Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208 results about "DIBENZOTHIAZYL DISULFIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical classification of 2,2'-dithiobisbenzothiazole is Allergens. FDA Pharmacology Summary from FDA Pharm Classes 2,2'-Dibenzothiazyl disulfide is an accelerator used in the processing process for natural and synthetic rubber and plastic regeneration.

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

Activator compositions for cyanoacrylate adhesives

InactiveUS6995227B2Decreases base strengthAdhesive processesNon-macromolecular adhesive additivesQuinolineSulfide

Owner:HENKEL IP & HOLDING GMBH

Preparation of rubber vulcanization accelerator dibenzothiazyl disulfide

ActiveCN101463018AReduce displacementReduce the burden onOrganic chemistryDIBENZOTHIAZYL DISULFIDEMercaptobenzothiazole

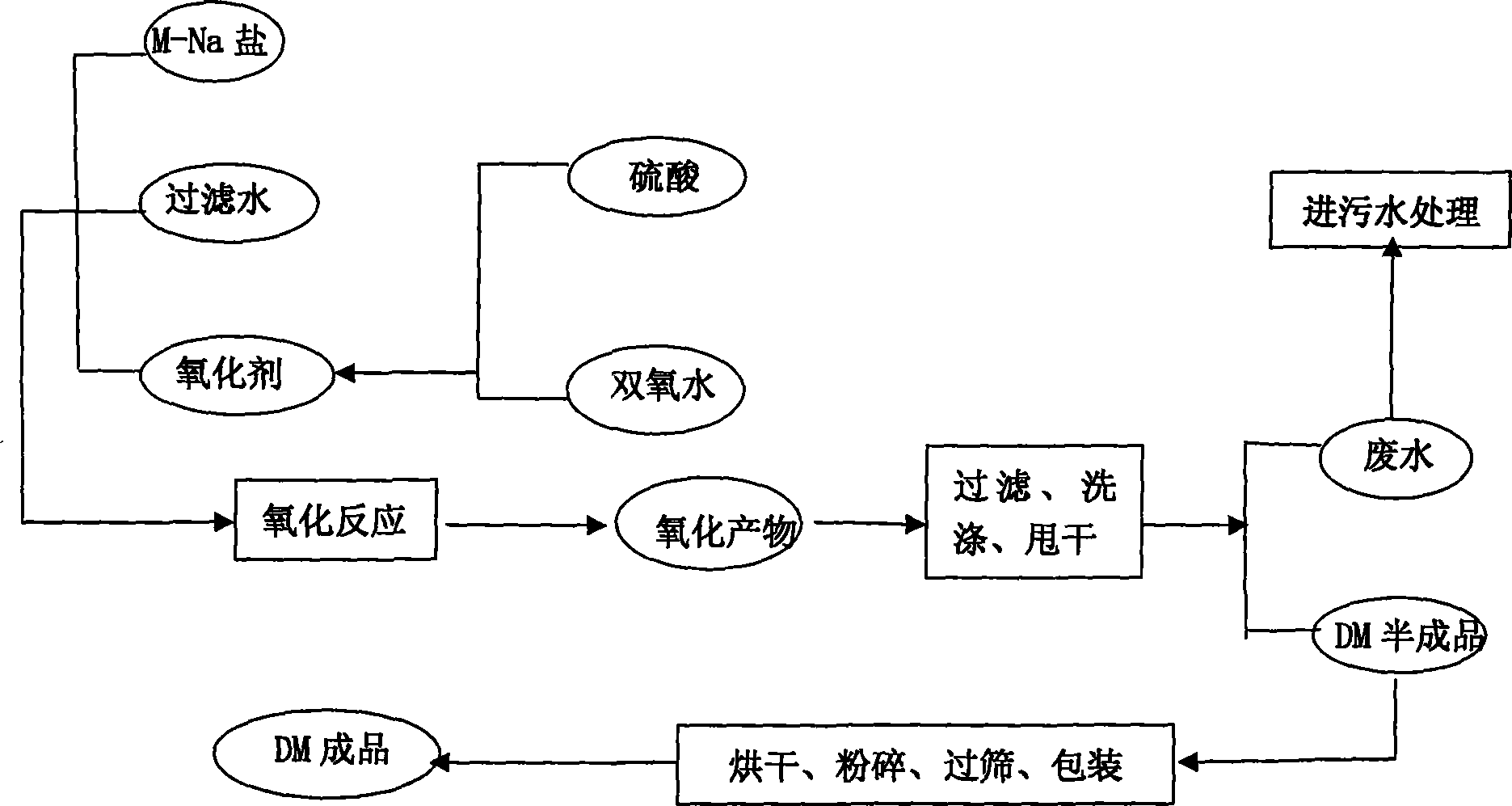

The invention relates to a preparation method of a thiofide (dibenzothiazyl disulfide), wherein, 2-mercaptobenzothiazole sodium salt is taken as a raw material, mixture of hydrogen peroxide and sulfuric acid is taken as an oxidizing agent, and the mol ratio of the hydrogen peroxide to the sulfuric acid is 0.5-2.5:1, and the method comprises the following steps (1) preparation process of the oxidizing agent: evenly mixing the hydrogen peroxide and the sulfuric acid in a container according to the mol ratio; and (2) oxidization process of the product: dropwise adding the mixture of the hydrogen peroxide and the sulfuric acid to a reaction kettle with the 2-mercaptobenzothiazole sodium salt at the temperature of 55 DEG C-65 DEG C while stirring for oxidization reaction for 60-80 minutes, keeping warm for about 0.5 hour after the oxidizing agent is added dropwise; then measuring pH value of the reaction solution, performing solid-liquid separation at the temperature of 30 DEG C when the pH value is stabilized within a range of 6.5-7.5, drying, crushing, screening and packaging the obtained solid to obtain the product. The method can help effectively enhance quality of the product, save energy and lower consumption and reduce 'three wastes' pollution.

