Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1100results about "Digesters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

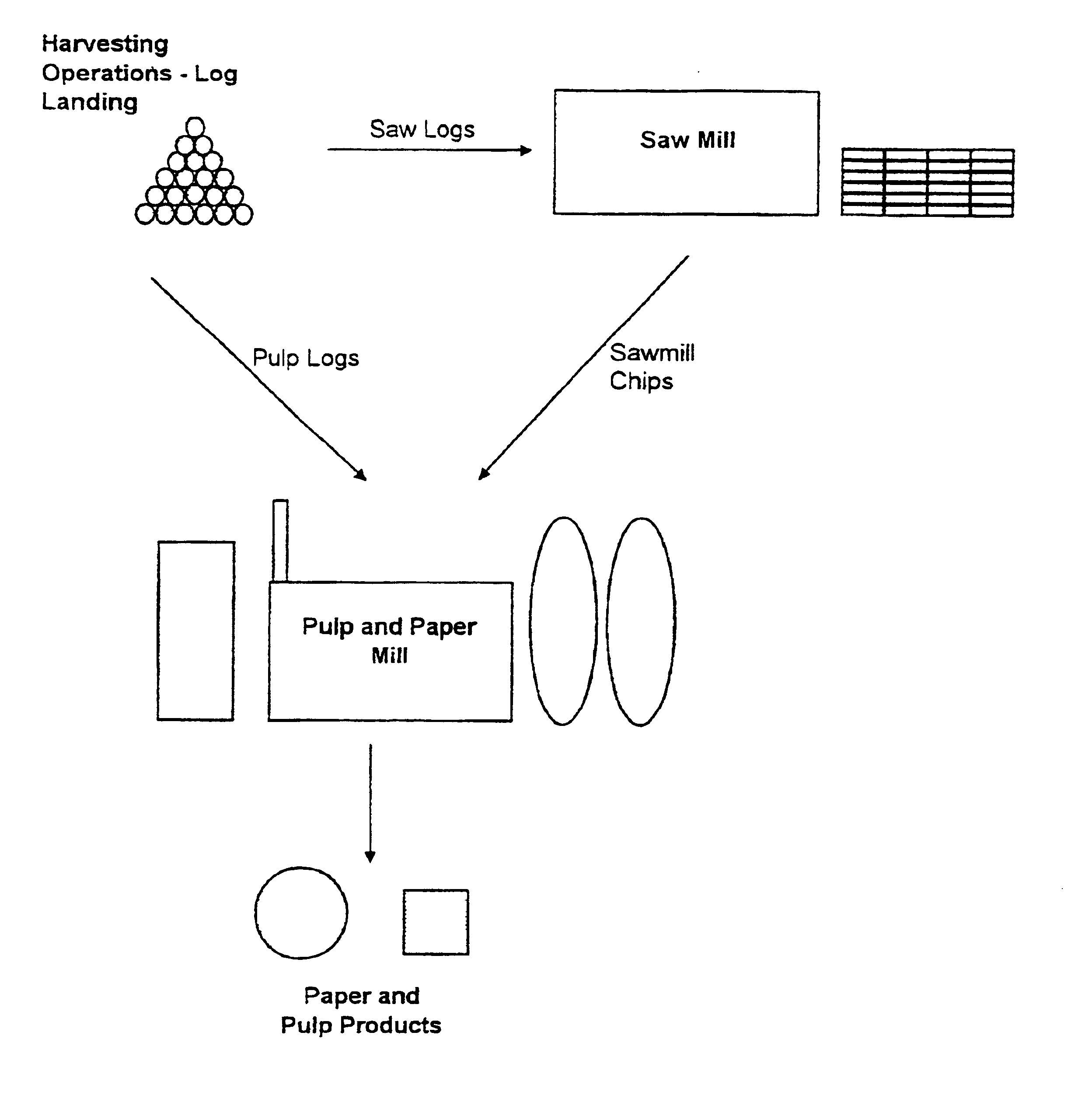

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

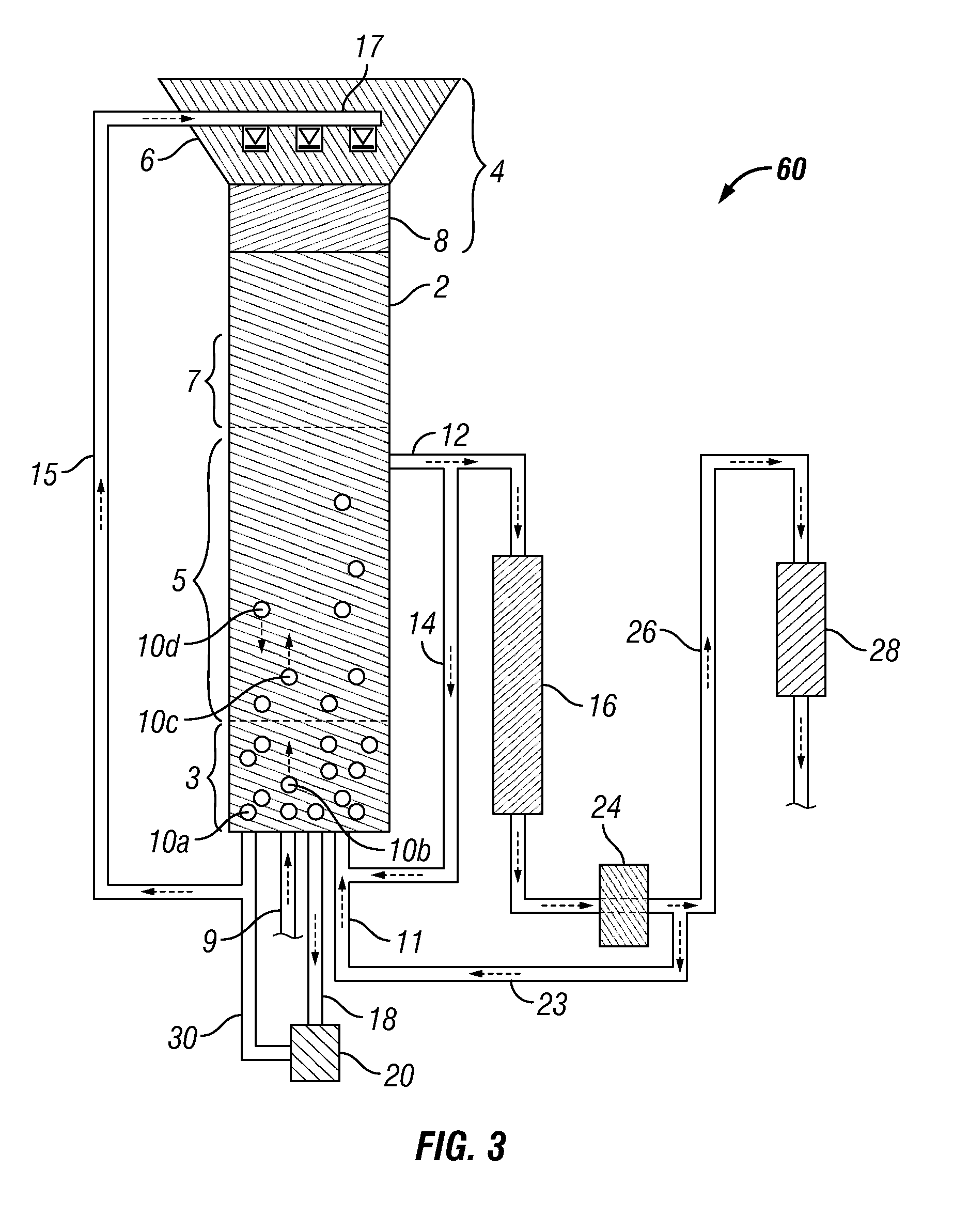

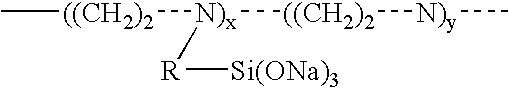

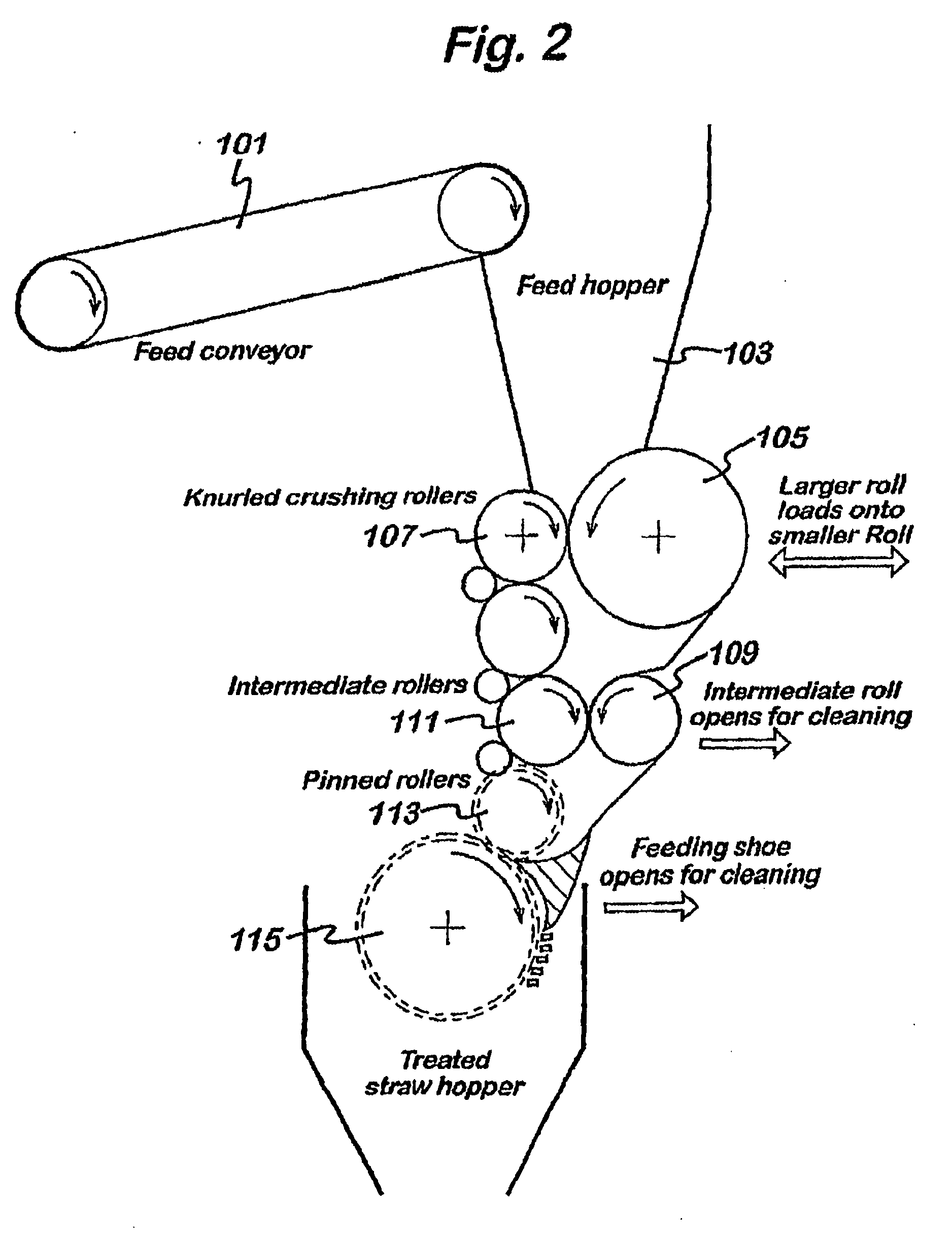

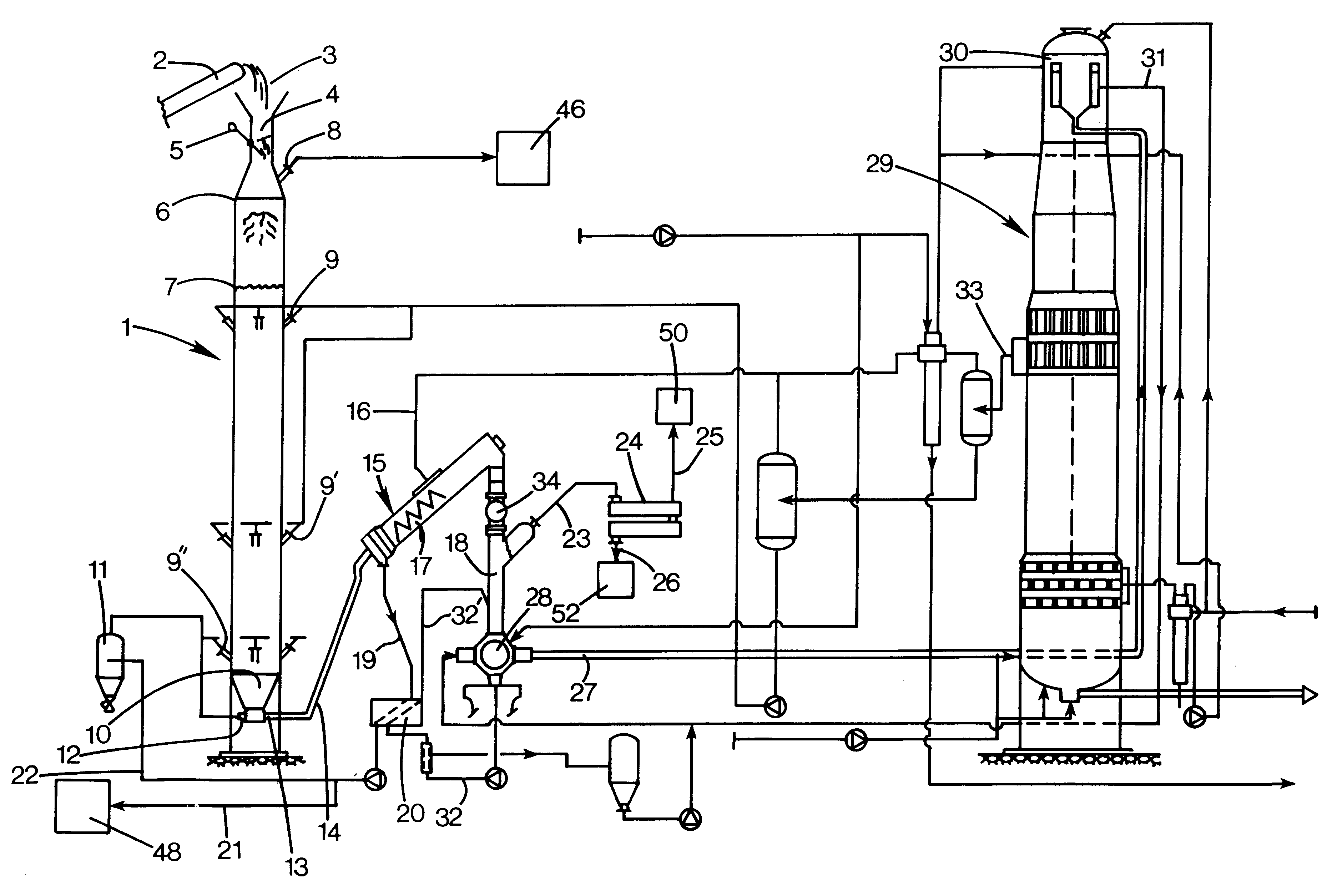

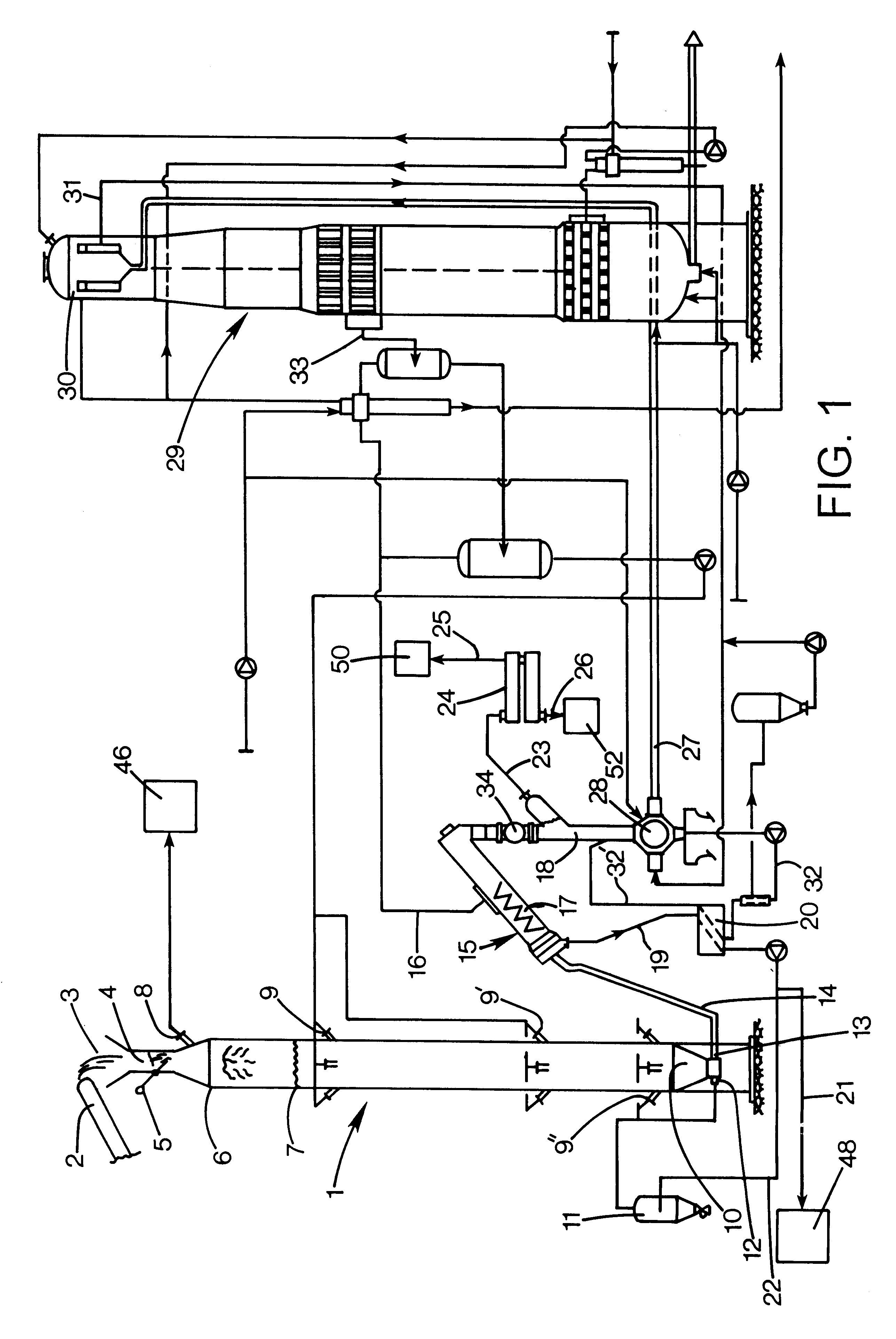

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

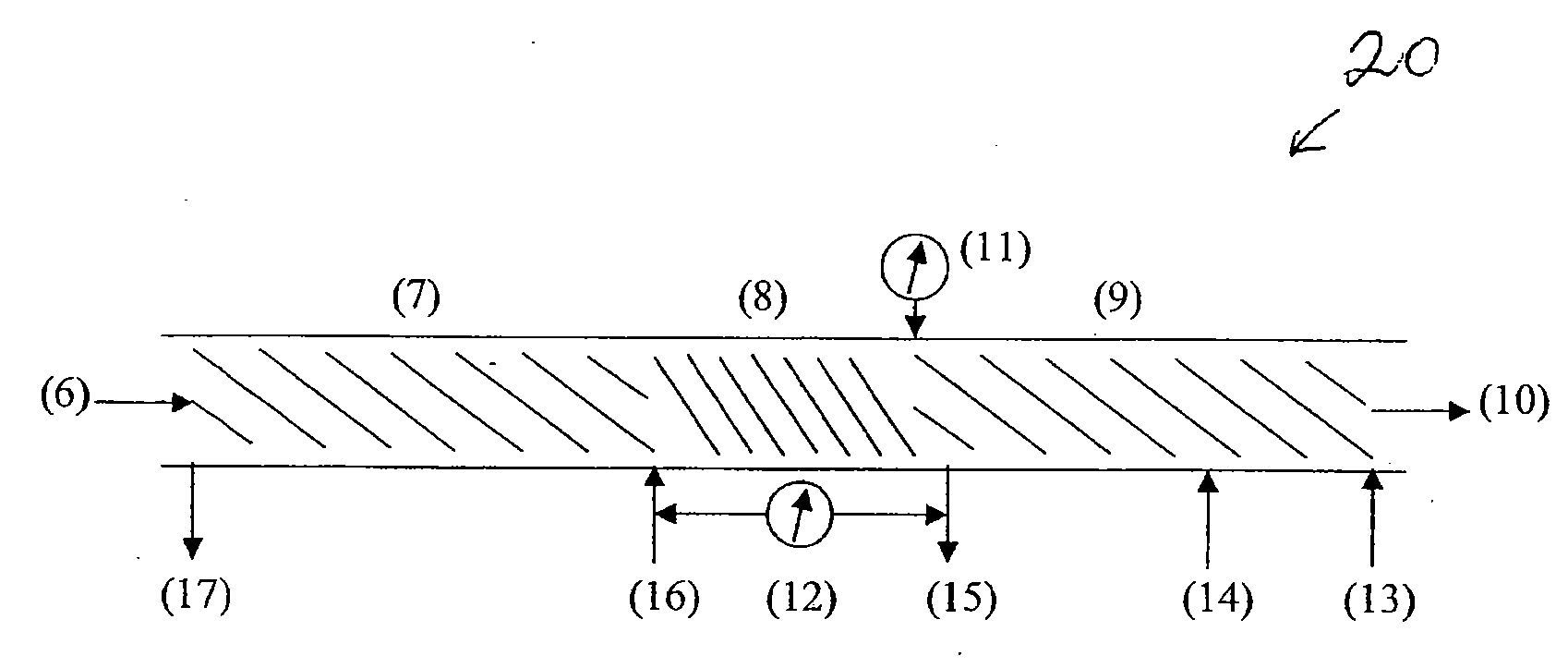

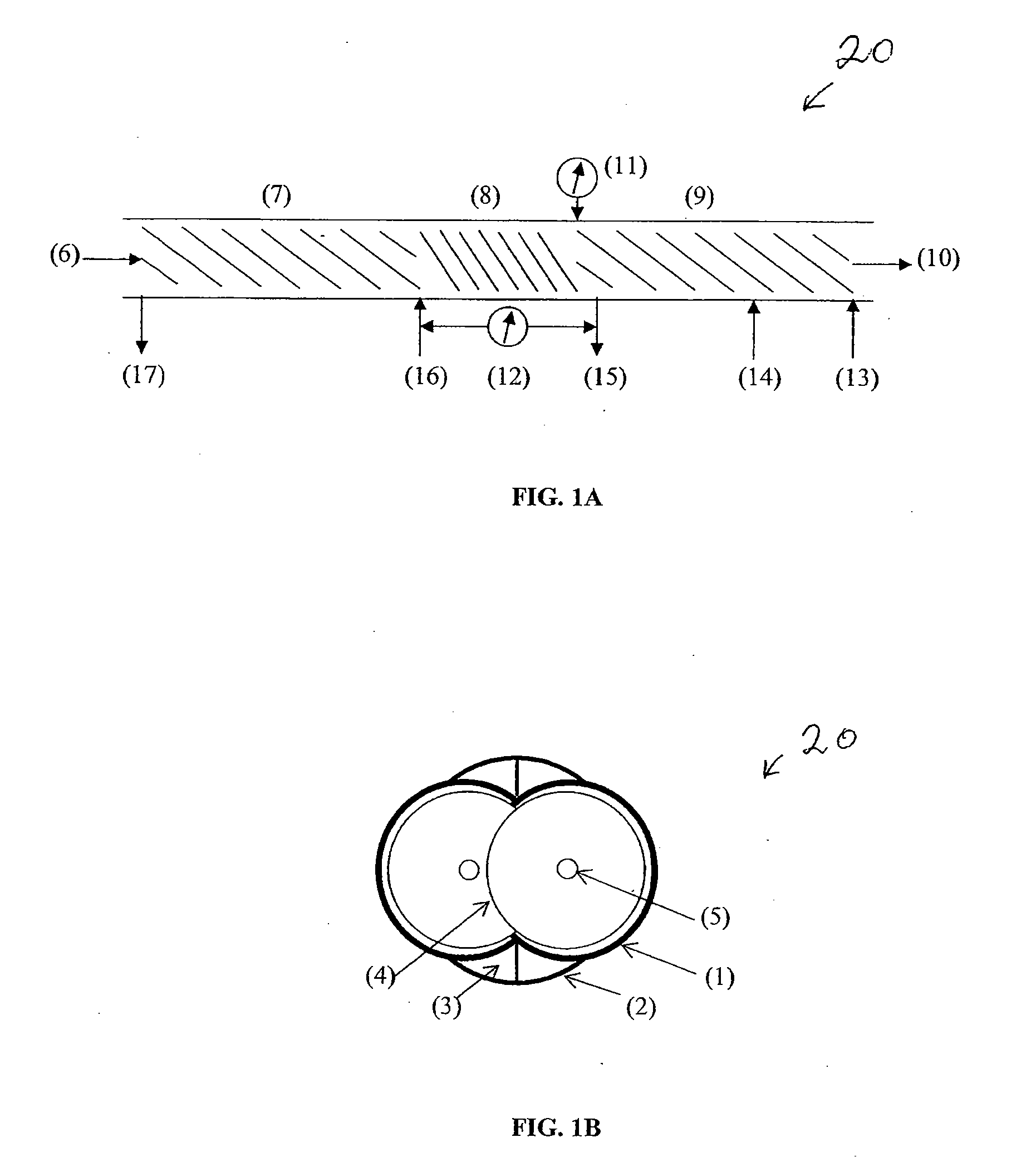

