Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188results about How to "Increase shear rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surfactant Thickened Systems Comprising Microfibrous Cellulose and Methods of Making Same

Surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

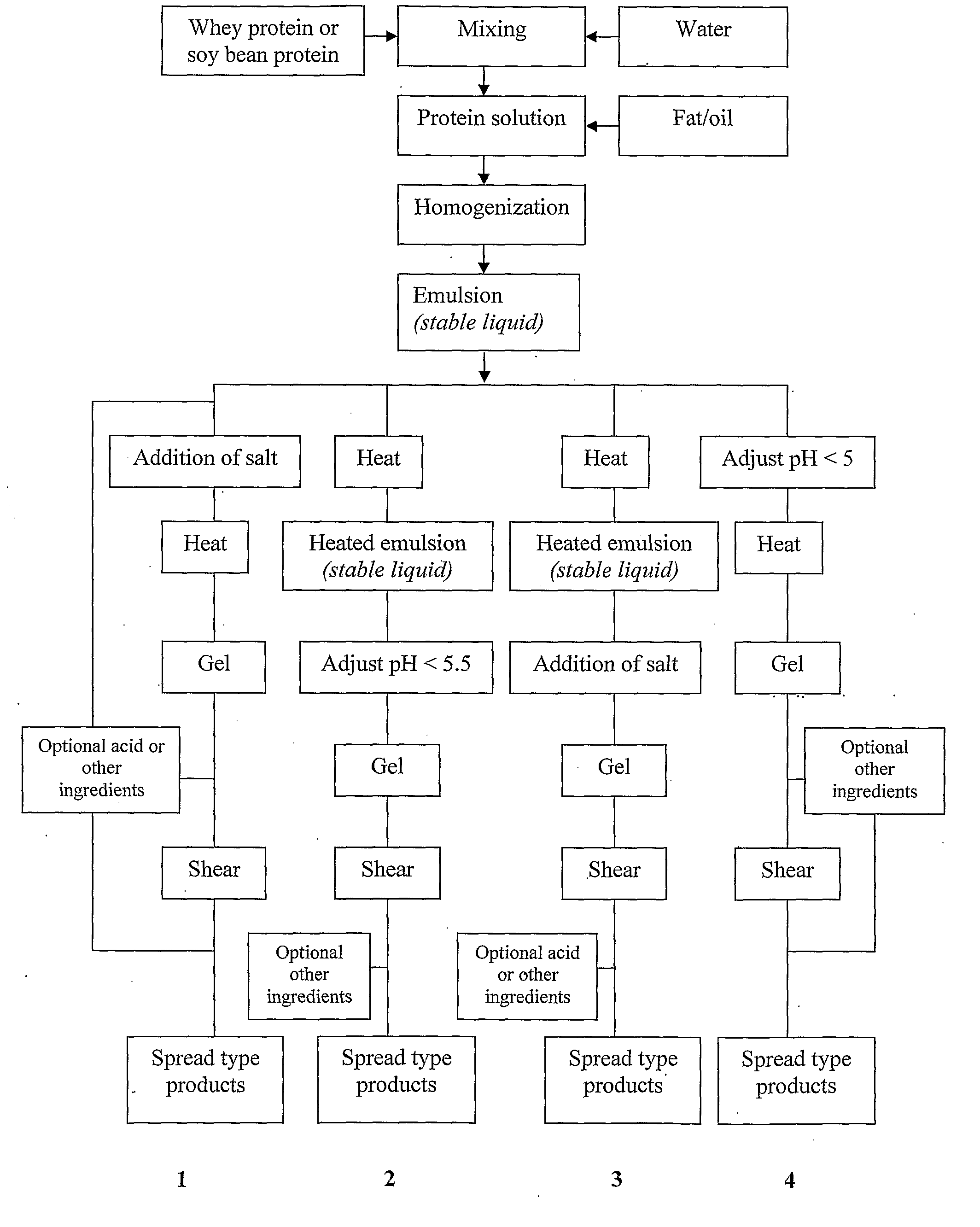

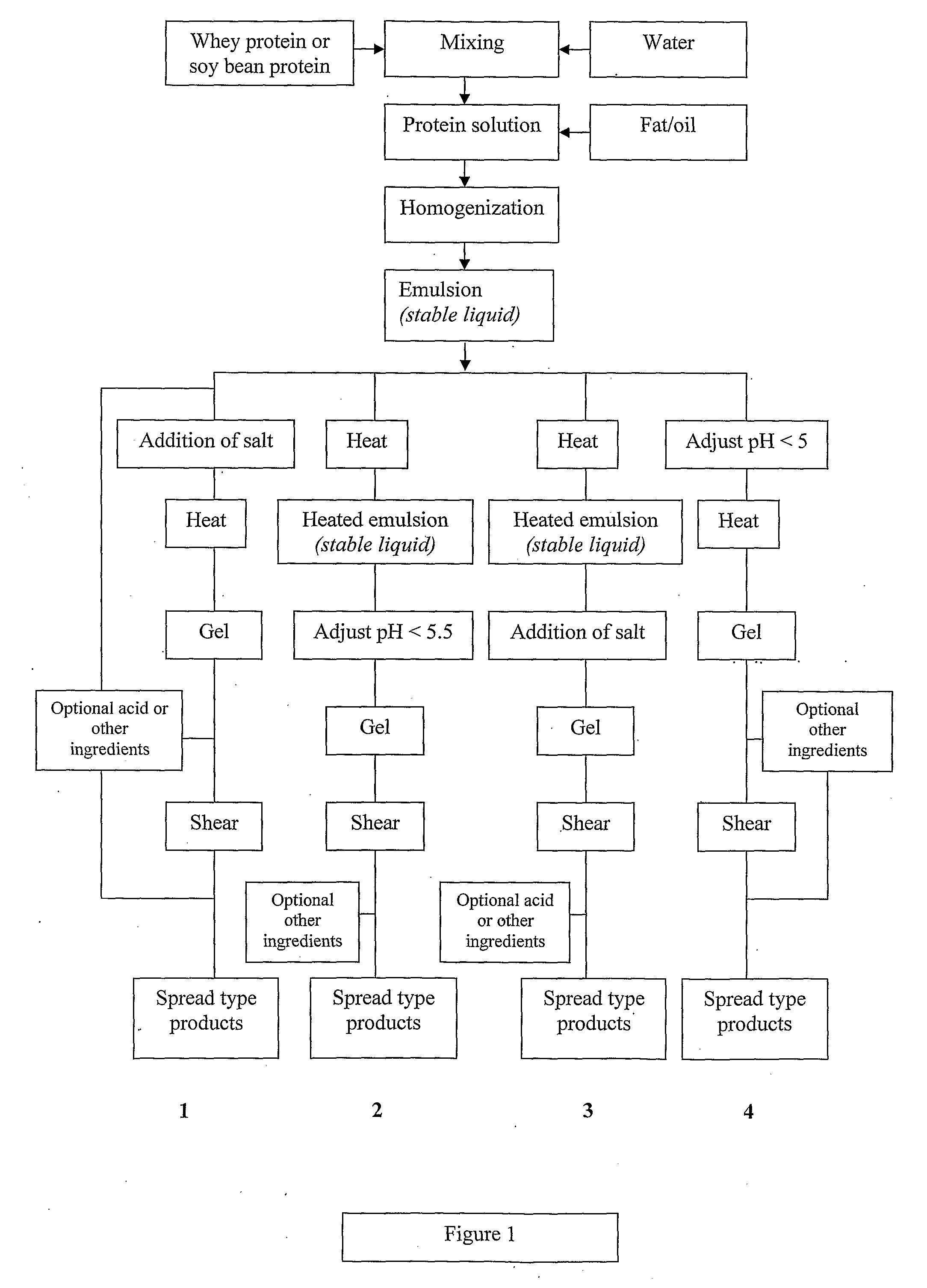

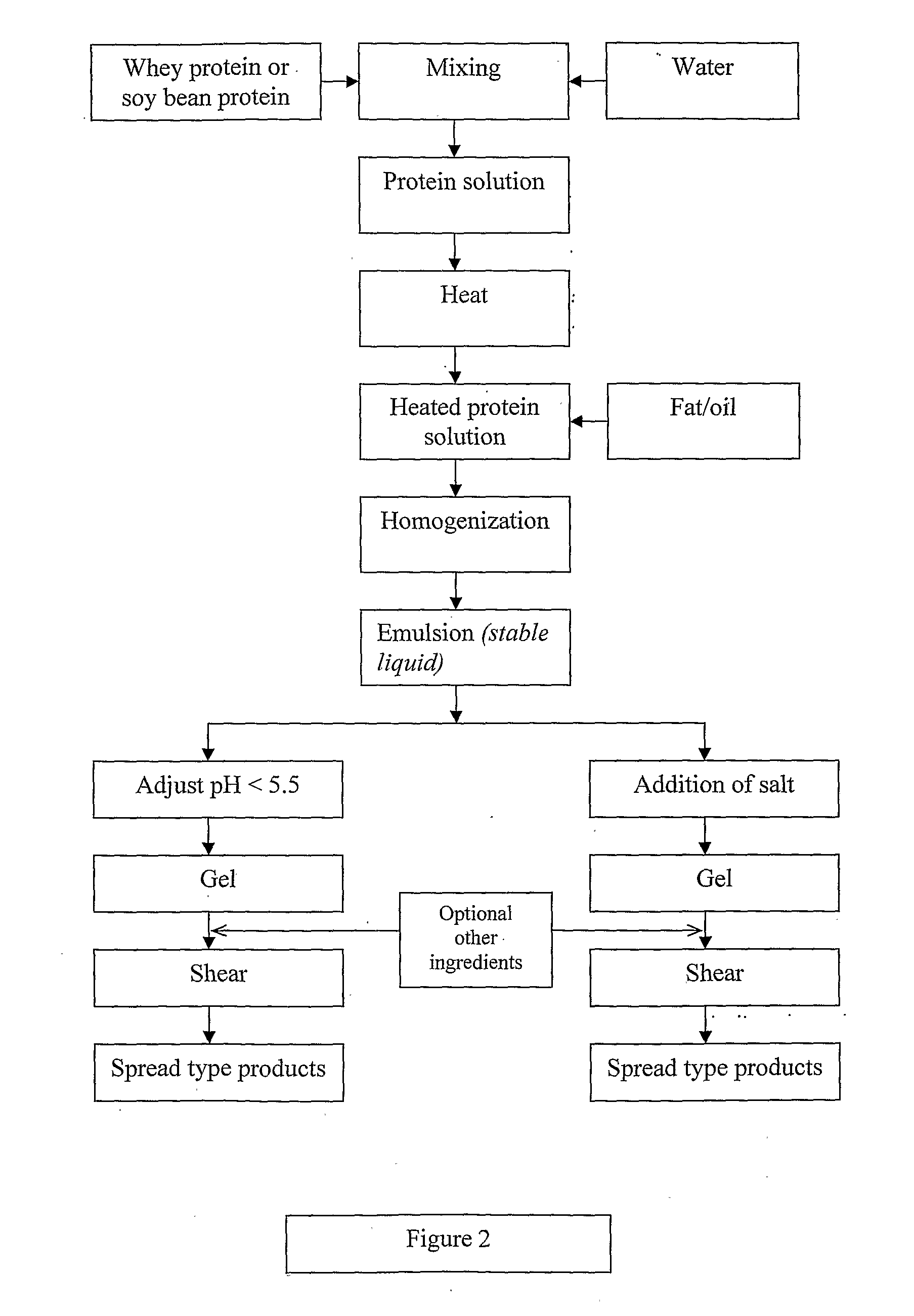

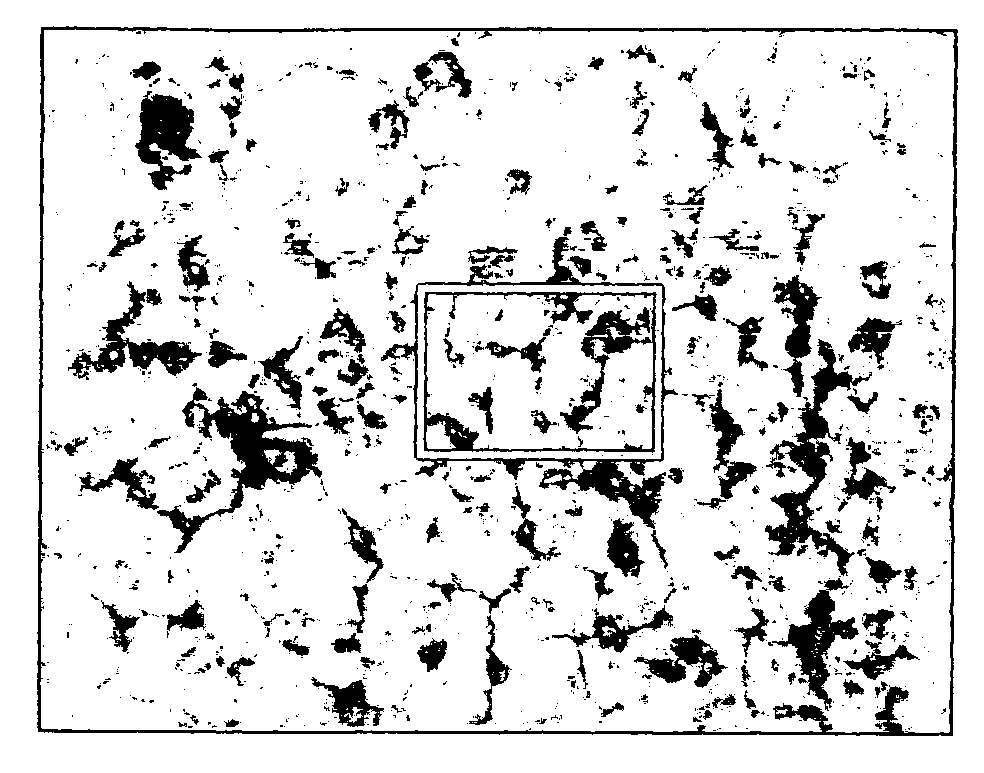

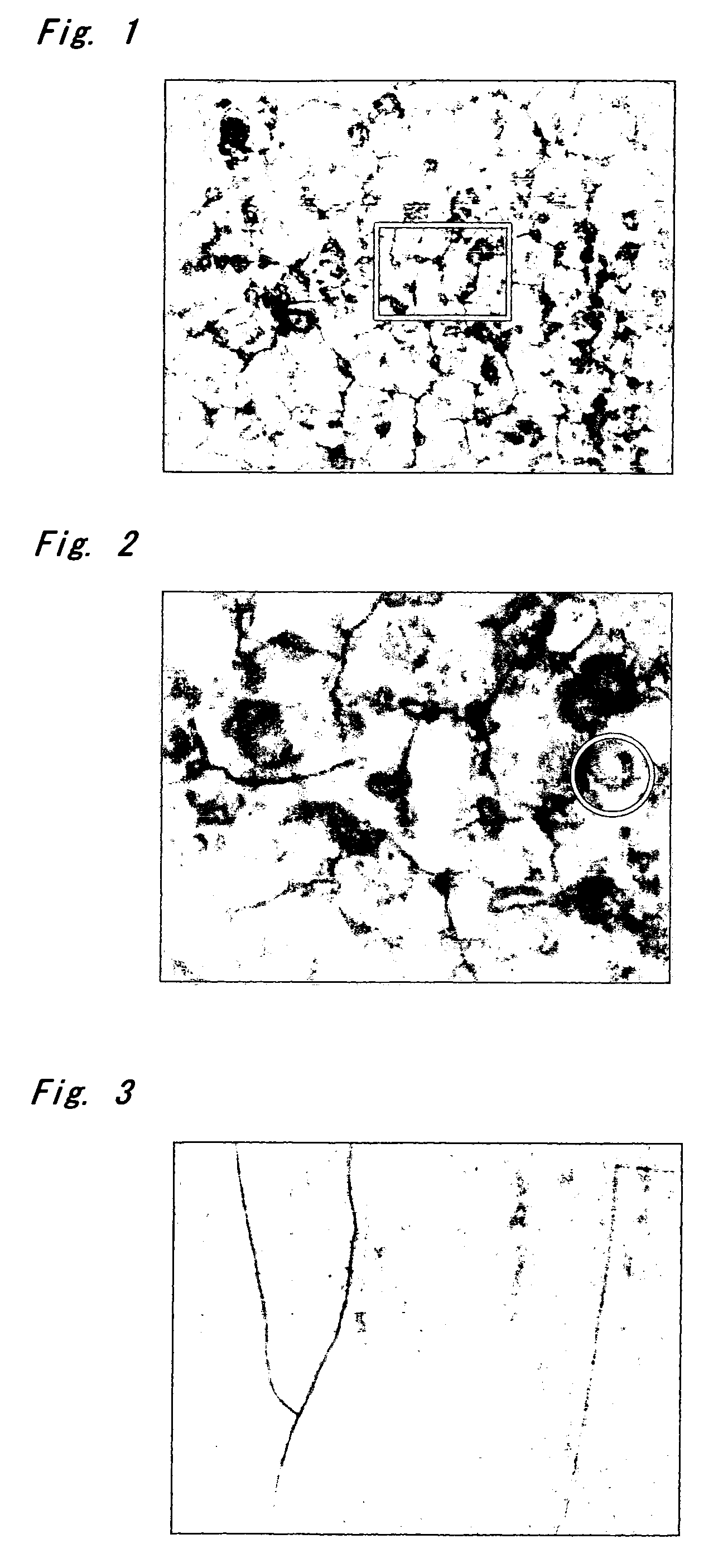

Dairy product and process

InactiveUS20100143567A1Lower pHLow viscosityMilk preparationEdible oils/fats ingredientsWhey proteinHeat treated

A viscoelastic fluid is prepared by shearing a gelled emulsion. The emulsion is an oil-in-water emulsion comprising 2% 12% (w / w) of a heat-treated protein that can form a heat-set gel and 5% 40% fat. The proteins used include whey protein and soy protein. The viscoelastic fluid may be used as a spread. It may also be used for the preparation of a plurality of different ultimate products formed from the original gel.

Owner:FONTERRA COOP GRP LTD

Surfactant Thickened Systems Comprising Microfibrous Cellulose and Methods of Making Same

ActiveUS20080108541A1Increase shear rateCosmetic preparationsSurface-active detergent compositionsCelluloseParticulates

Surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

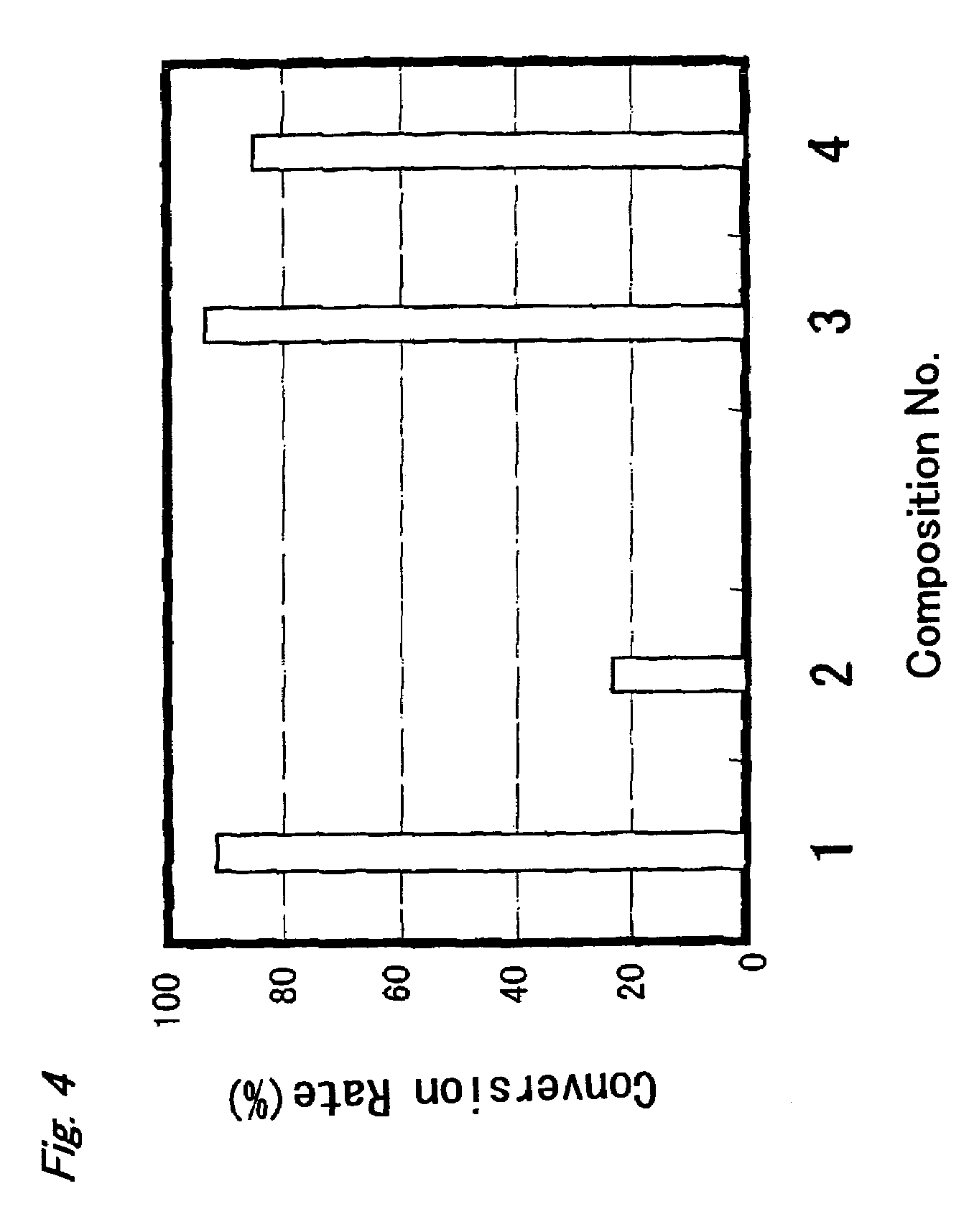

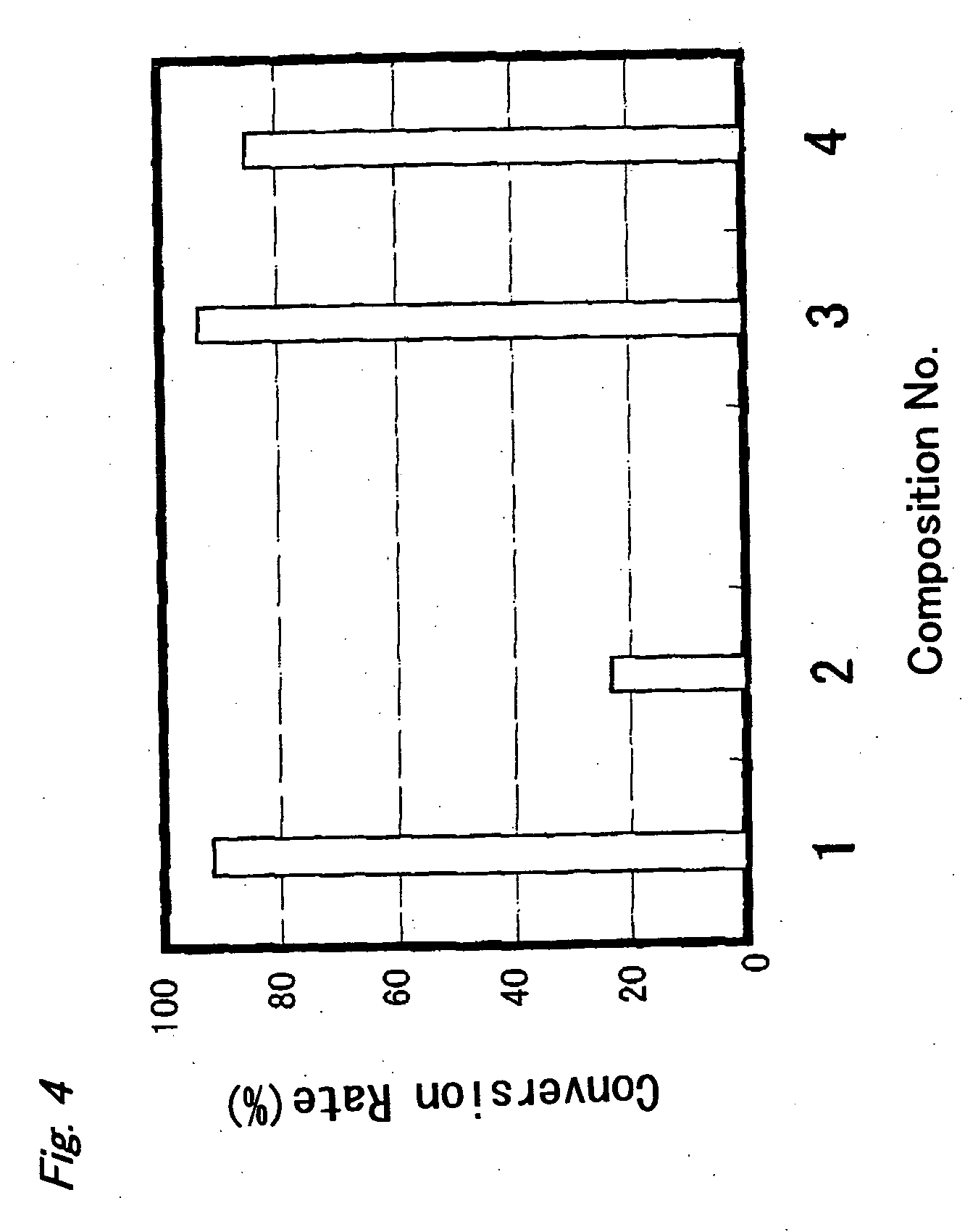

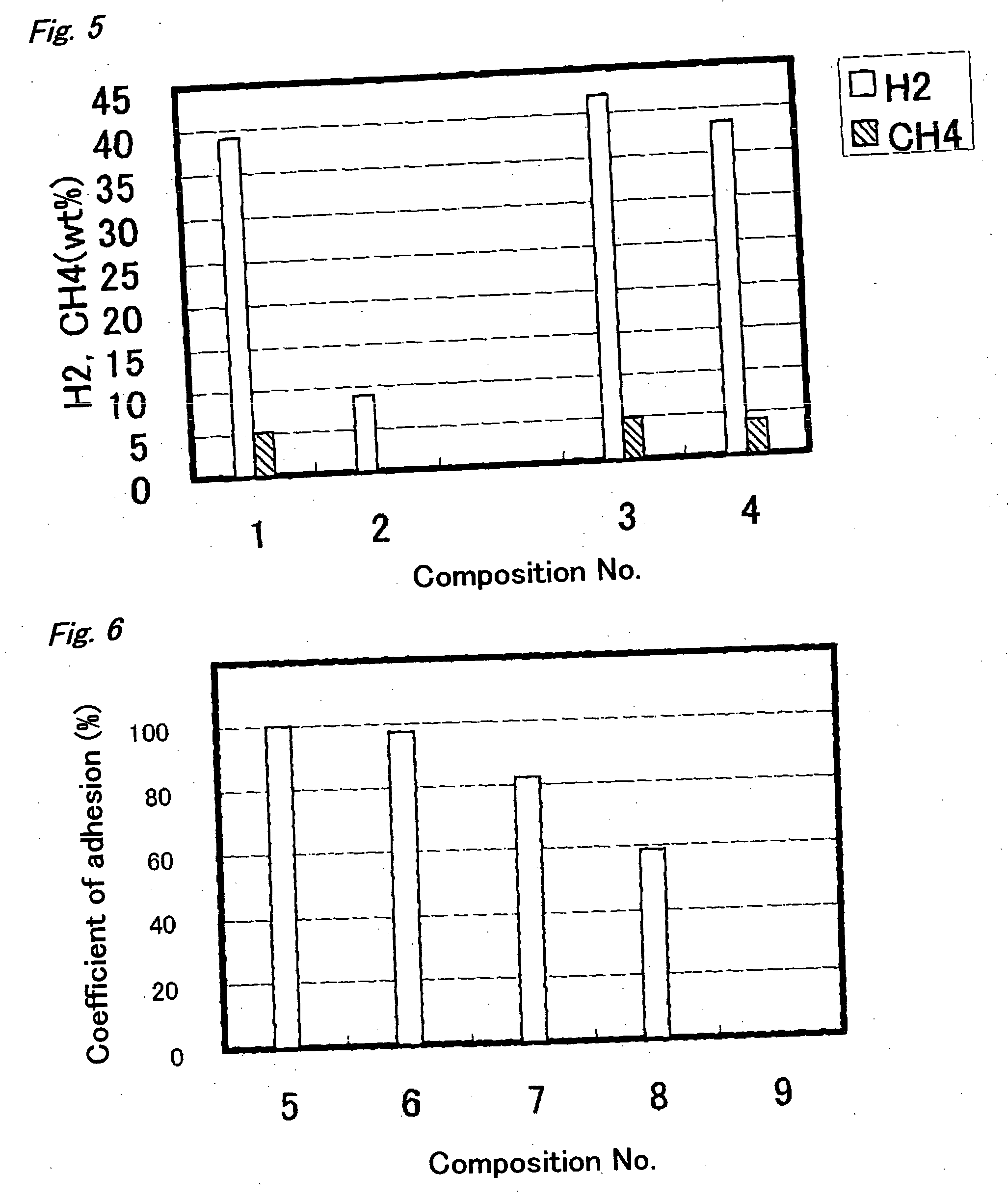

Catalyst support and method of producing the same

ActiveUS7618919B2Improve adhesionImprove reforming performanceHydrogenCatalyst activation/preparationRare-earth elementAlkali metal oxide

A method of producing a catalyst support comprising a substrate, and coating formed on the surface of the substrate and including powder of a first metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, wherein the coating is obtained by heat treating the substrate after applied with a coating composition obtained by mixing the first metal oxide powder together with a fluid raw material composition containing raw material of a second metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, at a shear rate of 1000 sec−1 or higher.

Owner:TOYOTA CENT RES & DEV LAB INC

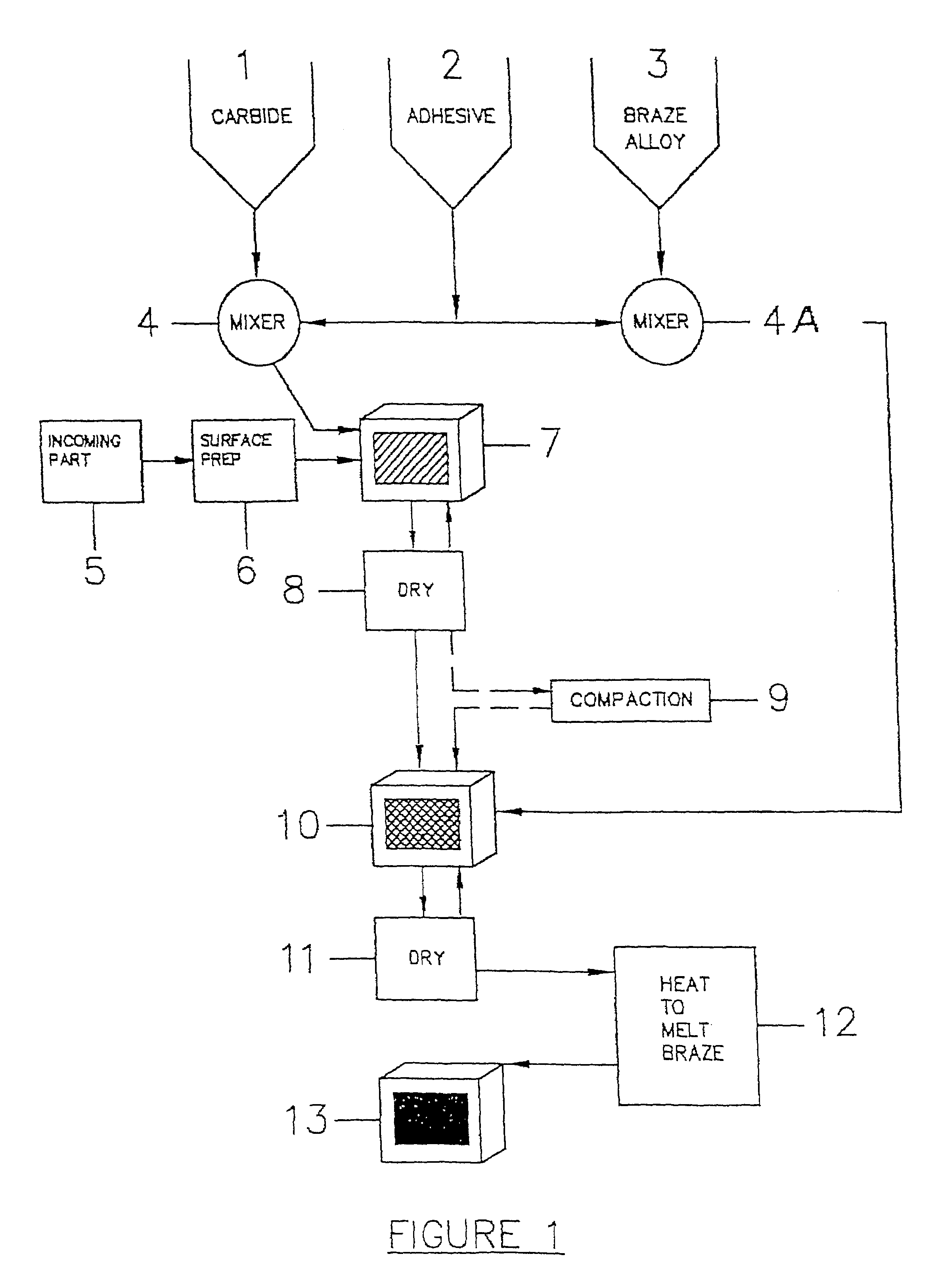

Process for making wear-resistant coatings

InactiveUS7262240B1Readily be sprayed onto substrateHigh viscosityAnti-corrosive paintsMetallic material coating processesCross-linkWear resistant

A paint system and process are disclosed for hardfacing metal surfaces. In one embodiment of the process, a paint including a dispersion of hard particles is first applied as a coating to a surface. Next, a paint including a dispersion of a braze alloy is applied over the layer of hard particles. The surface is then heated to cause the braze alloy to melt and infiltrate into the hard particles thereby bonding them to the metallic surface. In another embodiment, a first layer of adhesive is applied, and a hardfacing powder is applied onto the adhesive. Then a second layer if adhesive is applied, and a braze alloy powder is applied onto the second adhesive. Then the material is heated as in the first embodiment. In another embodiment, paint containing hard particles is coated onto the substrate, and an acid-containing cross-linked copolymer in the paint is then neutralized to increase the viscosity of the paint to prevent running.

