Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1689results about How to "Solve the strength problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

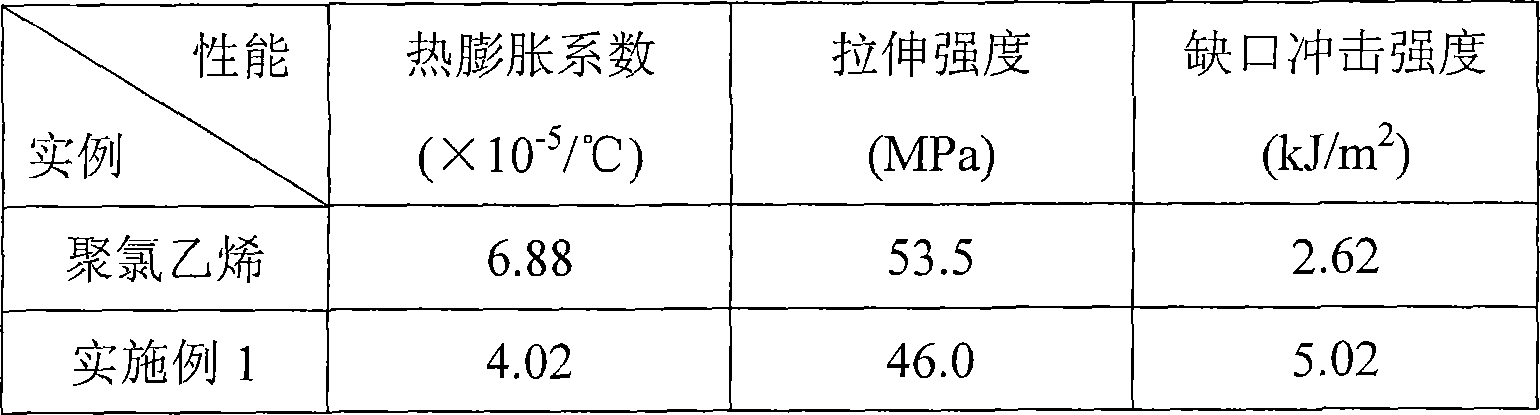

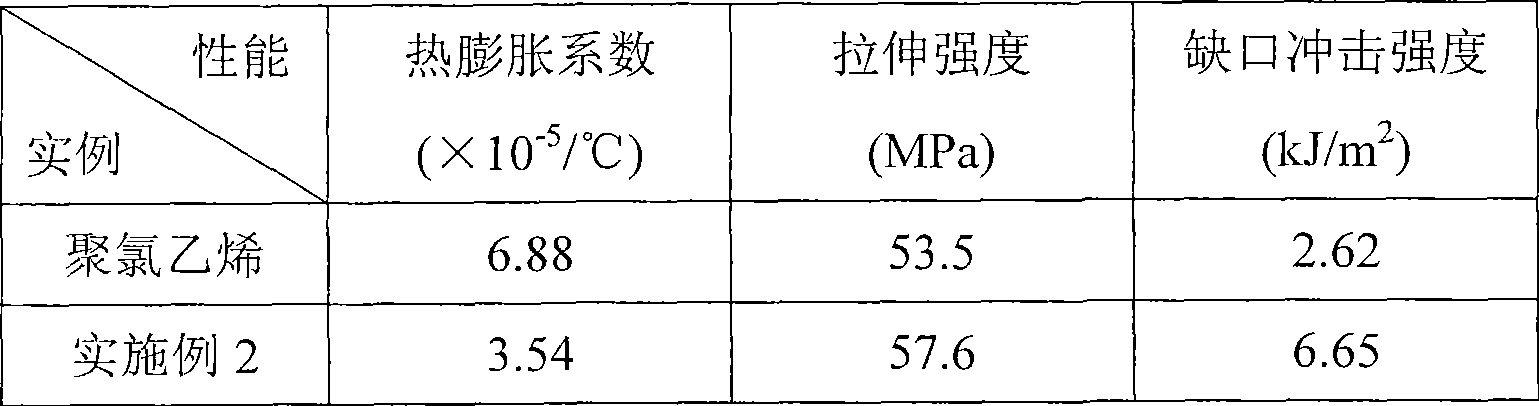

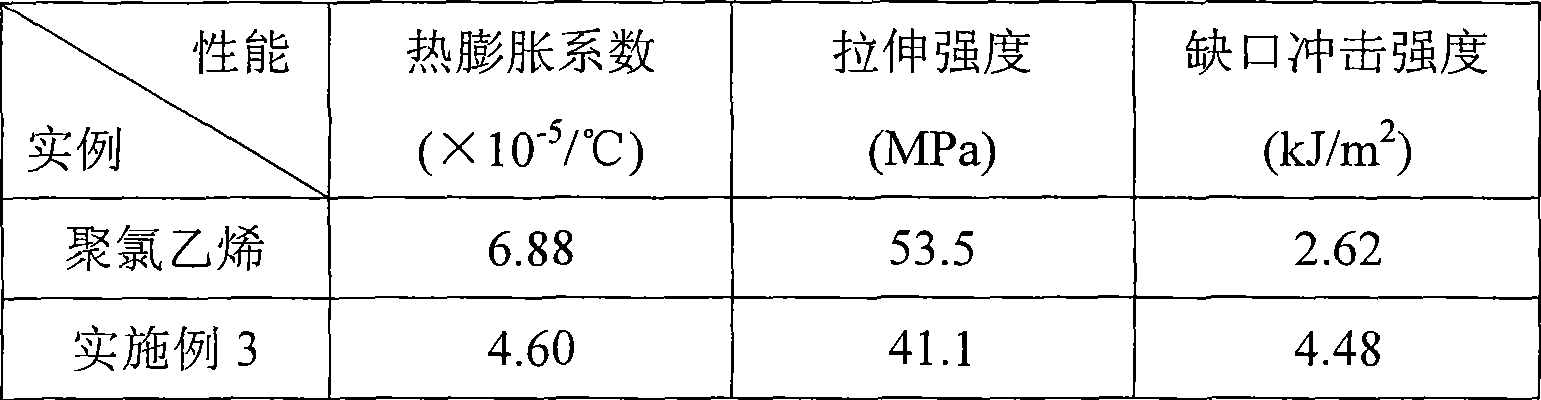

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

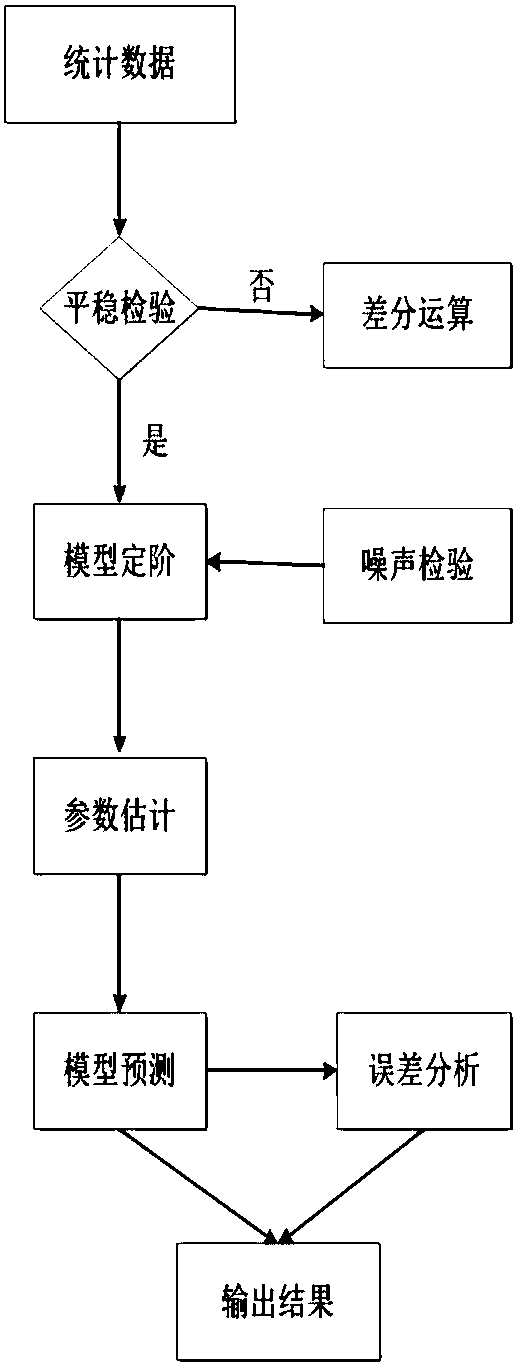

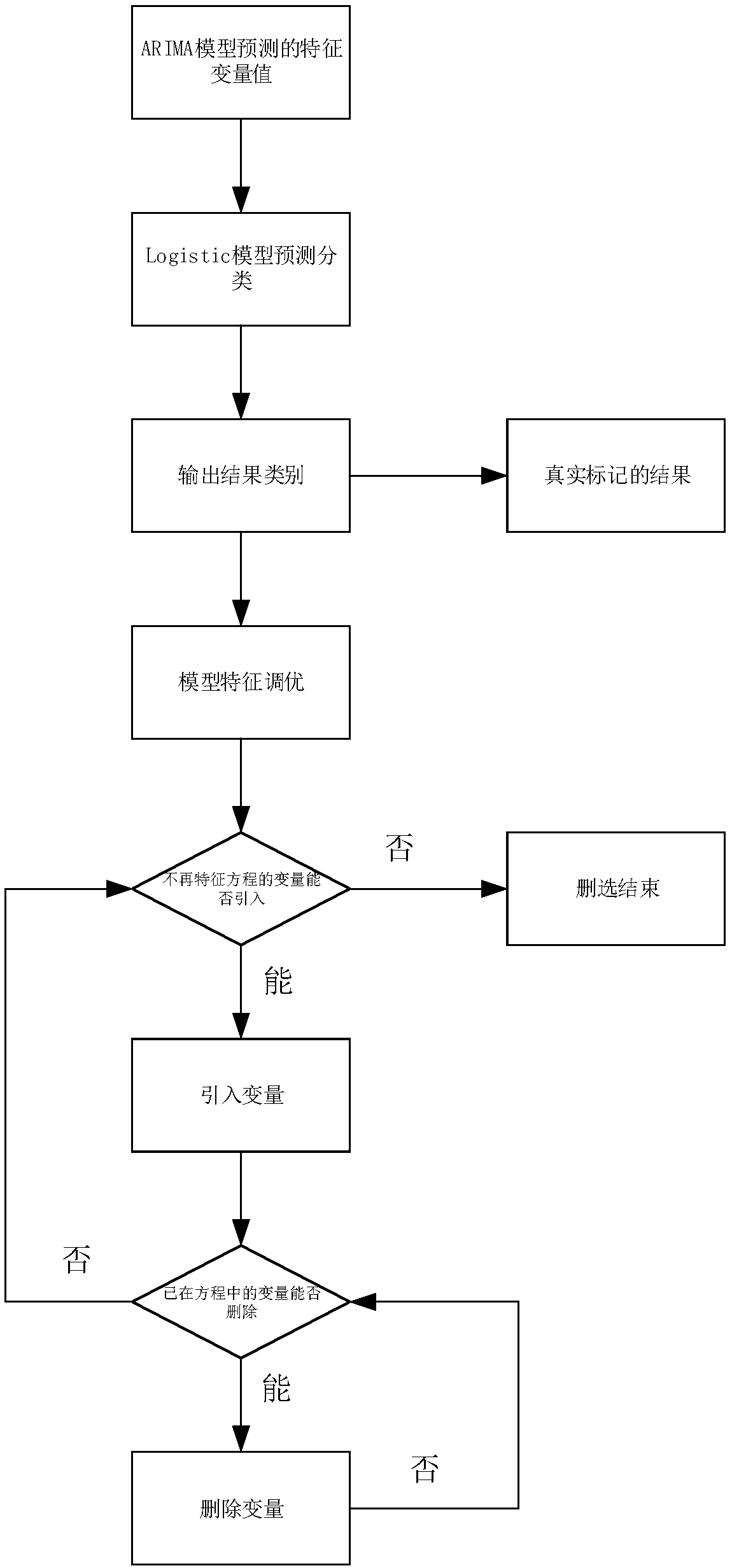

Time sequence classification early warning method for storage device

InactiveCN108052528AMitigating the effects of errorsEasy to optimizeCharacter and pattern recognitionSpecial data processing applicationsHysteresisEffective solution

The invention discloses a time sequence classification early warning method for a storage device. The method comprises the steps of collecting storage device parameters in real time; cleaning data; performing ARIMA time sequence analysis; and performing logistic regression analysis and early warning mechanism output. Under the background of a big data environment, time sequence prediction analysisis performed by adopting an ARIMA model according to historical data and hard disk SMART information obtained by statistics; the correlation between a SMART eigenvalue and a fault rate of the storagedevice is analyzed; and an eigenvalue more suitable for a Logistic model is selected out to perform classification prediction. A machine learning method is adopted for predicting the fault rate of the storage device, so that the problems of classification singleness and low early warning intensity in final prediction of the storage device are solved, the defects of hysteresis, low accuracy, pooractual early warning effect and difficult application to the big data environment for a disk early warning mechanism in the prior art are overcome, the occurrence probability of each early warning intensity can be predicted, and an effective solution is provided for real-time operation maintenance and monitoring in a data center environment.

Owner:HUAZHONG UNIV OF SCI & TECH

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

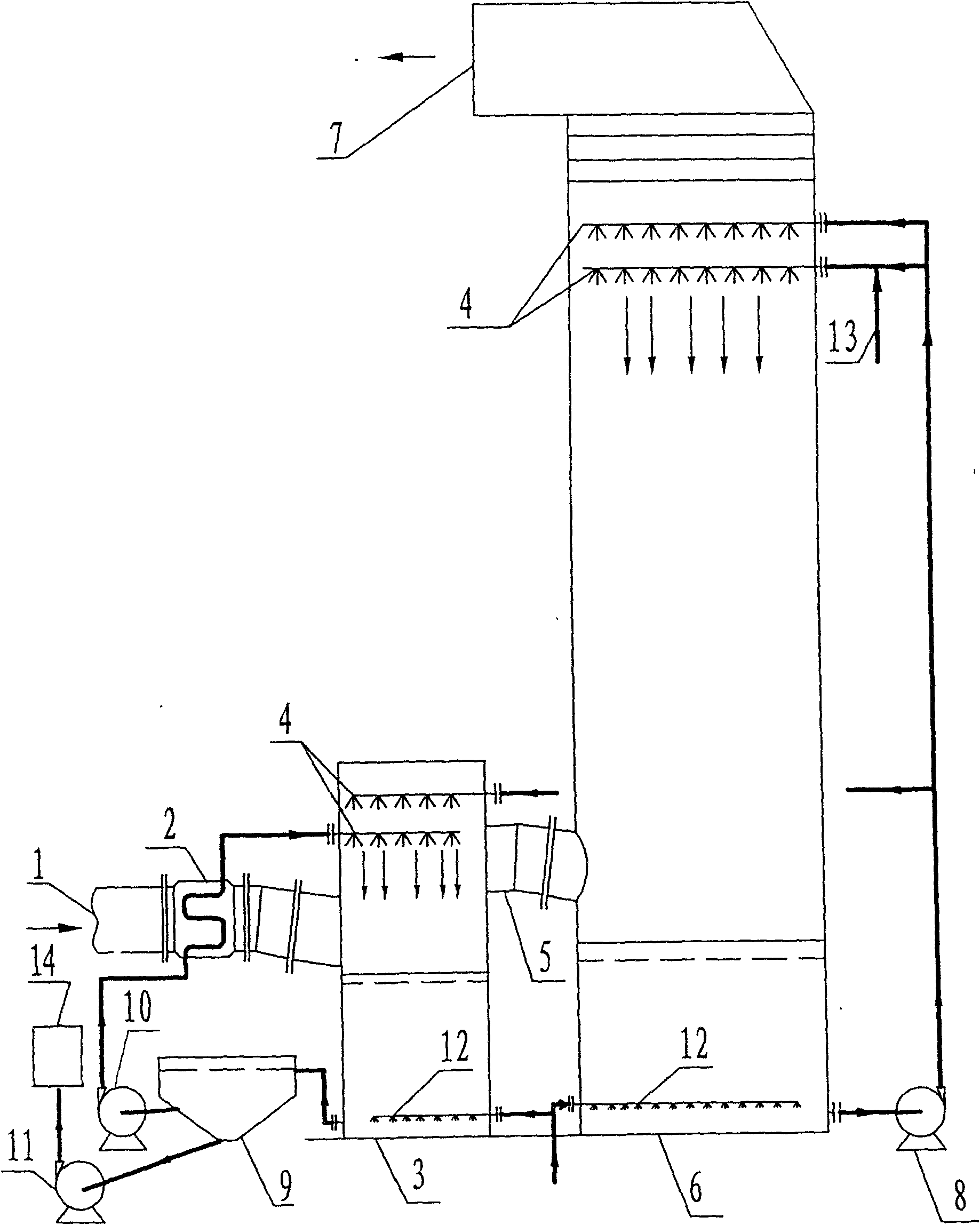

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

ActiveCN101670231ASolve the strength problemSolve highDispersed particle separationSolution crystallizationMagmaDistributor

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, andthe upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

3D printing core material

InactiveCN104710548AImprove liquidityHigh speedAdditive manufacturing apparatusNanoparticle3d printer

The invention provides a 3D printing core material, which comprises photosensitive resin, a photoinitiator, a terminator, functional nanoparticles and a color additive, the fluidity and moulding speed of the prepared 3D printing core material is matched with a 3D printer, and the problems of low intensity and difficult coloring of the 3D printing material can be solved.

