Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3400 results about "Rice straw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

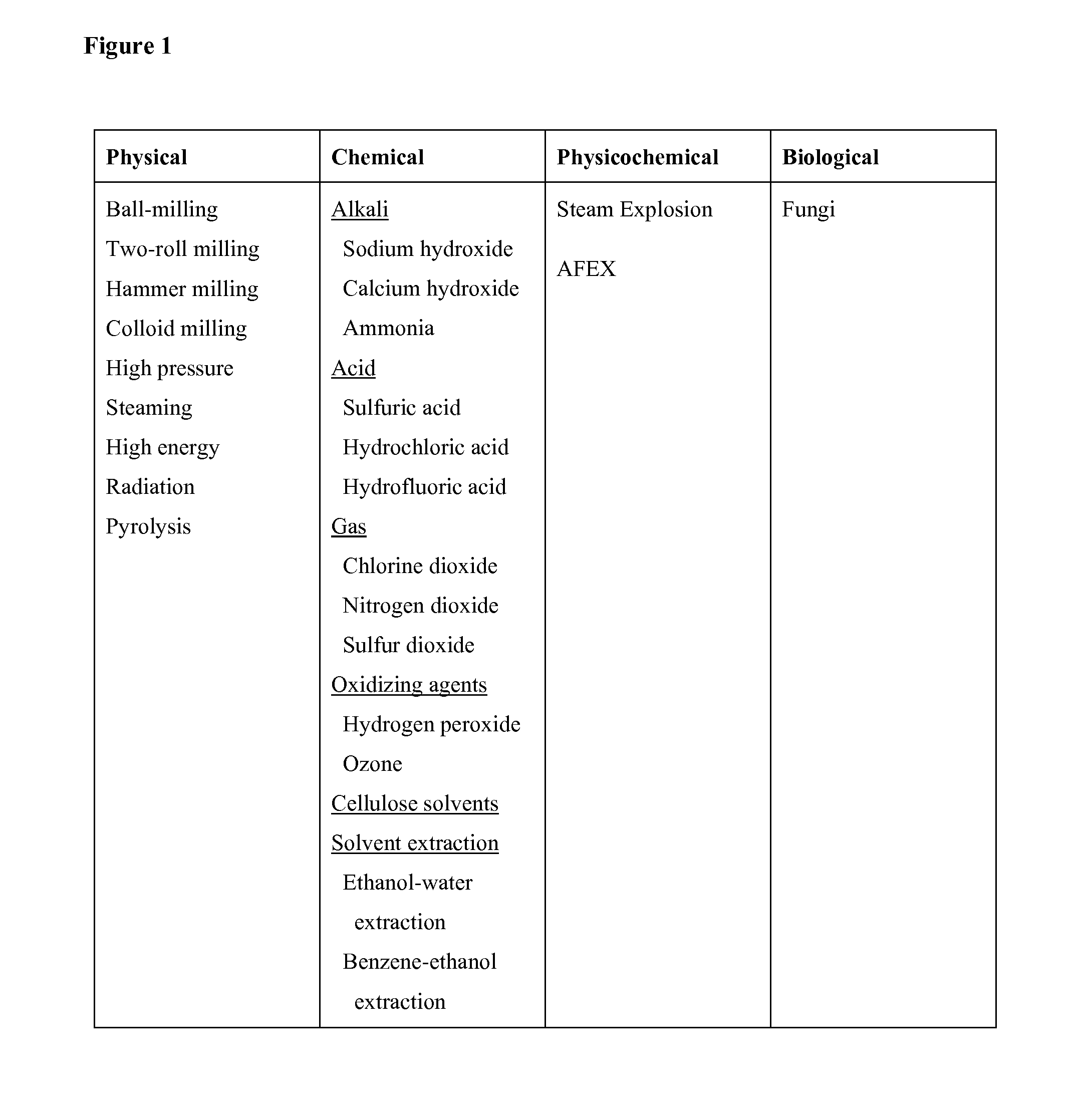

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

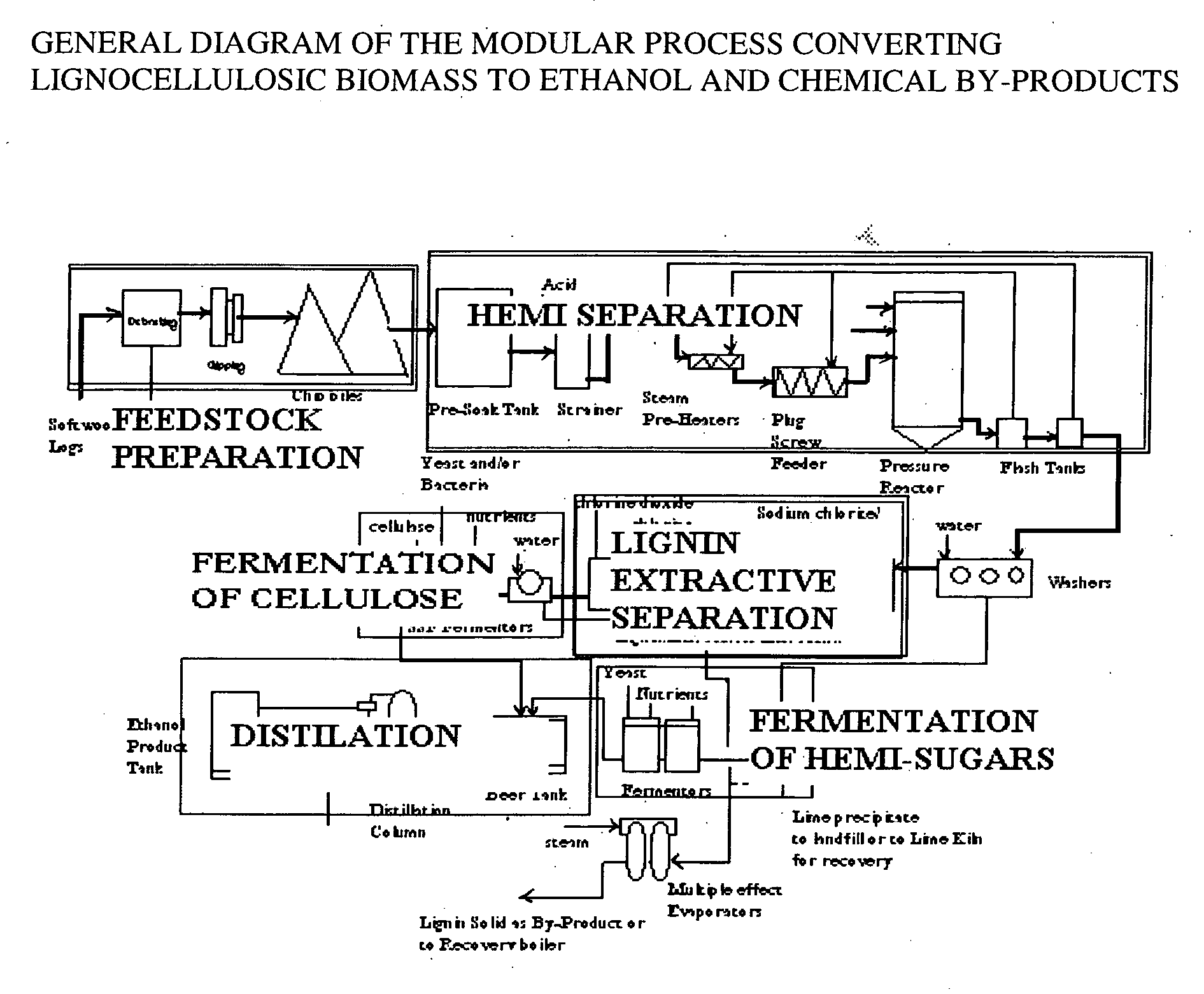

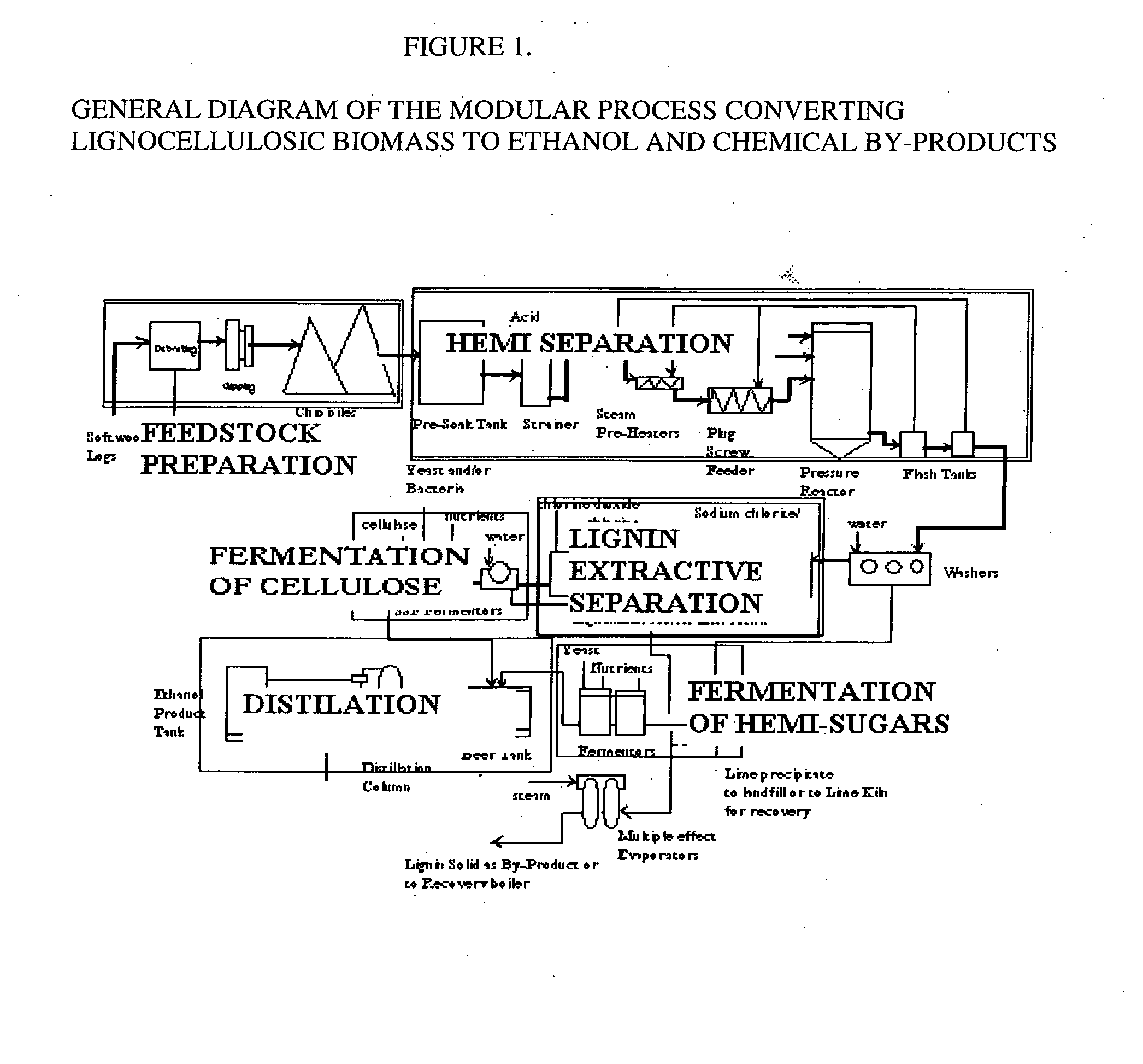

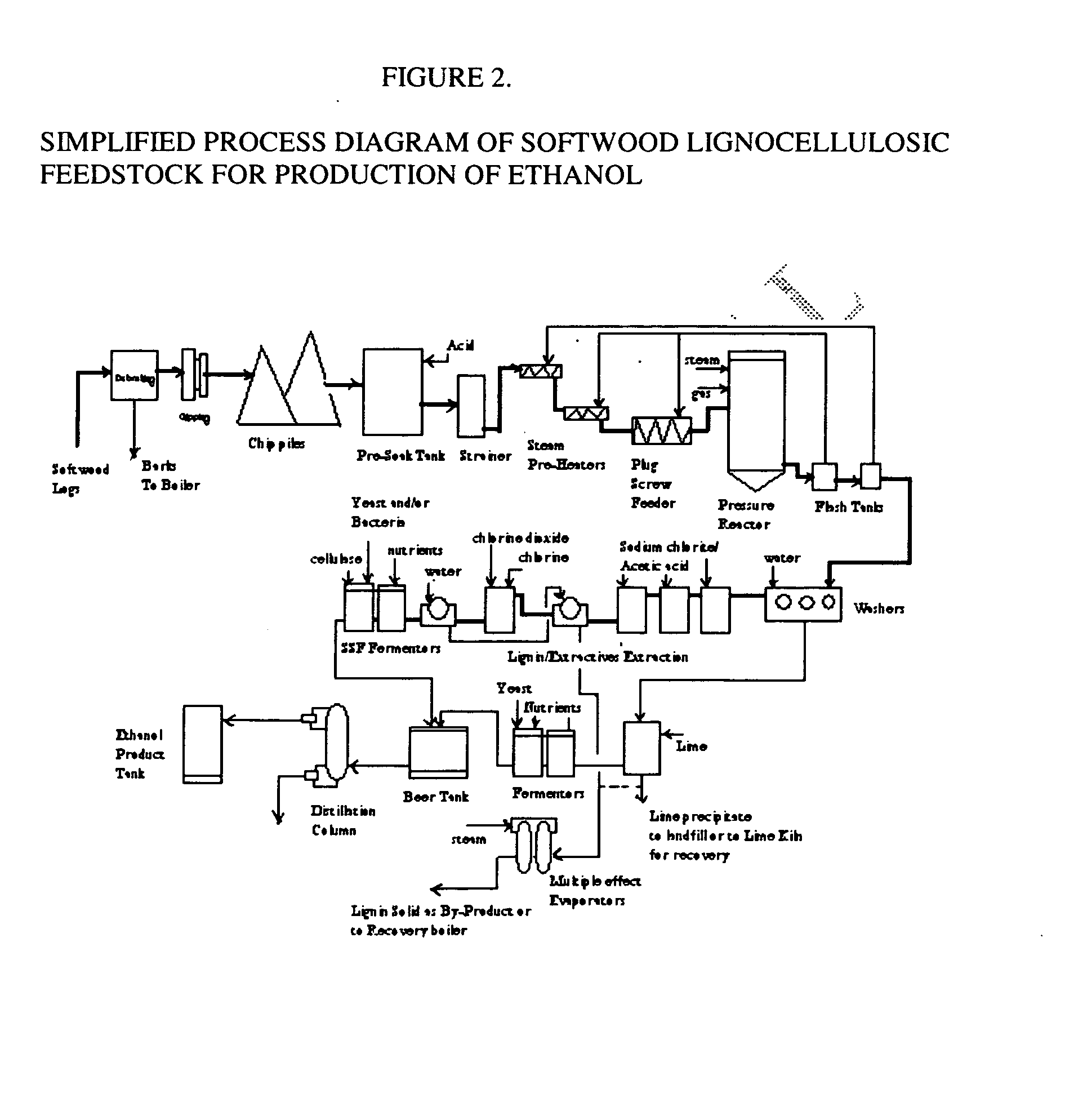

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

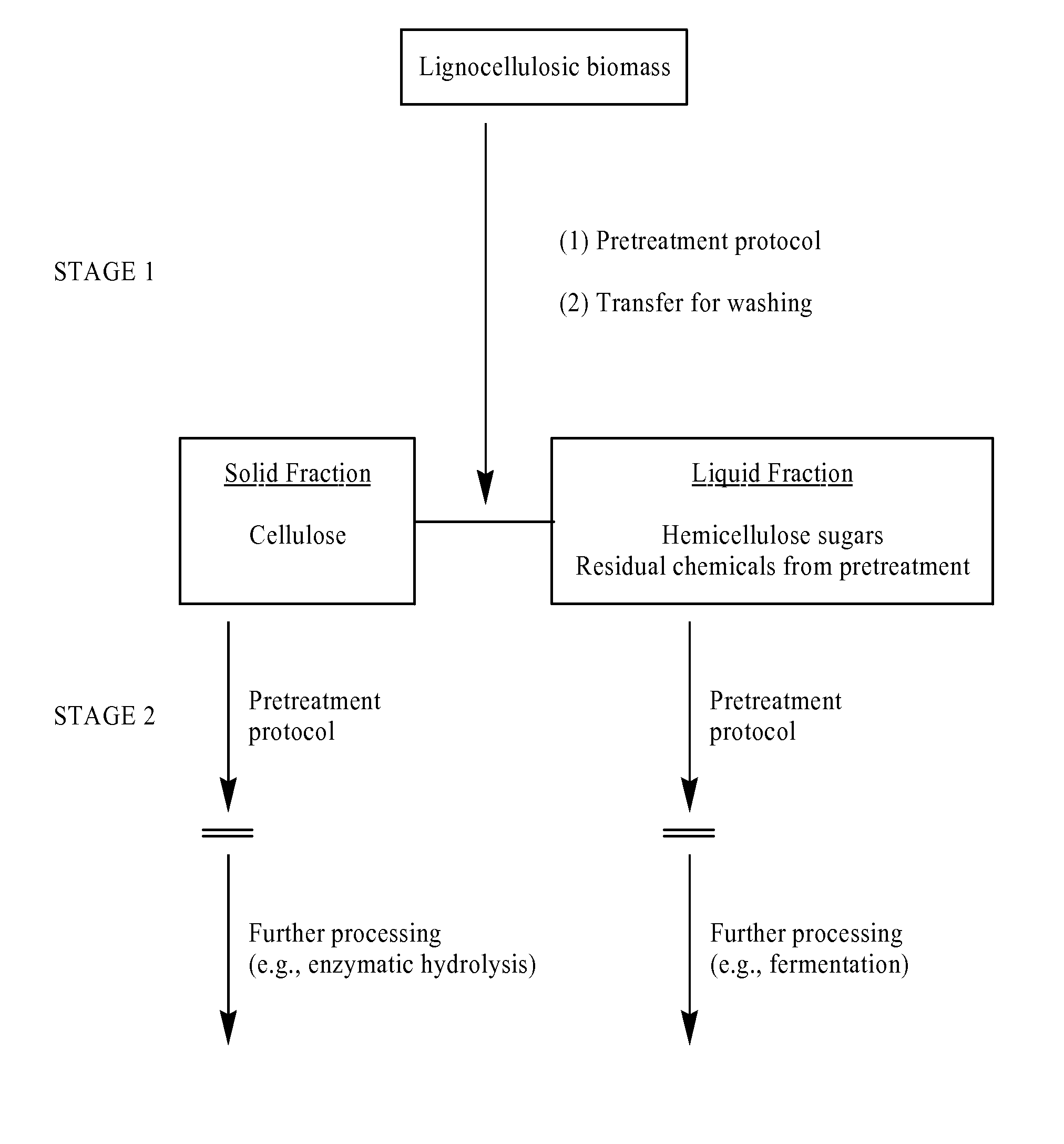

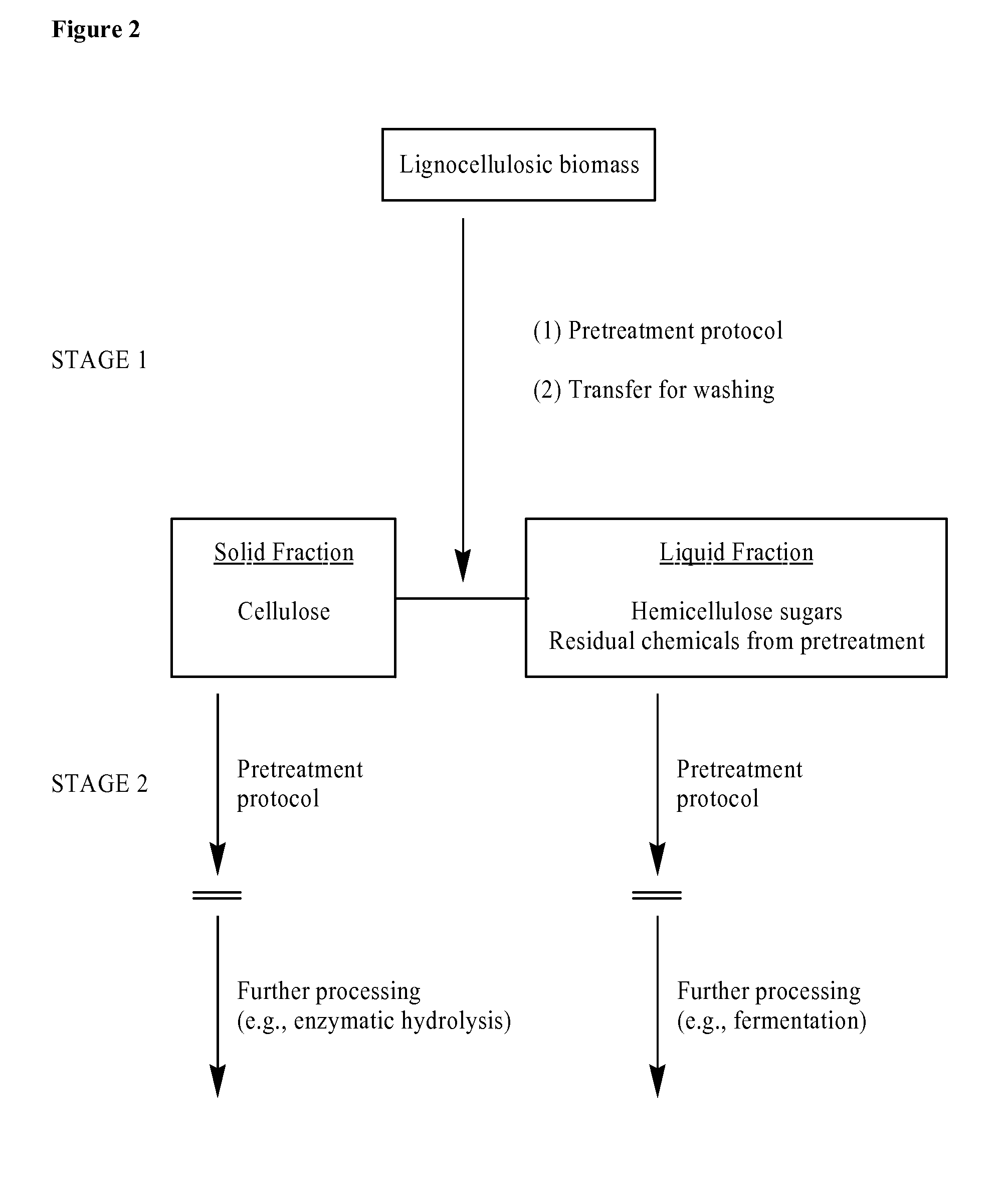

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

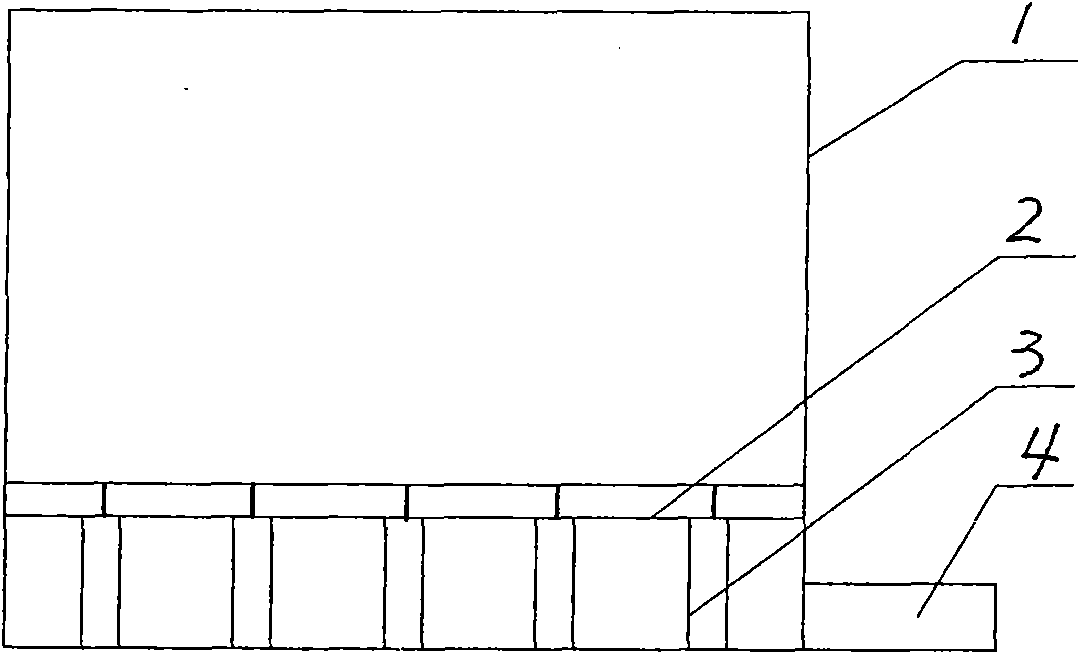

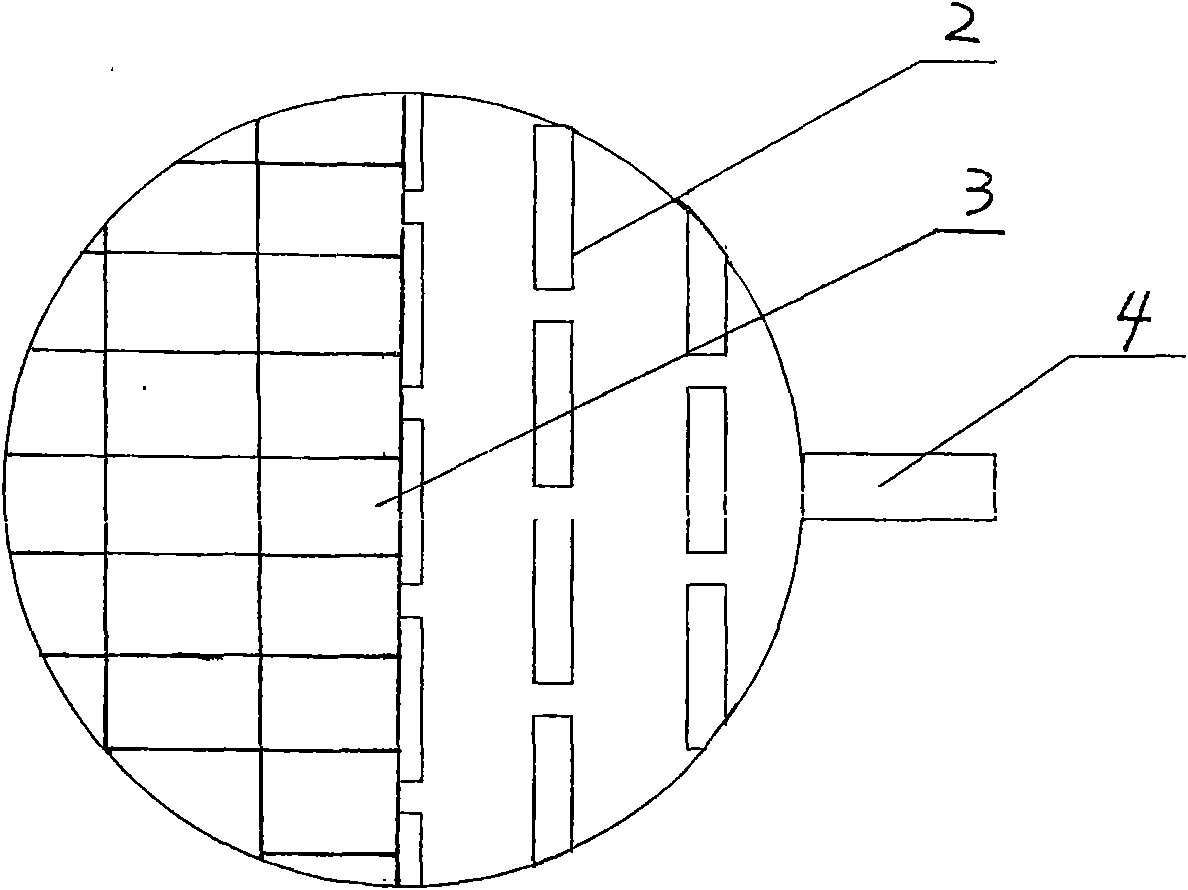

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

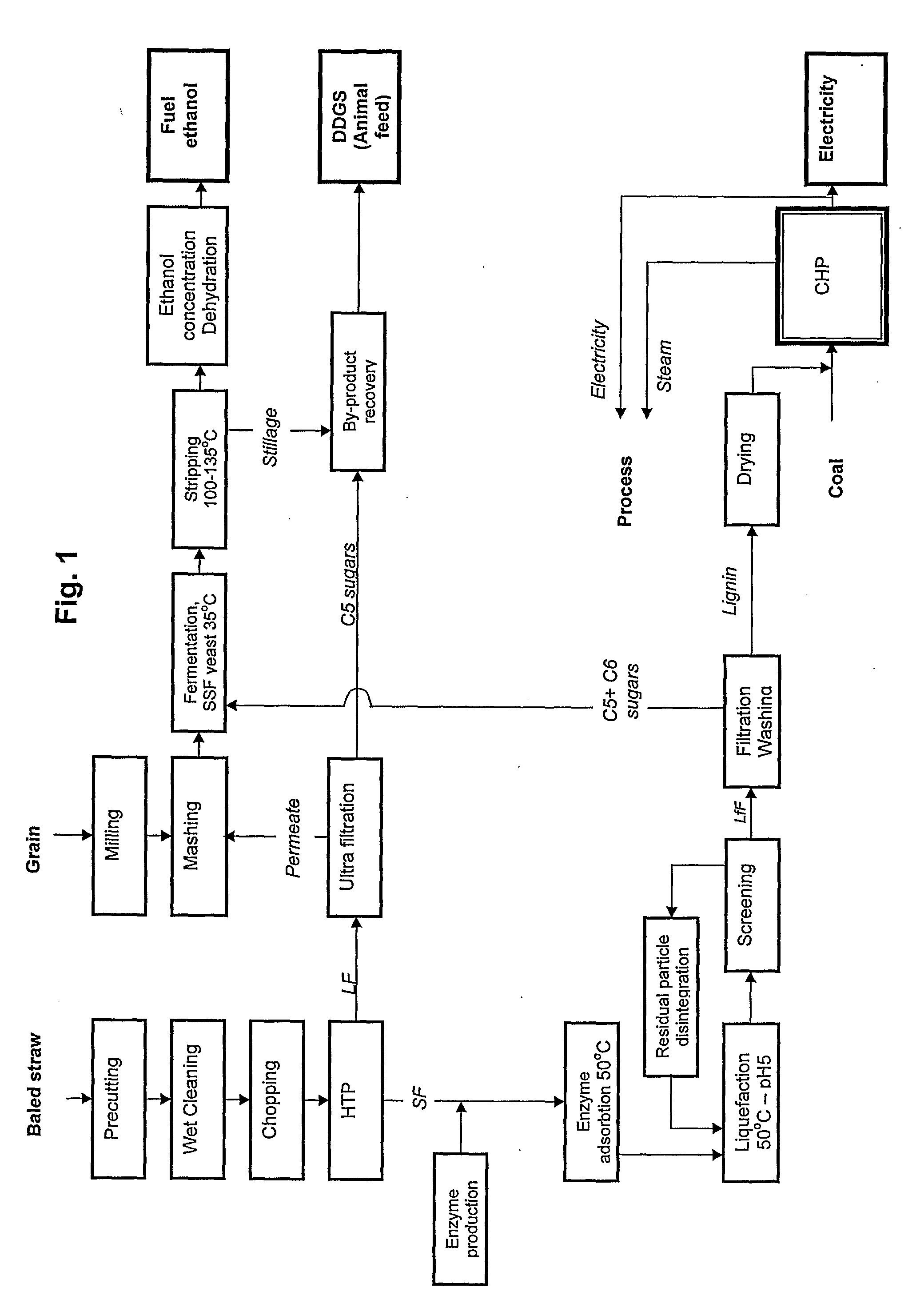

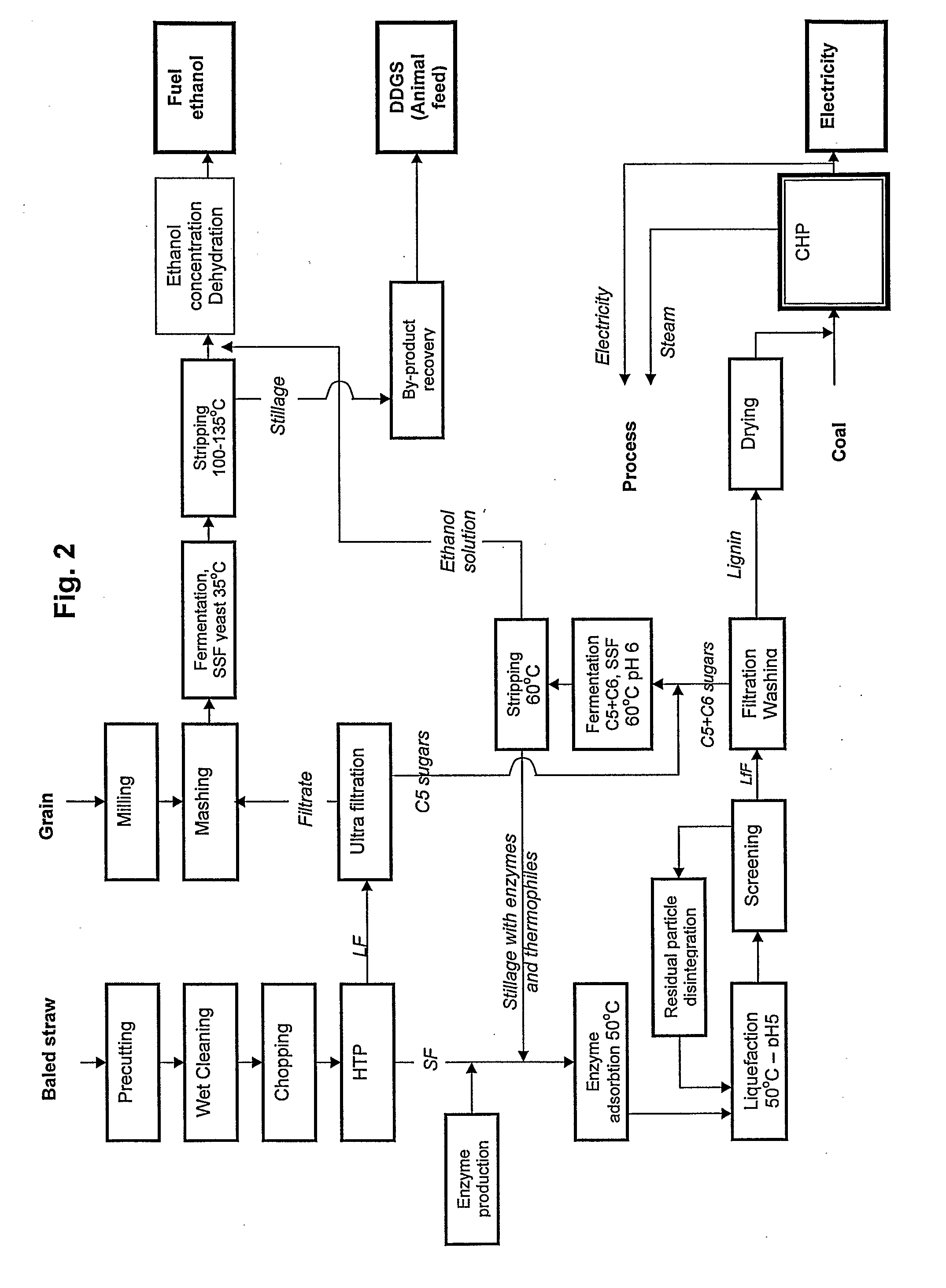

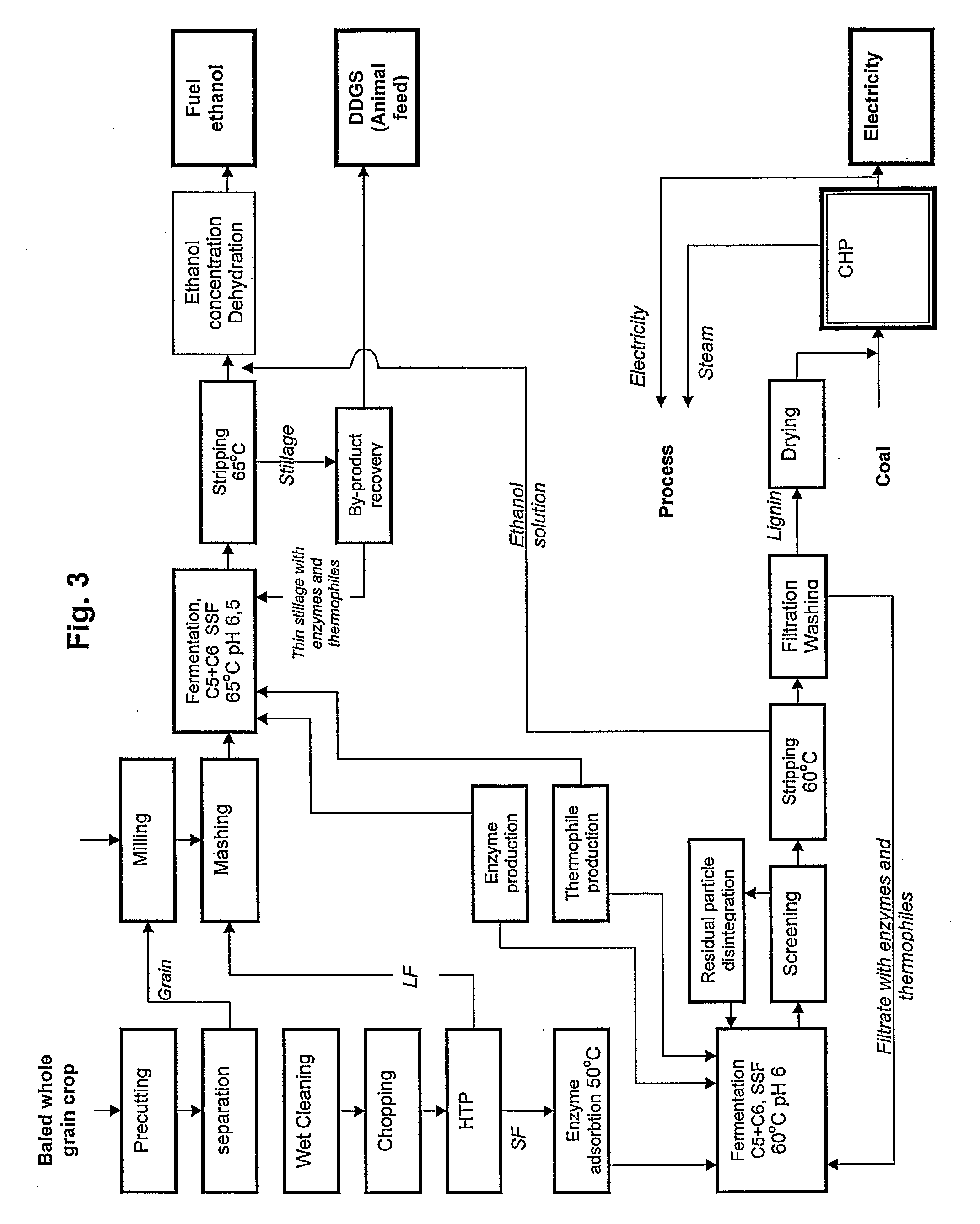

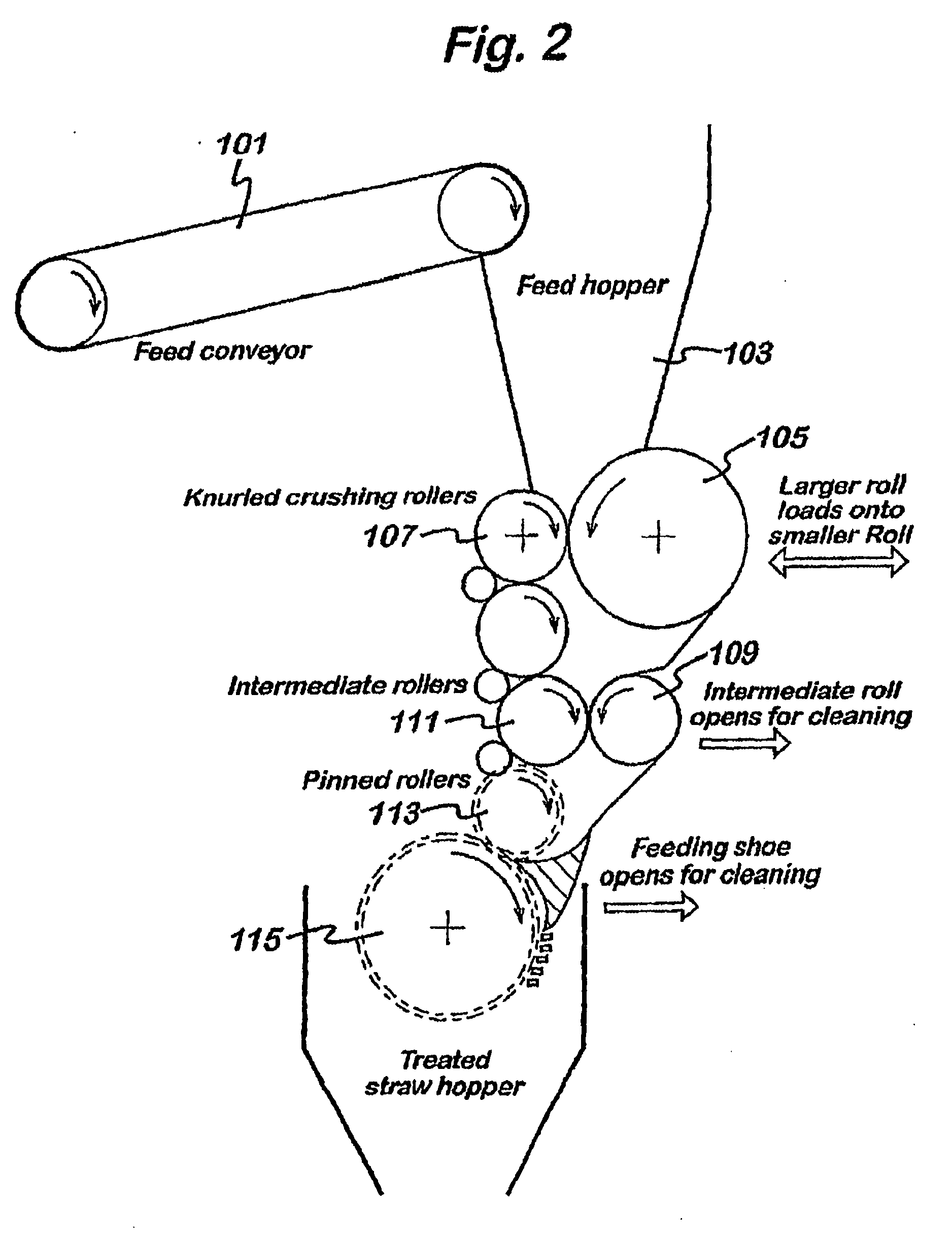

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

Soil improvement type straw compound organic fertilizer and preparation method of soil improvement type straw compound organic fertilizer

InactiveCN105777429AImprove physical and chemical propertiesImprove qualityCalcareous fertilisersBio-organic fraction processingCompound organicPhosphate

The invention provides a soil improvement type straw compound organic fertilizer and a preparation method of the soil improvement type straw compound organic fertilizer. The soil improvement type straw compound organic fertilizer is prepared from the following raw materials in parts by weight: 30 to 35 parts of rice straw, 25 to 30 parts of animal excrement, 20 to 25 parts of biological charcoal, 10 to 15 parts of soybean meal, 5 to 10 parts of cassava residue, 5 to 10 parts of diatom ooze, 2 to 2.5 parts of plant ash, 2 to 2.5 parts of turfy soil, 2 to 3 parts of zeolite powder, 3 to 4 parts of a microorganism bacterium agent, 2 to 3 parts of sodium benzoate, 2 to 3 parts of ammonium monohydrogen phosphate, 1 to 2 parts of calcium chloride, 1 to 2 parts of amino acid, 1 to 2 parts of starch, 1 to 2 parts of molasses