High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

An advanced composite material and epoxy matrix technology, which is applied in the field of high temperature modified multifunctional epoxy matrix resin for advanced composite materials and its preparation, can solve the problems of unpublished literature or patent reports, polyetherimide resin High cost, unfavorable large-scale promotion and application, etc., to achieve the effect of low cost, convenient source and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

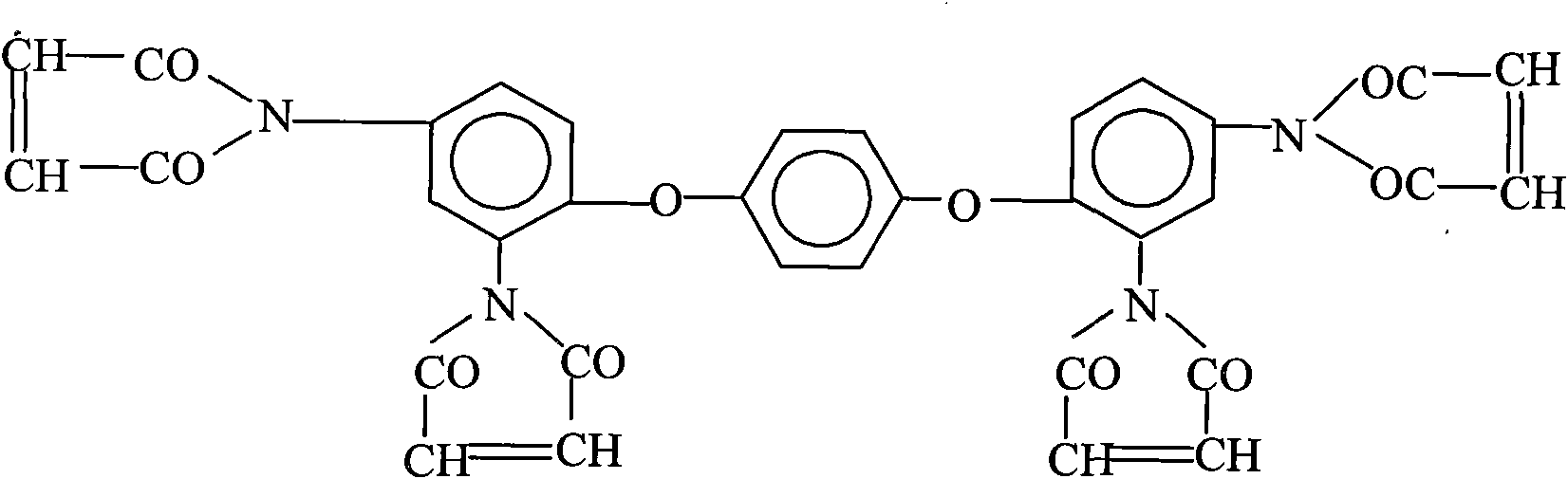

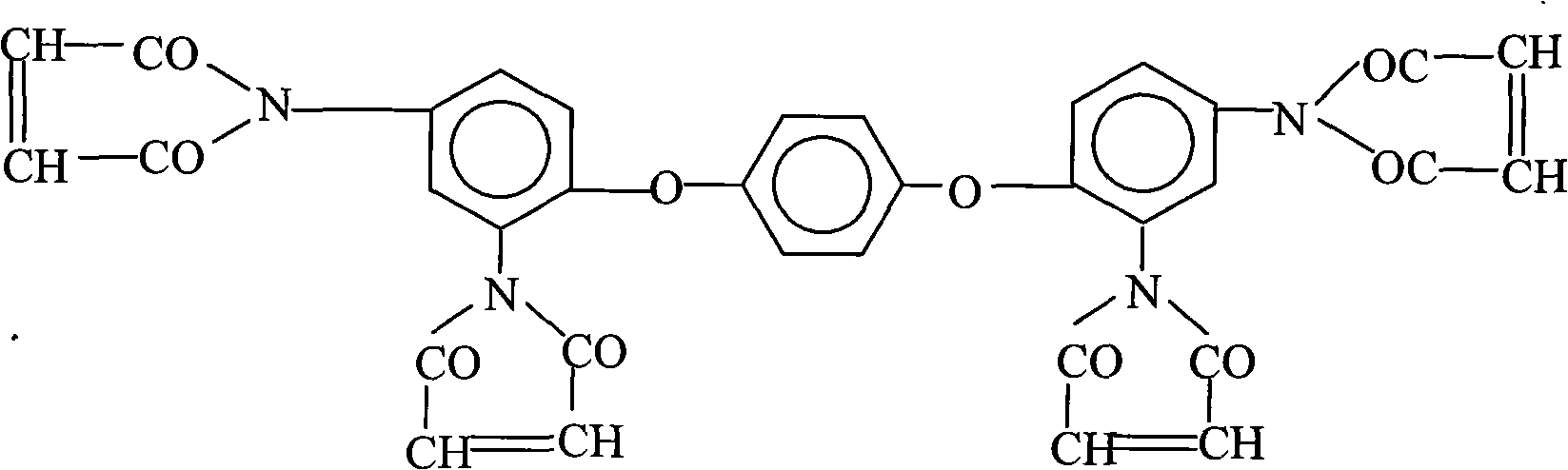

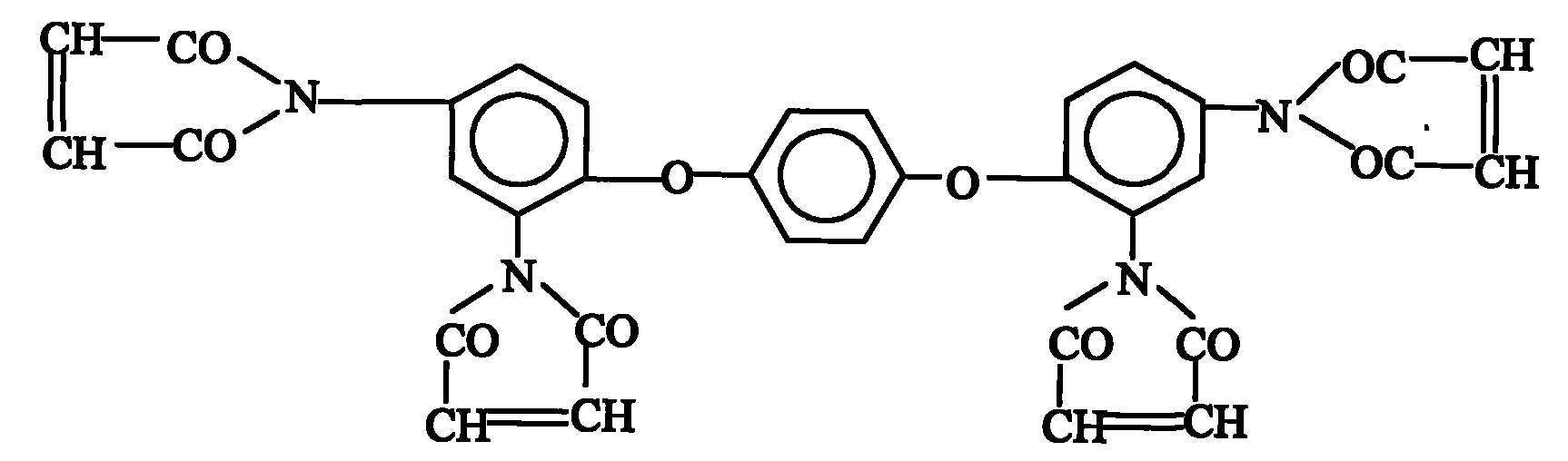

Image

Examples

Embodiment 1

[0033] 50.0 grams of tetramaleimide resin, 50.0 grams of carboxy-terminated nitrile rubber (supplied by Lanzhou Petrochemical Company Petrochemical Research Institute), 250.0 grams of N, N, N', N'-tetraglycidyl-4, 4′-Diaminodiphenylmethane and 100.0 g of N, N, O-triglycidyl-4-aminophenol polyfunctional epoxy resin were added to the reaction kettle, reacted at 110°C for 1 hour, cooled to room temperature, and added 50.0 An organic solvent of gram of N,N-dimethylformamide and 100.0 gram of acetone was stirred and dissolved at room temperature to form a homogeneous transparent viscous liquid, and component A was obtained.

[0034] With 10.0 grams of 2-ethyl-4-methylimidazole, 20.0 grams of 4,4'-diaminodiphenylsulfone and 20.0 grams of 1,4-bis(4-aminophenoxy)benzene curing agent with 350.0 grams of N, N-dimethylformamide is mixed with an organic solvent, stirred and dissolved at room temperature, and a homogeneous and transparent component B solution is obtained.

[0035] Mix com...

Embodiment 2

