Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1266 results about "Polyetherimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyetherimide (PEI) is an amorphous, amber-to-transparent thermoplastic with characteristics similar to the related plastic PEEK. Relative to PEEK, PEI is cheaper, but is lower in impact strength and usable temperature.

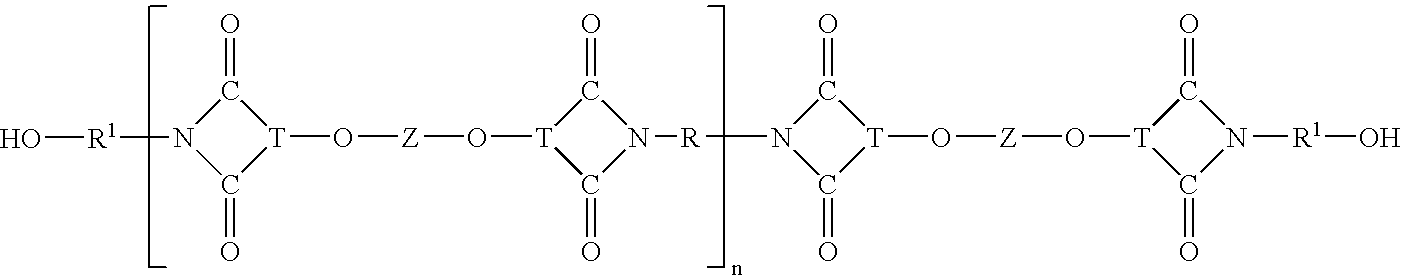

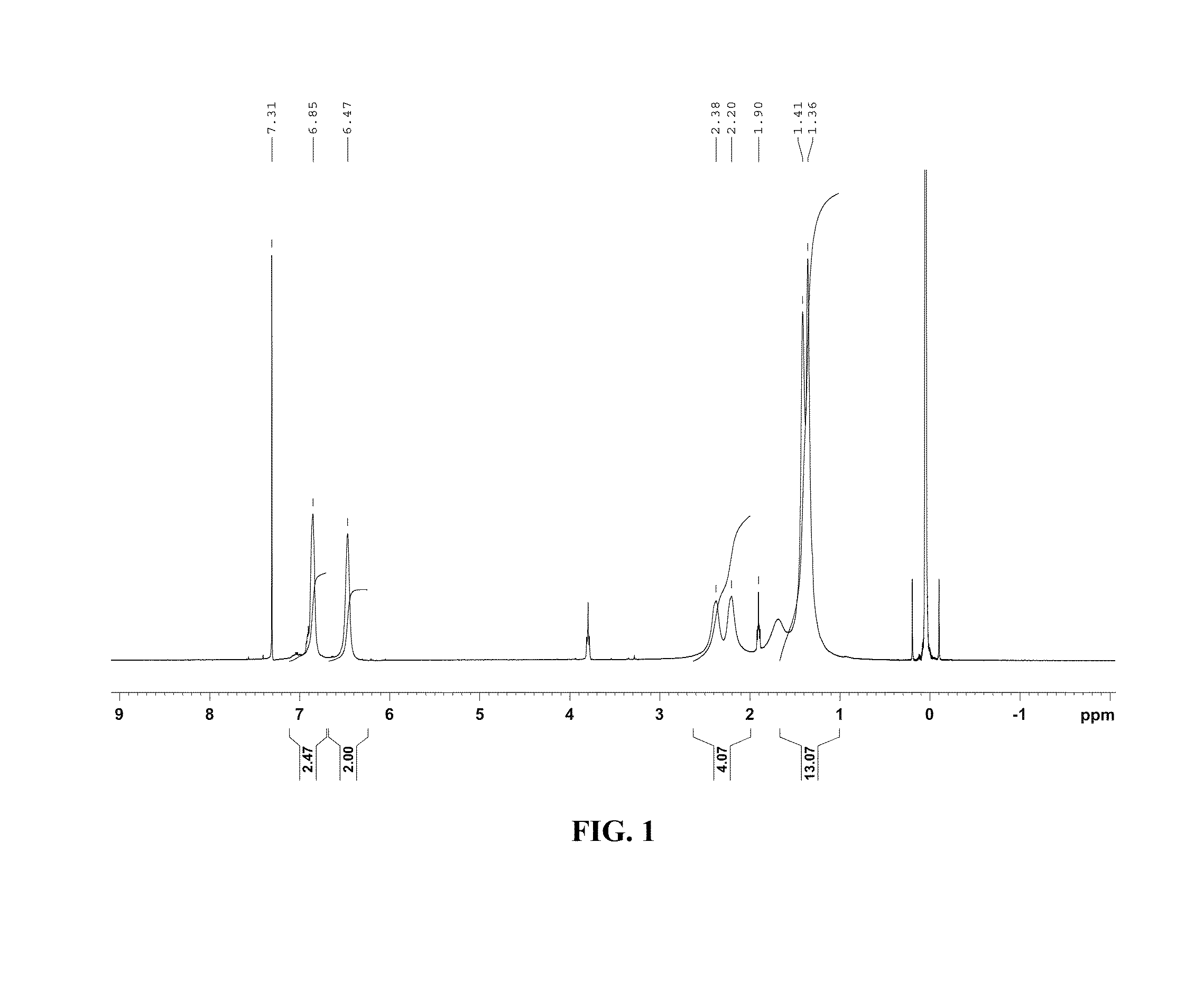

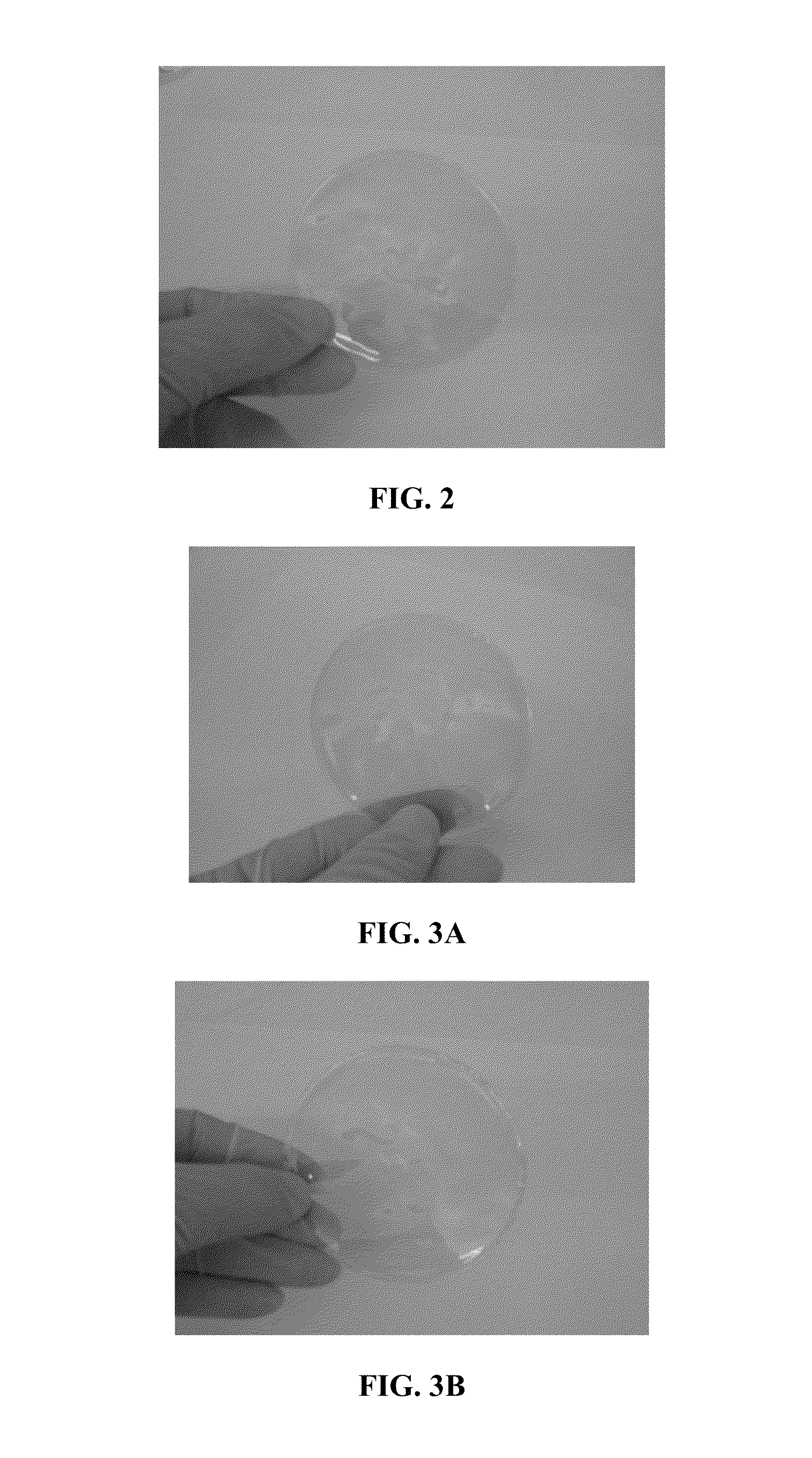

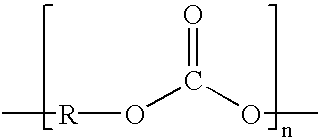

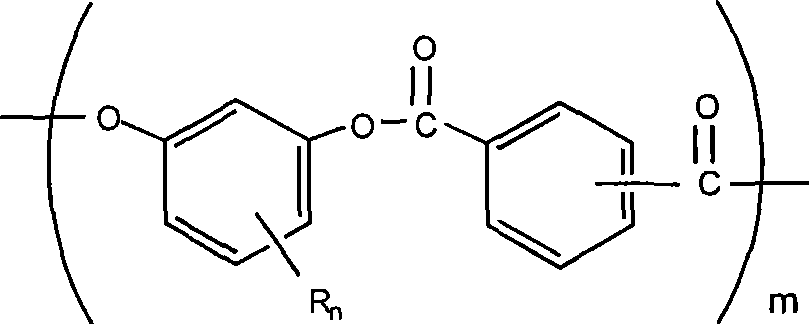

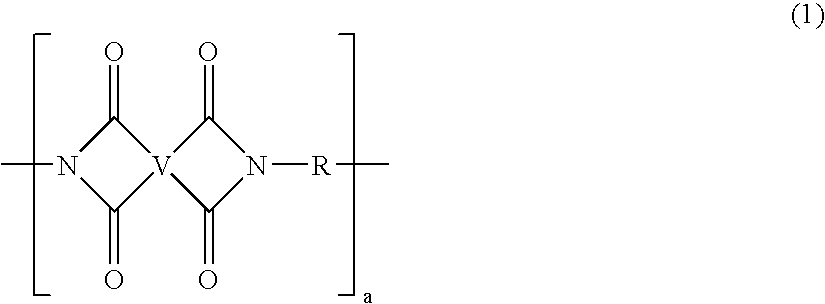

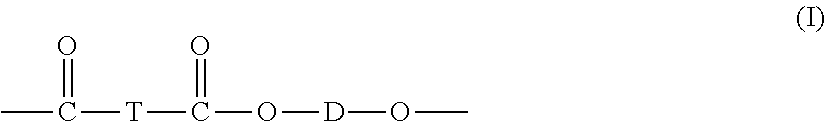

Polycarbonate-ultem block copolymers

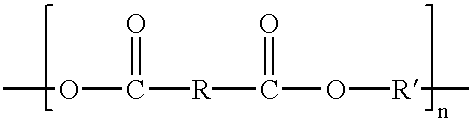

The present invention provides novel block copolycarbonates comprising residues from a hydroxy terminated polyetherimide or polyimide, residues from a dihydroxy compound, and residues from an activated carbonate. In a preferred embodiment of the present invention the polyetherimide or polyimide blocks exhibit high Mw while the resulting block copolycarbonate exhibits a single Tg. The novel block copolycarbonates of the present invention are produced under melt polymerization conditions in the presence an activated carbonate source.

Owner:SABIC GLOBAL TECH BV

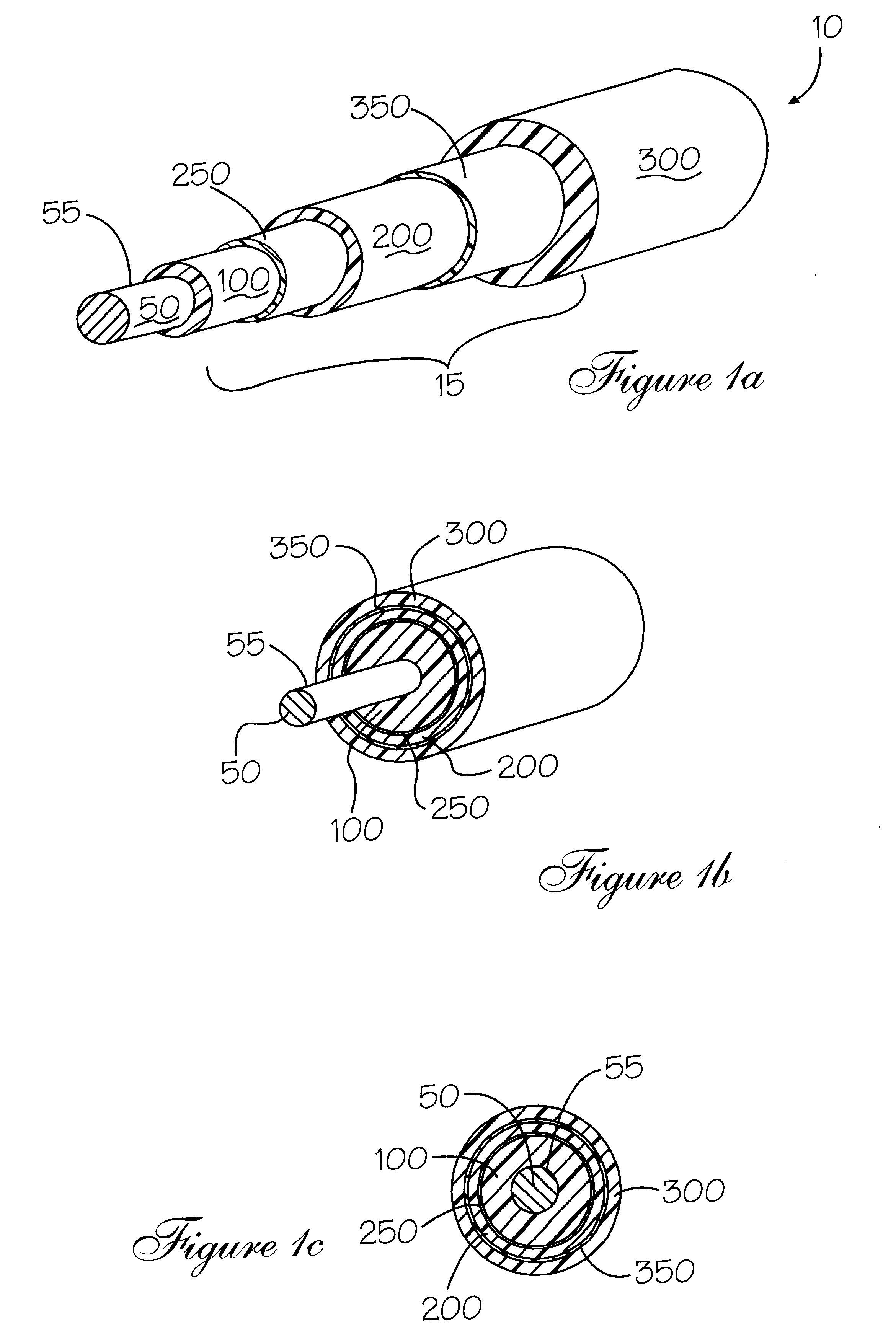

Automotive-wire insulation

InactiveUS6359230B1Excellent physical toughnessResistant to oxidationPlastic/resin/waxes insulatorsInsulated cablesPolyesterInter layer

The invention pertains to multi-layer polymeric formulations for protecting or insulating metallic objects, and, more particularly, to an integrated, tri-layer, thin-wall insulation composite, for use in a high temperature, automotive-wire article. The tri-layer design comprises an inner layer of a fluoropolymer, polyether sulfone, polyether-ketone, polyetherimide, or thermoplastic polyester; a middle layer comprising a polyolefin; and an outer layer comprising a fluoropolymer. The inner and outer layers serve to protect the middle polyolefinic layer from degradation.

