Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11524 results about "Pelletizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, and more.

Process for preparing a simulated in situ polyethylene blend

A process comprising:(i) providing a first polyethylene, prepared independently, having a melt index in the range of about 5 to about 3000 grams per 10 minutes and a density in the range of about 0.900 to about 0.975 gram per cubic centimeter and a second polyethylene, prepared independently, having a flow index in the range of about 0.01 to about 30 grams per 10 minutes and a density in the range of about 0.860 to about 0.940 gram per cubic centimeter, the weight ratio of the first polyethylene to the second polyethylene being in the range of about 75:25 to about 25:75;(ii) blending the first polyethylene with the second polyethylene;(iii) melting the blend; and, prior to extrusion or pelletizing,(iv) passing the molten blend through one or more active screens, in the case of two or more active screens, positioned in series, each active screen having a micron retention size in the range of about 2 to about 70, at a mass flux of about 5 to about 100 pounds per hour per square inch.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

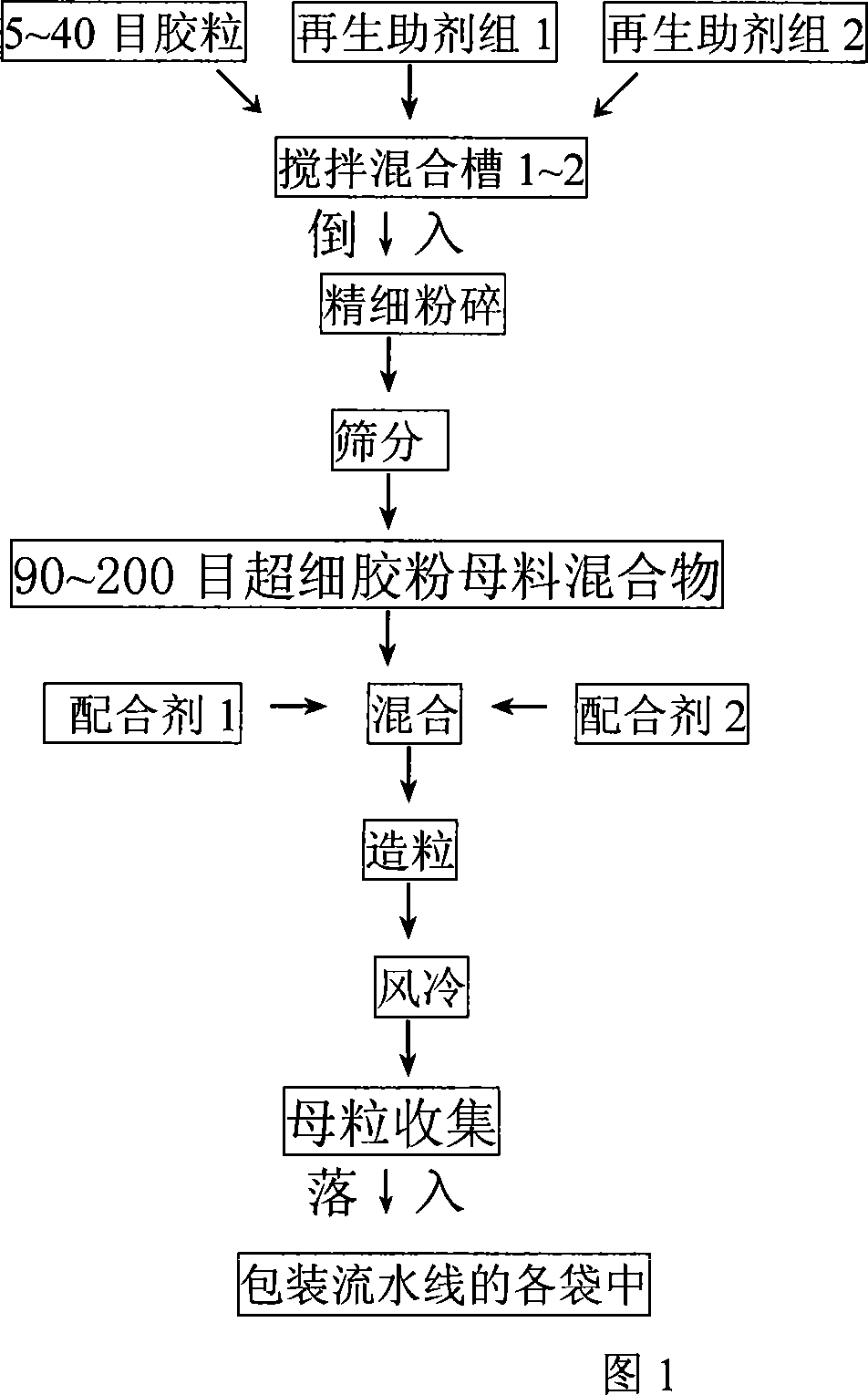

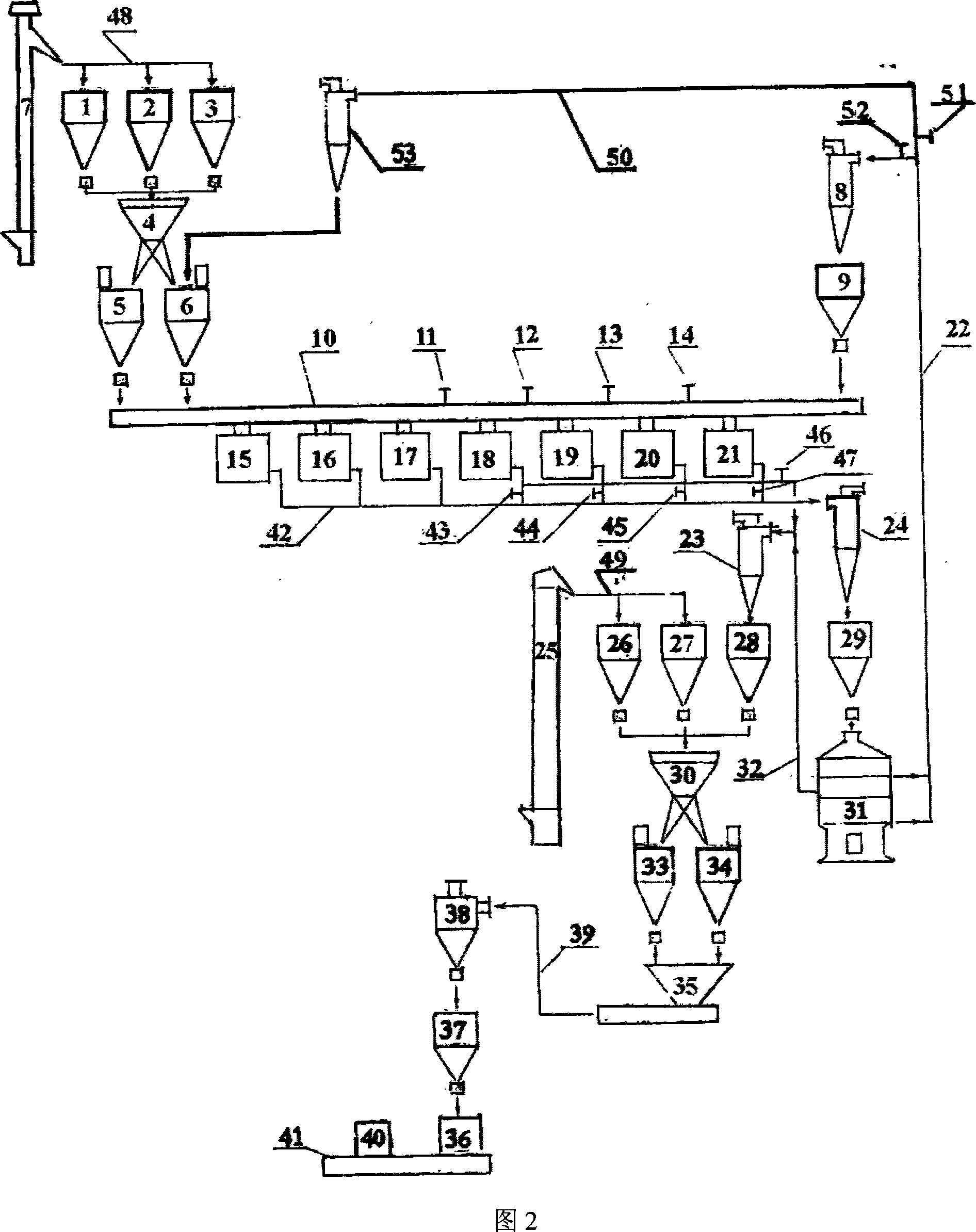

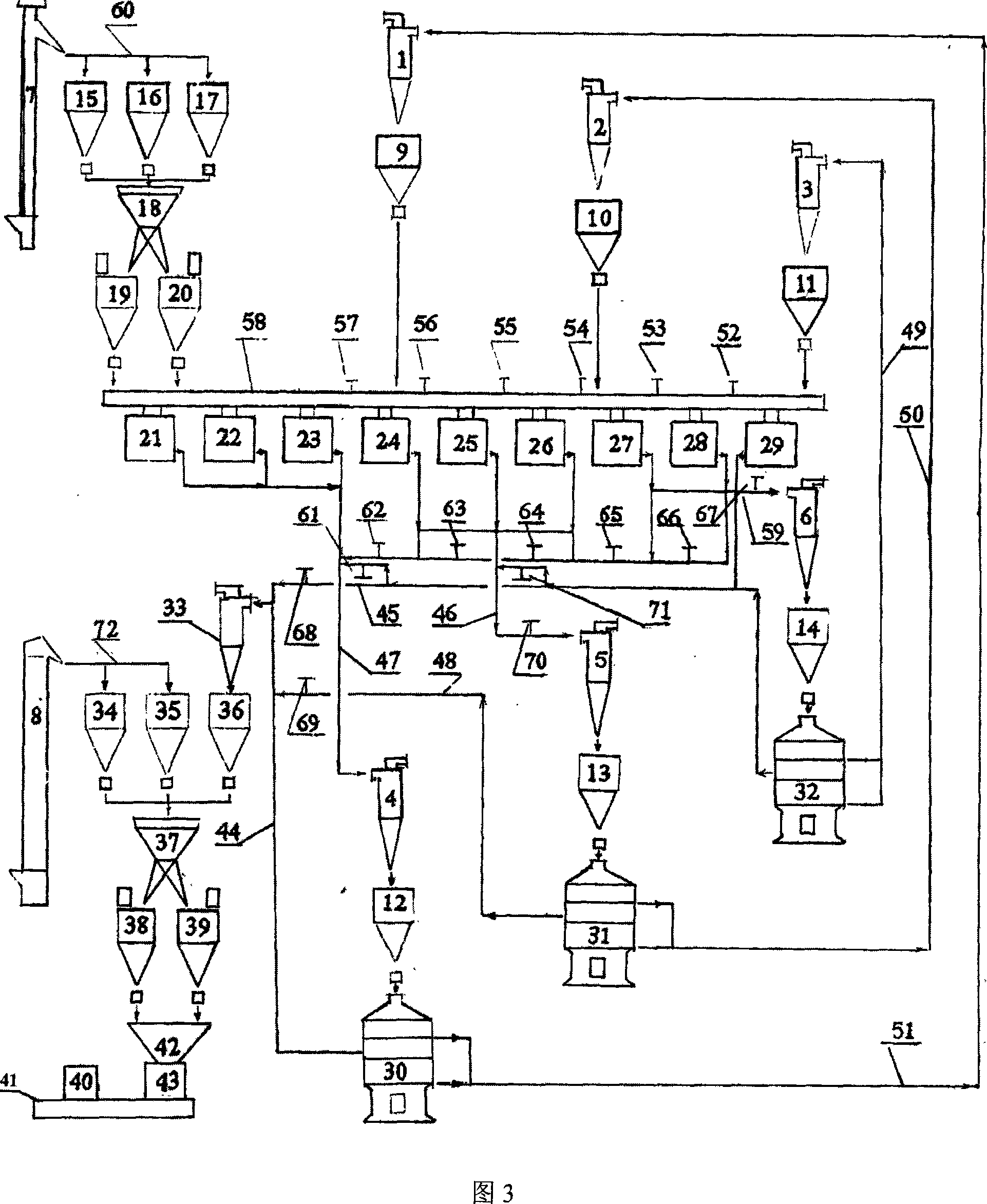

Reproduction new method for waste elastomer and plastic

InactiveCN101041725AThe ratio is roughly constantReduce or eliminate the impact of flow fluctuationsPlastic recyclingElastomerEngineering

The invention discloses a new regenerating method of waste elastics and plastic, which comprises the following steps: 1. blending waste elastics or / and plastic with grain size between 5 and 80 order and non-polluted regenerative adjuvant according to proportion; placing into the manufacturing machine; grinding; sieving; heating to desulfurize; bulking; soaping; emulsifying; kneading; pressing; graining; obtaining composite product 1 with mother material or mother particle or mother gel of plastic elastic powder; 2. weighing product 1 and non-polluted mating agent into mixing machine according to proportion; kneading; blending evenly; pressing; graining; obtaining the product 2 of mother material or mother particle or mother gel with 5-95% waste elastic or / and plastic.

Owner:陈书怡 +1

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

an air purifier

InactiveCN103861421BLarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

Owner:QINGDAO CHUANSHAN NEW MATERIALS

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

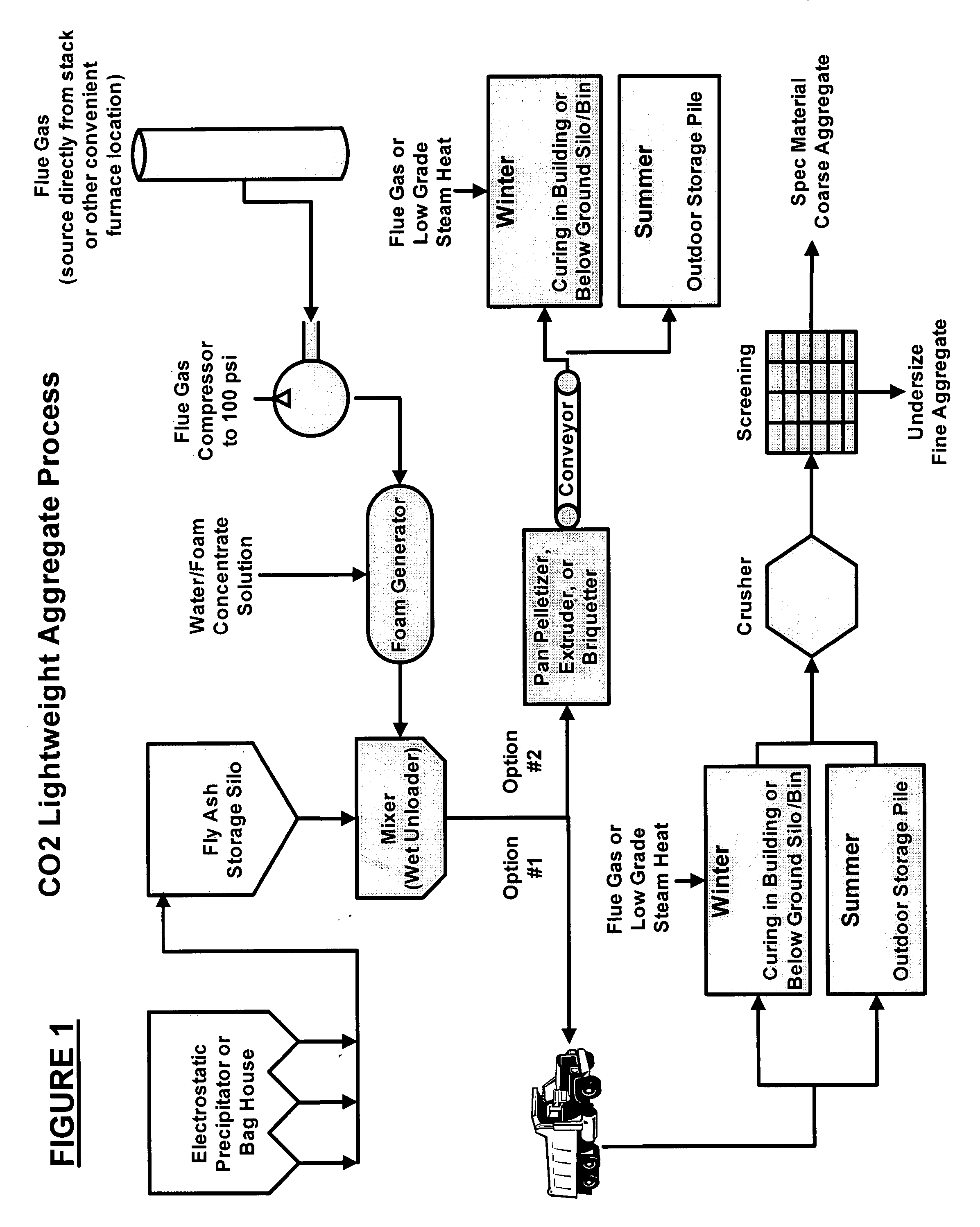

Carbon dioxide sequestration in foamed controlled low strength materials

InactiveUS20060185560A1Improve the environmentEasy to useProductsReagentsCombustion chamberMaterials science

