Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2997 results about "3d print" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

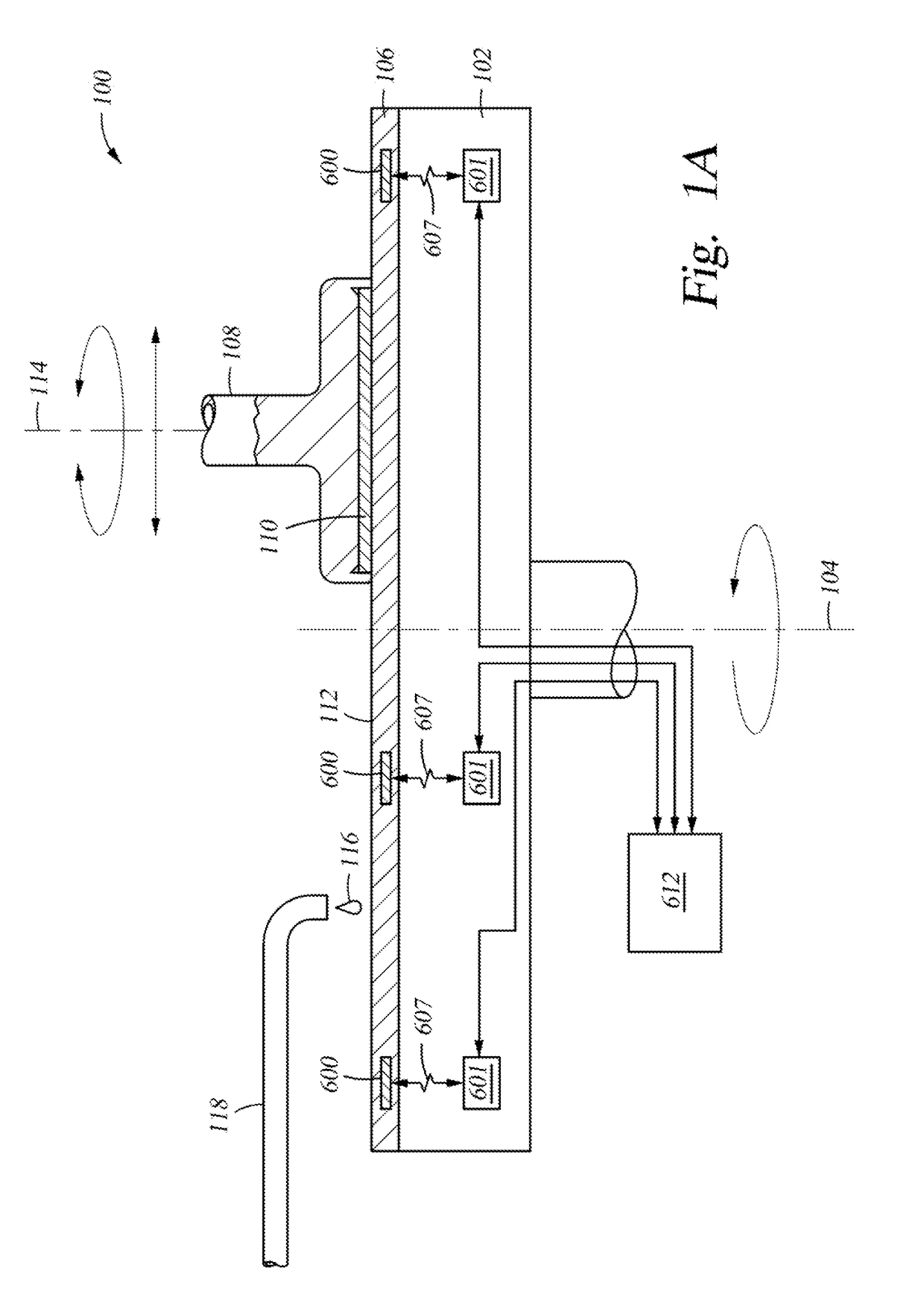

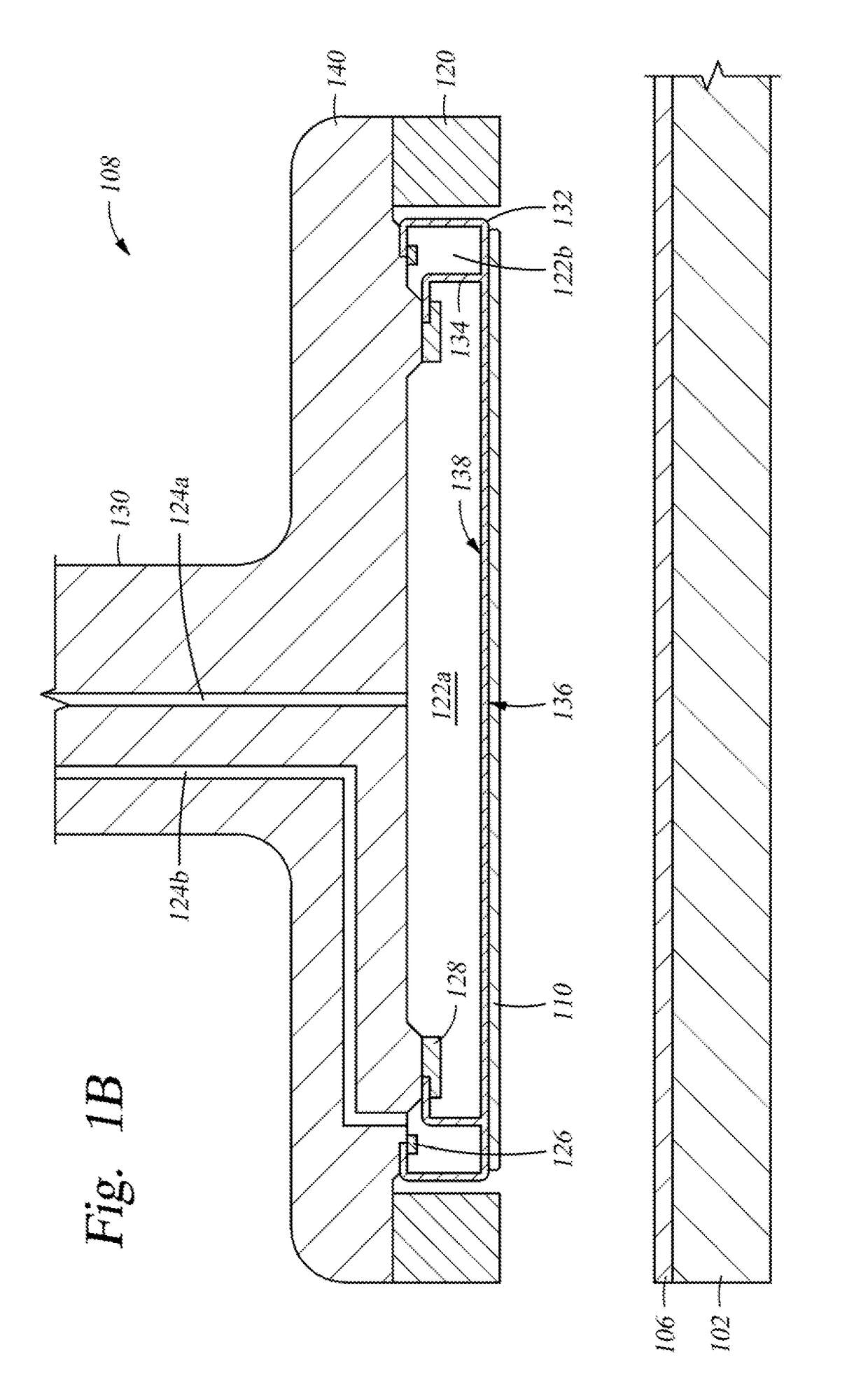

Single/multiple axes six degrees of freedom (6 DOF) inertial motion capture system with initial orientation determination capability

