Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6658 results about "Paraffin wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin wax (or petroleum wax) is a soft colorless solid, derived from petroleum, coal or shale oil, that consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms. It is solid at room temperature and begins to melt above approximately 37 °C (99 °F), and its boiling point is above 370 °C (698 °F). Common applications for paraffin wax include lubrication, electrical insulation, and candles; dyed paraffin wax can be made into crayons. It is distinct from kerosene and other petroleum products that are sometimes called paraffin.

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

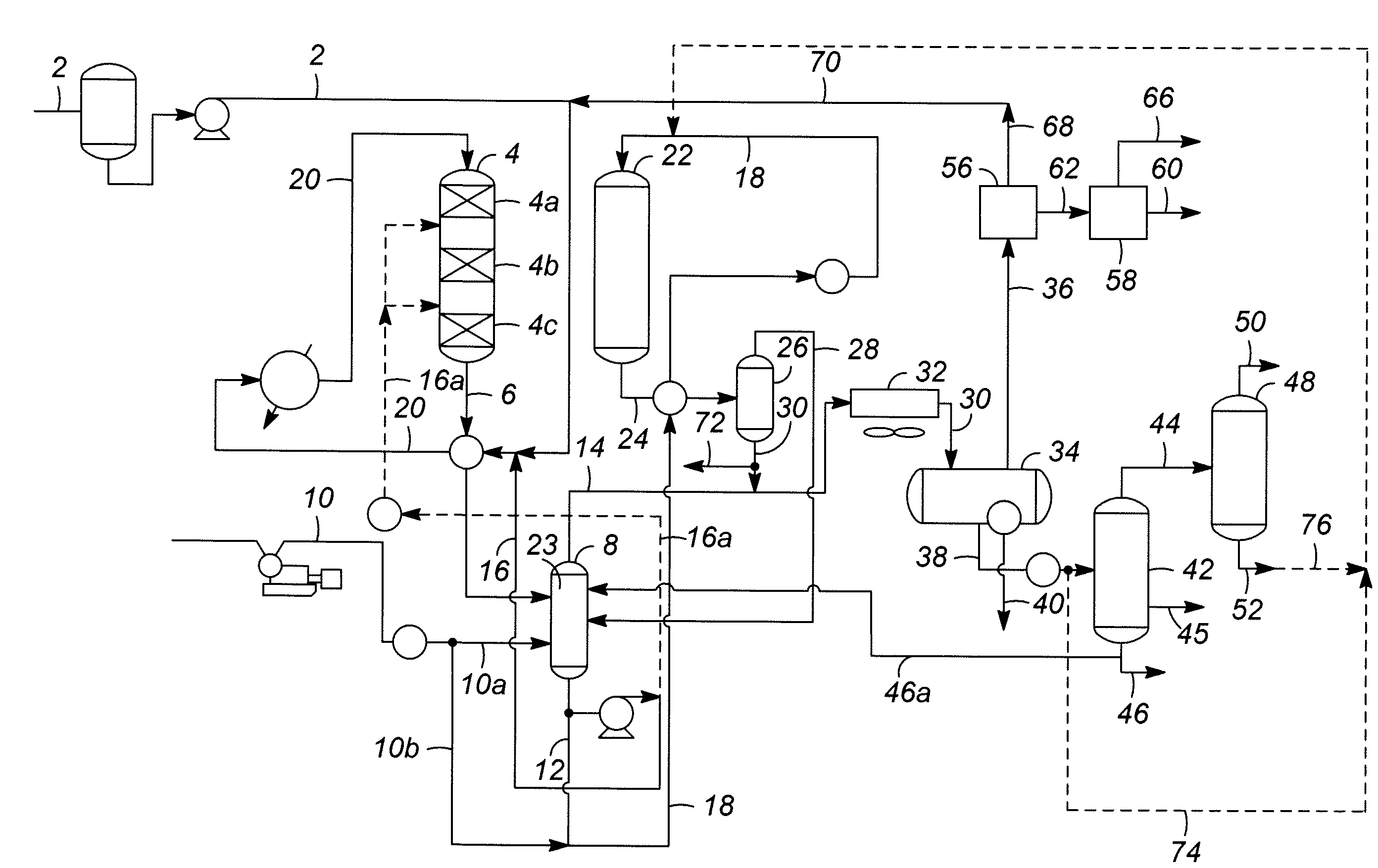

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

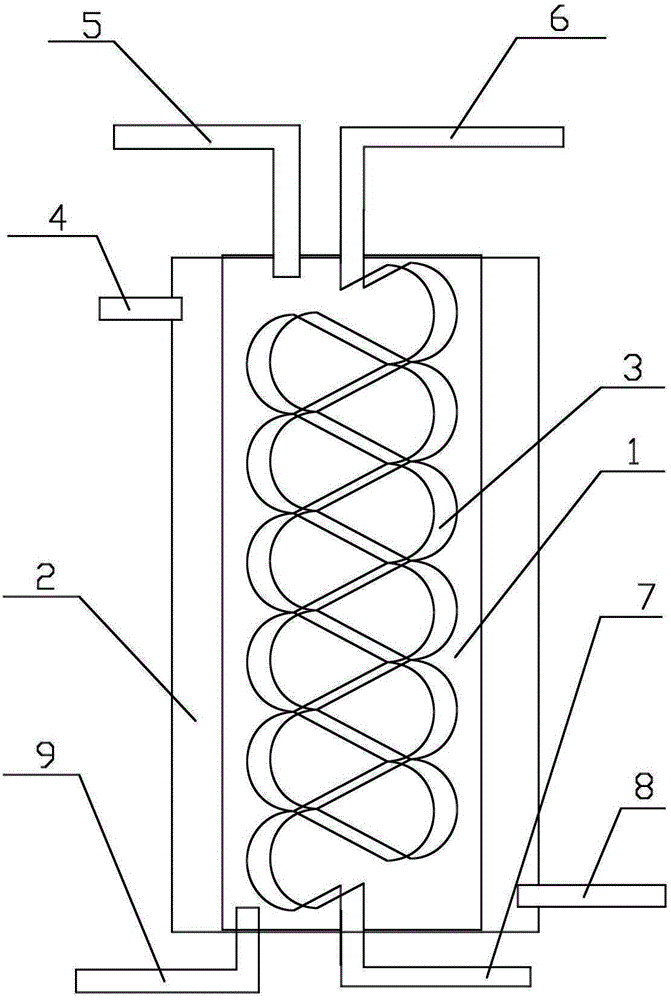

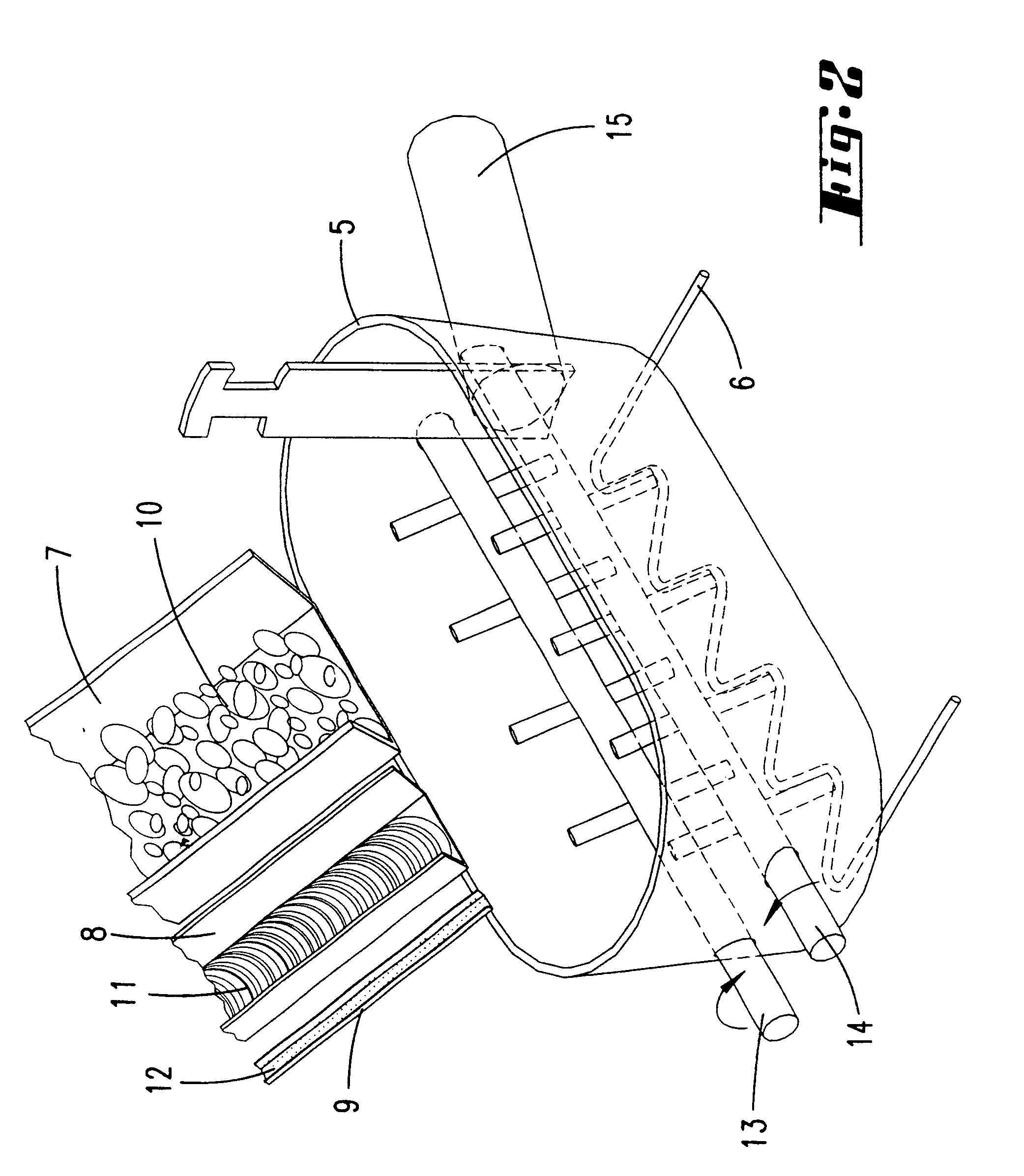

Efficient paraffin sweatbox

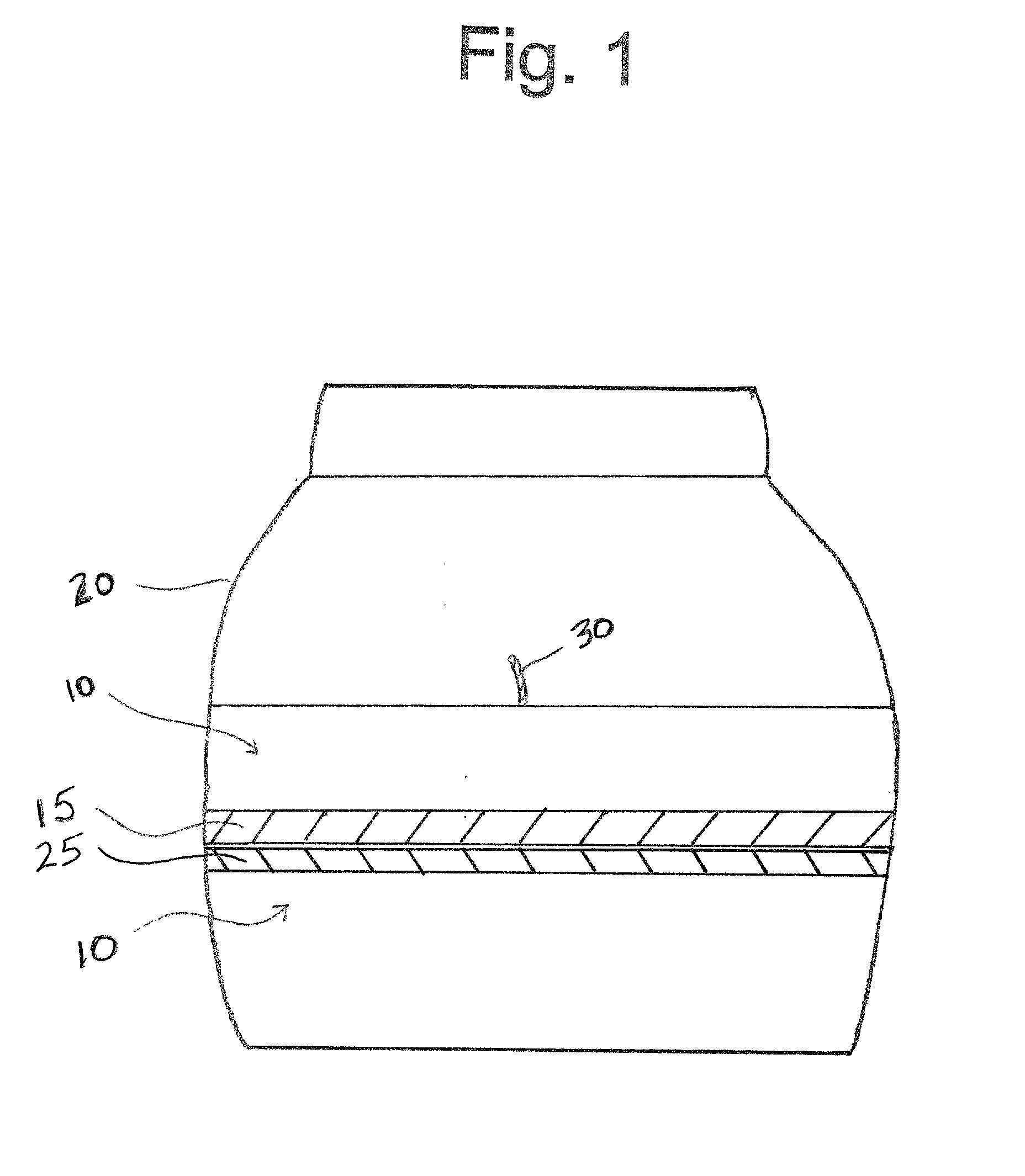

InactiveCN102977917AHeating evenlyMeet production requirementsPetroleum wax recoveryParaffin waxParaffin oils

