Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125 results about "Polyether block amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyether block amide or PEBA is a thermoplastic elastomer (TPE). It is known under the tradename of PEBAX® (Arkema) and VESTAMID® E (Evonik Industries). It is a block copolymer obtained by polycondensation of a carboxylic acid polyamide (PA6, PA11, PA12) with an alcohol termination polyether (Polytetramethylene glycol PTMG), PEG). The general chemical structure is...

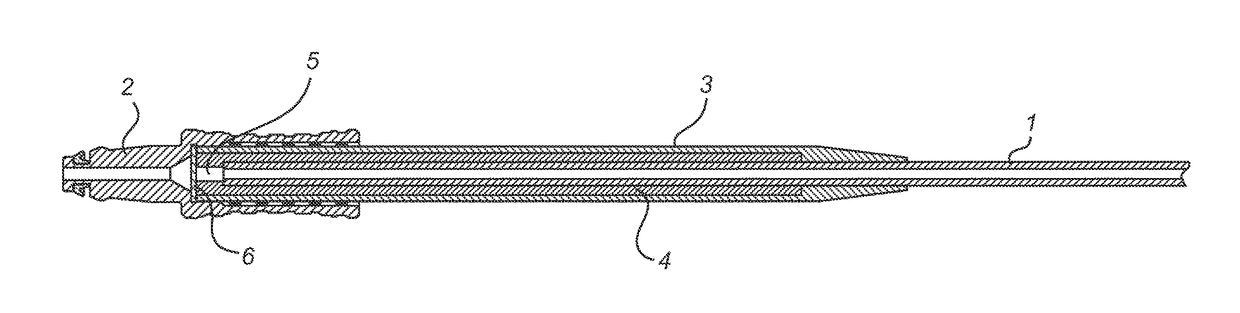

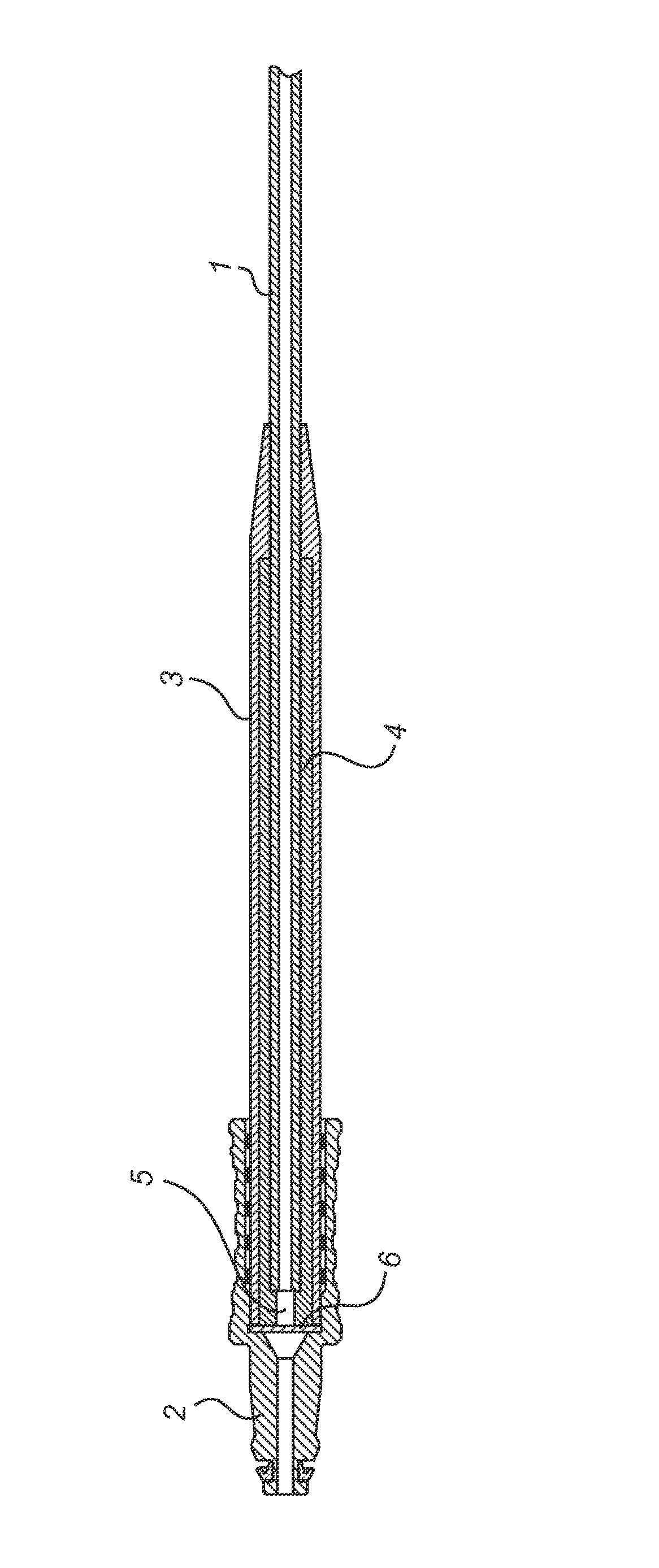

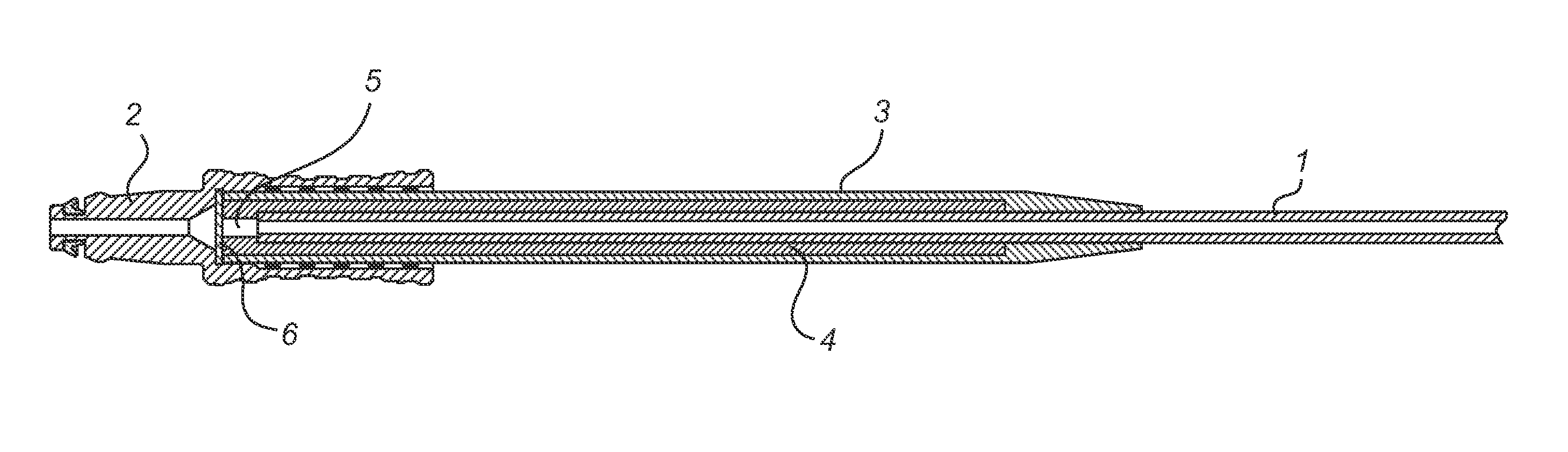

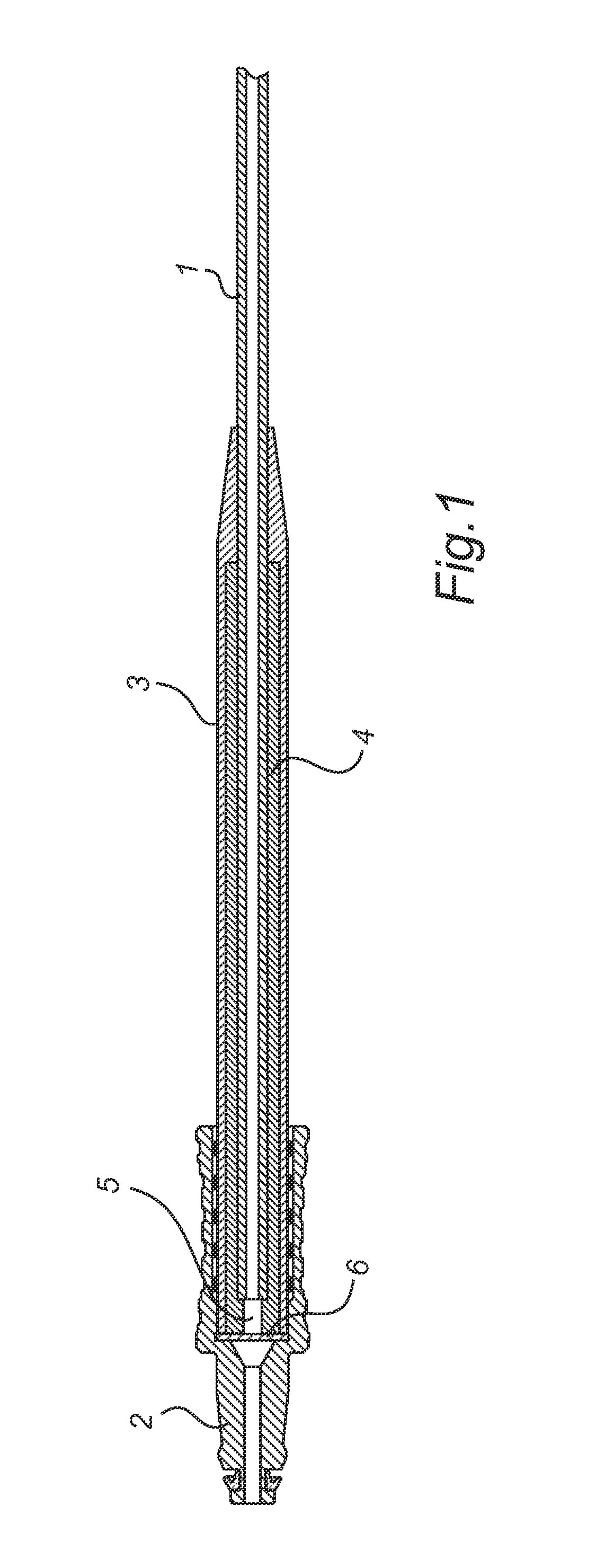

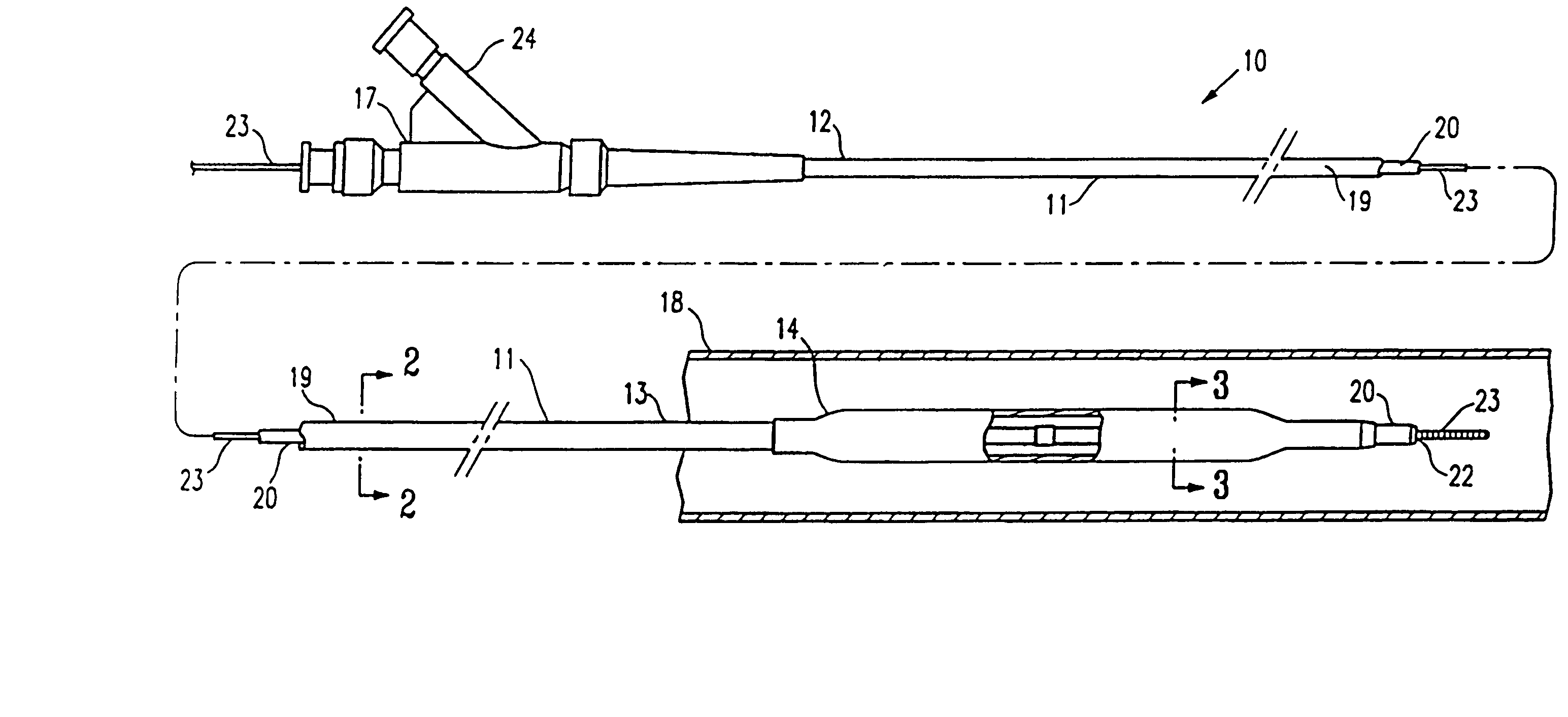

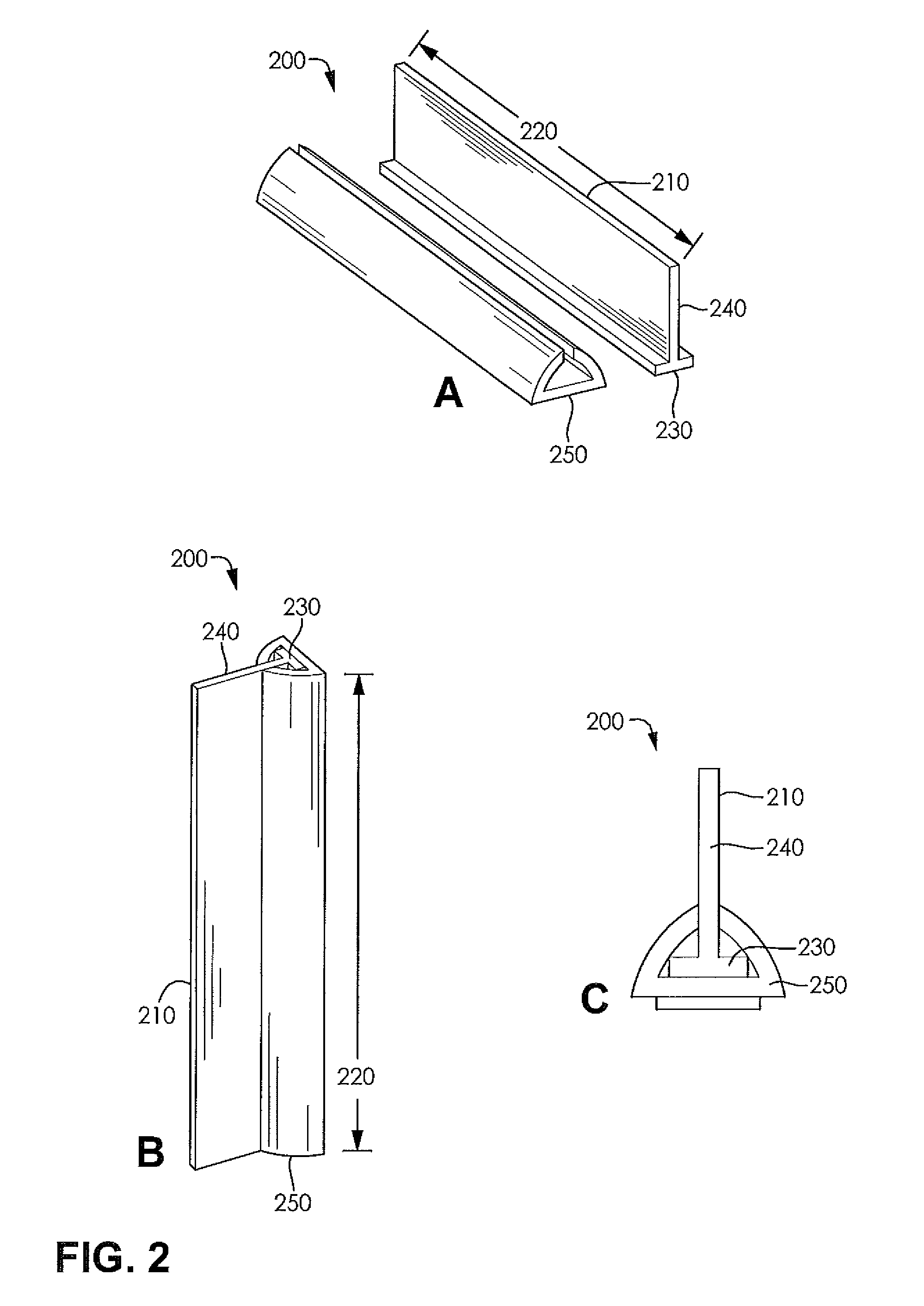

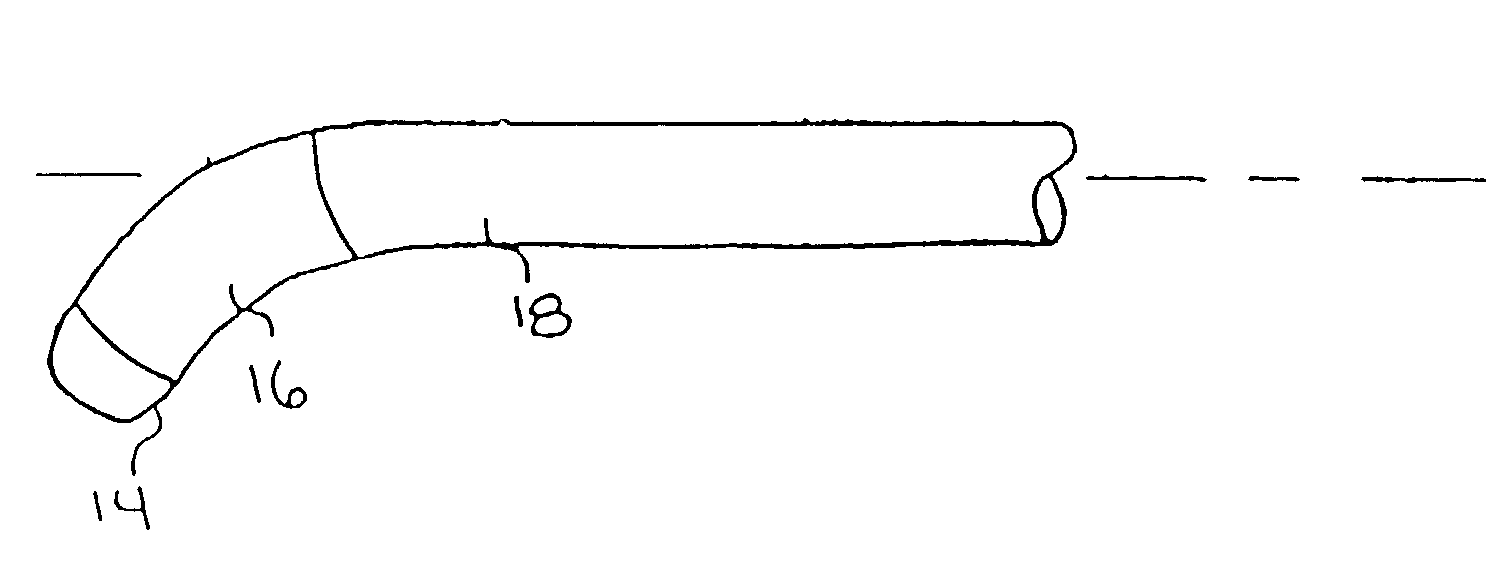

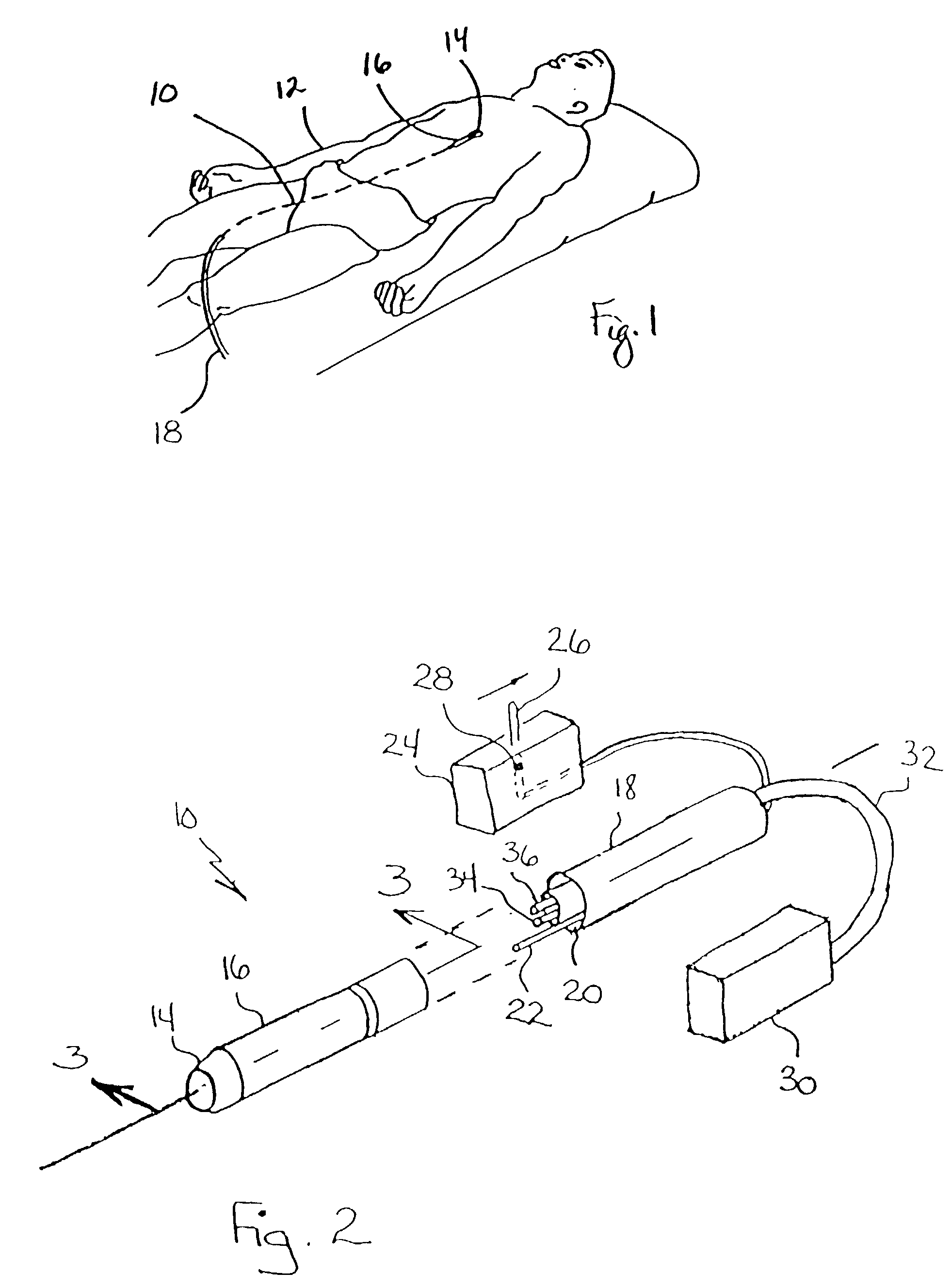

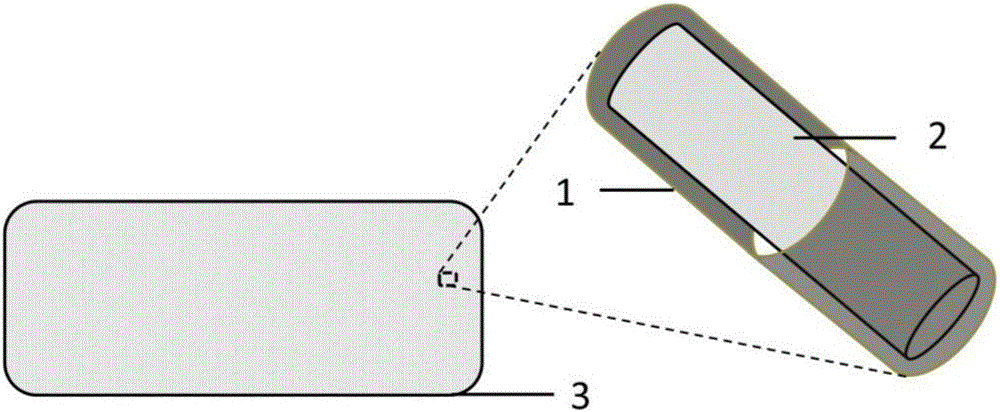

Gas sampling line

ActiveUS9861298B2Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisLine tubing