Owner:CHAMPLAIN CABLE CORP

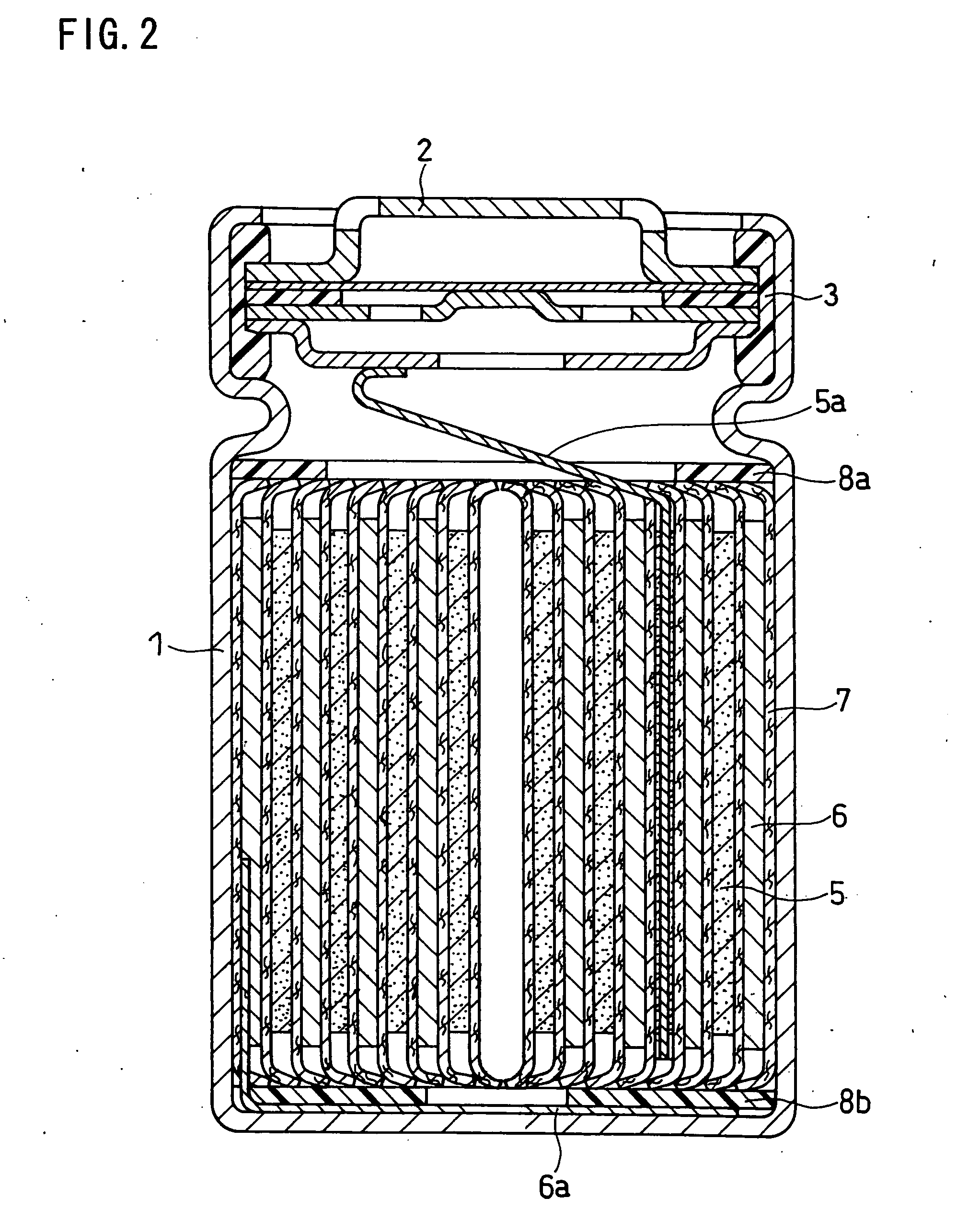

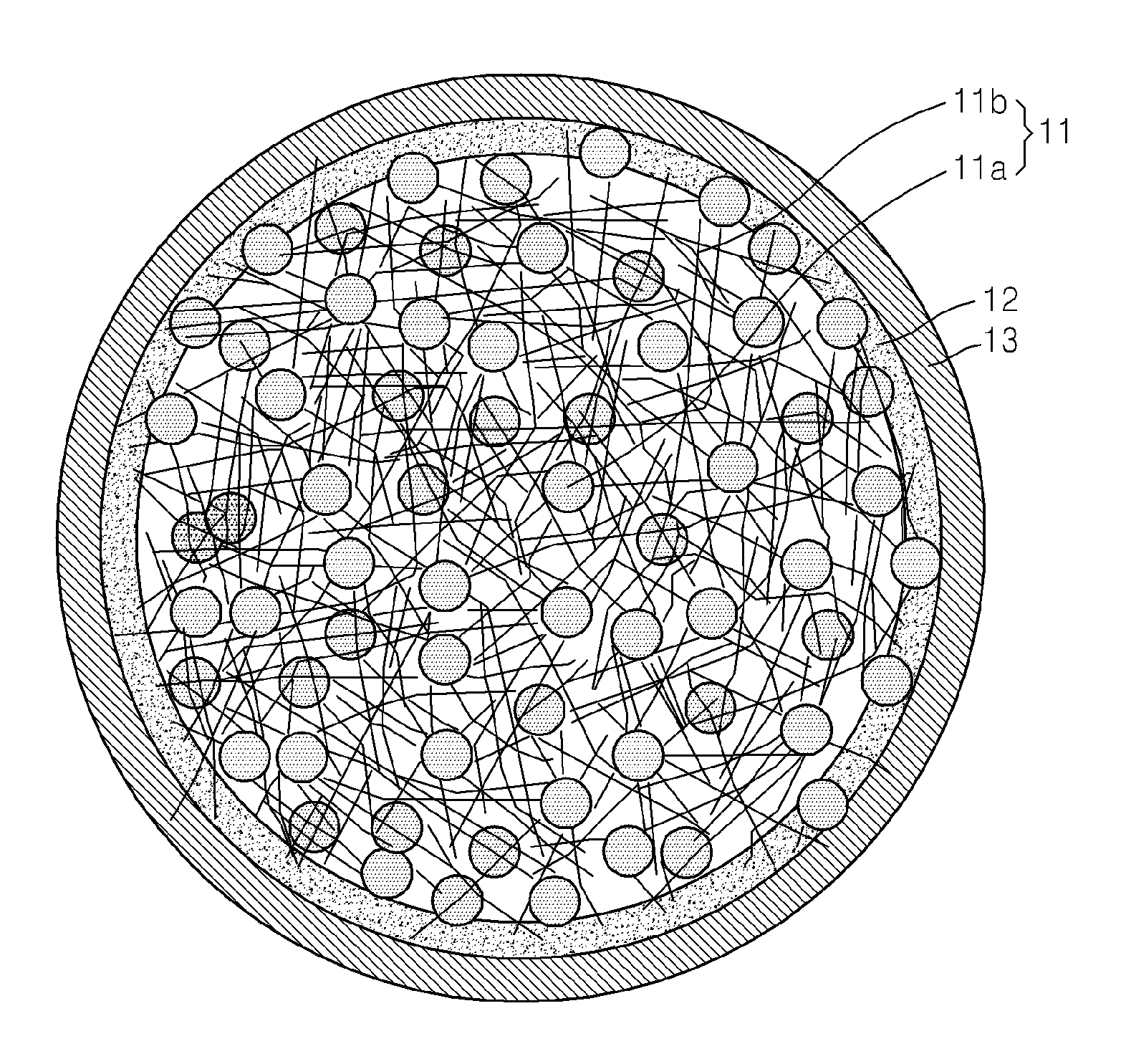

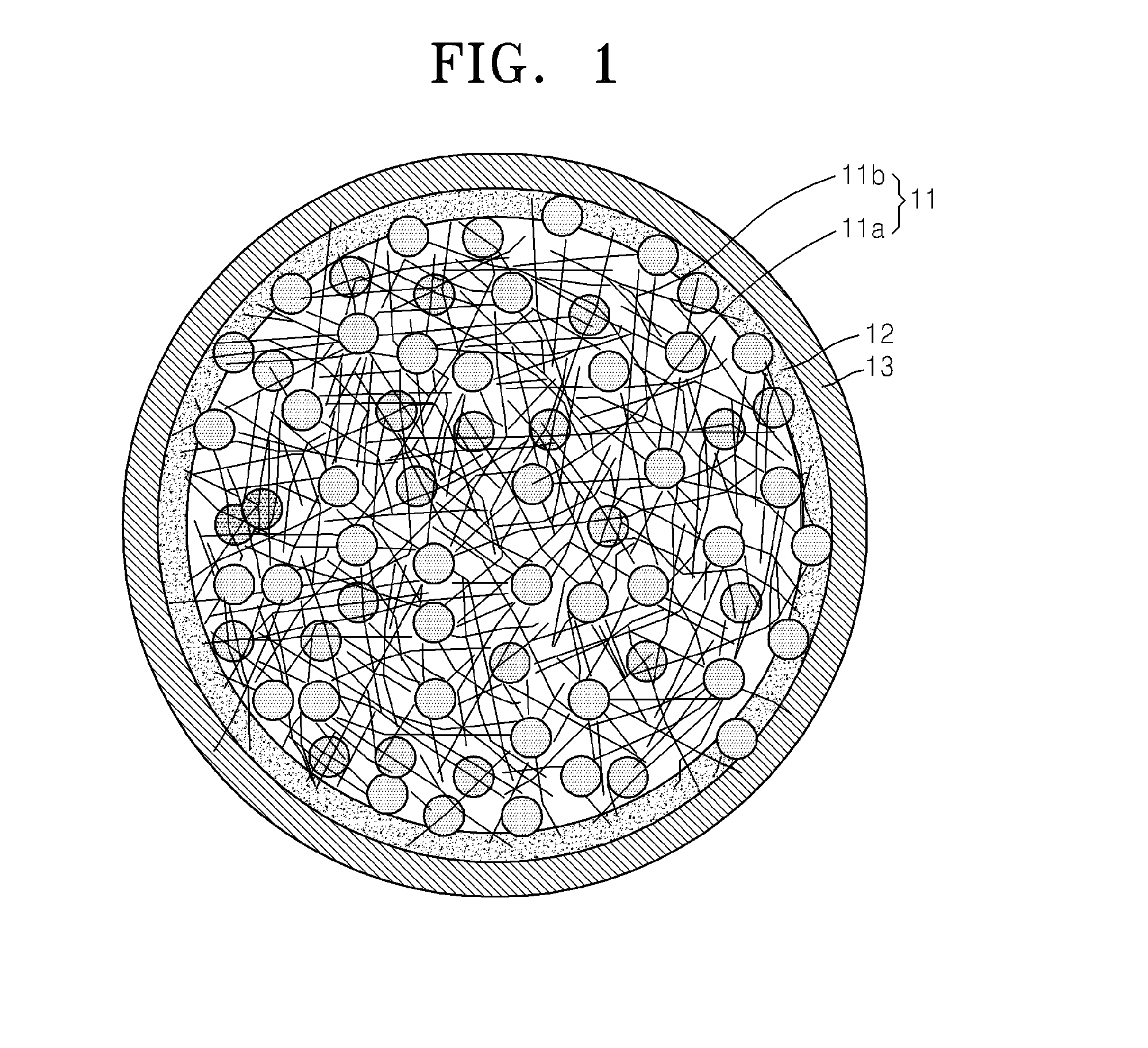

Non-aqueous electrolyte secondary battery

InactiveUS20070099081A1Improve reliabilityHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsPolyetherimidePolyamide

A non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, a separator interposed between the positive and negative electrodes, and a non-aqueous electrolyte. The negative electrode includes composite particles and a binder. Each of the composite particles includes: a negative electrode active material including an element capable of being alloyed with lithium; carbon nanofibers that are grown from a surface of the negative electrode active material; and a catalyst element for promoting the growth of the carbon nanofibers. The binder comprises at least one polymer selected from the group consisting of polyimide, polyamide imide, polyamide, aramid, polyarylate, polyether ether ketone, polyether imide, polyether sulfone, polysulfone, polyphenylene sulfide, and polytetrafluoroethylene.

