Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

915results about "Chemical/chemomechanical pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent article comprising a fibrous structure comprising synthetic fibers and a hydrophilizing agent

InactiveUS20070232180A1Layered productsSynthetic cellulose/non-cellulose material pulp/paperEngineeringSynthetic fiber

Owner:THE PROCTER & GAMBLE COMPANY

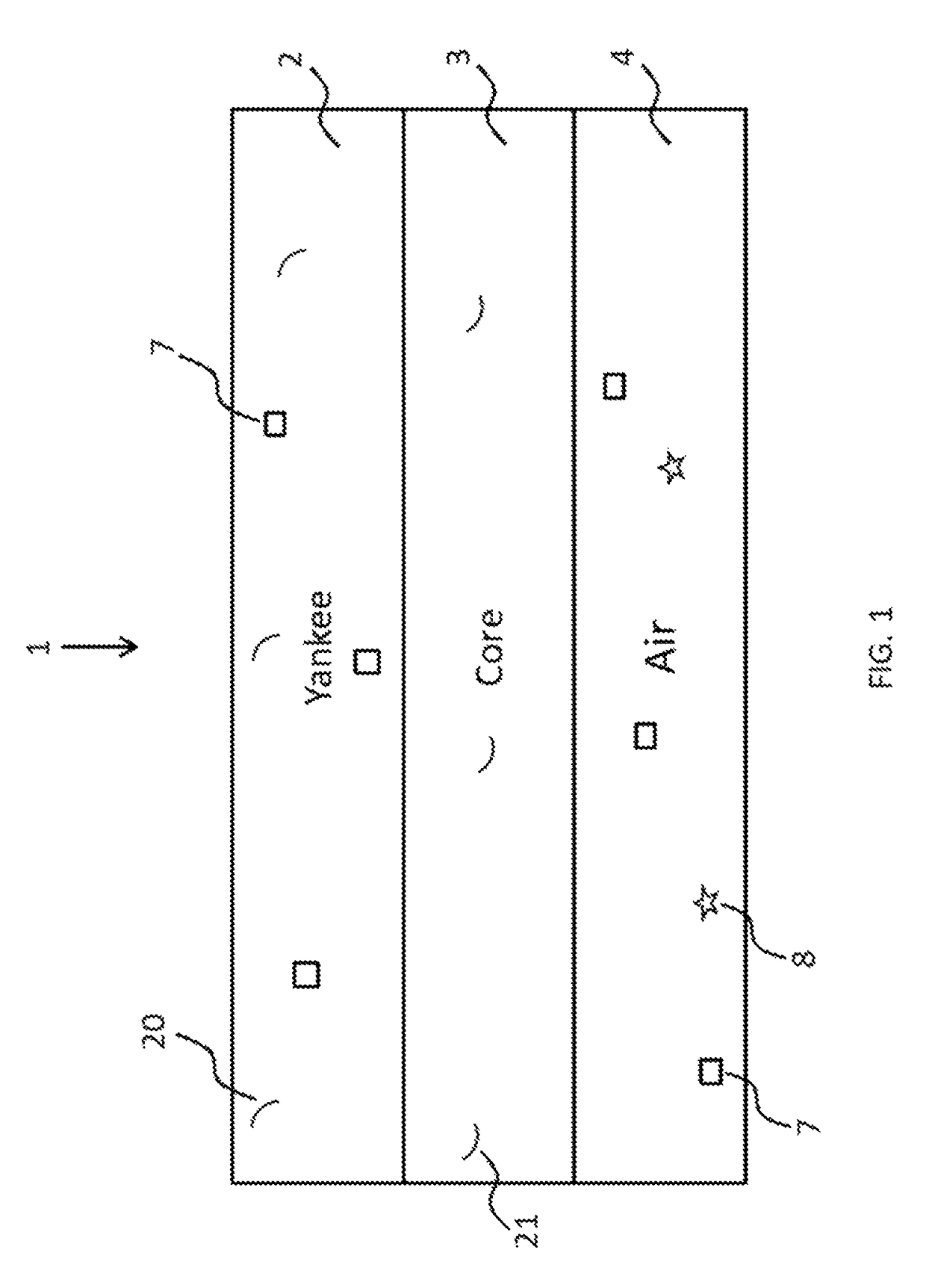

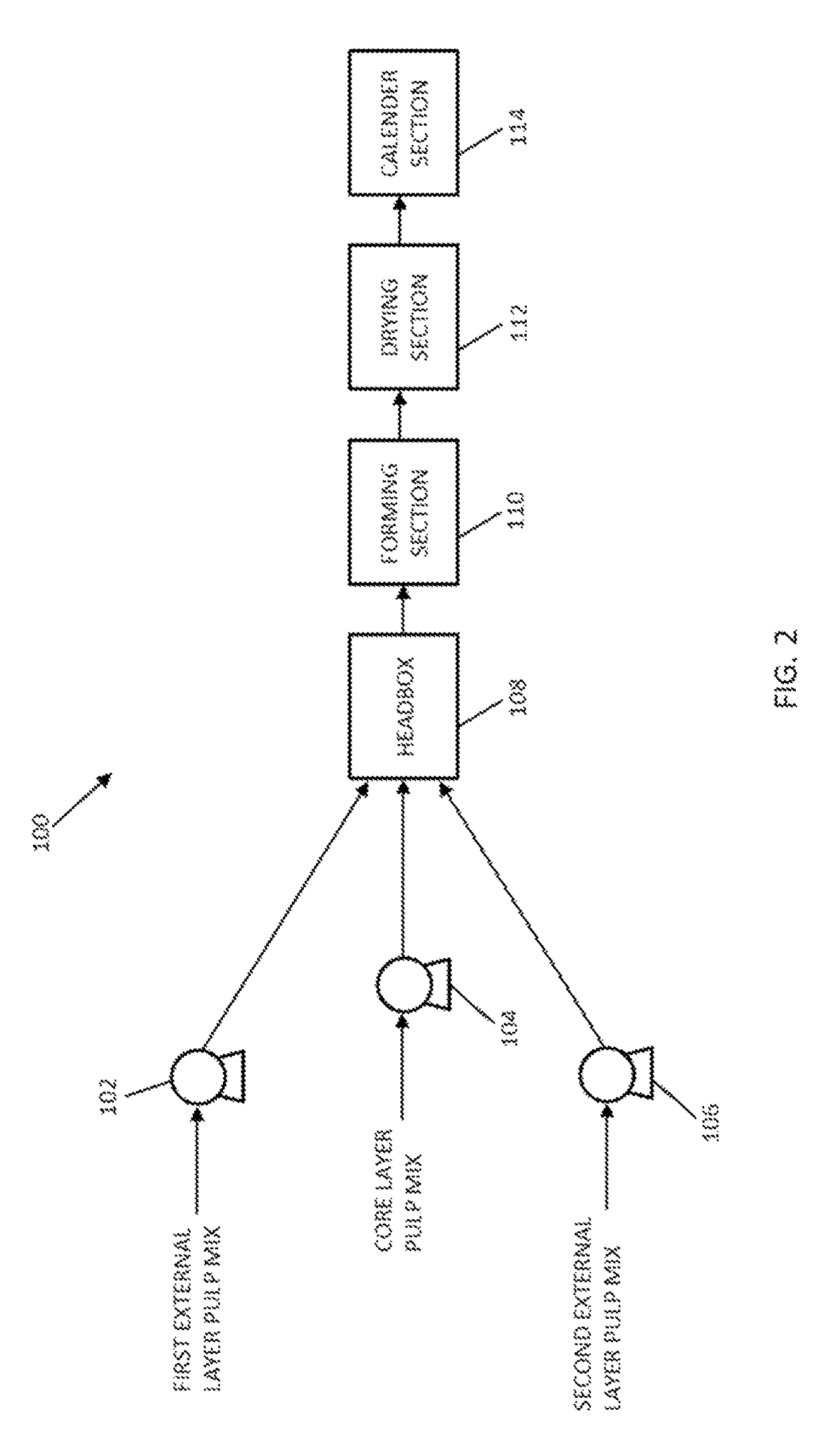

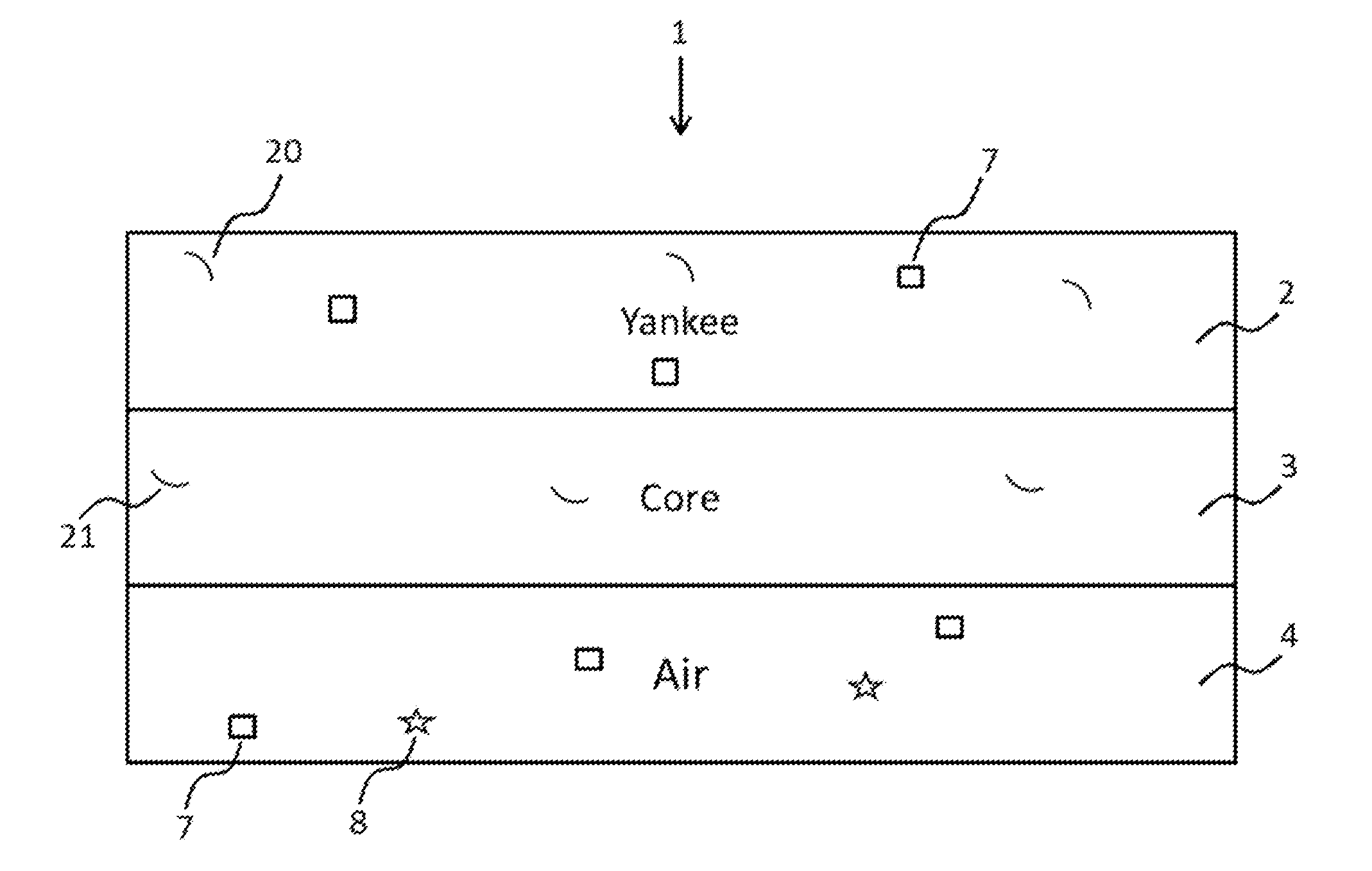

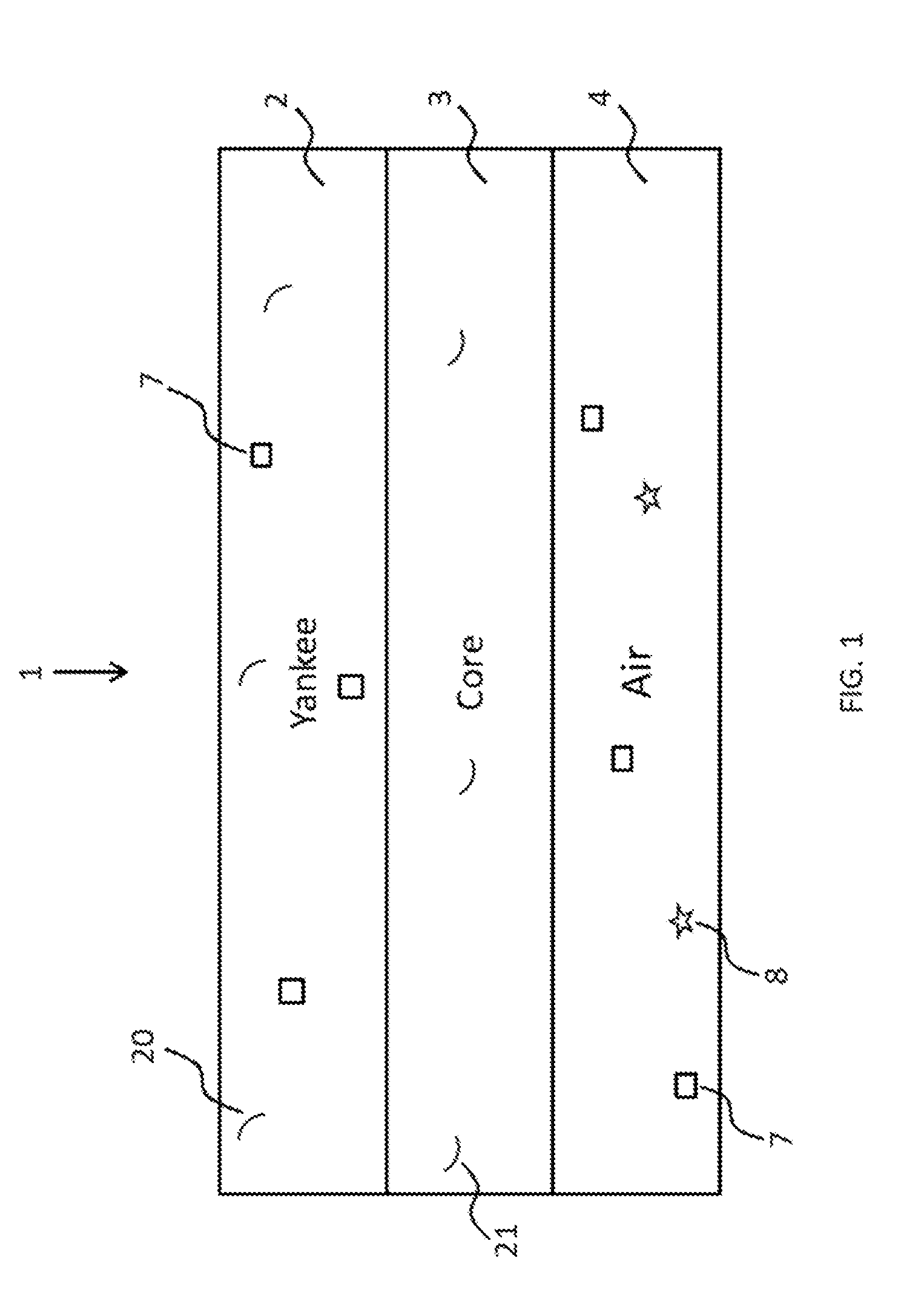

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

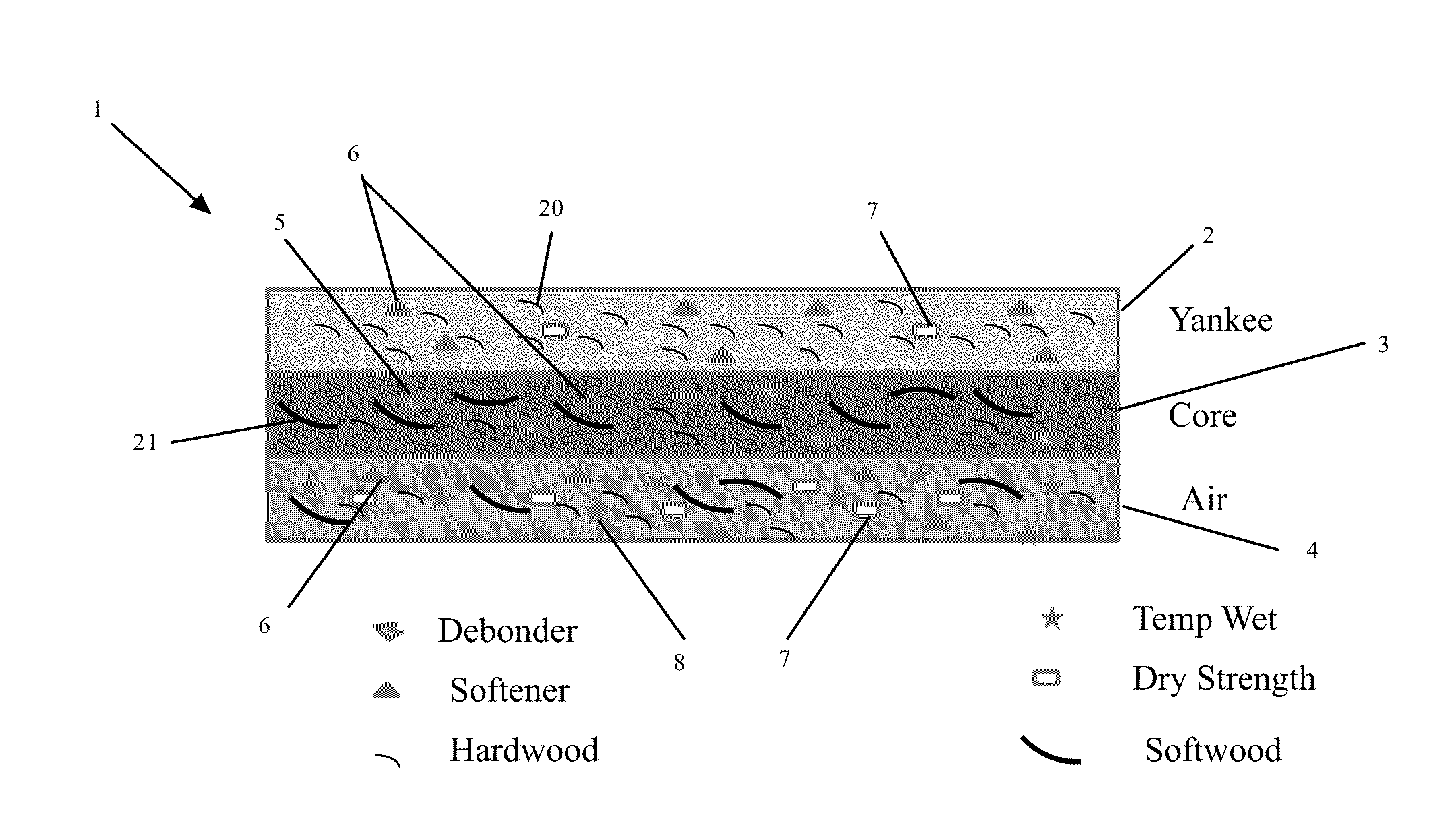

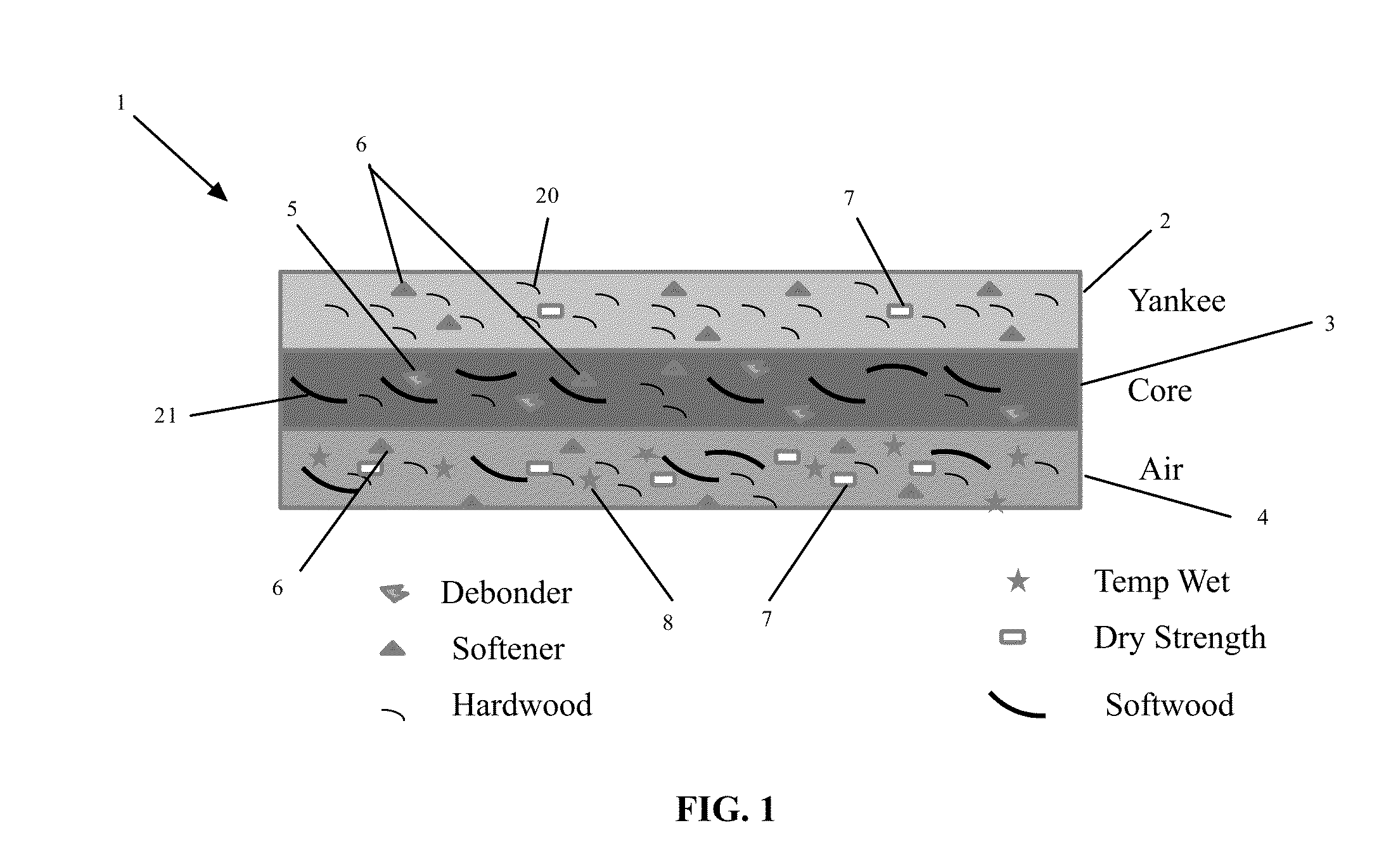

High Softness, High Durability Bath Tissues With Temporary Wet Strength

ActiveUS20130029105A1Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

Owner:GPCP IP HLDG LLC

Ligno cellulosic materials and the products made therefrom

ActiveUS20060260773A1Reducing functional groupGood drainage propertyBiocidePaper after-treatmentCelluloseHypochlorite

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

Decorative base paper with an ink-jet receiving layer

InactiveUS6706372B2Increase consumptionImage definition is often inadequateDecorative surface effectsSpecial ornamental structuresPulp and paper industry

