Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

766 results about "Mixed matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lipid particles on the basis of mixtures of liquid and solid lipids and method for producing same

InactiveUS8663692B1Promote formationImprove stabilityPowder deliveryCosmetic preparationsLipid particleSolid content

The invention relates to drug-free or drug-loaded lipid particles of a mixed matrix made of solid and liquid lipids, and to a method for producing highly concentrated lipid particle dispersions of solid-liquid particles having a lipid content of from 30% to 95% or a solids content of from 30% to 95% (lipid and stabilizer), which in contrast to biamphipileic cremes are integer particles, and / or which upon dilution of the highly concentrated particle dispersions with the outer phase result in free-flowable particle dispersions.

Owner:PHARMASOL

Ordered mesopore silica mixed matrix membranes, and production methods for making ordered mesopore silica mixed matric membranes

InactiveUS20070022877A1Enhanced interactionEffectively incorporated into polymer structureSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsMesoporous silicaSilicon dioxide

Mixed matrix membranes are prepared from mesoporous silica (and certain other silica) and membrane-forming polymers (such as polysulfone), in a void free fashion where either no voids or voids of less than 100 angstroms are present at the interface of the membrane-forming polymer and the silica. Such silica-containing mixed matrix membranes are particularly useful for their selectivity (such as carbon dioxide selectivity) and permeability. Methods for separating carbon dioxide are provided.

Owner:VIRGINIA TECH INTPROP INC

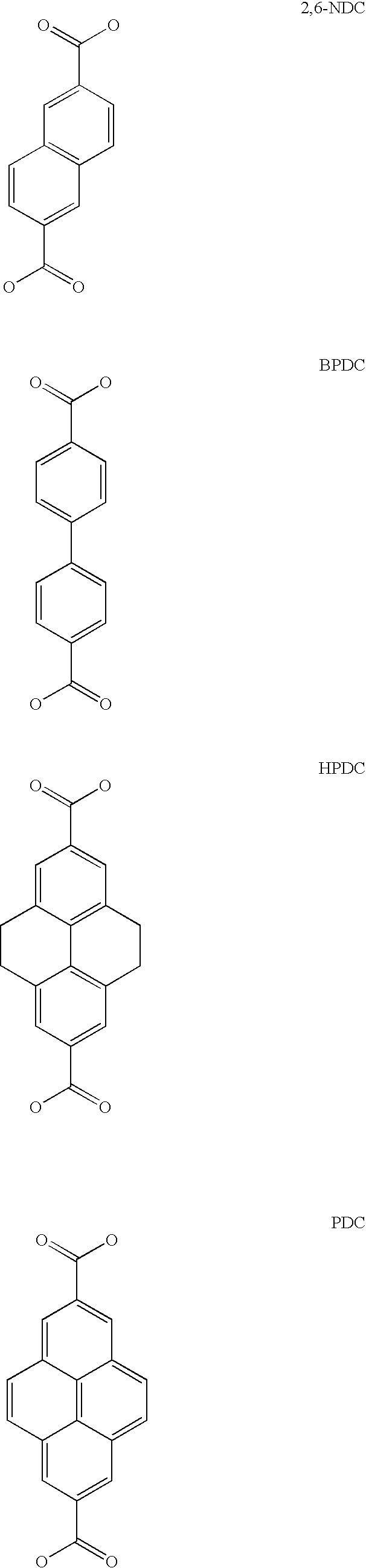

Metal organic framework-polymer mixed matrix membranes

InactiveUS7637983B1Reduce hydrocarbon fouling problemEnhanced gas separation permeability performanceSemi-permeable membranesSolid sorbent liquid separationMetal-organic frameworkPermeation

Metal-organic framework (MOF)-polymer mixed matrix membranes (MOF-MMMs) have been prepared by dispersing high surface area MOFs (e.g. IRMOF-1) into a polymer matrix (e.g. Matrimid 5218). The MOFs allow the polymer to infiltrate the pores of the MOFs, which improves the interfacial and mechanical properties of the polymer and in turn affects permeability. Pure gas permeation tests show the incorporation of 20 wt-% of IRMOF-1 in Matrimid 5218 polyimide matrix results in 280% improvement in CO2 permeability without a loss of CO2 / CH4 selectivity compared to those of the pure Matrimid 5218 membrane. This type of MOF-MMMs has significantly improved gas separation performance with dramatically high CO2 permeability (>35 barrer) and higher than 29 CO2 / CH4 selectivity at 50° C. under 100 psig pressure, which are attractive candidates for practical gas separation applications such as CO2 removal from natural gas.

