Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "High expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

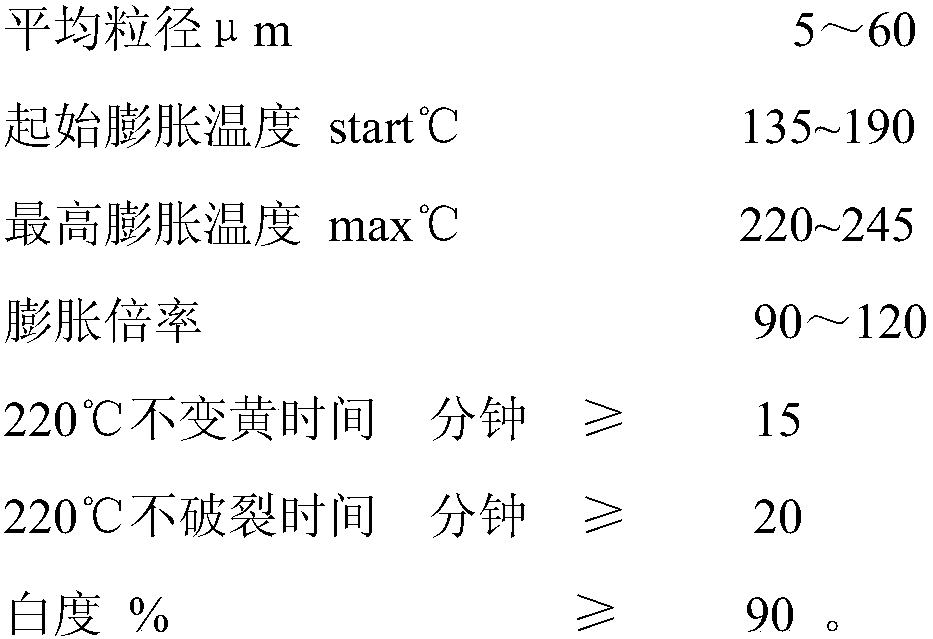

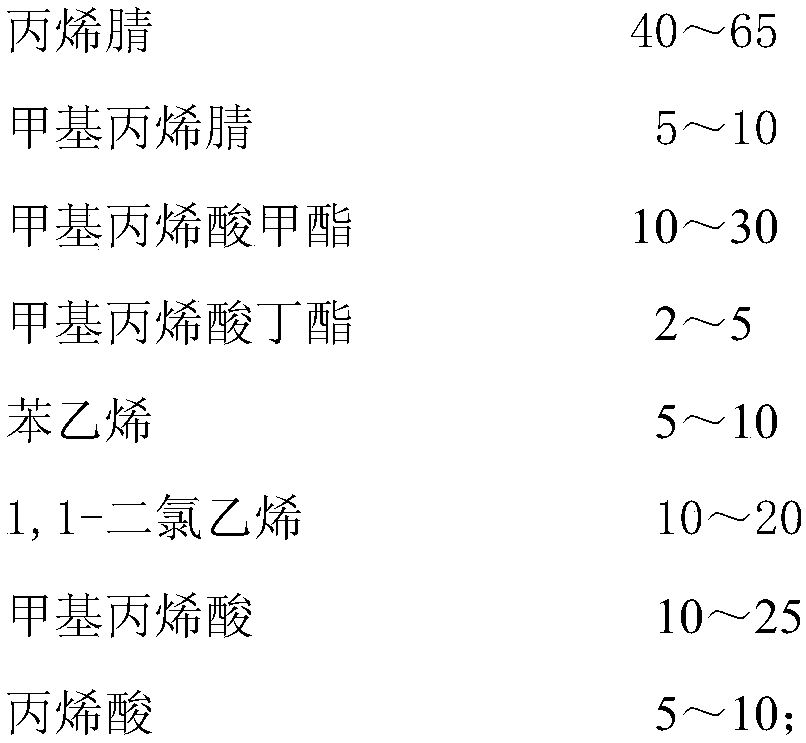

High-temperature expanded polymer microspheres and preparation method thereof

The invention provides high-temperature expanded polymer microspheres and a preparation method thereof and belongs to expandable particles. The high-temperature expanded polymer microspheres are prepared from a thermoplastic resin shell body and a foaming agent packaged in the shell body, wherein an oil-phase composition composed of a polymerizable monomer and a crosslinking agent can be dispersedinto a water-phase dispersed composition; in the presence of the foaming agent, the polymer microspheres coated with the foaming agent are directly prepared through carrying out suspension polymerization reaction and coating the foaming agent in situ; the high-temperature expanded polymer microspheres are characterized in that the oil-phase composition contains the polymerizable monomer and the crosslinking agent, and also comprises a silane coupling agent; the foaming agent is a mixture of isopentane, isooctane and n-octane; the high-temperature expanded polymer microspheres provided by theinvention have the advantages of complete core-shell structure, uniform grain diameter distribution, high foaming agent coating efficiency, good heat resistance of a shell-layer polymer, relatively high initial temperature in an expansion process, relatively high highest expansion temperature and high foaming ratio, have a relatively wide foam stabilizing temperature range, and are suitable for being applied to a thermoplastic resin, rubber or thermoplastic elastomer foaming and processing technology.

Owner:SHANDONG RUIFENG CHEM

Method for preparing polyurethane/rubber interpenetrating network type water-swellable rubber

The invention belongs to the technical field of sealing materials and relates to a method for preparing polyurethane / rubber interpenetrating network type water-swellable rubber. The method comprises the following steps: firstly, mixing rubber and super-absorbent resin for 10 to 40 minutes in an open mill; further adding solid softener, colorant, anti-ager and promoter to the open mill, and mixing for 10 to 40 minutes; then, adding zinc oxide, reinforcing agent and plasticizer to the open mill, and mixing for 10 to 50 minutes; further adding vulcanizer to the open mill, and mixing to obtain a mixture A; evenly mixing polyethylene glycol and MDI (methyl-di-p-phenylene isocyanate) by equal molar weight to obtain a mixture B; blending the mixture A and the mixture B in the open mill to obtain a product; and finally, vulcanizing the product in a mold on a plate vulcanization machine with the temperature and pressure being respectively controlled at 150 to 160 DEG C and at 10MPa to 15MPa, to obtain the interpenetrating network type water-swellable rubber. The method of the invention has the advantages of simple preparation process, high product expansion ratio, high ion resistance and controllable water absorption rate and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

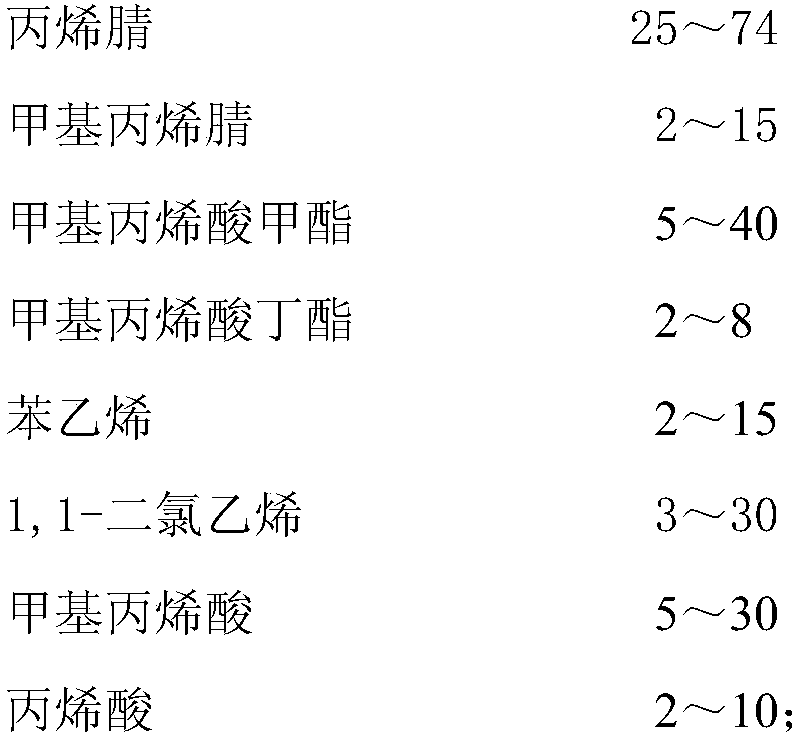

Thermally-expandable polymer microsphere special for polyvinyl chloride resin foaming and preparation method thereof

The invention relates to a thermally-expandable polymer microsphere for polyvinyl chloride resin foaming and a preparation method thereof, and belongs to the field of expandable particles. The thermally-expandable polymer microsphere consists of a thermoplastic resin shell and a foaming agent encapsulated in the shell; an oil phase composition composed of a polymerizable monomer and a crosslinkingagent is dispersed in an aqueous phase dispersion composition; and in the presence of the foaming agent, the foaming agent is coated in situ through a suspension polymerization reaction to directly prepare the polymer microsphere coated with the foaming agent. The thermally-expandable polymer microsphere is characterized in that the oil phase composition comprises a silane coupling agent in addition to the polymerizable monomer and the crosslinking agent, and the foaming agent is a mixture of isopentane, isooctane and n-octane. The invention provides a thermally-expandable polymer microspherewhich has the advantages of complete core-shell structure, uniform particle size distribution, high foaming agent coating efficiency, good heat resistance of a shell polymer, high initial temperatureduring expansion, high maximum expansion temperature, high foaming ratio, and wide foam stabilizing temperature range, and is special for foaming polyvinyl chloride resin.

Owner:SHANDONG RUIFENG CHEM

Water-based halogen-free steel structure ultra-thin expansion fireproof coating and preparation method thereof

The invention relates to a water-based halogen-free steel structure ultra-thin expansion fireproof coating and a preparation method thereof; the fireproof coating comprises components in the following content by weight percentage: 22 to 25 percent of acrylic latex, 33 to 40 percent of fire retarding agent, 5 to 9 percent of filler, 1 to 3 percent of film forming additive, and the balance water. Compared with the prior art, the invention adopts the acrylic latex as the film forming substance and adopts expandable graphite as the expansion reinforcing filler, so as to improve the expansion rate and the carbonized layer quality of the fireproof coating, so that the expansion carbonized layer can reach 25 times of the thickness of the traditional coating; when the coating thickness is 2mm, the fire resistance limit can reach 90min; and therefore, the invention has the advantages of higher fire resistance limit, good fireproof and waterproof performance, excellent brushing and spraying performance, simple and convenient construction, low cost, wide application, simple preparation process, environment friendliness and the like.