Owner:WILLING NEW MATERIALS TECH CO LTD

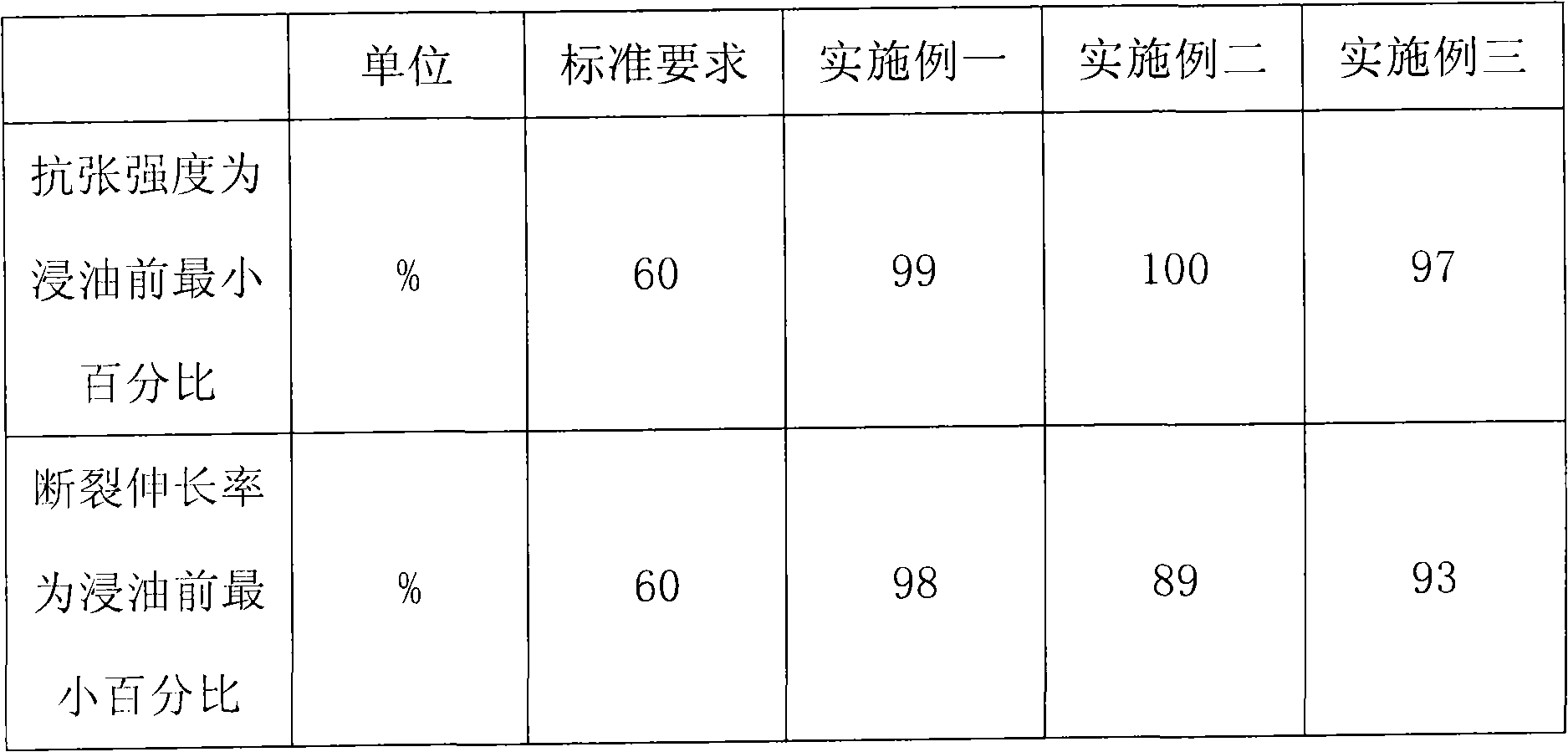

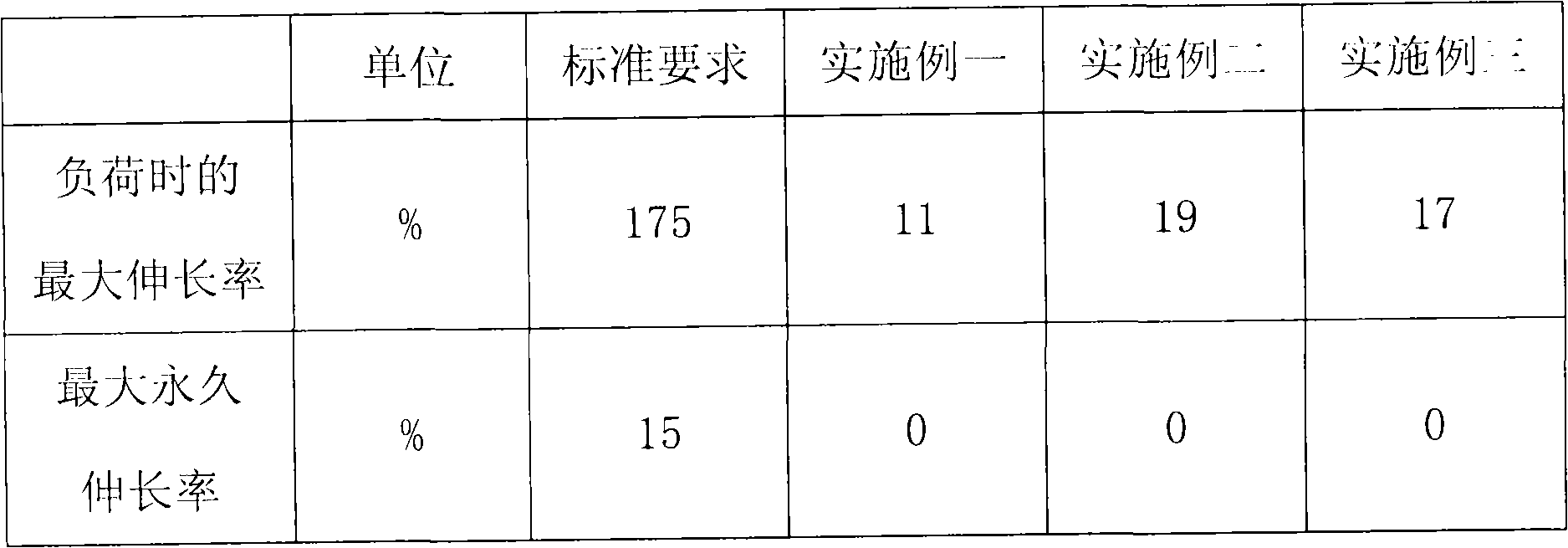

Oil resistant rubber

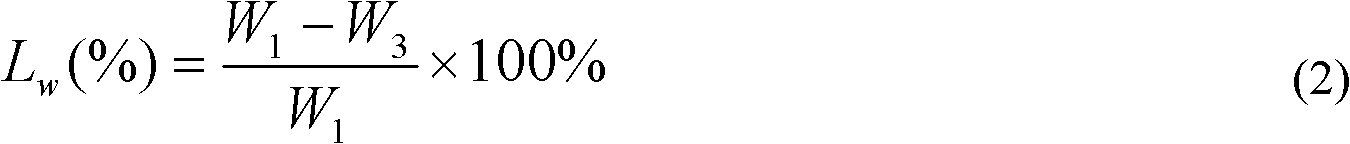

The invention discloses an oil resistant rubber, which contains the following substances in part by weight: nitrile rubber, sulfur, zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent 4010NA, paraffin, carbon black N660, carbon black N330, dibutyl phthalate, calcium carbonate, dibenzothiazyl disulfide, tetramethylthiuram disulfide and tetraethylthiuram disulfide. Compared with the prior art, the oil resistant rubber has the advantages that: the oil resistance of the oil resistant rubber produced by using the rubber formula is less than 8.5 percent, and the oil resistant rubber has good heat resistance and air tightness.