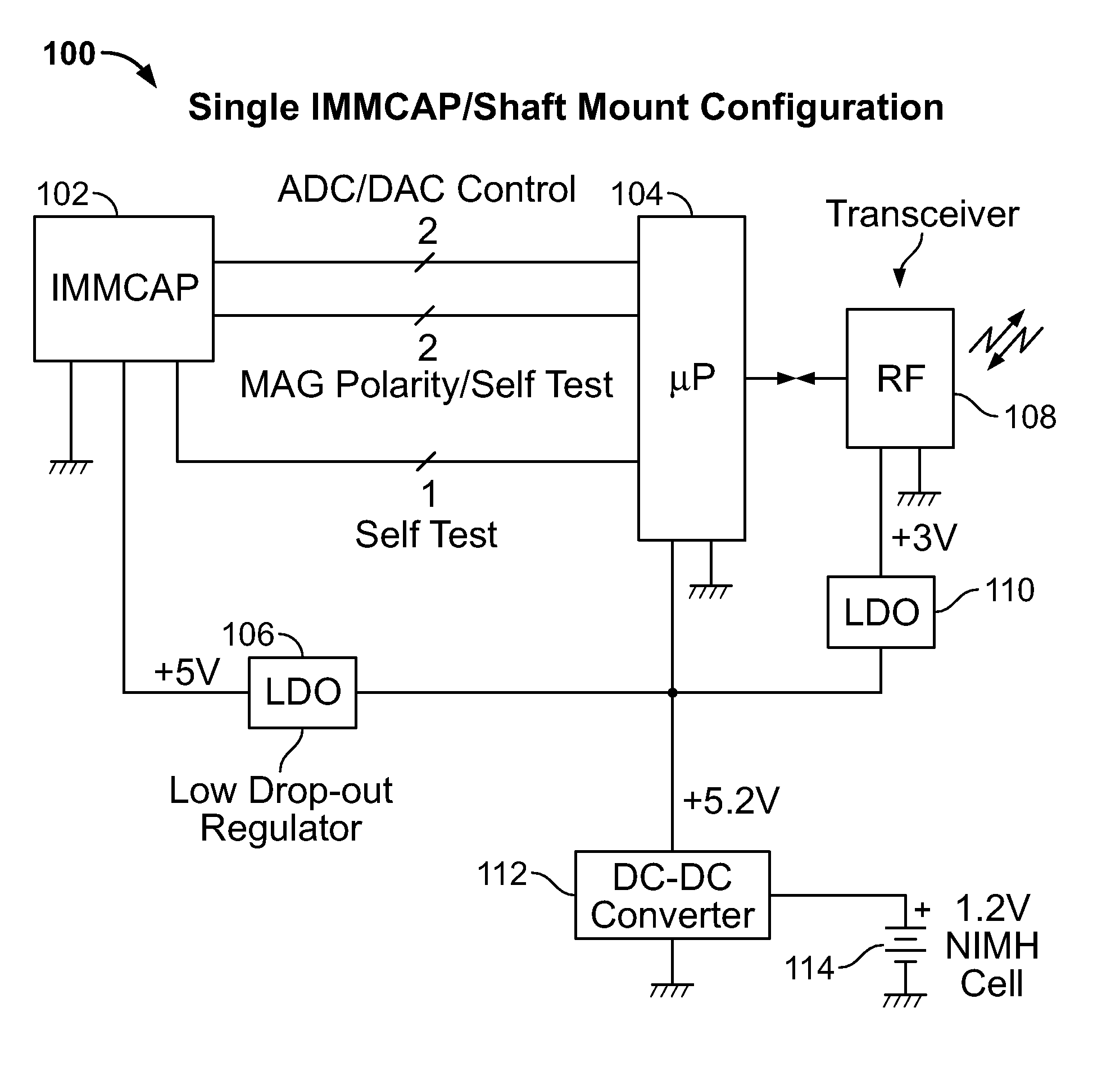

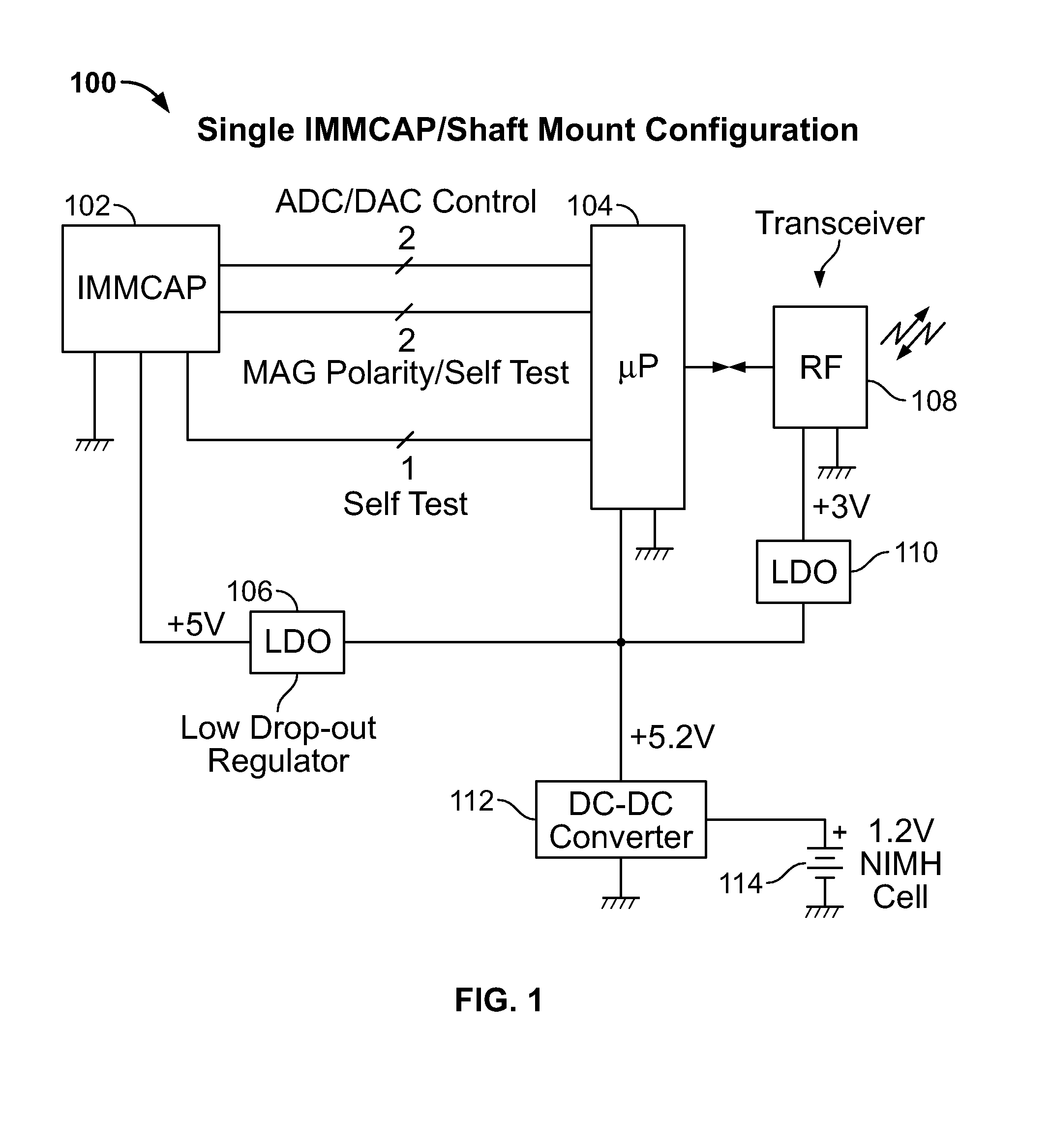

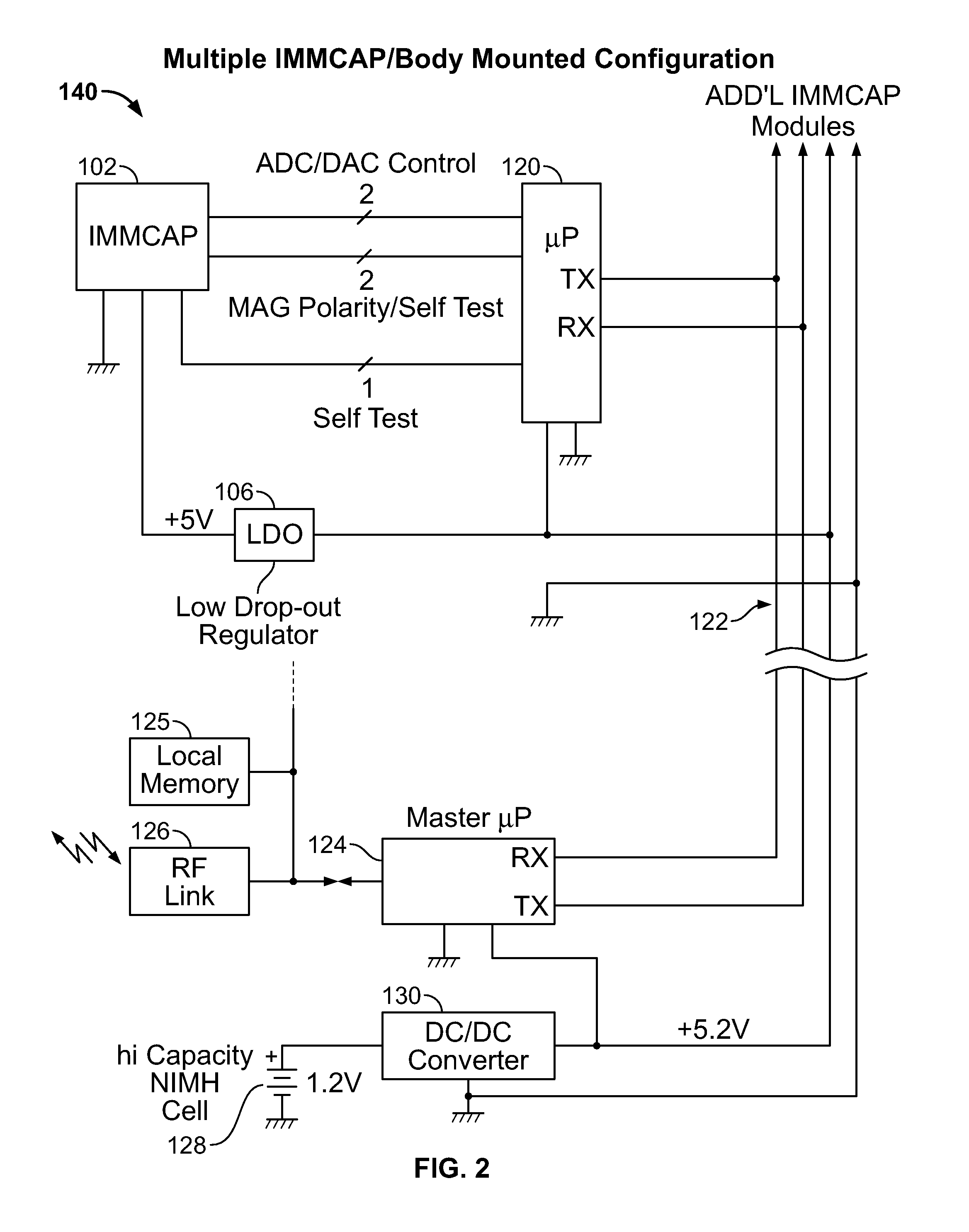

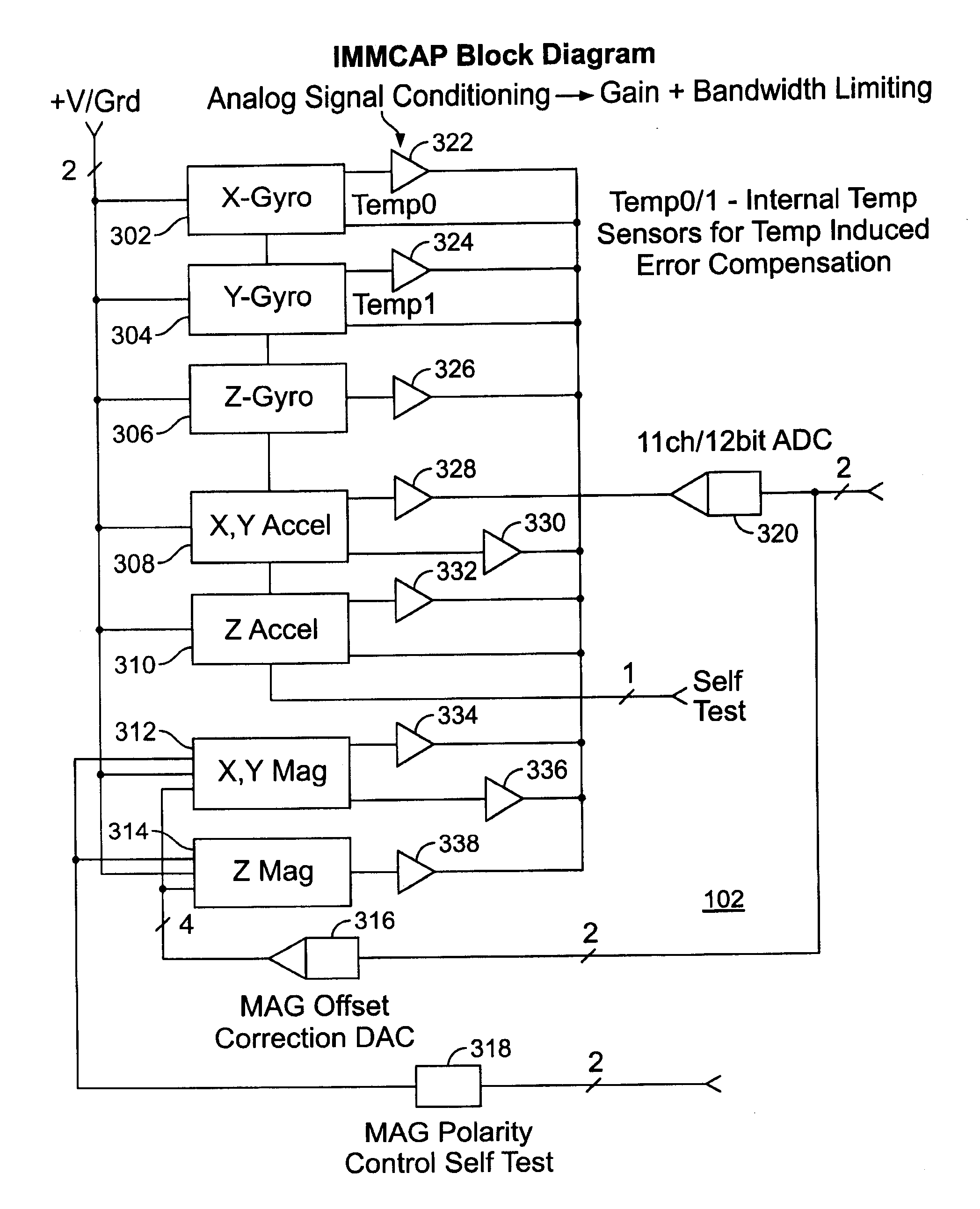

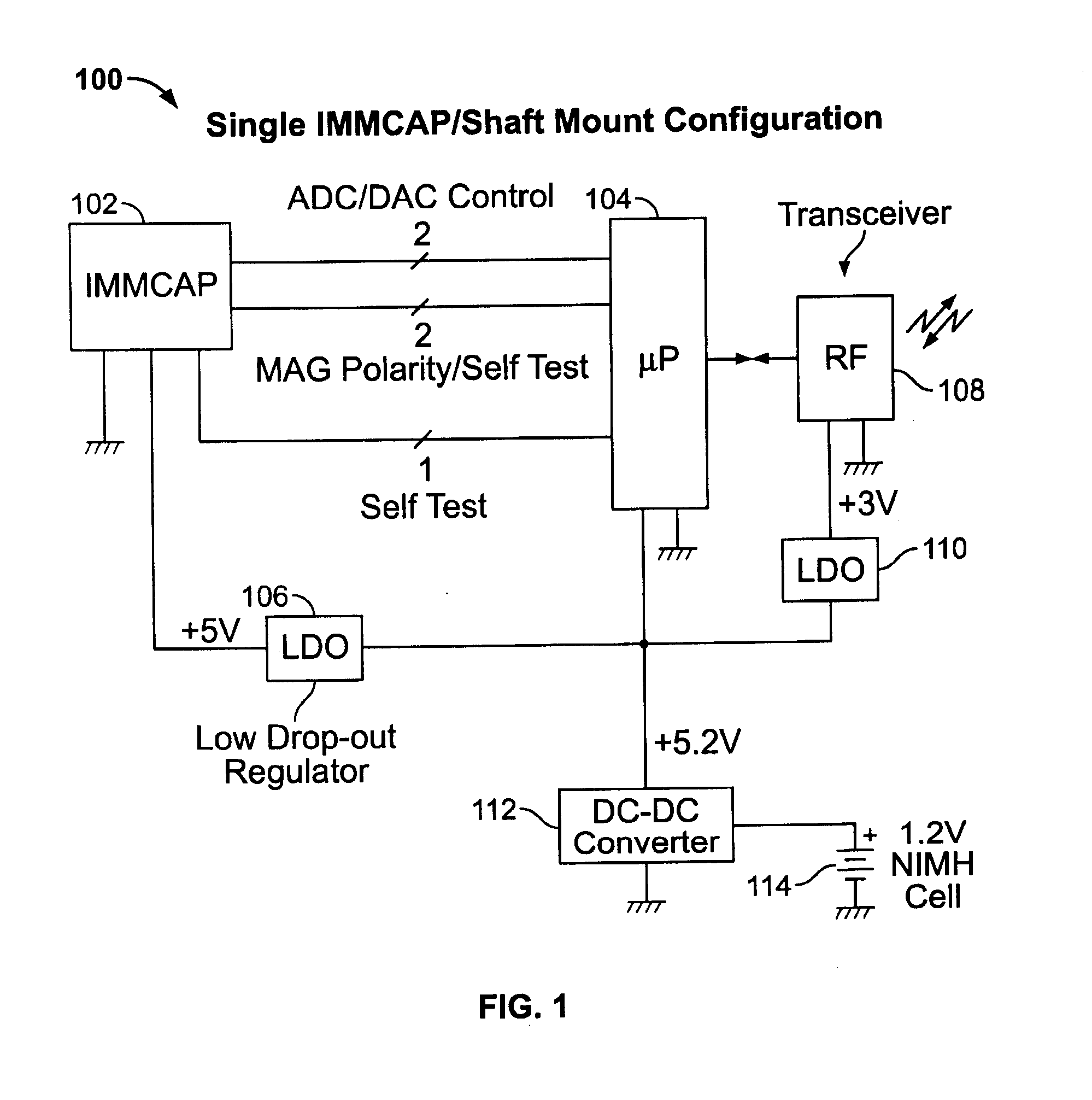

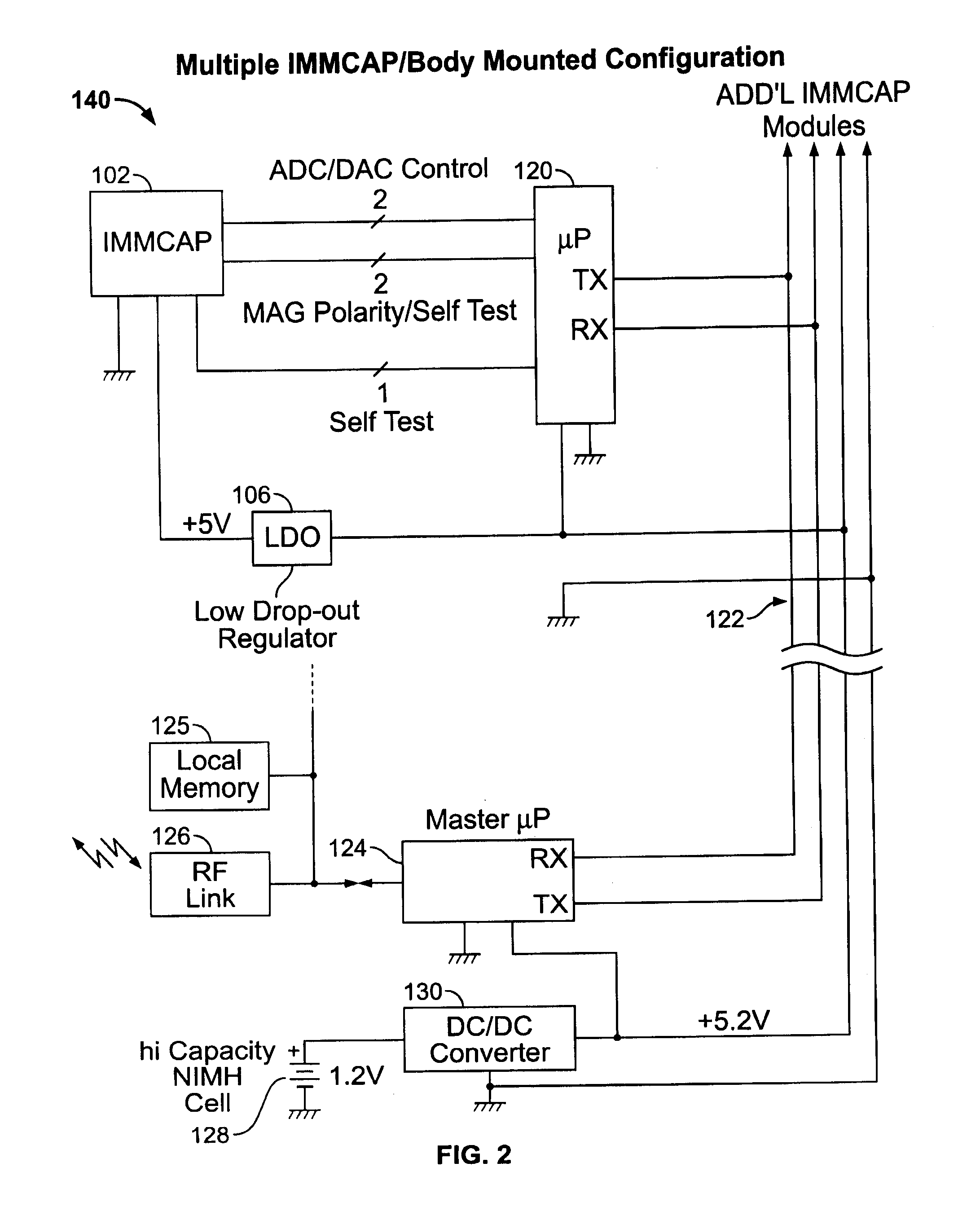

A highly miniaturized electronic data acquisition system includes MEMS sensors that can be embedded onto moving device without affecting the static / dynamic motion characteristics of the device. The basic inertial magnetic motion capture (IMMCAP) module consists of a 3D printed circuit board having MEMS sensors configured to provide a tri-axial accelerometer; a tri-axial gyroscope, and a tri-axial magnetometer all in communication with analog to digital converters to convert the analog motion data to digital data for determining classic inertial measurement and change in spatial orientation (rho, theta, phi) and linear translation (x, y, z) relative to a fixed external coordinate system as well as the initial spatial orientation relative to the know relationship of the earth magnetic and gravitational fields. The data stream from the IMMCAP modules will allow the reconstruction of the time series of the 6 degrees of freedom for each rigid axis associated with each independent IMMCAP module.

Owner:MAGNETO INERTIAL SENSING TECH

Motion sensing apparatus, systems and techniques

InactiveUS20070219744A1Gymnastic exercisingNavigation by speed/acceleration measurementsDigital data3d print

A highly miniaturized electronic data acquisition system includes MEMS sensors that can be embedded onto moving device without affecting the static / dynamic motion characteristics of the device. The basic inertial magnetic motion capture (IMMCAP) module consists of a 3D printed circuit board having MEMS sensors configured to provide a tri-axial accelerometer; a tri-axial gyroscope, and a tri-axial magnetometer all in communication with analog to digital converters to convert the analog motion data to digital data for determining classic inertial measurement and change in spatial orientation (rho, theta, phi) and linear translation (x, y, z) relative to a fixed external coordinate system as well as the initial spatial orientation relative to the know relationship of the earth magnetic and gravitational fields. The data stream from the IMMCAP modules will allow the reconstruction of the time series of the 6 degrees of freedom for each rigid axis associated with each independent IMMCAP module.