Owner:TONGJI UNIV

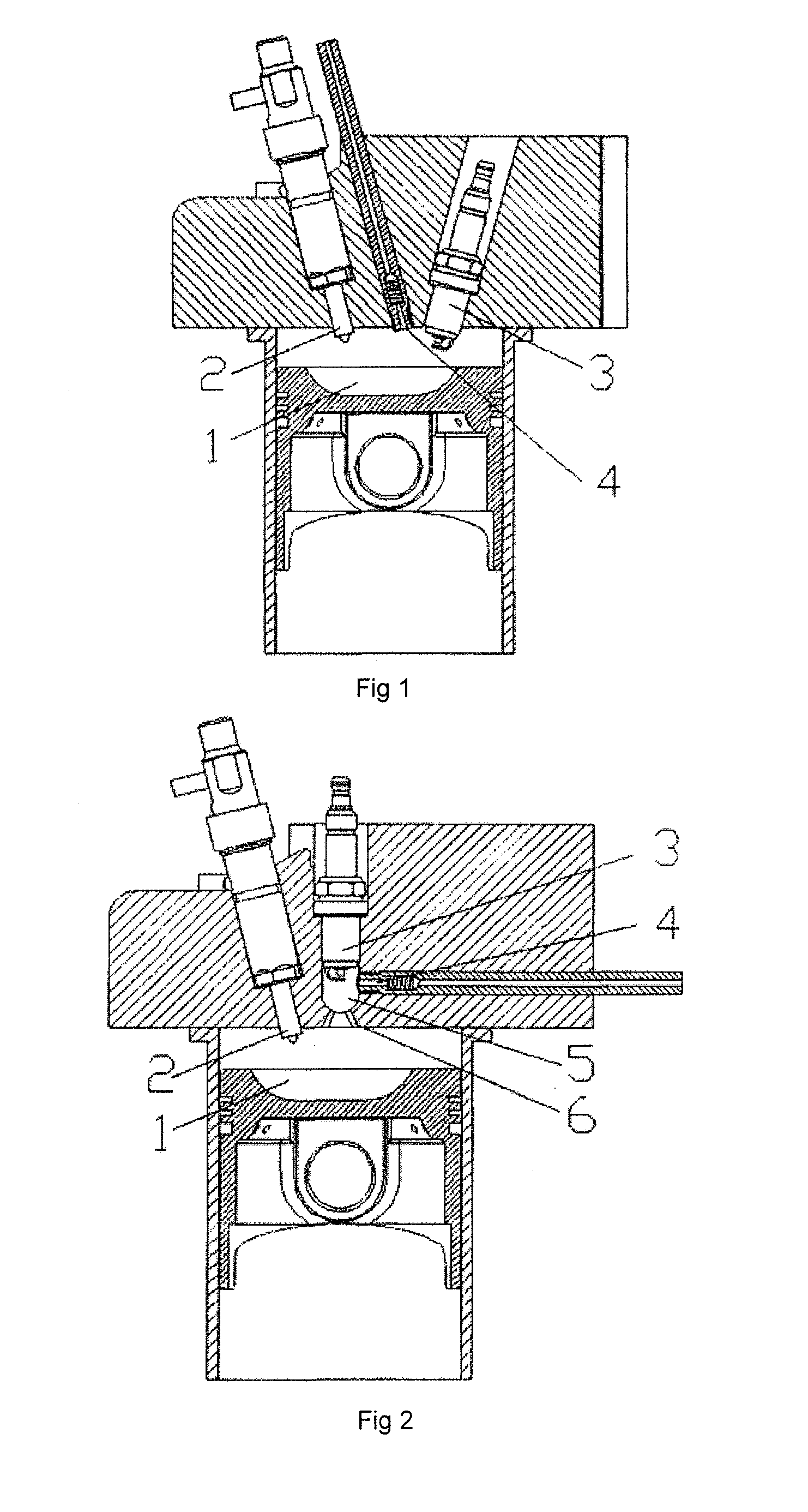

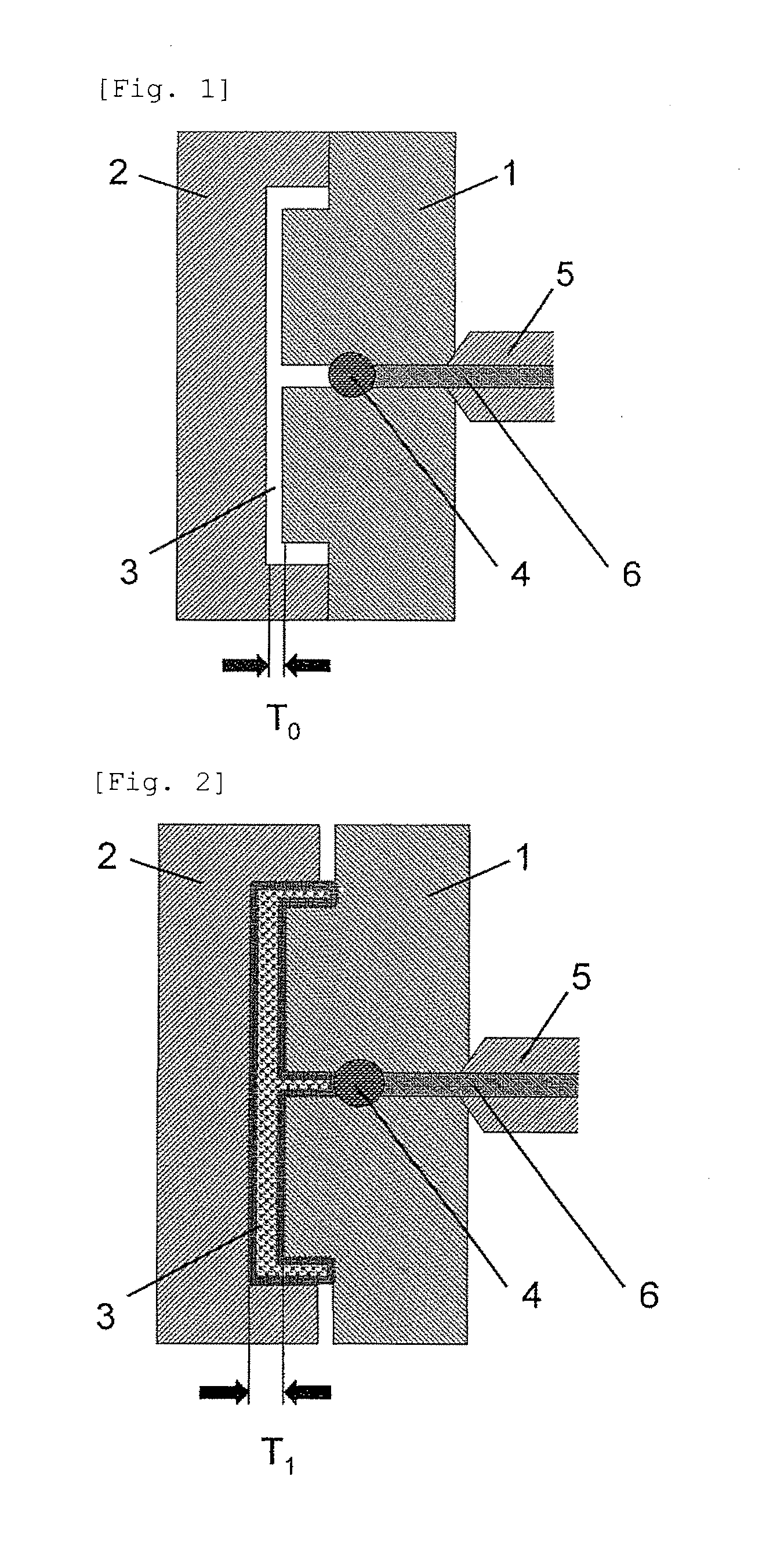

Multi-fuel pre-mixed combustion system of internal combustion engine

InactiveUS20130104850A1Improve performanceLow costInternal combustion piston enginesNon-fuel substance addition to fuelCombustion systemSpray nozzle

A multi-fuel pre-mixed combustion system of an internal combustion engine includes a main fuel spray nozzle (2), which injects a mixed fuel of compression-ignition-suitable fuels, spark-ignition-suitable fuel, or a wide cut fuel to form a homogeneous primary pre-mixed gas. An auxiliary spray nozzle (4) injects a spark-ignition-suitable fuel to form a secondary mixed gas, which is ignited by the spark plug (3) by means of spray guiding or an ignition chamber (5), and the primary pre-mixed gas in the combustion chamber (1) is compression ignited. Consequently, the ignition point of the primary mixed gas is effectively controlled and knock is avoided, and a homogeneous pre-mixed compression ignition is achieved over the whole range of operating conditions. The combustion rate is controlled by exhaust gas recirculation or spray of water into a cylinder or intake port, and high thermal efficiency is ensured by a high expansion ratio.

Owner:DALIAN UNIV OF TECH

Ultrathin steel structure waterproof coating and preparation method thereof

ActiveCN105838171AImprove fire resistanceImprove insulation performanceFireproof paintsFiberSodium Bentonite

Ultrathin steel structure waterproof coating is characterized by being made from the following materials according to parts by weight: 5-20 parts of nano silicon dioxide aerosol, 15-45 parts of acrylic emulsion, 30-80 parts of melamine, 30-60 parts of pentaerythritol, 50-80 parts of ammonium polyphosphate, 10-15 parts of titanium dioxide, 5-15 parts of sepiolite fiber, 5-15 parts of talc, 5-15 parts of expansible graphite, 0.2-0.8 part of a waterborne wetting dispersant, 0.02-0.08 part of modified organic bentonite, and 0.05-0.2 part of a waterborne leveling agent. The preparation method comprises: weighing the components according to their ratio; adding the components sequentially into a high-speed dispersing machine for mixing and dispersing; standing and aging for 10-15 h; metering and packaging. The fireproof coating of the invention can reduce the increase in the steel structure loading to the coating and has no influence in the expanding and foaming process, expansion rate of a coating layer is high, heat isolating capacity of the fireproof coating can be improved greatly, and fire resistance of a steel structure can be improved greatly.

Owner:SICHUAN TIANFU FIRE MATERIAL

Method for preparing polyurethane elastomer capable of rapidly expanding when contacting water

InactiveCN102010498ANo pollutionWell mixedArtificial islandsUnderwater structuresEpoxyPolyurethane elastomer

The invention relates to a method for preparing a polyurethane elastomer capable of rapidly expanding when contacting water, which comprises the following steps of: preparing a hydrophilic polyurethane prepolymer and a hydrophobic polyurethane prepolymer in a component A; then preparing a component B, namely an epoxy resin modified triethylene tetramine waterborne curing agent; and calculating mass parts of the components A and B according to the molar ratio of isocyanate groups to active hydrogen groups of 1:0.8-0.9, adding 0 to 0.5 mass part of black paste, uniformly mixing, carrying out vacuum defoaming, pouring into a die of which the temperature is 120 DEG C, heating, pressurizing and vulcanizing to obtain the polyurethane elastomer material capable of rapidly expanding when contacting water. Compared with other polyurethane elastomers capable of expanding when contacting water, the polyurethane elastomer material capable of expanding when contacting water, which is prepared by the method of the invention, has the advantages that: expansion multiplying power and expansion speed are high, expansion rate in fresh water can reach 400 to 600 percent, hardness can reach Shore A 40 to 60, tensile strength can reach 4.0 to 6.0MPa and time required for total expanding is 120 to 240 minutes; and the elastomer material has excellent mechanics characteristic and water expansibility and is convenient to use. The mass fraction of the components A and B is calculated according to the molar ratio of the isocyanate groups to the active hydrogen groups of 1:0.8-0.9 and the components A and B are uniformly mixed and the mixture is directly used for in-site concreting, solidification and sealing.

Owner:SHANXI NUOBANG POLYURETHANE

Foam

ActiveUS20090012194A1High closed cell contentHigh expansion ratioFoundry mouldsAbsorbent padsPolyolefinPolystyrene

The present invention provides a foam comprising (a) a polylactic acid resin, (b) at least one thermoplastic resin selected from a polyolefin resin and a polystyrene resin, and (c) a block copolymer of a vinyl aromatic compound and a conjugated diene, wherein a ratio of (a) to (b) by weight (a / b) is 80 / 20 to 20 / 80, and the foam comprises 0.5 to 20 parts by weight of (c) with respect to 100 parts by weight of (a) and (b) in total.