Owner:芜湖禾田汽车工业有限公司

Formulation of high-concentration ozone resistant rubber tube

InactiveCN101555327AImprove performanceMaintain physical and mechanical propertiesHigh concentrationPolymer science

The invention relates to a formulation of a high-concentration ozone resistant rubber tube, which comprises the following compositions by mass parts: 100 parts of butyronitrile PVC rubber, 20 to 40 parts of fast extruding furnace black (FEF), 20 to 40 parts of MT-N990, 5 to 15 parts of diphenyl octyl phosphate(DOP), 5 to 15 parts of light magnesium oxide, 4 to 10 parts of zinc oxide ( ZnO ), 1.5 to 3 parts of dibenzothiazyl disulfide, 1.5 to 3 parts of 1, 4-bis(tert-butyl peroxy diisopropyl) benzene, 1.5 to 2.5 parts of trially isocyanurate, 0.2 to 0.4 part of sulfur, 3 to 5 parts of coumarone, 1 to 3 parts of stearic acid, 1 to 2 parts of microcrystalline wax, 1 to 2 parts of N-isopropyl-N'-diphenyl-para-phenylene diamine, and 1 to 2 parts of 2, 2, 4-trimethyl-1, 2-dihyaroquinoline polymer. Compared with the traditional formulation, the formulation of the invention improves the function of high-concentration ozone resistance of butyronitrile PVC rubber and leads the butyronitrile PVC rubber to be suitable to the extrusion processing for producing the rubber tube of fuel tank filler, thereby improving the service life of the rubber tube of an automobile fuel tank filler and better satisfying the requirements of fuel resistance and ozone resistance of the rubber tube of the automobile fuel tank filler.

Owner:TIANJIN PENGYI GRP CO LTD

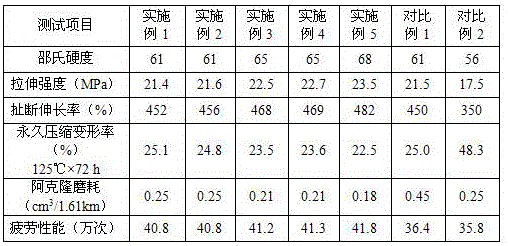

Formula of multi-functional rubber soles

InactiveCN102660057ATo achieve the purpose of multi-functionLow costSolesPolymer scienceStearic acid

The invention relates to a formula of a pair of multi-functional rubber soles, which comprises 50 to 70 parts of butadiene rubber, 8 to 12 parts of natural rubber SCR No.10, 18 to 22 parts of regenerated rubber, 5 to 5.5 parts of zinc oxide, 24 to 28 parts of N774 carbon black, 24 to 28 parts of N550 carbon black, 5 to 8.5 parts of polyisoprene, 1 to 1.5 parts of jianlumizuoxin, 1.5 to 2.5 parts of stearic acid, 1.5 to 2.5 parts of dibenzothiazyl disulfide, 2.5 to 3.5 parts of N-tertiary butyl-(2-benzothiazole) sulfenamide, 0.8 to 1.2 parts of dithiodimorpholine, 3.5 to 4.5 parts of barium sulfate, 5.5 to 8 parts of organic silicon rubber, 10 to 15 parts of nitrile rubber and 5 to 8 parts of polyurethane anti-static agent. According to the soles, the aim of a plurality of functions is achieved; and moreover, the cost is also very low, and the economic benefit is very considerable.

Owner:新疆泰安鞋业有限公司

Temperature-resistant damp-proof and insulating methyl vinyl silicone rubber cable material

InactiveCN103554922AImprove performanceImprove high temperature resistanceRubber insulatorsInsulated cablesLinear low-density polyethyleneStearic acid

The invention relates to a cable material, and in particular relates to a temperature-resistant damp-proof and insulating methyl vinyl silicone rubber cable material. The cable material comprises the following raw materials in parts by weight: 30-34 parts of methyl vinyl silicone rubber, 23-26 parts of precipitated silica, 10-12 parts of polyvinylidene chloride, 20-23 parts of linear low density polyethylene, 2-3 parts of anti-aging agent KY-405, 1-2 parts of anti-aging agent MB, 3-4 parts of magnesium oxide, 4-5 parts of stearic acid, 1-2 parts of dibenzothiazyl disulfide DM, 2-3 parts of paraffin, 3-5 parts of vaseline, 30-34 parts of spraying carbon black, 14-18 parts of nano bauxite, 20-25 parts of butyl rubber (CBK139), 5-7 parts of tributyl citrate, 2-3 parts of sulphur, 2-3 parts of zinc oxide and 4-5 parts of auxiliary. The cable material integrates the advantages of the raw materials such as the methyl vinyl silicone rubber, the butyl rubber, the polyvinylidene chloride and the linear low density polyethylene; the performance of the traditional silicone rubber cable material is improved; the temperature-resistant damp-proof and insulating methyl vinyl silicone rubber cable material provided by the invention has excellent high-temperature and low-temperature resistance and water-proof and damp-proof performance, as well as good insulation performance, can be adapted to a specific application environment condition, and therefore is wide in market prospect.

Owner:安徽文峰电子科技集团有限公司

Ion liquid high-temperature-resistant conveying belt rubber material and preparation method and application thereof

InactiveCN102336932AHeat-resistant temperature adjustableImprove thermal stabilityConveyorsRubber materialPhosphate

The invention discloses an ion liquid high-temperature-resistant conveying belt rubber material, which comprises the following raw material components in parts by weight: 80-100 parts of sizing material, 6-10 parts of DCP (Dicumyl Peroxide) vulcanizing agent, 0.5-2 parts of DM (Dibenzothiazyl Disulfide) accelerator, 1-5 parts of TT (Tetramethylthiuram Disulfide) accelerator, 5-10 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of RD (2-dihydroquinoline polymer) anti-aging agent, 0.5-1.5 parts of BLE (Acetone-Diphenylamine High-Temperature Condensate) anti-aging agent, 6-12 parts of TCP (Triorthocresol Phosphate) flame retardant, 2-5 parts of chlorinated paraffin, 3-8 parts of terpine resin, 5-8 parts of coumarone, 50-90 parts of carbon black, 3-8 parts of NO.300 paraffin oil, 0.5-1 part of sulfur and 1-10 parts of ion liquid phyllosilicate. The invention has the advantages: the ion liquid phyllosilicate is added into a formula of an adhesive tape, so that the heat-resistant temperature of the adhesive tape is adjustable, and resistance to the temperature 300-500 DEG C can be realized.

Owner:NINGBO UNIV

Microwave vulcanized ethylene propylene diene monomer (EPDM) sponge sheath and processing method thereof

InactiveCN102336971AEasy to porosityEnsure completenessFlexible pipesPipe protection against damage/wearPolymer sciencePolyethylene glycol

The invention relates to a microwave vulcanized EPDM sponge sheath and a processing method thereof. Rubber components for the sponge sheath comprise EPDM rubber, fast extruding carbon black, light calcium carbonate, paraffin oil, white factice, a dehumidifying and antifoaming agent, zinc oxide, stearic acid, polyethylene glycol, azodicarbonamide, N-cyclohexyl-2-benzothiazolesulfenamide, dibenzothiazyl disulfide, tetramethyl-thiuram disulfide and sulphur. According to the invention, mixed stock is extruded by an extruder which works under the condition that temperatures of a head, a screw section, a plasticizing section and a feeding section are set; microwave vulcanization is carried out by allowing a semi-finished product extruded by the extruder to directly enter into microwave vulcanizing equipment for vulcanization, with microwave total power maintained to be in range of 6000 to 8000 W, temperature of a microwave section set to be 200 DEG C, and temperature of a heating section set to be 200 to 220 DEG C from beginning to end. The invention enables a uniformly distributed closed pore bubble structure to be formed easily and dimension of a product to be controlled easily. Rapid heat generation of microwave enables vulcanization time to be reduced to some extend, thereby improving production efficiency.