powder and 1 to 2 parts of humic acid. The soil improvement type straw compound organic fertilizer takes plant wastes as raw materials; the quality of soil can be easily improved and the production cost can also be reduced, so that the physicochemical properties of the soil are improved, and the structure of the soil is comprehensively improved, and furthermore, the soil quality has the effects of softness, air permeability, water retention and fertilizer conservation; the aim of producing an environment-friendly high-quality organic fertilizer through preferably selecting heavy metal capable of being passivated, the biological charcoal capable of improving the fertilizer efficiency of the organic fertilizer, and conversion products of organic wastes including the biological humic acid and the like as composting base materials, and optimizing a composting process.

Owner:JIXI YUANDAO AGRI IND TECH

Method for cultivating tea

InactiveCN1663350ARich biodiversityImprove the ecological environmentCultivating equipmentsDry seasonTea plantation

The invention discloses a method for cultivating tea comprising the steps of, tea plantation sun screening, planting deciduous arbor around the tea plantation and between the tea trees, covering the tea plantation through rice straw and planting bean green manure, applying special-purpose fertilizer for organic tea, inoculating beneficial soil organisms and soil creatures including right amount of earthworm, finally carrying out irrigation through mini- sprinkling irrigation system in high temperature dry seasons.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

High-Purity Xylooligosaccharide Compositions

To provide a high-purity xylooligosaccharide composition while preventing the formation of UV-absorbing substances and coloring matters.A high-pure xylooligosaccharide composition containing reduced UV-absorbing substances and reduced coloring matters and a method of producing the same which comprises alkali-treating or pressure- and heat-treating a plant