Graphene/phosphoric acid iron-lithium composite material with sandwich structure and preparation method thereof

A lithium iron phosphate and composite material technology, applied in the field of nanomaterials, can solve the problems of limited material application, poor rate charge and discharge performance, etc., and achieve the effects of improving material purity, low process temperature, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

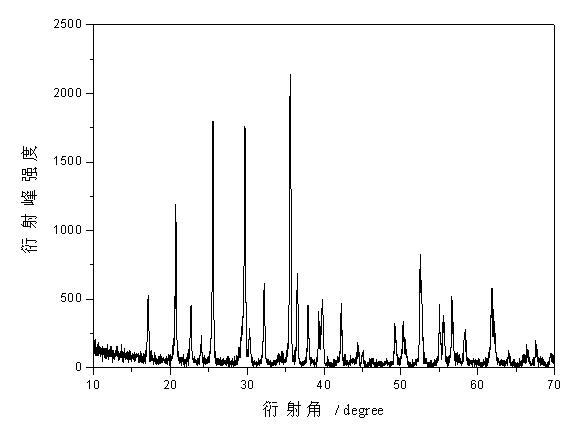

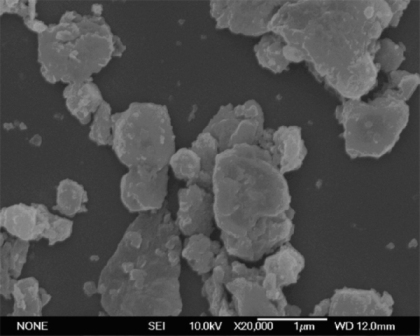

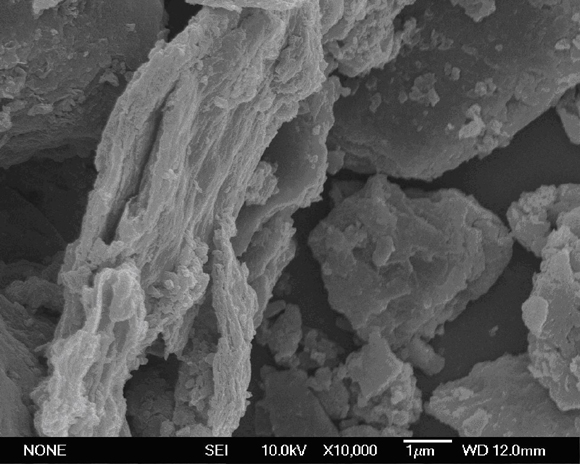

Image

Examples

Embodiment 1

[0035] Weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide, dissolve them in 12mL of concentrated sulfuric acid, and heat to 80°C; add 3g of natural graphite powder to the above solution, keep it at 80°C for 4 hours; cool to room temperature, and deionize with 500mL After diluting with water, let it stand overnight; filter and dry in a vacuum oven at 60°C; dissolve the above product in 120mL of concentrated sulfuric acid, slowly add 15g of potassium permanganate into the solution, stir at 35°C for 2 hours, then slowly dilute with 250mL of water , let stand for 2 hours; put 20mLH 2 o 2 (30wt%) was added to the above solution; filtered and then washed with 1 L of HCl solution with a volume ratio of 1:10, and ultrasonicated for 15 minutes; 5ml of isopropanol was added, and then ultrasonicated for 15 minutes to obtain a graphene solution.

[0036] Take 67mL of the above solution, add deionized water to dilute to 500mL, add 1.40 g FeSO 4 ·7H 2 O, stirred at room...

Embodiment 2

[0041] Take 56 mL of graphene solution with a concentration of 3 mg / mL, add deionized water to dilute to 500 mL, add 1.0 g FeCl 2 4H 2 O, stirred at room temperature for 10 min, then added 0.61 g of diammonium hydrogen phosphate, stirred for 10 min; added dropwise 0.33 g of H 2 o 2 (30wt%), stirred at room temperature for 3 hours, centrifuged and washed three times with deionized water, the resulting paste was placed in a blast oven, dried at 80°C for 5 hours, ground into powder, placed in a tube furnace, and Under the condition of nitrogen protection, annealing at 400°C for 4 hours and then cooling naturally, a graphene / iron phosphate composite material with crystal water removed was obtained.

[0042] Dissolve 4.02 g LiI in 60 mL of acetonitrile, then add 1.50 g of annealed graphene / iron phosphate composite material; stir at room temperature for 12 hours, centrifuge and wash with acetonitrile for 3 times, and place the obtained precipitate in a vacuum drying oven and dry ...

Embodiment 3

[0044] Take 74 mL of graphene solution with a concentration of 3 mg / mL, add deionized water to dilute to 500 mL, add 1.98 g Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O, stirred at room temperature for 10 min, then added 0.41 g of phosphoric acid, stirred for 10 min; added dropwise 0.27 g of H 2 o 2 (30wt%), stirred at room temperature for 4 hours, centrifuged and washed three times with deionized water, the resulting paste was placed in a blast oven, dried at 80°C for 4 hours, ground into powder, placed in a tube furnace, and Under the condition of nitrogen protection, annealing at 400°C for 5 hours and then cooling naturally, a graphene / iron phosphate composite material with crystal water removed was obtained.

[0045] Take 1.13 g of annealed graphene / iron phosphate composite material, add lithium carbonate raw material at a molar ratio of Fe ion and Li ion 1:1, fully grind and mix for 1 hour, then place the mixture in a tube furnace, (Ar / H 2 The volume ratio is 95:5), calcined at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com