Owner:TIANJIN PENGYI GRP CO LTD

Chlorosulfonated polyethylene lead-free recipe for power steering pipe

The invention relates to a chlorosulfonated polyethylene lead-free recipe for a power steering pipe. The recipe contains the following components: 100 parts of chlorosulfonated polyethylene rubber (CSM), 30-50 parts of fast extruding furnace black (N550), 15-35 parts of softener T810T, 5-20 parts of dioctyl sebacate (DOS), 10-20 parts of light calcium carbonate, 0.5-2 parts of flow promotor WS1 80, 0.5-2 parts of flow promotor WA 48, 0.5-2 parts of antiager NDBC, 0.5-3 parts of N'N-m-phenylene dimaleimide (HVA-2), 0.5-2 parts of dipentamethylenethiuram tetrasulfide (DPTT) and 0.5-1 part of dibenzothiazyl disulfide DM. The recipe has the characteristics of high strength, high hardness, low compression residual deformation, oil resistance and the like, thereby completely meeting the demands of the power steering pipes; meanwhile, the recipe has no toxin or odor and is stable in storage.

Owner:TIANJIN PENGYI GRP CO LTD

Cable insulated rubber for ship hydrophone equipment and preparation method thereof

InactiveCN102093643AImprove insulation performanceImprove mechanical propertiesRubber insulatorsQuinonePolymer science

The invention discloses cable insulated rubber for the ship hydrophone equipment and a preparation method thereof. The rubber comprises the following components in parts by weight: 11 parts of ethylene propylene rubber 2470, 7-9 parts of ethylene propylene rubber 578K, 0.1-0.3 part of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 0.5-0.8 part of 2-Mercaptobenzimidazole, 0.4-0.7 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1-1.5 parts of titanium white powder, 1.5-2.0 parts of microcrystalline wax, 0.2-0.5 part of stearic acid, 2-3 parts of white carbon black, 8-12 parts of ultrafine coupling agent, 0.2-0.4 part of calcined clay, 5-8 parts of ultrafine talcum powder, 1-1.5 parts of red lead masterbatch, 1-1.5 parts of dicumyl peroxide and 0.15-0.25 part of quinone dioxime. The preparation method comprises the following steps: mixing ethylene propylene rubber, then adding zinc oxide and some components, filtering rubber, rolling, cooling, adding dibenzothiazyl disulfide, finally adding dicumyl peroxide and quinone dioxime, performing triangle packaging, thinning, and discharging the prepared rubber sheets. The insulated rubber of the invention has good insulating property and long service life and can meet the operational requirements of the ship hydrophone equipment.

Owner:JIANGSU YUANYANG DONGZE CABLE

Buoy communication cable sheath rubber for ship and manufacturing method thereof

InactiveCN102140209AImprove compactnessStrong water resistanceRubber insulatorsCommunication cablesParaffin waxPolyethylene glycol

The invention discloses a buoy communication cable sheath rubber for a ship and a manufacturing method thereof; raw materials of the buoy communication cable sheath rubber comprises the following components: 20 portions of chlorosulfonated polyethylene Haplon-40, 1 to 1.5 portion of magnesium oxide, 3.5 to 4.5 portions of yellow lead masterbatch, 0.5 to 1 portion of paraffin wax, 0.5 to 1 portion of polyethylene glycol, 0.5 to 1 part of coumarone, 1.5 to 2 portion(s) of antimonous oxide, 2.5 to 3 portions of dioctyl phthalate, 5.0 to 6.5 portions of semi-reinforcing carbon black, 4.5 to 6 portions of talcum powder, 0.3 to 0.5 portion of dipentamethylenethiuram hexasulfide, 0.4 to 0.6 portion of dibenzothiazyl disulfide and 0.2 to 0.5 portion of nickel dibutyldithiocarbamate. Firstly, the chlorosulfonated polyethylene Haplon-40 is mixed, then magnesium oxide and the like are added to be mixed so that the mixed material is evenly stirred; then the dipentamethylenethiuram hexasulfide, the dibenzothiazyl disulfide and the nickel dibutyldithiocarbamate are added into the mixed material and mixed; finally, the mixed raw materials are tableted and dissipated; simultaneously, five cornucoplas are turned on an open mill, then are evenly turned and pulled to be thin and finally are produced by a three-roller leaf rolling machine.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-performance composite cable jacket material for cables

InactiveCN104610666ALow costDelay agingInsulated cablesInsulated conductorsStearic acidChlorinated paraffins

The invention discloses a high-performance composite cable jacket material for cables. The high-performance composite cable jacket material is prepared from the following raw materials in parts by weight: 35-45 parts of ethylene propylene terpolymer, 30-50 parts of EVA resin, 30-45 parts of modified nanokaolin, 1-2 parts of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 1-3 parts of zinc dimethyldithiocarbamate, 1-2 parts of anti-aging agent ODA, 45-55 parts of high abrasion furnace black, 25-35 parts of calcined clay, 20-30 parts of nano calcium carbonate, 1-1.8 parts of dioctyl phthalate, 1-3 parts of stearic acid, 0.5-1.5 parts of chlorinated paraffin, 2-4 parts of solid calcium-zinc stabilizer and 1-2.5 parts of anti-aging agent RD. The high-performance composite cable jacket material for cables disclosed by the invention has good ageing resistance, good mechanical properties and low cost.

Owner:ANHUI HONGYI CABLE GROUP

Sheathing material for power cables and preparation method thereof

InactiveCN103788517AAvoid premature vulcanizationHigh tensile strengthRubber insulatorsInsulated cablesPotassiumPolyethylene glycol

The invention discloses a sheathing material for power cables. The sheathing material comprises the following raw materials in parts by weight: 12-16 parts of chlorosulfonated polyethylene, 3-6 parts of butadiene-acrylonitrile rubber, 6-9 parts of chlorinated butyl rubber, 0.3-0.5 part of zinc dimethyldithiocarbamate, 0.3-0.7 part of dibenzothiazyl disulfide, 1.2-1.7 parts of an activator zinc oxide, 2-3 parts of stearic acid, 0.6-1 part of N-(cyclohexylthio)phthalimide, 0.5-1 part of chlorinated paraffin, 1-2 parts of a surfactant polyethylene glycol, 1.5-2 parts of potassium chloroplatinate, 1-4 parts of dioctyl phthalate, 4-7 parts of a reinforcing agent carbon black 330, 4-6 parts of a filler ultrafine talcum powder, and 2.5-4 parts of a filler calcium carbonate. The invention also discloses a preparation method of the sheathing material for power cables. According to the invention, the sheathing material for the power cables is good in mechanical properties, high in tensile strength, good in tear strength and wear resistance, excellent in aging resistance, simple in preparation process, and low in production cost.