Owner:UOP LLC

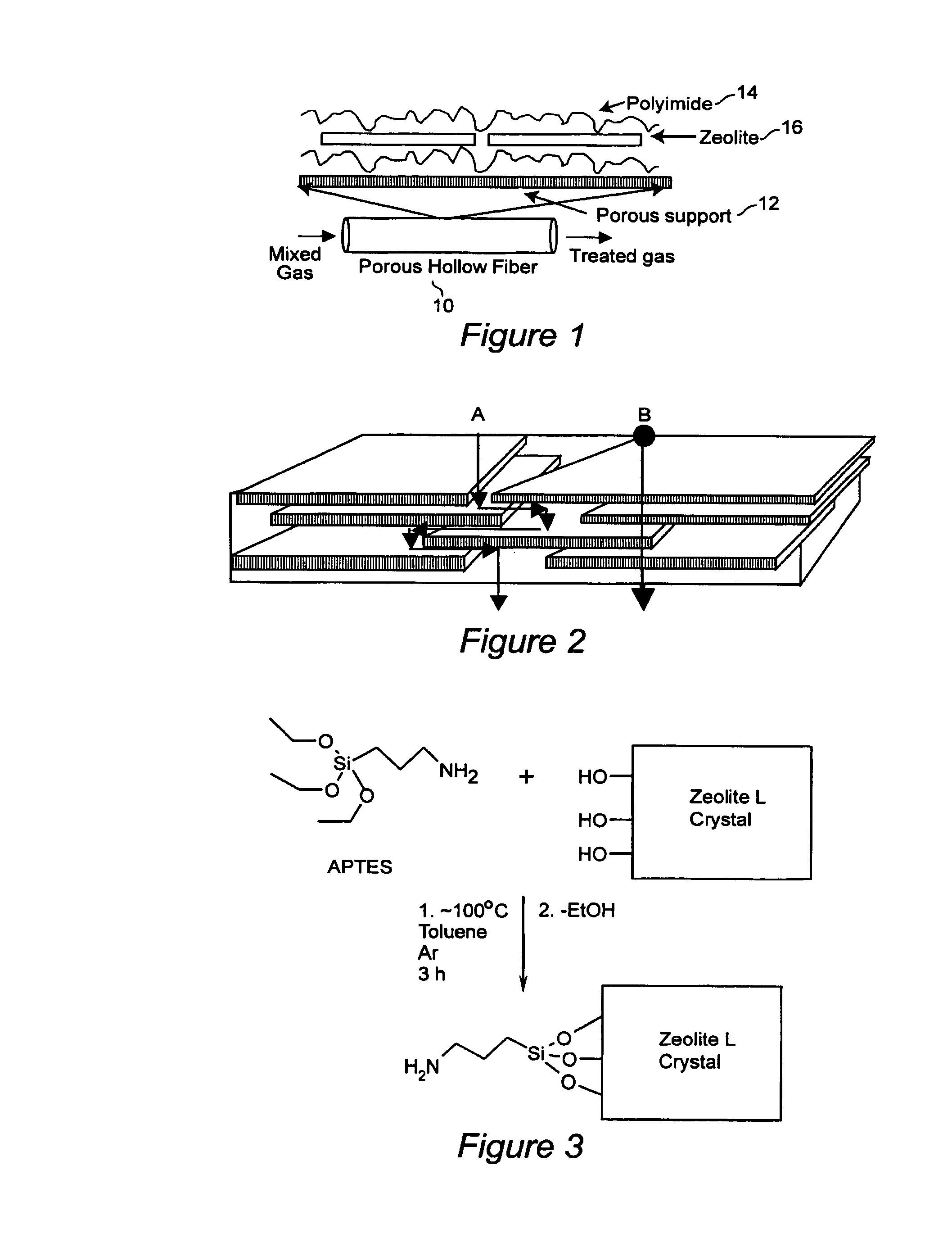

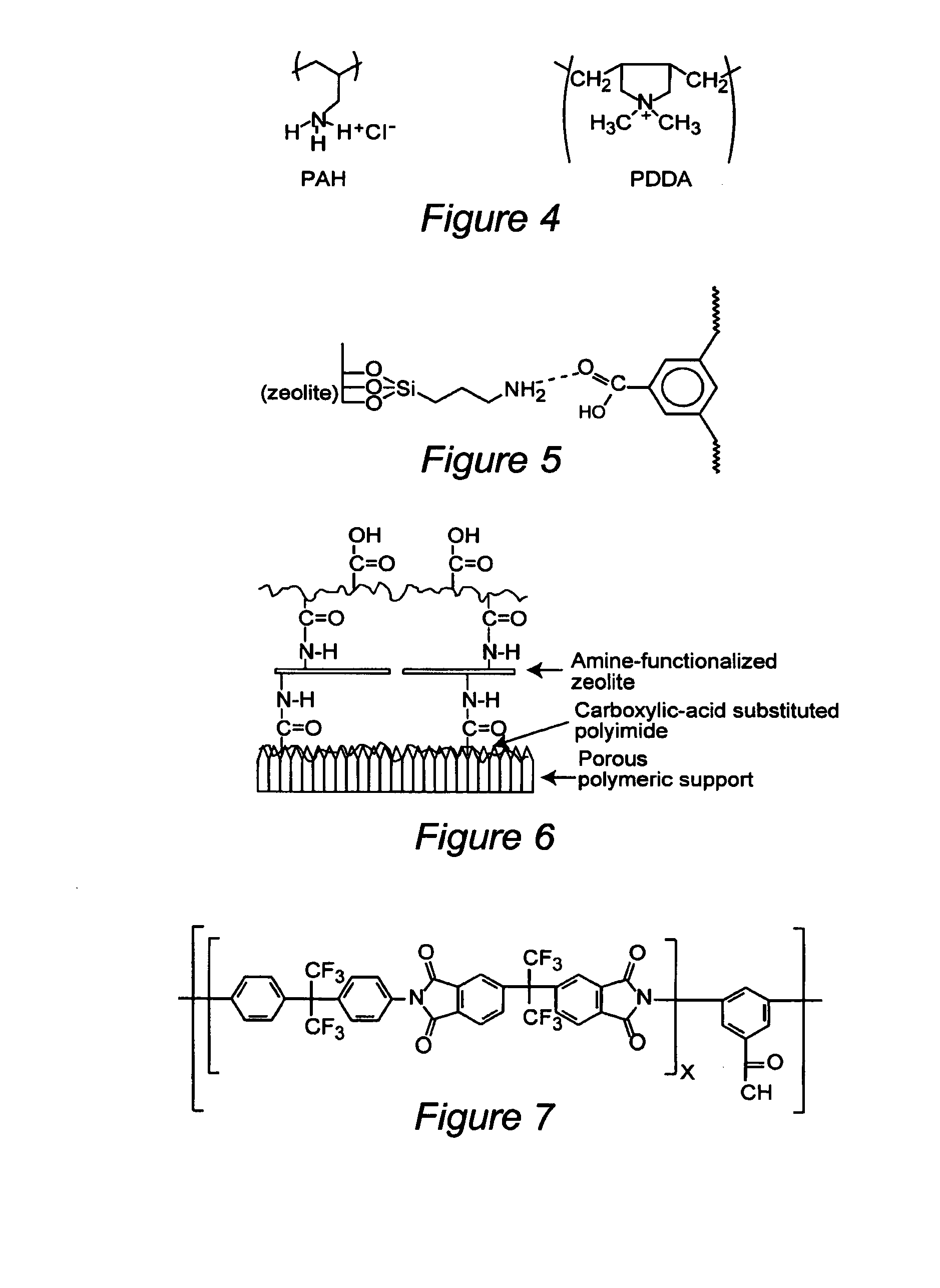

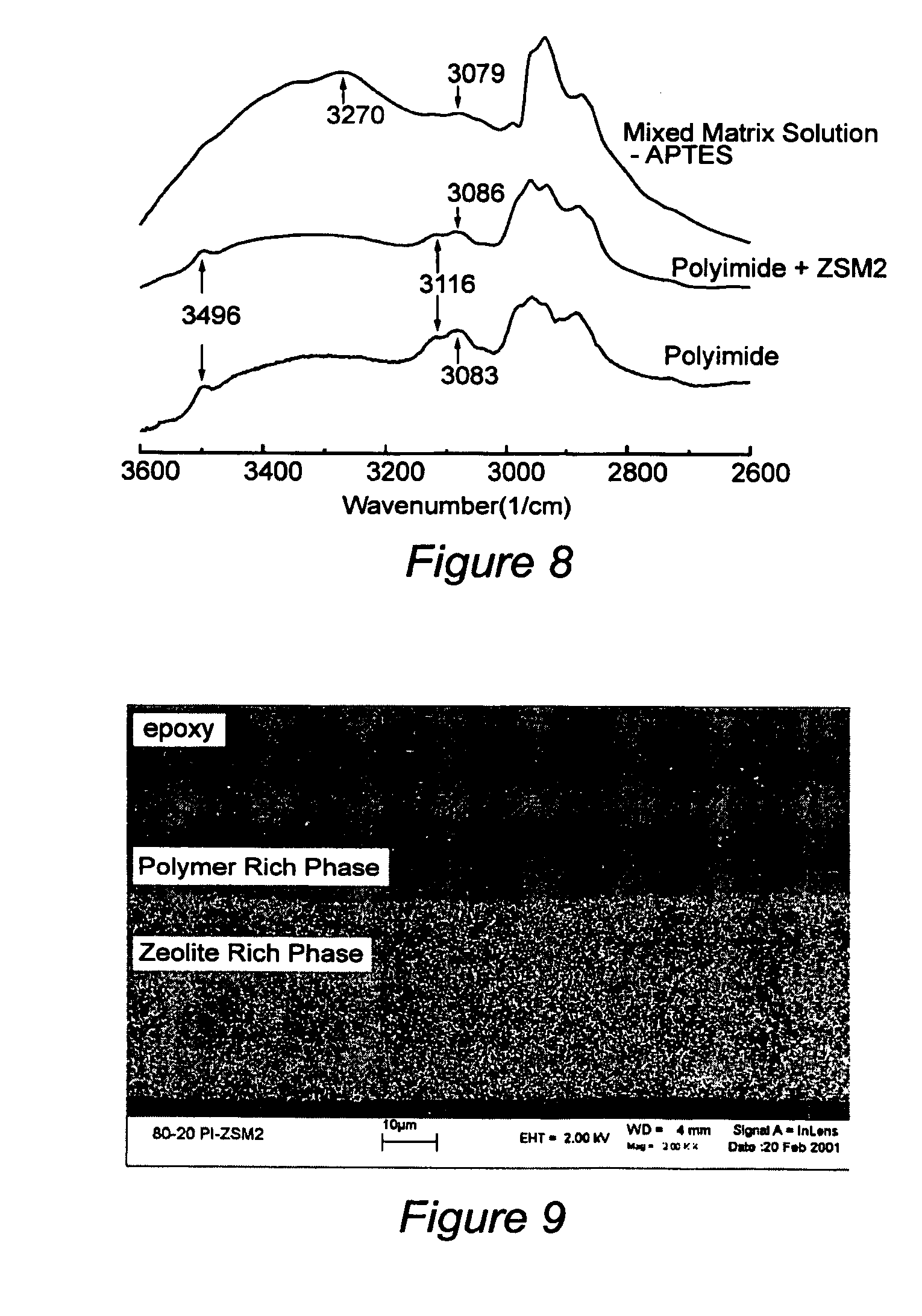

Mixed matrix membranes

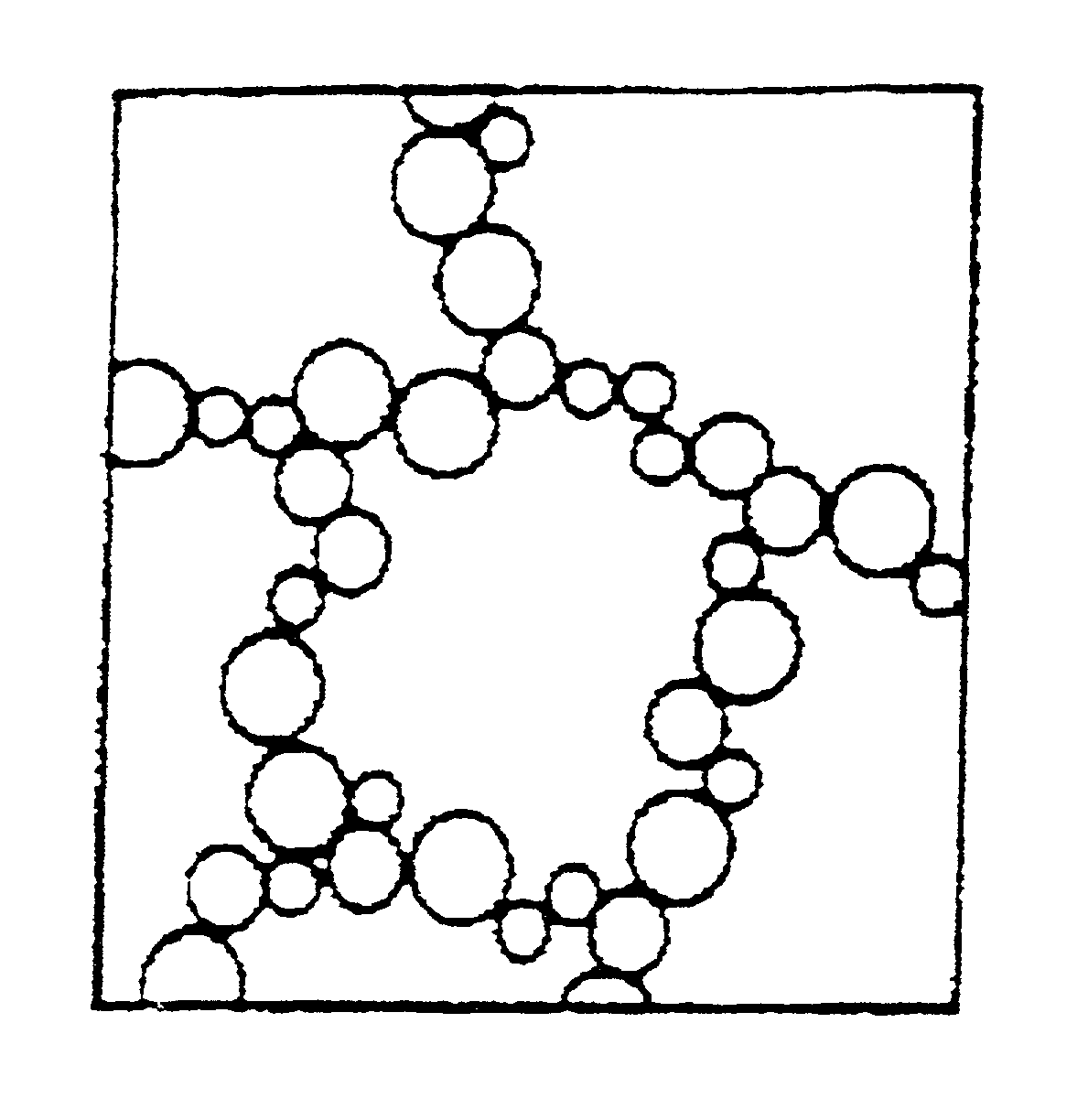

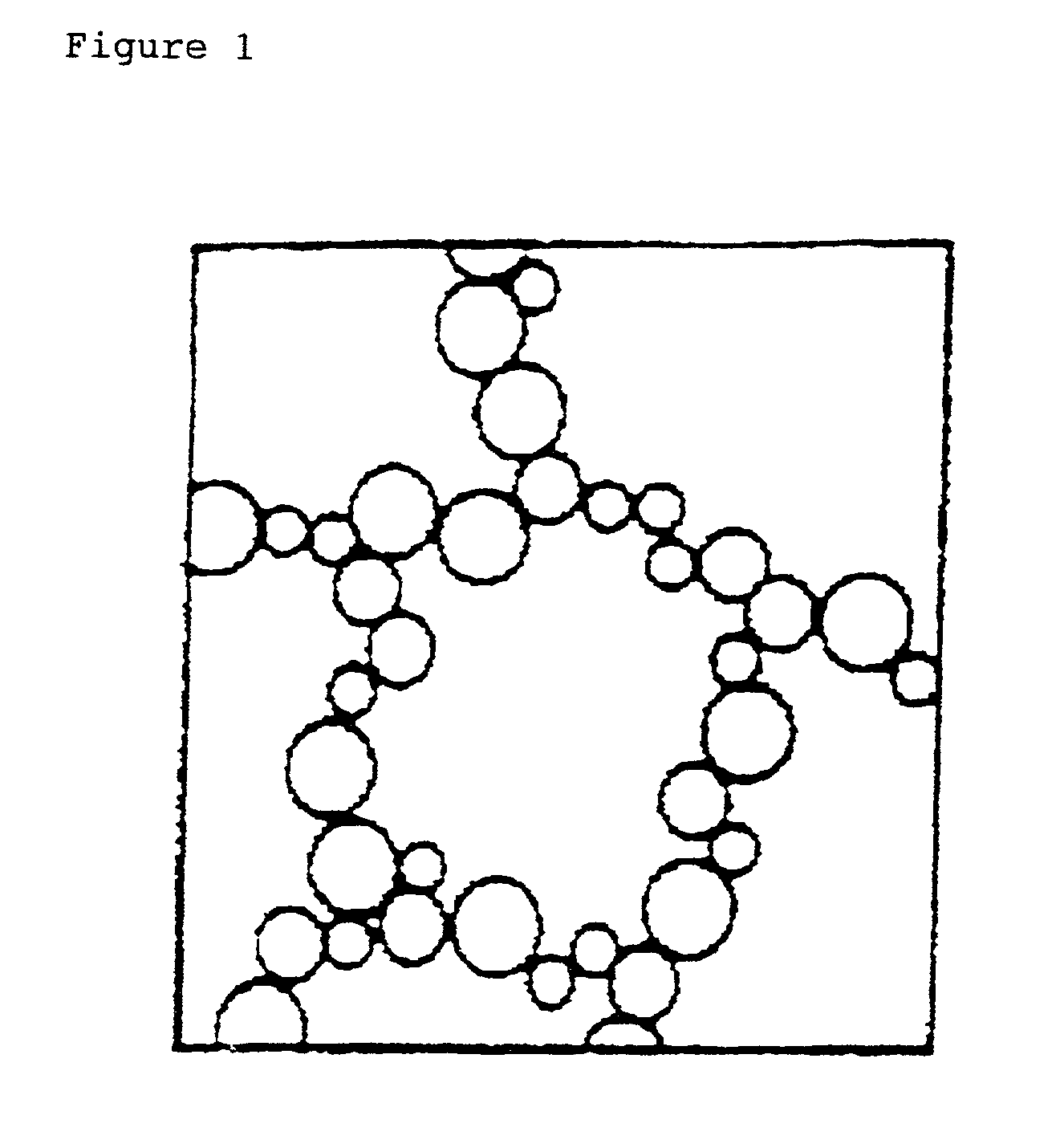

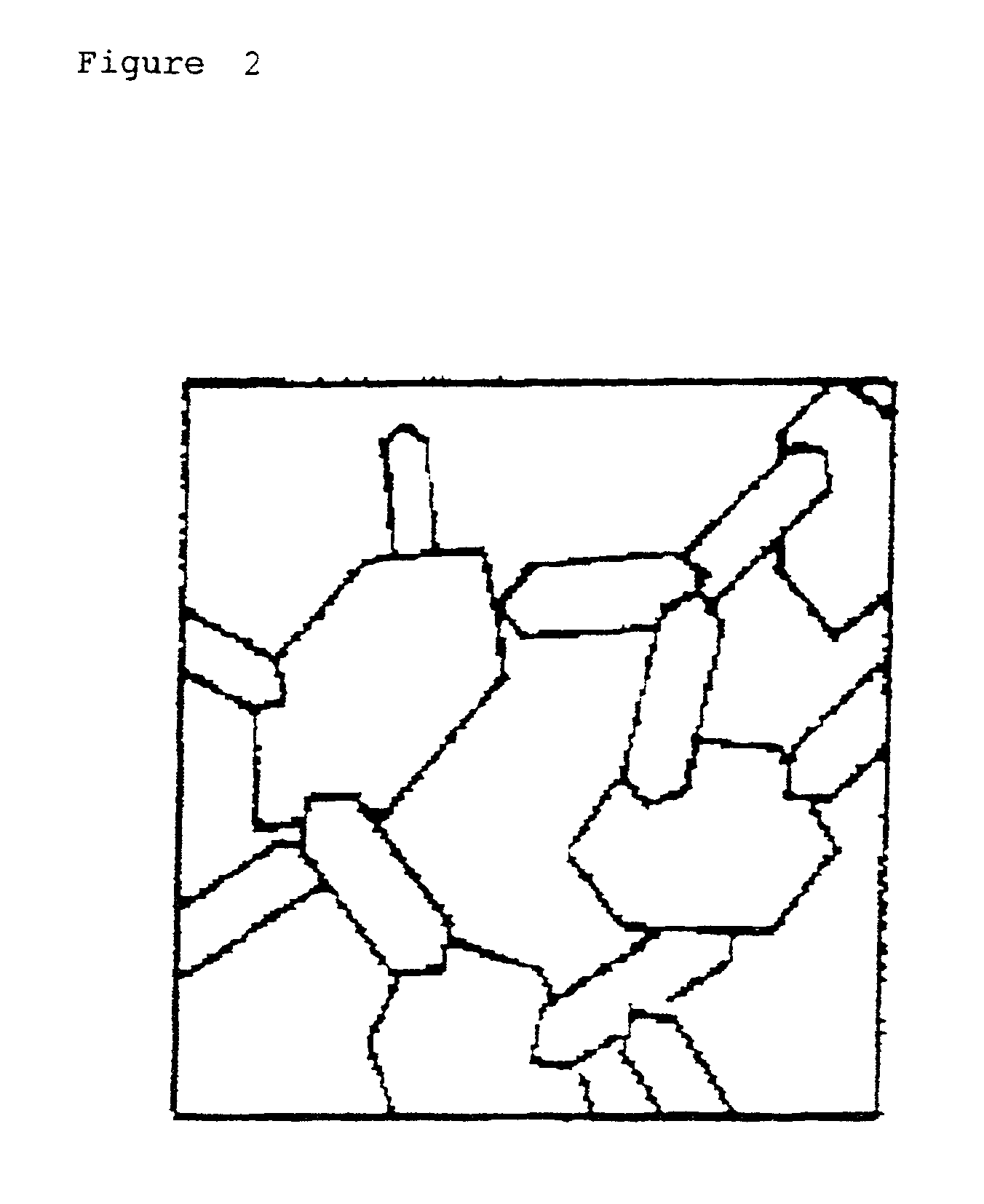

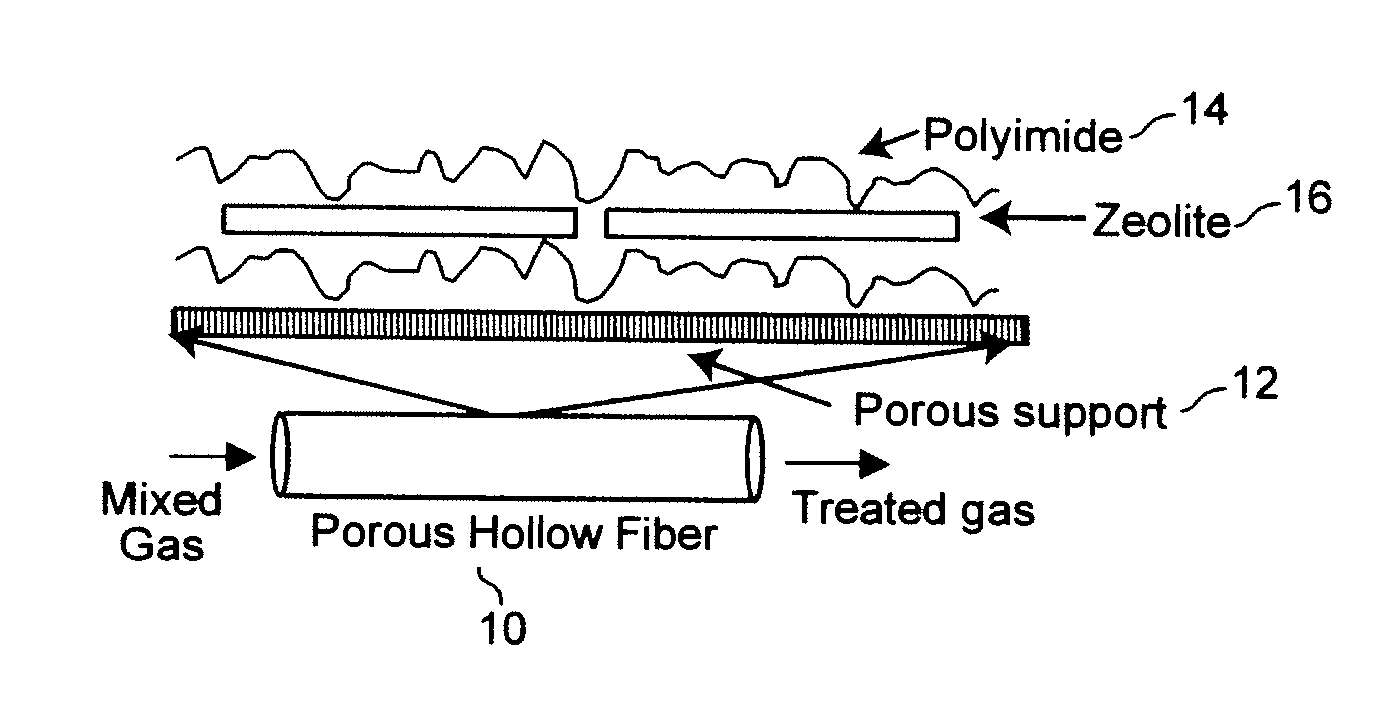

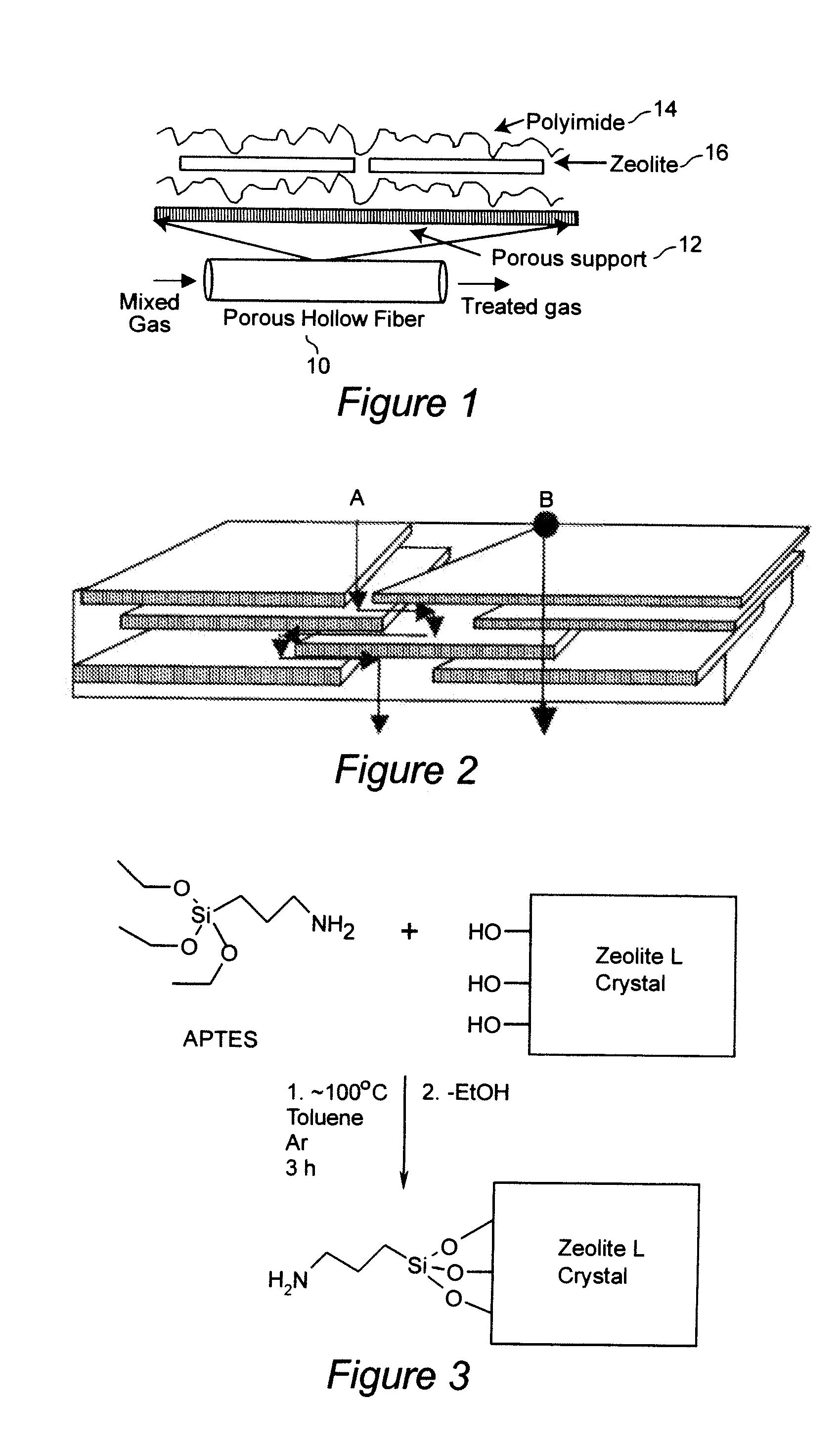

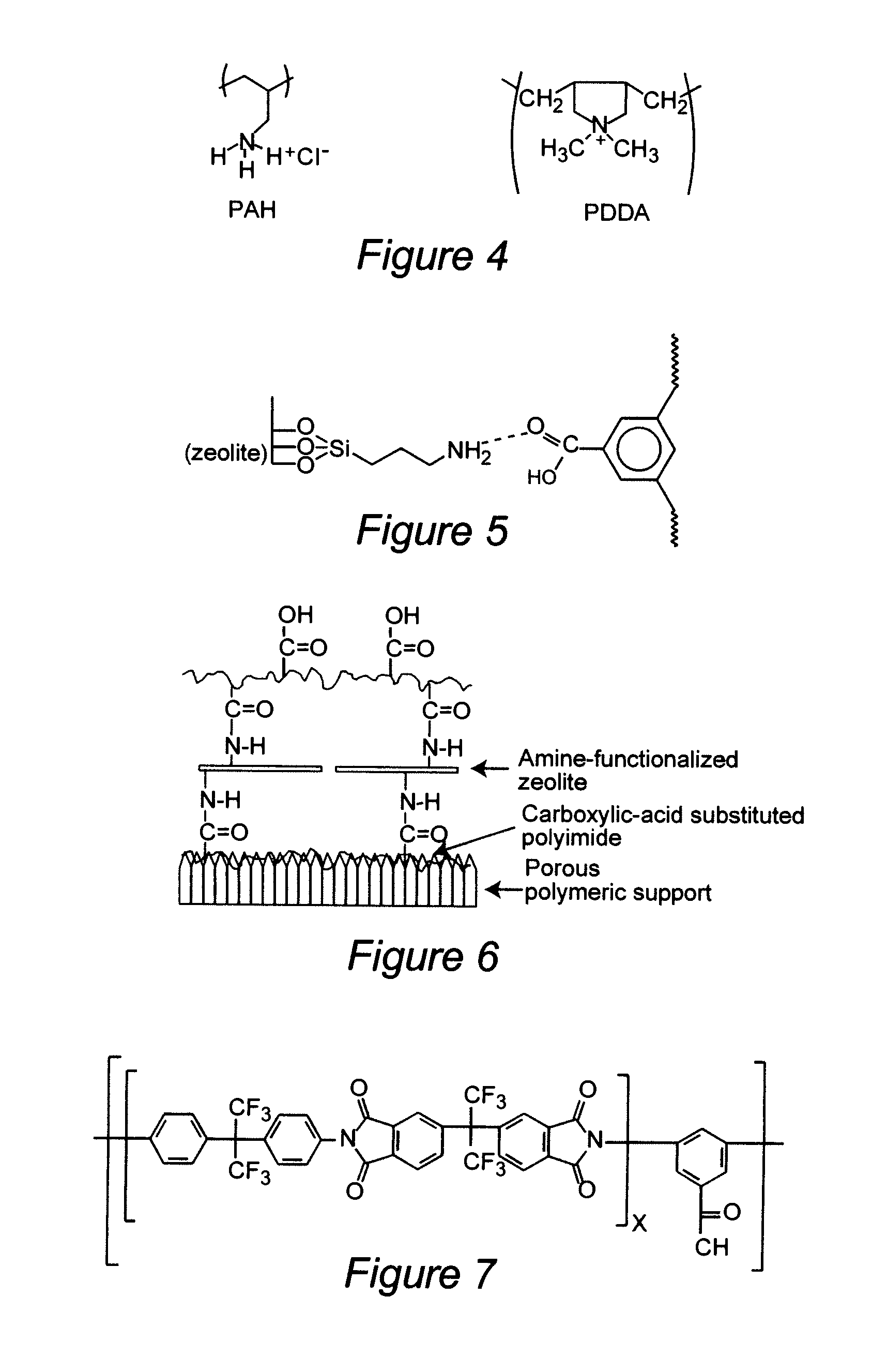

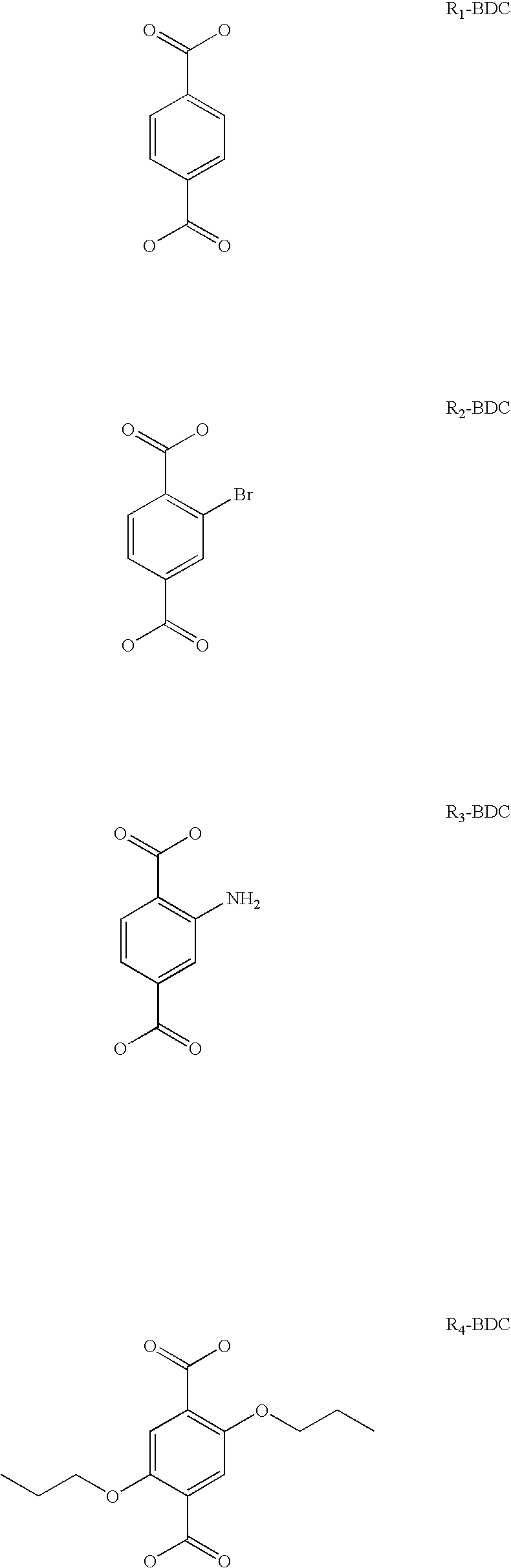

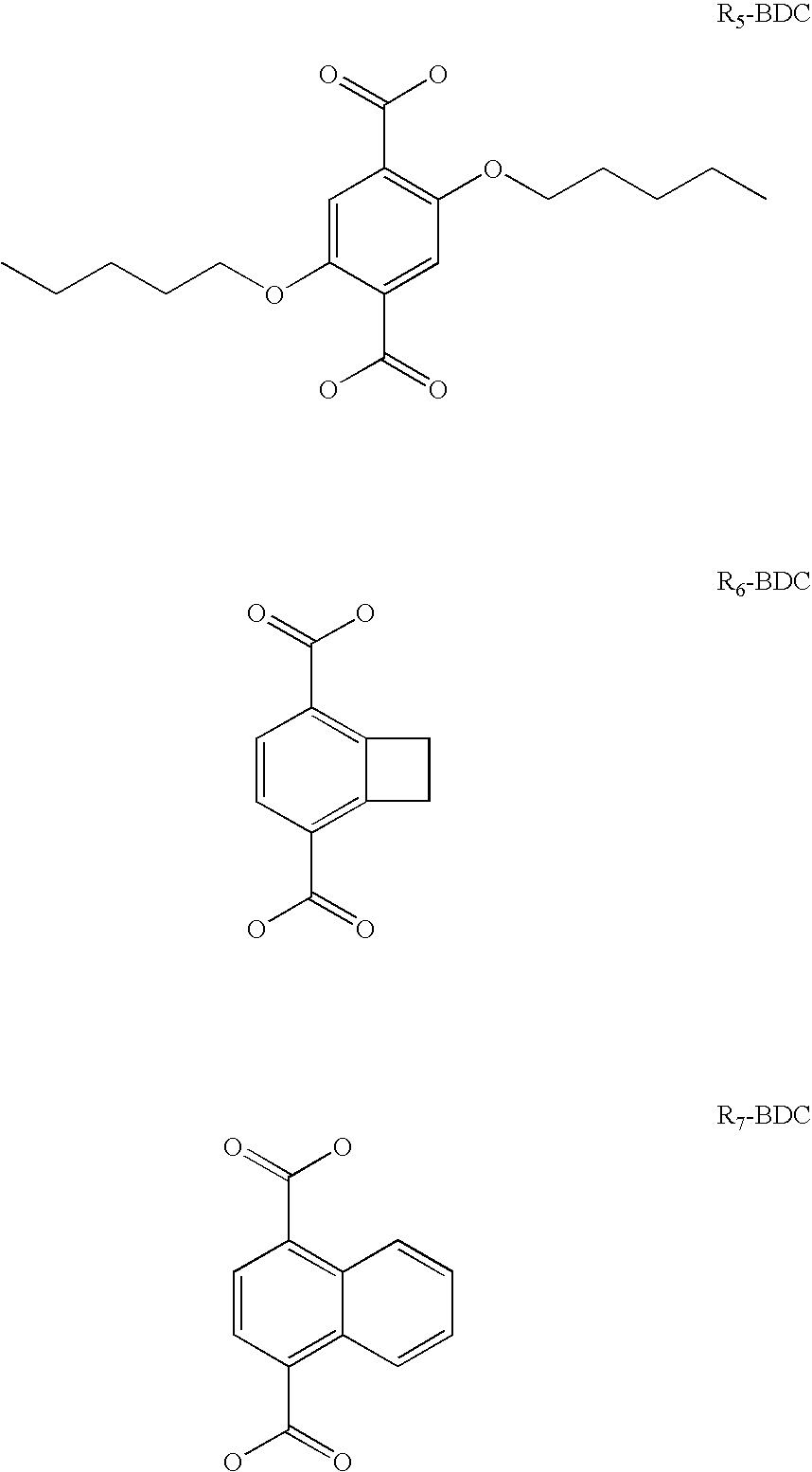

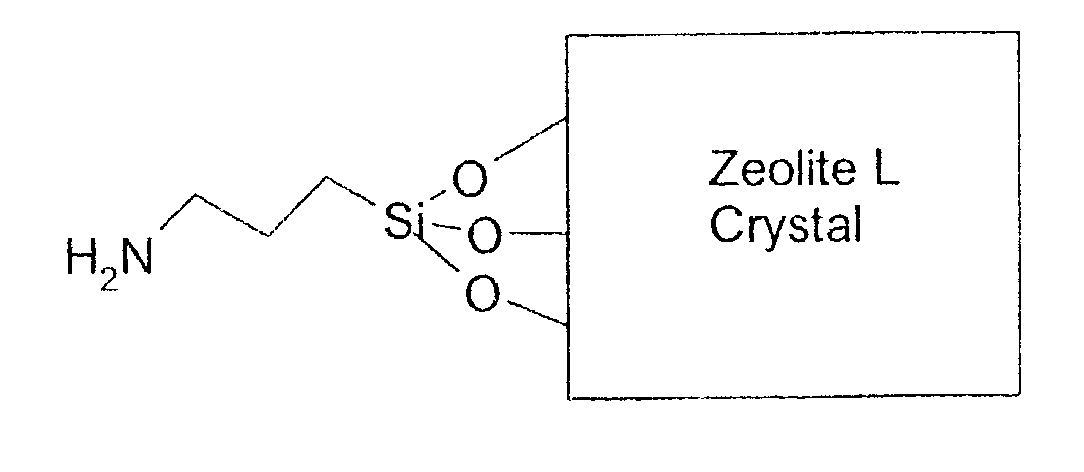

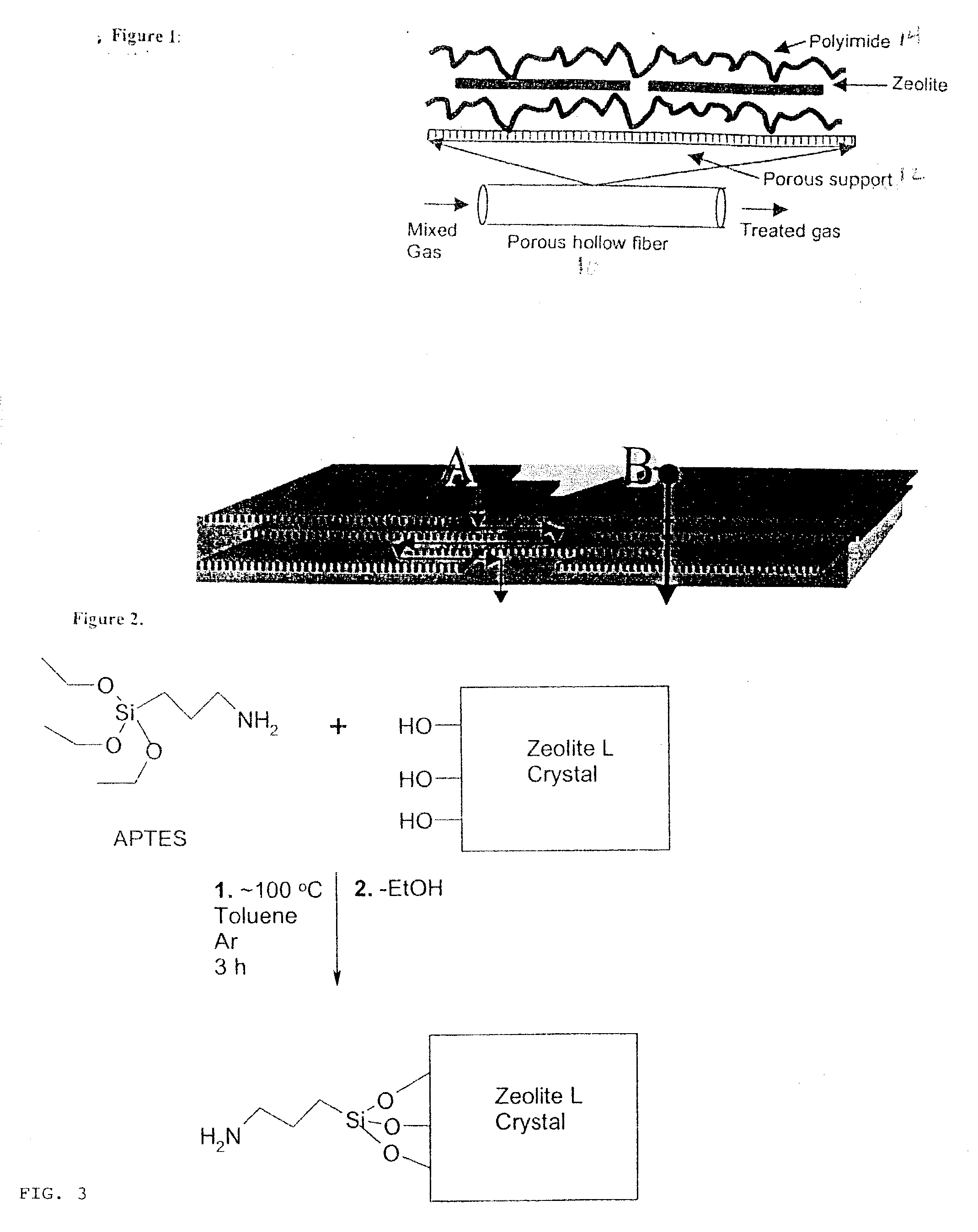

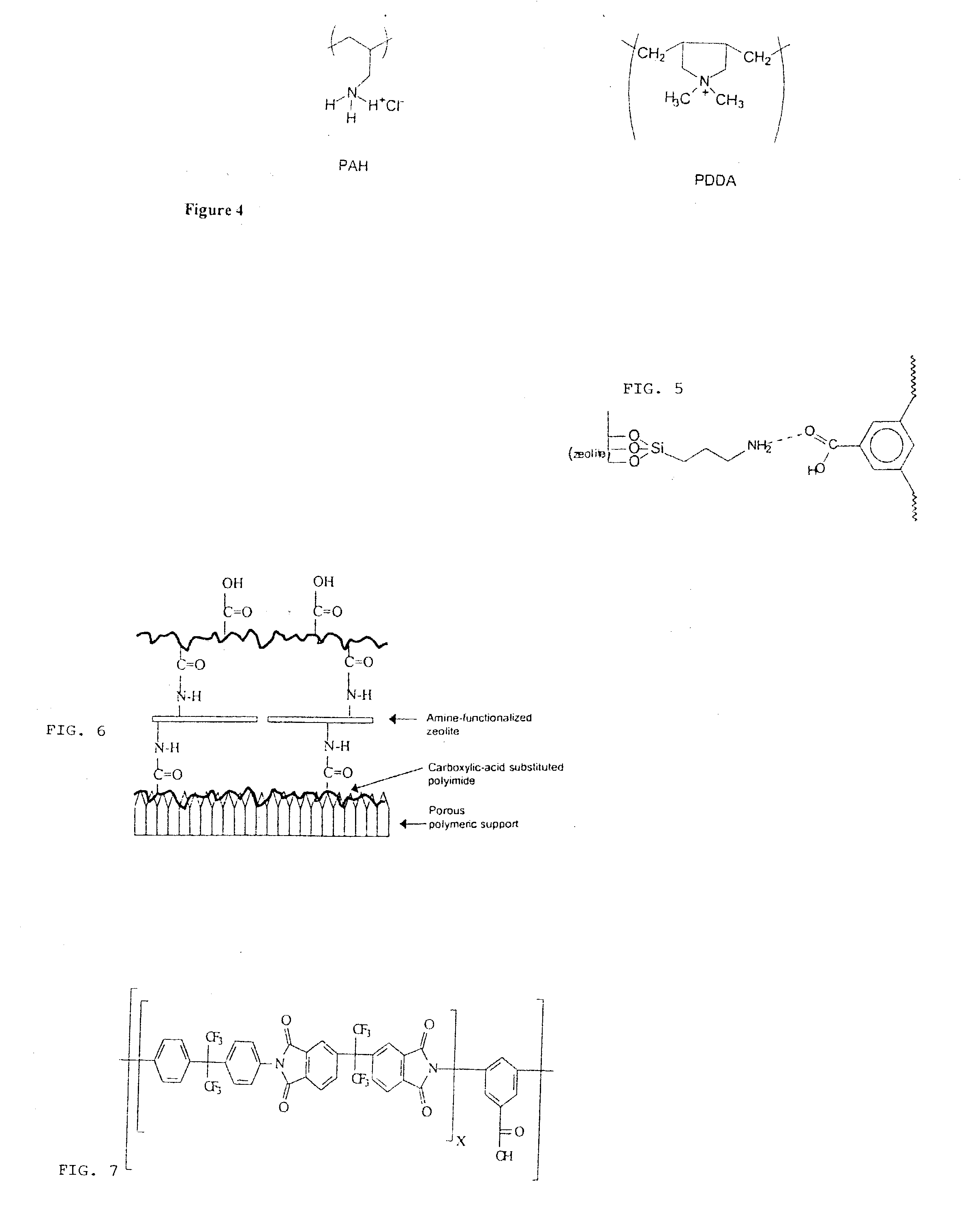

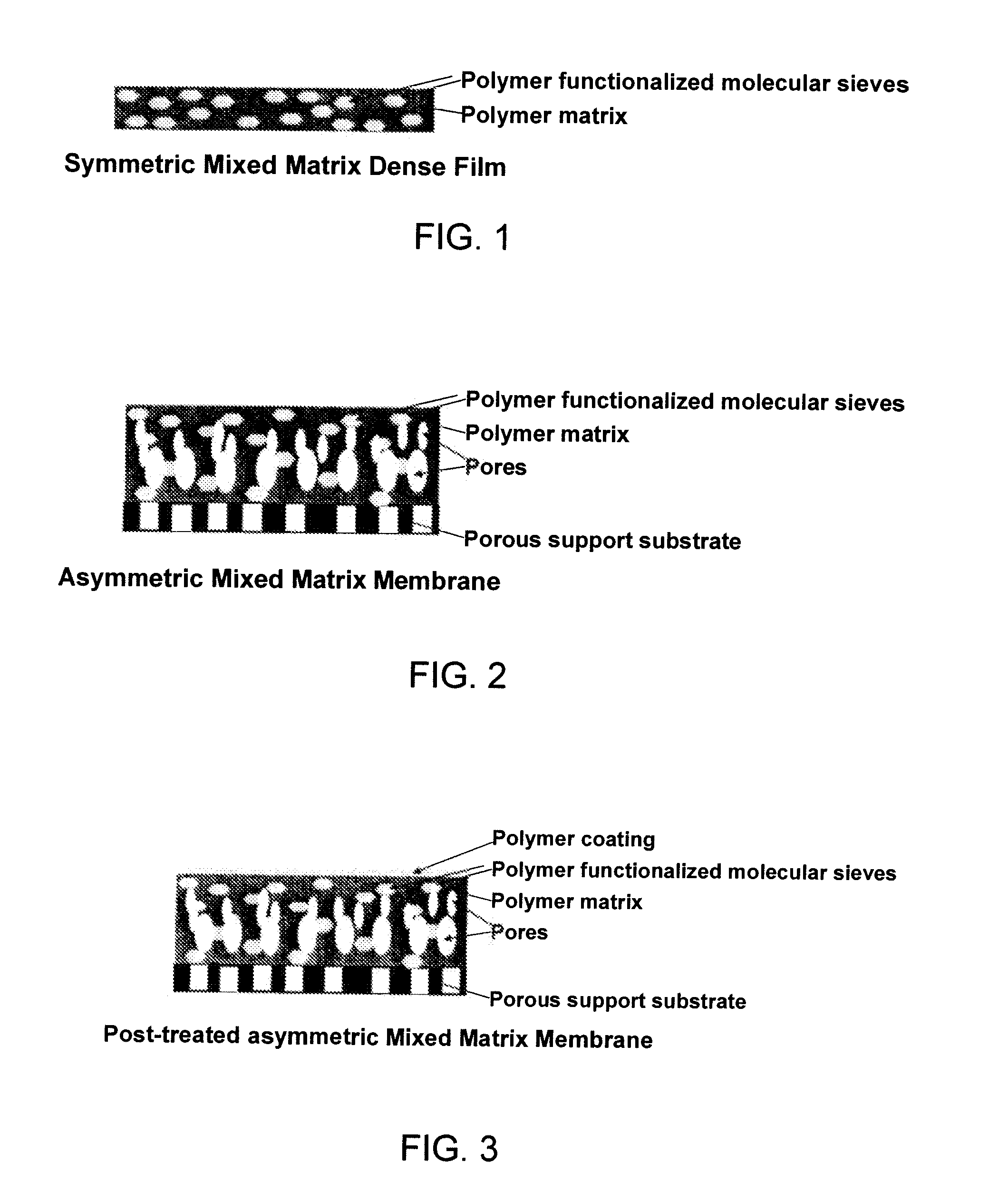

InactiveUS7109140B2Enhanced interactionEffectively incorporated into polymer structureSemi-permeable membranesMembranesFiberHollow fibre

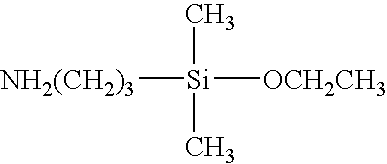

Mixed matrix membranes are prepared from zeolites and polymers, such as polyimides, in a void free fashion where either no voids or voids of less than several Angstroms are present at the interface of the polymer and the zeolite by bonding (hydrogen, ionic, or covalent) functional groups on the zeolite with functional groups on the polymer. The mixed matrix membranes may be cast or formed by ISAM processes, and may be present on a variety of supports including hollow fibers.

Owner:VIRGINIA TECH INTPROP INC +1

Mixed matrix membranes

InactiveUS20030220188A1High selectivityIncrease productivitySemi-permeable membranesMembranesFiberHollow fibre

Mixed matrix membranes are prepared from zeolites and polymers, such as polyimides, in a void free fashion where either no voids or voids of less than several Angstroms are present at the interface of the polymer and the zeolite by bonding (hydrogen, ionic, or covalent) functional groups on the zeolite with functional groups on the polymer. The mixed matrix membranes may be cast or formed by ISAM processes, and may be present on a variety of supports including hollow fibers.