A gas sampling line having a channel for conducting respiratory gases from a patient respiratory interface to a gas monitor, the gas sampling line comprising, i.a., a gas sampling tube comprised of a polyether block amide material, the polyether segments of which comprise polyethyleneoxide. Use of a tube comprised of a polyether block amide material, the polyether segments of which comprise polyethyleneoxide, for sampling of respiratory gases; and a method for sampling of respiratory gases, the method comprising conducting respiratory gases through such a tube. A gas analysis system for analyzing respiratory gases, comprising a gas sampling line as defined above and a gas monitor connectable to the gas sampling line.

Owner:JPMORGAN CHASE BANK NA

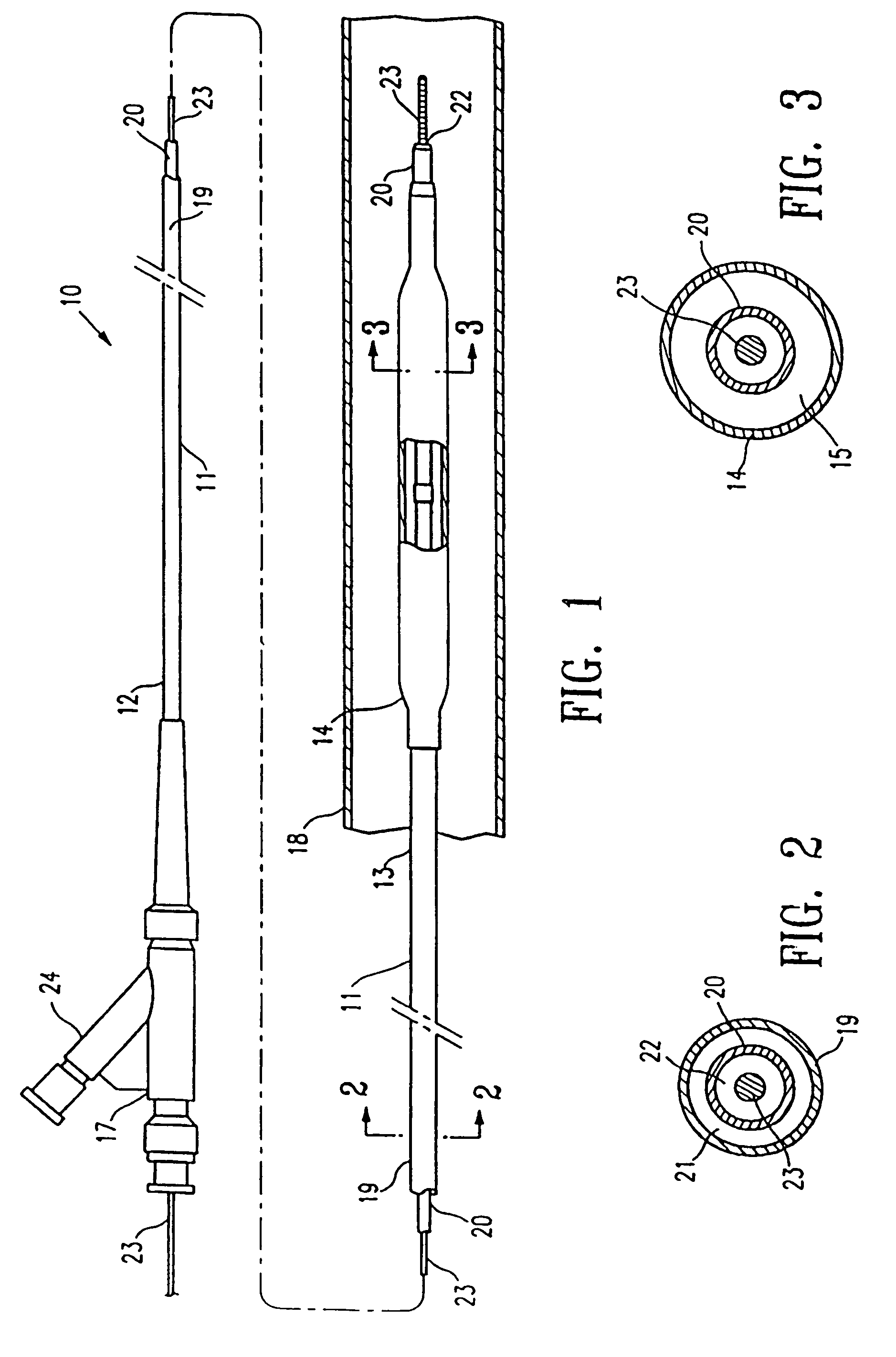

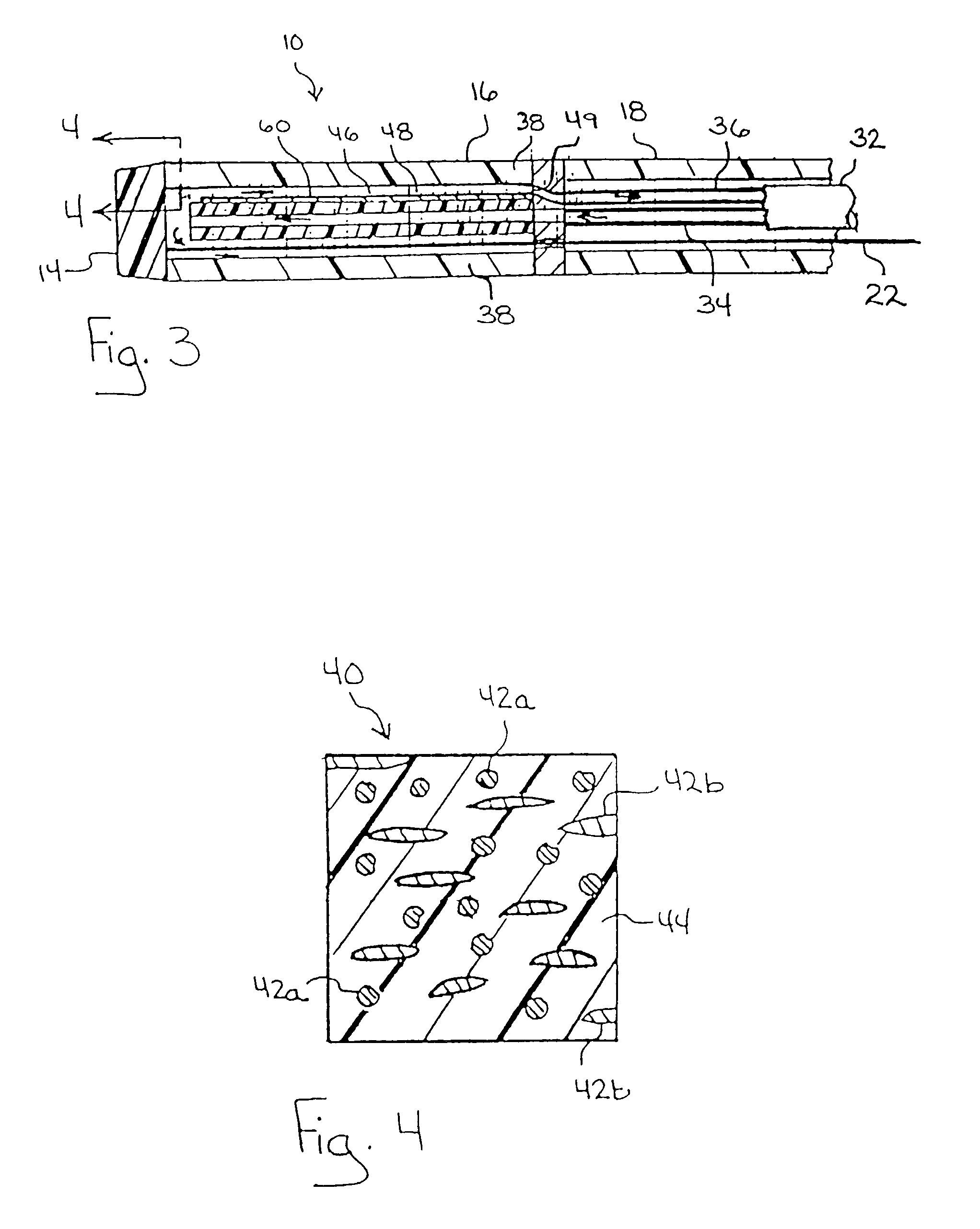

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

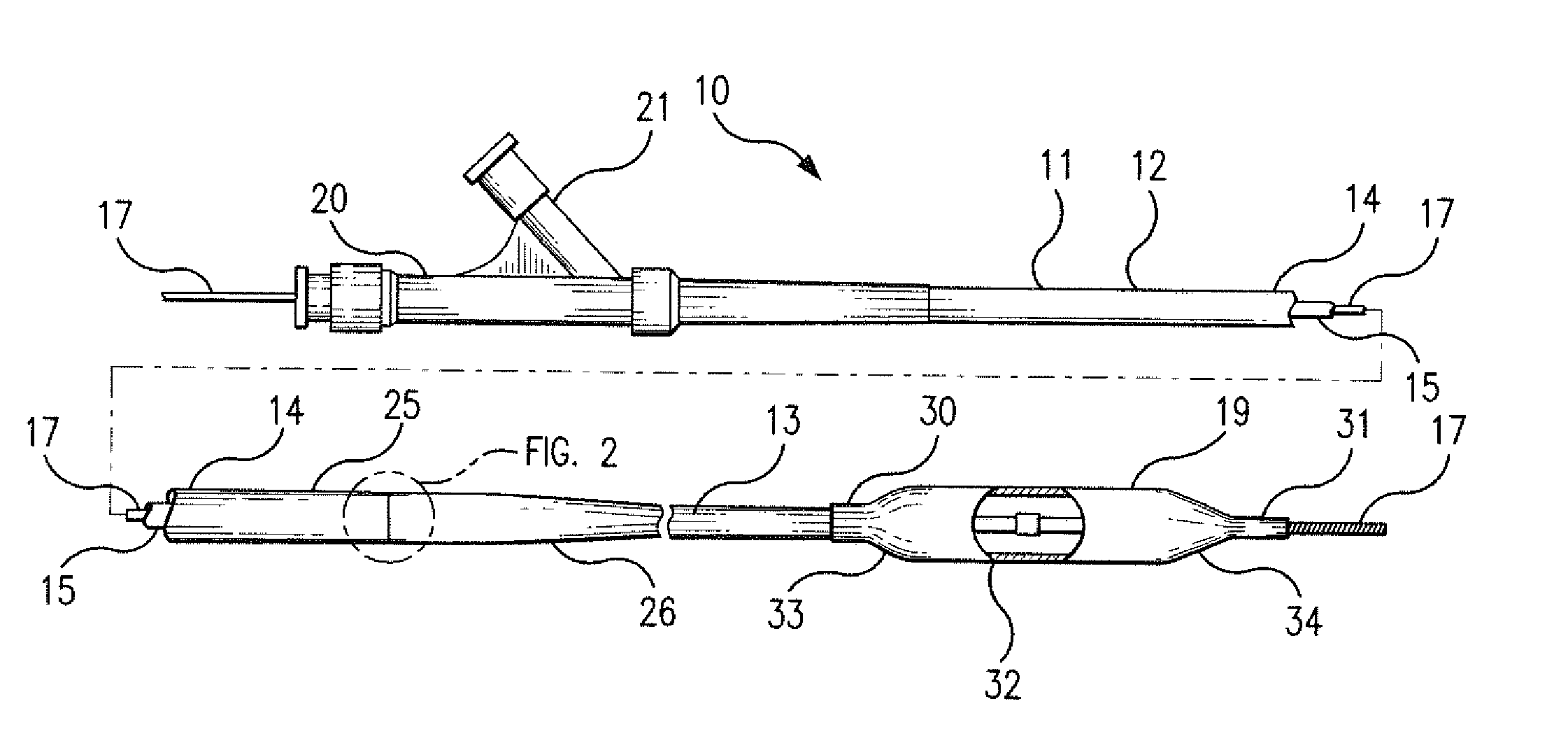

Medical device balloon

InactiveUS7074206B2Good flexibilityIncrease flexibilitySynthetic resin layered productsSurgeryMedicinePliability

