Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

826 results about "Dimer acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimer acids, or dimerized fatty acids, are dicarboxylic acids prepared by dimerizing unsaturated fatty acids obtained from tall oil, usually on clay catalysts. The CAS number of the material is [61788-89-4]. Dimer acids are used primarily for synthesis of polyamide resins and polyamide hot melt adhesives. They are also used in alkyd resins, adhesives, surfactants, as fuel oil additives, lubricants, etc. It is a light yellow or yellow viscous transparent liquid. It is non-toxic.

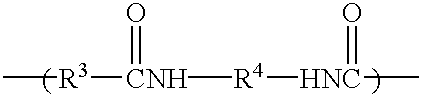

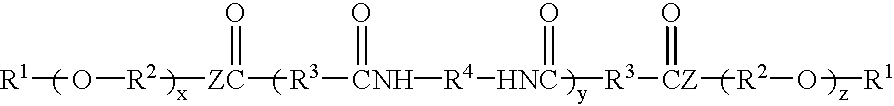

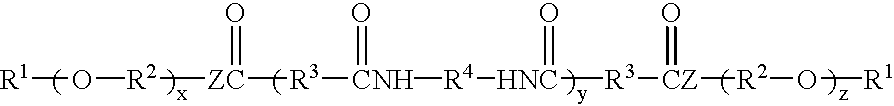

Hydrocarbon-terminated polyether-polyamide block copolymers and uses thereof

A composition comprising (a) a resin composition comprising a block copolymer of the formula hydrocarbon-polyether-polyamide-polyether-hydrocarbon; and (b) a polar liquid. The block copolymer may be prepared by a process comprising reacting together reactants comprising dimer acid, diamine, and a polyether having termination at one end selected from amine, hydroxyl and carboxyl, and termination at another end selected from hydrocarbons. The polar liquid may be one or more of an aromatic liquid, a polar aprotic liquid, a ketone-containing liquid, an ester-containing liquid, an ether-containing liquid, an amide-containing liquid and a sulfoxide-containing liquid. The composition may be a gel at room temperature.

Owner:CRODA INT PLC

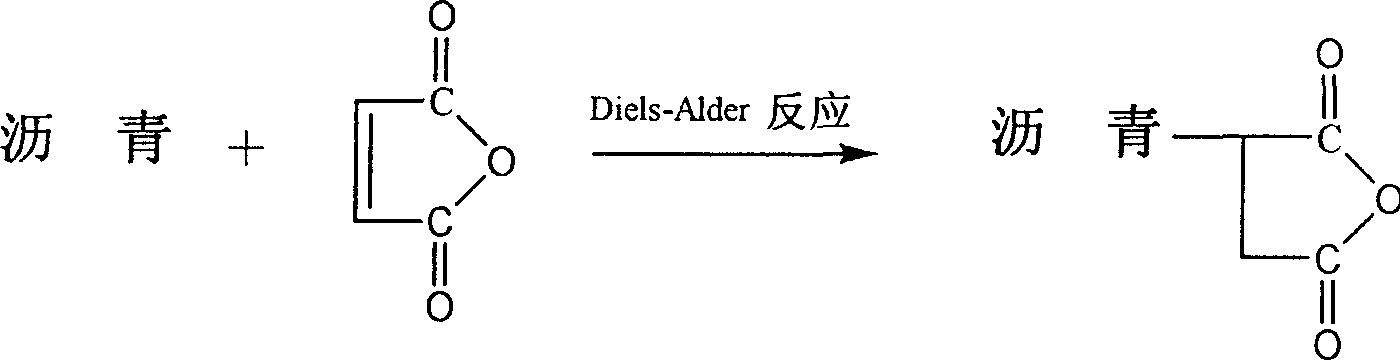

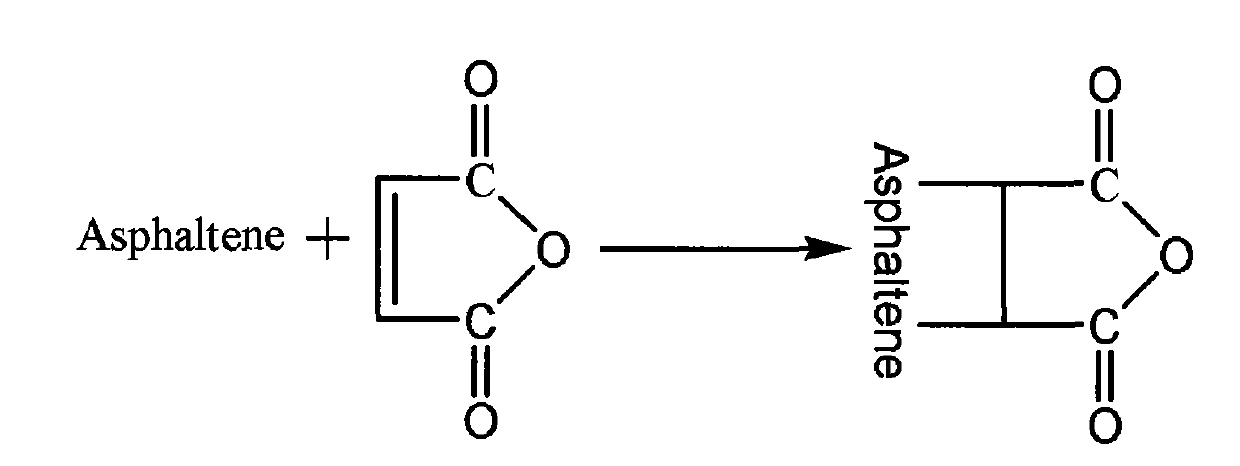

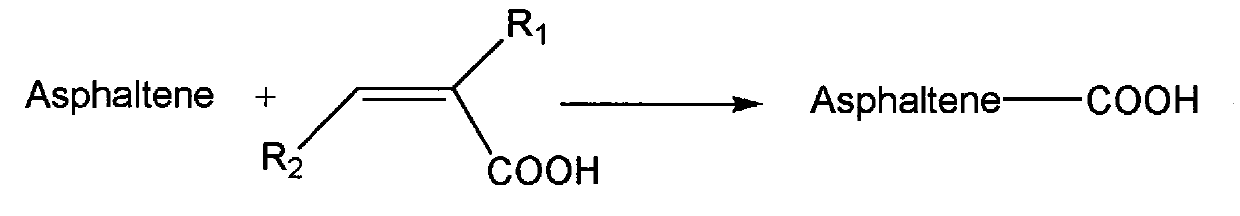

Thermosetting epoxy asphalt materials for pavement and bridge and process for preparing same

ActiveCN1837290AImprove performanceHigh strengthIn situ pavingsBuilding insulationsBituminous materialsTar

