Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

815results about How to "Low process temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

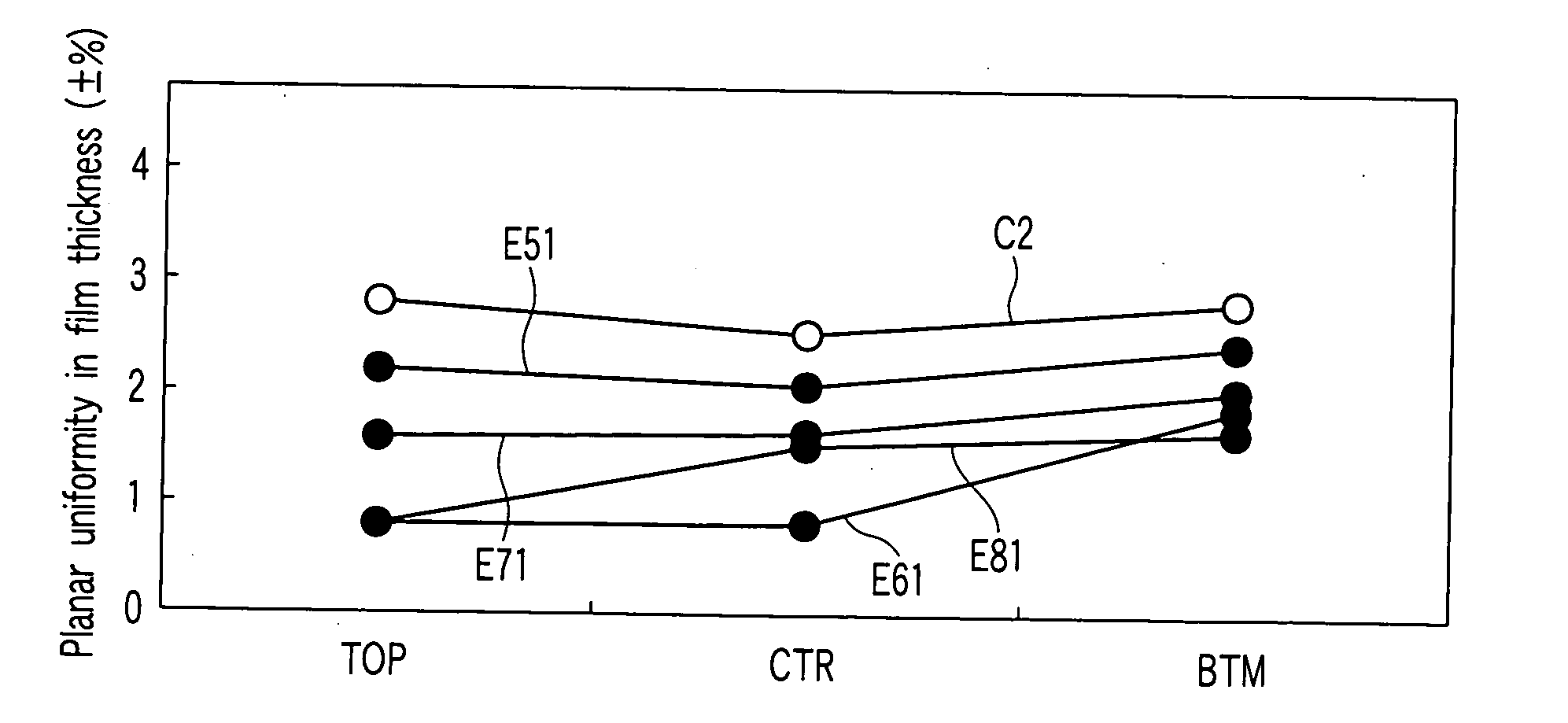

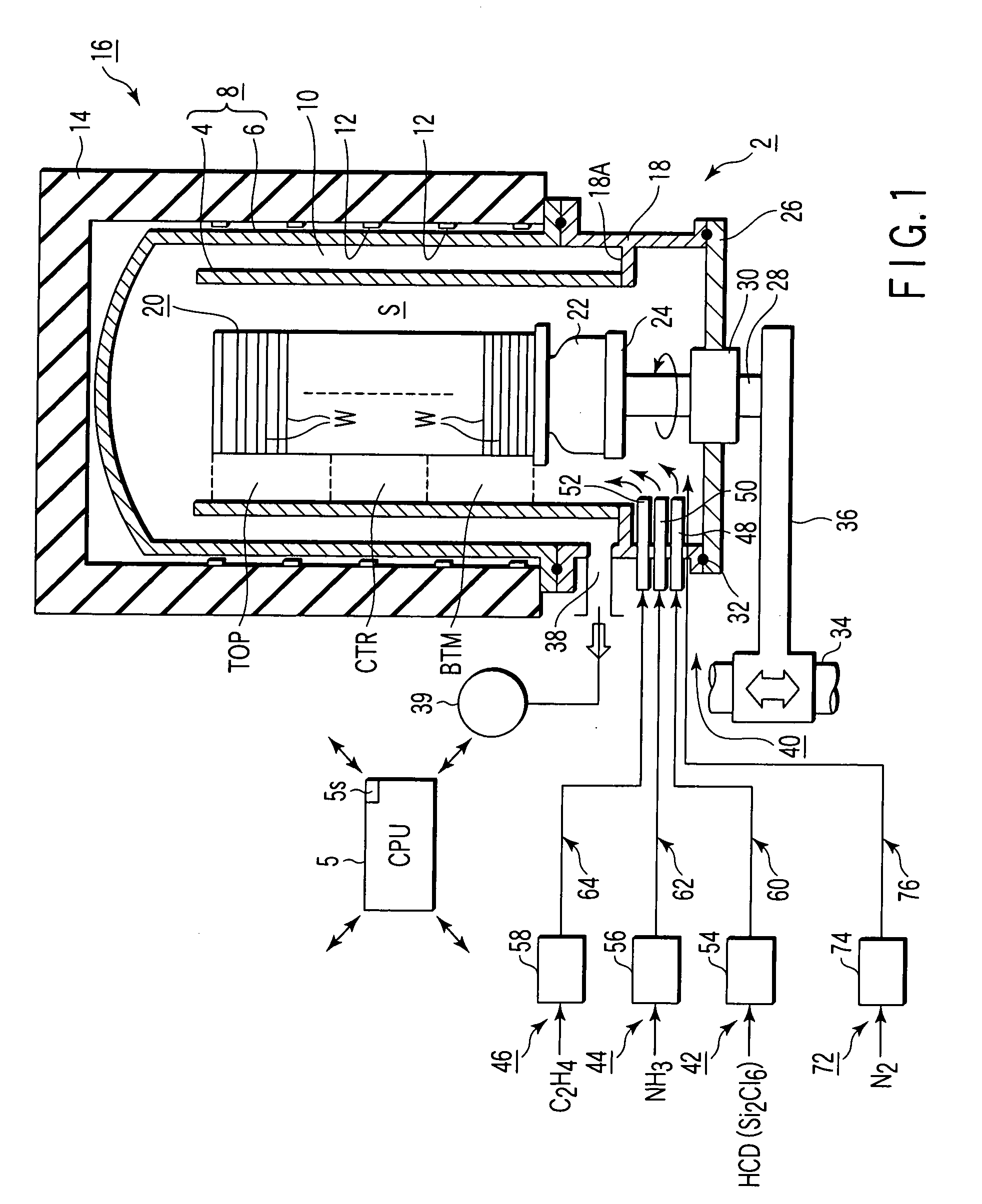

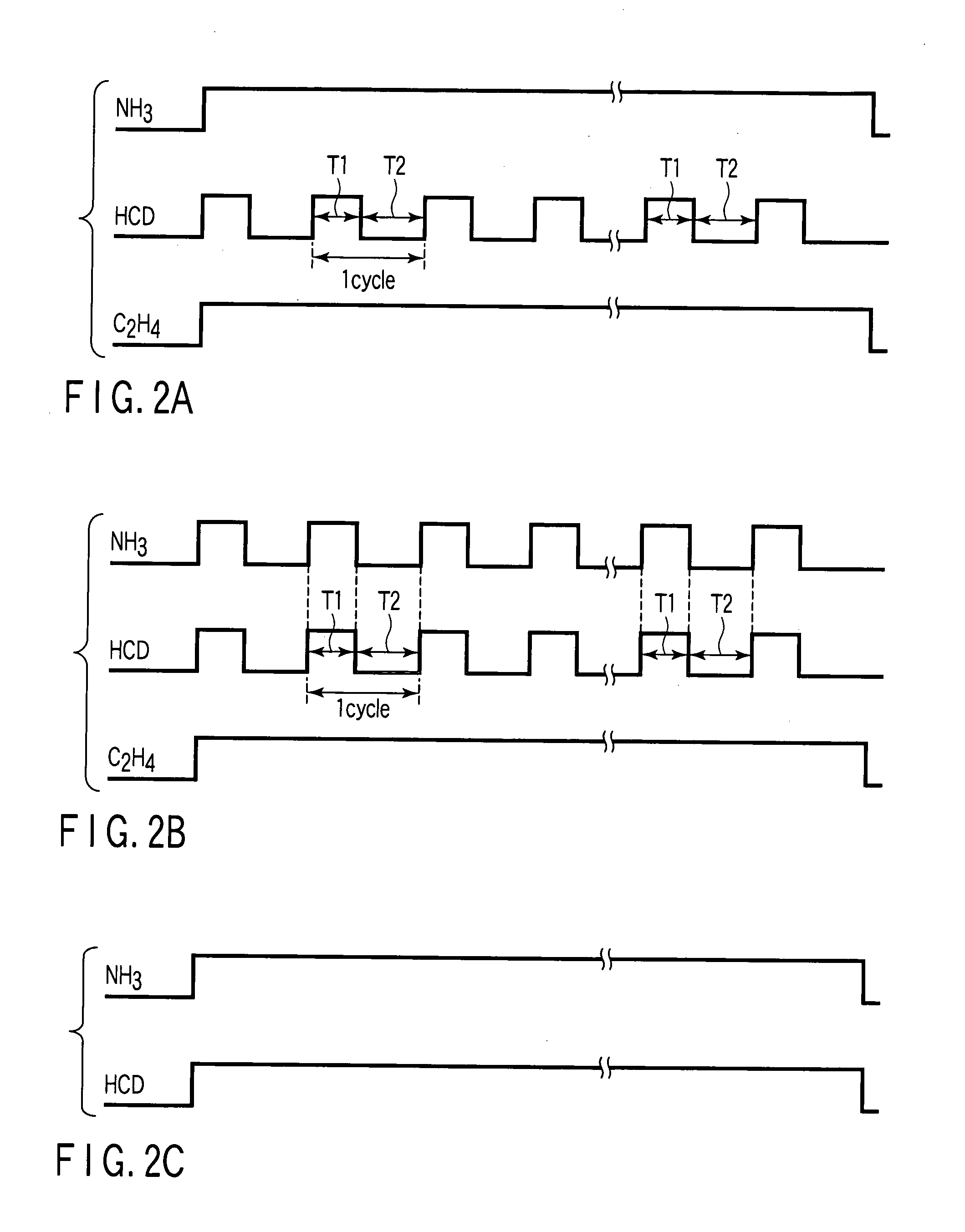

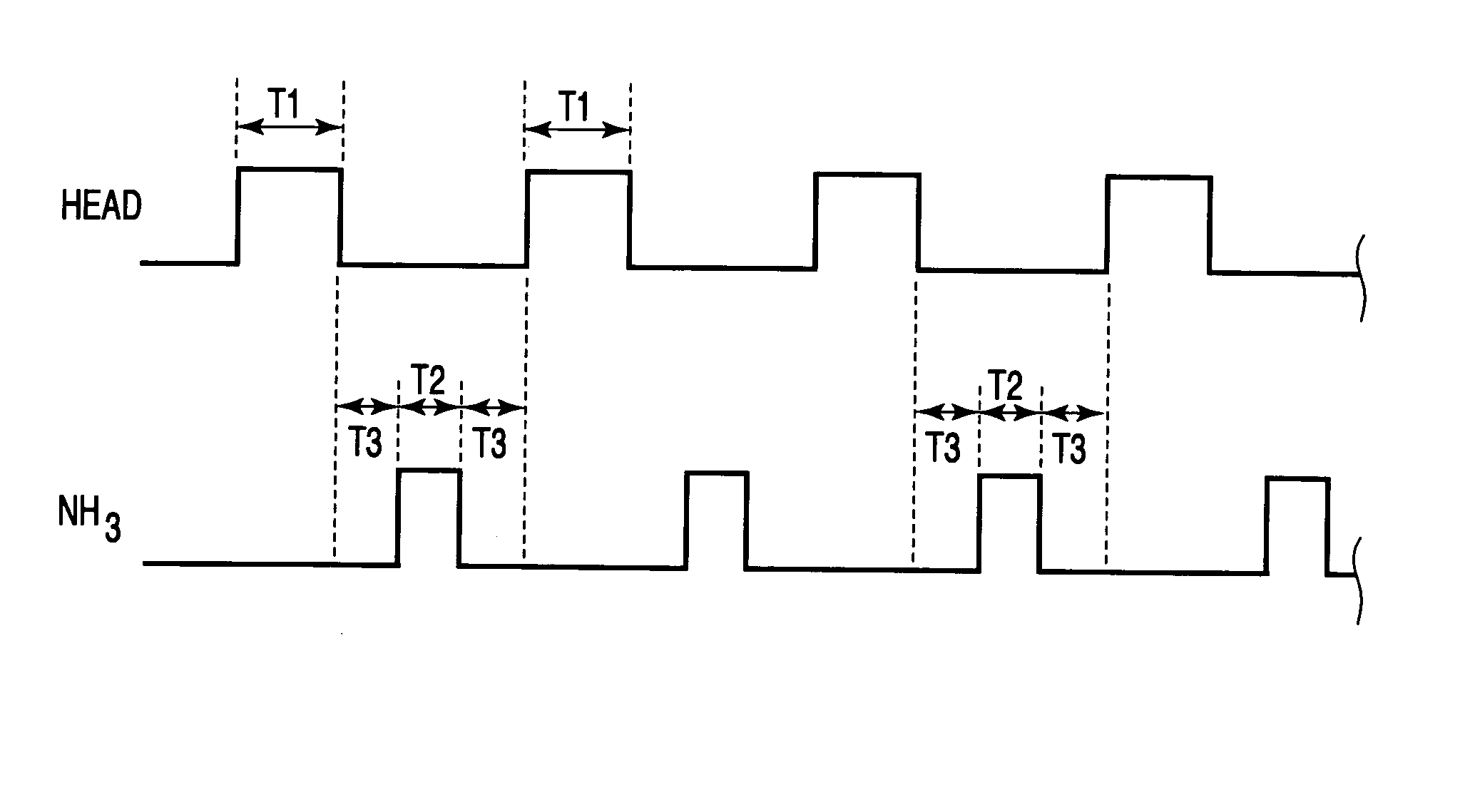

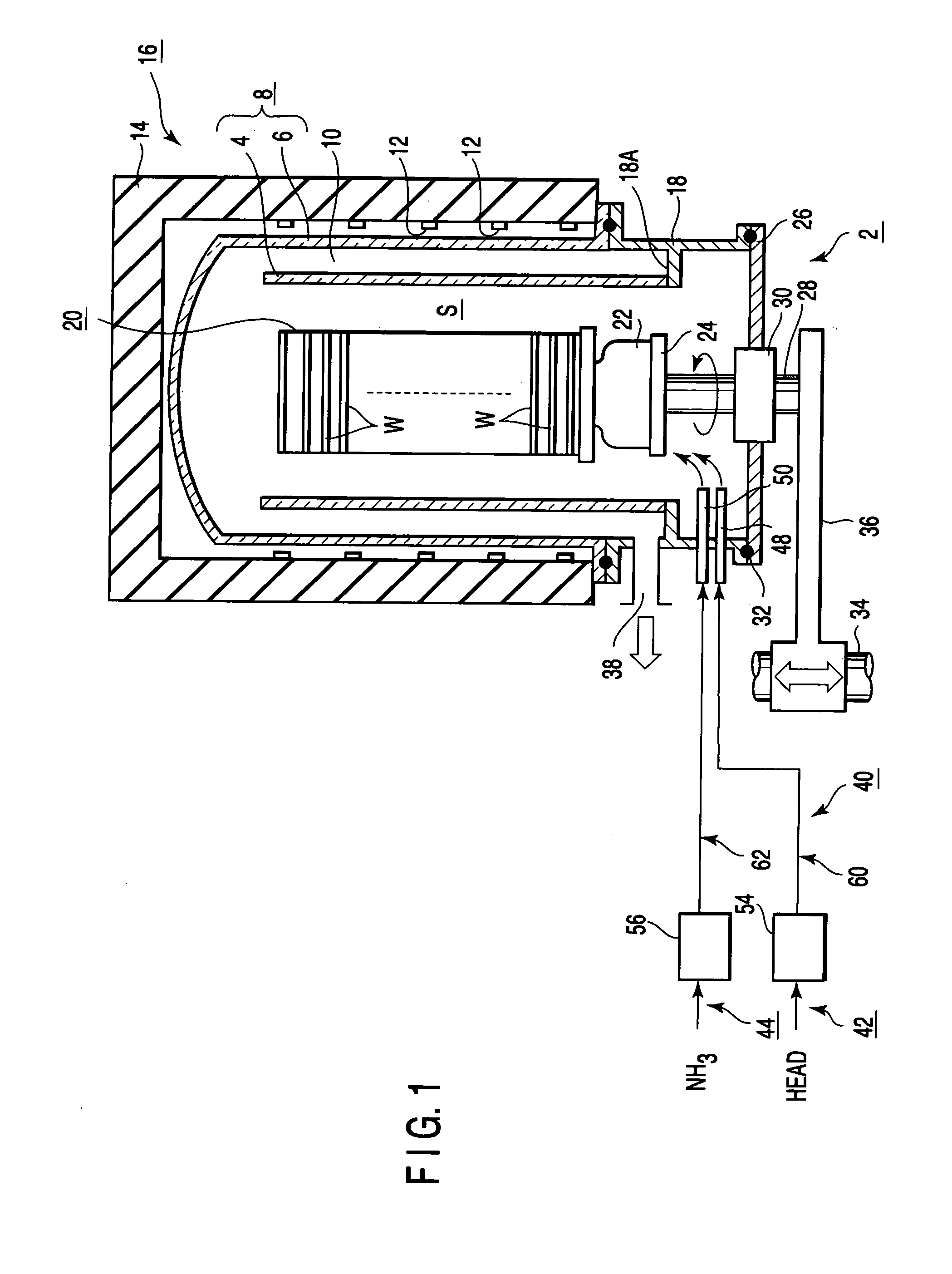

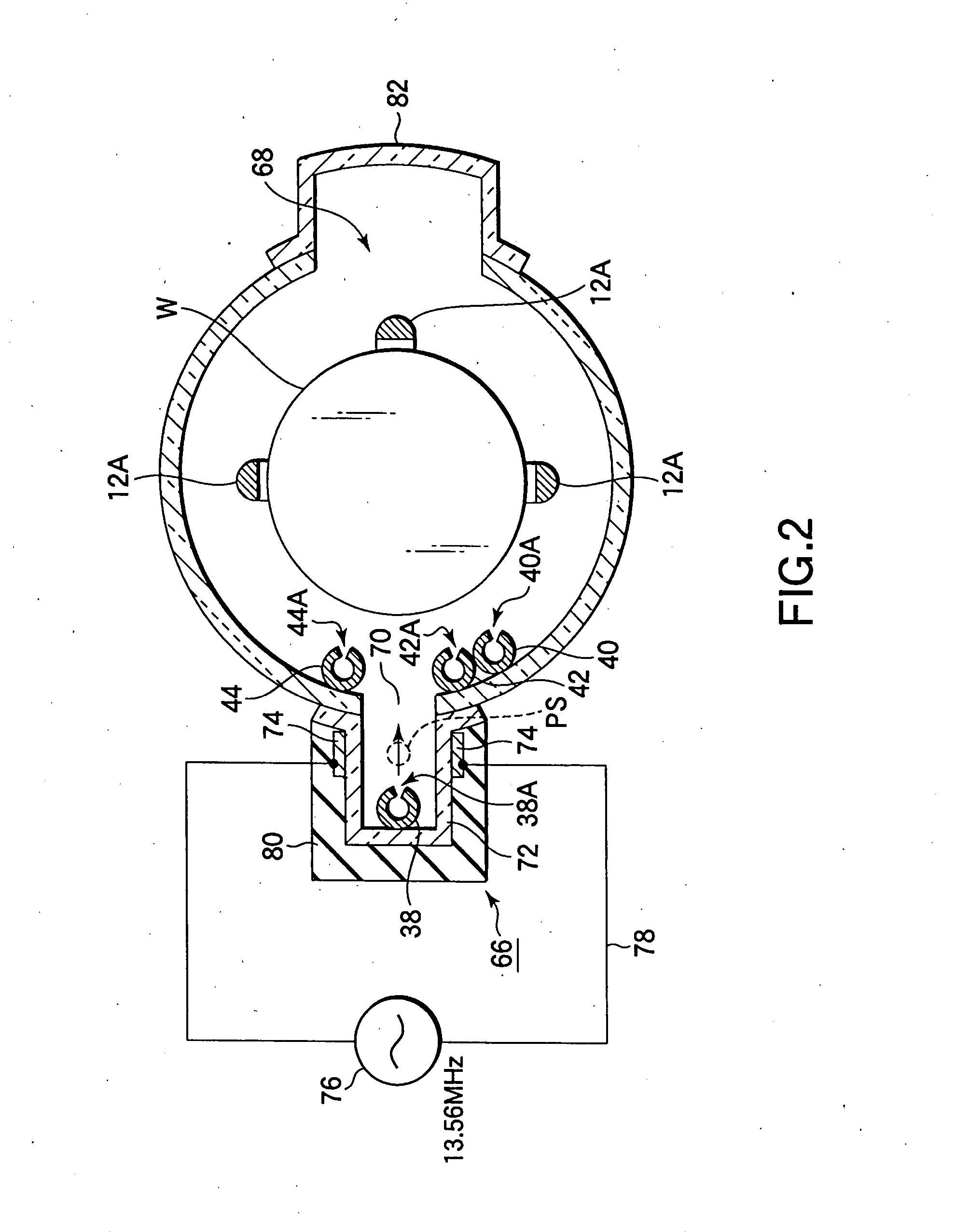

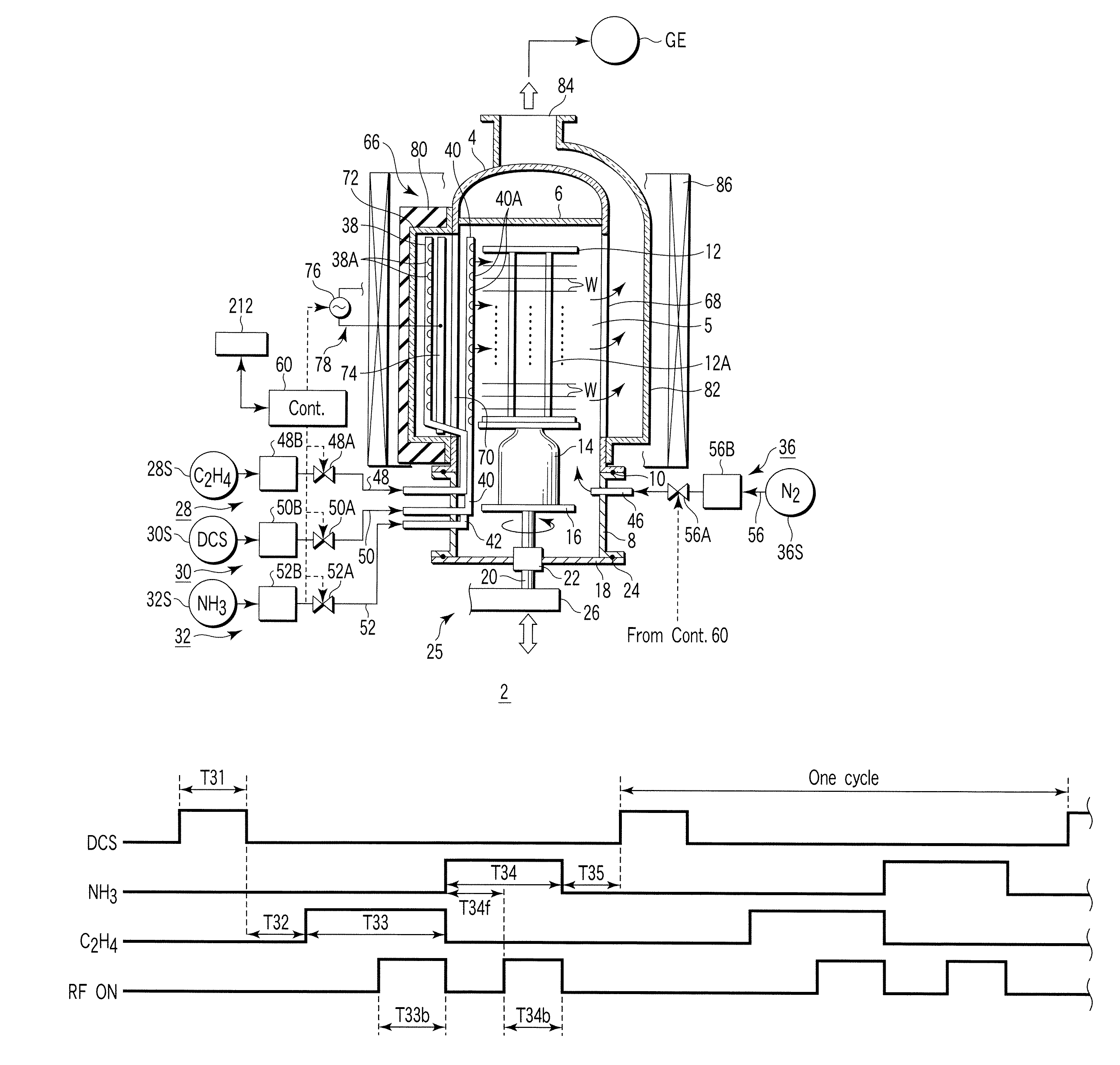

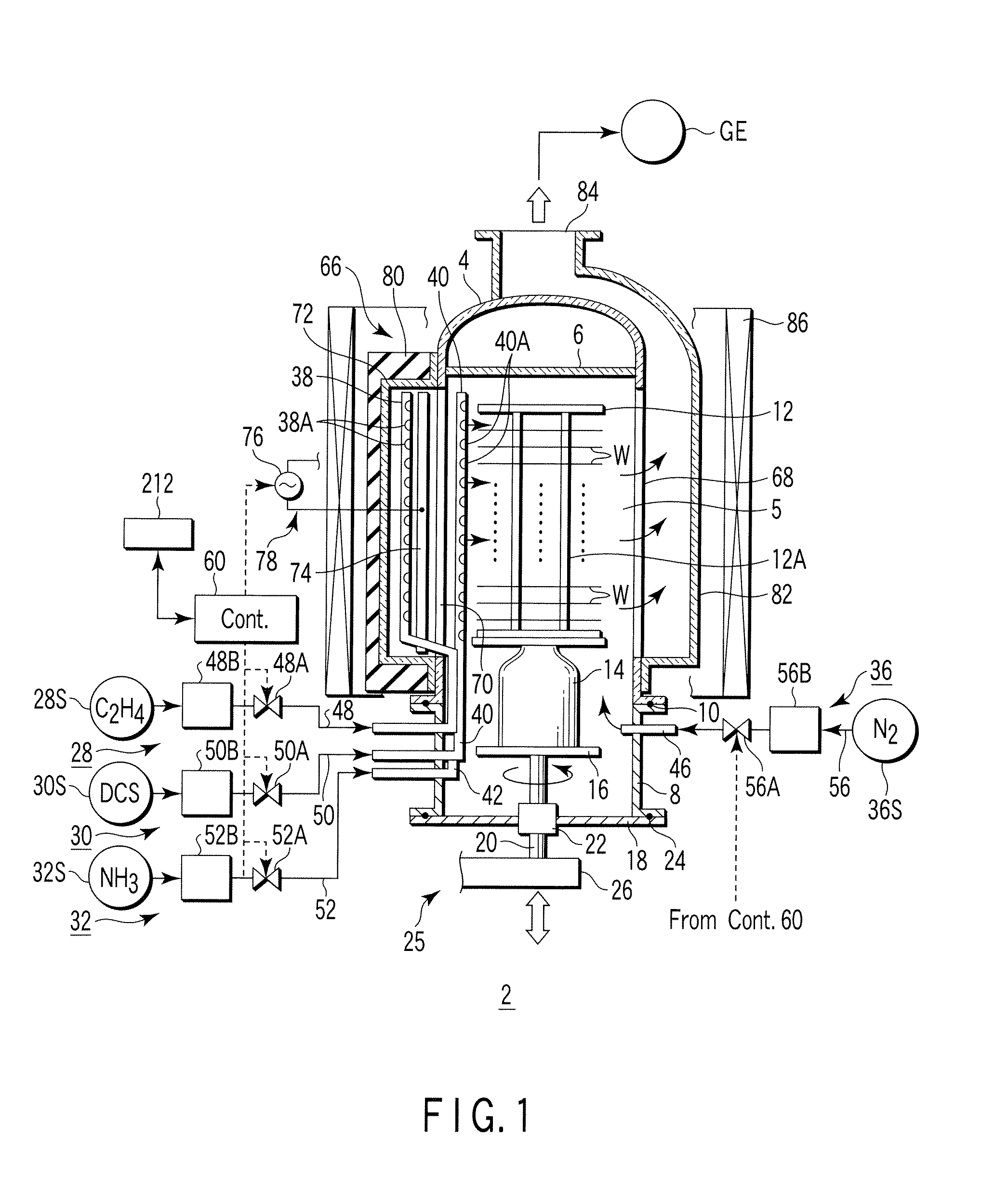

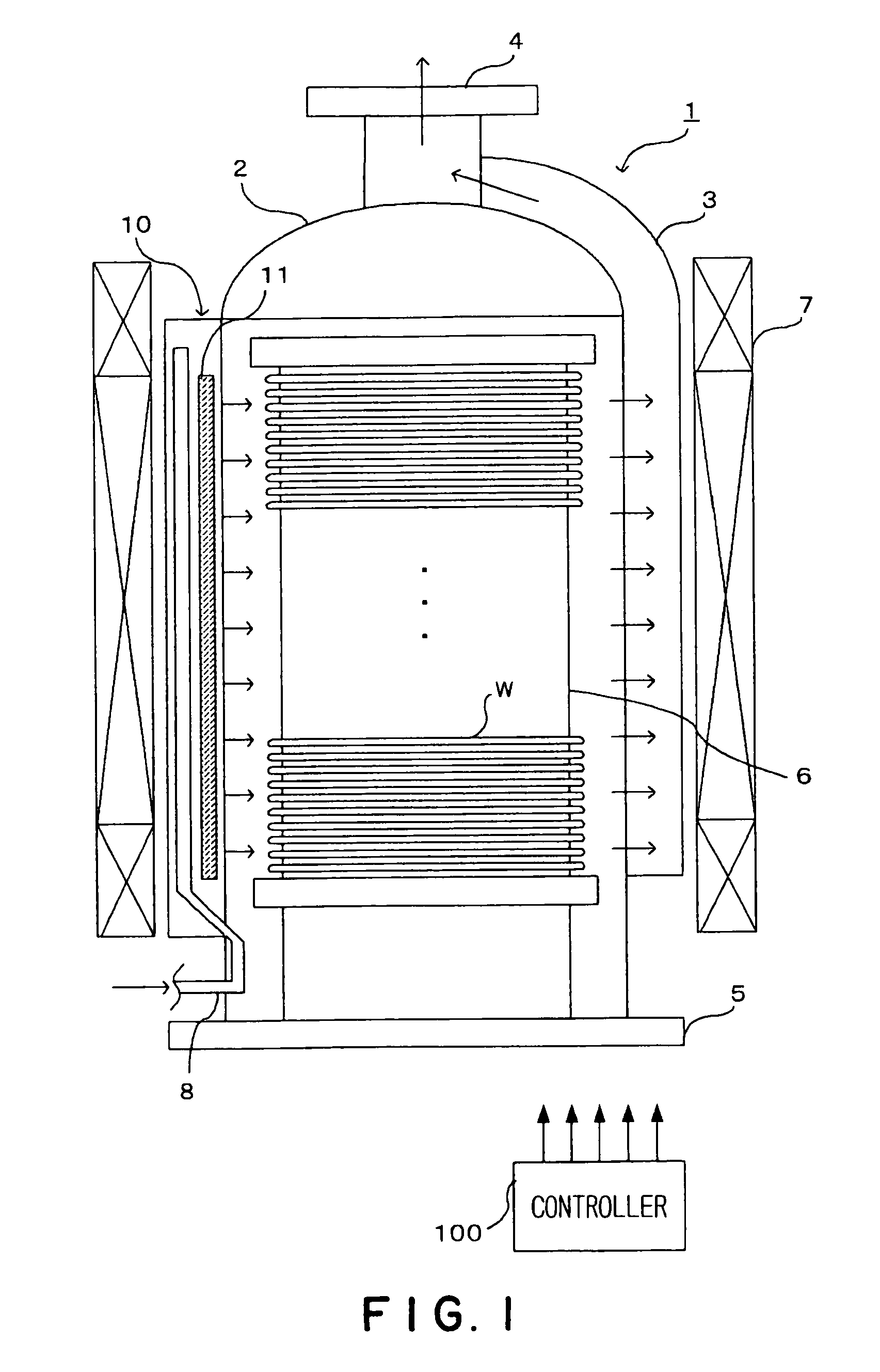

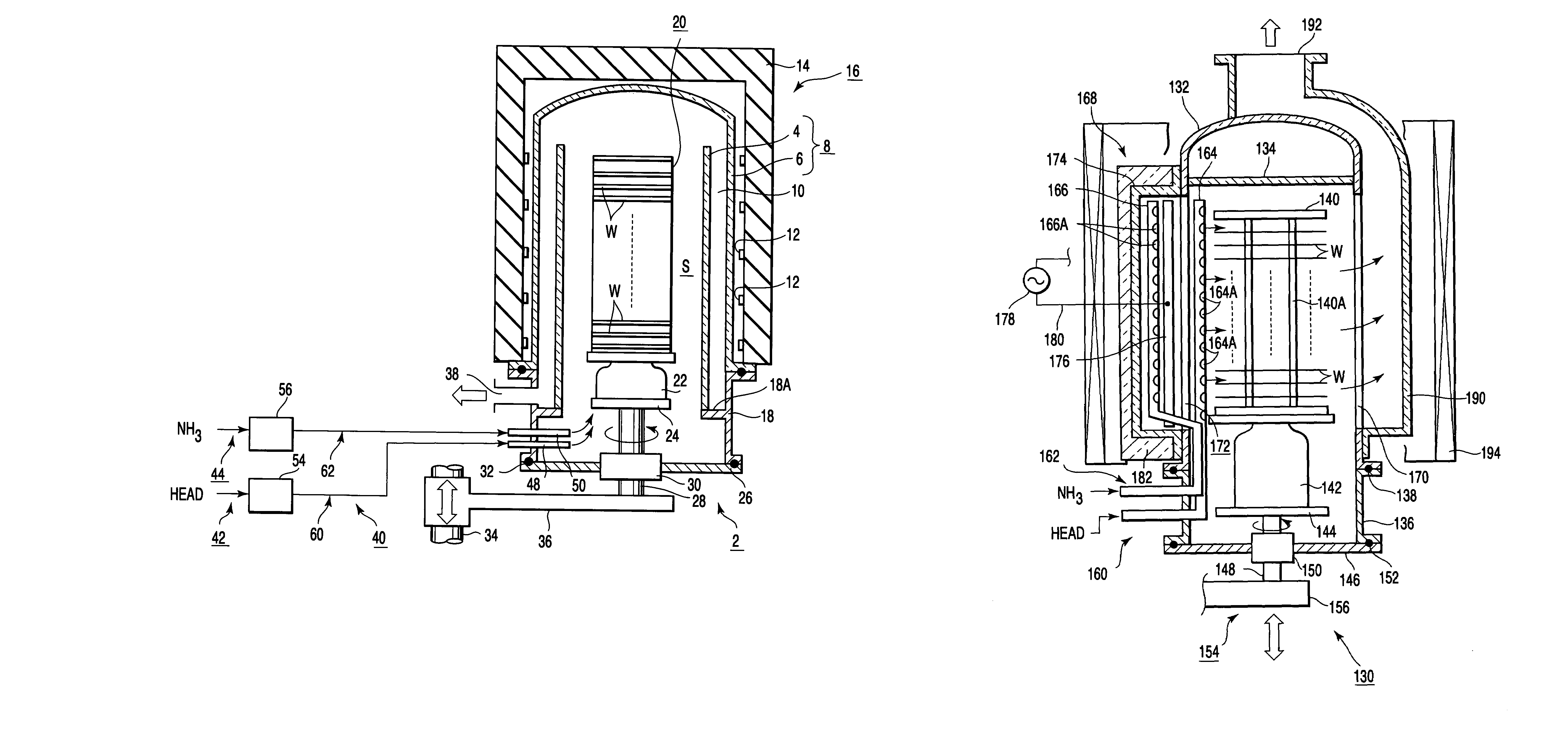

Cvd method for forming silicon nitride film

ActiveUS20060286817A1Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesAmmonia gas

A CVD method for forming a silicon nitride film includes exhausting a process chamber (8) that accommodates a target substrate (W), and supplying a silane family gas (HCD) and ammonia gas (NH3) into the process chamber, thereby forming a silicon nitride film on the target substrate by CVD. Said forming a silicon nitride film on the target substrate alternately includes a first period of performing supply of the silane family gas (HCD) into the process chamber (8), and a second period of stopping supply of the silane family gas.

Owner:TOKYO ELECTRON LTD

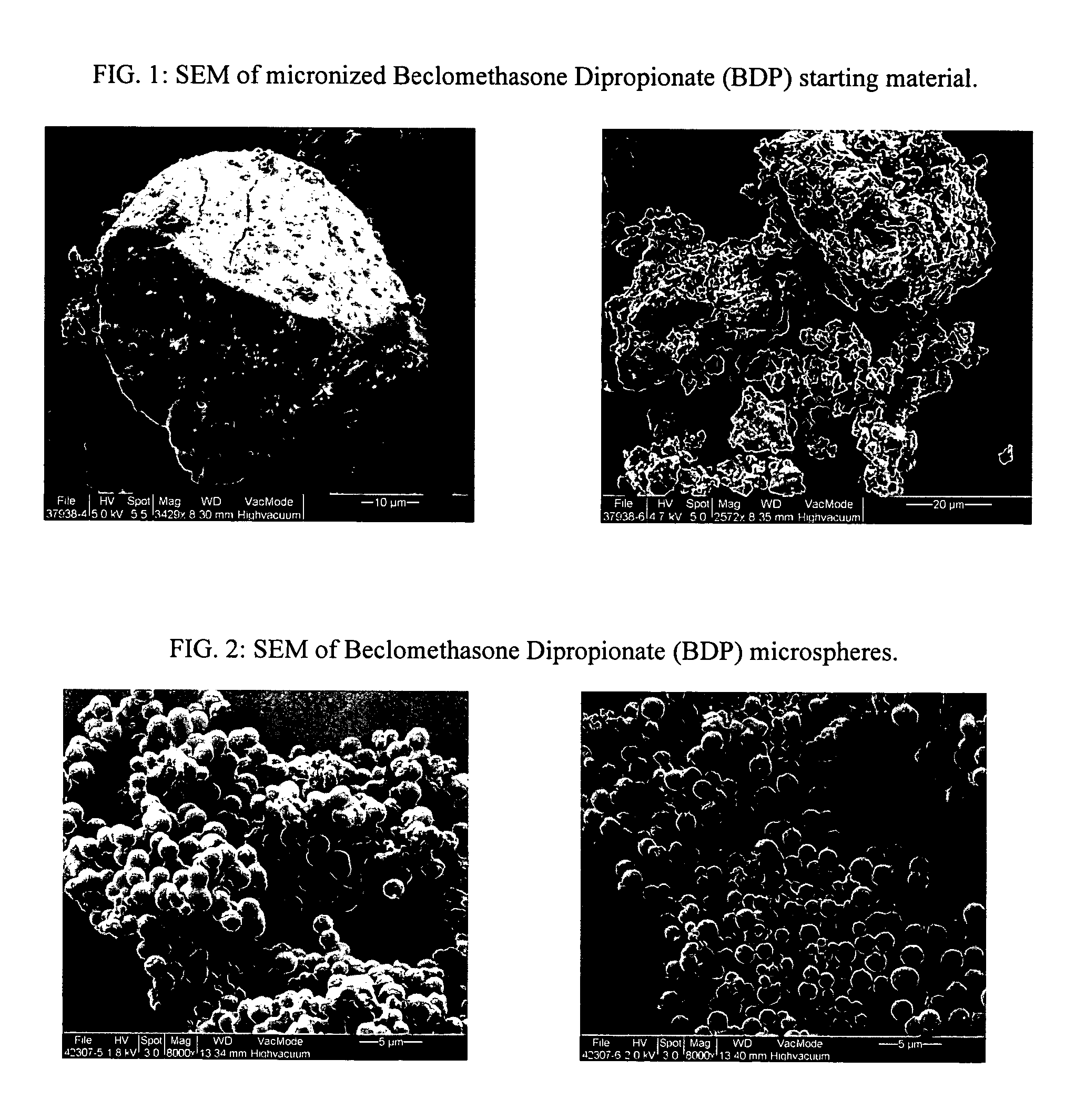

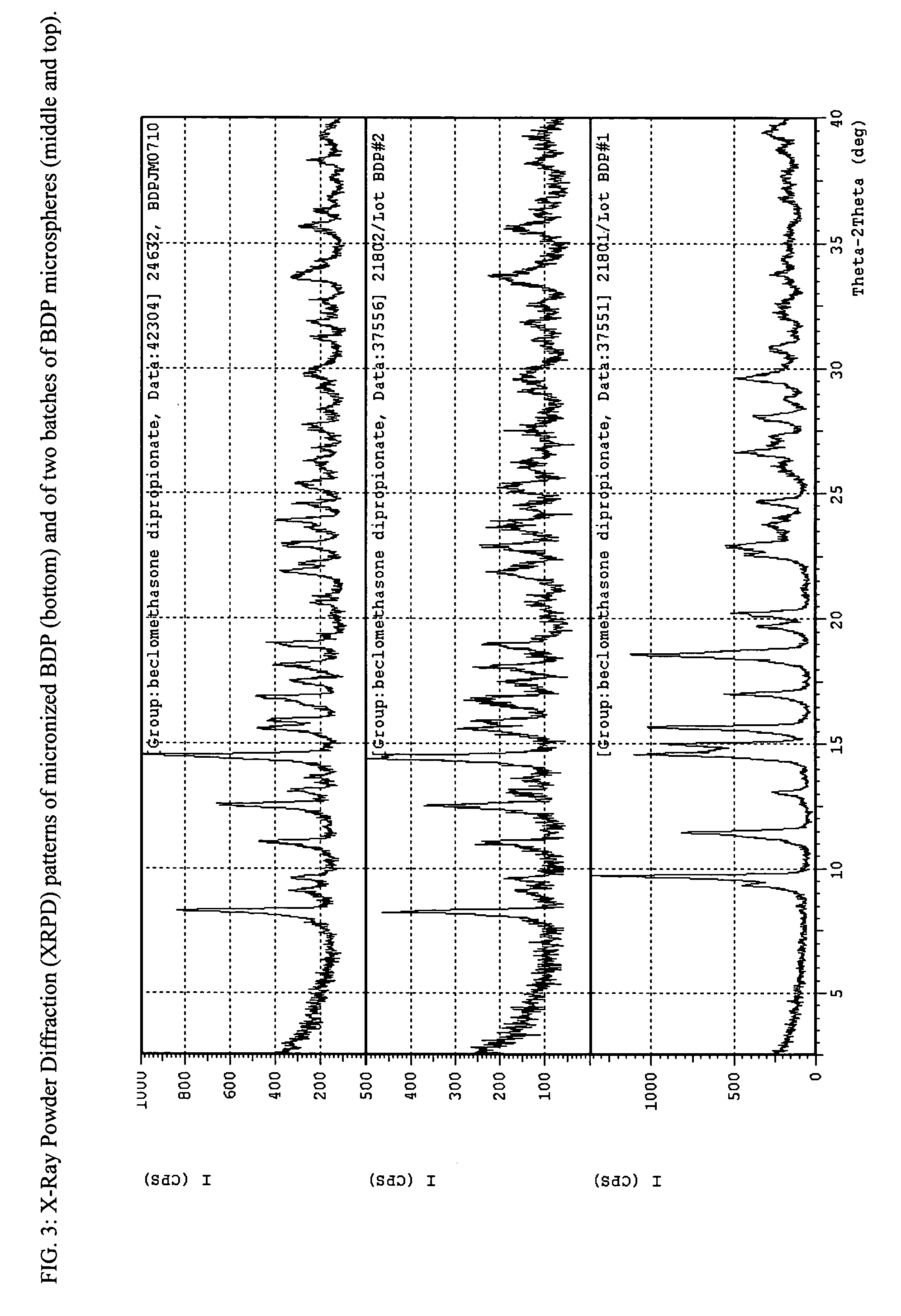

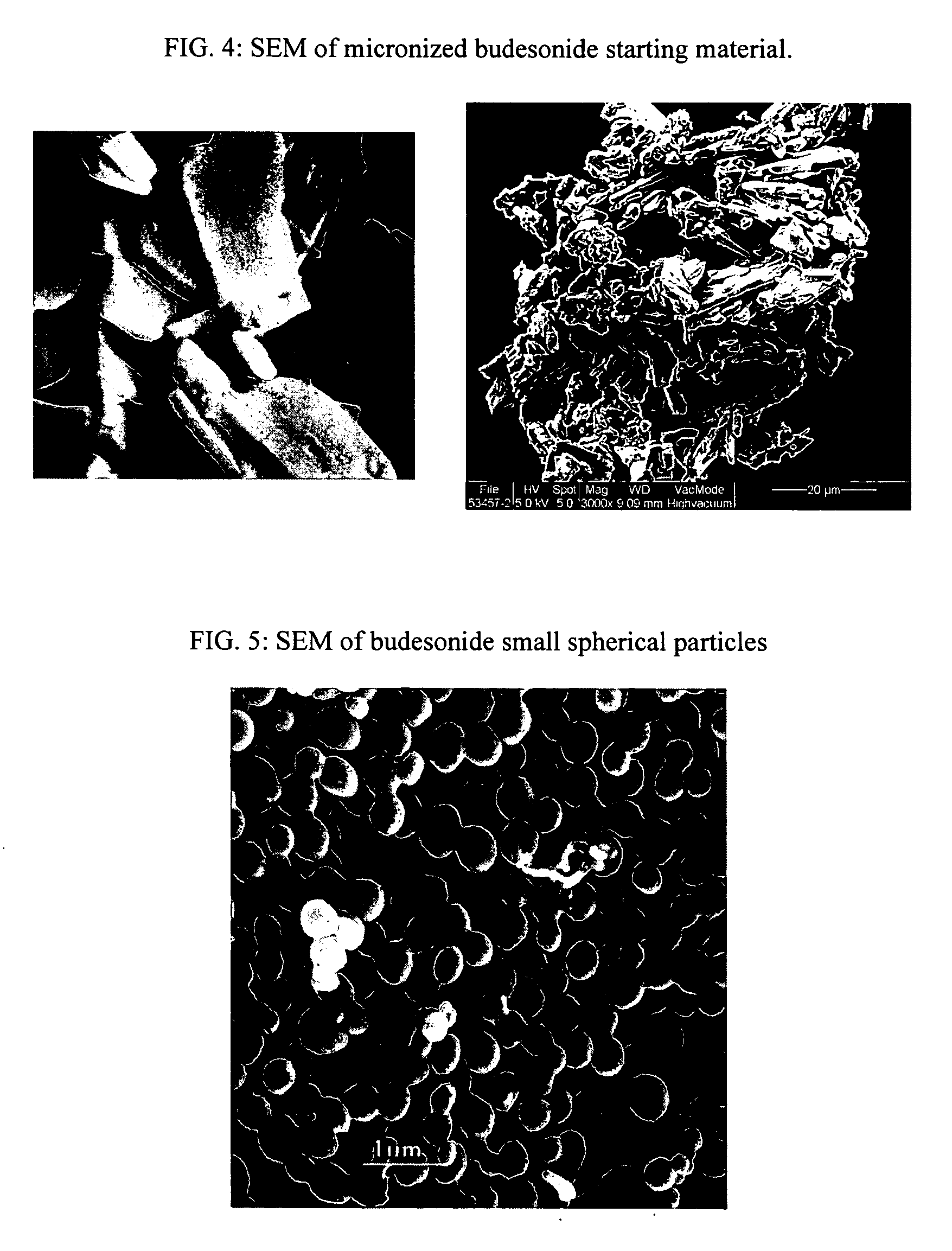

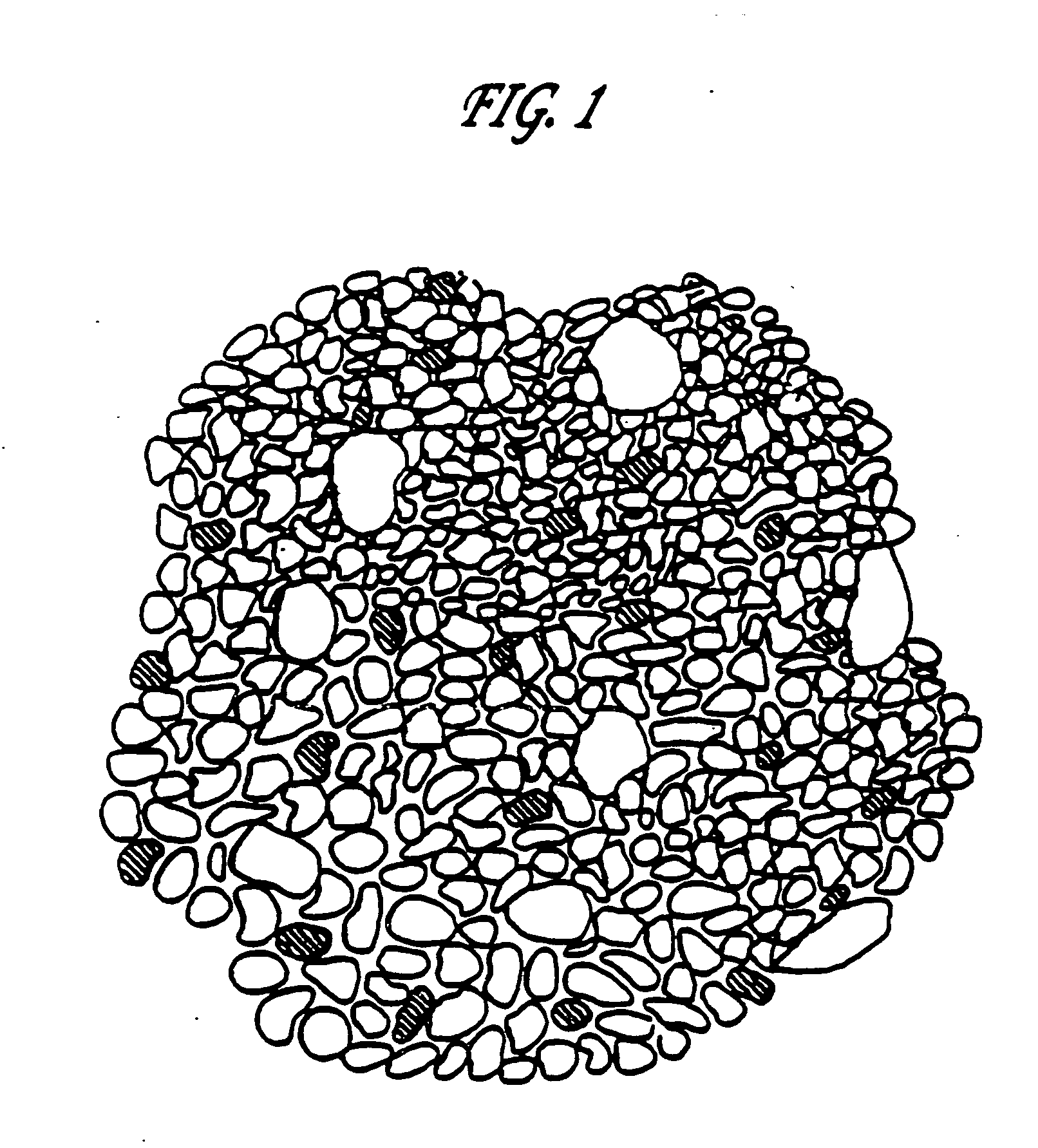

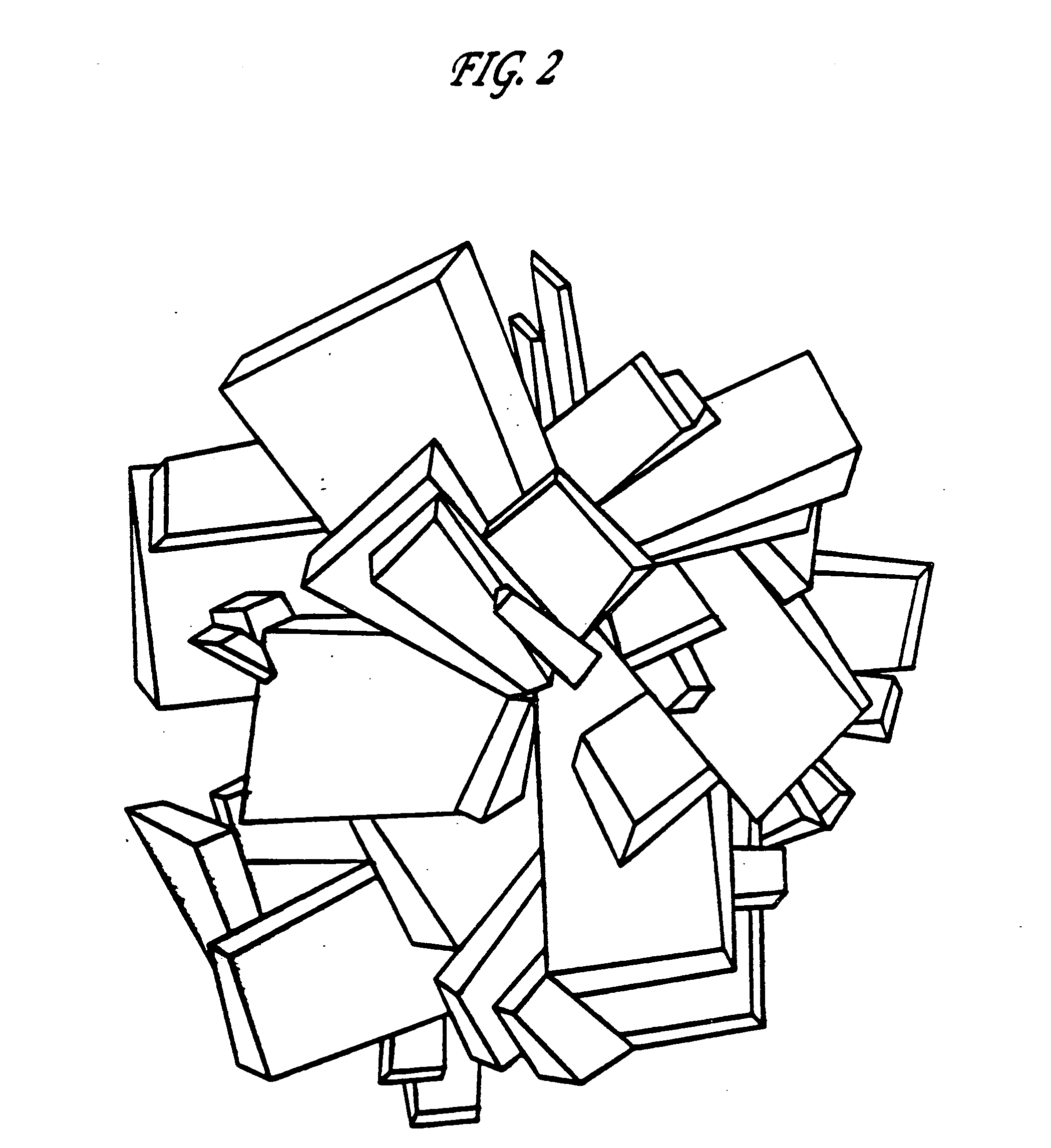

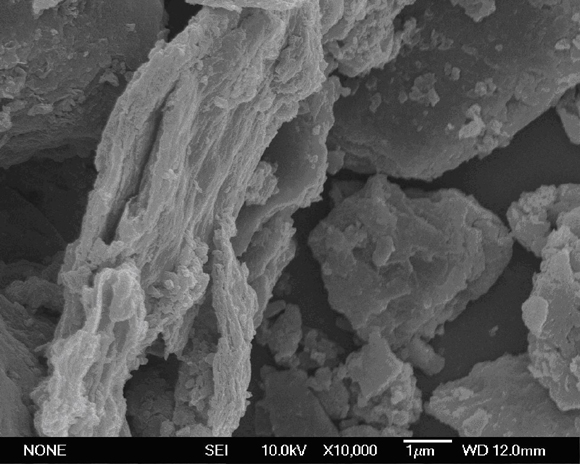

Small spherical particles of low molecular weight organic molecules and methods of preparation and use thereof

InactiveUS20050048127A1Uniform sizeHigh ratio of surface areaPowder deliveryChemical physicsNanosized particle

The invention provides homogeneous small spherical particles of low molecular weight organic molecules, said small spherical particles having a uniform shape, a narrow size distribution and average diameter of 0.01-200 μm. The invention further provides methods of preparation and methods of use of the small spherical particles. These small spherical particles are suitable for applications that require delivery of micron-size or nanosized particles with uniform size and good aerodynamic or flow characteristics. Pulmonary, intravenous, and other means of administration are among the delivery routes that may benefit from these small spherical particles.

Owner:BAXTER INT INC +1

Method of cvd for forming silicon nitride film on substrate

InactiveUS20050255712A1Improve controllabilityLow process temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgySilicon nitride

A CVD method is to form a silicon nitride film on a target substrate (W). The method includes heating the substrate (W) accommodated in a process container (8), at a process temperature, and supplying a process gas including hexaethylamino-disilane gas and ammonia gas onto the substrate (W) heated at the process temperature, thereby depositing a silicon nitride film on the substrate (W).