Owner:KENNAMETAL INC

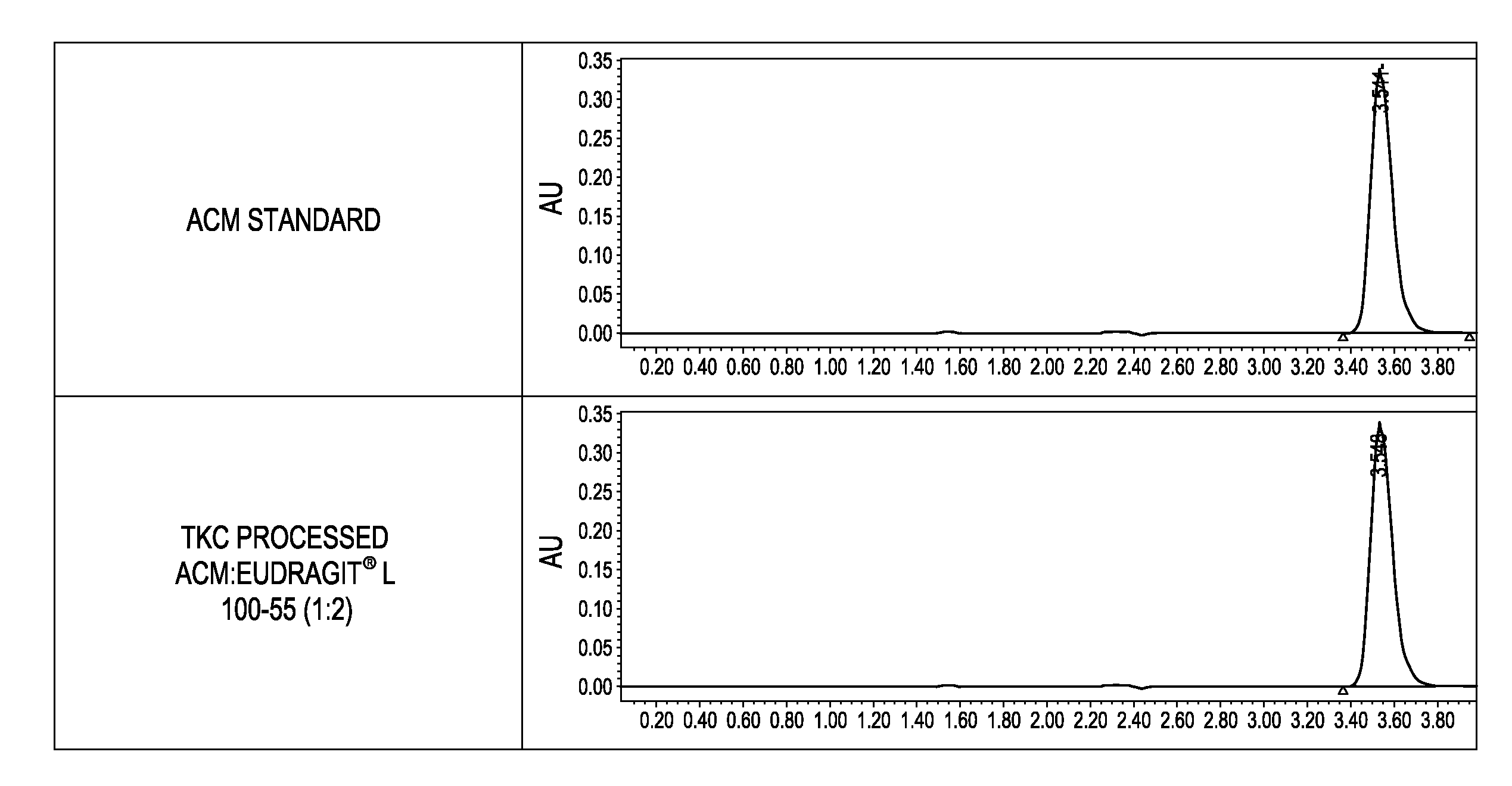

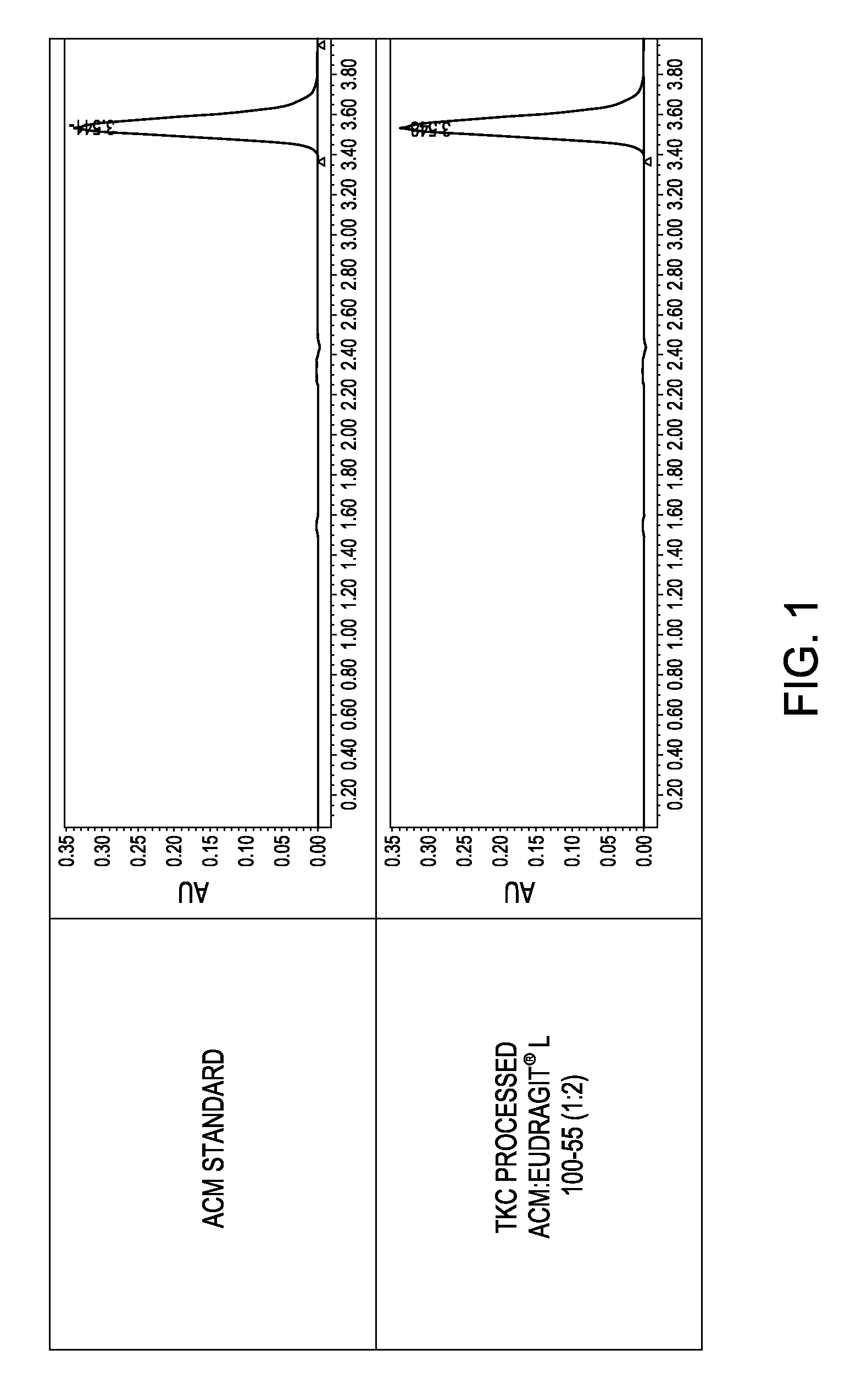

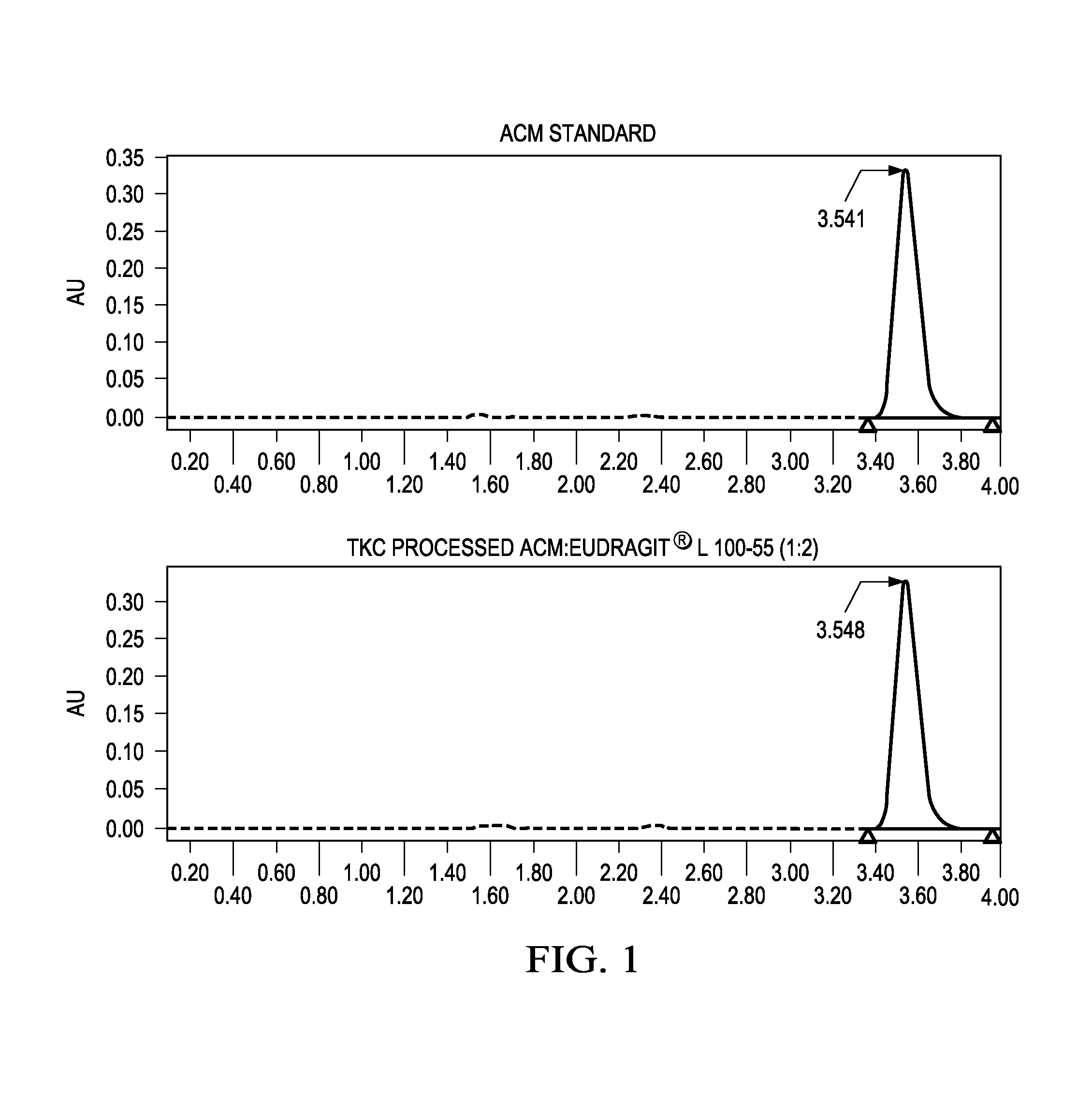

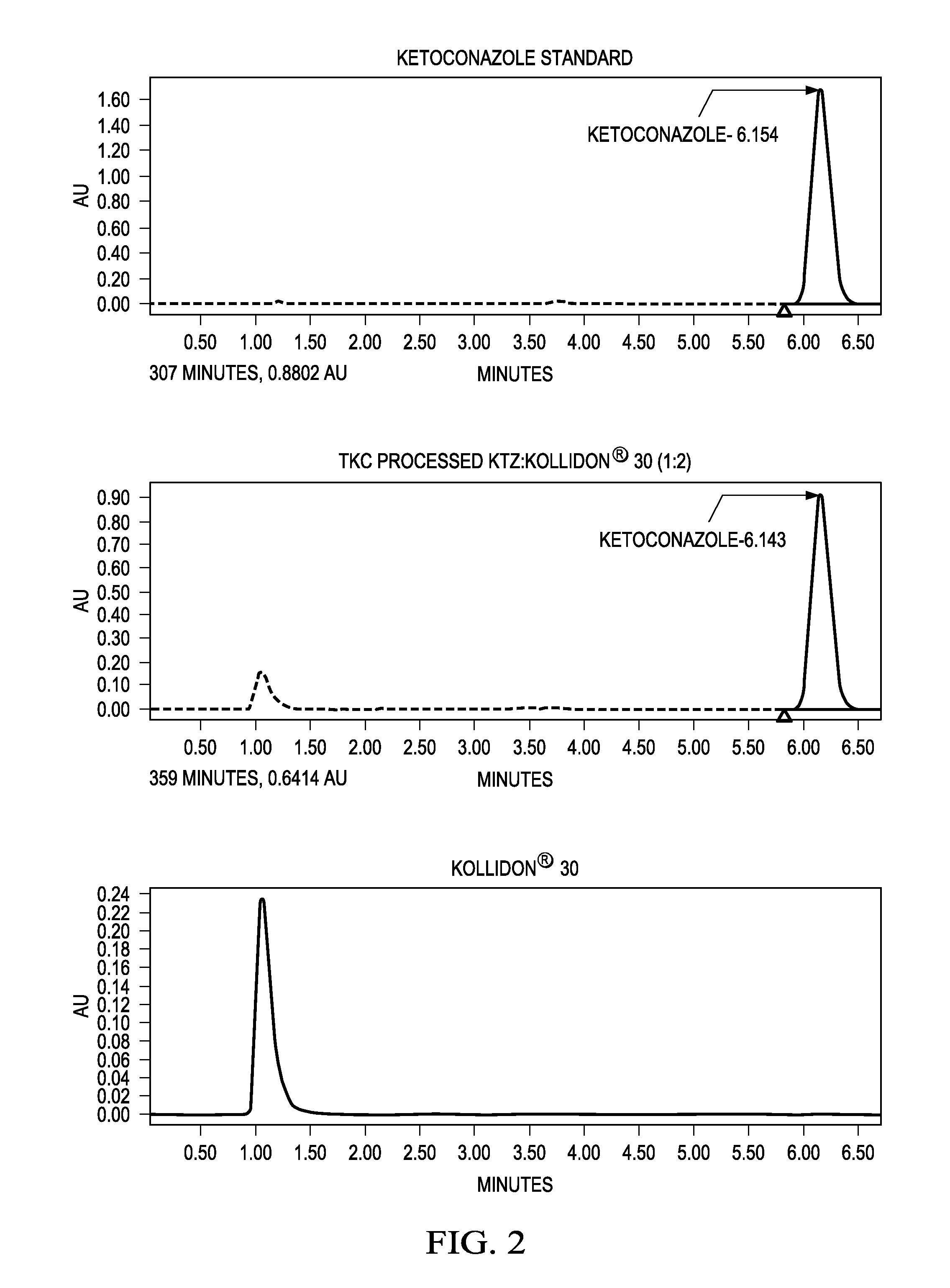

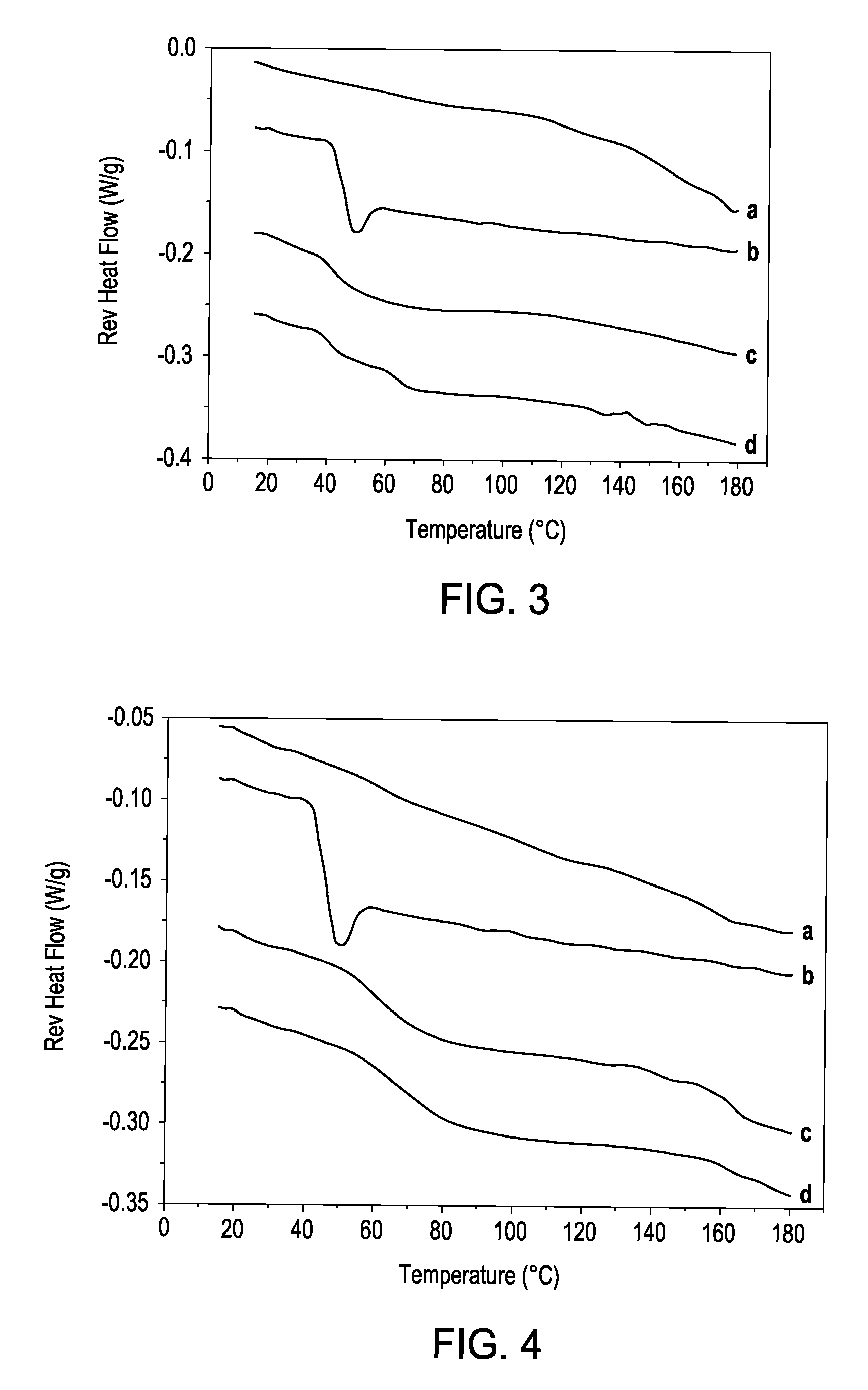

Thermo-Kinetic Mixing for Pharmaceutical Applications

ActiveUS20090053315A1Low process temperatureIncrease shear ratePowder deliveryOrganic active ingredientsCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

Particles for electro-rheological fluid

The present invention can provide particles for electro-rheological fluid for providing a high electro-rheological effect over a wide temperature range at low electric power consumption, and having high strength and excellent durability, not being susceptible to break-up due to the load of stress. Particles for an electro-rheological fluid of the present invention comprise spherical carbonaceous particles, obtained substantially from a solvent and a condensation product of a methylene type bond of aromatic sulfonic acid or a salt thereof.

Owner:NIPPON COKE & ENG

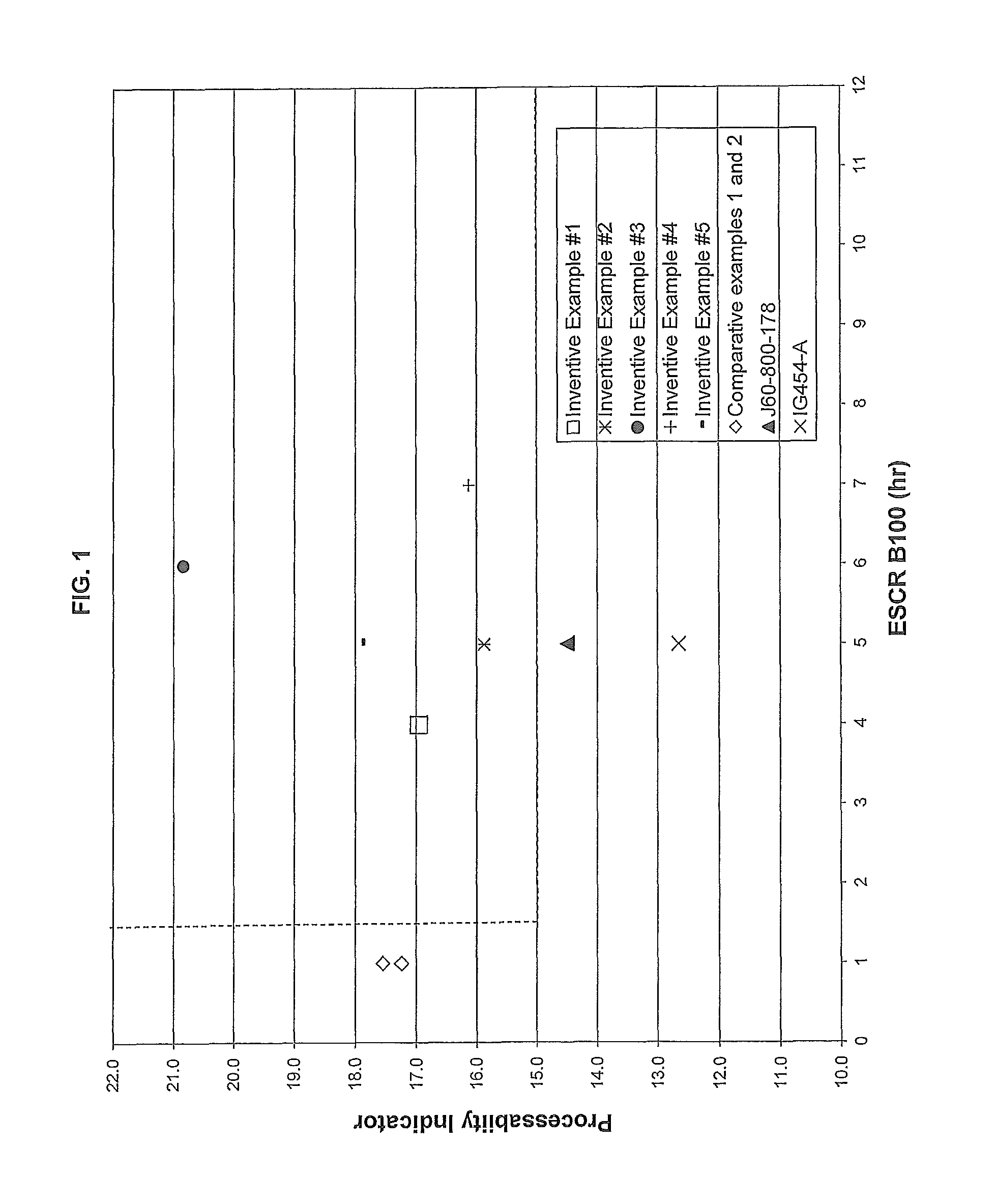

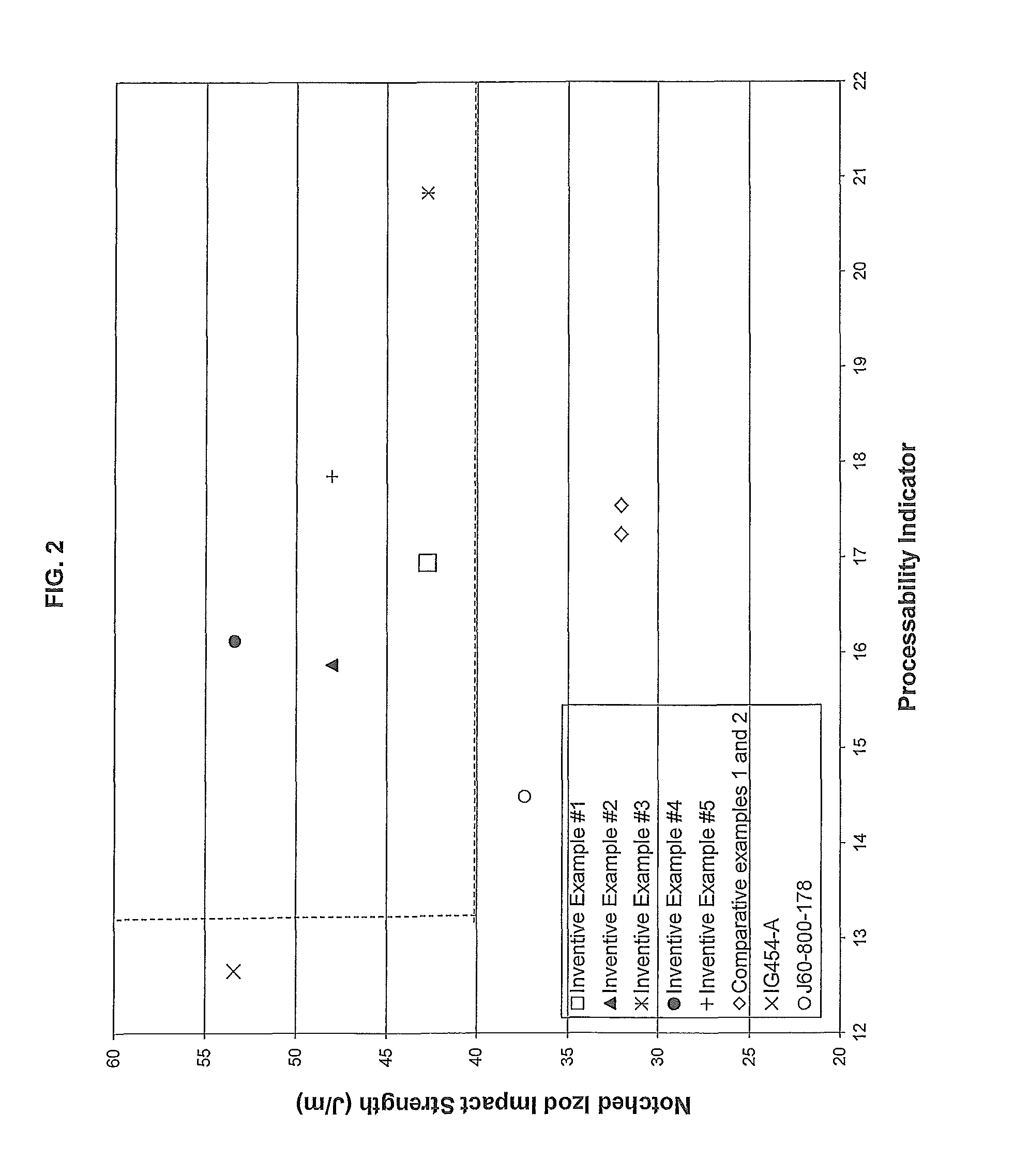

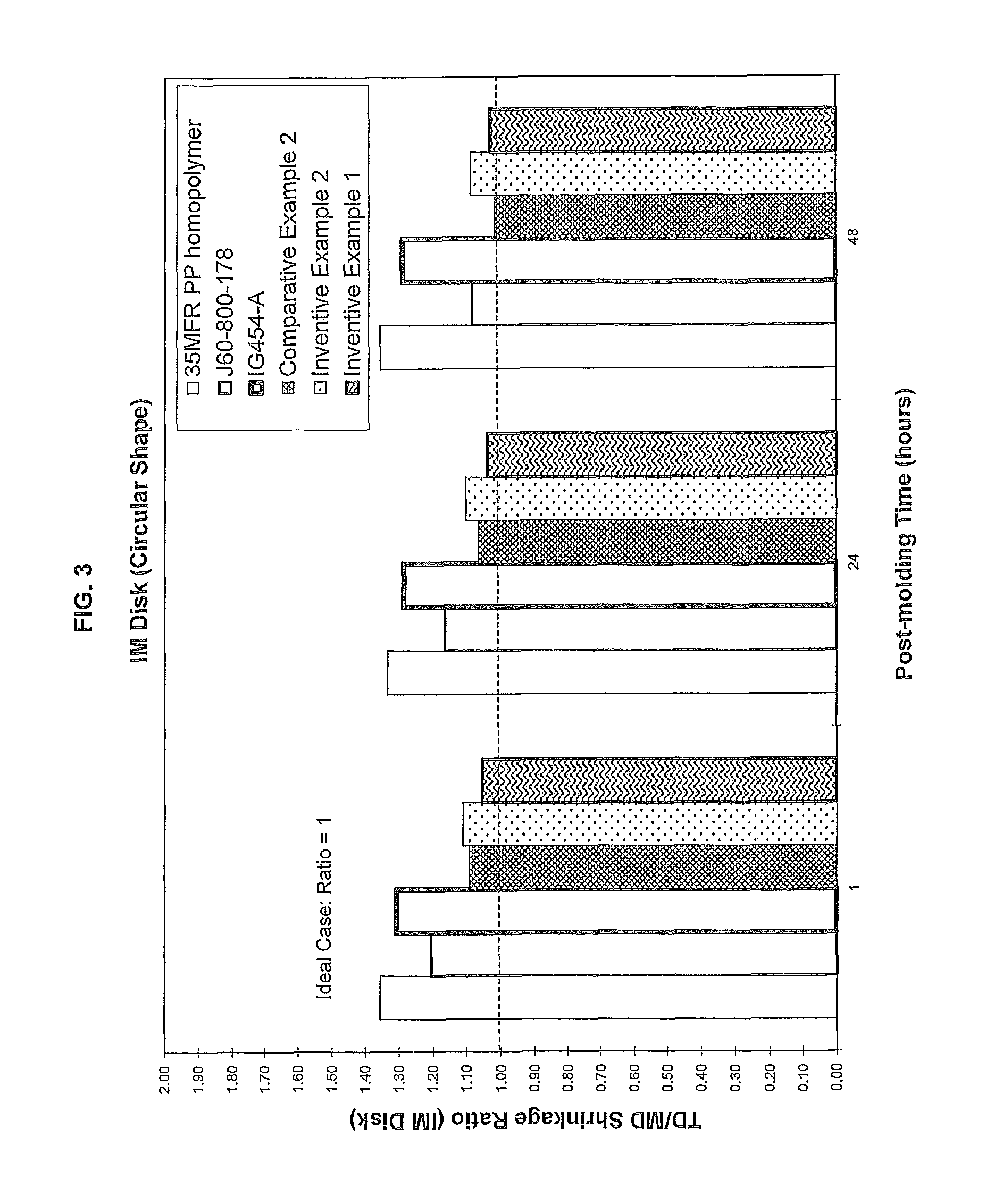

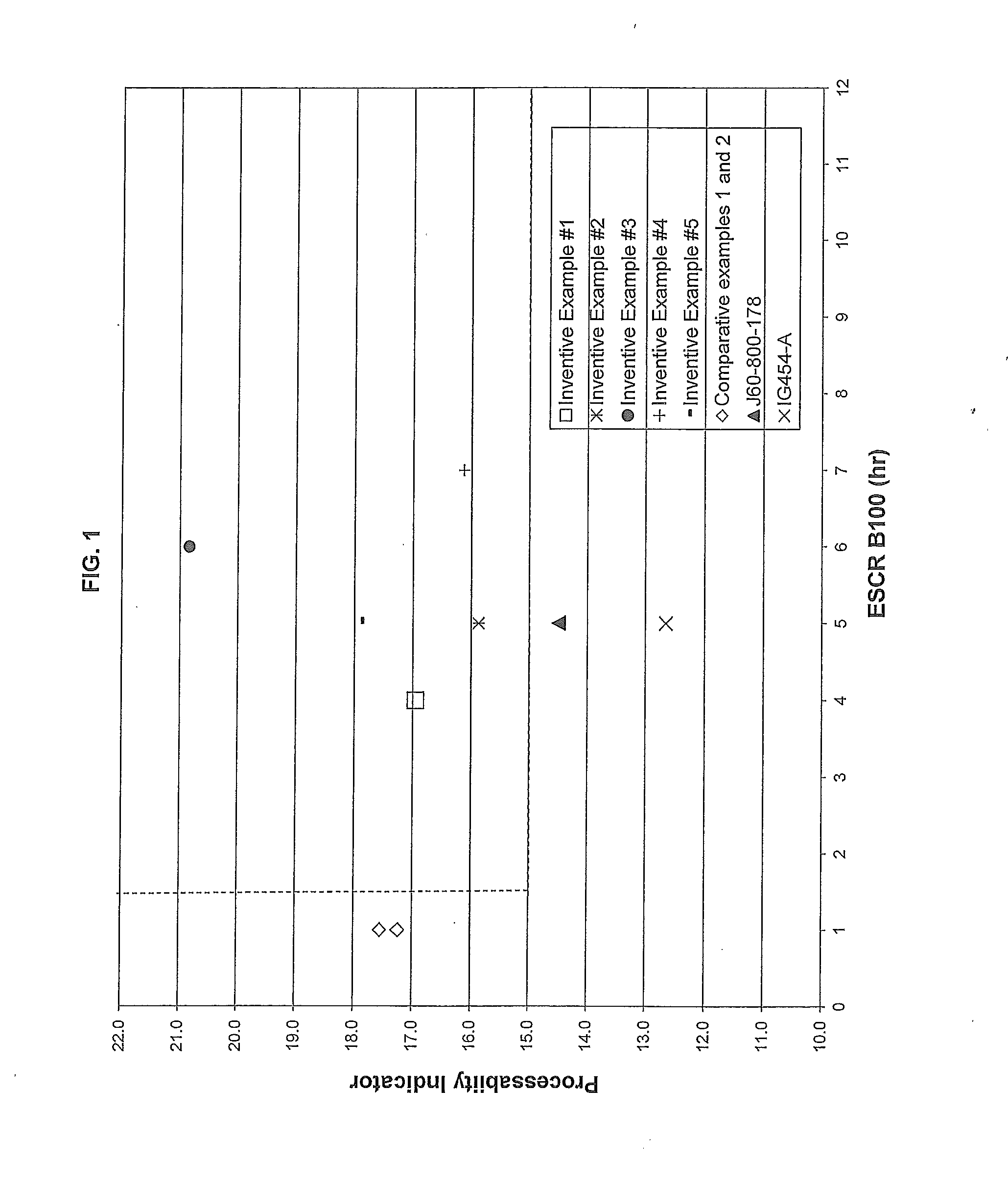

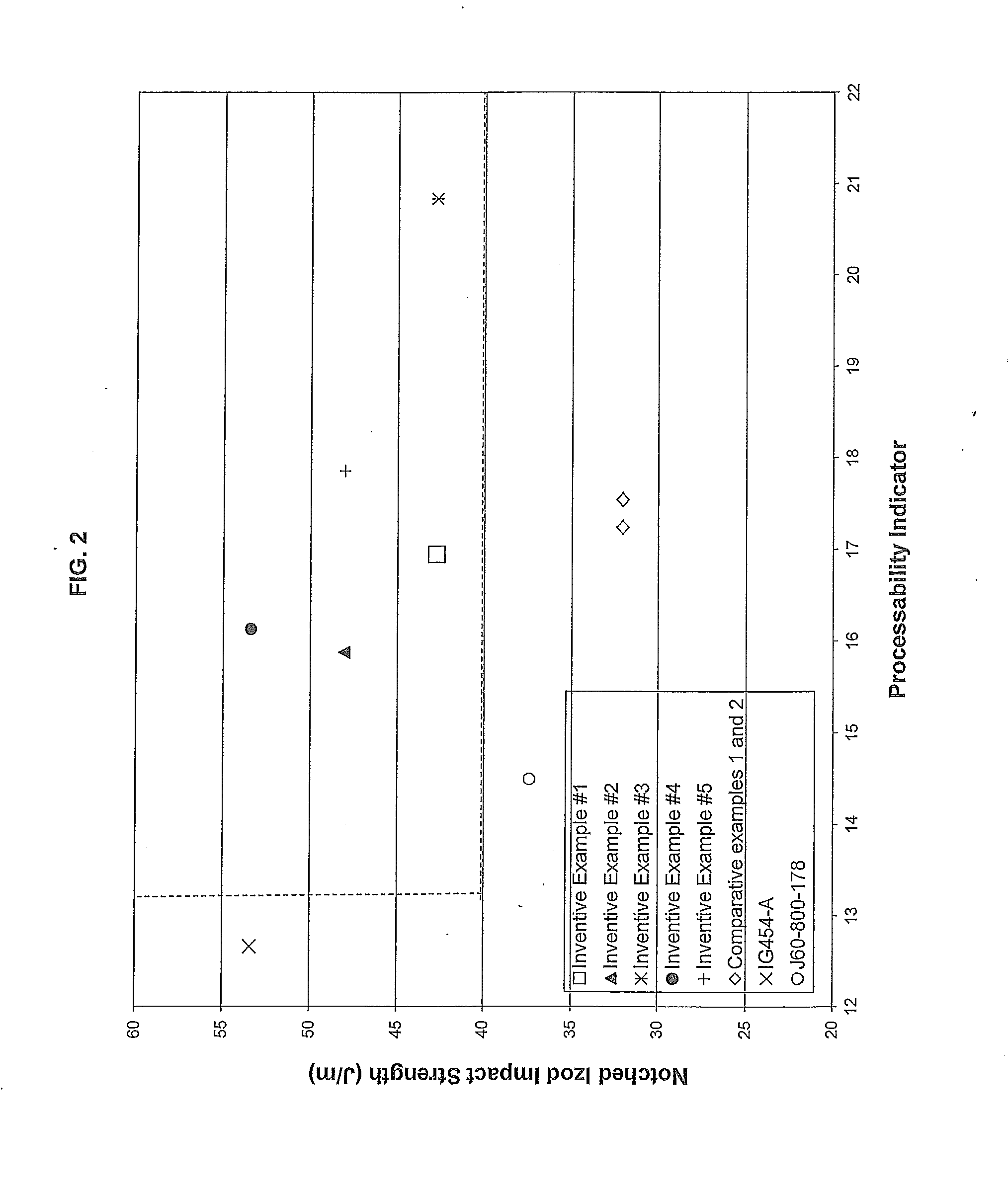

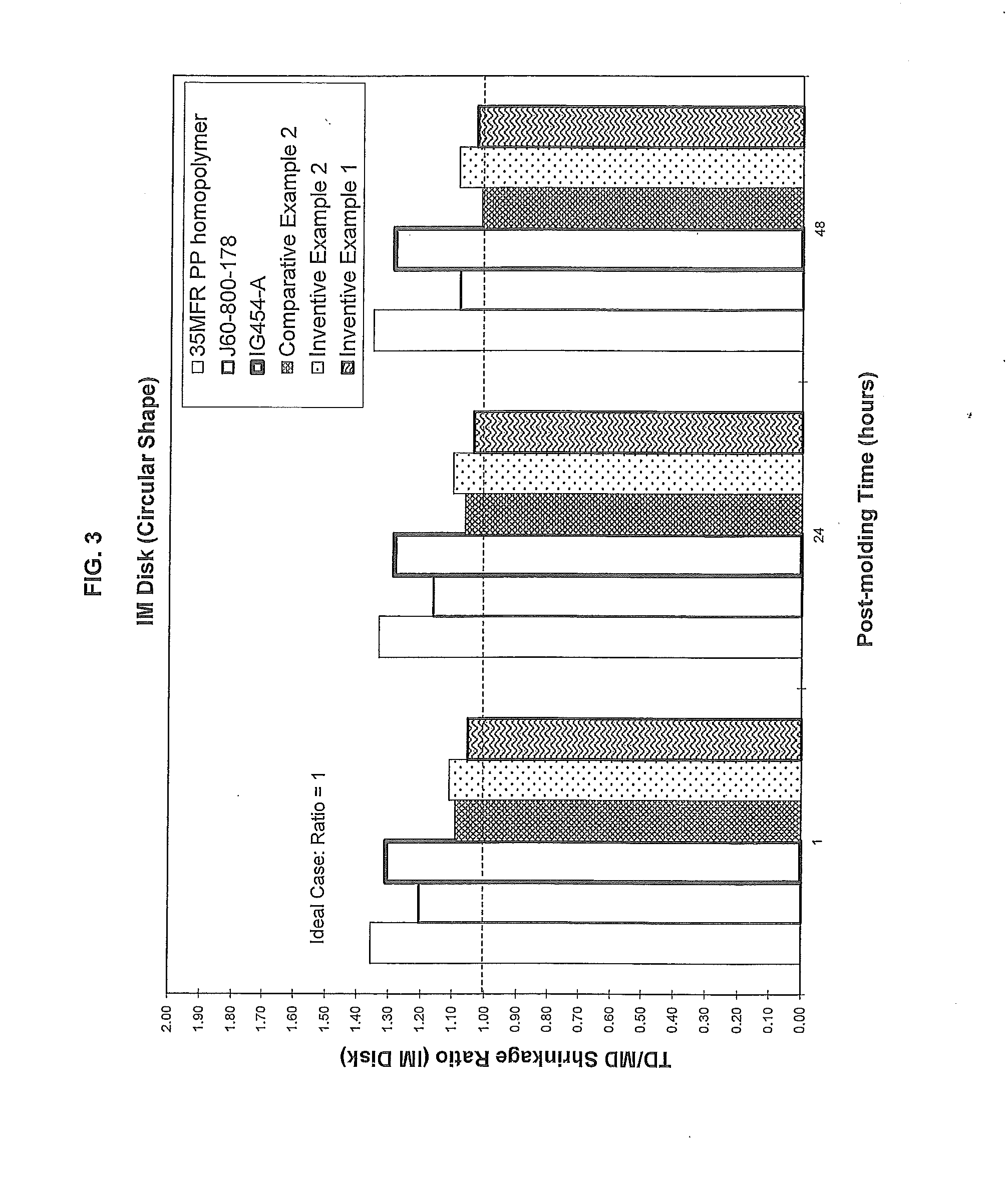

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

Range separation devices and processes

InactiveUS7316780B1Increase shear rateEfficient use ofMilk preparationMembranesChemical physicsPorous medium

Separation device comprising a feed channel including a shear region, permeate passage(s) extending perpendicular to the direction of the feed flow and a porous medium positioned between the shear region of the feed channel and the permeate passage(s). Separation process comprising generating a shear layer in a feed fluid and passing permeate into the permeate passage(s).