material such as wood, corn cob, cotton seed hull, bagasse or rice straw, further enzymatically treating the same, and purifying the crude saccharide solution containing the residues thus obtained, wherein the solution is concentrated and then optionally subjected to desalting and active carbon-treatment. According to the method of the invention, the saccharified solution is concentrated followed by the desalting and active-carbon treating so that a high-purity xylooligosaccharide composition can be produced while preventing the formation of UV-absorbing substances and coloring matters.

Owner:SUNTORY HLDG LTD +1

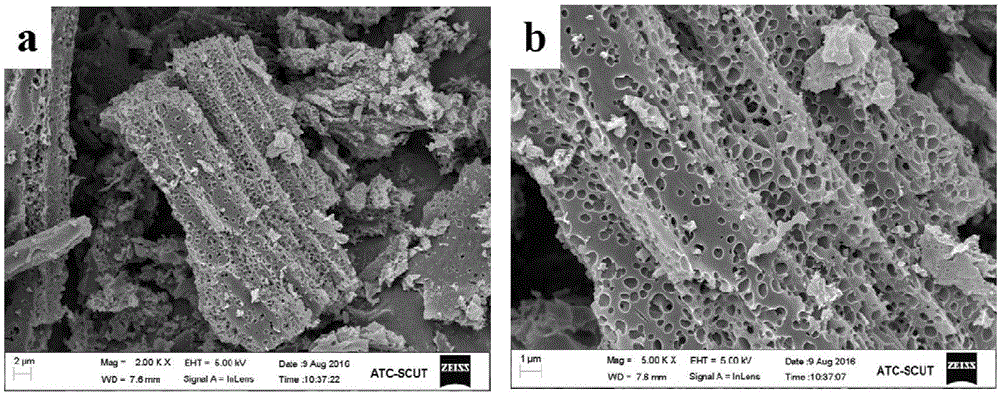

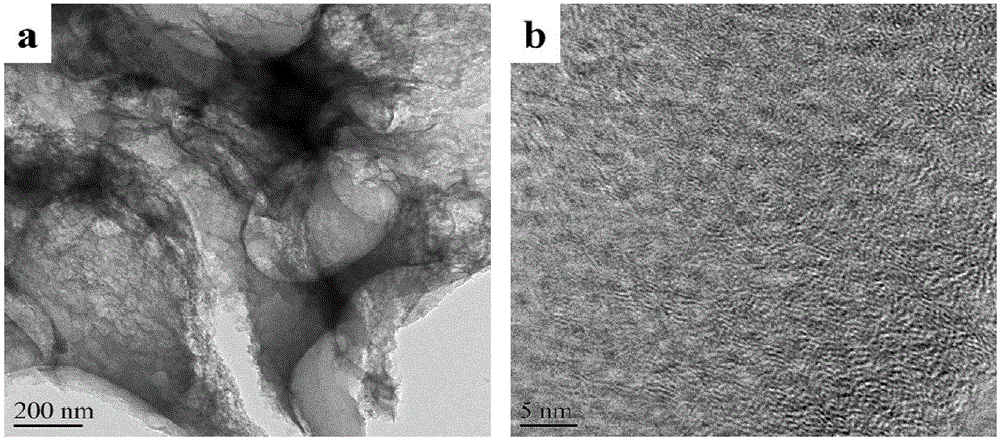

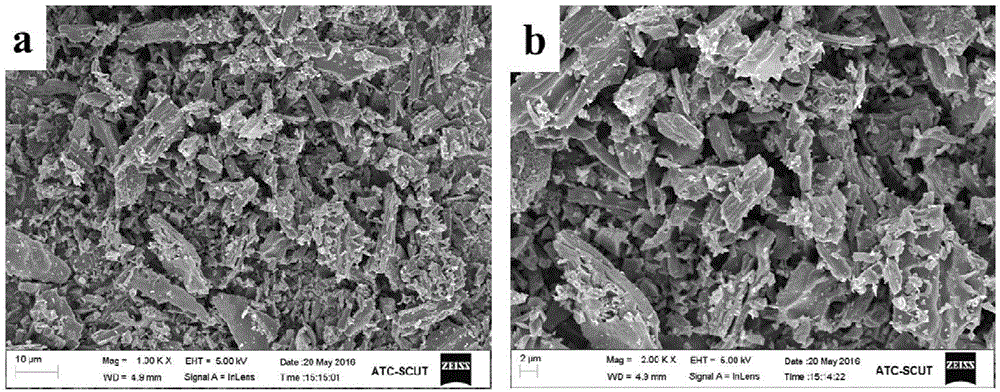

Biomass-based porous carbon material, preparation method thereof, and application thereof in supercapacitor

InactiveCN106587055AWide variety of sourcesLow priceCarbon compoundsHybrid capacitor electrodesPorous carbonBiological activation

The invention belongs to the field of material science and energy storage and discloses a biomass-based porous carbon material, a preparation method thereof, and an application thereof in a supercapacitor. The method includes the steps of: 1) drying and crushing rice straws; 2) non-carbonizing or pre-carbonizing the crushed rice straws, uniformly mixing the rice straws with an activator water solution and drying the mixture, or non-carbonizing or pre-carbonizing the crushed rice straws and directly mixing the rice straws with a solid activator uniformly to produce a mixed product; and 3) placing the mixed product in a tube furnace to perform carbonizing activation in an inert gas atmosphere at high temperature; 4) washing the carbonized product in an acid solution and an alkali solution, and washing the carbonized product with deionized water to neutral, and drying the washed product to prepare the biomass-based porous carbon material. The porous carbon material has excellent supercapacitor performance and is simple in preparation method.