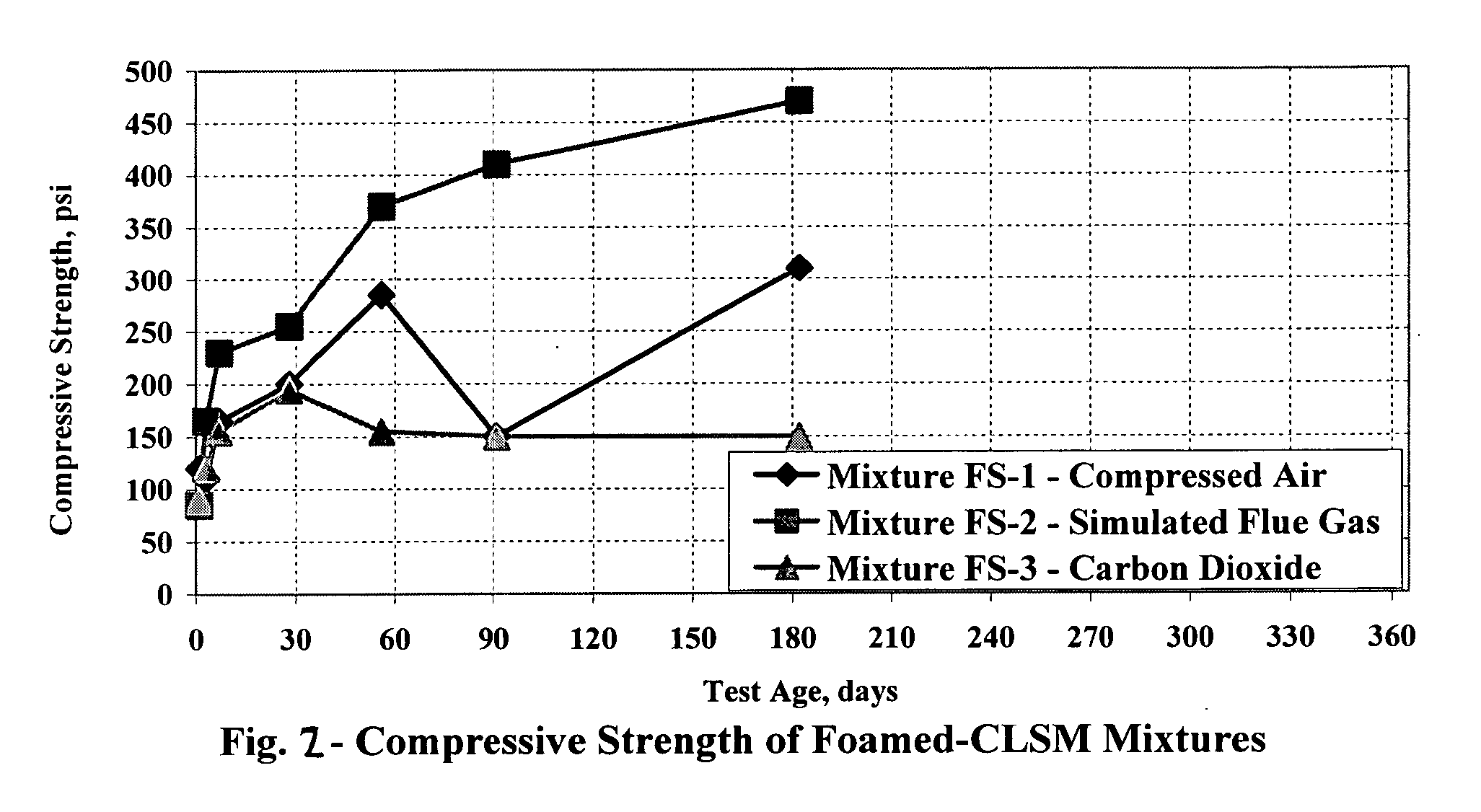

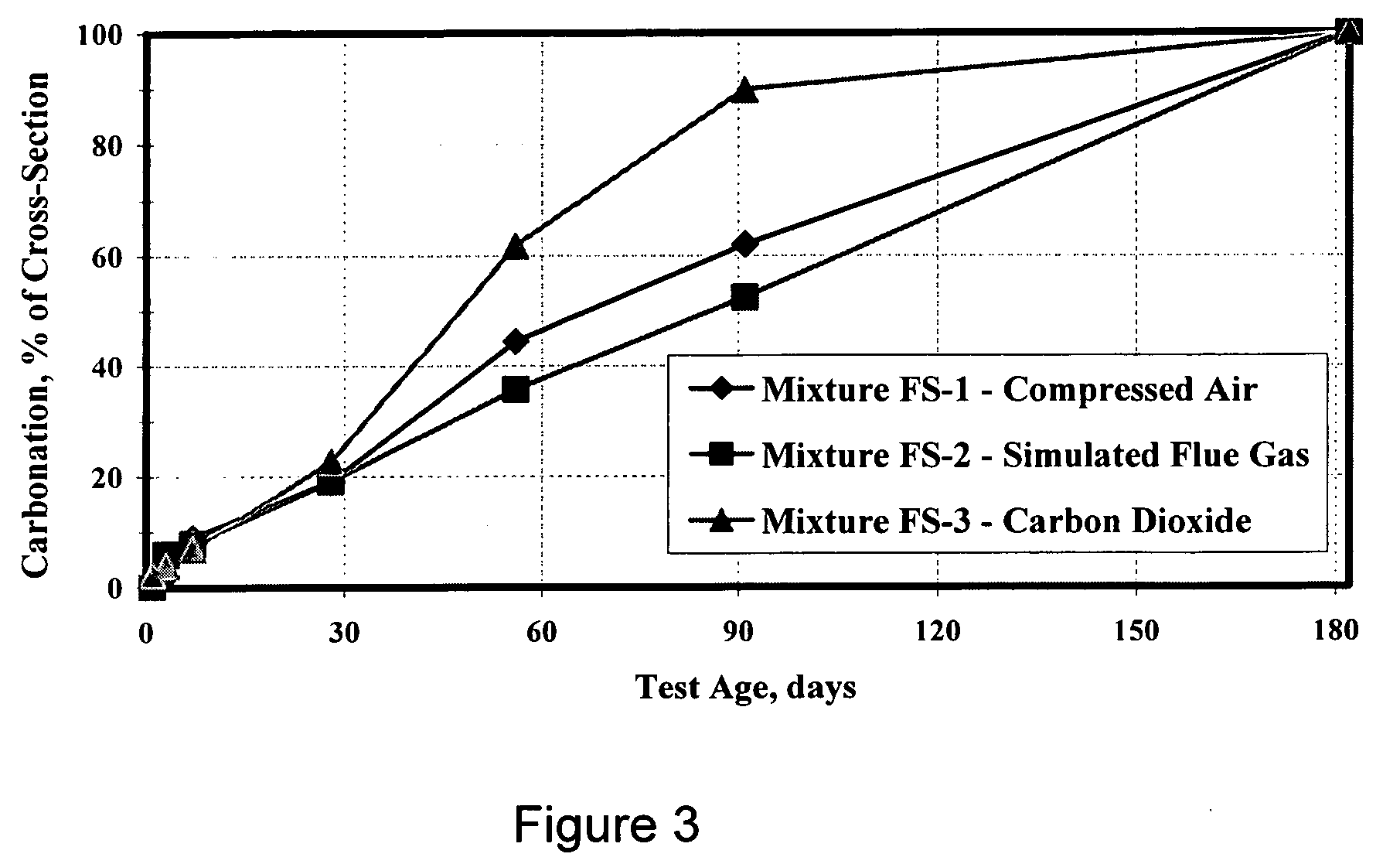

A process for sequestering carbon dioxide from the flue gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the flue gas is formed, and the foam is added to a mixture including a cementitious material (e.g., fly ash) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the flue gas and waste heat reacts with hydration products in the controlled low-strength material to increase strength. In this process, the carbon dioxide is sequestered. The CLSM can be crushed or pelletized to form a lightweight aggregate with properties similar to the naturally occurring mineral, pumice.