Owner:ASAHI KASEI CHEM CORP

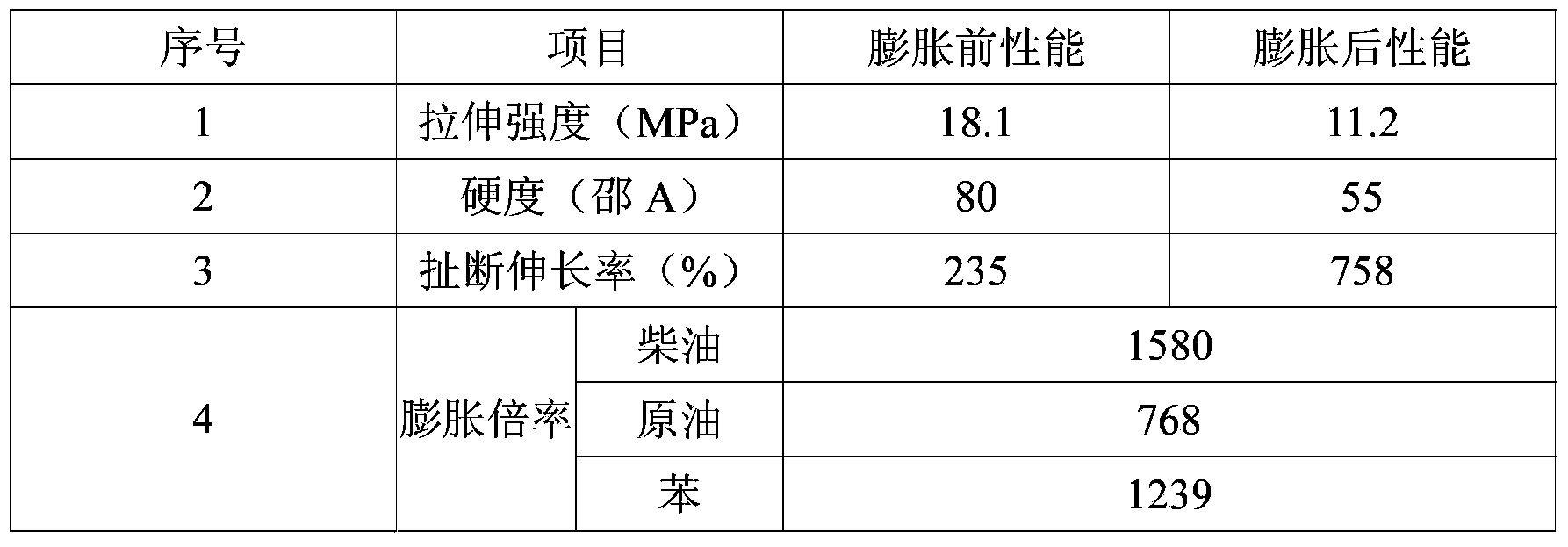

Process for producing expanded polyolefin resin particles and expanded polyolefin resin particles

ActiveUS20100267850A1High expansion ratioHigh dimensional accuracyThin material handlingPolyolefinPolyethylene glycol

Provided is a process for producing expanded polyolefin resin particles whose cells are not made nonuniform or extremely smaller as seen in conventional expanded particles, whose cell diameter and expansion ratio can be easily controlled independently, and which, when subjected to in-mold expansion molding, give in-mold expanded molded products satisfactory in fusibility and excellent in surface properties. The process is a process for producing expanded polyolefin resin particles by: dispersing polyolefin resin particles together with an aqueous dispersion medium into a closed vessel; heating the polyolefin resin particles up to or above a softening temperature of the polyolefin resin particles; and releasing the polyolefin resin particles into a zone whose pressure is lower than an internal pressure of the closed vessel, with use as a foaming agent of water serving as the dispersion medium, the polyolefin resin particles being composed of a polyolefin resin composition including: polyolefin resin; a substance selected from among polyethylene glycol, polyvalent alcohol having a carbon number of not less than 3 to not more than 6, and a water-absorbing substance having no function of forming foaming nuclei; and a foam nucleating agent.

Owner:KANEKA CORP

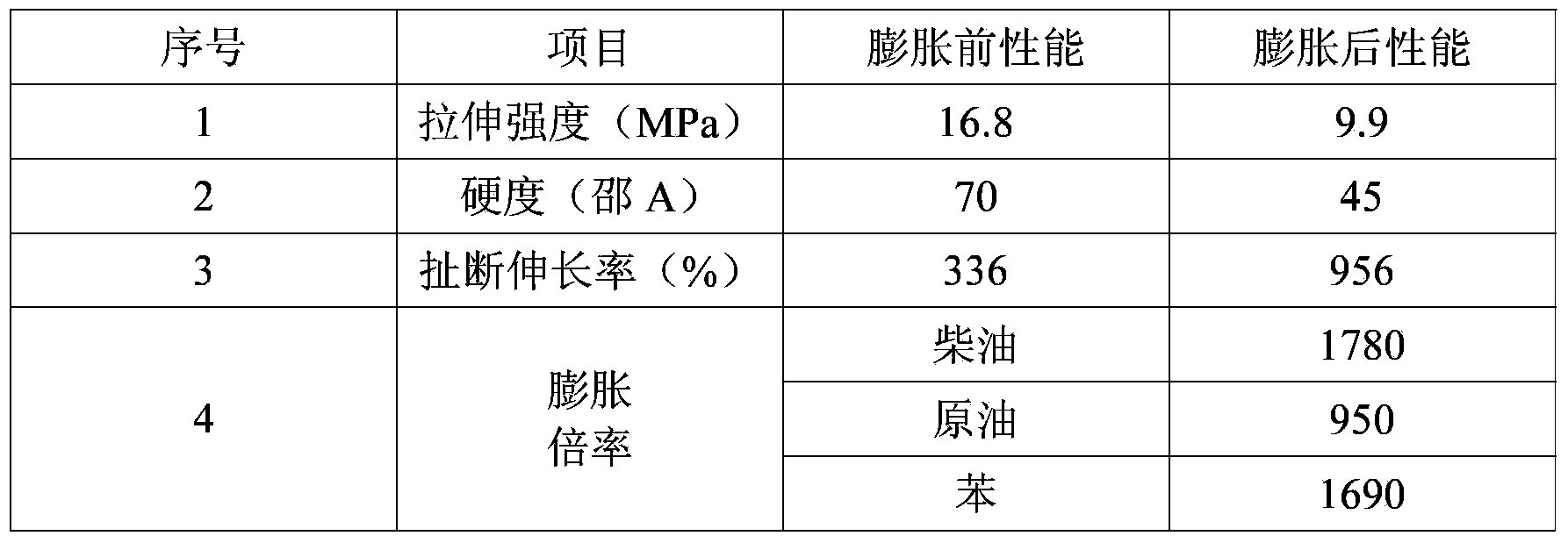

Oil-absorptive resin and oil-absorptive expanding rubber comprising same

ActiveCN103848935AHigh expansion ratioGood oil absorption performanceDrilling compositionActive agentPorosity

The invention provides oil-absorptive resin and oil-absorptive expanding rubber comprising the same. The oil-absorptive resin comprises the following components in parts by weight: 60 to 75 parts of polymer monomer, 0.5 to 2.5 parts of catalyst, 0.5 to 1 part of initiator, 0.01 to 0.03 part of cross-linking agent and 25 to 30 parts of dispersing phase. The invention also provides expanding rubber comprising the oil-absorptive resin. The oil-absorptive expanding rubber comprises the following components in parts by weight: 100 parts of rubber, 40 to 100 parts of oil-absorptive resin, 40 to 80 parts of reinforcing agent, 10 to 20 parts of softening agent, 0.5 to 2 parts of vulcanizing agent, 0.5 to 2 parts of promoter, 0.5 to 2 parts of anti-aging agent and 6 to 8 parts of active agent. By utilizing the characteristic of the oil-absorptive resin that the oleophylic group (ester group) is interactively affine to oil molecules to absorb the oil, the prepared oil-absorptive resin has porosity, so that the expanding rubber utilizing the oil-absorptive resin has better oil-absorptive effect in comparison with the traditional oil-absorptive expanding rubber, and the pressure resisting effect is also improved.

Owner:PETROCHINA CO LTD

Expanded polymer grouting material for high pressure and large flow karst water inrush treatment and preparation method

Belonging to the technical field of underground engineering plugging materials, the invention relates to a preparation method of an expanded polymer grouting material for high pressure and large flowkarst water inrush treatment. The method includes: 1) adding a crosslinking agent into acrylic acid, and then adding a macromolecular water-absorbent resin comonomer for polymerization reaction to obtain a precursor; 2) adding an initiator into the precursor obtained in step 1), raising the temperature and carrying out reaction to obtain hydrogel, and mincing the hydrogel to obtain primary macromolecular water-absorbent resin; 3) sprinkling a surface cross-linking agent to the surface of the primary macromolecular water-absorbent resin obtained in step 2), and then drying the product; and 4) preparing an inorganic water conducting agent into a suspension liquid, sprinkling the suspension liquid to the product obtained in step 3), and performing drying to obtain the expanded polymer grouting material. The polymer grouting material provided by the invention effectively solves the technical problem of difficult retention of grouting materials under a water inrush condition, and has the characteristics of green and no pollution, adjustable expansion time, and an expansion ratio up to 304 times.

Owner:SHANDONG UNIV

Aqueous indoor smoke-free fire-proof coating

InactiveCN102702885AHigh strengthHigh expansion ratioFireproof paintsChloropene polymer coatingsEmulsionChemistry

The invention relates to an aqueous indoor smoke-free fire-proof coating, which comprises the following components in parts by weight: 20-28 parts of water, 3-5 parts of multi-wall carbon nanotube, 2-3 parts of 10 percent sodium hexametaphosphate, 0.1-0.2 parts of antifoaming agent, 0.1-0.2 parts of wetting agent, 0.1-0.5 parts of filming auxiliary agent, 0.1-0.3 parts of dispersing agent, 10-20 parts of dehydration catalyst, 8-10 parts of foaming agent, 7-85 parts of carbonizing agent, 10-14 parts of smoke suppression flame retardant, 11-15 parts of titanium dioxide, 11-23.5 parts of acetic styrene-acrylic emulsion, 0.2 parts of bactericide, 0.6-1.2 parts of thickening agent and 0.1-0.2 parts of adjusting agent. The multi-wall carbon nanotube modified by amphiphilic polymer is added, so that the strength and the expansion ratio of a charring layer after firing of the fire-proof coating are improved.

Owner:TIANCHANG YINHU PAINT

Preparation method of expandable graphite

The invention relates to a preparation method of expandable graphite. The preparation method comprises the following steps of: 1, adding an oxidizing agent to an intercalation agent to form an oxidized intercalation system, and cooling a reaction system through circulating water to control the temperature to be not more than 40 DEG C; 2, transferring a mixed solution of the oxidizing agent and the intercalation agent into a mixing machine, then adding crystalline flake graphite, starting the stirring device, electrifying a water cooling device at the same time, stirring for 30 minutes, shutting down, standing for 30 minutes, and then leading out materials; 3, washing the led materials till the pH value is 6-7; and 4, carrying out drying treatment on the washed neutral materials under the condition that the drying temperature is not more than 120 DEG C to finally obtain an expandable graphite finished product. According to the invention, a small usage amount of the intercalation agent is about 40%-50% of the usage amount of the intercalation agent in the traditional method; and the prepared expandable graphite has the advantages of high expansion magnification, no dead segment, cost saving and outstanding commercial value.