Owner:南京波斯塔新材料科技有限公司

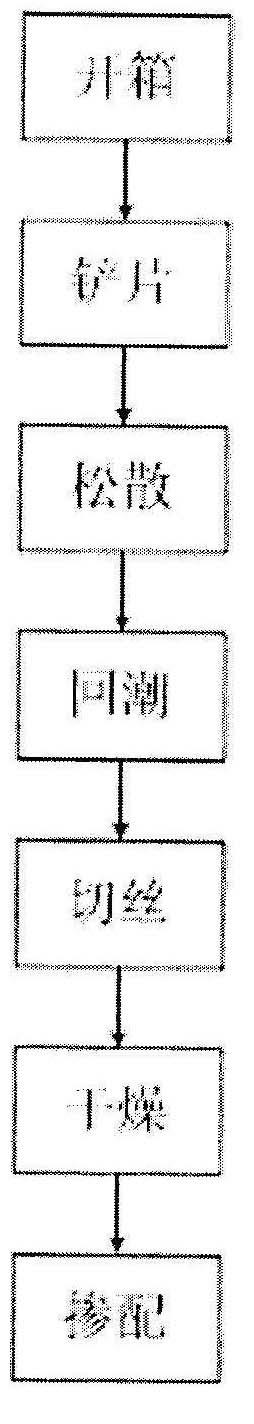

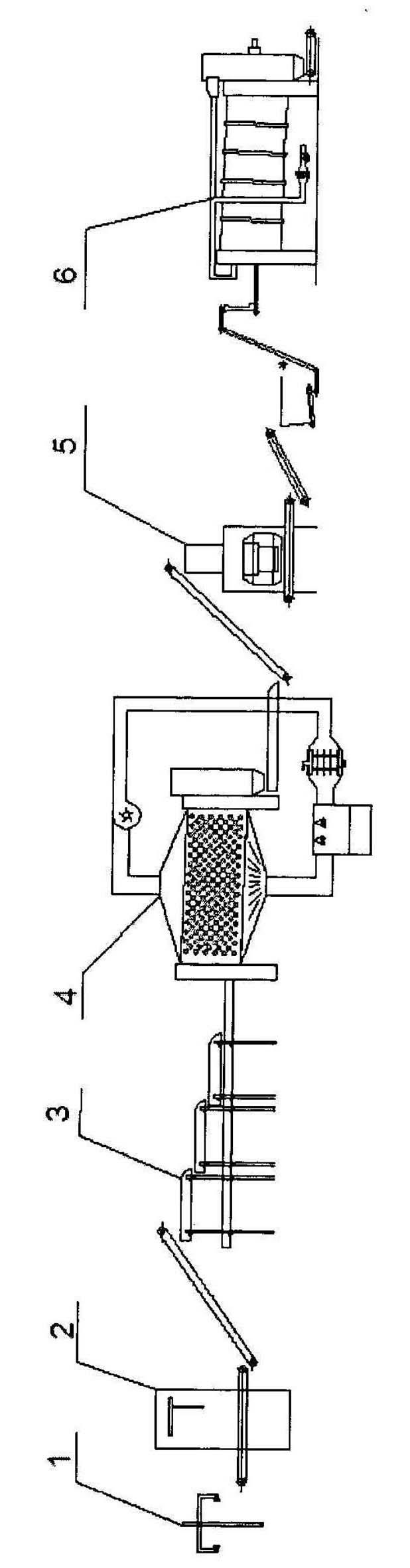

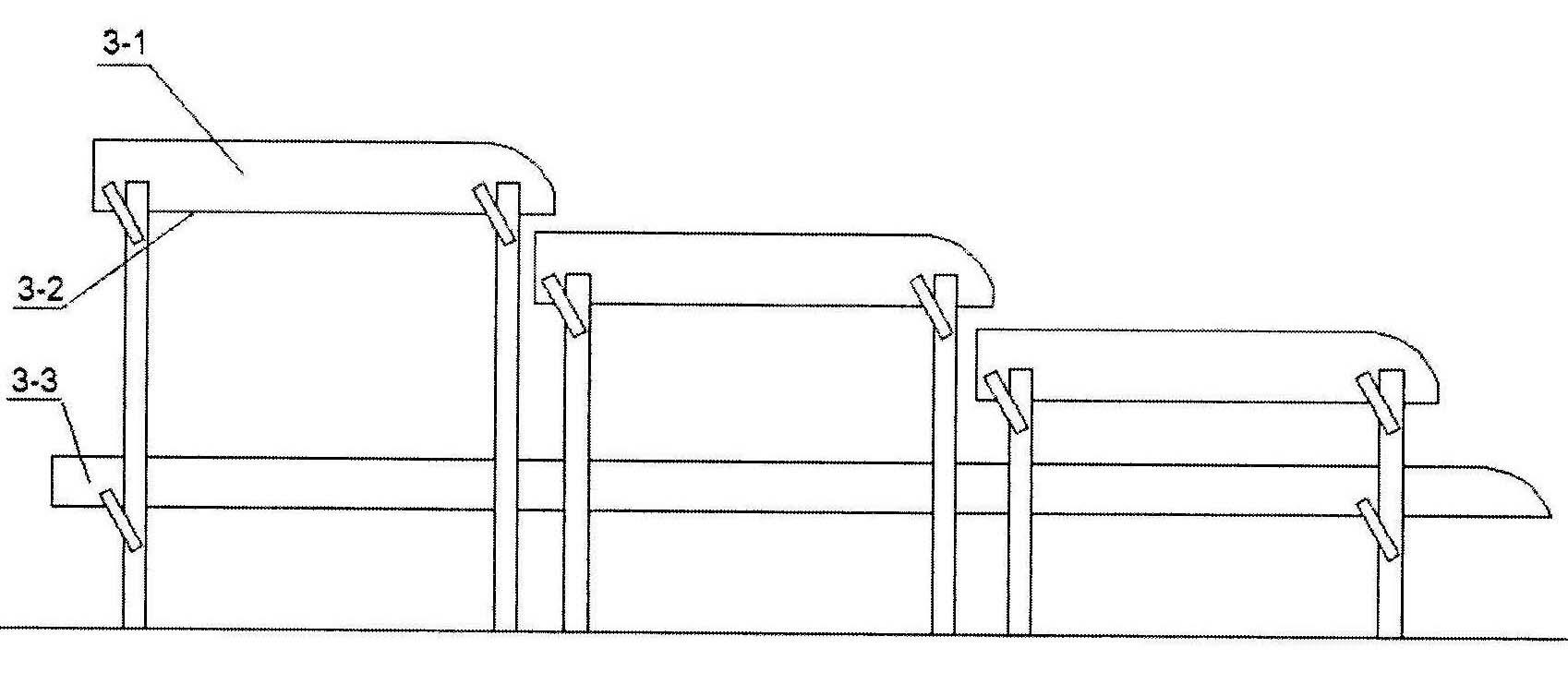

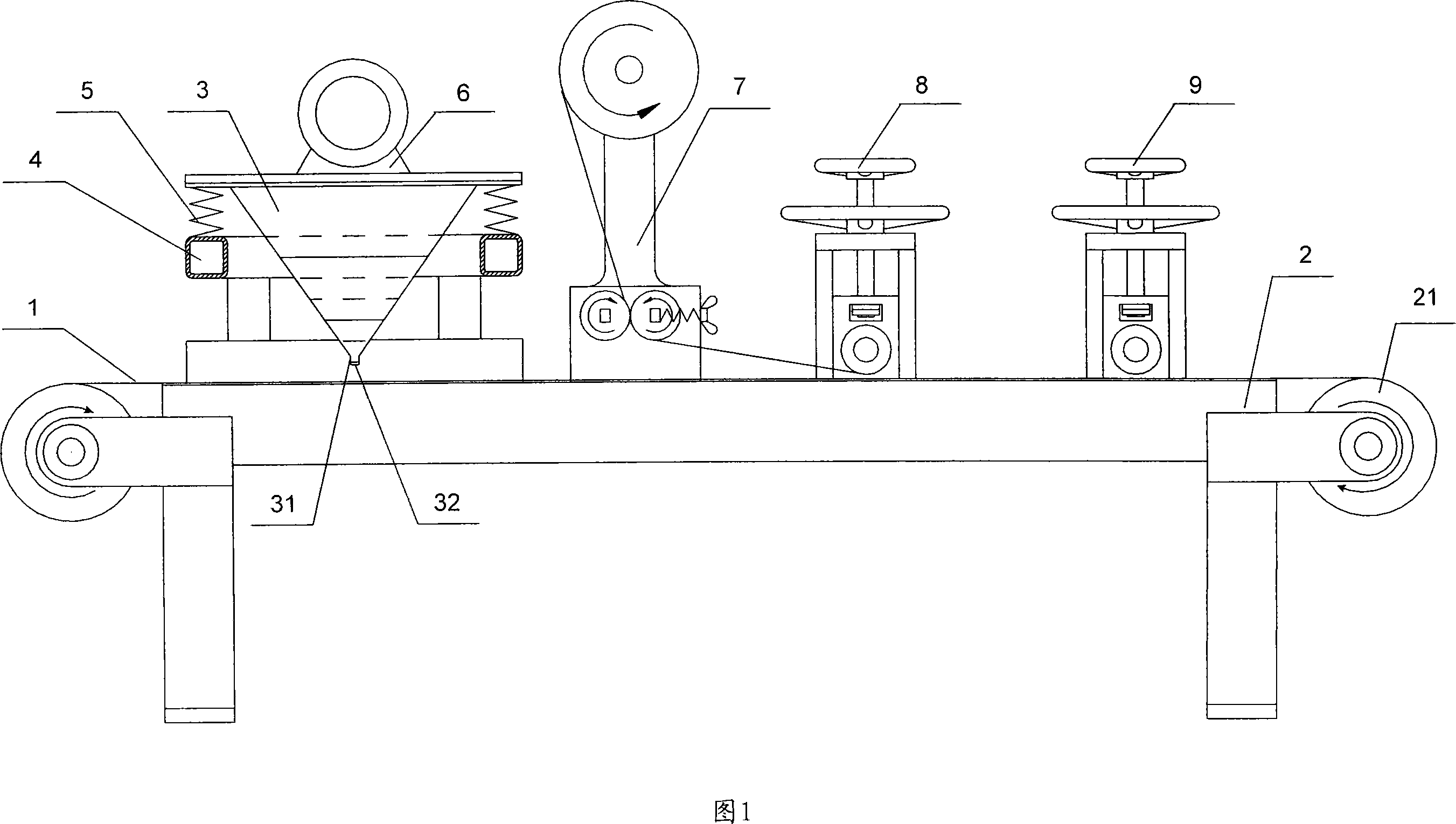

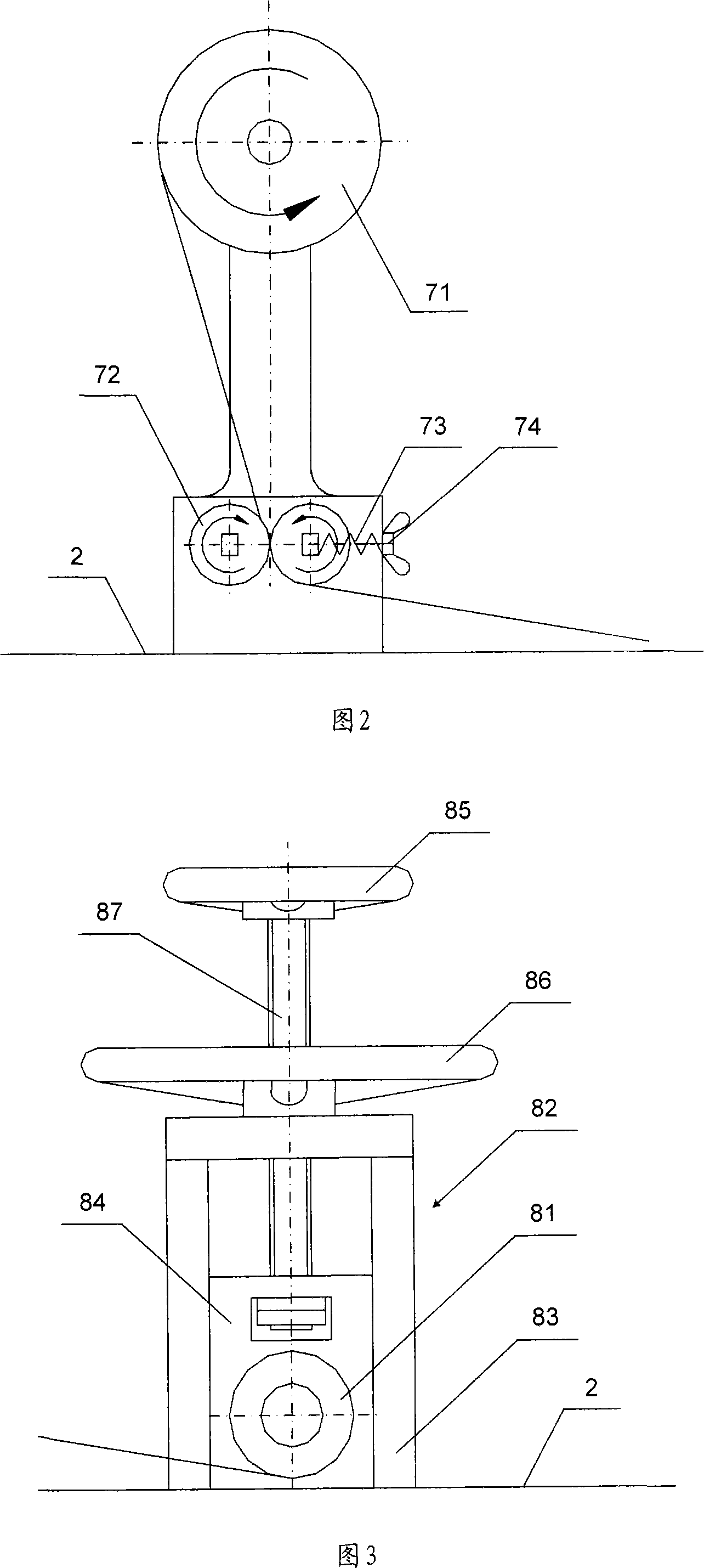

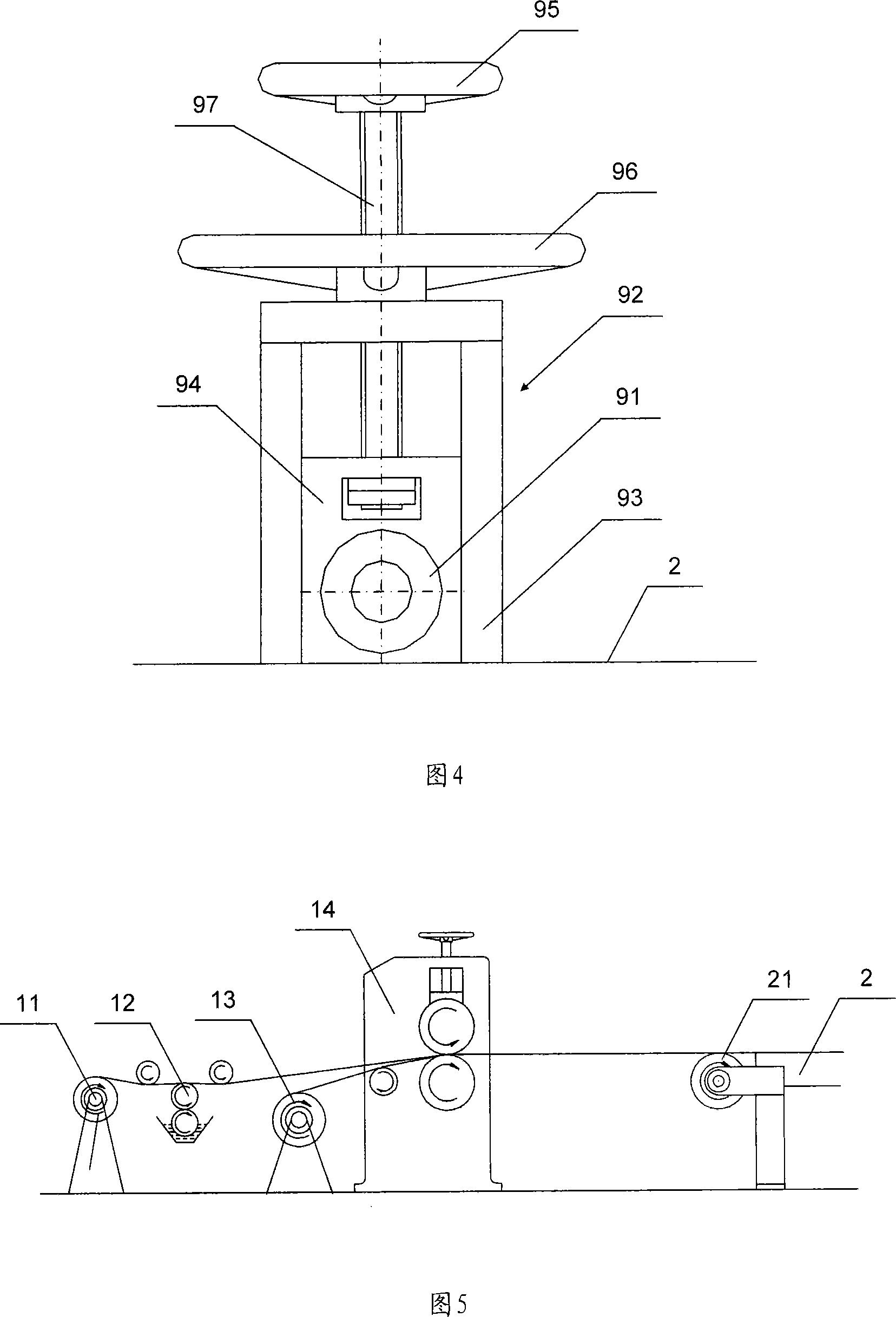

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Concrete cement foaming insulation brick and manufacturing method thereof

The present invention discloses a concrete cement foaming insulation brick, taking a concrete perforated brick as a main body. The concrete perforated brick is injected with a cement foam material, so that the cement foam material and the concrete perforated brick are fully combined. By adjusting the formulation and improving the process, the present invention makes full use of industrial wastes such as fly ash and coal gangue, does not need autoclaved curing, and is small in investment and simple in process. The foaming brick produced by the present invention has excellent heat insulation and sound insulation properties, and is high in strength, good in impact resistance, low in moisture absorption, light in weight, compression resistant, good in weather resistance, environmental-friendly and energy-saving, and non-toxic. The brick has great market space and development prospects in the application field of building energy efficiency.

Owner:嵊州市万顺新型墙体材料有限公司

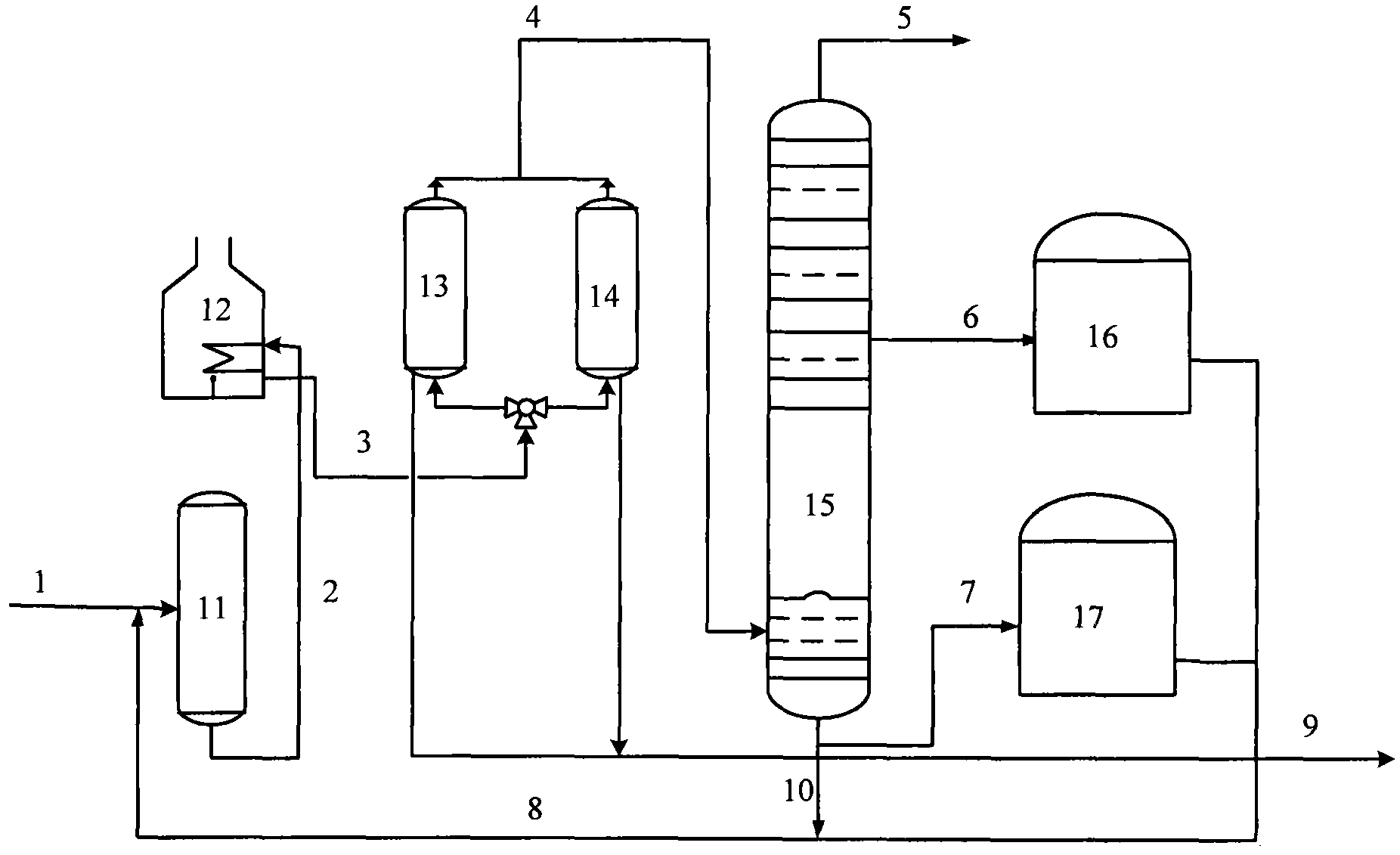

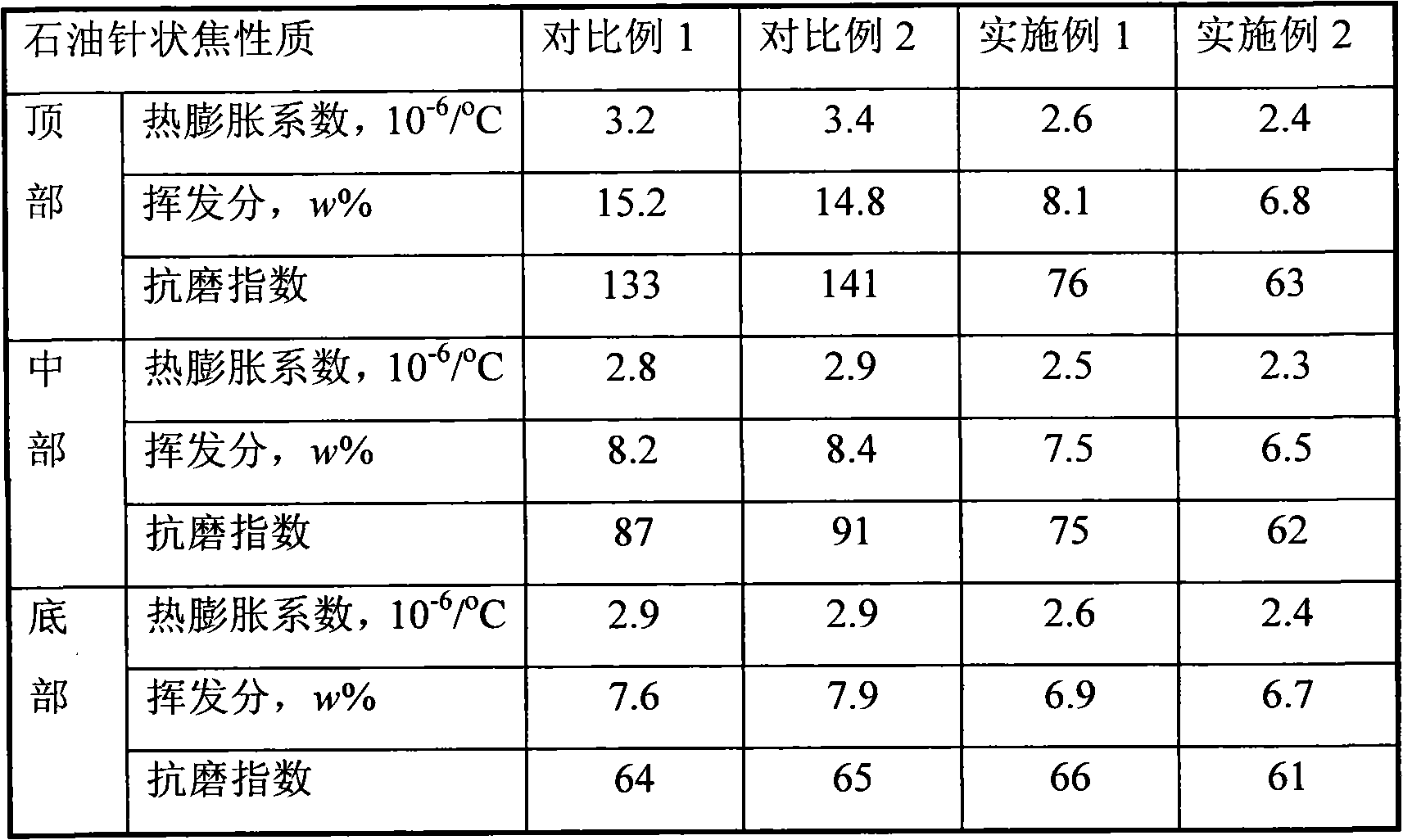

Production method of homogeneous petroleum needle coke

ActiveCN103184057AImproved Anti-wear IndexSolve for uniformityTreatment with plural serial stages onlyCoking carbonaceous materialsHeating furnaceTower

The invention relates to a production method of a homogeneous petroleum needle coke. The method comprises the steps of: (1) heating the raw material for needle coke production to a relatively low temperature of 400-480DEG C by a heating furnace, then leading the raw material into a coking tower to make the coking raw material form flowable