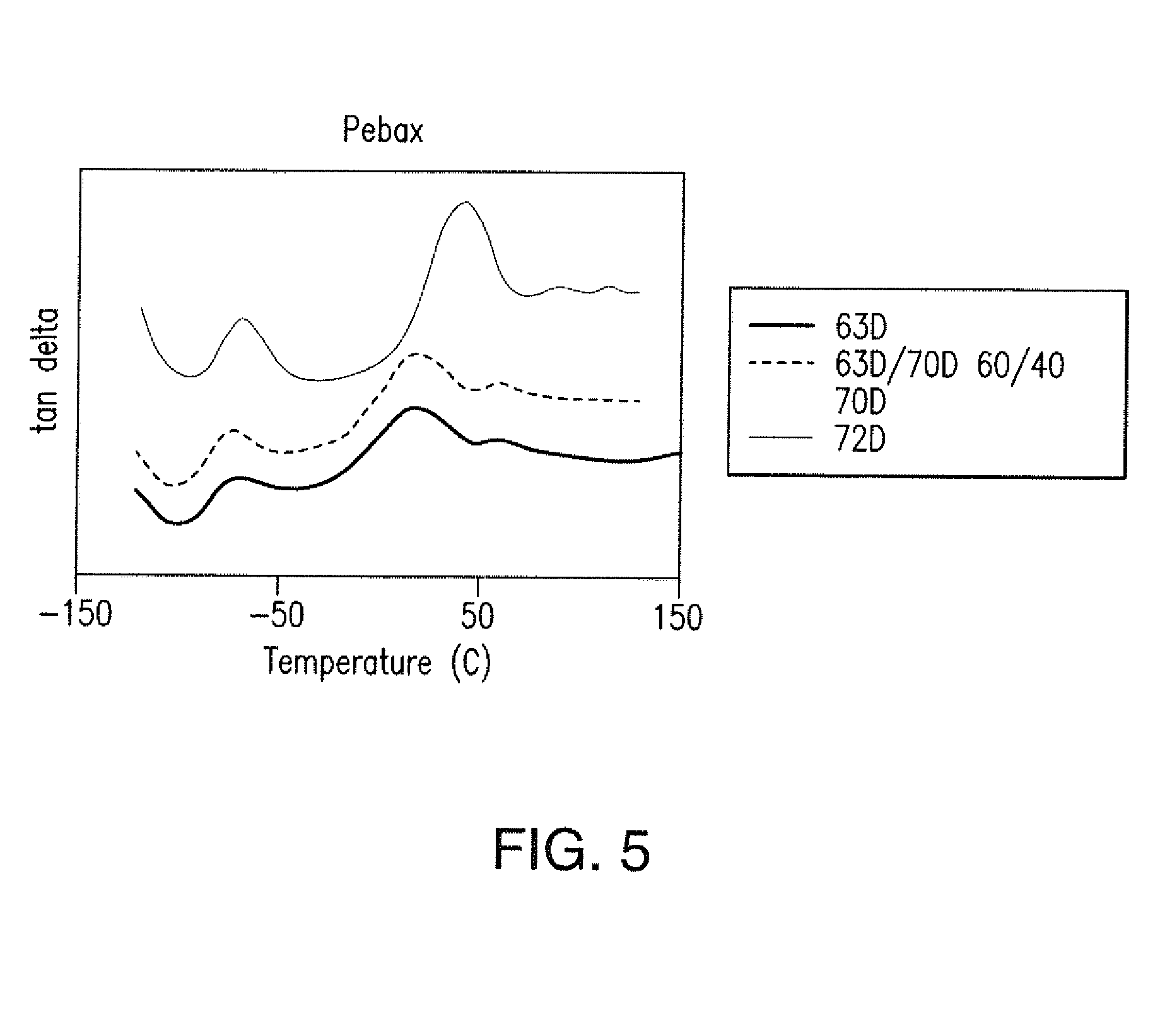

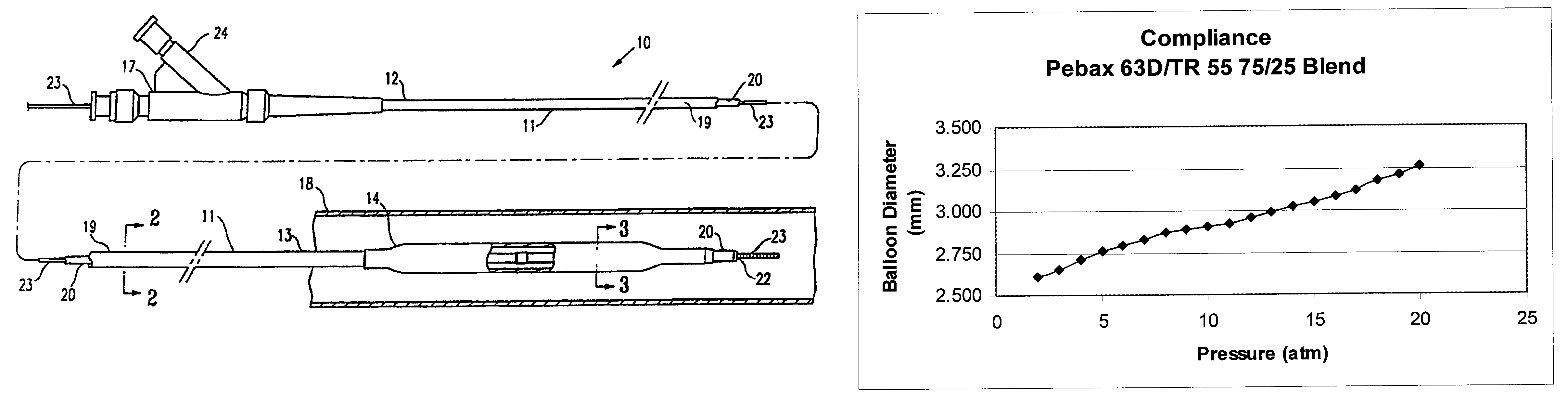

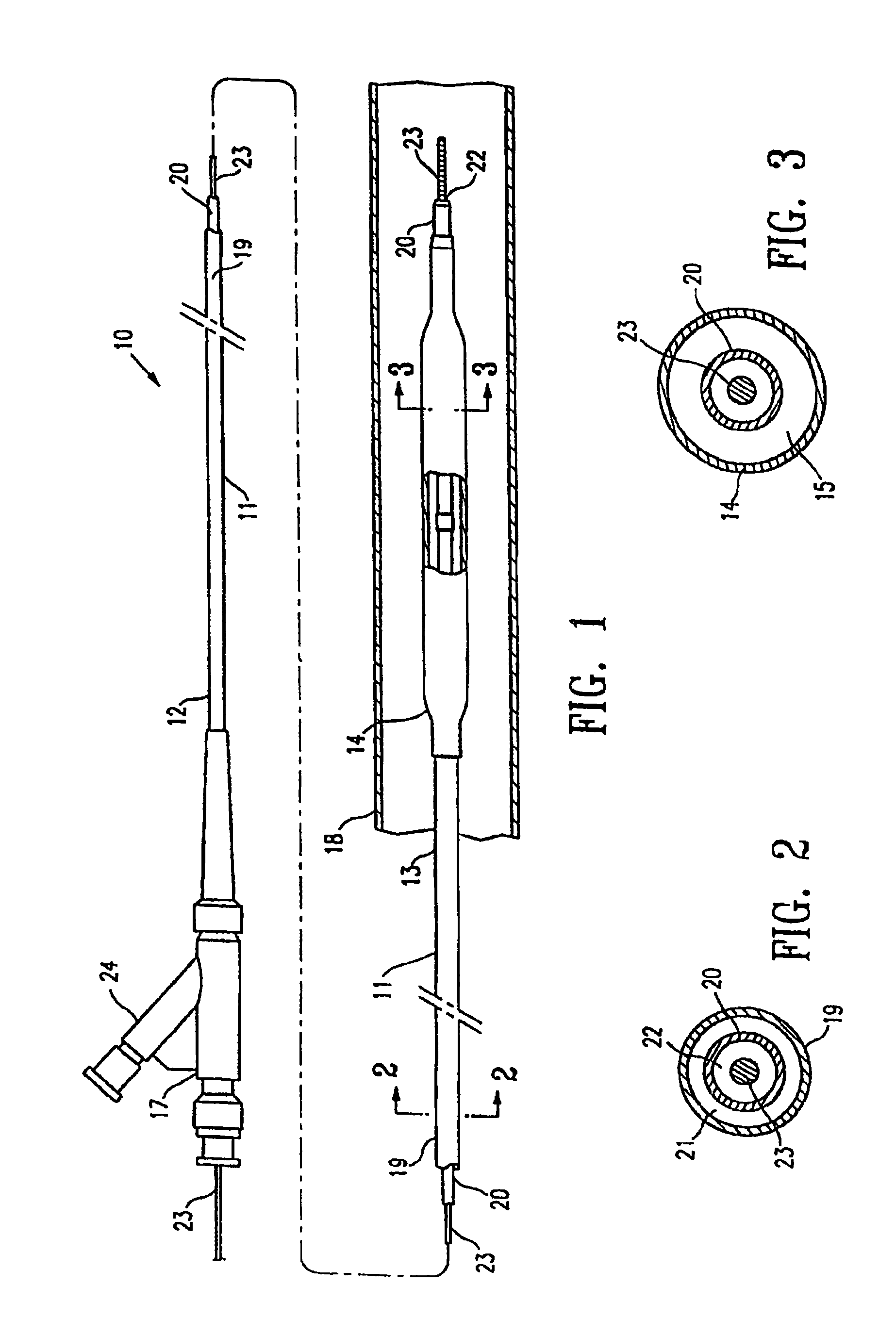

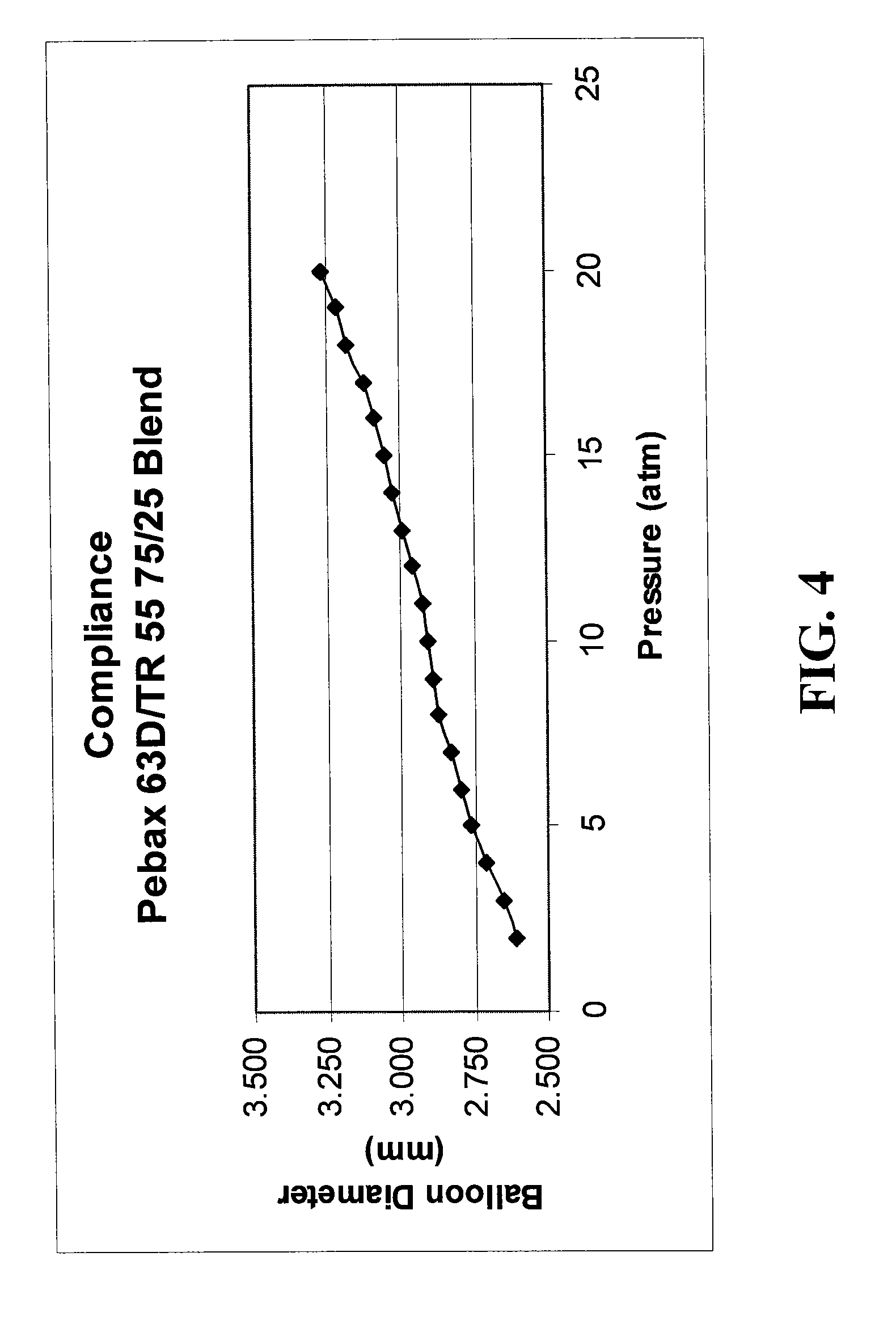

A balloon catheter having a balloon formed at least in part of a blend of a first polymeric material having a first Shore durometer hardness, and at least a second polymeric material having a second Shore durometer hardness less than the Shore durometer hardness of the first polymeric material. The balloon of the invention has enhanced softness and flexibility due to the presence of the second polymeric material, and a lower than expected compliance. In a presently preferred embodiment, the balloon is formed of a blend of polymeric materials comprising polyether block amides.

Owner:ABBOTT CARDIOVASCULAR

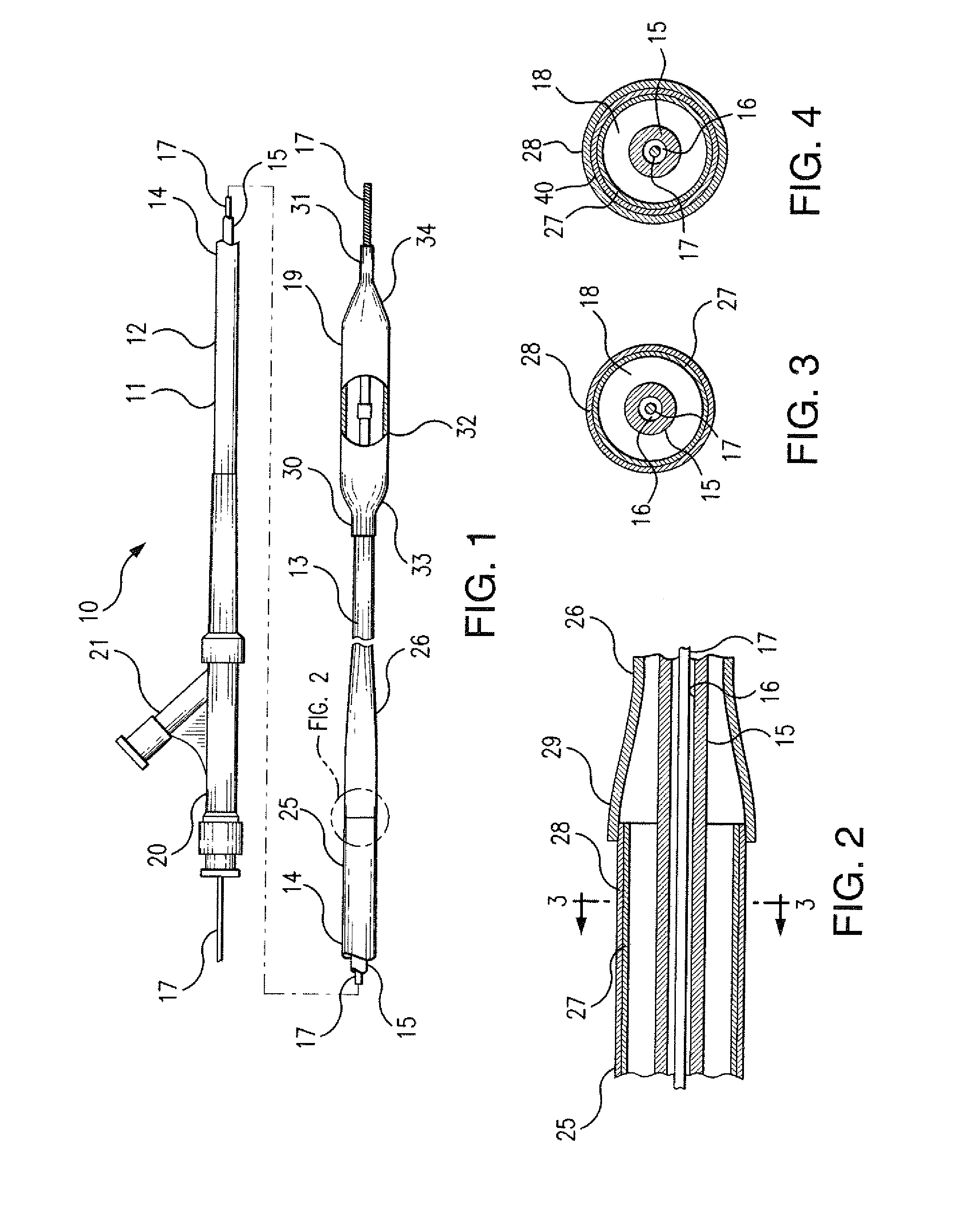

Catheter Shaft and Method of Forming Same

InactiveUS20140276401A1Increase thrustBalloon catheterSurgeryPolytetramethylene terephthalateHeat deflection temperature

Elongate, flexible catheter includes an elongated shaft having a proximal end, a distal end, and a lumen defined therein. The shaft includes a tubular member having an outer layer and an inner layer. The outer layer includes a first polymer selected from the group consisting of nylon 12, polyether block amide, and combinations thereof. The inner layer includes a second polymer having a heat deflection temperature greater than about 53° C. selected from the group consisting of nylon 11, nylon 6, nylon 6,6, nylon 6,12, polyamide-imide, polyetherimide, polypropylene, polyethylene terephthalate, polybutylene terephthalate, polyethereetherketone, and combinations thereof. Method of making an elongate, flexible catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

Breathable coated fabric

A water vapor-permeable, air-impermeable and water-impermeable sheet material comprises a film bonded to a fibrous substrate. The film comprises a reaction extrusion-processed blend comprising a first block copolymer which comprises a polyether block amide copolymer and a second block copolymer which comprises a copolyether ester. The fibrous substrate may be woven or non-woven, and may comprise polyethylene, polypropylene, polyethylene terephthalate, a polyamide, glass mat, felt, paper, or combinations thereof. The water vapor transmission rate of the extruded film is substantially higher than that of a film made from either one of the component block copolymers. The sheet material has uses which include housewrap, roofing underlayment, breathable apparel, desiccant packaging and others.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Low compliant catheter tubing

ActiveUS8070719B2Improve complianceImproves strength and modulusStentsSurgeryPolyamideBalloon catheter