Owner:乌兰察布市大盛石墨新材料股份有限公司

Water-swelling rubber composite material, and preparation method and application thereof

InactiveCN103570985AImprove mechanical propertiesHigh expansion ratioDrilling compositionPolyethylene glycolAccelerant

The invention discloses a water-swelling rubber composite material. The rubber composite material is formed from the following components in parts by weight: 100 parts of rubber, 30-100 parts of super adsorbent resin, 2-10 parts of metal ion sealing agent, 0.5-2.5 parts of solid softening agent, 0.5-3.5 parts of coloring agent, 1-7 parts of anti-aging agent, 1-7 parts of accelerant, 1-8 parts of zinc oxide, 5-45 parts of reinforcing agent, 5-20 parts of plasticizer, 0.1-2.6 parts of vulcanizing agent, and 5-45 parts of mixture of PEG (polyethylene glycol) and MDI (diphenylmethane diisocyanate) at a molar ratio of 1:1. The invention further provides a preparation of the rubber composite material, in particular provides an application of the rubber composite material as superfine rubber swelling particles in a large pore path or high-permeability belt of a reservoir deep strata for profile control and water shutoff of an oil-water well.

Owner:CHINA PETROLEUM & CHEM CORP +1

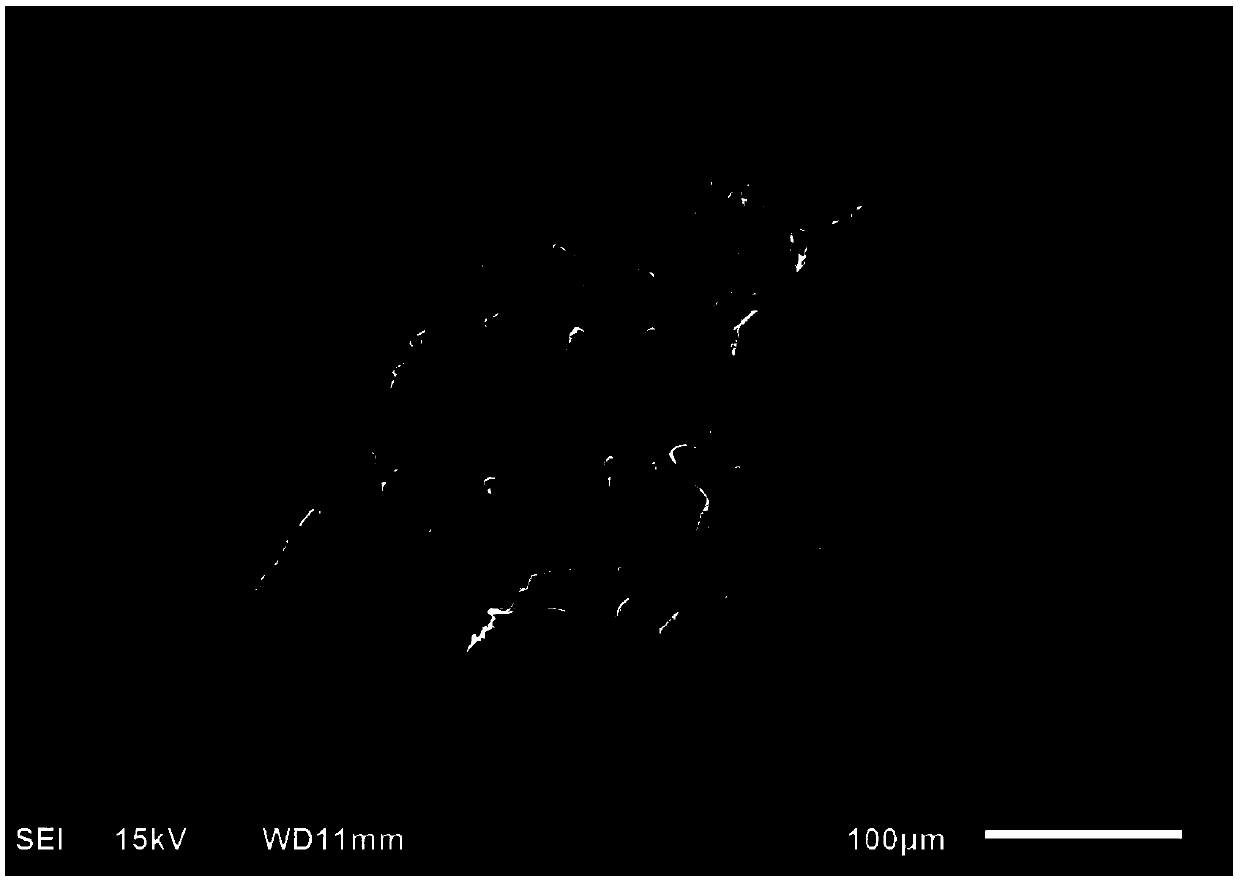

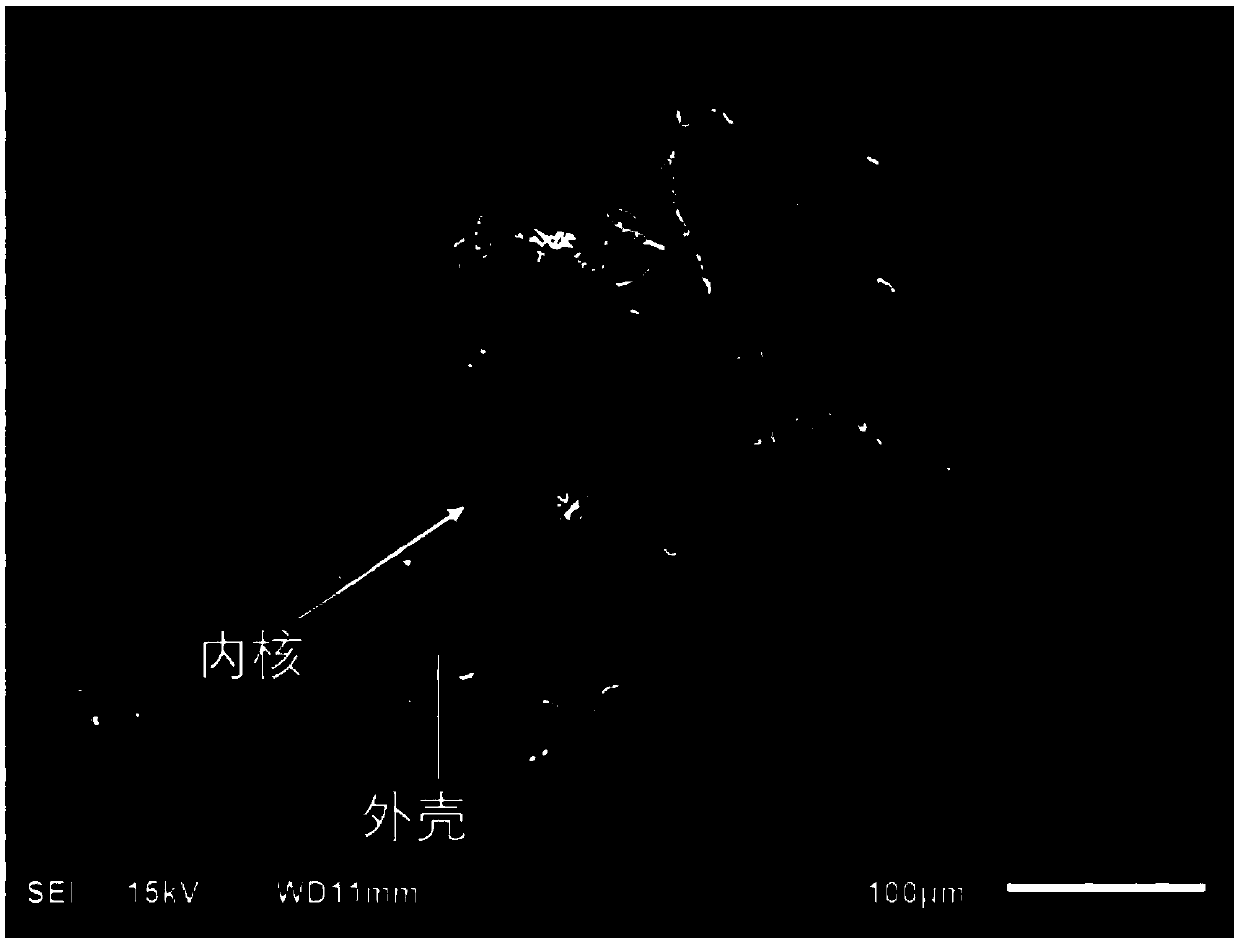

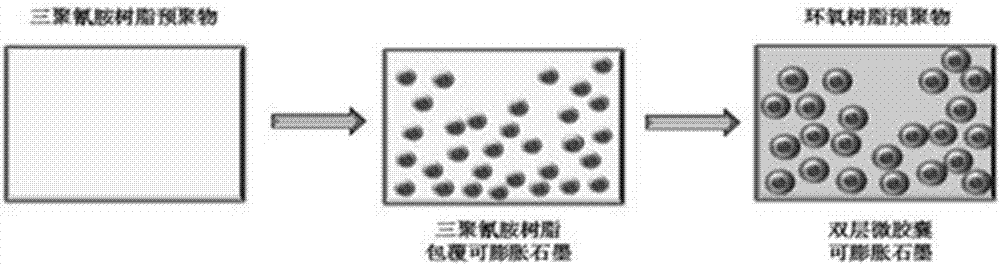

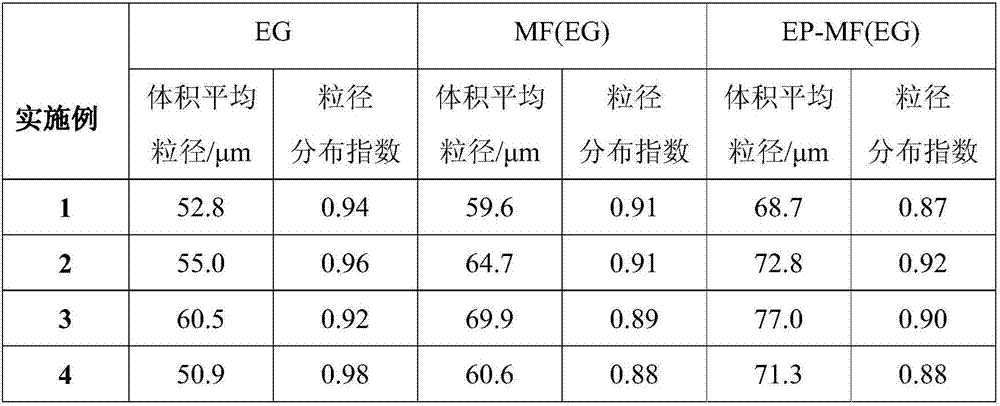

Microencapsulated expandable graphite, preparation method thereof, and application of microencapsulated expandable graphite in preparing composite rigid polyurethane foam

ActiveCN106928491AImprove compatibilityAdd lessPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsMelamine resinFire retardant

The invention relates to microencapsulated expandable graphite, which is melamine resin-epoxy resin double-coated expandable graphite, which is characterized by firstly coating a melamine microcapsule outside the expandable graphite, and then coating the microencapsulated expandable graphite with the melamine resin-epoxy resin double-coated expandable graphite of an epoxy resin microcapsule. The microencapsulated expandable graphite can be used as a fire retardant for preparing rigid polyurethane foam, and the prepared rigid polyurethane foam has the density being around 60kg.m<-3>, the heat conductivity coefficient being around 0.03W.(m.k)<-1>, the compression strength being around 0.60MPa, and the limit oxygen index being approximate to 30 percent. The invention discloses a preparation method of the microencapsulated expandable graphite.