intermediate phase liquid crystals; (2) when the low temperature fresh raw material charging stage is completed, gradually raising the temperature of a heating furnace outlet, and at the same time, charging the coking heating furnace with a fresh raw material and heavy distillate oil from a fractionating tower; and (3) when the materials in the coking tower reach a curing coking temperature, charging the coking heating furnace with the coking intermediate distillate oil generated in step (1), and simultaneously raising the coking heating furnace feed temperature to make the internal temperature of the coking tower reach 460-510DEG C, thus finishing high temperature curing of petroleum coke. The method provided in the invention can make the properties of needle coke at different parts inside the coking tower more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

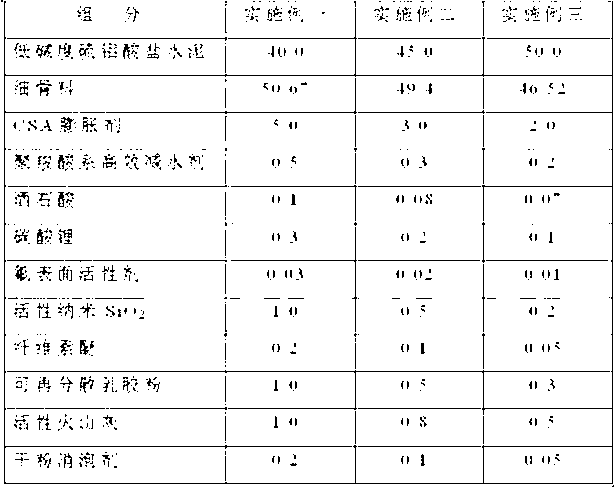

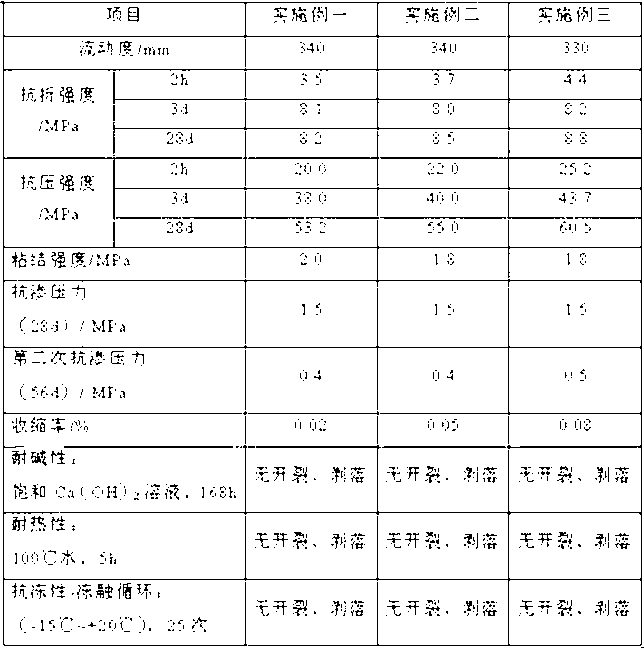

Concrete healant

The invention discloses concrete healant, which comprises following components by weight percent: 30 to 55 percent of gelatinization materials, 40 to 65 percent of fine aggregates, 0.1 to 0.5 percent of water reducing component, 0.05 to 0.5 percent of early-strengthening component, 0.05 to 0.2 percent of delayed-coagulation component, 0.2 to 1.0 percent of nano materials, 0.5 to 1.0 percent of high-activity substances, 0.01 to 0.2 percent of water retention thickening component, 0.2 to 2.0 percent of polymer and 0.02 to 0.2 percent of defoaming agent. The concrete healant not only has characteristics of good mobility, fast strength development, high adhesion strength and small retraction, but also can fill active substances into original concrete gaps and can produce compact crystals, so that the cohesion strength of the new and the old concrete interfaces can be remarkably improved, and the concrete healant is applicable to the concrete mending projects of bridges, caves, industrial workshops and civil construction.