Owner:TOKYO ELECTRON LTD

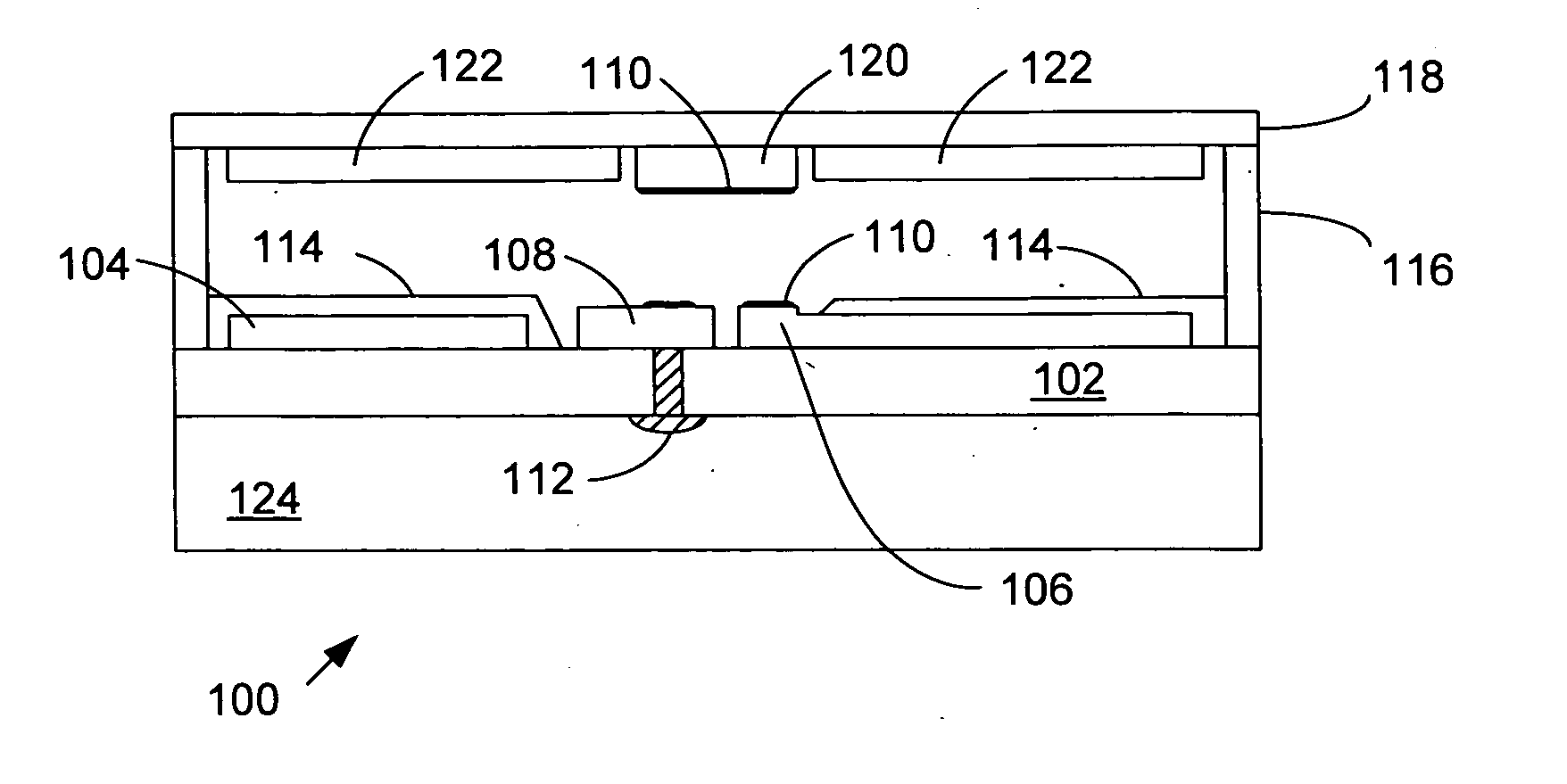

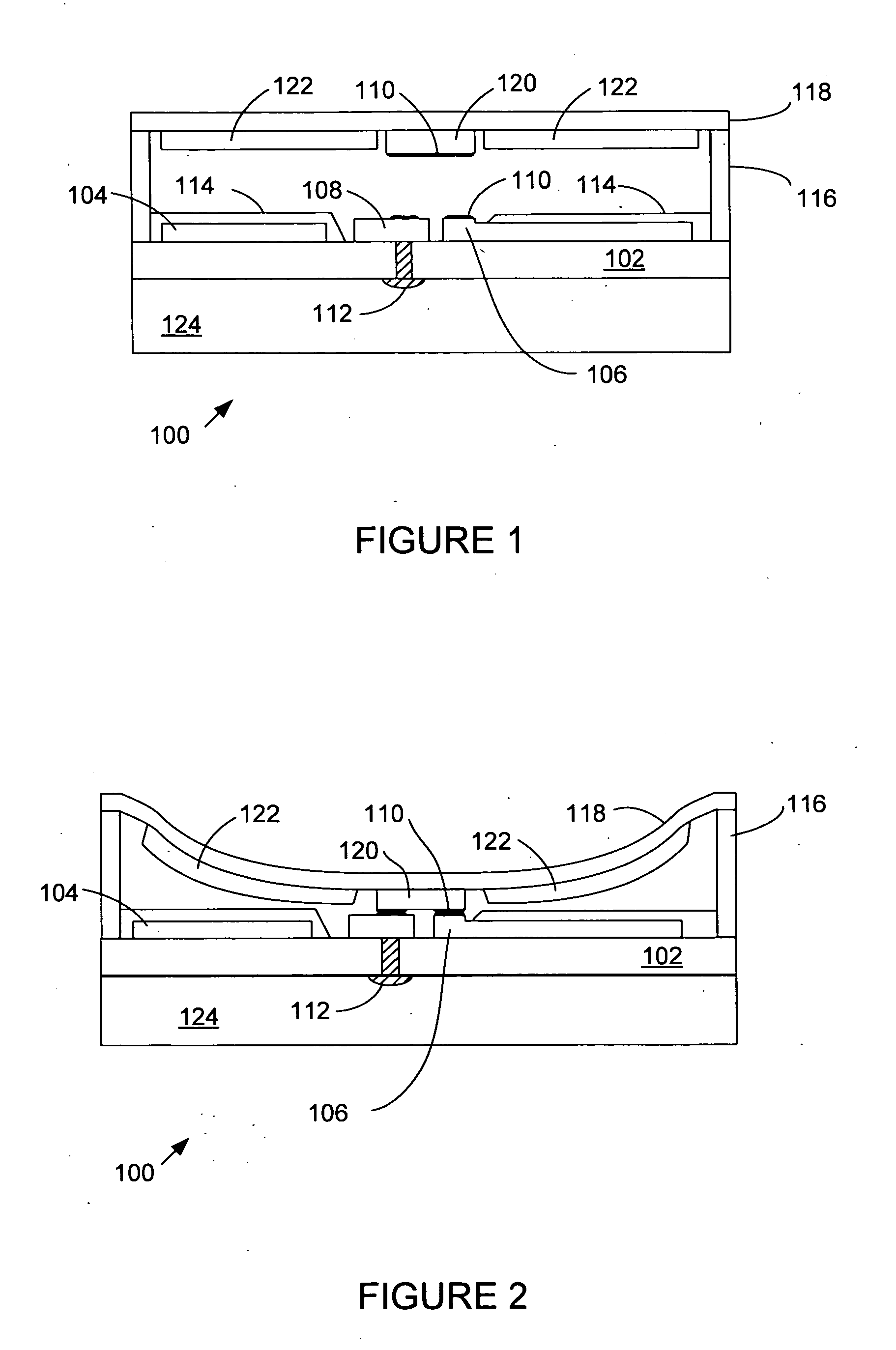

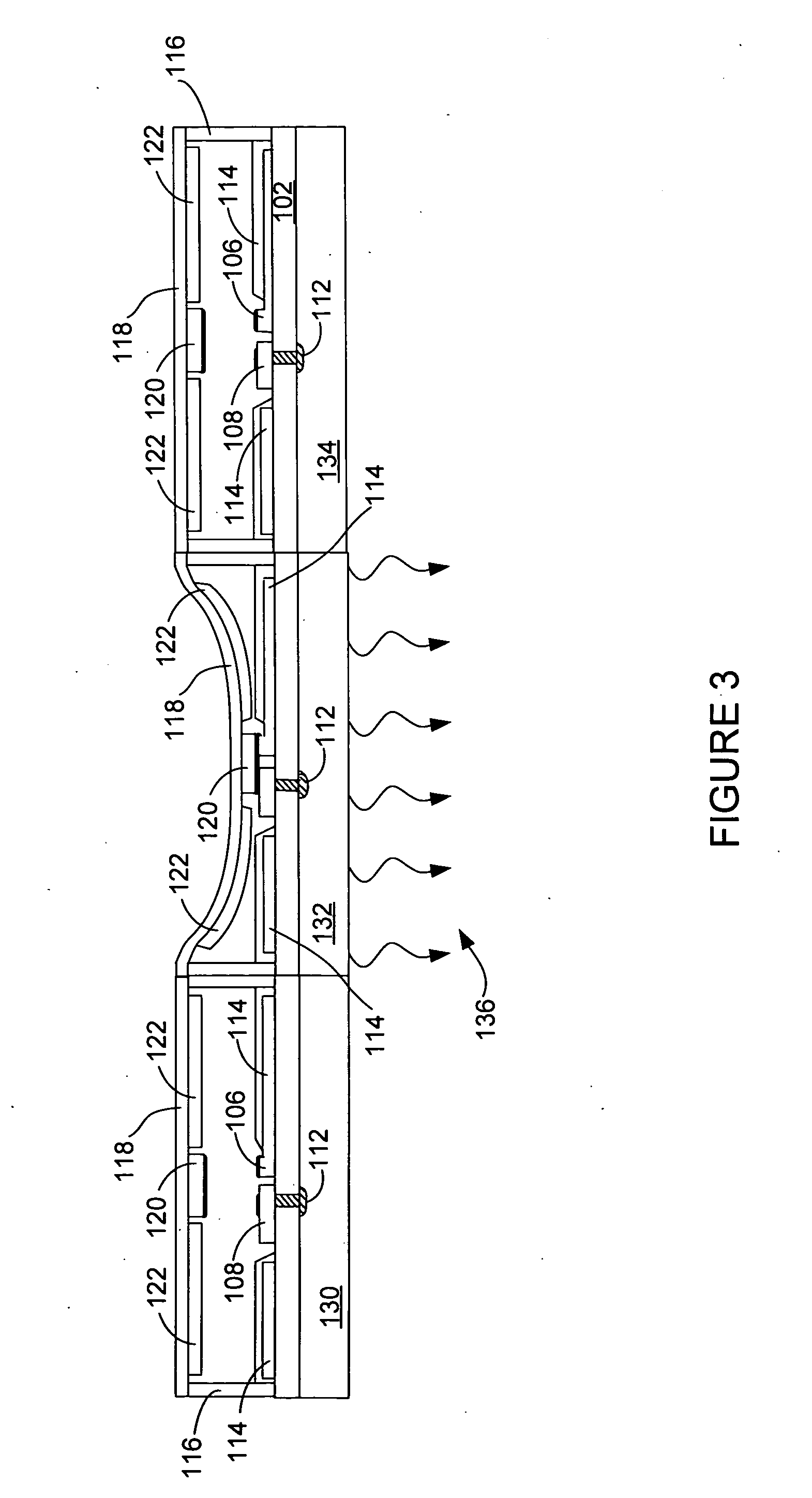

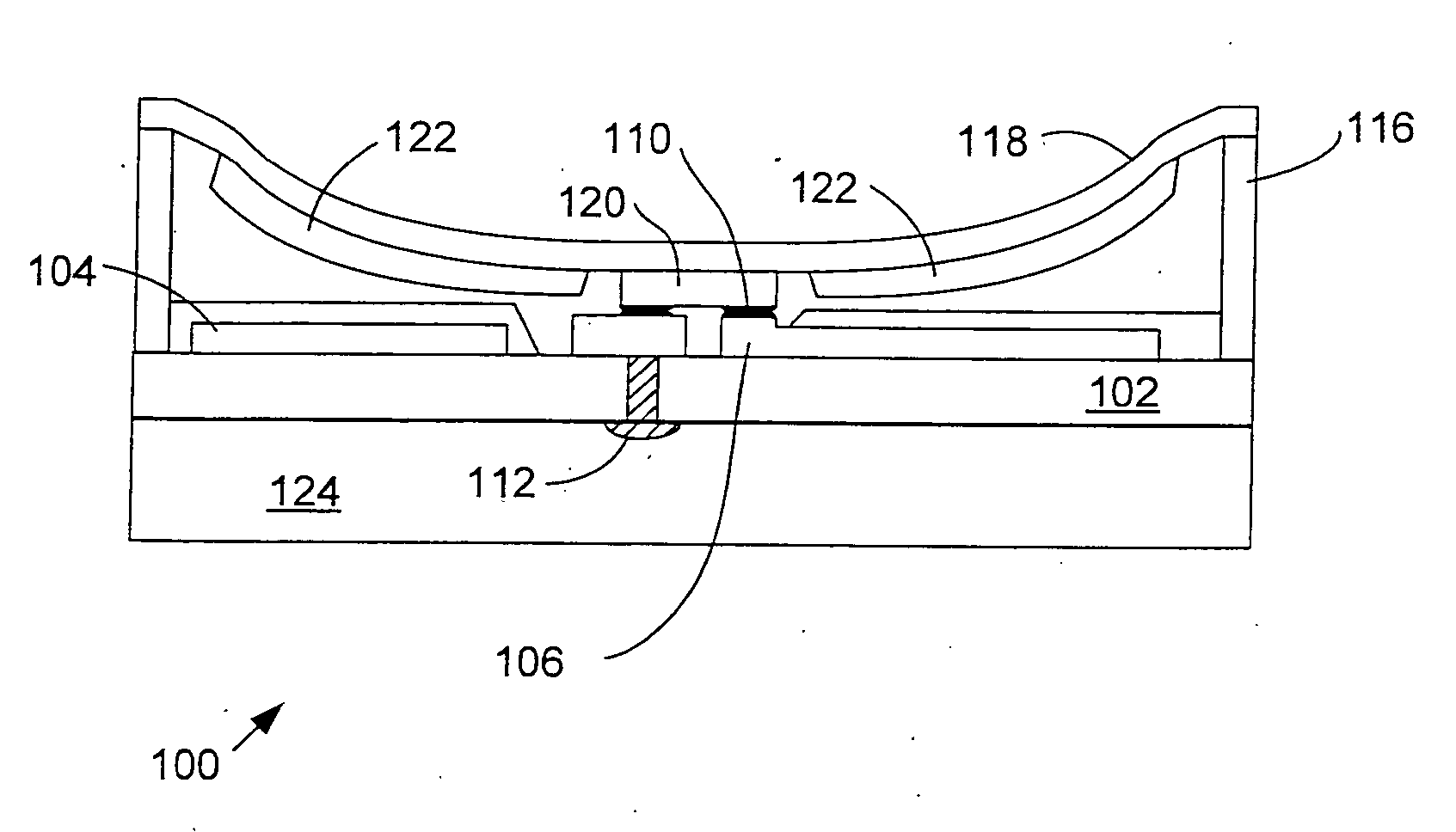

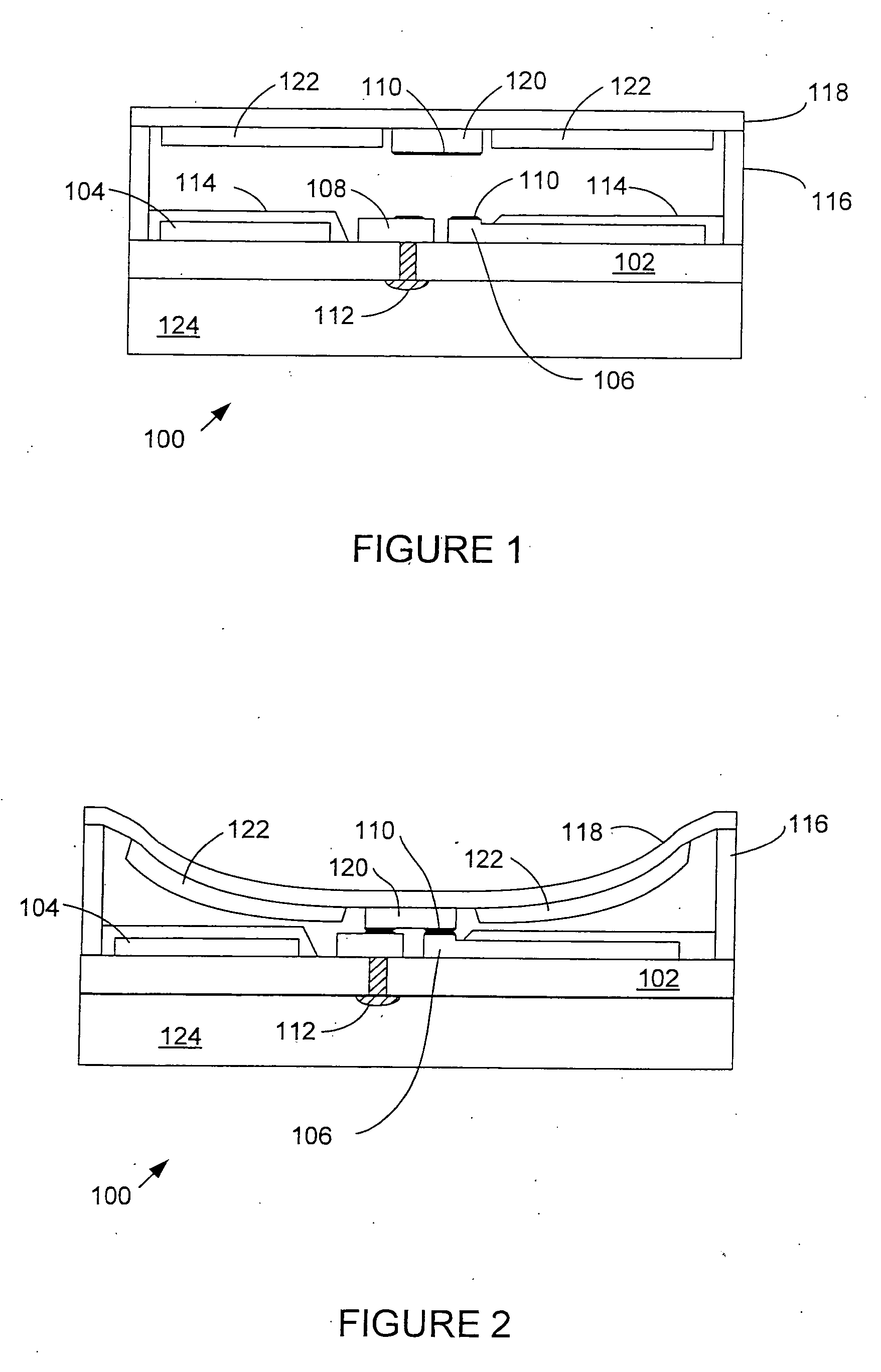

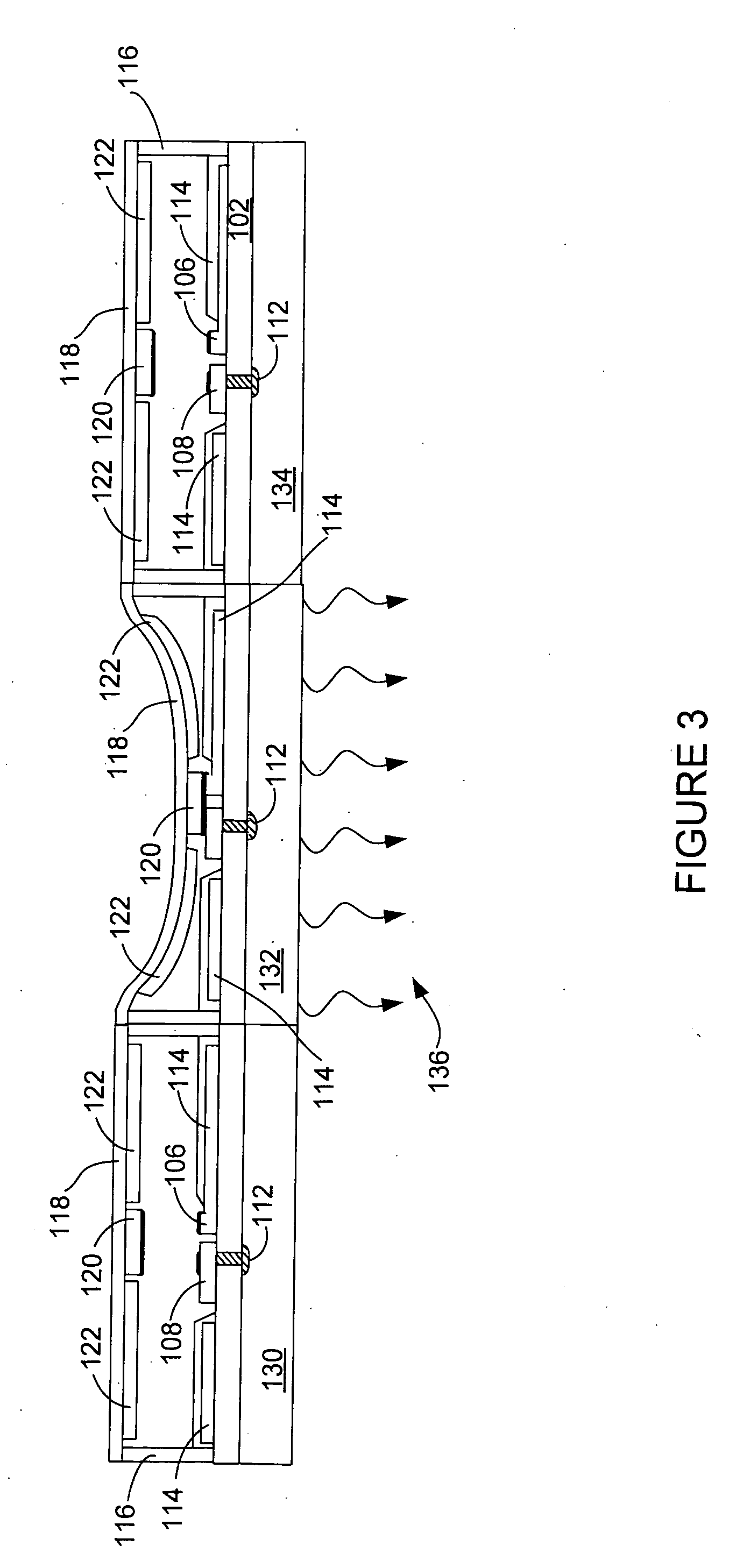

Micro-electromechanical switching backplane

InactiveUS20050116924A1Low costLow-cost techniqueElectrostatic/electro-adhesion relaysStatic indicating devicesDisplay deviceEngineering

A low cost, scalable backplane for black and white or color optical displays comprises a multi-membrane plastic structure on which is printed or deposited row and column drivers to form a matrix of micro electromechanical (MEM) switches. Each switch controls the state of a pixel in the optical display device. Critical to successful long-term operation, the backplane includes the controlled application of voltages to each switch so that the display functions correctly and display life is maximized. The MEM switches include a substantially non-pliable membrane and a substantially flexible membrane both of which include electrodes that when energized will create electrostatic forces that attracts the flexible membrane to the non-pliable membrane. The MEM switches are manufactured in an array with a pitch that provides a sufficient number of switches to drive an optical display device and each switch may be latched to eliminate the need to constantly refresh the device.

Owner:SEERTECH CORP

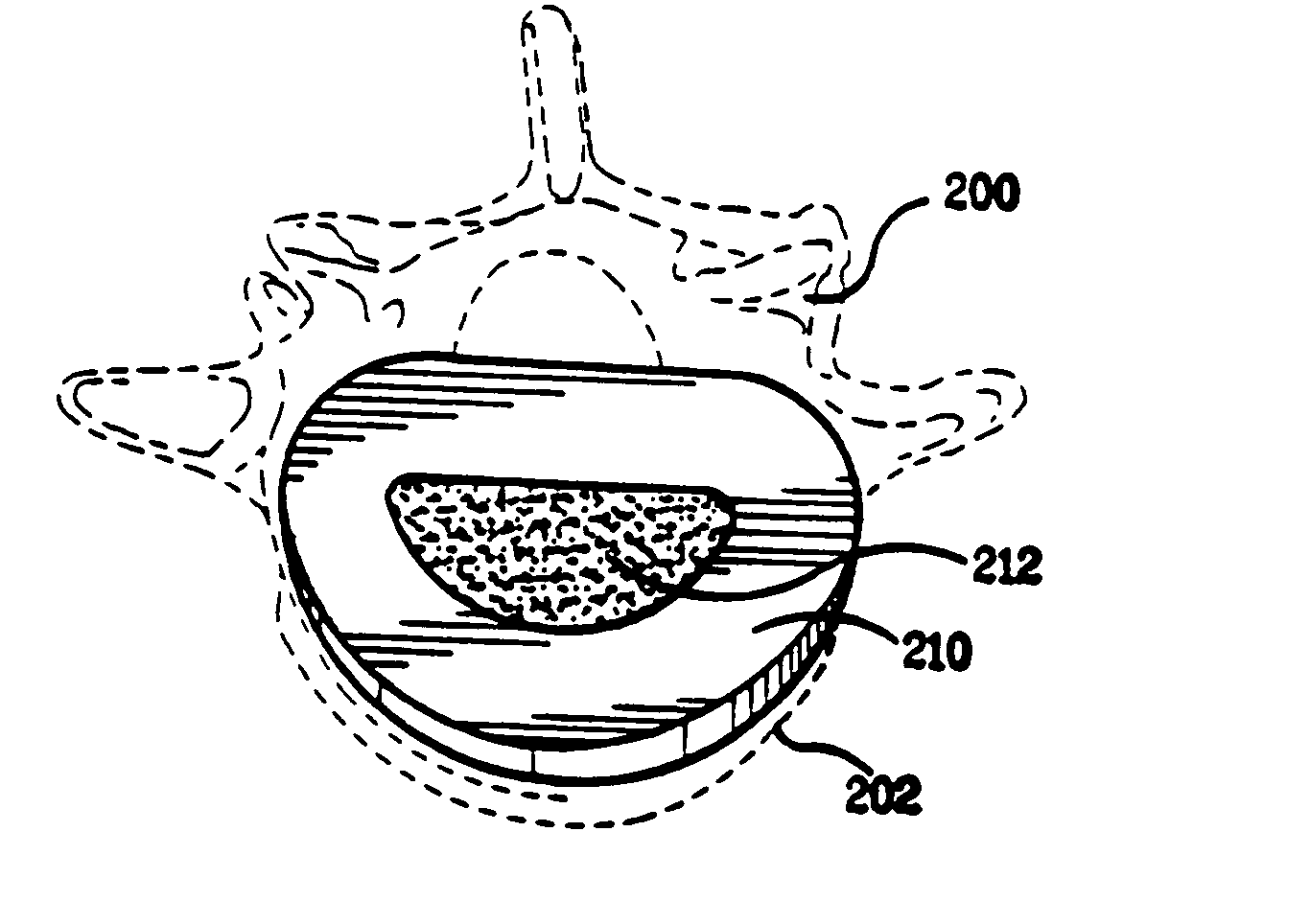

Composite shaped bodies and methods for their production and use

InactiveUS20050042288A1Increase productionLow process temperatureDental implantsPowder deliveryCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

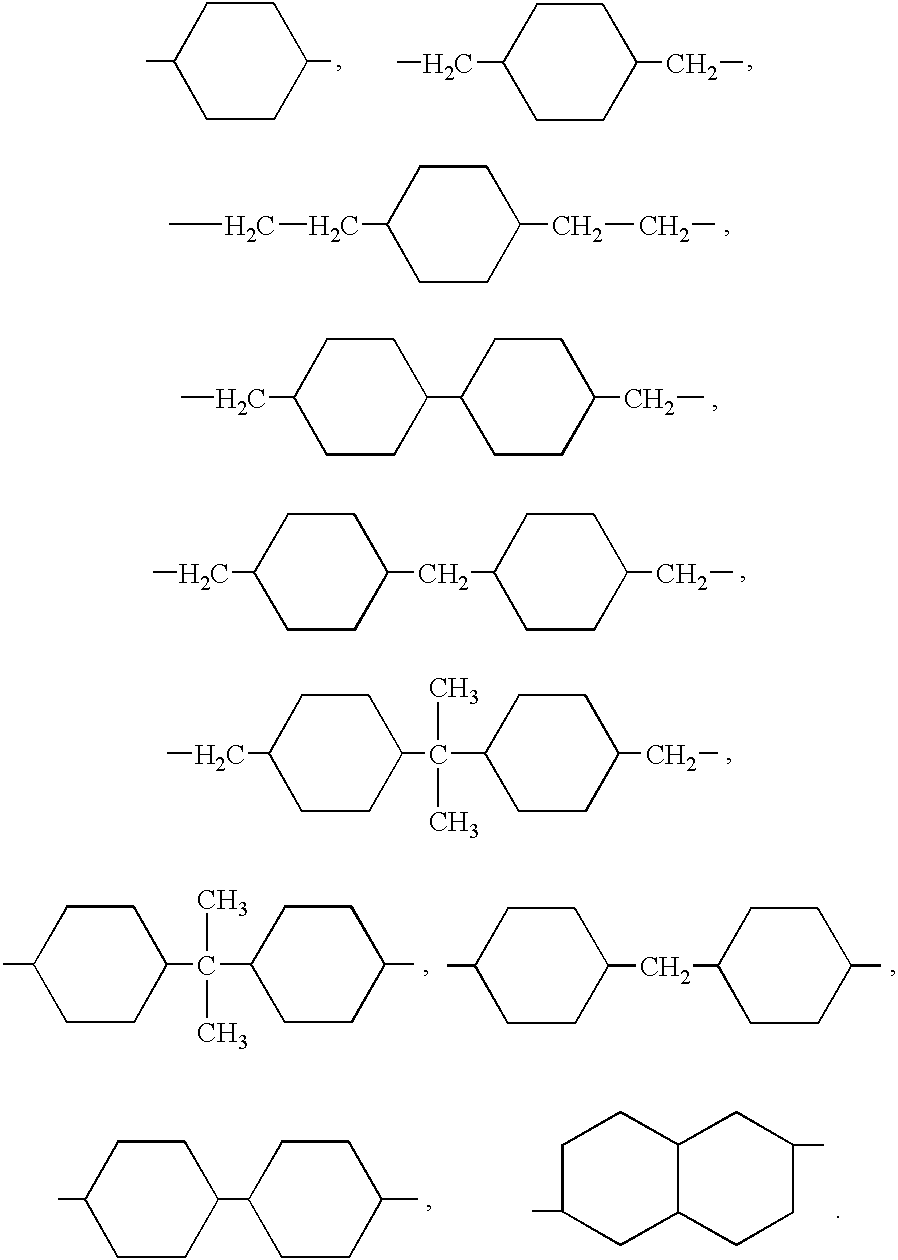

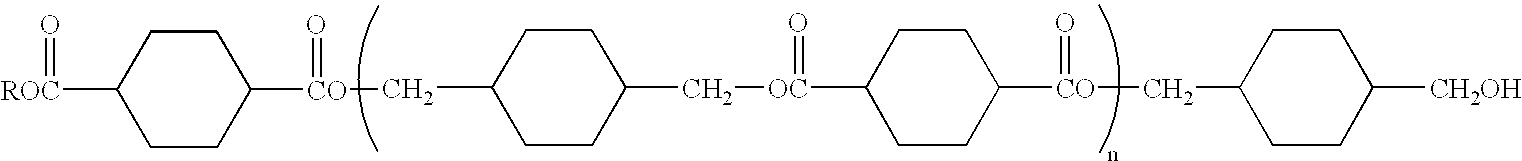

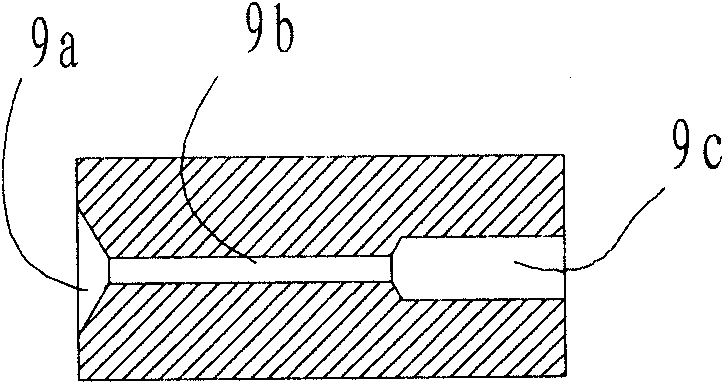

Insert molded article

InactiveUS6458913B1Prevent substrate deformationLow process temperatureSynthetic resin layered productsCeramic shaping apparatusPolymer substrateShell molding

A molded structure comprises a decorative film or substrate, and an adjacent injection molded polymeric base comprising a substantially transparent cycloaliphatic polyester resin which may have an opening for exposing the transparent polymeric base resin to the exterior of the molded article, and a process for making the molded structure is described.