Owner:TECHNOCELL DEKOR GMBH & CO KG

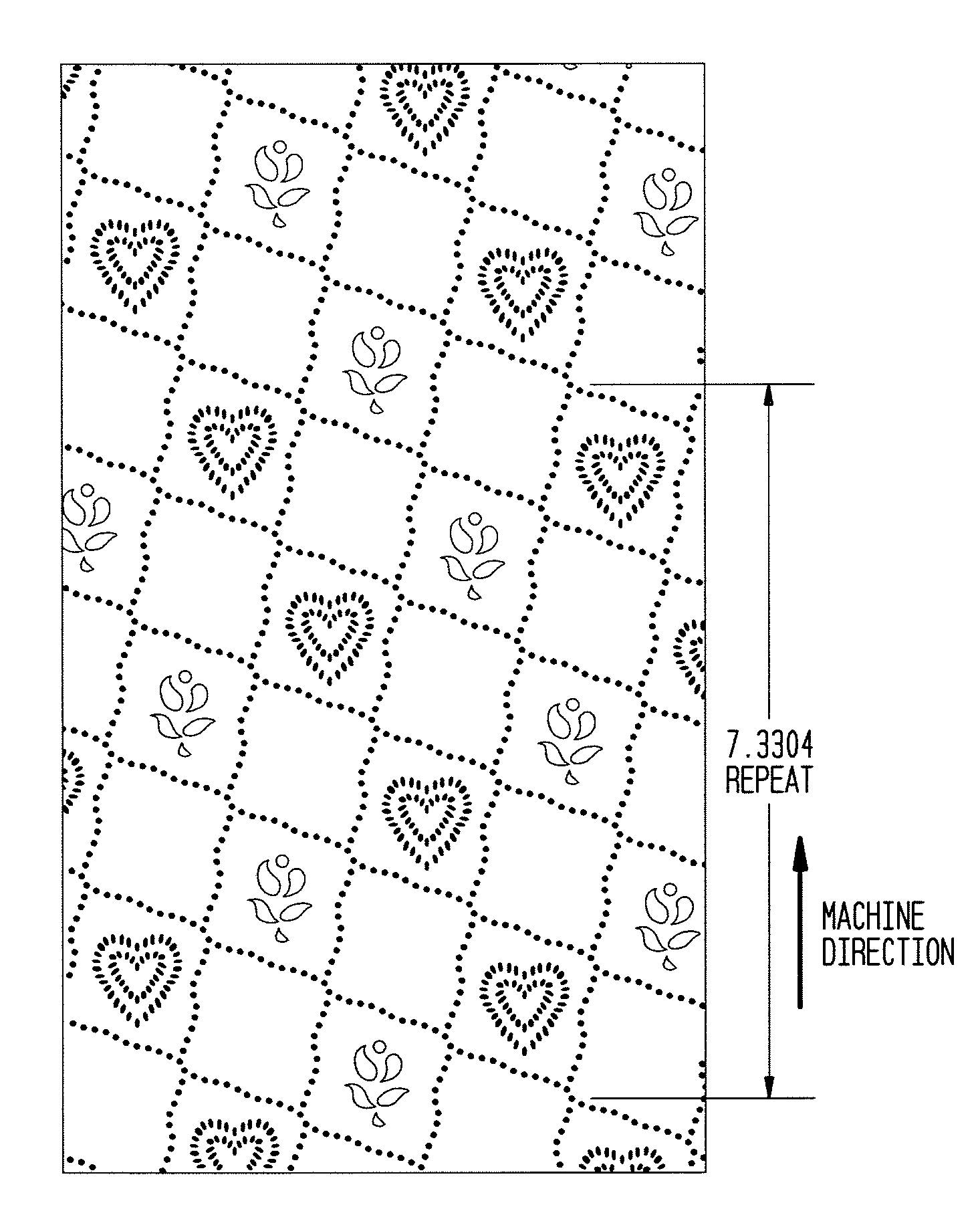

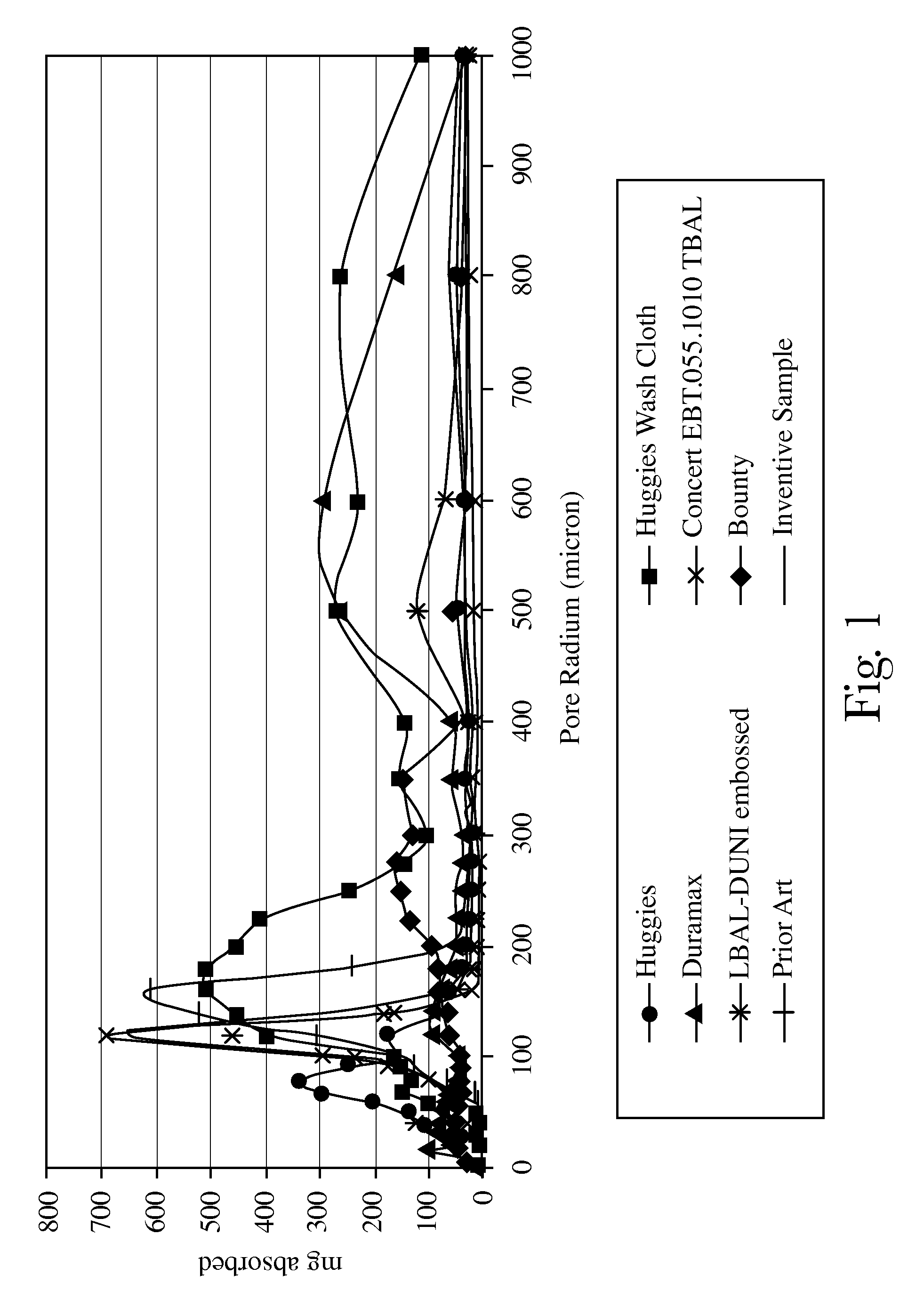

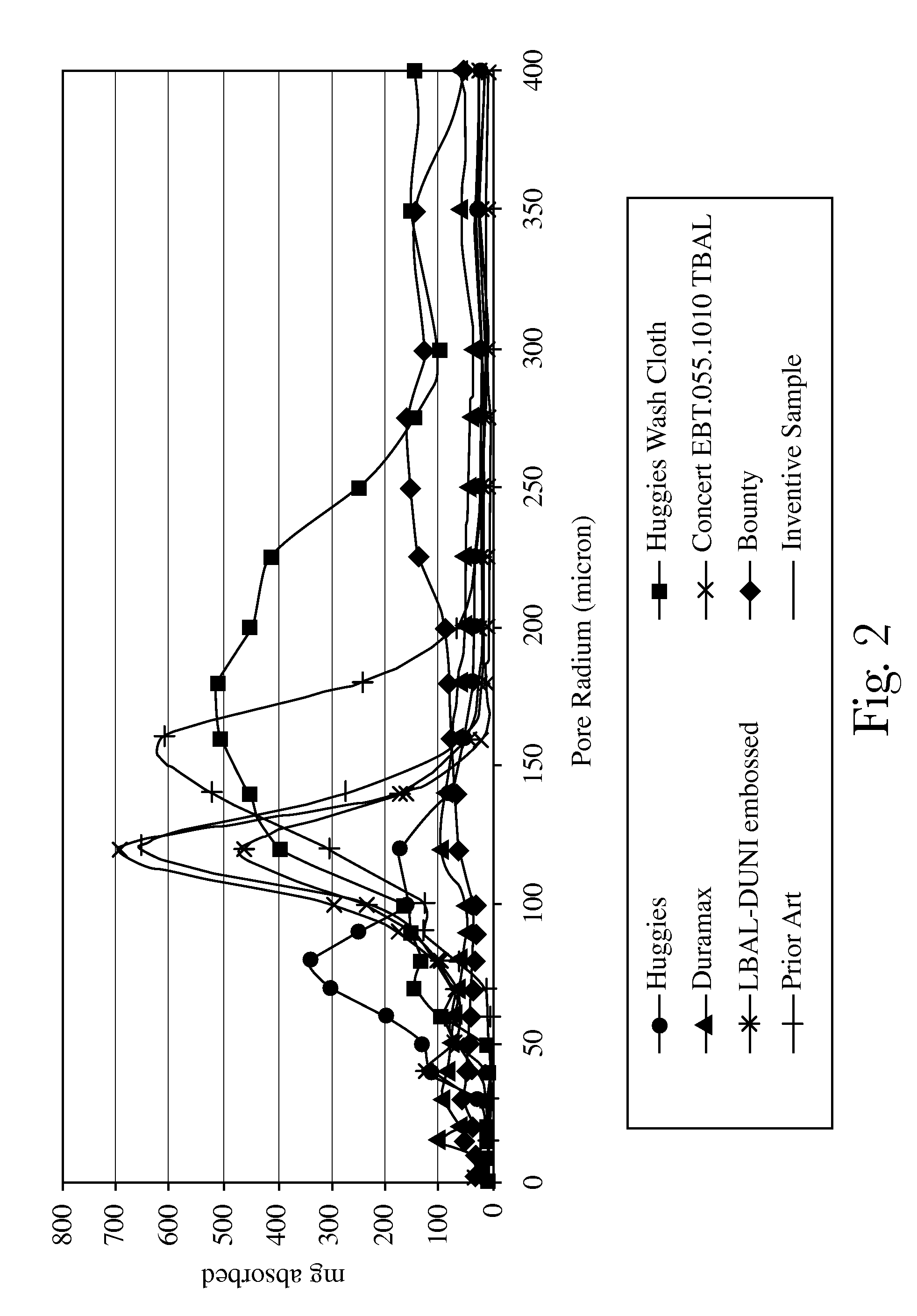

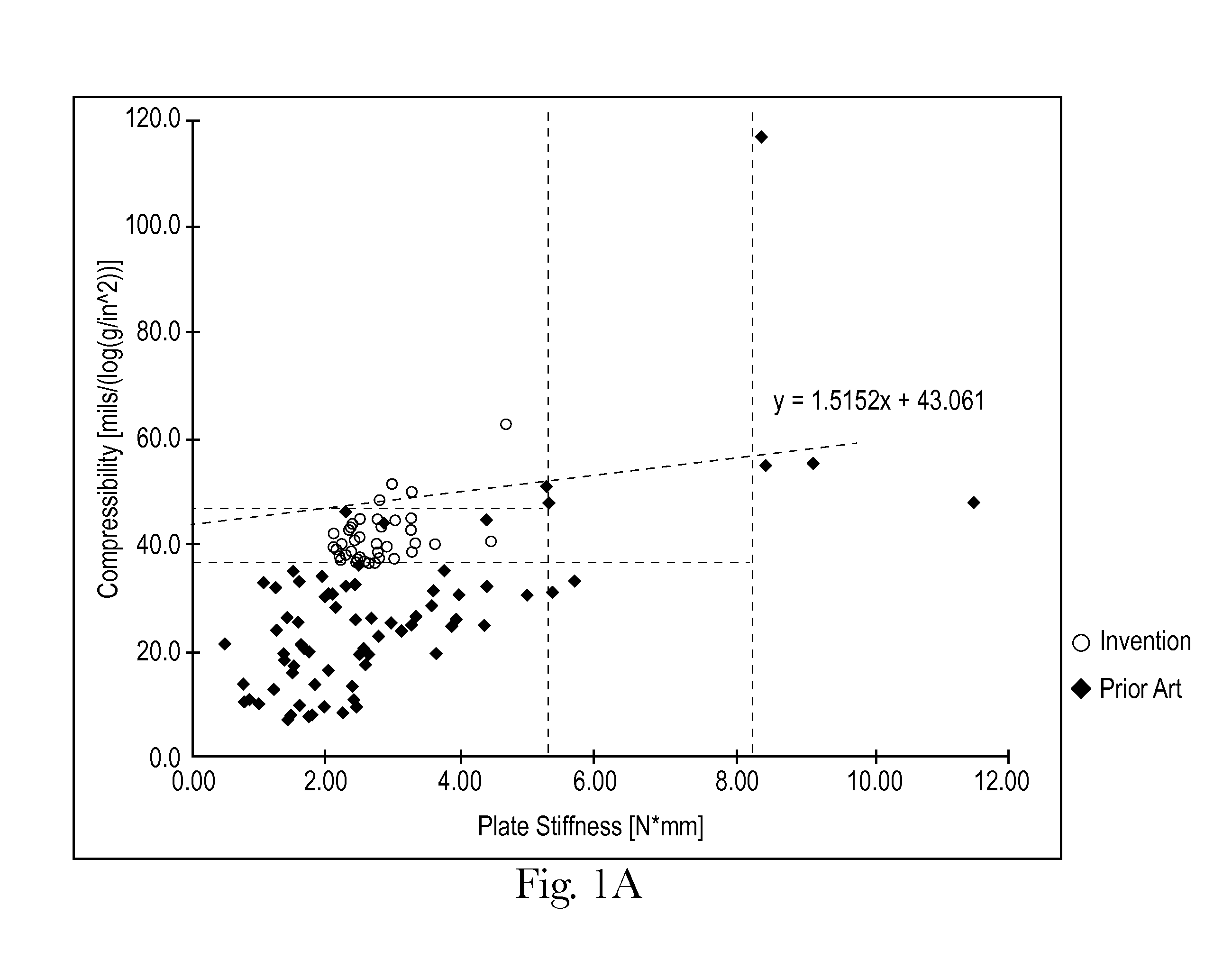

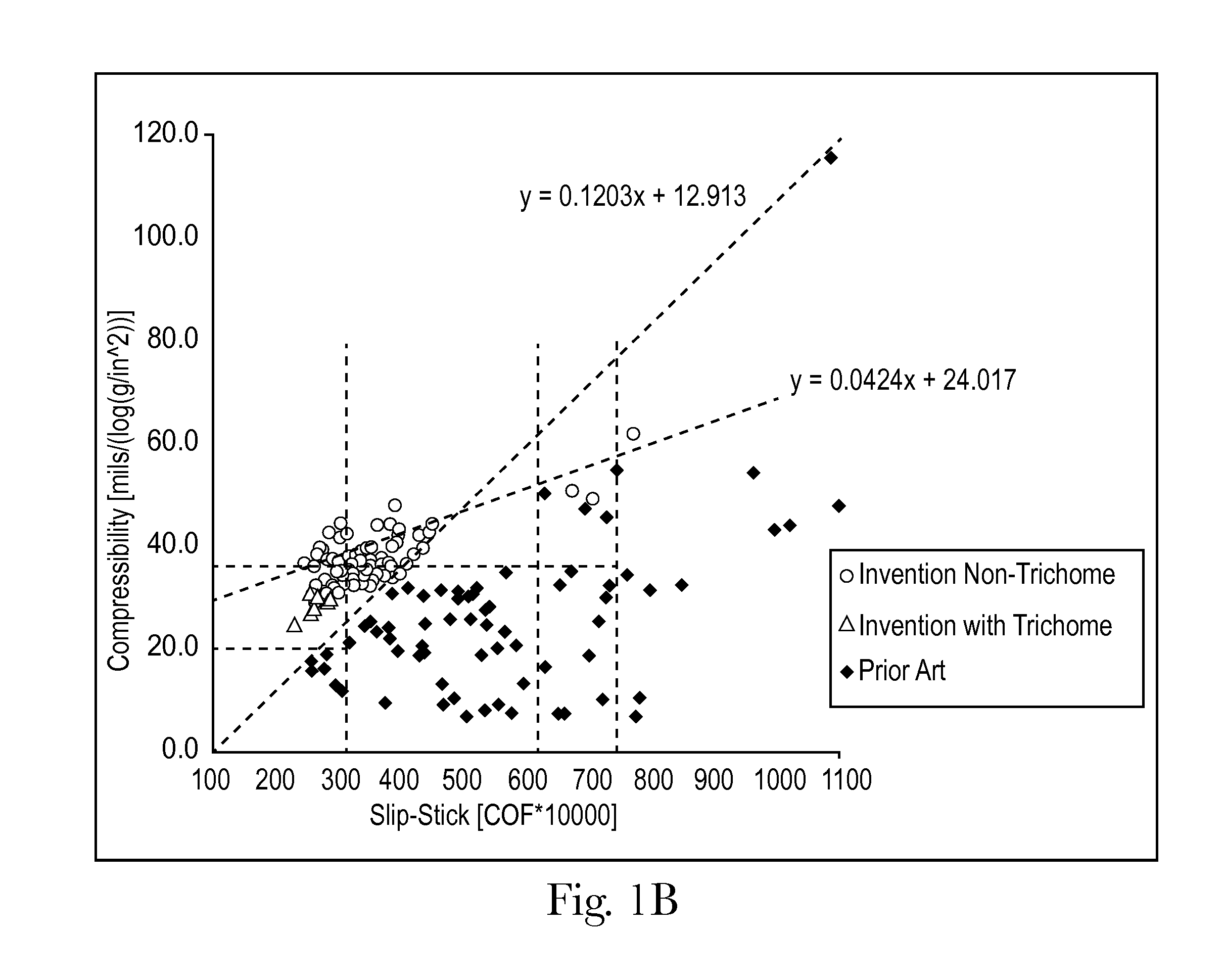

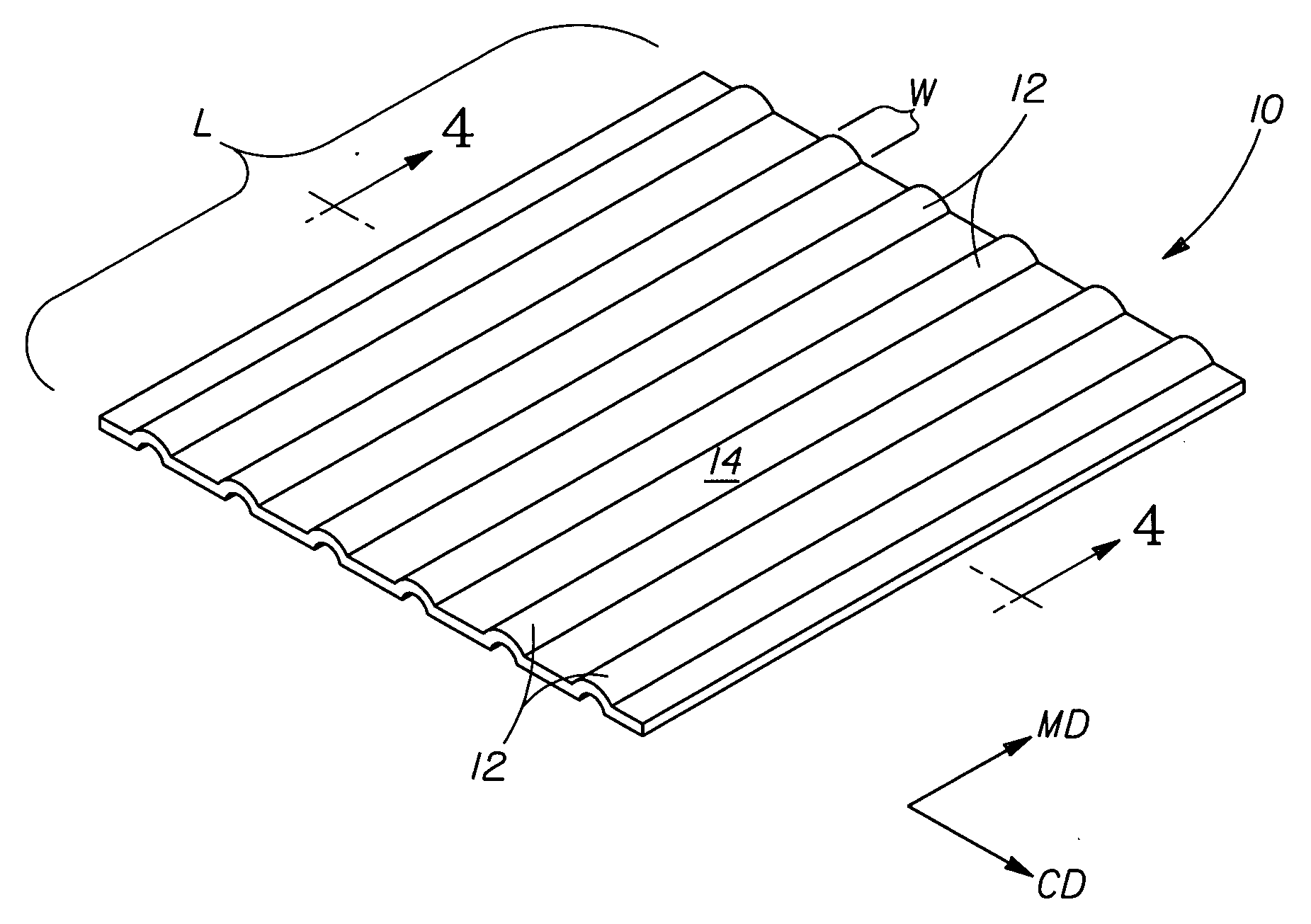

Sanitary tissue products

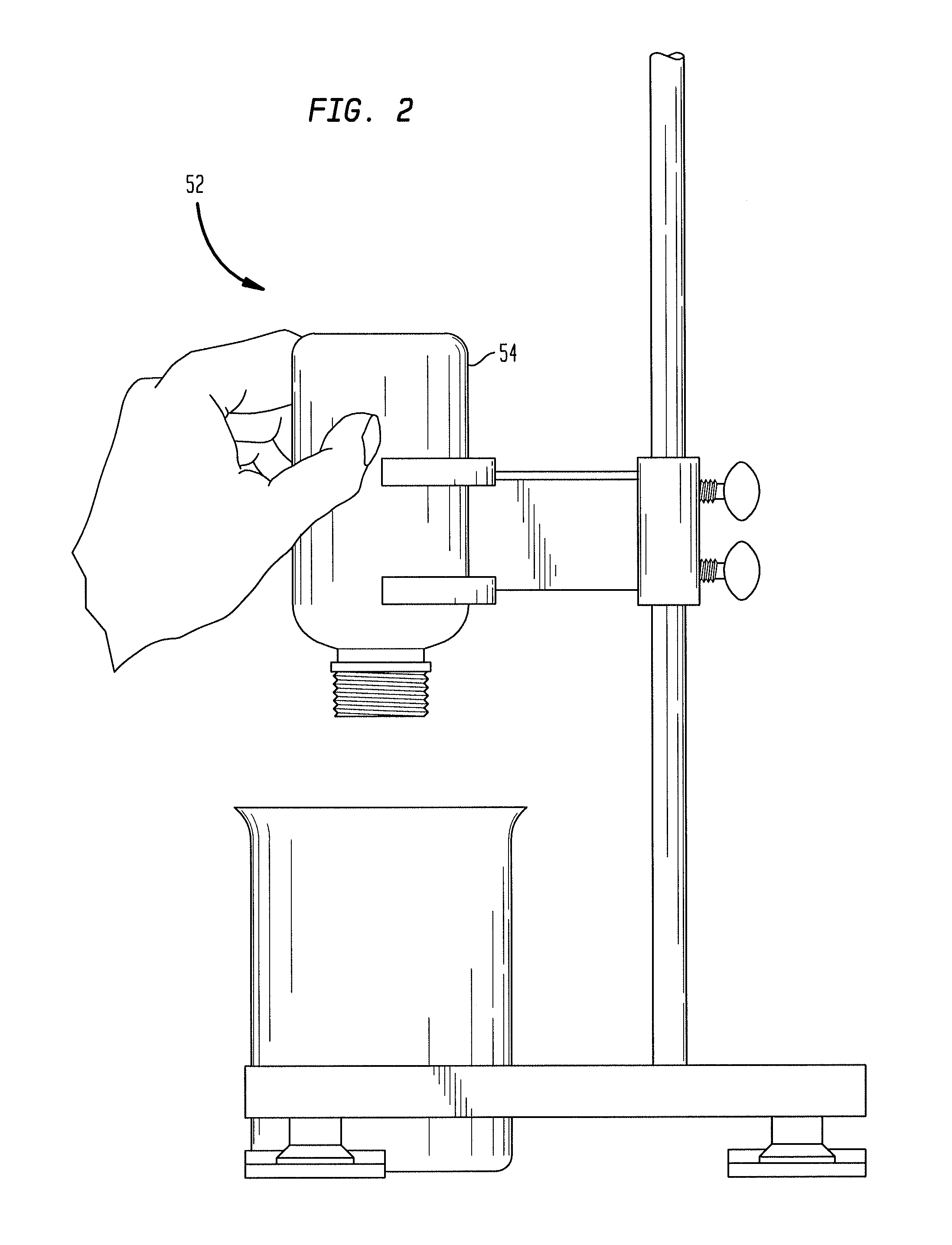

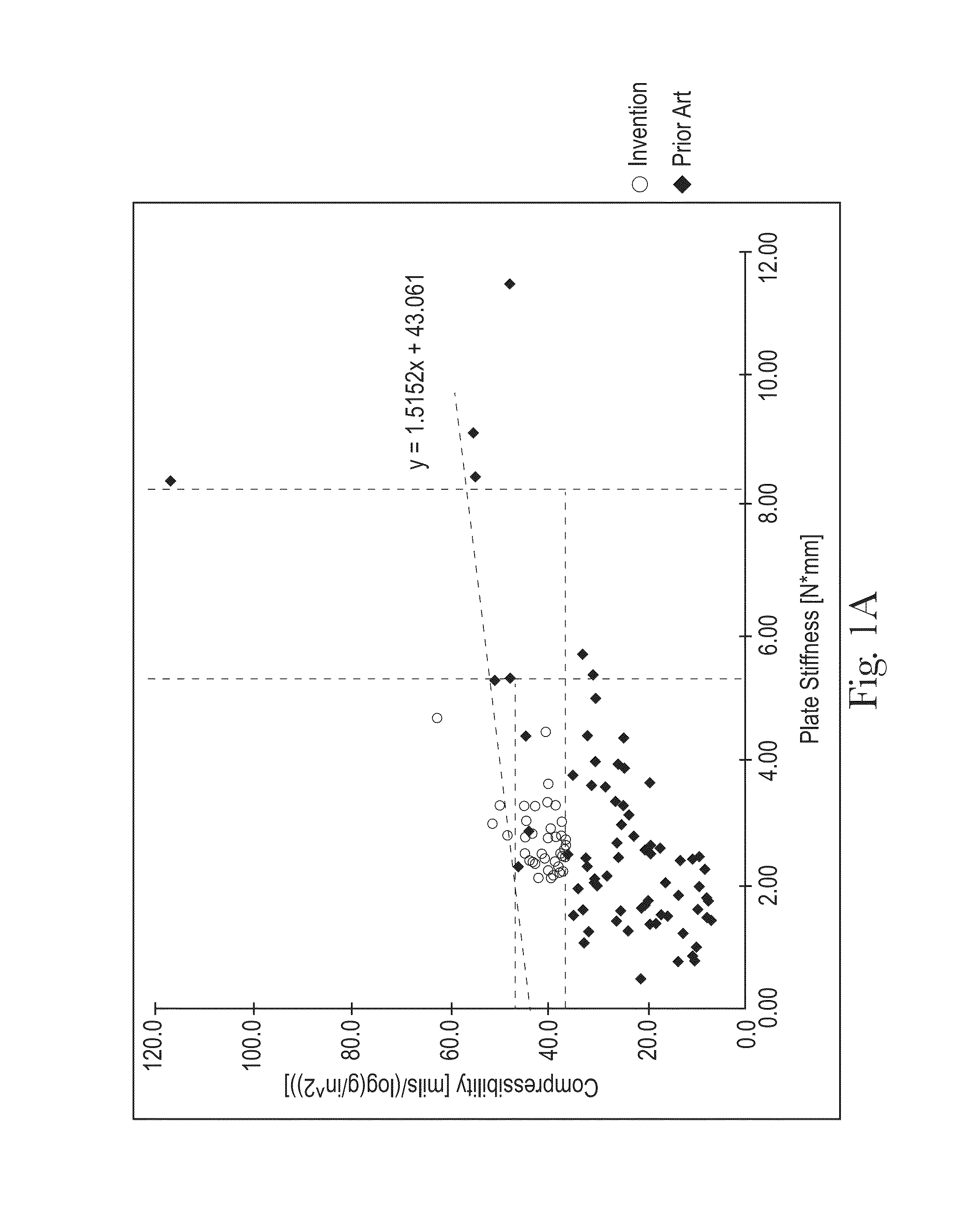