Owner:VIRGINIA TECH INTPROP INC +1

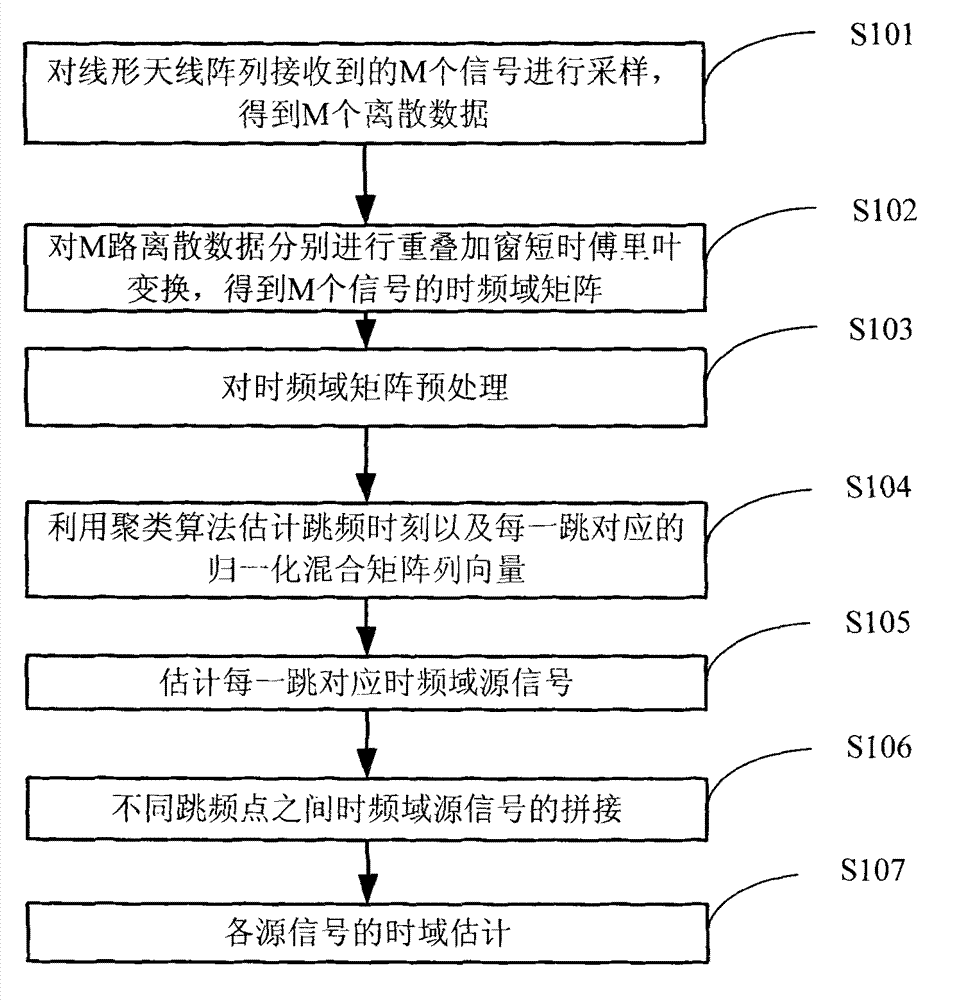

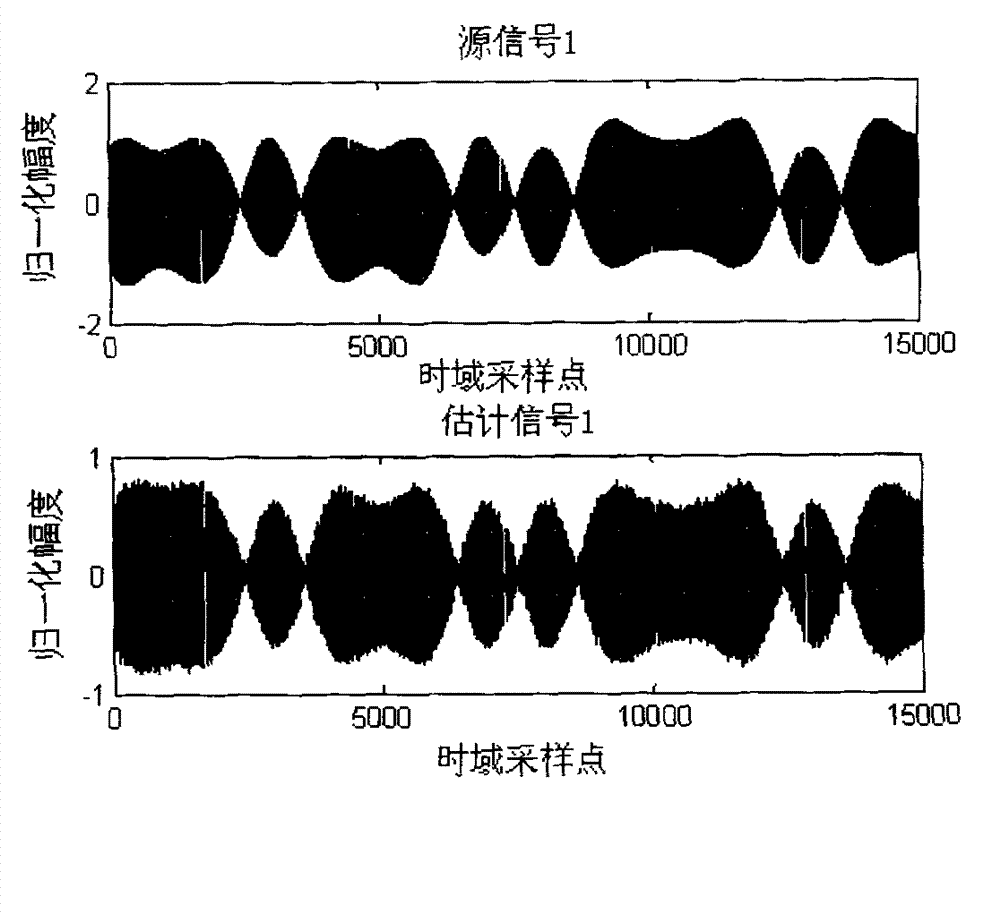

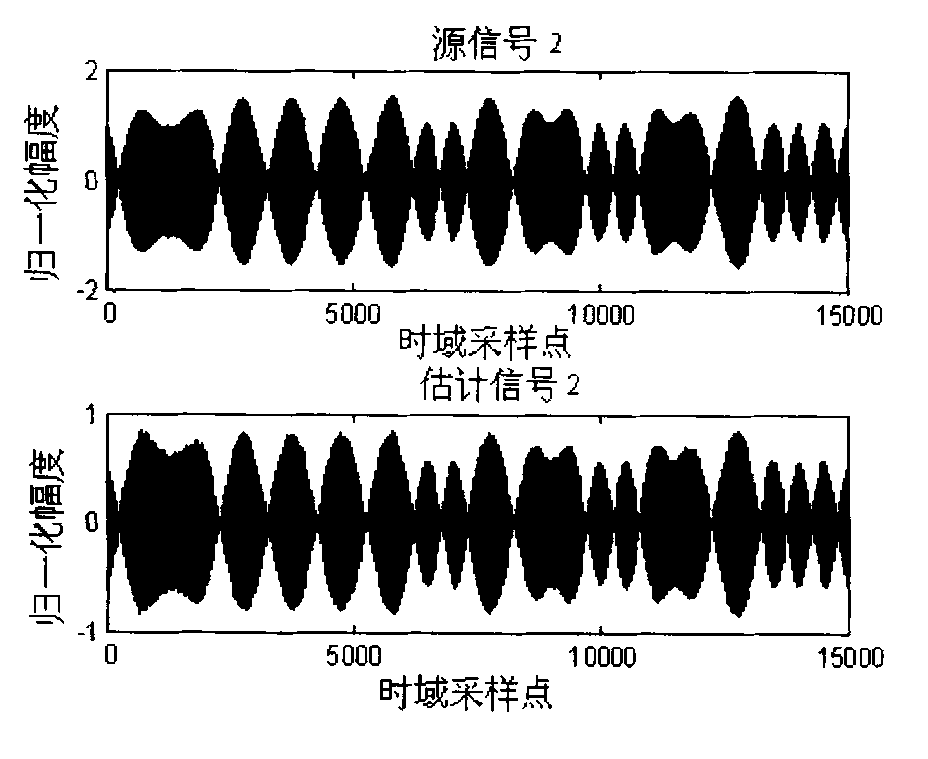

Clustering-based blind source separation method for synchronous orthogonal frequency hopping signals

InactiveCN103051367ASmall amount of calculationEasy to implementSpatial transmit diversityMulti-frequency code systemsTime domainDiscrete time domain

The invention discloses a clustering-based blind source separation method for synchronous orthogonal frequency hopping signals. The method comprises the following steps of: acquiring M sampled paths of discrete time-domain mixed signals; obtaining M time-frequency domain matrixes of the mixed signals; preprocessing the time-frequency domain matrixes of the frequency hopping mixed signals; estimating frequency hopping moments, normalized mixed matrix column vectors and frequency hopping frequency; estimating time-frequency domain frequency hopping source signals by utilizing the estimated normalized mixed matrix column vectors; splicing the time-frequency domain frequency hopping source signals between different frequency hopping points; and recovering time-domain source signals according to time-frequency domain estimate values of the source signals. According to the method, the frequency hopping source signals are estimated only according to the received mixed signals of a plurality of frequency hopping signals under the condition of unknown channel information, and the frequency hopping signals can be subjected to blind estimation under the condition that the number of receiving antennae is smaller than that of the source signals; short-time Fourier transform is utilized, so that the method is low in computation amount; and the frequency hopping signals are subjected to blind separation, and meanwhile, a part of parameters can also be estimated, so that the method is high in practicability.

Owner:XIDIAN UNIV

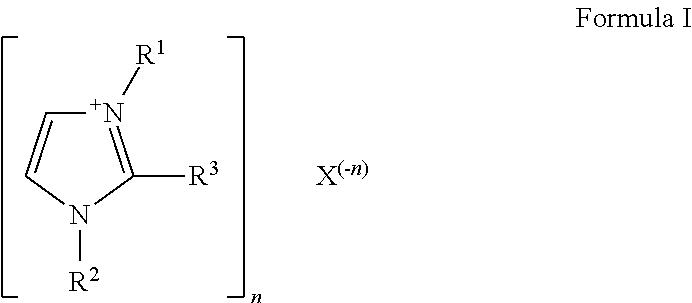

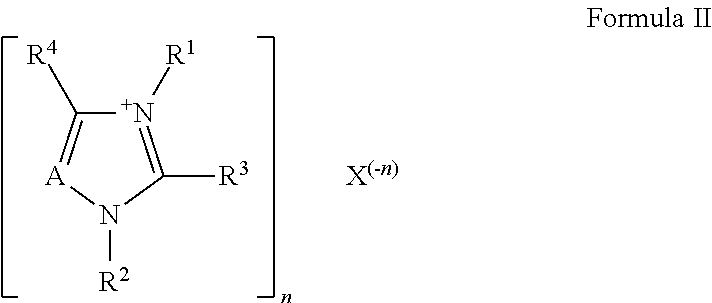

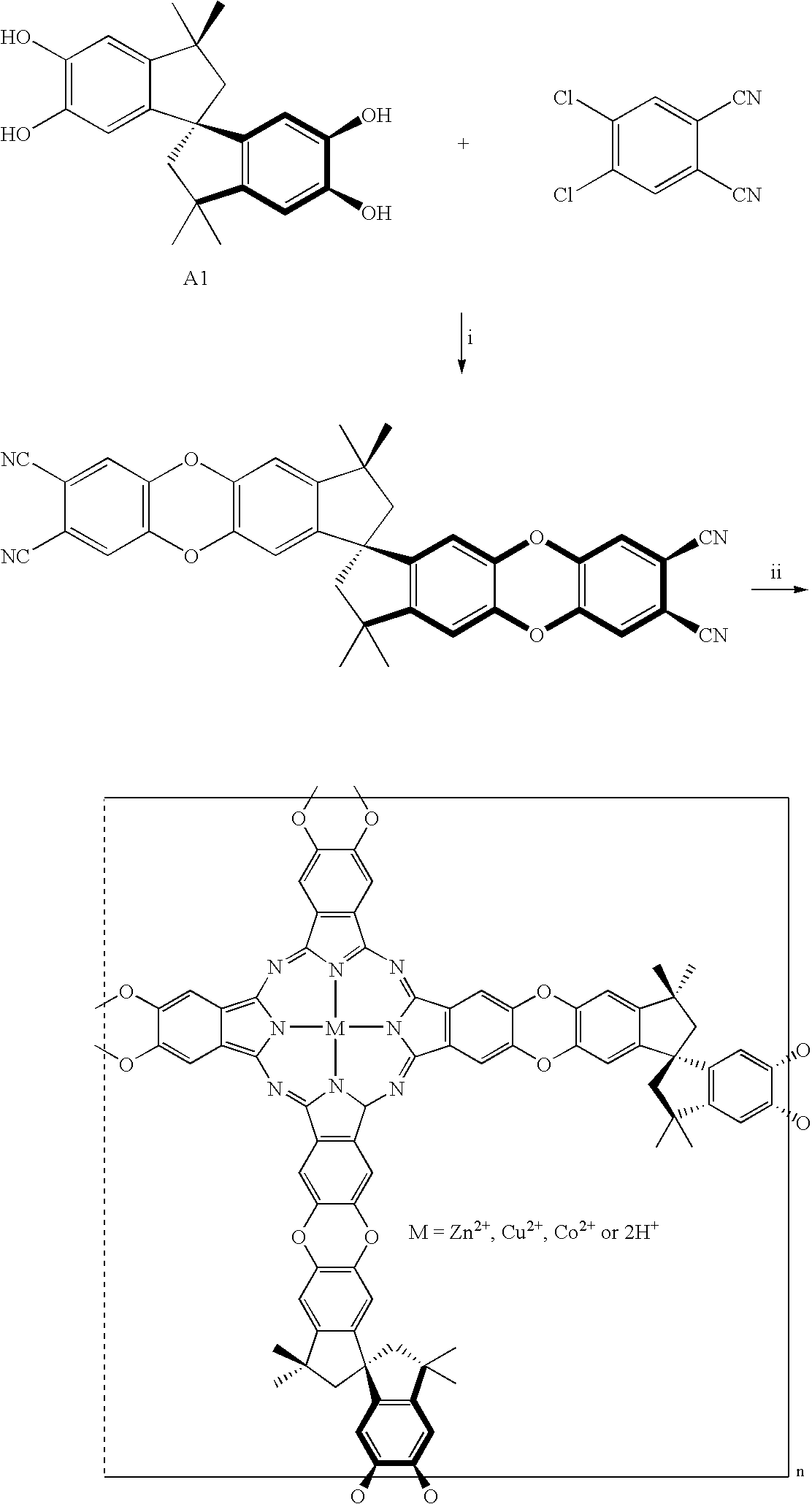

Ionic liquid-solid-polymer mixed matrix membranes for gas separations

InactiveUS7943543B1Good chemical stabilityImprove solubilitySemi-permeable membranesMembranesFlue gasMCM-41

New ionic liquid-solid-polymer mixed matrix membranes were proposed for gas separations such as CO2 removal from natural gas or N2. For the new mixed matrix membranes, the solids such as carbon molecular sieves, microporous molecular sieves, MCM-41 type of mesoporous molecular sieves, or polymer of intrinsic microporosity (PIM) are coated (or impregnated) with ionic liquids such as 1-butyl-3-methyl imidazolium bis[trifluoromethylsulfonyl]amide. The ionic liquids coated or impregnated solids are then dispersed in the continuous polymer matrix to form mixed matrix membranes. These hybrid mixed matrix membranes will combine the properties of the continuous polymer phase, the ionic liquids, and the dispersed ionic liquids coated or impregnated solids phase, which will possibly open up new opportunities for gas separation processes such as CO2 separation from natural gas or flue gas.