Owner:WISCONSIN ELECTRIC POWER

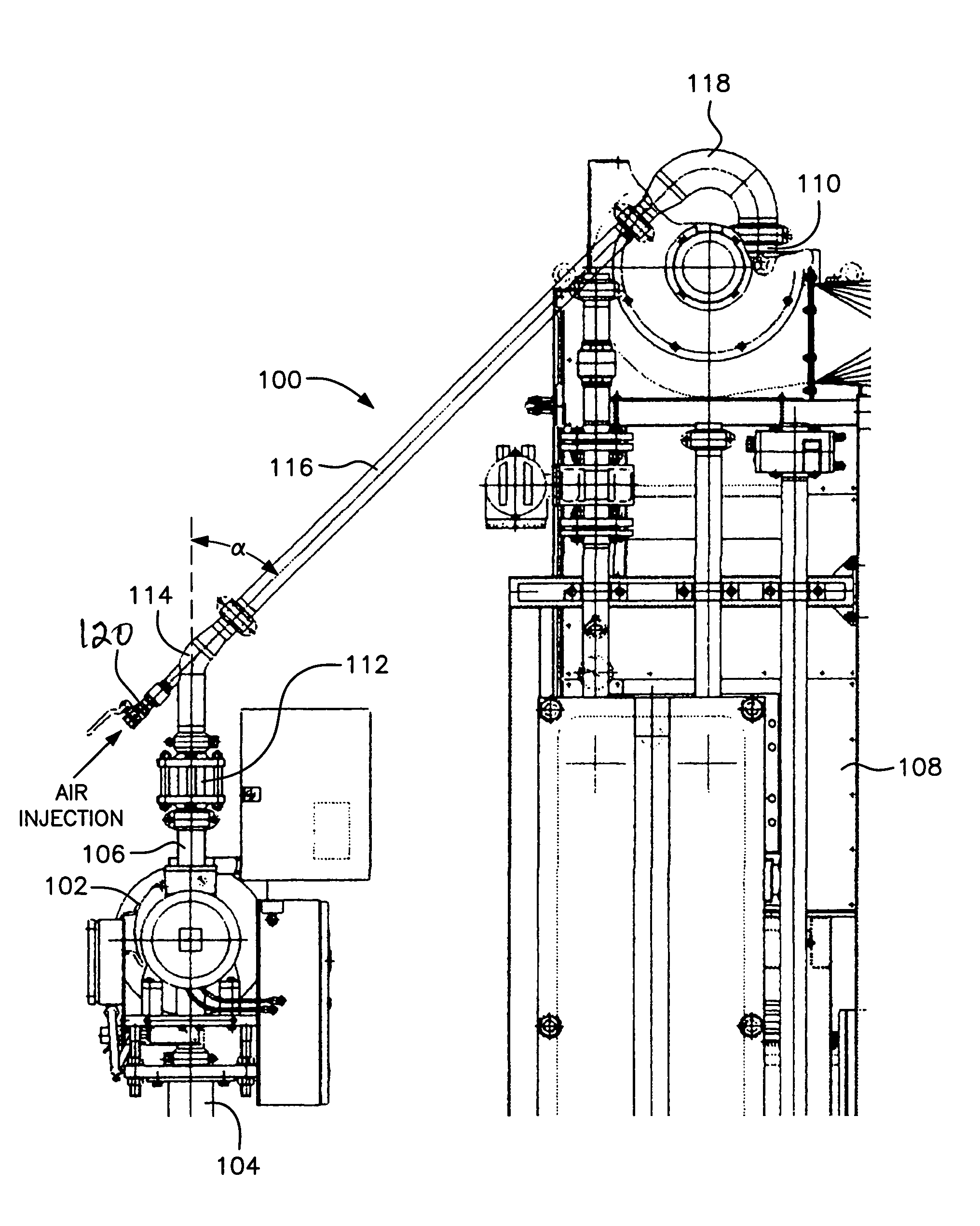

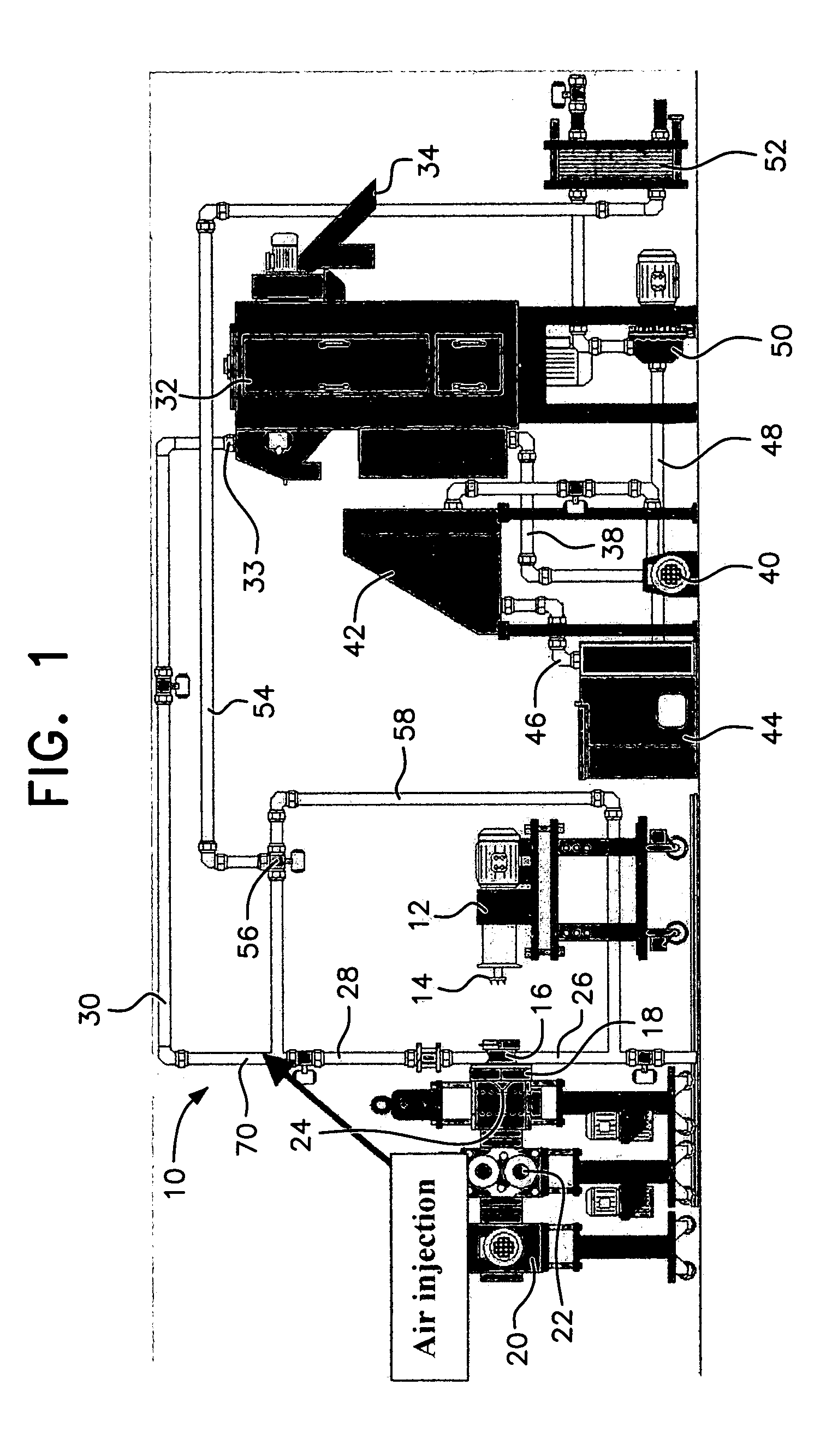

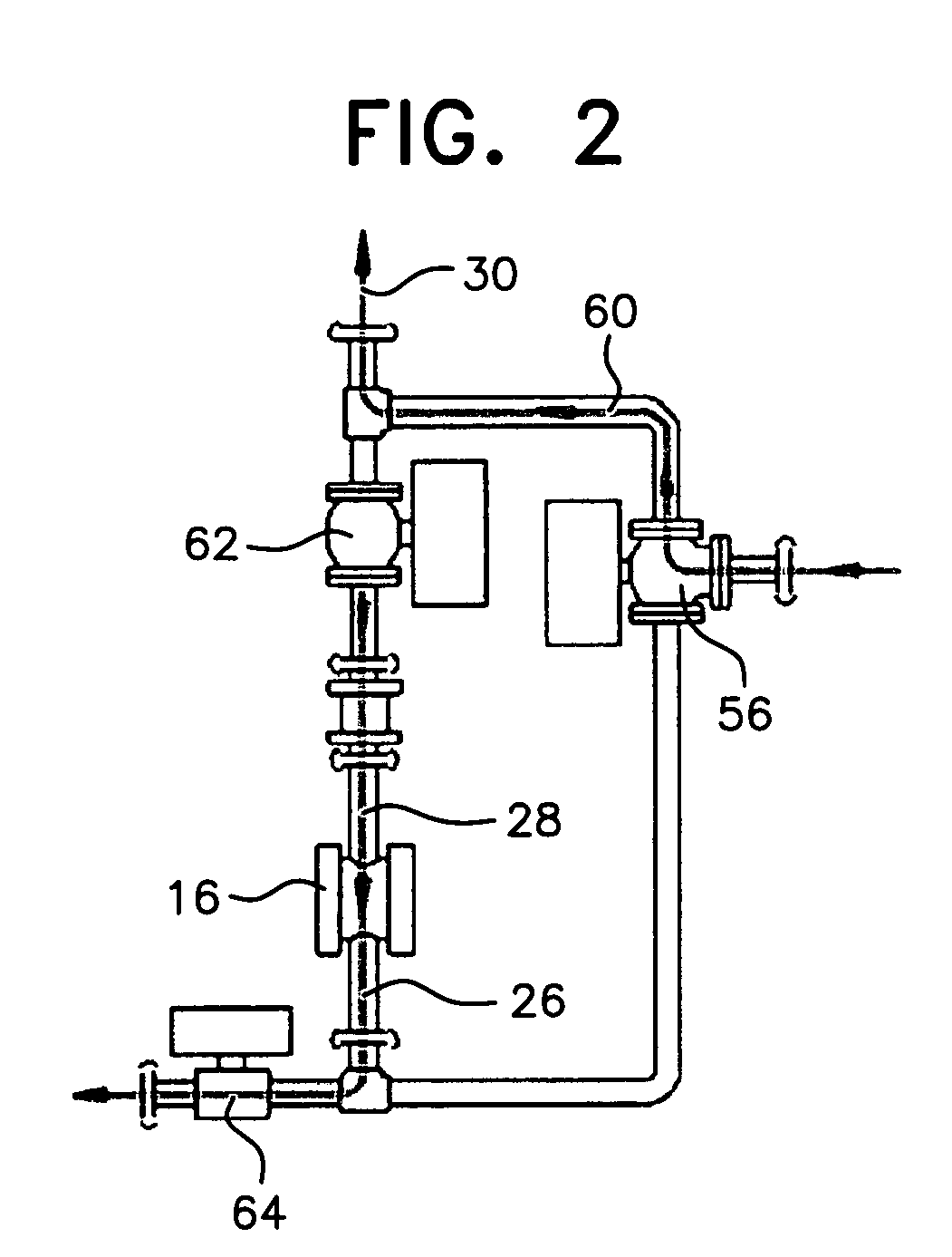

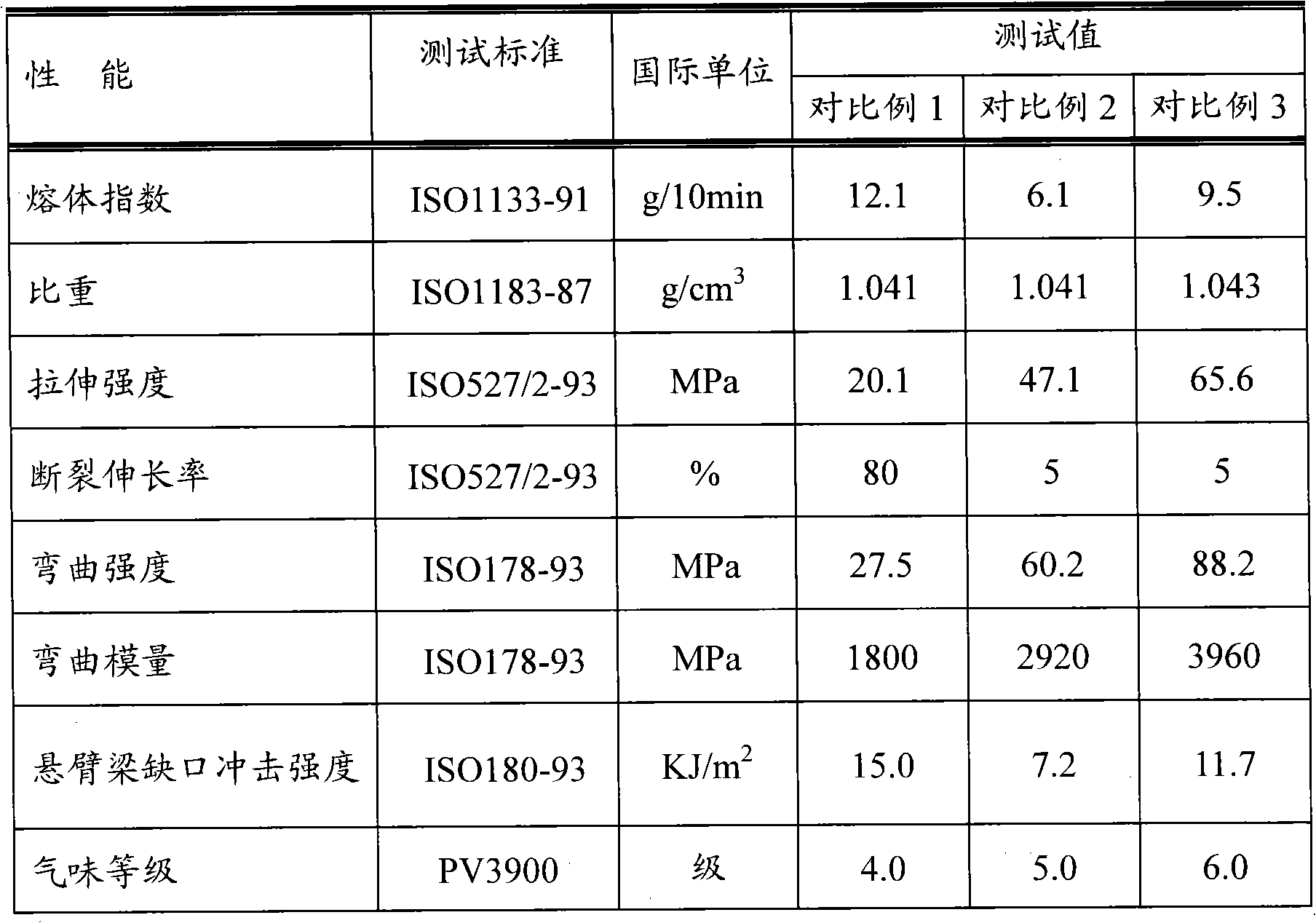

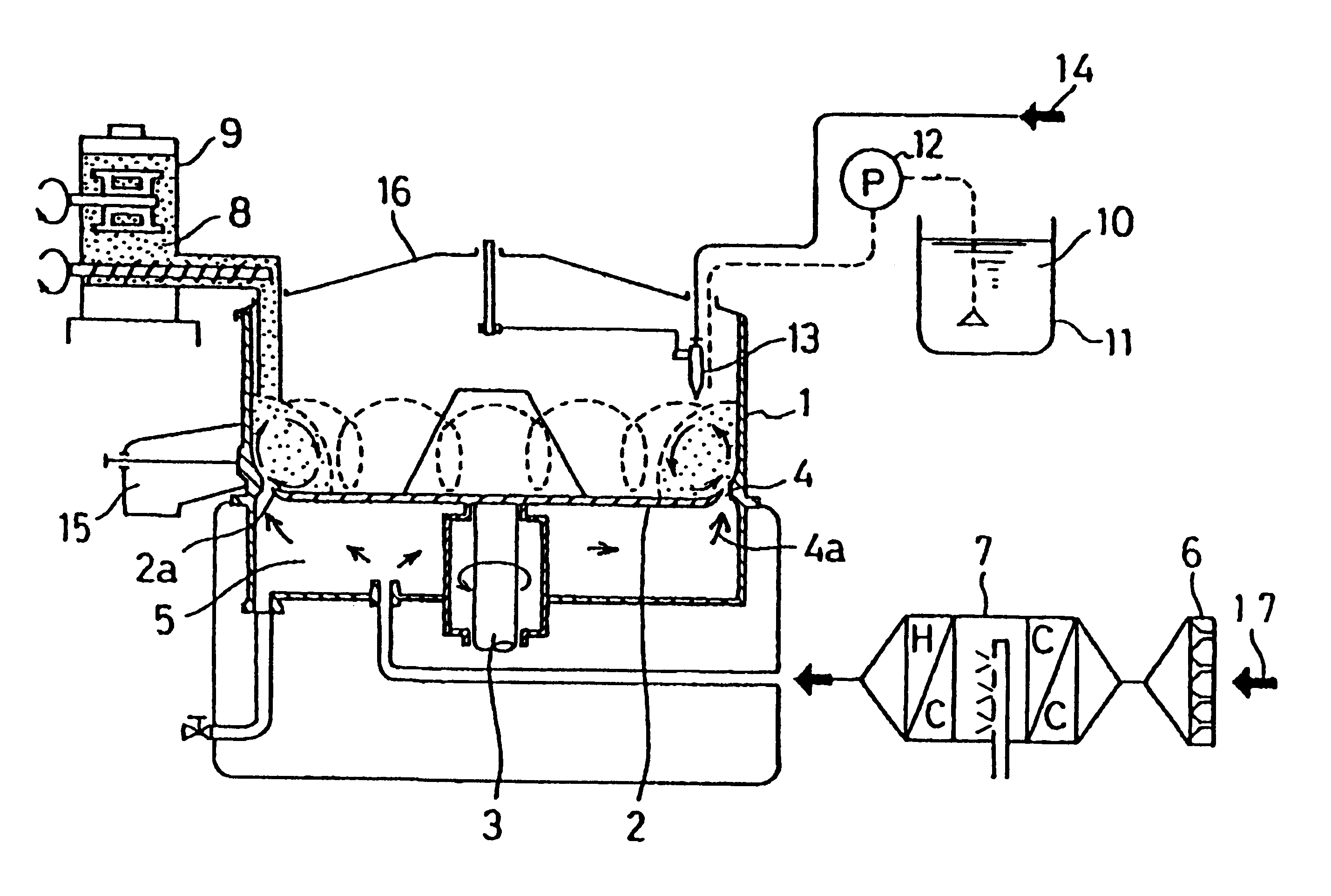

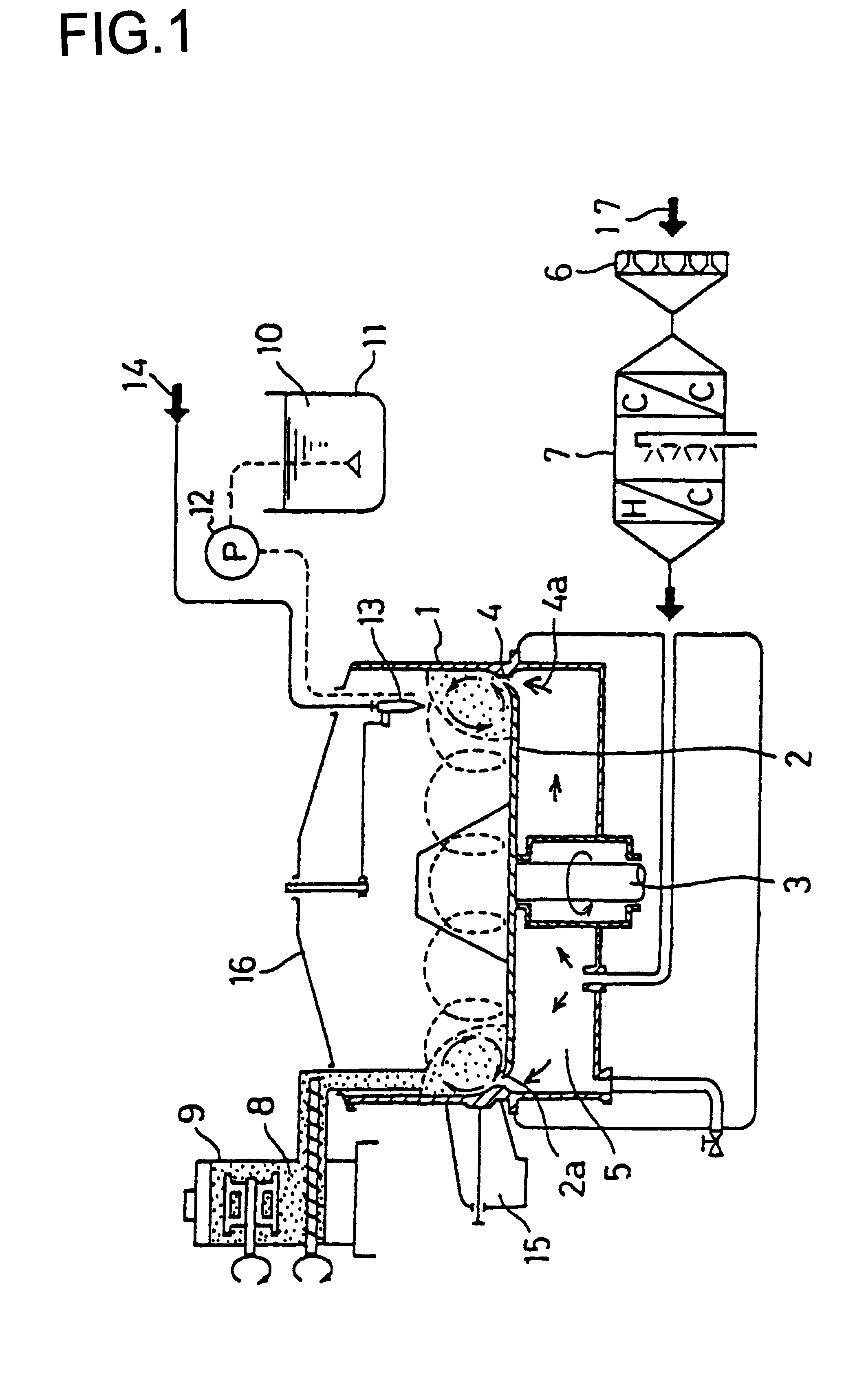

Method and apparatus for making crystalline PET pellets

InactiveUS20050110182A1Reduce dwell timeIncrease speedMouldsDrying solid materials without heatSlurryCrystallinity