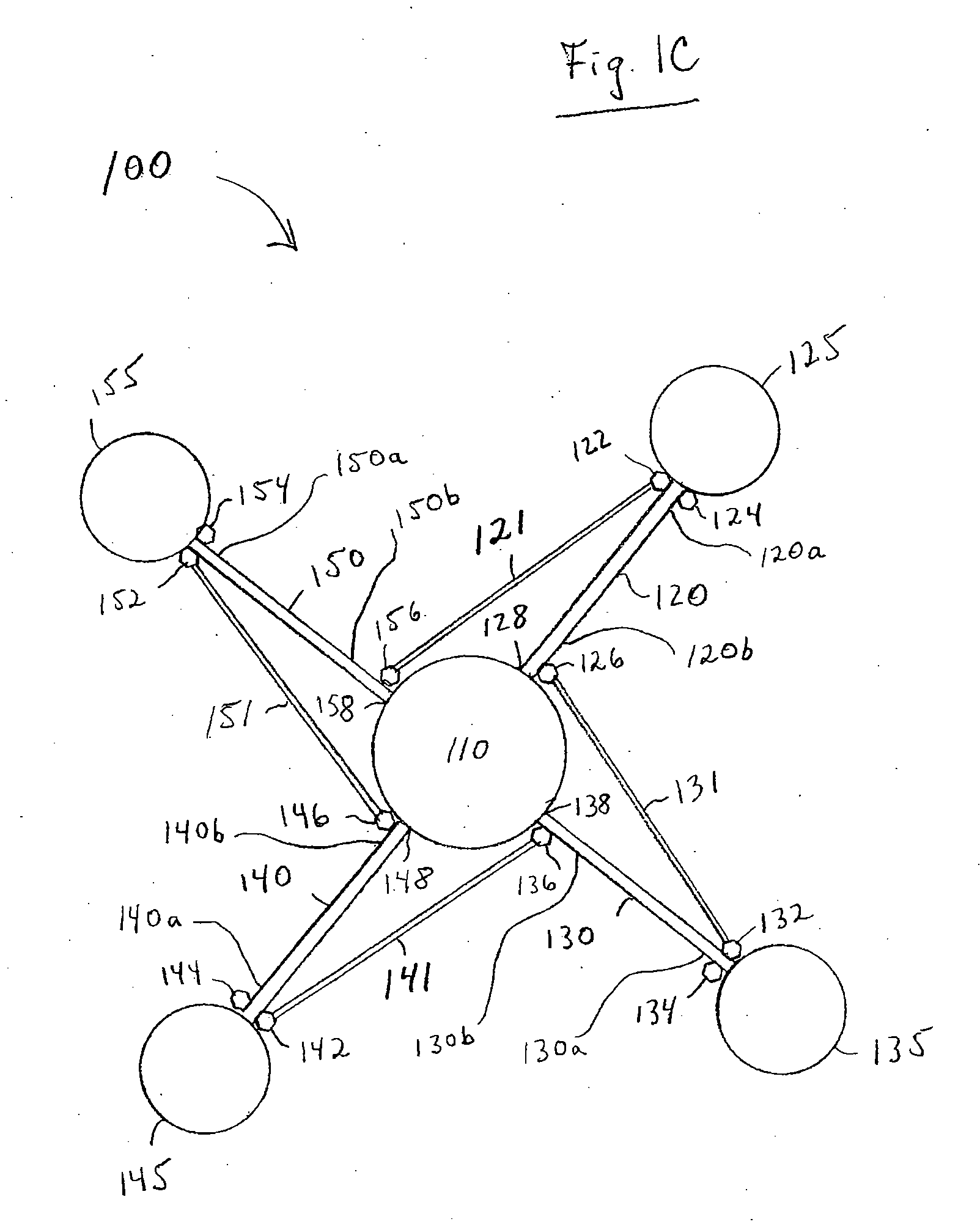

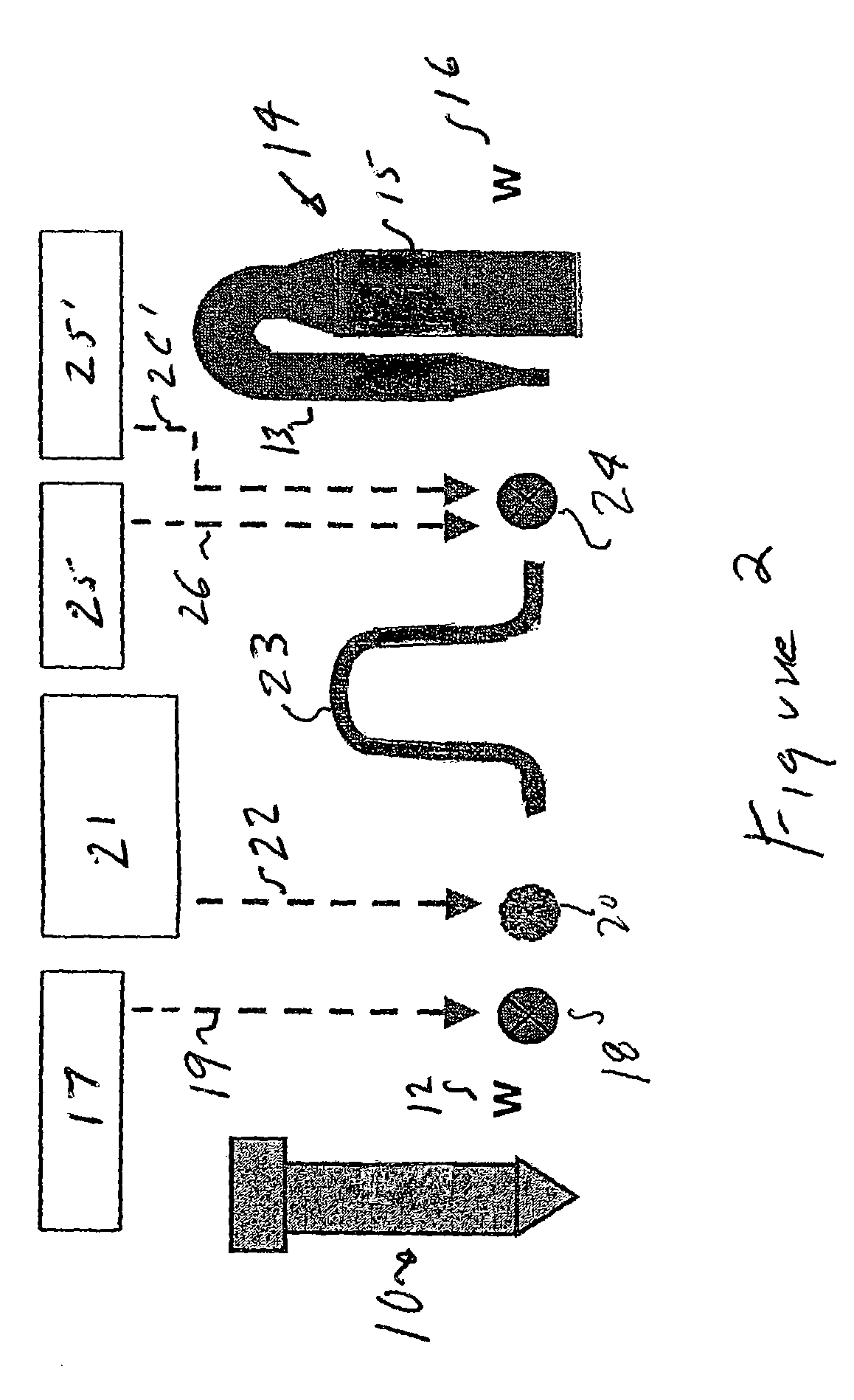

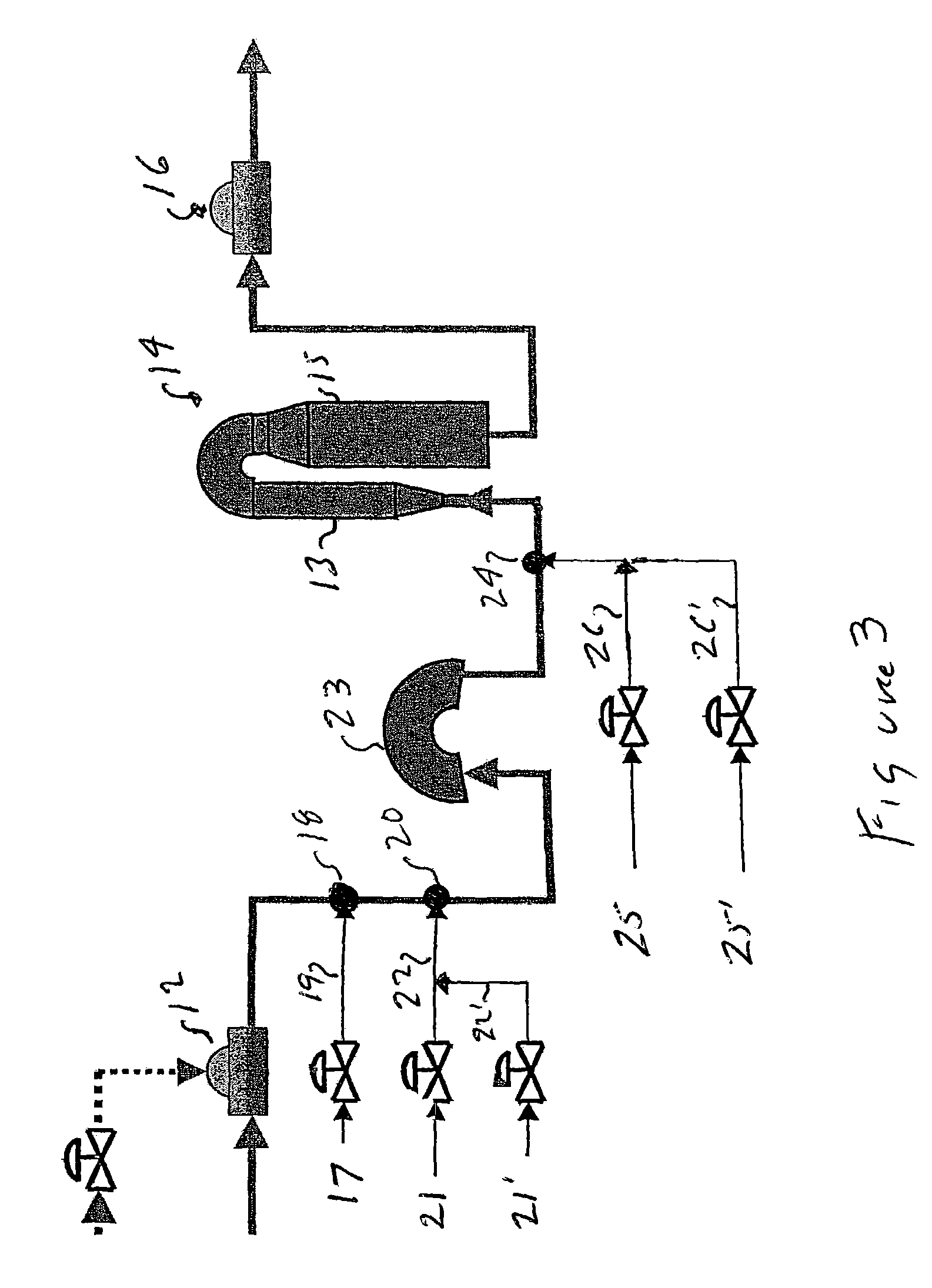

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

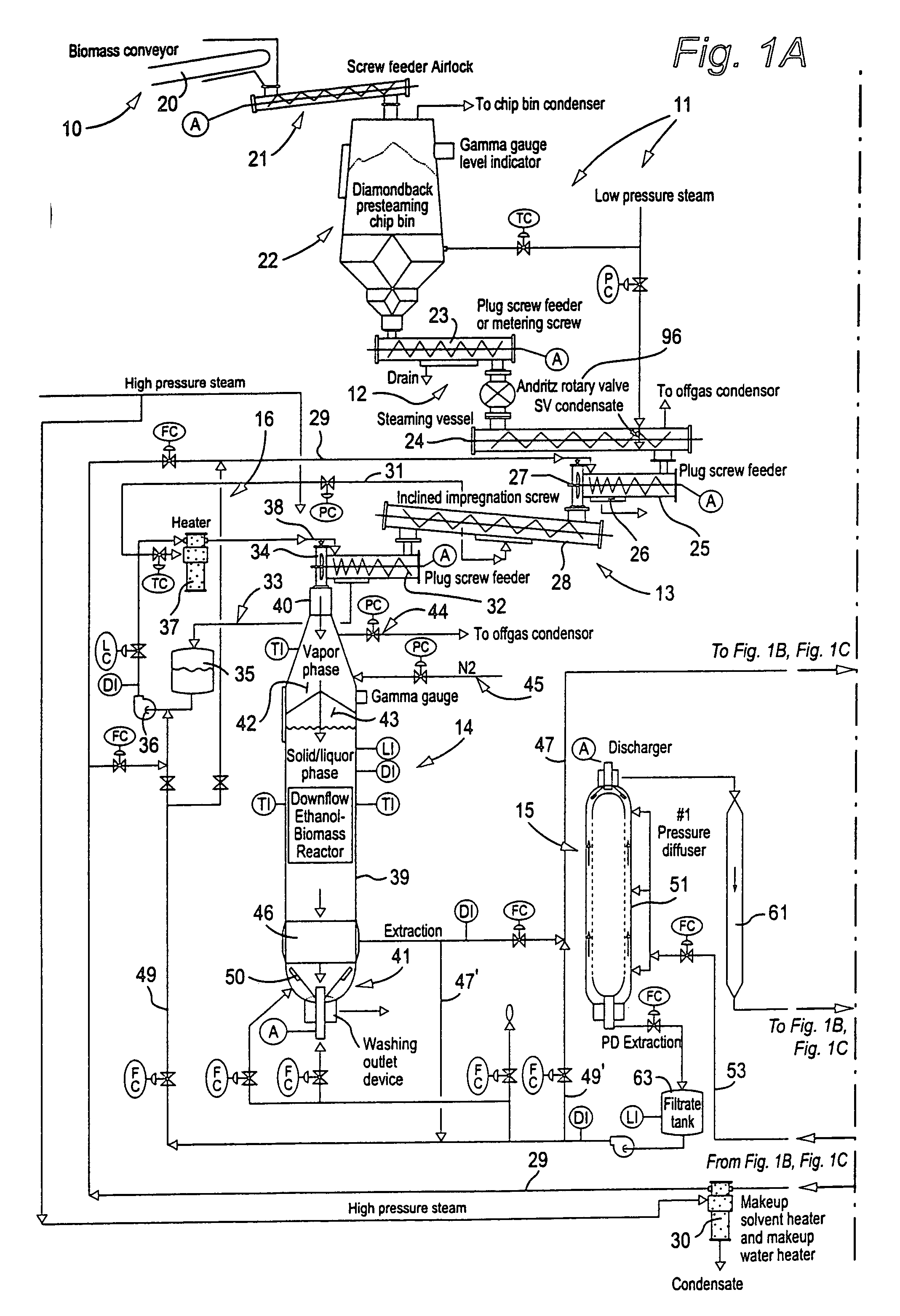

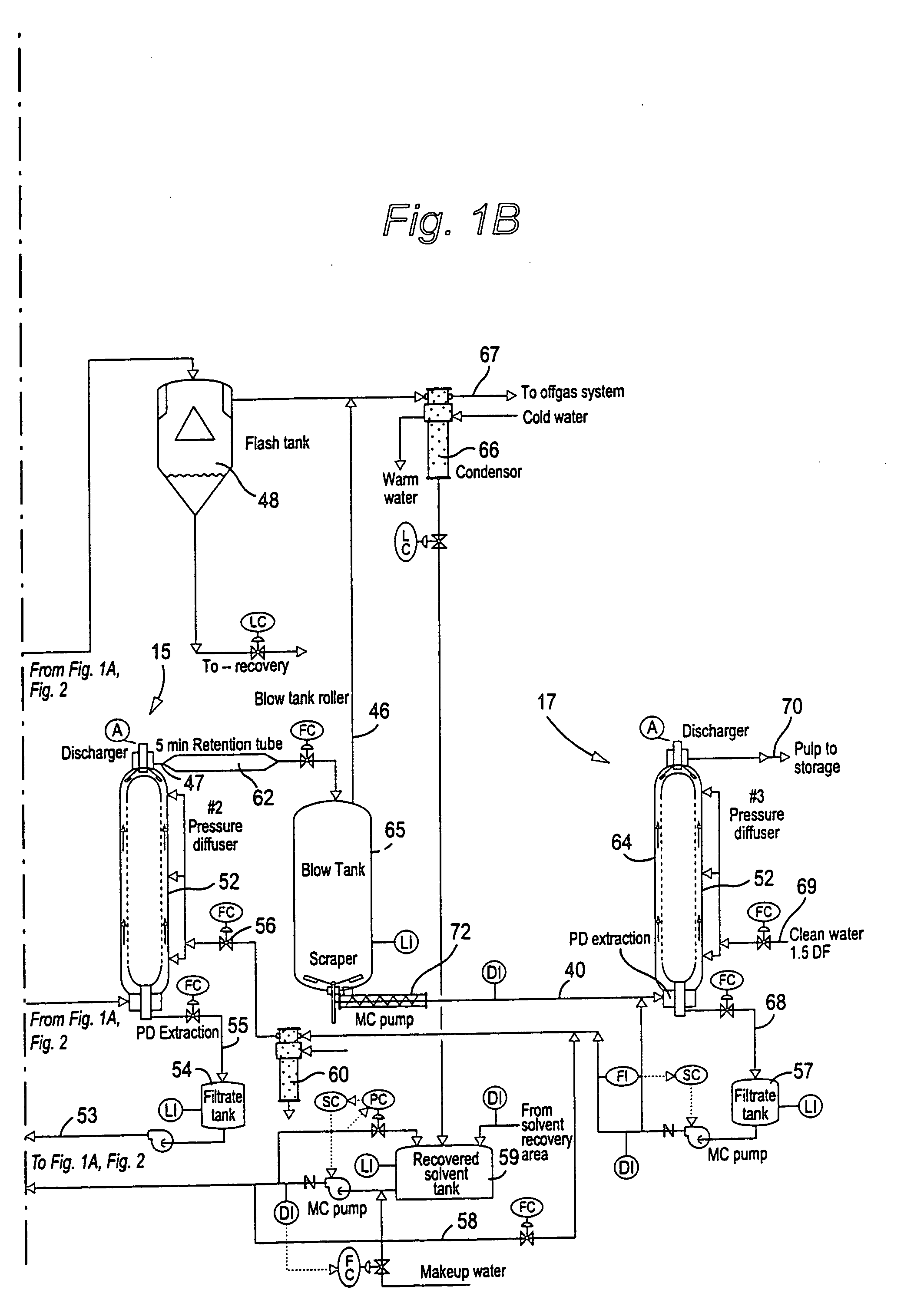

Solvent pulping of biomass

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

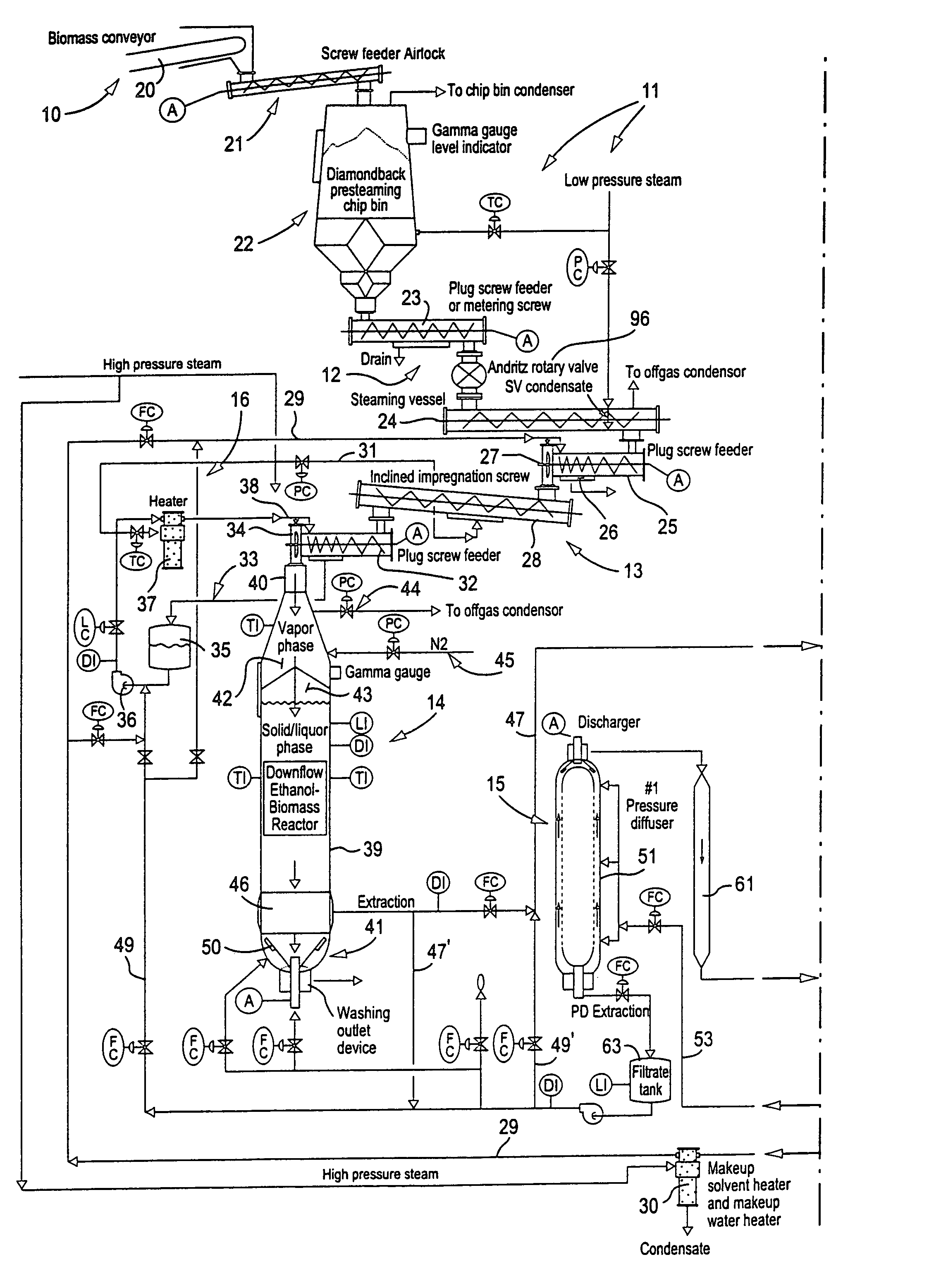

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

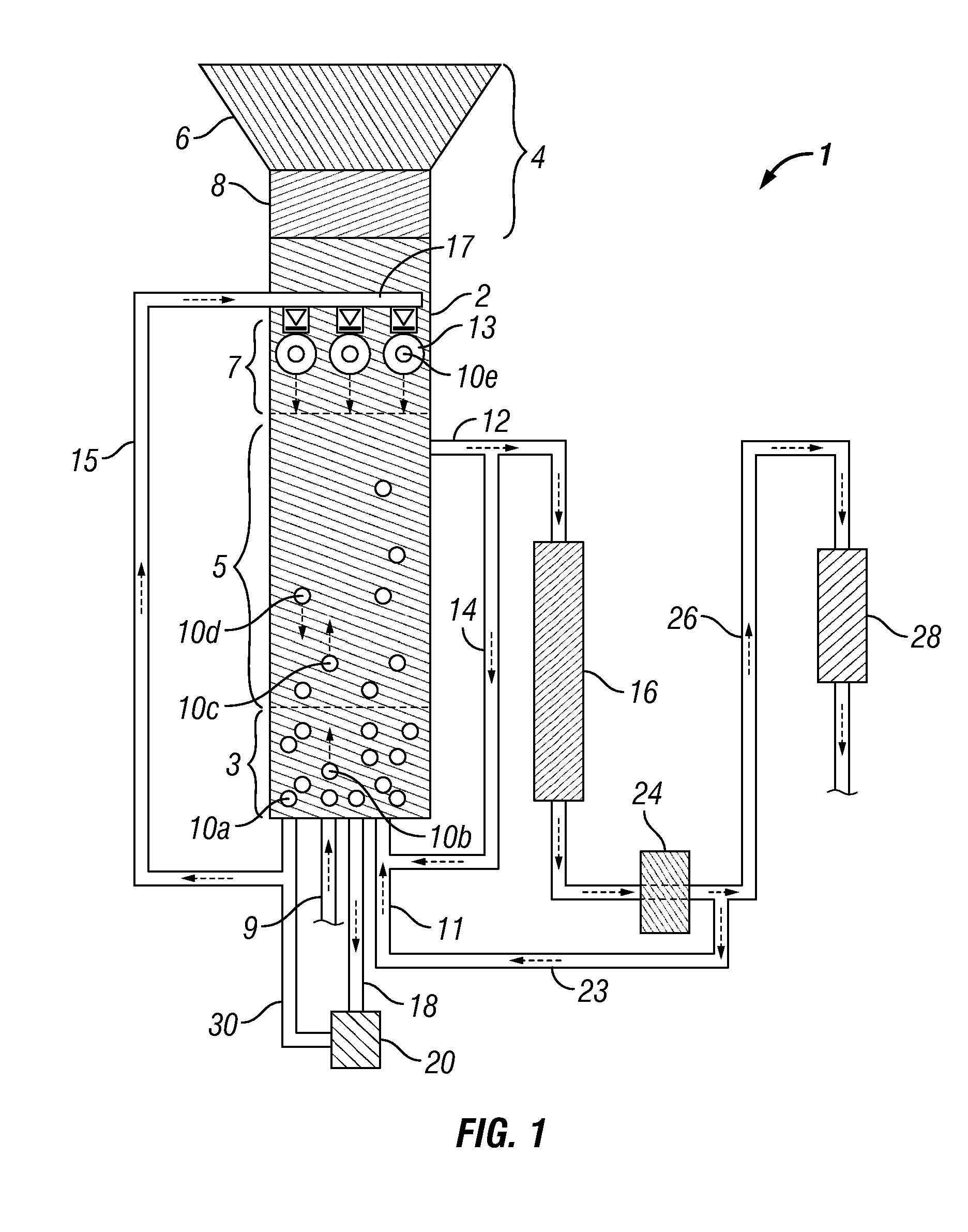

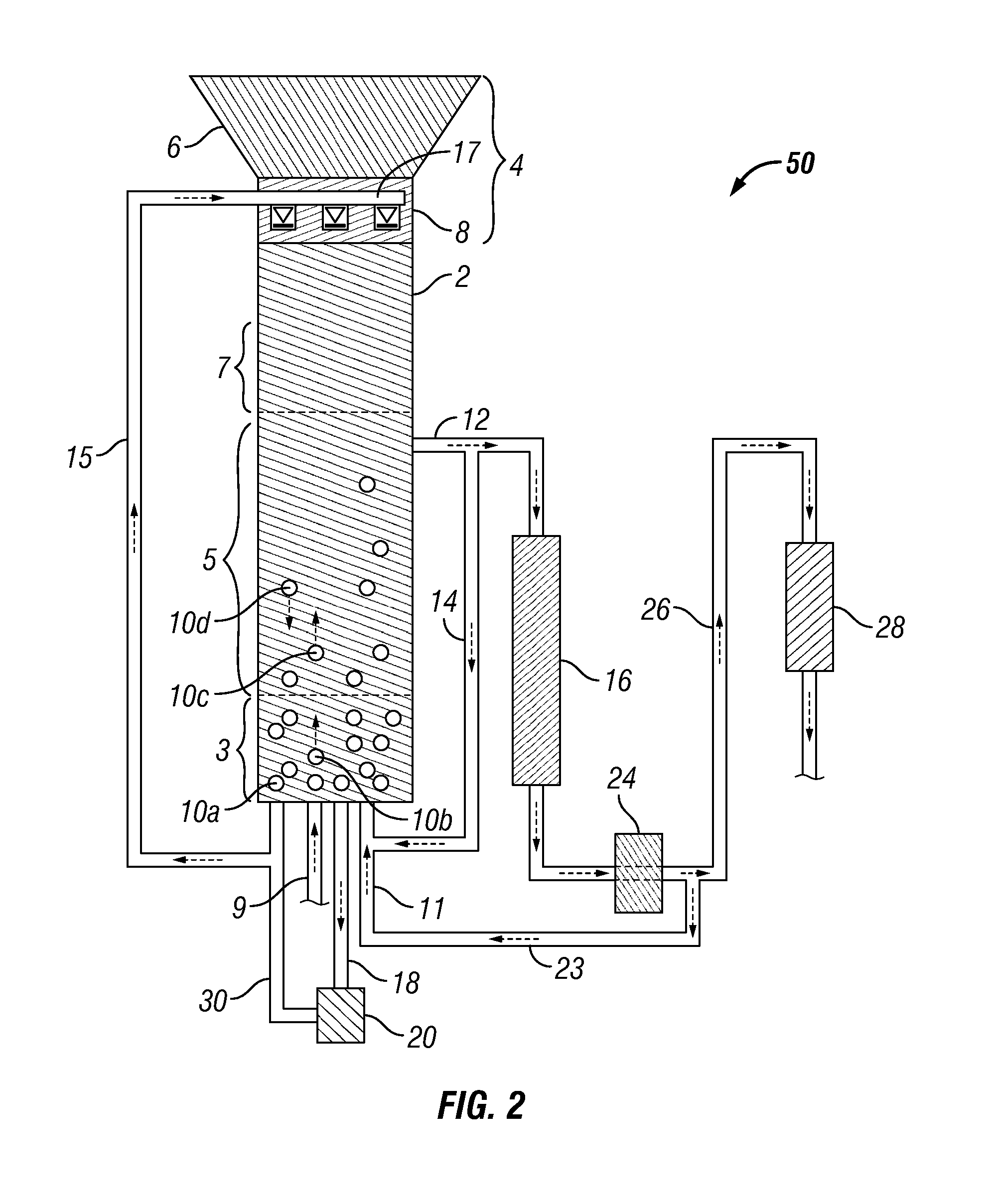

Methods and systems for distributing a slurry catalyst in cellulosic biomass solids

