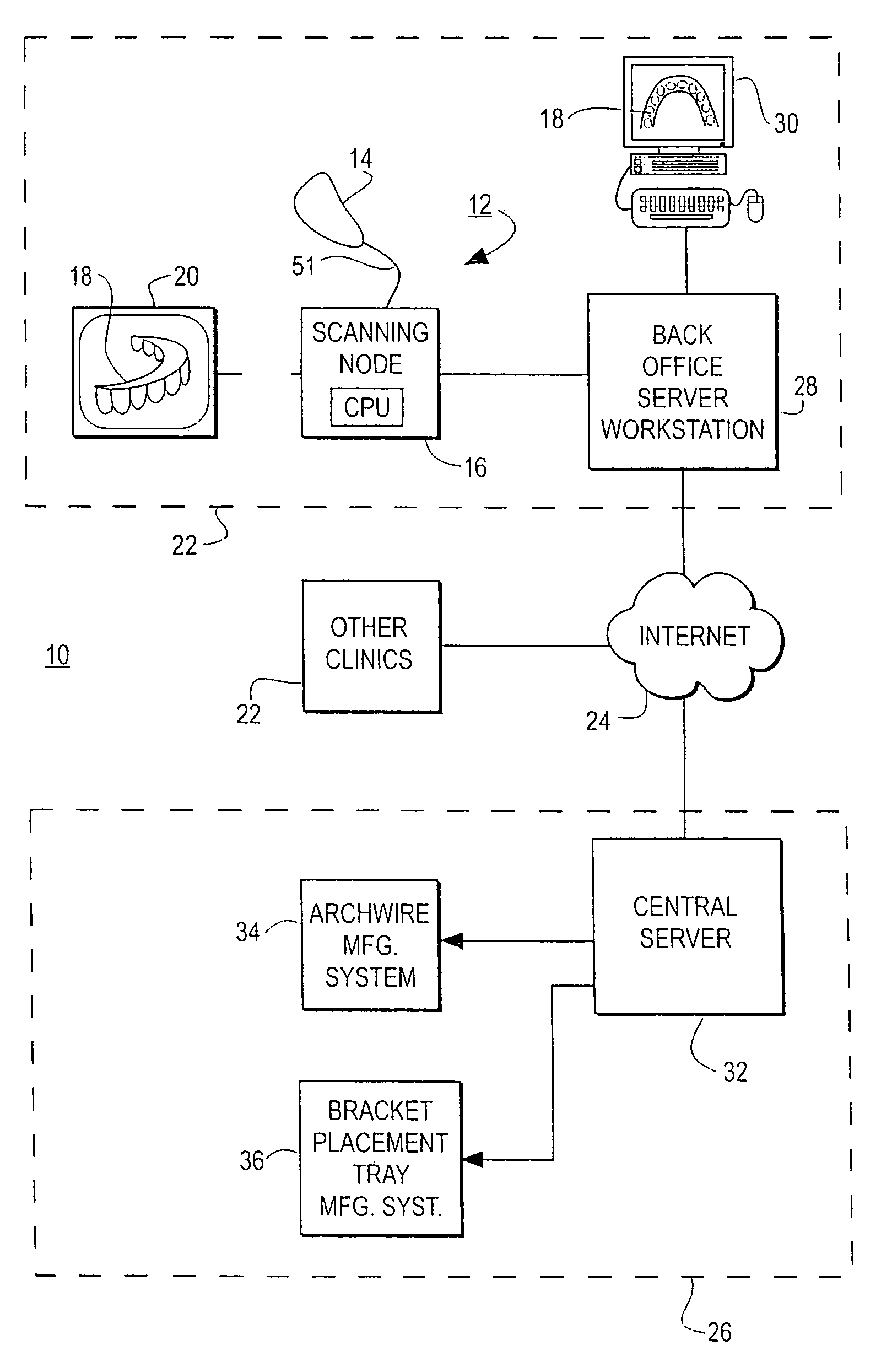

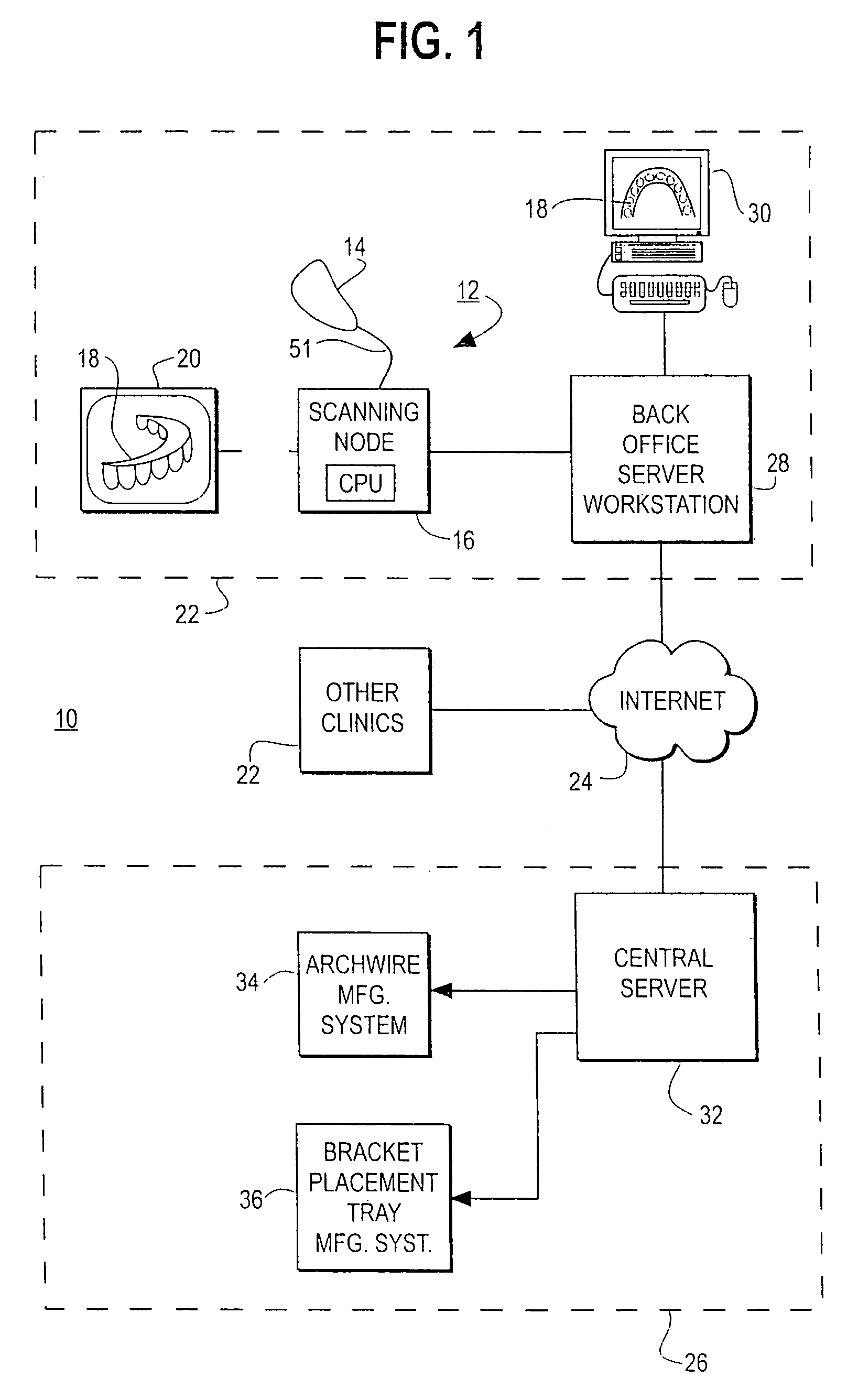

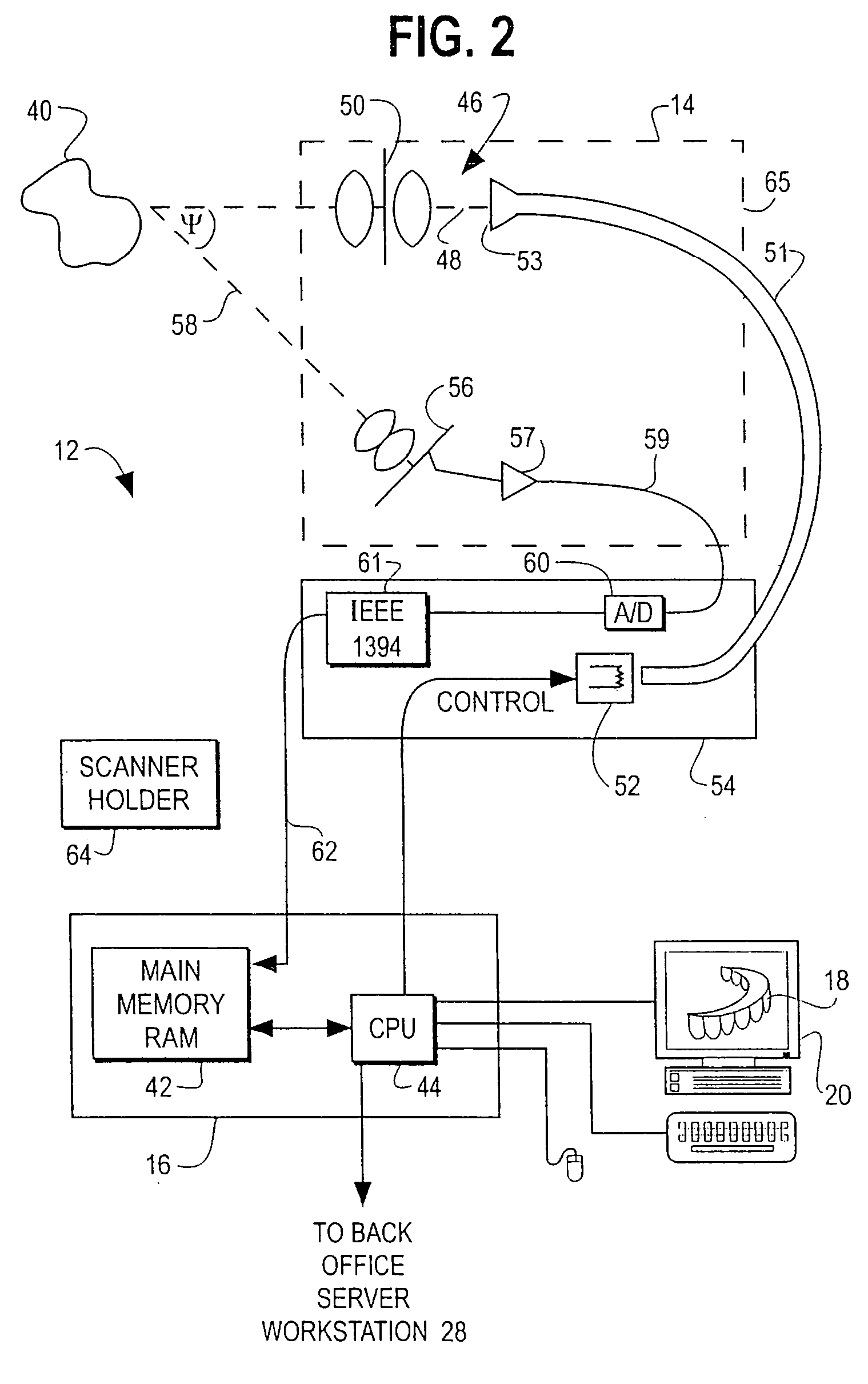

Interactive orthodontic care system based on intra-oral scanning of teeth

Interactive, computer based orthodontist treatment planning, appliance design and appliance manufacturing is described. A scanner is described which acquires images of the dentition which are converted to three-dimensional frames of data. The data from the several frames are registered to each other to provide a complete three-dimensional virtual model of the dentition. Individual tooth objects are obtained from the virtual model. A computer-interactive software program provides for treatment planning, diagnosis and appliance from the virtual tooth models. A desired occlusion for the patient is obtained from the treatment planning software. The virtual model of the desired occlusion and the virtual model of the original dentition provide a base of information for custom manufacture of an orthodontic appliance. A variety of possible appliance and appliance manufacturing systems are contemplated, including customized archwires and customized devices for placement of off-the shelf brackets on the archwires, and removable orthodontic appliances.

Owner:ORAMETRIX

System for real-time economic optimizing of manufacturing process control

InactiveUS6038540AEasy to operateEasy to deployMarket predictionsComplex mathematical operationsProcess measurementSelf adaptive

The present invention provides an adaptive process control and profit depiction system which is responsive to both process measurement input signals, economic inputs, and physical environment inputs. The process control system features an interactive optimization modeling system for determining manipulated process variables (also known as setpoints). These manipulated process variables are used to position mechanisms which control attributes of a manufacturing system, such as a valve controlling the temperature of a coolant or a valve controlling the flow rate in a steam line.

Owner:DOW GLOBAL TECH LLC

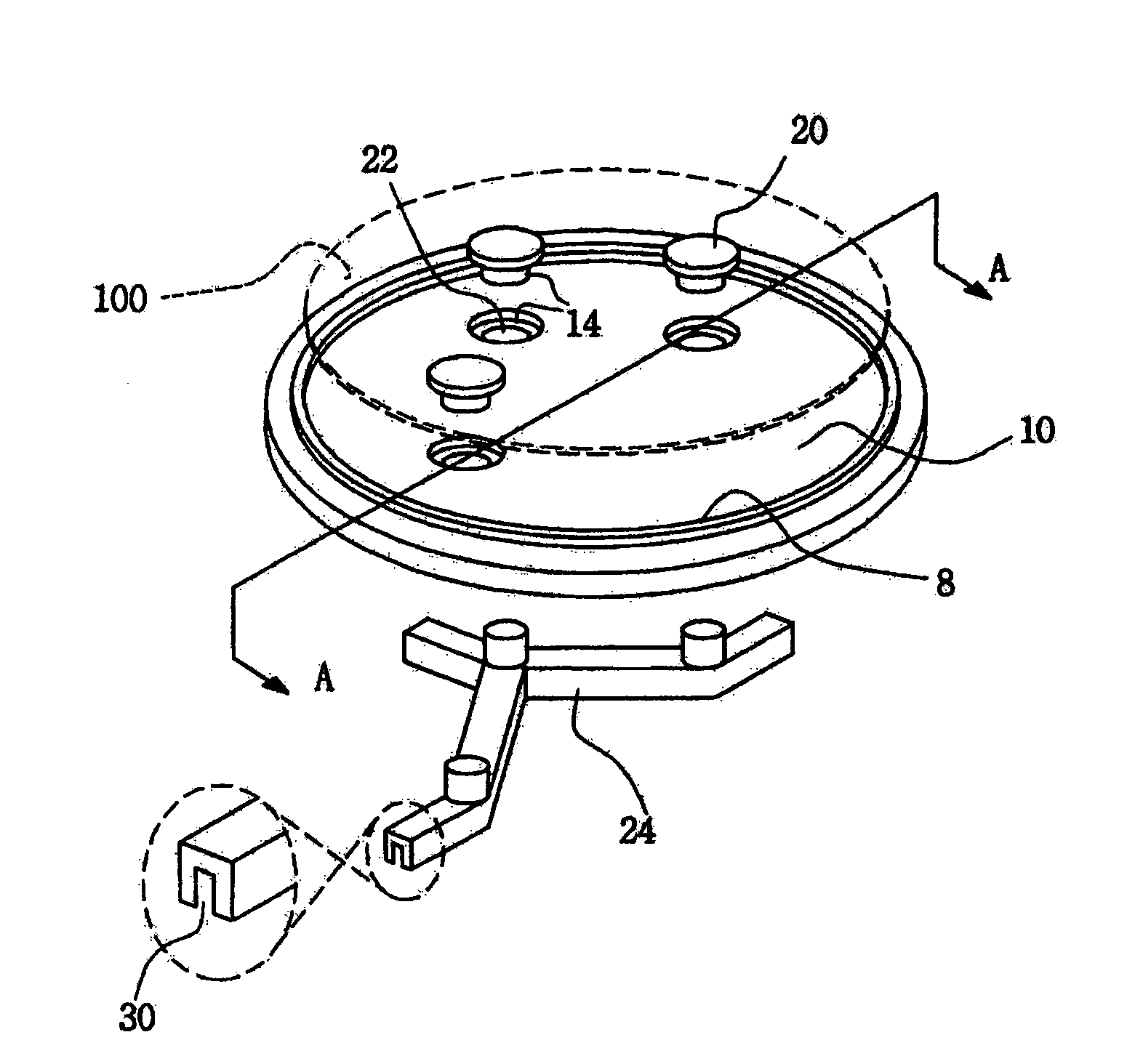

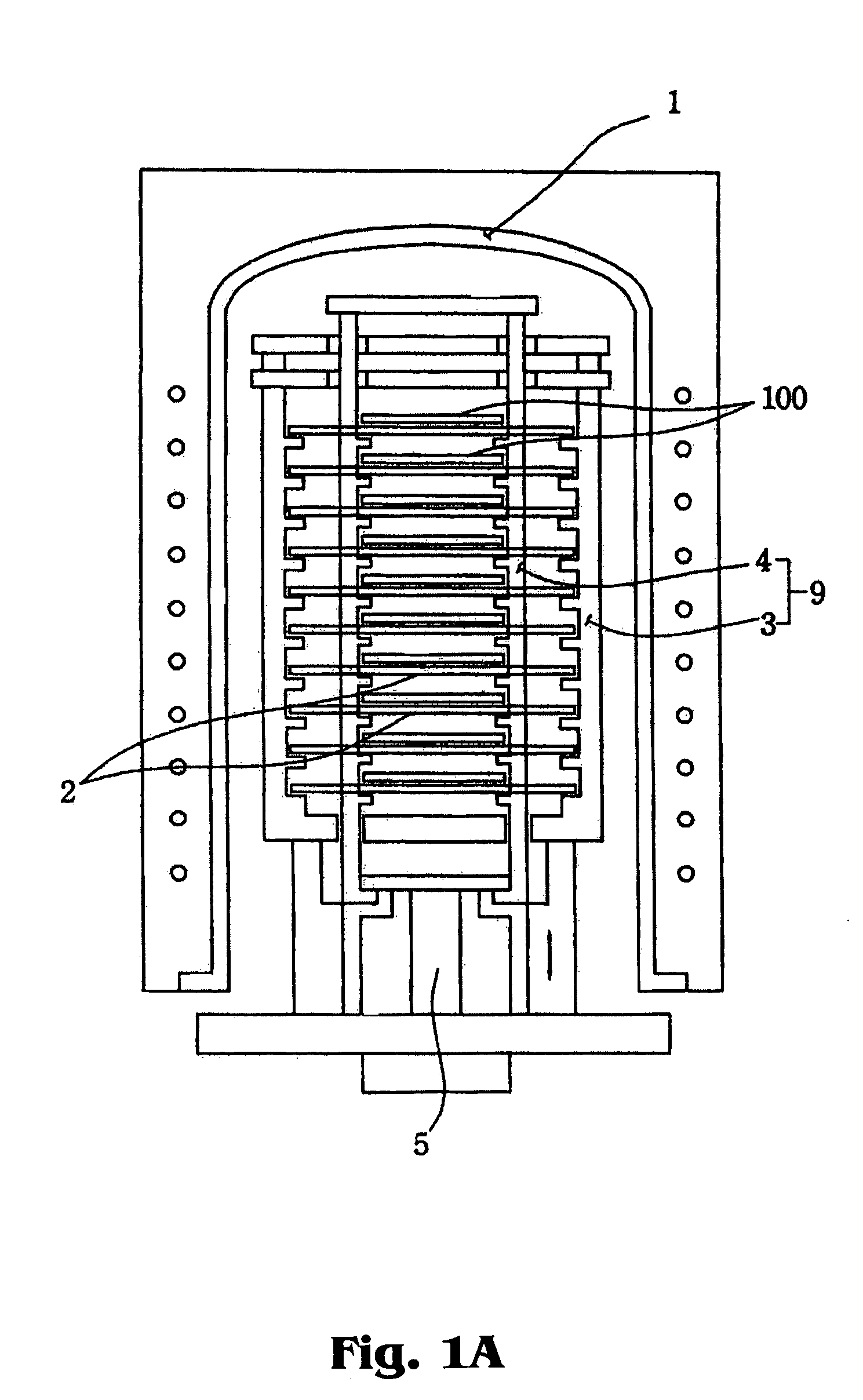

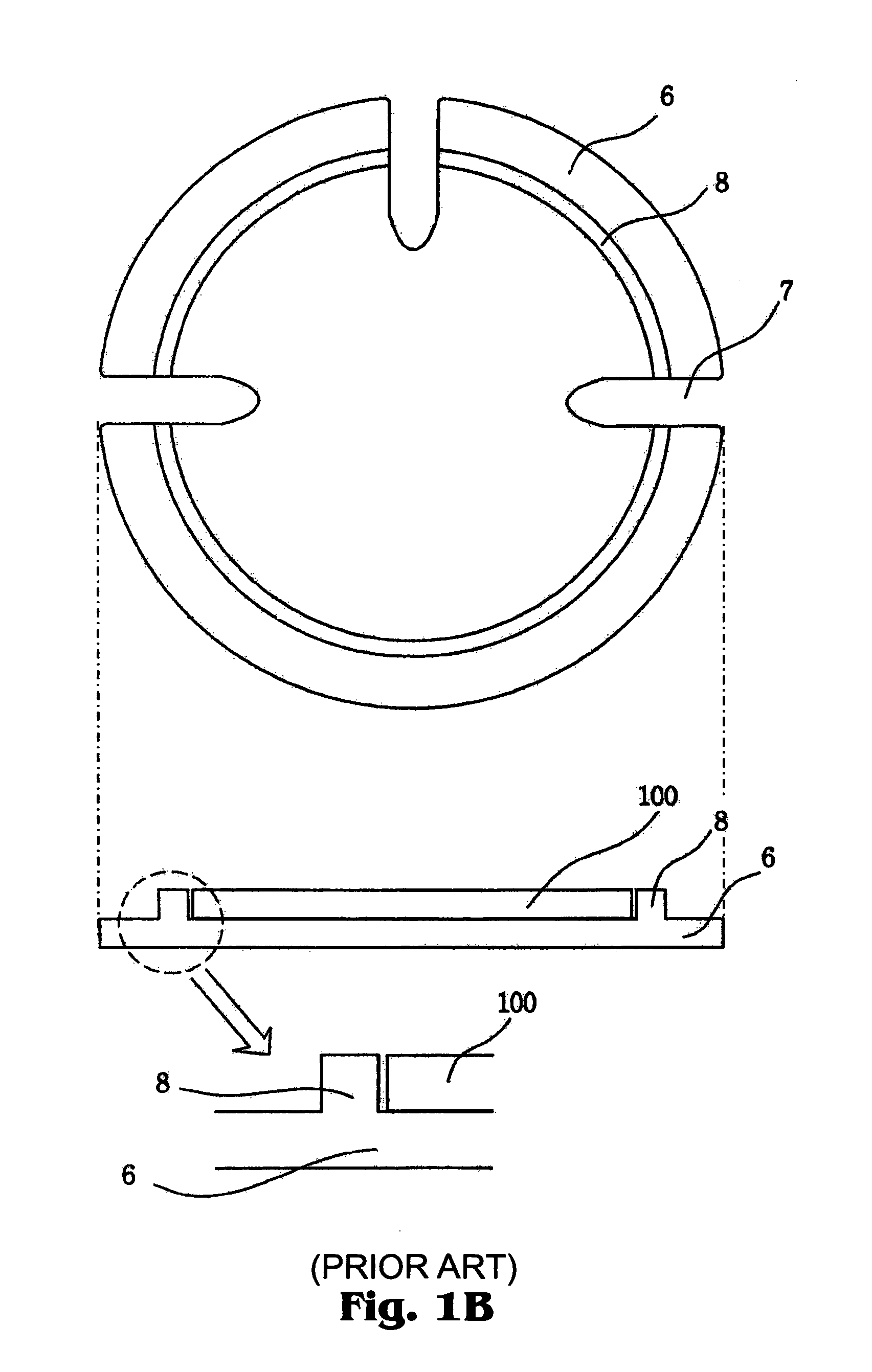

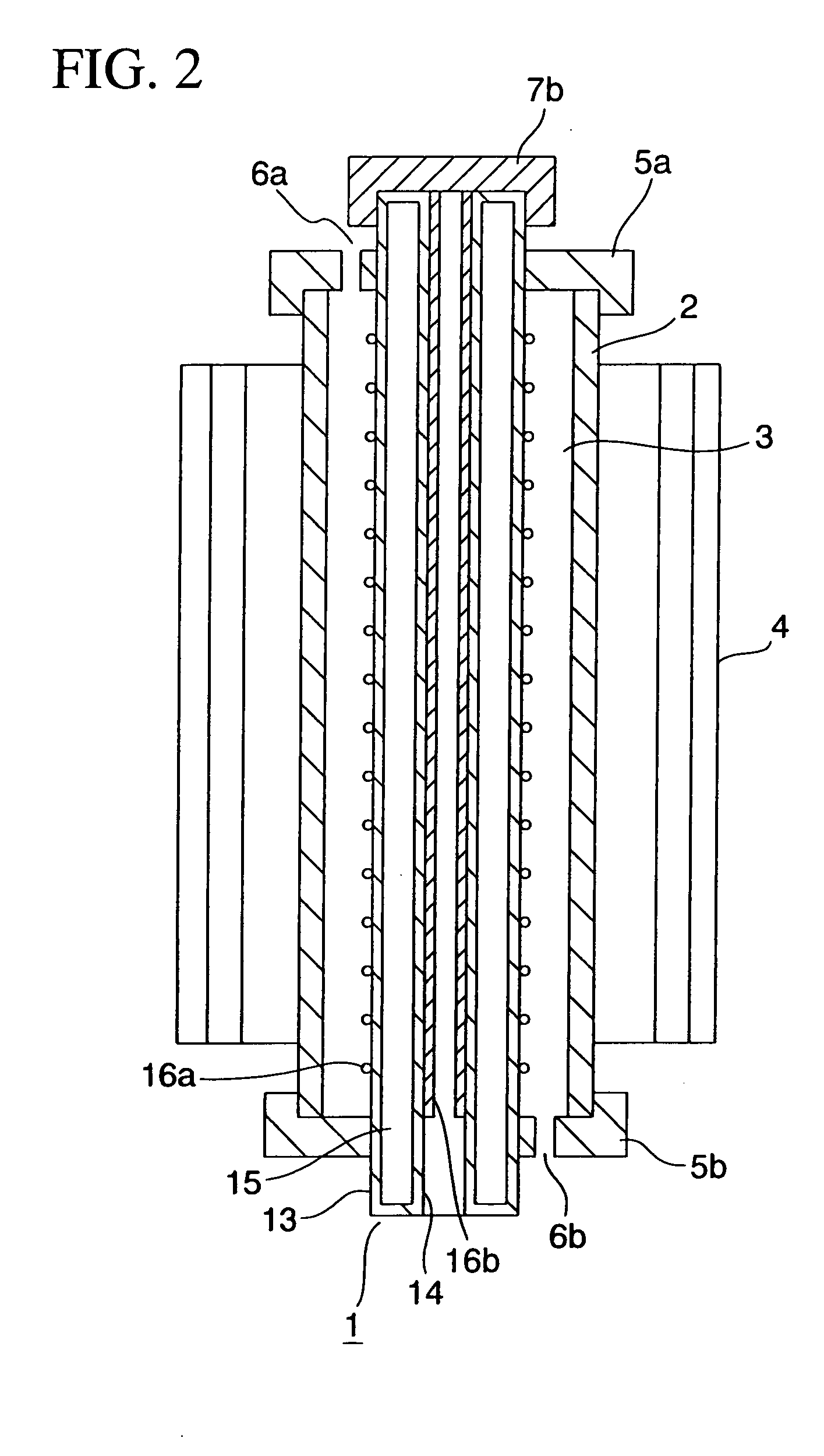

Semiconductor manufacturing system and wafer holder for semiconductor manufacturing system

InactiveUS7207763B2Improves yield and productivitySemiconductor/solid-state device manufacturingPlatesWaferingEngineering

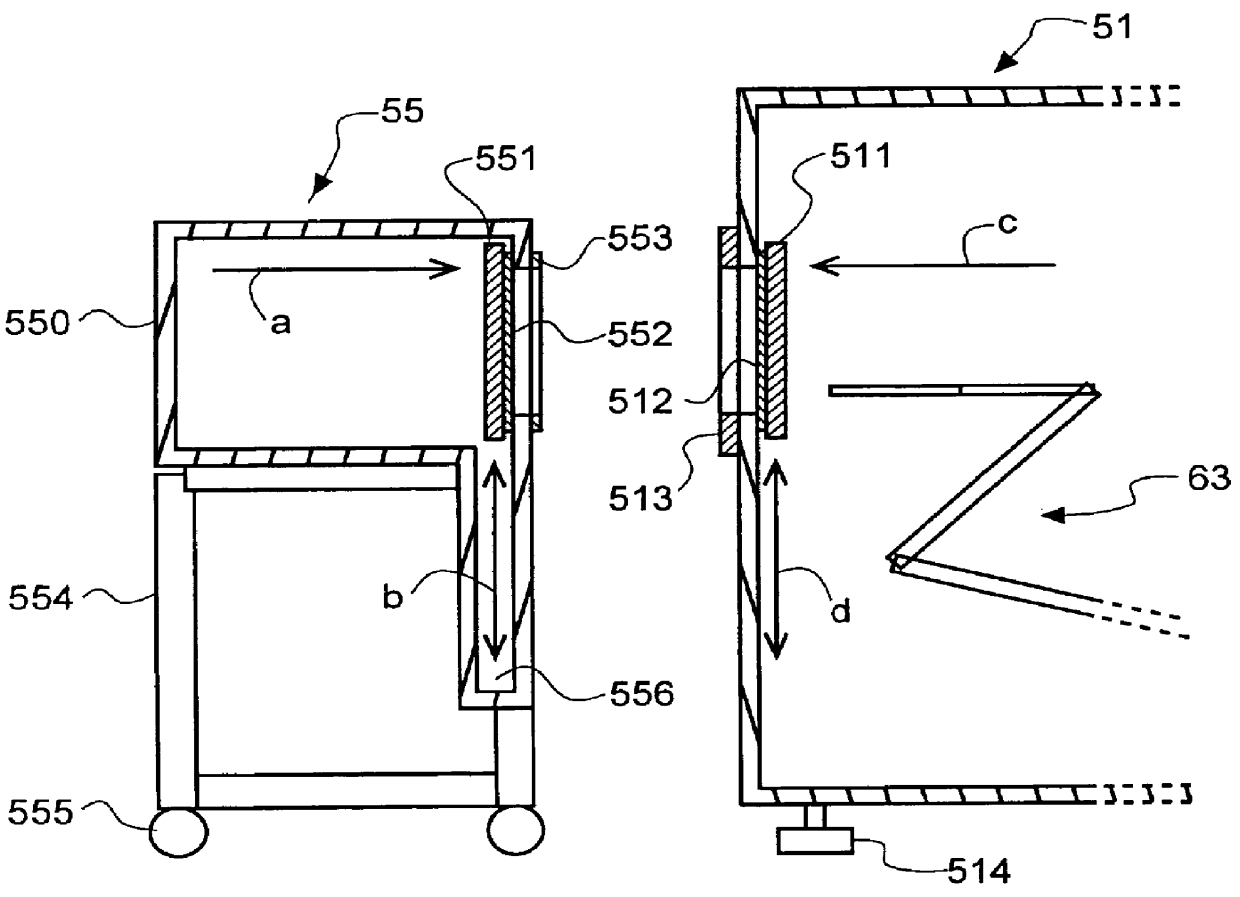

A semiconductor manufacturing system and wafer holder for a semiconductor manufacturing system which prevents a semiconductor wafer from being exposed to a process reaction and which includes a reaction tube for providing a sealed process space and a dual boat and which prevents the backside deposition by the wafer holder. The wafer holder includes a holder body to hide the backside of the semiconductor wafer during a process in the reaction tube and a wafer lifter having a portion that can be disengaged from and coupled to the holder body so that a lower portion of the semiconductor wafer is supported by the dual boat and so that the semiconductor wafer can be lifted up from the wafer body when the semiconductor wafer is loaded and unloaded. A separation boundary between the holder body and the wafer lifter includes a gas inflow interception surface to hinder reaction gas from flowing through the separation boundary.