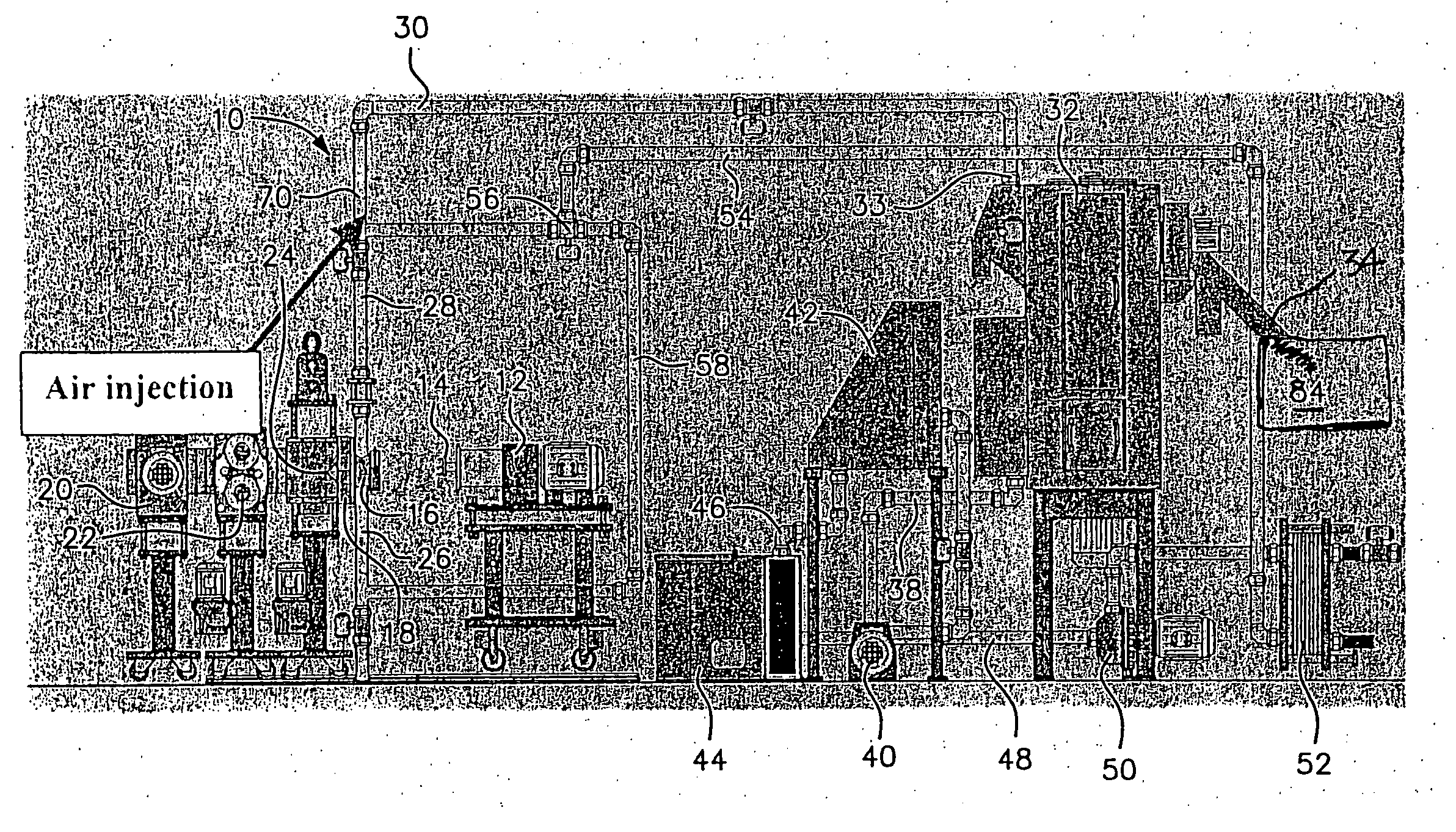

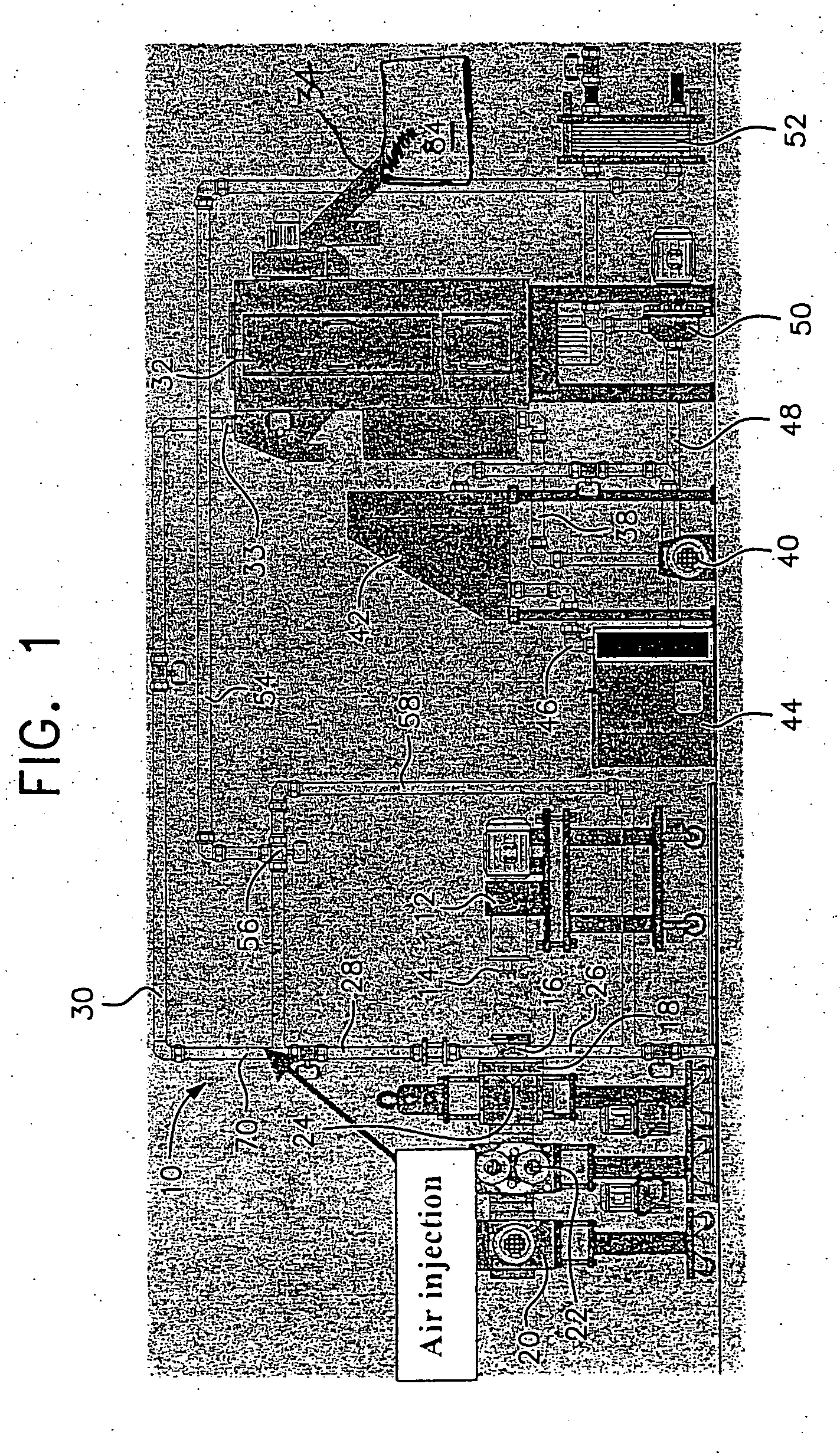

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. Air is injected into the slurry line at a velocity of from about 100 to about 175 m3 / hour, or more. Such high-speed air movement forms a vapor mist with the water and significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer at a temperature sufficient to self-initiate crystallization within the pellets. A valve mechanism in the slurry line after the gas injection further regulates the pellet residence time and a vibrating conveyor after the dryer helps the pellets to achieve the desired level of crystallinity and to avoid agglomeration.

Owner:GALA INDUSTRIES INC

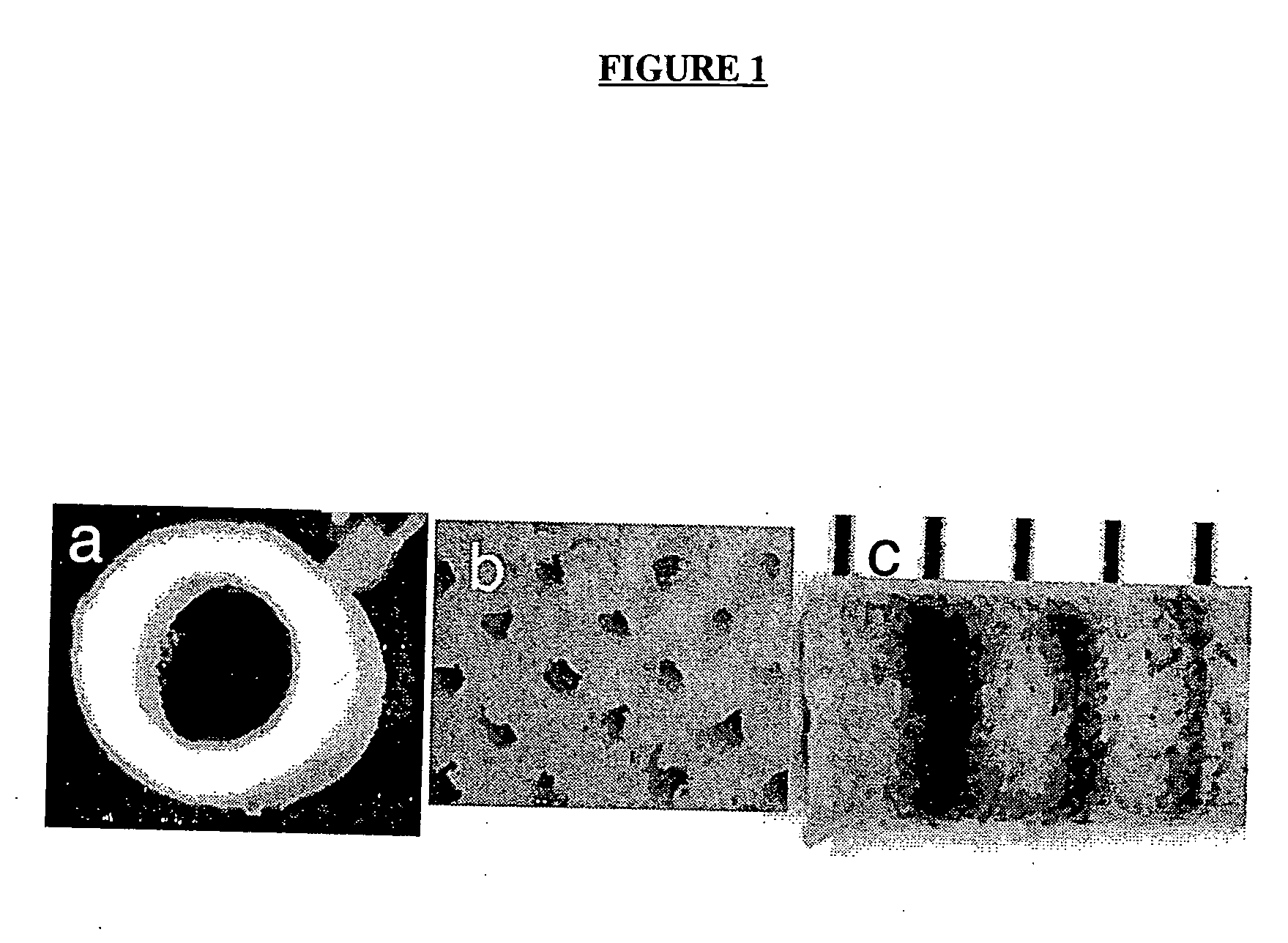

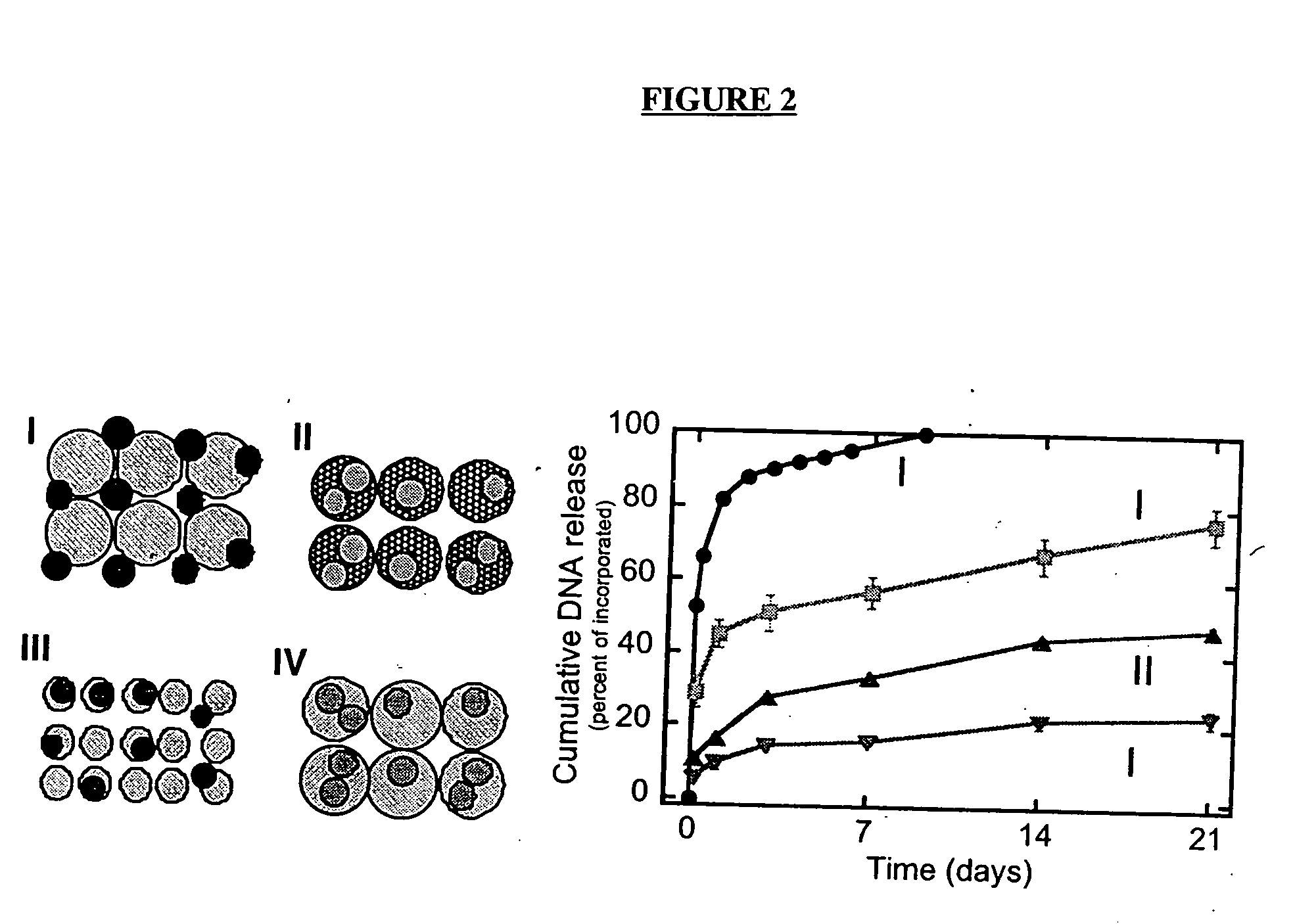

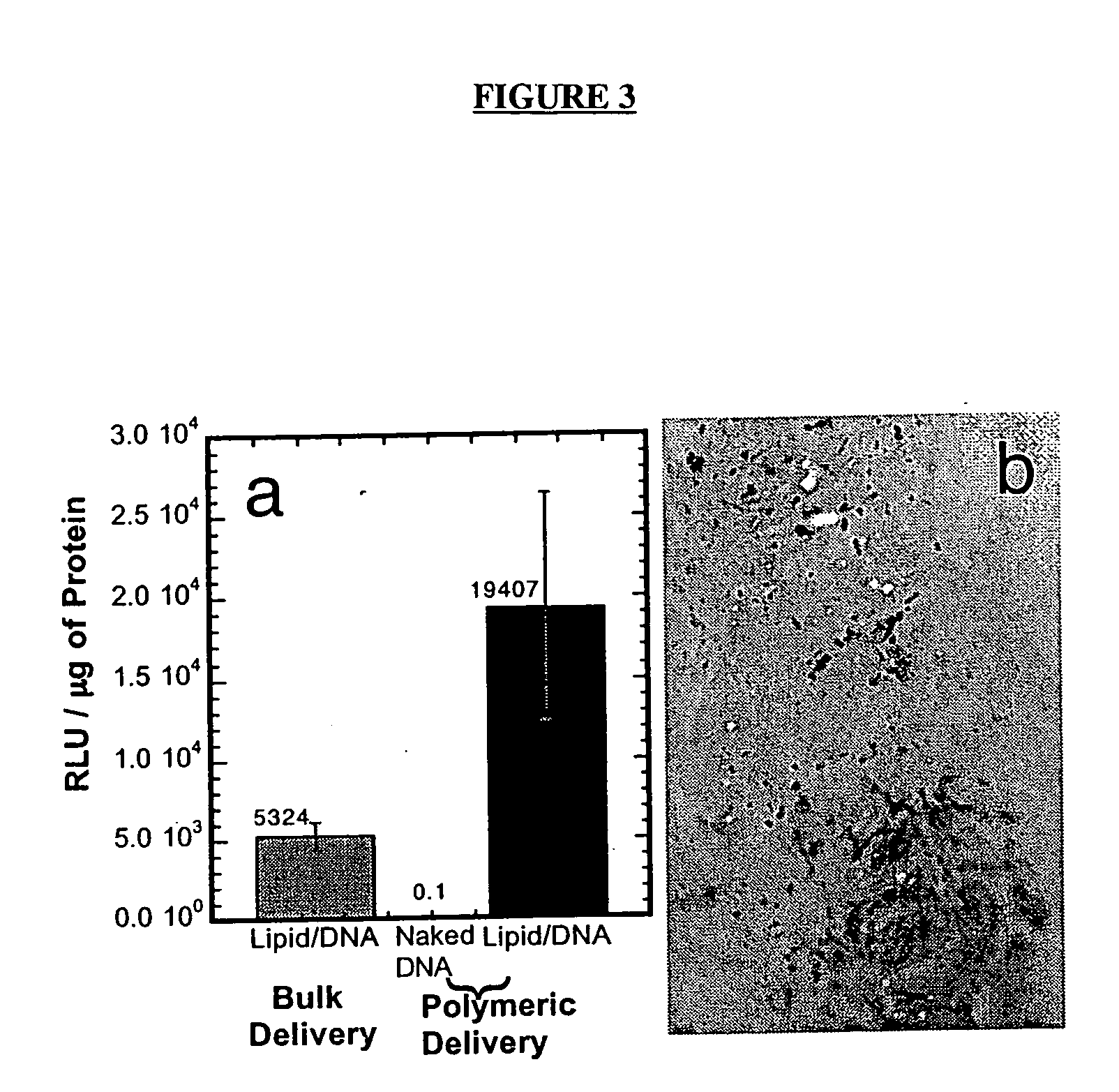

Biodegradable scaffolds and uses thereof

InactiveUS20060002978A1Strengthen cellsEnhanced tissue growthPowder deliveryPeptide/protein ingredientsBiodegradable scaffoldPolymer chemistry

The invention is directed to scaffolds containing porous polymer material prepared by a process of gas foaming / particulate leaching and a wet granulation step prior to gas foaming and particulate leaching, particularly having a characteristic interconnected pore structure, as well as sustained release of protein, DNA or cells, and to methods for using such porous polymer material for preparation of scaffolds, particularly for tissue engineering.