The invention discloses an efficient paraffin sweatbox. The sweatbox comprises an inner cavity, a heating layer, a heating tube, an outer water inlet tube, a feeding tube, an inner water inlet tube, an inner water outlet tube, an outer water outlet tube and a discharging tube, wherein a heating tube which is arranged in a rotating mode is arranged inside the inner cavity; the feeding tube is arranged on the upper part of the inner cavity; the discharging tube is arranged on the lower part of the inner cavity; the heating layer is arranged outside the inner cavity; the external water inlet tube is arranged on the upper part of the heating layer; the outer water outlet tube is arranged on the lower part of the heating layer; the inner water inlet tube connected to the outer side of the inner cavity is arranged on the upper part of the heating tube; and the inner water outlet tube connected to the outer side of the inner cavity is arranged at the lower side of the heating tube. The heating tube which is extended like a spring in a rotating mode is arranged inside the effective paraffin sweatbox, so that the paraffin is heated uniformly; and the efficient paraffin sweatbox is used in the industry.

Owner:DALIAN LONSIN NEW MATERIALS

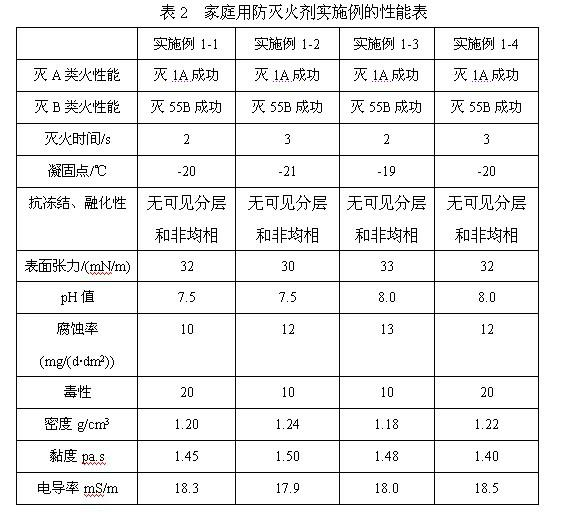

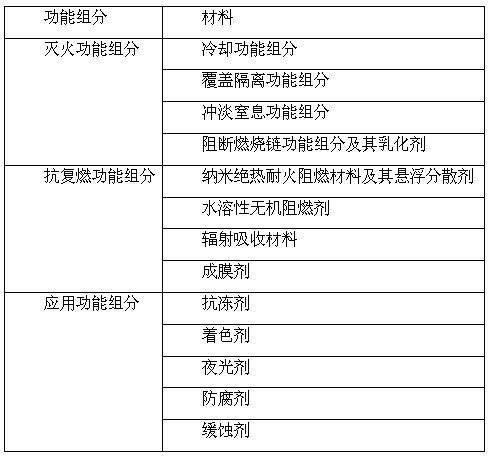

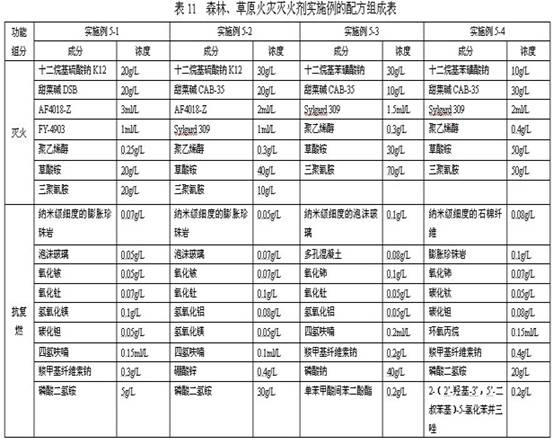

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

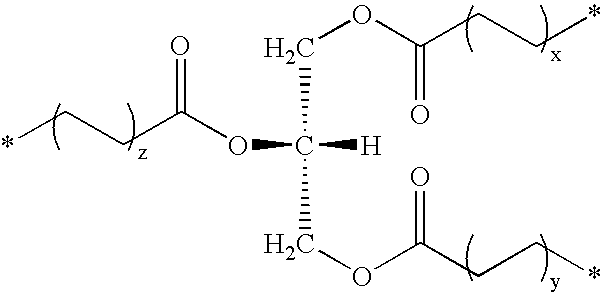

Production of Blended Fuel from Renewable Feedstocks

ActiveUS20090301930A1Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

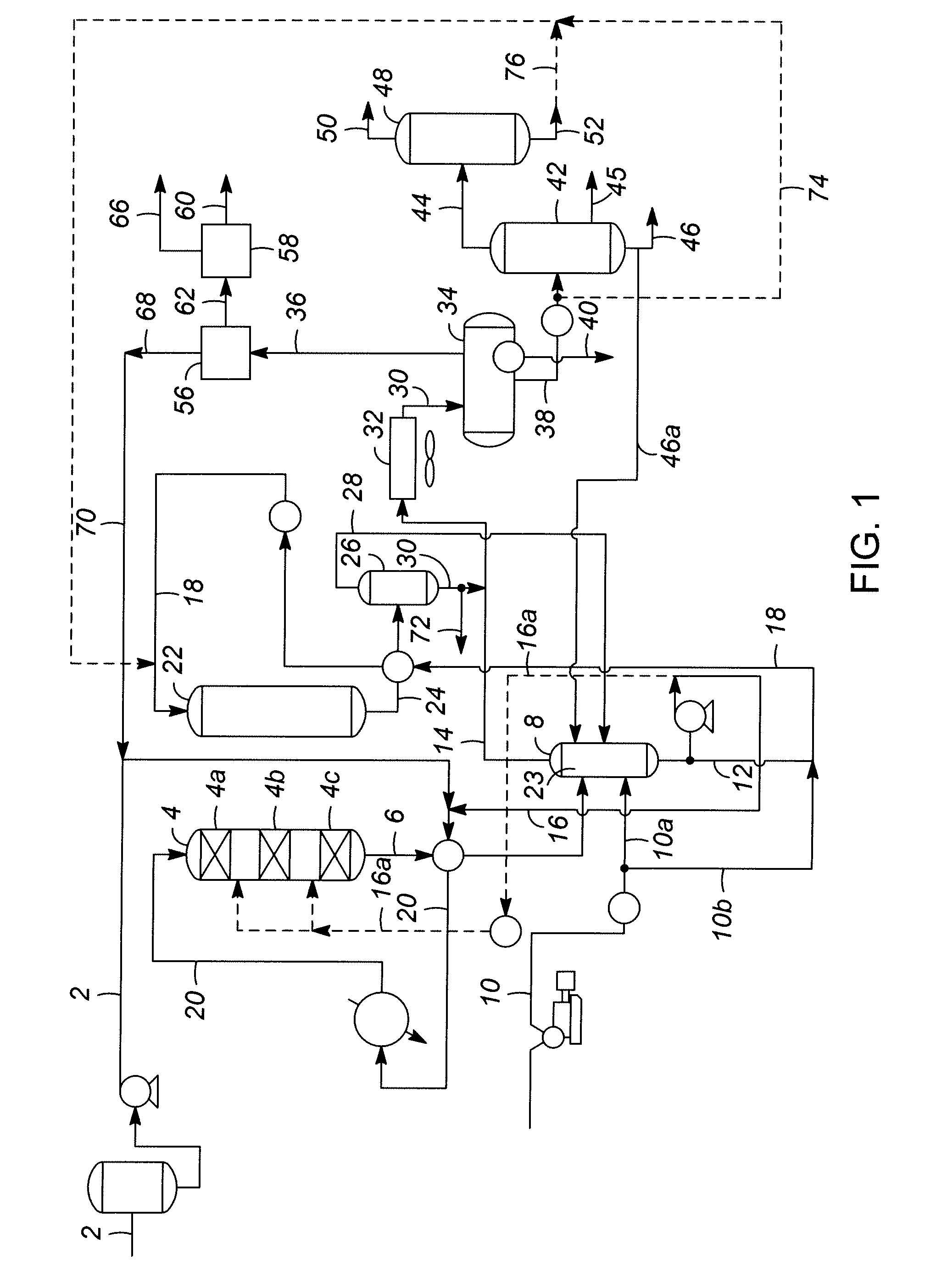

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

Bitumen or asphalt for producing a road topping, road topping and method for the production of bitumen or asphalt

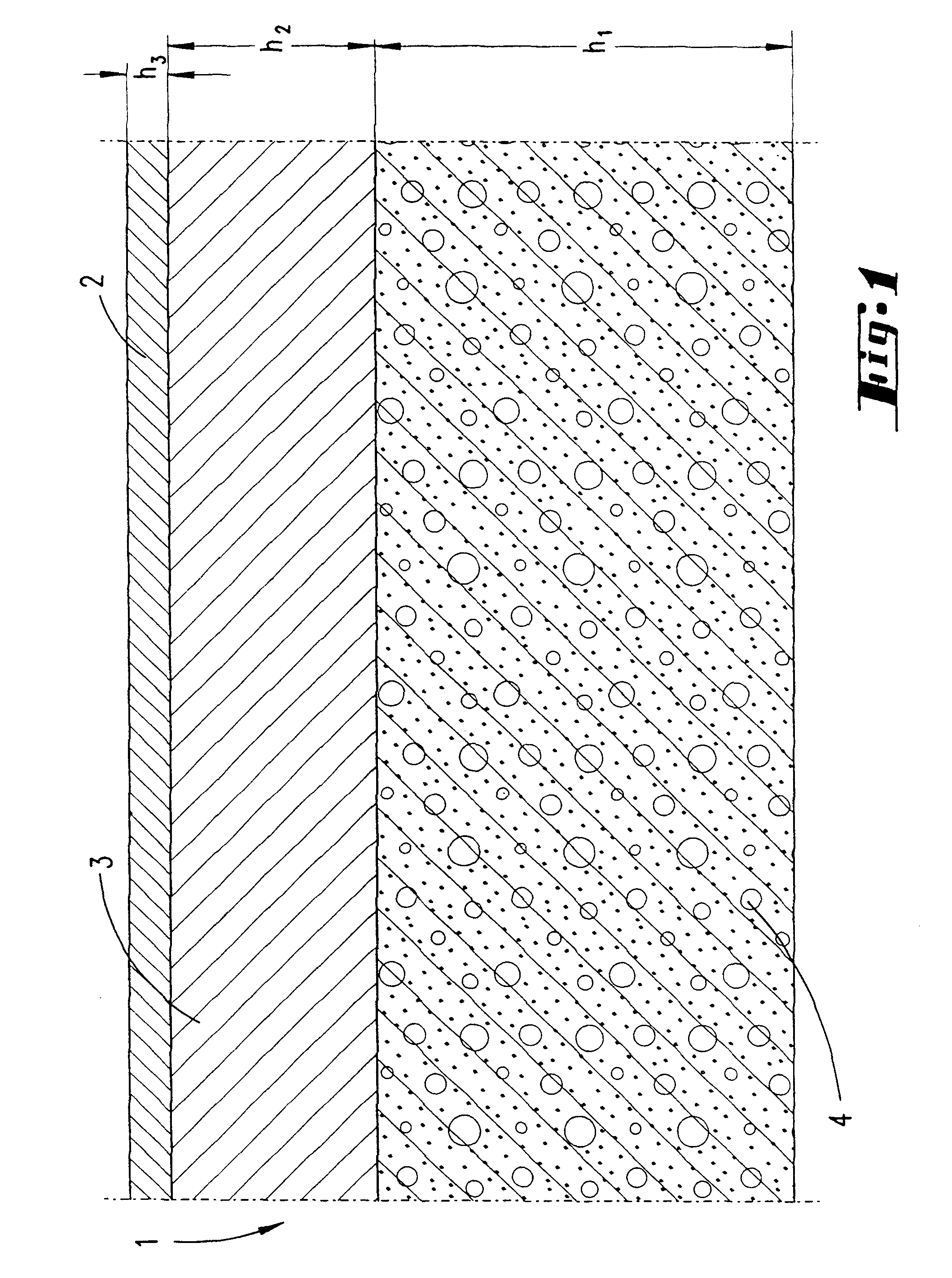

InactiveUS6588974B2Good effectReduction in strengthIn situ pavingsPaving detailsParaffin waxParaffin oils