Owner:苏州市姑苏新型建材有限公司

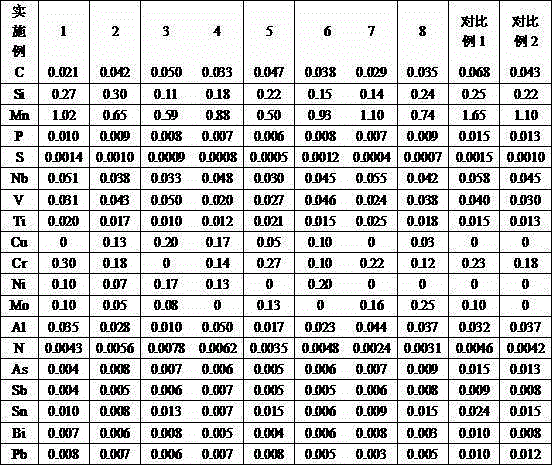

Pipeline steel excellent in acid corrosion resistance on seabed and production method

The invention discloses pipeline steel excellent in acid corrosion resistance on the seabed. The pipeline steel comprises, by weight, 0.020-0.050% of C, 0.10-0.30% of Si, 0.50-1.10% of Mn, 0.012% of P or less, 0.0015% of S or less, 0-0.20% of Cu, 0-0.30% of Cr, 0-0.20% of Ni, 0-0.25% of Mo, 0.030-0.055% of Nb, 0.020-0.050% of V, 0.010-0.025% of Ti, 0.010-0.050% of Al and 0.008% of N or less. A production method comprises the steps of heating after continuous casting and blank forming, rough rolling, precise rolling, cooling, reeling and cooling to indoor temperature. By means of the pipeline steel and the production method, an ideal complex-phase structure containing ultra-fine grain polygonal ferrite and a small number of methyl acrylate (MA) components which are distributed dispersively can be obtained, the Rt0.5 is equal to or higher than 485 MPa, the Rm is equal to or higher than 570 MPa, -20 DEG C KV2 is equal to or higher than 250 J, and -15 DEG C DWTT SA is equal to or higher than 85%. A hydrogen induced crack j (HICj) test and a sulfide stress corrosion cracking (SSCC) test indicate that no fracture or crack occurs.

Owner:武汉钢铁有限公司

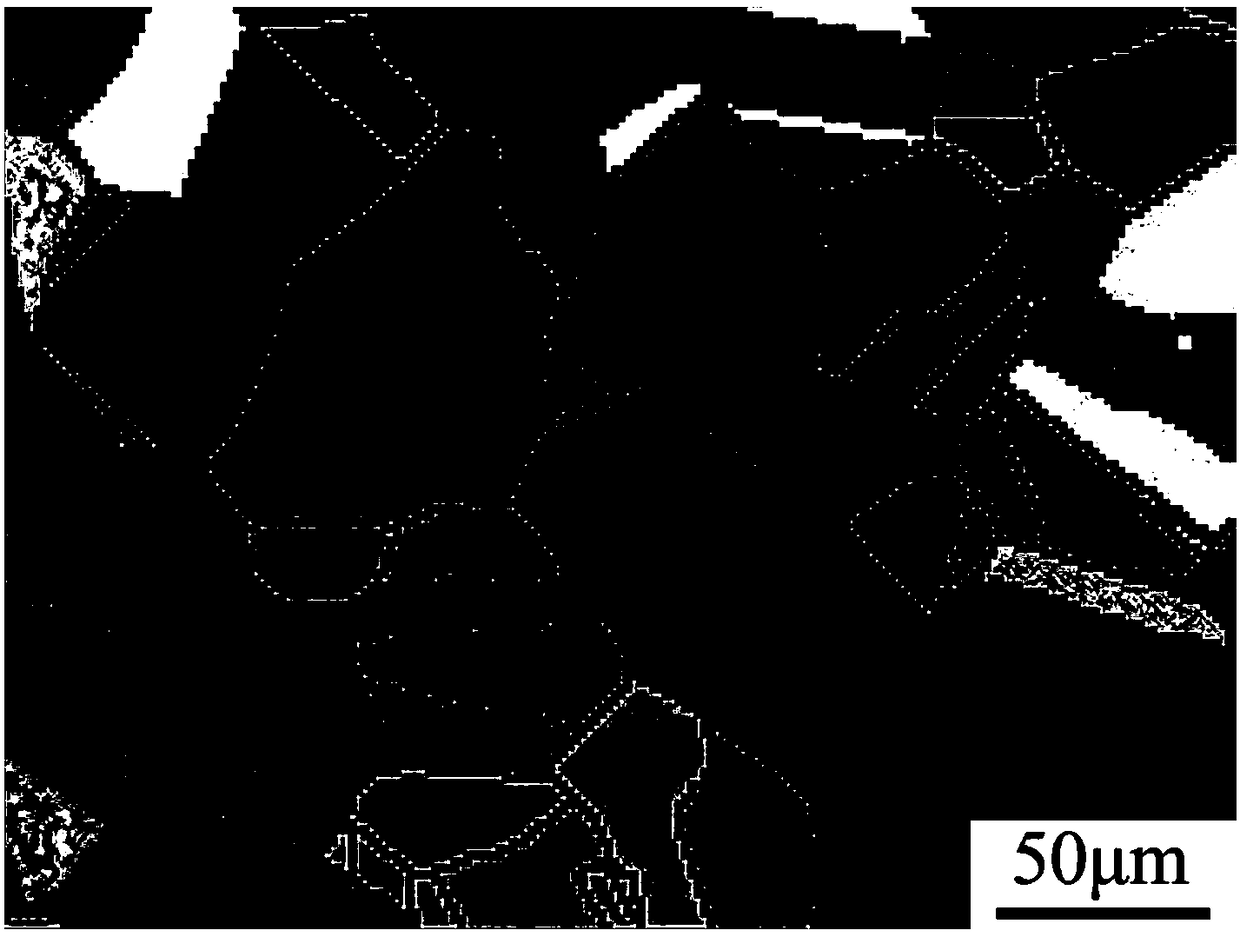

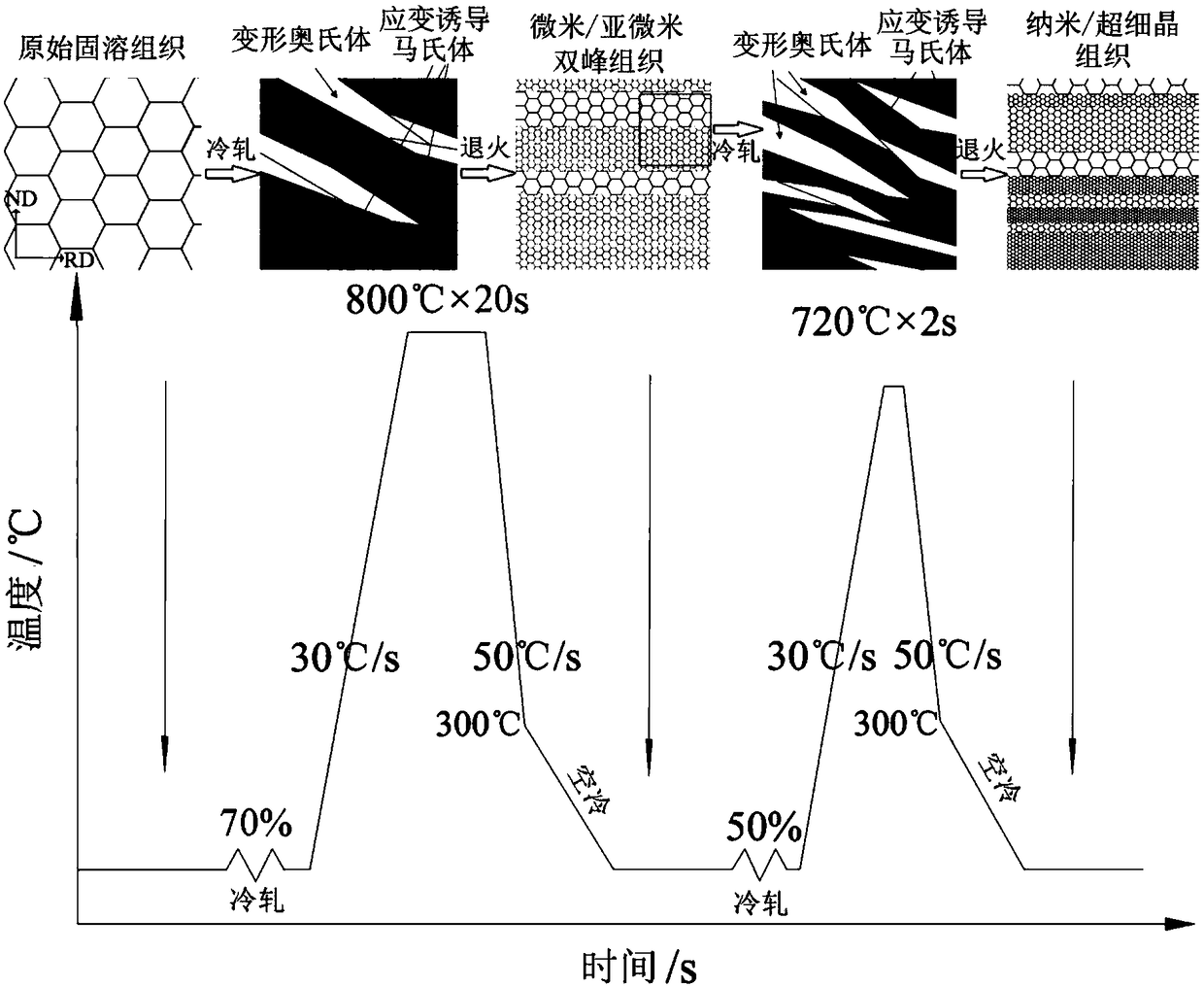

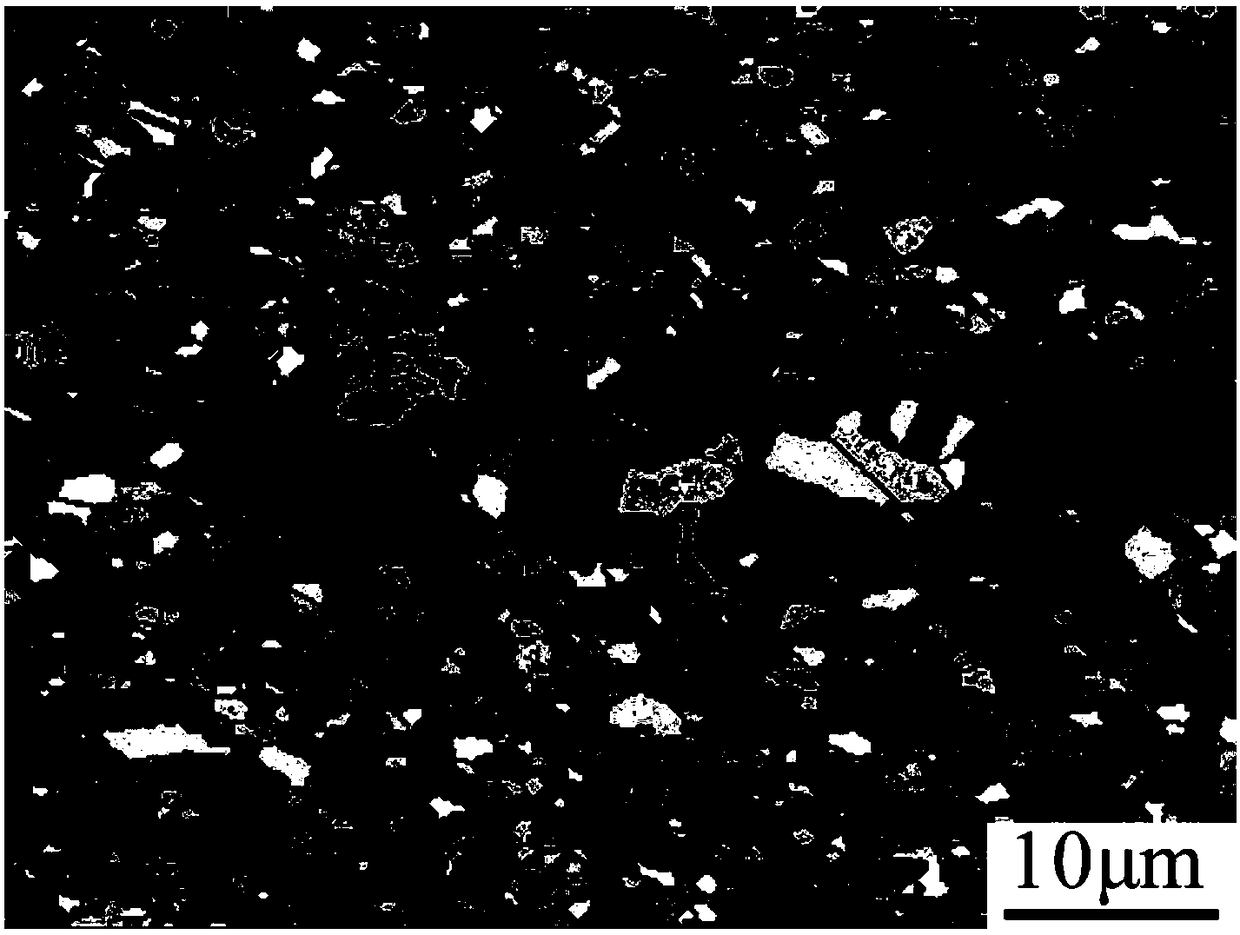

Nanometer/ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and preparation method

The invention discloses nanometer / ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and a preparation method, and belongs to the field of ultrahigh-strength plasticity alloy steel production. Raw materials comprise the following chemical components: 0.08-0.15% of C, 0.35-0.75% of Si, 7.5-10% of Mn, 0.5-0.9% of Cu, 1-1.5% of Ni, 14-16% of Cr, 0.1-0.25% of N, P notmore than 0.06%, S not more than 0.03%, and the balance of iron and inevitable impurities. After smelting by a vacuum induction furnace, a casting blank is forged, and a forging is hot rolled; twicecold rolling annealing is performed after the solid solution treatment; a nanometer / ultrafine crystal composite structure is obtained by using reversion of strain induction martensite and recrystallization of deformation austenite. The ultrahigh-strength plasticity of stainless steel is realized through fine crystal strengthening, back stress reinforcement, deformation induction twins effect and deformation induction martensite effect. The prepared stainless steel is prominent in comprehensive mechanical performance; the yield strength reaches 1150-1320 MPa, and is 3.2-4.5 times in an originalsolid solution state; the tensile strength reaches 1350-1440 MPa; the ductility still achieves a higher level of 39.2-47.3%; the cost is lower; and the preparation method is simple and feasible.