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: heating cellulosic biomass solids and a digestion solvent in the presence of molecular hydrogen and a slurry catalyst capable of activating molecular hydrogen, thereby forming a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase, the slurry catalyst being distributed in the cellulosic biomass solids and at least a portion of the slurry catalyst accumulating in the phenolics liquid phase as it forms; conveying at least a portion of the phenolics liquid phase and the slurry catalyst to a location above at least a portion of the cellulosic biomass solids; and after conveying the phenolics liquid phase and the slurry catalyst, releasing them such that they come in contact with the cellulosic biomass solids.

Owner:SHELL OIL CO

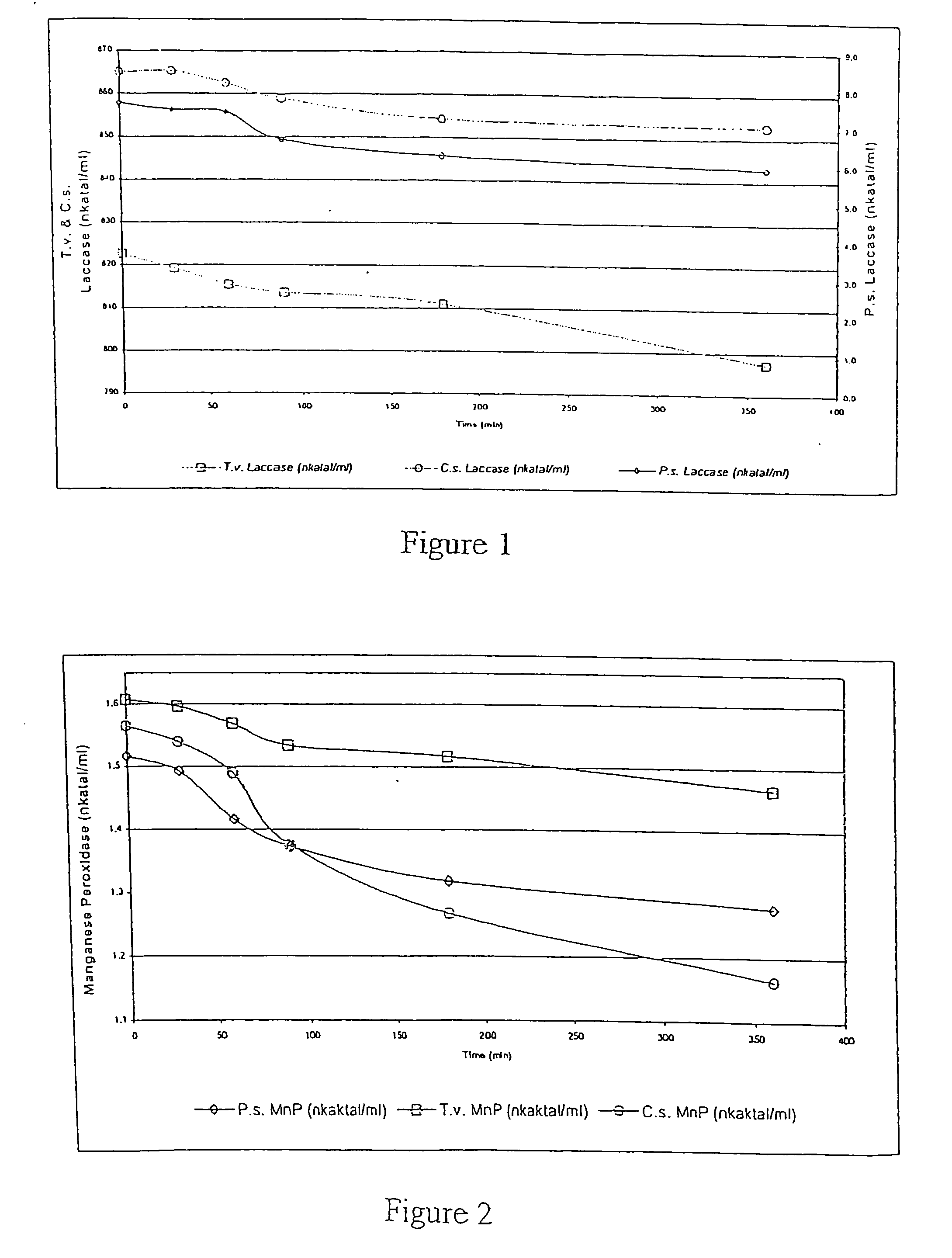

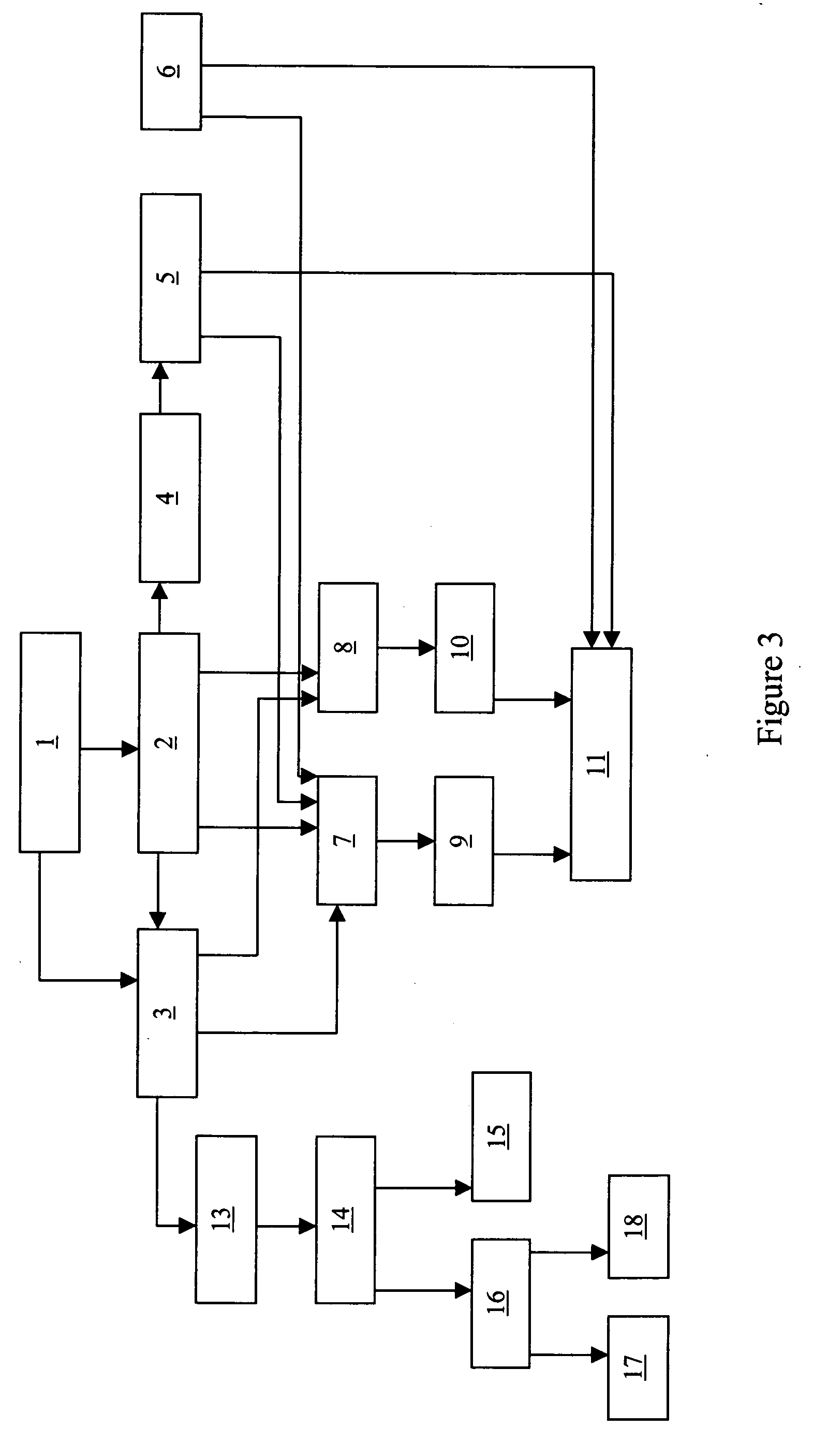

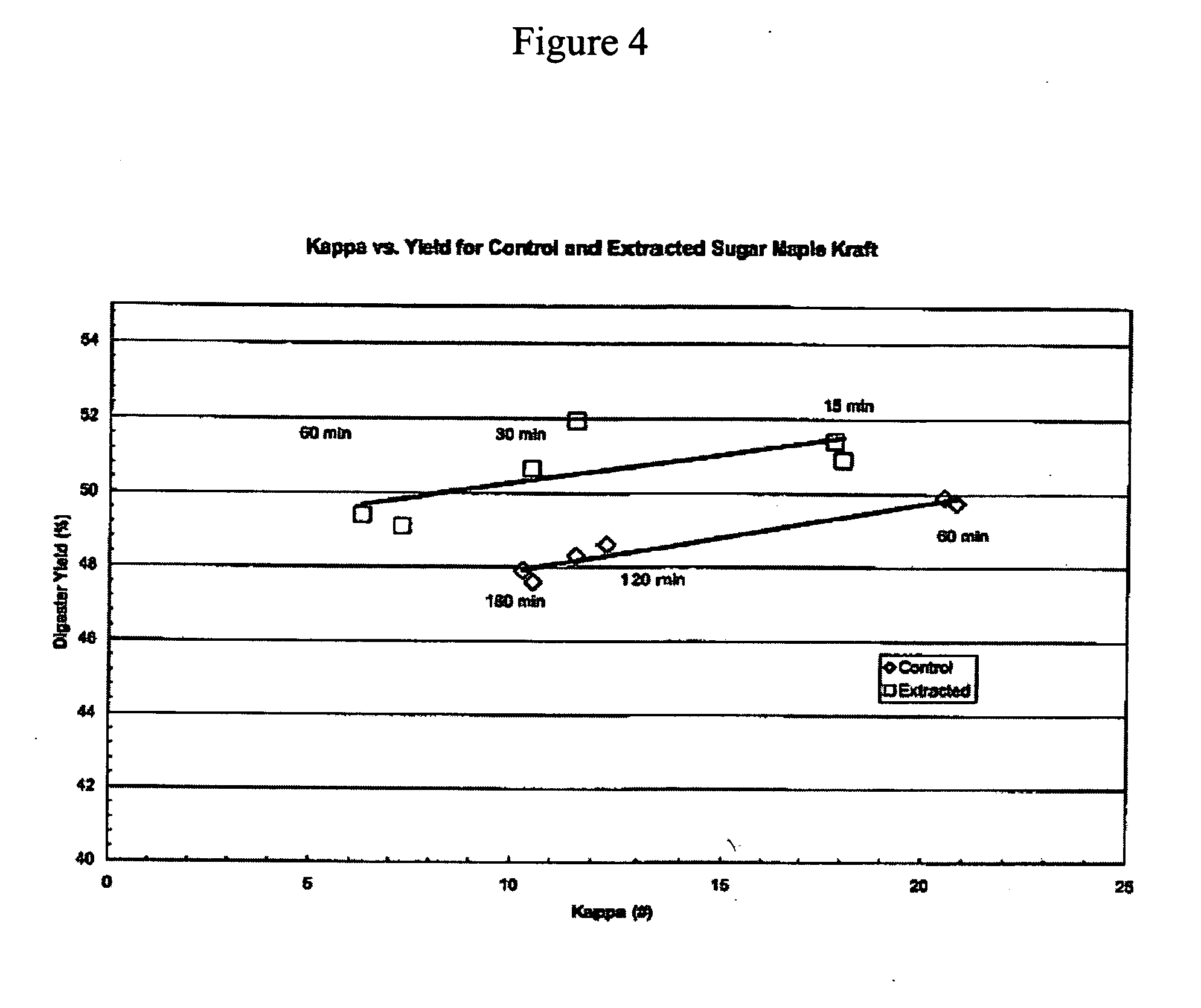

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

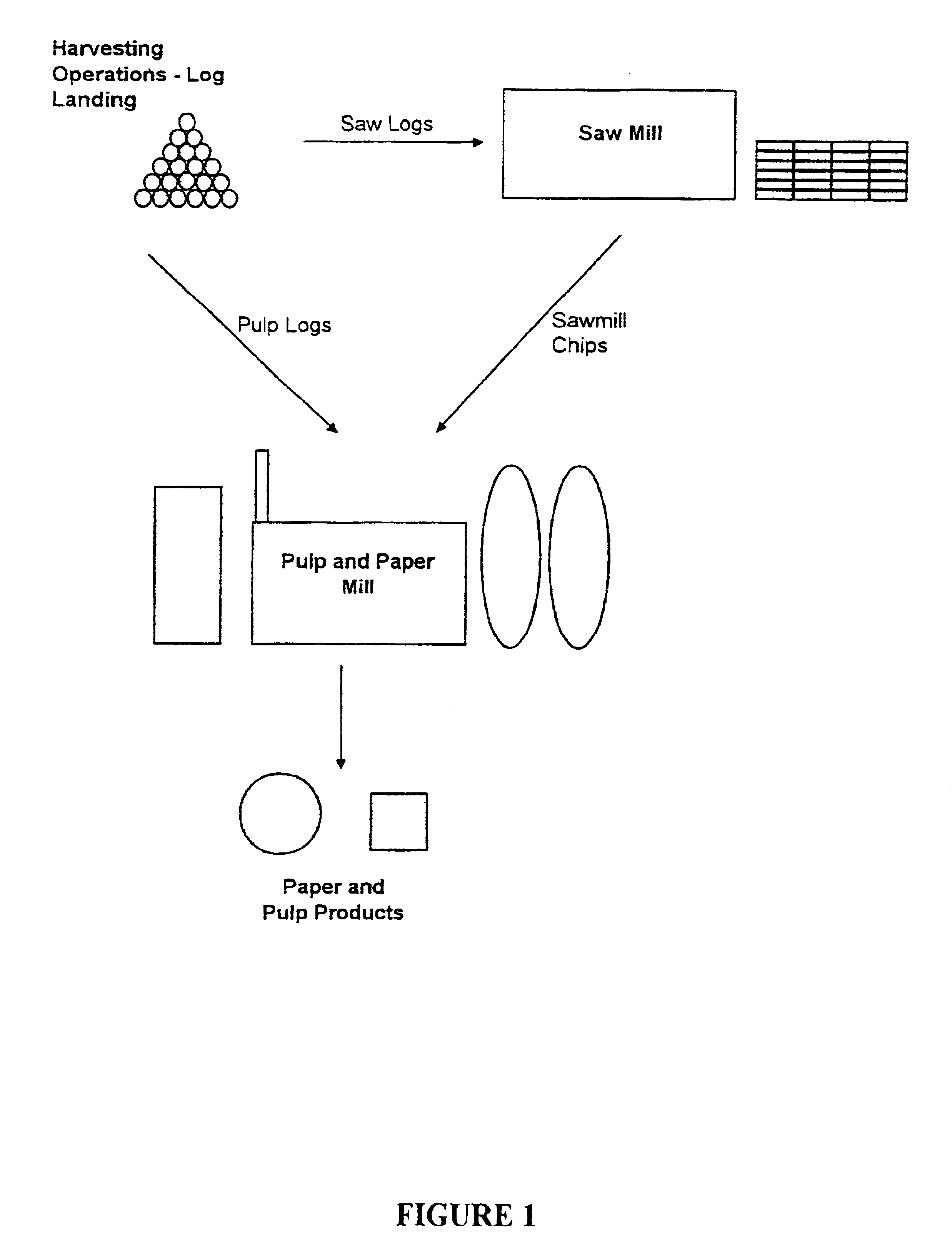

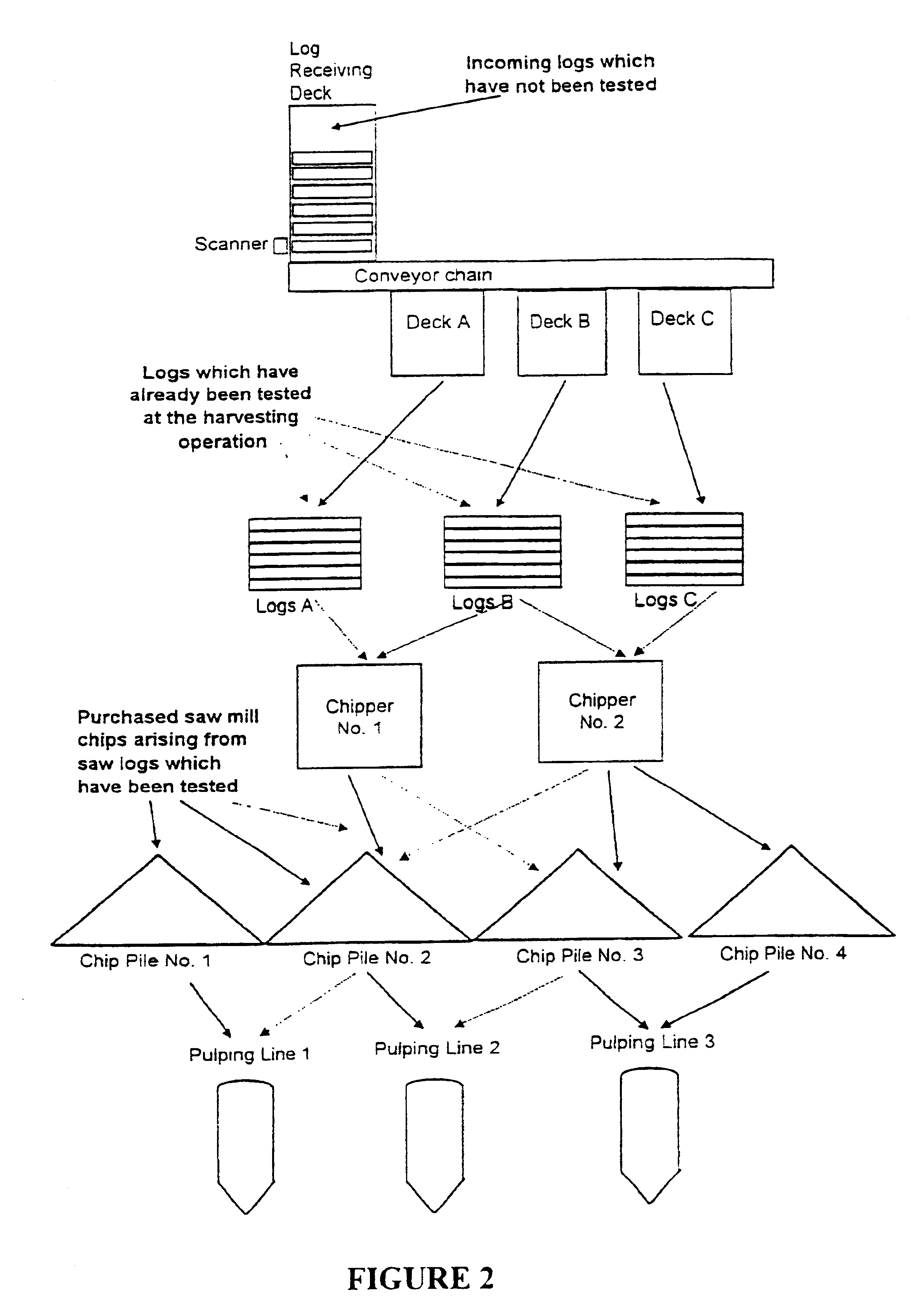

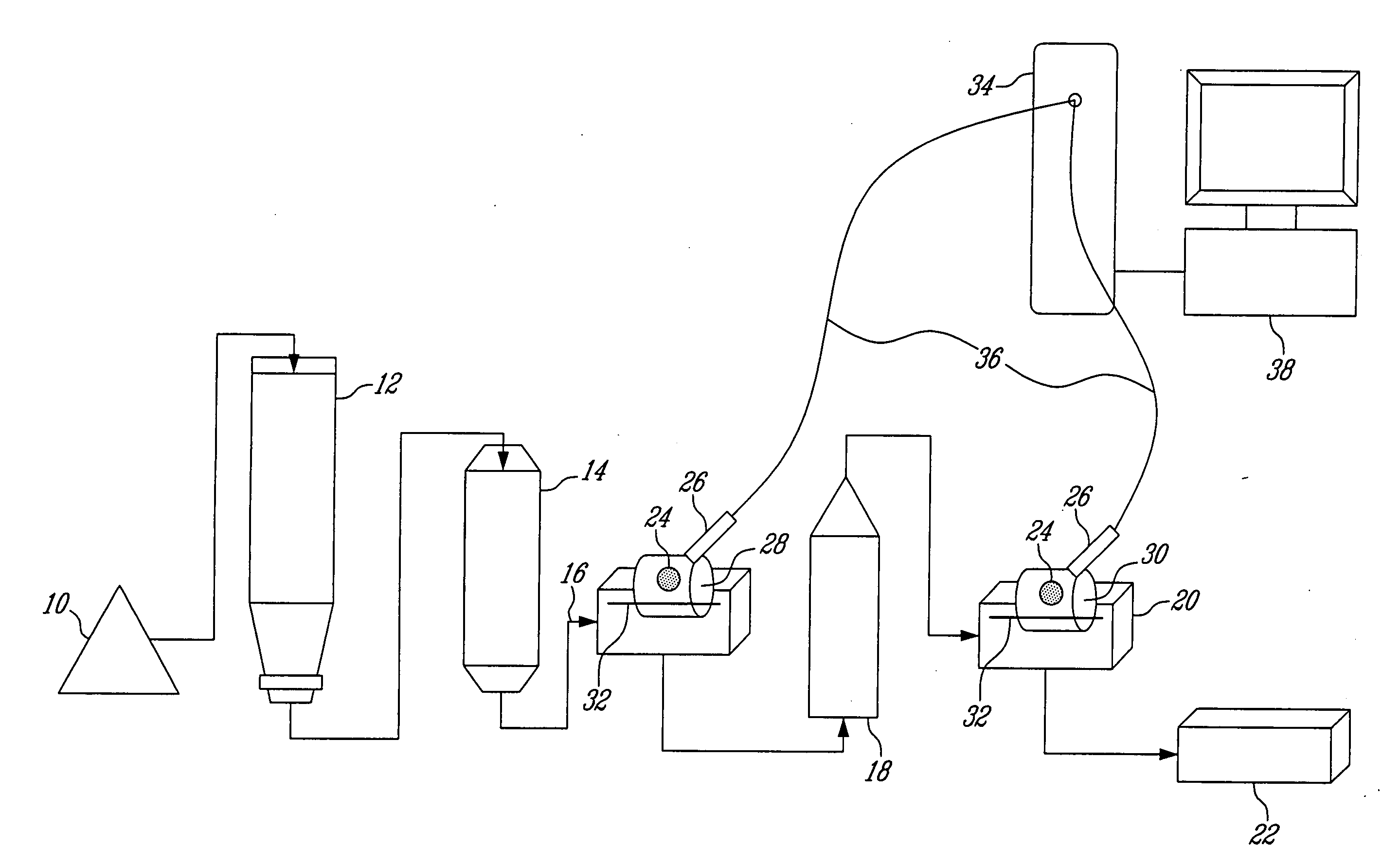

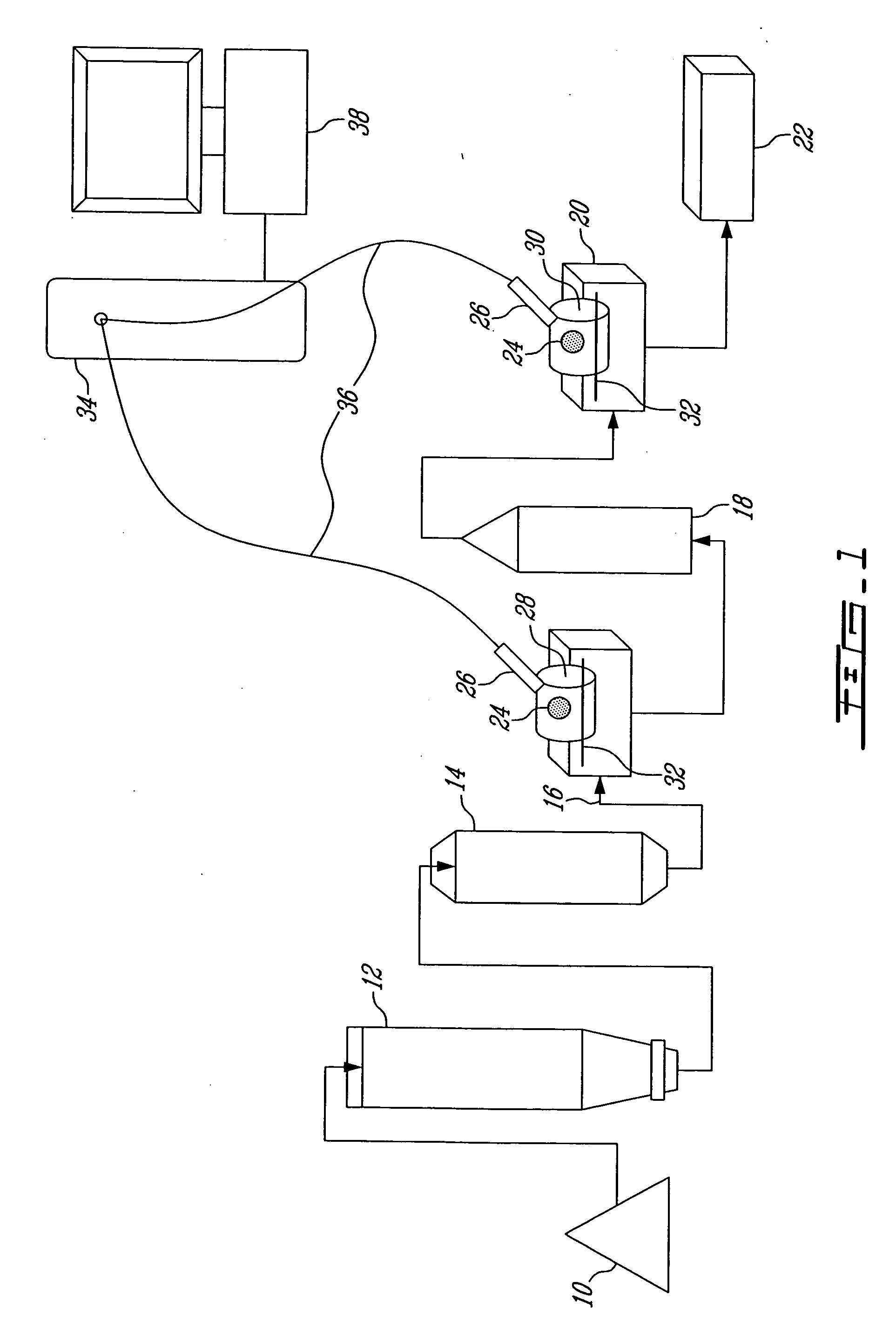

Method of selecting and/or processing wood according to fibre characteristics

InactiveUS6773552B1Analysing solids using sonic/ultrasonic/infrasonic wavesDigestersSolid woodWood fibre

The invention provides a method for predictively assessing one or more characteristics of wood pulp produced from solid wood. The method comprises the steps of determining the velocity of sound through the solid wood, and assessing characteristic(s) of wood fiber or wood pulp produced from the wood by reference to the velocity of sound through the solid wood. The method may also comprise the steps of causing a sound wave to be transmitted through the wood, determining the velocity of the sound wave through the wood, and comparing the result to stored information on fiber characteristic(s) versus sound velocity through the wood-type to determine the fiber characteristic(s) for the wood.

Owner:FIBER GEN INSTR

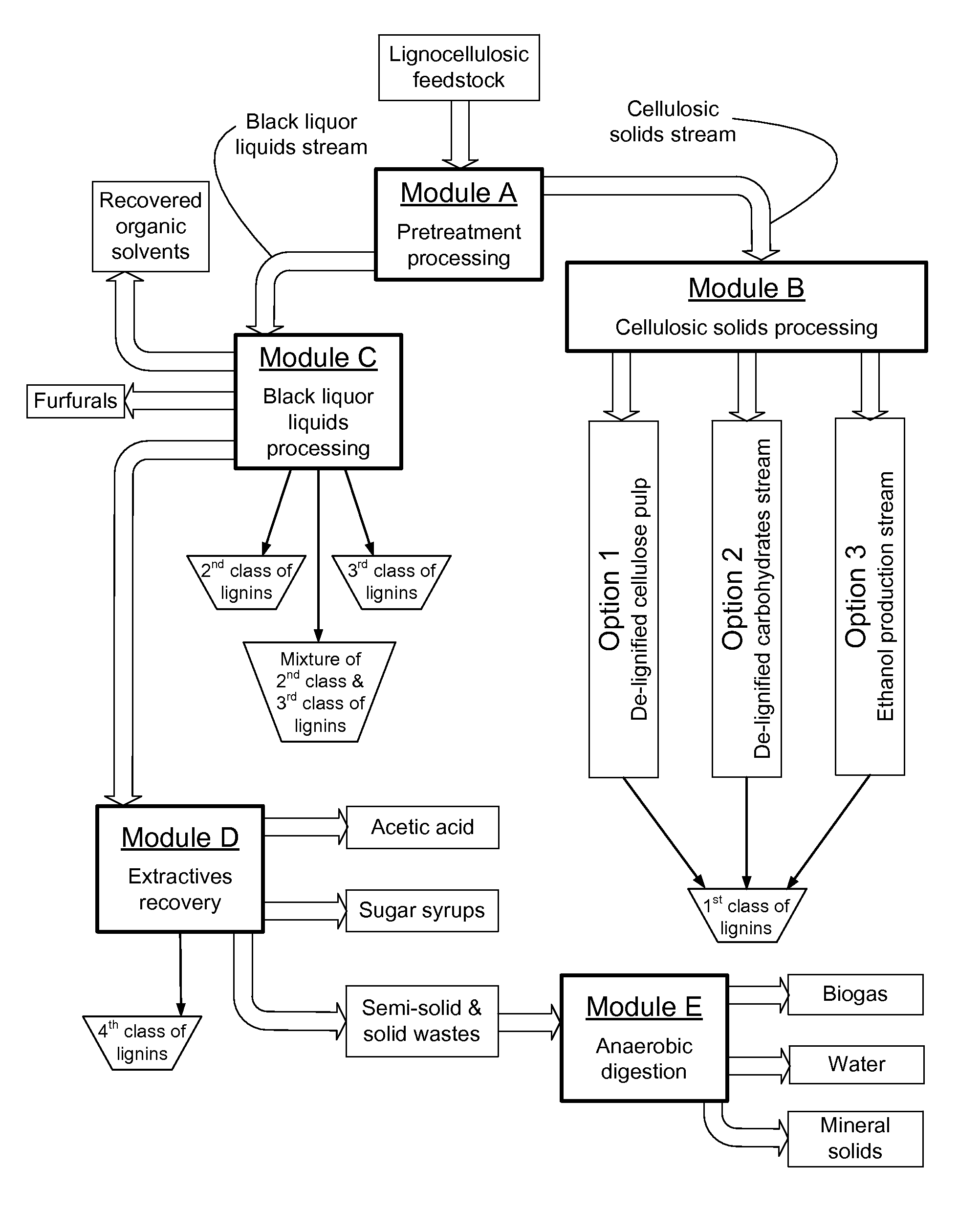