Owner:PANASONIC CORP

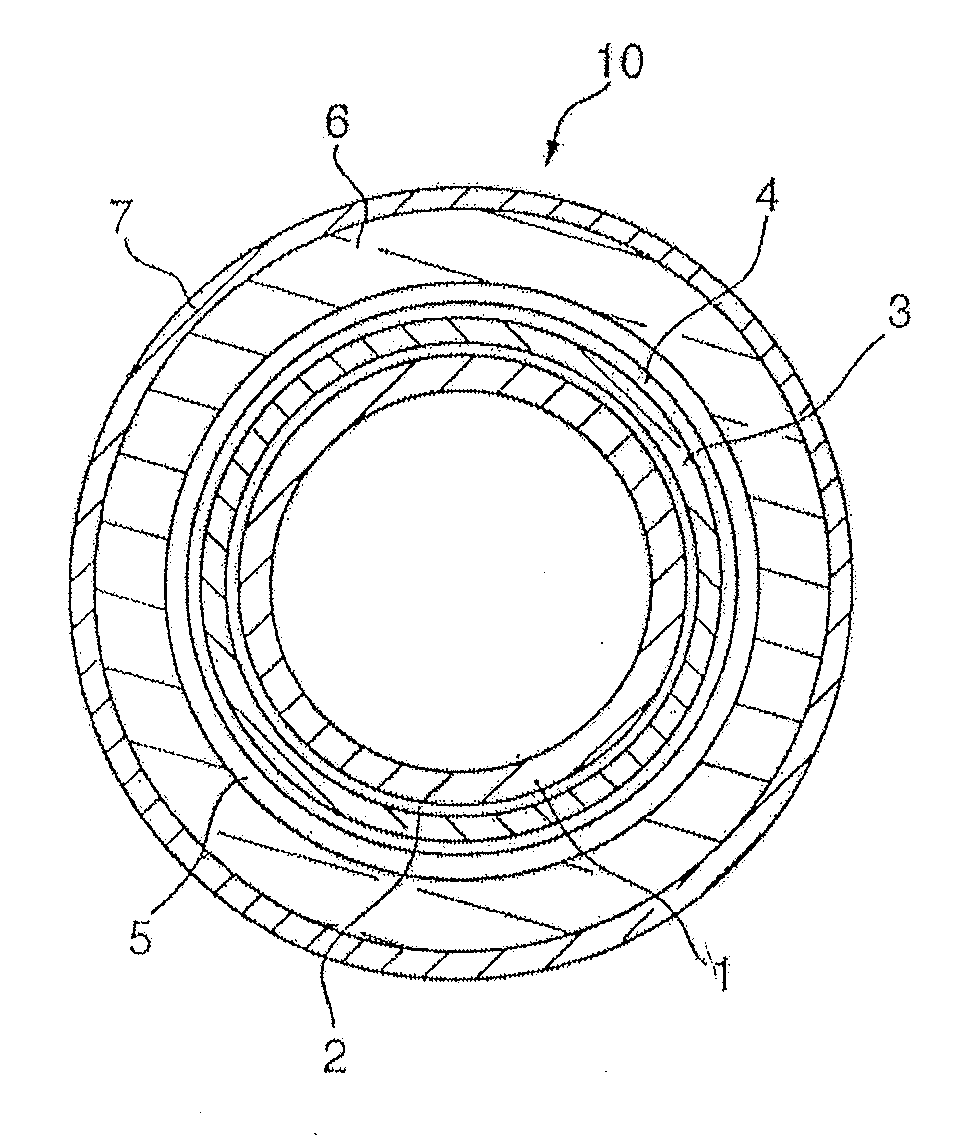

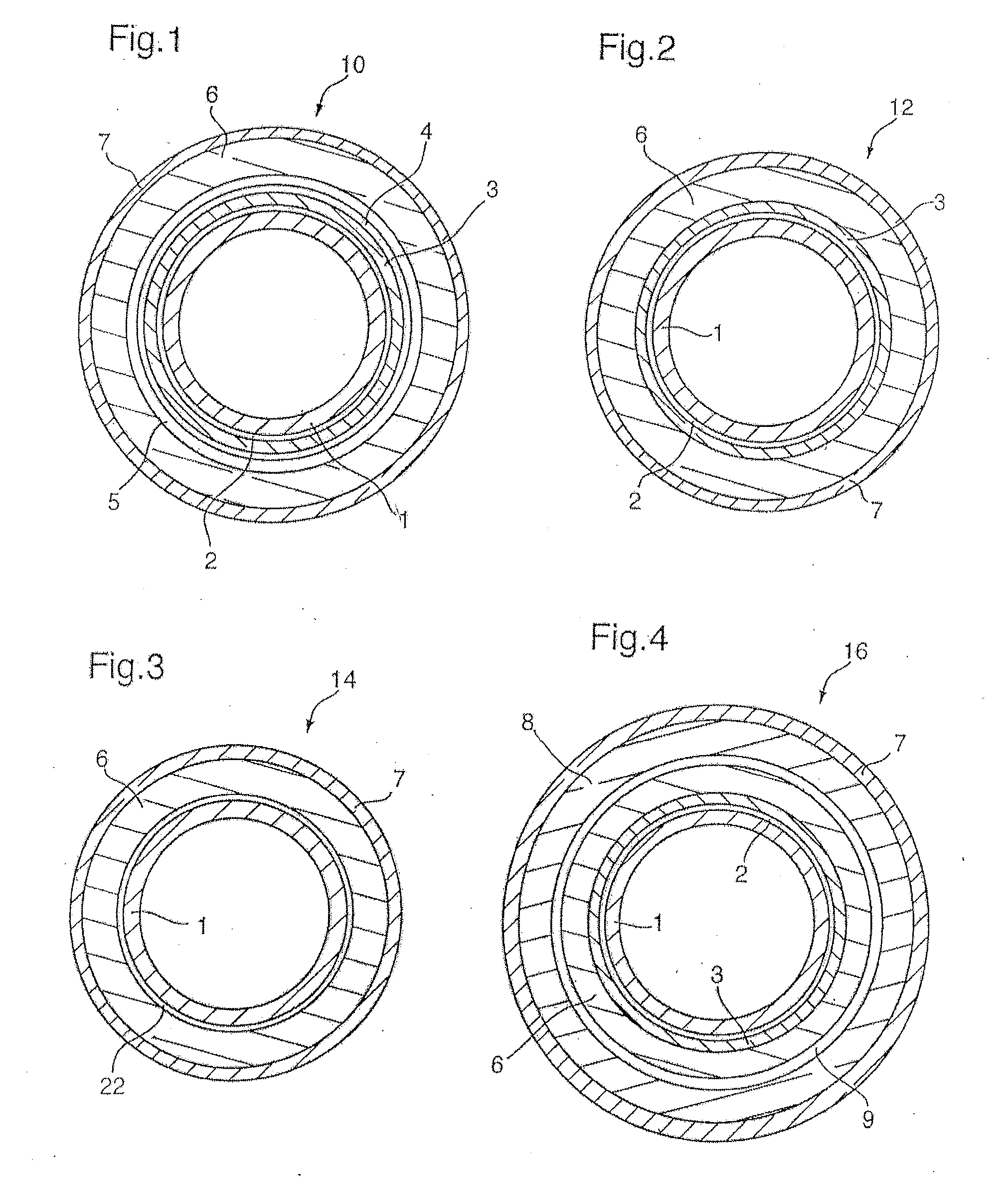

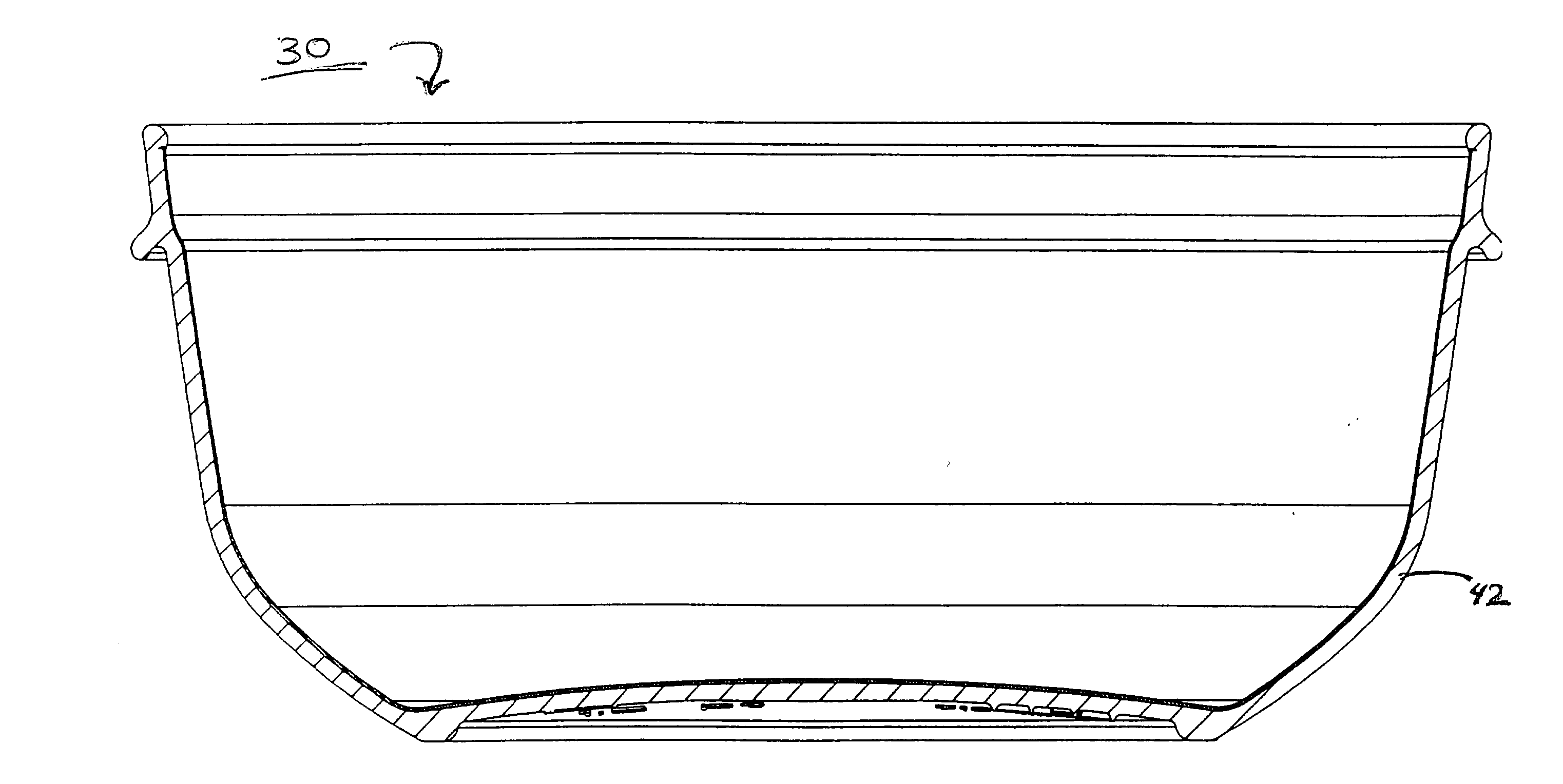

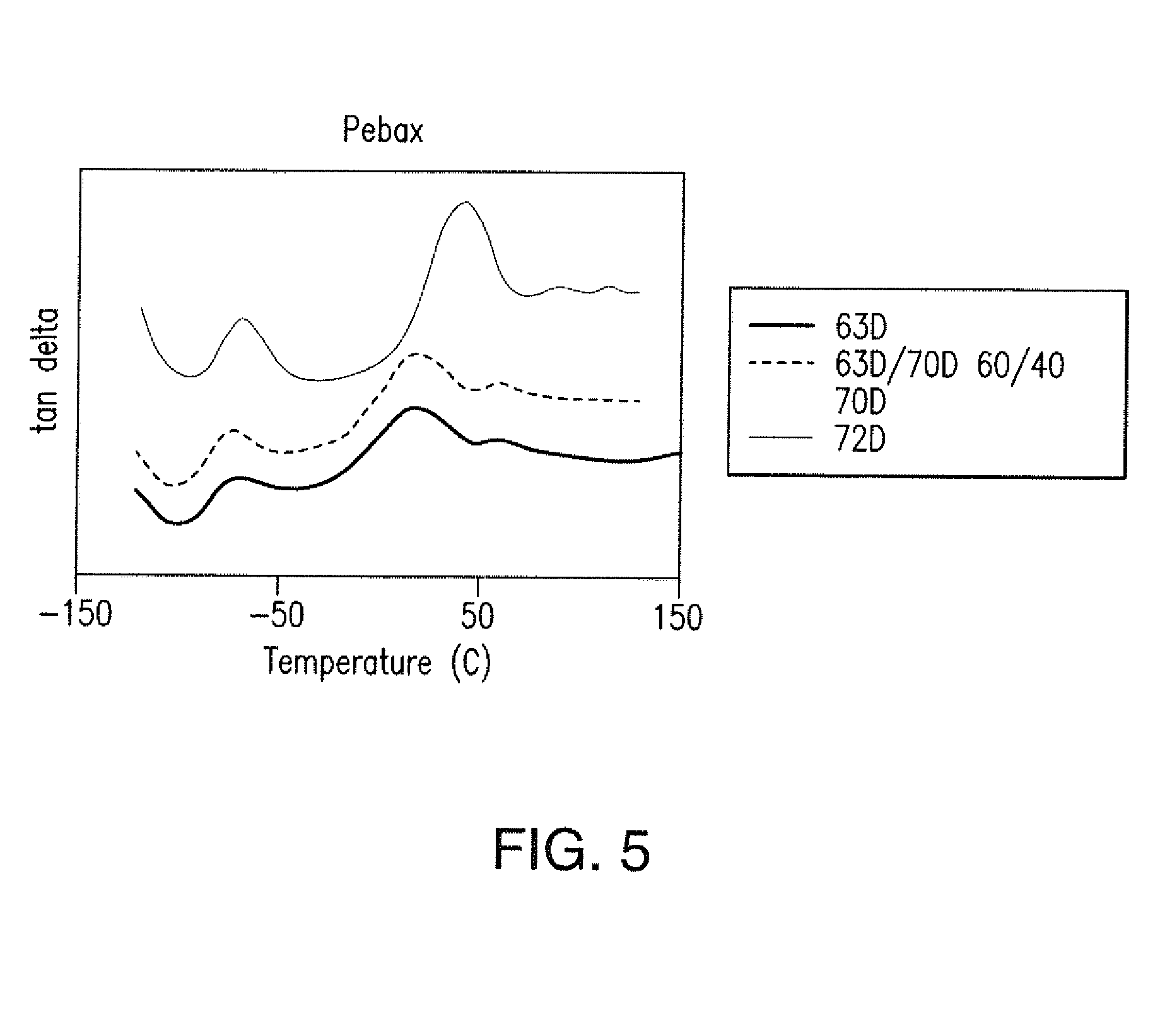

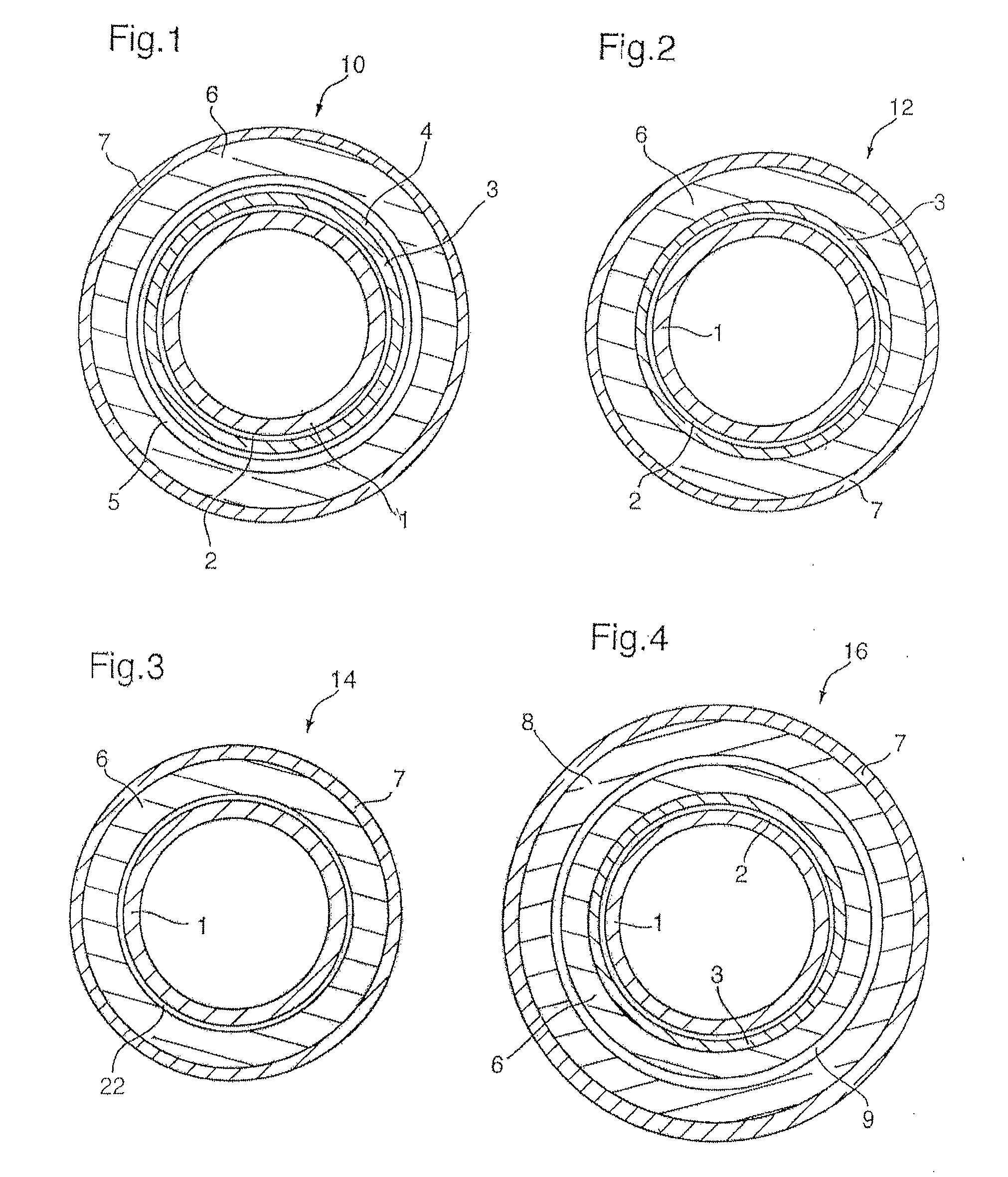

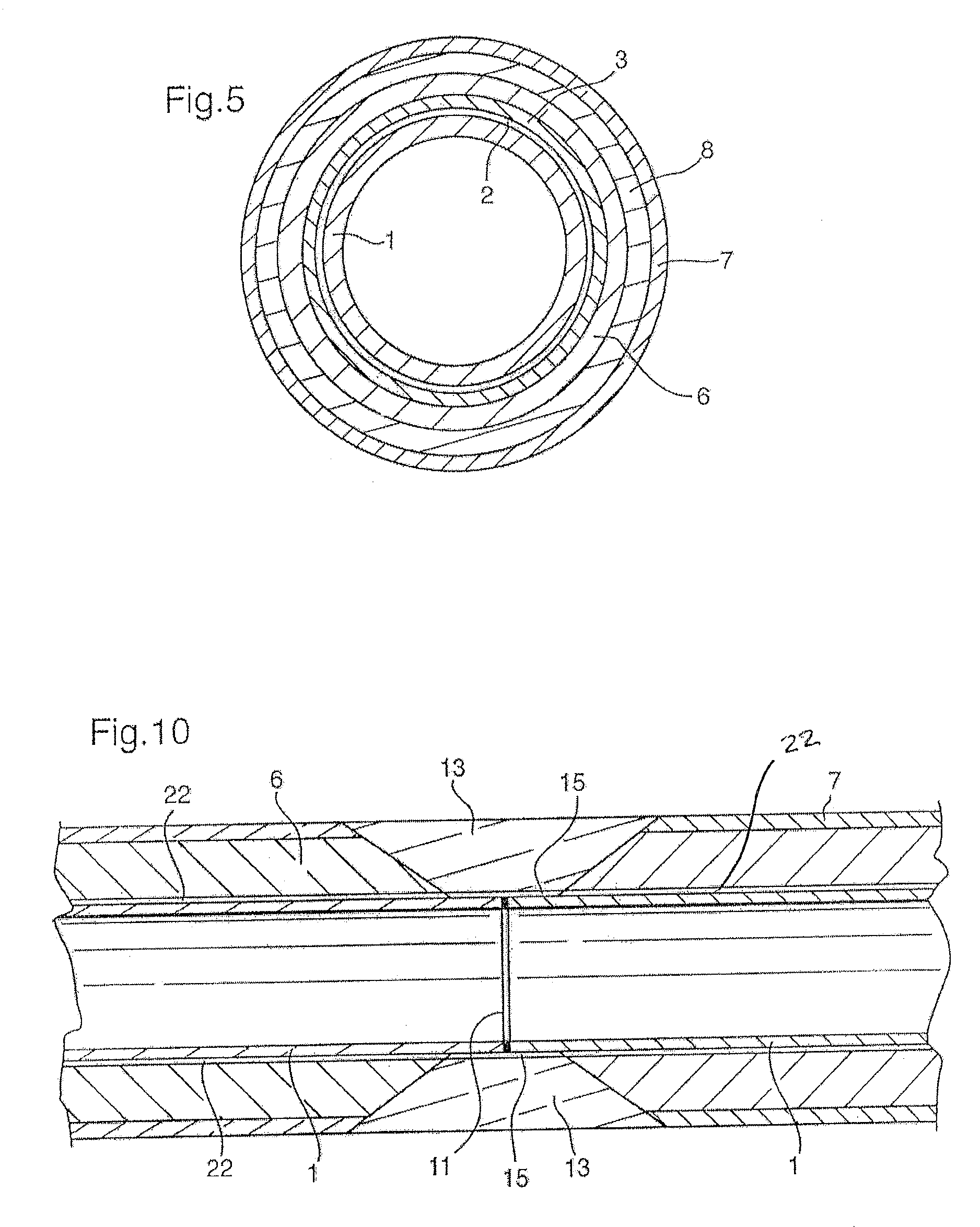

Annular or tubular shaped articles of novel polymer blends

The present invention is directed to a tubular article of manufacture in an annular or tubular shape having an outer diameter, an inner diameter and a length comprising one or more materials selected from the group consisting of: a) an immiscible blend of polymers comprising one or more polyetherimides, having more than one glass transition temperature wherein the polyetherimide has a glass transition temperature greater than 217° Celsius; b) a miscible blend of polymers, comprising one or more polyetherimides, having a single glass transition temperature greater than 180° Celsius; or, c) a single polyetherimide having a glass transition temperature of greater than 247° Celsius

Owner:SABIC INNOVATIVE PLASTICS IP BV

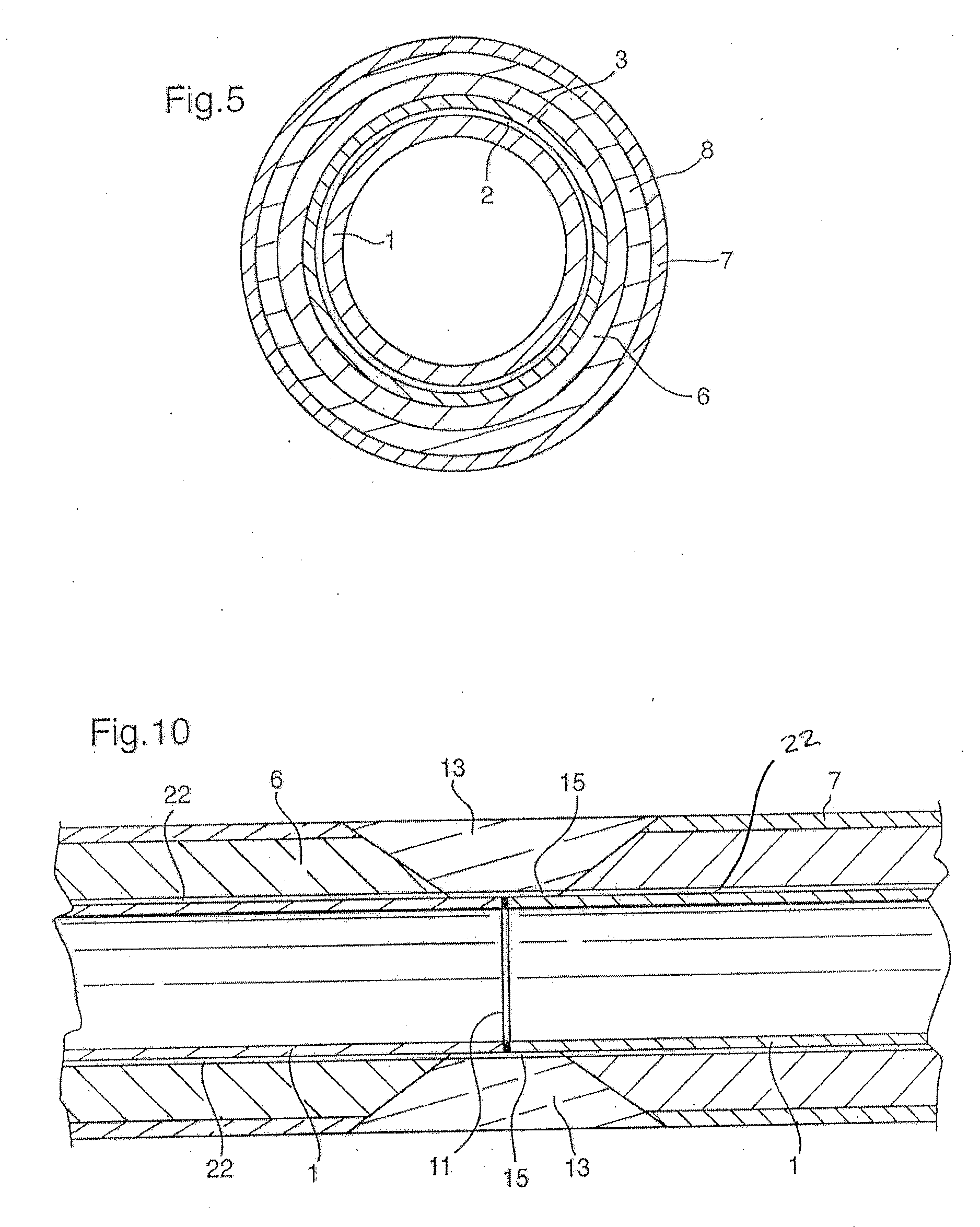

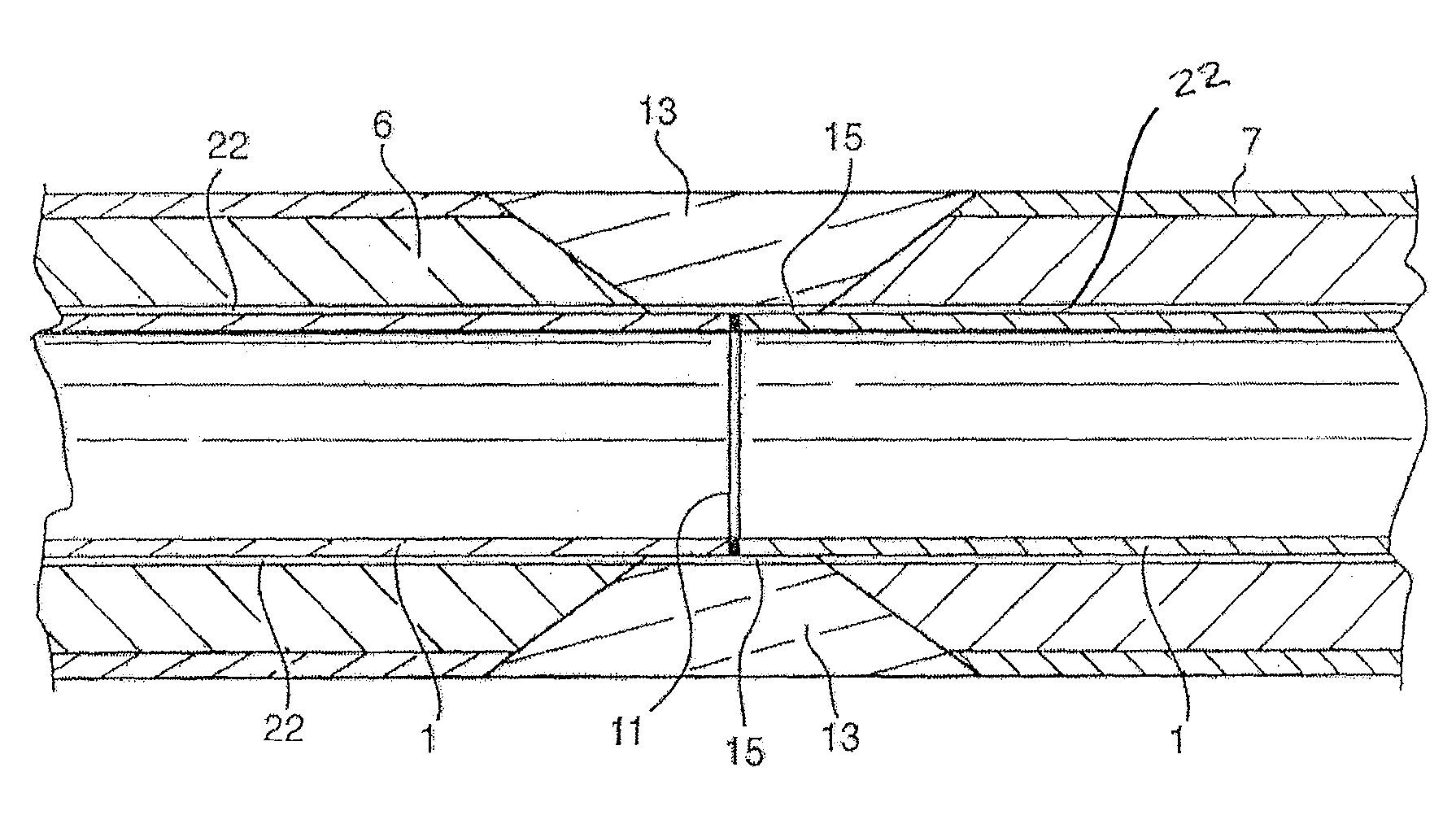

High temperature resistant insulation for pipe

ActiveUS20100043906A1Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsBisphenol-A-polycarbonatePolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

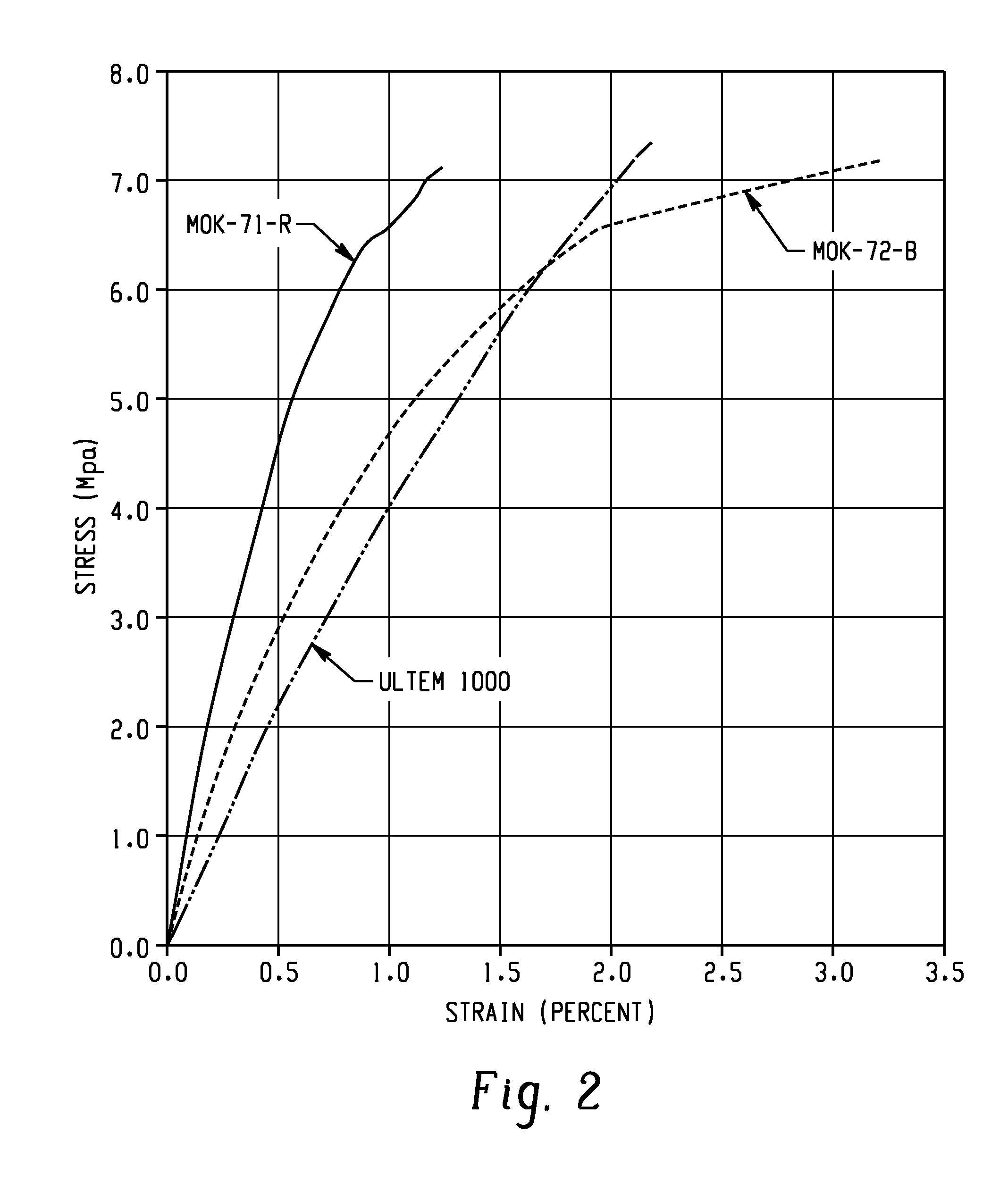

Polyetherimide resin compositions with improved ductility

A thermoplastic resin composition containing a polyetherimide resin, a siloxane-polyetherimide copolymer and a branched polycarbonate resin exhibits exhibit high heat distortion temperature, improved room temperature impact properties and improved impact strength and ductility at low temperatures.