Owner:NANJING UNIV

Meeting with water, inflated rubber made from resin capable of inflating if absorbing water, and preparation method

In the present invention, resin expending on water absorption is prepared by polymerization of synthetic monomer of propenoic acid ester containing polyoxyvinyl ether, catalyst, initiator and cross-linking agent; rubber expending on water contact is prepared from resin expending on water absorption, polychloroprene, filler, softener, promoter and antiager through mixing and valcanizing.

Owner:JIANGSU CHEM RES INST

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

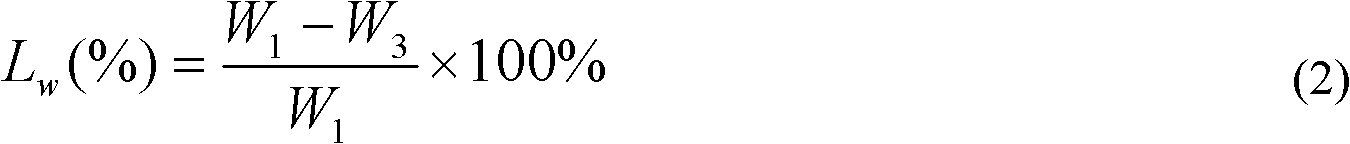

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

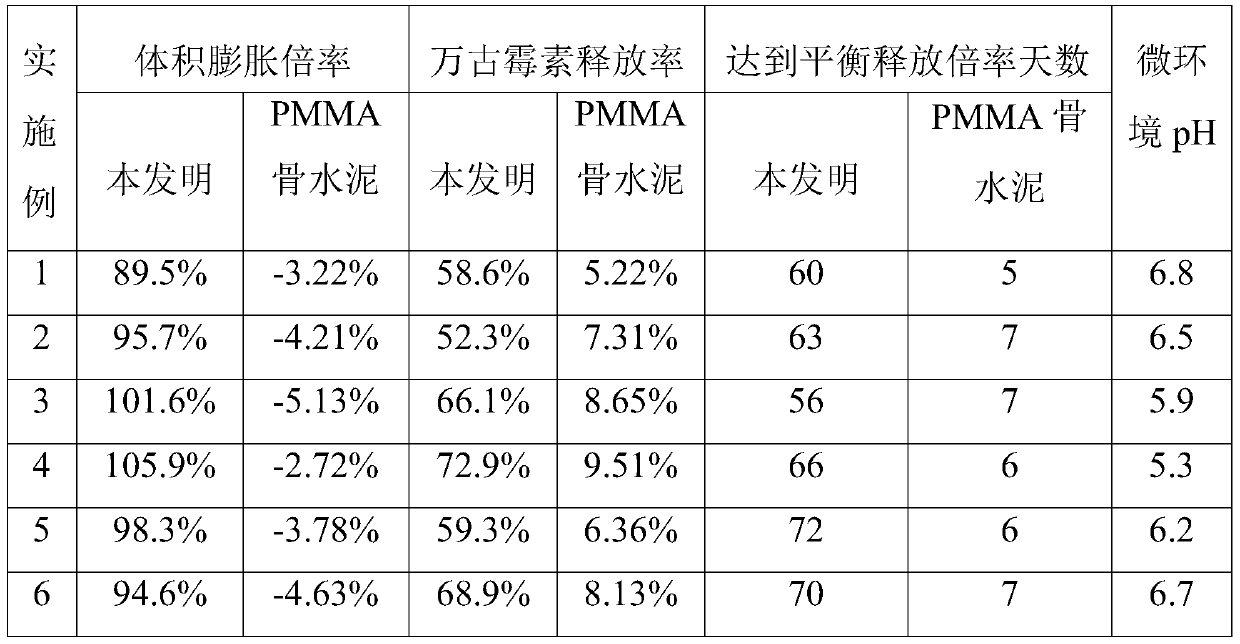

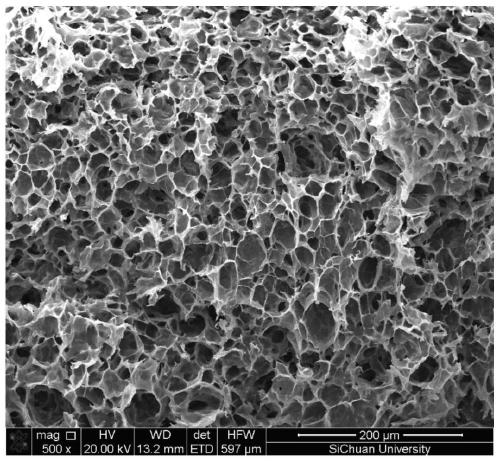

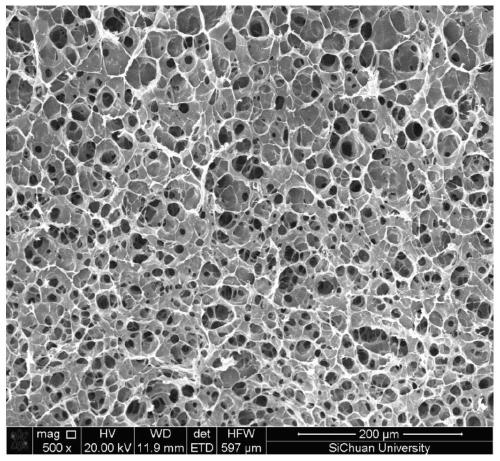

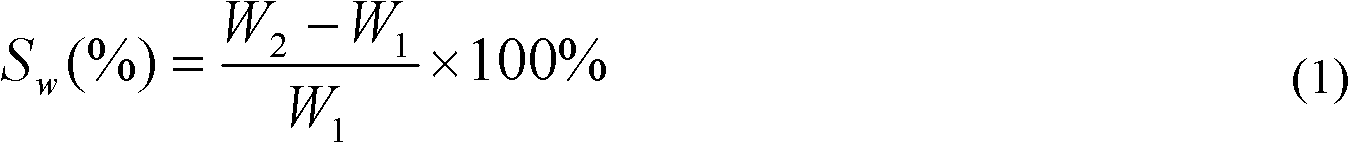

Controlled-release antibiotic expanded acrylic bone cement and preparation method thereof

ActiveCN111317861ATimely treatmentRelieve painTissue regenerationProsthesisMicrospherePolymethyl methacrylate

The invention discloses controlled-release antibiotic expanded acrylic bone cement prepared by mixing a solid phase and a liquid phase according to a ratio of 1g: (0.6ml-0.9ml), wherein the solid phase includes polymethyl methacrylate, antibiotic loaded microspheres with expandable core-shell structures and barium sulfate which are in the mass ratio of (5-7): (2.1-4.5): (0.5-0.9), and the antibiotic loaded microspheres with expandable core-shell structures contain carboxylated graphene; and the liquid phase includes methyl methacrylate, an accelerant and a retardant which are in the mass ratioof (8.5-9.5): (0.25-0.5): (0.25-1). The invention further discloses a preparation method of the controlled-release antibiotic expanded acrylic bone cement. The bone cement prepared by using the method has a better expansion ratio, also has a sensitive pH response function and is capable of realizing long-acting drug release as required according to the pH change of a microenvironment surroundingan implant, so that the release ratio of antibiotics is increased.

Owner:XIAN UNIV OF TECH

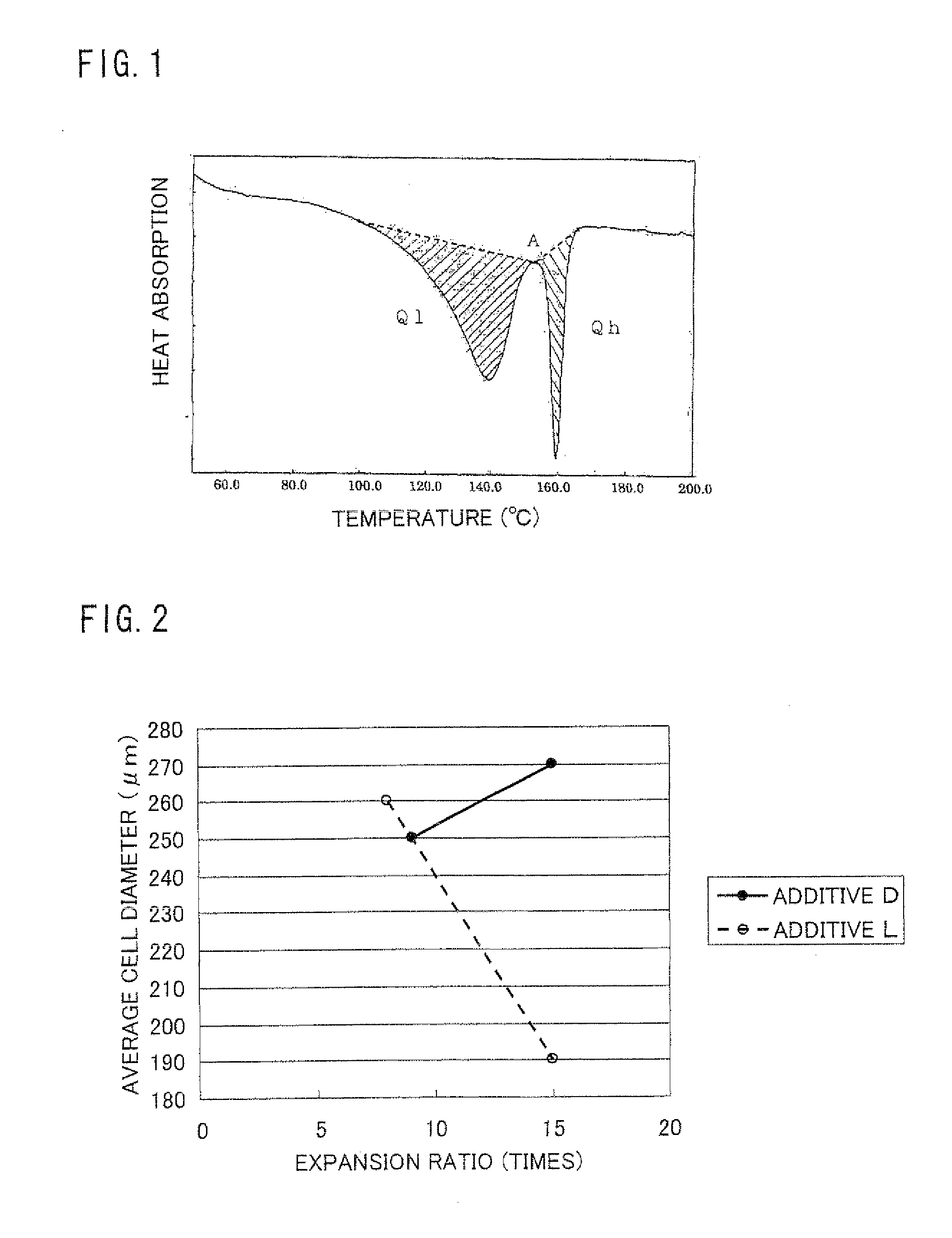

Thermally expandable microcapsule

ActiveUS20130065975A1High expansion rateHardly burstMicroballoon preparationMicrocapsule preparationMonomer compositionMasterbatch

The present invention provides a thermally expandable microcapsule that maintains a high expansion ratio and hardly bursts and shrinks even at a high temperature, a foamable thermoplastic resin masterbatch and a foam molded product that are produced using the thermally expandable microcapsule, and a method for producing the thermally expandable microcapsule. The thermally expandable microcapsule comprises a volatile expansion agent included in a shell as a core agent and the shell formed of a polymer, the shell containing a thermosetting resin and a polymer obtainable by polymerization of a monomer composition containing a nitrile-type monomer and a monomer having a carboxyl group, and the thermosetting resin having no radical-polymerizable double bond and at least two functional groups reactive with a carboxyl group per molecule.