Owner:SABIC GLOBAL TECH BV

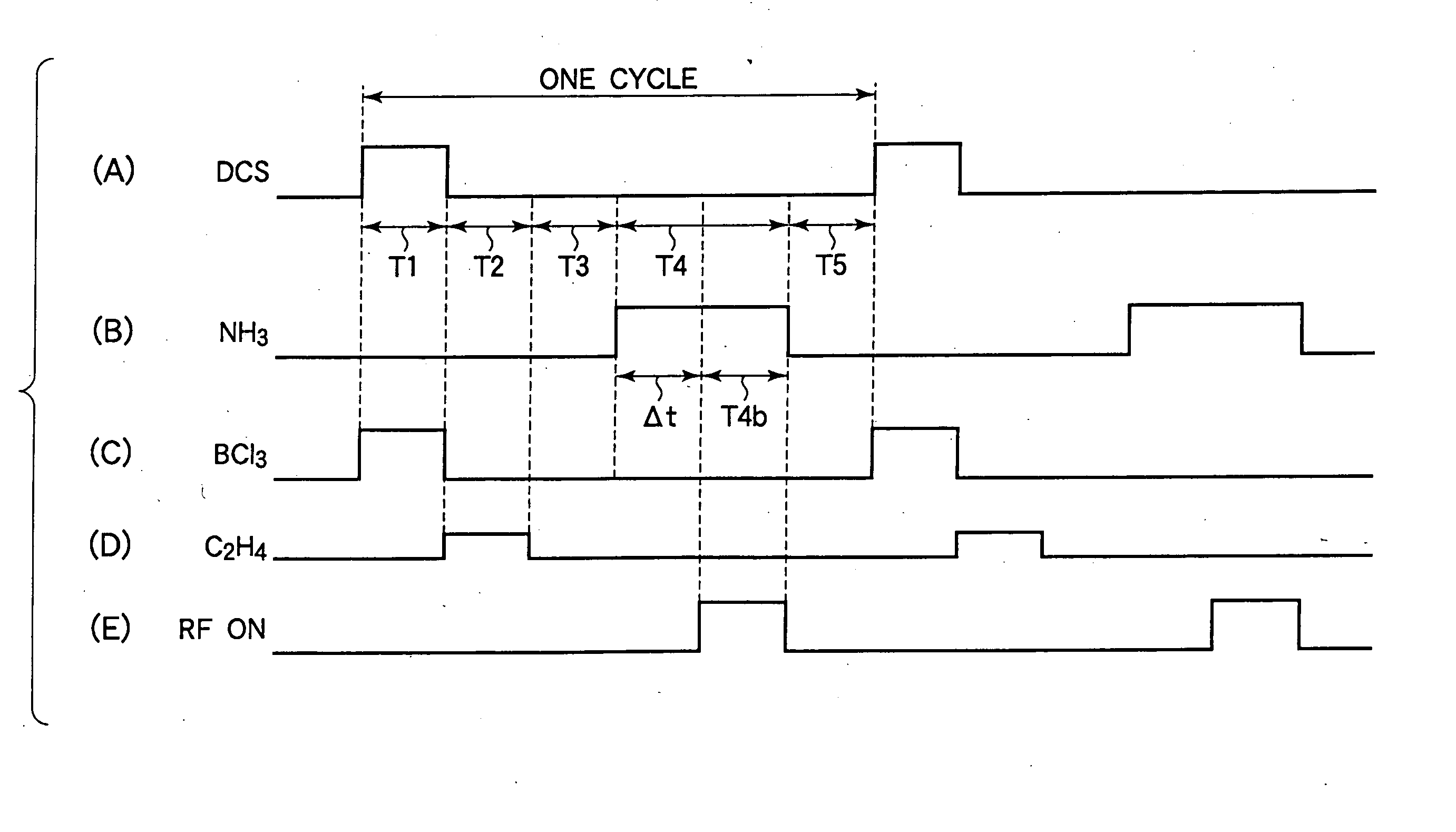

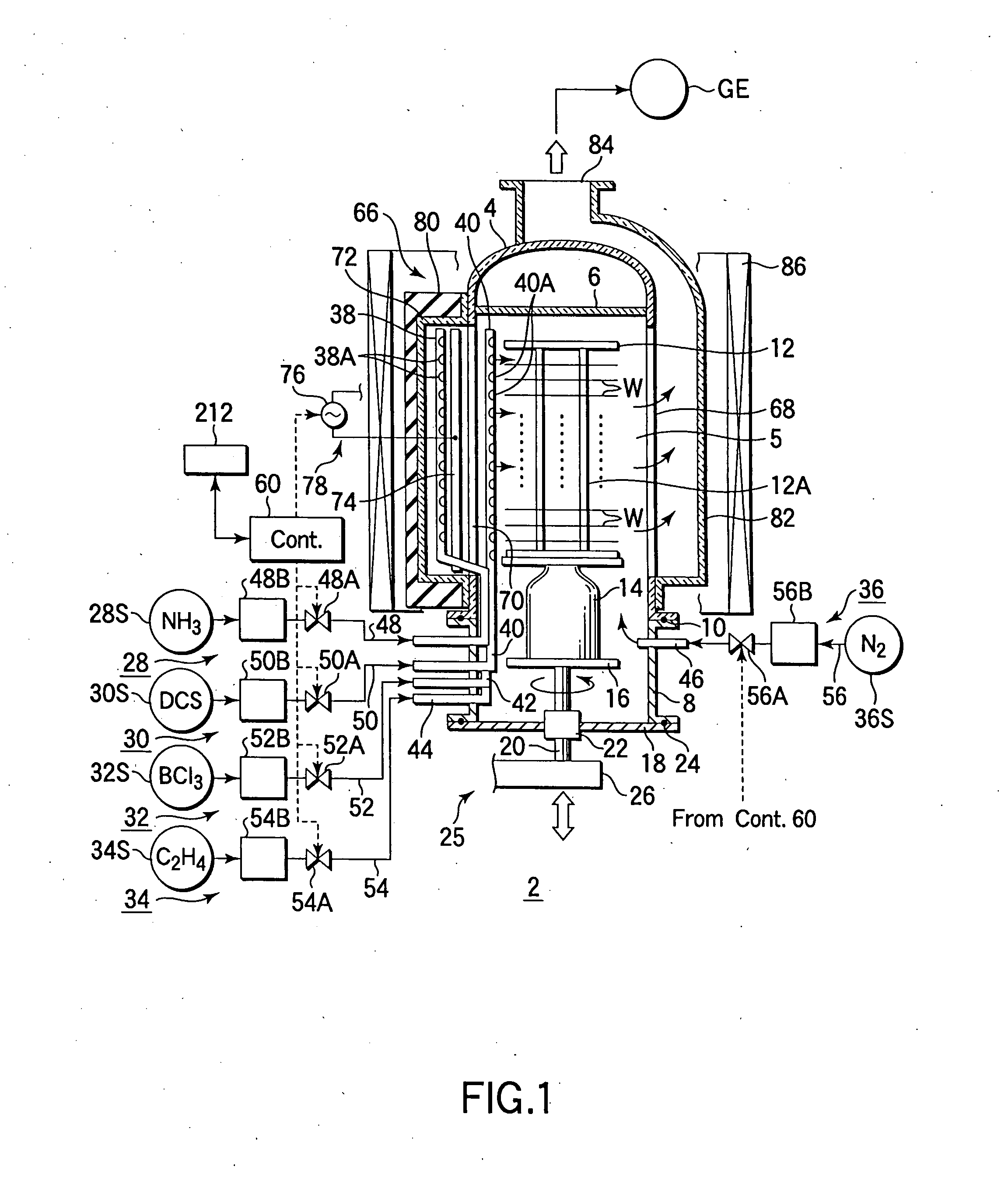

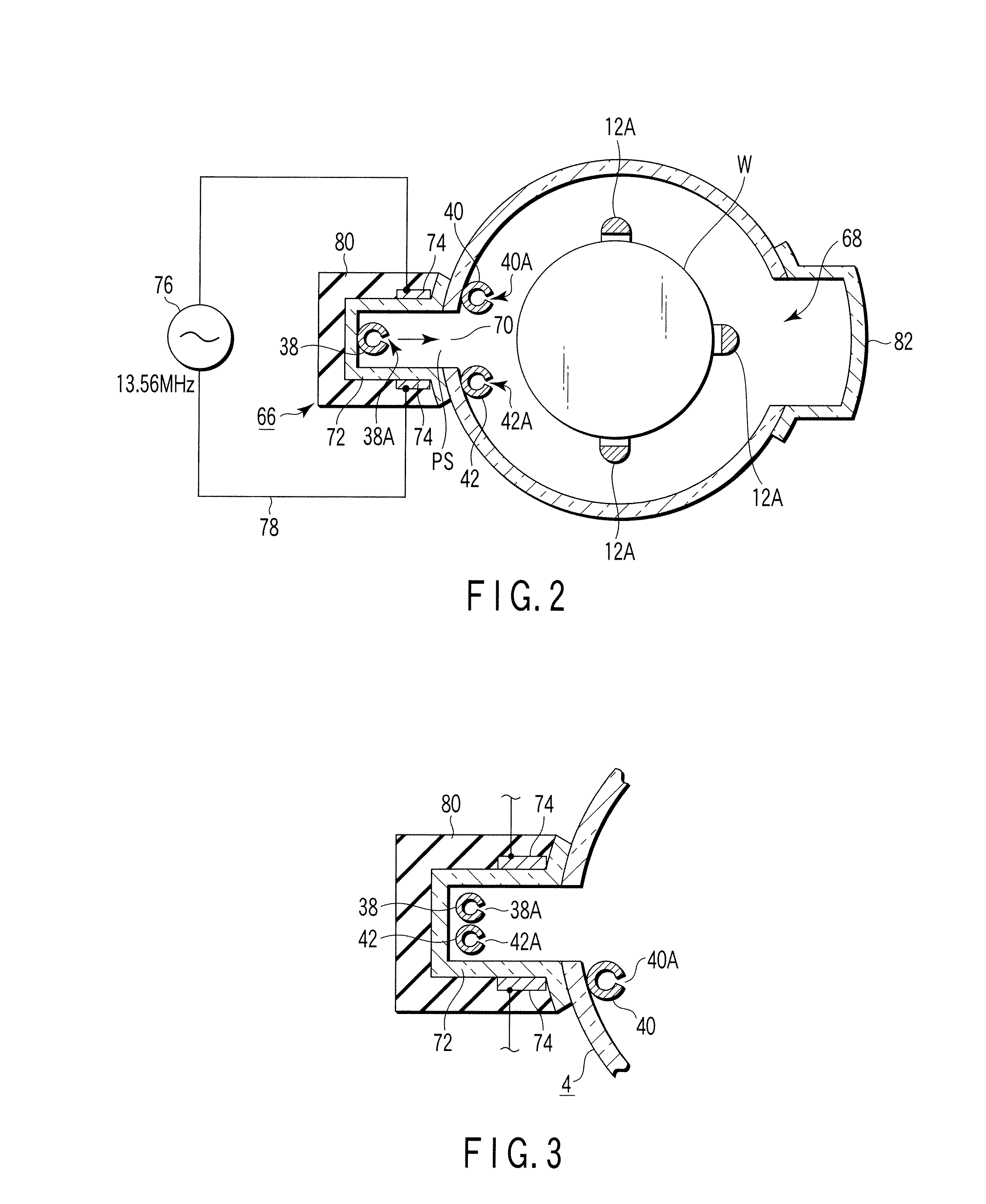

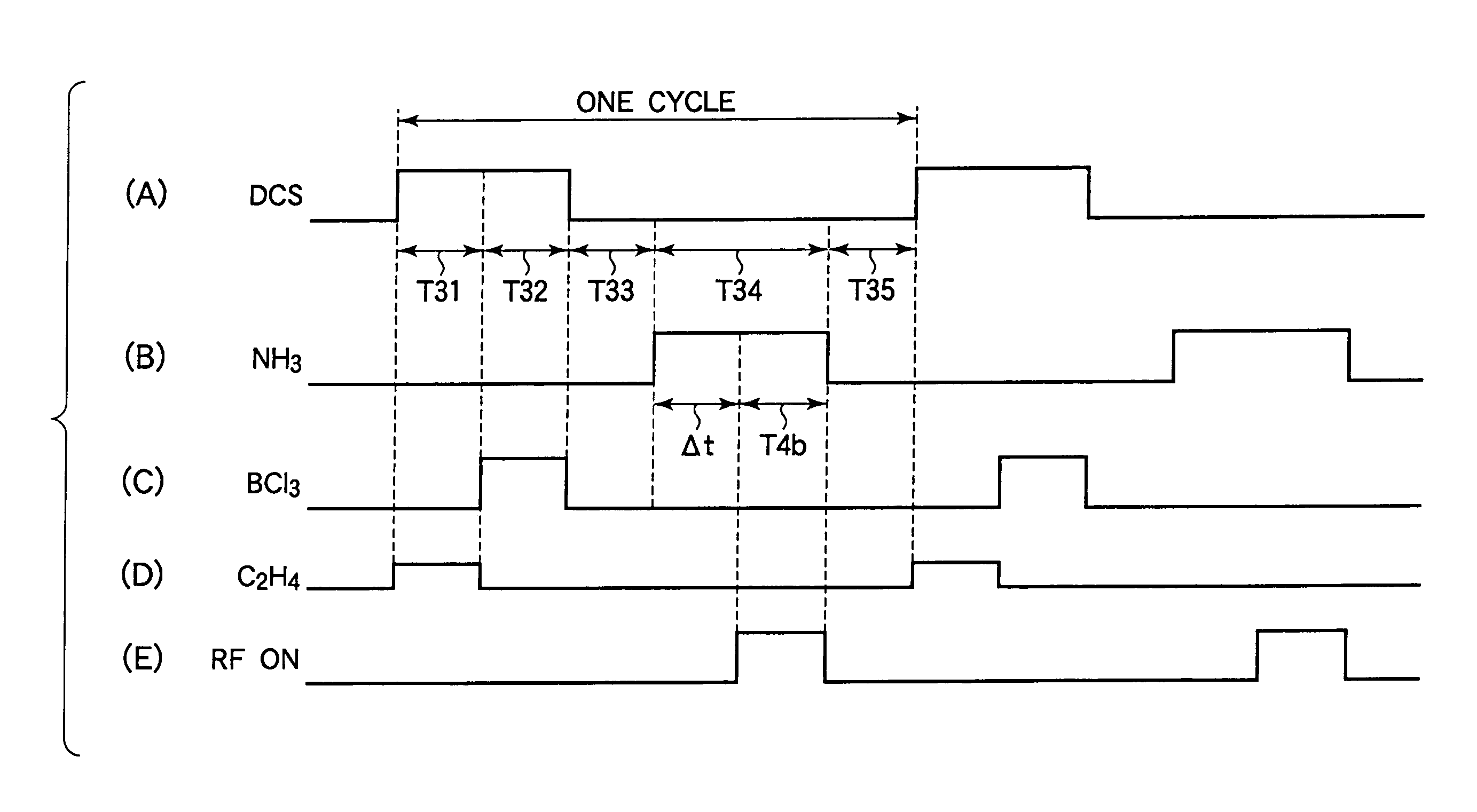

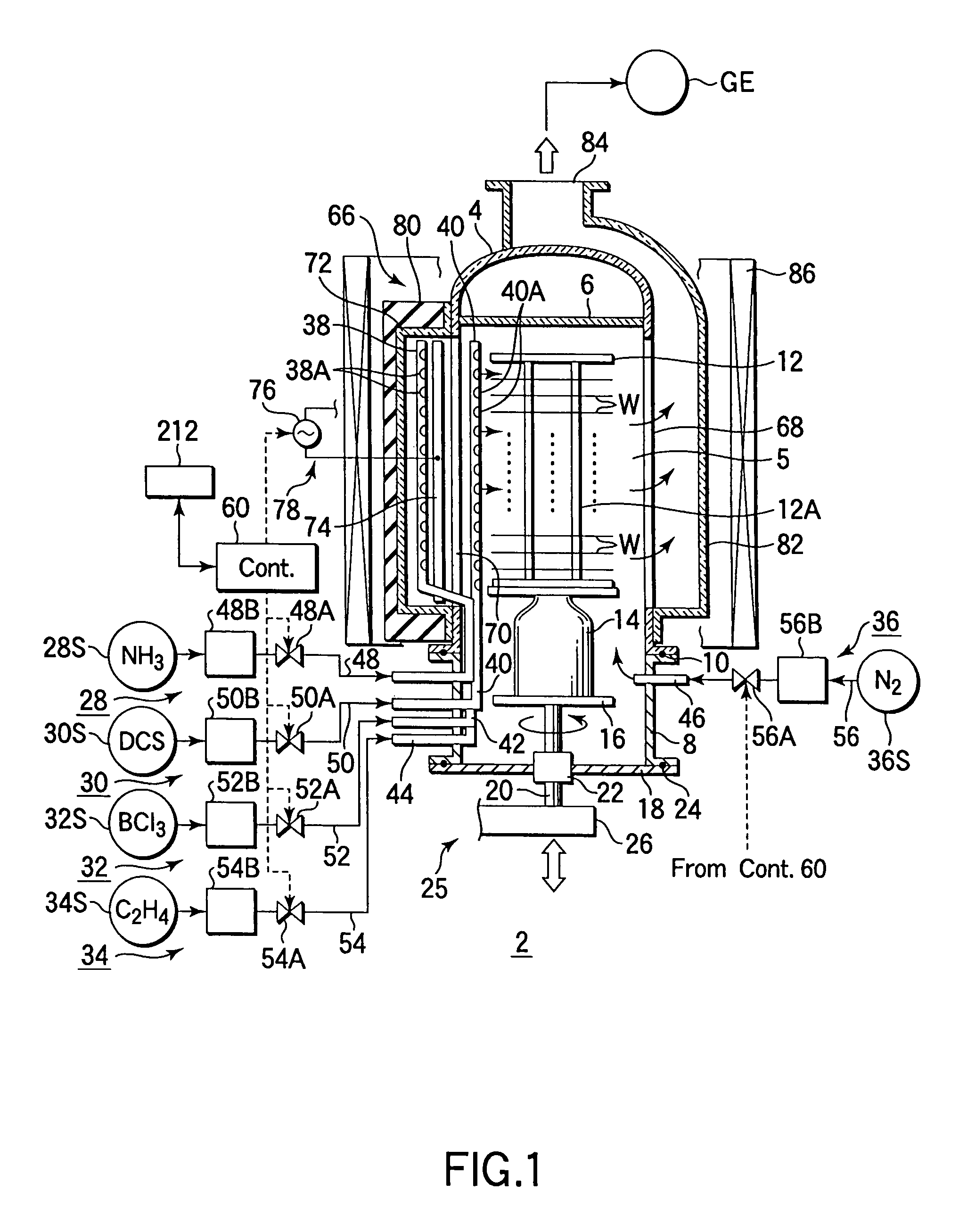

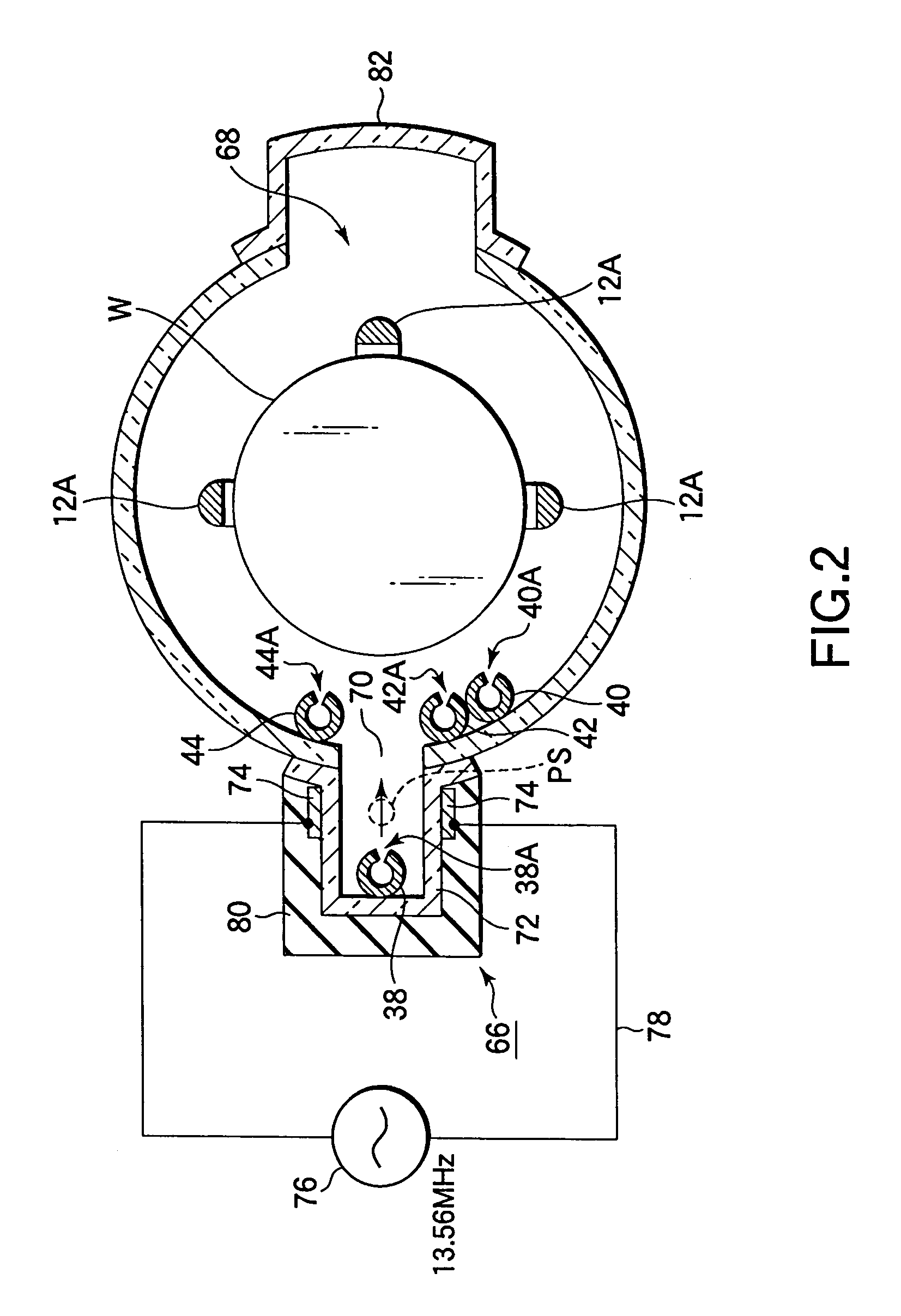

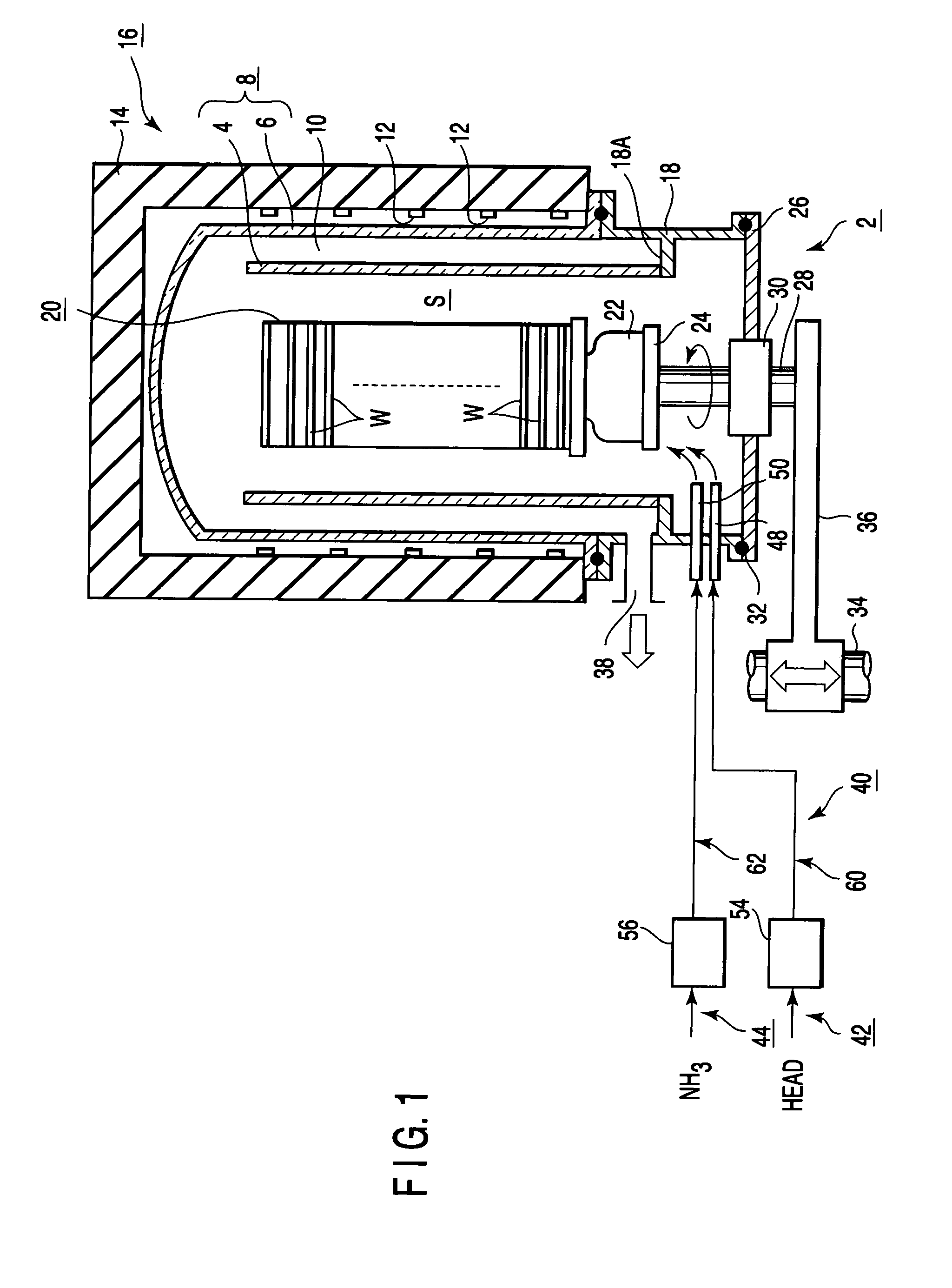

Film formation method and apparatus for semiconductor process

ActiveUS20080063791A1Improve controllabilityReduce the amount requiredVacuum evaporation coatingSputtering coatingSilanesBoron

An insulating film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding gas or oxynitriding gas, a third process gas containing a boron-containing gas, and a fourth process gas containing a carbon hydride gas. A first step performs supply of the first process gas and a preceding gas, which is one of the third and fourth process gases, while stopping supply of the second process gas and a succeeding gas, which is the other of the third and fourth process gases. A second step performs supply of the succeeding gas, while stopping supply of the second process gas and the preceding gas. A third step performs supply of the second process gas while stopping supply of the first process gas.