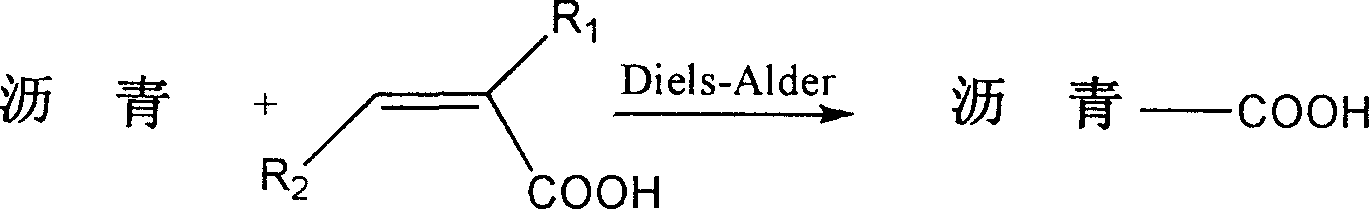

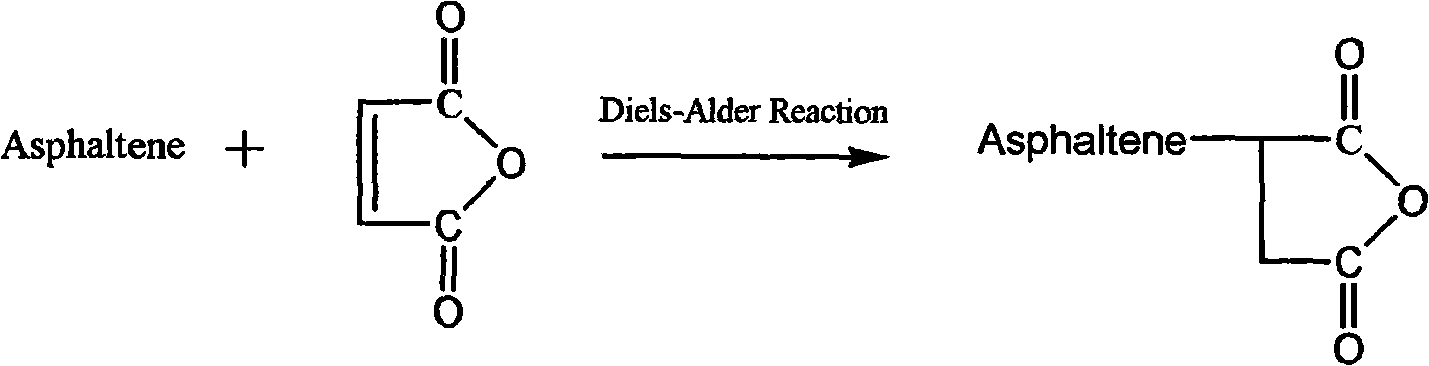

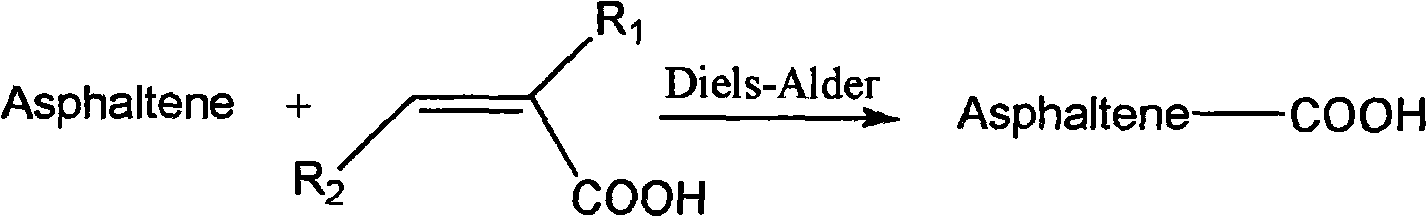

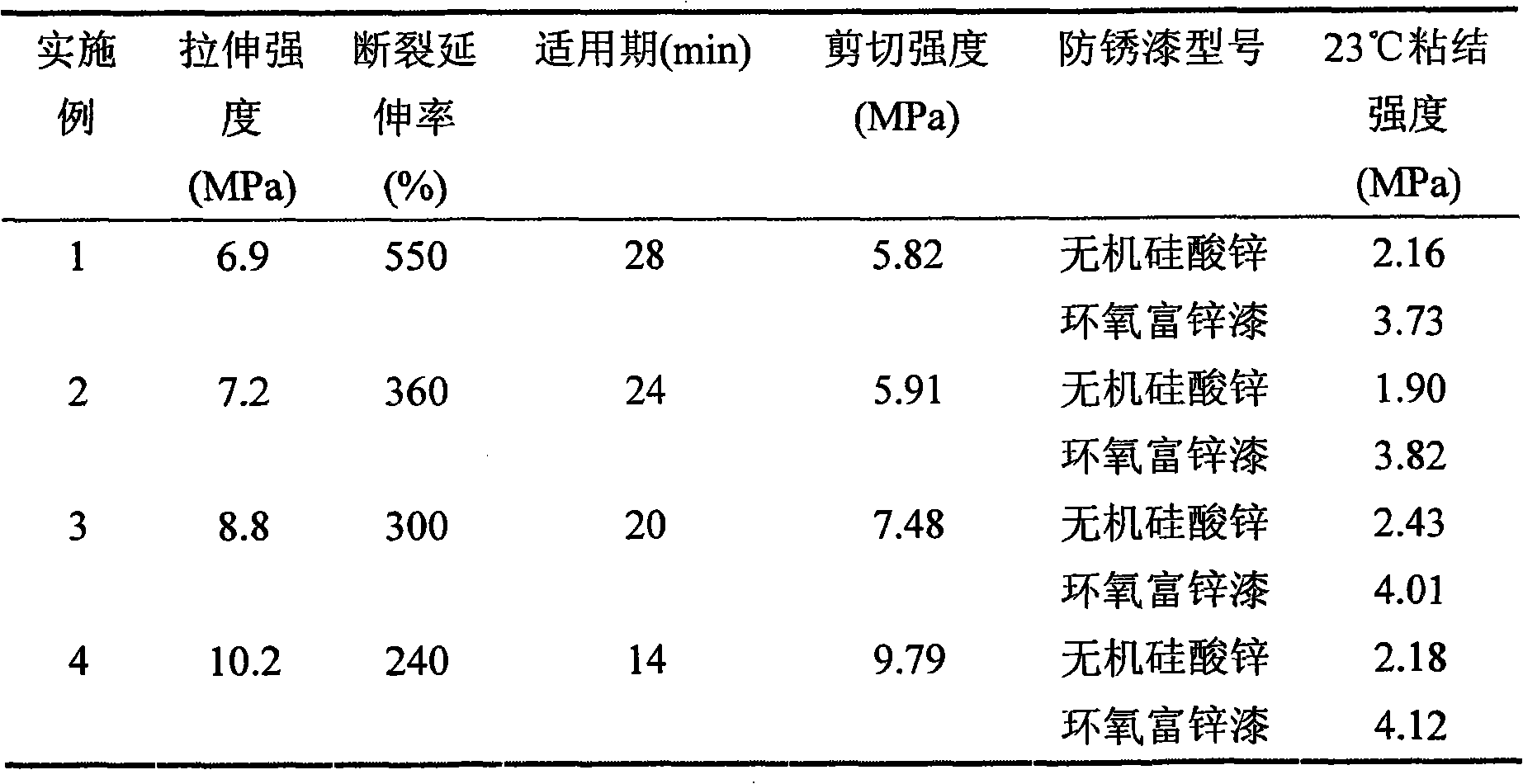

The invention discloses a bridge heat fixed epoxy tar material and preparing method, which consists of A and B, wherein A part quality component is 60-76 modified tar with carboxy group or acid anhydride, grease group diacid, 11-25 dimer acid or alkyd resin, 10-25 fatty acid and 0.05-0.65 solidifying celeratist; B is epoxy resin; the quality rate of A and B is 2:1-8:1. The invention possesses high strength and good flexibility, which is fit for higher occasion.

Owner:JURONG NINGWU SCI & TECH DEV

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

Water-based response type multifunctional metal machining liquid and preparation method thereof

InactiveCN101519622AImprove cooling effectImprove the lubrication effectLubricant compositionChemistryTriethanolamine

The invention relates to a water-based response type multifunctional metal machining liquid, the composition formula of which comprises a surfactant, a solvent, plant oleic acid, triethanolamine, sodium salts with a corrosion inhibitive function, an inhibiter, dimeric dibasic acid, a defoamer, a preservative, deionized water, defoamer 903, preservative 1227, deionized water, and the like. The metal machining liquid is nontoxic, harmless and pollution-free, has no harm to human bodies or corrosion to metal surfaces, has no abnormal taste or deterioration after long time usage, and has superior auxiliary machining functions of cooling, lubricating, cleaning, extreme pressure, rust prevention, and the like. The metal machining liquid can be used for the metal working of devices for machining, milling, planning, drilling, boring, punching, wire-electrode cutting, and the like, and is especially suitable for high-grade numerical control machines. The machining liquid has high physical stability and small surface mightiness, and can effectively reduce the machining temperature, reduce the thermal deformation of workpieces and cutting tools, increase the abrasion resistance of the cutting tools, increase the machining precision and the surface finish quality of the workpieces to a great extent, effectively remove dirt on the surfaces of the workpieces, and prolong the natural antirust time of the processed workpieces to be longer than 45 days.

Owner:天津市澳路浦润滑科技股份有限公司

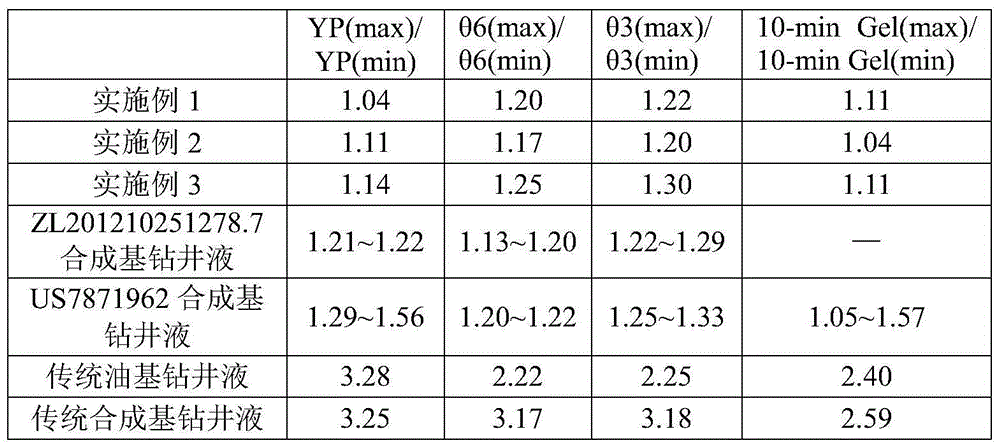

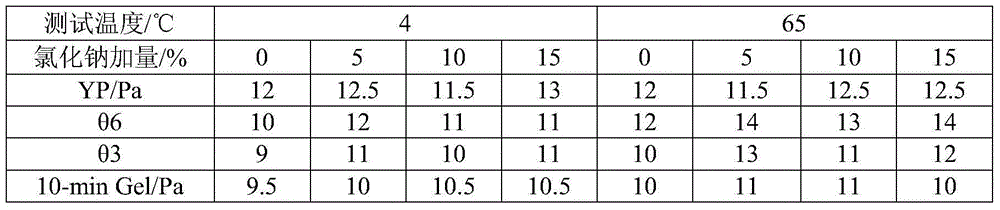

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

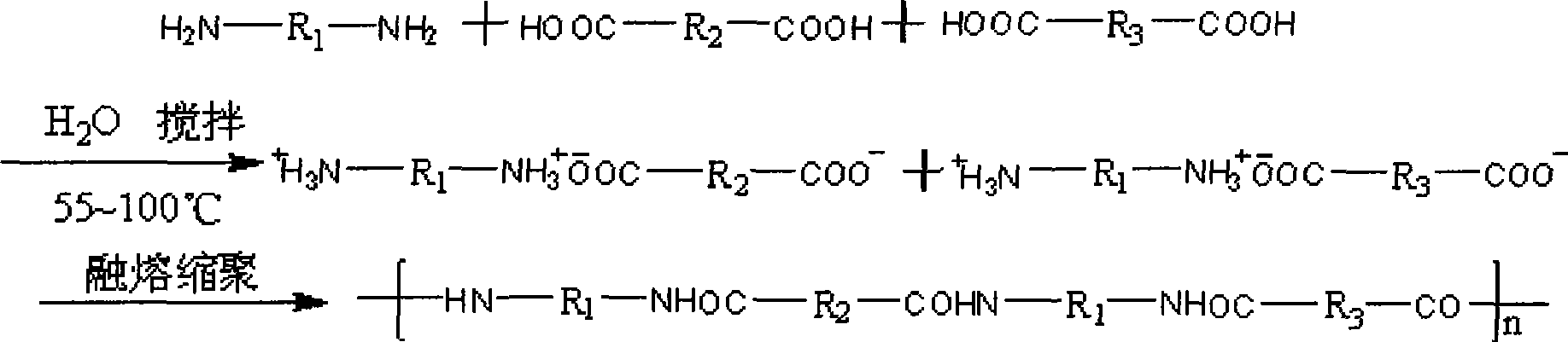

Transparent co-polyamide and preparation thereof

The invention discloses a transparent copolyamide and a preparation method thereof. The cheap domestic dimer acid, aromatic dibasic acid and aliphatic linear chain diamine are taken as raw materials to undergo melt polycondensation and obtain the copolyamide. The light transmittance of the copolymer is up to more than 90%, and the copolymer has high heat resistance and good forming and processing performance. By taking the dimer acid, the aromatic dibasic acid and the aliphatic linear chain diamine as the raw materials, compared with the existing salt forming method, the method for forming salt in aqueous solution greatly reduces the production cost, simplifies the production process and shortens the operation period. The transparent copolyamide is a polymer which has high molecular weight and is prepared by taking the dibasic acid and the aliphatic linear chain diamine as the raw materials, forming salt and polymerizing in the aqueous solution, and the intrinsic viscosity of the transparent copolyamide is up to 2.1dL.g<-1>.