Owner:SOUTH CHINA UNIV OF TECH

Culture medium for Agaricus bisporus production and its application

InactiveCN1788540ARaw materials are easy to getReduce manufacturing costCuttersCutting implementsHuskCrop field

The present invention relates to bispore mushroom cultivating technology, and is especially one kind of bispore mushroom cultivating medium and its application. The cultivating medium consists of grass material 45í½55 wt%, dung material 35í½45 wt%, cake fertilizer 1í½8 wt%, urine 0.5í½1.0 wt%, gypsum powder 0.5í½1.5 wt%, calcium superphosphate 0.8í½1.5 wt%, lime powder 0.2í½1.5 wt%, calcium carbonate 0í½2.0 wt% and dichlorovos 0í½0.5 wt%. The grass material including rice straw, wheat straw, cotton seed husk, corn cob and corn stalk, and the dung material including cow dung, house dung and chicken dung account for at least 90 wt%. The cake fertilizer may be soybean cake, soybean powder, cotton seed cake and / or corn powder. The cultivating medium is used for cultivating bispore mushroom in tall stalk crop field and has biological conversion efficiency over 60 % and bispore mushroom yield over 25 kg / sq m.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Cultivation medium for Pleurotus geesteranus and method for producing the same

InactiveCN101462900AImprove qualityBacteriaBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceSucrose

The invention discloses a pleurotus geesteranus medium and a preparation method thereof. The recipe of the medium comprises (by weight) 60-75% of cotton seed hull or wheat straw or rice straw or corn cob, 7-15% of weed tree sawdust, 8-15% of wheat bran or rice bran, 3-8% of corn flour, 0.5-1.5% of sucrose, 1-1.5% of dried gypsum, 2-2.5% of quicklime, 0.1-0.3% of potassium dihydrogen phosphate and 0.1-0.2% of magnesium sulfate. The preparation method of the medium comprises the following steps: dissolving the quicklime, the dried gypsum, the potassium dihydrogen phosphate and the magnesium sulfate into water; adding the cotton seed hull or the wheat straw or the rice straw or the corn cob and the weed tree sawdust for prewetting; then adding the rice bran, the corn flour, the wheat bran and the sucrose and mixing evenly; and returning the medium having been used for planting the pleurotus geesteranus to field and soil in situ. The technical scheme can cause the pleurotus geesteranus to grow better and avoids the defect of no special medium for the growth of the pleurotus geesteranus in the prior art.

Owner:许忠

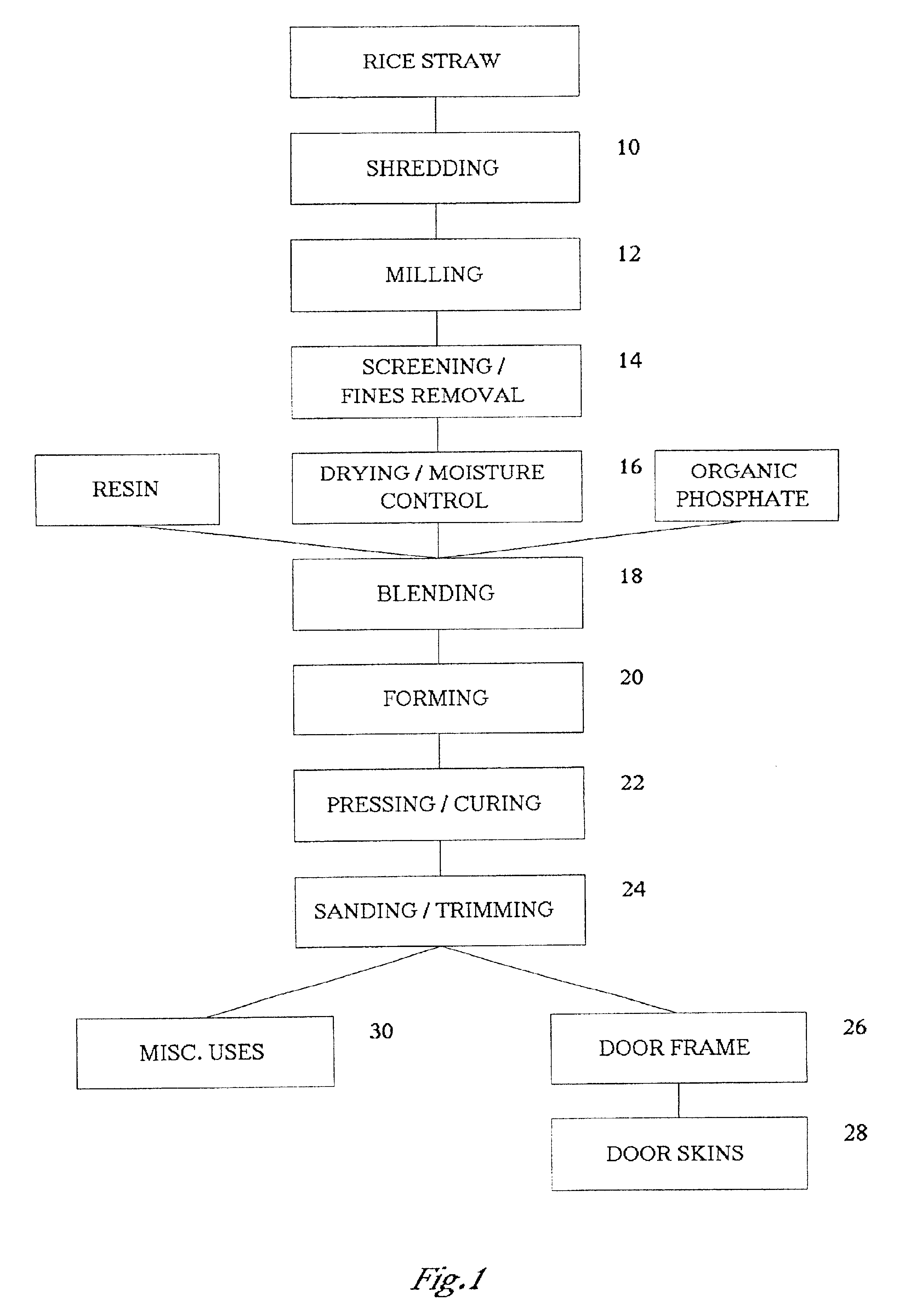

Fire-resistant material and method of manufacture

InactiveUS6886306B2Improve fire resistanceImprove the level ofConstruction materialClimate change adaptationCelluloseZinc borate

The present invention provides a building material derived from straw, such as rice straw, that has significantly improved fire-resistance properties over traditional cellulose-based materials. In one embodiment, the invention provides a method of fabricating a board from milled rice straw. The milled rice straw is blended with a binder to form a mixture. The mixture is then formed into a mat with sufficient size to achieve a predetermined board thickness and density. The mat is then pressed into the board. In another embodiment, the present invention provides a fire resistant board that includes milled rice straw, a resin binder, and a fire retardant material such as an organic phosphate, zinc borate, aluminum trihydrate, sodium silicate, or even rice hulls.

Owner:GREENCOR COMPOSITES

Decomposition maturing agent for degrading straw

The invention relates to a decomposition maturing agent for degrading straw. The agent comprises active ingredients, such as candida tropicalis, aspergillus oryzae, trichoderma viride and bacillus subtilis. The decomposition maturing agent can rapidly decompose wheat straw, rice straw, grain straw, sweet potato stems, broad bean stems, rape stalks, weeds, leaves and household garbage of which the fibrous matter content is high so as to prepare an organic fertilizer. The decomposition maturing agent has the advantages of short degradation time and capability of effectively killing diseases and pests and providing nutrients for crops.

Owner:HUBEI JINDI AGRI SCI & TECH +1

Straw matrix and production method thereof

InactiveCN102010259AFully absorbedIncrease vitalityBio-organic fraction processingOrganic fertiliser preparationSlagFarmyard manure

The invention relates to a rice seedling raising matrix and a production method thereof, and belongs to a seedling raising matrix and a production method thereof. The matrix is prepared by the following formula and method that: the formula comprises 50 to 70 percent of crushed corn stalk of 40 to 60 meshes, 10 to 30 percent of crushed rice straw of 40 to 60 meshes, 5 to 15 percent of farmyard manure of 40 to 60 meshes and 5 to 15 percent of industrial slag powder of 40 to 60 meshes; and the method comprises material preparation, raw material crushing, fermentation, mixing, drying and stirring. The method for producing the seedling raising matrix by using the raw materials such as straws, farmyard manure, slag and the like thoroughly solves the problems of vegetation destroy caused by taking soil for raising seedlings and difficult soil taking, reduces the production processes of taking soil, sieving soil, regulating acid, stirring fertilizers, stirring drugs and the like, and lightens the labor intensity of rice farmers. The method can be applied in rice seedling raising and vegetable and flower seedling raising production, and is a new effective path for making full use of straw resources and realizing energy conservation, emission reduction and agricultural circular economy.

Owner:前郭县百禾农业开发有限公司 +1

Method for preparing magnetic biochar from straw

InactiveCN105536700AOptimize structural configurationMeet greenOther chemical processesAlkali metal oxides/hydroxidesIron saltsCarbonization

A method for preparing magnetic biochar from straw includes the step of selecting of a straw material, wherein wheat straw, corn straw, rice straw or cotton straw is selected as the straw material, the straw material is pretreated by cleaning, then the straw material is dipped with a trivalent iron salt solution, and filtered by vacuum, then a filter cake is dried, and a finished magnetic biochar product can be obtained by carbonization treatment in inert gas conditions. The magnetic biochar can be obtained by dipping the straw material in the trivalent iron salt solution by a pyrolysis process, and a new way for the use of straw is provided.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

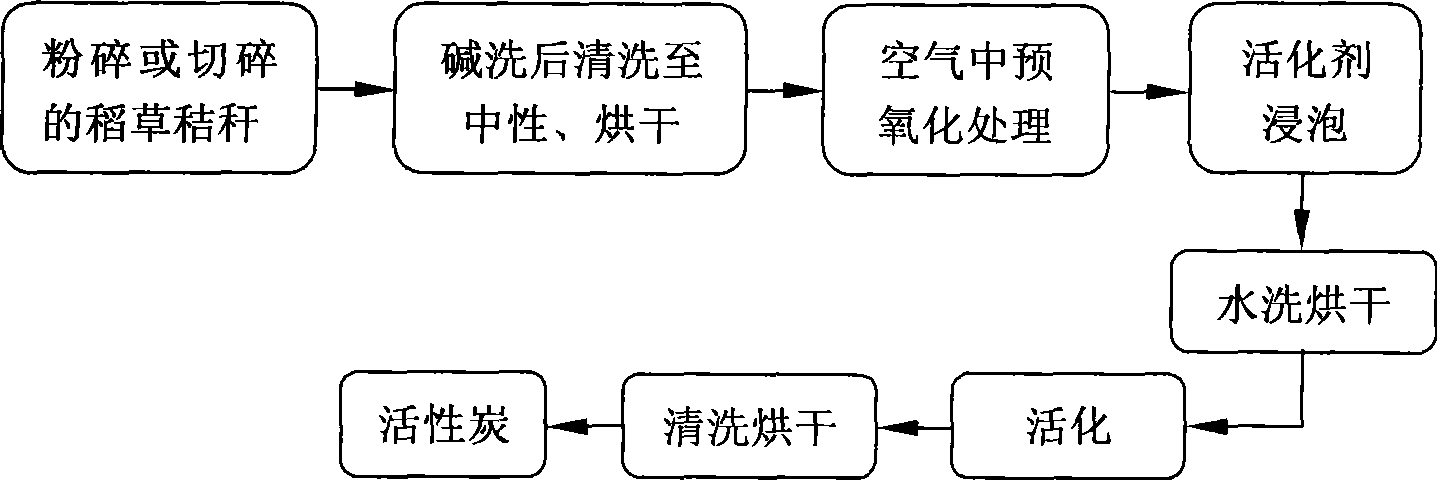

Method for preparing active carbon from straw stalk

The invention relates to a method for preparing active carbon from rice straw. The method comprises taht: (1) the collected rice straw is subjected to alkali cleaning, cleaned to neutrality, dried, and cut or pulverized; (2) the rice straw is added into an activator solution, evenly stirred, soaked for 12 to 24 hours, subjected to solid-liquid separation, cleaned and dried; (3) the rice straw prepared in step (2) is put in a barrate type oven and pre-oxygenated for 1 to 2 hours; (4) the pre-oxygenated rice straw is put in a tube-type carbide furnace, heated for temperature rise under the protection of nitrogen gas, and activated; and (5) the activated rice straw is washed by water till pH is between 6.5 and 7.5, and dried at 105 DEG C to prepare the active carbon. The active carbon prepared by the method has good adsorption performance; the adsorptive value of methylthionine chloride reaches between 200 and 300 mL / g; and the preparation process is simple, economical and environment-friendly, meets requirement of clean production and circular economy development, and has good industrial application prospect.