Owner:TERASEMICON CO LTD

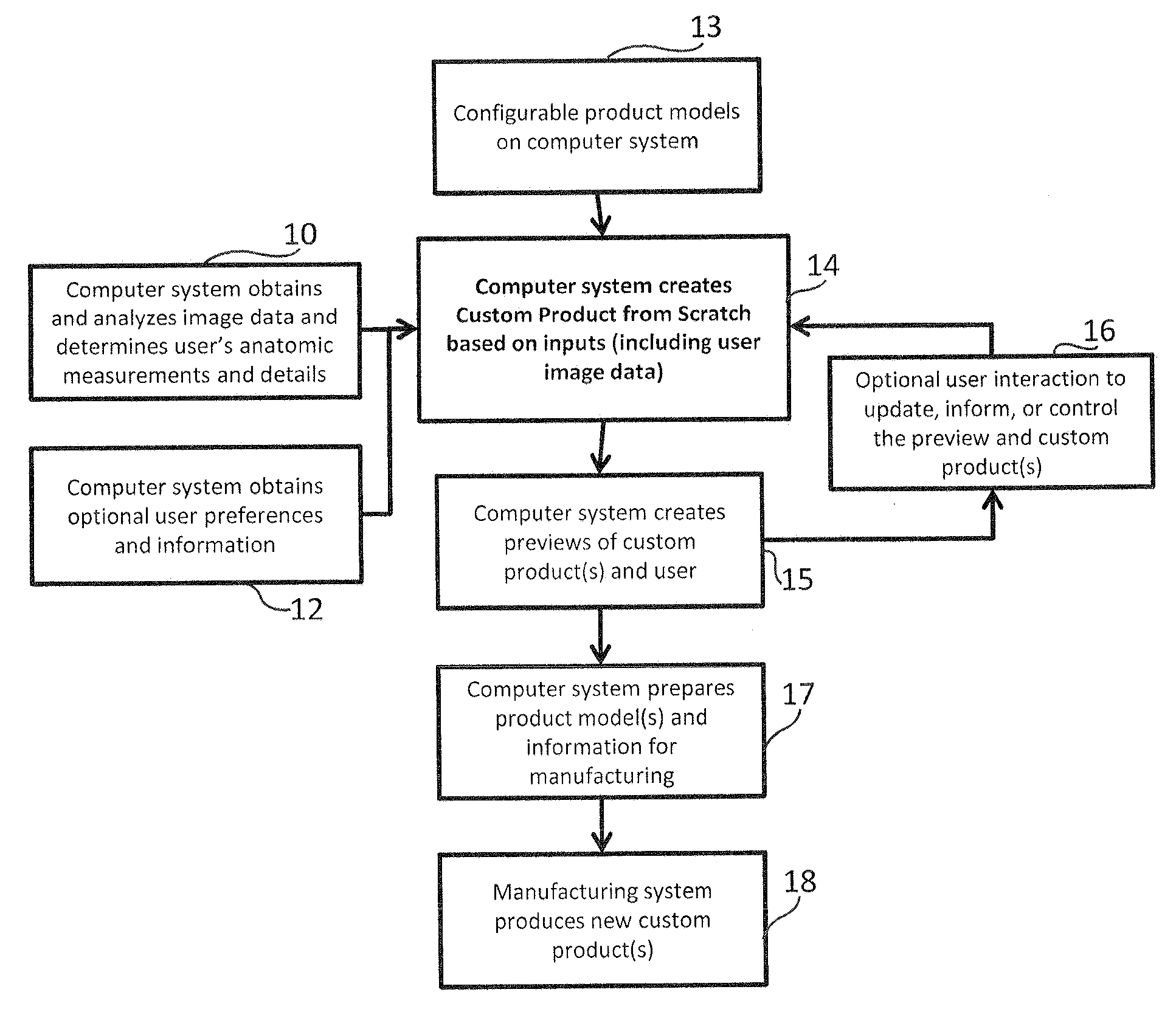

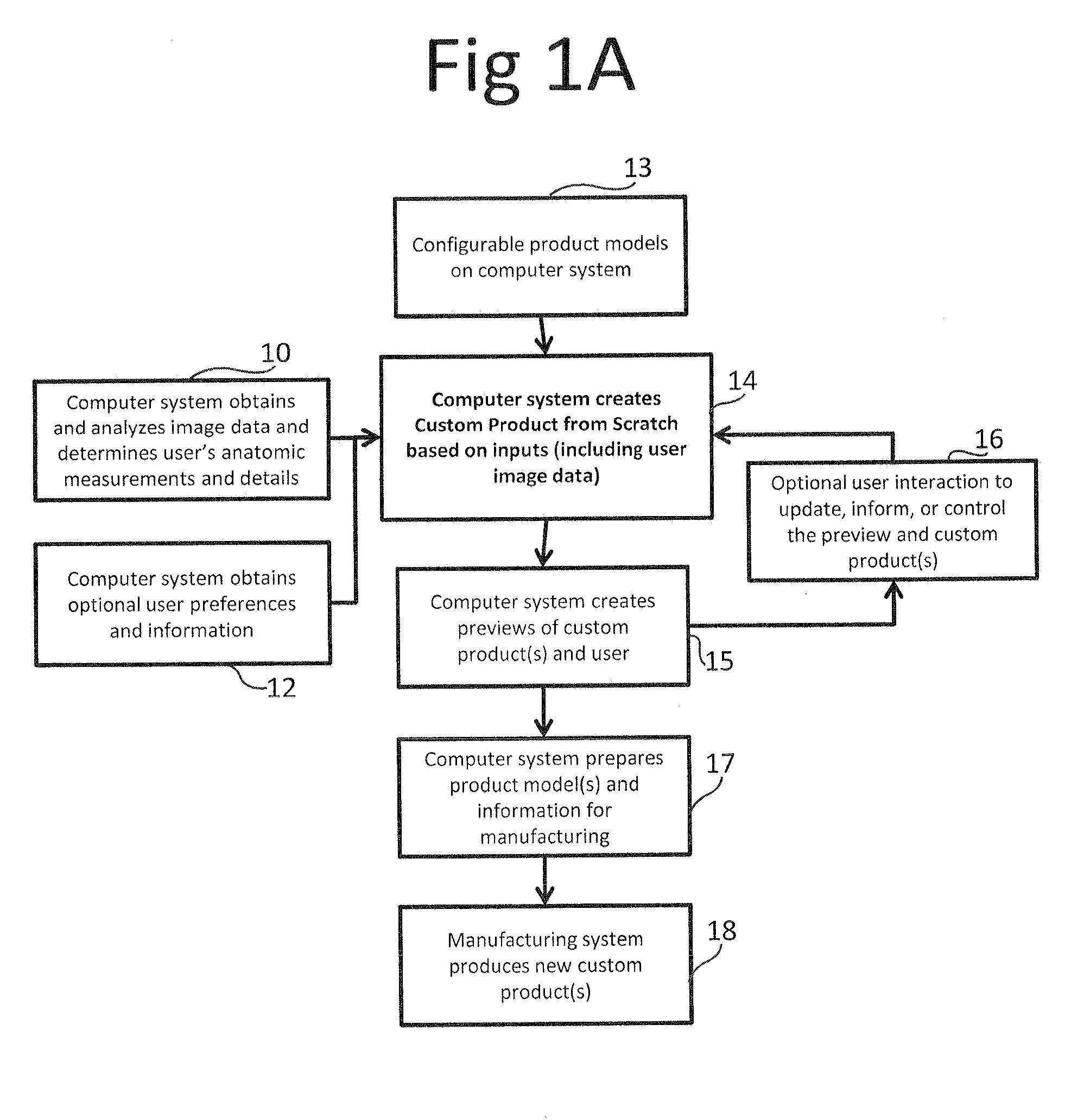

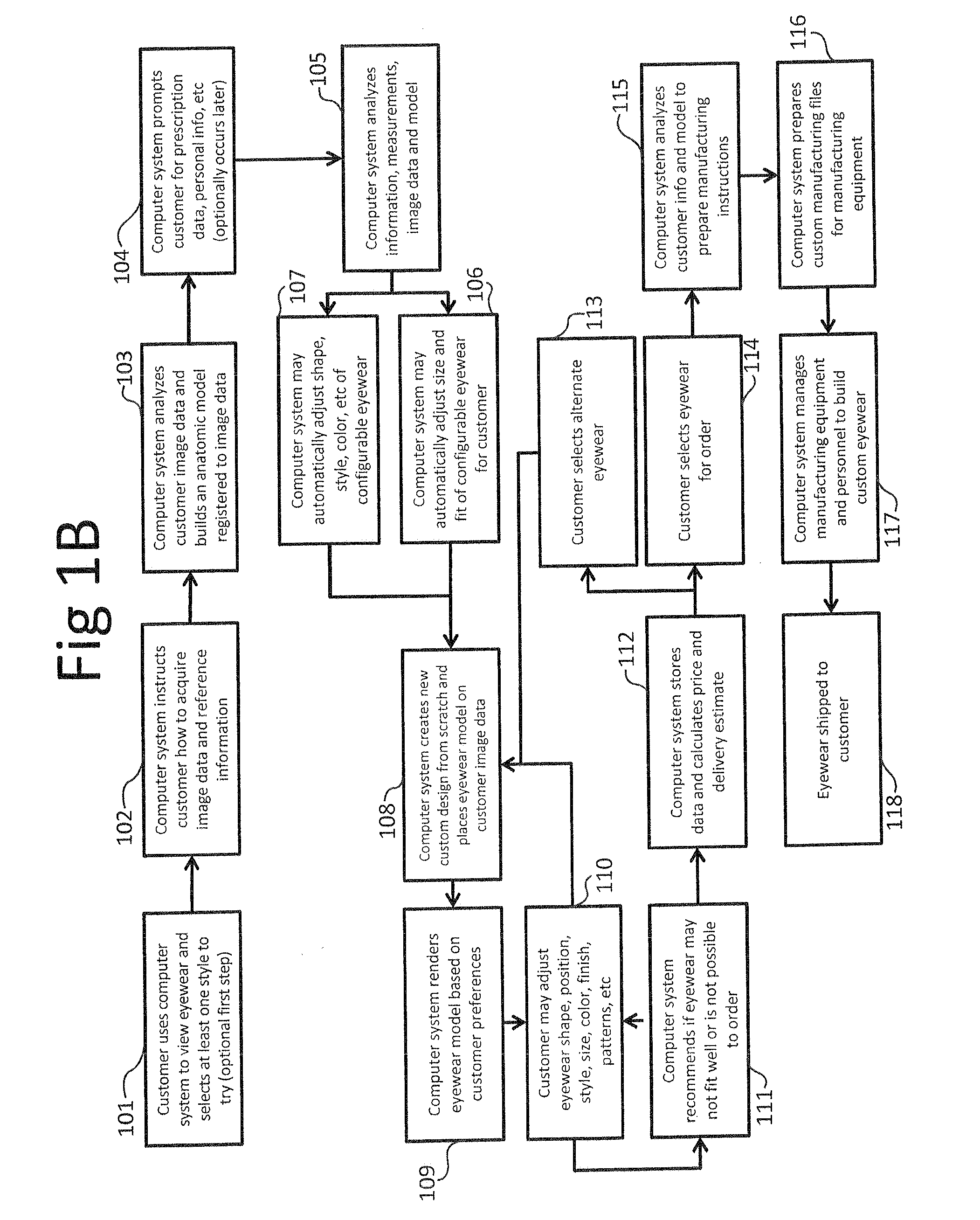

Method and system to create products

Systems and methods for creating fully custom products from scratch without exclusive use of off-the-shelf or pre-specified components. A system for creating custom products includes an image capture device for capturing image data and / or measurement data of a user. A computer is communicatively coupled with the image capture device and configured to construct an anatomic model of the user based on the captured image data and / or measurement data. The computer provides a configurable product model and enables preview and automatic or user-guided customization of the product model. A display is communicatively coupled with the computer and displays the custom product model superimposed on the anatomic model or image data of the user. The computer is further configured to provide the customized product model to a manufacturer for manufacturing eyewear for the user in accordance with the customized product model. The manufacturing system is configured to interpret the product model and prepare instructions and control equipment for the manufacturing of the customized product.

Owner:BIS

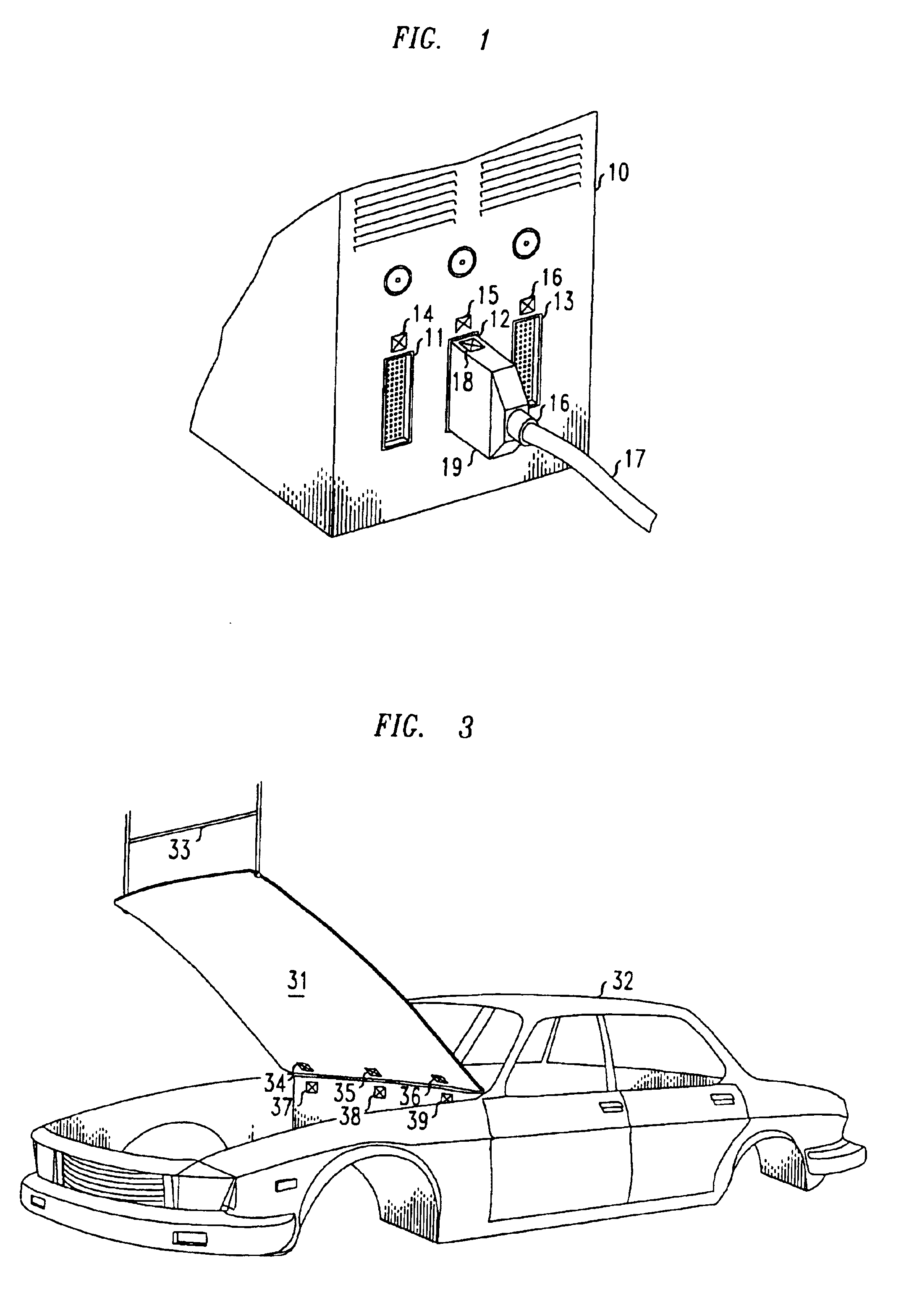

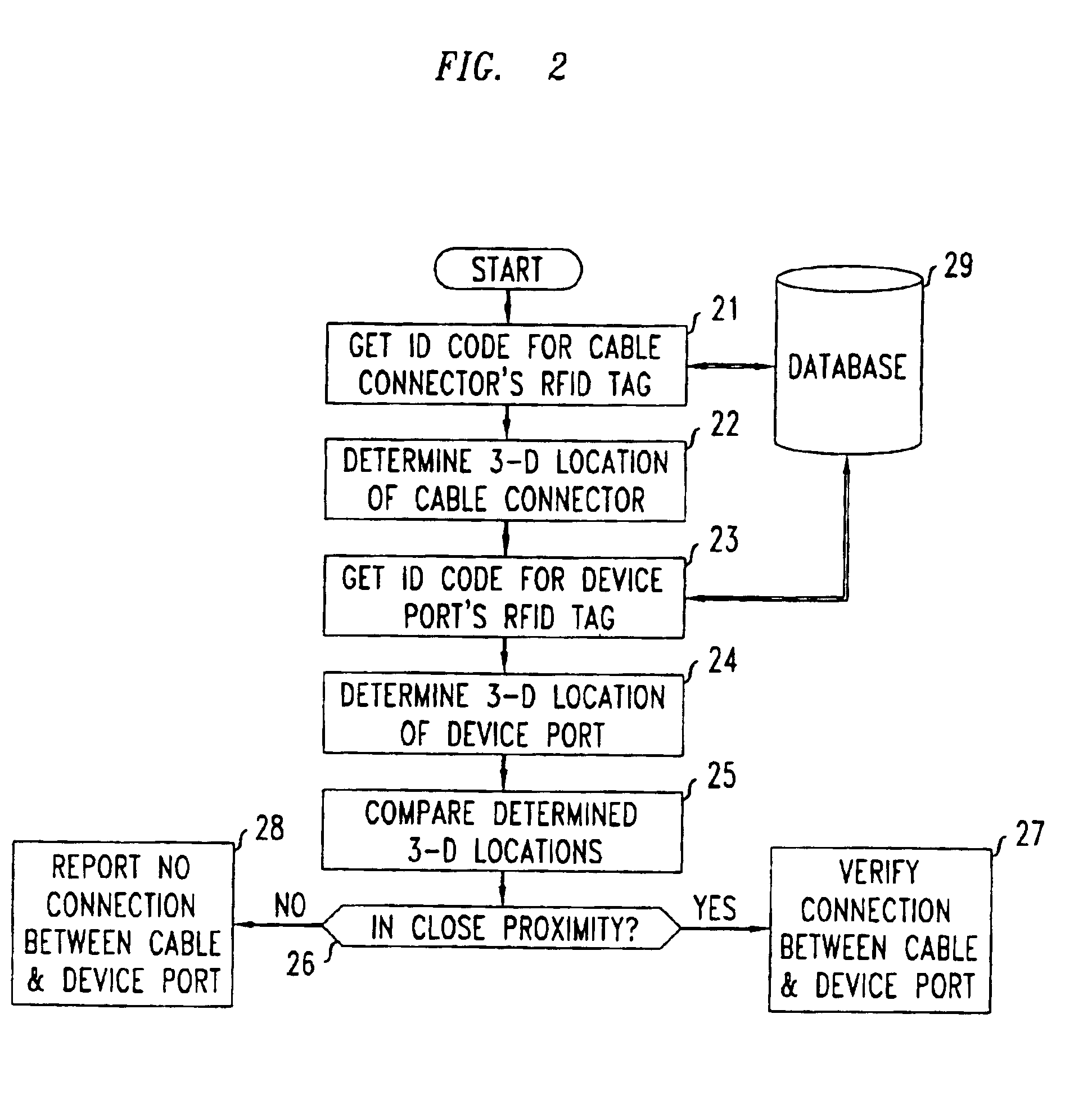

Method for determining juxtaposition of physical components with use of RFID tags

InactiveUS6847856B1Easy to useImprove accuracyDigital data processing detailsCo-operative working arrangementsEngineeringRadio frequency

Radio Frequency Identification (RFID) tags are used for automatically determining the connectivity or alignment between physical components, including, for example, connectivity of network cables and device ports, as well as alignment of components assembled by automated manufacturing systems. In one embodiment of the invention, accurate determinations of the physical three-dimensional locations of cables and equipment are employed to determine which cables are plugged into which device ports of which pieces of equipment. In another embodiment of the invention, multiple RFID tags are used to determine the appropriate alignment between components being assembled by an automated manufacturing system.

Owner:ALCATEL-LUCENT USA INC +1

Interactive orthodontic care system based on intra-oral scanning of teeth

InactiveUS20050043837A1Quantitative precisionHighly reliable mannerImpression capsTherapiesInteractive softwareOff the shelf

Interactive, computer based orthodontist treatment planning, appliance design and appliance manufacturing is described. A scanner is described which acquires images of the dentition which are converted to three-dimensional frames of data. The data from the several frames are registered to each other to provide a complete three-dimensional virtual model of the dentition. Individual tooth objects are obtained from the virtual model. A computer-interactive software program provides for treatment planning, diagnosis and appliance from the virtual tooth models. A desired occlusion for the patient is obtained from the treatment planning software. The virtual model of the desired occlusion and the virtual model of the original dentition provide a base of information for custom manufacture of an orthodontic appliance. A variety of possible appliance and appliance manufacturing systems are contemplated, including customized archwires and customized devices for placement of off-the shelf brackets on the archwires, and removable orthodontic appliances.

Owner:ORAMETRIX

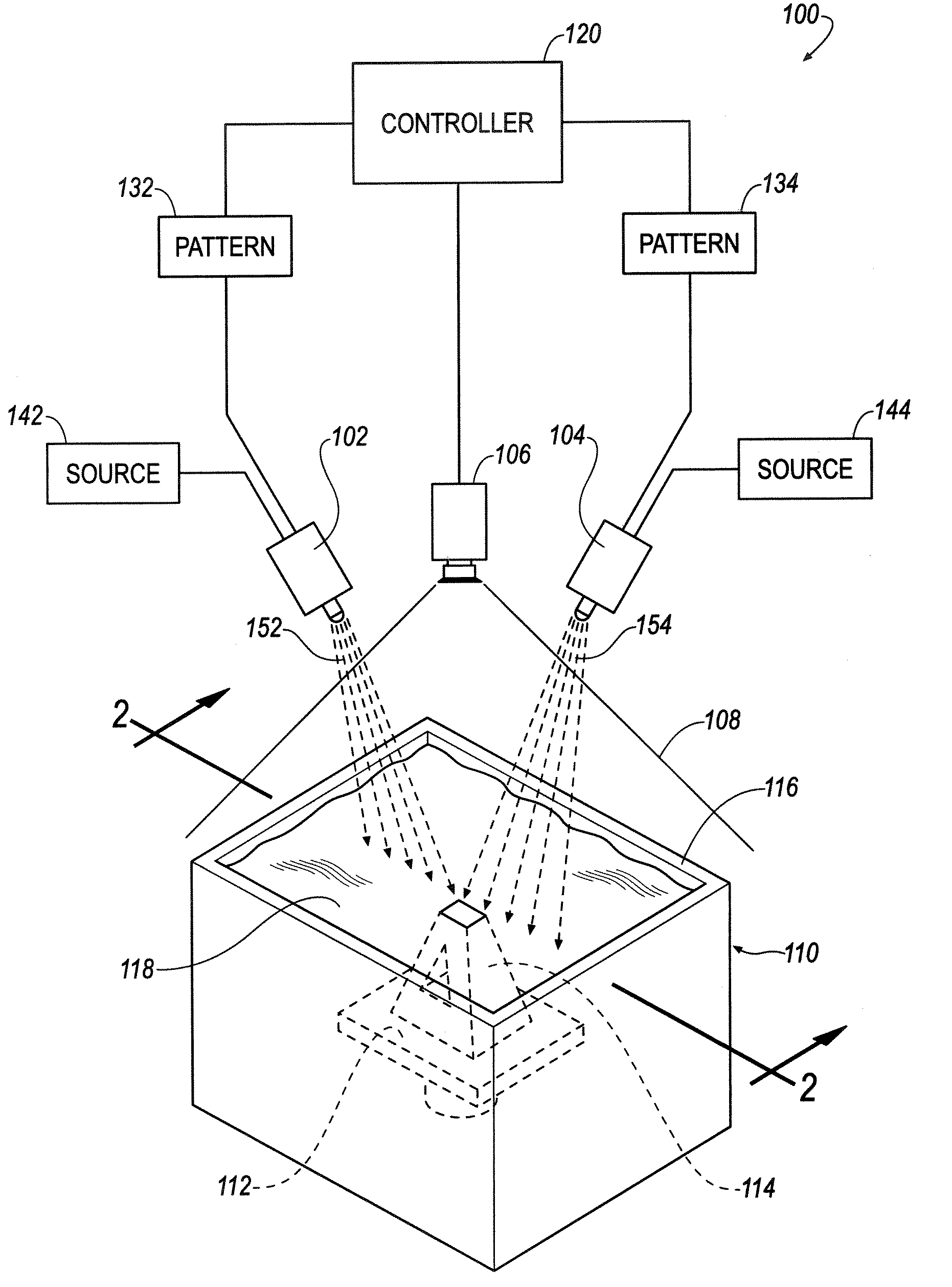

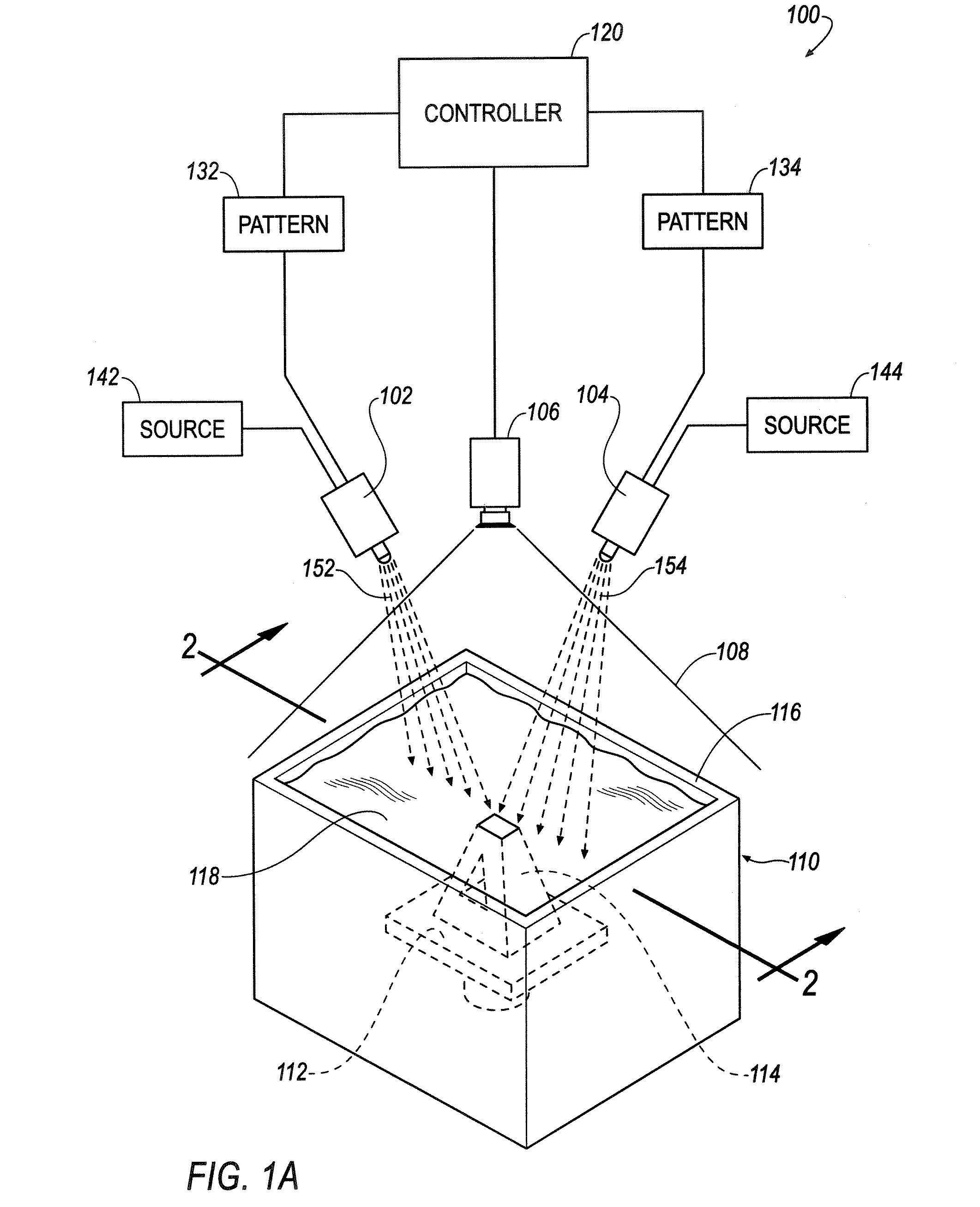

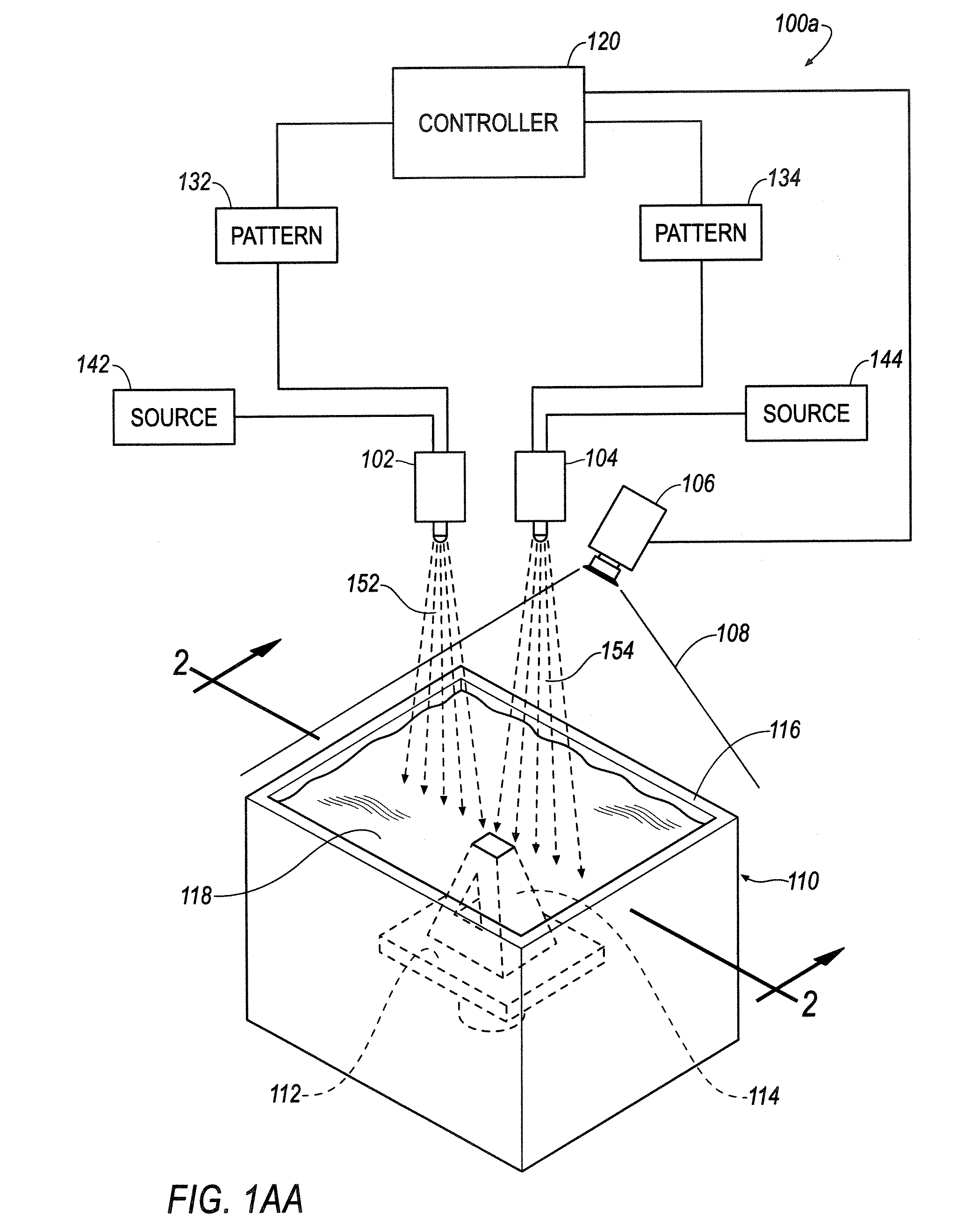

System and Method for Manufacturing

ActiveUS20100125356A1Image enhancementAdditive manufacturing apparatusComputer graphics (images)Reactive material

A method includes receiving a predetermined object pattern representing a portion of a three-dimensional object, modifying the predetermined object pattern to correct for geometric distortion of a pattern generator, and generating the modified pattern using the pattern generator. The generated pattern interacts with a reactive material to form the portion of the three-dimensional object defined by the predetermined object pattern.