Owner:SEKISUI CHEM CO LTD

Biodegradable polylactic acid foamed particles and preparation method thereof

The invention provides biodegradable polylactic acid foamed particles taking PDLA as a matrix material or taking PDLA and PLLA as matrix materials. A preparation method of the polylactic acid foamed particles include: (1), subjecting the PDLA, the PLLA, a plasticizer and a foam nucleating agent to mixing, extruding, wiredrawing and pelletizing to obtain polylactic acid foamed masterbatch; (2), putting the polylactic acid foamed masterbatch into a reaction kettle, feeding fluid serving as a foamer into the reaction kettle, holding for a period of time at 0-40 DEG C and 0.2-6MPa, and lowering pressure in the reaction kettle to normal pressure; (3), adopting a temperature rising method to foam the polylactic acid foaming masterbatch after being treated in the step (2) to obtain the polylacticacid foamed particles. By the preparation method, biodegradability of the polylactic acid foamed particles and polylactic acid foamed products prepared from the same can be improved.

Owner:SICHUAN UNIV

Method for preparing low-leaching-rate water-swellable rubbers

The invention relates to a method for preparing low-leaching-rate water-swellable rubbers. The prepared low-leaching-rate water-swellable rubber comprises the following raw materials in parts by weight: 100 parts of obtained modified rubbers, 10 to 40 parts of obtained super water absorbent resins, 5 to 30 parts of plant fiber powder, 2 to 8 parts of zinc oxide, 0.2 to 1 parts of stearic acid, 1 to 5 parts of sulphur, 0.5 to 4 parts of dibenzothiazyl disulfide, 10 to 80 parts of filler, and 5 to 50 parts of softener, and the method comprises the following steps: mixing the raw materials for 5 to 60 minutes; standing the obtained mixture for 10 to 12 hours; and carrying out vulcanization and pressure molding on the obtained deposit so as to obtain the low-leaching-rate water-swellable rubbers. The rubbers prepared by using the method of the invention have the characteristics of high expansion ratio, low leaching rate and good water retention performance. The invention overcomes the defects that strongly polar bibulous trees subjected to soaking in traditional water-swellable rubbers are easy to desorb from the rubbers, and the expansion rate of the traditional water-swellable rubber after used repeatedly is reduced; and the preparation method is simple, and low in equipment requirement.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

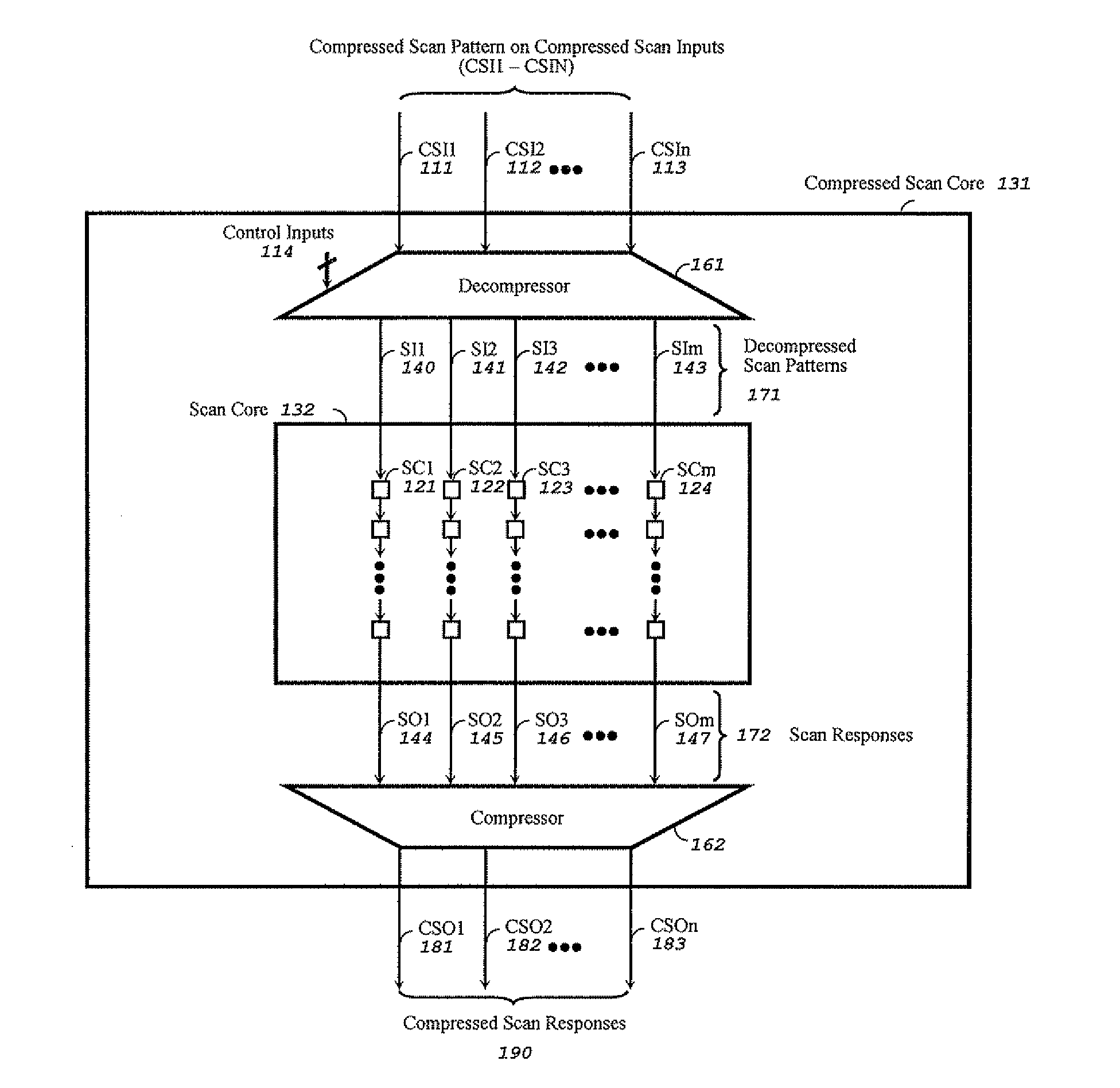

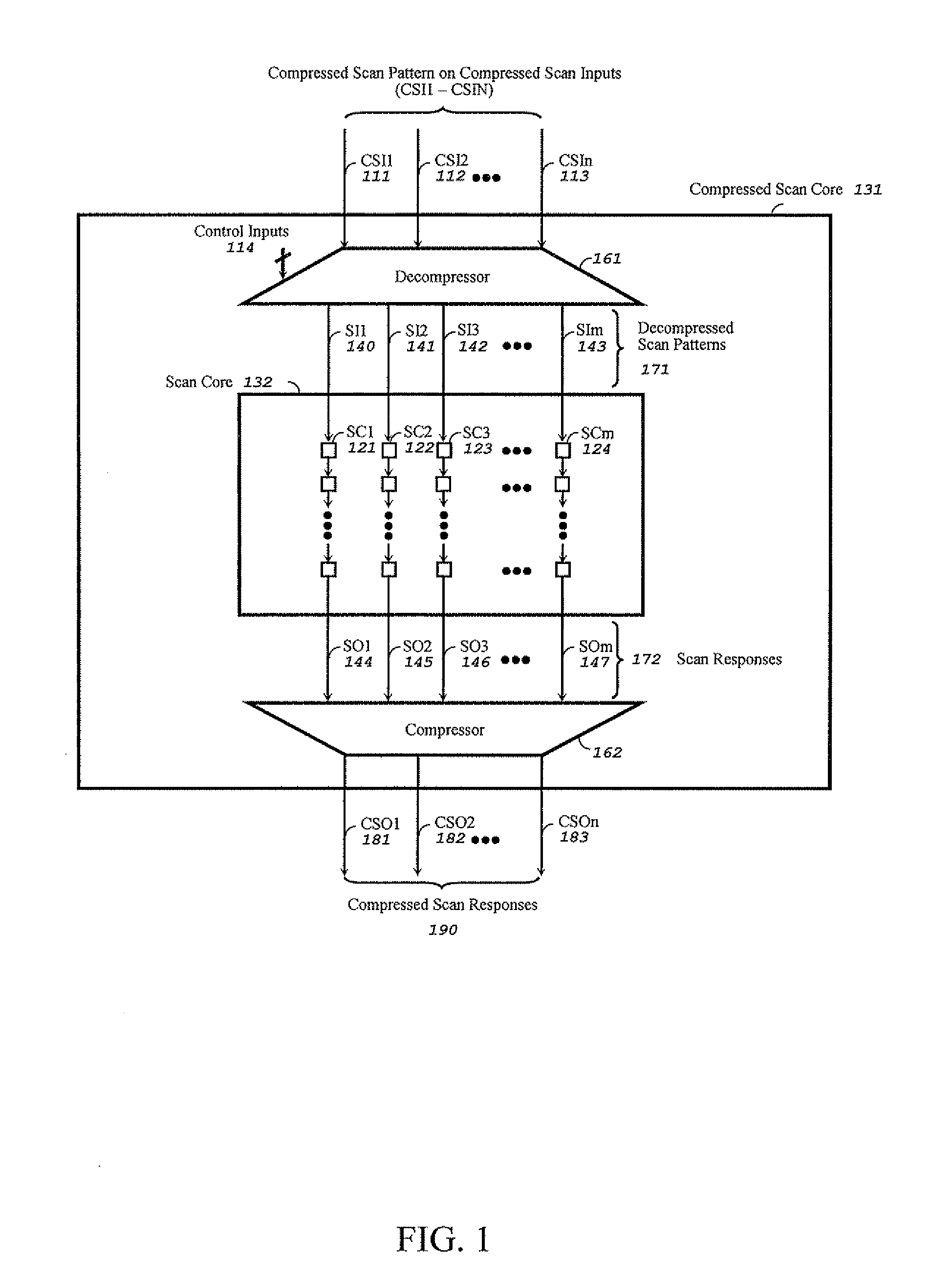

Method and apparatus for low-pin-count scan compression

InactiveUS20110258501A1Reduce testingReduce volumeElectronic circuit testingLogical operation testingShift registerLogic network

A low-pin-count scan compression method and apparatus for reducing test data volume and test application time in a scan-based integrated circuit. The scan-based integrated circuit contains one or more scan chains, each scan chain comprising one or more scan cells coupled in series. The method and apparatus includes a programmable pipelined decompressor comprising one or more shift registers, a combinational logic network, and an optional scan connector. The programmable pipelined decompressor decompresses a compressed scan pattern on its compressed scan inputs and drives the generated decompressed scan pattern at the output of the programmable pipelined decompressor to the scan data inputs of the scan-based integrated circuit. Any input constraints imposed by said combinational logic network are incorporated into an automatic test pattern generation (ATPG) program for generating the compressed scan pattern for one or more selected faults in one-step.