Owner:DONGHUA UNIV

Pulp using rice grass and wheatgrass as raw material and preparation method thereof

ActiveCN101089292AHigh mechanical strengthChemical/chemomechanical pulpNon-woody plant/crop pulpPulp and paper industryHardness

The present invention relates to a paper pulp prepared by using rice straw and wheat straw as raw material. The breaking length of said paper pulp is 4500-8100 km. and its tearing strength is 180-280 mN. Besides, said invention also provides its preparation method and concrete steps.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

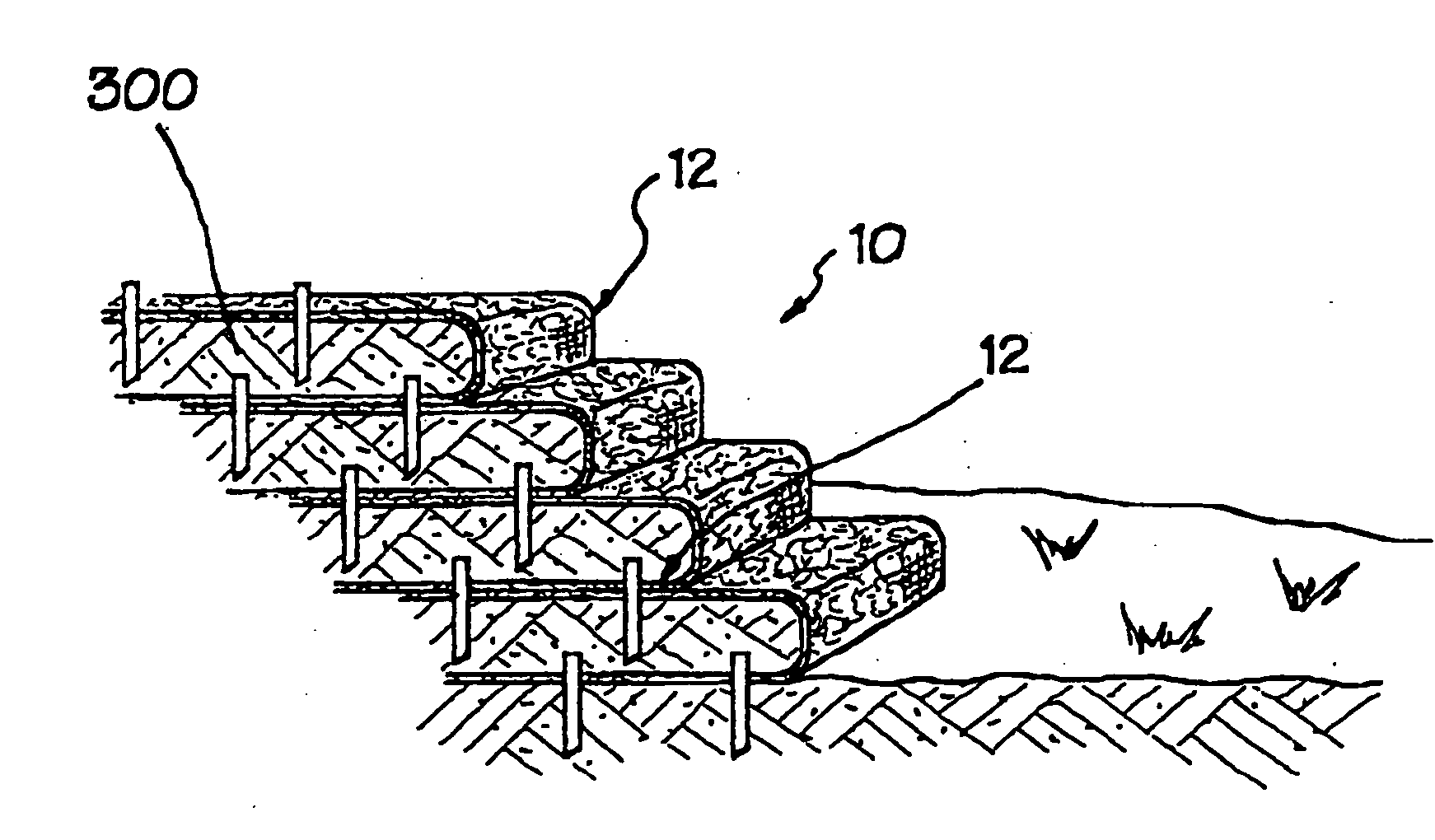

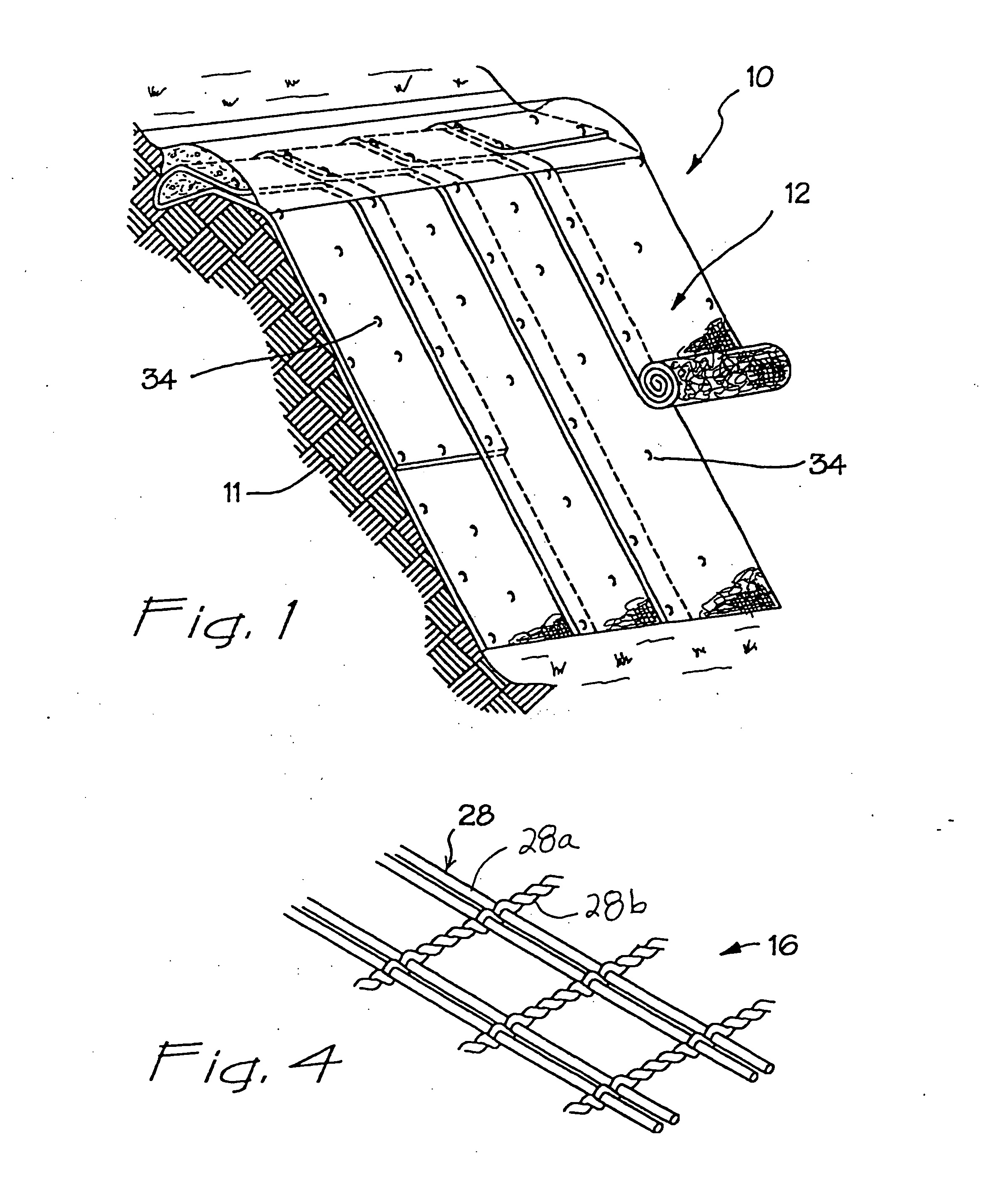

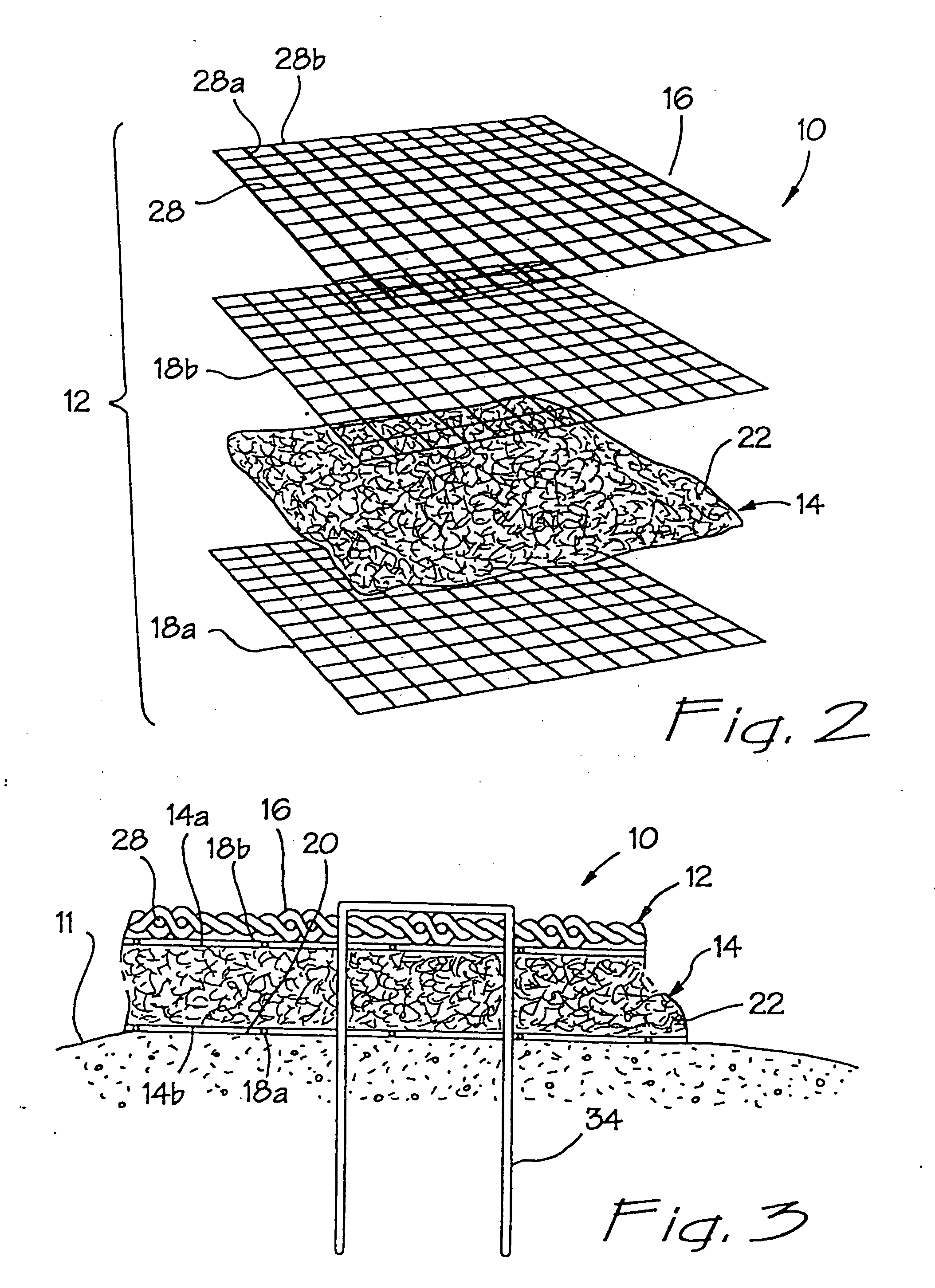

Erosion control system and method of manufacturing same

An erosion control system is provided which generally includes a flexible composite blanket or matting including a core layer formed of rice straw. In addition, the present invention provides a green pigmented rice straw fiber blanket and methods for making same.