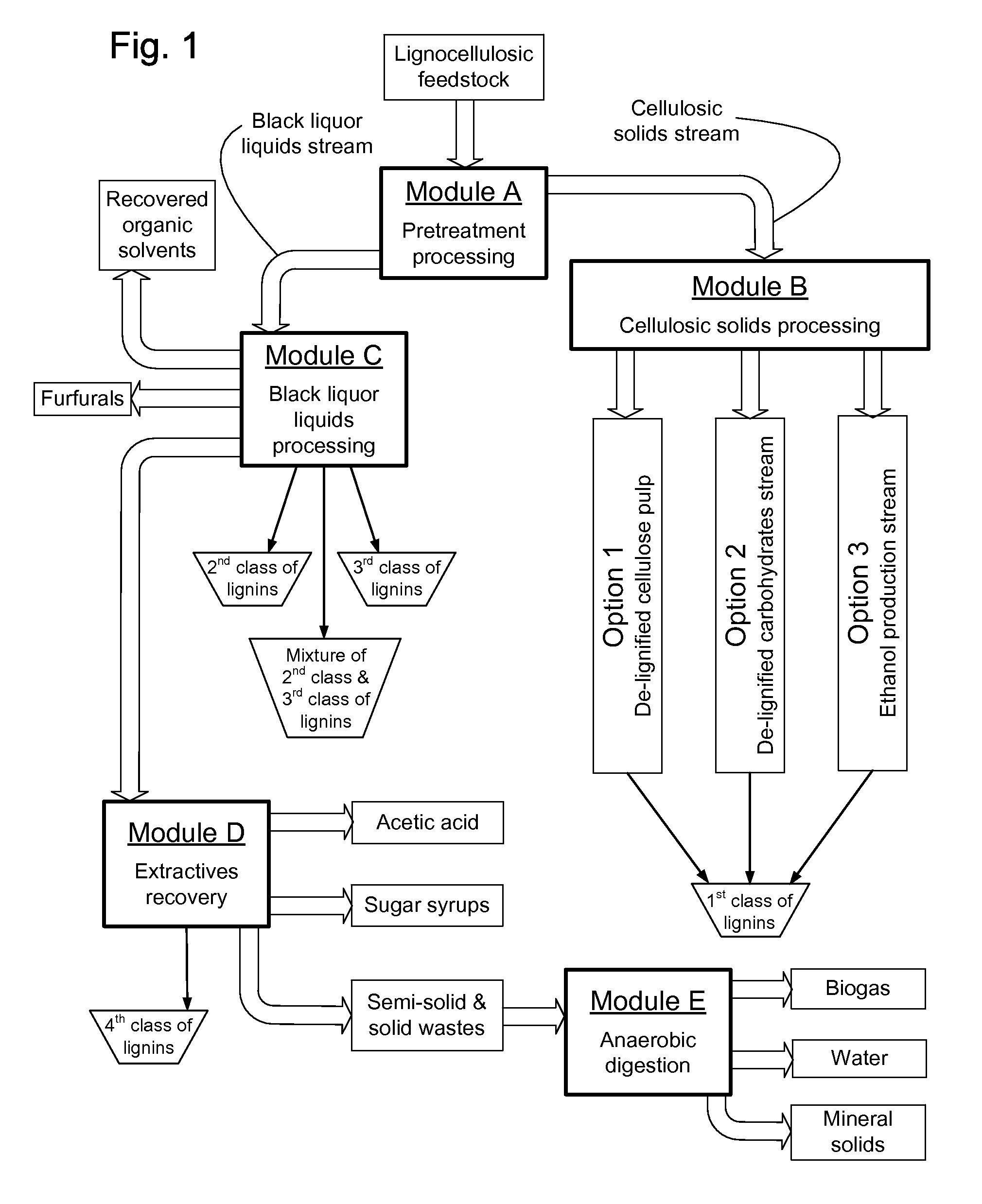

Continuous counter-current organosolv processing of lignocellulosic feedstocks

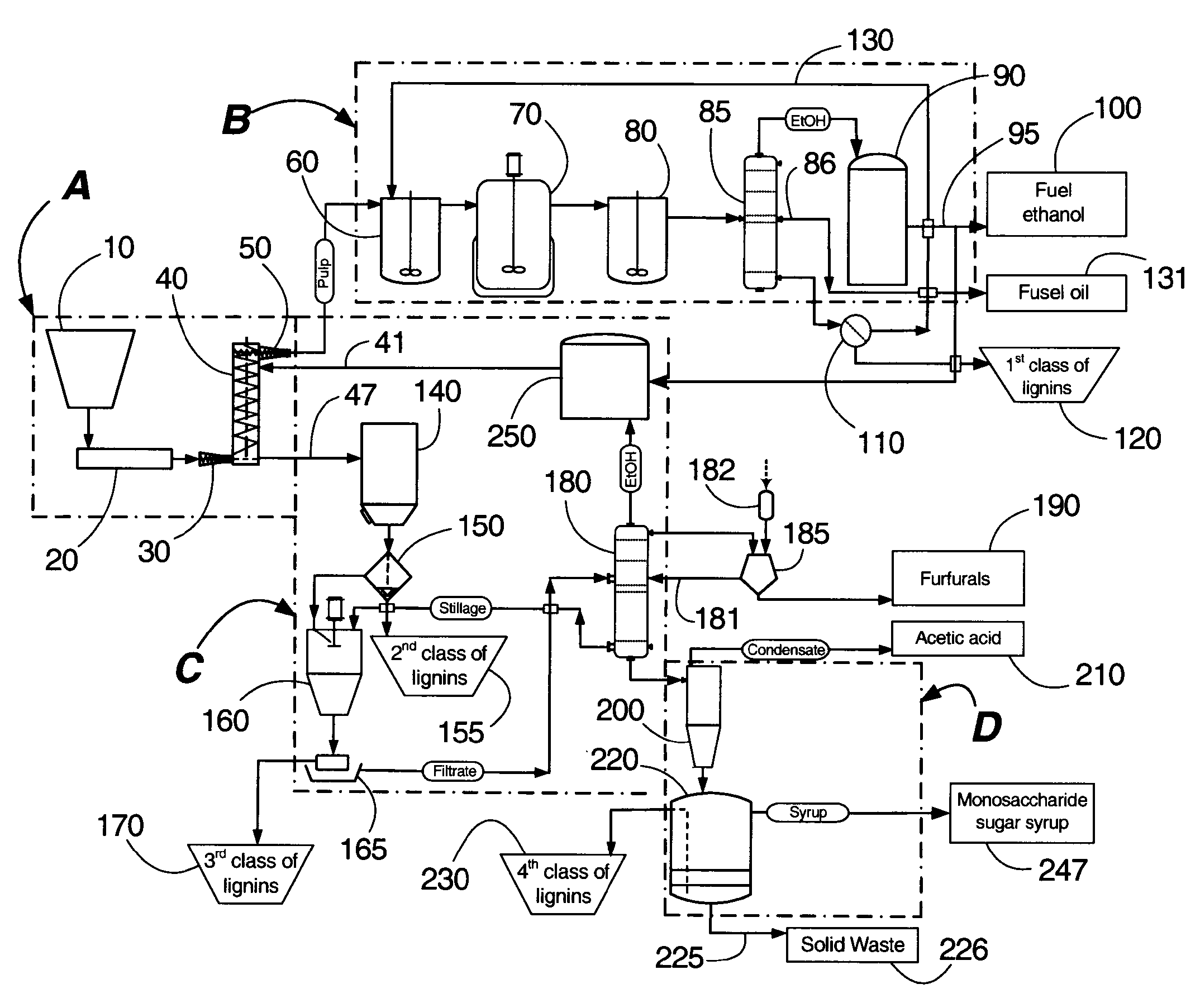

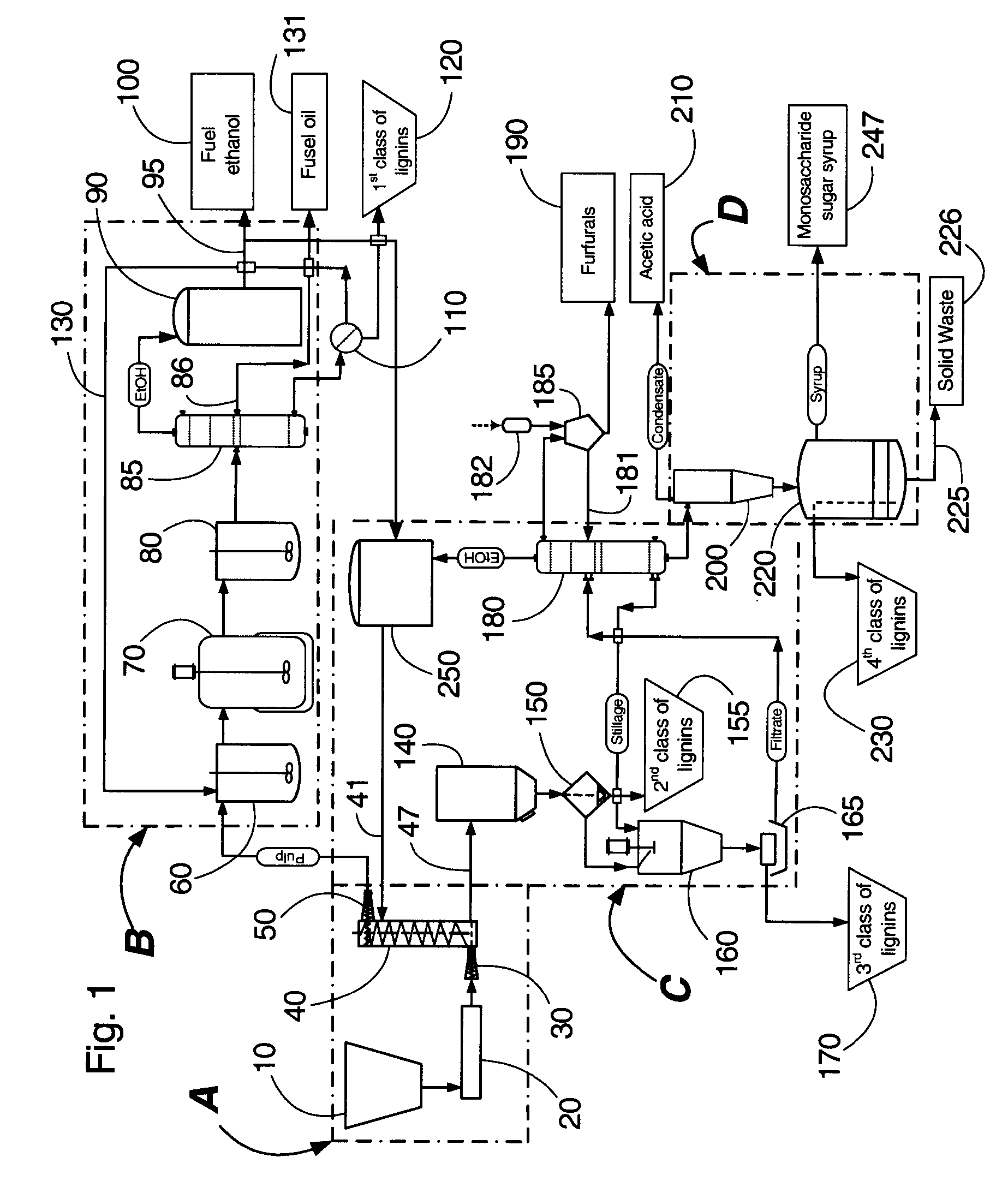

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

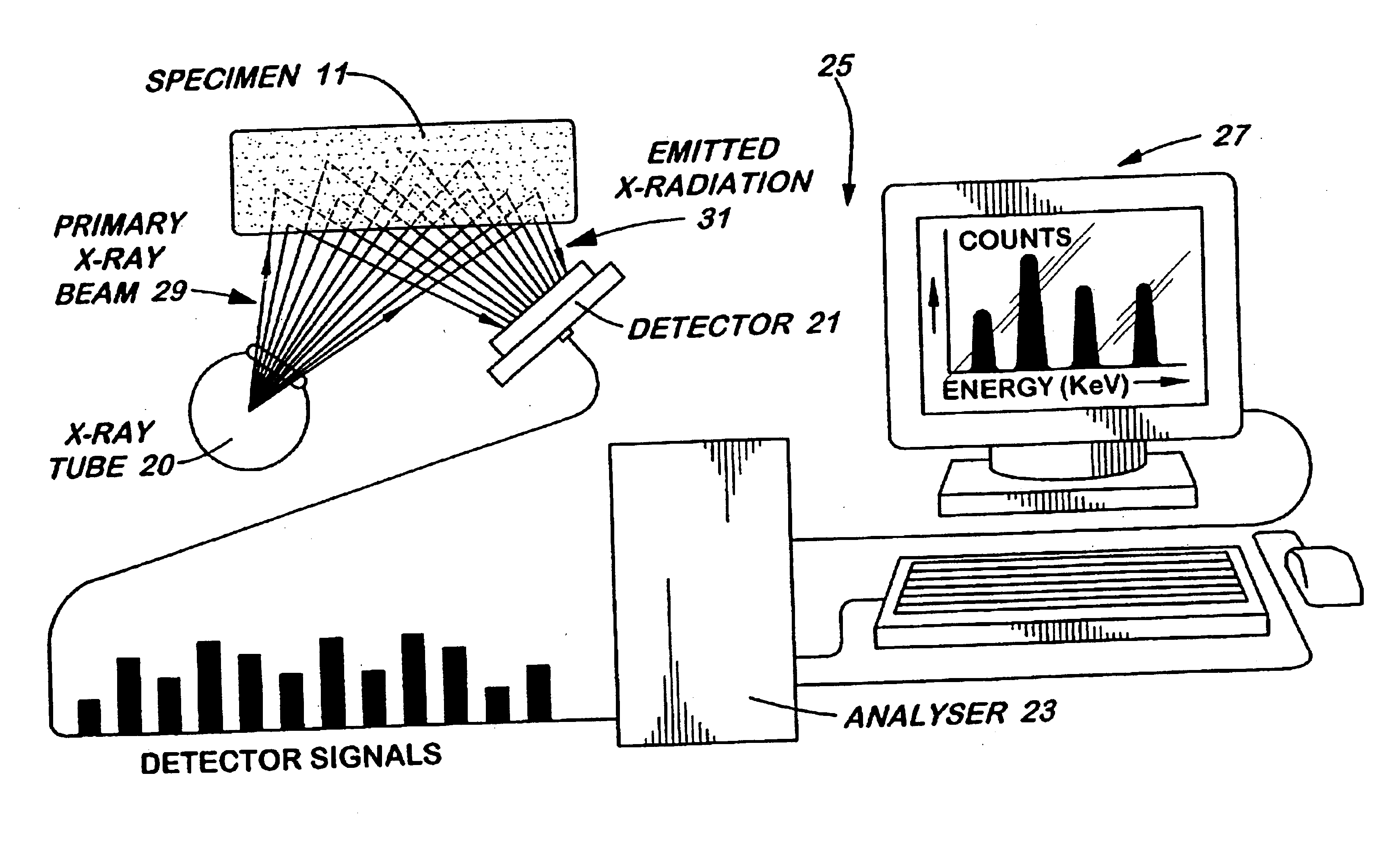

Methods for identification and verification using digital equivalent data system

Apparatus and methods in which one or more elemental taggants that are extrinsically placed in an object are detected by x-ray fluorescence analysis to identify or authenticate the object are described. The taggant is manufactured as part of the object or the taggant is placed into a coating, packaging, label, or otherwise embedded onto the object for the purpose of later verifying the presence or absence of these elements by x-ray fluorescence. The taggant is then analyzed by XRF and the analysis is then converted into a 2D symbol format that can be used in various security and authentication applications. By using x-ray fluorescence analysis, the apparatus and methods of the invention are simple and easy to use, without the limitations experience by current anti-counterfeiting technologies.

Owner:NASA +1

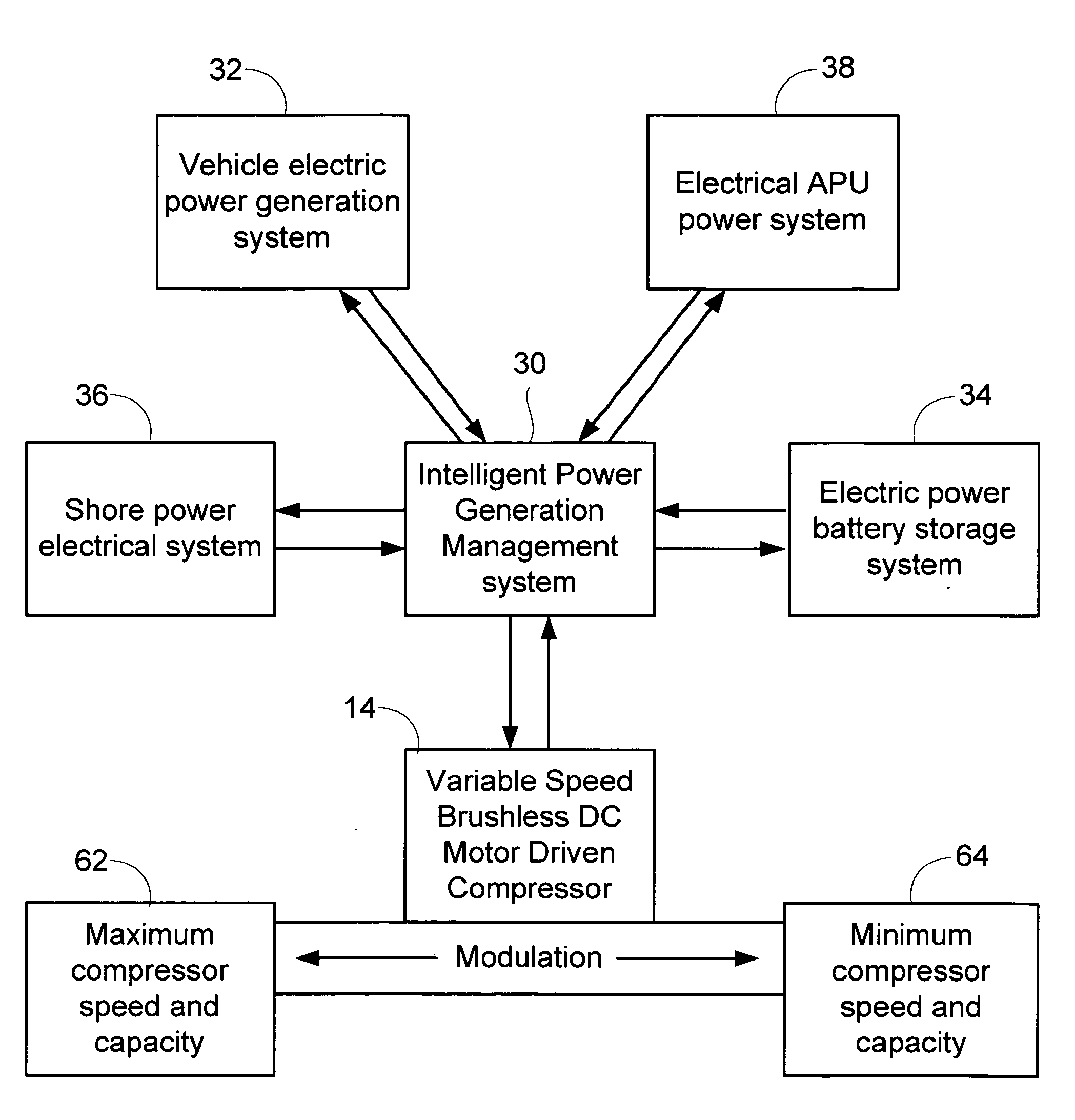

Vehicle air conditioning and heating system providing engine on and engine off operation

InactiveUS20050161211A1Solve insufficient capacityAccurate lifeAir-treating devicesCompression machines with non-reversible cycleMotor driveAir conditioning

An air conditioning system for use in an over-the-road or off road vehicle is provided that allows operation during both engine on and engine off conditions. The system utilizes a variable speed, motor driven compressor controlled by an intelligent power generation management controller. This controller selects from one of the available sources of power on the vehicle to drive the compressor, and modulates the compressor speed and capacity based on operational parameters and source availability and depletion. The controller may also operate a coolant or air heater to provide heating to the interior compartments.