Owner:TOKYO ELECTRON LTD

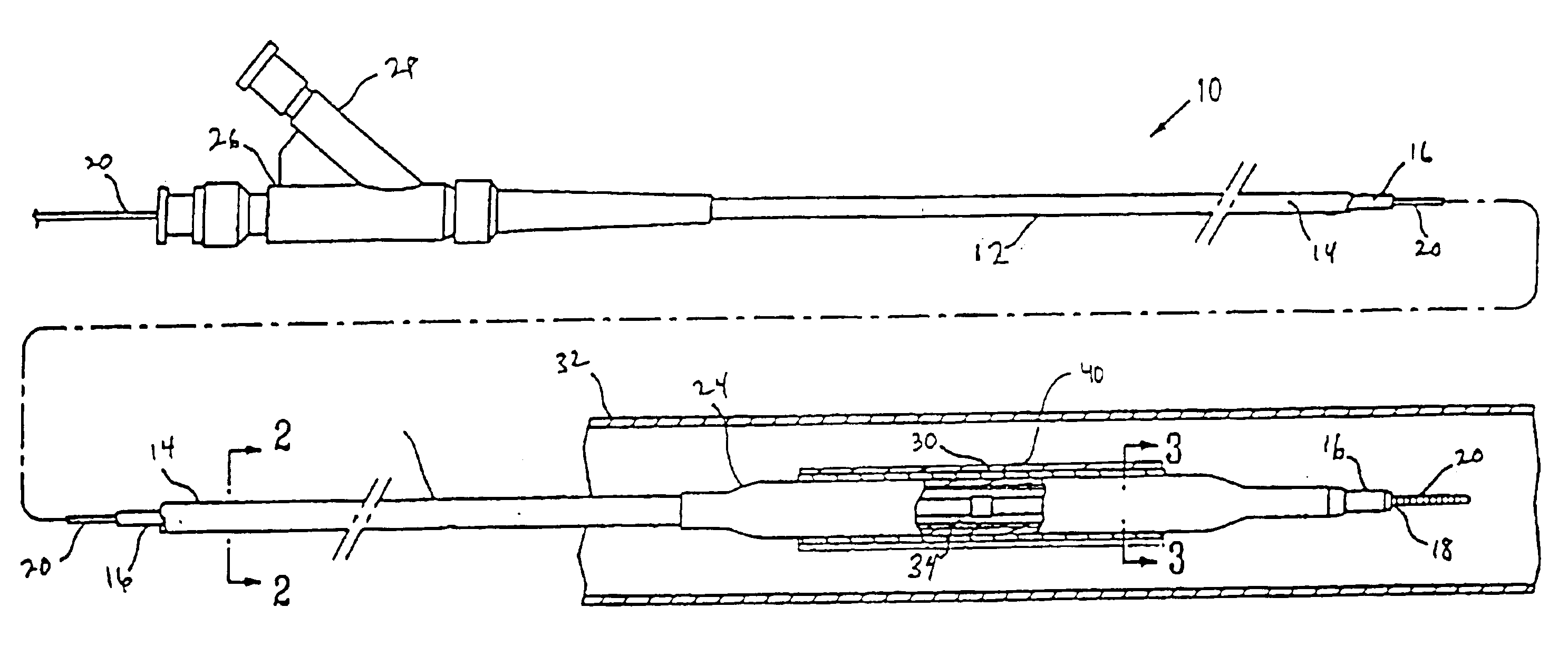

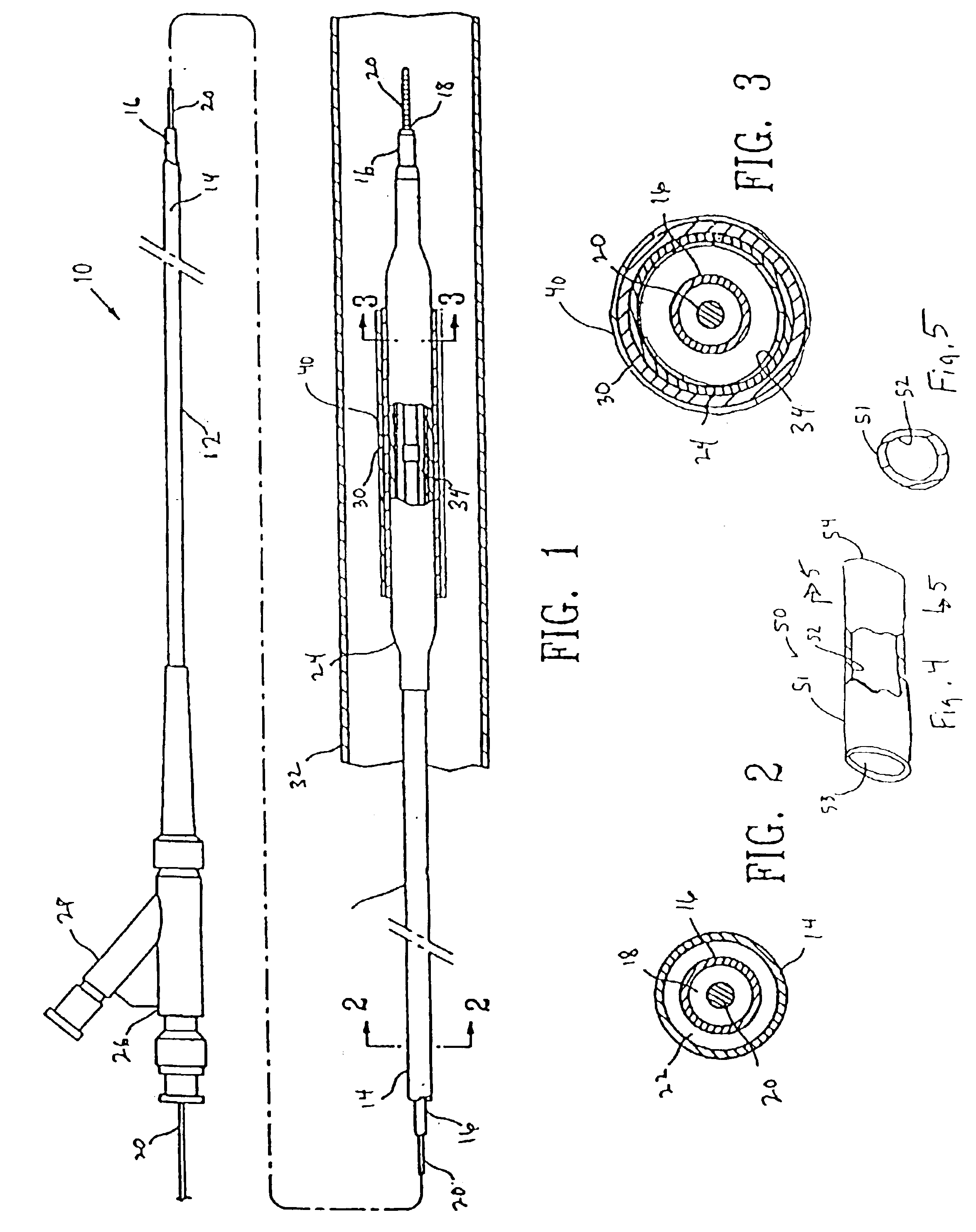

Medical device formed of ultrahigh molecular weight polyolefin

Medical devices having at least a component, such as a catheter balloon, stent cover and vascular graft, formed of ultrahigh molecular weight polyolefin, such as ultrahigh molecular weight polyethylene. The device component is formed from ultrahigh molecular weight polyethylene that has been processed so that it is microporous and has an oriented node and fibril structure. The device component expands compliantly at low strains and are substantially less compliant at higher strains. The invention also comprises methods for making such medical devices, including the steps of compacting a polyethylene powder and deforming it to impart the oriented structure.

Owner:ABBOTT CARDIOVASCULAR

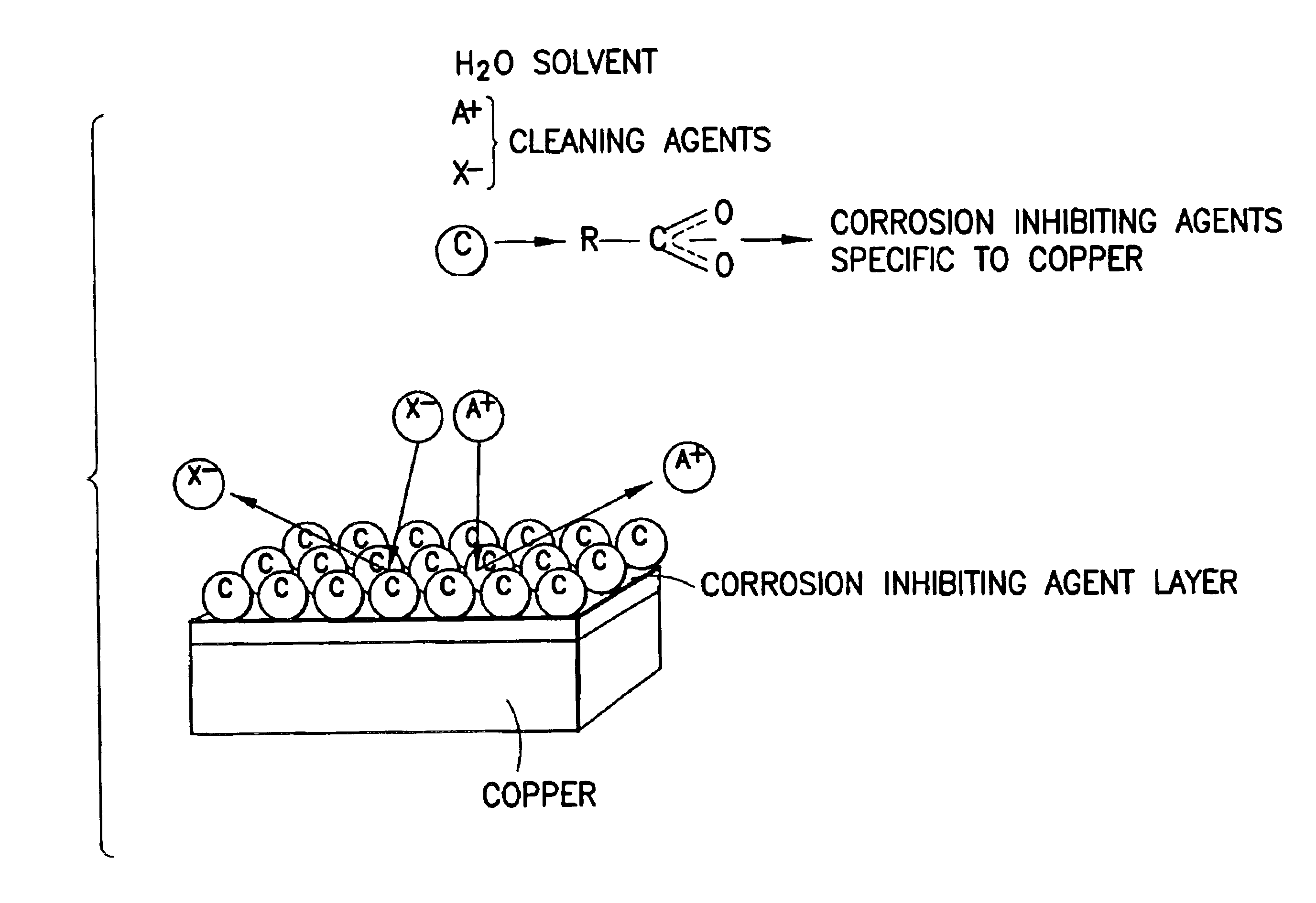

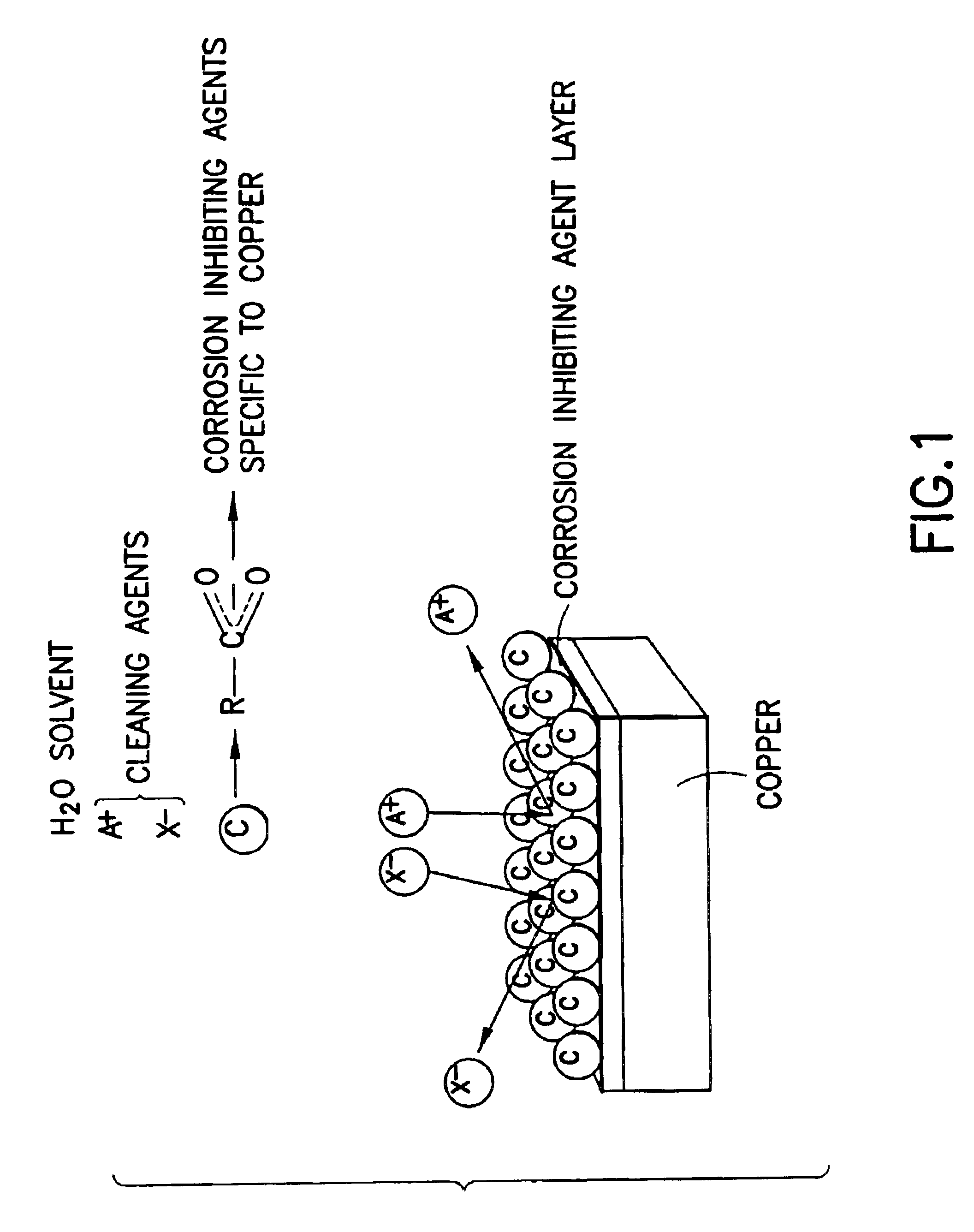

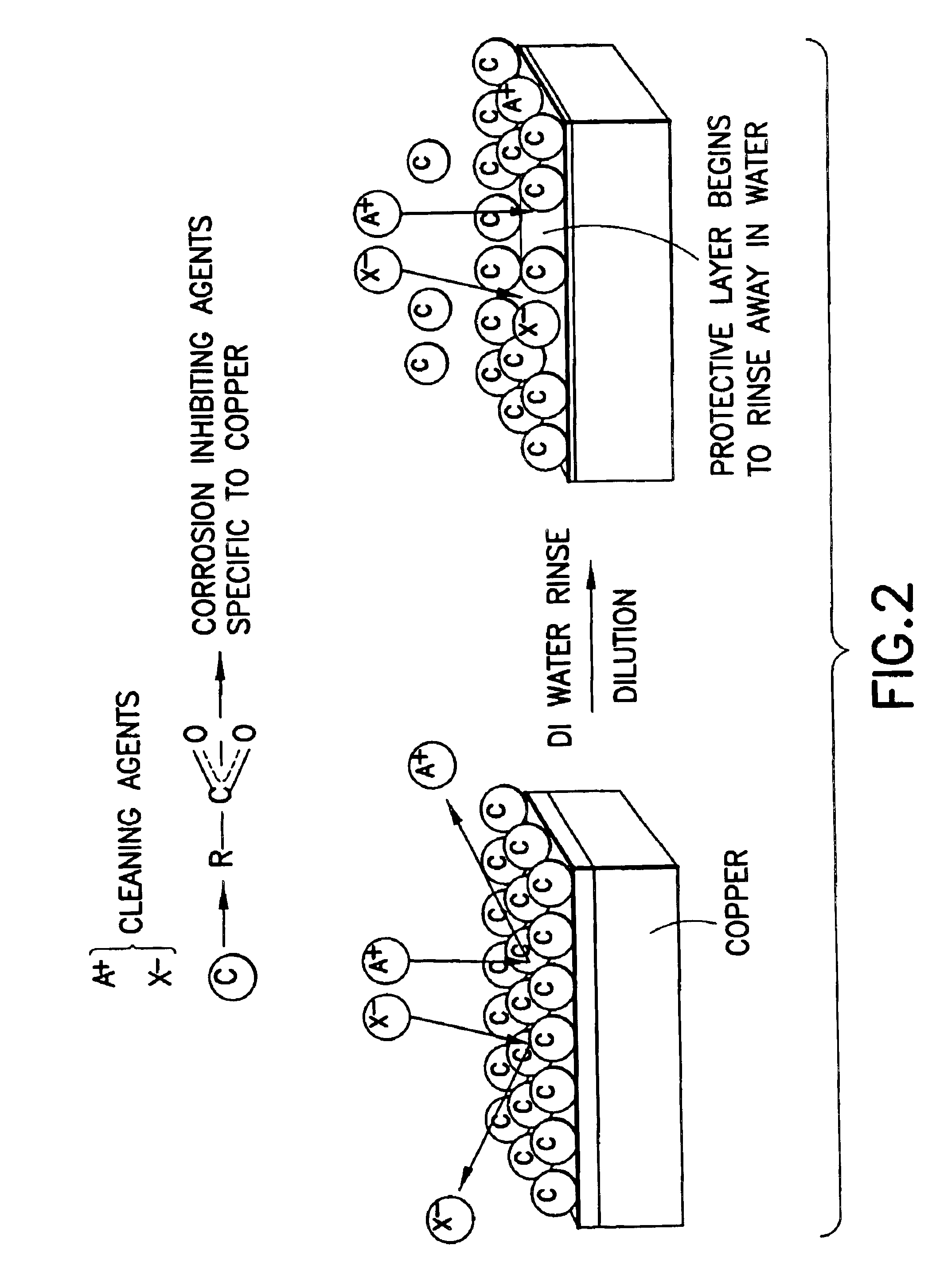

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS6896826B2Efficient removalExcellent peelabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsResistNitrogen

Owner:ENTEGRIS INC

Customized implants for bone replacement

InactiveUS20110144752A1Reduce the chance of solidificationLow process temperatureImpression capsAdditive manufacturing apparatusNatural boneCustom made implant

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

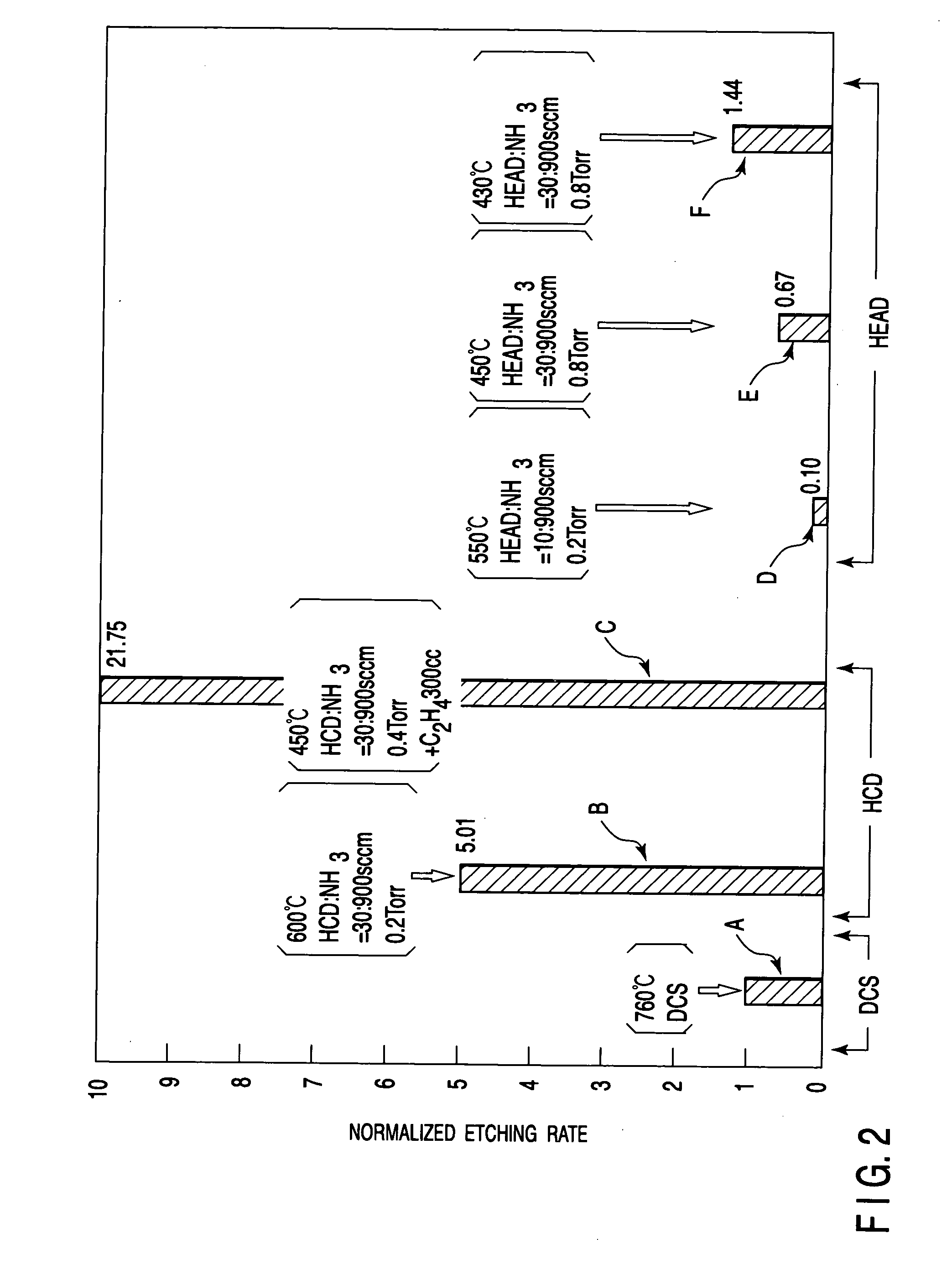

Film formation method and apparatus for semiconductor process

InactiveUS7507676B2Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesProcess region

An insulating film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding gas, and a third process gas containing a carbon hydride gas. This method includes repeatedly performing supply of the first process gas to the process field, supply of the second process gas to the process field, and supply of the third process gas to the process field. The supply of the third process gas includes an excitation period of supplying the third process gas to the process field while exciting the third process gas by an exciting mechanism.

Owner:TOKYO ELECTRON LTD

Film formation method and apparatus for semiconductor process

ActiveUS7964241B2Low process temperatureImprove controllabilityChemical vapor deposition coatingSilanesBoron containing

An insulating film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding gas or oxynitriding gas, a third process gas containing a boron-containing gas, and a fourth process gas containing a carbon hydride gas. A first step performs supply of the first process gas and a preceding gas, which is one of the third and fourth process gases, while stopping supply of the second process gas and a succeeding gas, which is the other of the third and fourth process gases. A second step performs supply of the succeeding gas, while stopping supply of the second process gas and the preceding gas. A third step performs supply of the second process gas while stopping supply of the first process gas.

Owner:TOKYO ELECTRON LTD

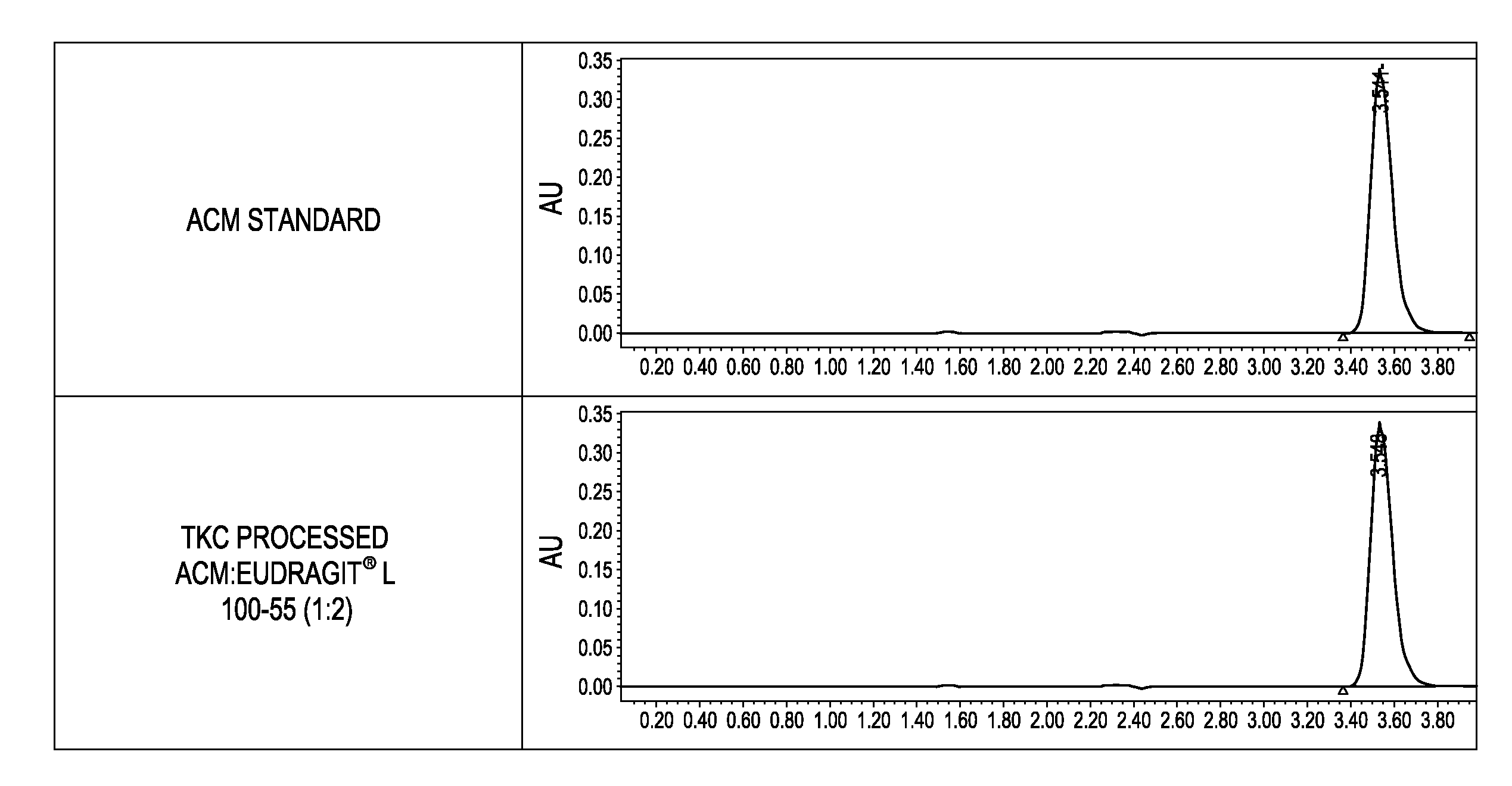

Thermo-Kinetic Mixing for Pharmaceutical Applications

ActiveUS20090053315A1Low process temperatureIncrease shear ratePowder deliveryOrganic active ingredientsCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

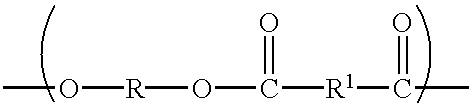

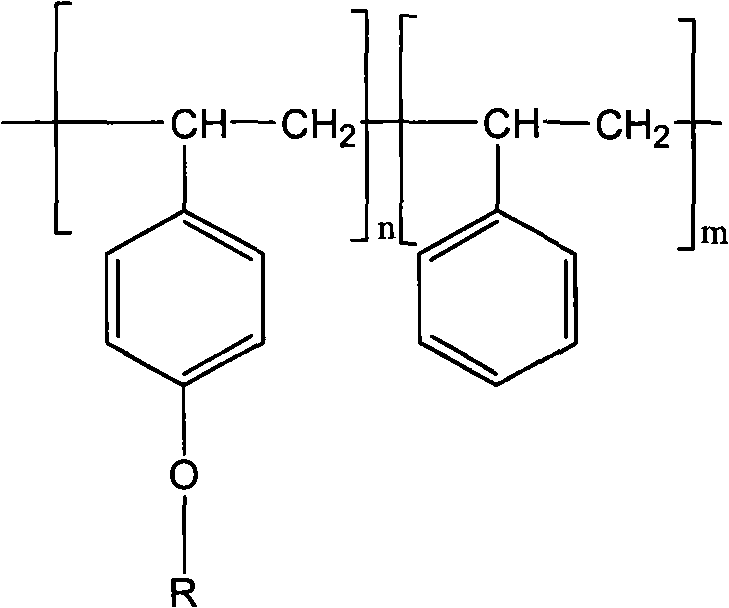

Waveplate and optical circuit formed using mesogen-containing polymer

InactiveUS7058249B2Improve the level ofLow process temperatureLiquid crystal compositionsPolarising elementsHemt circuitsBackbone chain

Waveplate, planar lightwave circuit incorporating the waveplate, and method of making an optical device. The waveplate is formed of a mesogen-containing polymer film having a backbone and sidechains containing mesogen groups. The waveplate may be formed by producing a mesogen-containing polymer film having a nonzero birefringence of suitable dimensions for insertion into a planar lightwave circuit. The waveplate may be so inserted into an optical circuit of a planar lightwave circuit so that an optical signal traversing the waveplate is changed, for instance, to have two polarization states.