Balloon catheter comprises a shaft having a proximal end, a distal end, and an inflation lumen extending therein, and a balloon on the shaft which has an interior in fluid communication with the inflation lumen. The balloon is formed of a blend of polymeric materials comprising a transparent amorphous nylon having a Shore D duromcter hardness of not less than 77D and being not more than about 40% by weight of the blend, and a polyamide or a polyether block amide having a Shore D duromcter hardness of no more than 73D. An increase in radial diameter of the balloon above nominal pressure for one atmosphere of pressure is no greater than 0.025 mm / atm. A guidewire catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

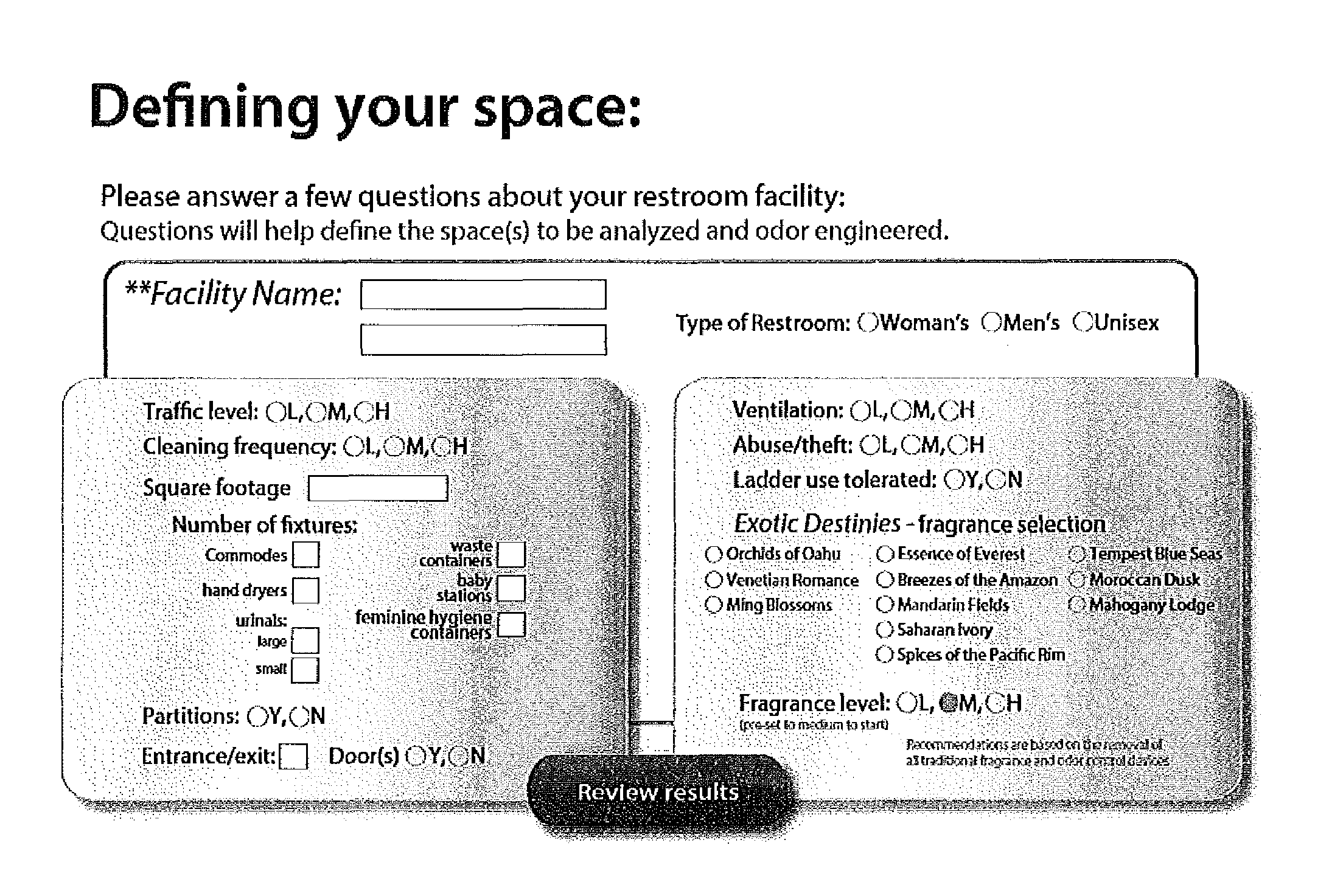

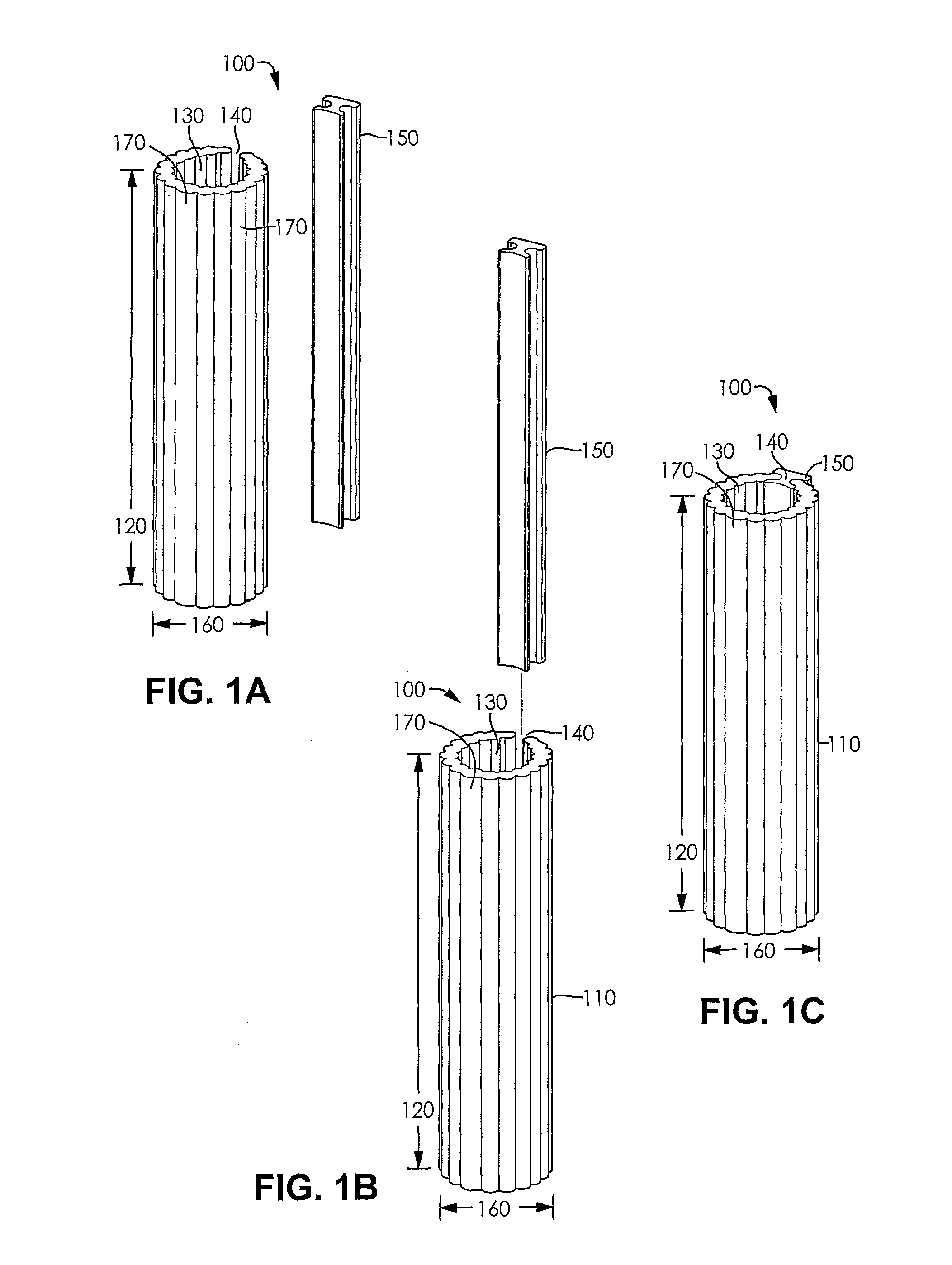

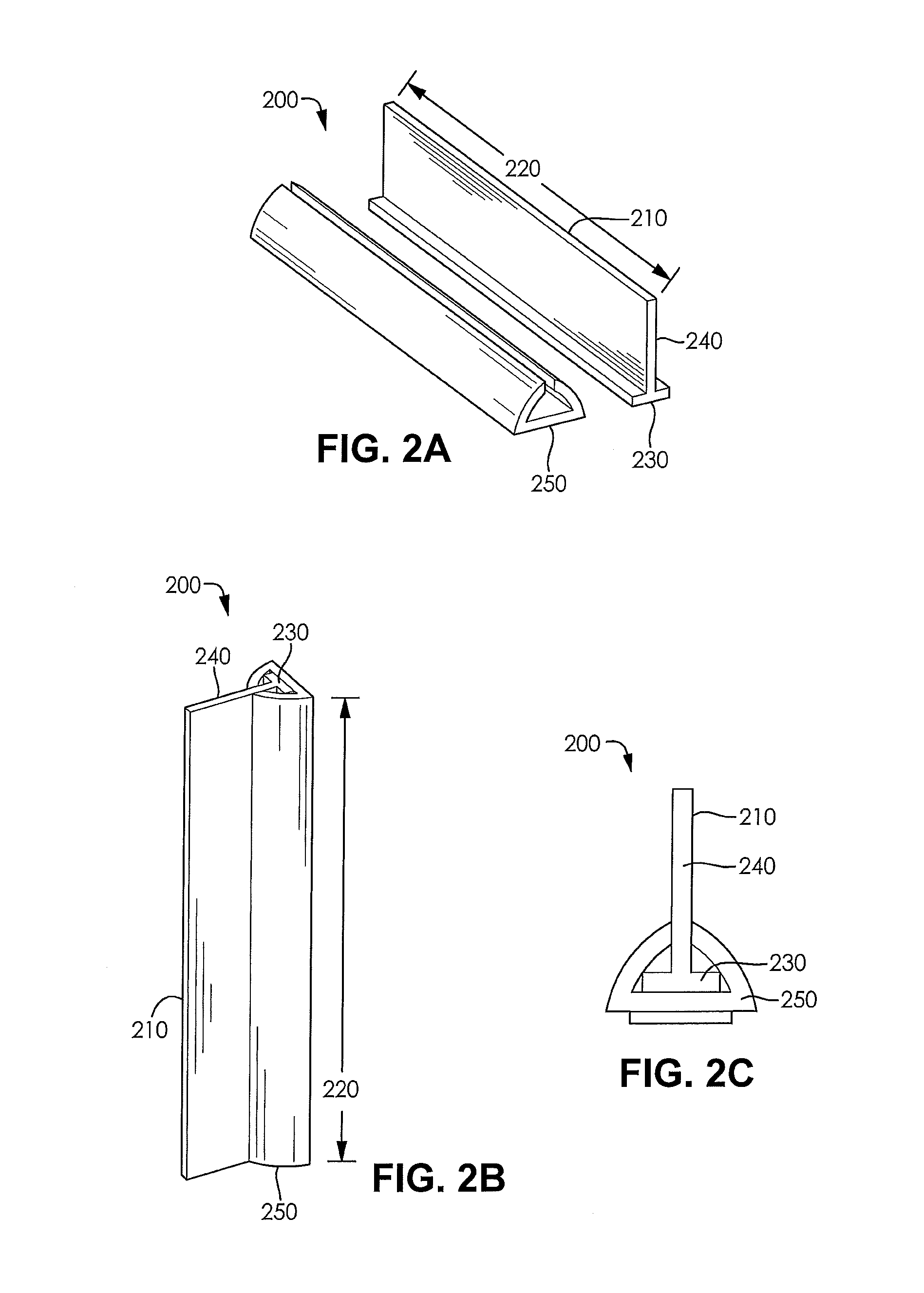

Solid state fragrancing

ActiveUS20140076991A1Easy to manufactureEffective scent coverageUrinalsDomestic plumbingElastomerPolyolefin

Fragrance control is provided by articles of manufacture including various solid state fragrancing objects, methods of using such objects, and systems that employ one or more such objects. The fragrancing object can be easy to manufacture, long lasting, provide fragrance that is consistently released over time, provide an indication to the user that the object needs to be replaced, and can hold a desired ratio of fragrance. The fragrancing object can include a first material comprising a polyether block amide, a second material comprising a polyolefin elastomer (POE), and a fragrance component such as a fragrance oil.

Owner:IMPACT PRODS

Polymer material

A polymer material, in particular for a medical instrument such as a balloon catheter, is provided. The polymer material comprising a combination at least of a first constituent comprising a partly crystalline polymer and a second constituent for increasing the flexibility of the material, wherein the polymer material is in the form of a polymer alloy, and wherein the first constituent is formed of a polyamide or a polyether block amide and the second constituent is formed at least partly by a thermoplastic elastomer based on polystyrene (TPE-S). A process for producing the polymer material and a medical device incorporating the polymer material are also provided.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