Owner:NORTHWESTERN UNIV

Active alumina/active carbon composite material and preparation method thereof

InactiveCN102319557ASolve the strength problemSolve the problem of longevityCatalyst carriersOther chemical processesActivated carbonSludge

The invention discloses an active alumina / active carbon composite material and a preparation method thereof. The composite material comprises the following ingredients: 70-90 weight portions of sludge, 10-30 weight portions of active carbon, and 15-35 weight portions of binder, and is prepared by uniformly mixing, pelleting, aging, molding, drying in the air, sintering, rinsing and drying. Using sludge as raw material has an important meaning to environmental protection and recycling of waste. The invention has the advantages of simple preparation method, easy obtainment of raw material, and low cost, and can be widely applied in the fields of industry, agriculture, environmental protection, air cleaning, water treatment and the like.

Owner:FUZHOU UNIV

Appearance-improving spraying-free aesthetic resin and its preparation method

The invention relates to an appearance-improving spraying-free aesthetic resin and its preparation method. The resin comprises the following components by weight part: 90 of matrix resin, 0.1-2.0 of a lubricant, 0.1-1.0 of an antioxidant, and 10-30 of a magnetic metallic pigment masterbatch, which consists of the following components by weight part: 100 of the matrix resin, 1.0-20 of a magnetic metallic pigment, 1.0-30 of a pearlescent pigment, 0.1-2.0 of the lubricant, 0.1-1.0 of the antioxidant. The preparation method includes: preparing the magnetic metallic pigment masterbatch; and mixingthe above raw materials, then conducting mixing, extrusion, bracing, cooling, and pelletizing, thus obtaining the aesthetic resin. The aesthetic resin of the invention can effectively improve the affinity of an aluminum powder pigment and a plastic substrate, mitigate flow marks and weld lines that appear during injection molding or extrusion of aluminum powder pigment-containing aesthetic resin,and simultaneously strengthens the metal effect a made piece, greatly reduces consumption of the aluminum powder pigment, and saves cost. The present invention is green and environmental aesthetics resin instead of traditional paint scheme provides technical support. The aesthetic resin and the preparation method provided in the invention provide technical support for green and environmentally friendly aesthetic resin to substitute traditional paint spraying schemes.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

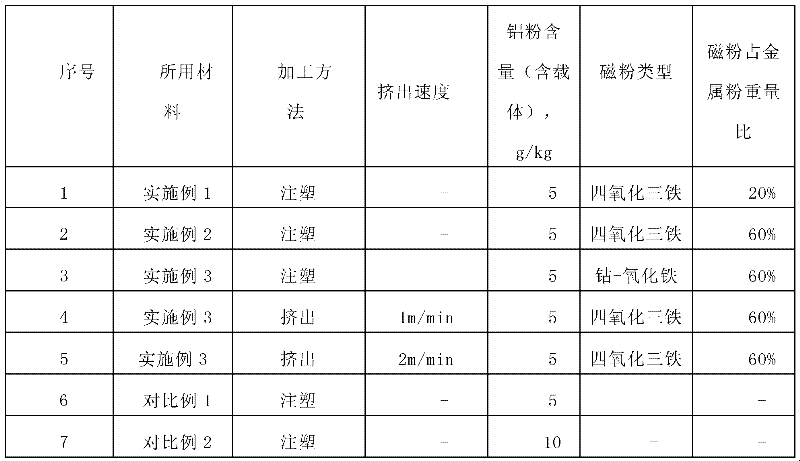

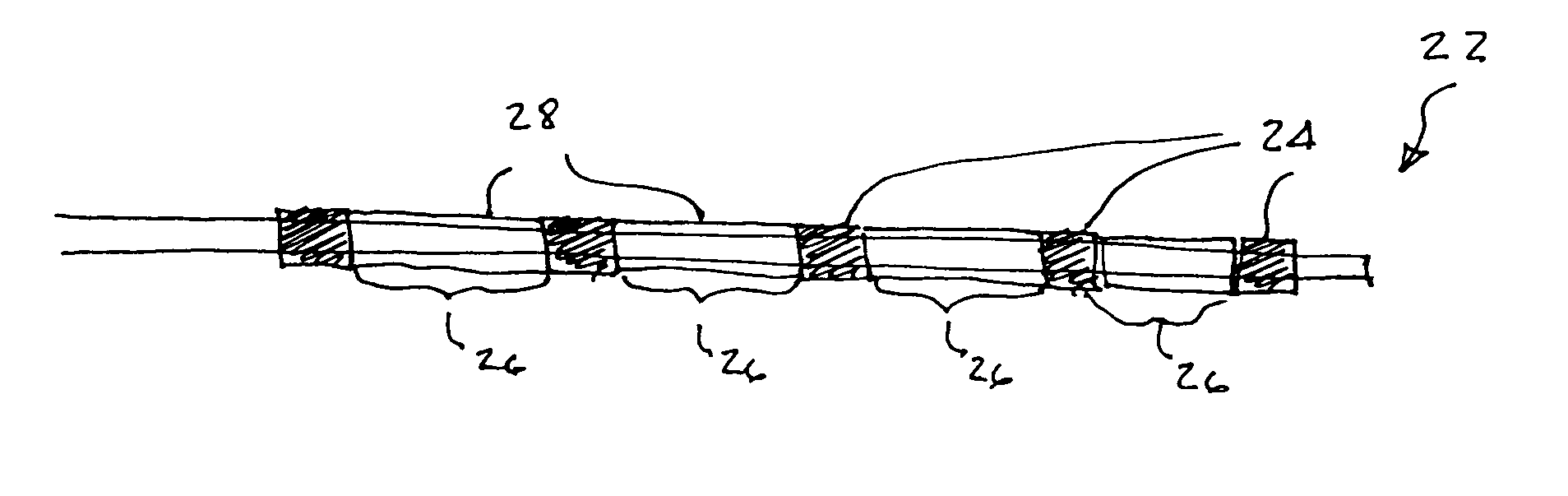

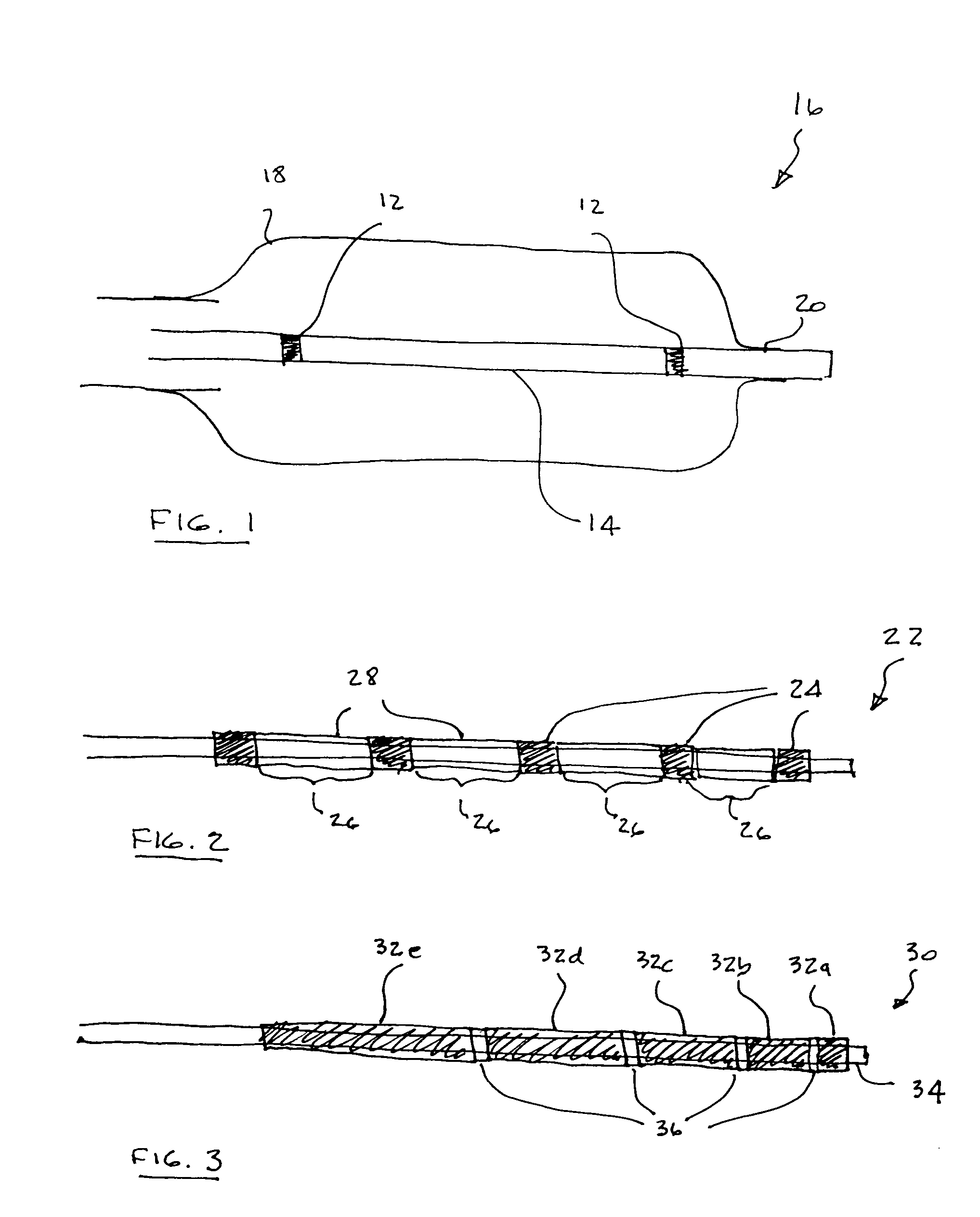

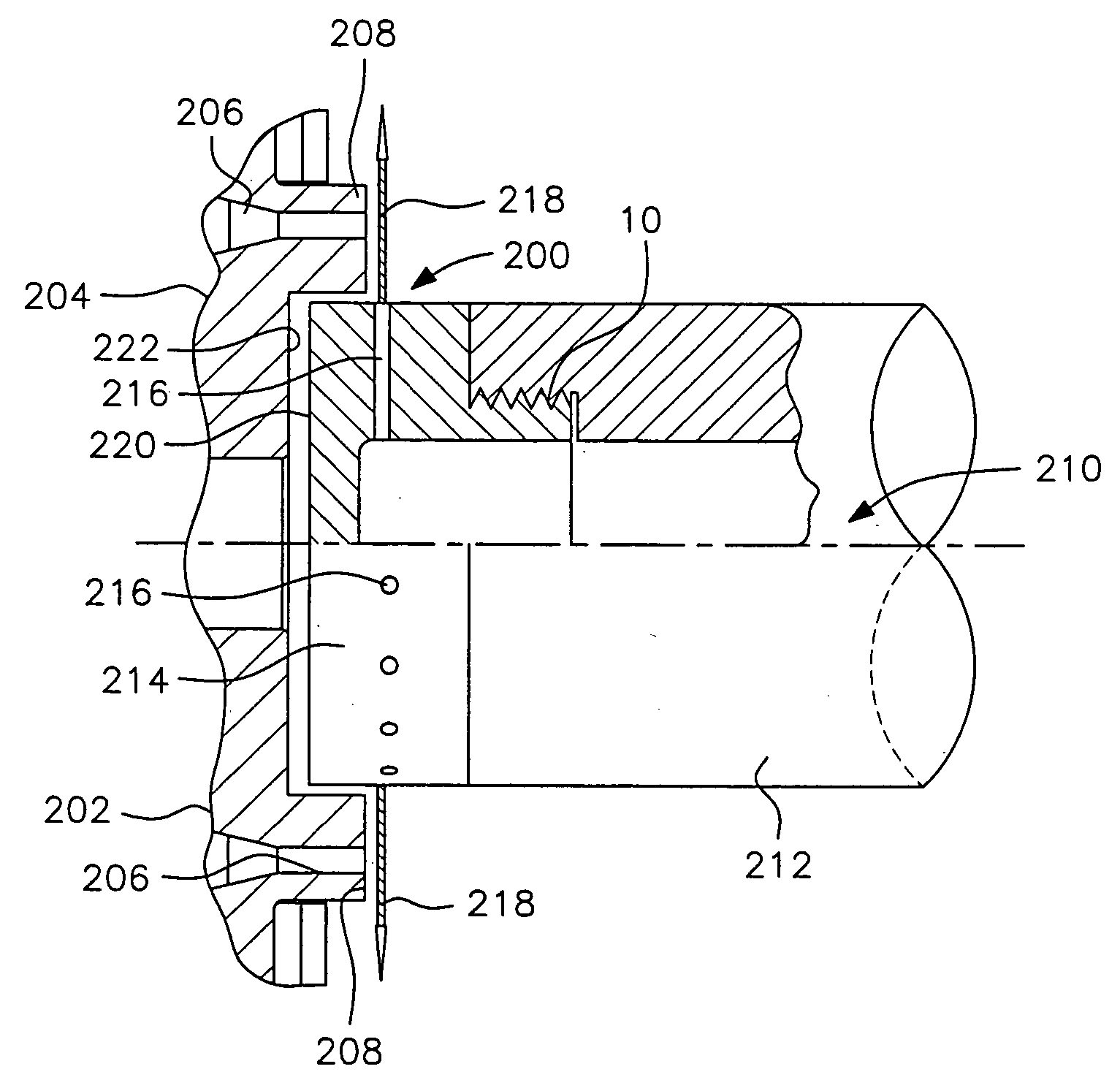

Polymeric marker with high radiopacity

InactiveUS20050064223A1Overcomes shortcomingImprove fill rateSurgeryConductive materialPolymer resinRadiopaque agent

High radiopacity is achieved in a polymeric marker by combining a polymeric resin, a powdered radiopaque agent having uniformly shaped particles of a specific particle size distribution and a vetting agent. The method to produce the marker calls for the blending and pelletization of these materials followed by extrusion onto support beading. The resulting supported tubing is subsequently cut to length with the beading still in place. After ejection of the beading remnant the marker is slipped into place on the device to be marked and attached by melt bonding. Marking of a guidewire allows lesions to be measured while the marking of balloon catheters allow the balloon to be properly positioned relative to a lesion.