Owner:C LAN WIRELESS

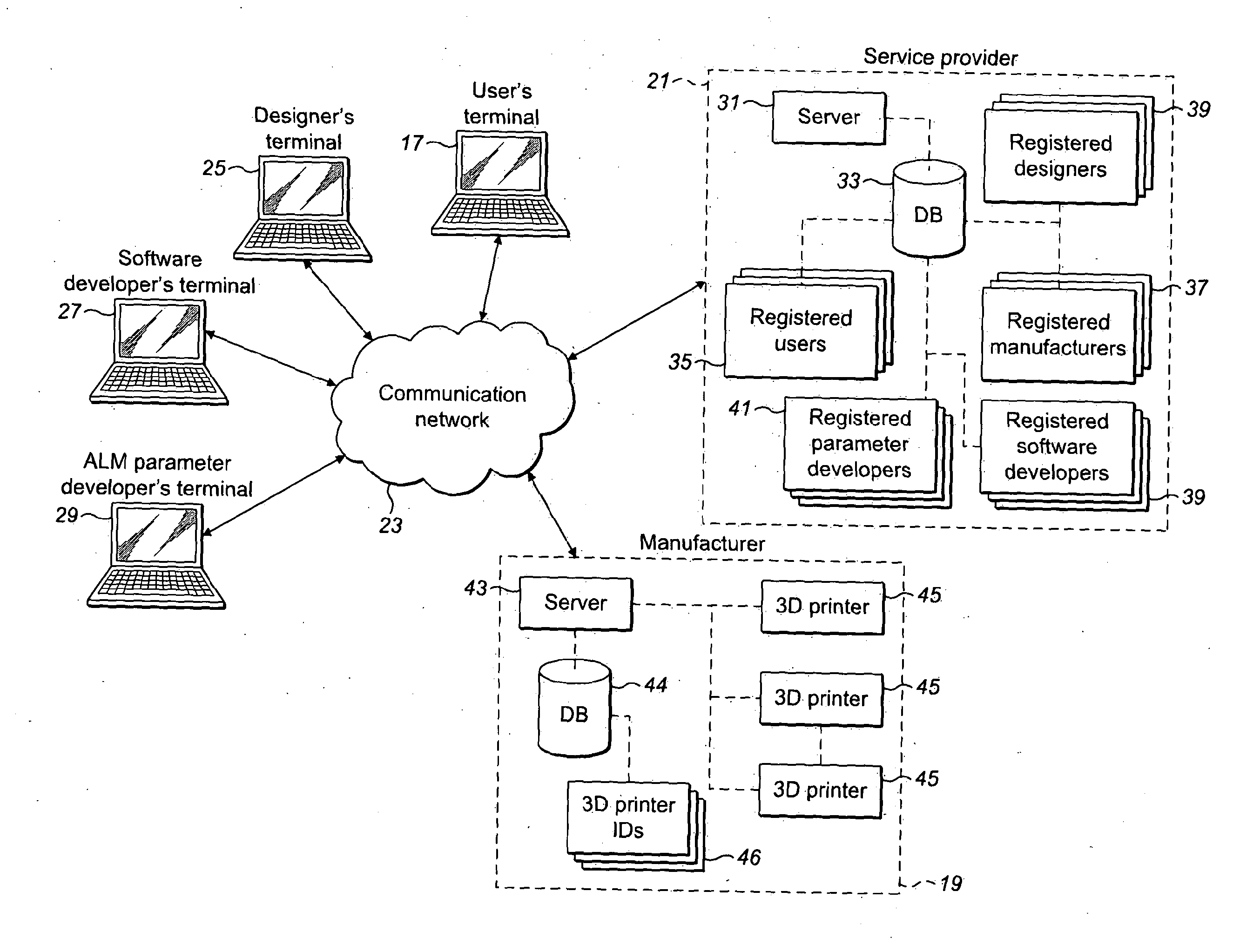

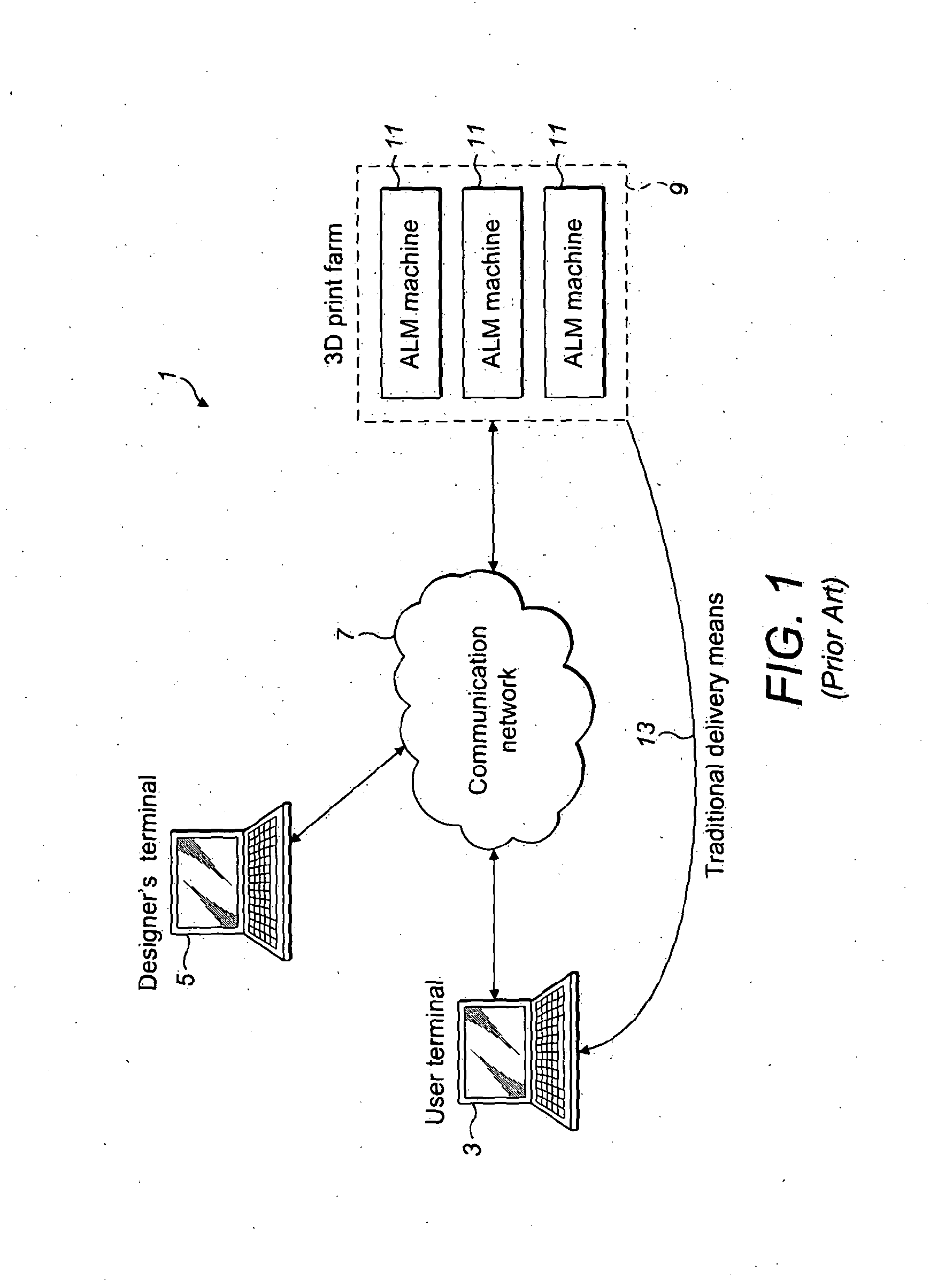

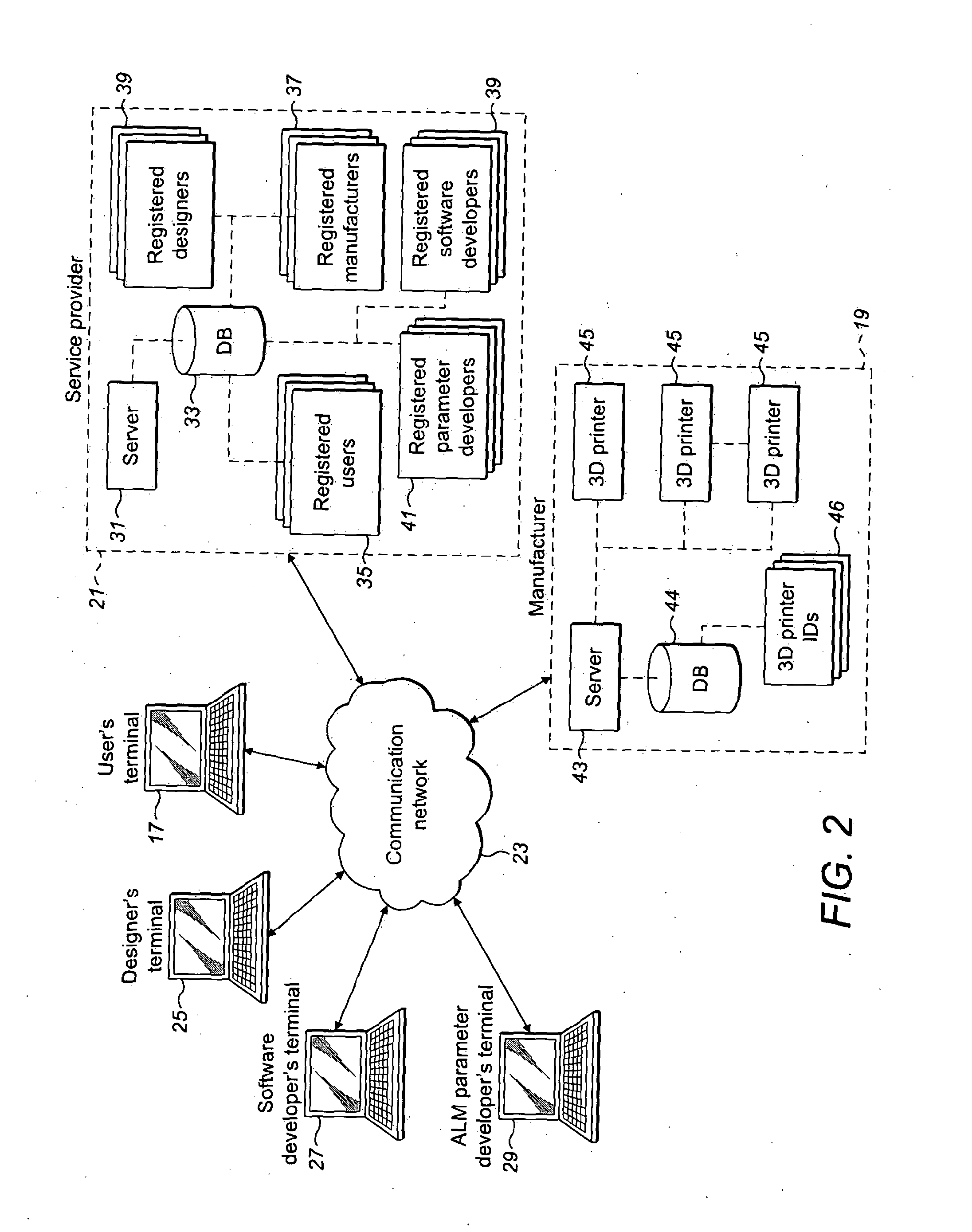

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

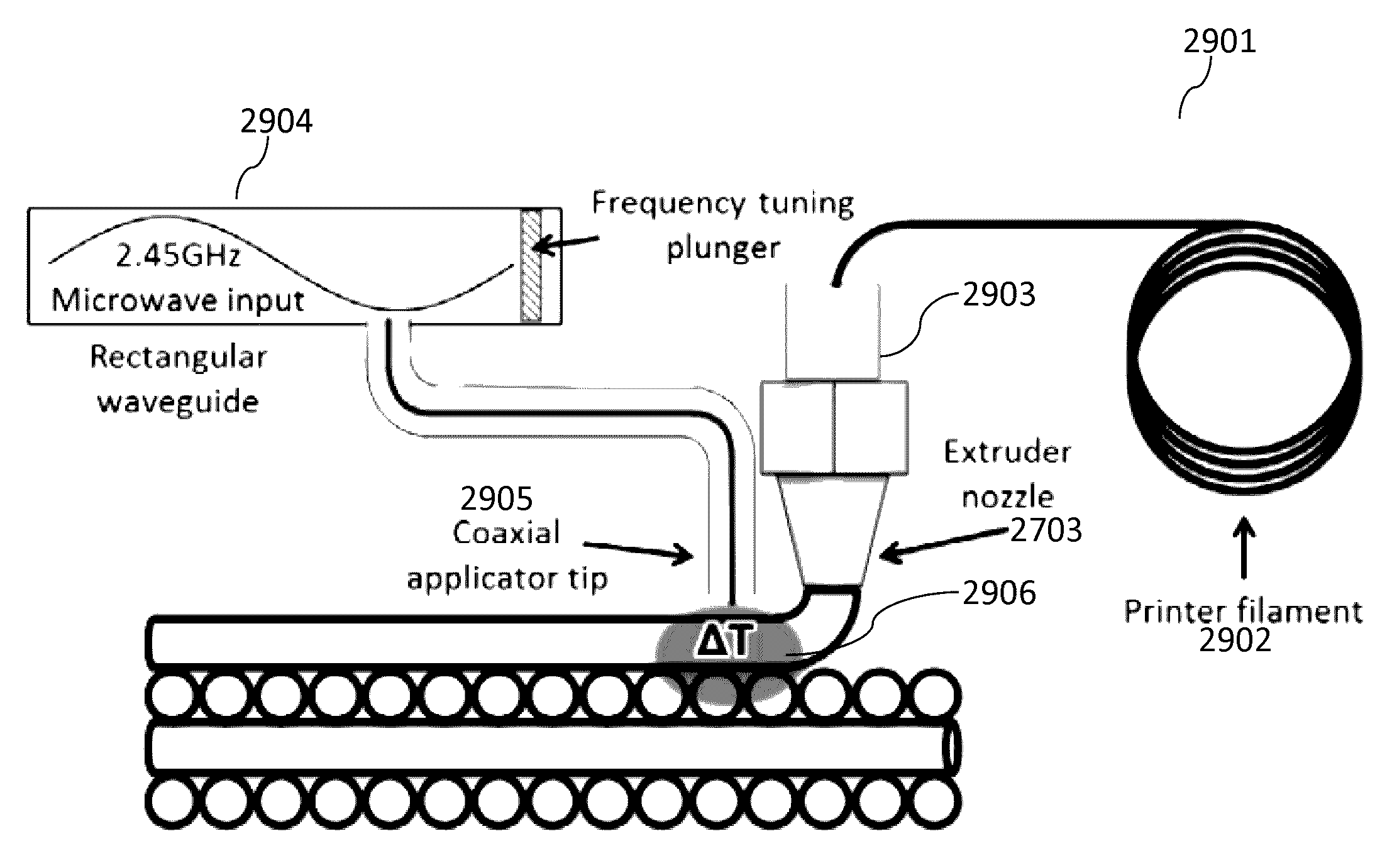

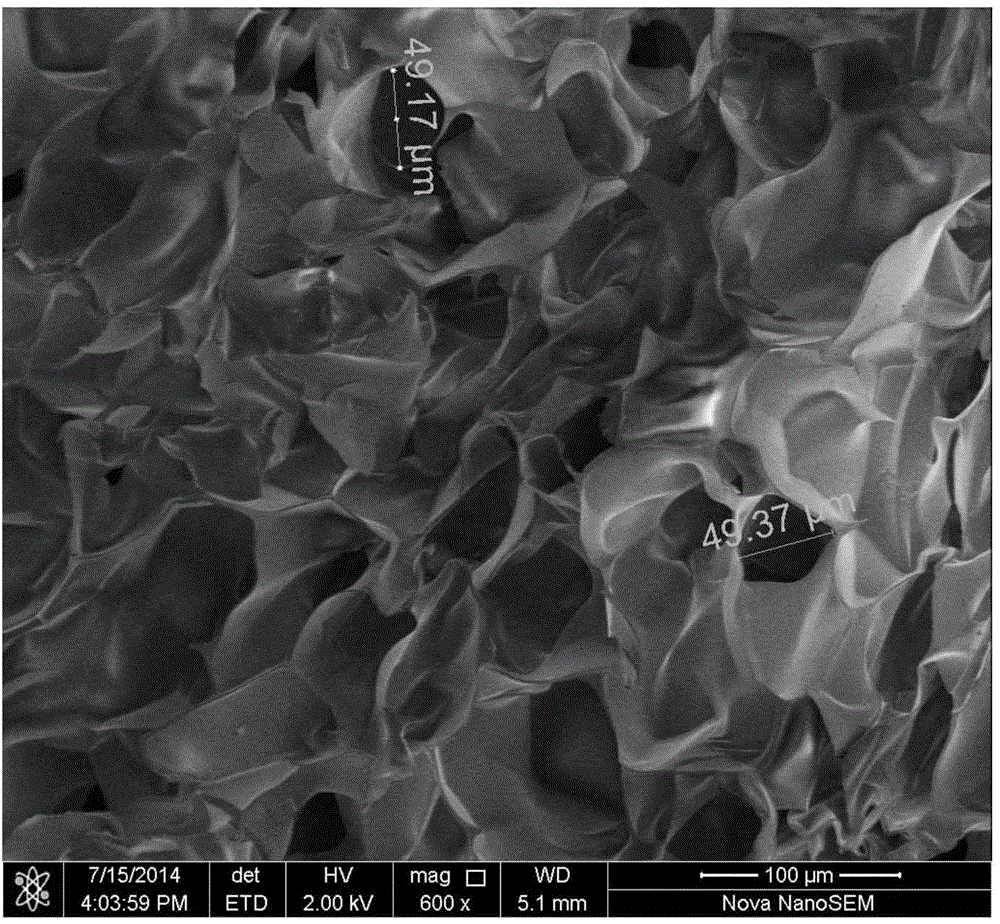

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

Multicolour extrusion-based 3D print process

A 3D extrusion print process for producing multicolored three-dimensional objects is provided. The process produces mechanically stable, multicolored 3D objects with good color definition. The process according to the invention is based on coating, upstream of the printing head, of the polymer strand used for producing the actual object, and on fixing of the coating upstream of entry of the polymer strand into the printing head. Downstream of the extrusion process in the printing head, the coating remains predominantly at the surface of the extruded strand.

Owner:EVONIK OPERATIONS GMBH

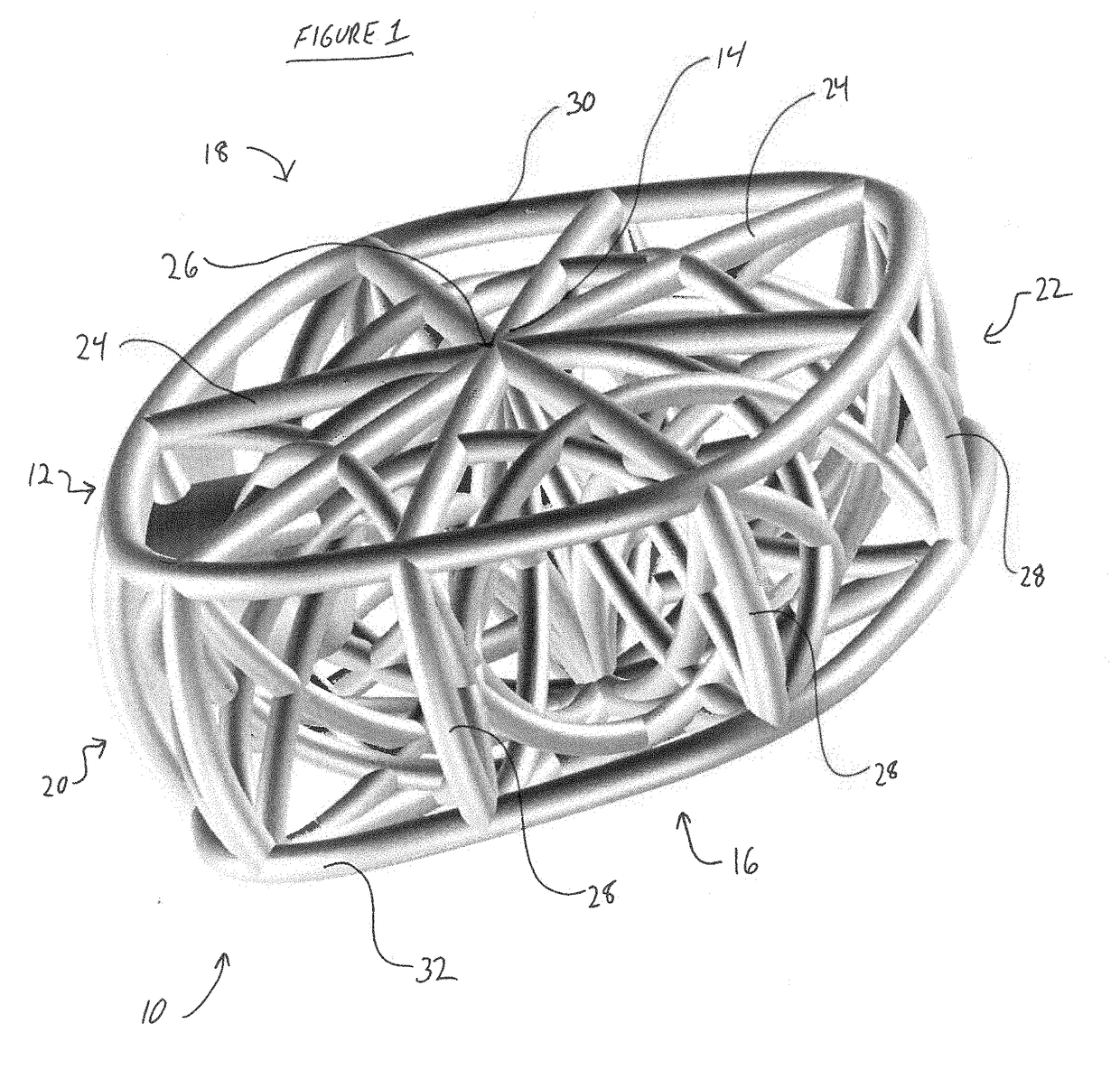

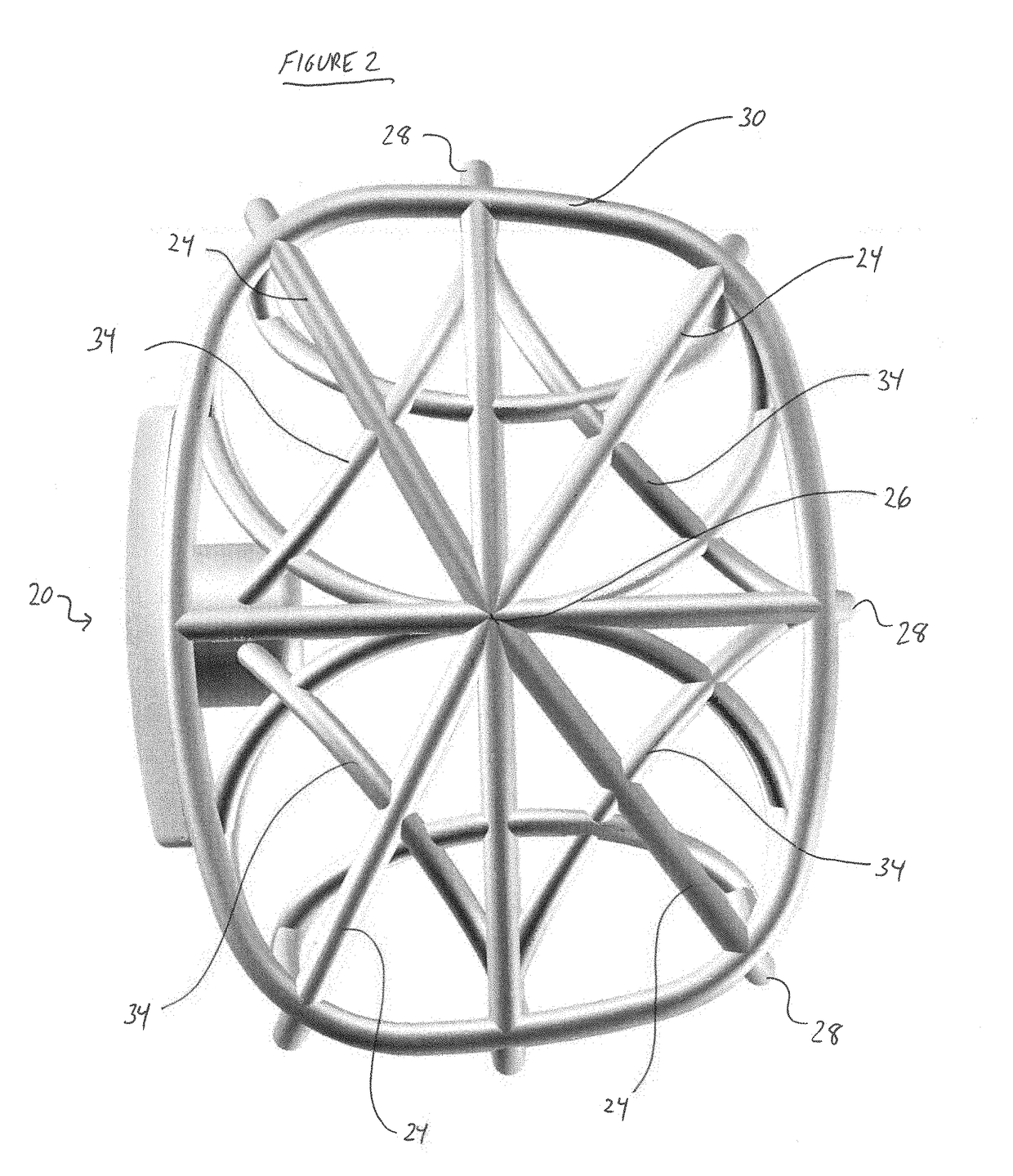

3D printed osteogenesis scaffold

Osteogenesis scaffold such as for spinal fusion or an intermedullary nail includes a number of arcuate struts. The scaffold may have a functional modulus of elasticity that is a result of the modulus of the material of the struts together with the architecture of the struts, and may be within the range of 5 GPa and 75 GPa. An anisotropy of a physical property such as stiffness, compressive strength or elastic modulus corresponds to the same physical property of native bone in the vicinity of the intended implantation site.

Owner:AFZAL THOMAS

Method for preparing powder metallurgy complex shape part by using 3D printing mold

The invention provides a method for preparing a powder metallurgy complex shape part by using a 3D printing mold. A 3D printing technology and a gel-casting forming technology are combined, namely a 3D printer is used for printing a thin-wall hollow part minus mold in a complex shape, the gel-casting technology is used for preparing metal slurry, after a catalyst and an initiator are added, the metal slurry is injected into the part minus mold, the metal slurry is solidified and dried, then organic solvent is used for dissolving a plastic mold or the plastic mold is subjected to thermal decomposition to be removed, so that a formed part blank body is obtained, and after the part blank body is dried, degummed and sintered, the needed powder metallurgy part is obtained. The method is capable of being used for preparing powder metallurgy parts of any complex shape, even and small in part tissue, stable and reliable in technology, high in operability, short in consumed time, high in efficiency, low in cost and beneficial to industrial production for preparation of the powder metallurgy parts through the 3D printing technology.

Owner:UNIV OF SCI & TECH BEIJING

Support ink for three dimensional (3D) printing

An ink composition for use as a support ink in three dimensional (3D) printing processes comprises a dispersion of solid particles in liquid carrier, compatible with an inkjet print head, wherein after removing the liquid carrier, the solid particles serve as support material for a Three Dimensional (3D) printed object, wherein the support material is separable from the 3D printed object.