Owner:UNIV OF SCI & TECH BEIJING

Short linen viscose fiber and preparation method thereof

ActiveCN102181956ARetain bacteriostasisHigh whitenessPretreatment with acid reacting compoundsPulp de-wateringPre treatmentUltimate tensile strength

The invention discloses short linen viscose fiber and a preparation method thereof. The viscose fiber is produced by preparing linen pulp from linen and then using the linen pulp. The preparation method comprises the following steps of: pre-processing, washing, digesting, washing, pulping, degritting, concentrating, alkali refining, whitening, performing acid treatment, washing, finely selecting, degritting, concentrating, papermaking, soaking, squeezing, smashing, aging, yellowing, grinding, dissolving, filtering, defoaming, filtering, spinning, drafting, cutting off, performing post treatment, drying, packaging and the like. The preparation method has the advantages that: the performance of bacterial resistance and bacterial resistance of the linen fiber can be kept better, a finished product has high whiteness, the production period is short, the problems of large digesting intensity, complicated digesting process and the like are solved, and the pollution generated during production is low.

Owner:潍坊欣龙生物材料有限公司

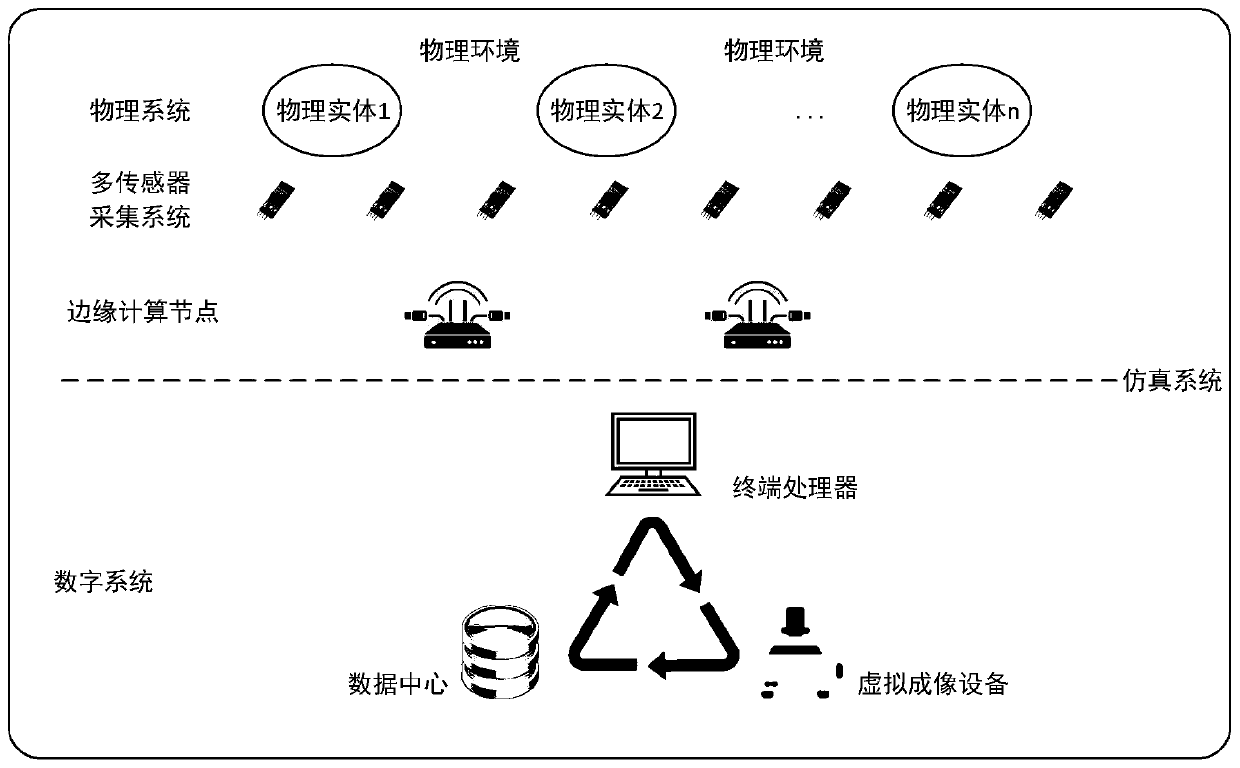

A digital twinning system based on a virtual imaging technology

ActiveCN109819233ASolve the strength problemSolve the incomplete display of digital entity informationTransmissionImage data processingEdge computingMultiple sensor

The invention relates to a strong mapping digital twin system based on a virtual imaging technology. According to the system, a multi-information cooperative communication mechanism is established between digital twin bodies, morphological information, state information and behavior information of a physical entity system are collected through multiple sensors and sent to an edge computing node, and the edge computing node is responsible for receiving sensor information and carrying out edge computing processing on the received information; A virtual imaging technology is applied to project digital entities of the digital twin system into a real space in a three-dimensional visualization mode, meanwhile, state information of the physical entities is displayed in a virtual reality mode, thedetail display effect of the digital twin system is enhanced, and the requirements for multi-view observation and immersion experience are met; According to the system, strong information mapping isestablished between a physical entity and a digital entity through the process, and it is guaranteed that information is transmitted between twin bodies in real time at a high speed in an undistortedmode.

Owner:合肥哈工热气球数字科技有限公司

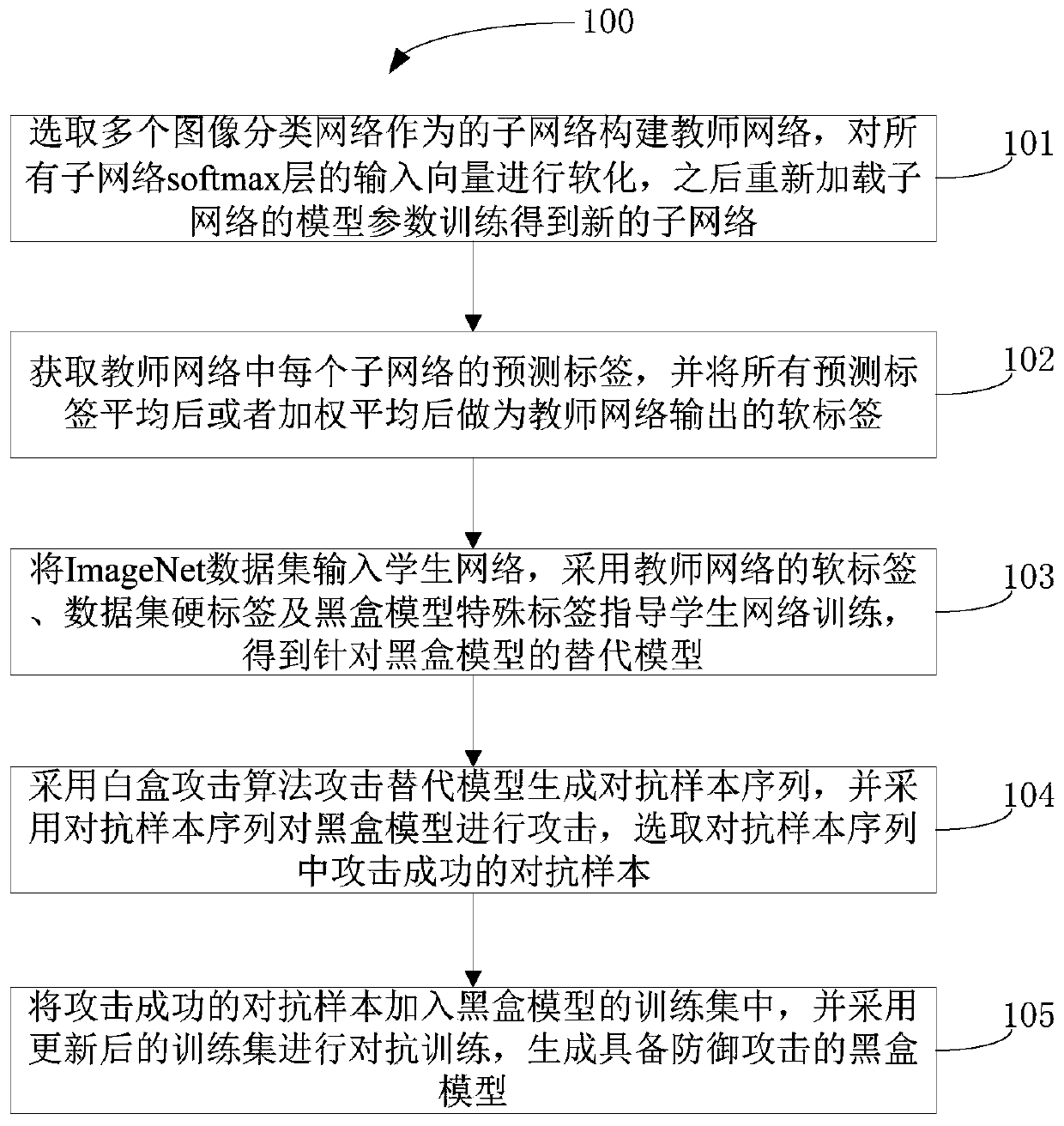

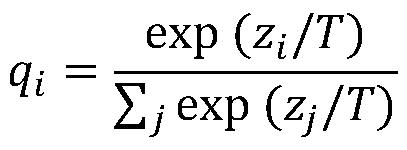

Neural network black box aggressive defense method based on knowledge distillation

ActiveCN111027060AGuaranteed successful attackReduce the pitfalls of losing variance between classesPlatform integrity maintainanceNeural architecturesData setSample sequence

The invention discloses a neural network black box aggressive defense method based on knowledge distillation, and the method comprises the steps: selecting a plurality of sub-networks to construct a teacher network, softening the input vectors of softmax layers of all sub-networks, and then reloading the model parameters of the sub-networks for training to obtain a new sub-network; obtaining a prediction label of each sub-network, and taking all prediction labels as soft labels after averaging or weighted averaging; inputting the Image Net data set into a student network, and guiding student network training by adopting a soft label, a data set hard label and a black box model special label to obtain a substitution model; adopting a white box attack algorithm to attack the substitution model to generate an adversarial sample sequence, adopting the adversarial sample sequence to attack the black box model, and selecting an adversarial sample successfully attacked in the adversarial sample sequence; and adding the successfully attacked countermeasure sample into a training set of the black box model, and performing countermeasure training by adopting the updated training set to generate the black box model with attack defense.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

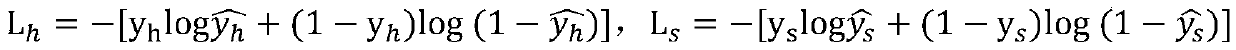

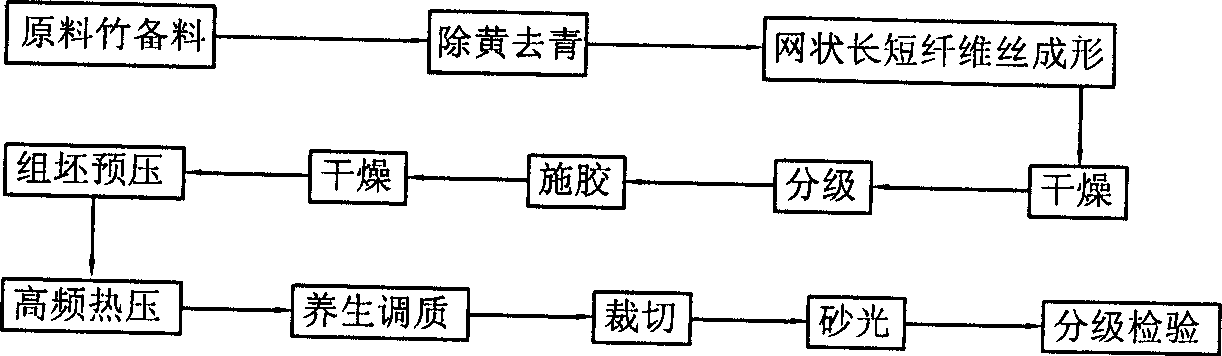

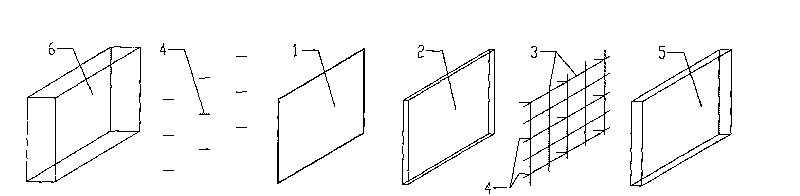

Reinforced composite bamboo board and its manufacturing method

InactiveCN1769621ALight weightEnvironmentally friendlyWood working apparatusDomestic articlesSurface layerFiber bundle

The invention discloses a strengthening composite bamboo board and preparing method, which consists of net bamboo fiber bundle layer and surface layer, wherein the net bamboo fiber bundle layer is composed of parallel grain and cross grain. The invention is prior to wood fiber board, which prevents the common bamboo board (bar structure of multiple-layer parallel adhesion) from deforming and uneven strength.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