Owner:ABBOTT CARDIOVASCULAR

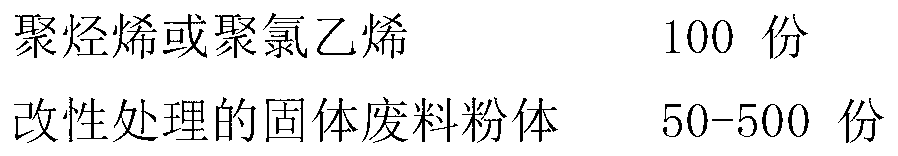

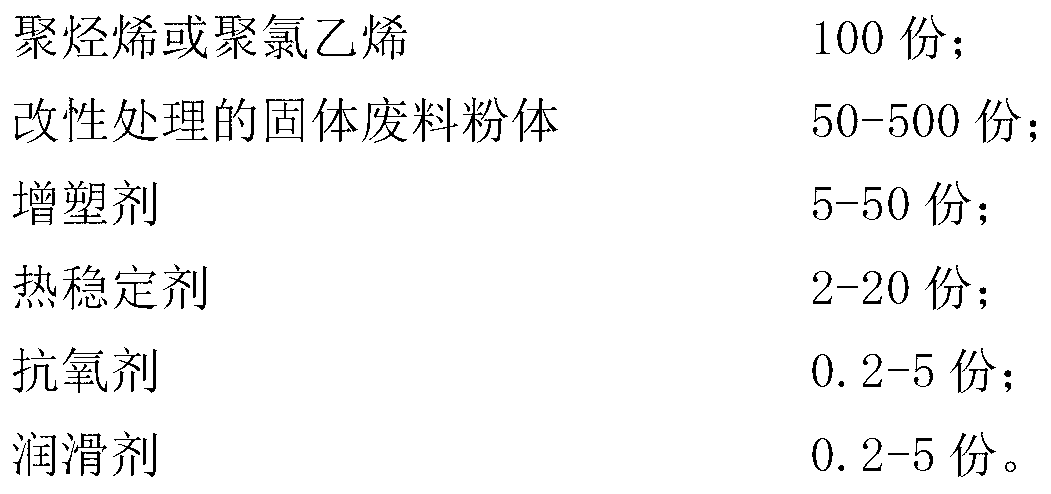

Method for preparing high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes

The invention discloses a method for preparing a high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes and belongs to the field of chemical materials. According to the method, the industrial solid wastes and polyvinyl chloride or polyolefin serve as main raw materials, the industrial solid wastes are subjected to surface modification, the compatibility between the industrial solid wastes and the polyvinyl chloride or polyolefin is improved, the liquidity and processability of the composite material is improved by utilizing a compound plastifier, and the composite material is subjected to mixing and pelleting under the coaction of a proper amount of aids, so that the high filling polyvinyl chloride or polyolefin composite material is prepared. The method is simple in process, low in cost and high in additional value of products. The composite material has the characteristics of high filling amount of industrial solid wastes, enough strength and toughness, environment friendliness, stable performance and the like and can be widely applied to preparing green building materials and advanced engineering products in various fields of national economy.

Owner:TSINGHUA UNIV

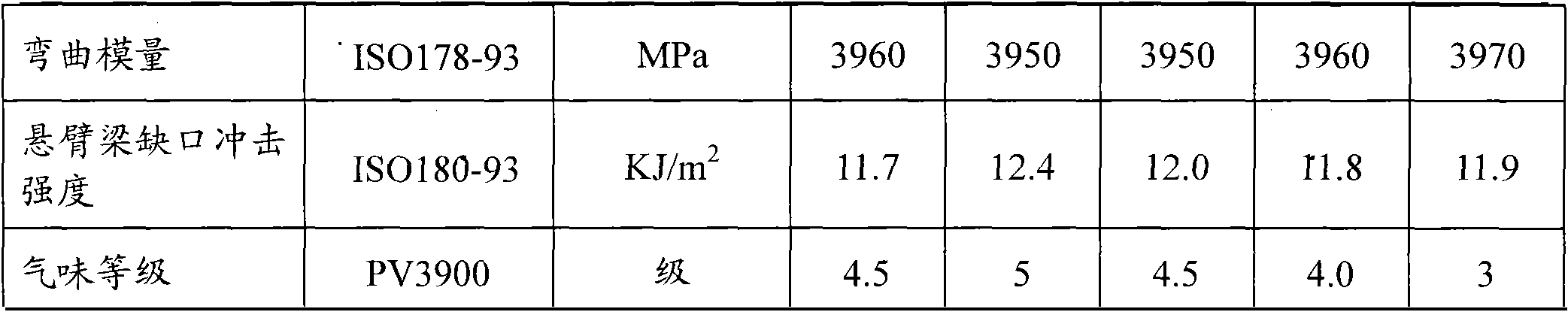

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

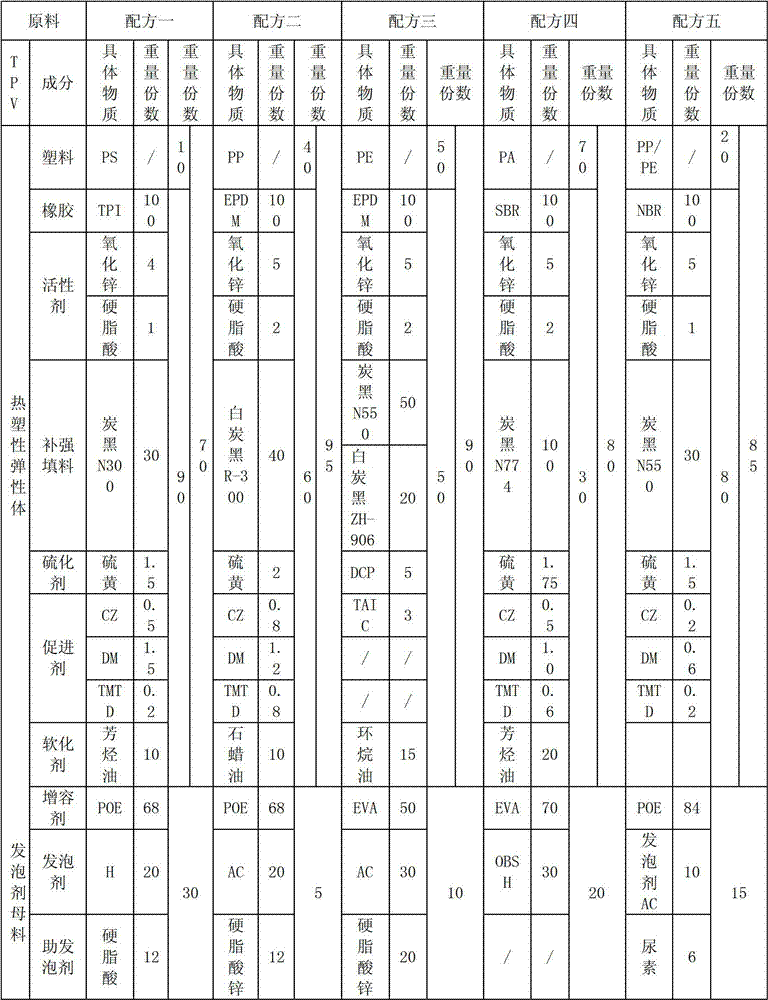

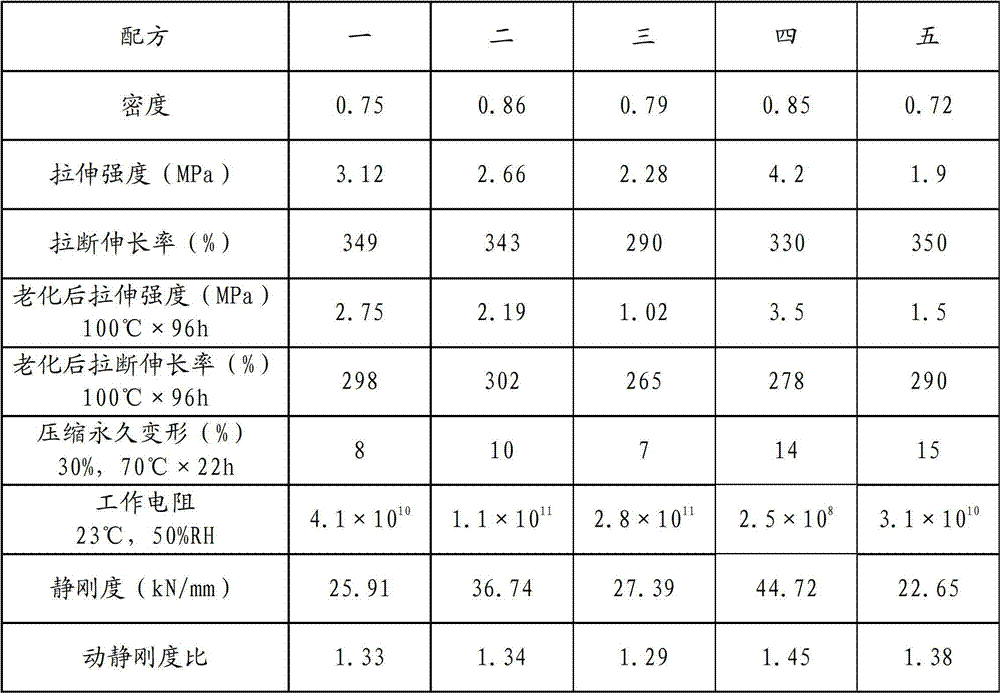

Thermoplastic elastomer micropore foaming material and preparation method thereof

The invention discloses a thermoplastic elastomer micropore foaming material and a preparation method thereof. The material comprises the following componnets in parts by weight: 70-95 parts of thermoplastic elastomer and 5-30 parts of foaming agent master batch. The preparation method comprises the following steps of: based on weight parts, placing 50-90 parts of compatibilizers, 6-30 parts of foaming agent and 4-20 parts of auxiliary foaming agents into a double-roller open mill for mixing to prepare foaming agent master batch; sequentially adding 100 parts of matrix rubber, 5-10 parts of active agent, 20-100 parts of reinforced fillers, 0-20 parts of softening agents, 0.5-5 parts of vulcanizing agents and 1-10 parts of accelerating agents into the open mill or an internal mixer for uniformly mixing to prepare a rubber compound; chopping the rubber compound and uniformly mixing the chopped rubber compound with 10-70 parts of plastics by a high-speed mixer; and extruding and pelleting the mixture to prepare thermoplastic vulcanizate (TPV) aggregates; and uniformly mixing the foaming agent master batch with the TPV aggregates to extrude and form again to prepare a high-performance micropore foaming material for vibration attenuation. The TPV foaming material is high in physical and mechanical properties and thermal ageing performance, is simple in process, can be widely popularized, and is suitable for being used in the field of rail transit.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method and apparatus for making crystalline PET pellets

InactiveUS7157032B2Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA INDUSTRIES INC

Moldable-foam moldings composed of expandable pelletized filled polymer materials

InactiveUS20070112082A1High compressive strengthLow thermal conductivityPelletizingThermoplastic polymer

Moldable-foam moldings whose density is in the range from 8 to 200 g / l, obtainable via fusion of prefoamed foam beads composed of expandable pelletized filled thermoplastic polymer materials, and a process for preparing the expandable pelletized polymer materials.

Owner:BASF SE

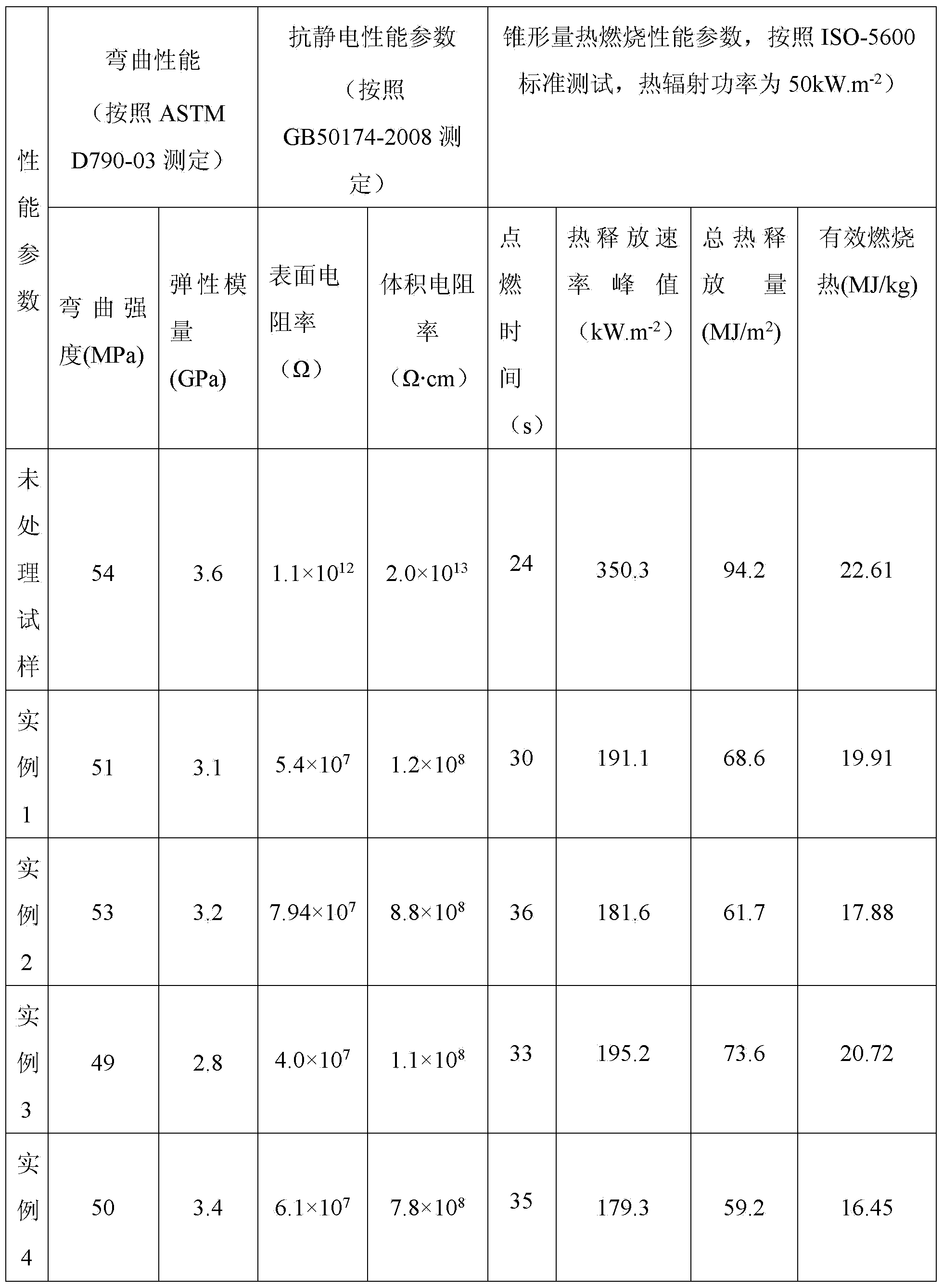

Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

ActiveCN104327530AAchieve flame retardant and antistatic effectImprove flame retardant performanceThermoplasticFiber

The invention discloses a flame-retardant and antistatic wood-plastic composite material and a preparation method thereof and relates to a wood-plastic composite material and a preparation method thereof. The invention aims at solving the problems of relatively poor flame retardance and relatively high cost of the existing antistatic wood-plastic composite material. The wood-plastic composite material is prepared from the following components in parts by weight: a lignocellulosic material, thermoplastic, a lubricant, an antistatic agent, a flame retardant, a coupling agent and an inorganic filler. The method comprises the following steps: 1) performing hot mixing on the lignocellulosic material, the thermoplastic and the lubricant to obtain a hot-mixed material; 2) putting the hot-mixed material into a cold mixing machine for cold mixing, and adding the weighed antistatic agent, the flame retardant, the coupling agent and the inorganic filler into the cold mixing machine for re-mixing when the temperature is lowered to 40-60 DEG C to obtain a premix; 3) putting the premix into a twin-screw extruder to perform melting, mixing and granulation; and 4) performing extrusion molding or thermoforming to prepare the flame-retardant and antistatic wood-plastic composite material. The flame-retardant and antistatic wood-plastic composite material is used in the fields of indoor buildings, decorations, decoration materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

High thermal conducting composite material and preparation method thereof

InactiveCN101775213AImprove thermal conductivityEasy to processHeat-exchange elementsGlass fiberMixed materials

This invention relates to a high thermal conducting composite material for injecting or extrusion molding, which is prepared from the following components in parts by weight: 100 parts of plastic substrate, 30 to 100 parts of thermal conducting filler with a diameter between 50 to 300 microns, 0 to 50 parts of thermal conducting filler with a small diameter between 1 to 10 microns, 10 to 50 parts of fiberglass or silicon whisker, 0 to 5 parts of coupling agent and 0 to 8 parts of additive. The preparation of the high thermal conducting composite material comprises the following steps: adding the coupling agent to the thermal conducting filler with a small diameter and the thermal conducting filler with a big diameter respectively to do surface treatment for later use; putting the plastic substrate material, the processed thermal conducting filler with a big diameter and other additives to a super mixer to mix for 1 to 5 minutes; adding the processed thermal conducting filler with a small diameter into the super mixer to mix for 2 to 3 minutes; putting the mixed material into a feeding bucket of a twin screw extruder; adding the fiberglass into a glass fiber orifice; and pelleting after melting and extruding. The composite material prepared by the invention has good thermal conducting property and processing property.