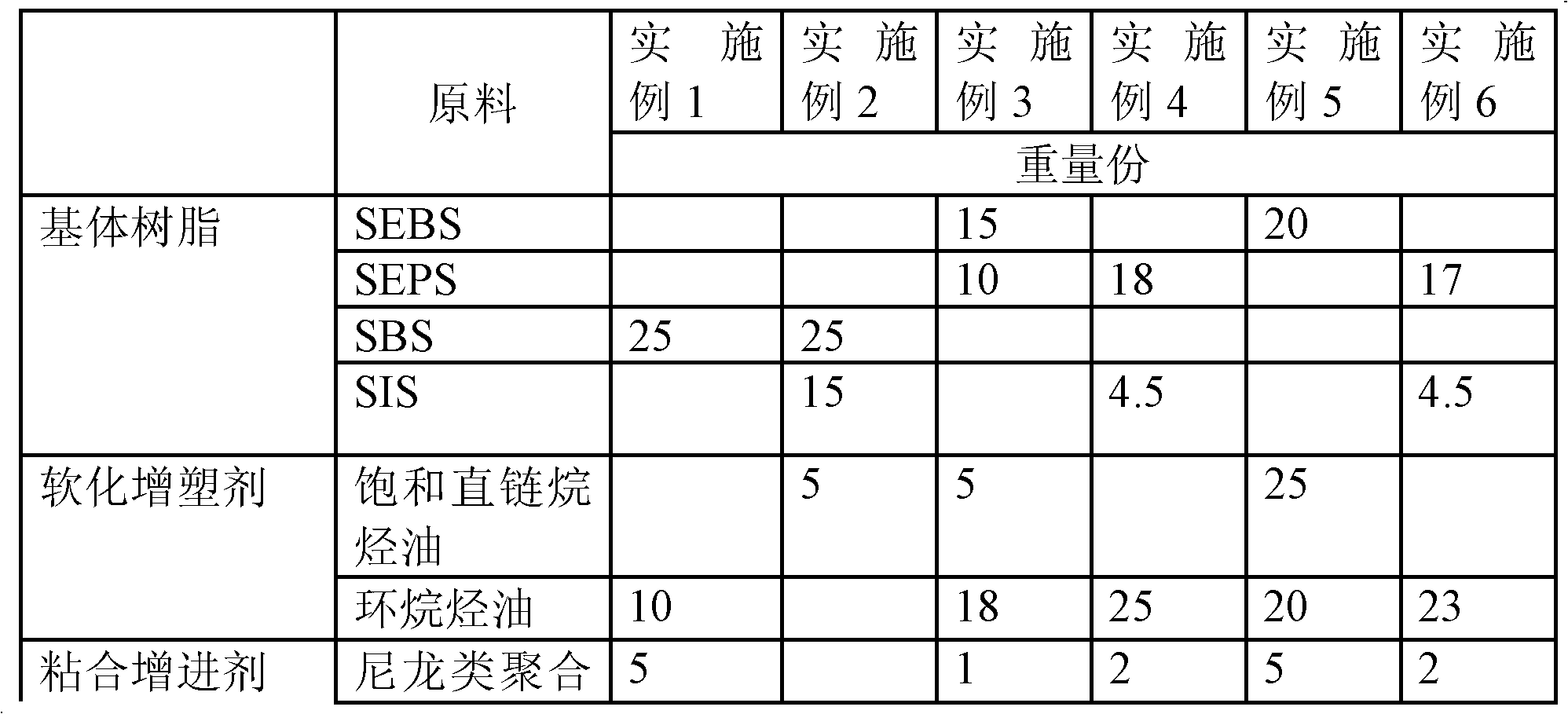

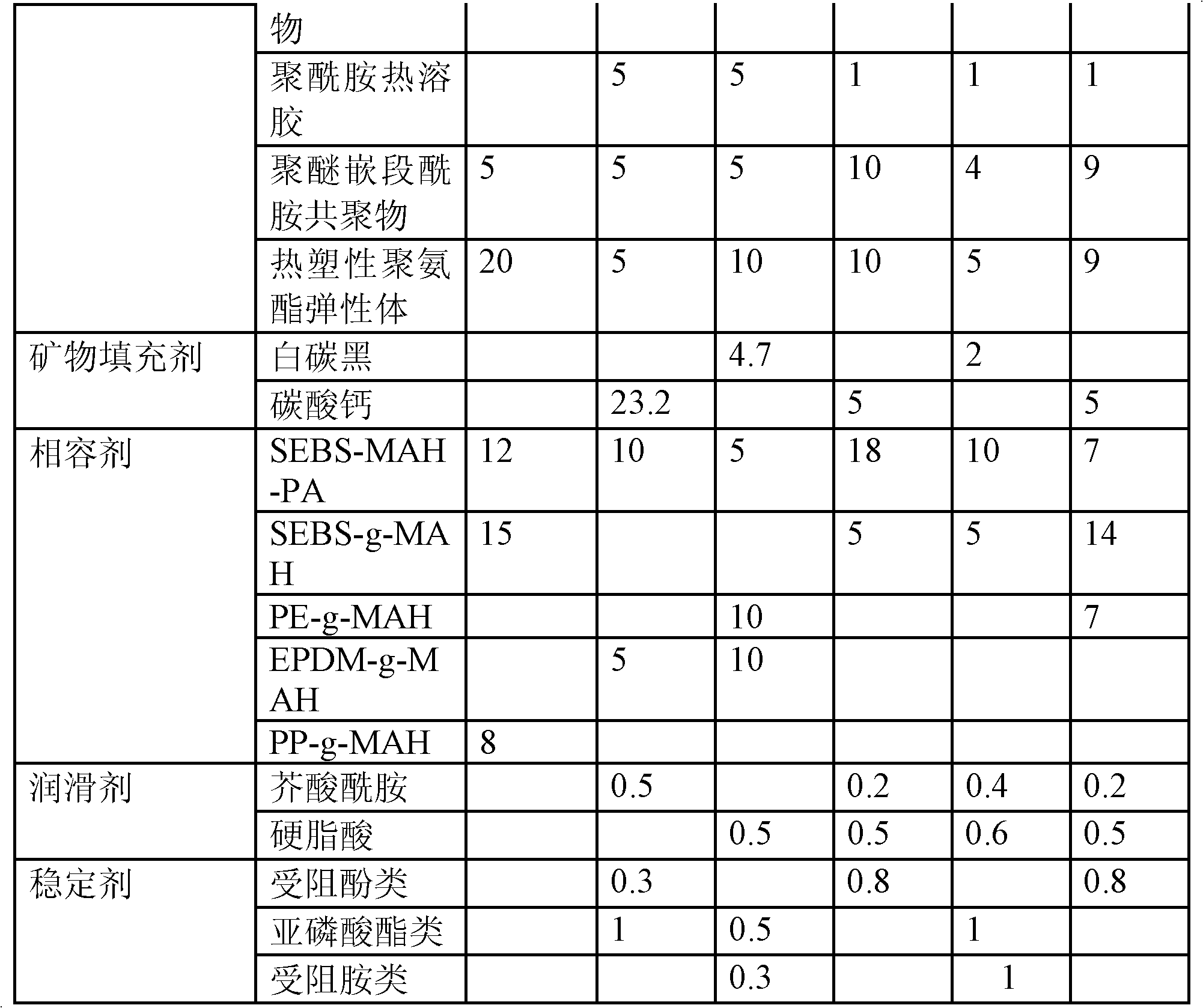

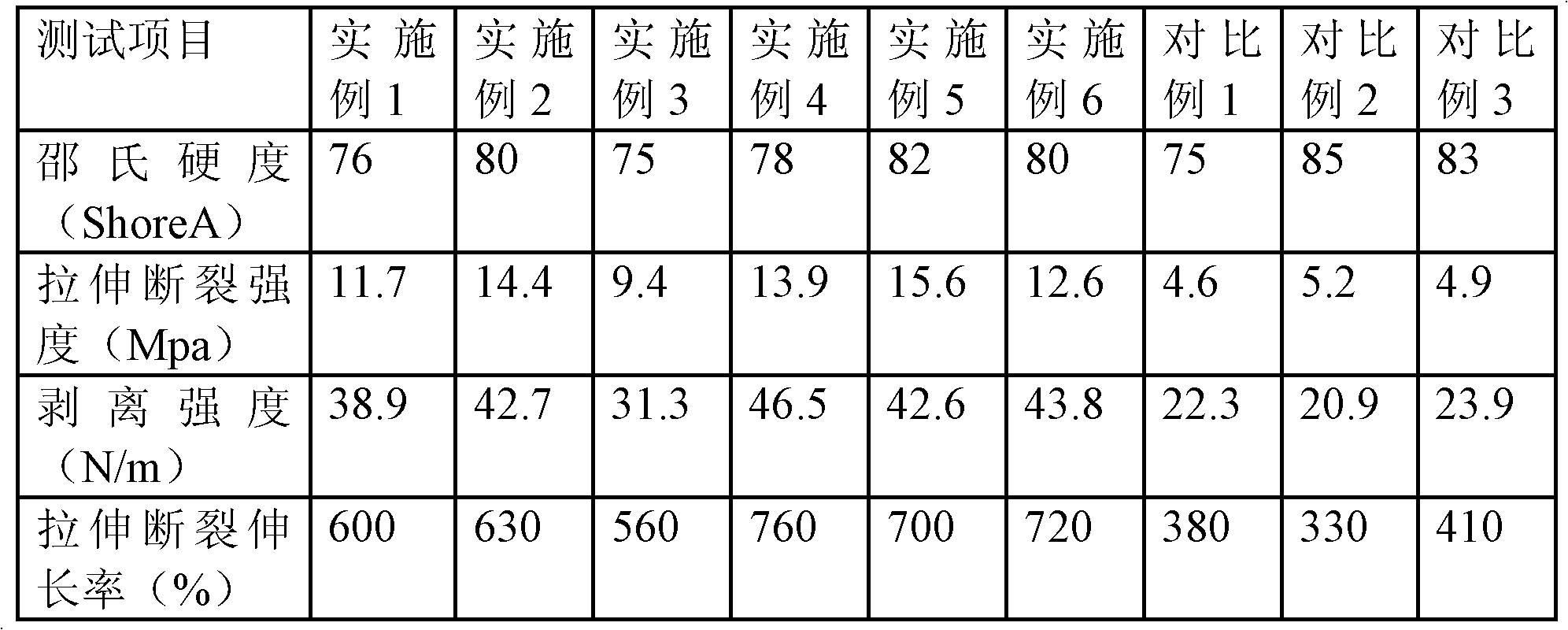

Thermoplastic elastomer capable of coating and bonding with glass fibre filling reinforced nylon

The invention provides a thermoplastic elastomer capable of coating and bonding with a glass fibre filling reinforced nylon, comprising the following raw materials in percentages by weight: 20-40% of matrix resin, 5-45% of softened plasticizer, 15-30% of adhesion promoter, 0-30% of mineral filler, 15-35% of compatilizer, 0-1% of lubricant and 0-2% of stabilizer, wherein the adhesion promoter includes a first adhesion promoter and a second adhesion promoter; the first adhesion promoter is at least one of a polyamide thermosol and a nylon polymer; and the second adhesion promoter is a mixture of a thermoplastic polyurethane elastomer and a polyether block amide copolymer; meanwhile, the invention further provides a method for preparing the elastomer. The elastomer is far higher than contrast products in tensile strength at break, tensile elongation at break and peel strength. The elastomer of the invention has good mechanical property.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Breathable, deet-resistant polyether block polyamide

The invention relates to a polyether block amide film, having both resistance to N,N-diethyl-3-methylbenzamide (DEET) insecticide according to MTL-DTL-31011B along with a high level of breathability (>700 g / m2 / day) according to ASTM E96 B (50% R.H. & 23° C.). The polyether block polyamides of the invention can be applied to a substrate to produce water barrier, DEET-resistant and breathable apparel.

Owner:ARKEMA INC

Fragrance control

Fragrance control is provided by articles of manufacture including various fragrancing objects, methods of using such objects, and systems that employ one or more such objects. The fragrancing object can be easy to manufacture, long lasting, provide fragrance that is consistently released over time, provide an indication to the user that the object needs to be replaced, and can hold a desired ratio of fragrance. The fragrancing object can include a first material comprising a polyether block amide, a second material comprising a polyolefin elastomer (POE), and a fragrance component such as a fragrance oil.

Owner:IMPACT PRODS

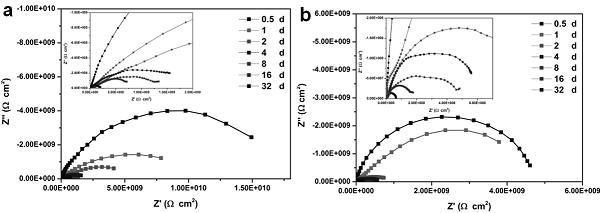

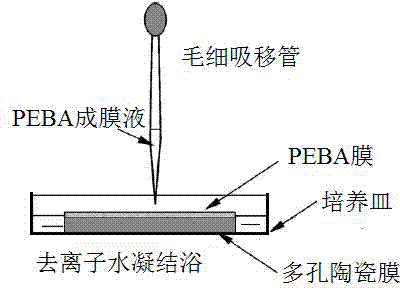

Zeolite imidazate-doped polyether block amide gas separation membrane, and preparation method and application thereof

ActiveCN108097070AThe preparation process is simple and controllableMild conditionsNitrogen purification/separationSemi-permeable membranesPolyamideInorganic materials

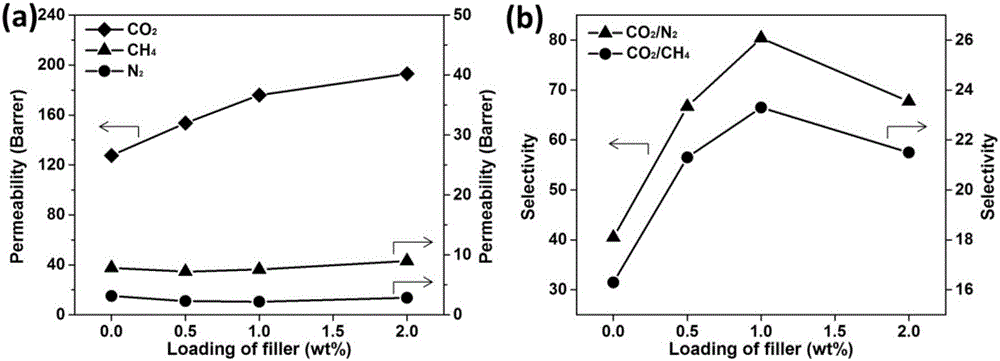

The invention discloses a zeolite imidazate-doped polyether block amide (PEBA) gas separation membrane, and a preparation method and application thereof. According to the preparation method provided by the invention, two inorganic nano-materials, i.e. ZIF-8 and Zn / Ni-ZIF-8 are successfully prepared and are mixed and stirred with polyether block amide at 40 to 80 DEG C, and a ZIF-8-PEBA and Zn / Ni-ZIF-8-PEBA mixed matrix membrane is prepared through a dry phase transformation method. The zeolite imidazate-doped polyether block amide gas separation membrane, and the preparation method and the application thereof provided by the invention have the advantages that the preparation method of the inorganic materials is simple, the conditions are mild, the operation is easy, and the inorganic material is environmentally friendly; the prepared membrane is acid and alkali resistant and good in flexibility; the membrane has excellent comprehensive performance when being used for gas separation; particularly, the Zn / Ni-ZIF-8-PEBA mixed matrix membrane with the adding content being 10 percent by weight has high CO2 permeation flux and CO2 / N2 selectivity.

Owner:TAIYUAN UNIV OF TECH

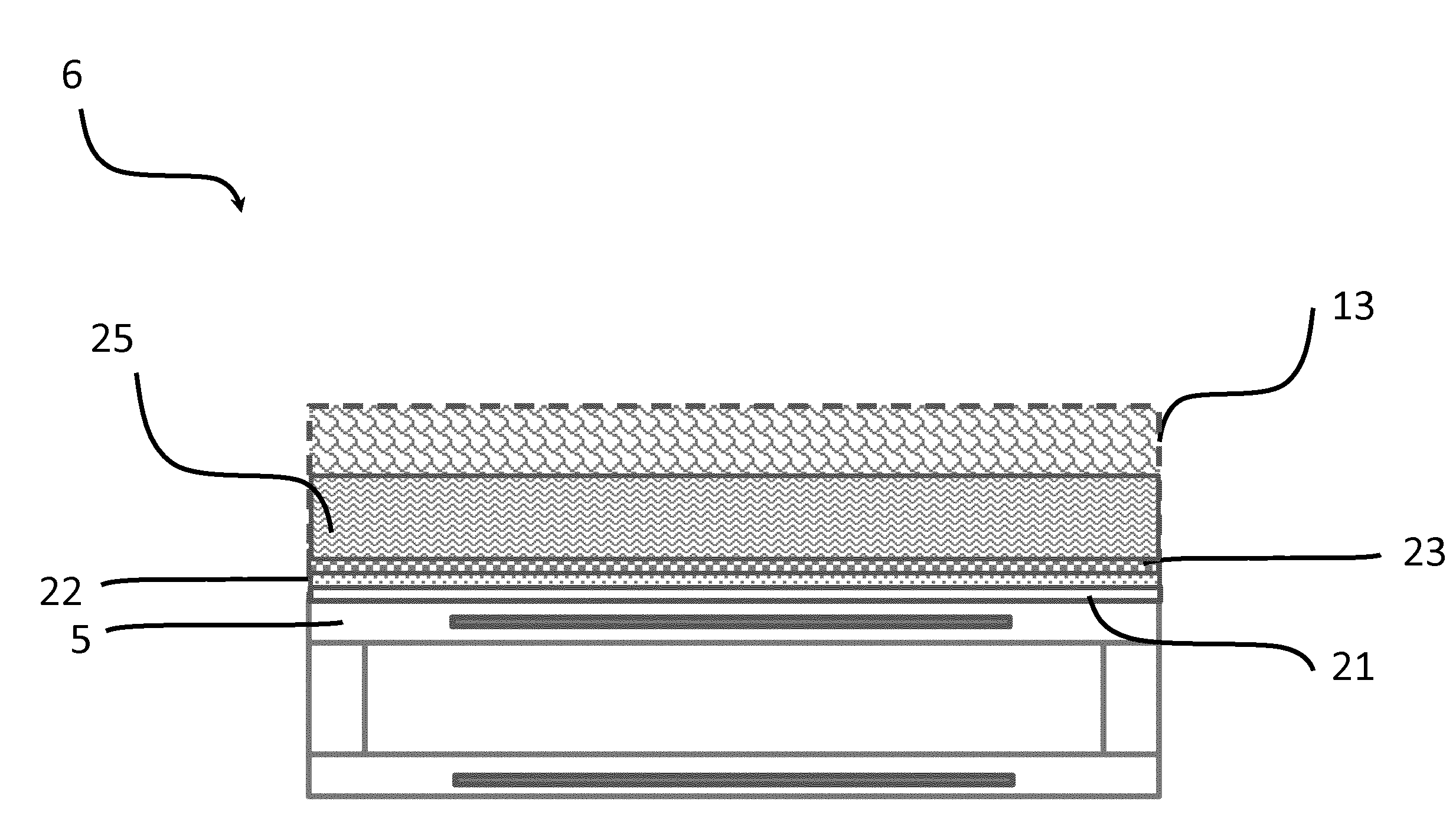

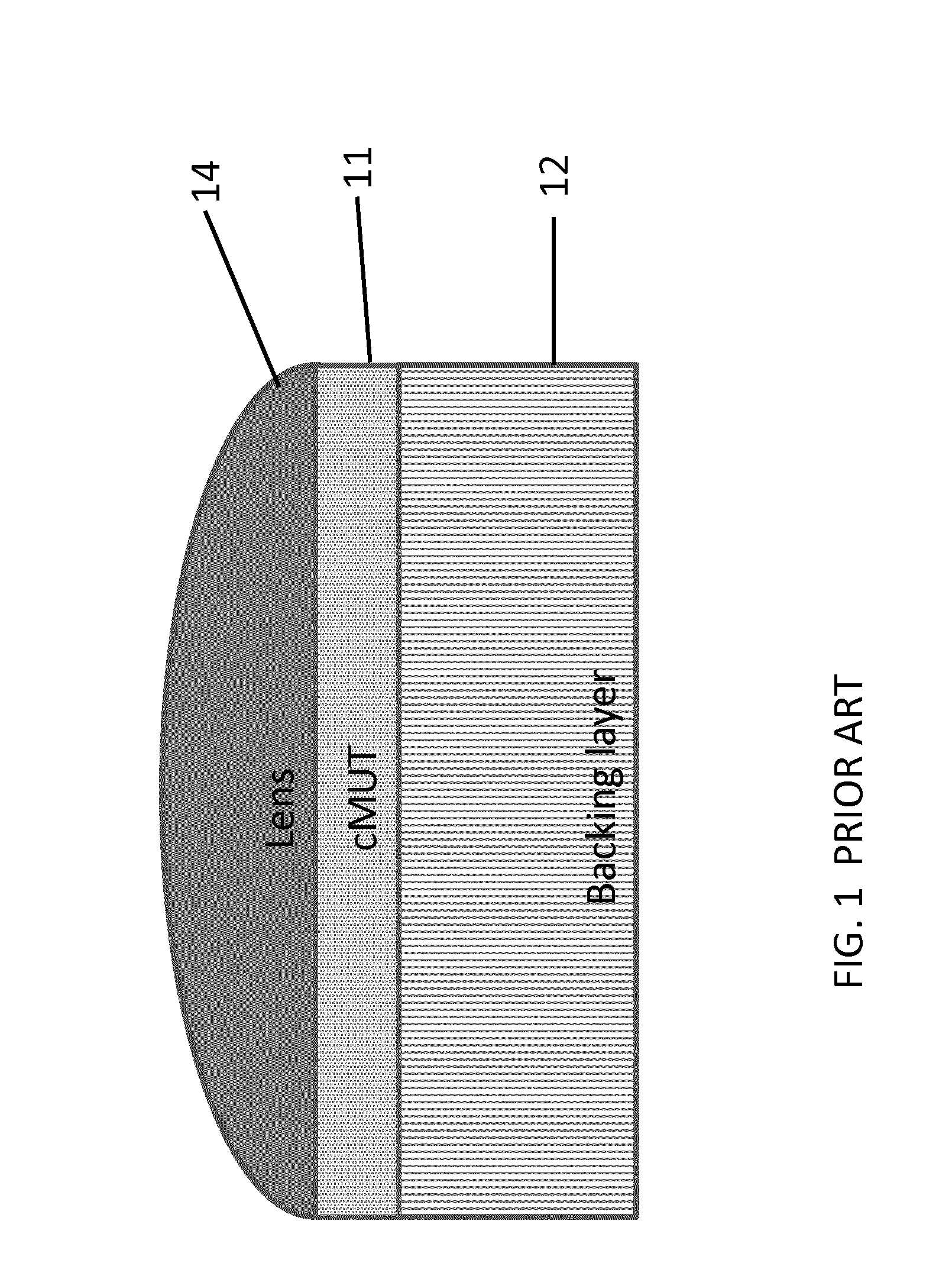

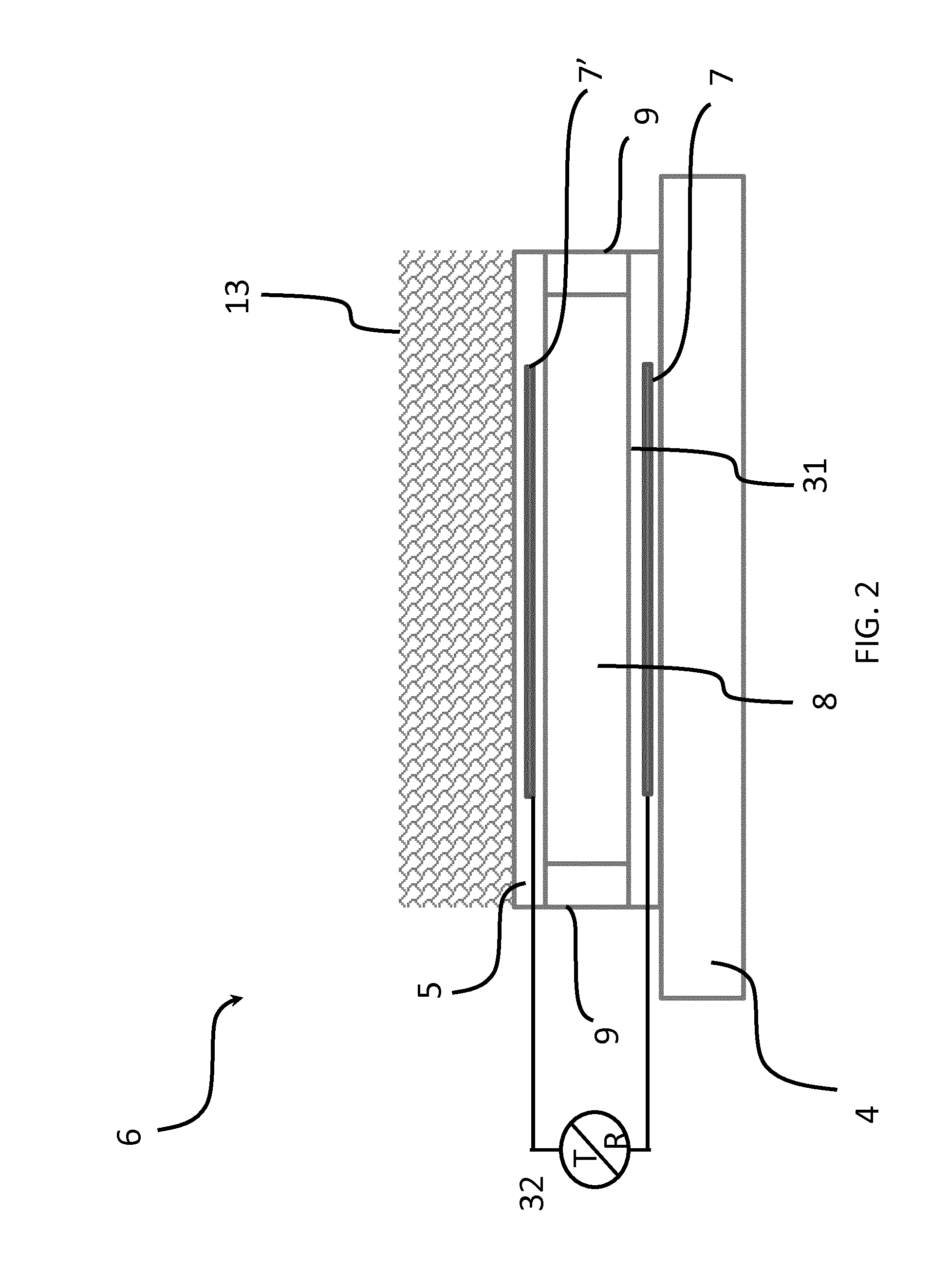

Capacitive micro-machined ultrasound transducer cell

ActiveUS20160203809A1Superior coupling and propagationReduce frequencyUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationSonificationAcoustic energy

The invention relates to a capacitive micro-machined ultrasound transducer (CMUT) cell (6) comprising a cell floor (31) having a first electrode (7); a cell membrane (5) having a second electrode (7′) which opposes the first electrode and vibrates during transmission or reception of acoustic energy; a transmitter / receiver coupled to the first and second electrodes which causes the cell membrane to vibrate at an acoustic frequency and / or receives signals at an acoustic frequency; and an acoustic lens (13), overlaying the cell membrane, and having an inner surface opposing the cell membrane and an outer, patient-facing surface. According to the present invention the acoustic lens comprises at least one layer of a material selected from the group of: polybudatiene, polyether block amide (PEBAX), polydimethylsiloxane (PDMS) and buthylrubber.