Owner:UOP LLC

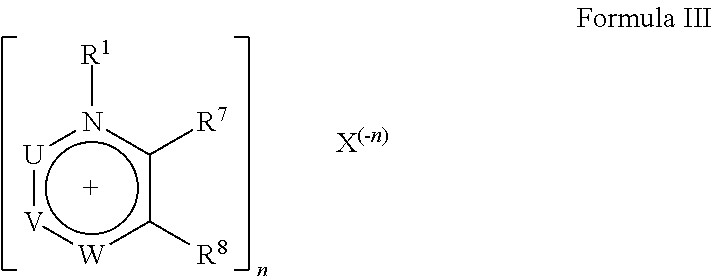

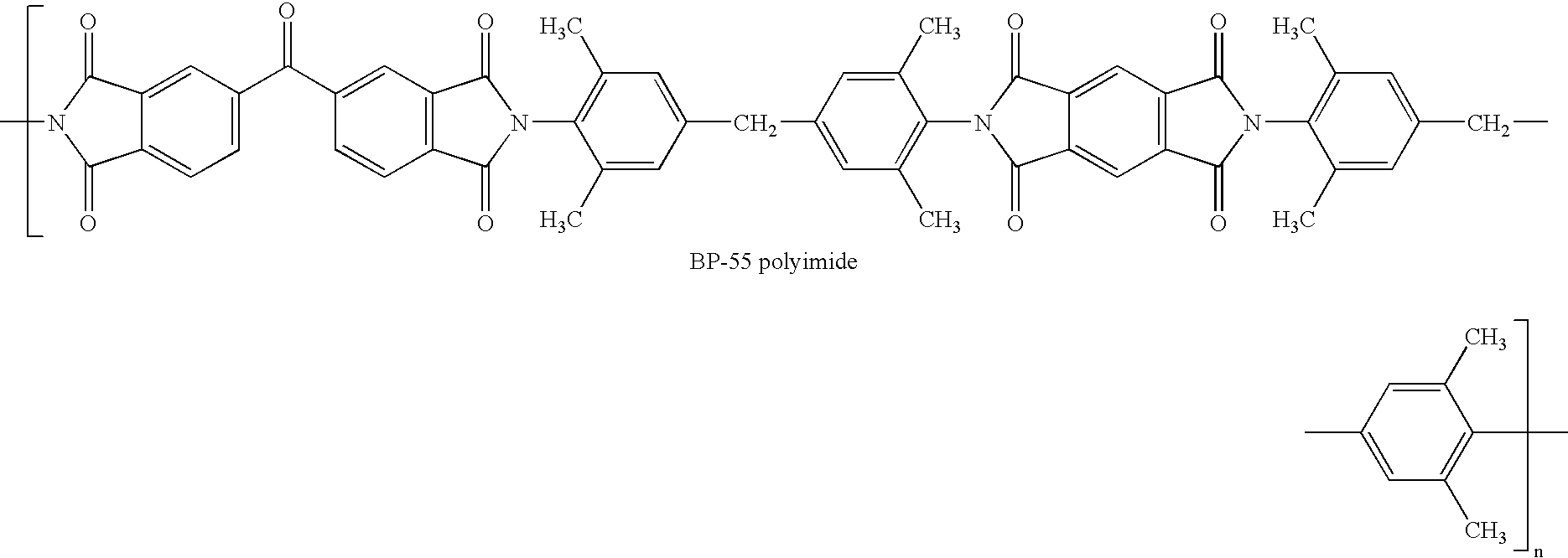

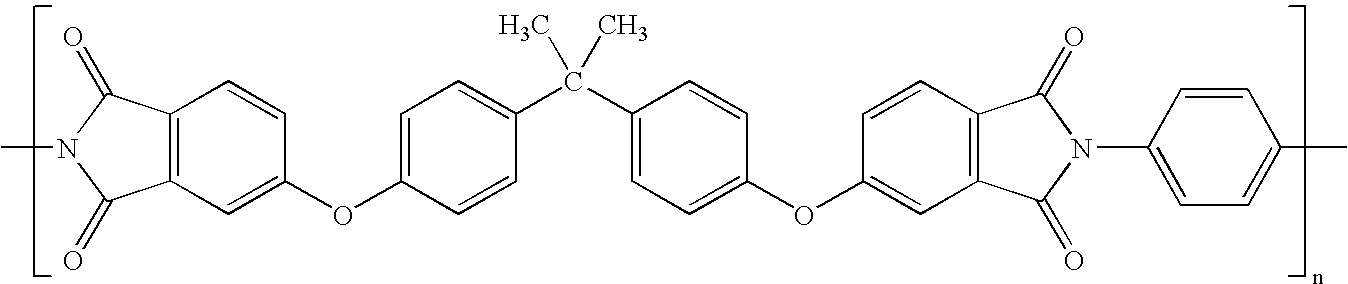

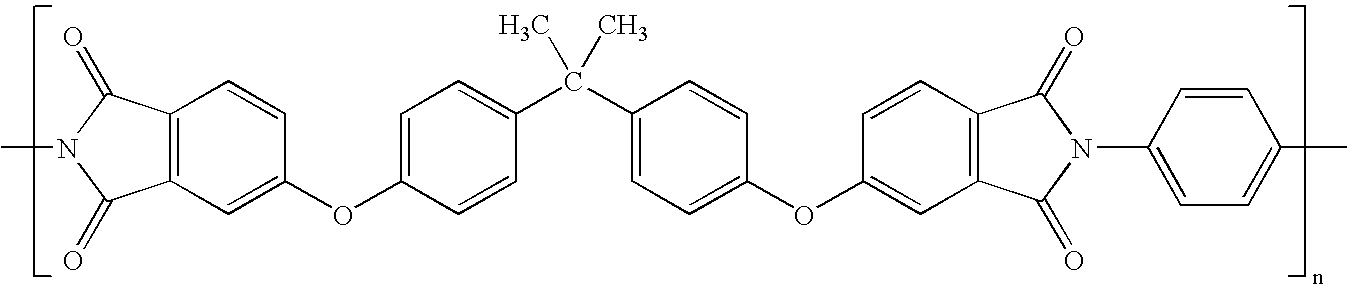

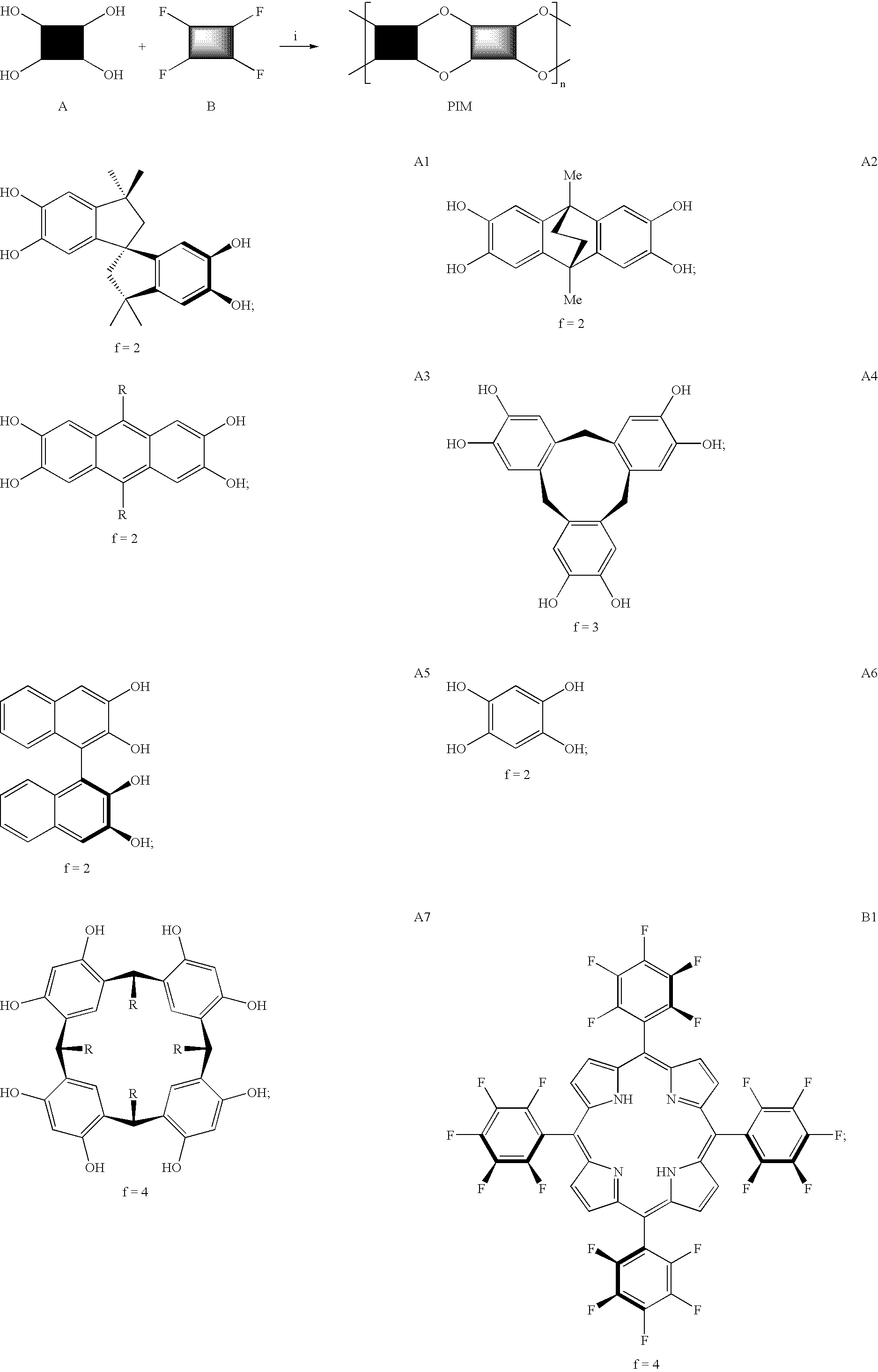

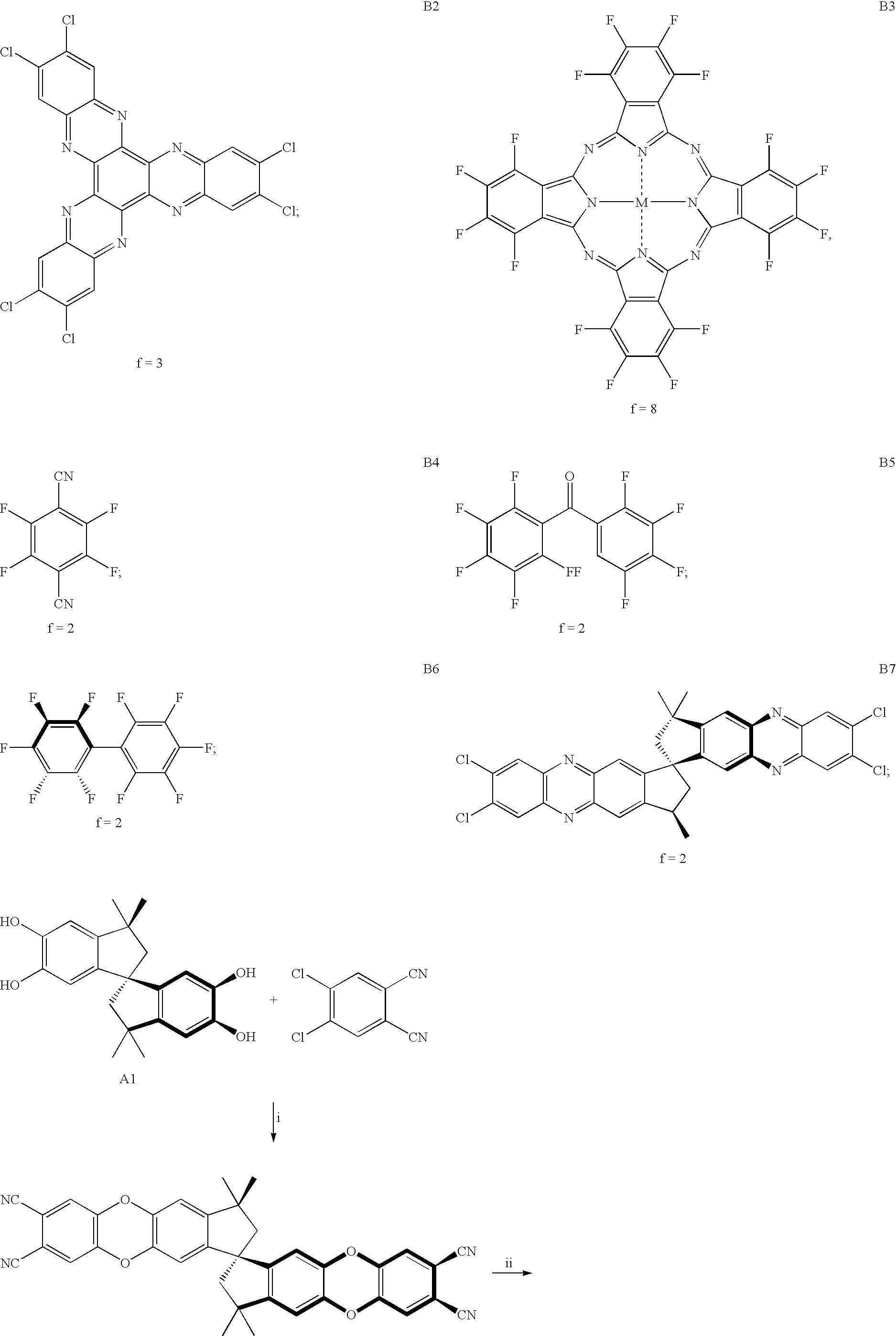

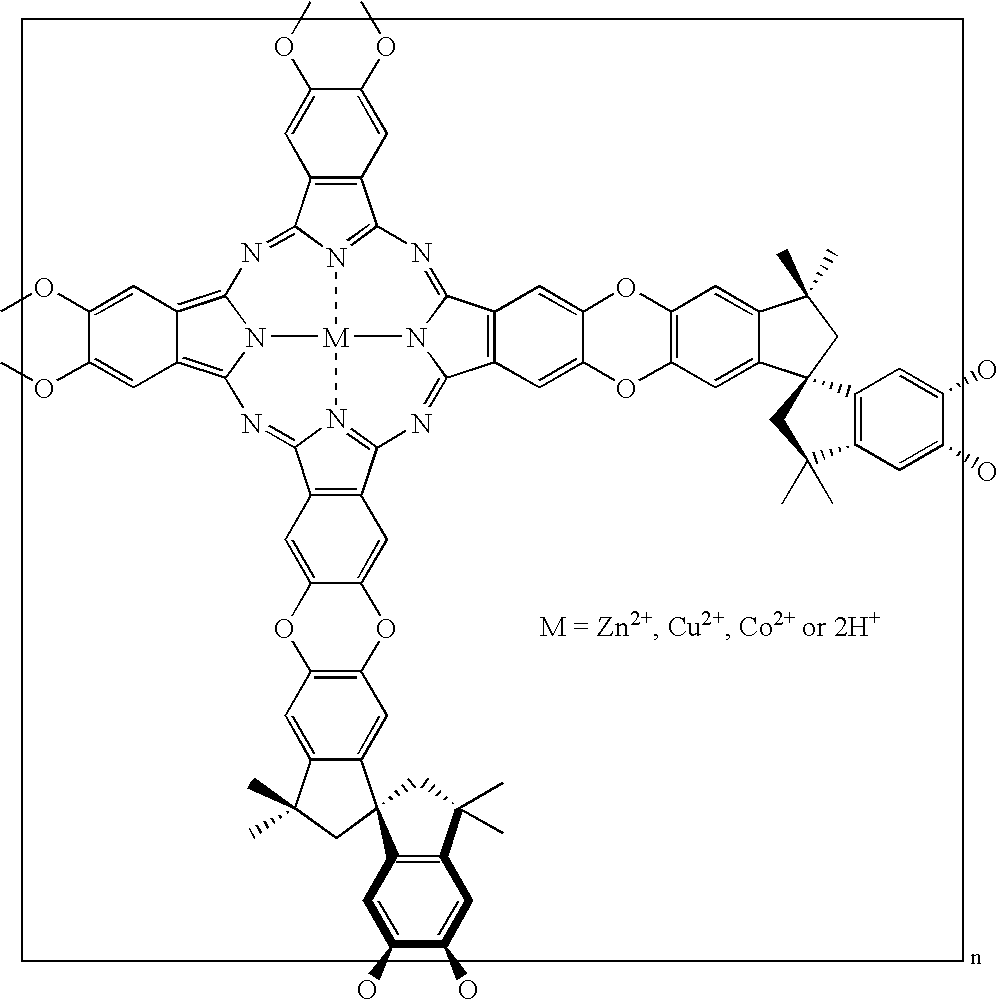

Cross-linkable and cross-linked mixed matrix membranes and methods of making the same

InactiveUS7485173B1High selectivityImprove permeabilitySemi-permeable membranesMembranesMolecular sieveCross-link

The present invention is for novel high performance cross-linkable and cross-linked mixed matrix membranes and the use of such membranes for separations such as for CO2 / CH4, H2 / CH4 and propylene / propane separations. More specifically, the invention involves the preparation of cross-linkable and cross-linked mixed matrix membranes (MMMs). The cross-linkable MMMs were prepared by incorporating microporous molecular sieves or soluble high surface area microporous polymers (PIMs) as dispersed microporous fillers into a continuous cross-linkable polymer matrix. The cross-linked MMMs were prepared by UV-cross-linking the cross-linkable MMMs containing cross-linkable polymer matrix such as BP-55 polyimide. Pure gas permeation test results demonstrated that both types of MMMs exhibited higher performance for CO2 / CH4 and H2 / CH4 separations than those of the corresponding cross-linkable and cross-linked pure polymer matrices.

Owner:UOP LLC

Mixed matrix membranes with small pore molecular sieves and methods for making and using the membranes

Owner:CHEVROU USA INC

Metal organic framework polymer mixed matrix membranes

InactiveCN102652035AReduces hydrocarbon fouling problemsImprove separation permeability performanceSemi-permeable membranesGas treatmentCo2 removalPolymer science

Metal-organic framework (MOF)-polymer mixed matrix membranes (MOF-MMMs) can be prepared by dispersing high surface area MOFs into a polymer matrix. The MOFs allow the polymer to infiltrate the pores of the MOFs, which improves the interfacial and mechanical properties of the polymer and in turn affects permeability. These mixed matrix membranes are attractive candidates for practical gas separation applications such as CO2 removal from natural gas.

Owner:UOP LLC

Mixed matrix membrane with mesoporous particles and methods for making and using the same

InactiveUS20060107830A1More productivity per unit costImprove the level ofSemi-permeable membranesIsotope separationPorous particleMembrane configuration

A mixed matrix membrane for separating gas components from a mixture of gas components is disclosed. The membrane comprises a continuous phase polymer with inorganic porous particles, preferably molecular sieves, interspersed in the polymer. The polymer has a CO2 / CH4 selectivity of at least 20 and the porous particles have a mesoporosity of at least 0.1 cc STP / g. The mixed matrix membrane exhibits an increase in permeability of least 30% with any decrease in selectivity being no more than 10% relative to a membrane made of the neat polymer. The porous particles may include, but are not limited to, molecular sieves such as CVX-7 and SSZ-13, and / or other molecular sieves having the required mesoporosity. A method for making the mixed matrix membrane is also described. Further, a method is disclosed for separating gas components from a mixture of gas components using the mixed matrix membrane with mesoporous particles.

Owner:CHEVROU USA INC

Orchid aseptic sowing and test tube seedling propagation method and broad-spectrum culture medium adopted

InactiveCN102283114ARapid emergenceSeedlings of good qualityHorticulture methodsPlant tissue cultureHigh rateShoot

The invention discloses a breeding method for aseptic seeding and test tube seedling formation of orchids and the adopted broad-spectrum culture medium. In this method, a healthy orchid mother plant is selected, and artificially pollinated when it blooms, and the fruit that develops to maturity after pollination and has not cracked is used as an explant, or the orchid fruit that is basically mature and not cracked is taken from the wild as an explant. Implants undergo reproductive steps such as aseptic sowing, seed germination, strong seedling cultivation, and test-tube seedling transplantation. The specially prepared medium is used for aseptic sowing and seed germination to obtain small plants, and then the small plants are cultivated on the specially prepared strong seedling medium, and the seedlings are hardened under natural light in the greenhouse for 7-14 hours before being released from the bottle. One day, the test-tube seedlings were taken out, the root medium was washed off, and they were planted in a mixed substrate of bark, bluestone and peat, and further cultivated into seedlings. The invention has the characteristics of high seed germination rate, fast seedling growth, good seedling quality, low cost, etc., can obtain a large number of test-tube seedlings in a short period of time, and the transplanting survival rate of the seedlings can be kept above 90%. An effective way can be provided for the production of orchid seedlings.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Mixed matrix membranes with small pore molecular sieves and methods for making and using the membranes

A mixed matrix membrane is provided which comprises a continuous phase organic polymer and small pore molecular sieves dispersed therein. The molecular sieves have a largest minor crystallographic free diameter of 3.6 Angstroms or less. When these molecular sieves are properly interspersed with a continuous phase polymer, the membrane will exhibit a mixed matrix membrane effect, i.e., a selectivity increase of at least 10% relative to a neat membrane containing no molecular sieves. Finally, methods for making and using such mixed matrix membranes to separate gases from a mixture containing two or more gases are also disclosed.

Owner:CHEVROU USA INC

Metal organic framework polymer mixed matrix membranes

InactiveUS20110138999A1Reduce hydrocarbon fouling problemEnhanced gas separation permeability performanceSemi-permeable membranesGas treatmentPolymer scienceMetal-organic framework

Metal-organic framework (MOF)-polymer mixed matrix membranes (MOF-MMMs) can be prepared by dispersing high surface area MOFs into a polymer matrix. The MOFs allow the polymer to infiltrate the pores of the MOFs, which improves the interfacial and mechanical properties of the polymer and in turn affects permeability. These mixed matrix membranes are attractive candidates for practical gas separation applications such as CO2 removal from natural gas.

Owner:UOP LLC

Mixed matrix membranes with low silica-to-alumina ratio molecular sieves and methods for making and using the membranes

InactiveUS7138006B2Low molar ratioReduce contentSemi-permeable membranesIsotope separationMolecular sieveProduct gas

A mixed matrix membrane is provided which comprises a continuous phase organic polymer and small pore alumina containing molecular sieves dispersed therein. The molecular sieves have a silica-to-alumina molar ratio of less than 1.0, more preferably, less than 0.3, and most preferably less than 0.1. In some cases, the molecular sieves have no appreciable amounts of silica. Exemplary compositions include aluminophosphates (AlPO) and silicoaluminophosphates (SAPO). When these molecular sieves are properly interspersed with a continuous phase polymer, the membrane will exhibit a mixed matrix membrane effect, i.e., a selectivity increase of at least 10% relative to a neat membrane containing no molecular sieves. The molecular sieves have pores with a largest minor crystallographic free diameter of 4.0 Angstroms or less. Finally, methods for making and using such mixed matrix membranes to separate gases from a mixture containing two or more gases are also disclosed.