Owner:SOUTH CHINA UNIV OF TECH

Polyesters, polyester compositions, pressure-sensitive adhesive compositions, pressure-sensitive adhesive layers and pressure-sensitive adhesive sheets

ActiveUS20110135924A1Excellent pressure-sensitive adhesive propertyMaintain good propertiesPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterDimer acid

The present invention provides a polyester, a polyester composition and a pressure-sensitive adhesive composition capable of obtaining a pressure-sensitive adhesive which is global-environmentally friendly and is excellent in pressure-sensitive adhesion properties, using a plant-derived raw material; and a pressure-sensitive adhesive layer and a pressure-sensitive adhesive sheet which can be obtained by using the same. A polyester of the present invention is a polyester comprising at least a lactic acid unit, a dibasic acid unit and a glycol unit, wherein the dibasic acid unit contains dimer acid, and the polyester has a glass transition temperature as measured at a temperature rising rate of 20° C. / minute using a differential scanning calorimeter, of −70 to −20° C., a weight average molecular weight of 20,000 to 300,000 and a hydroxyl value of 1 to 100 mgKOH / g.

Owner:NITTO DENKO CORP +1

High-performance thermosetting epoxy asphalt material with wide temperature field and preparation method thereof

InactiveCN101792606AMeet different requirementsAdjustable performanceBuilding insulationsPliabilityDimer acid

The invention discloses a high-performance thermosetting epoxy asphalt material with wide temperature field and a preparation method thereof. The high-performance thermosetting epoxy asphalt material consists of a part A and a part B, wherein the part A comprises the following components in part by mass: 30 to 76 parts of modified asphalt with carboxyl or acid anhydride, 2 to 20 parts of monohydric alcohol or polyol or benzene ring plasticizer, 11 to 25 parts of aliphatic diacid, dimer acid or alkyd, 10 to 25 parts of fatty acid anhydride and 0.05 to 0.65 part of curing accelerator; and the part B is epoxy resin. The mass ratio of the part A to the part B is 2.2: 1-10: 1. The high-performance thermosetting epoxy asphalt material has the advantages of high strength, good flexibility, prominent high and low temperature performance, excellent fatigue resistance and environment friendliness, is applicable to the places with higher requirements such as expressways, roads and bridges and the like under various temperature conditions, and can be used as a road and bridge surfacing material, a waterproof roof material, a sealing agent and an advanced elastic damping de-noising material for the expressways.

Owner:SOUTHEAST UNIV +1

Bio-based biodegradable multi-block copolymer as well as preparation method and application thereof

InactiveCN108192105AGuaranteed biodegradabilitySolve the melting point is too lowFlexible coversWrappersDimer acidMechanical property

The invention discloses bio-based biodegradable multi-block copolymer as well as a preparation method and application thereof. The multi-block copolymer comprises a chain segment A and a chain segmentB; the chain segment A is fat-aromatic coplyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on C2-C36 fatty diacid and derivatives thereof, C6-C20 aromatic diacid and derivatives thereof, C2-C36 divalent alcohol, and 0.0 to 10% by weight of polyhydroxyl or polycarboxyl compound and performing condensation polymerization; the chain segment B is fatty copolyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on dimer acid and derivatives thereof, C2-C12 fatty diacid and derivatives thereof, C2-C36 divalent alcohol as well as 0.0 to 10% of polyhydroxyl or polycarboxyl compound and performing condensation polymerization. The chain segment A and the chain segment B react with a polyfunctional chain extender of polyisocyanate, a polyepoxy compound and carbodiimide which is 0.01 to 10% of the polymer to form the multi-block copolymer. The product prepared by the method has high biodegradability, mechanical property and processing property, and can be widely applied to the fields of packaging, biological medicine, medical treatment and thelike.

Owner:王肖桦

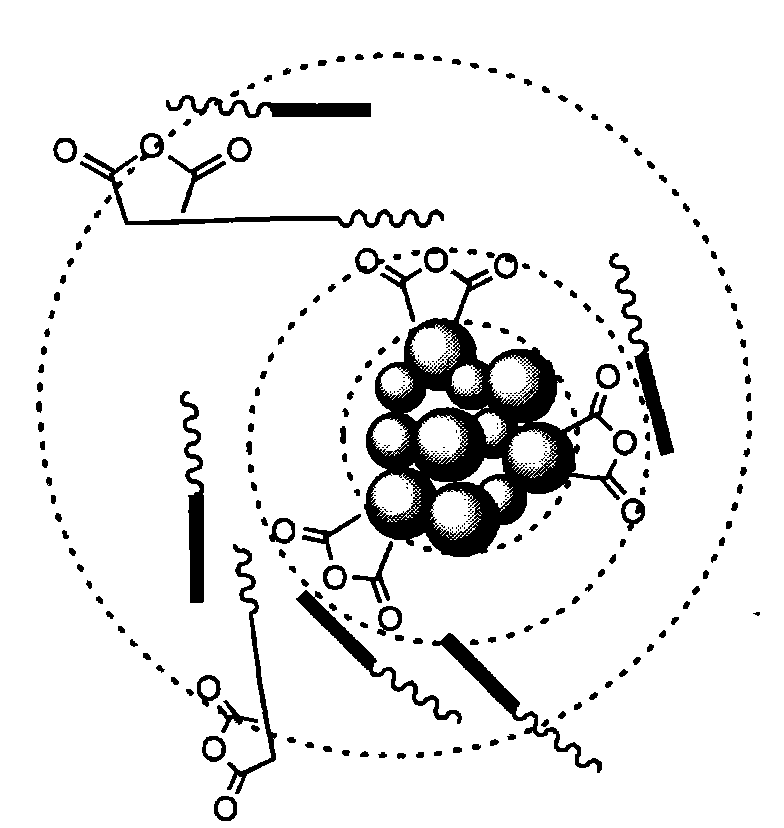

Drilling fluid additive composition application thereof and water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof

ActiveCN106634878AImprove pressure bearing capacityEnhance smoothness and densityDrilling compositionWell drillingDimer acid

The invention relates to the field of well drilling in petroleum industry, in particular to a drilling fluid additive composition application thereof and a water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof. The composition contains a plugging agent, a nano blocking agent, a shear strength improving agent, a bionic wall fixing agent and a bionic shale inhibitor, wherein the plugging agent is a weak crosslinking copolymer, the content of a crosslinking structure in the weak crosslinking copolymer is 0.1-1% by weight, the nano blocking agent is modified silicon dioxide nano-particles, the shear strength improving agent is a dimer acid-organic amine copolymer, and the bionic wall fixing agent is carboxymethyl chitosan grafted with groups deviated from dopamine on main chains. The composition can make a water-based drilling fluid added with the composition as an additive produce an excellent plugging effect in the process of plugging while drilling through the matching effect of the plugging agent, the nano blocking agent, the shear strength improving agent, the bionic wall fixing agent and the bionic shale inhibitor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