Owner:BERGSTROM INC

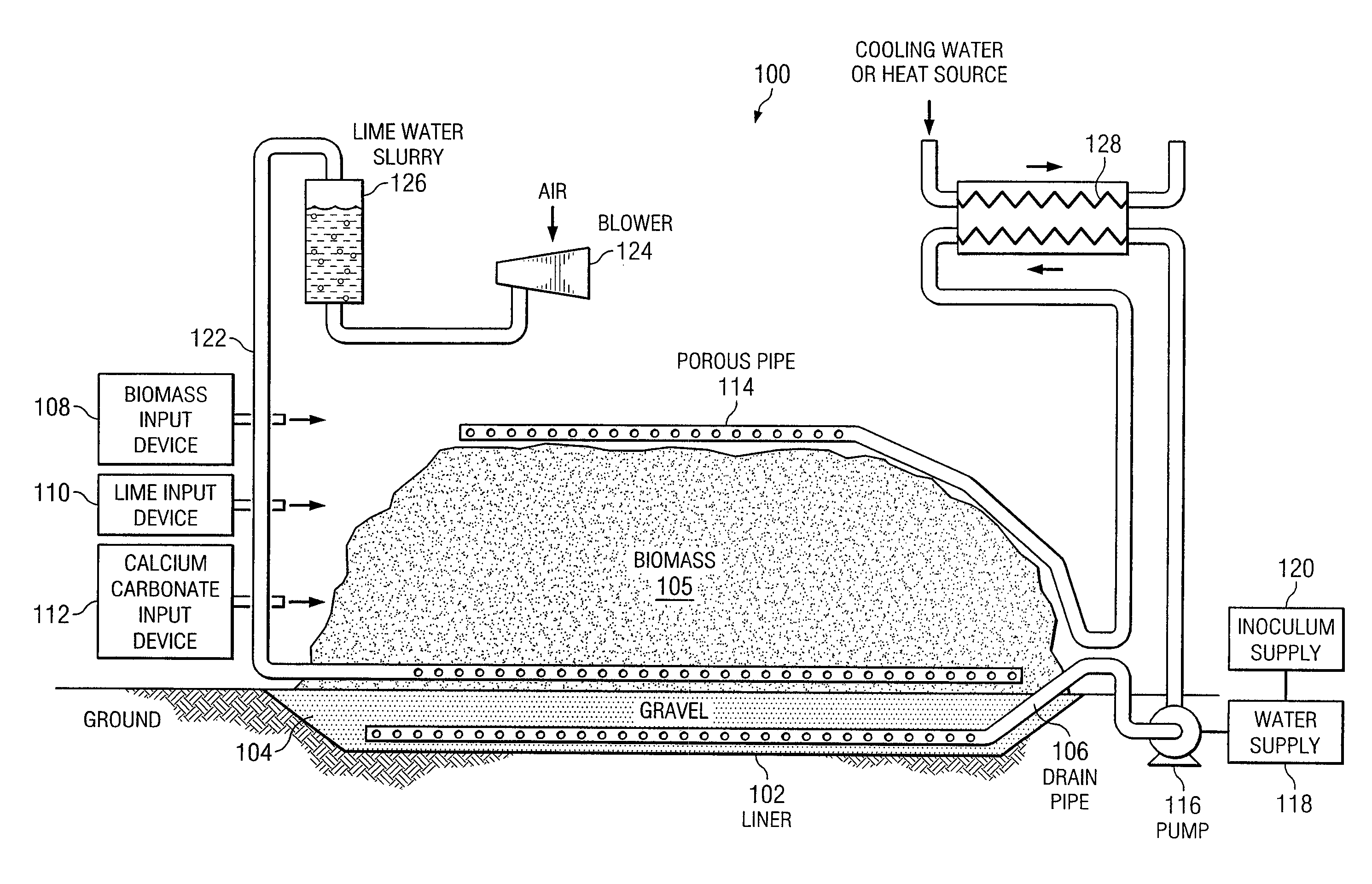

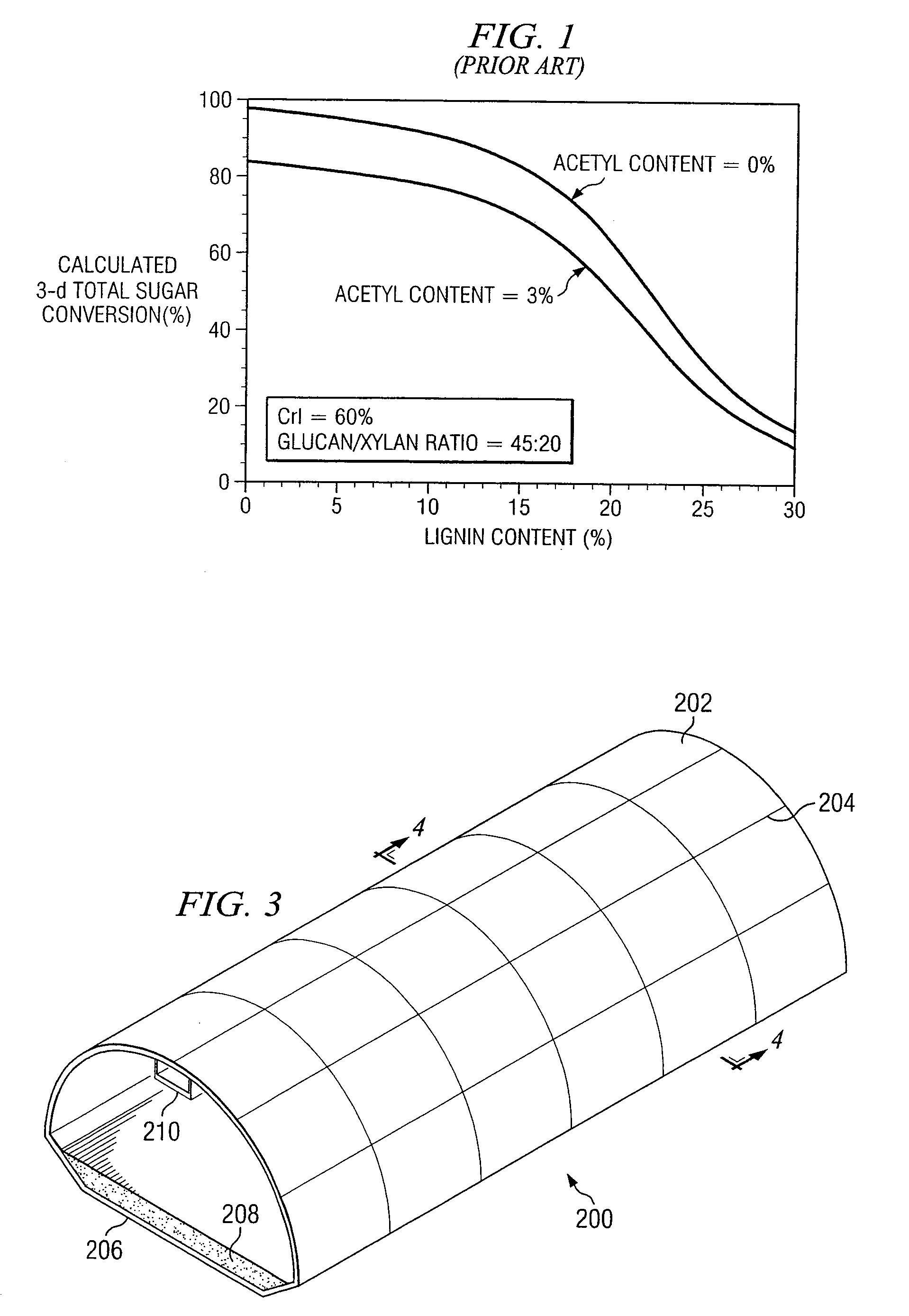

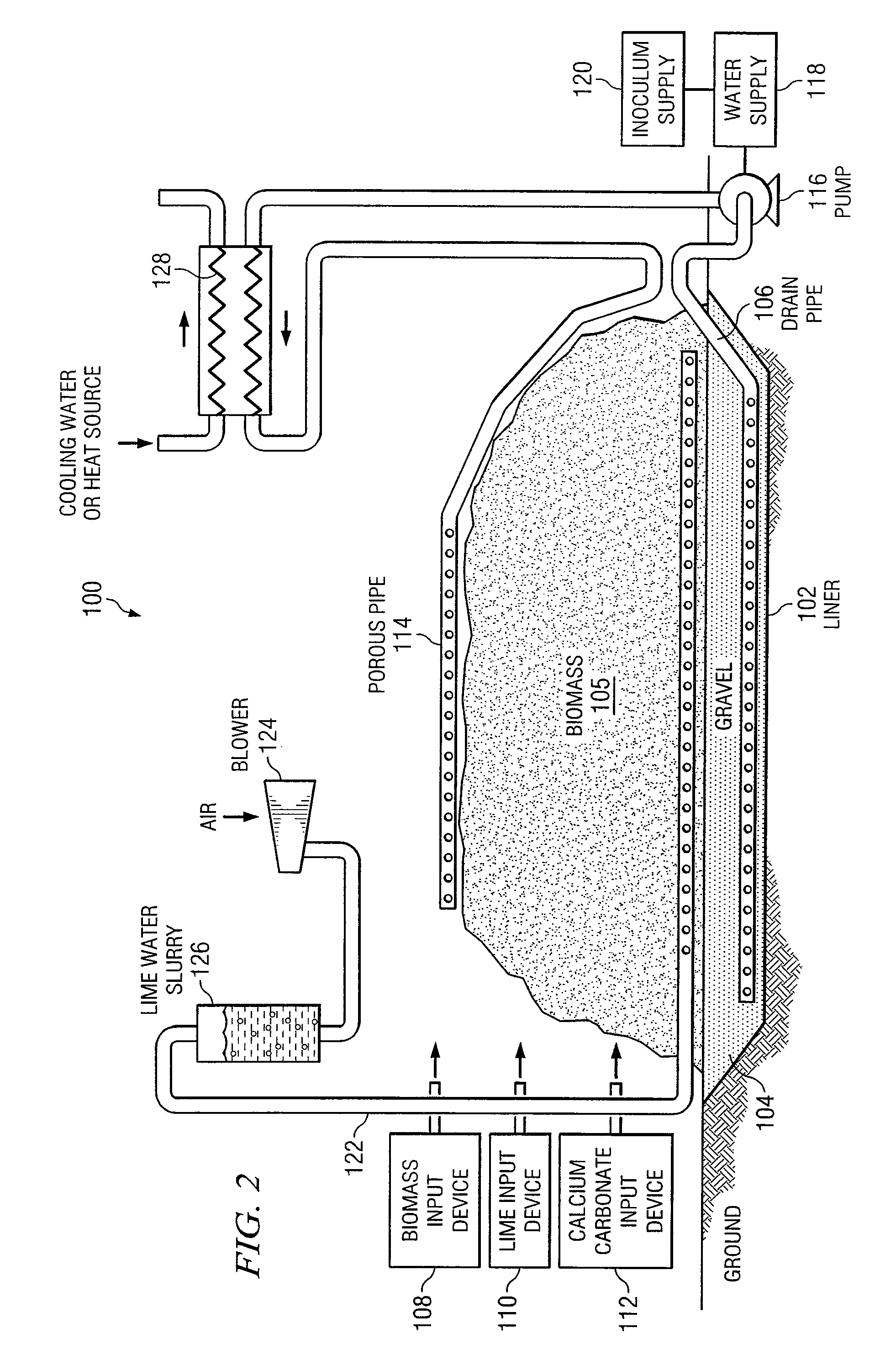

Methods and Systems for Pretreatment and Processing of Biomass

InactiveUS20080121359A1Increasing enzyme digestibilityLow lignin contentBio-organic fraction processingProductsEnzymatic digestionCellulose

According to one embodiment of the invention, a system for processing biomass includes a water-impermeable bottom liner, a gravel layer supported by the bottom liner, a drain pipe disposed within the gravel layer, a biomass input device operable to deliver biomass over the gravel layer to form a biomass pile, a lime input device operable to deliver lime to the biomass for pretreating the biomass, a distribution pipe elevated above the gravel layer, and a pump operable to circulate water through the biomass pile by delivering water to the distribution pipe and receiving water from the drain pipe after it has traveled through the biomass pile.According to another embodiment, a method for biomass pretreatment with alkali, conducted at ambient pressure for approximately 4-16 weeks at temperatures ranging from approximately 25° C. to 95° C. Biomass may be lignocellulosic biomass and may be rendered suitable for enzymatic digestion or pulp production.

Owner:TEXAS A&M UNIVERSITY

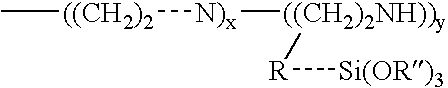

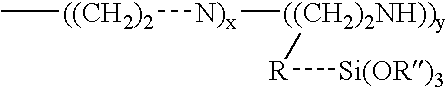

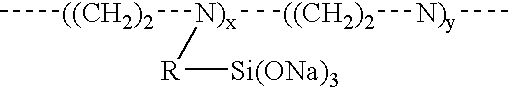

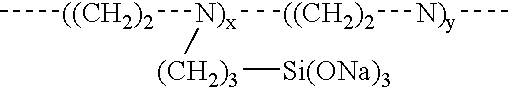

Method of preventing or reducing aluminosilicate scale in kraft pulp mills

InactiveUS20050274926A1Reduce and eliminate aluminosilicate scalingReduce and even prevent formationAluminium compoundsDigestersEnd-groupPulp mill

Materials and a method are provided whereby polymers with least 0.5 mole % of the pendant group or end group containing —Si(OR″)3 (where R″ is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in an industrial process having an alkaline process stream such as a pulping mill process stream. When materials of the present invention are added to the alkaline process stream, they reduce and even completely prevent formation of aluminosilicate scale on equipment surfaces such as evaporator walls and heating surfaces. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

Apparatus for making carboxylated pulp fibers

InactiveUS7001483B2Little additional equipmentDelay transitionNon-fibrous pulp additionSpecial paperFiberBleach

Owner:WEYERHAEUSER CO

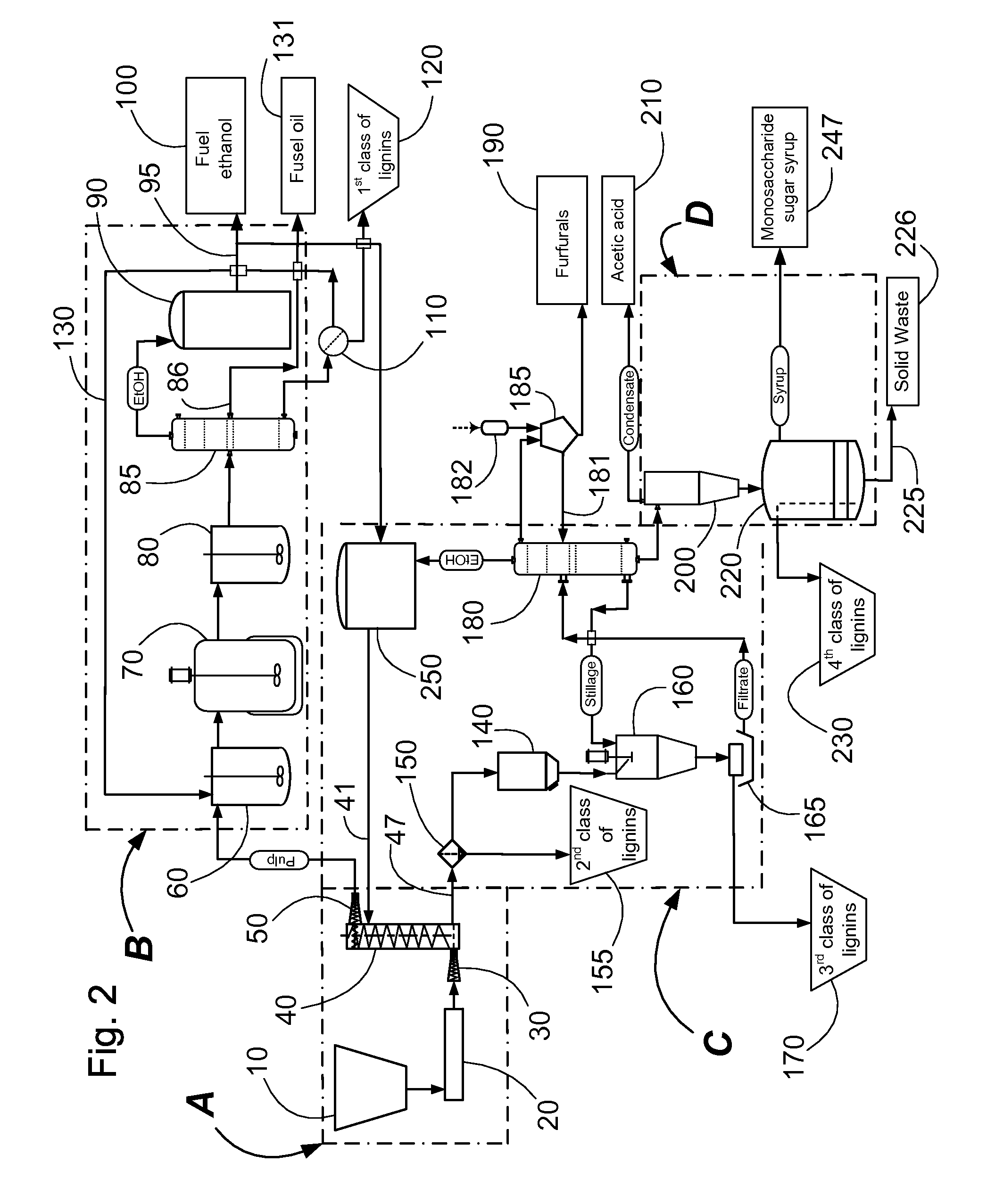

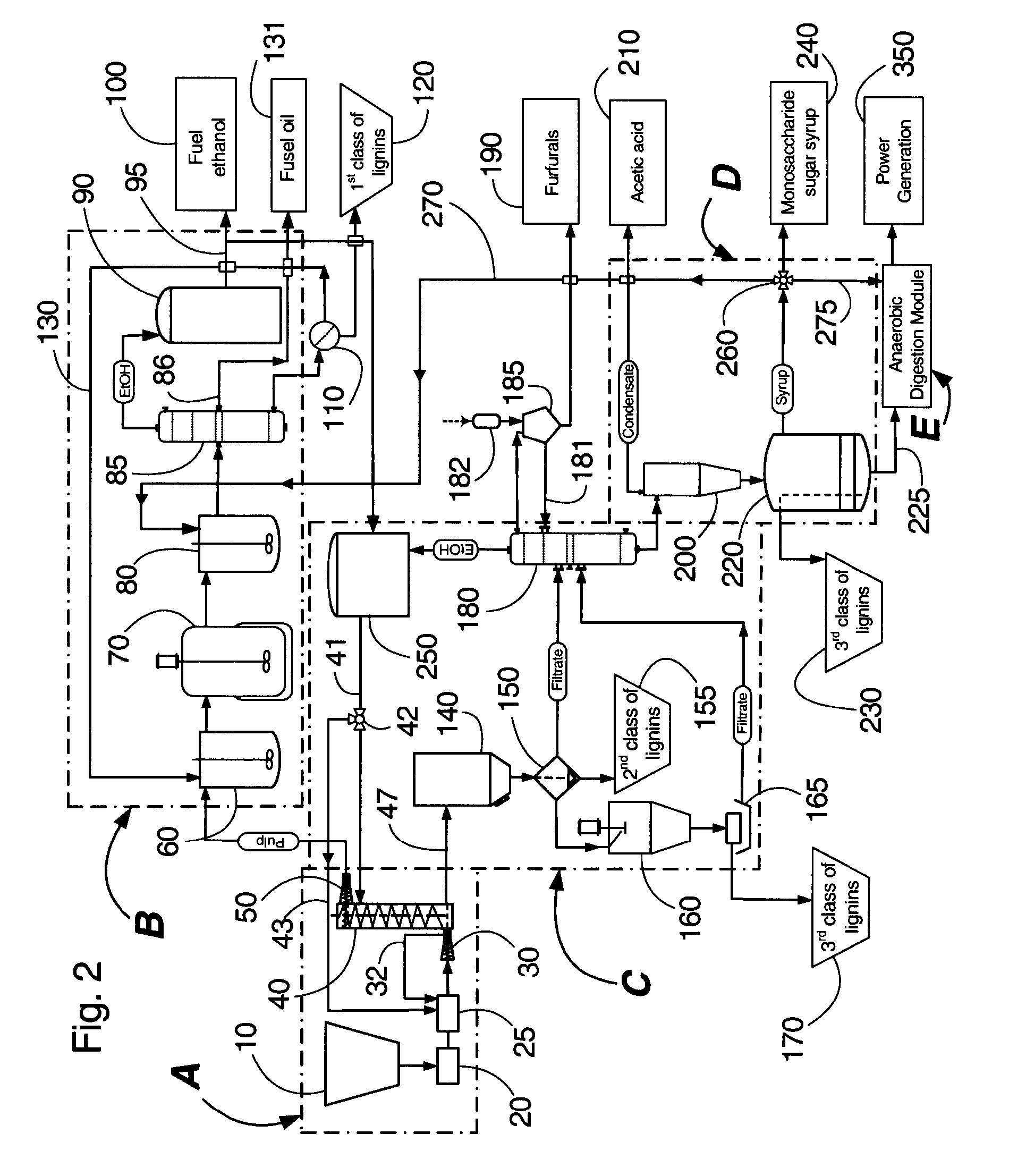

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

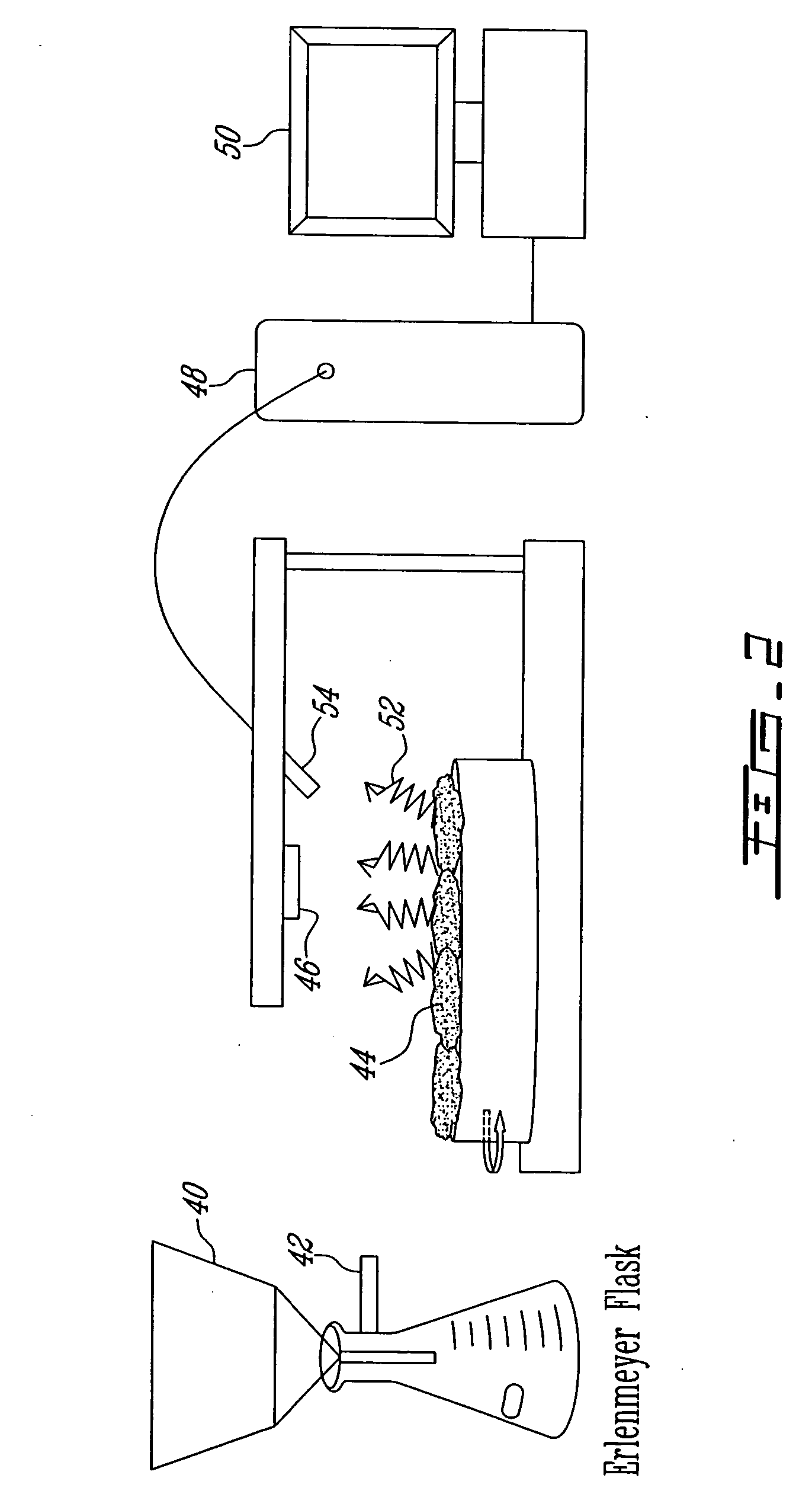

Method for determining chemical pulp Kappa number with visible-near infrared spectrometry

ActiveUS20060196622A1Overcomes shortcomingCellulosic pulp after-treatmentRadiation pyrometryContinuous measurementPresent method

A method for the determination of cellulosic-fibre properties, such as, but not limited to, residual lignin content of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising the steps of obtaining a sample from the process line, minimally removing some excess water, exposing the fibres in the sample to a large beam light source, optionally moving the sample at a constant speed, and acquiring the spectral data over a pre-determined length of time, and correlating the spectrum to a previously determined calibration so as to determine the Kappa number. Alternatively, as an arrangement for process control, along with other varying configurations, the instant invention includes the mounting of the excitation light source and fibre-optic probe along the various locations of the kraft cooking and bleaching process, such as 1) at the drum brownstock washers and 2) throughout the bleach plant deckers, located just before the doctored blade, the probe being connected to a fast scanning spectrometer, via fibre optic cables, with a computer sequencing spectral acquisition and correlating the spectrum against a predetermined calibration, and logging the results. The process configuration, with the use of the instant invention, overcomes all limitations of prior art, including sampling hardware and sample preparation, and provides true online Kappa number determinations of the order of seconds, as compared to current state of the art Kappa analyzers which require 10 to 15 minutes per analysis. The present method is capable of measuring residual lignin content of chemical pulps with varying consistency, accounts for species effects to provide species insensitivity and can provide analysis in less than 10 seconds. The method can provide true online continuous measurement of Kappa number for feedforward and feedback control of the bleaching, paper machine and kraft cooking processes.