Owner:PALL CORP

Conductive fluoropolymers

InactiveUS6533955B1Improve conductivityEasy to processNon-metal conductorsConductive materialConductive polymerFluoropolymer

The invention provides a melt-processable conductive fluorothermoplastic composition comprising three components. The first component is at least one melt-processable, thermoplastic fluoropolymer component having its interpolymerized units derived from (i) at least 50 wt % of TFE, and (ii) one or more ethylenically-unsaturated monomers represented by the formulas (a) CF2=CF-Rf, (b) CF2=CF-O-Rf', and (c) CH2=CR2, wherein Rf is a perfluoroalkyl of 1 to 8 carbon atoms, Rf' is Rf or a perfluoroalkoxy of 1 to 8 carbon atoms, and R is selected from H, F, Cl, or an aliphatic group having from 1 to 8 carbon atoms which may have F or Cl substituents. The thermoplastic fluoropolymer component is substantially free of interpolymerized units derived from VDF. The second component is from about 0.1 to about 10 weight percent of a hydrocarbon polymer, and the third component is from about 1 to about 20 weight percent of conductive filler. The invention also provides a method for making fluorothermoplastic compositions and shaped articles comprising a conductive fluorothermoplastic composition.

Owner:3M INNOVATIVE PROPERTIES CO

Crosslinked polysaccharide gel compositions for medical and cosmetic applications

InactiveUS20130136780A1Enhanced release propertiesGood sustained releasePowder deliveryCosmetic preparationsDiseasePolysaccharide

Methods of producing a biocompatible polysaccharide gel composition having sustained release properties are disclosed. Also disclosed is a biocompatible polysaccharide gel composition having sustained release properties, a method of treating a disease or condition using the present biocompatible polysaccharide gel composition, and a method of controlling rate of release of at least one target solute from the biocompatible polysaccharide gel composition. Pharmaceutical compositions which include the present biocompatible polysaccharide gel composition also are disclosed.

Owner:ALLERGAN INC

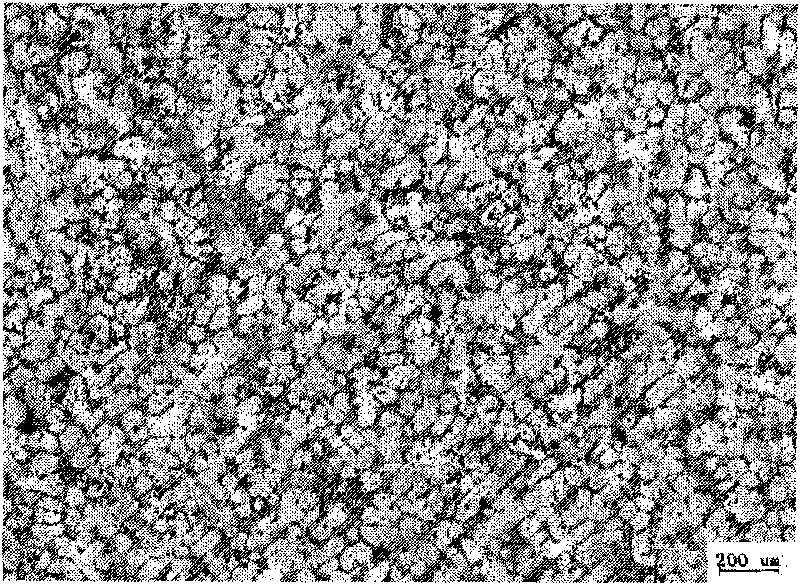

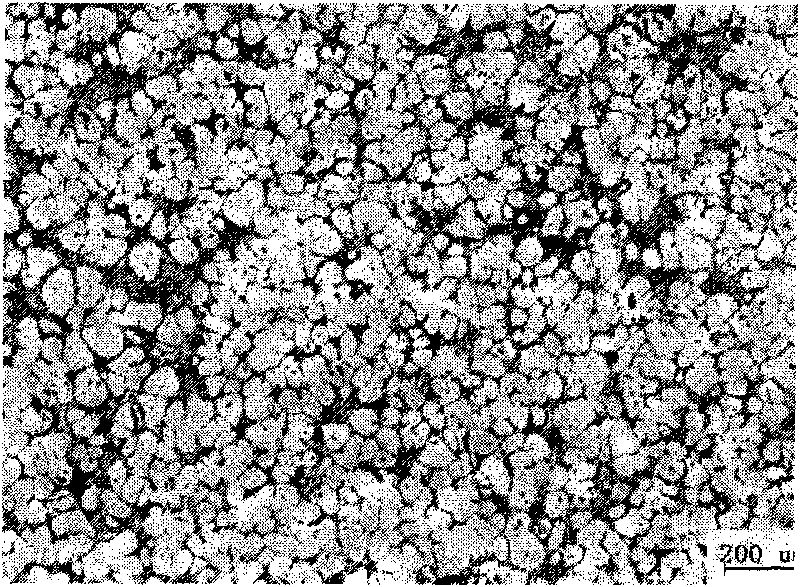

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Rheology Modifiers

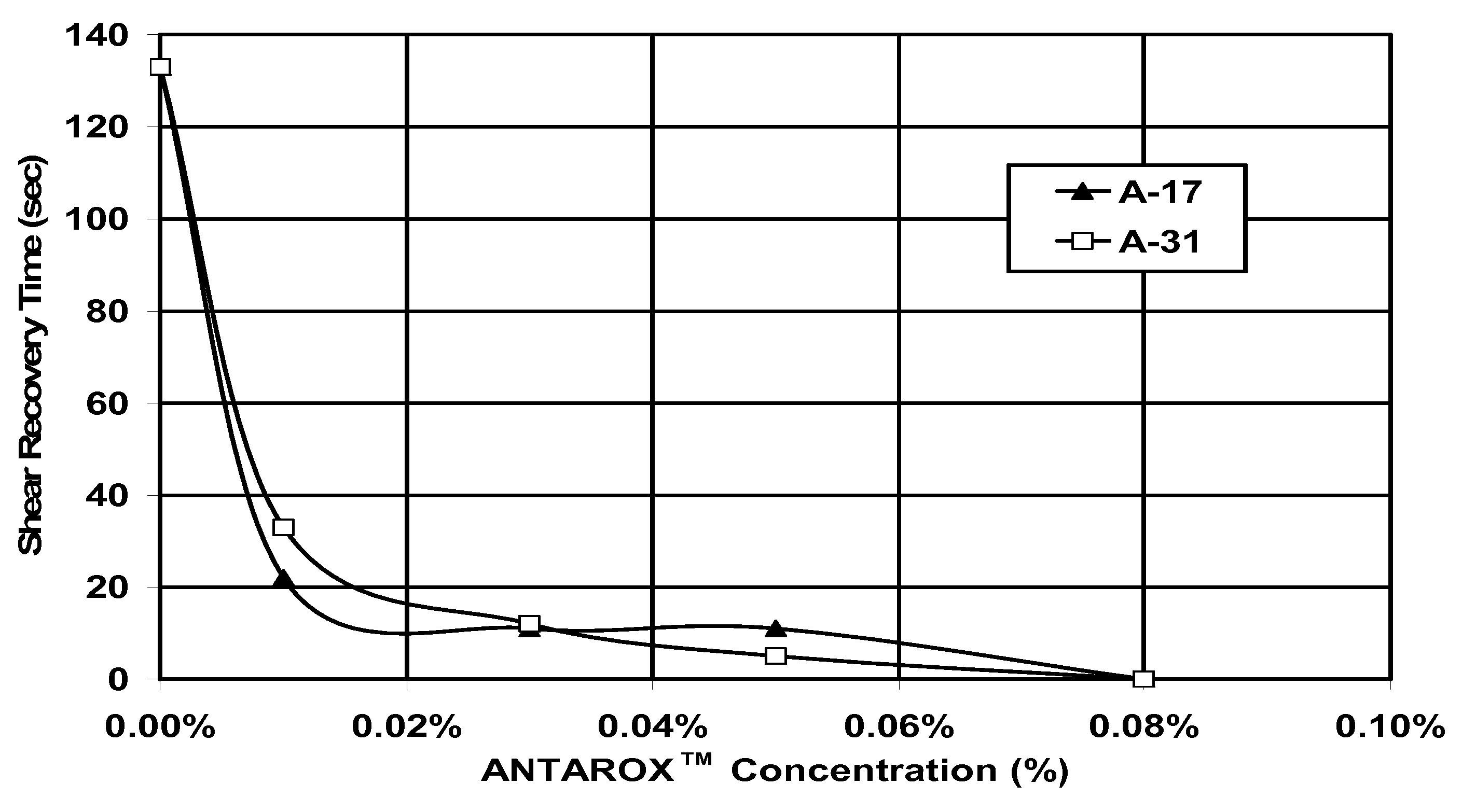

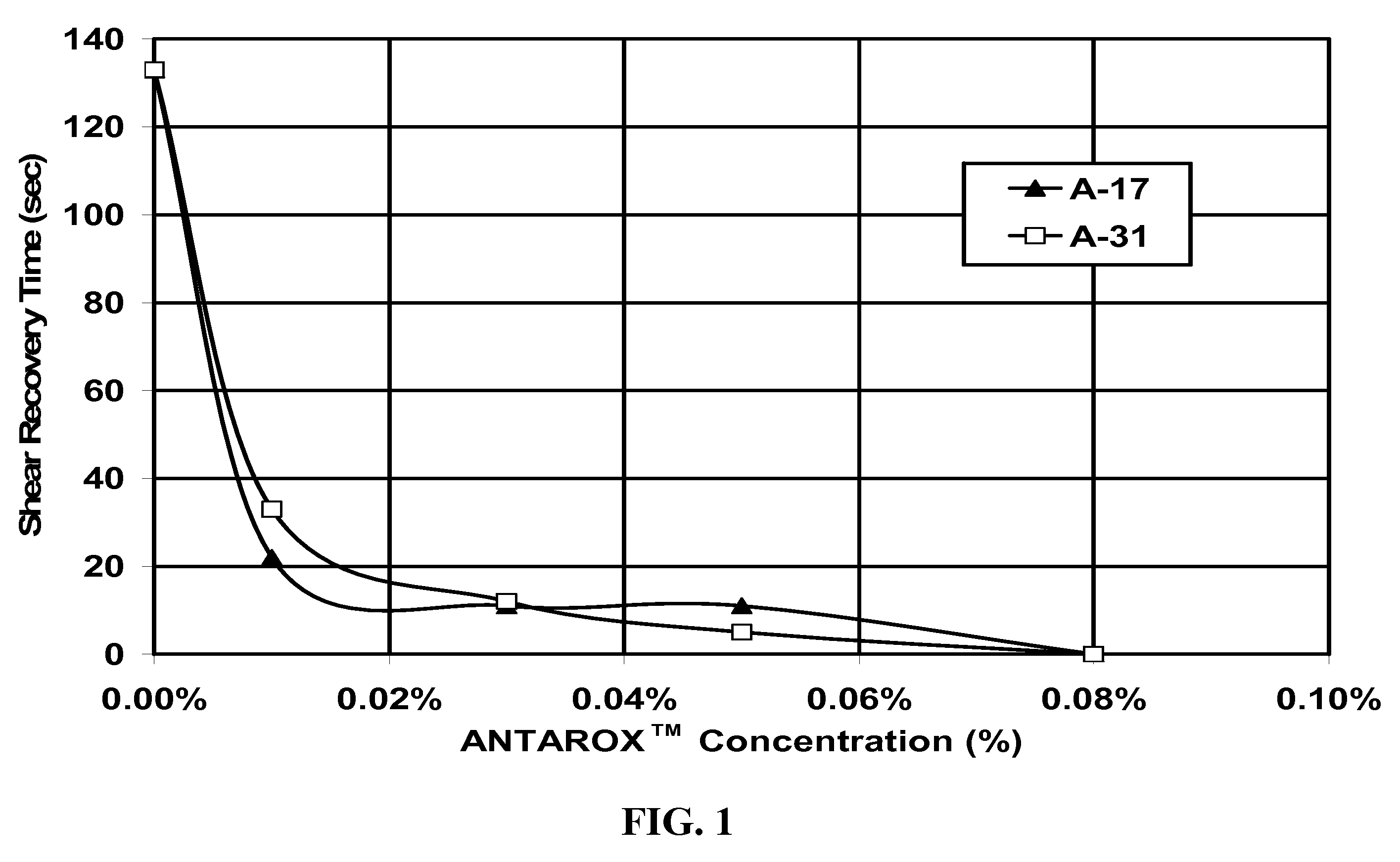

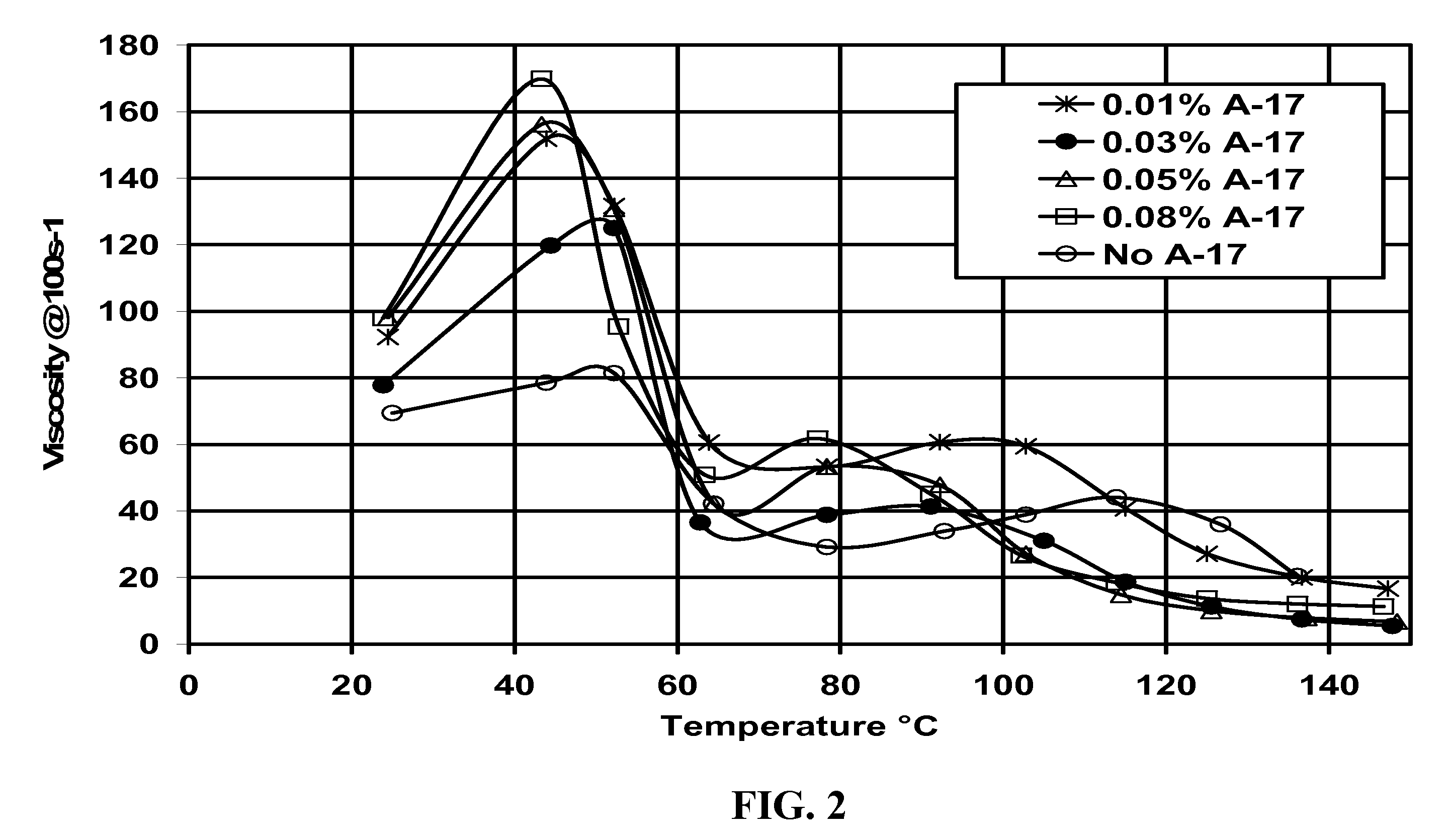

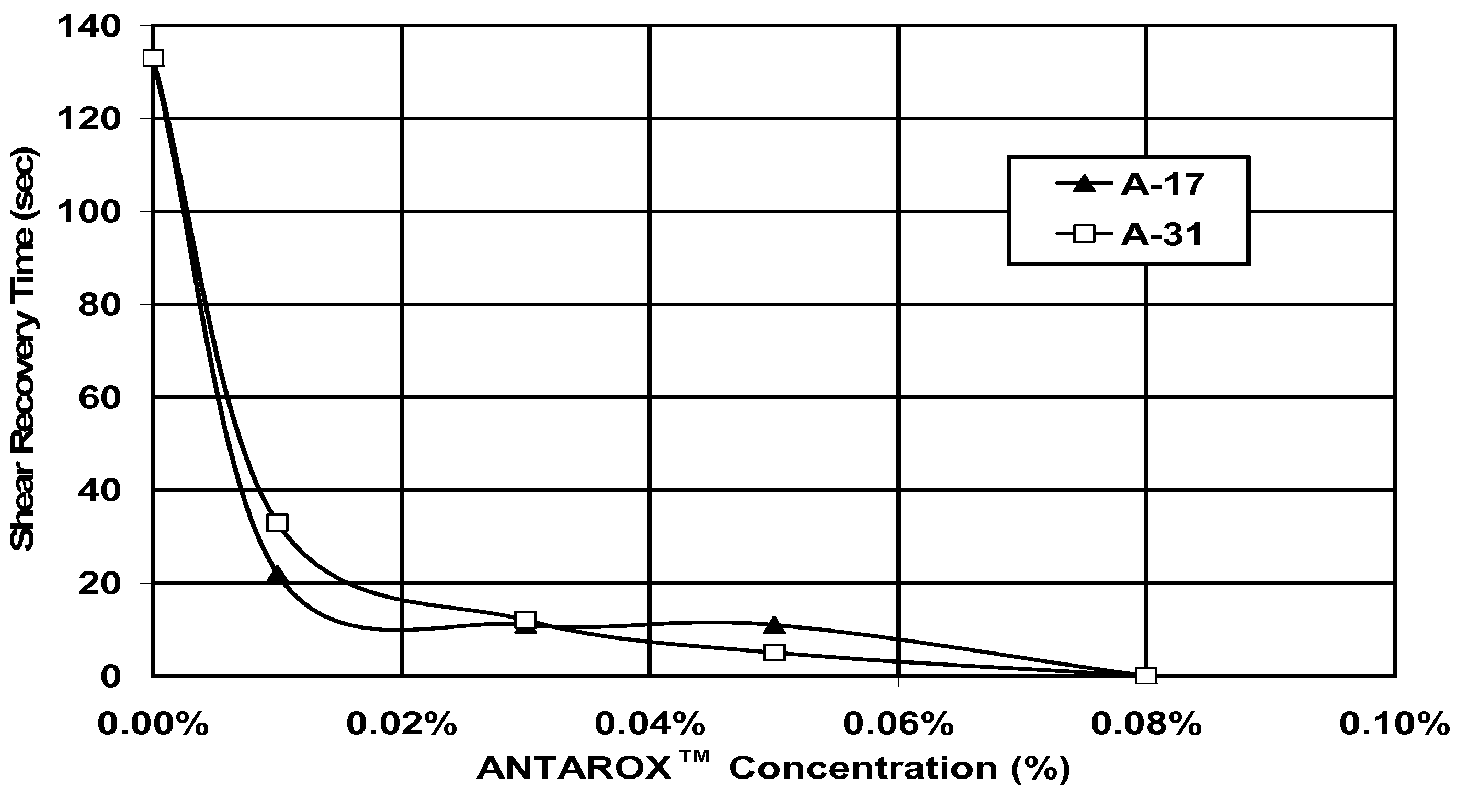

InactiveUS20060185842A1Increase ratingsIncrease shear rateCleaning apparatusFluid removalPolymer scienceBetaine

A method for increasing the rate of shear rehealing of fluids made with cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of a polymeric rheology enhancer selected from polypropylene glycols and block copolymers of polypropylene glycol and polyethylene glycol. For applications in which rapid shear rehealing is required, the rheology enhancer allows fluids to be made and used at lower viscoelastic surfactant concentrations. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

Rheology modifiers

InactiveUS7387987B2High viscosityIncrease ratingsCleaning apparatusFluid removalPolymer scienceBetaine

A method for increasing the rate of shear rehealing of fluids made with cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of a polymeric rheology enhancer selected from polypropylene glycols and block copolymers of polypropylene glycol and polyethylene glycol. For applications in which rapid shear rehealing is required, the rheology enhancer allows fluids to be made and used at lower viscoelastic surfactant concentrations. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