Owner:XJET

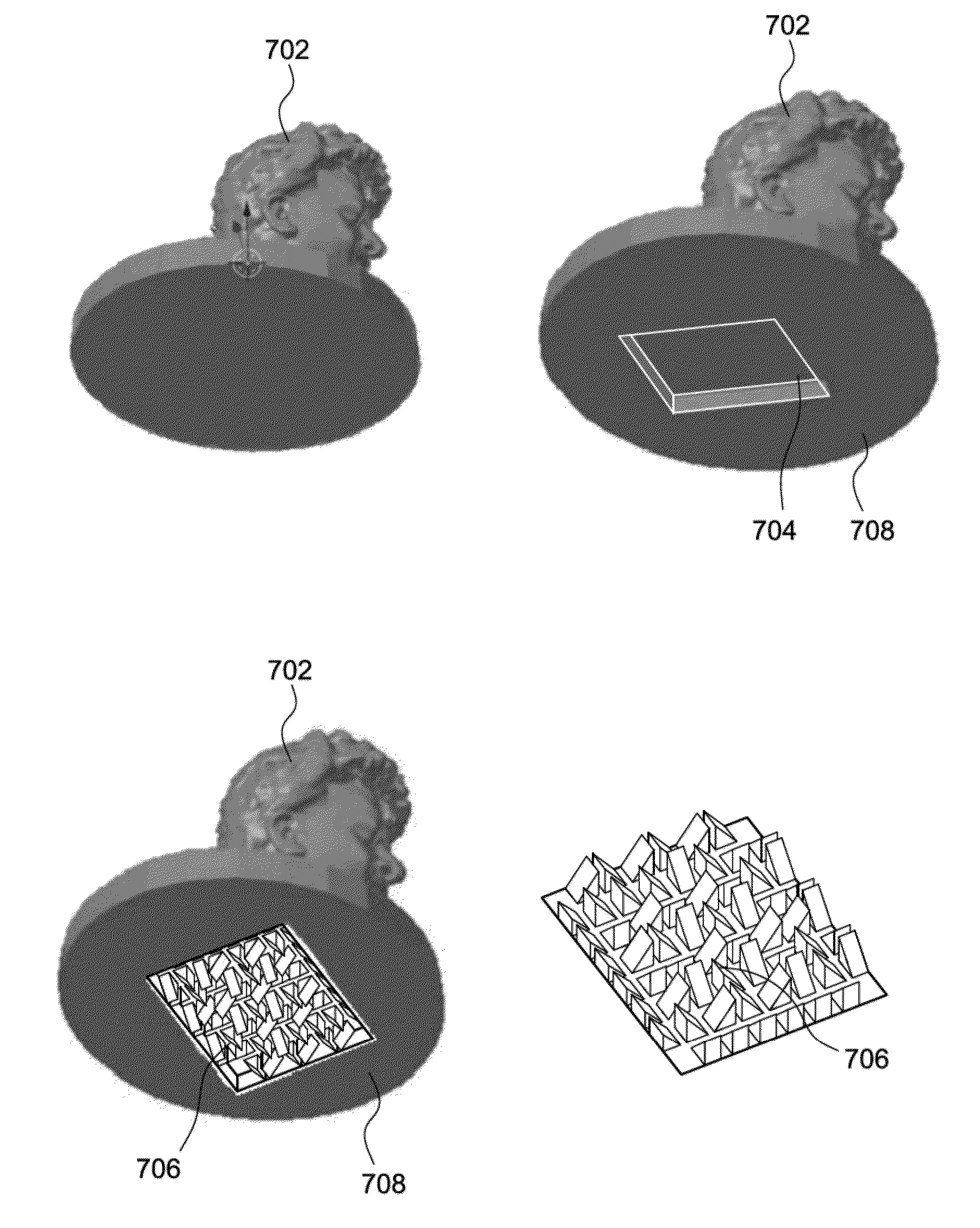

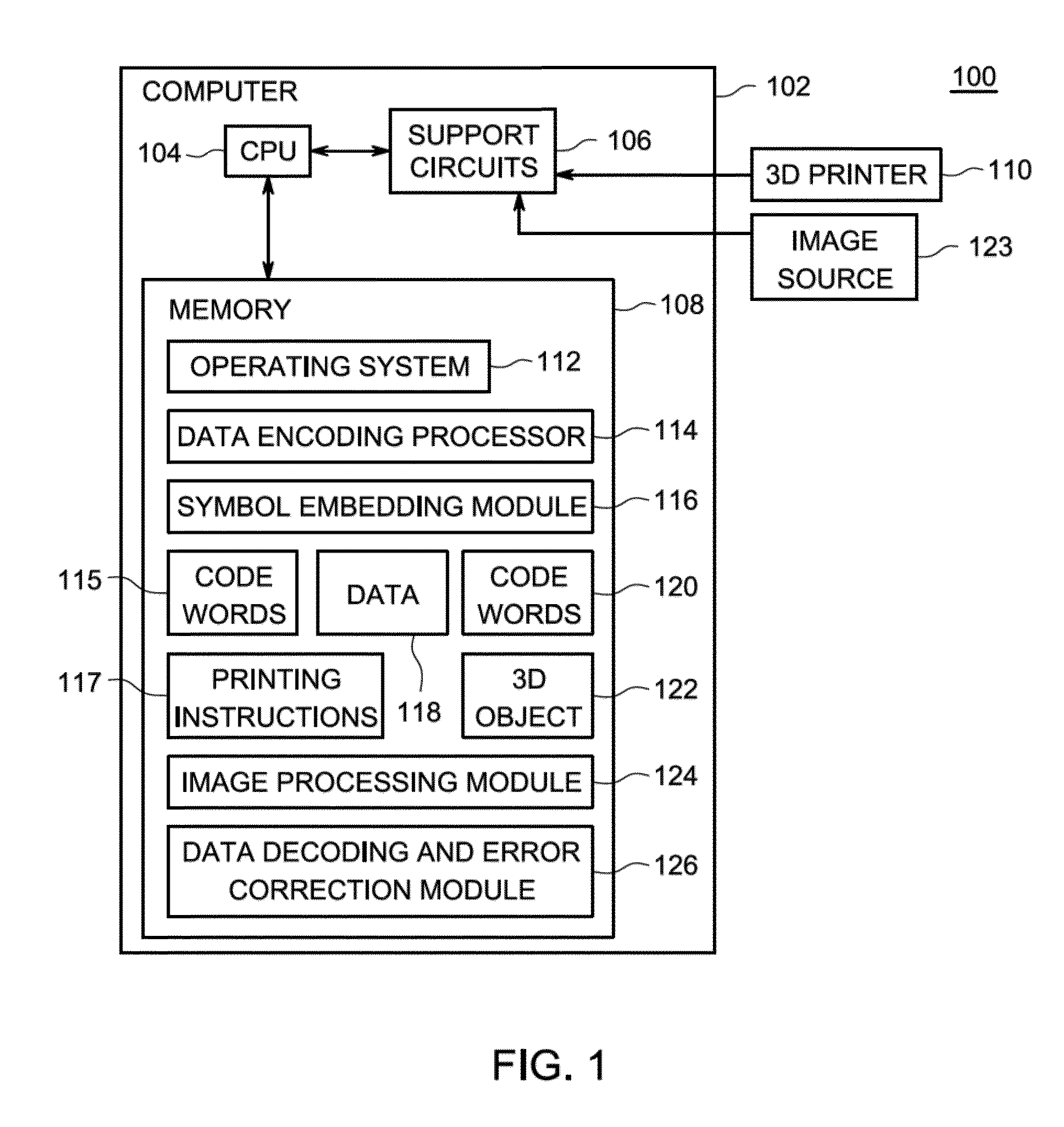

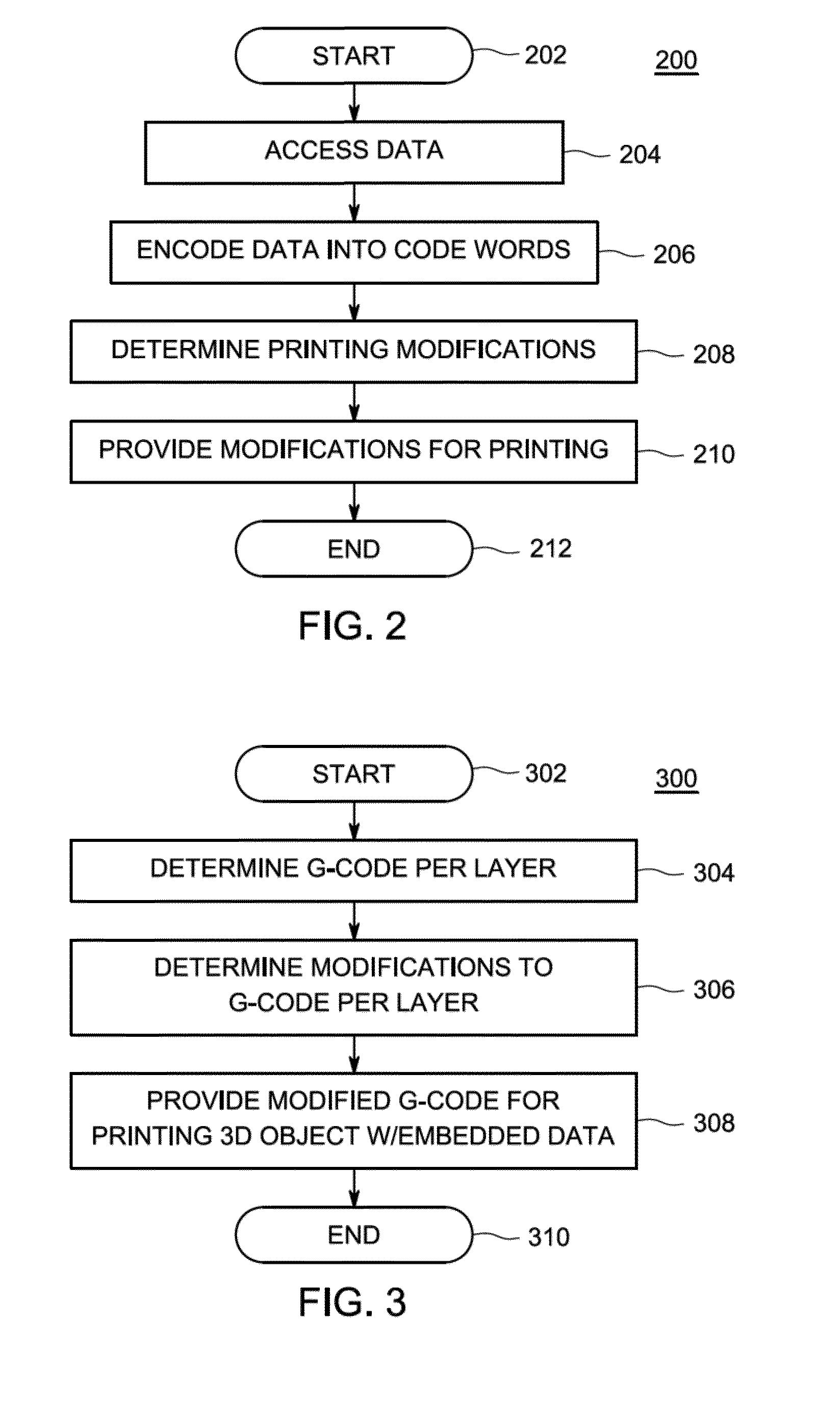

Method and apparatus for storing and retrieving data embedded into the surface of a 3D printed object

ActiveUS20150235069A1Well formedAdditive manufacturing apparatusRecord carriers used with machines3d printSymbolic Systems

A computer implemented method and apparatus for storing and retrieving data embedded into the surface of a 3D printed object is described. The method and apparatus develops an electronic file used for printing a 3D object which embeds as structure into the 3D object, a 3D symbol matrix representative of data to be printed concurrently with the 3D object, such as a 3D barcode. A selected symbology is used for making the symbol matrix in accordance with the type of printing process to be used to print the 3D object.

Owner:ADOBE INC

Aluminum alloy powder capable of being used for 3D printing and preparing method and application of aluminum alloy powder

ActiveCN109487126AReduce H

<sub>2</sub>

O contentReduce generationAdditive manufacturing apparatusIncreasing energy efficiencyMechanical propertyCorrosion

The invention provides an aluminum alloy powder capable of being used for 3D printing and a preparing method and application of the aluminum alloy powder. The aluminum alloy powder comprises the following components including, by weight, 1.00%-10.00% of Mg, 0.10%-1.80% of Sc, 0.1%-1.60% of Zr, 0.05%-3.50% of Mn, 0.01%-0.90% of Fe, 0.01%-3.00% of Cu, 0.01%-3.00% of Si, 0.01%-3.50% of Zn, 0.01%-0.08% of Cr, 0.01%-0.08% of Ni and the balance Al. A 3D printing workpiece prepared through the aluminum alloy powder has the beneficial effect of being fine in tissue, good in mechanical property, high in stress corrosion resistance and the like.

Owner:CRRC IND INST CO LTD +1

Material for 3D printing, process for preparing the same and article thereof

ActiveUS20170253681A1High strengthImprove efficiencyAdditive manufacturing apparatusCeramic shaping apparatusSolventAdhesive

The present invention provides a composition for 3D printing, a process for preparing the same and an article thereof. By the solidifying method of UV irradiation, 3D printing is implemented. During said implementation, there is no need of high temperature heating, thus energy consumption is reduced, and there is no need for special solvent, thus harm to the environment is reduced. Meanwhile, the present invention uses micro-nano powder as the main material and polymer resin as adhesive, and at the same time, adds irradiation sensitizer. After electron beam irradiation, the polymer resin forms three-dimensional crosslinked network, thereby the strength, heat resistance and chemical resistance are improved after resin adhesion. Additionally, the present invention, by the addition of UV crosslinking agent, and by UV irradiation, cross-links the unsaturated resin after extrusion in 3D printing to form three-dimensional network structure, thus greatly improves the heat resistance, chemical resistance and mechanical strength of the shaping material, and makes the unsaturated resin have broader application prospects in 3D printing material.

Owner:INST OF CHEM

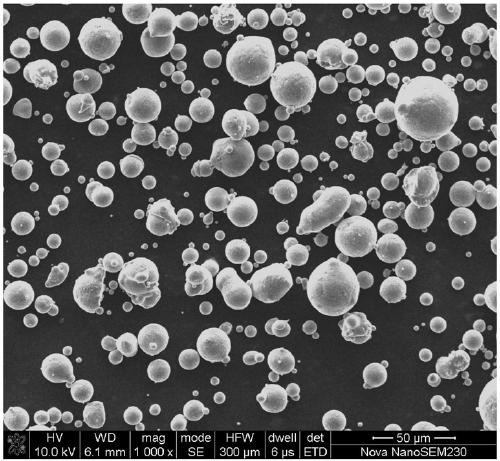

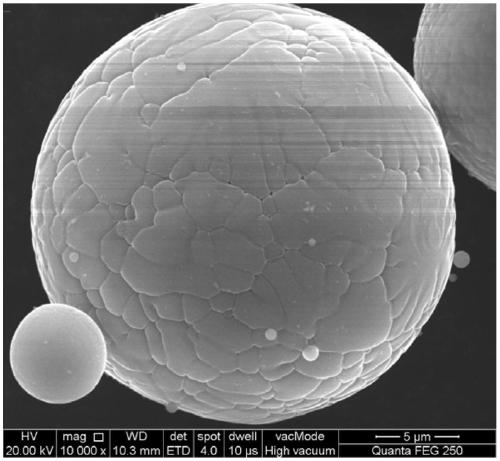

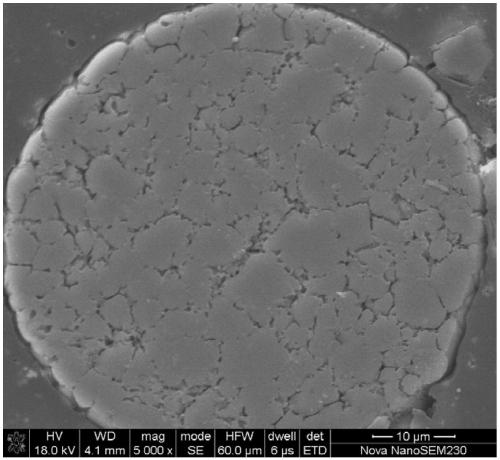

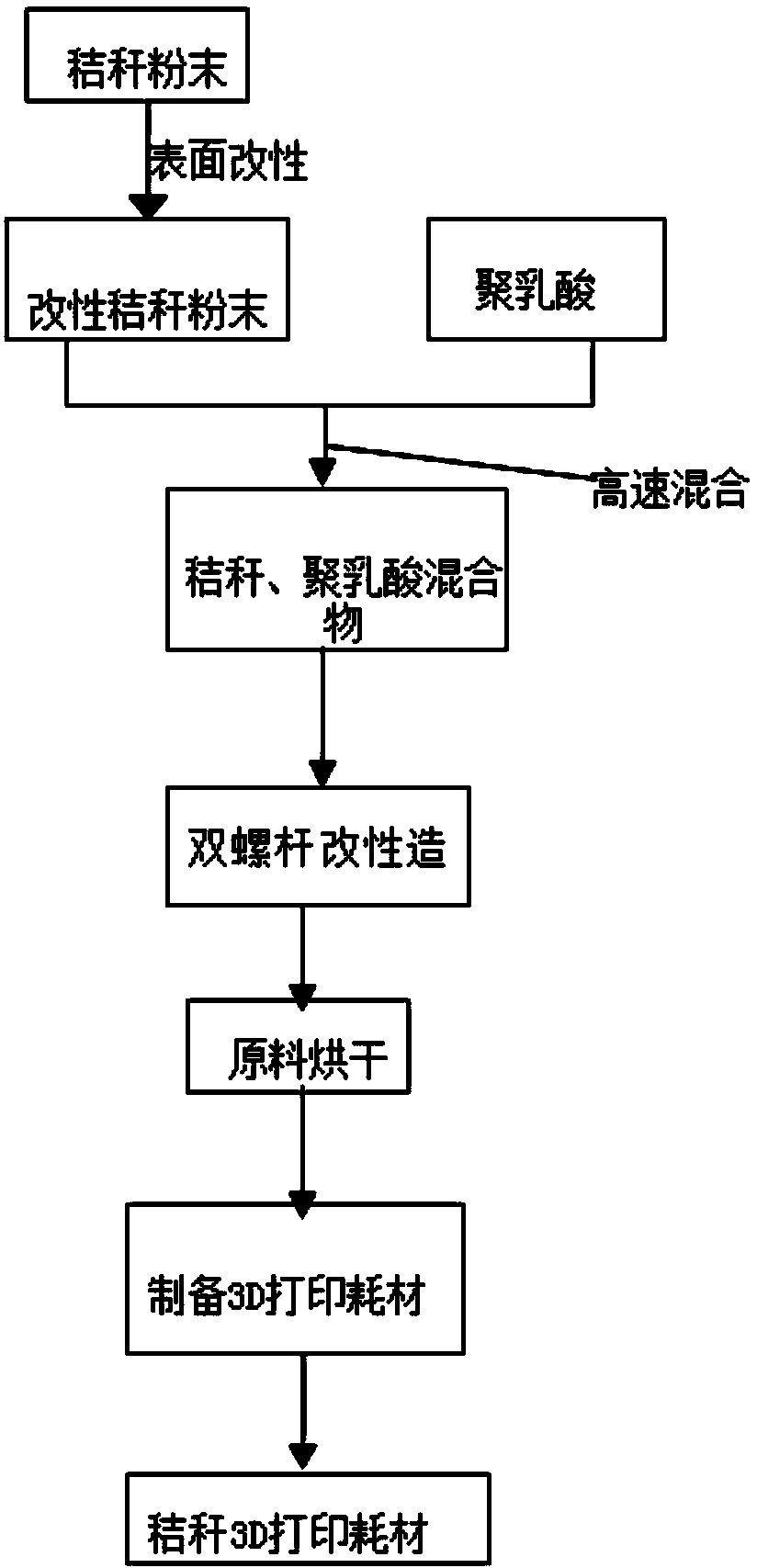

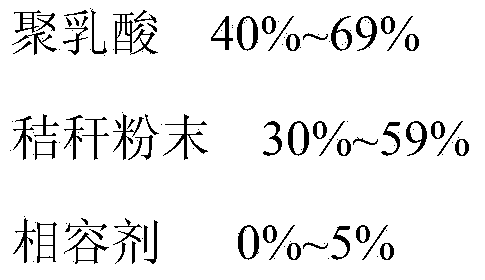

Straw 3D printing consumable and preparation method thereof

The invention provides a straw 3D printing consumable and a preparation method thereof. The formula includes the following raw materials in mass percentage: 40 to 69 percent of polylactic acid, 30 to 59 percent of straw powder, 0 to 5 percent of a compatilizer, and 0.2 to 3 percent of other additives. Straws, a crop byproduct, are fully utilized by the straw 3D printing consumable for surface modification, and the degradable material polylactic acid is added for melt blending. Compared with the prior art, the 3D printing material provided by the invention has stable performances, can replace common 3D plastic consumables in 3D printing, is non-toxic, low-carbon and environment-friendly, and has superior comprehensive performances, thereby achieving considerable economic value and broad market prospects.