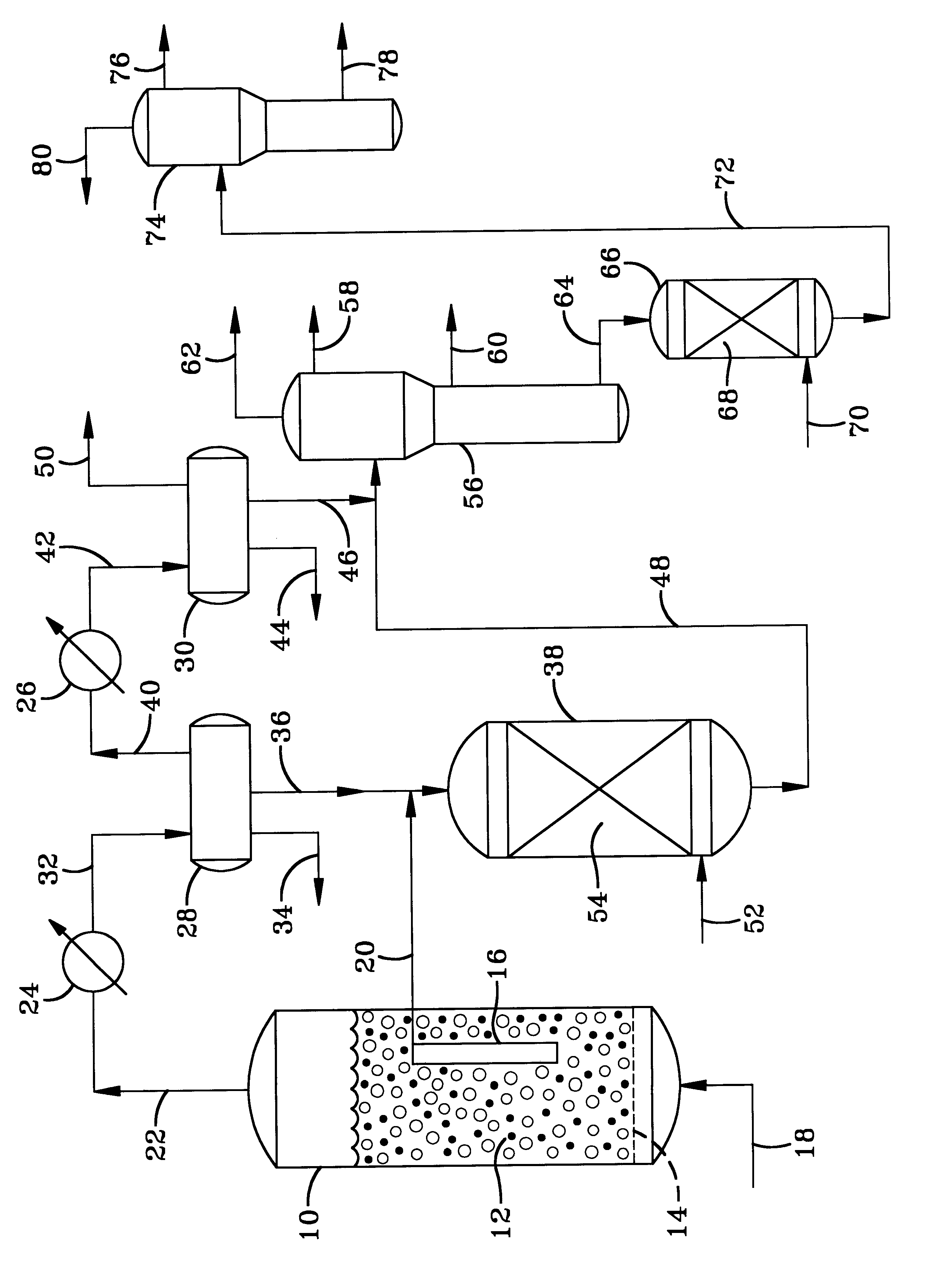

The invention relates to bitumen or asphalt for producing a road topping, whereby said bitumen or asphalt contains a proportion of paraffin obtained by Fischer-Tropsch synthesis (FT paraffin). The invention also relates to a road topping with said bitumen and to a method for producing a corresponding road topping or roadway / covering using said bitumen.

Owner:SCHUMANN SASOL SOUTH AFRICA

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

Oily cosmetic composition in aerosol form

InactiveUS20080031908A1Process stabilityHappy to useCosmetic preparationsHair cosmeticsParaffin waxSolid particle

Aerosol product containing an oily composition containing at least one oil, and at least one hydrocarbon compound having a melting point greater than or equal to 30° C., the compound being in the form of solid particles and one or more propellants. The hydrocarbon compound can notably be a paraffin or a fatty acid amide. Used for cleaning and / or make-up removal of the skin and / or of the hair, care of the skin and / or of the hair, for protecting the skin against the sun, and for make-up of the skin.

Owner:LOREAL SA

Vegetable oil candle

InactiveUS6730137B2Novel burning and fragrance characteristicBiofuelsSolid fuelsParaffin waxVegetable oil

A candle composition has a paraffin wax mixture of a high melting point paraffin wax and a low melting point paraffin wax, and a hydrogenated vegetable oil that is present in a greater amount than the mixture of the varying grades of paraffin wax, and the vegetable oil contains no more than 0.15% free fatty acid, with the remainder being triglycerides. Candles of the composition have good burn characteristics, particularly good fragrance intensity and produce a unique crystallization effect after the first burn.

Owner:BEAUTYAVENUES

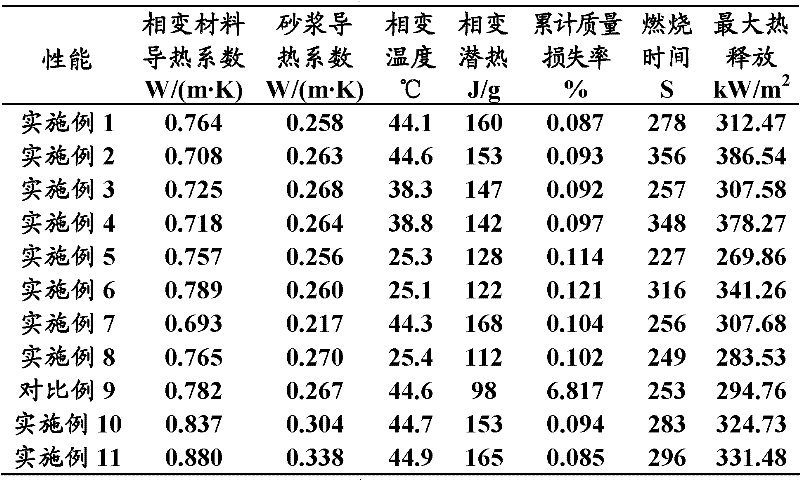

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

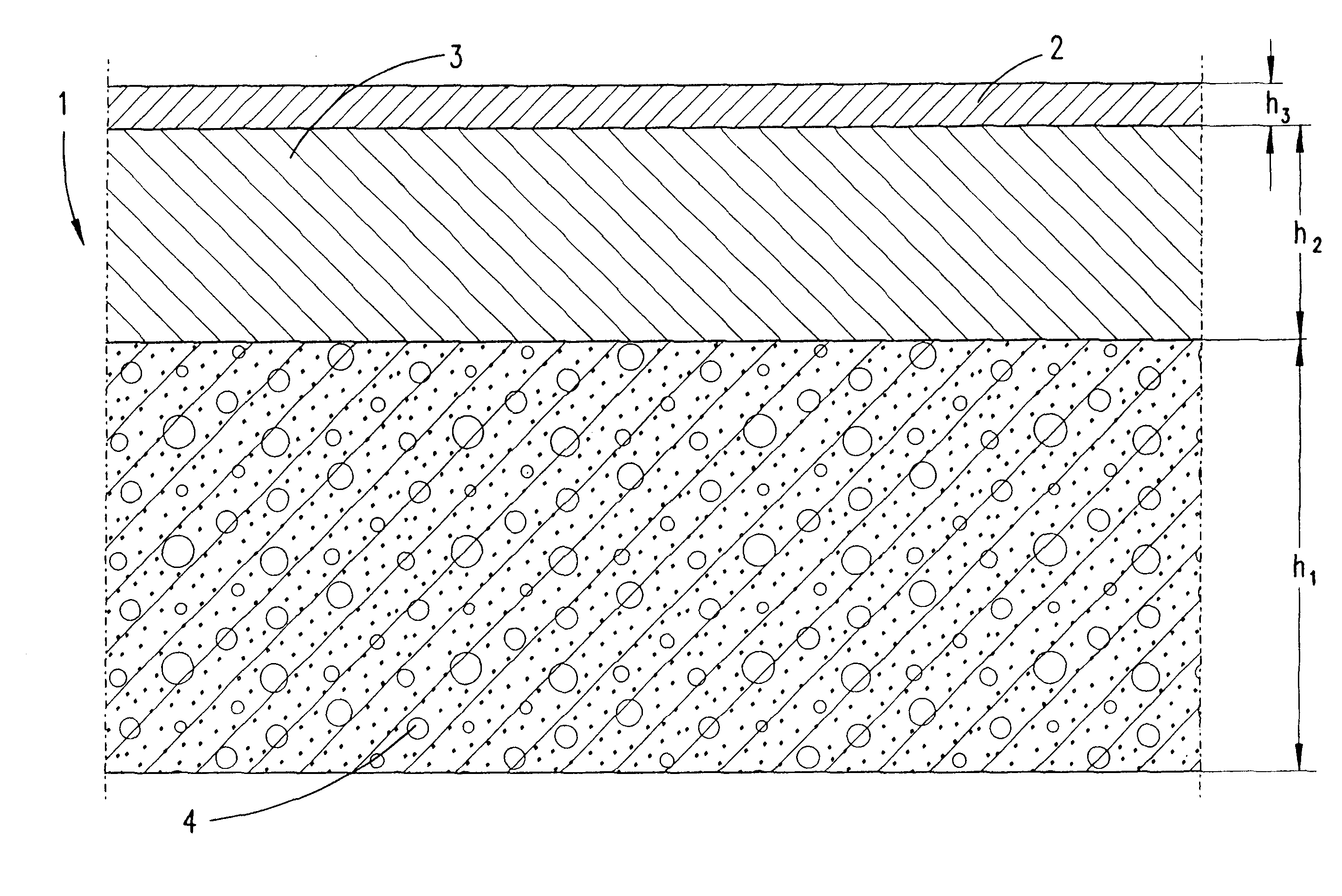

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

Oil-based ink-jet recording ink

InactiveUS6730153B2Maintain good propertiesSatisfactory pigment dispersibilityDuplicating/marking methodsInksParaffin waxVegetable oil

An ink-jet recording oil-based ink which has satisfactory pigment dispersibility both at the beginning of storage and even during long-term storage and provides excellent spouting stability without being influenced by temperature changes in printing circumstances. The ink comprises a pigment; a dispersing agent comprising a reaction product of a polyamine compound and a self condensation product of 12-hydroxystearic acid; a saturated hydrocarbon solvent comprising a liquid paraffin as a main component; and a vegetable oil, the ink having a surface tension of 26 to 30 dyne / cm at 25° C. and a contact angle on a polytetrafluoroethylene plate of 40° to 50° at 25° C., and satisfying the following relationship:wherein WHC is the weight of the saturated hydrocarbon solvent and WVC is the weight of the vegetable oil.