Owner:GLOBAL FILTRATION SYST

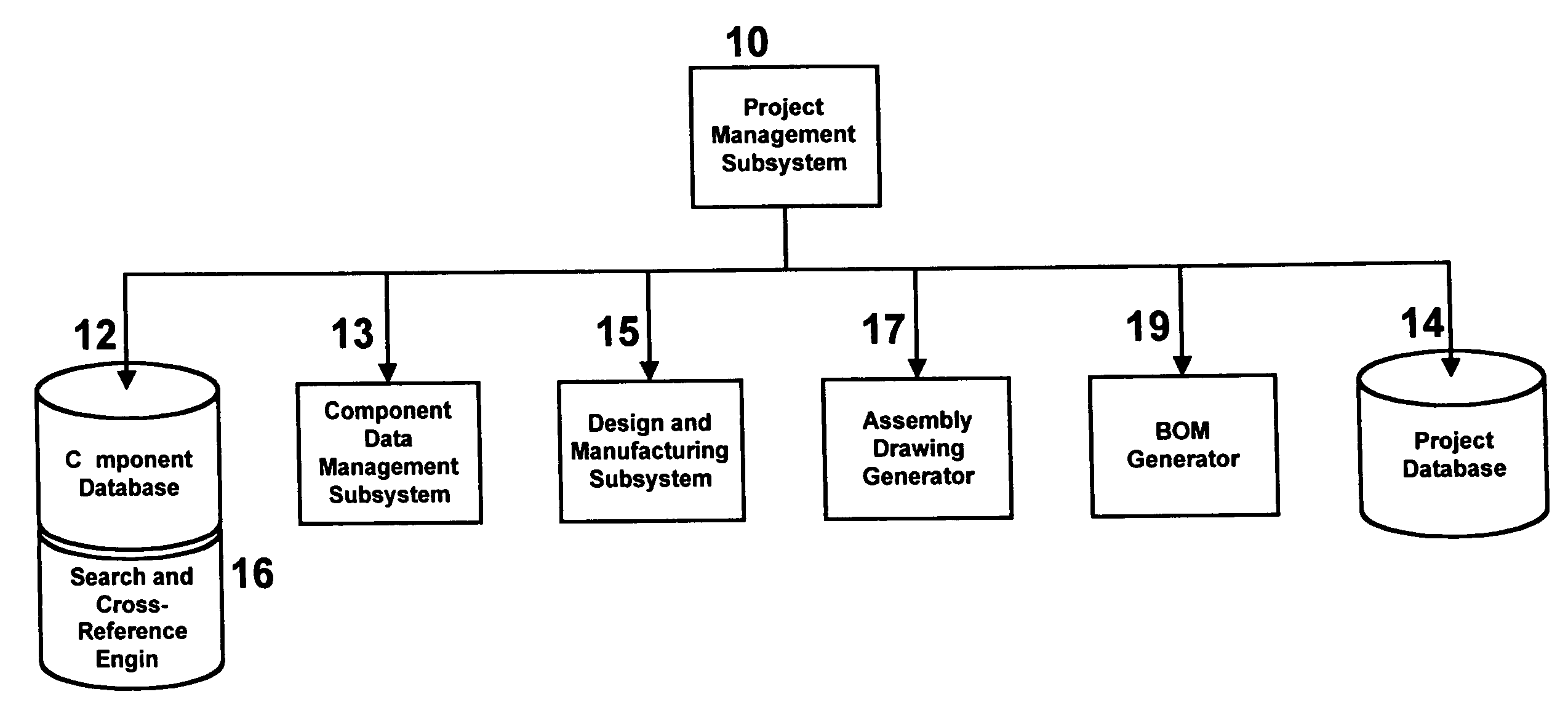

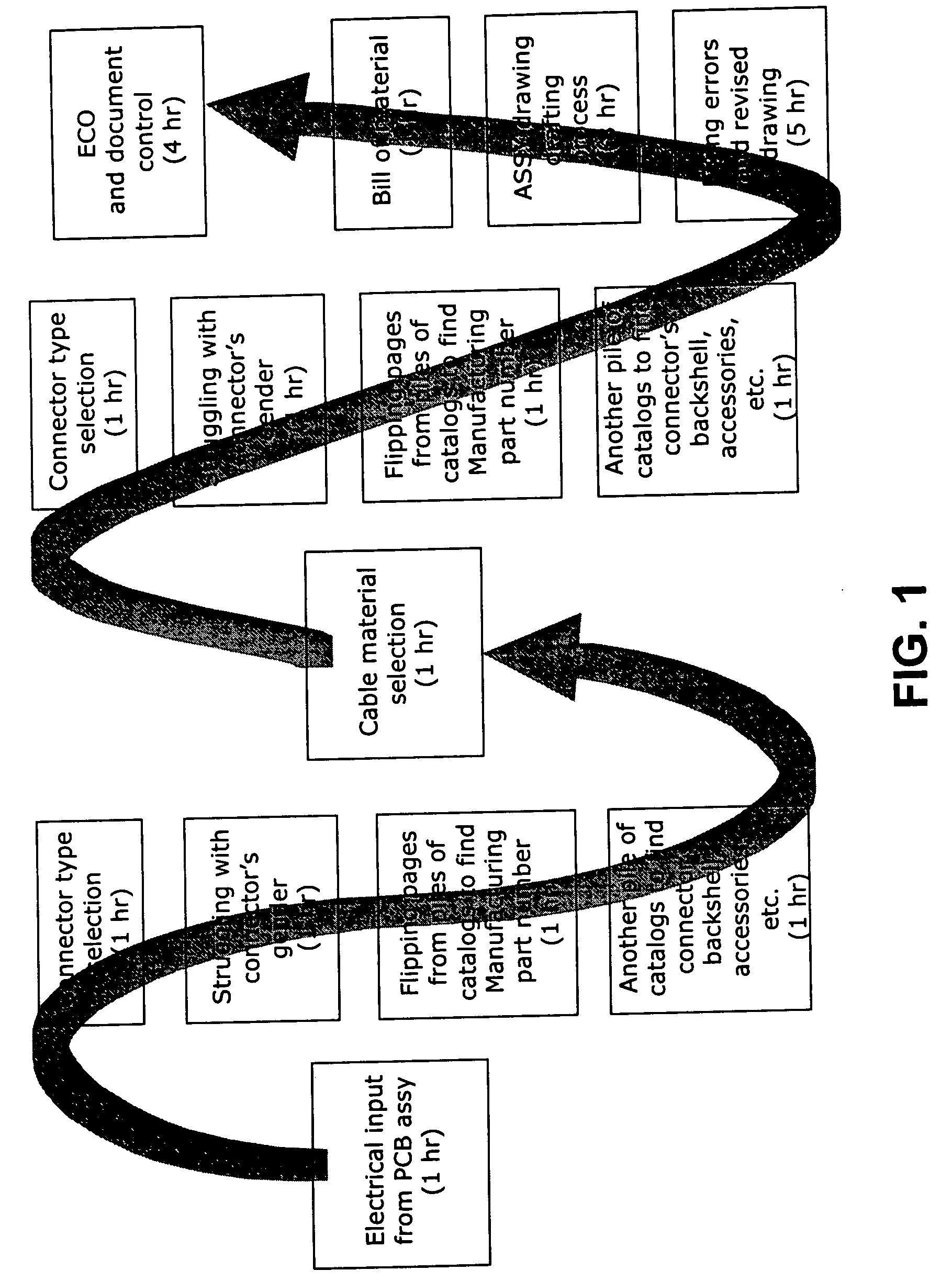

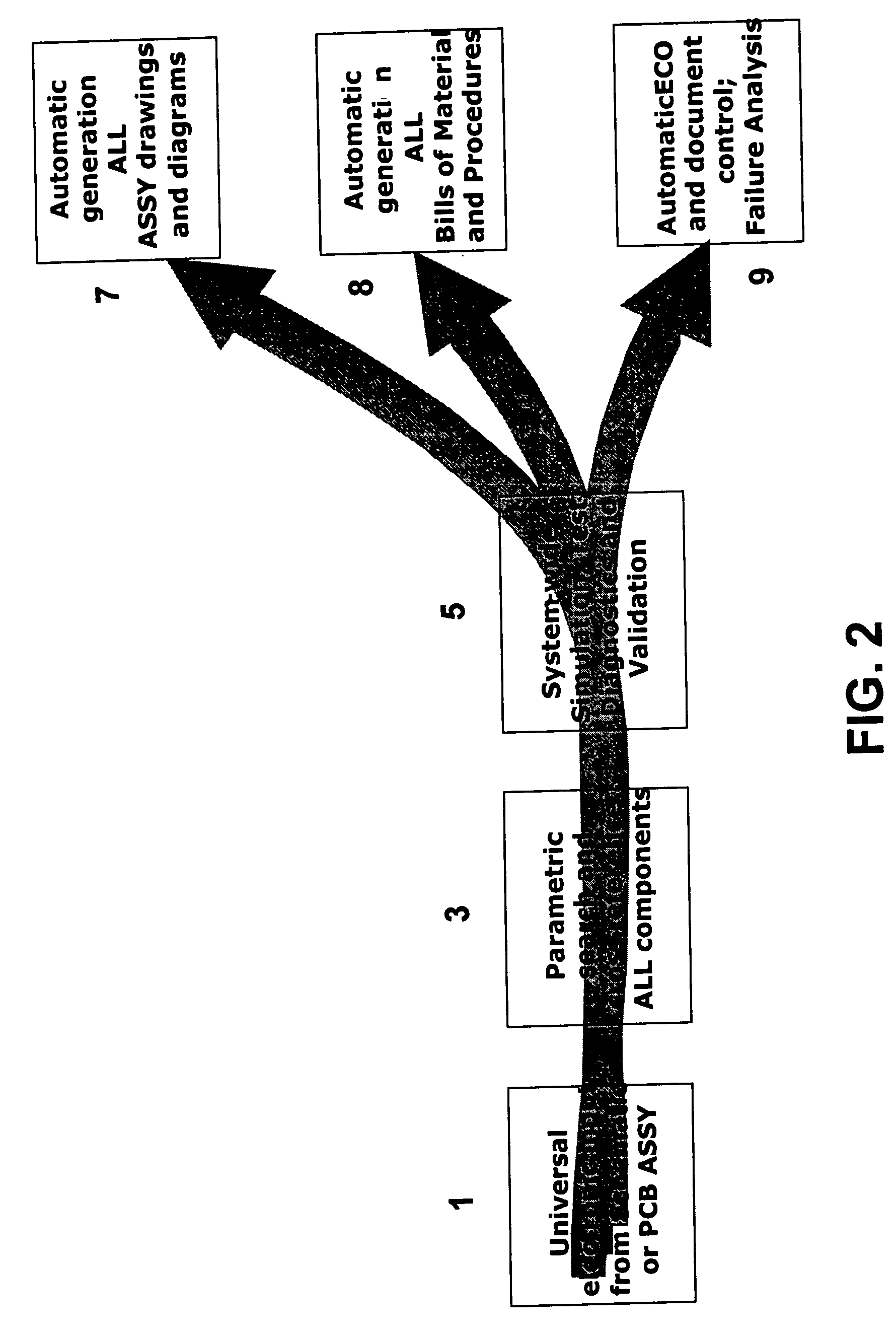

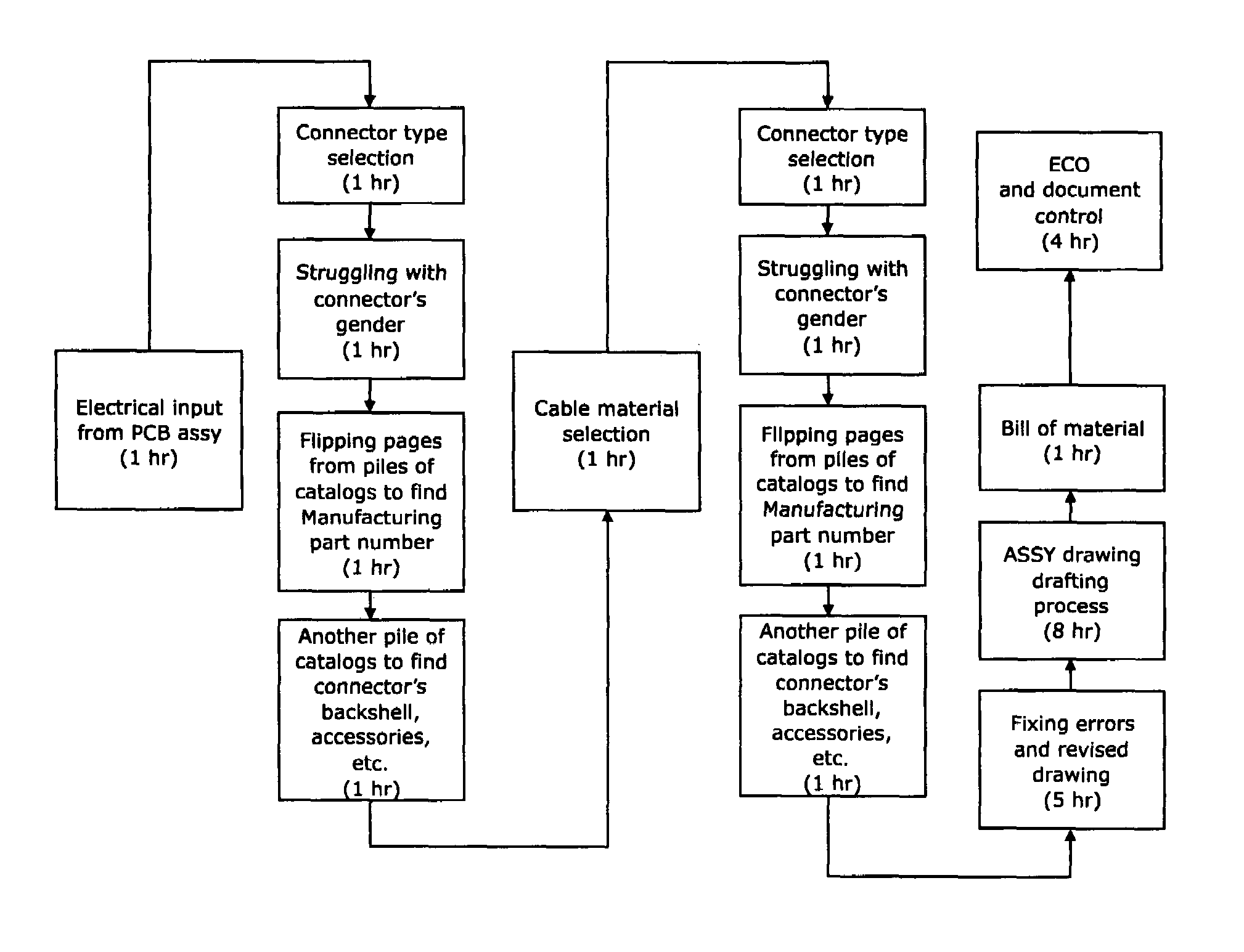

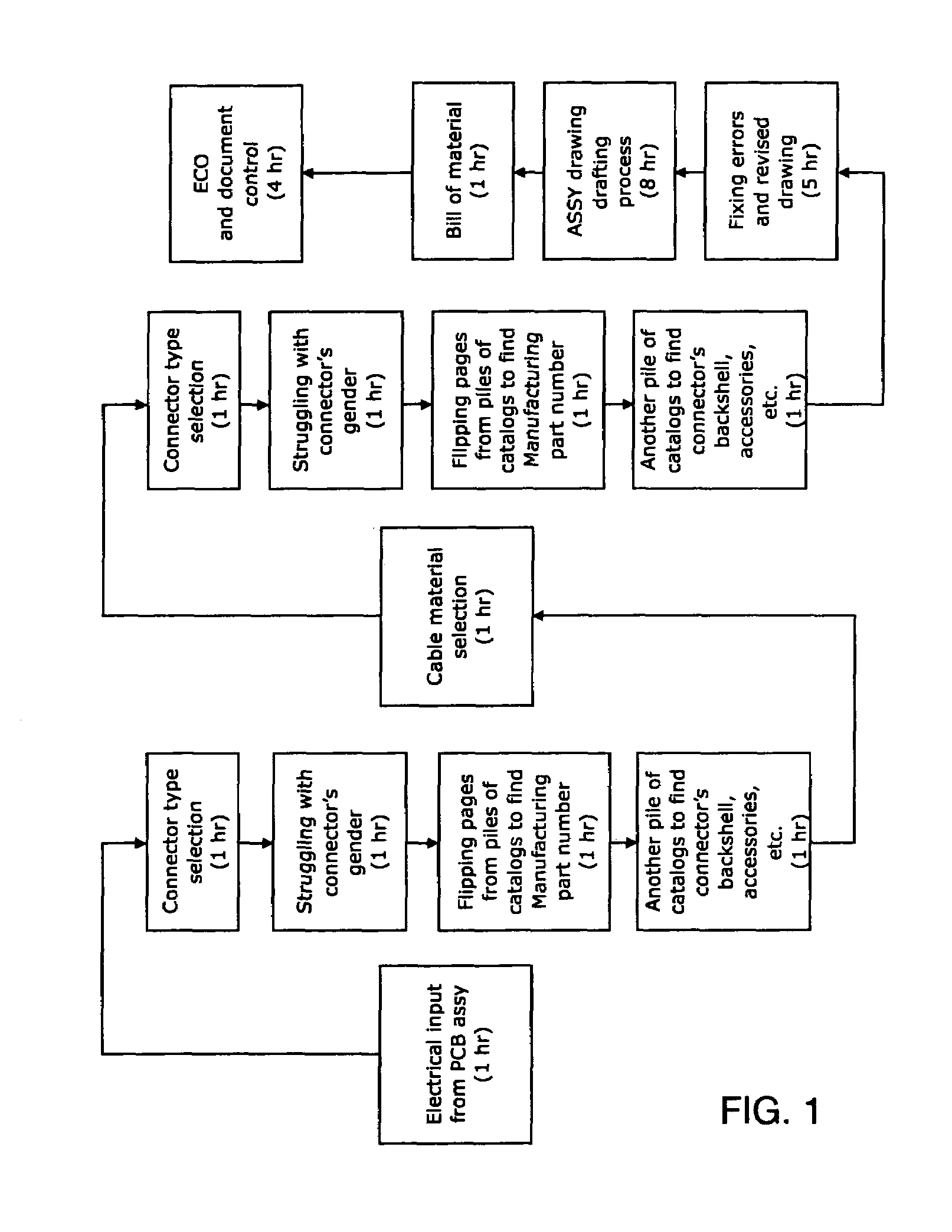

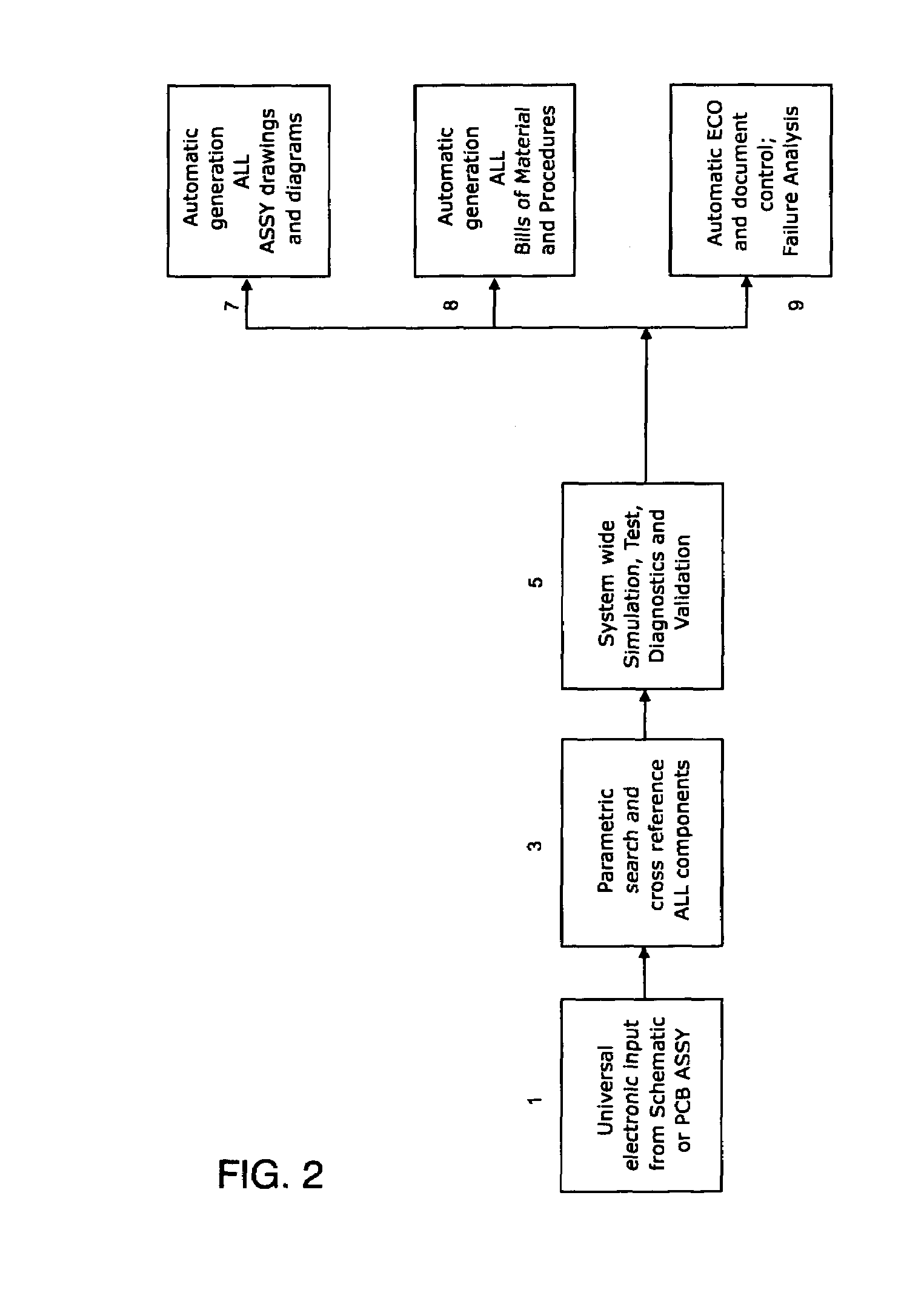

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

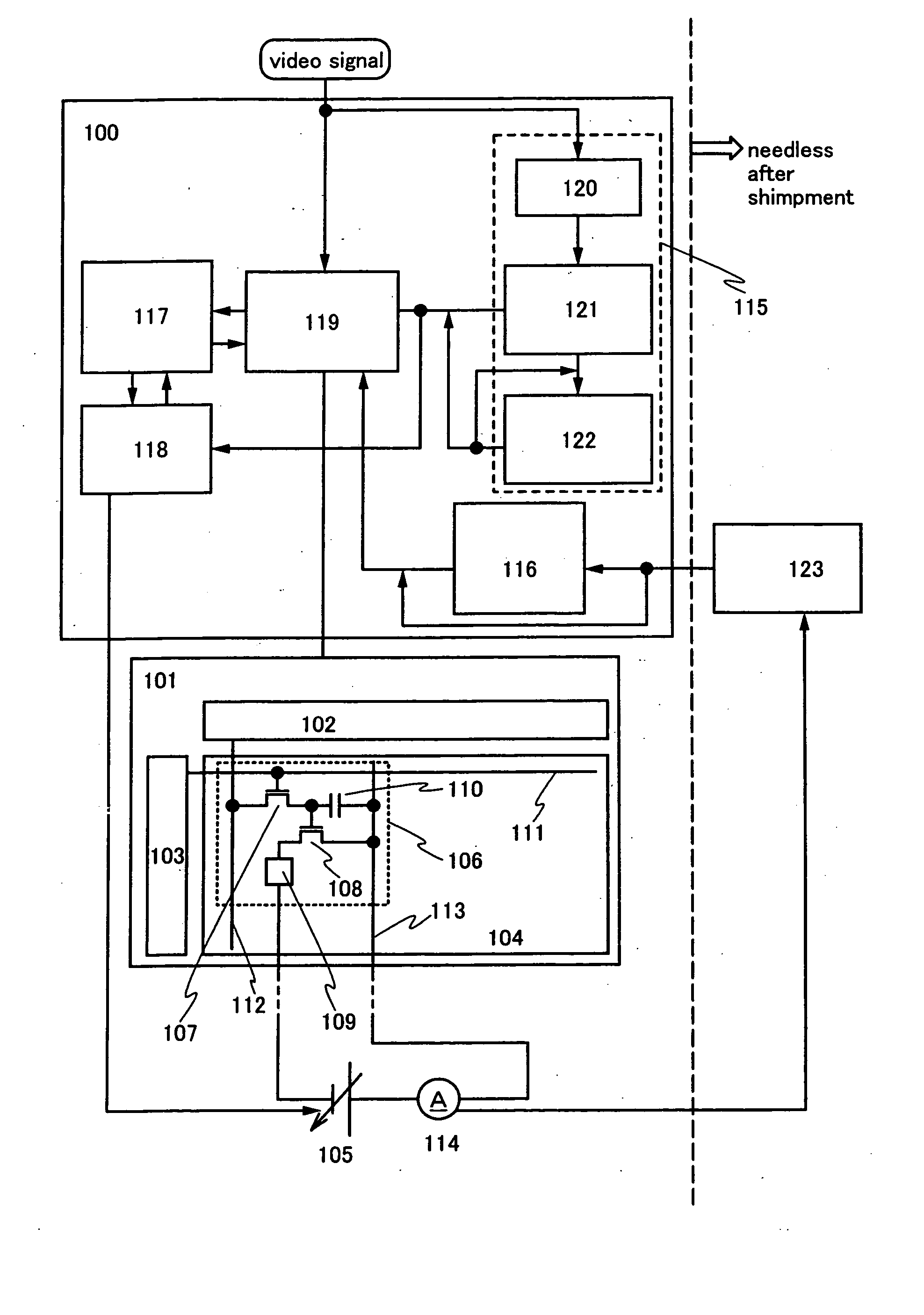

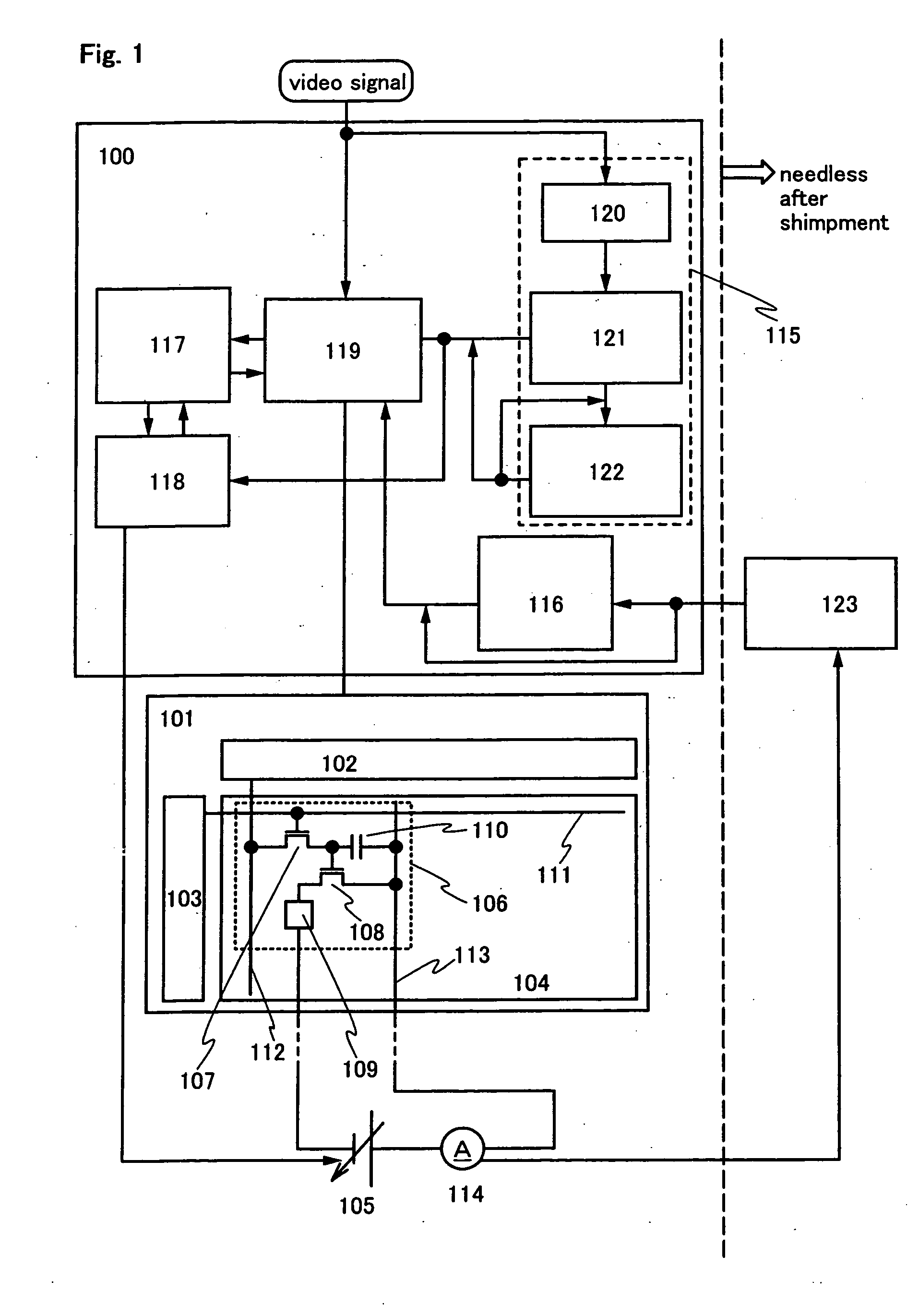

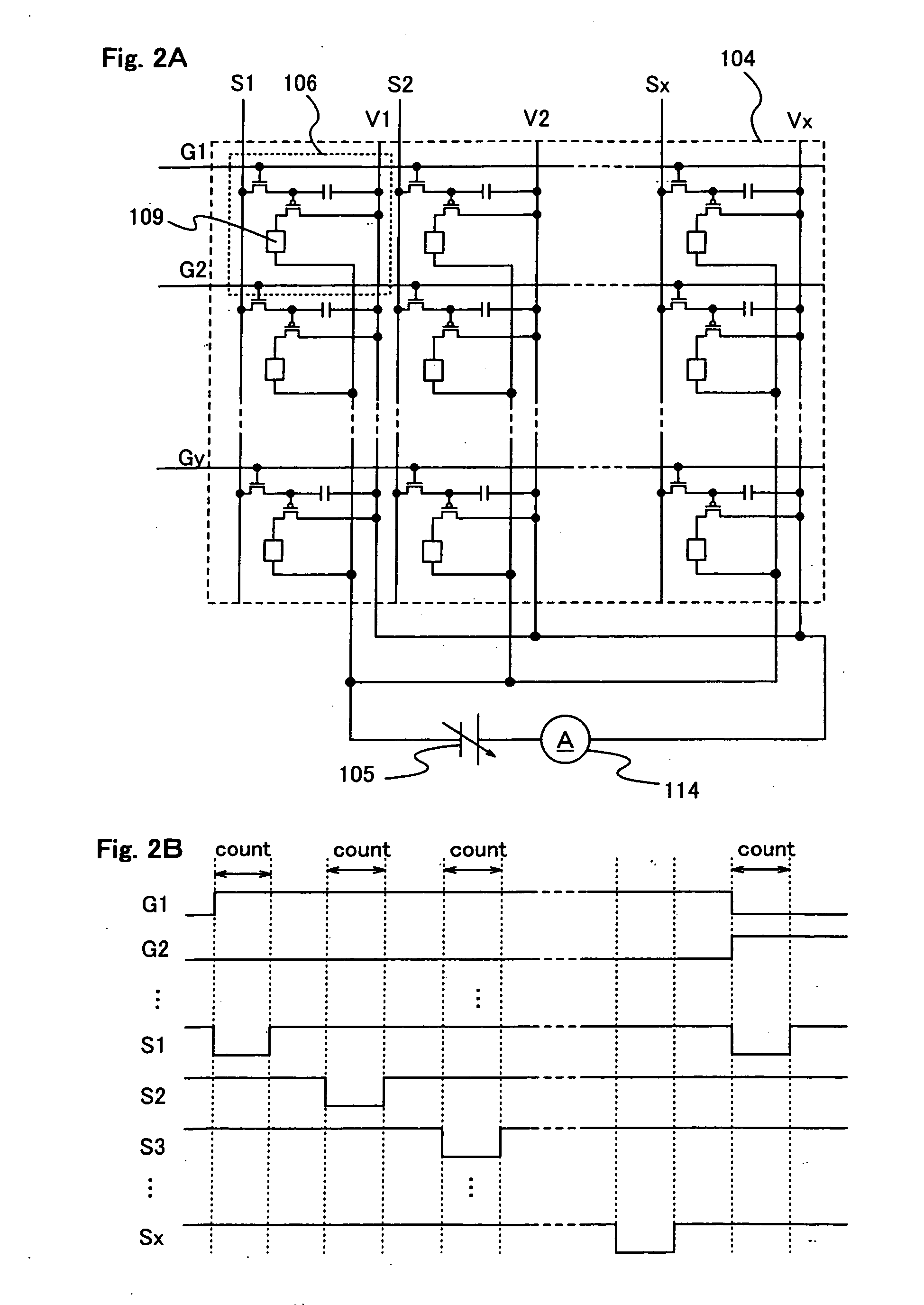

Light emitting device and production system of the same

InactiveUS20050156831A1Avoid uneven brightnessDecrease in luminanceCathode-ray tube indicatorsInput/output processes for data processingLight emitting deviceLightness

To provide a light emitting device without nonuniformity of luminance, a correcting circuit for correcting a video signal supplied to each pixel to a light emitting device. The correcting circuit is stored with data of a dispersion of a characteristic of a driving TFT among pixels and data of a change over time of luminance of a light emitting element. Further, by correcting a video signal inputted to the light emitting device in conformity with a characteristic of the driving TFT of each pixel and a degree of a deterioration of the light emitting element based on the over-described two data, nonuniformity of luminance caused by a deterioration of an electroluminescent layer and nonuniformity of luminance caused by dispersion of a characteristic of the driving TFT are restrained.