Owner:KONINKLJIJKE PHILIPS NV

Polymer material

InactiveUS20030153685A1Increase flexibility of materialIncrease flexibilityCatheterIntravenous devicesPolymer alloyThermoplastic elastomer

A polymer material, in particular for a medical instrument such as a balloon catheter, is provided. The polymer material comprising a combination at least of a first constituent comprising a partly crystalline polymer and a second constituent for increasing the flexibility of the material, wherein the polymer material is in the form of a polymer alloy, and wherein the first constituent is formed of a polyamide or a polyether block amide and the second constituent is formed at least partly by a thermoplastic elastomer based on polystyrene (TPE-S). A process for producing the polymer material and a medical device incorporating the polymer material are also provided.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

Conjugate fibers for stockings

InactiveUS20120128975A1High transparencySoft textureFilament/thread formingConjugated synthetic polymer artificial filamentsProduction ratePolymer science

(A1) Translate this text A composite fiber for stockings which has water-absorbing properties, hygroscopicity, antistatic properties, crimp properties, and cool touch is obtained without sacrificing productivity, transparency, and soft touch. The composite fiber for stockings is an eccentric composite fiber comprising a fiber-forming resin (B) and a polyether block amide copolymer (A). The fiber is characterized in that the polyether block amide copolymer (A), in a cross section of the fiber, is exposed in the surface at an angle of 5-90, and the fiber has 1-10 filaments and a fineness of 1-55 dtex. The fiber especially preferably has a percentage crimp of 10% or higher.

Owner:KB SEIREN LTD

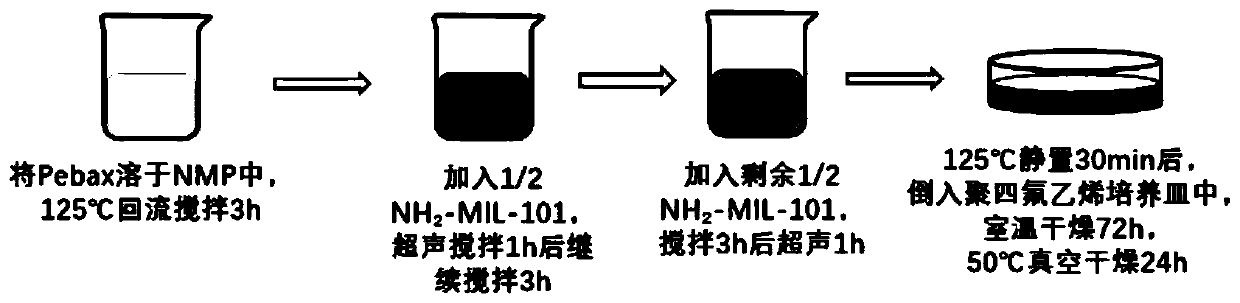

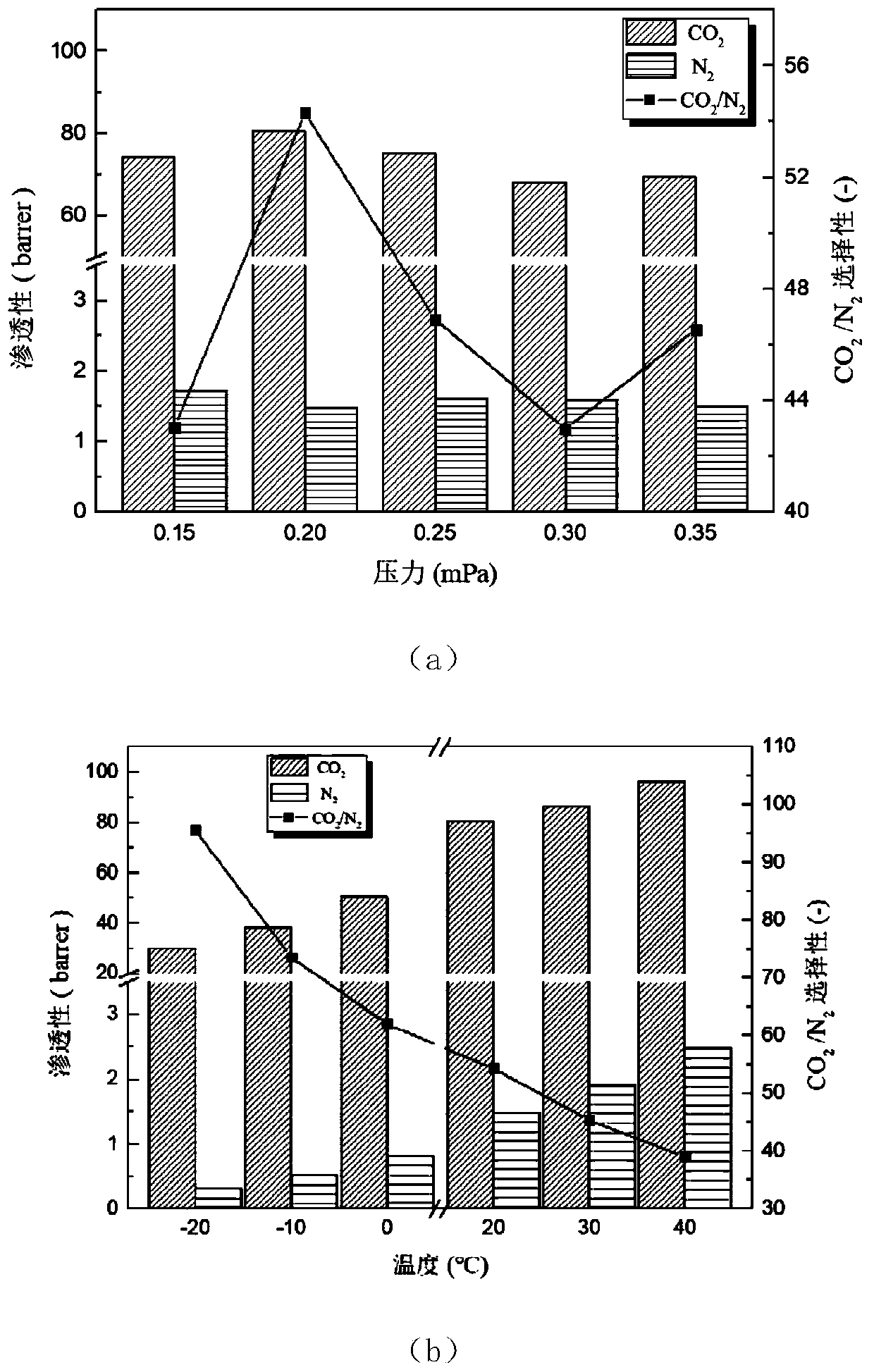

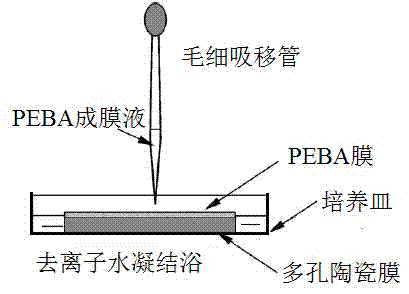

Preparation method of Pebax/NH2-MIL-101 mixed-matrix membrane

InactiveCN110787656AEasy to separateImprove mechanical propertiesMembranesSemi-permeable membranesMetal frameworkOrganosolv

The invention designs a mixed-matrix membrane based on block polyether amide and an amino modified chromium metal coordinated framework material and a preparation method thereof. Based on amination modification of a chromium atom MIL-101 which is a metal framework material, the modified framework material is mixed with a polyether block amide material that is Pebax-1657, and the mixed-matrix membrane with uniform form and high CO2 separation performance is prepared through a solution evaporation method. The preparation method comprises the following steps: dissolving the polymer matrix into anorganic solvent that is N-methyl pyrrolidone (NMP) to form a polymer solution, adding the amino-modified MIL-101 in a proper ratio into the solution to form a suspension of an organic polymer and aninorganic filler, stirring for a certain period of time, then performing ultrasonic treatment to further improve the dispersity of the filler, then putting the suspension into a culture dish, coolingto room temperature, and curing to form the membrane. The Pebax / NH2-MIL-101 mixed-matrix membrane prepared by the method disclosed by the invention has relatively good CO2 / N2 separation performance atroom temperature or low temperature.

Owner:TIANJIN UNIV

Preparation method and application of mixed substrate membrane with laminar and cage-shaped synergetic sieving effect

ActiveCN108745004AImprove permeabilityEasy to separateSemi-permeable membranesGas treatmentPliabilityProduct gas

The invention discloses a preparation method and application of a mixed substrate membrane with a laminar and cage-shaped synergetic sieving effect. The preparation method is characterized in that firstly, a zeolite imidazole framework ester material ZIF-8 is introduced into g-C3N4 (graphitized carbonitride) dispersion liquid in site; then, a composite material is dispersed into a polyether blockamide copolymer; a polyether block amide gas separation membrane with the laminar and cage-shaped synergetic sieving effect is prepared by a solution tape casting method; the prepared membrane is a homogeneous dense membrane; the wet membrane thickness is controlled to be 50 to 500mum. The provided inorganic material preparation process is easy to control; holes in tri-s-triazine rings of g-C3N4 and between nanosheet layers of a g-C3N4 and ZIF-8 composite material provide passages for CO2; the prepared membrane has acid and alkali resistance and good flexibility; when the membrane is used forgas separation, the excellent comprehensive performance is realized; the CO2 can be effectively and selectively separated; a fast migration passage is provided for CO2 transfer.

Owner:TAIYUAN UNIV OF TECH

Conjugate Fibers Excellent in Antistatic Property, Water Absorption and Cool Feeling by Contact

ActiveUS20100047572A1Practical dyeing propertyIncrease production capacityConjugated synthetic polymer artificial filamentsYarnFiberPolyester

The invention provides a novel conjugated fiber which is excellent in productivity and which has excellent moisture absorption, antistatic property and cool touch feeling, namely, a conjugated fiber which is composed of a sheath made from a fiber-forming resin such as polyamide or polyester and a core made from a polyether block amide copolymer at a core / sheath area ratio of 5 / 95 to 95 / 5 and which has an exposure angle of the core to the surface of 5 to 90 DEG. It is still preferable that the core / sheath area ratio be 10 / 90 to 90 / 10 and the exposure angle of the core to the surface be 5 to 80 DEG with a percentage of crimp of 2 to 30%.

Owner:KB SEIREN LTD

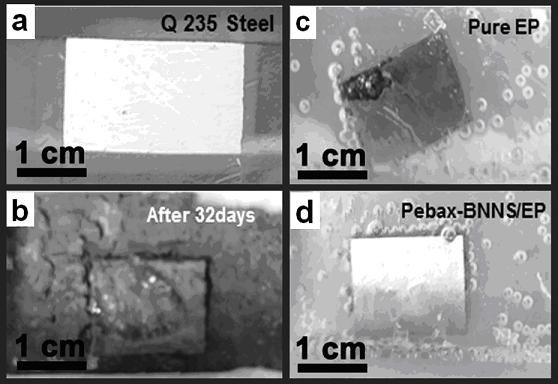

Macro preparation method of boron nitride epoxy resin transparent coating

InactiveCN111978825ASolve the difficulty of large-scale preparationSolved due to nanoparticlesAnti-corrosive paintsEpoxy resin coatingsHexagonal boron nitrideFirming agent

The invention relates to a macro preparation method of a boron nitride epoxy resin transparent coating. The macro preparation method comprises the following steps: (1) performing mixing on hexagonal boron nitride and polyether block amide 1657, and carrying out mechanical shearing, extrusion and cooling to obtain a Pebax functionalized hexagonal boron nitride nanosheet composite material, whereinthe composite material is marked as a Pebax-BNNSs composite material; (2) dissolving the Pebax-BNNSs composite material in an ethanol water solution, and performing heating in an oil bath until the Pebax-BNNSs composite material is fully dissolved to obtain a suspension; carrying out filtering and dispersing on the suspension to obtain a Pebax-BNNSs dispersion liquid; and (3) adding the Pebax-BNNSs dispersion liquid into the epoxy resin, uniformly mixing by ultrasonic and thermal stirring, removing the solvent by using a rotary evaporation method, finally adding an epoxy resin curing agent, and violently stirring for 5 minutes to obtain the boron nitride epoxy resin transparent coating. The method is simple and easy to implement, and the obtained coating has good light transmission performance, has continuous and long-acting protection performance on a metal matrix and is expected to be applied to the fields of marine mechanical equipment, ultra-precision machinery and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

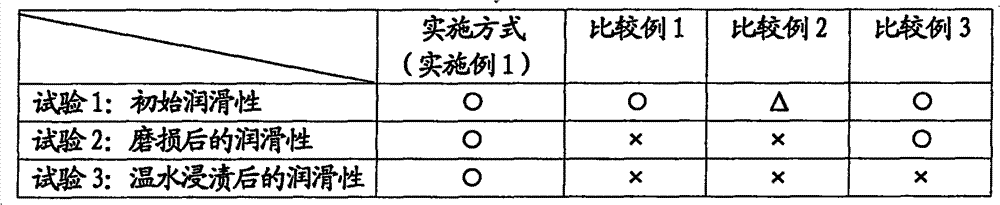

Medical apparatus with lubricity and manufacturing method of same

The present disclosure provides a medical instrument with a coating that provides excellent lubricity when wet. The medical instrument possesses a coating including a wet lubricating film with high peel durability and anti-eluting properties. In embodiments, an intermediate film made of bisphenol A type epoxy resin is coated on a base material of a medical instrument made of metal, and a wet lubricant coating produced by alkaline processing of a polymer alloy containing a methyl vinyl ether maleic anhydride copolymer and a polyether block amide is then applied thereto. Methods for making these medical instruments are also provided.

Owner:TYCO HEALTHCARE GRP LP

Polyether block amide/polyion liquid semi-interpenetrating polymer network film and thermosetting preparation method thereof

ActiveCN103665403AImprove stabilityHigh mechanical strengthSemi-permeable membranesBulk chemical productionPolymer scienceSolvent

The invention belongs to the field of preparation of gas separation films, and particularly relates to a polyether block amide / polyion liquid semi-interpenetrating polymer network film and a thermosetting preparation method thereof. The preparation method comprises the following steps: 1) preparing a film preparation solution, namely uniformly mixing polyether block amide, a solvent and an ionic liquid monomer at 65 DEG C to form the film preparation solution; 2) crosslinking to form an interpenetrating network polymer film: adding a crosslinking agent and a thermal initiator into the film preparation solution to perform crosslinking reaction at 65 DEG C for 10-26 hours, thereby obtaining a film casting solution; and 3) after-treatment: carrying out ultrasonic treatment on the film casting solution subjected to crosslinking reaction, drying in air for 48 hours, transferring into a vacuum drying oven, and drying at room temperature for 12 hours. The polymerizable ionic liquid monomer used as one component in the semi-interpenetrating polymer network film has the advantages of favorable compatibility with other components, high stability and low tendency to loss, and can ensure the physical structure and enduring and stable properties of the film.

Owner:JIANGNAN UNIV

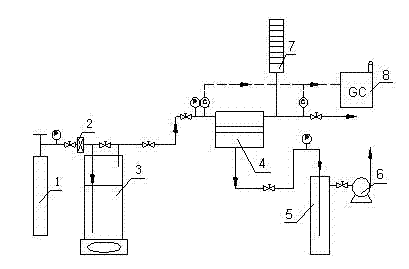

Organic/inorganic composite membrane for use in oil gas recovery and preparation method thereof

ActiveCN102389723AImprove high temperature resistanceImprove stabilitySemi-permeable membranesDispersed particle separationPhysical chemistryCeramic membrane

The invention belongs to the technical field of oil gas recovery and particularly relates to an oil gas recovery organic / inorganic composite membrane and a preparation method thereof. In the invention, the composite membrane is formed by combining and overlapping polyether block amide (PEBA) and titanium dioxide (TiO2); and the composite membrane uses compact membrane PEBA as a strippable skin layer and uses ceramic membrane TiO2 as a supporting layer and has a good separation effect and high efficiency.