Owner:GREENFIX AMERICA

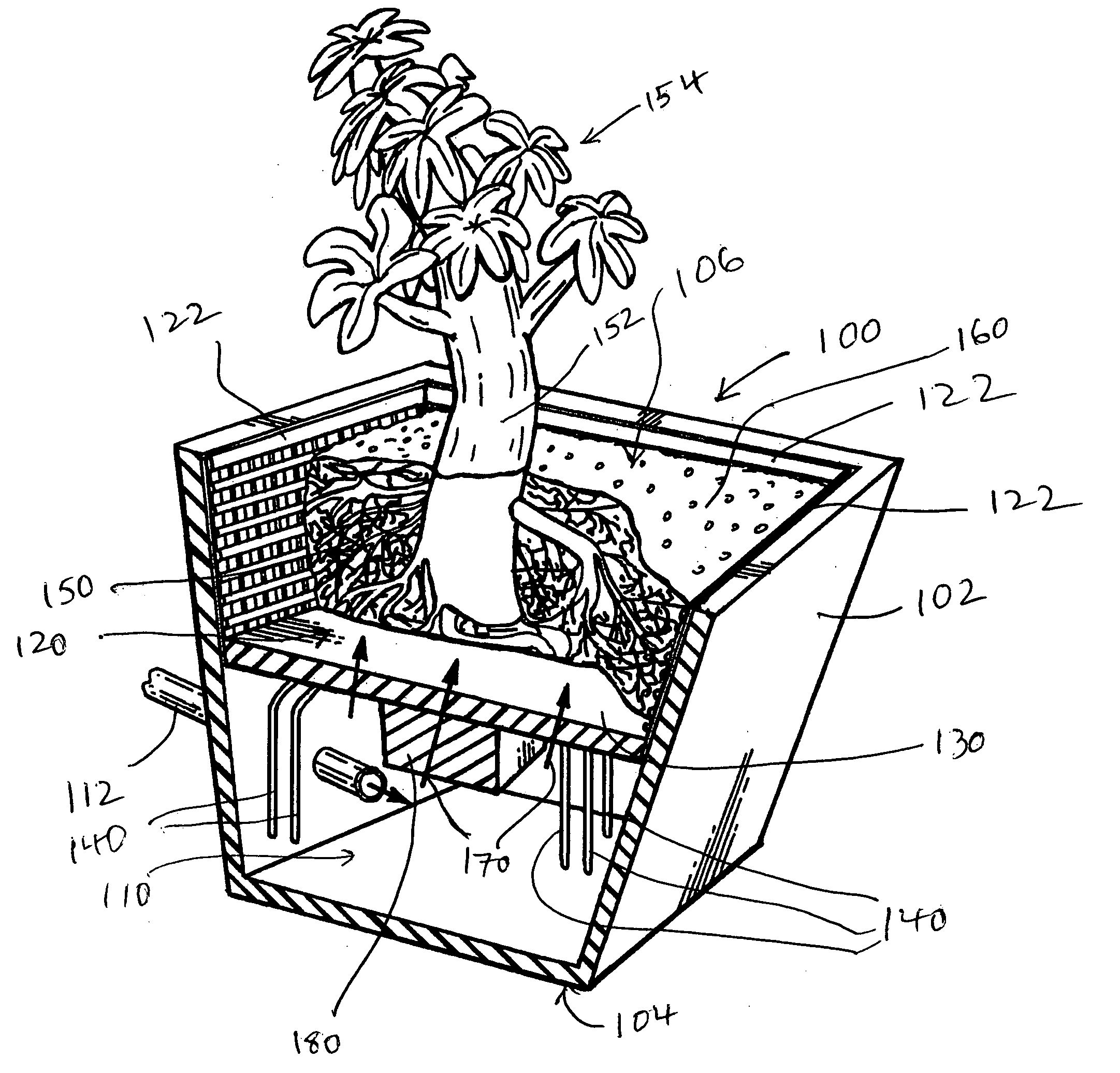

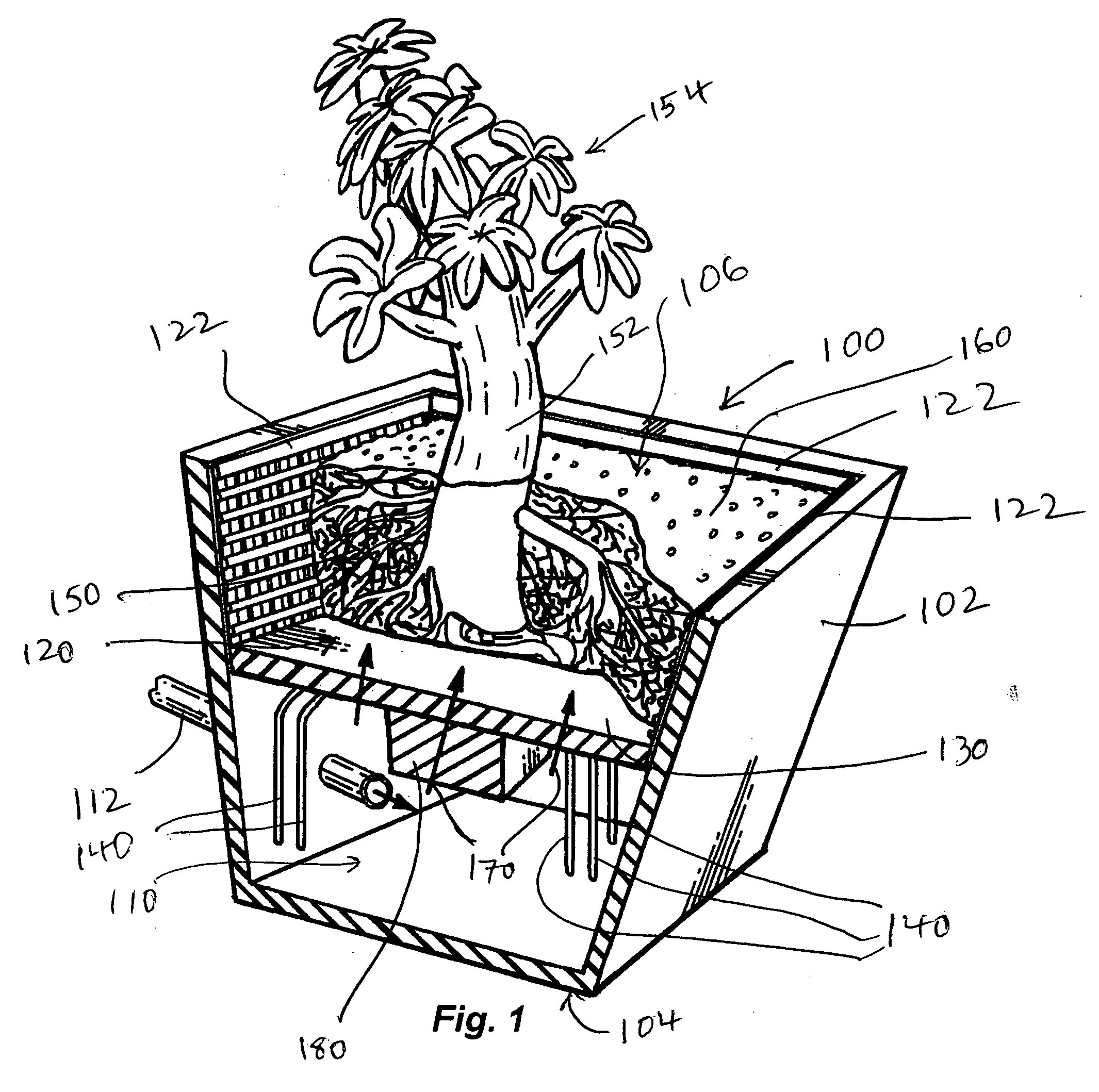

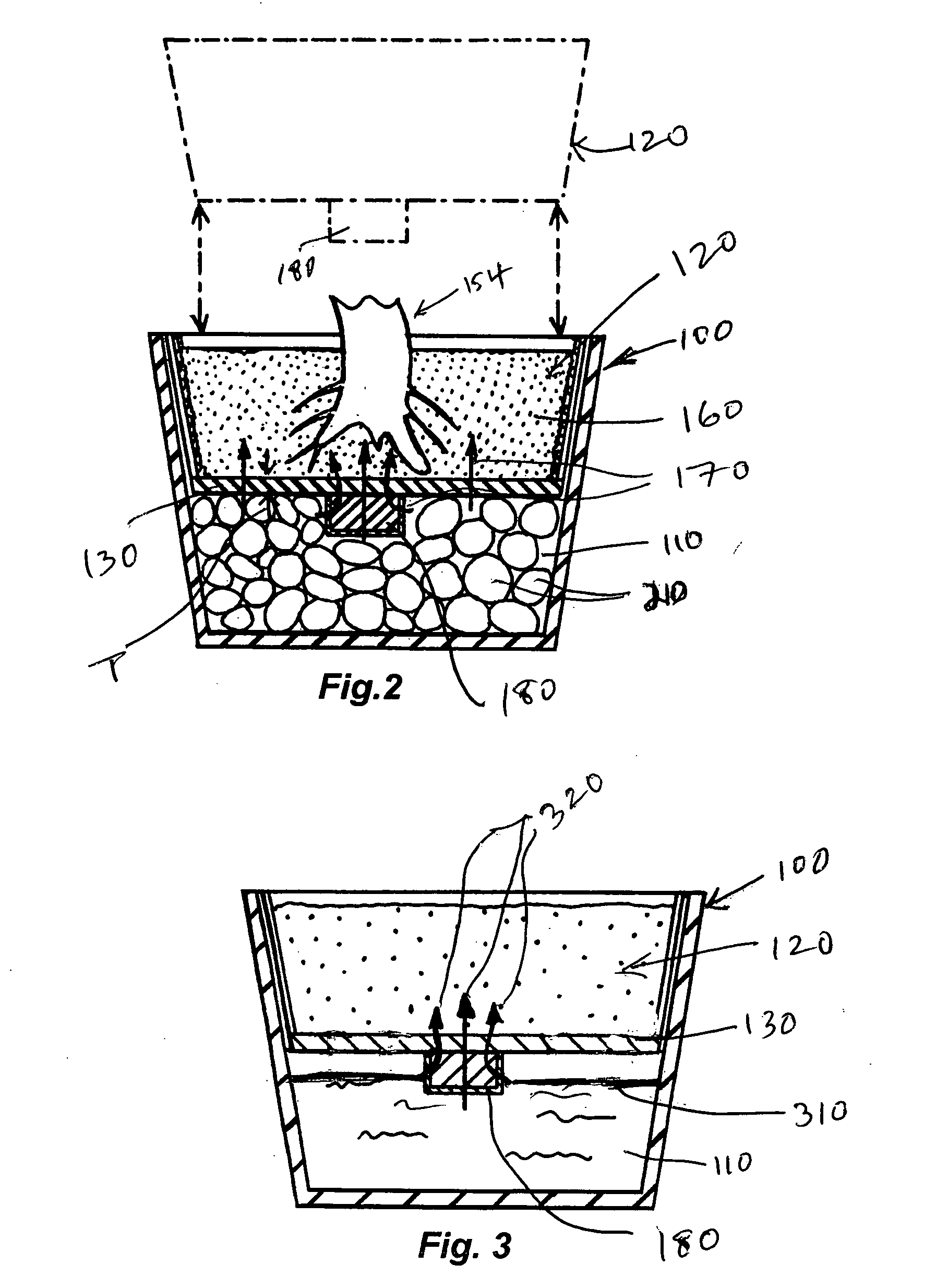

System and method for promoting growth of multiple root systems in a hydroponic environment

InactiveUS20050252080A1Minimize impactAccelerate evaporationSelf-acting watering devicesWatering devicesEvaporationEngineering

This invention provides a container and associated growing process that promotes the growth of at least two different, specialized types of roots and that provides the optimal conditions for these two types of roots. In particular, the container defines an upper section that promotes growth of a fine intricate web of roots that is surrounded by an organic, non-organic or mixed organic and non-organic nutrient-rich medium. This upper section is separated by a permeable medium divider that allows predetermined quantities of water to pass into the upper section (to maintain desired moisture in the nutrient medium (soil), while a lower / bottom section contains a reservoir of hydroponic water that may be relatively free of any nutrients (e.g. “non-nutrient” water). Extending from the upper root ball are a series of water-drinking straw-like roots that transpire water directly from the non-nutrient reservoir and that are continually exposed to massive amounts of atmospheric oxygen. A transport (capillary) device allows water to wick from the reservoir into the upper section to maintain a desired level of moisture in the upper roots, and carrying with it additional dissolved oxygen via evaporation and transpiration. The bottom section can be filled with an acceptable porous, water-storing medium such as gravel or rock wool. The permeable medium divider can include one or more capillary devices that allow transfer of water from the lower reservoir into the upper section. In certain embodiments, the divider can include a series of formations that allow it to sit in an elevated manner on a water-containing structure (such as a sponge-like medium).

Owner:WRIGHT PAUL L

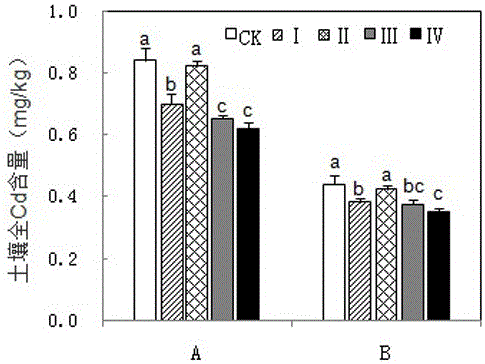

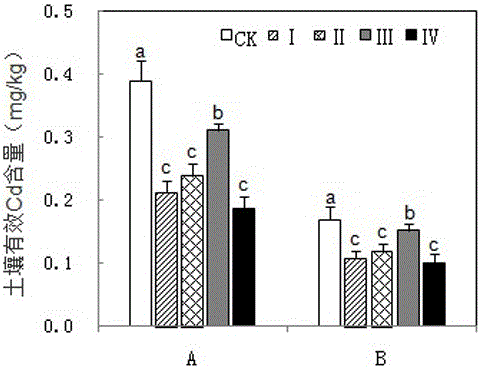

Method for reducing content of cadmium in middle rice

InactiveCN106069429AEfficient use ofHigh in nutrientsHorticulture methodsRice cultivationResource utilizationSoil heavy metals

The invention discloses a method for reducing the content of cadmium in middle rice. The method includes the following steps that after middle rice of the first year is harvested, middle rice straw is returned to the field directly, and tillage is conducted so that the middle rice straw can be evenly mixed with soil; hyperaccumulation plants are planted in a paddy; after the hyperaccumulation plants are removed from March to May in the second year, soil heavy metal passivator is scattered on the surface of soil of the paddy; tillage is conducted, and base fertilizer is applied 3-5 days later; tillage is conducted, and rice is transplanted; during planting of rice, a foliar resistance control agent is sprayed in the later tillering stage and the booting stage of rice respectively, wherein spraying time interval is 5-10 days; field drying is conducted in the later tillering stage, natural drying is conducted in the maturation stage, and flooding irrigation is conducted in other development stages. According to the method, crop production and straw resource utilization are not affected, the dual targets of reducing the paddy soil cadmium content and reducing the rice cadmium content are achieved under the combined action of plant extraction, soil passivation, foliar resistance control and water management, and effects are more remarkable compared with other combination technologies.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

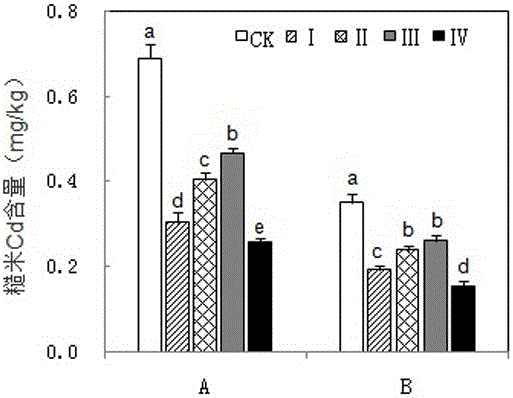

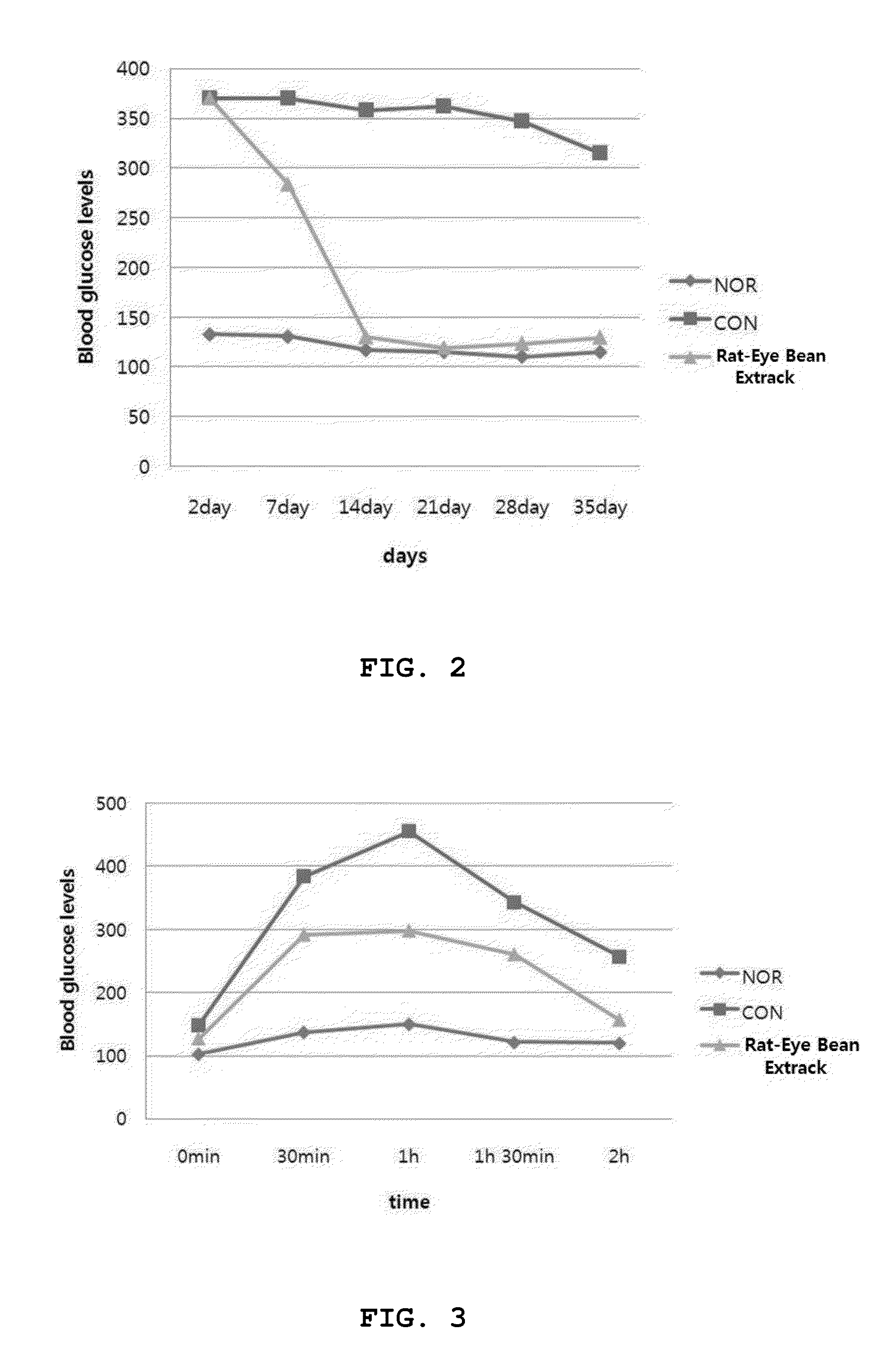

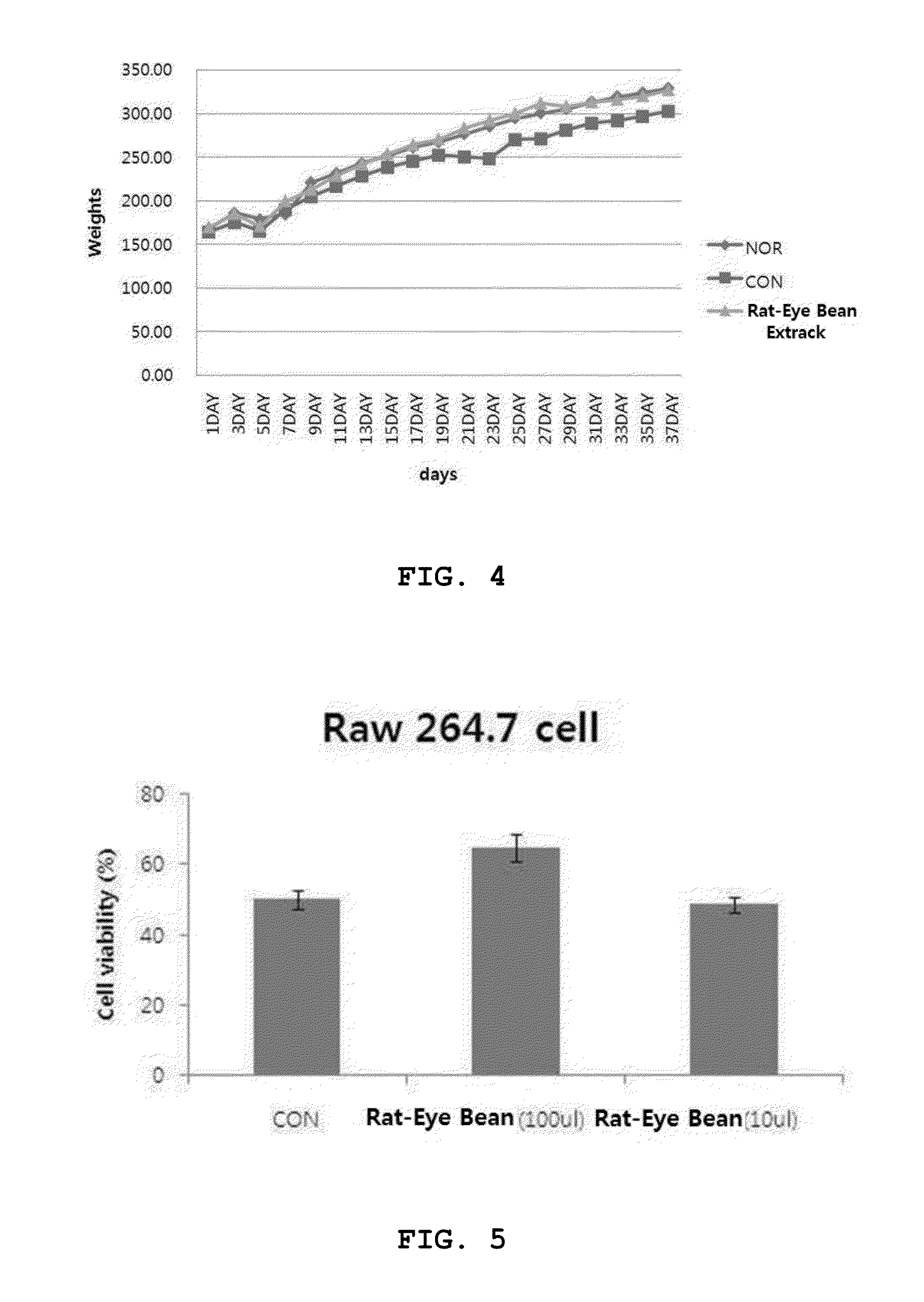

Rat-eye bean extract improving blood glucose control and bioactivity and method of producing the same

InactiveUS20140004211A1Improving bioactivityImproving blood glucose controlBiocideAnimal repellantsGlycemicBean extract

Provided are a rat-eye bean extract improving blood glucose control and bioactivity, which is produced from rat-eye beans as health food so as to be able to improving storability, portability and potability, and a method of producing the same. The rat-eye bean extract is produced by putting rat-eye beans, which are cleanly washed without foreign materials and are soaked in water for five hours, and water into a steam pot at a volume ratio of 3:1 along with rice straw, fermenting water, which is boiled to steam the rat-eye beans in weak flames for five hours, in a hot-floored room for two to three days, putting the fermented water and a grapefruit juice into the steam pot at a weight ratio of 99:1, and heating a mixture of the fermented water and the grapefruit juice in a closed state at a temperature of 110 to 120° C. for four to five hours.