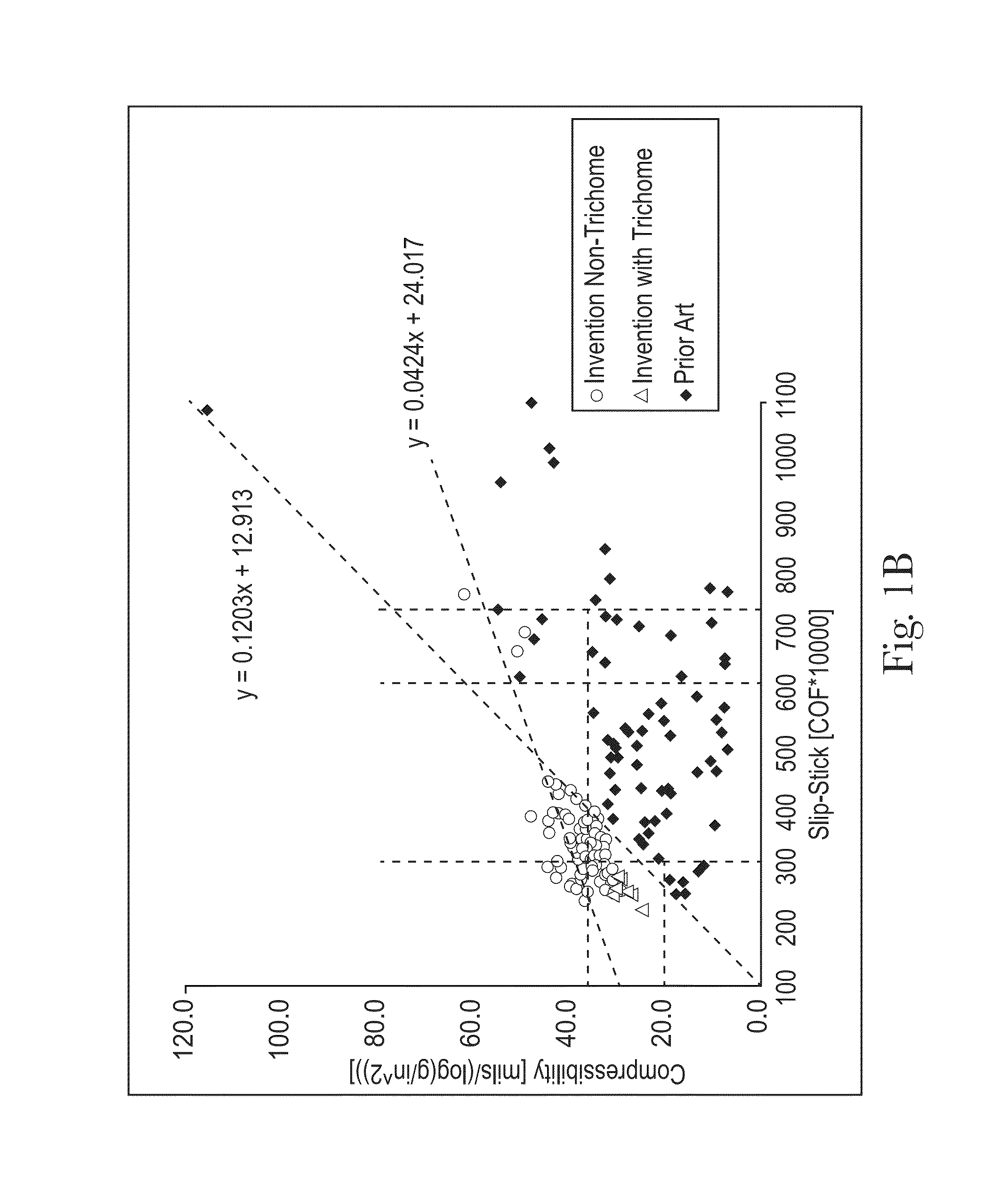

ActiveUS9322136B2Cushier and more flexibleImprove compression performanceMechanical working/deformationPersonal careFiberCompressibility

Sanitary tissue products employing fibrous structures that exhibit novel compressibility properties alone and in combination with plate stiffness properties and methods for making same.