Owner:黄晓峰

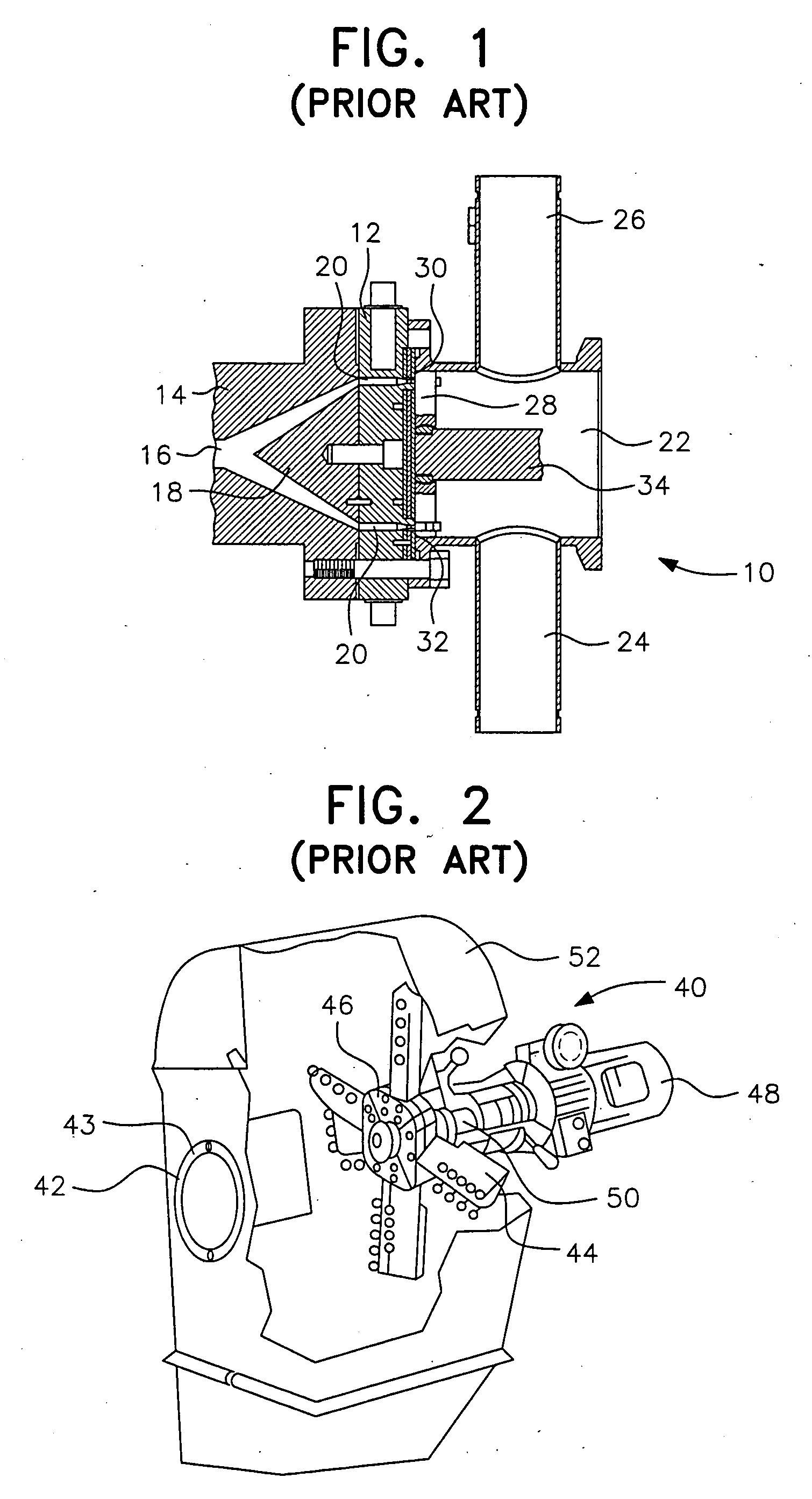

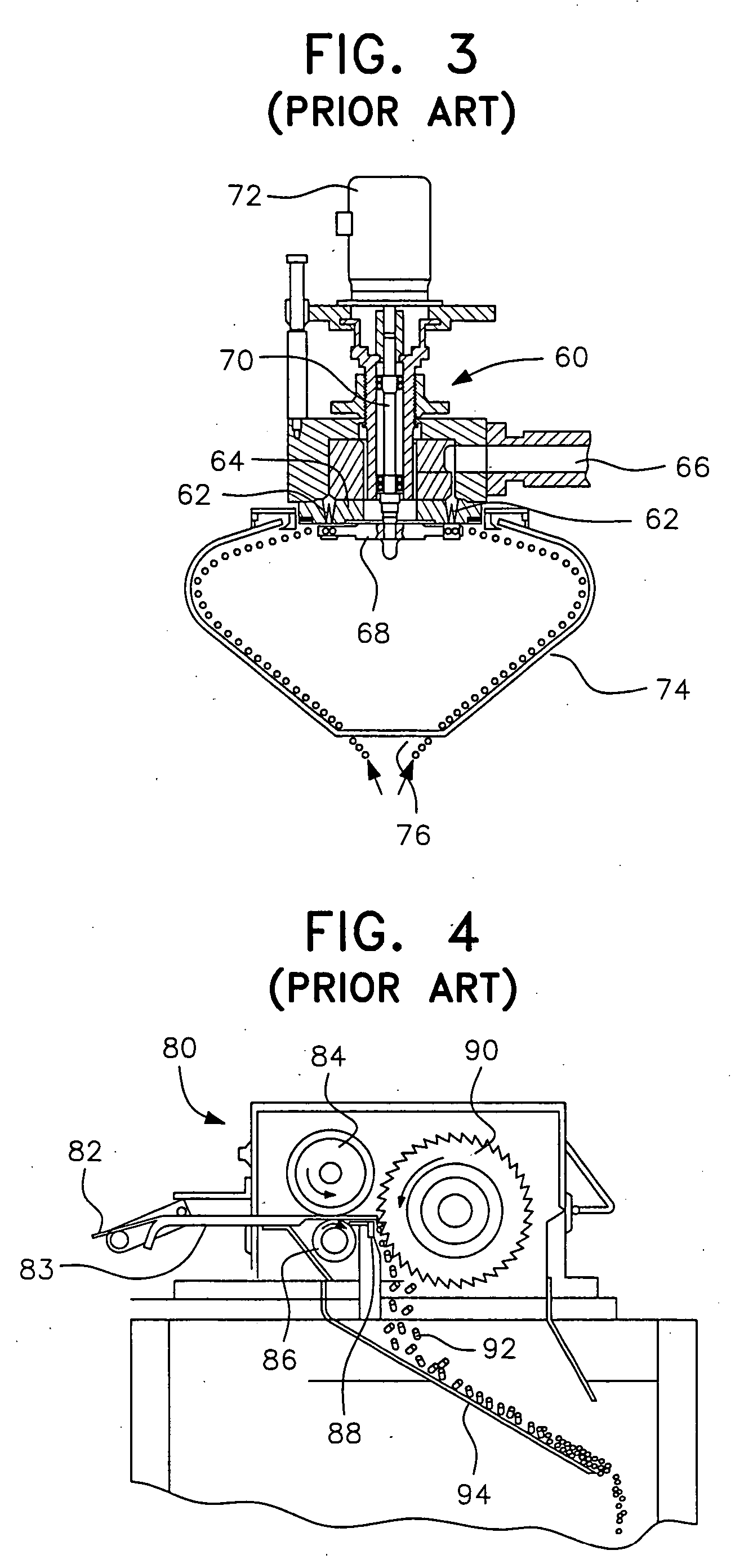

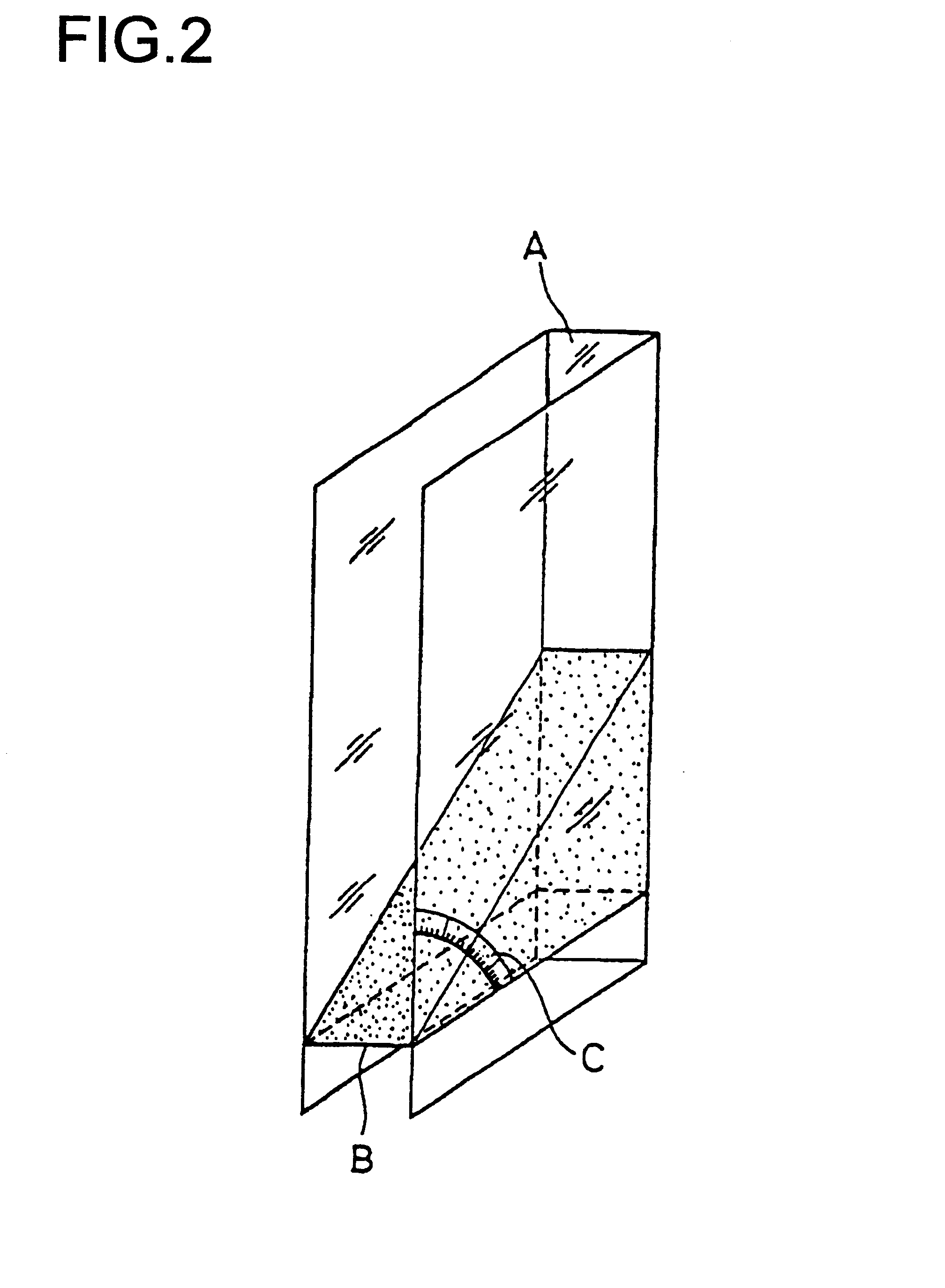

High pressure liquid jet cutting system and method for forming polymer pellets

InactiveUS20050077644A1Without unnecessary down timeContinuous operationMouldsConfectioneryWater basedLiquid jet

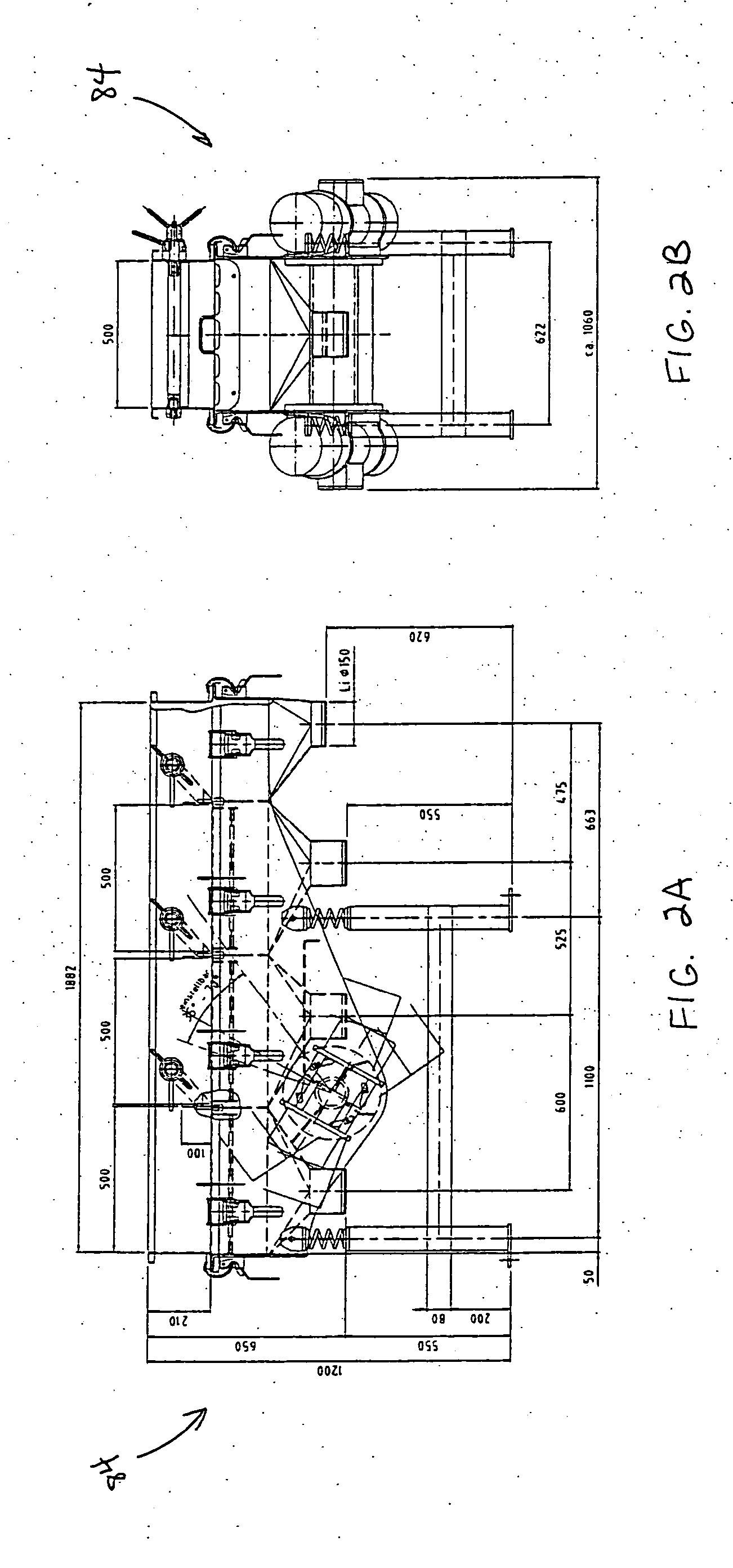

A system and method for pelletizing extruded materials, such as thermoplastic polymers in various pelletizing applications, including underwater, hot face, and strand pelletizing applications, utilizes a high pressure liquid delivered to one or more nozzles which direct a high pressure liquid jet cutting stream at the extruded polymer strand to cut the strand into pellets. The system and method are particularly applicable to underwater pelletizers utilizing water or water-based solutions. In a preferred underwater pelletizing embodiment, a plurality of nozzles are mounted on a rotating nozzle hub which is fed high pressure water through sealed hollow pelletizer and hollow motor shafts. The high pressure water jet cutting streams exiting the rotating nozzles are preferably in the form of a flat V-shaped spray with a spread angle of about 15° to about 45° and an approach angle between 0° and 60°, depending upon the pelletizing application.