Owner:GENERAL ELECTRIC CO

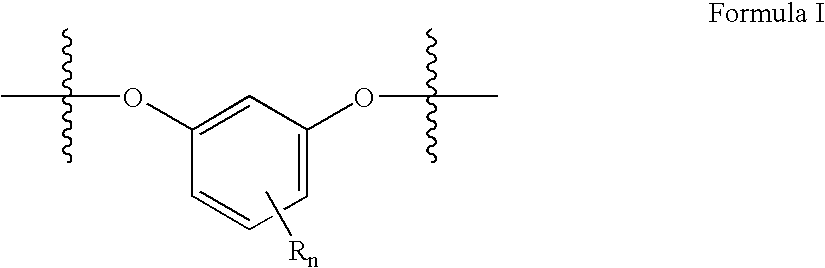

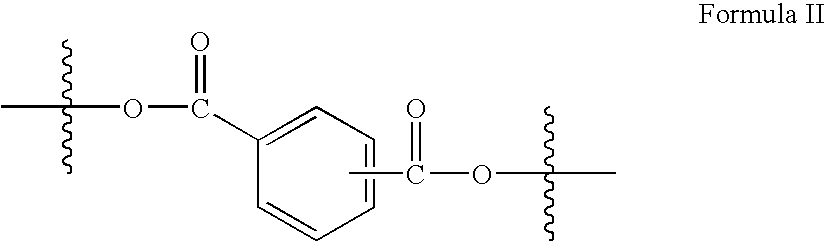

Flame retardant polymer blends

InactiveUS20070066737A1Improve flame retardant performanceGood solvent resistancePolyesterPolyetherimide

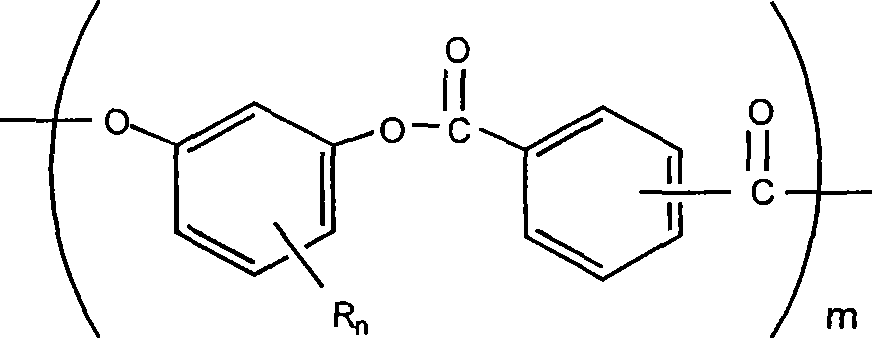

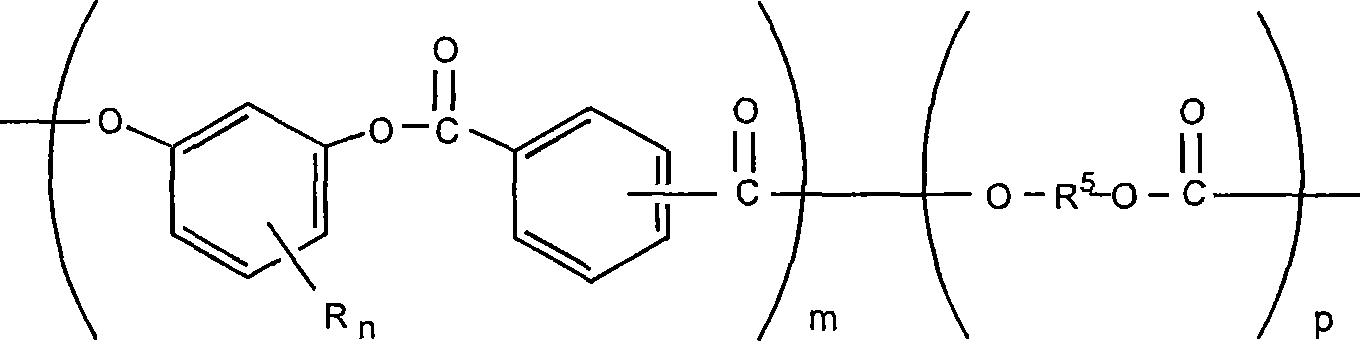

Blends of polyimides, polyetherimides or polyetherimide sulfones with resorcinol based polyesters, or resorcinol based polyester carbonate polymers, and silicone copolymers, have improved flame resistance. Peak heat release energy is reduced and the time to reach peak heat release is increased. In some instances the flame retardant blends show high percent transmission with low haze. Addition of metal oxides may further improve flame resistance.

Owner:SABIC GLOBAL TECH BV

Low smoke polycarbonate composition, method of manufacture and product made therefrom

A composition containing a polycarbonate, a polycarbonate-polysiloxane copolymer, an impact modifier, and a polyetherimide, wherein the polycarbonate comprises greater than or equal to about 50% by weight of the combined weights of the polycarbonate, polycarbonate-polysiloxane copolymer, impact modifier and polyetherimide and wherein a 3.2 millimeter thick, 7.6 centimeter square sample of the composition produces a smoke density (Ds) of less than 275 after a 4-minute bum, measured according to ASTME 662-03. In one embodiment, a composition may contain about 50 to about 97 wt. % polycarbonate, about 0.5 to about 25 wt. % polycarbonate-polysiloxane copolymer, about 0.5 to about 20 wt. % impact modifier, and about 2 to about 15 wt. % polyetherimide.

Owner:SABIC INNOVATIVE PLASTICS IP BV

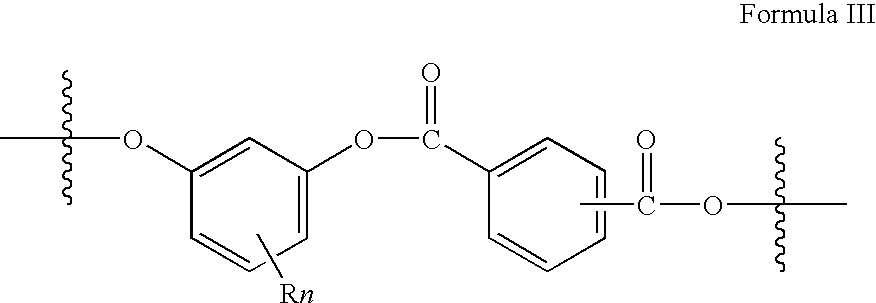

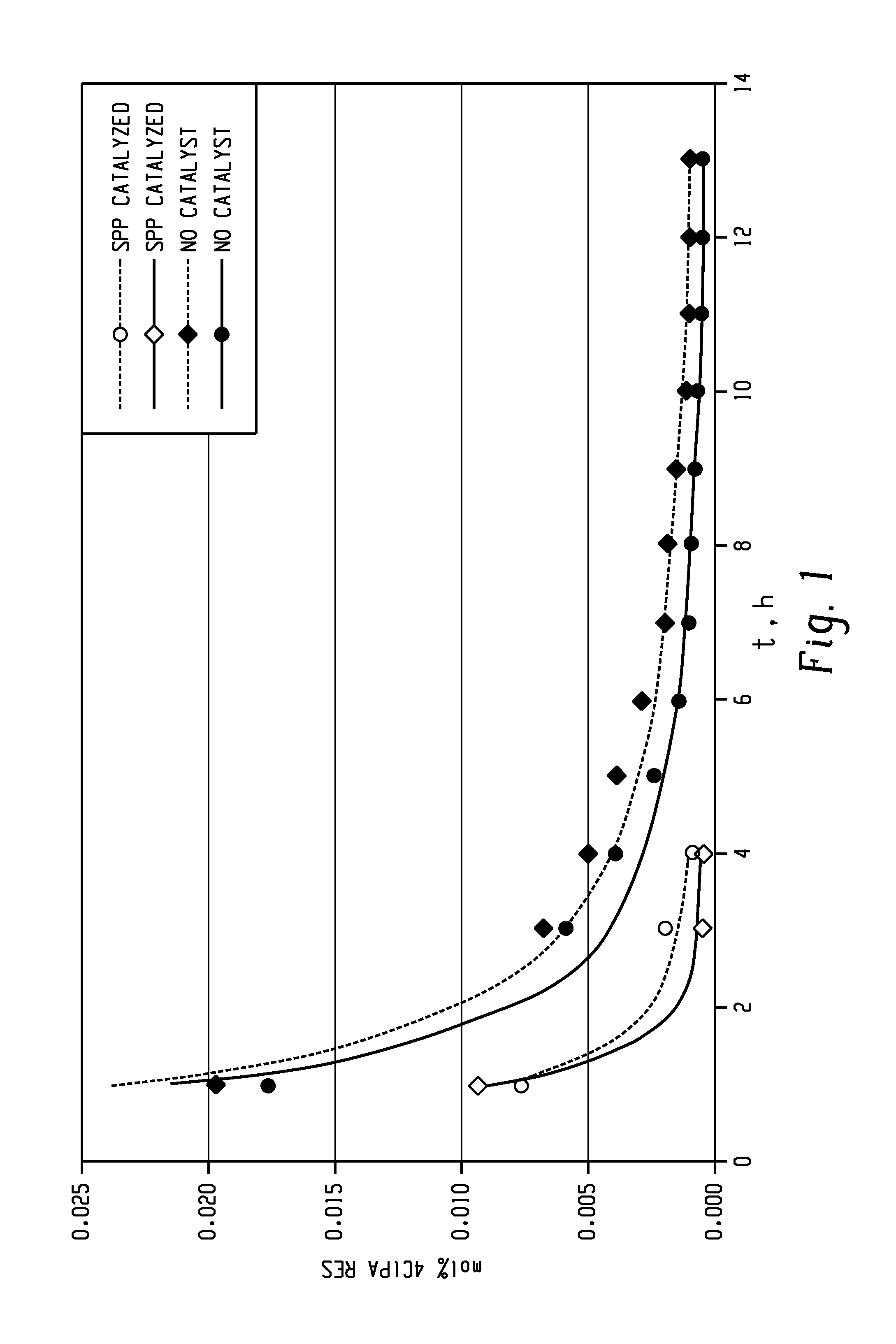

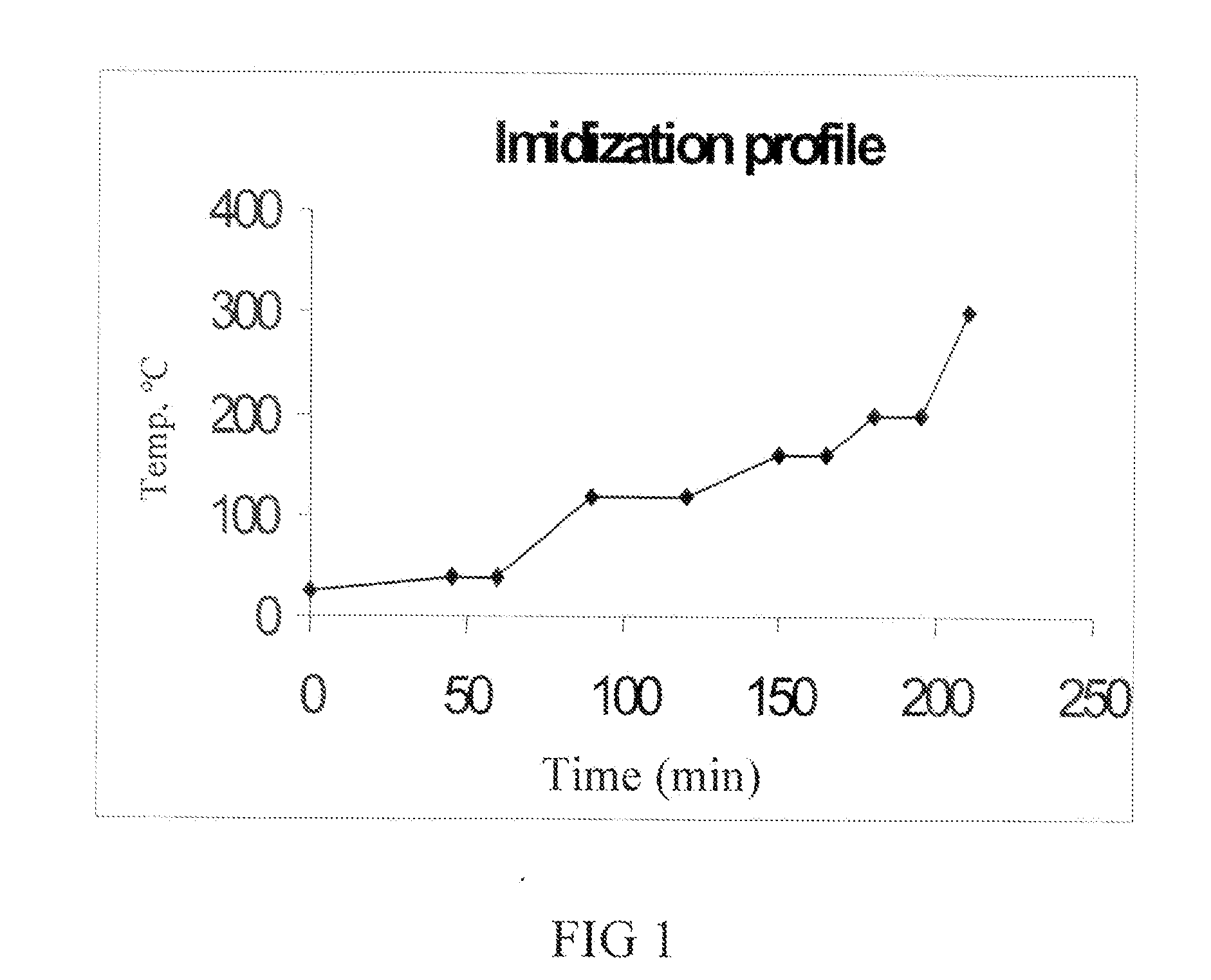

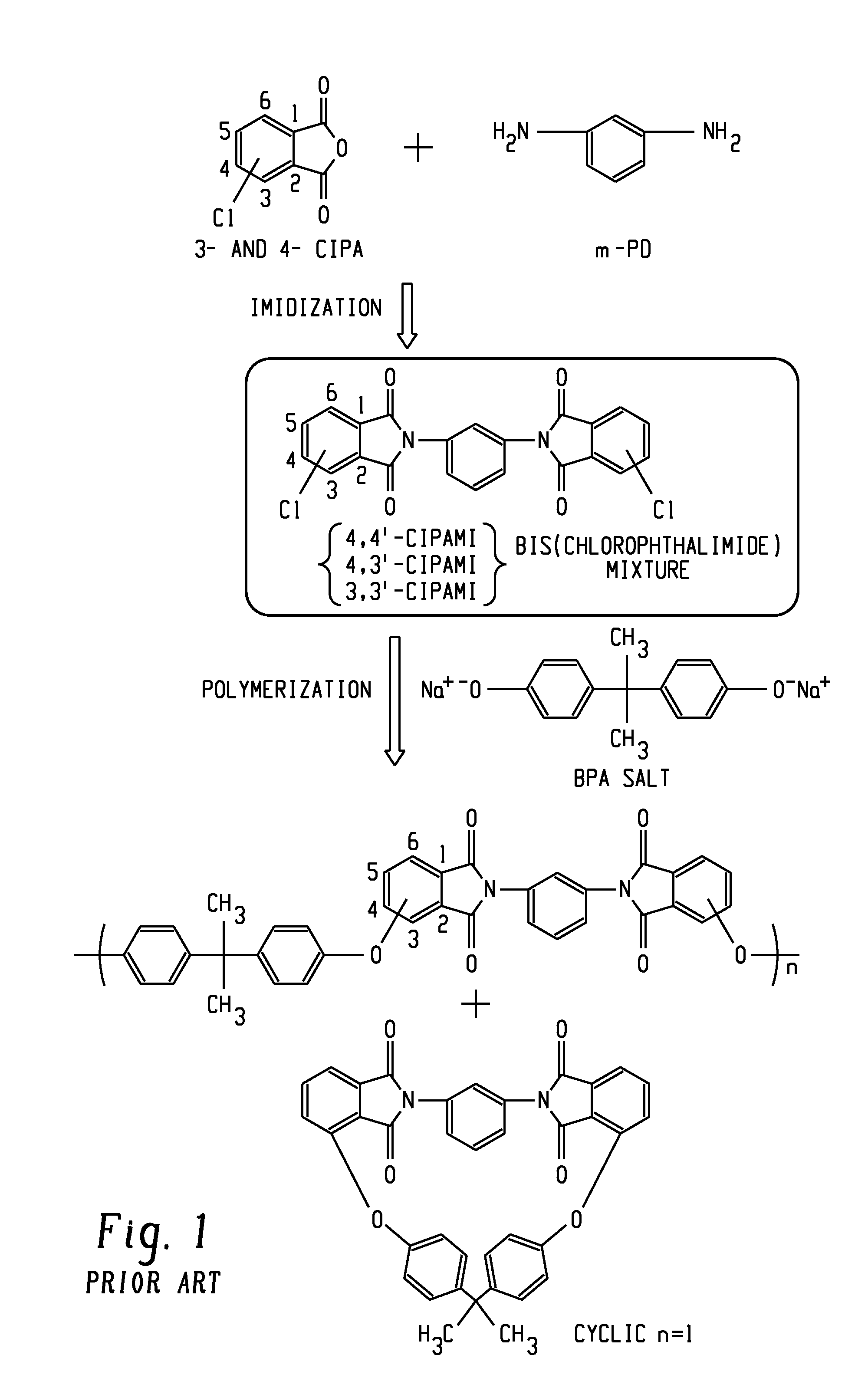

Methods of manufacture of bis(phthalimide)s and polyetherimides, and bis(phthalimide)s, and polyetherimides formed therefrom

A method of manufacture of a bis(phthalimide) composition includes reacting, in the presence of a solvent and a catalytically active amount of an imidization catalyst selected from quaternary ammonium salts, quaternary phosphonium salts, and combinations thereof, a substituted phthalic anhydride with an organic diamine, wherein conversion to the bis(phthalimide) is 99% complete in less than 6 hours.