Owner:SAKATA INX

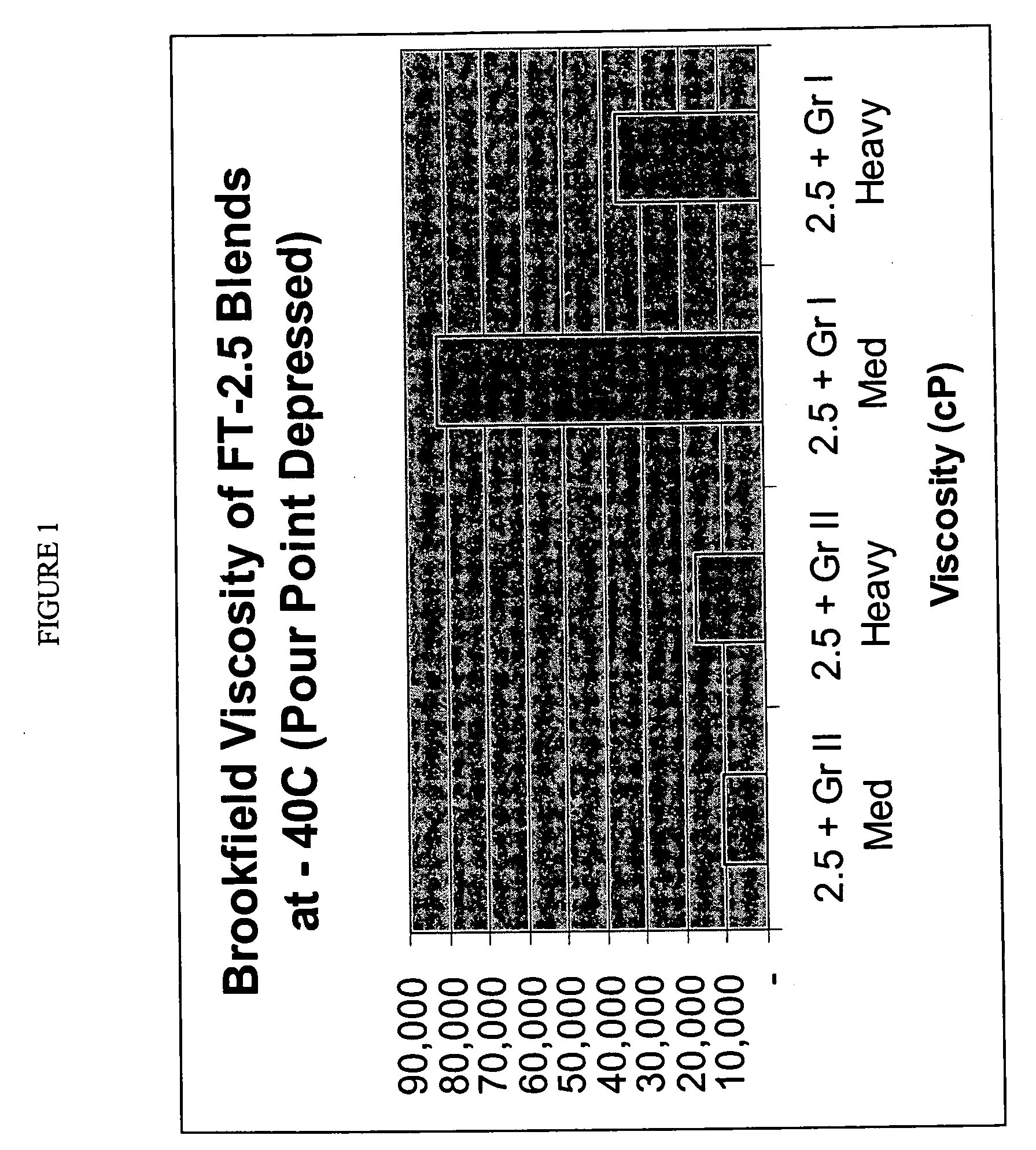

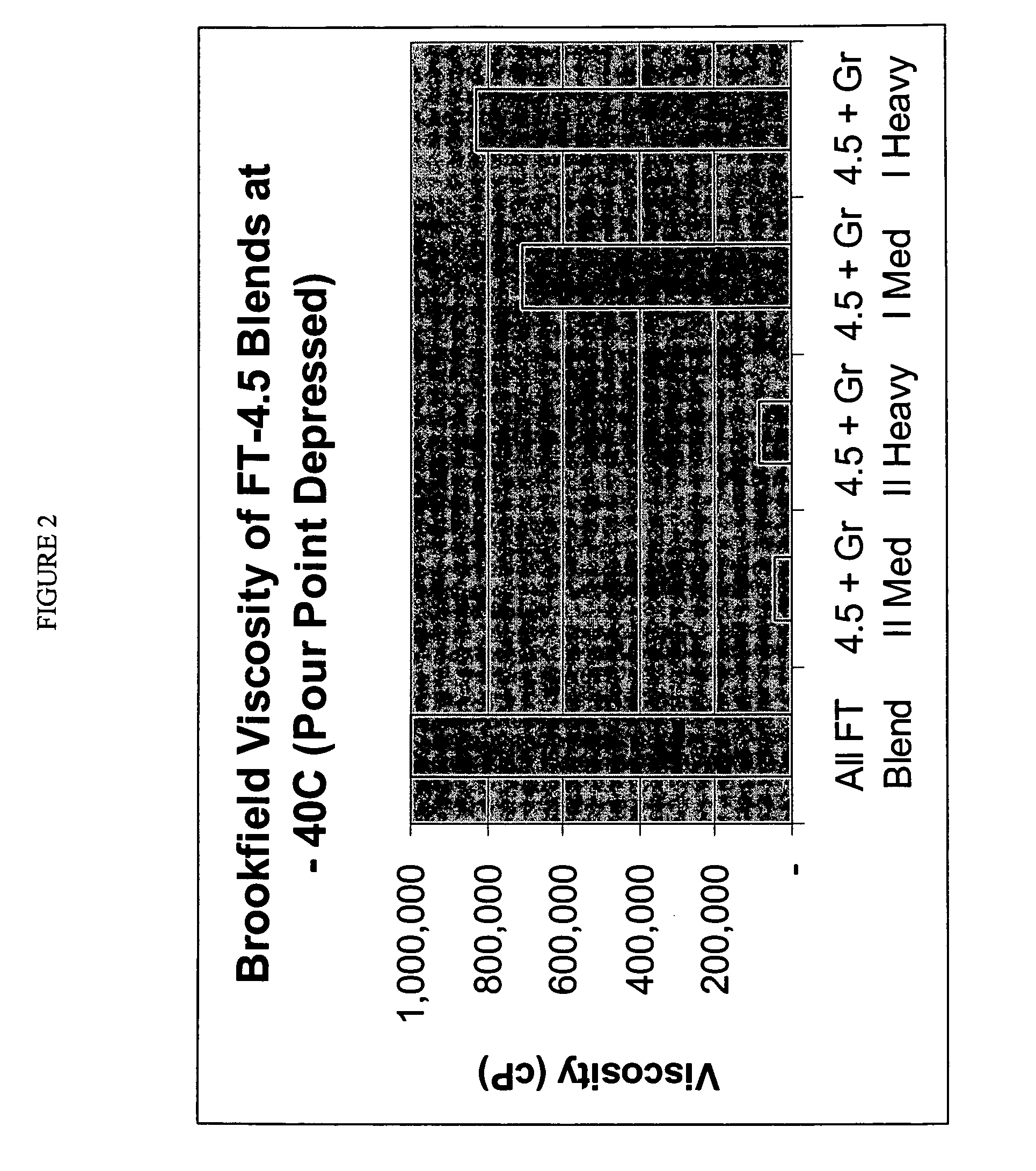

Processes for making lubricant blends with low brookfield viscosities

InactiveUS20050261146A1Improve low temperature performanceLow viscosityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Paraffinic Biologically-Derived Distillate Fuels With Bio-Oxygenates For Improved Lubricity And Methods Of Making Same

ActiveUS20090031617A1Improve the lubrication effectImprove efficiencyFatty acid chemical modificationRefining to change hydrocarbon structural skeletonParaffin waxIsomerization

The present invention is generally directed to methods for making fuels from biomass comprising triglyceride species, whereby the biomass is subjected to partial hydrodeoxygenation and (optionally) catalytic isomerization. The partial-hydrodeoxygenation of the triglyceride species produces a fuel that retains some oxygenates for enhanced lubricity.