Owner:GALA INDUSTRIES INC

Glass fiber reinforced polypropylene composite material with low odor and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composite material with low odor and a preparation method thereof. The glass fiber reinforced polypropylene composite material comprises the following components: 32-91% of polypropylene resin, 5-50% of glass fiber, 2-8% of compatilizer, 1-6% of odor inhibitor and 1-4% of other auxiliary agent. The reinforced polypropylene material with low odor is prepared by fusing, extruding and granulating the components through a double screw extruder under the temperature control condition of 220-240 DEG C. The odor inhibitor comprises 30-50% of ricinoleic acid zinc, 20-40% of metal oxide and 10-30% of a clay mineral system. The odor of the glass fiber reinforced polypropylene composite material can be inhibited through combining a physical method and a chemical method. The glass fiber reinforced polypropylene composite material prepared by the method has excellent odor performance; the odor level can be reduced below level 3; the physical property of the glass fiber reinforced polypropylene composite material per se is not influenced after the odor inhibitor is added; and the application field of the glass fiber reinforced polypropylene material in vehicle interior trim parts and a part of home appliance parts can be widened.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

Spherical single-substance particles, medicines and foodstuffs containing the particles, and method of production thereof

The present invention relates to a process for producing a spherical particle comprising an aggregate of particles containing at least 95% of a water-soluble single substance having a viscosity of 10 mPa.s or less as determined in the form of a saturated aqueous solution, the process comprising: preparing moist spherical particles of the single substance by charging, as cores, crystalline particles or granulated particles of the single substance on a rotary disc in a processing vessel of a centrifugal tumbling granulating apparatus, wherein the granulated particles are prepared by granulating a powder of the single substance, and dispersing over the cores a powder of the single substance and simultaneously spraying on the cores a liquid such as water or the like while supplying slit air to provide a fluidized condition; and then fixation treating the moist spherical particles by drying them while spraying an aqueous solution of the single substance or the like on the spherical particles in a fluidized bed apparatus; to the spherical particle produced by the process; and to a pharmaceutical preparation and a food containing the spherical particle.

Owner:FREUNT IND +1

Flame retardant high-wood content wood-plastic composite material and preparation method thereof

A flame retardant high-wood content wood-plastic composite material and a preparation method thereof relate to a wood-plastic composite material and a preparation method thereof, wherein the problem of easy burning of the wood-plastic composite material with high wood content and the problems of high fire retardant addition amount, low anti-flaming efficiency and high cost of the existing flame retardant treatment technology are solved. The material is prepared from a fire retardant for wood fibers, a wood fiber material, thermoplastic plastics, a fire retardant for plastics, a coupling agent, a lubricant, an antioxidant, a smoke eliminating agent and auxiliaries. The method comprises the following steps of: weighing raw materials; preparing a flame retardant processing fluid; preparing aflame retardant wood fiber material; performing melting granulation on the thermoplastic plastics and the fire retardant for plastics to obtain flame retardant thermoplastic plastic base particles; mixing the flame wood fiber material with the flame retardant thermoplastic plastic base particles, the coupling agent, the lubricant, the antioxidant, the smoke eliminating agent and the auxiliaries, thereby obtaining a premix; performing melting compounding on the premix to obtain a melt material; and molding the melt material to obtain the flame retardant high-wood content wood-plastic compositematerial. The dosage of the fire retardant in the flame retardant high-wood content wood-plastic composite material is low; and the flame retardant high-wood content wood-plastic composite material is high in flame retardant efficiency and low in cost.

Owner:NORTHEAST FORESTRY UNIVERSITY

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

Ultraviolet-proof environmental-friendly polyvinyl chloride (PVC) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Advanced polymer wood composite

InactiveUS20020106498A1High modulusHigh modulus of elasticityFibreboardWood working apparatusThermoplasticPolymer science

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprise, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of an elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

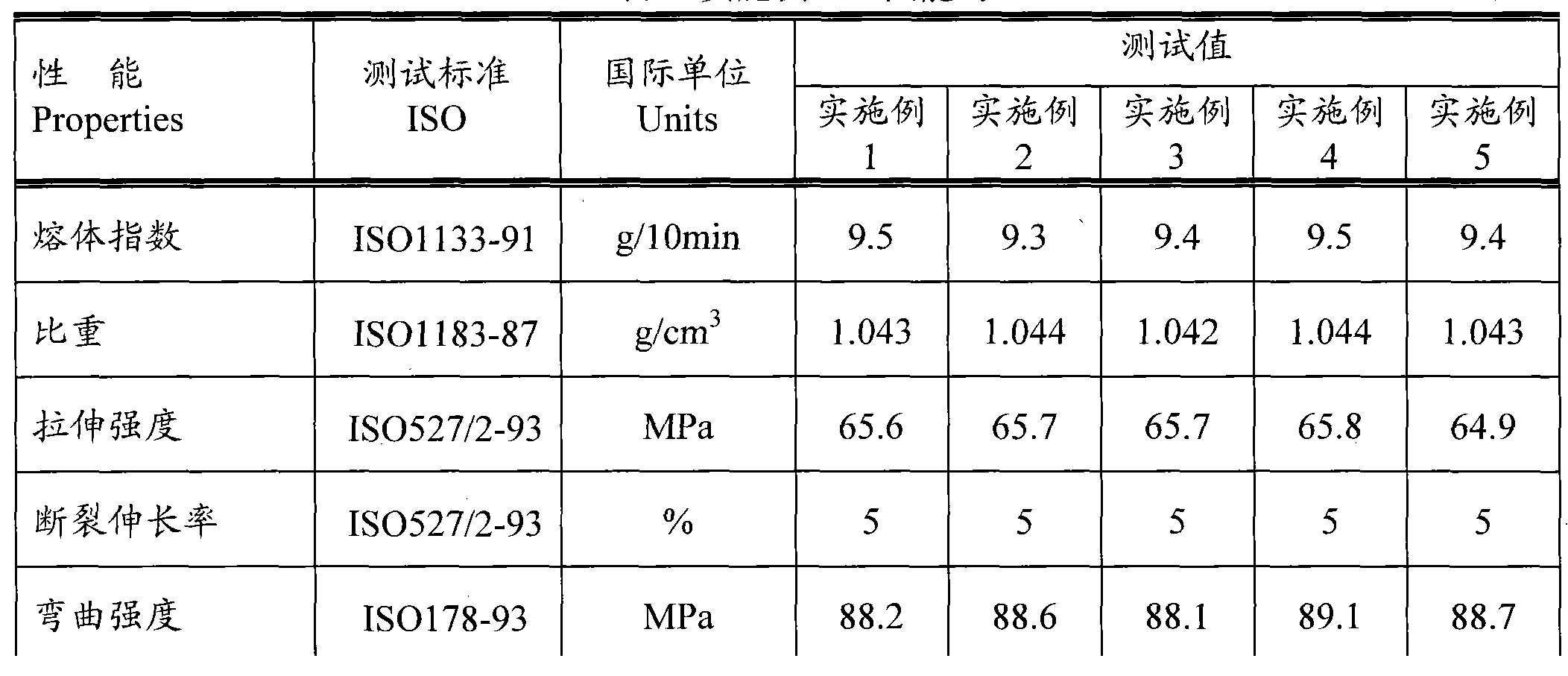

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Macromolecule heat conduction and dissipation blended composite material and automatic preparation method

The invention discloses a macromolecule heat conduction and dissipation blended composite material. The macromolecule heat conduction and dissipation blended composite material is prepared from, by mass, 35-75 parts of matrix resin, 0-10 parts of flexibilizer, 20-50 parts of heat conduction filler, 0.2-1.0 part of antioxidant 1010, 0.2-1.0 part of phosphite ester antioxidant 168, 0.5-1.5 parts of powder surface activation treating agents and 0.5-1.5 parts of lubricant. An automatic preparation method of the macromolecule heat conduction and dissipation blended composite material includes the steps of firstly, conducting surface treating on heat conduction filler for 20 min through powder surface activation treating agents in a high-speed stirring machine; secondly, making the heat conduction filler enter another high-speed stirring machine through an automatic conveying device to be evenly mixed with other materials; thirdly, automatically conveying the mixture obtained in the second step to an internal mixer to be mixed and kneaded for 15 min; fourthly, making the obtained mixture directly enter a double-screw extruder to be extruded and granulated. The prepared heat conduction and dissipation material has the high mechanical property and heat conduction performance, automatic and continuous production is achieved, a large amount of labor is saved, the production period is greatly shortened, the production cost is greatly reduced, and the macromolecule heat conduction and dissipation blended composite material can be widely applied to the fields of LED illumination, electronic electrical appliances, automobiles and the like where good heat conduction and dissipation performance is required.

Owner:东莞市万江明冠实业有限公司

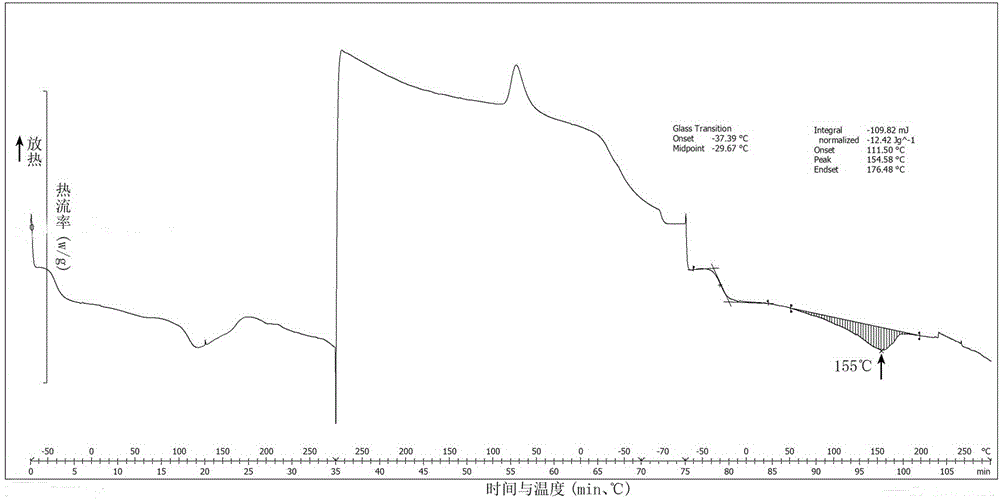

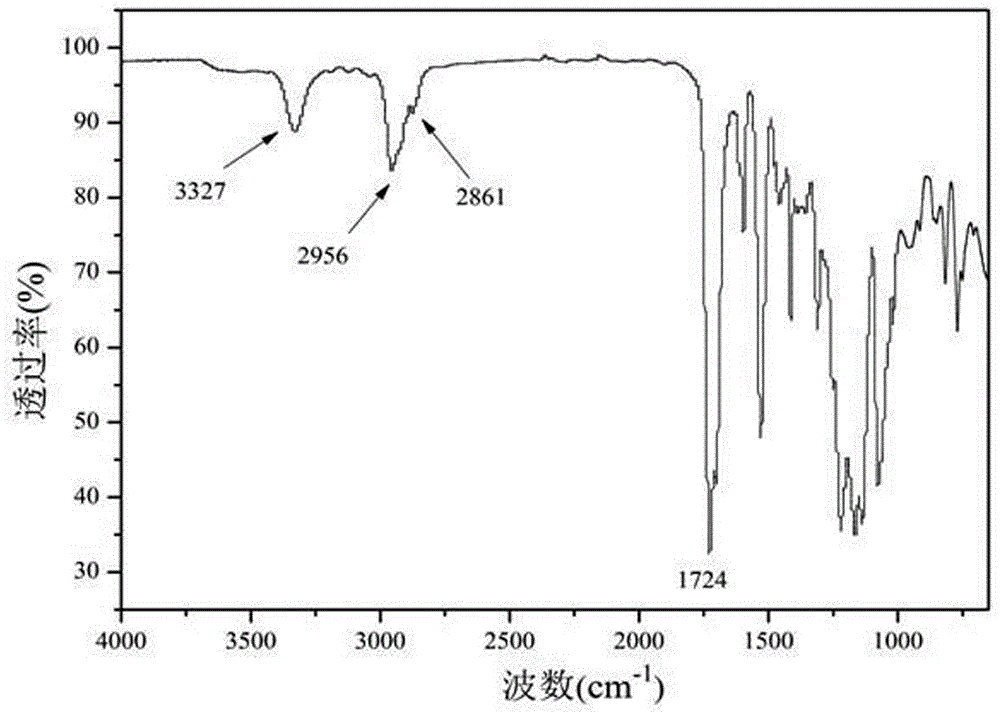

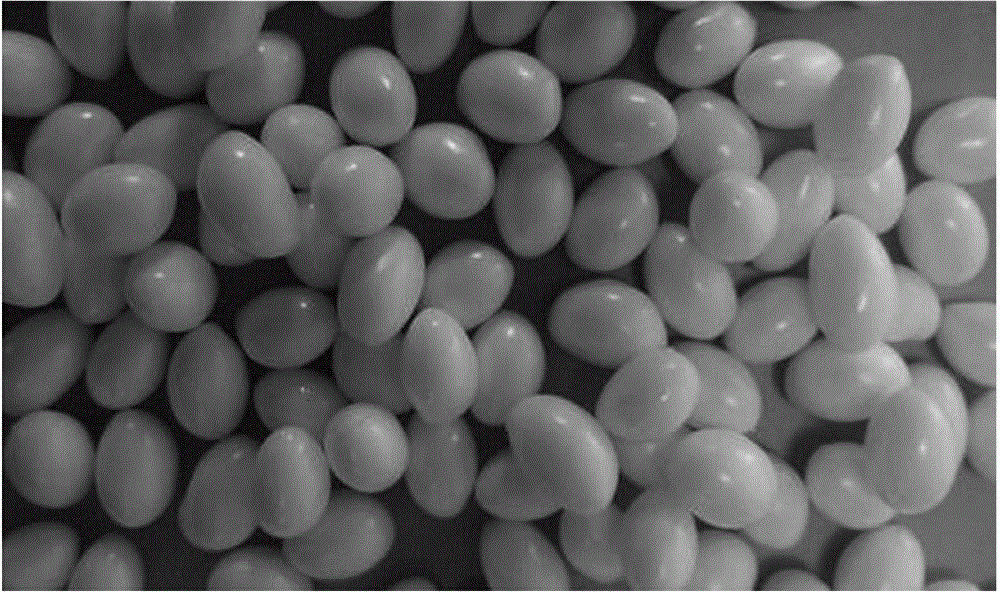

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Preparation Method of Lithium-Metal Composite Oxides

ActiveUS20100227221A1High Capacity FeaturesImproved cycle life characteristicsLithium compoundsActive material electrodesLithium metalElectrochemistry

Disclosed is a method for preparing a lithium-metal composite oxide, the method comprising the steps of: (a) mixing an aqueous solution of one or more transition metal-containing precursor compounds with an alkalifying agent and a lithium precursor compound to precipitate hydroxides of the transition metals; (b) mixing the mixture of step (a) with water under supercritical or subcritical conditions to synthesize a lithium-metal composite oxide, and drying the lithium-metal composite oxide; and (c) subjecting the dried lithium-metal composite oxide either to calcination or to granulation and then calcination. Also disclosed are an electrode comprising the lithium-metal composite oxide, and an electrochemical device comprising the electrode. In the disclosed invention, a lithium-metal composite oxide synthesized based on the prior supercritical hydrothermal synthesis method is subjected either to calcination or to granulation and then calcination. Thus, unlike the prior dry calcination method or wet precipitation method, a uniform solid solution can be formed and the ordering of metals in the composite oxide can be improved. Accordingly, the lithium-metal composite oxide can show crystal stability and excellent electrochemical properties.

Owner:HANWHA CHEMICAL CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com