Owner:CHEVROU USA INC

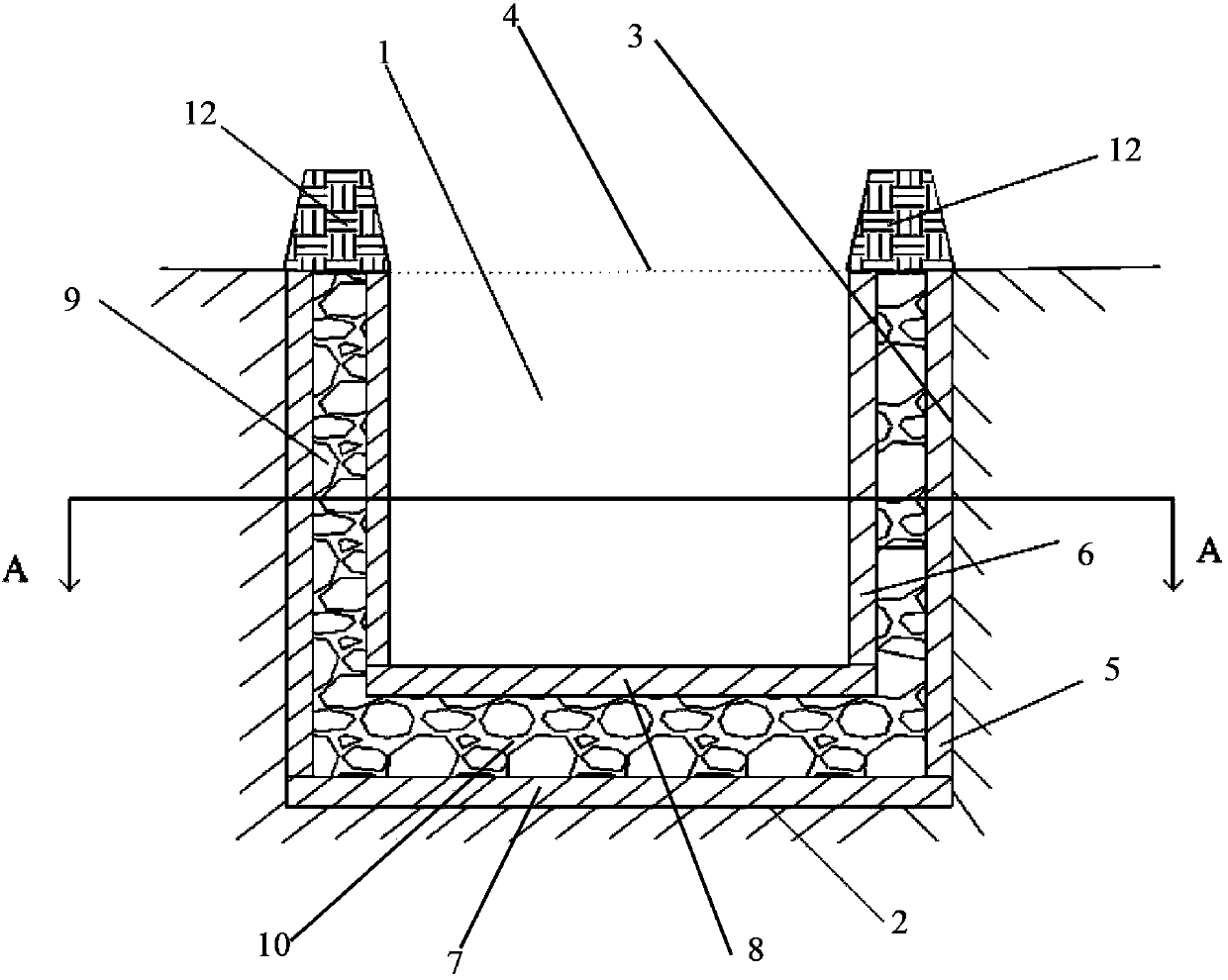

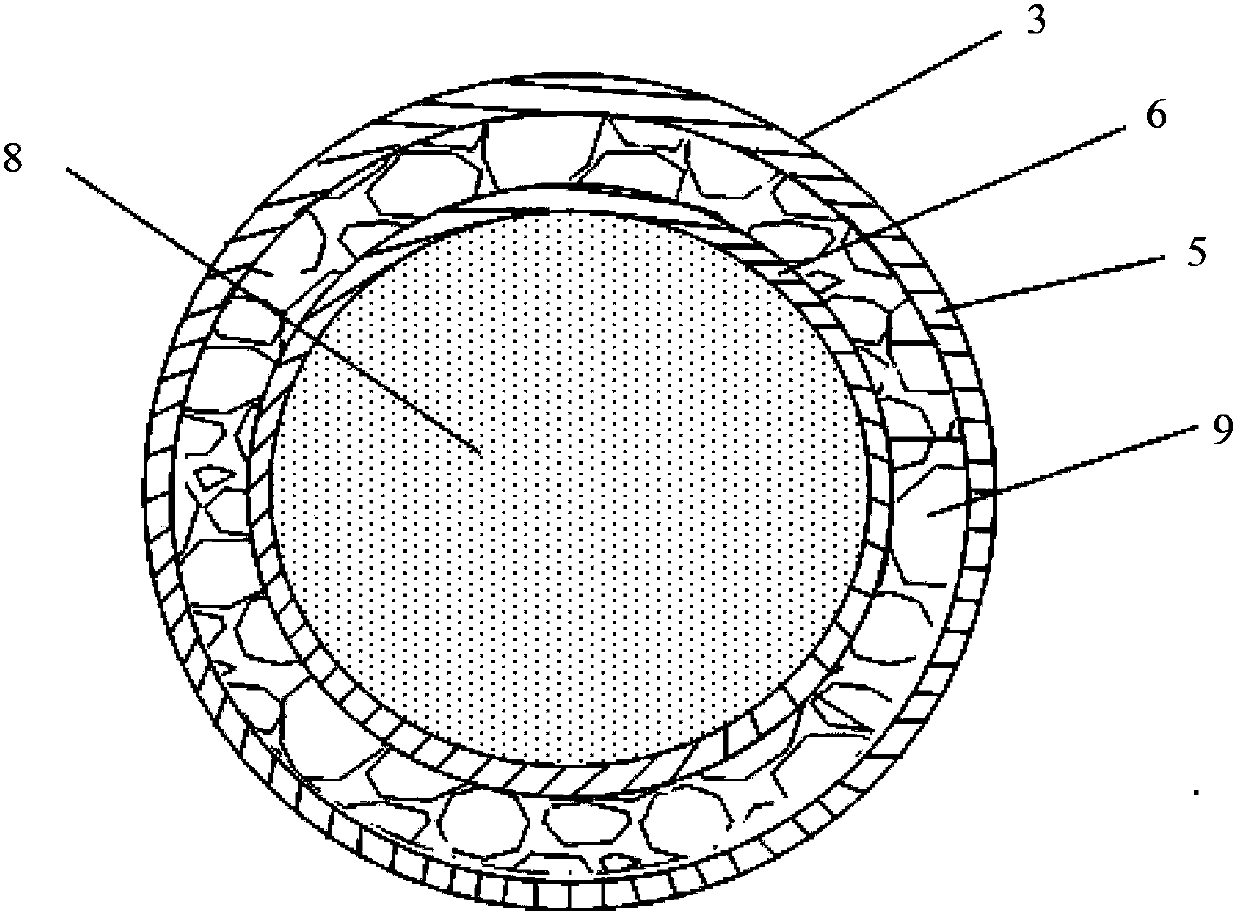

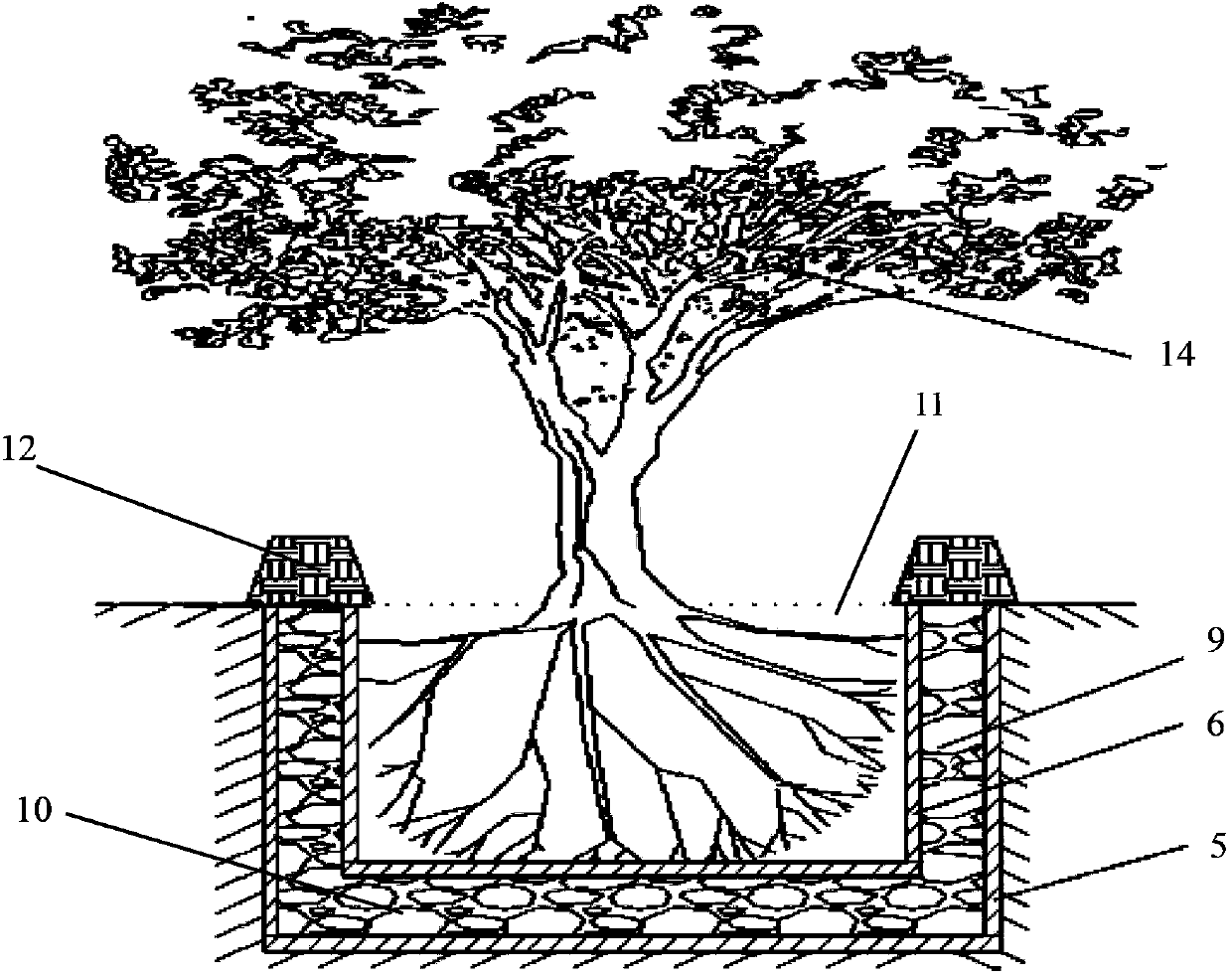

Method for conducting afforestation on saline-alkali soil

ActiveCN103392456ANew comprehensive measures for effective soil reduction and soil improvementLow cost of improvementClimate change adaptationAfforestationRevegetationPlant roots

The invention discloses a method for conducting afforestation on saline-alkali soil. The method includes the steps of firstly, digging deep planting pits in the saline-alkali soil; secondly, paving two layers of isolating curtains at the bottom of each planting pit and the inner wall of each planting pit respectively; thirdly, arranging filtering layers between each isolation layer and the bottom of each planting pit and between each isolating layer and the inner wall of each planting pit; fourthly, preparing mixed matrix, filling the matrix into the pits and tamping down the matrix; fifthly, planting seedlings; sixthly, conducting maintenance management. According to the method for conducting afforestation on the saline-alkali soil, the difficult problems of lowering the salt content, improving the soil and conducting afforestation on the saline-alkali soil are solved. Through the measures of discharging salt and blocking salt, the salt content in the distribution range of the plant root systems is lowered, the plant root systems are promoted to absorb nutrient and water and discharge salt in a unidirectional mode, and a soil environment which is beneficial to plant growth is created. According to the method for conducting afforestation on the saline-alkali soil, the survival rate and the preserving rate of the seedlings are improved, and the method is low in cost compared with a traditional method for improving the saline-alkali soil by merely paving the salt isolating layers, replacing soil and conducting afforestation, is suitable for the saline-alkali soil afforestation and the plant cover recovery project, and can also be used in the manual construction and the machine and human coordinated construction.

Owner:BEIJING QIANJING LANDSCAPE CO LTD

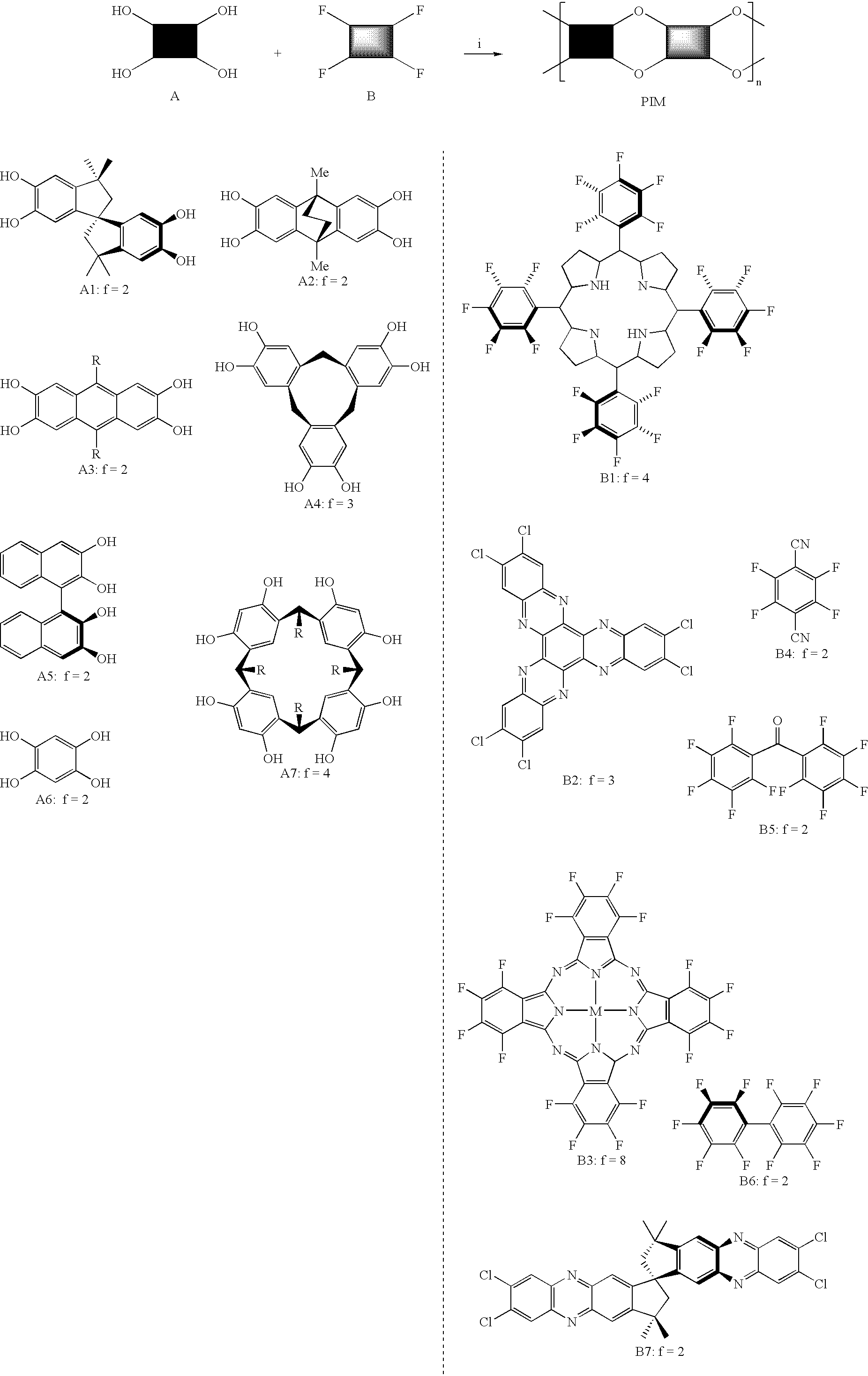

High Flux Mixed Matrix Membranes for Separations

InactiveUS20070209505A1High selectivityIncrease fluxSemi-permeable membranesIsotope separationParaffin waxPetrochemical

The present invention discloses a new class of high flux mixed matrix membranes that are made by incorporating porous inorganic fillers (e.g. microporous and mesoporous molecular sieves, carbon molecular sieves, porous metal-organic frameworks) into a high flux high surface area microporous organic polymer matrix. These microporous organic polymers are referred to as “polymers of intrinsic microporosity” or PIMs. The high flux membranes are promising for a wide range of separations including liquid separations such as pervaporation of phenol / water and also gas separations in the petrochemical, refinery, and natural gas industries such as methane / carbon dioxide, olefin / paraffin and iso / normal paraffins separations.

Owner:UOP LLC

Method for Making High Performance Mixed Matrix Membranes

InactiveUS20090149565A1Good flexibilityHigh mechanical strengthMembranesSemi-permeable membranesFiberHollow fibre