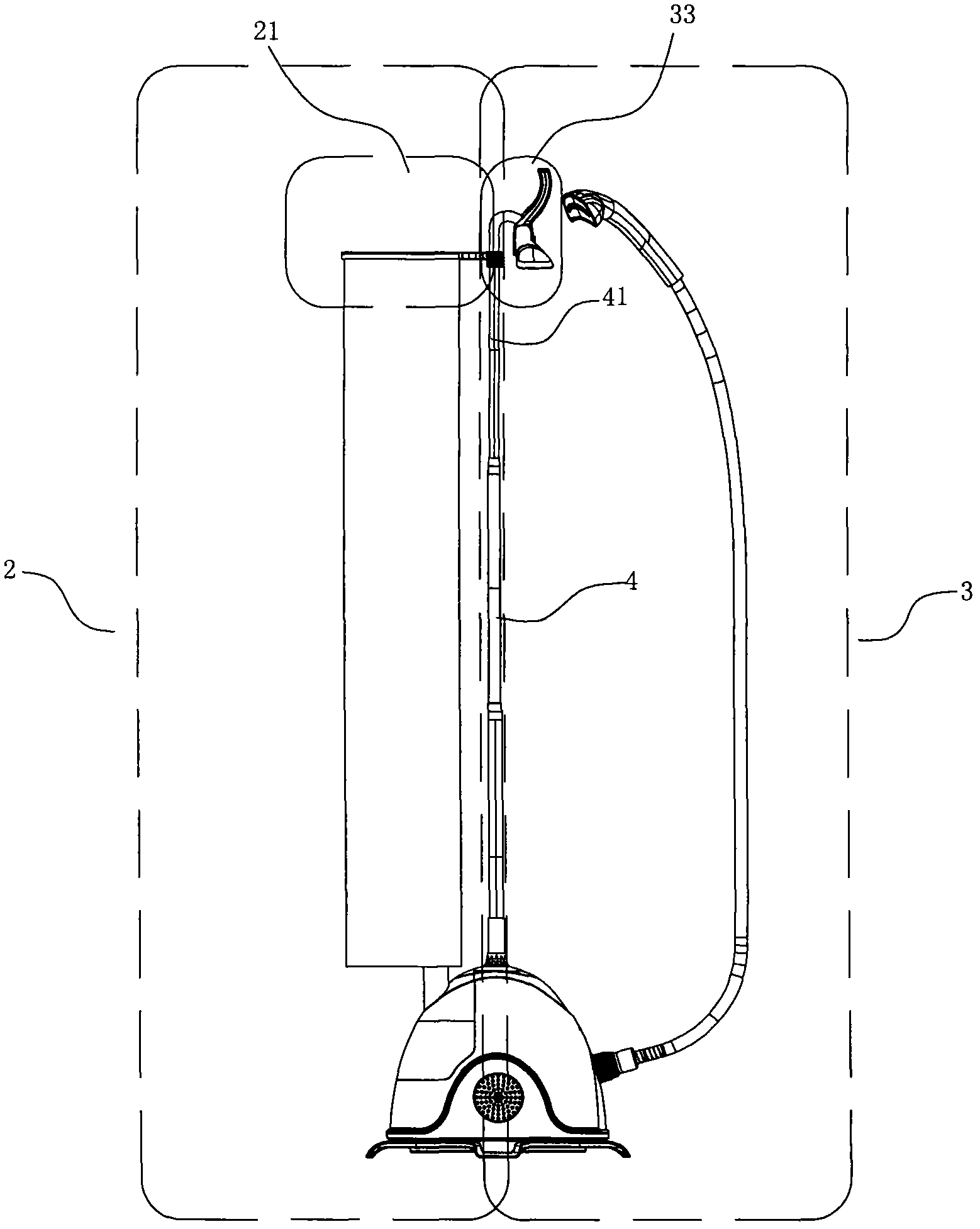

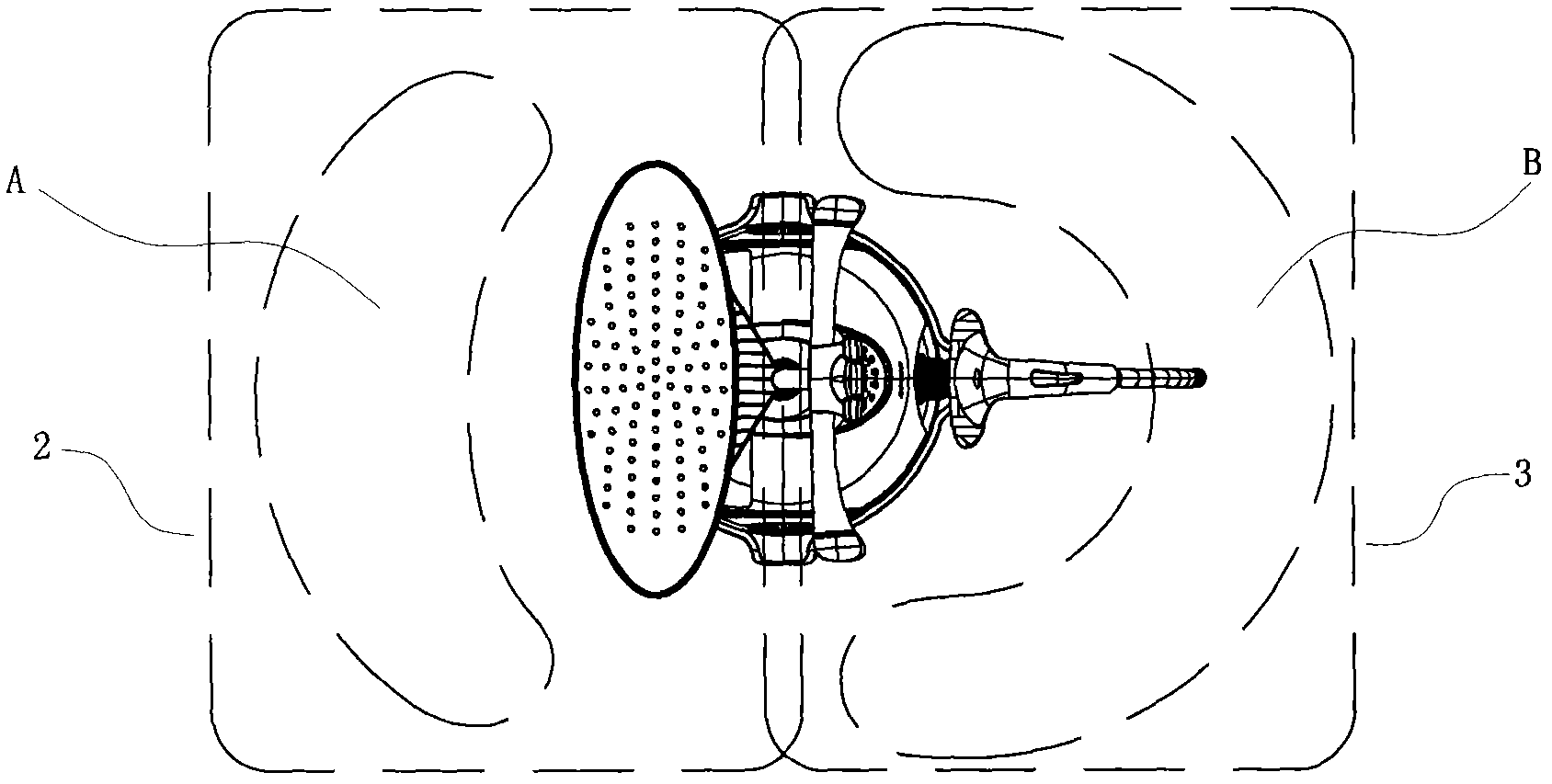

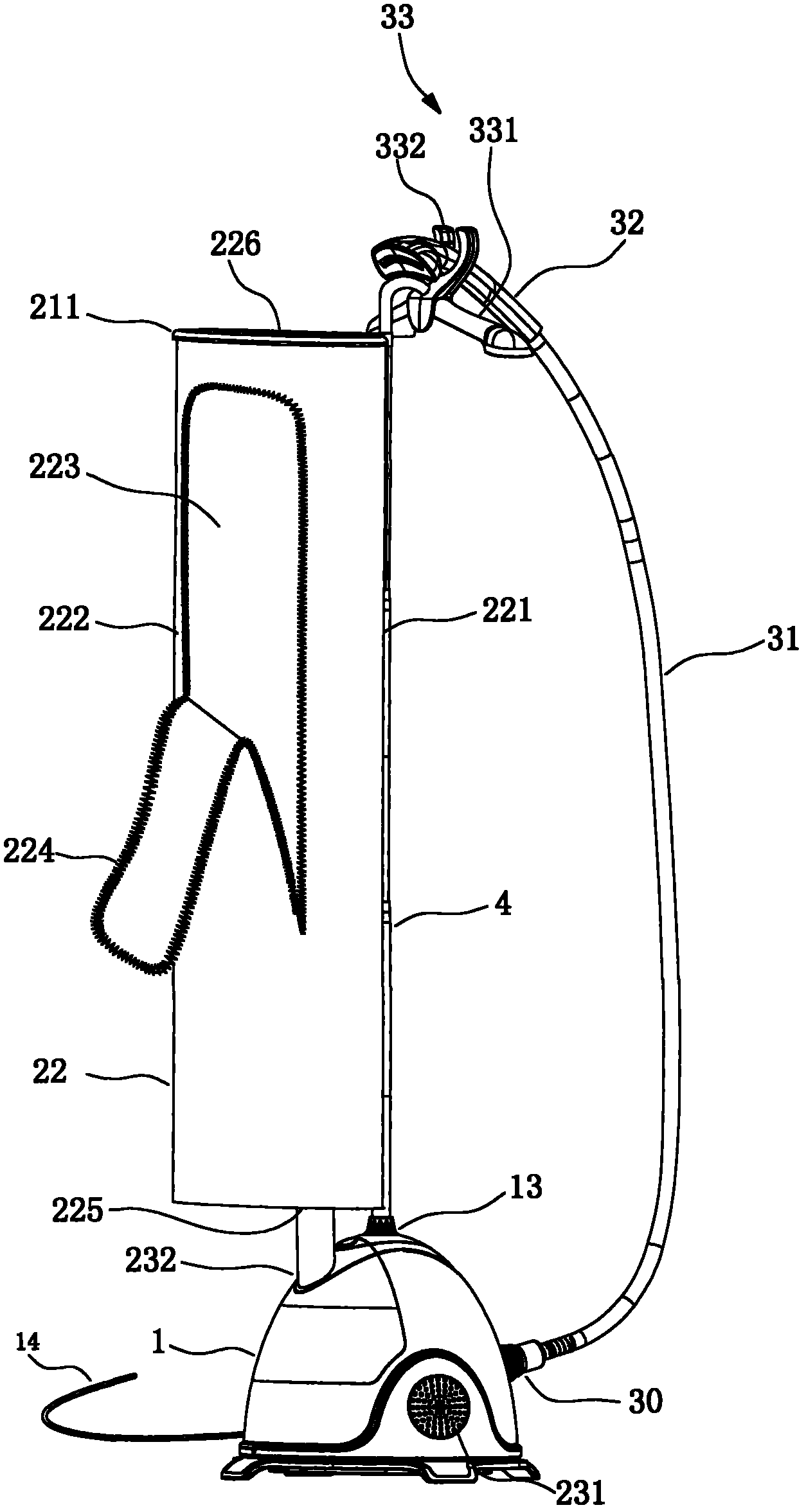

Drying and ironing integrated machine

The invention discloses a drying and ironing integrated machine, comprising a support body, a vertical column position on the support body, a drying unit and an ironing unit. The drying unit comprises a drying frame part, a cover body and a heating part, wherein the drying frame part is fixed on the upper end of the vertical column, the cover body is supported on the drying frame part and naturally drops along one side of the stand column to form an accommodating space, the heating part is used for supplying hot air to the accommodating space, an air outlet interface of the heating part is in sealed and through communication with an air inlet of the cover body, and a drying area is formed on the drying unit adjacent to one side of the vertical column; and the ironing unit comprises an ironing device and a coat hanger, wherein an ironing area is formed on the ironing unit adjacent to the other side of the vertical column. The drying and ironing integrated machine can be used for ironing and drying clothes at the same time, ironing and drying are not interfered with each other, so that the capability of the machine in processing dry and wet clothes, the use convenience is promoted, the operation difficulty in a use process is improved, energy waste is completely eliminated, less space is occupied, and the drying and ironing integrated machine is particularly suitable for being widely applied to families with small houses.

Owner:胡杰波

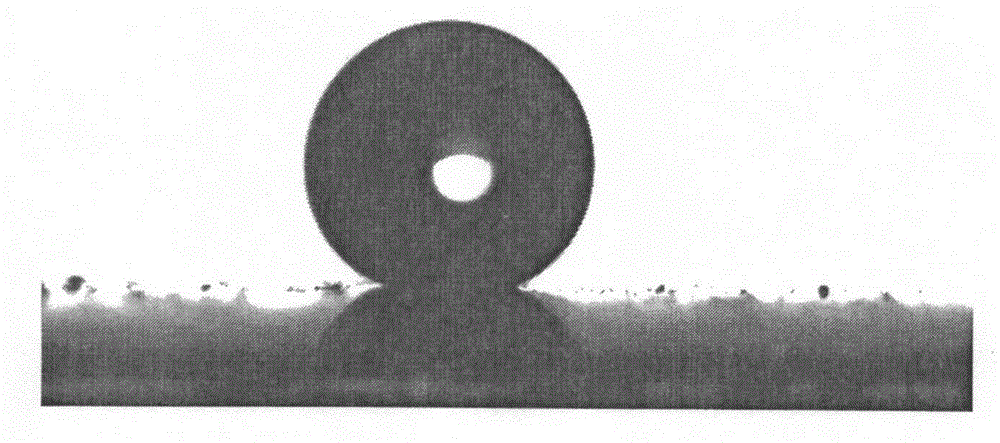

Preparation method for super-hydrophobic self-luminous coating

InactiveCN104479437ASolve the problem of water instabilityHas superhydrophobic self-cleaning propertiesLuminescent paintsPolyurea/polyurethane coatingsCross-linkLuminous intensity

The invention provides a preparation method for a super-hydrophobic self-luminous coating. The method comprises the following two steps of 1, uniformly mixing a high-molecular polymer monomer, a cross-linking agent, an initiating agent, nano-particles and long-lasting phosphor materials to obtained a mixture; 2, uniformly coating the surface of a base material with the mixture, and carrying out polymerization to obtain the super-hydrophobic self-luminous coating. The preparation method for the super-hydrophobic self-luminous coating overcomes the shortcomings of the prior art, the application range of the long-lasting phosphor materials is widened, and meanwhile the problem that the super-hydrophobic self-luminous coating is decomposed or the luminous intensity is reduced when water is encountered is solved. The preparation method for the super-hydrophobic self-luminous coating is simple in process and high in universality, and the manufacturing cost is saved.