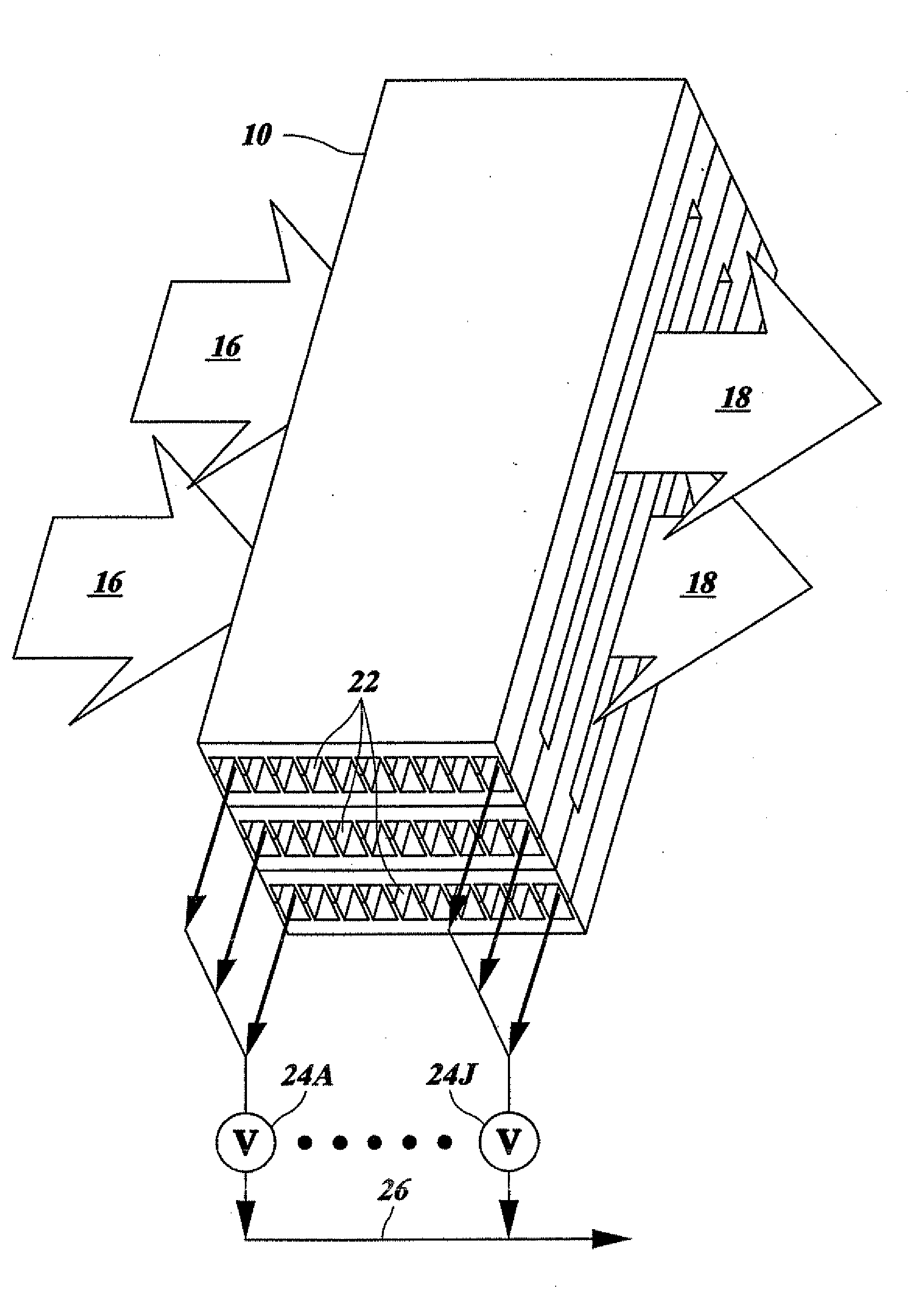

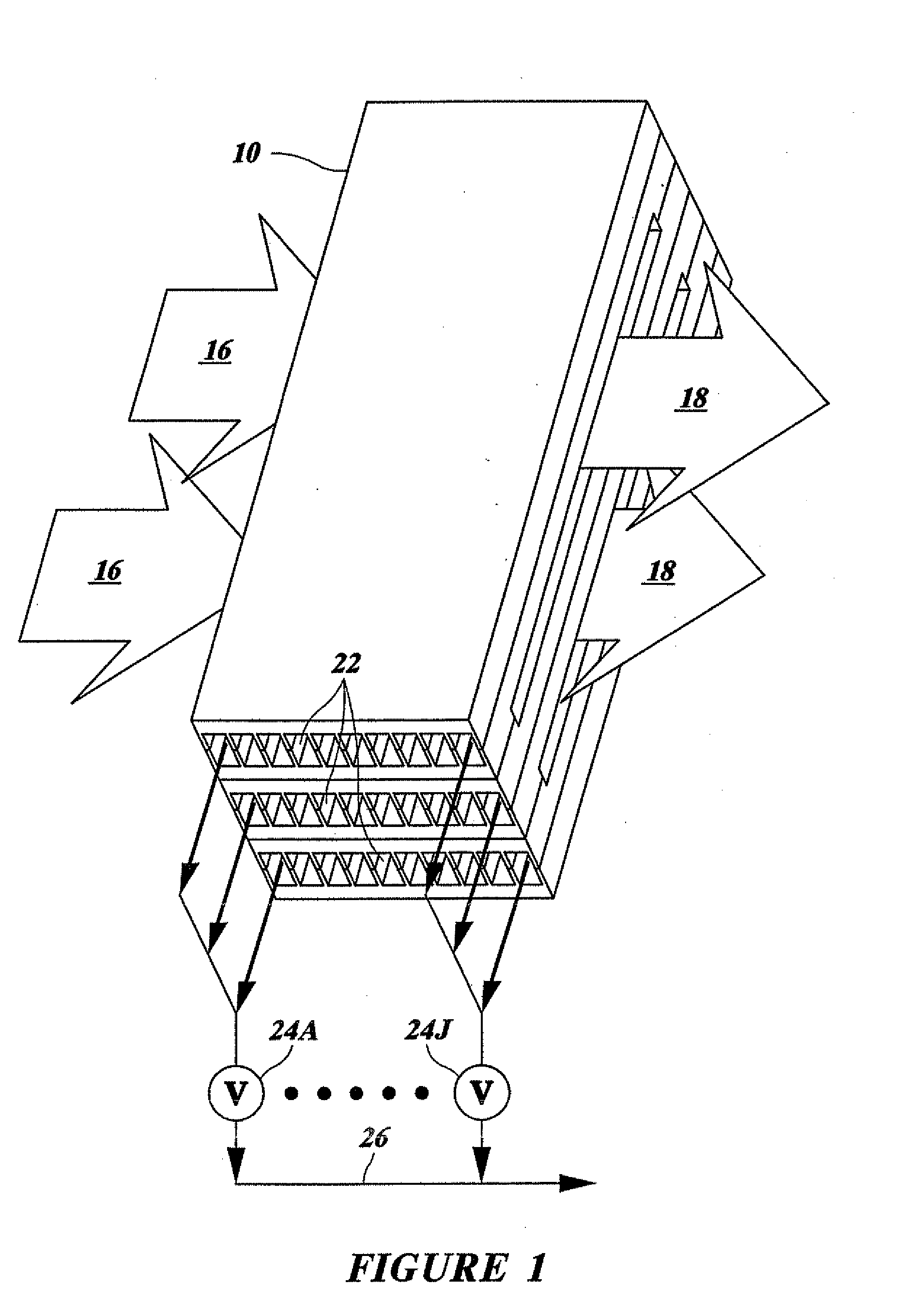

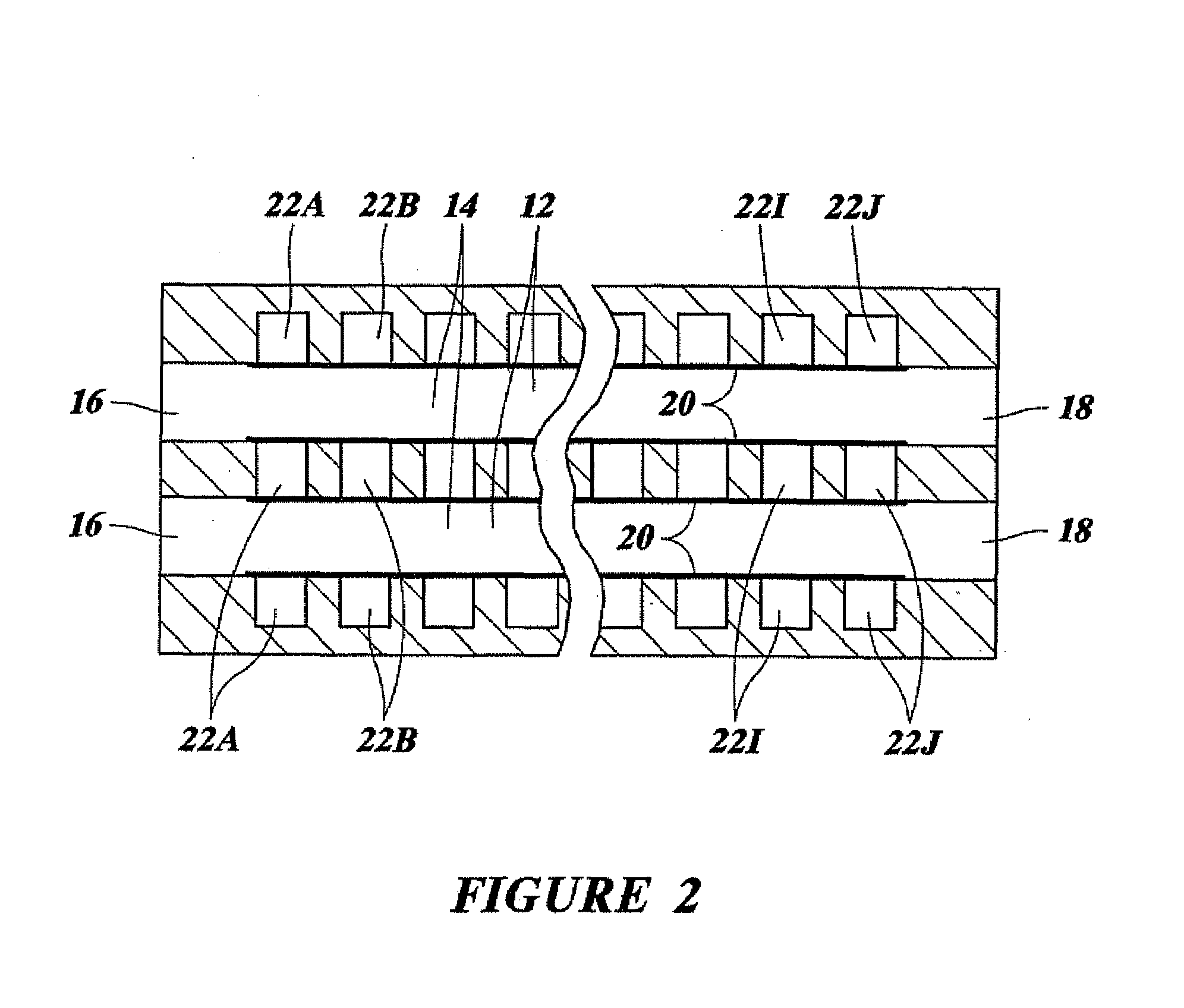

Pressure sensing device for rheometers

InactiveUS6892583B2Accurate viscosityImprove measurement accuracyMachine gearing/transmission testingFluid pressure measurement using elastically-deformable gaugesSmooth surfaceLocal pressure

An improved rheometer plate includes a smooth sensing surface with monolithically integrated miniature pressure sensors which do not interfere with the smooth surface. Pressure sensing diaphragms formed by the smooth surface deflect in response to local pressures against the surface to enable the measurement of unperturbed local pressures of materials sheared between plates. The pressure sensors are sufficiently small that measured pressures are considered to be significantly local properties compared to the size of the plate. Normal stress differences and viscosity of fluid are measured accordingly. The membrane covers a plurality of wells or recesses with pressure sensors located in the wells to measure the deflection of the membrane over the wells. Capacitive or other sensors may be used. The rheometer plate can be used as part of a slit rheometer with a slit of varying dimensions.

Owner:RHEOSENSE

Separation devices and processes

InactiveUS20080251444A1Increase shear rateEfficient use ofMilk preparationMembranesPorous mediumPermeable channel

A separation device comprises a cylindrical separation pack including a spirally wound porous medium, a feed channel including a shear region, a plurality of permeate passages extending along the permeate side of the porous medium opposite the shear region and perpendicular to the feed channel, a feed inlet, a retentate outlet, and a plurality of permeate outlets.