Owner:UOP LLC

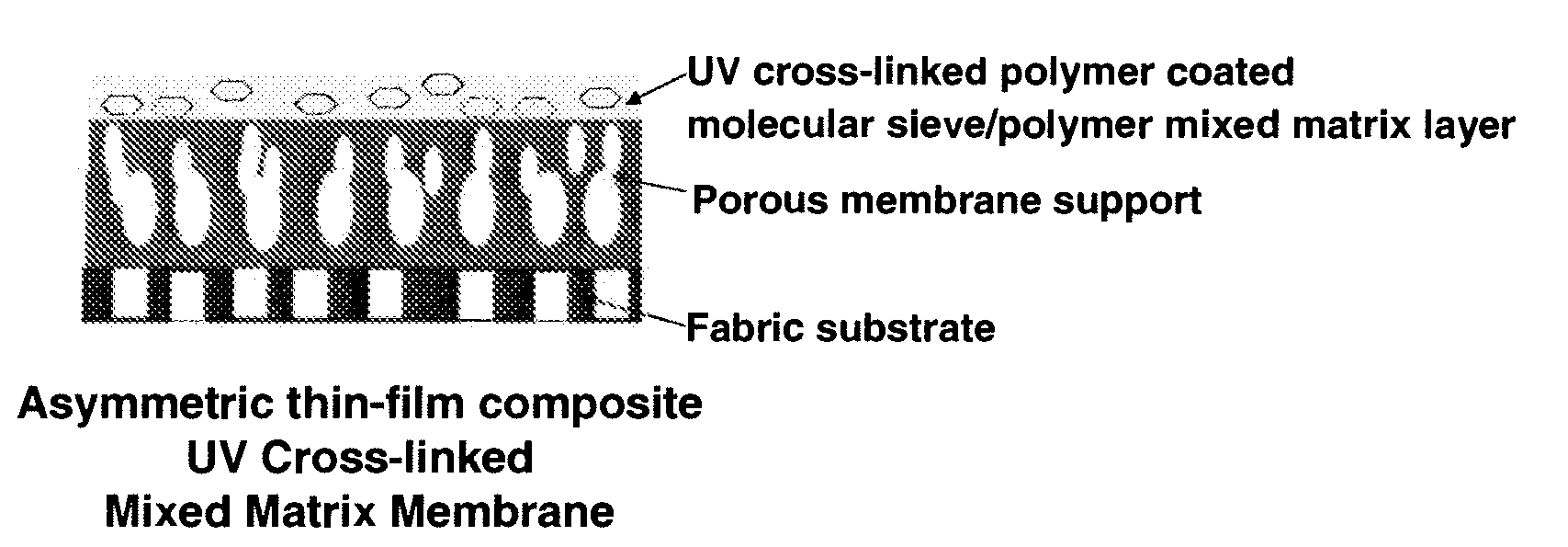

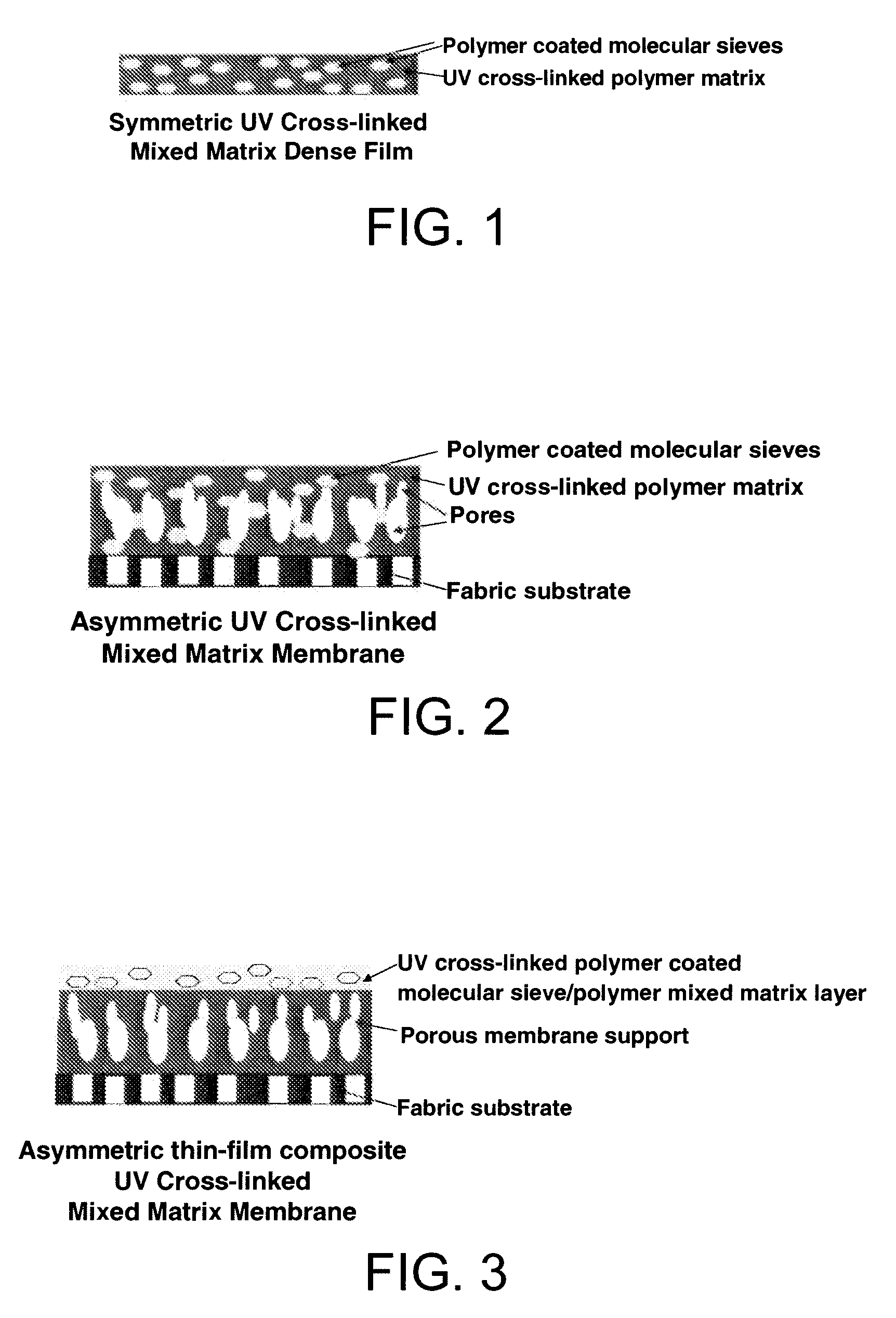

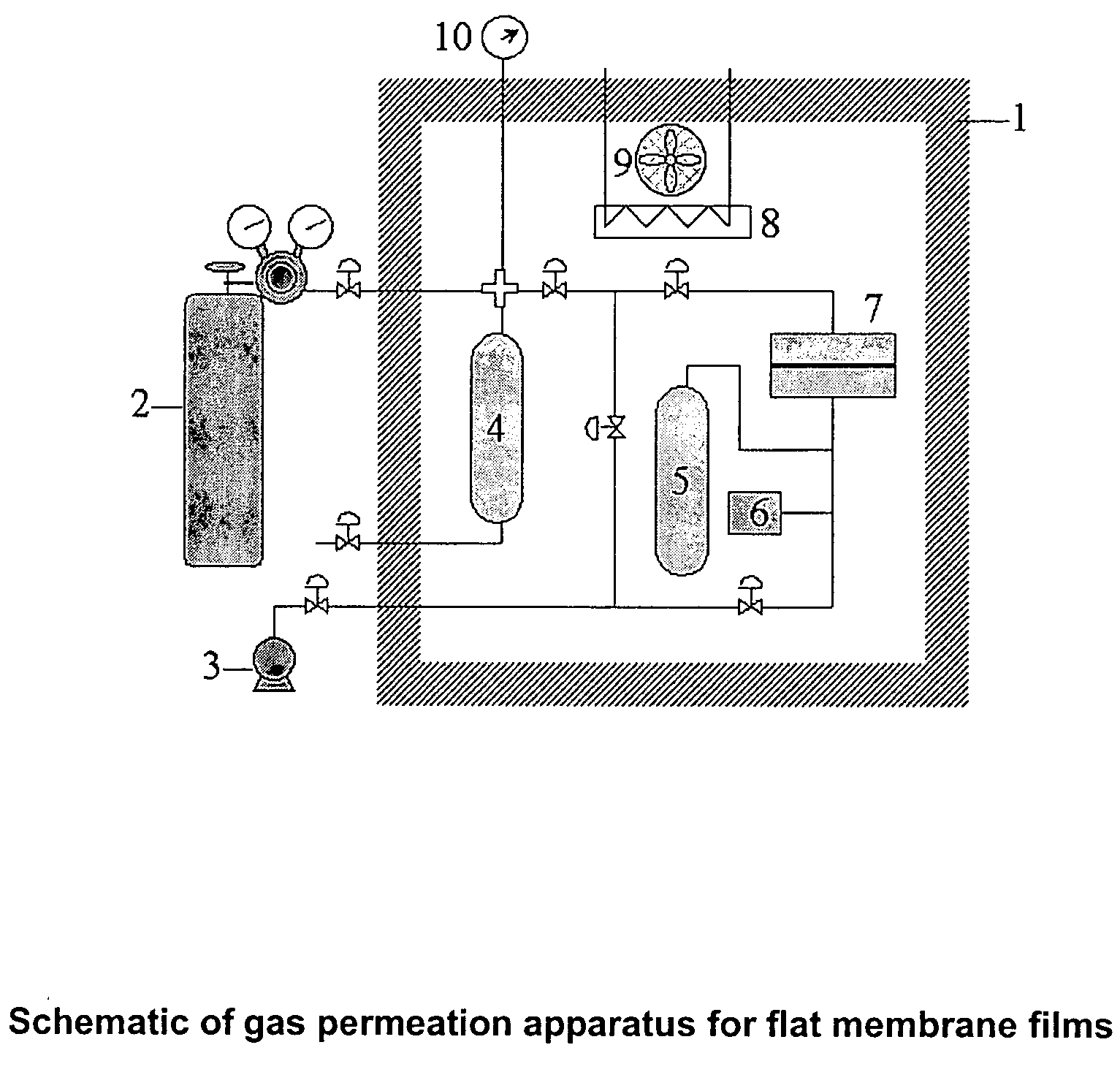

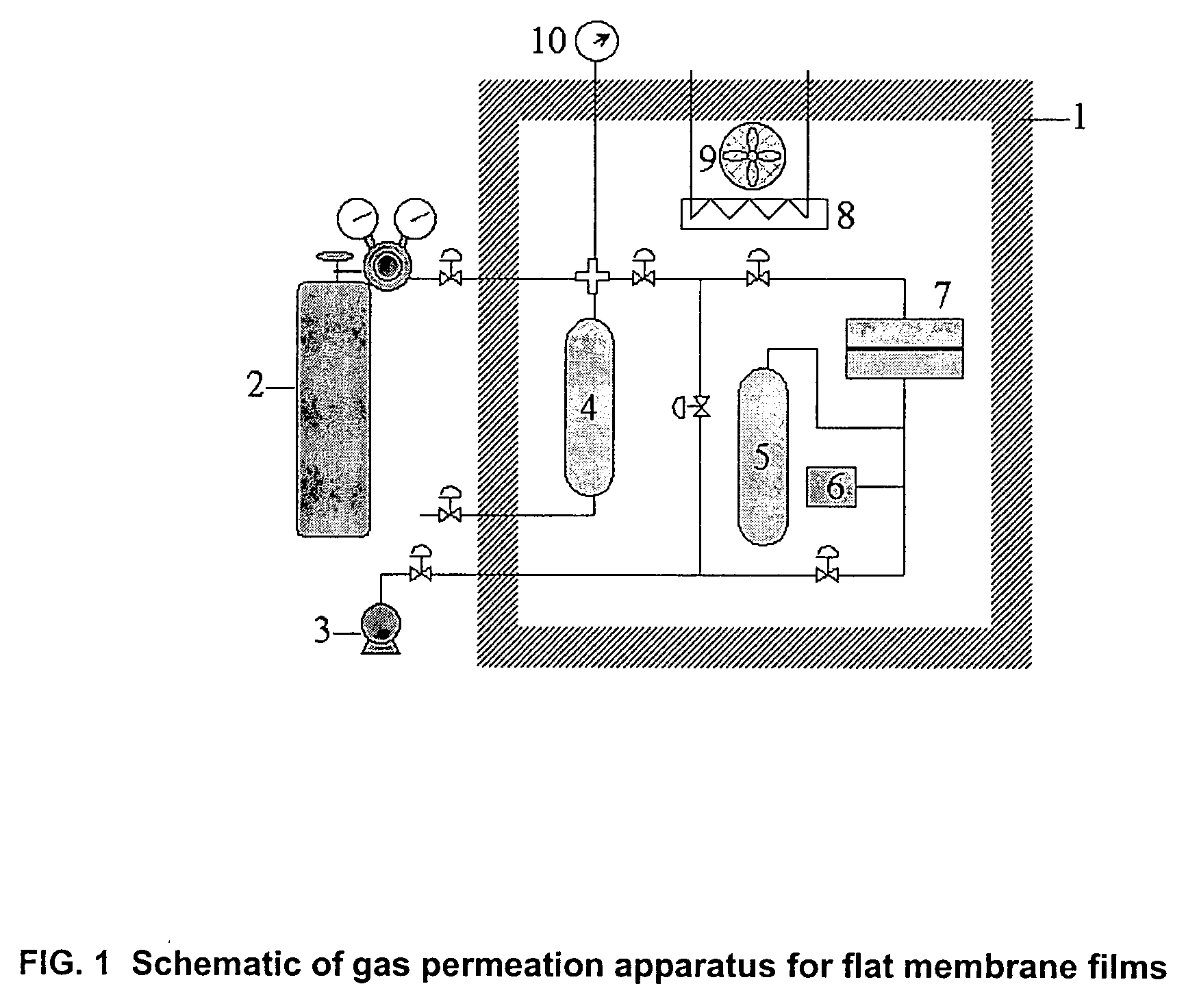

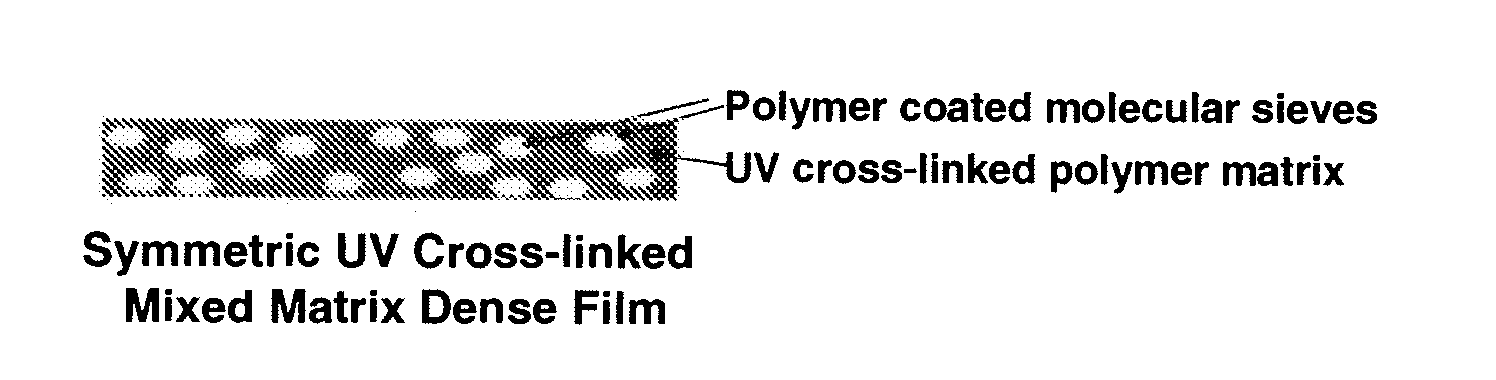

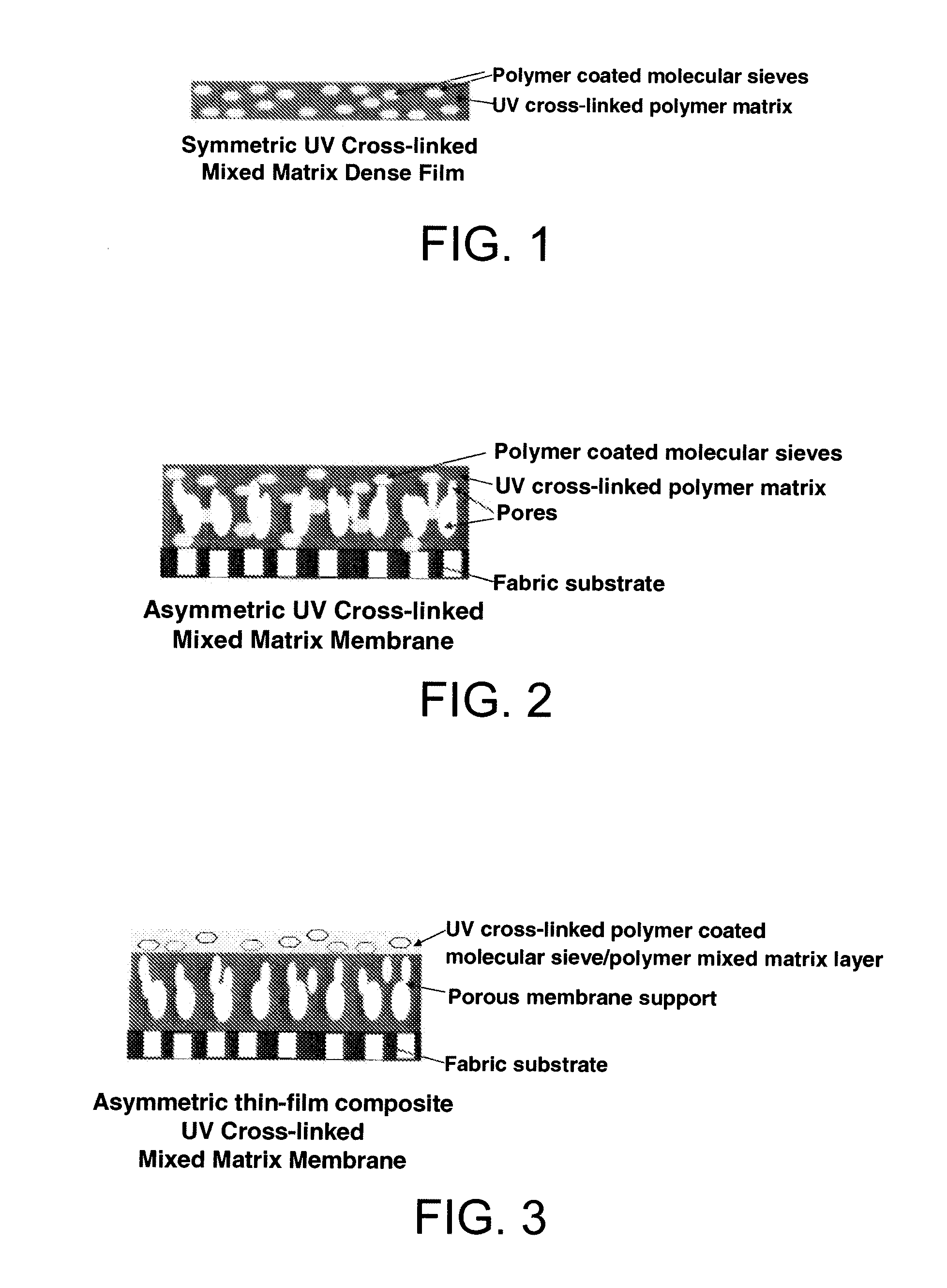

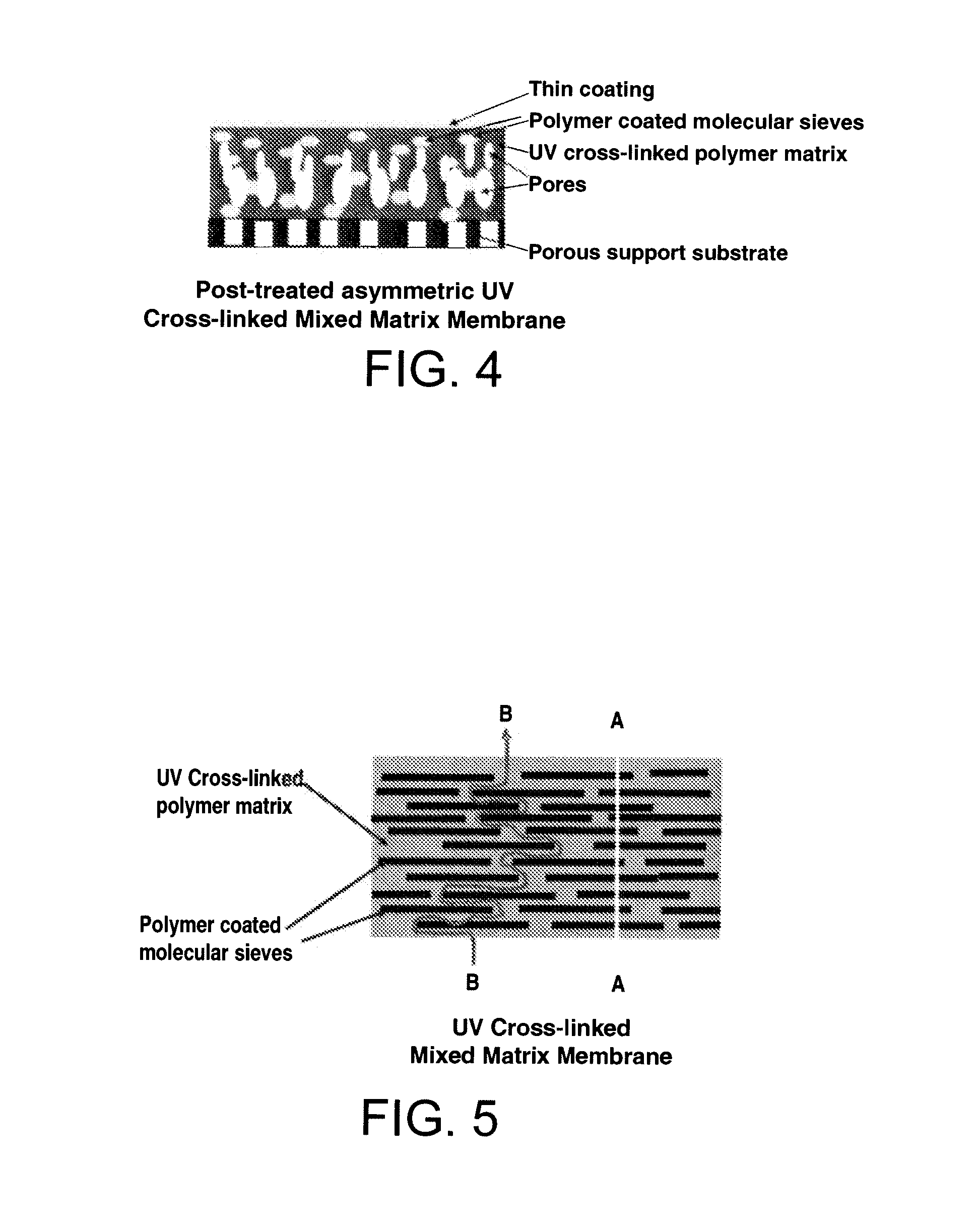

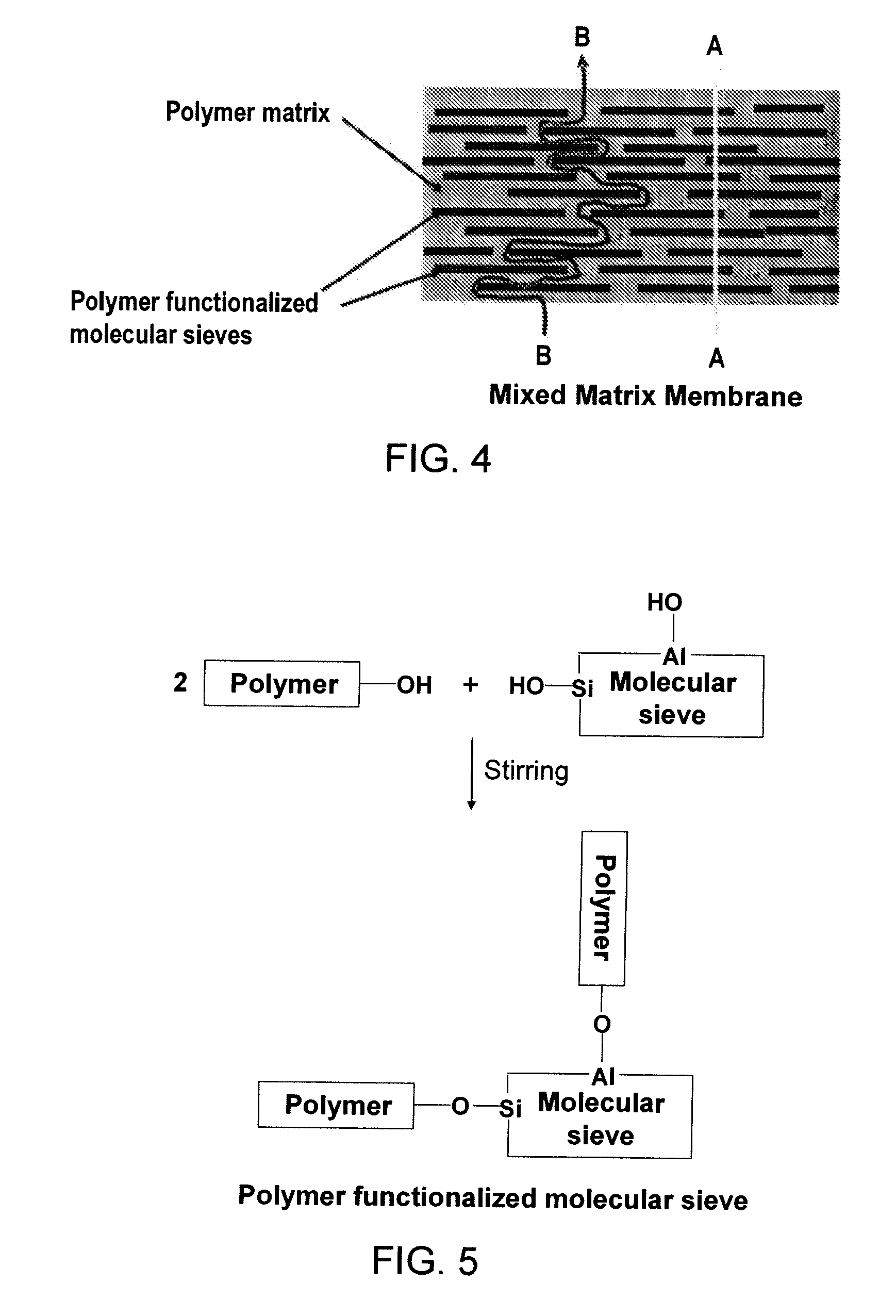

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

Mixed Matrix Membranes Containing Ion-Exchanged Molecular Sieves

InactiveUS20100018926A1Improve permeabilityHigh selectivityMembranesIsotope separationFiberReverse osmosis

The present invention discloses mixed matrix membranes (MMMs) comprising ion-exchanged molecular sieves such as UZM-5 zeolite ion-exchanged with Li+ cation (Li-UZM-5) and a continuous polymer matrix and methods for making and using these membranes. These MMMs, comprising ion-exchanged molecular sieves, in the form of symmetric dense films, asymmetric flat sheets, asymmetric hollow fibers, or thin-film composites, have exhibited simultaneously increased selectivity and permeability (or permeance) over polymer-only membranes and the mixed matrix membranes made from molecular sieves that have not been ion exchanged for gas separations. These MMMs are suitable for a variety of liquid, gas, and vapor separations such as desalination of water by reverse osmosis, deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

Mixed matrix membranes with low silica-to-alumina ratio molecular sieves and methods for making and using the membranes

InactiveUS20050139065A1Low silica contentGood choiceSemi-permeable membranesIsotope separationMolecular sieveSilicon dioxide

A mixed matrix membrane is provided which comprises a continuous phase organic polymer and small pore alumina containing molecular sieves dispersed therein. The molecular sieves have a silica-to-alumina molar ratio of less than 1.0, more preferably, less than 0.3, and most preferably less than 0.1. In some cases, the molecular sieves have no appreciable amounts of silica. Exemplary compositions include aluminophosphates (AIPO) and silicoaluminophosphates (SAPO). When these molecular sieves are properly interspersed with a continuous phase polymer, the membrane will exhibit a mixed matrix membrane effect, i.e., a selectivity increase of at least 10% relative to a neat membrane containing no molecular sieves. The molecular sieves have pores with a largest minor crystallographic free diameter of 4.0 Angstroms or less. The molecular sieves may be selected from the group having IZA structure types including AEI, CHA, ERI, LEV, AFX, AFT, and GIS. Examples of preferred molecular sieves include: AIPO-18, SAPO-18, AIPO-34, SAPO-34, SAPO-44, SAPO-47, AIPO-17, SAPO-17, CVX-7, SAPO-35, SAPO-56, ALPO-52, and SAPO-43. Finally, methods for making and using such mixed matrix membranes to separate gases from a mixture containing two or more gases are also disclosed.

Owner:CHEVROU USA INC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080296527A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPliability

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

High Performance Mixed Matrix Membranes Incorporating at Least Two Kinds of Molecular Sieves

InactiveUS20090120875A1High selectivityNot to damageMembranesSemi-permeable membranesMolecular sievePolymer science

The present invention discloses a new type of high performance mixed matrix membranes (MMMs) and methods for making and using the same. The MMMs comprise a continuous polymer matrix and at least two types of molecular sieves dispersed therein. The continuous polymer matrix in the MMM contains at least one type of polymer. The MMM in the form of a dense film, asymmetric flat sheet membrane or otherwise prepared exhibits simultaneously improved selectivity and permeability for gas separations compared to polymer membranes made from a continuous polymer matrix without any molecular sieves or with only one type of molecular sieve. MMMs of the present invention are suitable for a wide range of gas, vapor, and liquid separations such as alcohol / water, CO2 / CH4, H2 / CH4, O2 / N2, CO2 / N2, olefin / paraffin, iso / normal paraffins, and other light gases separations.

Owner:UOP LLC

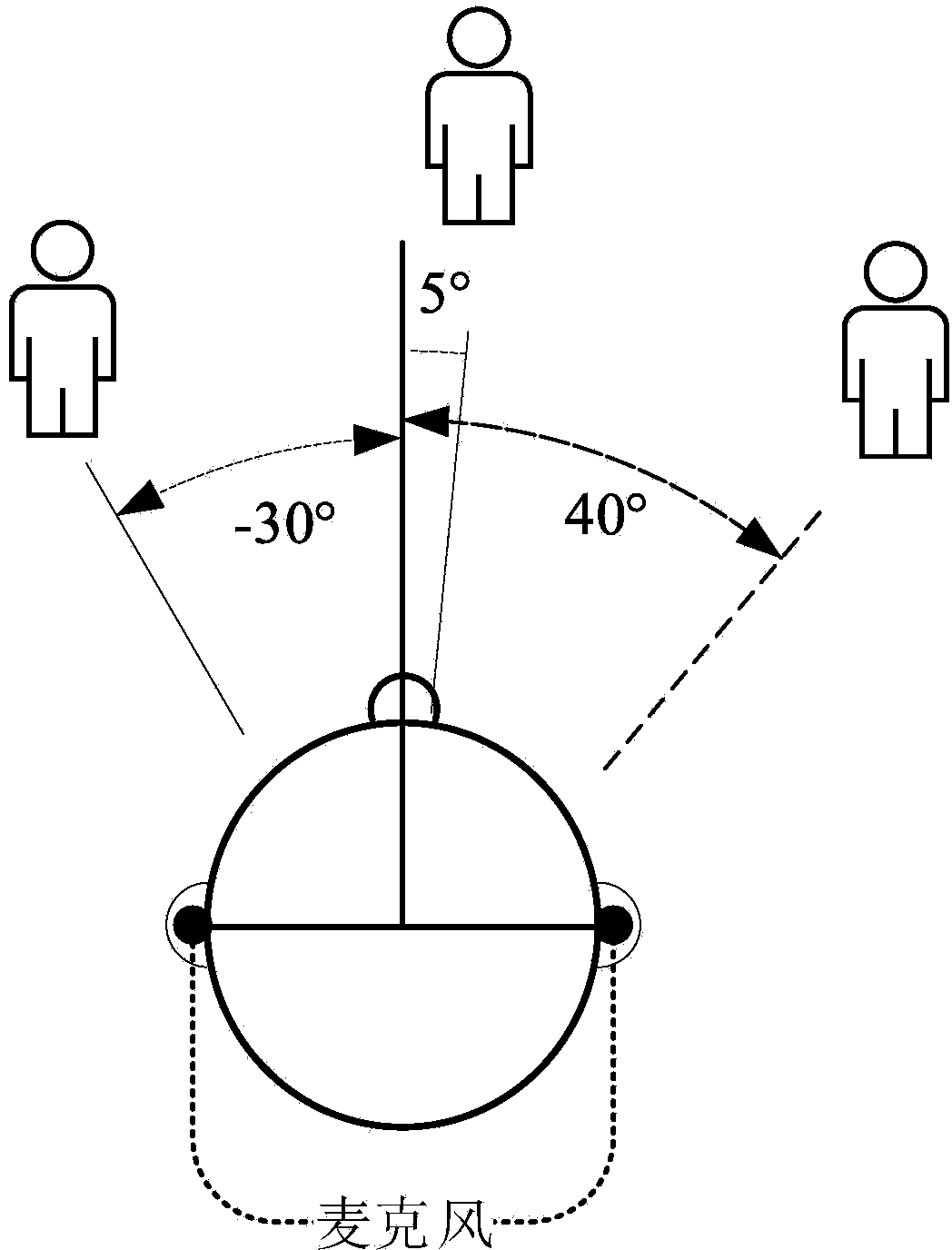

Voice separation method based on binaural sound source localization

ActiveCN104464750AHigh precisionEasy to separateSpeech analysisPosition fixationAuditory senseSound sources

The invention discloses a voice separation method based on binaural sound source localization. Multiple sound sources are separated through data training, multiple-sound-source localization and voice separation according to sound source directions, and a separation voice of each sound source is obtained. The voice separation method can simulate the auditory sense of human ears based on the cocktail party effect of the human ears, the number of the sound sources and the directions of the sound sources can be accurately located, and an accurate mixed matrix is obtained through the information of the located sound source directions. Thus, the voice separation process is conducted, and the separation performance of the voice separation method is effectively improved.

Owner:SOUTHEAST UNIV

Gas separations using high performance mixed matrix membranes

InactiveUS7998246B2Easy to separateHigh selectivitySemi-permeable membranesIsotope separationMolecular sievePolymer science