Owner:FPINNOVATIONS INC

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

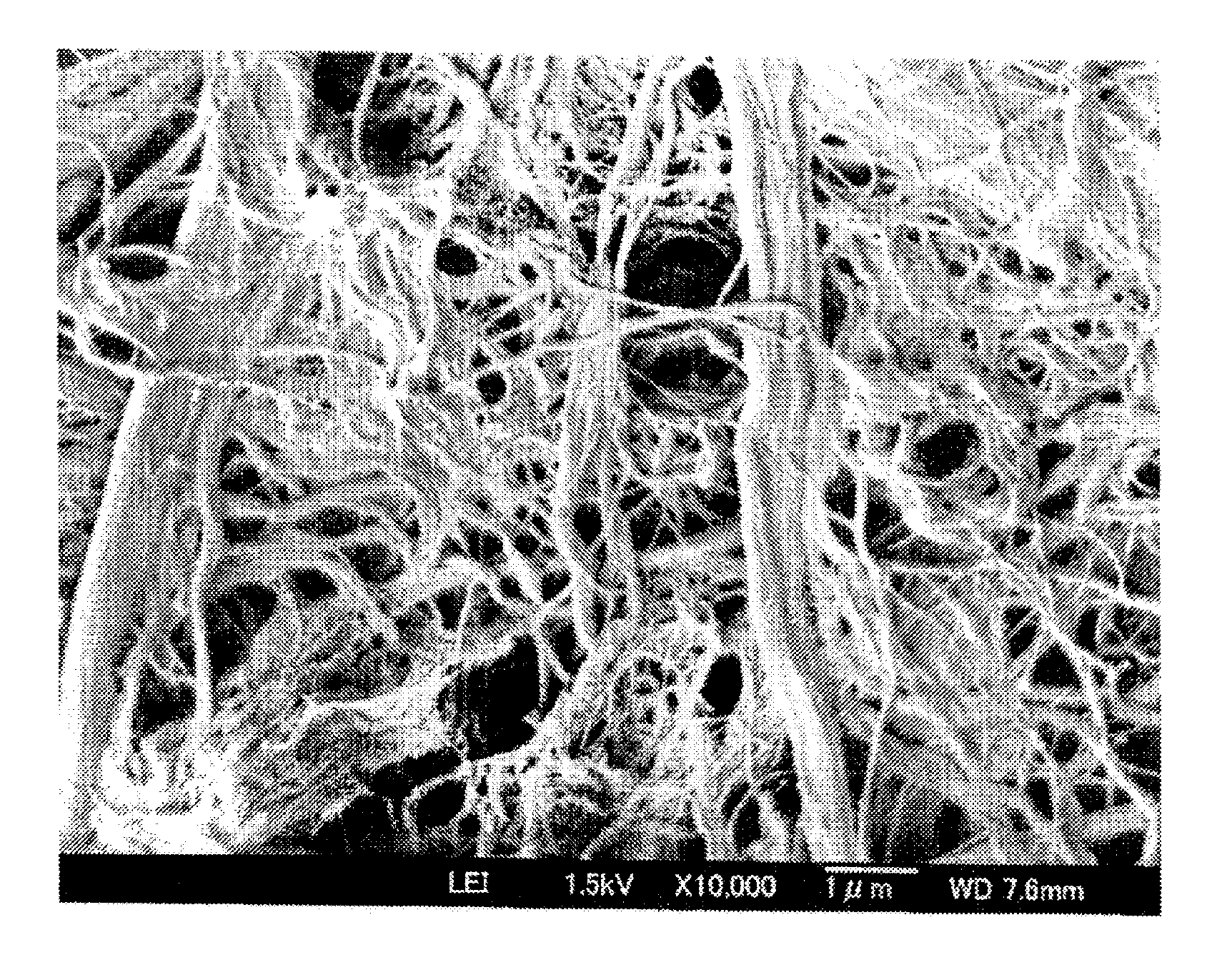

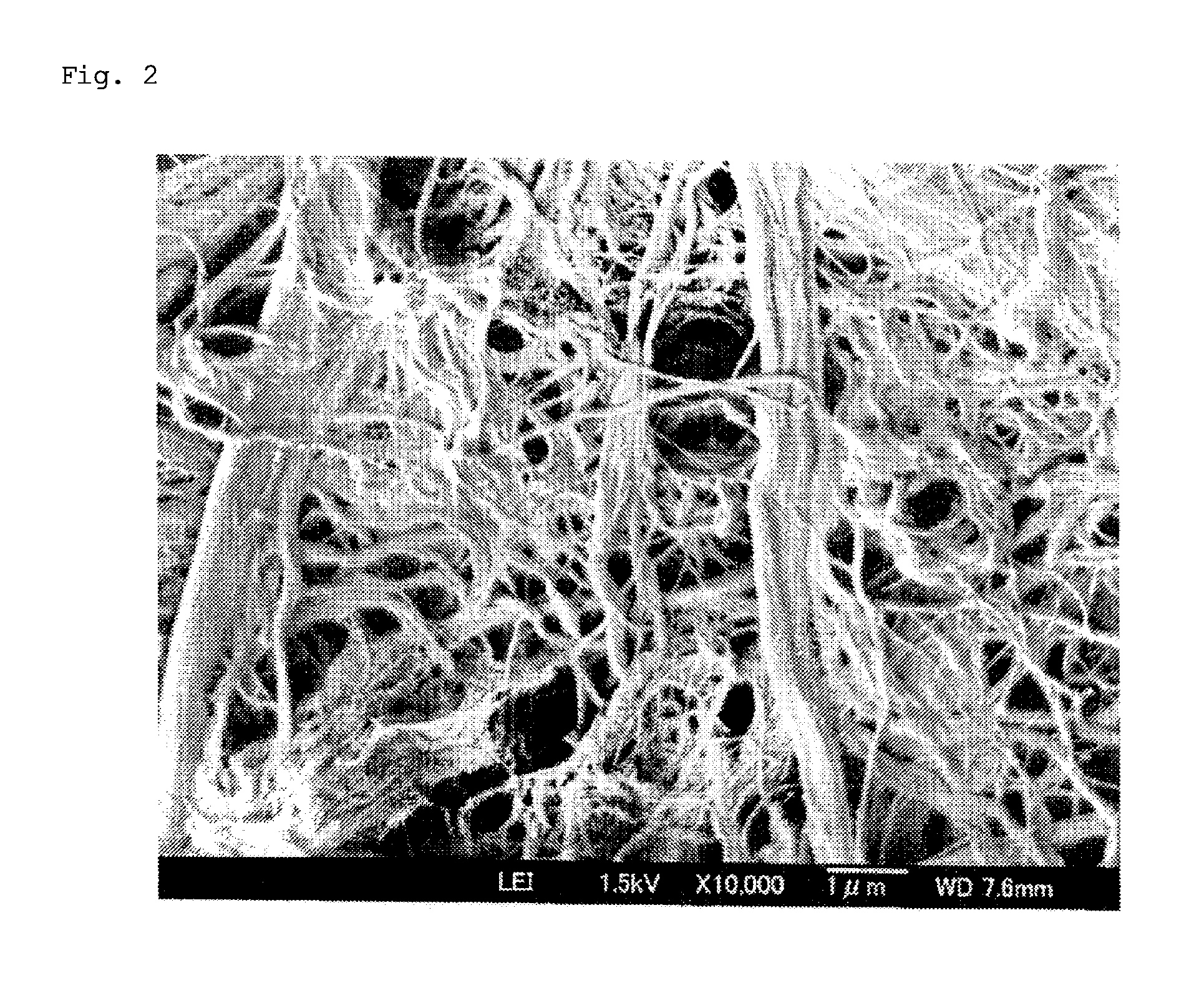

Cellulose nanofibers

ActiveUS20120277351A1Excellent water filtering propertyIncrease shear rateCellulosic pulp after-treatmentDigestersFiberCellulose

The present invention provides a novel production method of a cellulose nanofiber and a novel cellulose nanofiber.A method for producing a cellulose nanofiber comprising defibrating pulp by a single- or multi-screw kneader in the presence of water, the single or multi-screw kneader having a screw circumferential speed of 45 m / min. or more.

