Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272results about How to "Good flexibility at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

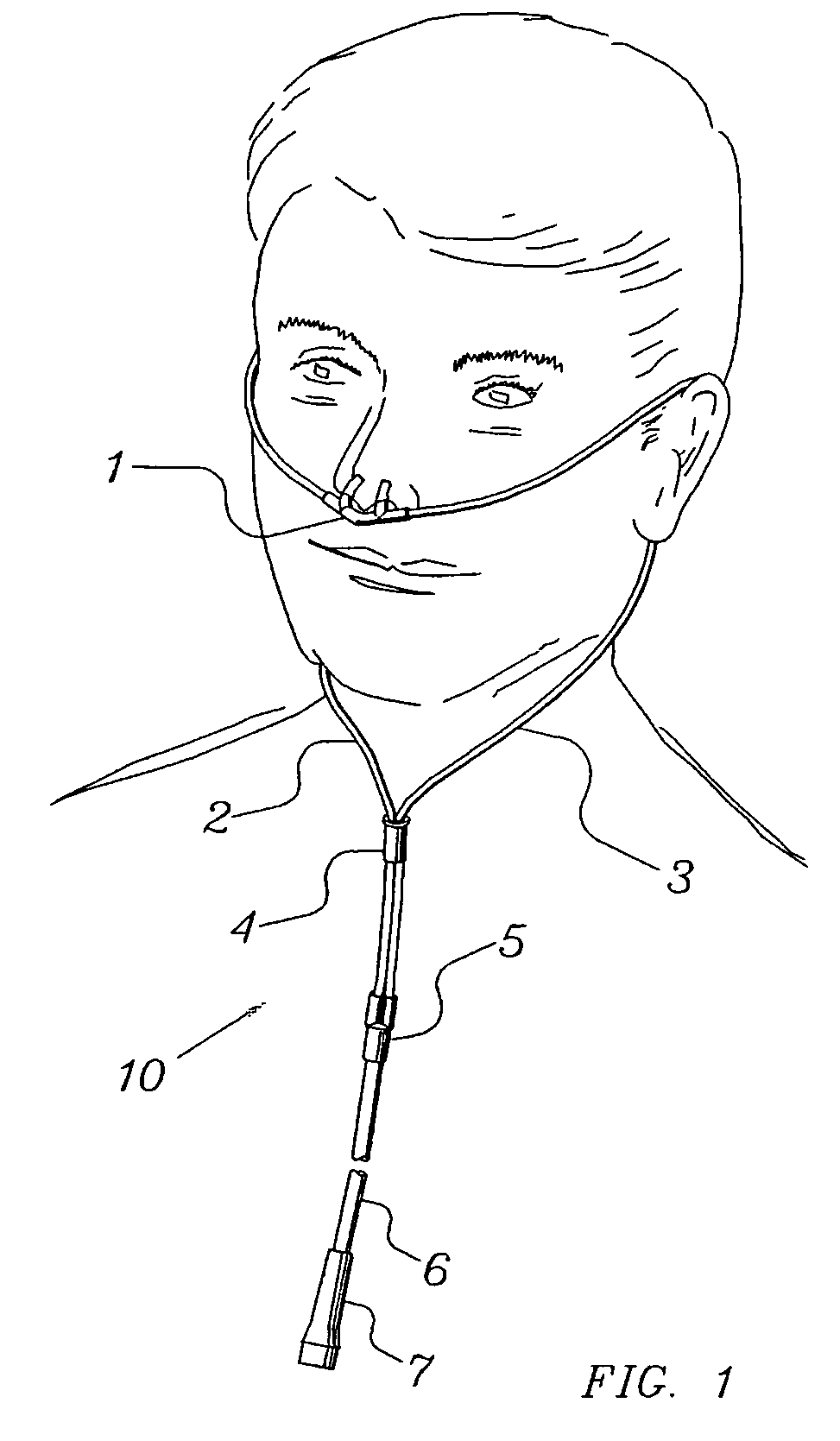

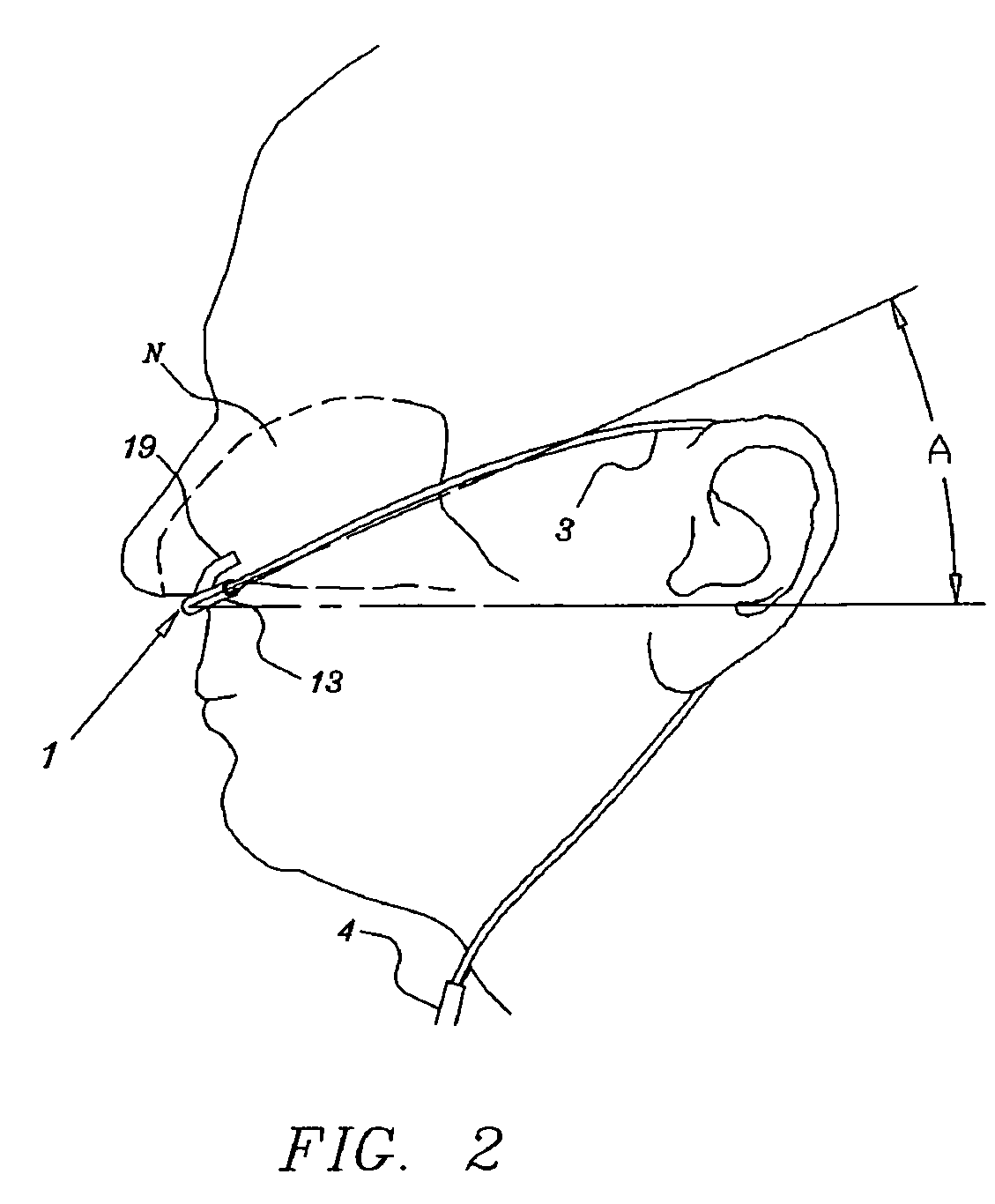

Nasal cannula assembly

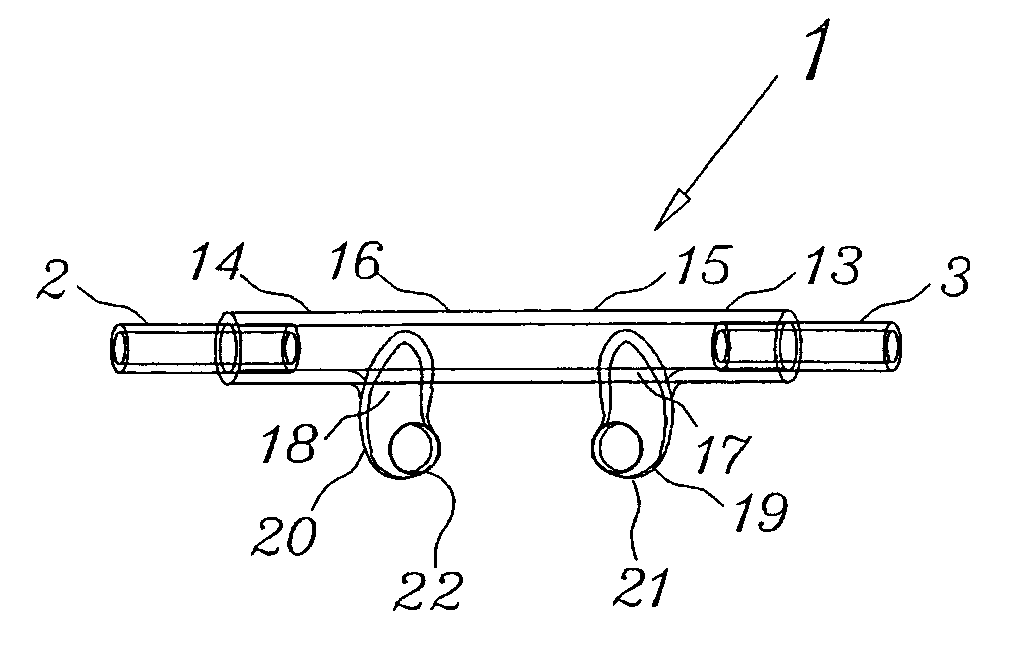

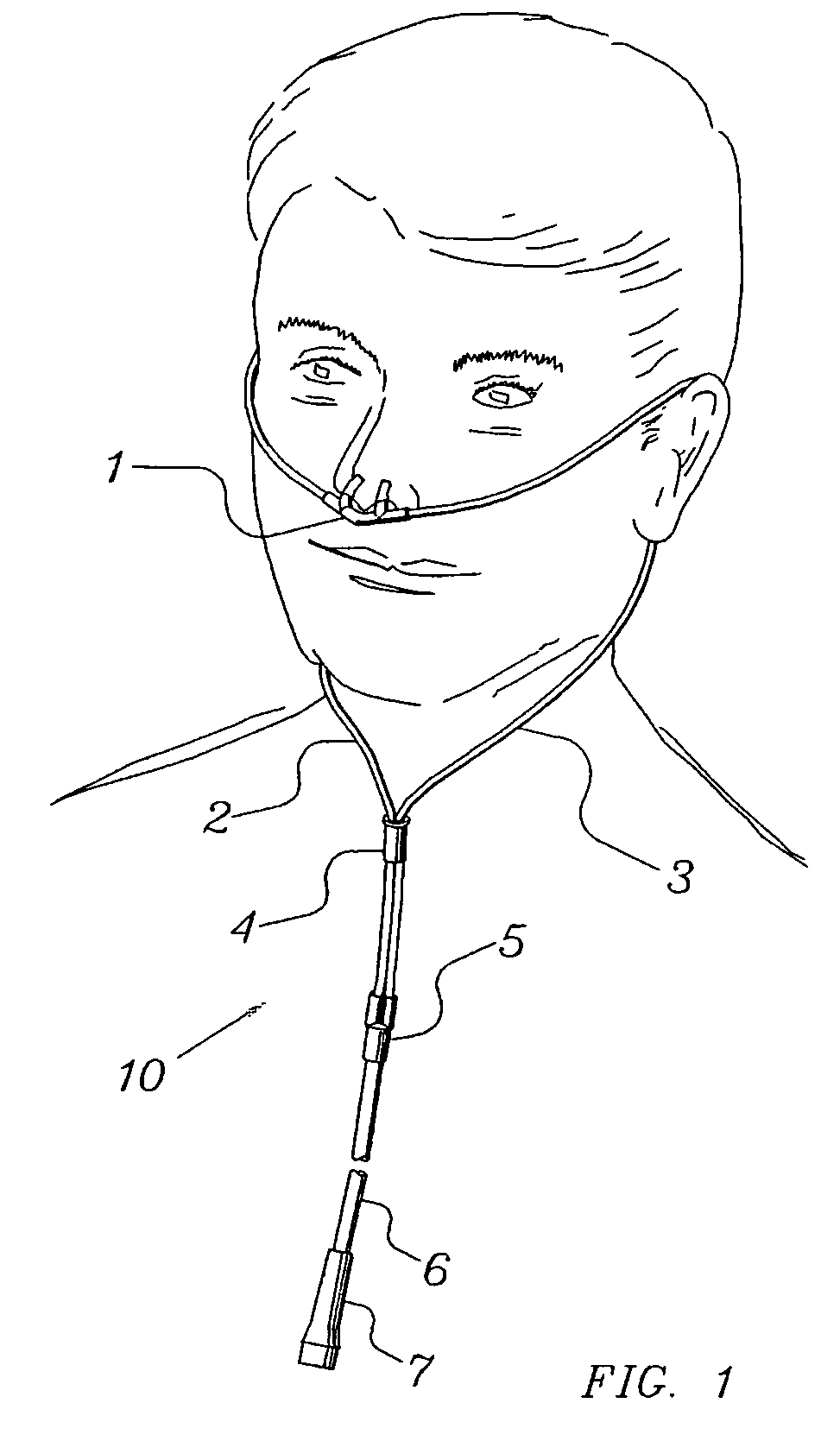

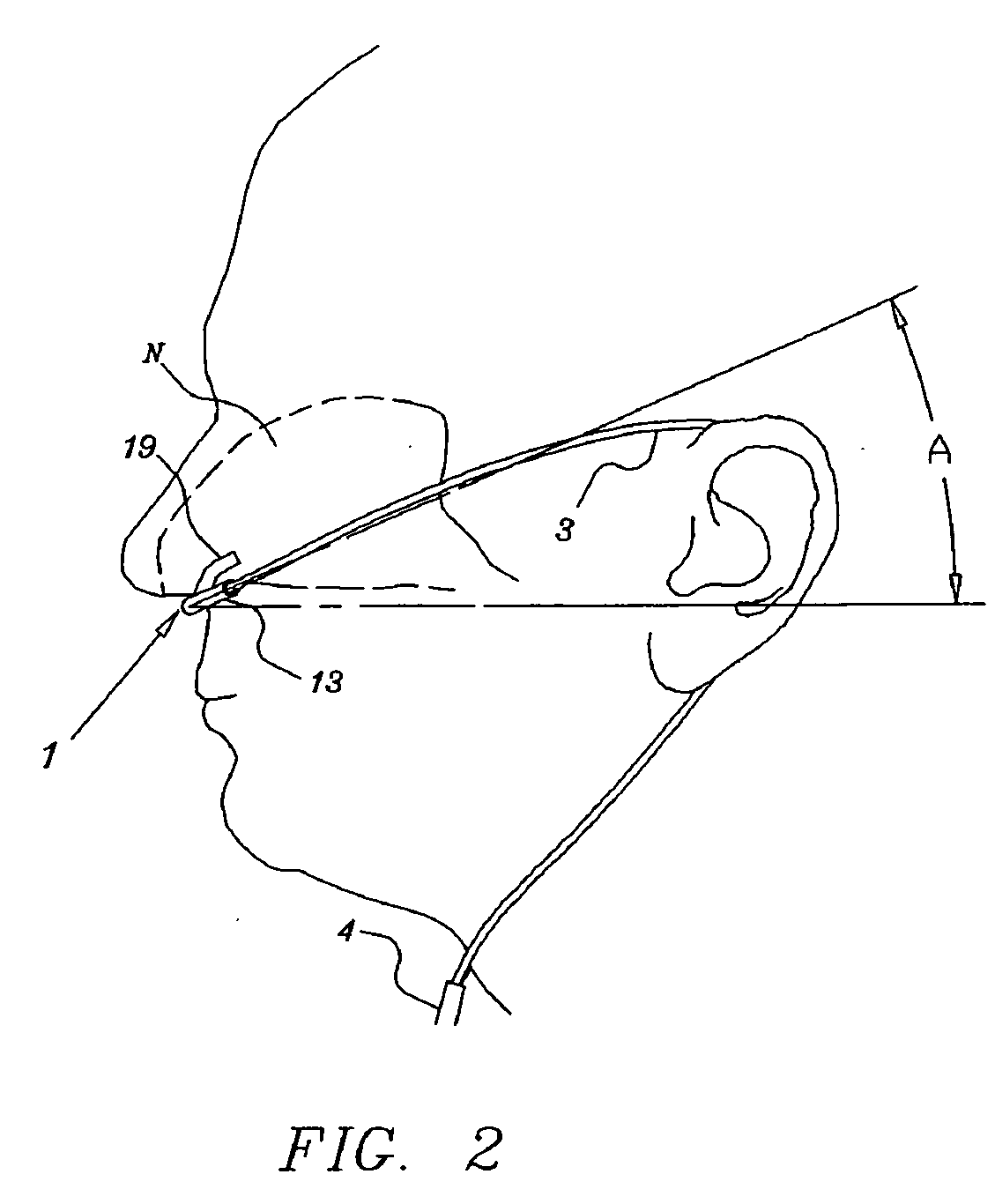

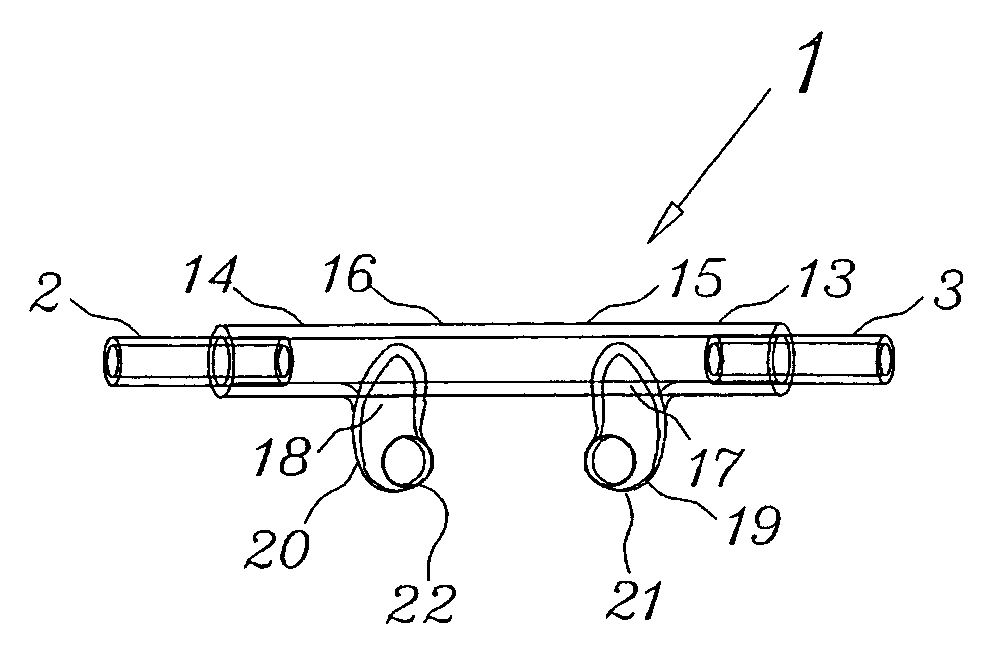

A nasal cannula assembly designed for contact with the nasalabidial area of a patient's face comprising a nasal cannula, a pair of oxygen supply tubes connected to opposite ends of the nasal cannula and a main oxygen supply line. The nasal cannula is made of a flexible plastic material molded into a light-weight hollow tubular member having a main body portion formed at an acute angle in the center and having a pair of spaced exterior orifices projecting from the body at an angle and curved upwardly and inwardly for directing gas flow into a patient's nostrils. Attachment points for oxygen supply tubes are above center of gravity of the nasal cannula to make it self-righting thus eliminating need for stiff supply tubing to orient cannula. Oxygen supply tubes made from ultra-high molecular weight PVC possess superior flexibility and low compression set so that little tension on the tubing is required to hold cannula in proper position. A main oxygen supply line made from ultra-high molecular weight PVC resists the formation of twisted loops that tend to block oxygen flow.