Owner:NEOPHOTONICS CORP

Formation of silicon nitride film

ActiveUS7625609B2Increase pressureLow process temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingChemical species

Owner:TOKYO ELECTRON LTD

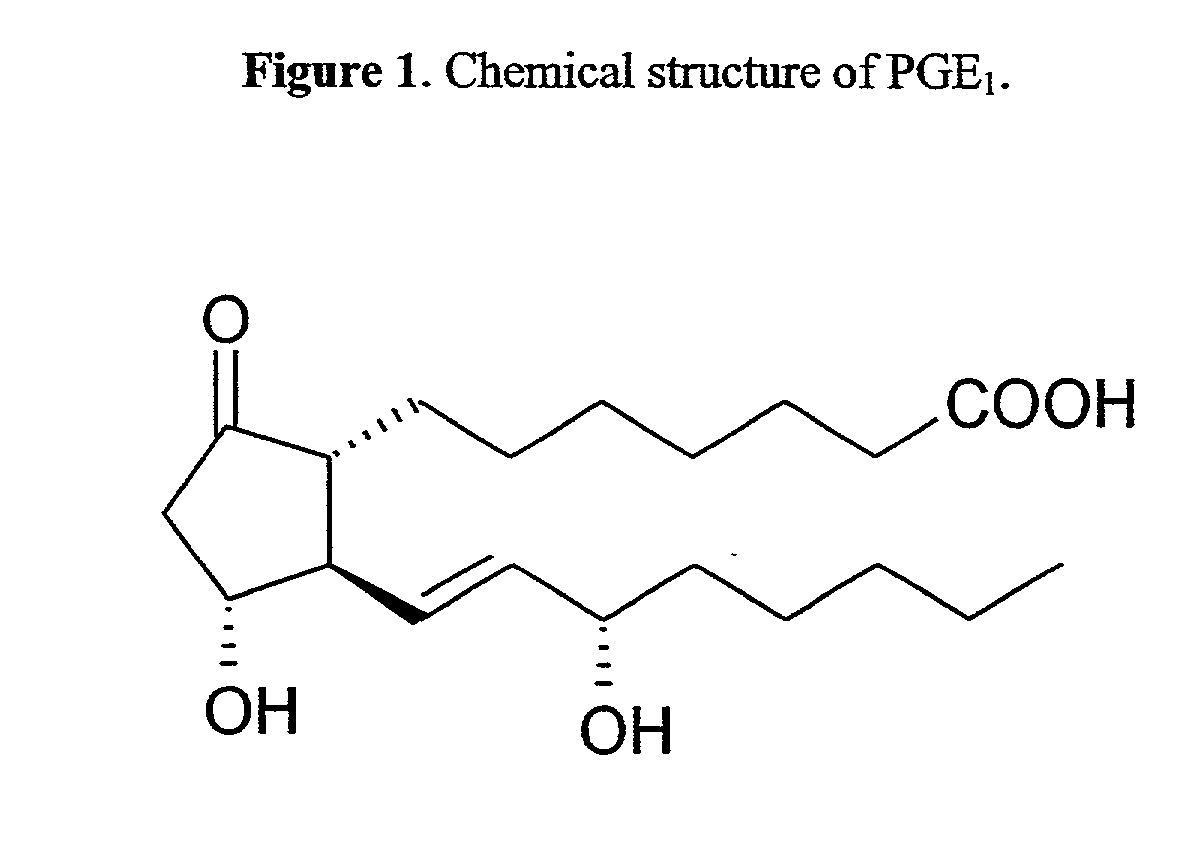

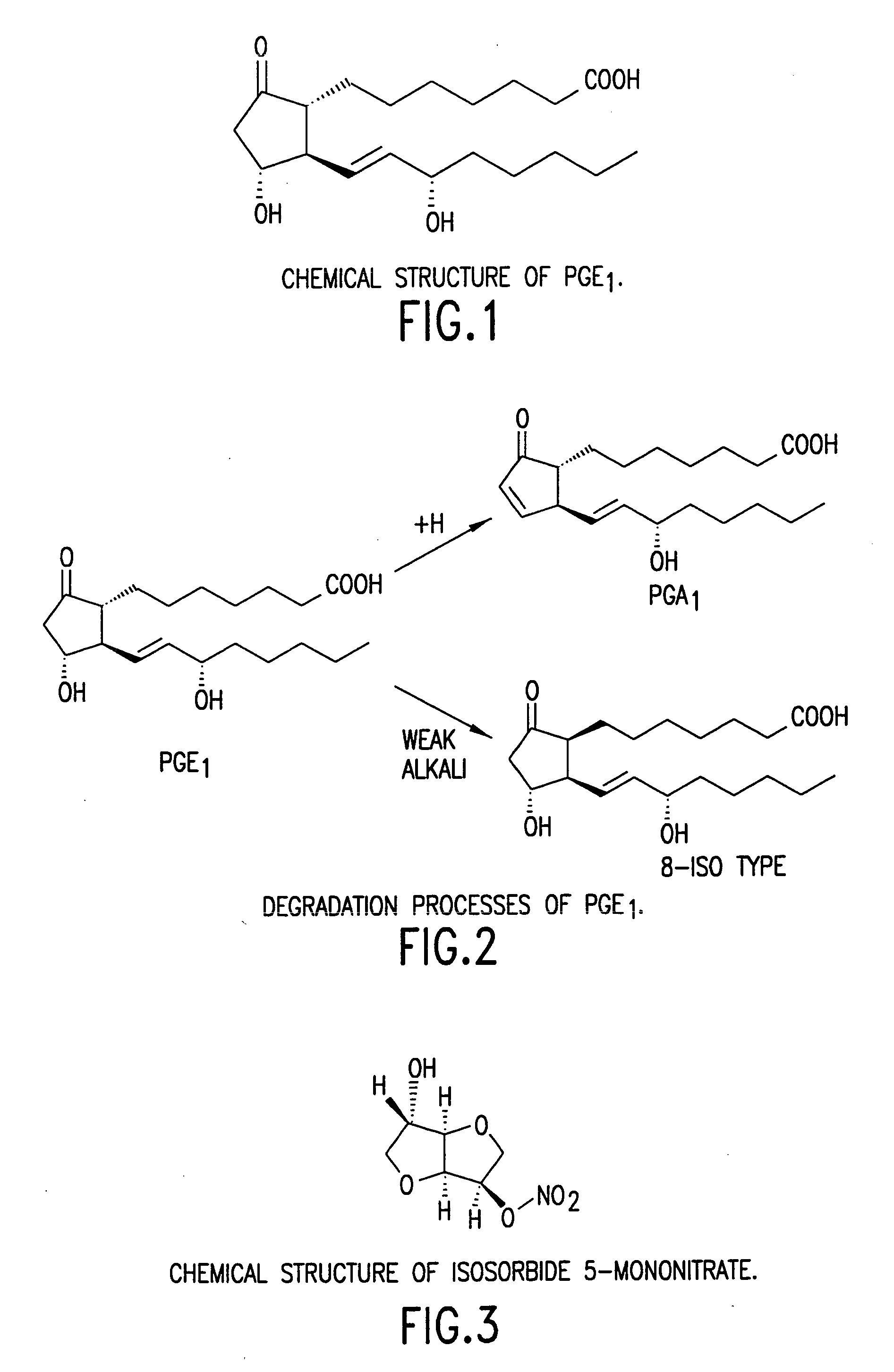

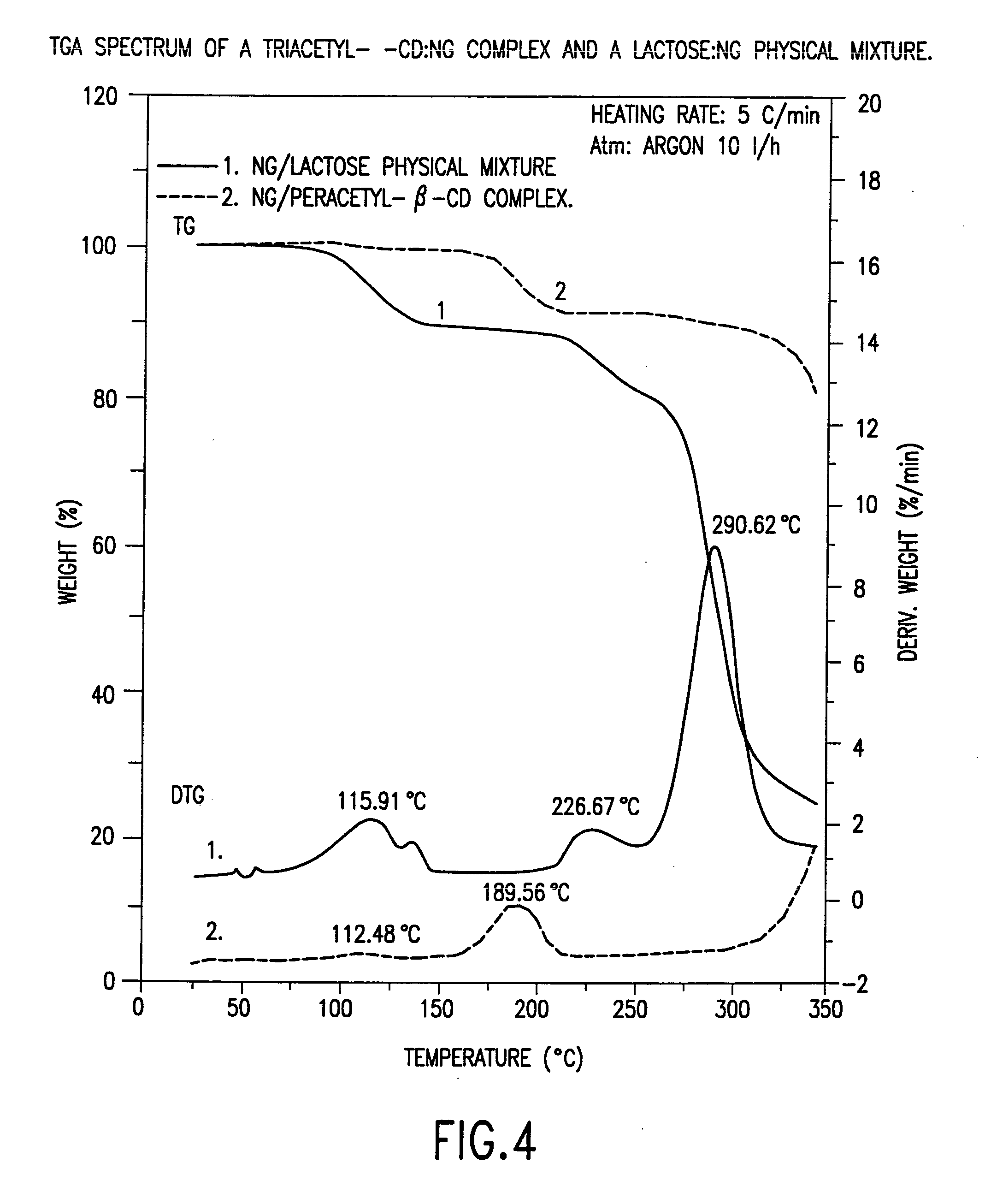

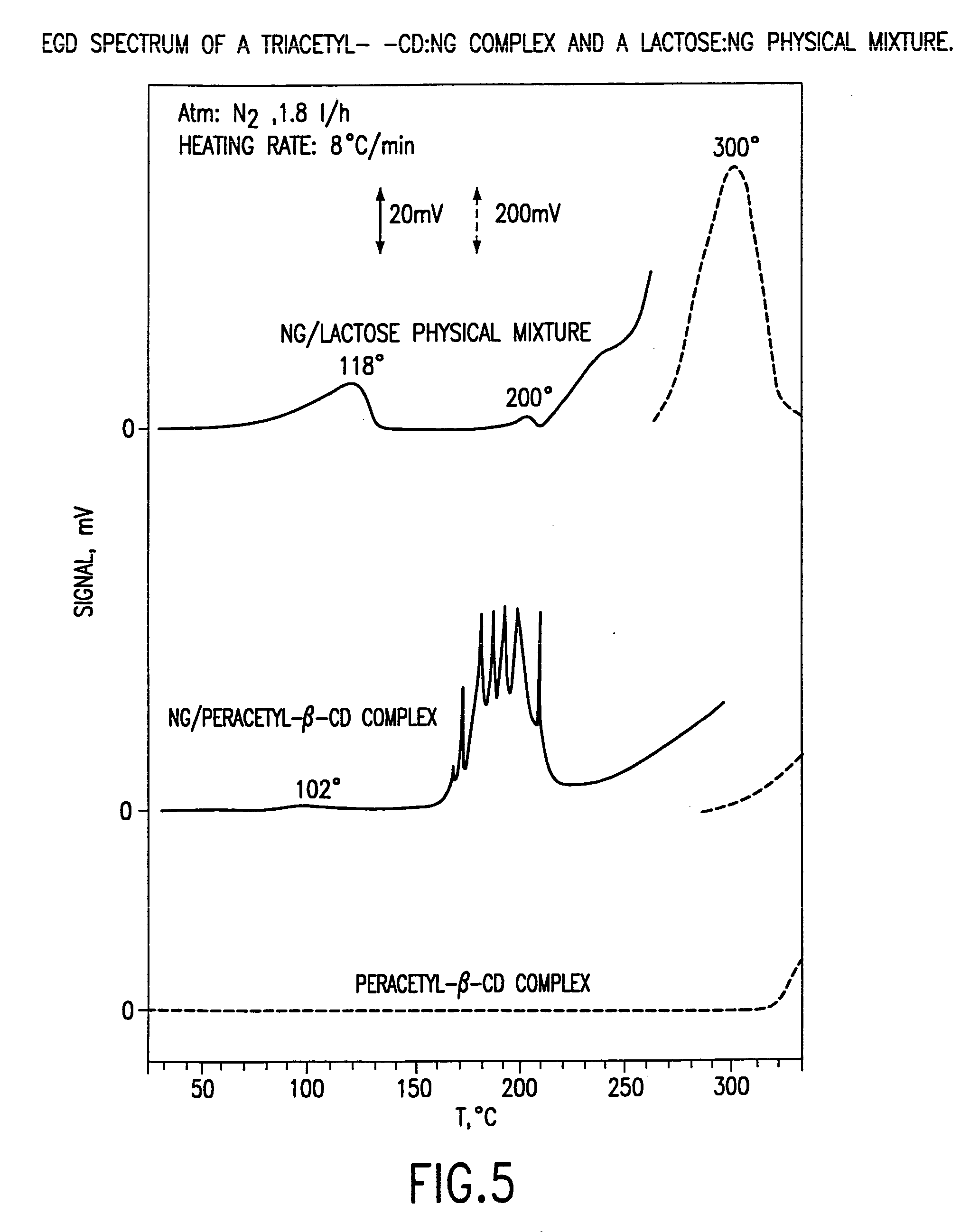

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20020025946A1Improve processing efficiencyImprove stabilityBiocideOrganic chemistryCyclodextrinAqueous medium

The present invention is directed to a method of making an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the method comprises the steps of: a)contacting the acylated cyclodextrin host molecule and the guest molecule to form an inclusion complex; and b) precipitating the inclusion complex in an aqueous medium. The present invention is further directed to an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the guest molecule comprises from about 2% (wt.) to about 15% (wt.) of the inclusion complex. Moreover, the present invention relates to a composition comprising a polymer and an inclusion complex, wherein the inclusion complex comprises an acylated cyclodextrin host molecule and a guest molecule and medical devices and solid pharmaceutical compositions comprised thereof.

Owner:EASTMAN CHEM CO

Micro-electromechanical display backplane and improvements thereof

InactiveUS20070002009A1Low costLow-cost techniqueElectrostatic/electro-adhesion relaysStatic indicating devicesDisplay deviceEngineering

A low cost, scalable backplane for electrophoretic displays comprising a multi-membrane plastic array of micro electromechanical (MEM) switches. Each switch controls the state of a pixel in the electrophoretic display device. Each switch may be latched to eliminate the need to constantly refresh the device and each switch may function as an enunciator

Owner:SEERTECH CORP

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20040063663A1Inhibited DiffusionLow process temperatureBiocidePowder deliveryCyclodextrinAqueous medium

Owner:BUCHANAN CHARLES M +4

Method of CVD for forming silicon nitride film on substrate

InactiveUS7094708B2Improve controllabilityLow process temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyAmmonia gas

A CVD method is to form a silicon nitride film on a target substrate (W). The method includes heating the substrate (W) accommodated in a process container (8), at a process temperature, and supplying a process gas including hexaethylamino-disilane gas and ammonia gas onto the substrate (W) heated at the process temperature, thereby depositing a silicon nitride film on the substrate (W).

Owner:TOKYO ELECTRON LTD

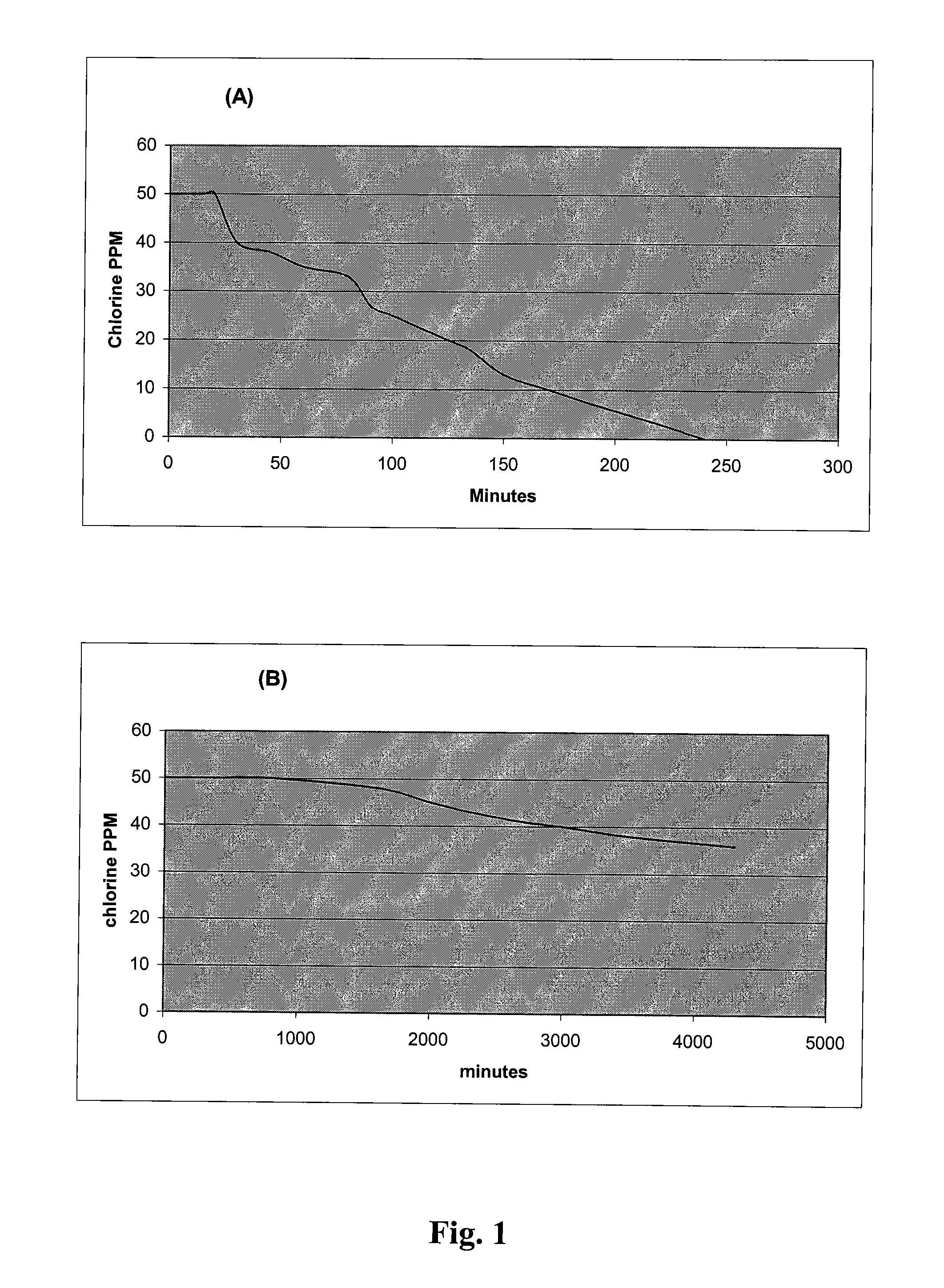

Antimicrobial Compositions And Methods Of Use Thereof

ActiveUS20090192231A1Reduce discolorationReduce turbidityBiocideDead plant preservationBiotechnologyActive agent

The invention provides antimicrobial compositions comprising one or more acid and one or more organic diol. In one embodiment, the invention's compositions have an acidic pH. The compositions may optionally further contain one or more oxidizing agent (including stabilized oxidizing agent and / or unstabilized oxidizing agent), and / or one or more surfactant. In particular embodiments, the acid lacks one or both of —NH group and —NH2 group. The invention's compositions are useful in all stages of handling agricultural products, in hospitals, and in commercial and household applications.

Owner:SMARTWASH SOLUTIONS

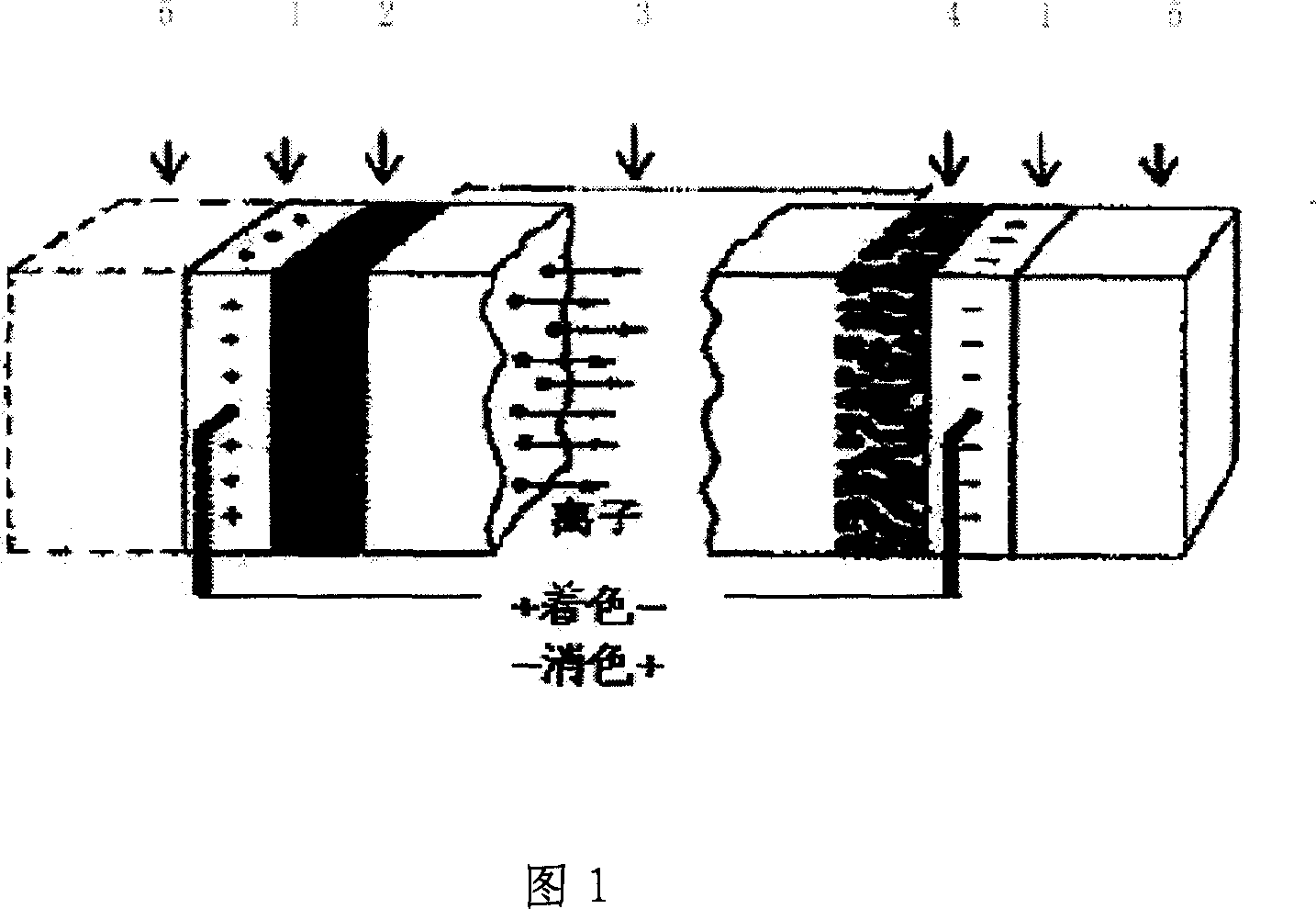

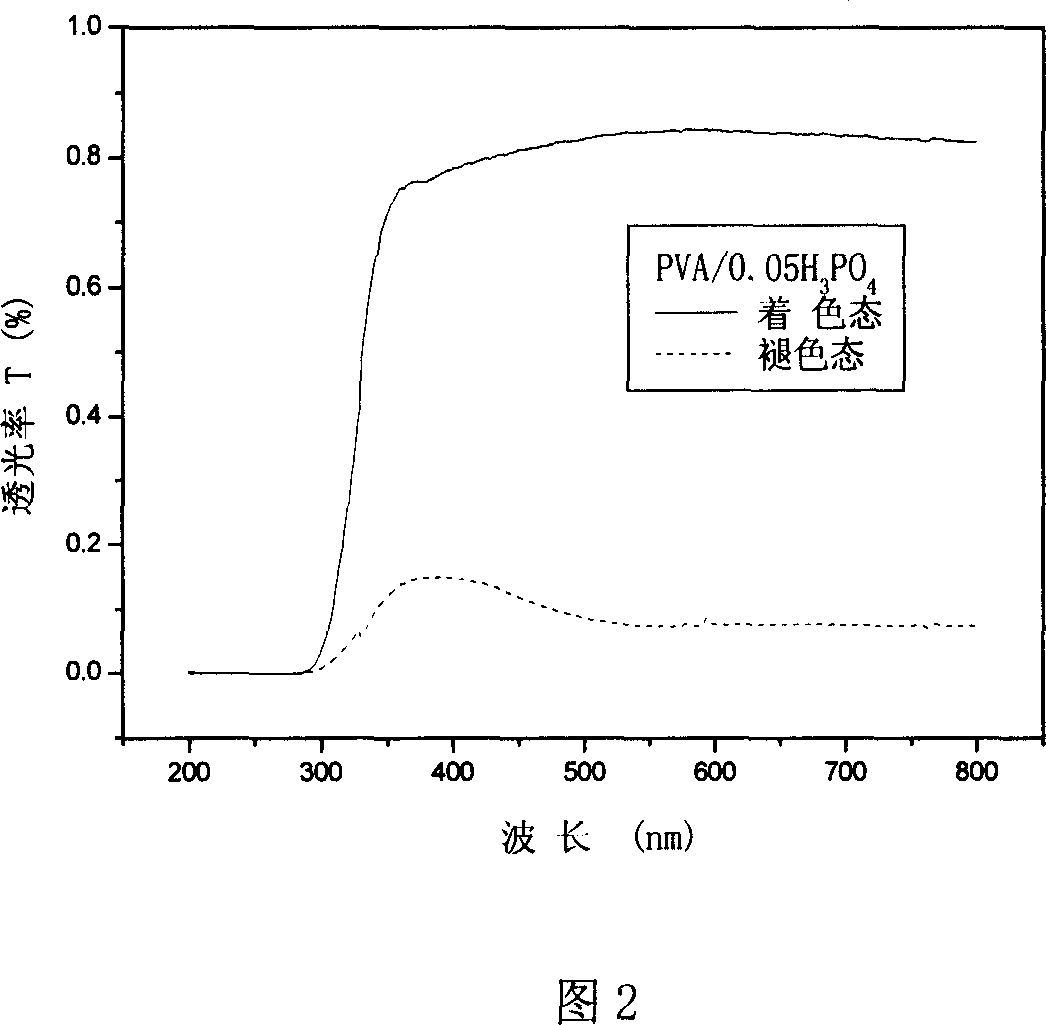

Method for preparing full solid electrochromic device with sol-gel

The related manufacture method for full-solid photochromic device comprises: with sol-gel method, preparing the transparent conductive layer, the photochromic layer, the ion conductive layer and the ion storage layer in turns; then assembling together. Compared with prior art, this invention is low cost and easy controlled, and fit to large-scale industrial production.