Owner:ANHUI ZHONGTONG CABLE TECH

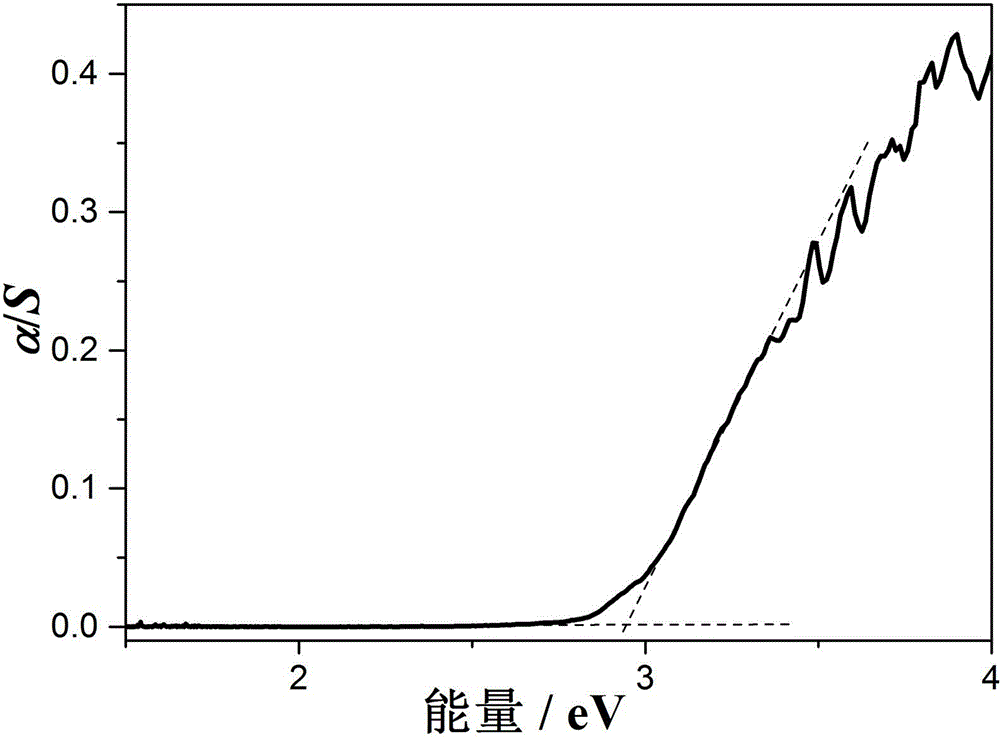

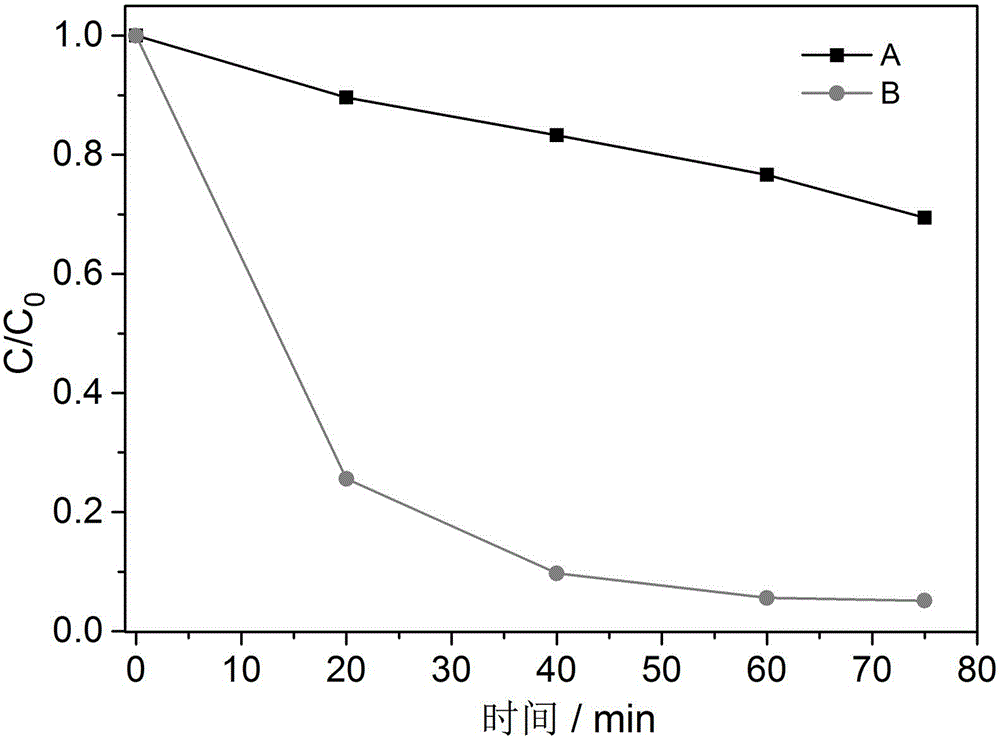

AgI-based inorganic-organic hybrid semi conducting material synthesis and application for photocatalytic degradation of dye

InactiveCN104399531AWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsSilver iodideSemiconductor materials

The invention relates to an AgI-based inorganic-organic hybrid semi conducting material synthesis and an application for photocatalytic degradation of a dye. A purpose of the present invention is synthesis of an inorganic-organic hybrid semi conducting material (Et2mbt)Ag2I3 capable of effectively catalyzing and degrading a methyl orange dye, wherein Et is ethyl; mbt is 2-mercaptobenzothiazole. According to the invention, organic molecules containing N and S elements are introduced in inorganic AgI, so that inorganic AgI performance can be kept, and Ag content can be reduced. In the invention, silver iodide, dibenzothiazyl disulfide, ethanol and hydroiodic acid are taken as the reaction raw materials, and monocrystalline of the compound (Et2mbt)Ag2I3 can be obtained under heat condition of a solvent. According to the invention, excellent photocatalysis performance of the hybrid semi conducting material can be used for degradation of methyl orange pollutant in life and industrial sewage, and the semiconductor performance of the hybrid semi conducting material can be used for manufacturaing the semiconductor devices.