Owner:PALL CORP

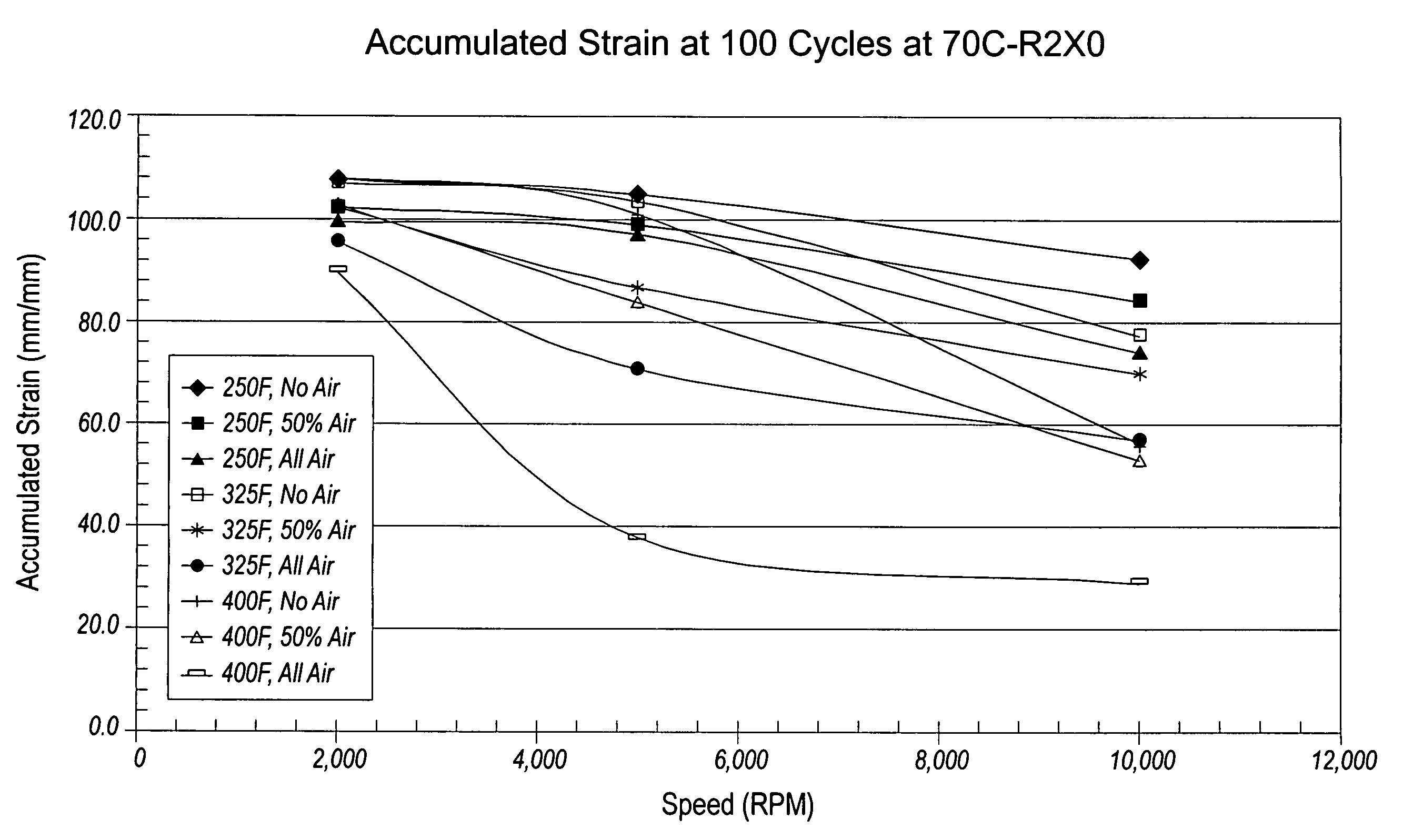

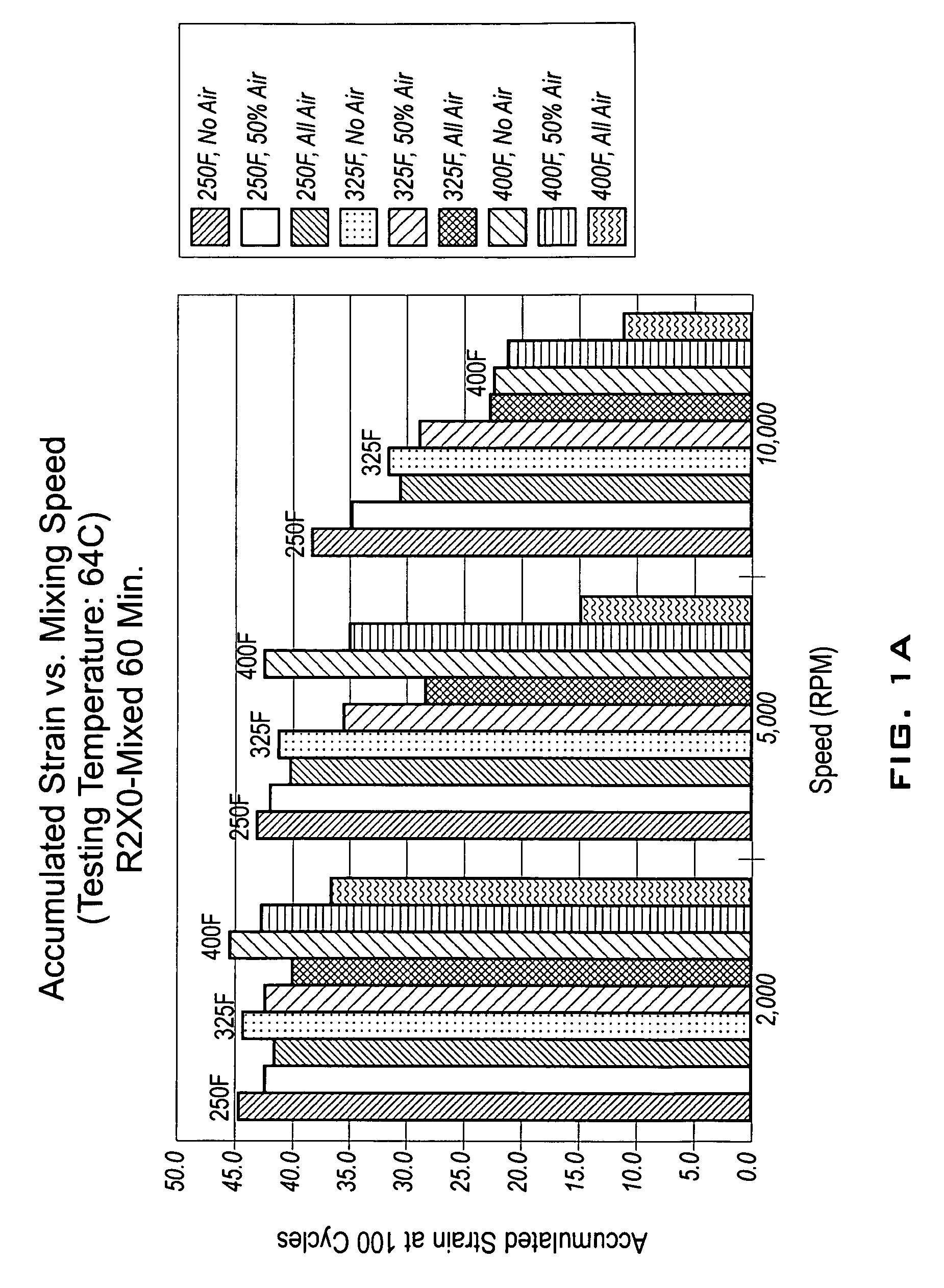

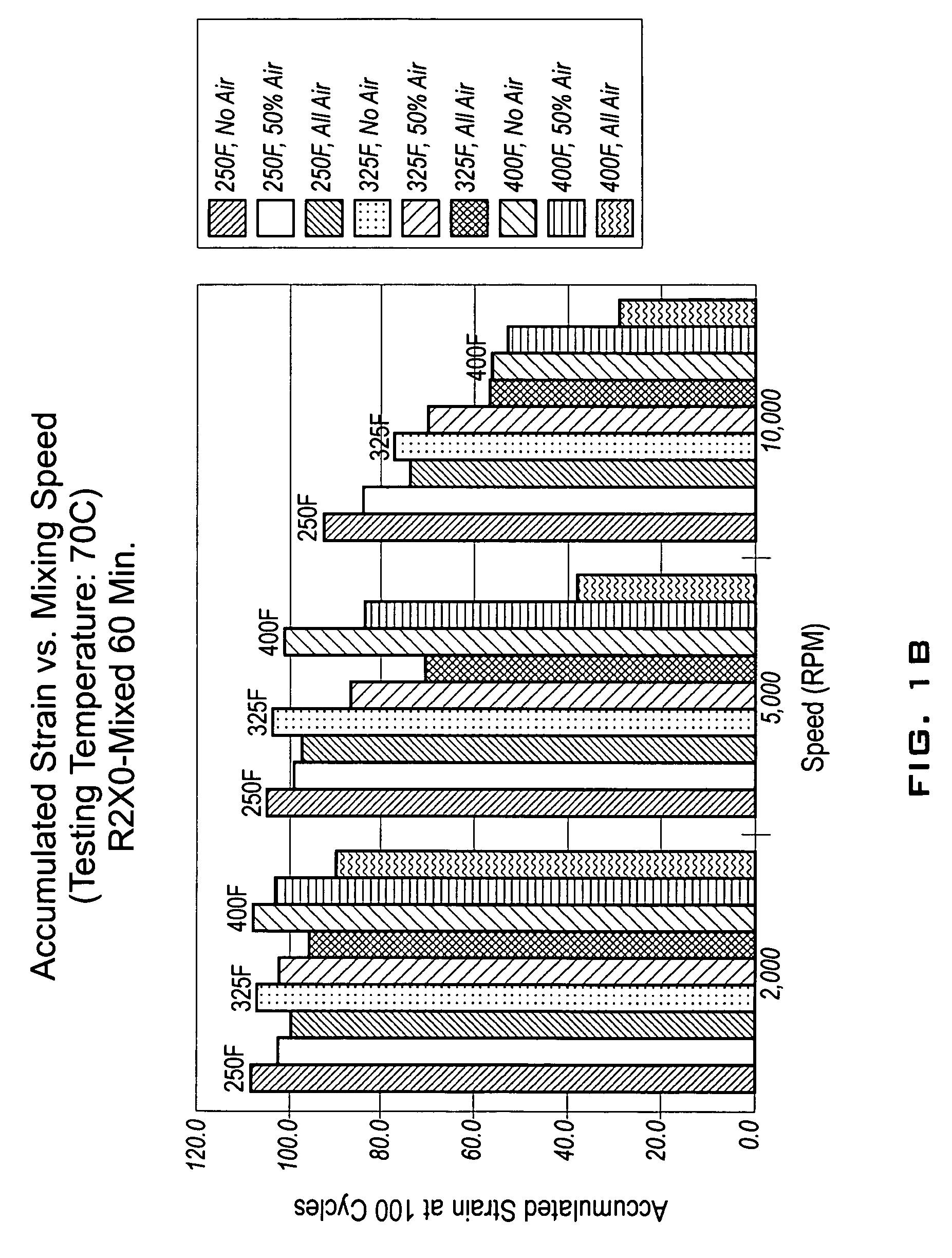

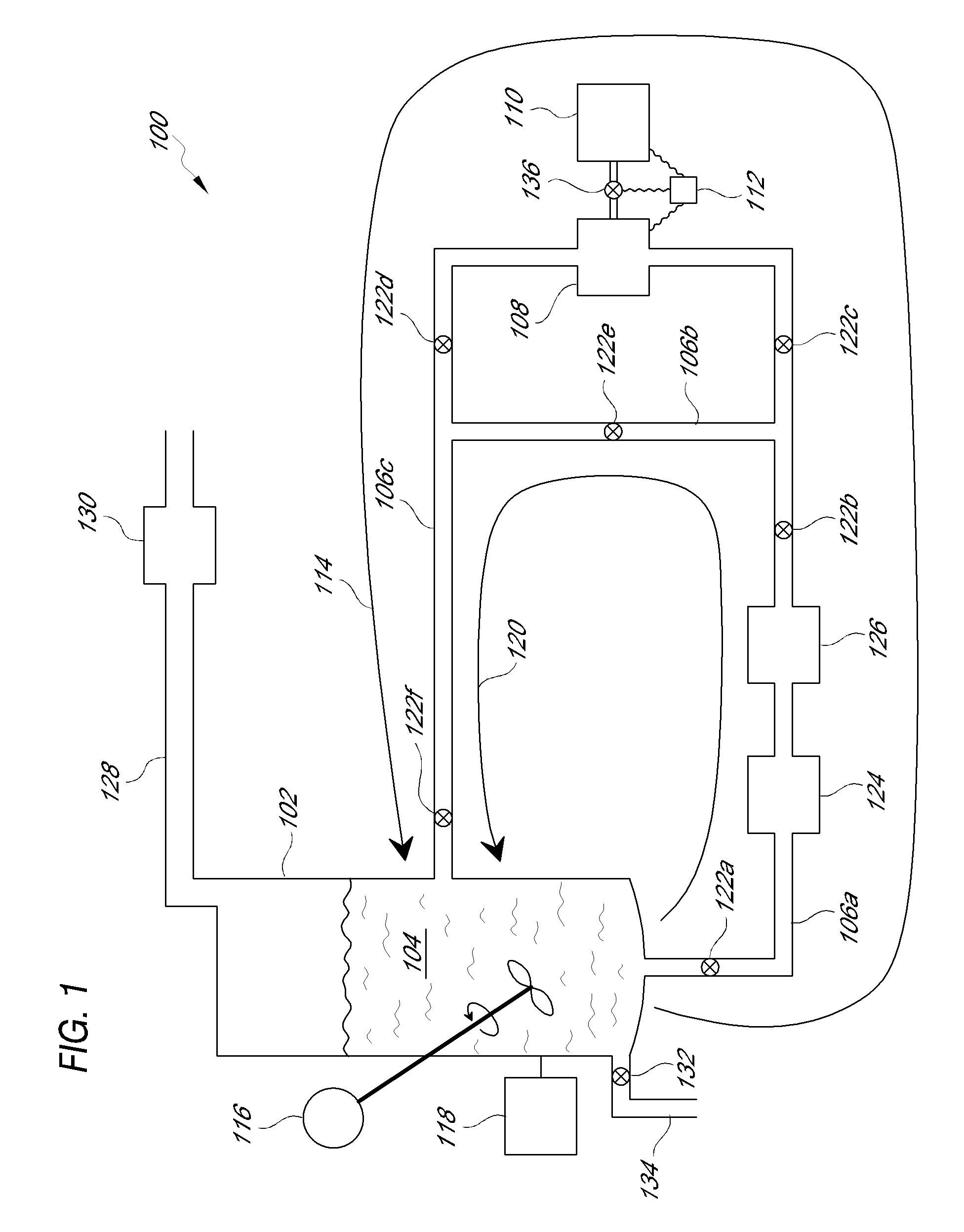

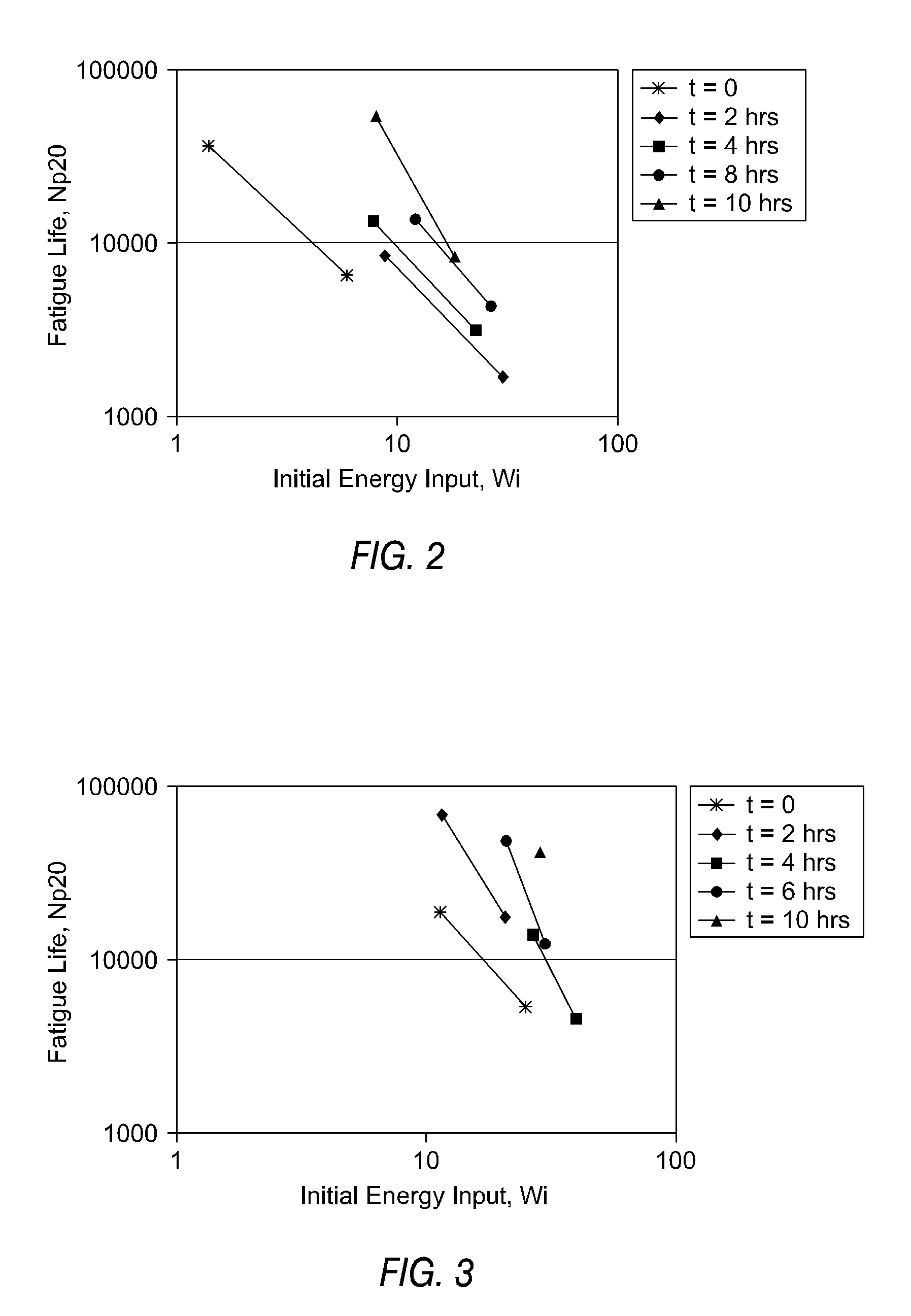

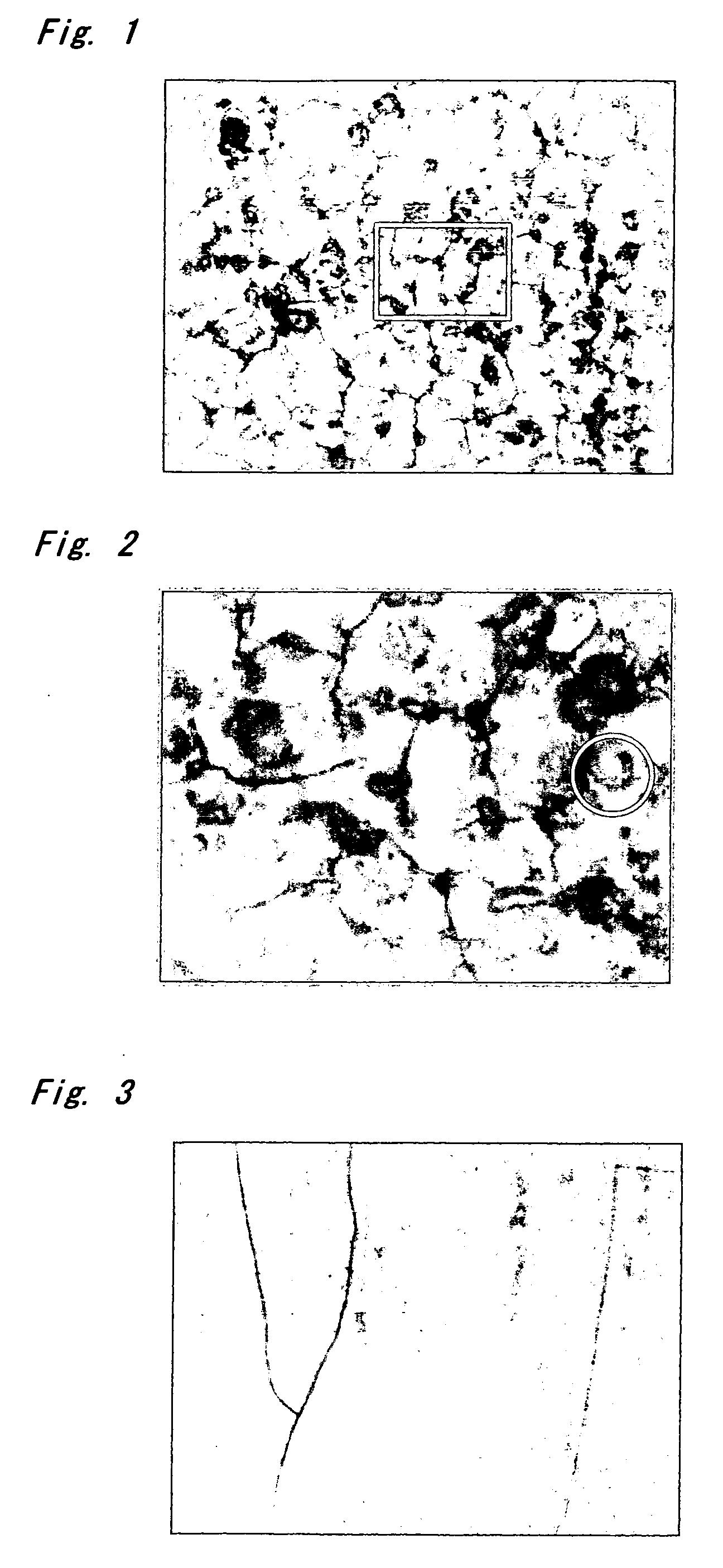

Methods and systems for modifying asphalts

ActiveUS7374659B1Improve the immunityImprove fatigue resistanceWorking-up pitch/asphalt/bitumen by chemical meansTar working-up by chemical refiningShear rateEngineering

A method for modifying asphalt comprises blowing an oxygen-containing gas through a base asphalt at a high gas flow rate while simultaneously agitating the base asphalt at a high shear rate and at an elevated temperature for a period of time that is effective to substantially improve at least two paving properties of the base asphalt. In preferred embodiments, modified asphalts are produced having both substantially improved rutting resistance and substantially improved fatigue resistance as compared to the base asphalt.

Owner:FLEX PROD LLC

Fluoropolymer composition

InactiveUS20070117929A1Increase melt viscosityImprove the extrusion effectTetrafluoroethyleneMolten state

A melt-mixed composition of non-melt flowable polytetrafluoroethylene (PTFE) and melt-fabricable perfluoropolymer is provided that exhibits thixotropy at increasing shear rate in the molten state and high elongation at break even at PTFE concentrations well above 4 wt %, based on the combined weight of the PTFE and the perfluoropolymer, e.g. at least 200% up to at least 30 wt % PTFE, the composition also exhibiting the structure of a dispersion of submicrometer-size particles of the PTFE in a continuous phase of the melt-fabricable perfluoropolymer.

Owner:EI DU PONT DE NEMOURS & CO

Thermo-kinetic mixing for pharmaceutical applications

ActiveUS8486423B2Low process temperatureIncrease shear rateBiocidePowder deliveryCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

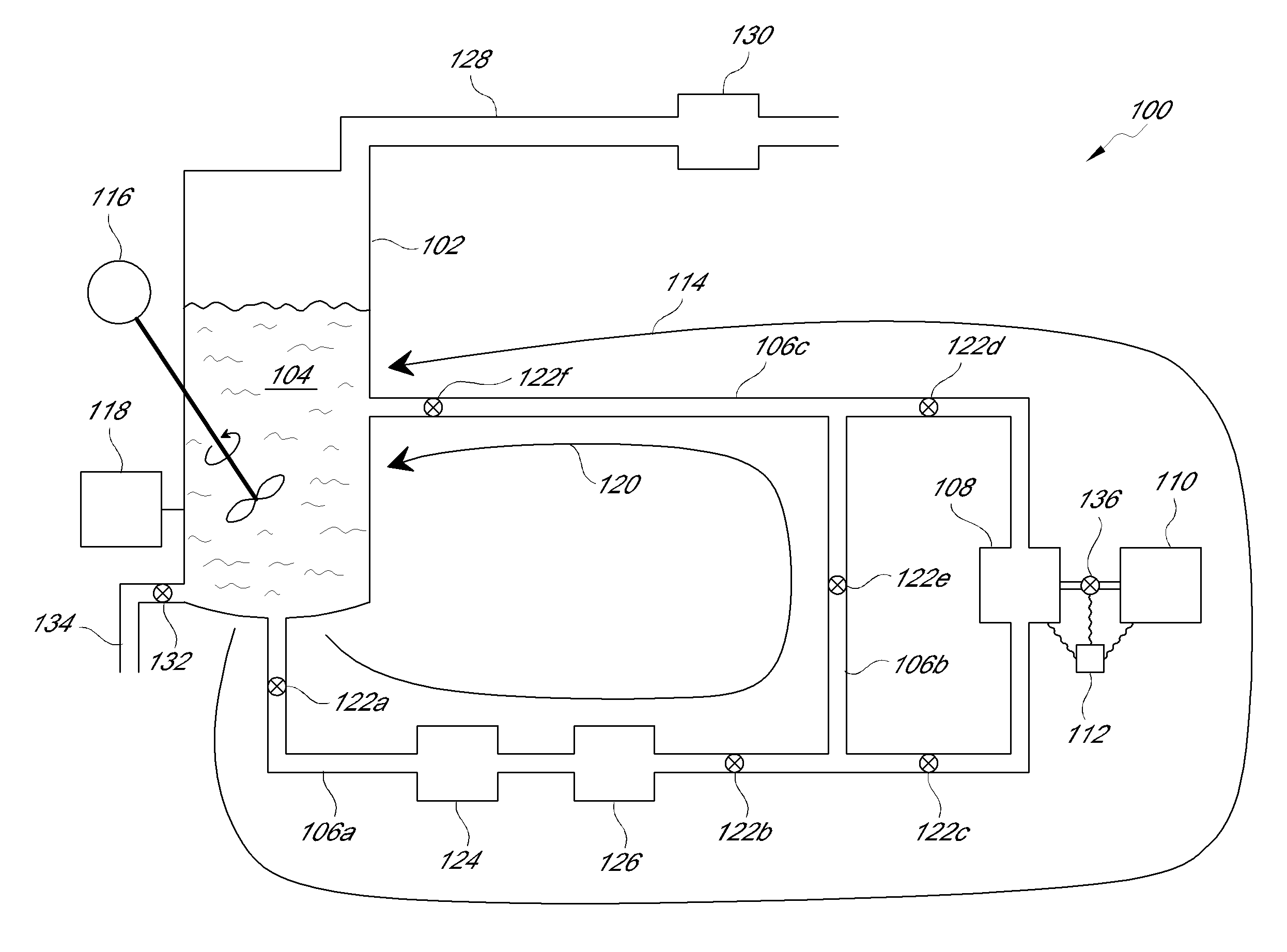

Methods and systems for manufacturing modified asphalts

InactiveUS20090312872A1Efficient preparationImprove the level ofFlow mixersRotary stirring mixersBituminous materialsShear rate

Methods and systems for efficiently manufacturing modified asphalt materials include agitating a base asphalt at a high shear rate using an in-line mixer equipped with a rotor-stator mixing tool while simultaneously exposing the asphalt to oxygen by blowing an oxygen-containing gas at a high gas flow rate through openings in the rotor-stator mixing tool and heating the asphalt at an elevated temperature.

Owner:FLEX PROD LLC

Catalyst support and method of producing the same

ActiveUS20060172886A1Improve adhesionImprove reforming performanceHydrogenCatalyst activation/preparationRare-earth elementAlkali metal oxide

A method of producing a catalyst support comprising a substrate, and coating formed on the surface of the substrate and including powder of a first metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, wherein the coating is obtained by heat treating the substrate after applied with a coating composition obtained by mixing the first metal oxide powder together with a fluid raw material composition containing raw material of a second metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, at a shear rate of 1000 sec−1 or higher.

Owner:TOYOTA CENT RES & DEV LAB INC

Surfactant thickened systems comprising microfibrous cellulose and methods of making same

Surfactant systems are provided using microfibrous cellulose to suspend particulates. In one embodiment the surfactant system includes a microfibrous cellulose at a concentration from about 0.05% to about 1.0% (w / w), a surfactant at a concentration of about 5% to about 50% (w / w active surfactant), and a particulate. Also provided herein are methods for preparing surfactant systems including microfibrous cellulose.

Owner:CP KELCO U S INC

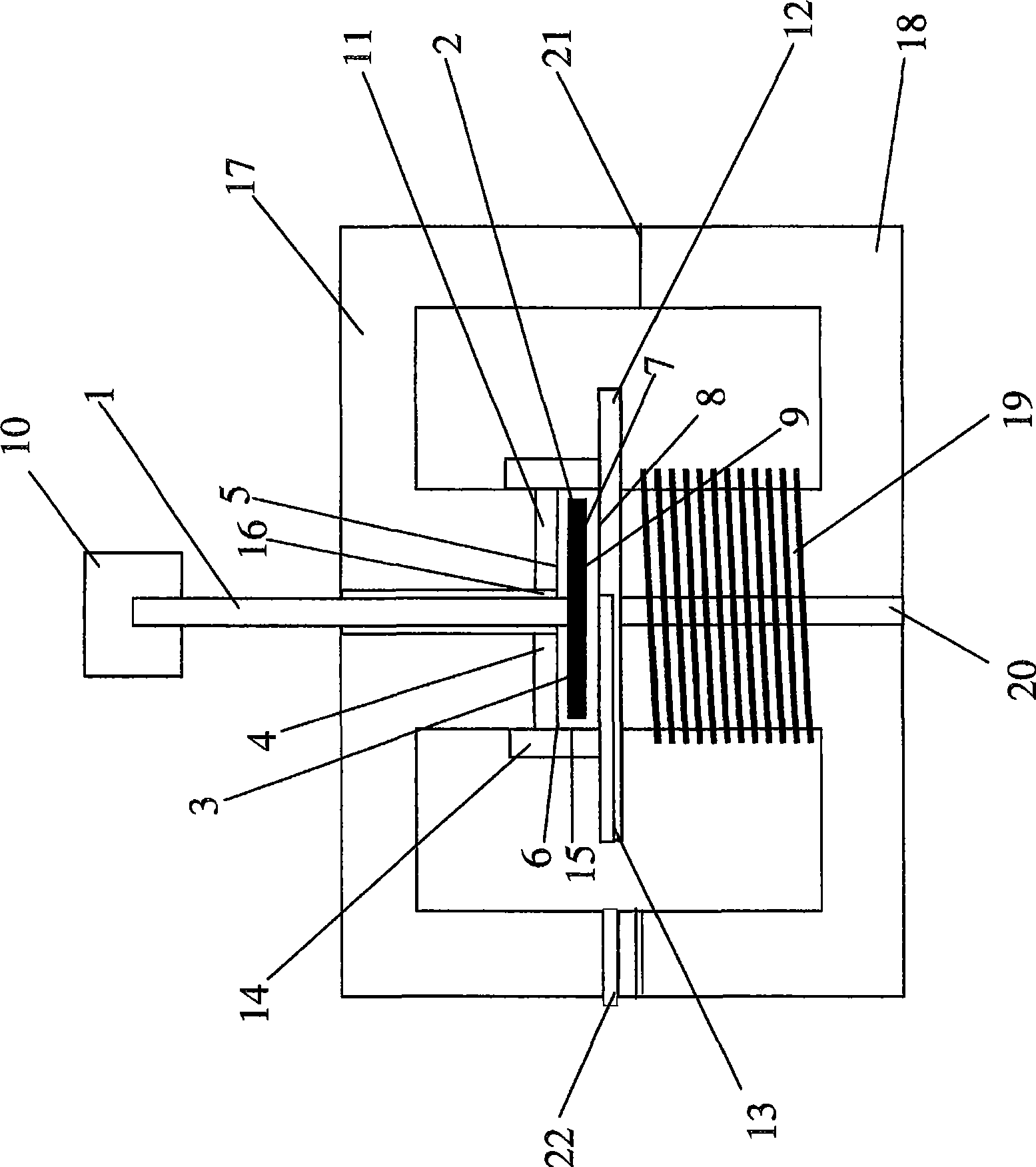

Rheometer

ActiveCN101506640AIncrease shear rateHigh magnetic flux densityMaterial analysis by electric/magnetic meansFlow properties on non-Newtonian fluidsEngineeringMagnet

The invention relates to a rheometer, comprising a rotatable shaft (1), to which a rotor plate (2) is fixed, and a measuring device (10), for measuring torques exerted on the rotor plate (2) by a substance under investigation during a rotation of the shaft (1), wherein a first measuring gap (5), for accommodating the substance (6) under investigation, is formed between a first side (3) of the rotor plate (2) and a first shear surface (4) and a second measuring gap (9), for accommodating the substance (6) under investigation, is formed between a second side (7) of the rotor plate (2) away fromthe first and a second shear surface (8). The rheometer contains a magnet for generating a magnetic field in the first and second measuring gaps (5, 9).

Owner:安东帕有限责任公司

Surfactant thickened systems comprising microfibrous cellulose and methods of making same

ActiveUS8772359B2Increase shear rateCosmetic preparationsSurface-active detergent compositionsCelluloseParticulates

Surfactant systems are provided using microfibrous cellulose to suspend particulates. In one embodiment the surfactant system includes a microfibrous cellulose at a concentration from about 0.05% to about 1.0% (w / w), a surfactant at a concentration of about 51% to about 99% (w / w active surfactant), and a suspended particulate. Also provided herein are methods for preparing surfactant systems including microfibrous cellulose.

Owner:CP KELCO U S INC

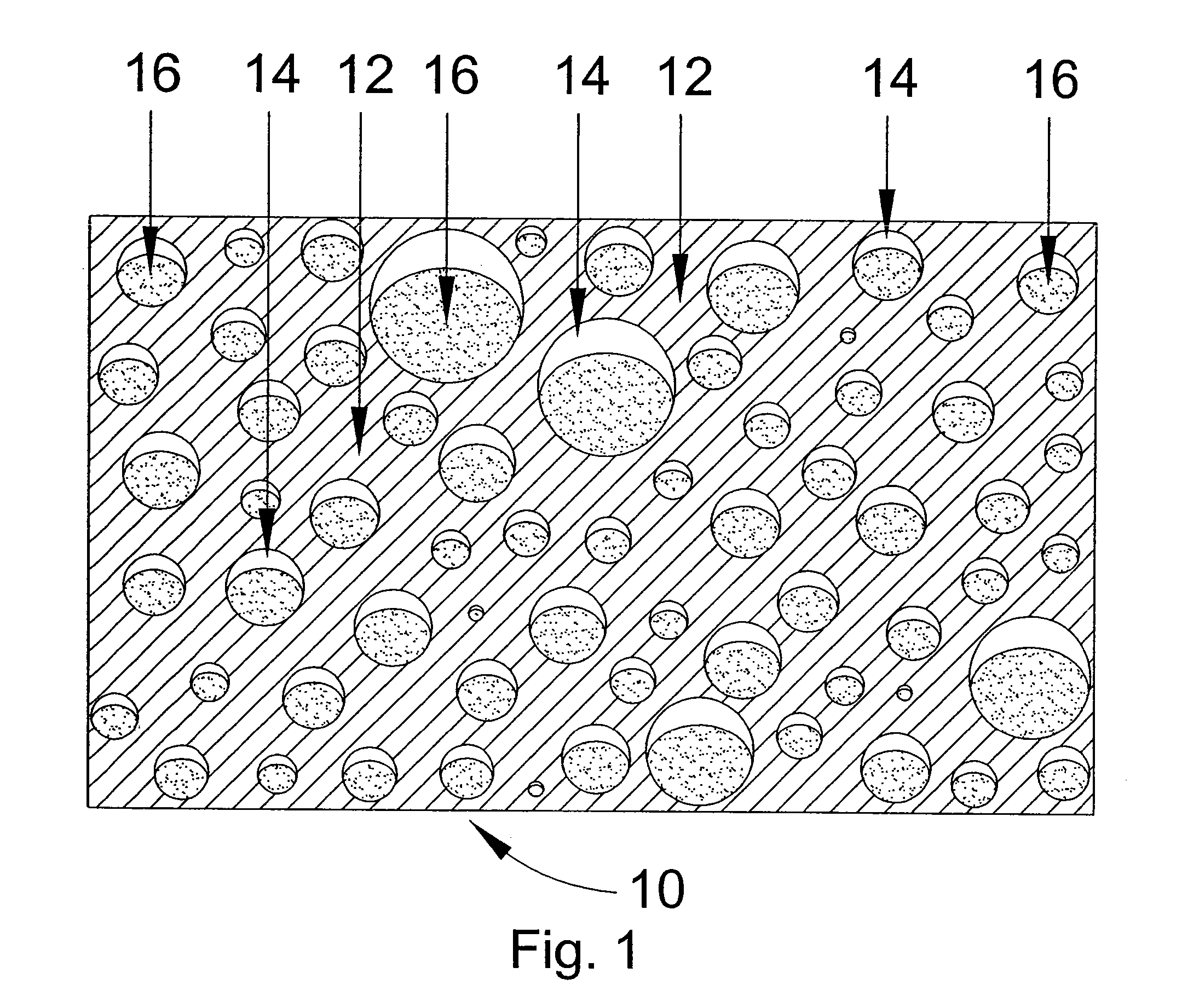

Topical ointment and method for making and using same

InactiveUS20070026025A1Reduce shear rateIncrease shear ratePowder deliveryCosmetic preparationsMicrobubblesMedicine

A topical ointment comprises a base material of plasticized hydrocarbon gel and methylcellulose in which are dispersed a plurality of microbubbles containing liquid. The microbubbles containing liquid are encapsulated by the base material to form microencapsulations which are dispersed in the base material to form a hydrogel. Application of the topical ointment to a body area provides for the moisturizing and the slow delivery of the liquid in the microencapsulations to the applied area. Body heat melts the base material and the contents of the microencapsulations are thereby released.