Owner:PROCTER & GAMBLE CO

Molding base paper and molded paper vessel produced from it

InactiveUS20020012759A1Mechanical working/deformationSpecial paperCompressive strengthUltimate tensile strength

A molding base paper used for forming paper vessels such as a cup or tray for foods and various industrial products is disclosed which satisfies the following conditions (1) to (4): (1) a tensile strength (JIS-P 8113) of at least 2.0 kN / m, (2) an elongation at break (JIS-P 8113) of at least 1.5%, (3) a critical compression stress, defined by the following formula, in the range of 1 to 10 MPa: <paragraph lvl="0"><in-line-formula>critical compression stress=A / B < / in-line-formula>wherein A represents the compression strength determined by JIS-P 8126, and B represents the area of loaded part of the test piece in the determination of the compression strength, and (4) an amount of the compression deformation, caused by applying compression stress of 20 kgf / cm2in thickness direction, of at least 10 %. The paper vessels are prepared by controlling the water content of the molding base paper at 10 to 20% and then drawing the molding base paper at 100 to 150° C.

Owner:OJI PAPER CO LTD

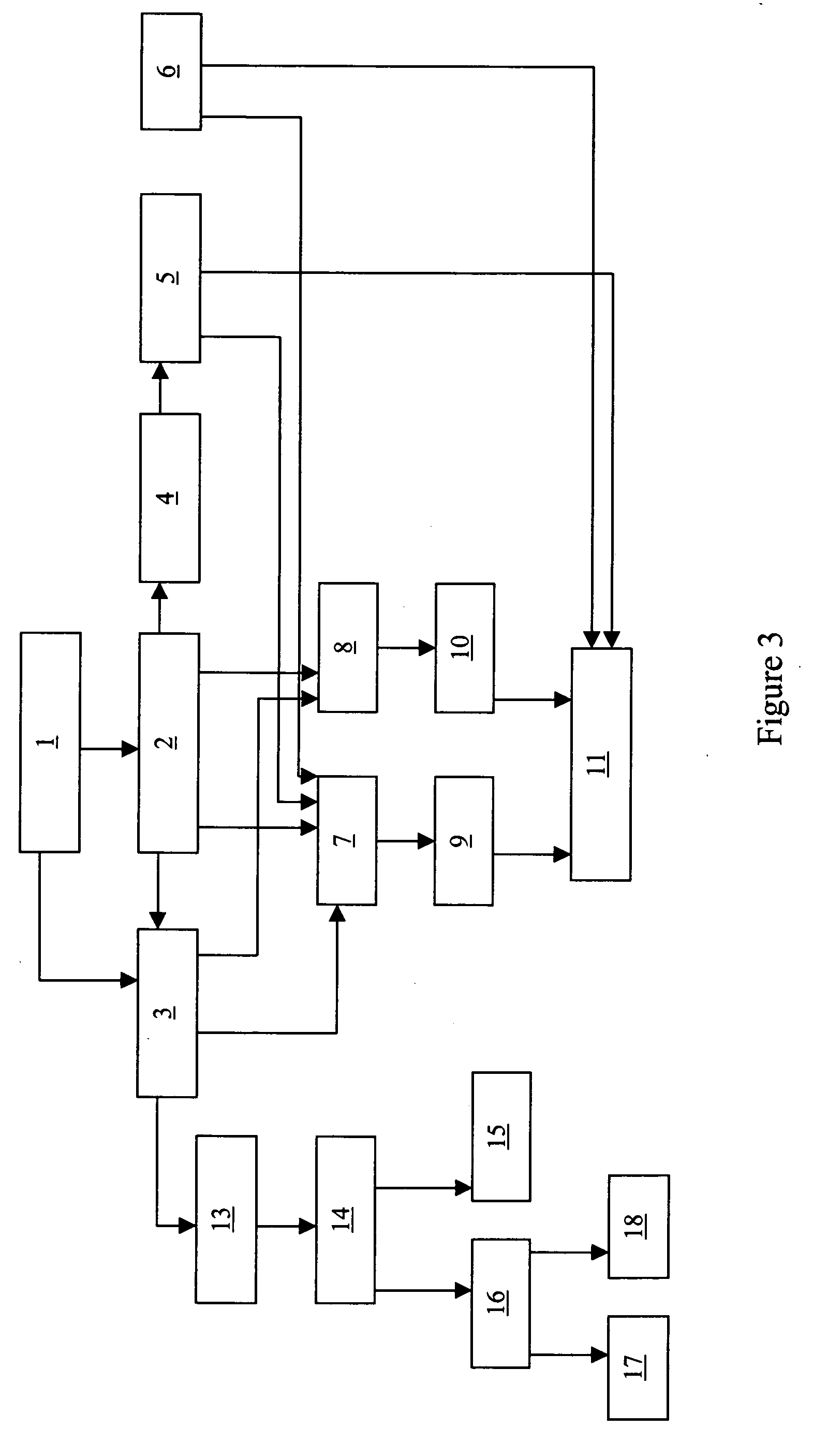

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

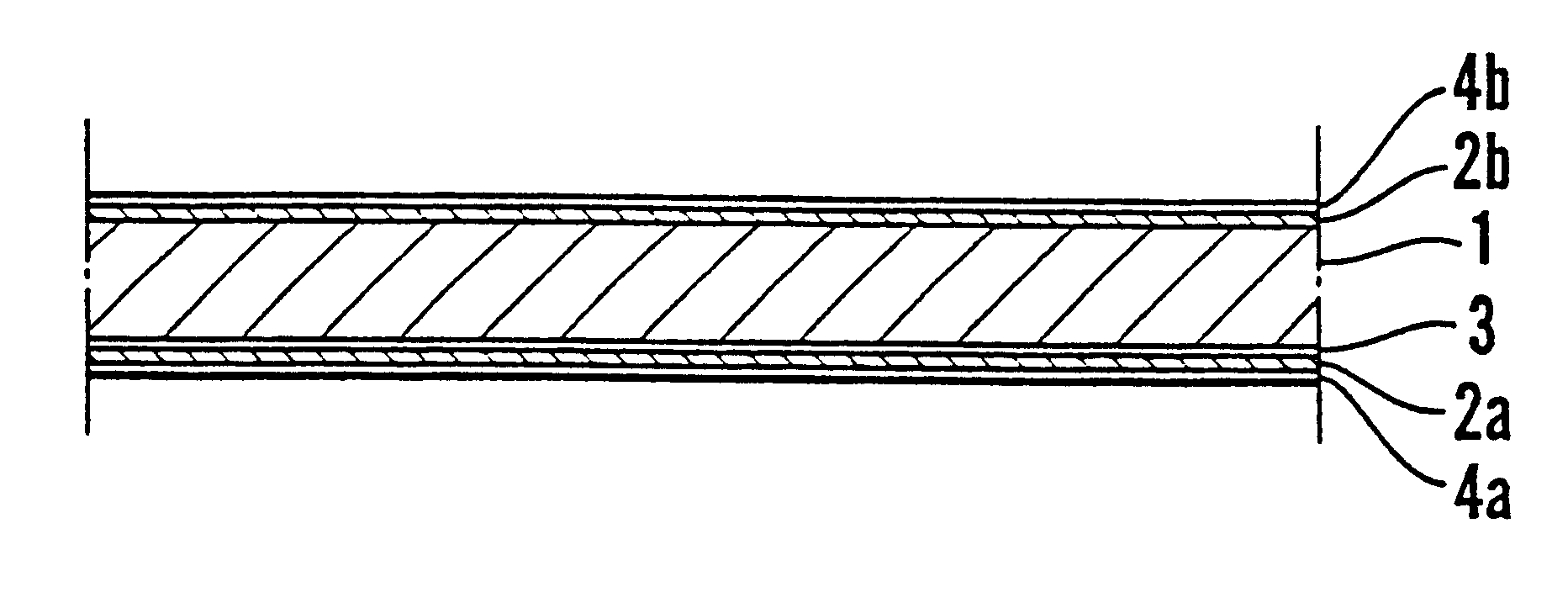

Paper or paperboard laminate and method to produce such a laminate

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

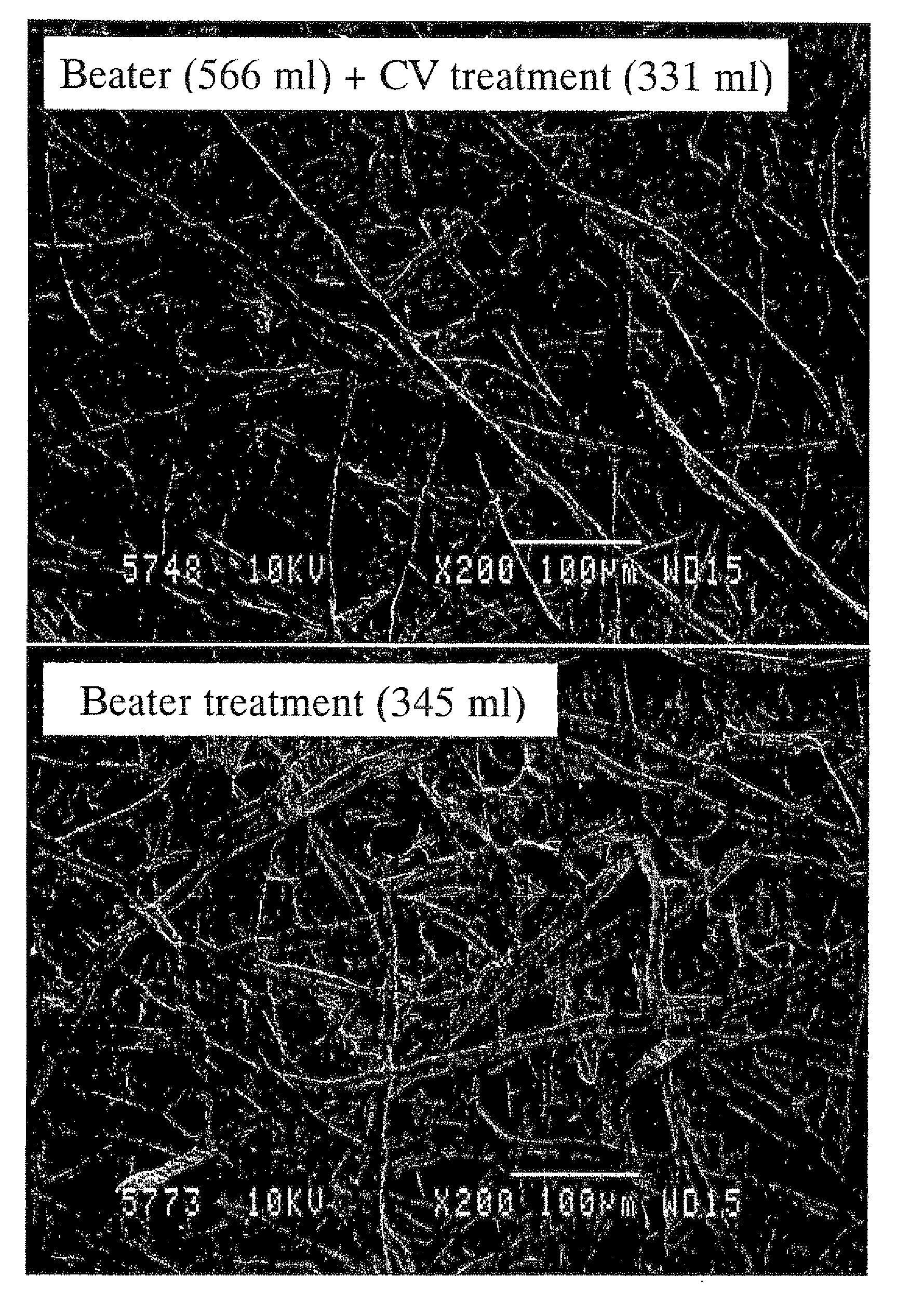

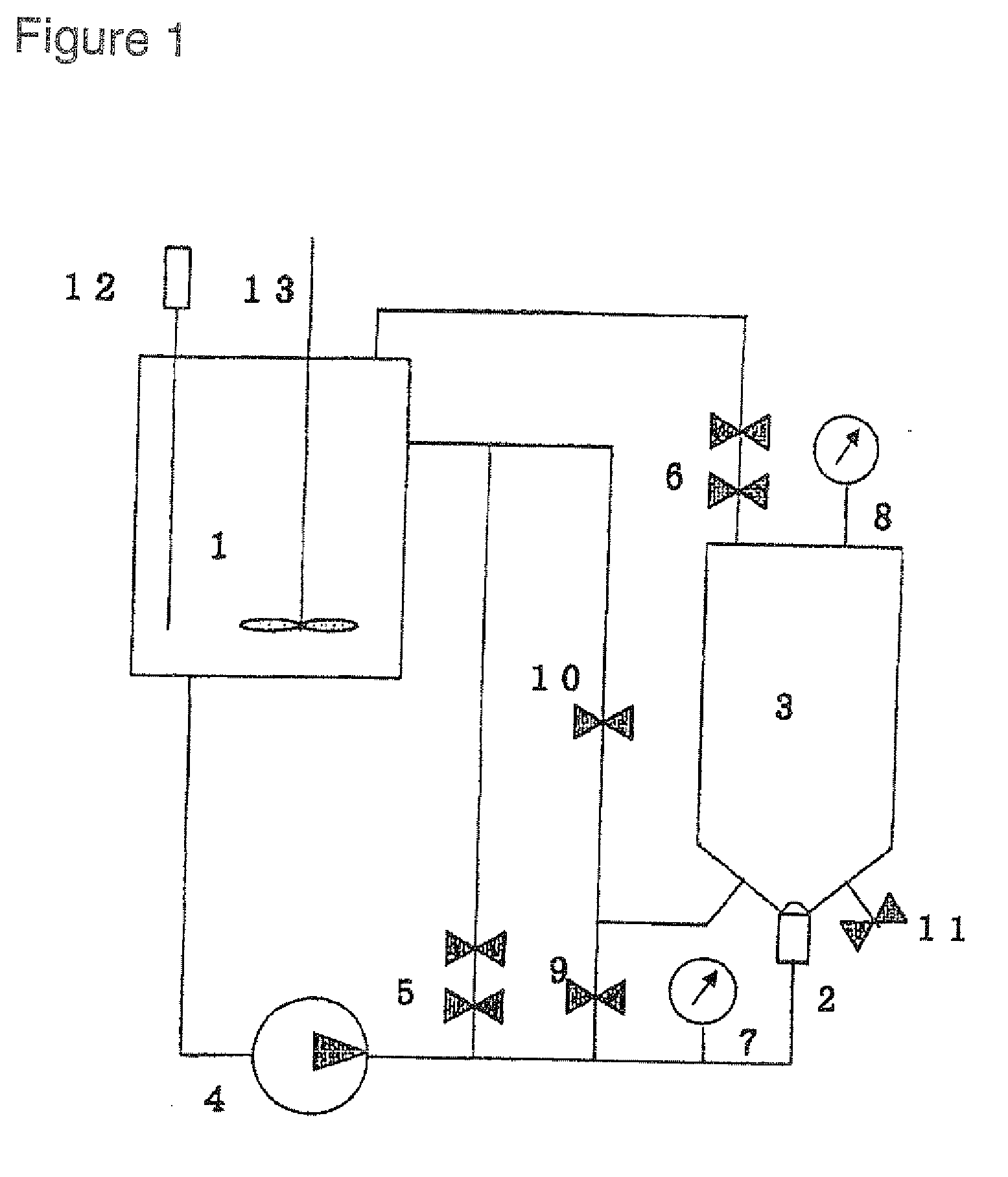

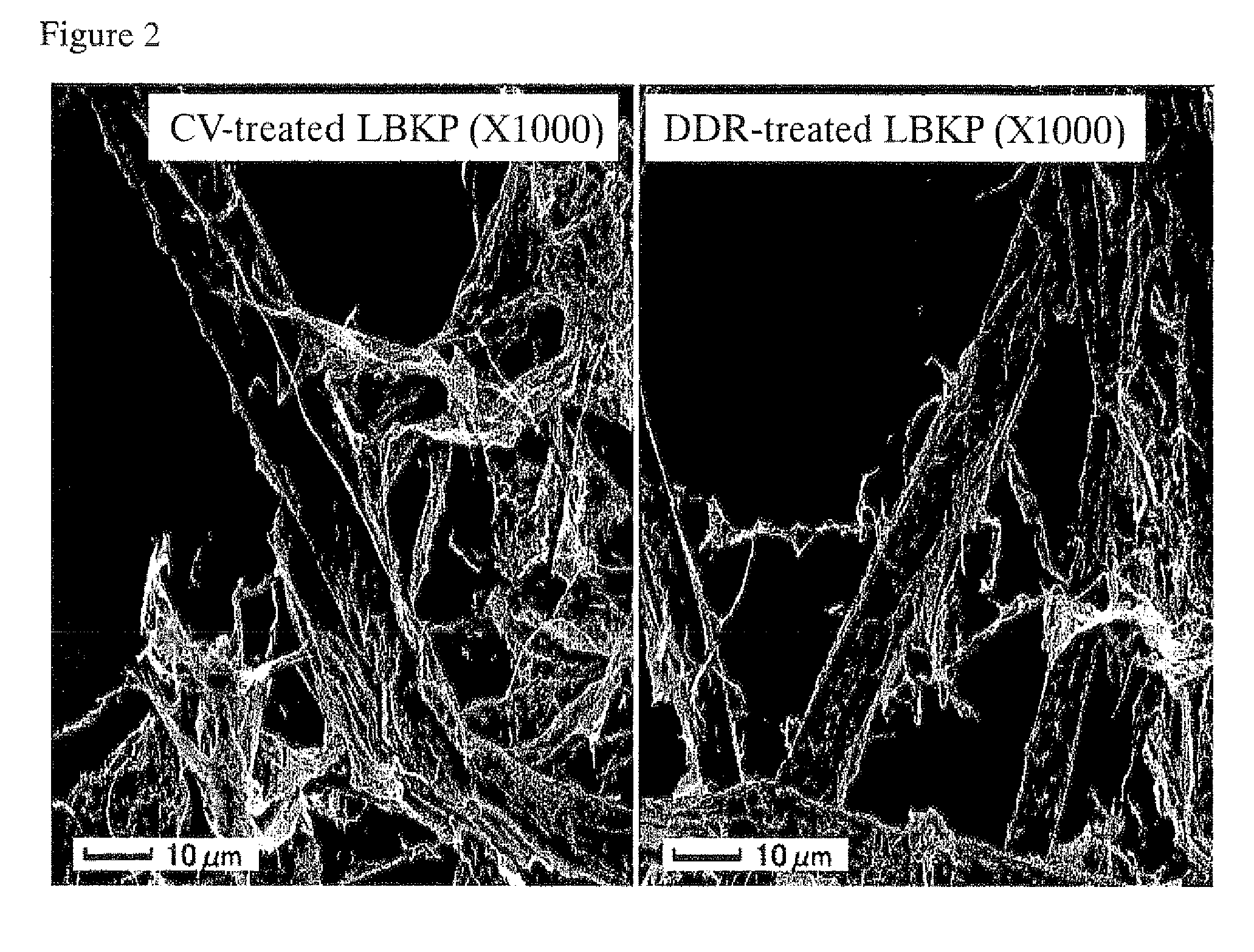

Cellulose-based fibrous materials

ActiveUS20090065164A1Low densityImprove surface qualityCellulosic pulp after-treatmentReinforcing agents additionFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