Owner:SABIC GLOBAL TECH BV

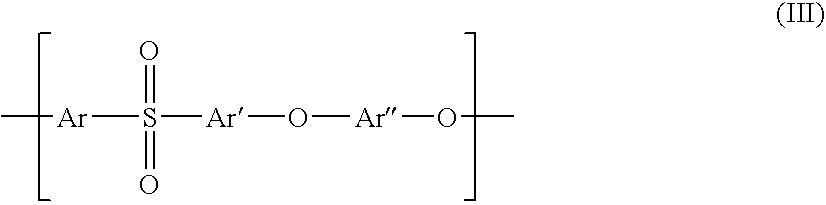

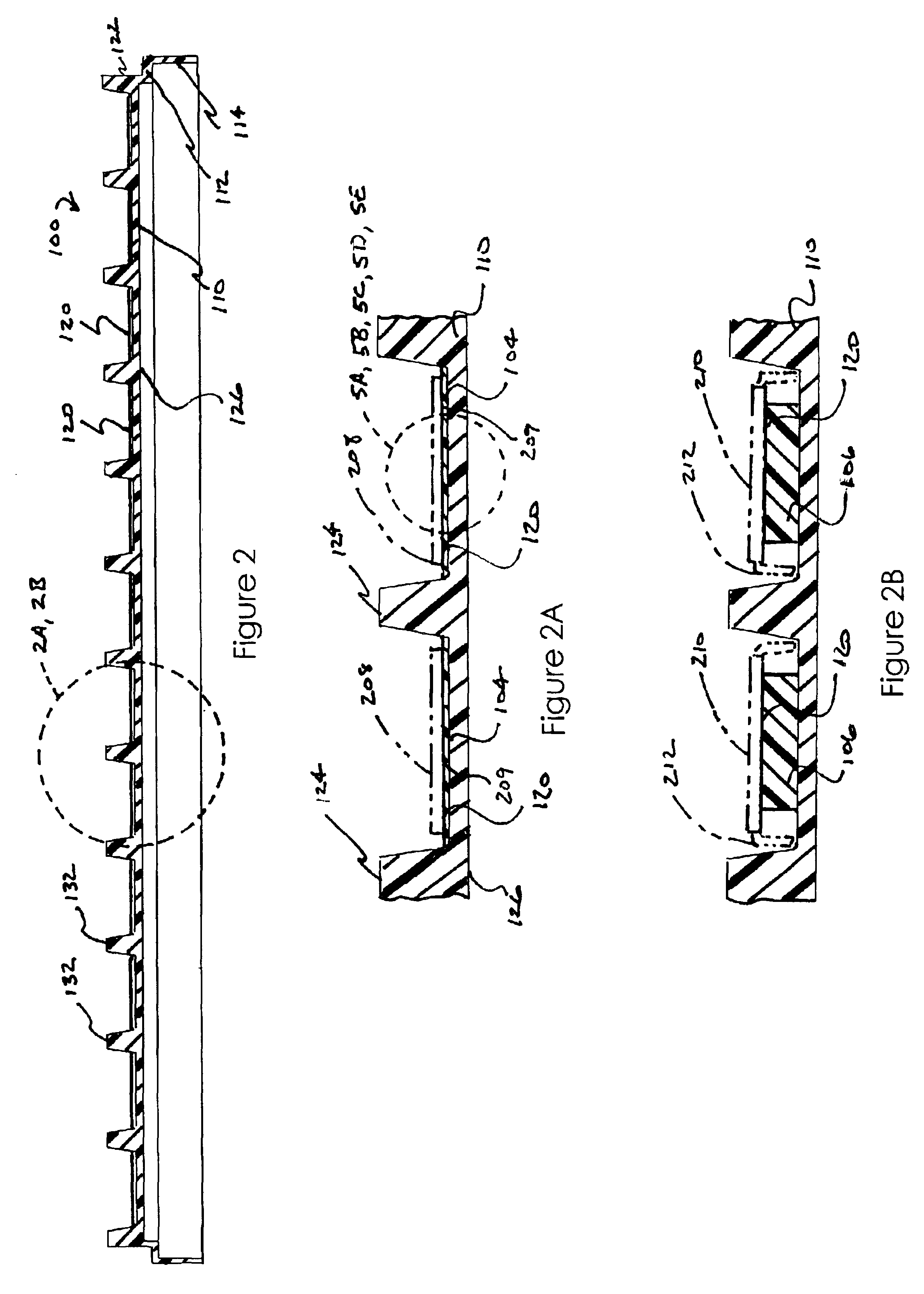

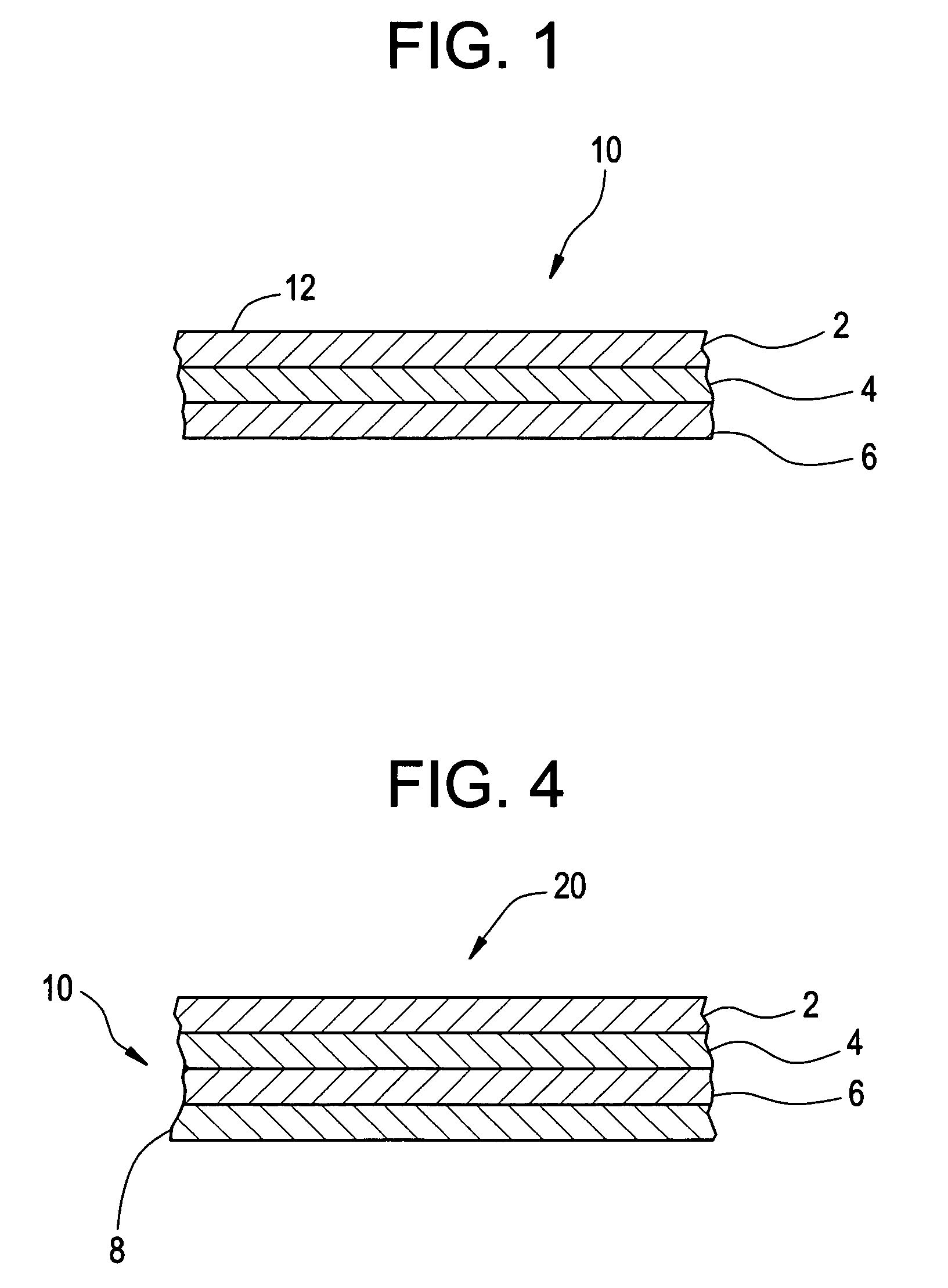

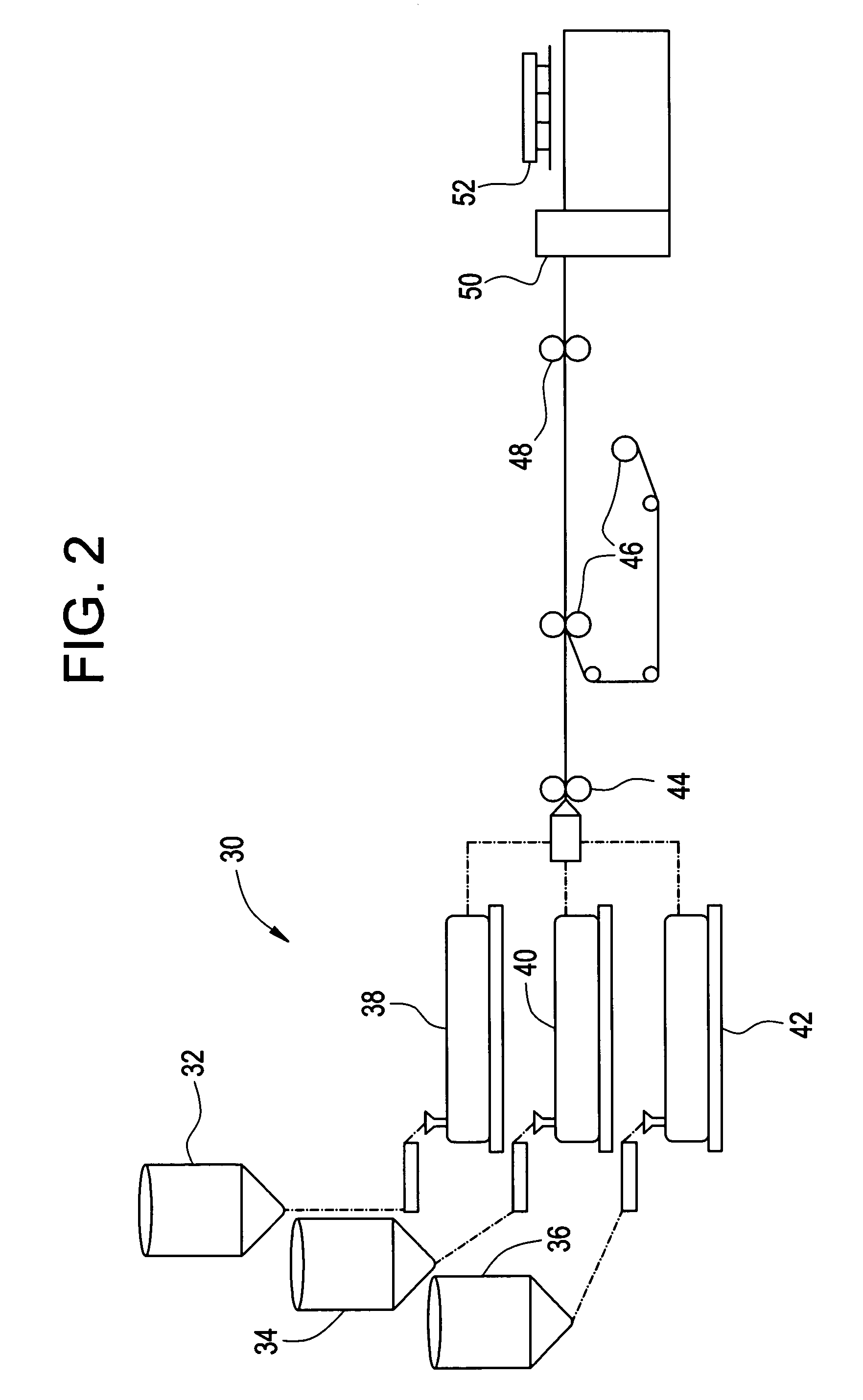

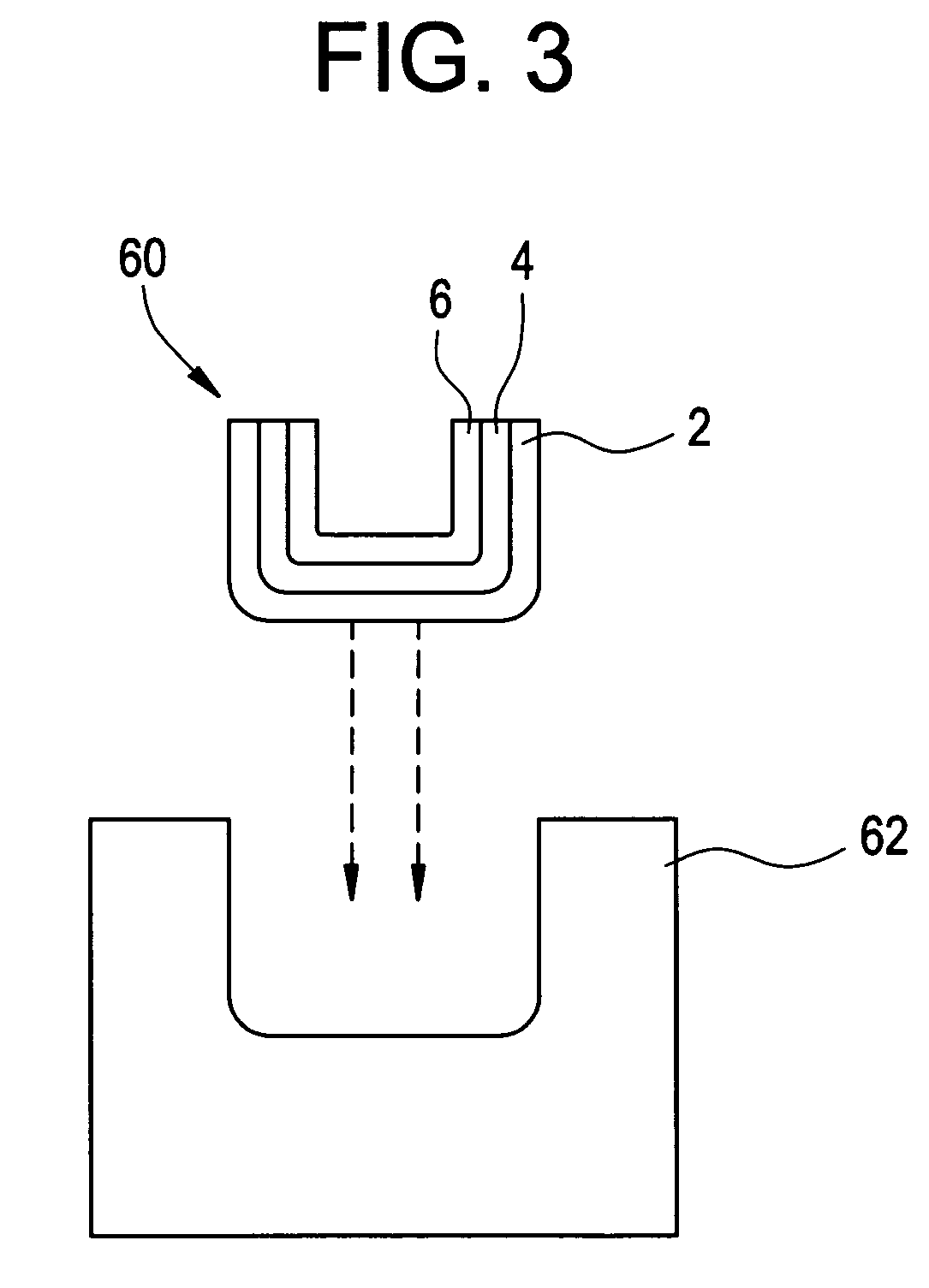

Multilayer insulated wire and transformer using the same

InactiveUS7087843B2Plastic/resin/waxes insulatorsSynthetic resin layered productsPolyetherimideElectrical conductor

A multilayer insulated wire having two or more extrusion-insulating layers provided on a conductor to coat the conductor, wherein at least one layer of the insulating layers is composed of a polyethersulfone resin (i), or a resin mixture (ii) made by blending: 100 parts by weight of a resin (A) of at least one selected from polyetherimide resins and polyethersulfone resins, and 10 parts by weight or more of a resin (B) of at least one selected from polycarbonate resins, polyarylate resins, polyester resins and polyamide resins; and wherein at least one layer other than the insulating layer composed of the resin (i) or resin mixture (ii) is provided as an outer layer to the insulating layer and is composed of a polyphenylenesulfide resin. A transformer can also have the mentioned multi-layered insulated wire.

Owner:FURUKAWA ELECTRIC CO LTD

Preparation method of graphene oxide and magnetic mesoporous silica composite material capable of adsorbing pollutants in water

InactiveCN103432996AAdjust the content of magnetic substancesLow costOther chemical processesAlkali metal oxides/hydroxidesAlkanePolyetherimide

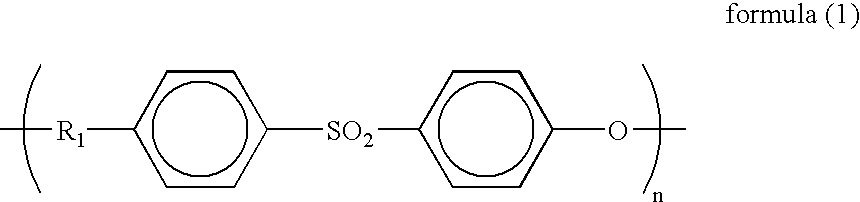

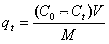

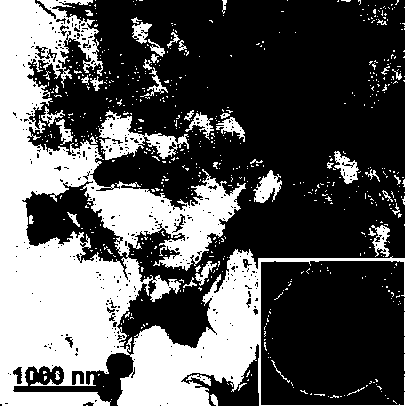

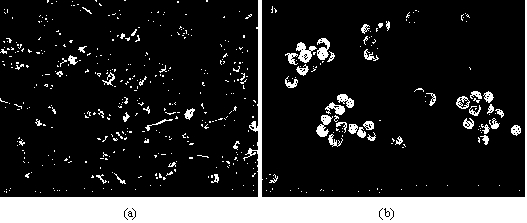

The invention relates to a preparation method of a composite material prepared by graphene oxide and magnetic mesoporous silica microspheres through chemical bonding interaction. The magnetic particles are prepared by a hydrothermal process; after acid ultrasonic treatment, the magnetic particles are firstly coated with a thin silicon oxide shell layer by a sol-gel method; after that, long-chain alkane is taken as a pore-forming agent, the magnetic particles are copolymerized with tetraethyl orthosilicate (TEOS) in the sol-gel reaction, and then the pore-forming agent is removed by thermal etching, so that the magnetic mesoporous silica particles with certain hydroxyl on the surfaces can be obtained; polyetherimide (PEI) surface modification is carried out on the magnetic mesoporous silica particles, and strong interaction between PEI and silicon hydroxyl is utilized; finally, the carboxyl on ethylene dichloride (EDC) activated graphene oxide reacts with amino on the PEI, so that the graphene oxide magnetic mesoporous silica composite material can be obtained. The preparation method is simple, convenient and controllable and is favorable for amplification preparation. The composite material has large specific surface area and good magnetic controllability, and can adsorb humic acid and heavy metal ions Pb (II) at the same time by virtue of surface groups.