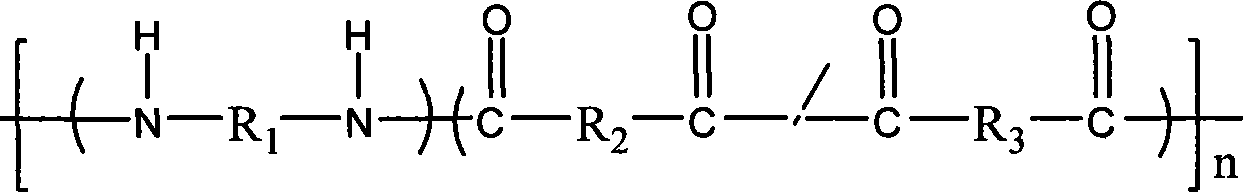

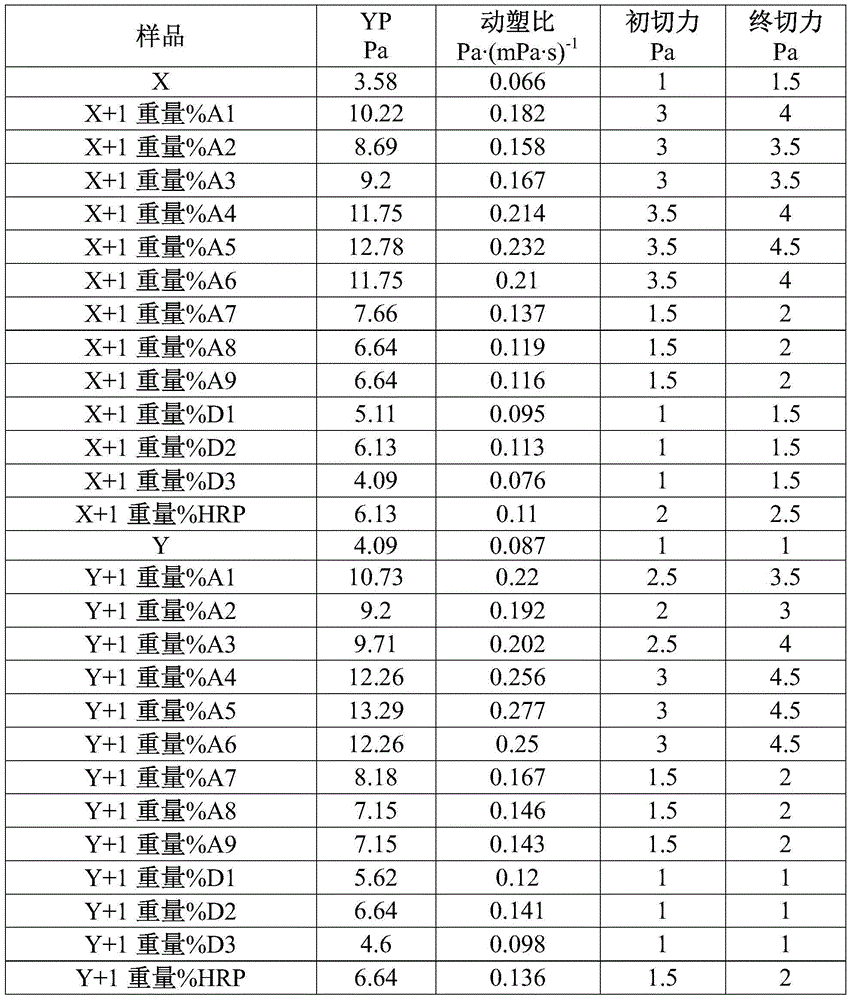

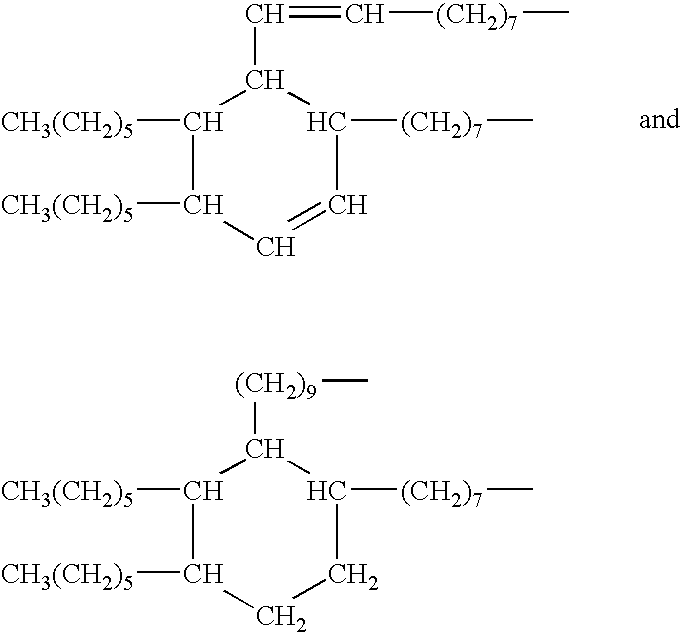

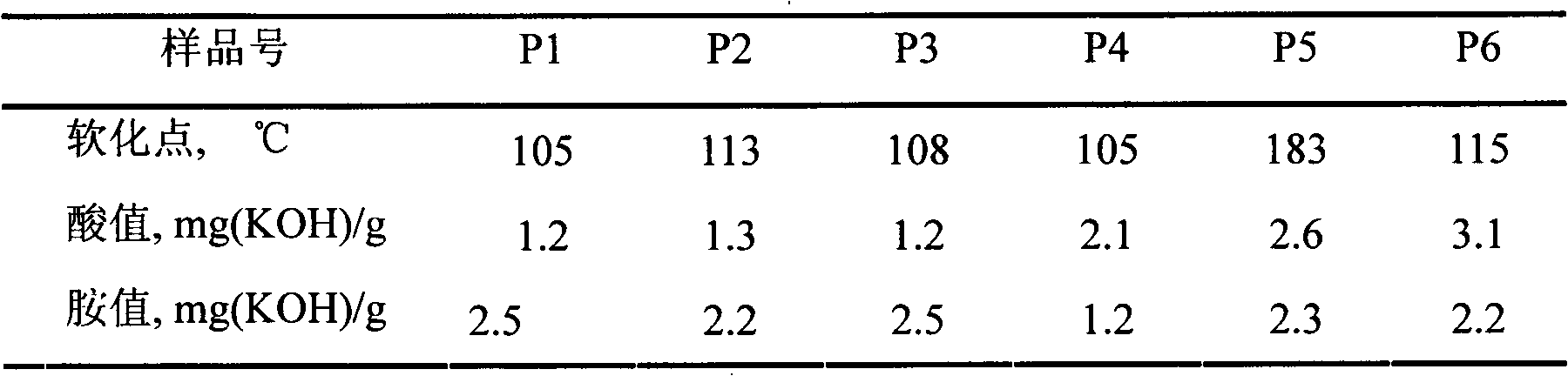

Dimer acid-organic amine copolymer, preparation method and application thereof, water-in-oil emulsified drilling fluid shear strength improving agent and drilling fluid

ActiveCN104893691AIncrease dynamic shear forceHigh ratio of dynamic plasticOrganic compound preparationCarboxylic acid amides preparationDimer acidAniline

The invention relates to a dimer acid-organic amine copolymer which comprises a structural unit from dimer acid, a structural unit from alkylamine and a structural unit from aromatic amine, wherein the dimer acid is an oleic acid-linoleic acid dimer; the alkylamine is one or more of C10-C20 alkyl primary amines, and the aromatic amine is aniline and one or more of anilines of which the benzene ring is subjected to single-point substitution or multipoint substitution by C1-C3 alkyl. The invention also relates to a preparation method of the dimer acid-organic amine copolymer, application of the dimer acid-organic amine copolymer as a shear strength improving agent, a water-in-oil emulsified drilling fluid shear strength improving agent, and a drilling fluid containing the shear strength improving agent. The shear strength improving agent provided by the invention can obviously enhance the dynamic shear force, dynamic plastic ratio and static shear force of the water-in-oil emulsified drilling fluid under the condition of lower consumption, and can be used in the water-in-oil emulsified drilling fluid which contains or does not contain organic soil.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Optical fiber with reduced attenuation loss

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

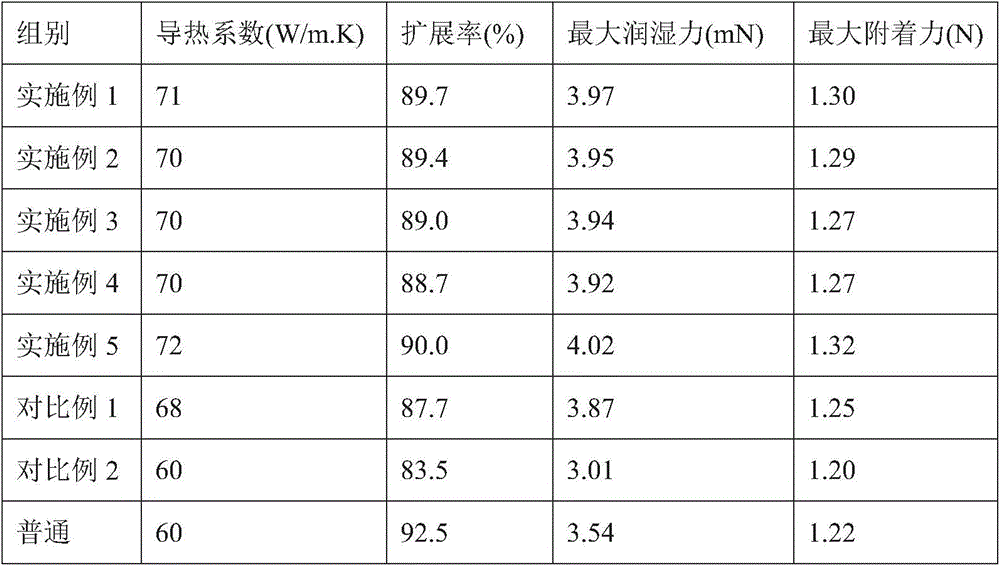

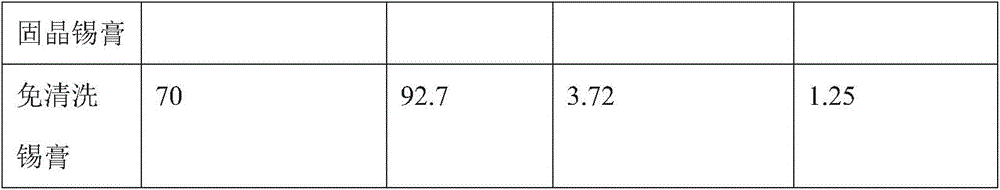

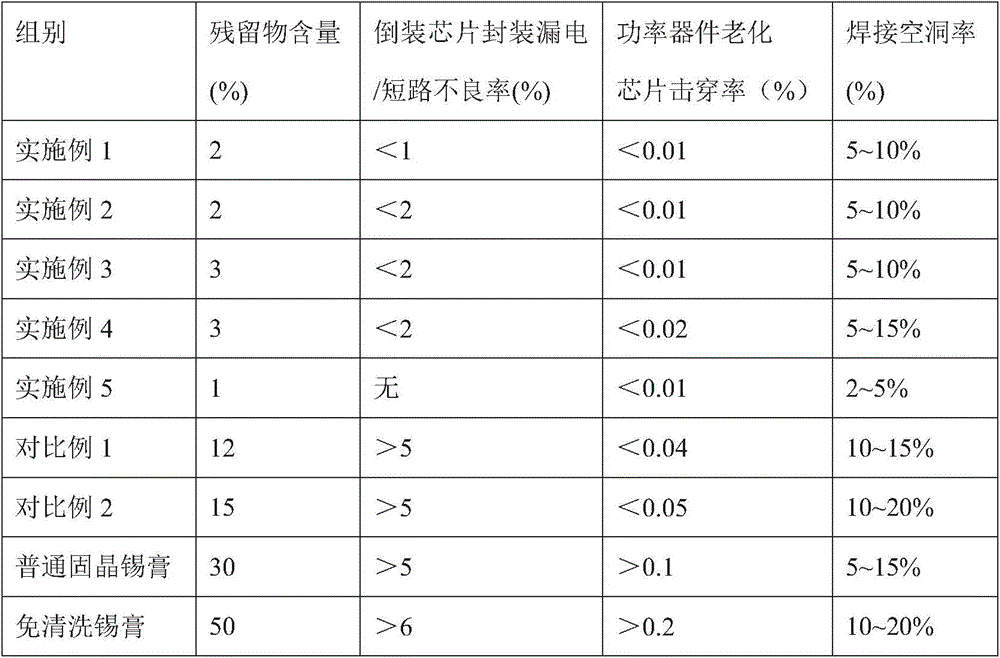

Washing chip solid crystal solder paste and preparing method thereof

ActiveCN105855749AProtectiveImprove wettabilityWelding/cutting media/materialsSoldering mediaHeat resistanceMetal alloy

The invention belongs to the field of electronic welding materials, and discloses washing chip solid crystal solder paste and a preparing method thereof. The solid crystal solder paste comprises, by weight percent, 82%-88% of metal alloy powder and 12%-18% of washing flux paste. The metal alloy powder is one of Sn96.5Ag3Cu0.5, Sn89.5Sb10Ni0.5 and SnPb92.5Ag2.5. The solid crystal solder paste comprises, by weight percent, 8%-12% of rosin resin, 40%-50% of a solvent, 5%-15% of an activating agent, 4%-12% of polymine, 4%-8% of dimer acid and 10%-15% of a surface active agent. By means of the solid crystal solder paste, the packaging yield and reliability of high-precision LED flip chips can be obviously improved, by means of the washing technology, active residues are avoided, welding spots are full and bright, the void content and heat resistance are low, and electric conductivity is high.