Owner:芜湖瀚博电子科技有限公司

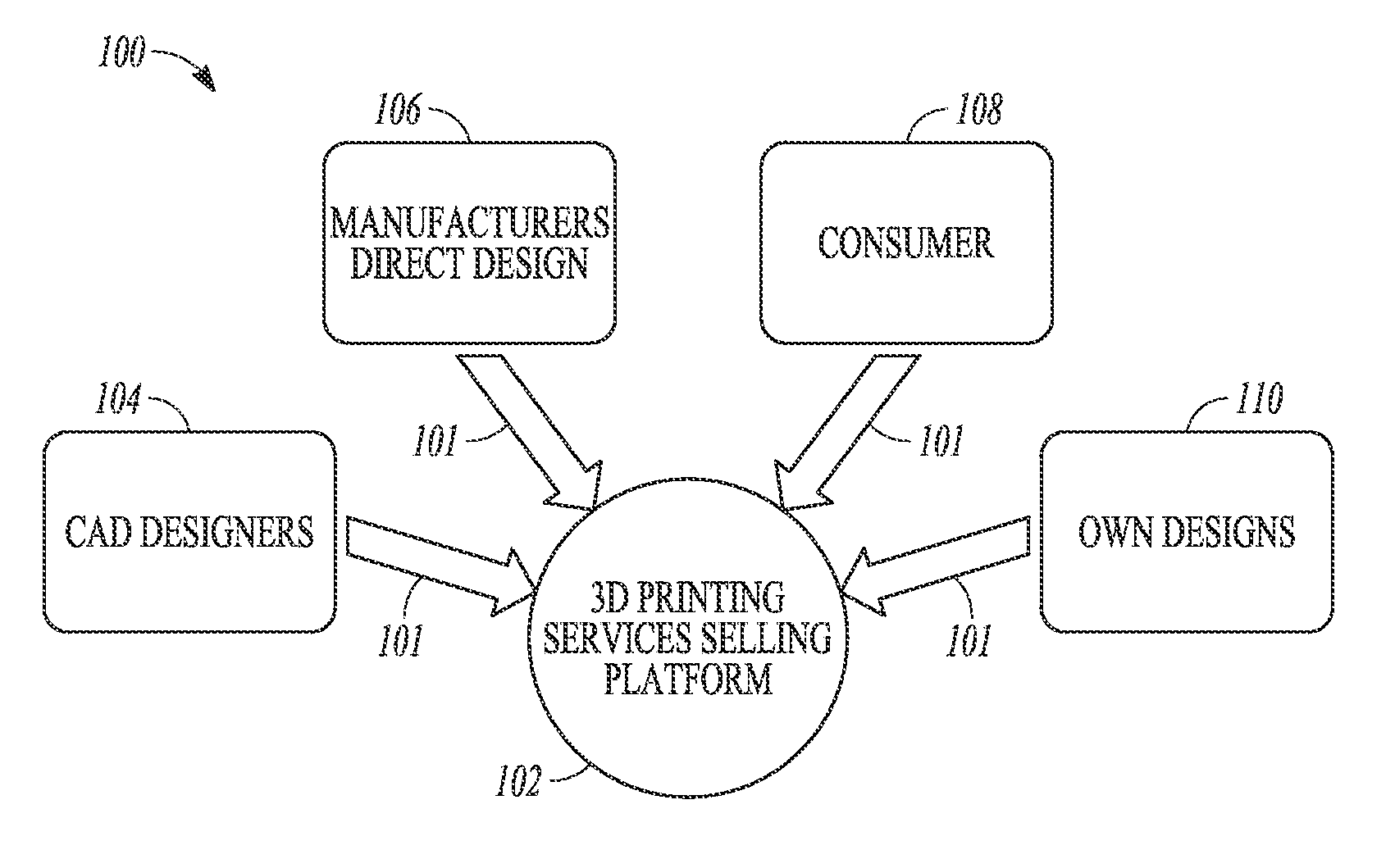

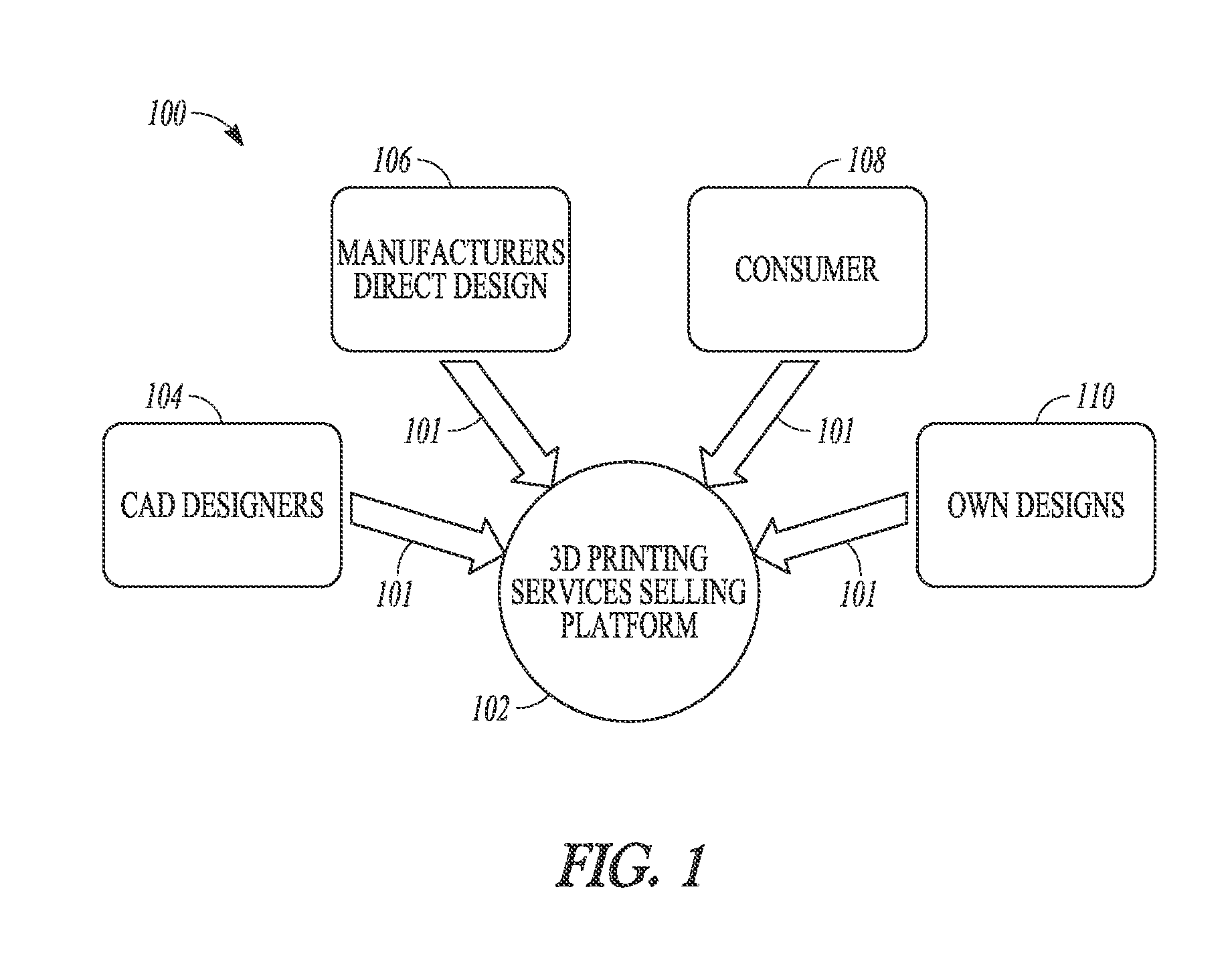

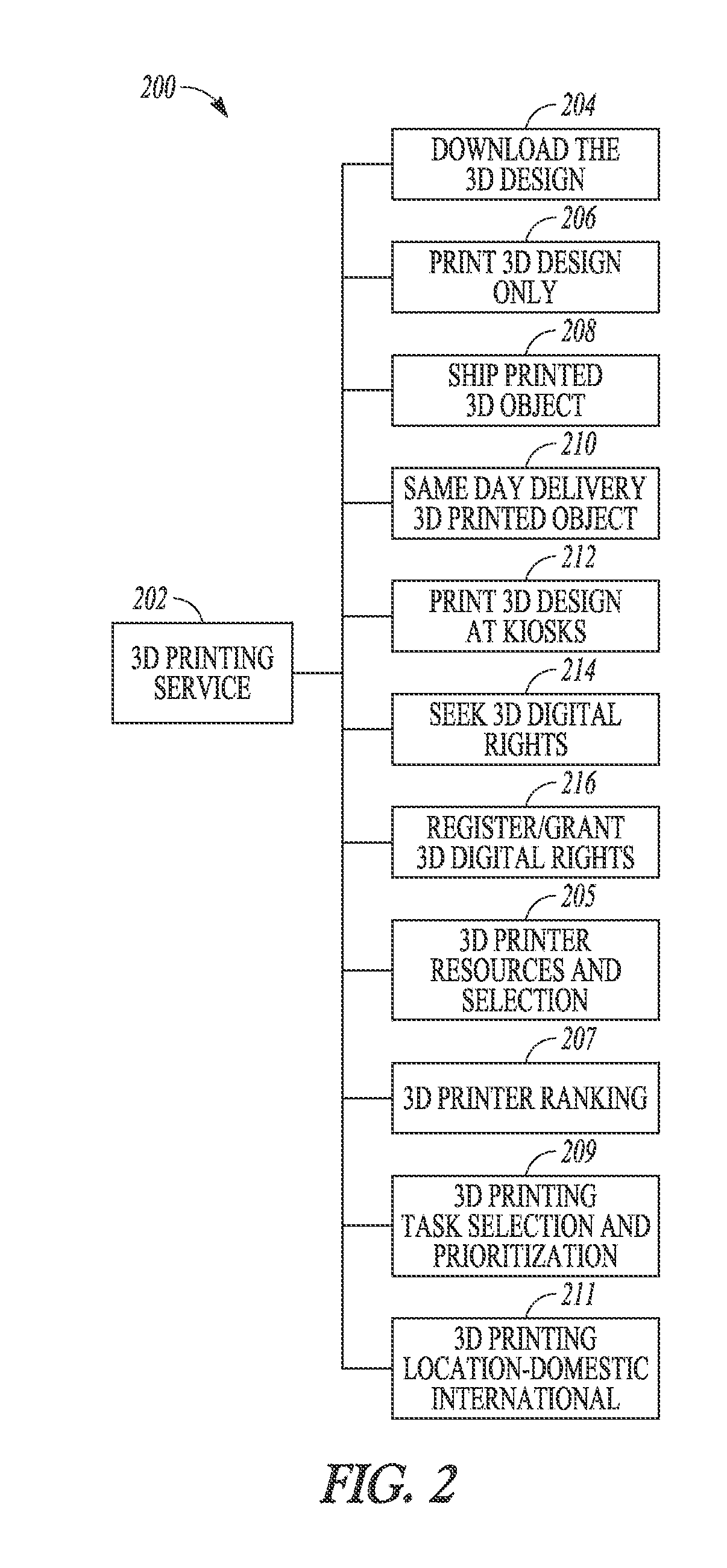

3D printing in marketplace environments

InactiveUS20150220748A1Facilitate authorizationImprove performanceDigital data processing detailsAnalogue secracy/subscription systemsConsumer unitDigital mockup

Systems, methods, and media for authorizing 3D printing services in a marketplace environment are provided. In one example, a system comprises a computing device that implements a 3D printing marketplace component. The marketplace component comprises a merchant unit, a transaction unit, a consumer unit, and a digital rights authorization unit which cooperatively act to receive a request from a consumer for a 3D printing task, rank a plurality of 3D printing service providers based on an availability or a suitability to fulfil the 3D printing task, and facilitate the authorization of performance of the 3D printing task based on a grant of digital rights associated with the digital model or object.

Owner:EBAY INC

Three-dimensional part printing method

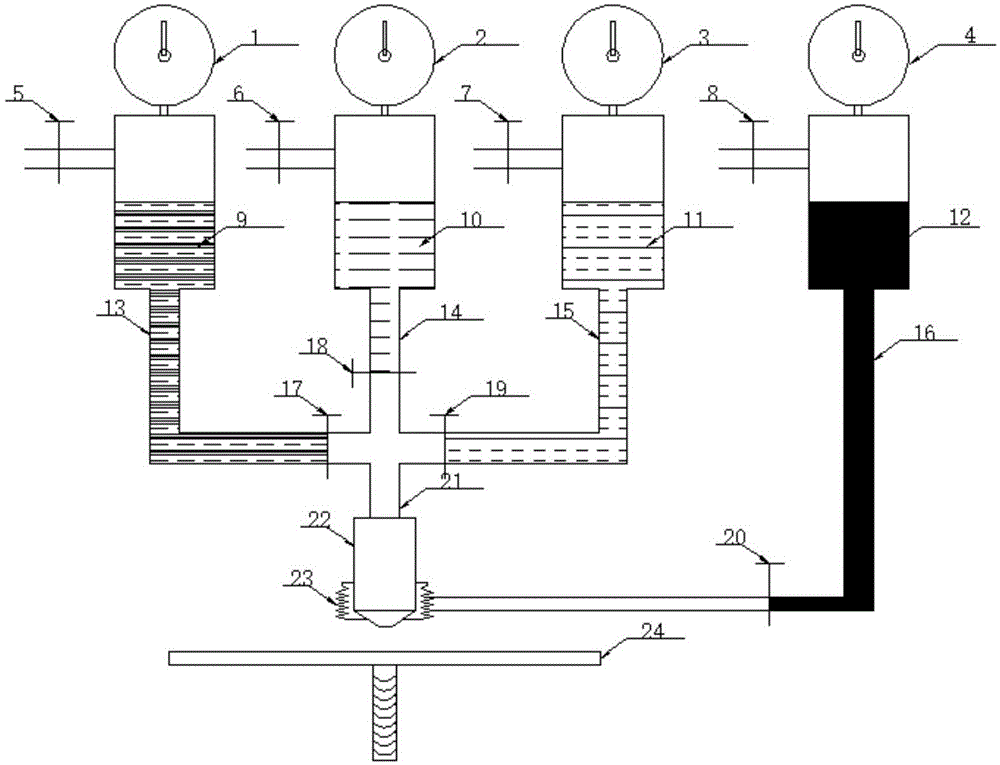

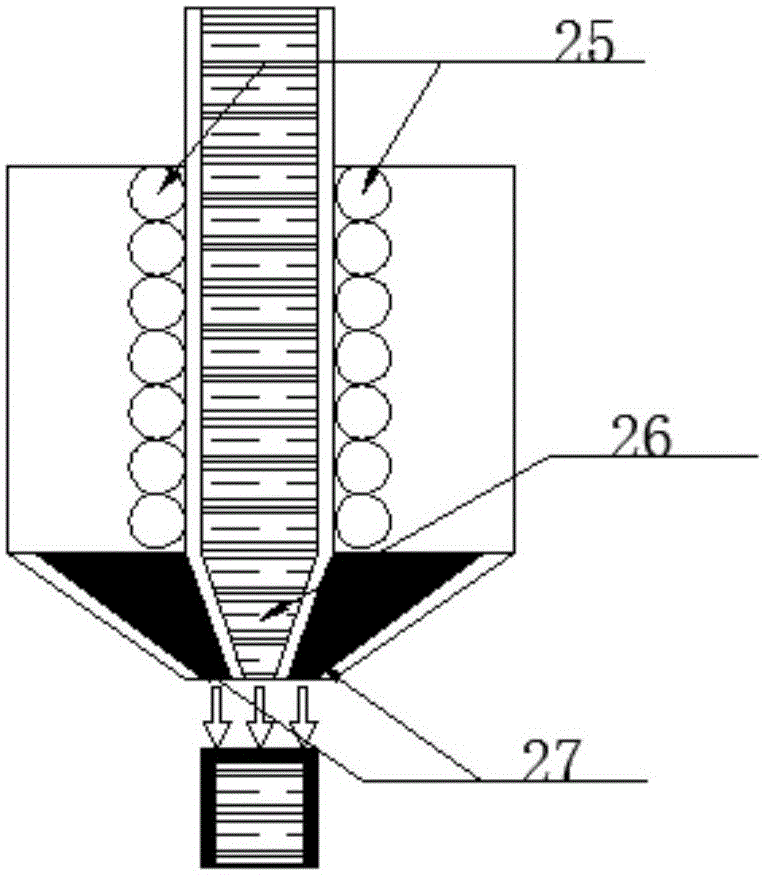

InactiveCN105057665ASolve the problem of moldless complex shape parison formingFast preparation3d printColloid

The invention provides a three-dimensional part printing method. The method comprises the following steps that firstly, metal slurry is prepared; secondly, parameters of a parison model are designed; thirdly, a parison is printed in a three-dimensional manner and solidified in an entire manner, wherein the third step comprises that the metal slurry is placed in a stock bin of a slurry pressure storing and quantitative feeding system of a three-dimensional printing device; the metal slurry is conveyed to the portion of a slurry three-dimensional printing spraying head of the three-dimensional printing device through the slurry pressure storing and quantitative feeding system in a channelized manner; according to a scanning route of each layer, the slurry three-dimensional printing spraying head is controlled to squeeze out the metal slurry, micro-cell three-dimensional stacking building is carried out on a printing platform of the three-dimensional printing device, and during the stacking building, thermal initiation solidifying and / or chemical solidifying initiation are / is carried out; fourthly, degumming is carried out on a solidifying type parison, and solvent and a rubber matrix are removed; and fifthly, sintering is carried out, and a metal part which is in a target shape is obtained. According to the method, the operability is strong, the technology is stable, and the wide application prospect is achieved.

Owner:王海英

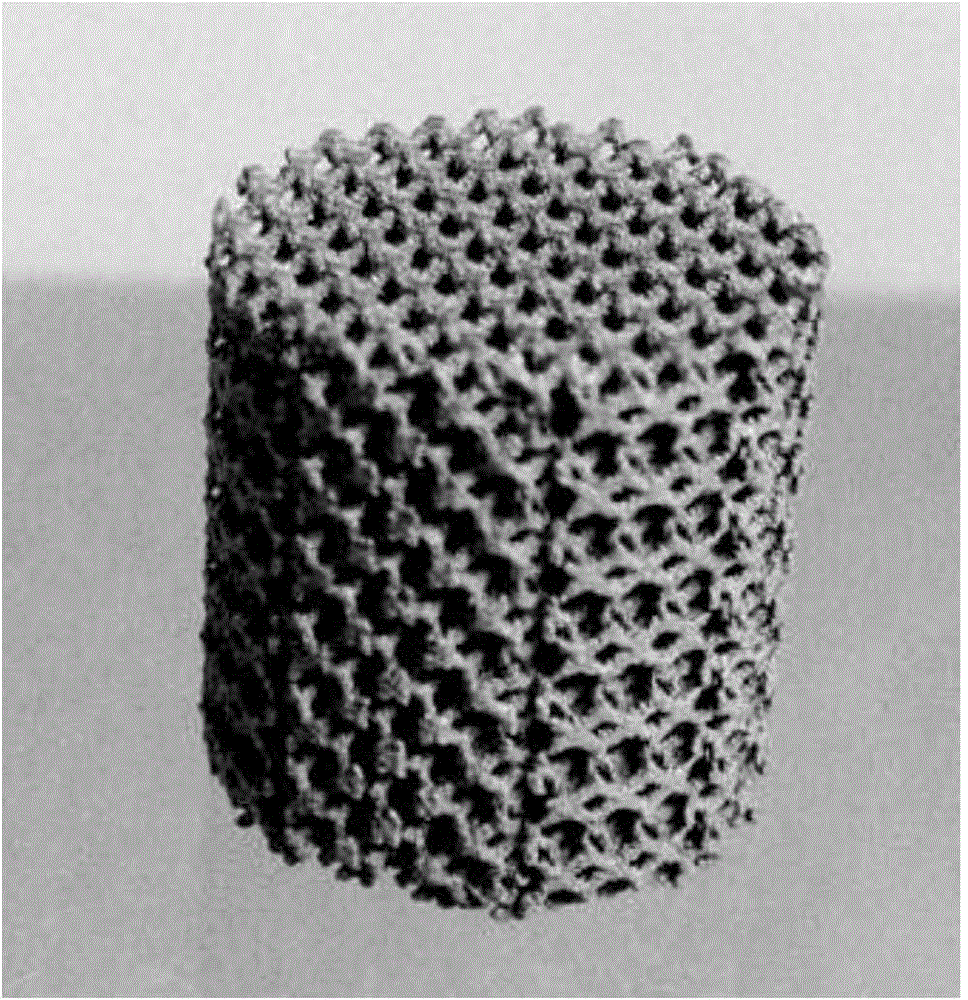

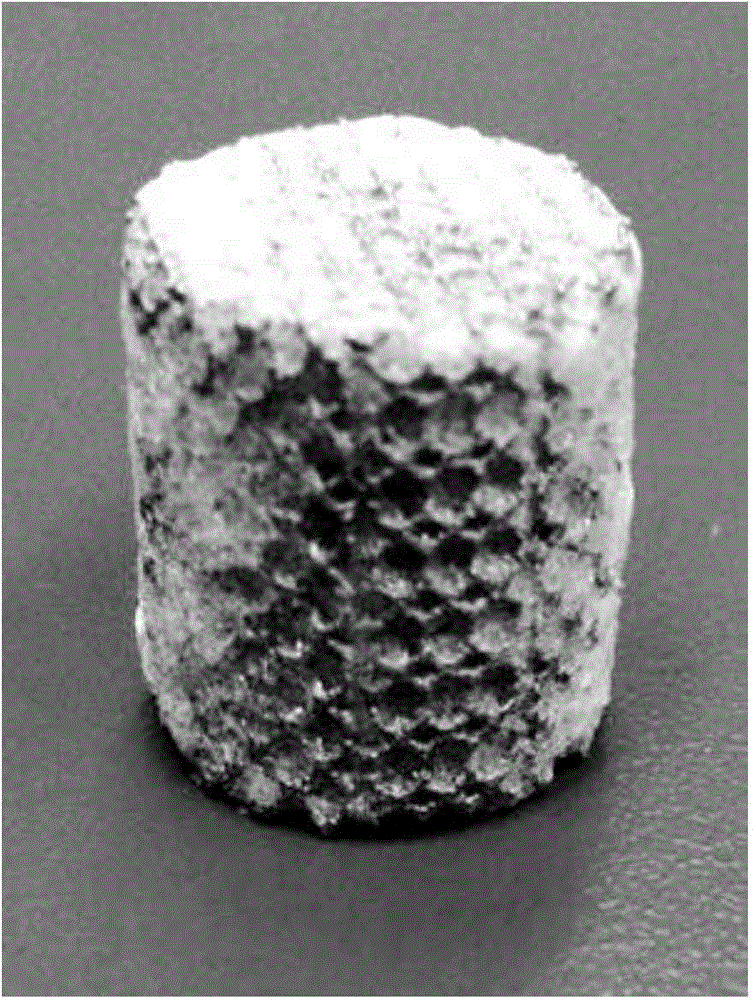

3D printed porous metal with bionic three-dimensional (3D) micro-scaffold and preparation method of 3D printed porous metal

ActiveCN104353122AEarly recovery of weight bearing functionPrevent relapseProsthesisLarge poreBone tissue

The invention relates to the technical field of biological medicinal materials, and particularly relates to a 3D printed porous metal with a bionic three-dimensional (3D) micro-scaffold and a preparation method of the 3D printed porous metal. The bionic 3D micro-scaffold is constructed in each hole of a metal scaffold, and an excellent environment is provided to proliferation and differentiation of cells; the problems in the prior art that cells can only climb and grow on the two-dimensional (2D) space of a pore wall of the metal scaffold due to too large pore, and 3D growth in the whole hole cannot be realized can be solved. The bionic 3D micro-scaffold provided by the invention is possibly used for completely curing patients with bone tissue defect caused by diseases, accidents and other reasons, can be used as a novel interbody fusion cage, is suitable for spinal fusion surgeries, brings hopes for more and more patients, and has an important clinical application value.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

Photosensitive resin used in 3D printing, and its preparation method

The invention provides a photosensitive resin used in 3D printing, and its preparation method. The photosensitive resin is prepared by using 35-40 parts of acrylate, 35-40 parts of epoxy resin, 20-30 parts of a diluent, 0.1-5 parts of an antifoaming agent, 0.1-5 parts of a leveling agent, 1-10 parts of a cationic initiator and 1-10 parts of a free radical photopolymerization initiator. The photosensitive resin prepared in the invention has the characteristics of fast forming speed, small irritation, simple process, low cost and the like, and can be directly applied in 3D printing to make products with complex structures.