Owner:TONGJI UNIV

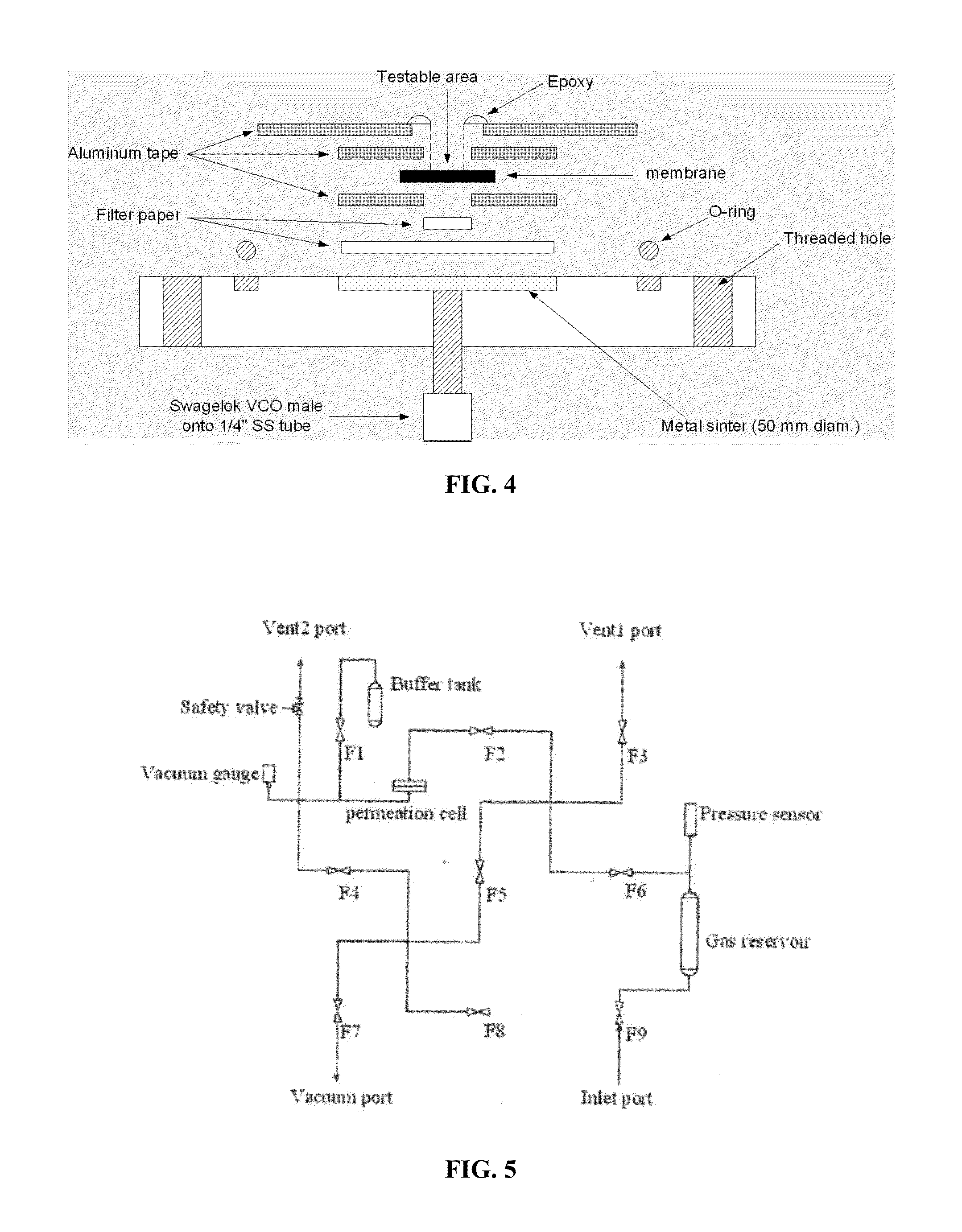

High temperature gas separation membrane suitable for OBIGGS applications

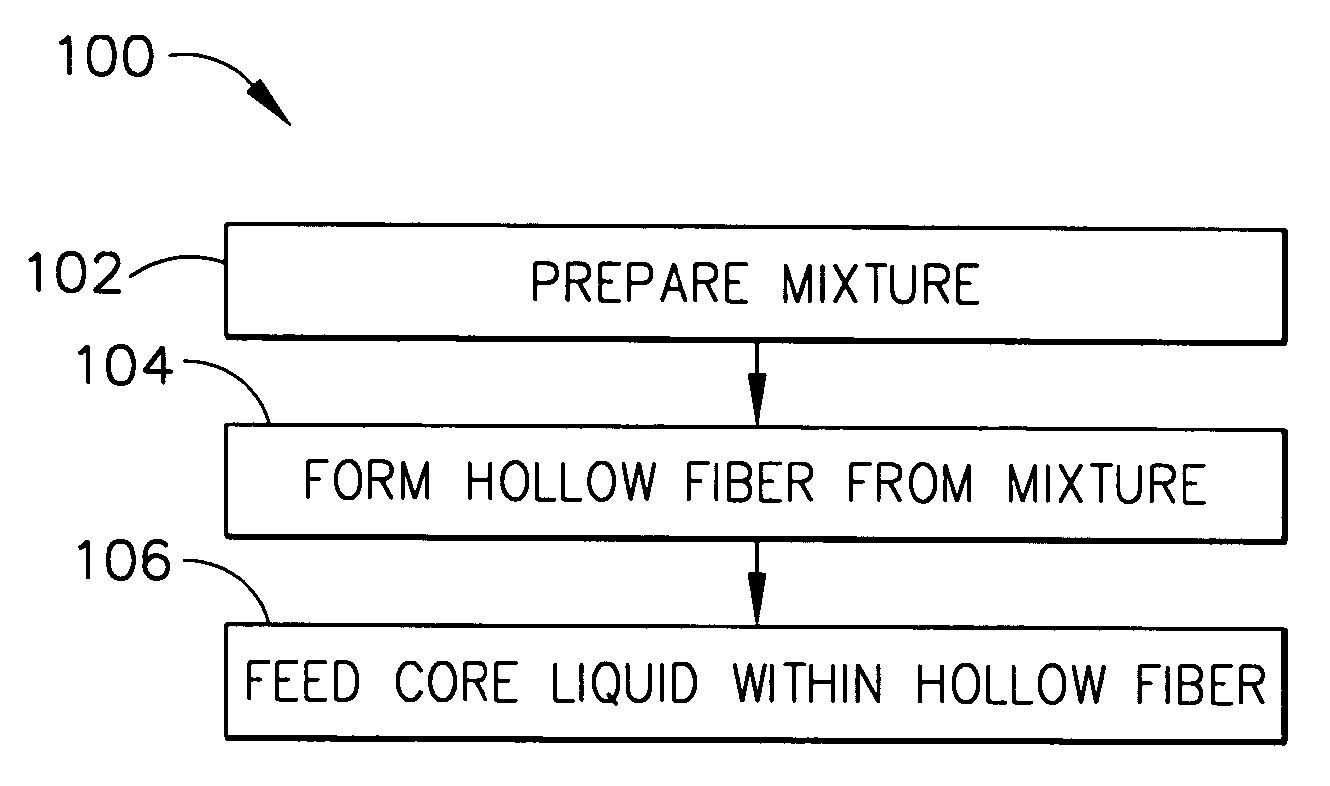

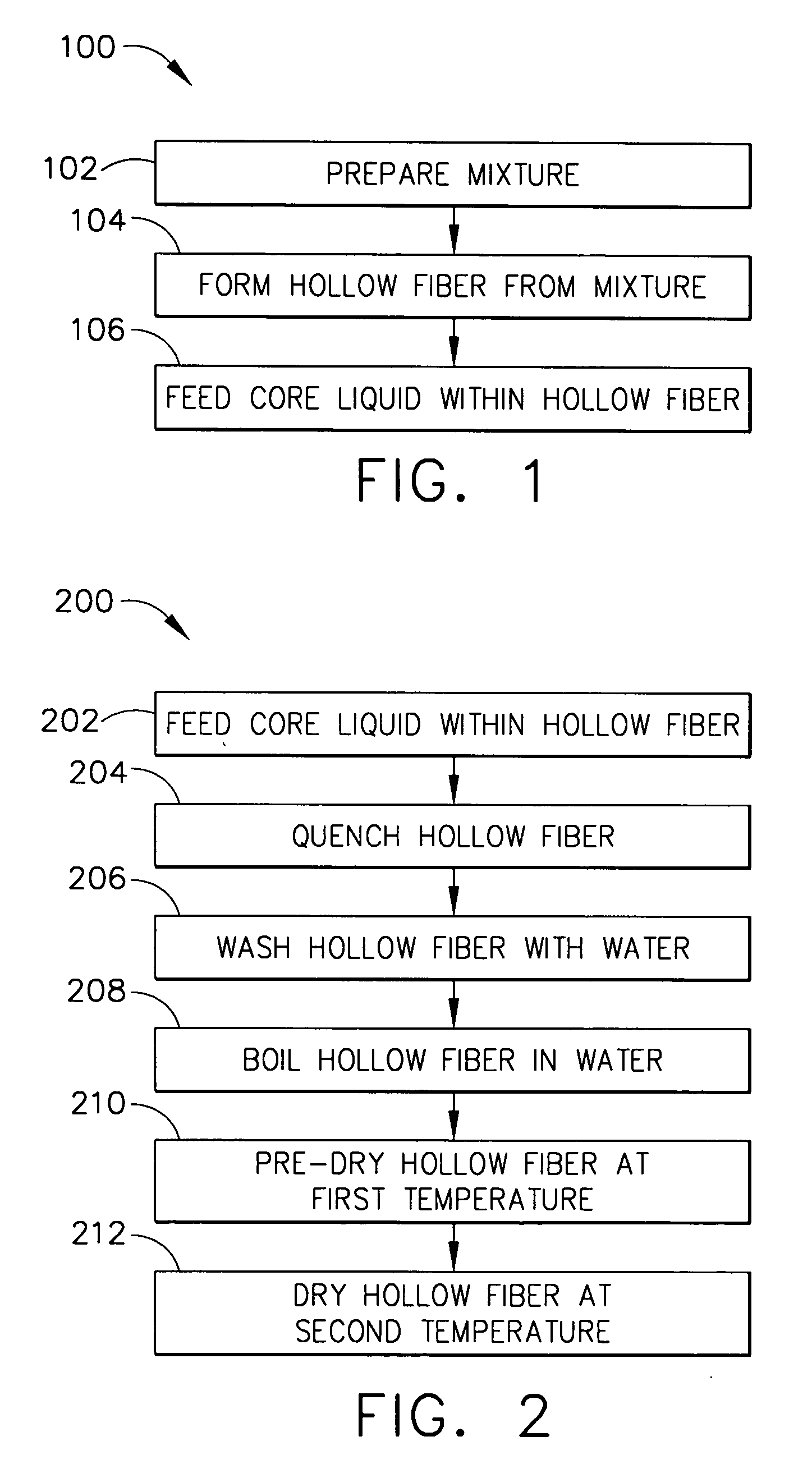

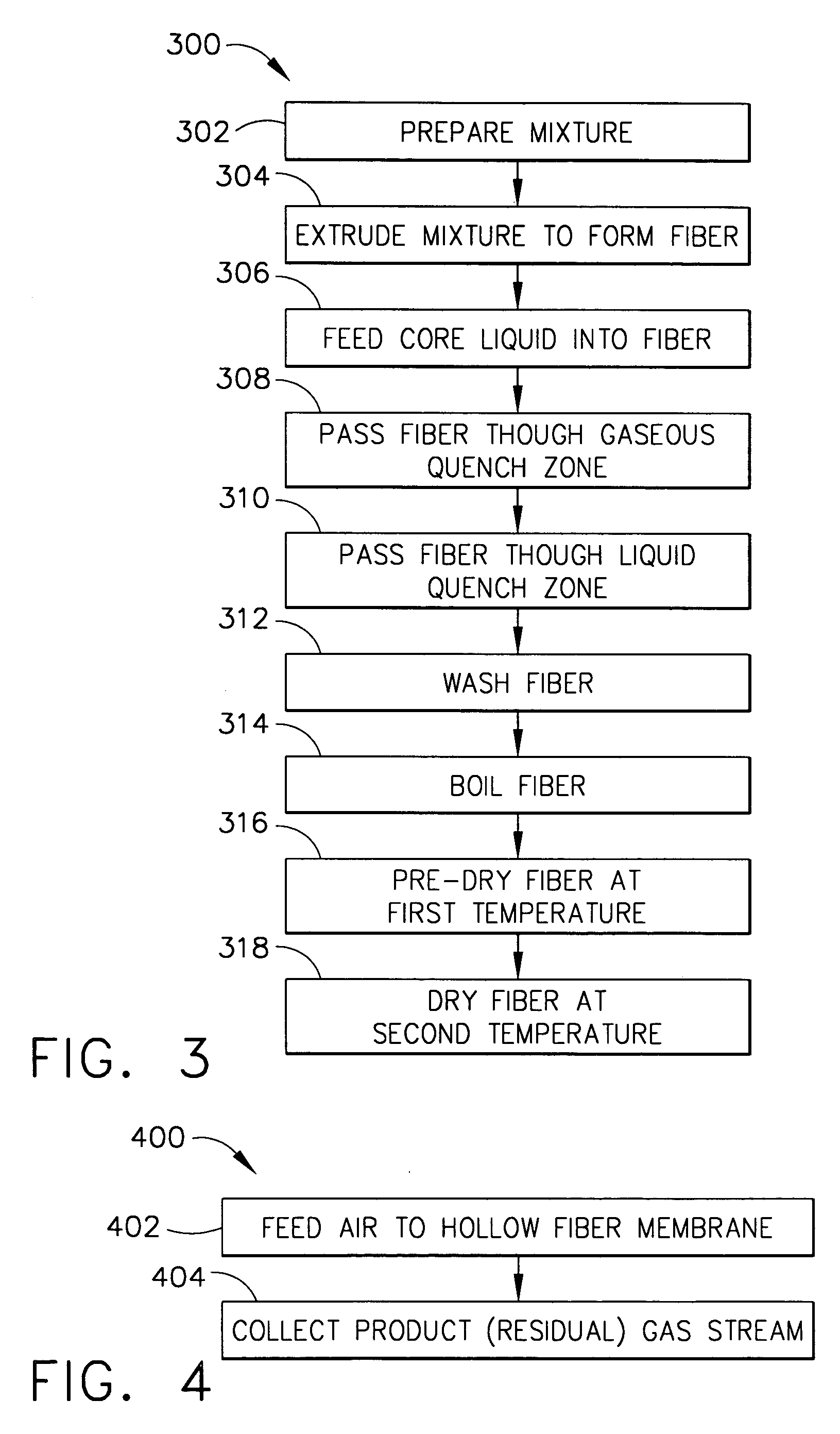

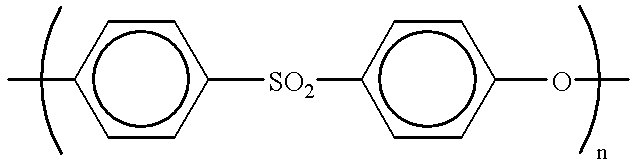

Gas separation membranes and methods for preparing such membranes. The gas separation membranes of the instant invention can separate oxygen and nitrogen in air to provide nitrogen enriched air (NEA), and are stable during exposure to temperatures of at least about 160° C. The gas separation membranes of the instant invention may be formed from polyetherimide by extruding a hollow fiber using a core liquid, quenching the extruded fiber in dry air to promote loss of solvent and non-solvent, and drying the fiber. Methods for separating bleed air fed directly from an aircraft precooler to a high temperature gas separation hollow fiber membrane, to provide NEA, are also disclosed.

Owner:HONEYWELL INT INC

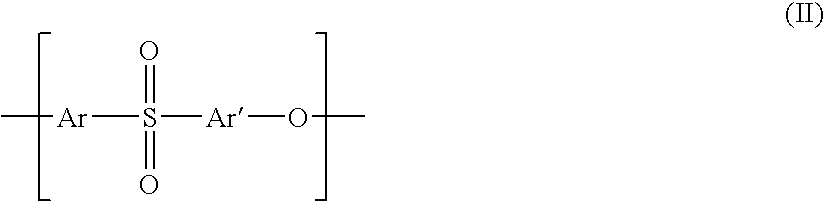

Multilayer insulated wire and transformers made by using the same

InactiveUS6329055B1Good effectLowered in electric propertyPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolymer sciencePolyetherimide

There is disclosed a multilayer insulated wire which comprises a conductor and solderable extrusion-insulating layers made up of two or more layers for covering the conductor, wherein at least one insulating layer is formed by a mixture comprising 100 parts by weight of a resin (A), of at least one selected from the group consisting of polyetherimide resins and polyethersulfone resins, 10 parts by weight or more of a resin (B), of at least one selected from the group consisting of polycarbonate resins, polyarylate resins, polyester resins, and polyamide resin, and 15 to 200 parts by weight of an inorganic filler (C). There is also disclosed a transformer which utilizes the multilayer insulted wire. The multilayer insulated wire is excellent in heat resistance, solderability, high-frequency characteristic, and coilability, and it is favorably suitable for industrial production. Further, the transformer utilizing the multilayer insulated wire is excellent in electrical properties and high in reliability, since when used at high frequencies, electric properties are not lowered and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

Annular or tubular shaped articles of novel polymer blends

The present invention is directed to a tubular article of manufacture in an annular or tubular shape having an outer diameter, an inner diameter and a length comprising one or more materials selected from the group consisting of: a) an immiscible blend of polymers comprising one or more polyetherimides, having more than one glass transition temperature wherein the polyetherimide has a glass transition temperature greater than 217° Celsius; b) a miscible blend of polymers, comprising one or more polyetherimides, having a single glass transition temperature greater than 180° Celsius; or, c) a single polyetherimide having a glass transition temperature of greater than 247° Celsius.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Process of making dispersed polyetherimide micronized particles and process of coating and further forming of these particles products made therefrom

InactiveUS20140272430A1Improve interface adhesionImprove performanceSynthetic resin layered productsPretreated surfacesFiberPolymer science

Processes involving wetting fibers with an aqueous dispersion of micronized thermoplastic powders; processes for producing an aqueous dispersion of micronized thermoplastic powders; processes of chemically surface cross-linking micronized particles; and articles of produced therefrom.

Owner:SABIC GLOBAL TECH BV

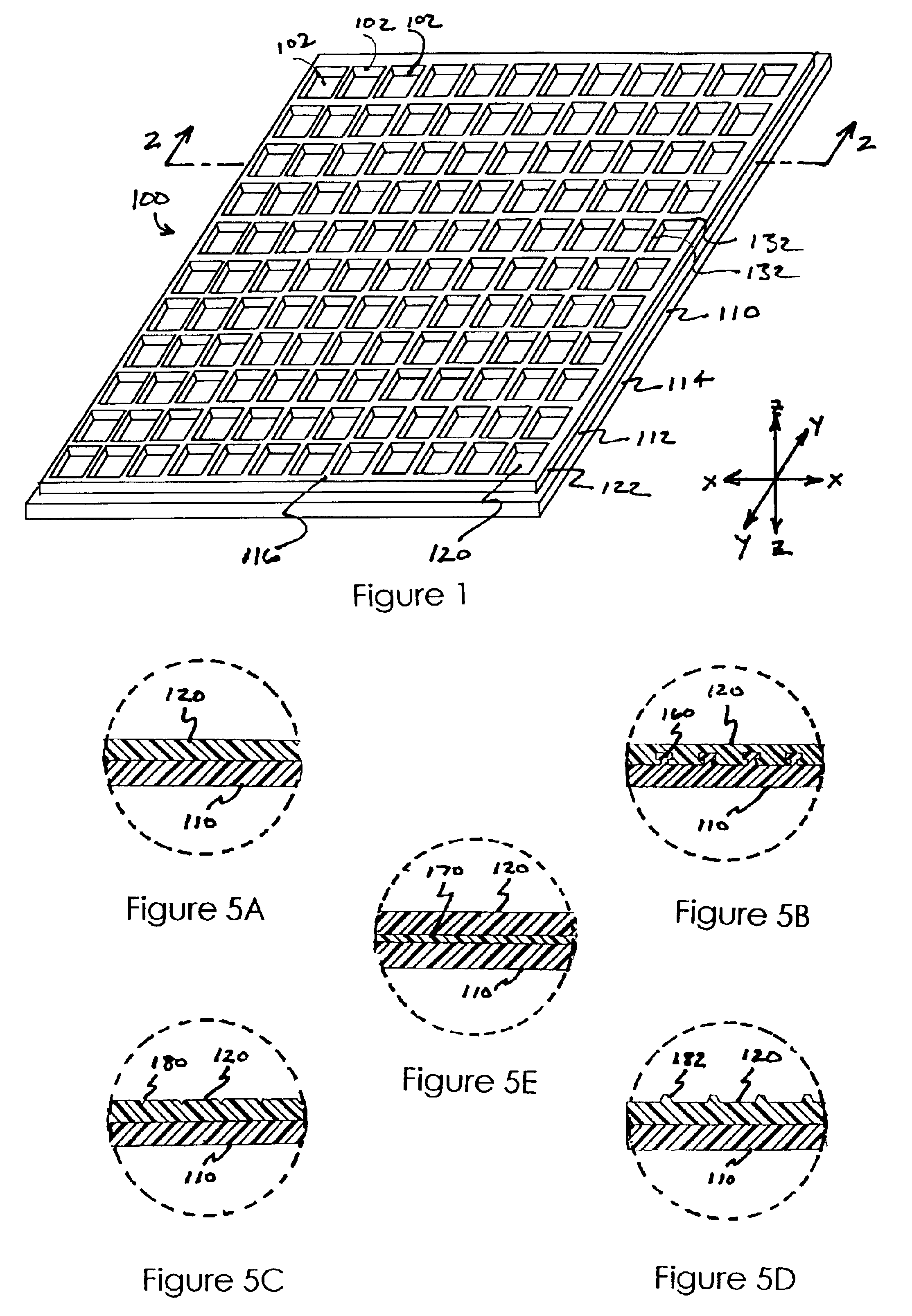

High performance plastic pallets

The invention relates to plastic pallets that pass the Underwriters Laboratory UL 2335 protocol for pallets wherein said pallets comprises at least one resin selected from the group consisting of: (a) polyphenylene ether resin and blends containing polyphenylene ether resin, (b) polycarbonate resin and blends containing polycarbonate resin, (c) vinyl aromatic graft copolymer resin; (d) polyetherimide resin and blends containing polyetherimide resin, and thermosetting resins. In a preferred embodiment, the plastic pallet has an open deck design. The invention also relates to a method to make pallets that pass the UL 2335 protocol.

Owner:SABIC GLOBAL TECH BV

Polymeric Membranes

InactiveUS20140255636A1Improve permeabilityGood choiceLayered productsIsotope separationPolymer sciencePolyetherimide

Disclosed are blended polymeric membranes that include at least a first polymer and a second polymer that is UV treated, wherein the first and second polymers are each selected from the group consisting of a polymer of intrinsic microporosity (PIM), a polyetherimide (PEI) polymer, a polyimide (PI) polymer, and a polyetherimide-siloxane (PEI-Si) polymer.

Owner:SABIC GLOBAL TECH BV

Multi-layer plastic articles and methods of making the same

A three-dimensional, multi-layer plastic product that is resistant to damage caused by environmental factors such as heat, chemicals, desiccants, oxygen, and / or weather is disclosed. The multi-layer product includes an engineering resin layer affixed to a commodity resin layer. The engineering resin layer of the multi-layer film may be directly fused to the commodity resin or post-consumer regrind layer. Alternatively, the engineering resin layer may be tied to the commodity resin or post-consumer regrind layer through the use of one or more adhesive and / or tie layers. The commodity resin layer may be manufactured from an economical polymer material such as a polypropylene, polyethylene, polystyrene or post-consumer regrind. Suitable engineering resins may be any of a variety of suitable materials such as a polysulphone, polymethylpentene, polyester, polycarbonate, polyetherimide, nylon, polyarylate, polyphenylenesulphide, polyphenylene oxide, polyethersulphone, aromatic polyketone, liquid crystal polymer, and mixtures thereof, for example, a method for manufacturing a three-dimensional multi-layer plastic product is also disclosed which includes the steps of providing an extruded or laminated sheet comprising an engineering resin layer, thermoforming a three-dimensional shell from the sheet, and injection molding a commodity resin layer onto the thermoformed shell.

Owner:RUBBERMAID

Annular or tubular shaped articles of novel polymer blends

The present invention is directed to a tubular article of manufacture in an annular or tubular shape having an outer diameter, an inner diameter and a length comprising one or more materials selected from the group consisting of: a) an immiscible blend of polymers comprising one or more polyetherimides, having more than one glass transition temperature wherein the polyetherimide has a glass transition temperature greater than 217 DEG C; b) a miscible blend of polymers, comprising one or more polyetherimides, having a single glass transition temperature greater than 180 DEG C; or, c) a single polyetherimide having a glass transition temperature of greater than 247 DEG C.