Owner:UNIV OF JINAN

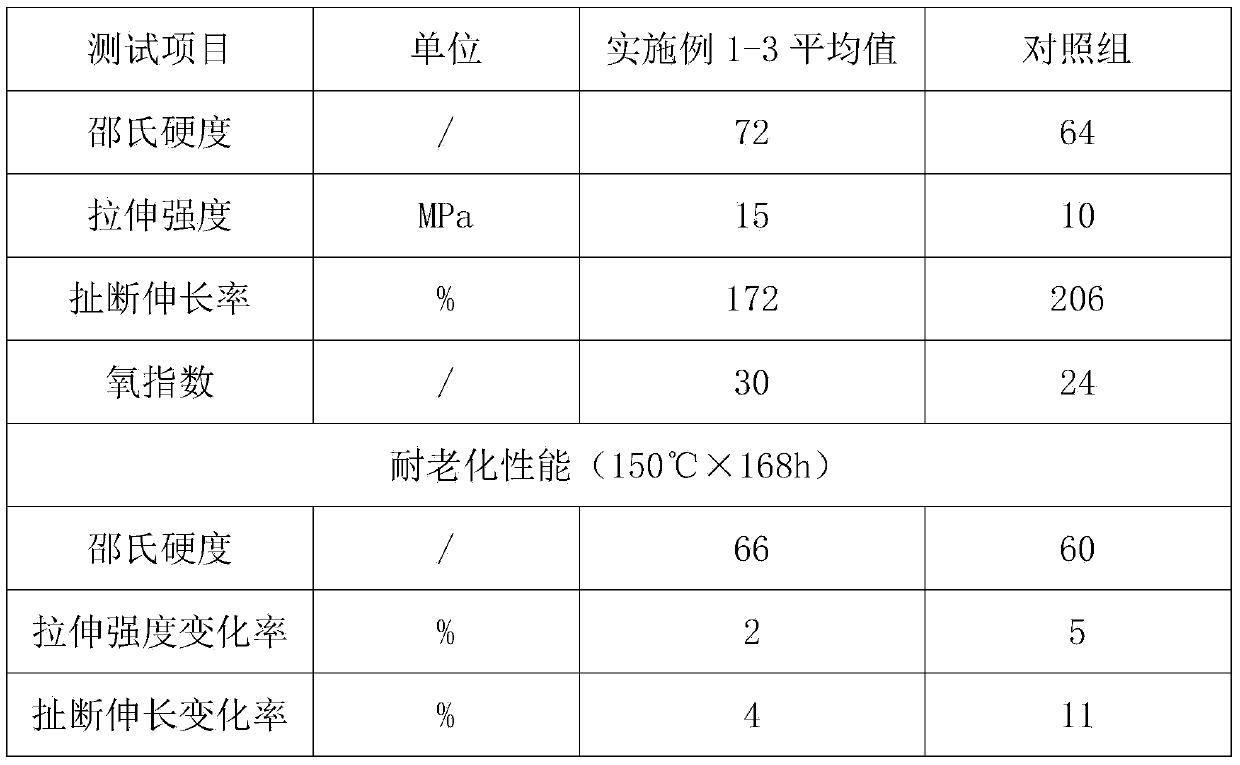

Aging-resistant and high-hardness cable material and preparation method thereof

InactiveCN106317855AStrong weather resistanceHigh strengthRubber insulatorsPlastic/resin/waxes insulators2-mercaptoacetatePolystyrene

The invention discloses an aging-resistant and high-hardness cable material and a preparation method thereof. The cable material is prepared from materials in parts by mass as follows: 20-35 parts of a modified polyurethane composite, 15-30 parts of styrene butadiene rubber, 5-8 parts of polystyrene resin, 3-10 parts of pentaerythritol tetrakis(2-mercaptoacetate), 0.5-1.5 parts of ammonium dichromate, 1-3 parts of dibenzothiazyl disulfide, 20-30 parts of nano-silica, 45-50 parts of activated calcium carbonate, paraffin and the like. The cable material has very high weather resistance, the effect of the environment on a cable sheath is reduced, and besides, the cable material is high in strength, good in hardness, high in shock resistance, excellent in stability, long in service life, good in thermo-oxidation stability, aging-resistance and excellent in mechanical property.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Ethylene propylene diene monomer hose for microwave vulcanization

InactiveCN101985504ASlow initial sulfur pointEasy extrusionFlexible pipesPolyethylene glycolStearic acid

Owner:TIANJIN PENGYI GRP CO LTD

Method for preparing low-leaching-rate water-swellable rubbers

The invention relates to a method for preparing low-leaching-rate water-swellable rubbers. The prepared low-leaching-rate water-swellable rubber comprises the following raw materials in parts by weight: 100 parts of obtained modified rubbers, 10 to 40 parts of obtained super water absorbent resins, 5 to 30 parts of plant fiber powder, 2 to 8 parts of zinc oxide, 0.2 to 1 parts of stearic acid, 1 to 5 parts of sulphur, 0.5 to 4 parts of dibenzothiazyl disulfide, 10 to 80 parts of filler, and 5 to 50 parts of softener, and the method comprises the following steps: mixing the raw materials for 5 to 60 minutes; standing the obtained mixture for 10 to 12 hours; and carrying out vulcanization and pressure molding on the obtained deposit so as to obtain the low-leaching-rate water-swellable rubbers. The rubbers prepared by using the method of the invention have the characteristics of high expansion ratio, low leaching rate and good water retention performance. The invention overcomes the defects that strongly polar bibulous trees subjected to soaking in traditional water-swellable rubbers are easy to desorb from the rubbers, and the expansion rate of the traditional water-swellable rubber after used repeatedly is reduced; and the preparation method is simple, and low in equipment requirement.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Low-cost flame-retardant cable sheath material

Owner:ANHUI MENTOR CABLE GROUP

Oil-resistant rubber cushion

InactiveCN103540038AGood oil resistanceImprove heat resistanceHeat resistanceEthylene-propylene-diene-monomer

The invention relates to an oil-resistant rubber cushion which comprises 90 parts of ethylene propylene diene monomer, 75 parts of tetrapropyl fluororubber, 7 parts of calcium carbonate, 3 parts of dibenzothiazyl disulfide, 5 parts of paraffin and 6 parts of plasticizing and softening agent. The rubber pipe clamp also comprises 3 parts of stearic acid. The rubber pipe clamp also comprises 5 parts of tetraethylthiuram disulfide. Compared with the prior art, the high-temperature-resistant rubber foot pad enhances the oil resistance of the natural rubber to 8-10%, and has favorable heat resistance and air tightness.

Owner:QINGDAO BOYUTE RUBBER & PLASTIC PRODS

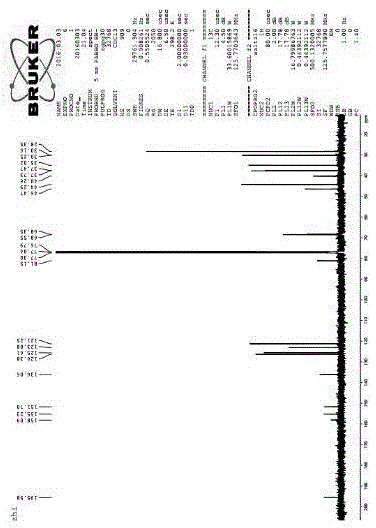

Preparation method of rubber accelerator dibenzothiazyl disulfide

The invention relates to a preparation method of rubber accelerator dibenzothiazyl disulfide. The preparation method comprises the following steps of: measuring 500 ml of M-Na salt solution; dropwise adding mixed oxidant into a container with the M-Na salt solution according to a proportion of 58-80 ml of mixed oxidant per every liter of M-Na salt solution under a stirring condition at 70-80 DEG C; controlling the pH (Potential of Hydrogen) to be stable in a range of 6.5 to 7.5; adding 0.1-0.2 g of 30 percent sodium hydroxide solution after the pH is stabilized; directly oxidizing the M-Na salt to obtain a DM product. The preparation method has the advantages that (1) a hydrogen peroxide stabilizer is added, so that the oxidation of the oxidant is improved, (2) no toxic gas is produced in a production process, so that the environmental pollution is less, the operation is easy and the production period is short, (3) a product has white appearance, high purity and a melting point of greater than or equal to 173 DEG C, (4) a small amount of caustic soda liquid is added, so that the product quality and the purity are improved, and (5) separation can be performed without cooling after the reaction is finished, so that the process period is shortened, the energy consumption is reduced and the cost is saved.