Owner:SYNTEST TECH

High-strength cold-rolled steel sheet and method for manufacturing the same

InactiveUS20180127856A1High elongationHigh expansion rateFurnace typesHeat treatment furnacesChemical compositionMartensite

A high-strength cold-rolled steel sheet excellent in terms of elongation (EL) and hole expansion ratio (A) having a low yield ratio (YR), as well as a method for manufacturing the steel sheet. The steel sheet has a chemical composition containing, by mass %, C: 0.15% to 0.25%, Si: 1.0% to 2.0%, Mn: 1.8% to 2.5%, P: 0.10% or less, S: 0.010% or less, Al: 0.10% or less, N: 0.010% or less, and the balance being Fe and inevitable impurities, and a multi-phase microstructure including ferrite having an average crystal grain diameter of 5 μm or less in an amount of 30% to 55% in terms of volume fraction, retained austenite having an average crystal grain diameter of 2 μm or less in an amount of 5% to 15% in terms of volume fraction, and tempered martensite having an average crystal grain diameter of 2 μm or less in an amount of 30% to 60% in terms of volume fraction, in which the number of grains of the retained austenite existing in an area of 1000 μm2 is 10 or more.

Owner:JFE STEEL CORP

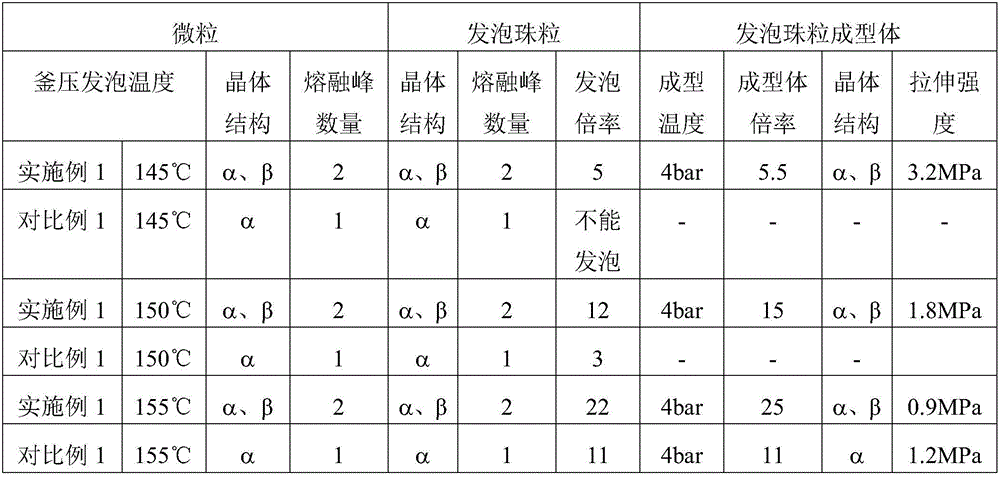

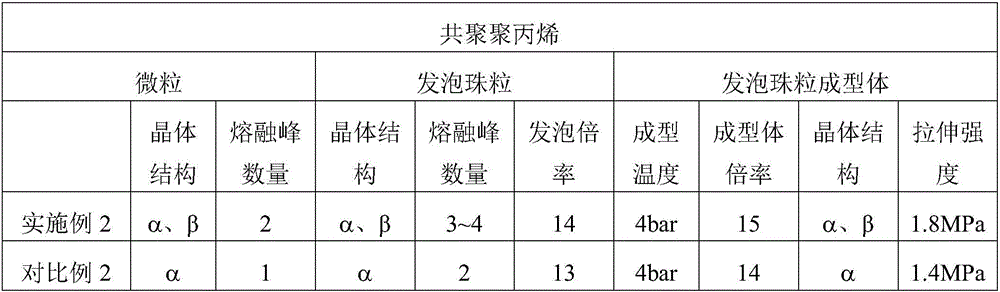

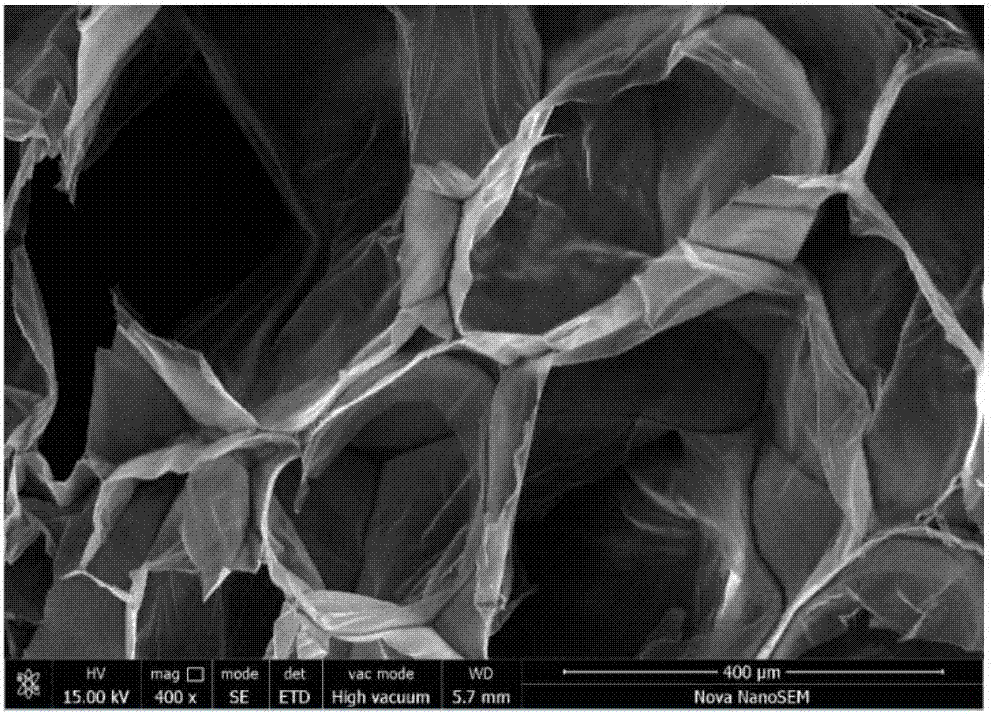

Foamed polypropylene bead containing beta crystal and preparation method thereof

The invention discloses a foamed polypropylene bead containing a beta crystal, belonging to the field of foamed materials. The foamed polypropylene bead containing the beta crystal comprises, by weight, 100 parts of polypropylene resin, 0.2 to 5 parts of beta nucleating agent master batch, 0.5 to 2 parts of an antistatic agent and 1 to 10 parts of a foaming nucleating agent. The invention also discloses a preparation method for the foamed polypropylene bead. According to the invention, a high-pressure fluid is used as a foaming agent; autoclave foaming technology is employed; double or multiple melting peaks including alpha and beta are formed through introduction of the beta crystal into a polypropylene particle, the foamed polypropylene bead and a foamed polypropylene bead preform material; the foamed polypropylene bead with a low foaming temperature and a high expansion ratio is prepared in virtue of the characteristics of low melting point / low crystallization temperature, small crystal size and high crystal density of the beta crystal; and the foamed polypropylene bead preform material containing the beta crystal has high tensile strength, increased by 15 to 50% compared with samples of a same kind under the condition of same density.

Owner:广东炜林纳新材料科技股份有限公司

Light polyether-ether-ketone or composite material thereof with different degrees of crystallinity and preparation method thereof

ActiveCN107177052AHigh crystallinityHigh strengthBulk chemical productionMolecular materialsRoom temperature

The invention discloses light polyether-ether-ketone or a composite material thereof with different degrees of crystallinity thereof and a preparation method thereof and belongs to the technical field of preparation of high molecular materials. The preparation method comprises the following steps of: putting polyether-ether-ketone or the composite material thereof in a near critical or supercritical CO2 fluid, swelling and permeating the same at 320-360 DEG C and the saturated pressure of 5-30MPa for 30min to 3h, then quickly unloading to constant pressure and cooling to room temperature; and repeating the operations for 1-3 times and finally performing annealing treatment to obtain the light polyether-ether-ketone or the composite material thereof with different degrees of crystallinity, different bubble dimensions and high foaming rates. The preparation method disclosed by the invention overcomes defects that crystallized polyether-ether-ketone or the composite material thereof prepared in the prior art is small in foaming swelling rate, single in bubble dimension, hard to saturate gas and the like, expands the application field of polyether-ether-ketone, and improves the bottleneck of existing crystallized polyether-ether-ketone or the composite material thereof in the foaming technology.