Owner:SEMICON ENERGY LAB CO LTD

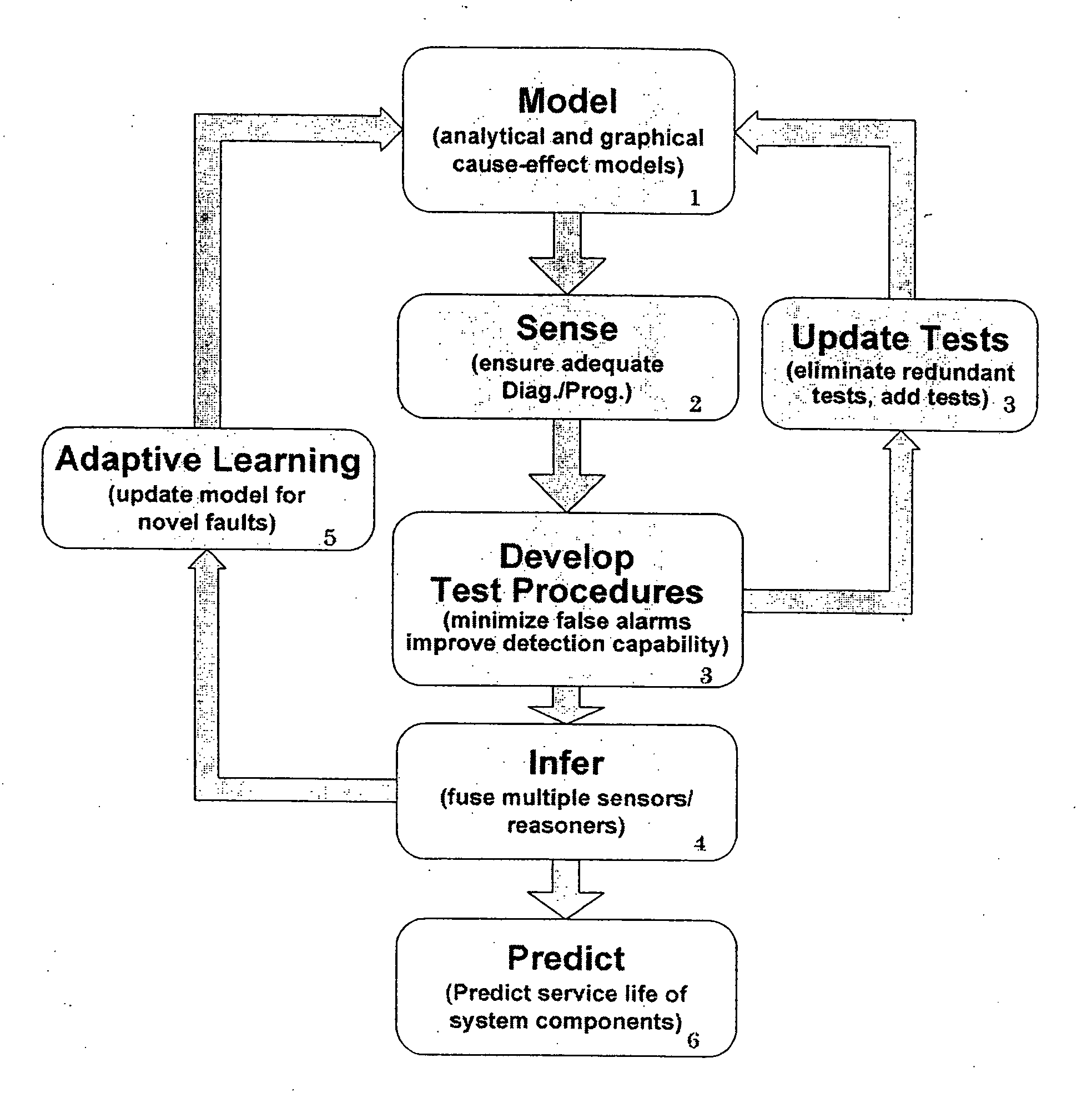

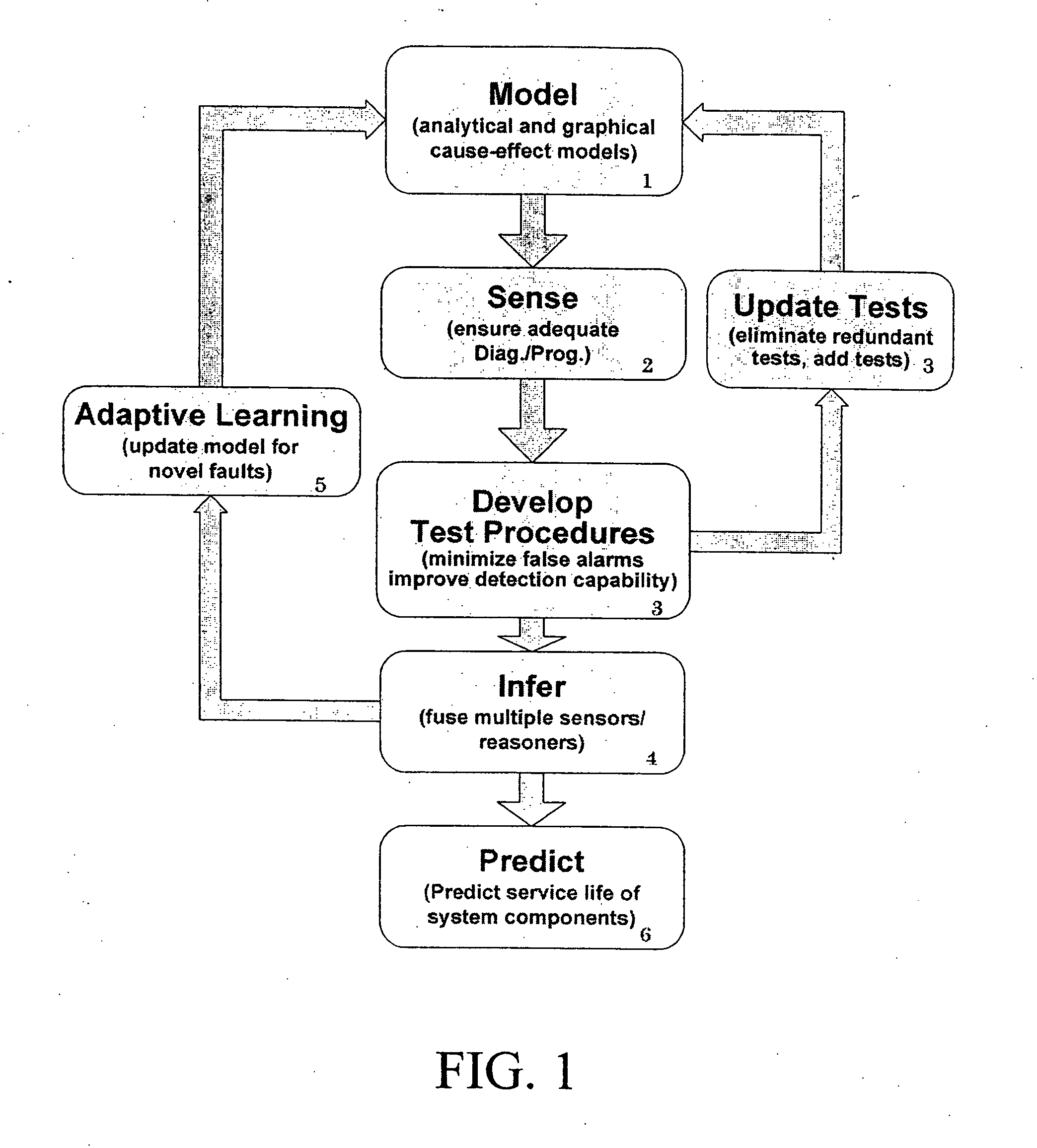

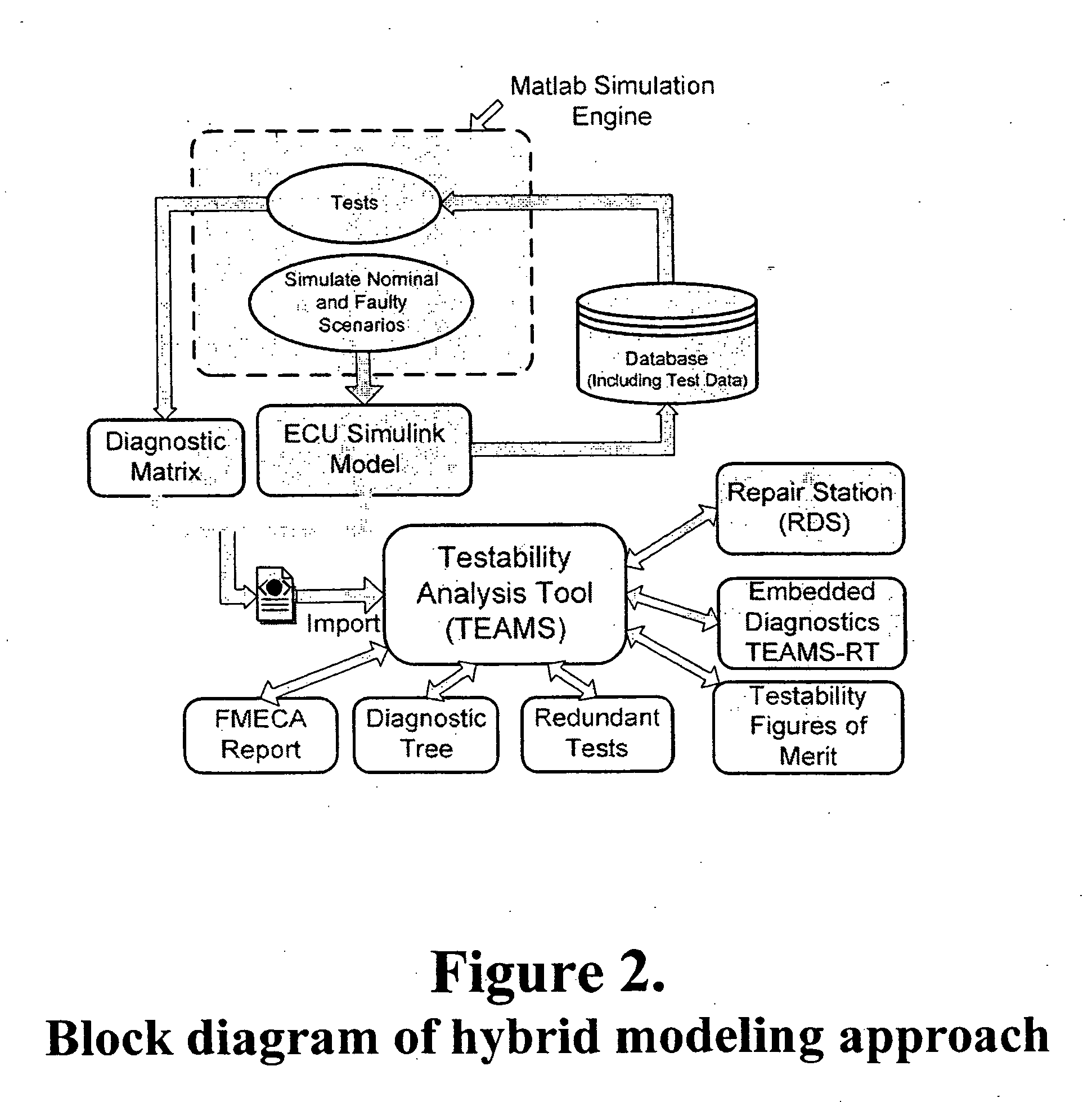

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS20060064291A1Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsElectric power systemCompound (substance)

Systems and methods are provided for monitoring, diagnosis and condition-based maintenance of mechanical systems. The disclosed systems and methods employ intelligent model-based diagnostic methodologies to effectuate such monitoring, diagnosis and maintenance. According to exemplary embodiments of the present disclosure, the intelligent model-based diagnostic methodologies combine or integrate quantitative (analytical) models and graph-based dependency models to enhance diagnostic performance. The disclosed systems and methods may be employed a wide variety of applications, including automotive, aircraft, power systems, manufacturing systems, chemical processes and systems, transportation systems, and industrial machines / equipment.

Owner:TOYOTA TECHN CENT USA +1

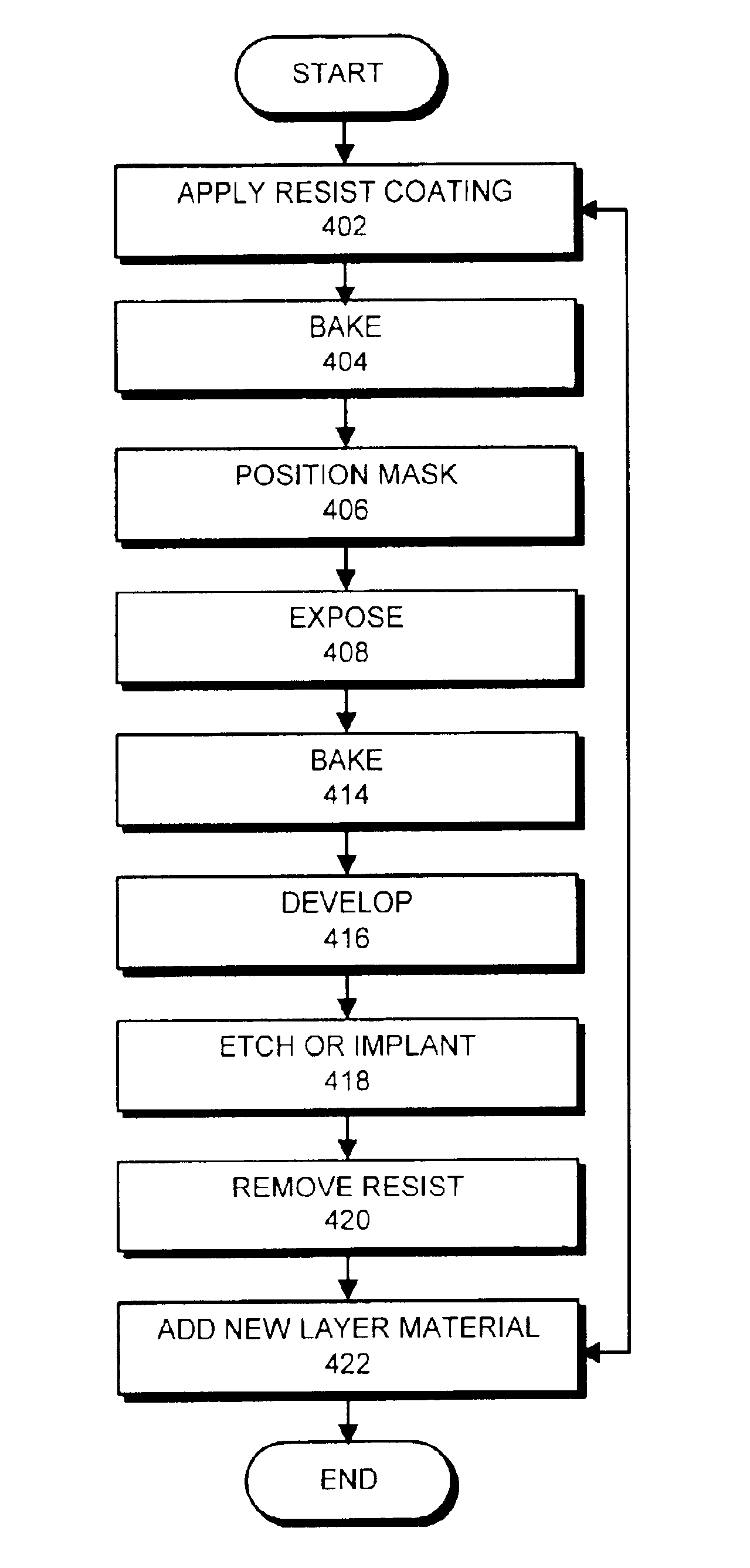

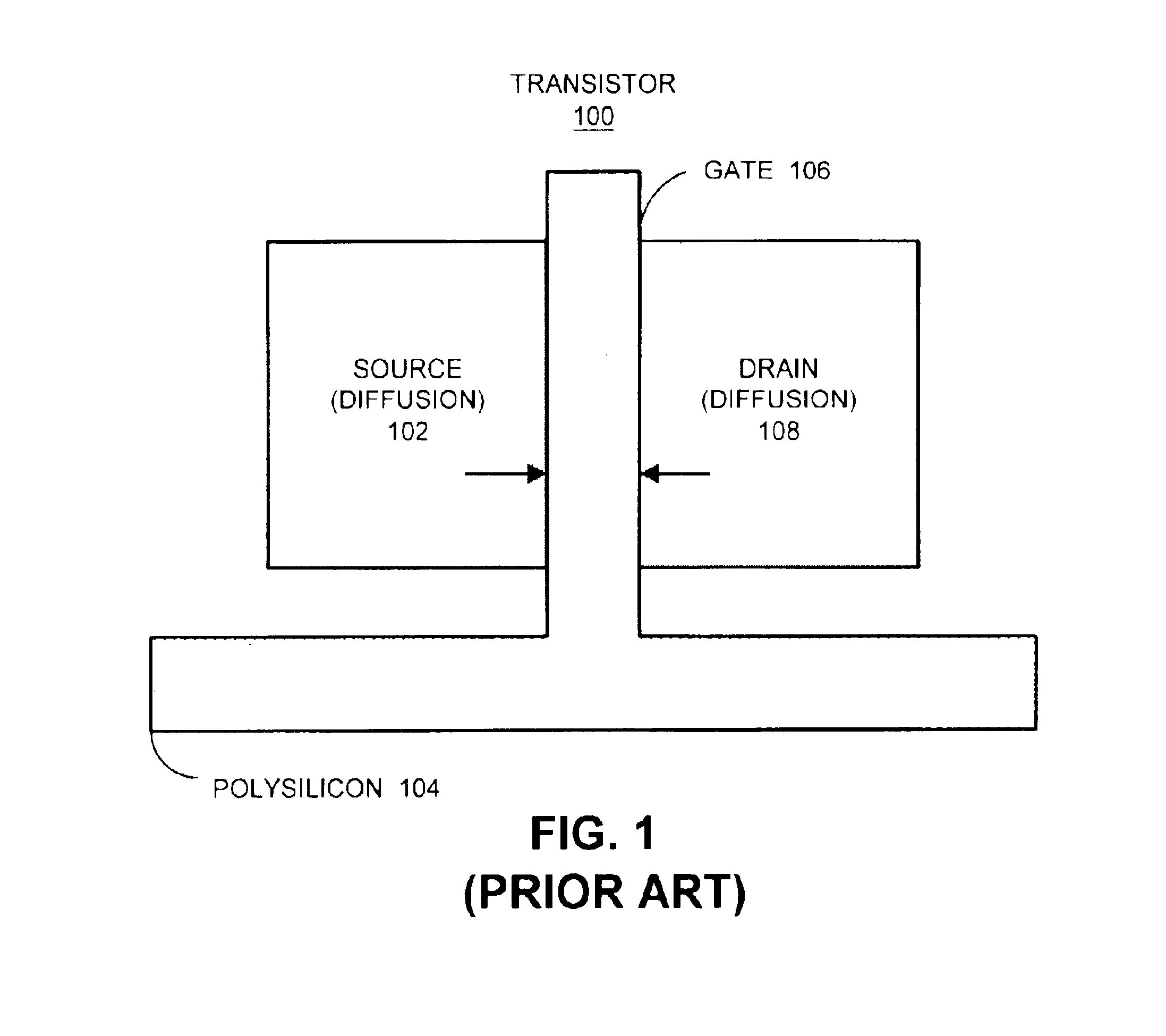

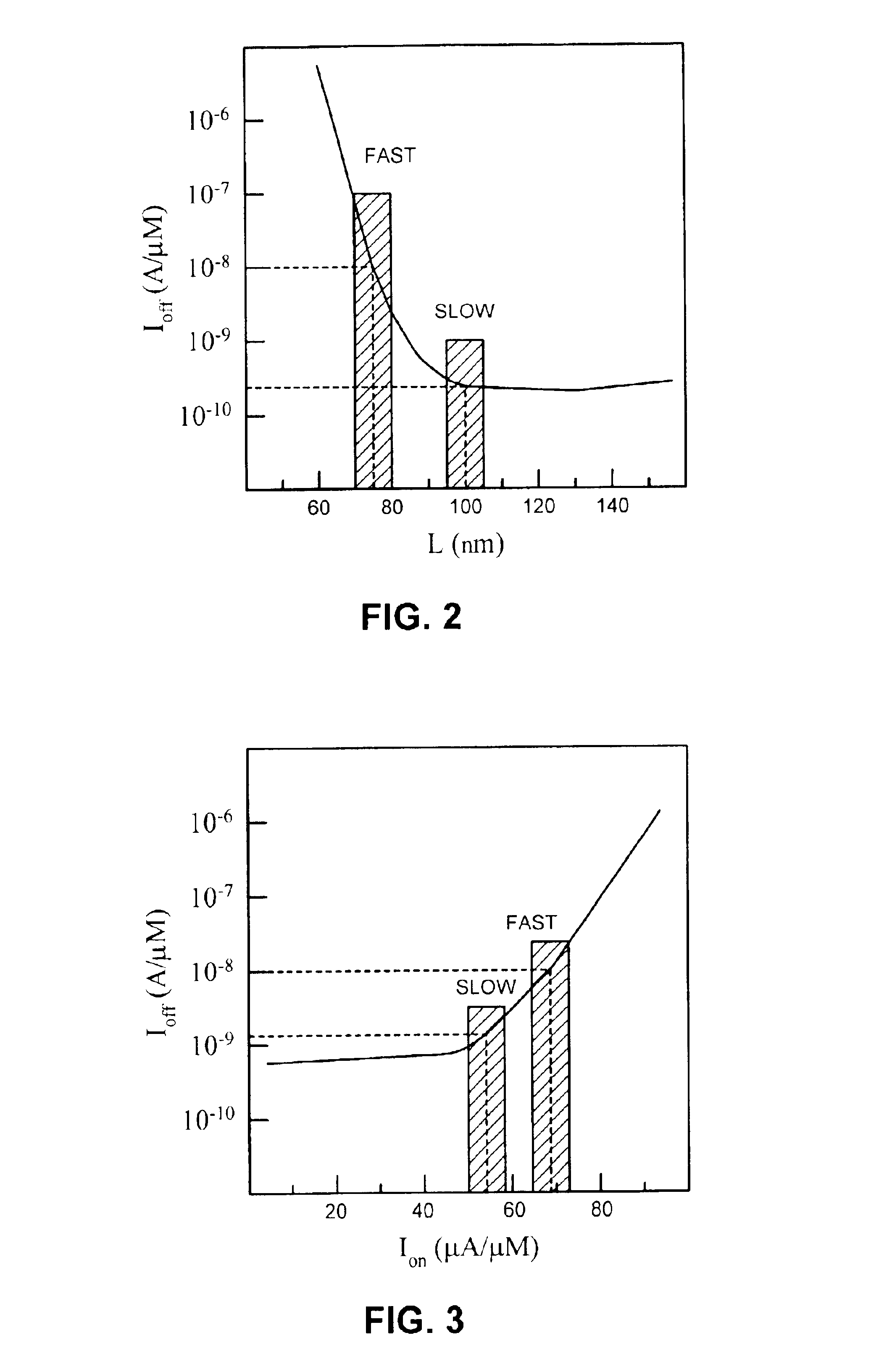

Selectively applying resolution enhancement techniques to improve performance and manufacturing cost of integrated circuits

InactiveUS6928635B2Reduce delaysReduction of gate lengthSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResolution enhancement technologiesImage resolution

One embodiment of the present invention provides a system that applies resolution enhancement techniques (RETs) selectively to a layout of an integrated circuit. Upon receiving the layout of the integrated circuit, the system identifies a plurality of critical regions within the layout based on an analysis of one or more of, timing, dynamic power, and off-state leakage current. The system then performs a first set of aggressive RET operations on the plurality of critical regions. The system also performs a second set of less aggressive RET operations on other non-critical regions of the layout.