Owner:KEMAI CHEM

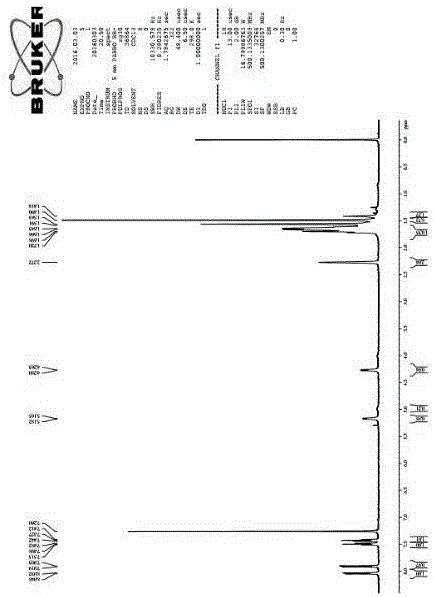

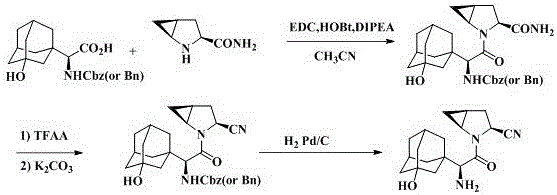

Amino-protected 3-hydroxy adamantane glycine benzothiazole-2-thiol active ester as well as preparation method and application thereof

ActiveCN106349185AIncrease structural diversityCheap and easy to getOrganic chemistryChemical recyclingSaxagliptinChemical structure

The invention relates to an amino-protected 3-hydroxy adamantane glycine benzothiazole-2-thiol active ester as well as a preparation method and application thereof. The thiol active ester is prepared by virtue of reaction between amino-protected 3-hydroxy adamantane glycine and dibenzothiazyl disulfide. The invention further discloses application of the compound in the preparation of a saxagliptin intermediate and saxagliptin. The invention provides a brand new chemical structure. The preparation method is simple and low in cost; the compound is applicable to the preparation of saxagliptin, so that the preparation process can be effectively simplified; and the reaction is mild, and the compound has a wide generalization prospect.

Owner:艾博仕医药科技石家庄有限公司

High-performance fluorine rubber gasket and manufacturing method thereof

The invention discloses a high-performance fluorine rubber gasket. The high-performance fluorine rubber gasket comprises, by weight, 40-80 parts of binary fluorine rubber, 20-30 parts of silane-modified fluororubber, 12-20 parts of atomized carbon black, 5-10 parts of barium sulfate, 5-15 parts of calcium hydroxide, 1-5 parts of calcium titanate, 1-3 parts of chelate titanate coupling agents, 2-6 parts of molybdenum disulfide, 2-6 parts of phenyl methylpolysilicone resin, 1-2 parts of magnesium oxide, 1-3 parts of dicumyl peroxide, 0.5-1.2 parts of dibenzothiazyl disulfide, 0.5-1.2 parts of triallyl isocyanurate, 1-1.8 parts of bisphenol A, 1-3 parts of hexafluoride isopropylidene diphenol, 1-3 parts of benzyl triphenyl phosphoric chloride, 1-2 parts of sodium stearate, 1-3 parts of palm wax, 1-3 parts of fluorinated polyamide and 1-2 parts of fatty alcohol. The invention further discloses a manufacturing method of the high-performance fluorine rubber gasket. The compression deformation and high-temperature steam resistance of the fluorine rubber gasket are excellent, and the manufacturing method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

Novel process for producing medical intermediate DM (dibenzothiazyl disulfide)

ActiveCN102863401AImprove conversion efficiencyNo pollutionOrganic chemistryReaction rateTechnical grade

The invention relates to a novel process for producing a medical intermediate DM (dibenzothiazyl disulfide). The process comprises the following step of: oxidizing 2-thiolbenzothiazole under the catalytic action of benzyltriethylammonium chloride serving as a catalyst at the temperature of lower than 50 DEG C by taking hydrogen peroxide as an oxidant and taking an isopropanol aqueous solution as a solvent. The benzyltriethylammonium chloride serving as the catalyst is adopted, so that the conversion rate of M is almost up to 100 percent, and the reaction rate is increased; isopropanol is selected as a reaction solvent, is recycled in a production process, is environmentally-friendly, and is low in toxicity; an obtained product has very ideal quality (the melting pint is more than or equal to 178.0 DEG C, and the content is more than or equal to 98.0 percent); all used raw materials are industrial grade products, are low in cost, are readily-available, and have good economic benefits; and in an entire reaction process, a normal pressure state is kept, the temperature does not surpass 50 DEG C, the safety coefficient is high, and the entire reaction process is suitable for industrial large-scale production.

Owner:温州市嘉力新材料有限公司

High-property modified nitrile butadiene rubber cable material used for ships

InactiveCN105153497AImprove thermo-oxidative stabilityGood mechanical propertiesRubber insulatorsAlkaneFiber

The invention discloses a high-property modified nitrile butadiene rubber cable material used for ships. The cable material comprises the following raw materials in parts by weight: 20-40 parts of nitrile butadiene rubber, 5-10 parts of modified polyurethane composite material, 12-18 parts of styrene butadiene rubber, 5-15 parts of butadiene rubber, 1-2 parts of oleic acid, 0.5-1.5 parts of stearic acid, 1-2 parts of ammonium dichromate, 0.8-1.4 parts of dibenzothiazyl disulfide, 15-30 parts of kaolin, 8-12 parts of pottery clay powder, 42-55 parts of white carbon black, 5-10 parts of graphite, 1-3 parts of octyl-phenolic tackifying resin, 10-30 parts of ceramic fibers, 20-40 parts of modified active fibers, 0.5-1.5 parts of diisooctyl phthalate, 1-1.4 parts of aromatic hydrocarbon oil, 0.4-0.8 part of naphthenic hydrocarbon oil, 0.5-1.4 parts of antioxidant AT-215, 1-3 parts of ultraviolet absorber UV-531 and 1-2 parts of ultraviolet absorber TB75. The cable material has good thermal oxidative stability and excellent mechanical properties and is resistant to aging.

Owner:安徽华润仪表线缆有限公司

Automotive abrasion-resistant damping rubber and preparation method thereof

The invention provides automotive abrasion-resistant damping rubber and preparation method thereof. The preparation method comprises the following steps that 1, natural rubber and polybutadience rubber are added to a mixer for mixing; 2, the rubber material obtained in the step 1, high-abrasion-resistance carbon black N330, zinc oxide, stearic acid, N-isopropyl-N'-phenyl para-phenylenediamine, styrenated phenol, dibenzothiazyl disulfide, tetramethyl thiuram disulfide, polyether urethane modified epoxy resin, polyacrylate toughened and modified epoxy resin, nano silicon carbide, calcium sulfate whiskers and magnesium borate whiskers are added to the mixer for mixing; (3) sulfur is added to the rubber material in the step 2 for mixing again; 4, the rubber material obtained in the step 3 is vulcanized in a vacuumizing and vulcanizing machine. The automotive abrasion-resistant damping rubber has good elasticity, mechanical properties and abrasion-resistant properties.