Owner:SINO HIGH CHINA

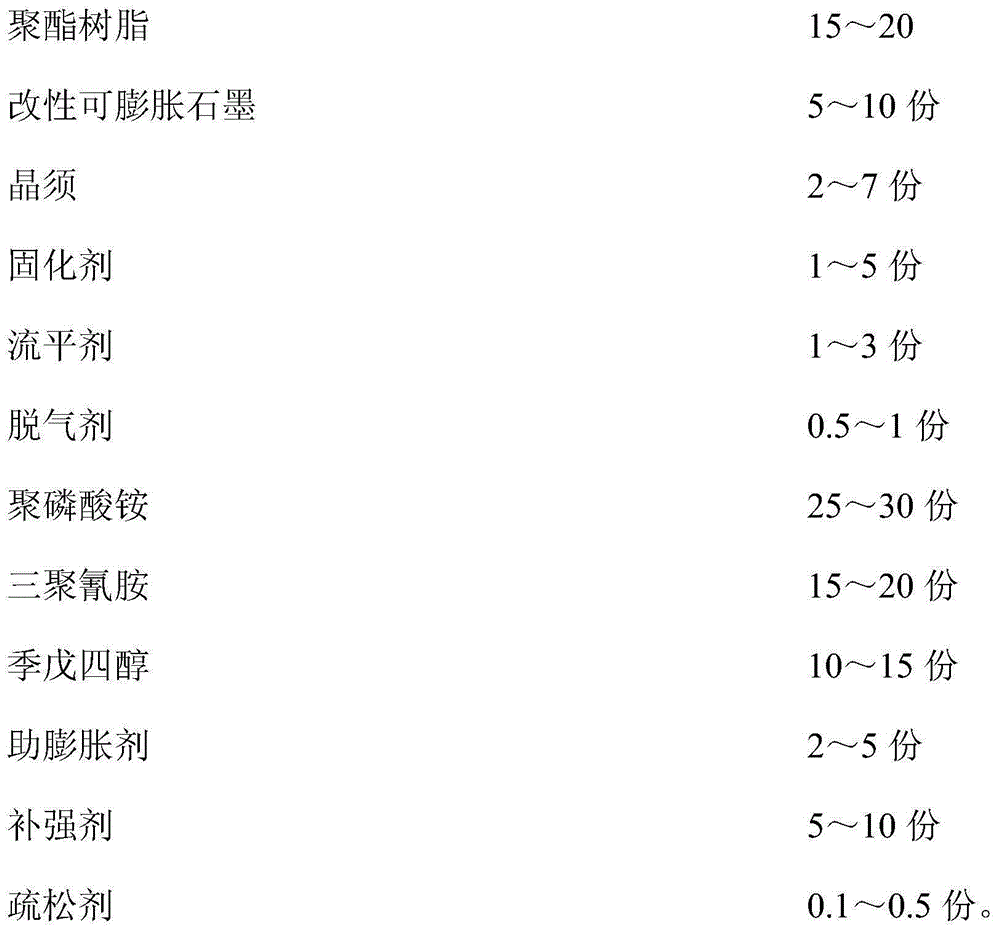

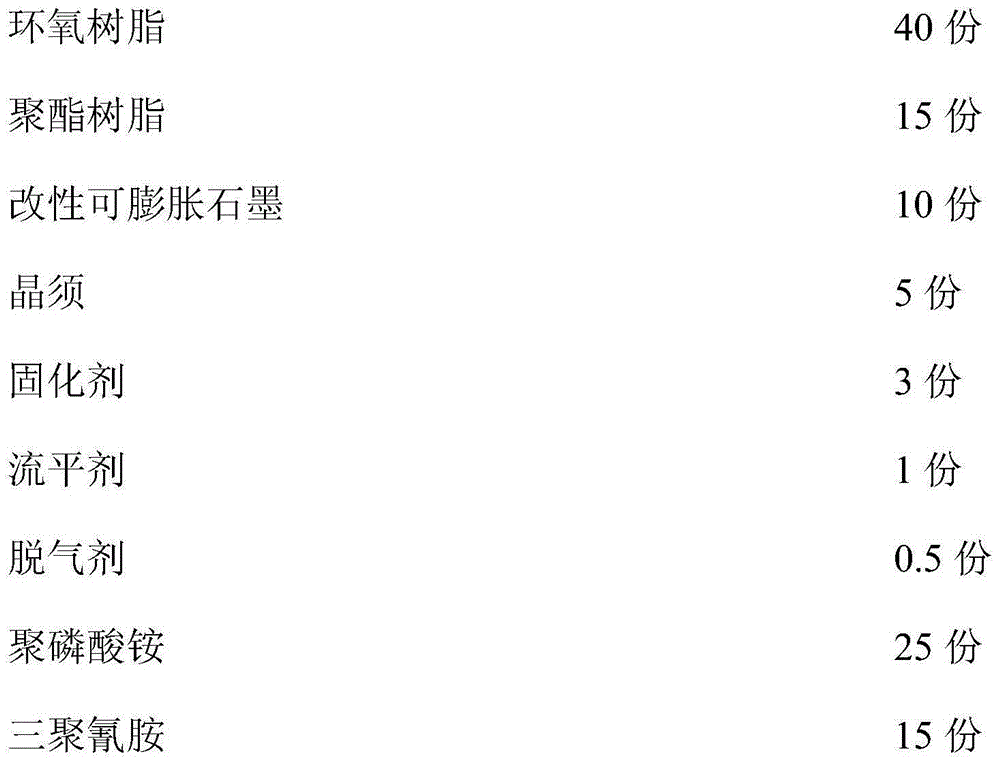

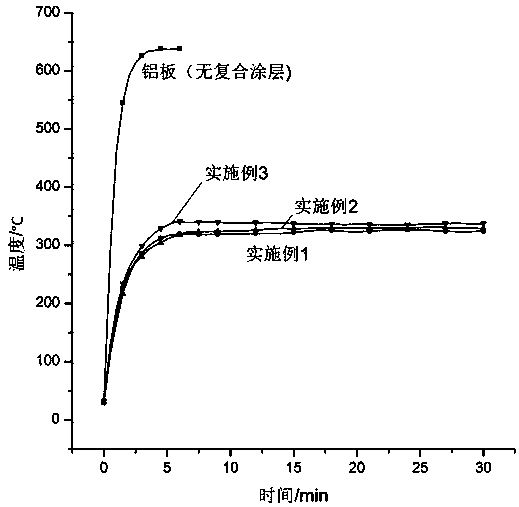

Expansion type fireproof powder coating for steel structure

InactiveCN105086764AHigh expansion ratioImprove fire resistanceFireproof paintsPowdery paintsEpoxyFoaming agent

The invention provides an expansion type fireproof powder coating for a steel structure and belongs to the technical field of building coatings. The expansion type fireproof powder coating is prepared from raw materials including epoxy resin, polyester resin, modified expansible graphite, whiskers, a curing agent, a catalyst, a carbon forming agent, a foaming agent, an expansion auxiliary, a reinforcing agent, a flexibilizer, a leveling agent, a degassing agent and a flowable agent with a conventional powder coating production method. The expansion type fireproof powder coating has the advantages of ultrathin property and excellent fire retardance and heat-insulating property.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Foaming polypropylene resin composition and molded foam using the same

InactiveUS20110206922A1Excellent cell formation abilityHigh mechanical strengthLayered productsDomestic articlesTetralinPropylene Polymers

An object of the invention is to provide foaming polypropylene resin compositions that are suited for injection foam molding, have excellent balance between flowability and melt tension, are foamable at high expansion ratio, and can give lightweight molded foams having excellent appearance and mechanical strength. Another object is to provide injection-molded foams using the compositions.A foaming polypropylene resin composition of the invention includes: 50 to 90 parts by weight of a high-molecular weight component-containing impact polypropylene (AB); 10 to 30 parts by weight of a rubber component (C); and 0 to 20 parts by weight of an inorganic filler (D) (wherein the total of (AB), (C) and (D) is 100 parts by weight); and the high-molecular weight component-containing impact polypropylene (AB) contains 4.5 to 31.0 wt % of a propylene / ethylene copolymer that is identified as a normal temperature paraxylene soluble component, and the high-molecular weight component-containing impact polypropylene (AB) contains 0.2 to 3.7 wt % of a propylene polymer component having an intrinsic viscosity [η] at 135° C. in tetralin of 13.5 to 20.0 dl / g.

Owner:PRIME POLYMER CO LTD

Micro-arc oxidation composite aqueous fire retardant coating and preparation method thereof

ActiveCN107815196AProvides comprehensive fire protectionNovel methodFireproof paintsSpecial surfacesMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro-arc oxidation composite aqueous fire retardant coating and a preparation method thereof. A micro-arc oxidization film layer is formed on the surface of a valve metallicmatrix by using a micro-arc oxidation method by adopting alkaline electrolyte, and then an aqueous fire retardant coating is compounded on the surface of the micro-arc oxidization film layer, whereinthe coating takes ammonium polyphosphate, pentaerythritol and melamine as a flame-retardant system, titanium dioxide as a pigment filler, and water as a solvent. When meeting fire, the flame-retardant system of the aqueous fire retardant coating on the outer layer achieves concerted reaction to form a dense spongy expanded carbonaceous layer, a two-dimensional lamellar structure of graphene oxideundergoes multilayer stacking in the carbonaceous layer to form a dense physically blocked layer so as to isolate transfer of outside heat to the inner layer, while the heat conductivity of the micro-arc oxidization film layer on the inner layer is low, so as to further isolate transfer of the heat to the matrix. The micro-arc oxidation composite aqueous fire retardant coating has excellent fireretardant and heat insulating performances, is applicable to valve metals of aluminum, magnesium, titanium and the like, and is strong in binding force, simple and environment-friendly in processing technology and low in cost.

Owner:GUANGXI UNIV +1

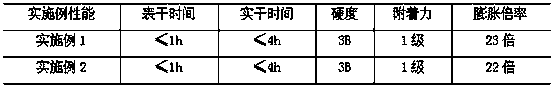

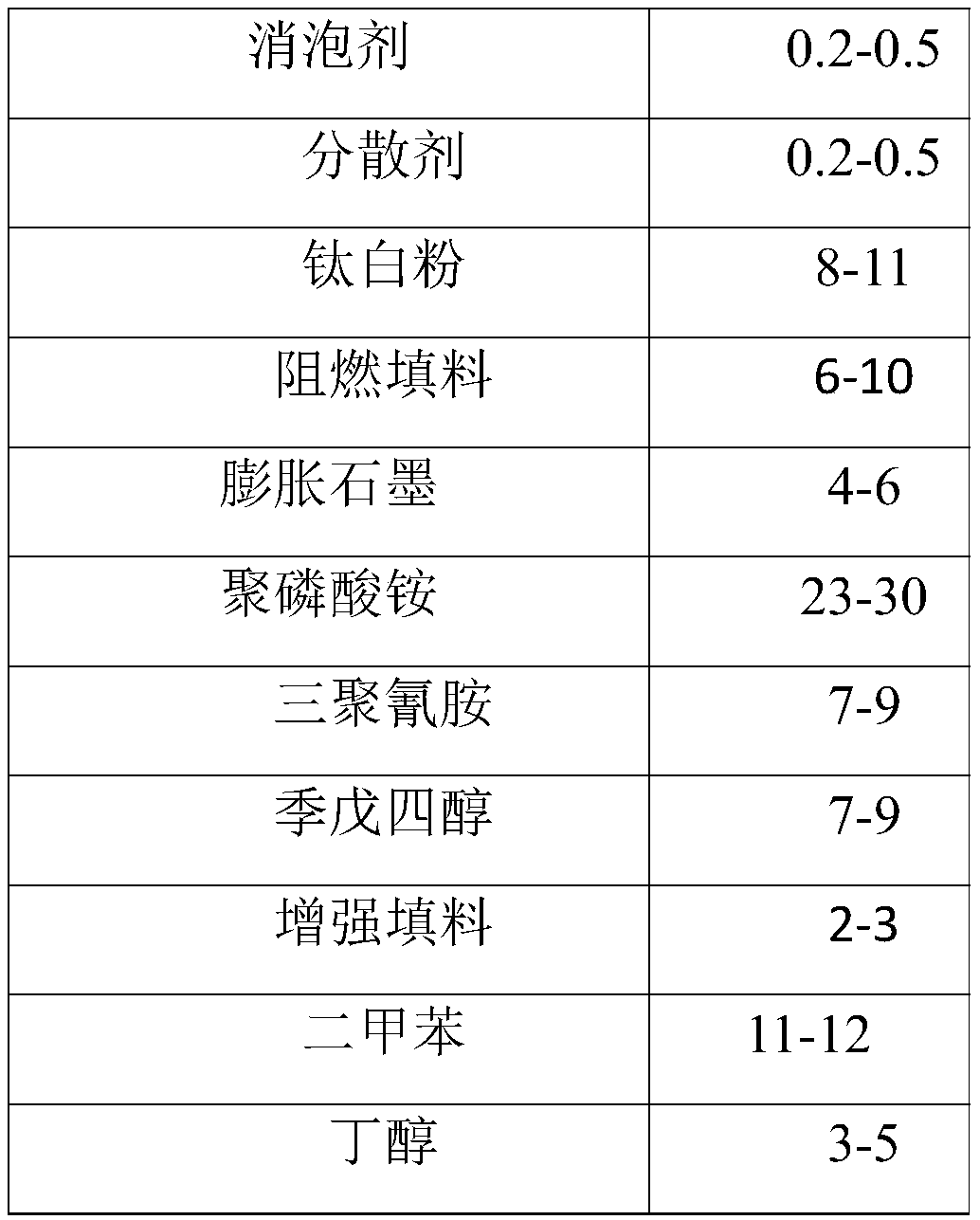

Double-component expansion type fireproof coating and preparation method thereof

InactiveCN110591502AStrong adhesionImprove cohesionFireproof paintsEpoxy resin coatingsEpoxyDefoaming Agents

The invention discloses a double-component expansion type fireproof coating which consists of a component A and a component B, wherein the component A consists of the following raw materials in partsby weight: 14-18 parts of an epoxy resin, 2-3 parts of an amino resin, 0.2-0.6 part of bentonite, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of a dispersant, 8-11 parts of titanium dioxide, 6-10parts of flame-retardant filler, 4-6 parts of expanded graphite, 20-30 parts of Ammonium Polyphosphate, 5-9 parts of melamine, 5-9 parts of pentaerythritol, 2-3 parts of reinforcing filler, 11-12 parts of xylene and 3-5 parts of butanol; and the component B is a modified polyamide epoxy curing agent. The fireproof coating is excellent in flame retardancy, high in mechanical strength and excellentin water resistance.

Owner:石家庄市油漆厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com