Owner:CHEVROU USA INC

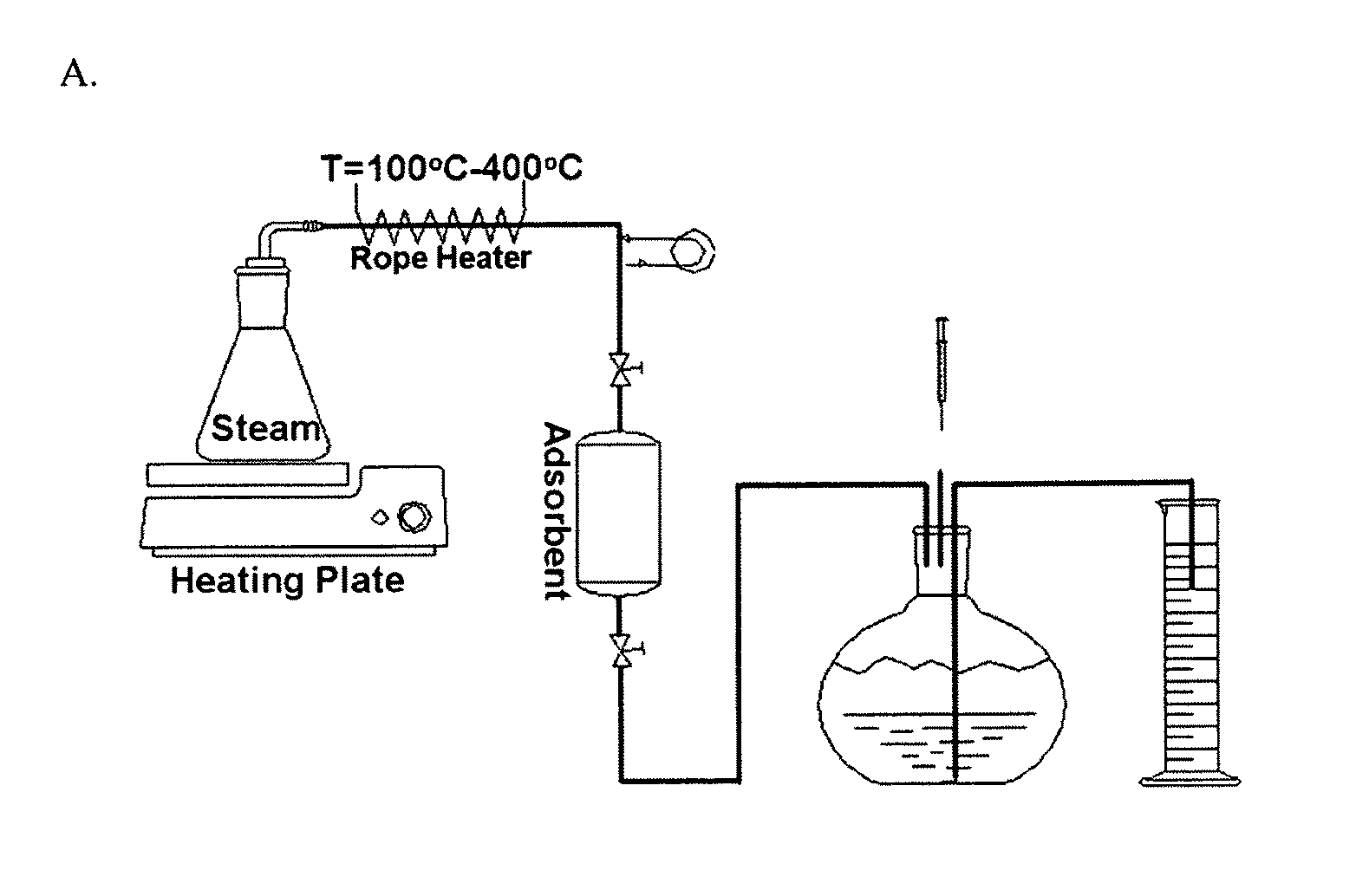

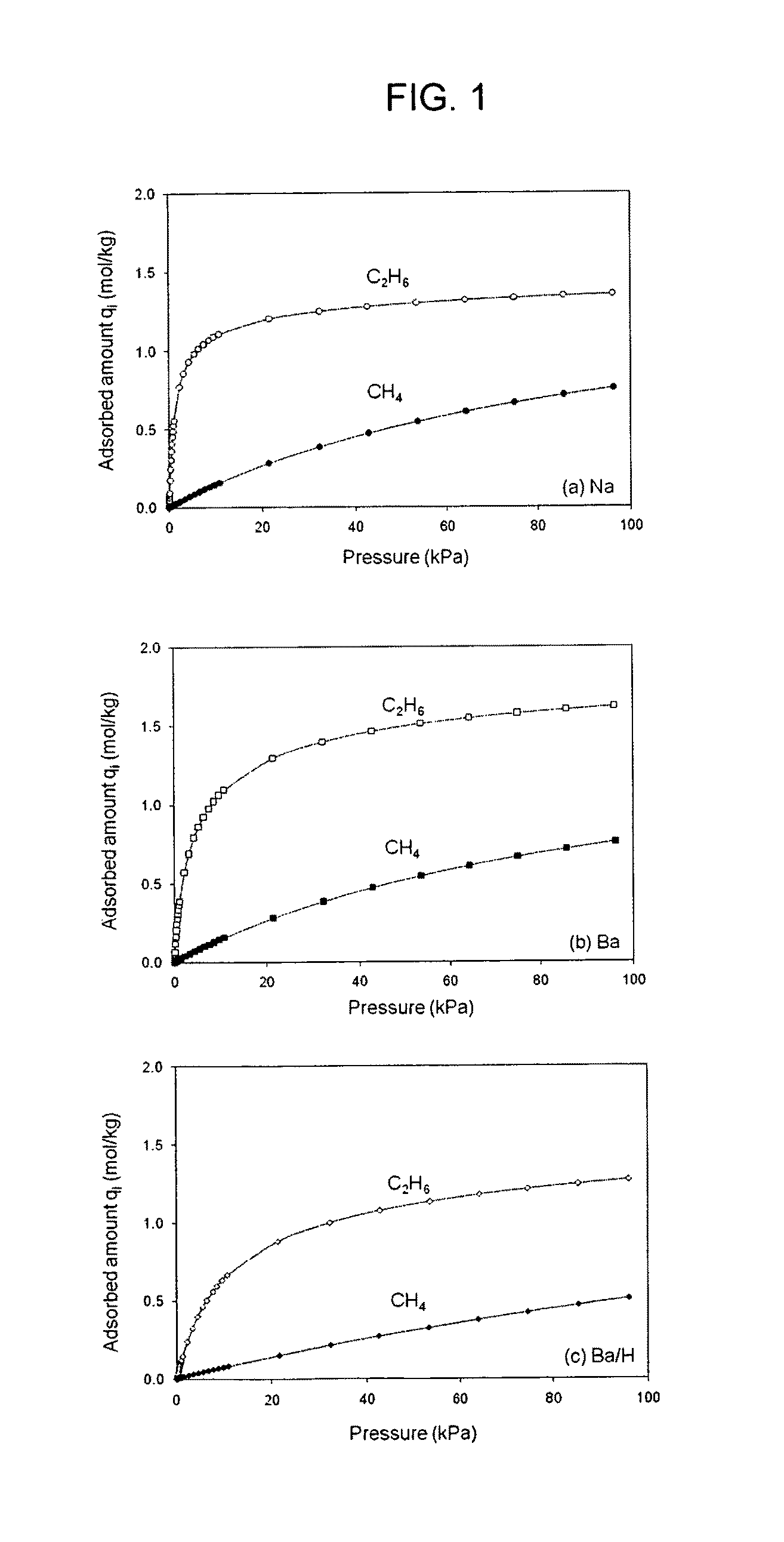

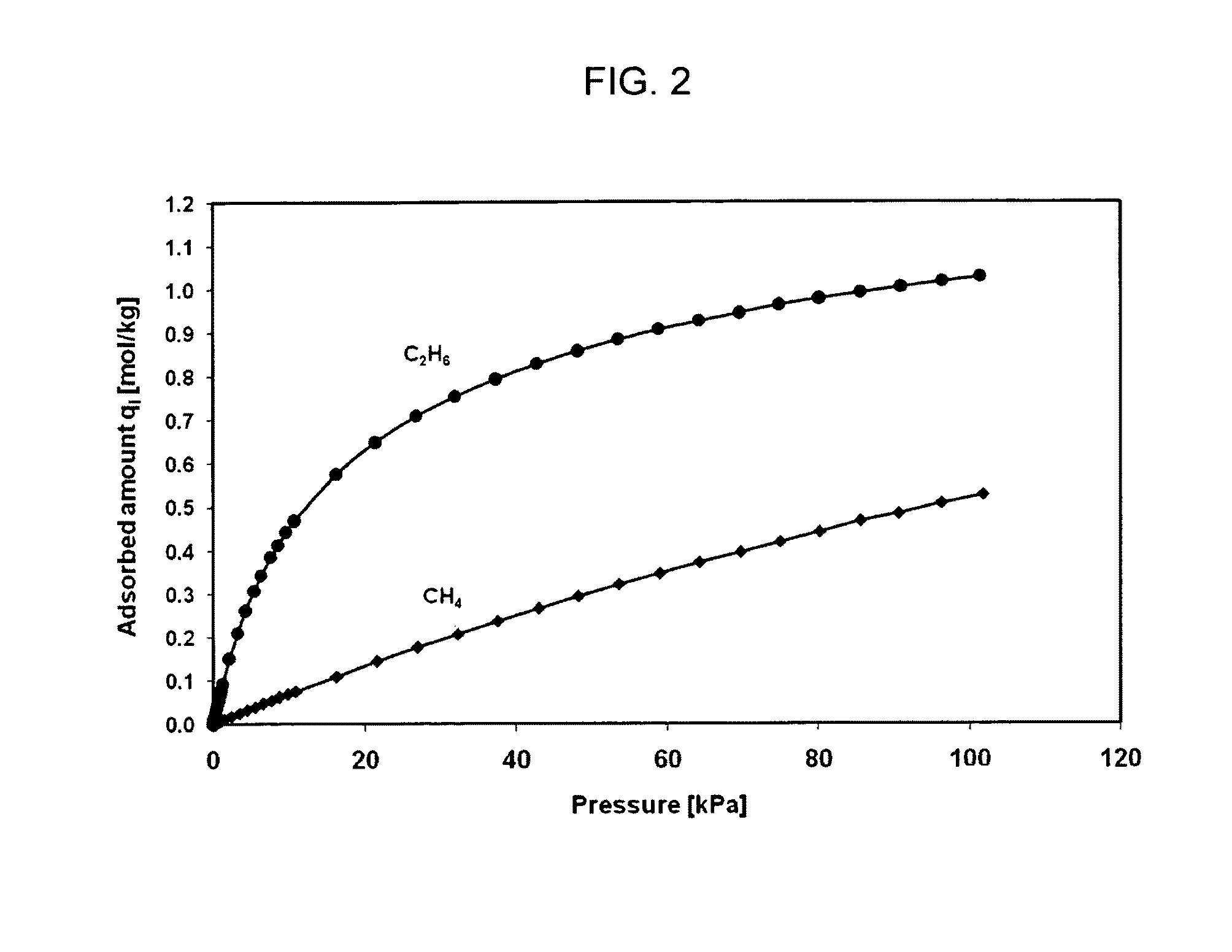

Removal of ethane from natural gas at high pressure

ETS-10 type materials preferentially adsorb ethane and, if present, C3+ paraffins from mixtures comprising methane, ethane and optionally C3+ paraffins at pressures above 200 psia. A process in which ETS-10 type materials are used to separate ethane and C3+ paraffins from natural gas streams at over 200 psia is provided.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Vegetable oil candle

InactiveUS20030091949A1Novel burning and fragrance characteristicBiofuelsSolid fuelsParaffin waxVegetable oil

A candle composition has a paraffin wax mixture of a high melting point paraffin wax and a low melting point paraffin wax, and a hydrogenated vegetable oil that is present in a greater amount than the mixture of the varying grades of paraffin wax, and the vegetable oil contains no more than 0.15% free fatty acid, with the remainder being triglycerides. Candles of the composition have good burn characteristics, particularly good fragrance intensity and produce a unique crystallization effect after the first burn.

Owner:BEAUTYAVENUES

Process for preparing MgC12-ol-organic complexing agent as spherical carrier of catalyst

A spherical MgCl2-alcohol-organic complexing agent composition as the carrier of catalyst is prepared through sublimation reaction of anhydrous MgCl2 on alcohol to obtain a molten mixture, adding organic complexing agent, low speed stirring in the mixture of methylsilica oil and atoleine, quick cooling, washing and drying.

Owner:ZHEJIANG UNIV

Process for producing a paraffin-based object and such an object

The invention relates to a process for producing a paraffin-based object, especially a candle, with a proportion of a perfume which exceeds 10% by weight, in which the perfume is dissolved in a solvent containing an organic ester, and the solution is in turn added to or disolved in paraffin.

Owner:SCHUMANN SASOL SOUTH AFRICA

Materials for selective deposition modeling

InactiveUS6133355AHandling dimensionalToughness handlingAdditive manufacturing apparatusPaper coatingParaffin waxMicrocrystalline wax

A novel thermopolymer material adapted for use in thermal stereolithography. More particularly, a thermopolymer material comprising a mixture of: a low shrinkage polymer resin; a low viscosity material such as paraffin wax; at least one microcrystalline wax; a toughening polymer; a plasticizer. Alternative embodiments further include components to improve the materials ability to transfer heat and to improve strength. The subject material, together with the described process greatly reduce part building distortions while retaining desirable toughness, strength and jetting properties.

Owner:3D SYST INC

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

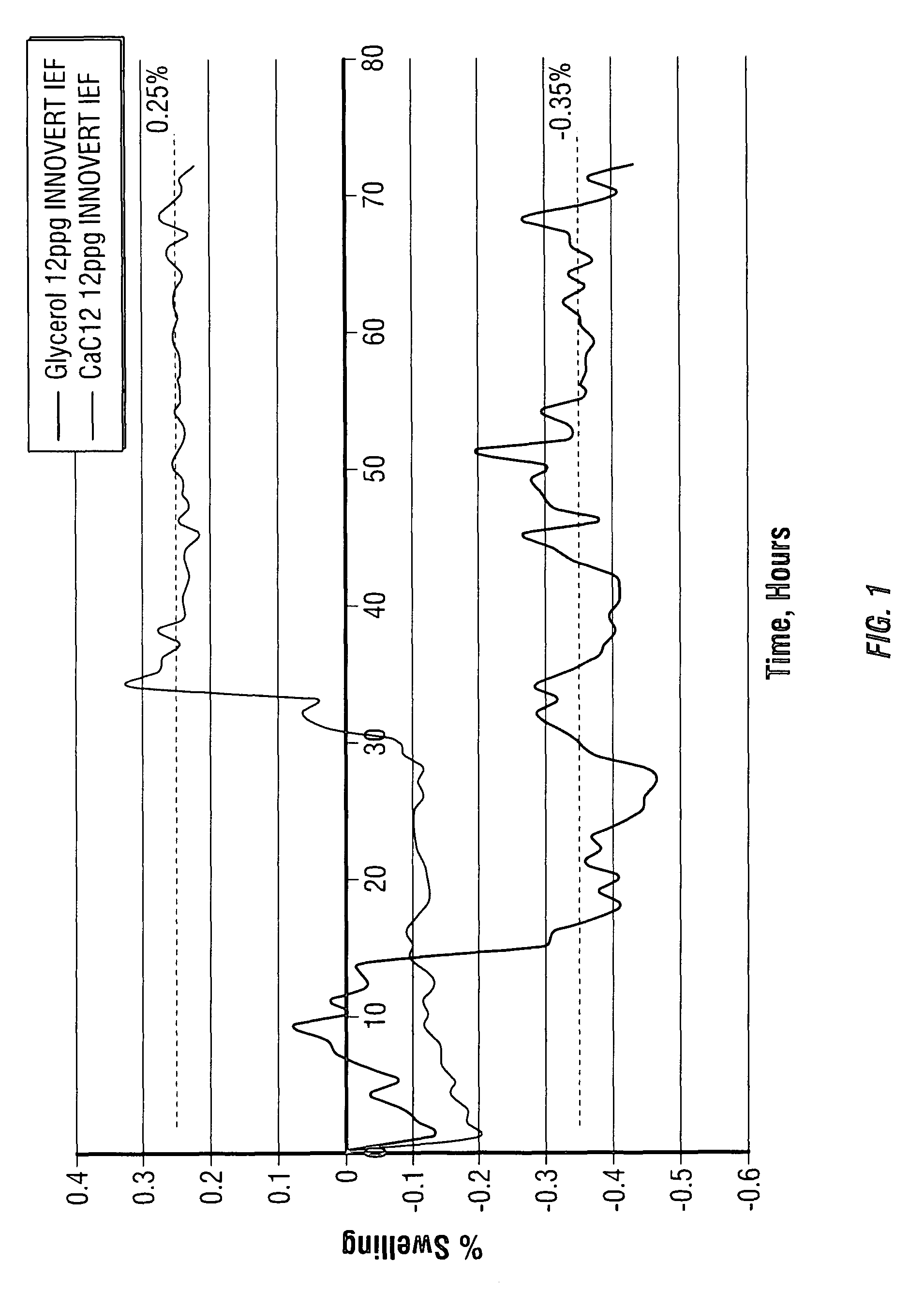

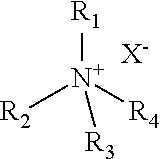

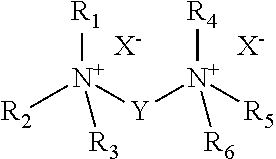

Invert emulsion drilling fluids comprising quaternary ammonium emulsifiers and argillaceous solids and methods of drilling boreholes

ActiveUS7939470B1Improve pressure resistanceImprove stabilityOther chemical processesMixing methodsParaffin waxChemistry

An invert emulsion drilling fluid, and a method for the use thereof in drilling wellbores, with good rheological properties at high temperatures and pressures. One embodiment of the drilling fluids are free of organophilic clays and lignites, free of calcium chloride, and comprise an alcohol in the internal phase, a quaternary ammonium emulsifier, and argillaceous solids. In one embodiment, the alcohol is a glycerol, a polyglycerol, or a mixture thereof. In one embodiment, the base oil for the emulsion is a paraffin and / or mineral oil. The drilling fluids provide good lubricity and high rates of penetration.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of Treating Flow Conduits and Vessels with Foamed Composition

InactiveUS20090114247A1Lower hydrostatic loadingReduce liquid volumeHollow article cleaningCleaning apparatusFoaming agentMedicine

The annular surface between the tubing and casing of an oil or gas well as well as flow conduits and vessels may be contacted with a foamed treatment composition containing a gas, a foaming agent and a treatment agent. The treatment agent may be an inhibitor or removal agent for scales, corrosion, salts, paraffins or asphaltenes. The foam, upon destabilization, renders a thin film of concentrated treatment agent on the external surfaces of the tubing, inside the casing and in the perforations of the oil or gas well or on the flow conduits or vessels.