Owner:DONGHUA UNIV

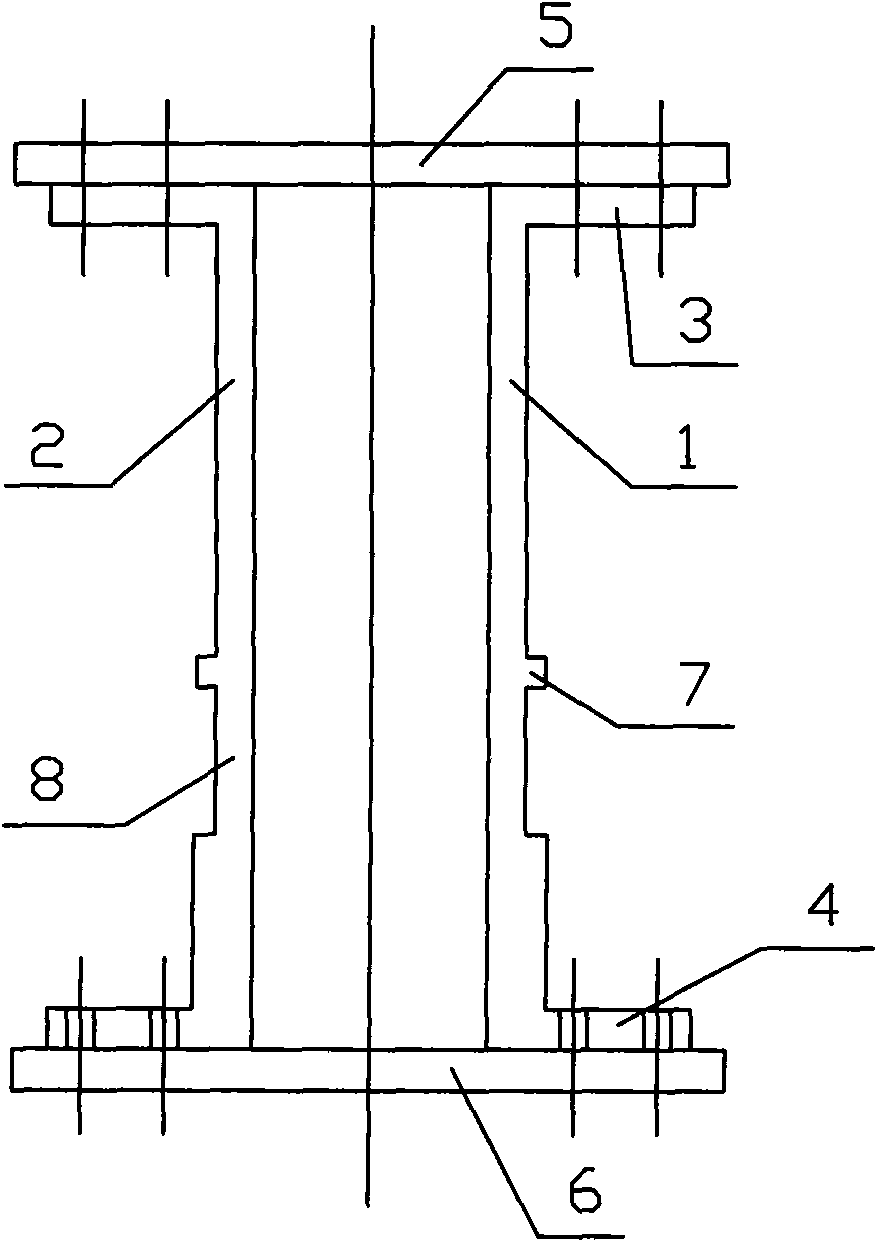

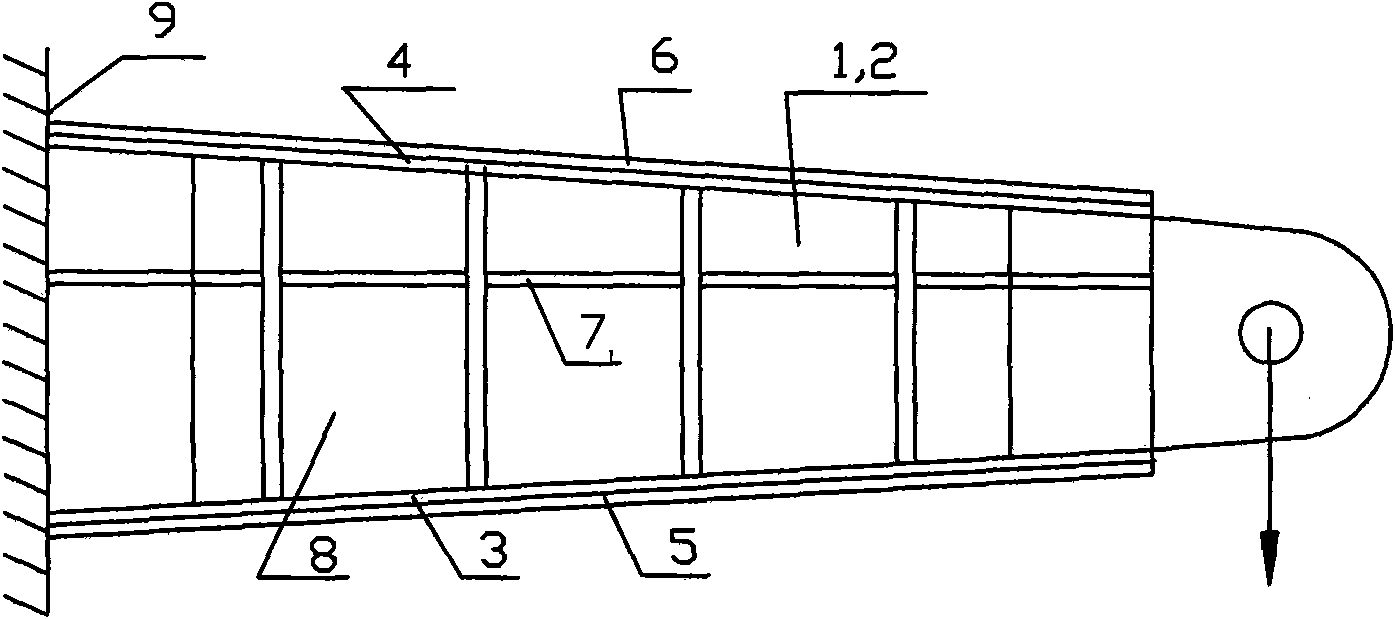

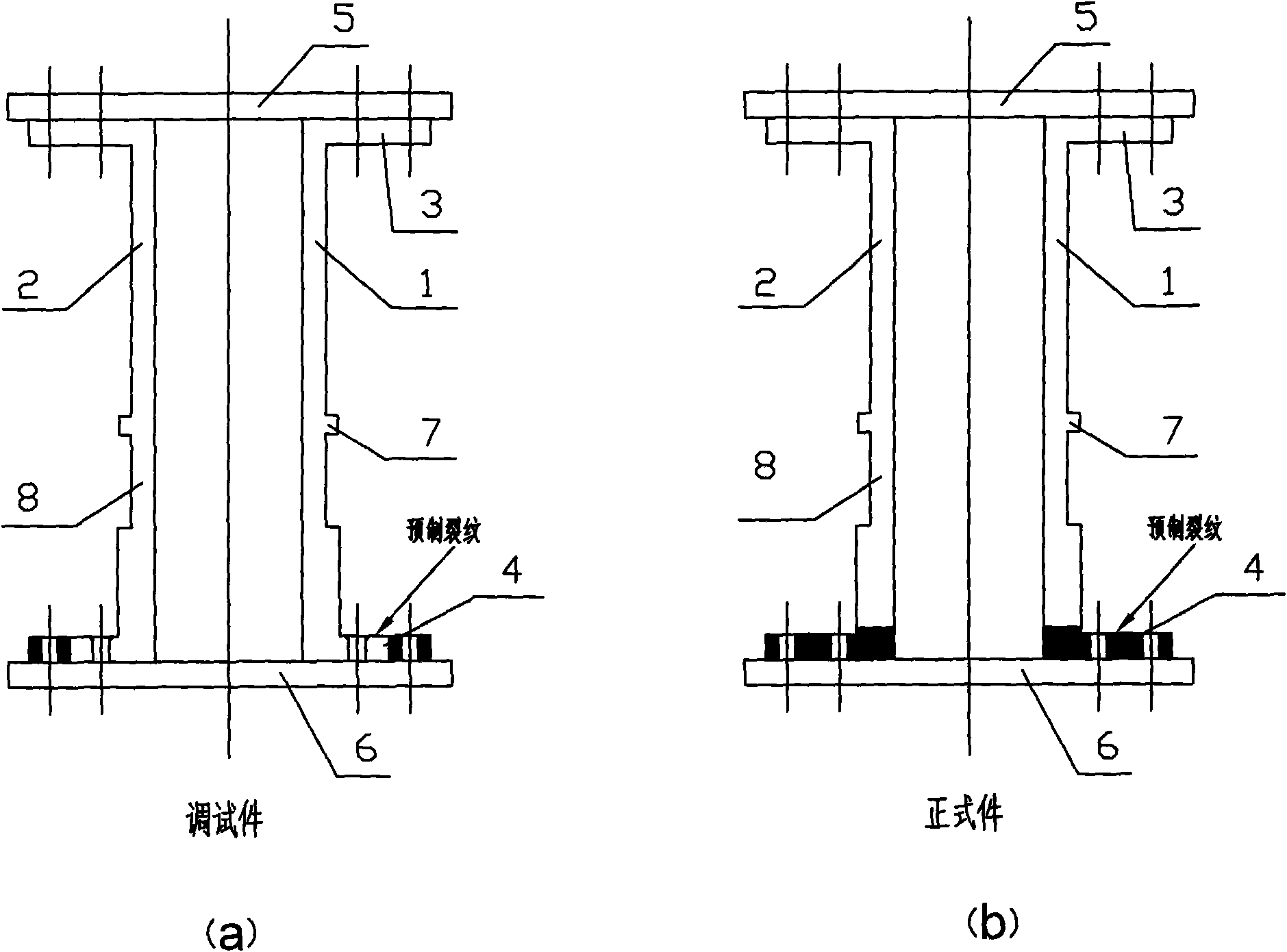

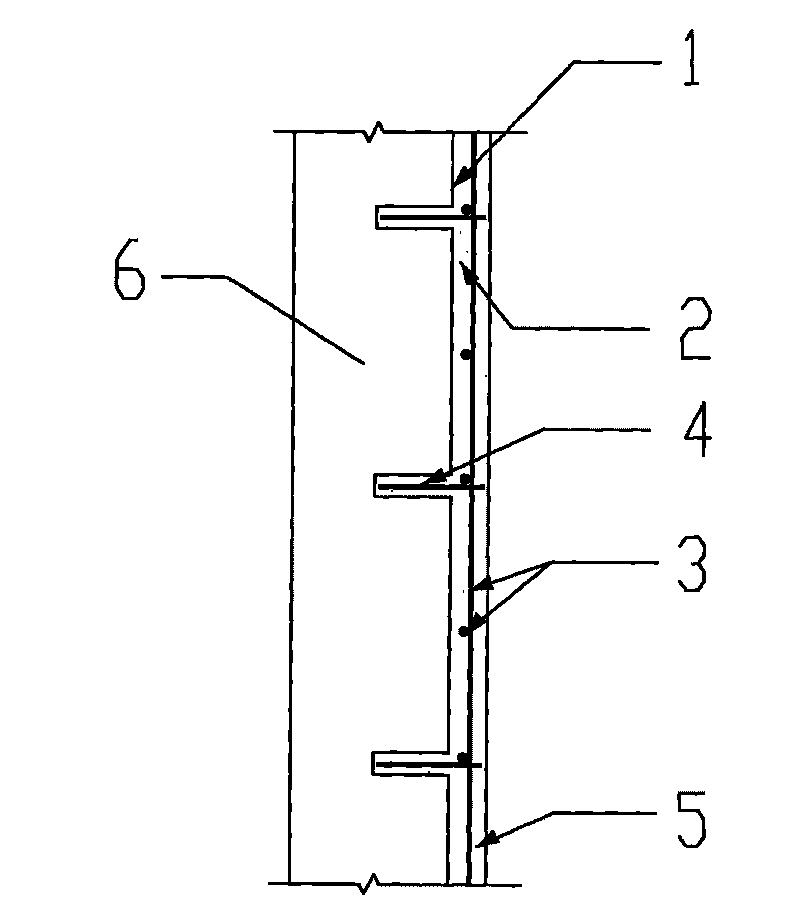

Damage-tolerance testing method for whole wing spar of airplane

InactiveCN101561365ASolve scalabilitySolve the strength problemStructural/machines measurementJet aeroplaneResidual strength

The invention pertains to airplane fatigue and damage-tolerance testing technologies, and relates to a damage-tolerance testing method for the whole wing spar of an airplane. The method comprises the steps of: (I) choosing a part with large load from the whole wing spar for serving as a testing part examining segment, (II) producing two same testing parts according to the examining segment, (III) reserving an interval of 20 to 30mm between the two back-to-back testing parts which are respectively provided with a coating in the upper part and the lower part (the coating is connected with an upper spar edge strip and a lower spar edge strip to form a case segment), (IV) fixing the root of the testing case segment completing assembly on a load-bearing wall, (V) exerting concentrated load at one end of the testing parts to simulate the bending moment of the spar at the testing segment and the shearing force of a web, without considering the influence of the shearing flow of the coating and (VI) using a finite element method to conduct damage tolerance analysis on the testing parts and comparing testing results. The method solves the difficulty that the crack expansion and remaining strength of the present airplane whole wing spar structure lack theoretical evidence; and the design of the testing parts adopts a method of simultaneously conducting tests to the two back-to-back testing parts, thereby eliminating the distortion of a single spar.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Building strengthening method

InactiveCN101691818AGood reinforcing effectWork together wellBuilding repairsPolymer modifiedFireproofing

The invention discloses a building strengthening method, which comprises the following steps of: 1) clearing the surface of a structure to be strengthened to expose a hard part; 2) carrying out water spray wetting on the structure to be strengthened; 3) implanting pins connecting a reinforcing steel bar net and the structure to be strengthened, and bonding the reinforcing steel bar net; 4) spraying an interface agent coating on the surface of the structure to be strengthened; and 5) spraying a polymer modified cement mortar bond layer and a polymer modified cement mortar protective layer by layers on the interface agent coating. The method can effectively improve the bearing capacity of the structure to be strengthened, improves the rigidity of the structure to be strengthened, and has less occupied space; a molded surface strengthening structure and the structure to be strengthened have the advantages of reliable bond, compactness, no crack, waterproofing, permeability resistance, fireproofing, high-temperature resistance, Cl-corrosion resistance, carbonization prevention, rust resistance and good durability; and a construction process is simple, formworks are not needed to be built, the speed of improving the strength of polymer modified cement mortar is high, and a construction period is greatly shortened. The method can be simultaneously applied to repairing and strengthening of the existing concrete structures and masonry structures, and solves the problems of breakage and aging of materials and insufficient structural strength of an old building.

Owner:上海维固工程实业有限公司

Polyurethane anti-corrosion priming paint sprayed on steel structure in abyssal environment

InactiveCN102676029AEliminate pinholesAvoid damageAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention relates to a polyurethane anti-corrosion priming paint sprayed on a steel structure in an abyssal environment. The priming paint is polyurethane modified epoxy solvent-free priming paint; after being subjected to polyurethane modification, the epoxy solvent-free priming paint has higher compressive strength than a common solvent-free epoxy coating, and has higher adhesion strength with the steel structure and sprayed polyurethane. After the matching of the polyurethane modified epoxy solvent-free priming paint and the spray polyurethane, the drawing strength between the whole coating and the steel structure is tested to be larger than or equal to 10 MPa. The polyurethane modified epoxy solvent-free priming paint solves the problems of low compressive strength and polyurea adhesion strength of the common solvent-free epoxy priming paint used in the abyssal environment, and also solves the problem of low steel structure adhesion strength of a polyurethane type priming paint in the abyssal environment.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

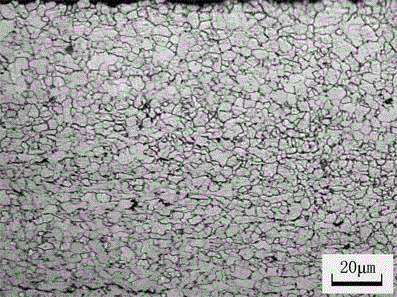

Method for preparing ultra-fine crystal grain high-strength high-toughness copper alloy strip

The invention discloses a method for preparing an ultra-fine crystal grain high-strength high-toughness copper alloy strip. The method comprises the following steps of: performing hot-rolling with the distortion of 40 to 70 percent after performing high-temperature annealing on a copper alloy cast ingot to obtain a plate blank; performing cold-rolling with the distortion of 30 to 60 percent; performing intermediate annealing after the cold-rolling; after soaking the plate blank in liquid nitrogen for 5 to 30 minutes, taking the plate blank out and performing the cold rolling immediately; performing cryogenic treatment and the cold-rolling repeatedly after performing the cold-rolling; after accumulated strain capacity reaches 40 to 90 percent, performing low-temperature annealing to obtain the ultra-fine crystal grain high-strength high-toughness copper alloy strip with the average size of about 0.8 mu m, wherein the tensile strength of the copper alloy strip is 650 to 880 MPa and the elongation rate is 10 to 30 percent. The method has a simple production process and low processing cost, and can implement cold-deformation and annealing after the cryogenic treatment on a copper alloy on conventional production equipment; crystal grains are thinned by generated deformation twin and annealing twin, simultaneously both the strength and the tensility of the copper alloy are improved; therefore, the method has a very good industrial application prospect.

Owner:CENT SOUTH UNIV

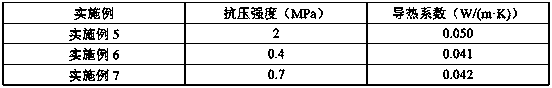

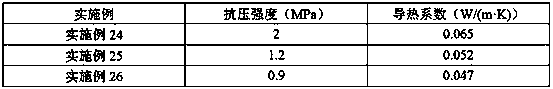

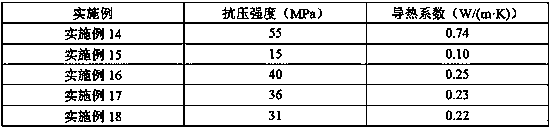

Manufacturing method for microorganism heat-insulation building material

PendingCN108530013ASolve the strength problemSolve insulation problemsBacteriaMicroorganism based processesNutrient solutionMechanical property

The invention discloses a manufacturing method for a microorganism heat-insulation building material. The manufacturing method for the microorganism heat-insulation building material comprises the following steps: taking a bacteria solution which has a mineral deposition function and is prepared from microorganisms and a corresponding nutrient solution as raw materials; directly carrying out mineral deposition on various lightweight aggregates or compounding inorganic or organic cementing materials; and carrying out microorganism inactivation and pore forming to obtain novel microorganism heat-insulation plates, heat-insulation blocks, heat-insulation concrete, heat-insulation mortar and the like. By the method, the physical and mechanical properties of an existing traditional heat-insulation material can further be improved through a microorganism mineralization function and an inactivation process. Microorganism mineral deposition products are used as cementing material manufacturingand modifying building heat-insulation materials, contradiction between strength and heat insulation of the heat-insulation materials can be solved effectively, cementing materials such as cement arereduced and are even prevented from being used, resource consumption are reduced remarkably, mine excavation frequency is reduced, pollution emission is eliminated, and environment stress and haze influence are relieved. The manufacturing method for the microorganism heat-insulation building material is an environmentally friendly building material manufacturing method, and has good economic benefit, environment benefit and social benefit.