Owner:SABIC INNOVATIVE PLASTICS IP BV

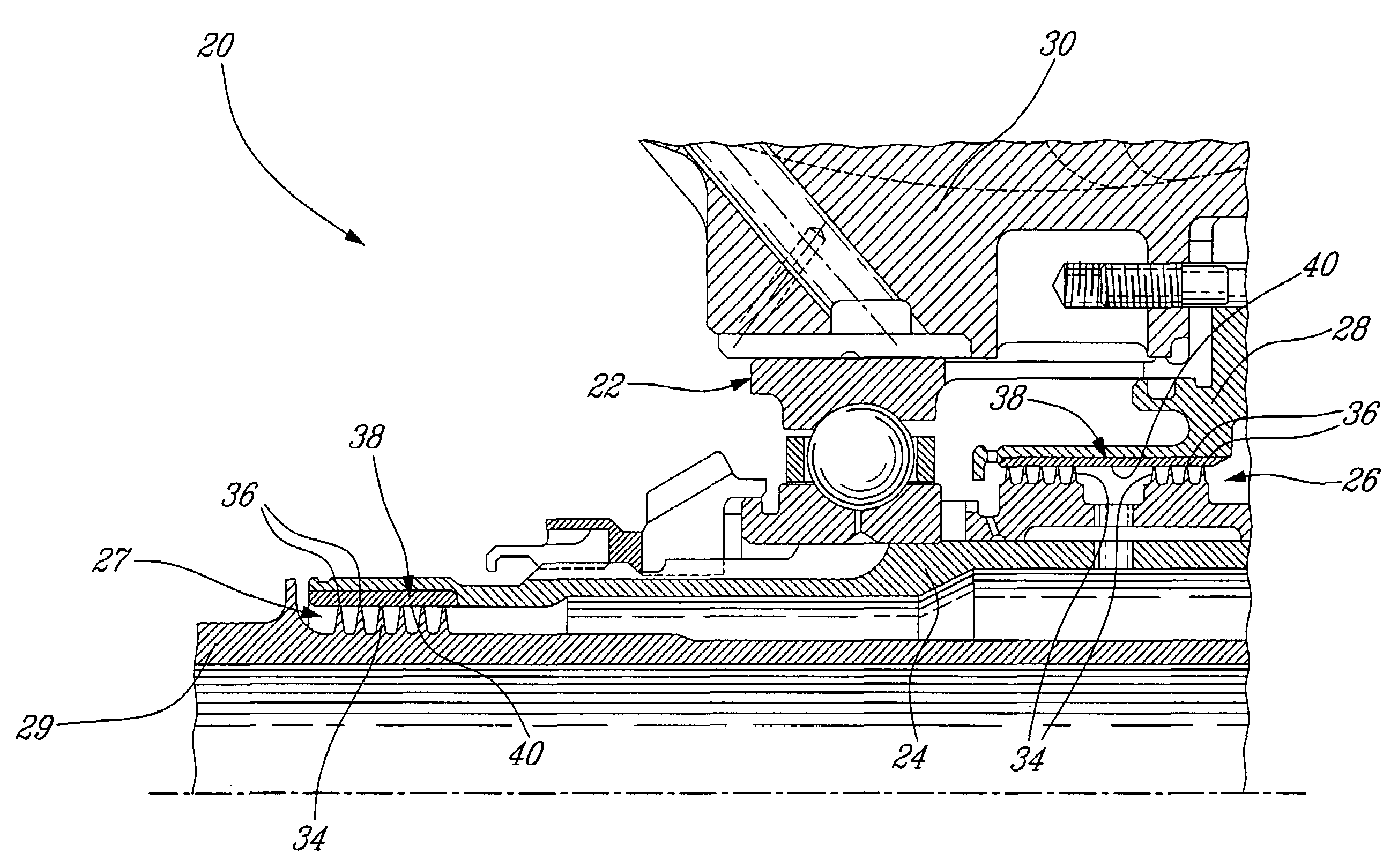

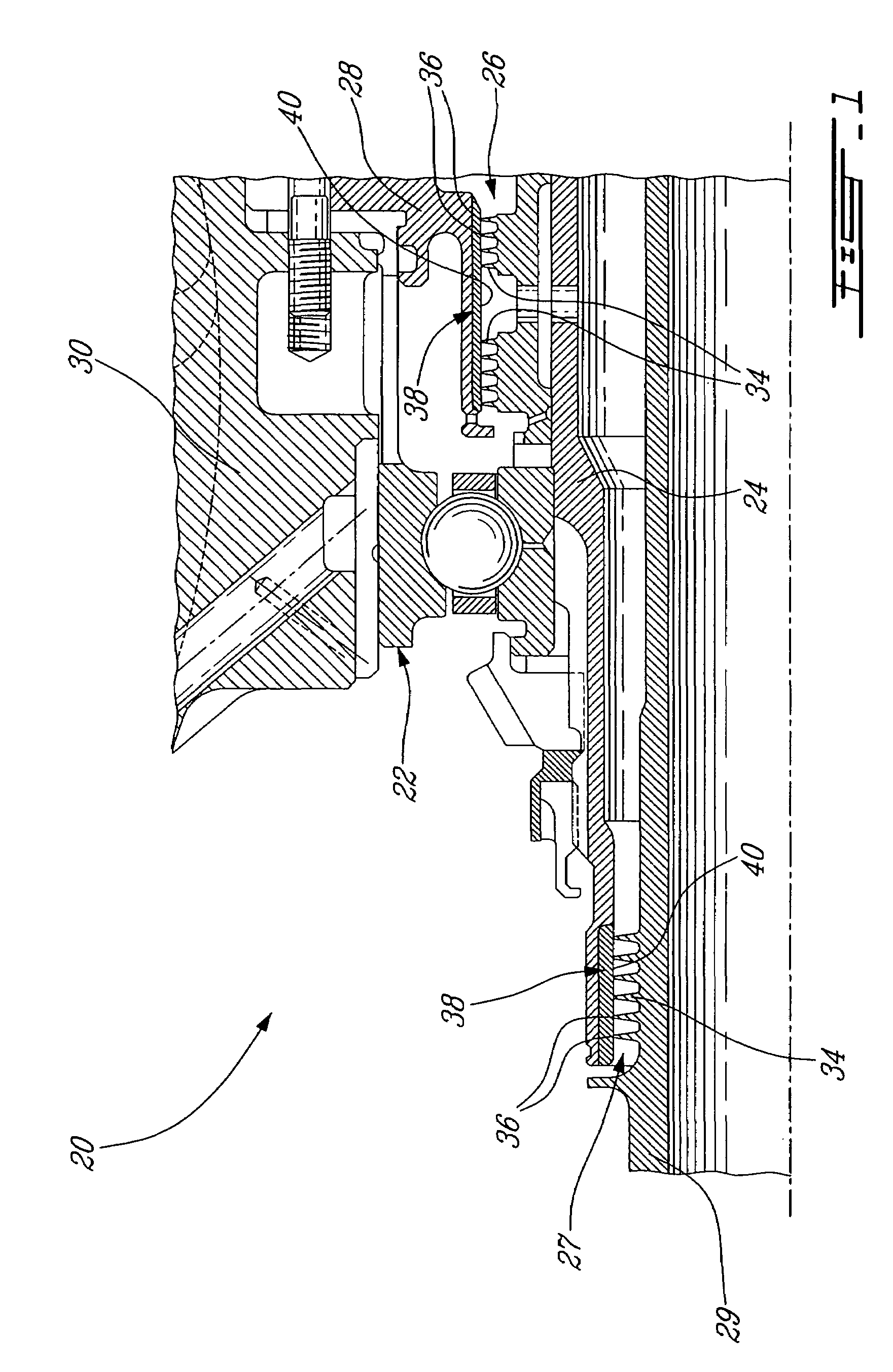

Air-oil seal

An air-oil seal having a runner surface comprising at least one component selected from the group consisting of: polyetheretherketone; polyetherimide; polyphenylene sulfide; and polyetherketoneketone.

Owner:PRATT & WHITNEY CANADA CORP

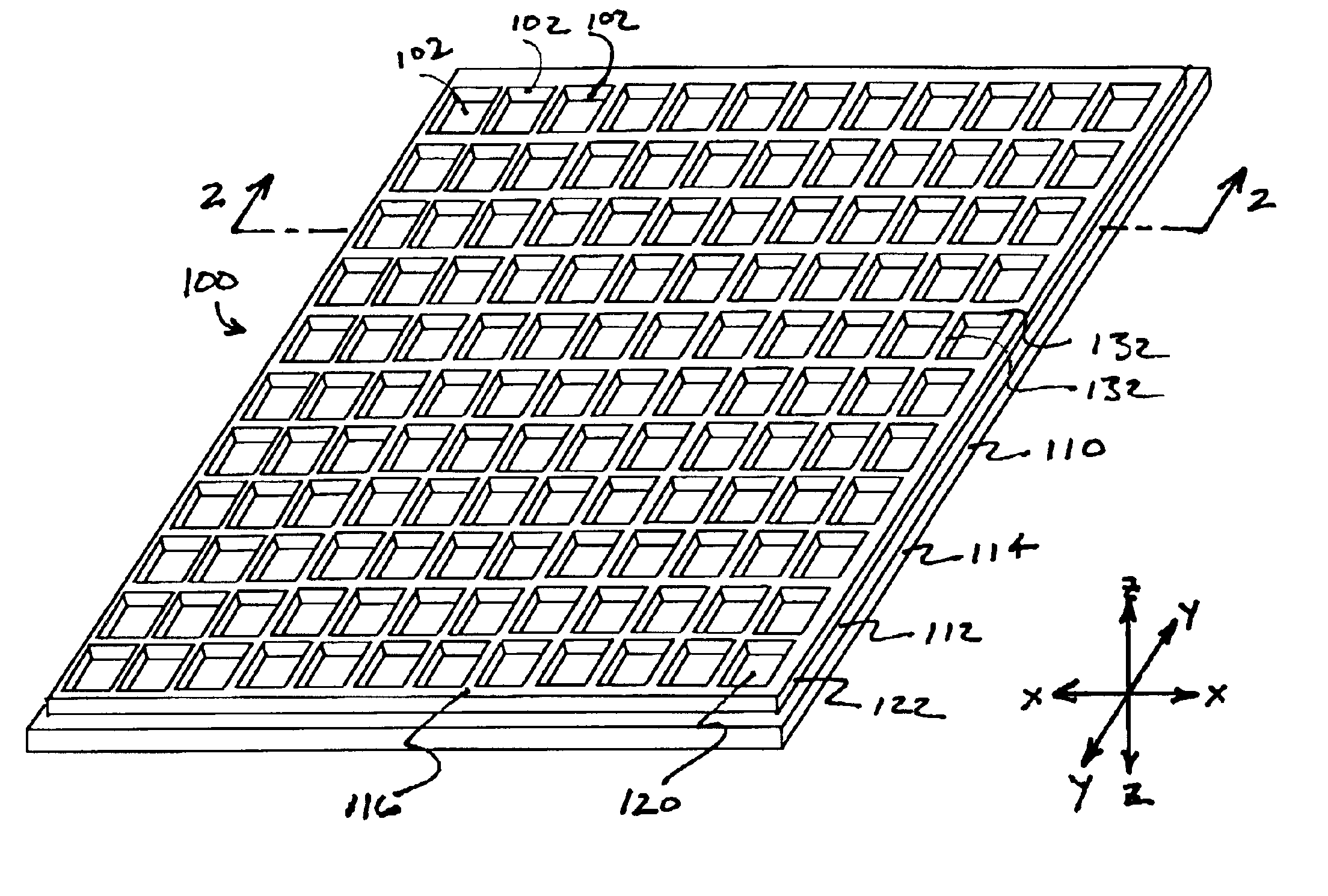

Matrix tray with tacky surfaces

InactiveUS6926937B2Widen meansSufficient forceEnvelopes/bags making machinerySemiconductor/solid-state device detailsPolyetherimidePolybutylene terephthalate

A tray for handling and retaining a plurality of small components comprising a rigid body portion with a plurality of pockets formed therein. Each of the pockets has an elastomeric contact surface for contacting and retaining a component. The contact surface may be formed from a thermoplastic material having a surface energy between 20 dyne / cm and 100 dyne / cm, and a surface electrical resistivity of between about 1×104 ohms / square and 1×1012 ohms / square. The material for the contact portion may be urethane, polybutylene terephthalate, polyolefin, polyethylene terephthalate, styrenic block co-polymer, styrene-butadiene rubber, polyether block polyamide, or polypropylene / crosslinked EDPM rubber. The body portion may be formed from acrylonitrile-butadiene-styrene, polycarbonate, urethane, polyphenylene sulfide, polystyrene, polymethyl methacrylate, polyetherketone, polyetheretherketone, polyetherketoneketone, polyether imide, polysulfone, styrene acrylonitrile, polyethylene, polypropylene, fluoropolymer, polyolefin, or nylon. The body portion may have a peripheral border region and a downwardly projecting skirt portion to facilitate stacking of multiple trays.

Owner:ENTEGRIS INC

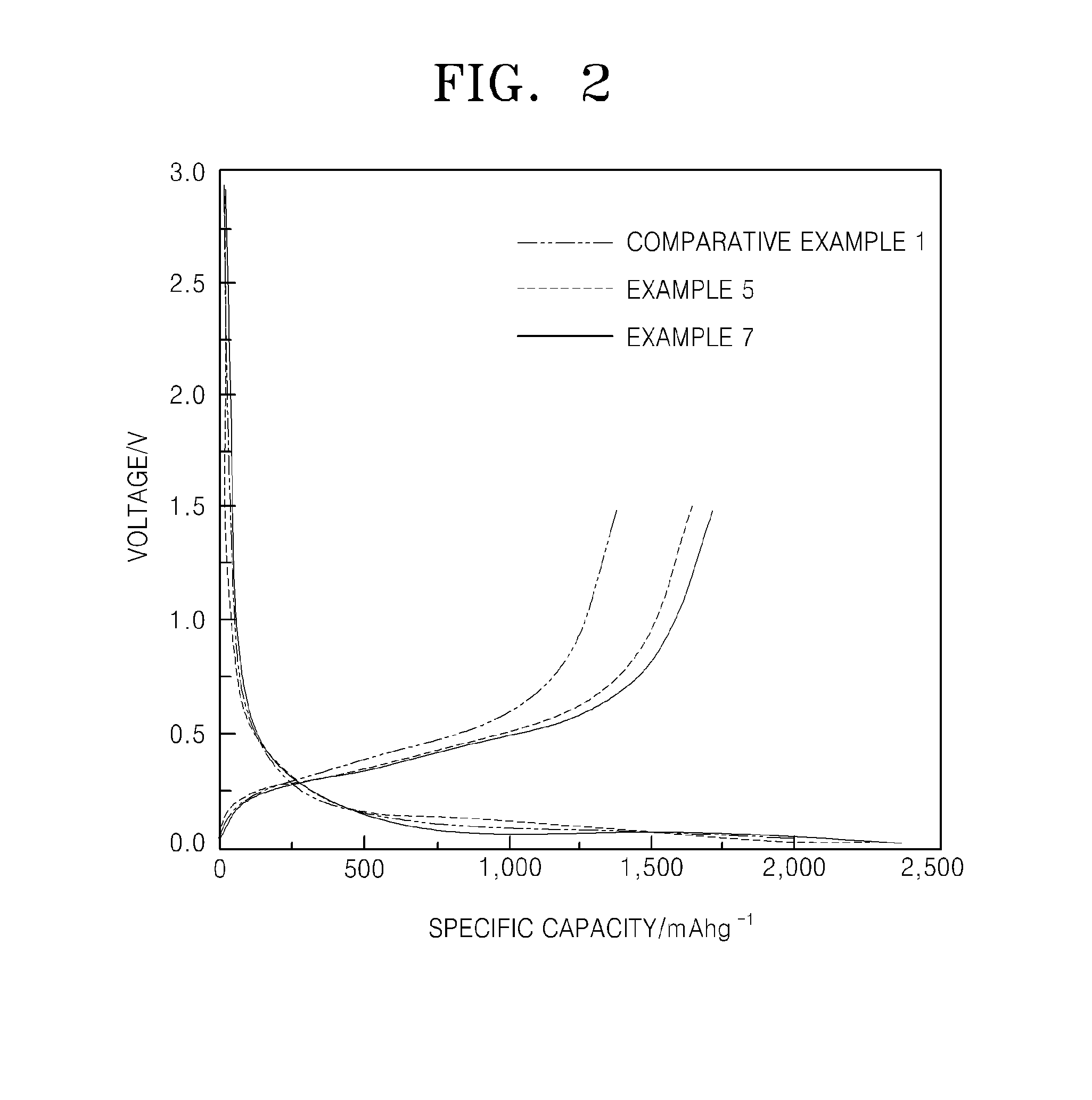

Anode for lithium secondary battery and lithium secondary battery including the same

ActiveUS20140242461A1Improve initial efficiencyHigh reversible capacityConductive materialElectrode collector coatingLithiumPolyetherimide

An anode for a lithium secondary battery including: a composite anode active material including an anode active material, and a water-soluble polymer disposed on a surface of the anode active material; and a binder disposed on the composite anode active material, the binder including one or more selected from a polyimide, a polyamideimide, a polyamide, and a polyetherimide.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Low smoke polycarbonate composition and laminates, method of manufacture and product made therefrom