Owner:AQUEGEL COSMETICS

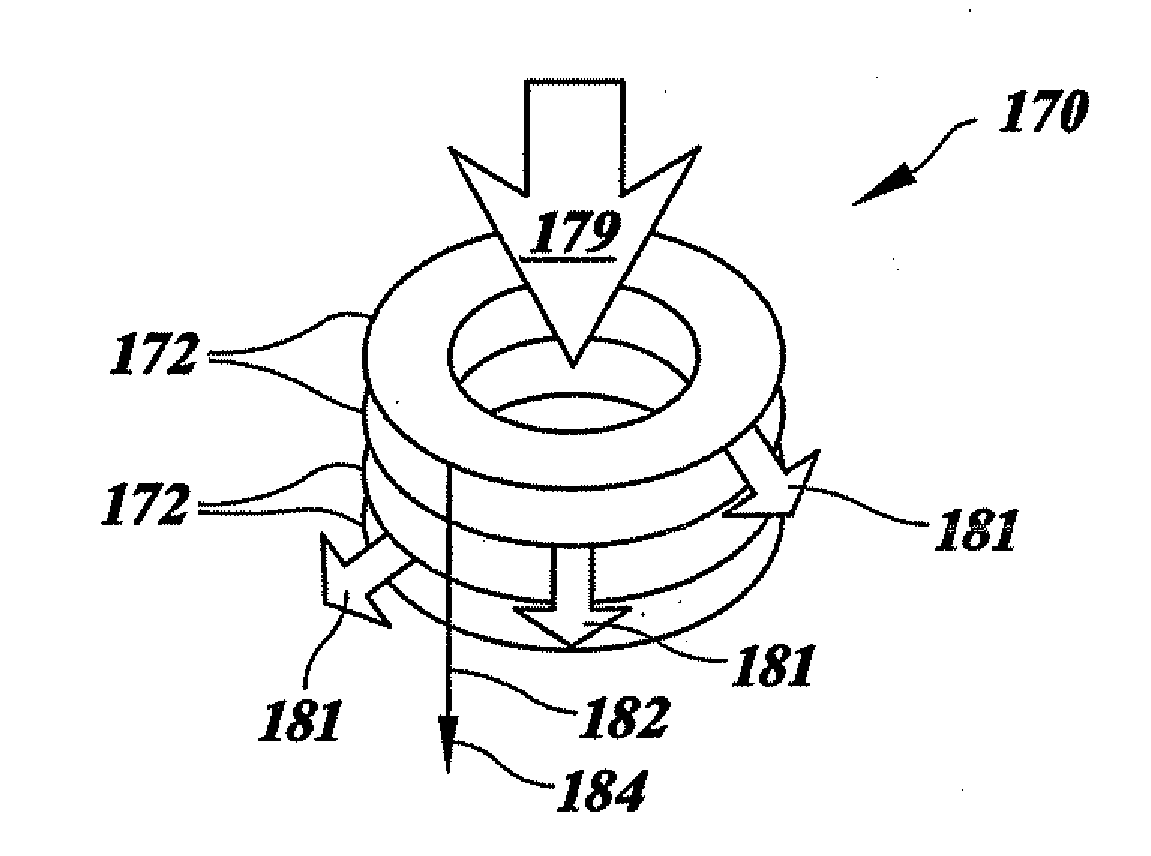

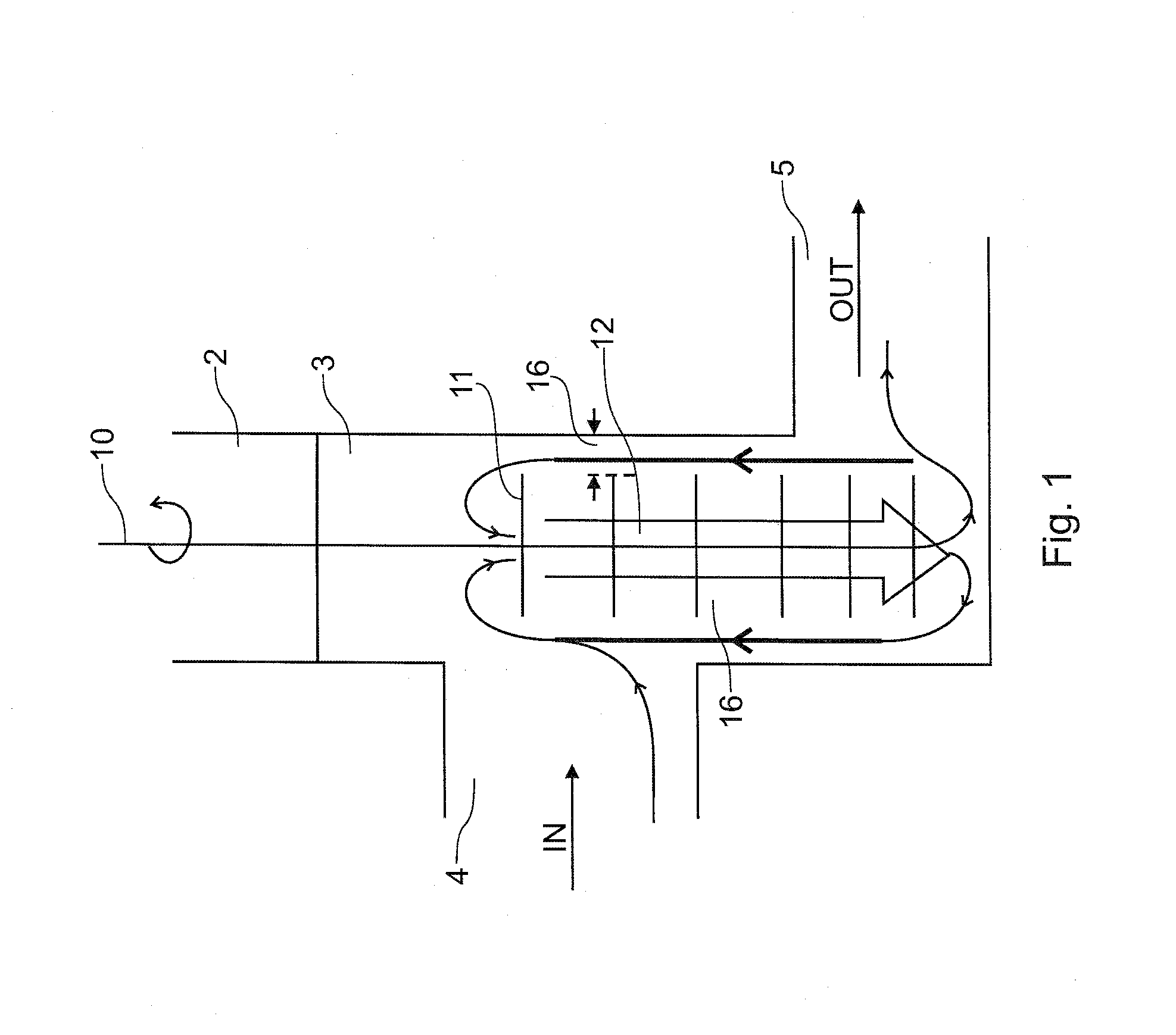

Method and device for homogenizing glass melt

ActiveUS20080148780A1Efficient HomogenizationEasy to adjustRotary stirring mixersGlass furnace apparatusEngineeringMechanical engineering

The invention relates to a method and to a device for homogenizing a glass melt in a melt receptacle, wherein at least one stirring device (10, 11) is disposed in the melt receptacle, which comprises a stirrer shaft (10) and a plurality of stirrer blades (11), and wherein a gap (16) is formed between a wall region of the melt receptacle (2) and the stirrer blades (11).According to the invention, the respective stirring device causes an axial feed action in an inner stirring region (12) between the stirrer shaft (10) and the stirrer blades (11) in order to feed the melt in the stirring region along the stirrer shaft (10). A melt flow brought about by the axial feed action seals the gap (16) against direct passage of the melt.According to the invention, a very high gap width can be achieved, thus preventing the abrasion of materials in the region of the marginal gap. This also reduces the complexity required for adjusting the device. According to the invention, a high level of homogenization can be achieved regardless of the entry point of the inhomogeneities.

Owner:SCHOTT AG

Compatibilized polymer processing additives

ActiveUS8178479B2Impart desired physical characteristicImprove economyBiocideOrganic chemistryPolymer scienceMaterials science

Owner:STRATSYS INC

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS20140171582A1Isotropic shrinkage ratioShrinkage differentialMixingCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

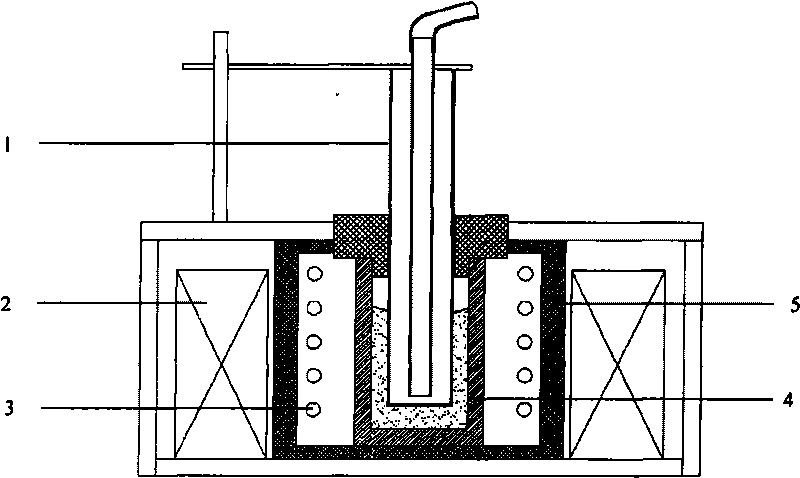

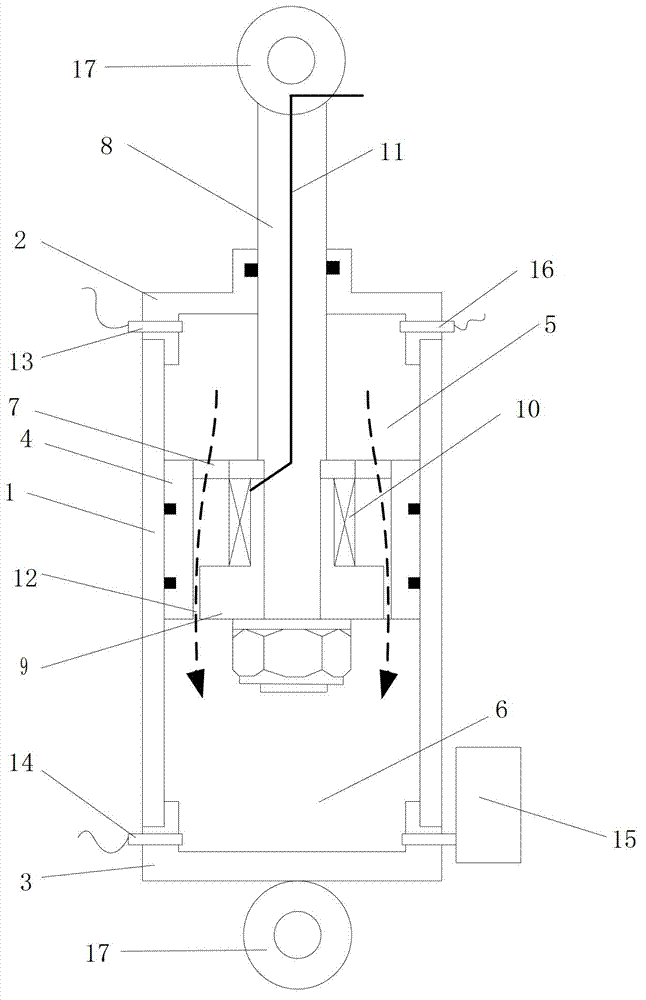

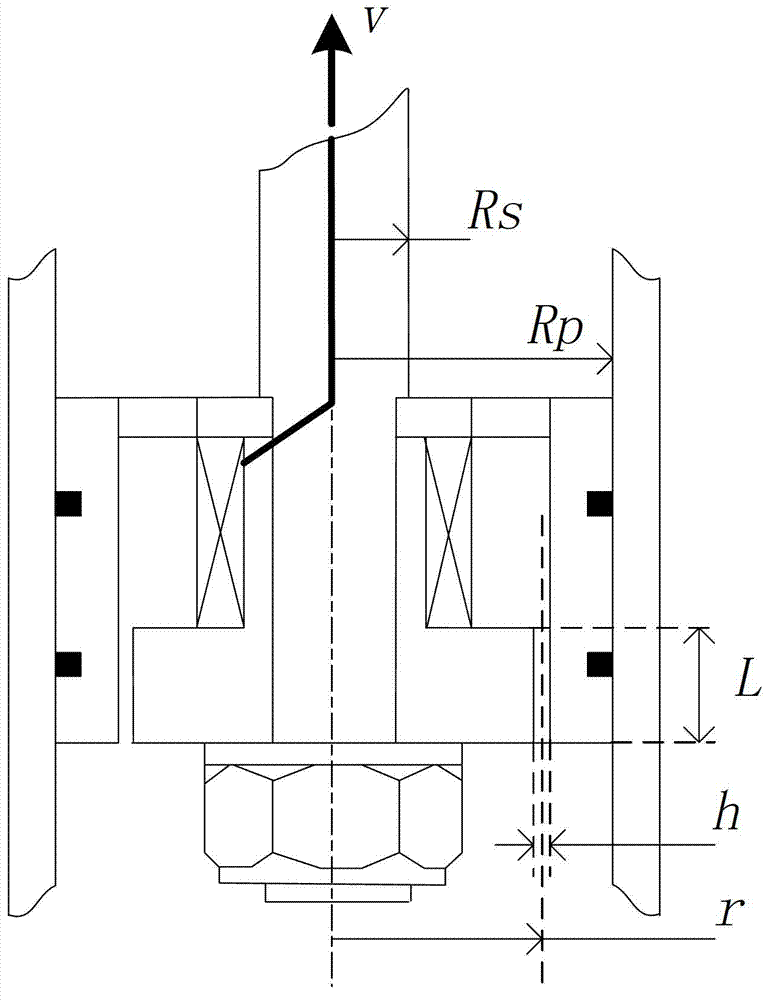

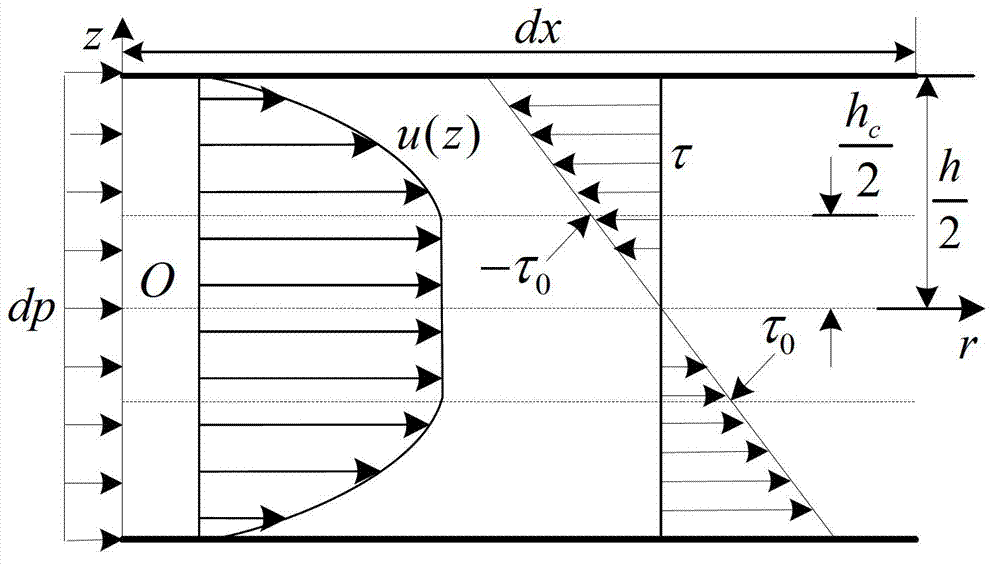

Device and method for testing high-shear rate rheological behavior of magnetorheological fluid

ActiveCN103196795AIncrease shear rateEliminate the effects ofDirect flow property measurementShear rateBarrel Shaped

The invention provides a device and a method for testing the high-shear rate rheological behavior of a magnetorheological fluid. The device comprises a cylindrical housing, wherein the upper end and the lower end of the housing are respectively provided with an upper end cover and a lower end cover; the housing is internally provided with a piston, the housing is internally divided into an upper cavity and a lower cavity, the piston is inverted barrel-shaped, the bottom surface of the piston is opened, and the top surface of the piston is provided with a normal through hole; a piston rod is arranged in the piston in a penetrating manner, and the piston rod is arranged in the upper end cover in the penetrating manner to the outer part of the housing; a part of the position rod, arranged in the piston, is provided with a magnetic core in a winding way, the upper part of the magnetic core is provided with a coil in a winding way, and the coil is electrically connected with the outside through a conducting wire; the diameter of the lower cross section of the magnetic core is slightly less than the lower inner diameter of the piston to form a ring-shaped damp gap; the upper part of the upper cavity is provided with an upper oil pressure sensor, and the lower part of the lower cavity is provided with a lower oil pressure sensor; and the housing is internally provided with a temperature sensor. According to the device and the method, the influence of friction force on a test result can be removed, the influence of temperature factors can be sufficiently considered, and the device and the method have the advantages of being high in shear rate and exact in result.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