Owner:深圳市晨日科技股份有限公司

Oil base and external preparation containing same

ActiveUS20070269470A1Appropriate hardnessAppropriate spreadabilityCosmetic preparationsBiocideGlycerolHydroxystearic Acid

[Problems to be Solved] To provide an oil base having appropriate hardness and viscosity and excellent spreadability, a process for producing same, and a cosmetic material containing the oil base [Solution means] The oil base of the present invention is an oil base containing an ester condensate obtained by a reaction between polyglycerol, 12-hydroxystearic acid, and hydrogenated dimer acid, the oil base having a three-dimensional network structure in which hydrogenated dimer acid is condensed with a hydroxyl group of each of the polyglycerol and 12-hydroxystearic acid.

Owner:KOKYU ALCOHOL KOGYO

Preparation method of dimer acid type polyester polyol

InactiveCN103113560AEasy to operateHigh yieldPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyesterDimer acid

The invention provides a preparation method of dimer acid type polyester polyol, belonging to the technical field of esterification polymerization in oil chemistry. The method comprises the following steps of: carrying out esterification polymerization reaction in the presence of an organic catalyst under the protection of nitrogen based on long-chain dimer acid of binary acid and dihydric alcohol as main raw materials; and further carrying out vacuum dehydration and demonomerization to obtain dimer acid type polyester polyols of different specifications, wherein the acid value is lower than 1mgKOH / g, and the number-average molecular weight is lower than 1,300-3,000. The preparation method provided by the invention has the characteristics of easy technical operation, high product yield, stable product quality and low operation cost.

Owner:江苏永林油脂科技有限公司

Waste rubber powder modified epoxy asphalt material and preparation method thereof

InactiveCN102516783AEnhance high and low temperature crack resistanceImprove fatigue resistanceWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsWaste rubberDimer acid

The invention discloses a waste rubber powder modified epoxy asphalt material and a preparation method thereof. The epoxy asphalt material consists of two components A and B, wherein the component A consists of 90 to 120 mass parts of modified asphalt with carboxyl or acid anhydride group, 5 to 10 mass parts of aliphatic dibasic acid, dimer acid or alcohol acid resin, 0.1 to 5 mass parts of aliphatic acid anhydride and 5 to 15 mass parts of waste rubber powder; and the component B is epoxy resin. The mass ratio of the component A to the component B is (8-13): 1. The material has good high and low-temperature mechanical property. The epoxy asphalt is modified by adding the waste rubber, so that the low-temperature performance of the epoxy asphalt is improved, and the production cost of the epoxy asphalt is reduced; and waste tyres are utilized, so that environmental pollution is reduced. The material can be used as a renewal and replacement material for paving roads and bridges, and is suitable for occasions of expressways, cement viaducts, urban trunks and the like.

Owner:SOUTHEAST UNIV

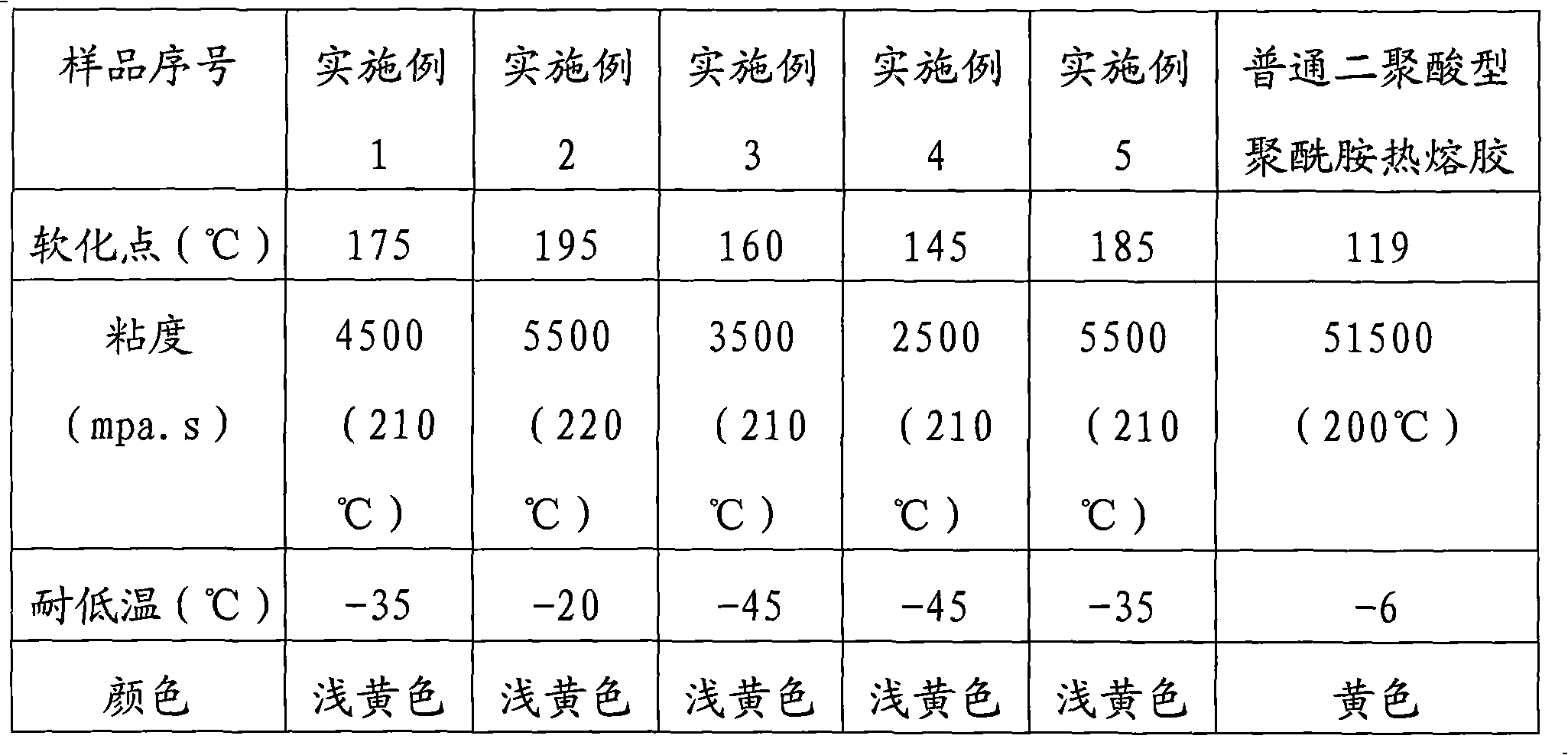

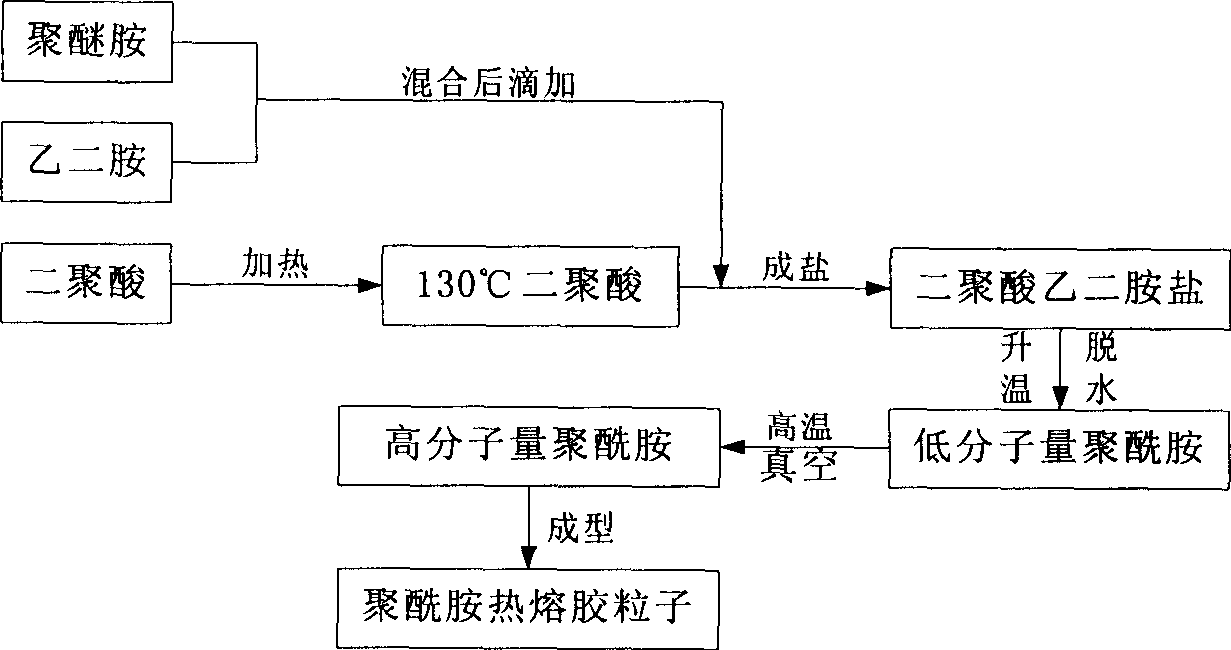

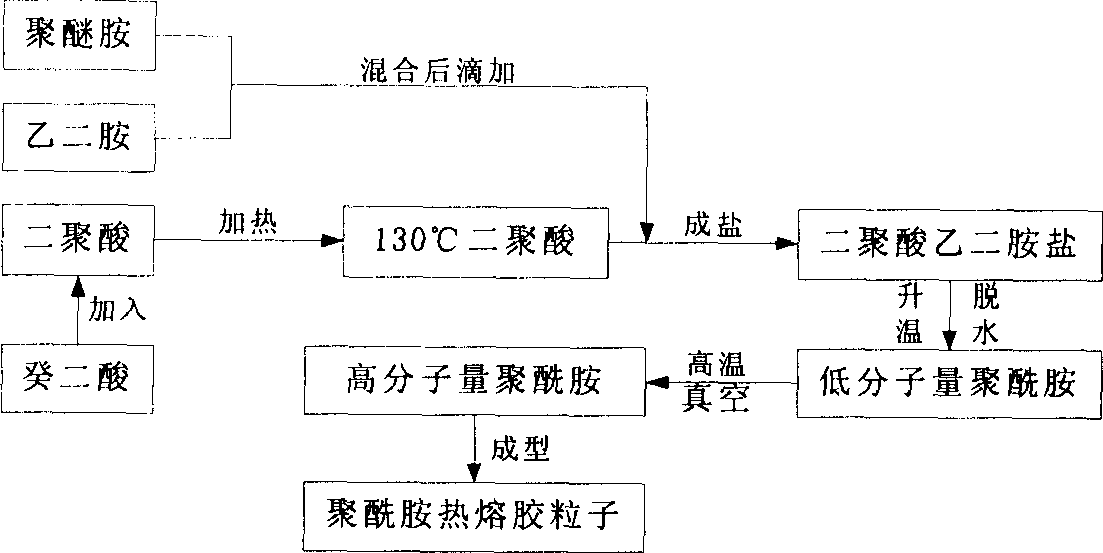

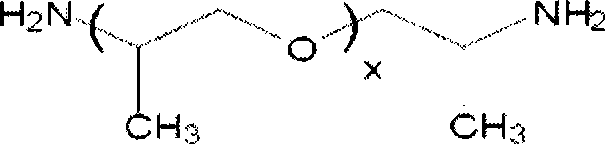

Low-viscosity dimer acid type polyamine hot melt adhesive and preparation method thereof