Owner:ZHEJIANG BAILANGSHI RUBBER & PLASTIC TECH CO LTD

Method for producing pharmaceutical grade dibenzothiazyl disulfide (DM) by using sodium nitrite as oxidant

The invention discloses a method for producing pharmaceutical grade dibenzothiazyl disulfide (DM) by using sodium nitrite as an oxidant. The method comprises the following steps of: adding water and rubber accelerator M into a reaction kettle in a weight ratio of (1-20): 1, adding sodium hydroxide solid in a weight ratio of the sodium hydroxide solid to the accelerator M of 100: (24-60), reacting, and generating M sodium salt liquid; filtering the solution; adding the filtrate into an oxidation pot, and adding sodium nitrite in a weight ratio of the sodium nitrite to the M of 100: (41-410) and 10 to 25 mass percent copper acetate dissolved by aqueous ammonia, wherein the weight ratio of the catalyst to the M sodium salt is 1: (2,000-10,000); and adding a solvent in a weight ratio of the solvent to the M sodium salt liquid of 1: (1-5), dripping 10 to 80 mass percent of sulfuric acid into the oxidation pot at the temperature of between 20 and 80 DEG C and at the stirring speed of 50 to 1,000 revolutions per minute, controlling the flow rate at 1 to 8m<3> / h, introducing air, controlling the reaction at 1 to 20 hours, and stopping dripping the oxidant solution till the pH value of the solution reaches 4 to 9 hours. According to the method, the solvent is low in loss and has no poison to a person. The purity of the product is over 99 percent, and the melting point of the product reaches over 178 DEG C.

Owner:KEMAI CHEM

Braiding wave prevention sleeve for aviation

The invention discloses a braiding wave prevention sleeve for aviation. The braiding wave prevention sleeve for aviation comprises a plurality of cable intertwisted with each other. The plurality of cables are coated with a cable sleeve. The cable sleeve material comprises nitrile rubber, butadiene styrene rubber, nano copper oxide, nano aluminum oxide, graphite, tetramethyl-thiuram disulfide, dibenzothiazyl disulfide, manganese powder and aluminum powder. The cable sleeve material comprises, by weight, 50-100 parts of butadiene styrene rubber, 1-5 parts of nano copper oxide, 0.5-3 parts of nano aluminum oxide, 3-10 parts of graphite, 1-5 parts of tetramethyl-thiuram disulfide, 1-5 parts of dibenzothiazyl disulfide, 3-7 parts of manganese powder and 1-10 parts of aluminum powder relative to 100 parts of nitrile rubber. Good shielding property is achieved, and the braiding wave prevention sleeve has a long service life when used in the aviation field.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

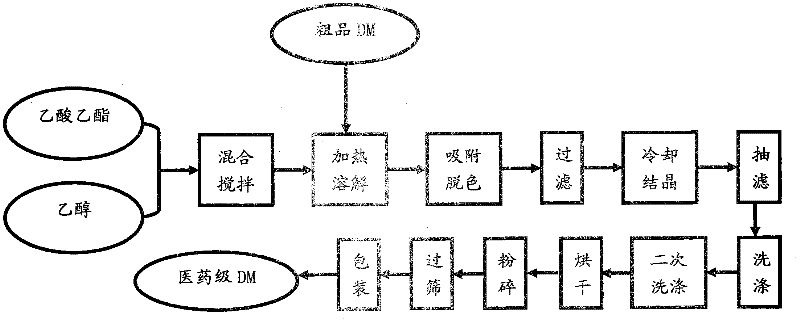

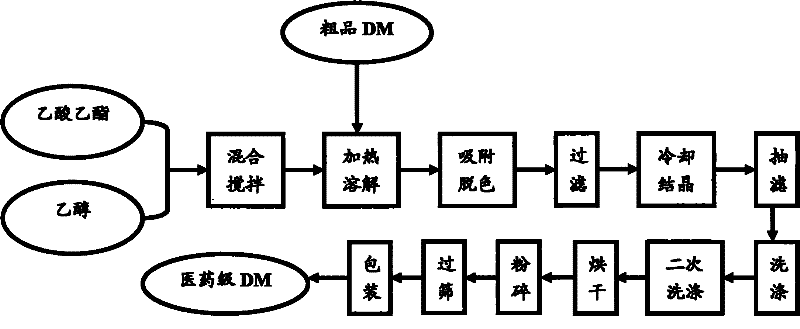

Method for refining pharmaceutical dibenzothiazyl disulfide

The invention provides a method for refining pharmaceutical dibenzothiazyl disulfide (DM). In the method, a crude product DM, an ethyl acetate solvent and an ethanol solvent are used as the raw materials. The method comprises the following steps of: mixing ethyl acetate and ethanol according to the volume ratio of 1: (4 to 8); adding the crude product DM into the mixture with stirring, wherein the mass ratio of the crude product DM to ethyl acetate is 1.00: (0.35 to 0.55); controlling a temperature in the range of 65 to 75 DEG C so that the crude product DM is totally dissolved, then adding 0.1 to 5 percent of activated carbon into solution, stirring the solution for 1 to 2 hours, carrying out extraction filtration to separate out the activated carbon, cooling mother liquor to the temperature of 0 to 30 DEG C and separating out DM crystals; and stopping stirring, carrying out vacuum extraction filtration, washing by mixed solution with the volume ratio of ethyl acetate to ethanol of 1: (4 to 8) to obtain wet refined DM, drying the wet refined DM to obtain white acicular crystals, i.e. the pharmaceutical DM. The crude product DM has the initial melting point of lower than or equal to 176 DEG C and purity of lower than or equal to 98 percent and contains impurities of resin, M (2-mercaptobenzothiazole) and the like. Due to the adoption of the method, the pharmaceutical DM can be produced greenly, efficiently and safely. The obtained pharmaceutical DM product has high quality and low integrated cost, is obviously superior to the product obtained by the existing refining process and can meet the requirement of the international high-end market.

Owner:WILLING NEW MATERIALS TECH CO LTD

Foamed elastic cushion block for high-speed rail and preparation method thereof

The invention discloses a foamed elastic cushion block for a high-speed rail. The foamed elastic cushion block comprises the following components in parts by weight: 80-120 parts of EPDM (Ethylene-Propylene-Diene Monomer), 40-70 parts of carbon black, 10-30 parts of white carbon black, 1-3 parts of stearic acid, 3-7 parts of zinc oxide, 4-8 parts of coupling agent Si69, 10-30 parts of paraffin hydrocarbon oil, 1.0-2.0 parts of anti-aging agent RD, 0.5-1.5 parts of sulfur, 0.5-1.5 parts of accelerator TMTD (Tetramethyl Thiuram Disulfide), 0.5-1.5 parts of accelerator DPTT (Dipentamethylene Thiuram Tetrasulfide), 0.5-1.5 parts of accelerator DM (2,2'-dibenzothiazyl disulfide), 0.5-1.5 parts of accelerator EZ (Zinc Diethyldithiocarbamate) and 2-4 parts of foaming agent OBHS (4,4'-Oxybis(benzene sulfonyl hydrazide)). The strength of the foamed elastic cushion block can reach over 4 MPa, the dynamic multiplying power is less than 1.35; and the foamed elastic cushion block has the advantages of high strength, low dynamic multiplying power, superior heat resistance and weather resistance and good insulation performance, so that good vibration absorption and endurance performance are guaranteed.

Owner:ANHUI ZHONGDING SEALING PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com