Owner:THOMPSON PAUL S

Nasal cannula assembly

A nasal cannula that combines extremely flexible tubing and a novel vee-shaped nosepiece that fits the contour of the face and provides a stable footing and is self-righting because more than half its weight is below the tubing attachment points. Gas delivery prongs are molded at an angle relative to the body to direct gas into the center of the nostrils. The tubing is made from ultra-high molecular weight PVC resin with hardness between 40 and 75 Shore A.

Owner:THOMPSON PAUL S

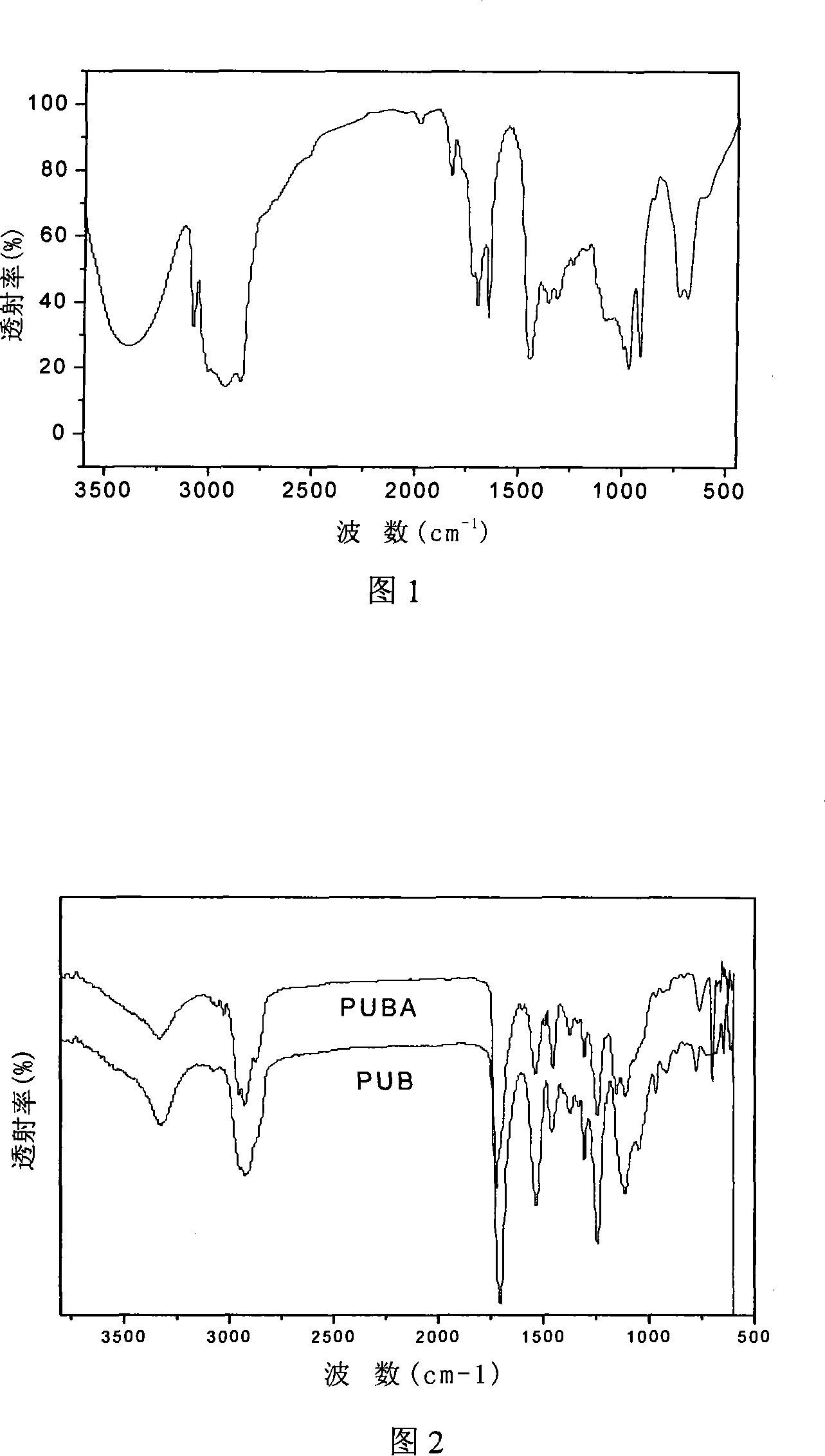

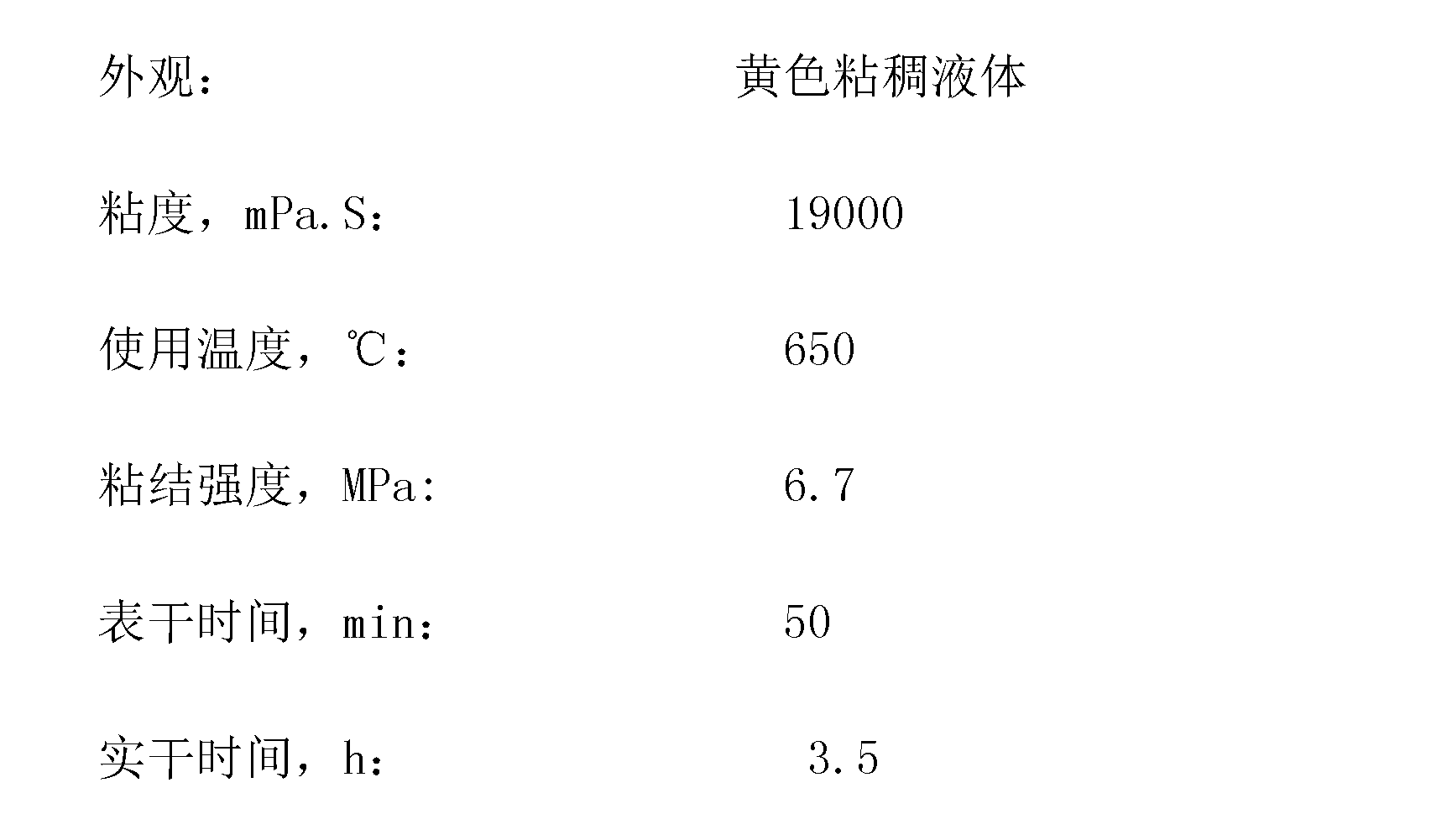

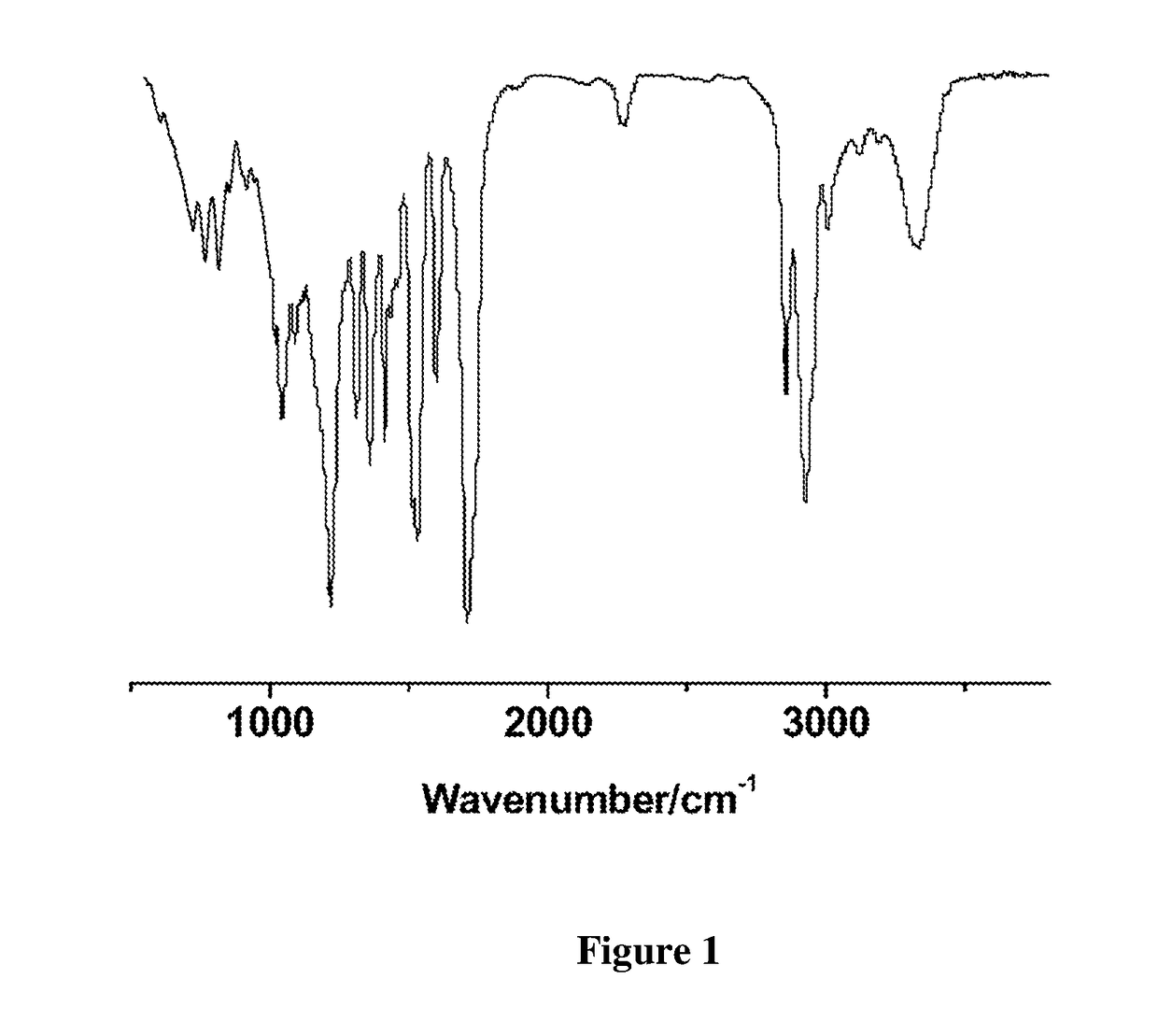

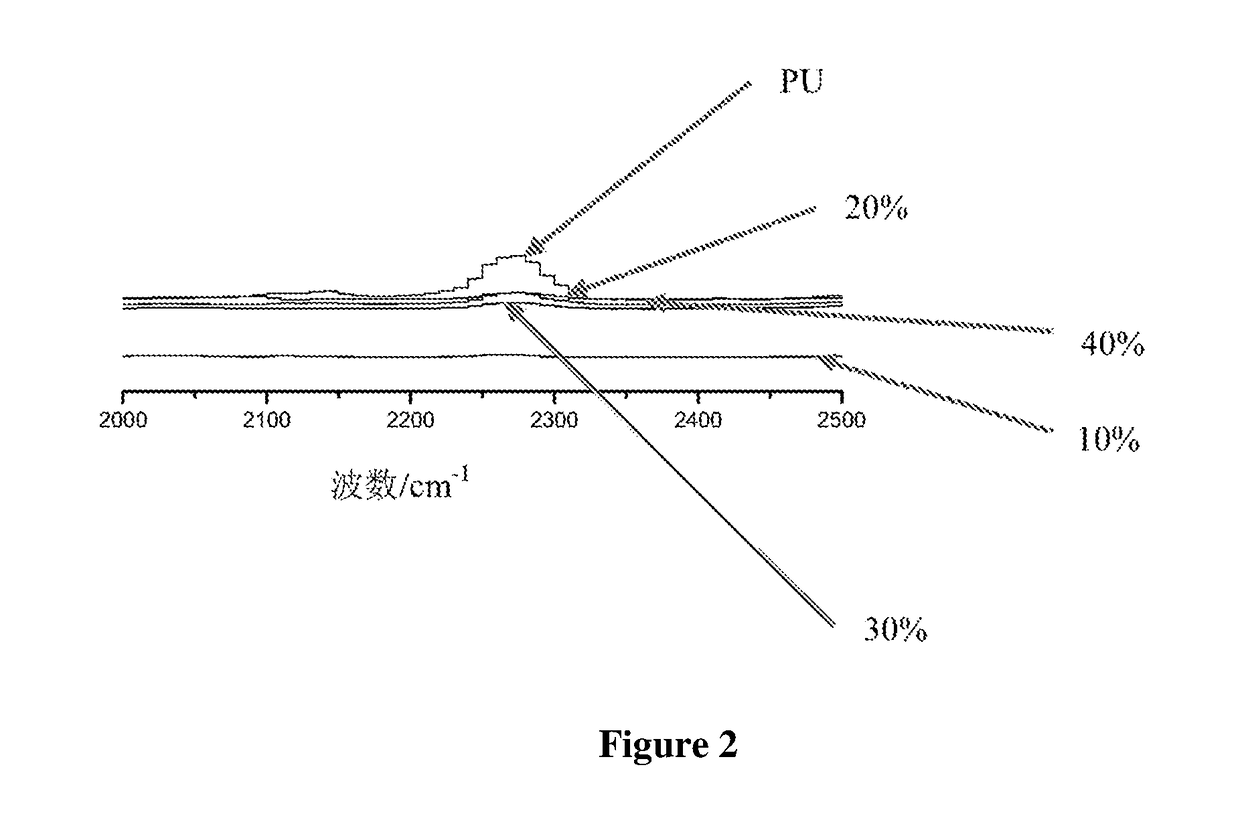

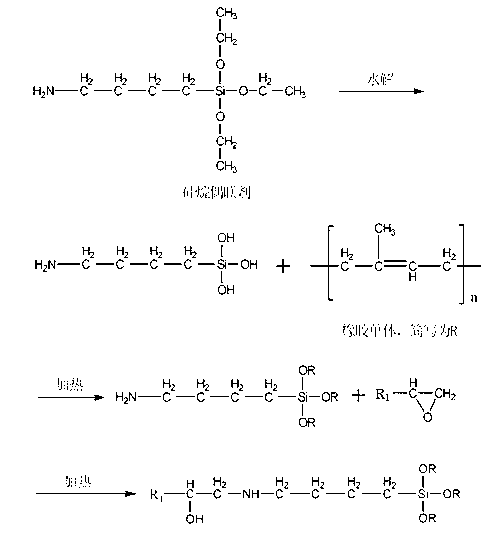

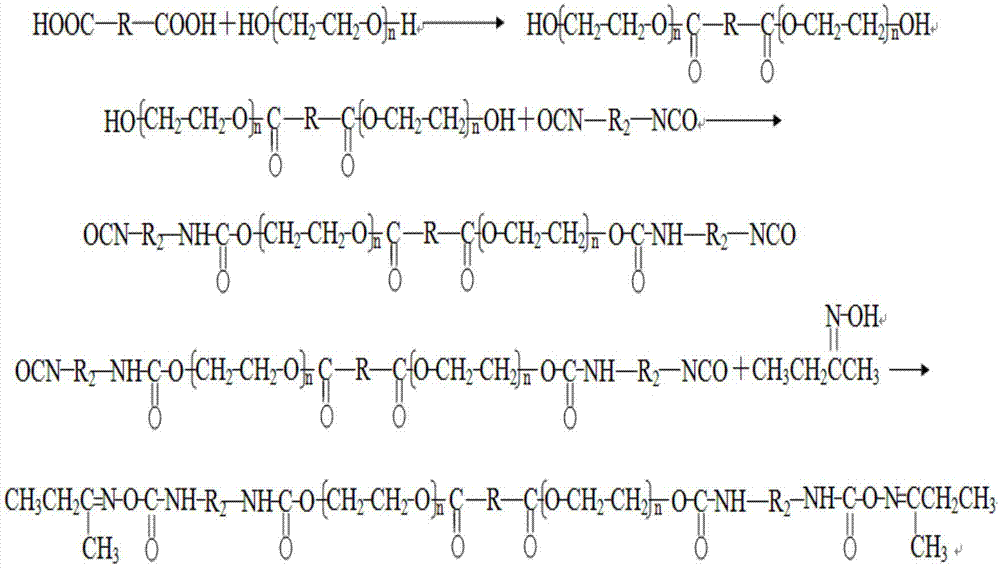

Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

InactiveCN101235129ASolve the problem of environmental protectionGood compatibilityPolymer scienceAlcohol

The invention discloses a polybutadiene aqueous polyurethane and a preparation method of relative modified emulsion, which is characterized by reacting low polymer polyatomic alcohol and hydroxy-terminated butadiene rubber and isocyanate, adding hydrophilic chain extender and catalyst to be reacted, cooling and emulsifying to obtain polybutadiene aqueous polyurethane, mixing polybutadiene aqueous polyurethane, emulsifier, water and inducer uniformly, adding ethenyl monomer to carry out emulsion polymerization to obtain polybutadiene aqueous polyurethane modified emulsion. The invention uses hydroxy-terminated butadiene rubber to synthesize aqueous polyurethane which can be modified by ethenyl to obtain environment-friendly, stable and low temperature resistant aqueous resin with better mechanical property. The resin can be used in weaving, leather processing, paint and adhesive or the like.