Owner:SYNOPSYS INC

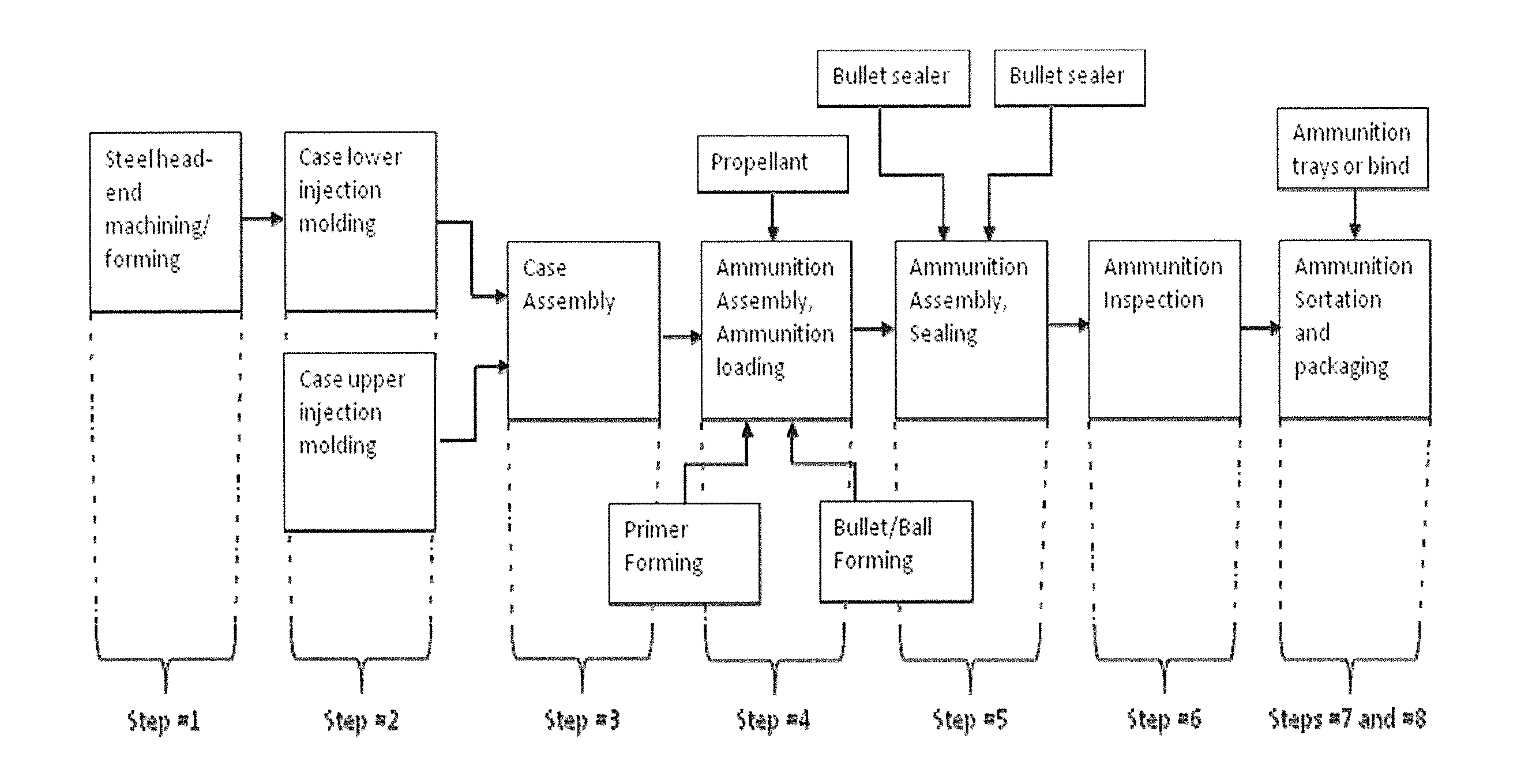

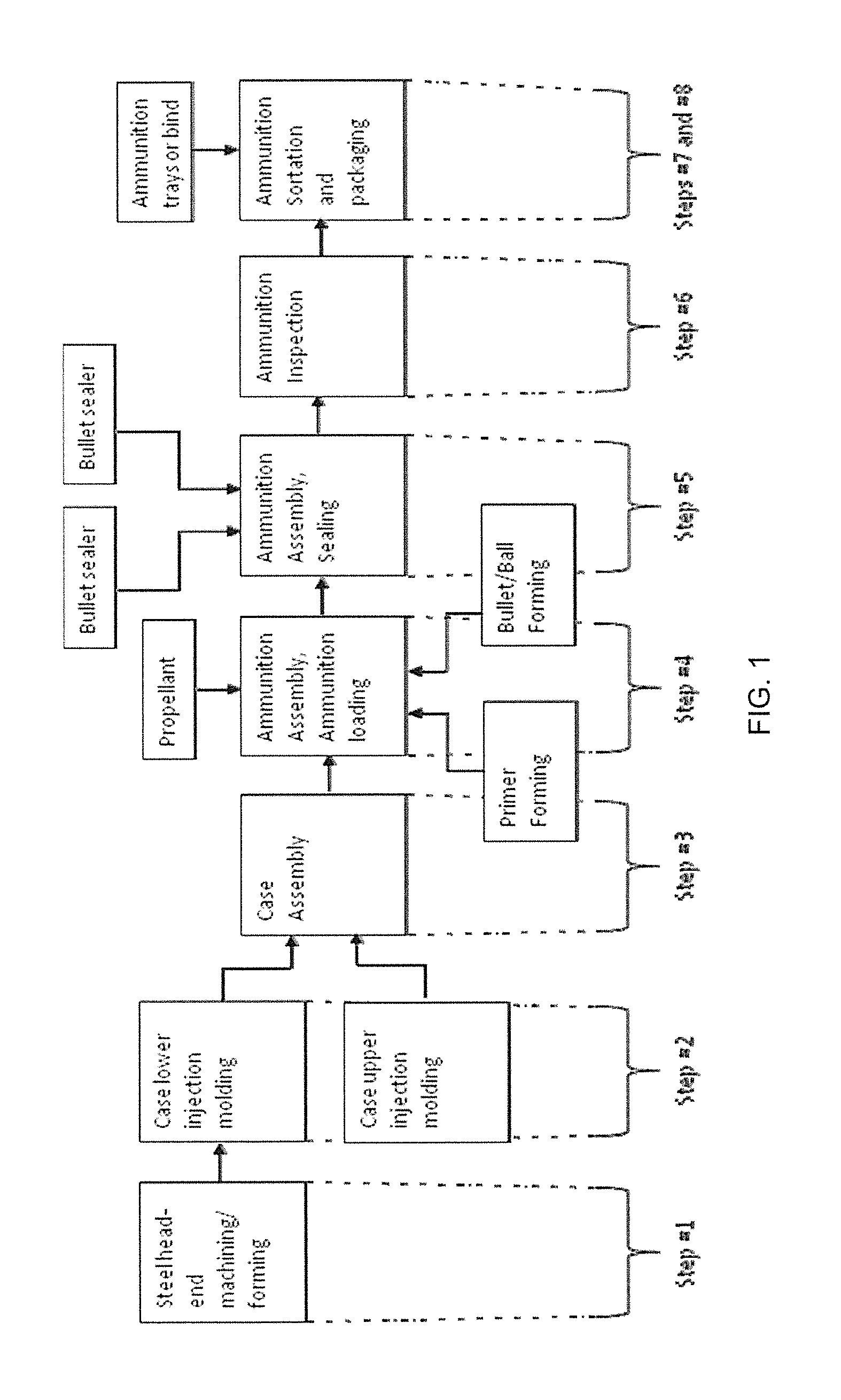

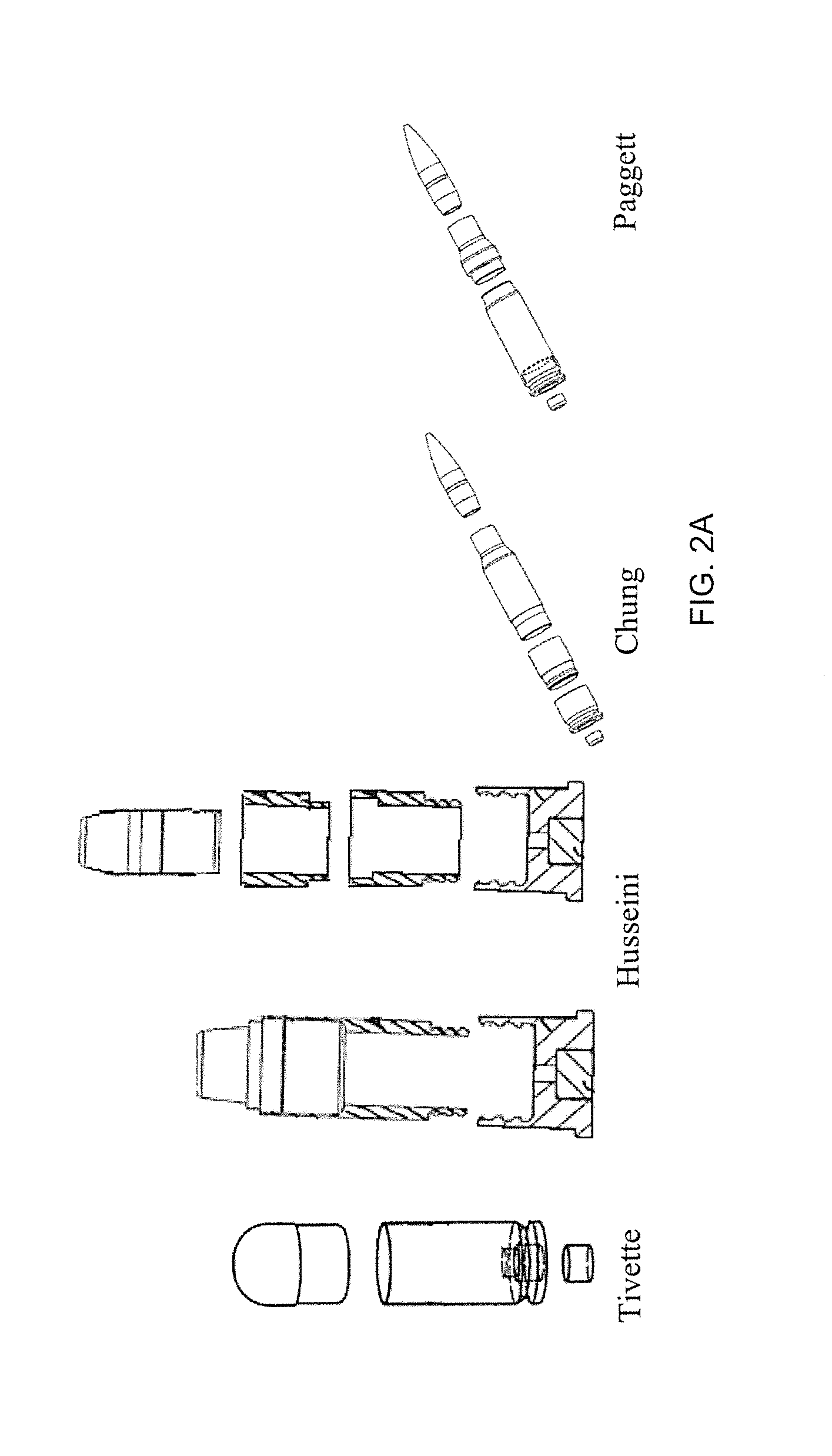

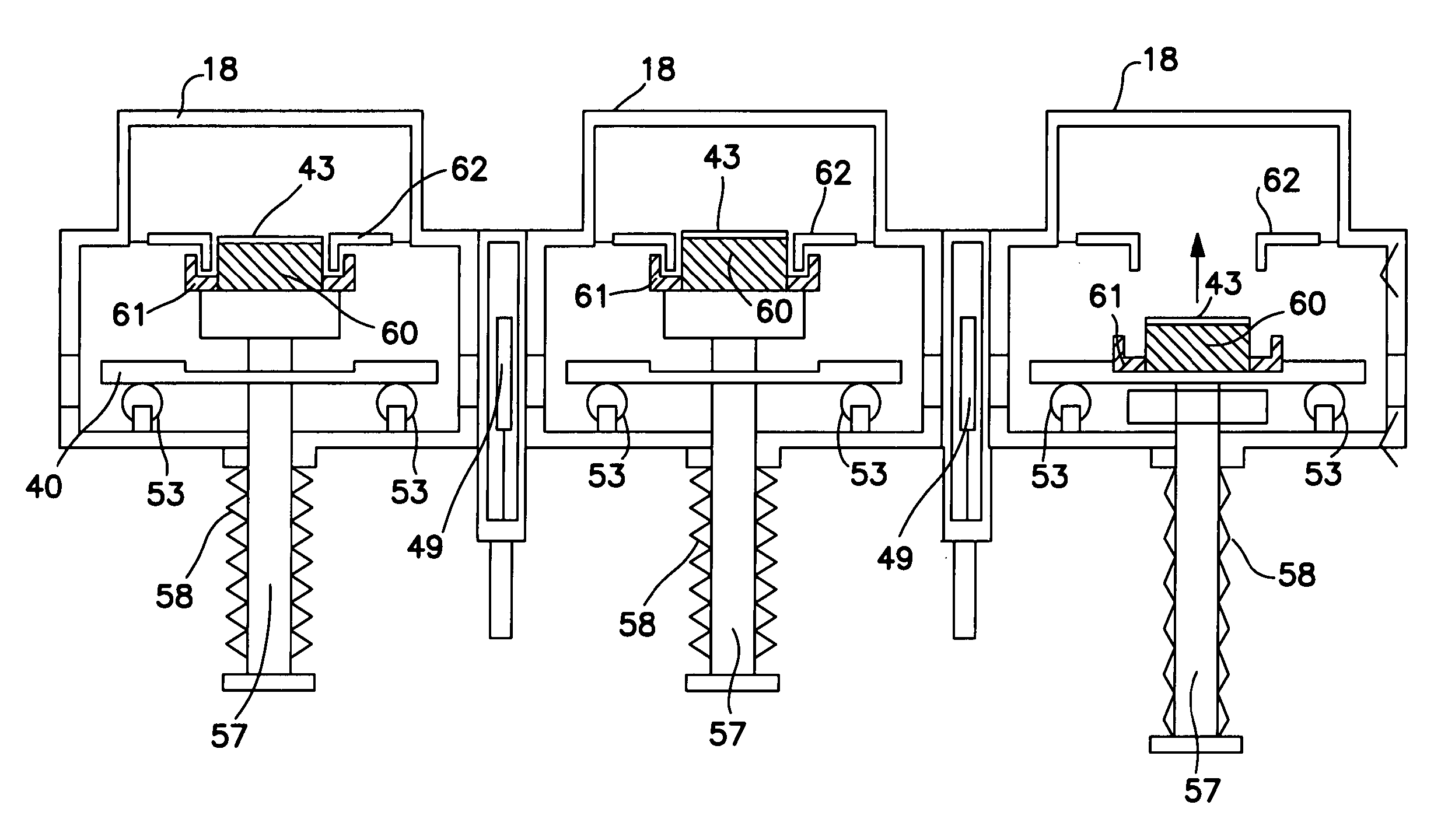

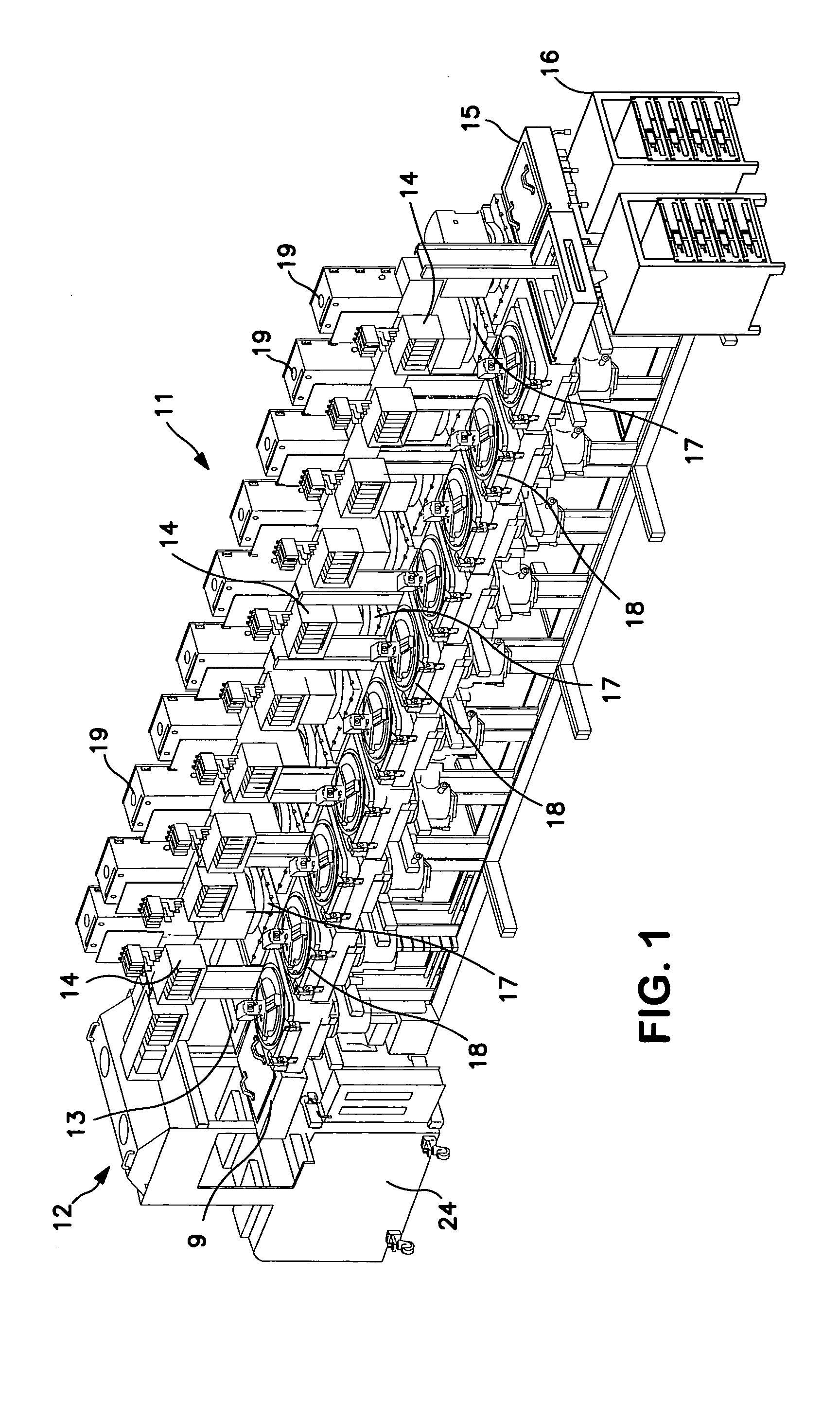

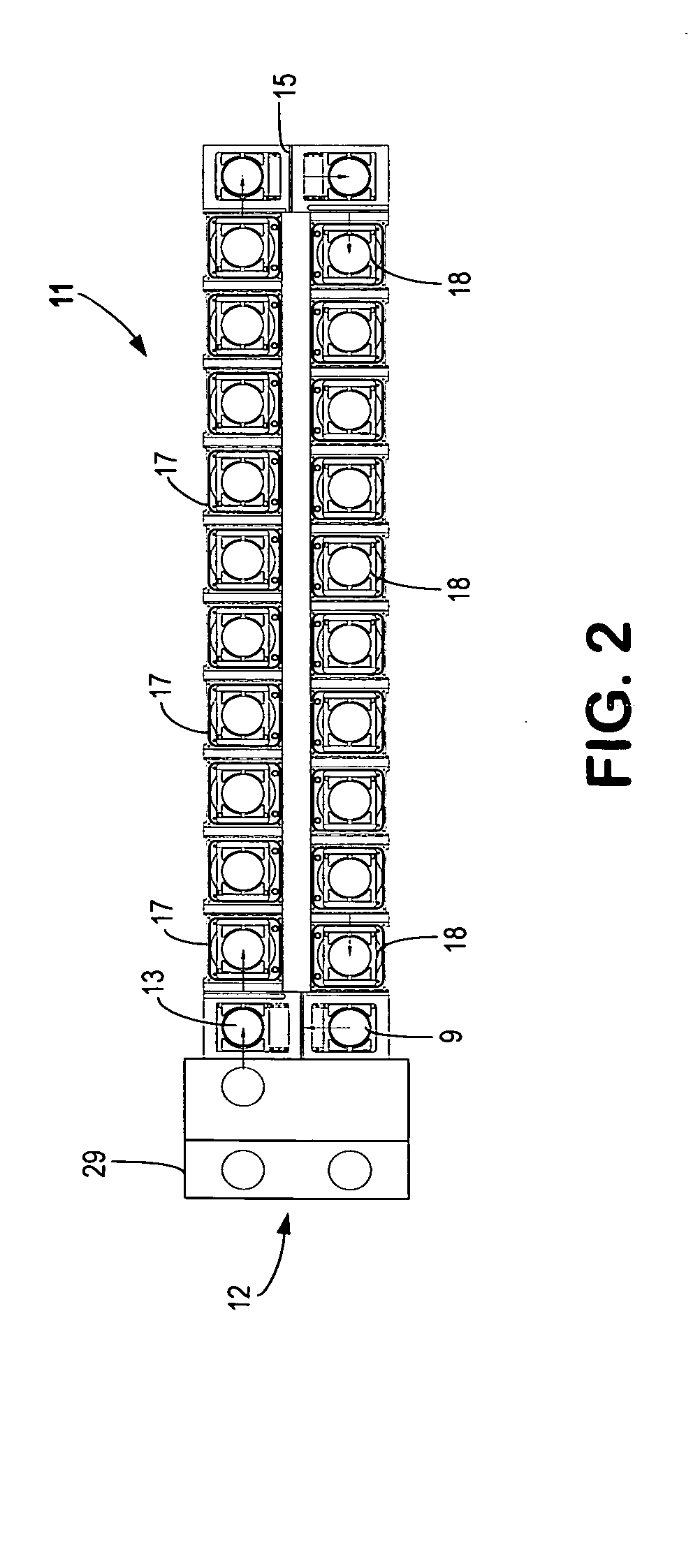

Integrated polymer and metal case ammunition manufacturing system and method

A fully automated, integrated, end-to-end synchronized and compact manufacturing system produces polymer or metal case ammunition. Manufacturing stations support case assembly, sealing (gluing / welding), final product inspection, cartridge packaging or binning, and loading. Station modularity facilitates rapid changeover to accommodate ammunition of differing calibers. Sensors and apparatus may be provided to place a manufacturing cell in a wait state until all components or materials are received in a preferred orientation for proper assembly. The system may join and use multipart cases, each including a lower portion with a head end attached thereto and at least one upper portion having a necked-down transition to the open top end. Elevator feeders, vibratory bowl feeders, and robotic pick-and-place feeders may be used to deliver components for assembly.

Owner:CYBERNET SYST

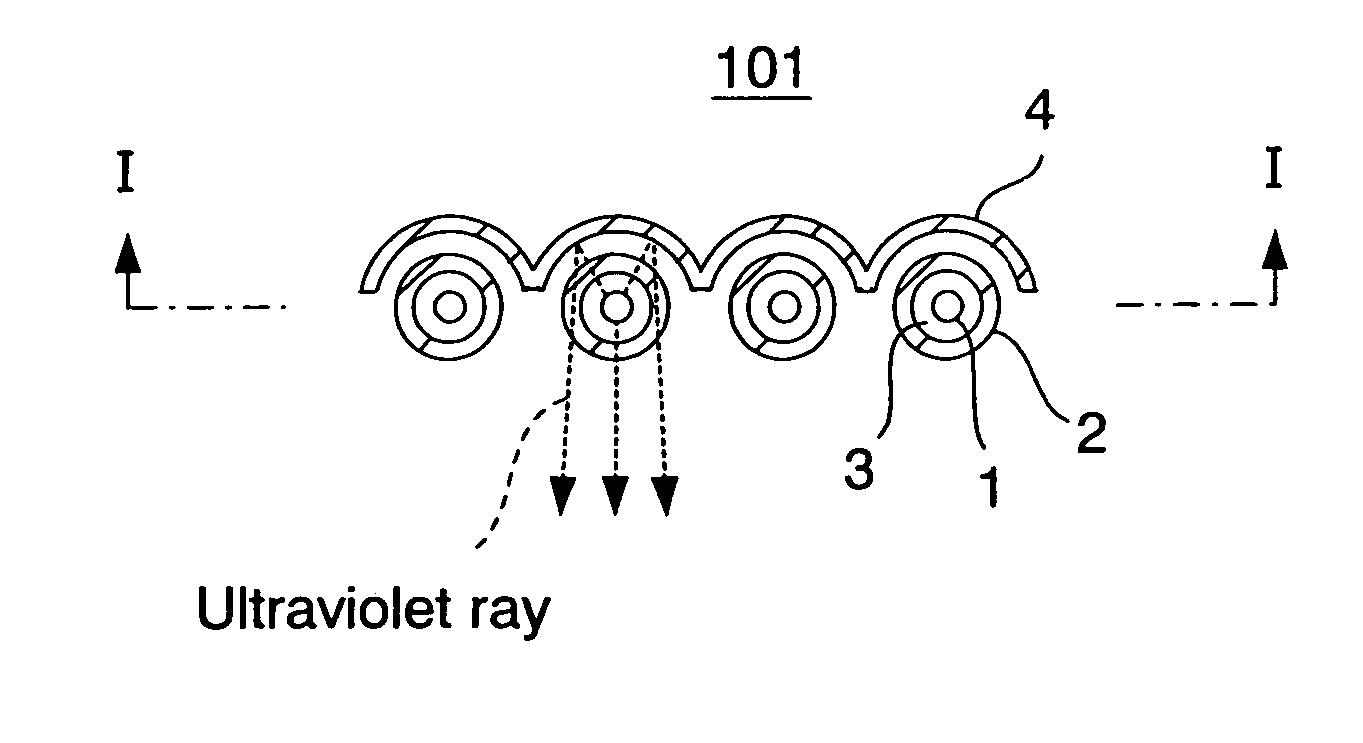

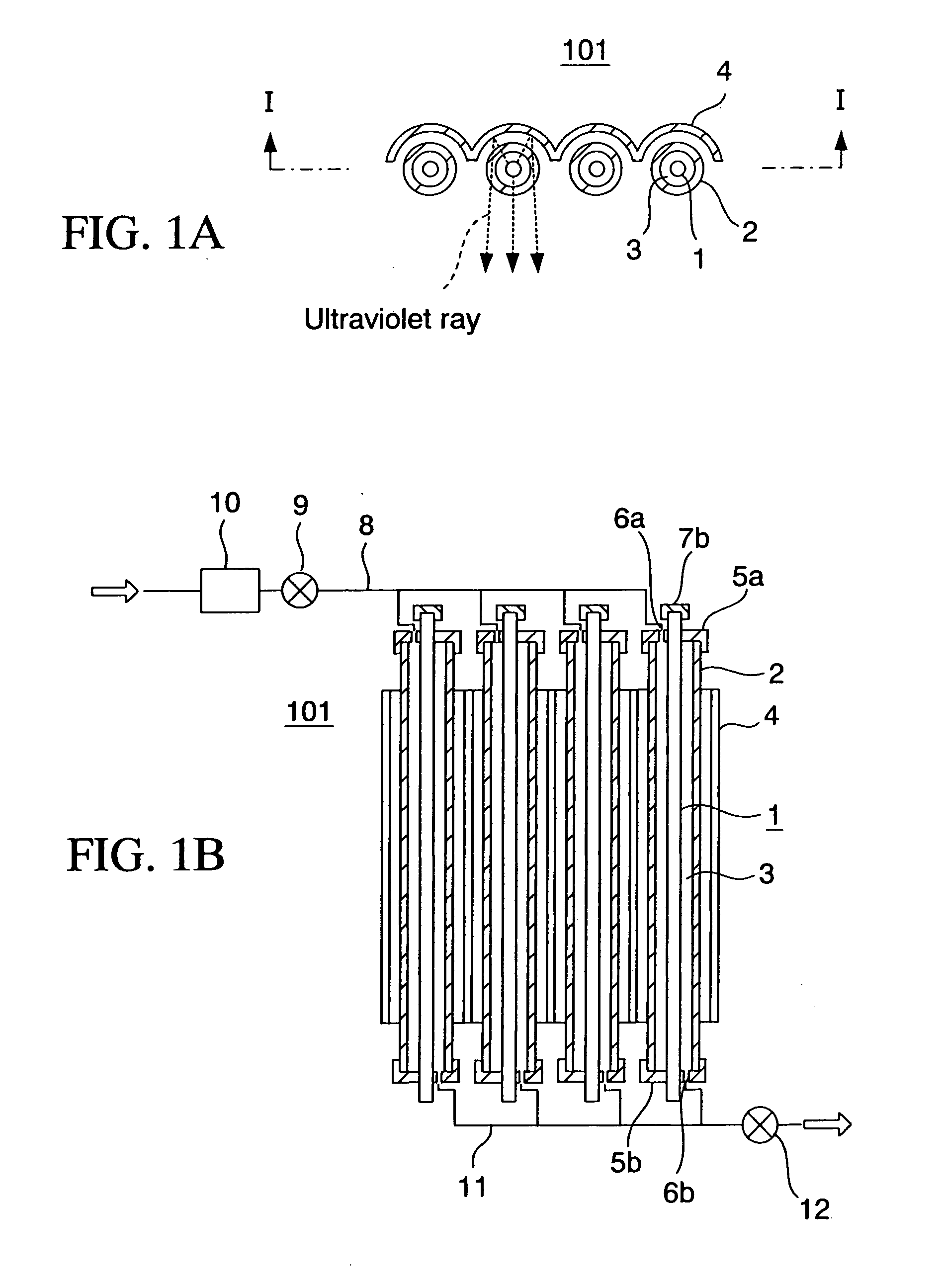

Ultraviolet ray generator, ultraviolet ray irradiation processing apparatus, and semiconductor manufacturing system

InactiveUS20050263719A1High dielectric constantReduce transmission intensityFurnace componentsLiving organism packagingUltravioletNitrogen gas

The present invention relates to an ultraviolet ray generator 101, and the generator 101 has an ultraviolet ray lamp 1, a protective tube 2 being made of a material which is transparent with respect to ultraviolet ray and housing the ultraviolet ray lamp 1, and gas introduction port 6a introducing nitrogen gas or inert gas into the protective tube 2.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

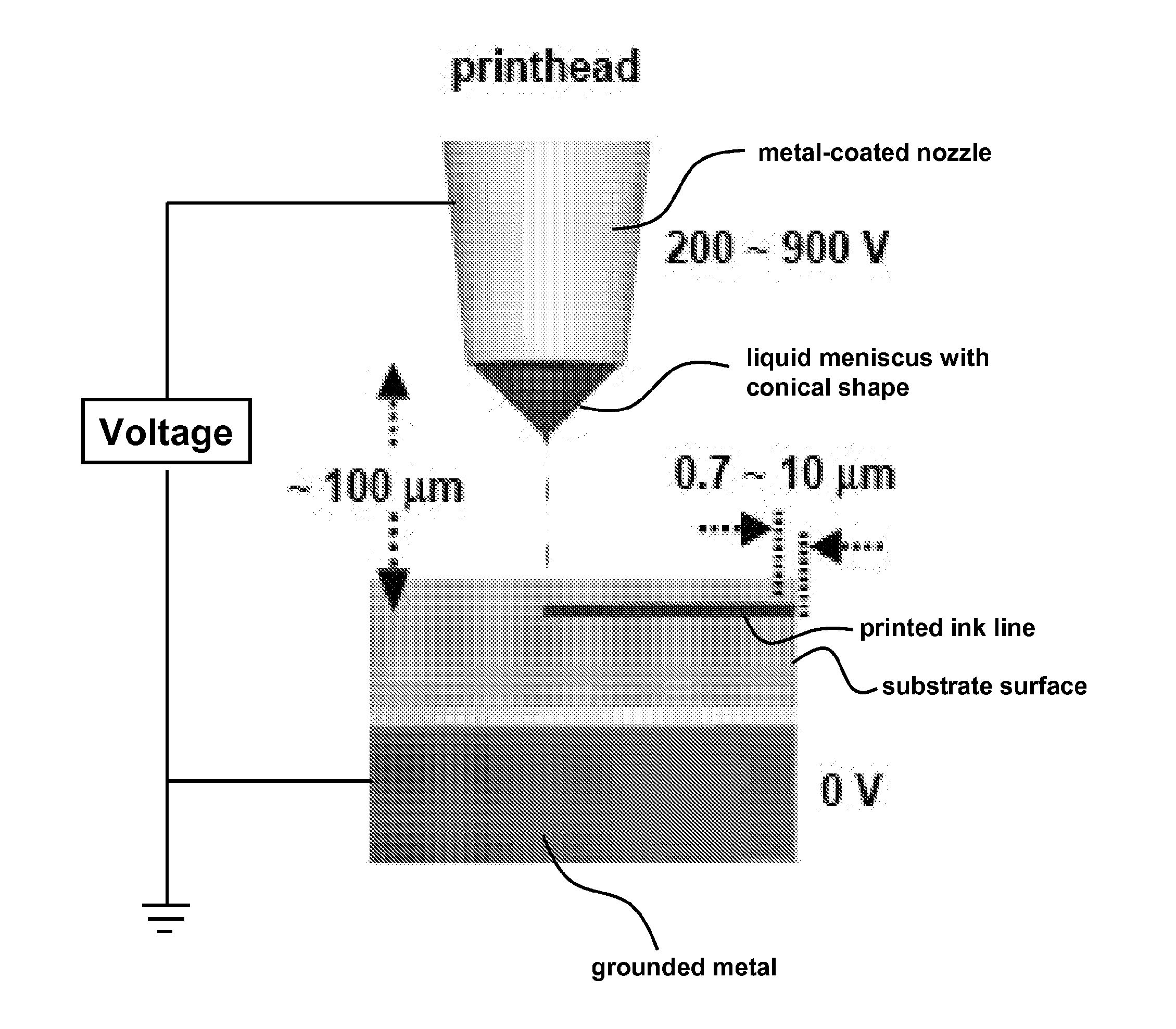

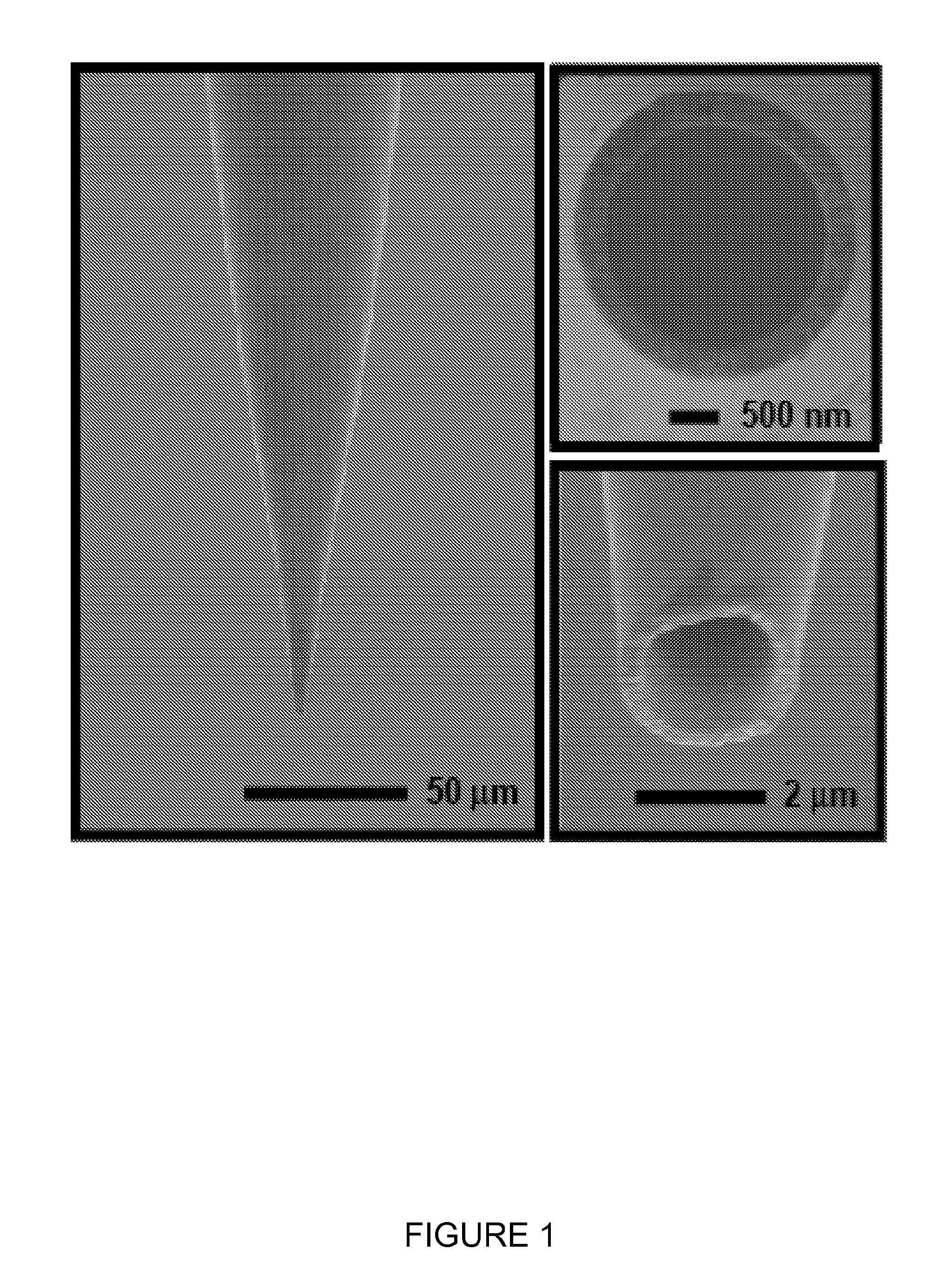

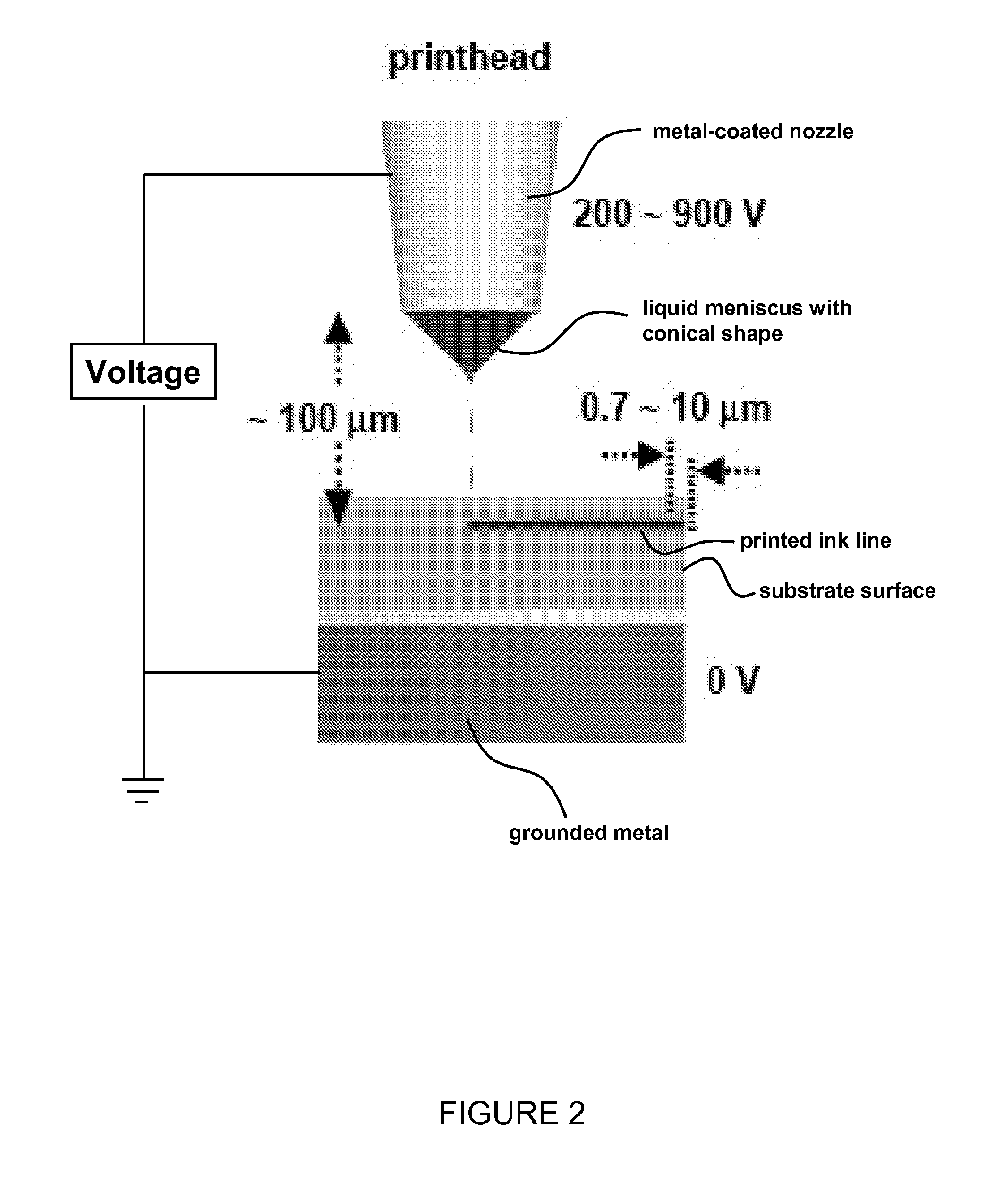

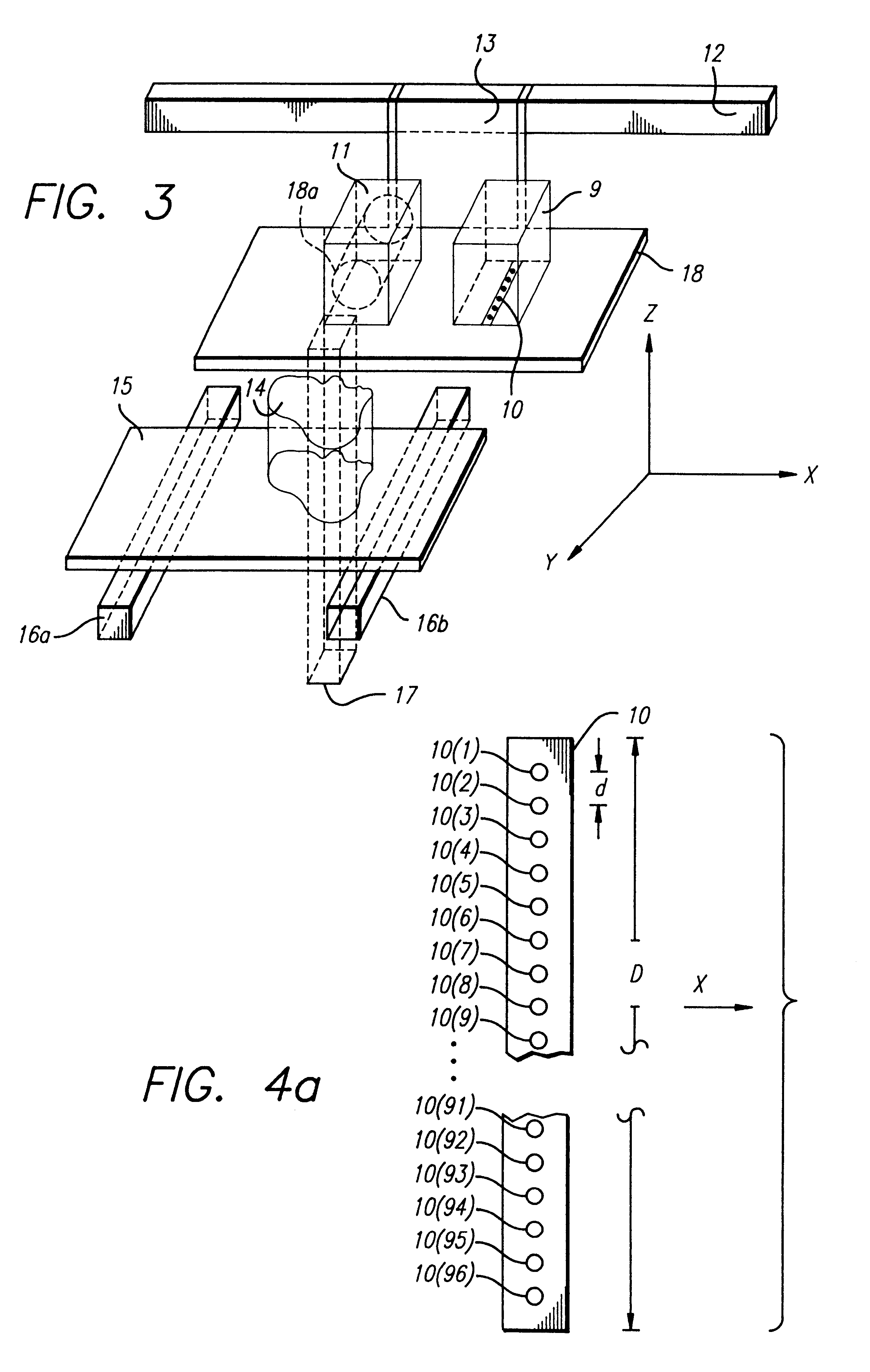

High Resolution Electrohydrodynamic Jet Printing for Manufacturing Systems

ActiveUS20110187798A1Improve placement accuracyBetter confinedPrintingImage resolutionVoltage source

Provided are high-resolution electrohydrodynamic inkjet (e-jet) printing systems and related methods for printing functional materials on a substrate surface. In an embodiment, a nozzle with an ejection orifice that dispenses a printing fluid faces a surface that is to be printed. The nozzle is electrically connected to a voltage source that applies an electric charge to the fluid in the nozzle to controllably deposit the printing fluid on the surface. In an aspect, a nozzle that dispenses printing fluid has a small ejection orifice, such as an orifice with an area less than 700 μm2 and is capable of printing nanofeatures or microfeatures. In an embodiment the nozzle is an integrated-electrode nozzle system that is directly connected to an electrode and a counter-electrode. The systems and methods provide printing resolutions that can encompass the sub-micron range.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

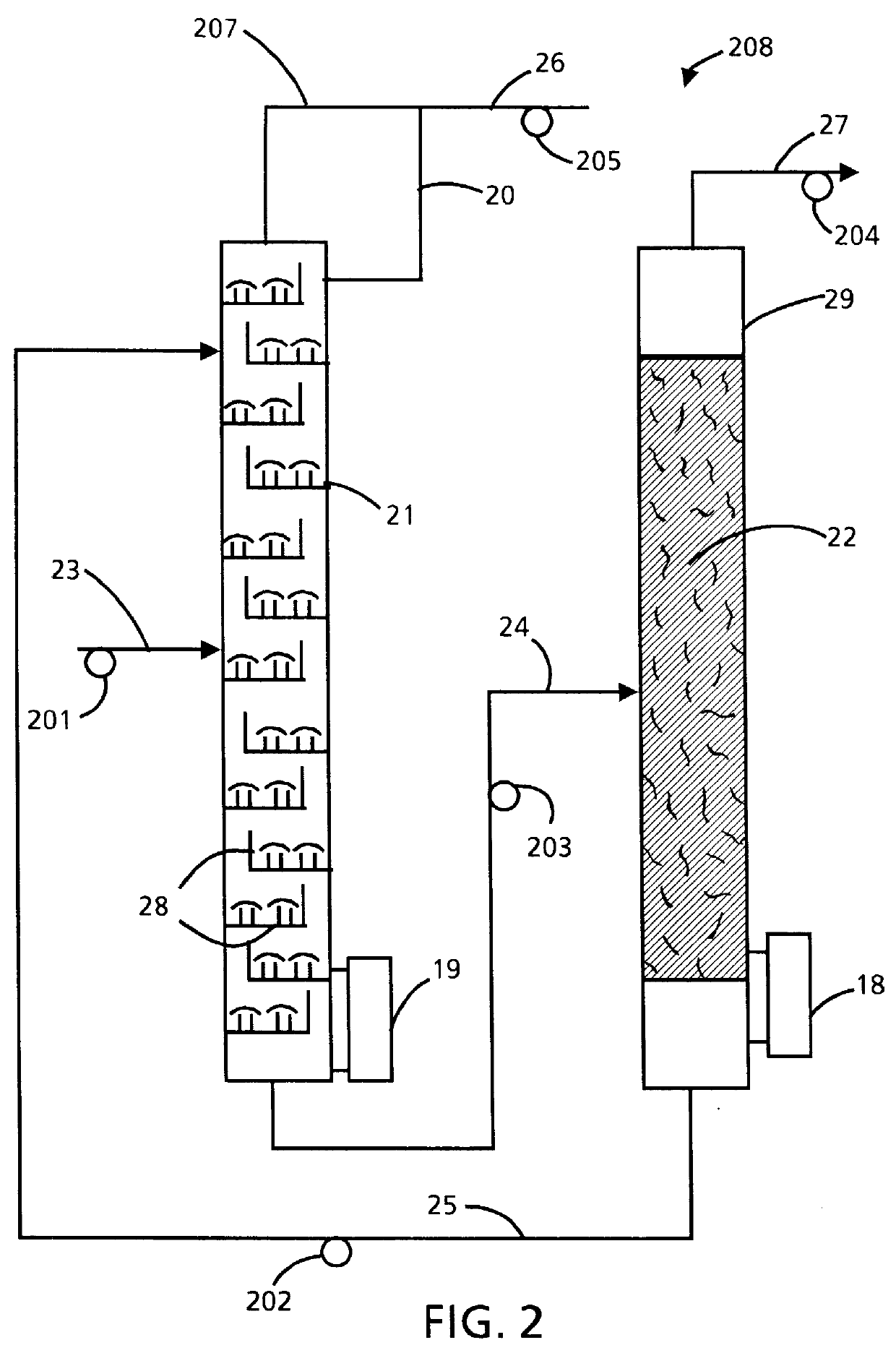

System and process for fabricating an organic electroluminescent display device

InactiveUS6132280ALow costHigh yet stabilized qualityElectroluminescent light sourcesSolid-state devicesEngineeringVacuum delivery