The present invention discloses a novel method of making high performance mixed matrix membranes (MMMs) using stabilized concentrated suspensions of solvents, uniformly dispersed polymer stabilized molecular sieves, and at least two different types of polymers as the continuous blend polymer matrix. MMMs as dense films or asymmetric flat sheet or hollow fiber membranes fabricated by the method described in the current invention exhibit significantly enhanced permeation performance for separations over the polymer membranes made from the continuous blend polymer matrix. MMMs of the present invention are suitable for a wide range of gas, vapor, and liquid separations such as alcohol / water, CO2 / CH4, H2 / CH4, O2 / N2, CO2 / N2, olefin / paraffin, iso / normal paraffins, and other light gases separations.

Owner:UOP LLC

Method of Making High Performance Mixed Matrix Membranes Using Suspensions Containing Polymers and Polymer Stabilized Molecular Sieves

ActiveUS20080141863A1Easy to separateHigh selectivitySemi-permeable membranesMembranesMolecular sievePolymer science

The present invention discloses a novel method of making high performance mixed matrix membranes (MMMs) using stabilized concentrated suspensions of solvents, uniformly dispersed polymer stabilized molecular sieves, and at least two different types of polymers as the continuous blend polymer matrix. MMMs as dense films or asymmetric flat sheet or hollow fiber membranes fabricated by the method described in the current invention exhibit significantly enhanced permeation performance for separations over the polymer membranes made from the continuous blend polymer matrix. MMMs of the present invention are suitable for a wide range of gas, vapor, and liquid separations such as alcohol / water, CO2 / CH4, H2 / CH4, O2 / N2, CO2 / N2, olefin / paraffin, iso / normal paraffins, and other light gases separations.

Owner:UOP LLC

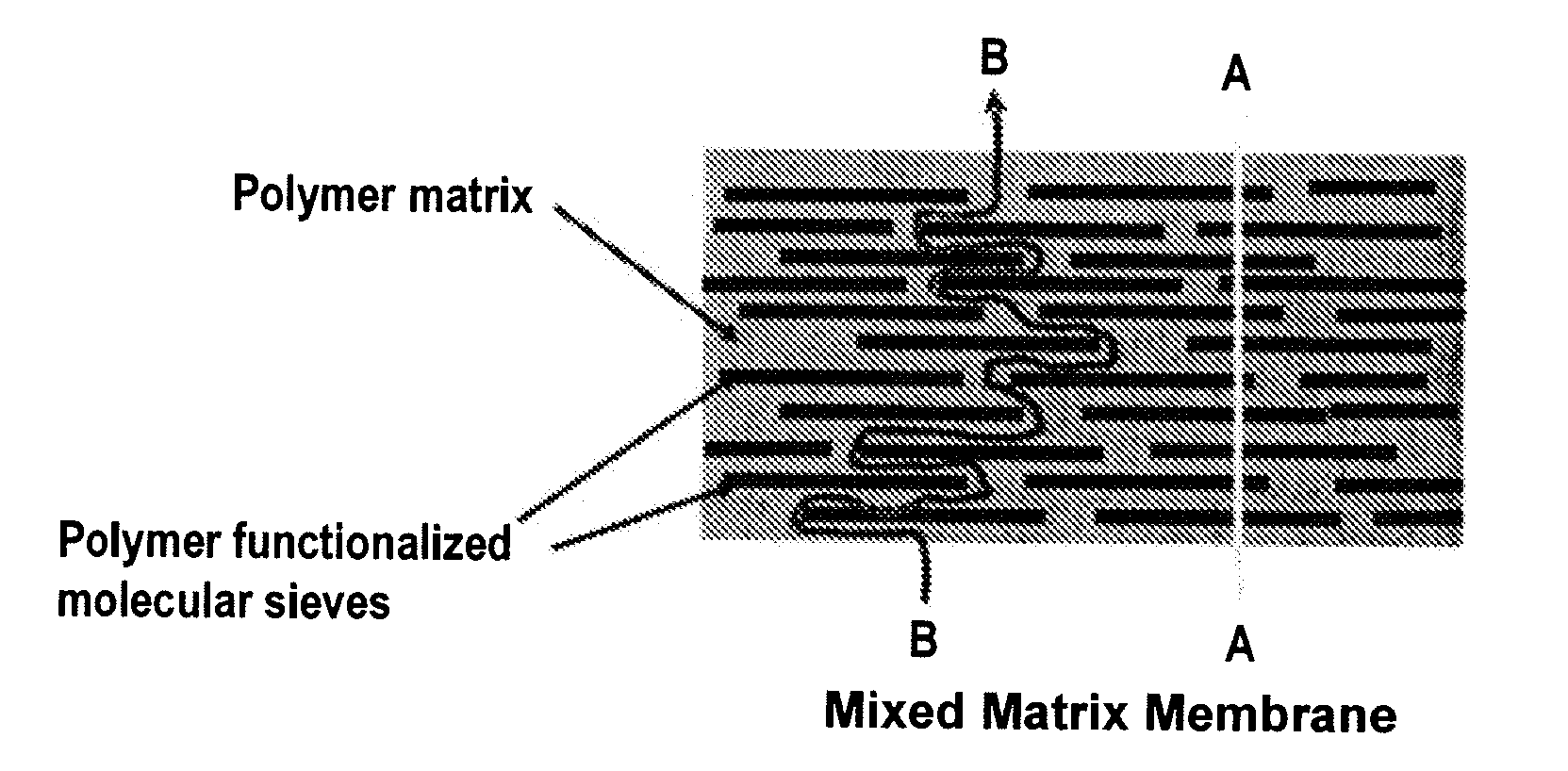

Mixed Matrix Membranes Containing Molecular Sieves With Thin Plate Morphology

InactiveUS20090126567A1Be consistentAverage permeabilitySemi-permeable membranesGas treatmentMolecular sieveComputational chemistry

The present invention discloses mixed matrix membranes (MMMs) comprising a polymer matrix and molecular sieve particles and methods for making and using these membranes. The molecular sieve particles contain micropores or mesopores and exhibit a thin plate morphology with high aspect ratio and the plate thickness no more than 300 nm. This invention also pertains to controlling the alignment of the thin plate molecular sieve particles in the continuous polymer matrix of the thin dense selective layer of the asymmetric mixed matrix membranes. These MMMs exhibited much higher selectivity improvement than those comprising molecular sieve particles with other kinds of morphology for gas separations such as CO2 / CH4 and H2 / CH4 separations. The thin plate morphology of molecular sieves is beneficial to make high performance mixed matrix membranes. The MMMs are suitable for a variety of liquid, gas, and vapor separations

Owner:UOP LLC

Method of Making Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090131242A1Easy to separateAverage permeabilitySemi-permeable membranesGas treatmentPolymer scienceCellulose acetate

The present invention discloses a method of making polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), and propylene / propane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulphurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

Molecular Sieve/Polymer Hollow Fiber Mixed Matrix Membranes

InactiveUS20090152755A1High selectivityIncrease fluxSemi-permeable membranesNon-woven fabricsMolecular sieveFiber

The present invention discloses a method for making mixed matrix membranes (MMMs) and methods for using these membranes. These MMMs contain a continuous polymer matrix and dispersed microporous molecular sieve particles. This invention also pertains to control the thickness of the thin dense selective mixed matrix layer equal to or greater than the particle size of the largest molecular sieve particles for making large scale asymmetric MMMs. In particular, the invention is directed to make asymmetric hollow fiber MMM by a phase inversion technique. The MMMs of the present invention exhibit at least 20% increase in selectivity compared to the polymer membranes prepared from their corresponding continuous polymer matrices. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

Liquid Separations Using High Performance Mixed Matrix Membranes

InactiveUS20080142440A1Easy to separateHigh selectivityUltrafiltrationDispersed particle separationMolecular sieveAlcohol

The present invention discloses a novel method of making high performance mixed matrix membranes (MMMs) using stabilized concentrated suspensions of solvents, uniformly dispersed polymer stabilized molecular sieves, and at least two different types of polymers as the continuous blend polymer matrix. MMMs as dense films or asymmetric flat sheet or hollow fiber membranes fabricated by the method described in the current invention exhibit significantly enhanced permeation performance for separations over the polymer membranes made from the continuous blend polymer matrix. MMMs of the present invention are suitable for a wide range of gas, vapor, and liquid separations such as alcohol / water, CO2 / CH4, H2 / CH4, O2 / N2, CO2 / N2, olefin / paraffin, iso / normal paraffins, and other light gases separations.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com