InactiveCN101962526AReduce high temperature viscosityLow water absorptionNon-macromolecular adhesive additivesAntioxidantNitrogen

The invention relates to a low-viscosity dimer acid type polyamine hot melt adhesive and a preparation method thereof. The hot melt adhesive consists of the following raw materials in percentage by mole: 55 to 95 percent of dimer acid, 5 to 45 percent of aliphatic dibasic acid, 60 to 95 percent of aliphatic diamine, 5 to 40 percent of polyoxypropylene polyamine, 0.1 to 5 percent of molecular weight regulator, and the balance of water and antioxidant, wherein the dosage of the water accounts for 1 to 30 percent of the total mass of the acide and the amine; and the dosage of the antioxidant accounts for 0.1 to 2 percent of total mass of the acid and the amine. The preparation method comprises the following steps: salifying in the protection of nitrogen by using the dimer acid, the aliphatic dibasic acid and the diamine, the antioxidant and the molecular weight regulator as raw materials and introducing proper water at early stage; and heating and polycondensating. The polyamine hot melt adhesive has high and low temperature resistance, low high-temperature viscosity and simple molding process, and is mainly applied in automobile and electronic industries.

Owner:YANTAI DARBOND TECH

Epoxy glue powder asphalt material and preparation method thereof

InactiveCN102796387AGood compatibilityGood flexibility at low temperatureBuilding insulationsElastomerFirming agent

The invention relates to an epoxy glue powder asphalt material and a preparation method thereof. A macromolecular curing agent, a rubber elastomer, a plasticizer and the like are used for improving the flexibility of the cured epoxy resin so as to improve the low-temperature performance of the epoxy resin curing material, but the epoxy asphalt is easy to separate caused by low compatibility of the macromolecular compound, the rubber elastomer and the asphalt. The preparation method comprises the following steps: soaking rubber particles into the hydrolysate of a silane coupling agent to obtain a surface and interface activated rubber particle curing agent, adding into the matrix asphalt, cutting, cooling, adding modified asphalt, plasticizer, aliphatic dibasic acid, dimer acid or alkyd resin and fatty acid anhydride and obtaining an epoxy asphalt component B under the action of a shearing and emulsifying machine; and mixing and stirring the epoxy asphalt component A namely the epoxy resin and the epoxy asphalt component B to obtain the activated rubber particle modified epoxy asphalt material. According to the invention, the low-temperature flexibility of the epoxy asphalt is obviously improved; and a large amount of activated rubber particles are added, so the cost of the epoxy asphalt is greatly reduced.

Owner:黄卫 +2

Polyacetal resin composition

A polyacetal resin composition comprises a polyacetal resin, and at least one carboxylic acid hydrazide selected from a saturated or unsaturated long-chain aliphatic carboxylic acid hydrazide, a saturated or unsaturated alicyclic carboxylic acid hydrazide, a dimer acid or trimer acid hydrazide, and an oxycarboxylic acid hydrazide corresponding to each of these hydrazides. The proportion of the carboxylic acid hydrazide may be about 0.001 to 20 parts by weight relative to 100 parts by weight of the polyacetal resin. The polyacetal resin composition may further comprise at least one member selected from an antioxidant, a heat stabilizer, a processing stabilizer, a weather (light)-resistant stabilizer, an impact resistance improver, a slip-improving agent, a coloring agent, and a filler. With the use of such a resin composition, stability of a polyacetal resin is improved, and formaldehyde emission is inhibited.

Owner:POLYPLASTICS CO LTD

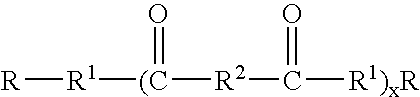

Capped dimer acid polyesters in personal care applications

InactiveUS6800275B1Decreased critical micelle concentrationImproved skin depositionCosmetic preparationsHair cosmeticsPolyesterPersonal care

The present invention is directed to a series of polyester compounds made from the reaction of (a) a difunctional hydroxy compound, specifically polyoxyalkylene glycols, (b) a difunctional carboxylic acid, specifically dimer acid and hydrogenated dimer acid, and (c) a capping carboxylic acid, which only contains one acid group. These compounds are very well suited to the preparation of products for the personal care market.

Owner:T C U S A

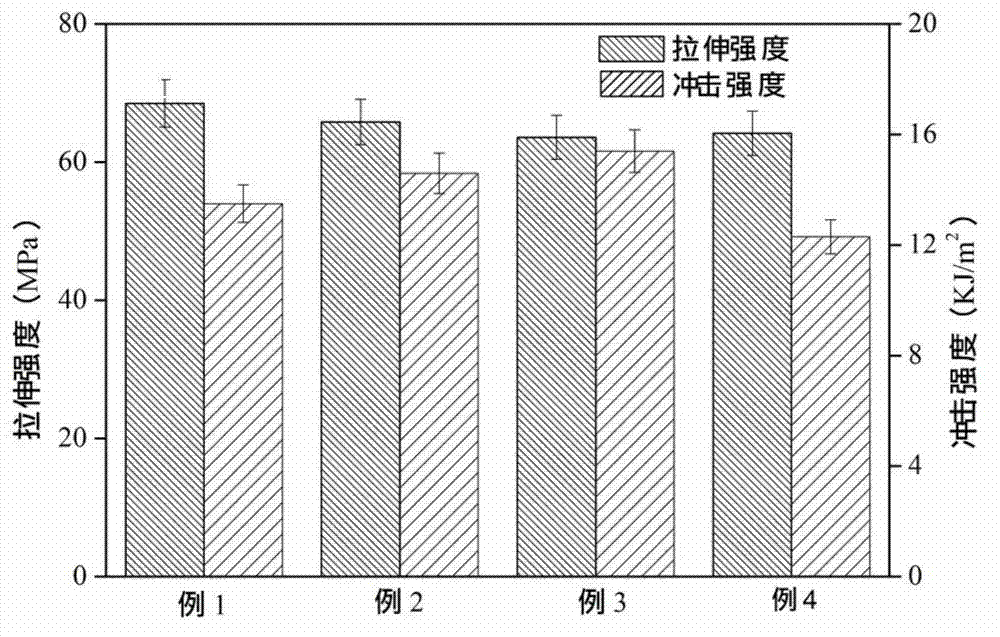

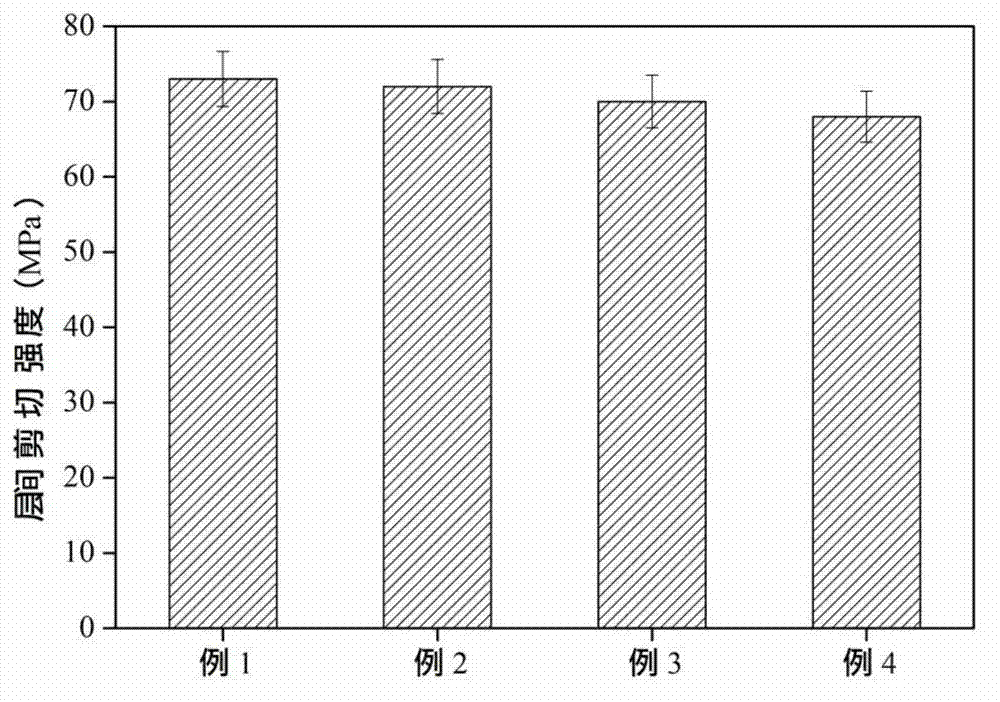

Preparation method of dimer acid modified epoxy resin toughened carbon fiber prepreg

The invention provides a preparation method of a dimer acid modified epoxy resin toughened carbon fiber prepreg, which comprises the following steps: by taking a component of which the molecular structure is similar to that of a carbon fiber sizing agent as toughener, preparing a dimer acid modified epoxy resin through a pre-reaction method; adding reactants into the mixed epoxy resin, adding a latent curing agent, and evenly mixing to obtain a resin system for the prepreg; and coating the resin system through a film coating machine, and then compounding with carbon fibers or a fabric made therefrom to prepare the moderate-temperature curing prepreg having fine operability and adhesivity. Compared with the traditional rubber toughened prepreg, the invention can enhance the wettability of the resin system on carbon fibers, reduce the moisture permeability of the prepreg and simultaneously improve the toughness and impact resistance of the composite material, thus being suitable for manufacturing of a prepreg for winding formation.