Owner:ANHUI UNIVERSITY

Borosiloxane and preparation method thereof

The invention relates to borosiloxane and a preparation method thereof. According to the method, a hydrolysis solvent and a boron compound are mixed proportionally and added to a reactor, the temperature keeps from 10 DEG C to 35 DEG C, and a mixed monomer is slowly dropwise added under the stirring condition for a hydrolysis reaction; the dropwise-adding time is controlled in 3-6 hours, the reactor is slowly heated to the temperature ranging from 55 DEG C to 65 DEG C after the dropwise-adding is finished, a stirring reaction is performed for 1 hour, and still standing is performed; acid water on the lower layer is separated and neutralized to be neutral, a saturated NaCl solution is used for washing, and an oil phase material is obtained; reduced pressure distillation is performed to remove the solvent, a catalyst I is added, the mixture is heated to 110-130 DEG C, and the rearrangement reaction is performed for 3-5 hours; the mixture is heated to 150-160 DEG C, the splitting cyclization reaction is performed for 2-5 hours, the reaction is finished, the mixture is cooled, and a polyborosiloxane prepolymer is obtained; an end-capping reagent and a catalyst II are added to a system and heated to 110-130 DEG C, and react for 2-4 hours; and pressure is reduced to remove a low-boiling-point substance, and a polyborosiloxane resin is obtained. The borosiloxane and the preparation method have the advantages of good temperature resistance, ageing resistance, impact resistance, toughness and low-temperature flexibility, high adhesion and the like.

Owner:上海爱世博有机硅材料有限公司

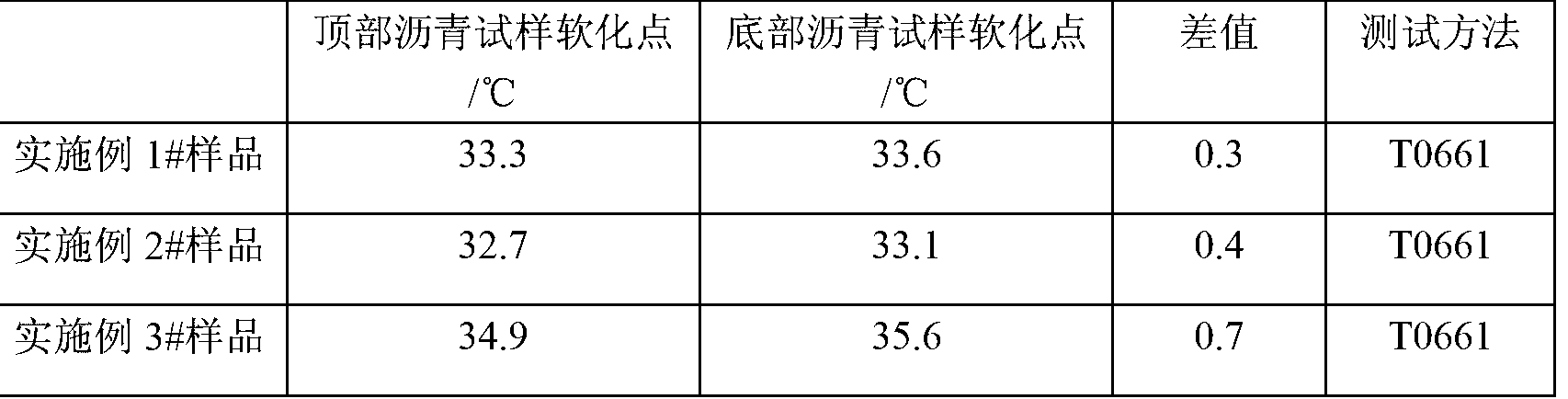

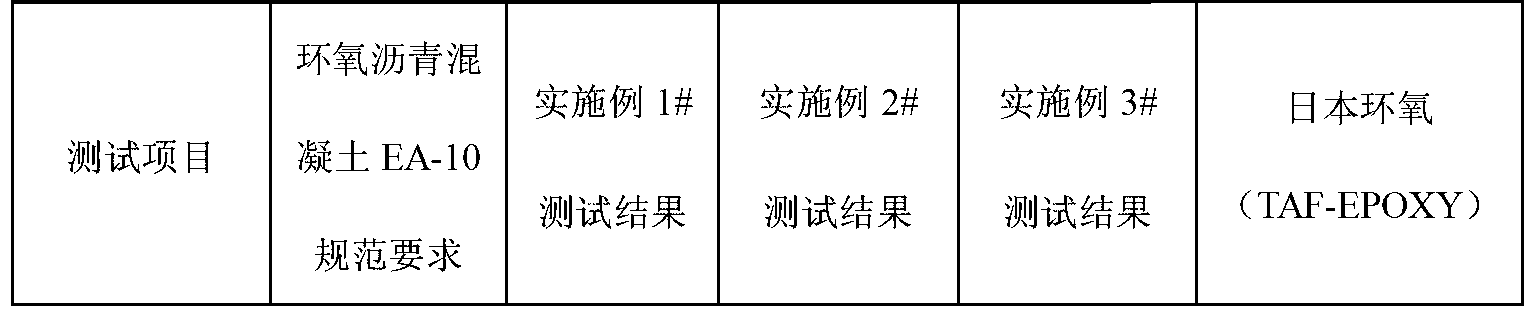

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437AChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

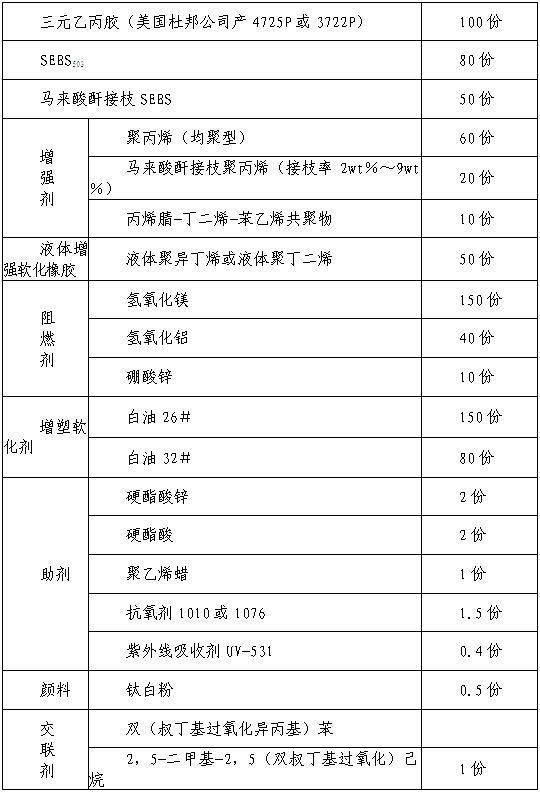

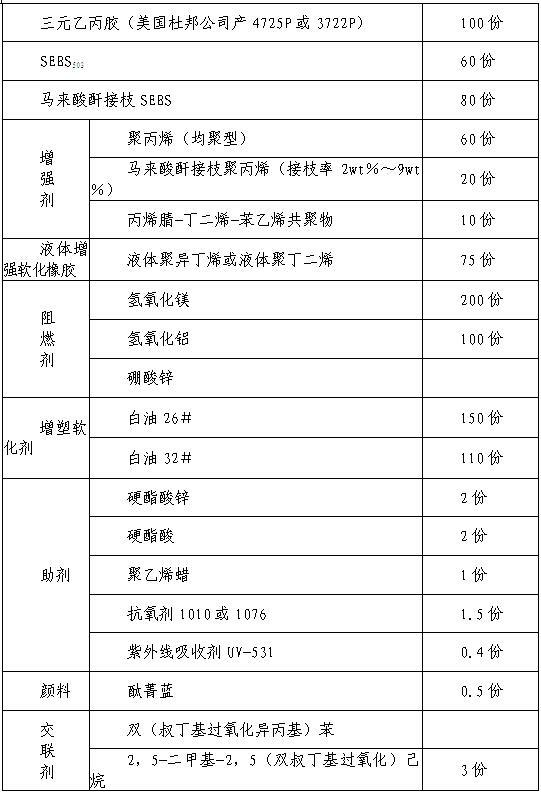

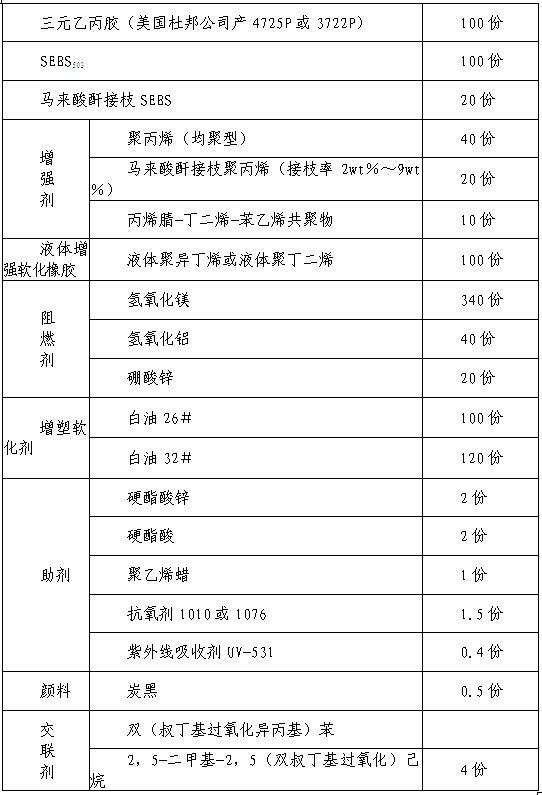

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

Glass laminate, and method for using block copolymer hydrogenation product as binder for glass laminate

InactiveUS20150104654A1Improve heat resistanceHigh glass transition temperatureAdhesive processesFilm/foil adhesivesPolymer scienceSilylene

A laminated glass may be obtained by integrally bonding glass sheets through an adhesive, the adhesive comprising a hydrogenated block copolymer obtained by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating unsaturated bonds of a block copolymer that comprises at least two polymer blocks and at least one polymer block, the polymer block comprising a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block comprising a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block in the block copolymer to a weight fraction wB of the polymer block in the block copolymer being 30:70 to 60:40. The laminated glass may employ a block copolymer hydrogenation product comprising an alkoxysilyl group and excellent light-fastness, heat resistance, moisture resistance and transparency.

Owner:ZEON CORP

Highly-elastic waterproof coating used for metal roof and preparation method thereof

InactiveCN103819990AEasy to useGood flexibility at low temperatureReflecting/signal paintsEmulsionIsopropylene glycol

The invention discloses highly-elastic waterproof coating used for a metal roof. The coating is prepared by adding propylene glycol, powder, a filling material and other auxiliary agents into pure acrylic acid emulsion adopted as the base. The coating comprises the following materials by weight: 30-60 parts of the pure acrylic acid emulsion, 1-3 parts of the propylene glycol, 30-50 parts of the powder, 1-5 parts of the filling material and 0.1-4 parts of the auxiliary agents. The coating has an integral protection function for the metal roof so as to prevent water leakage. In addition, integral construction of the roof makes the coating whitened and the coating has certain reflection effects for solar heat and ultraviolet ray, thus playing a function of energy conservation.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

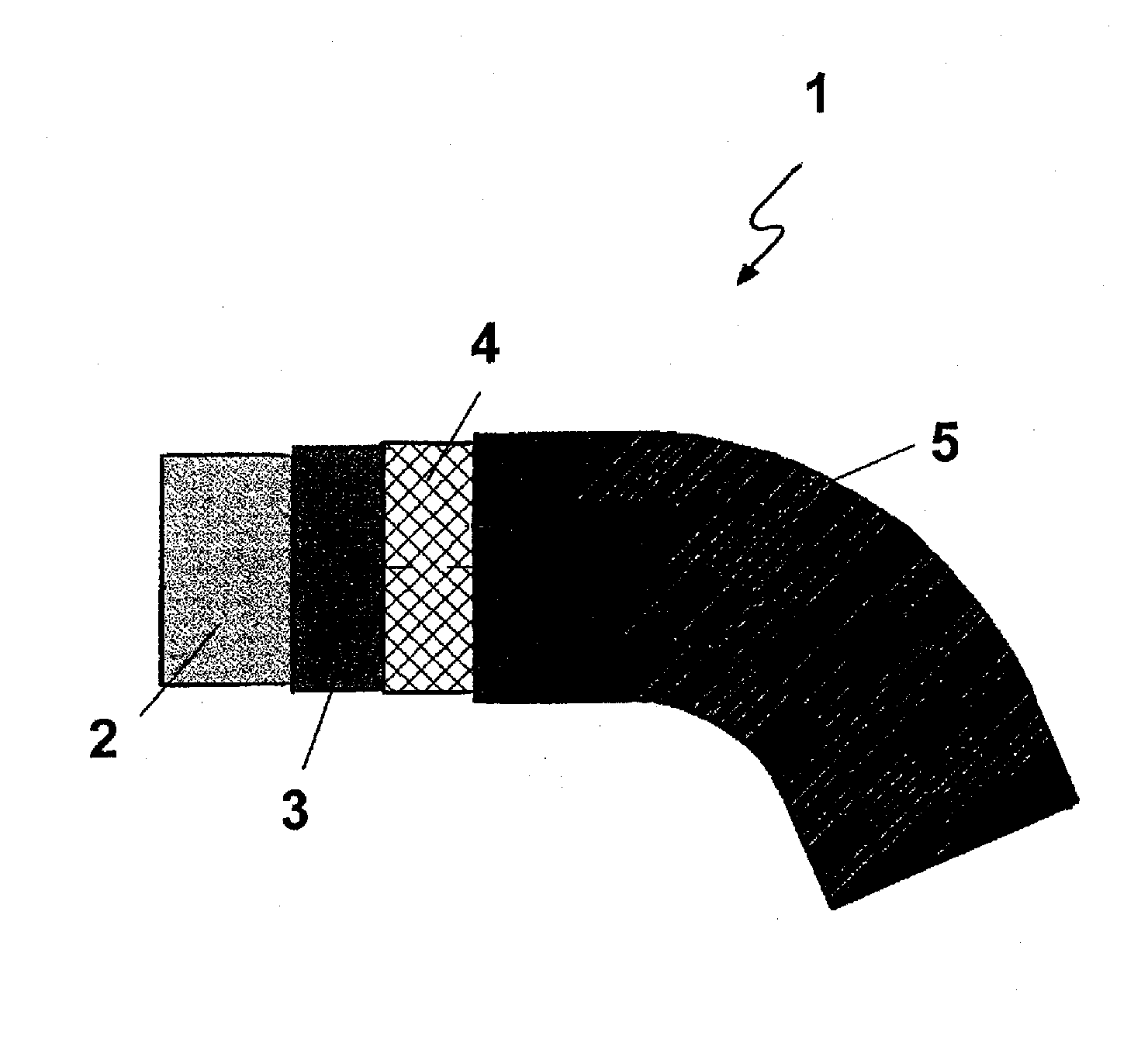

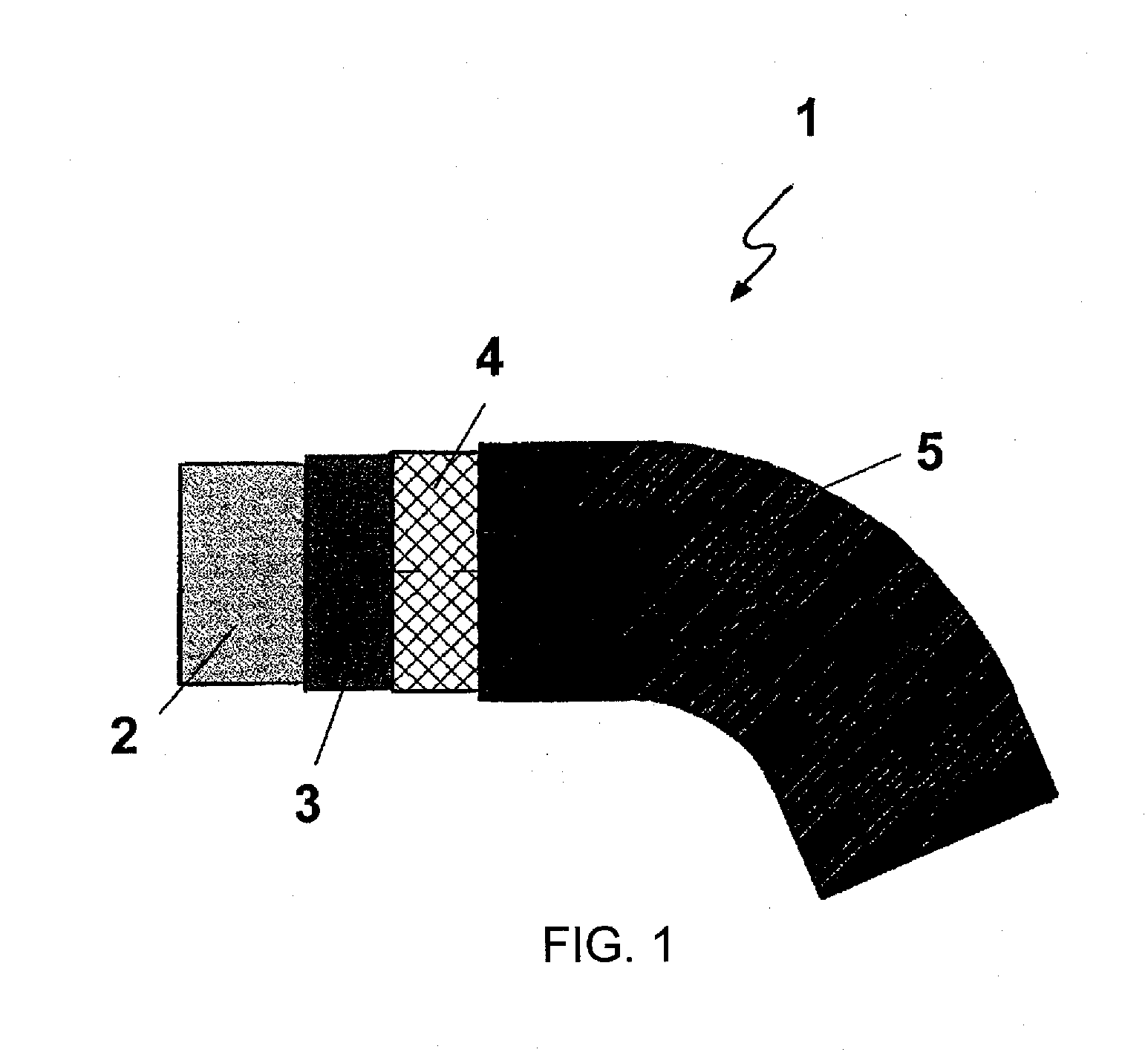

Hose having media-resistant inner layer, application and method for production thereof

InactiveUS20120145275A1Simple and inexpensiveIncrease resistanceHollow filament manufactureCombustion-air/fuel-air treatmentPolymer sciencePeroxide

A hose has at least the following layer structure: an inner layer made of an amine-bonded rubber mixture having media-resistance properties and an adhesion layer of a peroxide-bonded rubber mixture lying on the external side of the inner layer. The inner layer and the adhesion layer form an adhesive bond. The inner layer includes a rubber mixture based on unblended AEM or an AEM blend or on unblended ACM or an ACM blend and the adhesion layer includes a rubber mixture based on EPM or EPDM, each of which are unblended. The hose often includes a strengthening support layer and an external layer of a rubber mixture having resistance to external influences. The external layer preferably includes a peroxide-bonded rubber mixture based on unblended EPM or an EPM blend or on unblended EPDM or an EPDM blend.