Owner:李珠

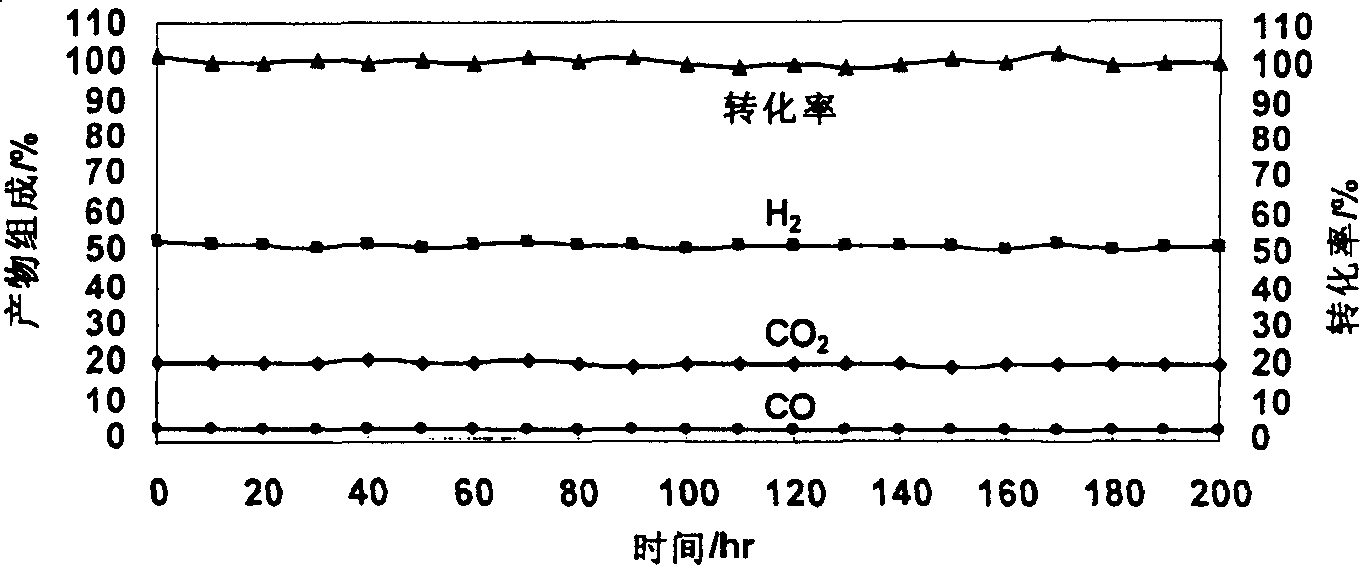

Catalyst for autothermal reformation of methanol to prepared hydrogen and its prepn process and application

InactiveCN1672789AHigh activityImprove heat stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsDecompositionAdhesive

The catalyst has metal oxide without copper and noble metal as main active component and the composite oxide of RE and transition metal as the catalytic assistant, heat stabilizing assistant, structure stabilizing assistant and active catalyst component support. The addition of the composite oxide of RE and transition metal raises the reaction activity of the catalyst as well as its strength and stability greatly. The preparation process may be co-precipitation one, isometric soaking one or hot decomposition one. In the co-precipitation process or soaking process, adhesive and pore creating agent are added, and the adhesive and pore creating agent is mixture water solution of organic acids, inorganic acids, pseudo-thin diasphore and polymer. The catalyst may be used in hydrogen source system of fuel cell with unstable operation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

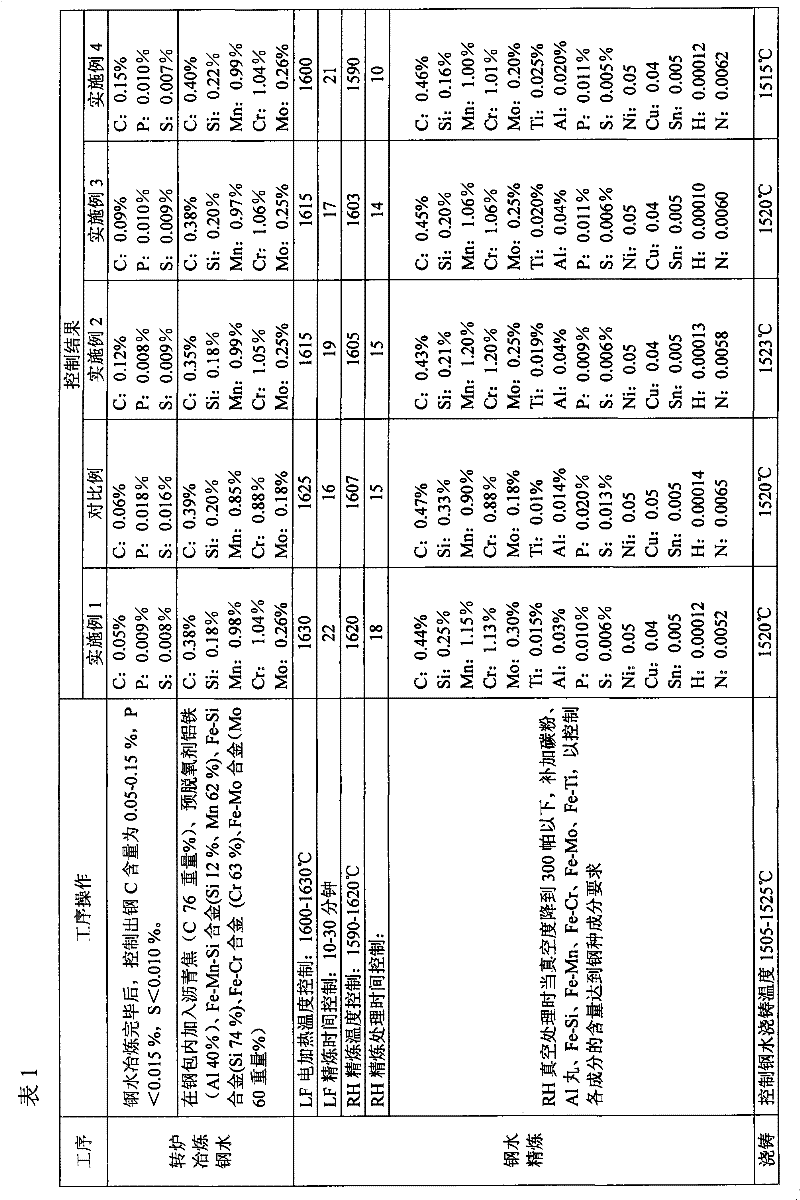

A kind of drill collar steel and its preparation method

The invention relates to drill collar steel and a preparation method thereof. The drill collar steel comprises the following components based on the total weight of drill collar steel: 0.41-0.47wt% of C, 0.15-0.3wt% of Si, 0.95-1.2wt% of Mn, 0.95-1.2wt% of Cr, 0.15-0.3wt% of Mo, 0.02-0.04wt% of Al, 0.01-0.03wt% of Ti, less than or equal to 0.02wt% of P, less than or equal to 0.015wt% of S, less than or equal to 0.2wt% of Ni, less than or equal to 0.2wt% of Cu, less than or equal to 0.05wt% of Sn, less than or equal to 0.0002 wt% of H, less than or equal to 0.007wt% of N and the balance of Fe;and T[O] is less than or equal to 0.0020wt%, and the A,B,C and D impurities are less than or equal to 1.5 levels. By using the preparation method, the problem that the strength of the drill collar steel is not matched with plastic toughness is solved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Double-foaming cellular concrete and production method thereof

The invention discloses double-foaming cellular concrete and a site production construction method thereof. The volume weight of the double-foaming cellular concrete ranges from 100 KG / M<3> to 400 KG / M<3>; the heat conduction coefficient is as little as 0.020 W / M.DEG C, and the intensity is up to 5 MPa. The double-foaming cellular concrete can be widely applied to the production of light-weight heat preservation materials such as roof heat preservation materials and external wall heat preservation materials and hanging pieces such as light-weight building hanging beams, and has the purposes of the filling of light-weight hollow bricks and hollow building covers; more importantly, the double-foaming cellular concrete can be applied to the construction of underwater facilities. The site production construction method for the double-foaming cellular concrete is simple in technology and simple and convenient to operate; by special equipment, full-automatic integrated productions, such as automatic foaming, metering and proportioning, are effectively realized; upon automatic control, the production construction of the double-foaming cellular concrete is finished highly efficiently at low cost.

Owner:河南华泰新材科技股份有限公司

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Nano-plate plane glue distributing device and method

InactiveCN101085563AConsistent thicknessImprove efficiencyLamination plant layoutLamination ancillary operationsFiberglass meshGlass fiber

The invention relates to the nanometer plate surface glue equipment and the cloth glue that comprises the working platform, cloth hopper distributing nanometer fluid on the compound extractor, vibrating device connected with the cloth hopper, cloth applying device setting the glass fiber net on the nanometer glue band, and the scraping device and compression device. The compound extraction band moving horizontally on the working platform and forming nanometer band, setting glass fiber net cloth with tension on the nanometer band, compressing the glass fiber net cloth and the nanometer band into nanometer compound band, compressing the compound band tightly. It is heat and sound insulation, radiation resistant, and improved in product feature and reduced in production cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

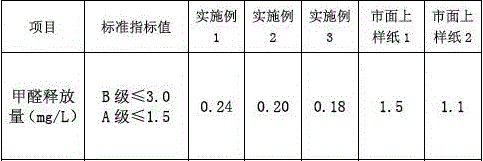

Production method of low-formaldehyde-releasing impregnating resin film paper

ActiveCN106498804AResolution timeGuaranteed surface physical and chemical propertiesPaper coatingPaper/cardboardPulp and paper industryHigh pressure

The invention provides a production method of low-formaldehyde-releasing impregnating resin film paper. The production method comprises the following steps: uncoiling raw paper and pre-treating; impregnating the raw paper into a urea formaldehyde resin impregnating solution; conveying the impregnated raw paper into a drying oven; drying at the temperature of 120 DEG C to 140 DEG C for 25s to 35s; cooling the resin film paper which is dried for the first time, coating double faces of the paper with an amine-aldehyde resin solution; conveying the coated resin film paper into the drying oven again, and drying at the temperature of 130 DEG C to 155 DEG C for 35s to 45s; after drying for the second time and cooling, conveying the resin film paper into a cutting machine, and cutting the resin film paper into needed length. According to the low-formaldehyde-releasing impregnating resin film paper provided by the invention, formaldehyde release can be effectively reduced, and the formaldehyde releasing amount is not increased after high-temperature and high-pressure attachment; the quality and applicability of the impregnating resin film paper can be improved.

Owner:GUANGDONG YAODONG FURNITURE BOARD +1

Environmental-protection composite quartz stone board and preparation method thereof

InactiveCN103009699ALow costExpand the scope of applicationCeramic shaping apparatusWater-setting substance layered productCeramic tilesSurface layer

The invention discloses an environmental-protection composite quartz stone board. The environmental-protection composite quartz stone board comprises a ceramic tile used as bottom layer base material, and quartz store material is used as surface layer material, wherein the ceramic tile takes waste powder material in the production and processing of ceramic material, ceramics and artificial quartz stone, and waste mud caused by mould pressing as main materials, and the artificial quartz stone takes the mixture of waste store material, glass, quartz sand, unsaturated polyester resin, a curing agent, a coupling agent, an anti-aging agent, an anti-shrinking agent and a heat stabilizer as the main materials. According to the environmental-protection composite quartz stone board, the quality of the ceramics is enhanced, the cost of the quartz store is lowered, the application range of the quartz store is enlarged, and the product chain of the composite quartz stone board is enriched.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

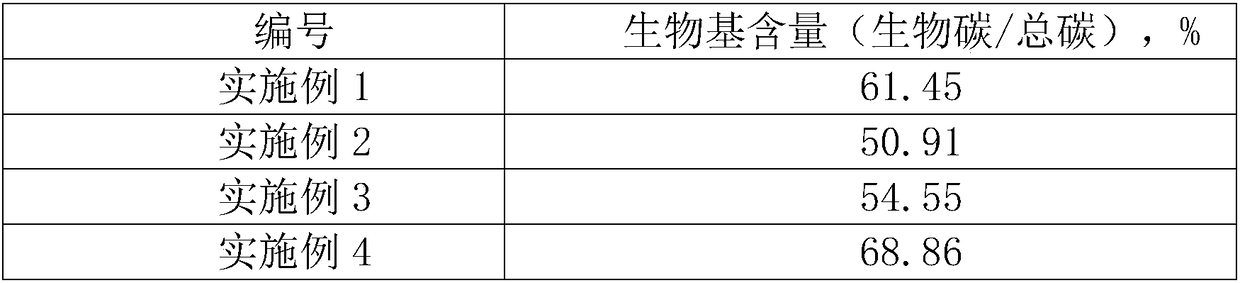

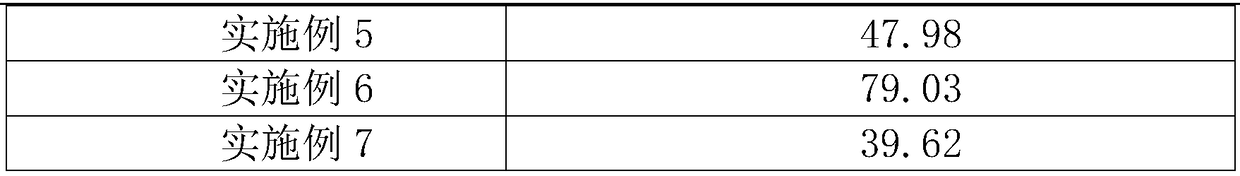

Bio-based biodegradable multi-block copolymer as well as preparation method and application thereof

InactiveCN108192105AGuaranteed biodegradabilitySolve the melting point is too lowFlexible coversWrappersDimer acidMechanical property

The invention discloses bio-based biodegradable multi-block copolymer as well as a preparation method and application thereof. The multi-block copolymer comprises a chain segment A and a chain segmentB; the chain segment A is fat-aromatic coplyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on C2-C36 fatty diacid and derivatives thereof, C6-C20 aromatic diacid and derivatives thereof, C2-C36 divalent alcohol, and 0.0 to 10% by weight of polyhydroxyl or polycarboxyl compound and performing condensation polymerization; the chain segment B is fatty copolyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on dimer acid and derivatives thereof, C2-C12 fatty diacid and derivatives thereof, C2-C36 divalent alcohol as well as 0.0 to 10% of polyhydroxyl or polycarboxyl compound and performing condensation polymerization. The chain segment A and the chain segment B react with a polyfunctional chain extender of polyisocyanate, a polyepoxy compound and carbodiimide which is 0.01 to 10% of the polymer to form the multi-block copolymer. The product prepared by the method has high biodegradability, mechanical property and processing property, and can be widely applied to the fields of packaging, biological medicine, medical treatment and thelike.

Owner:王肖桦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com