Owner:BAKER HUGHES INC

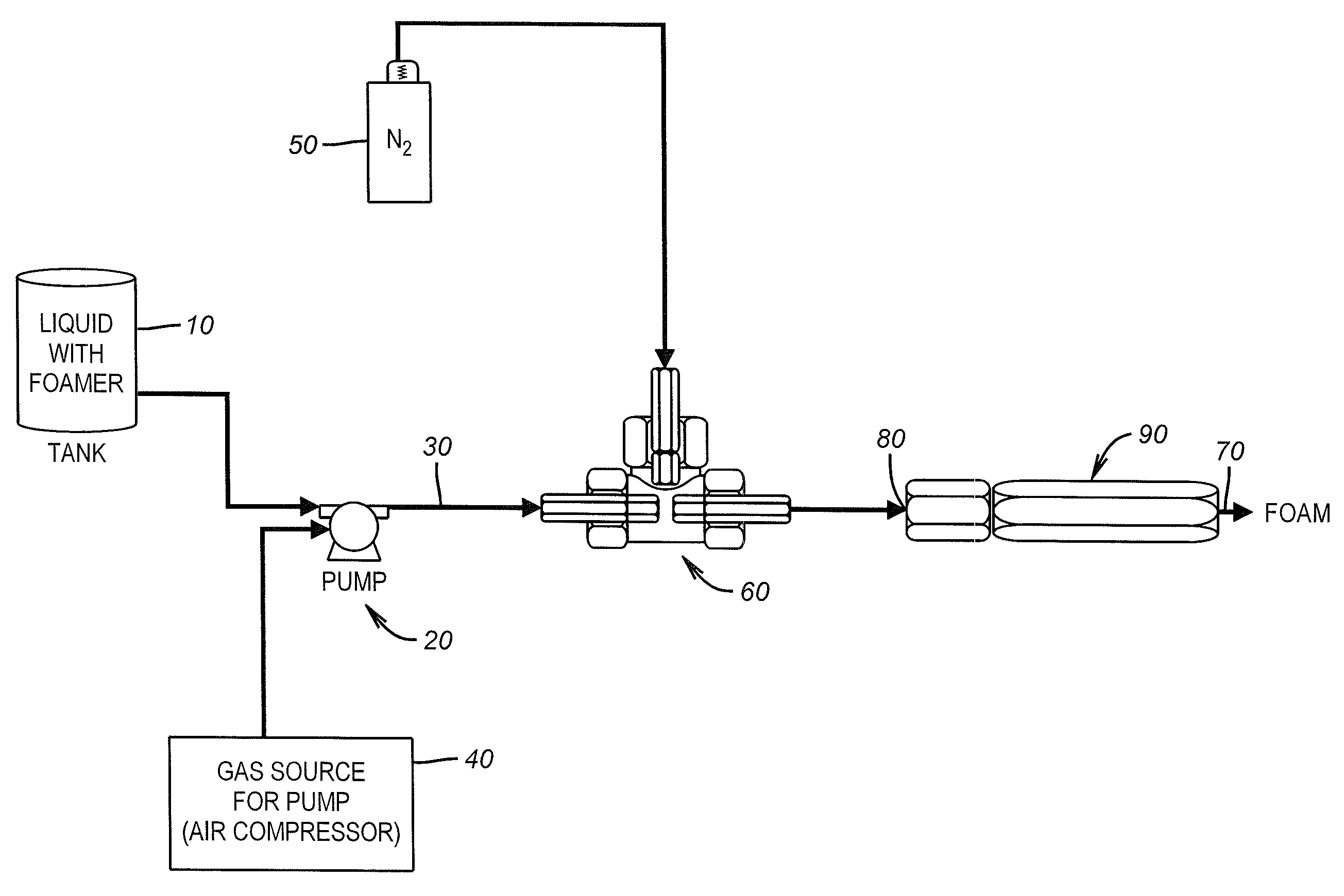

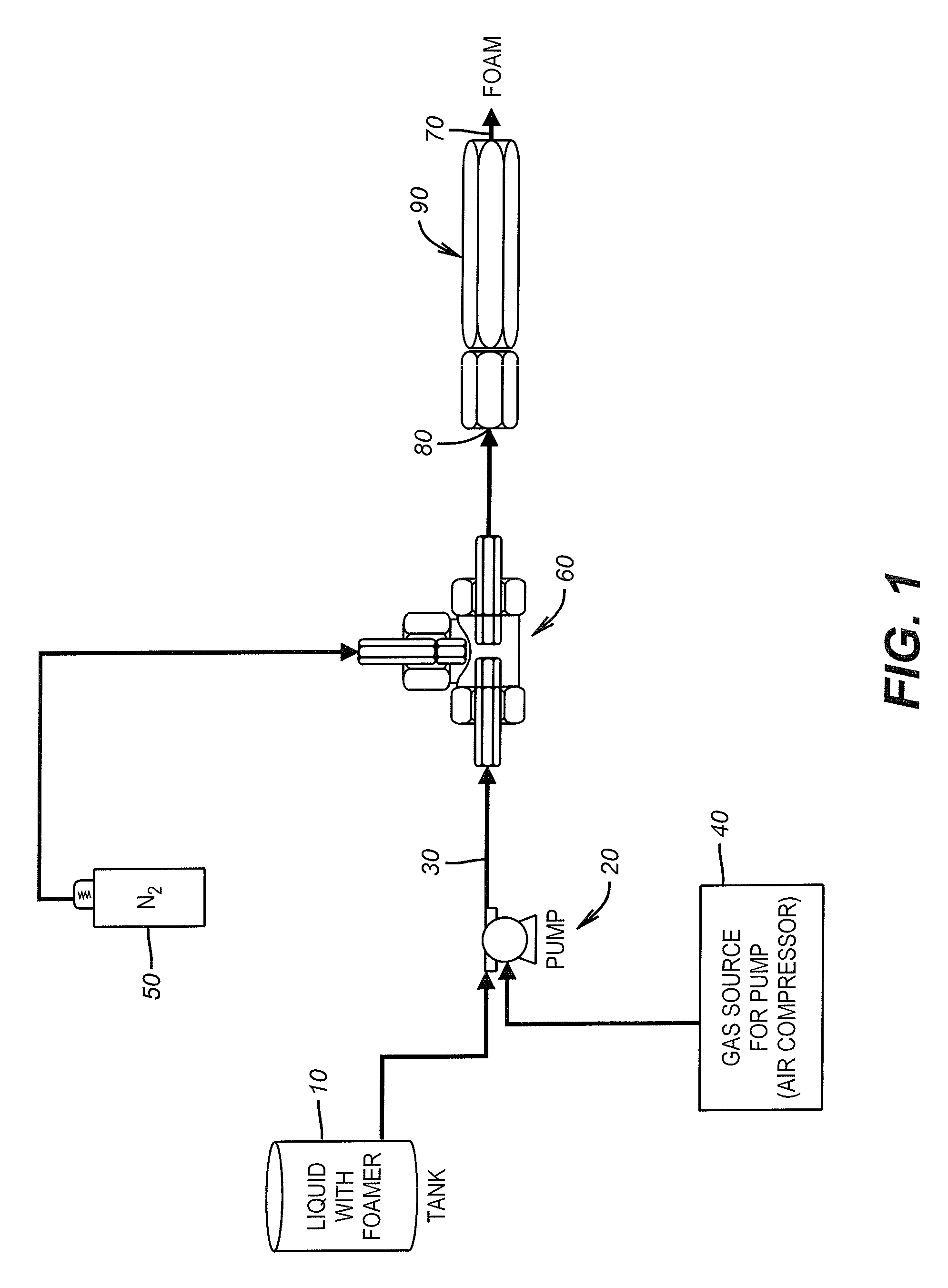

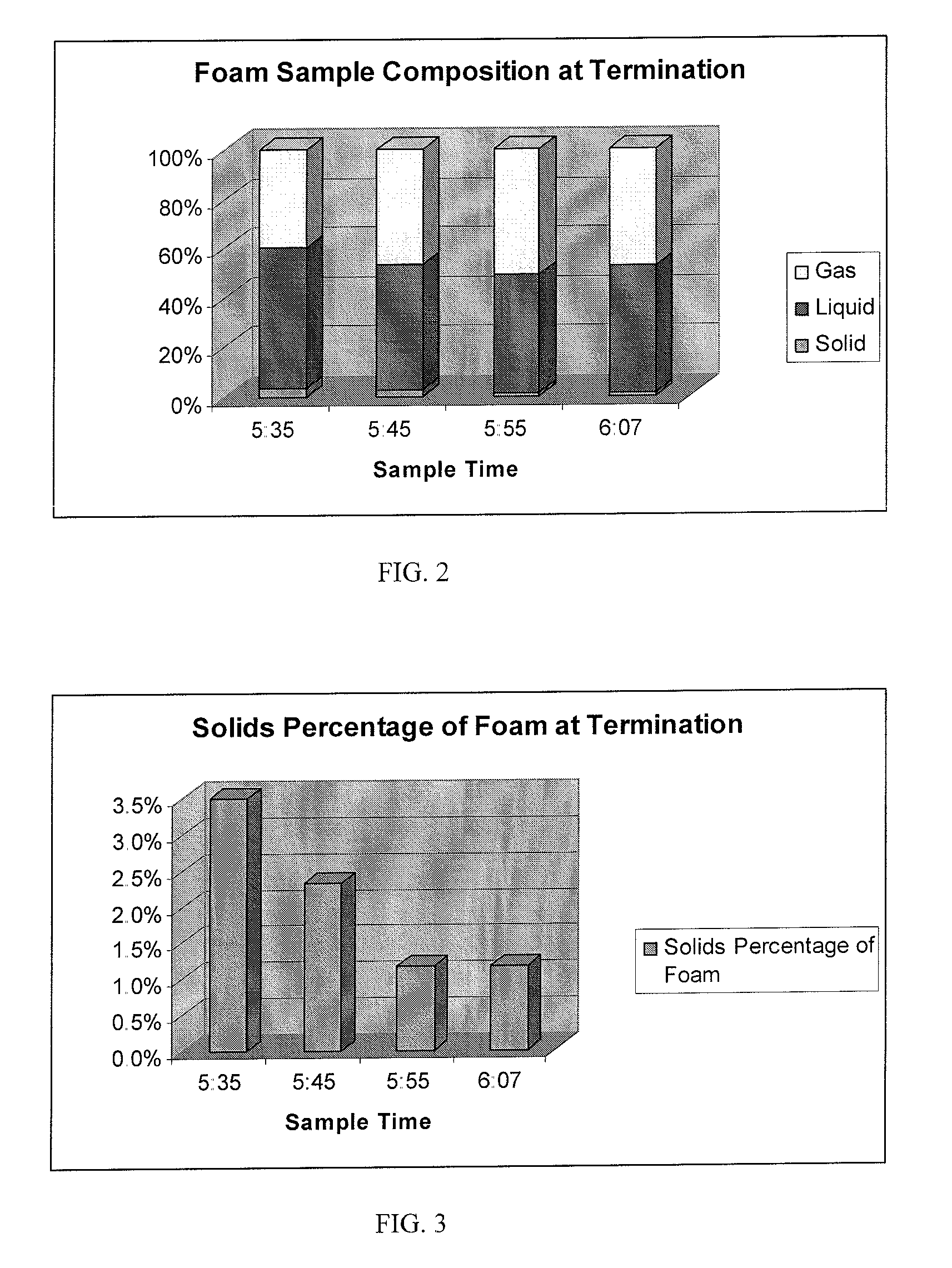

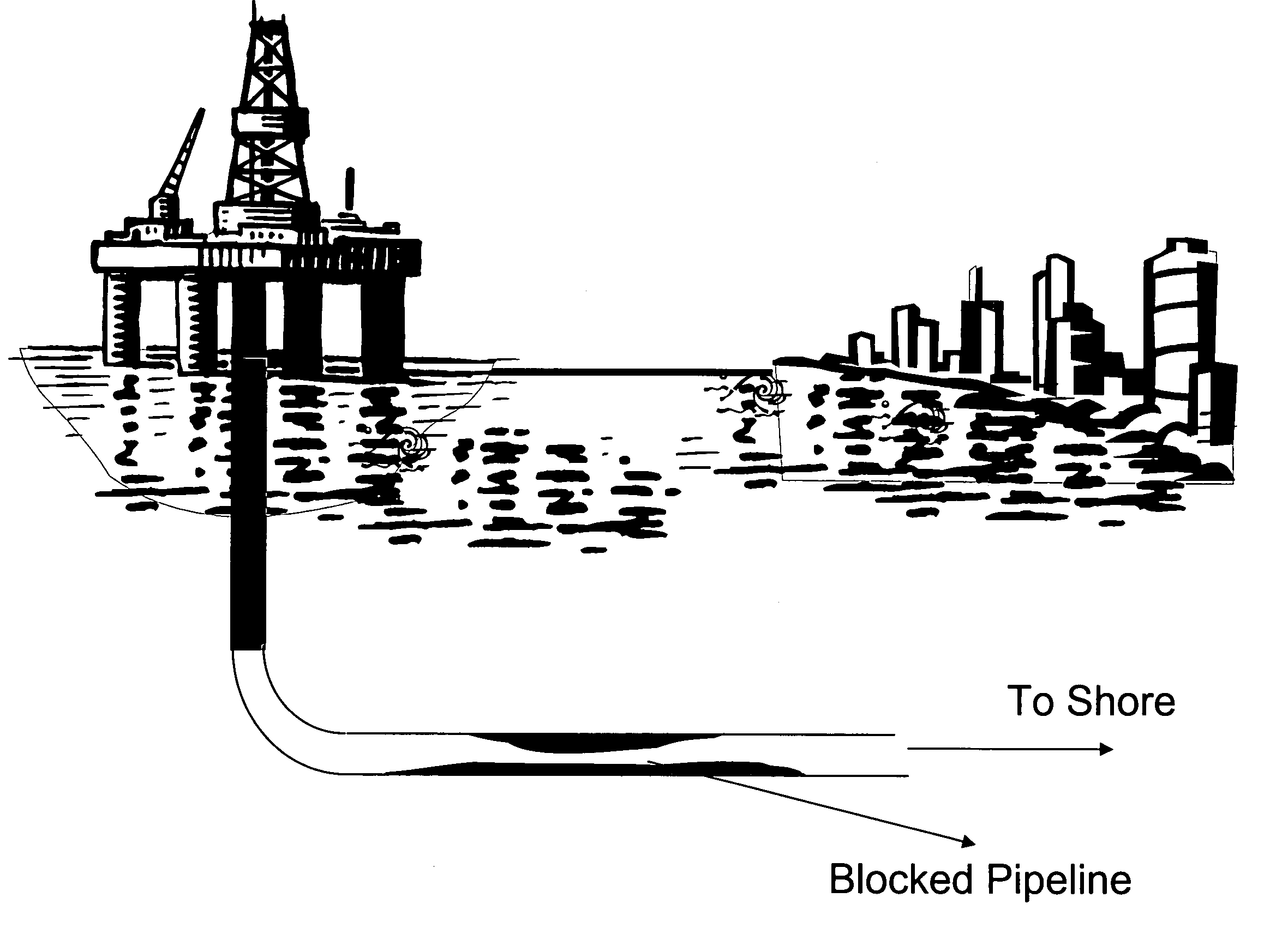

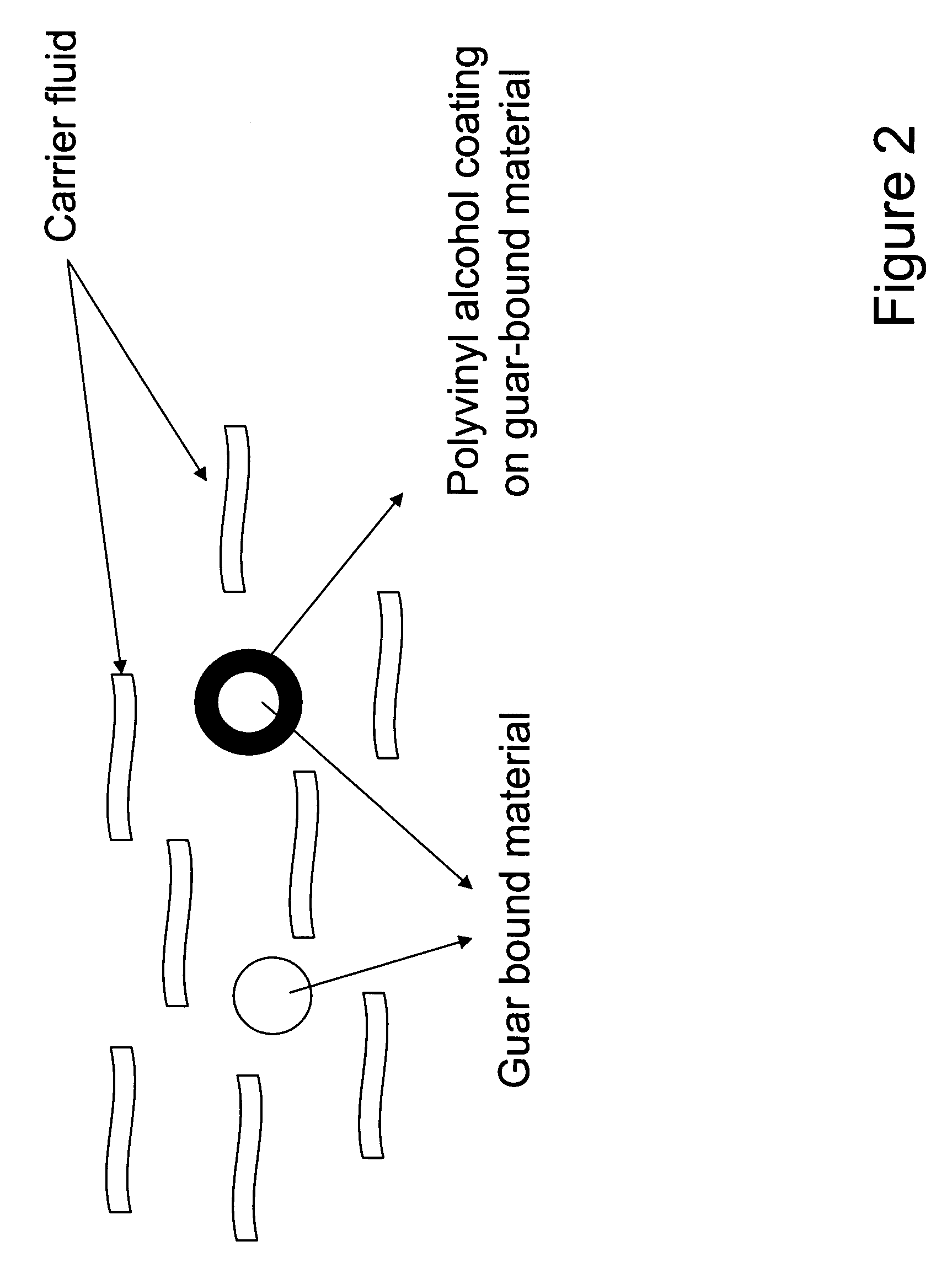