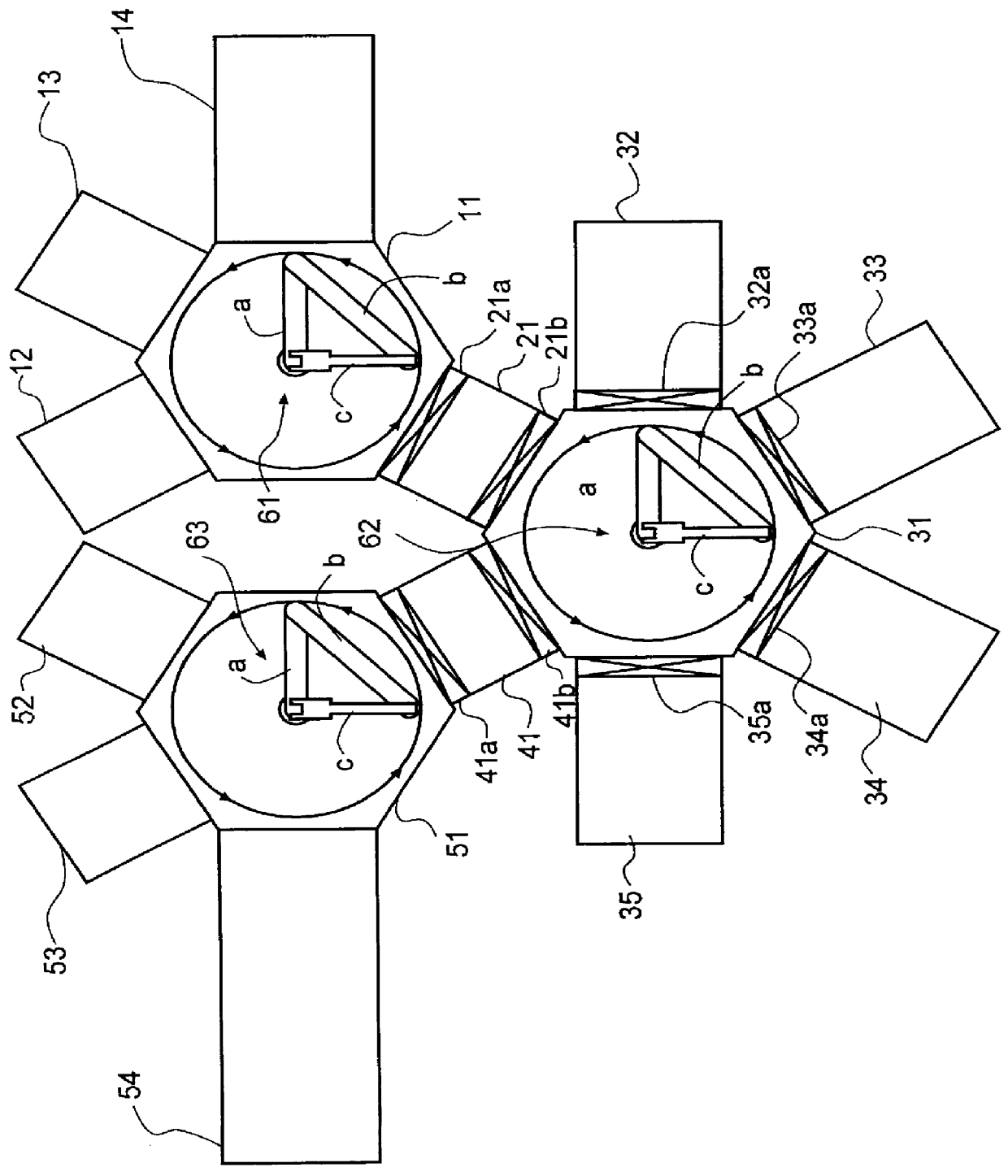

The invention provides an organic EL display device fabrication system comprising a loading side normal-pressure delivery chamber 11 including a first substrate delivery means 61 for delivering a substrate with no film formed thereon, and a loading chamber 21 connected thereto for introducing the substrate from loading side normal-pressure delivery chamber 11 at normal pressure into a vacuum delivery chamber 31 at a vacuum. The vacuum delivery chamber 31 is connected to loading chamber 21 and includes a second substrate delivery means 62 for delivering the substrate in a vacuum, and has one or two or more film formation chambers 32 to 35 connected thereto. The system further comprises an unloading chamber 41 connected thereto for delivering the substrate out of vacuum delivery chamber 31 at a vacuum into an unloading side normal-pressure delivery chamber 51 at normal pressure. The unloading side normal-pressure delivery chamber 51 is connected to unloading chamber 41 and includes a third substrate delivery means 63 for delivering a substrate with films formed thereon. An inert gas atmosphere having a moisture content of up to 100 ppm is maintained in both unloading chamber 41 and unloading side normal-pressure delivery chamber 51 at normal pressure. The invention also provides an organic EL display device fabrication process using this fabrication system.

Owner:FUTABA CORPORATION

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6270335B2Less distortionReduce the risk of bridgingAdditive manufacturing apparatusConfectioneryEngineeringSelective deposition

Owner:3D SYST INC

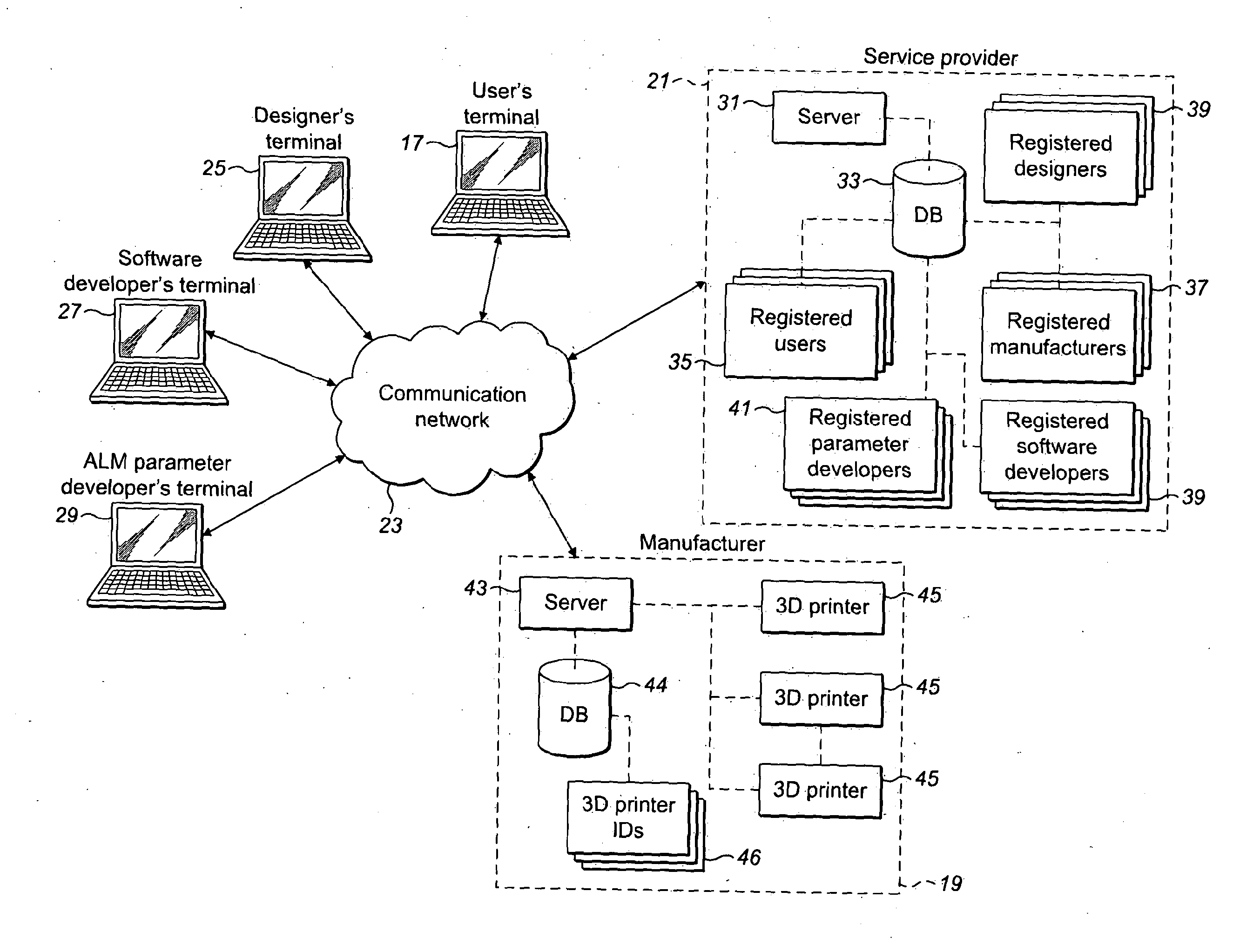

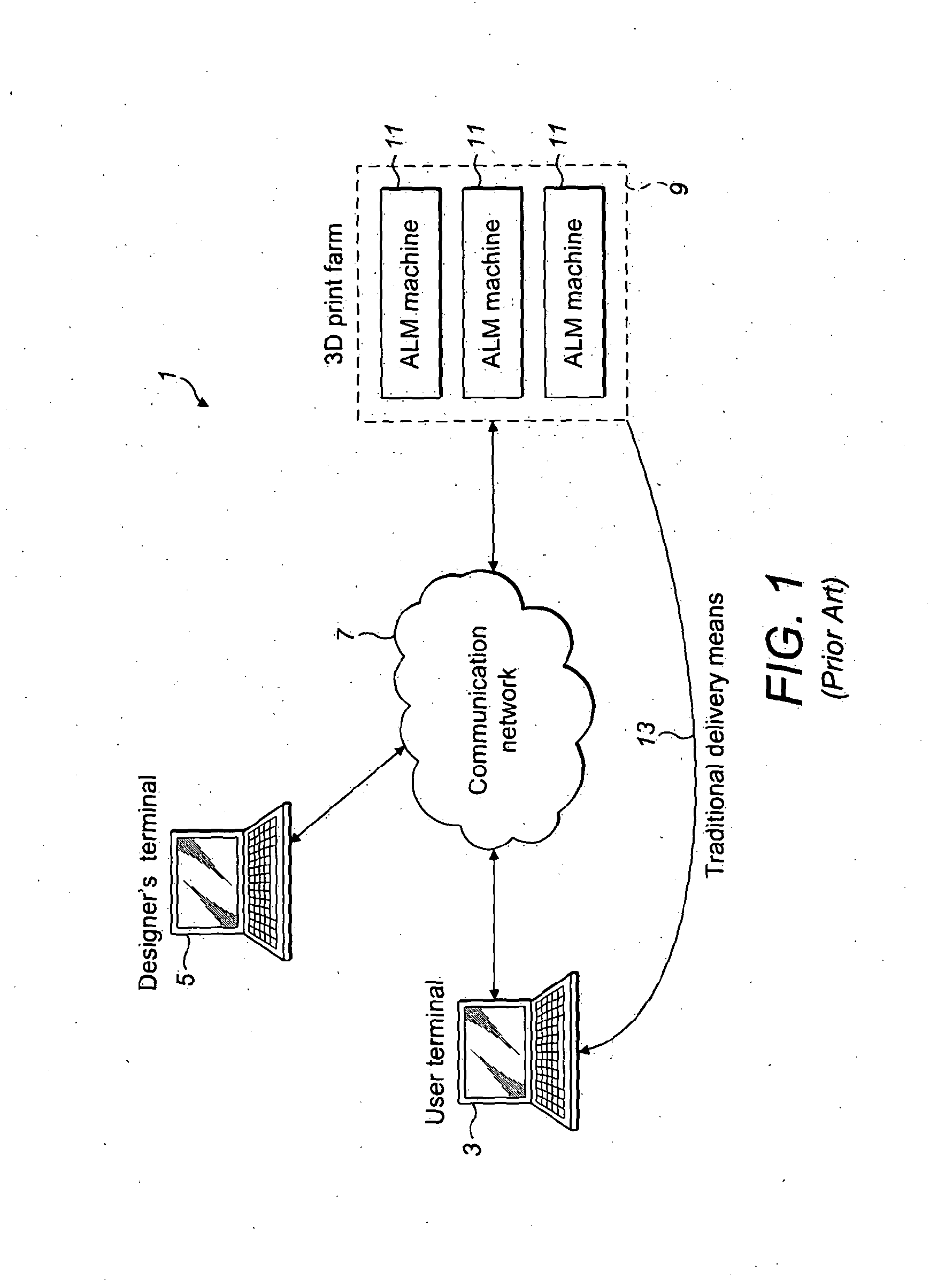

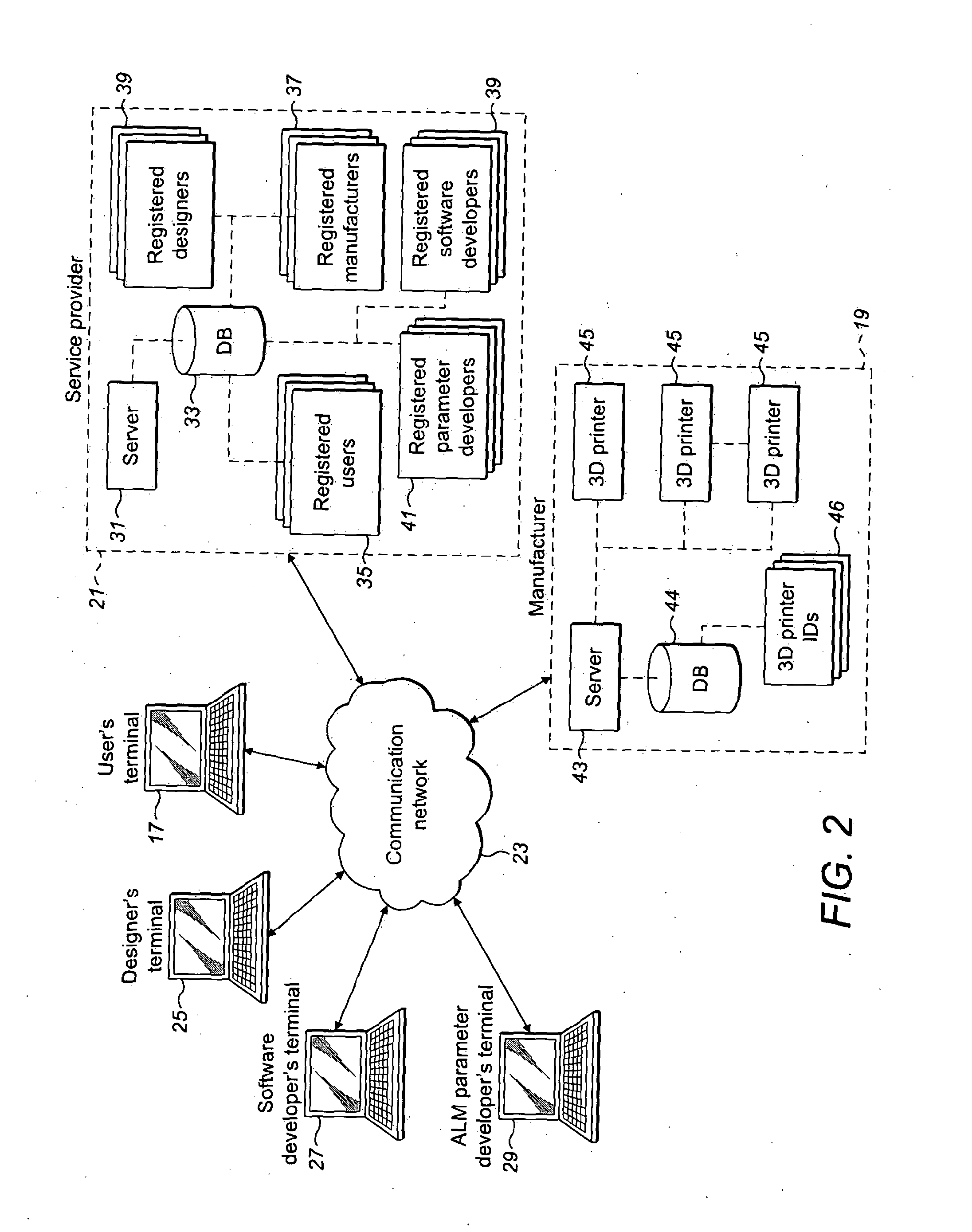

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

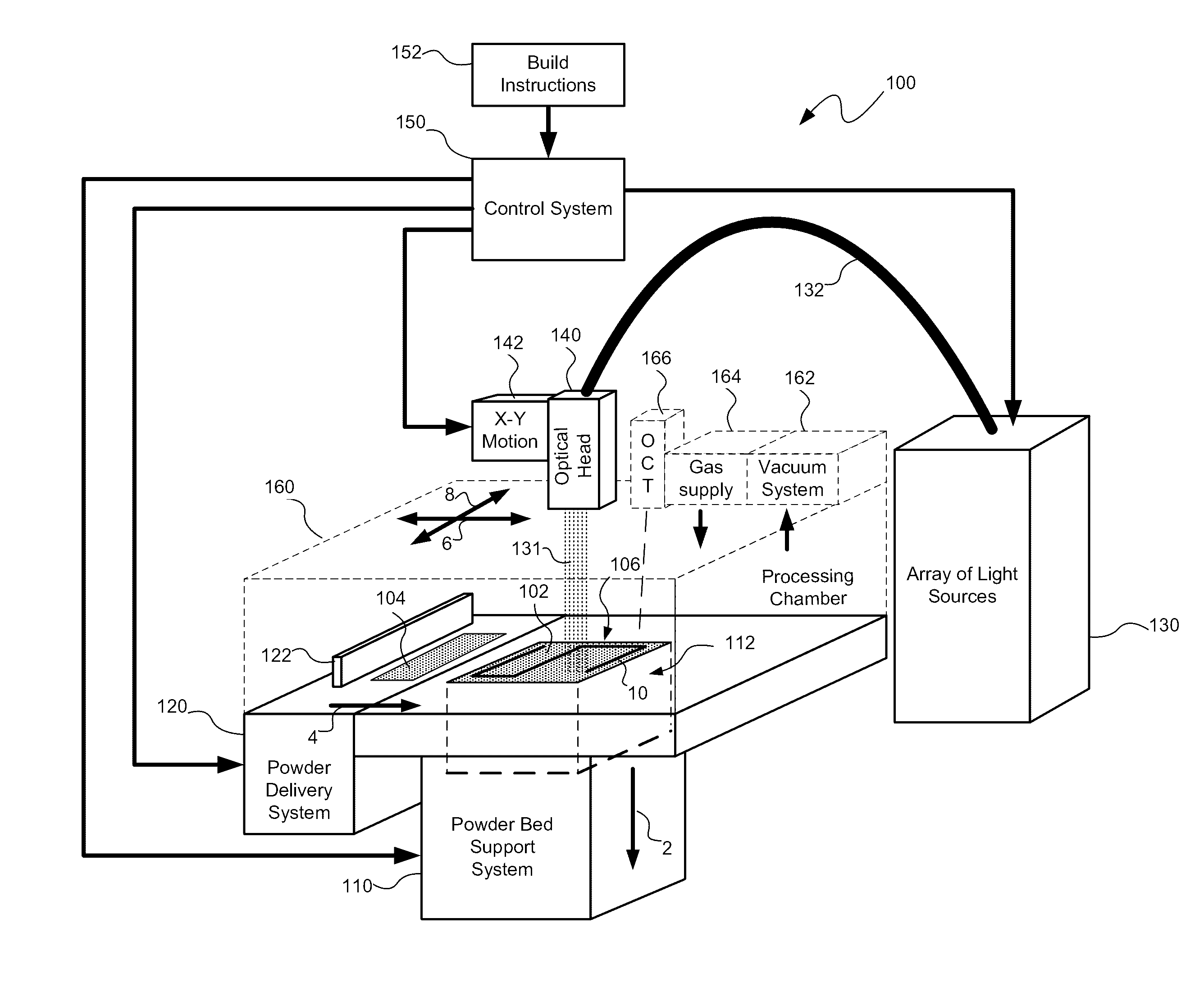

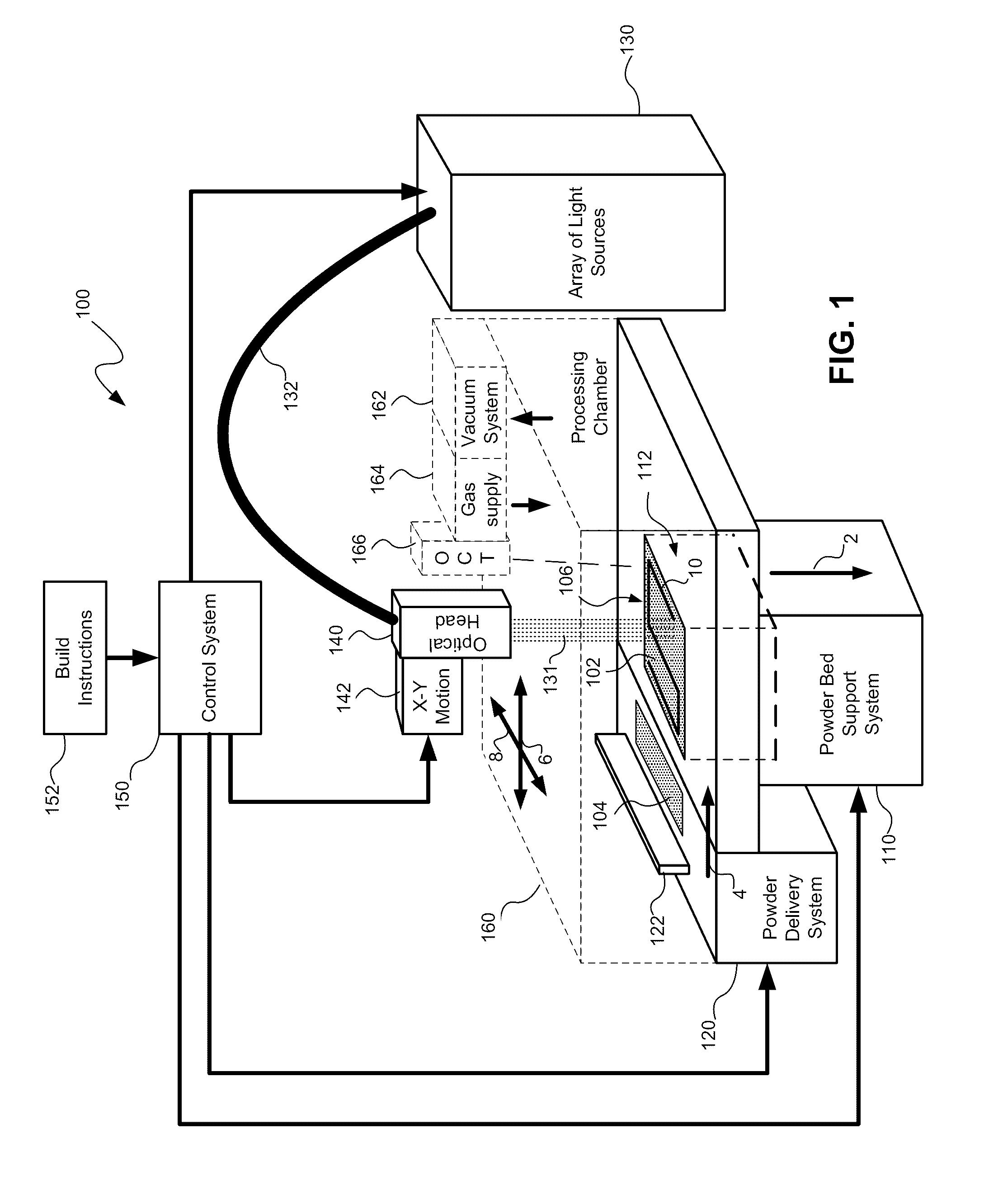

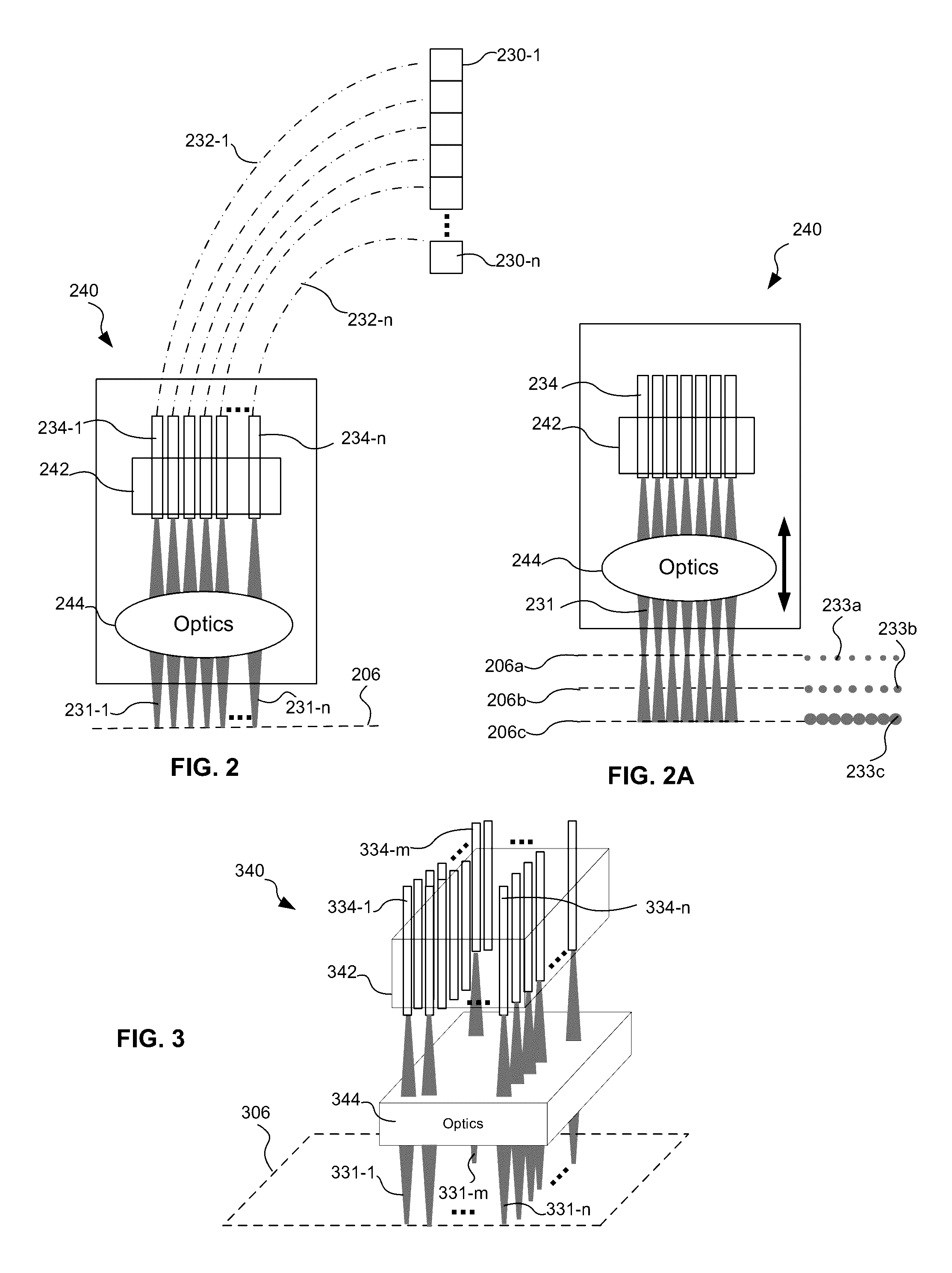

Multiple beam additive manufacturing

Systems and methods for multiple beam additive manufacturing use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses to form voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged in an optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

Owner:IPG PHOTONICS CORP

Interactive orthodontic care system based on intra-oral scanning of teeth

Interactive, computer based orthodontist treatment planning, appliance design and appliance manufacturing is described. A scanner is described which acquires images of the dentition which are converted to three-dimensional frames of data. The data from the several frames are registered to each other to provide a complete three-dimensional virtual model of the dentition. Individual tooth objects are obtained from the virtual model. A computer-interactive software program provides for treatment planning, diagnosis and appliance from the virtual tooth models. A desired occlusion for the patient is obtained from the treatment planning software. The virtual model of the desired occlusion and the virtual model of the original dentition provide a base of information for custom manufacture of an orthodontic appliance. A variety of possible appliance and appliance manufacturing systems are contemplated, including customized archwires and customized devices for placement of off-the shelf brackets on the archwires, and removable orthodontic appliances.

Owner:ORAMETRIX

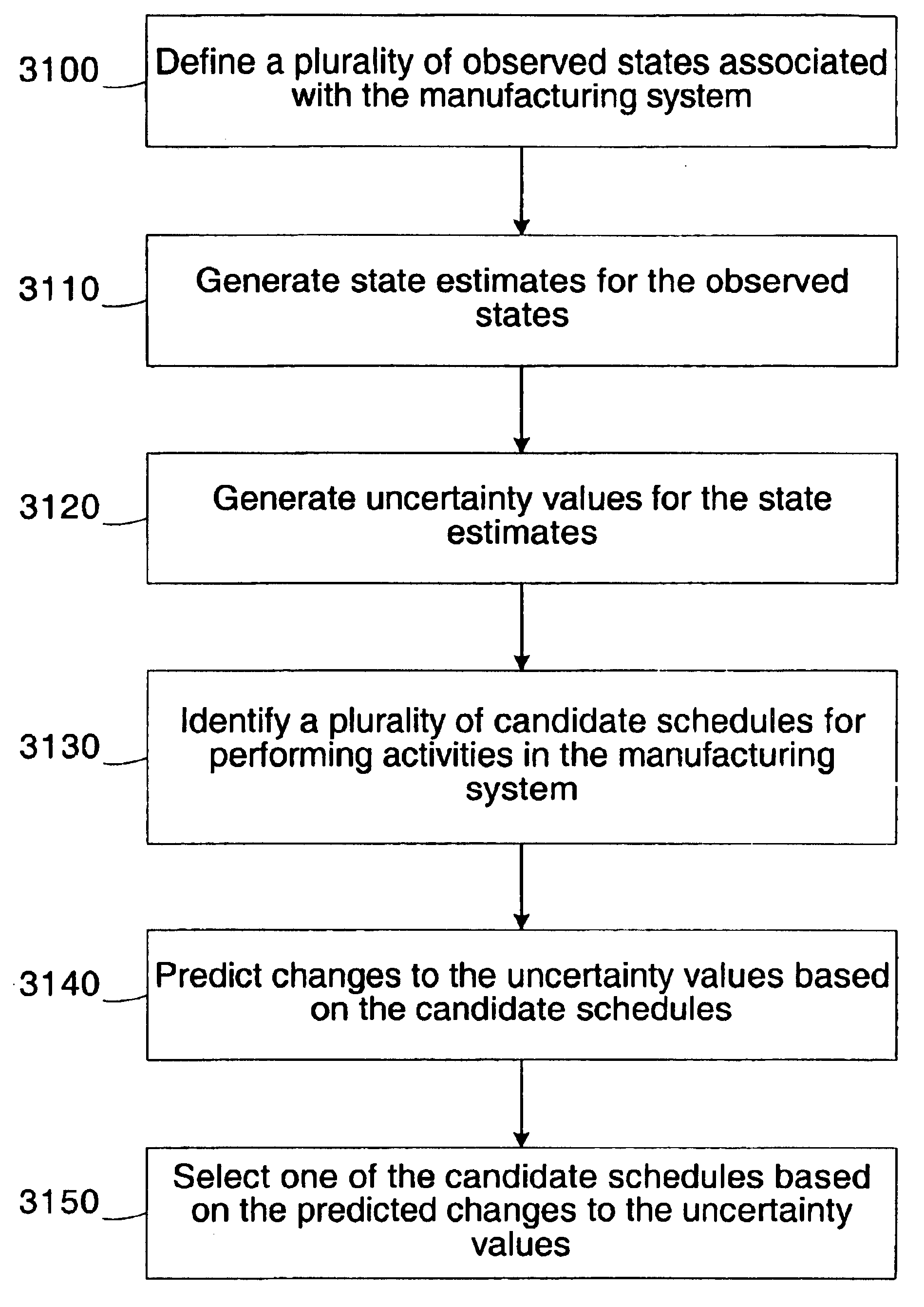

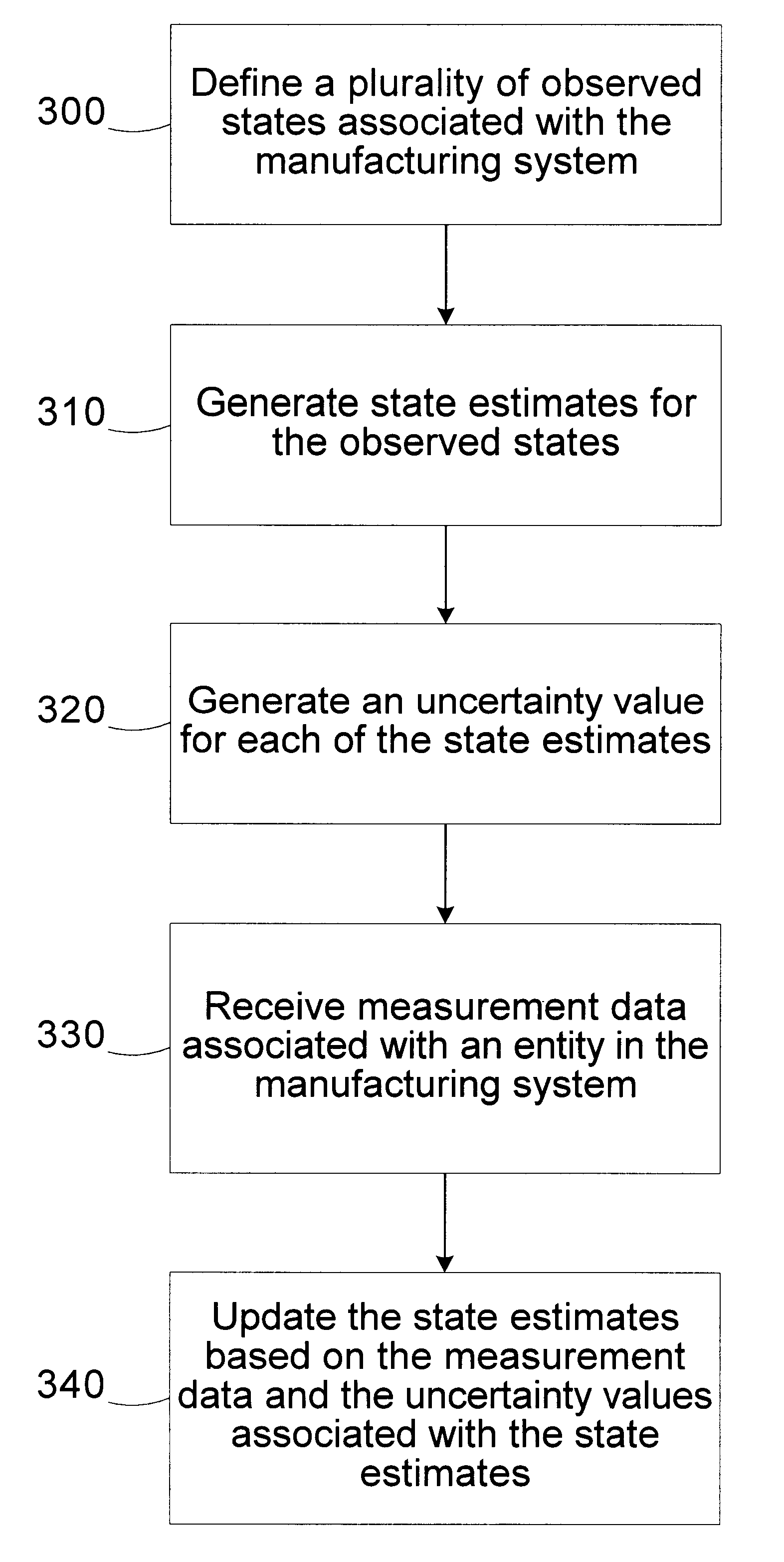

Method and apparatus for scheduling based on state estimation uncertainties

A method for scheduling activities in a manufacturing system includes defining a plurality of observed states associated with the manufacturing system. State estimates are generated for the observed states. Uncertainty values for the state estimates are generated. A plurality of candidate schedules for performing activities in the manufacturing system is identified. Changes to the uncertainty values are predicted based on the candidate schedules. One of the candidate schedules is selected based on the predicted changes to the uncertainty values.