Owner:CONTITECH MGW GMBH

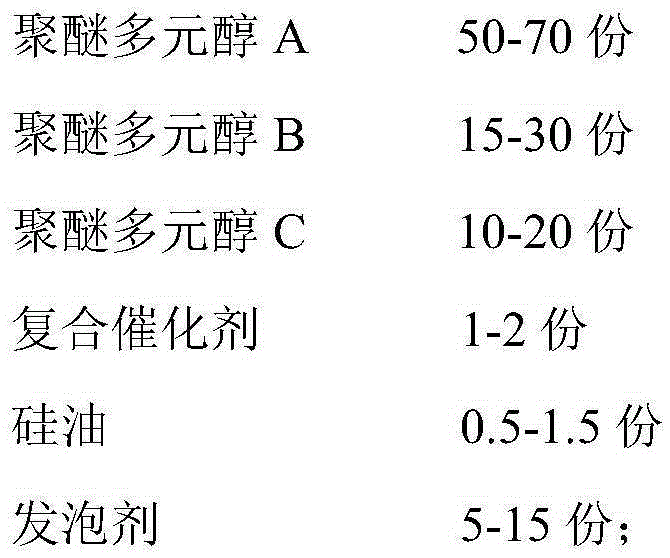

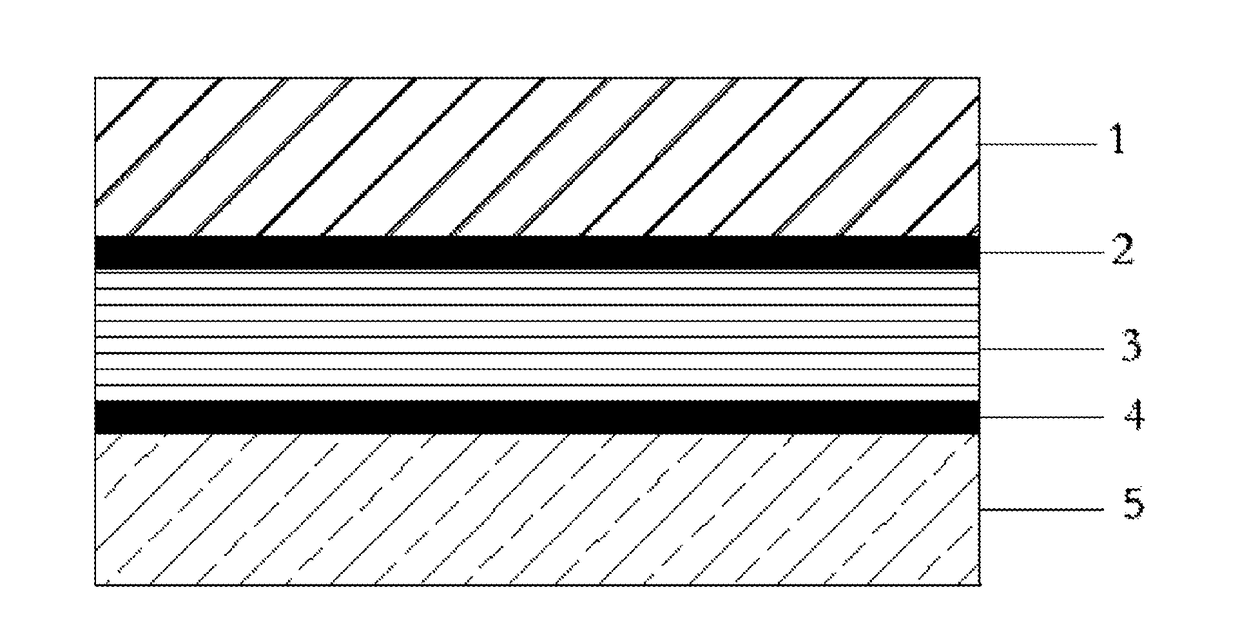

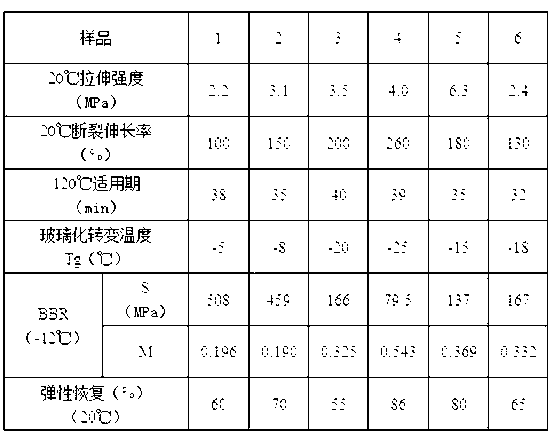

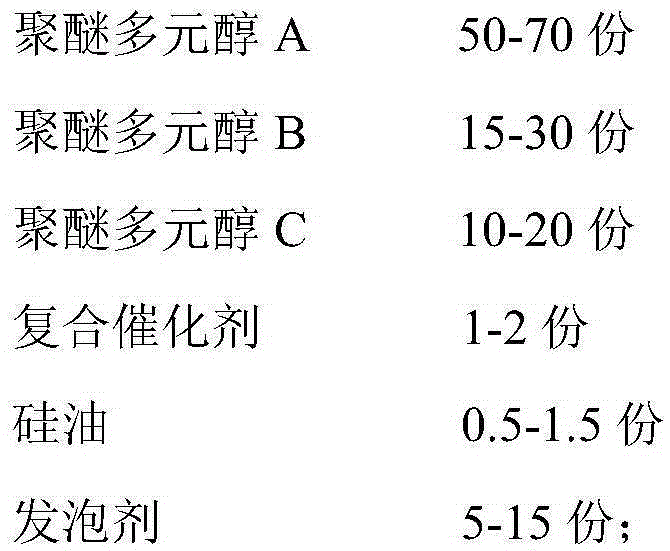

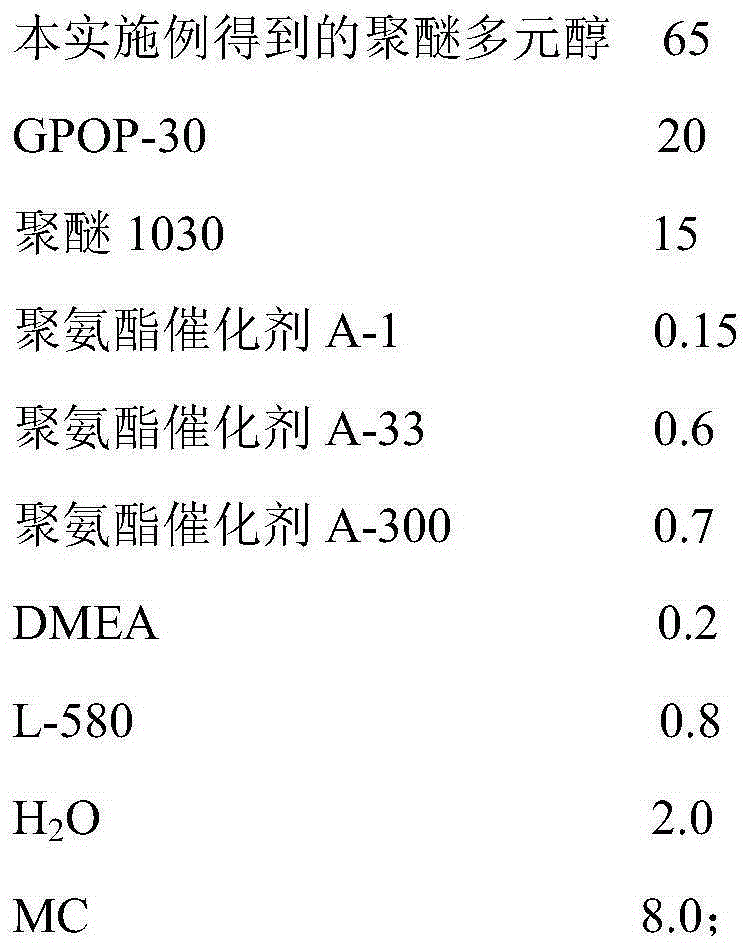

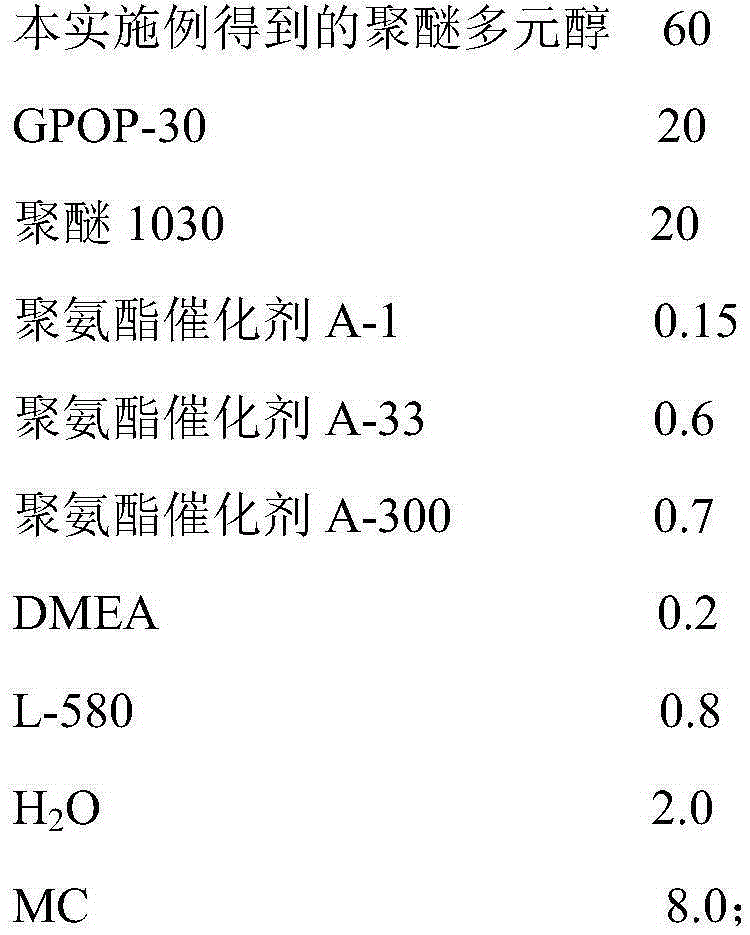

Slow-recovery polyether polyol and preparation method thereof and slow-recovery foam and preparation method thereof

The invention relates slow-recovery polyether polyol and a preparation method thereof and slow-recovery foam and a preparation method thereof, and belongs to the technical field of organic polymer synthesis. The slow-recovery polyether polyol is a copolymer of propylene epoxide and ethylene oxide, and the copolymer takes a composite small-molecular-weight polyhydric alcohol compound as initiator. The preparation method of the slow-recovery polyether polyol comprises the steps that the composite small-molecular-weight polyhydric alcohol compound and a catalyst are reacted in a pressure-proof reaction kettle, a polymeric monomer, water, phosphoric acid and magnesium silicate are sequentially added for reaction, and the slow-recovery polyether polyol is obtained; the slow-recovery foam is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol, a composite catalyst, silicone oil and a foaming agent, and the component B adopts modified DMI; the preparation method of the slow-recovery foam comprises the steps that the component A and the component B are evenly mixed and poured into a mold for curing, and the slow-recovery foam is obtained. The slow-recovery foam material has the advantages of being extremely low in depression residue, good in tensile property and capable of reducing the usage amount of an opening agent.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Polyurethane, modified asphalt and mixture material containing same and pavement structure

InactiveUS20180312437A1High strengthExtended service lifeIn situ pavingsBuilding insulationsHydrogenPolyol

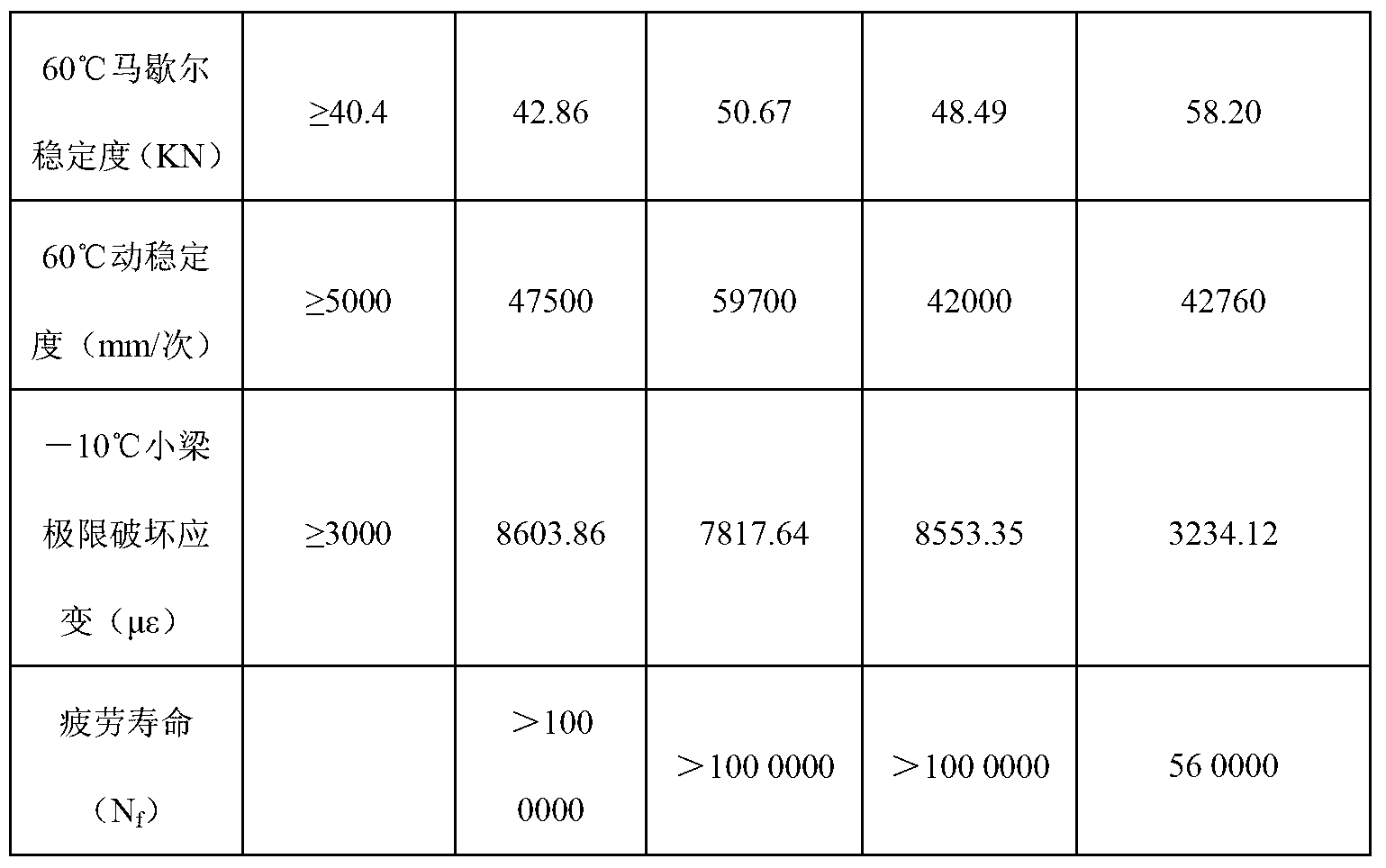

A polyurethane is obtained by continuously reacting a polyurethane prepolymer in an asphalt or asphalt mixture material system under high temperature. The prepolymer is prepared by: adding a polymerization inhibitor, catalyst and isocyanate component in a reaction container, adding a polyol to the reactor while stirring at room temperature under nitrogen, increasing the temperature to 50-80° C., and maintaining the temperature to react for 0.5-6 hours. A polyurethane modified asphalt, a mixture material containing the polyurethane and a polyurethane modified asphalt pavement structure can be prepared. The synthesis condition of the polyurethane is mild, and a secondary reaction with the air and an active hydrogen component in the asphalt can occur during maintenance and formation to further increase the strength of a mixture material. The standard Marshall stability at 60° C. meets the petroleum asphalt requirement, such that a service life of the asphalt pavement can be increased.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

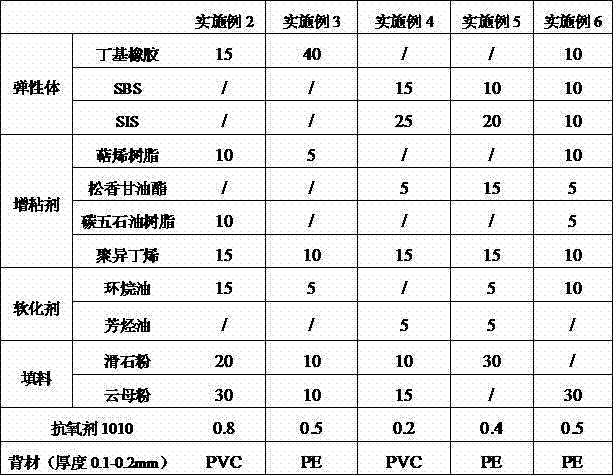

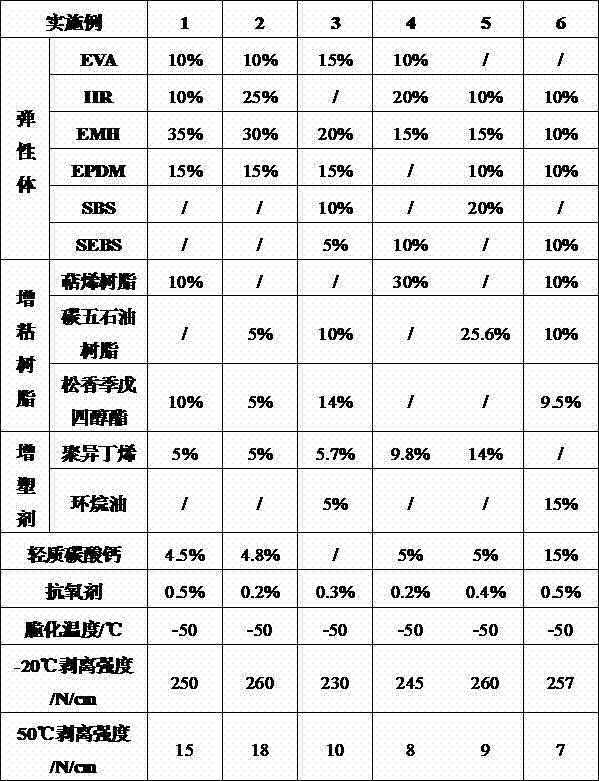

Anticorrosive pressure sensitive adhesive tape and preparation method thereof

InactiveCN102363717AGood self-adhesiveImprove sealingFilm/foil adhesivesCorrosion preventionElastomerPolymer science