Owner:HEFEI GENIUS NEW MATERIALS

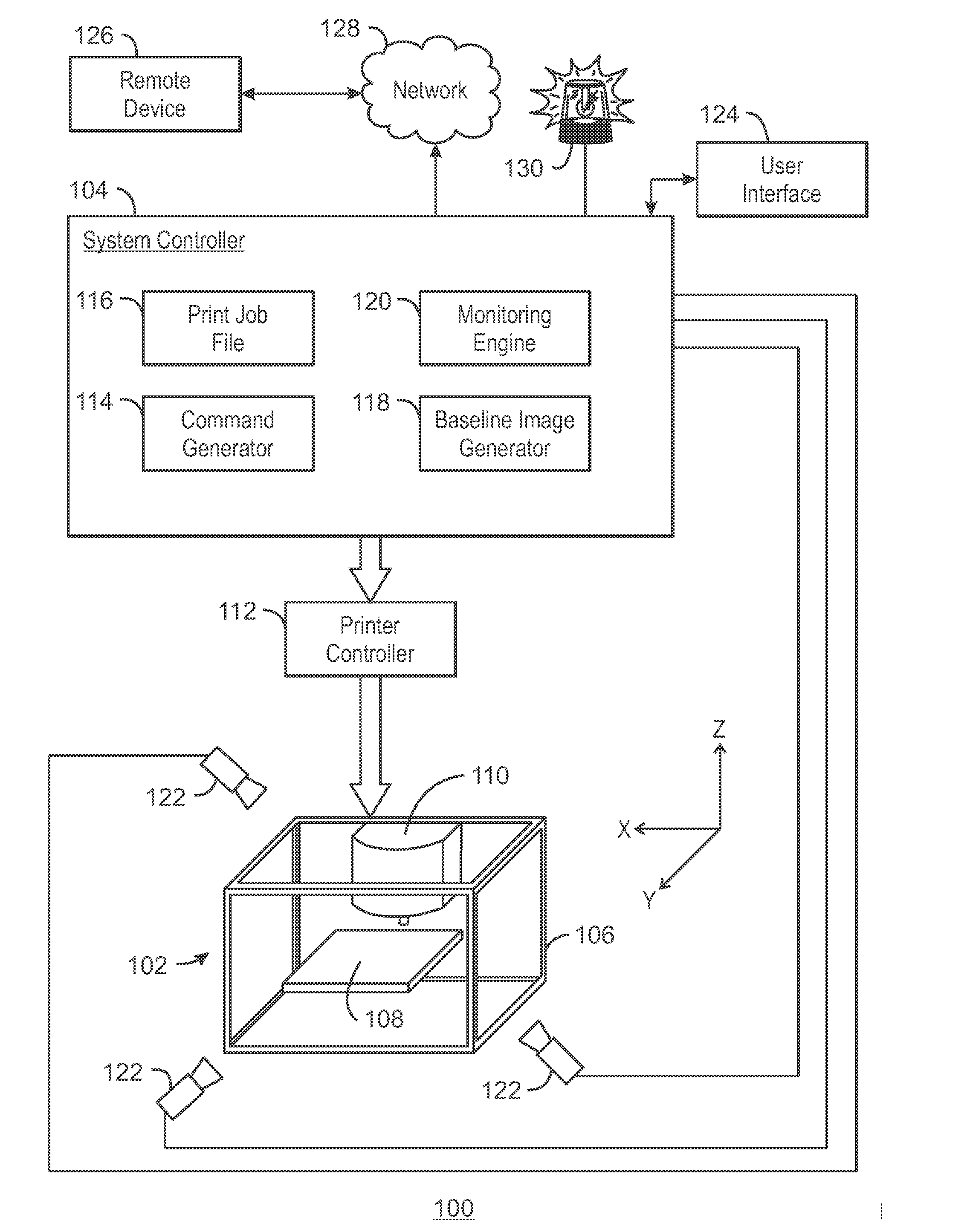

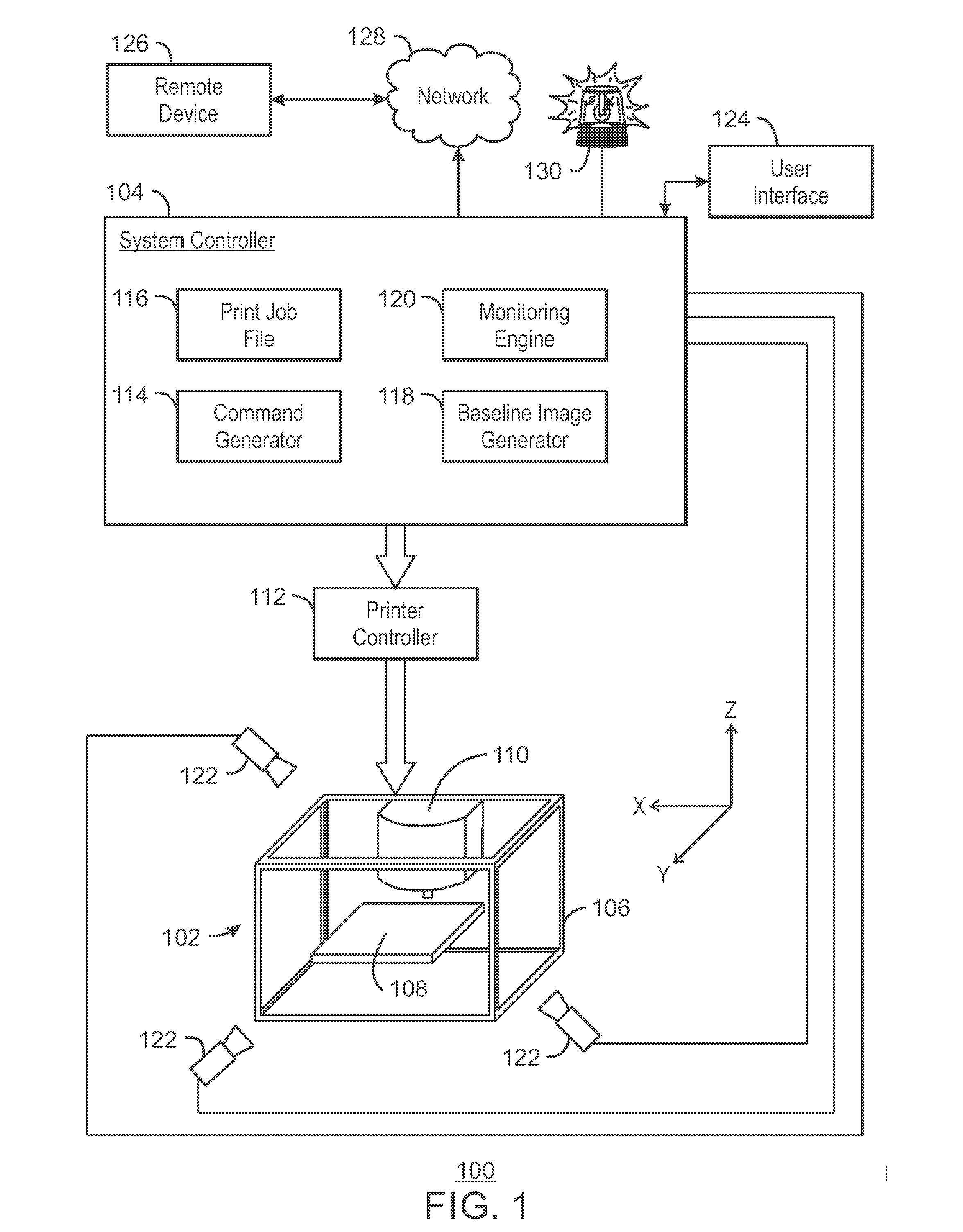

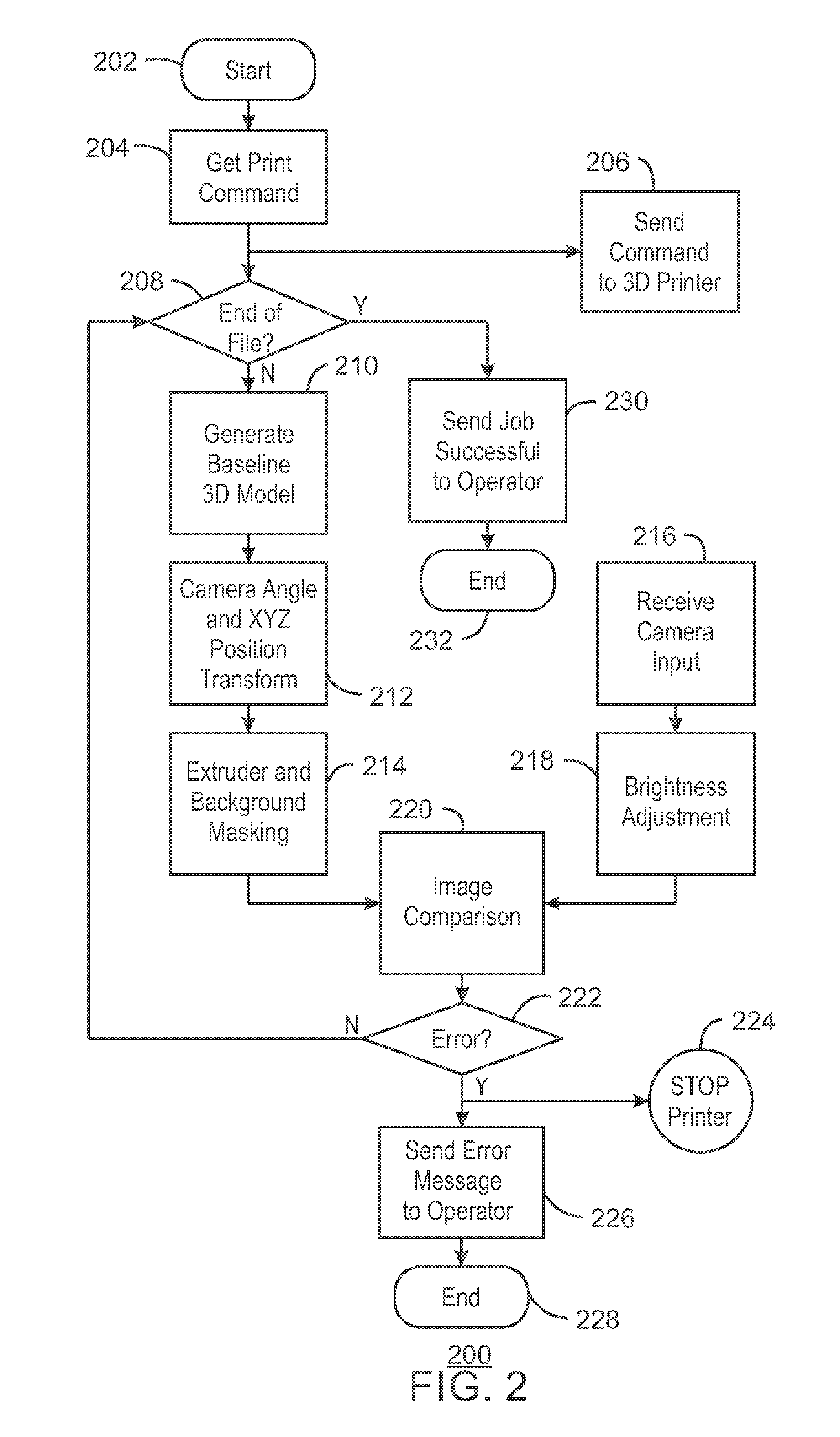

Printer monitoring

ActiveUS20160283833A1Additive manufacturing apparatusVisual presentation using printers3d printComputer printing

Techniques for monitoring a three-dimensional (3D) printer during the performance of a print job are described herein. An example of a system in accordance with the present techniques includes a camera to generate an image of a 3D print job in progress. The system also includes a baseline image generator to generate a baseline image based on a 3D model of the object to be printed. The system also includes a monitoring engine to compare the image with the baseline image to determine a status of the 3D print job and trigger an alarm if the 3D print job fails.

Owner:INTEL CORP

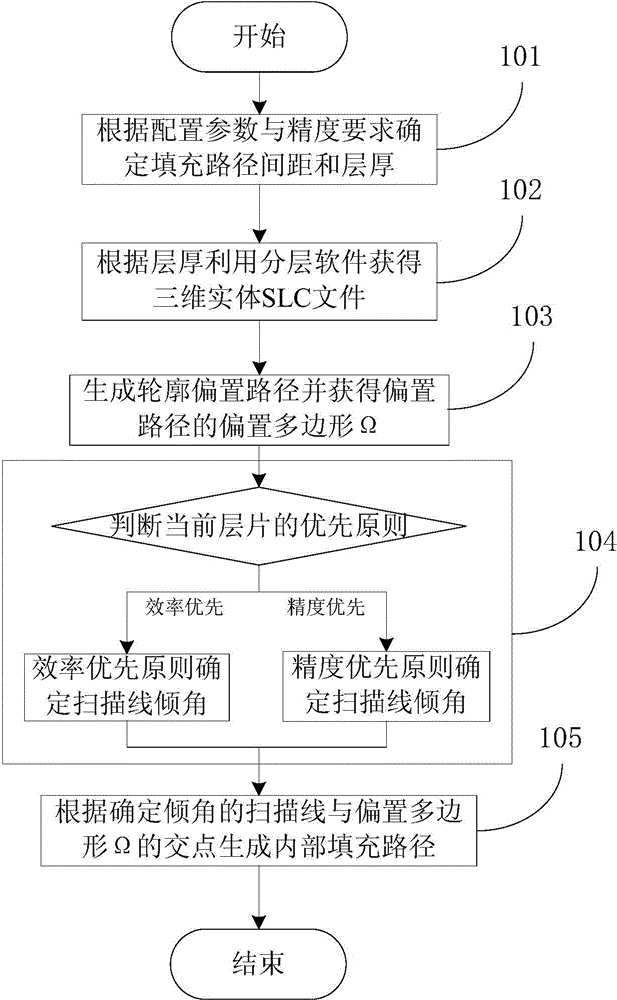

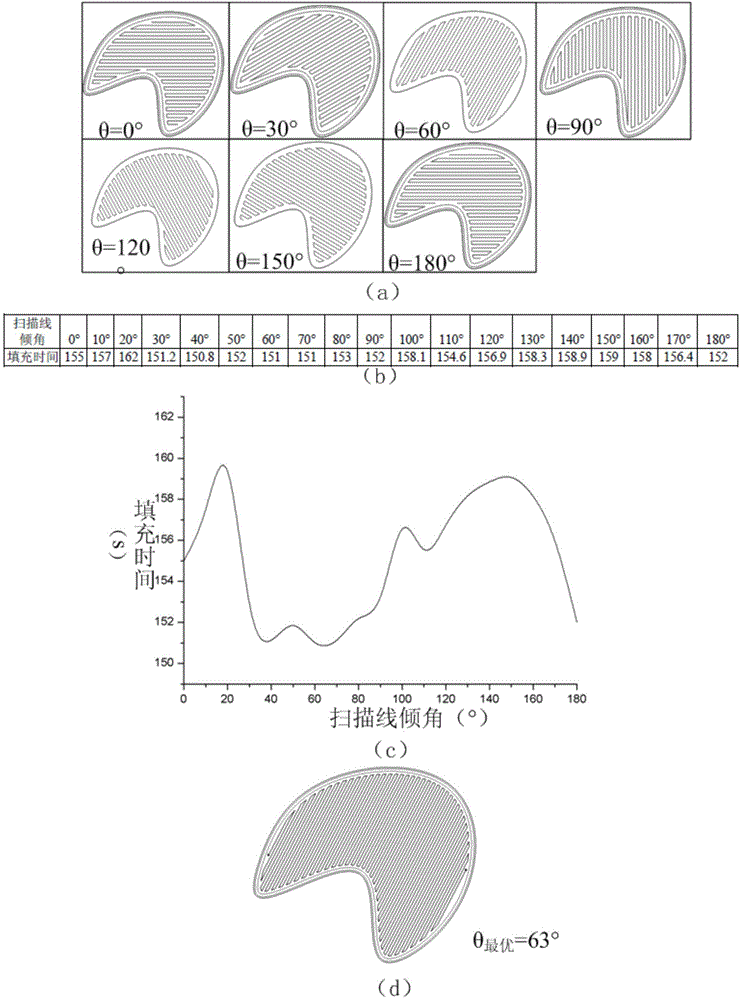

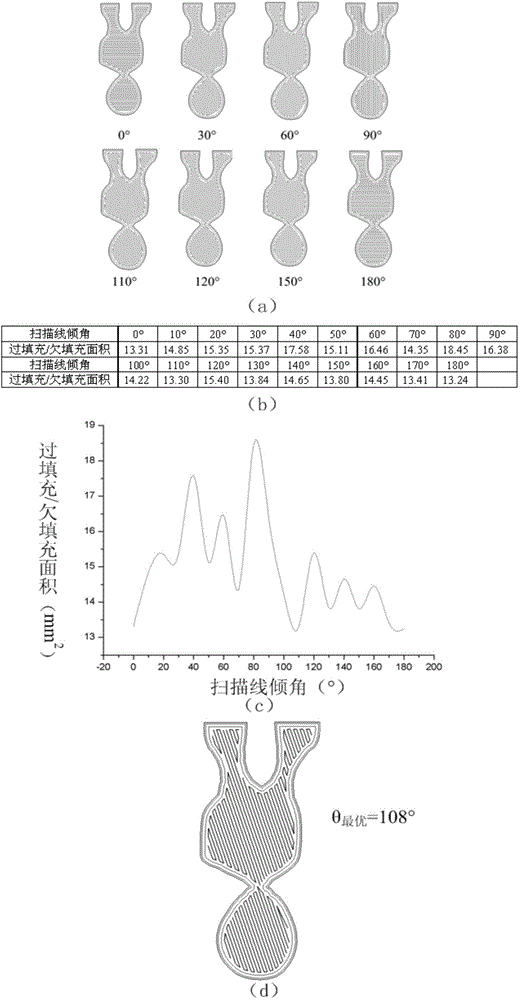

3D printing fill path generation method based on optimization of scanning line dip angle

The invention discloses a 3D printing technology fill path generation method based on optimization of a scanning line dip angle. The generation method comprises the following steps: determining a fill path interval, layer thickness, and an SLC (Single Level Cell) file of a to-be-processed entity; with the fill path interval as an offset distance, performing offset to obtain an offset polygon Omega; according to processing efficiency and printing precision requirements, judging the priority principle adopted by a current printing layer; if the priority principle refers to efficiency priority, determining the scanning line dip angle in an efficiency priority way, and if the priority principle refers to precision priority, determining the scanning line dip angle in a precision priority way; and finally, generating an internal fill path according to a point at which a scanning line with the determined dip angle is crossed with the offset polygon Omega. According to the provided 3D printing internal fill path generation method based on the optimization of the scanning line dip angle, the scanning line dip angle in generation of parallel reciprocating fill paths is optimized, the processing efficiency and the printing precision are further promoted, and the method is simple and effective, and good in universality.

Owner:ZHEJIANG UNIV

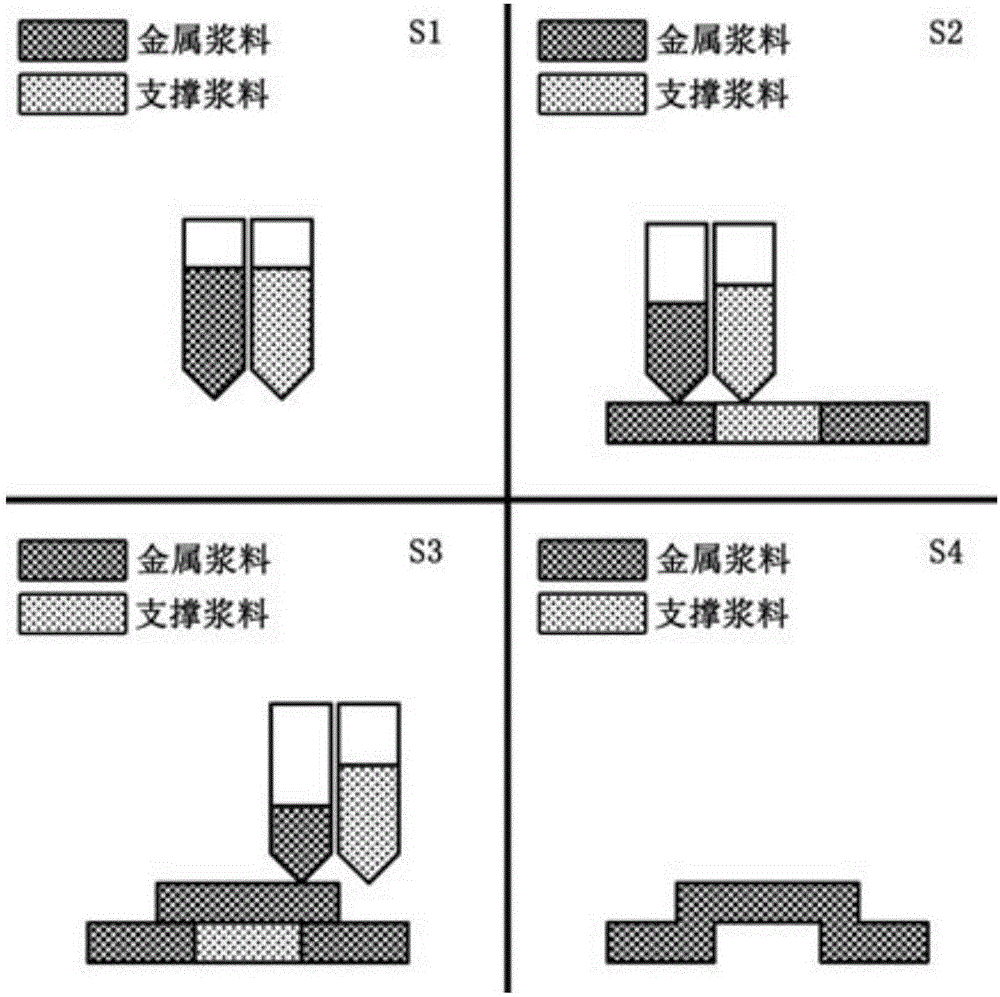

3D printing metal-complex-structure supporting slurry, metal slurry and printing method

InactiveCN106270512AFreeze fastGood removal effectAdditive manufacturing apparatusIncreasing energy efficiencySlurryEngineering

The invention discloses 3D printing metal-complex-structure supporting slurry, metal slurry and a printing method. The metal slurry and the supporting slurry are respectively charged into a storing device or a feeding device of a multi-nozzle 3D printer; in accordance with a mechanical control instruction, the metal slurry and the supporting slurry are respectively extruded at corresponding positions of a printing plate; a printing head raises or the printing plate descends a certain distance, and the metal slurry and the supporting slurry are respectively extruded again at corresponding positions in accordance with the mechanical control instruction, thereby overlapping the extruded metal slurry and supporting slurry on a previous layer of the metal slurry and supporting slurry. Hence, in accordance with the mechanical control instruction, the metal slurry and the supporting slurry are overlapped layer by layer until completion of printing of a model; by a series of post-processing procedures, the supporting slurry is removed and the metal slurry is sintered into dense metal parts, thereby completing manufacture of the metal parts with a complex structure. In the invention, the supporting slurry is easily removed from the metal parts, so as to realize more advantages in modeling of complex-metal-structure 3D printing.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