Owner:GLOBALFOUNDRIES US INC

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

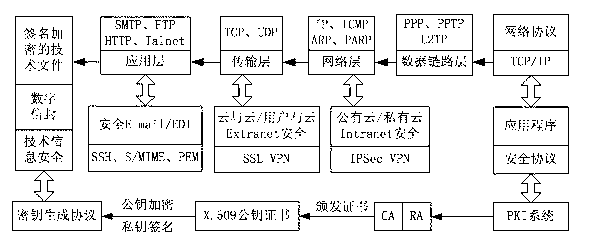

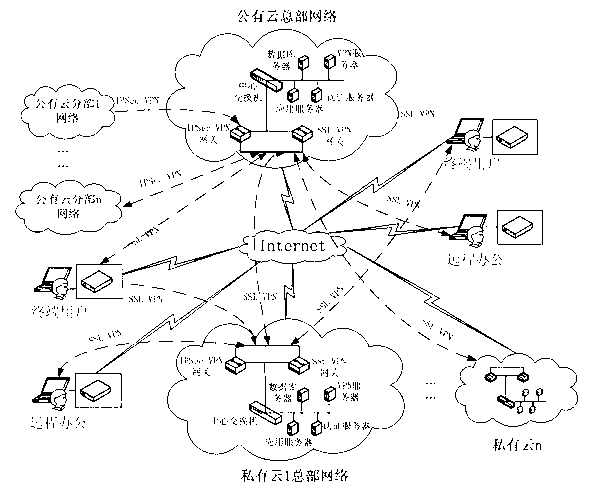

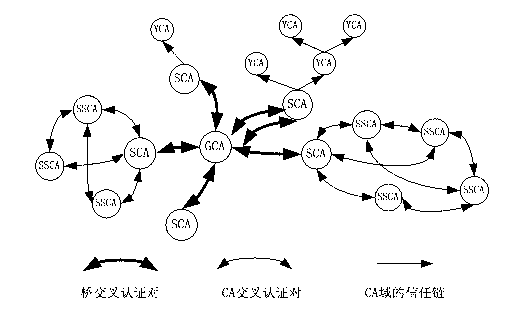

Information security management and control method under cloud manufacturing environment

InactiveCN102710605ASolve the problem of update and maintenanceAvoid complex proceduresPublic key for secure communicationUser identity/authority verificationConfidentialityPrivate network

The invention discloses an information security management and control method under a cloud manufacturing environment. On the basis of a network security protocol, a password technology and a public key infrastructure (PKI), comprehensive security guarantee is supplied to information interaction among cloud internal networks, between one cloud and another cloud, and between a user and each cloud by using implementation technologies and methods, such as a virtual private network (VPN) based on multiple layers of protocols, a digital envelope and a password algorithm; Intranet, Extranet and Internet of a cloud manufacturing system are covered; comprehensive management and control technical information files are stored and transmitted to each used loop; a session key (SK) which is randomly produced by using a key production protocol is used for symmetrically encrypting the technical information files; and a receiver public key obtained according to a PKI digital certificate asymmetrically encrypts the SK to form the digital envelope for protecting the technical information files and the SK. The information security management and control method has the characteristics of being high in confidentiality, high inefficiency, flexible in arrangement and the like and can be widely applied to the cloud manufacturing system and other network manufacturing systems.

Owner:CHONGQING UNIV

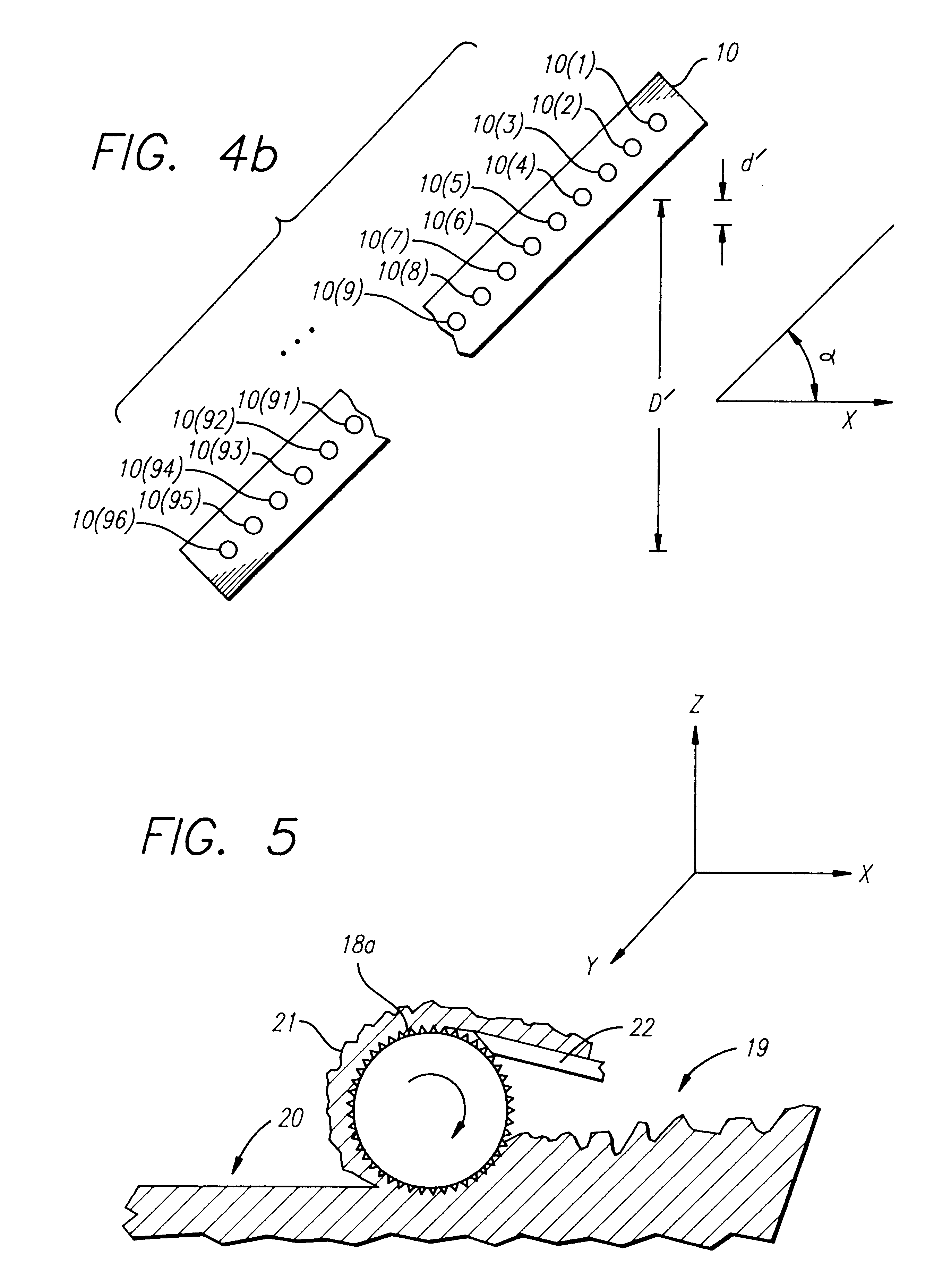

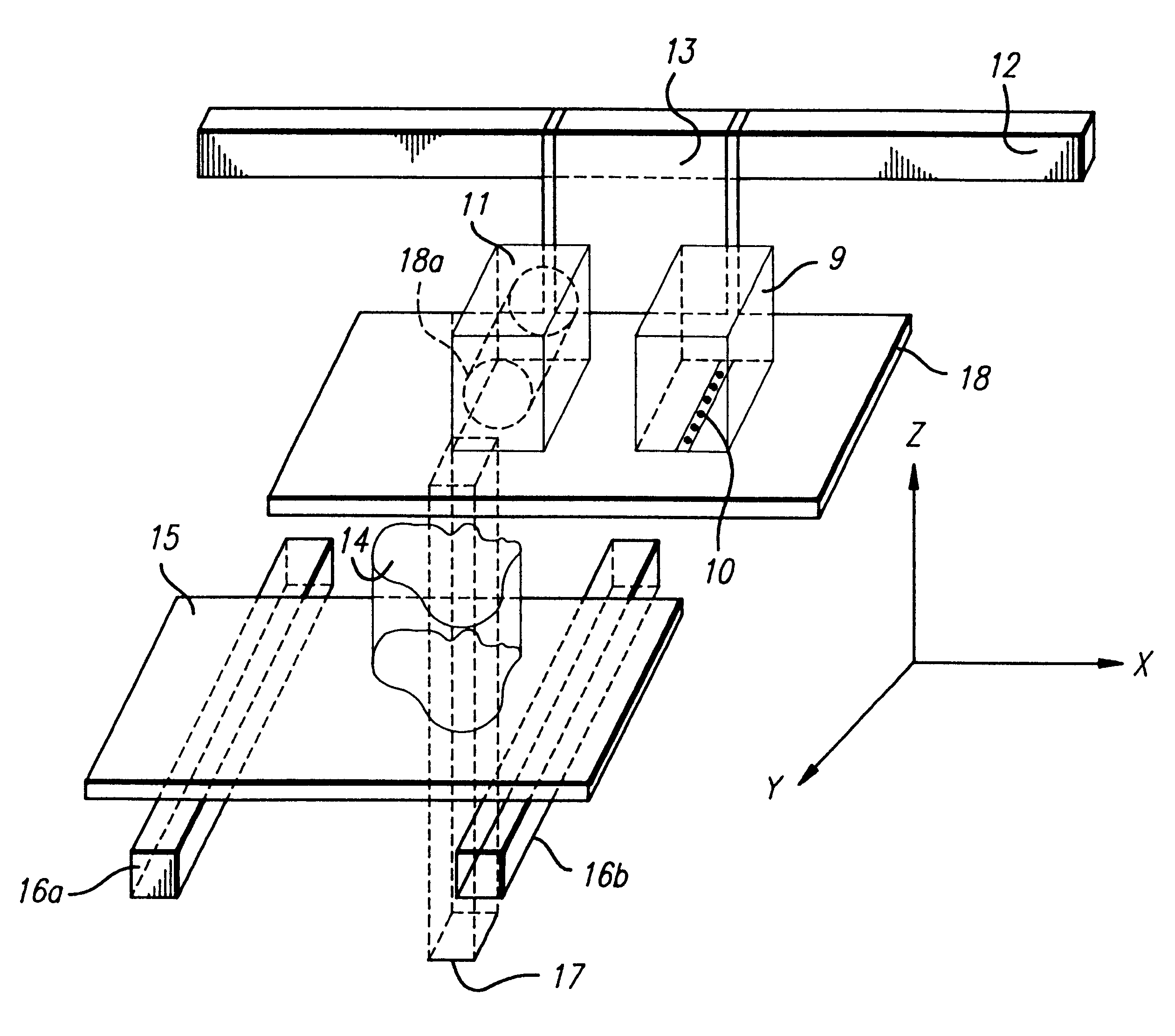

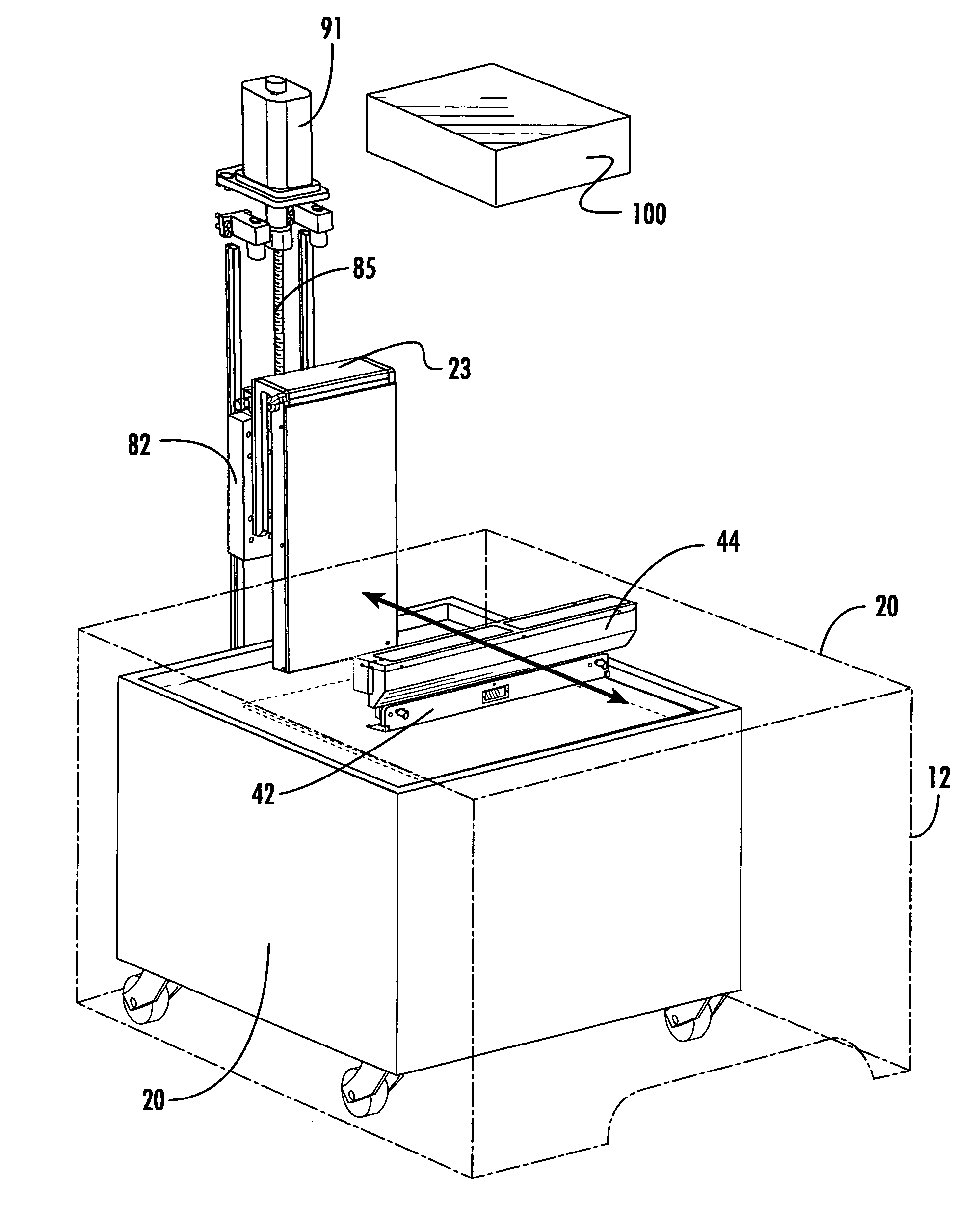

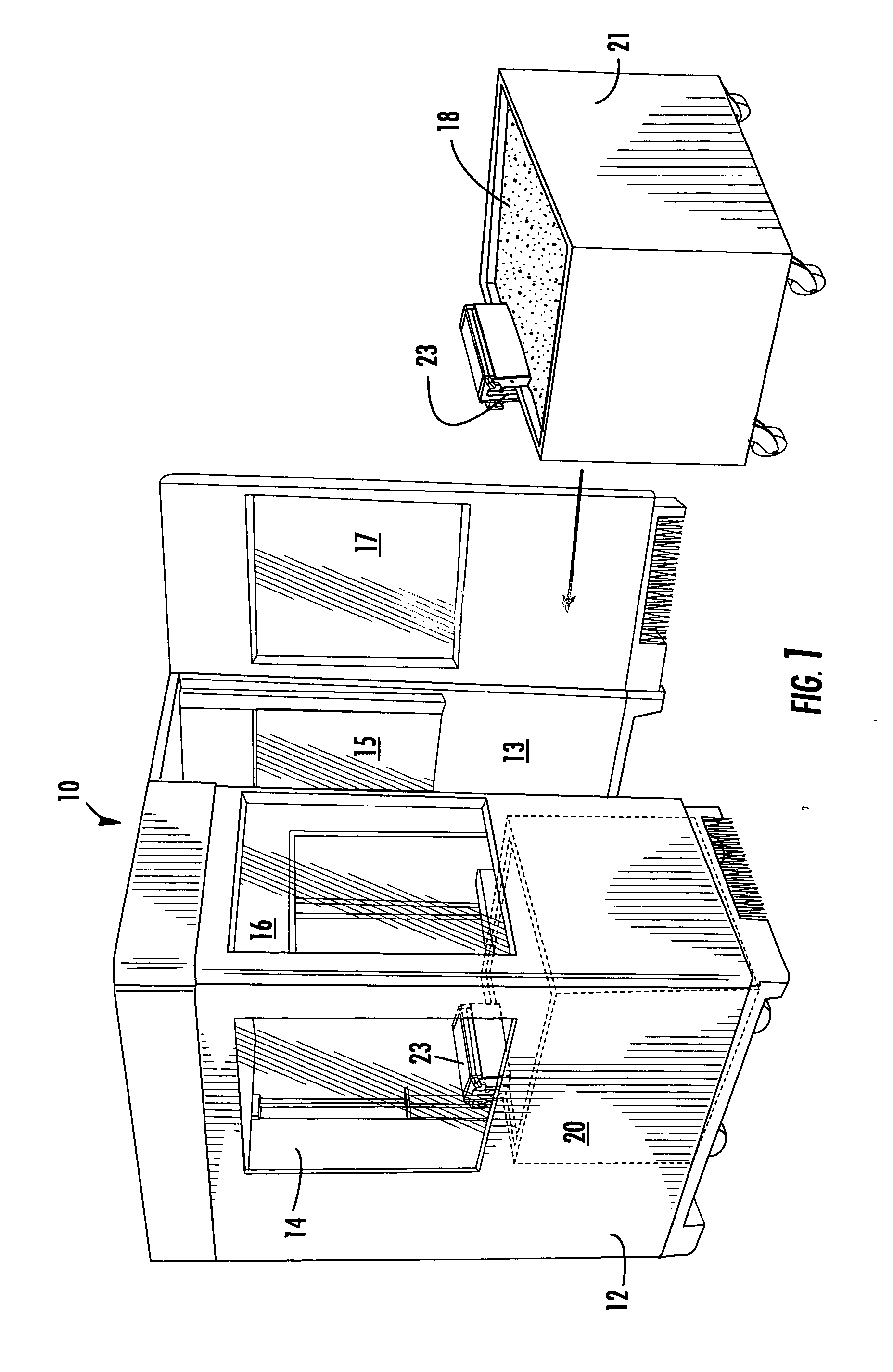

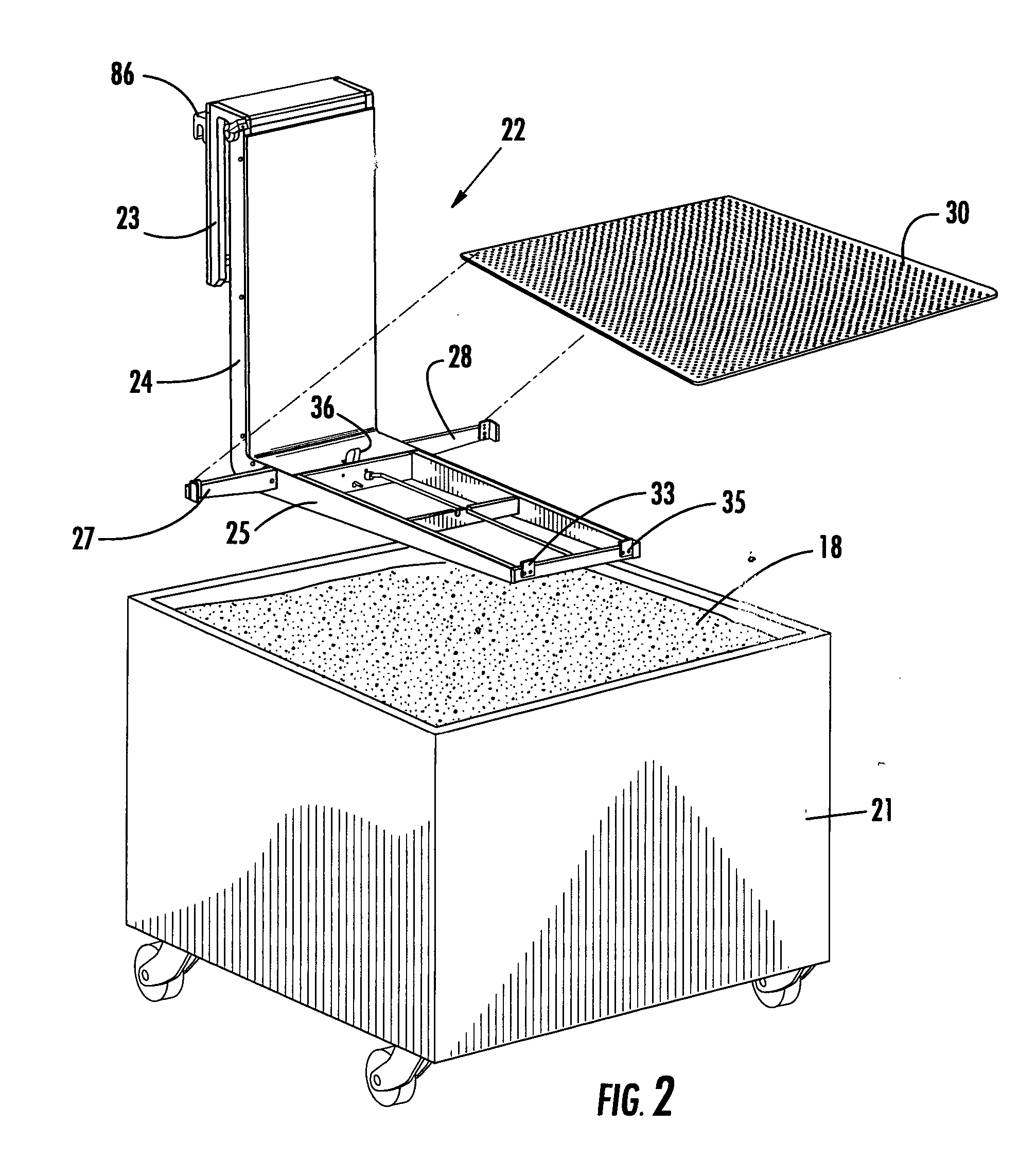

Rapid prototyping and manufacturing system and method

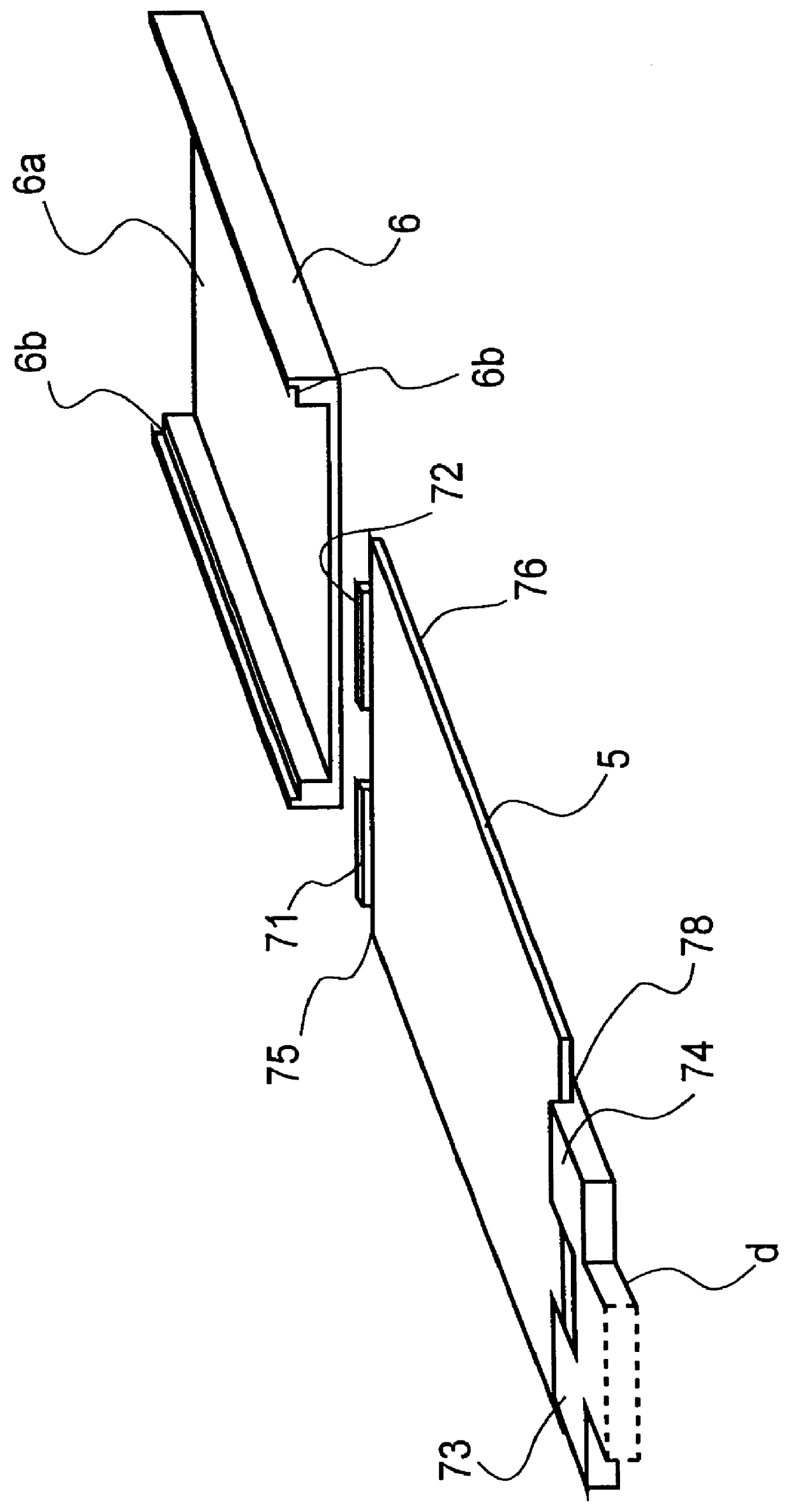

ActiveUS20070074659A1Simplify obtaining precisionFast preparationConfectioneryPretreated surfacesEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

Interactive orthodontic care system based on intra-oral scanning of teeth

InactiveUS7013191B2Quantitative precisionHighly reliable mannerImpression capsTherapiesInteractive softwareOff the shelf

Interactive, computer based orthodontist treatment planning, appliance design and appliance manufacturing is described. A scanner is described which acquires images of the dentition which are converted to three-dimensional frames of data. The data from the several frames are registered to each other to provide a complete three-dimensional virtual model of the dentition. Individual tooth objects are obtained from the virtual model. A computer-interactive software program provides for treatment planning, diagnosis and appliance from the virtual tooth models. A desired occlusion for the patient is obtained from the treatment planning software. The virtual model of the desired occlusion and the virtual model of the original dentition provide a base of information for custom manufacture of an orthodontic appliance. A variety of possible appliance and appliance manufacturing systems are contemplated, including customized archwires and customized devices for placement of off-the shelf brackets on the archwires, and removable orthodontic appliances.