Owner:溧阳常大技术转移中心有限公司

Heat transfer segment for a cryoablation catheter

A heat transfer segment for a cryoablation catheter includes a member, at least a portion of which is made of a thermally conductive composite material. The composite material includes a polymeric matrix material such as a polyether block amide (PEBA) and a filler material which can include metals, metal alloys, ceramics, carbon and combinations thereof. One particular composition for the composite material includes approximately twenty weight percent of filler material, with the balance being polymeric matrix material. The composite has a thermal conductivity that is significantly increased relative to the polymeric matrix material and a flexibility that is not significantly reduced relative to the polymeric matrix material. In use, the heat transfer segment is disposed within a patient's body and positioned adjacent target tissue. A refrigerant is then introduced into the heat transfer segment causing heat to flow from the target tissue, through the member and into the refrigerant.

Owner:CRYOCOR

Fragrance control

Fragrance control is provided by articles of manufacture including various fragrancing objects, methods of using such objects, and systems that employ one or more such objects. The fragrancing object can be easy to manufacture, long lasting, provide fragrance that is consistently released over time, provide an indication to the user that the object needs to be replaced, and can hold a desired ratio of fragrance. The fragrancing object can include a first material comprising a polyether block amide, a second material comprising a polyolefin elastomer (POE), and a fragrance component such as a fragrance oil.

Owner:IMPACT PRODS

High selectivity membranes for hydrogen sulfide and carbon dioxide removal from natural gas

ActiveUS20210039052A1Small sizeImprove permeabilitySemi-permeable membranesMembranesCo2 removalNitrogen gas

A thin film composite gas separation membrane comprising a polyether block amide copolymer coating layer and a nanoporous asymmetric support membrane with nanopores on the skin layer surface of the support membrane and gelatin polymers inside the nanopores on the skin layer surface of the support membrane. A method for making the thin film composite gas separation membrane is provided as well as the use of the membrane for a variety of separations such as separations of hydrogen sulfide and carbon dioxide from natural gas, carbon dioxide removal from flue gas, fuel gas conditioning, hydrogen / methane, polar molecules, and ammonia mixtures with methane, nitrogen or hydrogen and other light gases separations, but also for natural gas liquids recovery and hydrogen sulfide and carbon dioxide removal from natural gas in a single step.

Owner:UOP LLC

Gas separation film based on carbon nanotube/graphene oxide-polyether block amide

InactiveCN106166452ASemi-permeable membranesDispersed particle separationSeparation coefficientCarbon nanotube

The invention belongs to the field of film separation technique, and particularly relates to a gas separation film based on carbon nanotube / graphene oxide-polyether block amide. A preparation method of the gas separation film comprises the following steps of obtaining a carbon nanotube / graphene oxide novel nanometer carbon structure by a chemical oxidation method, and enabling a certain amount of carbon nanotube / graphene oxide to be dispersed ultrasonically in a mixed solution of ethanol and water (in a mass ratio of the ethanol to the water being 7 to 3) so as to obtain uniform dispersion fluid A; then dissolving a certain amount of polyether block amide into a solution of ethanol and water, with the same amount as the mixed solution of the ethanol and the water, and performing stirring until the polyether block amide is completely dissolved so as to obtain dispersion fluid B; and mixing the dispersion fluid A with the dispersion fluid B, allowing the mixed dispersion fluid to stand for deaeration, pouring the mixed dispersion fluid after deaeration into a culture dish, and performing drying and film forming so as to obtain the gas separation film based on the carbon nanotube / graphene oxide-polyether block amide. Compared with polyether block amide separation films, the gas separation film based on the carbon nanotube / graphene oxide-polyether block amide provided by the invention has better heat stability, higher gas permeation coefficients and higher separation coefficients, and has important application prospects in the field of gas separation films.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Masking film

InactiveUS6387503B1None is suitable for purposeIncrease surface tensionLiquid surface applicatorsSpraying apparatusPolytetramethylene terephthalatePolyolefin

The invention relates to a masking film, which may or may not be combined with a substrate, such as paper, for varnishing surface parts. According to the invention the film consists of at least one layer of an absorbent polar material, which material is preferably an engineering polymer. The absorbent material is according to the invention usually a polymer such as are polyamide, polycarbonate, polybuteneterephthalate, polyetheneterephthalate, polyetherblockamide, polyetherblockester, polyurethane etherblockcopolymer, and blends of said polymers with polyolefins, or mixtures thereof. Usually the film according to the invention comprises several layers, i.e. three, five, seven or more.

Owner:HYPLAST

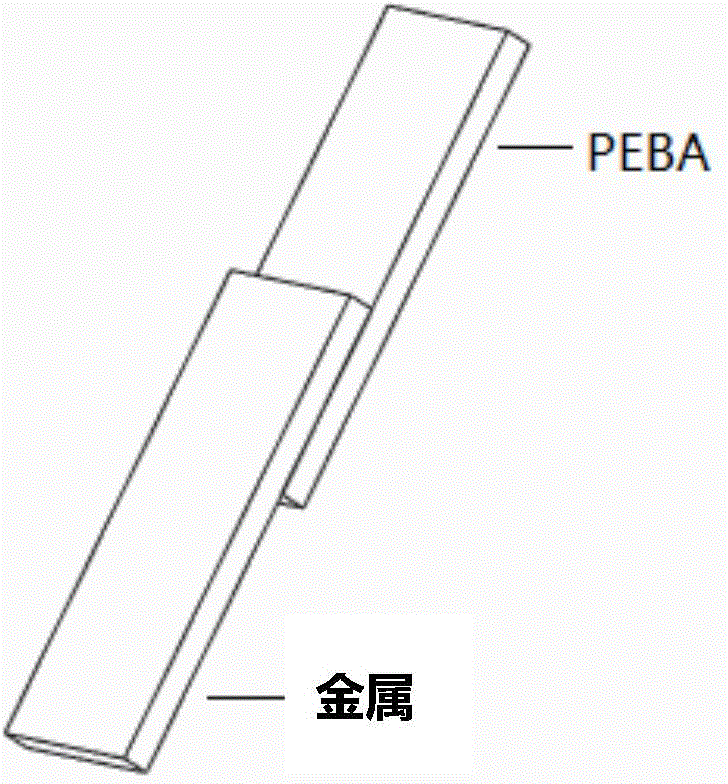

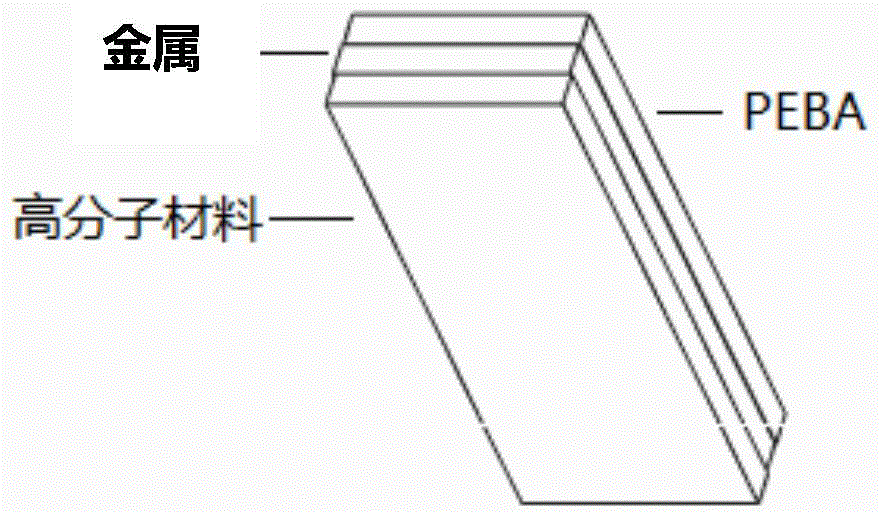

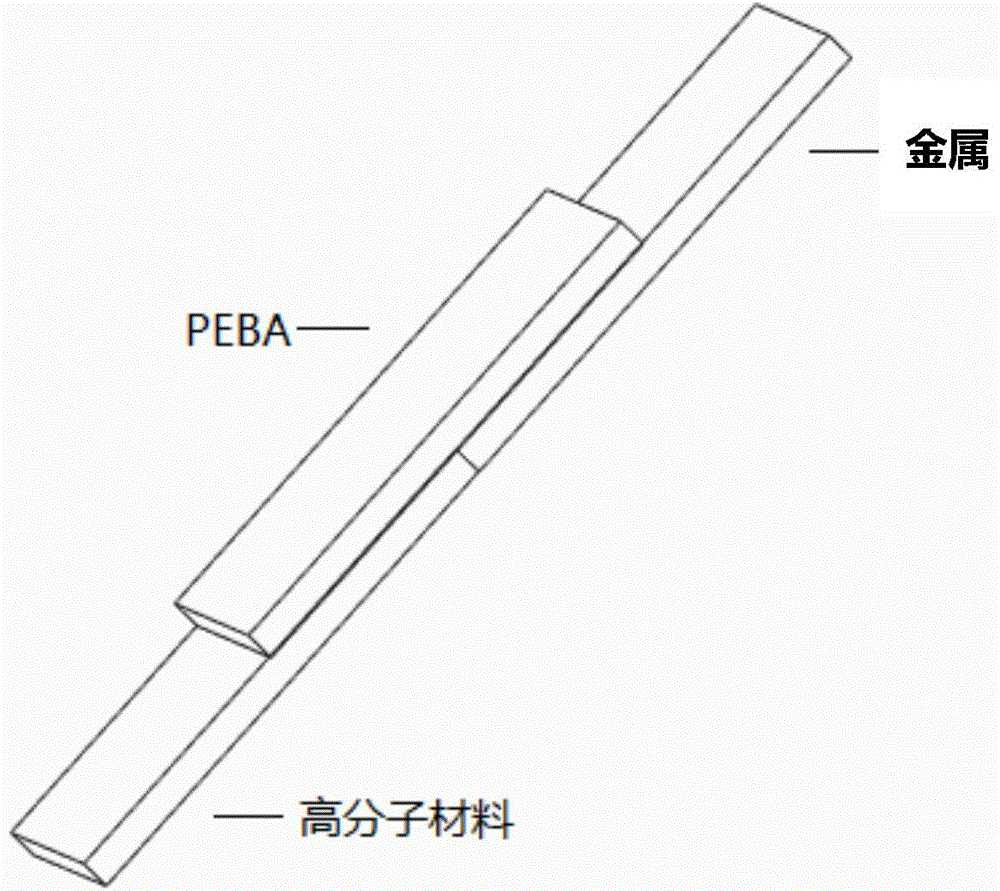

Complex of metal and plastic and manufacturing method of complex

ActiveCN105479659ATightly boundHigh bonding strengthSynthetic resin layered productsMetal layered productsChemical treatmentConvex structure

The invention relates to a complex of metal and plastic and a manufacturing method of the complex. The complex is formed by combining a metal member, of which a combining surface has at least a part of area in a nanoscale concave-convex structure after chemical treatment, with a plastic material; the metal member and the plastic material are tightly combined in an inserting structure in the area; the metal member comprises a metal material member or an alloy material member; the plastic material mainly contains polyether block amide, and is a single-layer or layered structure. Corresponding combining and treatment technologies are matched specifically for the characteristics of the selected plastic material, so that a binding force between metal and plastic is excellent, the sealing characteristic to a certain extent is provided, the impact resistance is excellent, and the appearance decorative effect is diversified.