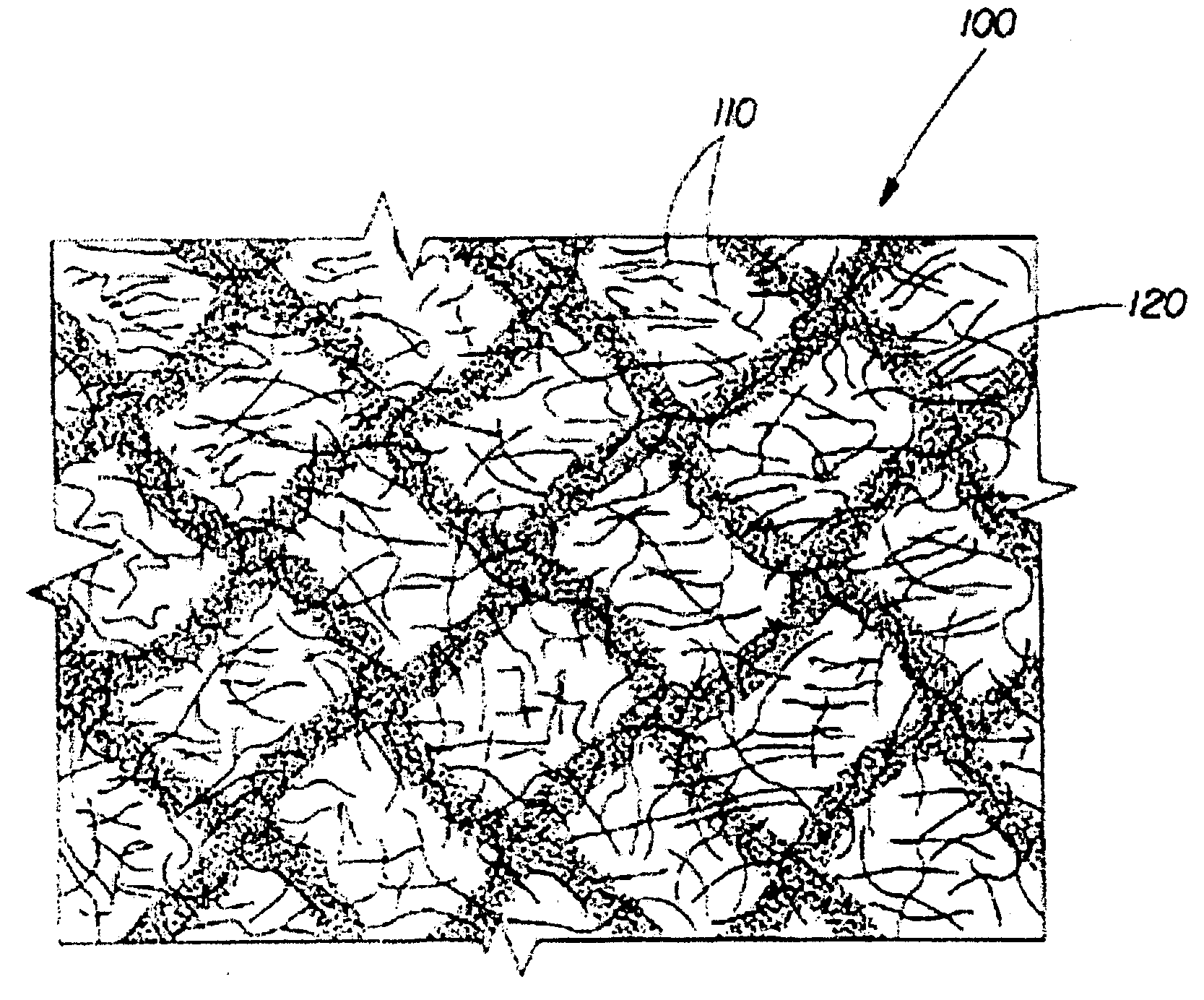

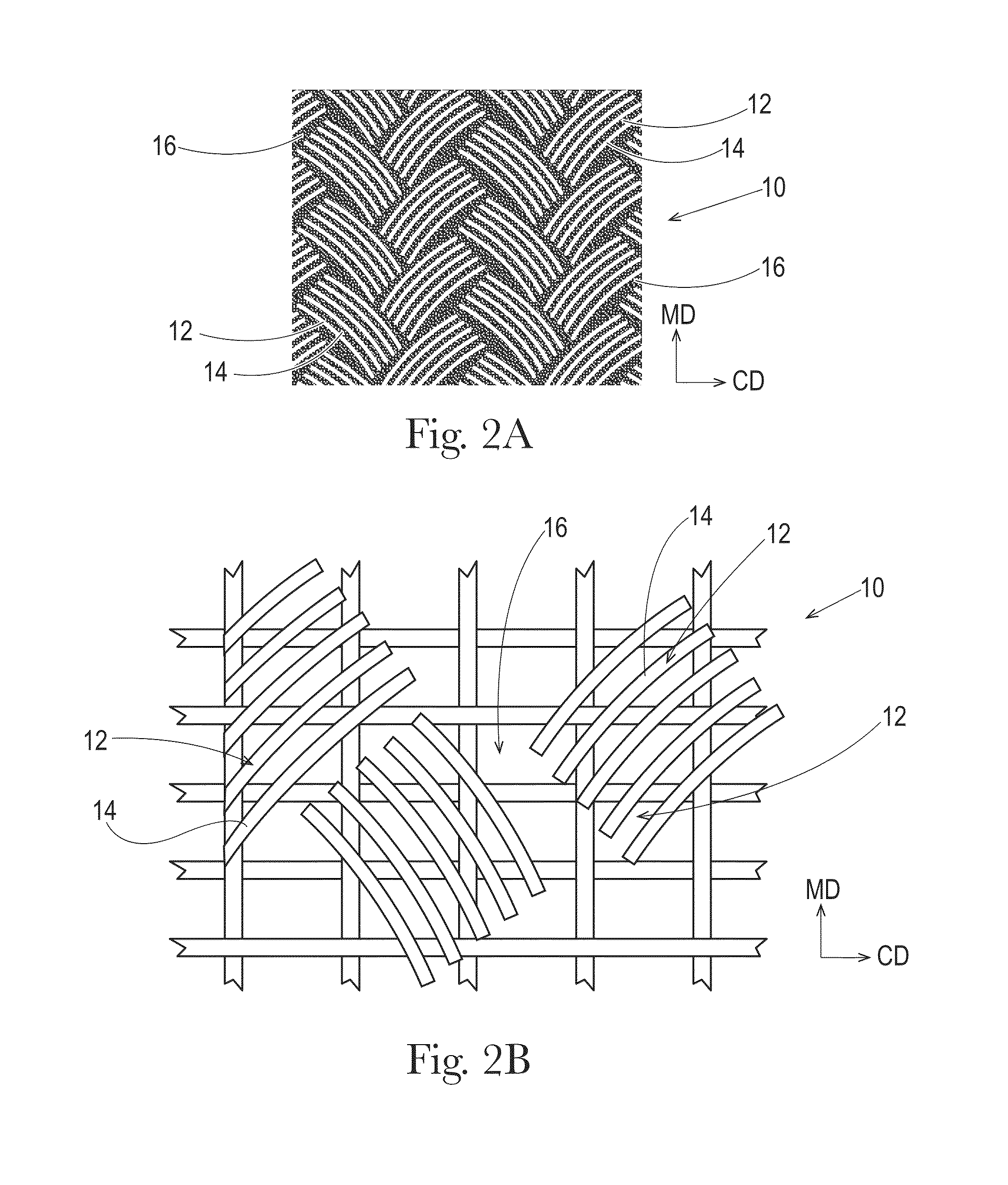

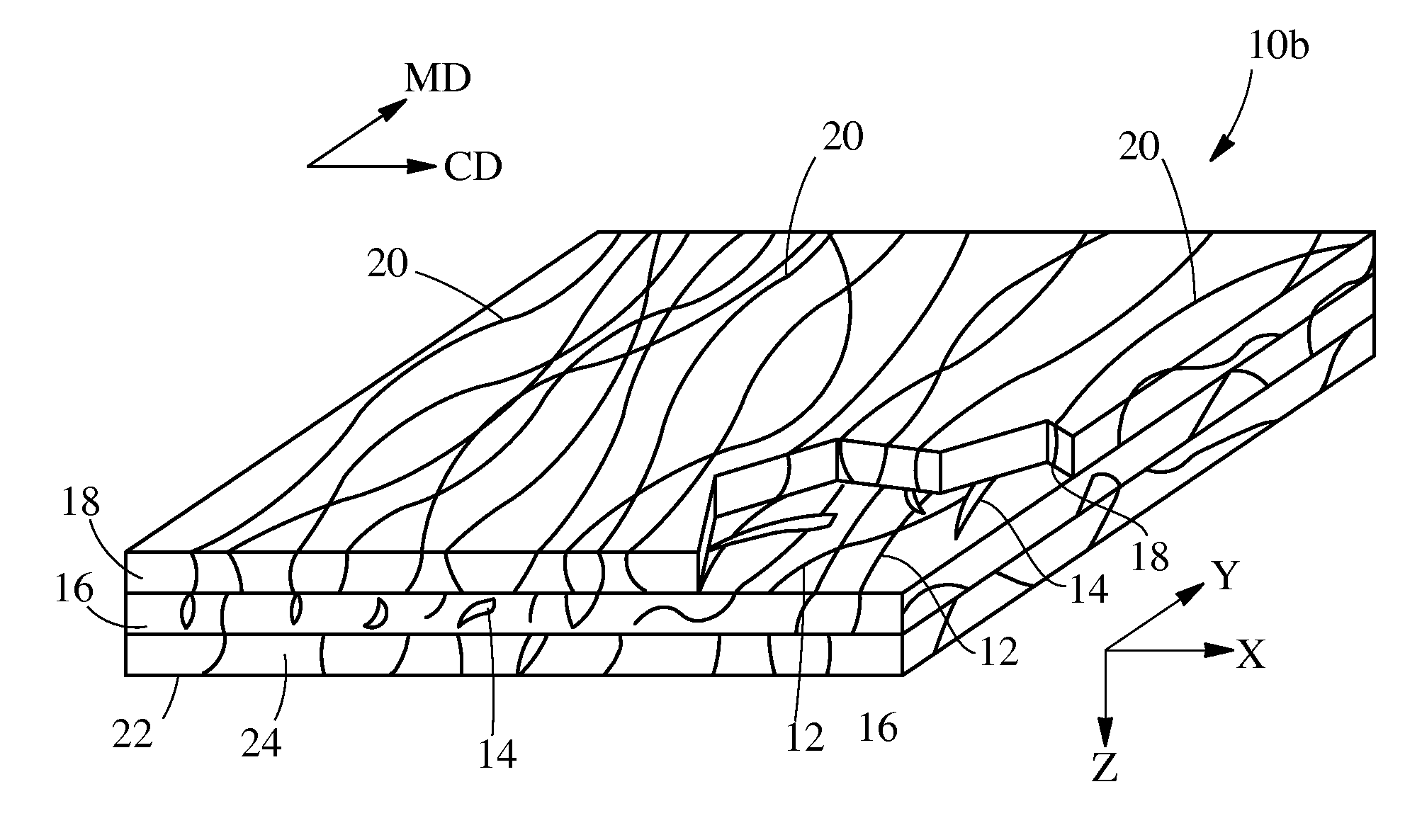

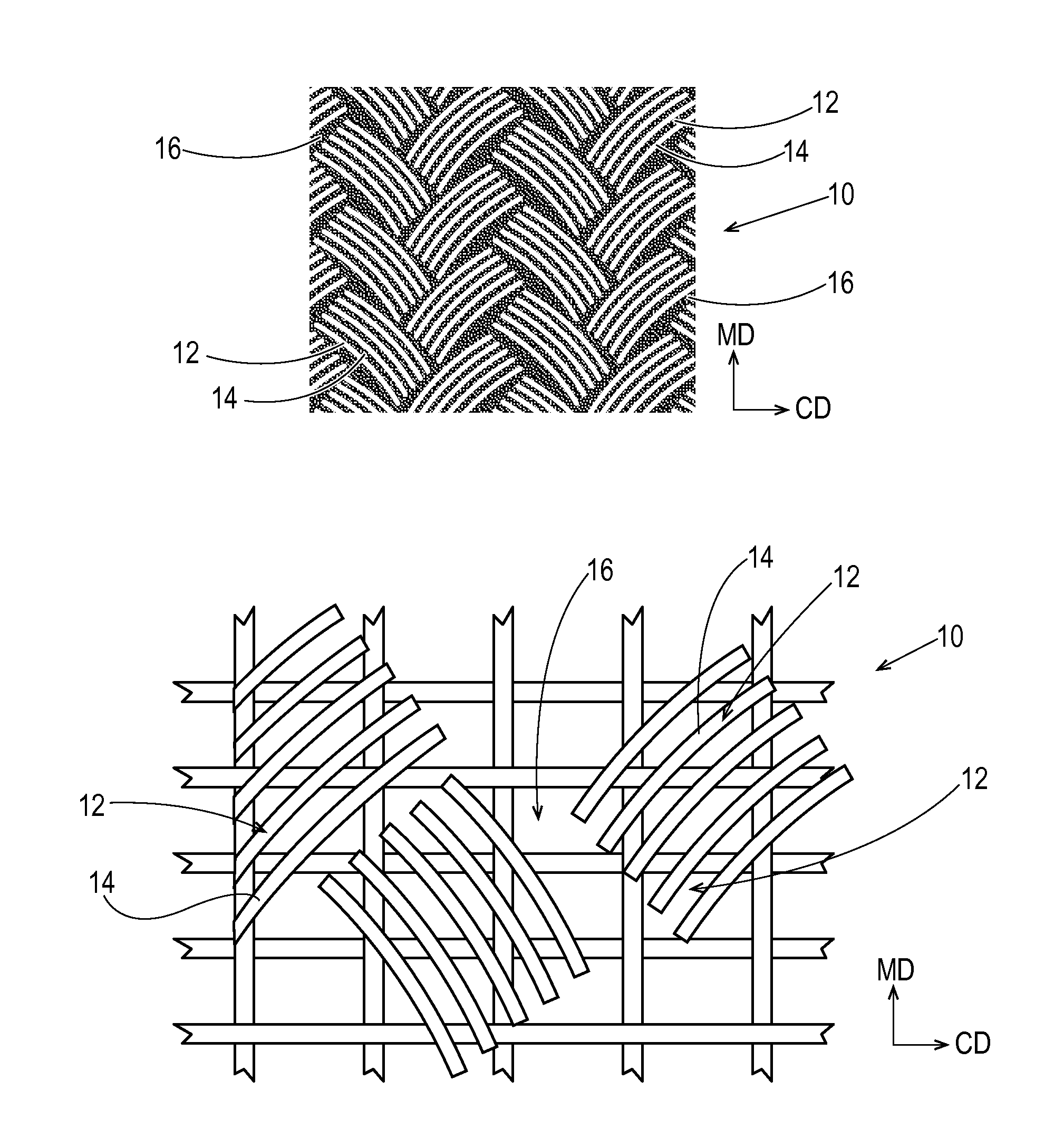

Fibrous structures

Owner:THR PROCTER & GAMBLE COMPANY ATTENTION CHEIF PATENT COUNSEL

Soft through air dried tissue

ActiveUS8968517B2Without compromising softness and cleaning abilityAvoid disadvantagesPaper after-treatmentPaper coatingNon ionicSURFACTANT BLEND

Owner:FIRST QUALITY TISSUE LLC

Fibrous Structures and Methods for Making Same

PendingUS20170009401A1Easy to optimizeOrganic non-cellulose fibresPaper/cardboardFiberPolymer science

Fibrous structures and more particularly fibrous structures containing a plurality of hydroxyl polymer fibrous elements, for example hydroxyl polymer filaments, such that the fibrous structures exhibit improved surface properties compared to known fibrous structures and methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous structures and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