Owner:中威北化科技有限公司

Method for synthesizing dimer acid type polyamide hot melt adhesive

The invention discloses a method for synthesizing a dimer acid type polyamide hot melt adhesive. The polyamide hot melt adhesive is prepared by adding a catalyst, an aqueous solution of alcohol and an aid into monomers of dimer acid, aliphatic dicarboxylic acid and aliphatic diamine which are taken as reaction raw materials and performing condensation reaction. The method is easy to operate, the loss of amine in the reaction process is low, and the chemical equivalent can be controlled easily, so that the reaction is more complete, and finally a product with stable high molecular weight can be obtained; meanwhile, the deviation among different batches of products can also be improved, so that the product can be stably produced.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Low temperature resistant polyamide thermosol adhesive and use thereof

The present invention provides a low-temperature polyamide hot-melt adhesive. The present invention contains unsaturated aliphatic dimer acid polymeric unit and polyamine polymeric unit; wherein, the polyamine polymeric unit contains 50 to 90 mol percent of C2-8 aliphatic diamine polymeric unit and 5 to 50 mol percent of polyether polyamine polymeric unit; the total mol number of polyamine polymeric unit is taken as the benchmark. The polyamide hot-melt adhesive provided by the present invention has excellent low temperature resistance and extensibility, and is especially suitable for automobile industry.

Owner:SHANGHAI LIGHT IND RES INST +1

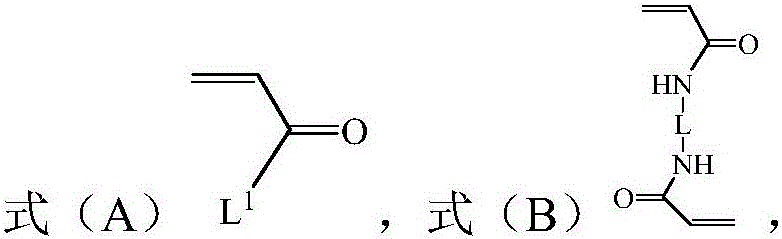

Dimer Acid-Derived Dimethacrylates and Use in Dental Restorative Compositions

ActiveUS20080318188A1Speed up the conversion processLow shrinkageImpression capsOrganic chemistryMeth-Dimer acid

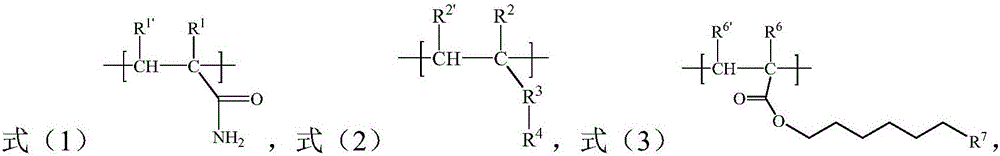

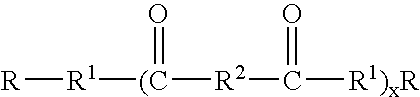

The present invention provides polymerizable dental compositions comprising a dimer acid-derived monomer such as a dimer acid-derived di(meth)acrylate monomer. In one embodiment, the dimer acid-derived monomer is of the formula (I): wherein R1, R2, R3, R4, R5 and R6 are independently selected from H and optionally substituted C1-C25 straight-chained or branched aliphatic, optionally containing 1 or more double or triple bonds, wherein one or more carbons are optionally replaced by R* wherein R* is —C(O)—, —C(O)C(O)—, —C(O)NR7—, —C(O)NR7NR8—, —C(O)O—, —OC(O)—, —NR7CO2—, —O—, —NR7C(O)NR8—, —OC(O)NR7—, —NR7NR8—, —NR7C(O)—, —NR7C(O)O—, —S—, —SO—, —SO2—, —NR7—, —SO2NR7— or —NR7SO2—, where R7 and R8 are independently selected from H and optionally substituted aliphatic, cycloalkyl, heterocycloalkyl, aryl or heteroaryl; provided that at least two of R1, R2, R3, R4, R5 and R6 are substituted C1-25 straight-chained or branched aliphatic wherein at least one carbon is replaced by R* and at least one of the substituents is an alkenyl group.

Owner:UNIV OF COLORADO THE REGENTS OF

Preparation method of papermaking wet strength agent

ActiveCN105085906AVolatileLow boiling pointReinforcing agents additionPaper/cardboardRoom temperatureWet strength

The invention discloses a preparation method of a papermaking wet strength agent. The preparation method comprises the following steps: (1) carrying out polymerization reaction on polyamine, adipate, dimer acid and a catalyst under a heating condition, so as to obtain a polyamide polyamine prepolymer water solution; and (2) adding water, a cationic etherifying agent and epoxy chloropropane into the prepolymer water solution to react at the room temperature, heating to react, and finally adding acid to regulate the pH value, so as to obtain the papermaking wet strength agent with the solid content of 15%-35%. The papermaking wet strength agent has the advantages that the polymerization process is mild, stable and controllable, the gelling of the product caused by overreaction is basically avoided, and the solid content is relatively high; the reaction of monomers is complete; and the product is high in polymerization degree, good in adhesive property, good in quality effect, relatively low in curing temperature, easy to cure, and good in water resistance.

Owner:GUANGDONG PAPER IND RES INST

Normal temperature solidified thermosetting epoxy bitumen material and preparation method thereof

InactiveCN102532924AFast deliveryExpress trafficBuilding insulationsBituminous materialsFirming agent

The invention provides a normal temperature solidified thermosetting epoxy bitumen material. The normal temperature solidified thermosetting epoxy bitumen material consists of a part A and a part B and is obtained by respectively evenly mixing the part A and the part B, then evenly mixing the part A with the part B and subsequently solidifying at the temperature of 0-60 DEG C, wherein the part A comprises the following components in parts by mass, 25-80 parts of dimer acidic diglycidyl ester and 20-50 parts of epoxy diluting agent; and the part B comprises the following components in parts by mass: 50-300 parts of bitumen and 28-100 parts of organic amine solidifying agent. According to the invention, the part A and the part B are respectively evenly stirred through a colloid mill and then blended and evenly stirred at normal temperature, and finally the mixture is solidified for 1-12 hours at the normal temperature, so as to obtain the thermosetting epoxy bitumen material; the bitumen material can be rapidly solidified at the normal temperature to form a high-strength high-flexibility thermosetting material in no need of complex construction equipment, thus work efficiency is improved, the volatilization of harmful substances in the bitumen is reduced, and the bitumen material provided by the invention is energy-saving and environment-friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

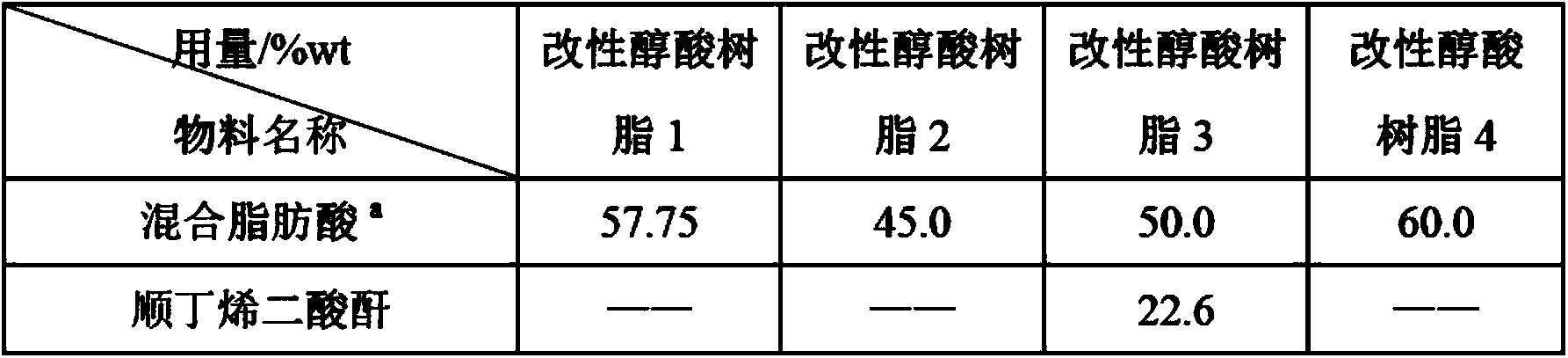

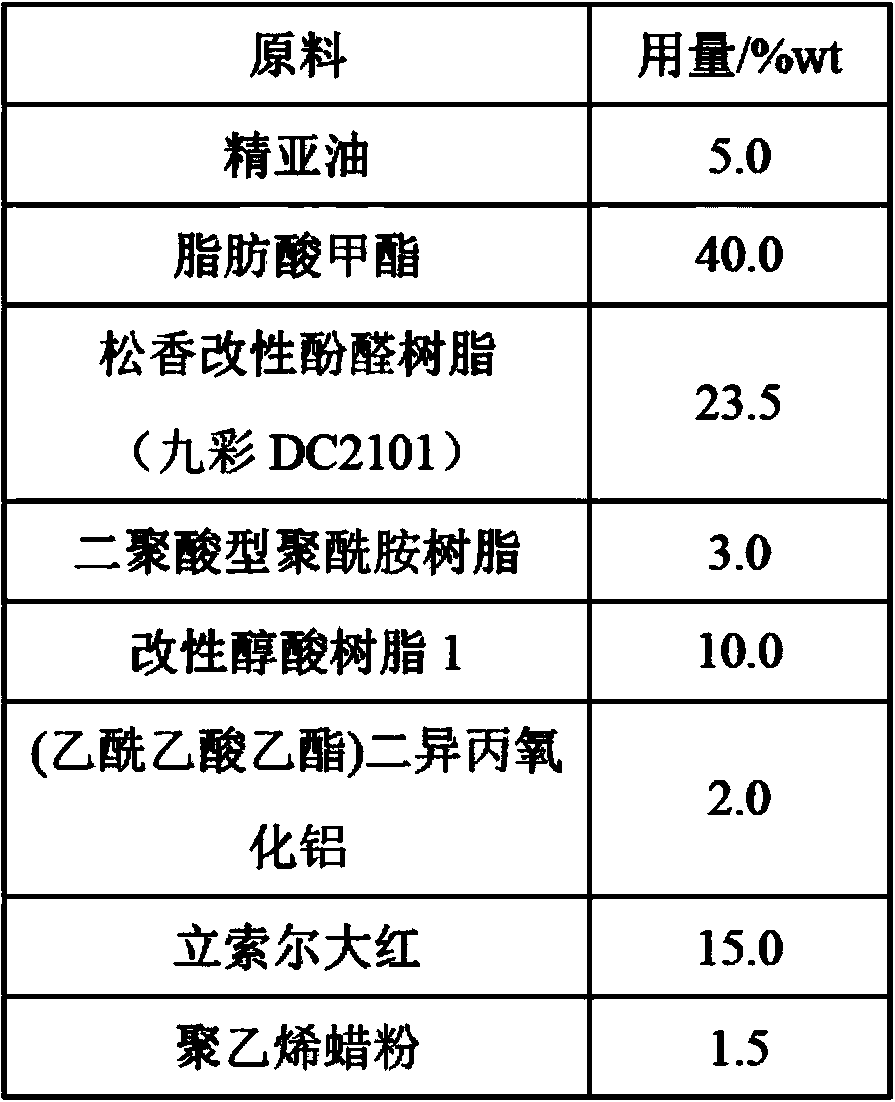

Stereoscopic offset printing ink prepared by using waste vegetable oil foots as well as preparation method and application of stereoscopic offset printing ink

