Biodegradable polylactic acid foamed particles and preparation method thereof

A technology of polylactic acid foaming and L-polylactic acid, which is applied in the field of biodegradable polylactic acid foamed particles and its preparation, can solve the problems of destroying the biodegradability of polylactic acid materials, unfavorable production costs, high saturation pressure, etc., and achieve reduction Production process, reduce production cost, increase the effect of expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

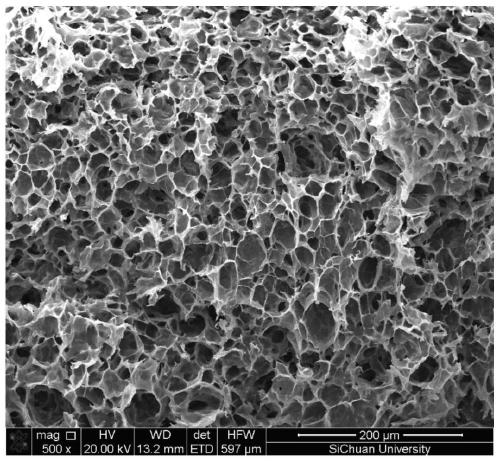

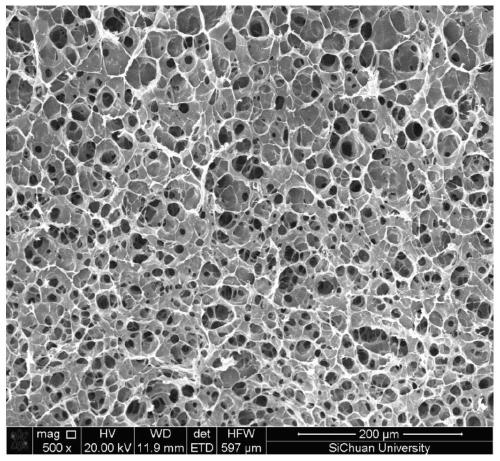

Image

Examples

Embodiment 1

[0030] In this embodiment, the preparation method of biodegradable polylactic acid expanded particles is as follows:

[0031] (1) Put the dextrorotatory polylactic acid into the extruder for melting and kneading, extrude it into a wire rod through a die, immediately introduce the wire rod into water for cooling, and then cut it into particles with a particle size of 0.8mm to prepare polylactic acid Foam masterbatch.

[0032] (2) Put the polylactic acid foaming masterbatch into the reactor, and feed CO as a foaming agent into the reactor. 2 Gas, control the temperature of the autoclave to 25°C and the pressure to 2.5MPa, maintain the aforementioned temperature and pressure for 60 minutes, then open the ventilation valve of the autoclave to reduce the pressure in the autoclave to normal pressure.

[0033] (3) Immediately place the polylactic acid foaming masterbatch with adsorbed gas obtained in step (2) in a heating tunnel heated to 70° C. to foam for 30 seconds to obtain poly...

Embodiment 2

[0036] In this embodiment, the preparation method of biodegradable polylactic acid expanded particles is as follows:

[0037] (1) Put 95 parts by mass of D-polylactic acid and 5 parts by mass of L-polylactic acid into an extruder for melting and kneading, extrude from a die into a wire rod, immediately introduce the wire rod into water for cooling, and then cut into particle size The polylactic acid foaming masterbatch was prepared with particles of 0.8mm.

[0038] (2) Put the polylactic acid foaming masterbatch into the reactor, and feed CO as a foaming agent into the reactor. 2 Gas, control the temperature of the autoclave to 25°C and the pressure to 2.5MPa, maintain the aforementioned temperature and pressure for 60 minutes, then open the ventilation valve of the autoclave to reduce the pressure in the autoclave to normal pressure.

[0039] (3) Immediately place the polylactic acid foaming masterbatch with adsorbed gas obtained in step (2) in a heating tunnel heated to 70°...

Embodiment 3

[0042] In this embodiment, the preparation method of biodegradable polylactic acid expanded particles is as follows:

[0043] (1) Put 97 parts by mass of D-polylactic acid, 3 parts by mass of L-polylactic acid, 3 parts by mass of dioctyl phthalate, and 1 part by mass of calcium carbonate into an extruder for melting and kneading, and extrude from a die To obtain a wire rod, immediately introduce the wire rod into water for cooling, and then cut the wire rod into particles with a particle diameter of 0.6 mm to prepare a polylactic acid foam masterbatch.

[0044] (2) Put the polylactic acid foaming masterbatch into the reactor, and feed CO as a foaming agent into the reactor. 2 Gas, control the temperature of the autoclave to 30°C and the pressure to 3MPa, maintain the aforementioned temperature and pressure for 30 minutes, then open the ventilation valve of the autoclave to reduce the pressure in the autoclave to normal pressure.

[0045] (3) Immediately place the polylactic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com