Owner:CHOI BYEONGCHEOL +2

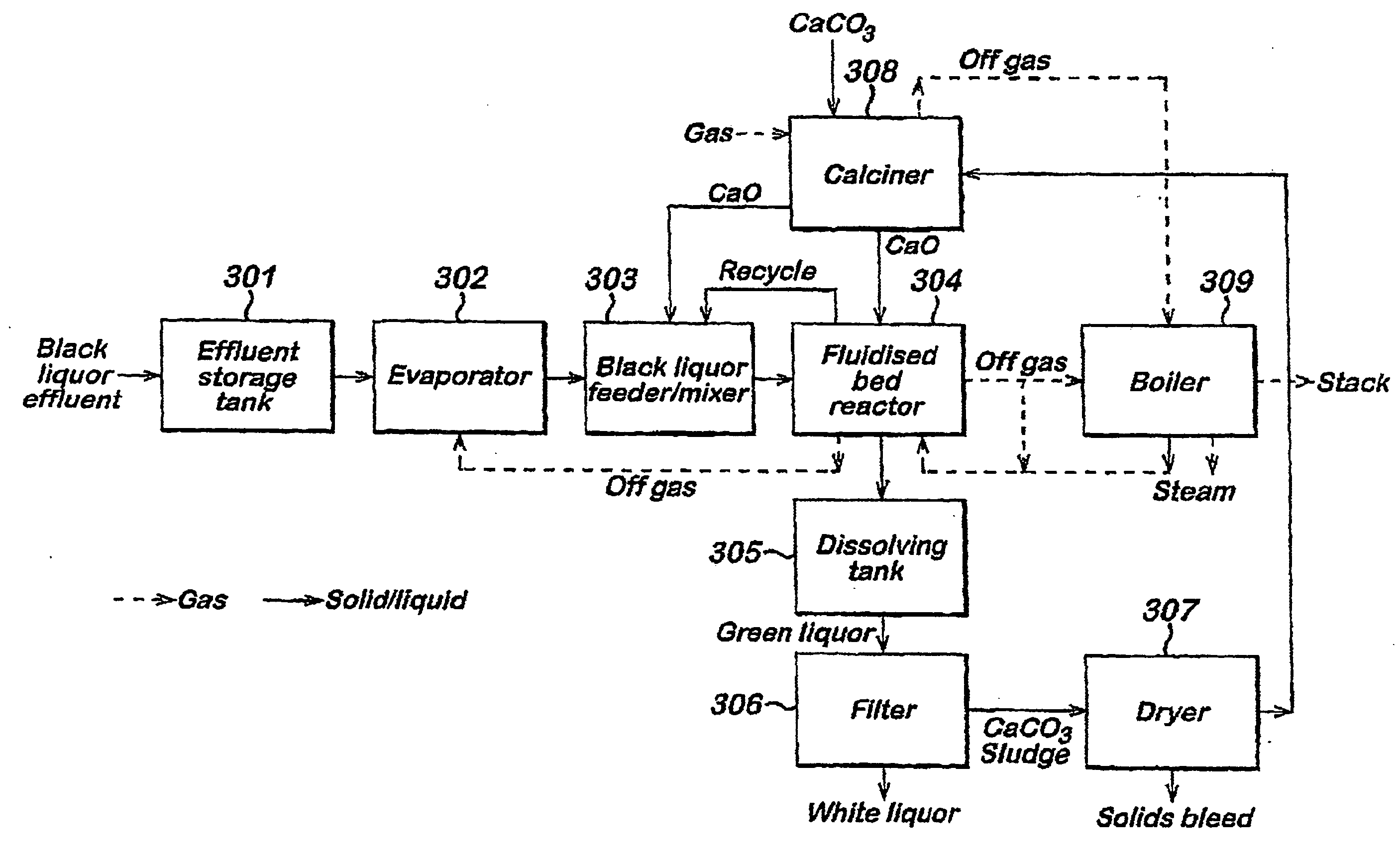

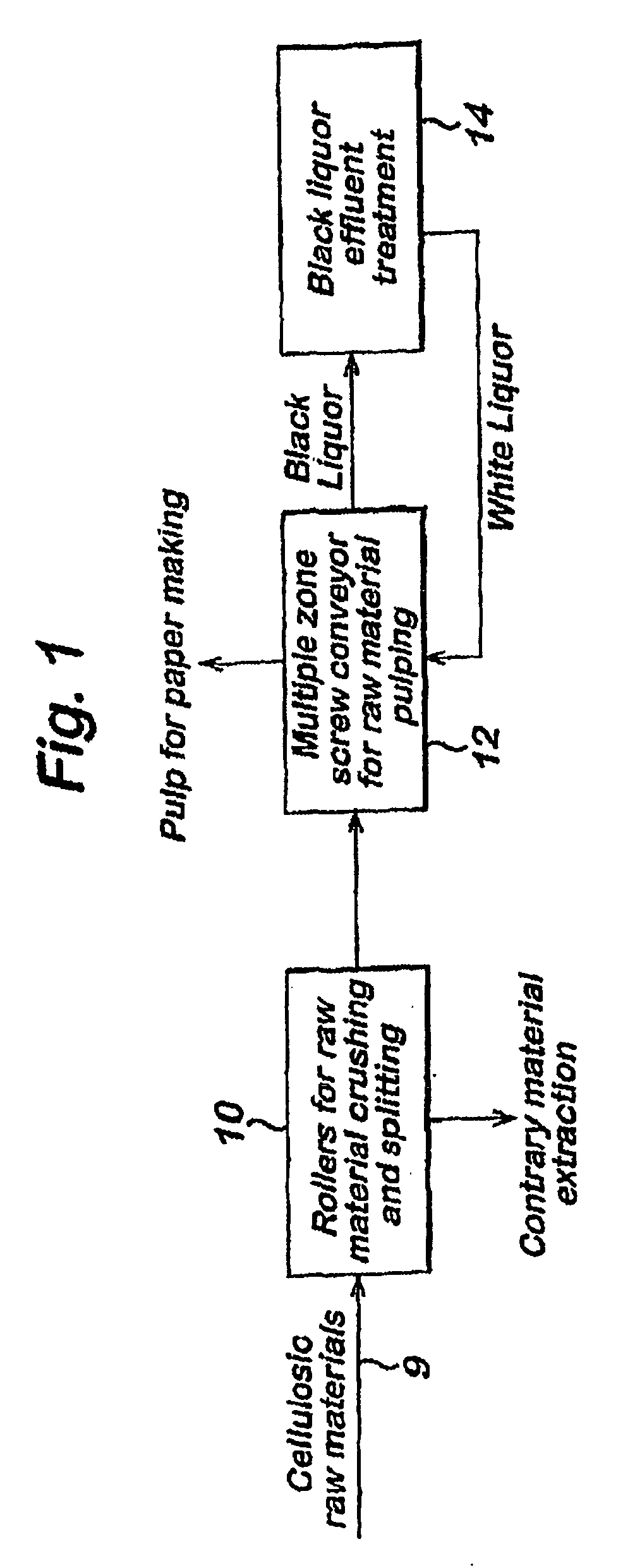

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

Composite biological activated carbon and rapid preparation method thereof

InactiveCN101643208AExtended service lifeSolve the technical problems of long carbonization timeSpontaneous combustionBiological activated carbon

The invention discloses a composite biological activated carbon and a rapid preparation method thereof, raw materials thereof comprise coconut shell, bamboo, rice hull, sawdust, wheat straw or rice straw, or the raw materials thereof comprise the rice hull, the sawdust, the wheat straw or the rice straw, corn stalk or corn core, the raw materials are smashed to prepare columnar granules, the direct heating method of the spontaneous combustion type granules is adopted for preparing the carbon, a fixed layer is paved at the bottom of a furnace by taking the granules as the raw materials, the fixed layer is ignited by using ignition materials, the feeding is adopted at the upper part of the furnace and the air induction is carried out at the lower part of the furnace for accelerating carbonization of the granules, the air induction is stopped after the carbonization of the granules, the temperature in the furnace is kept at 430-700 DEG C, the spray cooling method is adopted for activatingand cooling the granular carbon, and a finished product is prepared after 20-30 minutes. A plurality of raw materials are mixed, and more pores are naturally formed, thereby expanding the specific surface area of the carbon, greatly increasing effective micropores, leading the absorption performance to be greatly better than the existing activated carbon of single material and reflecting the unique advantages of the composite material.

Owner:徐克文

High-strength plant growing type porous concrete and preparation method thereof

InactiveCN102010155AGuaranteed compressive strengthHigh porositySolid waste managementEcological environmentCrushed stone

The invention discloses a high-strength plant growing type porous concrete and a preparation method thereof. The concrete comprises the following ingredients in proportioning by weight: water, cement, waste concrete or natural crushed stone aggregate, water reducing agents and rice straw. The preparation method comprises the steps of: firstly crushing the waste concrete or the natural crushed stone aggregate to be used as aggregate for later use; smashing the fully dried rice straw for later use; stirring the aggregate and a proper amount of water for a period of time; putting a proper amount of cement, the smashed rice straw and the water reducing agents into a stirrer for stirring; and finally, adding rest water and cement to be stirred. The high-strength plant growing type porous concrete can replace masonry flagstone with the strength of lower than M15, is applied to engineering projects such as raceways, parking lots, side slopes, riverbanks and the like and helps the growth of plants and restores the ecological environment destroyed by construction under the application condition.

Owner:孙学军 +1

Mixed feed formula for black goat

InactiveCN103859206ASuitable for growing needsShorten the breeding cycleFood processingAnimal feeding stuffPeanut mealSugarcane tops

The invention provides a mixed feed formula for a black goat. The formula comprises the following components: a green fodder including alfalfa, ryegrass, oat grass, mulberry leaves, locust tree leaves and sugarcane top; a coarse fodder including straw, cornstalk and bagasse; a concentrated feed including corn bran, wheat bran, peanut meal, bean cake and rice bran; an animal feed including fish meal, shrimp meal and mealworms powder; a mineral feed including bone meal, shell powder, urea, salt and aginomoto. The feed formula is low in cost, preferred by the black goat, quick for grow, healthy in physique and high in meat factor.