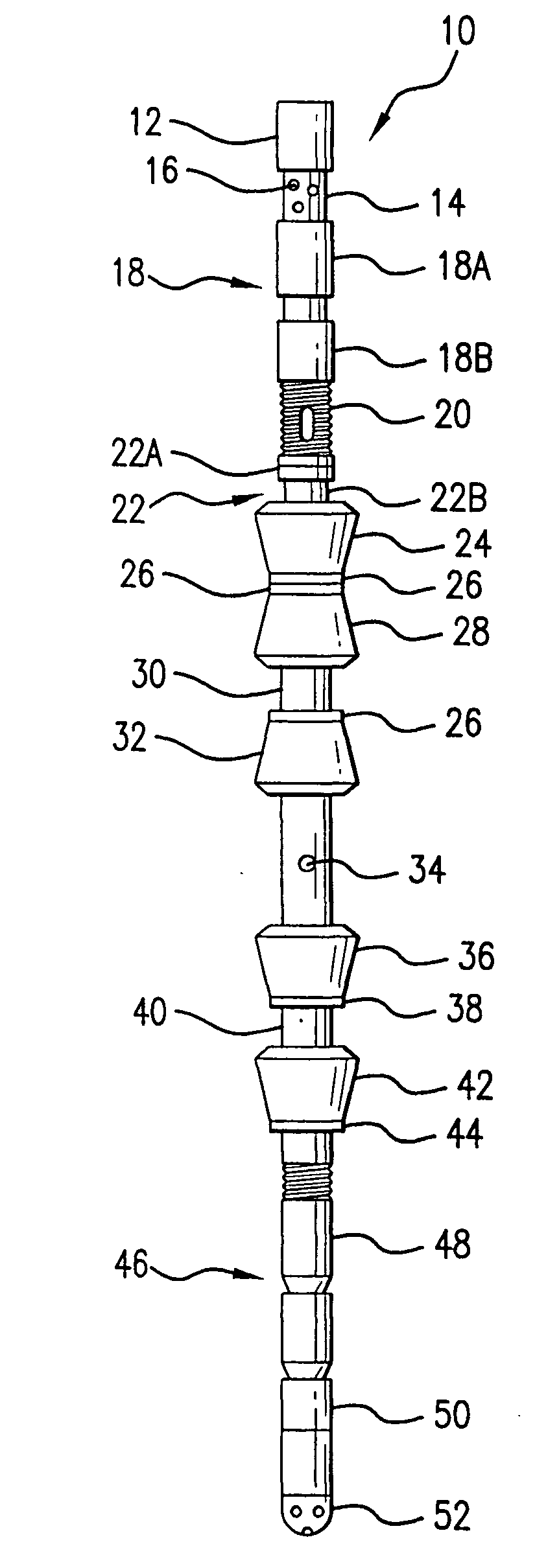

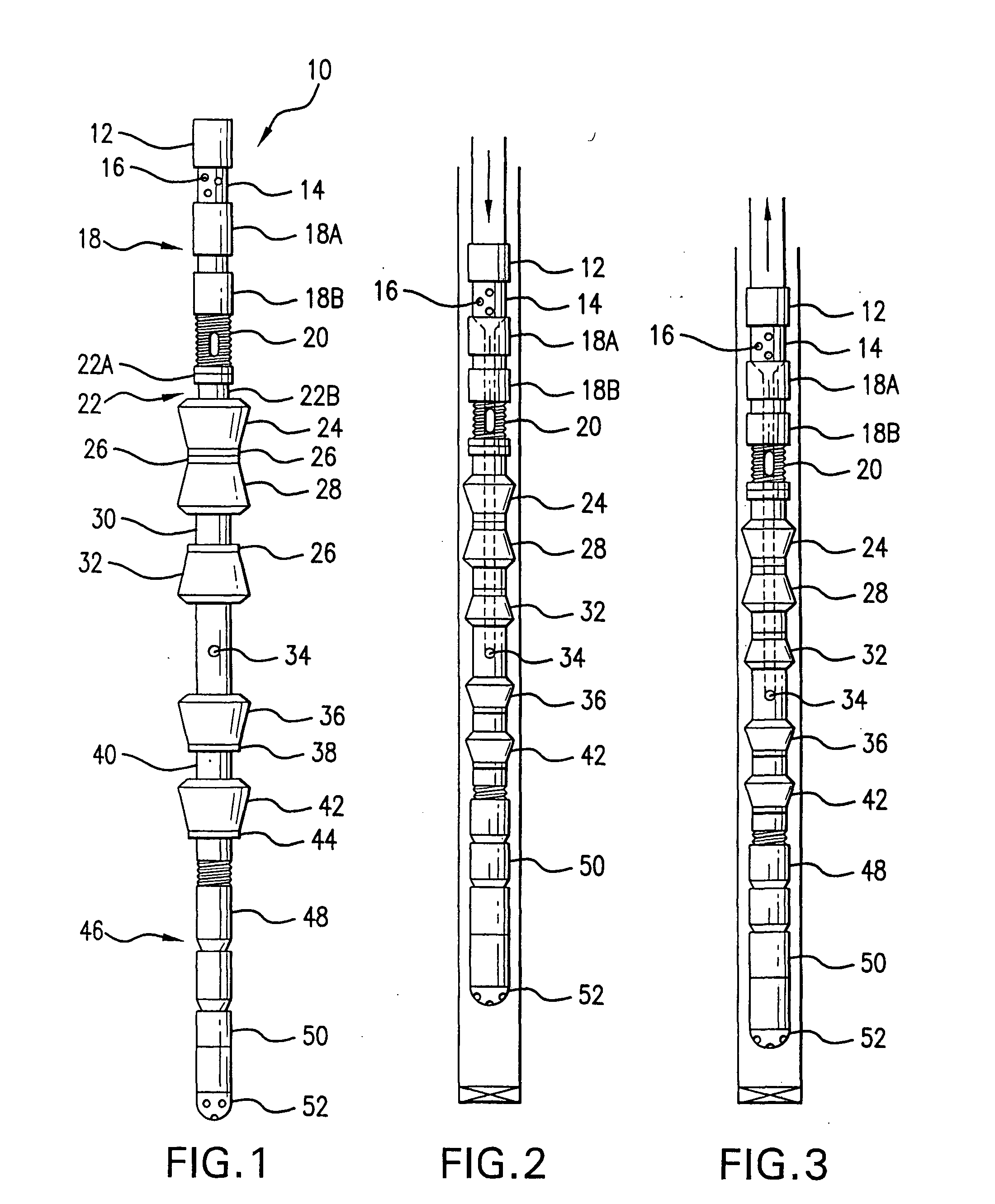

Methods and compositions for thermally treating a conduit used for hydrocarbon production or transmission to help remove paraffin wax buildup