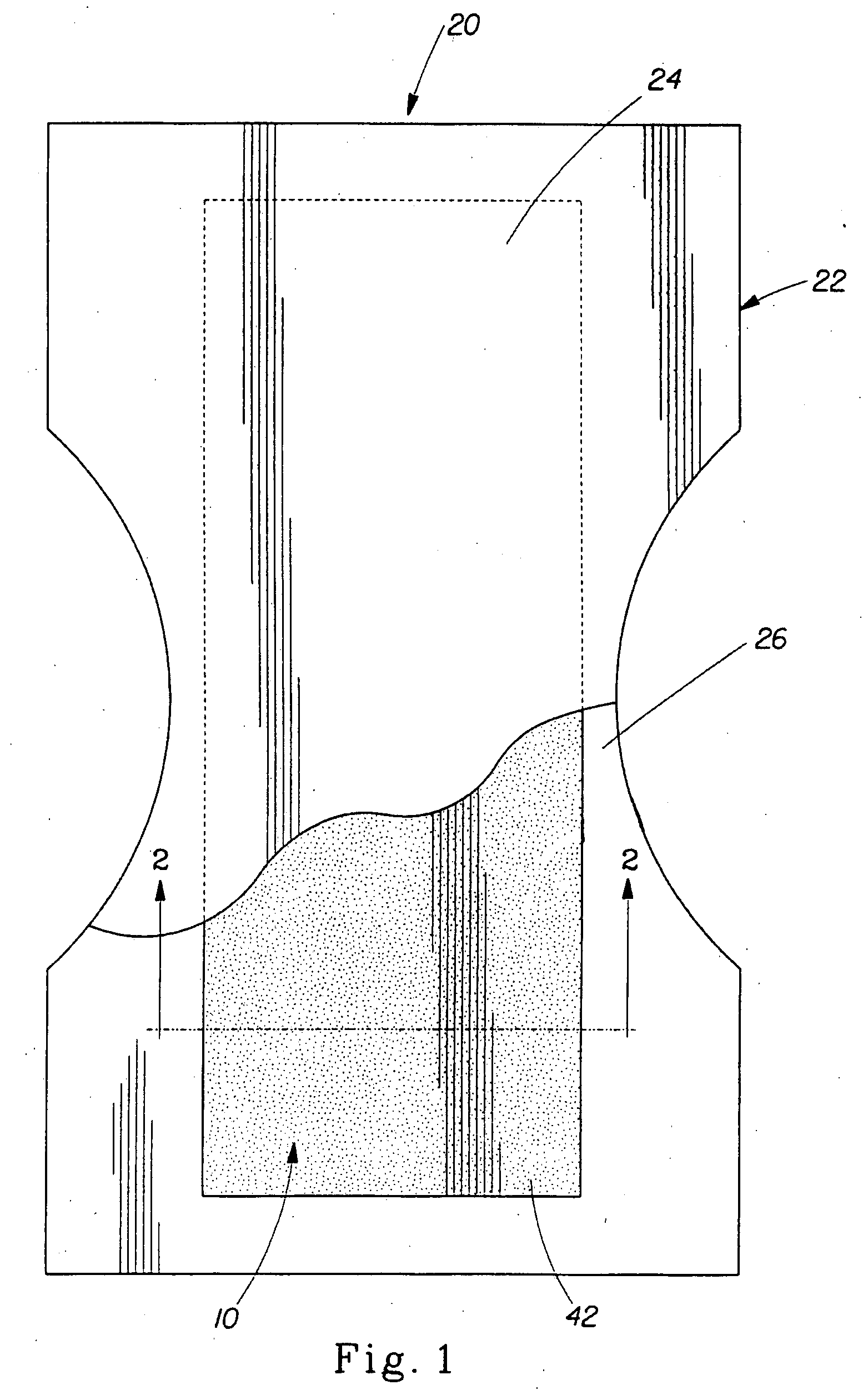

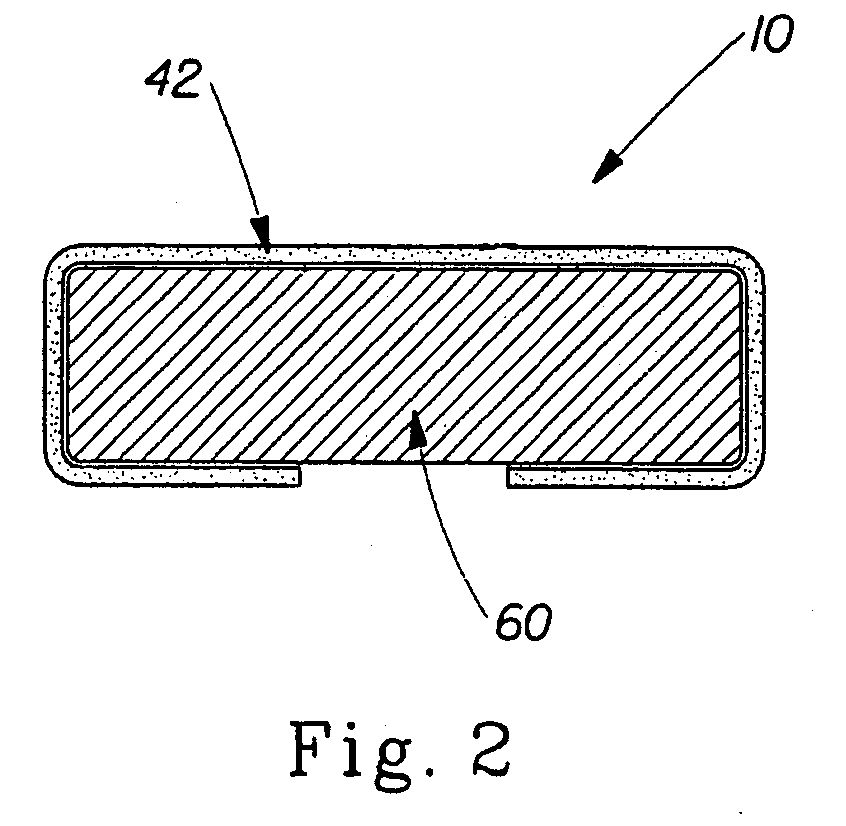

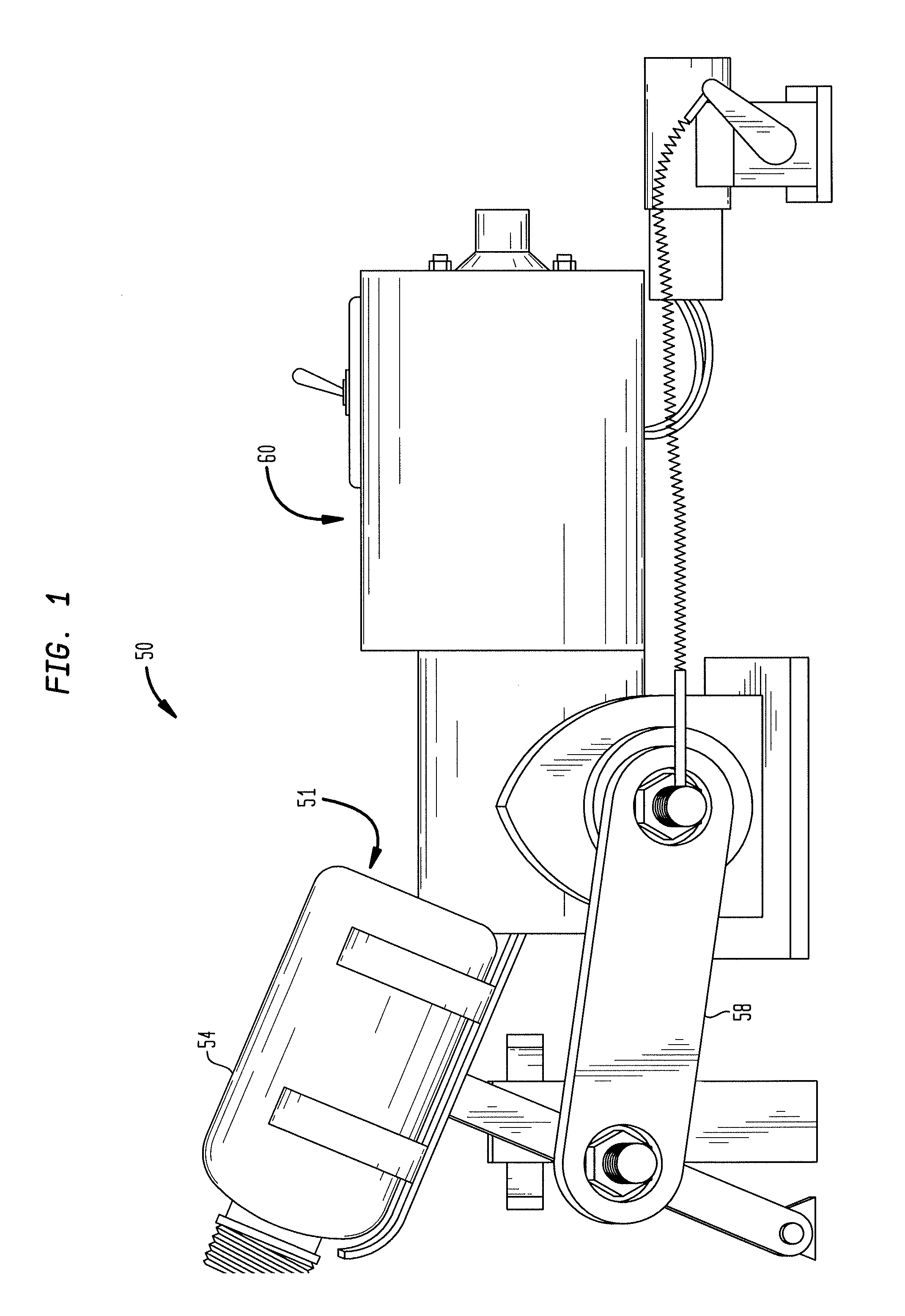

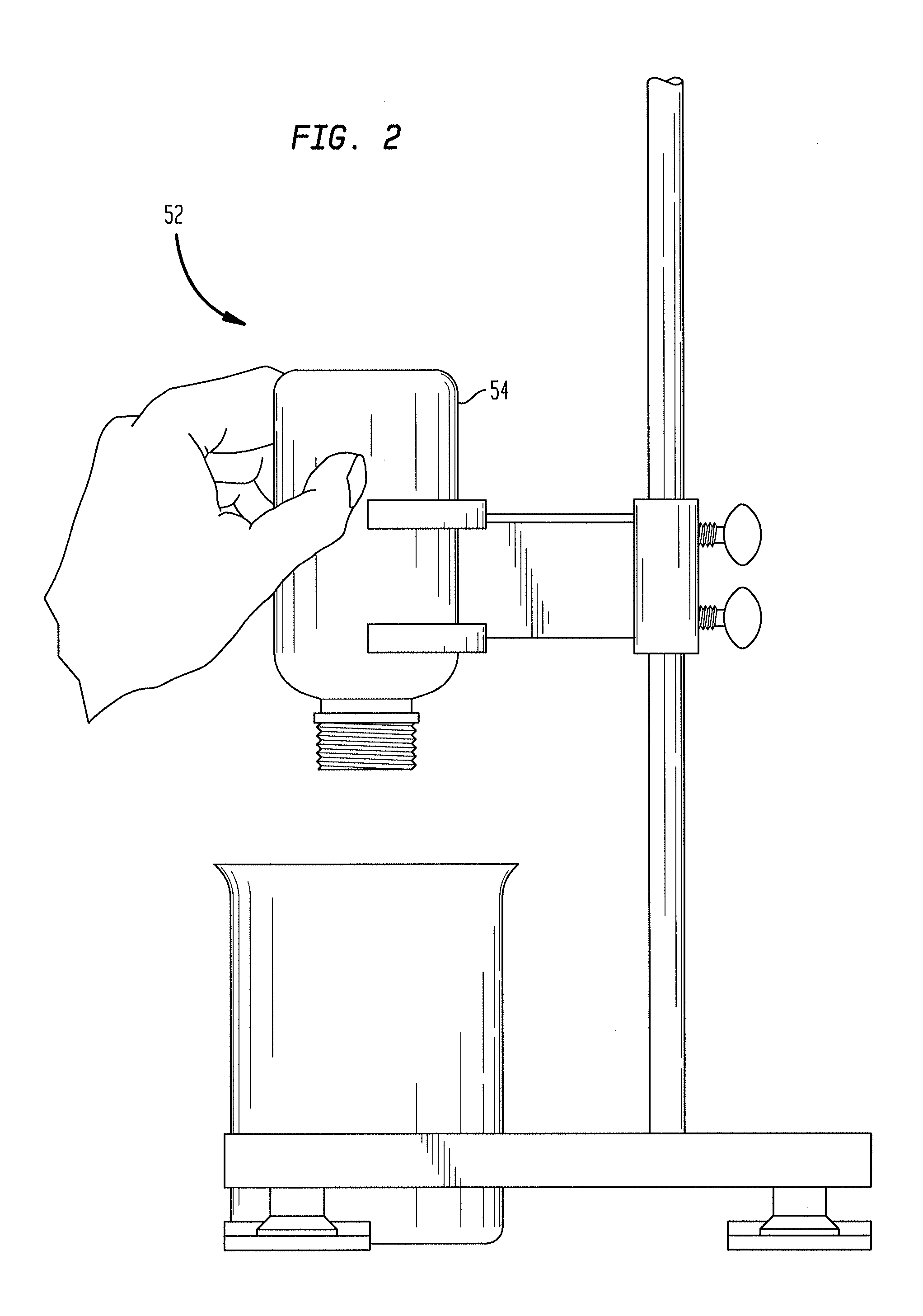

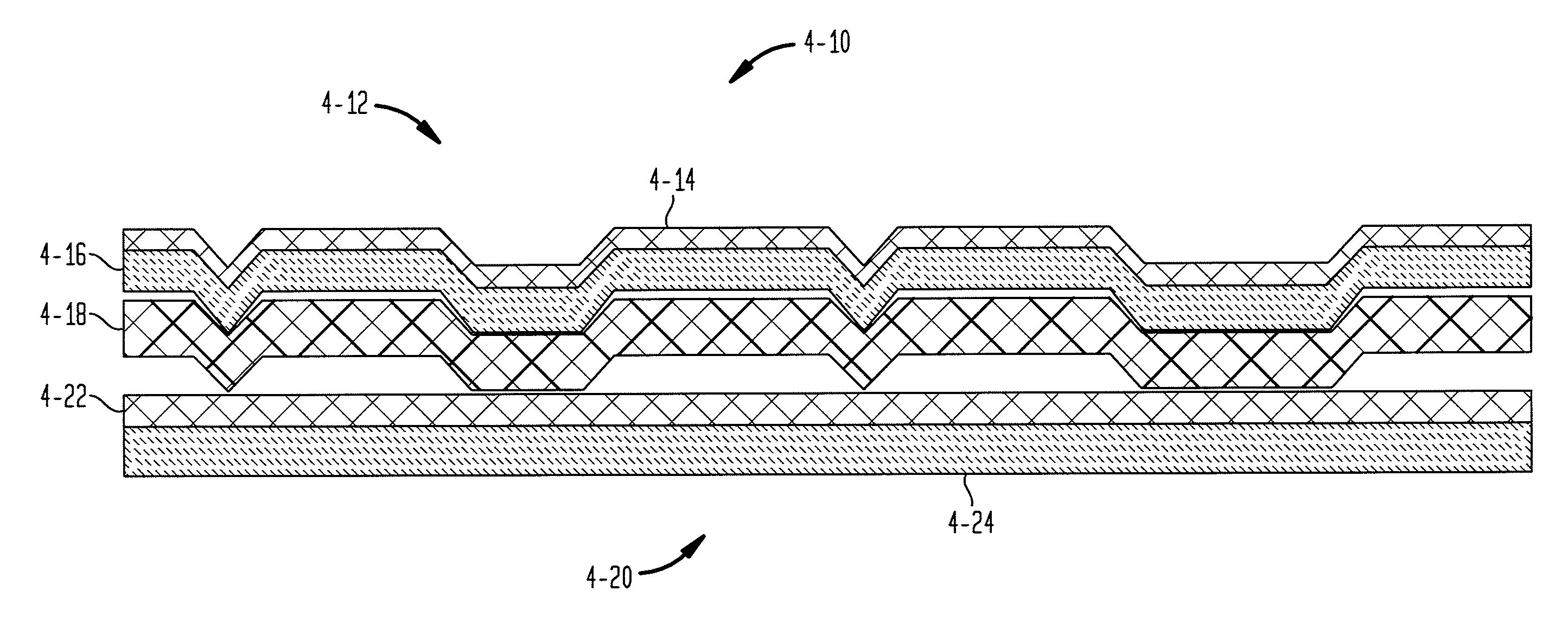

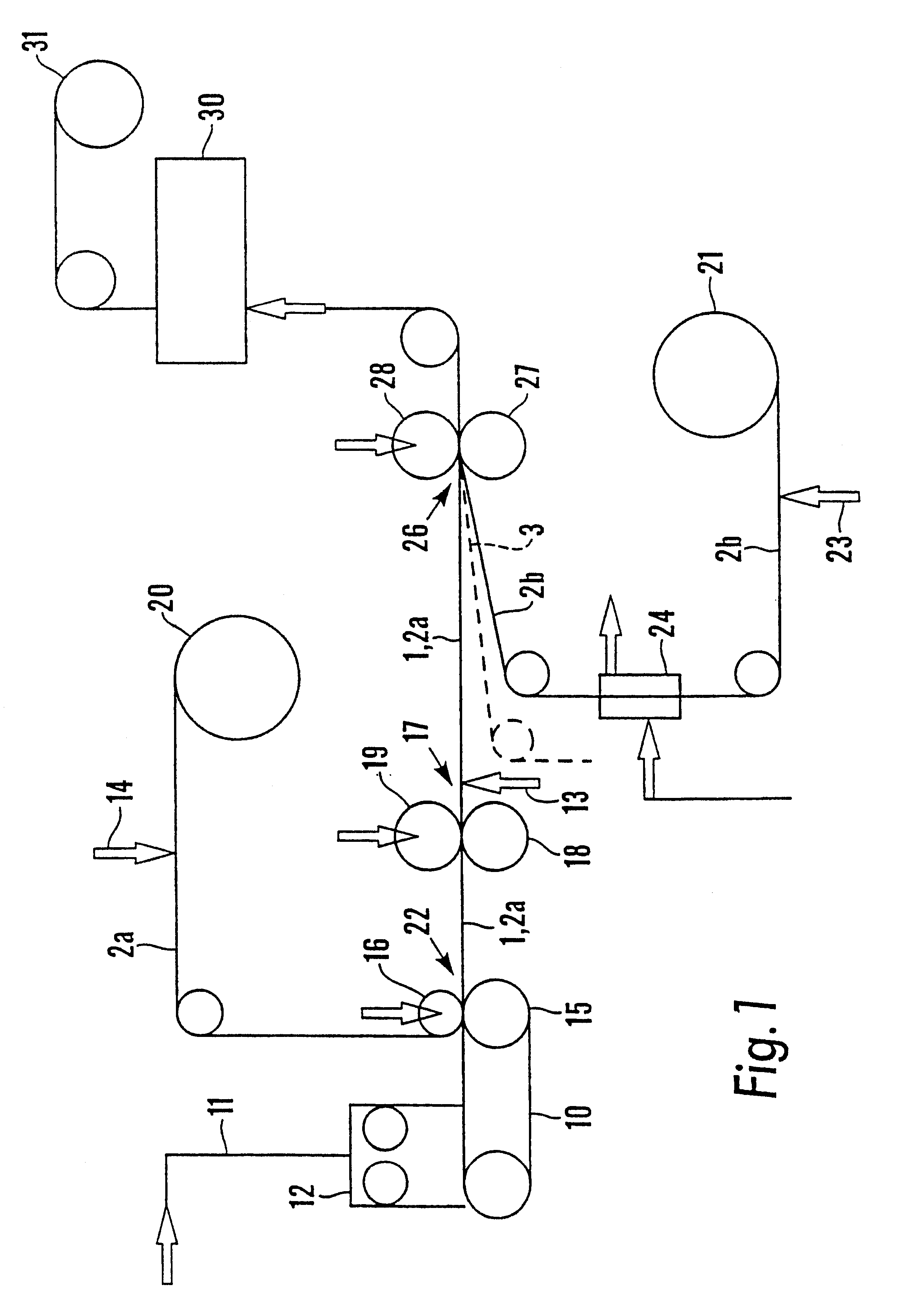

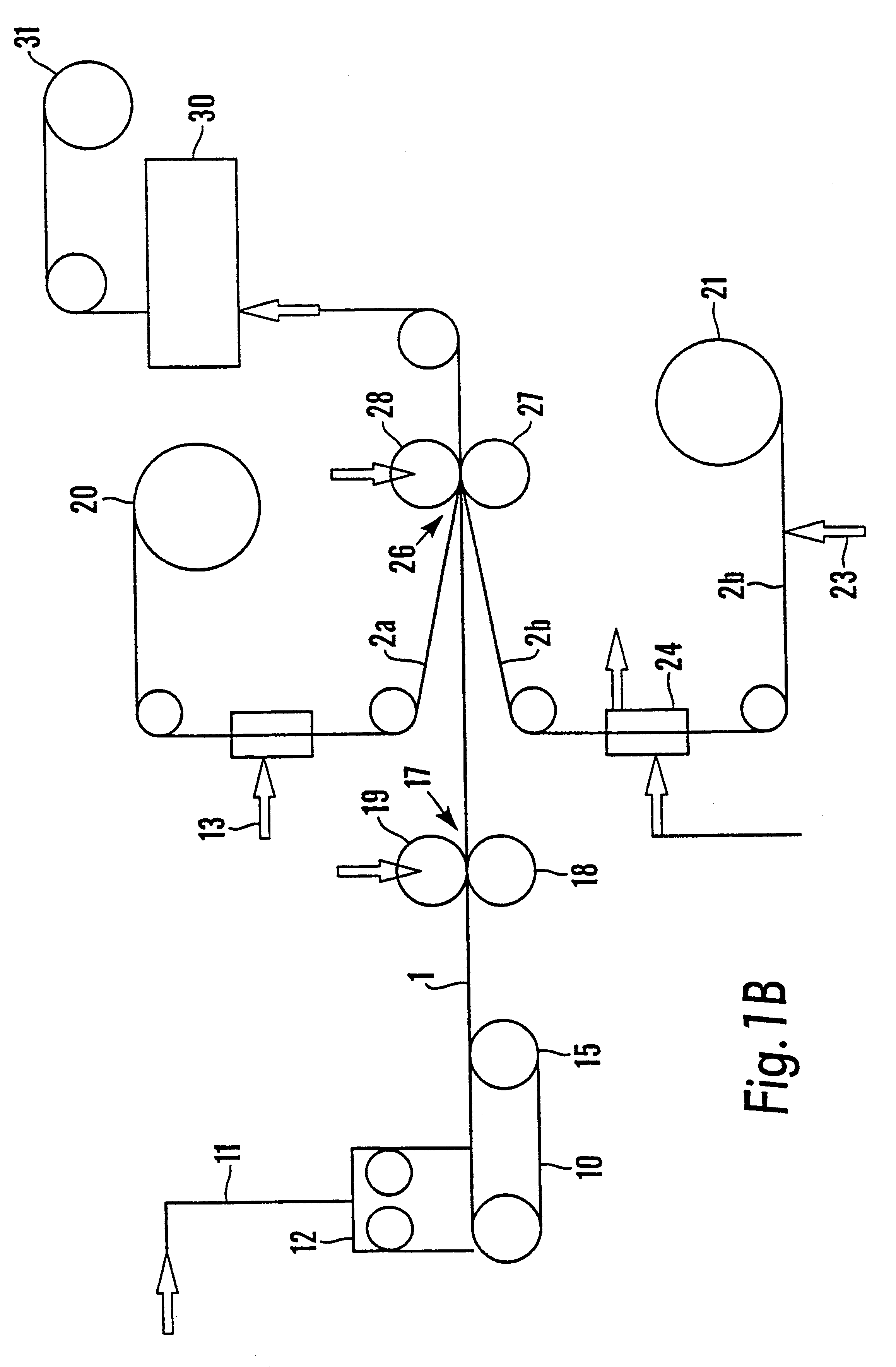

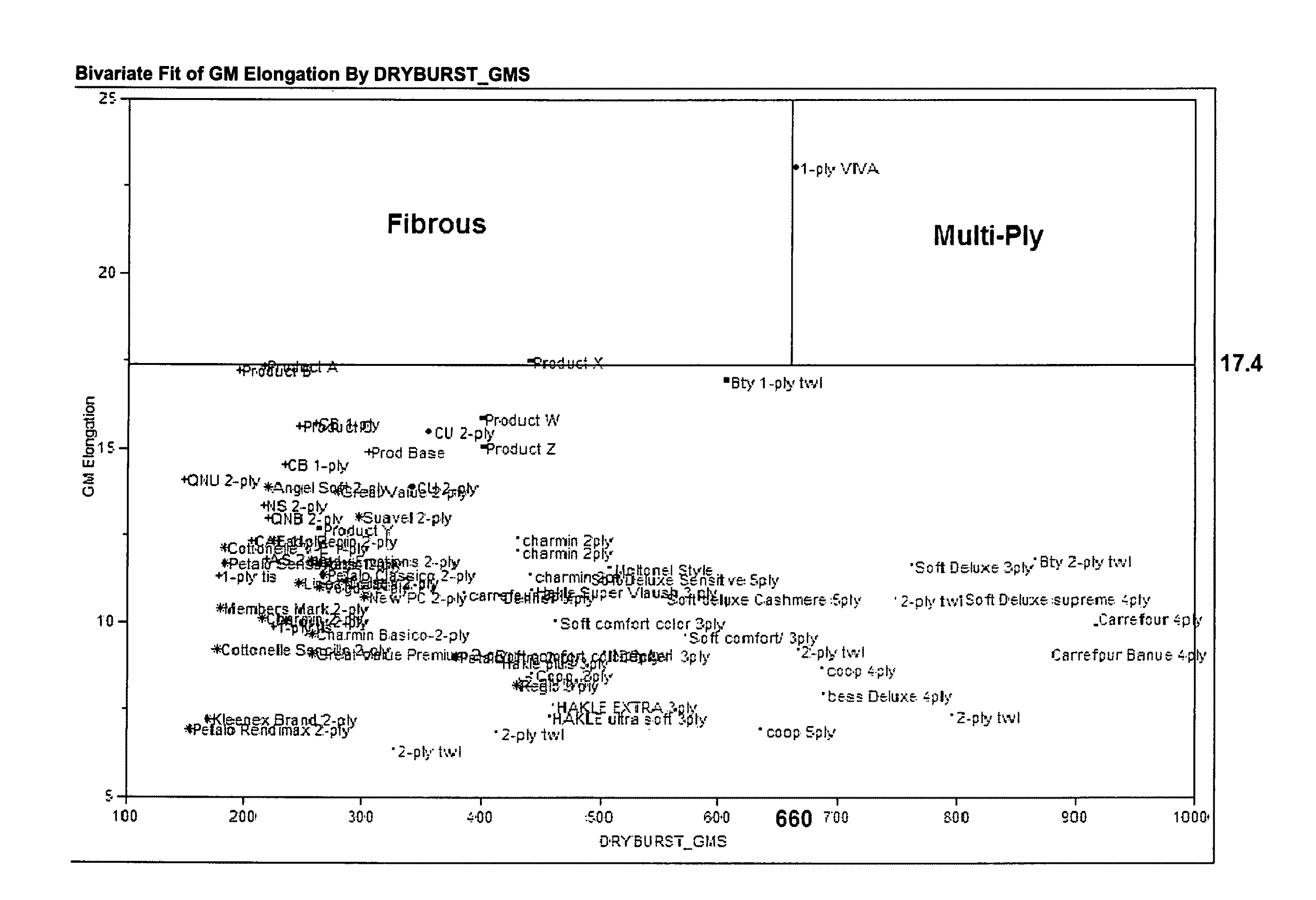

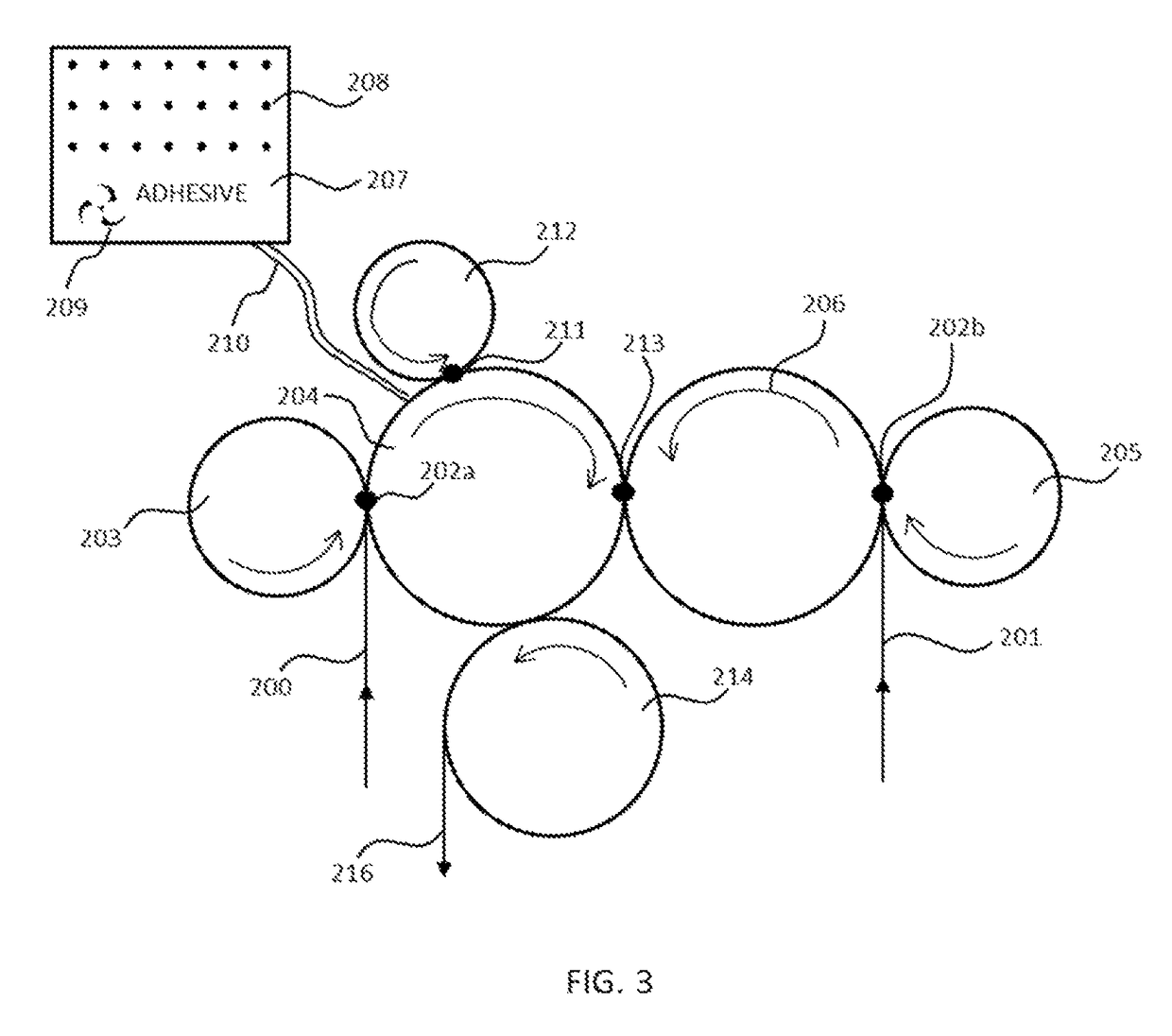

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

ActiveUS9719213B2Improve the level ofLose weightLamination ancillary operationsLaminationGramAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE LLC

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

ActiveUS20160160448A1Improve the level ofLose weightPaper after-treatmentOrnamental structuresFiberAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE

Lignocellulosic materials and the products made therefrom

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

Disposable nonwoven wiping fabric and method of production

InactiveUS7732357B2Improve wet strengthImprove aestheticsCosmetic preparationsMake-upPolymer scienceCellulose fiber