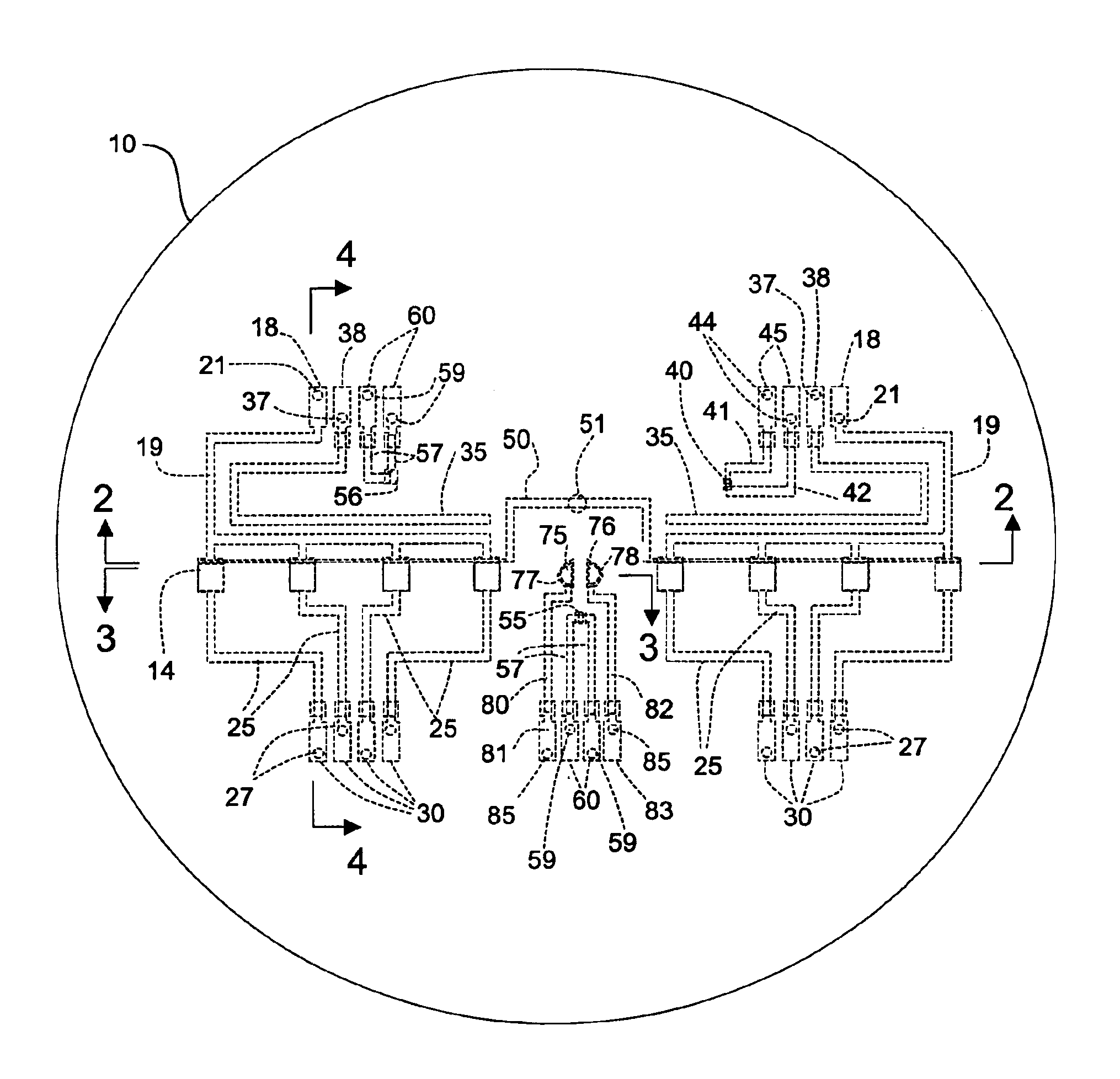

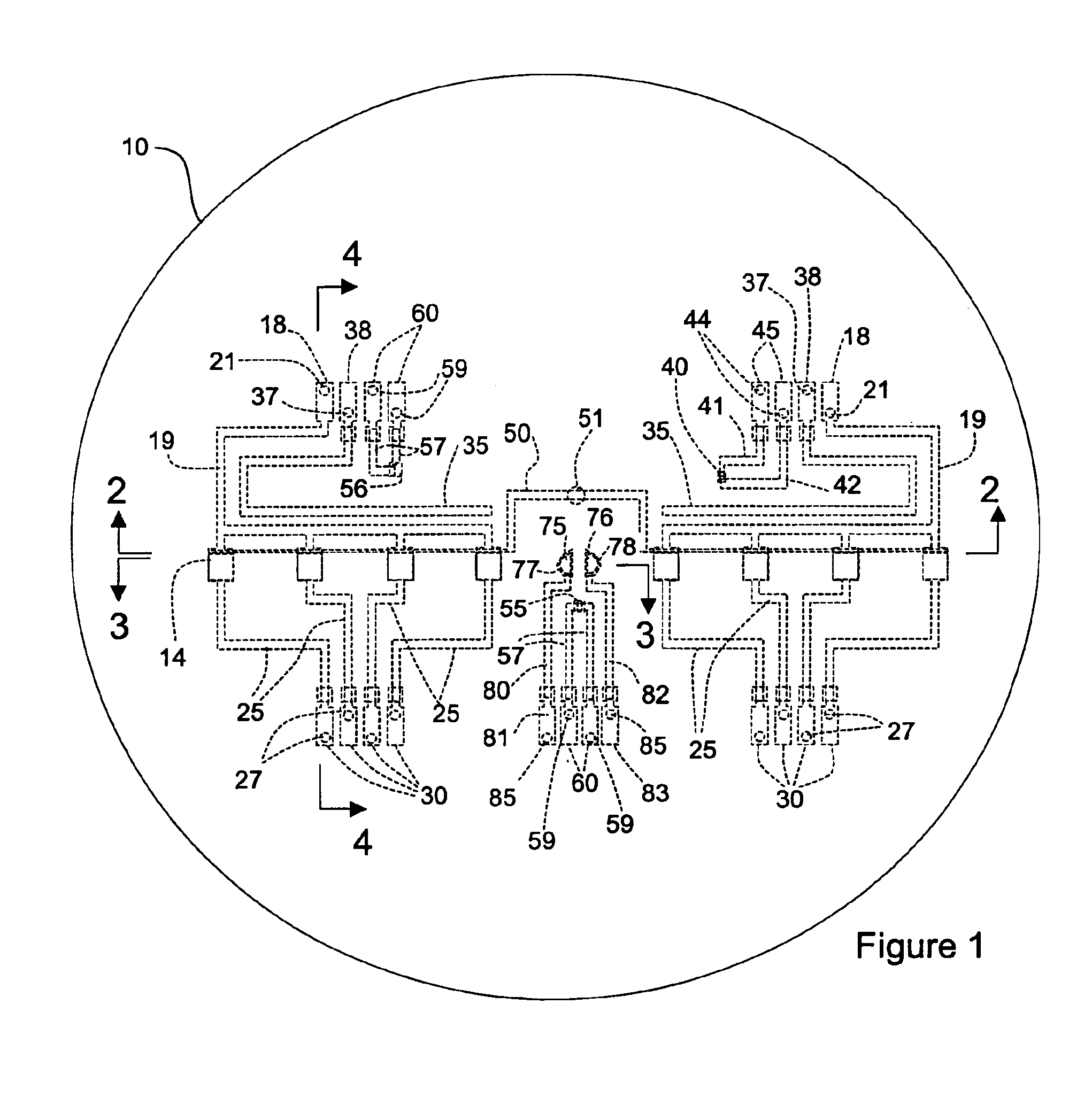

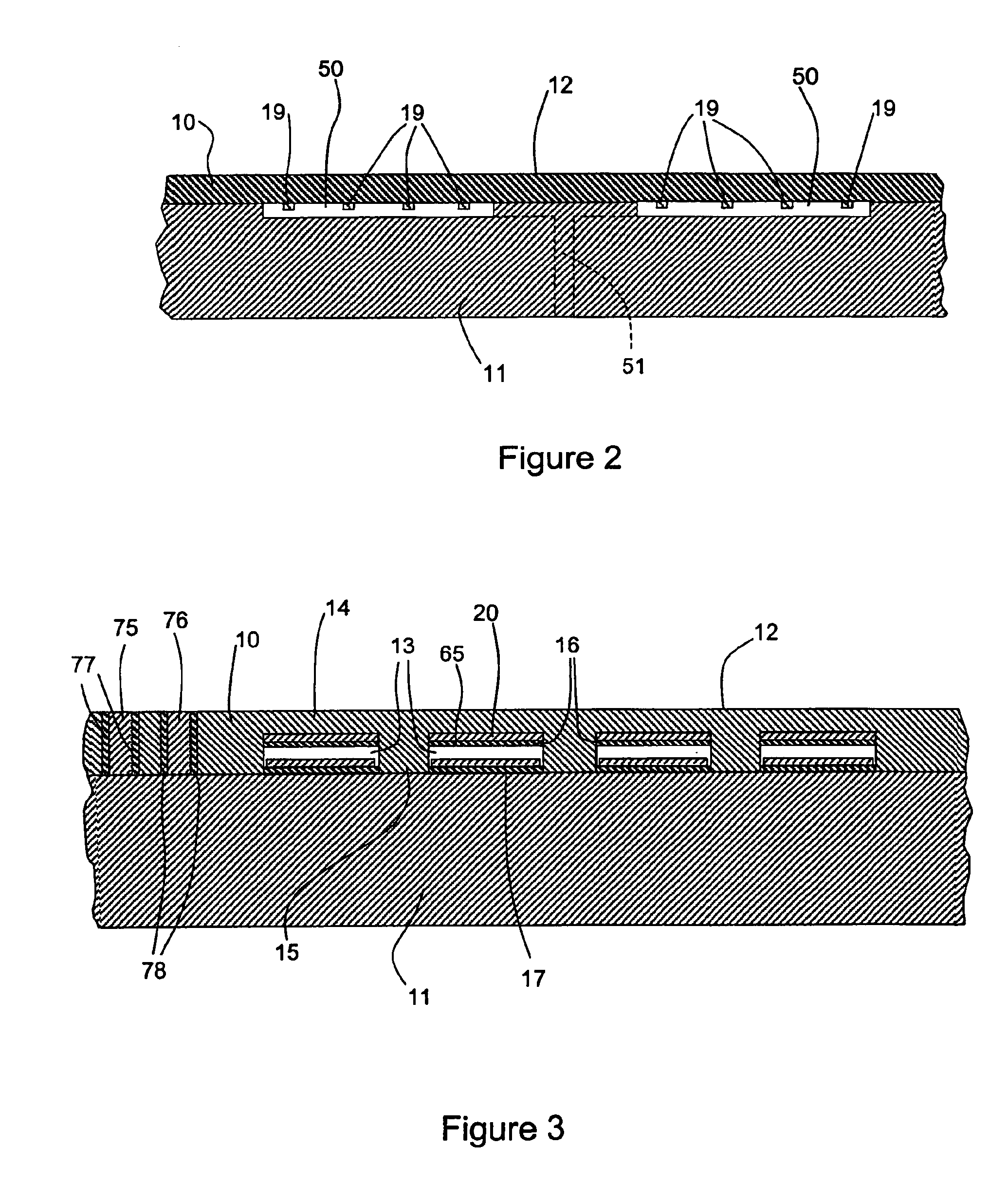

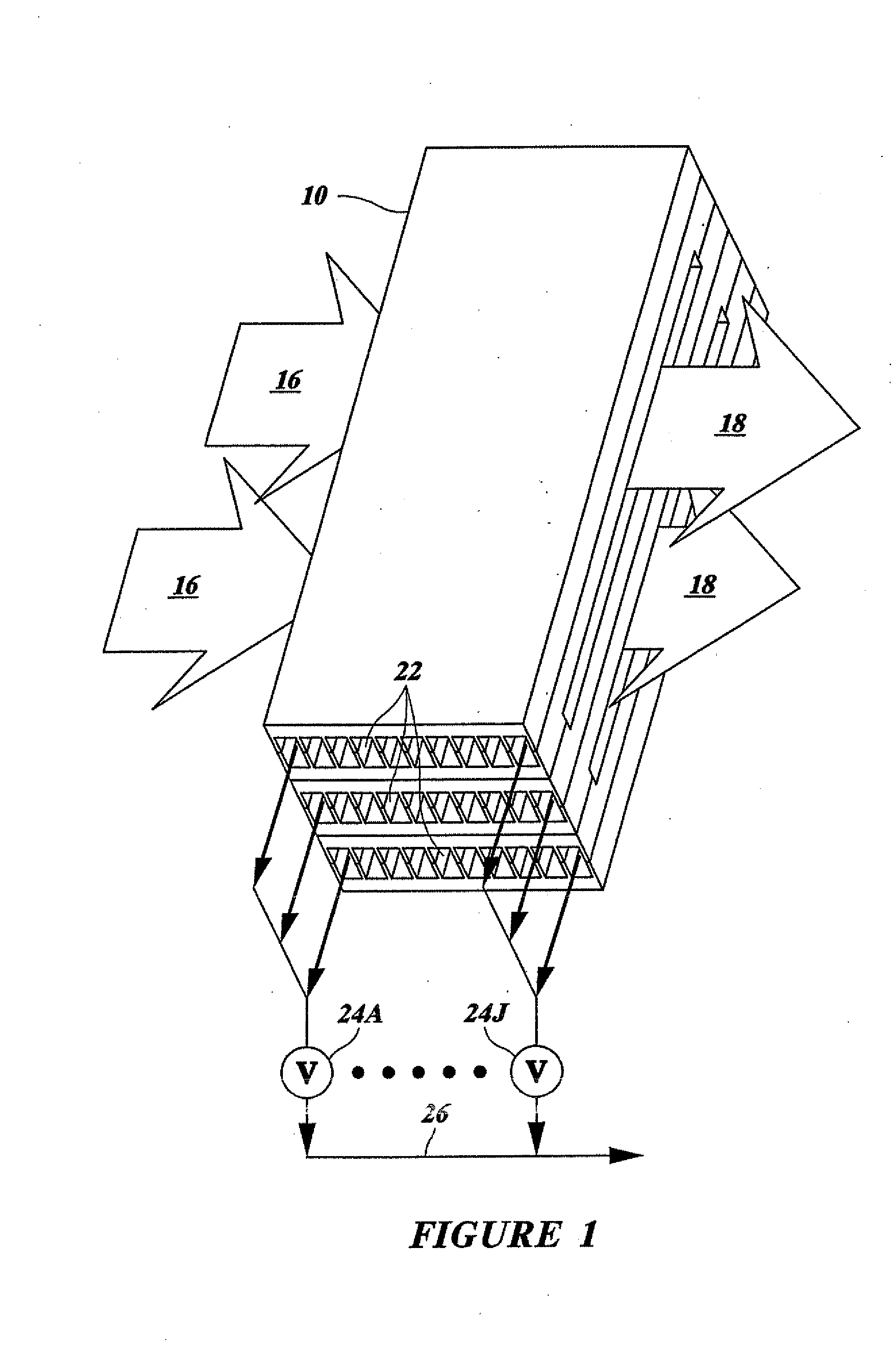

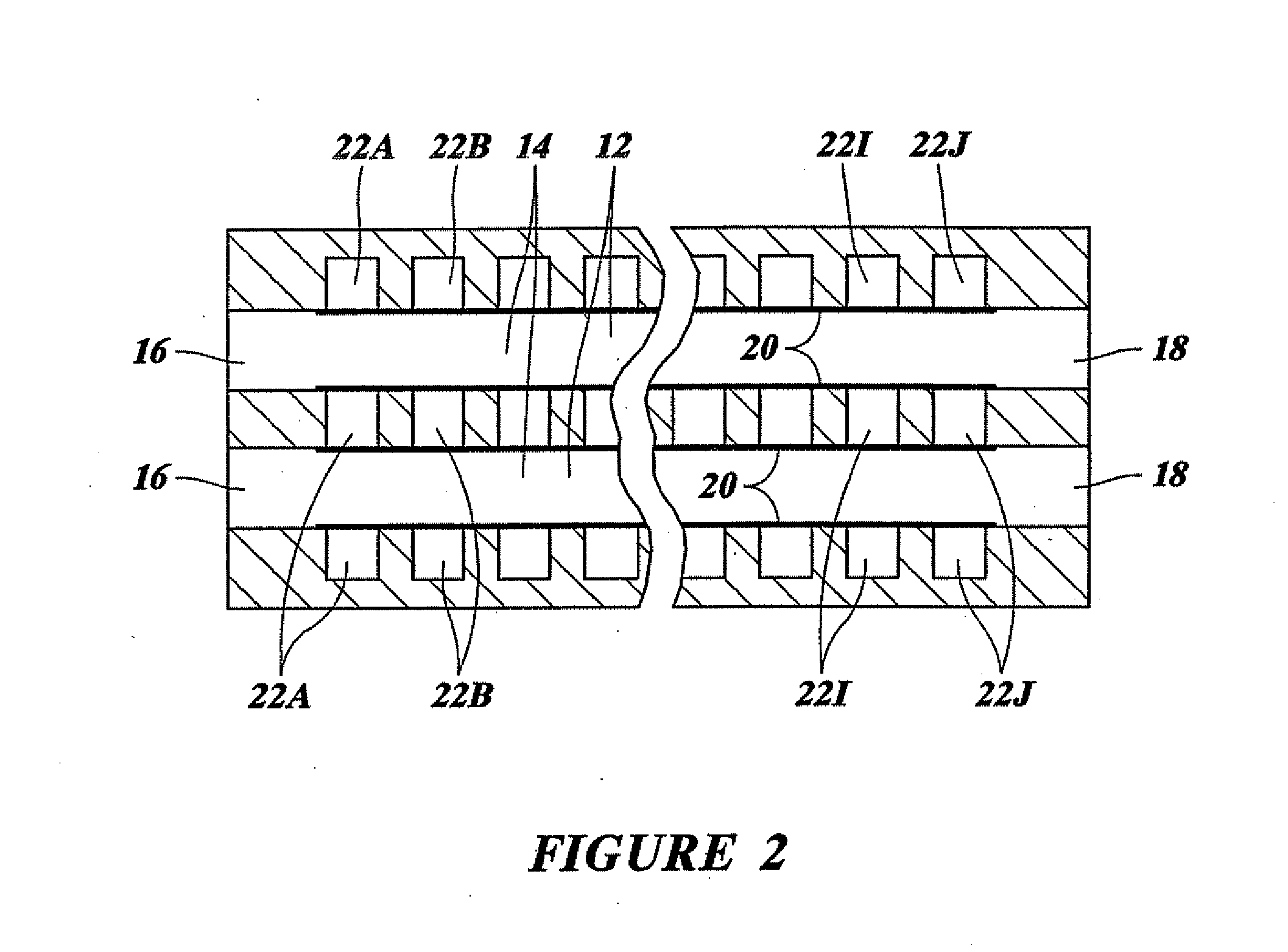

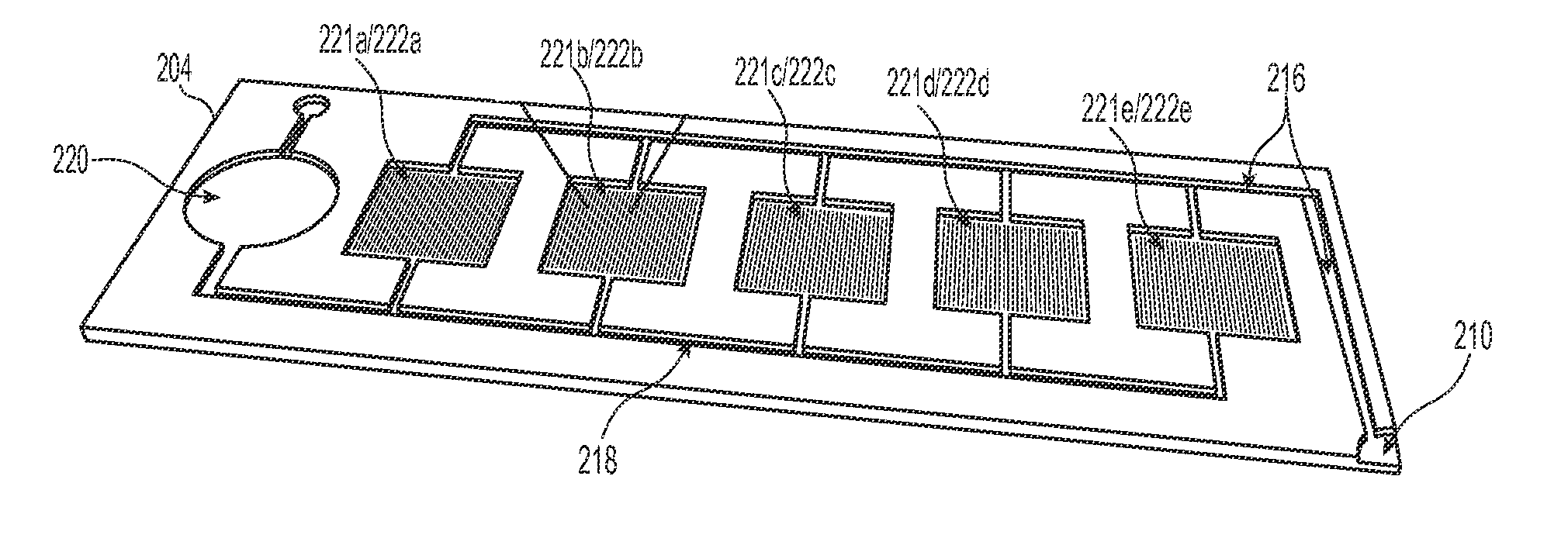

Fluidics devices for individualized coagulation measurements and associated systems and methods

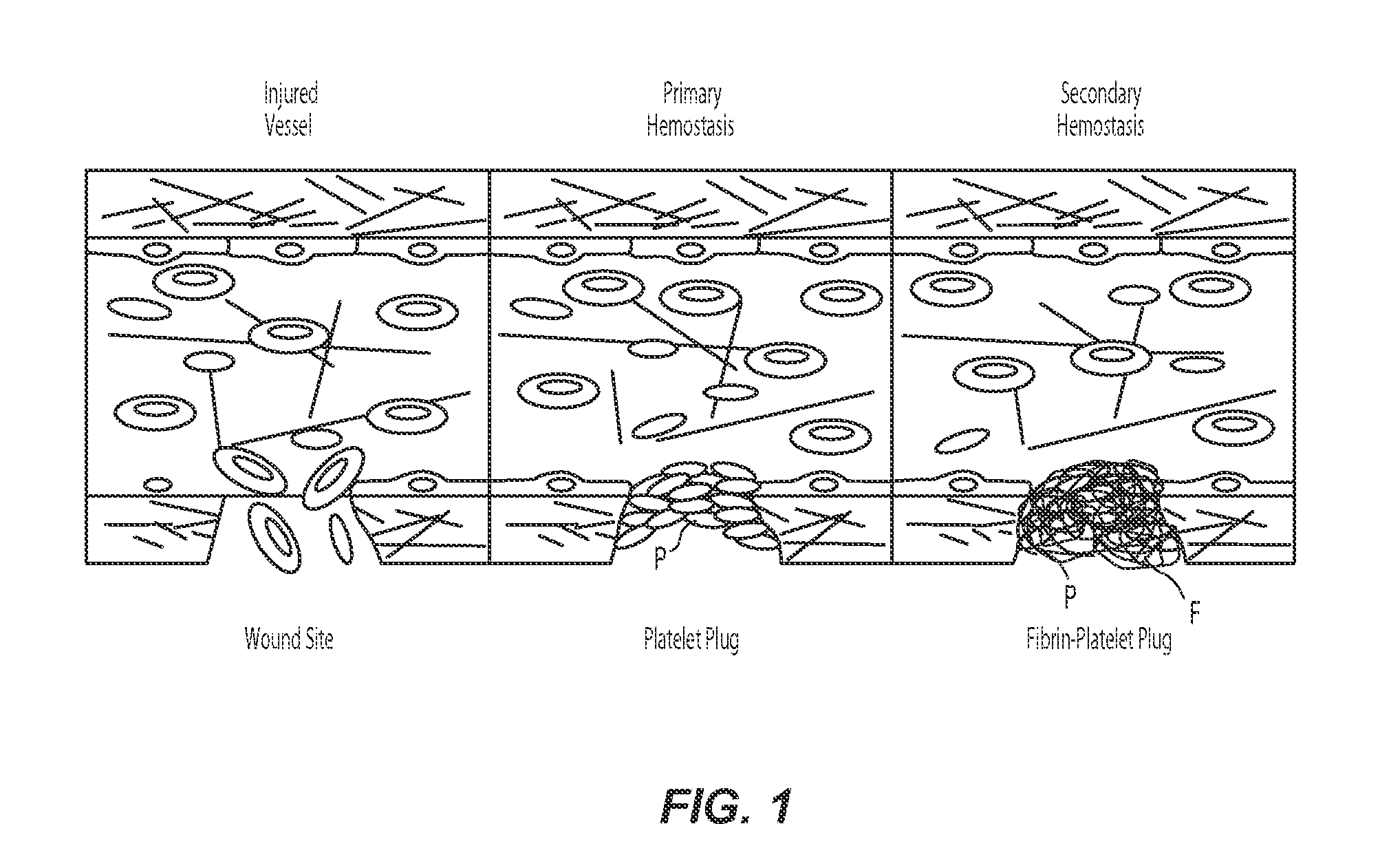

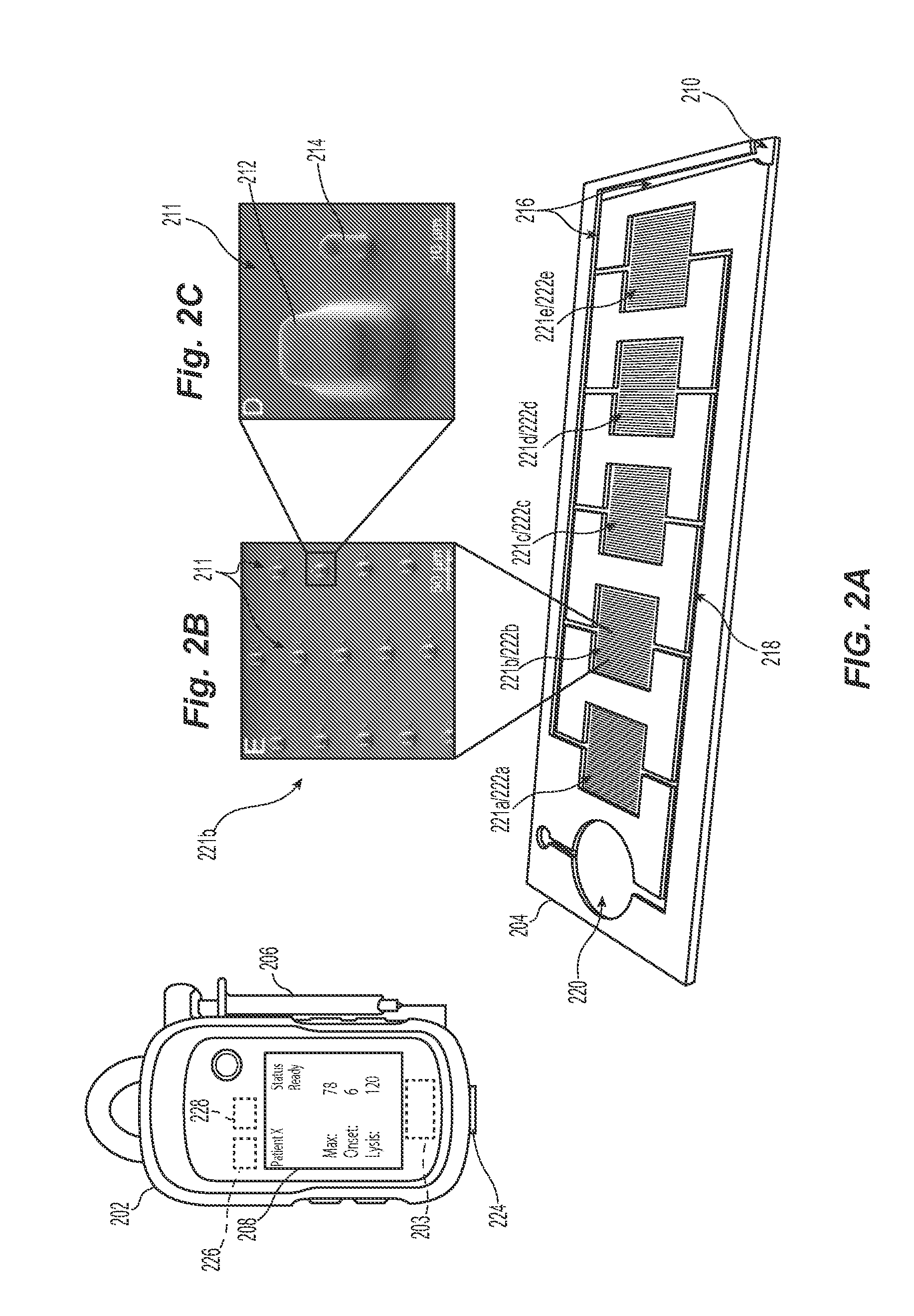

InactiveUS20160363600A1Reduced strengthStable formationLaboratory glasswaresDisease diagnosisFluidicsPlatelet

The present technology relates generally to fluidics devices for measuring platelet coagulation and associated systems and methods. In some embodiments, a fluidics device includes an array of microstructures including pairs of generally rigid blocks and generally flexible posts. The fluidics device further includes at least one fluid channel configured to accept the array. The fluidics device can further include a measuring element configured to measure a degree of deflection of one or more of the flexible posts in the array. In some embodiments, the fluidics device comprises a handheld device and usable for point of care testing of platelet forces and coagulation.

Owner:UNIV OF WASHINGTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com