Owner:ORAMETRIX

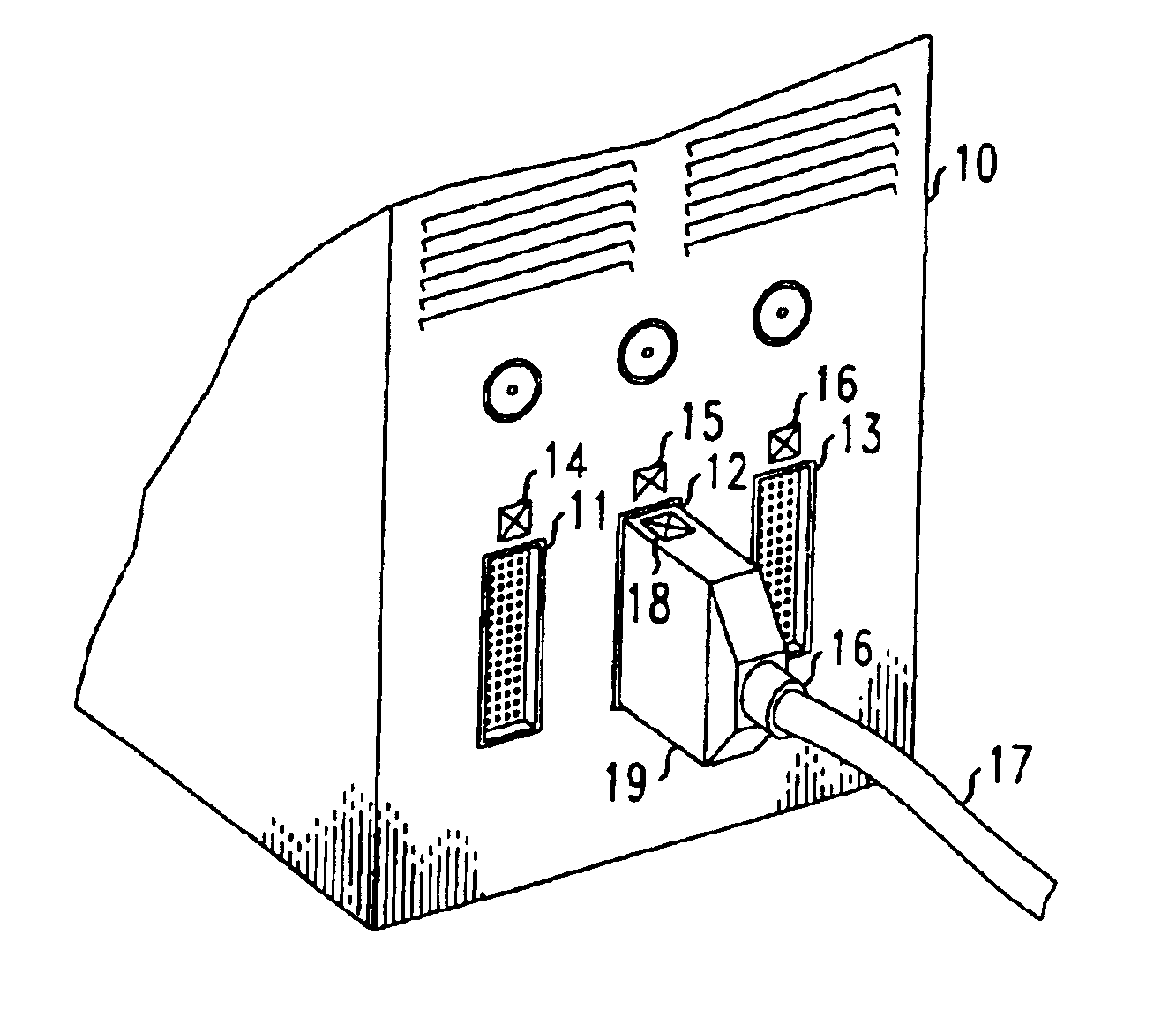

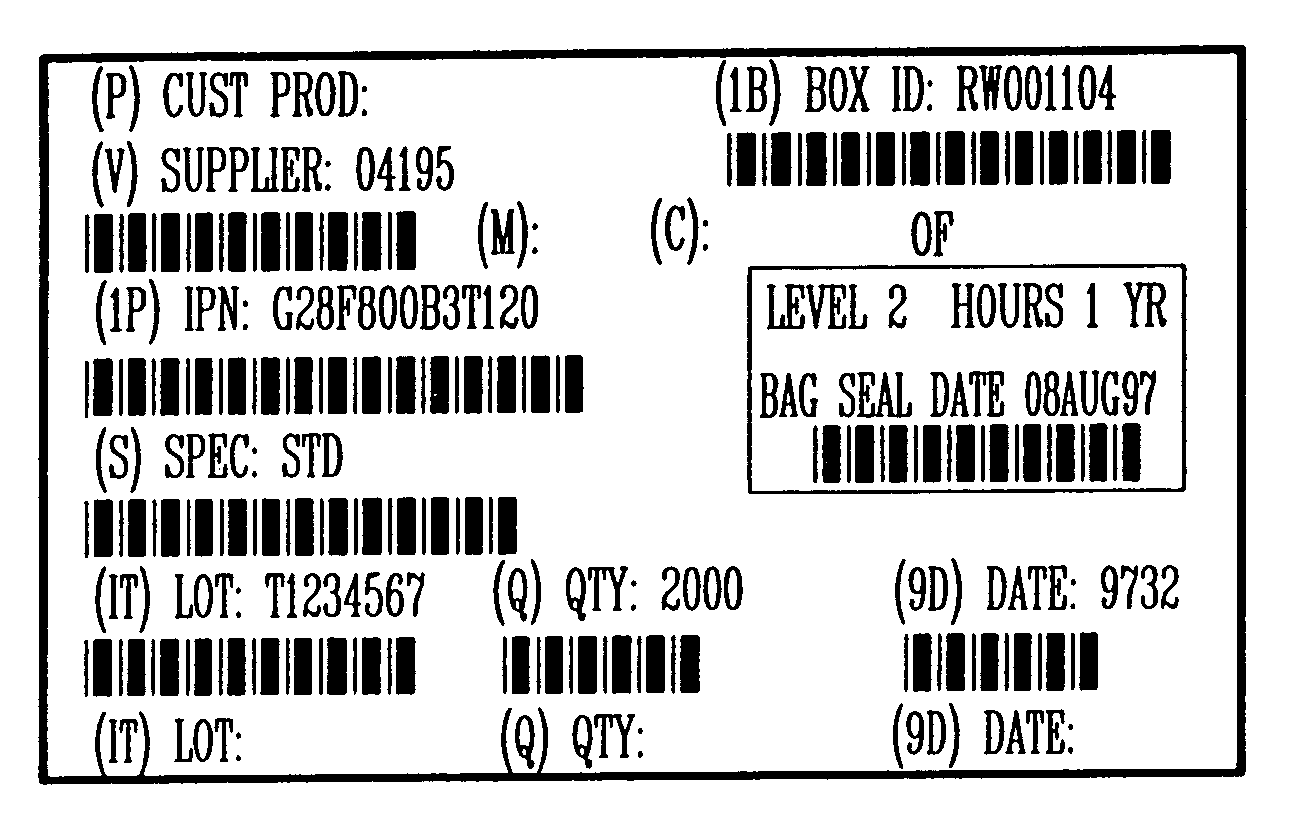

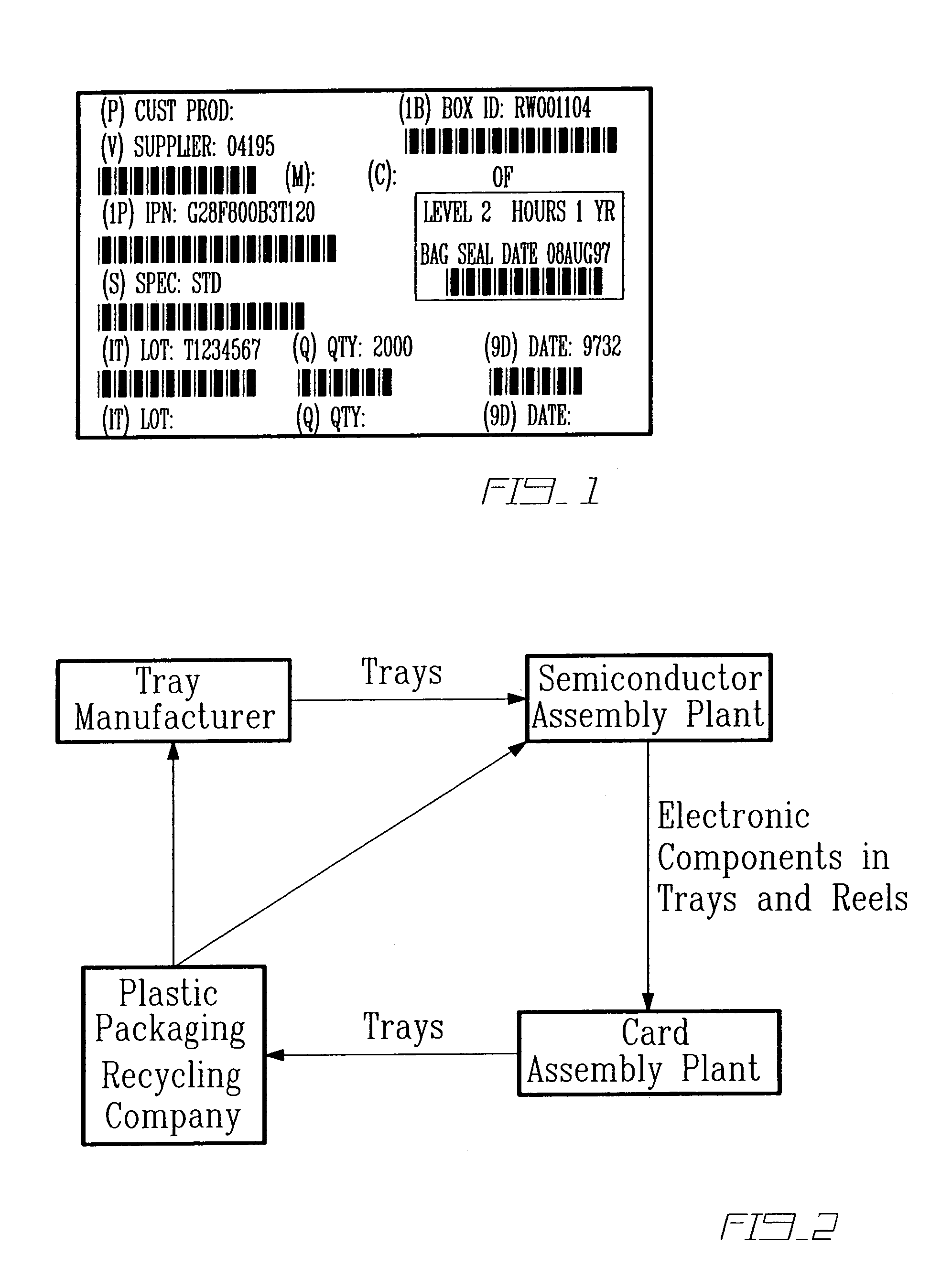

Automated manufacturing control system

InactiveUS7069100B2Reduce human interactionDigital data processing detailsTotal factory controlHuman interactionMachine

An automated manufacturing control system is proposed to greatly reduce the human interaction relative to the data transfer, physical verification and process control associated with the movement of components, tooling and operators in a manufacturing system. This is achieved by the use of data carriers which are attached to the object(s) to be traced. These data carriers (12) can store all the relevant identification, material and production data to required by the various elements, e.g. stations, of the manufacturing system. Various readers, integrated with controllers and application software, are located at strategic points of the production area, including production machines and storage areas, to enable automatic data transfer and physical verification that the right material is at the right place at the right time, using the right tooling.

Owner:COGISCAN

Wafer fab

InactiveUS20060102078A1Reduced space requirementsLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorManufacturing systems

Described is a method for manufacturing wafers and a manufacturing system in which the footprint is substantially contained in a size approximating the processing chambers. Single wafers move horizontally through the system and processing occurs simultaneously in groups of processing chambers. Various manufacturing processes employed in making semiconductor wafers are included as processing chambers in the system.

Owner:INTEVAC

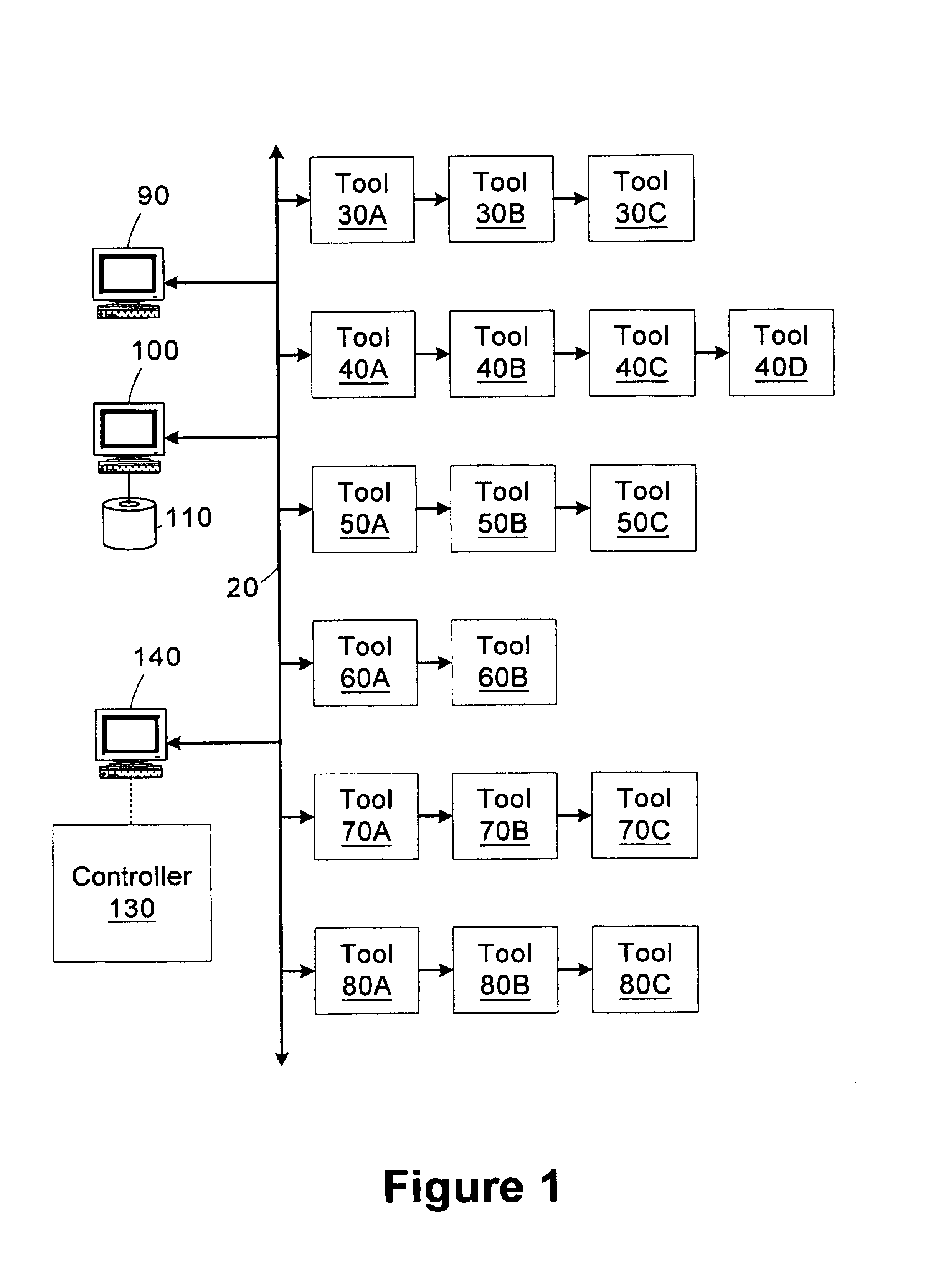

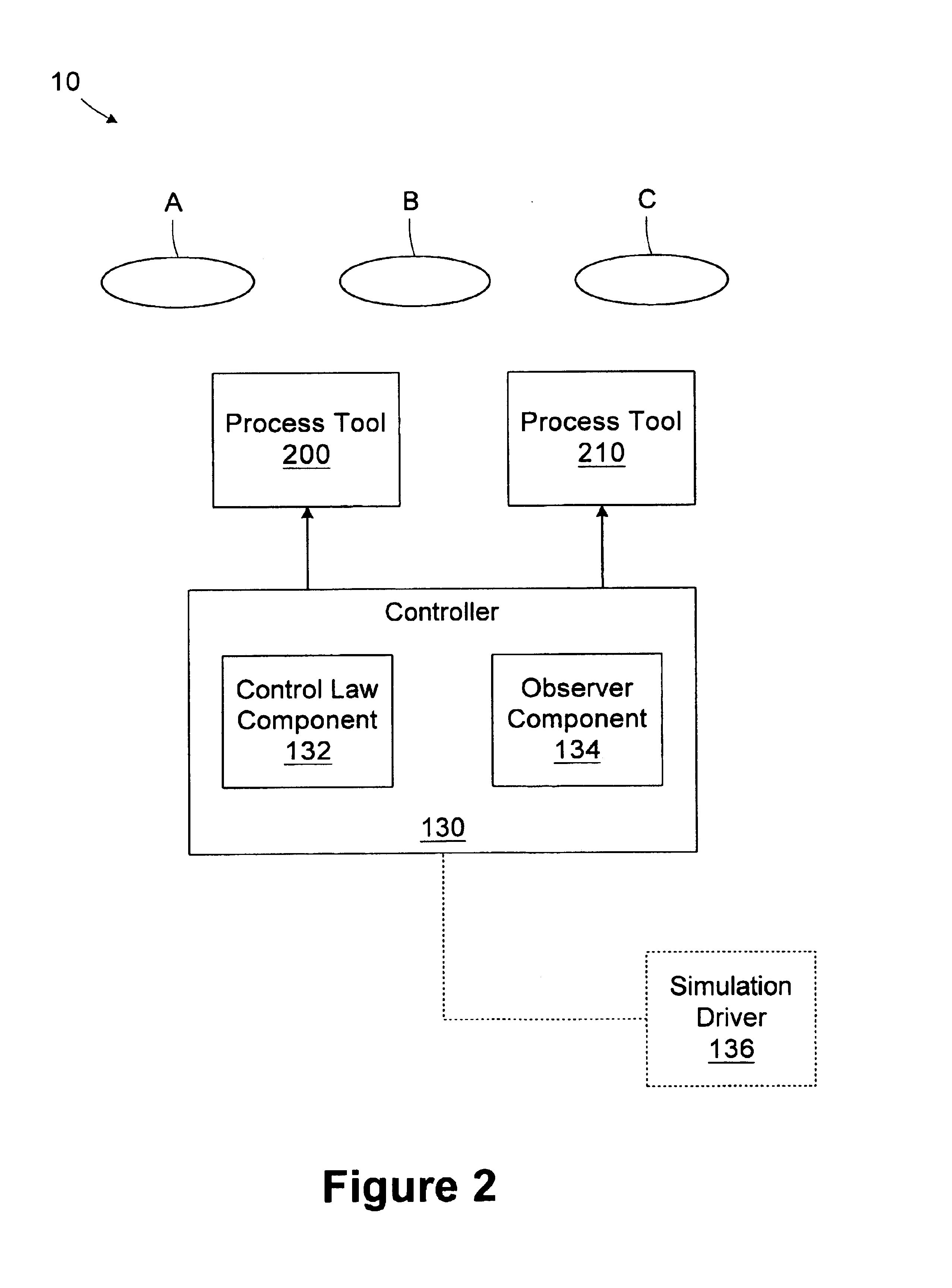

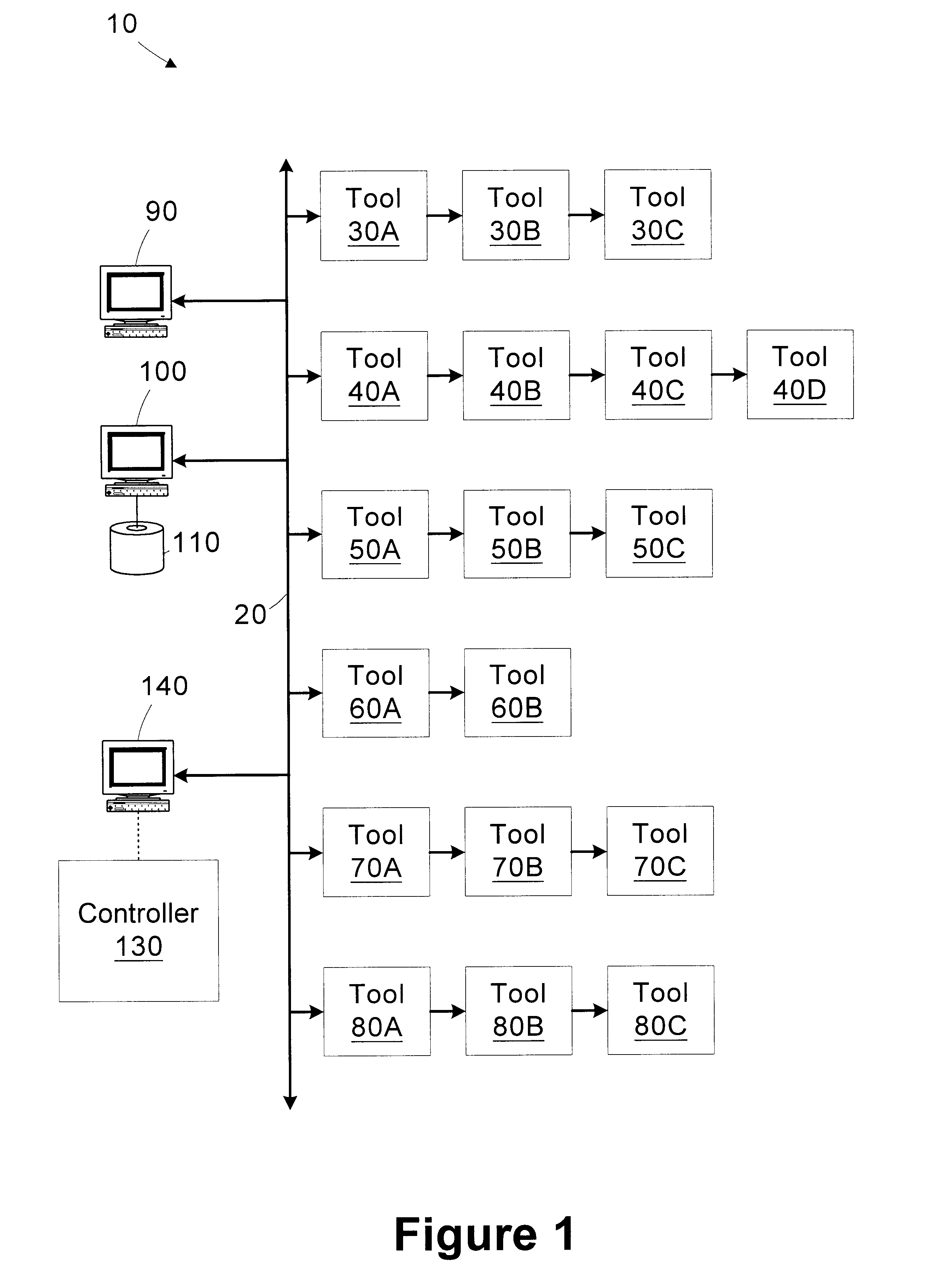

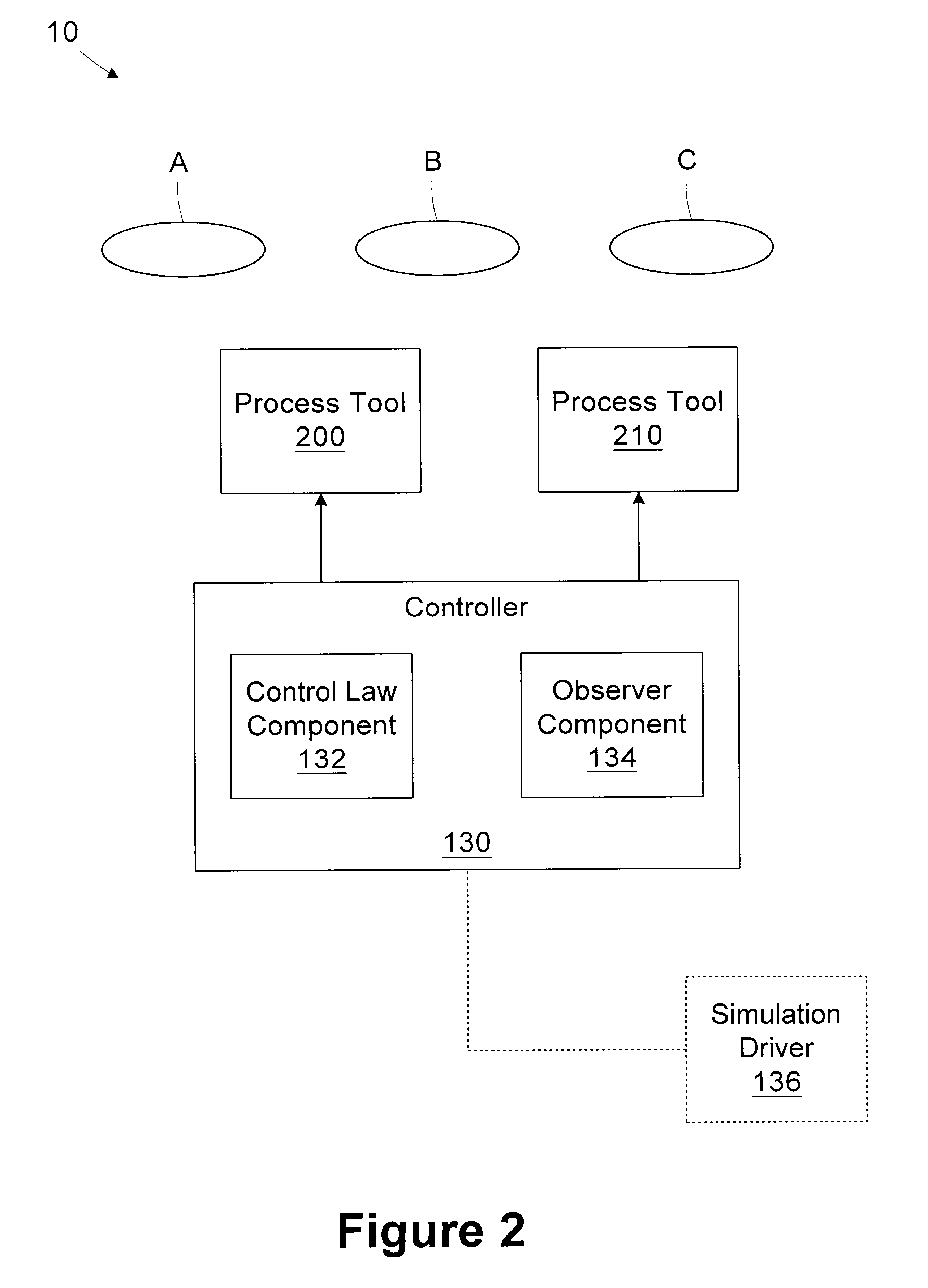

Kalman filter state estimation for a manufacturing system

InactiveUS6757579B1Error detection/correctionDigital computer detailsKaiman filterManufacturing systems

A method for monitoring a manufacturing system includes defining a plurality of observed states associated with the manufacturing system. State estimates are generated for the observed states. An uncertainty value is generated for each of the state estimates. Measurement data associated with an entity in the manufacturing system is received. The state estimates are updated based on the measurement data and the uncertainty values associated with the state estimates. A system for monitoring a manufacturing system includes a controller configured to define a plurality of observed states associated with the manufacturing system, generate state estimates for the observed states, generate an uncertainty value for each of the state estimates, receive measurement data associated with an entity in the manufacturing system, and update the state estimates based on the measurement data and the uncertainty values associated with the state estimates.

Owner:ADVANCED MICRO DEVICES INC

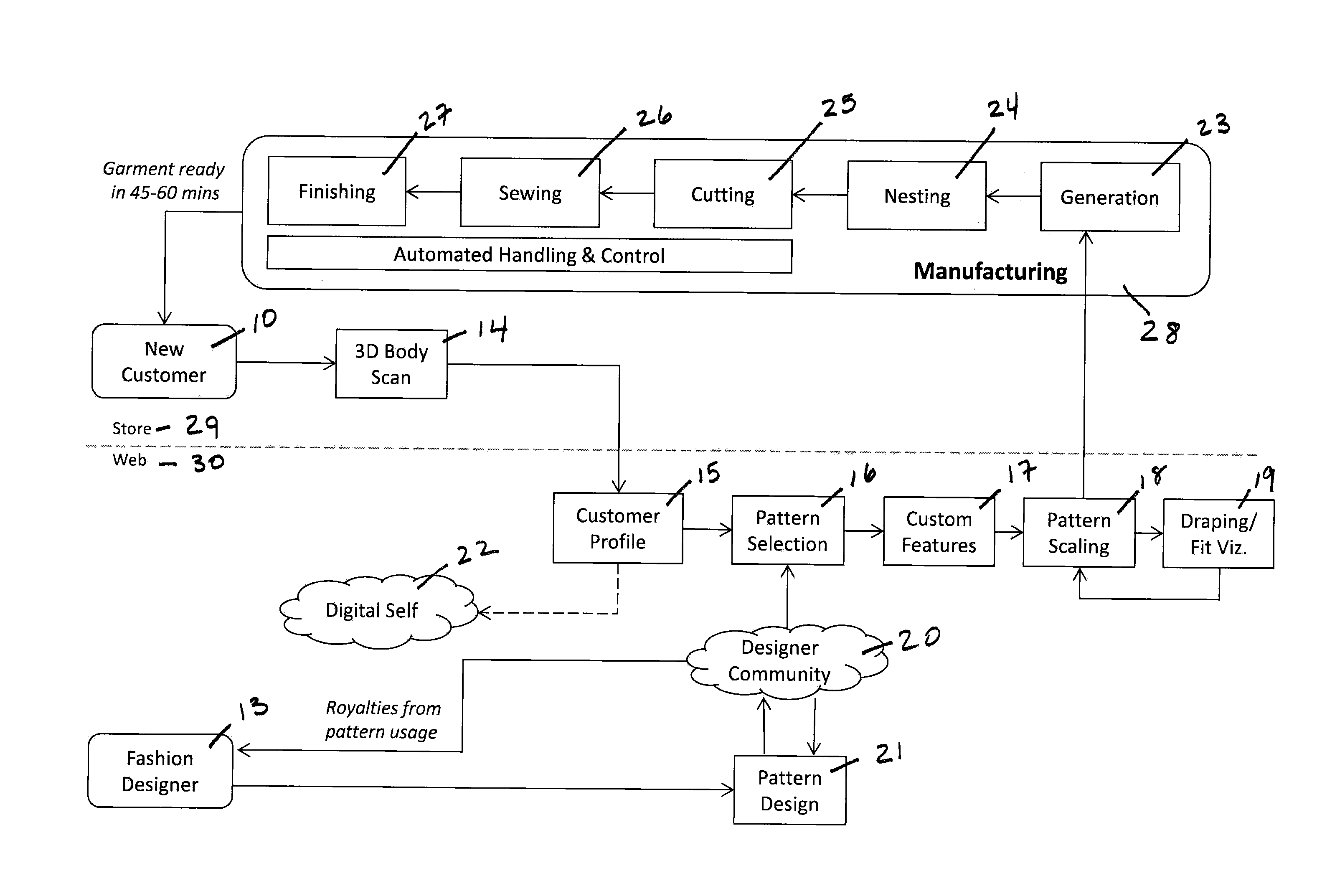

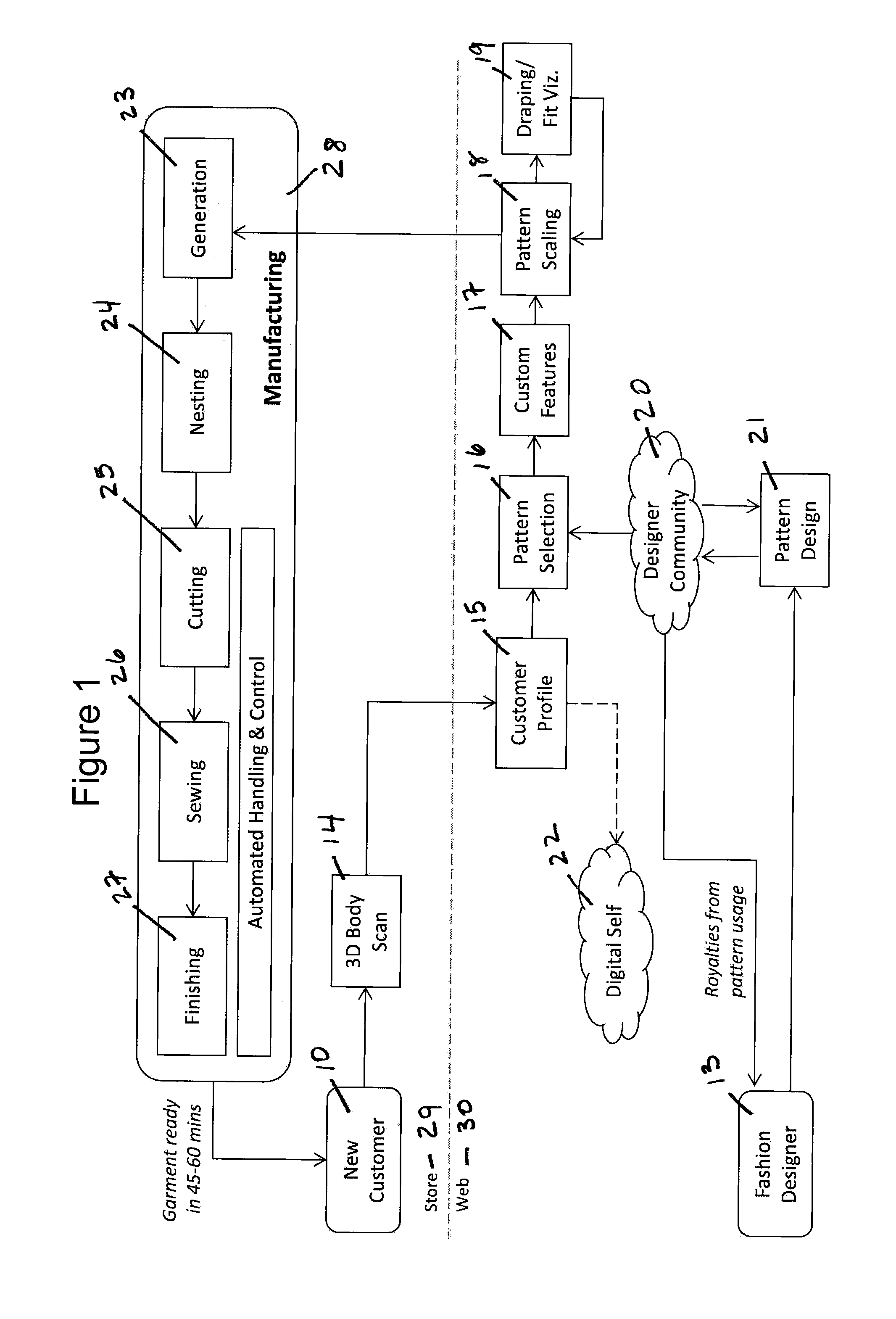

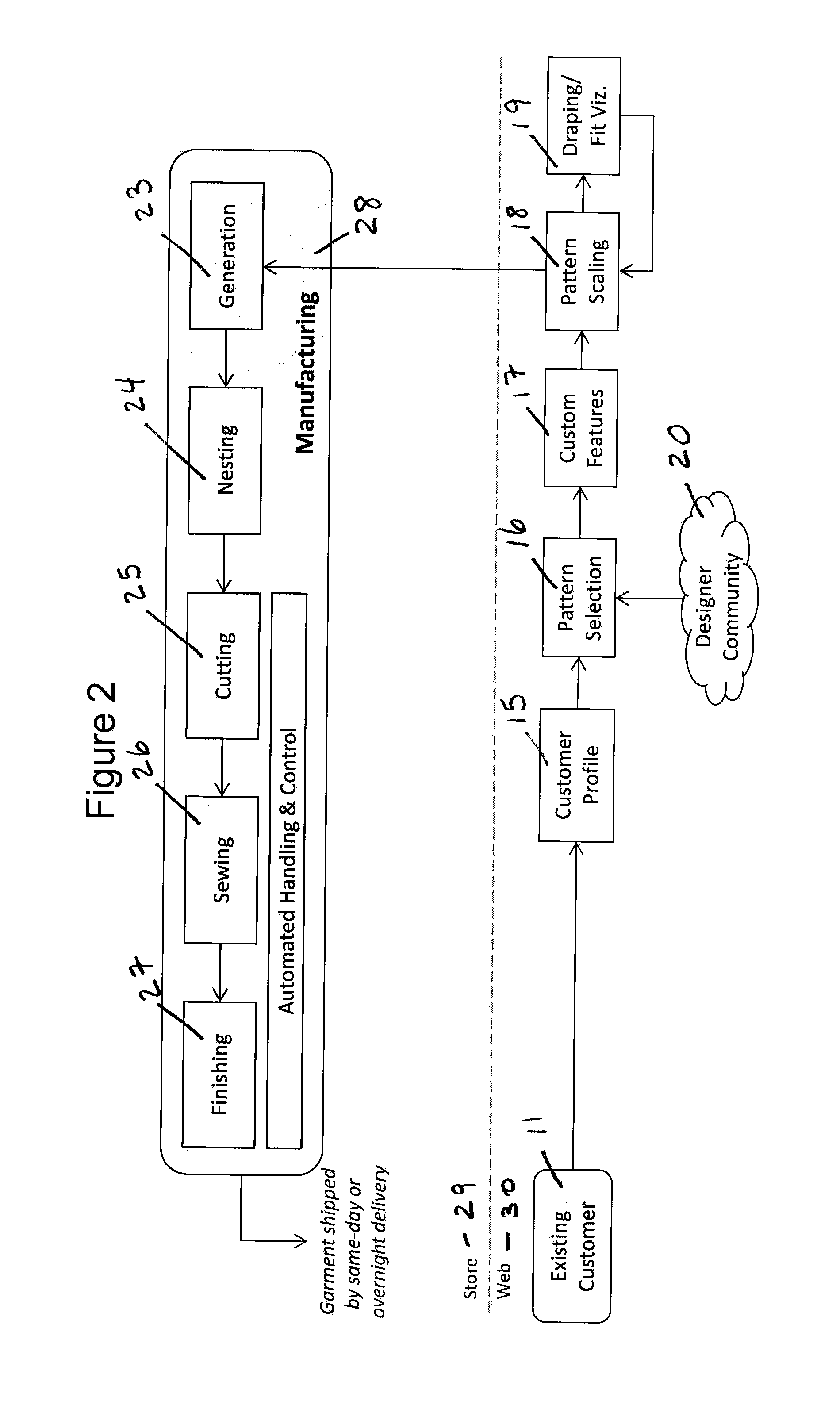

System and Method for Creating Custom-Fit Apparel Designs

InactiveUS20140277663A1Rapid visualizationShort amount of timeCommerceComputer aided designBody shapePersonalization

An automated system for the production of a personalized custom-fit garment comprises a scanner for obtaining a three-dimensional model of a customer's body shape; a computer having non-transitory computer algorithms for scaling a digital design to the customer's body shape, customizing the digital pattern with the customer's fit and style preferences, and visualizing the drape and fit of the garment; a database comprising a set of digital design patterns; and an automated garment manufacturing system networked to a central controller. A method for creating a personalized custom-fit garment comprises obtaining three-dimensional body measurements of a customer, having the customer select and customize a particular garment design, and manufacturing the personalized garment using an automated manufacturing process. The system and method can be used to prepare any kind of garments without substantive manual intervention or touch labor.

Owner:3D TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com