Owner:MITSUBISHI CHEM CORP +3

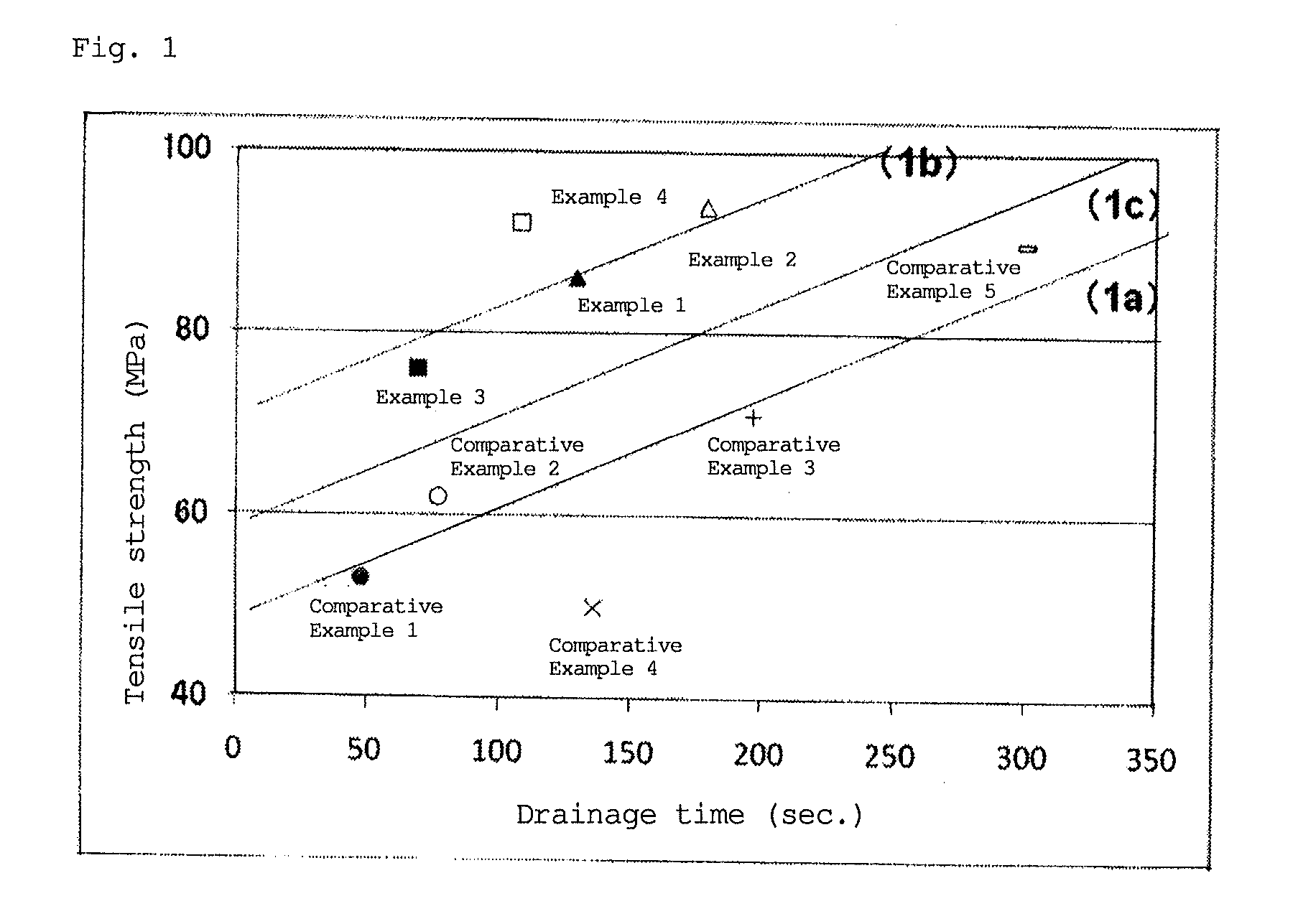

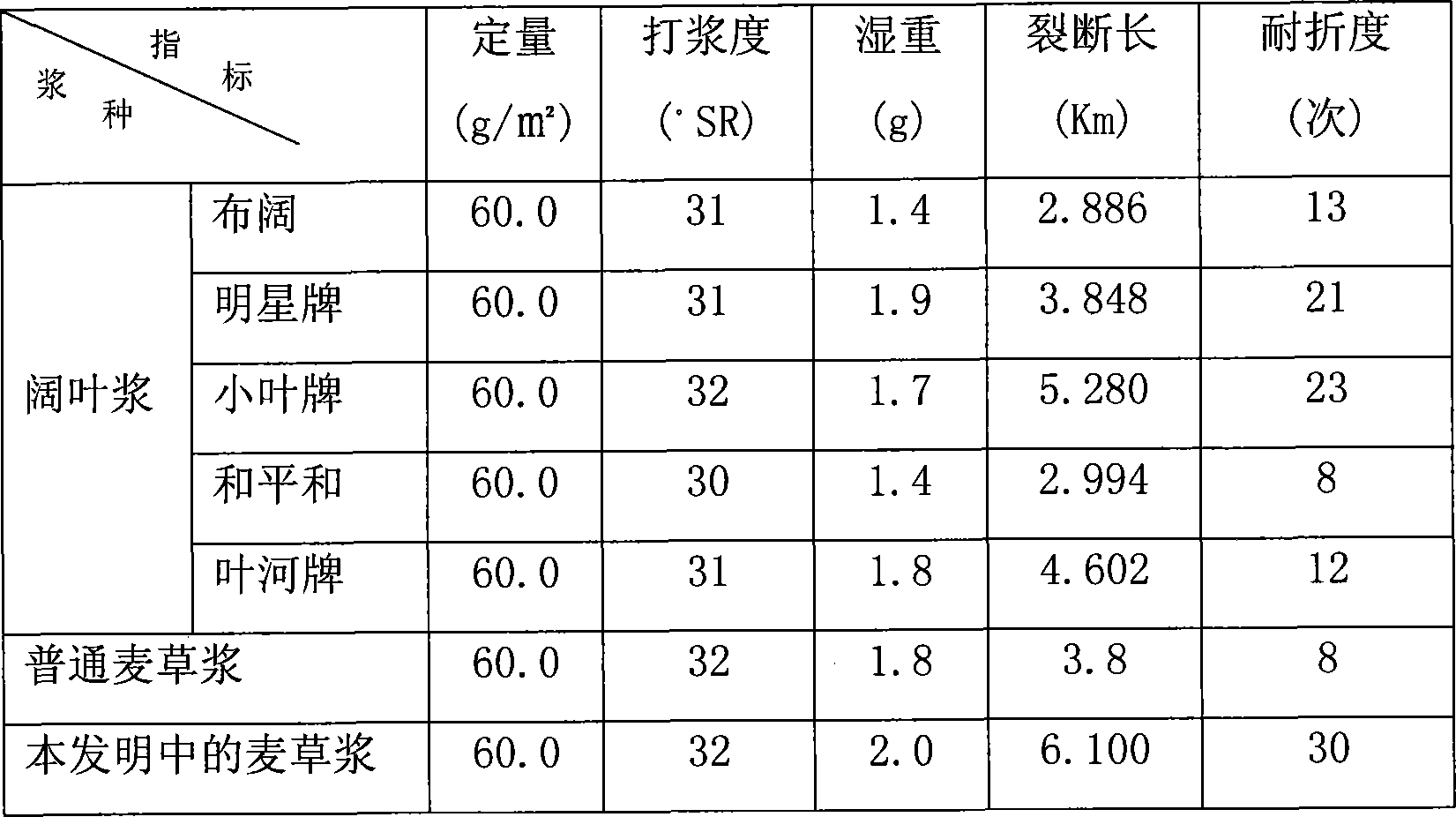

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

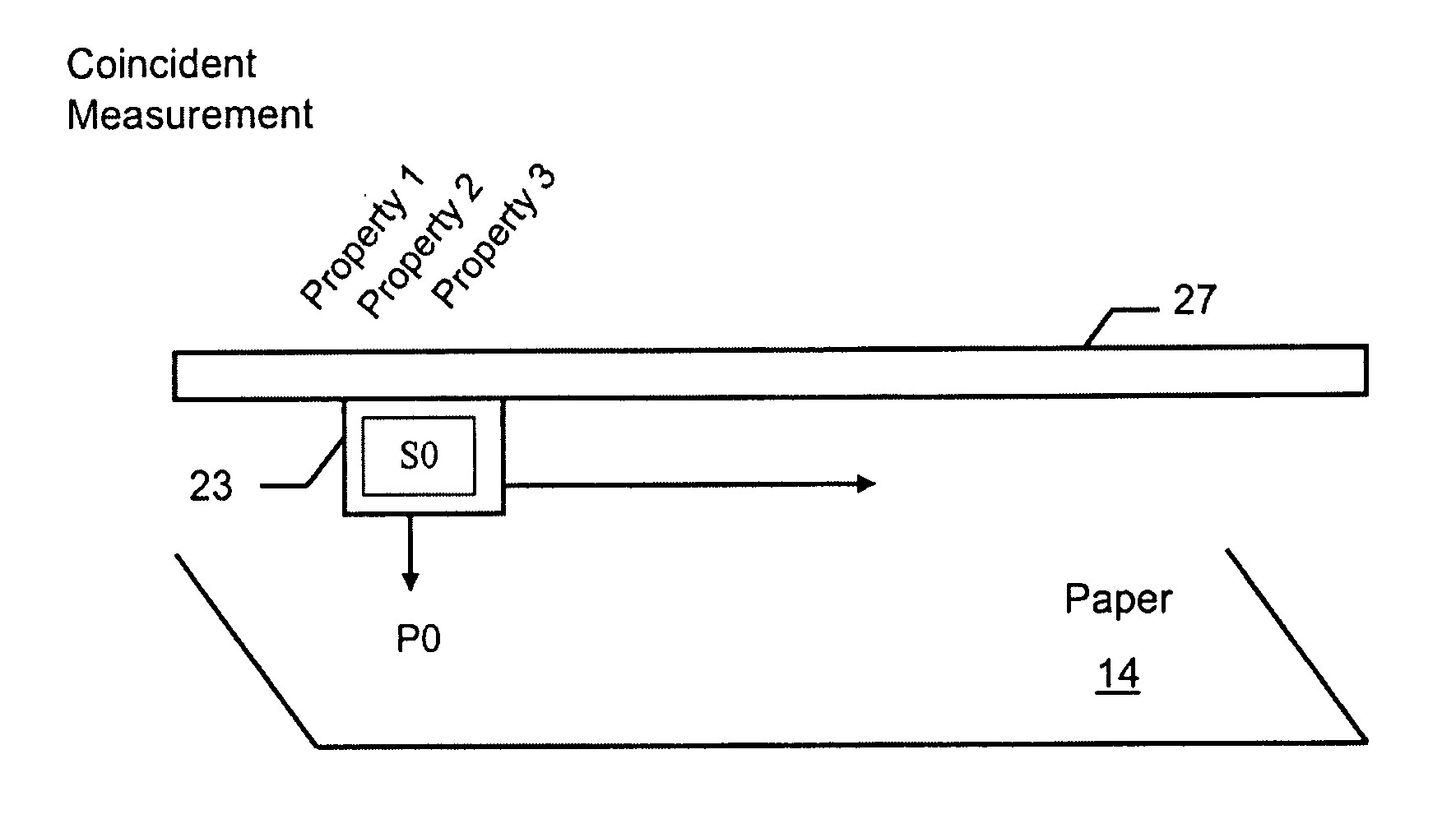

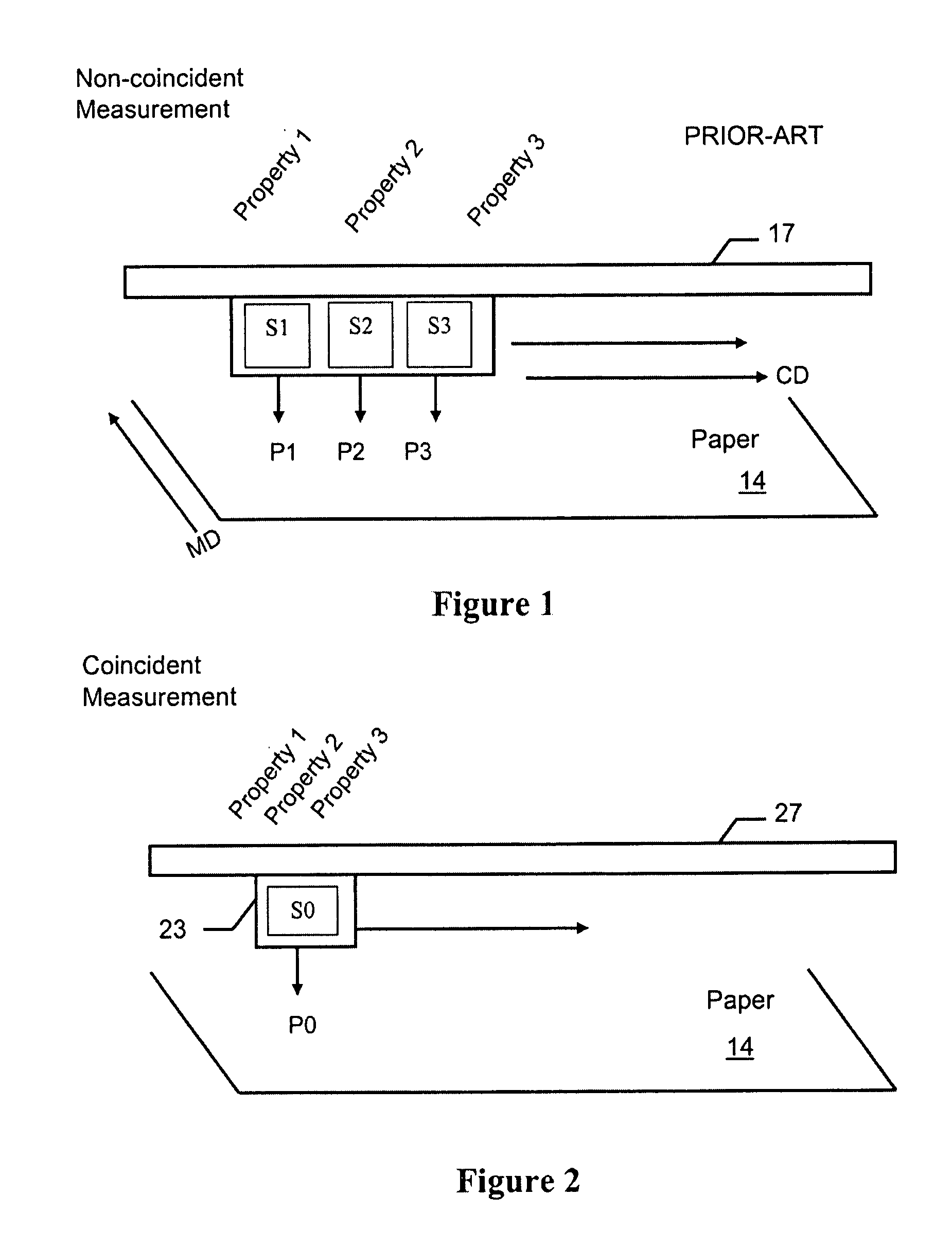

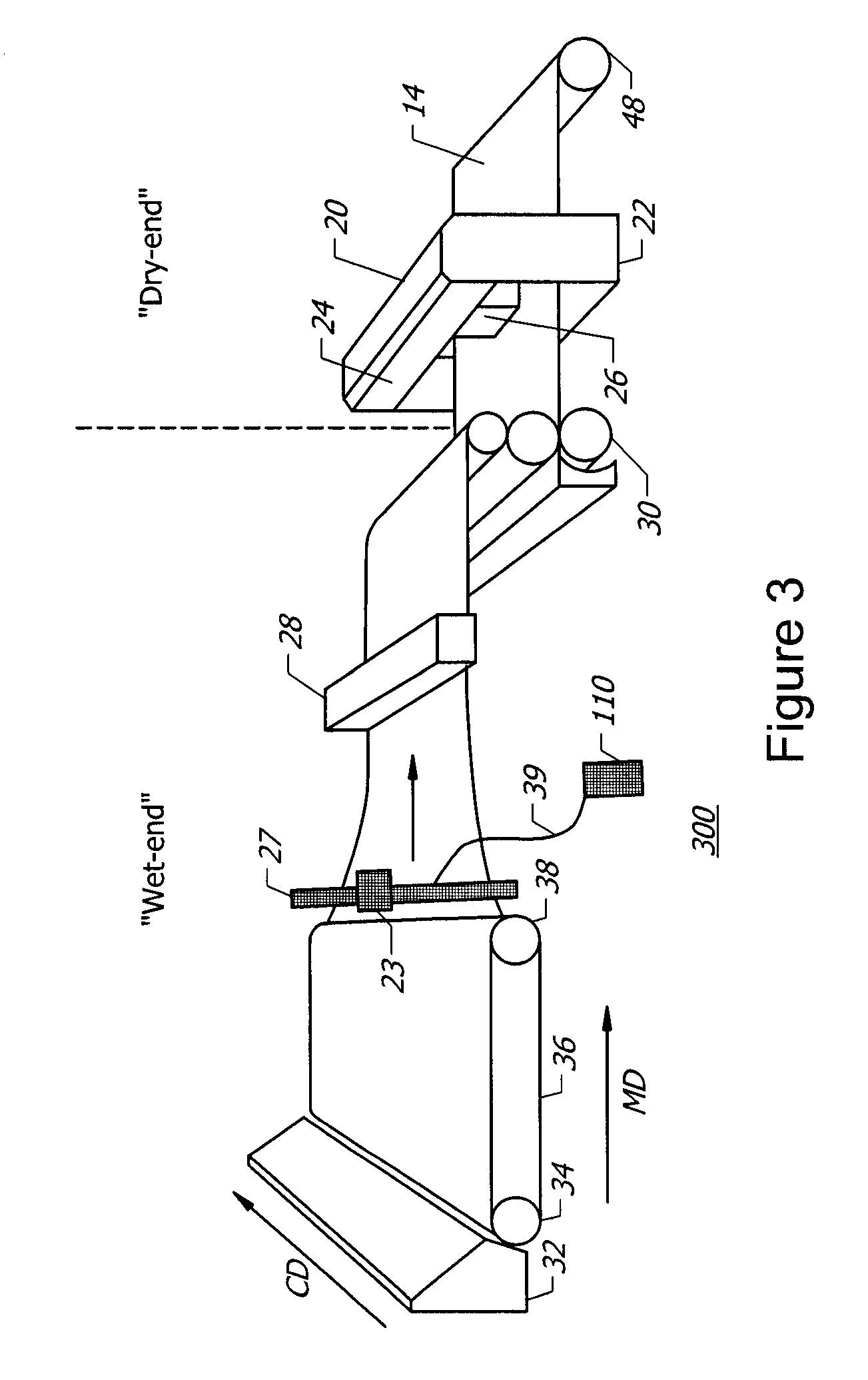

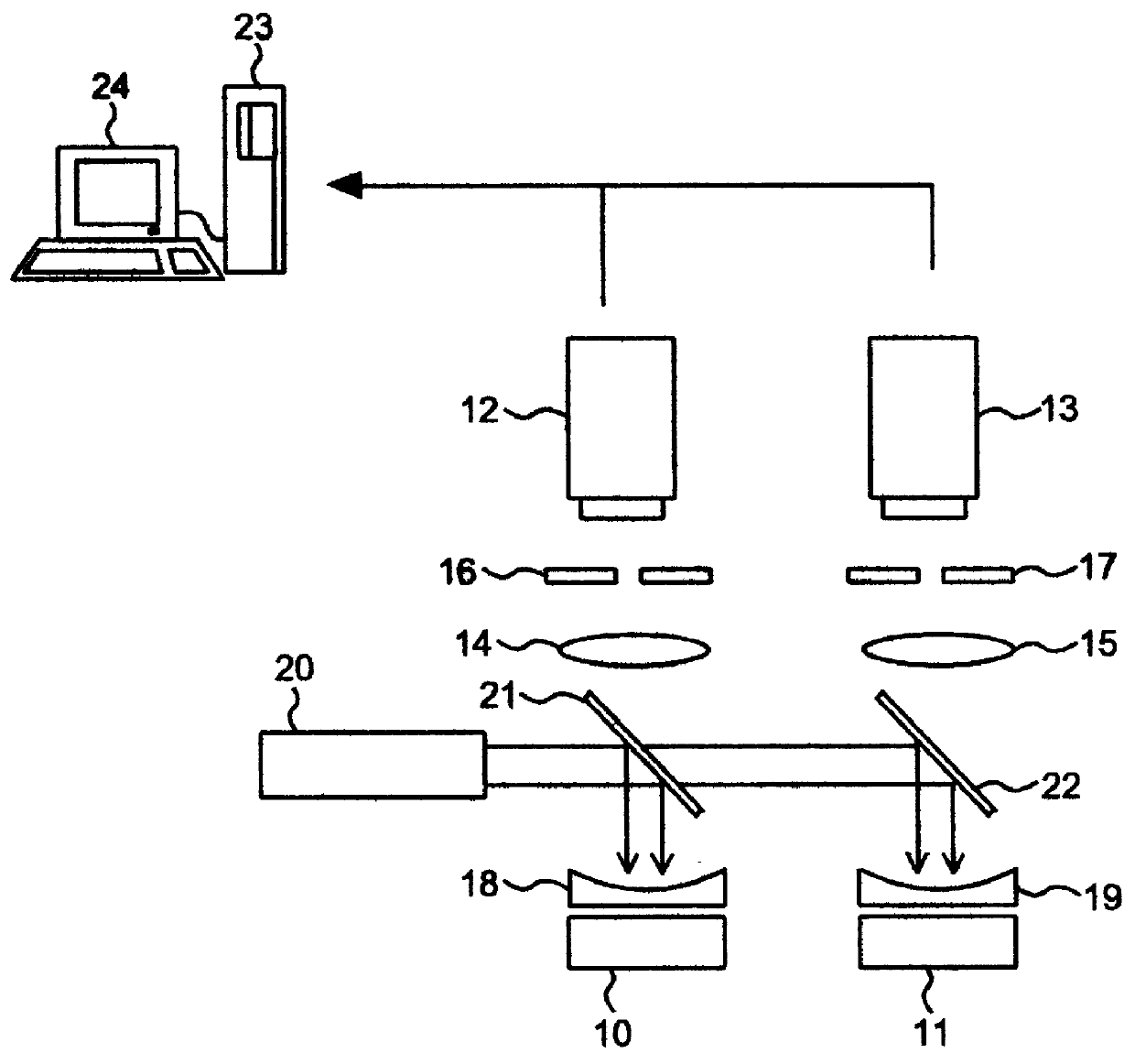

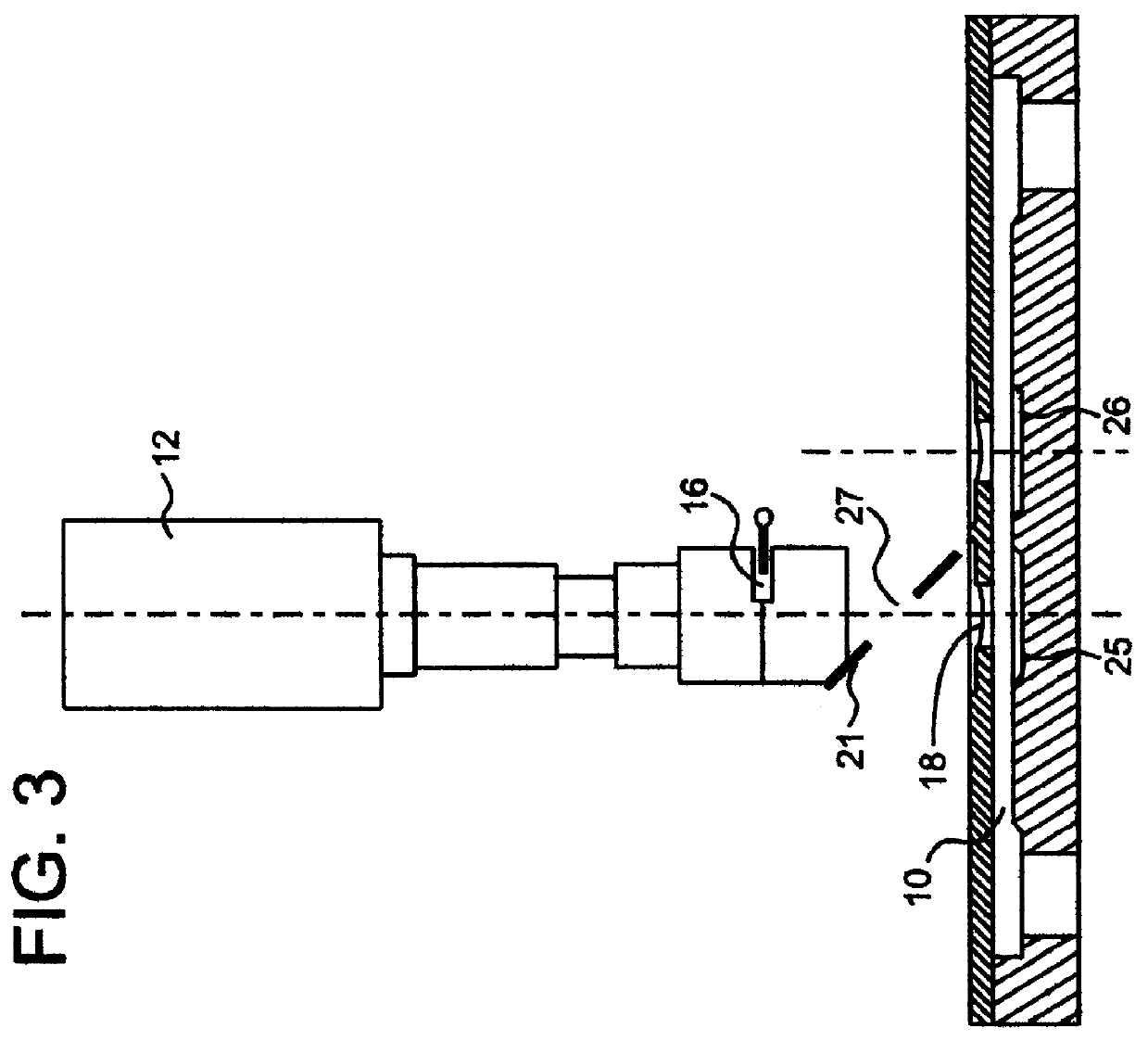

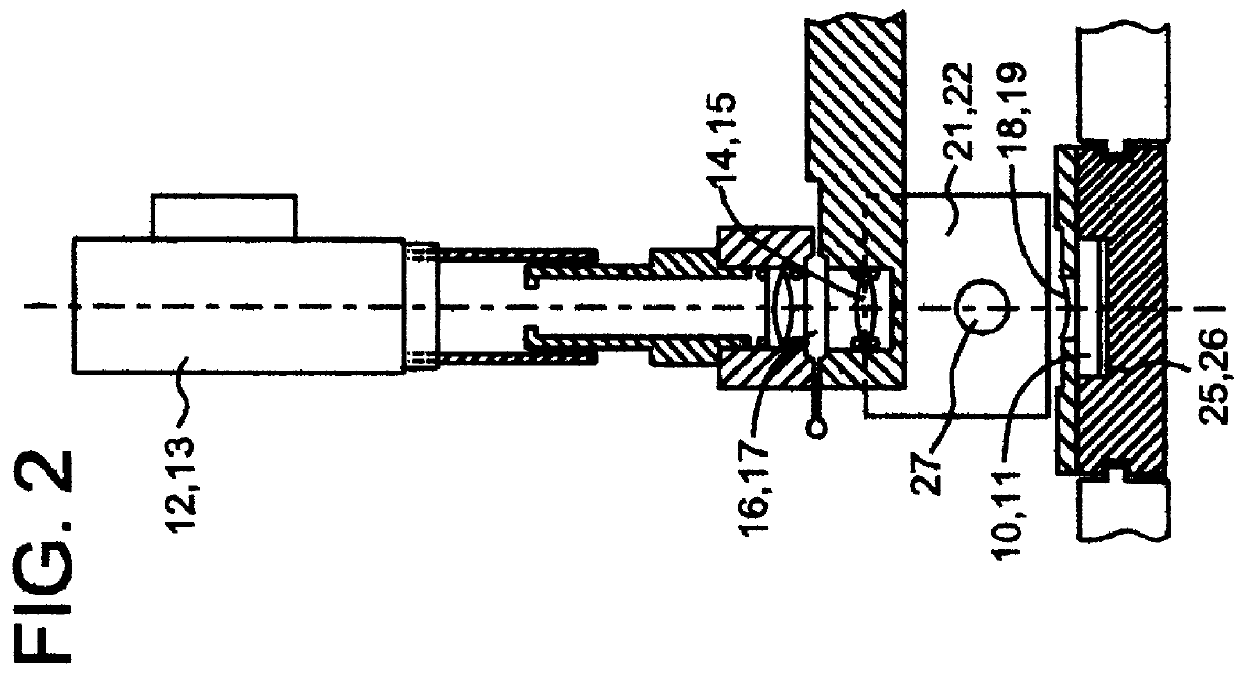

Material measurement system for obtaining coincident properties and related method

A material measurement system (500) includes a THz generator including at least one laser source (111) for emitting optical pulses, the optical pulses coupled to a THz emitter (51) operable for emitting pulsed THz radiation at a sample location on material while being processed (14) by a manufacturing system. A receiver (52) is operable to receive the optical pulses and to detect reflected or transmitted THz radiation from the sample location (14) synchronously with the optical pulses and provide electrical detection signals. Synchronizing optics (112, 113, 114) is operable to receive the optical pulses from said laser and provide the optical pulses to both the receiver (52) and the THz emitter (51). A controller (25) includes at least one processor (87) for receiving the electrical detection signals and providing a processed electrical detection signal, and an analyzer (88) operable to determine at least one, and generally a plurality of properties of the material from the processed electrical detection signal.

Owner:HONEYWELL ASCA INC

Method for comprehensive utilization of grass type stalk

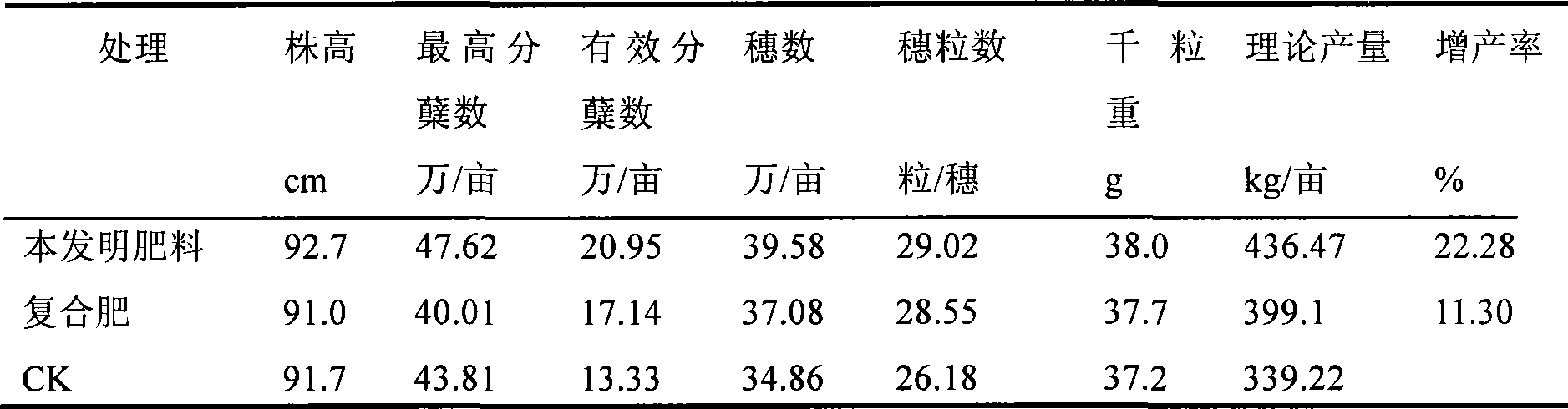

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

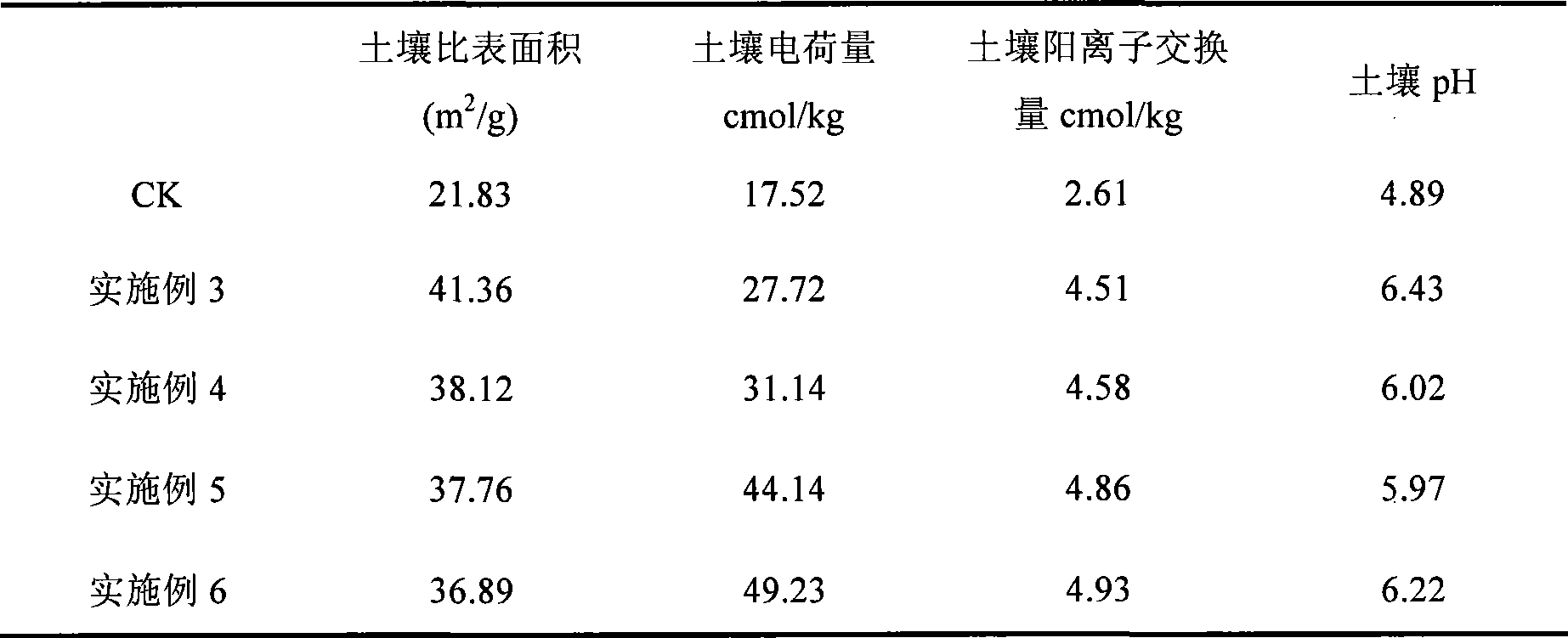

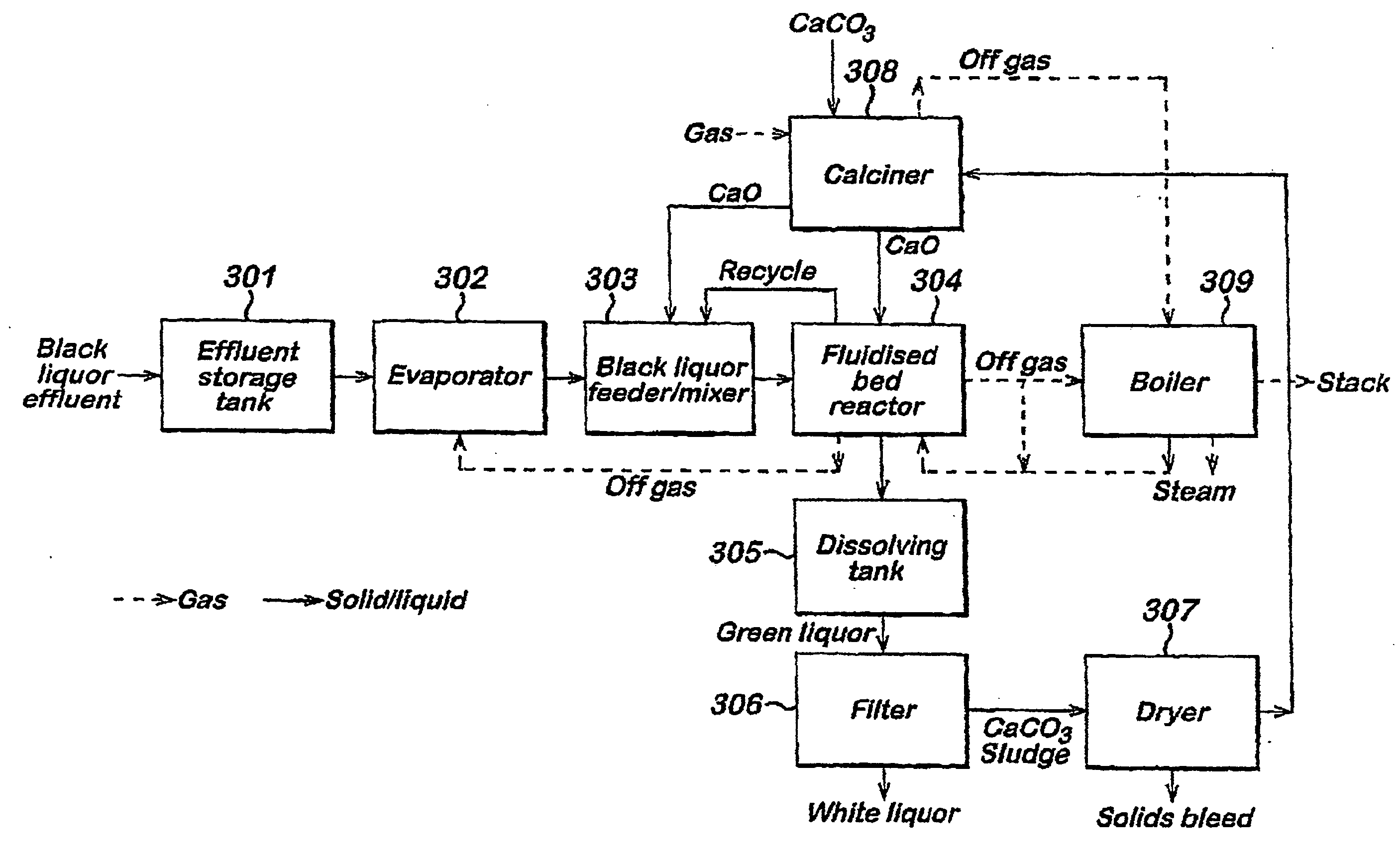

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

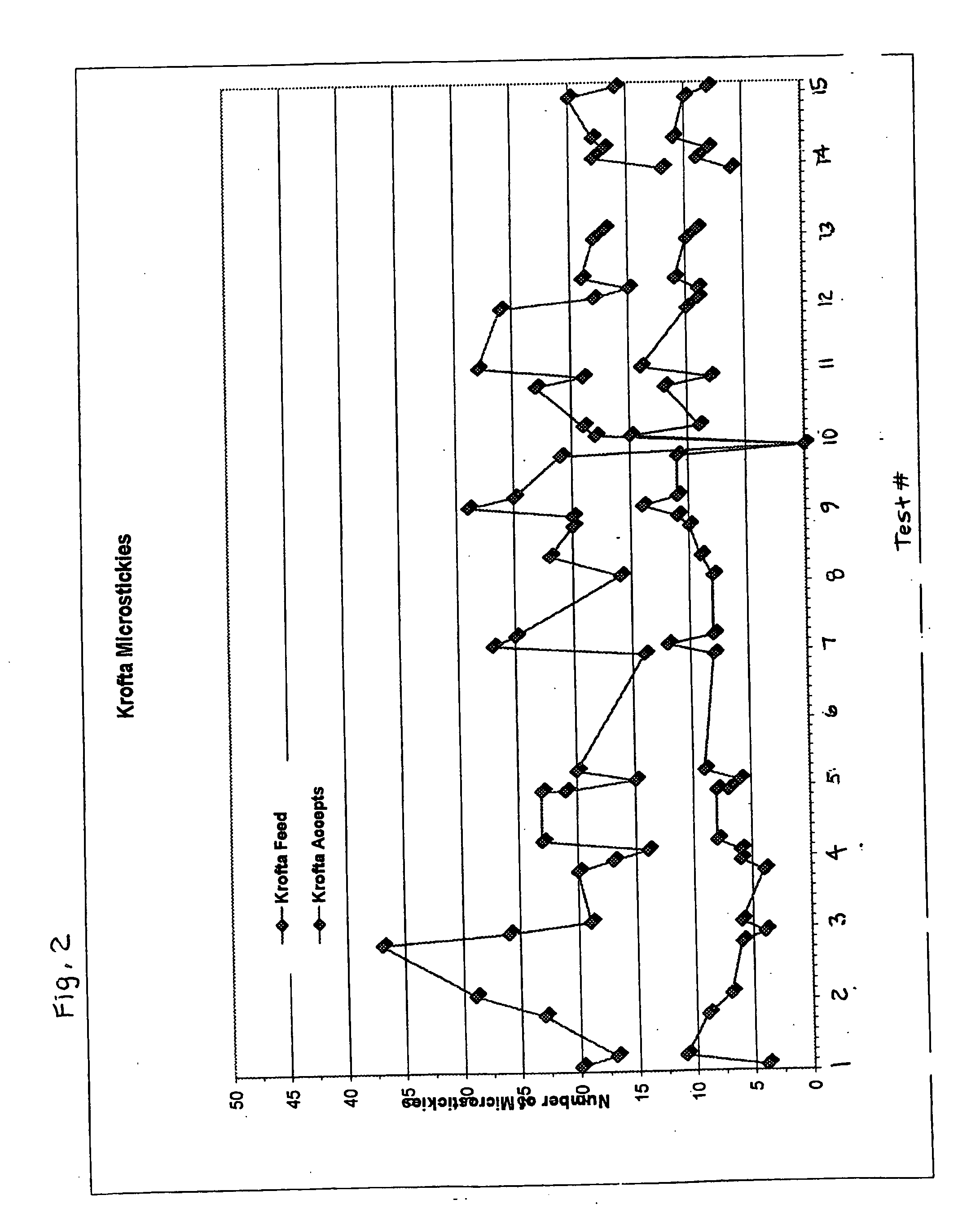

Process for regulating a paper pulp deinking line and device for continuously measuring the quantity of particles contained in a liquid

InactiveUS6010593AParticle size analysisIndividual particle analysisContinuous measurementEngineering

A process and device for continuously measuring the quantity of particles suspended in a liquid, which exist in at least two different physical states, such as detached or attached within the paper pulp. A separation assembly separates the particles into divisions depending on their size, and the separation assembly is continuously fed with liquid via an input pipe. A measuring and processing assembly has two channels or ducts coming from the separation assembly and are provided with translucent windows. A measurement and capture unit illuminates the windows, and at least two cameras located opposite each of the respective windows are synchronized with the illumination unit to capture, at regular intervals, an image of the windows. A system for digitizing the captured images and processing them to determine the quantity of particles for each physical states is forwarded to an output unit in a digital or analog form.