The invention discloses an anticorrosive pressure sensitive adhesive tape and a preparation method thereof. The anticorrosive pressure sensitive adhesive tape consists of a back material and pressure sensitive adhesive coated on the back material, wherein the pressure sensitive adhesive consists of the following components in part by weight: 15 to 40 parts of elastomer, 15 to 35 parts of tackifier, 5 to 15 parts of softening agent, 20 to 50 parts of filler, and 0.2 to 0.8 part of anti-aging agent. The preparation method comprises the following steps of: adding the elastomer, the tackifier, the softening agent, the filler and the anti-aging agent into a kneading machine, kneading for 30 to 70 minutes at the temperature of between 130 and 160 DEG C, and obtaining a self-adhesive material; adding the self-adhesive material into a double-screw extruder, performing melt extrusion, and obtaining the pressure sensitive adhesive; and coating the pressure sensitive adhesive on the back material, and thus obtaining the anticorrosive pressure sensitive adhesive tape. The anticorrosive pressure sensitive adhesive tape has good self-adhesive property, high adhesive strength and good sealing performance and durability.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

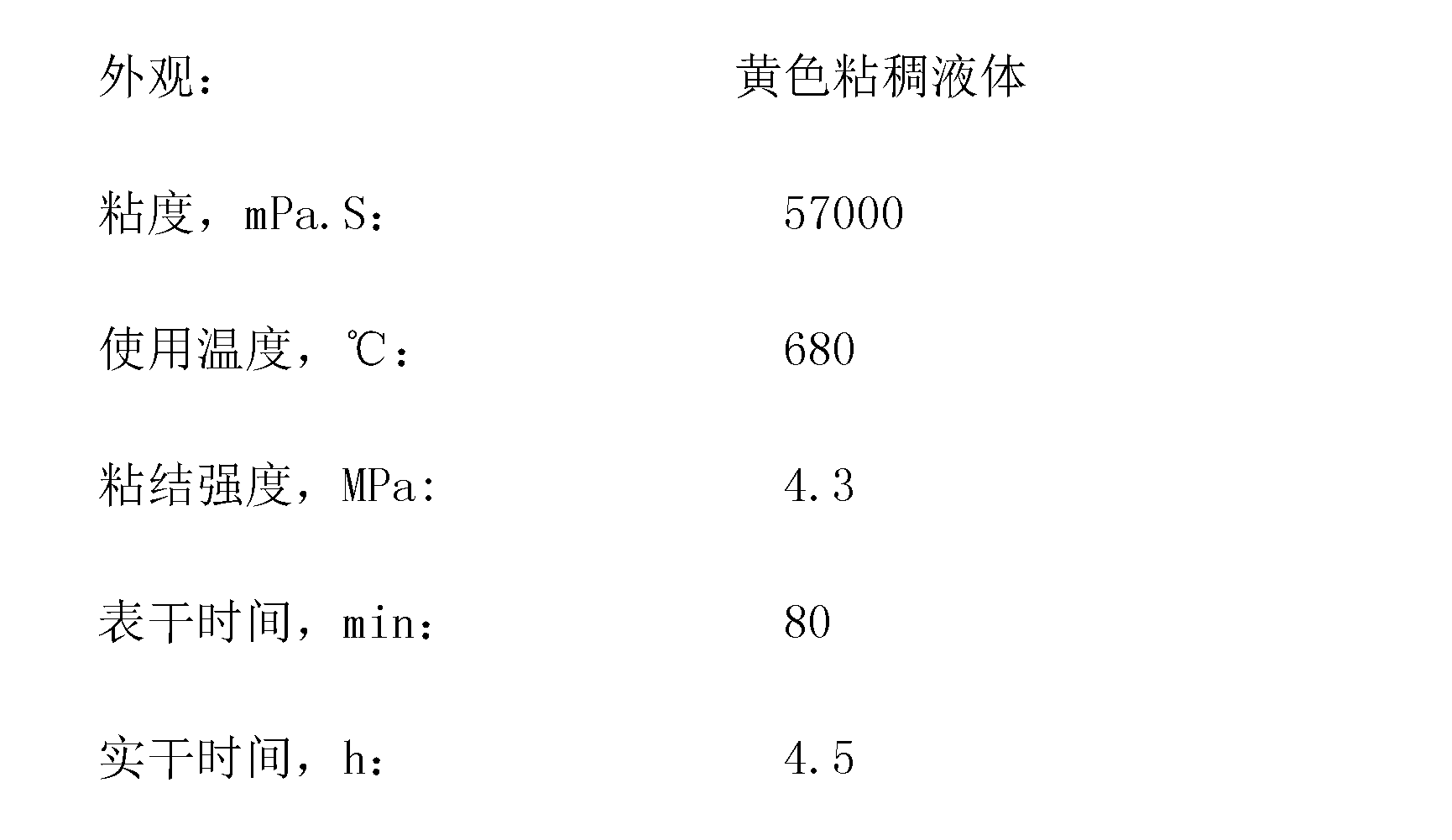

Cold spraying type epoxy thin bridge deck paving material and preparation method thereof

The invention relates to a cold spraying type epoxy thin bridge deck paving material and a preparation method thereof. The cold spraying type epoxy thin deck paving material is characterized by comprising a binder and a single grading fine aggregate, wherein 1-2kg / m<2> of the binder is smeared on a bridge deck so as to form a binder layer; 5-8kg / m<2> of the single grading fine aggregate is sprayed on the binder layer so as to form a single grading fine aggregate layer; the binder is formed by mixing a component A with a component B, and the weight ratio of the component A to the component B is (1-1.4):1; the component A comprises the following raw materials in parts by weight: 75-85 parts of epoxy resin, 15-25 parts of modified epoxy resin and 5-10 parts of diluent; and the component B comprises the following raw materials in parts by weight: 20-30 parts of cycloaliphatic amide curing agent, 10-20 parts of modified amine curing agent and 40-60 parts of cured accelerator. The cold spraying type epoxy thin bridge deck paving material has the characteristics of good skid-resisting and wear-resisting properties, high adhesion strength with the bridge deck, good waterproof and seepage-proofing properties and good low temperature flexibility.

Owner:武汉兴正源路桥复合材料有限公司 +1

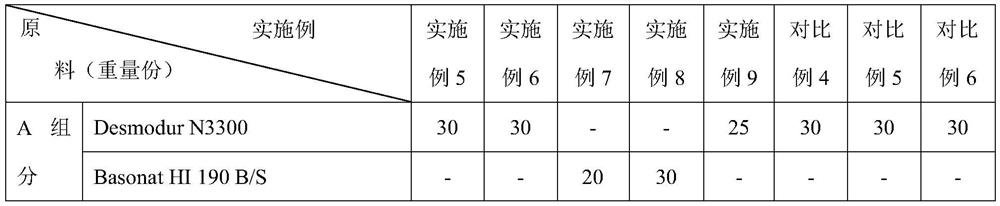

Modified polyaspartic acid ester polyurea coating and preparation method thereof

ActiveCN111793420AHigh strengthImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsIsocyanatePolyaspartic acid

The invention belongs to the technical field of coatings, and particularly relates to a modified polyaspartic acid ester polyurea coating and a preparation method thereof. The coating comprises a component A and a component B, and the component A and the component B are respectively prepared and independently stored. The component A comprises isocyanate and / or a polymer of isocyanate; and the component B is prepared from the following substances in parts by weight: 20 to 75 parts of organic silicon and epoxy dual-modified polyaspartic acid ester resin, 5 to 35 parts of a filler, 0.1 to 5 partsof a pigment, 0.5 to 10 parts of an auxiliary agent and 5 to 30 parts of a solvent. An organic silicon unit and an epoxy unit are introduced into a polyaspartic acid ester resin structure to obtain anovel polyurea coating with excellent low-temperature flexibility, bonding strength, weather resistance and mechanical properties, and the coating is simple in preparation method, good in controllability, low in cost, capable of being prepared in batches and suitable for industrial production.

Owner:SICHUAN JUNSHANG ACRYLIC MFG CO LTD

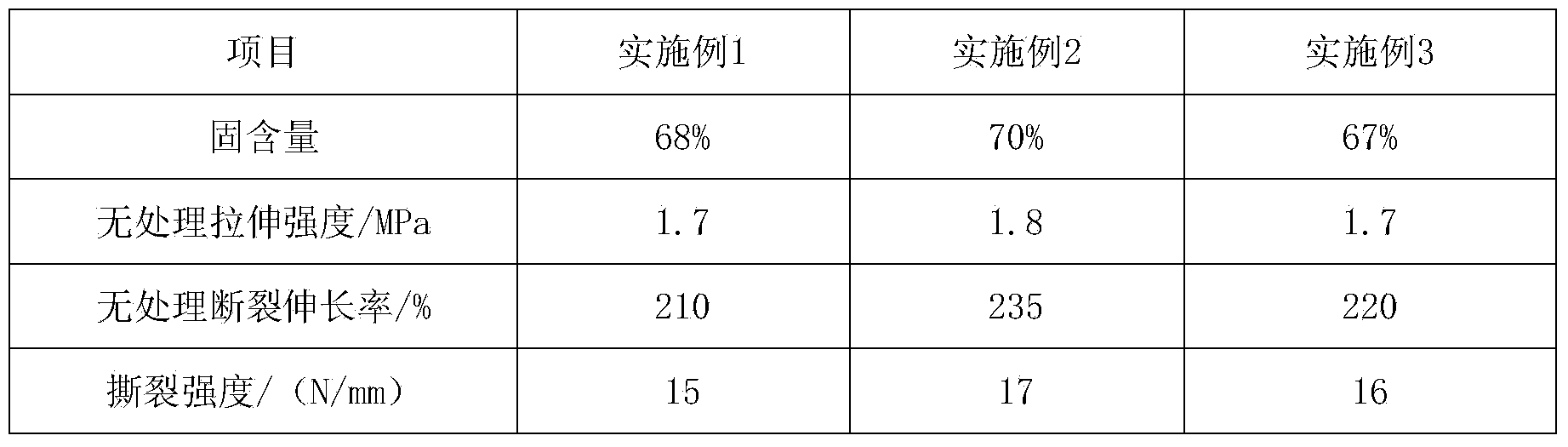

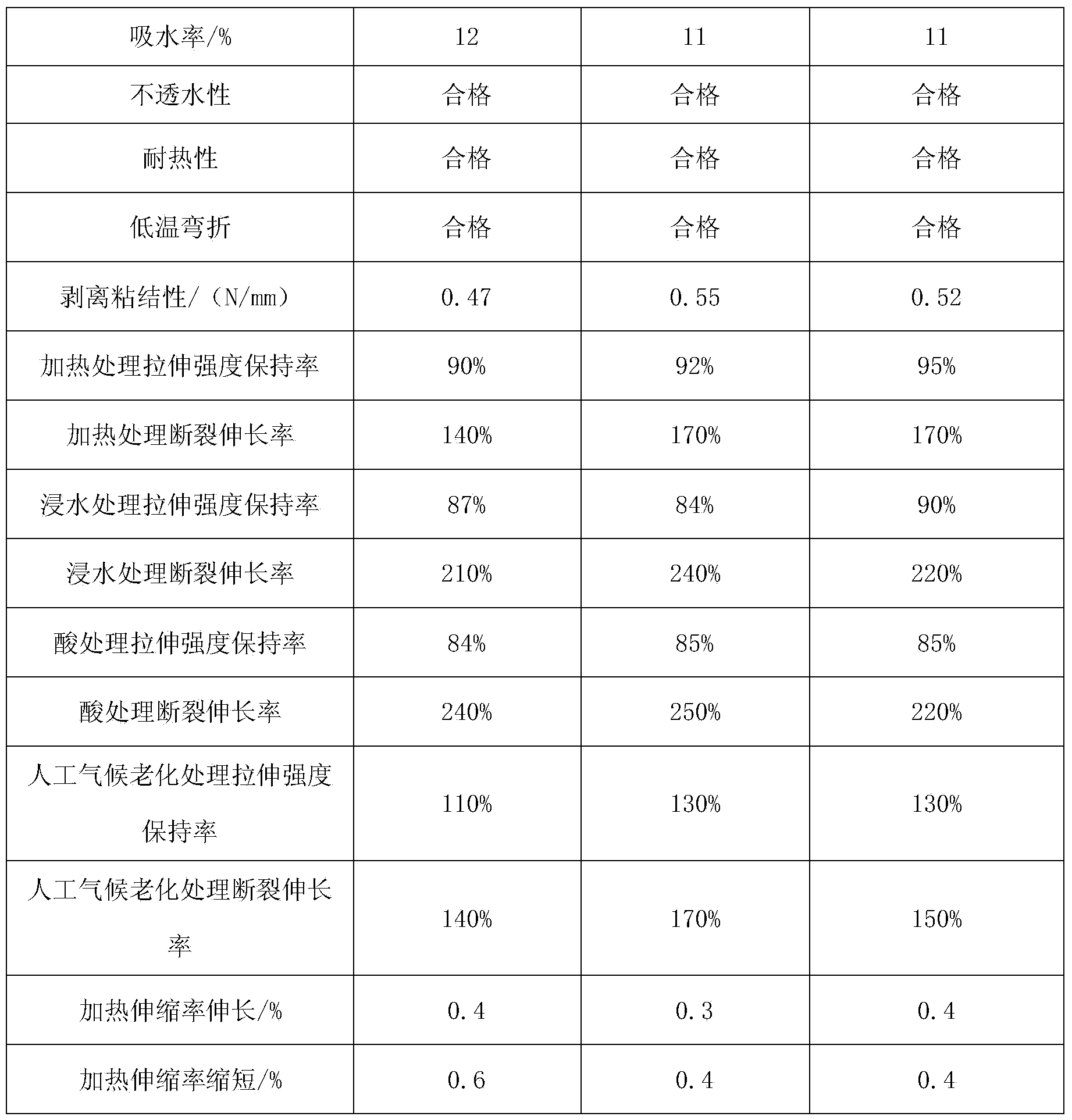

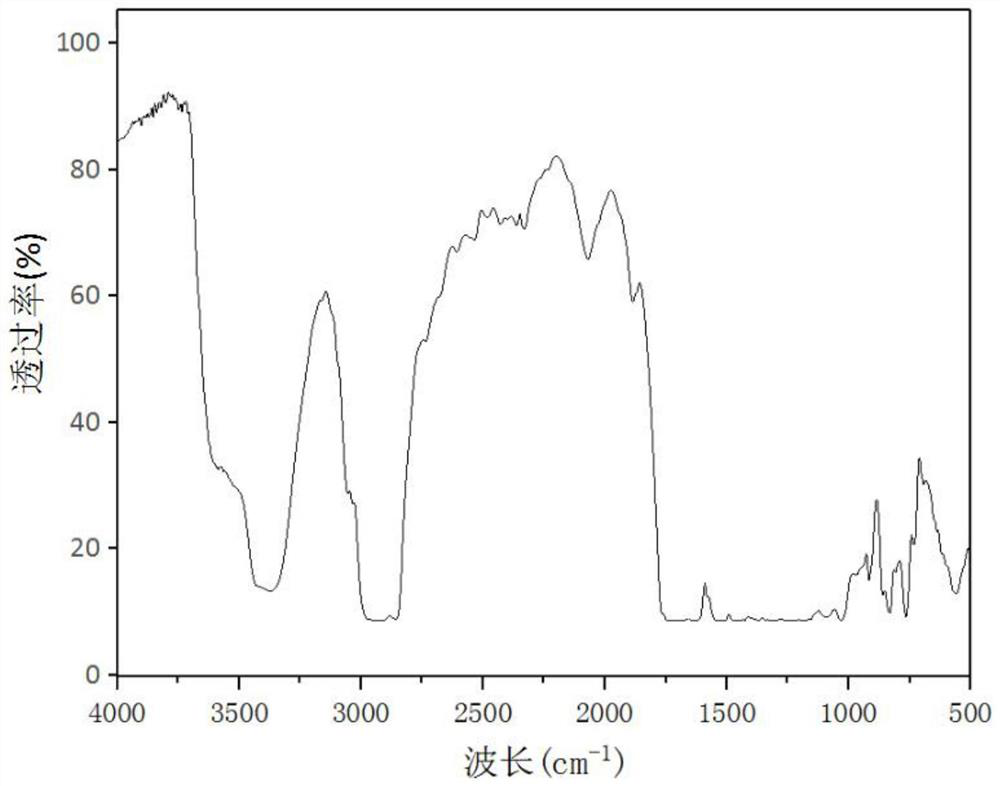

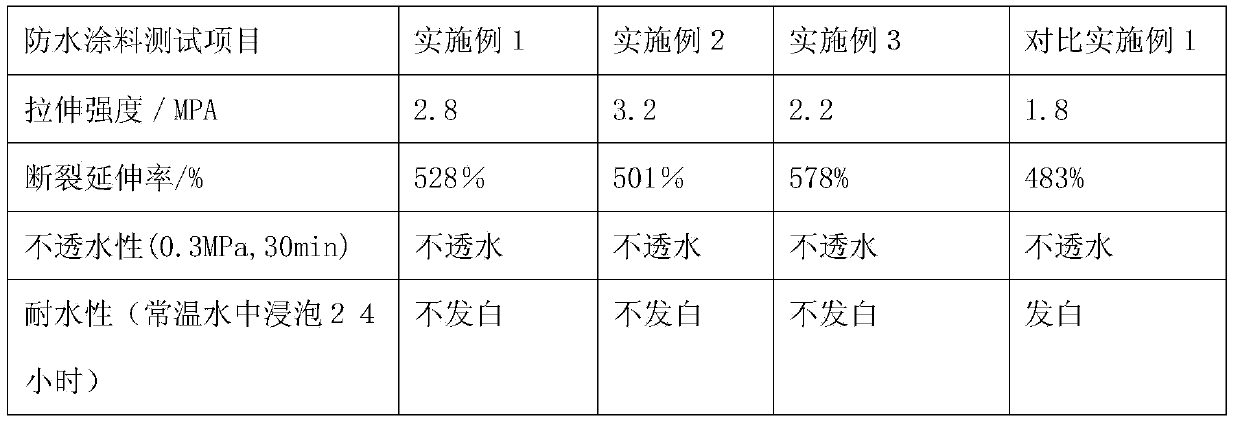

Self-crosslinked one-component polyurethane waterproofing coating

ActiveCN104194610ANo NCO residueImprove mechanical propertiesPolyurea/polyurethane coatingsPolyolPlasticizer

The invention discloses a self-crosslinked one-component polyurethane waterproofing coating composed of the components in parts by weight: 50-90 parts of polyol, 10-30 parts of isocyanate, 0-10 parts of a plasticizer, 0-5 parts of a hydrophilic chain extender, 0-10 parts of a small-molecular chain extender, 0-5 parts of a self-crosslinking modifier, 0-1 part of a catalyst and 0-5 parts of a solvent, wherein the self-crosslinking modifier contains hydroxyl or amino group, has a diacetone acrylamide structure and can be reacted with NCO. The self-crosslinked one-component polyurethane waterproofing coating disclosed by the invention is favorable in performance and capable of solving the problem of poor water resistance of a common waterborne coating.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Anti-aging high-flame-retardance natural rubber composite

InactiveCN105754155AGood heat resistanceExcellent weather and oil resistanceMaleic anhydrideDicumyl peroxide

The invention discloses an anti-aging high-flame-retardance natural rubber composite.The composite is prepared from natural rubber, ethylene-propylene-diene monomer rubber, polychloroprene, polyvinyl chloride, natural rubber grafting maleic anhydride, carboxyl liquid nitrile rubber, polypropylene carbonate, zinc oxide, stearic acid, sulphur, dicumyl peroxide, nanosilicon dioxide, kieselguhr, nano-microcrystalline cellulose, medium super abrasion furnace black, cerium oxide, silane coupling agent, accelerant, anti-aging agent, silicon phosphorus flame retardant, HAPCP, aluminum diethylhypophosphite and zinc borate.The composite is high in strength, good in aging resistance, excellent in flame retardance, capable of meeting use requirements of various fields of cables, electric appliances and the like and long in service life.