Disclosed is a fibrous nonwoven web material and a method of manufacture thereof. The fibrous nonwoven web material includes natural cellulose fibers, manmade cellulose fibers and synthetic fibers. The manmade cellulose fibers are preferably high crystallinity cellulose fibers. The fibrous nonwoven web material has appreciable wet strength yet is capable of dispersing in most aqueous environments with only mild agitation. The fibrous nonwoven web material can be wet laid from an aqueous dispersion of fibers.

Owner:SUOMINEN CORP

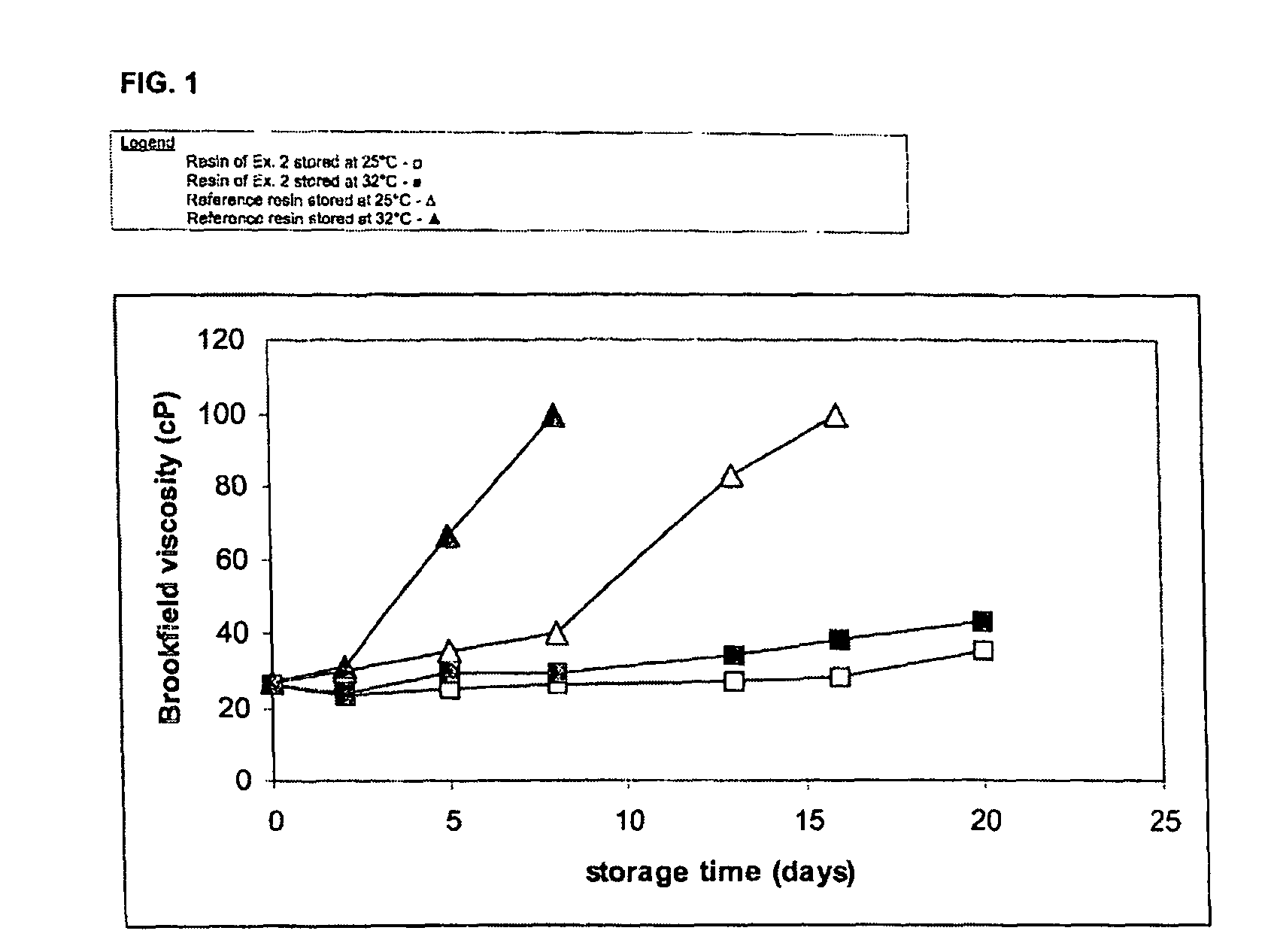

Reactive cationic resins for use as dry and wet strength agents in sulfite ion-containing papermaking systems

This invention relates to resins useful for imparting strength to paper, the process of incorporating these resins into paper and the paper produced containing the resins. In particular the invention relates to resins useful for imparting dry-strength and wet-strength to paper under conditions of high sulfite ion concentrations.

Owner:SOLENIS TECH CAYMAN

Sanitary Tissue Products

ActiveUS20150176220A1Cushier and more flexibleImprove compression performanceNon-fibrous pulp additionMechanical working/deformationFiberCompressibility

Sanitary tissue products employing fibrous structures that exhibit novel compressibility properties alone and in combination with plate stiffness properties and methods for making same.