Owner:SONIM COMM TECH (SHENZHEN) CO LTD

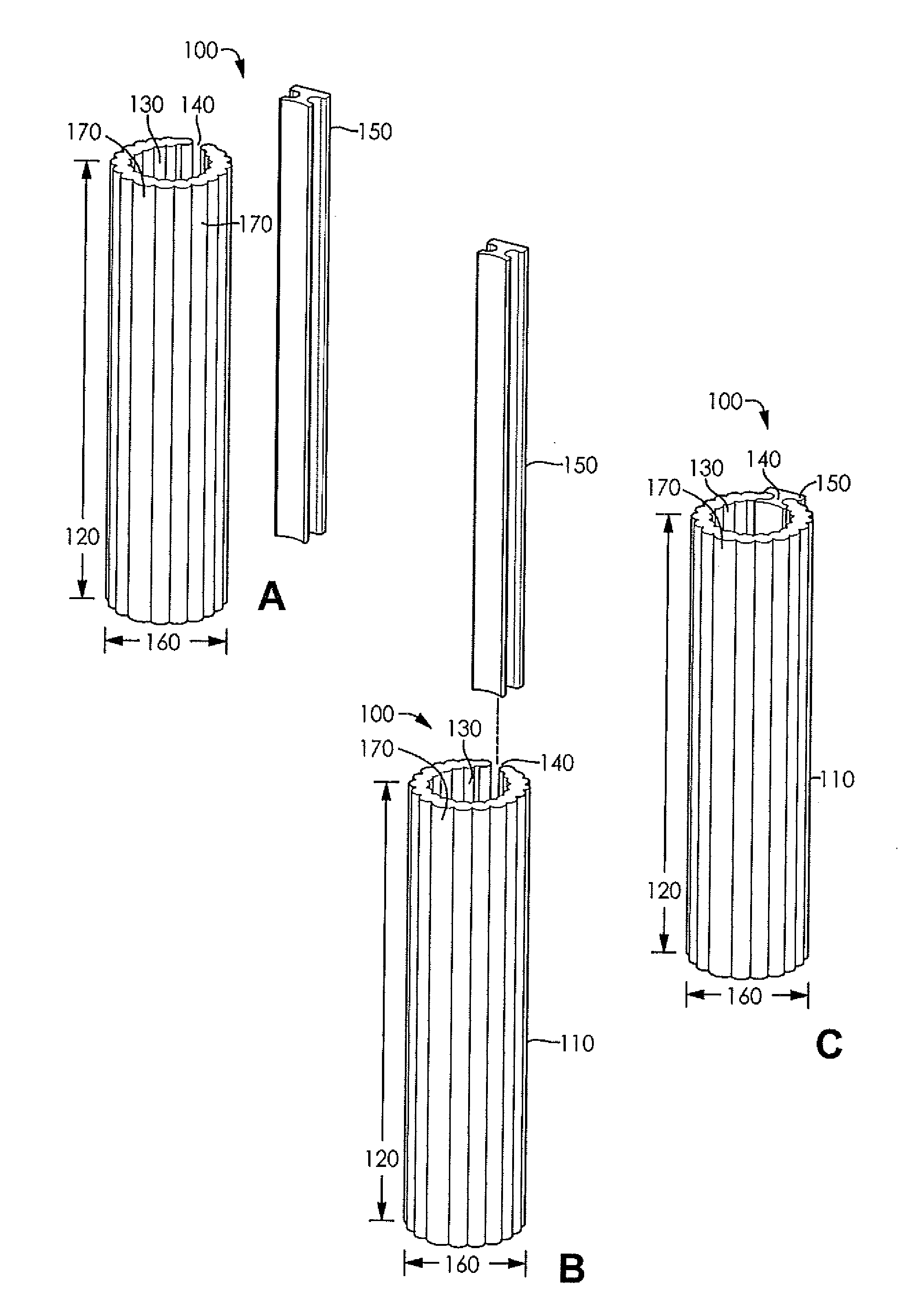

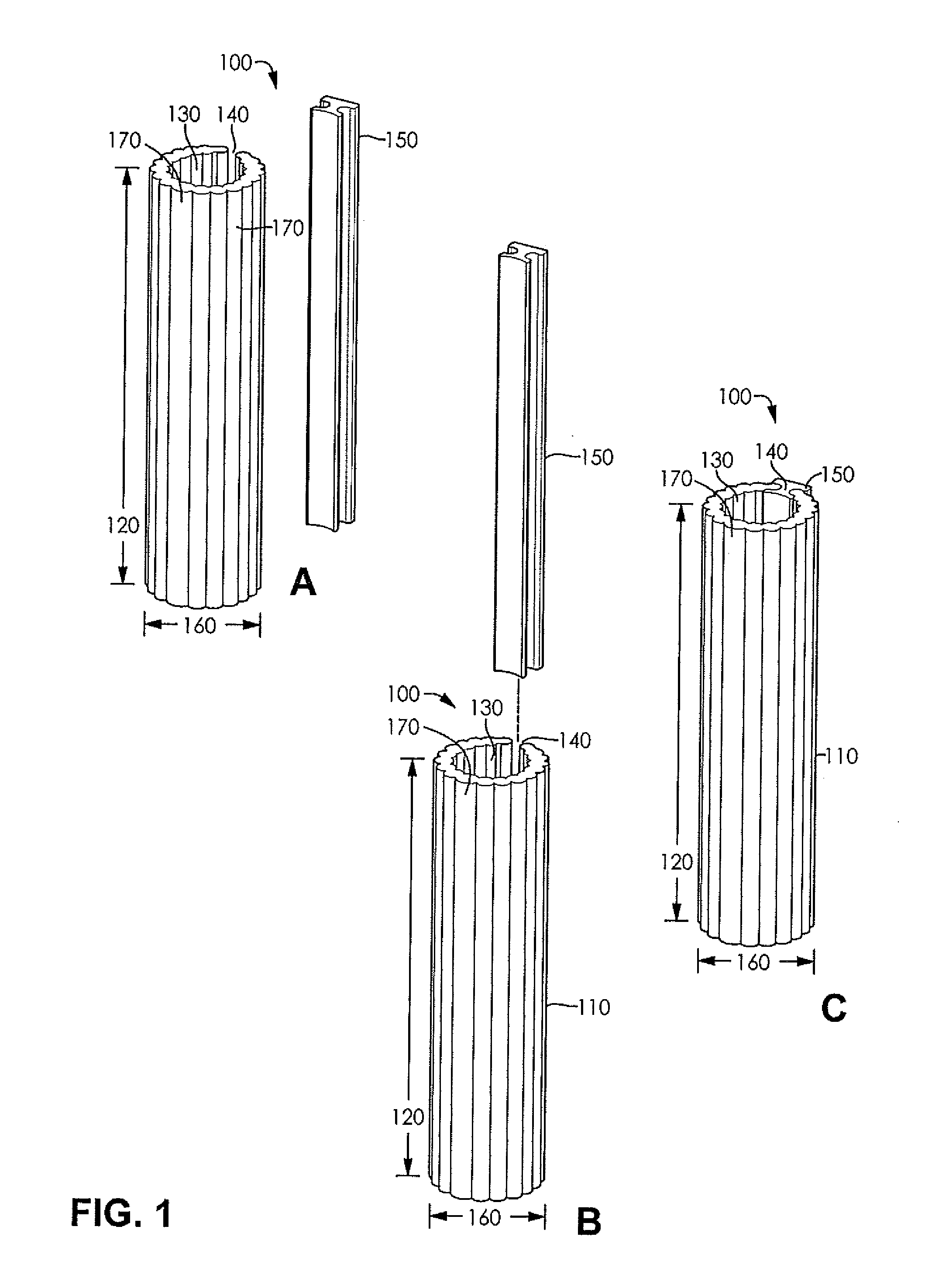

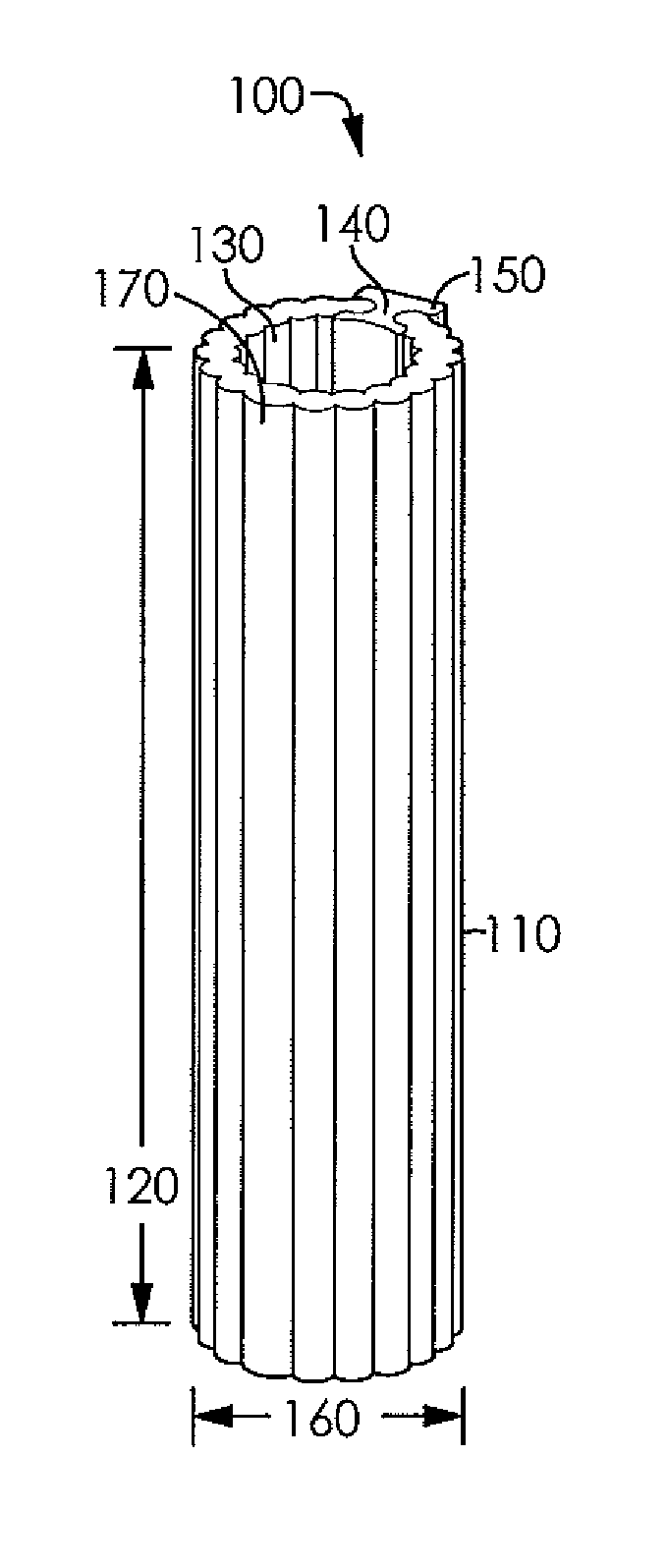

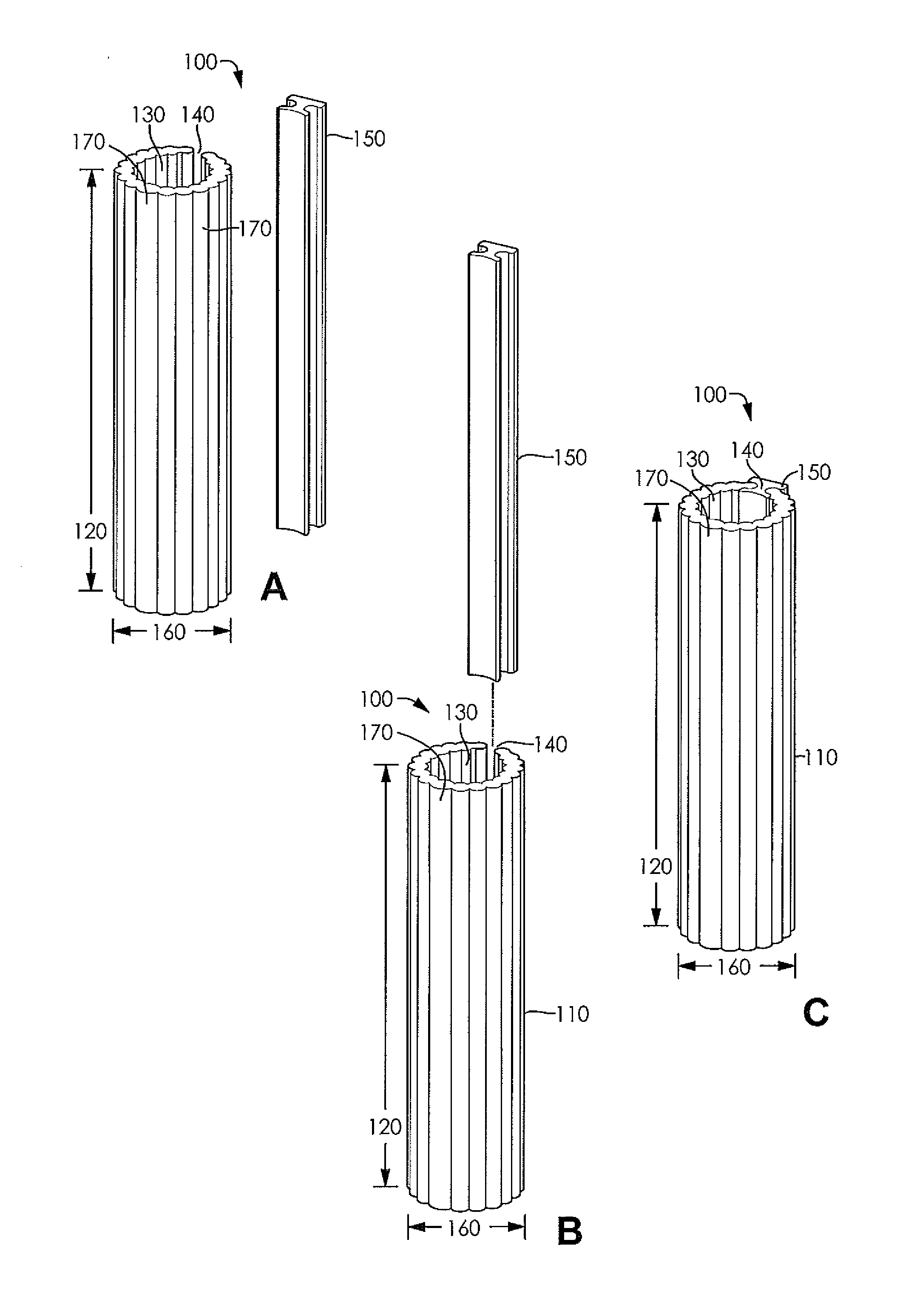

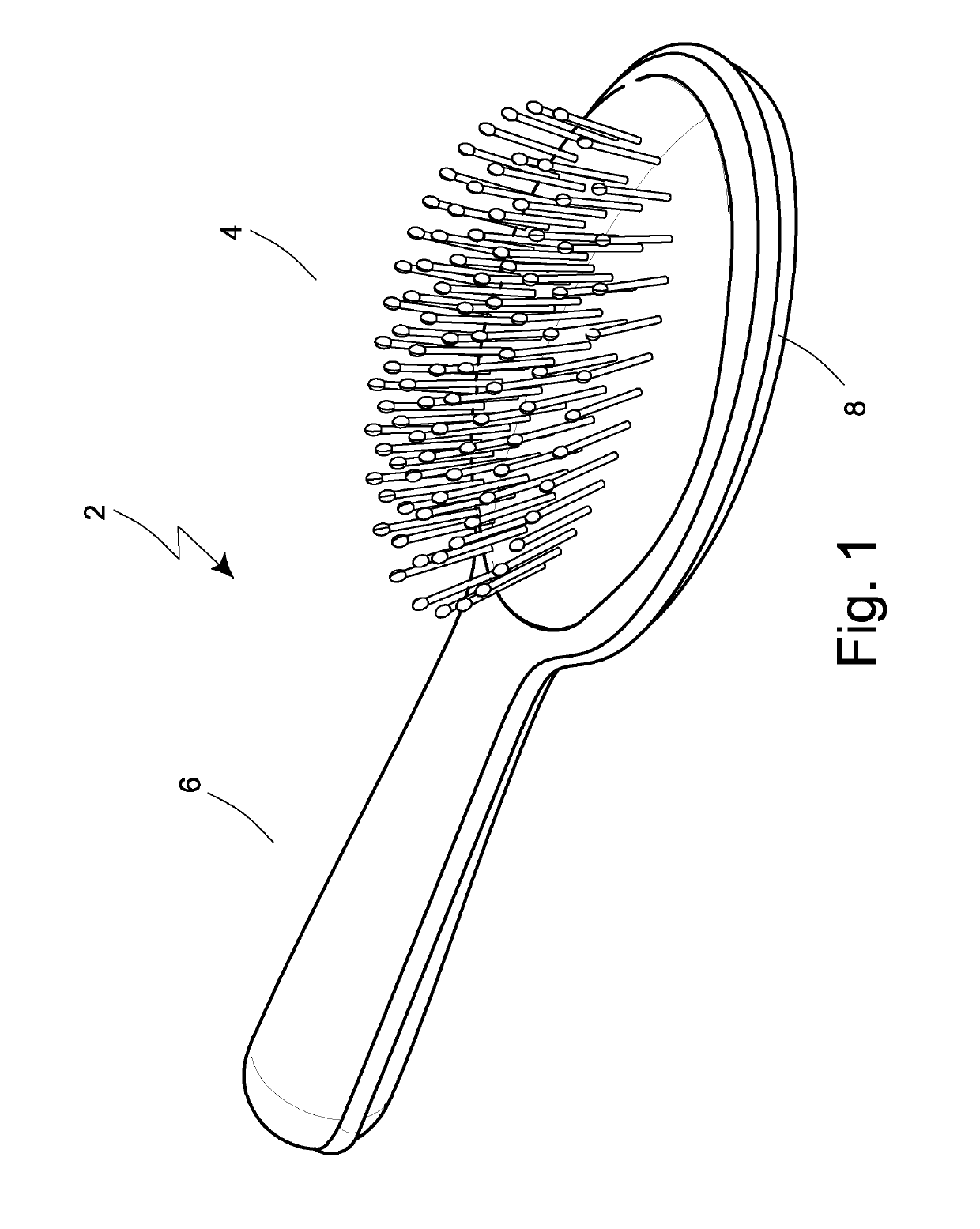

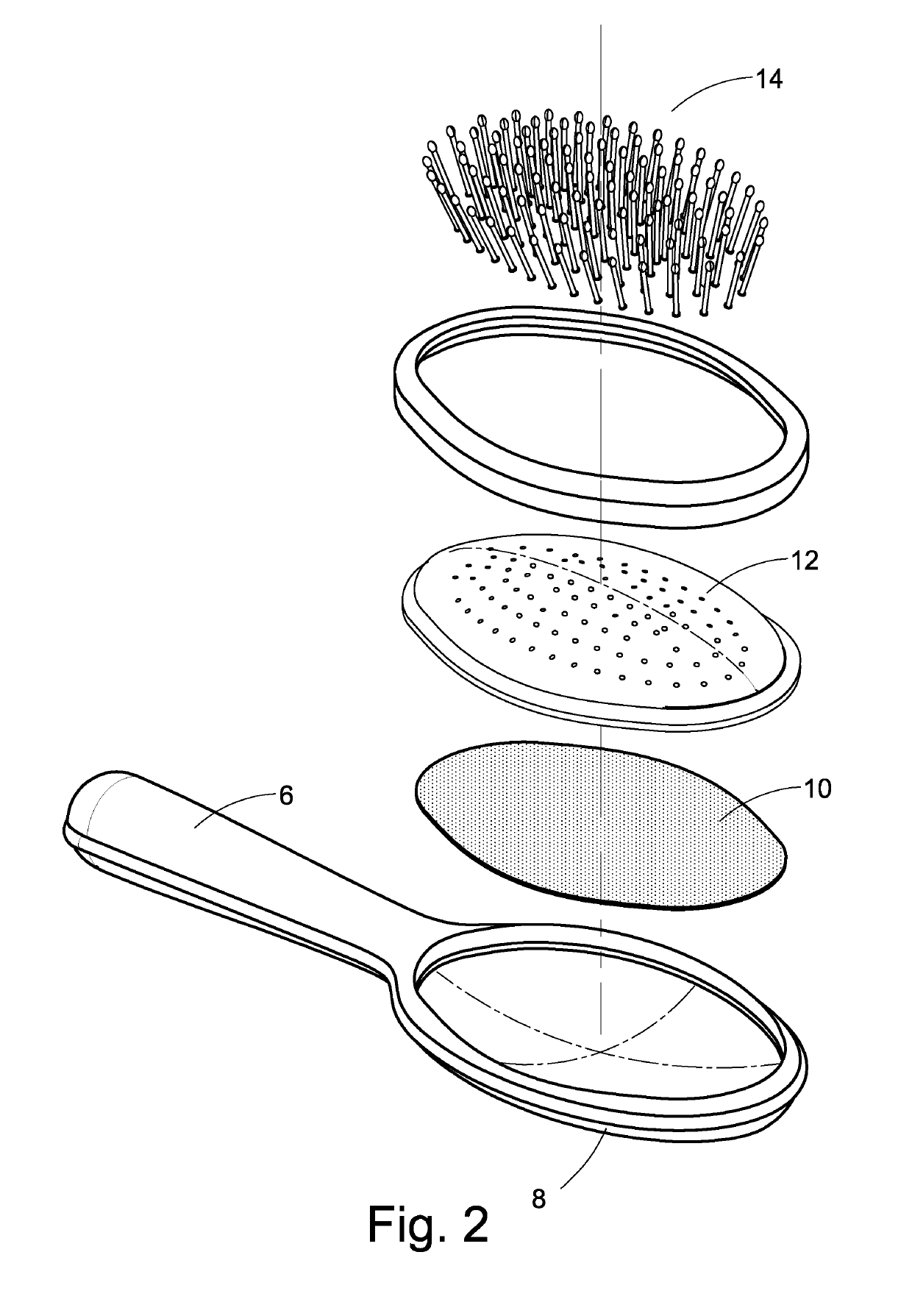

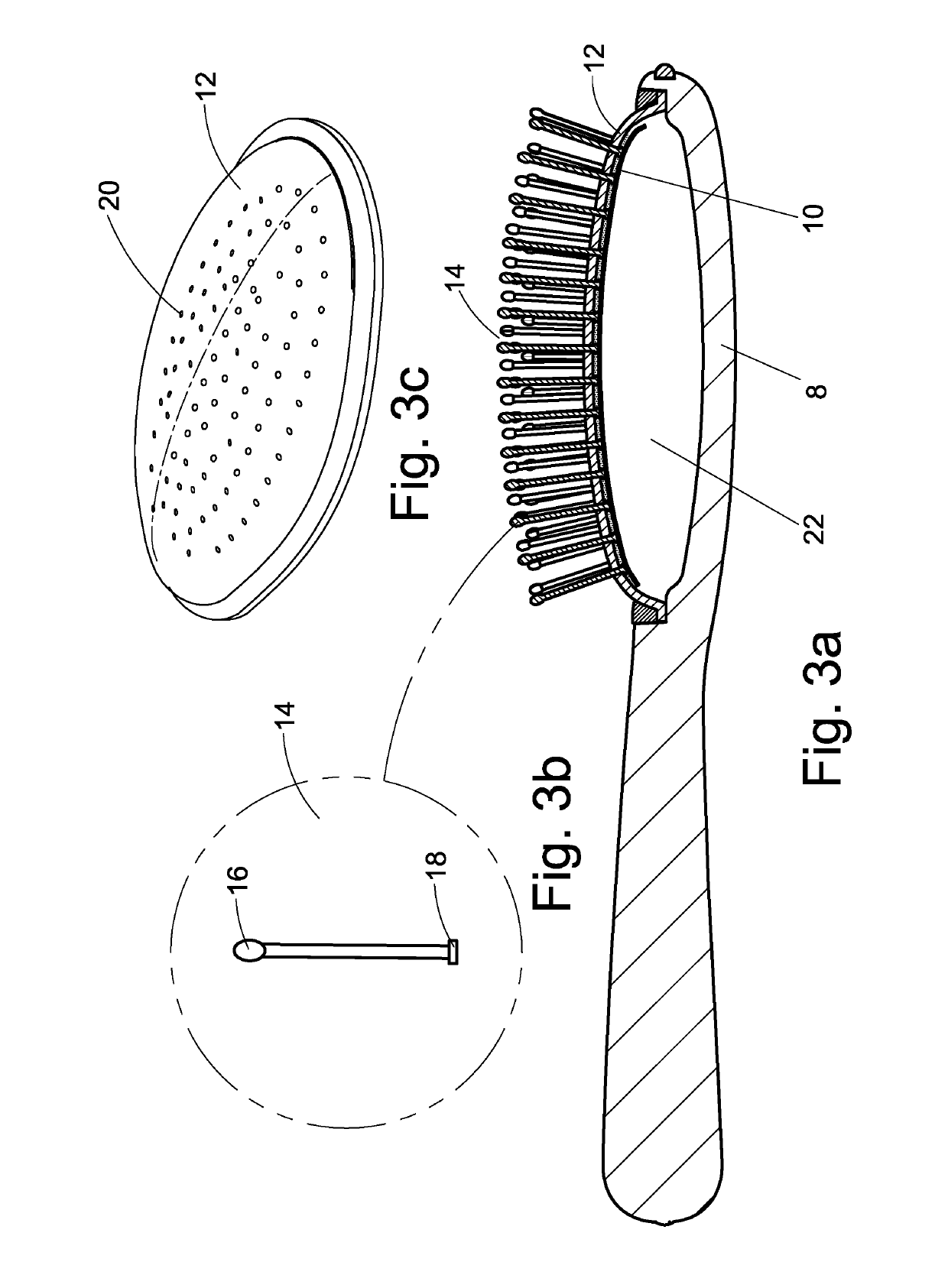

Hair brush

One aspect of the present invention is concerned with a method of manufacture of a hair brush. The method has the steps of providing a base member having connection means at circumferential region thereof, providing a sheet material having a plurality of spikes extending from outwardly facing surface of the sheet material, the sheet material and the spikes are integrally formed by injection molding of a plastic(s) material selected from the group consisting of thermoplastics polyester elastomer (TPE-E), polyether block amide copolymer (TPE-A), thermoplastic polyurethane (TPU) and polyurethane (PU), with a hardness from substantially Shore D50 to D65, and with a flexural modulus from 30,000 PSI to 40,000 PSI, assembling the sheet material by fitting perimeter thereof to the circumferential region of the base member, the base member and the connection means are configured to allow the sheet material to secure to the base member. The outwardly facing surface assumes a convex curvature. In an assembled configuration, a cavity is defined between the sheet material and the base member. In use, when the spikes are under pressure the spikes are movable in response to the pressure, causing corresponding movement to the sheet material, the movement creating a cushioning effect.

Owner:TUNG HING PLASTIC MFR LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com