Owner:TONGJI UNIV

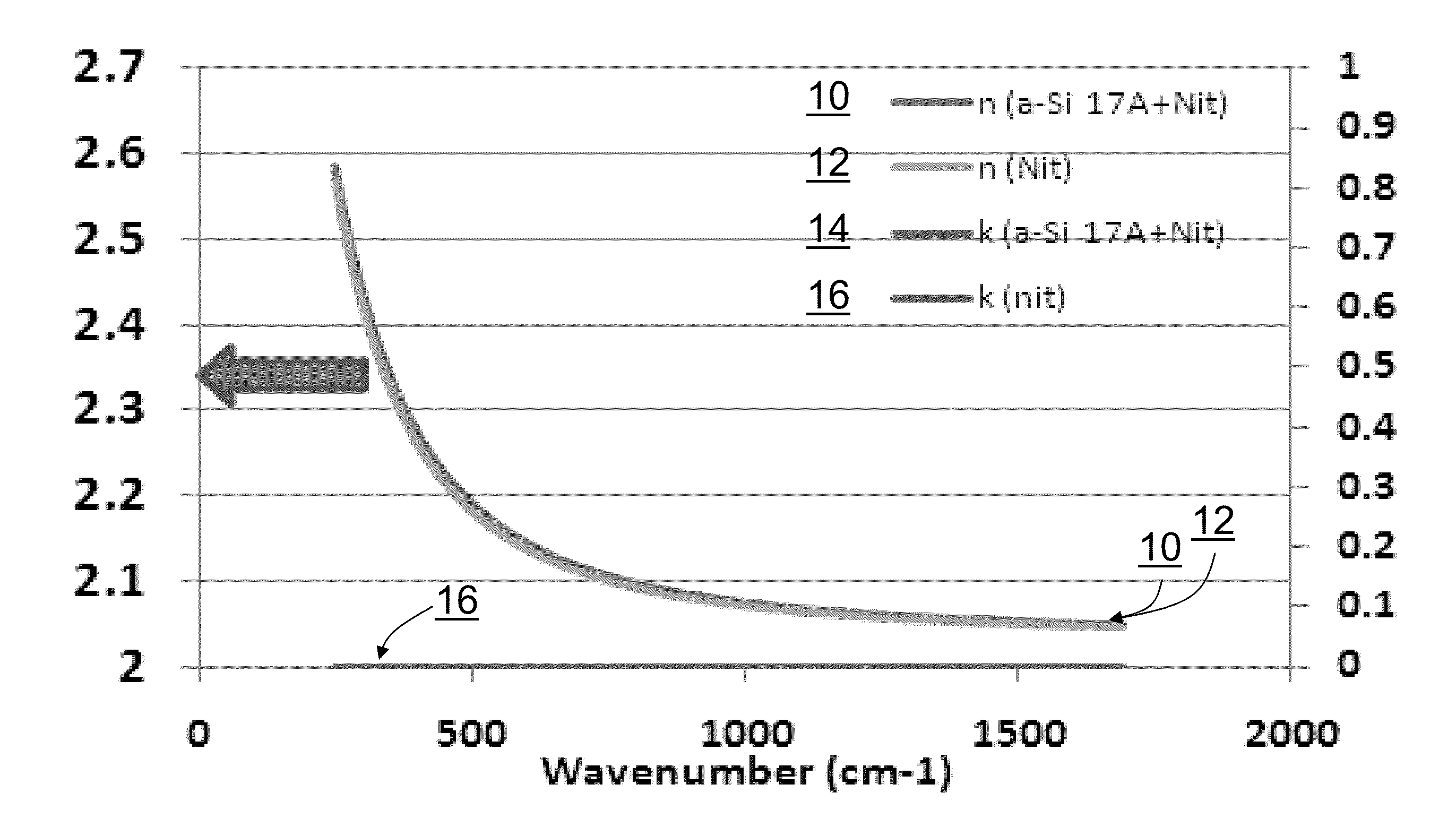

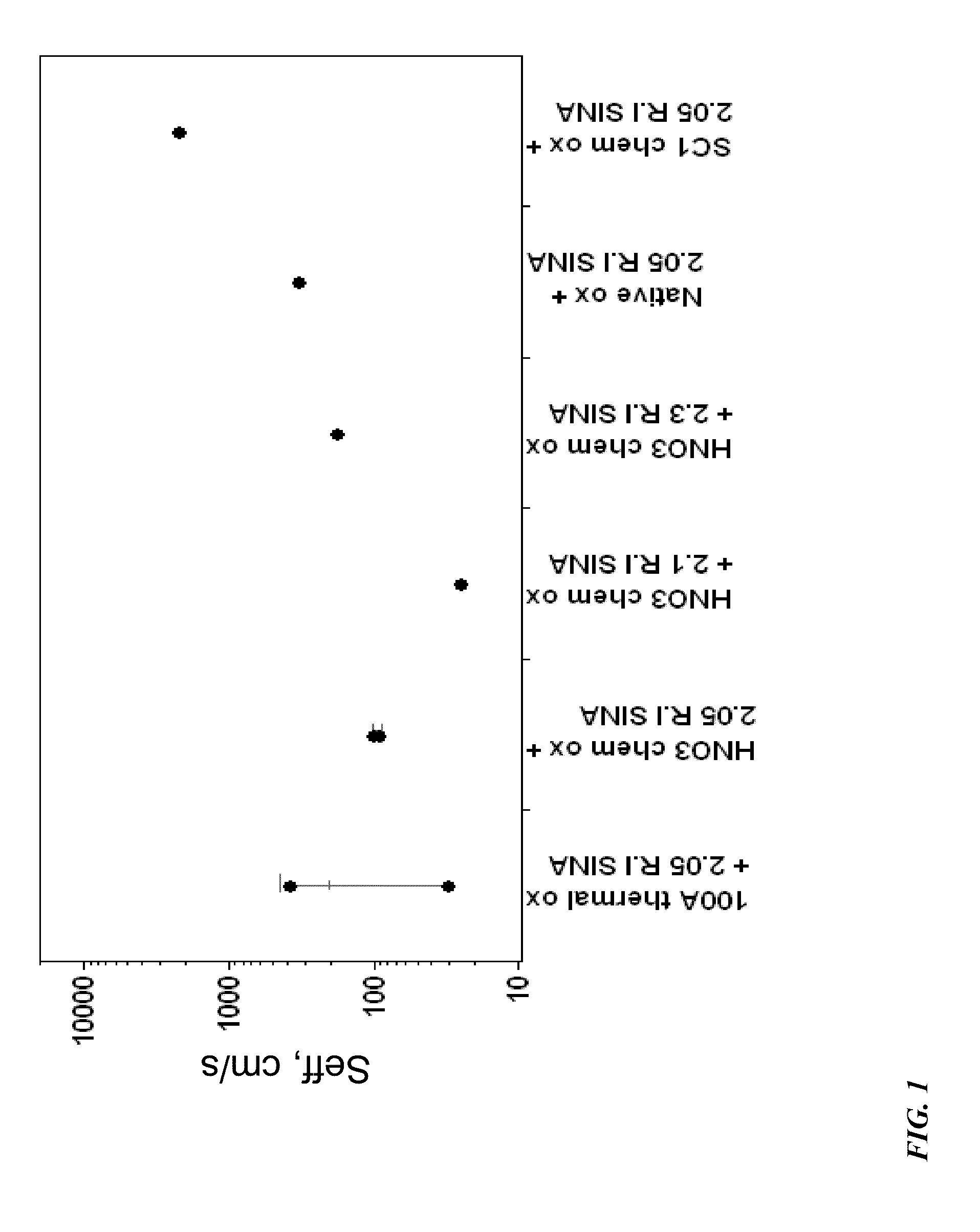

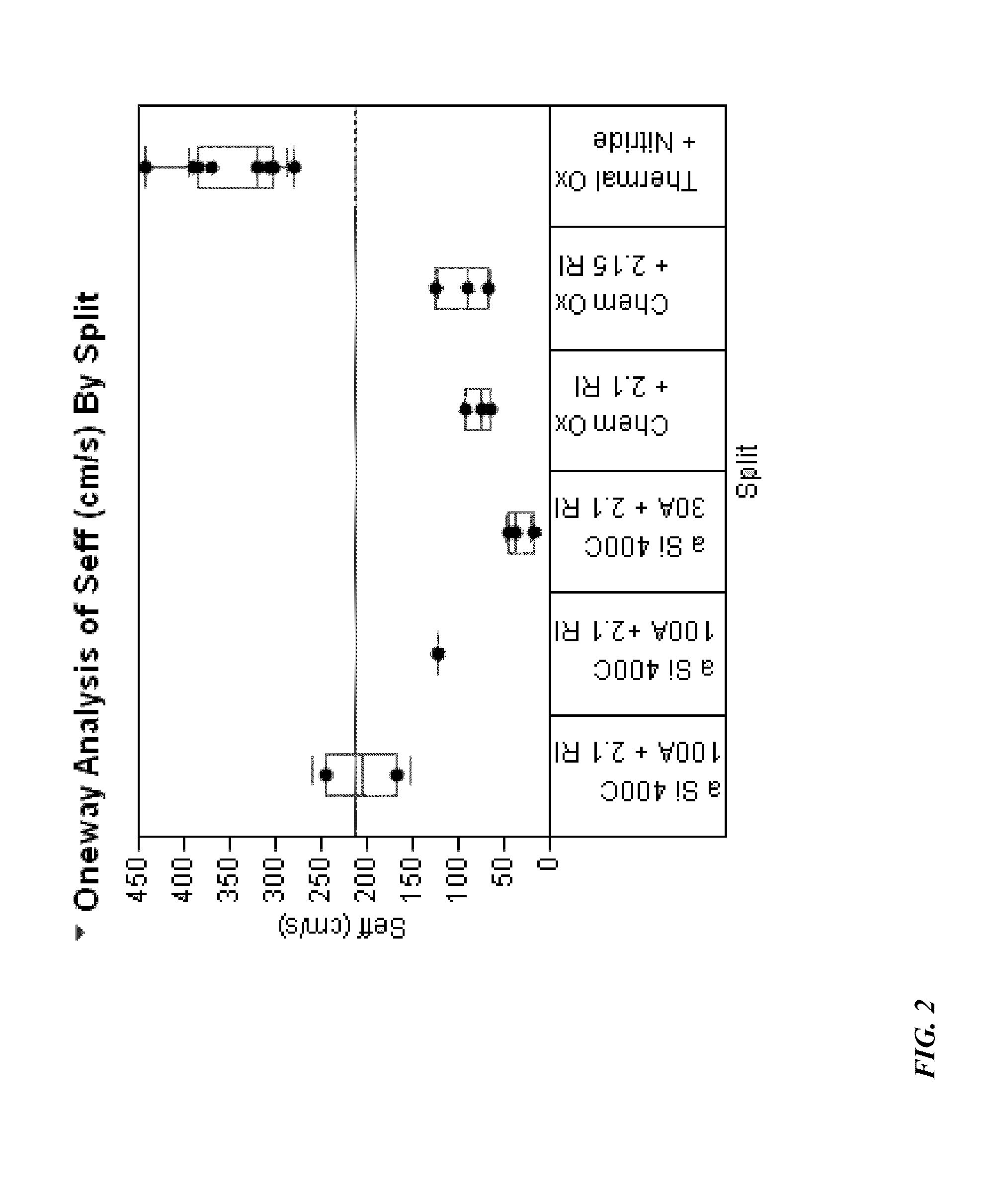

Passivation methods and apparatus for achieving ultra-low surface recombination velocities for high-efficiency solar cells

InactiveUS20110284068A1Good optical performanceEliminate and reduces disadvantageFinal product manufactureSemiconductor/solid-state device manufacturingSubject matterThin layer

The disclosed subject matter provides a method and structure for obtaining ultra-low surface recombination velocities from highly efficient surface passivation in crystalline silicon substrate-based solar cells by utilizing a bi-layer passivation scheme which also works as an efficient ARC. The bi-layer passivation consists of a first thin layer of wet chemical oxide or a thin hydrogenated amorphous silicon layer. A second layer of amorphous hydrogenated silicon nitride film is deposited on top of the wet chemical oxide or amorphous silicon film. This deposition is then followed by annealing to further enhance the surface passivation.

Owner:BEAMREACH SOLAR INC

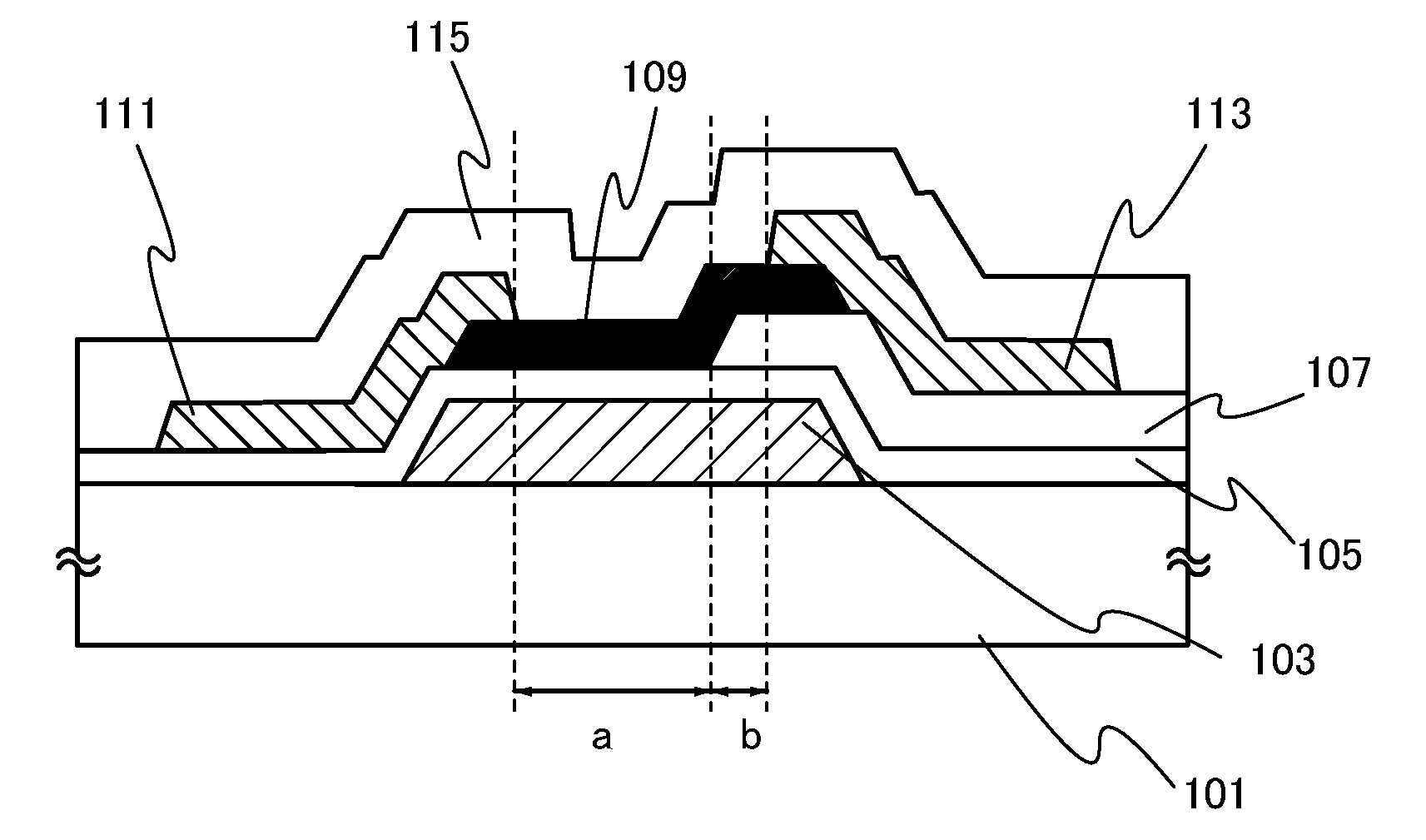

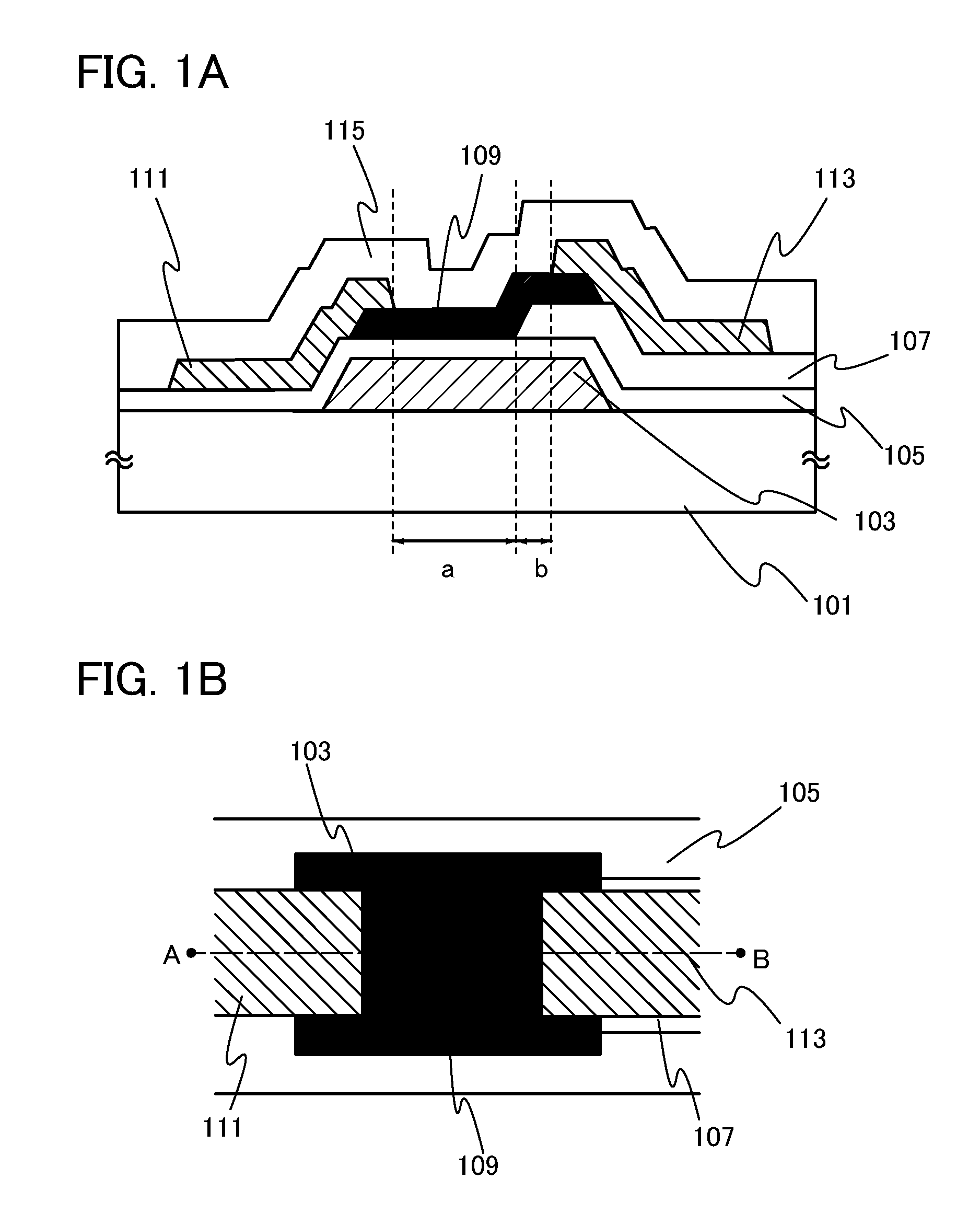

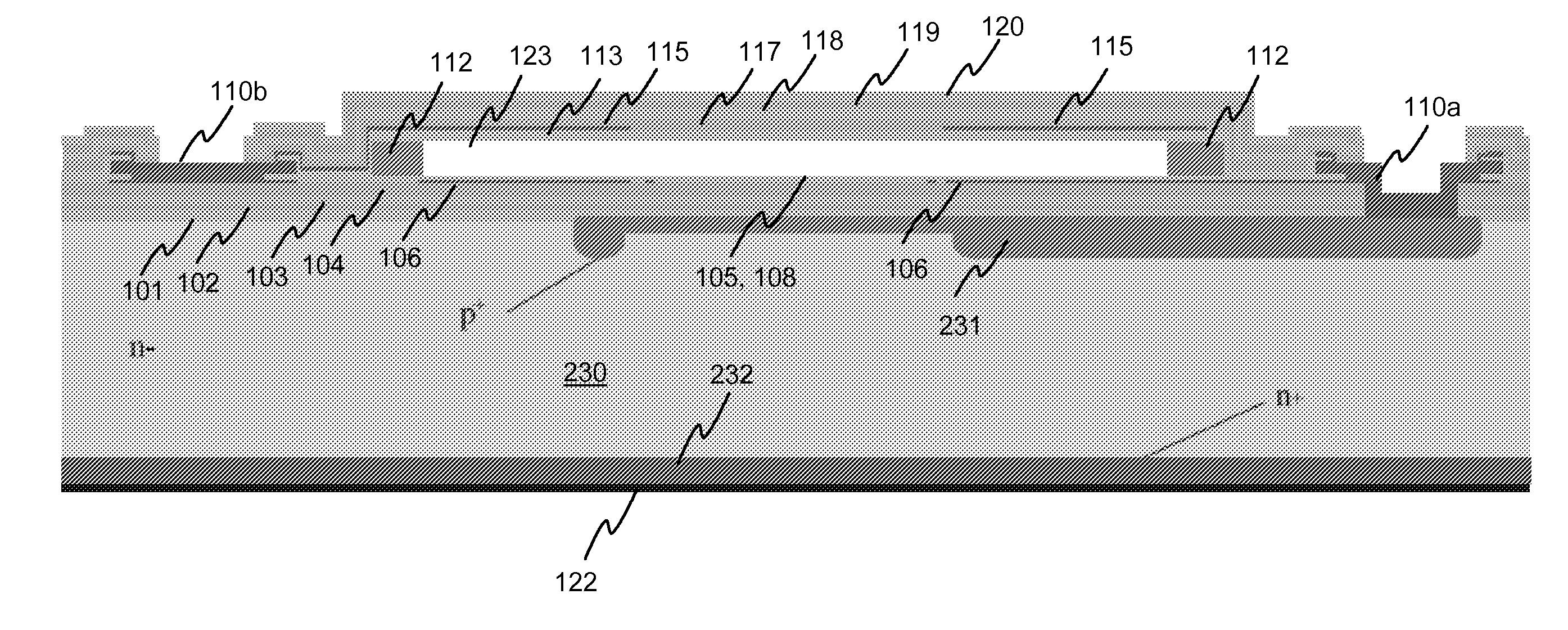

Transistor and semiconductor device

ActiveUS20120193620A1Increase in channel resistanceImprove the immunitySemiconductor devicesCapacitanceSemiconductor

A transistor which withstands a high voltage and controls large electric power can be provided. A transistor is provided which includes a gate electrode, a gate insulating layer over the gate electrode, an oxide semiconductor layer which is over the gate insulating layer and overlaps with the gate electrode, and a source electrode and a drain electrode which are in contact with the oxide semiconductor layer and whose end portions overlap with the gate electrode. The gate insulating layer includes a first region overlapping with the end portion of the drain electrode and a second region adjacent to the first region. The first region has smaller capacitance than the second region.

Owner:SEMICON ENERGY LAB CO LTD

Semiaromatic moulding compositions and uses of these

ActiveUS20110123749A1Low process temperatureSufficient compatibilityNon-metal conductorsEnvelopes/bags making machineryLaurolactamPolymer science

A polyamide moulding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of moulding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give mouldings.

Owner:EMS PATENT AG

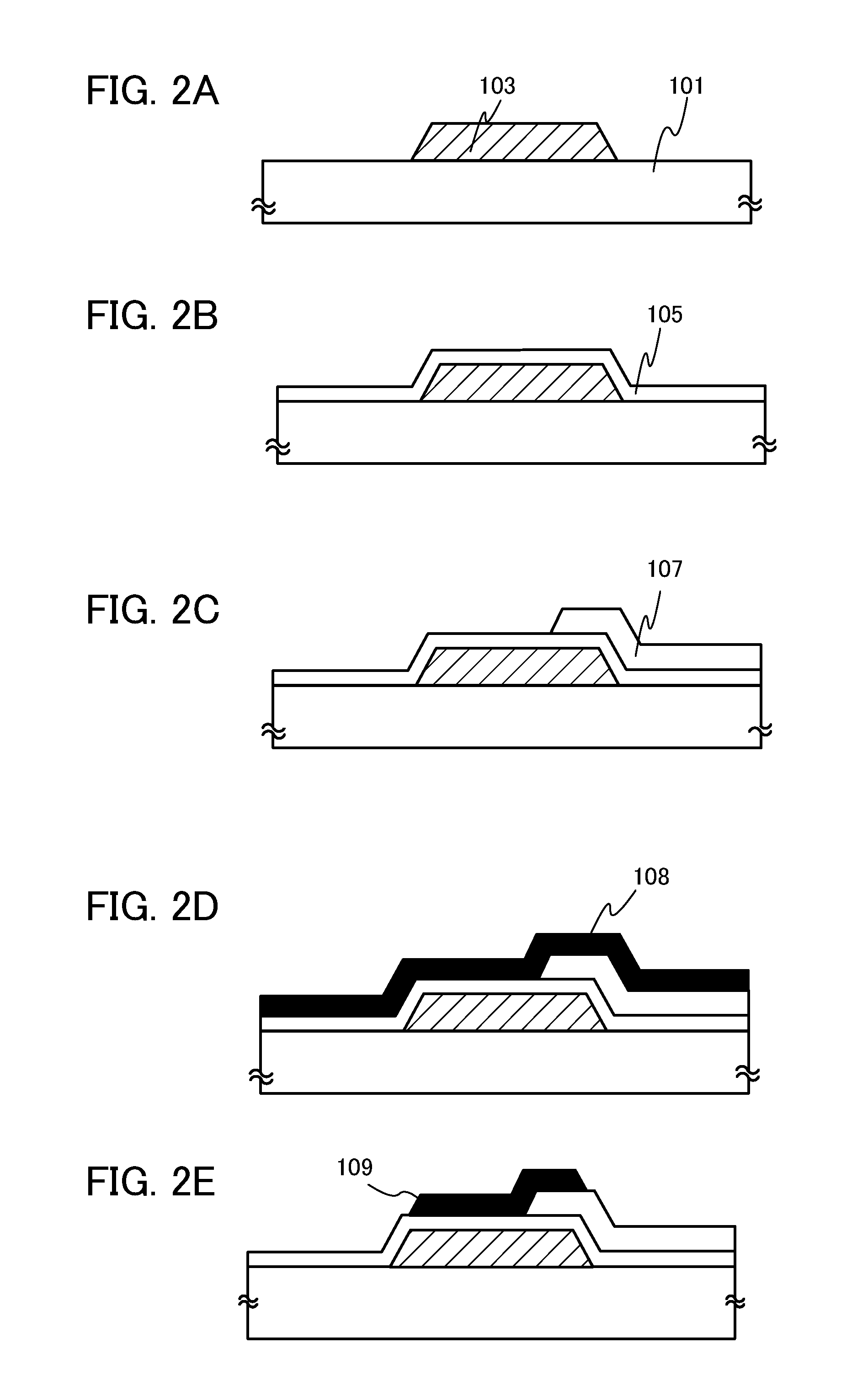

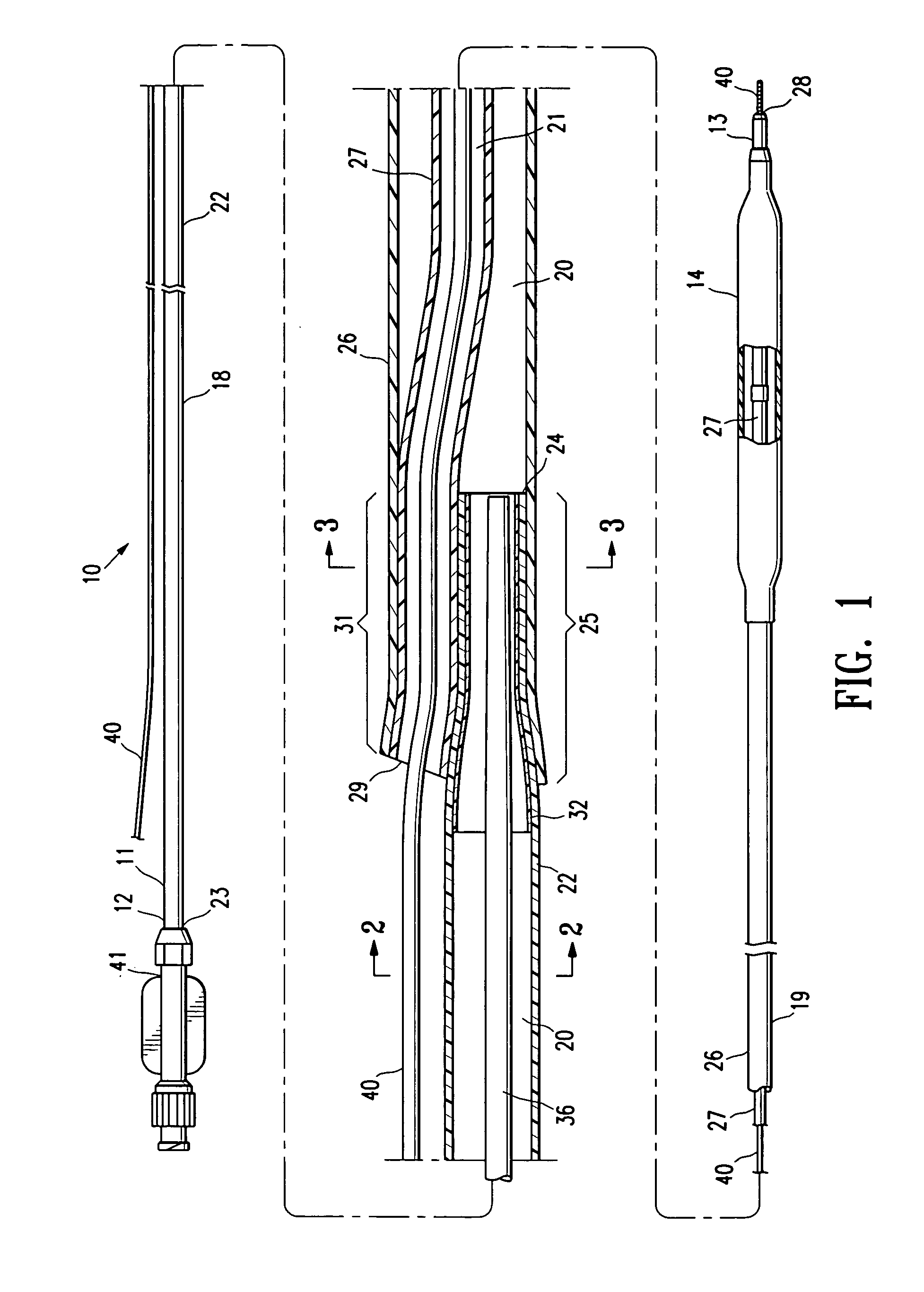

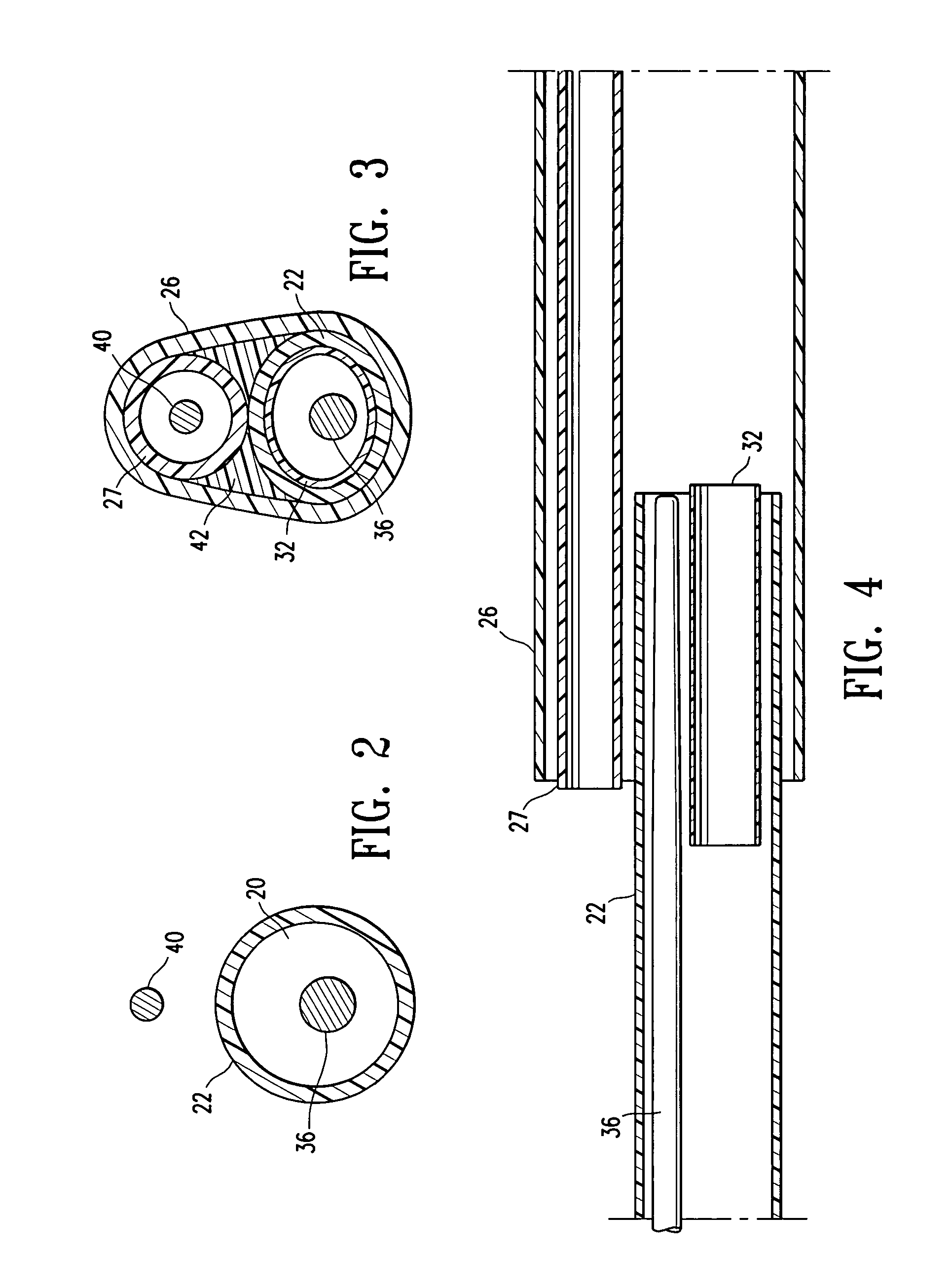

Catheter shaft junction having a polymeric multilayered sleeve with a low processing temperature outer layer

InactiveUS20050277878A1Good dimensional stabilityLow profileMulti-lumen catheterSurgeryVitrificationMedicine

One aspect of the invention is directed to a balloon catheter with a multilayered polymeric sleeve at the rapid exchange intermediate section, having an outer layer formed of a polymer with a relatively low processing temperature (i.e., melting temperature for semi-crystalline polymers or glass transition temperature for amorphous polymers), and having an inner layer.