Owner:宿州学院

Single/double-component construction type polyurethane joint pouring glue for ballastless track concrete expansion joint and preparation method thereof

ActiveCN107142069AEasy constructionLow tensile modulusNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantEngineering

The invention relates to the technical field of building sealants, and in particular to single / double-component construction type polyurethane joint pouring glue for a ballastless track concrete expansion joint and a preparation method thereof. The single / double-component construction type polyurethane joint pouring glue for the ballastless track concrete expansion joint is prepared from a main agent and an accessory ingredient, wherein the main agent is prepared from a polyurethane prepolymer, filler, a thickening agent, a diluent, a catalyst, a cementation accelerator, a defoaming agent, a light stabilizer, an antioxidant and a water removing agent; the polyurethane prepolymer is prepared from polypropylene oxide glycol, polypropylene triol, polyisocyanate, a plasticizer and the catalyst; the accessory ingredient is prepared from the plasticizer, a thickening agent and micromolecular polyol. The preparation method comprises the following steps: step one, preparation of the polyurethane prepolymer; step two, preparation of the main agent; step three, preparation of the accessory ingredient. After the single / double-component construction type polyurethane joint pouring glue disclosed by the invention is cured, the tensile modulus is low, the anti-displacement capacity is strong, and low-temperature flexibility is good.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Epoxy glue powder asphalt material and preparation method thereof

InactiveCN102796387AGood compatibilityGood flexibility at low temperatureBuilding insulationsElastomerFirming agent

The invention relates to an epoxy glue powder asphalt material and a preparation method thereof. A macromolecular curing agent, a rubber elastomer, a plasticizer and the like are used for improving the flexibility of the cured epoxy resin so as to improve the low-temperature performance of the epoxy resin curing material, but the epoxy asphalt is easy to separate caused by low compatibility of the macromolecular compound, the rubber elastomer and the asphalt. The preparation method comprises the following steps: soaking rubber particles into the hydrolysate of a silane coupling agent to obtain a surface and interface activated rubber particle curing agent, adding into the matrix asphalt, cutting, cooling, adding modified asphalt, plasticizer, aliphatic dibasic acid, dimer acid or alkyd resin and fatty acid anhydride and obtaining an epoxy asphalt component B under the action of a shearing and emulsifying machine; and mixing and stirring the epoxy asphalt component A namely the epoxy resin and the epoxy asphalt component B to obtain the activated rubber particle modified epoxy asphalt material. According to the invention, the low-temperature flexibility of the epoxy asphalt is obviously improved; and a large amount of activated rubber particles are added, so the cost of the epoxy asphalt is greatly reduced.

Owner:黄卫 +2

Low-temperature 3PE hot melt adhesive and preparation method thereof

InactiveCN104497917AGood adhesionImprove sealingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPlasticizer

The invention discloses a low-temperature 3PE hot melt adhesive which comprises the following components in parts by weight: 40-80 parts of an elastomer, 10-30 parts of tackifying resin, 0-15 parts of a plasticizer, 0.2-0.5 part of an antioxygen and 0-15 parts of fillers. The 3PE hot melt adhesive for corrosion prevention has good low-temperature resistance, adhesion performance and sealing performance, also has a certain protective capability at a high temperature and is excellent in corrosion effect. The preparation method of the low-temperature 3PE hot melt adhesive is simple in process and has the advantage of reducing energy consumption and is convenient to popularize.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

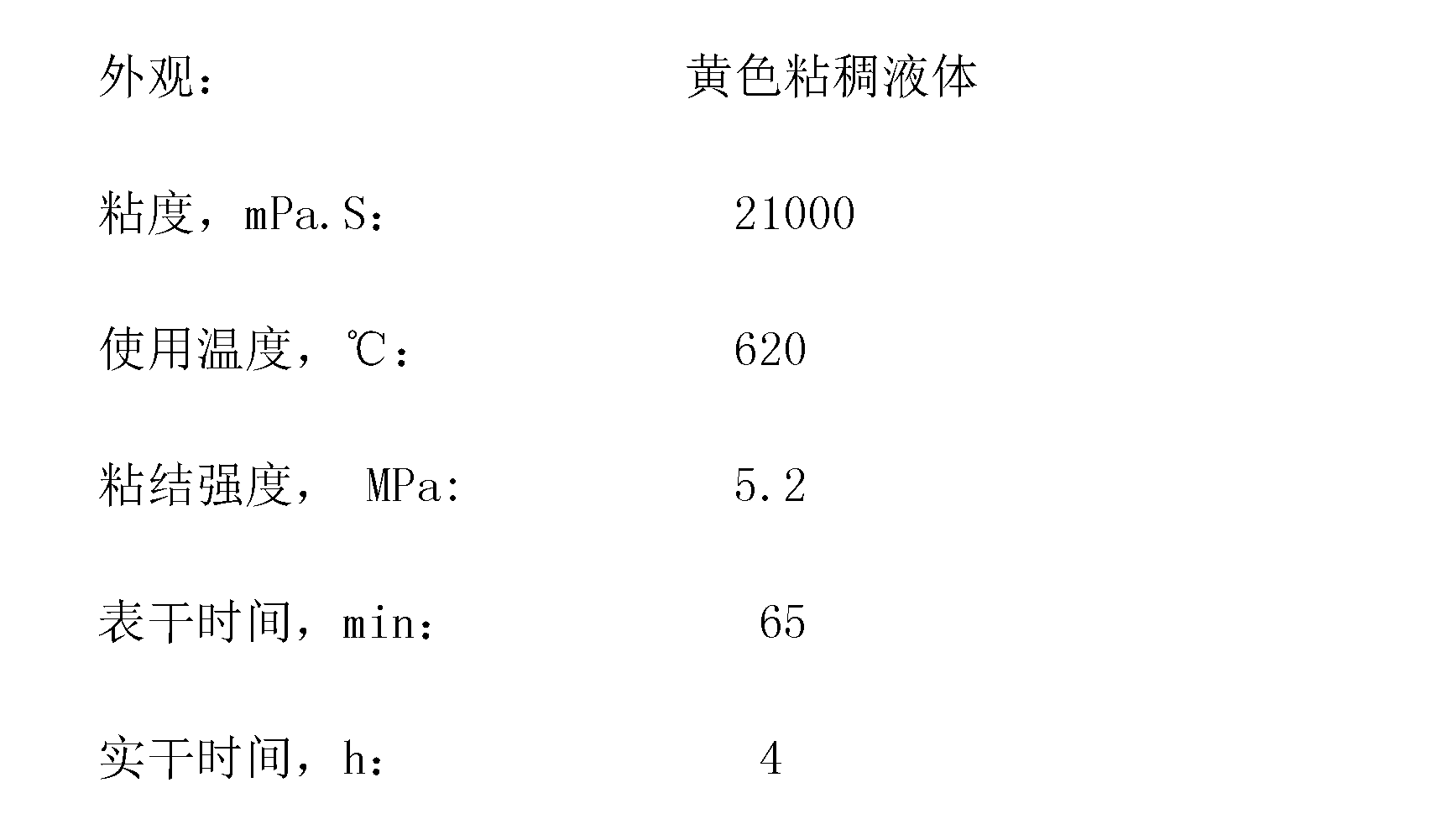

Room-temperature cured flexible epoxy adhesive and preparation method thereof

ActiveCN106281160AQuick responseImprove early strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesRoom temperatureReactive diluent

The invention relates to a room-temperature cured flexible epoxy adhesive and a preparation method thereof. The room-temperature cured flexible epoxy adhesive is characterized by being prepared from a component A epoxy resin and a component B epoxy curing agent; in a utilization process, the component A epoxy resin and the component B epoxy curing agent are selected at the weight ratio of the component A epoxy resin to the component B epoxy curing agent of (1.15 to 1.20) to 1; after the component A epoxy resin and the component B epoxy curing agent are sufficiently mixed, the room-temperature cured flexible epoxy adhesive is obtained, wherein the component A epoxy resin is prepared from the following components in parts by weight: 100.5 to 115 parts of epoxy resin, 0.5 to 20 parts of a reactive diluent and 0.5 to 20 parts of an epoxy accelerant; the component B epoxy curing agent is prepared from the following components in parts by weight: 5 to 15 parts of an alicyclic amines curing agent, 28 to 100 parts of a polyether amines curing agent, 10 to 80 parts of a curing accelerant and 0.5 to 2 parts of a bonding accelerant. The adhesive prepared by the method can be cured at room temperature, is high in bonding strength and good in low-temperature flexibility, and can be used for elastic bonding.

Owner:武汉拓路特铺技术工程有限公司

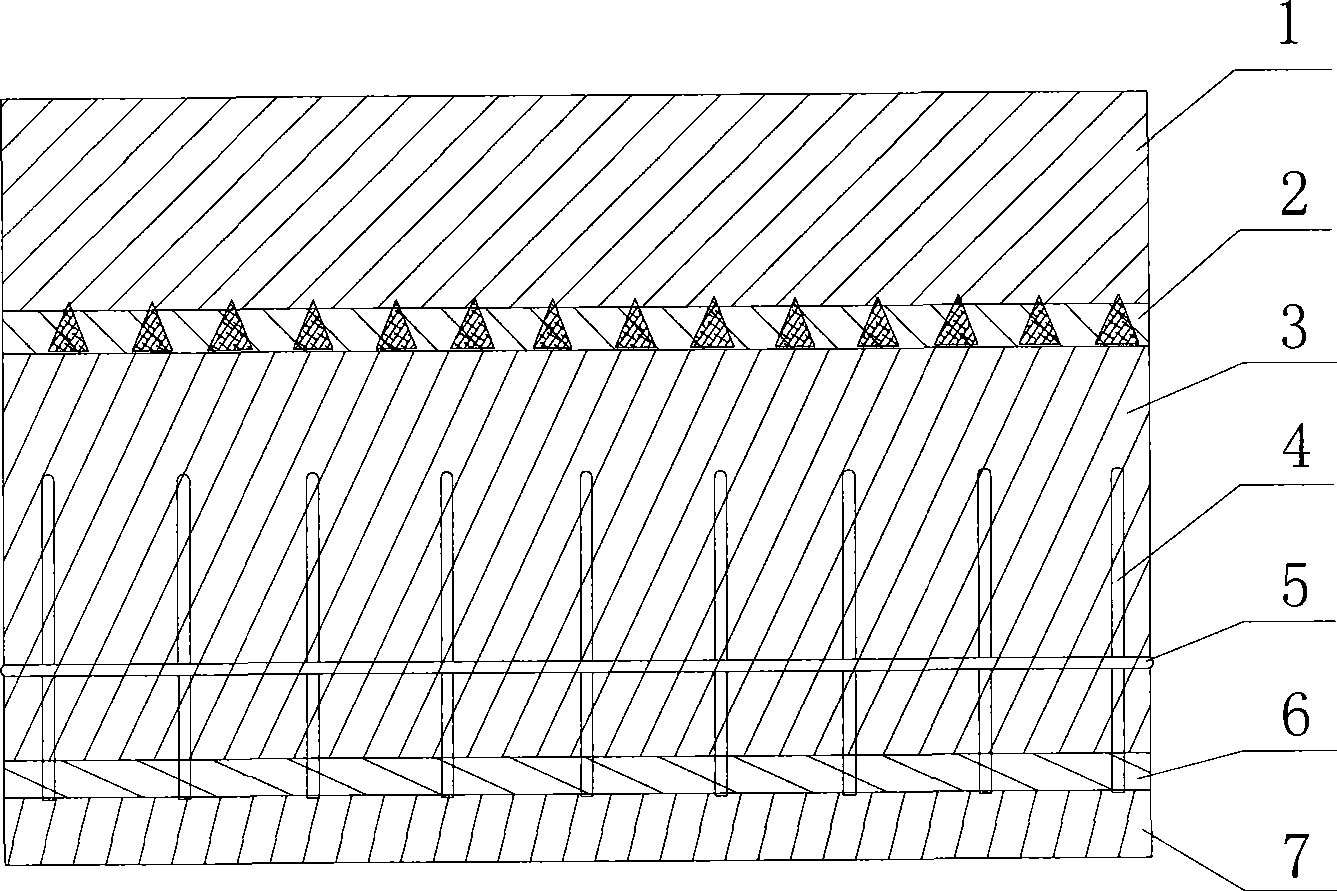

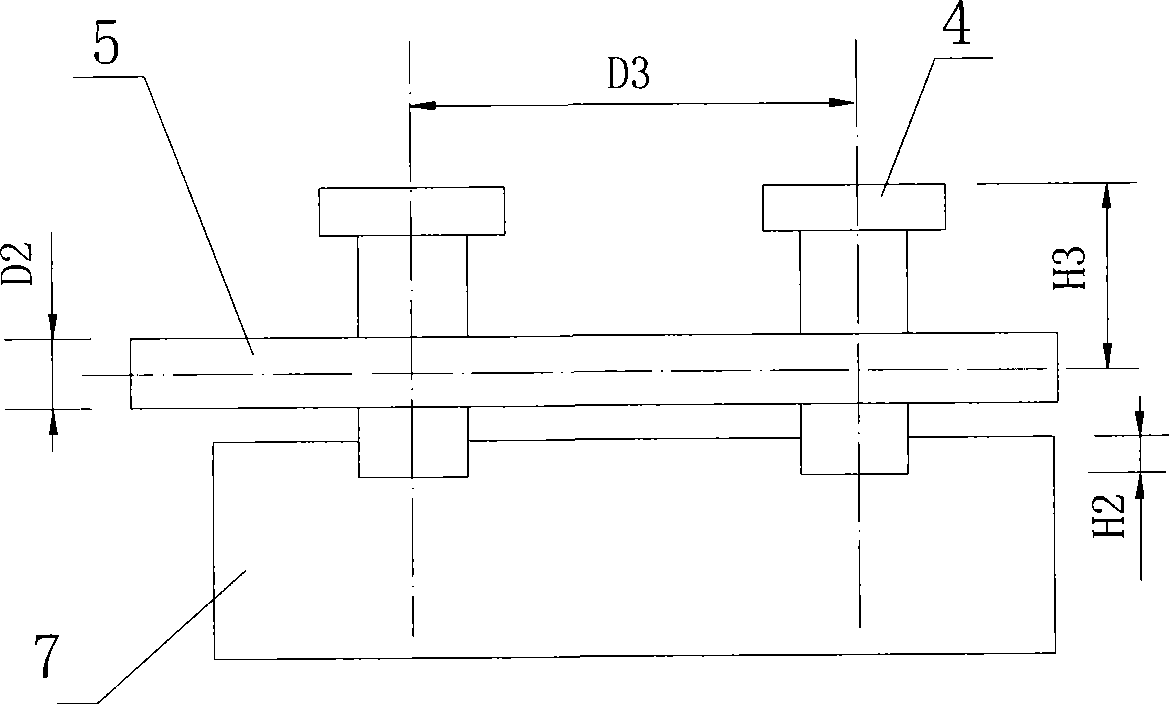

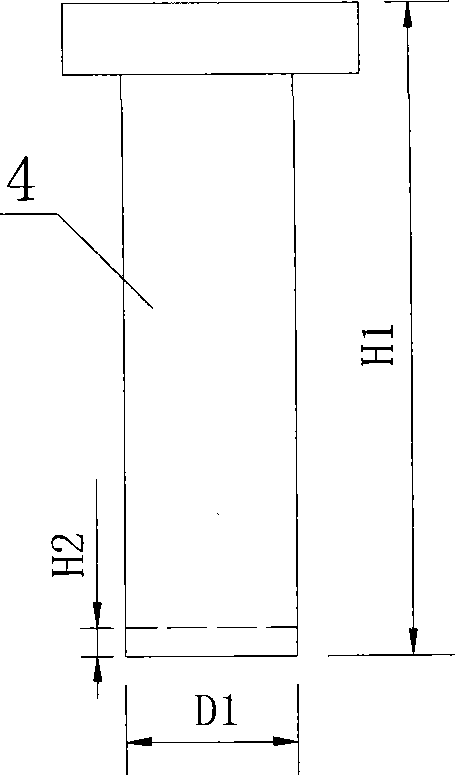

Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

ActiveCN101368368AImprove bindingIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelBridge deck

The invention relates to a method for paving combined anti-push structures on the surface of a large-span steel box girder bridge, including the following steps: 1) pretreating the armor plates of the large-span steel box girder bridge; 2), welding shear studs: welding shear studs on the armor plates of the large-span steel box girder bridge, with an interval at area of (35-45)cm X (35-45)cm between two shear studs; 3) colligating the reinforcement mats: fixing the reinforcement mats at specification of (95-105)cm X (95-105)cm on the shear studs; 4) mineral aggregate grading; 5)preparing and paving cast-type asphalt concrete; 6) paving a waterproof bond coat; and 7)paving anti-skid denoising wearing layer: paving a anti-skid denoising wearing layer at thickness of 3-5cm on the waterproof bond coat. The method has the advantages that cohesiveness at the interfaces is good, the paved layer and the armor plates are strong in coordinated deformability, and construction process is simple and convenient.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