The invention discloses stereoscopic offset printing ink prepared by using waste vegetable oil foots. The stereoscopic offset printing ink is prepared from the following raw materials: linolin, fatty acid methyl ester, a rosin modified phenolic resin, a dimer acid polyamide resin, a modified alkyd resin, aluminum gel, pigments, fillers and wax powder. The method for preparing the printing ink comprises the following steps: (1) weighing the linolin, rosin modified phenolic resin, dimer acid polyamide resin, modified alkyd resin and fatty acid methyl ester, raising the temperature until the resins are dissolved, raising the temperature again, and preserving the heat, thereby obtaining a resin linkage material; and (2) adding the pigments, fillers and aluminum gel, uniformly dispersing, grinding, adding the wax powder, and uniformly dispersing. The waste vegetable oil foots are taken as raw materials, the fatty acid methyl ester, is prepared, the wastes are changed into valuable materials, and the waste vegetable oil foots serve as solvents, so that the problems of plant oil base printing ink are solved. Meanwhile, an alkyd resin is synthesized by taking the waste vegetable oil foots as raw materials, the formula is adjusted, the drying speed of the printing ink is controlled, and the printing ink can be used for paper printing and film printing.

Owner:海盐华达油墨有限公司

Polyester polyols from thermoplastic polyesters and dimer fatty acids

ActiveUS20150344622A1Nice appearanceDesirable hydroxyl numberOrganic compound preparationPreparation by ester-hydroxy reactionPolyesterPolyurethane dispersion

Polyester polyols made from thermoplastic polyesters are disclosed. The polyols can be made by heating a thermoplastic polyester such as virgin PET, recycled PET, or mixtures thereof, with a glycol to give a digested intermediate, which is then condensed with a dimer fatty acid to give the polyol. The invention includes a polyester polyol comprising recurring units of a glycol-digested thermoplastic polyester and a dimer fatty acid. The polyester polyol can also be made in a single step by reacting the thermoplastic polyester, glycol, and dimer acid under conditions effective to produce the polyol. High-recycle-content polyols having desirable properties and attributes for formulating polyurethane products, including aqueous polyurethane dispersions, can be made. The polyols provide a sustainable alternative to bio- or petrochemical-based polyols.

Owner:RESINATE MATERIALS GRP

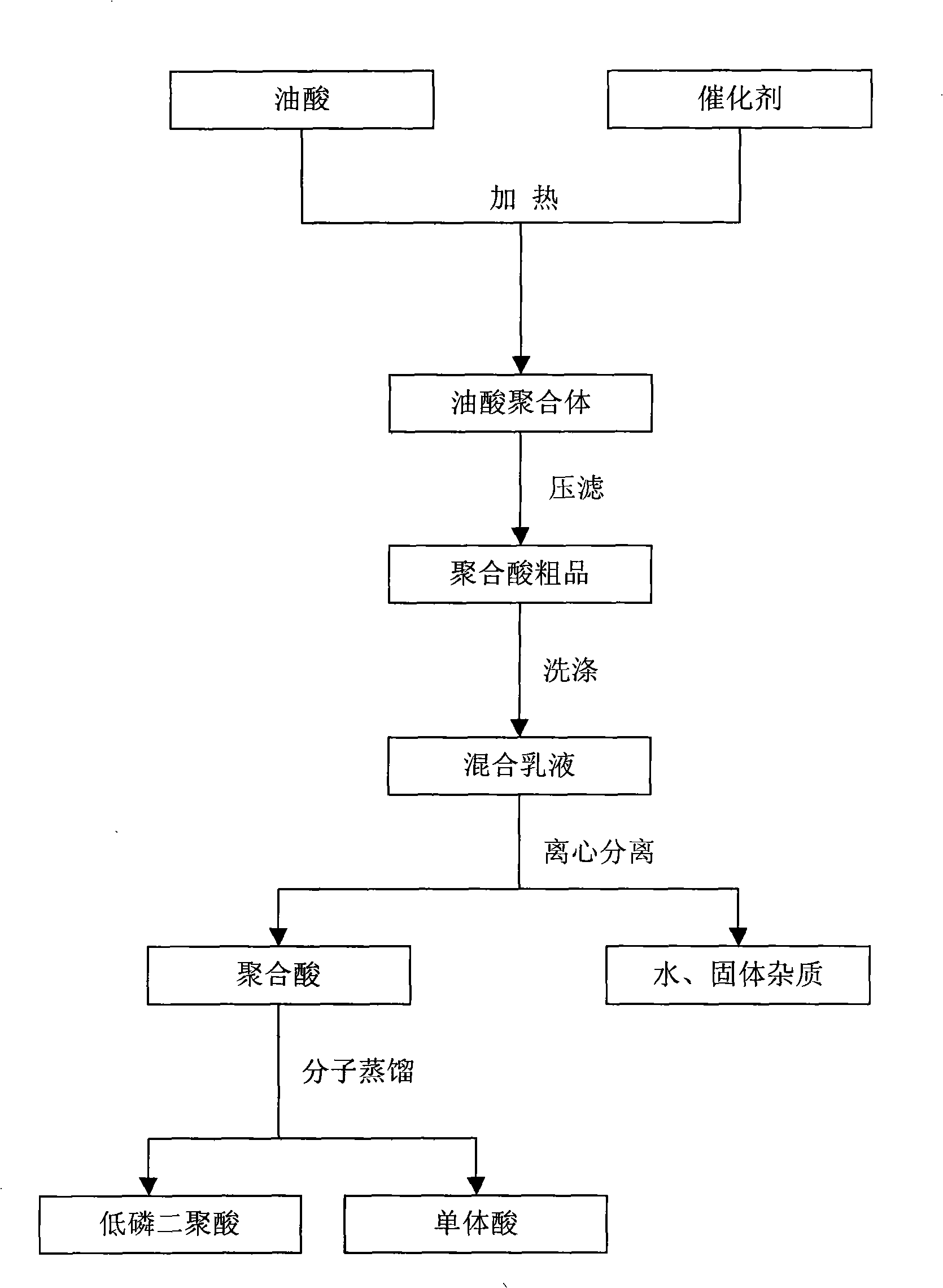

Method for producing low-phosphor dimer acid

ActiveCN101492358AImprove qualityContinuous separationOrganic compound preparationCarboxylic compound separation/purificationDistillationPhosphate

The invention relates to a method for producing low-phosphorous dimer acid and provides a method for producing dimer acid with low phosphor content. The method is characterized in that oleic acid is polymerized by catalysts of carclazyte, phosphoric acid and the like to obtain crude polymerized acid; the crude polymerized acid is washed by water; a centrifugal separation device is used for separating the polymerized acid from the water continuously to remove excessive phosphate and other filtered solid impurity to obtain low-phosphorous polymerized acid. The washing condition is as follows: the proportion of the polymerized acid and water (W / W) is 1: 0.1-10; the washing temperature is 10 DEG C to 100 DEG C; and the washing time is 0.1h to 3h. Molecular distillation is carried out on the low-phosphorous polymerized acid to obtain the low-phosphorous dimer acid and a side product of monomer acid. The invention increases the working procedures of washing and separating, thereby ensuring that the content of the phosphate of the dimer acid is reduced to be lower than 30mu g / g, reducing the content of the impurity in the dimer acid and improving the quality of the dimer acid and the downstream product.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

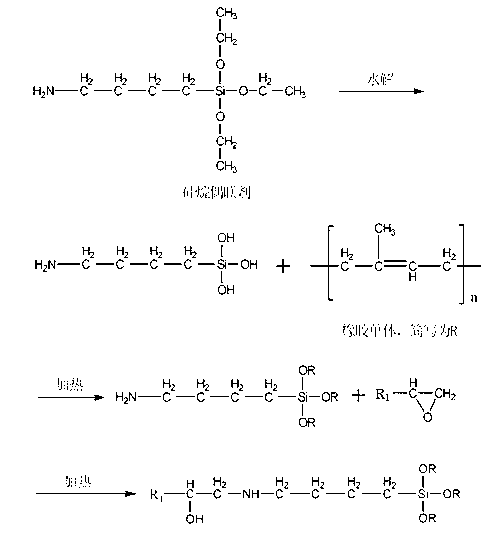

Self-repairing polymer material as well as preparation method and application thereof

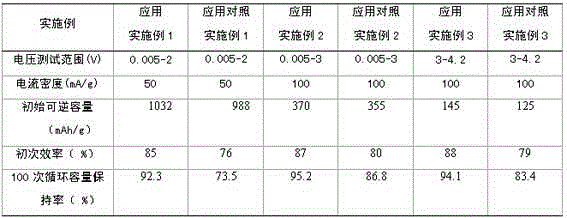

InactiveCN104559173AGood adhesivenessIncrease contactNon-macromolecular adhesive additivesCell electrodesElectrical batteryAdhesive

The invention discloses a self-repairing polymer material as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out reaction on dimer acid and diethylenetriamine for 24h under argon atmosphere to obtain an M-NH2 branched oligomer, wherein the temperature is controlled to be 160 DEG C, and the rotational speed is controlled to be 300-500r / min; and then mixing the M-NH2 branched oligomer and urea according to the mass ratio of the M-NH2 branched oligomer to the urea of 75:1, and sequentially mixing for 2h at the temperature of 130 DEG C, 1h at the temperature of 135 DEG C and 1h at the temperature of 140 DEG C to obtain the yellow colloidal self-repairing polymer material. According to the self-repairing polymer material as well as the preparation method and the application thereof disclosed by the invention, the raw material used in preparation is low in cost and wide in source, so that the preparation cost is low; when being used as an adhesive used for preparation of anode and cathode pieces of a lithium ion battery, the self-repairing polymer material is capable of effectively preventing separation of an active material and a current collector, and the prepared anode and cathode pieces of the lithium ion battery have the advantages of long cycle life and good safety.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com