[0039] 100.0 grams of tetramaleimide resin, 100.0 grams of carboxy-terminated nitrile rubber (supplied by Lanzhou Petrochemical Company Petrochemical Research Institute), 150.0 grams of N, N, N', N'-tetraglycidyl-3, 3'-Dimethyl-4,4'-diaminodiphenylmethane, 50.0 grams of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester, 50.0 grams of triglycidyl cyanurate Add amine and 50.0 grams of N, N, O-triglycidyl-4-aminophenol polyfunctional epoxy resin to the reaction kettle, react at 110°C for 1 hour, cool to room temperature, add 50.0 grams of N, N-dimethyl An organic solvent of acetamide and 100.0 g of acetone was stirred and dissolved at room temperature, and it was a homogeneous transparent viscous liquid to obtain component A.

[0040] With 10.0 grams of 2-ethyl-4-methylimidazole, 20.0 grams of 4,4'-diaminodiphenylsulfone, 15.0 grams of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane and 5.0 Mix 3,3'-diamino-4,4'-dihydroxybiphenyl curing agent with 300.0 grams of N,N-...

Embodiment 3

[0045] 50.0 grams of tetramaleimide resin, 50.0 grams of carboxy-terminated nitrile rubber (supplied by Lanzhou Petrochemical Company Petrochemical Research Institute), 50.0 grams of 4,5-epoxycyclohexane-1,2-dicarboxylic acid dicarboxylate Add glycidyl ester, 50.0 grams of thermoplastic novolac epoxy resin and 50.0 grams of N, N, O-triglycidyl-4-aminophenol polyfunctional epoxy resin into the reaction kettle, react at 110 ° C for 1 hour, and cool to room temperature , adding 150.0 g of N-methyl-2-pyrrolidone and 100.0 g of acetone as an organic solvent, stirring and dissolving at room temperature, and becoming a homogeneous transparent viscous liquid to obtain component A.

[0046] 20.0 grams of 2-ethyl-4-methylimidazole and 80.0 grams of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl] propane dianhydride curing agent and 400.0 grams of N-methyl - Mix 2-pyrrolidone with an organic solvent, stir and dissolve at room temperature to obtain a homogeneous and transparent component B soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com