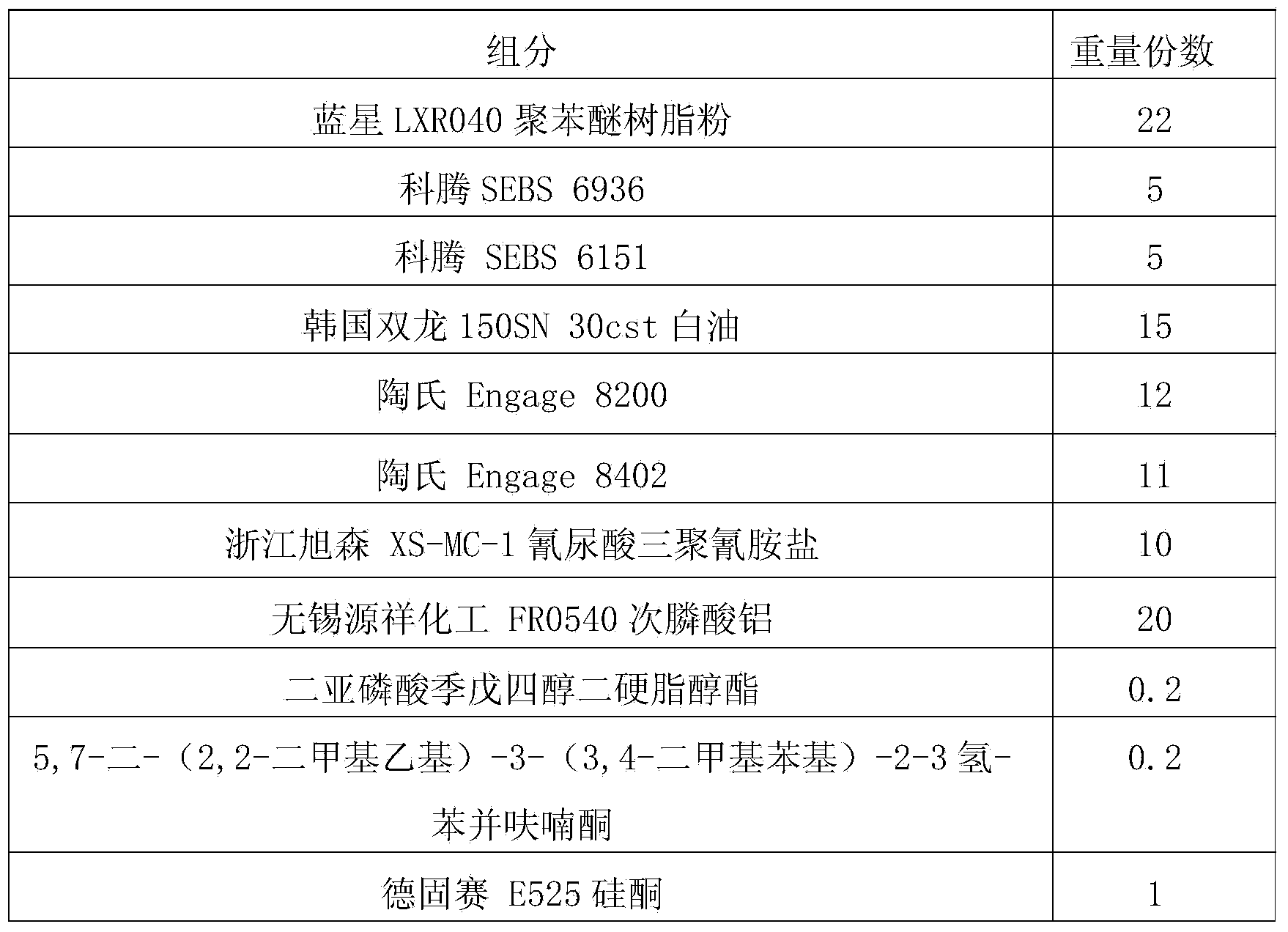

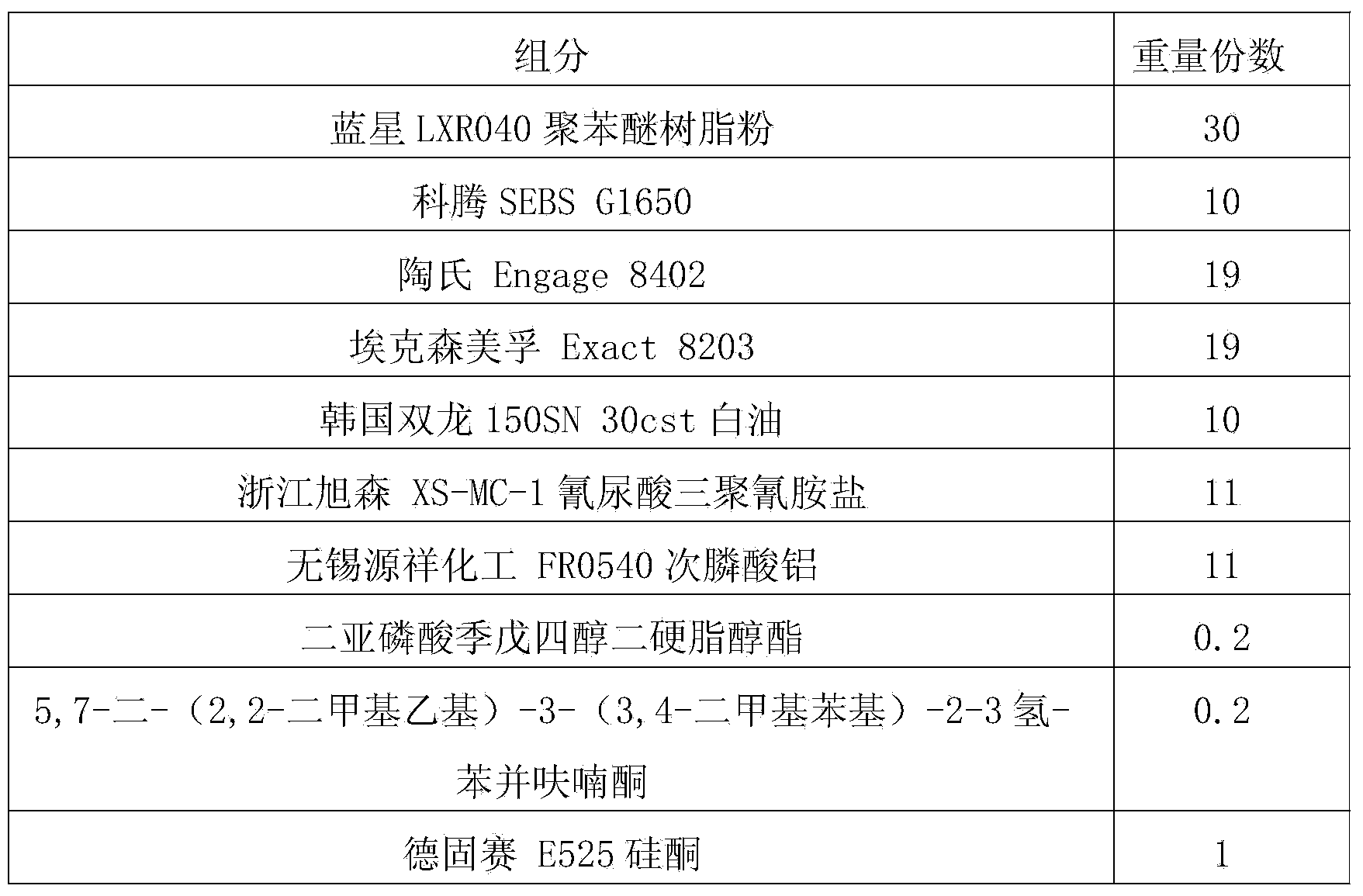

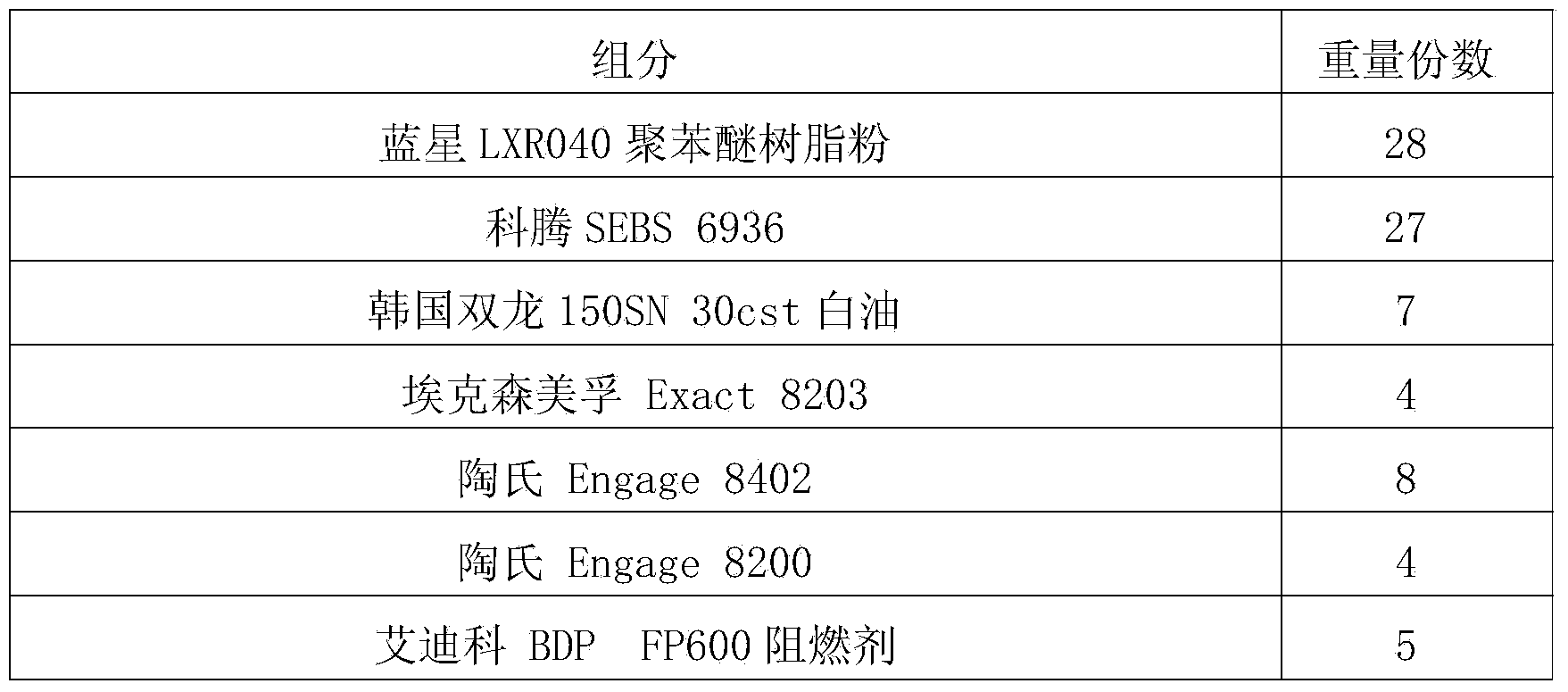

Thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and preparation method thereof

ActiveCN103910990ASimplify the proportioning processSimplify the manufacturing processThermoplasticElastomer

The invention discloses a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material and a preparation method thereof. The cable material is used for a soft type electric wire and cable coating, and comprises the following components: polyphenyl ether resin powder, styrene-series elastomers, a plasticizer, a polyolefin elastomer, a compound phosphor-nitrogen flame retardant, an antioxidant and a lubricant. The material components are uniformly stirred in a high-speed mixer, extruded by a twin-screw extruder, pelletized in water, dried and then packaged to obtain a thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material finished product. The thermoplastic halogen-free flame-retardant polyphenyl ether elastomer cable material designed by the invention has excellent performance such as good processing performance, halogen-free and flame-retardant performance, low density, high tensile strength, good scraping resistance, good softness, good low temperature resistance, capacity of being extruded at a processing temperature of 200 DEG C-280 DEG C and not decomposed, free of cracks on a sample sheet for seven days under a high-temperature high-humidity environment with 98% humidity and a temperature of 85 DEG C, free of precipitates on surface, and the like.

Owner:JIANGSU LINRY NEW MSTAR TECH

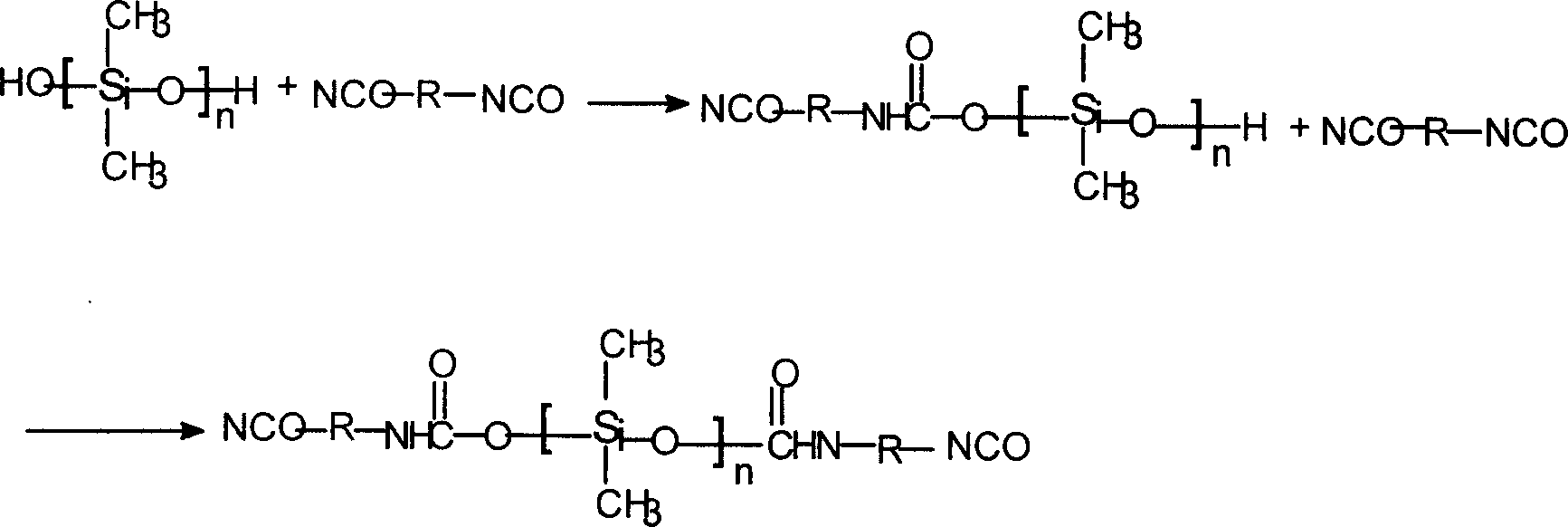

Organic silicon modified polyurethane gap-filling rubber for cement road

InactiveCN1616577AGood flexibility at low temperatureExcellent surface enrichmentPolyureas/polyurethane adhesivesPaving detailsIsocyanateHydrogen compounds

The organosilicon modified polyurethane gap-filling rubber for cement road consists of component A and component B in the ratio of 1 to 1-2. The component A is organosilicon modified polyurethane pre-polymer prepared with polyether polyol, hydroxy-terminated organosilicon, isocyanate and catalyst through copolymerization. The component B is prepared with active hydrogen compound, catalyst and stuffing and through mixing. The present invention has high elasticity, high coherence, antiageing property, fatigue resistance and moderate performance / cost ratio.

Owner:UNIV OF JINAN

Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

ActiveCN104531041AGood flexibilityExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveShock resistance

The invention belongs to the technical field of adhesives and relates to a polyether-type urethane acrylate UV-cured adhesive and a preparation method thereof. The polyether-type urethane acrylate UV-cured adhesive comprises, by weight, 20-70 parts of polyether-type urethane acrylate, 10-40 parts of auxiliary resin, 5-20 parts of ethylene-acrylate rubber, 5-40 parts of an acrylate monomer, 5-35 parts of isobornyl acrylate, 1-7 parts of a photoinitiator, 1-5 parts of fumed silica and 0.5-2 parts of a silane coupling agent. Through use of the polyether-type urethane acrylate, auxiliary resin, ethylene-acrylate rubber and acrylate monomer, the polyether-type urethane acrylate UV-cured adhesive has excellent long-term high temperature resistance, low temperature resistance, high temperature and high humidity resistance, excellent shock resistance and a low cost and can be prepared by simple processes.