Owner:CENT TECHN IND DIT CENT TECHN

System and method for treatment of cellulose-containing material prior to pulp digestion

The invention relates to a process system and a method for preliminary treatment of disintegrated cellulose-containing material, preferably wood chips, prior to pulp digestion. The process system and the method according to the invention make use of a process vessel intended to function both as a so-called chip bin and as a pre-impregnation vessel. The characteristics of the invention are that a sloping steaming vessel is arranged downstream of the process vessel for the purpose of separating an excess of pre-impregnation liquid from the pre-impregnated cellulose-containing material, that the sloping steaming vessel is arranged for supplying steaming vapor which preferably has been generated by flashing of extraction liquor from a pulp digester, and that the sloping steaming vessel is connected to a chip chute communicating with a condenser for connection to a system for managing foul-smelling process gases. The invention can be applied in the production of pulp which is intended for paper manufacture or other applications where cellulose fibers are used.

Owner:METABO PAPER SWEDEN

Process for producing cotton dissolving pulp

The invention relates to a production technique of a dissolved cotton pulp, in particular to a production technique that utilizes the raw material of cotton linters and adopts simple techniques to produce the dissolved cotton pulp with even fiber length, high fibrillation degree, good intensity, less water soluble substances, high methylcellulose content, stable polymerization degree and less dust, has low COD discharge in waste water, and lowers environmental pollution. The dissolved cotton pulp produced by the production technique is mainly used for producing paper that is used for wiping upper-scale precise instruments, steel paper that is used for precise machining, a novel medicine loading agent of microcrystalline cellulose, explosive nitrocellulose, high-level nitrolacquer and building coating materials, etc.

Owner:山东银鹰股份有限公司

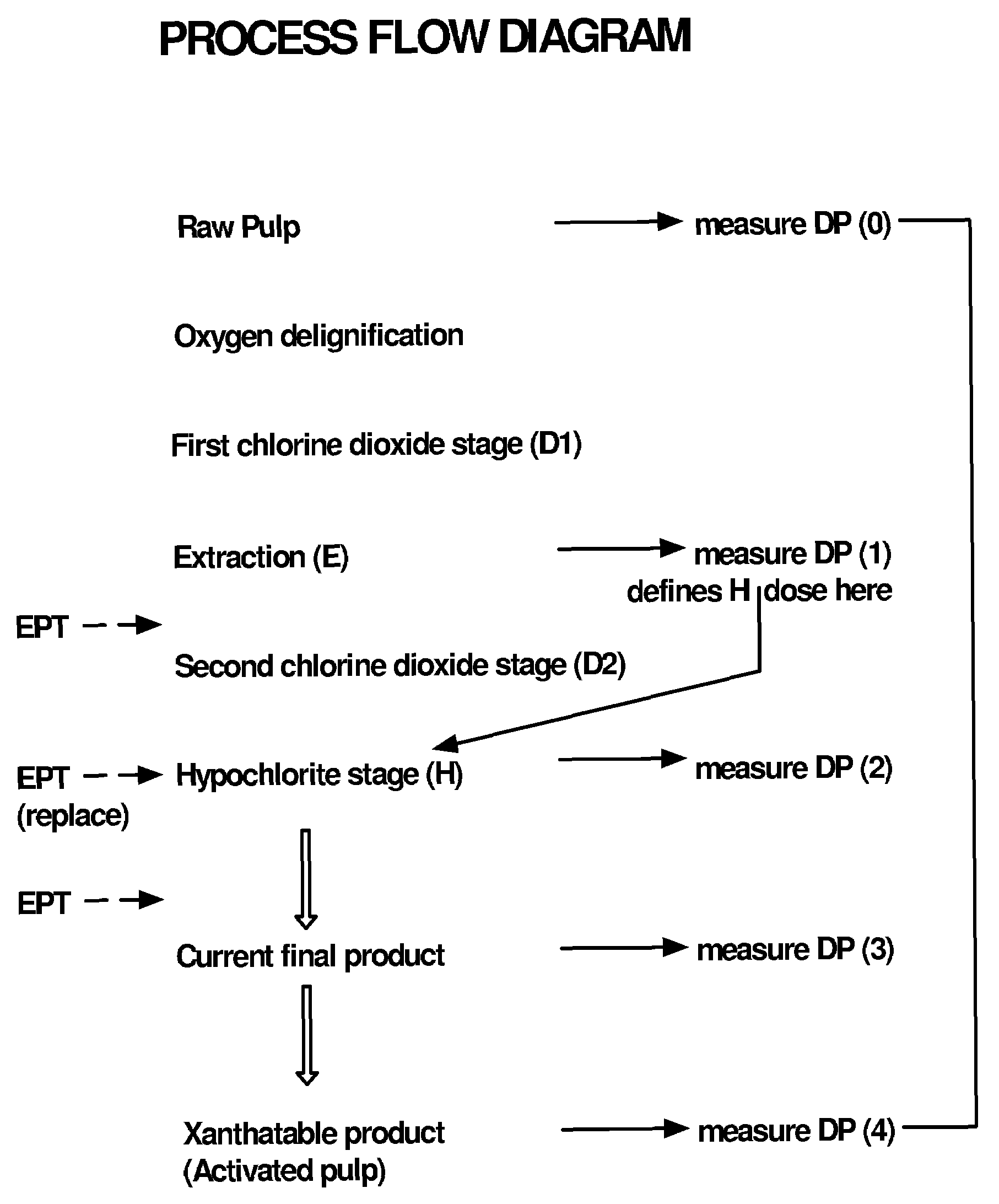

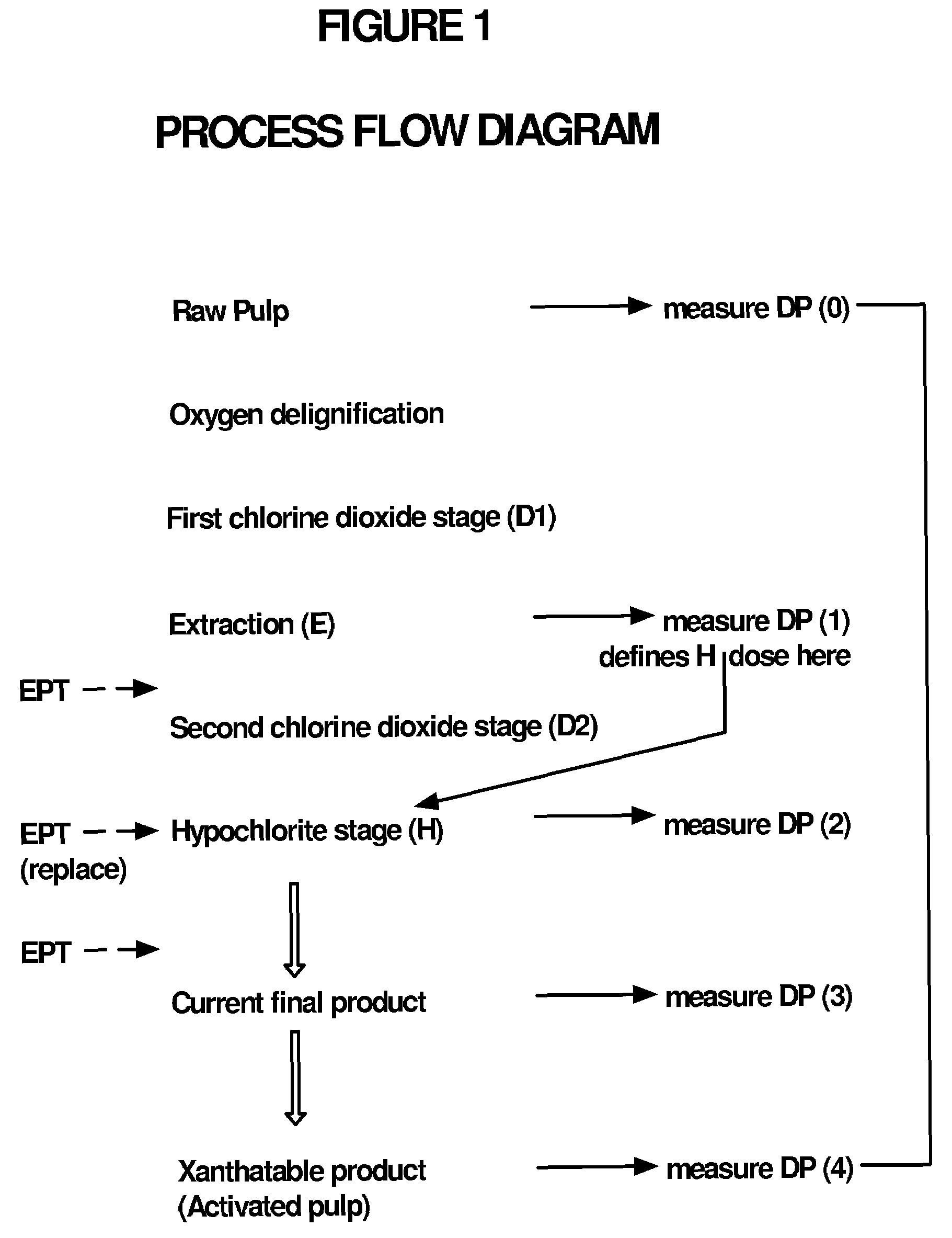

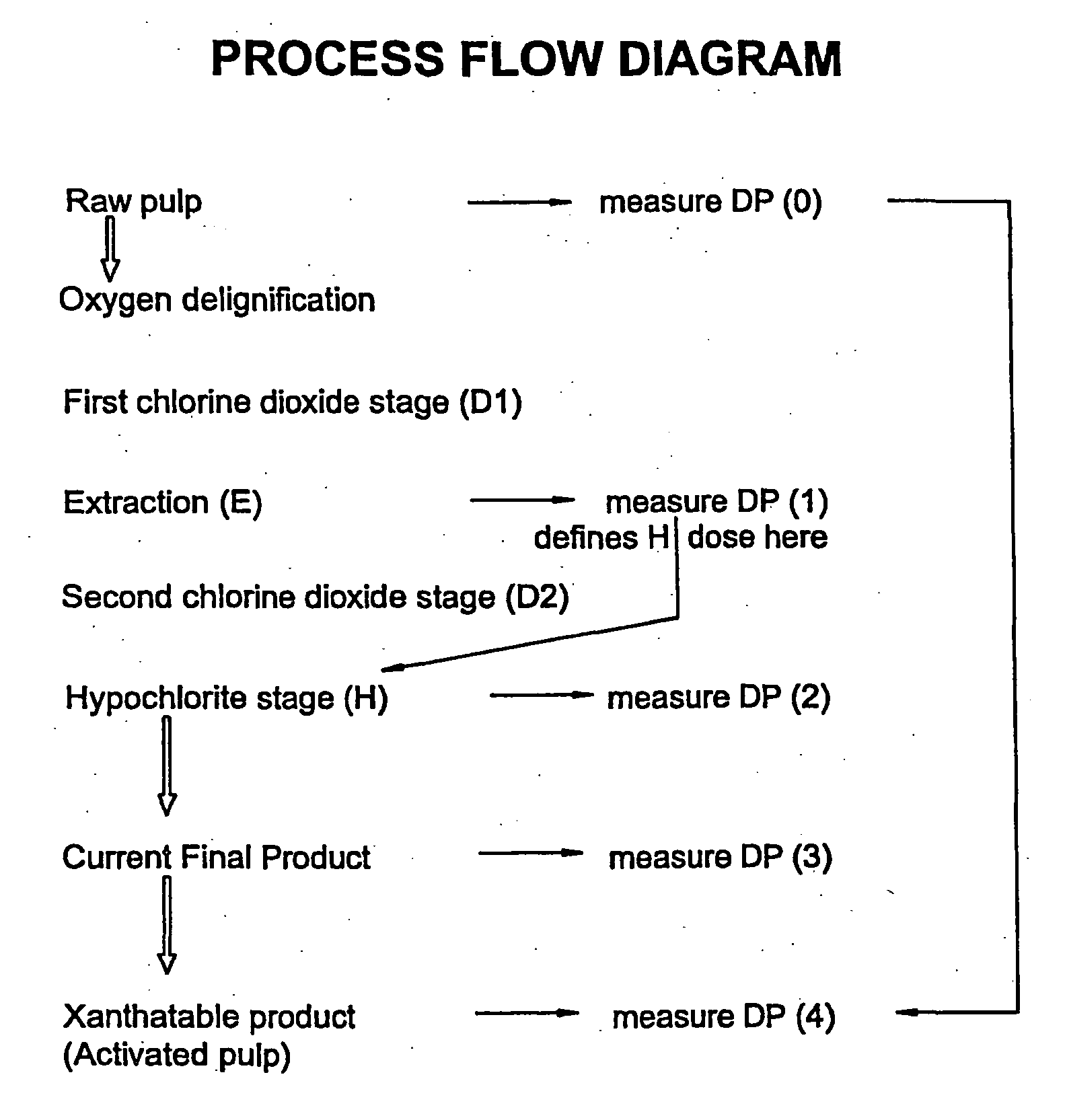

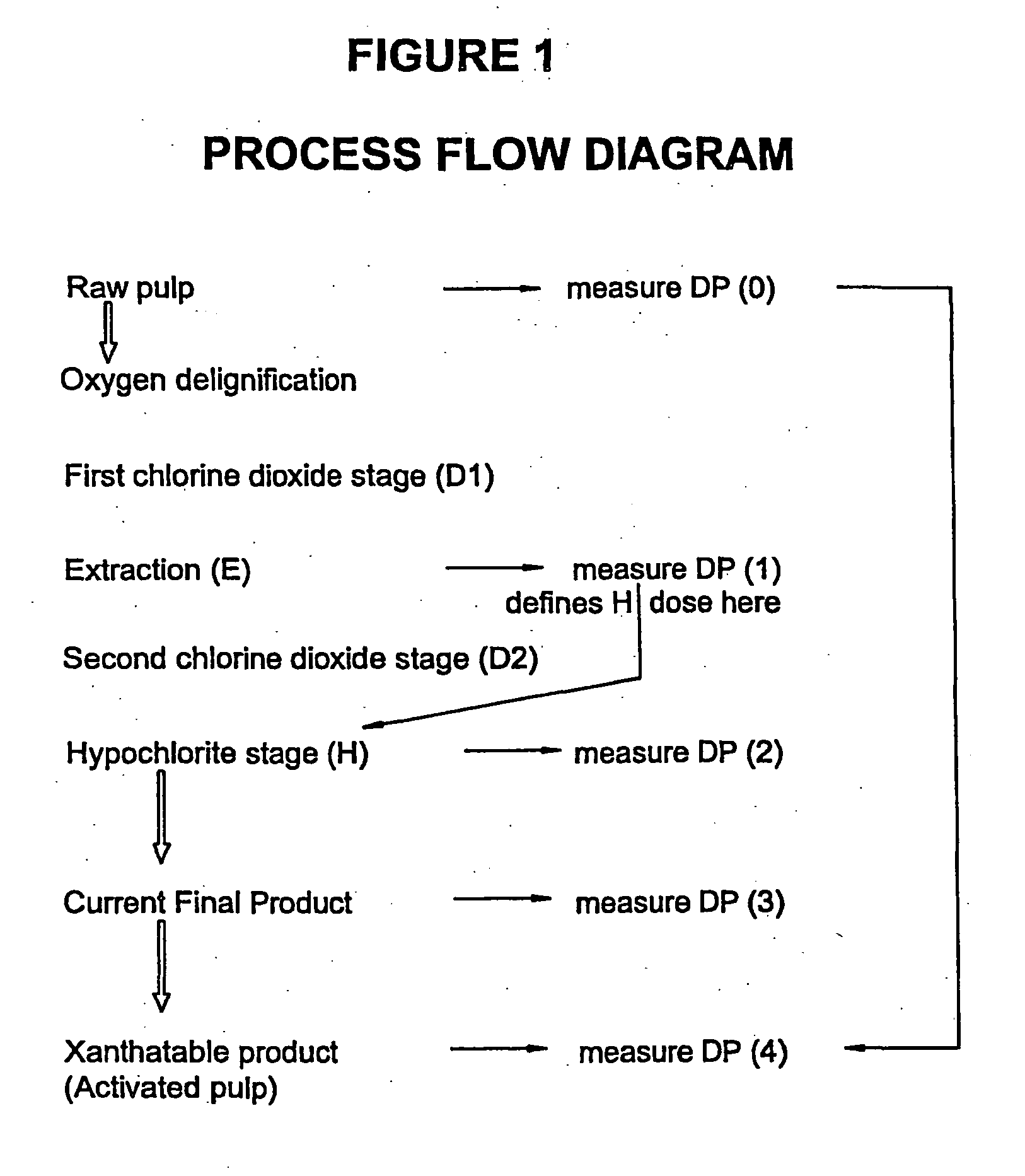

Pulp treatment and process

InactiveUS7267744B2Reduce stepsReduce in quantityElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

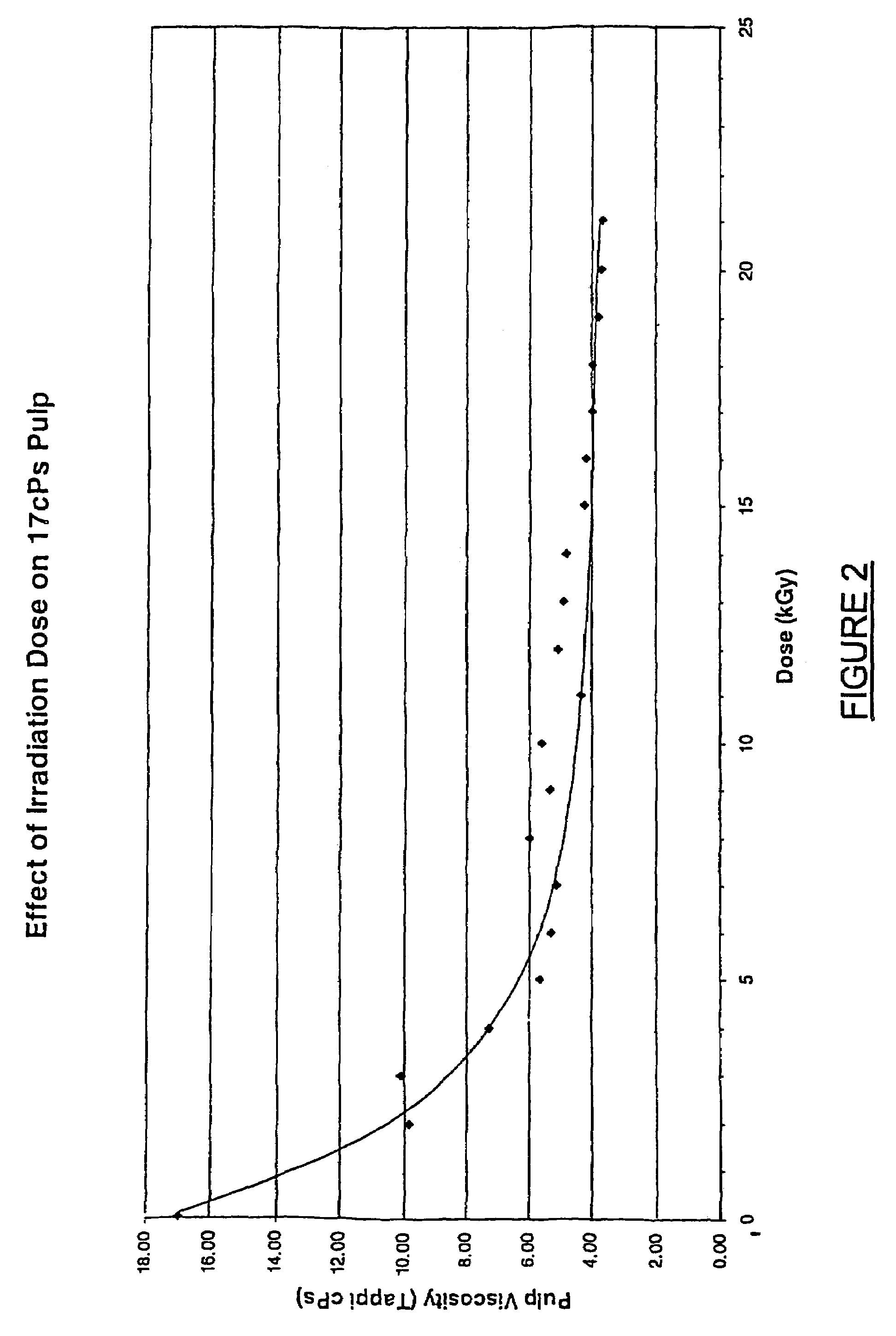

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerization (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

Method and compositions for preventing or reducing aluminosilicate scale in alkaline industrial processes

Materials and a method are provided whereby polymers with least 0.5 mole % of the pendant group or end group containing —Si(OR″)3 (where R″ is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in an industrial process having an alkaline process stream such as a pulping mill process stream. When materials of the present invention are added to the alkaline process stream, they reduce and even completely prevent formation of aluminosilicate scale on equipment surfaces such as evaporator walls and heating surfaces. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

Bamboo dissolved pulp manufacturing technique

InactiveCN101158122AHigh strengthAvoid degradationDigestersPulp bleachingAcetic acidCellulose acetate

The invention discloses a manufacturing technique of bamboo dissolving pulp. The manufacturing technique sequentially comprises cropping, screening and removing ashes, washing under standard temperature, sulfate cooking, serosity separation, scrubbing purification, chlorination treatment, alkali treatment, acetic acid bleaching +H2O2 oxidation organic bleaching, acid complex treatment and runnability. The invention effectively shortens the production process and enhances production efficiency of producing bamboo dissolving pulp by bamboo. The dissolving pulp can be used in rayon dissolving pulp, nitrocellulose dissolving pulp, cellulose acetate dissolving pulp and cellulose dissolving pulp. At the same time, the invention enhances the harvesting rate of making bamboo dissolving pulp by bamboo.

Owner:宜宾纸业股份有限公司

Methods To Detect Organic Contaminants In Pulp and Fiber

InactiveUS20090084510A1Accurate readingFats/resins/pitch/waxes removal in pulpDigestersFiberFluorescence

A method to detect organic contaminants in pulp and fiber is described which uses hydrophobic dyes, such as fluorescent dyes.

Owner:BUCKMAN LAB INT INC

Paper-making grade softwood pulp plate modifying production technique

ActiveCN101158125AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpTO-18Cooking methods

The invention provides a denaturizing production technique of paper making needle wood pulp plate, which solves the problems of uneven dipping, slow hemicelluloses stripping, difficult accumulation descending, uneven cooking, single cooking method, single bleaching method and violent conditions existing in denaturizing production technique of wood pulp in the prior art. The invention comprises the following steps: wood pulp plate paging, alkali soaking, pressing, untwining and dispersion, cooking, washing, impurity removal, bleaching, a secondary washing and pulping; wherein, the wood pulp plate paging, alkali soaking, pressing, untwining and dispersion are to send papers into a alkali dipping barrel with concentration of 6 percent to 18 percent after the paper making bleaching wood pulp plates are separated by a paging device. When the wood pulp plates are changed into pulp with concentration of 3 percent to 6 percent, the pulp with concentration of 3 percent to 6 percent is sent to a squeezer to be squeezed and to untwine and disperse fiber. By adopting the invention, the quality of the dissolved viscose fiber wood pulp can be better and more stable; furthermore, the invention provides wider selection range of raw material.

Owner:YIBIN GRACE GROUP CO LTD

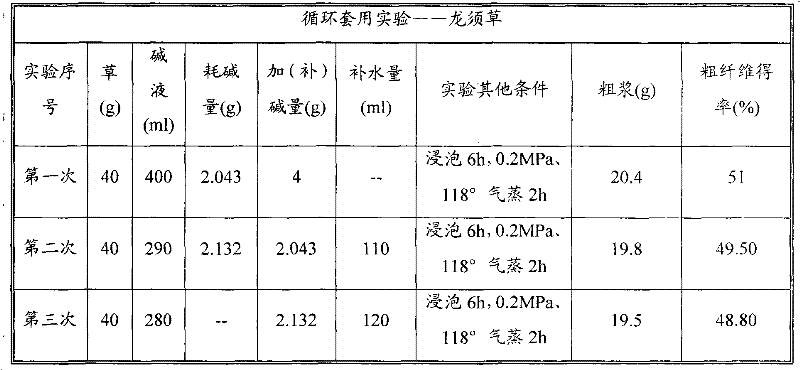

Novel cellulose extraction process

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

Pulp treatment and process

InactiveUS20040129394A1Reduce environmental problemsSmall DP rangeElectrolysis componentsWood treatment detailsPulp treatmentCompound (substance)

This invention provides a process for treating chemical woodpulp, or chemical cellulose including cotton linter, including the step of applying an electron processing technology (EPT) step to chemical woodpulp, or chemical cellulose, as the case may be, on an in-line basis to provide control of pulp viscosity or degree of polymerisation (DP). The invention also provides a method of process control in treating the aforementioned woodpulp or cellulose, including the step of using radiation dose-viscosity relationship curve for applying an EPT step on an in-line basis. The in-line EPT step may, in one form of the invention, replace and hence eliminate a chemical DP reduction step.

Owner:SAPPI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com