Owner:SHPP GLOBAL TECH BV

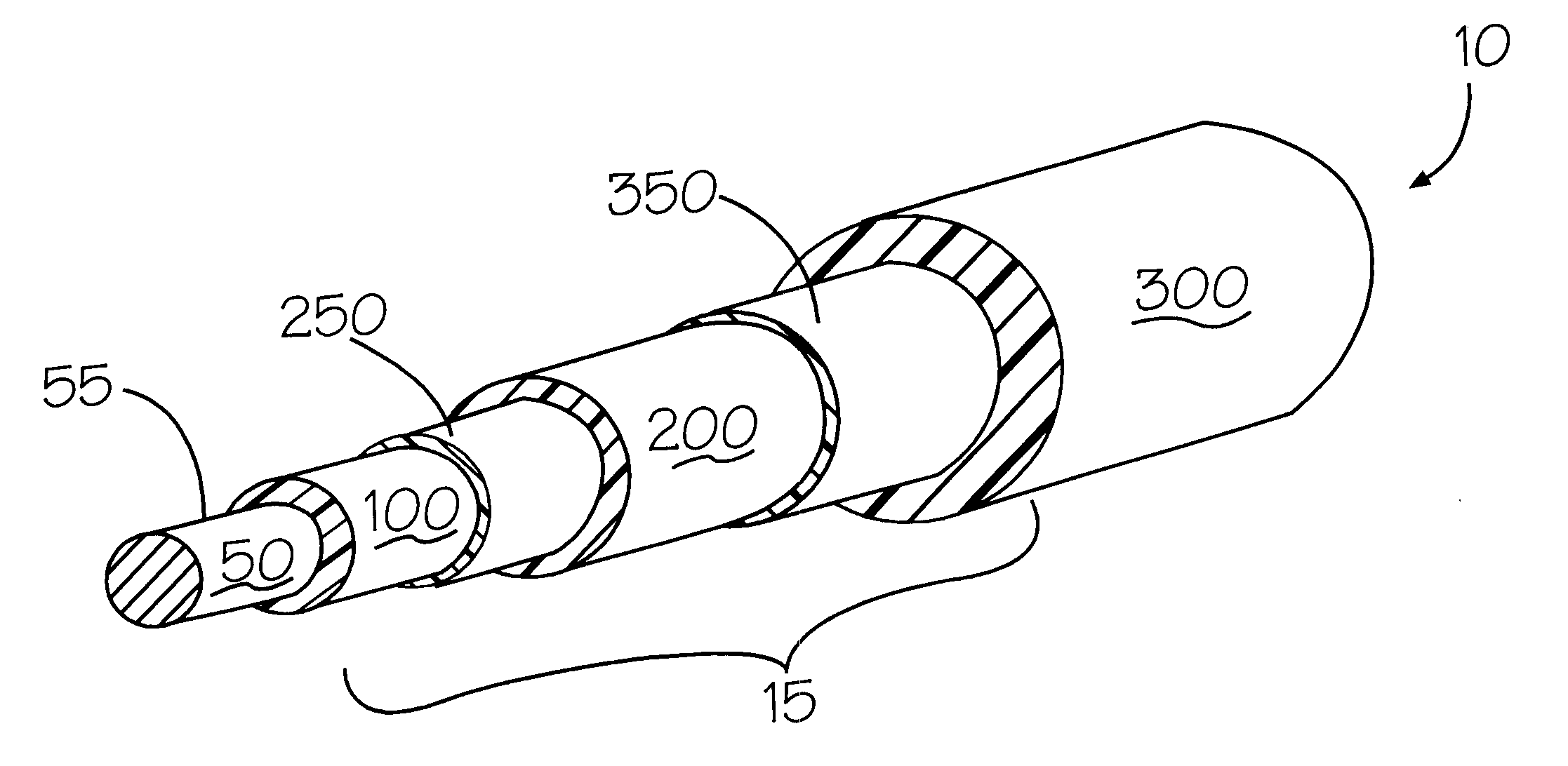

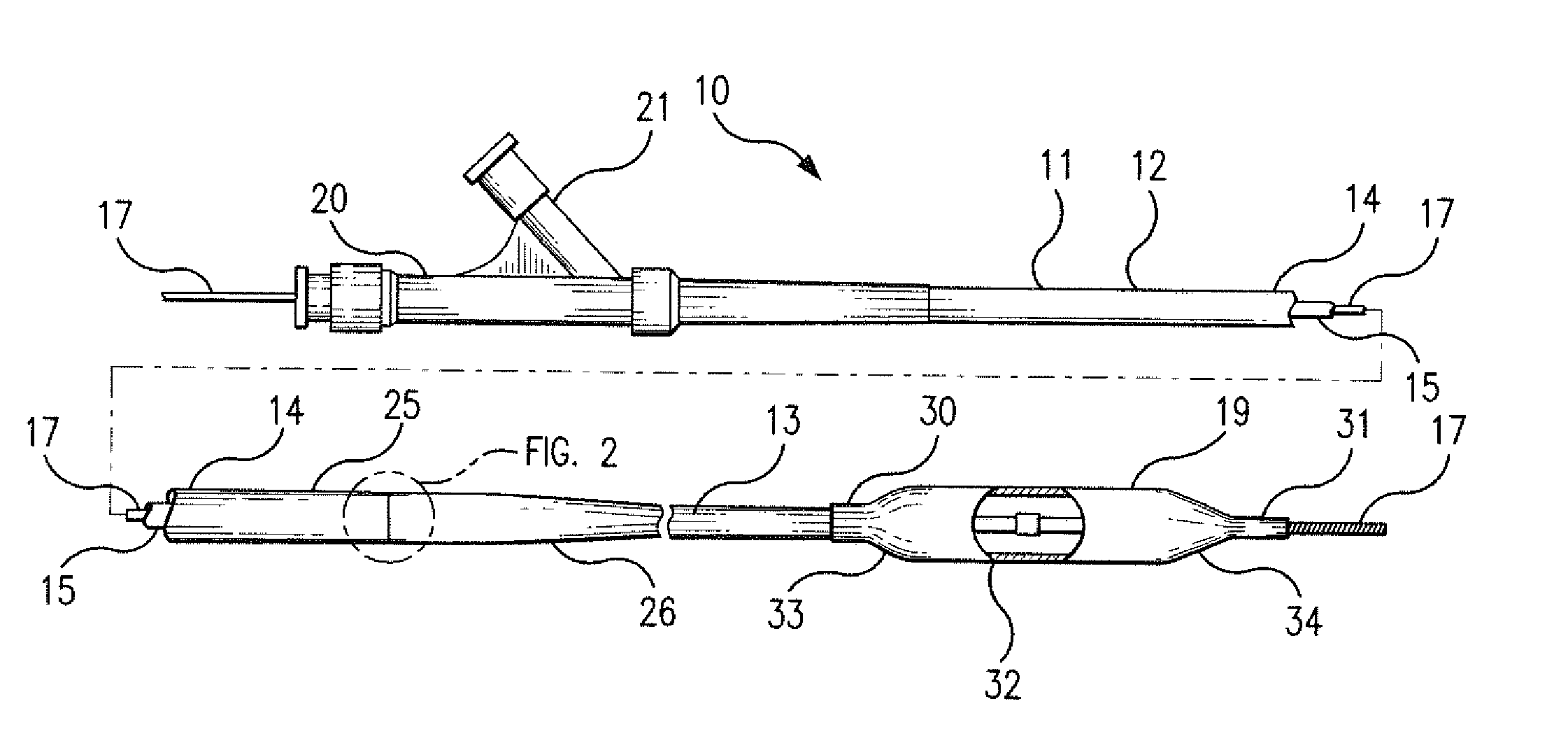

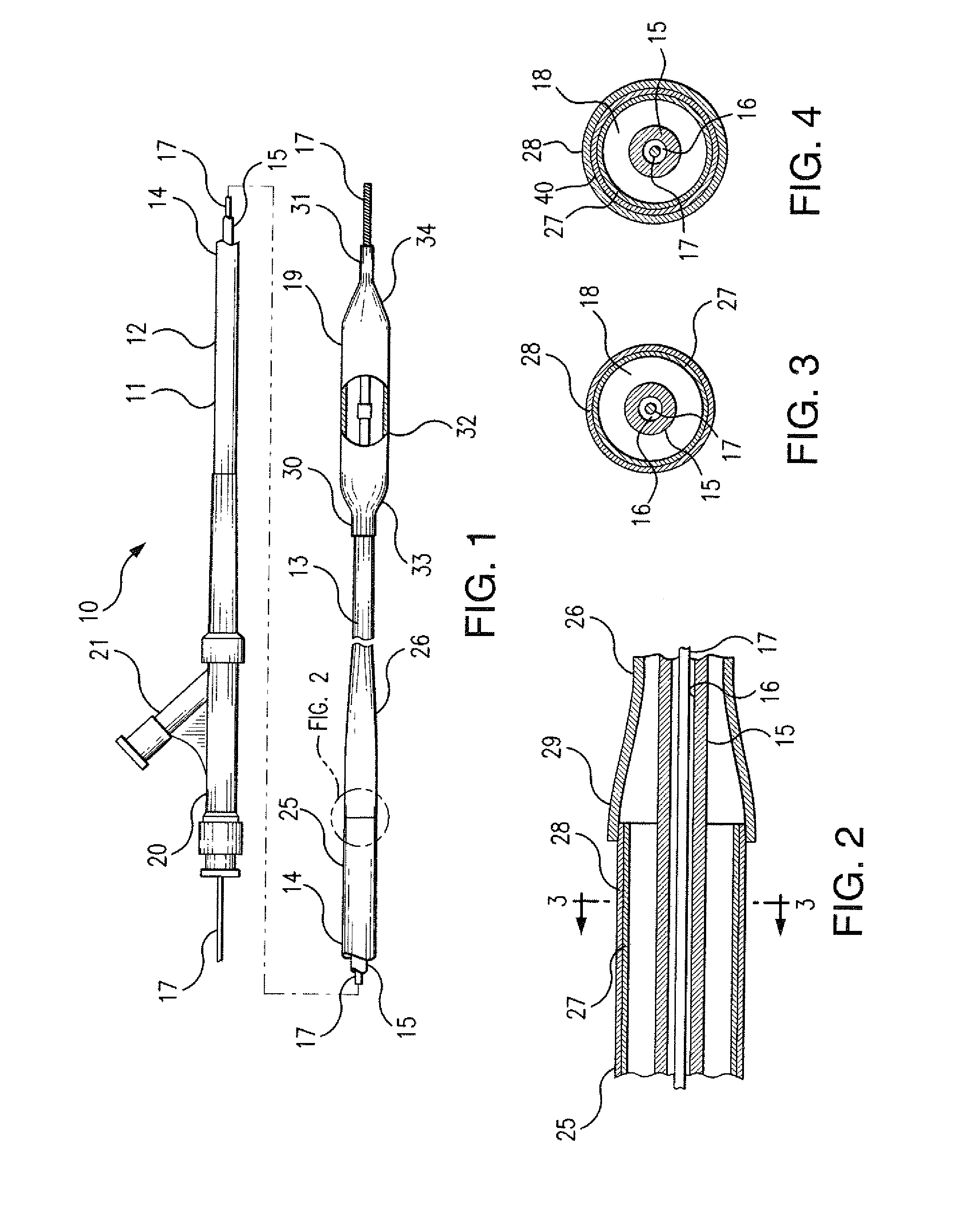

Catheter Shaft and Method of Forming Same

InactiveUS20140276401A1Increase thrustBalloon catheterSurgeryPolytetramethylene terephthalateHeat deflection temperature

Elongate, flexible catheter includes an elongated shaft having a proximal end, a distal end, and a lumen defined therein. The shaft includes a tubular member having an outer layer and an inner layer. The outer layer includes a first polymer selected from the group consisting of nylon 12, polyether block amide, and combinations thereof. The inner layer includes a second polymer having a heat deflection temperature greater than about 53° C. selected from the group consisting of nylon 11, nylon 6, nylon 6,6, nylon 6,12, polyamide-imide, polyetherimide, polypropylene, polyethylene terephthalate, polybutylene terephthalate, polyethereetherketone, and combinations thereof. Method of making an elongate, flexible catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

Resin composition and adhesive film for multi-layered printed wiring board

ActiveUS20050019554A1High mechanical strengthEasy to manufactureLayered product treatmentAdhesive articlesBenzoxazolePolyetherimide

Resin compositions, which contain: (a) a heat-resistant resin which is soluble in organic solvents wherein the heat-resistant resin is one or more heat-resistant resin(s) selected from the group consisting of a polyimide resin, a polyamide-imide resin, a polyamide resin, a polyether imide resin, a polybenzoxazol resin, a polybenzimidazole resin, copolymers thereof, and mixtures thereof; (b) a thermosetting resin; (c) a filler; and (d) resin having a polybutadiene structure and / or a polysiloxane structure, wherein: the heat-resistant resin (a) and the thermosetting resin (b) are present in a weight ratio of heat-resistant resin (a) to thermosetting resin (b) of from 100:1 to 1:1; the heat-resistant resin (a), thermosetting resin (b), and filler (c) are present in relative amounts such that weight ratio of the total amount of heat-resistant resin (a) and thermosetting resin (b) to filler (c) by weight is from 100:1 to 3:2; the resin having a polybutadiene structure and / or a polysiloxane structure (d) is present in an amount of 0.1 to 15 parts by weight based on 100 parts by weight of the heat-resistant resin (a); and the heat-resistant resin (a), thermosetting resin (b), filler (c), and resin having a polybutadiene structure and / or a polysiloxane structure (d) are present in a total amount of not less than 70% by weight, based on the total weight of the resin composition, are useful for preparing adhesive films, which are, in turn, useful for forming interlayer insulation layers for multi-layered printed wiring boards having an excellent mechanical strength and capable of being roughened by an oxidizing agent.

Owner:AJINOMOTO CO INC

Articles comprising a polyimide solvent cast film having a low coefficient of thermal expansion and method of manufacture thereof

ActiveUS20080044682A1Printed circuit aspectsSynthetic resin layered productsPolymer sciencePolyetherimide

An article comprises a solvent cast film comprising a polyetherimide comprising structural units derived from a dianhydride component selected from the group consisting of 3,4′-oxydiphthalic anhydride, 3,3′-oxydiphthalic anhydride, 4,4′-oxydiphthalic anhydride, and combinations thereof, and a diamine component. The polyetherimide has a glass transition temperature that is at least 190° C. The film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight. The film has less than 15 molar % of a member selected from the group consisting of biphenyltetracarboxylic acid, dianhydrides of biphenyltetracarboxylic acid, esters of biphenyltetracarboxylic acid, and combinations thereof.

Owner:SHPP GLOBAL TECH BV

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a polyester; from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

Polyetherimide resin compositions with improved ductility

A thermoplastic resin composition containing a polyetherimide resin, a siloxane-polyetherimide copolymer and a branched polycarbonate resin exhibits exhibit high heat distortion temperature, improved room temperature impact properties and improved impact strength and ductility at low temperatures.

Owner:GENERAL ELECTRIC CO

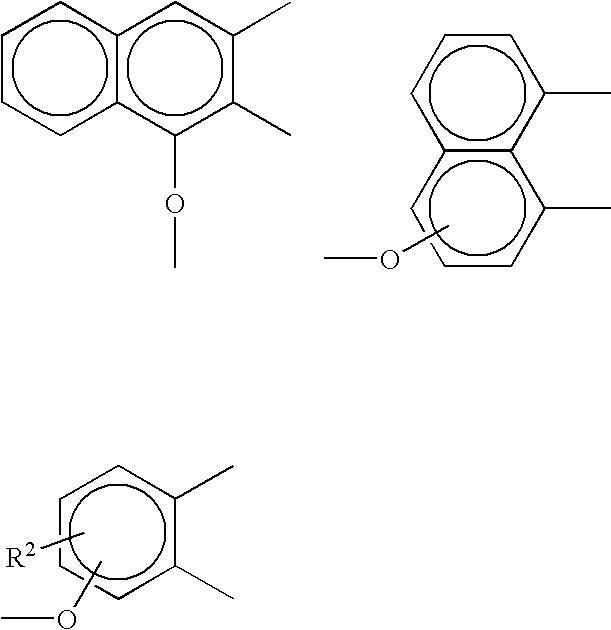

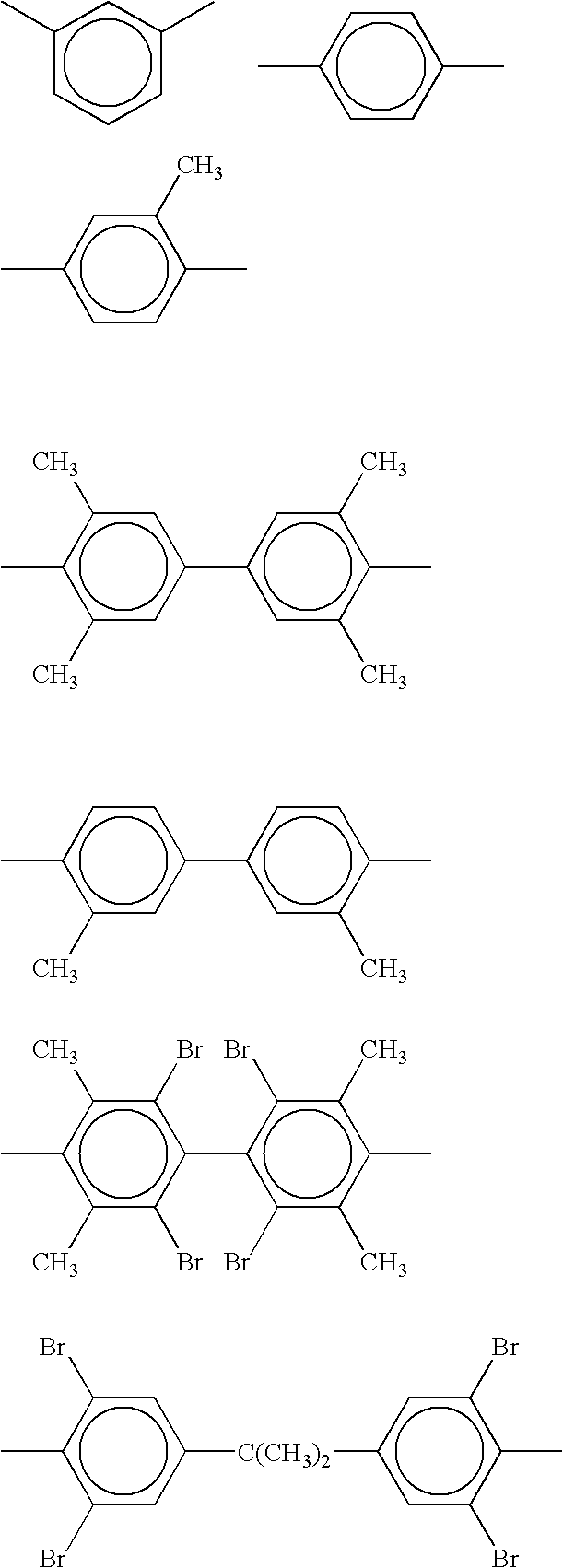

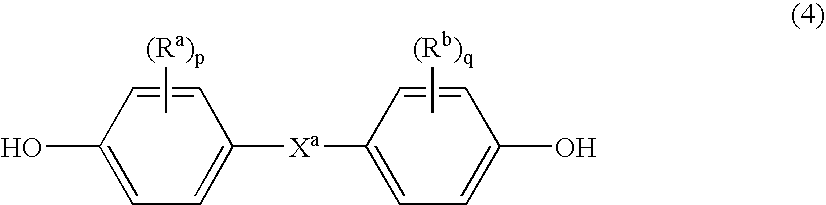

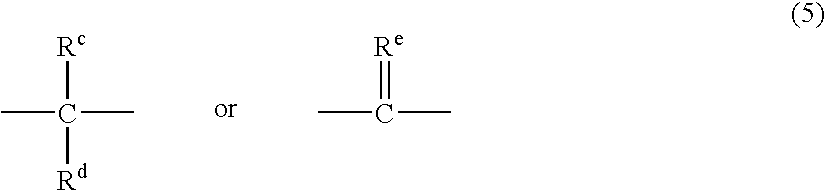

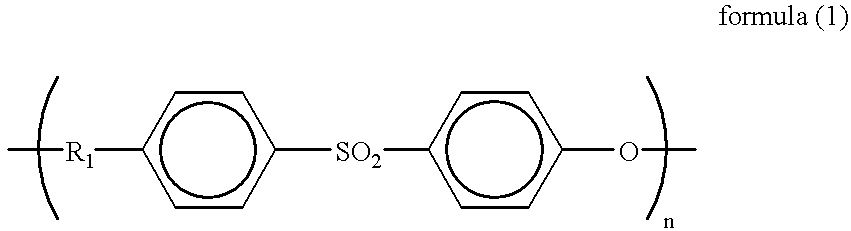

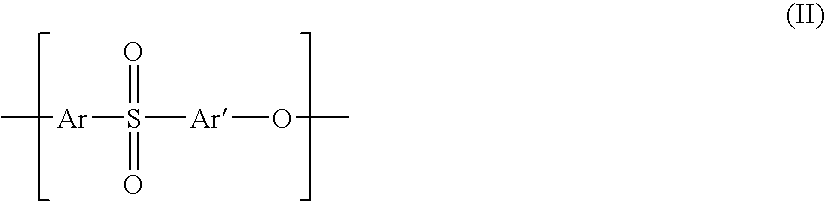

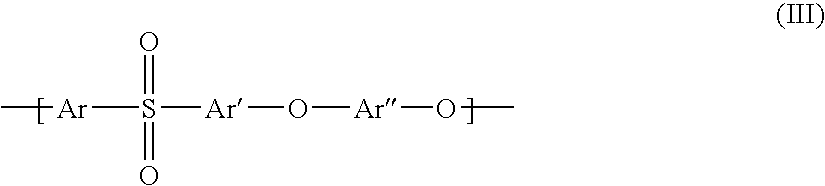

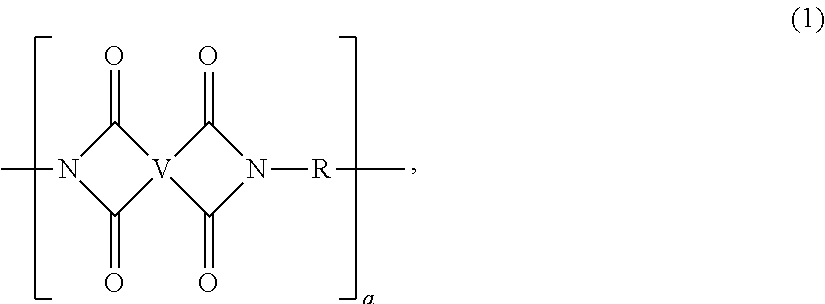

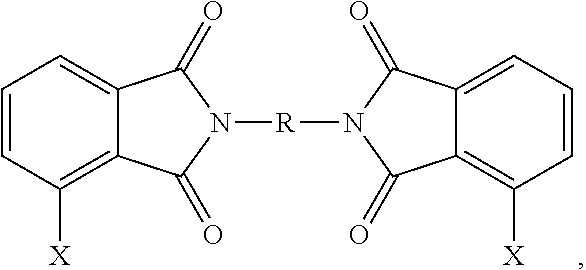

Polyetherimides, methods of manufacture, and articles formed therefrom

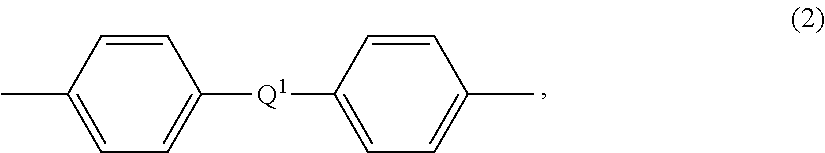

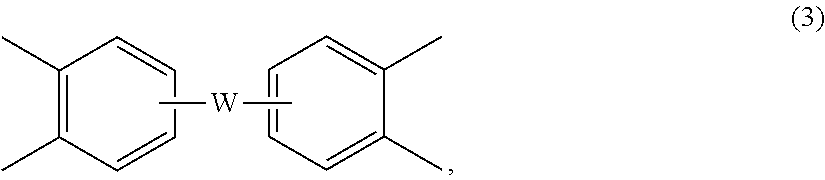

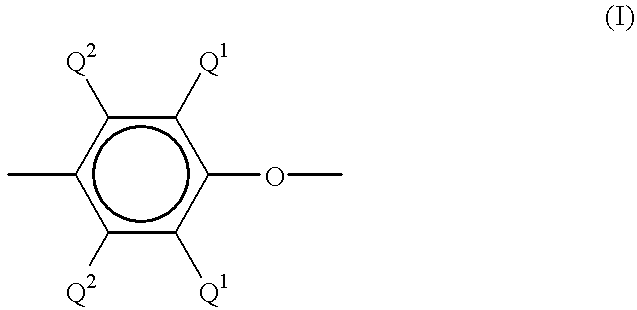

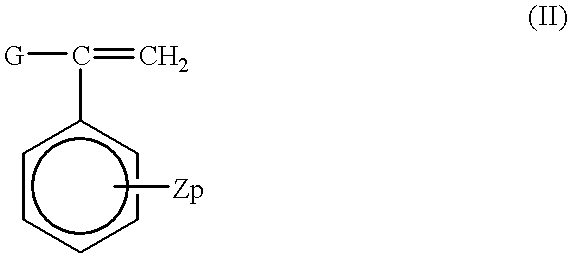

A polyetherimide manufactured by reaction of an alkali metal salt of a dihydroxy aromatic compound of the formulaMO—Z—OMwherein M is an alkali metal salt and Z is an aromatic C6-24 monocyclic or polycyclic moiety optionally substituted with 1 to 6 C1-8 alkyl groups, 1 to 8 halogen atoms, or a combination thereof,with a bis(halophthalimide) composition comprising, based on the weight of the bis(halophthalimide) composition,from more than 45 to less than 75 weight percent of a 3,3′-bis(halophthalimide) of the formulaless than 10 weight percent of a 3,4′-bis(halophthalimide) of the formulaandfrom more than 45 to less than 75 weight percent of a (4,4′-bis(halophthalimide) of the formula

Owner:SHPP GLOBAL TECH BV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com