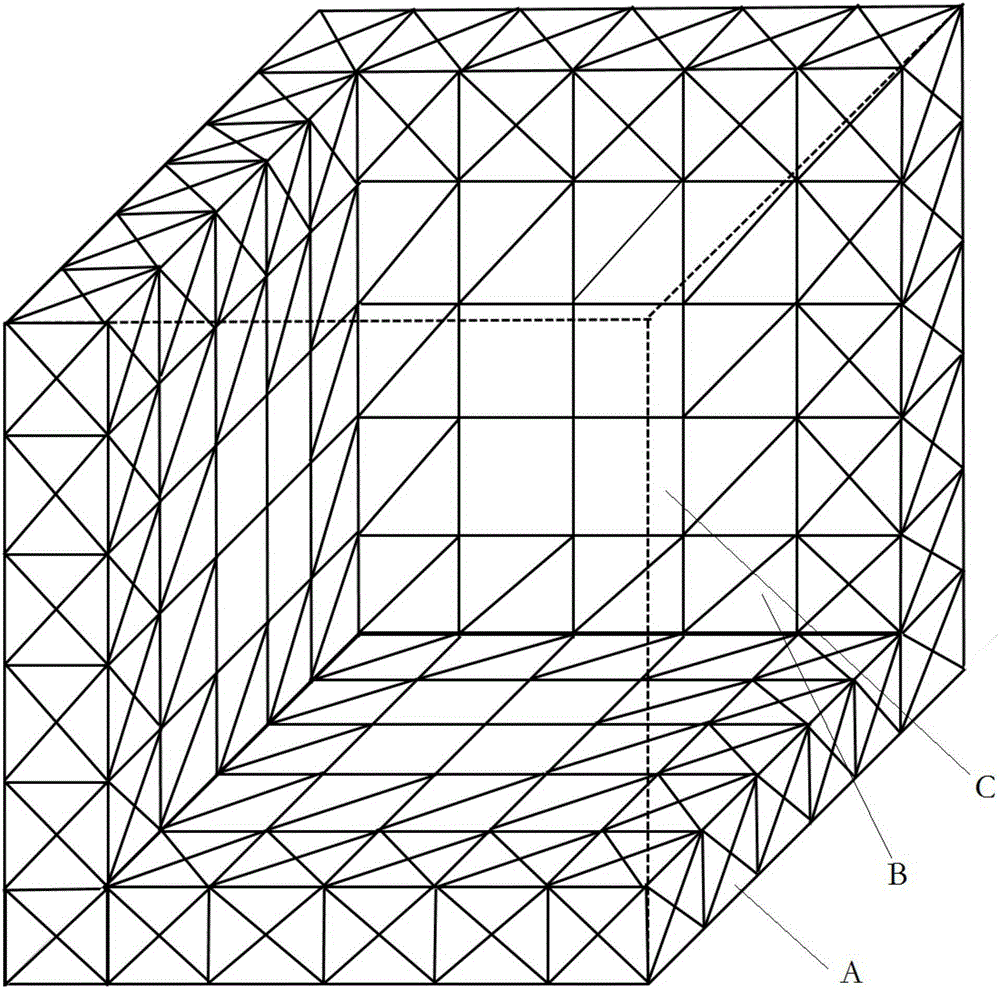

3D-printed gradient-diameter medical porous metal bone tissue scaffold

The invention discloses a 3D-printed gradient-diameter medical porous metal bone tissue scaffold and aims to solve the problems that a single repeated microporous structure in the prior art is adverse to bone tissue ingrowth and a bone tissue implant has difficulty in bony healing with self-bones. The scaffold is in a hexahedron structure as a whole, and comprises components A, components B and components C in tight arrangement, wherein the components A are arrayed on an outermost layer of the hexahedron structure; the components B are arrayed on a secondary outer layer; and the components C are arrayed on the innermost layer; all the components A, B and C are in a hexahedron frame structure; the pore diameter of the components A is greater than that of the components B; and the pore diameter of the components B is greater than that of the components C. Through the reinforcing structural design, the gradient-pore tissue engineering bone scaffold is produced; through regulating the ingrowth of bone tissues, fibroblasts and the like by gradient-change pores, the optimal bone healing can be achieved finally.

Owner:JILIN UNIV

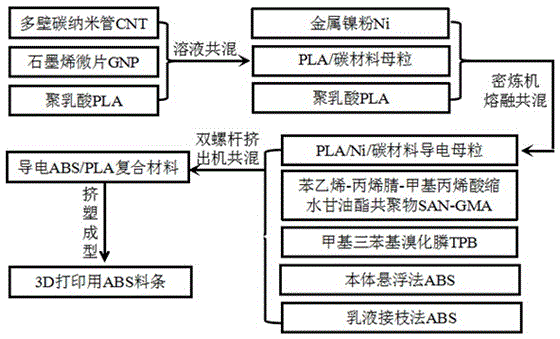

Electric conduction compound ABS/PLA material for 3D printing wires as well as preparation method and application of electric conduction compound ABS/PLA material

ActiveCN105001586AGood compatibility and co-continuityLow conductive additive contentAdditive manufacturing apparatus3d printGlycidyl methacrylate

The invention provides an electric conduction compound ABS / PLA material for 3D printing wires. The electric conduction compound ABS / PLA material is prepared from the following raw materials in percentage by weight: 15-30% of a synthetized material ABS by using a bulk method, 15-30% of a synthetized material ABS by an emulsion method, 1-10% of copolymers of styrene -acrylonitrile -2-methylpropenoic acid glycidyl ester, 0.01-0.05% of triphenylphosphonium bromide, 5-15% of metallic nickel powder , 30-50% of polylactic acid , 1-5% of walled carbon nanotubes and 1-5% of graphene microchips. According to the electric conduction compound ABS / PLA material disclosed by the invention, the nickel powder, the graphene microchips and the carbon nano tubes are optimized and collocated, so that the requirements for electrical conductivity by using lower volume resistivity under the low content of an electric conduction additive are met, the ABS material mixed in different particle diameters enables the particle diameters in the compound material to present bimodal distribution, and the toughness is enhanced; the consistency and the cocontinuity of ABS and PLA are good, so that the electric conduction compound ABS / PLA material is particularly suitable for strip-shaped high electric conduction materials required by 3D printing.

Owner:广州润锋科技股份有限公司

Photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and method for preparing ceramic mold cores

ActiveCN108083777AImprove liquidityEvenly dispersedAdditive manufacturing apparatusFoundry mouldsSlurryViscosity

The invention discloses photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and a method for preparing ceramic mold cores. The photo-curable 3D printing aluminum-base ceramic slurry comprises ceramic formula powder, photo-curable resin systems and additives. The photo-curable 3D printing aluminum-base ceramic slurry and the method have the advantages that the photo-curable 3D printing aluminum-base ceramic slurry is high in solid phase content, low in viscosity and applicable to photo-curable 3D printing photo-polymerization, the problems of high viscosity and poor flowability of existing slurry for photo-curable 3D printing ceramics, easiness in agglomerating ceramic particles in the existing slurry, uneven dispersion of the ceramic particles, low solid phase contents and the like can be solved, and application of photo-curable 3D printing to ceramic precision components can be expanded.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

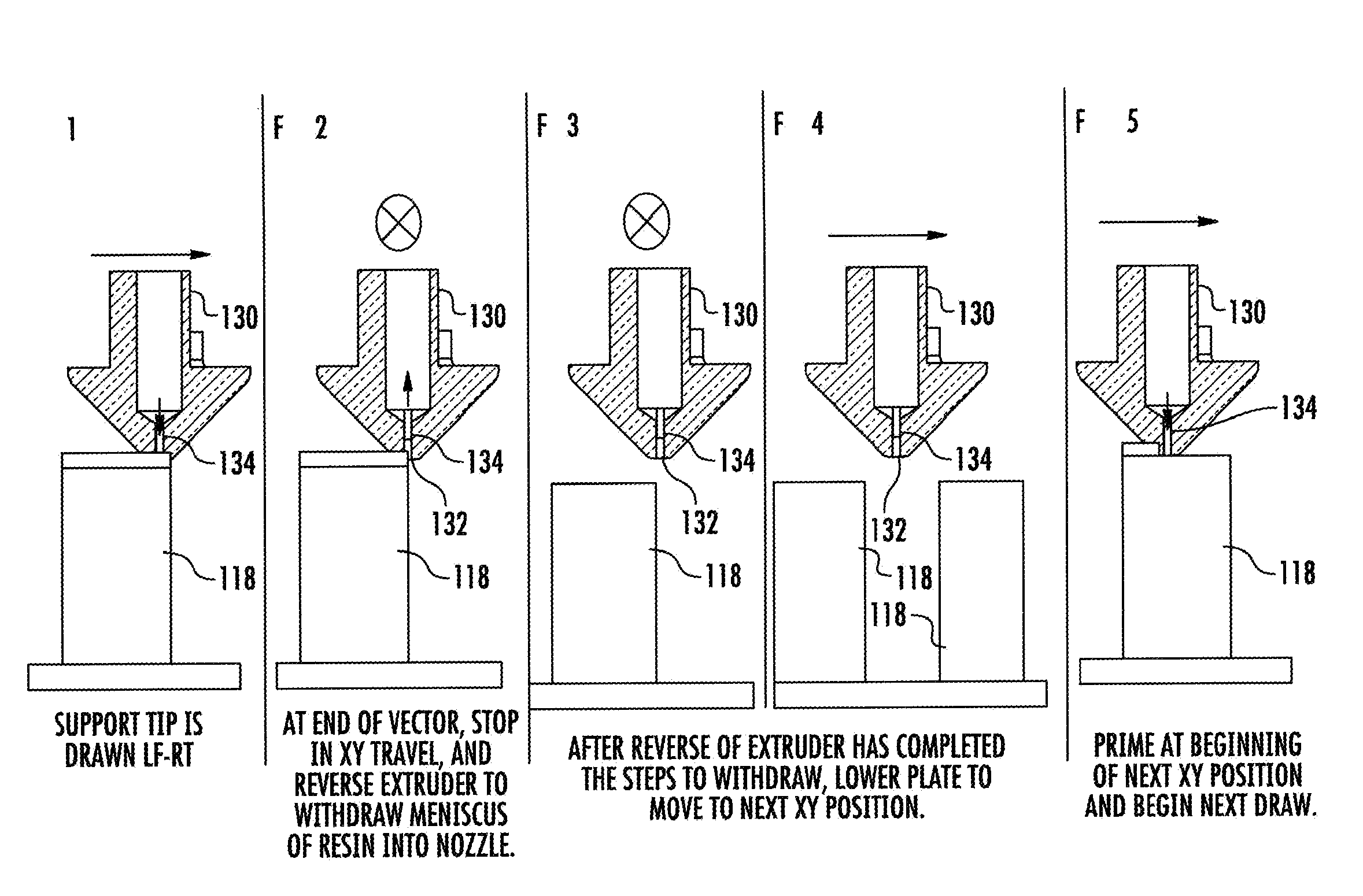

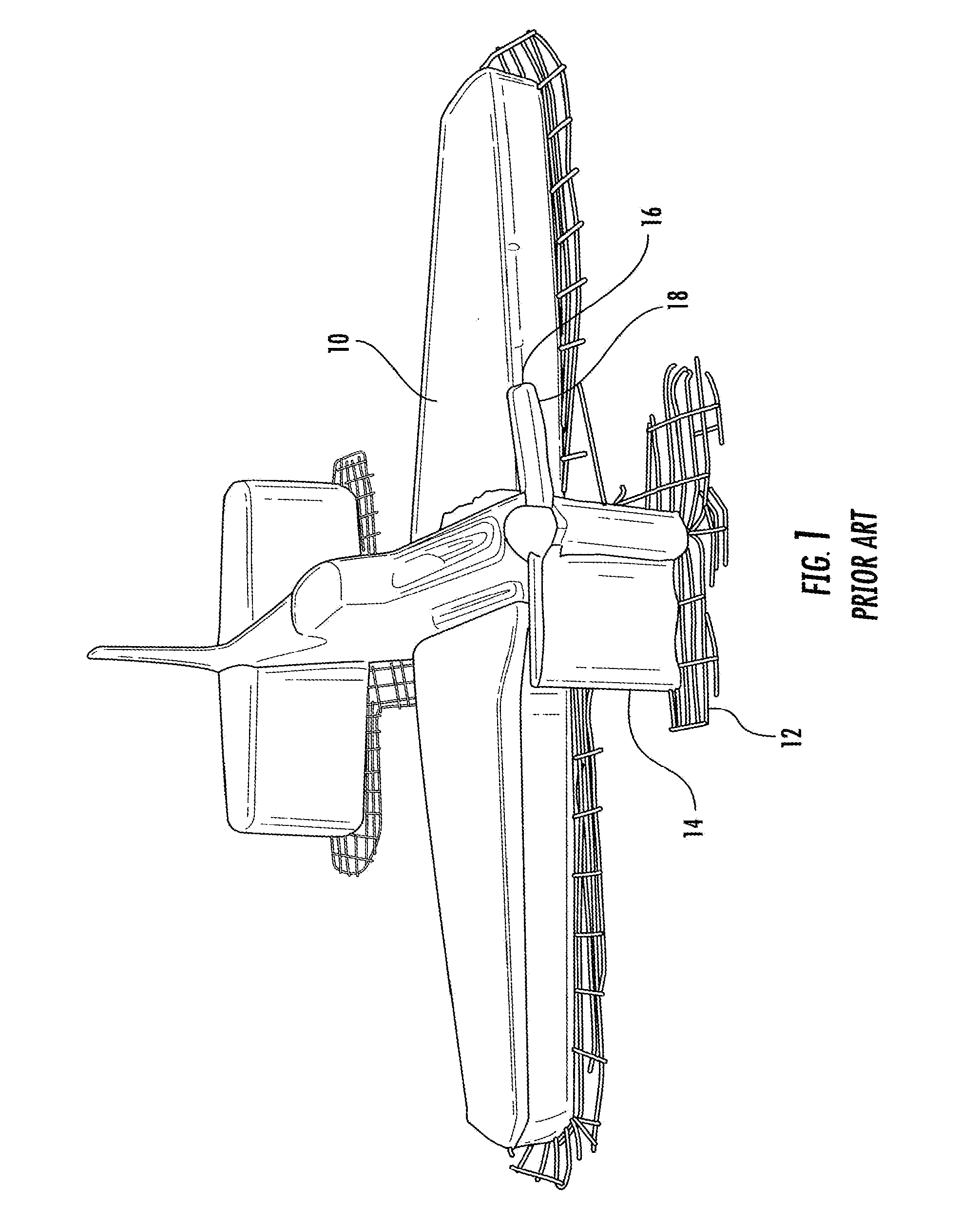

Support Structures and Deposition Techniques for 3D Printing

ActiveUS20130307193A1Easy to separateImproved down-facing surfaceManufacturing platforms/substratesUnsaturated ether polymer adhesivesComputer Aided Design3d print

Owner:3D SYST INC

3D printing mould-free injection forming method through metal sizing agents

The invention provides a 3D printing mould-free injection forming method through metal sizing agents. According to the method, a 3D printing technology and an injection forming technology are combined, an injection forming process is utilized for evenly mixing metal powder and organic binding agents to form the metal sizing agents, the sizing agents are adopted as the raw materials of 3D printing, layered printing is carried out through 3D printing equipment according to a data model, layer-by-layer accumulation is carried out to obtain a metal blank, and a metal part product in a complex shape is obtained through degreasing and sintering. The method can be used for manufacturing a part including a sealed cavity, a complex inner cavity and the like, the part cannot be manufactured through a traditional injection forming mode, the metal blank is directly formed through the 3D printing technology, a mould is not needed, the cost of single part and small scale production is low, requirements for powder materials are low, process reliability is high, repeatability is high, efficiency is high, and the industrialization of manufacturing the small thin-wall metal part in the complex shape through the 3D printing technology is easy to achieve.

Owner:UNIV OF SCI & TECH BEIJING

Thermo-curable 3D printing photosensitive resin and preparation method thereof

ActiveCN106947034AIncrease activation energyHigh tensile strengthAdditive manufacturing apparatus3D object support structuresDecompositionHalf-life

The invention discloses a thermo-curable 3D printing photosensitive resin and a preparation method and an application thereof. The photosensitive resin includes, by weight, 50-70 parts of a prepolymer, 30-50 parts of a diluent, 1-5 parts of a photo-initiator and 0.5-5 parts of a thermal-initiator, wherein the decomposition temperature of the thermal-initiator is higher than or equal to 100 DEG C when the half-life period thereof is 1 h. After photo-curing 3D printing shaping, the 3D printing photosensitive resin can be subjected to curing by heating as a post-curing method with a stable constant temperature heating device, such as a drying box and the like, so that the 3D printing photosensitive resin develops application in a non-transparent sample, a sample having complex shape, an ultra-thick sample, a colored sample and the like, and enables the samples to have better mechanical performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

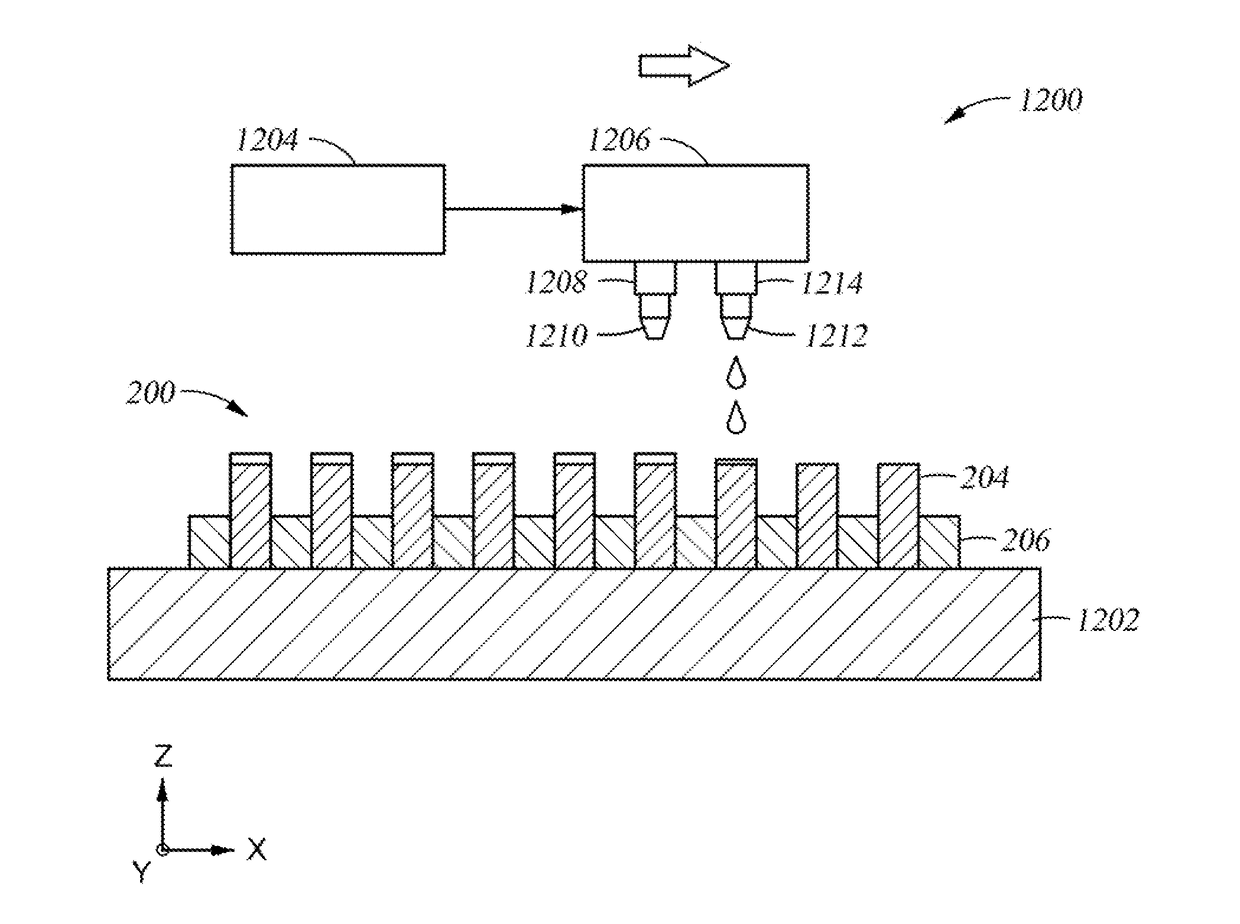

Techniques for combining cmp process tracking data with 3D printed cmp consumables

ActiveUS20170133252A1Additive manufacturing apparatusSemiconductor/solid-state device testing/measurement3d printEngineering

Chemical mechanical polishing (CMP) apparatus and methods for manufacturing CMP apparatus are provided herein. CMP apparatus may include polishing pads, polishing head retaining rings, and polishing head membranes, among others, and the CMP apparatus may be manufactured via additive manufacturing processes, such as three dimensional (3D) printing processes. The CMP apparatus may include wireless communication apparatus components integrated therein. Methods of manufacturing CMP apparatus include 3D printing wireless communication apparatus into a polishing pad and printing a polishing pad with a recess configured to receive a preformed wireless communication apparatus.