Owner:罗生芳

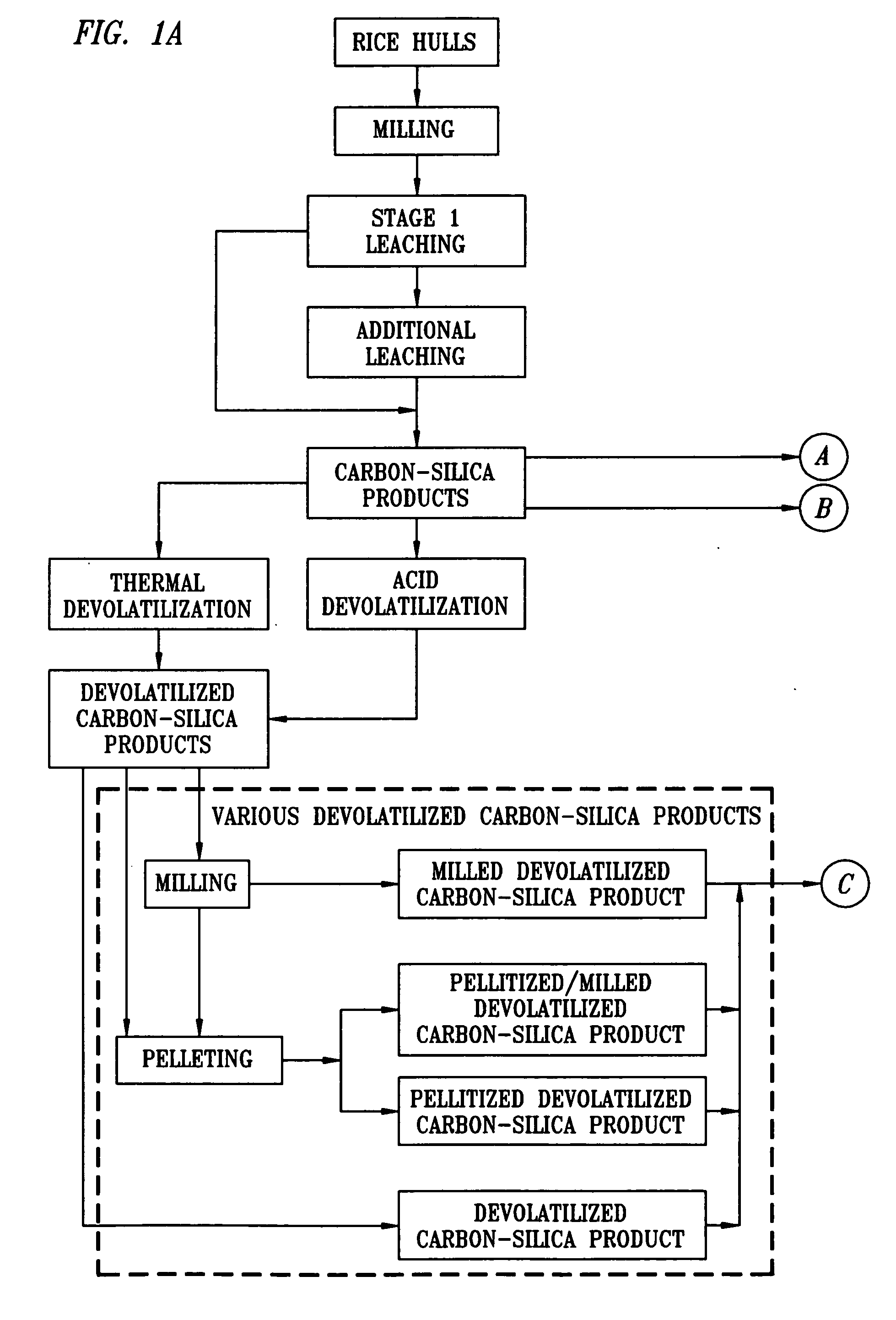

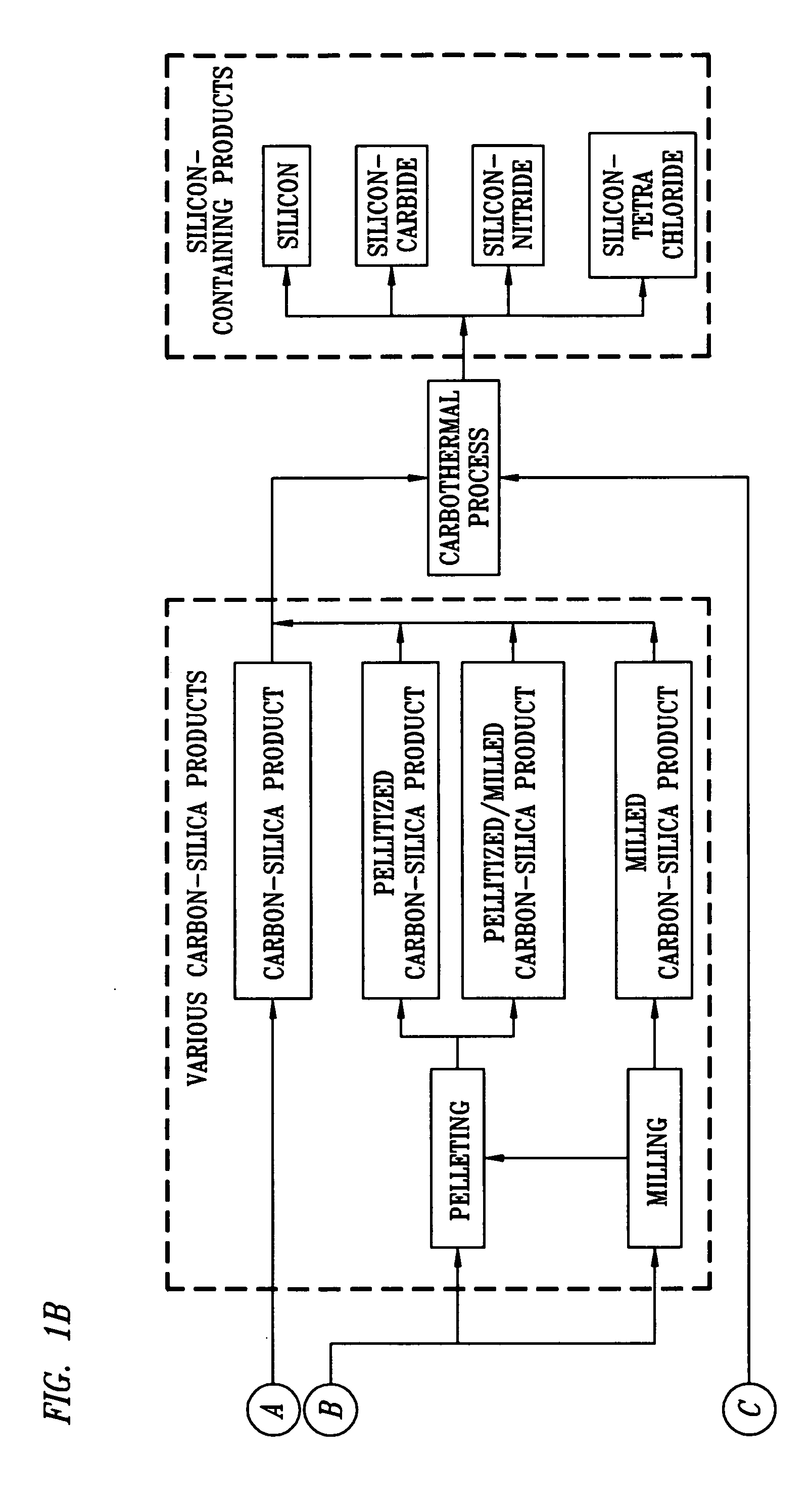

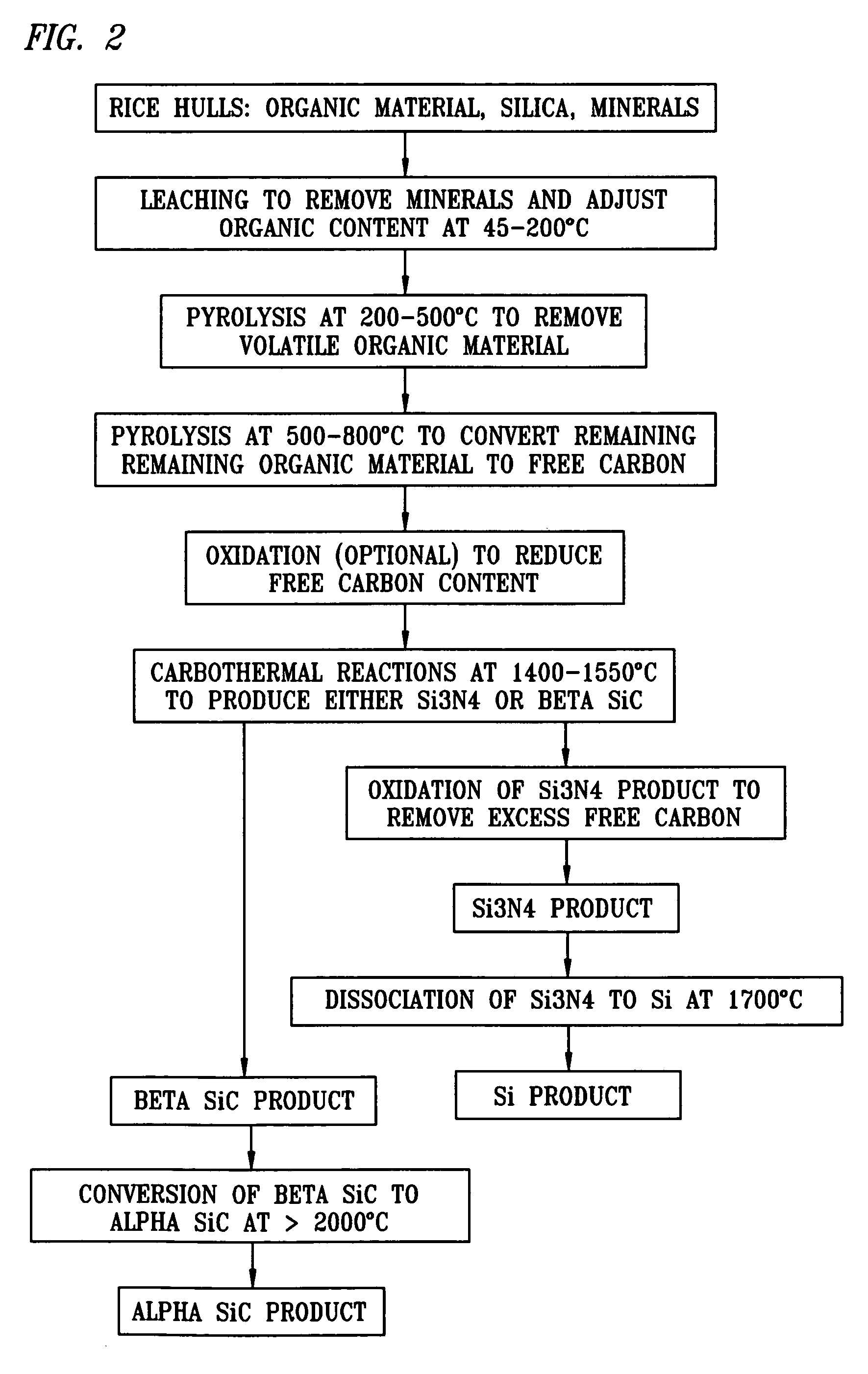

Composition and method for making silicon-containing products

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

Method for interplanting stropharia rugosannulata in vineyard

The invention discloses a method for interplanting stropharia rugosannulata in a vineyard. The method comprises the following steps of scarifying soil and drying the soil in the sun before seeding, so that the soil is cured and loosened; seeding at a temperature between 8 DEG C. and 30 DEG C.; soaking straws for 35 6 hours; soaking wheat straws, cornstalks and bean stalks for 48 hours; pre-stacking cultivation materials, wherein the stack width is 2 m, and the stack height is 1.5 m; turning the stacks after three days, and turning the stacks again after another two to three days; seeding when the water content is 75%; first spreading a humus soil layer which is 4-5 cm in thickness when seeding; forming a turtleback ridge-up bed which is 30 cm in height and 1.3 m in width, wherein sidewalks of 40 cm in width are left among the ridges, and a first spreading on the ridges is 8-10 cm in thickness; seeding 50% of strains; not spraying water on the stropharia rugosannulata bed within 20 days after seeding, but spraying on coverings; controlling the temperature of the cultivation materials at 20-30 DEG C.; uncovering films for ventilation when the temperature is higher than 30 DEG C. and spraying water on the coverings for cooling; and covering the ridges with mats or films when the temperature is below 20 DEG C., wherein the relative humidity on the ridge surface is between 90% and 95%; and the preferenpreferencetial temperature for fruiting is 14 to 25 DEG C.

Owner:ZUNYI CITY TONGGAN GRAPE SPECIALIZED COOP

Environment Protection type bioactive plant-growing container

InactiveCN1408205ANo pollution in the processGrow vigorouslyCultivating equipmentsNatural organic matterPlant fibre

The environment protection type bioactive plant-growing container for growing seedlings in planting consists of plant fiber powder 20-75 wt%, natural organic matter 10-60 wt%, bioactive nutrient 0.5-20 wt%, non-toxic adhesive 10-50 wt% and stuffing 3-10 wt%. The said plant fiber powder is husk powder, rice straw powder, corn straw powder, wheat straw powder, etc; the natural organic matter includes turf and sphagna; and the bioactive nutrient is algin. The plant-growing container is produced through mixing the said material and press molding at 80-160 deg.c.

Owner:金绿汀

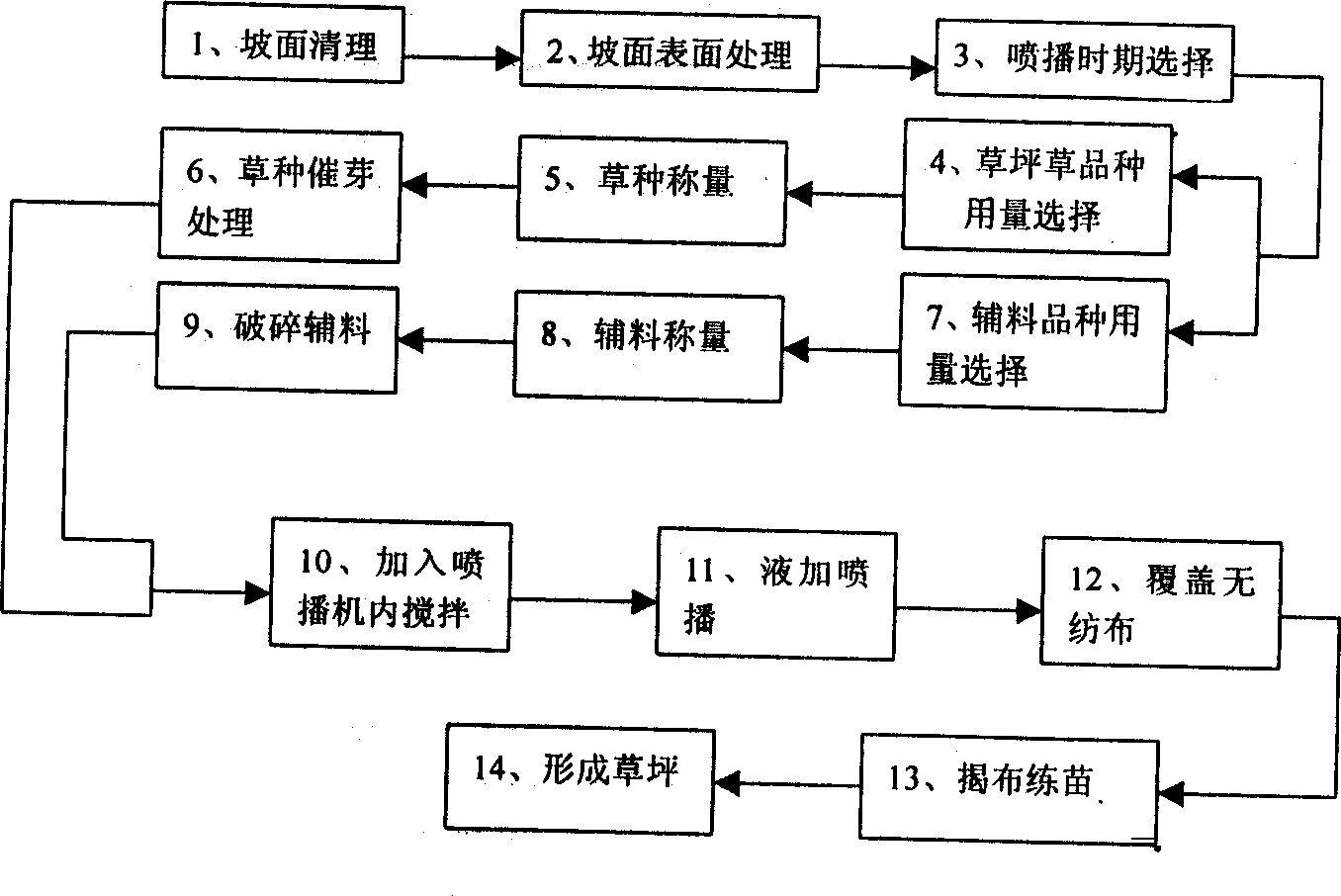

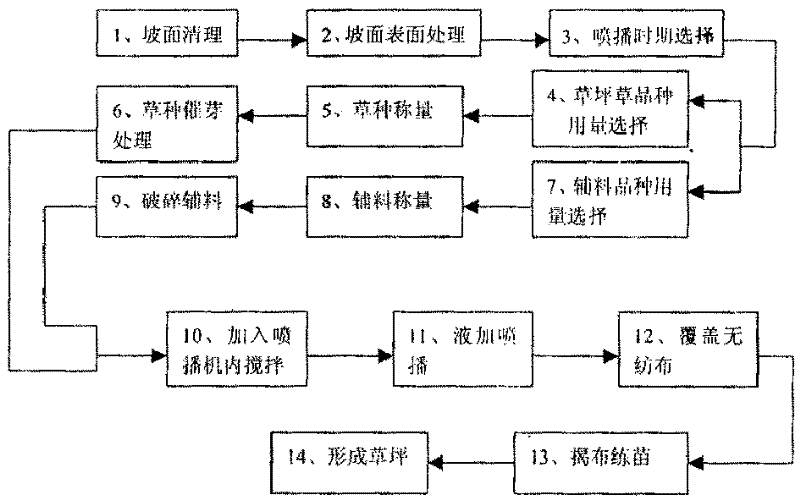

Method for planting lawnon slope of highway in south China

InactiveCN1356021ACalculate the weightWeight optimizationSeed and root treatmentExcavationsEngineeringSouth china

A method for planting lawn on the slope of highway in south region features that the seeds of warm temp-type lawn and cold temp-type lawn are mixed and then hydraulically sprayed on the said slope for sowing. It includes sowing, spraying water-preserving agent, covering with paper pulp, rice straw, or stalk, and covering non-woven fabric. Its advantages include high lawn-forming speed, high uniformity and constant green in different seasons.

Owner:曾昭安

Like-humic acid substance extracted from crop straw and preparation method of compound fertilizer thereof

InactiveCN103275333AImprove production environmentImprove stress resistanceOrganic chemistryFertilizer mixturesNutritionResource utilization

The invention relates to Like-humic acid substance extracted from crop straw and a preparation method of a compound fertilizer thereof. The resource utilization ratio is optimized by extracting humic acid and fulvic acid in rice straw; the pollution to the environment by rice straw is reduced indirectly; meanwhile, the crop production environment can be improved by utilizing the compound fertilizer prepared from the extracted humic acid-like substance; more nutrition is provided for the growth of crops; and the stress resistance of crops is intensified.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

A preparing method of an active-carbon/graphene composite

A preparing method of an active-carbon / graphene composite is disclosed. The active-carbon / graphene composite is prepared by uniformly mixing raw materials comprising 45-90% by weight of biomass, 5-50% by mass of carbonitride and 5-10% by mass of a transition-metal-containing compound, heating the material mixture at 300-500 DEG C for 2-5 h to obtain a gray block material with a fluffy structure, and heating the block material in a protective gas atmosphere at 600-900 DEG C for 5-60 min. The biomass is any one or a mixture of straw, saccharose residue, saw dust and rice straw. The method utilizing the biomass for directly synthesizing the active-carbon / graphene composite material is simple. Raw materials are simple and easily available. The obtained active-carbon / graphene composite material has the specific capacitance meeting requirements of electrode materials and is suitable for large-scale production and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com