Straw 3D printing consumable and preparation method thereof

A 3D printing and straw technology, applied in the field of straw 3D printing consumables and their preparation, can solve the problems of reducing the price of printing consumables and the difficulty of straw recycling, and achieve the effects of reducing material costs, broad market prospects and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

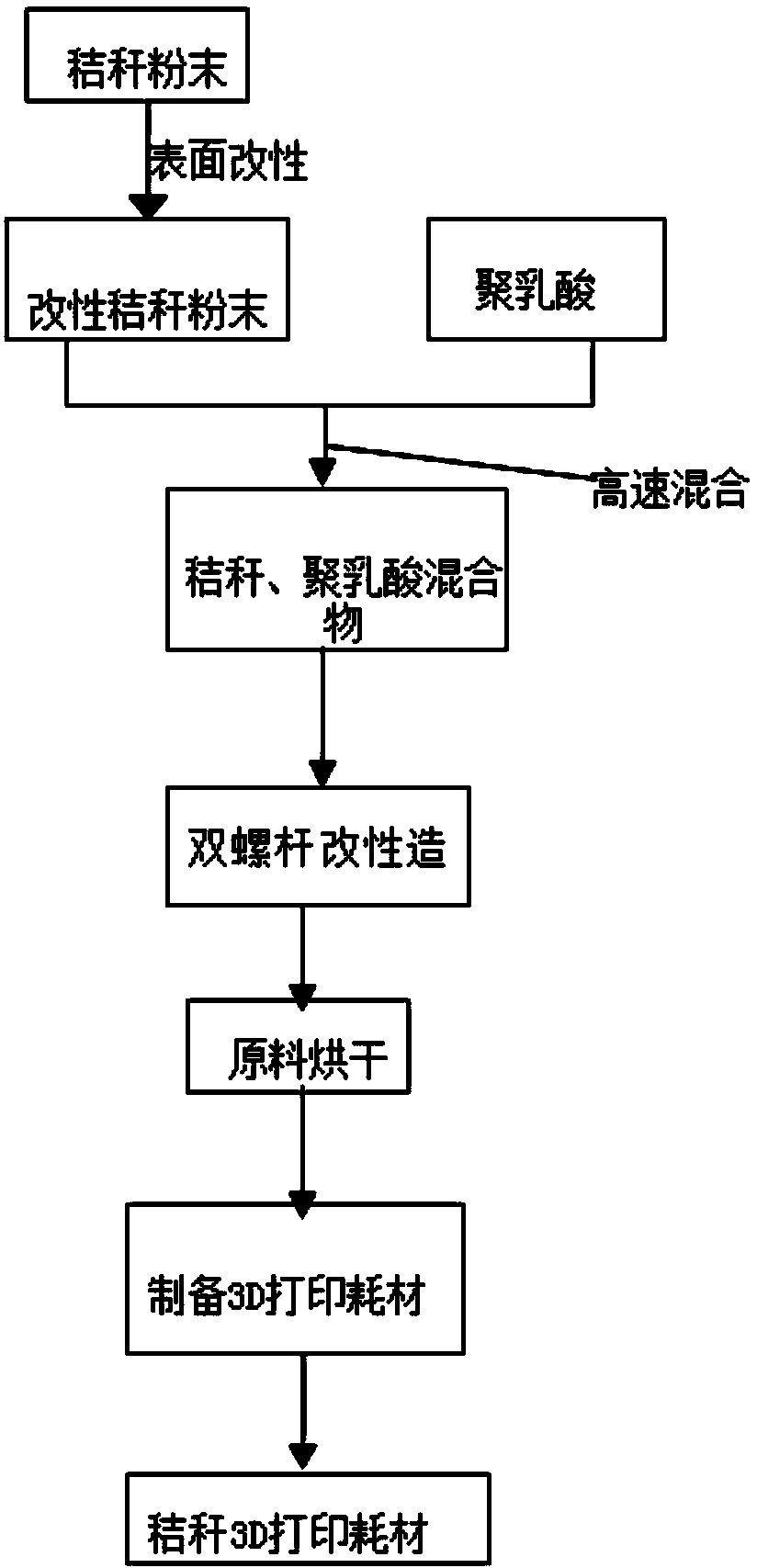

Method used

Image

Examples

Embodiment 1

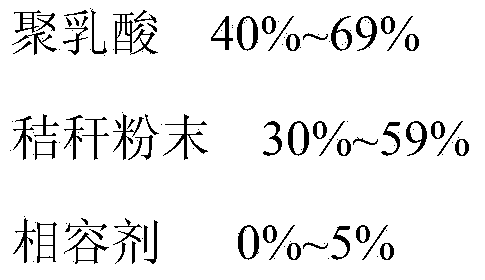

[0026] A straw 3D printing consumable, the formula is by weight, and the contents of each component are:

[0027] Polylactic acid 55%, rice straw powder 41.4%, silane coupling agent (KH550) 2%, ethylene bis stearic acid amide 1%, dioctadecyl alcohol pentaerythritol diphosphite 0.5%, oxidized polyethylene wax 0.1 %.

[0028] A method for preparing straw 3D printing consumables, comprising the following steps:

[0029] 1) After sieving the selected rice straw powder through an 80-mesh sieve, dry it at 85°C for 2.5 hours, and control the moisture content below 0.02%;

[0030] 2) Pour the dried straw powder into a high-speed mixer, set the high-speed mixer to 60°C, add a silane coupling agent for high-speed mixing, and mix at a low speed of 730RPM for 10 minutes to improve the dispersion ability of the surface modifier;

[0031] 3), then add polylactic acid and mix at low speed for 10 minutes, then add other additives and continue mixing for 10 minutes;

[0032] 4) Putting the ...

Embodiment 2

[0035] A straw 3D printing consumable, the formula is by weight, and the contents of each component are:

[0036] Polylactic acid 58%, rice straw powder 38.4%, aluminate / titanate composite coupling agent 2%, ethylene distearic acid amide 1%, dioctadecyl alcohol pentaerythritol diphosphite 0.5%, hard Fatty acid 0.1%.

[0037] A method for preparing straw 3D printing consumables, comprising the following steps:

[0038] 1) After sieving the selected rice straw powder through an 80-mesh sieve, dry it at 80°C for 3 hours, and control the moisture content below 0.02%;

[0039] 2) Pour the dried straw powder into a high-speed mixer, set the high-speed mixer to 57°C, add aluminate / titanate composite coupling agent according to the formula and mix at high speed, and mix at low speed for 10 minutes to improve surface modification. Dispersion ability of active agent;

[0040] 3), then add polylactic acid and mix at low speed for 10 minutes, then add other additives and continue mixin...

Embodiment 3

[0044] A straw 3D printing consumable, the formula is by weight, and the contents of each component are:

[0045] Polylactic acid 60%, wheat straw powder 36.4%, aluminate / titanate composite coupling agent 2%, ethylene distearic acid amide 1%, dioctadecyl alcohol pentaerythritol diphosphite 0.5%, hard Fatty acid 0.1%.

[0046] A method for preparing straw 3D printing consumables, comprising the following steps:

[0047] 1) After sieving the selected rice straw powder through an 80-mesh sieve, dry it at 90°C for 2 hours, and control the moisture content below 0.02%;

[0048] 2) Pour the dried straw powder into a high-speed mixer, set the high-speed mixer to 58°C, add aluminate / titanate composite coupling agent according to the formula and mix at high speed, and mix at low speed for 15 minutes to improve surface modification. Dispersion ability of active agent;

[0049] 3), then add polylactic acid and mix at low speed for 10 minutes, then add other additives and continue mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com