Owner:APPLIED MATERIALS INC

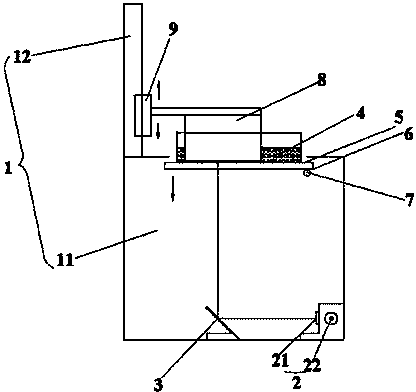

Rapid prototyping SLA 3D printer and printing method thereof

The invention relates to the technical field of 3D printers and printing methods, in particular to a rapid prototyping SLA 3D printer. The rapid prototyping SLA 3D printer comprises an SLA 3D printer body, wherein the SLA 3D printer body comprises a hollow cabinet body and a support which extends upwards along one side surface of the cabinet body, wherein a laser scanning device is arranged at the front end of the bottom surface of the cabinet body, a reflecting mirror is arranged at the center of the bottom surface of the cabinet body, a resin trough is arranged right above the reflecting mirror, the bottom surface of the resin trough is fixedly provided with a piece of high-transparency quartz glass, the high-transparency quartz glass is fixedly arranged on an iron plate, the iron plate is fixedly connected with a motor on the bottom surface of the cabinet body, a lifting platform is arranged right above the resin trough, the support is provided with a vertical slide rail, and the lifting platform can slide up and down along the vertical slide rail. The invention also discloses a printing method of the rapid prototyping SLA 3D printer. Compared with the prior art, the rapid prototyping SLA 3D printer has the advantages that the prototyping speed is high; since a downward-pulling mechanical structure for eliminating the vacuum force is arranged, the rate of finished products is greatly increased, the precision is high, and the printer is particularly suitable for producing a prototype with high precision requirement and a complicated structure; the structure is simple, the operation is convenient, and the production cost is greatly reduced; therefore, the rapid prototyping SLA 3D printer can be widely popularized and used.

Owner:DONGGUAN JINGJIZHE DIGITAL TECH

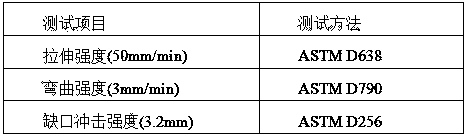

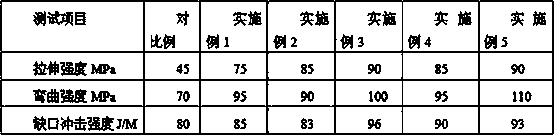

ABS (acrylonitrile butadiene styrene) material used for 3D (three dimensional) printing and manufacturing process thereof

The invention discloses an ABS (acrylonitrile butadiene styrene) material used for 3D (three dimensional) printing. The ABS material consists of the following materials in parts by weight: 50-70 parts of ABS resin, 10-30 parts of flexibilizer, 7-9 parts of diffusant, 3-5 parts of lubricant and 5-15 parts of binder. The invention further discloses a process for preparing the ABS material. According to the invention, main body ABS with different rubber grain sizes is mixed and aggregated, glass fiber, and the like, are added, so that ABS resin is strengthened and toughened, and therefore, the ABS resin can be used for 3D printing better. The ABS material provided by the invention can be used for preparing a printing material for three-dimensional printing, fusion-depositing and rapid-forming.

Owner:FLYBALL ELECTRONIC SHENZHEN CO LTD

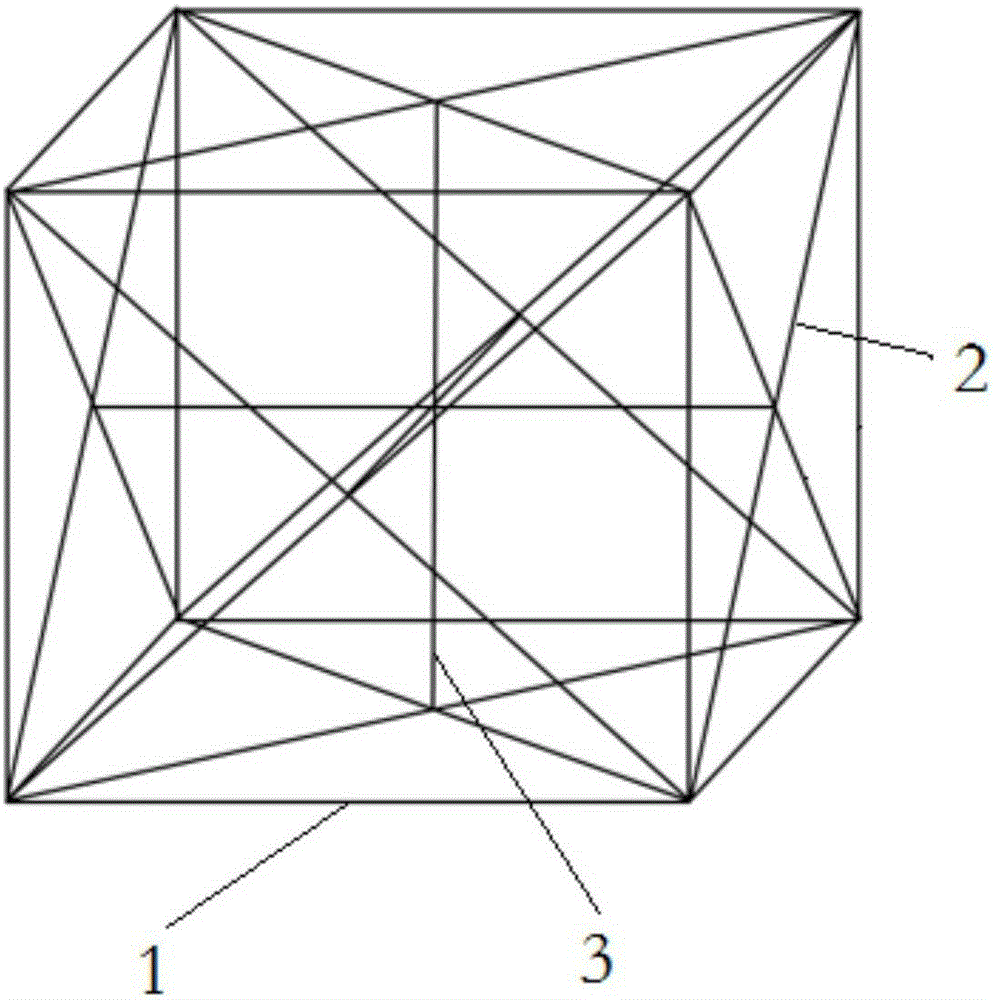

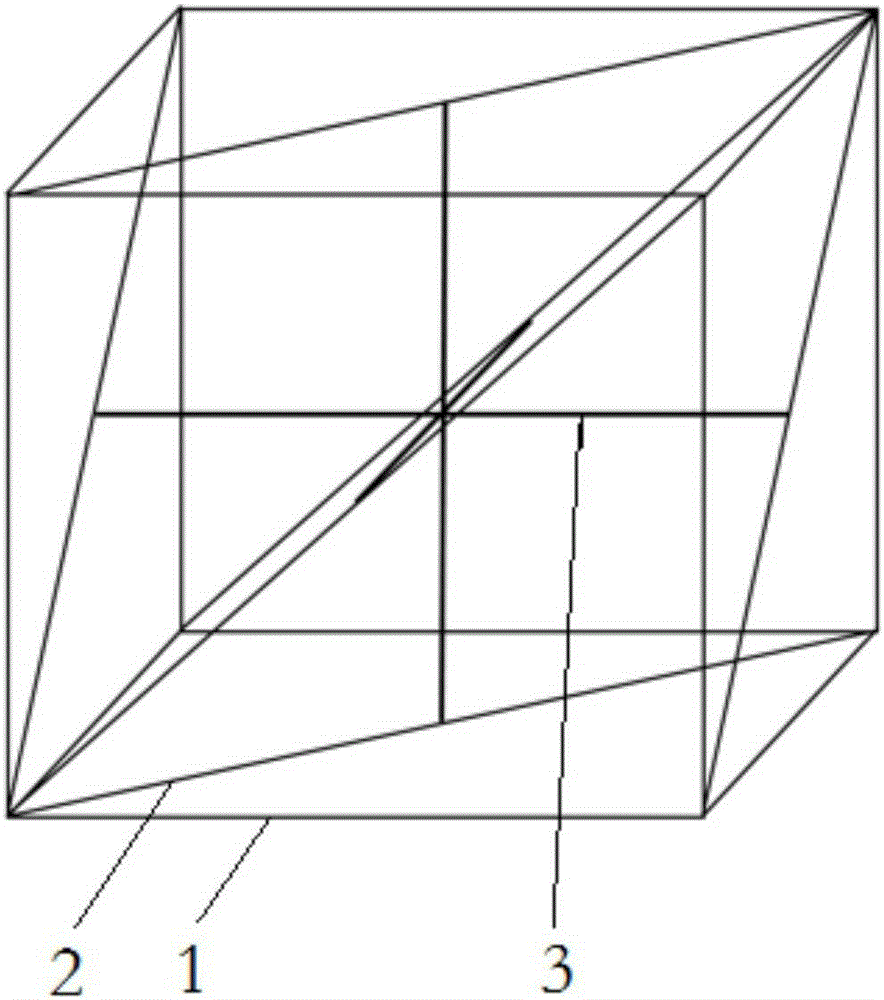

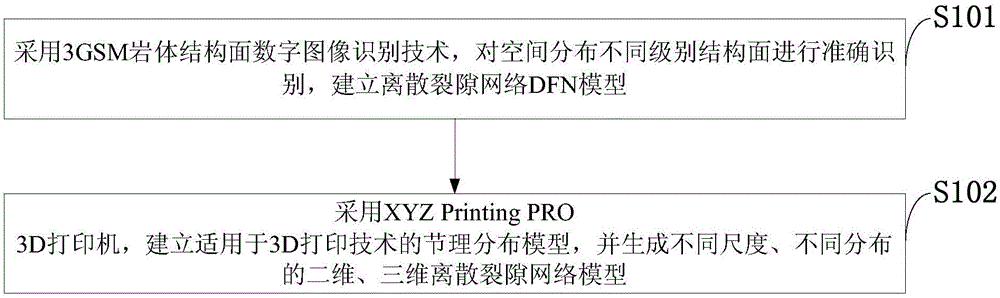

Complex fractured rock mass physical model manufactured based on 3D printing productionand modeling method

InactiveCN106447776ALow costSmall scaleDetails involving processing stepsAdditive manufacturing apparatusModel reconstructionPhysical model

The invention discloses a complex fractured rock mass physical model manufactured based on 3D printing production and a modeling method. By using 3D printing, a complex fractured network model entity is reconstructed and a model suitable for an indoor analog simulation experiment is established; the complex fractured rock mass physical model comprises a discrete fracture network DFN model and an entity discrete joint network DFN model. Based on the 3D printing, the complex fractured network model entity can be reconstructed and the model suitable for the indoor analog simulation experiment is established, and an effective method can be provided for an indoor laboratory research on complex fractured rock mass mechanical behaviors. A reliable and effective method is provided for the rock mechanical test field by adopting fractured rock mass model reconstruction and fractured network entity model construction through the 3D printing; with the help of the 3D printing technology, the problems that modeling is difficult to conduct and the cost is high in the current complex fractured rock mass physical model indoor experiment can be effectively solved.

Owner:UNIV OF SCI & TECH BEIJING

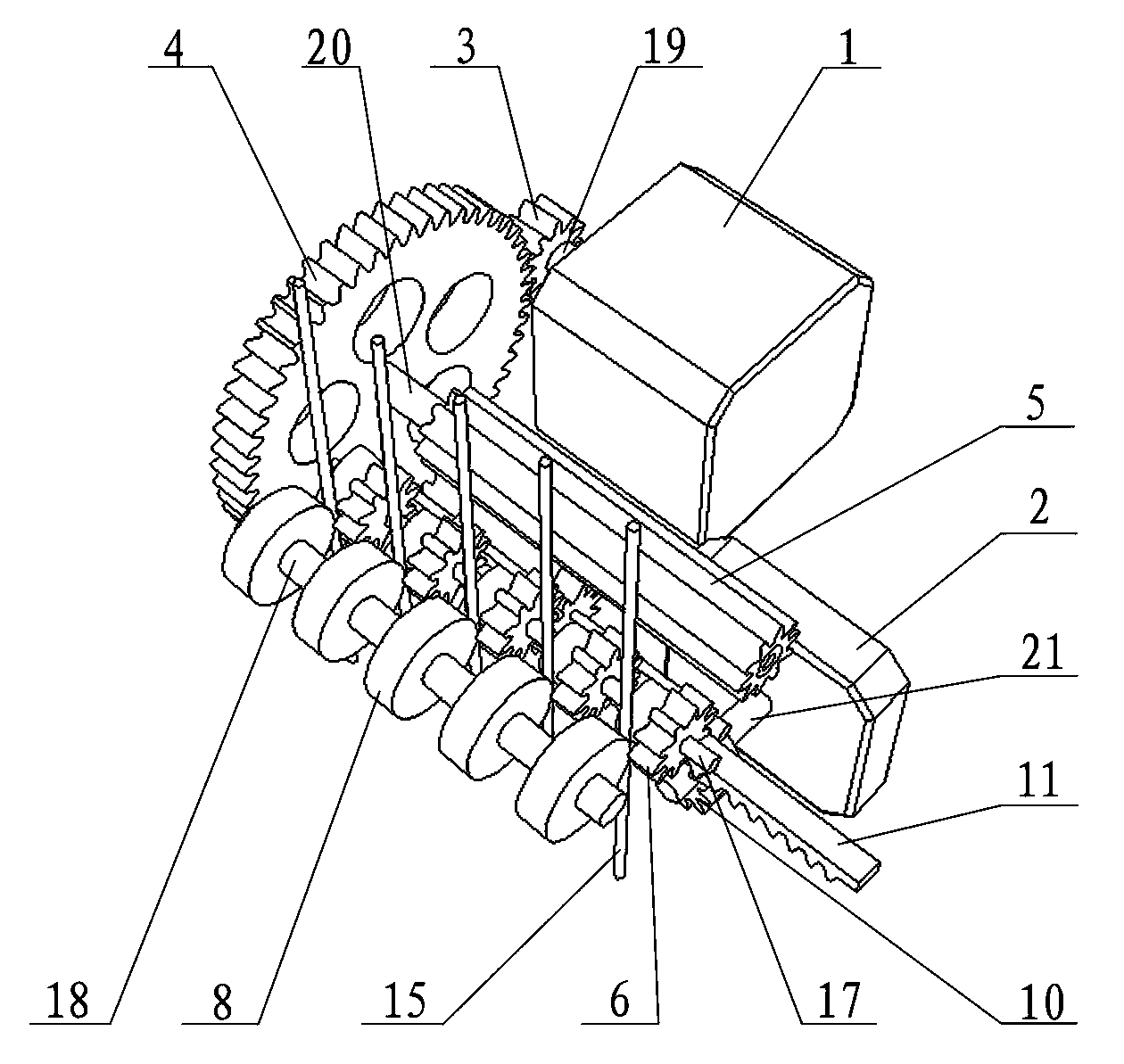

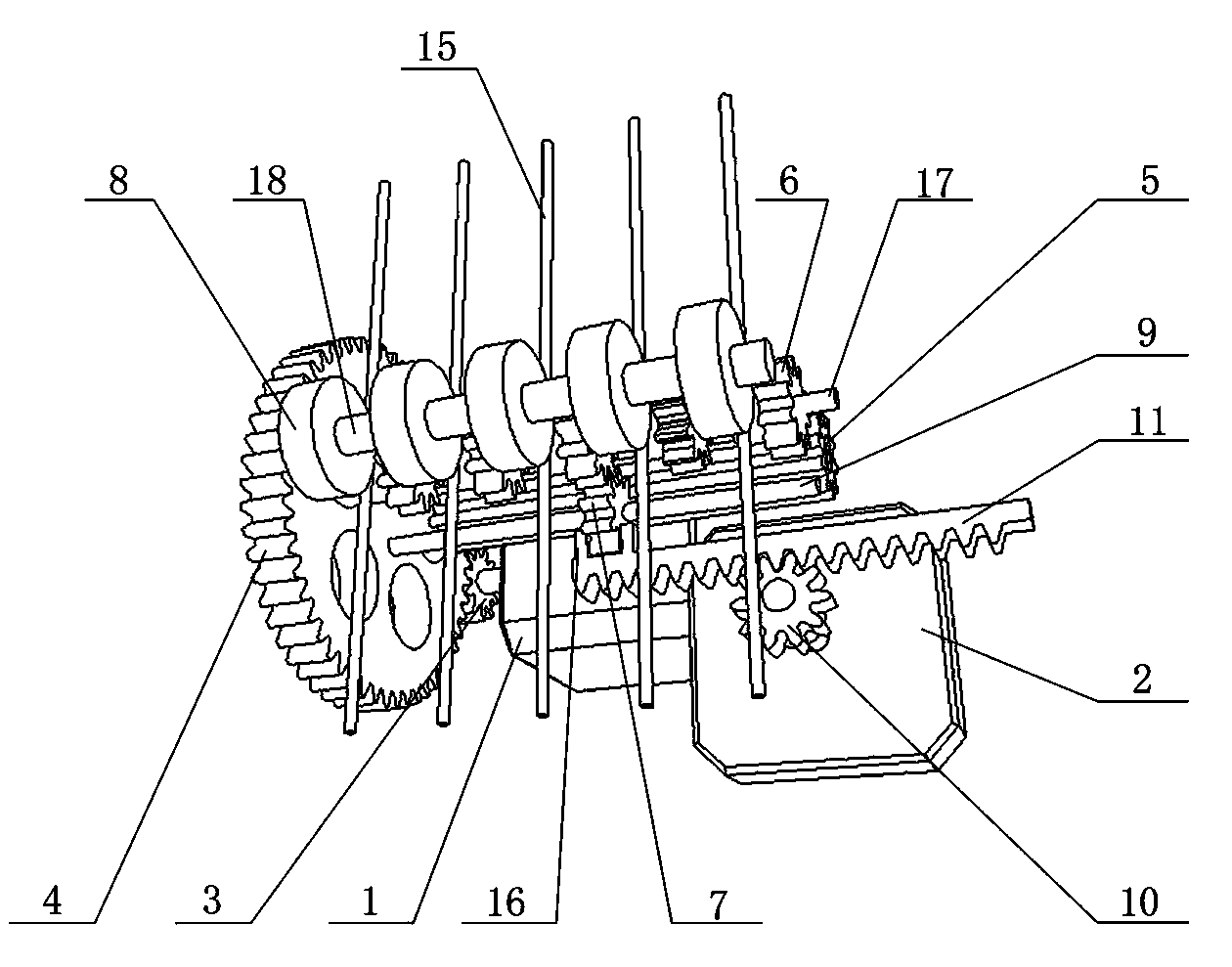

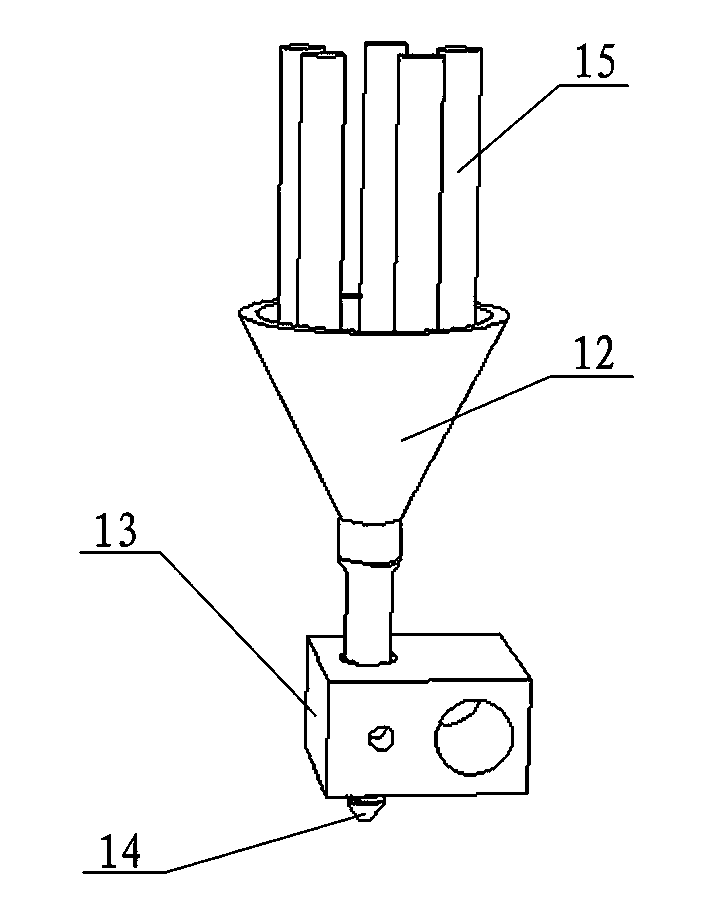

Multicolor three-dimensional forming device for 3D printer and forming method

The invention provides a multicolor three-dimensional forming device for a 3D printer and a forming method. The device includes a rack, as well as a feeding mechanism and a discharging mechanism both mounted on the rack, wherein the feed mechanism includes a feeding motor, a reloading motor, a gear shaft,a shifted gear, a plurality of feeding gears, a plurality of extruding wheels and a controller; the discharging mechanism includes a guide bin and a spray nozzle; the controller is used for controlling the feeding motor and the reloading motor to provide output power; under the control of the controller, material silks of different colors can be replaced through the closed cooperation of the gear shaft, the shifted gear, the feeding gears and the extruding wheels. The multicolor three-dimensional forming device for the 3D printer utilizes the two motors to enable the material silks of different colors to be sprayed from the same sprayer when the 3D printer is printing, so that products of various different colors can be printed, and the colors of the products are diversified; furthermore, due to the fact the sprayer does not need to be shifted during reloading, the cohesion degree is good during color changing, and manufacturing products are more exquisite.

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com