Owner:THE PROCTER & GAMBLE COMPANY

Soft through air dried tissue

ActiveUS20140041820A1Compromising softnessCompromising cleaning abilityPaper after-treatmentPaper coatingSURFACTANT BLENDChemistry

Owner:FIRST QUALITY TISSUE

Enzymatic straw material pulping process

InactiveCN1421570AWell mixedChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

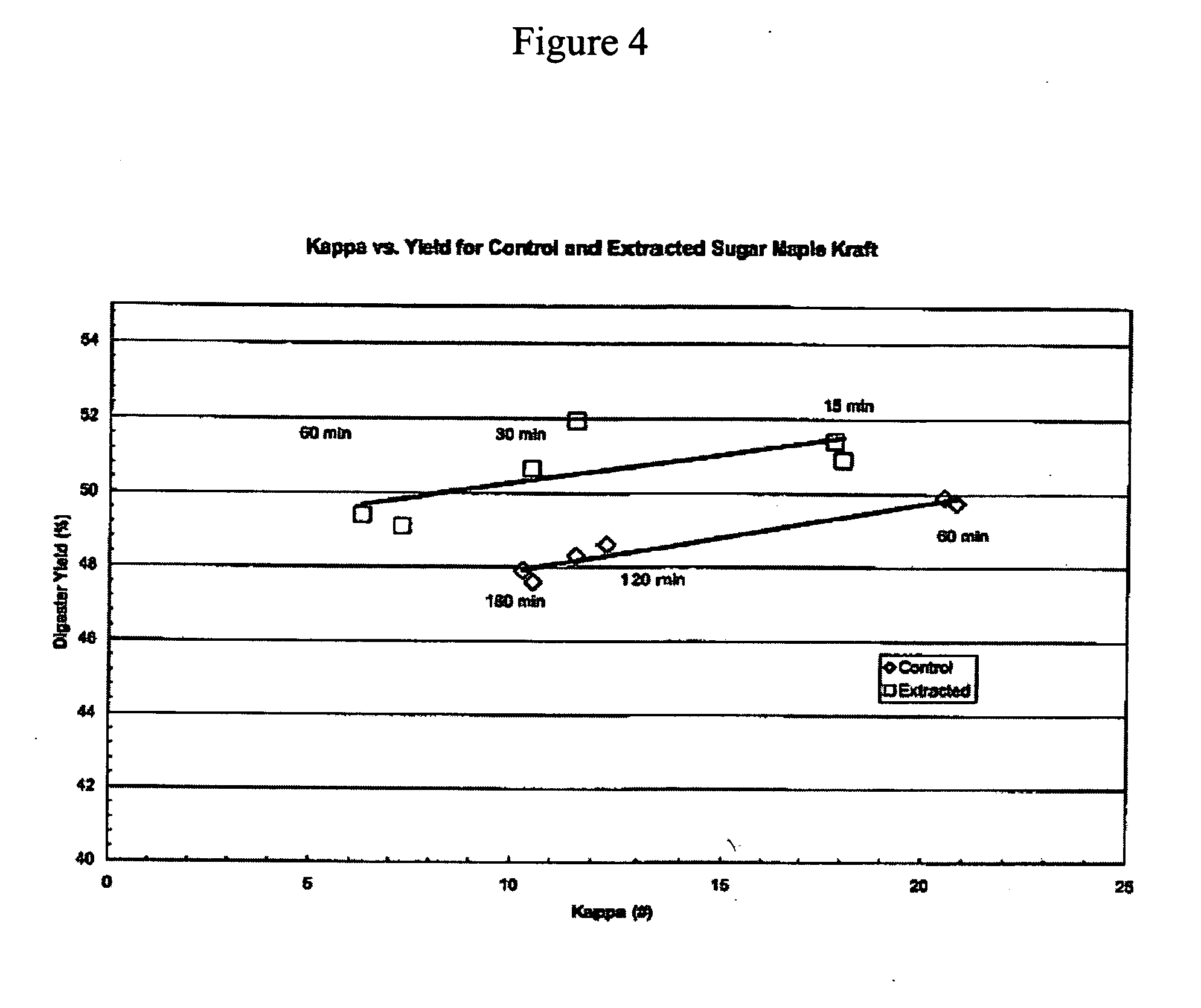

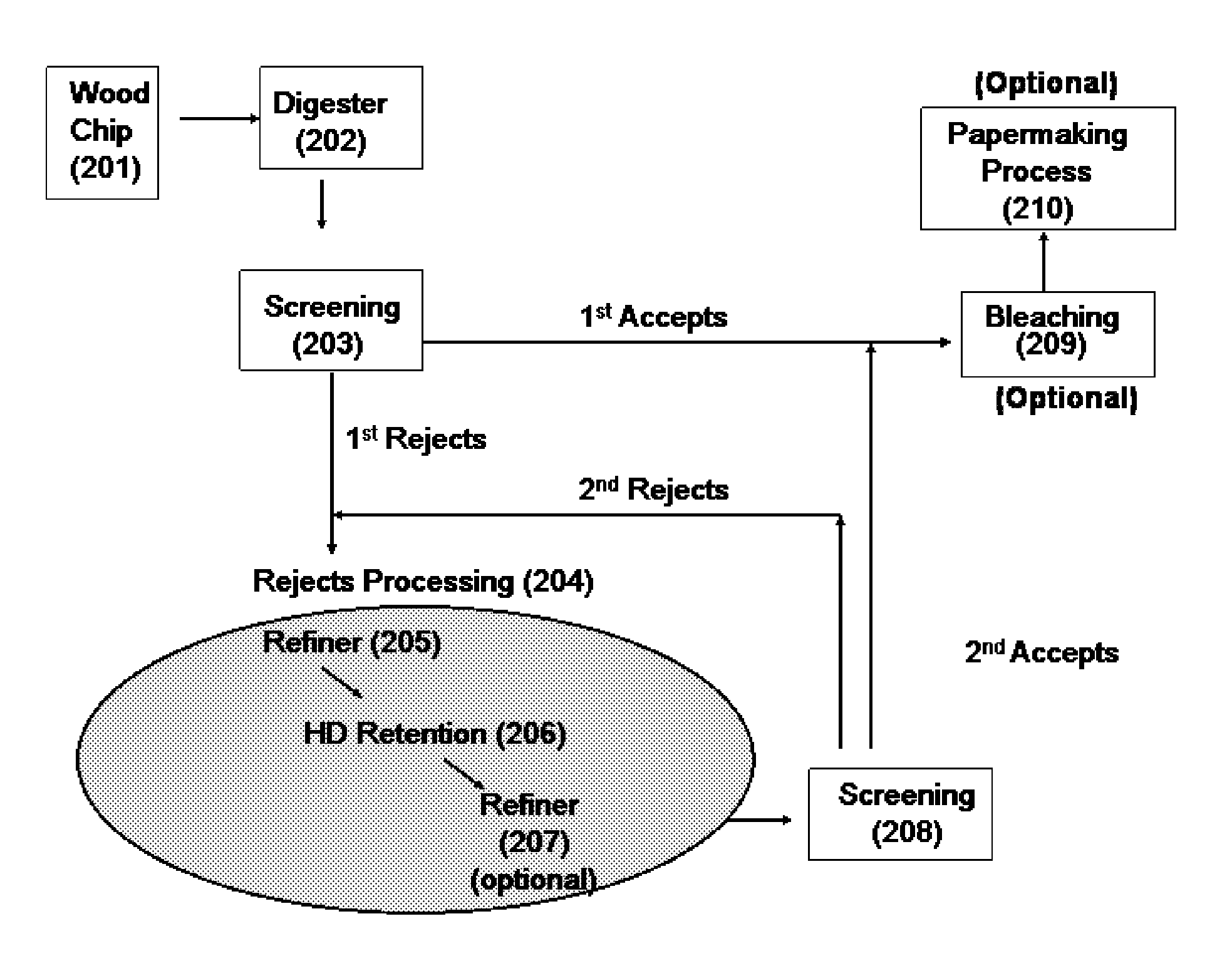

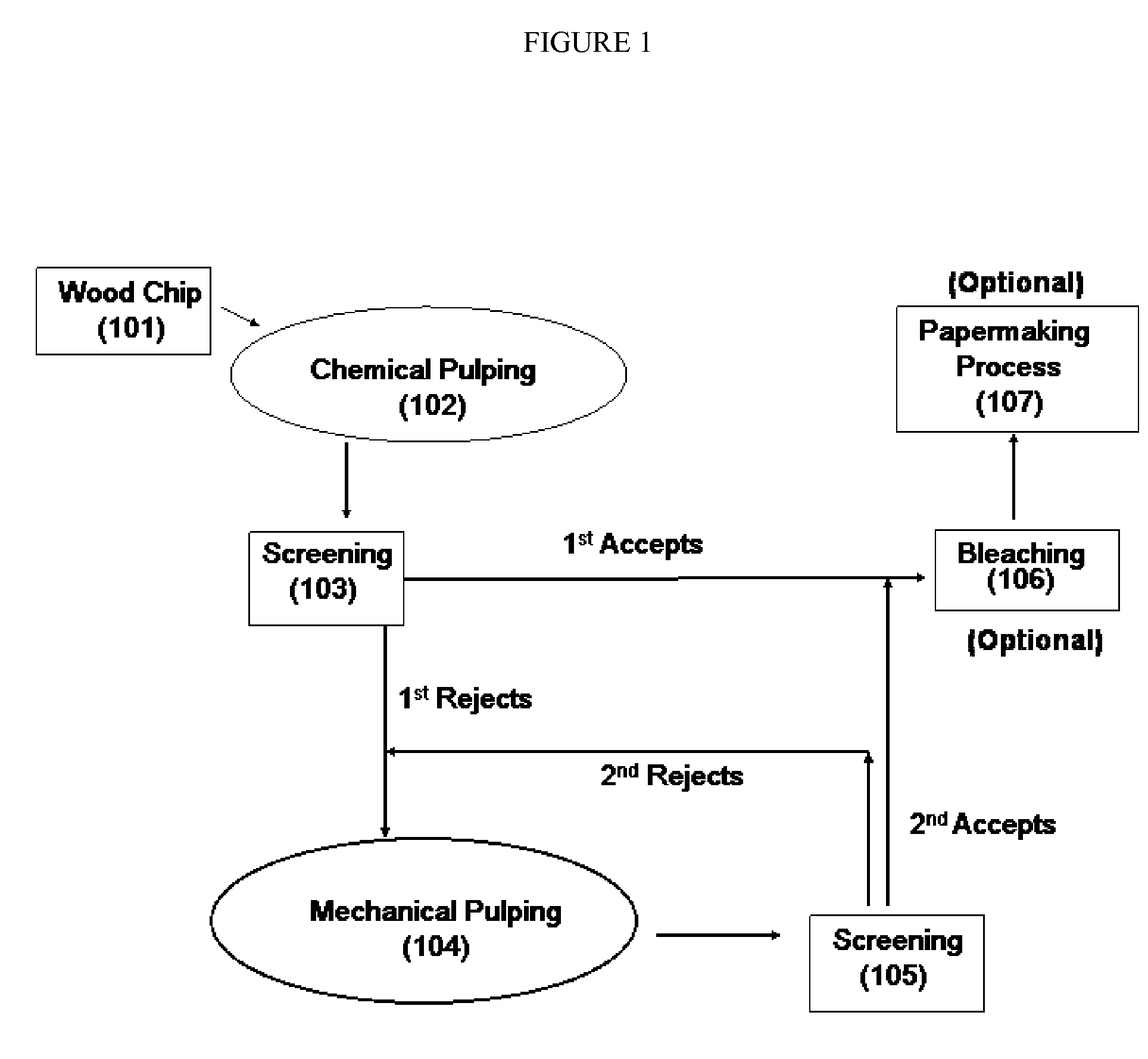

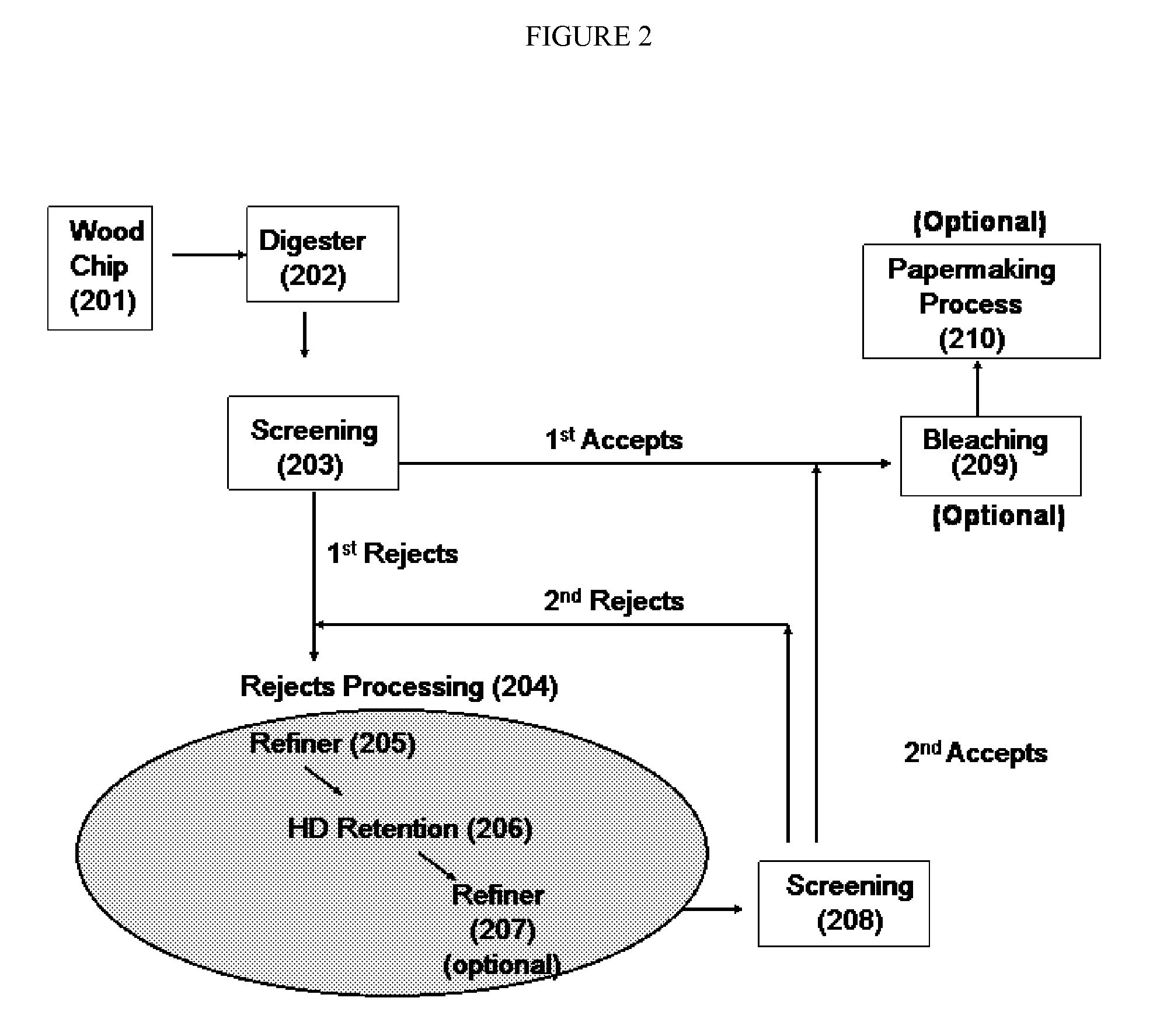

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

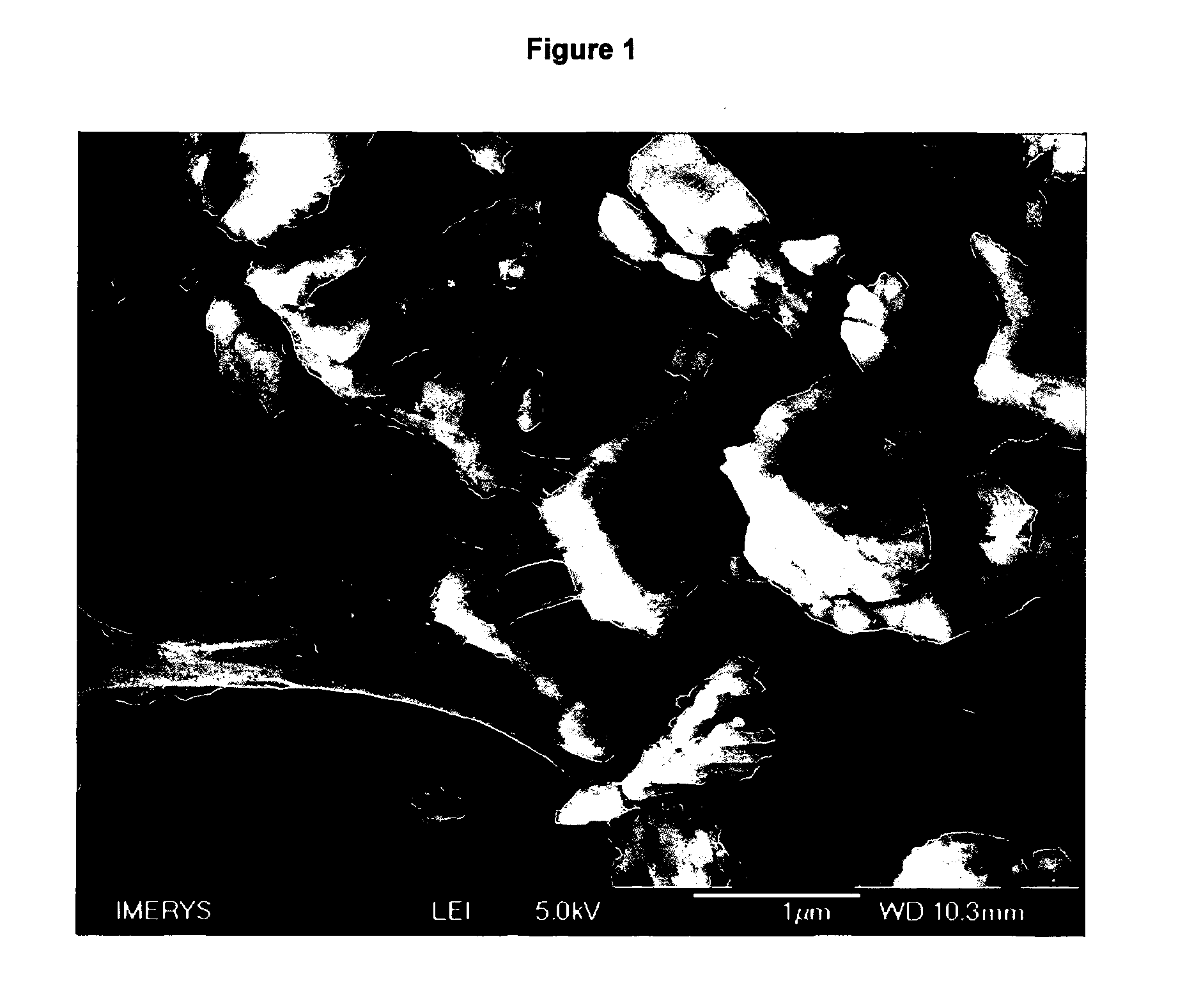

Compositions

Compositions such as filled and coated papers may include microfibrillated cellulose and inorganic particulate material.

Owner:FIBERLEAN TECH LTD

Pulp using rice grass and wheatgrass as raw material and preparation method thereof

ActiveCN101089292AHigh mechanical strengthChemical/chemomechanical pulpNon-woody plant/crop pulpPulp and paper industryHardness

The present invention relates to a paper pulp prepared by using rice straw and wheat straw as raw material. The breaking length of said paper pulp is 4500-8100 km. and its tearing strength is 180-280 mN. Besides, said invention also provides its preparation method and concrete steps.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Ligno cellulosic materials and the products made therefrom

ActiveUS20110287275A1Maintain good propertiesHigh strengthBiocideAnimal repellantsCellulosePolymer science

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Paper filler composition

A method for preparing an aqueous suspension comprising microfibrillated cellulose and inorganic particulate material, the method comprising a step of microfibrillating a fibrous substrate comprising cellulose in an aqueous environment in the presence of an inorganic particulate material.

Owner:FIBERLEAN TECH LTD

Fibrous structures

Owner:THR PROCTER & GAMBLE COMPANY ATTENTION CHEIF PATENT COUNSEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com