Owner:ABBOTT CARDIOVASCULAR

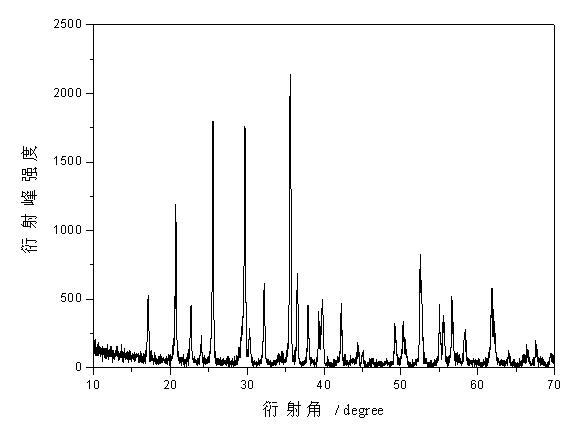

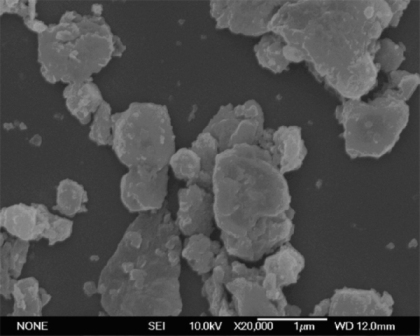

Graphene/phosphoric acid iron-lithium composite material with sandwich structure and preparation method thereof

InactiveCN102148371ASimple preparation processShort preparation cycleNon-aqueous electrolyte accumulator electrodesO-Phosphoric AcidLithium-ion battery

The invention relates to a graphene / phosphoric acid iron-lithium composite material with a 'sandwich' structure and a preparation method thereof. The structure characteristics of the graphene / phosphoric acid iron-lithium composite material are that: blocky particles are formed by a grapheme laminated sheet which is completely coated by a phosphoric acid iron-lithium shell; and the insides of the particles present a similar 'sandwich' structure overlapped by a plurality of layers of phosphoric acid iron-lithium and graphene one by one. The preparation method thereof adopts a 'two-step' method. The characteristic steps are as follows: a graphene / phosphoric acid iron precursor with a 'sandwich' structure is compounded by a liquid phase method during the first step; then lithium is embedded in the second step; lithium iodide liquid phase low temperature reaction is adopted for embedding the lithium; then the graphene / phosphoric acid iron-lithium composite material is obtained through high temperature calcination under reducing (inertia) atmospheres; moreover, the graphene / phosphoric acid iron-lithium composite material can also be formed by the embedding of the lithium through high temperature solid phase reaction. The graphene / phosphoric acid iron-lithium composite material prepared by the method has high capacity and good charging-discharging circulating performances, and is suitable to be used as an anode material of a lithium ion battery.

Owner:SHANGHAI UNIV

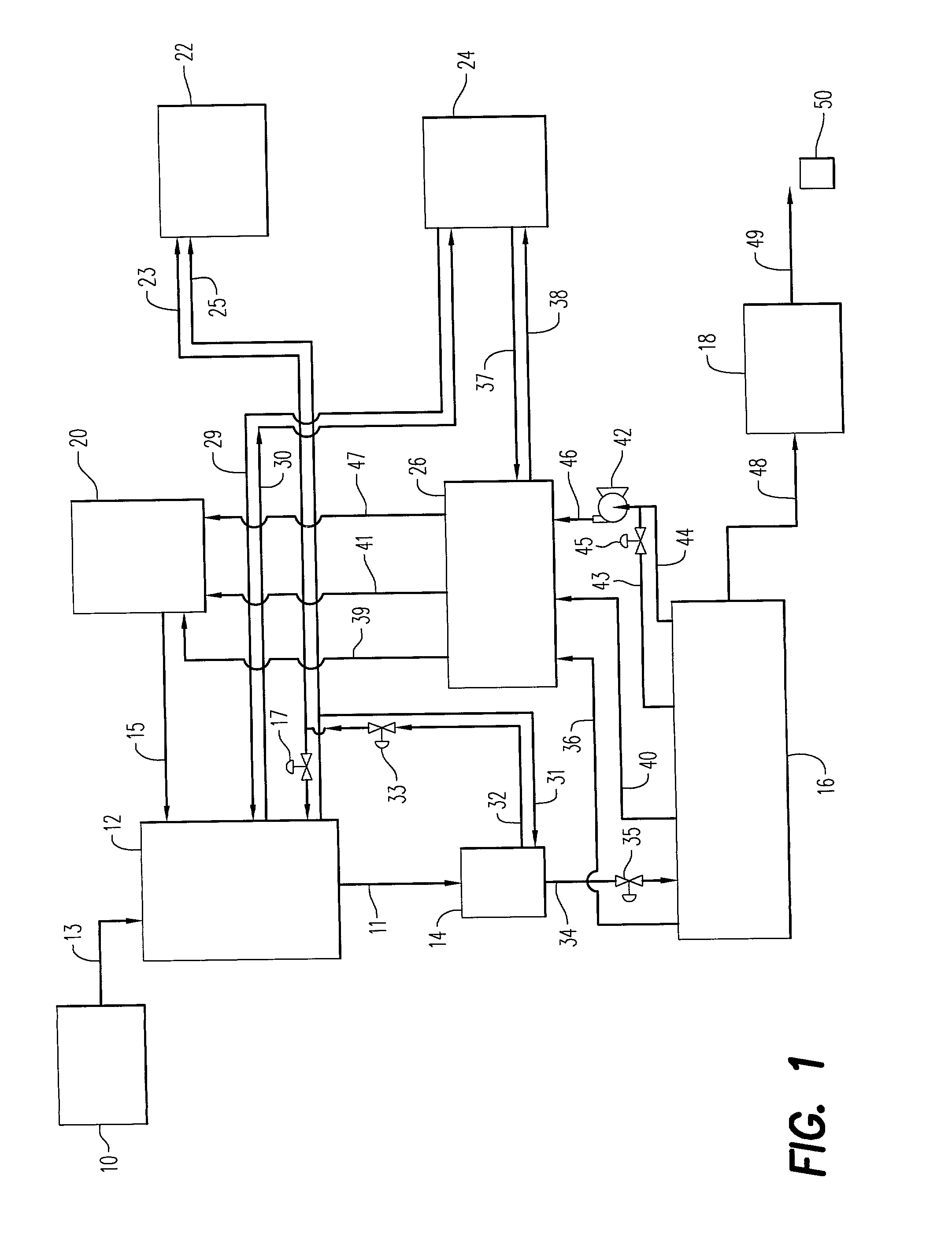

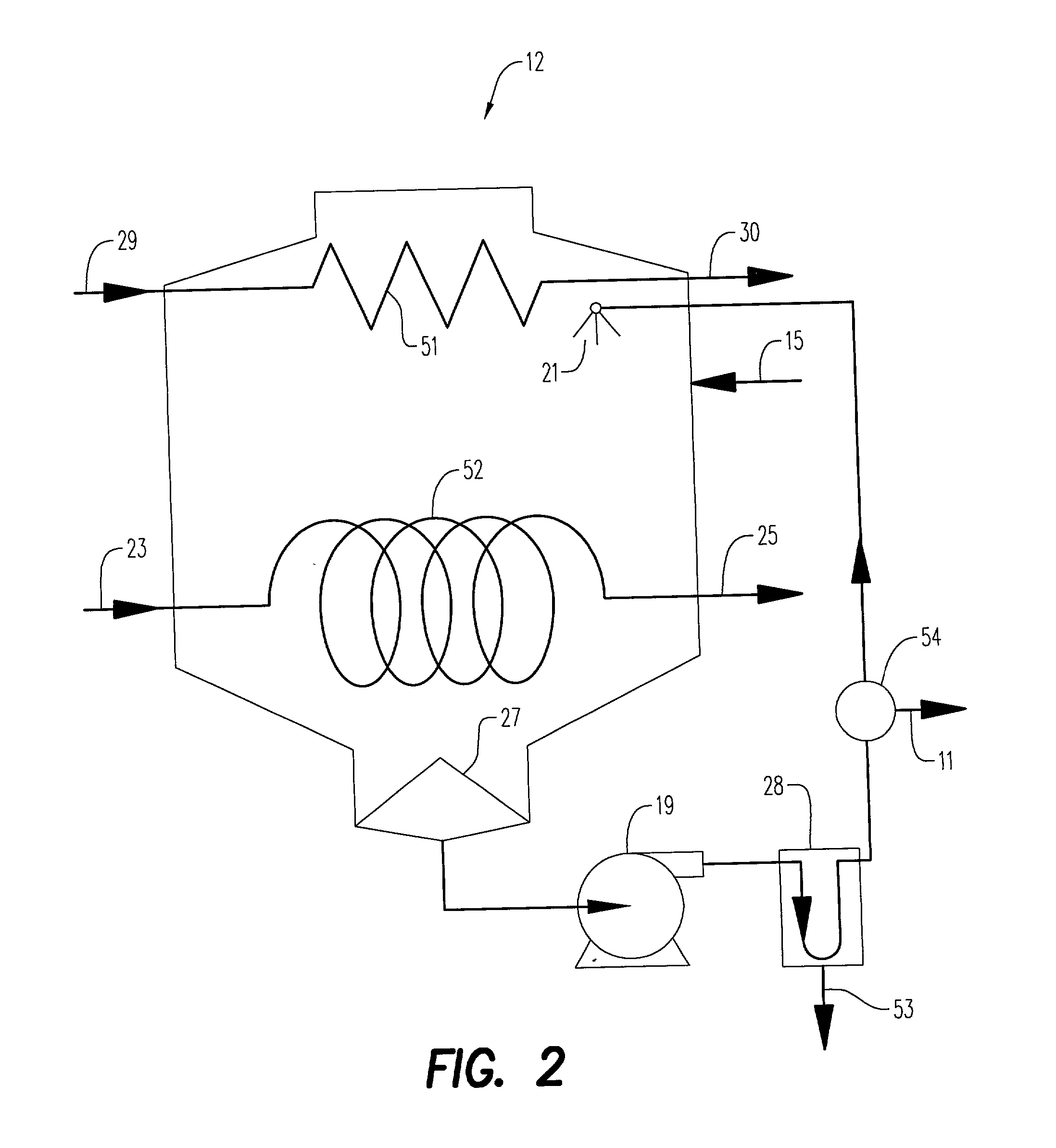

Polystyrene reclamation process

InactiveUS20020062054A1Avoid lostEasy to reuseHydrocarbon by hydrogenationPlastic recyclingPropyl bromideBoiling point

This disclosure concerns a process and apparatus for reclamation of waste polystyrene-type materials for reuse within the specification ranges of the input polystyrene-type material. The disclosed process and apparatus include dissolution of the waste polystyrene-type materials in a dissolve section utilizing a reusable solvent having a low boiling point and high vaporization rate, removal of solid contaminants in one or more filter sections, devolatilization of the dissolved polystyrene and recovery of the polystyrene-type material in a solid form in a recovery section. Preferably the process and apparatus provide a closed system and include recycling and reuse in the process of the vaporized solvent. The maximum temperature in the recovery section is 190° C. The reusable solvent is preferably environmentally safe and has a low boiling point and high vaporization rate. n-Propyl bromide, or environmentally safe mixtures thereof, including mixtures with isopropyl alcohol, is the preferred reusable solvent.

Owner:RESOURCE RECOVERY TECH

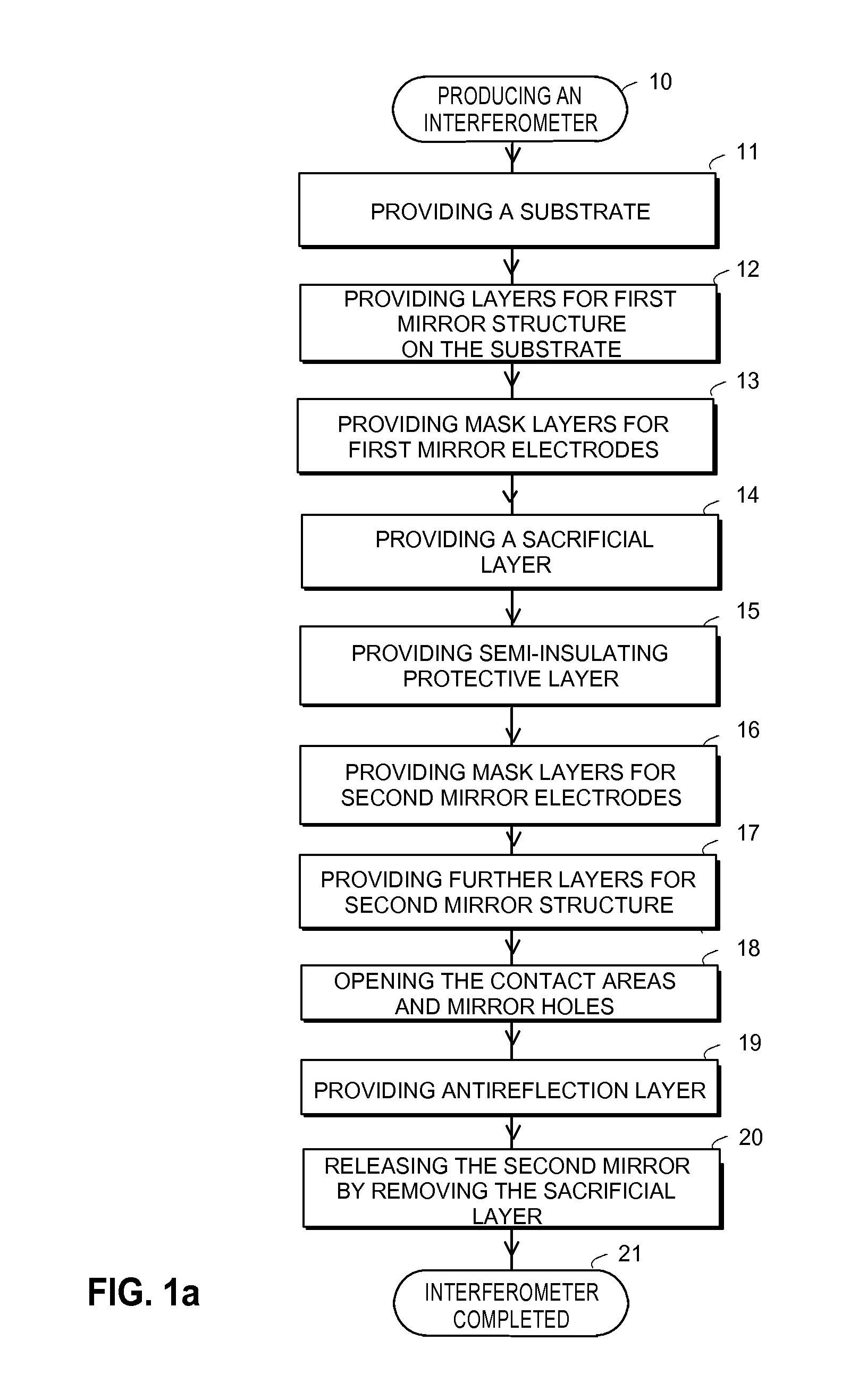

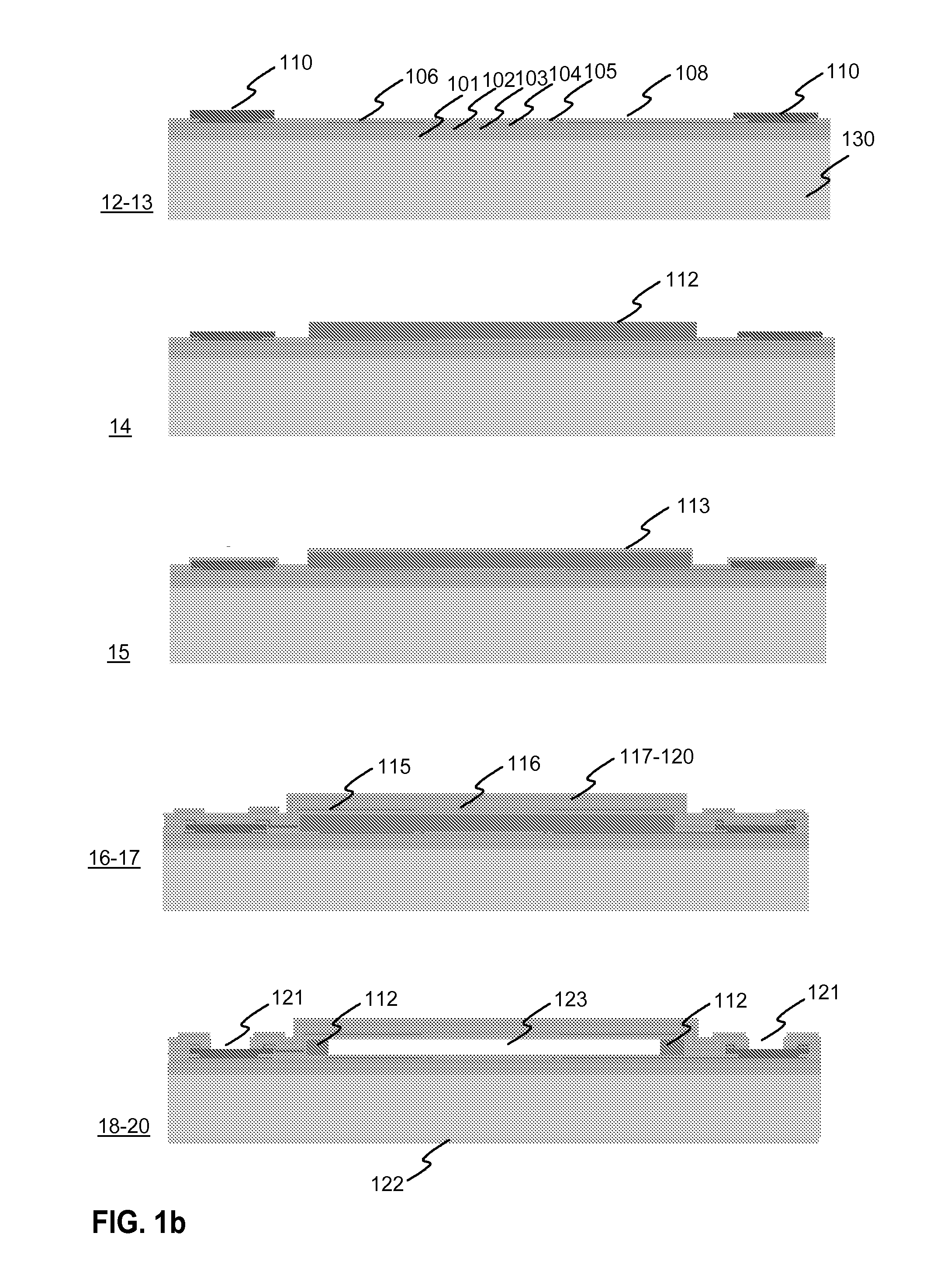

Electrically tunable fabry-perot interferometer, an intermediate product an electrode arrangement and a method for producing an electrically tunable fabry-perot interferometer

InactiveUS20110279824A1Prevents electrical short circuitPrevent electric chargeVacuum evaporation coatingSputtering coatingSputteringEvaporation

Electrically tunable Fabry-Perot interferometers which are produced with micromechanical (MEMS) technology. Producing interferometers with prior art processes includes costly and complicated production phases. Therefore, it has not been possible to apply interferometers in consumer mass products. According to the present solution, the Fabry-Perot cavity is made by removing a sacrificial layer (112) which has been polymer material. A mirror layer (113, 117-120) which is produced above the sacrificial layer can be made with atomic layer deposition technology, for example. According to a preferable embodiment, electrodes (106b, 115b) of the mirror structures are formed by using sputtering or evaporation. With the present solution it is possible to avoid the above mentioned problems related with prior art.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

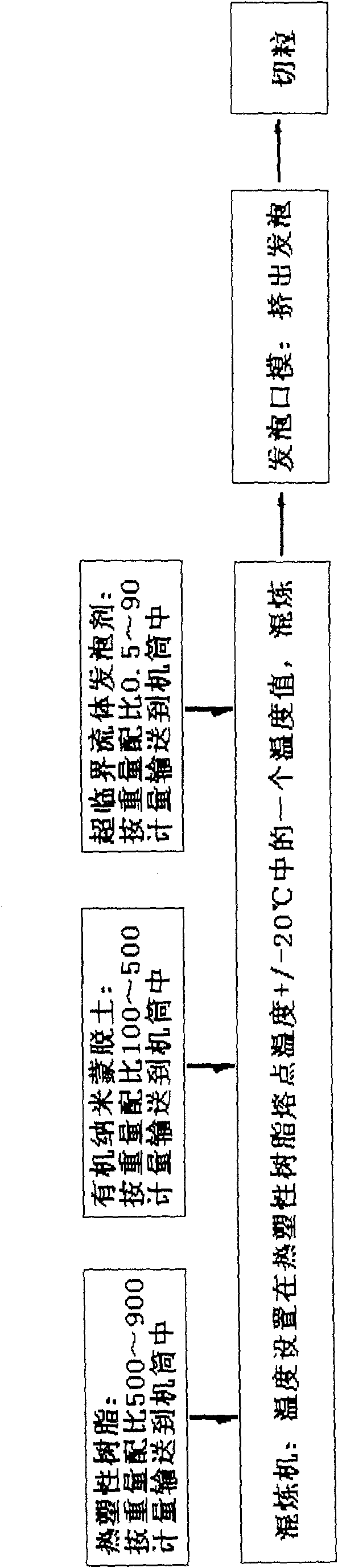

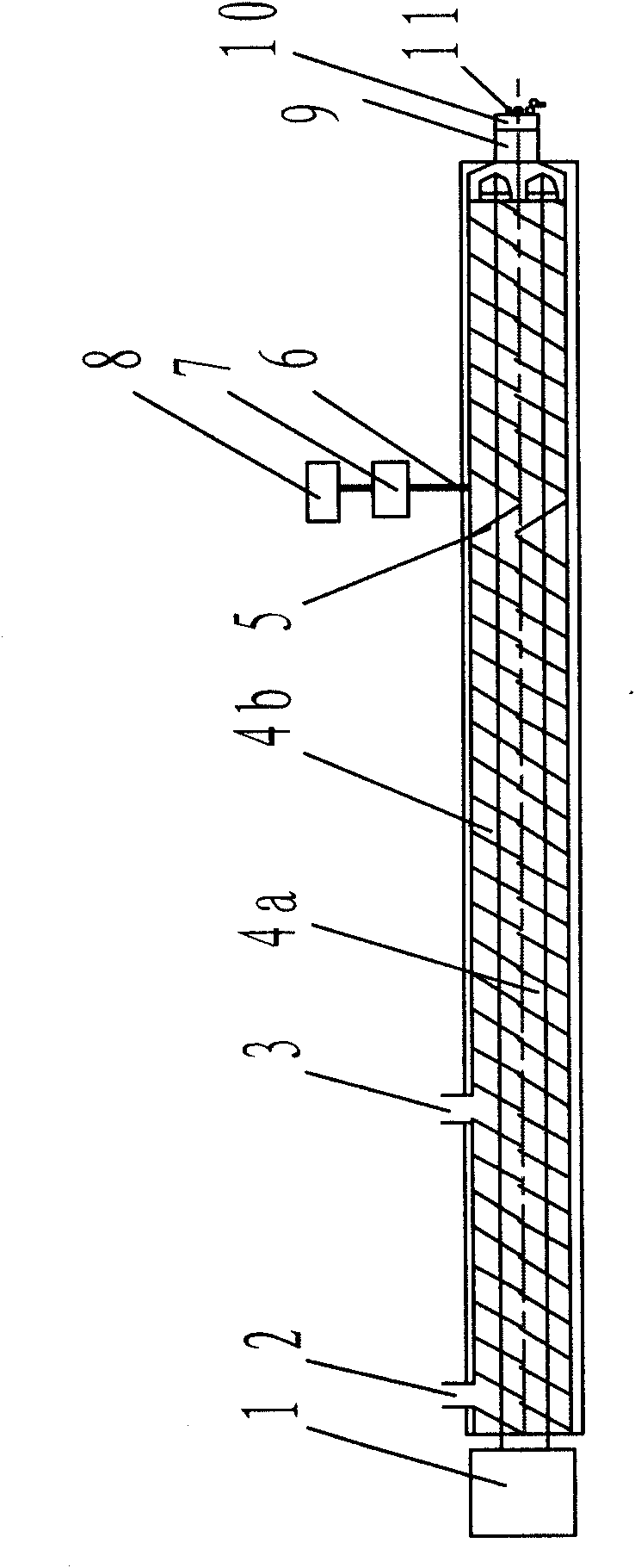

Nucleating agent master batches used for foaming of thermoplastic resin

ActiveCN101565550AConvenient injection foam moldingEasy extrusionVolumetric Mass DensityNitrogen gas

The invention relates to a nucleating agent and a method for preparing the nucleating agent, wherein the nucleating agent is used for reducing the dimension of the foaming hole and improving the density of the foaming hole when a supercritical fluid foaming agent (such as carbon dioxide or nitrogen) is used for producing thermoplastic foaming products. The raw materials of the nucleating agent mainly consists of an organic montmorillonite, a thermoplastic resin and a supercritical fluid foaming agent; the specific weight of the nucleating agent master batches is controlled within 100+ / -5% of that of the thermoplastic resin. The method has the advantages that a supercritical fluid foaming method is adopted to prepare the nucleating agent master batches which have approximate specific weights to the resin material adopted by the subsequent foam forming, thus facilitating the subsequent injection foam forming and extrusion foam forming; and the carbon dioxide or nitrogen in supercritical state is used for reducing the viscosity of the carrier resin during the mixing process, the dispersion uniformity of the peeled sandwich montmorillonite in the carrier resin is reinforced, the process temperature is reduced, the layer spacing of the sandwich nano-montmorillonite which may be not peeled is increased and the sufficient peeling is realized.

Owner:BEIJING CHN TOP MACHINERY

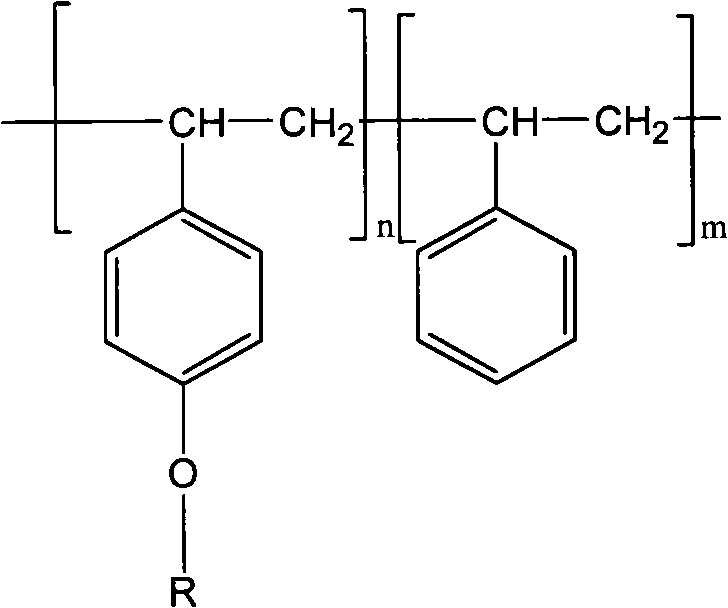

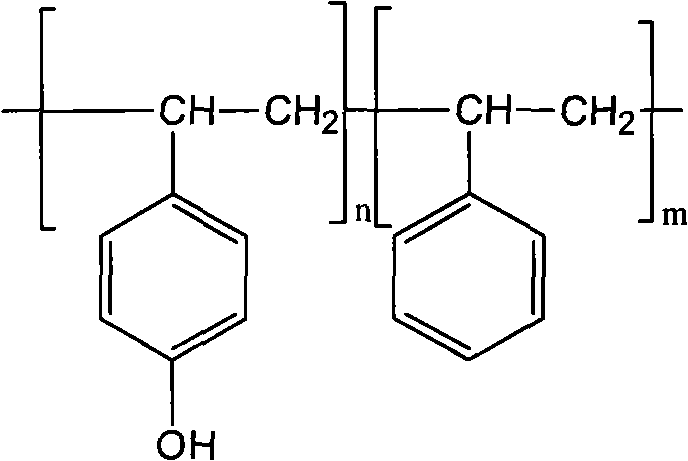

Composite material, high frequency circuit board prepared from same and preparation method thereof

ActiveCN101643565AExcellent dielectric propertiesImprove heat resistancePrinted circuit aspectsWoven fabricsHemt circuitsCopper foil

The invention relates to a composite material, a high frequency circuit board prepared from same and a preparation method thereof. The composite material comprises the following components: 20-70 parts of thermosetting mixture containing a hydrocarbon resin with the molecular weight of less than 11000 and more than 60% of ethylene group and a solid styryl resin with unsaturated double bond and medium or low molecular weight; glass fiber cloth; filler powder; and fire retardant and curing initiator. The prepared high frequency circuit board comprises a plurality of prepreg layers which are superimposed and prepared from the composite material, and copper coils which are pressed and coated on both sides of prepreg layers. The preparation of the prepregs prepared by the composite material ofthe invention is simple and the high frequency circuit board prepared from the prepregs has low dielectric constant and dielectric loss angle tangent, good heat resistance and convenient technologicaloperation so that the composite material of the invention is suitable to prepare circuit boards of high frequency electronic equipments.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com