ActiveUS7624743B2Increase temperaturePromote meltingLighting and heating apparatusOrganic-compounds/hydrides/coordination-complexes catalystsParaffin waxChemical reaction

Owner:HALLIBURTON ENERGY SERVICES INC

Mineral wax composite shape-setting phase-change material and process for preparation

The invention provides a mineral wax composite shape-setting phase-change material and process for preparation, wherein the material comprises 70-80 wt% paraffin wax substance with 44-50 deg. C melting point, 4-15% of cross bond high-density polyethylene, 4-15 wt% of styrene / ethane-butylene / styrene copolymer (SEBS), and 4-6 wt% of expanded graphite.

Owner:BEIJING UNIV OF TECH

Oil well cleaning compositions

InactiveUS20120234548A1Increase output flowEasy to useCleaning apparatusFluid removalDemulsifierHydrocarbon solvents

A method for cleaning oil wells to increase the flow of oil thereof by use of a unique cleaning emulsion comprising of water, hydrocarbon solvent, terpene hydrocarbon material, demulsifier, detergent, and optionally an acid. This one step method provides for the simultaneously cleaning / removal of asphaltene and / or paraffin and scale at a wide range of temperatures. This method can be used alone or with the assistance of a wash tool which is a combination pressure and surge wash tool having a nipple assembly, or a hydro self-rotating nozzle wash tool.

Owner:DYER RICHARD J

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

Compression-molded vegetable wax-based candle

InactiveUS20070144058A1Burn cleanSuperior compressed candle productSolid fuelsCandle ingredientsParaffin waxCompression molding

Prilled wax particles are formed from a vegetable wax-based composition. After compression, a predominantly paraffin wax-based composition is optionally poured over the vegetable wax-based composition to form an encased candle. The method of the present invention offers the possibility to incorporate a high fragrance load to the candle.

Owner:CHEN QIN +4

Spray Oil and Method of Use Therefor for Controlling Turfgrass Pests

InactiveUS20050261379A1Effective in controlling turfgrass pestEffective in controlling turfgrass pestsBiocideHydrocarbon active ingredientsParaffin waxOil phase

A paraffinic spray oil and a method of using the spray oil for controlling turfgrass pests is disclosed. The spray oil comprises paraffinic oil and a quick break emulsifier, which is formulated as an oil-in-water (O / W) emulsion for use. The paraffinic oil and emulsifier are present in a weight ratio ranging from about 95:5 to about 99.95:0.05, and preferably from about 98.5:1.5 to about 99.9:0.1. When applied to turfgrass, the O / W emulsion quickly releases the oil phase upon application to the turfgrass to contact pests thereon. When provided at sufficient paraffinic oil dosages, generally at least about 0.5 gal oil / acre and preferably in the range of about 0.5 gal / acre to about 60 gal / acre, the spray oil is effective in controlling a variety of turfgrass pests, particularly insect and fungal pests, with little or no phytotoxic effects. Further, use of the spray oil as indicated for controlling turfgrass pests also enhances the growth of turfgrass.

Owner:PETRO-CANADA

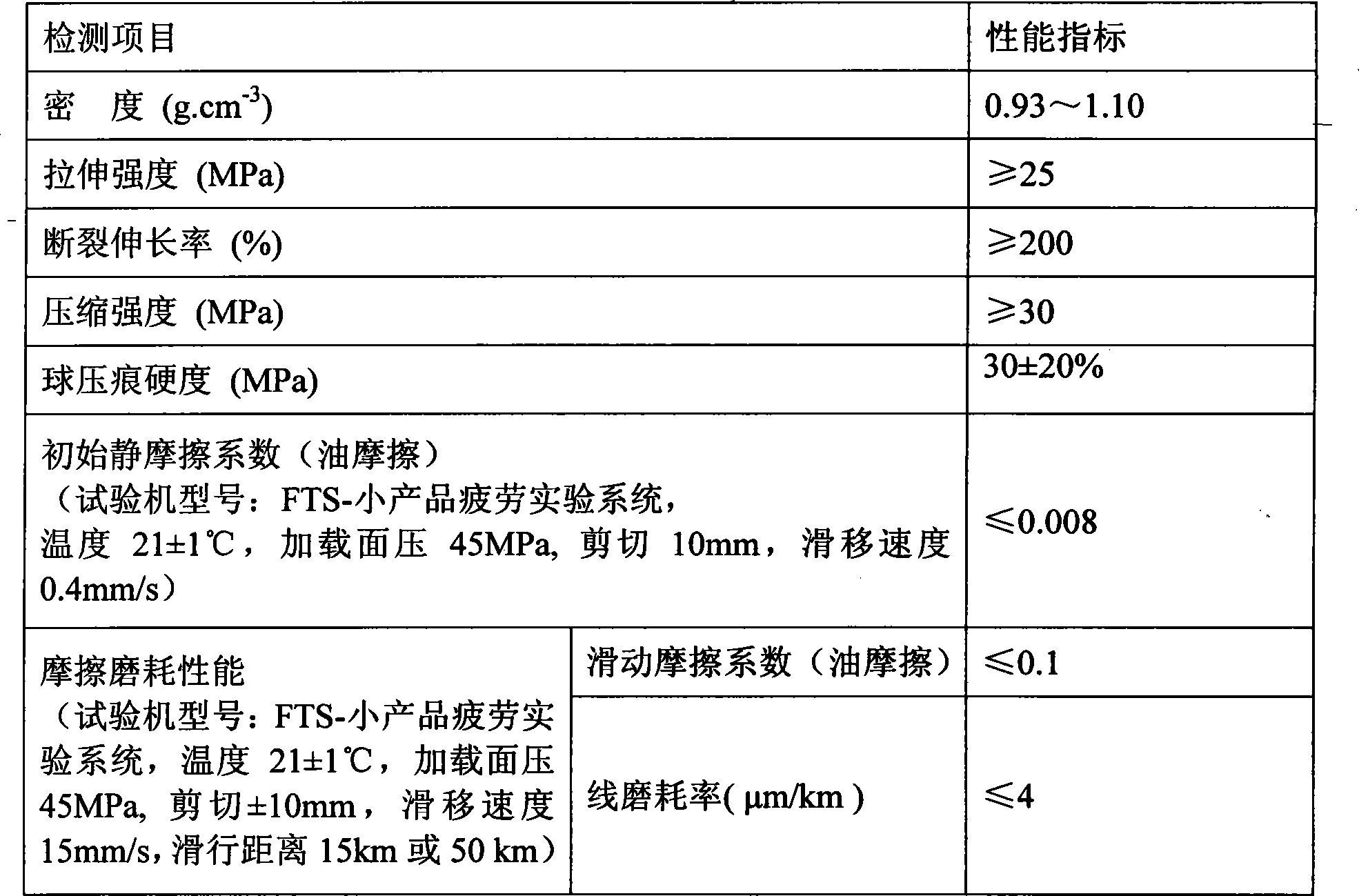

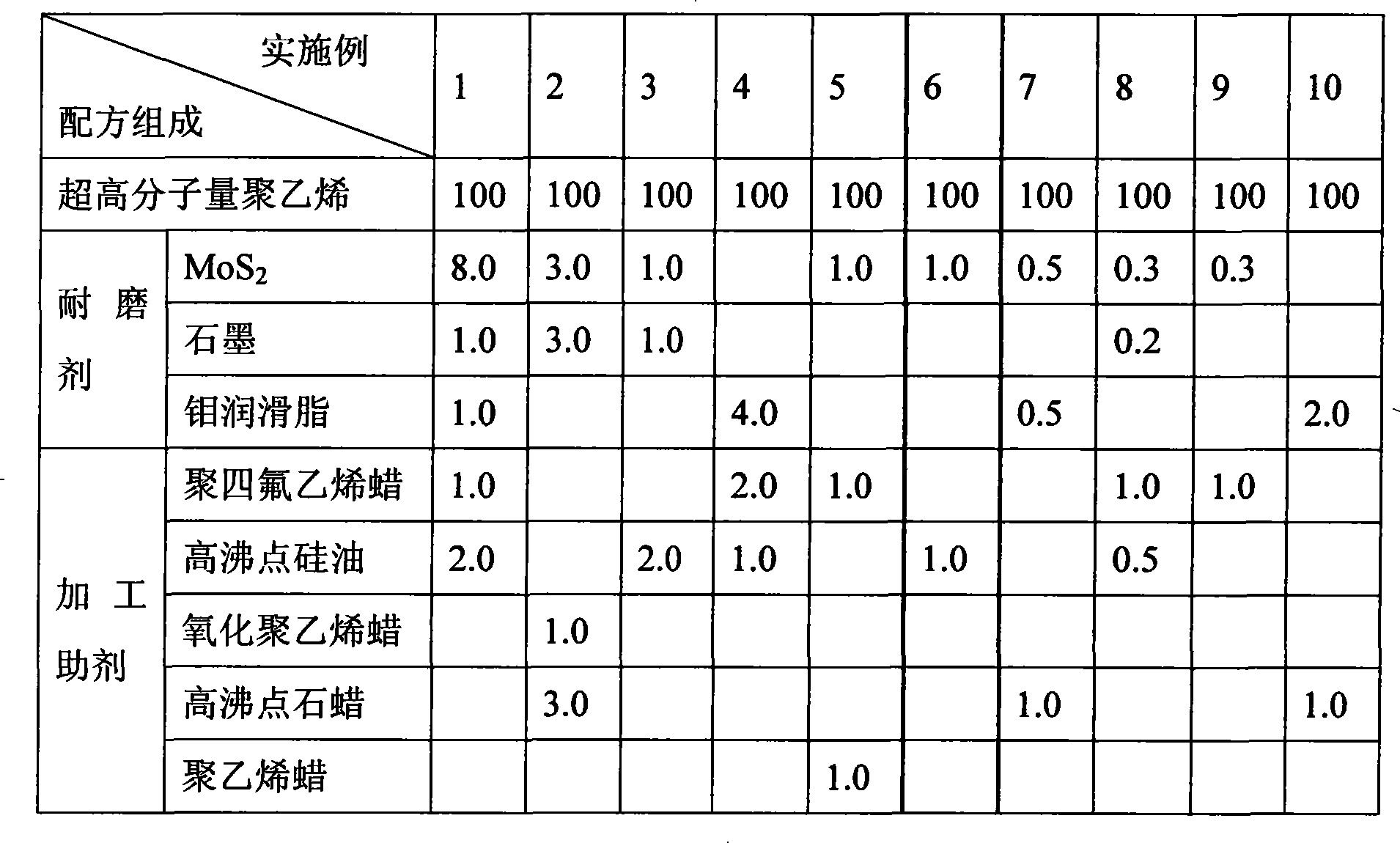

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Recipe of breviscapine drop pills and preparing method

InactiveCN1408392AReduce the number of medicationsSmooth releaseUnknown materialsPill deliveryParaffin waxIce water

The breviscaping drop pill prepared via a solid dispersing process has the recipe comprising breviscapine 20-30 wt%, polyglycol-6000 40-60 wt%, stearic acid 10-30 wt% and poloxamer-188 5-25 wt%. The preparation process includes heating to smelt polyglycol-6000, adding stearic acid and poloxamer-188, adding breviscaping powder while stirring, transferring to dropping pipe while maintaining the temperature, dropping the molten into liquid paraffin in ice water bath to solidify into pill and washing out the liquid paraffin. The present invention has high biological utilization of medicine, delays the medicine release time and reduces medicine taking times.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com