Owner:信泰永合(烟台)新材料有限公司

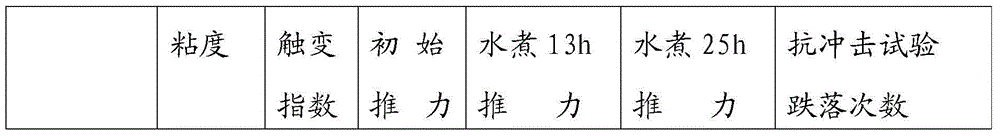

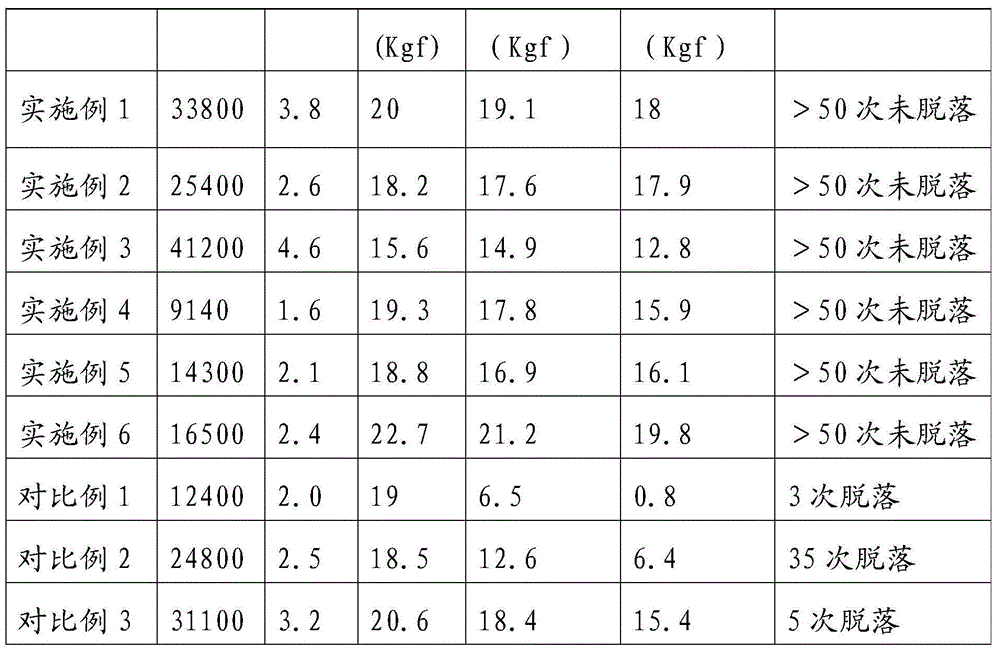

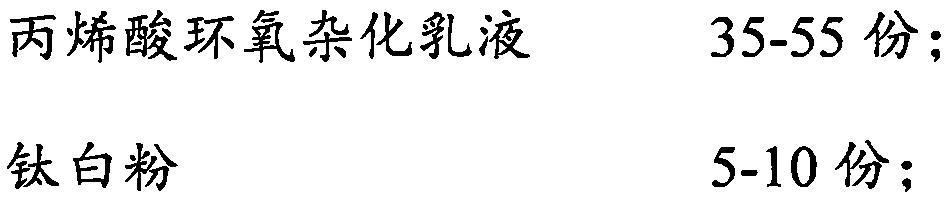

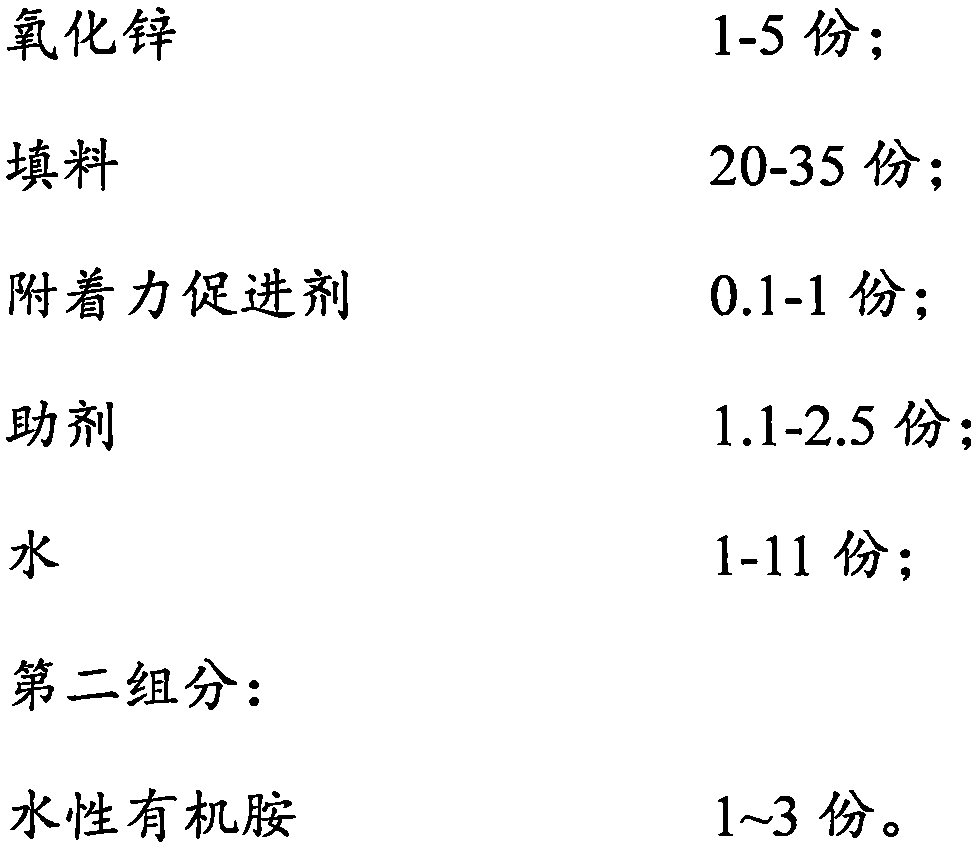

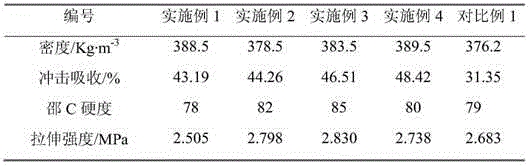

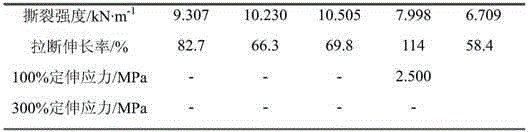

Two-component aqueous acrylate-epoxy resin hybrid coating

The invention discloses a two-component aqueous acrylate-epoxy resin hybrid coating. The epoxy resin part comprises 35-55 parts of an acrylate-epoxy resin hybrid emulsion, 5-10 parts of titanium dioxide, 1-5 parts of zinc oxide, 20-35 parts of a filler, 0.1-1 part of an adhesion promoter, 1.1-2.5 parts of an auxiliary agent and 1-11 parts of water. The curing agent part comprises 1-3 parts of aqueous organic amine. Through use of the hybrid system of an acrylate emulsion and epoxy resin, the anticorrosion coating with a fast drying rate, high film formation density, high weatherability and excellent salt mist resistance is prepared. Through formula optimization and curing agent mixing, the coating is a metal anticorrosion waterproof coating with a long service life, good application properties, good low temperature flexibility, good corrosion resistance, high hardness and good contamination resistance. The two-component aqueous acrylate-epoxy resin hybrid coating effectively prolongs a metal device usage time limit, can be used in terrace paint, saves a cost and provides a value for the society.

Owner:苏州匠品材料科技有限公司

Polyurethane sports knee-pad composition and preparation method thereof

The invention relates to a polyurethane sports knee-pad composition and a preparation method thereof. The invention relates to the technical field of polyurethane application. The polyurethane sports knee-pad composition provided by the invention is composed of a component A and a component B. A weight ratio of the component A to the component B is 100:30-60. The raw materials for the component A are special polyether polyol, high-activity polyether polyol, polymer polyol, a chain-extender, a foam stabilizer, a foaming agent, a catalyst, an antioxidant, a light stabilizer and a solid filling material. The raw materials for the component B are polyether polyol, isocyanate and a storage stabilizer. The polyurethane sports knee-pad composition provided by the invention has excellent shock cushioning performance and sport comfortableness. Compared with a traditional protection tool, with the product provided by the invention, protection effect is greatly improved. The invention also provides a preparation method of the polyurethane sports knee-pad composition. First, component A and component B are prepared; the component A and the component B are uniformly mixed manually or by using a manipulator; and the mixture is injected into an aluminum knee-pad mold. The cost is low, and the method is easy to implement.

Owner:SHANDONG INOV POLYURETHANE

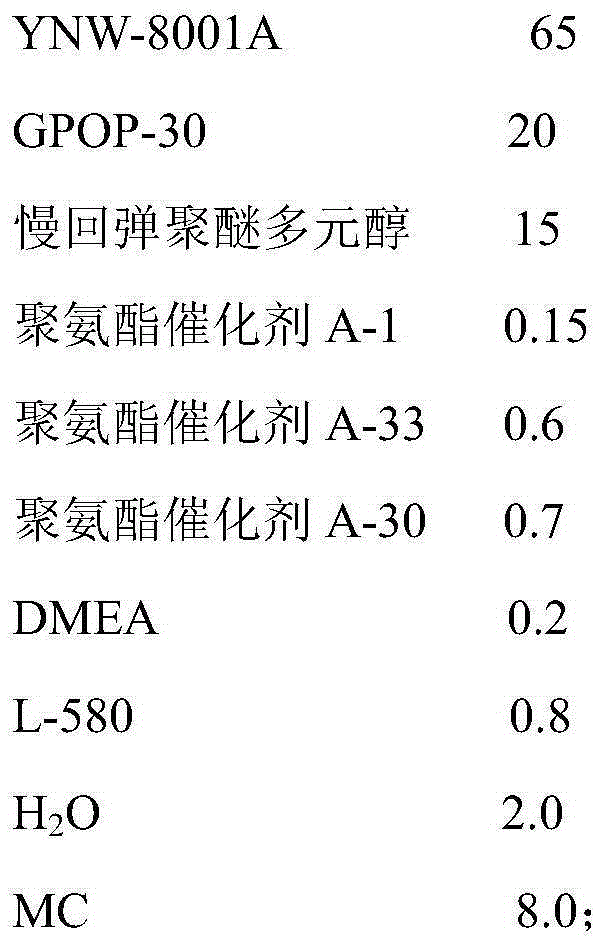

Polyether polyol used for low-density gaseousness and slow-resilience foam, preparation method of polyether polyol and slow-resilience foam and preparation method thereof

The invention relates to polyether polyol used for low-density gaseousness and slow-resilience foam, a preparation method of the polyether polyol and the slow-resilience foam and a preparation method thereof and belongs to the technical field of organic macromolecule synthesis. A polyhydric alcohol compound with small molecular weight serves as an initiator of the polyether polyol, and an end group is copolymer of epoxypropane with the end capped with ethylene oxide and ethylene oxide monomer; the preparation method of the polyether polyol comprises the steps of making the polyhydric alcohol compound with the small molecular weight and a catalyst be subjected to a reaction in a pressure-proof reaction kettle, then sequentially adding polymerization monomer, water, phosphoric acid and magnesium silicate for reaction, and obtaining the polyether polyol; the slow-resilience foam is prepared from a component A and a component B, wherein the component A comprises the polyether polyol, a composite catalyst, silicone oil and a foaming agent, and the component B is modified MDI; the preparation method of the slow-resilience foam comprises the steps of mixing the component A with the component B uniformly, then pouring the mixture into a mold for curing, and obtaining the slow-resilience foam. The slow-resilience foam prepared through the preparation method has the advantages of being low in density, good in gaseousness property and free of shrinkage, and the preparation method of the slow-resilience foam is simple and easy to operate.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

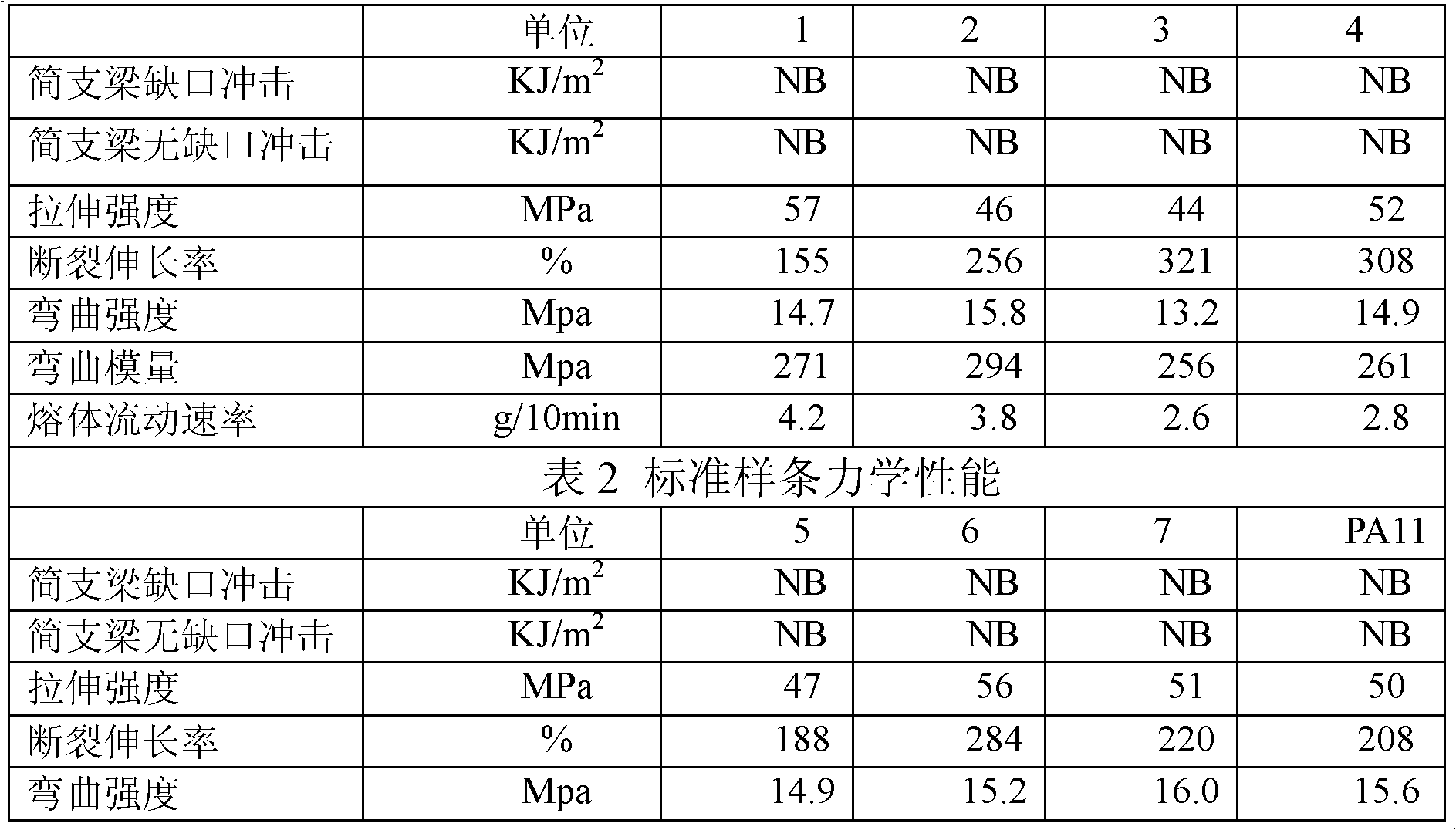

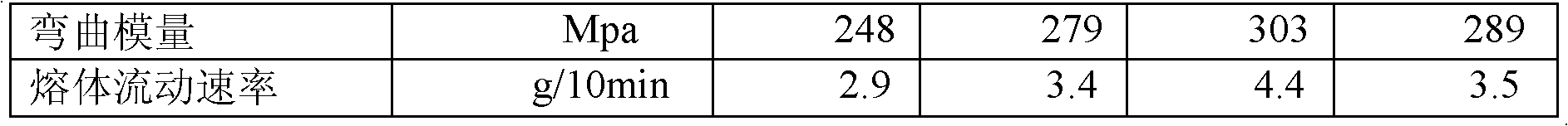

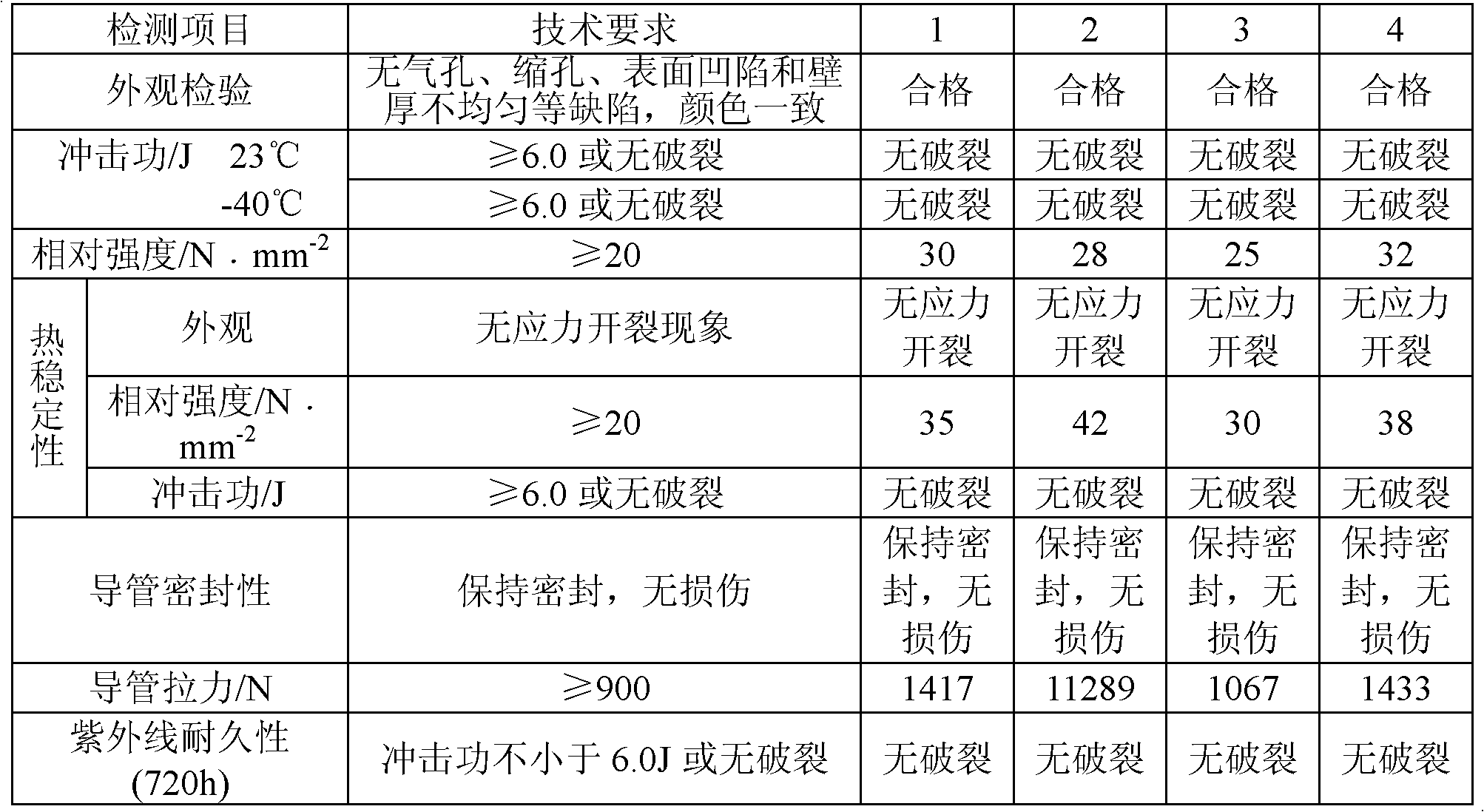

Formula of nylon hose

InactiveCN102604373AHigh strengthGood flexibility at low temperatureFlexible pipesPlasticizerLong chain

The invention relates to a formula of a nylon hose. The nylon hose prepared according to the formula provided by the invention is mainly applied to oil hoses and brake hoses of cars. The formula proportion of the nylon hose in parts by weight is as follows: 100 of long-chain nylon, 1-30 of polyamide elastomer, 0-30 of a plasticizer, 0.1-3.0 of an antioxidant, and 0.1-3.0 of a lubricant. The nylon hose prepared by the formula provided by the invention has the characteristics of high strength, good low-temperature flexibility, oil resistance, good dimensional stability, stable extrusion molding and the like; and after the nylon hose is processed into tubing, the tubing completely accords with the requirements of the standard of DIN73378:1996-02, and completely meets the requirements of replacing the imported tubing PA11 and PA12.

Owner:WUXI YINDA NYLON

Preparation method of single-component water-based polyurethane adhesive for use in flexible package compounding

ActiveCN103881640AImprove performanceEasy to useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterEpoxy

The invention discloses a preparation method of a single-component water-based polyurethane adhesive for use in flexible package compounding. The method comprises the following steps: reacting polyisocyanate with polyester polyol and polyether polyol, adding a chain extender, and continually reacting to obtain a polyurethane prepolymer; continually reacting epoxy resin with a modifier of a silane coupling agent to obtain a modified polyurethane prepolymer; cooling the modified prepolymer, neutralizing and salifying, and adding water for high-speed dispersion to obtain the single-component water-based polyurethane adhesive for use in flexible package compounding. The method is simple in preparation process, and the obtained single-component water-based polyurethane adhesive is convenient to use.

Owner:SHANDONG HUACHENG HIGH TECH ADHESIVE

Water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and preparation method thereof

The invention relates to a water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and a preparation method thereof. The cold-recycling agent is prepared from the following components in parts by mass: 100 parts of emulsified asphalt and 10-20 parts of water-borne epoxy composite, wherein the water-borne epoxy composite comprises a component A and a component B, the component A is prepared from the following ingredients in parts by mass: 100 parts of water-borne epoxy emulsion, 10-25 parts of waterborne blocked polyurethane, 0.5-2 parts of associated thickener and 0.5-2 parts of coupler, and the component B is prepared from the following ingredients in parts by mass: 100 parts of an amine water-borne epoxy curing agent and 10-20 parts of accelerant. Compared with the prior art, the water-borne epoxy composite-containing emulsified asphalt cold-recycling agent belongs to a homogeneous system, has an excellent low-temperature flexibility, high-temperature stability, excellent water stability, good abrasion resistance and high early strength while the strength is improved, and the mixed material has excellent pavement performances and can be directly applied to the surface layer of pavement.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com